Patents

Literature

2670 results about "Sand filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

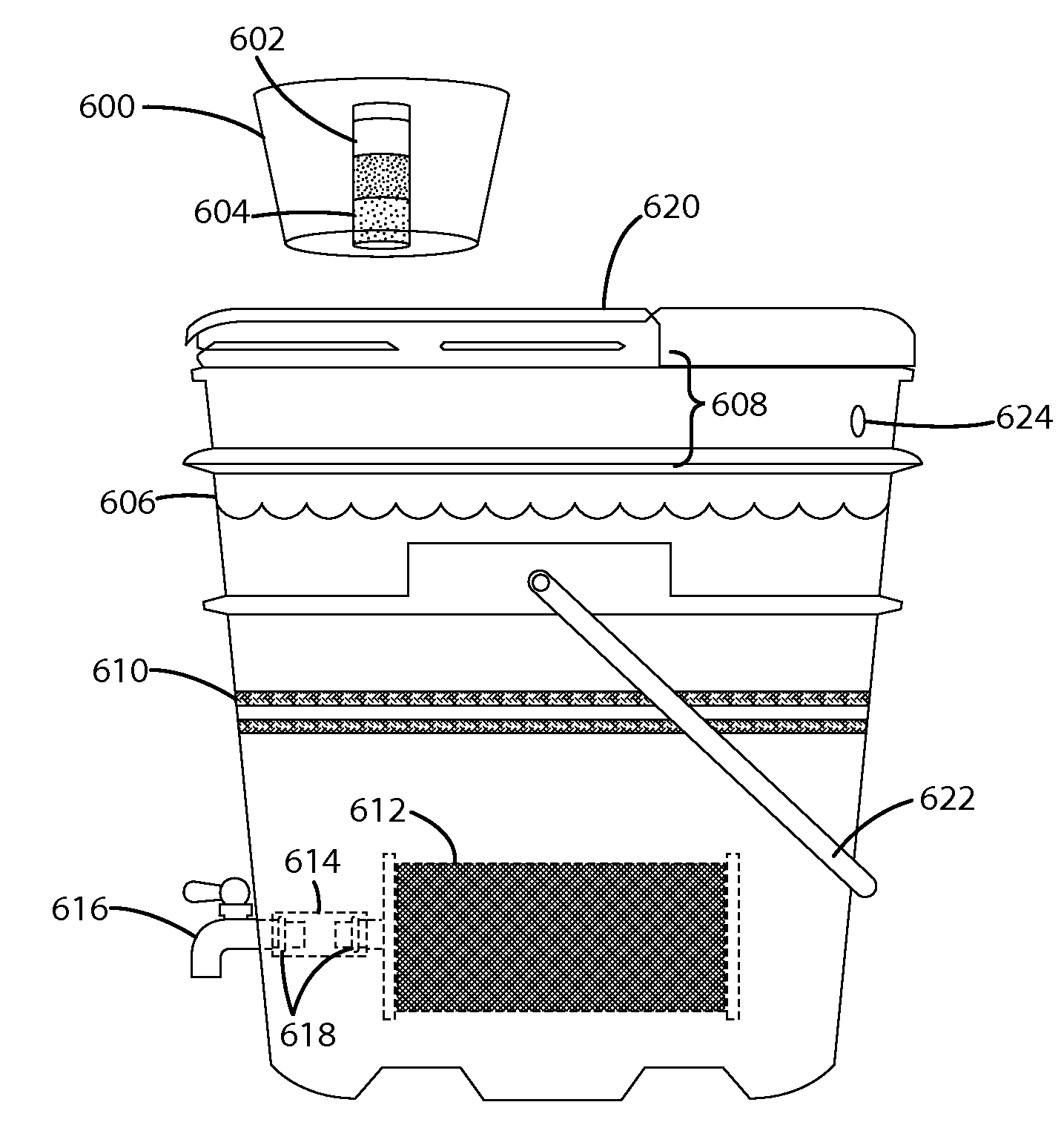

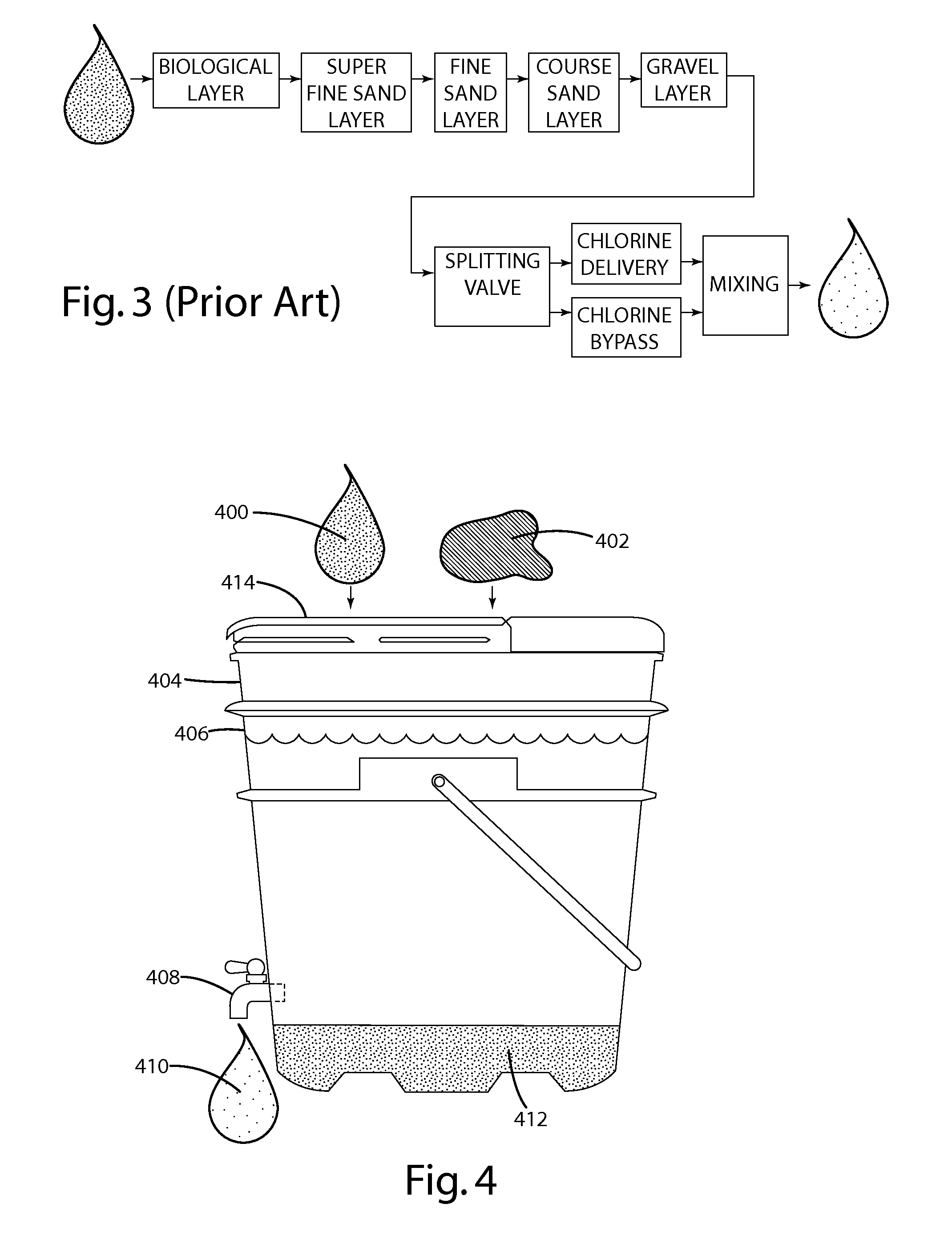

Sand filters are used as a step in the water treatment process of water purification. There are three main types; rapid (gravity) sand filters, upward flow sand filters and slow sand filters. All three methods are used extensively in the water industry throughout the world. The first two require the use of flocculant chemicals to work effectively while slow sand filters can produce very high quality water with pathogens removal from 90% to >99% (depending on the strains), taste and odour without the need for chemical aids. Sand filters can, apart from being used in water treatment plants, be used for water purification in singular households as they use materials which are available for most people.

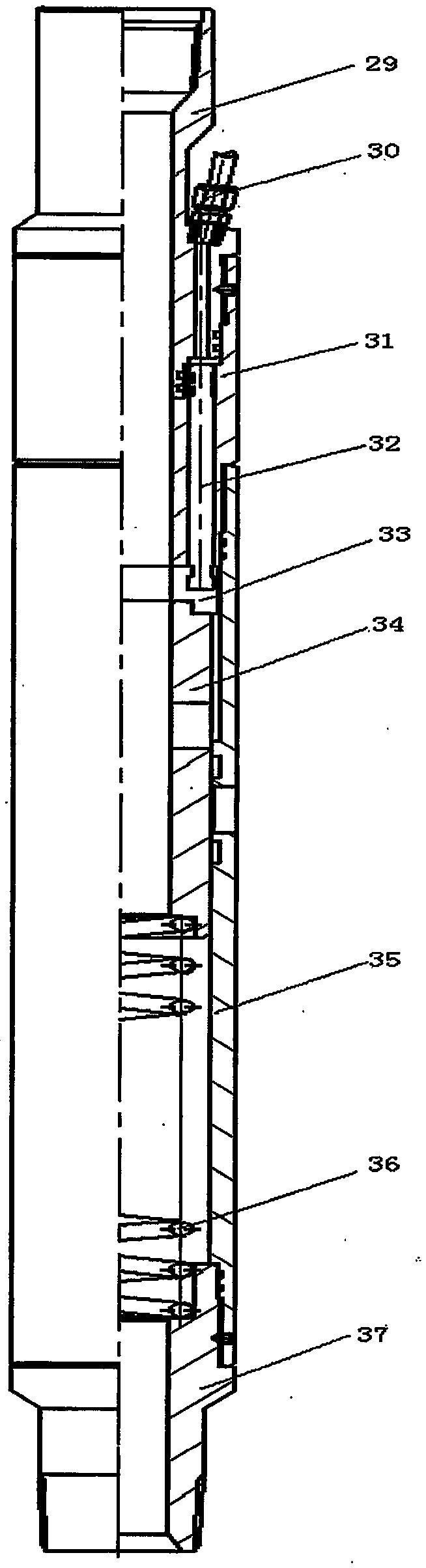

Methods and Apparatus for Completing a Well

ActiveUS20070017675A1Avoid enteringEasy to produceDrilling rodsFluid removalFracture zoneSand filter

Methods and tools are described to reduce sanding including the steps of fracturing the cement sheath in a localized zone around the casing and having the fractured zone act as sand filter between the formation and openings in the casing, with the openings being best pre-formed but temporarily blocked so as to allow a conventional primary cementing of the casing. The fracturing step can also be used for remedial operation to reopen blocked formation or screens.

Owner:SCHLUMBERGER TECH CORP

Methods and apparatus for completing a well

Methods and tools are described to reduce sanding including the steps of fracturing the cement sheath in a localized zone around the casing and having the fractured zone act as sand filter between the formation and openings in the casing, with the openings being best pre-formed but temporarily blocked so as to allow a conventional primary cementing of the casing. The fracturing step can also be used for remedial operation to reopen blocked formation or screens.

Owner:SCHLUMBERGER TECH CORP

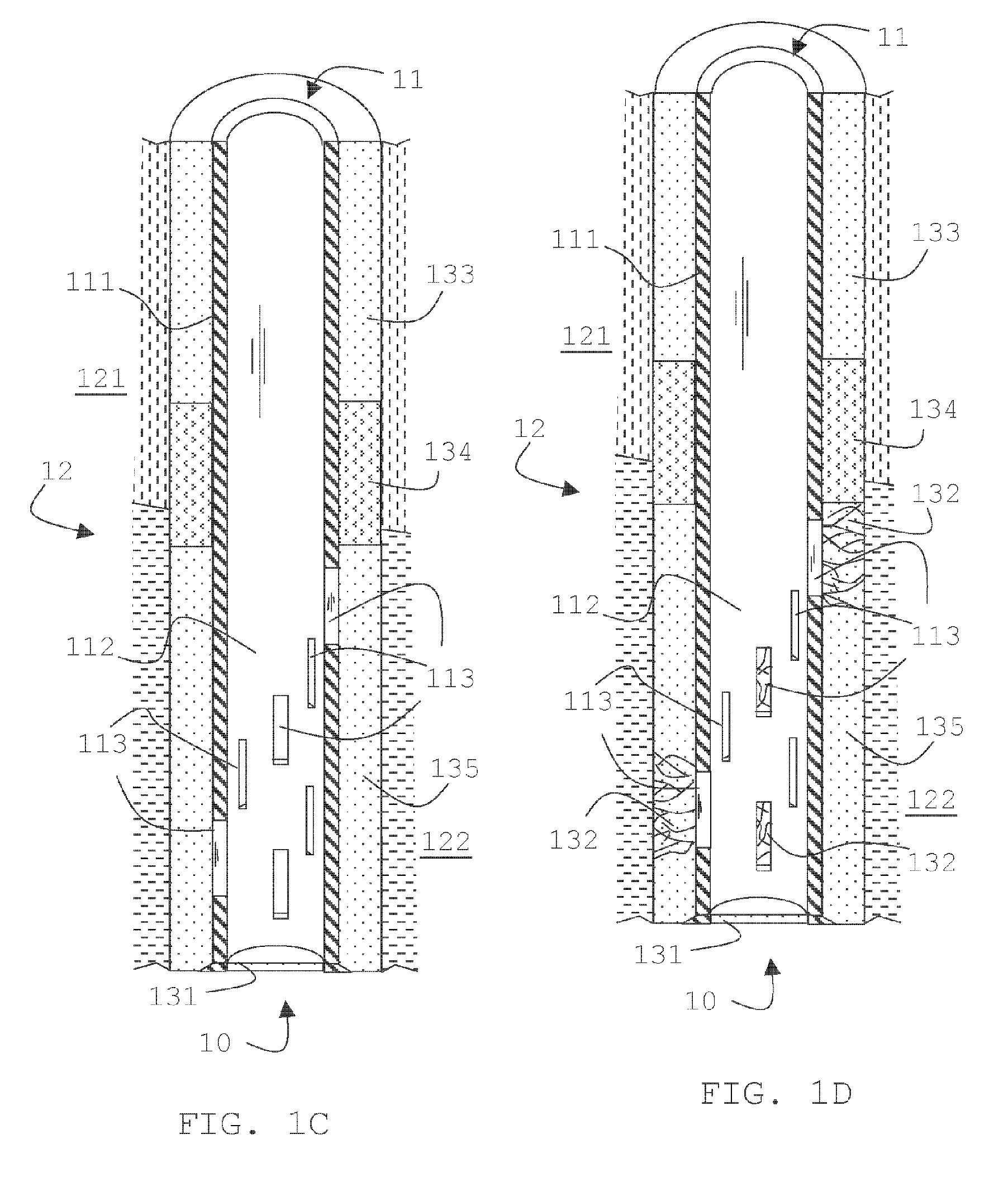

Gravity feed water treatment system

ActiveUS20110303589A1Increase flow rateHigh flow rateTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

A portable water treatment system includes at least one sub-system to treat water including a flocculation system, a chlorination system, and a bio-sand filter system. The water treatment system may include multiple sub-systems for treating water that feed into one another. The sand filter system may include a mini bio-sand filter, a foam filter, or a pressed block filter. The flocculation system may include a tank bottom that urges settling particles toward a sump and a ladle that removes settled particles. A manual pump or siphon may be included in the water treatment system.

Owner:ACCESS BUSINESS GRP INT LLC

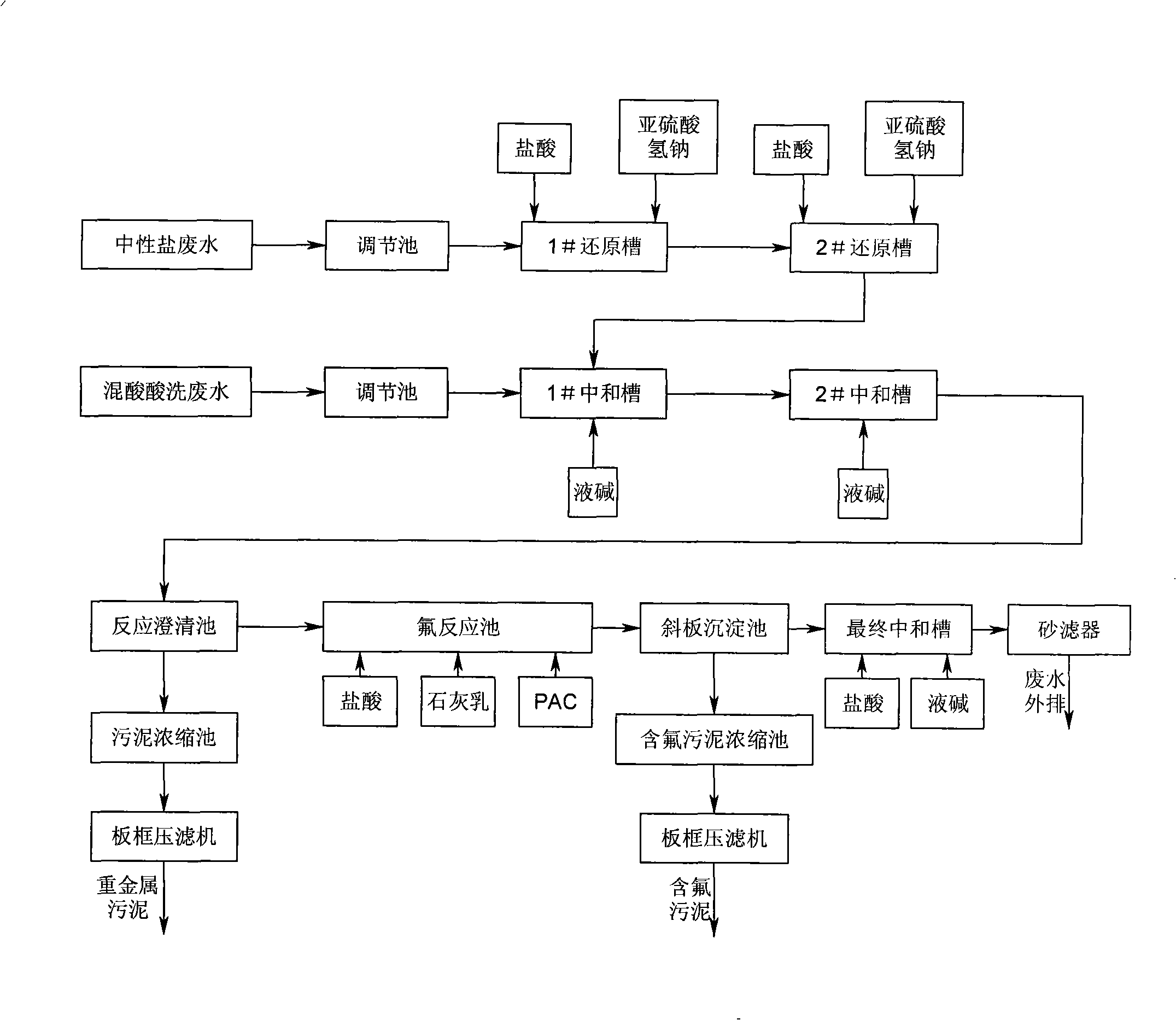

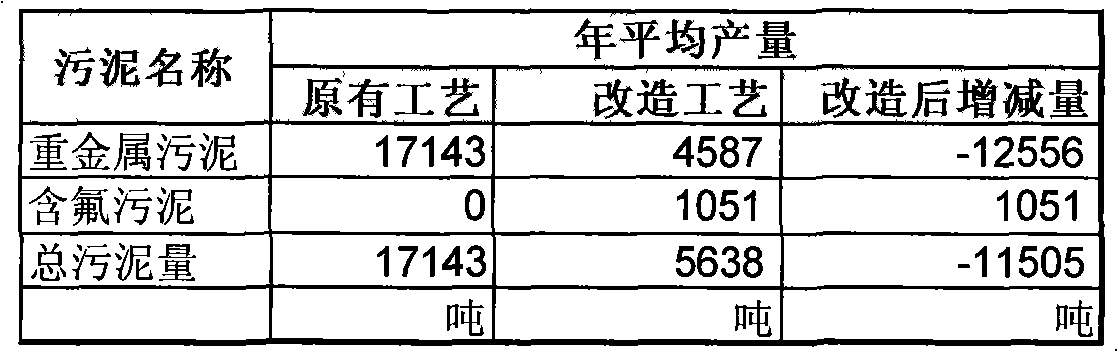

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

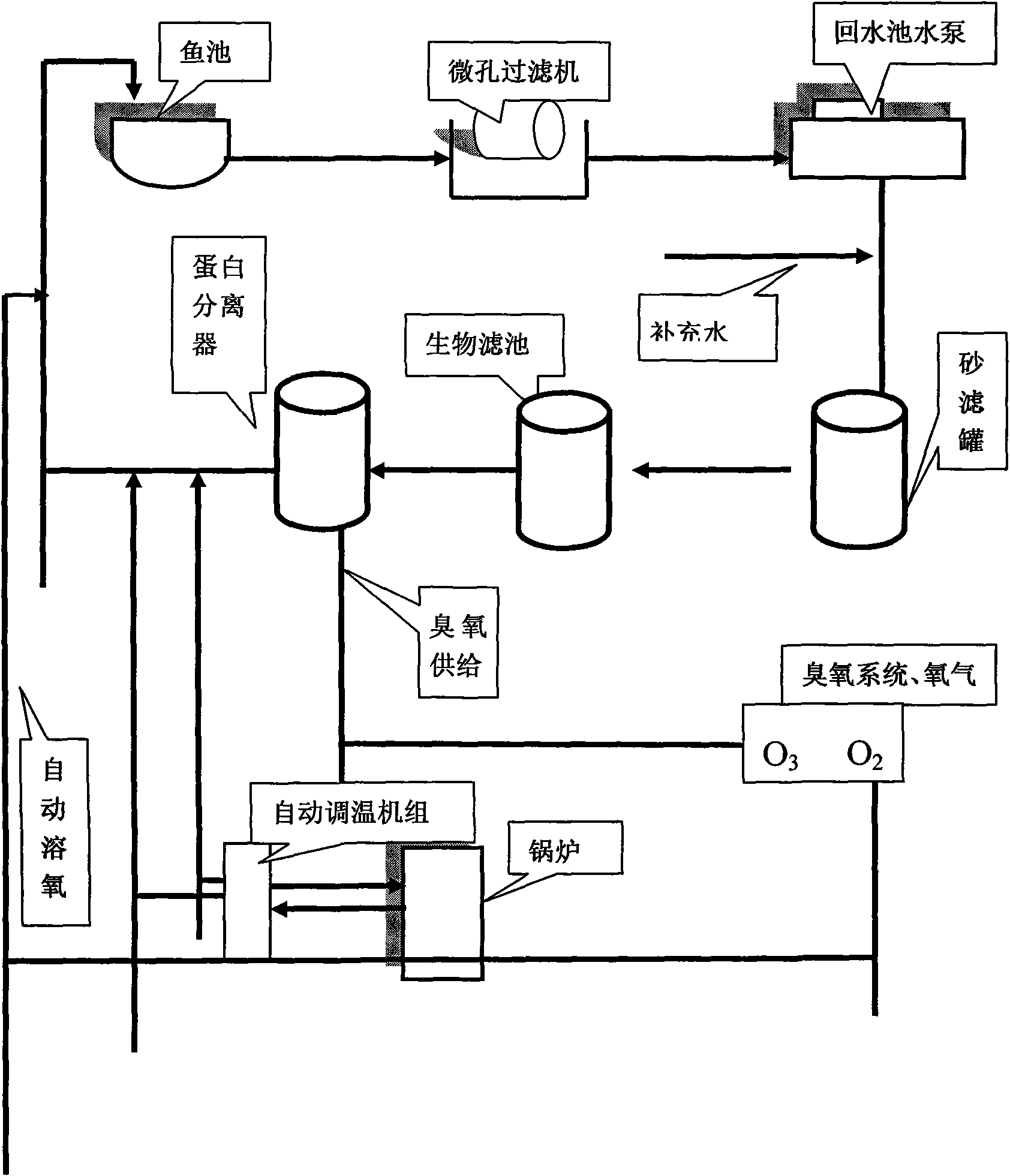

Intensive circulating water culture system

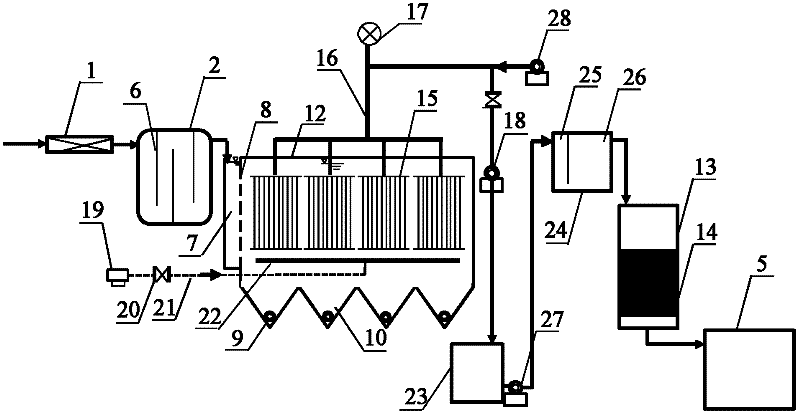

InactiveCN101606506AHigh densityImprove qualityPisciculture and aquariaMultistage water/sewage treatmentOzone generatorAquatic product

An intensive circulating water culture system comprises at least one water purification system which is configured in an aquaculture pond and mainly composed of a water pump, a filter and a sterilizing device. The water pump is at least arranged between a return water regulating pond and a sand filter tank, and the sand filter tank is then sequentially connected with a biofilter and a protein skimmer to form the filter; the water purification system is configured with a dissolved oxygen release device, and the device oxygenates the water purification system by connecting with the protein skimmer; and the water purification system is configured with an ozone generator and an automatic temperature regulating unit which are connected with the water purification system respectively by pipelines. The intensive circulating water culture system is characterized by simple structure, small occupied space, low cost, good circulating water treatment effect, meeting requirements for intensive aquaculture and the like.

Owner:陈能娟

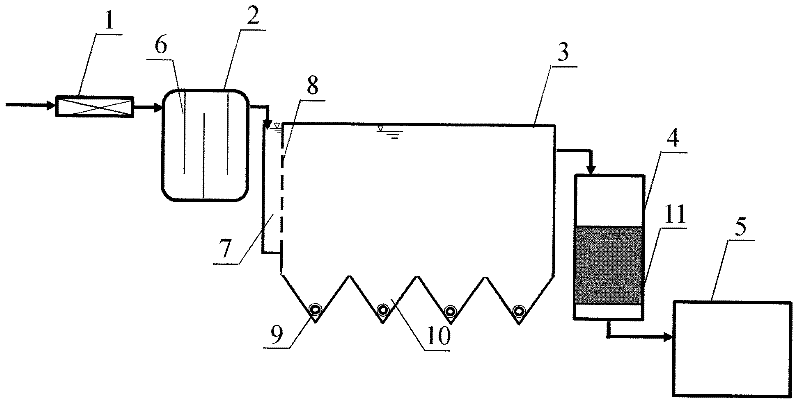

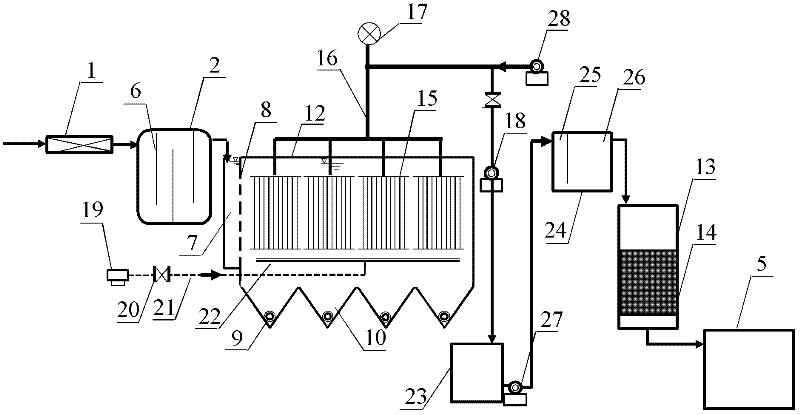

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

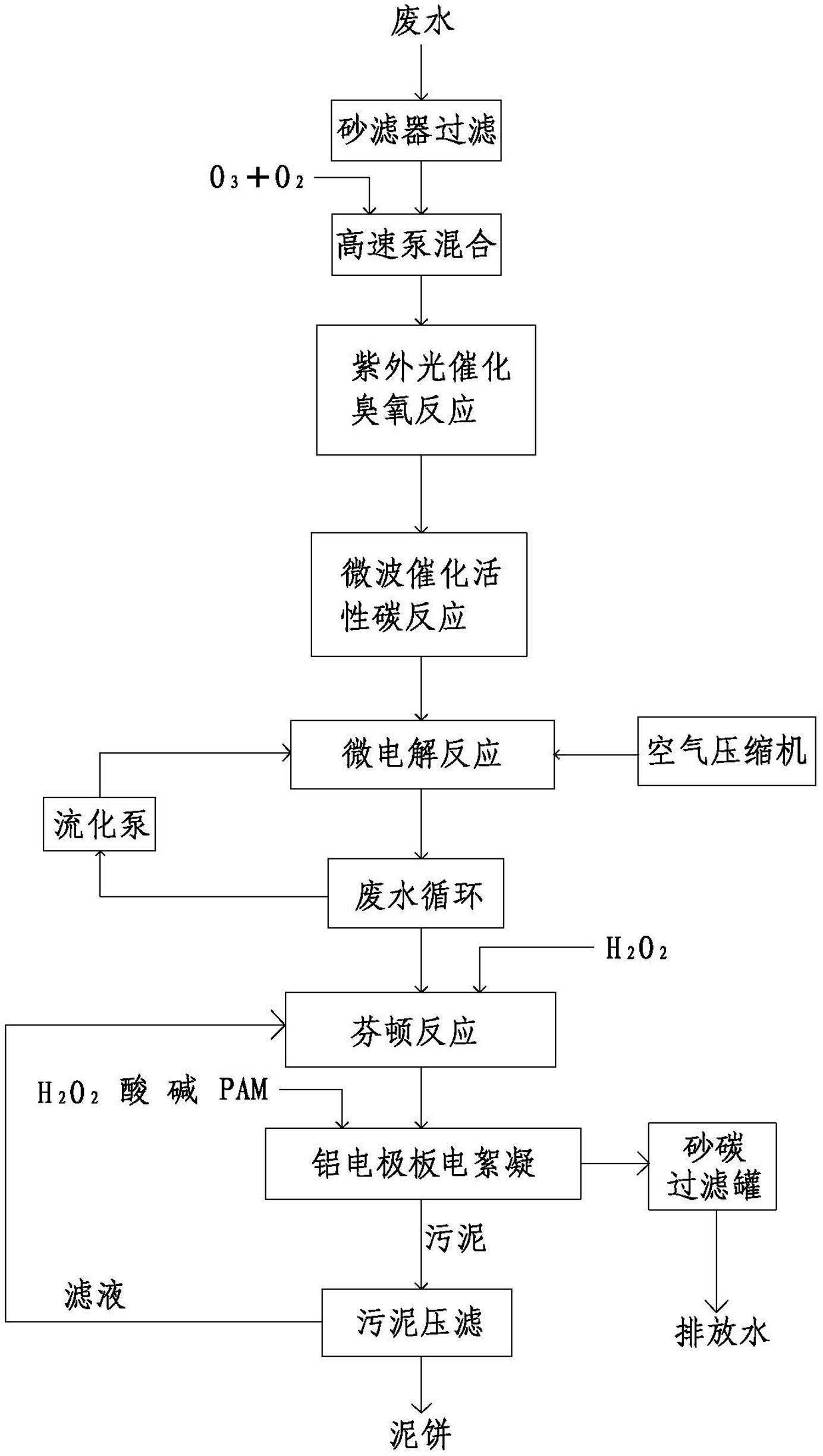

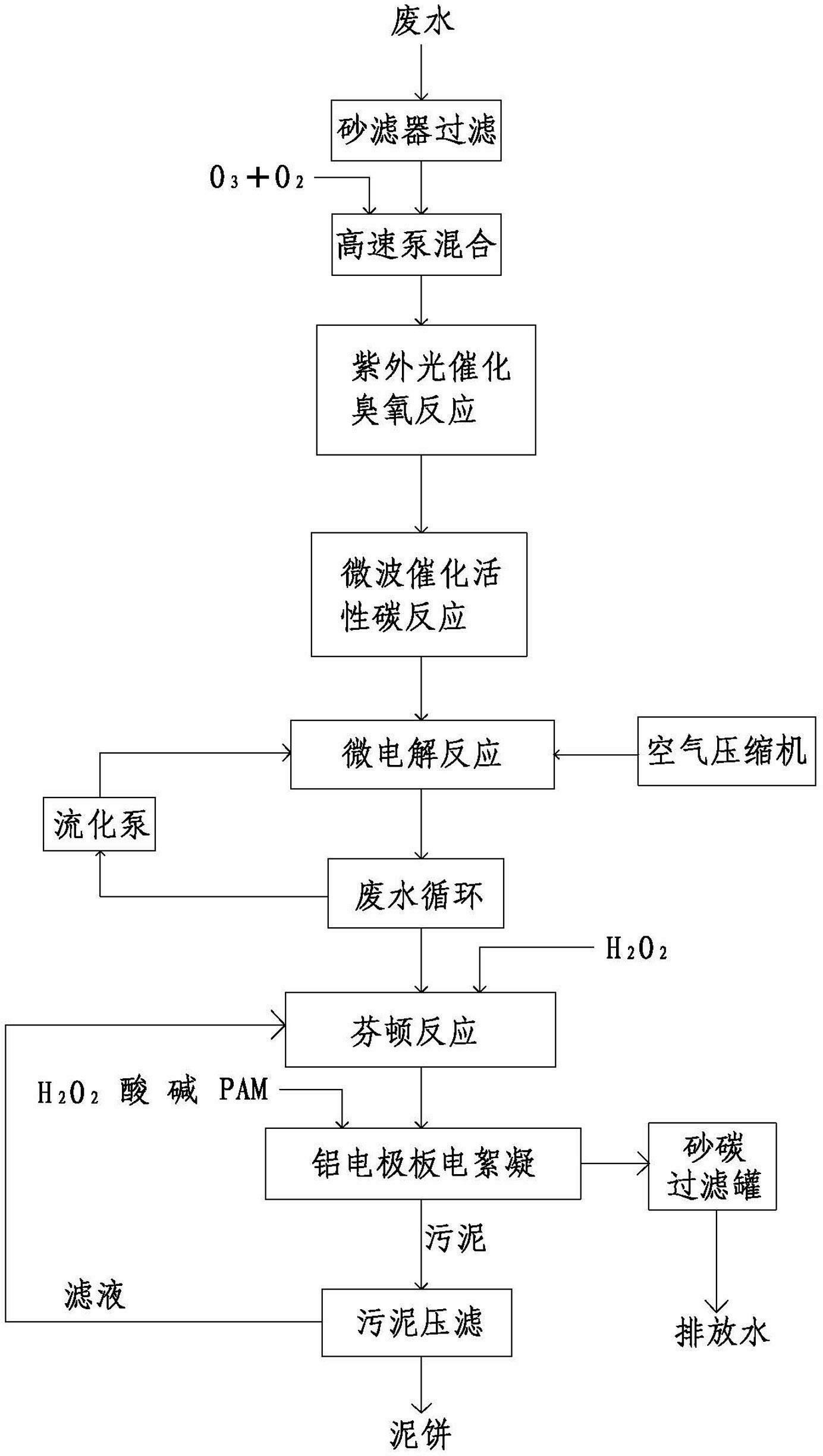

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

Urban road rainfall runoff ecological coprocessing device and method

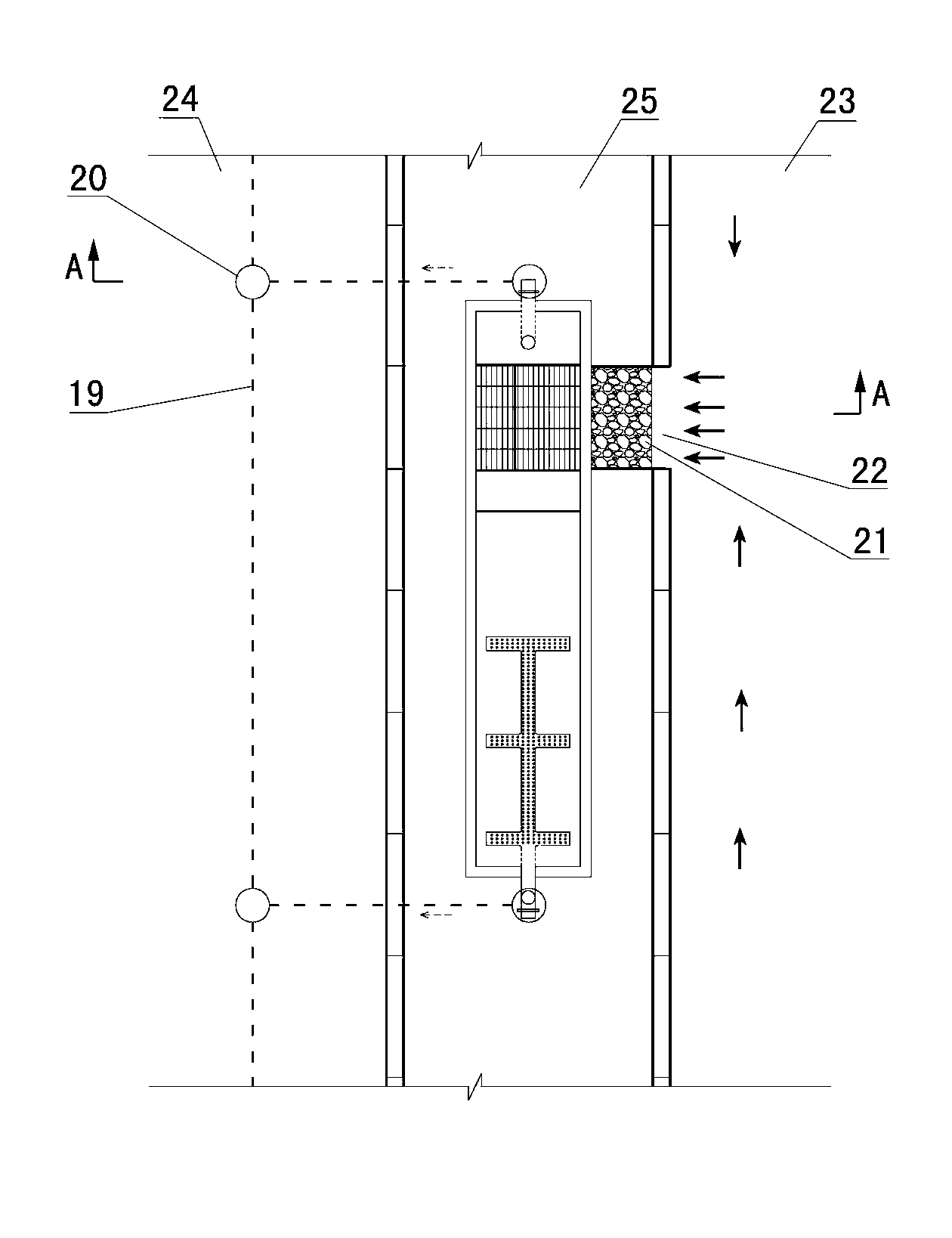

InactiveCN103073111AImprove retentionAlleviate severe flooding problemsFatty/oily/floating substances removal devicesSewerage structuresRainfall runoffWater quality

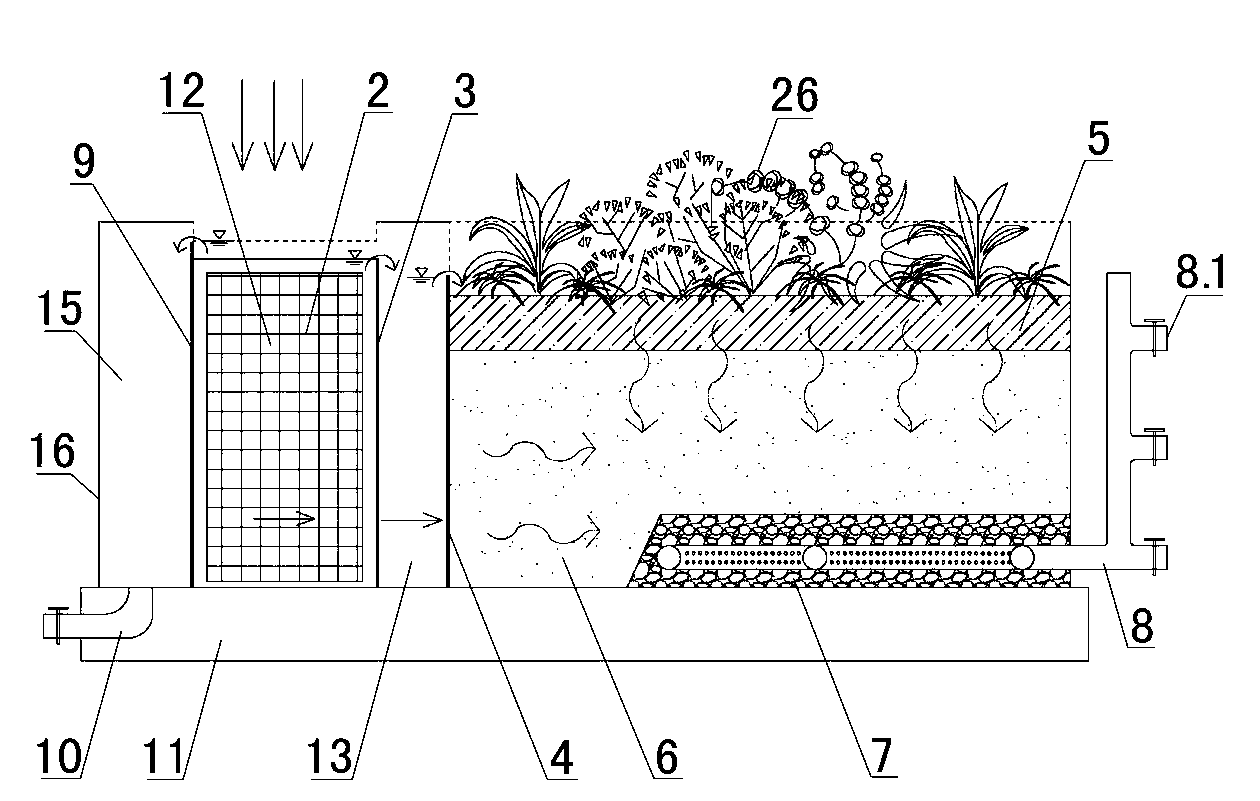

The invention discloses an urban road rainfall runoff ecological coprocessing device and a method. The device comprises an urban road rainfall runoff ecological coprocessing box and a bioretention purification unit, wherein an overflow weir board, a second screen mesh partition and a perforation partition are arranged in the urban road rainfall runoff ecological coprocessing box at intervals sequentially; the interior of a box body is divided into an overflow chamber, a water inlet chamber, a water distribution chamber and a bioretention purification chamber that are sequentially arranged by the overflow weir board, the second screen mesh partition and the perforation partition; and the bioretention purification unit is arranged in the bioretention purification chamber, and comprises a gravel layer, a sand filter layer, a planting soil layer and plants. The device and the method can sequentially remove floating matters, particles and soluble pollutants that are in different particle sizes in rainfall runoff, achieve hierarchical control of the pollutants in the rainfall runoff, can store a part of rainfall runoff to meet growth requirements of the plants in the bioretention unit, achieve a water conservation effect, and can also achieve multi-purpose control of water quality and water quantity of the urban road rainfall runoff.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE +1

Garbage leachate treatment technique

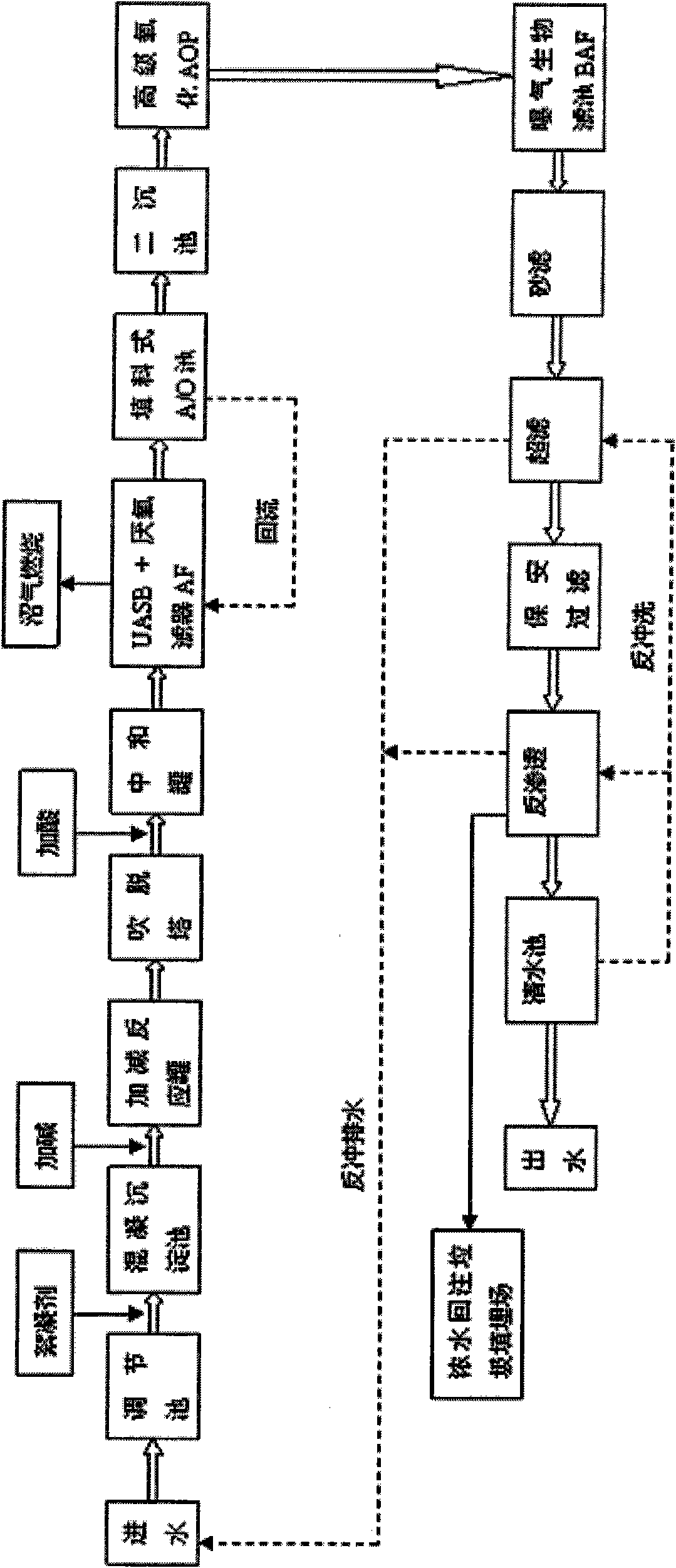

ActiveCN101671095AEfficient separationEfficient degradationTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisWater qualitySewage

The invention discloses a garbage leachate treatment technique, comprising: homogenizing the water quality of garbage leachate by an adjusting tank, and then leading the garbage leachate to enter a coagulative precipitation tank; then, alkalifying and deaminizing, and lifting into a UASB+AF tank through pump; after that, removing a great deal of organic matter, and leading the effluent to enter apacked A / O tank together with the sewage processed by the original sewage plant; removing the organic matter and the ammonia nitrogen which are difficult to degrade, and then passing through a secondary sedimentation tank and entering an advanced oxidation system for deep oxidation; leading the effluent to enter a biological aerated filter, processing by a sand filtering system and then entering amembrane processing system; and finally, ensuring the water quality of the effluent to be stable and reach the standard. As the garbage leachate treatment technique adopts the technology of 'biochemistry+ physical chemistry+ membrane separation' to treat the leachate, the effluent can reach the first grade discharge standard (GB16889-1997).

Owner:UNIVERSTAR SCI & TECH SHENZHEN

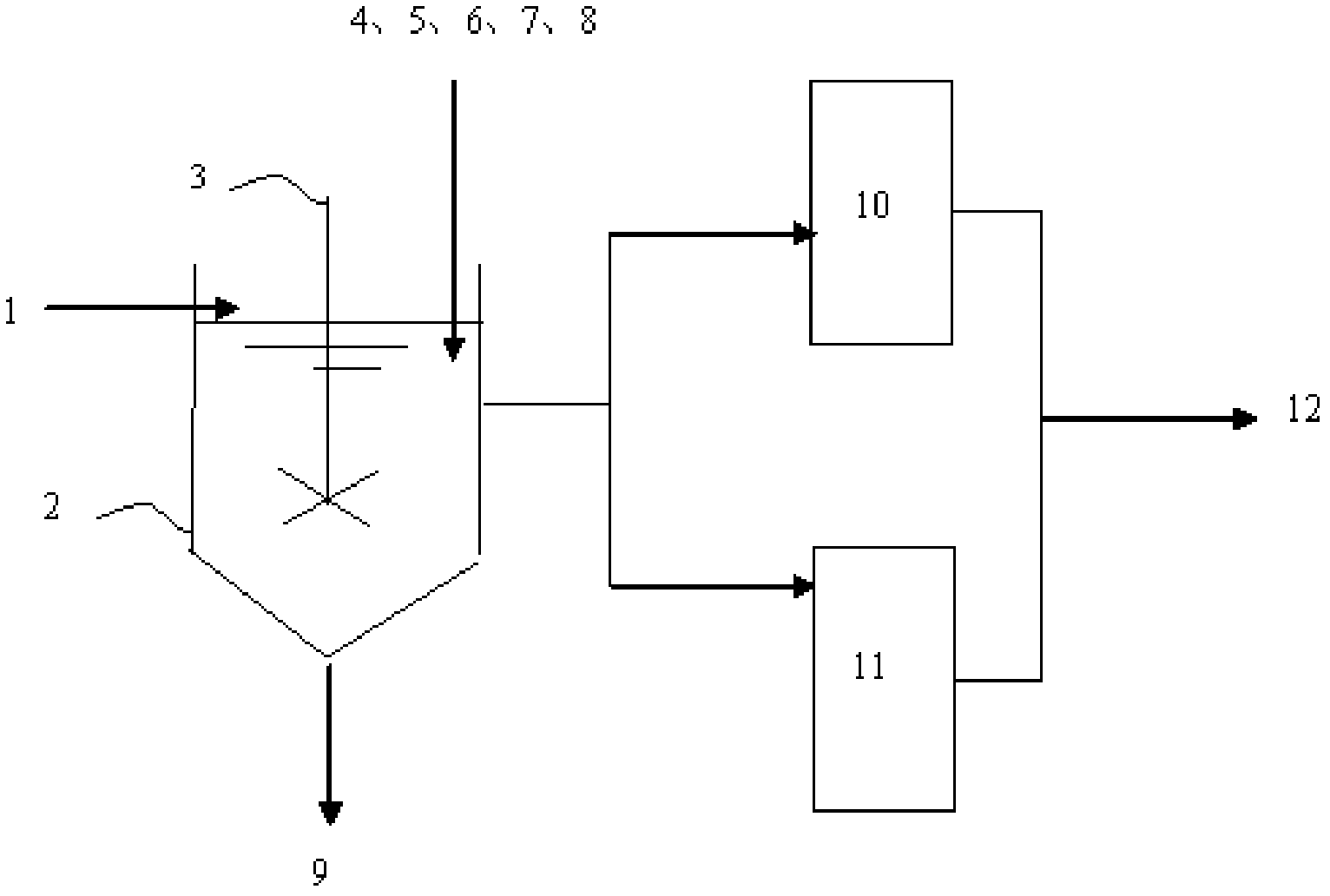

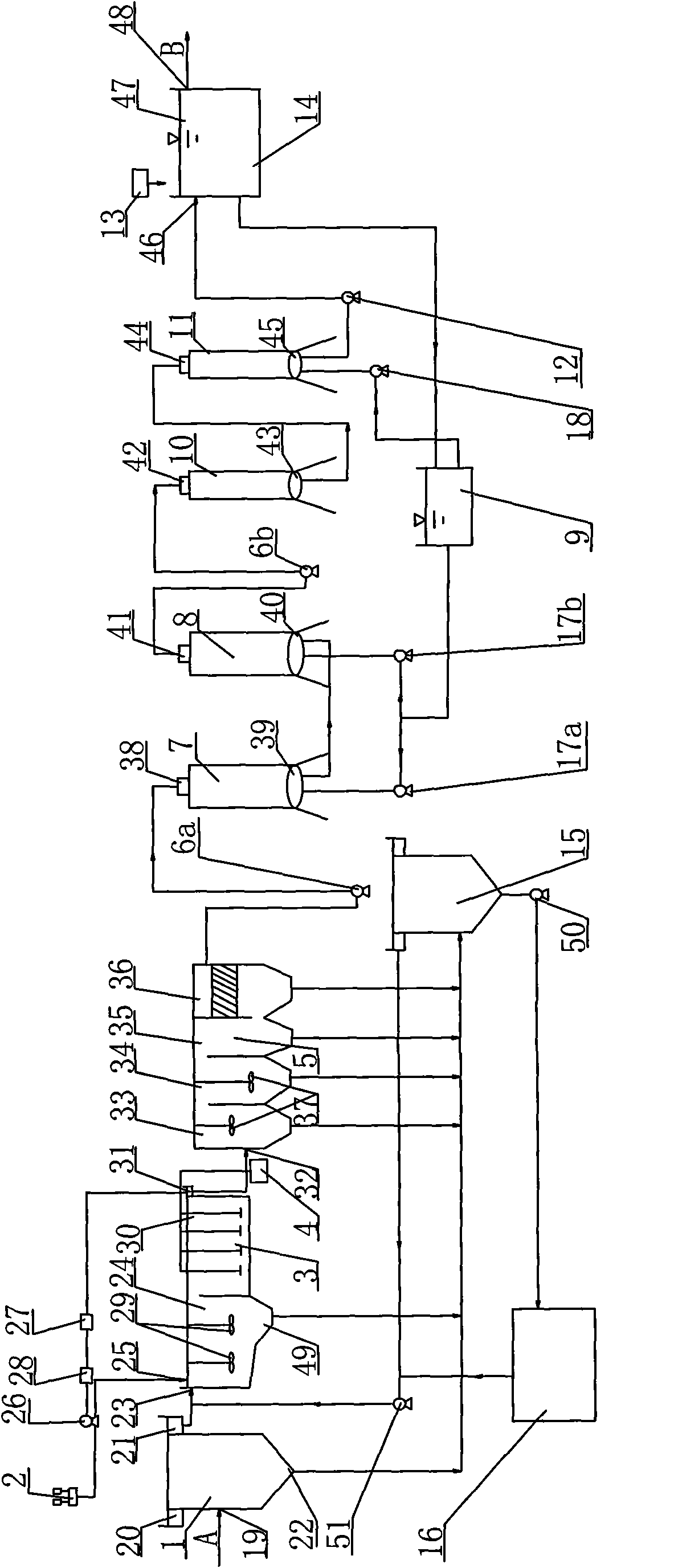

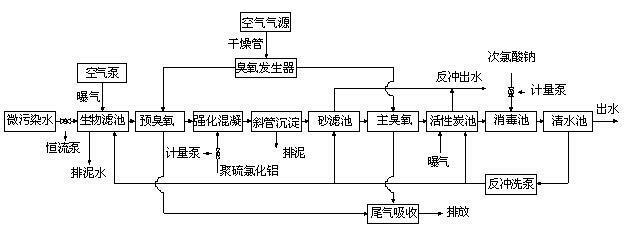

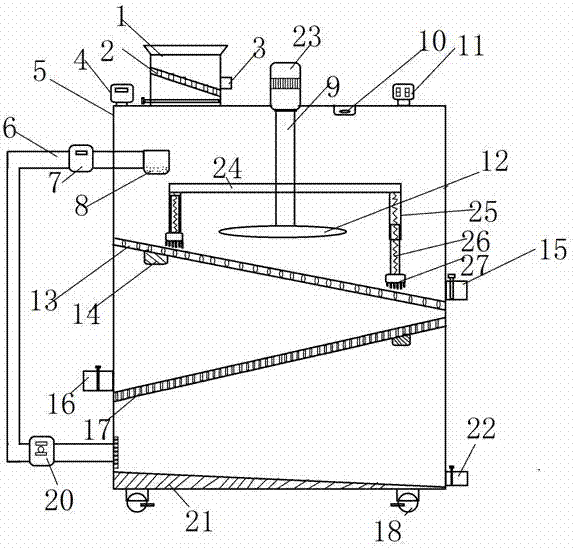

Printing and dyeing wastewater treatment system

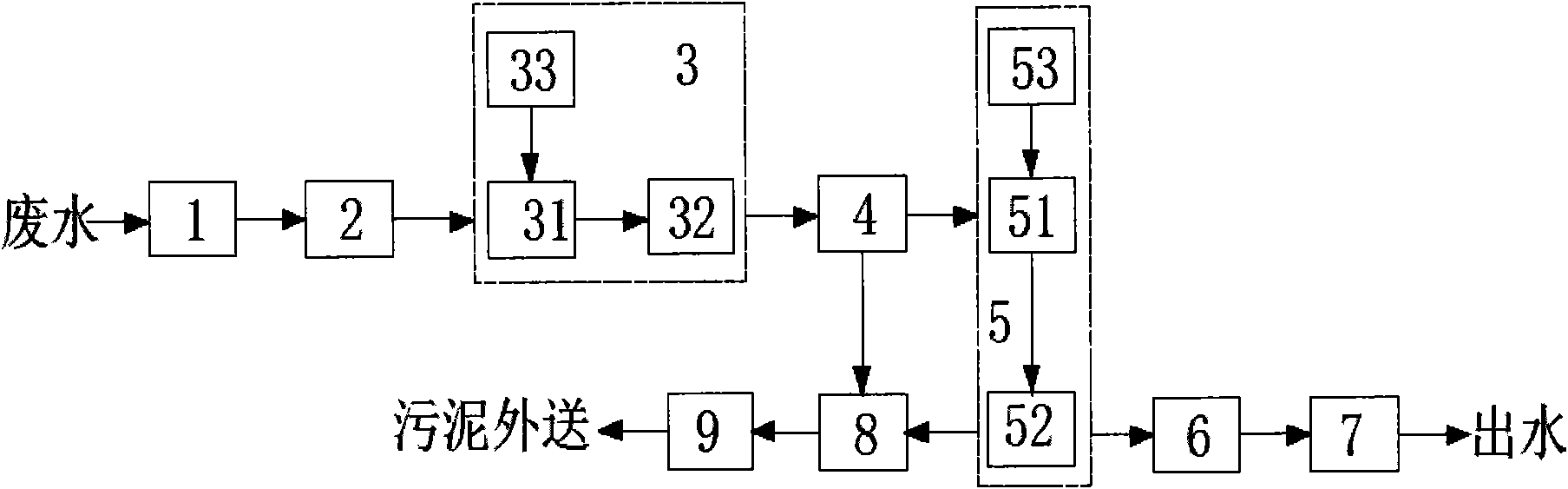

InactiveCN101591123ACompact structureSmall footprintSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesSludgeWater quality

The invention relates to a printing and dyeing wastewater treatment system, and belongs to the technical field of printing and dyeing wastewater treatment. The system consists of nine parts, namely an adjusting tank 1, a lift pump 2, a coagulating system 3, a primary sedimentation tank 4, a contact oxidation sediment system 5, a sand filtering tank 6, an active carbon adsorbing tank 7, a sludge pump 8 and a sludge concentrating tank 9. The printing and dyeing wastewater treatment system adopts the combined process of coagulation, contact oxidation, sand filtration and active carbon adsorption, and adds the deep treatment processes of the sand filtration and the active carbon adsorption after the physical-chemical treatment coagulation process and the biochemical treatment contact oxidation process. The printing and dyeing wastewater treatment system can be designed and manufactured respectively according to the wastewater quantities of printing and dyeing enterprises, and has the advantages of good treatment effect of printing and dyeing wastewater, stable operation, high degree of automation, simple operation, convenient maintenance, good and stable outlet water quality, superior level to the national emission primary standard and the like. The system particularly has good treatment effect of the printing and dyeing wastewater with high density and high chromaticity.

Owner:JIANGSU UNIV

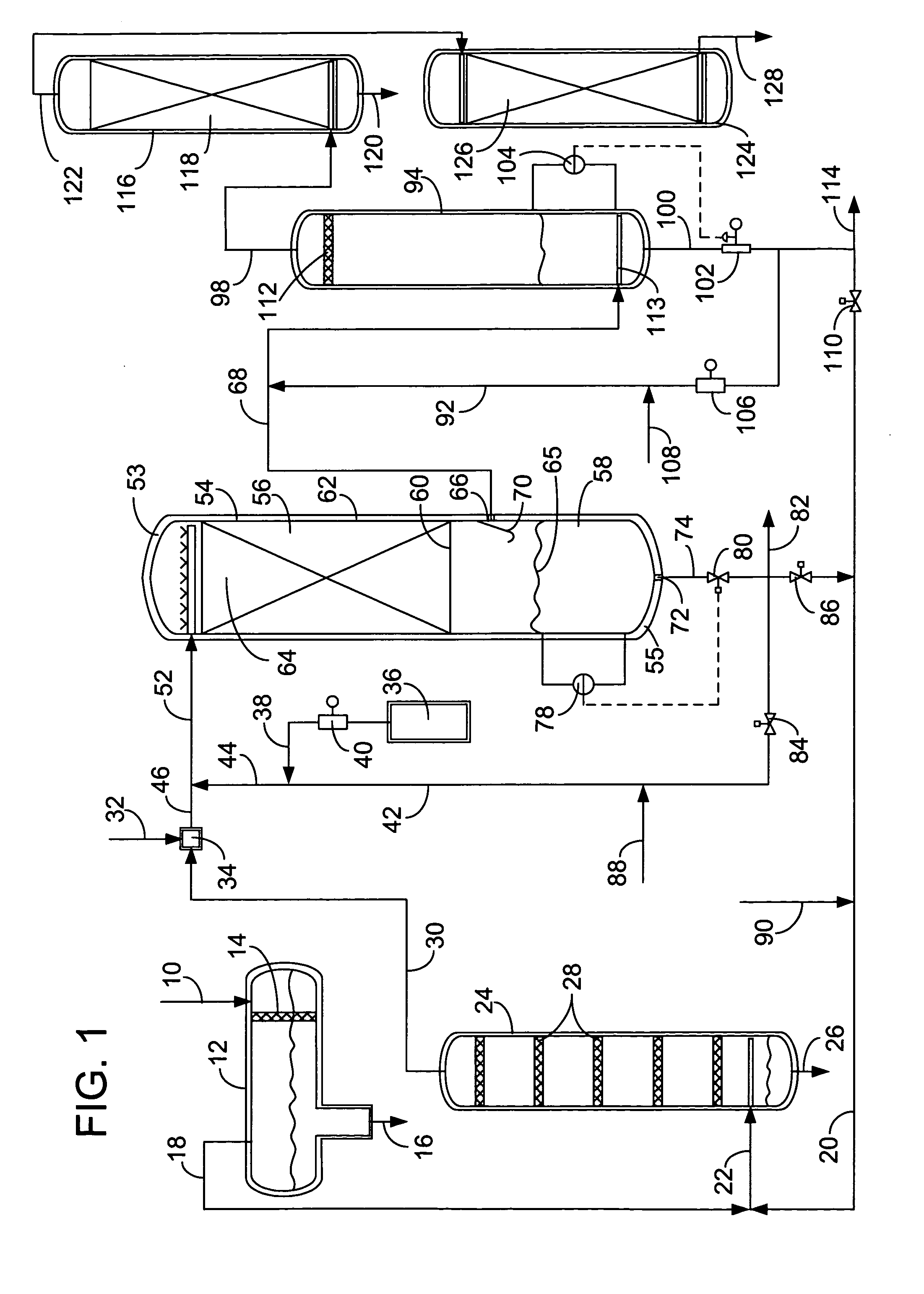

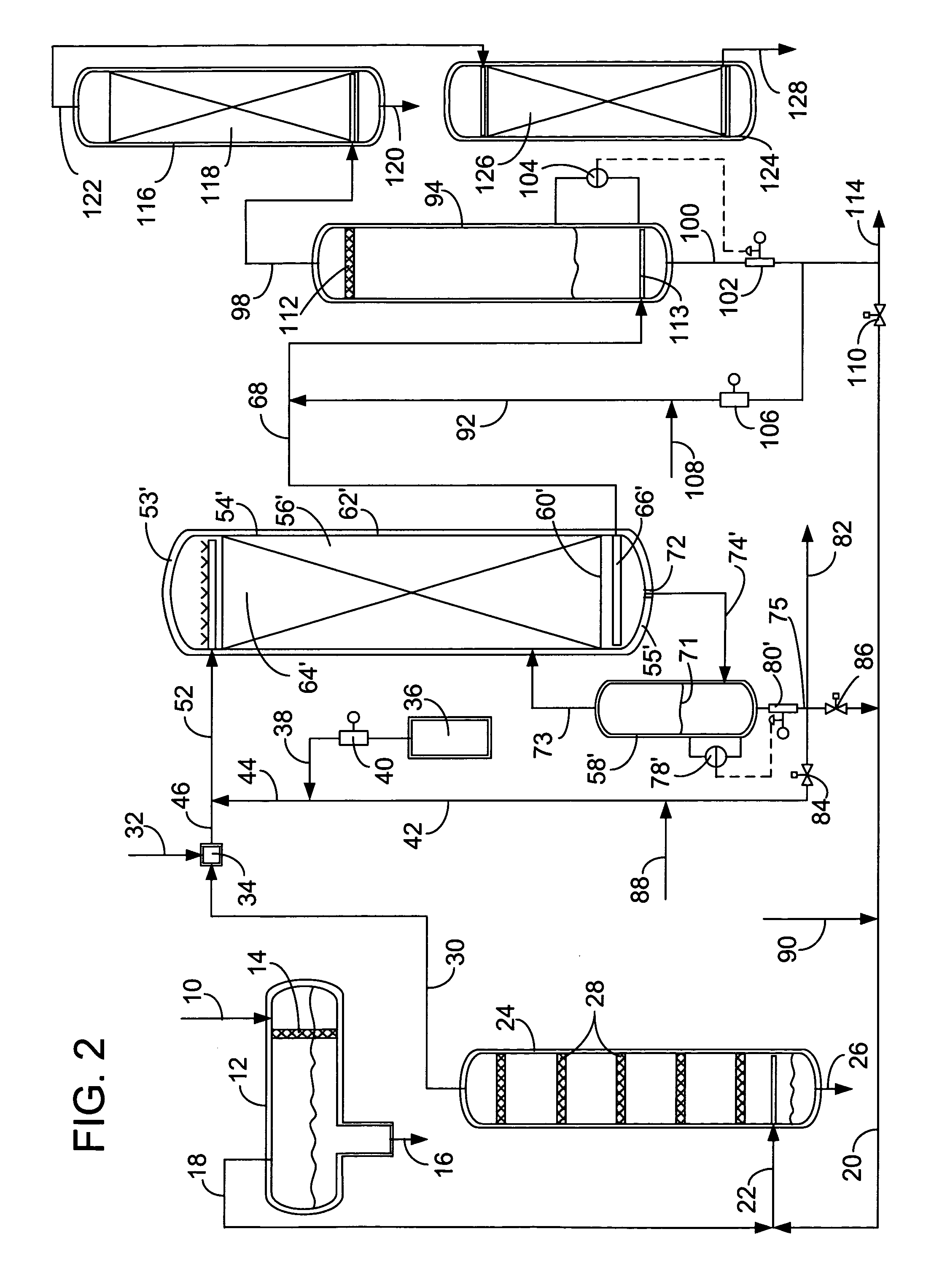

Reactor and process for mercaptan oxidation and separation in the same vessel

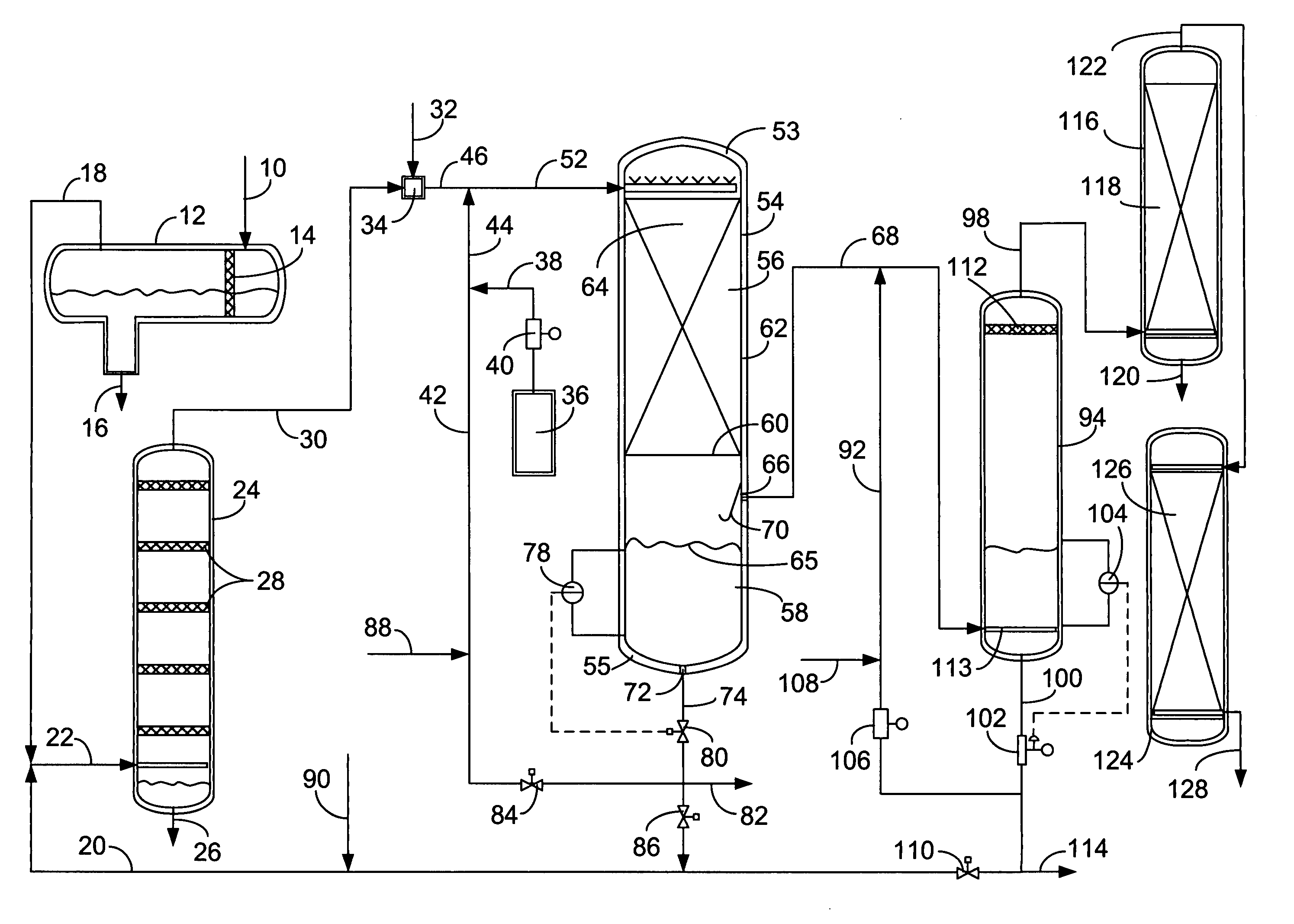

ActiveUS7223332B1Sweetening hydrocarbon streamSmall volumeRefining with oxygen compoundsLiquid displacementThiolKerosene

The present invention is an apparatus and process for oxidizing mercaptans in a preferably kerosene stream. By using a catalyst promoter, sufficient separation of hydrocarbon and aqueous alkali occurs in the reactor vessel to obviate the need for a settling tank. Hence, the sweetened kerosene can be withdrawn from the reactor vessel and sent directly to a residual alkali removal unit such as a sand filter vessel or to a water wash vessel if jet grade fuel is desired. In an embodiment, the reactor vessel used for this purpose includes a reaction section and a separation section in the same reactor vessel and an aqueous alkali outlet and a sweetened hydrocarbon outlet in the separation section.

Owner:UOP LLC

Advanced treatment method for arsenic-containing wastewater

InactiveCN103043812AImprove removal efficiencyConducive to aggregation and settlementMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeFerrous salts

The invention relates to a method for treating arsenic-containing wastewater by a process of preoxidation-composite coagulation deposition-filtering, and belongs to the technical field of wastewater treatment. The method comprises the steps of adding a certain amount of an oxidizing agent in a reaction tank for preoxidation in a condition that the wastewater contains trivalent arsenic so as to transform the trivalent arsenic into pentavalent arsenic completely, while for the wastewater only contains the pentavalent arsenic, the preoxidation process is not needed; adding a certain amount of a ferrous salt water solution; controlling a molar ration of Fe to As being 5-50; adding acid or alkali to adjust a pH value being 6-8; stirring for 0.1-1 min rapidly, so that a ferric arsenate precipitate is formed, at the same time, the ferrous salt is hydrolyzed into ferrous carbonyl to promote coagulation deposition of the ferric arsenate; adding a solution of 0.1-10 mg / L organic polymer flocculant; stirring for 0.1-1 min rapidly; stirring for 5-10 min slowly, precipitating for 10-30 min, discharging sludge from the bottom, introducing supernatant into a sand filter tank, a filter film or a filter bag, filtering and discharging the effluent. Arsenic content in water after treatment is lower than that of a drinking water standard (less than 10 [mu]g / L) regulated by the world health organization. The method has low sludge production and low cost, and can be used for advanced treatment of the arsenic-containing industrial wastewater and treatment of arsenic polluted underground water and drinking water.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

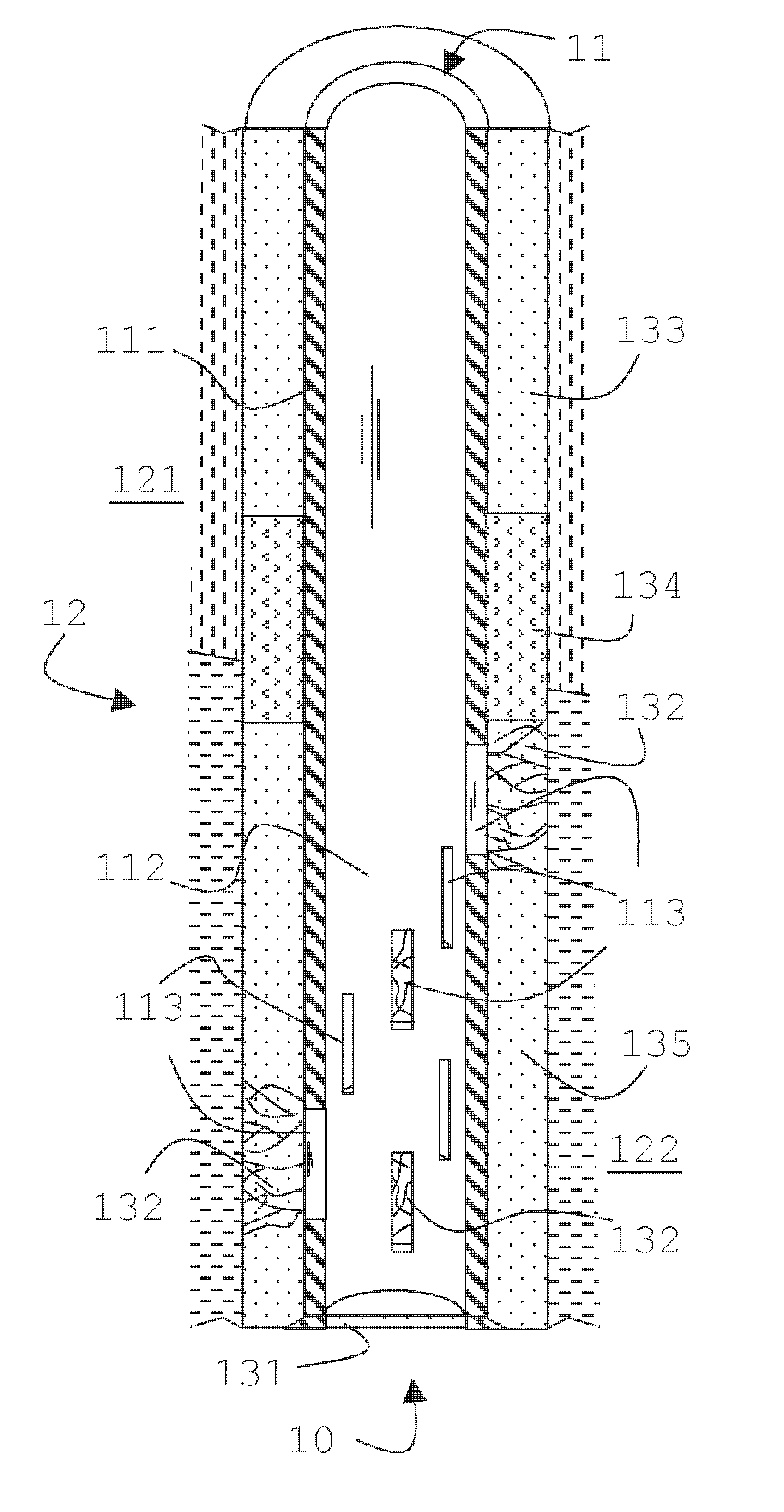

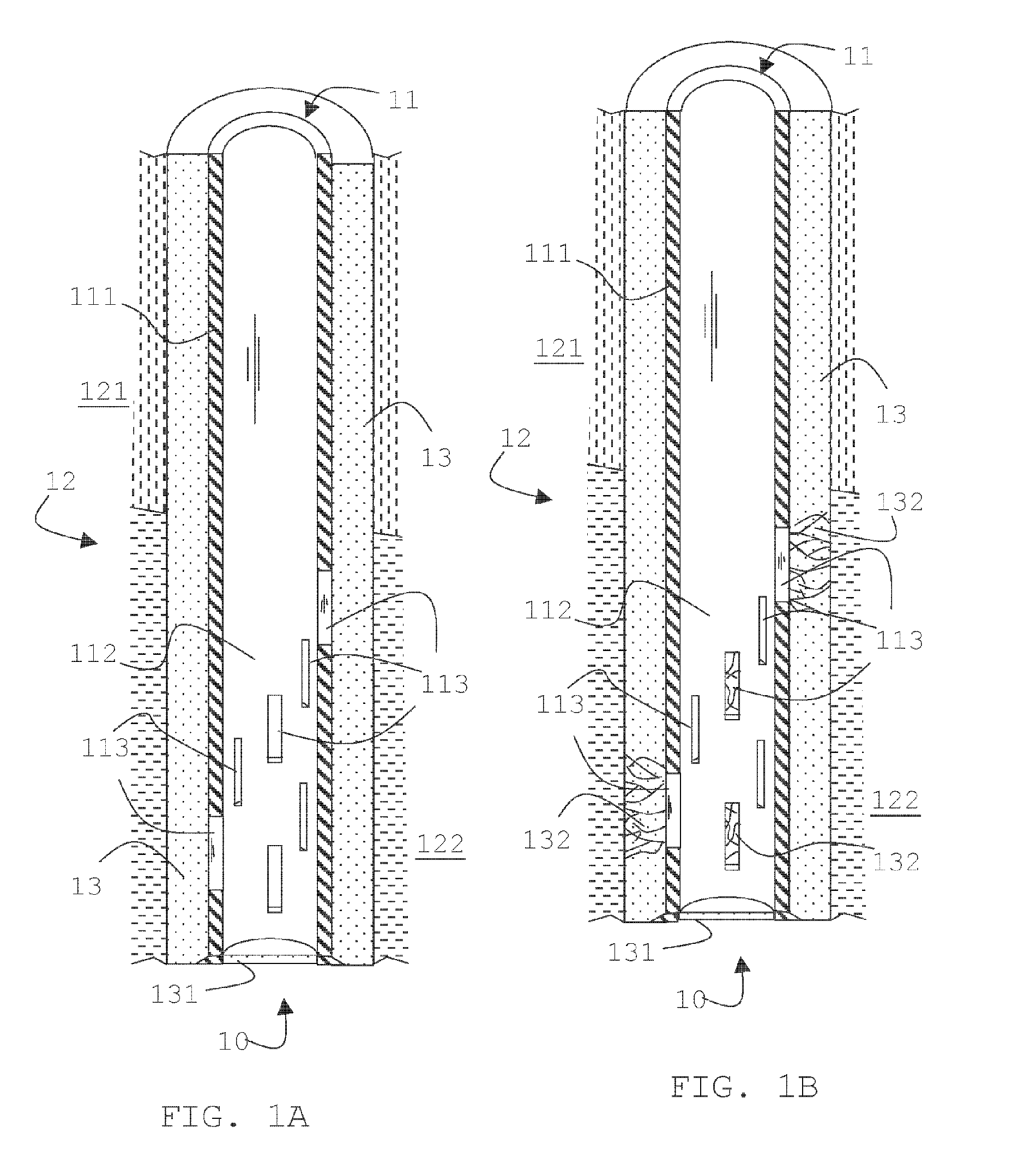

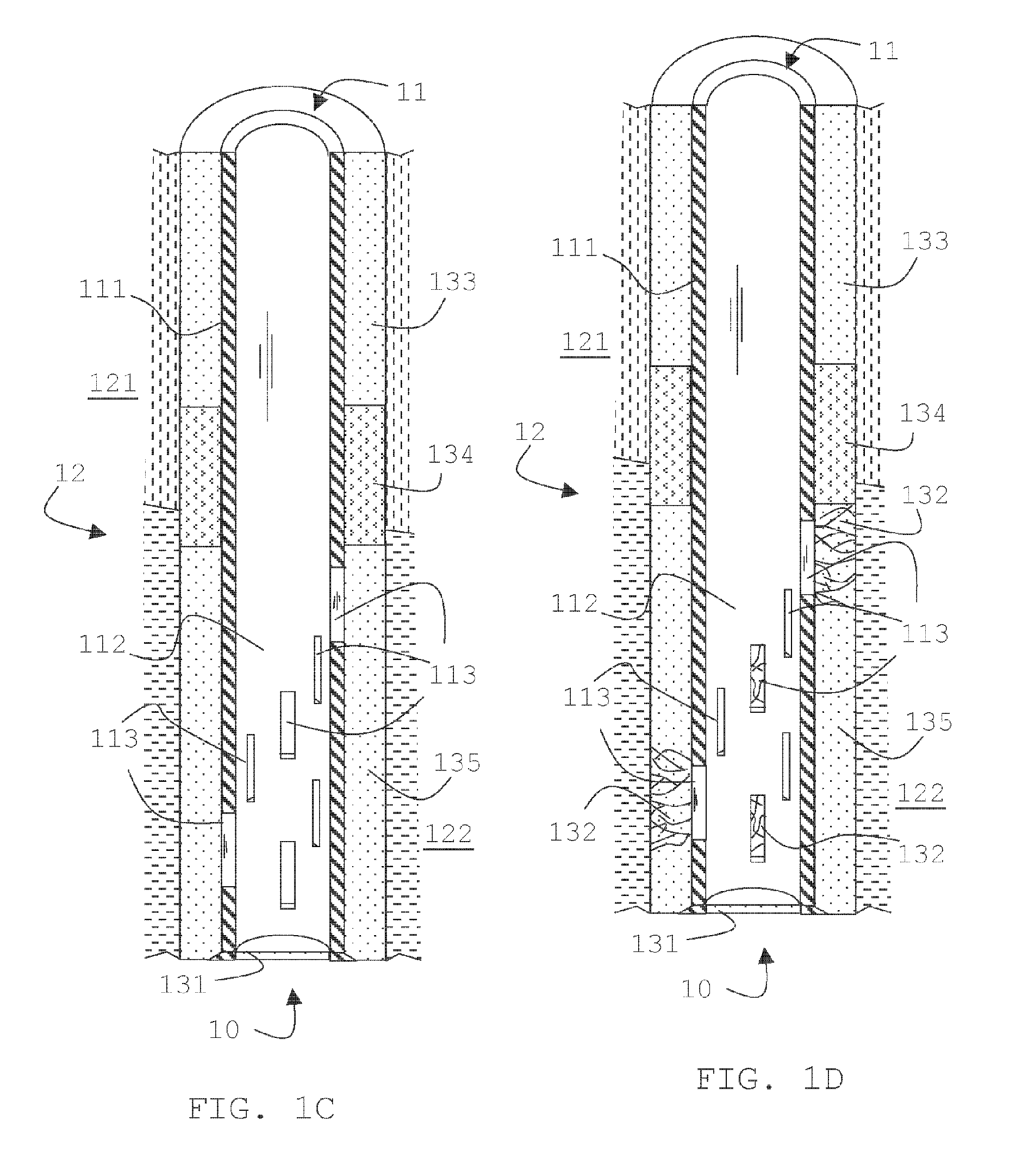

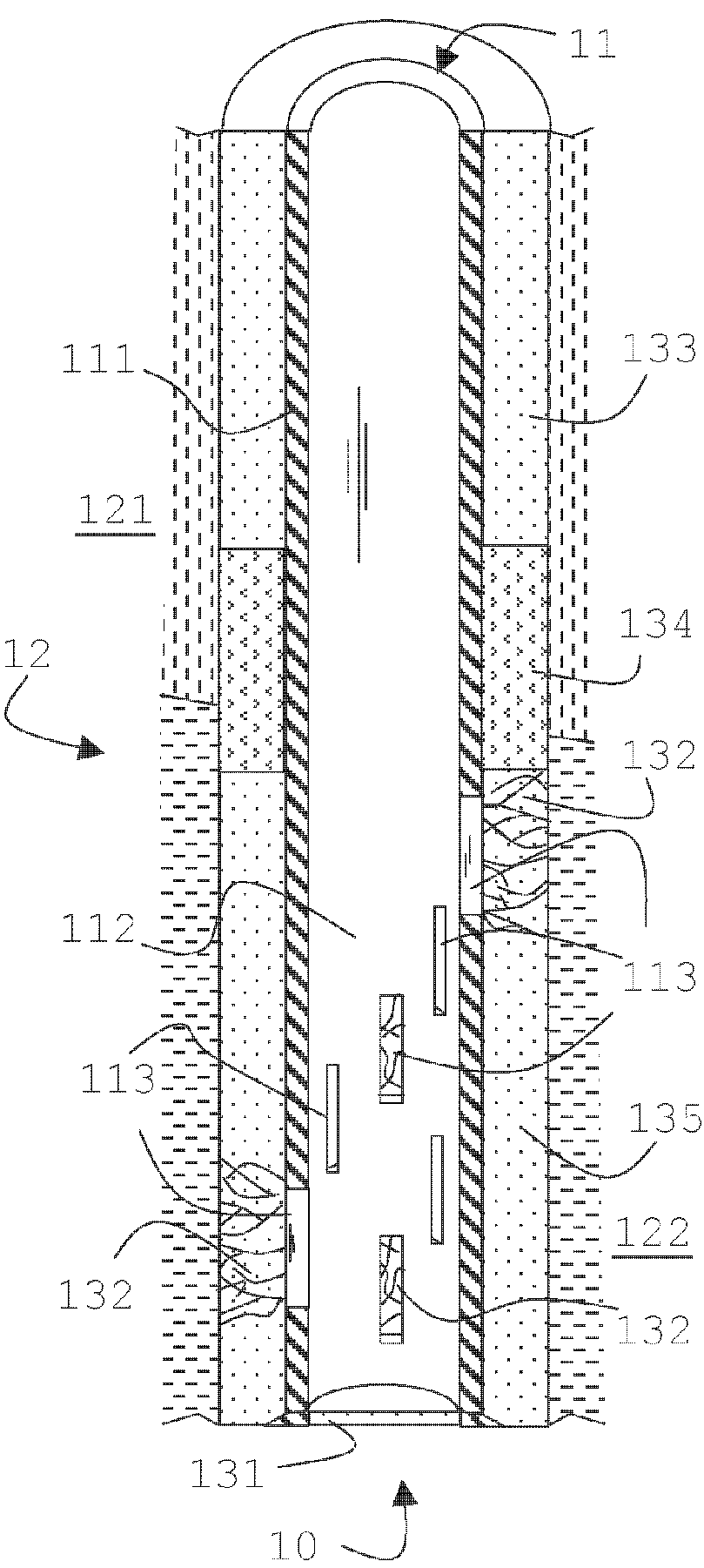

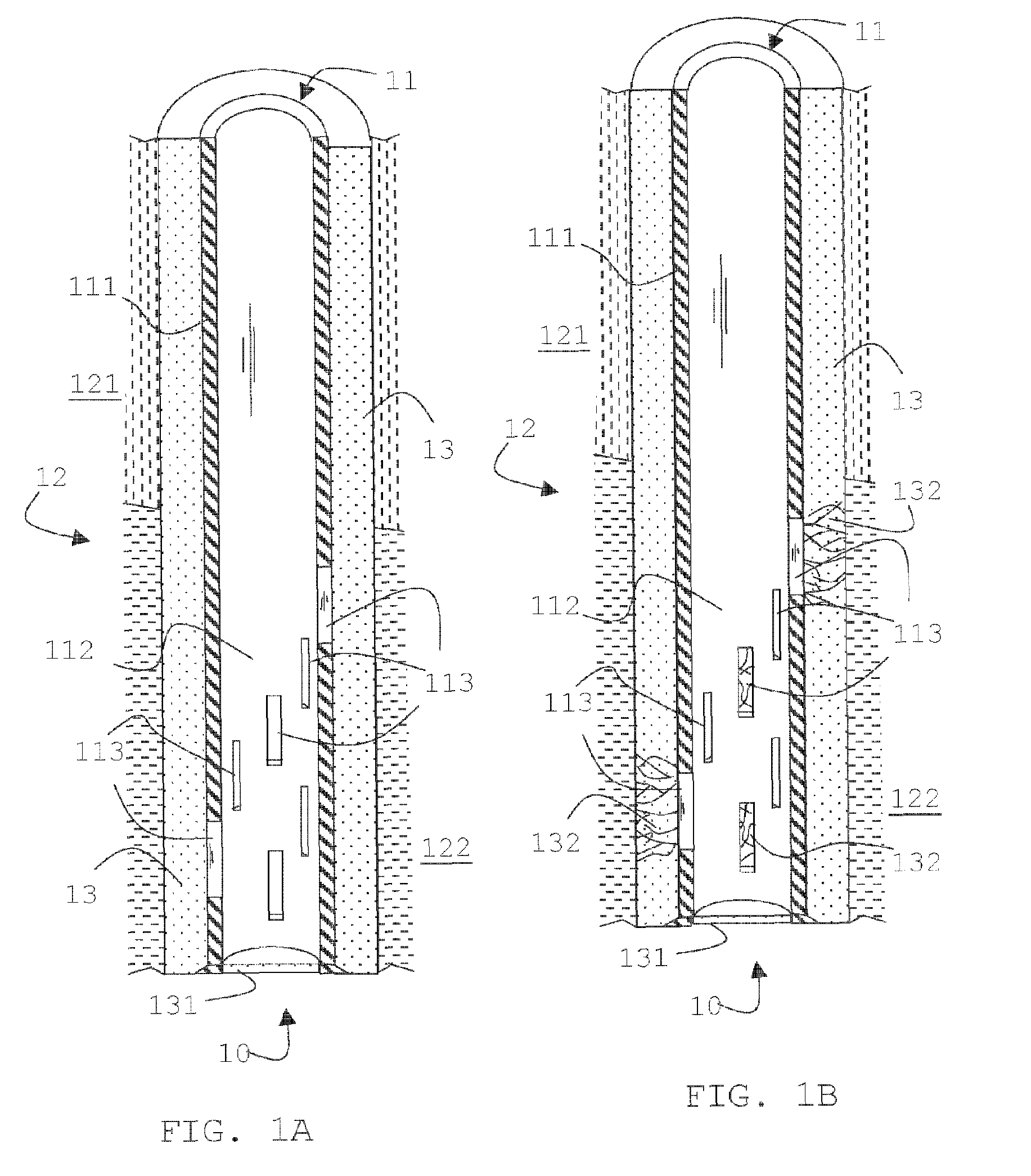

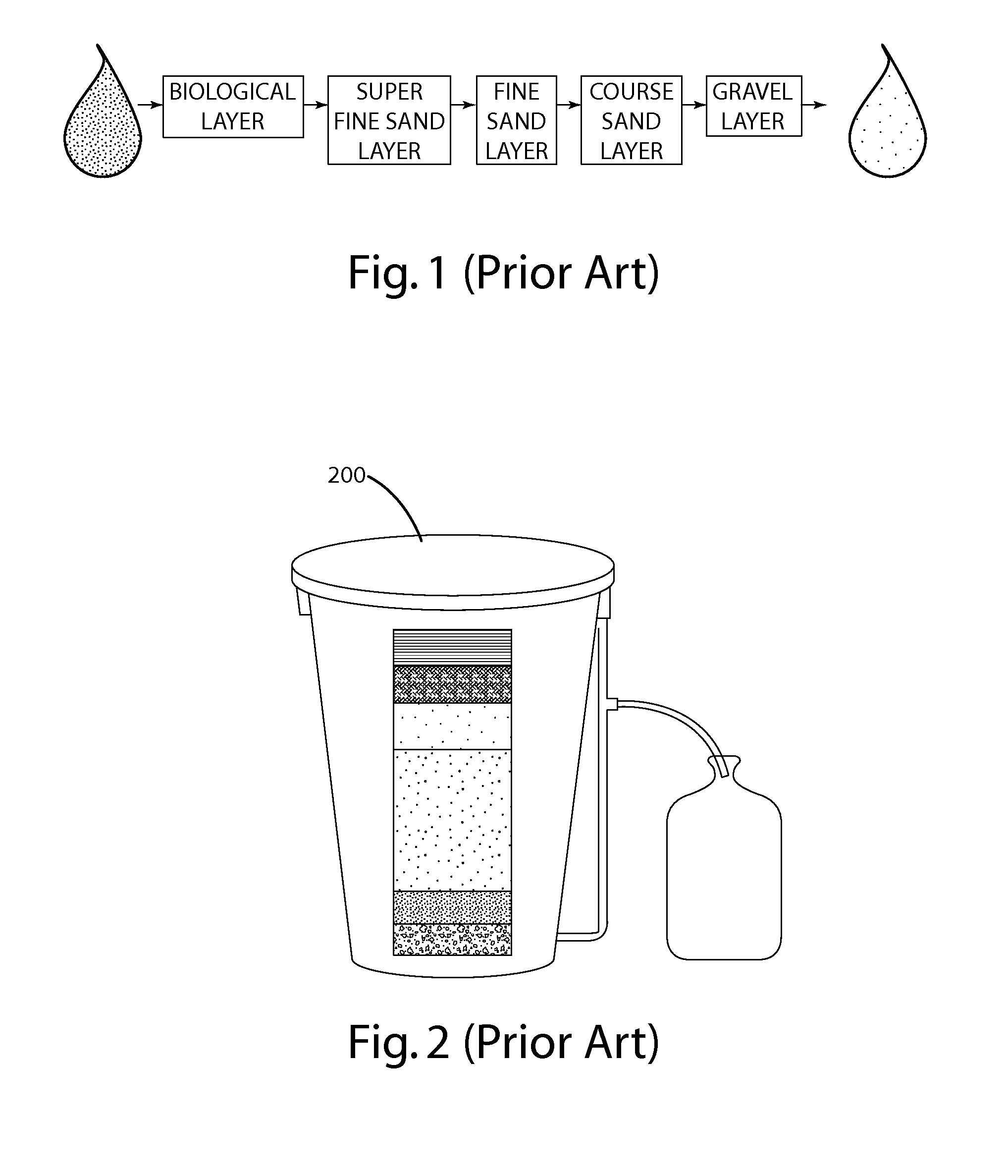

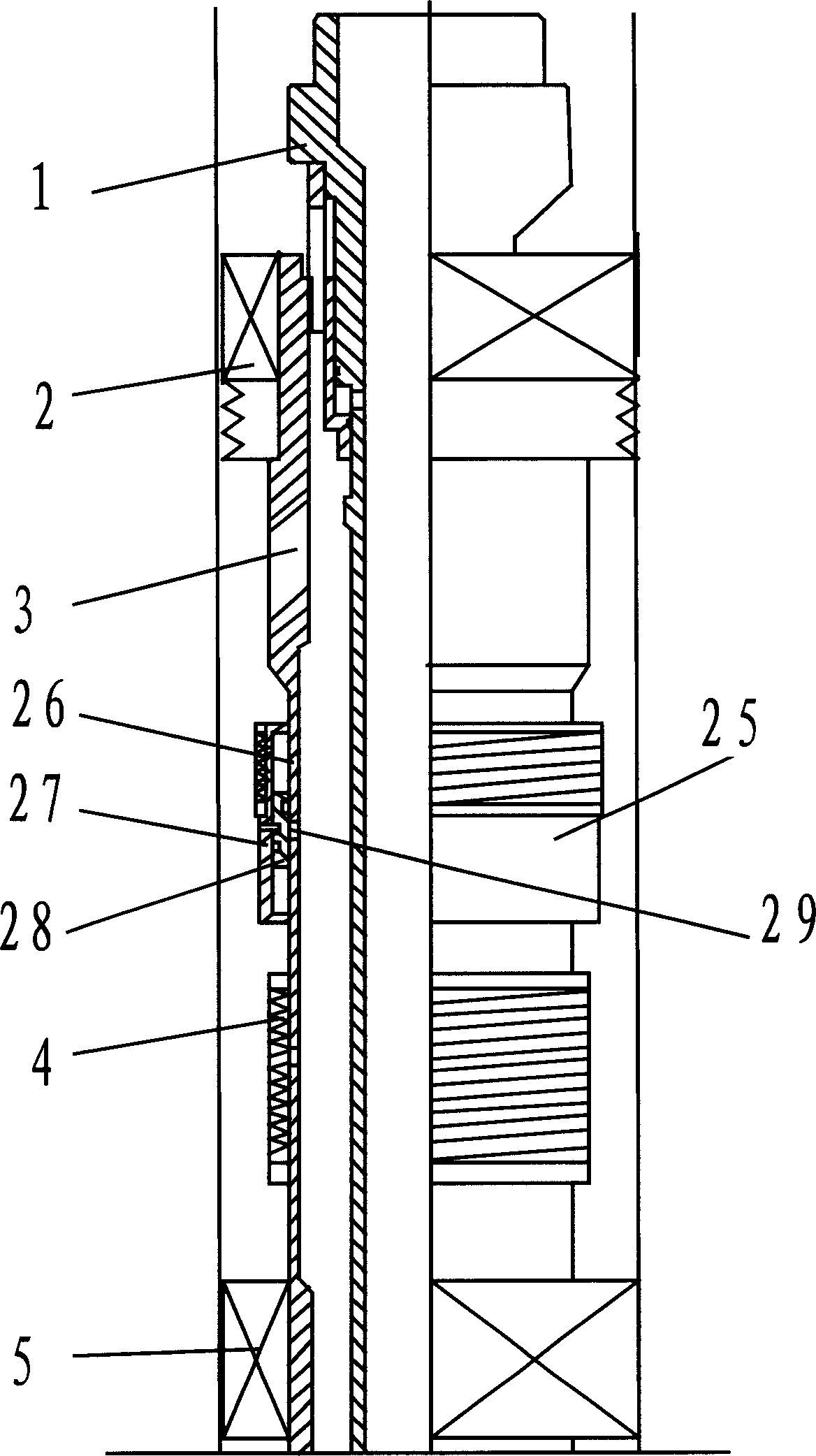

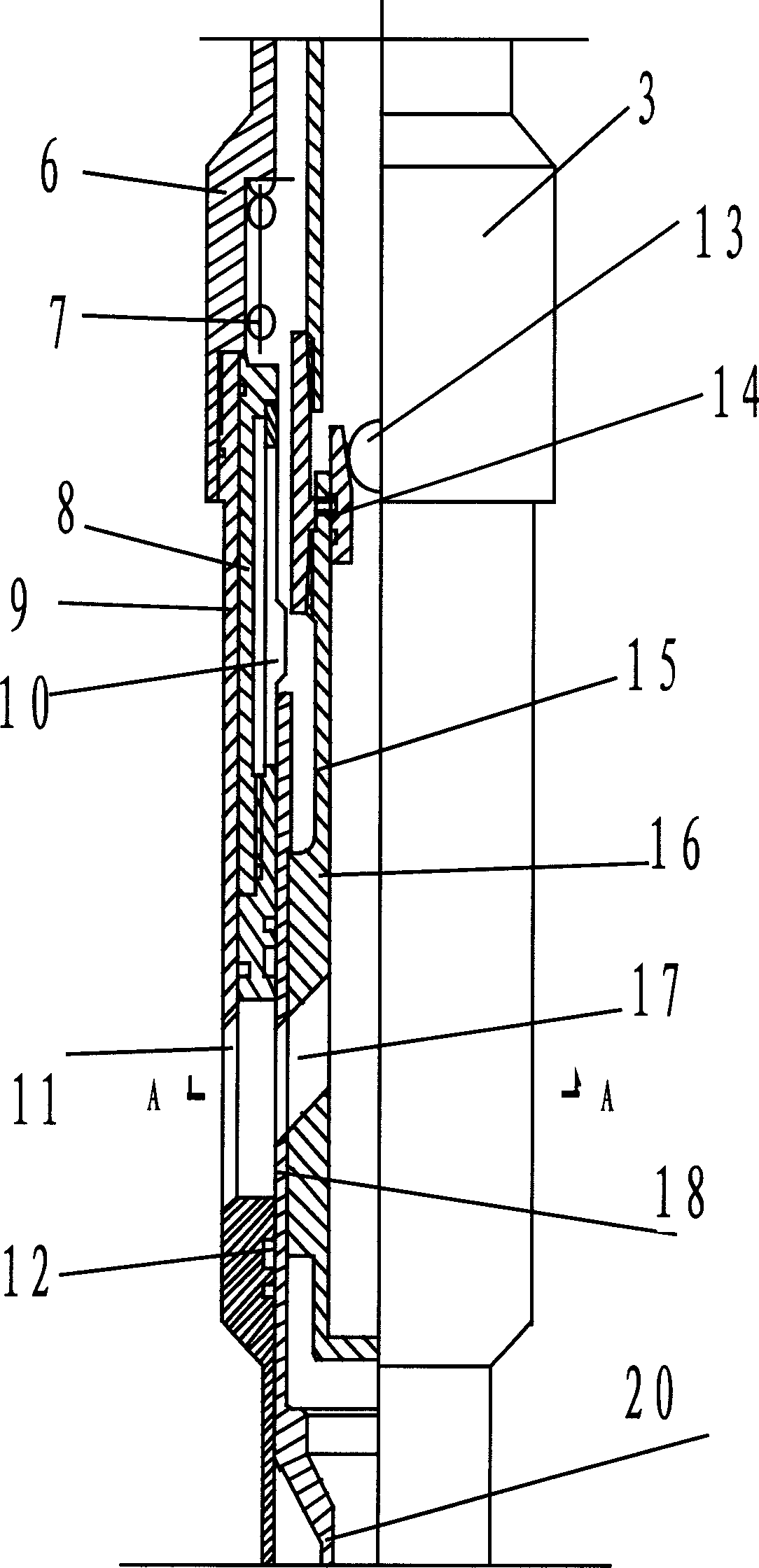

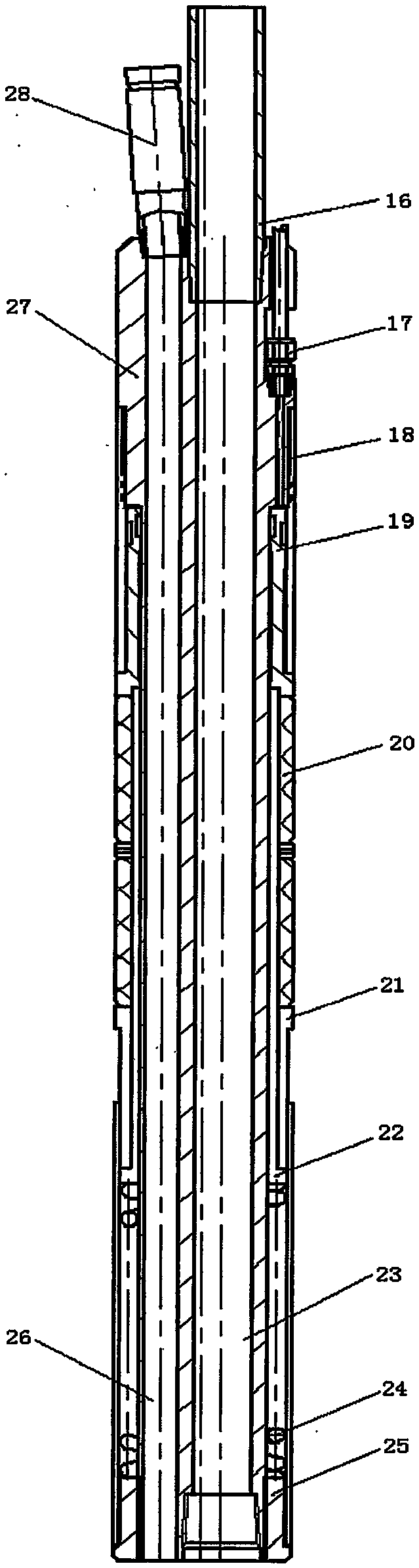

Layered pipe column for squeeze packing sand control process

ActiveCN1603574AIncrease productionUnblock pollutionFluid removalEngineeringUltimate tensile strength

The invention discloses the petroleum use lamination backlog to fill guards against sand pipes the column, was suitable to the multi- oil layers extrusion packing tube column, in was sufficient string of tubing including ram and in fills the tool, outside filled the tube column including the crown hook wall packer, outside filled the tool and the sand filter, outside filled on the tool to be equipped with fills the mouth. In fills the tube column to be equipped with the seat to seal washes one's hands of, outside fills the tube column to be equipped with the level the packer. After the seat seals washes one's hands of is hit the pressure to cause the crown to hang the packer place to seal, the seat seals washes one's hands of prearranges the hook wall packer separation, in fills the tube column to be able to fill in the tube column in outside to reciprocate sits the sealing course gap, fills the tool coordination backlog with outside to fill the stratum. Enhances guards against the granulated substance effect and the term of validity. The next tube column then completes many oil layers lamination backlog to fill guards against the granulated substance the construction, greatly reduced the production cost and worker's labor intensity.

Owner:OIL EXTRACTION TECH INST OF SINOPEC SHENGLI OILFIELD

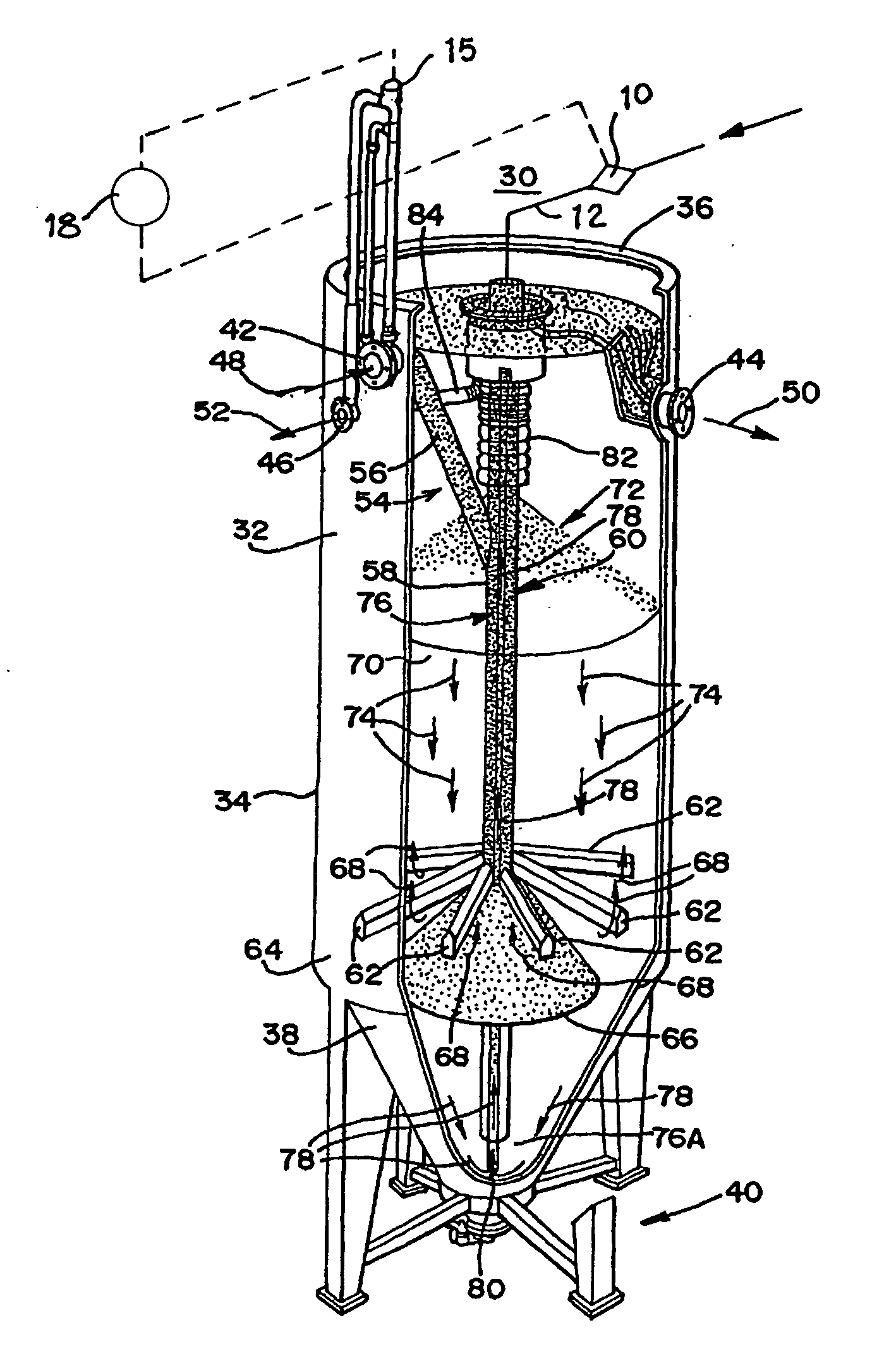

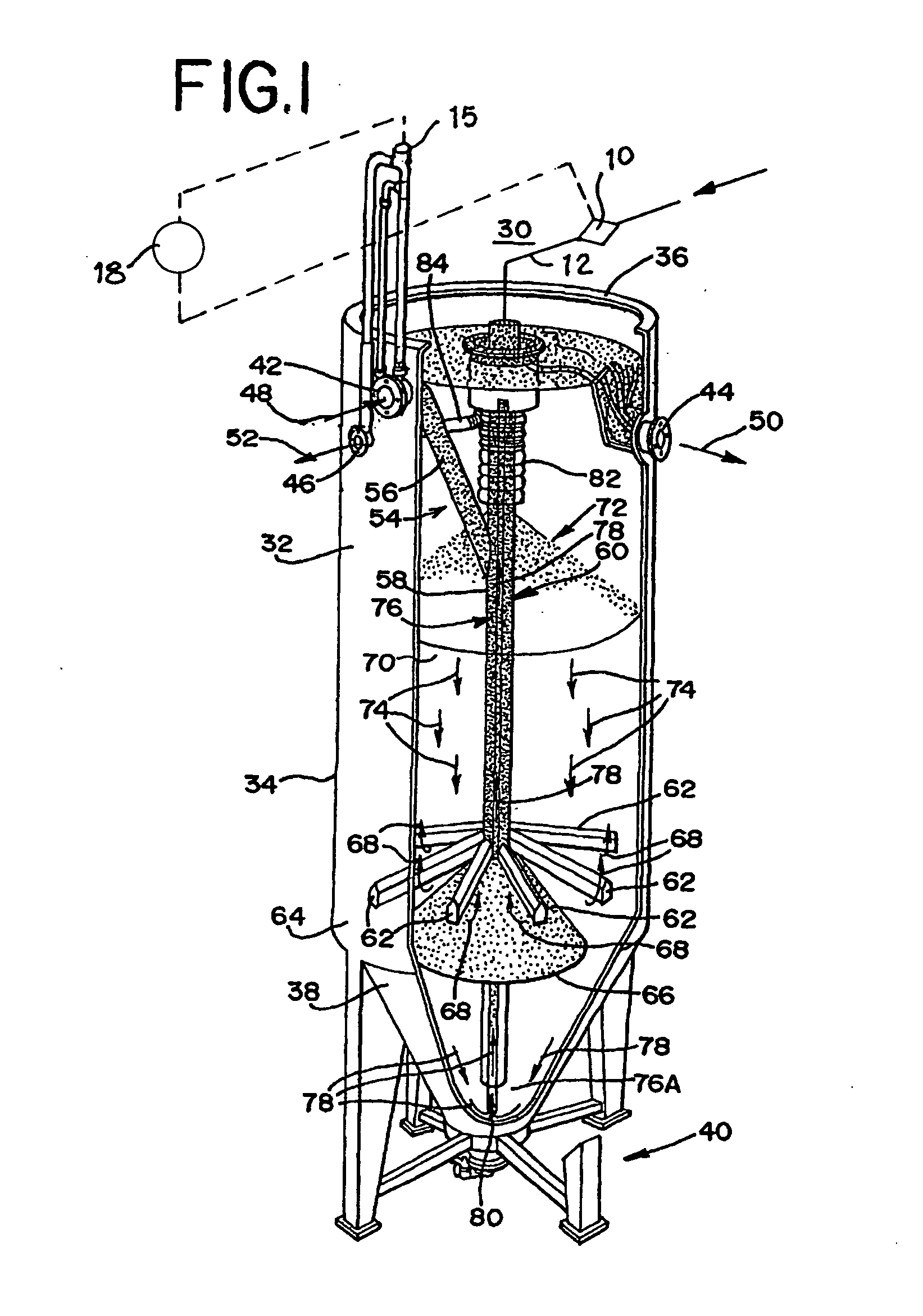

Automated water treatment system and method of use

ActiveUS20050077247A1Easy to moveEasy to operateSettling tanks feed/dischargeWater/sewage treatmentWater treatment systemSand filter

An automated method for controlling a solids inventory in a continuous backwashing upflow sand filter system treating a liquid inflow having impurities therein, includes the steps of: monitoring an influent inflow pressure and controlling the air pressure in an air lift pump to maintain a target ratio range between the size of a solids inventory of the system and the size of the sand bed of the system.

Owner:HYDRO INTERNATIONAL AG +1

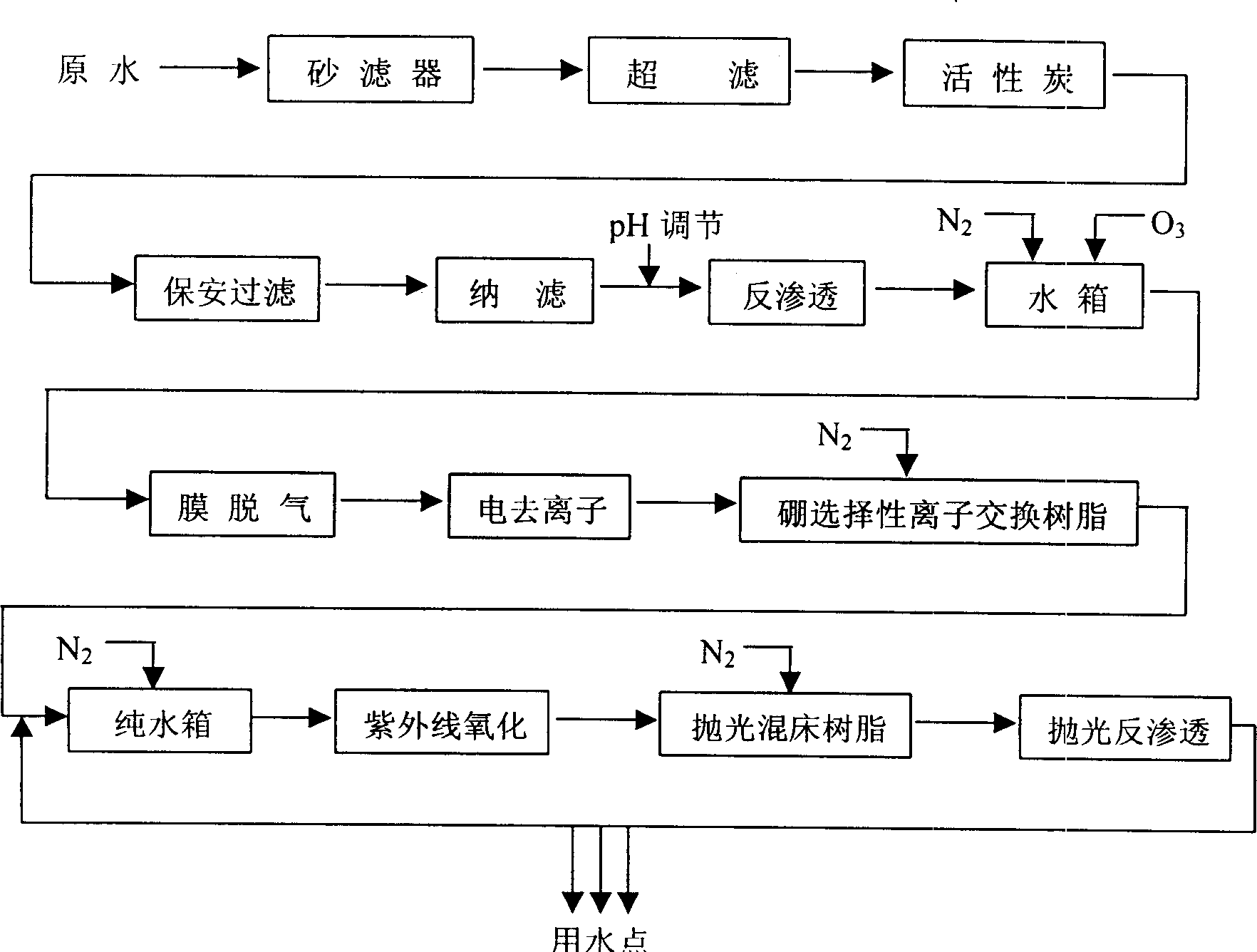

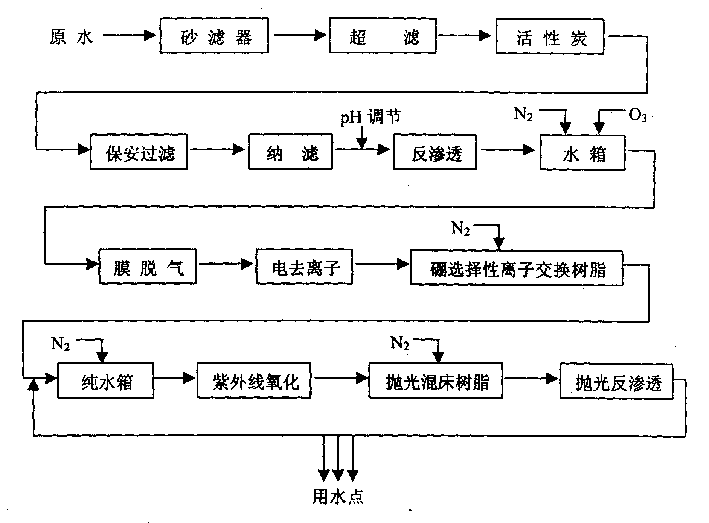

Producing process and technology for electronic grade water by intergrated film process

InactiveCN1408653AEfficient removalContinuous removalMultistage water/sewage treatmentEnvironmental engineeringPre treatment

In the production process, tap water as material water is treated in four parts including pre-treatment unit, the first water purifying system, the second water purifying system and the end film filtering treatment system to prepare electronic level super-pure water. For the treating process, the pre-treatment unit includes sand filtering, superfiltering, active carbon adsorption and nanofiltering; the first water purifying system consists of reverse osmosis, film deairing, electrically deionizing, selective ion exchange resin to eliminate boron impurity and other units; the second water purifying sytem consists of ultraviolet lamp oxidation and polishing mixed bed resin; and the end film filtering treatment is polished reverse osmosis film treatment. The water purifying system has high efficiency, and low cost.

Owner:TIANJIN UNIV

Reaction device for deep treatment of drinking water and method for deep treatment of drinking water by water factory

ActiveCN102336493ALarge amount of workIncrease the areaWater aerationWater/sewage treatment bu osmosis/dialysisUltrafiltrationWater treatment

The invention relates to the field of drinking water treatment, in particular to a reaction device for deep treatment of drinking water and a method for deep treatment of the drinking water by a water factory. In order to realize the goal of transforming the conventional drinking water treatment process into the deep treatment process, the reaction device and the method adopt the scheme that (1) a static mixer and a coagulation reaction pool are not changed; (2) a sedimentation pool is transformed into an ultrafiltration membrane pool; (3) a medium water pool and a lifting pump used for waterlifting are additionally arranged at the back end of the ultrafiltration membrane pool; (4) a main ozone oxidization pool is in additional arrangement; and (5) an original sand filter pool is transformed into a particular active carbon filter pool. The coagulation and the ultrafiltration are combined, particular colloid and macromolecular organic matters in the water are removed, difficult-to-degrade pollutants are damaged through ozone oxidization, in addition, the macromolecular organic matters are converted into middle and small molecular weight organic matters, and organic matters and pollutants such as ammonia nitrogen and the like in the water are further reduced through the absorption of particular active carbon and the biological degradation of microbes grown on the surface.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Acid mine water treatment system

InactiveCN101830585ALarge specific surface areaImprove settlement performanceWaste water treatment from quariesMultistage water/sewage treatmentWater treatment systemManganese

The invention discloses an acid mine water treatment system and belongs to the field of water treatment. The system consists of a neutralization system, a coagulation sedimentation system, a filtration system, a reverse osmosis system and a sterilization system which are connected in turn, wherein the coagulation sedimentation system comprises a mixing region, a reaction region, a transition region and a settling region; the mixing region is communicated with the reaction region, the transition region and the settling region in turn; the water inlet of the mixing region is communicated with the water outlet of the neutralization system; the water outlet of the settling region is communicated with the water inlet of the filtration system; and the filtration system comprises a manganese sand filter in which a modified manganese sand filter material modified by 1 to 7 mass percent potassium permanganate solution is arranged. Four regions are arranged in the coagulation sedimentation system of the system, so coagulation treatment effect is enhanced; and the modified manganese sand filter material is adopted in the manganese sand filter, so the effect of removing ferro-manganese ions in the mine water is enhanced and the aim of treating and recycling the acid mine water with high turbidity, high ferro-manganese content and high mineralization is fulfilled.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

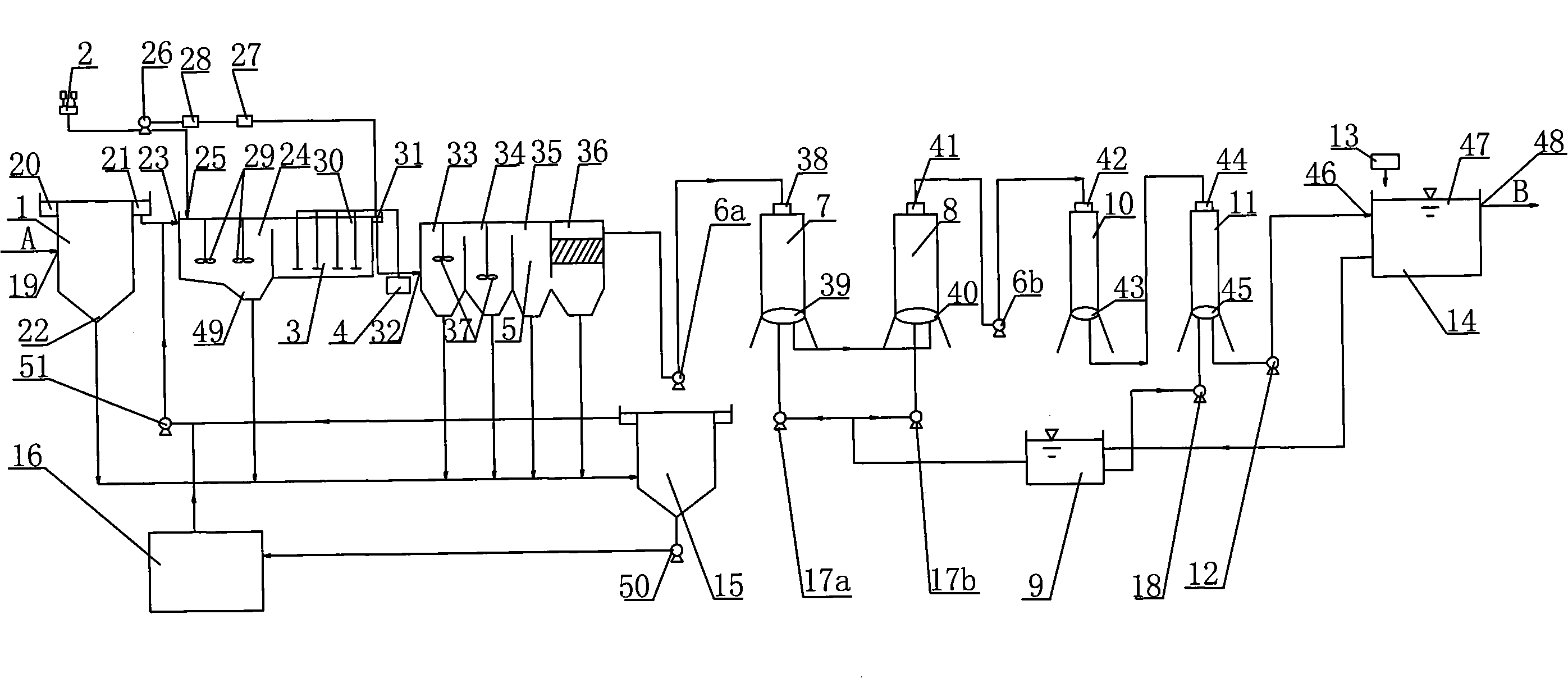

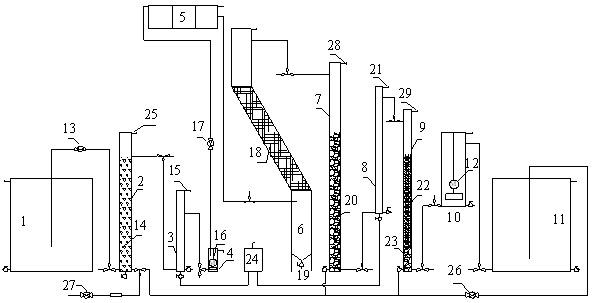

Technological method for controlling disinfection by-product and pathogenic microorganism risk of drinking water

InactiveCN102633409AGuaranteed inactivation effectGuarantee hygienic safety performanceMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processTurbidityWater quality

The invention relates to a technological method for controlling the disinfection by-product and pathogenic microorganism risk of drinking water, belonging to the field of drinking water treatment. The drinking water is produced by combining biological pretreatment, pre-ozonation, main ozonation, active carbon filter and conventional coagulation-precipitation-sand filtration-disinfectant fluid treatment technology, and the method is a feed water treatment technological method which is developed for the micro-pollution raw water and controls the disinfection by-product and pathogenic microorganism heath risk in the water purifying process. The micro-polluted raw water sequentially enters a biological pretreatment tank, a pre-ozonation contact tank, a folded-plate flocculating tank, an inclined-tube sedimentation tank, a sand filter, a main ozonation contact tank, an active carbon filter and a disinfection tank, and finally flows into a clean water reservoir. Through the application of the biological pretreatment, two-level ozone oxidation and active carbon technology, the removal effect on the turbidity, organic matters, the disinfection by-product precursor, the virus microorganism, bacteria microorganism and the like is obviously improved, and the water quality and safety are obviously superior to those of the traditional coagulation sedimentation technology.

Owner:FUDAN UNIV

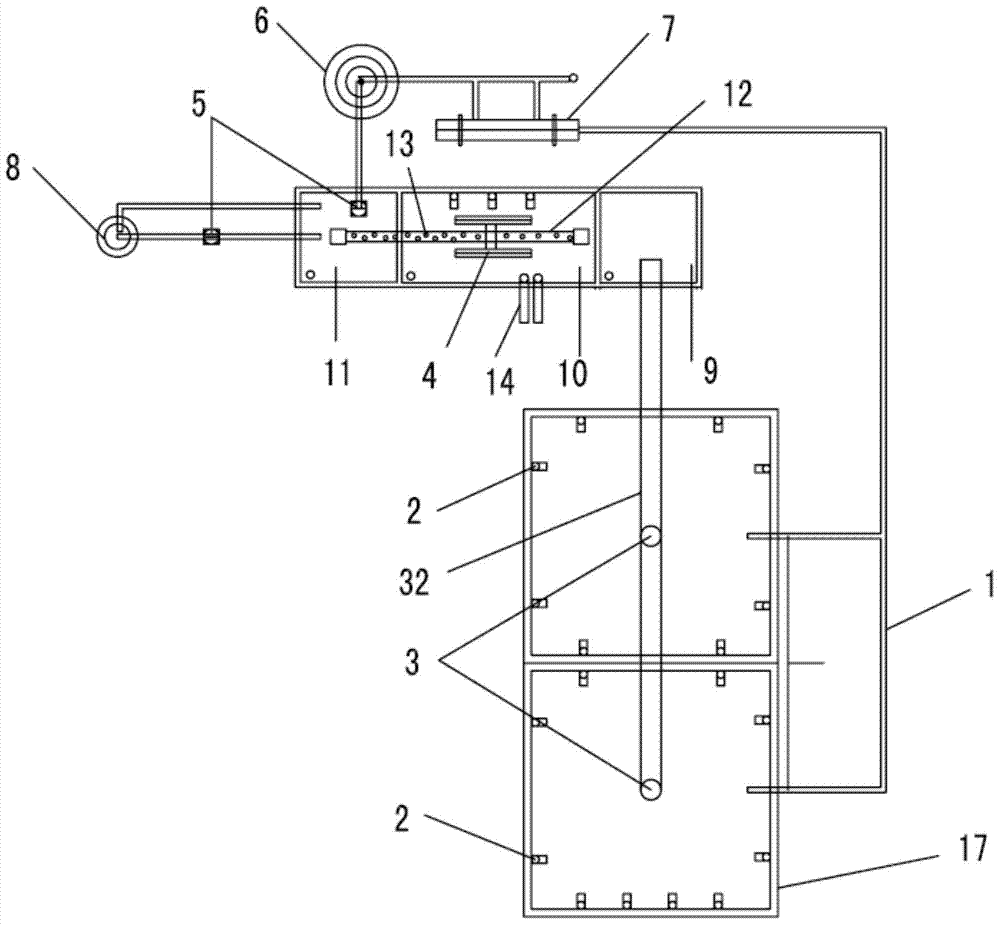

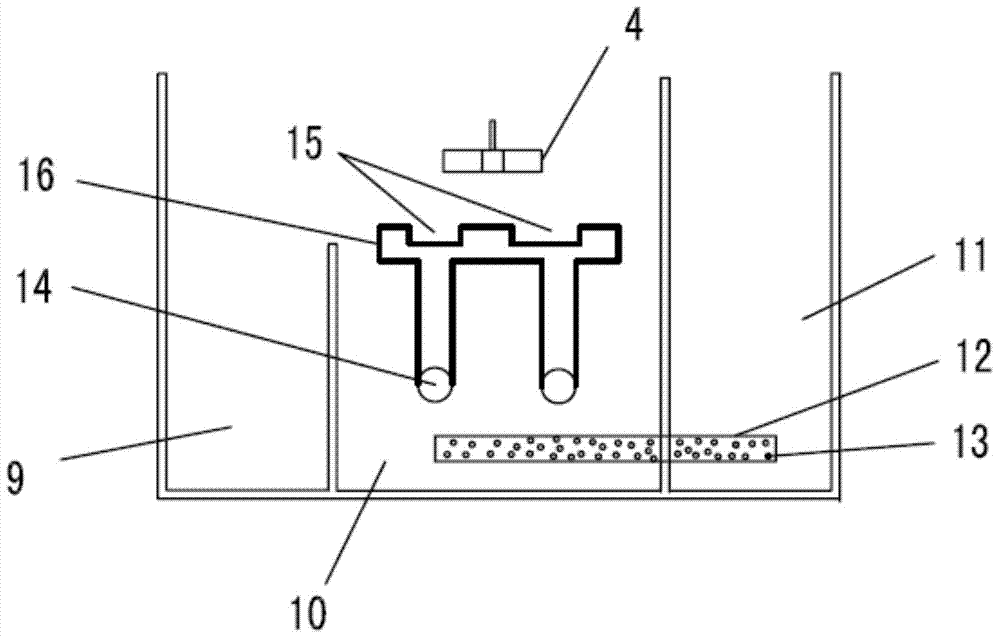

Indoor industrial penaeus vannamei culture device

InactiveCN103478055AReduce investmentEmission reductionClimate change adaptationPisciculture and aquariaWater useBiological filter

The invention discloses an indoor industrial penaeus vannamei culture device which comprises a plurality of culture ponds, a water inlet pipe and a culture water circulation system, wherein the culture water circulation system comprises a sedimentation pond, a floatation pond and a biological filter pond; the floatation pond is internally provided with an aerobiotic device, an aeration device and a foam sewage discharge device; the foam sewage discharge device comprises a foam guide pipe and a sewage pipeline; the foam guide pipe has a plurality of foam guide holes; the biological filter pond is connected with both protein separator and sand filtering tank; one end of the sand filtering tank is connected with the biological filter pond, and the other end of the sand filtering tank is connected with one end of an ultraviolet sterilizer; the other end of the ultraviolet sterilizer is connected with the water inlet pipe. The indoor industrial penaeus vannamei culture device disclosed by the invention has the advantages of simple structure, convenience in use and low investment cost, can be used for effectively pushing water inside a penaeus vannamei pond to flow so as to ensure that the water inside the penaeus vannamei pond is in a stable rotational flowing state, can effectively solve the problem that the sewage of the penaeus vannamei pond is effectively discharged in time in a low circulation volume state, is uniform in aeration, improves the utilization ratio of water used for culture, reduces the sewage discharge and reduces the medicine application.

Owner:HAINAN PROVINCIAL FISHERIES RES INST

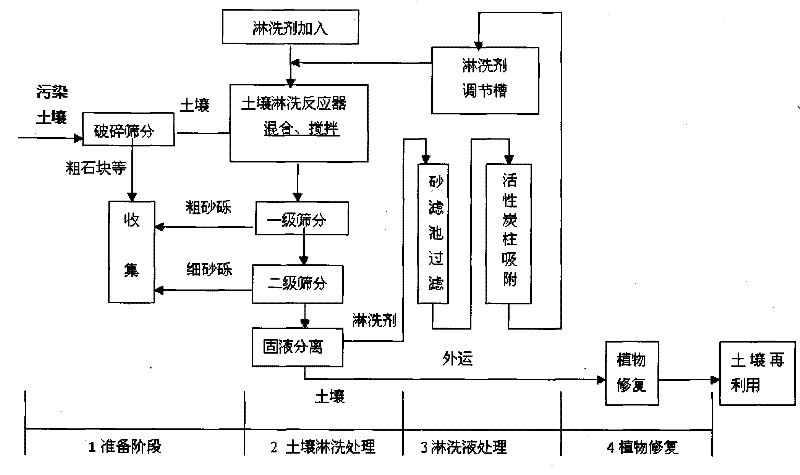

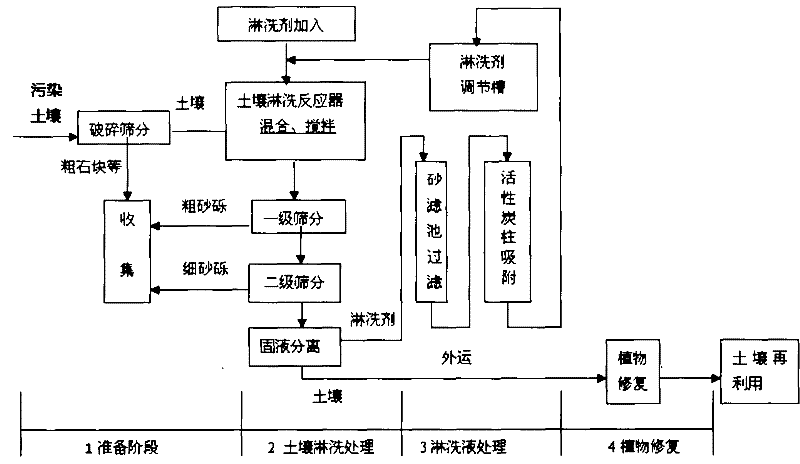

Ex-situ washing remediation method for nitrochlorobenzene-contaminated soil

InactiveCN102172614AThe process is easy to implementReduce labor inputContaminated soil reclamationEngineeringSlurry

The invention discloses an ex-situ washing remediation method for nitrochlorobenzene-contaminated soil, which comprises the following steps: crushing soil and sieving to remove stones and gravels; filling the soil into a washing reactor to fully mix the soil with a proper amount of washing solution, wherein the washing agent is ethanol; subjecting the washed mixture of slurry to two stages of sieving and filtering, wherein soil particles with large particle sizes are stopped by a screen; pumping the slurry mixture to soil-liquid separation equipment, recovering, filtering and purifying separated washing solution to regenerate the washing solution, regulating the concentration of the washing solution, and leaving the washing solution for washing at next time of washing. A sand filter column is used for filtering, active carbon is used for absorbing molecules of organic contaminants such as nitrochlorobenzene in the washing solution instead of molecules of ethanol serving as the washing agent, and thus, the washing solution is purified and can be recovered and recycling of resources is realized. The organic contaminant content of the washed soil reaches related standards. The soil particles which are sieved and filtered out can be used as building and road construction materials; and the soil particles obtained by solid-liquid separation can be used as raw materials for making concrete and fire bricks and also can be reclaimed. Thus, the whole soil remediation process is accomplished. In the invention, the process is easy to implement, small-scale industrial application can be realized, and an effective means is provided for scientific researchers for researching soil remediation.

Owner:南京市生态环境保护科学研究院

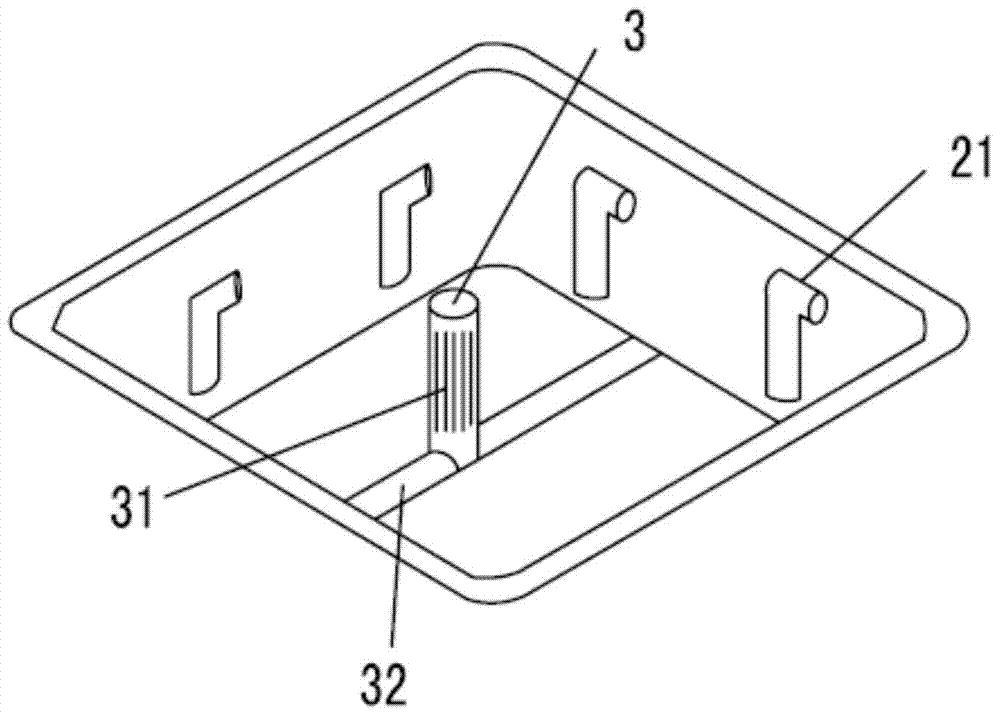

Efficient building sandstone screening and washing device

The invention discloses an efficient building sandstone screening and washing device which comprises a feeding pipe, a grid, a liquidometer, a box body, a water inlet pipe, a flowmeter, a spray head, a rotary shaft, a camera, a timer, an impeller, a screen plate, a vibration exciter, a coarse sandstone discharging pipe and a fine sandstone discharging pipe; the feeding pipe is arranged at the top end of the box body and internally and obliquely provided with the grid; the lowermost end of the grid is provided with an impurity discharging pipe, the liquidometer is arranged on the box body, the box body communicates with the water inlet pipe, the outlet end of the water inlet pipe is provided with the spray head, and the flowmeter is installed on the water inlet pipe; the camera is arranged on the inner wall of the top end of the box body, the rotary shaft is arranged in the box body, and the impeller is installed on the rotary shaft; and the screen plate is obliquely arranged in the box body, the vibration exciter is arranged on the lower surface of the screen plate, and the screen plate comprises a first screen plate body and a second screen plate body. The efficient building sandstone screening and washing device is capable of screening sandstone, improving the working efficiency and saving time and labor, simple in structure and convenient to use and popularize.

Owner:王剑

Overland runoff rainwater storing and purifying integrated device with flooded culvert pipes and overland runoff rainwater storing and purifying method

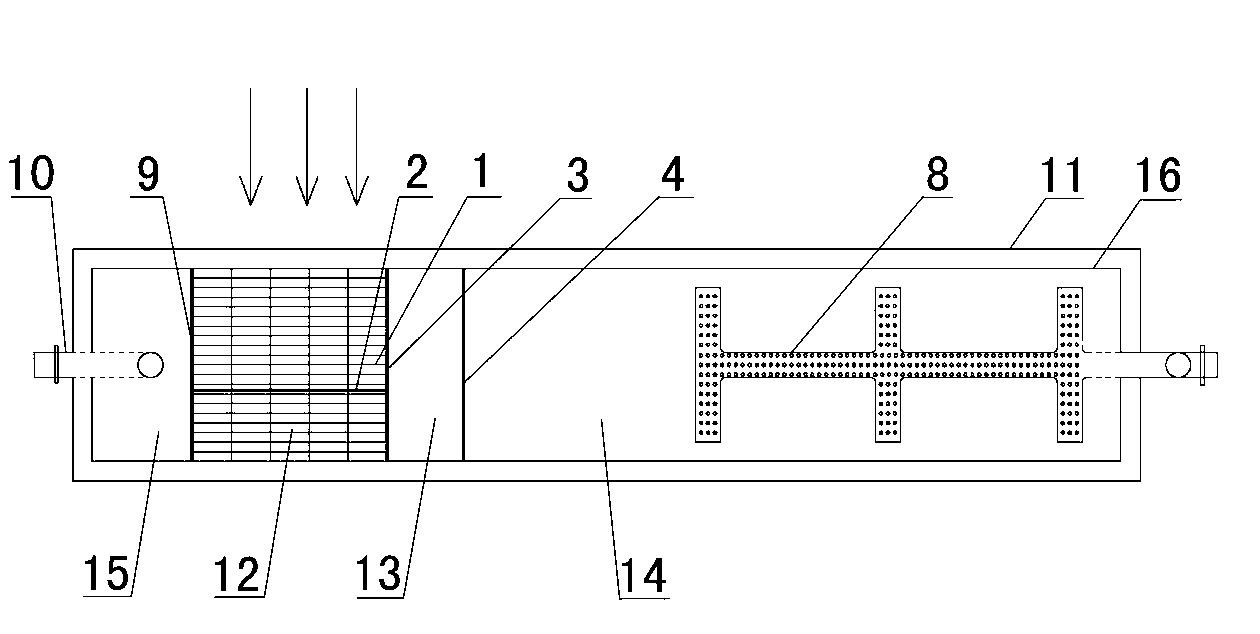

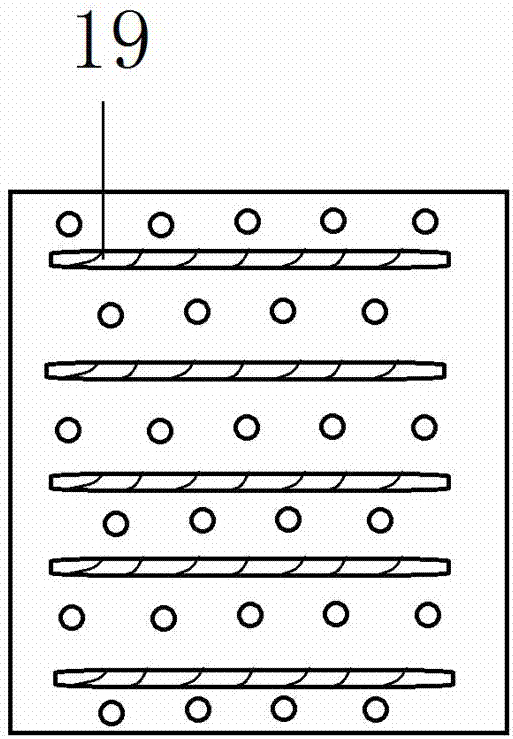

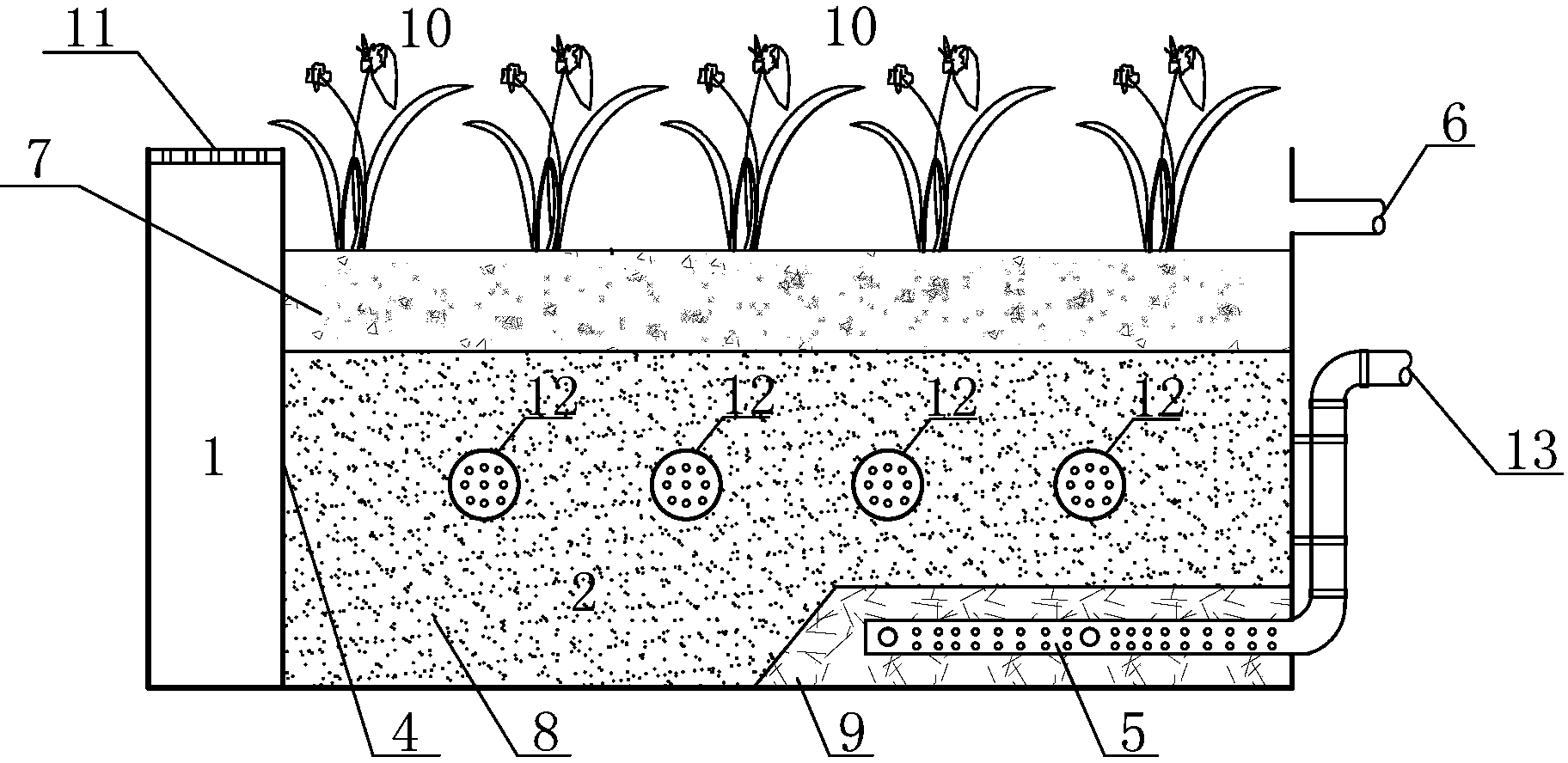

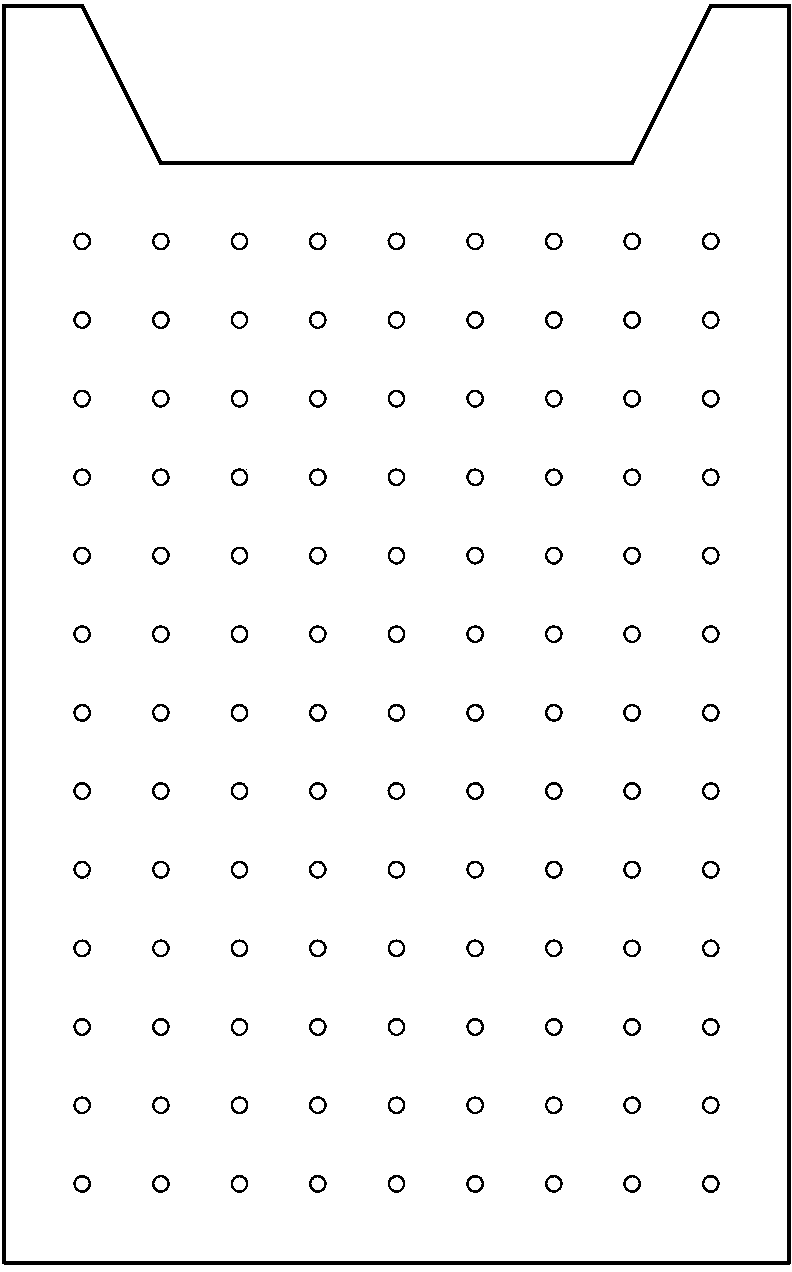

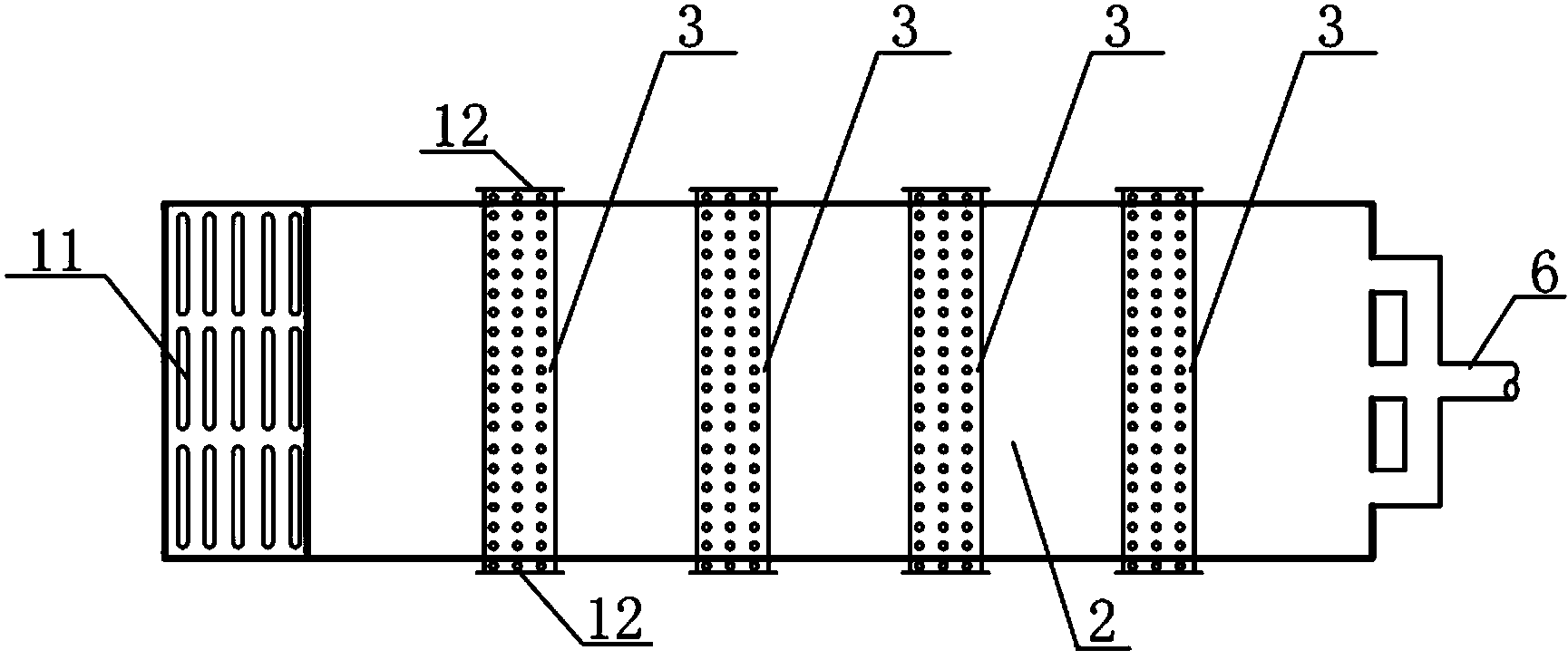

The invention relates to an overland runoff rainwater storing and purifying integrated device with flooded culvert pipes and an overland runoff rainwater storing and purifying method. The device comprises a pre-precipitating chamber (2) and a wet land unit (2), wherein overland runoff rainwater passes through a perforated partition (4) and enters the wet land unit (2) after being precipitated preliminarily; the perforated culvert pipes (3) are arranged in the wet land unit (2) side by side; the culvert pipes (3) transversely penetrate in two sides of the wet land unit (2); perforated plugs (12) are arranged at two ends of each culvert pipe (3); the wet land unit (2) comprises a gravel cushion layer (9), a sand filter layer (8) and a planting soil layer (7); and perforated drainage pipes (5) are buried in the gravel cushion layer (9). By using the device and the method, particles and soluble pollutants in the runoff rainwater can be removed, so that the pollutants in the runoff rainwater are eliminated; and the treated rainwater is stored in the device and the culvert pipes (3), wet land plants can grow by using the treated rainwater, the water seeps to surrounding soil by submerging two ends of each culvert pipe in a wet land, and the purpose of continuously cultivating and supplementing underground water is achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

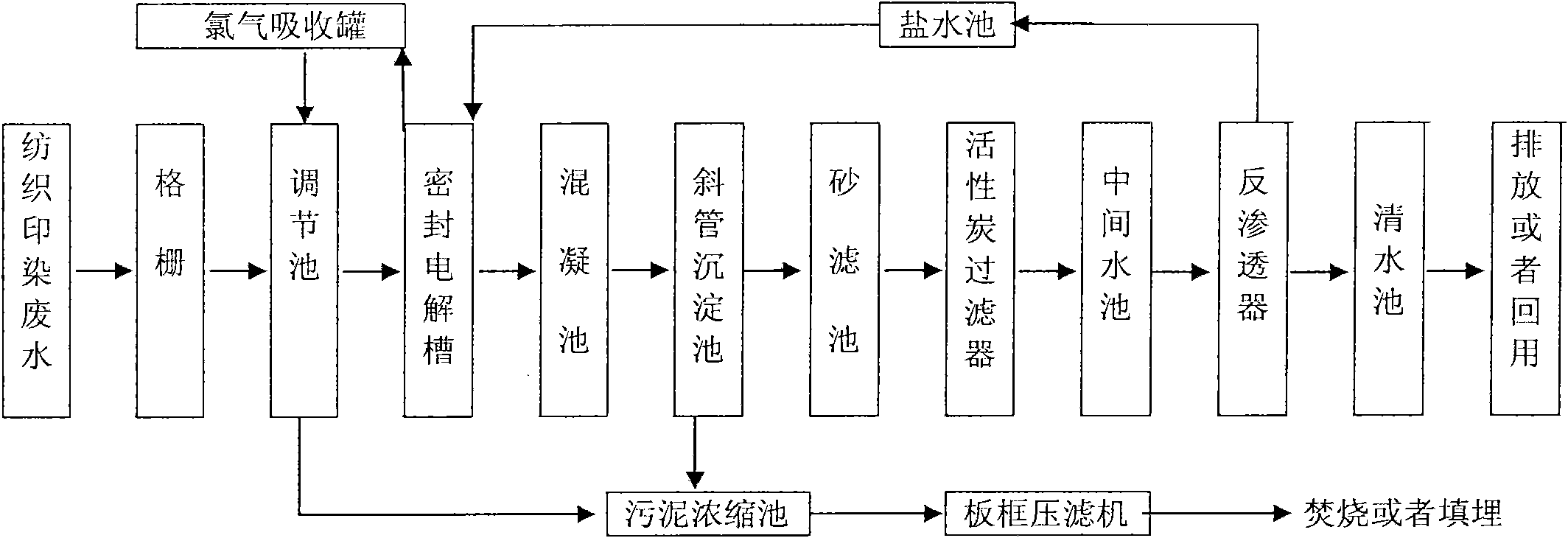

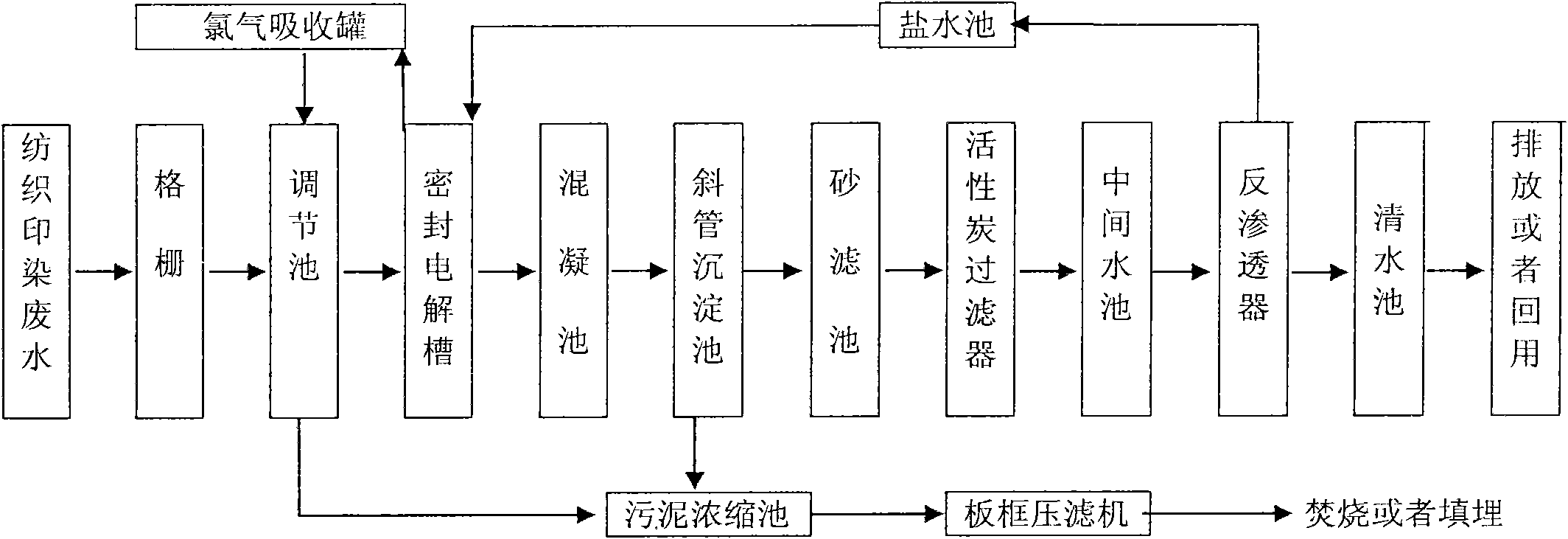

Spinning printing and dyeing waste water reclamation method, device and application thereof

InactiveCN101857328AEfficient removalReduce work stressWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAluminium chlorideActivated carbon filtration

The invention discloses a spinning printing and dyeing waste water reclamation method, a device and the application thereof. The method comprises the steps of: filtering spinning printing and dyeing waste water; sequentially carrying out homogenizing, equalizing quantity and primary sedimentation on filtrate; adding sodium chloride into waste water supernate, and evenly mixing for indirect electro-catalysis oxidation; sequentially evenly mixing the waste water treated by indirect electro-catalysis oxidation with basic aluminium chloride and polyacrylamide; removing the precipitated supernate, and sequentially treating by activated carbon adsorption and reverse osmosis; removing trace organic chloride generated in the electrolytic process and the rest COD and color; and obtaining recyclable water resource. The device for realizing the method comprises a grate, a regulating reservoir, a sealed electrolytic cell, a flocculation tank, an inclined tube sedimentation tank, a sand filter tank, an active carbon filter, an intermediate water tank, a reverse osmosis unit, a clear water reservoir, a brine tank, a chlorine absorbing tank, a sludge concentration tank and a plate-and-frame filter press. The invention can effectively treat spinning printing and dyeing waste water, and has the advantages of high treatment efficiency, stable effluent quality, simple technological process and the like.

Owner:DONGGUAN HONGJIE ENVIRONMENTAL PROTECTION TECH +1

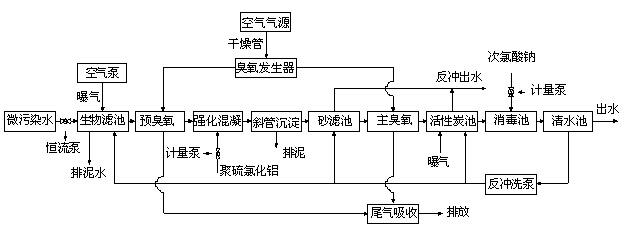

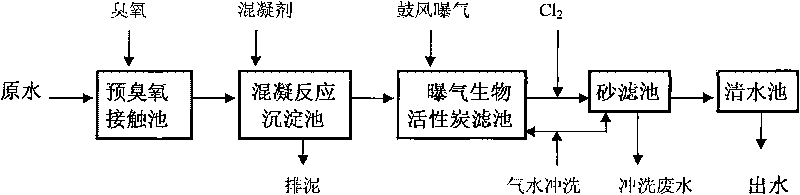

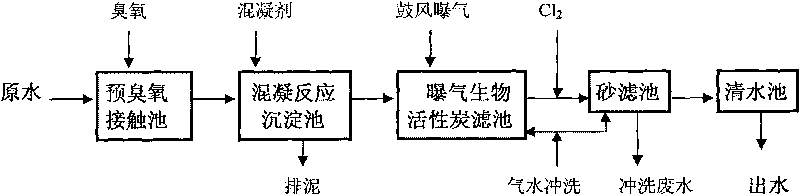

Feedwater treatment method by pre-ozonation and aerated biological activated carbon

InactiveCN101704609AAvoid breedingReduce qualityTreatment using aerobic processesMultistage water/sewage treatmentWater sourceWater quality

The invention discloses a method for applying pre-ozonation and aerated biological activated carbon processes to feedwater treatment. The method combines ozone pre-oxidation, an aerated biological activated carbon filter tank and a coagulation-sedimentation-sand filtering-disinfection conventional feedwater treatment process to produce drinking water, is a feedwater treatment process for improving water quality of feed water aiming at micro-polluted drinking water sources, and integrates the characteristics of an aerated biofilter biological pre-treatment process and an ozone biological activated carbon advanced water-purifying process. Raw water enters a pre-ozonation contact tank, a coagulation sedimentation tank and the aerated biological activated carbon filter tank orderly, is disinfected, enters a sand filtering tank, and finally flows into a clear water tank. Because the pre-ozonation contact tank and the aerated biological activated carbon filter tank are arranged in the conventional feedwater treatment process, the effect of removing organic matters, ammonia nitrogen, pathogenic microorganism, odor, chroma and the like is greatly improved, and the water quality safety of the method is obviously superior to that of the biological pre-treatment process and the ozone biological activated carbon advanced water-purifying process.

Owner:SOUTH CHINA UNIV OF TECH

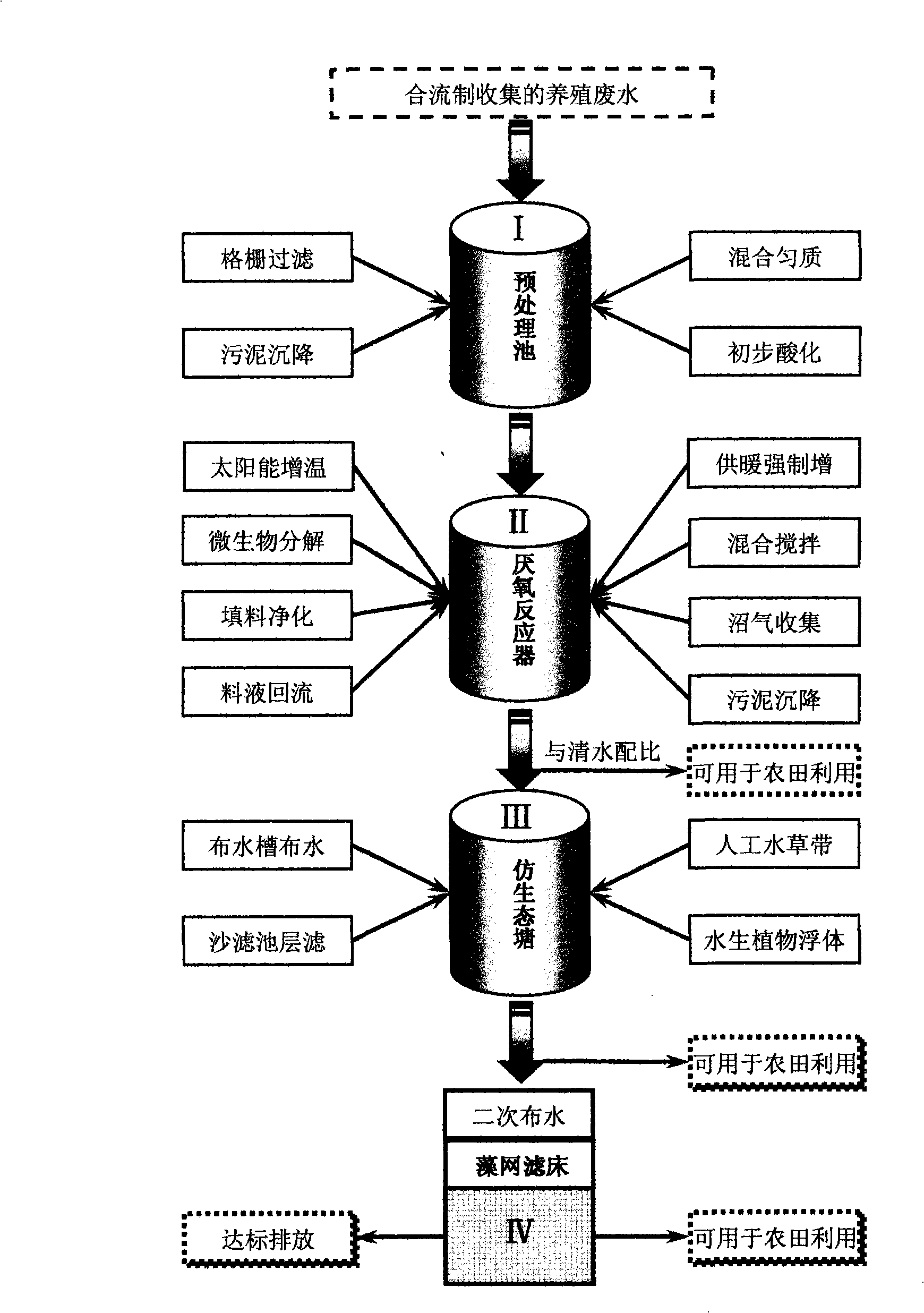

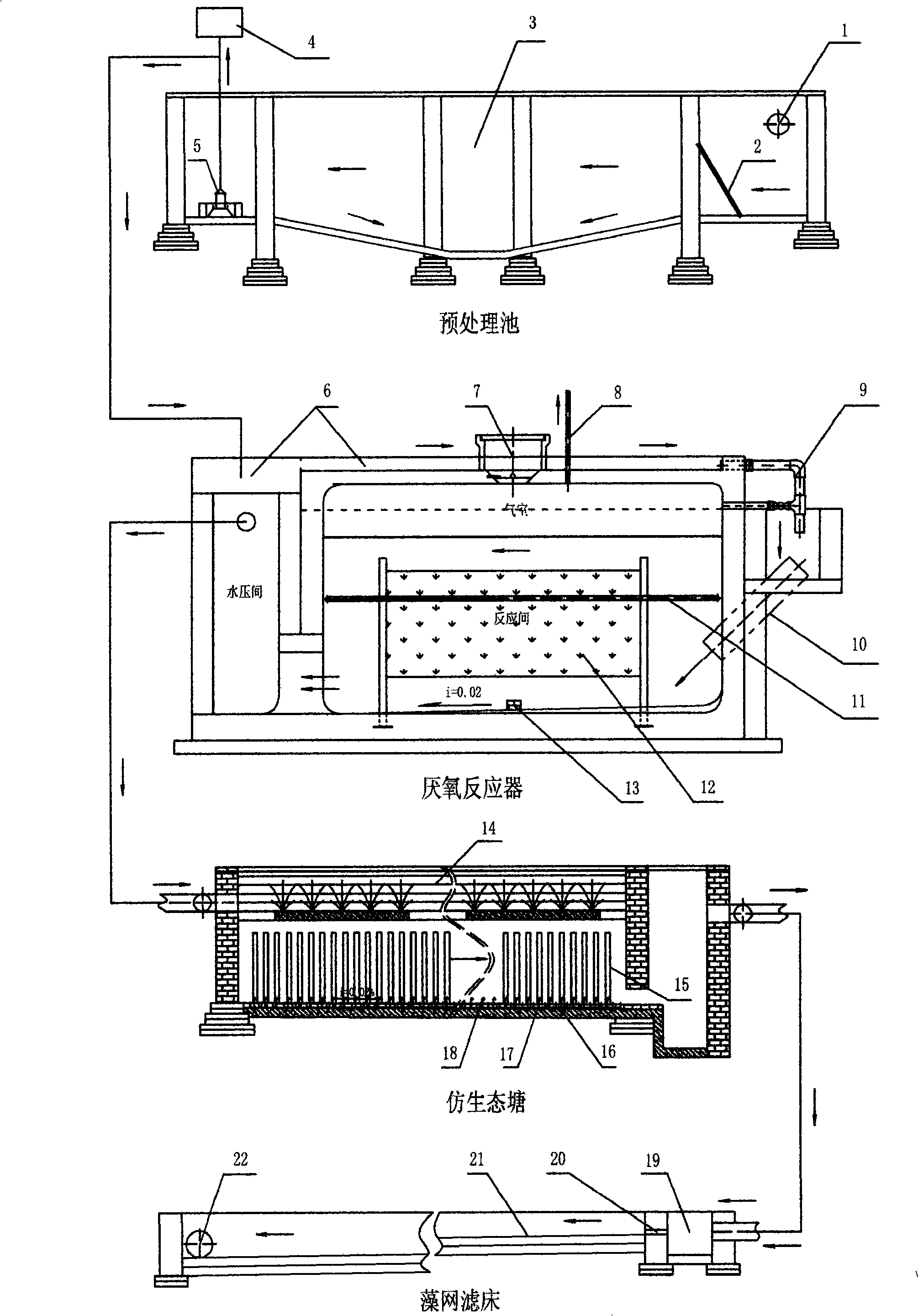

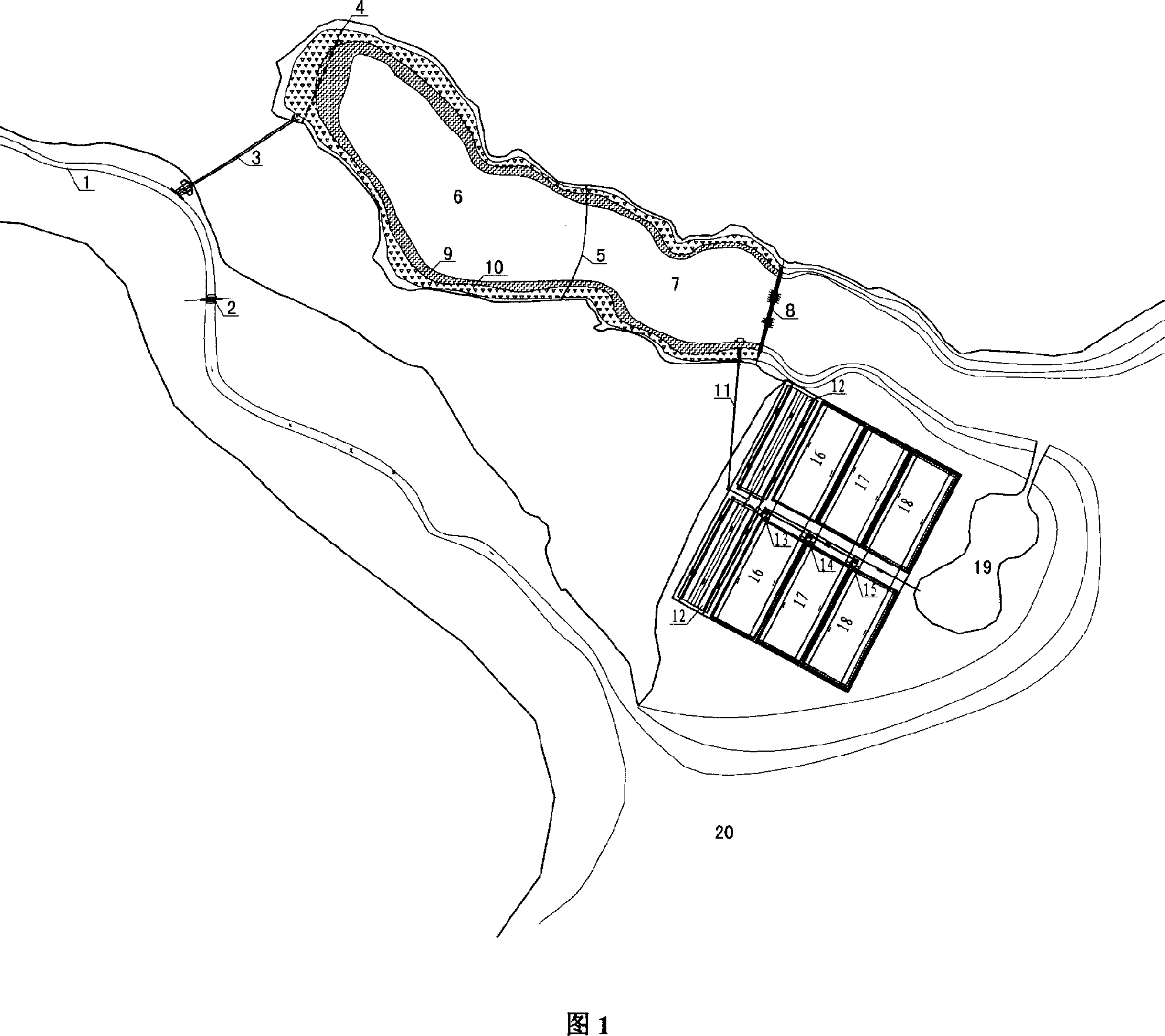

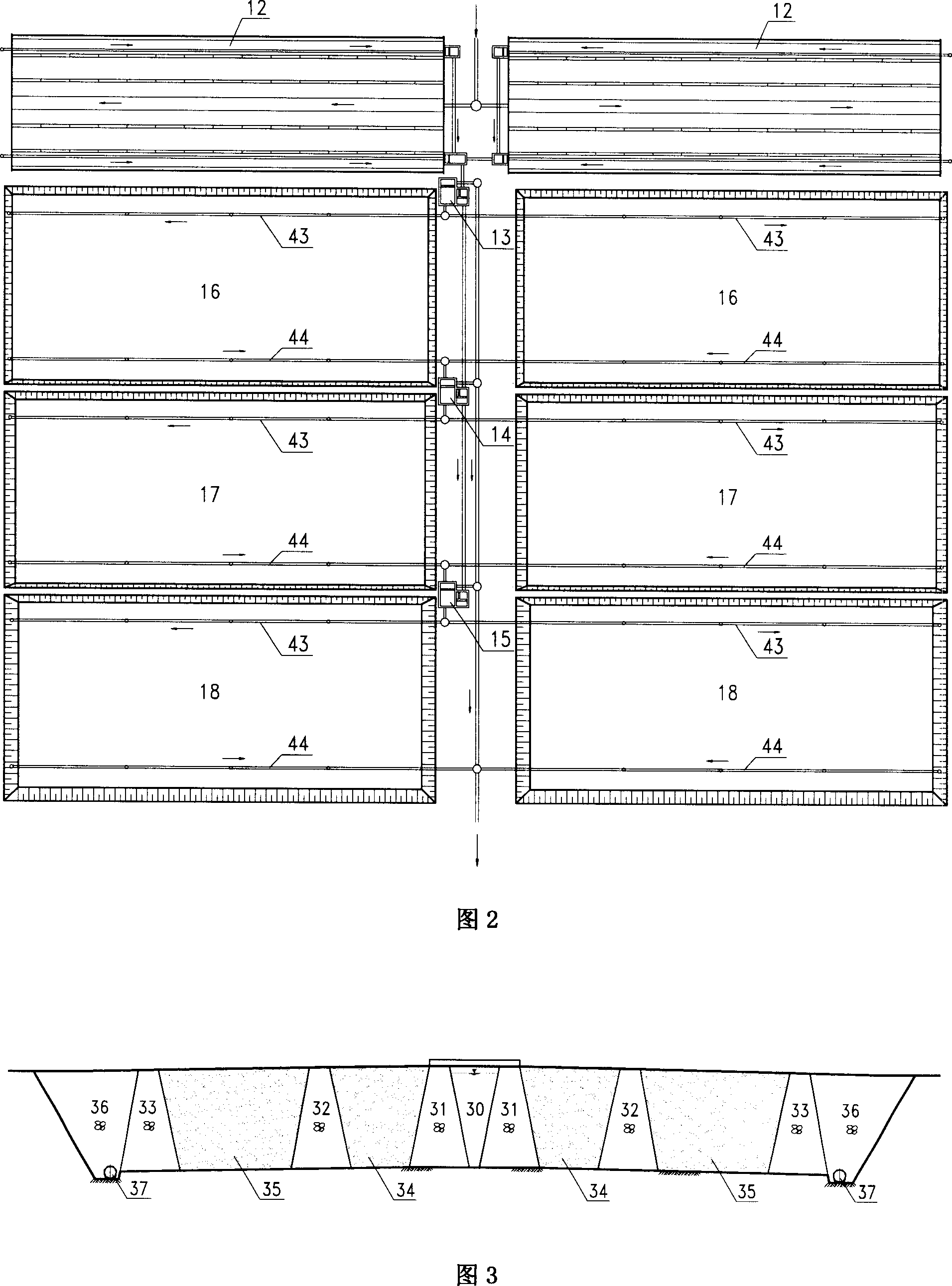

Comprehensive processing process and system for cultivation wastewater

InactiveCN101492230AMeet processingSimple processFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesSystem maintenanceAnaerobic reactor

The invention relates to a process and a system for treating breeding wastewater comprehensively, wherein the process comprises the following steps: firstly, performing grating filtration, mixed homogenization and silt sedimentation pretreatment in a pretreatment tank; secondly, performing heating and anaerobic fermentation in an anaerobic reactor; and thirdly, treating the wastewater in a bionic pond, wherein the material liquid in a water distribution trough of the bionic pond enters a sand filter through the bottom of the water distribution trough and then is raised to a water drop step; and the material liquid flows into a pond body and flows out of the pond body after being treated by an artificial float grass belt and hydrophyte floating bodies in the pond. The process and the system have the advantages of simple process, good commonality, high treatment efficiency, low running cost, low investment cost, and simple system maintenance.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

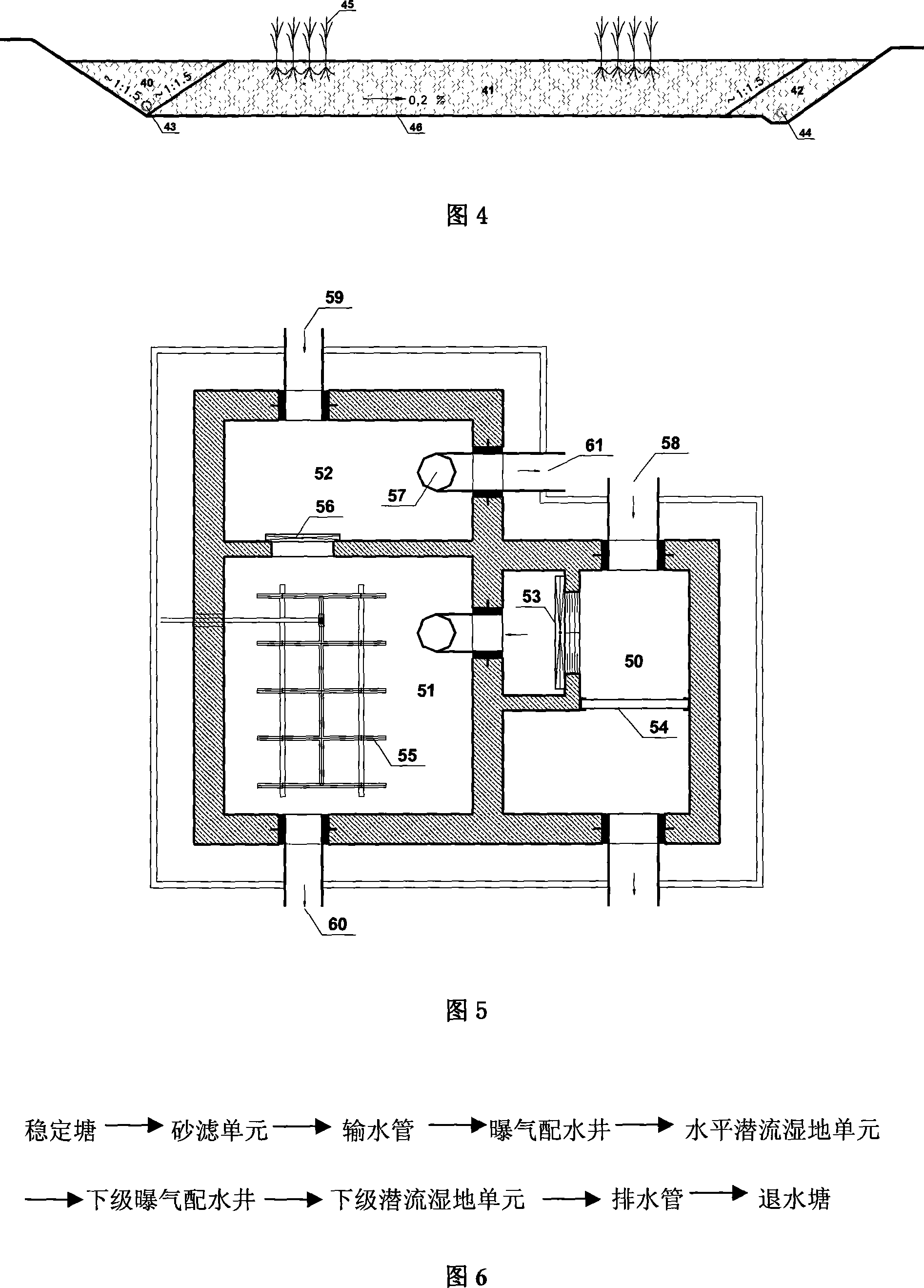

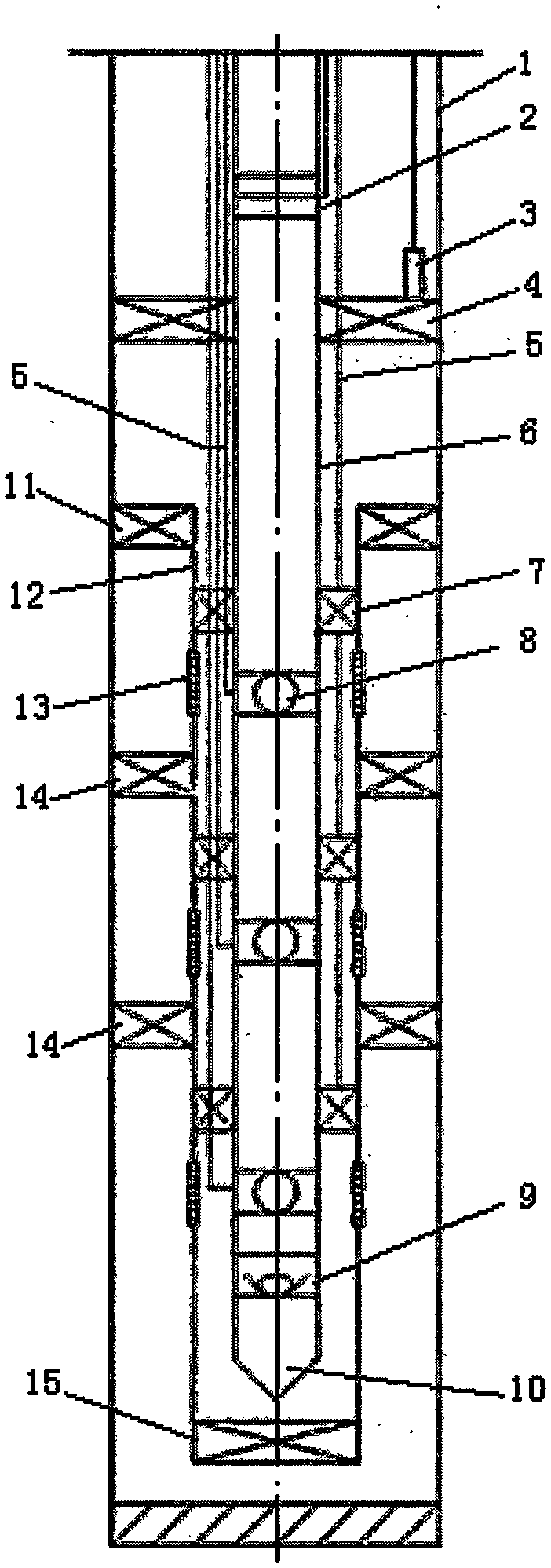

Composite artificial marshland water quality clarification system in north low-temperature area

InactiveCN101081713AImprove the ecological environmentTo achieve the purpose of purifying water qualityTreatment using aerobic processesSustainable biological treatmentConstructed wetlandWater quality

The composite water-purifying wetland system for northern low temperature region consists of three serially connected subsystems, including one stabilizing pond subsystem, one undercurrent wetland subsystem and one water draining pond subsystem. The stabilizing pond subsystem has one flexible partitioning wall to separate the pond into one front reservoir and one purifying area, and planted emergent vegetation zones and submerged plant zones. The undercurrent wetland subsystem consists of sand filtering modules, wetland modules and aerating water-distributing wells. The water draining pond subsystem consists of water draining canals and serially connected biological ponds. The present invention has well combined engineering measures and ecological measures to purifying polluted water for several times, saving in investment, high water purifying effect and high economic and ecological benefits.

Owner:北京市水利科学研究所

Tubular column for separated layer water injection

A tubular column for separated layer water injection comprises a subsurface safety valve, an exhaust valve, a multi-tube traverse packer, a hydraulic-control pipeline, hydraulic-control packers, sliding sleeve type water nozzles, a backwashing valve, a suspension packer, a sand-prevention bushing, sand filtering tubes and interlayer packers. An oil tube is sequentially connected with the subsurface safety valve, the multi-tube traverse packer, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the corresponding hydraulic-control packer, the corresponding sliding sleeve type water nozzle, the backwashing valve and a guide connector. The sand-prevention bushing is installed outside the oil tube in a connected mode. The suspension packer, the corresponding sand filtering tube, the corresponding interlayer packer, the corresponding sand filtering tube, the corresponding interlayer packer, the corresponding sand filtering tube and a plug are sequentially installed on the sand-prevention bushing in a connected mode, and a bushing is arranged on the outmost part. The exhaust valve is installed on the multi-tube traverse packer in a connected mode, the hydraulic-control pipeline is installed on the exhaust valve for control, the hydraulic-control packers are traversed, connected and controlled through the same hydraulic-control pipeline, the sliding sleeve type water nozzles are connected through the hydraulic-control pipeline for control, and the subsurface safety valve is connected with the hydraulic-control pipeline for control.

Owner:李永立

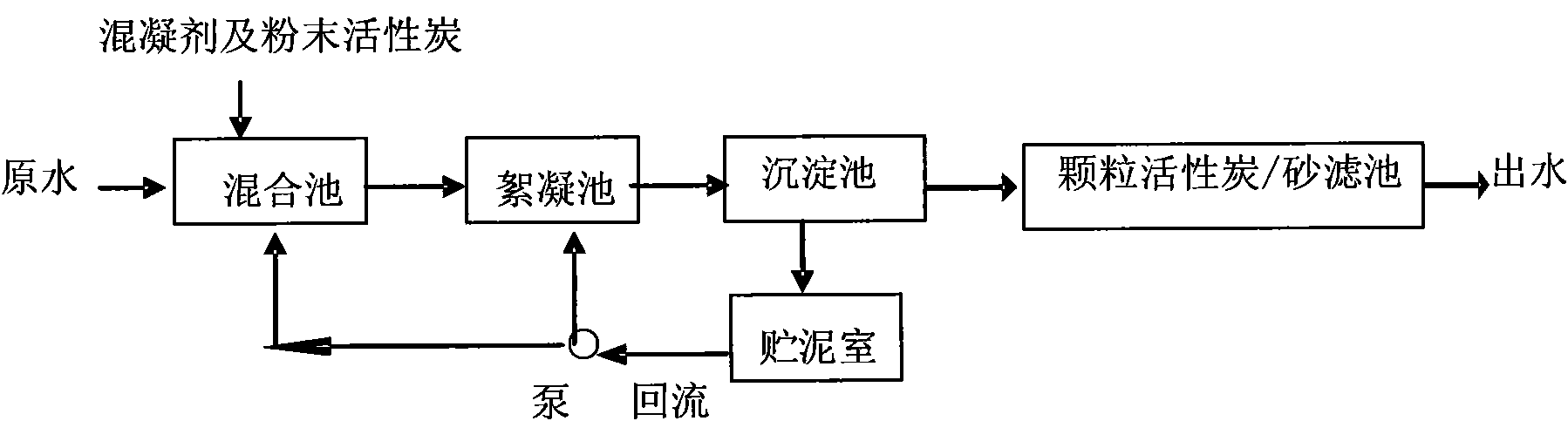

Powdered carbon backflow and carbon/sand filter combined process for treating polluted water

InactiveCN101962251AMake full use of the adsorption capacityEfficient removalMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSand filter

The invention discloses a powdered carbon backflow and carbon / sand filter combined process for treating polluted water, which belongs to the field of water treatment. A device comprises a mixing tank, a flocculating tank, a settling pond and a carbon / sand filter which are connected in series in turn, wherein powdered active carbon and a coagulant are added in raw water to be treated, and the raw water is mixed with the coagulant in the mixing tank; the mixed raw water enters the flocculating tank to undergo a flocculation reaction and then enters the settling pond to undergo solid-liquid separation, active carbon mud settled in the settling pond is concentrated in a mud storage chamber and flows back to the mixing tank or flocculating tank by a reflux pump, the concentrated active carbon mud flows back to the mixing tank when the coagulant is added and flows back to the flocculating tank when the coagulant is not added; and water after the settlement enters the carbon / sand filter, the granular active carbon is filled on the upper layer of the carbon / sand filter, and quartz sand is filled in the lower layer. In the invention, a powdered carbon backflow process is adopted, so that over 50 percent of medicinal preparation can be saved; and the physical absorption effect, biological degradation effect and strengthening coagulation effect of the active carbon act in coordination, and the carbon / sand dual-layer filter has the physical absorption and biological degradation effects at the same time.

Owner:BEIJING UNIV OF TECH +1

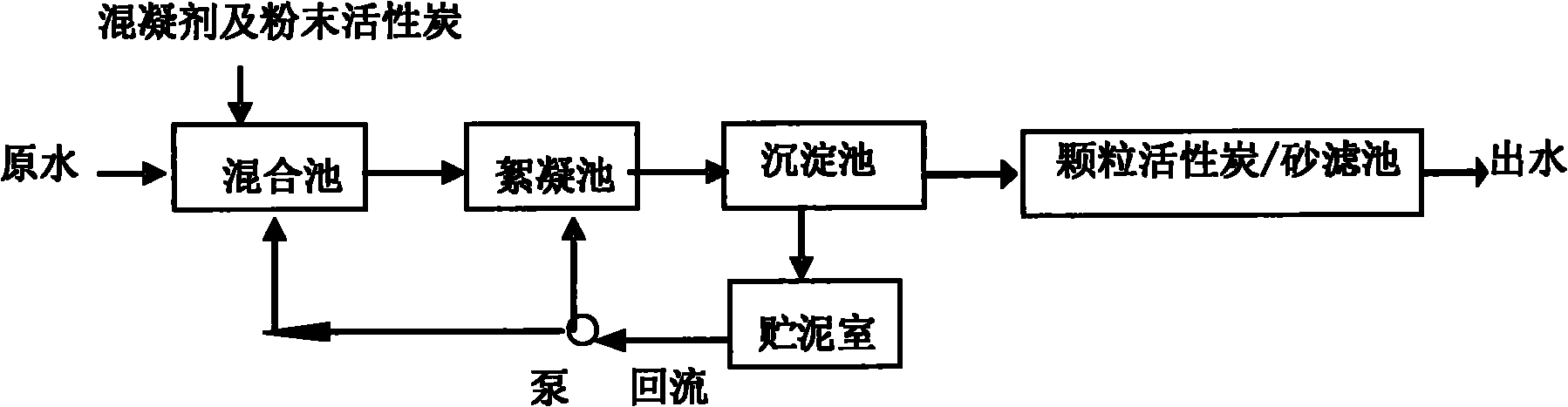

Leather waste water treatment system and treatment process

ActiveCN103224309AImprove efficiencyImprove utilizationWaste water treatment from animal processingMultistage water/sewage treatmentWater qualityEngineering

The invention discloses a leather waste water treatment system, which comprises a sludge thickener, a sludge dewaterer as well as a crude grating, a fine grating, a sand basin, an aeration equalizing tank, a coagulation sedimentation basin, an air floatation pool, a hydrolysis-acidification pool, a biological selection pool, an A / O nitrogen removing pool, a secondary sedimentation pool and a sand filtering pool which are connected by pipelines, sludge outlets of the sand basin, the coagulation sedimentation basin, the air floatation pool, the hydrolysis-acidification pool and the A / O nitrogen removing pool are connected by pipelines for connecting a sludge thickener; the invention also discloses a treatment process employing the leather waste water treatment system. The invention has the beneficial effects that ammonia nitrogen in the leather waste water converts into nitrate, thereby promoting utilization of nutrients in water by microorganism, and realizing high efficiency reduction of ammonia nitrogen and COD in leather waste water; the invention has the advantages of high waste water purifying capability, high efficiency and small land occupation area, and the waste water after treatment can reach the reuse water quality standard for reuse, thereby realizing the cyclic utilization of water after treatment and reducing waste of water resource.

Owner:XIHUA UNIV

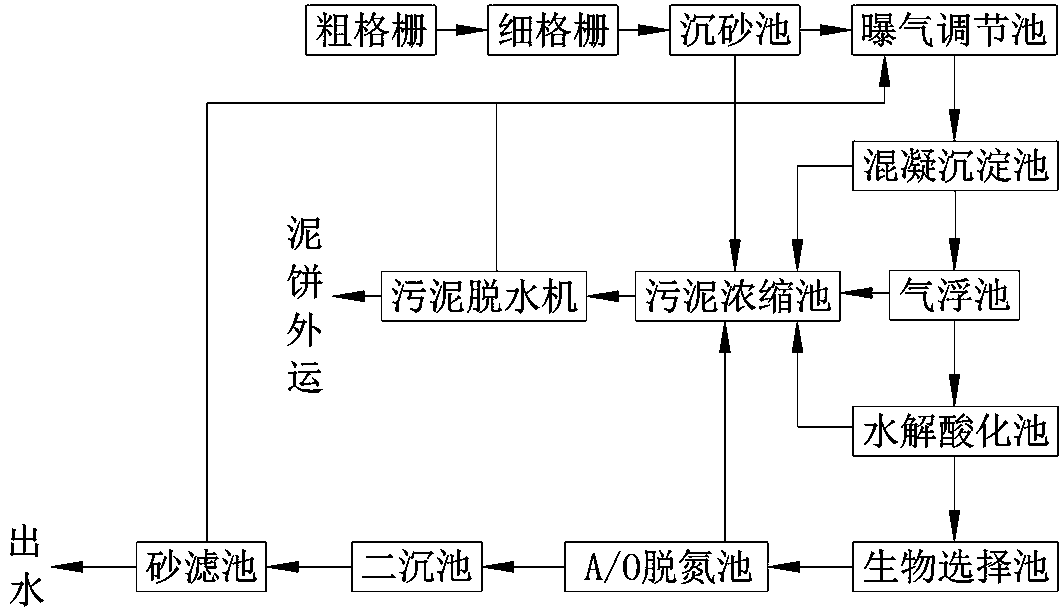

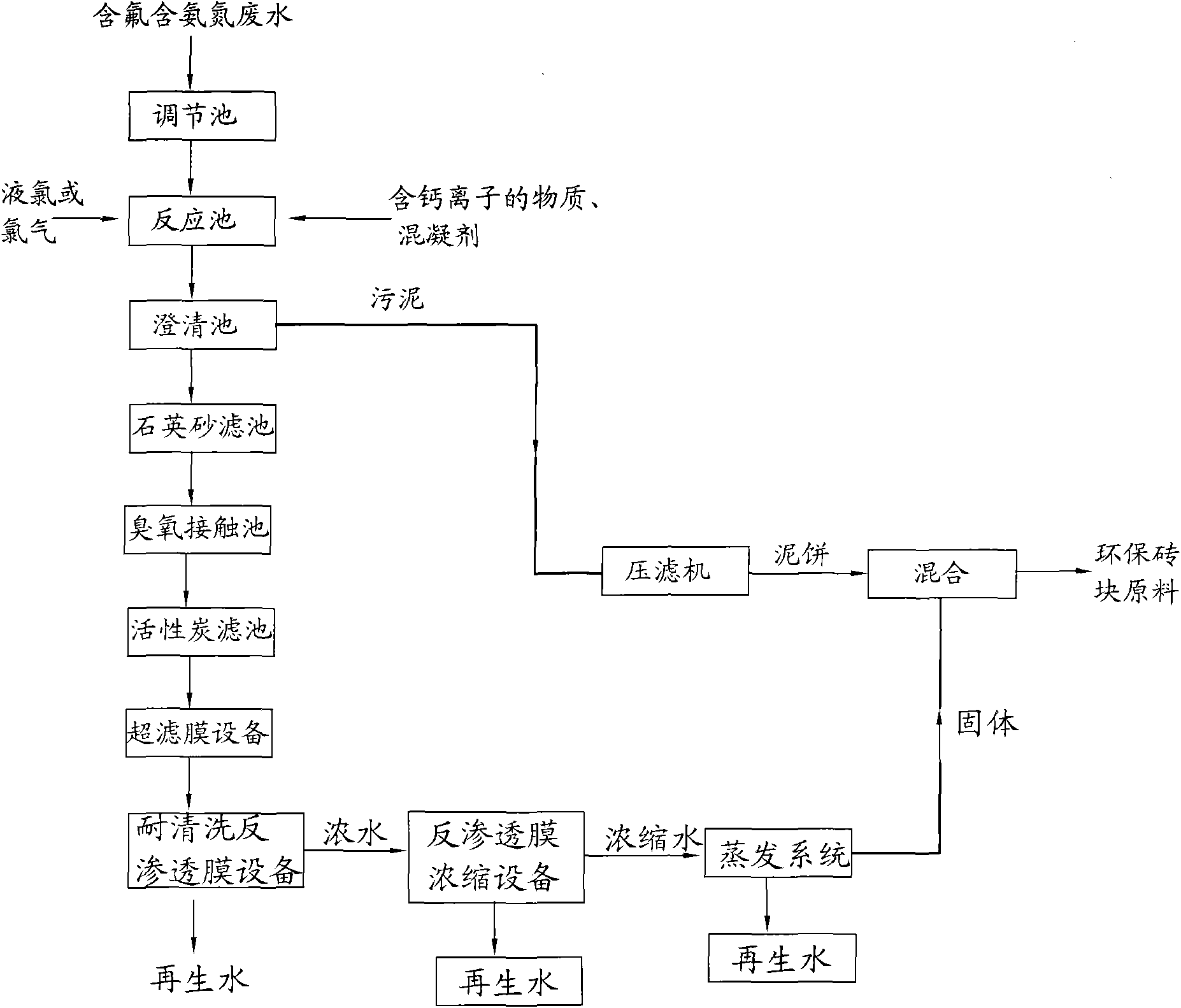

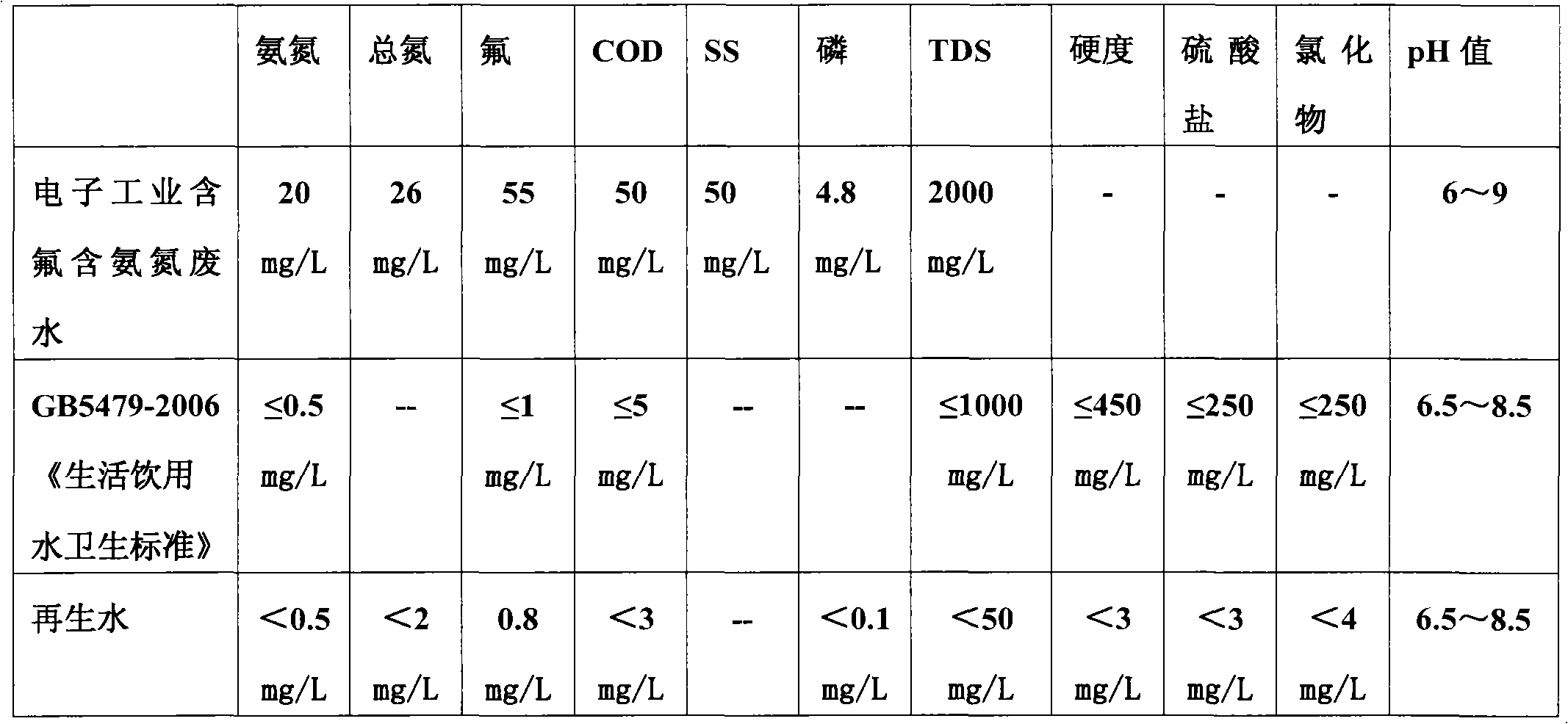

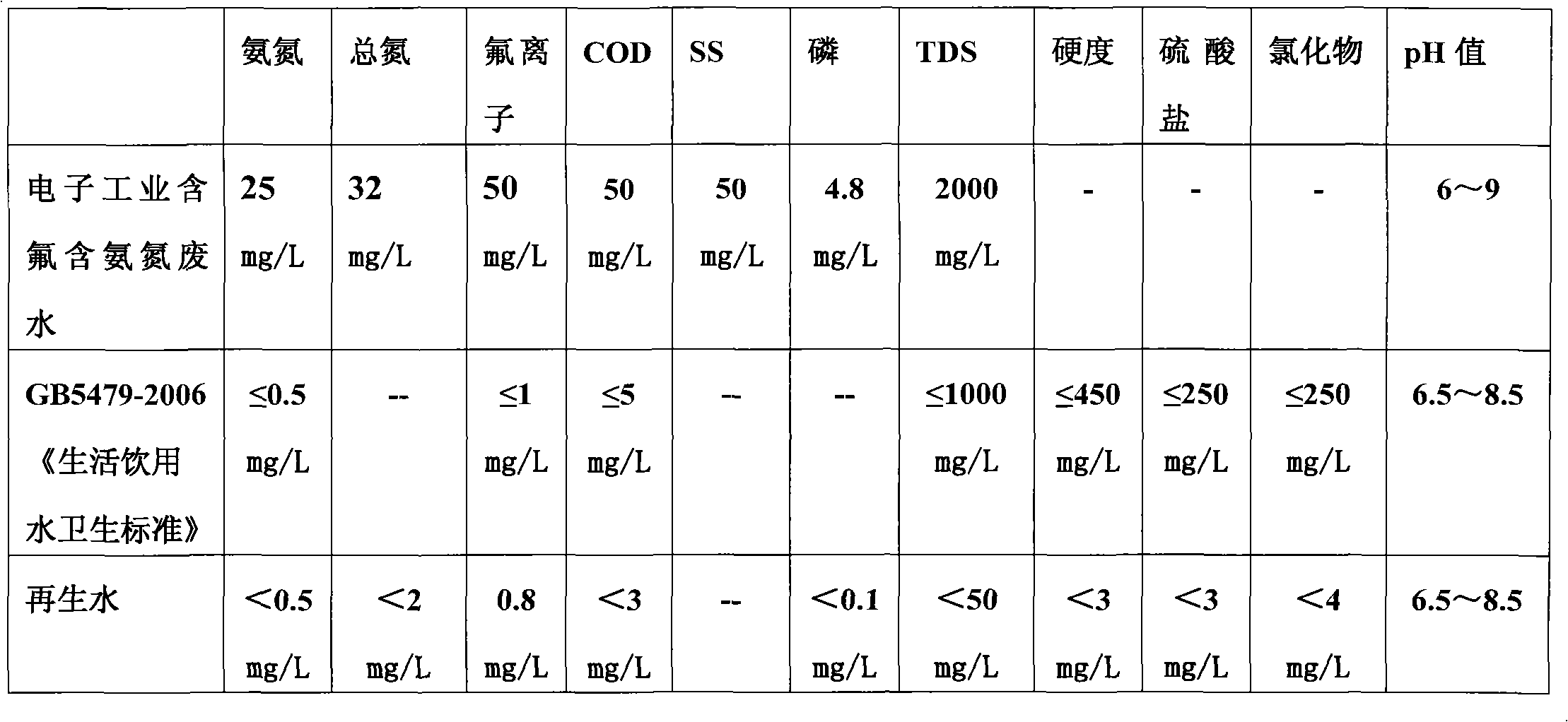

Method for completely recycling wastewater containing fluorine and ammonia nitrogen in electronic industry

ActiveCN102126806AReduce ammonia nitrogen contentTo achieve the treatment effectGeneral water supply conservationWater contaminantsWater useUltrafiltration

The invention relates to a method for completely recycling wastewater containing fluorine and ammonia nitrogen in an electronic industry. By the method, the wastewater passes through a 'three plants-in-one' integrated device formed by serially connecting a wastewater treatment plant treatment process, a tap water plant treatment process and a pure water treatment plant treatment process in turn to obtain recycled water. Devices of the wastewater treatment plant treatment process comprise a regulation tank, a reaction tank and a clarification tank; devices of the tap water plant treatment process comprise a quartz sand filter tank, an ozone contact tank and an activated carbon filter tank; and devices of the pure water treatment plant treatment process comprise ultrafiltration membrane equipment, washable reverse osmosis membrane equipment, reverse osmosis membrane concentration equipment and an evaporation system. By the method, the wastewater can be completely recycled, the water quality of the recycled water has high stability, and achieves and is superior to main indicators of GB5749-2006 'Sanitary Standard for Drinking Water' issued by the nation, and the recycled water can serve as primary pure water used in industrial production.

Owner:WUXI DEPPEL WATER INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com