Patents

Literature

475 results about "Pyrolusite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolusite is a mineral consisting essentially of manganese dioxide (MnO₂) and is important as an ore of manganese. It is a black, amorphous appearing mineral, often with a granular, fibrous or columnar structure, sometimes forming reniform crusts. It has a metallic luster, a black or bluish-black streak, and readily soils the fingers. The specific gravity is about 4.8. Its name is from the Greek for fire and to wash, in reference to its use as a way to remove tints from glass.

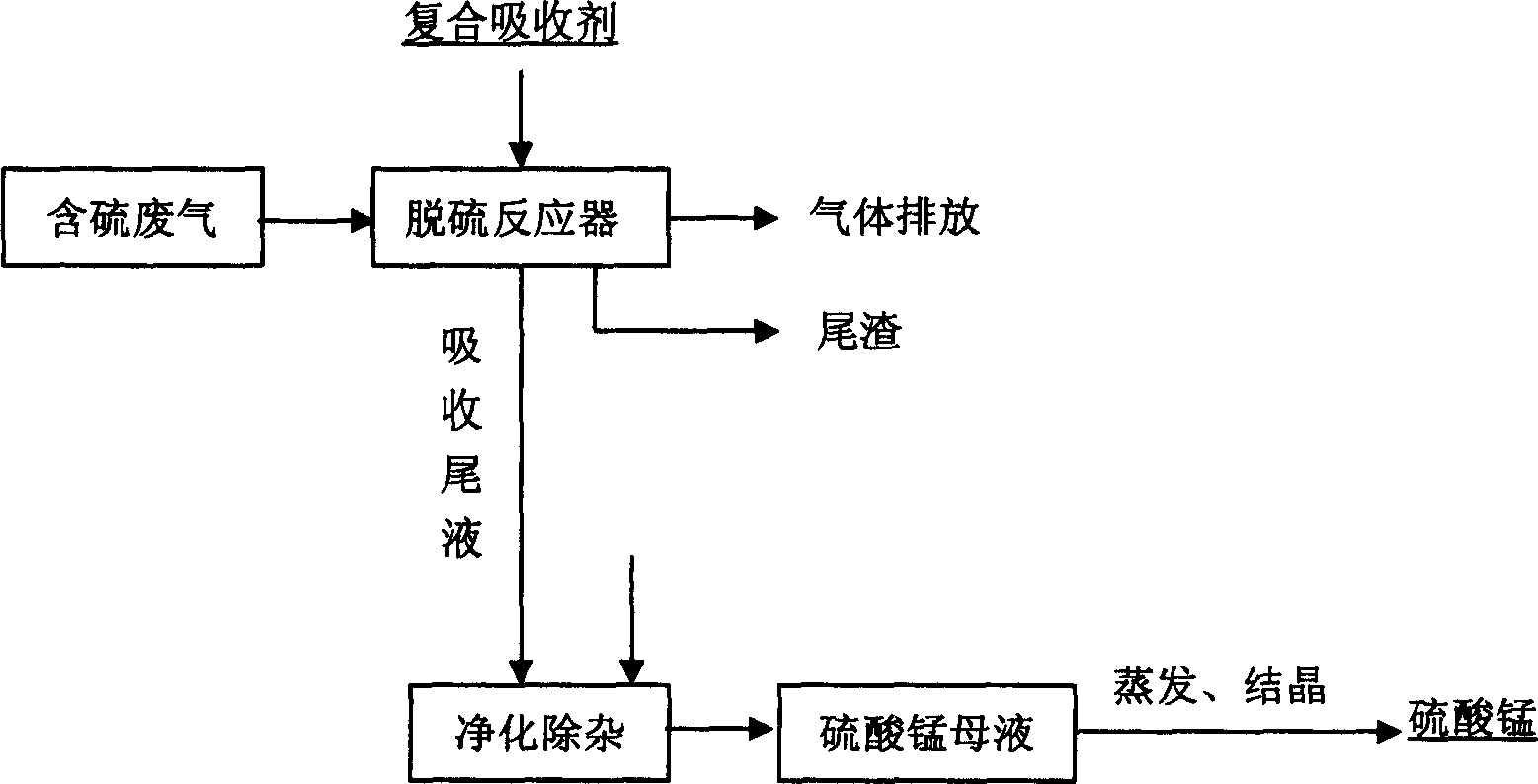

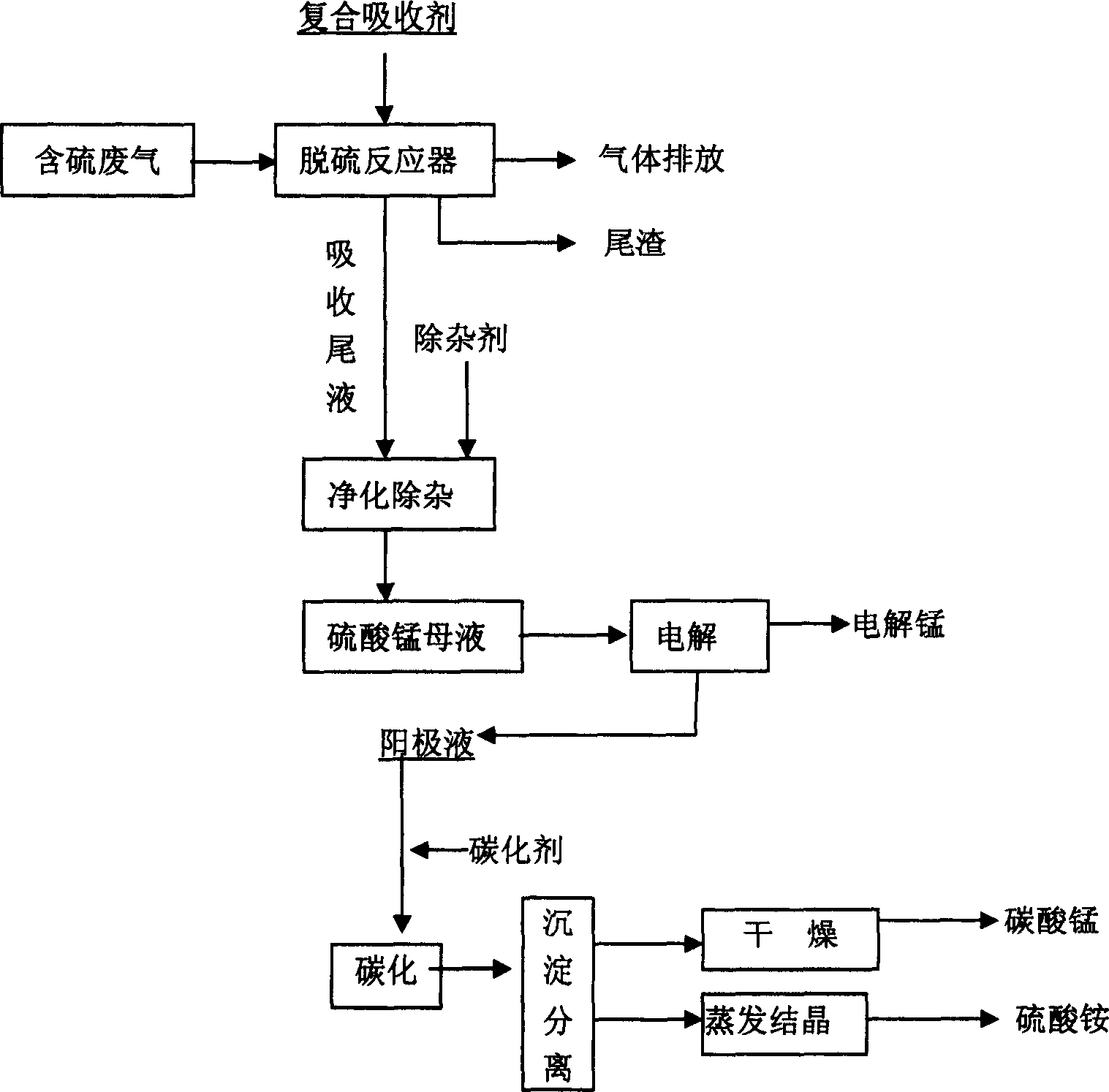

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

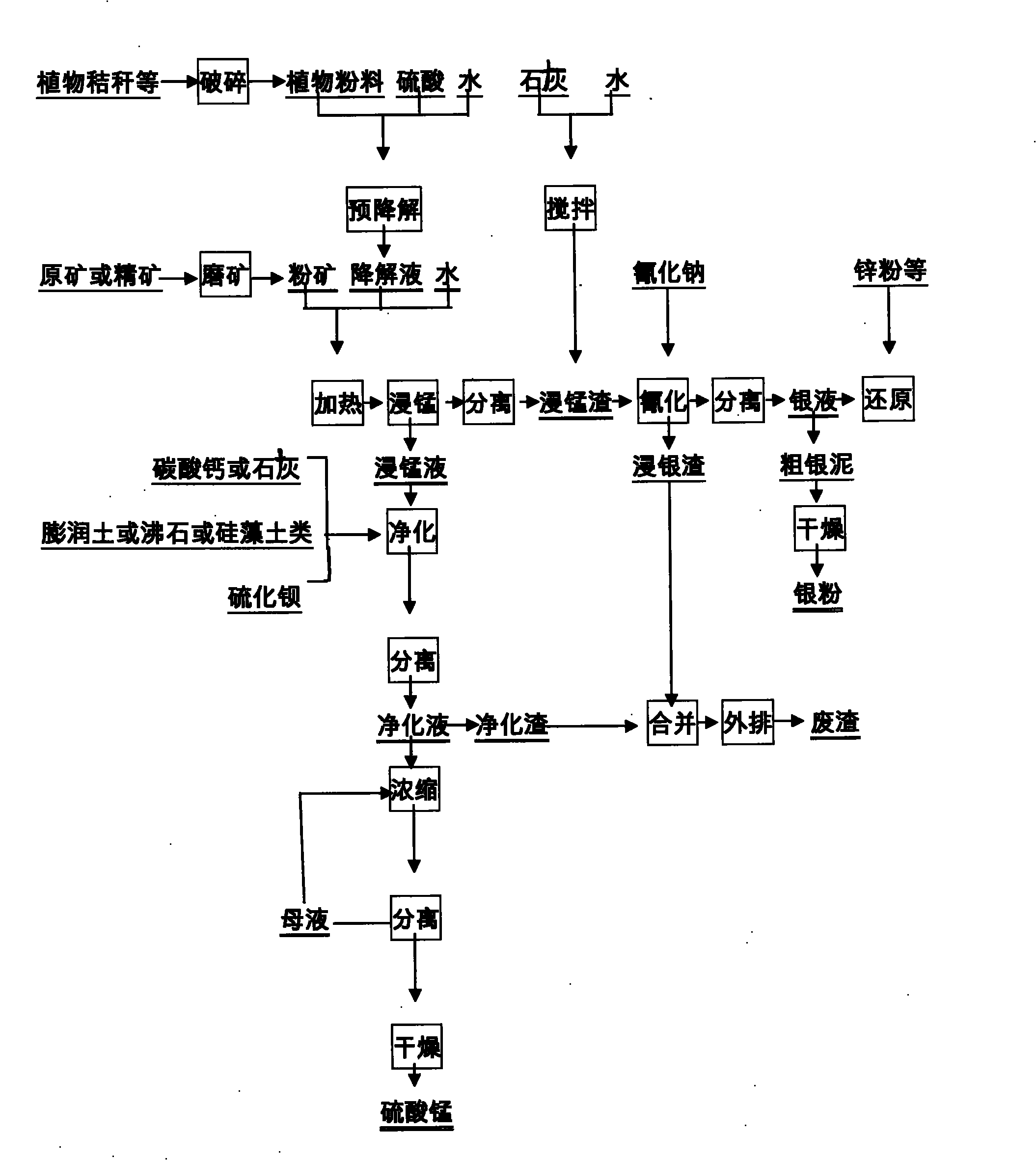

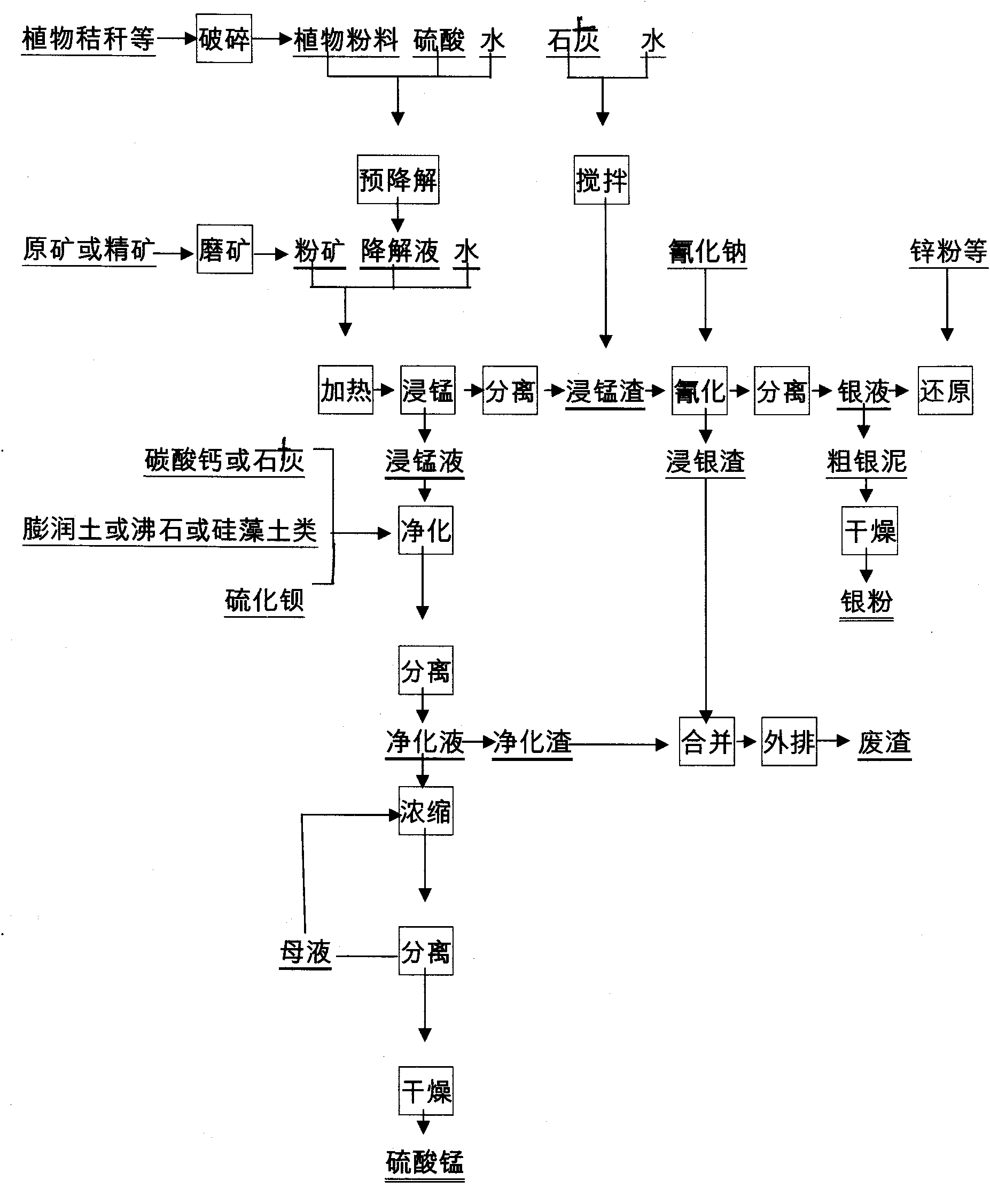

Method for separating manganese and silver of manganese-silver ore and extracting manganese sulfate by purifying manganese dipped solution

InactiveCN101831544AEasy to separateHigh recovery rateProcess efficiency improvementManganese sulfatesPyrolusiteSlag

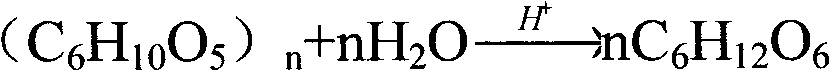

The invention discloses a method for separating manganese and silver of manganese-silver ore and purifying manganese dipped solution thereof. The method comprises the following steps of: 1) pre-degrading and saccharifying plant byproducts comprising straws, hulls and slag; 2) reacting the product obtained in the step 1) with crude manganese-silver ore or enriched mixed concentrate dipped manganese; 3) separating, neutralizing and adsorbing the manganese dipped solution in the step 2) to obtain solution for preparing manganese sulfate and the like by further purification and crystallization; and 4) obtaining manganese dipped slag in the step 3), wherein the manganese dipped slag has high reaction activity, and the leaching time is short and the energy consumption is low during silver leaching treatment. The purifying method is also suitable for purifying the manganese dipped solution by adopting a reducing agent similar to rice bran and the like to treat pyrolusite or ferromanganese ore, and the treated manganese solution can be used for the production of manganese sulfate, electrolytic manganese and the like. The method has the characteristics of wide separation raw material source, reasonable process route, low equipment investment, low treatment cost, stable product performance and the like; and the manganese sulfate prepared by the method can meet the standard requirements of the industries such as chemical engineering, feed, agriculture and the like.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

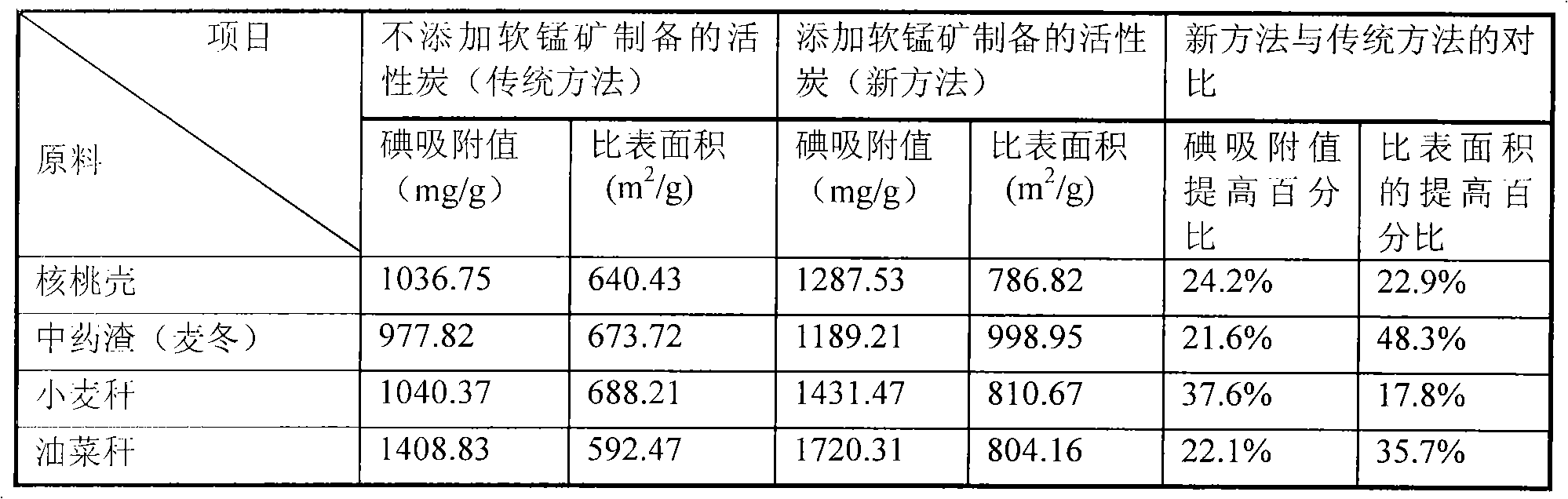

New method for producing active carbon by using biomass wastes

The invention discloses a new method for producing efficient active carbon by using biomass wastes (walnut shells, rape stems, wheat straws, Chinese medicinal dregs and the like) as raw materials, using pyrolusite as a hole forming agent and using zinc chloride as an active agent. The method comprises the following processes of: (1) drying the biomass waste raw materials till the water content is less than 15 percent, mechanically crushing the raw materials, and sieving the crushed raw materials with a sieve of 100 meshes; (2) adding 5 to 10 percent of pyrolusite into the raw materials, and mixing the pyrolusite and the raw materials uniformly; (3) soaking the pre-treated raw materials into 3 to 7mol / L zinc chloride solution for 24 hours, wherein the soaking ratio (the mass of the raw materials to the mass of the zinc chloride solution) is 1:1-1:2; (4) putting the soaked raw materials into a tubular furnace, introducing inert gas (such as nitrogen or carbon dioxide gas), heating to the temperature of between 400 and 600 DEG C, and performing one-step carbonization (synchronous carbonization and activation) for 0.5 to 1.5 hours; and (5) cooling, washing and drying the activated carbide to obtain the active carbon. The method improves the performance of the active carbon, reduces the preparation cost of the active carbon, and realizes recycling utilization.

Owner:CHENGDU UNIV OF INFORMATION TECH

Method for preparing electrolytic manganese metal with low-grade pyrolusite wet leaching

InactiveCN102094119AReduce pollutionWide variety of sourcesProcess efficiency improvementElectrolysisPyrolusite

The invention discloses a method for preparing electrolytic manganese metal with low-grade pyrolusite wet leaching, which comprises the following steps of: after low-grade pyrolusite is crushed and screened, mixing slurry with electrolytic manganese anolyte, adding sulfuric acid to control acidity, and reducing high-valent manganese insoluble in water into low-valent manganese readily soluble in water through a redox reaction by using reduced iron powder or waste iron scraps as a reducing agent; controlling certain acidity, reaction temperature and time, stirring and leaching, and then precipitating and filtering; purifying, decontaminating and separating a filter liquor to obtain a pure manganese sulfate solution; and electrolyzing the manganese sulfate solution to obtain an electrolytic manganese product, wherein the leaching rate of manganese is higher than 98%, the recovery rate of manganese is higher than 90%, and the purity of electrolytic manganese metal is higher than 99.8%. The method has the advantages that the raw materials of the reducing agent have wide sources and low price, the reaction time is short, the conditions of the leaching process are mild, the leaching rate of manganese is high, the purification process is simple, and the process route of the present carbonic acid manganese ore for preparing electrolytic manganese metal is not changed.

Owner:JISHOU UNIVERSITY +1

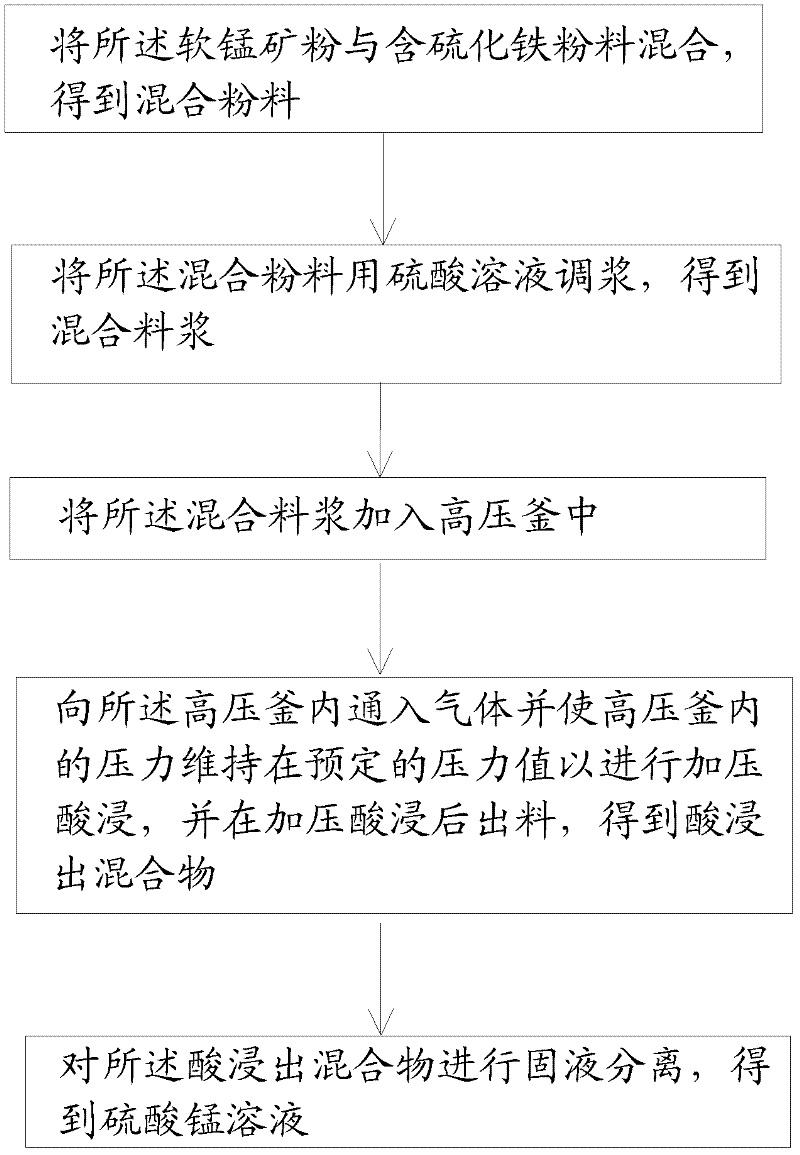

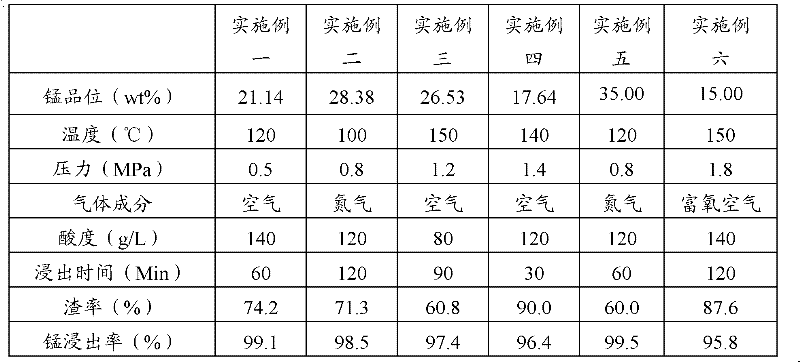

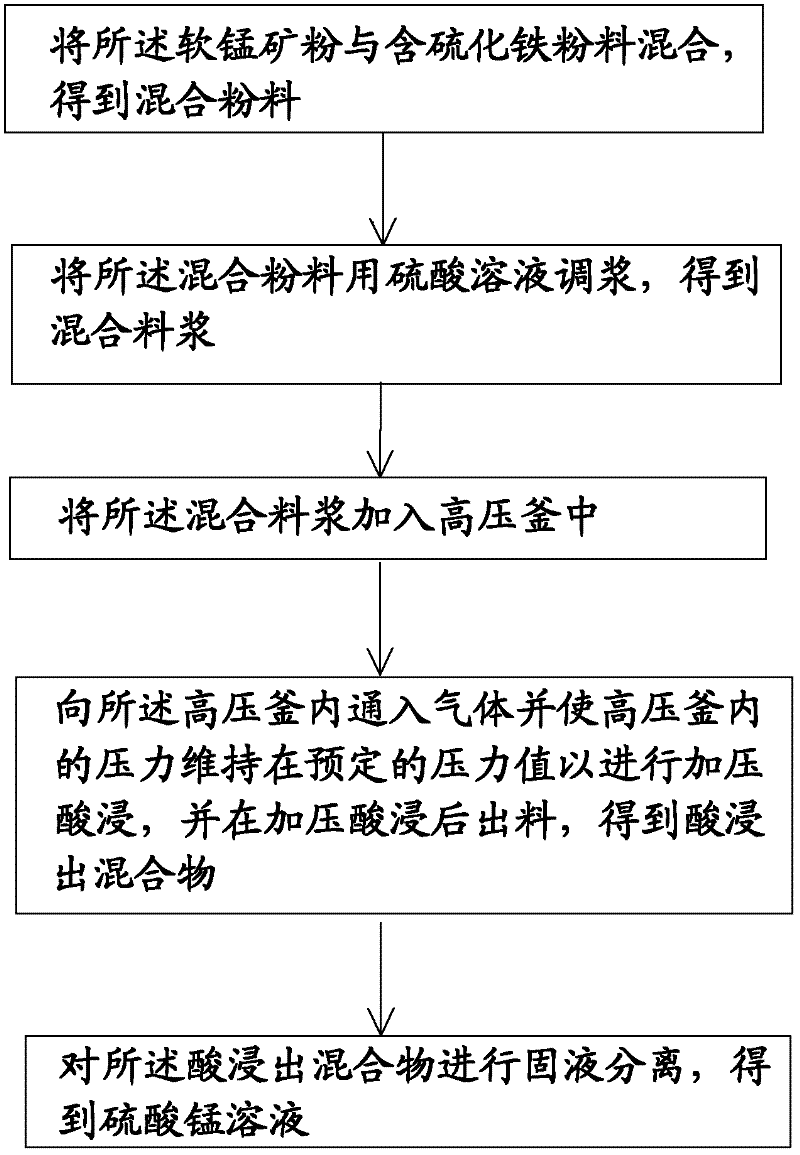

Pressurizing and reductive leaching method of pyrolusite powder

The invention discloses a pressurizing and reductive leaching method of pyrolusite powder. The method comprises the following steps of: a) mixing pyrolusite powder and iron sulfide powder to obtain mixed powder; b) adding a sulphuric acid solution in the mixed powder to pulp and obtain mixed slurry; c) adding the mixed slurry in an autoclave; d) injecting a gas in the autoclave to ensure that the inner pressure of the autoclave reaches a preset pressure value continuously and perform acid leaching under a pressure, then discharging to obtain an acid leaching mixture; and e) performing solid-liquid separation to the acid leaching mixture to obtain a manganese sulfate solution, wherein the pyrolusite powder contains 13-35wt% of manganese. According to the pressurizing and reductive leaching method of pyrolusite powder in the embodiment of the invention, by adopting the pressurizing and leaching method, the manganese in low-grade pyrolusite powder can be leached fast and effectively.

Owner:YUNNAN JIANSHUI MANGANESE

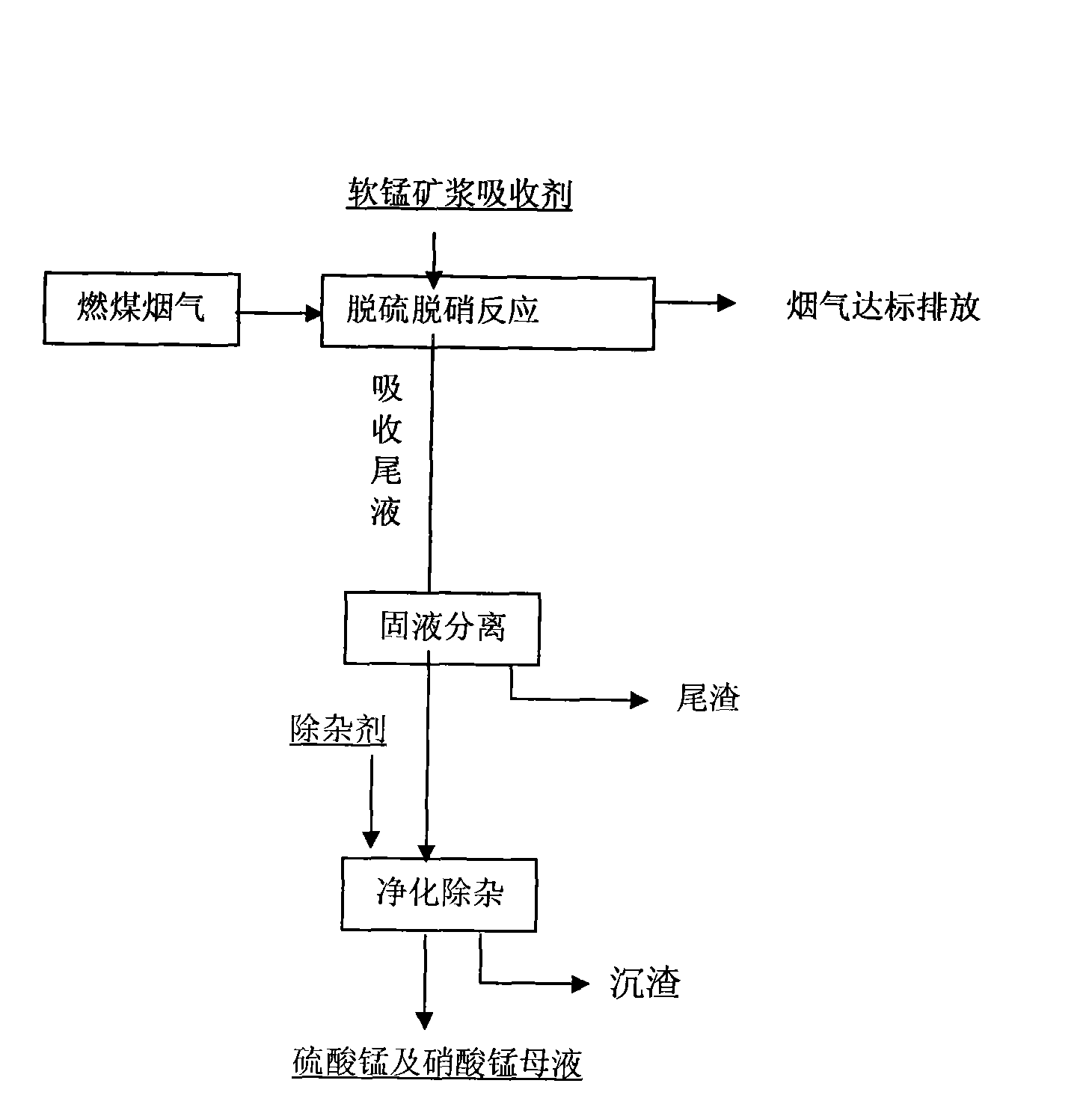

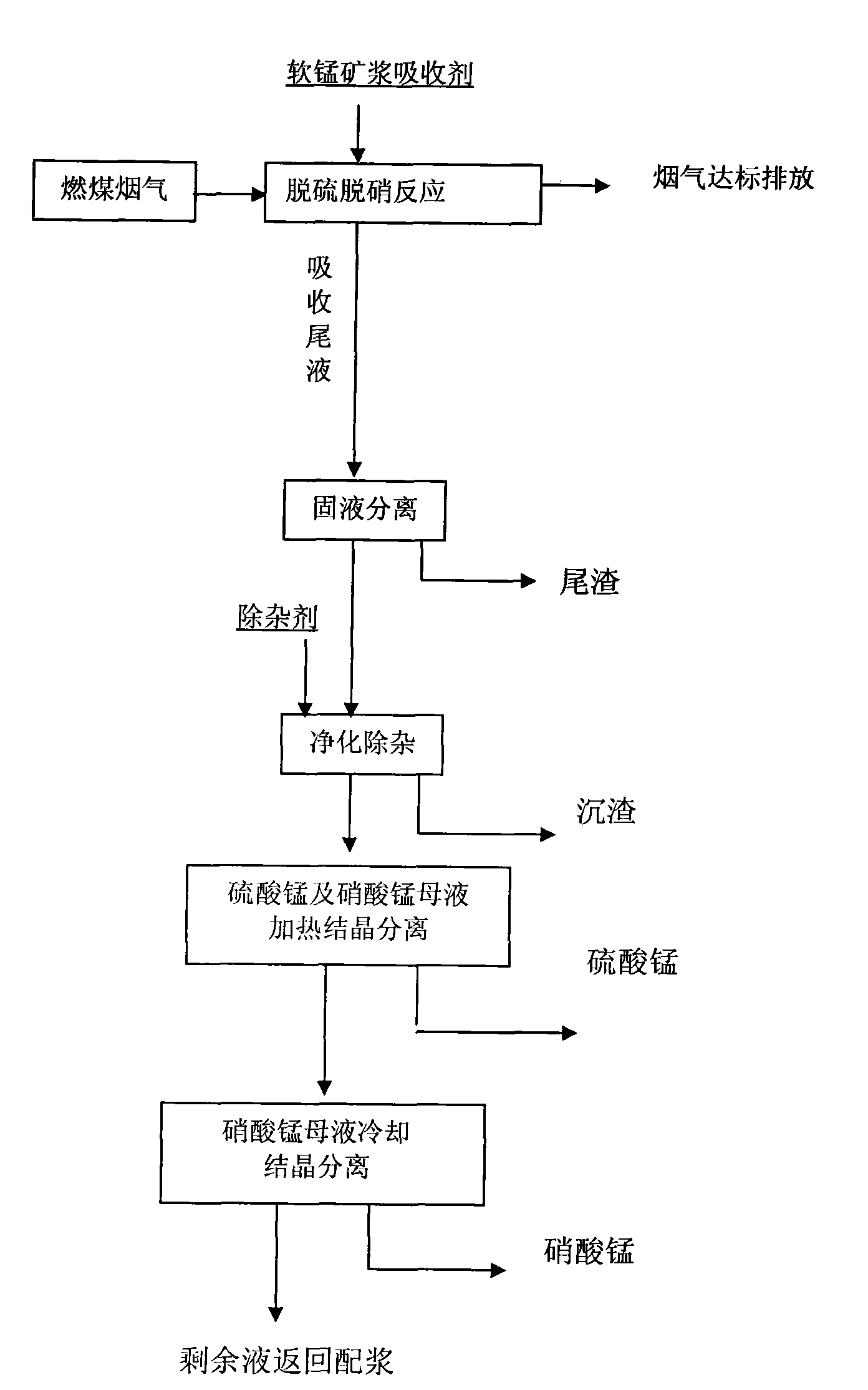

Synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation

ActiveCN101574617ARich reservesLow priceDispersed particle separationProcess efficiency improvementSolubilityPyrolusite

The invention discloses a synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation. The method mainly comprises the following steps: pyrolusite, water and metal-chelator are prepared into pulp which is taken as an absorbing agent; sulfur dioxide and nitrogen oxides in the flue gas are synchronously absorbed and removed by the absorbing agent; the flue gas is discharged when the purification reaches a standard; the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is obtained after absorbing tail solution is purified; and by utilizing the different solubility of manganese sulfate and manganese nitrate at same temperature, the mixed mother solution is heated firstly to cause the manganese sulfate therein to be crystallized and separated, next, the left mother solution is cooled to cause the manganese nitrate therein to be crystallized and separated, and the left solution is returned to preparation pulp for recycling. No waster water is discharged in the whole process, thereby achieving the purposes of controlling waste by waste, recycling sulfur resources and improving the comprehensive utilization value of pyrolusite. The method is characterized by high desulphrization and denitration efficiency and manganese utilization rate, little secondary pollution, obvious economic benefit and the like.

Owner:SICHUAN UNIV

Gray manganese ore leaching out process

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

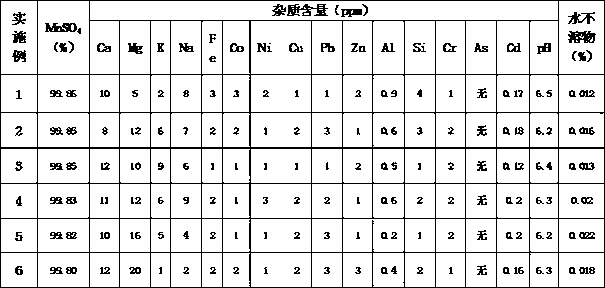

Method for production of high purity manganese sulfate by using pyrolusite as raw material

ActiveCN103011297AImprove controllabilityGood reproducibilityManganese sulfatesPyrolusiteAcid dissolution

The invention relates to a production method for high purity manganese sulfate. The production method is characterized in that pyrolusite is used as a raw material and is reduced by using a carbon fire method, then an acid is added for leaching, a vulcanizing agent is used to remove heavy metals consisting of cobalt and nickel, a fluoride is employed to remove calcium and magnesium, then filtering is carried out, ammonium bicarbonate or ammonium carbonate is added into a filtrate for deposition of manganese to realize separation of potassium and sodium, an obtained filtrate is used for recovery of the by-product ammonia sulfate for usage as an additive for metal manganese, the filter residue manganese carbonate is washed and then subjected to acid dissolution so as to obtain a manganese sulfate solution, and then crystallization is carried out to obtain a high purity manganese sulfate product, wherein mother liquor can be returned to a high purity system for reutilization. With the method provided by the invention, the high purity manganese sulfate product in which MnSO4 content is more than 99.8% and respective content of impurities consisting of Ca, Mg, K and Na is lower than 10 ppm is produced.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Method for restraining generation of manganous dithionate in process of leaching sulfur dioxide gas out of pyrolusite

The invention discloses a method for restraining the generation of manganous dithionate in the process of leaching sulfur dioxide gas out of pyrolusite, which comprises the following main technical measures: (1) pyrolusite pulp is prepared by stirring and mixing in the proportion that 100-500g of pyrolusite and 0.2-100g of granular active carbon are added into 1L of water; (2) in a synchronous reaction process of absorbing the sulfur dioxide gas by the pyrolusite pulp, desulphurizing and leaching manganese, the pH value of the pyrolusite pulp is controlled to be lower than 3.5 by blowing oxygen or air into the pyrolusite pulp. The method restraining the generation of the manganous dithionate does not need to extra consume sulphuric acid and guarantee an oxido-reduction potential by extra adjusting the concentration of Fe<3+> / Fe<2+>, is easy to meet the requirement of industrial process production and can guarantee the concentration of a manganese sulfate mother liquor.

Owner:成都合众新能源科技有限公司

Method for extracting manganese from manganese-enriched slag

InactiveCN102230088AEasy to separateImprove leaching rateProcess efficiency improvementPyrolusiteSilicic acid

The invention relates to a method for extracting manganese from manganese-enriched slag. In the method, the manganese-enriched slag is subjected to alkali leaching on the basis of taking sulfuric acid as a leaching agent. The method comprises the following steps of: putting the manganese-enriched slag into a stirring tank, and adding sodium hydroxide solution to perform the alkali leaching; 2, standing, precipitating, preparing into a filter cake, and washing by water to obtain desiliconized and desulfurized manganese-enriched slag; 3, putting the desiliconized and desulfurized manganese-enriched slag into a leaching tank to perform acid leaching; and 4, separating by suction filtration to prepare acid leaching solution containing manganese sulfate, wherein before the acid leaching is performed, the water and pyrolusite also can be added to oxidize sulfur in the manganese-enriched slag further. In the method, gel silicic acid can be prevented during desilicication, so the actual extracting rate of the manganese; and hydrogen sulfide gas can be prevented from generating and escaping during desulfurization to prevent the adverse effect on operators. The method also has the advantages that the operation is simple and convenient, various reaction conditions are easy to control, and the loss of manganese-enriched ores in the integral process is small.

Owner:CHONGQING UNIV

Method for circularly producing mangano-manganic oxide by manganous sulfate

The invention relates to a method for circularly producing mangano-manganic oxide by manganous sulfate, which fulfills the aim of circularly producing the mangano-manganic oxide by the manganous sulfate by absorbing a mixed gas of sulfur dioxide and sulfur trioxide generated by calcining the manganous sulfate at a high temperature by mixed slurry which is formed by pyrolusite (or manganese dioxide), manganese carbonate and water. The method for producing the mangano-manganic oxide has the advantages of low cost, high product purity, no pollution and the like.

Owner:湖南昊宏新材料科技有限公司

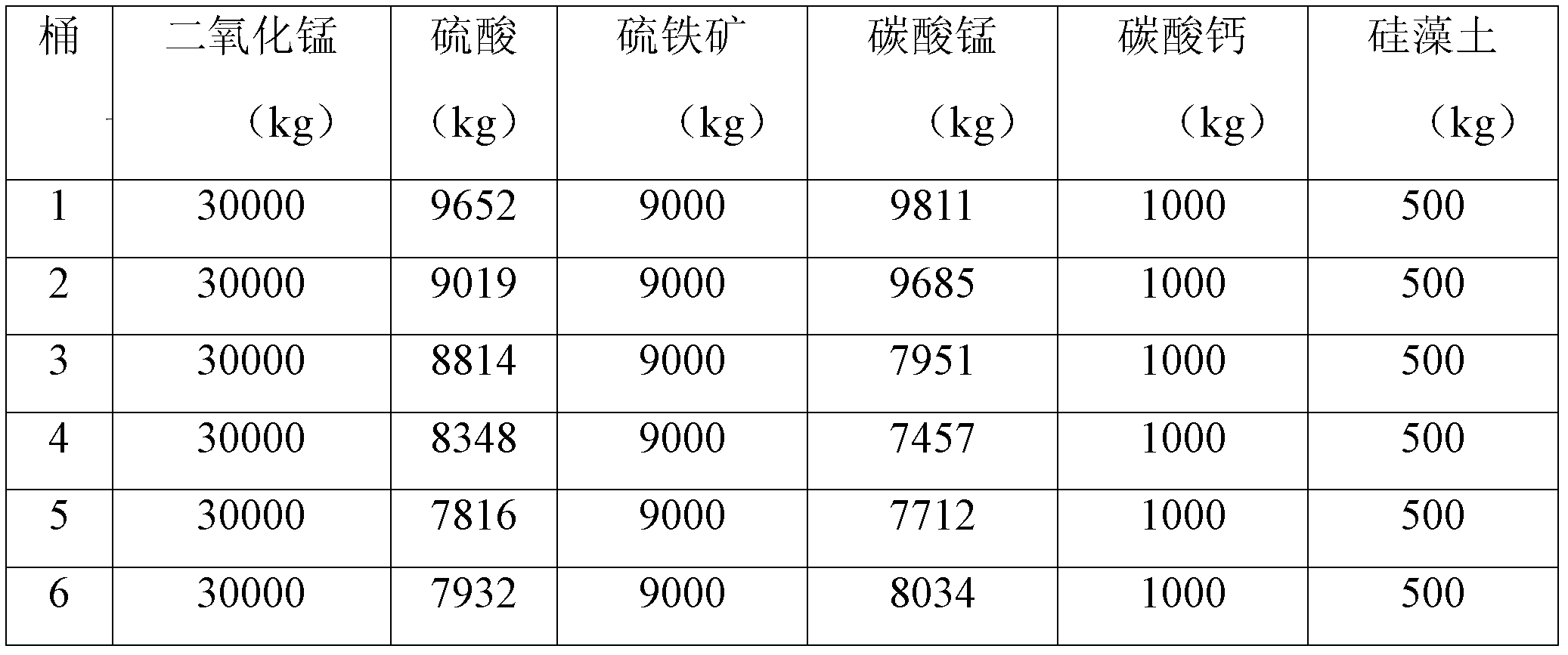

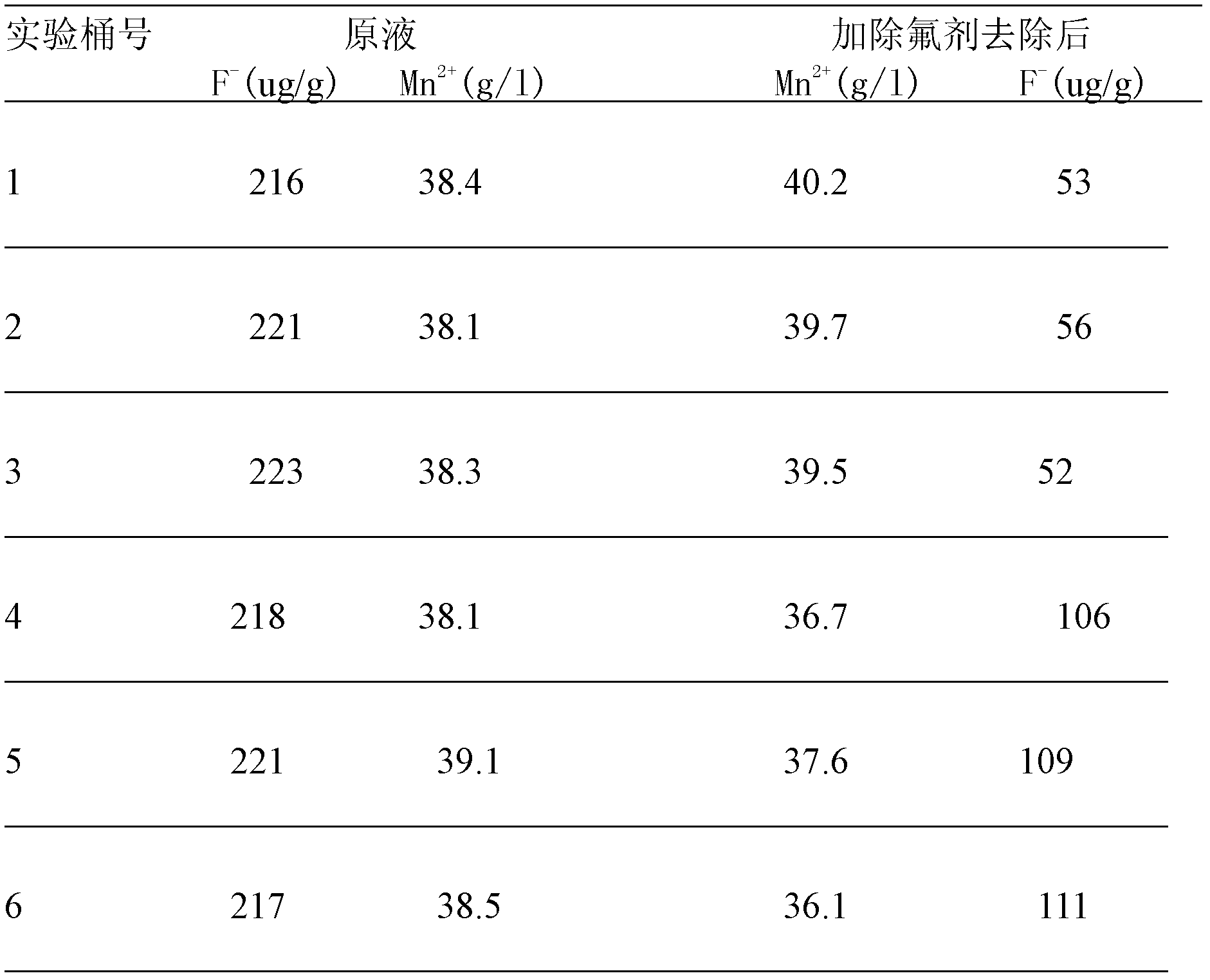

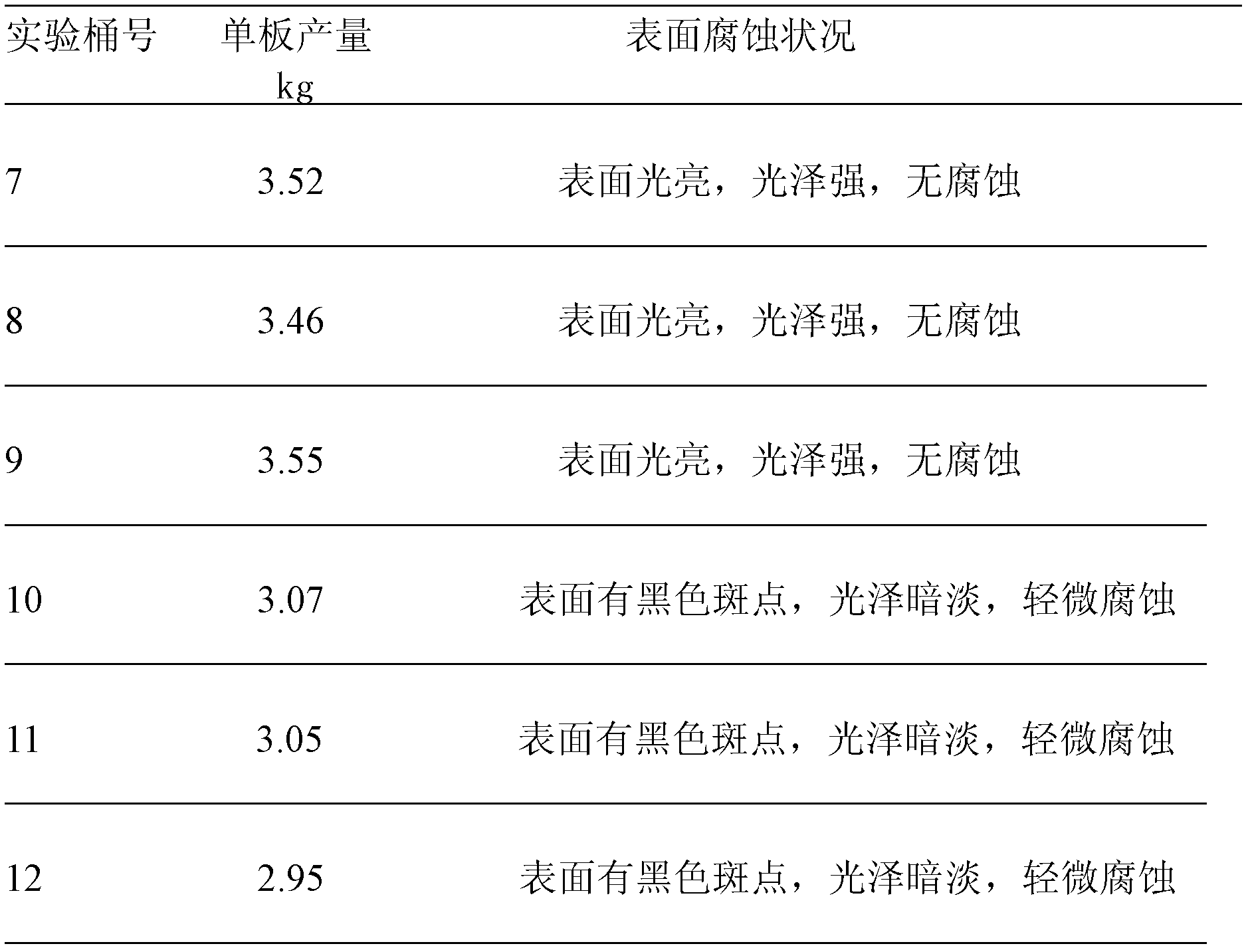

Method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal

The invention provides a method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal, which comprises the following step of: when the manganese sulfate solution for producing the electrolytic manganese metal is prepared from rhodochrosite, pyrolusite, pyrite and vitriol, adding fluorine removing agent calcium carbonate and kieselguhr to remove the fluorine ion from the solution, so that the fluorine ion content in the manganese sulfate solution is less than or equal to 60mug / g. The method is simple to operate, the loss of the manganese in the solution can be avoided when the fluorine ion is removed, a cathode can not be corroded when a metal sheet is produced by the fluorine ion-free manganese sulfate solution in an electrolysis way, and the single plate is high in yield.

Owner:广西靖西市一洲锰业有限公司

Method for quickly leaching gold and silver by using mixed leaching agent

The invention discloses a method for quickly leaching gold and silver by using a mixed leaching agent, which comprises the following steps of: crushing gold-containing pyrite smelting slag, a sulfide-containing visible gold ore or / and a gold-containing oxidized ore serving as raw materials, conditioning the raw materials with water to form slurry, adding ammonium thiocyanate, thiocarbamide, urea and an oxidant, namely manganese dioxide or ferric chloride, into the ore slurry and stirring and leaching the mixed slurry to leach the gold and silver out. The method has the advantage that: the mixed leaching agent formed by adding the urea into the ammonium thiocyanate can quickly leach the gold and the silver out of the sulphur and arsen-containing gold ore by adding the urea with a low cost, particularly the gold and the silver which are contained in pyrolusite can be leached out with a lower cost. At the same time, beneficial elements in the ores can be comprehensively used.

Owner:梁伟基 +1

Method for treating ammonia nitrogen wastewater

ActiveCN101559988AEasy to desorbLow costOther chemical processesCombustible gas purificationPyrolusiteSorbent

The invention provides a method for treating ammonia nitrogen wastewater, which relates to a method for treating the ammonia nitrogen wastewater by using an adsorption method. The method is characterized in that in the treating process, a natural manganese mineral is used as an adsorbent to perform adsorption reaction with the ammonia nitrogen wastewater so as to remove the ammonia nitrogen in thewastewater. The natural manganese mineral is crushed into a manganese mineral adsorbent of 0-2 millimeters, the pH value of the wastewater containing the ammonia nitrogen is adjusted to be between 2and 12 by using acid or alkali, then the manganese mineral adsorbent contacts and is mixed with the ammonia nitrogen wastewater to perform adsorption, and the adsorption can be performed by adopting afixed bed adsorption column or in a stirring and mixing mode. When the fixed bed adsorption column is adopted for adsorption, the manganese mineral after being crushed is classified to remove fine particles for the best so as to improve the permeability of the adsorption column; and in the same way, when the stirring and mixing mode is adopted, the manganese mineral after being crushed is classified to remove coarse particles for the best so as to reduce the abrasion to equipment. The natural manganese mineral applicable to the method comprises a terrestrial manganese oxide mineral, an oceanpolymetallic nodule, an ocean cobalt-rich incrustation and a terrestrial manganese nodule, the natural manganese minerals usually contain manganese minerals of cryptomelane, todorokite, birnessite, vernadite, rancieite, pyrolusite and the like, have good pore structure and large specific surface area so as to have good adsorption property, and can be used as the adsorbent for treating the ammonianitrogen wastewater after being crushed into certain particle size, and the manganese minerals have the advantages of simple process, easy reproduction and stable performance.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for dry desulfurization and demercuration of sintering flue gas containing mercury by means of low-grade pyrolusite

InactiveCN105688647AReduce the cost of desulfurization and mercury removalSpeed up entryGas treatmentDispersed particle separationPyrolusiteFlue gas

The invention discloses a method for dry desulfurization and demercuration of sintering flue gas containing mercury by means of low-grade pyrolusite. The method comprises the steps that 1, the low-grade pyrolusite is obtained and placed in a reactor; 2, dedusting is conducted on the sintering flue gas to remove dust containing sulfur and mercury in the sintering flue gas, then the dedusted sintering flue gas with the temperature of 100-200 DEG C is introduced into the reactor at the flow rate of 1-8 L / min to enable the sintering flue gas to make contact with the low-grade pyrolusite, SO2 in the sintering flue gas reacts with the low-grade pyrolusite to achieve desulfurization, and residual mercury in the sintering flue gas is adsorbed by pyrolusite to achieve demercuration; 3, the sintering flue gas subjected to desulfurization and demercuration is directly discharged through an exhaust port of the reactor. The method has the advantages that desulfurization and demercuration cost is low, desulfurization and demercuration efficiency is high, the process is simple, and the recovery rate of byproducts is high.

Owner:GUIZHOU UNIV

Preparation method of concave convex rod stone clay desulfur adsorption catalyst

InactiveCN1597088AImprove adsorption and catalytic efficiencySimplify the desulfurization processOther chemical processesDispersed particle separationPtru catalystPyrolusite

A desulfurizing adsorption catalyst is prepared from attapulgite clay through adding composite Fe, pyrolusite and water, stirring, die pressing and calcining for activating it.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

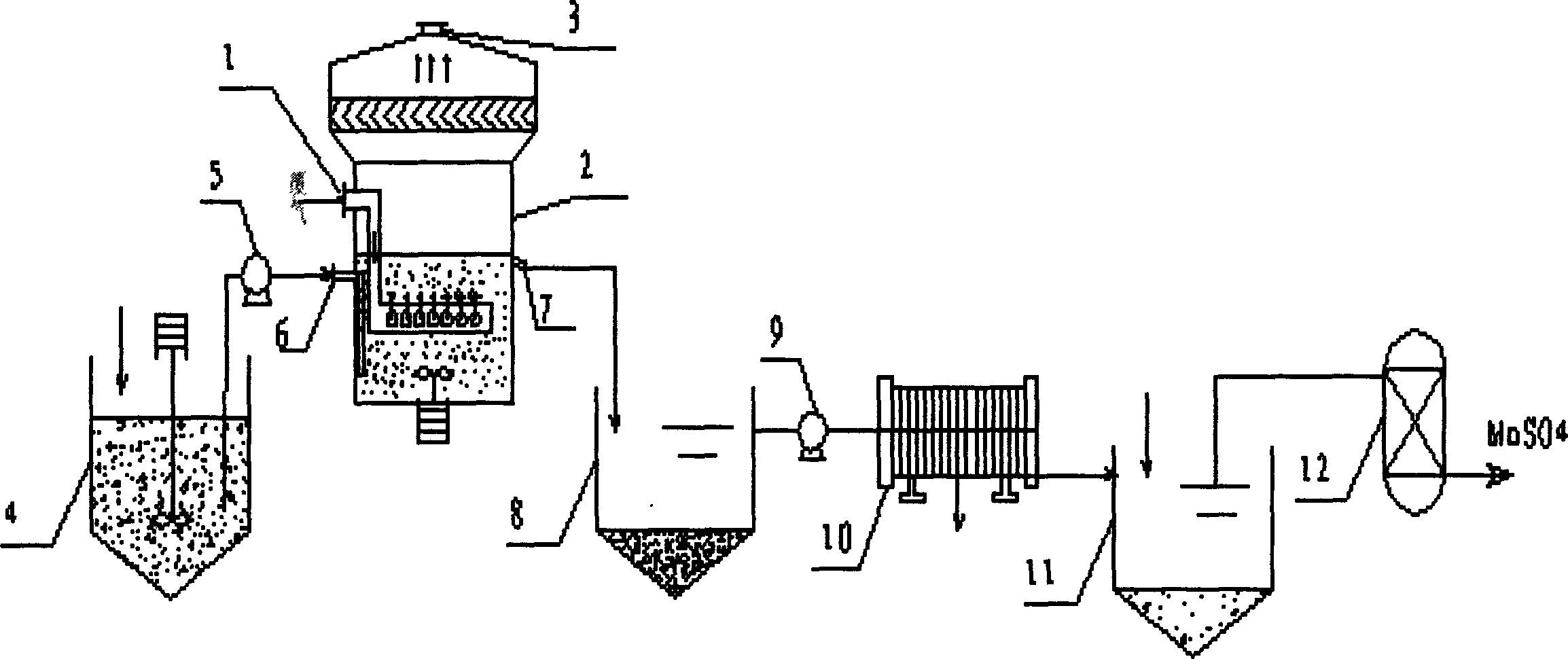

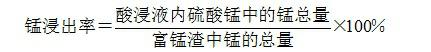

Method for leaching manganese sulfate from low grade pyrolusite

InactiveCN102358917ATo achieve the purpose of leachingPromote redox processElectrolysis componentsPyrolusiteSlurry

The invention provides a method for leaching manganese sulfate from low grade pyrolusite. The method comprises the steps of crushing low grade pyrolusite and pyrite, placing crushed pyrolusite and pyrite in a leaching tank and mixing crushed pyrolusite and pyrite with sulfuric acid to prepare ore slurry. According to the invention, the mass percentage of manganese in pyrolusite is 9% to 21%, the mass ratio of pyrolusite to pyrite is 5-3:1, the molar concentration of sulfuric acid is 1 to 1.2 mol / L, and the mass ratio of sulfuric acid to pyrolusite and pyrite is 6-8:1; electrocatalytic reinforcement is carried out on the ore slurry so as to accelerate a reduction reaction. The method for leaching manganese sulfate from poor pyrolusite provided in the invention has the advantages of low cost, easy operation, short time, a high leaching rate of manganese, etc.

Owner:CHONGQING UNIV

Method for reducing pyrolusite and co-producing sulfuric acid by utilizing sulfur in fluidized bed furnace

The invention discloses a method for reducing pyrolusite and co-producing sulfuric acid by utilizing sulfur in a fluidized bed furnace, which comprises the following steps of: blending the sulfur and the pyrolusite in a certain ratio, conveying the mixture into the fluidized bed furnace, reducing manganese dioxide in the pyrolusite into manganese oxide by using the sulfur and sulfur dioxide generated by combustion, discharging the manganese oxide into sulfuric acid solution or electrolytic manganese anode solution, slurrying and leaching manganese sulfate; and blowing air into the fluidized bed furnace from the upper section thereof, making sublimed sulfur fully combusted, performing temperature reduction and dedusting on sulfur dioxide generated by reaction, conveying the sulfur dioxide to a purification process, and producing the sulfuric acid by a sulfuric acid production process. By utilizing the conventional sulfuric acid producing fluidized bed furnace equipment, the production method can reduce the pyrolusite into the manganese sulfate, also can produce a great deal of sulfuric acid, greatly reduces equipment investment, saves investment, and reduces cost; meanwhile, in the reaction process, waste gas such as CO2, CO and SO2 and dust cannot be discharged, the operating conditions are good, and the environment is not influenced.

Owner:湖南省泸溪县金旭冶化有限责任公司

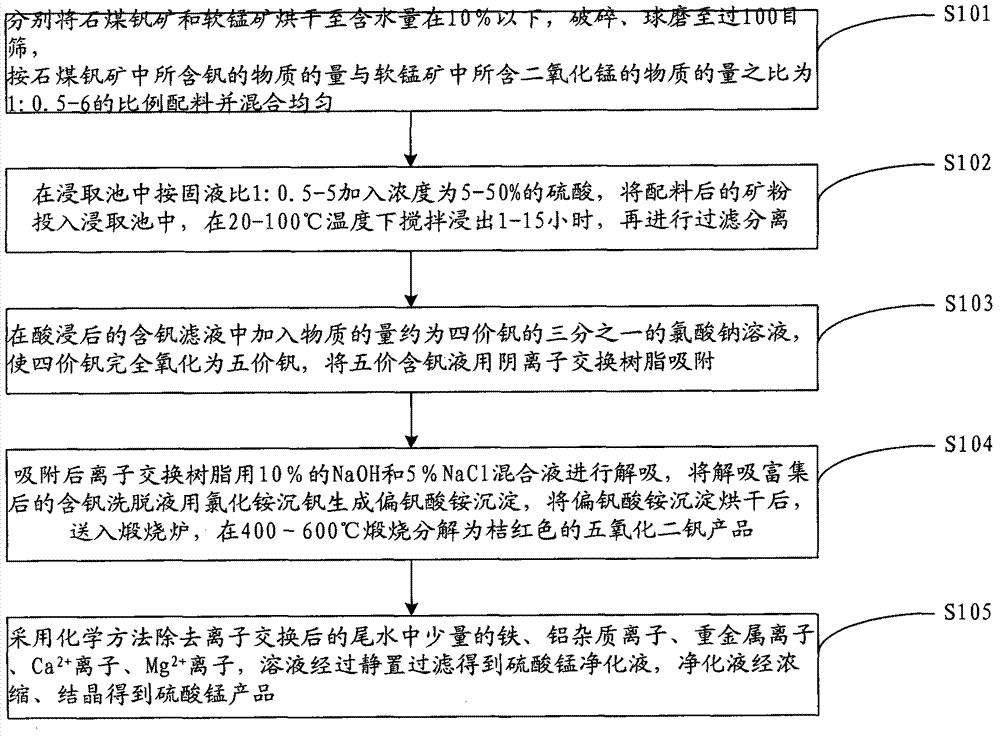

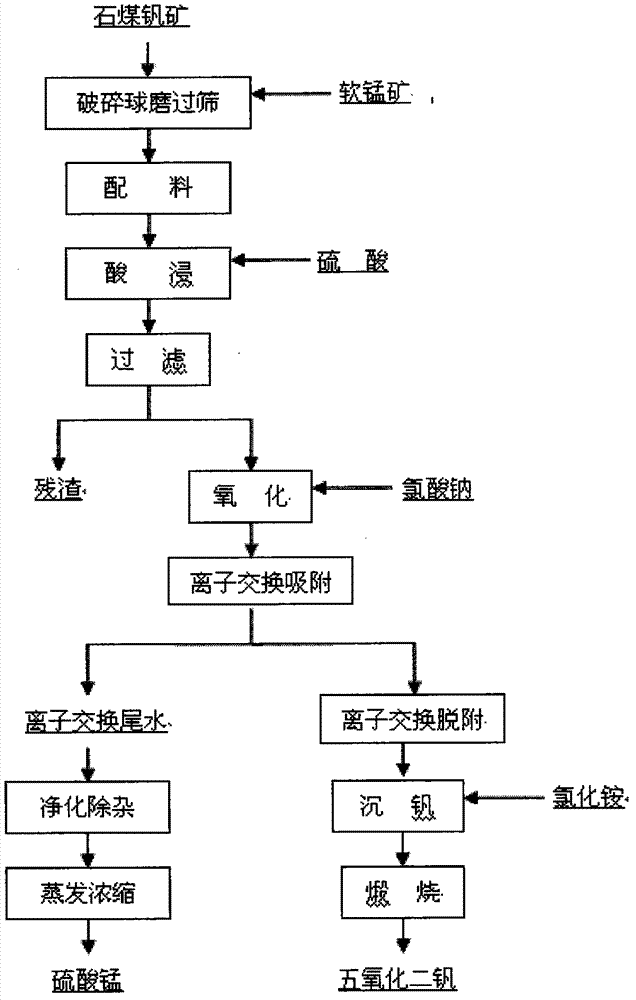

Method for producing vanadium pentoxide and by-product manganese sulfate from by using coal vanadium ore and pyrolusite together

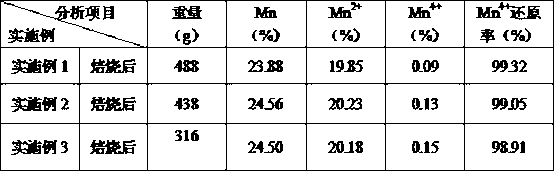

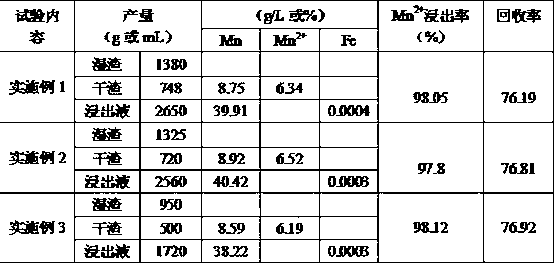

The invention belongs to the technical field of wet metallurgy of vanadium and provides a method for producing vanadium pentoxide and by-product manganese sulfate by using stone coal vanadium ore and pyrolusite together. The method orderly comprises the steps of: crushing, ball-milling and sieving, material proportioning, acid leaching, oxidizing, ion exchange adsorption, ion exchange desorption, molybdenum precipitation, burning, tail water purification and edulcoration by ion exchange, evaporation and concentration, and the like; the stone coal vanadium ore is directly leached without being roasted; the roasting process of the stone coal is omitted; the energy consumption is reduced; the pollution of the burnt gas to the environment is avoided; the purity of the vanadium pentoxide product is greater than 98%; the leaching rate of vanadium is greater than 95%; and the total recovery rate of vanadium is greater than 85%. Compared with the conventional vanadium extraction technology, the leaching rate and the total recovery rate of the vanadium are improved by 20-30%; meanwhile, a manganese sulfate product can be produced as a byproduct; the purity of the manganese sulfate product is greater than 98%; the leaching rate of manganese is greater than 96%; the total recovery rate of manganese is greater than 88%; the metal recovery rate is effectively improved; the production cost is reduced; the environment is protected; and the method has strong popularization and application value.

Owner:JISHOU UNIVERSITY

Improved process of extracting manganese from dialozite

The present invention is improved process of extracting manganese form dialozite, and belongs to the field of wet metallurgy of dialozite. The materials include dialozite and sulfuric acid in the weight ratio of 1 to 0.3-0.8, as well as reductant in 1-18 wt% of dialozite and including sulfite, thiosulfate, SO2, iron pyrite, ascorbic acid and hydroxylamine. The process includes the following steps: filtering the acid leachate of dialozite, adding pyrolusite with MgO2 content of 15-90 wt%; ferrous compound eliminating reaction at 40-80 deg.c for over 20 min; and adding alkali, ammonia, lime, sodium carbonate, sodium bicarbonate and sodium hydroxide into the acid leachate of dialozite to regulate pH value to 5.0-8.0. The present invention has the advantages of less pyrolusite consumption,high Mg leaching rate and low Mg content in slag.

Owner:邹兴

Method for preparing manganese sulfate by using sulfur-containing carbonaceous manganese carbonate ore

The invention provides a method for preparing manganese sulfate by using sulfur-containing carbonaceous manganese carbonate ore. The method comprises the following steps: 1, uniformly mixing manganese carbonate ore powder and pyrolusite powder in proportion and carrying out roasting; 2, immersing the roasted ore obtained in step 1 with anolyte, or industrial sulfuric acid or a composition thereof and carrying out filtering so as to obtain a filtrate which is a leachate containing manganese sulfate; and 3, adding ammonia water into the leachate, then adding a vulcanizing agent into the filtrate and carrying out filtering so as to obtain another filtrate which is a manganese sulfate solution meeting requirements for further processing indexes of a manganese salt. According to the invention, reduction roasting of the pyrolusite is carried out by using reductibility of the sulfur-containing carbonaceous manganese carbonate ore which looks like coal, has a low grade of manganese (with manganese content of about 10%) and can hardly be separated by using magnetism, the pyrolusite can be successfully reduced without usage of a reducing agent in the process of roasting, and the integral graded of manganese is improved; and economic benefit assessment results show that cost for reduction roasting of the manganese carbonate ore and the pyrolusite is lower than that for reduction roasting of the pyrolusite and reduction coal and a substantial effect is obtained through reduction roasting of the manganese carbonate ore and the pyrolusite.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Production process for high purity manganese sulfate through reduction with pyrolusite powder as raw material

ActiveCN103011296AImprove controllabilityGood reproducibilityManganese sulfatesManganese sulphatePyrolusite

The invention relates to a production process for high purity manganese sulfate. The process is characterized in that pyrolusite powder is used as a raw material and is added into concentrated sulfuric acid for pretreatment, filtration is carried out after most impurities like calcium, magnesium, potassium and sodium are leached, an obtained filtrate is delivered to a common manganese sulfate production line for recovery and utilization, hydrogen peroxide used as a reducing agent is added into filter residue having undergone washing so as to reduce and leach pyrolusite powder, and a leachate undergoes condensation crystallization and primary recrystallization to obtain a high purity manganese sulfate product.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

New technology for preparing electrolytic manganese metal solution and recycling iron by reducing pyrolusite with iron scraps

InactiveCN101988154ASimple processMild conditionsProcess efficiency improvementElectrolysisPyrolusite

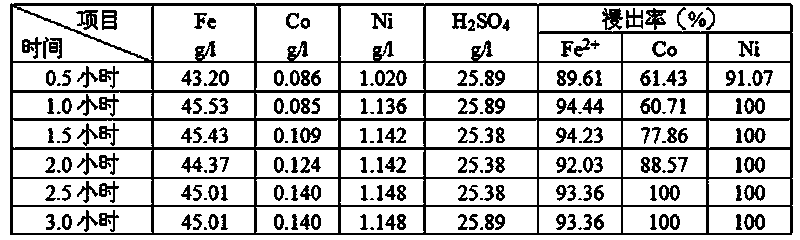

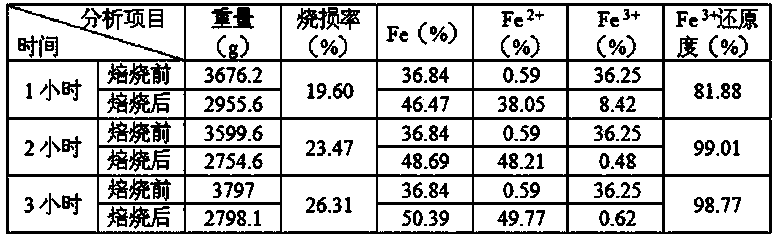

The invention discloses a new technology for preparing manganese sulfate solution which is used for electrolyzing manganese metal and recycling iron through the atmospheric pressure leaching of pyrolusite and iron scraps. The technology comprises the following steps: adding pyrolusite in a certain concentration of sulphuric acid solution, mixing evenly; adding iron scraps used as the reductant in a reaction tank, performing mechanical agitation for 1h-3h under different reaction temperatures to obtain reaction leachate; according to the changes of the reaction time and the pH value, adding heavy calcium carbonate and ammonia water in turn to adjust the pH value of the solution to 6.3-6.7; then adding sodium N,N-dimethyl dithiocarbaminate (SDD) to remove impurities such as heavy metal ions and purify; filtering, adding additive to obtain manganese sulfate solution used for electrolyzing manganese; and recycling iron from filter residue through alkali leaching and acid leaching to produce polyferric sulfate. The invention has the advantage that iron scraps are used as the reductant which have wide sources and rich raw materials and can be leached out under the atmospheric pressure; and iron scraps can be recycled to produce the water purification agent and have great economic benefit.

Owner:HUNAN UNIV OF SCI & TECH +1

Remediation agent for leaching soil polluted by heavy metal chrome

The invention relates to a remediation agent for leaching soil polluted by heavy metal chrome. The invention belongs to the technical field of heavy-metal-polluted soil remediation. The remediation agent comprises mixed components of, by weight: 95% to 99% of citric acid and 1% to 5% of pyrolusite. The leaching agent provided by the invention has advantages of low raw material cost, high remediation speed, good effect, and easy recycling of waste liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

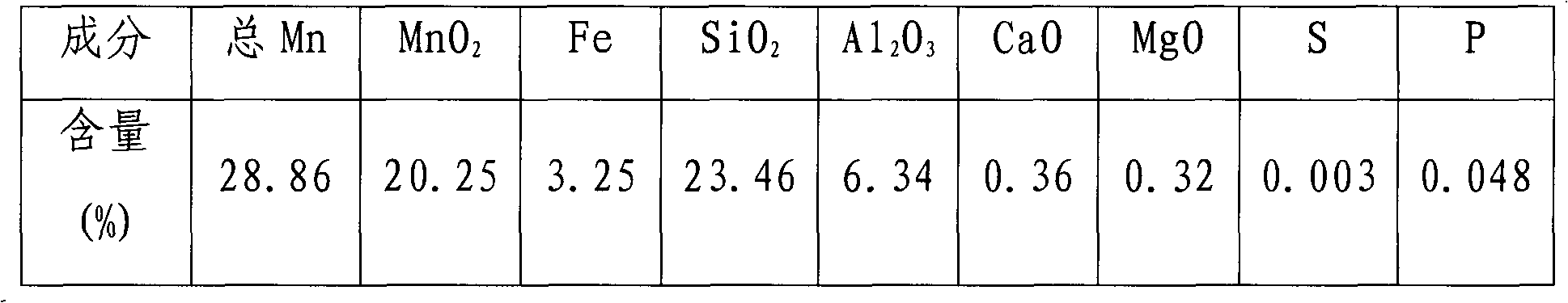

Method for preparing manganese sulfate from waste byproducts obtained in the production of titanium white and low-grade pyrolusite

InactiveCN101920998AReduce energy consumptionLow costSolid waste disposalManganese sulfatesPyrolusiteSlurry

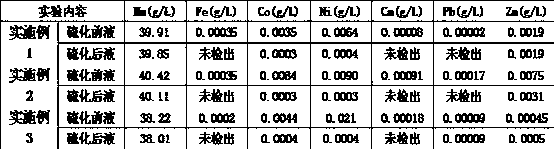

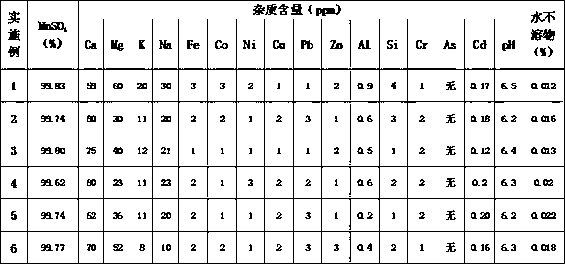

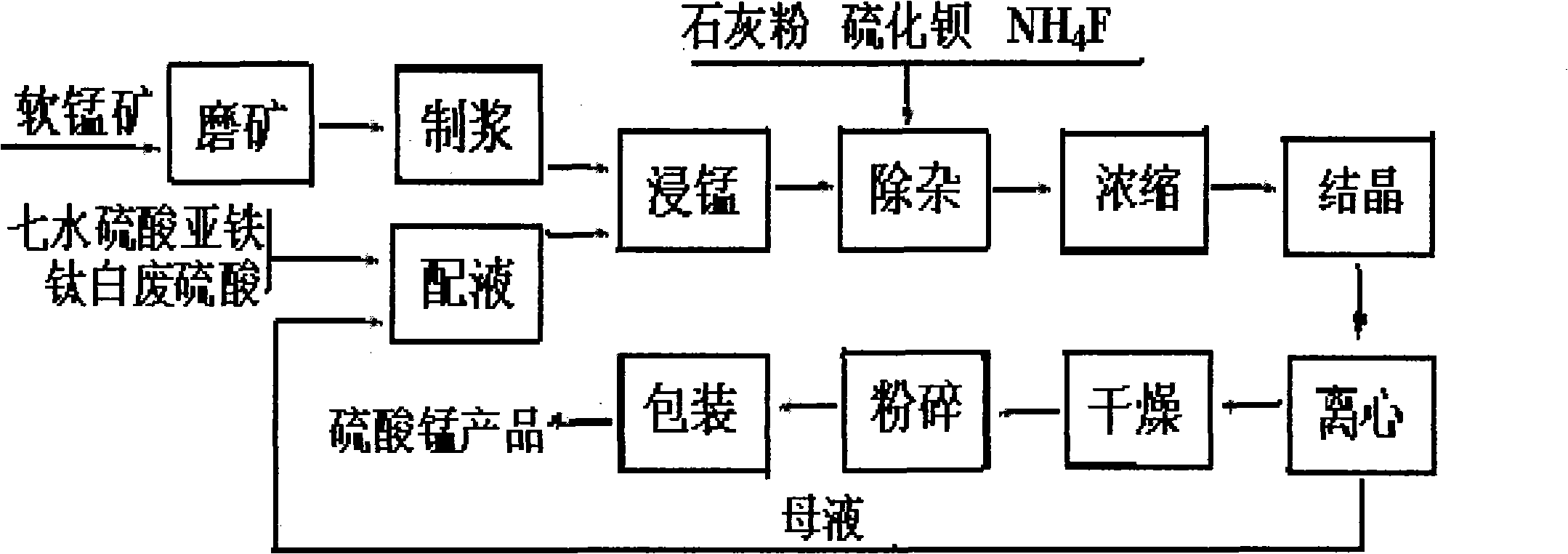

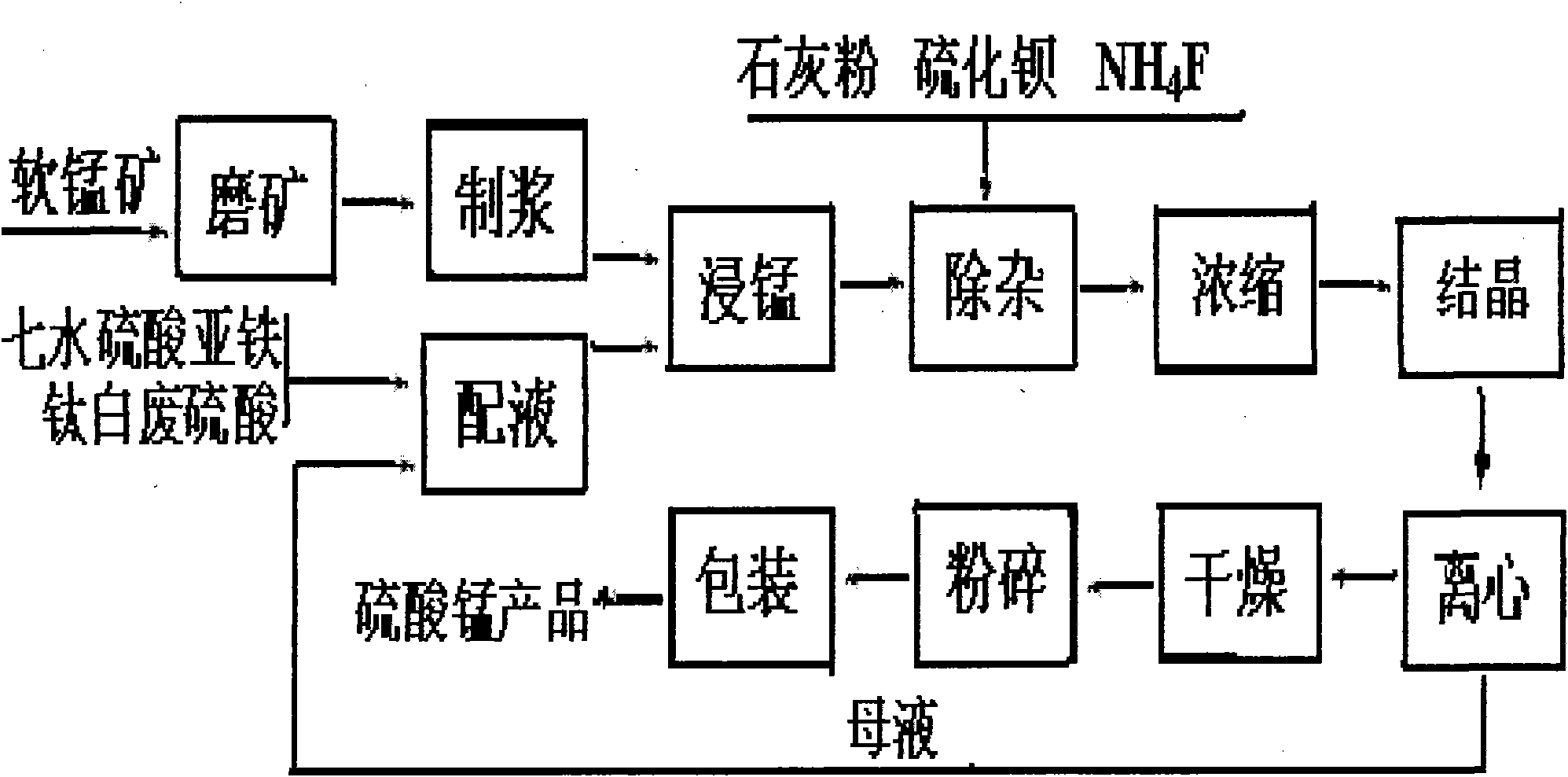

The invention discloses a method for preparing manganese sulfate from waste water, waste sulphuric acid and a byproduct, namely iron vitriol obtained in the production of titanium white and low-grade pyrolusite or medium-grade pyrolusite with content of 10 to 20 percent, which has the advantages of low energy consumption, low cost and simple operation. The method comprises the following processes of grinding ore to prepare slurry, preparing reducing fluid, performing manganese leaching reaction, removing impurities, performing concentrative crystallization, performing centrifugal separation, drying, pulverizing and sieving and packaging, wherein the manganese leaching reaction is performed at the temperature of between 20 and 45 DEG C without vapor heating and pressurizing, so the method has the advantages of the comprehensively utilizing the iron vitriol, the waste water and the waste sulphuric acid during the production of the titanium white, turning waste into wealth, along with the leaching rate of manganese of more than 98 percent, the yield of the manganese of more than 85 percent, and good double benefits of environmental protection and circular economy development.

Owner:蓝星安迪苏股份有限公司

Ozone catalyst and preparation method thereof

InactiveCN105381804AReduce manufacturing costImprove adsorption capacityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsEnvironmental resistancePyrolusite

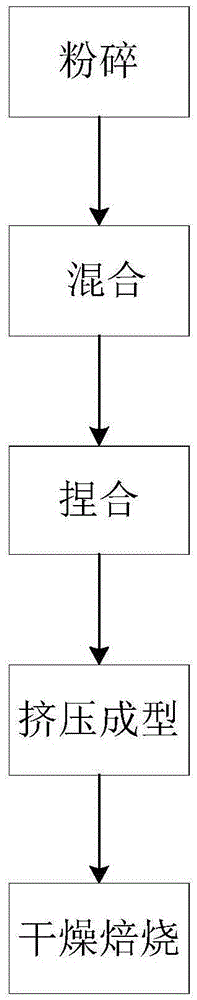

The invention relates to the technical field of catalyst preparation, in particular to an ozone catalyst which is low in cost and free of pollution and a preparation method of the ozone catalyst. A manganese sand filter material or pyrolusite ore serves as the raw material, adhesive, peptizer and a pore-expanding agent are added, and the ozone oxidation catalyst is finally formed through a series technologies of grinding, mixing, kneading, extrusion forming, drying and calcination and the like. According to the technical scheme, the catalyst is prepared by taking natural manganese sand or the pyrolusite ore as the raw material, the catalyst contains catalytic active components of manganese dioxide and iron, metallic elements do not need to be added, the production cost of the ozone catalyst is reduced, porous matter with the adsorptive action serves as the adhesive, the adsorption performance of the catalyst is effectively enhanced, the peptizer is added, the strength of the catalyst is enhanced, and certain pore expanding action is achieved. Due to the fact that the ozone catalyst is prepared through the method, nitrogen oxide pollution caused by calcination in the ordinary preparation process of an ozone catalytic oxidation catalyst is avoided, and the ozone catalyst and the preparation method thereof have the advantages of being low in cost, green and environmentally friendly.

Owner:BEIJING ORIGIN WATER FILM TECH

Process for the manufacture of bio-release iron-manganese fertilizer

InactiveUS7691171B2Improve usabilityBetter bio availabilitySuperphosphatesPhosphatesPyrolusiteWater insoluble

This invention provides a process for the preparation of water insoluble, bio-release iron-manganese fertilizer which comprises, heating phosphoric acid with a mixture of (i) source of iron oxide such as goethite and hematite, (ii) pyrolusite and (iii) one or more basic compound(s) selected from oxide(s) or carbonate(s) of magnesium, calcium, sodium and potassium, (b) neutralisation followed by drying and pulverisation.

Owner:AGTEC INNOVATIONS

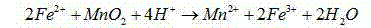

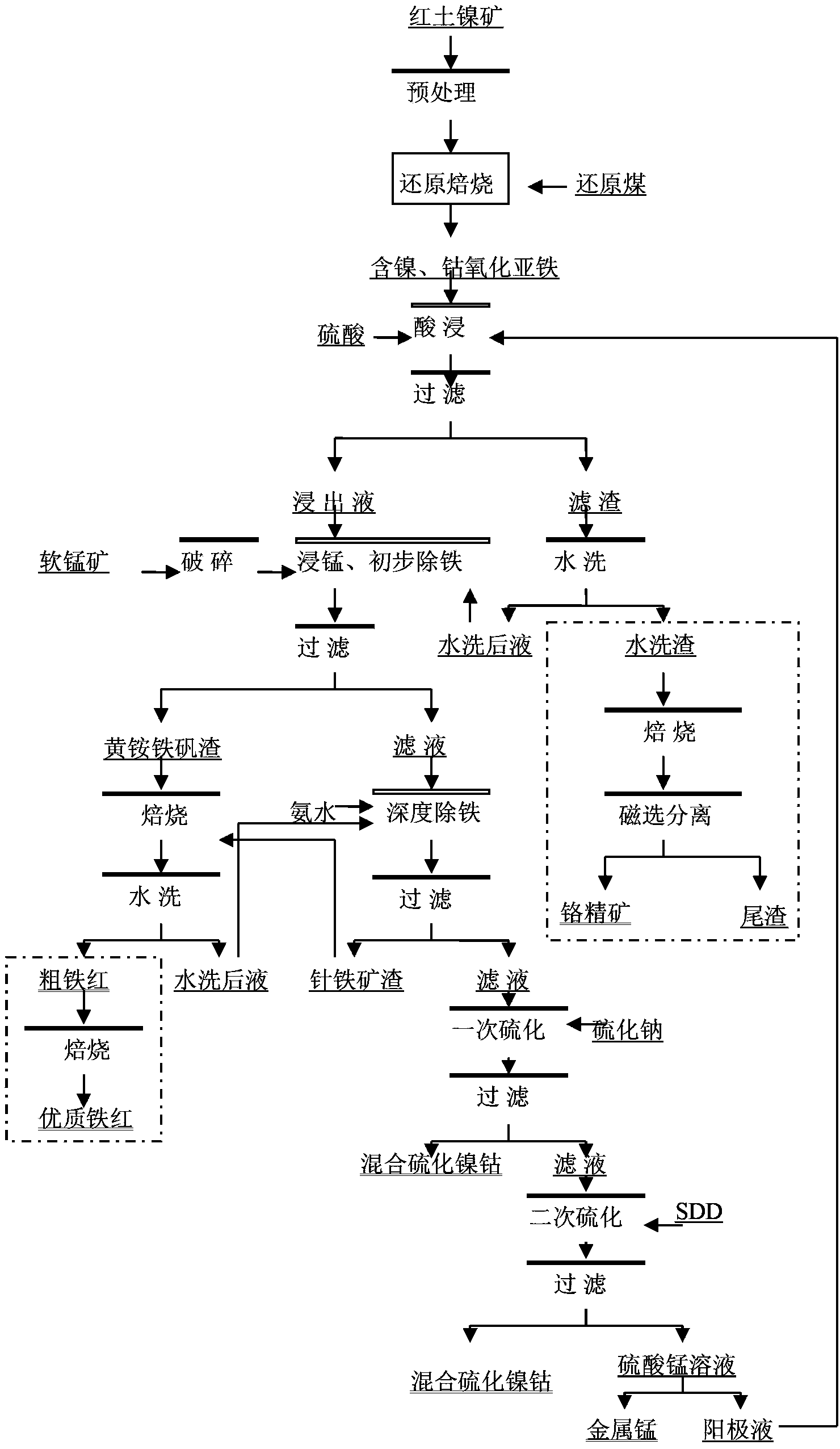

Two ore combined process for treatment of laterite nickel ore and pyrolusite

The invention relates to a two ore combined process for treatment of laterite nickel ore and pyrolusite. The process includes the following steps: mixing laterite nickel ore with coal and roasting to obtain a ferrous oxide powder containing nickel and cobalt; leaching the ferrous oxide powder containing nickel and cobalt with concentrated sulfuric acid; after filtering, adding ammonium sulfate to the solution, controlling the concentration of H2SO4, adding pyrolusite to oxidize Fe<2+> into Fe<3+> and reduce Mn<4+> into Mn<2+>, and filtering to obtain a MnSO4-containing solution and an ammonium jarosite precipitate; adding a vulcanizing agent to the MnSO4-containing solution to produce sulfide nickel and cobalt sulfide precipitates, drying the precipitates to obtain a mixed powder of sulfide nickel and cobalt sulfide; and roasting the obtained ammonium jarosite precipitate, washing by water and drying to obtain crude iron red. The process can extract valuable metallic elements nickel, cobalt, iron and manganese from the two ores; and compared to respective treatment on the laterite nickel ore and manganese ore, the process saves production cost and improves production efficiency.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

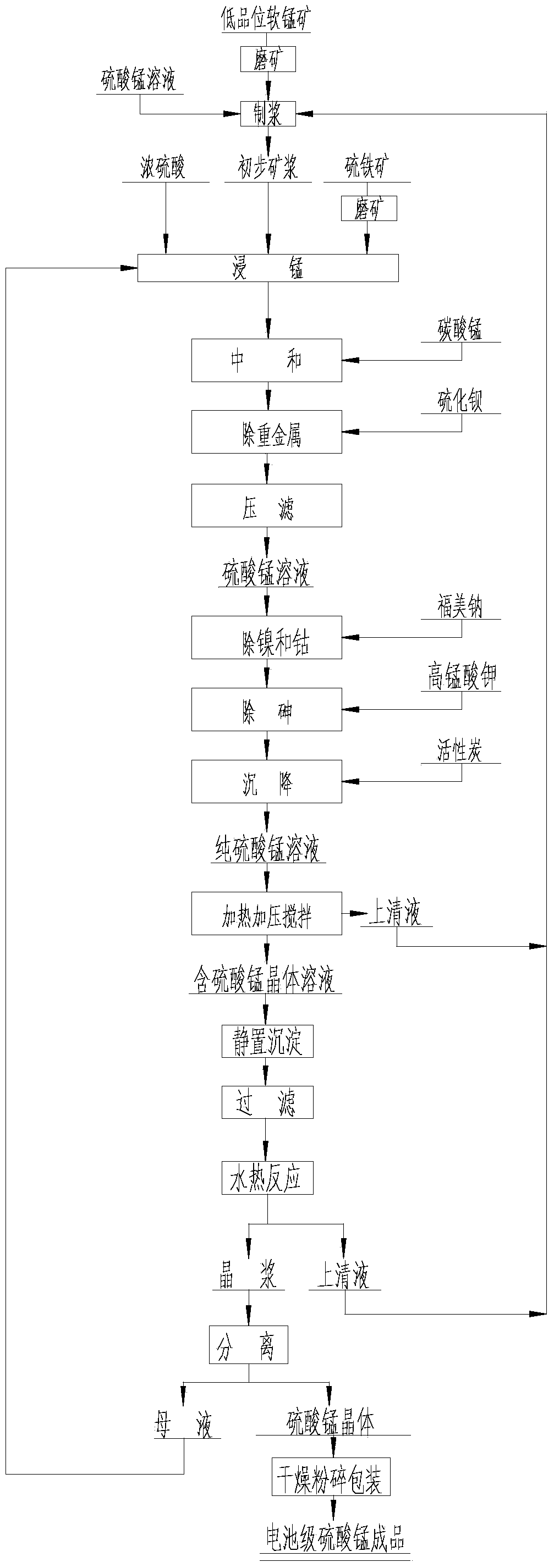

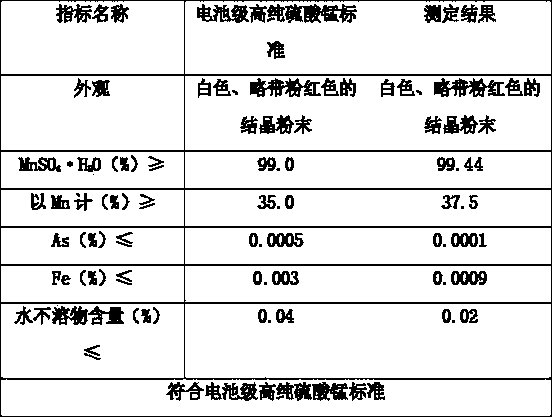

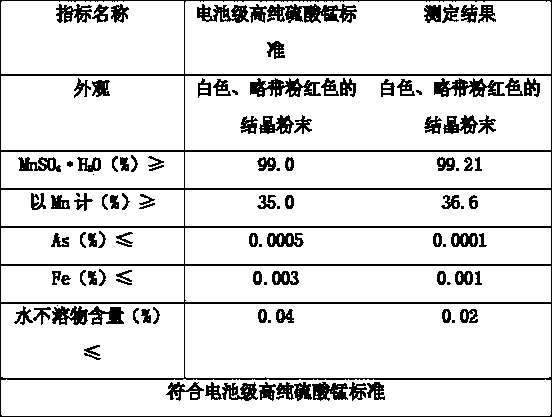

Method for preparing cell-grade high-purity manganese sulfate by low-grade manganese ore high-pressure crystallization

The invention discloses a method for preparing cell-grade high-purity manganese sulfate by low-grade manganese ore high-pressure crystallization. The method comprises the following steps of grinding low-grade pyrolusite and pyrite into powder particles, preparing a manganese sulfate solution, mixing the manganese sulfate solution and the pyrolusite powder particles to obtain preliminary pulp, mixing the preliminary pulp, concentrated sulfuric acid and the pyrite powder particles according to a certain ratio, carrying out heating, stirring and manganese impregnation on the mixture, adding a neutralizer into the mixture to adjust a pH value, adding barium sulphide and sodium dimethyldithiocarbamate into the mixture to remove impurities so that a pure manganese sulfate solution is obtained, carrying out heating pressurization stirring on the pure manganese sulfate solution, discharging a supernatant to obtain a manganese sulfate crystal-containing solution, carrying out standing precipitation of the manganese sulfate crystal-containing solution at a normal temperature, carrying out filtration to obtain a high-concentration manganese sulfate solution, adding the high-concentration manganese sulfate solution into a high-pressure autoclave, carrying out crystallization at a high temperature under high pressure, discharging a supernatant after crystallization to obtain manganese sulfate crystal-containing magma, separating the manganese sulfate crystal-containing magma to obtain high-purity manganese sulfate crystals, and drying and crushing the high-purity manganese sulfate crystals to obtain the cell-grade high-purity manganese sulfate.

Owner:CENT SOUTH UNIV +1

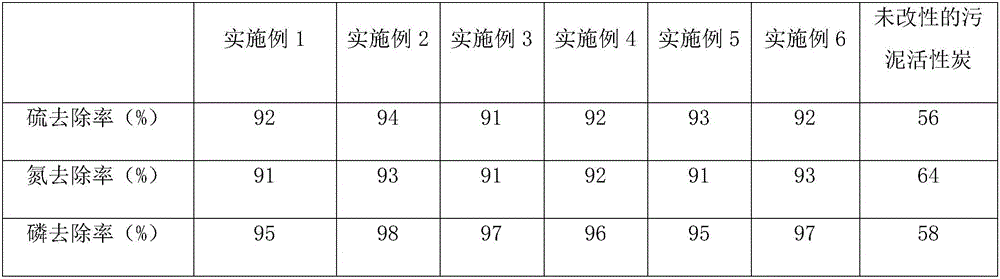

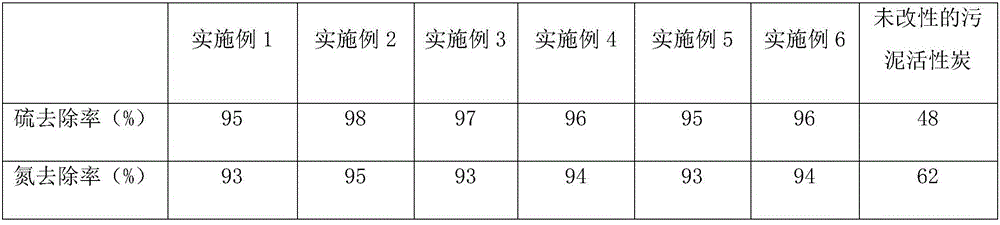

Rare metal-based sludge activated carbon and application thereof in removal of sulfur, ammonia and phosphorus

ActiveCN106345411AImprove adsorption capacityAchieve separationOther chemical processesWater contaminantsActivated sludgePorosity

The invention provides a rare metal-based sludge activated carbon and application thereof in the removal of sulfur, ammonia and phosphorus. The rare metal-based sludge activated carbon includes sludge activated carbon and metal elements such as manganese, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium and the like, and is specifically prepared by a method comprising the following steps: mixing pyrolusite powder with activated sludge, adding a zinc chloride compounded activating agent into the mixture, activating the mixture at a high temperature, carbonizing the mixture to obtain pyrolusite compounded activated sludge, mixing the activated sludge with rare earth oxide powder and a chelating agent after the activated sludge is modified by potassium hydroxide solution, heating the mixture in a microwave oven, carbonizing the mixture to obtain rare earth compounded activated sludge, and mixing the compounded activated sludge to obtain a product. The rare metal-based sludge activated carbon prepared by the method has the advantages of high activity, high porosity, uniform pore size distribution, high adsorption capacity, capability of chelating a plurality of metals and microorganisms, high capacity of adsorbing sulfur, ammonia and phosphorus and high rate of removing the sulfur, the ammonia and the phosphorus in sewage and waste.

Owner:徐海燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com