Patents

Literature

8562 results about "Filter press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

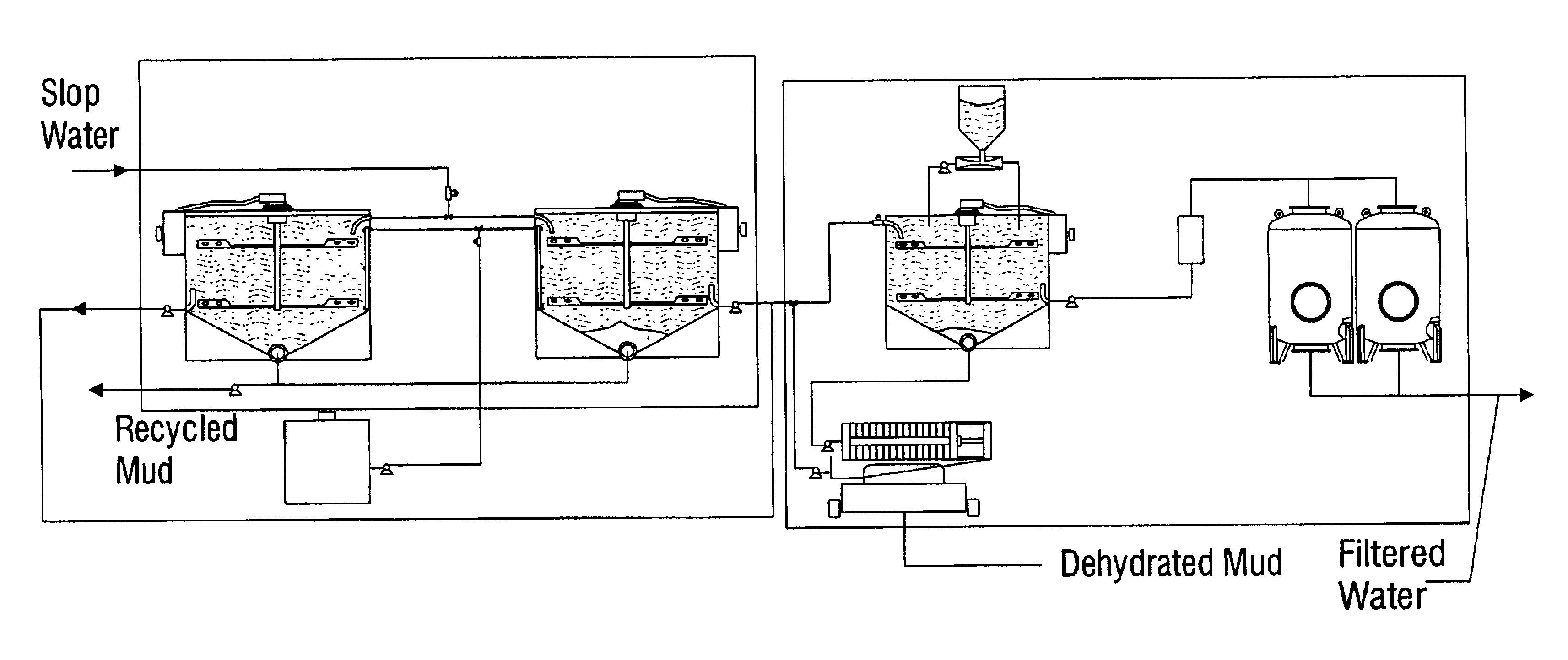

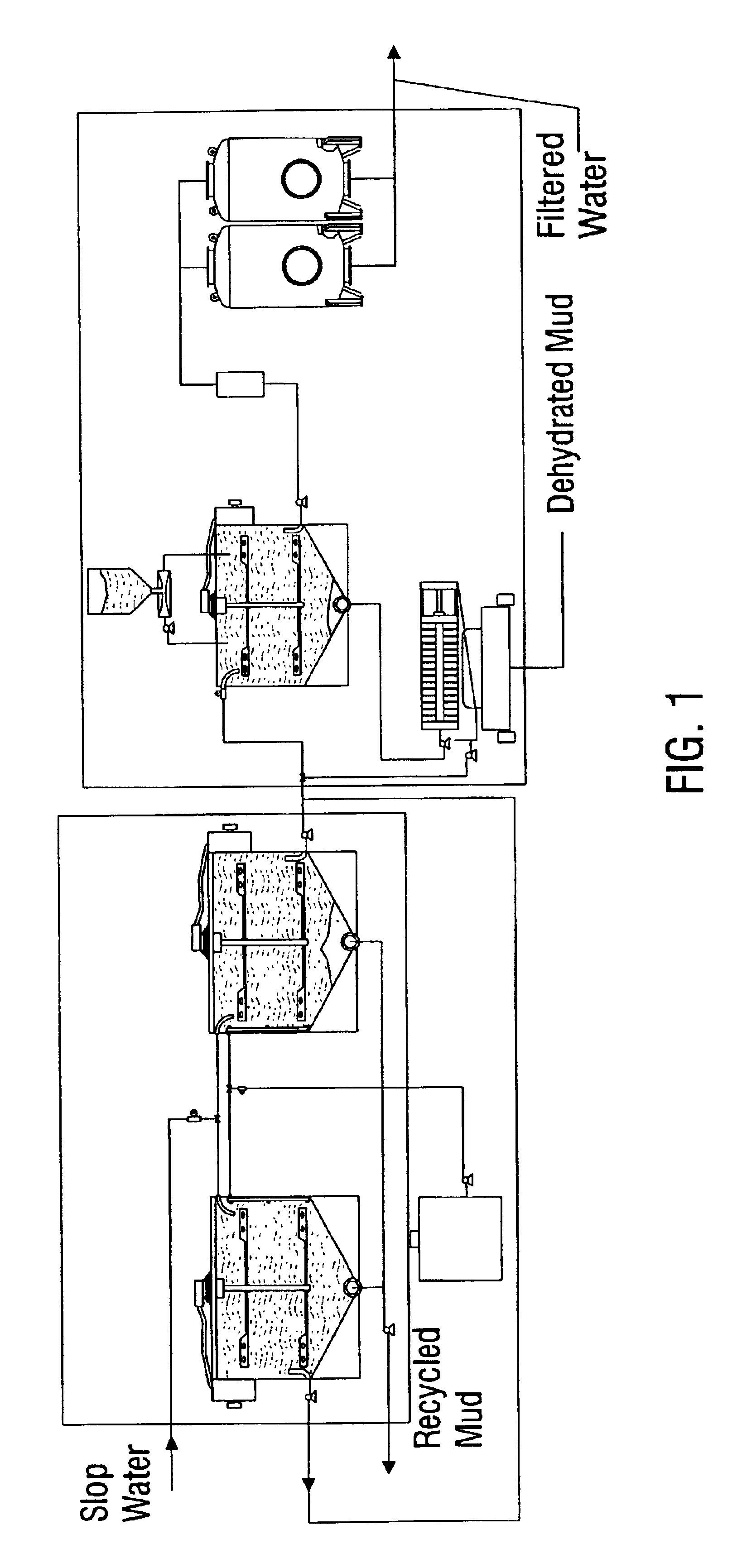

An industrial filter press is a tool used in separation processes, specifically to separate solids and liquids. The process uses the principle of pressure drive, as provided by a slurry pump. Among other uses, filter presses are utilized in marble factories in order to separate water from mud in order to reuse the water during the marble cutting process.

Procedure for the production of ethanol from lignocellulosic biomass using a new heat-tolerant yeast

InactiveUS20050069998A1Low conversion rateReduce yieldFungiBiological substance pretreatmentsFiltrationSolid fraction

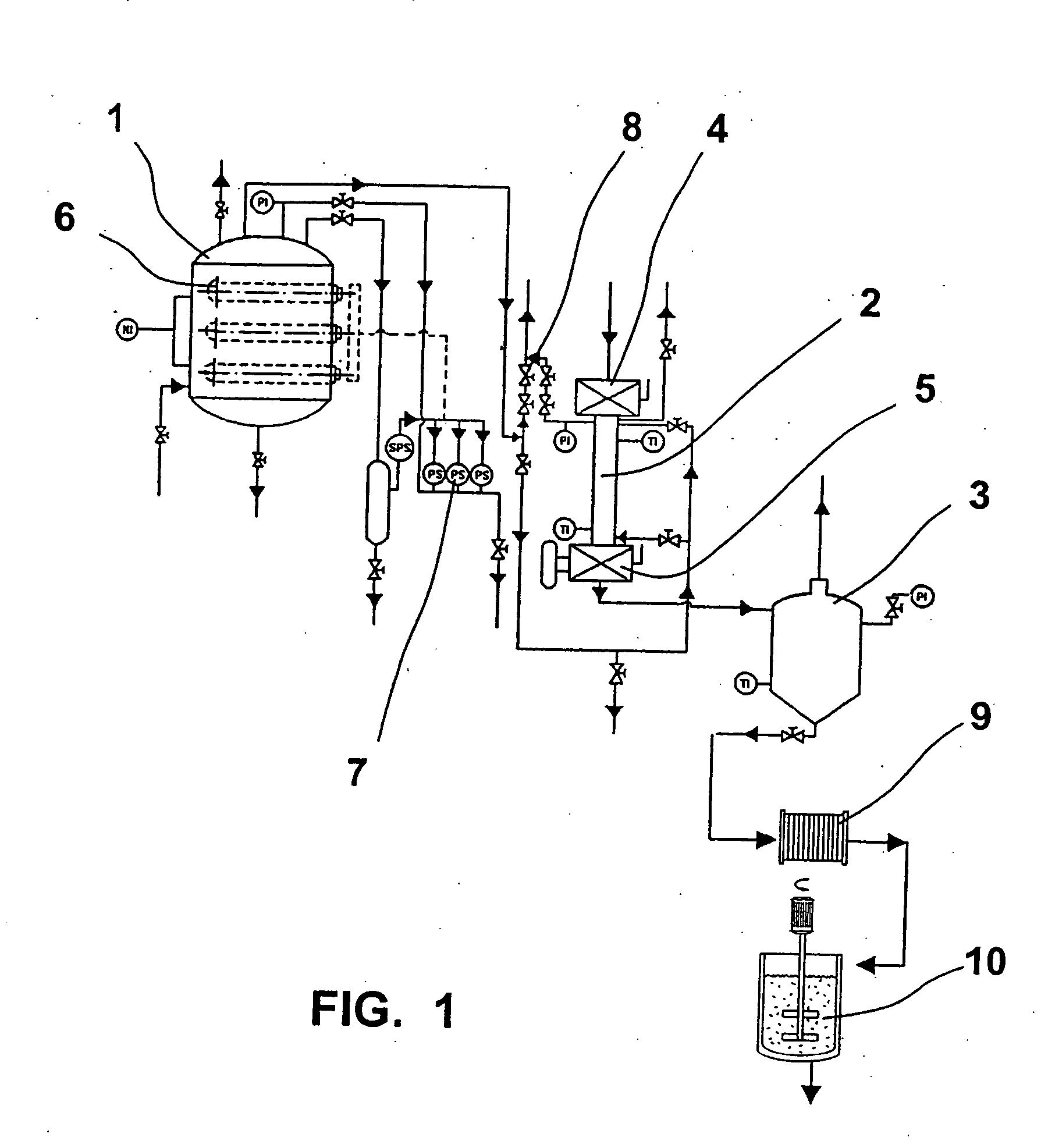

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230° C. for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of β-glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42° C.

Owner:CENT DE INVESTIGACIONES ENERGETICAS MEDIO AMBIENTALLES Y TECNOLOGICAS (C I E M A T)

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

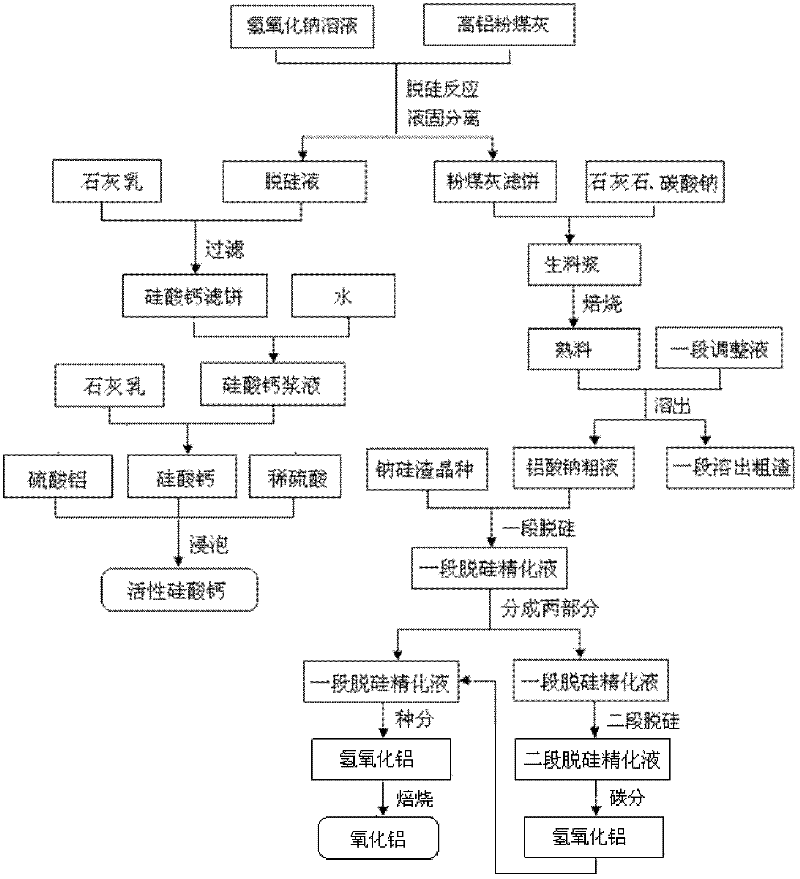

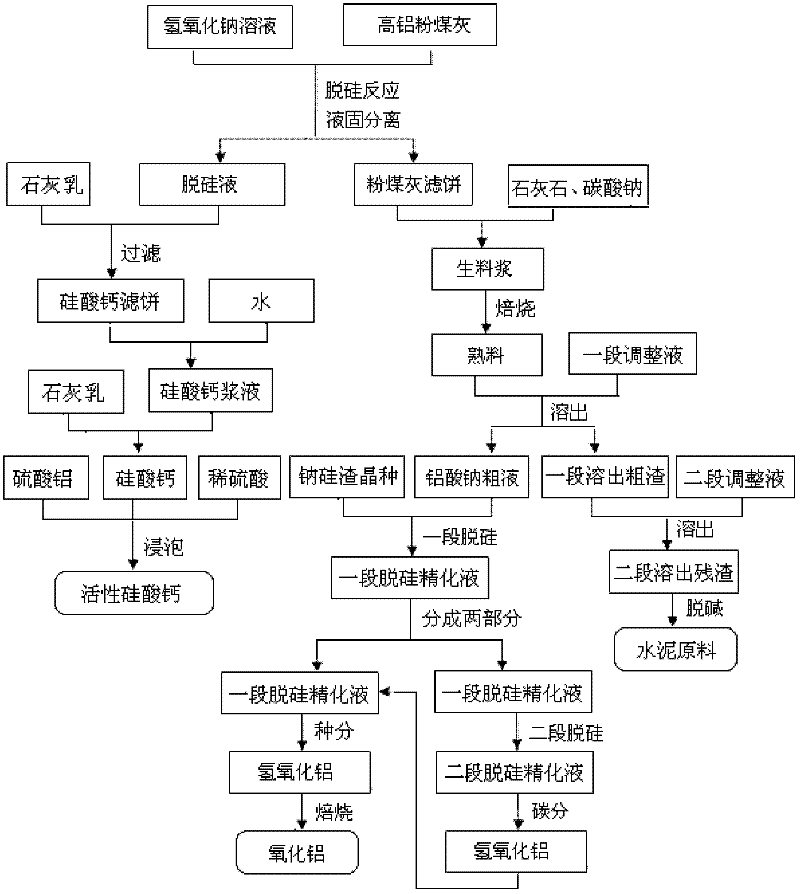

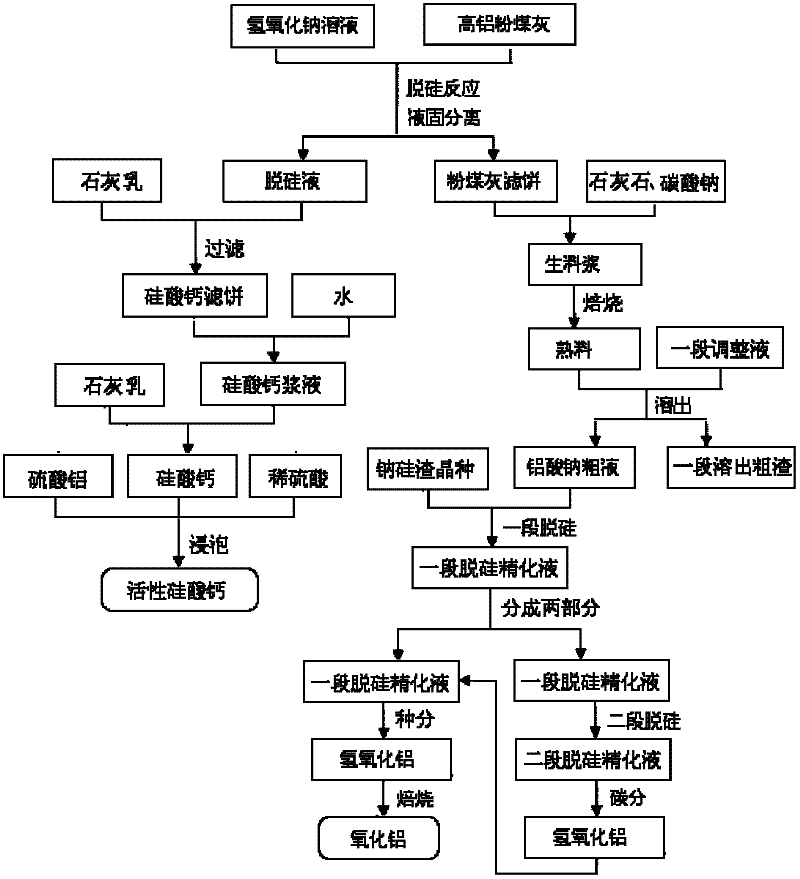

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

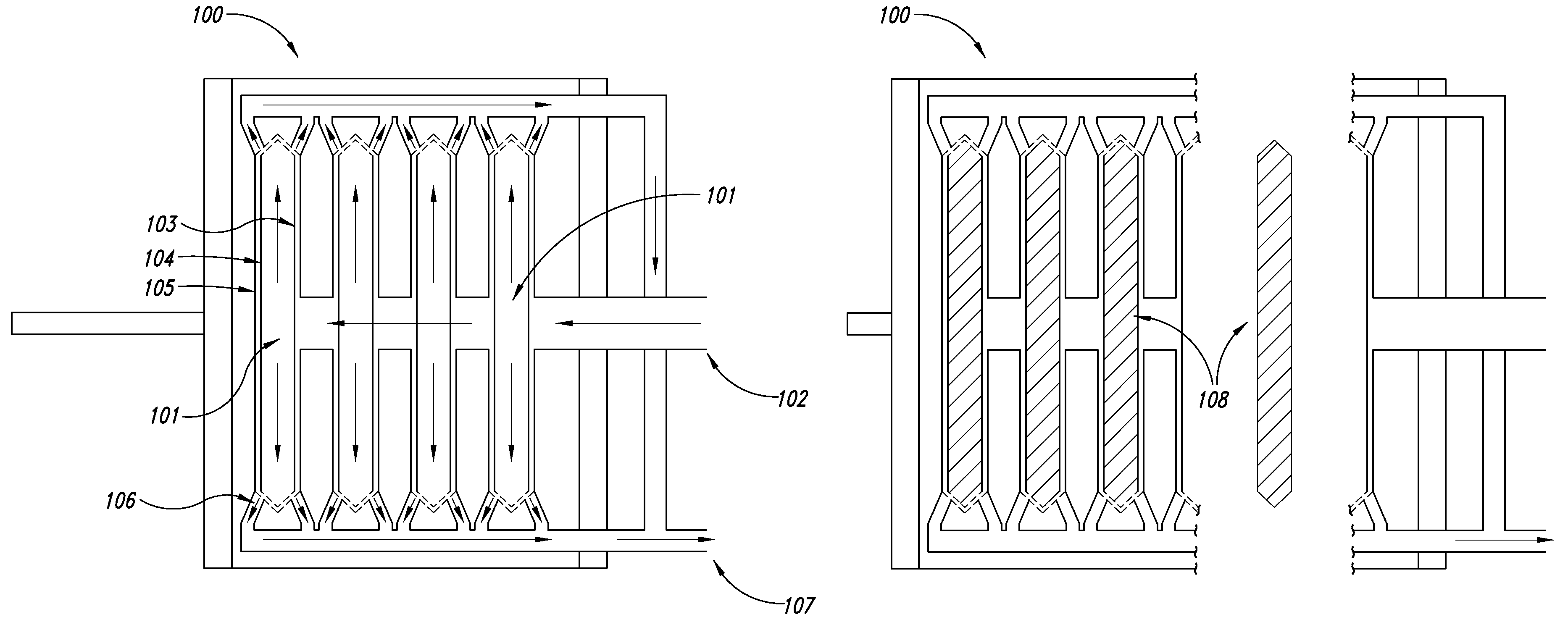

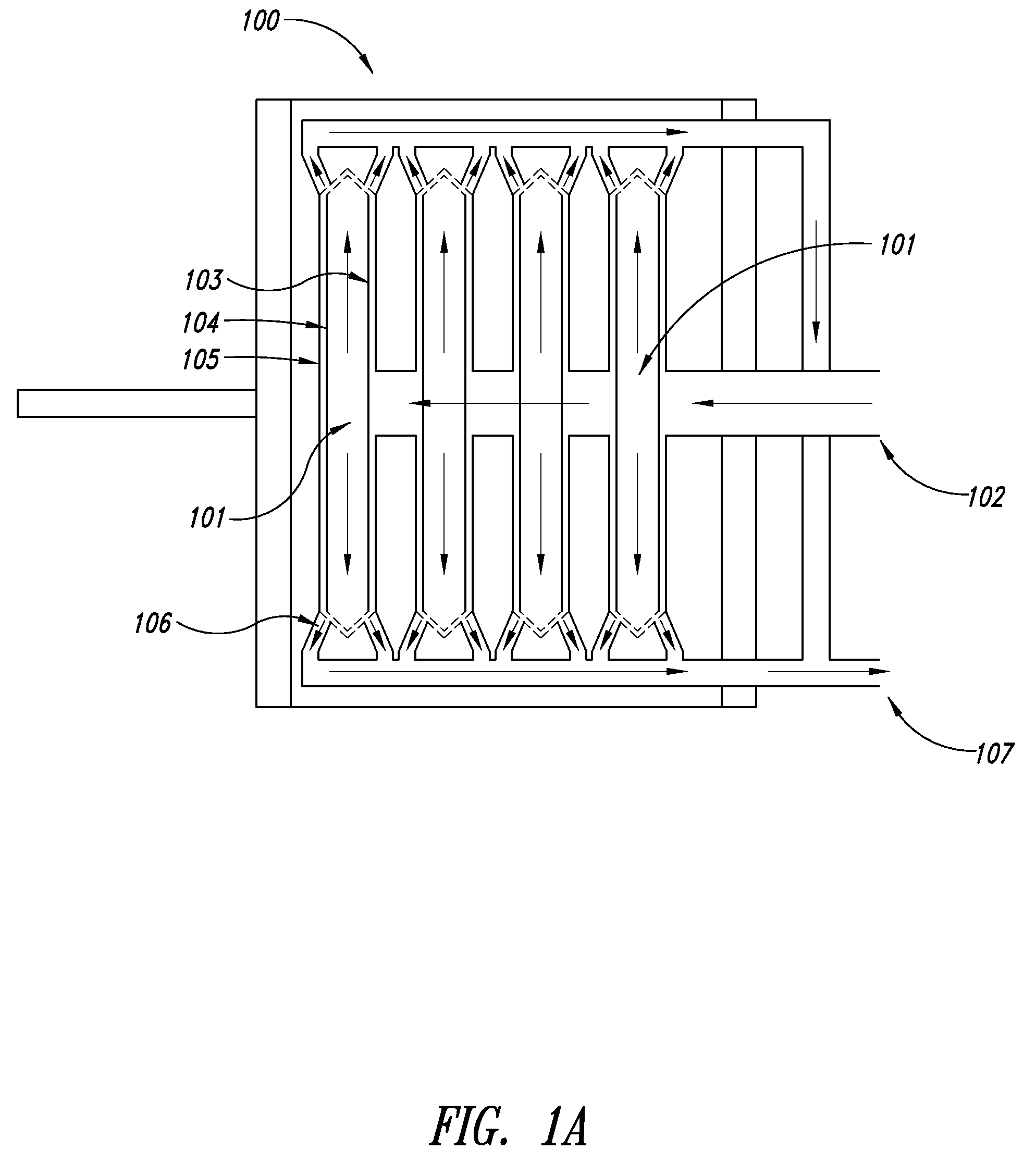

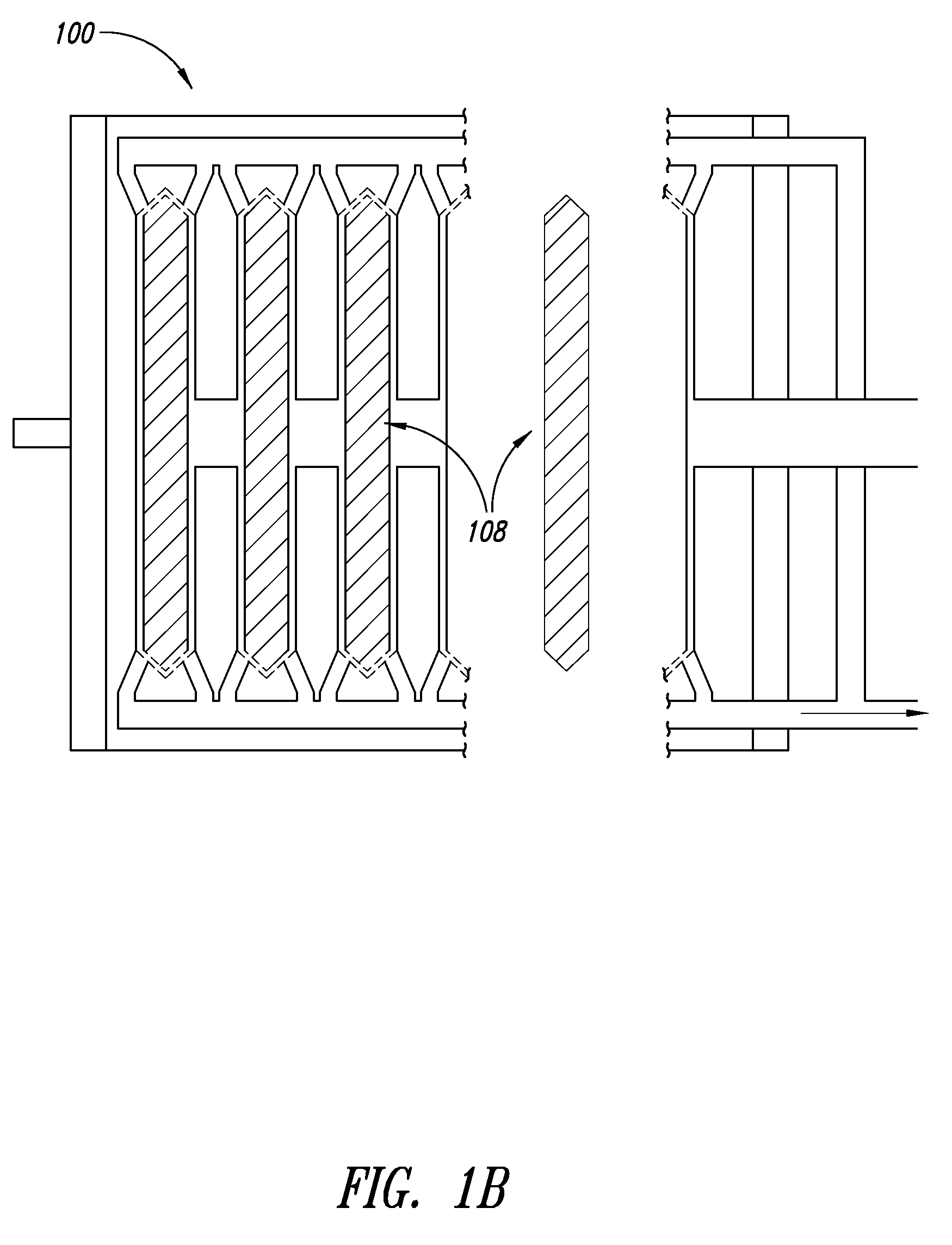

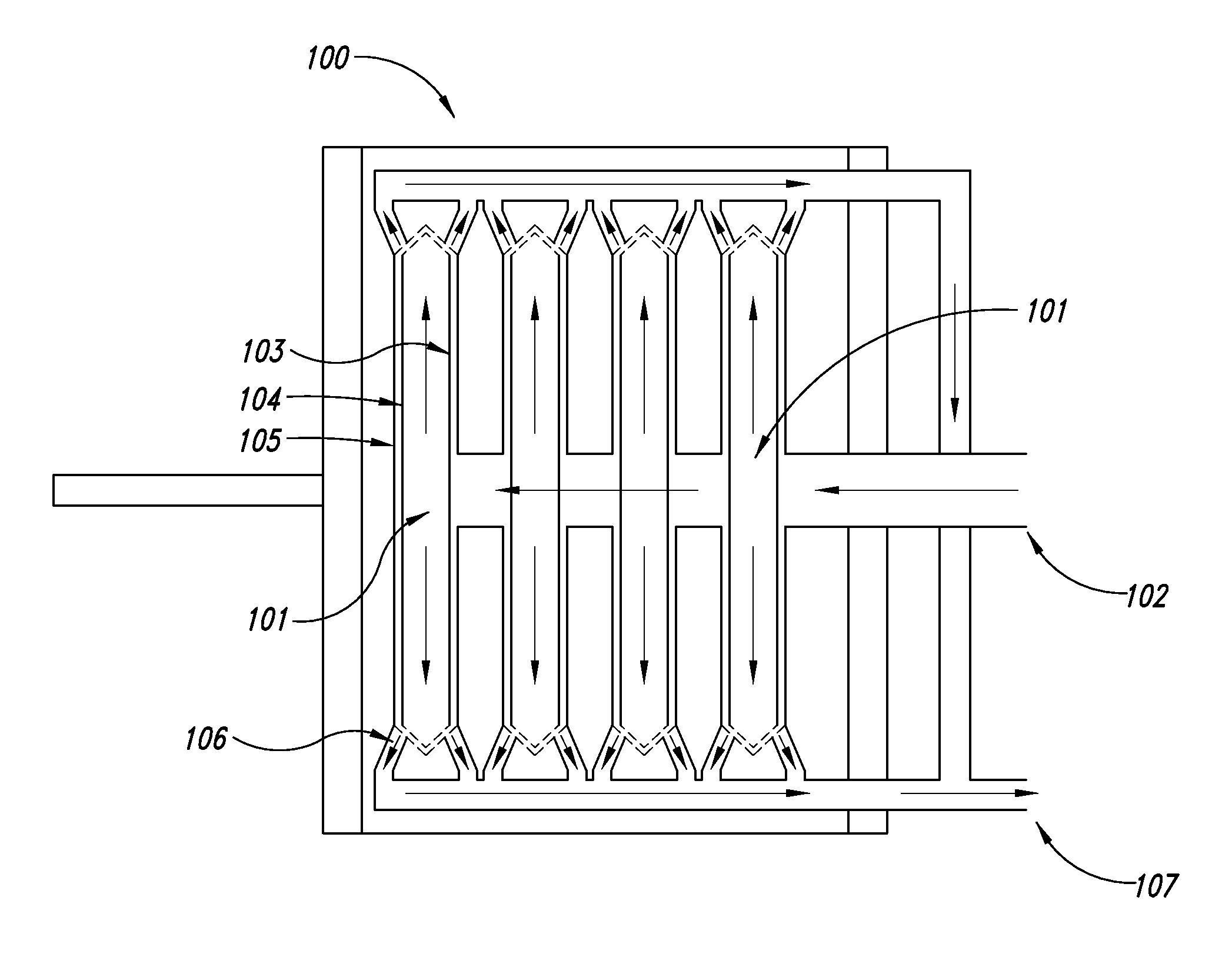

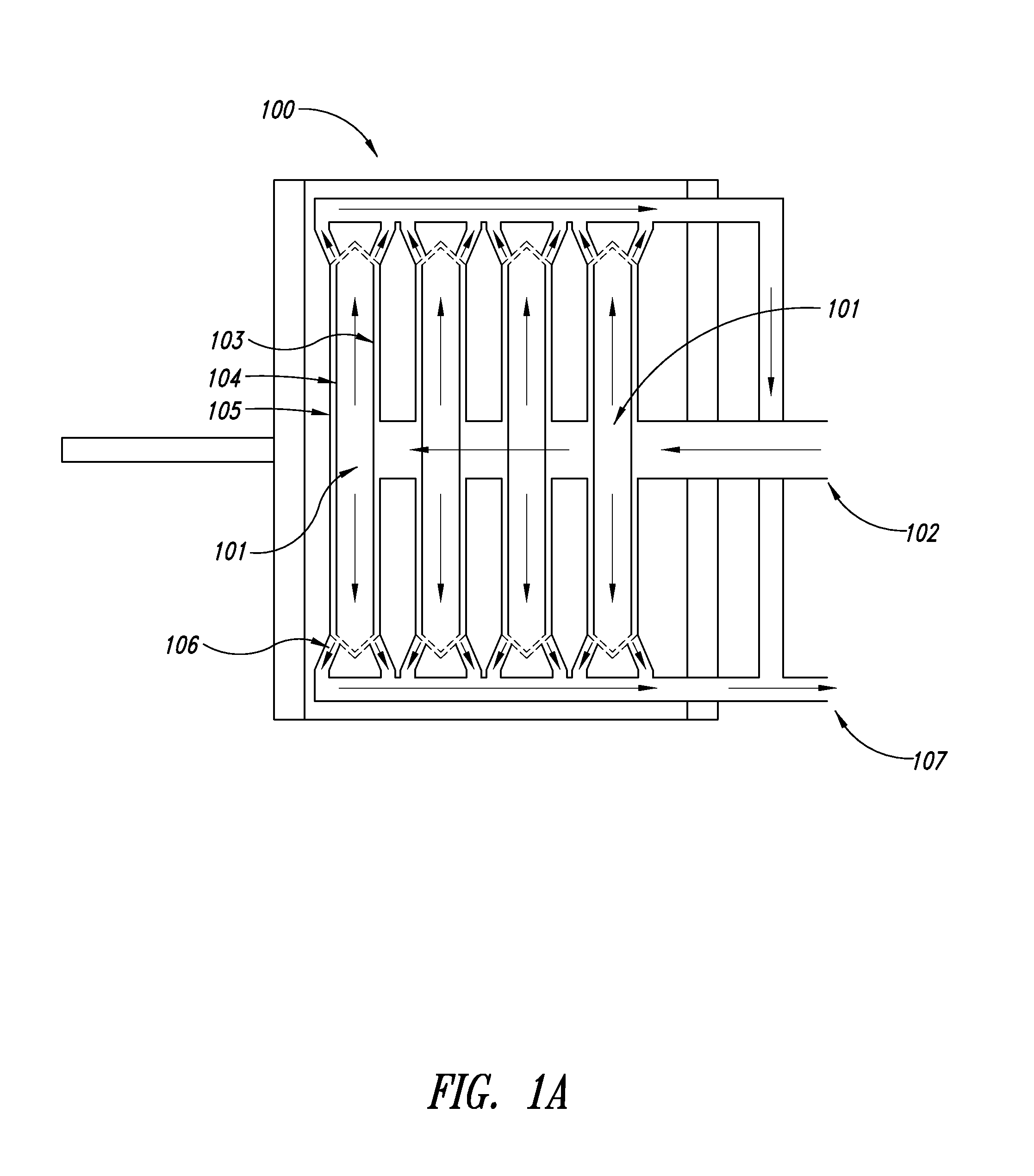

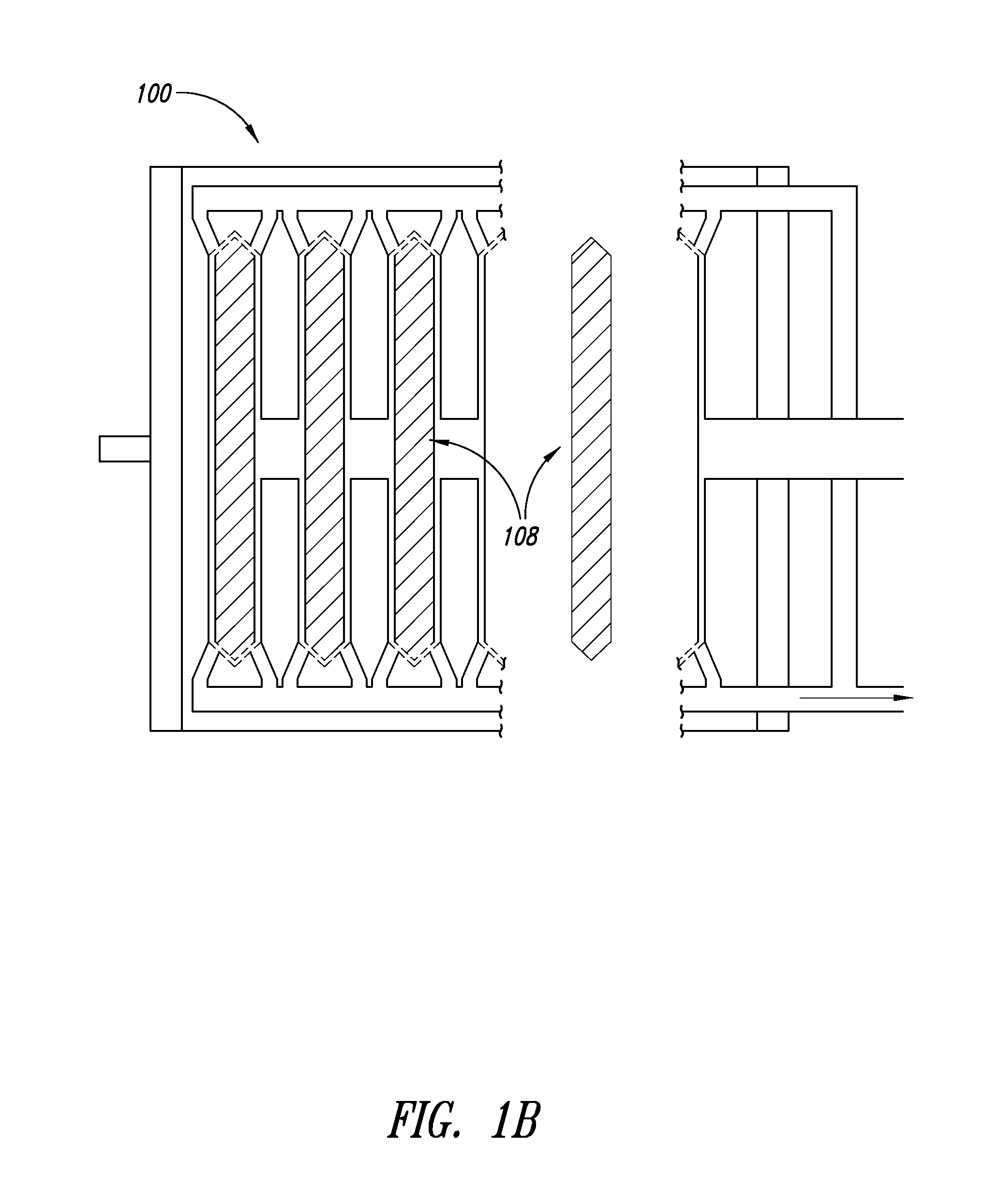

Water management in bipolar electrochemical cell stacks

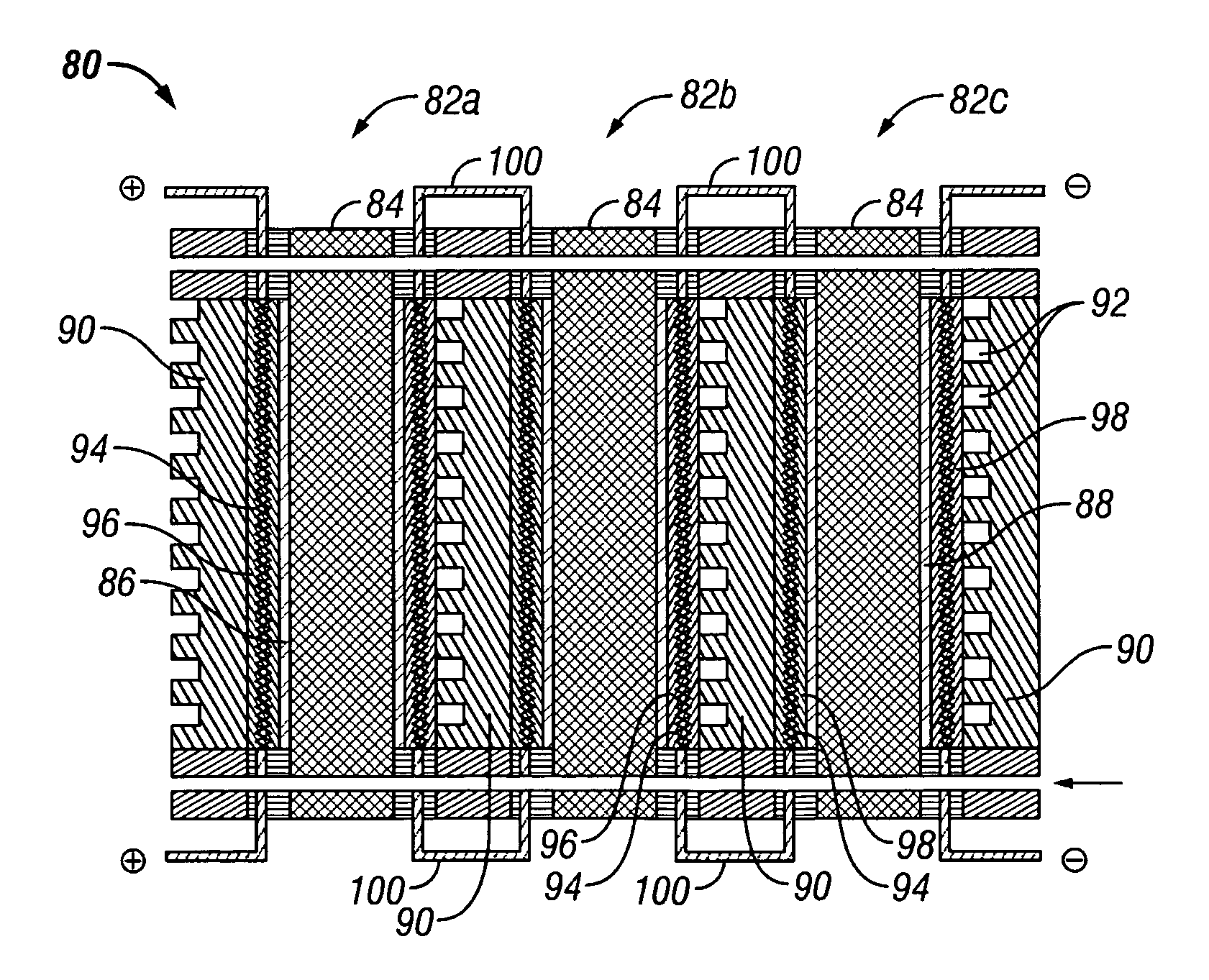

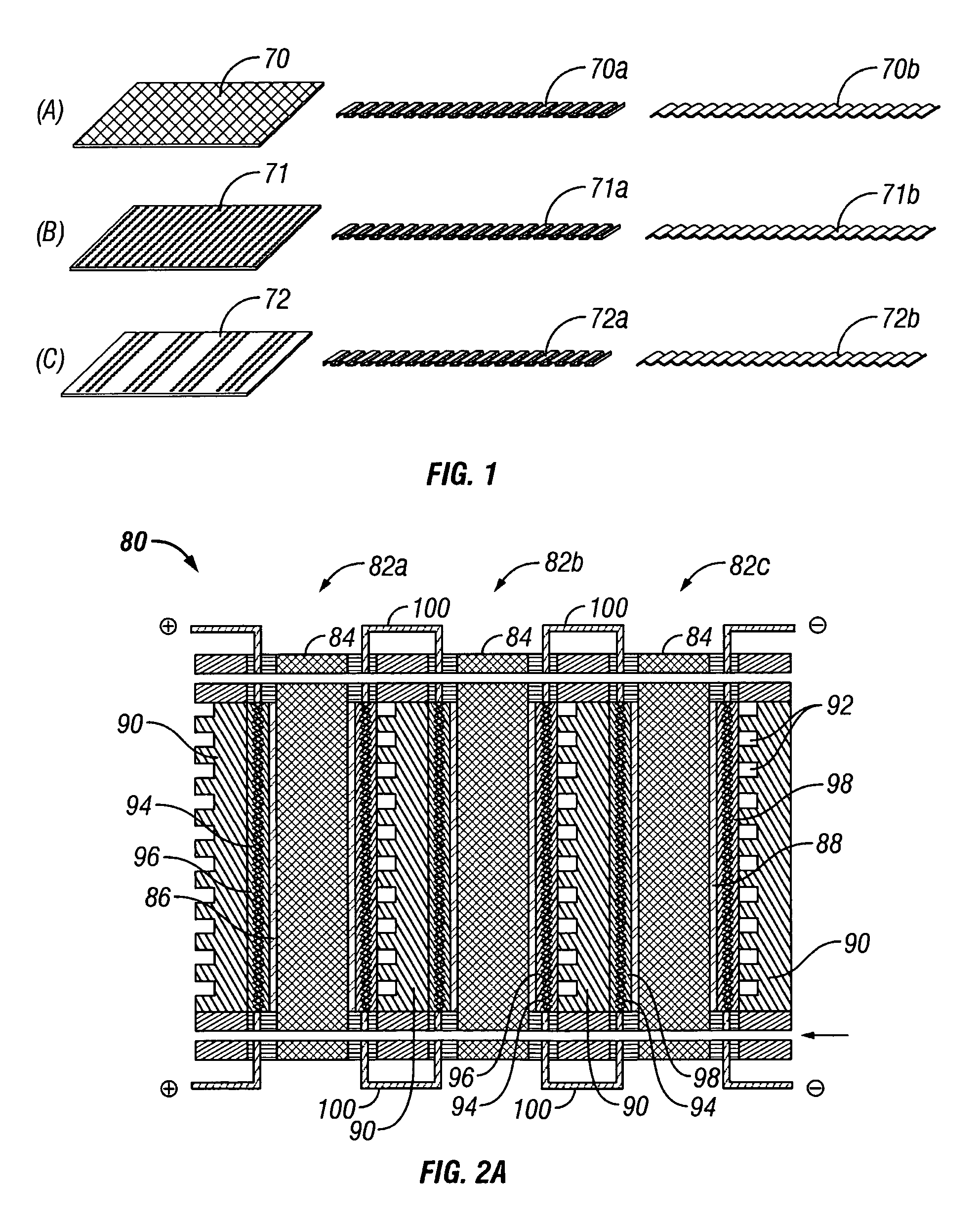

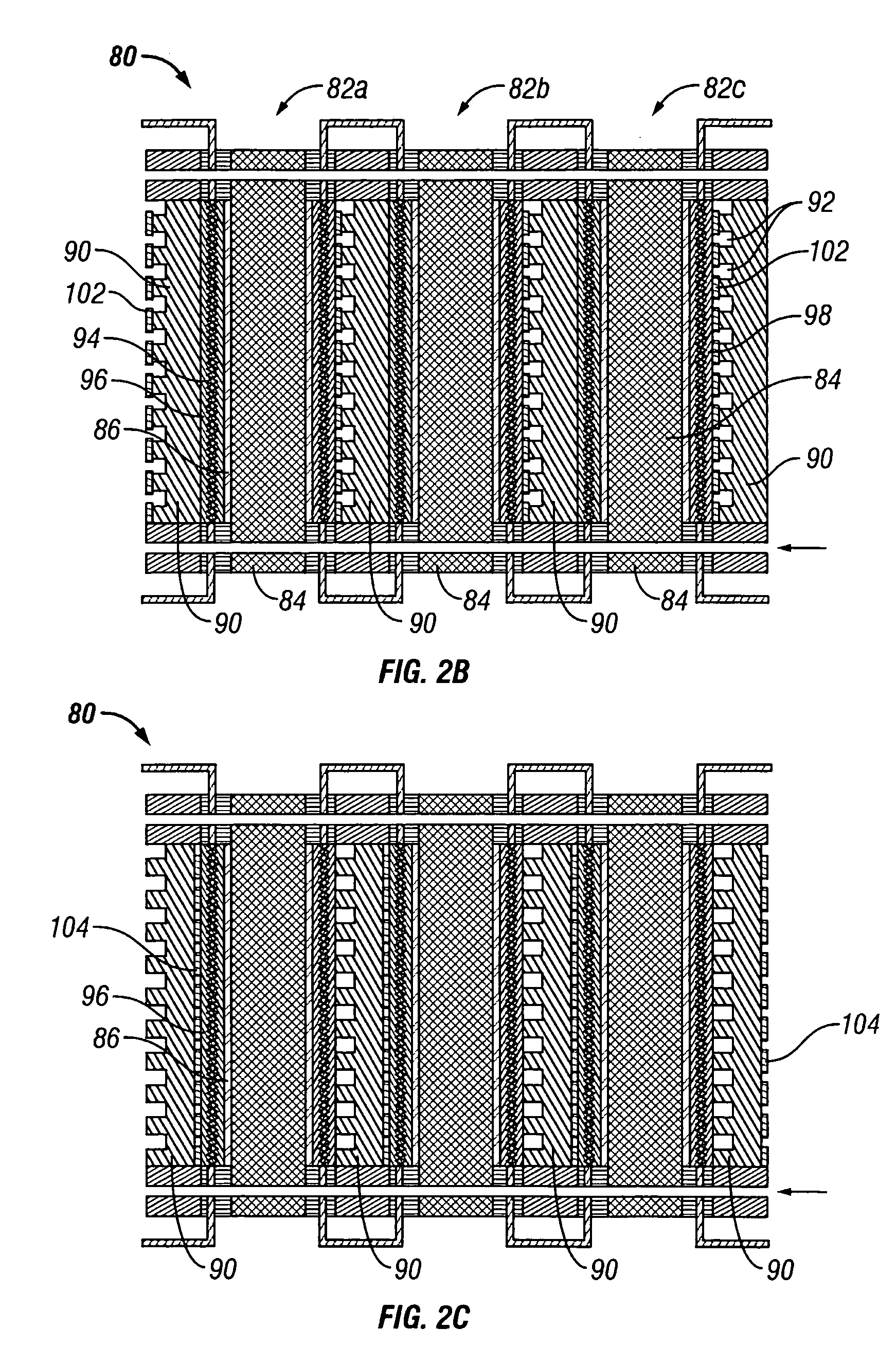

InactiveUS20060199061A1Reduce probabilityPromote loss of waterFuel cells groupingWater management in fuel cellsPolymer electrolytesLiquid water

A bipolar, filter press-like electrochemical cell stack comprising a plurality of electrochemical cells, where each electrochemical cell is supplied with a gaseous anodic reactant and either supplied with a gaseous cathodic reactant or produces a gaseous cathodic product, and where each electrochemical cell avoids drying out the ion exchange membrane polymer electrolyte, avoids flooding at the cathode, facilitates recovery of liquid water at the anode, and reduces water losses from at least one of the electrodes. A water retention barrier is variously positioned, such as between a gas diffusion electrode and a fluid flow field. The barrier may be either: (i) a thin, gas permeable, liquid water impermeable membrane; (ii) a thin, porous sheet of material; or (iii) a thin, substantially solid sheet of material except for a plurality of small through-holes that penetrate from one side of the sheet to an opposing side of the same sheet. The barrier is advantageously used at the cathode and facilitates air cooling of the cell.

Owner:LYNNTECH

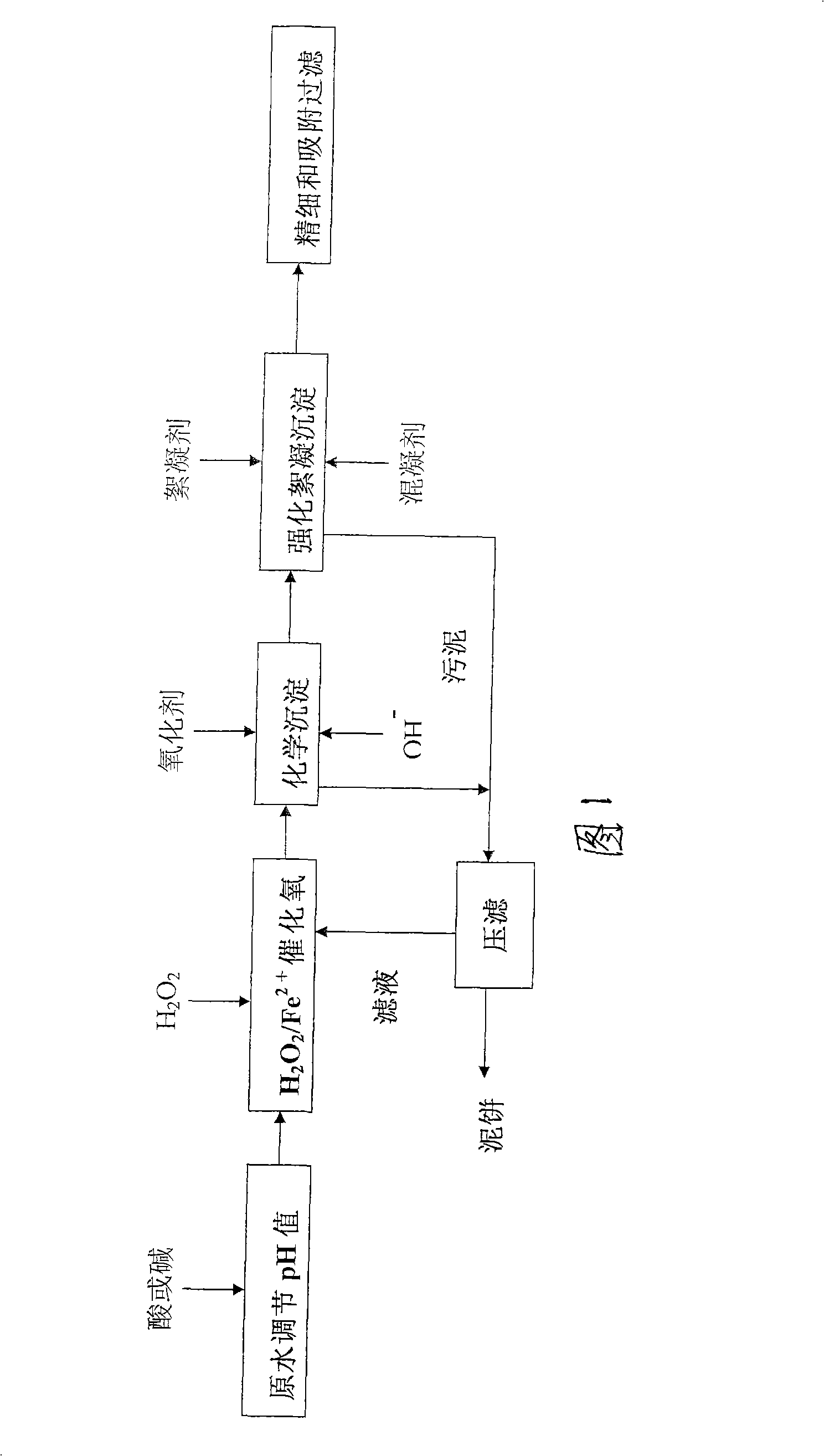

Method for processing oil-gas field fracturing waste liquor

ActiveCN101302065AMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteBrick

The invention provides a method for treating fracturing waste fluid in an oil-gas field, belonging to the oil-gas field waste fluid treatment technology, which overcomes the problems existed in other methods. The process steps of the method are as follows: the water quality achieves a recirculation standard or accords with the II grade discharge standard of the integrated sewage discharge standard GB8978-1996, through technical treatments of raw water (pH) adjustment, H2O2 / Fe<2+> catalytic oxidation, chemical precipitation, enhanced flocculation and sedimentation, fine filter and adsorption filtration, and system settling sludge, then the settled sludge is subject to filter pressing and dehydrating, press filtrate returns to the front end for after-treatment, and mud cake is desiccated and manufactured into bricks for application or is treated through using the incinerating treatment technology. The method is an effective method for treating the fracturing waste fluid in the oil-gas field.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for isolation of nanomaterials

Methods for isolation and / or purification of nanomaterials, such as nanowires, are provided. The disclosed methods include isolation of nanomaterials via a filter press and are amenable to large-scale production of nanomaterials. Related methods for isolation, purification and / or doping of nanomaterials are also provided.

Owner:SILURIA TECH INC

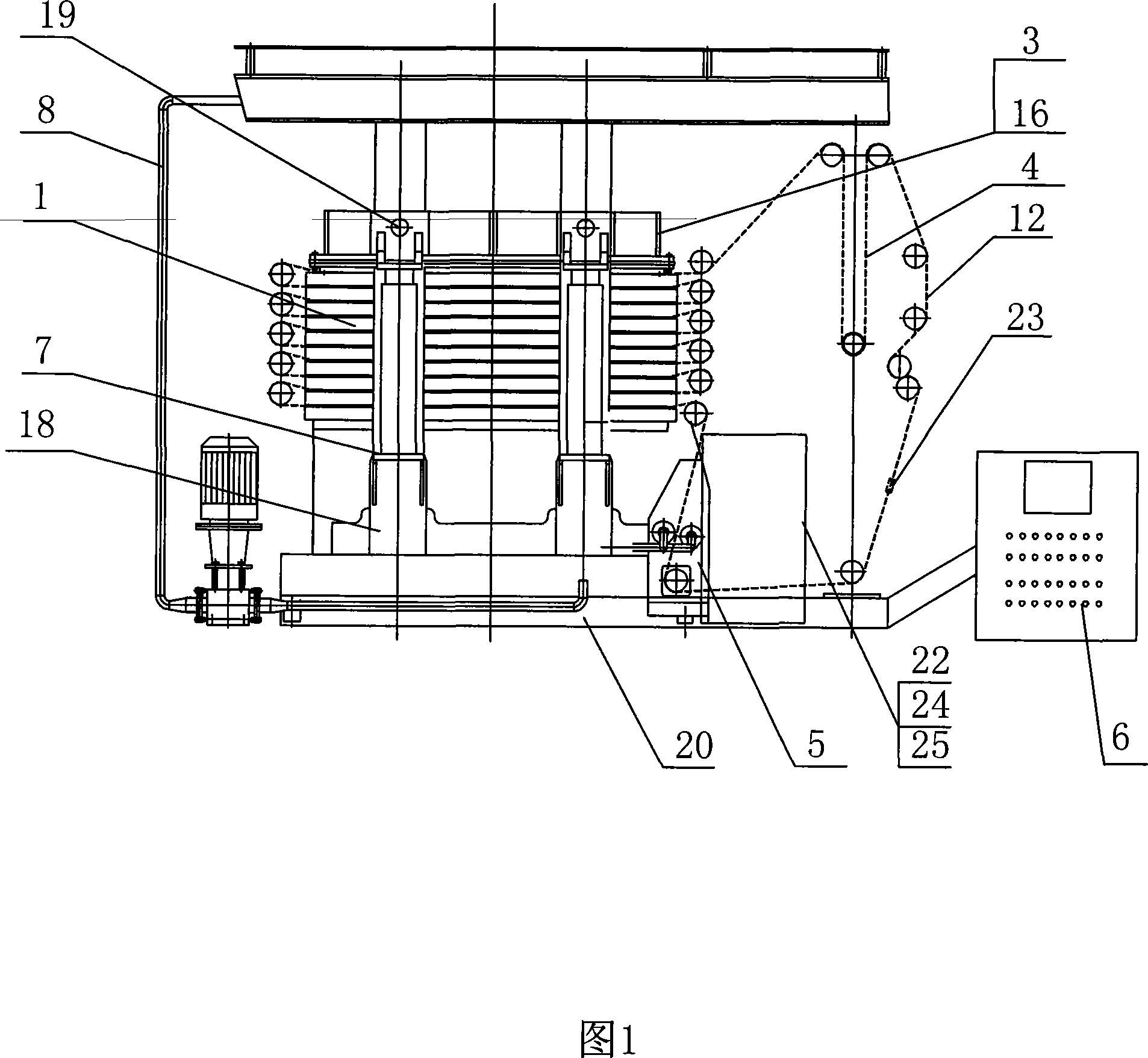

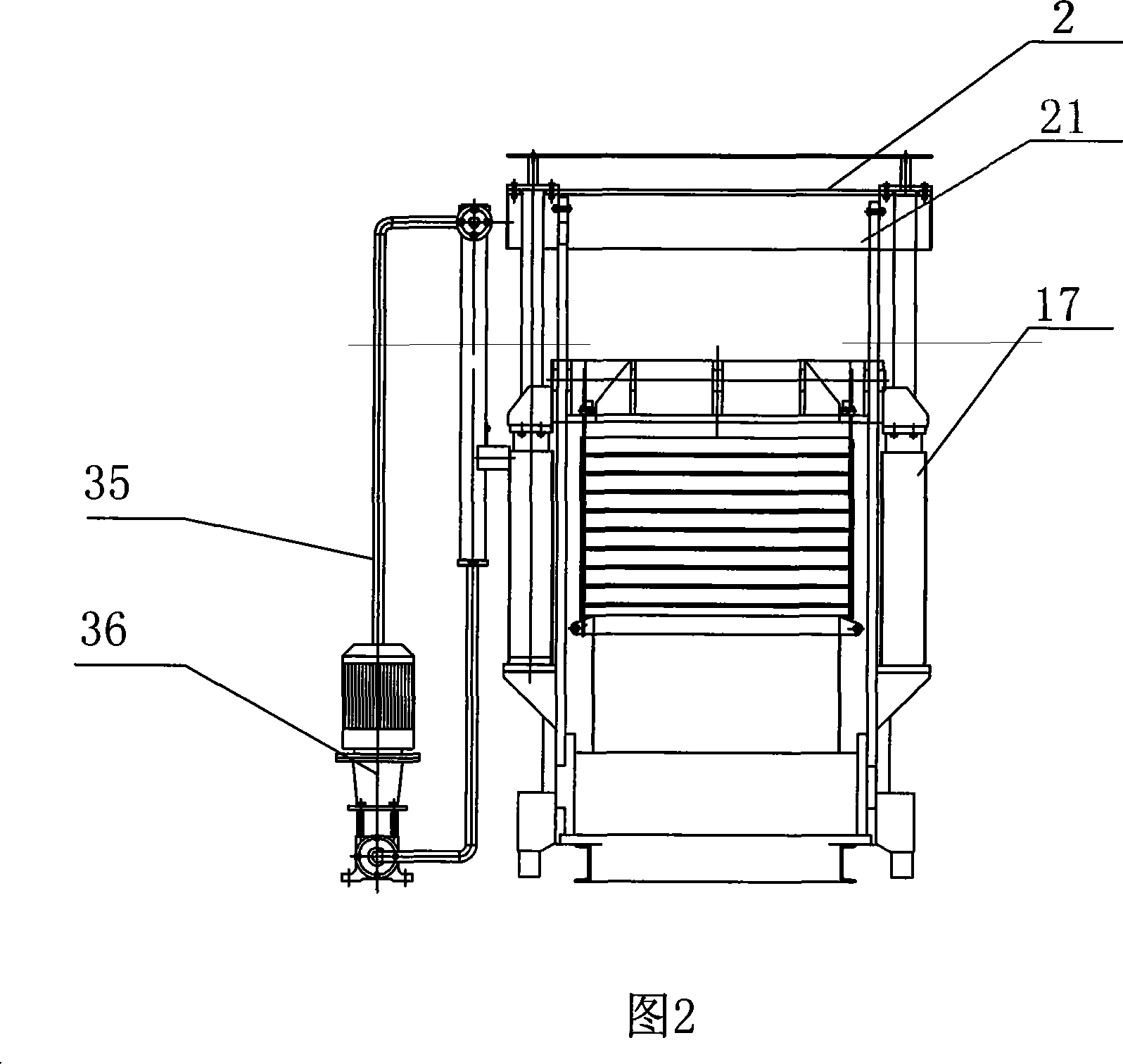

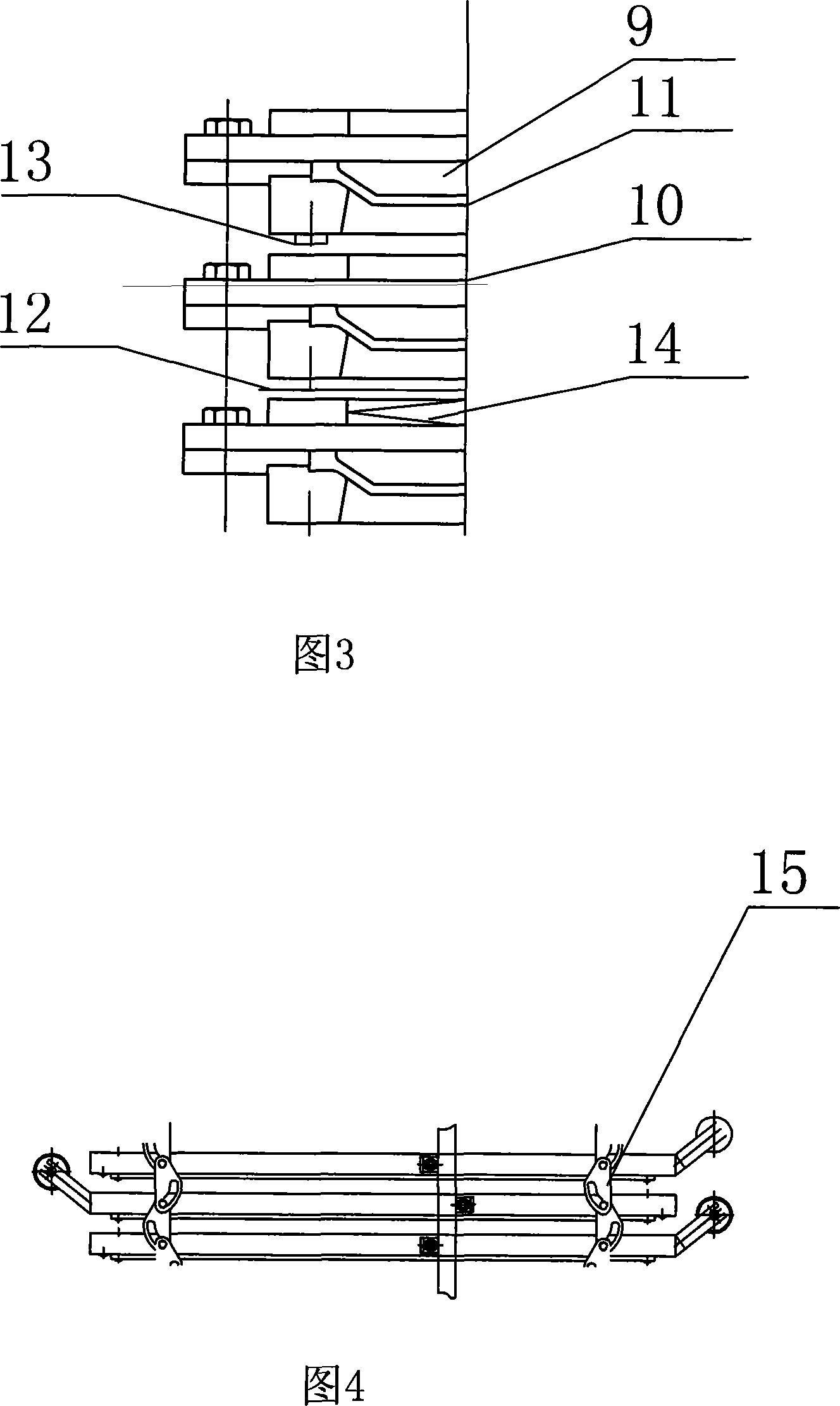

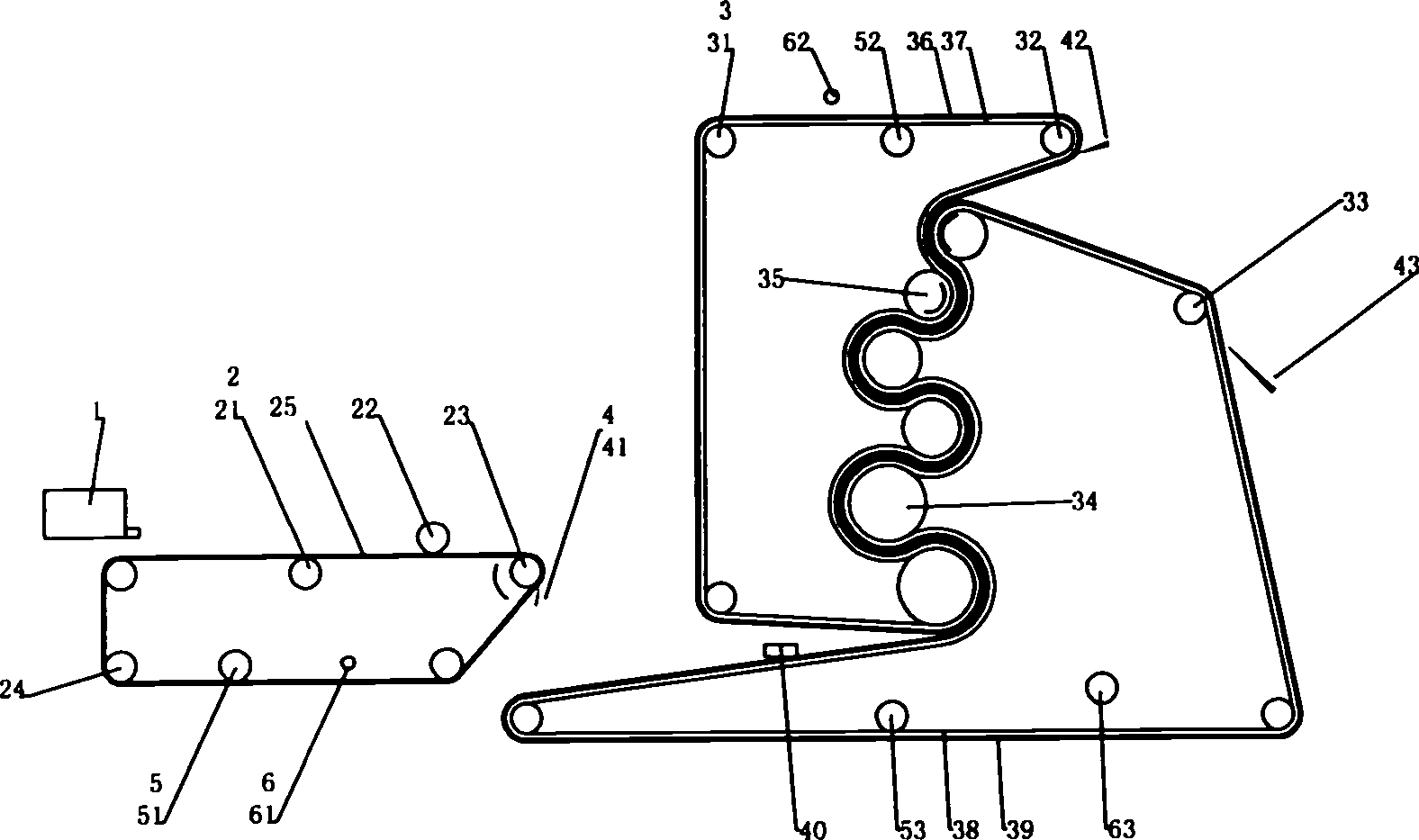

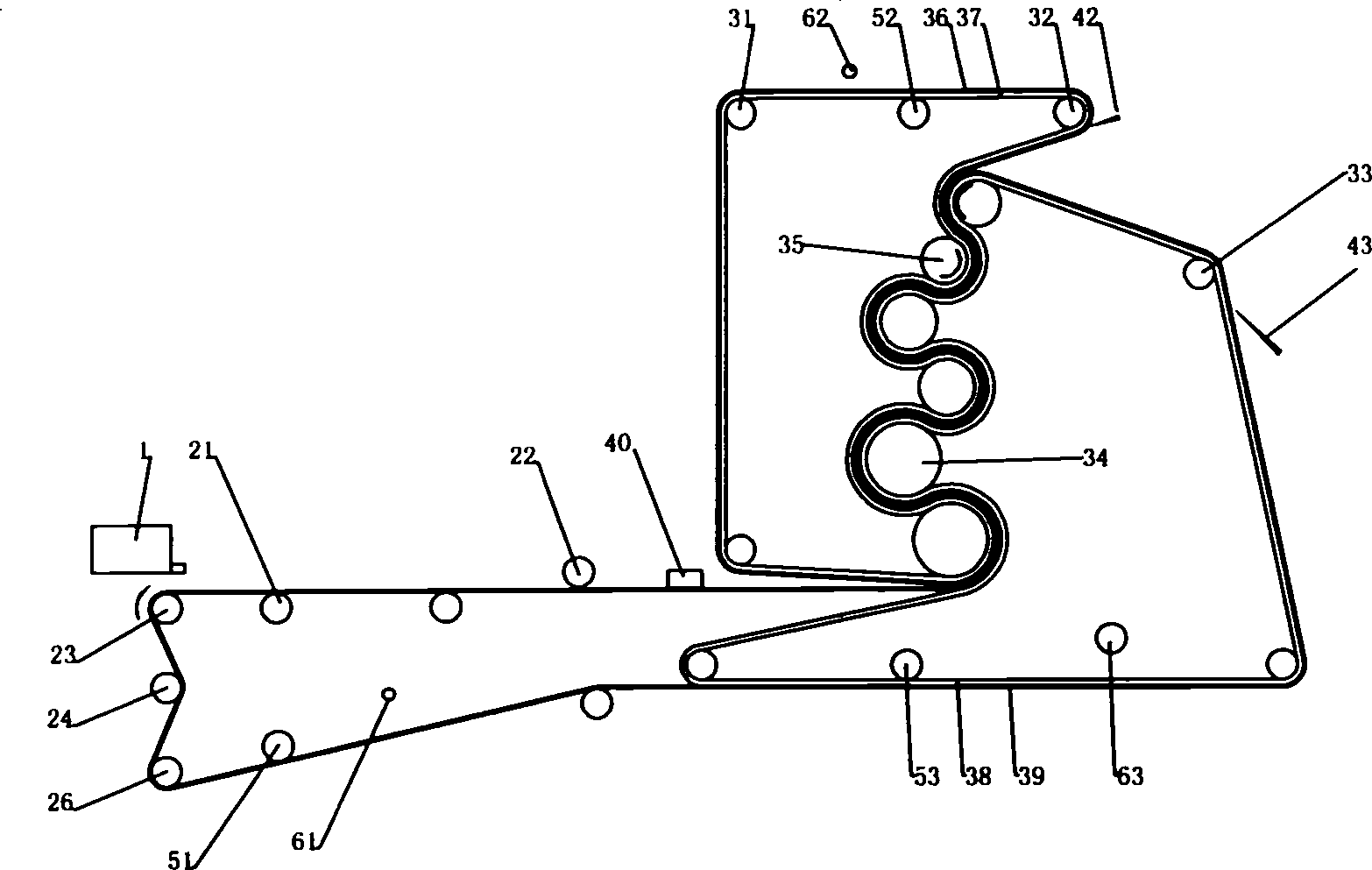

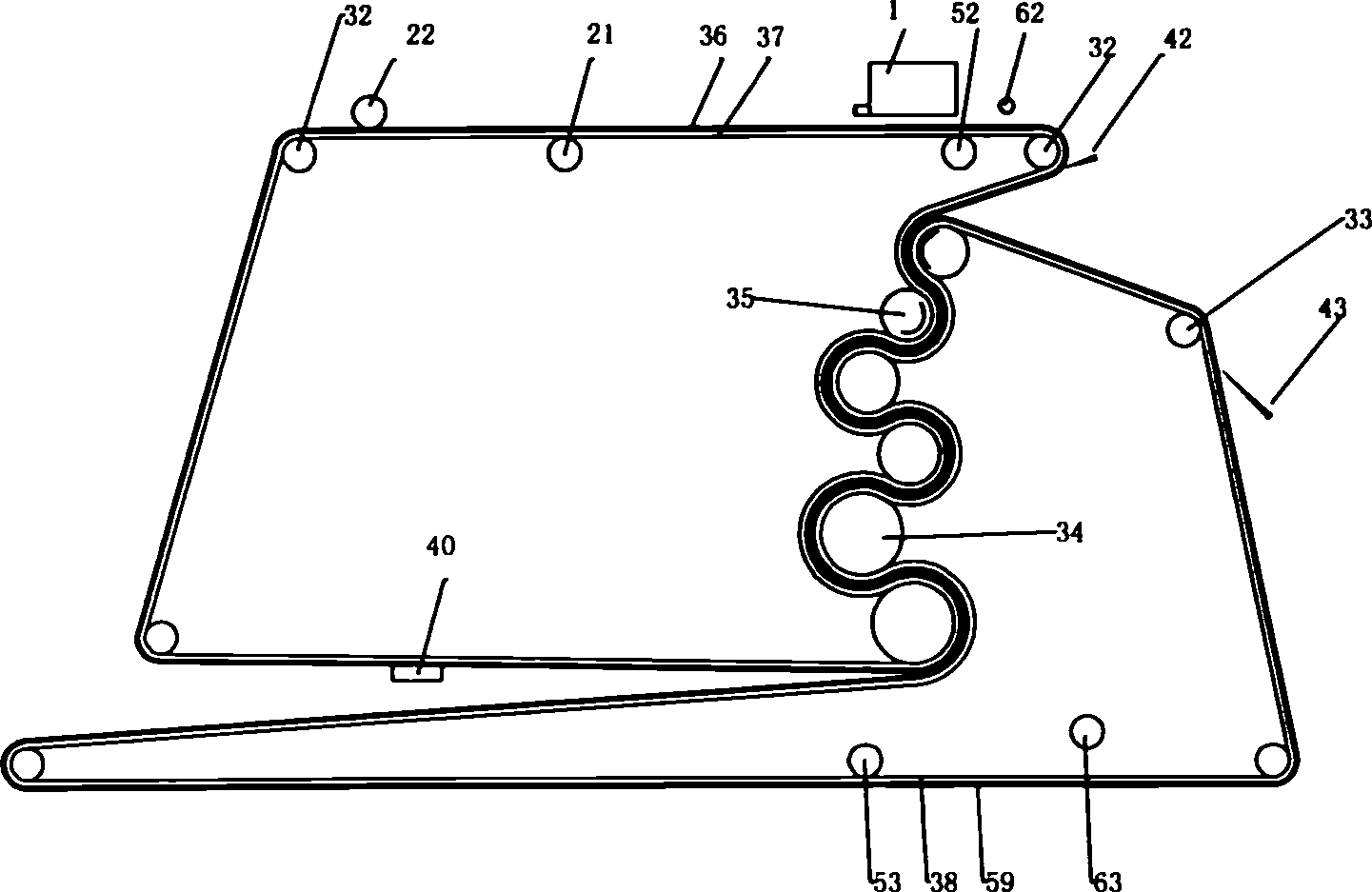

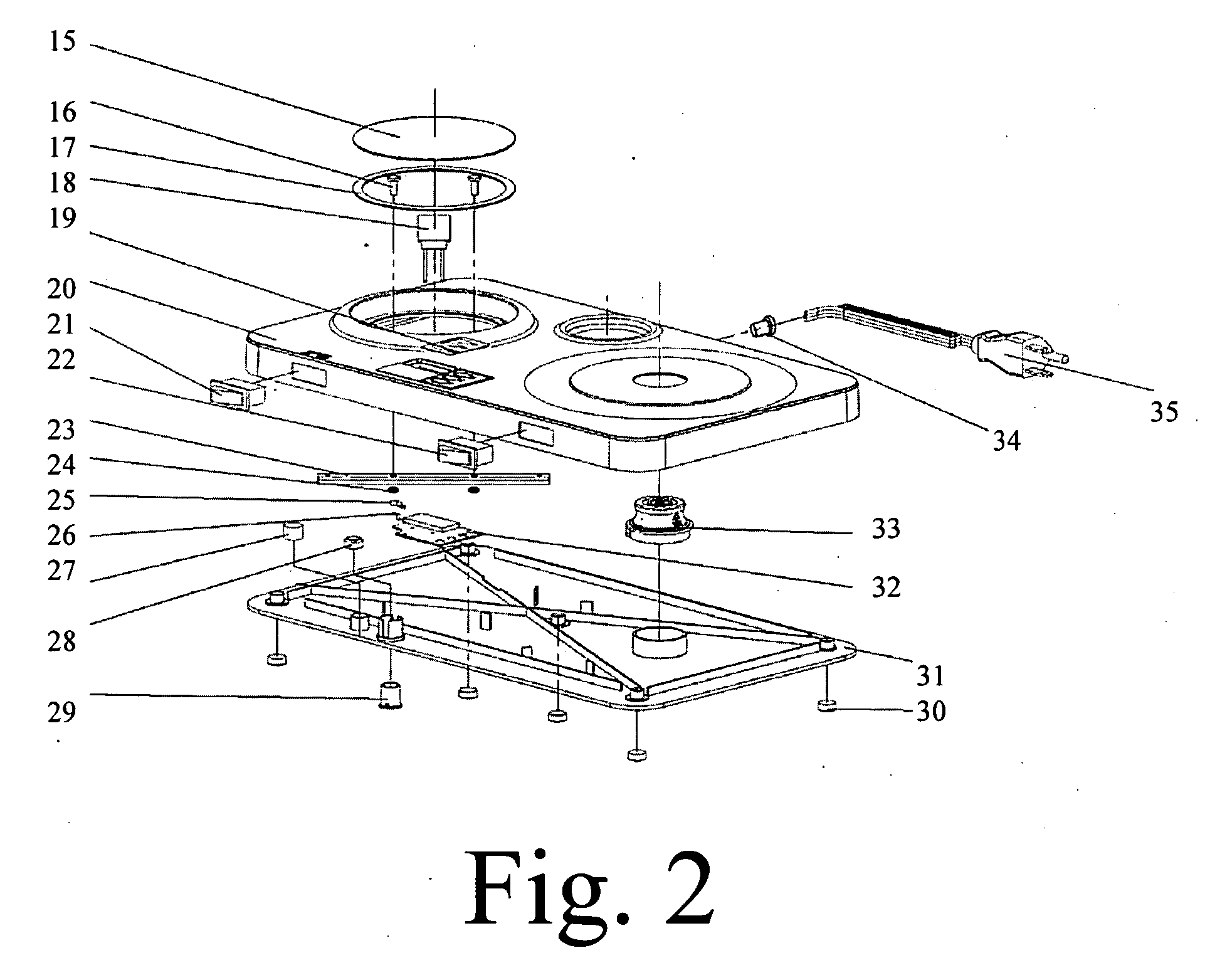

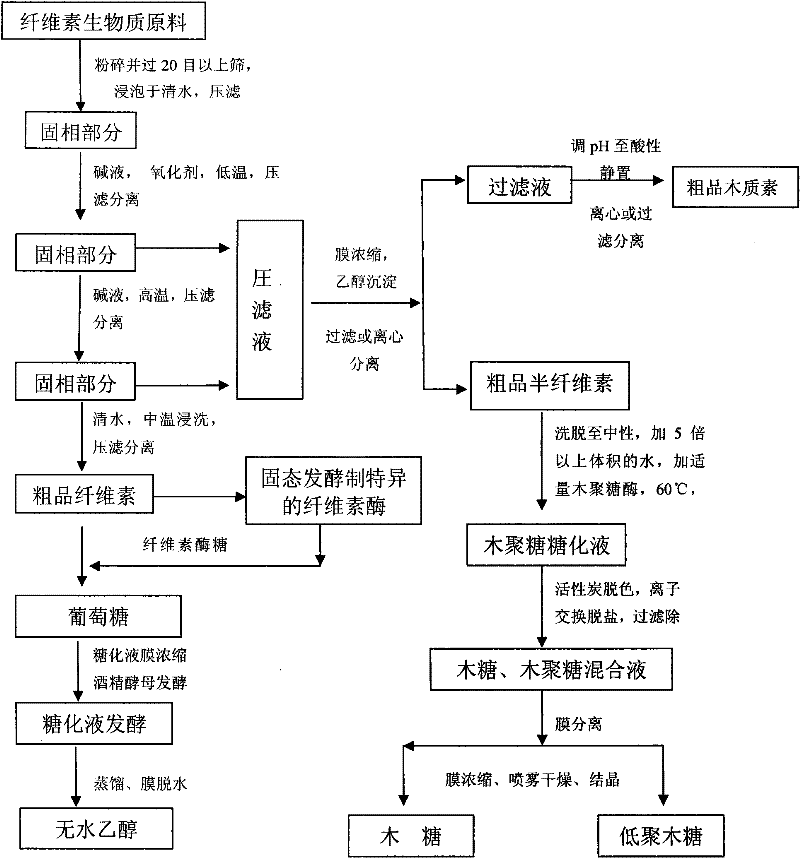

Vertical type full automatic plate-and-frame filter press, and filter technique

ActiveCN101091846AReduce moistureExtend working lifeFiltration separationAutomatic controlFiltration

The invention relates to a vertical full automation filter press. The existing filtration filter pressing installment as a result of the structure technology, ,the horizontal hand movement filtration frame which uses the plastic has low production efficiency and big environmental pollution; because the semiautomatic pressure filtration installment also uses the electrical controlled method, but the automated coordination performance of other organization is bad, its stability and the production efficiency are low, specially when the seal cavity bearing, the equipment presents vibration and spray phenomenon. The filter press includes the leveling board frame group, the main body support structure, the board frame group opening and holding apparatus, the filtering cloth automatic cycle running gear, the filtering cloth washing device, automatic control system, hydraulic system, craft circuitry and so on. It uses the vertical structure to realize the full automatic operation, thus has high filter efficiency, low energy consumption, high automaticity, high product quality, easy operation, the simple maintenance, and no pollution.

Owner:西安航天华威化工生物工程有限公司

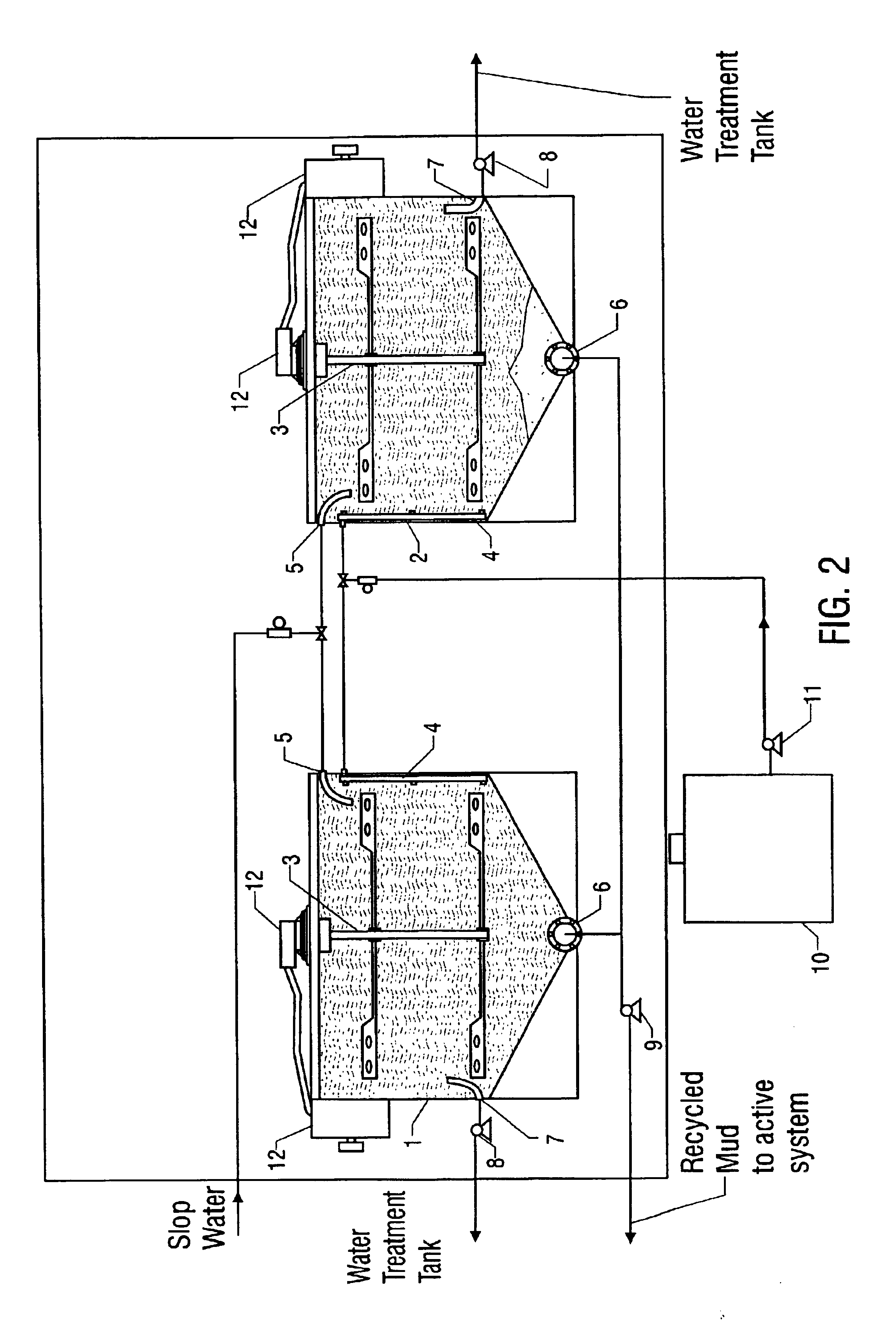

Method for recycling of oil based drilling fluid contaminated with water and water contaminated with oil based drilling fluid

InactiveUS6881349B2Waste water treatment from quariesDewatering/demulsification with chemical meansDemulsifierAlkyl polyglycoside

A mobile apparatus and method for recycling an invert emulsion based drilling fluid, in which the invert emulsion based drilling fluid includes an oleaginous component and an aqueous component. The apparatus includes an emulsion breaking tank, a water treatment tank, a filter press, and hydrocarbon filters. The method includes: mixing said invert emulsion drilling fluid with a emulsion breaker, wherein the emulsion breaker is a mixture of an alkyl glucoside and an alkane sulfonate; and separating the oleaginous component of the invert emulsion drilling fluid from the aqueous component of the invert emulsion drilling fluid. The method preferably utilizes an emulsion breaker that is a combination of an anionic surfactant, a nonionic surfactant and an alkyl polyglycoside surfactant.

Owner:MI

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

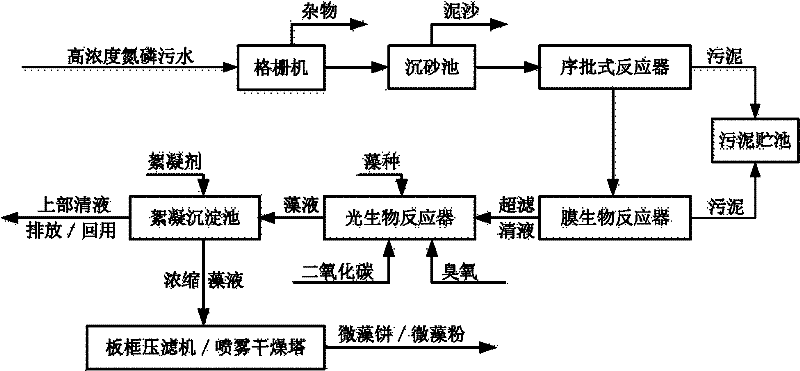

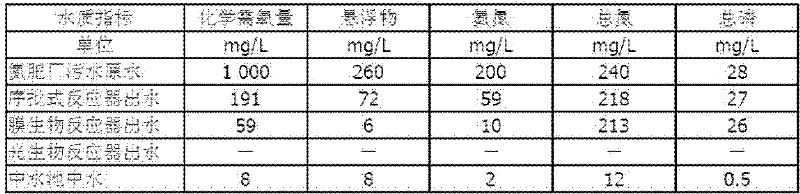

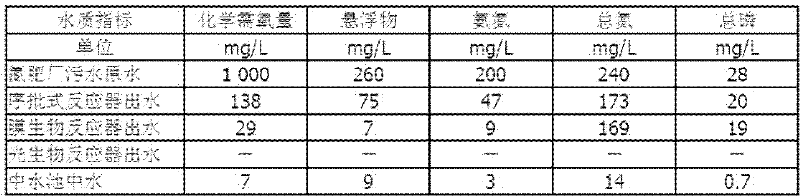

Nitrogen-phosphorus wastewater treating method by sequencing batch reactor coupled photobioreactor

ActiveCN102336498AWater quality varies widelyMultistage water/sewage treatmentSequencing batch reactorHigh concentration

The invention relates to the field of environmental wastewater treatment, specifically to a nitrogen-phosphorus wastewater treating method by a sequencing batch reactor coupled photobioreactor. The method provided by the invention is characterized in that it comprises the following steps of: removing impurities and sediments of high concentration nitrogen-phosphorus wastewater and then treating the wastewater by using active sludge in the sequencing batch reactor, decanting a supernatant from the sequencing batch reactor, adding the supernatant into a membrane bioreactor for further aerobic treatment, filtering by ultrafiltration membrane in the membrane bioreactor to remove micro-suspension and bacteria, adding a generated ultrafiltration supernatant into a photobioreactor, disinfecting by ozone and adding algae filament as well as a few necessary nutrient salt, filling with carbon dioxide waste gas to perform microalgae cultivation, discharging a algae liquid after a microalgae growth cycle and adding the algae liquid into a flocculating settling pool for sedimentation, standardly discharging or reusing a supernatant liquor, compressing the concentrate algae liquid at the bottominto a microalgae cake by a plate and frame filter press. The invention has advantages of wide range of treated nitrogen-phosphorus wastewater water quality variation and production of economical microalgae with the utilization of nitrogen and phosphorus nutrients in wastewater as more as possible.

Owner:DALIAN DAKAI SEWAGE TREATMENT

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

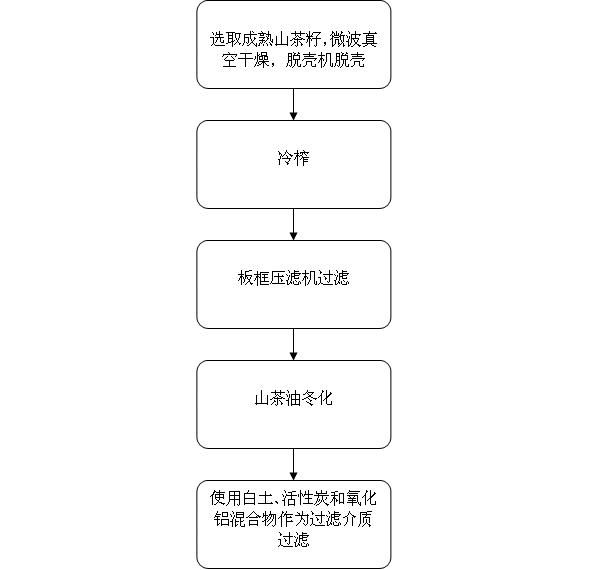

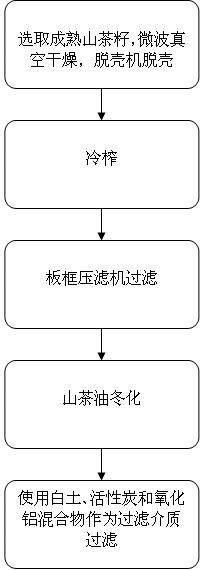

Cold pressing and physical refining process of camellia oil

ActiveCN102504938ASolve perishableImprove stabilityFatty-oils/fats refiningFatty-oils/fats productionOil and greaseDistillation

The invention relates to a cold pressing and physical refining process of camellia oil. The cold pressing and physical refining process of the camellia oil is characterized by comprising the following steps of: (1) selecting ripe camellia seeds and drying the ripe camellia seeds by microwave vacuum until the water content is 3-6%; and conveying the dried camellia seeds into a huller to be hulled;(2) carrying out cold pressing on the hulled camellia seeds to squeeze the camellia oil, wherein the temperature of a barrel is in a range of 100-150 DEG C and an oil output temperature is in a rangeof 80-120 DEG C; (3) removing solid impurities in the squeezed camellia oil through a plate and frame filter press; (4) winterizing the camellia oil filtered by the plate and frame filter press at a temperature in a range from below 5 DEG C to 5 DEG C; (5) carrying out molecular distillation on the winterized camellia oil to remove free fatty acid, oil peroxide products, moisture and other low-boiling-point substances from the camellia oil; and (6) taking a mixture of carclazyte, active carbon and aluminum oxide as a filtering medium to filter; and removing impurities and pigments of the camellia oil treated by the molecular distillation to obtain the finished product. The cold pressing and physical refining process of the camellia oil has the advantages of environmental friendliness, high oil yield, and high retention ratio of micronutrients in finished oil.

Owner:温州瑞雪农业开发有限公司

Sludge biological carbonizing technology based on hydrothermal reaction

ActiveCN102875005ALow running costImprove energy efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhysical chemistryCombustible gas

The invention discloses a sludge biological carbonizing technology based on hydrothermal reaction. The sludge biological carbonizing technology comprises the steps as follows: 1) dewatering the sludge, and transferring the sludge into a sludge pre-storage bin to be stored; 2) preheating the dewatered sludge; 3) transferring the preheated dewatered sludge into a hydrothermal reactor, thus obtaining hydrothermal lysis solution; 4) returning the hydrothermal lysis solution into a preheating system to preheat the dewatered sludge, and cooling the hydrothermal lysis solution so as to obtain a gaseous product; 5) transferring the cooled hydrothermal lysis solution into a filter press for filter pressing, thus obtaining a reacting filtrate and a solid product; 6) drying the solid product produced in previous step, and then transferring the solid product into a dry type carbonizing furnace to be carbonized, so as to obtain the solid biological carbon and other products, and transferring the other products into a gas-liquid separating device to be separated so as to obtain combustible gas and tar; and 7) transferring the gaseous product obtained in step 4) and the combustible gas and tar obtained in step 6) into a firebox to be burnt so as to generate heat; and supplying the generated heat to a hydrothermal reactor and the dry type carbonizing furnace. With the adoption of the sludge biological carbonizing technology disclosed by the invention, the product with high additional value can be obtained; and meanwhile, the energy can be saved.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

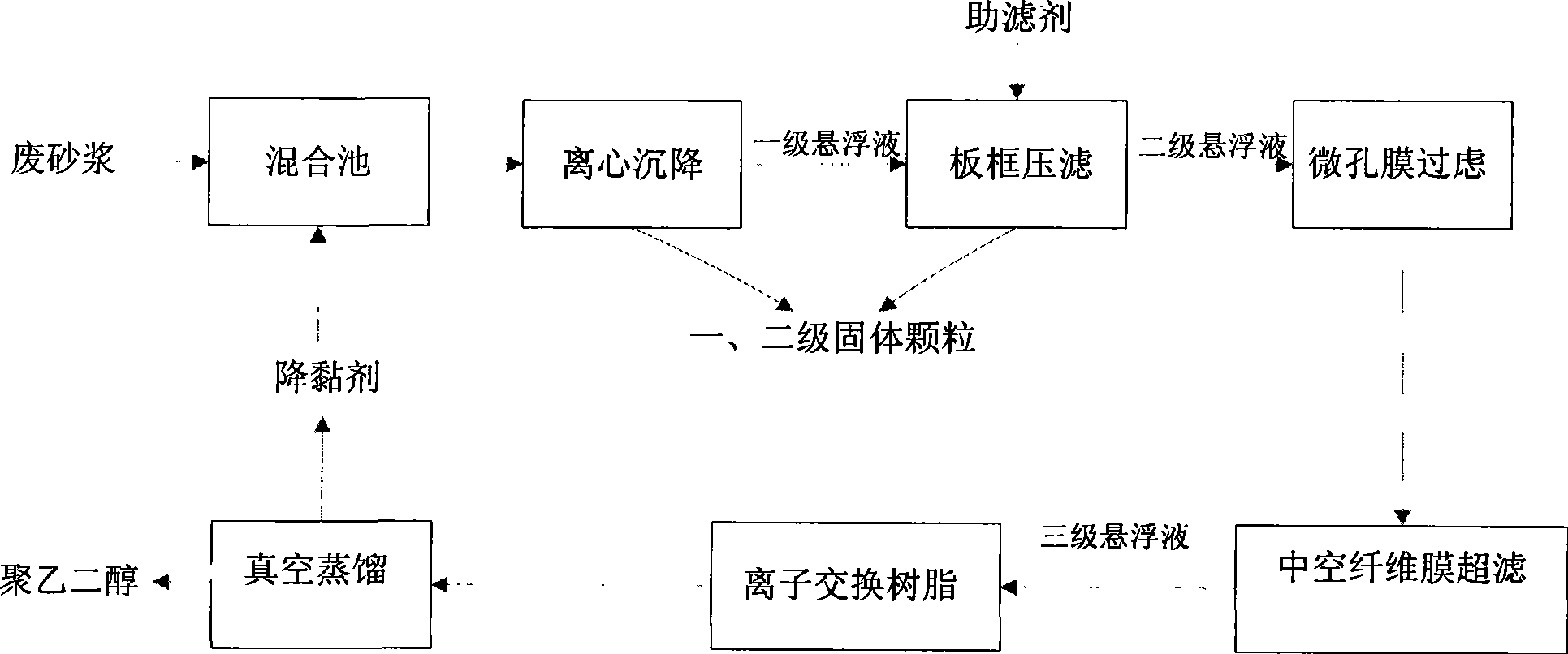

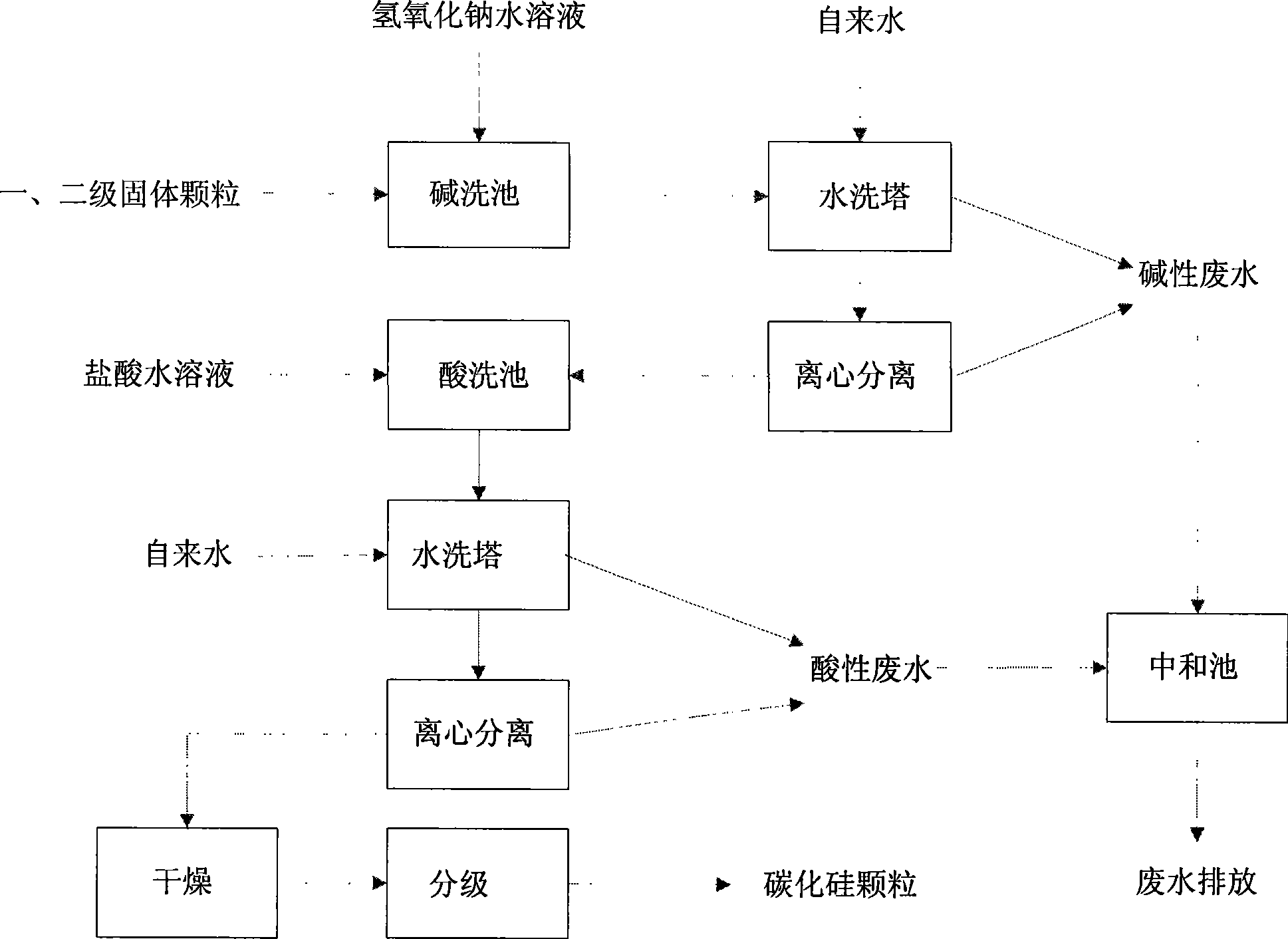

Process for recovering polyethylene glycol and silicon carbide in waste mortar from silicon wafer wire cutting

InactiveCN101474511AFacilitates flocculation and filtrationAvoid pollutionPlastic recyclingFiltration circuitsFiberHollow fibre

The invention relates to the field of silicon wafer wire-electrode cutting and discloses a method for recycling carborundum and cutting polyethyleneglycol in waste mortar by silicon wafer wire-electrode cutting. In monocrystalline silicon piece processing technique, a viscosity reduction agent is firstly added before waste mortar linear cutting, and then a suspending liquid part and a solid particles part are obtained by the solid-liquid separation; The suspending liquid part is added with a filter aid, then filter pressing with a plate frame, micro porous filtration, hyper filtration with hollow fiber and ion exchange are carried out sequentially, and finally, the suspending liquid is distillated in vacuum and polyethyleneglycol is recycled. Alkali reaction cleaning, water scrubber washing, centrifugalization, acid reaction cleaning, the second water scrubber washing, the second centrifugalization, the second acid reaction cleaning, drying and drying classification are carried out on the solid particles in sequence, and finally, recyclable silicon carbide particles are obtained.

Owner:西安通鑫半导体辅料有限公司

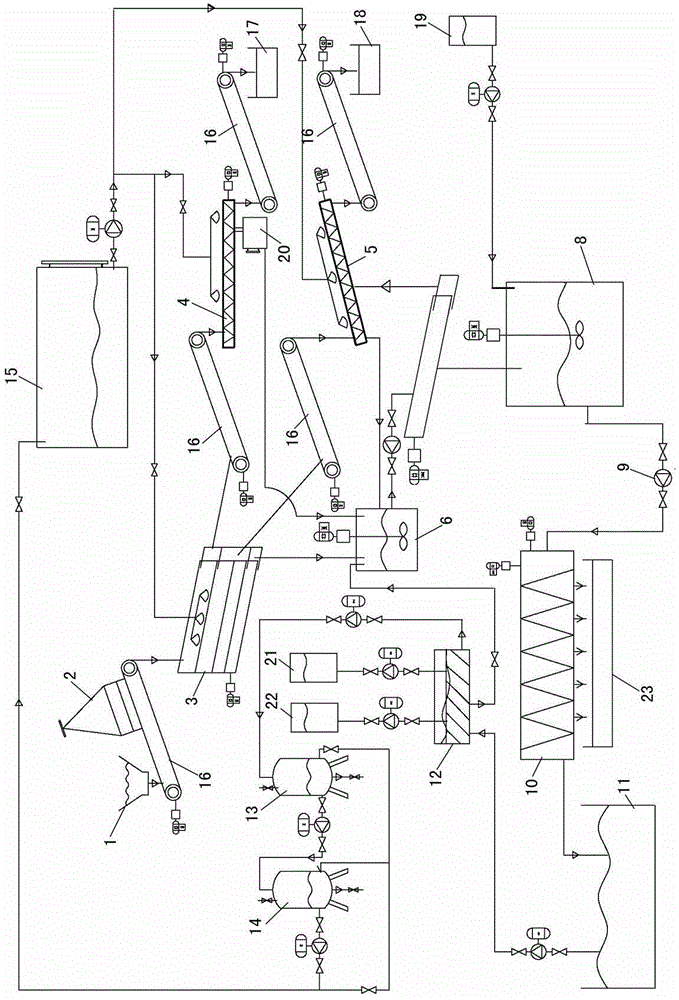

Soil washing restoration system based on reduction concentration design concept and method thereof

ActiveCN104475441AShort stayImprove production efficiencyContaminated soil reclamationSoil washingCompound (substance)

The invention discloses a soil washing restoration system based on a reduction concentration design concept and a method thereof. The washing restoration system comprises the following four module units which are sequentially connected with one another: a feeding and screening unit, an ore washing unit, a sludge dewatering unit and a tail-end sewage treatment recycling unit. The pollutants on the surface of coarse particles are eluted, transferred and concentrated into the filter-pressed mud cake by virtue of washing, so that pollutant-containing fine particles in contaminated soil can be effectively separated from crude particles such as gravel and grit. The repaired and discharged clean gravel and grit can be directly recycled to serve as building material. According to the system, purified water serves as a washing solution, so that secondary pollution caused by addition of a chemical washing agent is avoided, and the washing solution is treated by a tail-end sewage treatment system so as to be recycled. The reduction of remediation of contaminated soil is realized, the comprehensive repair cost is greatly reduced, the washed and discharged materials can be recycled, the contaminated soil is repaired, and a novel profit point is created.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

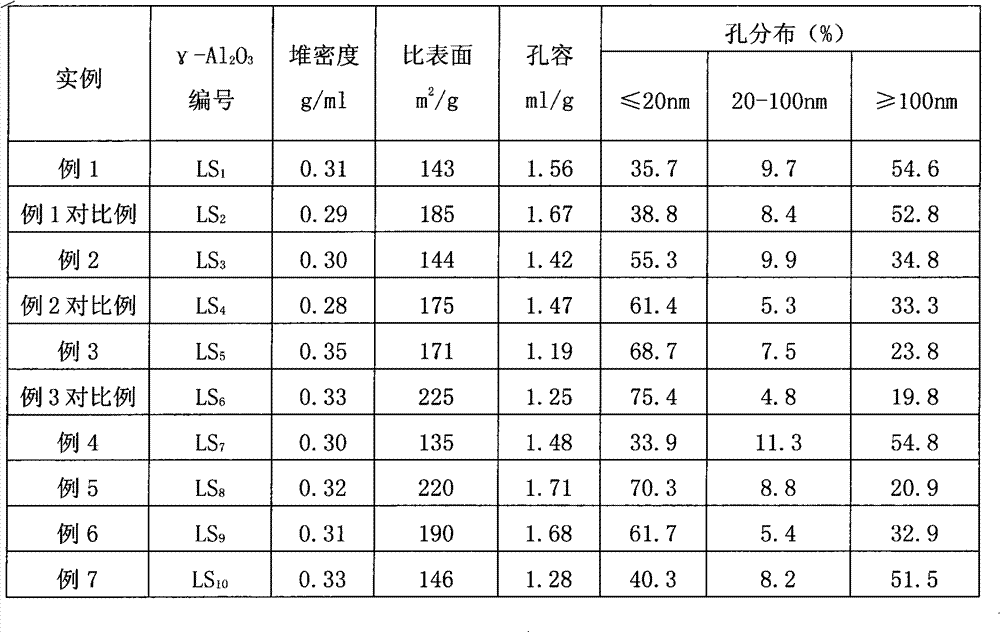

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

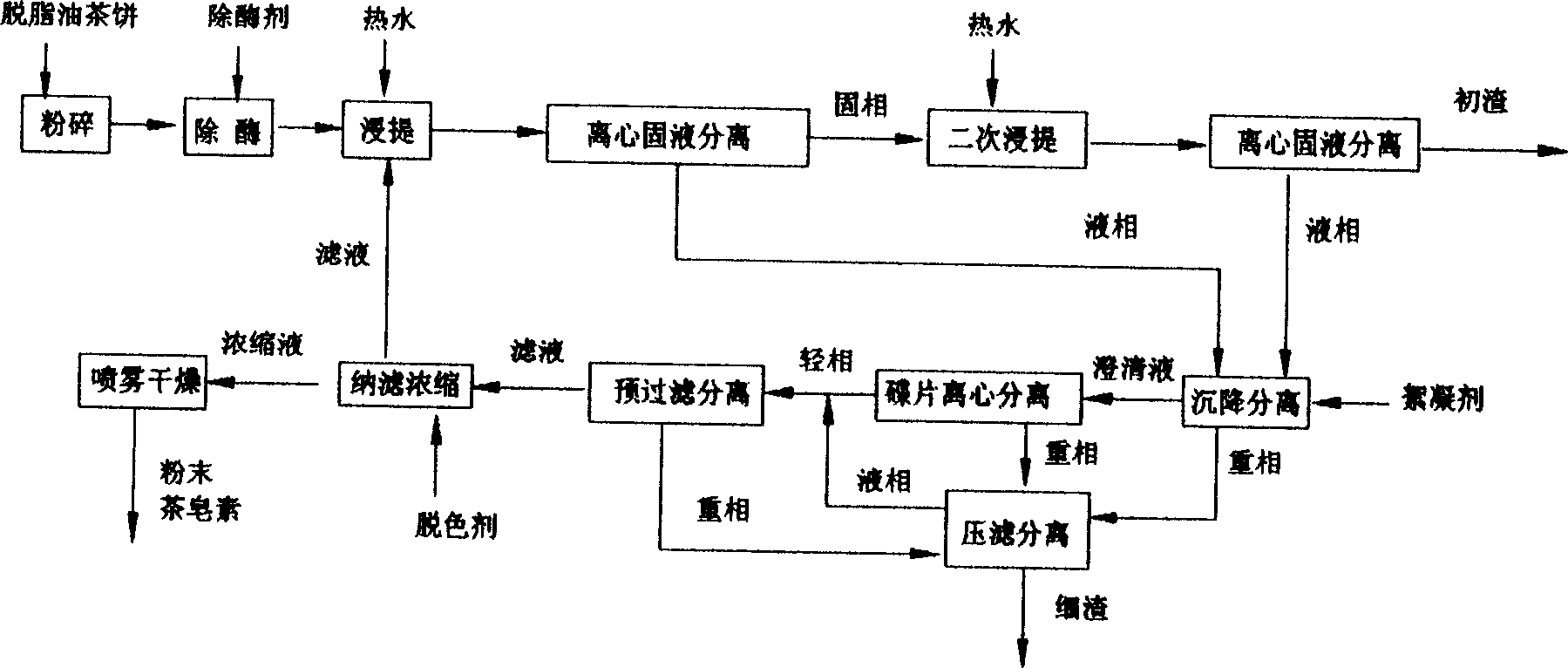

Production process for extracting tea saponin from tea-oil tree cake by using water as dissoluent

InactiveCN1754883AAvoid hydrolysisEfficient removalSugar derivativesGlycosidesChemical treatmentCamellia oleifera

The preparation method to extract tea saponin from oil meal, which comprises smashing, removing enzyme, leaching with hot mixing to boost infiltration capacity, centrifugal solid-liquid separating to add flocculant, deposition separating, disc centrifugal separating for cleaning solution, prefiltration separating for flocculation deposition, nano-membrane concentrating, and spray drying. Wherein, using chemical treatment to inhibit and eliminate hydrolase activity before leaching. This invention is simple and low cost with yield more than 70% and 80% purity.

Owner:NANHUA UNIV

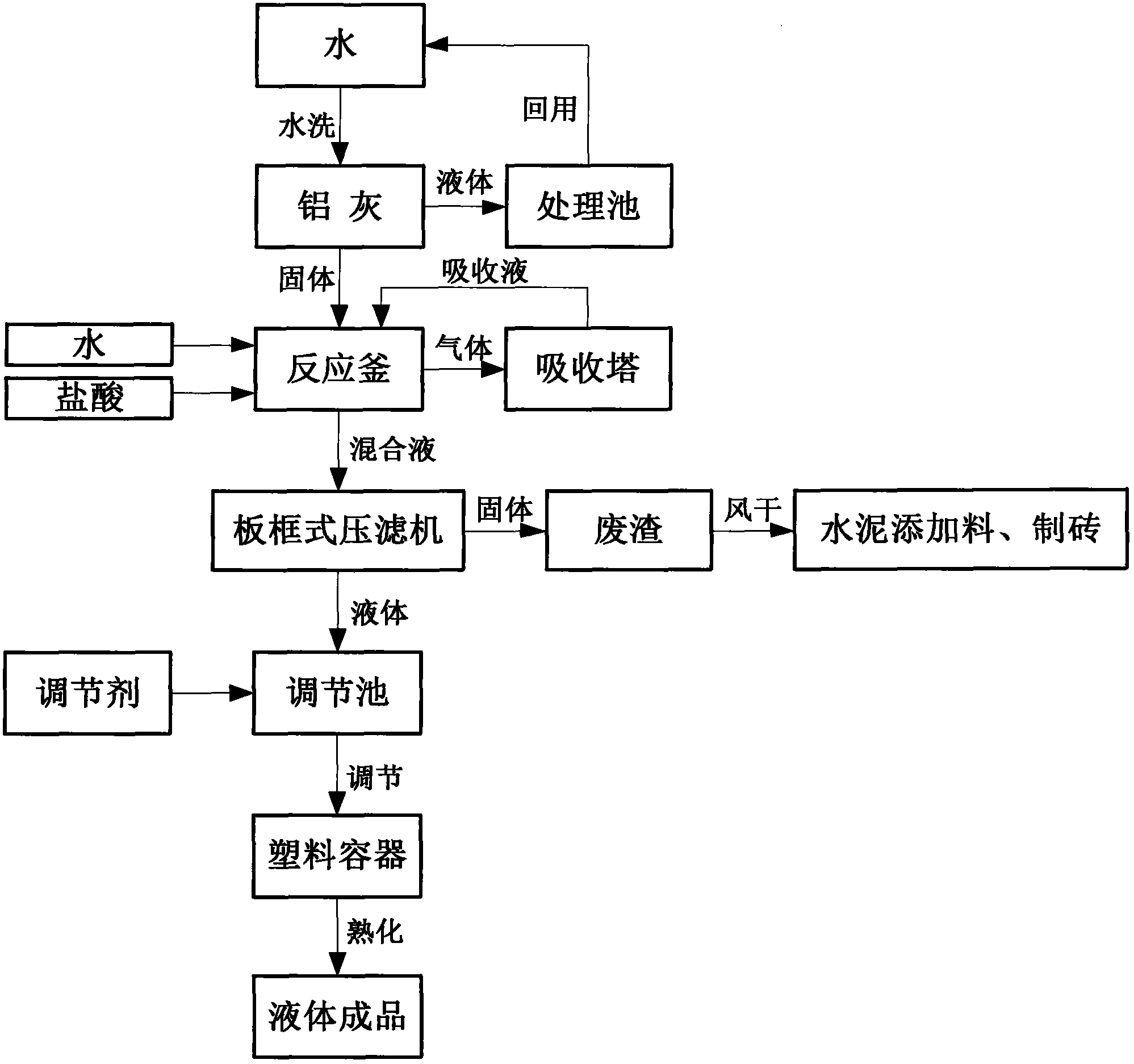

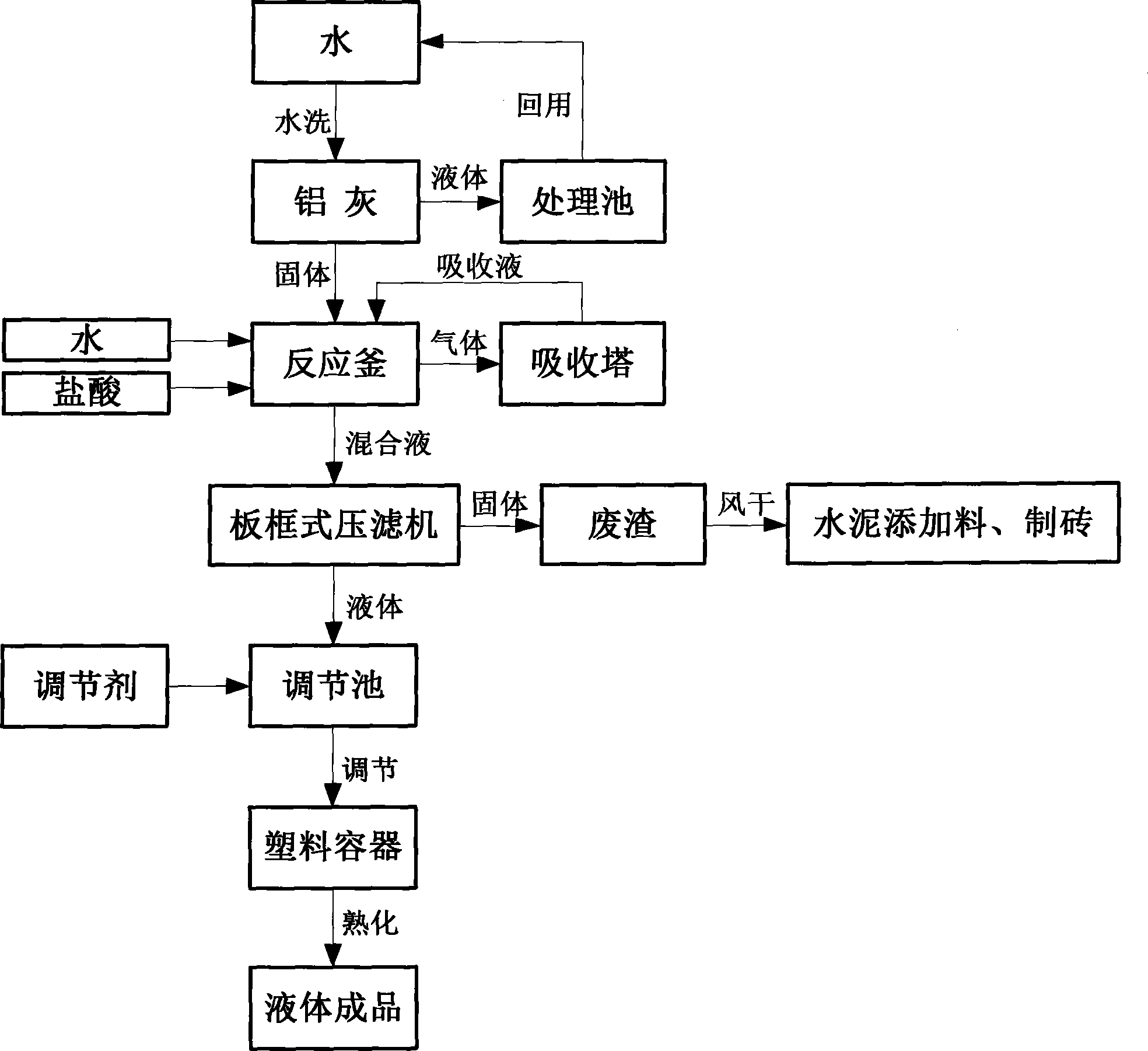

Method for preparing flocculant liquid polyaluminum chloride from aluminum ash

InactiveCN102674422ANo secondary pollutionAvoid secondary pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminate

The invention discloses a method for preparing flocculant liquid polyaluminum chloride from aluminum ash, belonging to the technical field of solid waste treatment environment protection. The method comprises the following steps: uniformly mixing and stirring aluminum ash and water in a volume ratio of 1:(3-5), and soaking for 5-8 hours; pumping the solution into a reaction kettle, adding hydrochloric acid and water in an aluminum ash / hydrochloric acid / water volume ratio of 1:(2.5-3.0):(3.0-4.0), and reacting at 85-100 DEG C for 2-3 hours; carrying out solid-liquid separation with a plate and frame type filter-press, and adding a regulator to regulate the aluminum oxide content and basicity of the liquid, wherein if quicklime is used as the regulator, the volume ratio of the liquid to the quicklime is 1:(0.054-0.086), if aluminum dust is used as the regulator, the volume ratio of the liquid to the aluminum dust is 1:(0.023-0.04), and if solid calcium aluminate is used as the regulator, the volume ratio of the liquid to the solid calcium aluminate is 1:(0.042-0.063); and standing and aging for 48-72 while controlling the temperature at 50-60 DEG C, thereby obtaining the liquid polyaluminum chloride finished product. The invention has the advantages of simple technique, low cost and no secondary pollution, and is a good method for recycling aluminum ash.

Owner:李松 +2

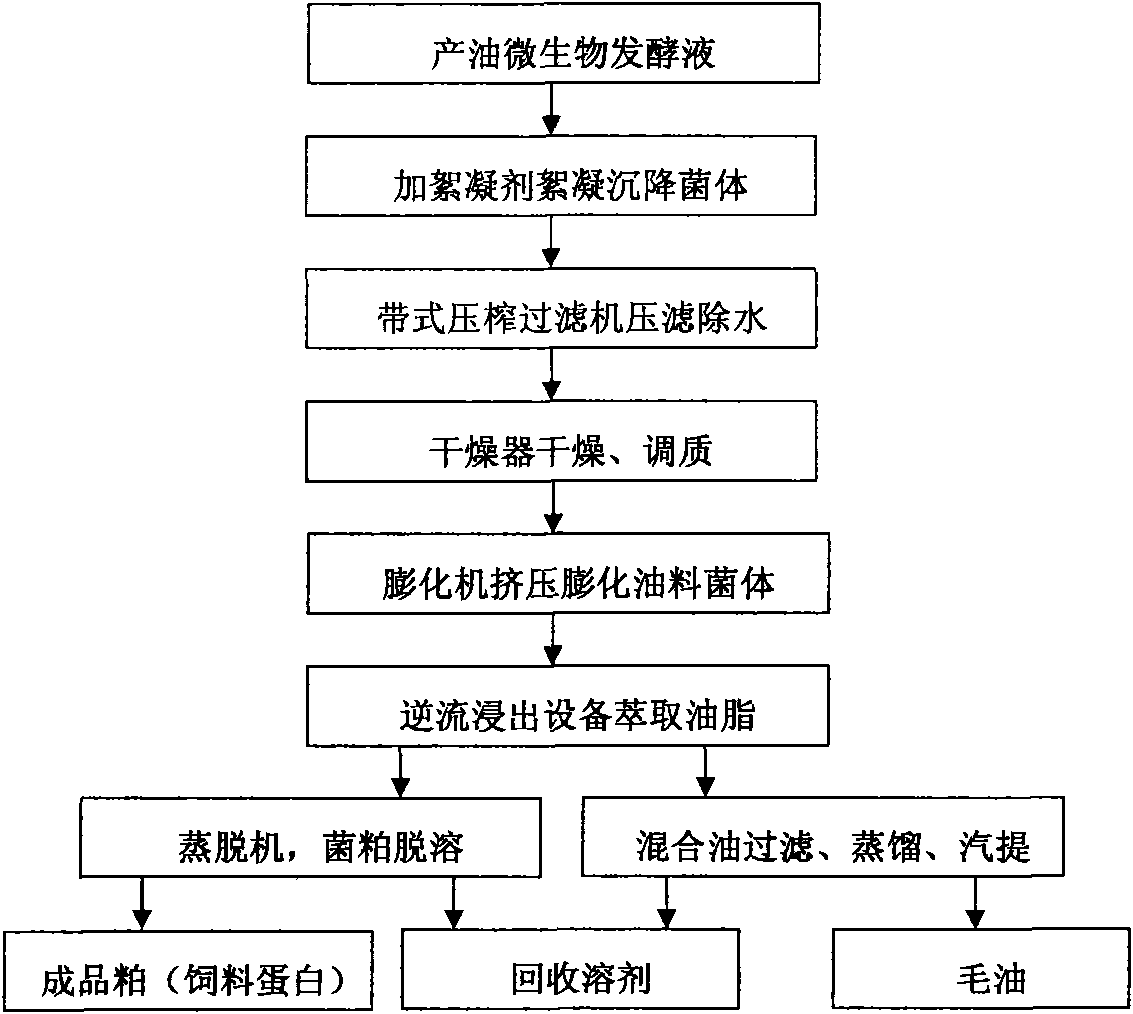

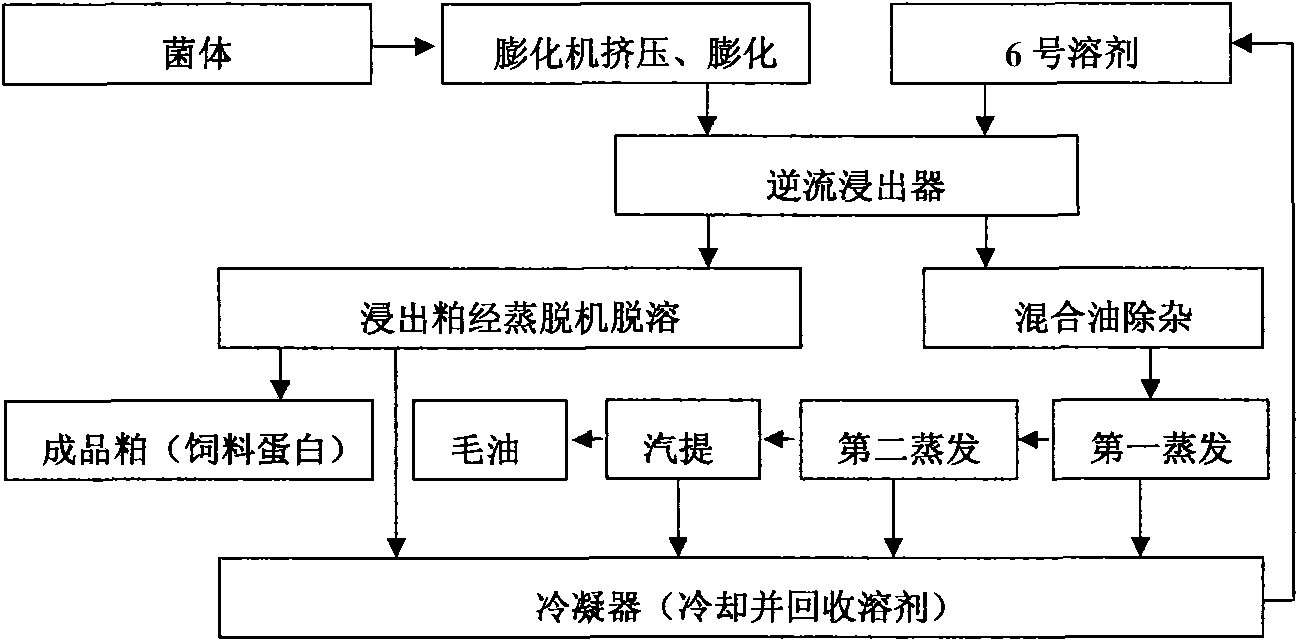

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

Hot Beverage Center

A hot beverage center that utilizes a thermostat in the handle of an electric carafe. The handle thermostat has settings to bring liquids to a precise pre-determined setting for boil, coffee, tea, and cocoa brewing. When the desired temperature is achieved, the thermostat cycles as needed to maintain the liquid at the desired temperature for any period of time. The hot beverage center also uses an interchangeable coffee press filter / tea infuser basket. This unit is designed so that a center rod attaches to a press filter that unscrews so that an interchangeable tea infuser basket can be added. The tea infuser provides that when the center rod is lifted from the top, via a knob, at the point at which the center rod clears the top, it can lay across the top, suspending the tea basket above the water in the carafe.

Owner:MELZER STEVEN +2

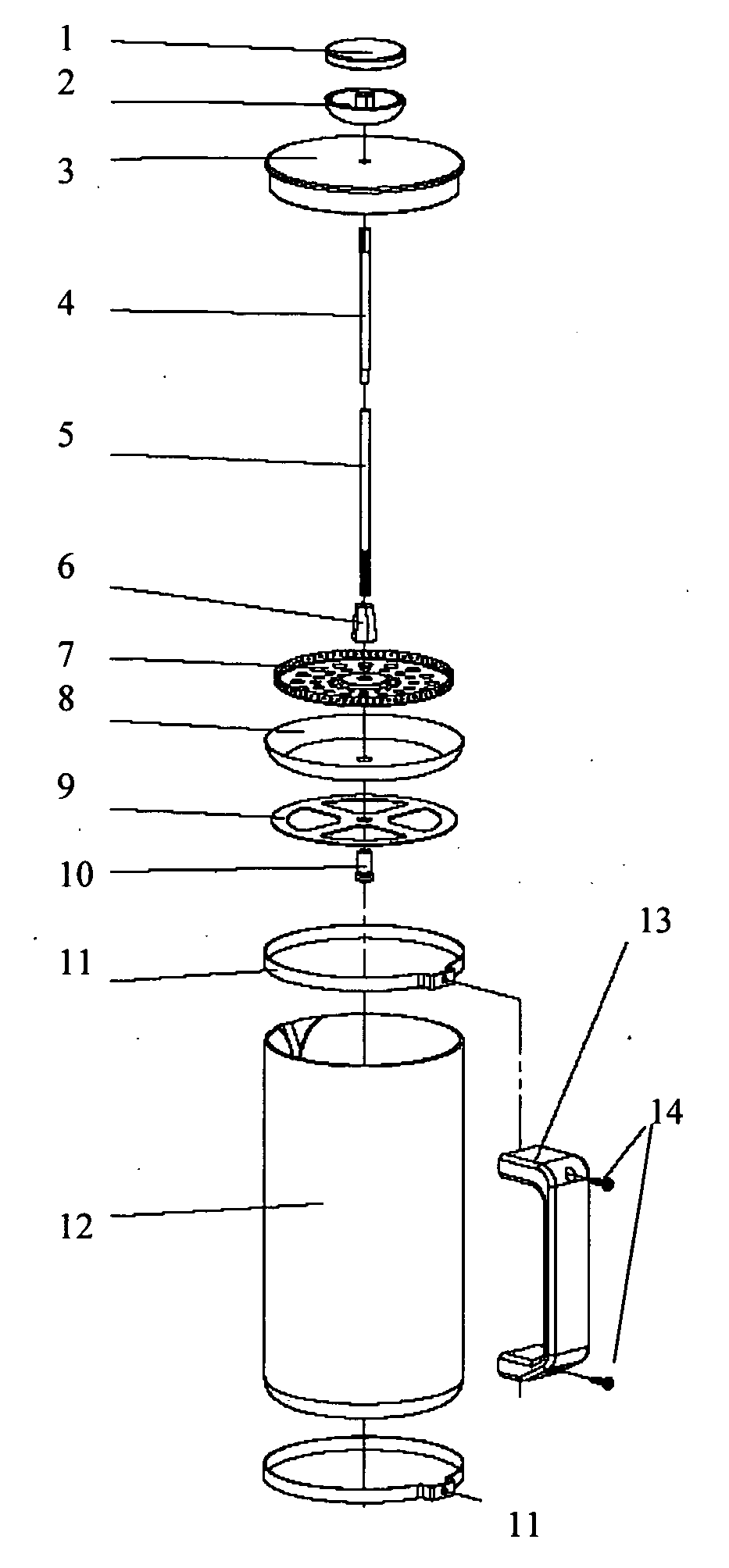

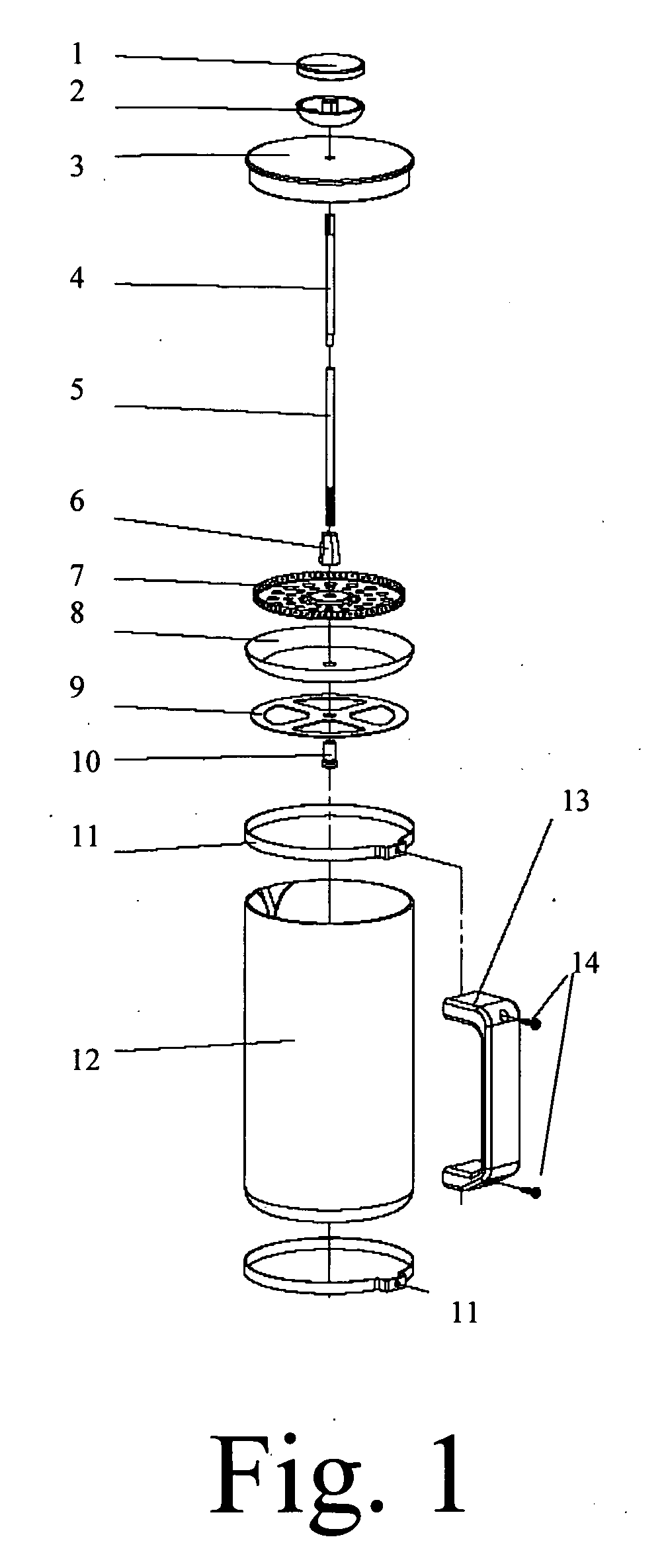

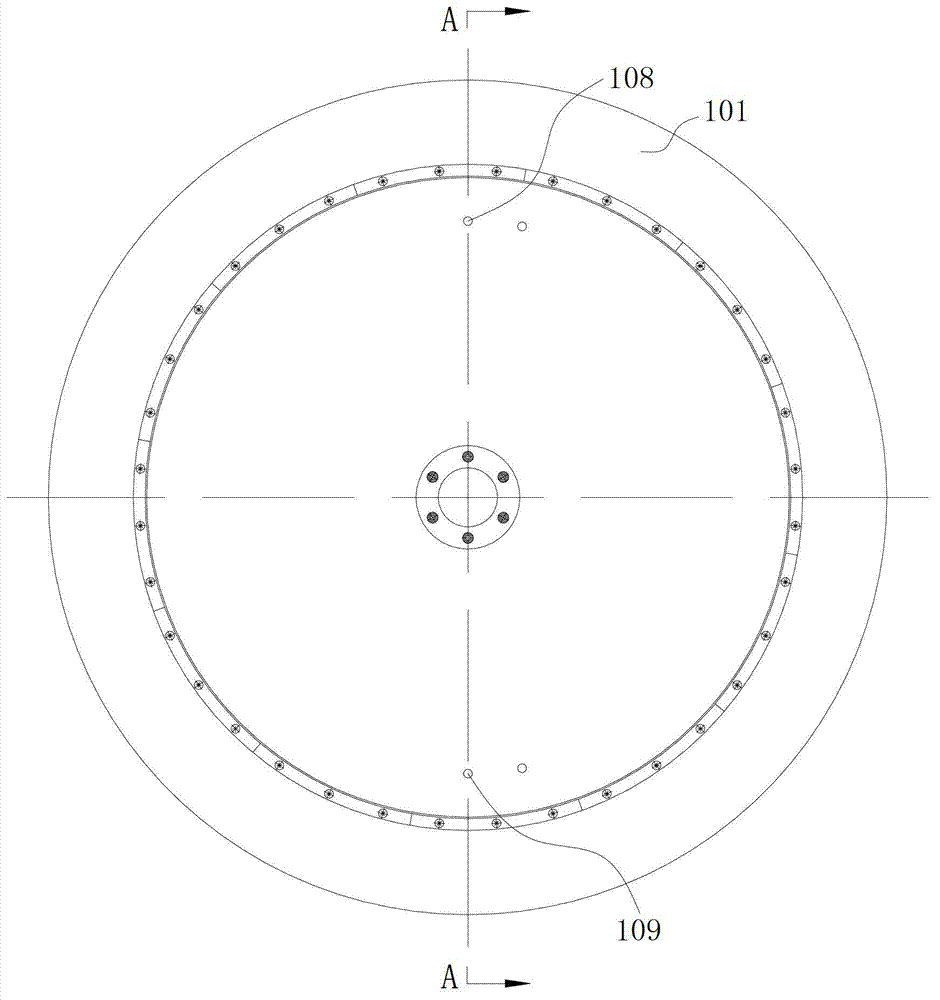

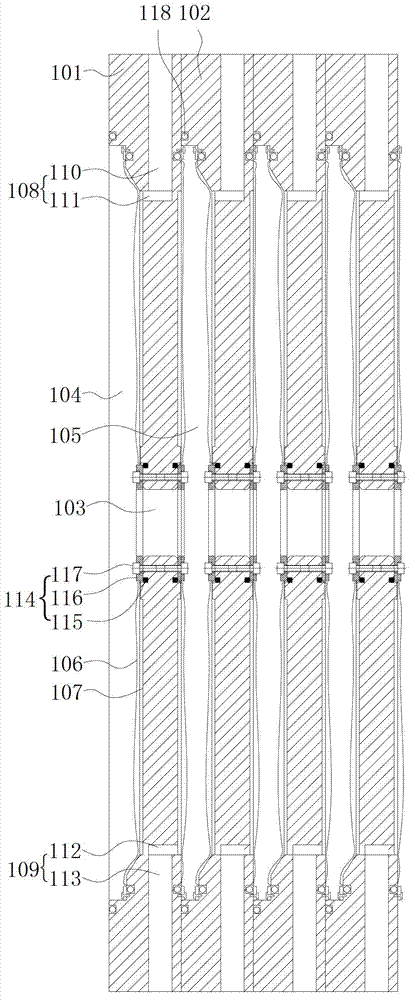

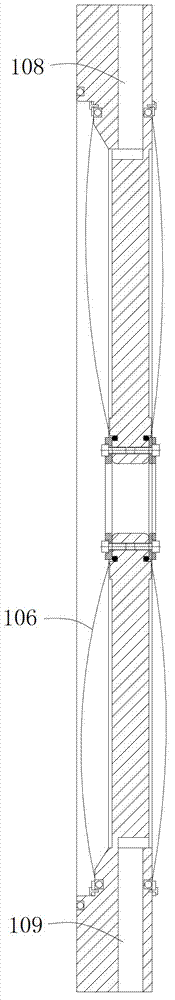

Pressure filter and pressure filtration method thereof

InactiveCN102814063AFew partsThe overall structure is simple and reliableFiltration separationPlate pressureFiltration

The present invention discloses a pressure filter, which comprises multiple groups of filter plates, wherein the adjacent filter plates are arranged in a contact manner, and each filter plate is provided with a material channel and a pressure filtration space with a variable volume and for accommodating a material. One end of the material channel is communicated with the pressure filtration space, and the other end is communicated with the pressure filtration space of the adjacent filter plate. Each filter plate is further provided with an air channel for communicating the filter plate pressure filtration space and a liquid channel for communicating the pressure filtration space of the adjacent filter plate. Filter screens are arranged on both sides of the filter plates and are positioned inside the adjacent pressure filtration space, wherein a filter cloth is covered outside the filter screen. The pressure filter of the present invention has characteristics of fewer components, simple and reliable structure, and low equipment maintenance workload. The present invention provides a pressure filtration method. According to the pressure filtration method of the present invention, two-stage pressure filtration and one-stage drying are adopted, wherein the first stage is that a driving pump is adopted to feed the material to carry out pressure filtration, the second stage is that high pressure air pressurizes the filter cloth to carry out pressure pressing, and the third stage is that the material is dried with high temperature air, such that pressure filtration efficiency is improved, and effects of automatic material unloading and filter cloth cleaning are achieved through the high pressure air.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

Method and system for processing desulphurization waste water

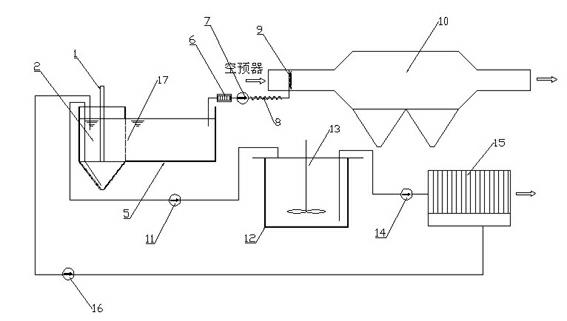

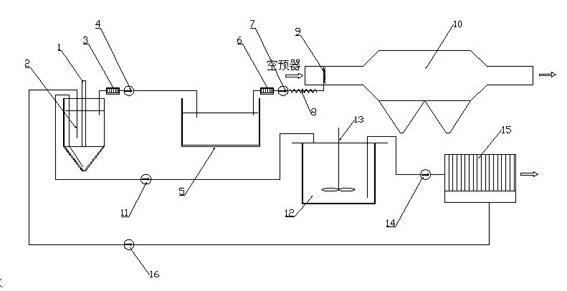

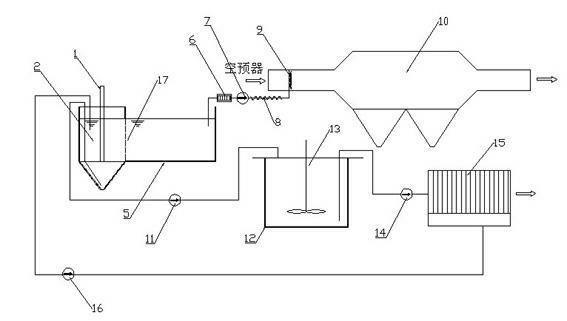

ActiveCN101417826AReduce process water consumptionReduce energy consumptionWater/sewage treatmentEnergy based wastewater treatmentFlue gasWastewater

The invention discloses a method and a system for treating desulfurization wastewater, which are applied to treating the wastewater generated from limestone-plaster wet flue gas desulfurization and other wastewater with high salt content. The system comprises a drying tower, a circular spray system, a flue gas stirring device and a filter press. The method comprises the steps: in the drying tower, hot flue gas and desulfurization wastewater exchange heat through convection contact so as to lead the wastewater to evaporate and concentrate to generate crystal; the filter press is adopted to carry out solid-liquid separation; and mother liquor continually refluxes and is treated. The method and the system have the advantages of low cost, little area occupation and low energy consumption, which can realize zero discharge of the wastewater of the limestone-plaster wet flue gas desulfurization technology and improve contribution.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

Method and system for zero emission treatment of desulfured waste water

ActiveCN102180549AConvenient zero-emission disposalSimple processWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeWater filter

The invention discloses a method for zero emission treatment of desulfured waste water. The method comprises the following steps: 1) discharging the desulfured waste water obtained after desulfuration in a desulfuration tower into a preliminary sedimentation tank, carrying out primary separation in the preliminary sedimentation tank, and transporting an upper clear liquid separated out to a buffer pool through a slurry pump; 2) successively passing the desulfured waste water in the buffer pool through an atomization plant and a static dust catcher; 3) transporting the waste water which is from the lower part of the preliminary sedimentation tank and has large solid content to a filter press through an another sludge pump; and 4) feeding the waste water filtered back to the preliminary sedimentation tank through the slurry pump. Simultaneously, the invention also discloses a system for zero emission treatment of desulfured waste water. The zero emission treatment is conveniently carried out on the desulfured waste water through the method, the process is simple and labor is saved; and the system has a compact structure, the method is simple to implement, energy is saved, the quality of smoke at the inlet of the dust catcher is improved, the zero emission of the desulfured waste water can be really achieved, thus the system has the advantage of popularization value.

Owner:CHENGDU SHUKE TECH

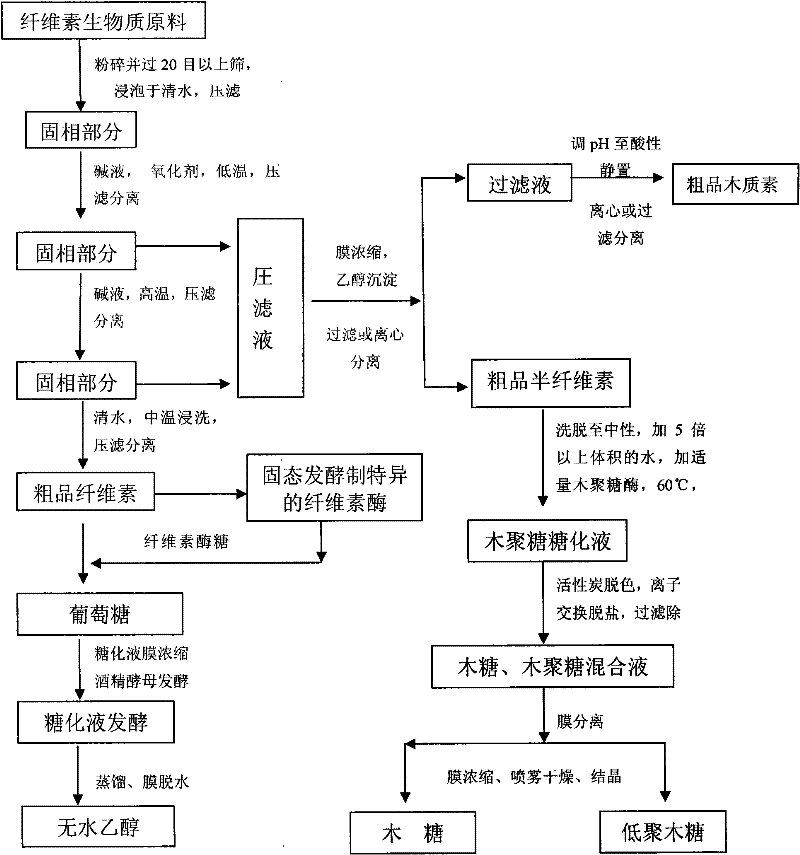

A method for fractional separation of full components of agricultural and forestry cellulose biomass and preparation of fuel alcohol and xylooligosaccharides by using the separated components

InactiveCN102261007AHigh extraction rateImprove heat utilization efficiencyPretreatment with alkaline reacting compoundsBiofuelsChemical industryFiltration membrane

The invention discloses grading and separating of all components of forestry cellulose biomass and preparing of fuel alcohol and xylo-oligosaccharide by utilizing the separated components. The method comprises the following steps of: (a) crushing, immersing and filter pressing dry substances of the forestry cellulose biomass; (b) immersing the filter pressed solid phase part using an alkaline solution, adding an oxidizing agent, extracting and solidifying phase to form a cellulose crude product; (c) concentrating pressure filtrate through a nano-filtration membrane, adding alcohol with the final concentration of above 50% to the concentrated solution, filtering or centrifugally separating after standing to obtain precipitate and supernatant, wherein the precipitate is a hemi-cellulose crude product; and (d) adjusting the supernatant obtained in the step (c) to be acid, and filtering, separating and precipitating to obtain a lignin crude product. According to the method disclosed by the invention, the resource utilization is maximized; the independence on imported oil in our country can be reduced; the environment pollution is reduced; establishment of a new energy industry and a biological chemical industry can also be promoted; the economic growth pattern in our country is changed; and social and economic sustainable development can be realized.

Owner:陈方和

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Processing equipment for pulverizing kitchen solid rubbish

InactiveCN101274330AReduce water contentAvoid the effects of processingSolid waste disposalFiltration separationConvex structureEngineering

The invention relates to a smashing device for processing solid kitchen wastes, which comprises a wet crusher and a pressure filter, wherein, an upper knife and a lower knife are arranged inside a shell of the wet crusher and fixedly arranged on the same rotating shaft, a fixed pore plate and a movable pressure plate are arranged inside the shell of the pressure filter, the pressure plate is positioned above the pore plate and provided with a pressure filtering drive mechanism that drives the pressure plate to move upward and downward, and a material outlet of the wet crusher is connected with a material inlet of the wet crusher through a connecting tube. The upper knife and the lower knife both take a shape of a leaf blade and keep a certain distance between each other, a ring-shaped inward convex structure is arranged on a channel inside the shell that is between the upper knife and the lower knife, the pore plate is arranged on an accessory with a fourth height at the lower part of the crusher shell, and a screw rod is connected with the pressure plate. The smashing device with the system has simple structure and strong applicability, and can smash the solid kitchen wastes, press and filter the solid kitchen wastes into filter mass, thus being favorable for subsequent processing and using.

Owner:BEIJING HENGYECUN S&T

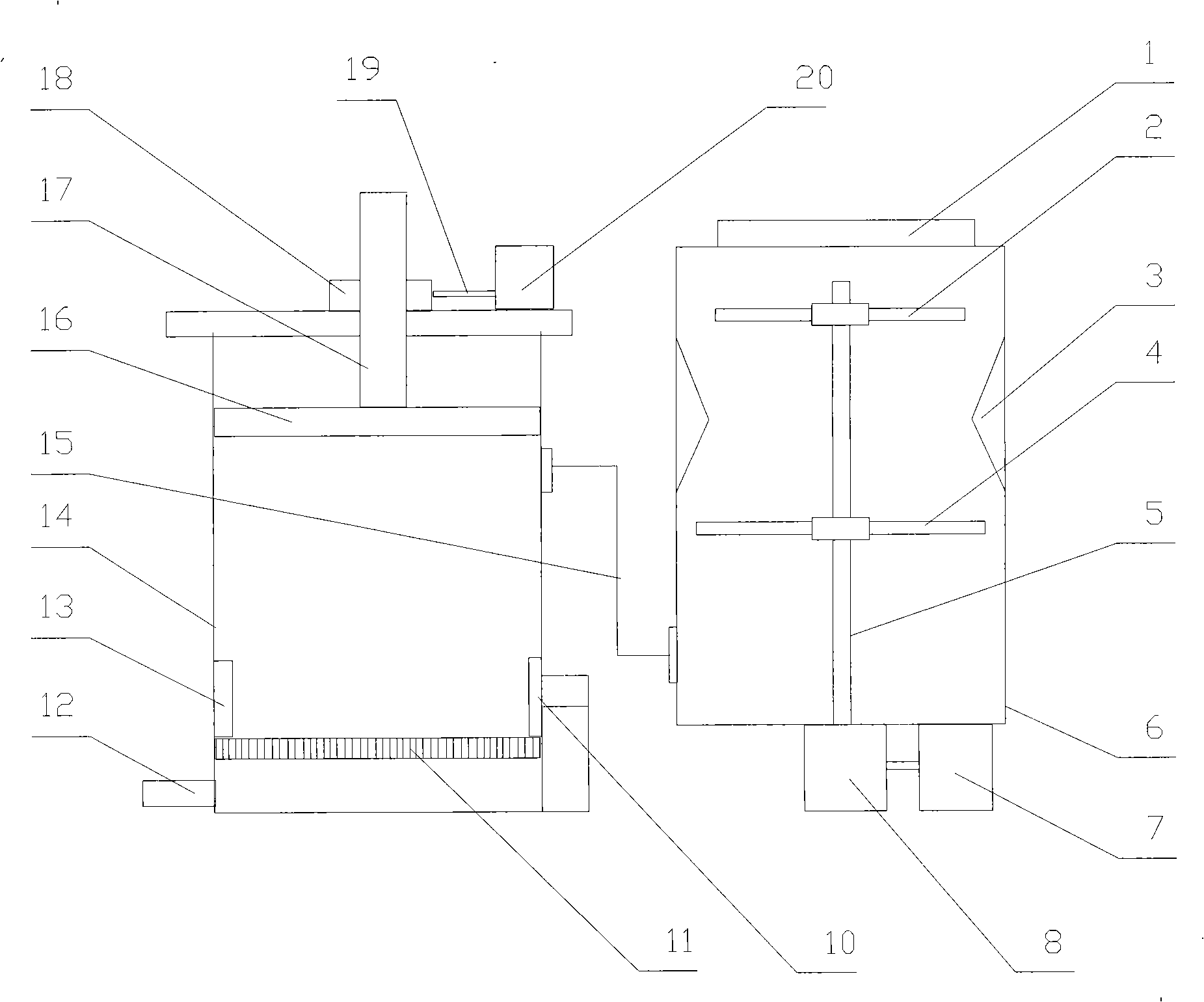

Comprehensive utilization method for red mud

InactiveCN101463426APromote environmental protectionGood benefitSolid waste managementProcess efficiency improvementWash waterRed mud

The invention discloses a method for comprehensively utilizing red mud, comprising the following steps: chloridizing roasting, namely roasting the mixture of the red mud, coal and calcium chloride; cinder treatment, namely obtaining magnetic iron slag and non-magnetic slag after magnetic separation is carried out to levigated cinder, and then separating the magnetic iron slag and non-magnetic slag; adding calcined soda or oxalic acid after levigation liquid and wash water are rich in mischmetal due to cyclic use, and then precipitating mischmetal slag; treatment of dry dust and circulation liquid, namely, after dry powder for roasting dust collection is collected, mixing the dry powder with scouring water which is used for tail gas circulation and then leaching soluble ScCl3 and GaCl3; after filter pressing, precipitating scandium by adding oxalic acid crystal in filtrate; carrying out filter pressing again, precipitating gallium and Ti(OH)4 by adding ammonia into the filtrate, dissolving obtained gallium-titanium slag with acid and then using P2O4 extractant to extract the gallium; and using extractant to extract the scandium after scandium precipitate is dissolved by acid, carrying out precipitation again by adopting back-extraction acid dissolving, and obtaining Sc2O3 by means of roasting. The method can realize recovery of valuable metals from the red mud, and secondary residual slag is totally used for building material production; and the method has environment protection effects and economic benefits, plays an important role in the development of recycling economy and is applicable to enterprises generating red mud.

Owner:张钦

Method for isolation of nanomaterials

Owner:SILURIA TECH INC

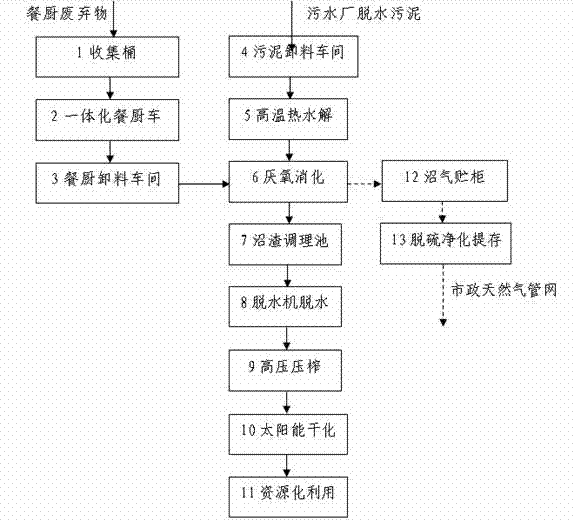

Cooperative treating method of kitchen waste and sludge of sewage plant

InactiveCN106964633AReduce the impactAvoid pollutionSludge treatment by de-watering/drying/thickeningWaste processingSolar dryingSewage

The invention discloses a cooperative treating method of kitchen waste and sludge of a sewage plant. The method comprises the following steps that A, a kitchen waste source is pretreated; B, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion; C, biogas residues are dehydrated and pressed; and D, drying treatment is conducted to obtain finished products. The cooperative treating method has the advantages that after the comprehensive treating processes that the kitchen waste source is pretreated, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion, the biogas residues are dehydrated through a dehydrator and pressed directly through a high-pressure filter press and subjected to solar drying, stabilization, harmlessness and reduction of the sludge can be achieved, and meanwhile waste is changed into treasures, specifically, available biogas and garden greening soil and forest land are produced.

Owner:江苏泓润生物质能科技有限公司

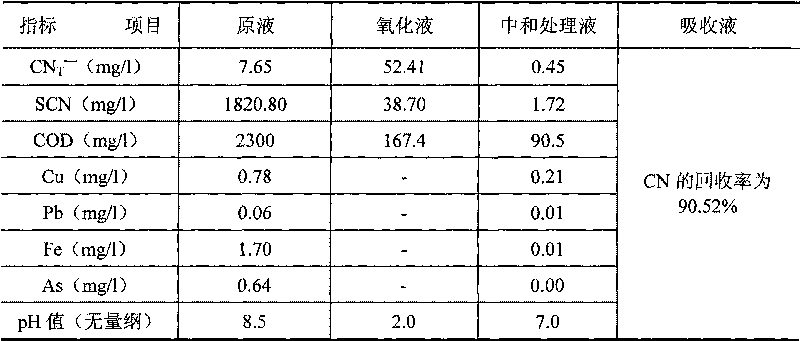

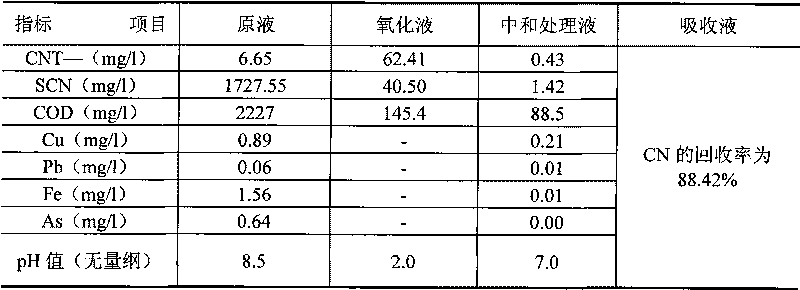

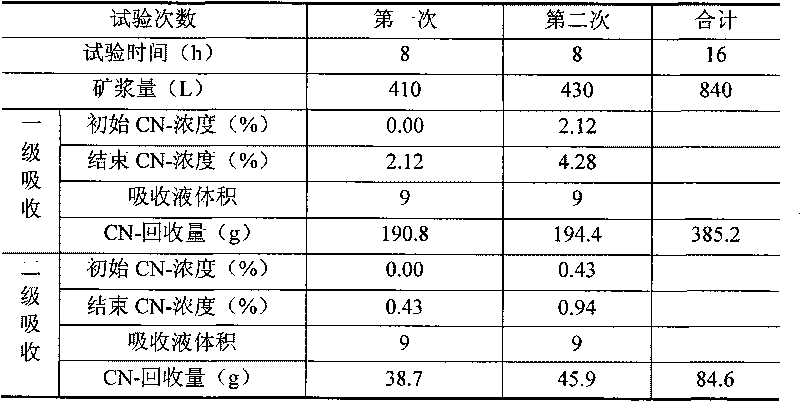

Recycling and harmless treatment method for cyaniding tailing slurry

ActiveCN101759274AIncrease contact areaToxicWaste water treatment from quariesWater contaminantsSlagGas phase

The invention discloses a recycling and harmless treatment method for cyaniding tailing slurry. In the method, the cyaniding tailing slurry containing cyanogen, thiocyanate, heavy metal and arsenic and liquid containing hydrogen peroxide are subjected to direct mixing treatment; the method utilizes high specific surface area of micro-fine granular ore to add the contact opportunity between the thiocyanate and the hydrogen peroxide and the contact area between gas phase and liquid phase through surface adsorption to accelerate a speed of oxidation-reduction reaction and an acidifying and stripping speed, utilizes metallic substances contained in slag to accelerate the reaction rate of the oxidation-reduction reaction without the addition of catalyst, and can reduce cost; meanwhile, in neutralization, Fe3+ in the slag is utilized to meet the requirement of arsenic precipitation without the addition of an arsenic precipitation reagent; when residual cyanides is removed from the hydrogen peroxide liquid, the hydrogen peroxide liquid and cyano complexes which are difficult to remove through the oxidation-reduction reaction form sediment so that the residual thiocyanate is further removed; the method can make the conversion rate of the thiocyanate in the ore slurry more than or equal to 88 percent; and compared with the treatment of filter pressing clear liquid of homogeneous ore slurry, the total reclaiming rate can be increased by over 20 percent.

Owner:CHANGCHUN GOLD RES INST +1

Method for modifying and dewatering sludge

InactiveCN102153267AStable and low priceLow running costSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention belongs to the technical field of environmental protection, and particularly relates to a method for modifying and dewatering sludge. The method provided by the invention comprises the following steps: adding water to sludge which is subjected to primary dewatering by a sewage treatment plant, thereby enhancing the flowability of the sludge; adding fine particles with high water permeability into the sludge, and evenly stirring; adding a polymeric flocculant into the mixture, so that the fine particles are coated by the sludge to form a complicated structure; and finally, pumping the mixture into a plate-and-frame filter press to carry out pressure filtration, thereby obtaining a secondary dewatered filter cake of which the water content is lower than 60%. The invention has the advantages of stable technique, simple process, low price of additive materials, low operating cost, and short pressure filtration time; heavy metals in the sludge precipitate in the sludge due to the coprecipitation action; and the effluent water of pressure filtration is clear.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com