Patents

Literature

5657 results about "Tube furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tube furnace is an electric heating device used to conduct syntheses and purifications of inorganic compounds and occasionally in organic synthesis. One possible design consists of a cylindrical cavity surrounded by heating coils that are embedded in a thermally insulating matrix. Temperature can be controlled via feedback from a thermocouple. More elaborate tube furnaces have two (or more) heating zones useful for transport experiments. Some digital temperature controllers provide an RS232 interface, and permit the operator to program segments for uses like ramping, soaking, sintering, and more. Advanced materials in the heating elements, such as molybdenum disilicide offered in certain models can now produce working temperatures up to 1800 °C. This facilitates more sophisticated applications. Common material for the reaction tubes include alumina, Pyrex, and fused quartz.

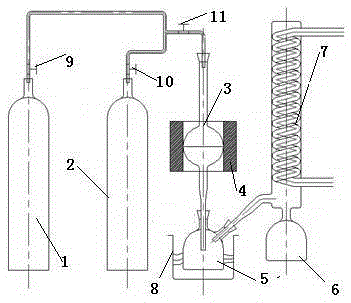

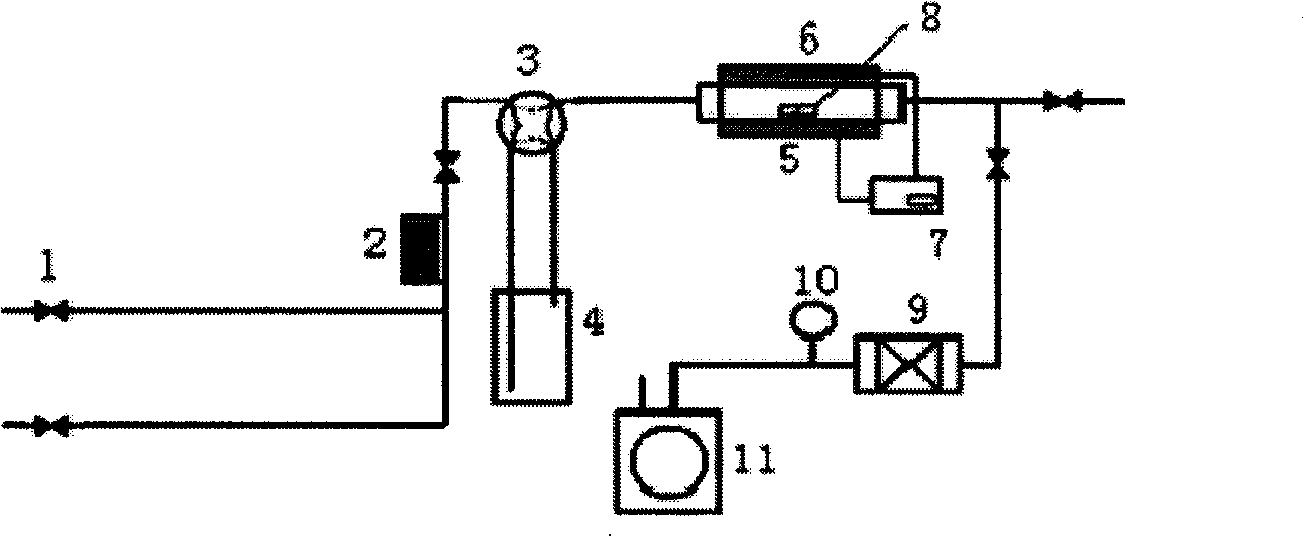

Method for preparing precursor for chemical vapor deposition of metallic rhenium

The invention discloses a method for preparing a precursor for chemical vapor deposition of metallic rhenium and belongs to the technical field of material preparation. According to the method, ReCl5 is made to react in an oxidizing atmosphere, efficient solid-liquid-gas separation is conducted on reactants and products with a sand core filter bulb so that reactants, reaction products and waste gas can be effectively separated, the reaction products ReOCl4 and ReO3Cl are gathered in a collection vessel heated by an oil bath pan at the same time, oxygen introduction is stopped after reaction ends, circulation of inert gases is maintained, a tube furnace is cooled, the oil bath pan is heated at the same time to enable ReO3Cl to volatilize to enter a rectification unit to be collected, ReOCl4 is purified, and then the high-purity precursor ReOCl4 for chemical vapor deposition of metallic rhenium is obtained. By the adoption of the method, reaction efficiency is high, ReOCl4 and ReO3Cl are separated through rectification, and the purity of the product ReOCl4 is improved.

Owner:海朴精密材料(苏州)有限责任公司

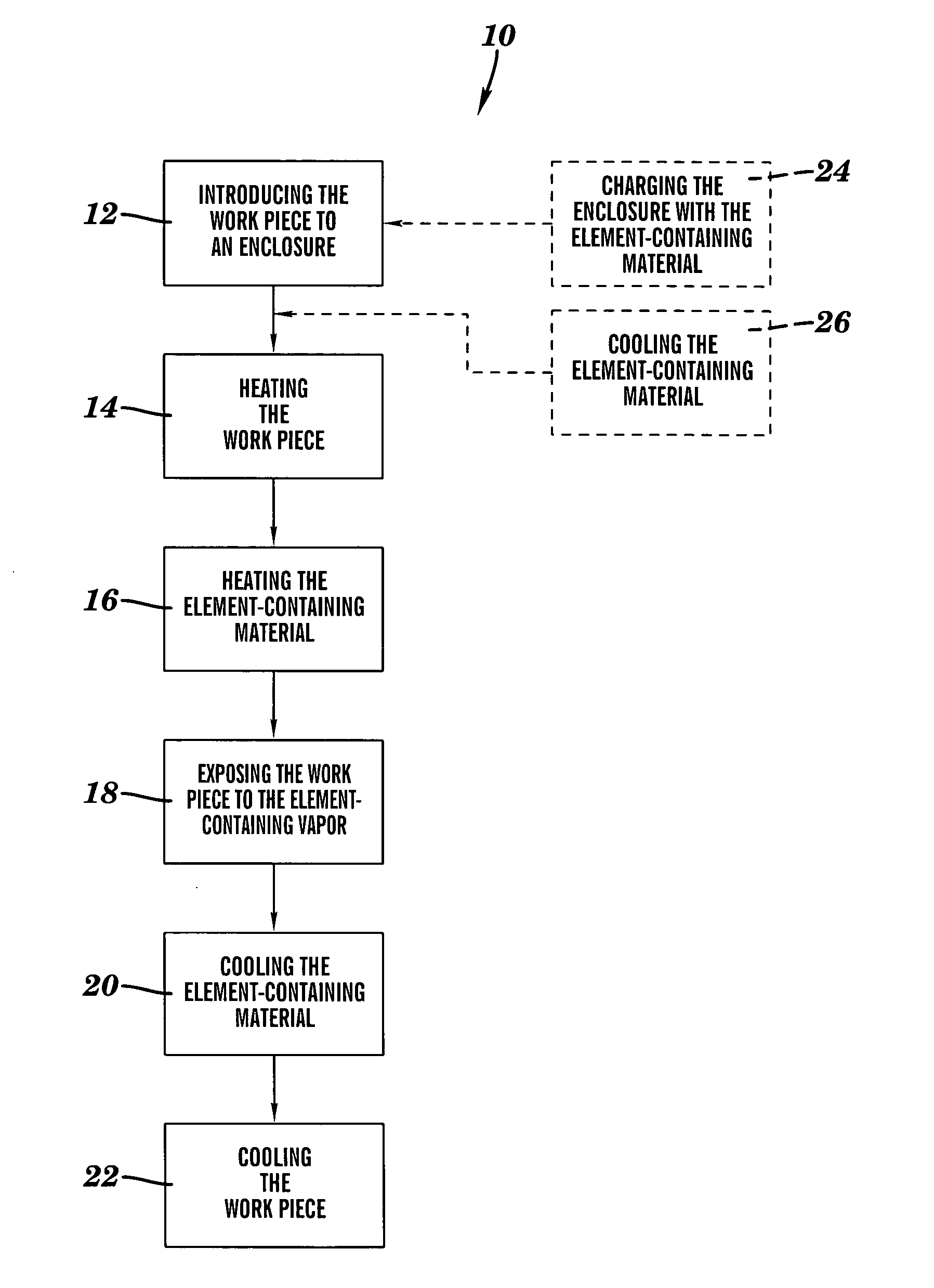

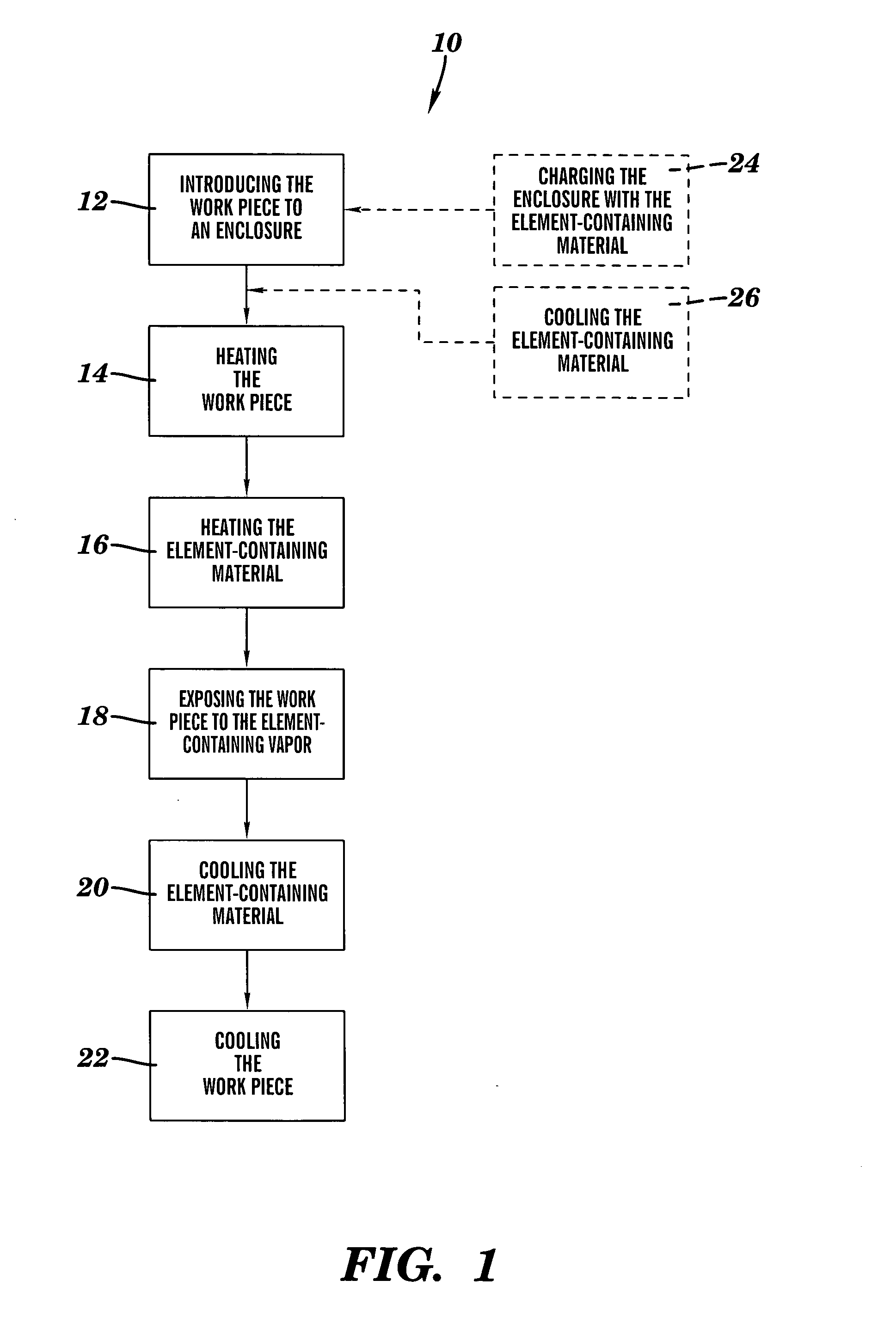

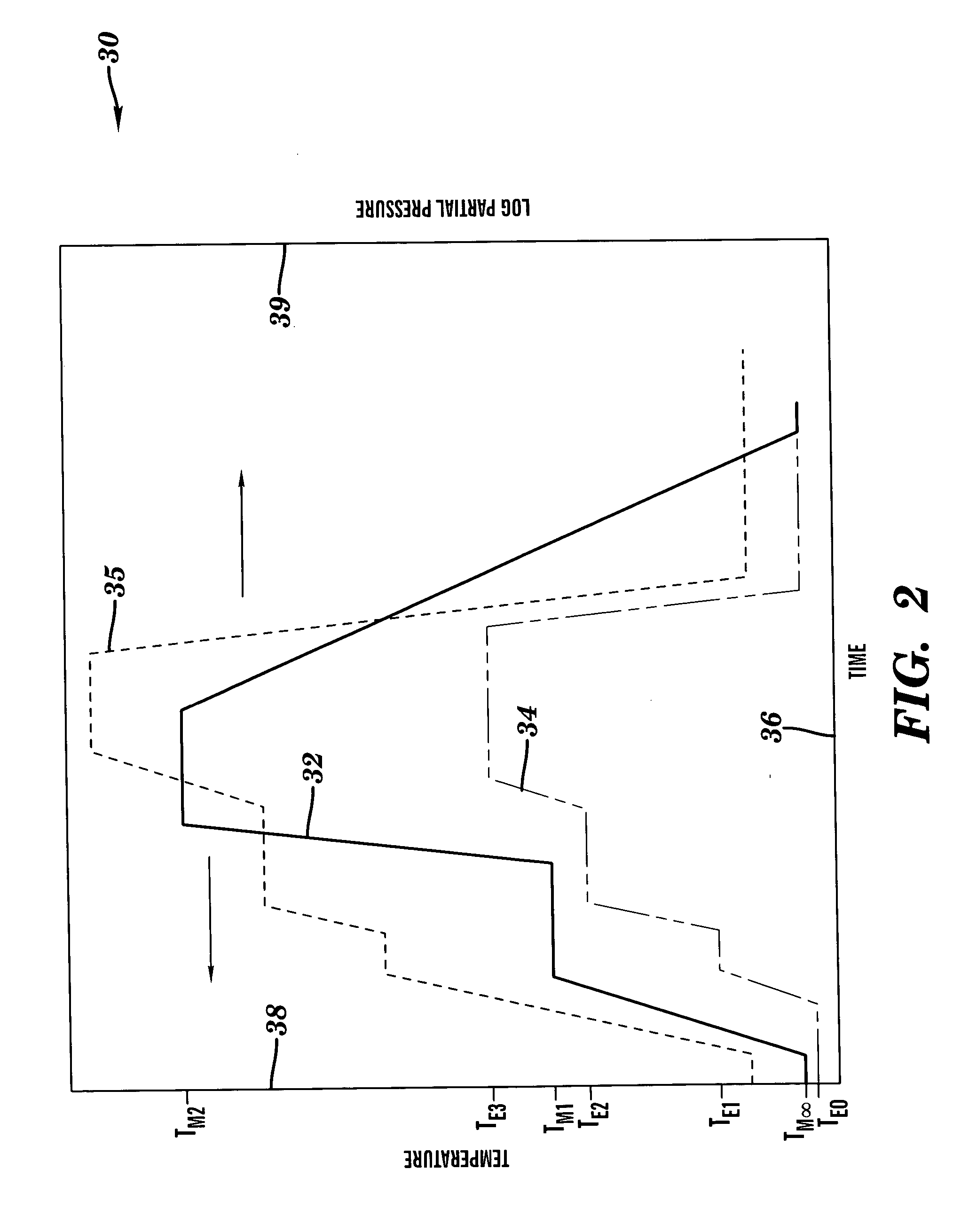

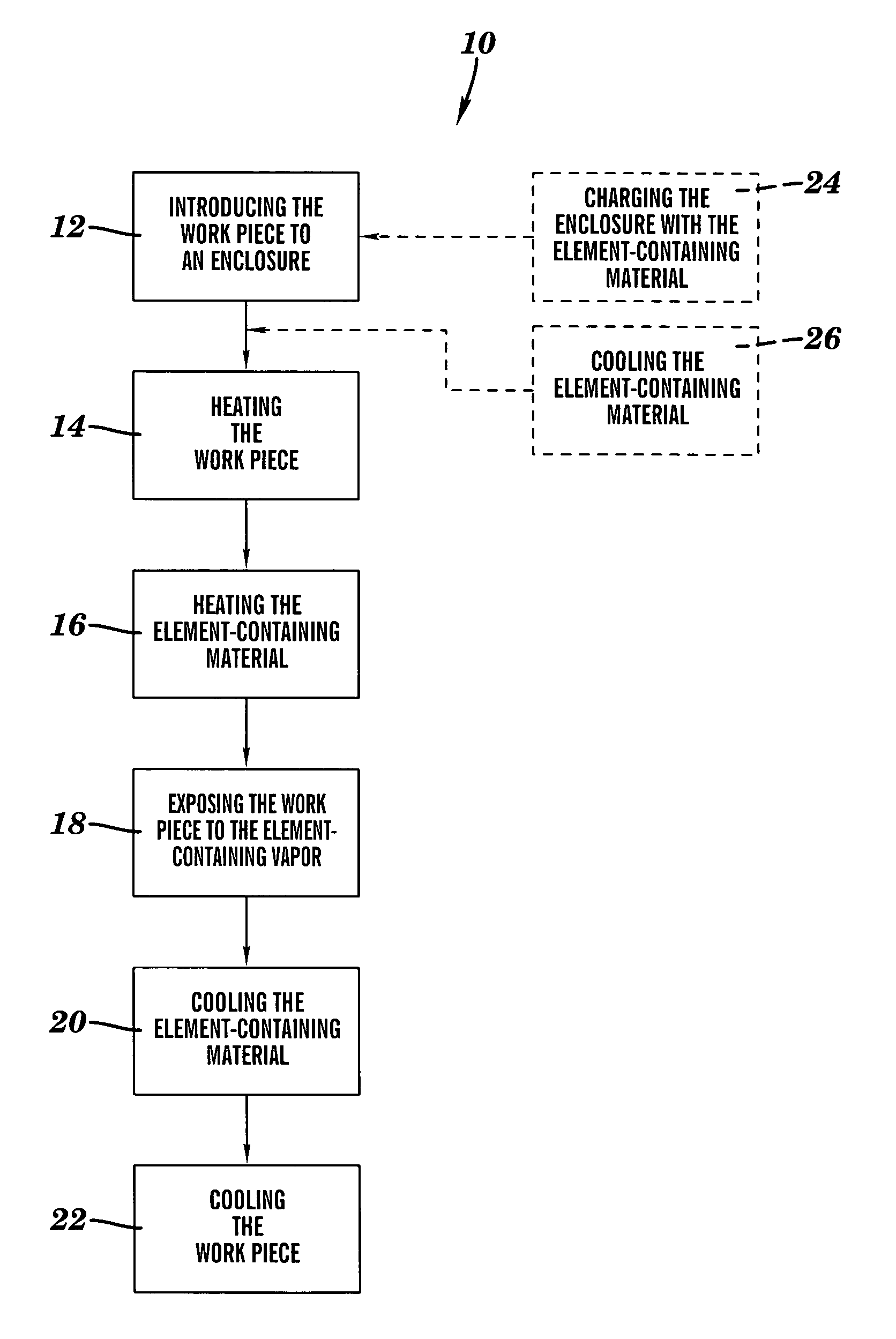

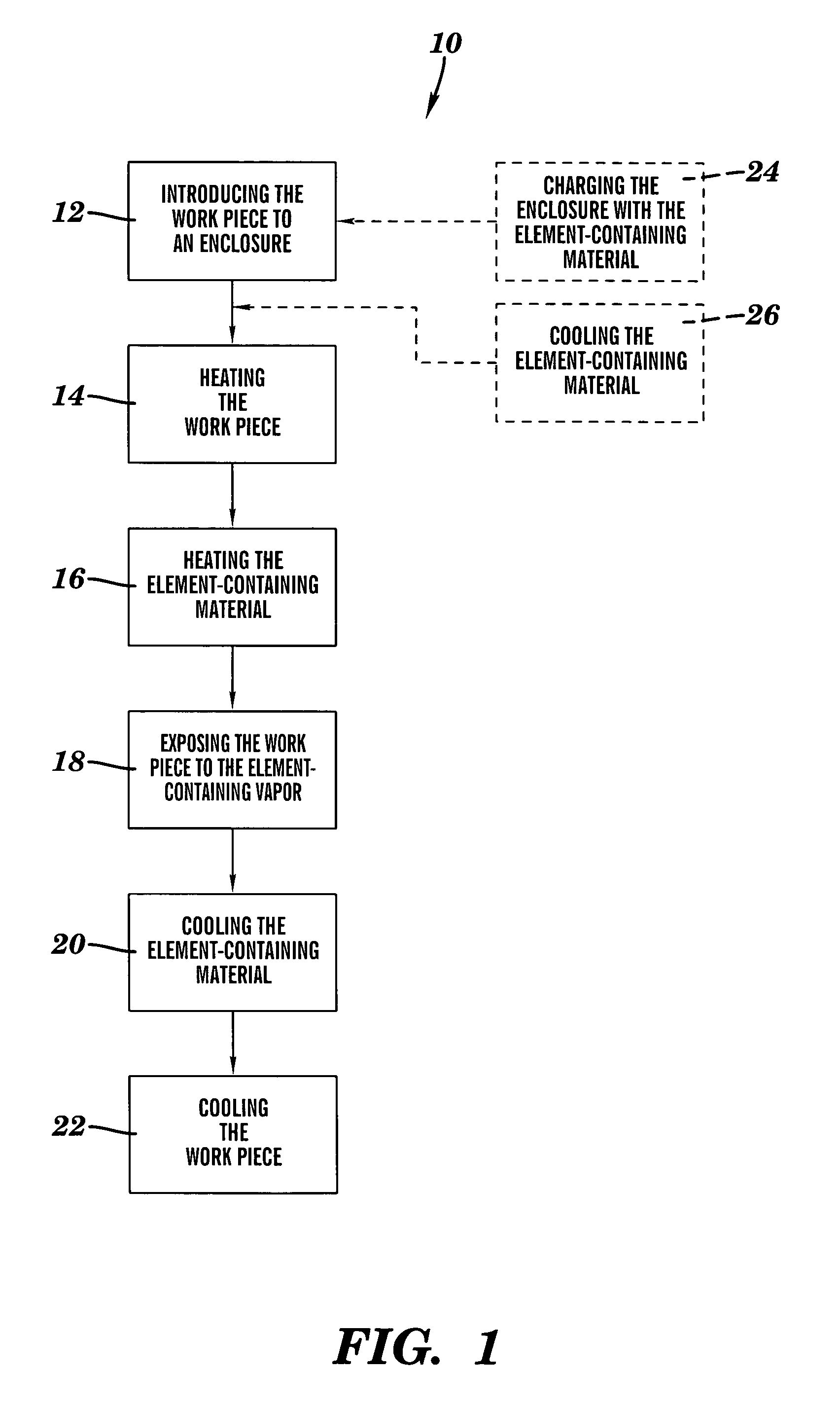

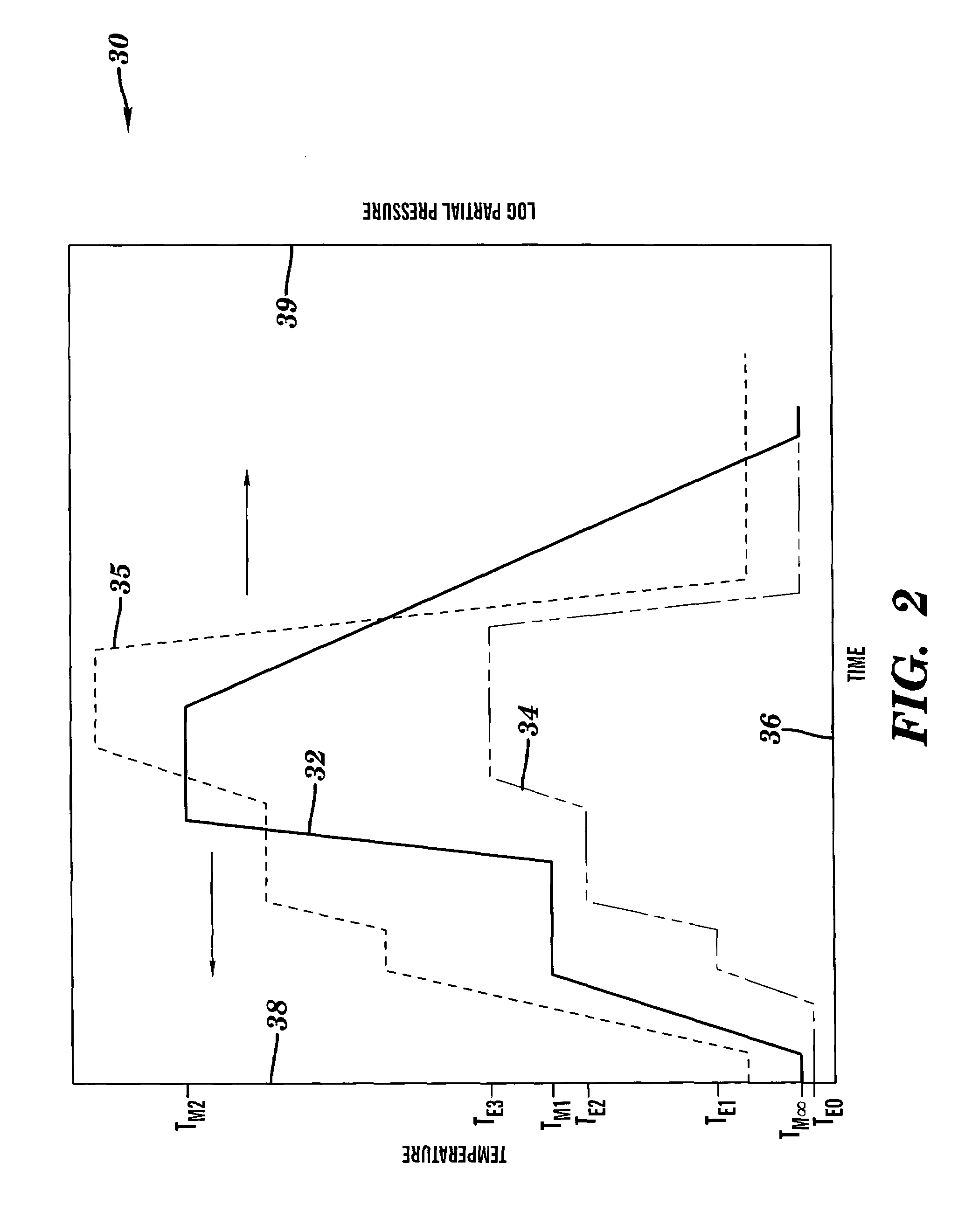

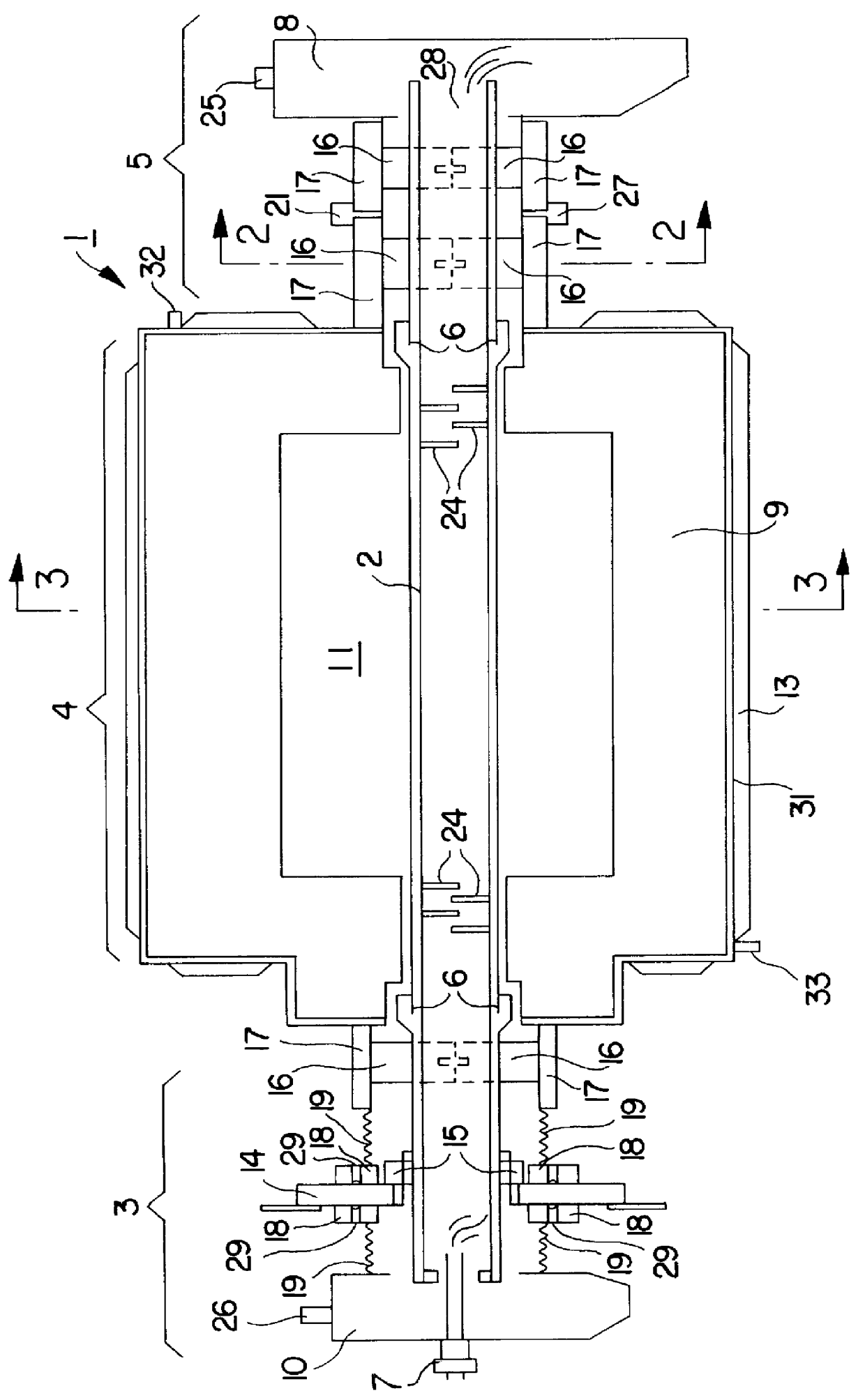

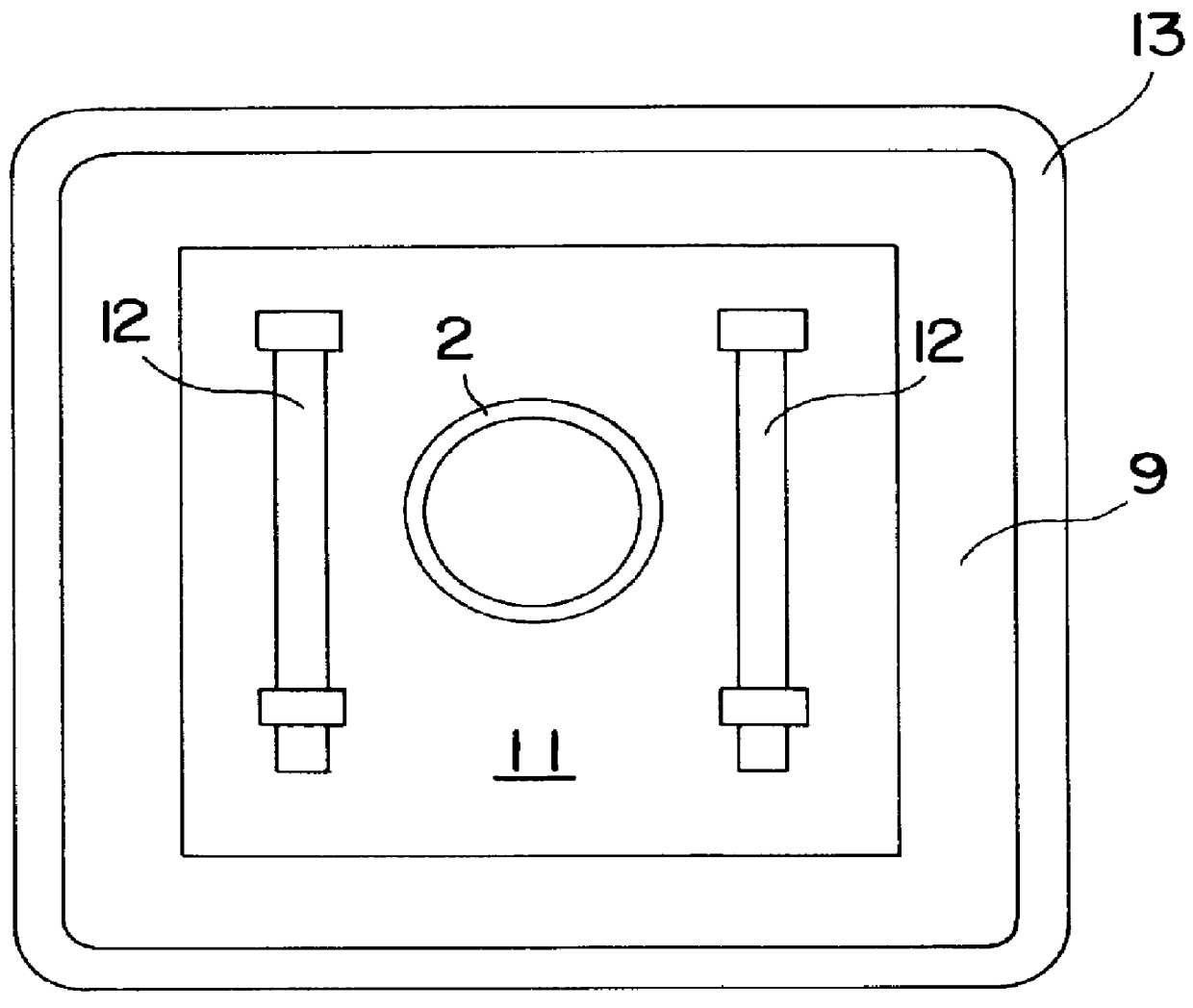

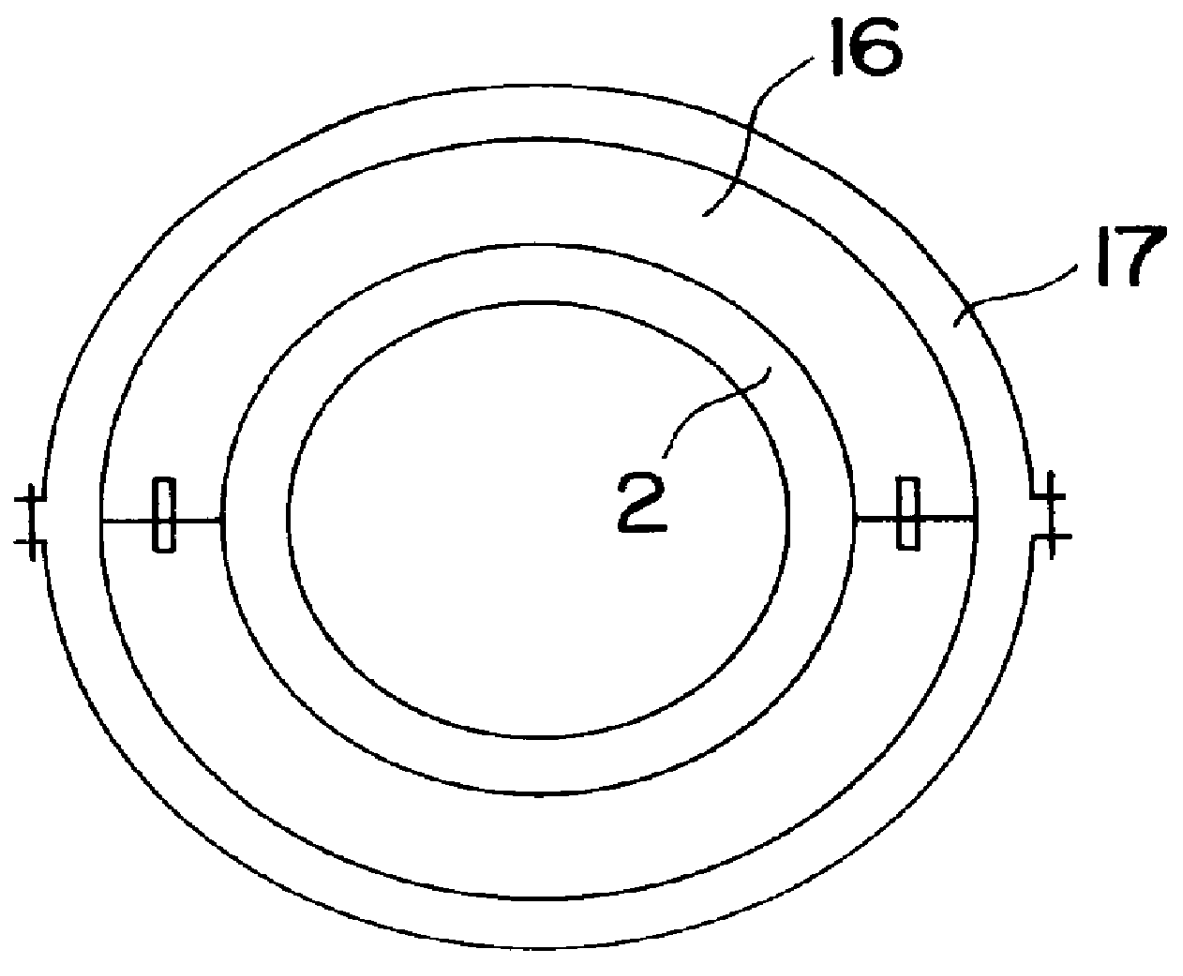

Methods and apparatus for treating a work piece with a vaporous element

InactiveUS20070116892A1Improve versatilityImprove adaptabilityFurnaces without endless coreVacuum evaporation coatingGaseous elementCell processing

Methods and apparatus for controlling and delivering a vaporous element or compound, for example, selenium or sulfur, from a solid source to a work piece are provided. The methods and apparatus may be used in photovoltaic cell manufacturing. The apparatus may comprise a treatment chamber, for example, a box furnace or a tube furnace. The chamber may include an inner enclosure, an outer enclosure, and heating sources capable of independent thermal control, for example, in compliance with a predetermined heating schedule. The apparatus include devices and mechanisms for isolating the treatment chambers from the ambient environment. The methods and apparatus may be adapted to control metalloid vapor delivery in photovoltaic cell processing, for example, the processing of CIGS and CIGSS photovoltaic cells.

Owner:DAYSTAR TECHNOLOGIES

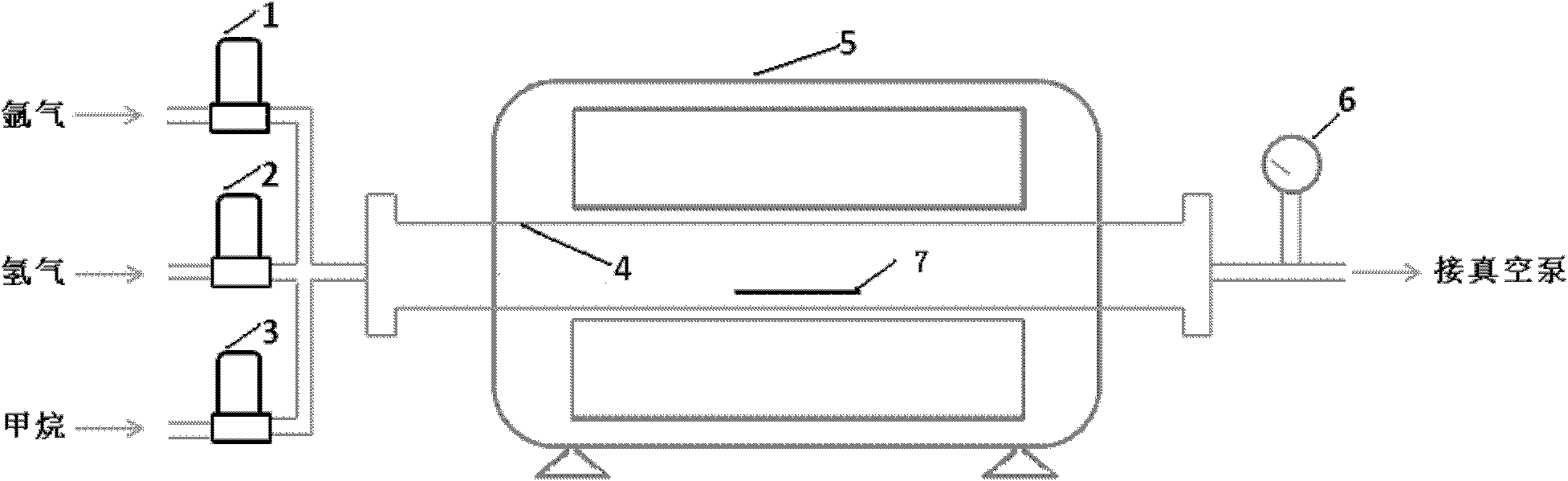

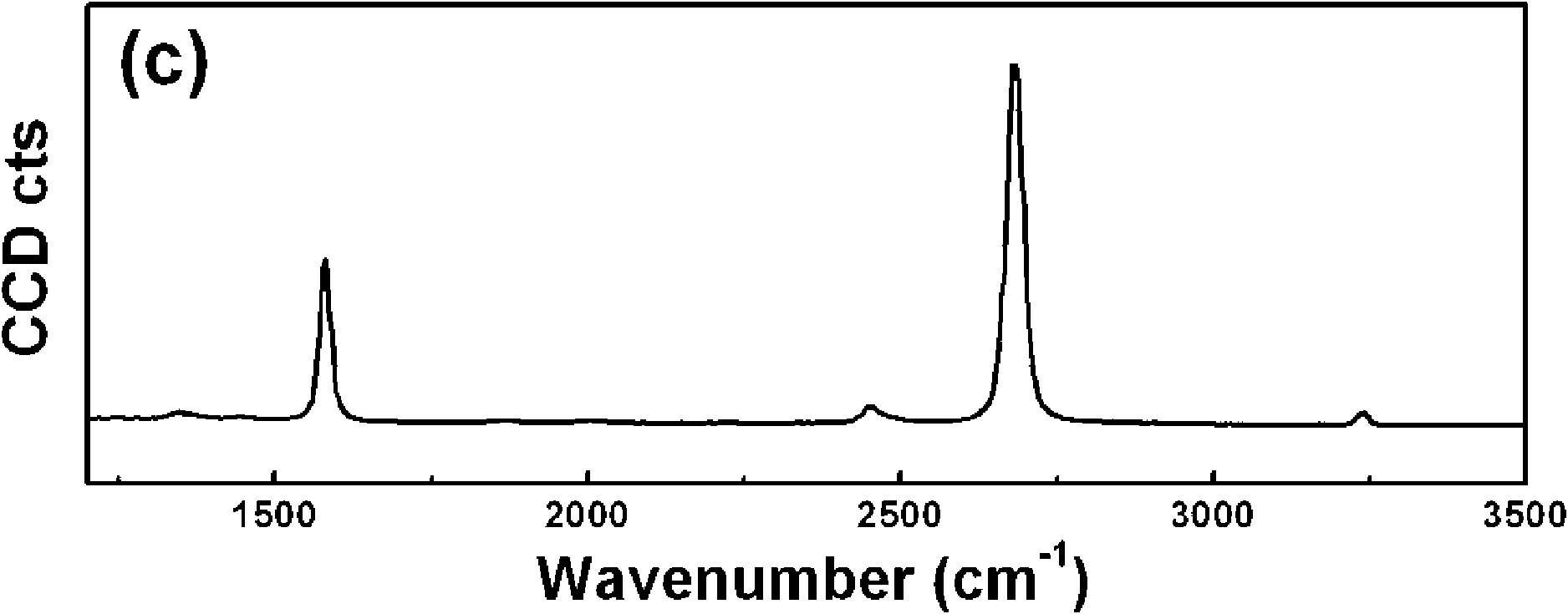

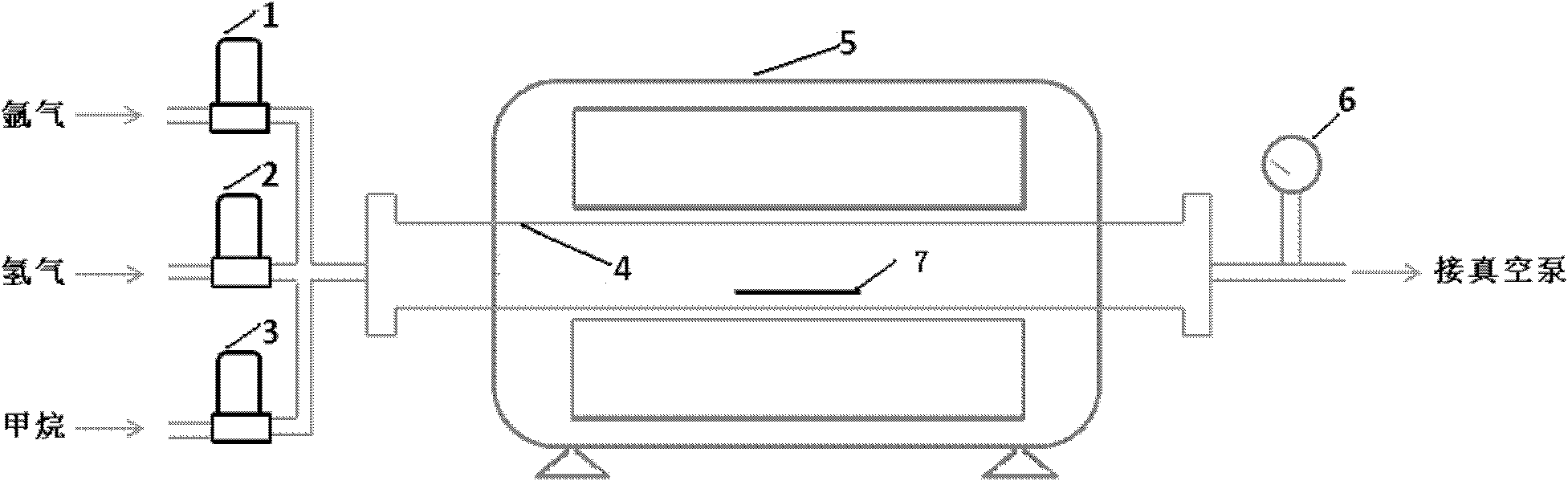

Method for preparing single-layer or multi-layer graphene through chemical vapor deposition

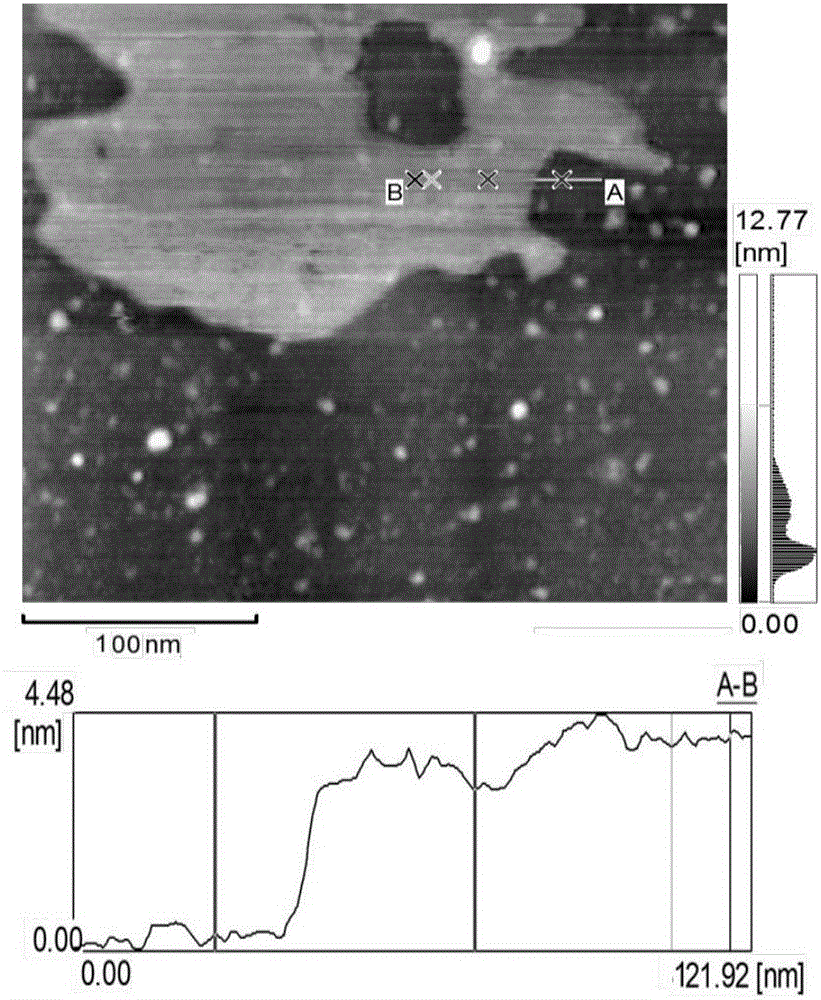

InactiveCN102220566ADefect peak lowImprove crystal qualityMaterial nanotechnologySingle layer grapheneGas phaseCopper foil

The invention discloses a method for preparing single-layer or multi-layer graphene through chemical vapor deposition, and relates to a method for preparing a graphene material. The method comprises the following steps of: placing a metal substrate in a vacuum tubular furnace or a vacuum atmosphere furnace; injecting hydrogen into a vacuum cavity under the situation of removing the oxygen in the vacuum cavity; heating to 800-1,100 DEG C; and injecting a carbon source gas into the vacuum cavity to obtain the metal substrate for depositing graphene. According to the method disclosed by the invention, a graphene film is deposited by cracking methane or other carbon source gases on the metal substrate (such as a copper foil or a nickel foil and the like) at a high temperature by using the chemical vapor deposition method; and therefore, the invention provides a method for preparing the single-layer or multi-layer graphene with an ultra-large area.

Owner:无锡第六元素高科技发展有限公司

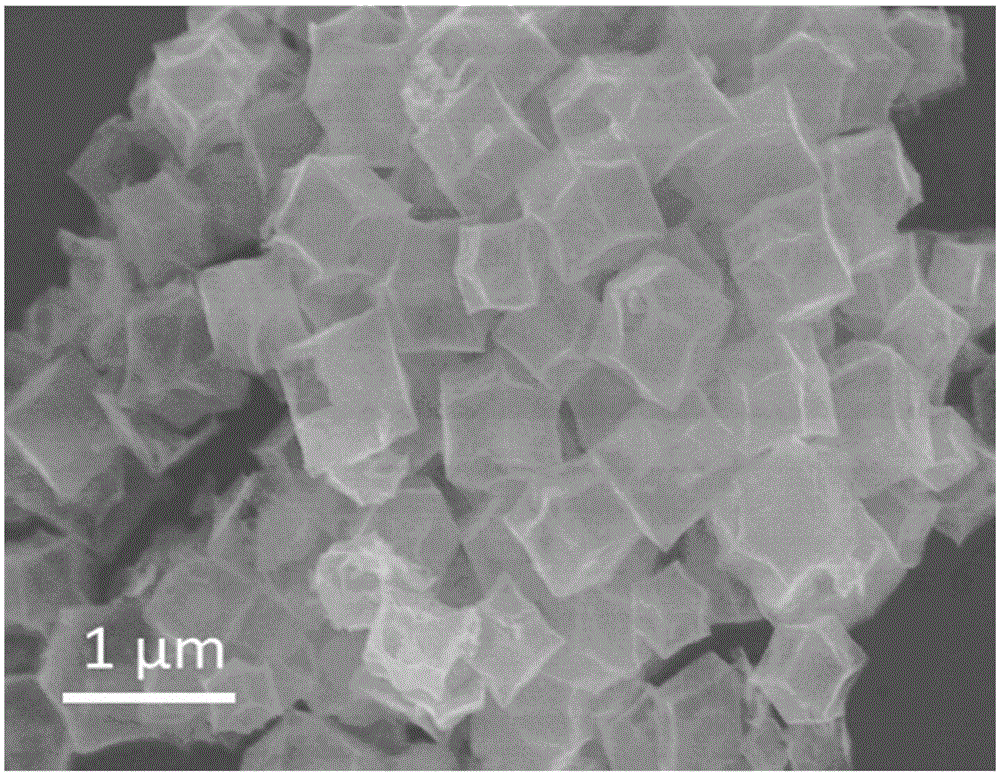

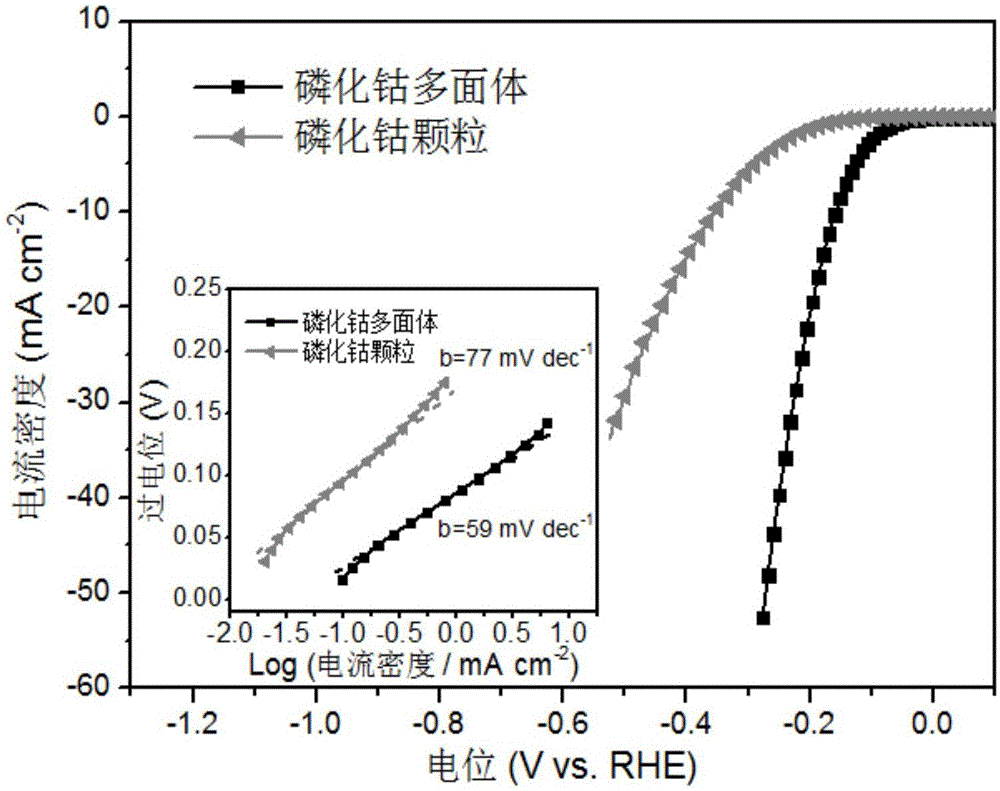

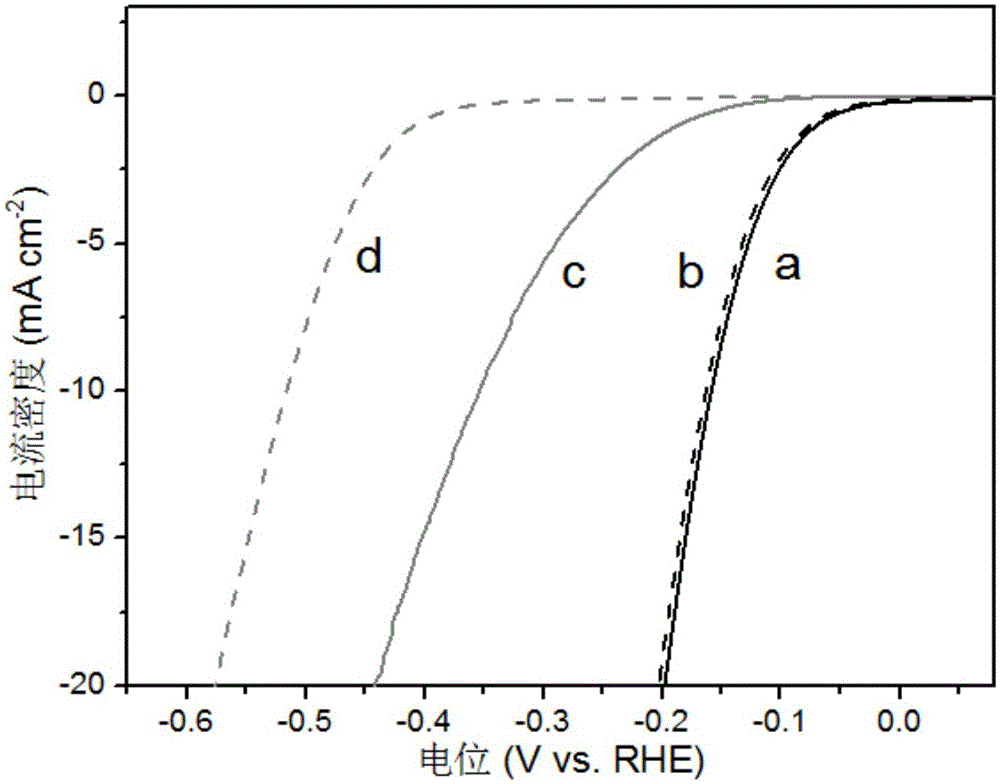

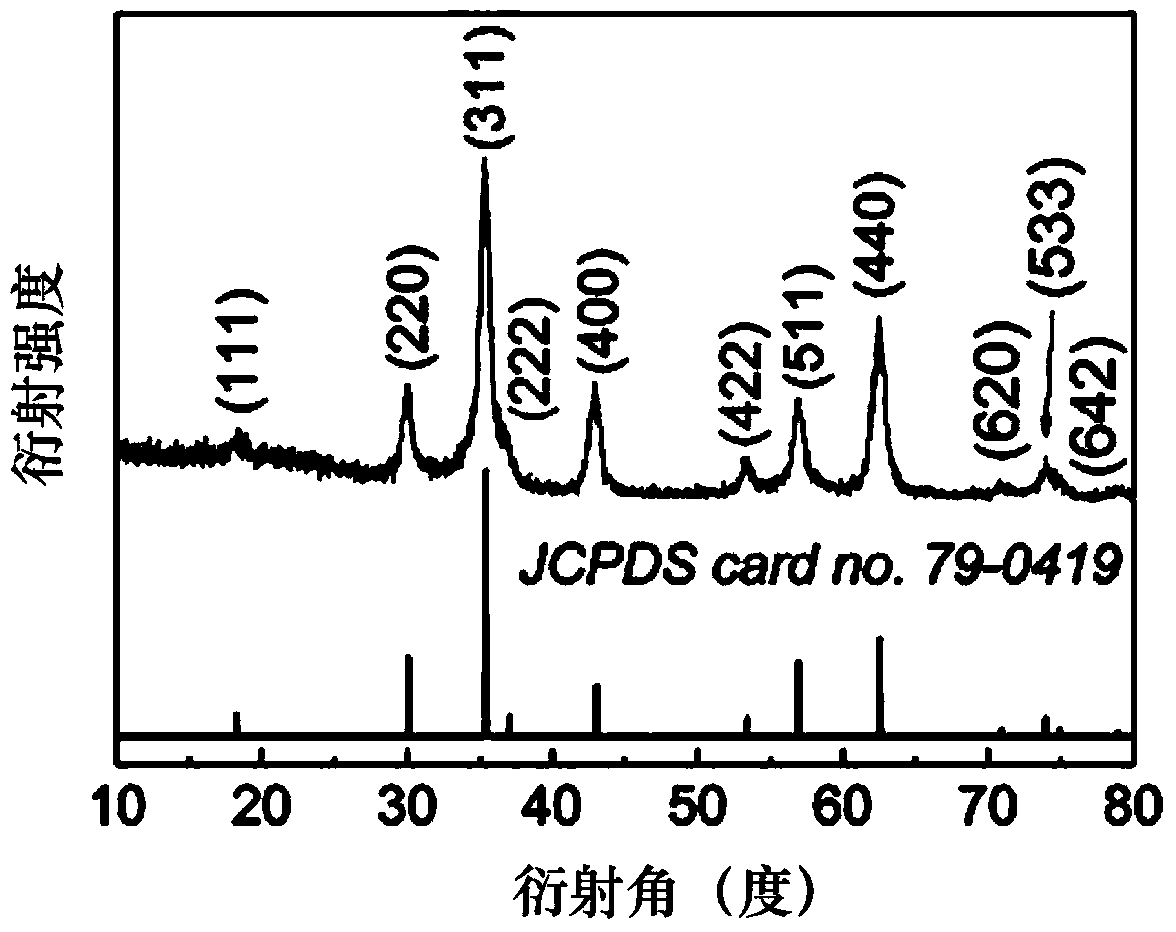

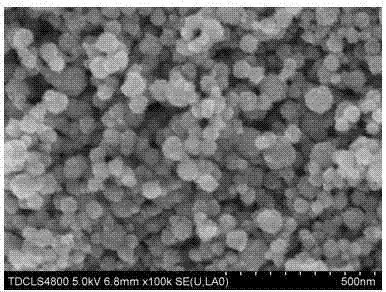

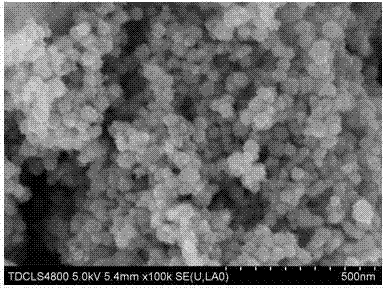

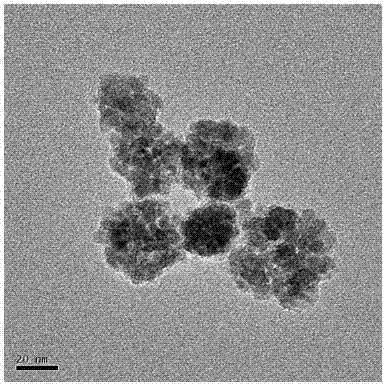

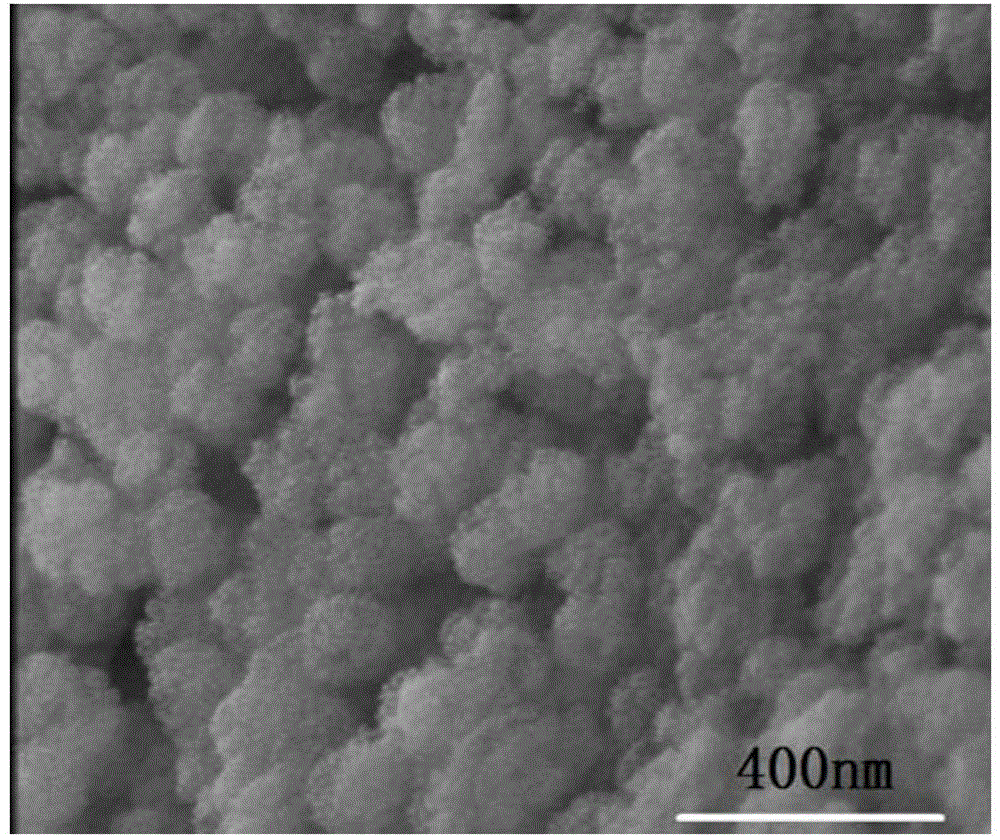

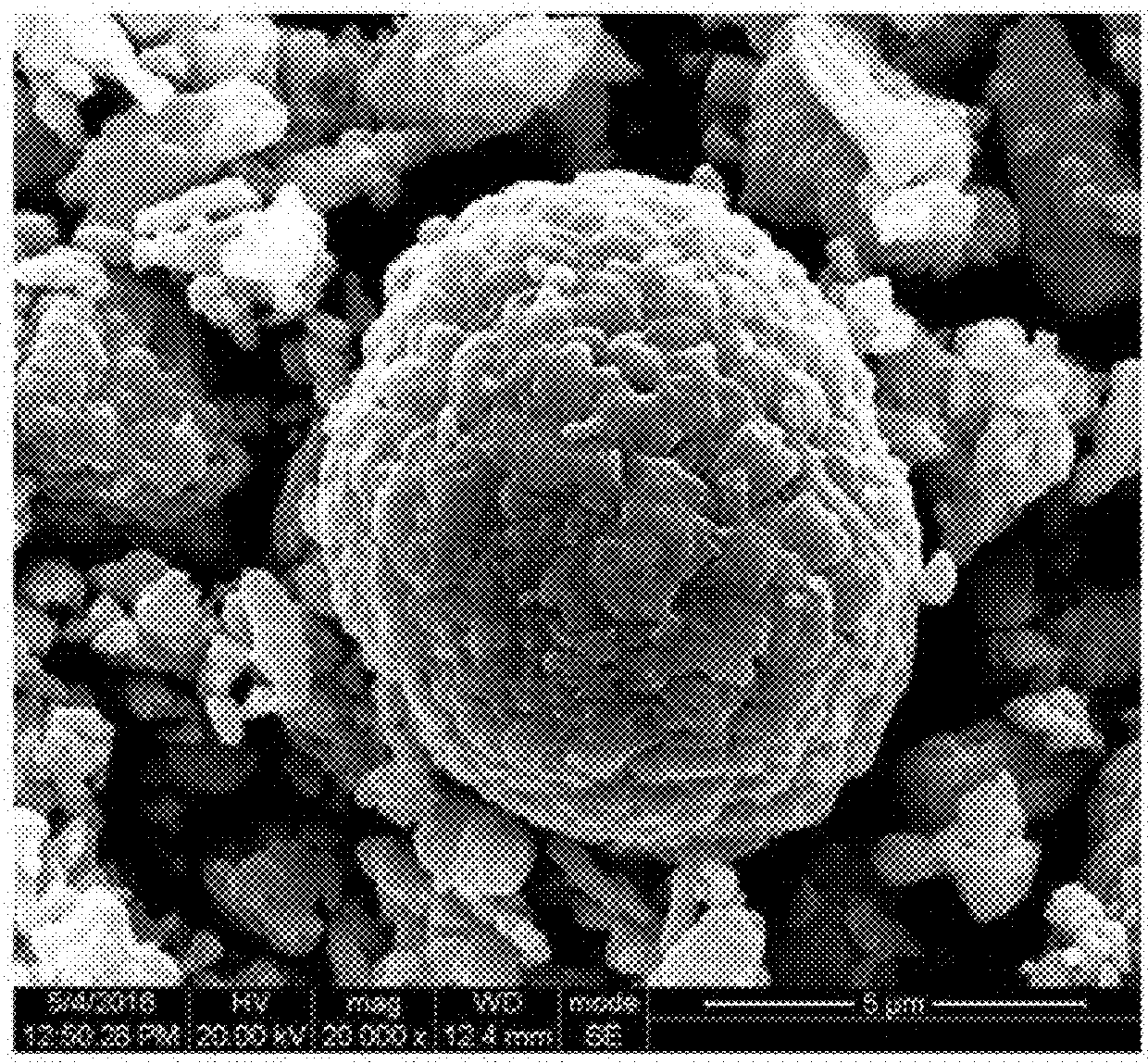

Preparation method of polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis

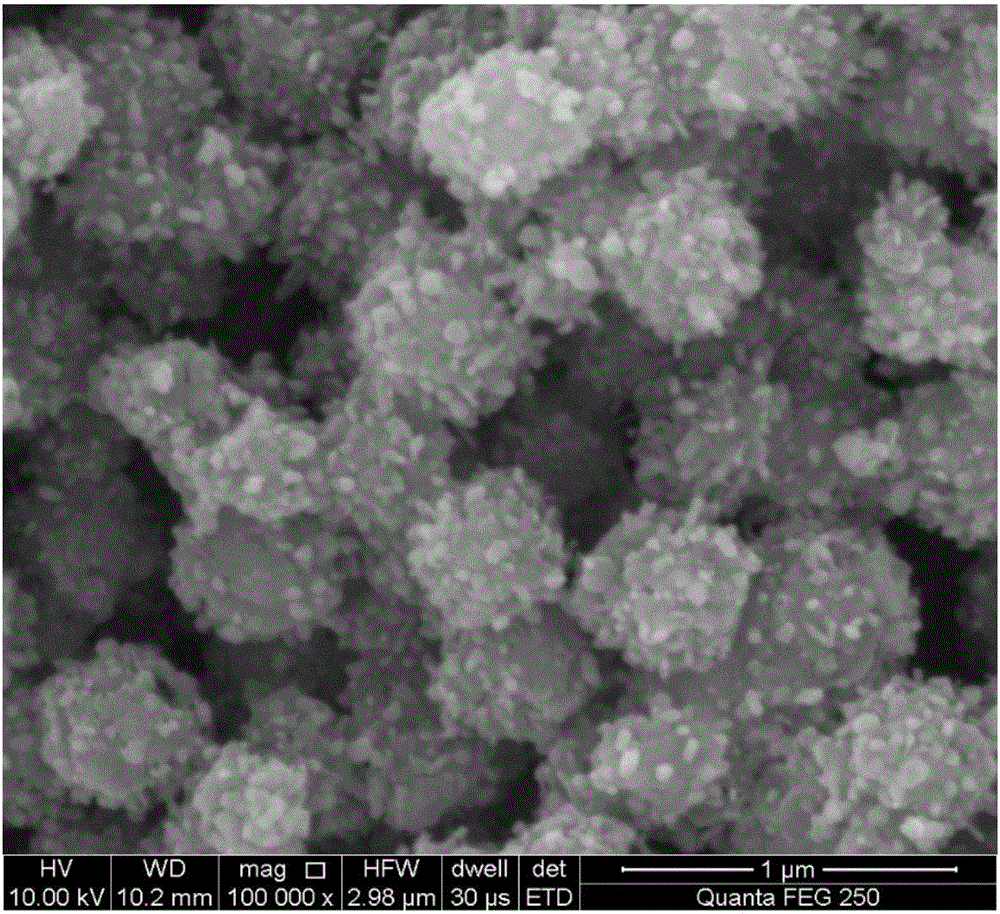

ActiveCN105107536AHigh crystallinityIncrease the areaElectrolysis componentsPhysical/chemical process catalystsAir atmosphereElectrolysis

A preparation method of a polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis comprises steps as follows: Co(NO3)2*6H2O and 2-methylimidazole are dissolved in methanol respectively, a 2-methylimidazole solution is poured into a Co(NO3)2 solution, the mixture is stirred and then aged at the room temperature, a product is centrifugally separated, vacuum drying is performed after washing with methanol, and a polyhedral metal organic frame ZIF-67 is obtained; then the polyhedral metal organic frame ZIF-67 is placed in a tube furnace, cobaltosic oxide is obtained through calcination in the air atmosphere, then the cobaltosic oxide and NaH2PO2*H2O are placed at two ends of a porcelain boat respectively, the NaH2PO2*H2O is located in the windward position of the tube furnace, and the polyhedral cobalt phosphide catalyst for hydrogen production through water electrolysis is obtained through calcination in the inert atmosphere. The crystallinity of the prepared cobalt phosphide catalyst material is high, the polyhedral morphology of a metal organic frame template is kept, the catalyst shows excellent properties in an electrocatalytic hydrogen evolution reaction, and the preparation technology is simple in process.

Owner:TSINGHUA UNIV

Methods and apparatus for treating a work piece with a vaporous element

InactiveUS7442413B2Enhances versatility and adaptabilityFurnaces without endless coreVacuum evaporation coatingCell processingTube furnace

Methods and apparatus for controlling and delivering a vaporous element or compound, for example, selenium or sulfur, from a solid source to a work piece are provided. The methods and apparatus may be used in photovoltaic cell manufacturing. The apparatus may comprise a treatment chamber, for example, a box furnace or a tube furnace. The chamber may include an inner enclosure, an outer enclosure, and heating sources capable of independent thermal control, for example, in compliance with a predetermined heating schedule. The apparatus include devices and mechanisms for isolating the treatment chambers from the ambient environment. The methods and apparatus may be adapted to control metalloid vapor delivery in photovoltaic cell processing, for example, the processing of CIGS and CIGSS photovoltaic cells.

Owner:DAYSTAR TECHNOLOGIES

Preparation method of nano porous metal oxide/carbon lithium ion battery cathode material

ActiveCN104045116AImprove cycle performanceImprove conductivityMaterial nanotechnologyCell electrodesHigh energyManganese oxide

The invention provides a preparation method of a nano porous metal oxide / carbon lithium ion battery cathode material. The preparation method comprises the following steps: firstly, weighting ferric salt or manganese salt and carboxylate organic ligands, and putting into a high-pressure reaction kettle; and after a polar solvent is added and dissolved, carrying out a hydrothermal reaction for 10-72h at 100-180 DEG C to generate a transition metal coordination polymer precursor; and after the transition metal coordination polymer precursor is washed and dried, decomposing the precursor for 0.5-6h at a temperature of 300-600 DEG C in an inert atmosphere in a tube furnace, thus obtaining a nano porous metal oxide / carbon lithium ion battery cathode material containing iron oxides or manganese oxides. According to the preparation method, since the transition metal coordination polymer precursor which is structurally designable and controllable is used as a template-type precursor, a nano porous metal oxide / carbon lithium ion battery cathode material is obtained by using an in-situ thermal decomposition method. The method is simple in process, and the obtained products have the advantages of high electrical conductivity, high specific capacity, good cycle stability, excellent high-ratio discharge performance and high energy density.

Owner:JIANGSU UNIV

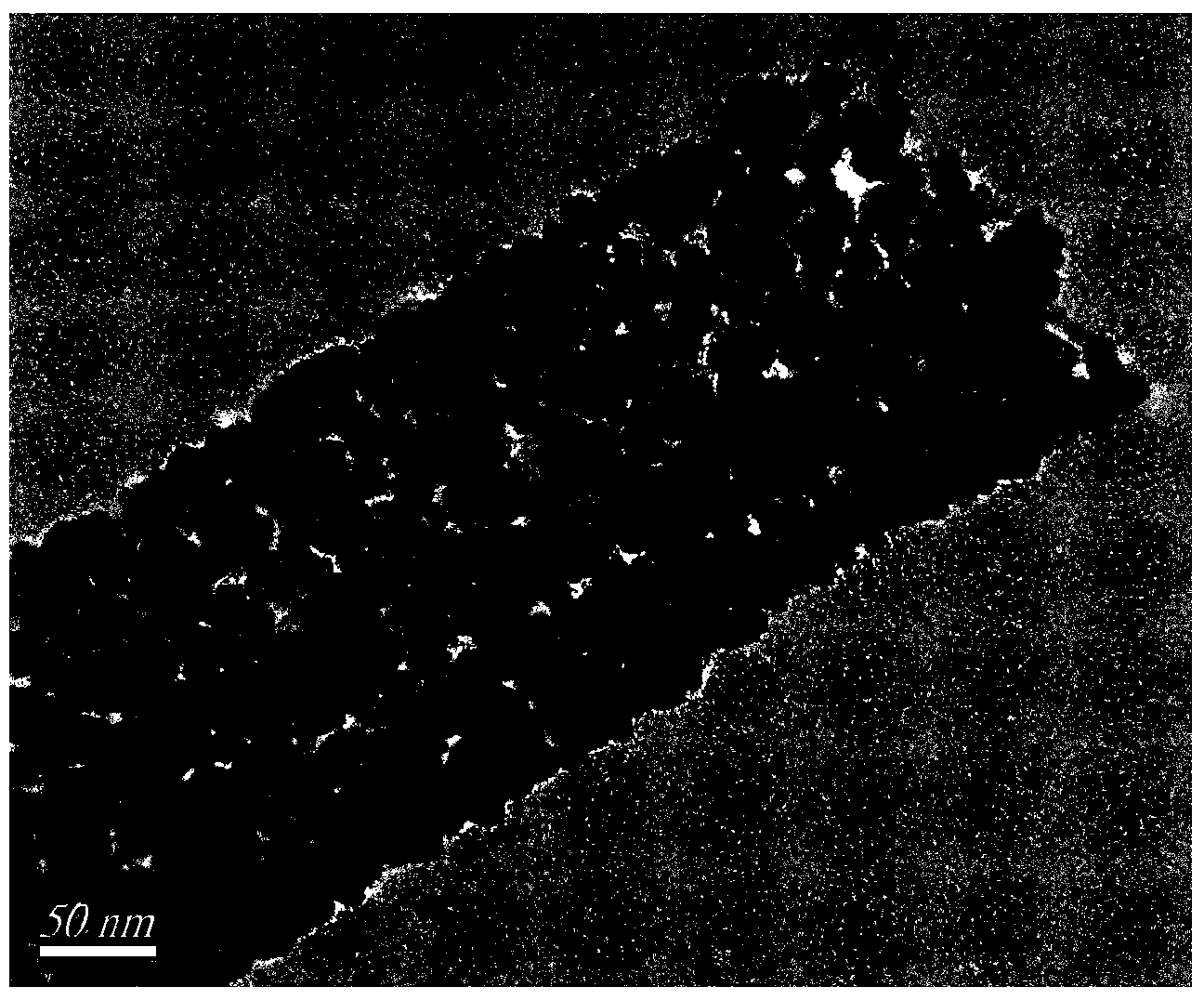

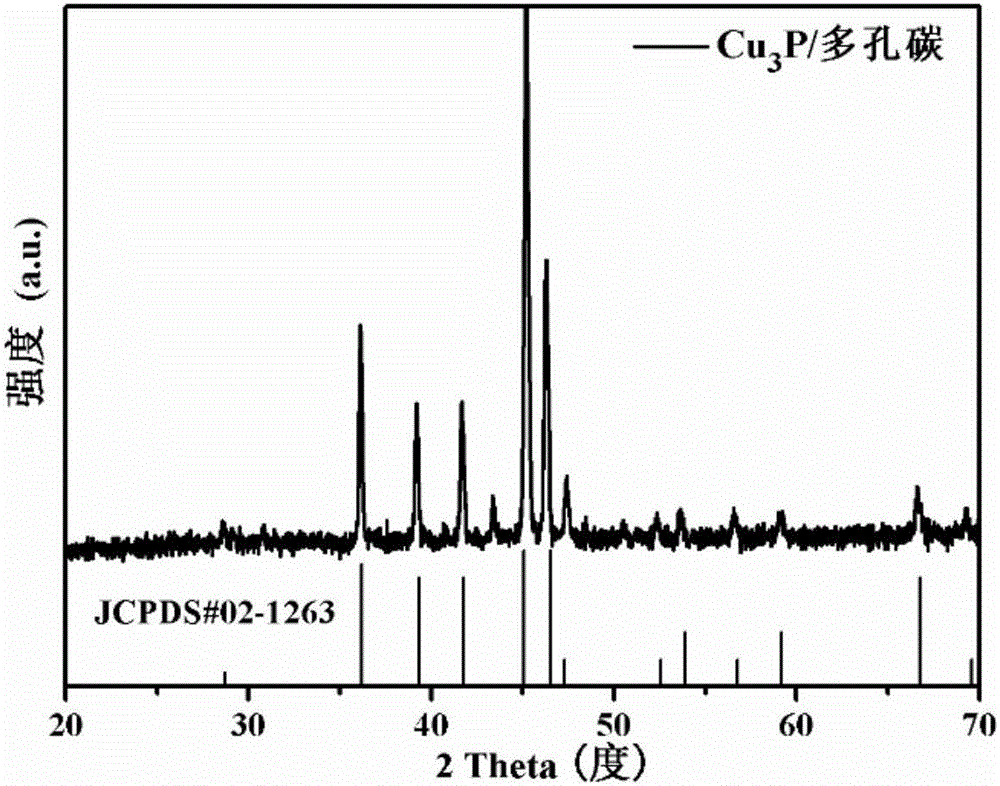

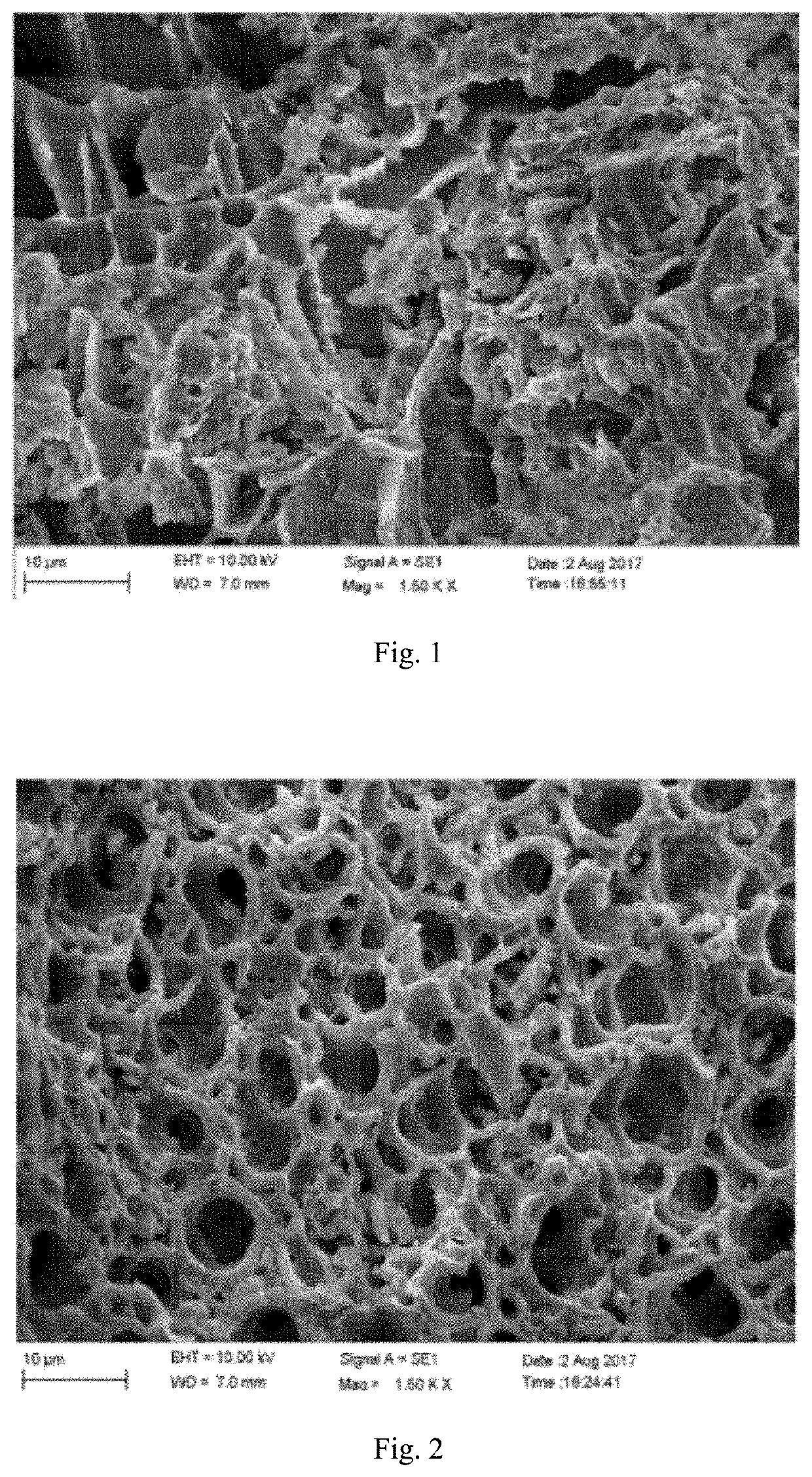

Transition metal phosphide/porous carbon anode composite material for sodium-ion battery and preparation method thereof

InactiveCN105895886AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesPorous carbonTube furnace

The invention discloses a transition metal phosphide / porous carbon anode composite material for a sodium-ion battery and a preparation method thereof. The composite material is formed by dispersive distribution of transition metal phosphide nano-particles in a porous carbon material. A preparation process of the composite material comprises the following steps of preparing a transition metal organic frame structure by transition metal salt and organic ligands through an in-situ growth method; respectively placing the transition metal organic frame structure and a phosphorus source on two ends of a tube furnace, heating the tube furnace, and meanwhile, circulating liquid inert gas into one end of the tube furnace with the inorganic phosphorus source to carry out heat treatment; and washing and drying a heat treatment product in sequence to obtain the composite material. The prepared transition metal phosphide / porous carbon anode composite material used as the anode material of the sodium-ion battery has high specific capacity, good rate capability, simple preparation method, low cost and wide industrial application prospect.

Owner:CENT SOUTH UNIV

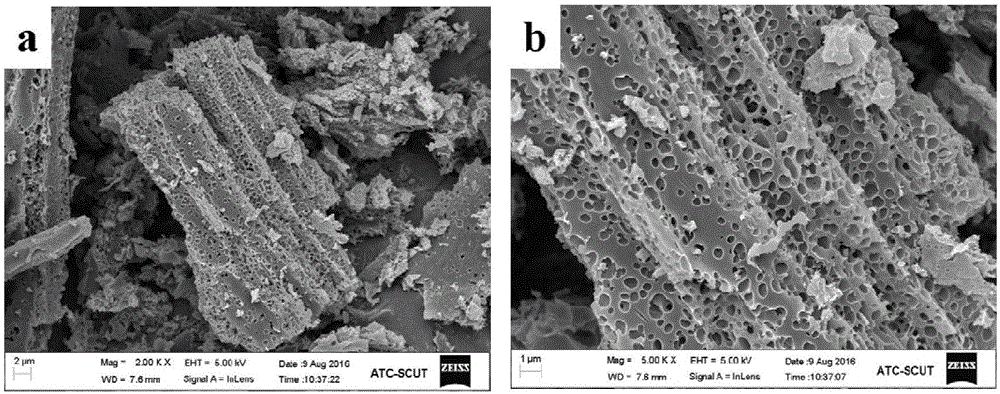

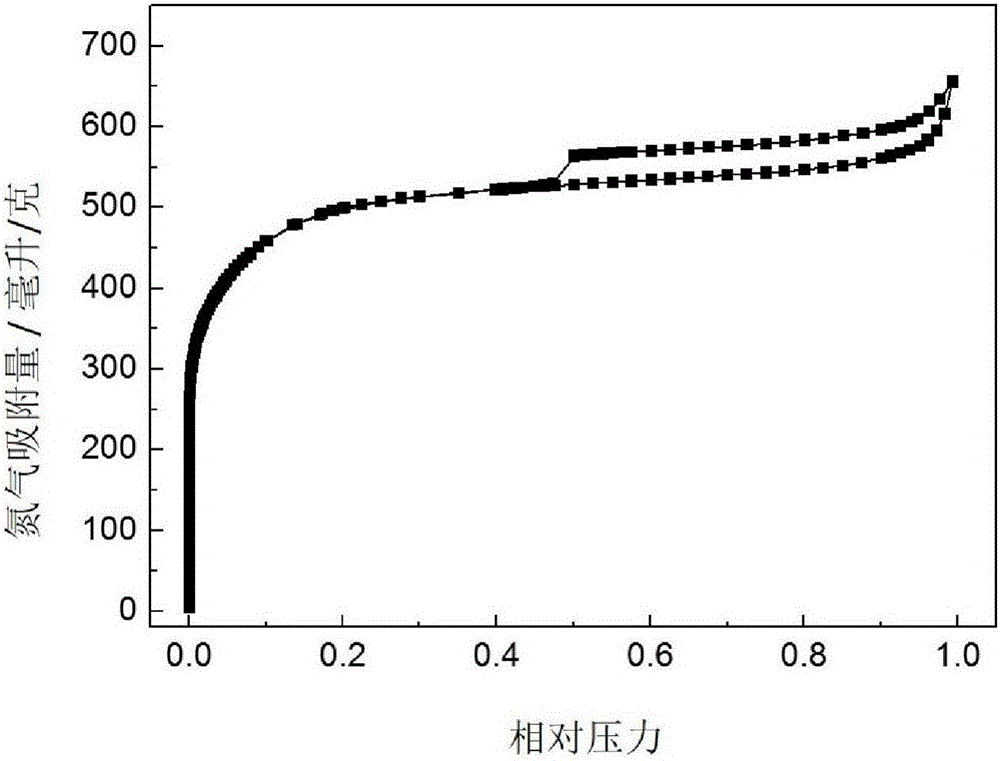

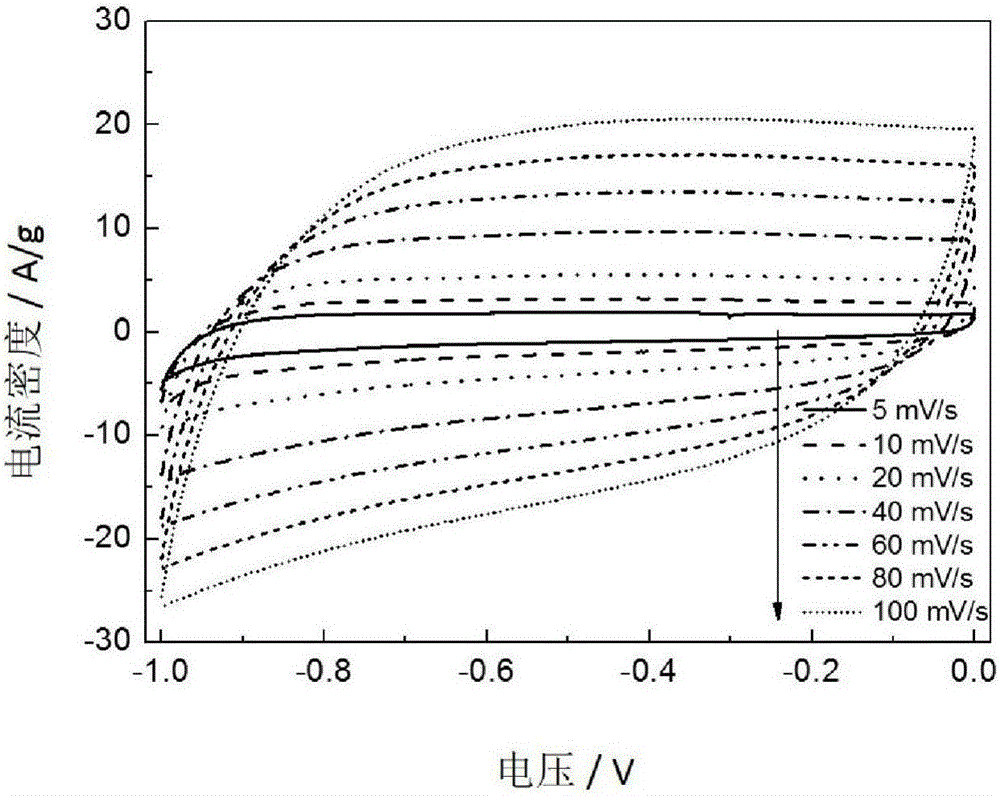

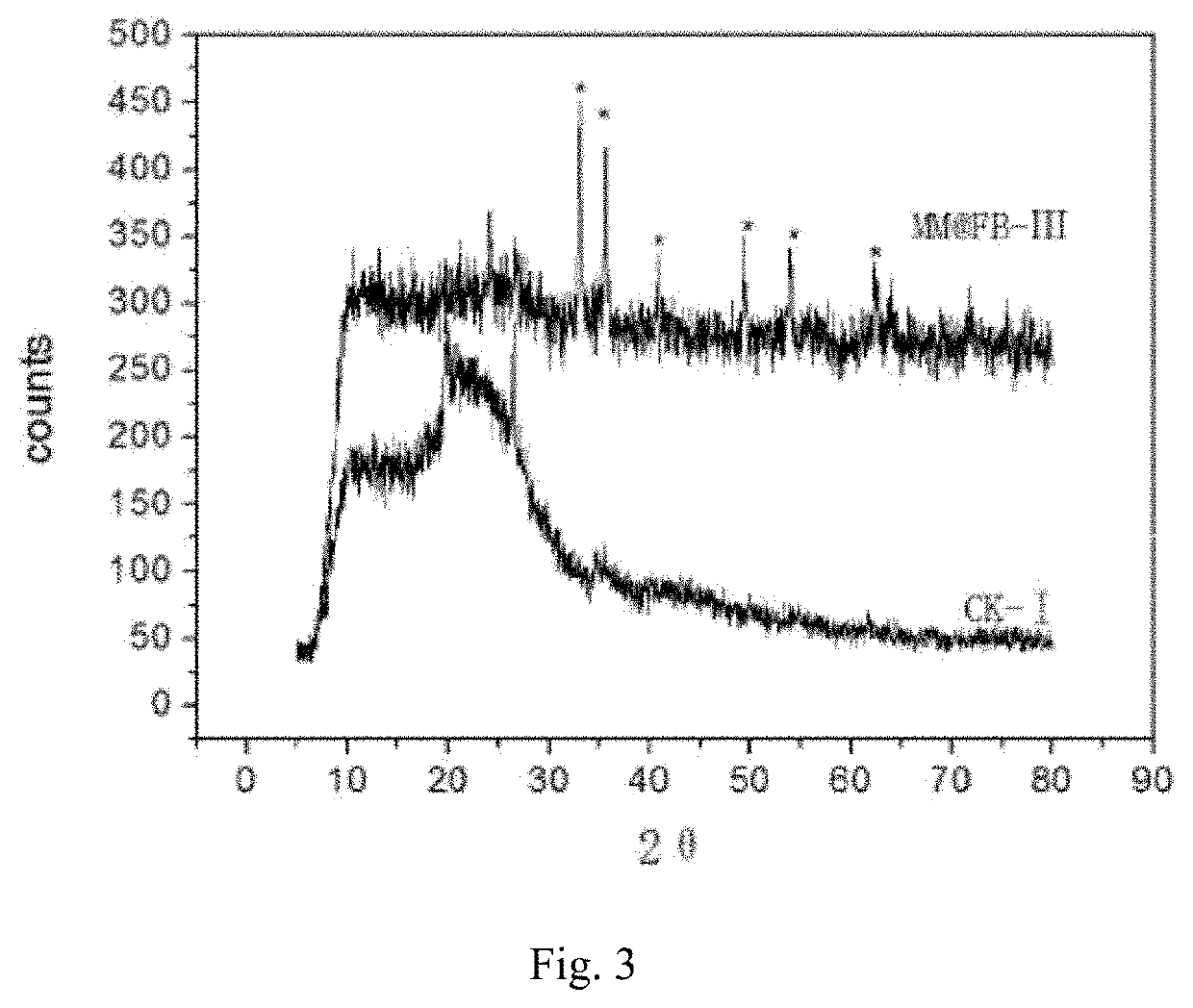

Biomass-based porous carbon material, preparation method thereof, and application thereof in supercapacitor

InactiveCN106587055AWide variety of sourcesLow priceCarbon compoundsHybrid capacitor electrodesPorous carbonBiological activation

The invention belongs to the field of material science and energy storage and discloses a biomass-based porous carbon material, a preparation method thereof, and an application thereof in a supercapacitor. The method includes the steps of: 1) drying and crushing rice straws; 2) non-carbonizing or pre-carbonizing the crushed rice straws, uniformly mixing the rice straws with an activator water solution and drying the mixture, or non-carbonizing or pre-carbonizing the crushed rice straws and directly mixing the rice straws with a solid activator uniformly to produce a mixed product; and 3) placing the mixed product in a tube furnace to perform carbonizing activation in an inert gas atmosphere at high temperature; 4) washing the carbonized product in an acid solution and an alkali solution, and washing the carbonized product with deionized water to neutral, and drying the washed product to prepare the biomass-based porous carbon material. The porous carbon material has excellent supercapacitor performance and is simple in preparation method.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing cathode material of sodium-ion battery, namely sodium vanadium fluorophosphates

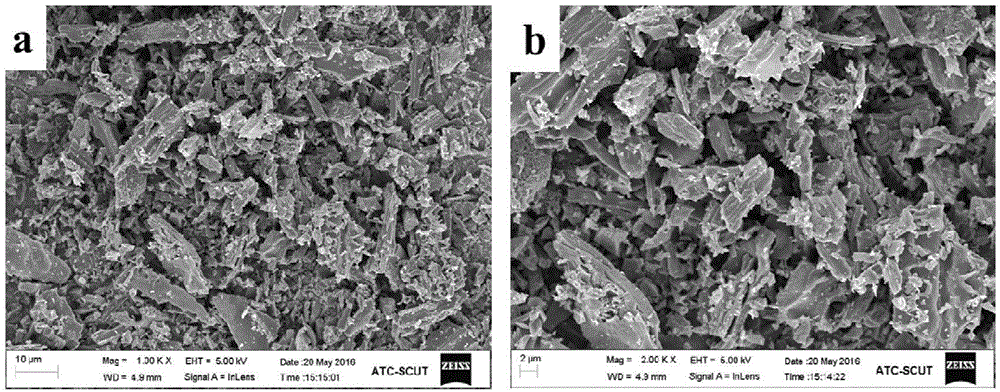

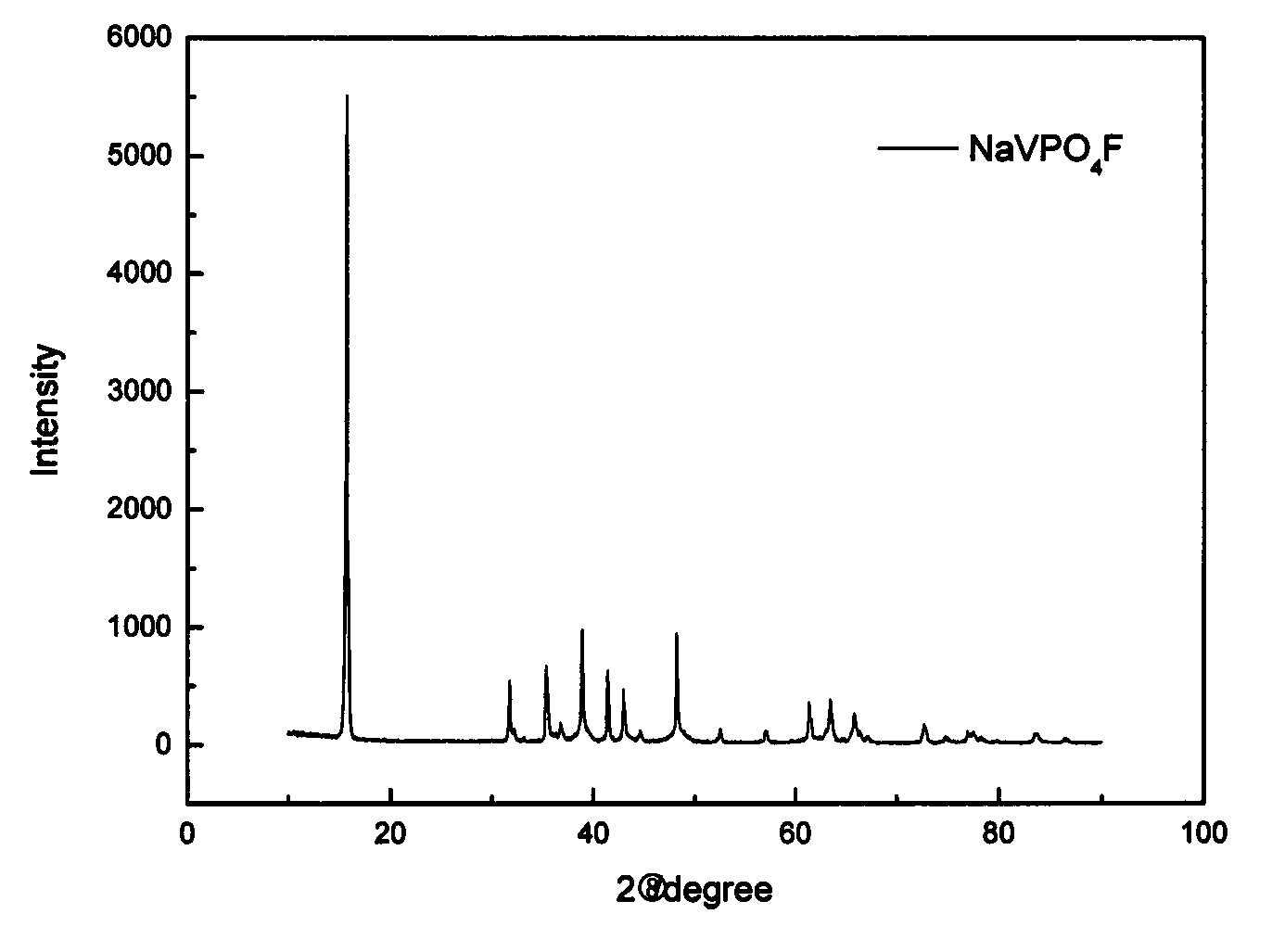

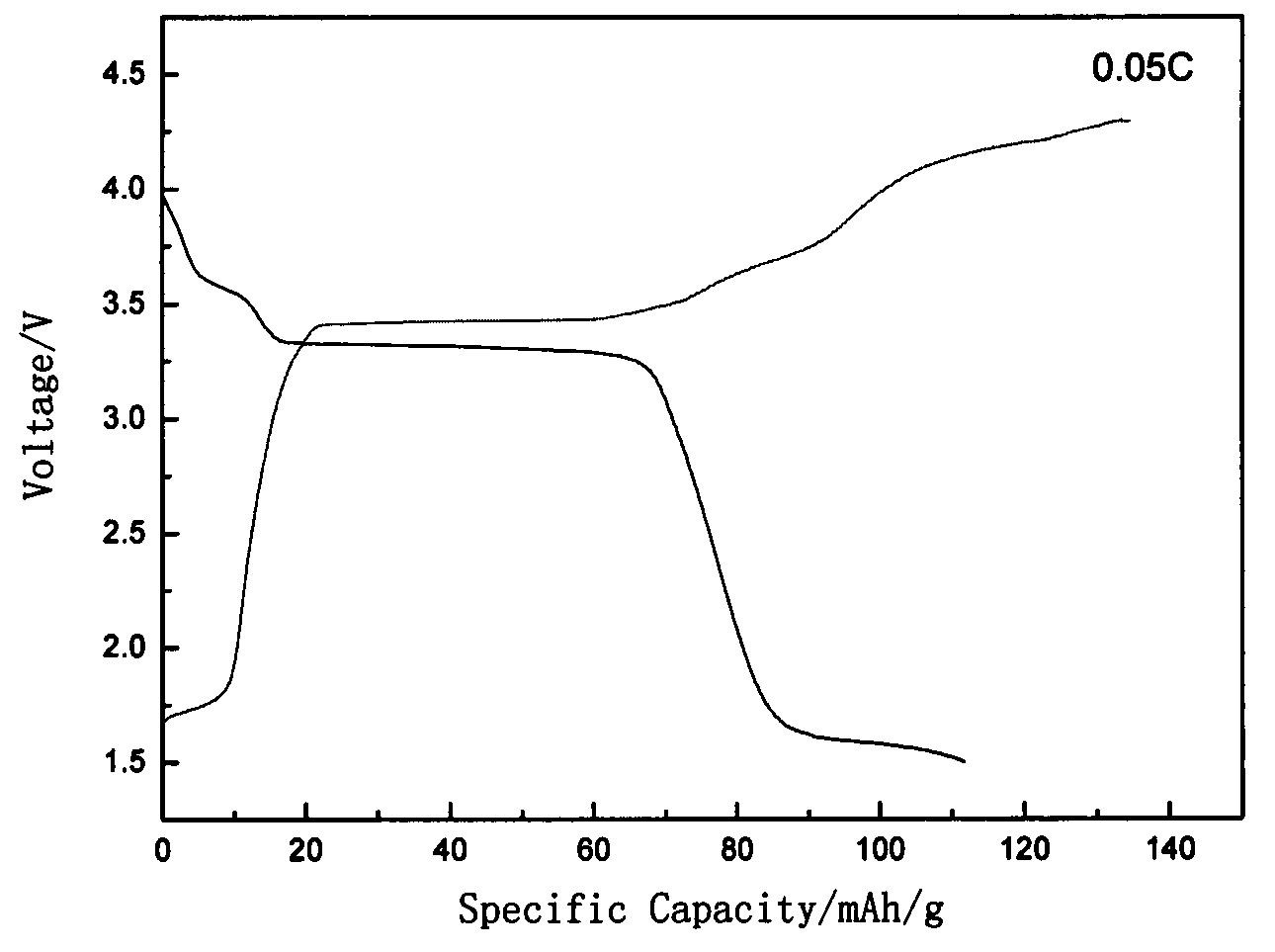

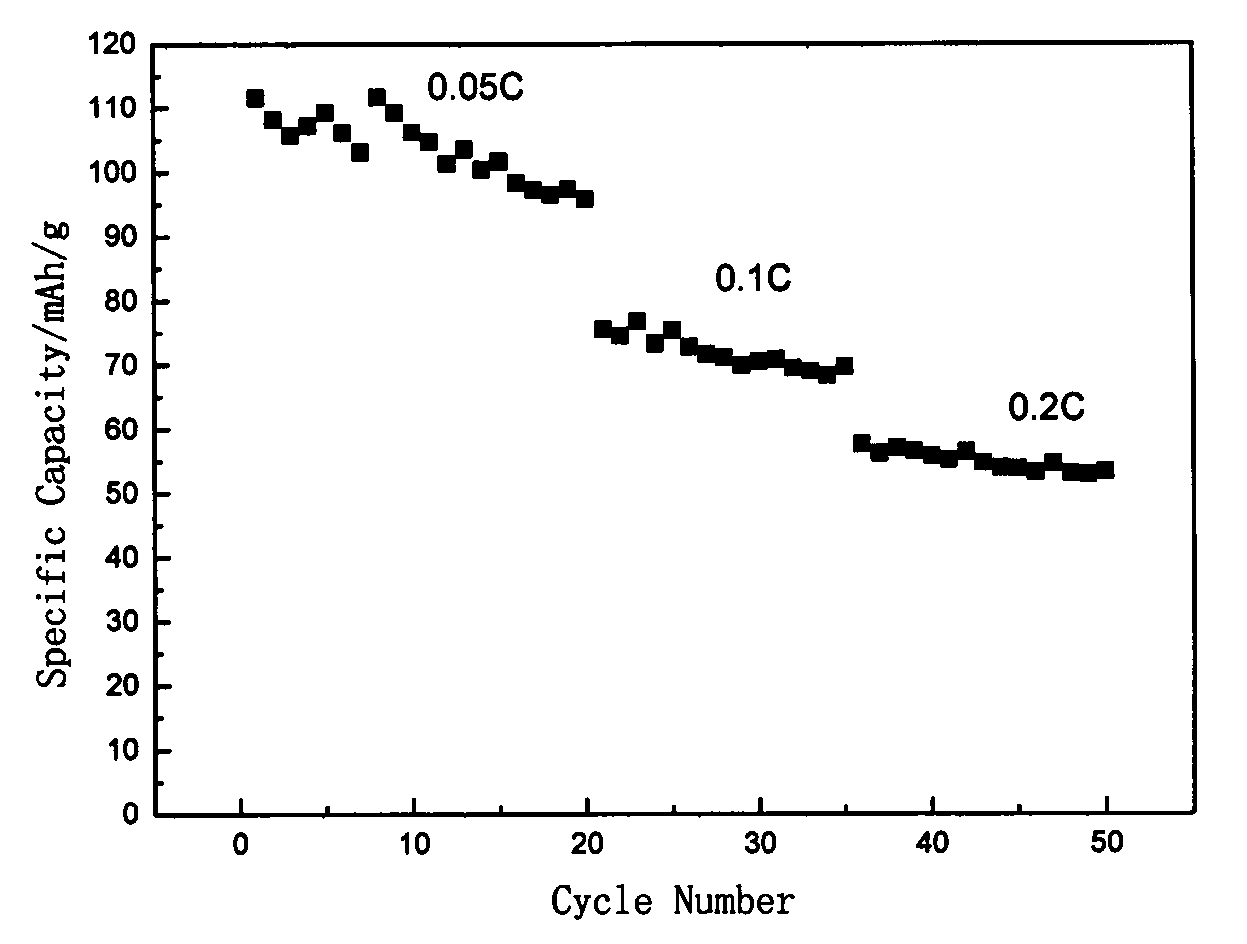

InactiveCN103594716AImprove electrochemical performanceThe synthesis process is simpleCell electrodesWater bathsSodium-ion battery

The invention discloses a method for preparing a cathode material of a sodium-ion battery, namely sodium vanadium fluorophosphates. The method comprises the following steps: using a vanadium source, a phosphorus source and a carbon source as main synthetic raw materials; dissolving into deionized water according to the molar ratio 1:1:1.2 of vanadium: phosphorus: carbon, heating in water bath, and continuously stirring to obtain light green pulp; after vacuum drying, grinding, then transferring into a tube furnace, preburning in an inert atmosphere at a certain temperature rise rate, cooling and then taking out to obtain black VPO4 / C precursor powder; mixing the VPO4 / C with NaF according to a stoichiometric ratio, ball-milling for 3 hours, sending into the tube furnace, then roasting in the inert atmosphere at the certain temperature rise rate, and cooling along with the furnace to obtain a positive active material NaVPO4F / C. According to the invention, cheap and easily-obtained pentavalent vanadium oxide or trivalent vanadium oxide is used as the main raw materials to prepare the sodium vanadium fluorophosphates cathode material through a sol gel activated auxiliary two-step high-temperature solid phase method, and the sodium vanadium fluorophosphates cathode material has the advantages of good stability, uniform particle size and good electrochemical performance. Meanwhile, the method has the advantages of simple synthesis process, short period and low cost and is convenient for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

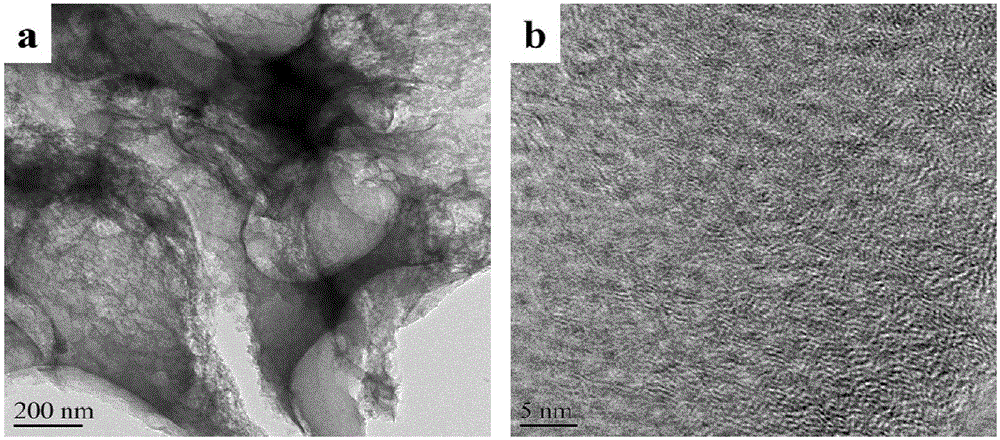

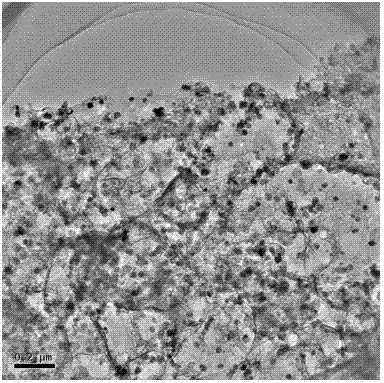

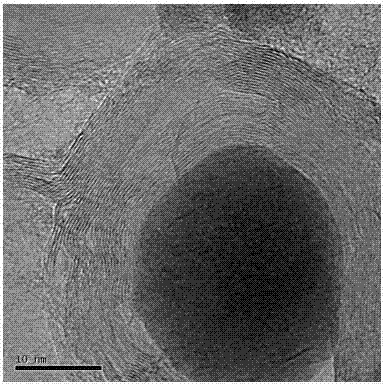

Preparation method of carbon nano-tube loaded nano-cobalt catalyst

ActiveCN103816905ALow costSimple production processMetal/metal-oxides/metal-hydroxide catalystsFiltrationCarbon nanotube

The invention discloses a preparation method of a carbon nano-tube loaded nano-cobalt catalyst. The method comprises the following steps: (1) dissolving a cobalt salt in an organic solvent and then adding a ligand to obtain a mixed liquid; (2) transferring the mixed liquid to a high-pressure kettle, performing a thermostatic heating reaction, naturally cooling to room temperature and then orderly performing filtration, washing and vacuum drying treatment on the generated crystal or powder to obtain a metal organic skeleton product Co-MOF of cobalt; and (3) roasting the metal organic skeleton product Co-MOF for 100-180 minutes at a roasting temperature of 400 DEG C to 1000 DEG C in a calcination atmosphere of argon inside a tubular furnace so as to obtain the carbon nano-tube loaded nano-cobalt catalyst. The preparation method disclosed by the invention has the advantages that the raw materials are low in cost, the production process is also simple, the reaction condition is easy to control, no template agent and surfactant are needed, the prepared product is good in consistency and environment-friendly; and the preparation method is beneficial to batch production and application of carbon nano-tube loaded nano-cobalt.

Owner:NANKAI UNIV

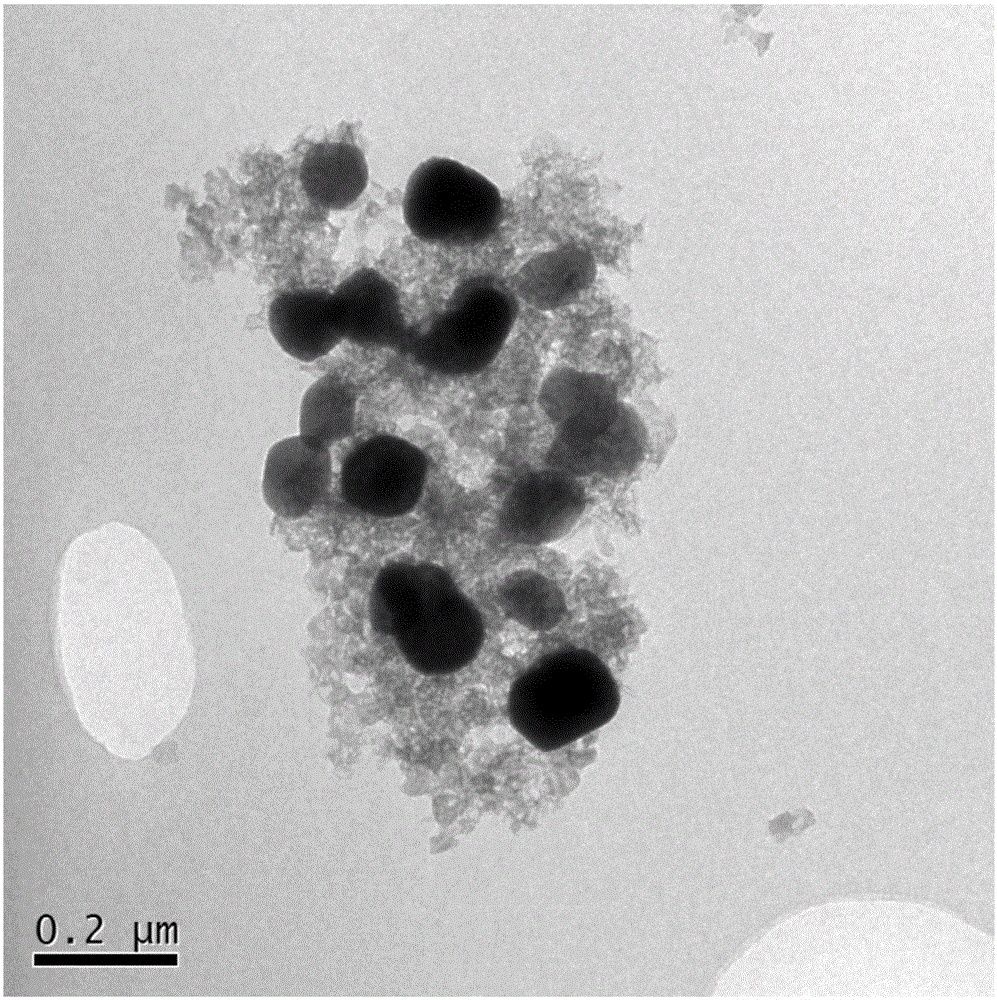

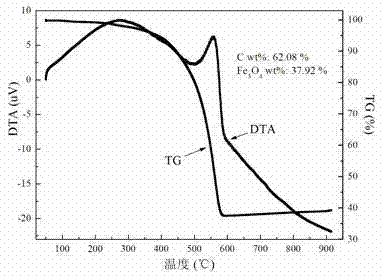

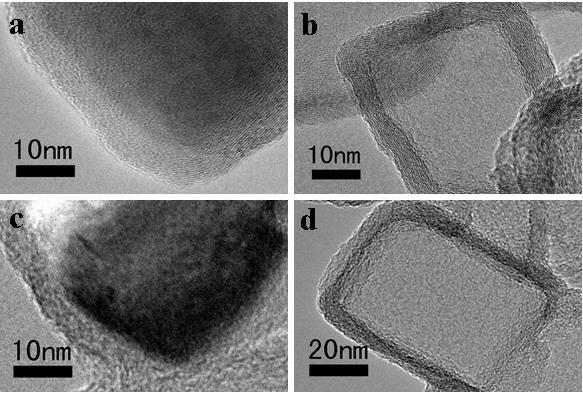

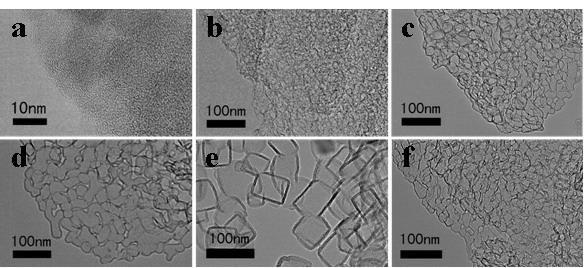

Carbon cladded ferriferrous oxide negative electrode material of lithium ion battery and preparation method thereof

InactiveCN102790217AHigh degree of graphitizationLarge specific surface areaCell electrodesSolid carbonButton battery

The invention discloses a carbon cladded ferriferrous oxide negative electrode material of a lithium ion battery and a preparation method thereof. The negative electrode material is a carbon cladded Fe3O4 composite material and has a particle size in a range of 1 to 100 nm. The preparation method comprises the following steps: with NaCl used as a dispersing agent and a supporter, fully mixing NaCl with a metal oxide source and a solid carbon source; drying an obtained mixed solution under vacuum to obtain a mixture; placing the mixture into a tubular furnace for calcination in an inert atmosphere so as to obtain a calcined product; and rinsing and grinding the calcined product to obtain carbon cladded metal oxide nanometer particles. The method is safe and non-toxic and is simple to operate; during charging and discharging tests of a lithium ion button cell made of the carbon cladded ferriferrous oxide negative electrode material, discharge specific capacity can be maintained at 620 to 900 mAh / g after 30 cycles of charging and discharging at a current of 0.1C (with current density being 92 mA / g), and discharge specific capacity can be maintained at 600 to 760 mAh / g after 50 cycles of charging and discharging at a current of 1C (with current density being 920 mA / g); and the negative electrode material of the lithium ion battery has high reversible capacity and good cycling stability.

Owner:TIANJIN UNIV

Nitrogen-doped active carbon catalyzer and application thereof in chloroethylene synthesis

InactiveCN104525237AImprove catalytic performanceImprove conversion ratePhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonTube furnace

The invention discloses a nitrogen-doped active carbon catalyzer and application of the nitrogen-doped active carbon catalyzer in chloroethylene synthesis. The preparation method of the nitrogen-doped active carbon catalyzer comprises the following steps that a nitrogen-containing compound is dissolved in water to obtain a nitride solution, then active carbon is added in the nitride solution to be dipped, at last the dipped active carbon is dried completely and calcined in nitrogen, and the nitrogen-doped active carbon catalyzer is prepared. Additionally, the active carbon can be placed in a tube furnace, nitrogen is pumped in the tube furnace at high temperature, and the nitrogen-doped active carbon catalyzer is prepared. The nitrogen-doped active carbon catalyzer has a good catalytic performance in catalyzing ethyne and chlorine hydride to react with each other to synthesize chloroethylene. The catalyzer is more environmental friendly than an active carbon catalyzer carrying metal ions in the prior art.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

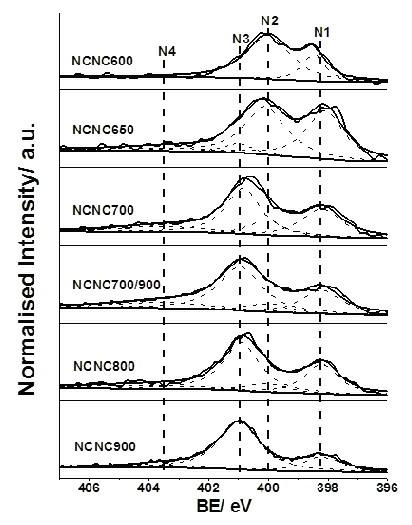

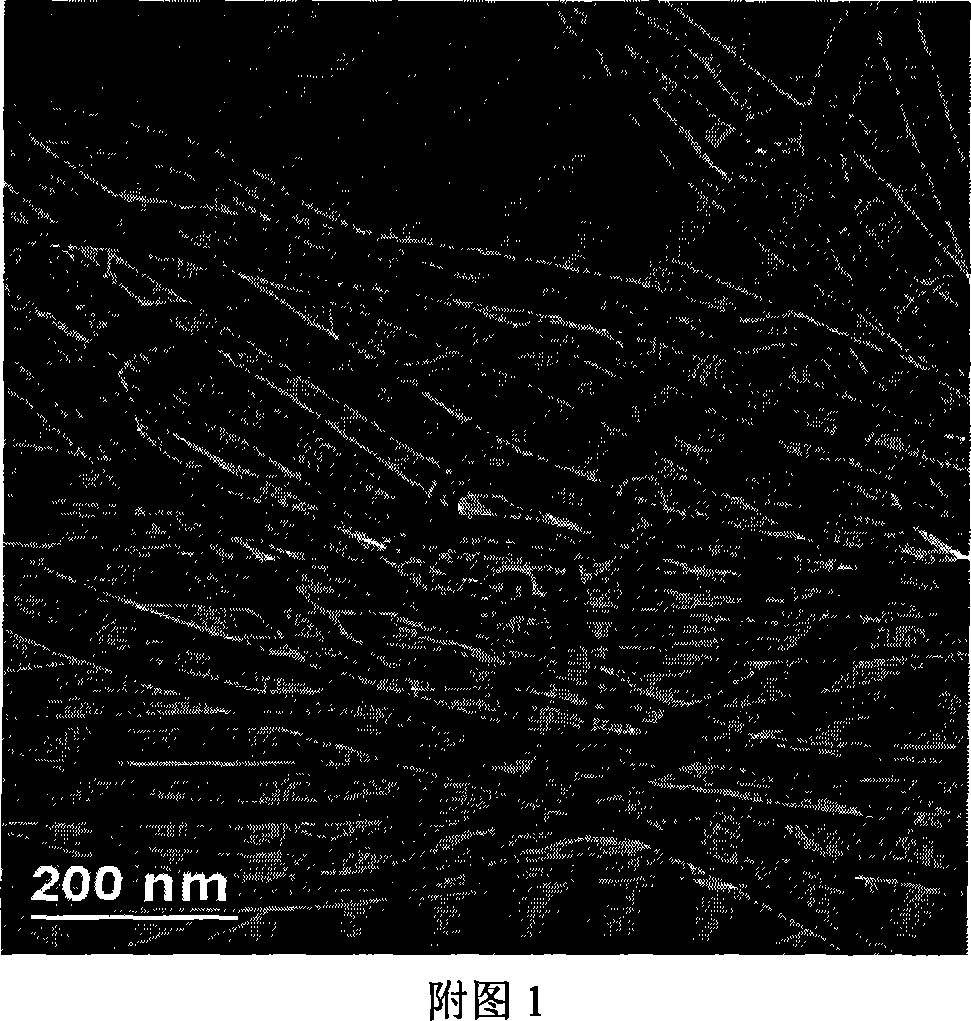

Method for preparing nitrogen doping hollow carbon nanocages

InactiveCN102530922AHigh purityHigh mesoporosityMaterial nanotechnologyNano-carbonPtru catalystCarbonate

The invention relates to a method for preparing nitrogen doping hollow carbon nanocages, which comprises the following steps that: (1) basic magnesium carbonate or magnesium carbonate is taken to be added into a reaction tube and is uniformly dispersed, then the reaction tube is placed in a tube furnace, air in the tube furnace is extracted, inert gases are filled into the tube furnace, under the condition of 10-500sccm of inert gases, the temperature of the tube furnace is increased to 650-1,100 DEG C, then the inert gas flow is guided into steam which contains carbon (C) and nitrogen (N), and after reacting for 5-240min, the temperature of the tube furnace is reduced to a room temperature; and (2) powder in the reaction tube is collected, put into hydrochloric acid or sulfuric acid solution to be soaked for 5-720min, filtered, cleaned by deionized water and dried, so a nitrogen doping hollow carbon nanocage is obtained. The nitrogen doping hollow carbon nanocage which is produced by the method has the advantages of high specific surface area, large pore volume, high mesoporous ratio, good graphitization degree and the like, and is a metal-free oxygen reduction reaction catalyst with excellent performance.

Owner:NANJING UNIV

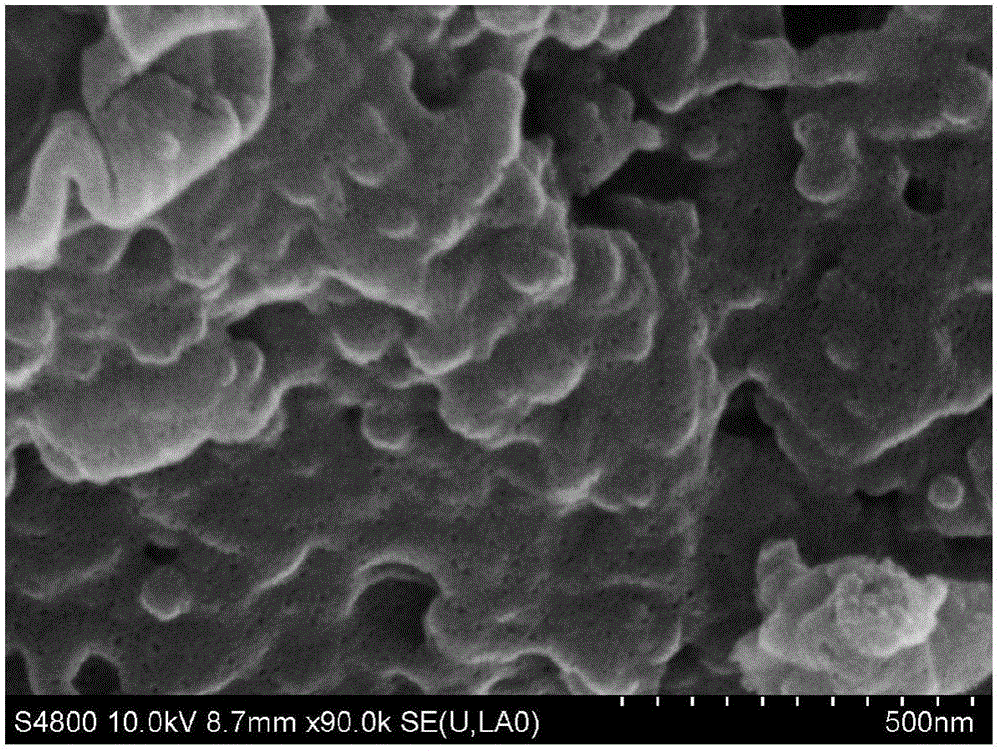

Preparation method of biomass-based nitrogenous porous carbon, porous carbon prepared by method and use thereof

ActiveCN106601490AWidely distributedAbundant resourcesHybrid capacitor electrodesCarbon preparation/purificationPorous carbonNitrogen doped

The invention discloses a preparation method of biomass-based nitrogenous porous carbon, the porous carbon prepared by the method and the use of the prepared nitrogenous porous carbon in a super capacitor. The preparation method comprises the steps of (1) drying a biomass material, and grinding the biomass material into fine powders, (2) evenly mixing the biomass material powders and water or a dilute acid solution, (3) placing the above mixture into a reactor for hydrothermal reaction, and (4) drying and grinding an obtained hydrothermal reaction product, and calcining the hydrothermal reaction product in a tube furnace to obtain a nitrogen-doped porous carbon material with a large surface area. According to the method of the invention, cheap and renewable plant is used as carbon and nitrogen precursors, and the porous nitrogen-doped carbon material is prepared through a hydrothermal method. The method has the advantages of simple preparation process, no need of an activator or template agent, low cost, environmental protection, and convenient operation, problems of strong corrosion, a high price of transition metal and environmental pollution caused by heavy metal are avoided, and the method is suitable for mass production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

High nitrogen doped corrugated carbon nanotube material and its synthesis process

InactiveCN101066758AWide variety of sourcesSimple production processNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsIron(II) oxideCarbon nanotube

The present invention relates to high nitrogen doped corrugated carbon nanotube material and its synthesis process. The synthesis process includes the following steps: mixing Fe source and proper amount of distilled water, soaking porous molecular sieve to carry ferric oxide or ferrous oxide, stoving and roasting at 300-1000 deg.c for 0.5-24 hr to obtain catalyst; setting the catalyst inside a pipe furnace, leading organic amine into the furnace under the protection of Ar or N2 and reacting at 650-1000 deg.c for 0.2-4.0 hr to obtain high nitrogen doped corrugated carbon nanotube mixture containing the catalyst; soaking the mixture in proper amount of or excessive hydrofluoric acid, sulfuric acid, nitric acid or acid for 0.5-24 hr; and washing in distilled water, suction filtering and drying to obtain high nitrogen doped corrugated carbon nanotube material. The material has nitrogen content of 10-40 %, reinforced surface polarity, etc, and is suitable for industrial production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

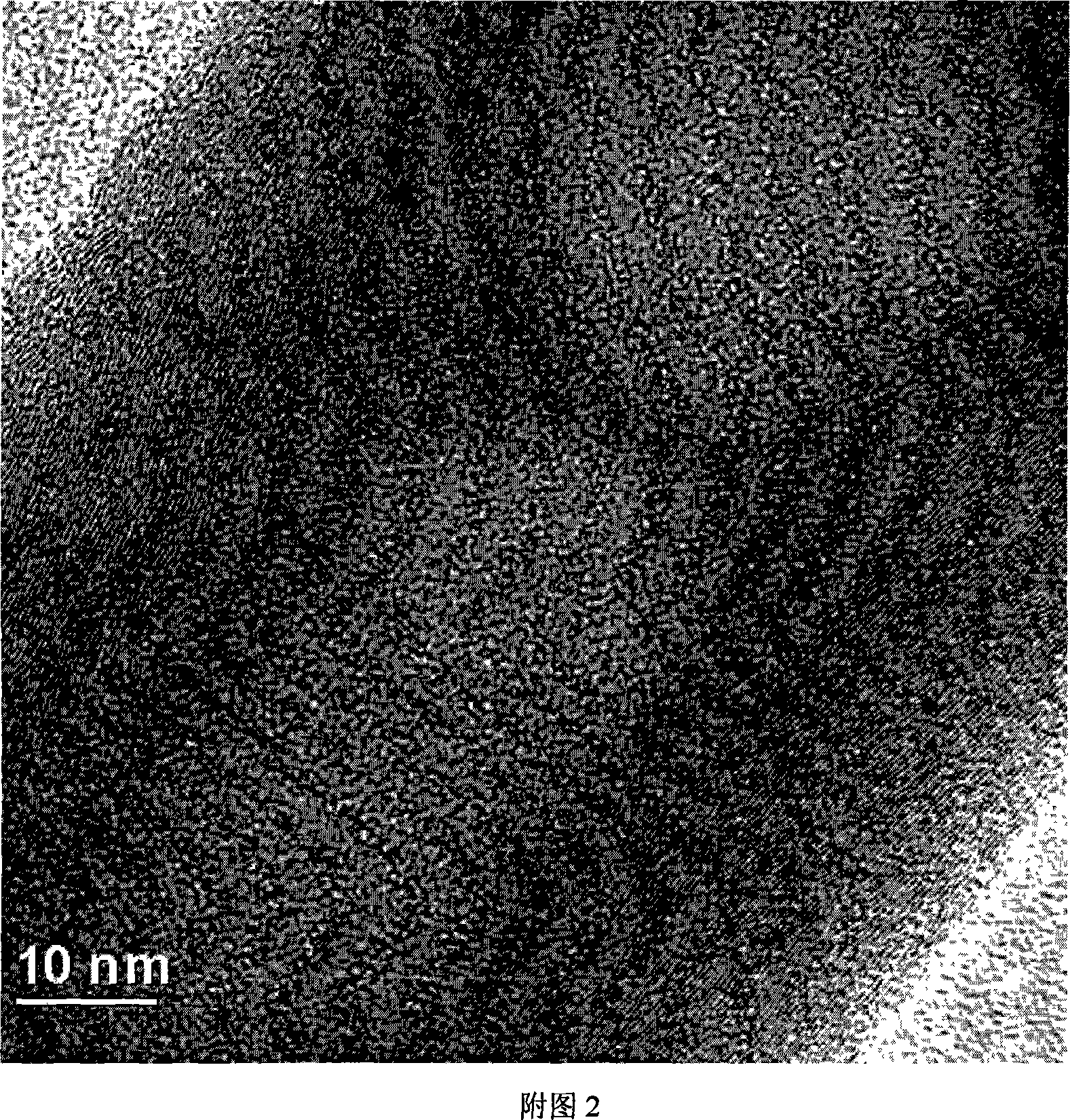

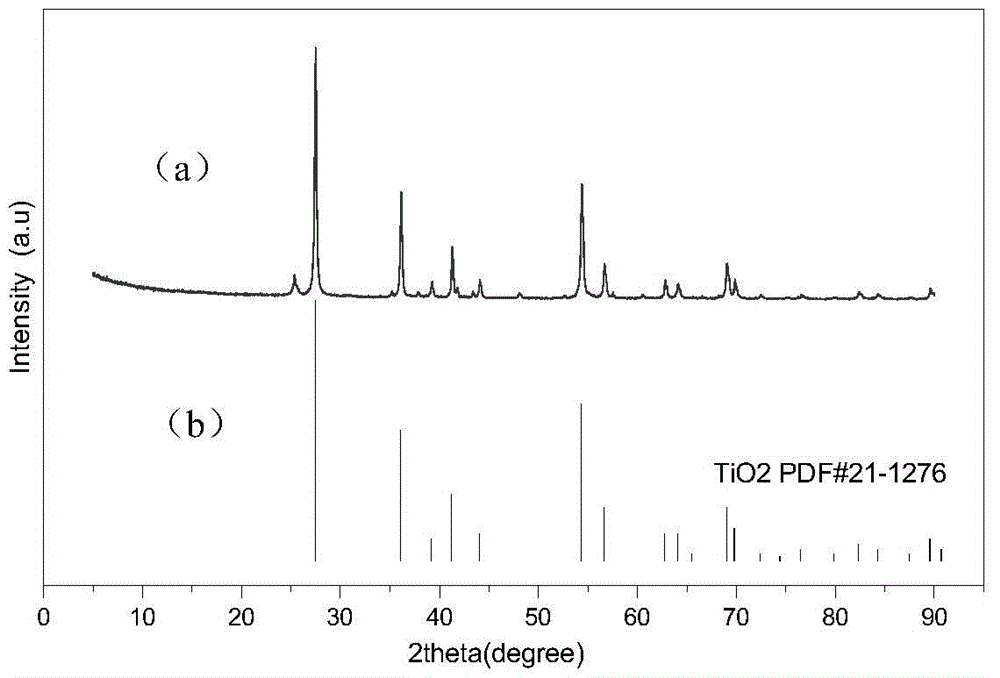

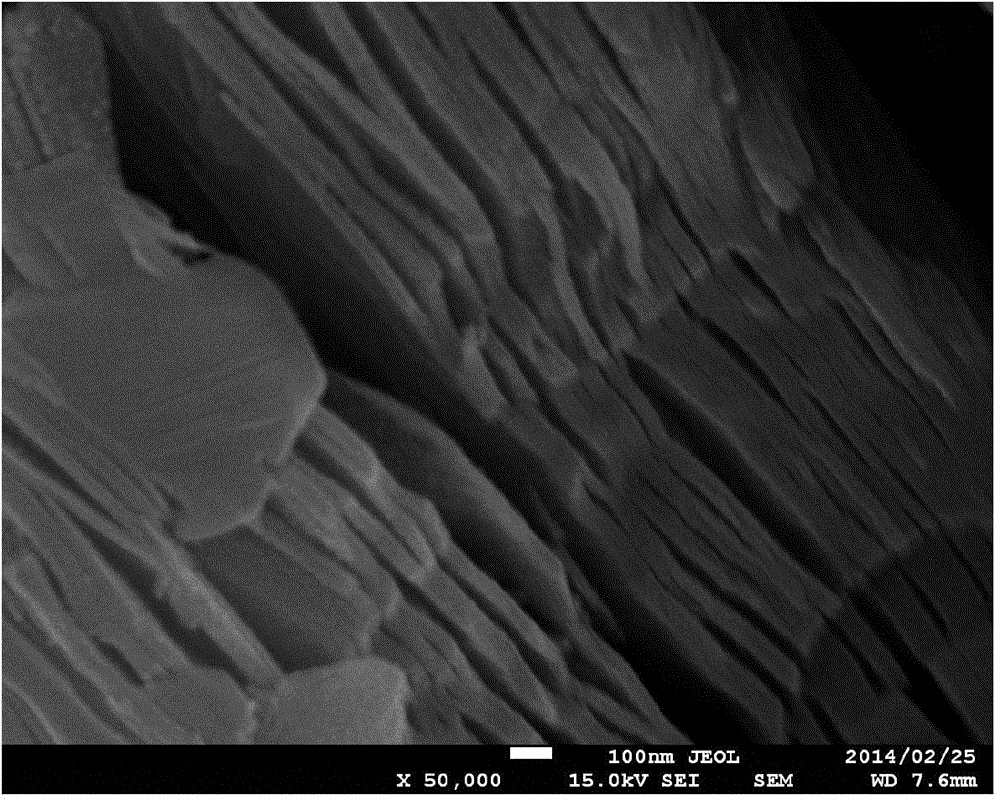

Preparation method for two-dimensional sheet-shaped titanium dioxide nanosheet material

InactiveCN104085920AHigh purityHigh crystallinityMaterial nanotechnologyTitanium dioxideCrystallinityRutile

The invention discloses a preparation method for a two-dimensional sheet-shaped titanium dioxide nanosheet material. The preparation method comprises the following steps: soaking three-dimensional laminated Ti3AlC2 powder in an aqueous solution of HF at a room temperature, and removing an Al atom layer by use of a chemical liquid-phase dissection method to prepare a two-dimensional Ti3C2 nanosheet with laminated characteristics still kept; then, placing Ti3C2 in a tubular furnace, ventilating a gas mixture of flowing oxygen gas and argon gas after vacuumizing, realizing in-situ oxidization of the two-dimensional Ti3C2 nanosheet at a high temperature, then cooling, taking out powder, and grinding to obtain the TiO2 nanosheet. According to the preparation method disclosed by the invention, any organic solvent and additive are not needed to be added in the preparation process, process parameters are stable, the procedure is simple, the process is controllable, the efficiency is high and the cost is low; the prepared two-dimensional titanium dioxide nanosheet has transverse dimension of 5-10 microns, and single-layer average thickness of 50 nanometers; the prepared rutile type titanium dioxide nanosheet is high in purity and good in degree of crystallinity, and only contains very little antase phase.

Owner:HOHAI UNIV

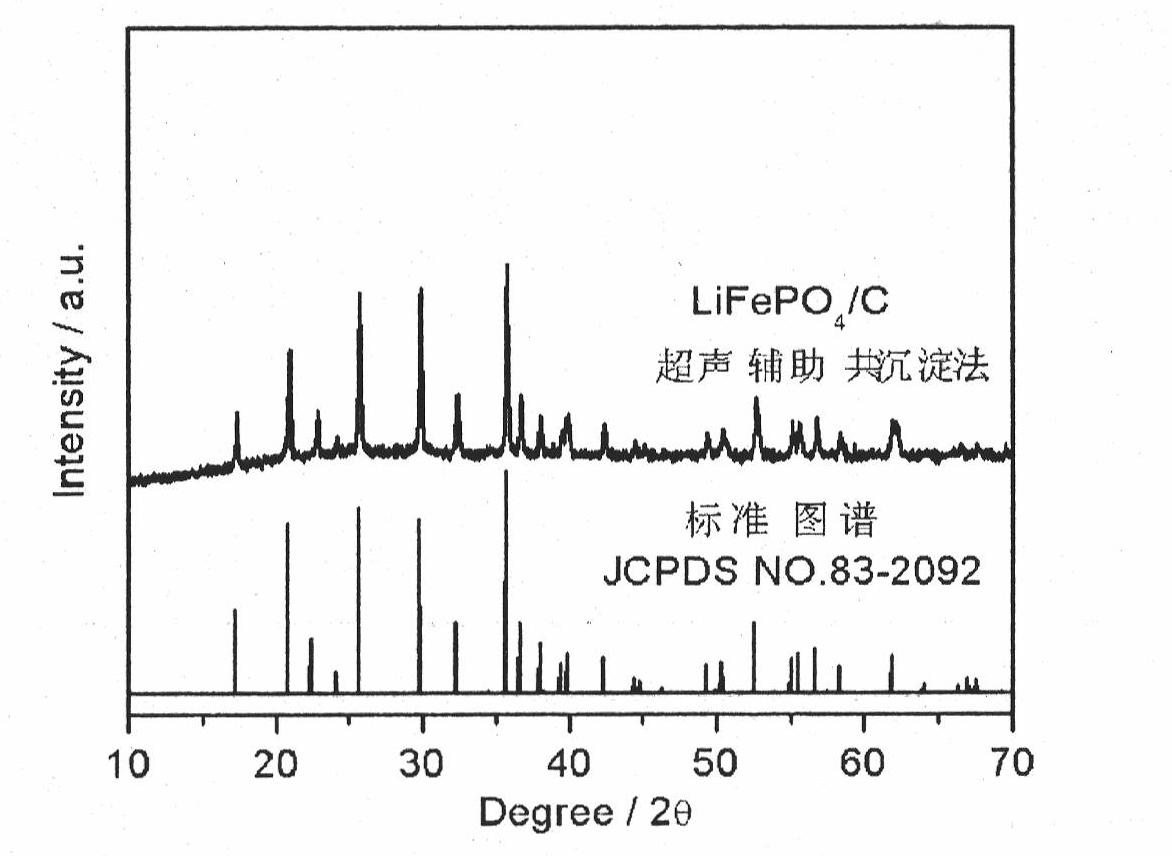

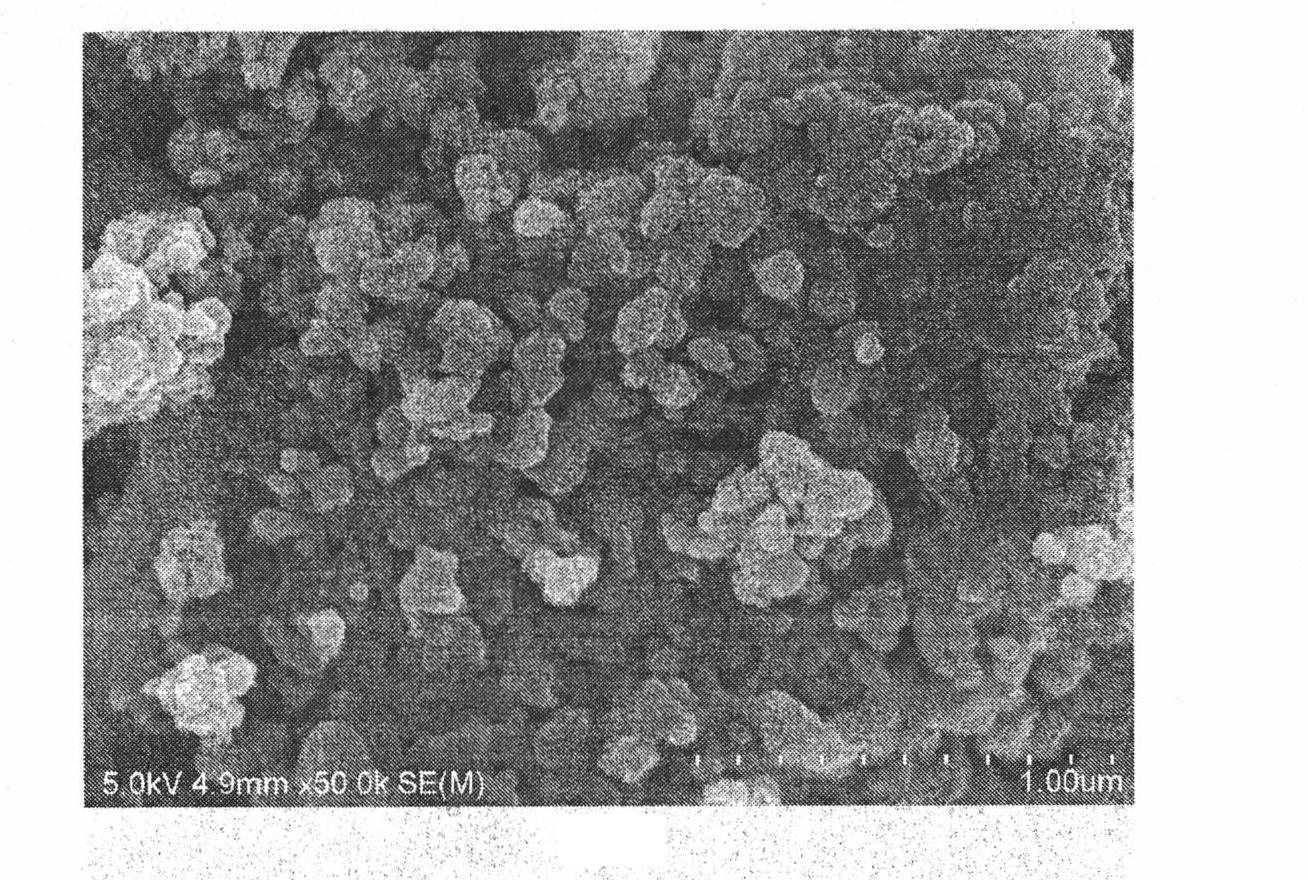

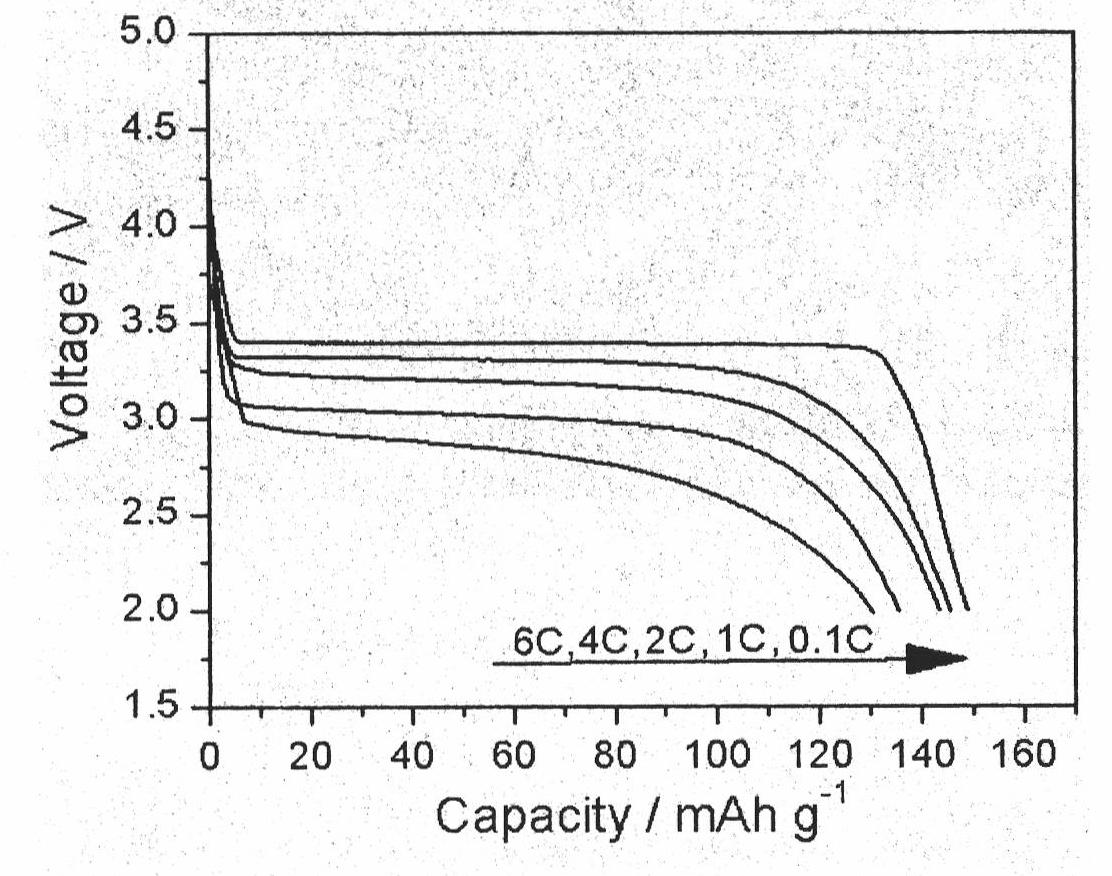

Method for preparing lithium iron phosphate with high rate discharge by using ultrasonic coprecipitation

InactiveCN101800311AImprove discharge rateImprove electrochemical performanceCell electrodesHigh rateLithium iron phosphate

The invention relates to a method for preparing lithium iron phosphate with high rate discharge by using ultrasonic coprecipitation, belonging to the technical field of energy source materials. The method comprises the following steps of: adding a ferrous source water solution, a phosphorus water solution and a lithium source water solution into a reaction kettle under a non-oxidizing atmosphere for coprecipitation, stirring and ultrasonic-processing to obtain a LiFePO4 precursor; adding the LiFePO4 precursor and a carbon source compound into water and mixing to obtain a mixture of the carbon source compound and LiFePO4, i.e. a final LiFePO4 precursor; merging the mixture into a tubular furnace for processing to obtain nanometer carbon coated LiFePO4. In the invention, the obtained nanometer carbon coated LiFePO4 has high rate charge, favorable electrochemical property and uniform grain diameter size distribution. The invention has the advantages of low cost, simple process route and low energy consumption.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation Method for Combined Modified Straw Active Particulate Carbon Adsorption Material and Use of Same

ActiveUS20200298202A1Small sizeOutstanding capabilityMagnesium fertilisersOther chemical processesPhosphateTube furnace

A preparation method for a combined modified straw active particulate carbon adsorption material and use of same. The preparation method for the combined modified straw active particulate carbon adsorption material comprises the following steps: 1) mixing straw powders, distilled water, a binder and a composite mineral, then pelletizing same, and then placing same in a tube furnace for pyrolysis to prepare straw particulate carbon; 2) introducing an inert gas into a modification reagent, adjusting the pH value combined and 3) soaking the straw particulate carbon into the combined modification solution for 30 min, and performing cleaning and drying, so as to obtain a combined modified straw active particulate carbon adsorption material. The combined modified straw active particulate carbon has a good adsorption effect on phosphate group in low-pollution water.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

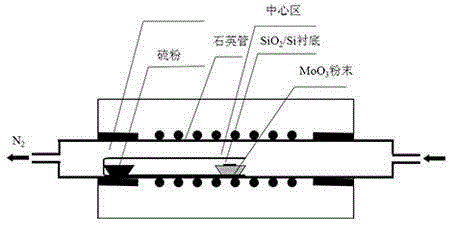

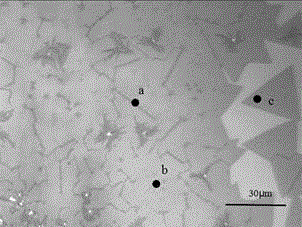

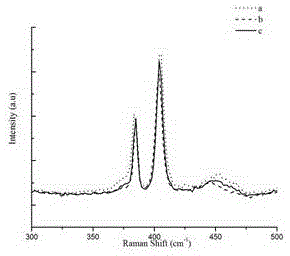

Preparation method for a large-area single-layer or few-layer molybdenum disulfide film

The invention discloses a preparation method for a large-area single-layer or few-layer molybdenum disulfide film. The main steps of the preparation method are as follows: firstly, sulfur powder and molybdenum trioxide powder are placed in two quartz boats respectively, a substrate is placed on the quartz boat loaded with molybdenum trioxide powder, and the obverse surface faces downwards; secondly, the two quartz boats loaded with sulfur powder and molybdenum trioxide powder are placed at a bottom end and an orifice of a quartz test tube respectively; thirdly, the above quartz test tube is placed in a tubular furnace, the bottom end and the orifice of the test tube are located at the edge area and the central area of the tubular furnace respectively; fourthly, protection gas argon or nitrogen is inputted into the tubular furnace, a normal pressure is kept until the experiment is over; fifthly, the tubular furnace is heated at a certain heating speed, thus the edge area and the central area of the tubular furnace are in proper temperatures respectively, the temperatures are kept for some time, sulfur powder sublimates and reacts with gas phase molybdenum trioxide, and a large-area single-layer or few-layer molybdenum disulfide film is generated on the substrate; sixthly, the tubular furnace is cooled to the room temperature, and the preparation process is finished. The method is slightly affected by air flow, the repetition rate is high, preparation of high-quality large-area single-layer or few-layer molybdenum disulfide film can be achieved at a normal pressure.

Owner:XIANGTAN UNIV

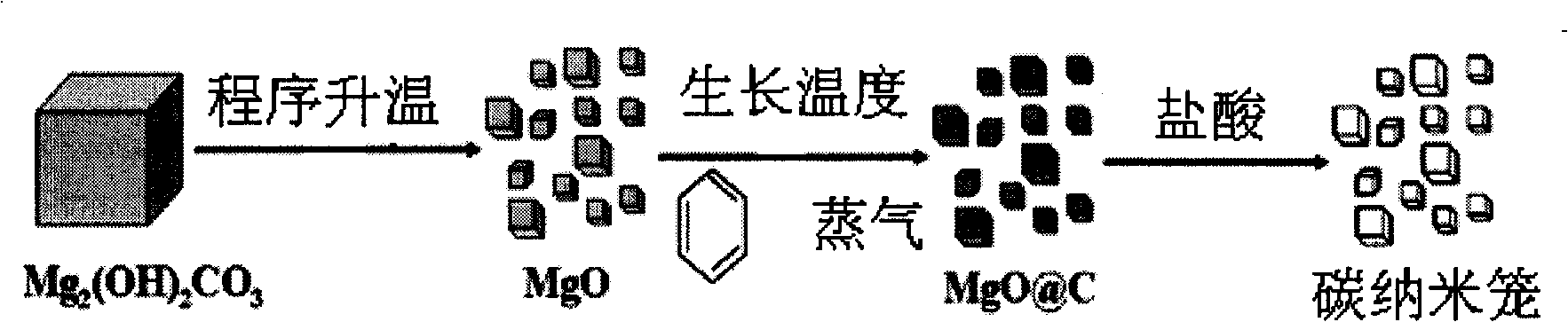

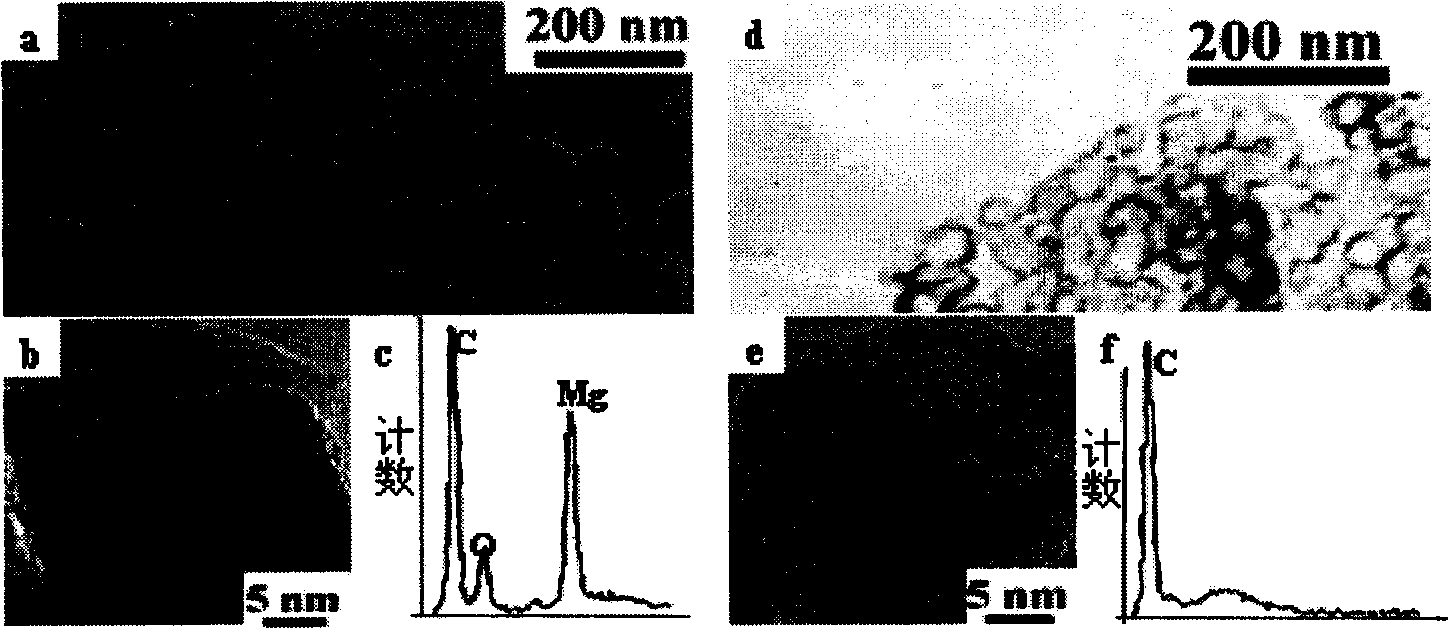

Method for mass preparing hollow nano cages in high quality

InactiveCN101284663AHigh purityHigh mesoporosityIndividual molecule manipulationMagnesiaMagnesium saltReaction temperature

A method for mass production of high-quality hollow carbon nanocages comprises the following steps: 1) light magnesium carbonate or magnesium carbonate is added into a reaction tube and spread evenly, the tube is put into a tubular furnace, air is pumped out of the tube, inert gas such as N2 and Ar is injected; the reaction temperature is increased to 670 DEG C-900 DEG C, (C) source vapor is introduced, and reaction is carried out for 5 to 240 minutes under the protection of 10-500sccm inert gas atmosphere; the (C) source gas is led to the reaction area of the tubular furnace by the inert gas flow, carbonized on the surfaces of nano particles generated in situ, and covered to form a MgO@C structure; after the reaction, the temperature inside the reaction tube drops to the room temperature under the protection of the inert gas; 2) powder is collected from the reaction tube, dipped in sufficient hydrochloric acid or sulphuric acid for 5 to 720 minutes to remove the kernel of MgO, filtered, washed to neutrality by using deionized water, and dried to obtain the hollow carbon nanocages; and 3) the magnesium salt filtrate is recycled. The nanocages prepared by the method have high purity, and the price for the precursor is low, thereby facilitating recovery and reuse.

Owner:NANJING UNIV

Preparation method of nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material

InactiveCN108160077ARaw materials are easy to getLow costMetal/metal-oxides/metal-hydroxide catalystsElectrodesFiltrationAcid washing

Belonging to the technical field of material preparation, the invention relates to a preparation method of a nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The technical scheme includes: firstly, dissolving a metal salt and a carbon-nitrogen source in water, ethanol or ethylene glycol, mixing the substances evenly, and then performing drying and grinding to obtain a precursor; then putting the precursor in a tubular furnace, in a nitrogen atmosphere, conducting programmed heating to a roasting temperature, and conducting high temperature roasting and grinding to obtain a black powder sample; and then subjecting the black sample to pickling treatment until the pH value of the solution is neutral, and conducting pumping filtration and naturaldrying, thus obtaining the nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The obtained composite material can be used as a good electrocatalytic hydrogen evolution catalyst. The composite material prepared by the method provided by the invention has the characteristics of easily available raw materials and low cost, and has important significance inelectrochemical application.

Owner:JIANGSU UNIV

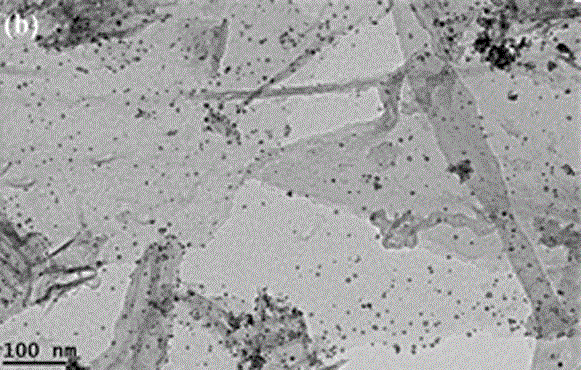

Doped hexagonal boron nitride nano sheet, preparation method thereof, catalyst using same as carrier, and applications thereof

ActiveCN105293453AReduce catalytic activityImprove conversion rateMaterial nanotechnologyPhysical/chemical process catalystsPtru catalystHexagonal boron nitride

The invention relates to a doped hexagonal boron nitride nano sheet, a preparation method thereof, a catalyst using the same as the carrier, and applications thereof. The preparation method comprises the following steps: adding a single substance or compound of hetero atoms, a single substance or compound of boron, and a nitrogen compound into water, evenly mixing, drying to remove water; then grinding the solid, placing the powder in a tubular furnace, introducing inert gas into the tubular furnace, heating the tubular furnace to a temperature of 800 to 1200 DEG C by program to carry out reactions, after reactions, cooling to the room temperature; grinding the reaction products, then boiling the grinded products in hot water, filtering when the water is still hot, washing the filter residue by hot water and ethanol, and drying. The doped hexagonal boron nitride nano sheet is taken as the carrier to prepare a catalyst, the active components loaded on the carrier can be one or more of transition metals, and the catalyst is used to catalyze organic reactions. A high temperature pyrolysis method is adopted, and the controllable preparation of nano material is achieved through controlling the ratio of each element in raw materials. The method is simple, the operation is easy, and the yield is high. The doped hexagonal boron nitride nano sheet can be used as the catalyst carrier, and is capable of improving the dispersity and catalytic activity of metal nano particles.

Owner:SHANTOU UNIV

Hydrothermal preparation method for carbon cladded nanometer ferriferrous oxide particles

InactiveCN102786097ANo pollution in the processSimple processMaterial nanotechnologyInorganic material magnetismPtru catalystFreeze-drying

The invention discloses a c hydrothermal preparation method for carbon cladded nanometer ferriferrous oxide particles. The method comprises the following steps: mixing an glucose carbon source solution with a ferric nitrate solution; subjecting an obtained mixture to a hydrothermal reaction; collecting sediment through centrifugation after the hydrothermal reaction and dispersing the sediment in ionic water again; carrying out freeze-drying so as to obtain powder; and calcining the powder in a tubular furnace in an inert atmosphere so as to obtain the carbon cladded nanometer ferriferrous oxide particles. The nanometer particles have good stability, do not easily get agglomerated and have a particle size controllable within a range from 50 nm to 500 nm; and the preparation method is simple, safe and non-toxic, has high output and is applicable to industrial production and utilization. The carbon cladded nanometer ferriferrous oxide particles can be used in a wide variety of fields like magnetic materials, catalyst supporters, magnetic resonance imaging and targeting drug carriers; and the particles can also be used for a negative electrode material of an electrode of a novel lithium ion battery and show a reversible lithium storage property.

Owner:TIANJIN UNIV

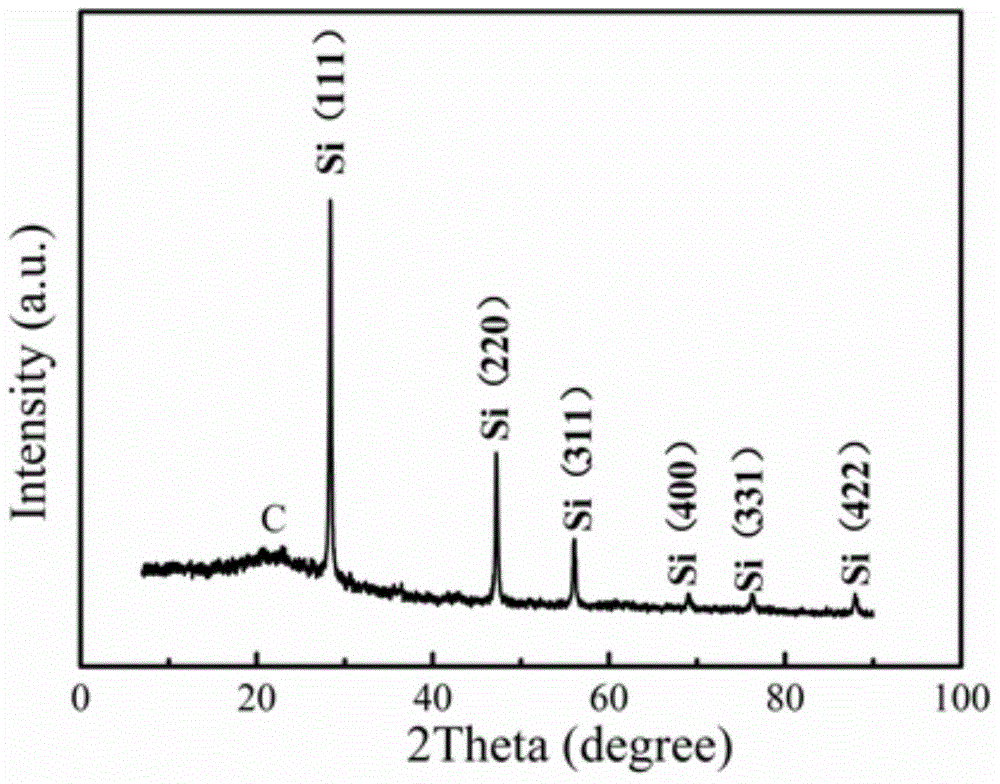

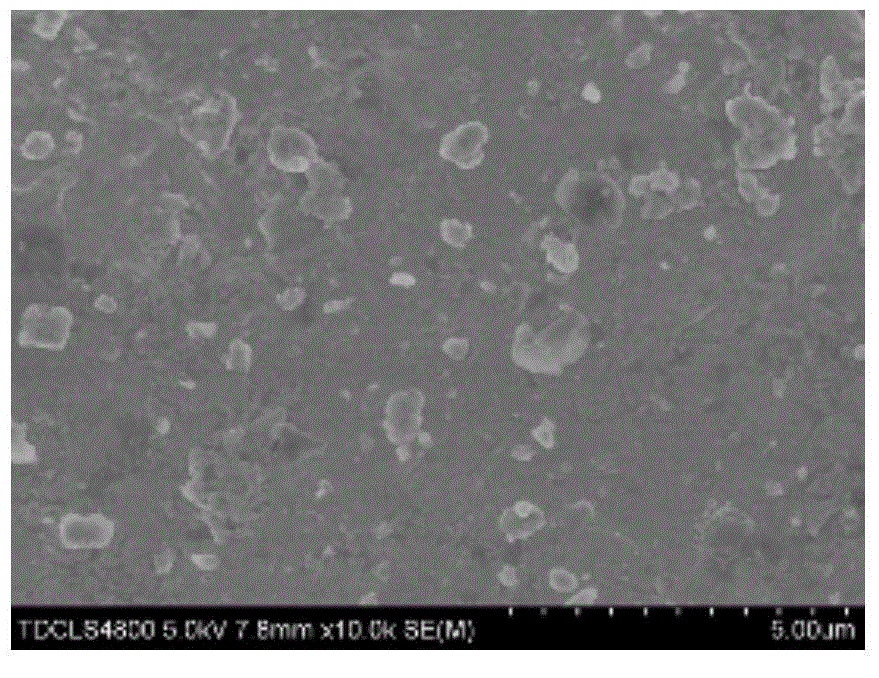

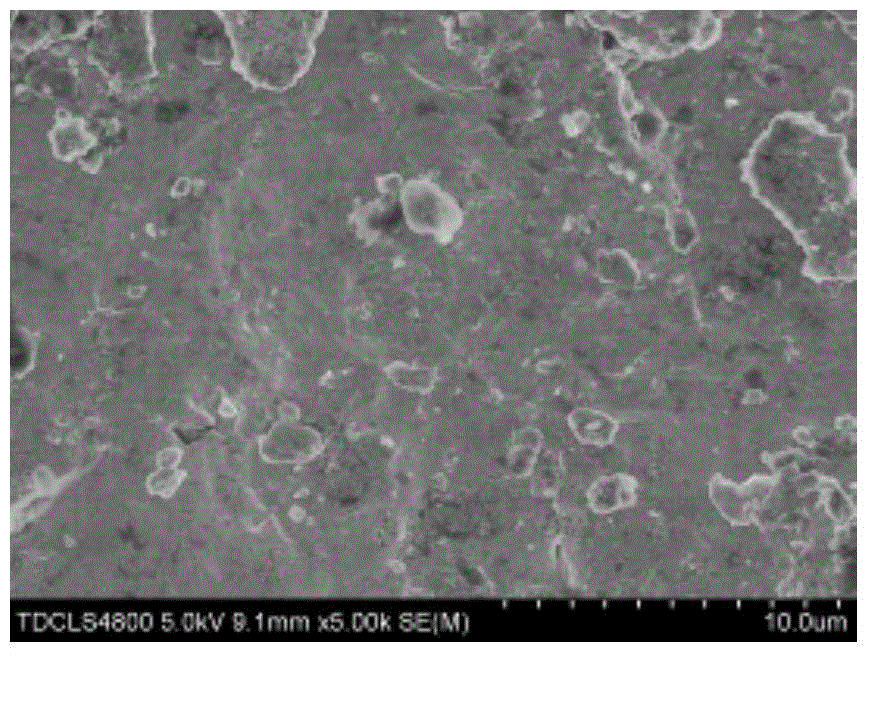

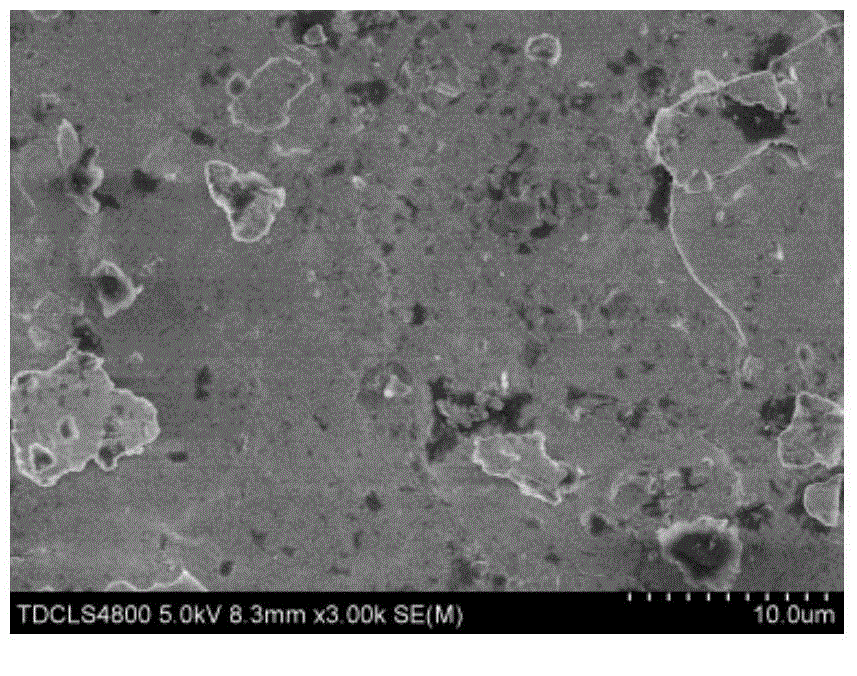

Method for preparing silicon-carbon compound from silicon-containing biomass as raw material as well as prepared silicon-carbon compound and application thereof

InactiveCN104617275AUniform particle size distributionEvenly distributedMaterial nanotechnologyCell electrodesCarbon compositesReaction temperature

The invention provides a method for preparing a silicon-carbon compound from silicon-containing biomass as a raw material. The method comprises the following steps: performing acid boiling treatment on the silicon-containing biomass so as to remove inorganic salt ion impurities, washing, drying, grinding into powder, carbonizing in inert atmosphere so as to obtain a composite product of silicon dioxide and carbon, uniformly mixing the carbonized product, magnesium powder and molten salts, and putting into a tubular furnace to react in inert atmosphere, thereby obtaining a porous silicon-carbon composite material that porous silicon nanoparticles are uniformly distributed in carbon. The method is simple and feasible in process and rich and cheap in raw material, the reaction temperature is controlled as heat is absorbed when the added molten salts are molten, the structure that silicon dioxide is naturally embedded into organisms in original silicon-containing biomass is well maintained in the obtained silicon-carbon compound, and moreover, the obtained silicon nanoparticles are uniform in particle size distribution and can be applied to the field of lithium ion battery cathode materials.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing graphene/copper composite material by in-situ catalysis of solid carbon source on surfaces of copper powders

The present invention relates to a method for preparing a graphene / copper composite material by in-situ catalysis of a solid carbon source on surfaces of copper powders. The method comprises the steps of: adding steel balls, the copper powders and polymethyl methacrylate at the mass ratio of 150: 10: (0.1-0.3) into a ball milling tank, and filling argon as protective atmosphere after vacuum pumping; after ball milling, preparing cooper-polymethyl methacrylate powders which are uniformly dispersed; performing reduction treatment in a tubular furnace to catalyze the polymethyl methacrylate into graphene, and obtaining graphene / copper composite powders with graphene in-situ growth; and then preparing a graphene copper-based composite material block. Tensile property of the graphene reinforced copper-based composite material prepared by the method is better than tensile property of that prepared by a traditional adding method, that is a method of adding reduction-oxidation graphene or graphene sheets. Reinforcement of a cooper-based material is achieved, and high-strength copper materials have a better application prospect on electronic devices.

Owner:TIANJIN UNIV

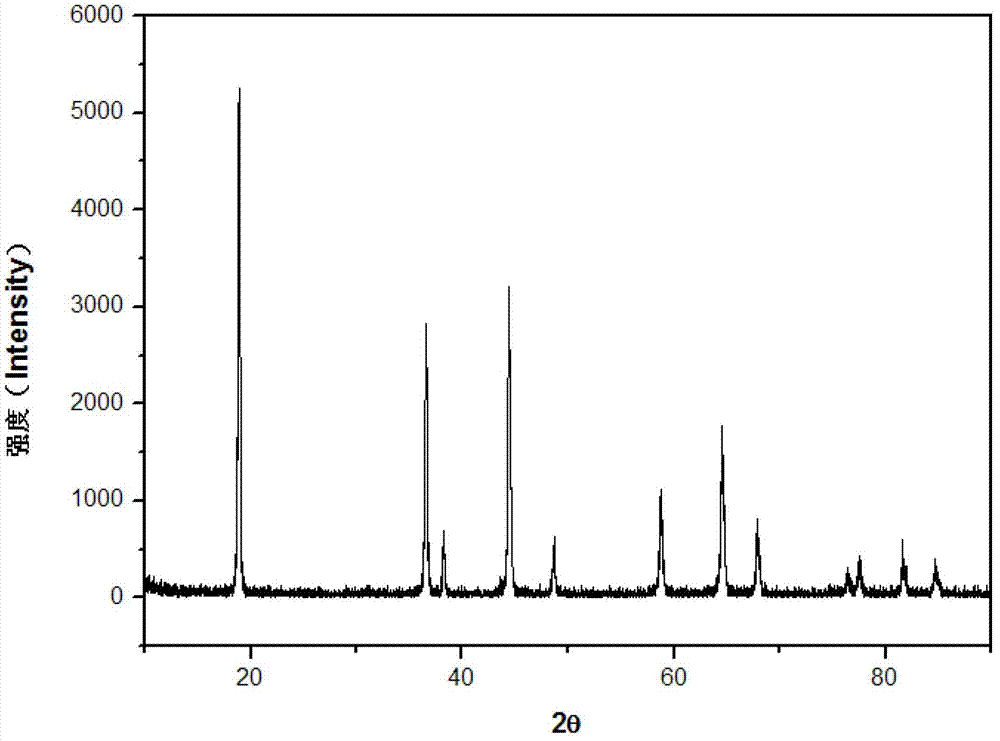

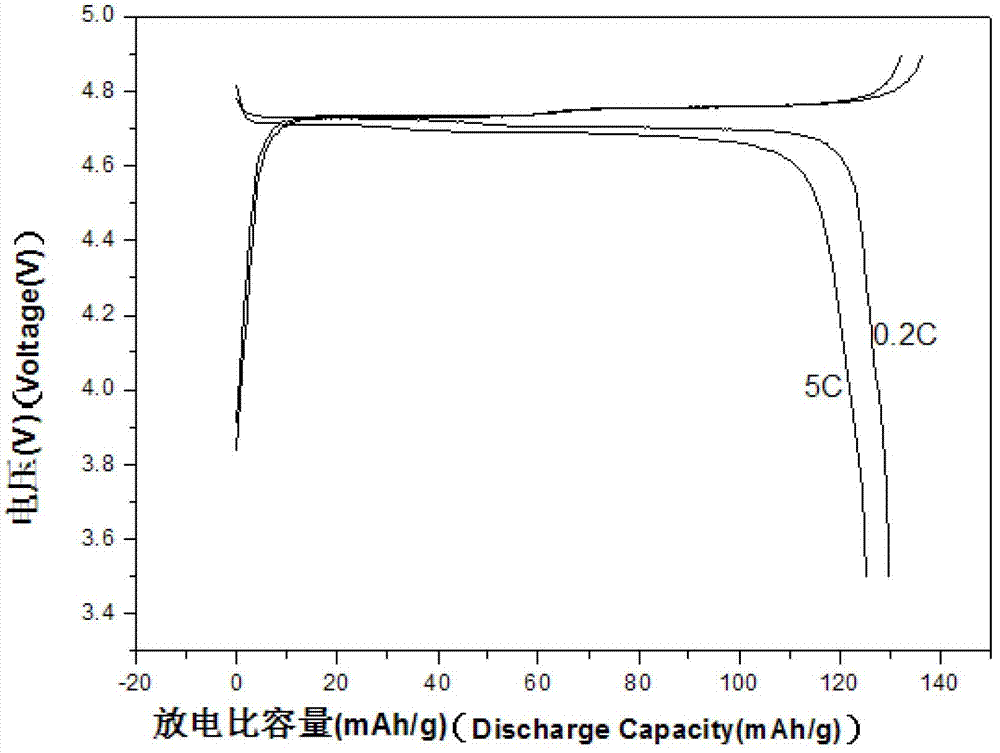

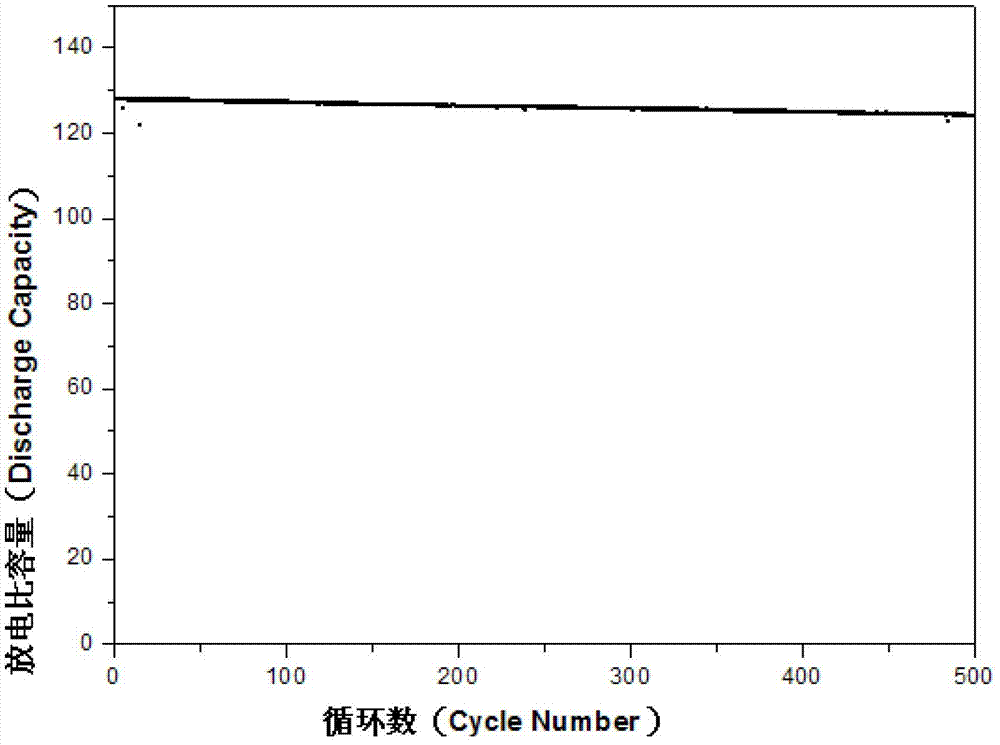

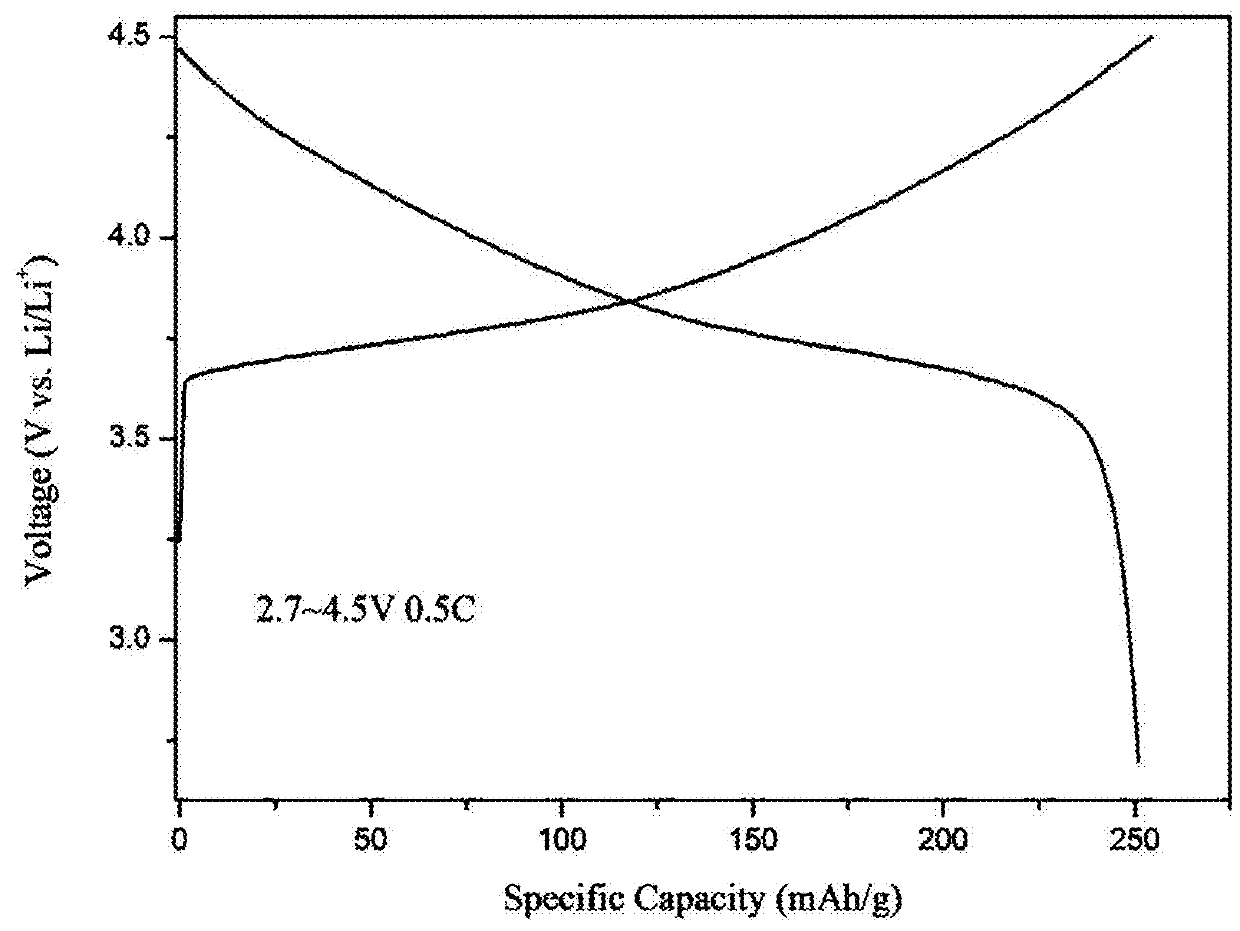

Surface coating method of 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4

ActiveCN103094552AImprove surface chemistryImprove conductivityElectrode thermal treatmentTube furnacePhysical chemistry

The invention discloses a surface coating method of a 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4, which comprises the following steps: (1) grinding and mixing a coating material or precursor thereof and a positive pole active material in a mass ratio of (1-50):100; (2) dispersing the mixture in a certain liquid-phase medium, and carrying out ultrasonic pulverization; (3) mixing the mixture and the medium by ball milling; (4) filtering and drying; and (5) putting the dried mixture in the step (4) into a pipe furnace, heating in inert gas at the heating speed of 1-30 DEG C / minute, calcining at the constant temperature of 200-500 DEG C for 1-5 hours, carrying out quick cooling or furnace cooling to room temperature, and grinding the coated high-voltage lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4. The product obtained by the method disclosed by the invention has high reversible specific capacity: the capacity retentivity after 500 2C charging / discharging cycles is higher than 95%, and the specific capacity of 5C discharge is more than 96% of 0.2C. The method has the advantages of simple and controllable synthesis technique and uniform coating, and is suitable for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

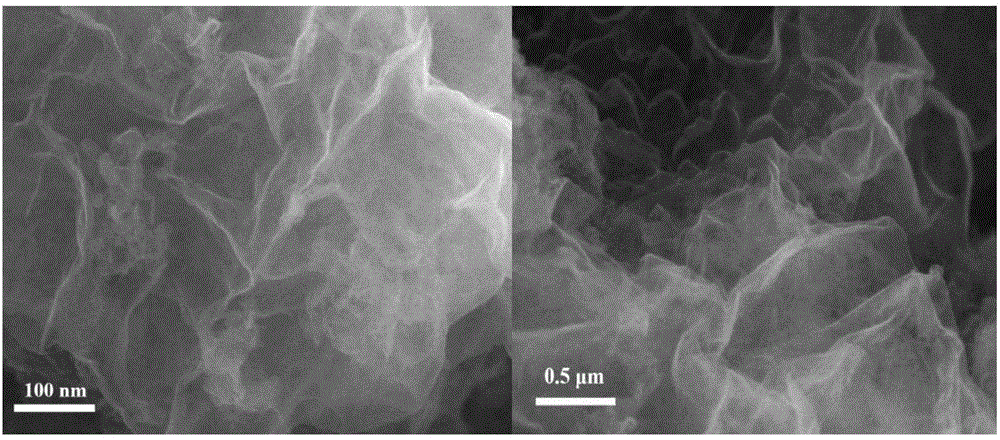

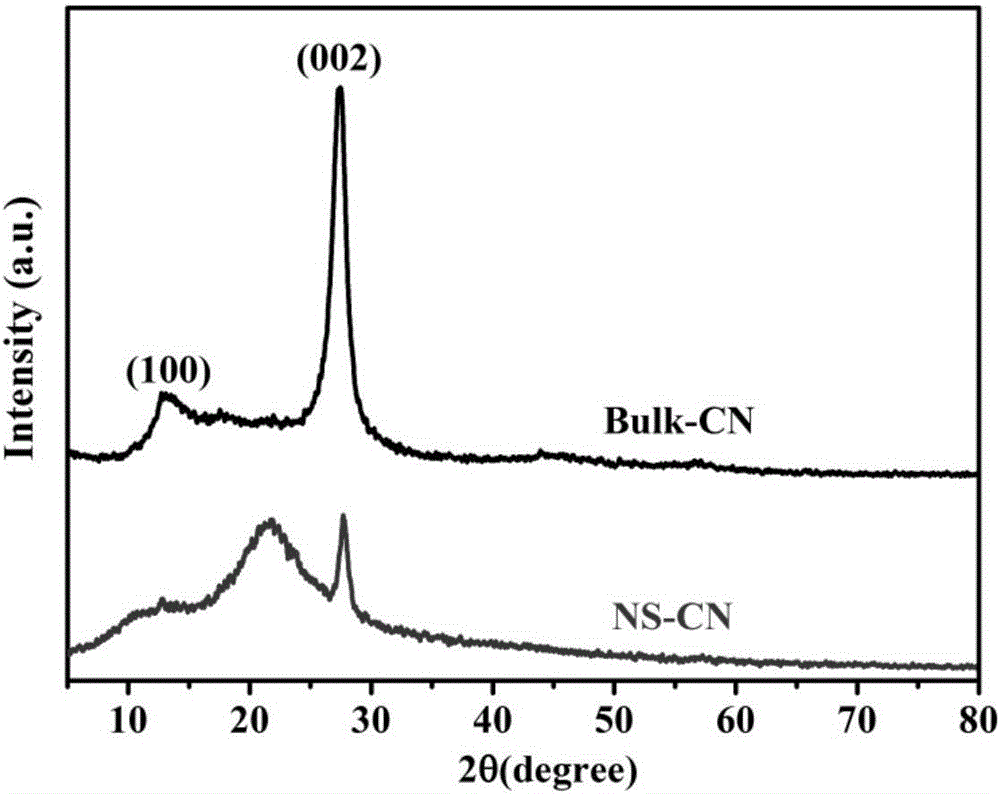

Ammoniated ultrathin graphite-phase carbonitride photocatalyst and preparation method thereof

ActiveCN106563481AScattering effect is smallEasy to separateCatalyst activation/preparationTube furnaceGraphite

The invention discloses an ammoniated ultrathin graphite-phase carbonitride photocatalyst material and a preparation method thereof. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material resembles wrinkled tulle, is in the shape of tulle with wrinkles and has a uniform thickness of 3 to 5 nm; and the surface of the material is smooth and contains rich amino groups. The preparation method comprises the following steps: acidifying melamine so as to obtain a protonated melamine supermolecular structure crystal, carrying out calcining in an inert protective atmosphere so as to prepare a graphite-phase carbonitride material and carrying out uniformization so as to obtain ultrafine powder of a graphite-phase carbonitride photocatalyst material; and placing the ultrafine powder of the graphite-phase carbonitride photocatalyst material and an ammonia-source substance capable of producing ammonia gas through thermal decomposition into a tubular furnace, introducing inert gas for deoxygenation and then carrying out gradient calcining in the inert protective atmosphere, i.e., carrying out heating to 500 to 540 DEG C at first, maintaining the temperature for 2 to 4 h, then carrying out heating to 560 to 600 DEG C, maintaining the temperature for 2 to 3 h and then carrying out cooling. The ammoniated ultrathin graphite-phase carbonitride photocatalyst material has substantially improved photocatalysis efficiency and present excellent photocatalysis performance when applied to catalytic reduction of CO2.

Owner:WUHAN UNIV OF TECH

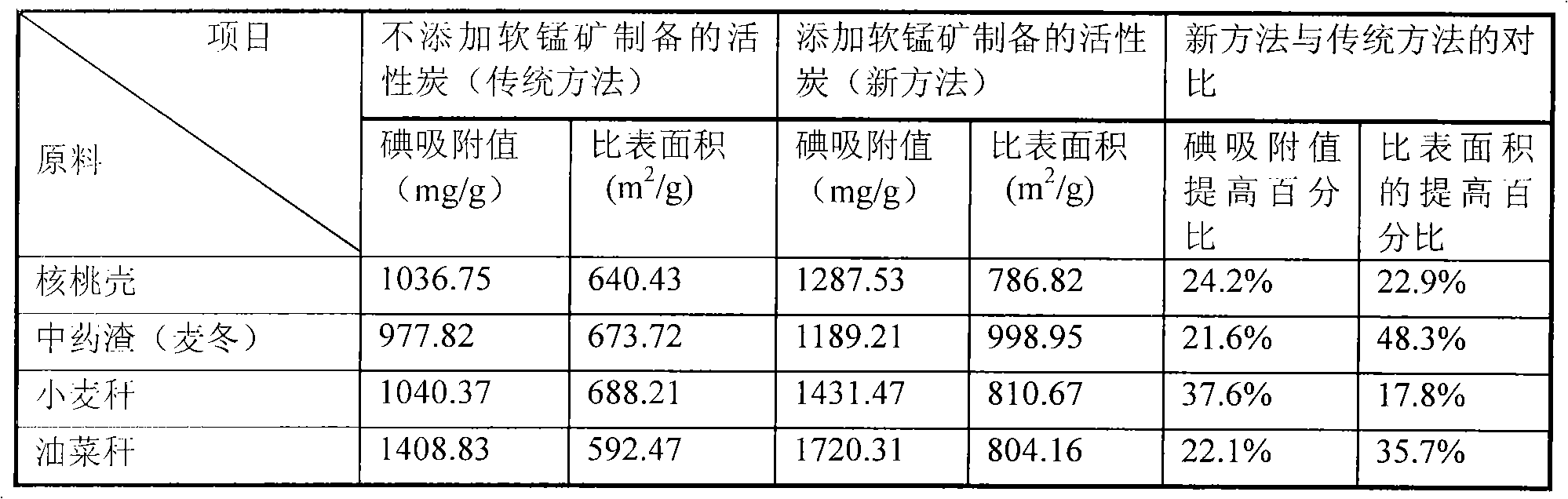

New method for producing active carbon by using biomass wastes

The invention discloses a new method for producing efficient active carbon by using biomass wastes (walnut shells, rape stems, wheat straws, Chinese medicinal dregs and the like) as raw materials, using pyrolusite as a hole forming agent and using zinc chloride as an active agent. The method comprises the following processes of: (1) drying the biomass waste raw materials till the water content is less than 15 percent, mechanically crushing the raw materials, and sieving the crushed raw materials with a sieve of 100 meshes; (2) adding 5 to 10 percent of pyrolusite into the raw materials, and mixing the pyrolusite and the raw materials uniformly; (3) soaking the pre-treated raw materials into 3 to 7mol / L zinc chloride solution for 24 hours, wherein the soaking ratio (the mass of the raw materials to the mass of the zinc chloride solution) is 1:1-1:2; (4) putting the soaked raw materials into a tubular furnace, introducing inert gas (such as nitrogen or carbon dioxide gas), heating to the temperature of between 400 and 600 DEG C, and performing one-step carbonization (synchronous carbonization and activation) for 0.5 to 1.5 hours; and (5) cooling, washing and drying the activated carbide to obtain the active carbon. The method improves the performance of the active carbon, reduces the preparation cost of the active carbon, and realizes recycling utilization.

Owner:CHENGDU UNIV OF INFORMATION TECH

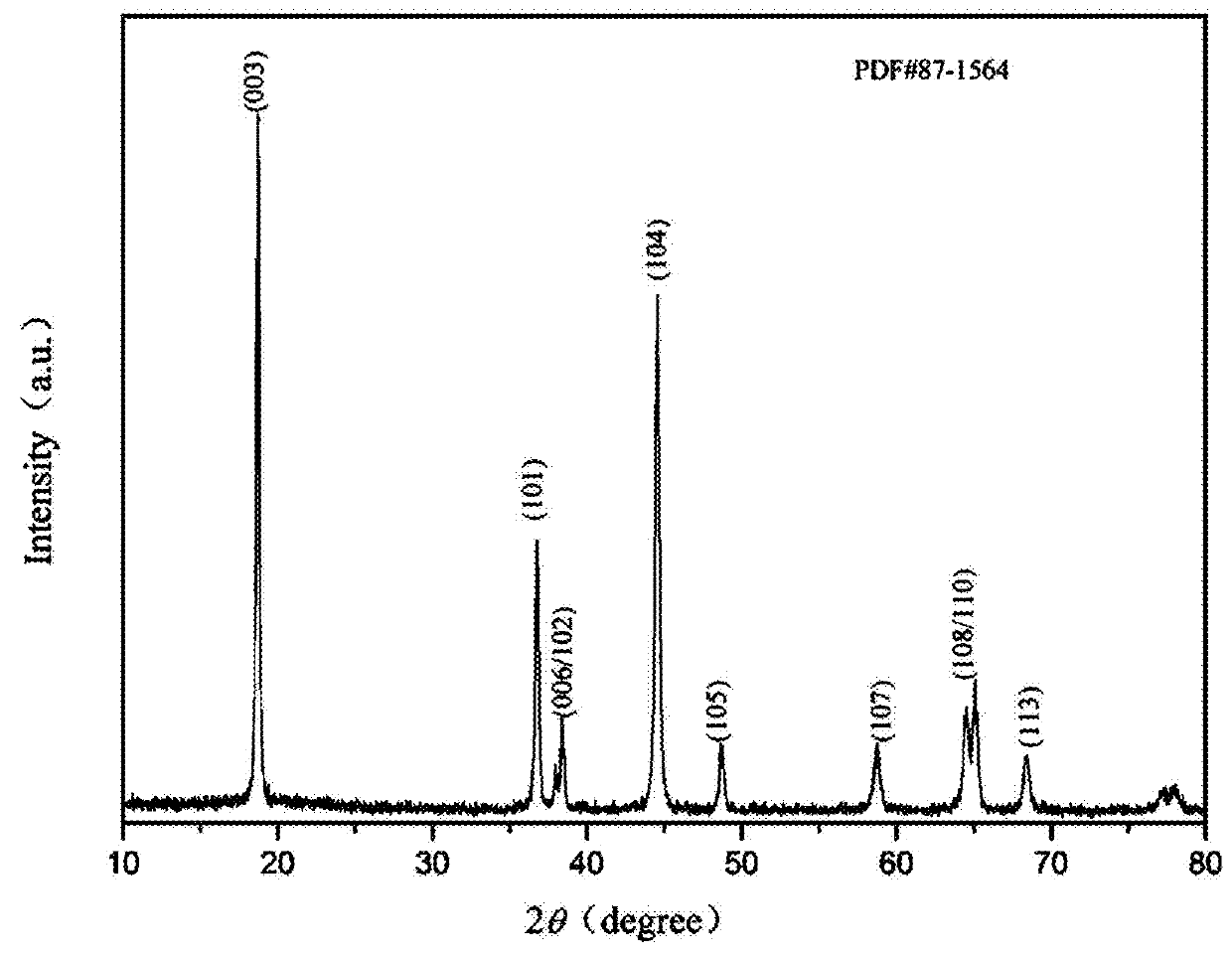

High-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof

ActiveUS20180183045A1Improve cycle stabilityGood chemical uniformityCell electrodesSecondary cellsAir atmosphereHigh energy

The present invention discloses a high-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof. The chemical formula of the material is LiNi0.6-xMgxCo0.2-yAlyMn0.2-zTizO2-dFd, wherein 0<x,y,z,d≤0.05. The precursor of the positive electrode material is synthesized by gradient co-precipitation method and the positive electrode material is prepared by solid phase method. The content of nickel in the synthesized precursor particles has a gradient distribution from the inside to the outside. The obtained precursor is mixed and grinded evenly with the lithium source and the fluorine source at a certain ratio and put into the tube furnace. The obtained precursor is then pre-sintered in the oxygen-enriched air atmosphere and then heated up to be sintered, to obtain the target product. The positive electrode material for lithium-ion battery prepared by the method is free from impurity phase and has a good crystallinity, which is a high energy density positive electrode material.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com