Patents

Literature

238results about How to "High esterification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

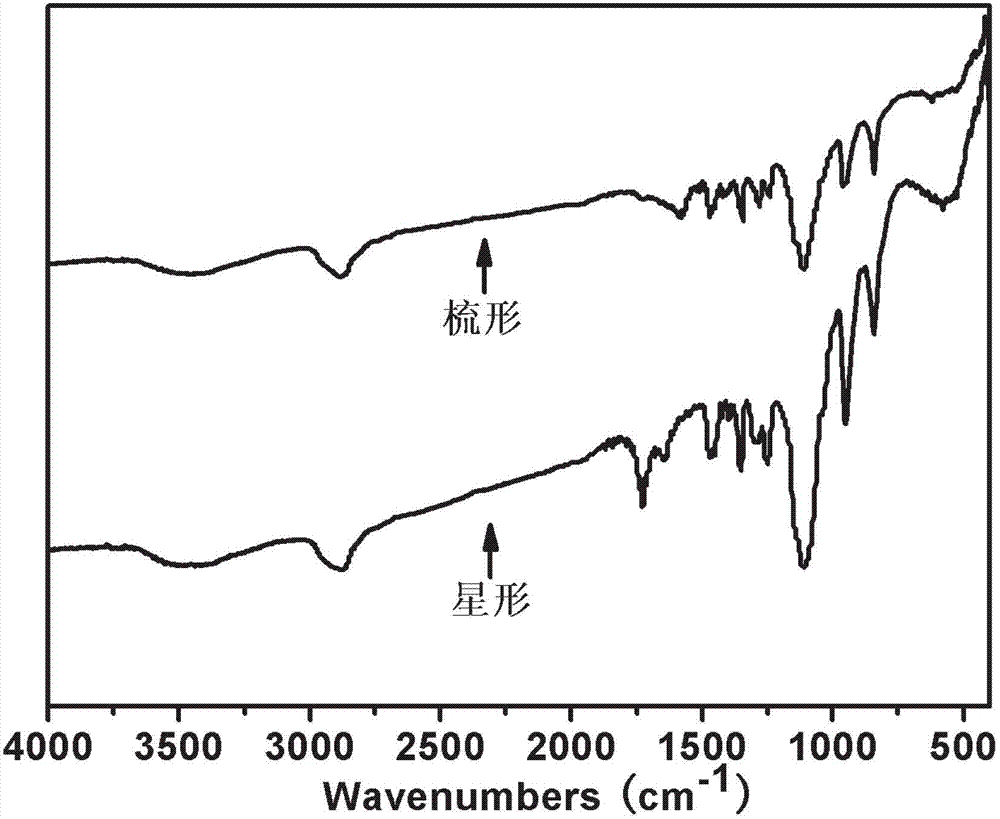

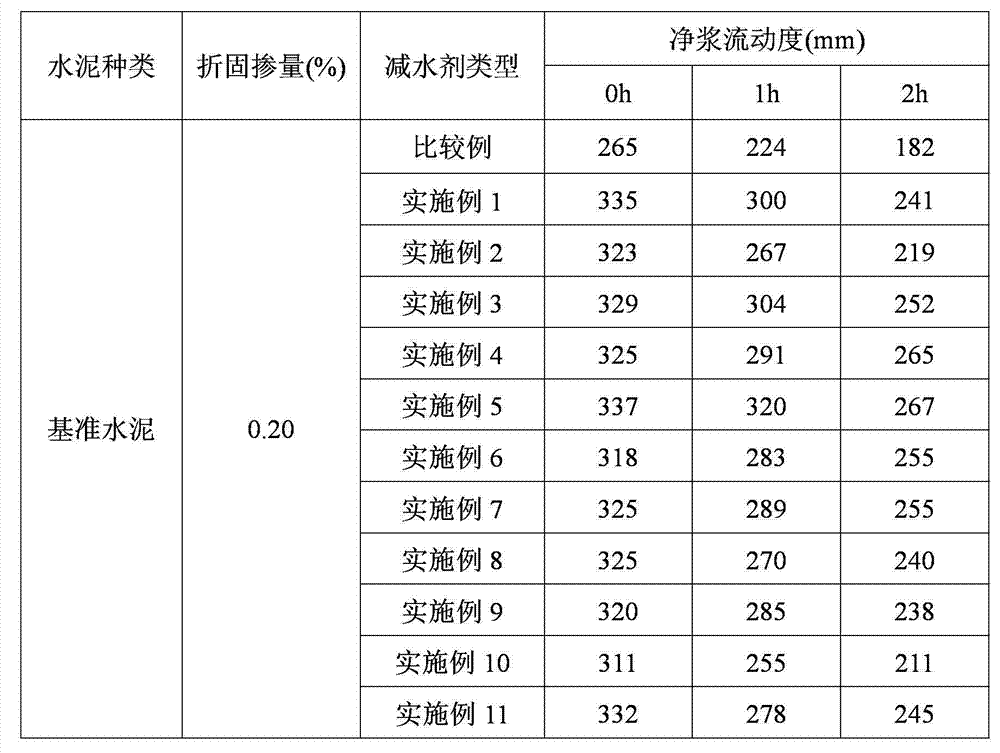

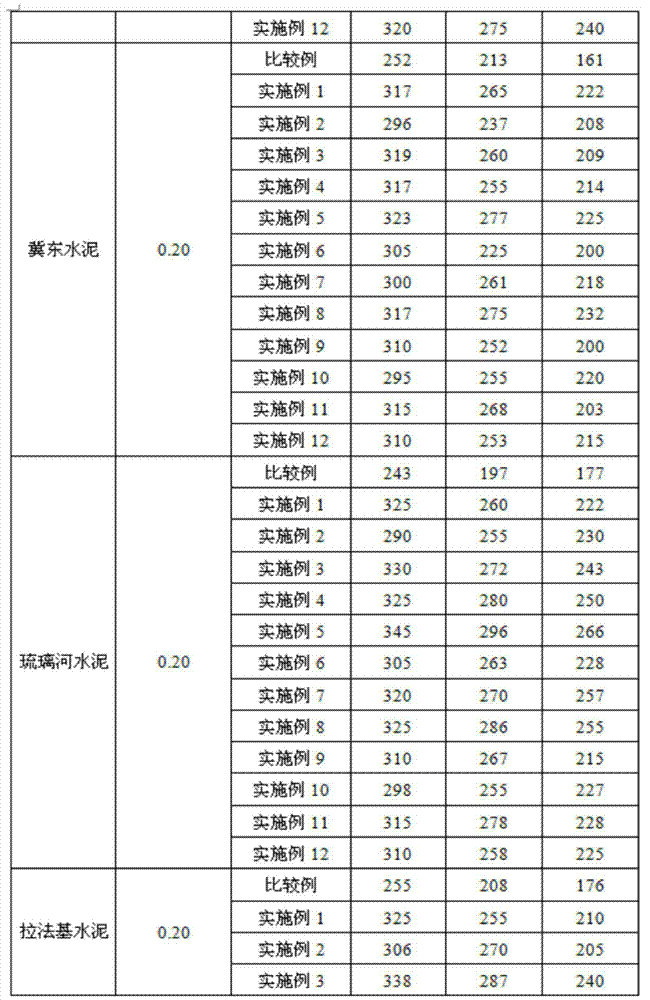

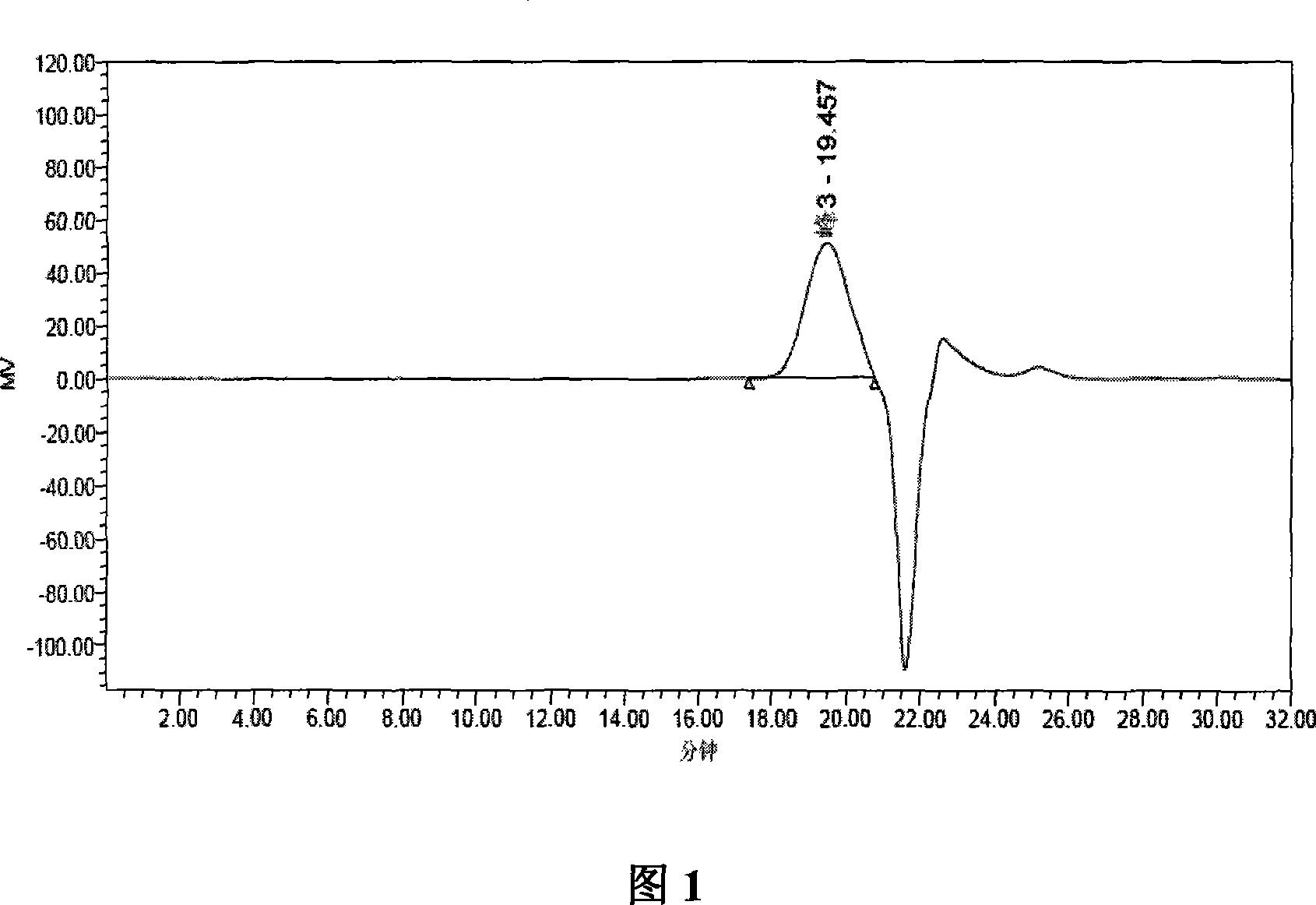

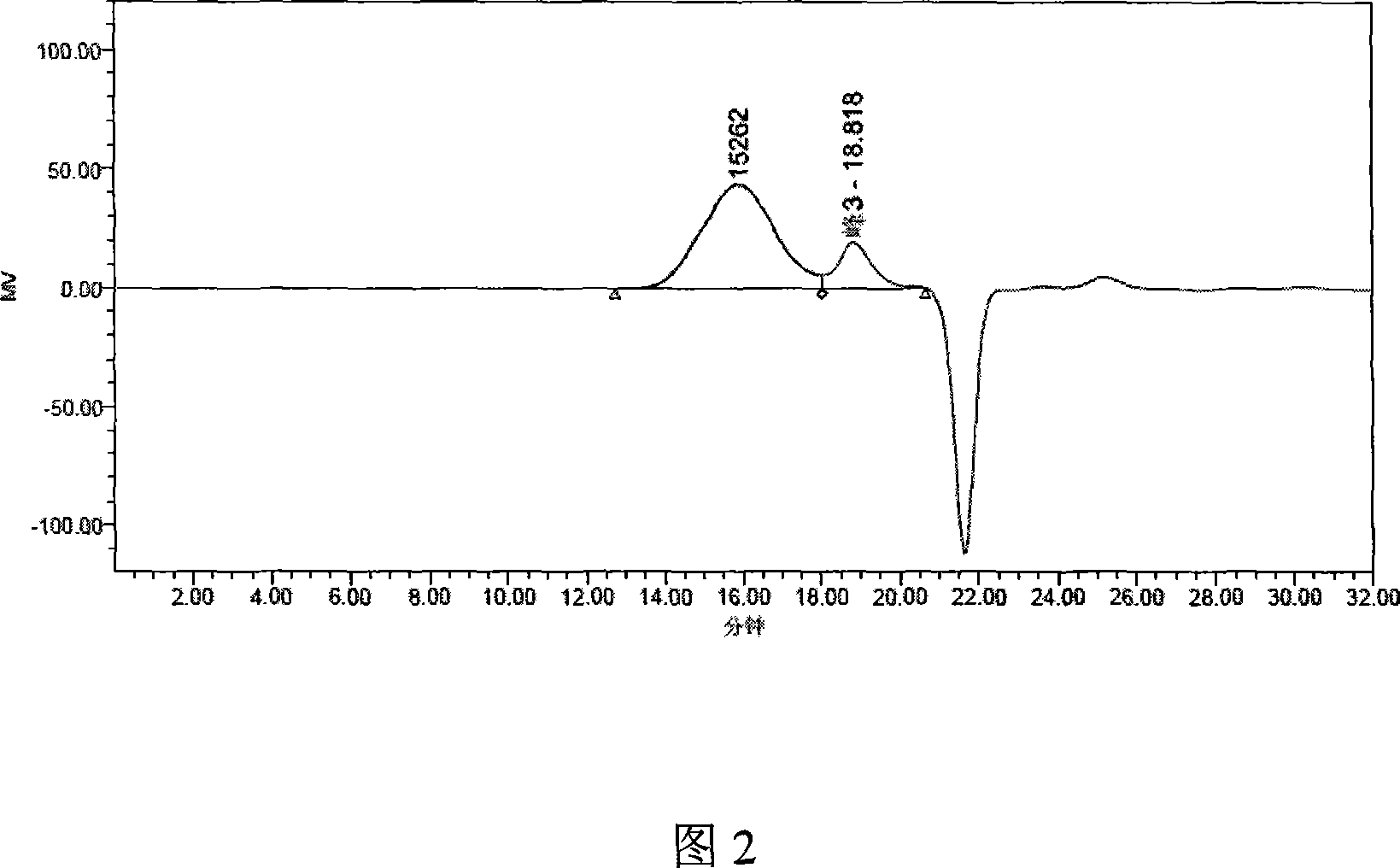

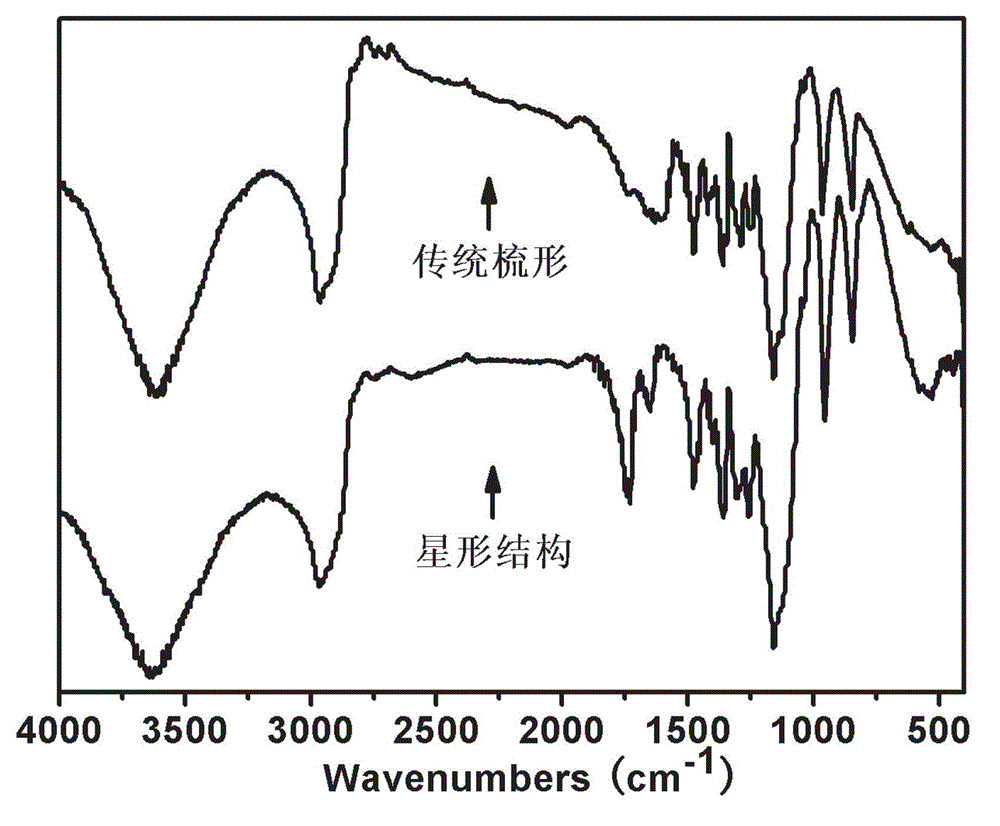

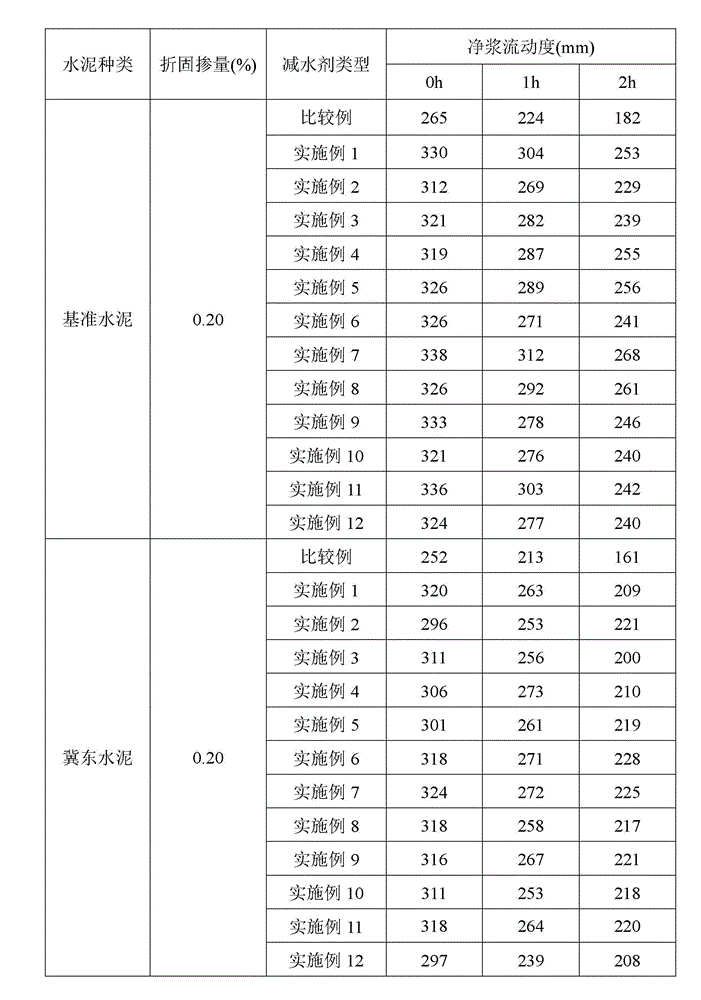

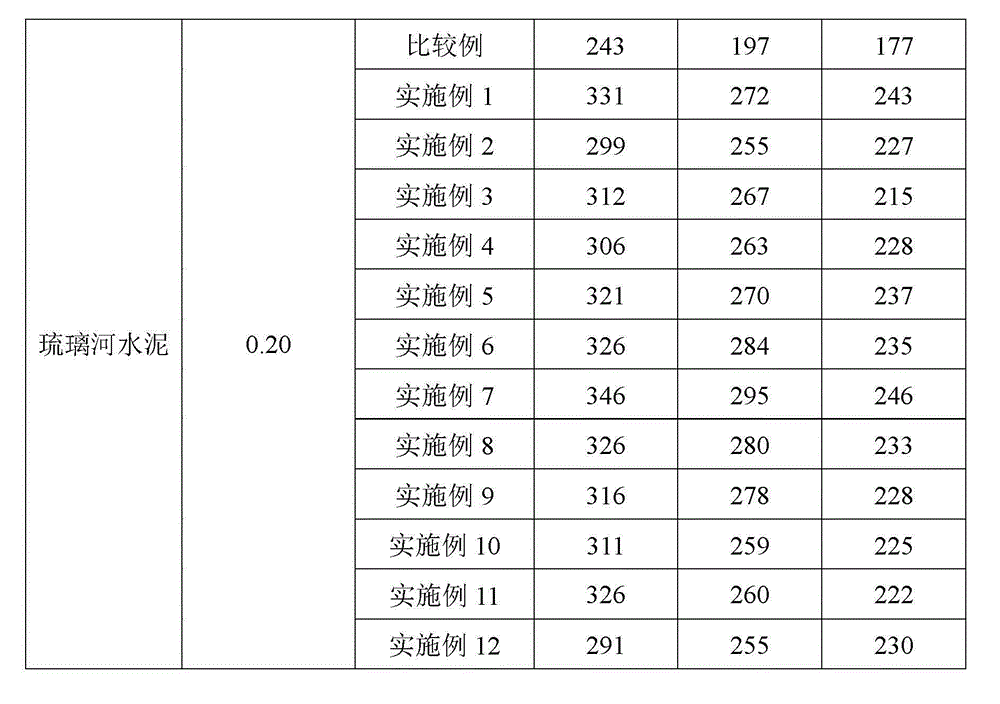

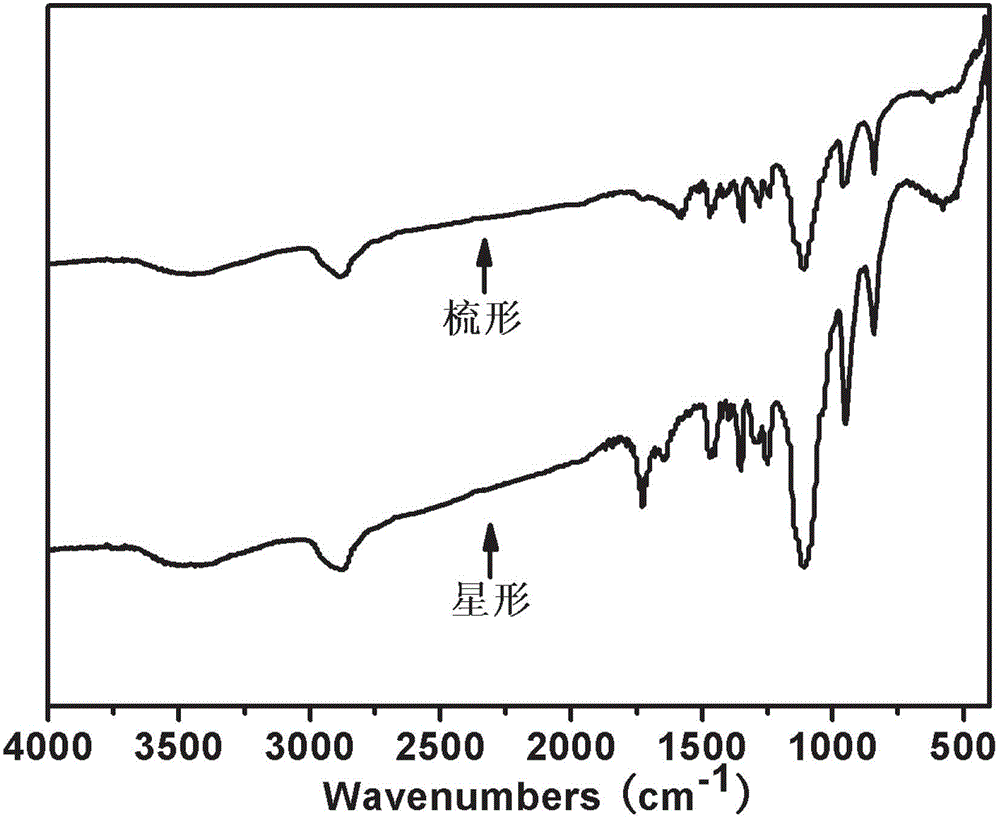

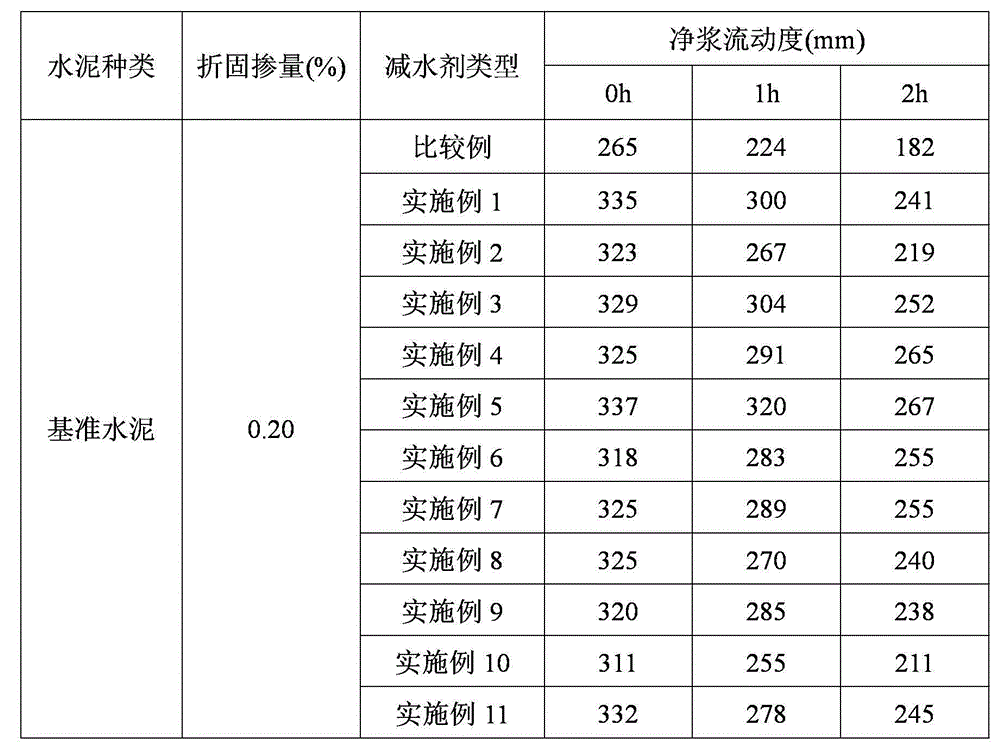

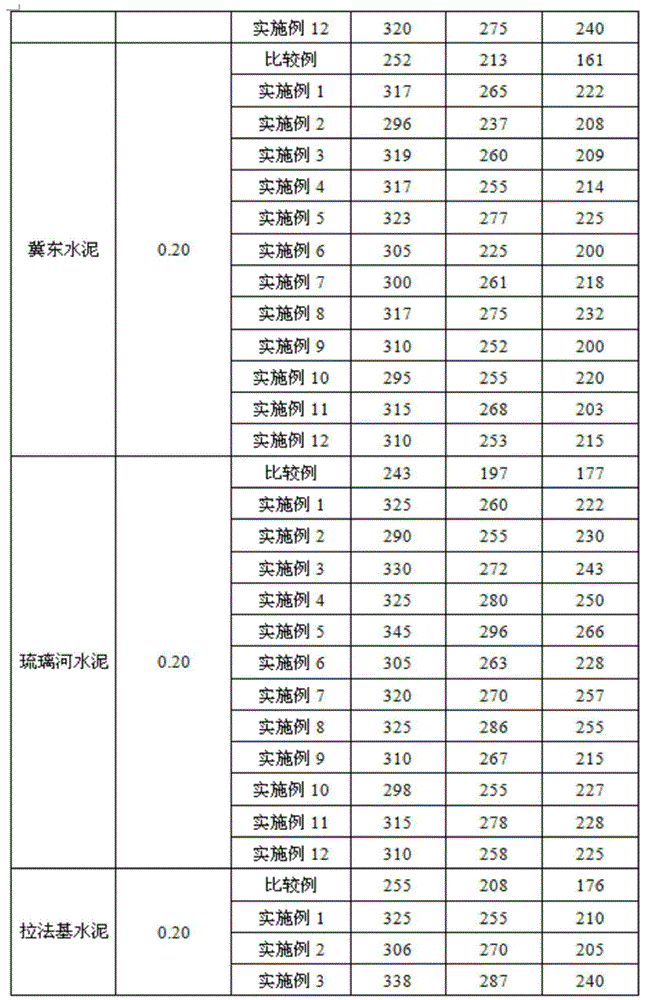

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

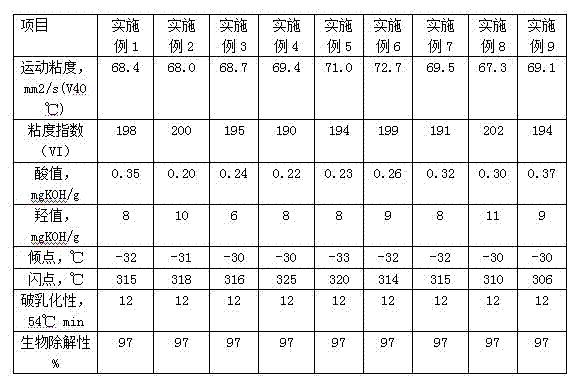

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

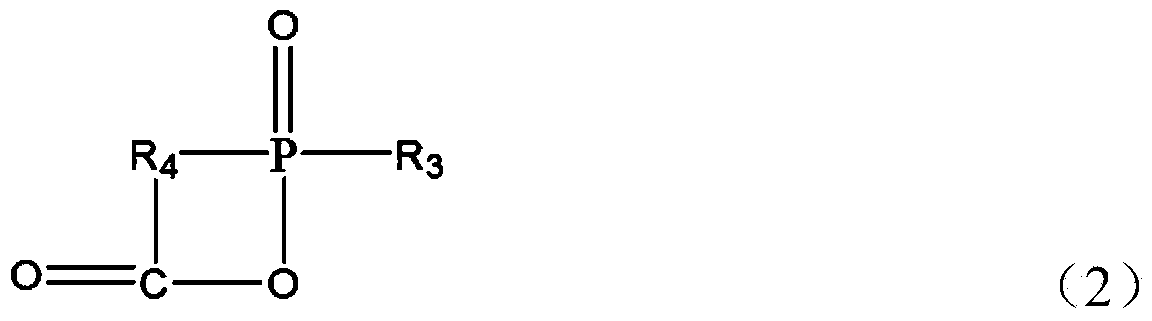

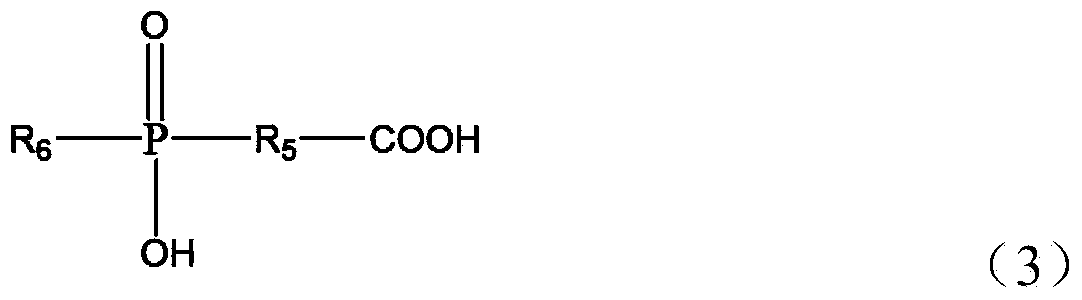

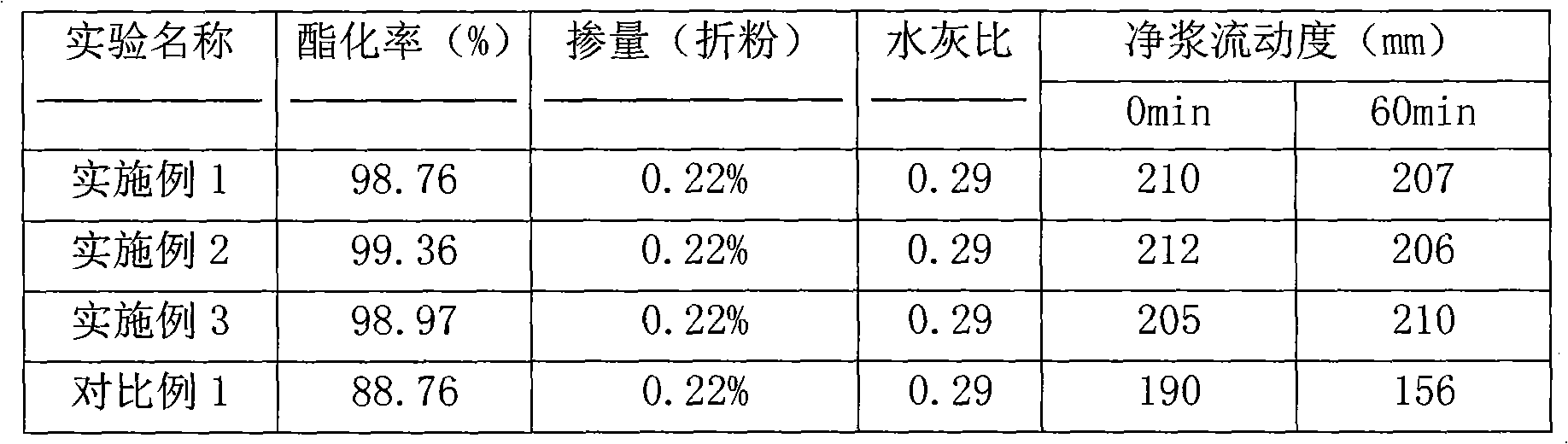

Preparation method and application of polycarboxylate water reducer containing phosphate group

ActiveCN105418857ASolve solubilitySolve the problem of competing esterificationOrganic solventAlcohol

The invention provides a preparation method and application of a polycarboxylate water reducer containing a phosphate group. According to the preparation method, the defects that the structure and the molecular weight of the water reducer cannot be accurately controlled due to the chain transfer action of the phosphate group can be overcome. The preparation method comprises the steps that an unsaturated polyether macromonomer, unsaturated carboxylic ester and unsaturated alcohol are subjected to a copolymerization reaction in organic solvent to obtain a polycarboxylate water reducer pre-polymer; phosphorylated modification is performed on the polycarboxylate water reducer pre-polymer; on the condition that an acid aqueous solution exists, a carboxylic ester group on a product obtained after phosphorylated modification is hydrolyzed, and the organic solvent is removed; neutralization is performed to obtain the polycarboxylate water reducer containing the phosphate group; the unsaturated polyether macromonomer does not contain hydroxyl, phosphorylated modification is achieved through the step that an alcoholic hydroxyl group in the polycarboxylate water reducer pre-polymer and a phosphate esterification reagent are subjected to an esterification reaction, and the using amount of the phosphate esterification reagent is sufficient to completely esterify the alcoholic hydroxyl group in the polycarboxylate water reducer pre-polymer.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

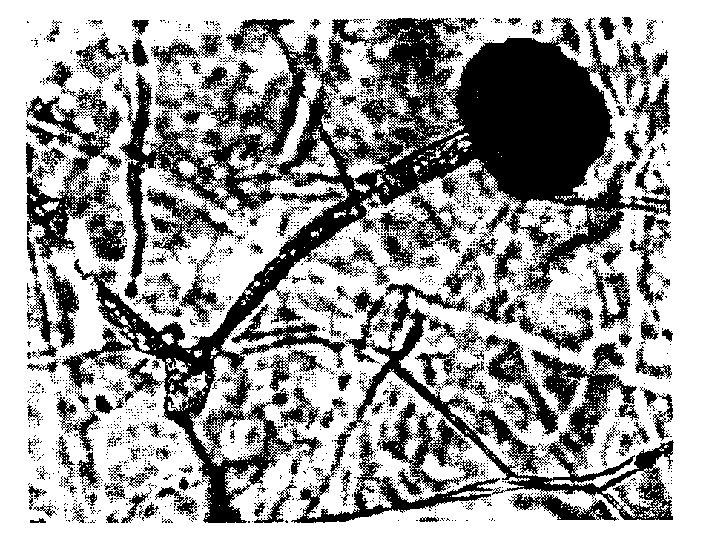

Lipasegenous bactenia, its screening method and industrial application

InactiveCN1443841AHigh esterification rateIncrease enzyme activityFungiHydrolasesFreeze-dryingFluorescence

The present invention relates to a lipasegenic bacterium, its screening method and its industrial application. Said strain is a rhizopchin obtained by separating Chinese daqu liquor, its name is Rhizopus chinensis CCTCC M201021. Its screening method includes the following steps: taking daqu liquor sample or unstrained spirits, diluting and coating on plate, slant culture, shake-flask culture, centrifugal separation, injecting supernatant fluid into preliminary screen plate hole, selecting bacterium with larger transparent ring and / or fluorescent ring to make shake-flask fermentation and rescreening, freeze-drying thallus so as to obtian whole cell rhizopchin lipase enzyme preparation. It can be used for conversion synthesis of aromatic ester in orgnaic phase.

Owner:JIANGNAN UNIV

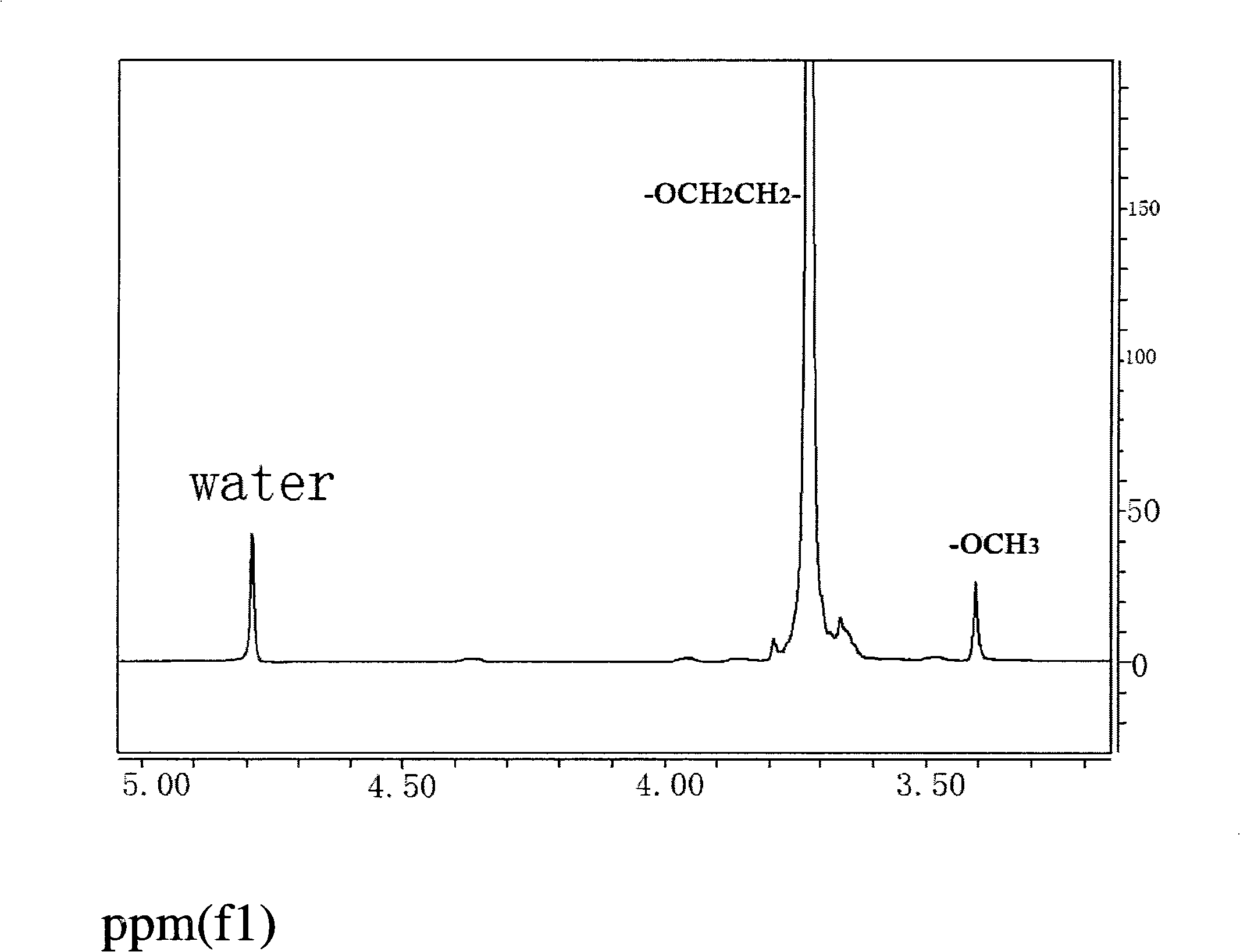

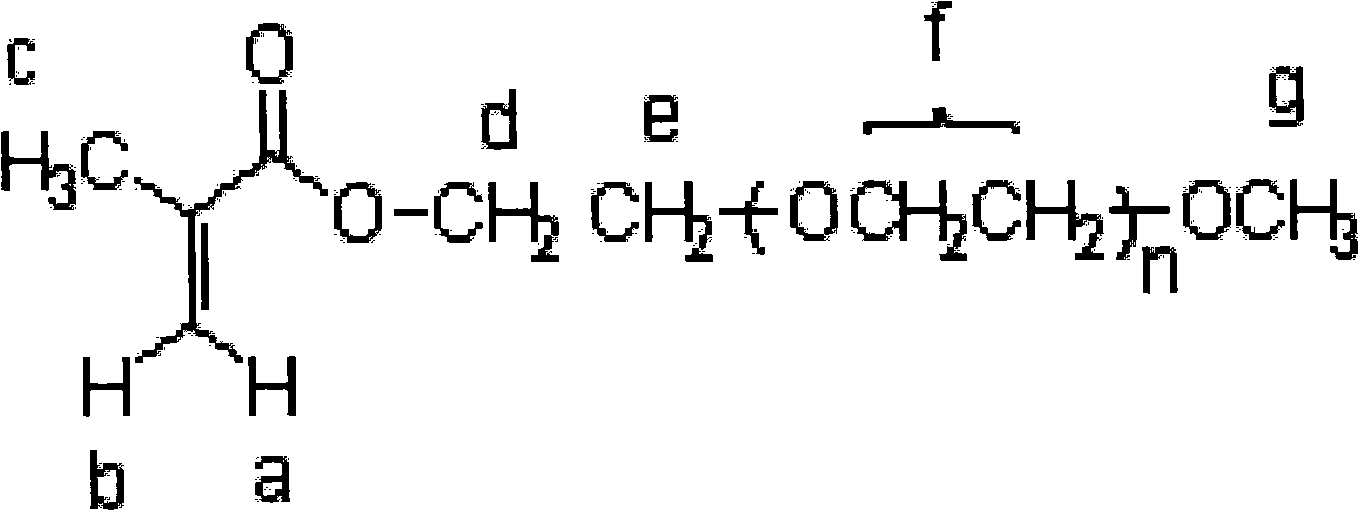

Method for synthesizing polyethyleneglycol monomethyl ether metacrylic acid ester

The invention discloses a method for synthesizing poly (ethylene glycol) methyl ether methacrylate. Methyl methacrylate and PGME are synthesized to generate the poly (ethylene glycol) methyl ether methacrylateby through the ester exchange reaction. The catalyst used in the ester exchange reaction is a base catalyst and has high catalytic activity; an inhibitive substance is added in the reaction system to avoid the polyreaction in the process of reaction and air is put into the reaction system; the reaction temperature is moderate and is between 80 and 85 DEG C; the reaction side product of methanol and a reaction medium form an azeotrope which is taken out of the reaction system, thereby ensuring that the reaction is done completely. The method quantificationally converts the PGME into the poly (ethylene glycol) methyl ether methacrylate, has esterification rate close to 100 percent, avoids the polyreaction and other side reactions, has simple steps and is suitable for the industrial production.

Owner:SUN YAT SEN UNIV

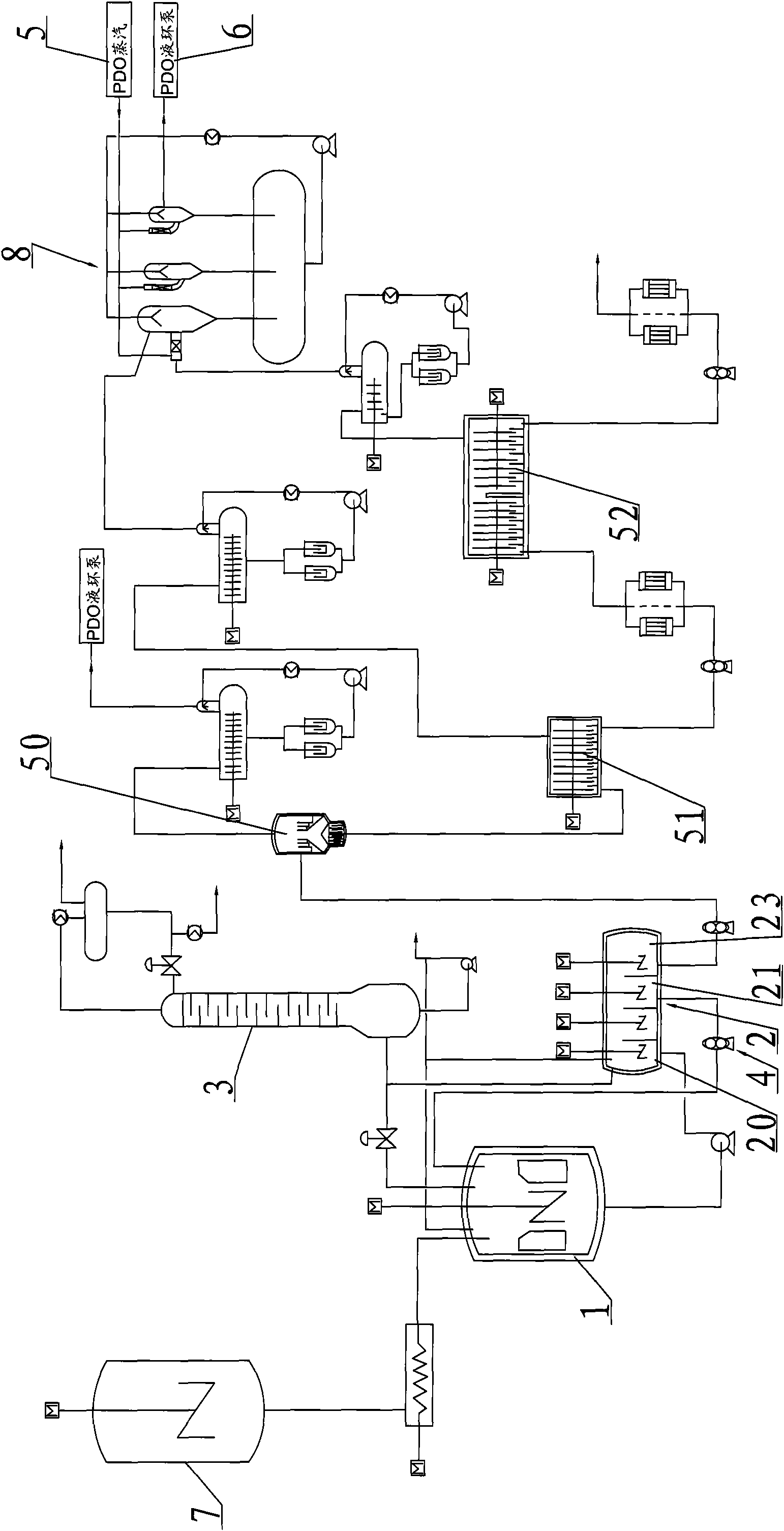

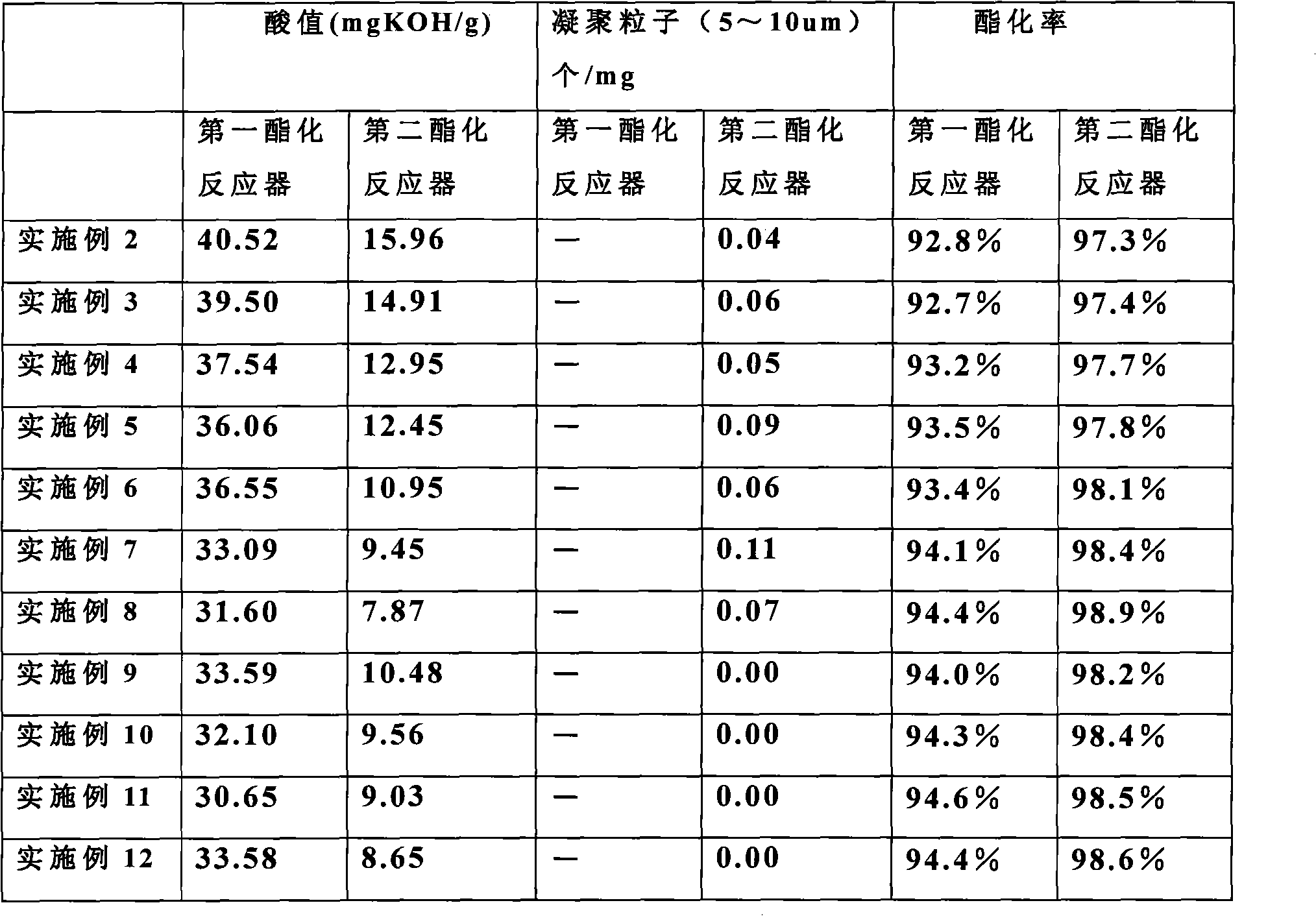

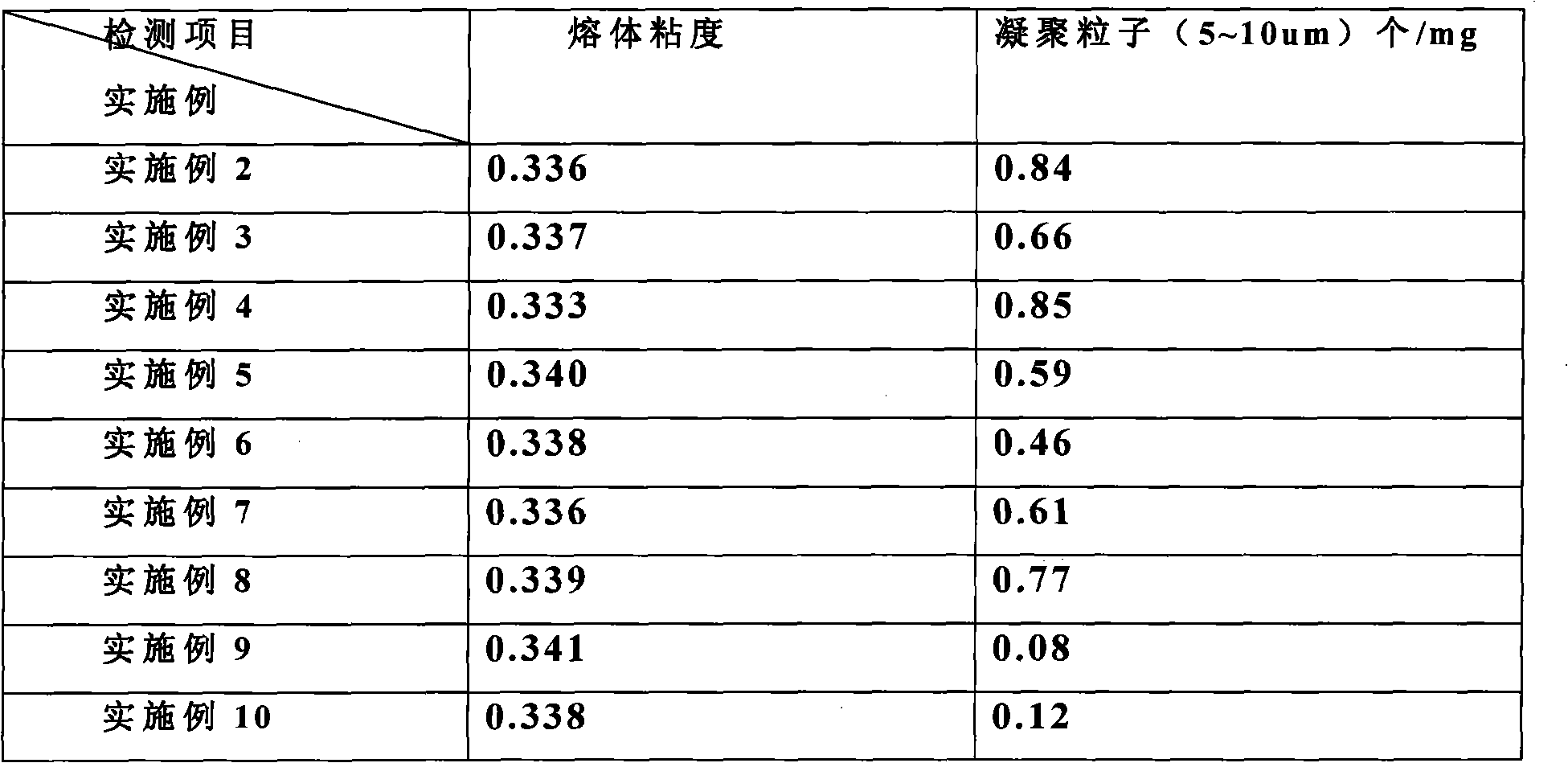

Method and device for continuously producing terephthalic acid-1,3-propylene glycol ester

ActiveCN101654513AHigh esterification rateReduces agglomerated particle formationPropylene glycolIsopropylene glycol

The invention relates to a method and a device for continuously producing terephthalic acid-1,3-propylene glycol ester. In the method, an esterifiction product is obtained by esterfying terephthalic acid-and 1,3-propylene glycol ester in the presence of an esterifiction catalyst, and the terephthalic acid-1,3-propylene glycol ester is obtained by polymerizing in the presence of a polymerization catalyst. The esterifiction is carried out in at least two phases, i.e. an initial first phase and a subsequent second phase, wherein the second phase is carried out in a reactor having a plurality of communicated reaction chambers, and the reaction chambers comprise at least one initial reaction chamber, an intermediate reaction chamber and a final reaction chamber so that the materials after finishing the reaction in the first phase carries out the second phase of esterifiction reaction by sequentially passing through the initial reaction chamber, the intermediate reaction chamber and the final reaction chamber, wherein the esterifiction rate for esterifiction in the intermediate reaction chamber reaches 95-99 percent. The method comprises the steps as follows: the esterifiction catalyst and the polymerization catalyst are added from the intermediate reaction chamber, and part materials in the intermediate reaction chamber circulate to return to the first phase of reactor for esterifiction. By adopting the invention, high-quality terephthalic acid-1,3-propylene glycol ester can be produced with lower cost and higher efficiency.

Owner:JIANGSU ZHONGLU TECH DEV

Preparation method of cationic dyeable flame-retardant polyester resin

The invention discloses a preparation method of cationic dyeable flame-retardant polyester resin. The manufacturing method is characterized by comprising the following steps: performing an esterification reaction on a halogen-free copolymerized phosphorus-based flame retardant, ethylene glycol and a composite catalyst to prepare an esterification solution of the halogen-free copolymerized flame retardant; performing ester exchange reaction on sulfoisophthalic acid dimethyl ester and the ethylene glycol to prepare a sulfonate-based bis(hydroxyethyl) isophthalate solution; performing an esterification reaction on terephthalic acid (or dimethyl terephthalate), the ethylene glycol and auxiliaries, then adding a catalyst, a stabilizer, the auxiliaries, the esterification solution of the phosphorus-based flame retardant (or a prepolymer solution of the phosphorus-based flame retardant) and the sulfonate-based bis(hydroxyethyl) isophthalate solution, performing condensation polymerization reaction, and cooling and dicing after the end of reaction to prepare the cationic dyeable flame-retardant polyester resin. The cationic dyeable flame-retardant polyester resin prepared by the method disclosed by the invention has the characteristics of good spinnability, polyester fiber cationic dye boiling dyeing under normal pressure conditions, complete chromatogram and strong dye adhesion.

Method for effectively synthesizing phytosterol ester

InactiveCN101845473AThe synthesis process is simpleSuitable for large-scale industrial productionMicroorganism based processesFermentationDiseasePhytosterol esters

The invention relates to a method for effectively synthesizing phytosterol ester, belonging to the technical fields of food, medicine and cosmetics. The method has the technical scheme that the high-purity phytosterol ester is synthesized by the steps of directly mixing phytosterol and fatty acid, adding biocatalyst and organic solvent for reaction at the temperature of 35-55 DEG C for 24-96h, and controlling the water activity of a reaction system to be 0.1-0.9. By adopting a biological method to prepare the phytosterol ester, the method has high-efficiency and green processing technique, safety and high conversion rate, and the obtained product has the functional characteristics of reducing cholesterol, preventing and curing cardiovascular and cerebrovascular diseases, antioxidation and the like, so that the invention can be widely applied to multiple fields such as food, medicine, cosmetics and the like.

Owner:JIANGNAN UNIV

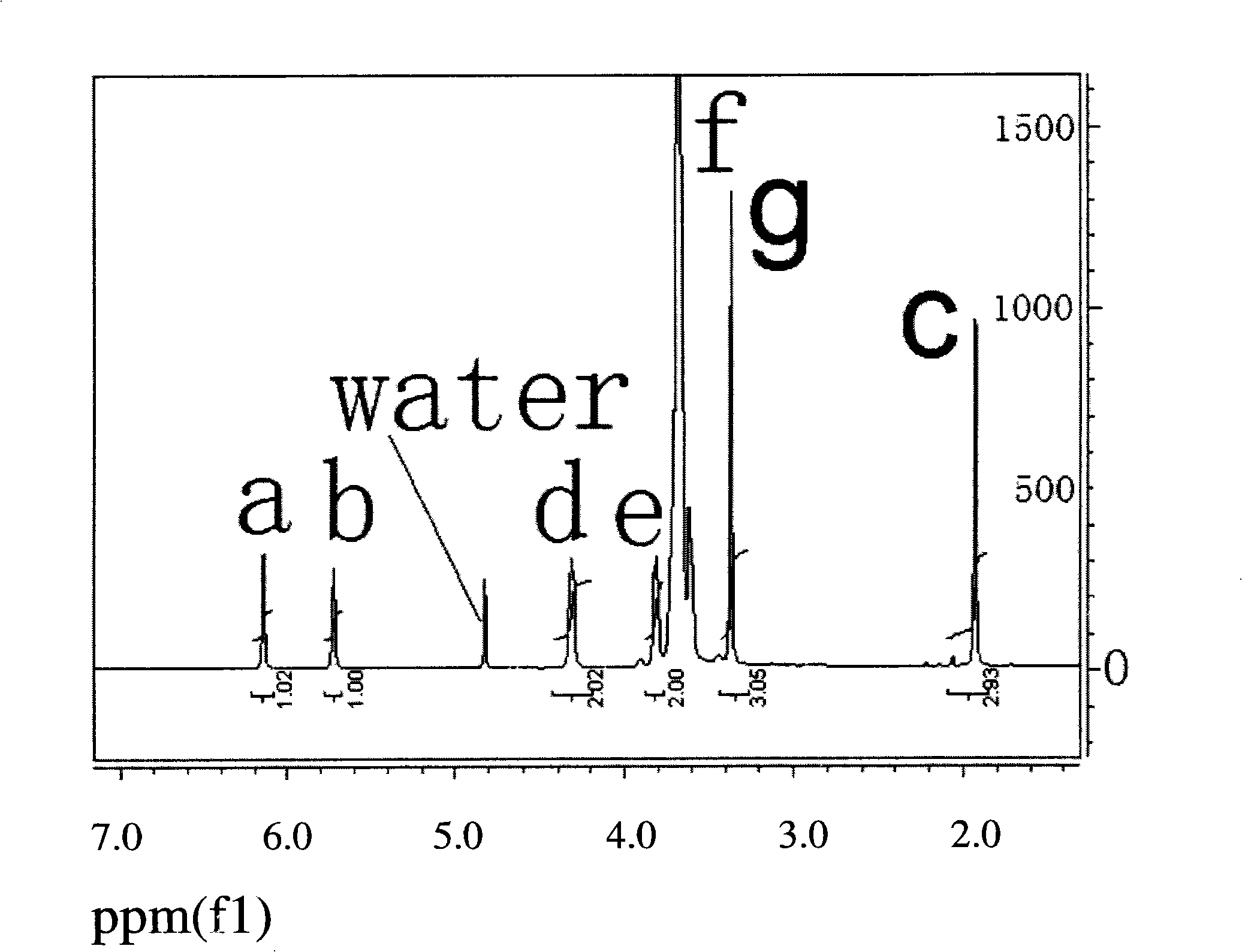

Method for preparing polycarboxylic acid water reducer macromer

The invention discloses a method for preparing a polycarboxylic acid water reducer intermediate, namely the method for preparing polyethylene glycol monomethyl ether methacrylate or polyethylene glycol monomethyl ether acrylate, in particular the method for preparing a polycarboxylic acid water reducer macromer. The method for preparing the polycarboxylic acid water reducer macromer comprises the following steps of: putting polyethylene glycol monomethyl ether, methacrylic acid or acrylic acid into a reaction kettle; adding a polymerization inhibitor and a catalyst into the reaction kettle, stirring and heating the mixture; raising the temperature of esterificatin reaction, then introducing inert gas into the reaction kettle, and keeping certain pressure in the reaction kettle; and then preserving the heat for hours to obtain the polyethylene glycol monomethyl ether methacrylate or the polyethylene glycol monomethyl ether acrylate. The invention mainly aims to provide the simple and fast method for preparing the polycarboxylic acid water reducer macromer so as to overcome the defects of the conventional production technique and process of the macromer.

Owner:浙江五龙新材股份有限公司

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

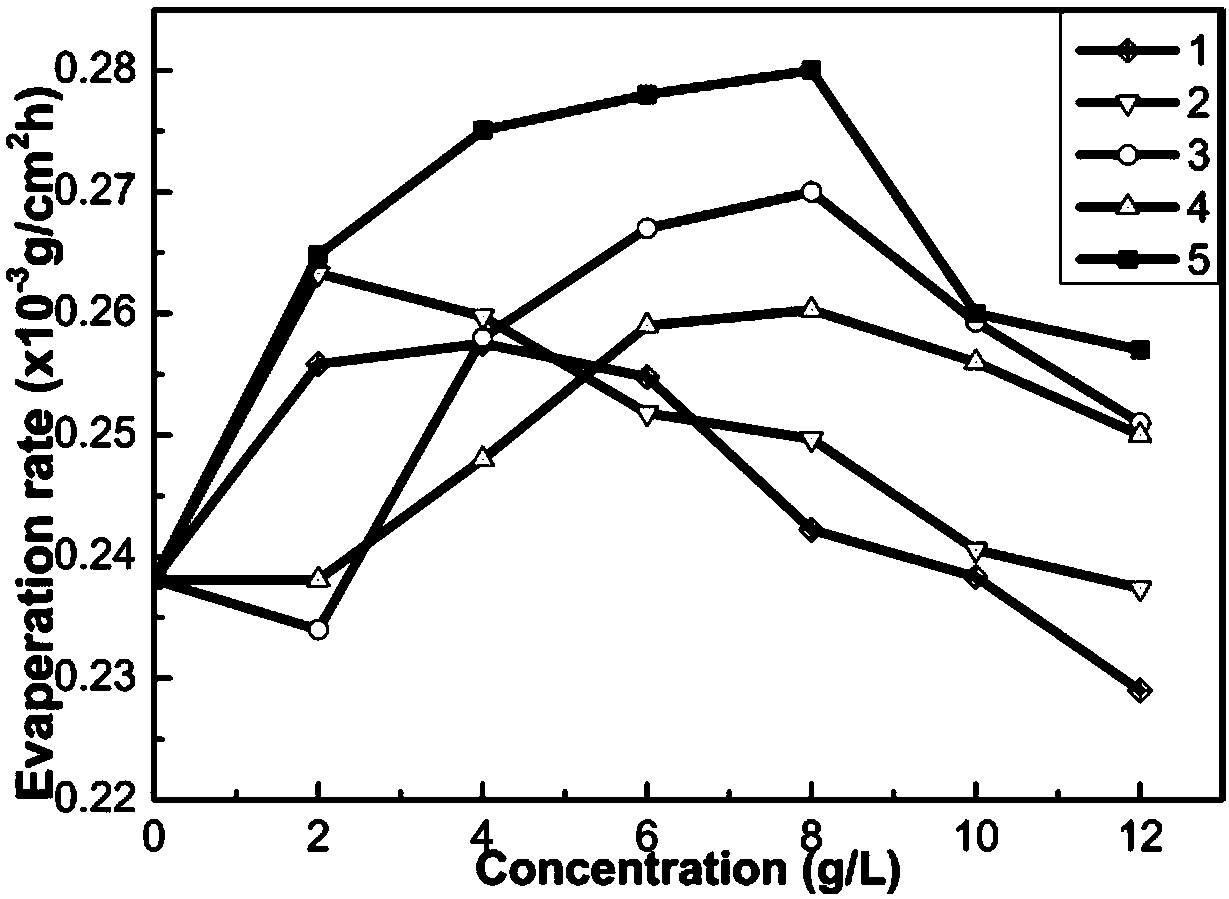

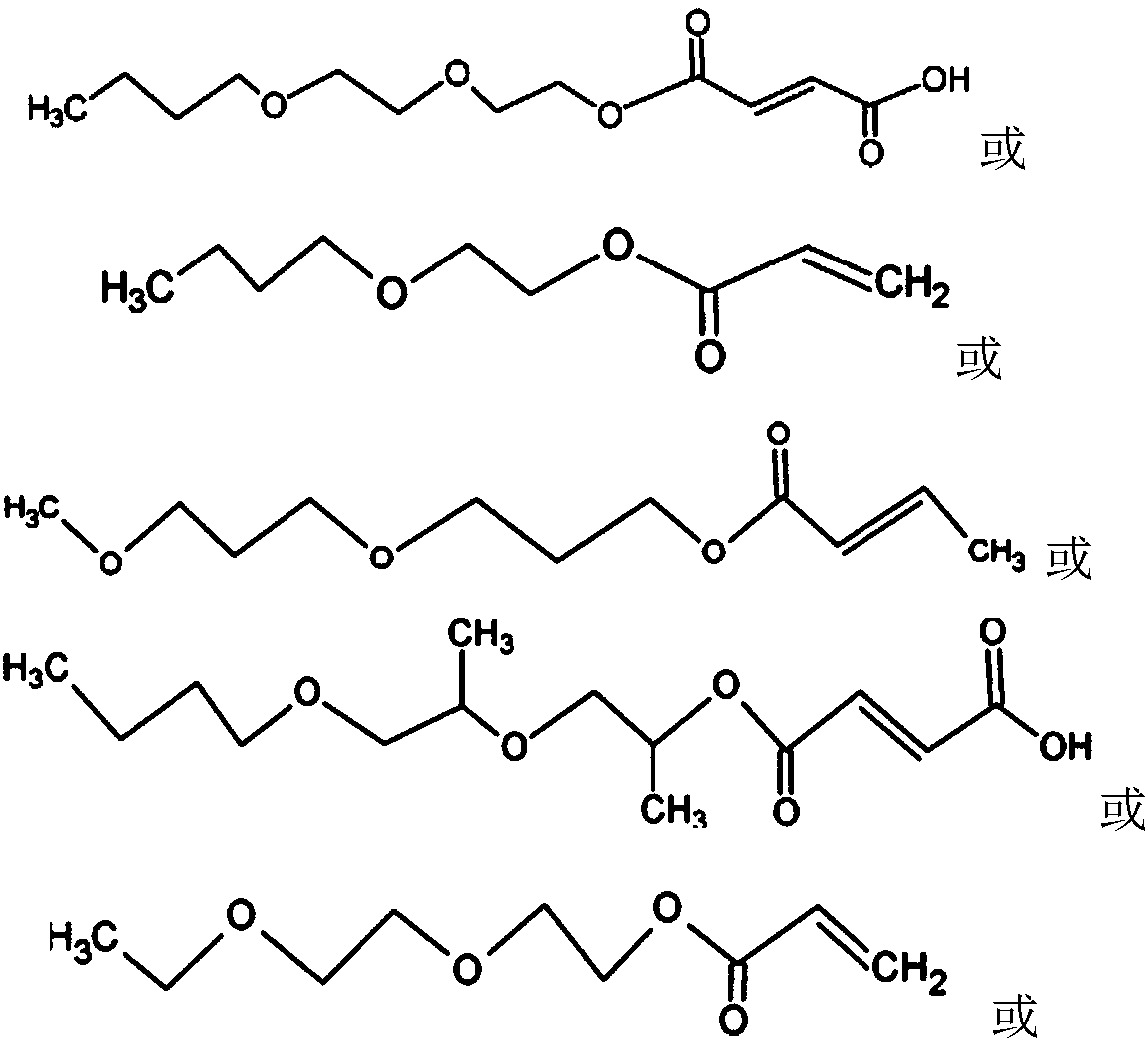

Reduced-type polycarboxylic acid water reducer and preparation method thereof

The invention relates to a reduced-type polycarboxylic acid water reducer and a preparation method thereof. An esterification method is employed for synthesizing a reduced monomer having a low surfacetension, and the reduced polycarboxylic acid water reducer is prepared through polymerization; acid anhydride or unsaturated carboxylic acid and ethers molecules are subjected to an esterification reaction to prepare the reduced monomer under effect of a catalyst, and then the reduced monomer, nonsaturated polyoxyethylene ether, unsaturated carboxylic acid or a mixture of unsaturated carboxylic acid or its acid anhydride, and a molecular weight conditioning agent are subjected to a free radical copolymerization reaction under effect of an initiator. The method has the advantages of easy control, high yield, low cost, environmental protection, and no pollution. During a polymerization process, a reduced group is introduced, so that the water reducer has low surface tension, an anchoring group is introduced, has good cement slurry-cleaning fluidity under common doping, reduces the surface tension force of a cement aperture solution, and reduces evaporation rate of the solution so as toeffectively reduce the mortar contraction. The obtained water reducer presents good water-reducing and reduction characteristic.

Owner:BEIJING UNIV OF TECH

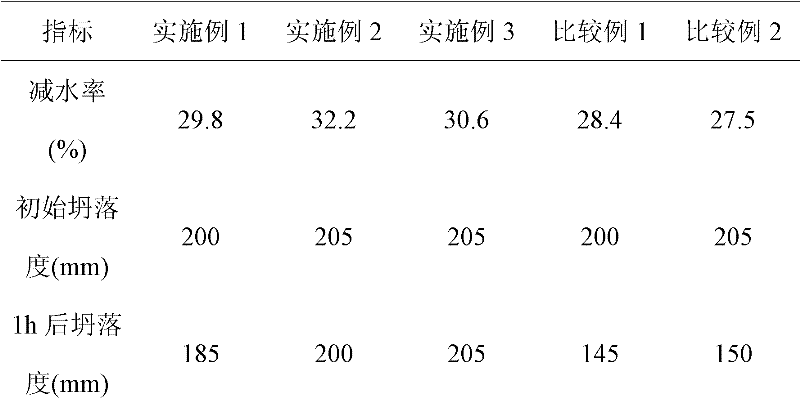

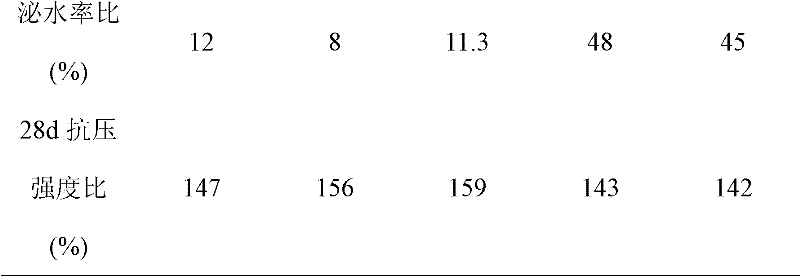

Polycarboxylene high-performance water reducing agent and preparation method thereof

The invention provides a polycarboxylene high-performance water reducing agent, which is obtained by copolymerization of following monomer components: ester macro monomer, ether macro monomer, micro-molecule monomer and bulking agent. The invention also discloses a preparation method of the polycarboxylene high-performance water reducing agent. The polycarboxylene high-performance water reducing agent of the invention not only can show good adaptability for different concrete construction materials, but also reduces usage of a retarder, improves water-reducing rate, and has good bleeding rate and compressive strength rate. The product has more stable quality; the shortcomings that the polycarboxylene product in the prior art has single type and narrow adaptability is overcome.

Owner:湖北恒利建材科技有限公司

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

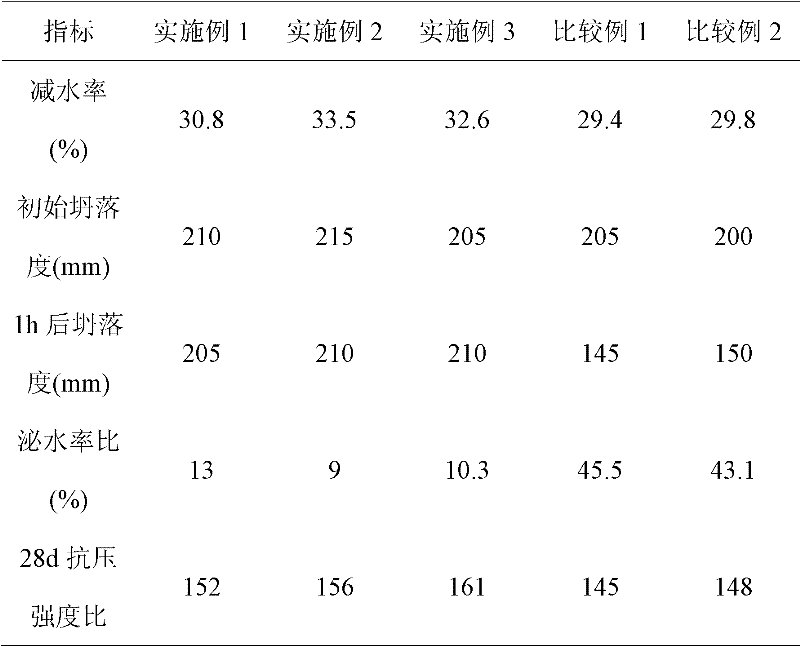

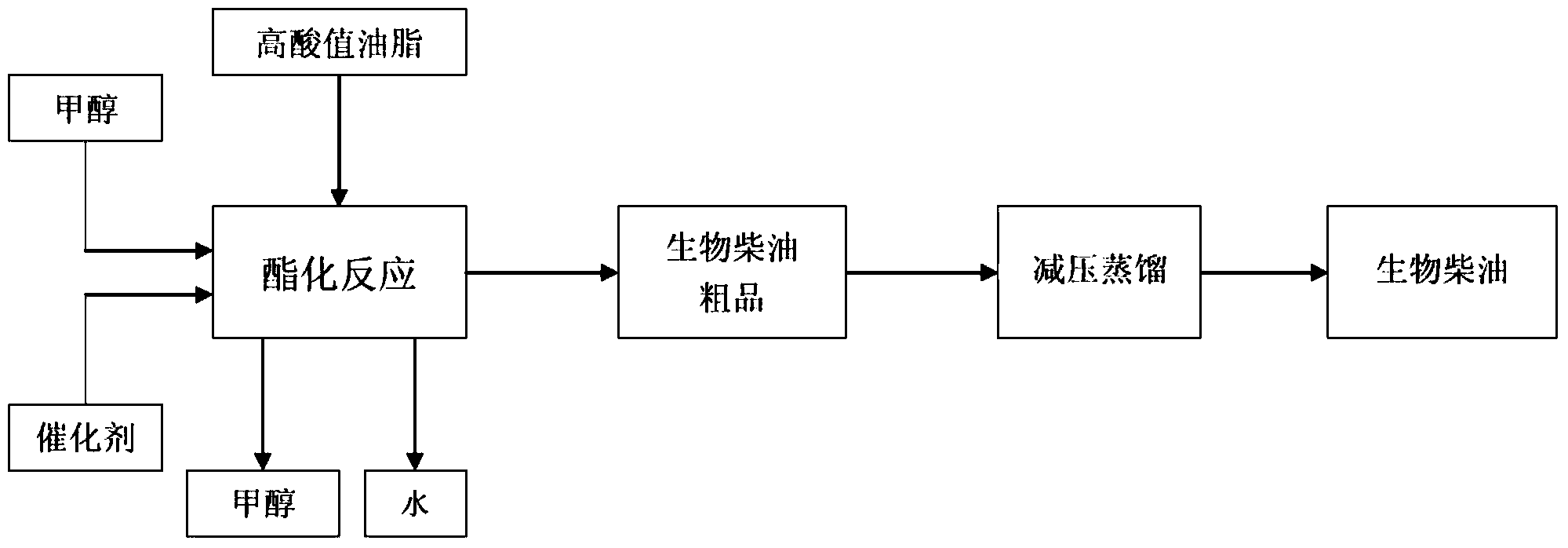

Method for preparing biodiesel through high-temperature esterification reaction of high acid value oil

ActiveCN103710155AIncrease productionHigh esterification rateFatty acid esterificationBiofuelsProcess engineeringOil and grease

The invention discloses a method for preparing biodiesel through high-temperature esterification reaction of high acid value oil, belonging to the technical field of biodiesel preparation. The method comprises the following steps: (1) esterification reaction, adding the high acid value oil and a catalyst into an esterification reactor, dripping methanol into the esterification reactor by using a dripping device for esterification reaction, meanwhile, cooling unreacted methanol and moisture generated in reaction by using a condensing device, and after the reaction is finished, removing the methanol and the moisture through distillation to obtain a biodiesel crude product; and (2) distillation treatment, distilling the obtained biodiesel crude product under reduced pressure, and collecting fraction, namely a biodiesel finished product. The method disclosed by the invention realizes the one-step esterification reaction of the high acid value oil under the conditions of normal pressure and high temperature, and the esterification process and the water cooling and removal are carried out simultaneously for the preparation of the biodiesel, so that the method has the advantages of easy process, short production cycle, low energy consumption and the like, is easy to industrially produce, and can significantly increase the yield of the biodiesel per unit time and the output of a single kettle.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

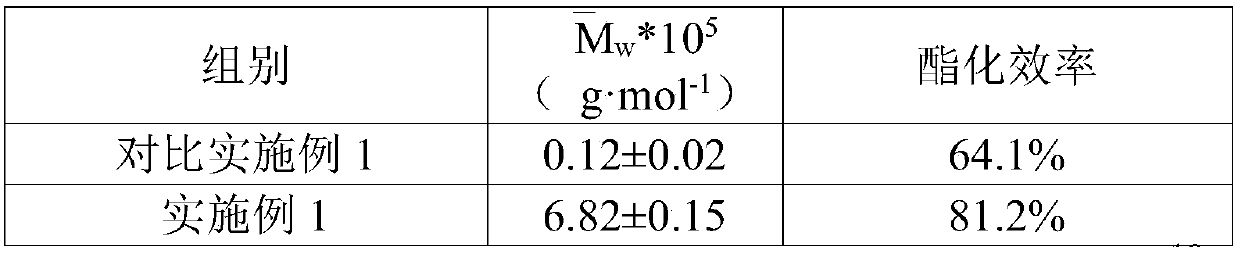

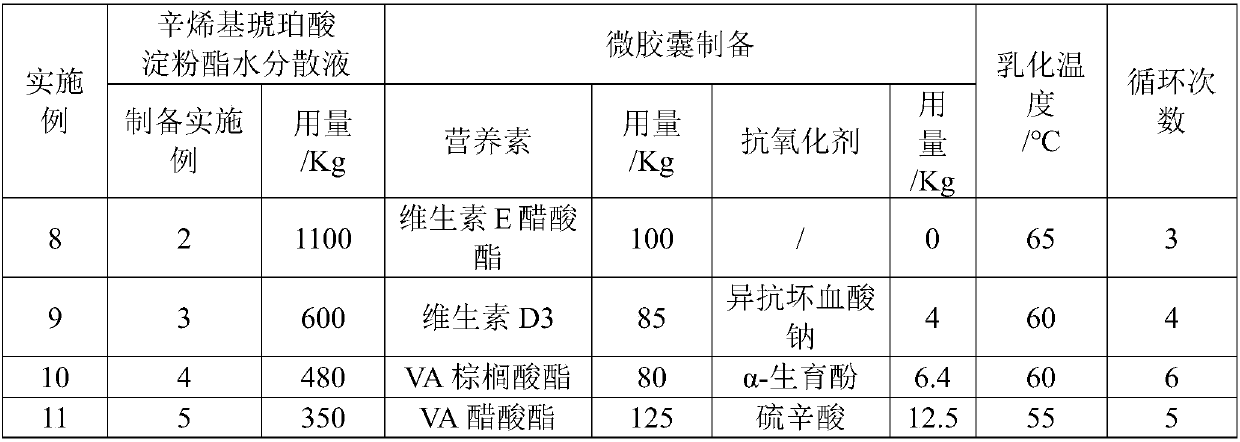

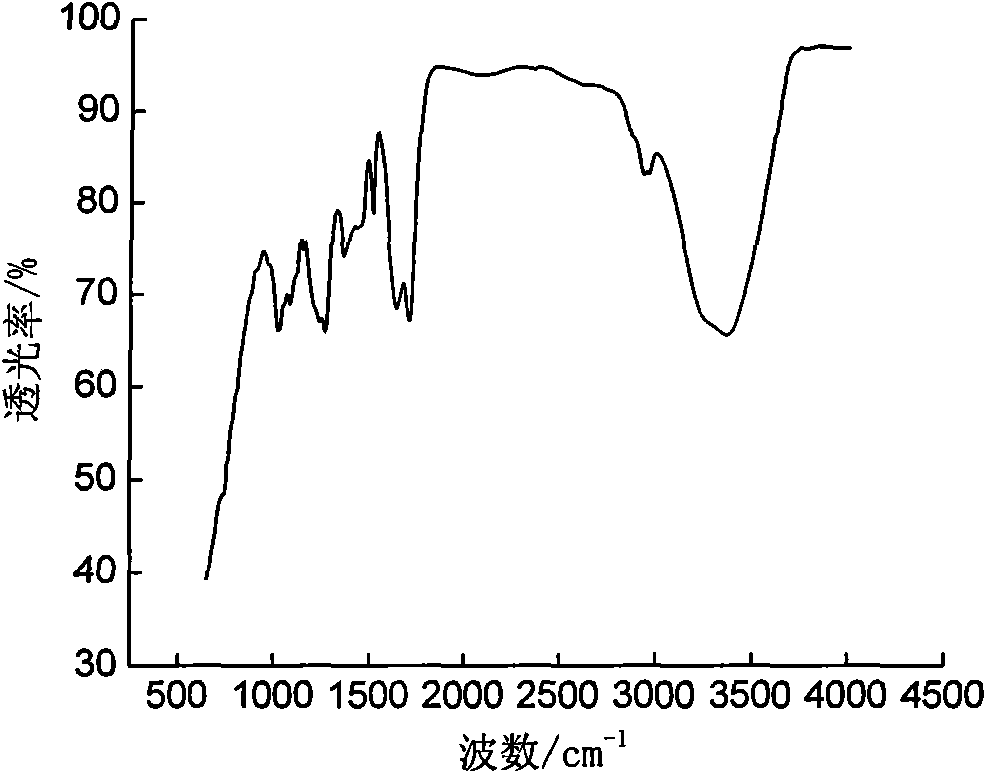

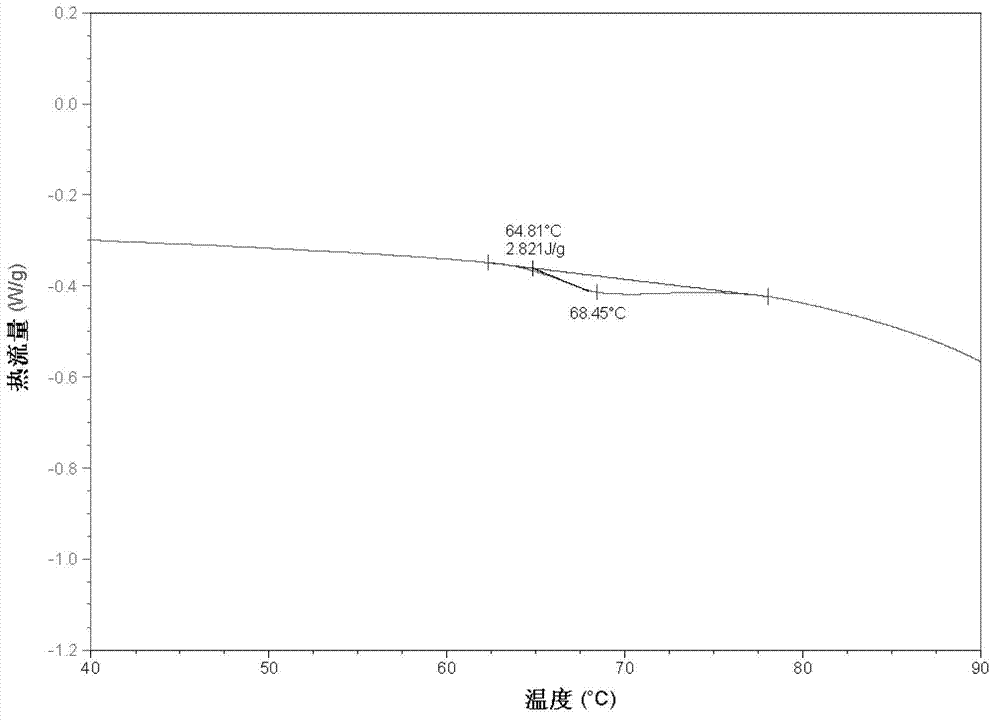

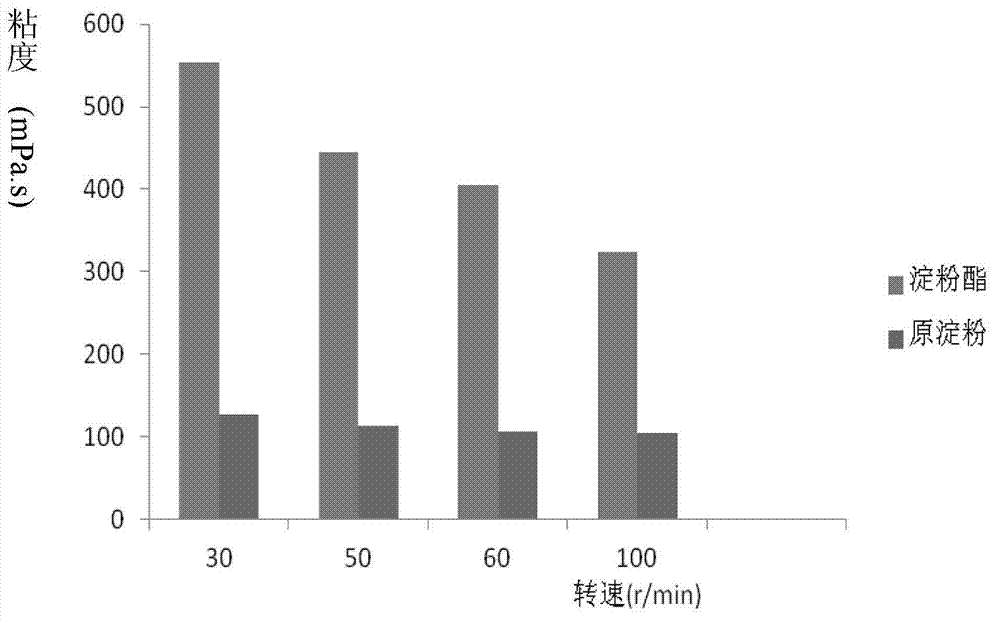

Octenyl succinic acid starch ester, lipid-soluble nutrient microcapsule as well as preparation method application of lipid-soluble nutrient microcapsule

ActiveCN109517080AHigh esterification rateGood emulsifying effectAccessory food factorsFood ingredientsChain lengthSuccinic acid

The invention relates to octenyl succinic acid starch ester, a lipid-soluble nutrient microcapsule as well as a preparation method application of the lipid-soluble nutrient microcapsule. A preparationmethod of octenyl succinic acid starch ester comprises the step of carrying out esterification reaction on gelatinized starch and octenyl succinic anhydride in a cavitation emulsification process, soas to obtain octenyl succinic acid starch ester. According to the preparation method, the esterification reaction is promoted and intensified by virtue of the cavitation emulsification process, remarkably substitution occurs in a crystallization region and an amorphous region of the starch through the molecular collision of the collision between gelatinized starch and octenyl succinic anhydride,so that the esterification rate of prepared octenyl succinic acid starch ester is increased, and the emulsifying property is greatly improved. The method is rapid and efficient, and a hydrolysis stepis omitted after the esterification, so that the problems that molecular chains are damaged in different degrees due to the hydrolysis, the chain length and content of amylose are remarkably decreased, the compactness of a film formed by octenyl succinic acid starch ester is decreased, and the film easily absorbs moisture and conducts heat and is crispy are avoided, and the application performanceof octenyl succinic acid starch ester is improved.

Owner:ZHEJIANG UNIV +2

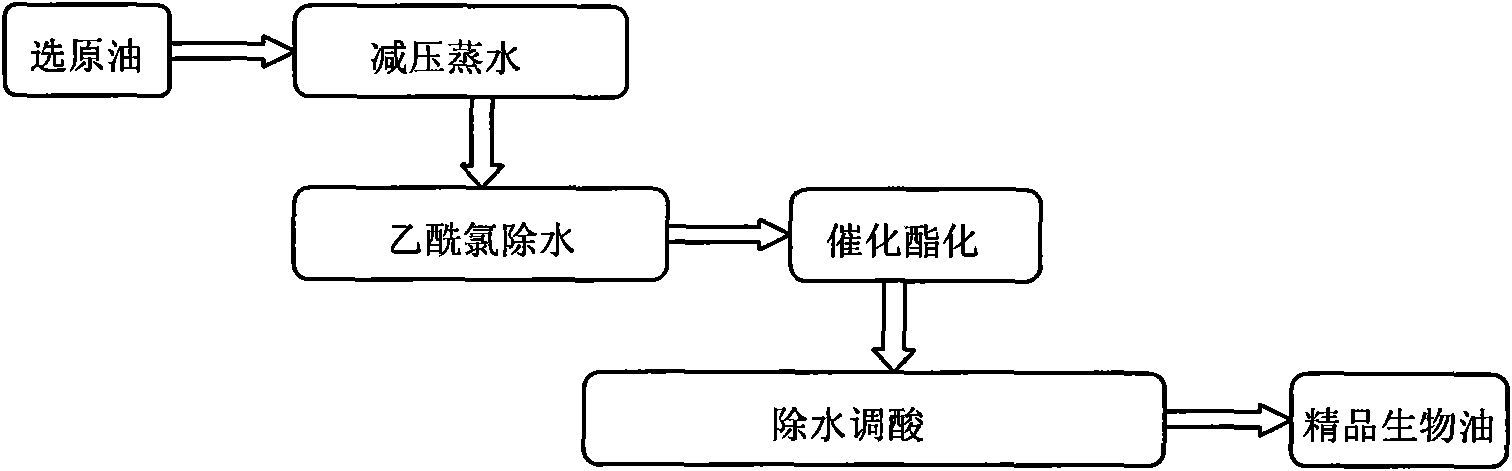

Biomass pyrolysis oil refining method

InactiveCN101899334AWith surfactantRaise the pHLiquid carbonaceous fuelsHydrocarbon oils treatmentWater bathsMass ratio

The invention belongs to the technical field of biomass energy conversion, and relates to a biomass pyrolysis oil refining method. The method comprises the following steps: mixing biological oil stock solution and isooctyl alcohol in the volume ratio of 5:1, adding 2-10 zeolite grains, keeping the low vacuum of 0.02 Mpa, and distilling under reduced pressure in a 80 DEG C water bath until no water can be distilled off, thereby obtaining low-water biological oil; during magnetic stirring, adding equal volume of acetyl chloride to react until no bubbles burst out, thereby obtaining anhydrous biological oil; calculating the generation amount of acetic acid according to the amount of the anhydrous biological oil, adding ethanol to acetic acid in the mol ratio of 2.8:1, mixing catalyst and theanhydrous biological oil in the mass ratio of 1:35, adding 2-10 zeolite grains, stirring, heating for back flow at 80 DEG C, and esterifying to obtain the esterified biological oil; adding anhydrous magnesium sulfate to esterified biological oil in the mass ratio of 1:5 to dehydrate and regulate the acidity; and filtering under reduced pressure to remove solid, thereby obtaining the refined biological oil. The invention has the advantages of simple process route, favorable dehydration effect and high product yield.

Owner:QINGDAO UNIV

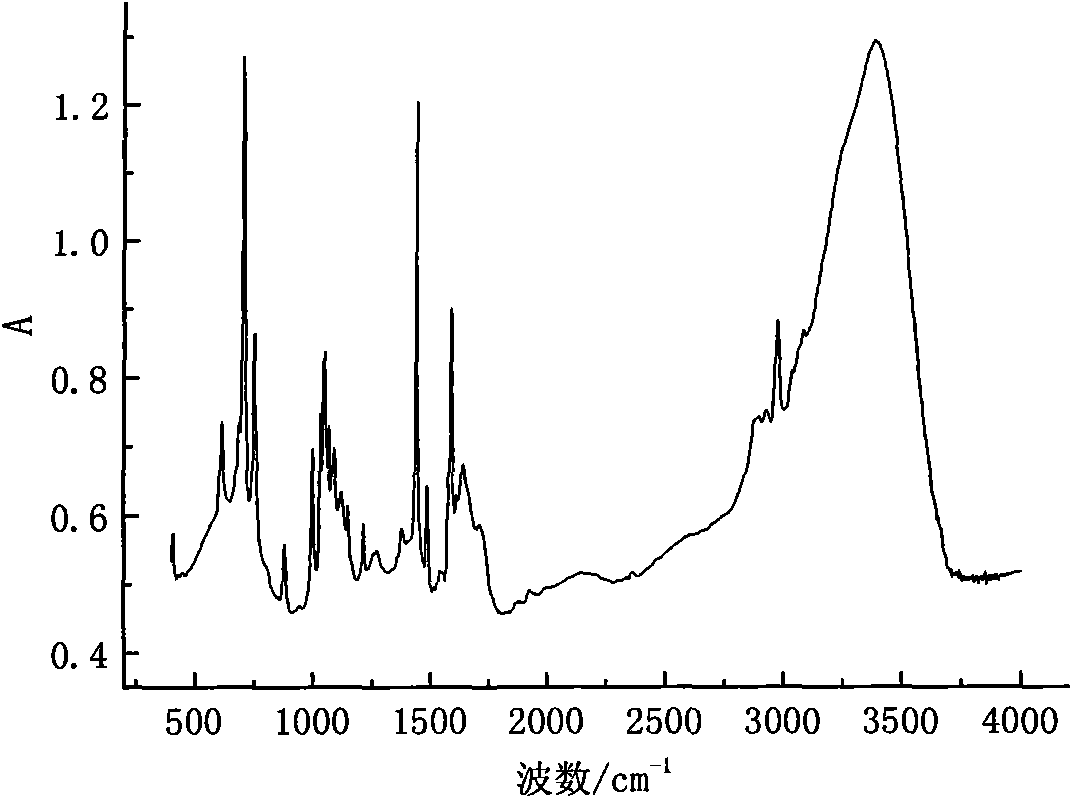

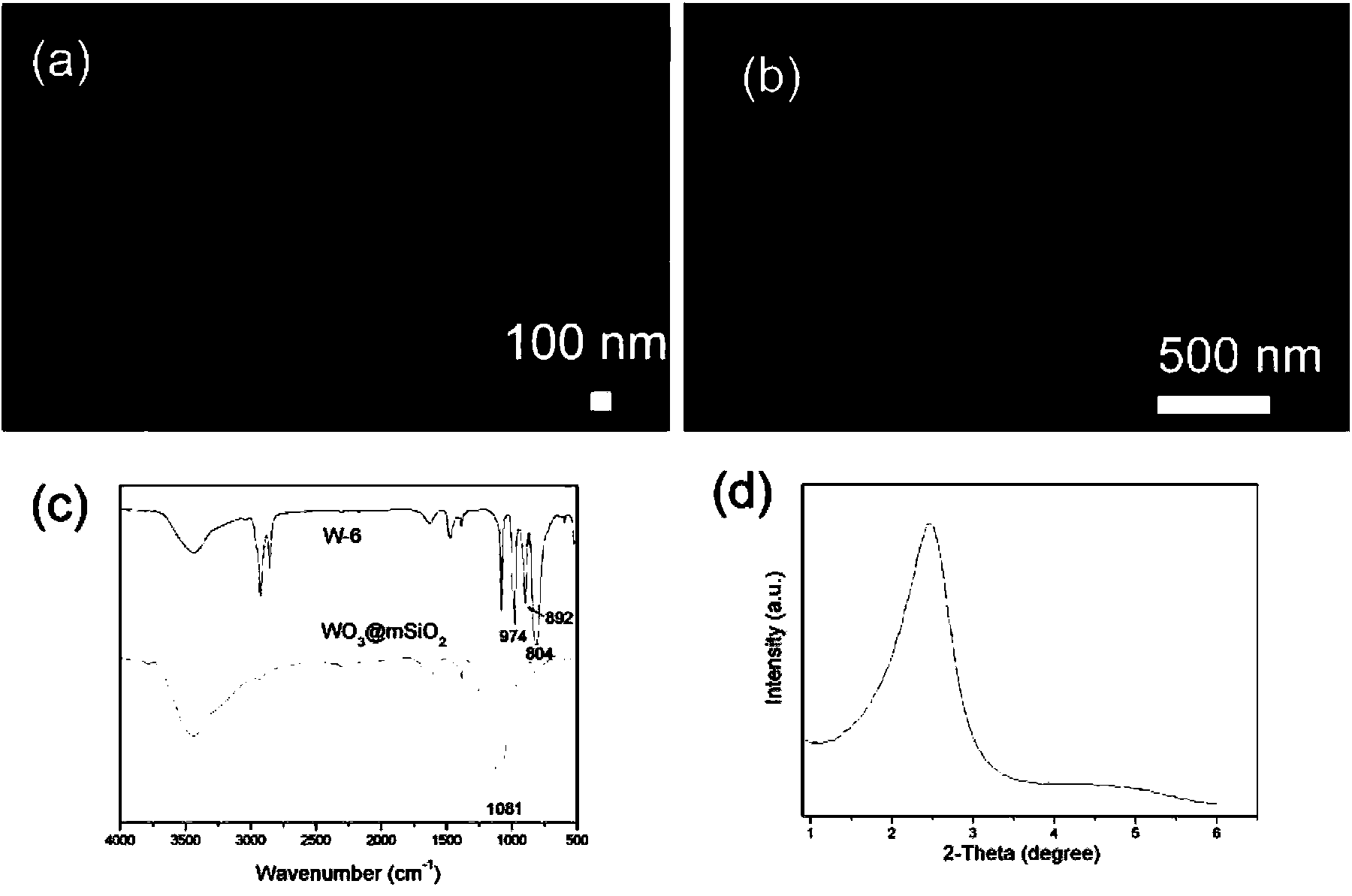

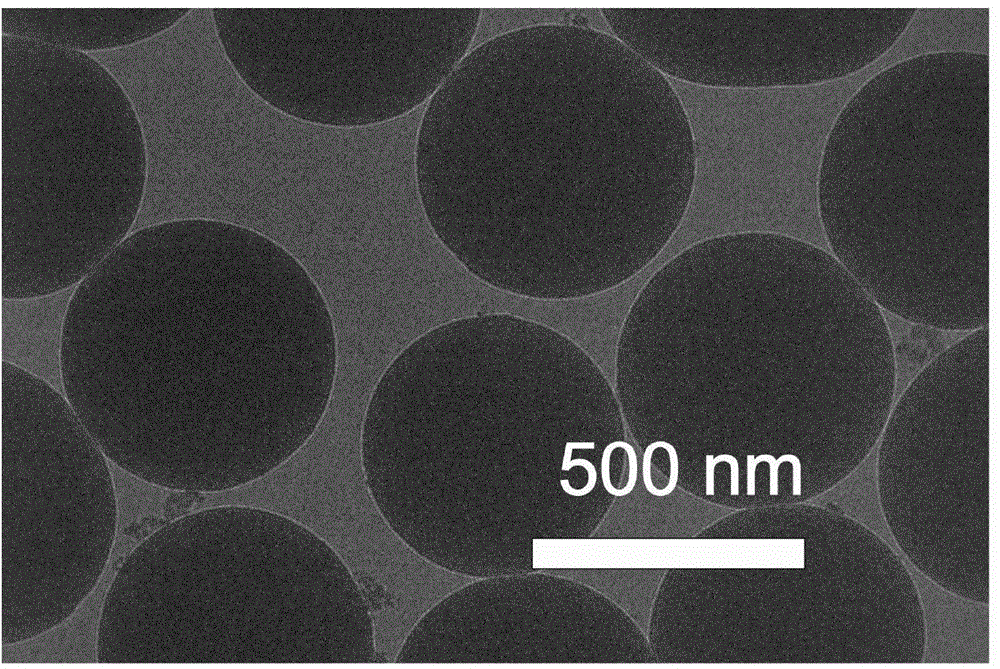

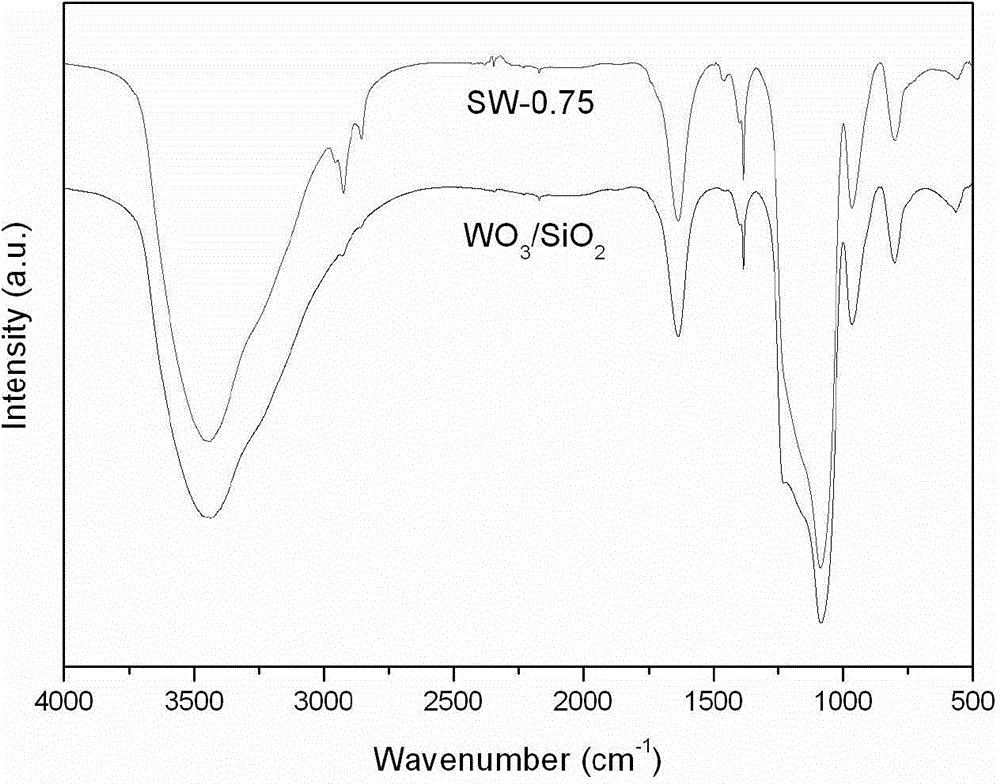

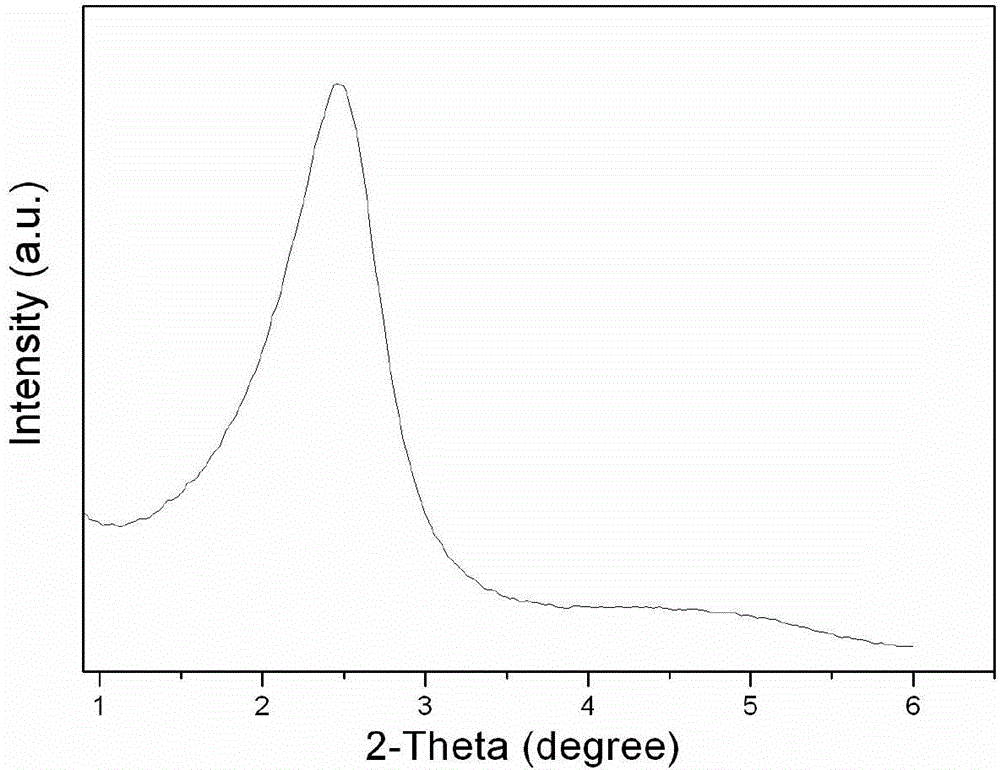

WO3@mSiO2 microballoon sphere with nuclear shell hollow structure as well as preparation method and application thereof

ActiveCN103433032AHigh esterification rateInhibit aggregationFatty acid esterificationOrganic compound preparationDispersityBiodiesel

The invention discloses a prepared WO3@mSiO2 microballoon sphere as well as a preparation method and an application thereof, belonging to the technical field of preparation of nano materials. The preparation method comprises the steps of utilizing hexadecyl trimethyl ammonium phosphotungstate as a nucleus and covering one layer of SiO2 by adopting a sol-gel method; then calcining to obtain the WO3@mSiO2 microballoon sphere with a nuclear shell hollow structure. The WO3@mSiO2 microballoon sphere is good in dispersity, has a grain diameter of 500nm-600nm and has the nuclear shell hollow structure; the nucleus is WO3 and the shell is porous SiO2. The microballoon sphere has a very good catalytic effect on an esterification reaction for synthesizing methyl oleate (biodiesel) by taking oleic acid and methanol as raw materials; the reaction temperature is 90 DEG C and the reaction time is 8 hours; the mass ratio of the oleic acid to the methanol is 1 to 5.2; the esterification rate of the oleic acid can be up to 97.6% under the condition that the use amount of a catalyst is 36% of the mass of the oleic acid.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

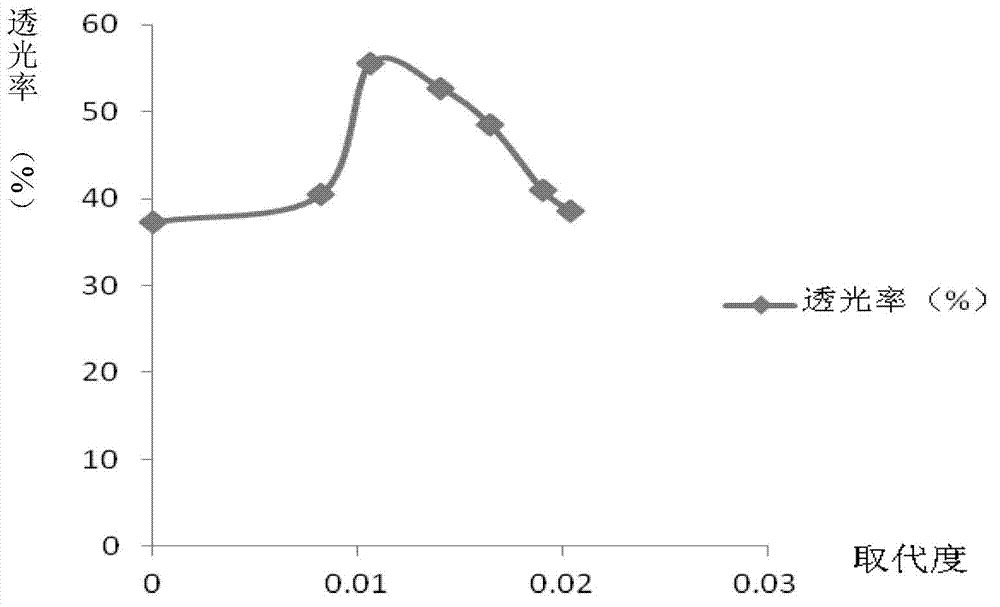

Method for preparing cassava starch octenyl succinate by sub-gelatinization technology

The invention provides a method for preparing cassava starch octenyl succinate by a sub-gelatinization technology. The method comprises the following steps of: adding cassava starch into an ethanol solution with concentration of 45-65% by volume; gelatinizing at 60-85 DEG C for 1-3 hours while stirring to obtain sub-gelatinized cassava starch emulsion; in a condition with pH value of 7.2-9.2, adding the octenyl succinic anhydride diluted by an organic solvent into the sub-gelatinized cassava starch emulsion to enable esterification reaction; and processing the reaction product to obtain the cassava starch octenyl succinate. According to the method provided by the invention, the raw materials are widely available, and the cost is low; moreover, the technology is simple, the gelatinization degree of starch is proper, the esterification reaction is uniform, and the reaction efficiency is high; and the prepared cassava modified starch has high esterification substation degree and relatively good transparency, thickening property and emulsifying property.

Owner:ZHEJIANG UNIV

Method for fine purification of lactic acid

InactiveCN101492367AHigh esterification rateAchieve complete esterificationOrganic compound preparationChemical industryHigh energyReboiler

The invention relates to a method for refining lactic acid by cation resin column bed catalysis and reactive rectification technology. The method solves the problems that the traditional esterification-hydrolysis technology uses concentrated sulfuric acid as a catalyst, thereby causing the environmental pollution, and high energy consumption, etc. Crude lactic acid after the pretreatment and concentration is subjected to the esterification reaction with methanol or ethanol by a cation resin column; then a mixture after the esterification reaction is subjected to reduced pressure distillation to obtain a mixture A of methyl lactate or ethyl ester, the methanol or the ethanol, water and the like and a distillation residue B; and B is mixed with the methanol or the ethanol and introduced into the cation resin column to take the esterification reaction. Subsequently, A is mixed with deionized water and introduced into the other cation resin column to be hydrolyzed to obtain a hydrolysis mixture C. The hydrolysis mixture C is introduced into a reaction rectifying tower to continue hydrolysis, the methanol or the ethanol is eluted from the top of the tower, lactic acid aqueous solution is obtained from a reboiler, and a high purity lactic acid product is obtained after concentration and can reach (Chinese and American) pharmacopoeia grade standard.

Owner:HEFEI UNIV OF TECH

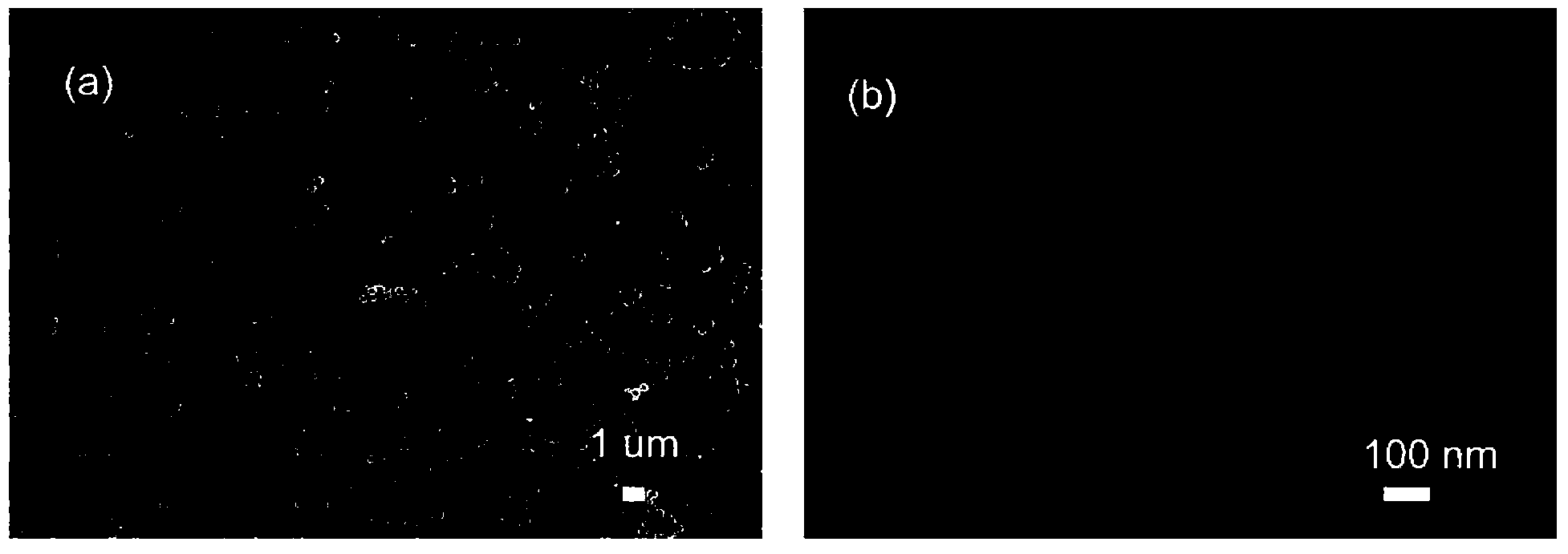

Acidified mesoporous WO3/SiO2 multi-component colloidal sphere and application thereof

ActiveCN104056643AHigh catalytic efficiencyReduce pollutionPhysical/chemical process catalystsOrganic compound preparationLong chain fatty acidAlcohol

The invention discloses an acidified mesoporous WO3 / SiO2 multi-component colloidal sphere, belonging to the field of chemical catalysts. An active component of the colloidal sphere is SO4<2-> / WO3 / SiO2 of which the structure is like a colloidal sphere; the active component has a mesoporous structure and is high in dispersion property; the particle size is 100-900nm, and the aperture is 3-5nm. The acidified mesoporous WO3 / SiO2 multi-component colloidal sphere disclosed by the invention is used as the catalyst; during catalysis of the esterification reaction between different long-chain fatty acids and alcohols, the acidified mesoporous WO3 / SiO2 multi-component colloidal sphere is excellent in catalyst performance and high in stability. During esterification reaction in which the long-chain fatty acids are oil acids and the alcohols are methanol, and when the using amount of the colloidal sphere catalyst is 3 percent, the esterification rate of the oil acid can reach 97.0 percent; after the oil acids are continuously and cyclically used for 5 times, the conversion rate of the oil acids can be still kept at about 97 percent.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

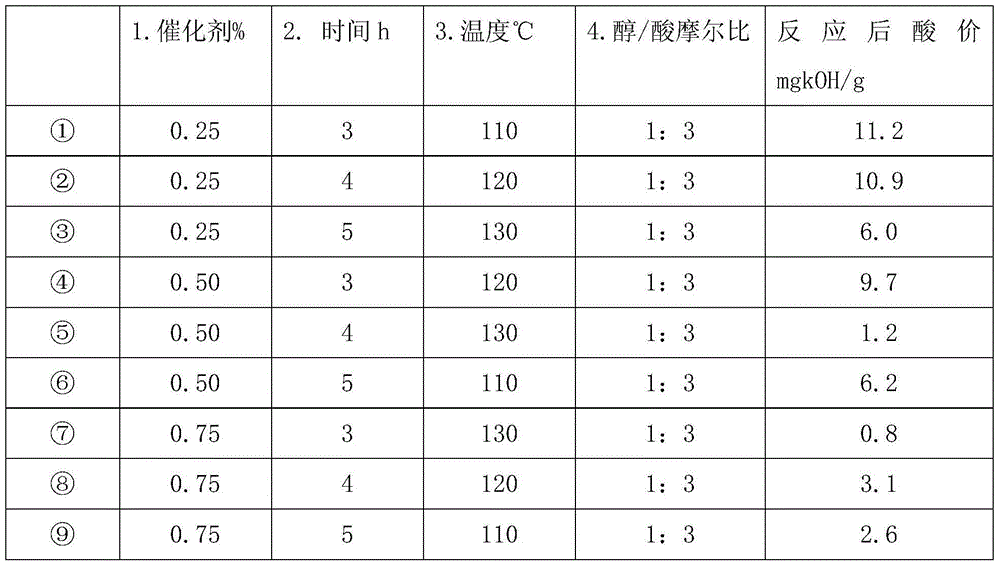

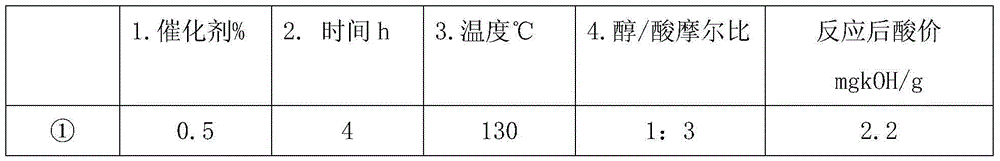

Synthesis of trimethylolpropane organic acid ester and application in special oil

ActiveCN104672085AAdd lessShort reaction timeOrganic compound preparationCarboxylic acid esters preparationOctanoic AcidsSynthesis methods

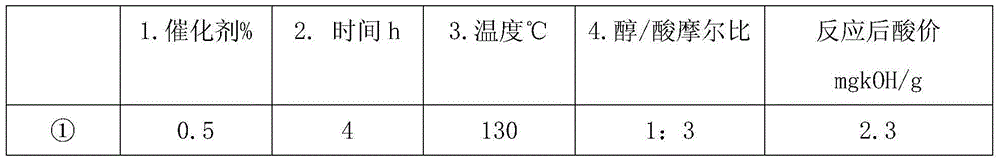

The invention discloses a synthesis method of trimethylolpropane organic acid ester, which is characterized by comprising the following steps of: taking organic acid and organic alcohol as raw material, further adding proper amount of catalyst, reacting for 3-5 hours under normal pressure at 110-130 DEG C, thereby obtaining the trimethylolpropane organic acid ester; the organic acid is selected from any one of Oleic acid, lauric acid, octanoic acid, stearic acid and palmitic acid, the organic alcohol is trimethylolpropane, and molar ratio of organic acid to organic alcohol is 1:3; the catalyst is N-alkyl pyrrolidone group methyl phosphate ion liquid catalyst. In the synthesis method, the N-alkyl pyrrolidone group methyl phosphate ion liquid catalyst is selected for synthesizing the trimethylolpropane organic acid ester, the synthesis method has the characteristics of low reaction temperature, small dosage of catalyst, short reaction time, high esterification rate, and so on, and products produced by the synthesis method has small acid value.

Owner:NEUFTECH BIOTECH HEFEI

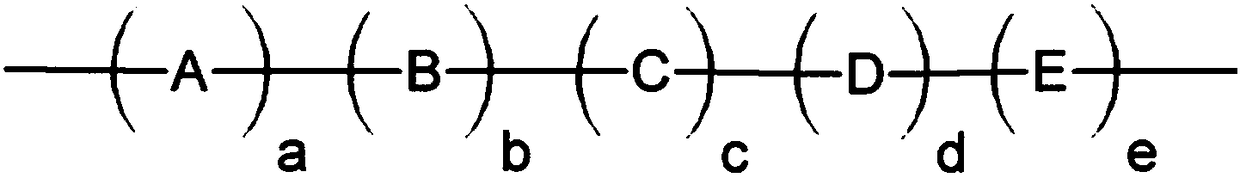

Preparation method of super-sustained release ester-ether crosslinking polycarboxylic acid water reducer

ActiveCN102660037AHigh esterification rateGood slump performancePolymer science(Hydroxyethyl)methacrylate

A preparation method of a super-sustained release ester-ether crosslinking polycarboxylic acid water reducer is provided. The method which combines synthesis of an ester water reducer and synthesis of an ether water reducer allows the polycarboxylic acid water reducer synthesized from large monomers containing different chain lengths and simultaneously containing long side chains and short side chains to be researched and developed, and the method which can guarantee good dispersity and good fluidity keeping ability brings conveniences for the concrete construction process. In the esterification reaction process, hydroxyethyl methacrylate is introduced to increase active hydroxy side chains, and the activity of methacrylic acid is effectively controlled, so the esterification rate of a reaction system is high, product performances are high, and the synthetic method of optimized ester polycarboxylic acid water reducer intermediates is researched and developed through utilizing above principles. A certain synergistic effect is reached by introducing high activity ester monomers in the copolymerization process and combining the long side chains and the short side chains of produced polycarboxylic acid, so performances of the ester-ether crosslinking polycarboxylic acid water reducer of the invention are better than the performances of common ester and ether polycarboxylic acids, and the water reducing rate and the fluidity keeping ability are improved.

Owner:湖南加美乐素新材料股份有限公司

Compounding method of allyl polyoxyethylene methyl acrylate

The invention discloses a compounding method of allyl polyoxyethylene methyl acrylate, which uses propyl ethylene polyoxyethylene and crylic acid as raw materials. The raw materials are subjected to esterification reaction under the function of a toluenesulfonic acid catalyst and a thiodiphenylamine polymerization resistor, and air dried by silicon gel is supplied to bring out the water generated by the reaction. The invention has the advantages that in the reaction process, the dried air is used for bringing out the water generated by the reaction, the reaction cost is effectively lowered, wet air is discharged, and the environmental pollution is avoided; the paratoluenesulfonic acid is used as the catalyst, the thiodiphenylamine and the oxygen molecules in the air are used as the polymerization resistor, the reaction condition is reasonable, the reaction time is short and the process is simple and easy to control; the allyl polyoxyethylene methyl acrylate compounded by the method has the characteristics of high unsaturation degree, high esterification degree, high reaction activity, and the like, and is suitable for the compounding field of high-performance polycarboxylic-acid water reducer.

Owner:JIAHUA CHEM +1

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979BExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSuperplasticizerCarboxylic acid

This invention relates to a method for preparing a star-shaped polycarboxylate superplasticizer by the first esterification step with polyol and (meth)acrylic acid as main reactants and the second polymerization step. In the first step, the star-shaped polymerizable active ends were synthesized by esterification between polyol and (meth)acrylic acid in the presence of catalyst. In the second step, the final star-shaped polycarboxylate superplasticizer was prepared by radical polymerization among the product obtained in first step, unsaturated polyoxyethylene ethers, molecular weight regulator and unsaturated carboxylic acid in the presence of initiator. The production process of this invention exhibits some characteristics including simple, easily controllable, high polymerization degree, low cost and pollution free. The star-shaped molecular structure of polycarboxylate superplasticizer can be achieved through synthesizing active “core” by esterification and “arm” by radical polymerization. It showed better cement paste fluidity and fluidity retention, which manifested as better adaptability to cement and application performance in concrete, than both traditional linear and comb-shaped polycarboxylate superplasticizer at common or lower dosage.

Owner:GUIZHOU DR SHI TECH

Method for synthesizing phenylalanine esterified bagasse xylan-g-CHMA (cyclohexyl methacrylate) with anti-tumor activity

InactiveCN109438622AImprove biological activityHigh grafting rateAntineoplastic agentsBulk chemical productionMethacrylateSide chain

The invention discloses a method for synthesizing phenylalanine esterified bagasse xylan-g-CHMA with anti-tumor activity. The method comprises taking bagasse xylan as the raw material, and in an ionicliquid of [Hemim]Cl, taking ammonium persulfate as an initiator and cyclohexyl methacrylate as grafting monomers to synthesize a bagasse xylan-g-CHMA derivative; taking Boc-L-phenylalanine as esterification agent and 4-dimethylaminopyridine as catalysts for catalytic esterification in ionic liquid solvent to synthesize a bagasse xylan esterified grafted derivative phenylalanine esterified bagassexylan-g-CHMA; performing deprotection through trifluoroacetic acid to obtain the product of the phenylalanine esterified bagasse xylan-g-CHMA. Under the reaction environment of the ionic liquid, themethod for synthesizing the phenylalanine esterified bagasse xylan-g-CHMA with the anti-tumor activity introduces active groups to the main chain and the side chain of bagasse xylan through grafting and esterification reaction, thereby enhancing the bioactivity of raw bagasse xylan; the prepared phenylalanine esterified bagasse xylan-g-CHMA has a broad application prospect in the fields of biologyand medicine.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Integrated process for synthesizing acetyl tributyl citrate (ATBC) from active carbon solid-carried sulphuric acid catalyst

ActiveCN102304045AEasy to separateAvoid pollutionPhysical/chemical process catalystsOrganic compound preparationActivated carbonAcetic anhydride

The invention relates to an integrated process for synthesizing acetyl tributyl citrate (ATBC) from an active carbon solid-carried sulphuric acid catalyst. The integrated process comprises the following steps of: (1) preparing the catalyst: immersing wooden active carbon in a 5-20 times of sulphuric acid solution, stirring and solid-carrying at normal temperature, and obtaining the active carbon solid-carried sulphuric acid catalyst after filtering and drying; (2) preparing TBC (Tributyl Citrate): reacting (hydrate) citric acid, n-butyl alcohol and the catalyst at 130-160 DEG C for 3.0-6.0 h, and dealcoholizing; and (3) preparing the ATBC: adding acetic anhydride into the TBC, reacting at 70-90 DEG C for 0.5-1.5 h, filtering a reaction solution after cooling, adding water, recycling acetic acid, and post-processing to obtain the ATBC finished product. According to the method disclosed by the invention, the catalyst is low in use amount and easy for being separated and recycled and also has decolourization function; after being dealcoholized, the TBC is unnecessary to be separated and the acylation reaction is directly carried out; the steps of refining the TBC, decolourizing and the like are saved; the three wastes (waste gas, waste water and industrial residue) are reduced obviously; the cost is reduced; the product yield is increased; and the integrated process is applied to industrial application.

Owner:NANJING UNIV OF TECH

Preparation method of thermal degradation-resistant degradation PBT polyester with high viscosity

The invention discloses a preparation method of thermal degradation-resistant PBT polyester with the high viscosity. The preparation method comprises the technology process that the thermal degradation-resistant PBT polyester with the specific viscosity of 1.25-1.35 L / g is finally prepared through slurry preparing, negative-pressure esterification reacting, pre-polycondensation reacting, low-viscosity final polycondensation reacting, chain-extension liquid-phase tackifying reacting and discharging and grain-sized dicing in sequence. According to the preparation method, by adopting lower negative pressure and longer esterification retention time in the esterification stage, the esterification rate of the esterification stage is effectively increased and reaches 99.5% or above, and the terminal carbonyl group content in melt of a consequent reaction is decreased; by controlling the reacting time and the melt viscosity in final polycondensation and adding a carboxyl-terminated chain extender in the liquid-phase tackifying stage, the terminal carbonyl group content in the melt is further decreased, the chain extending and tackifying effects are achieved, the effect of quickly achieving tackifying in short time is achieved, and the production efficiency is improved; the chain extender is stable in property, does not influence the product hue, is high in boiling point and cannot be taken away from a reaction system along with liquid-phase tackifying vacuumizing.

Owner:WUXI XINGSHENG NEW MATERIAL TECH

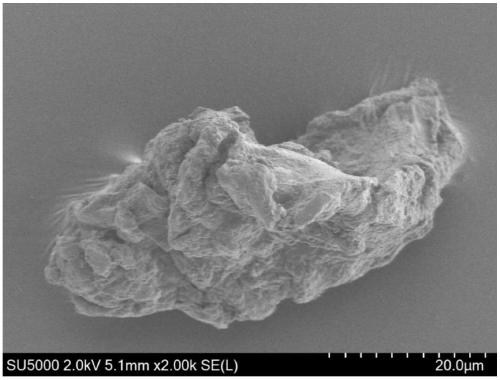

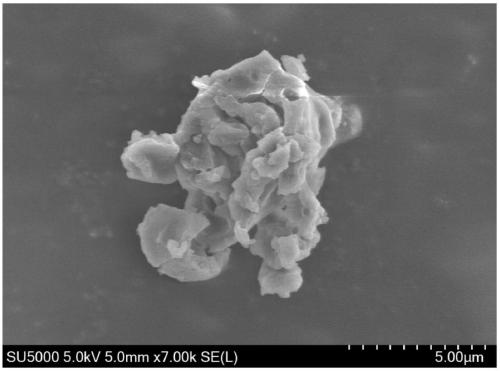

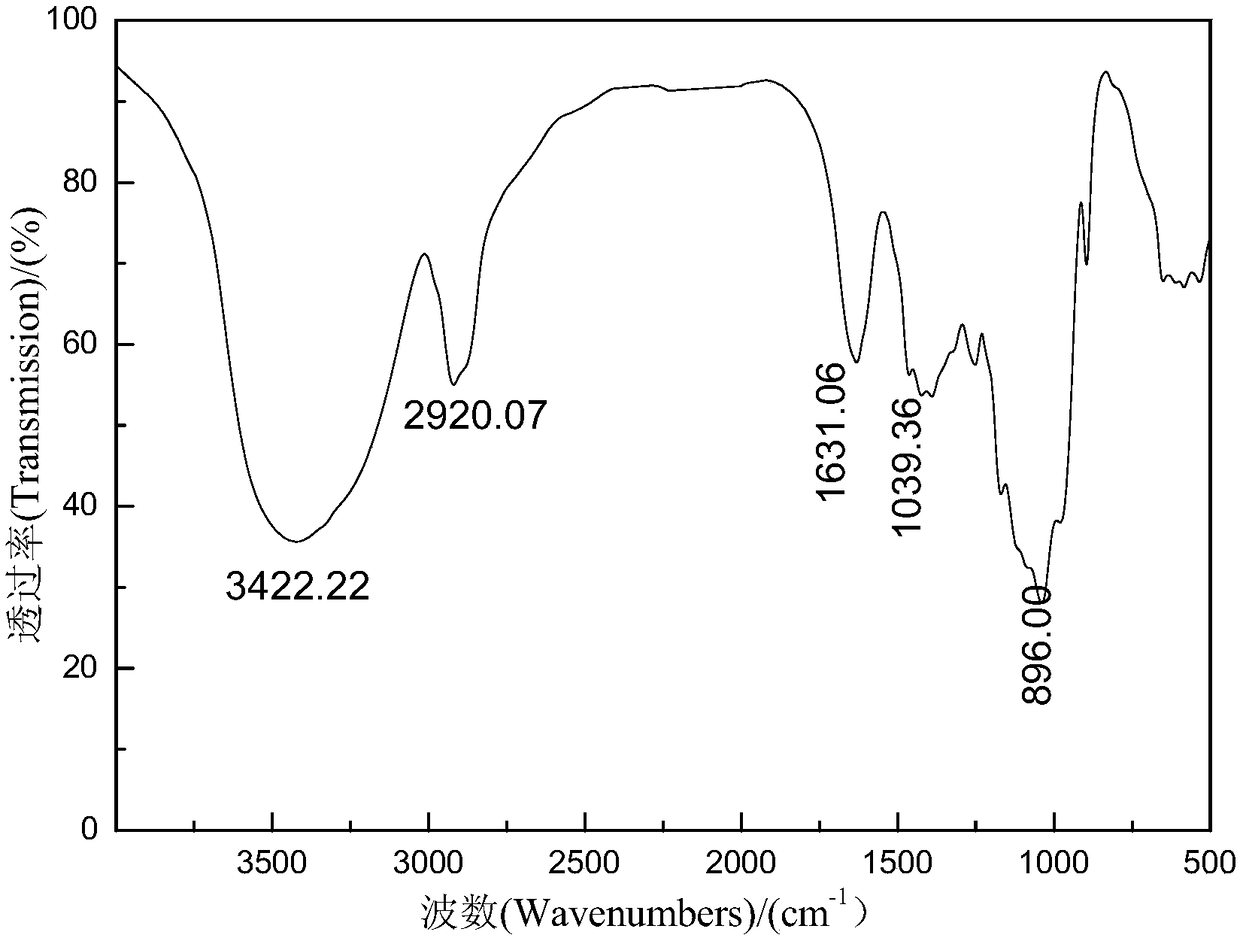

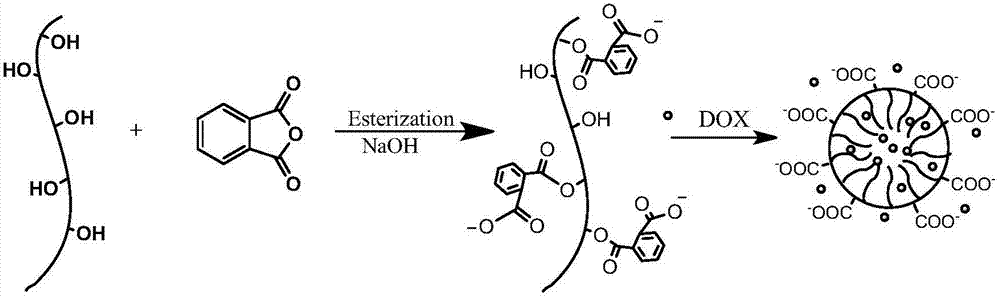

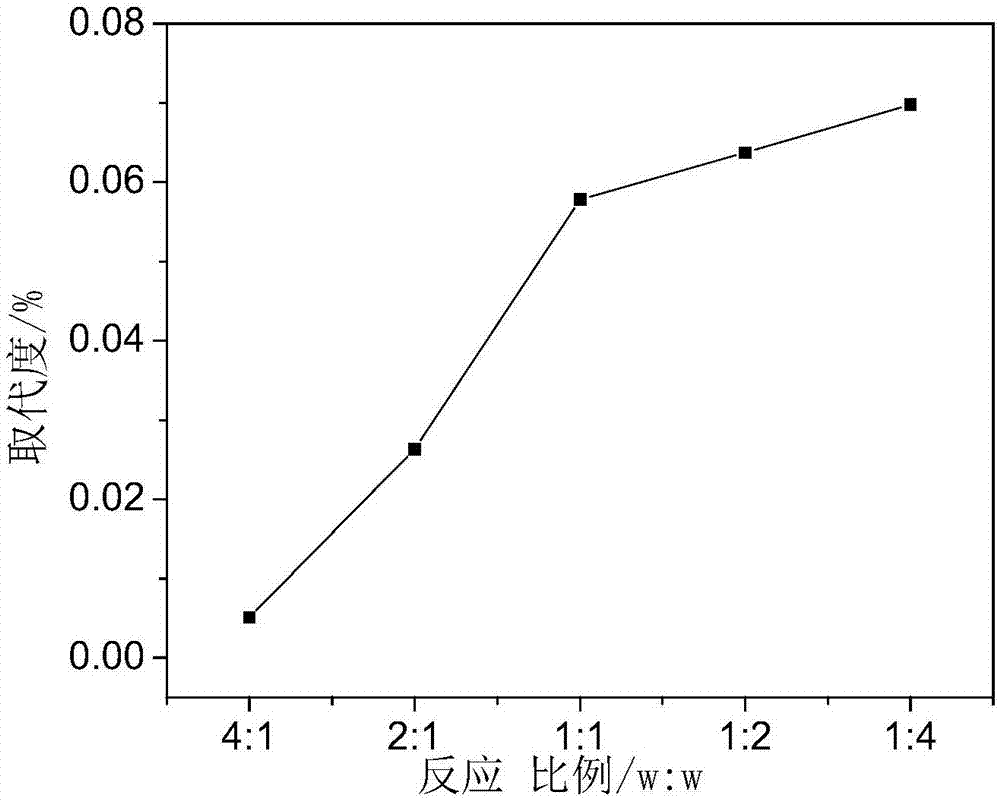

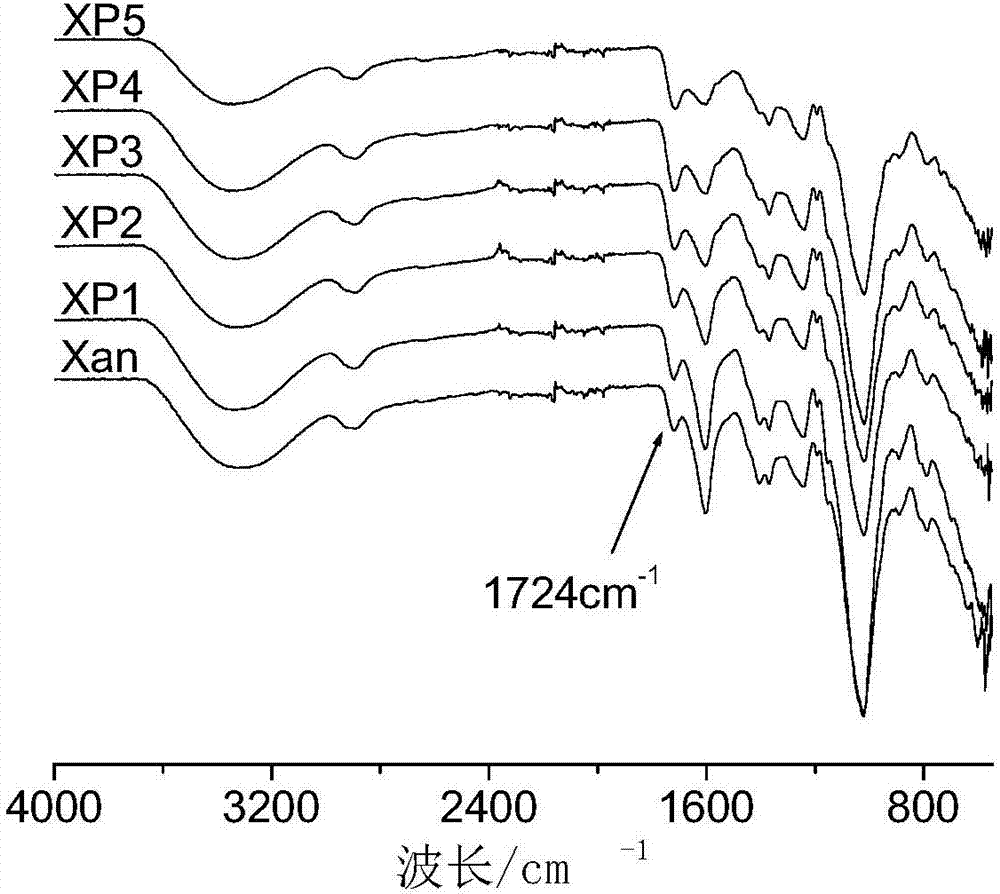

Modified xanthan gum nano-micelle preparation method

ActiveCN107308112ASimple and gentle reactionPost-processing is simpleOrganic active ingredientsPharmaceutical non-active ingredientsSolventAnti cancer drugs

The invention relates to the technical field of biological and medical materials, in particular to a preparation method of injection type modified xanthan gum nano-micelle. The preparation method comprises the steps: performing esterification reaction on phthalic anhydride and xanthan gum, preparing amphipathic modified xanthan gum polymer by a one-step method and then self assembling and preparing modified xanthan nano-micelle by a selective solvent method. The xanthan gum is anhydride modified, so that biocompatibility and oxidation resistance of the xanthan gum are improved. The xanthan gum nano-micelle has a hydrophobic cavity with a benzene ring and a hydrophilic outer layer of the xanthan gum, so that circulation stability of the nano-micelle in a biological body is improved; in addition, the modified xanthan gum contains carboxylic groups, so that the nano-micelle has certain pH response; a charge effect of the nano-micelle can also be utilized to load medicine doxorubicin, so that the medicine loaded nano-micelle has a certain slow-release function. The preparation method disclosed by the invention has simple synthetic steps and is green, and the nano-micelle can be completely degraded in the body and hopefully serves as a carrier of anti-cancer drug to control release.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com