Patents

Literature

577 results about "Methyl oleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl oleate is a fatty acid ester formed by the condensation of oleic acid and ethanol. It is a colorless to light yellow liquid. Ethyl oleate is produced by the body during ethanol intoxication. Ethyl oleate is used as a solvent for pharmaceutical drug preparations involving lipophilic substances such as steroids.

Spontaneous emulsions containing cyclosporine

A pharmaceutical composition contains cyclosporine as the active ingredient. More specifically, the composition is an orally administered pharmaceutical formulation in the form of a spontaneous emulsion comprising cyclosporine, ethanol ethyl oleate and polyoxyethylene glycerol trioleate. A method for preparing an orally administered pharmaceutical composition involves first dissolving cyclosporine in ethanol. Polyoxyethylene glycerol trioleate and an oil component are then added, mixed and diluted in an aqueous media to form a spontaneous emulsion.

Owner:WOCKHARDT EU OPERATIONS SWISS

Metathesis of unsaturated fatty acid esters or unsaturated fatty acids with lower olefins

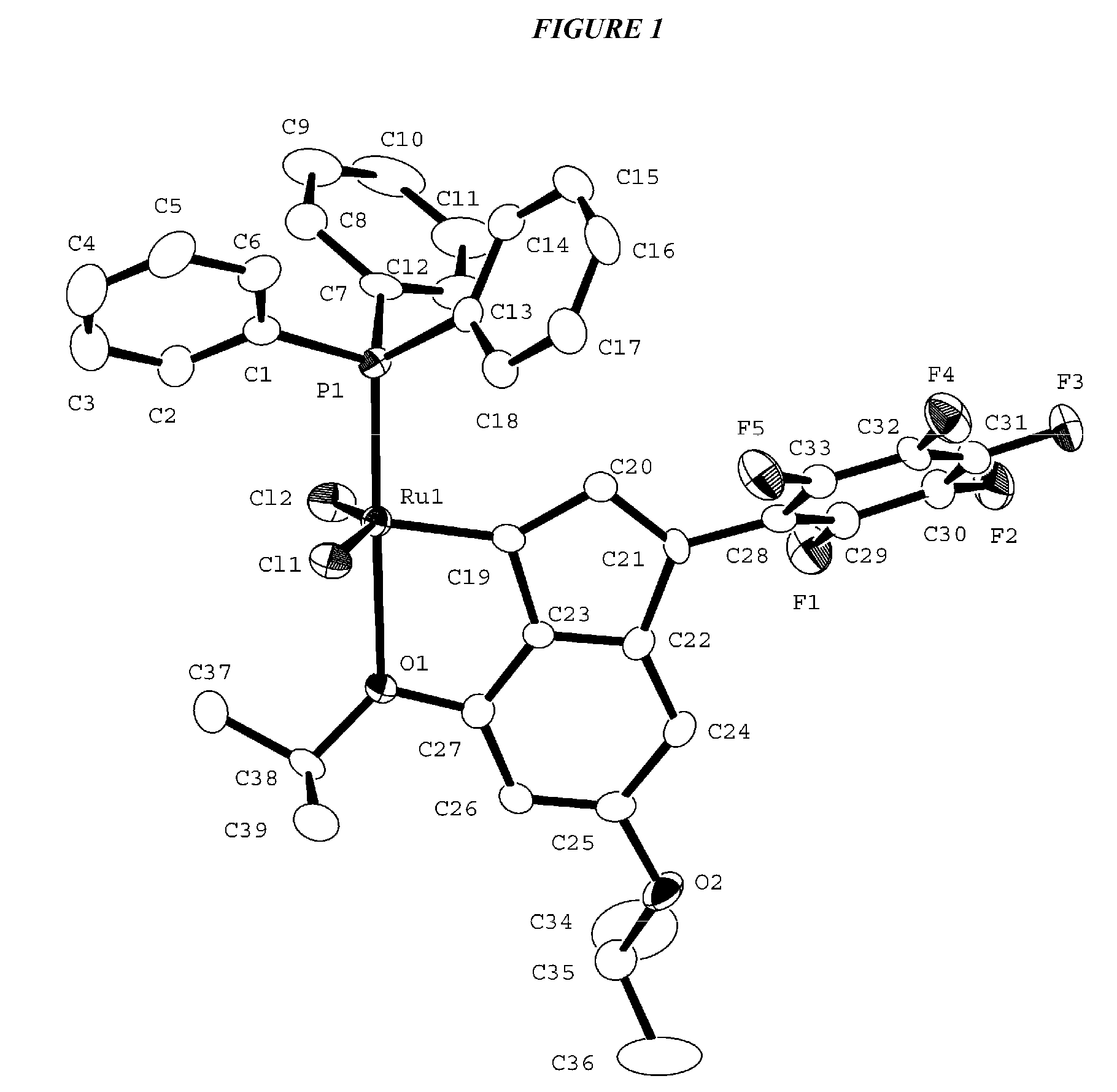

ActiveUS20050070750A1Excellent activityGood activity and efficiencyFatty acid chemical modificationFatty acids production/refiningOleic Acid TriglycerideOlefin metathesis

An olefin metathesis process involving contacting an unsaturated fatty acid ester or unsaturated fatty acid, such as methyloleate or oleic acid, with a lower olefin, preferably ethylene, in the presence of a metathesis catalyst so as to prepare a first product olefin, preferably, a reduced chain α-olefin, such as methyl-9-decenoate or 9-decenoic acid, respectively. The metathesis catalyst contains ruthenium or osmium and a chelating ligand, preferably, a chelating ligand containing a carbene moiety and a second donor moiety of a Group 15 or 16 element Optionally, the catalyst can be supported on a catalyst support, such as, a cross-linked polymeric resin.

Owner:DOW GLOBAL TECH LLC

Metathesis process for preparing an alpha, omega-functionalized olefin

InactiveUS7812185B2Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

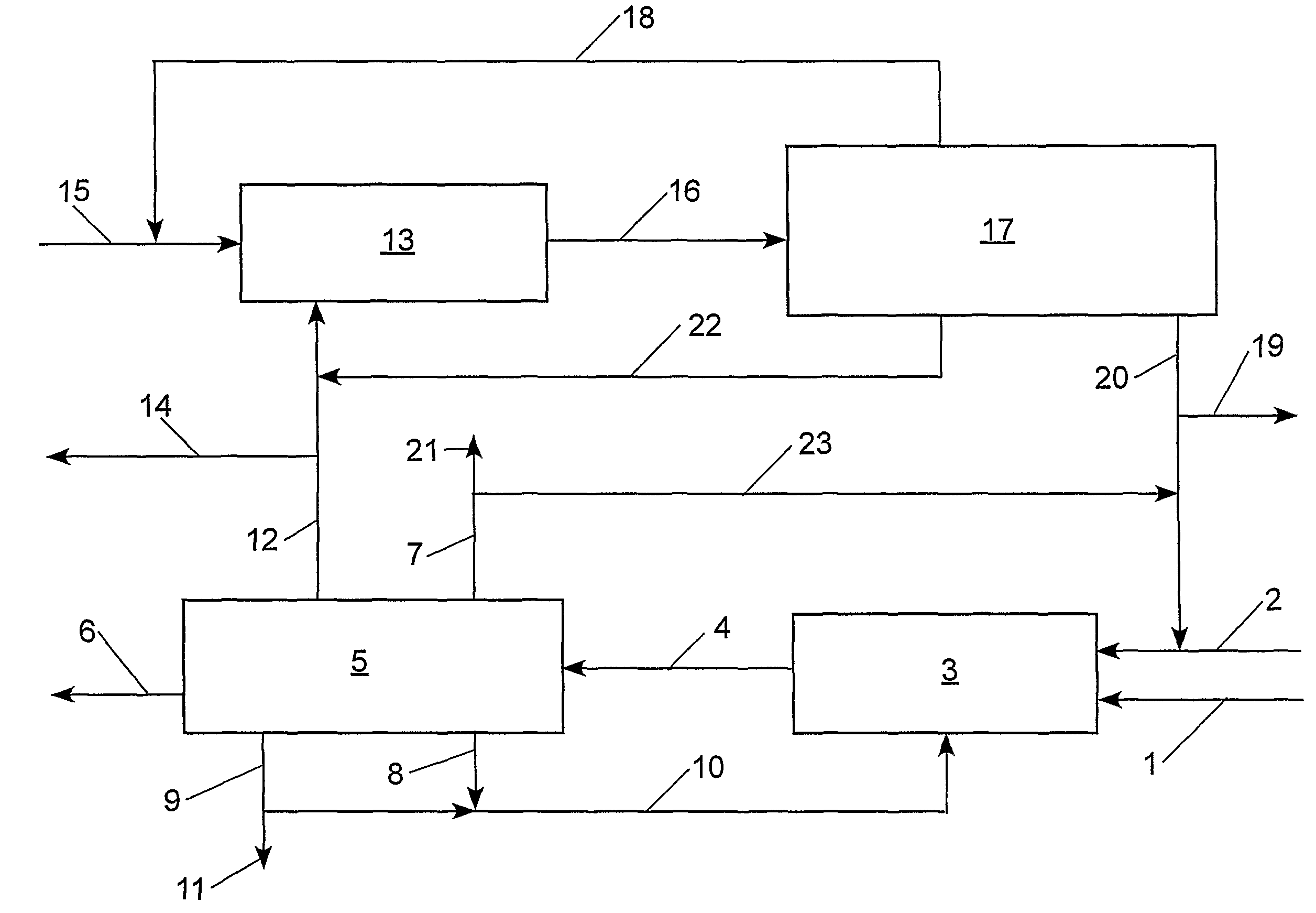

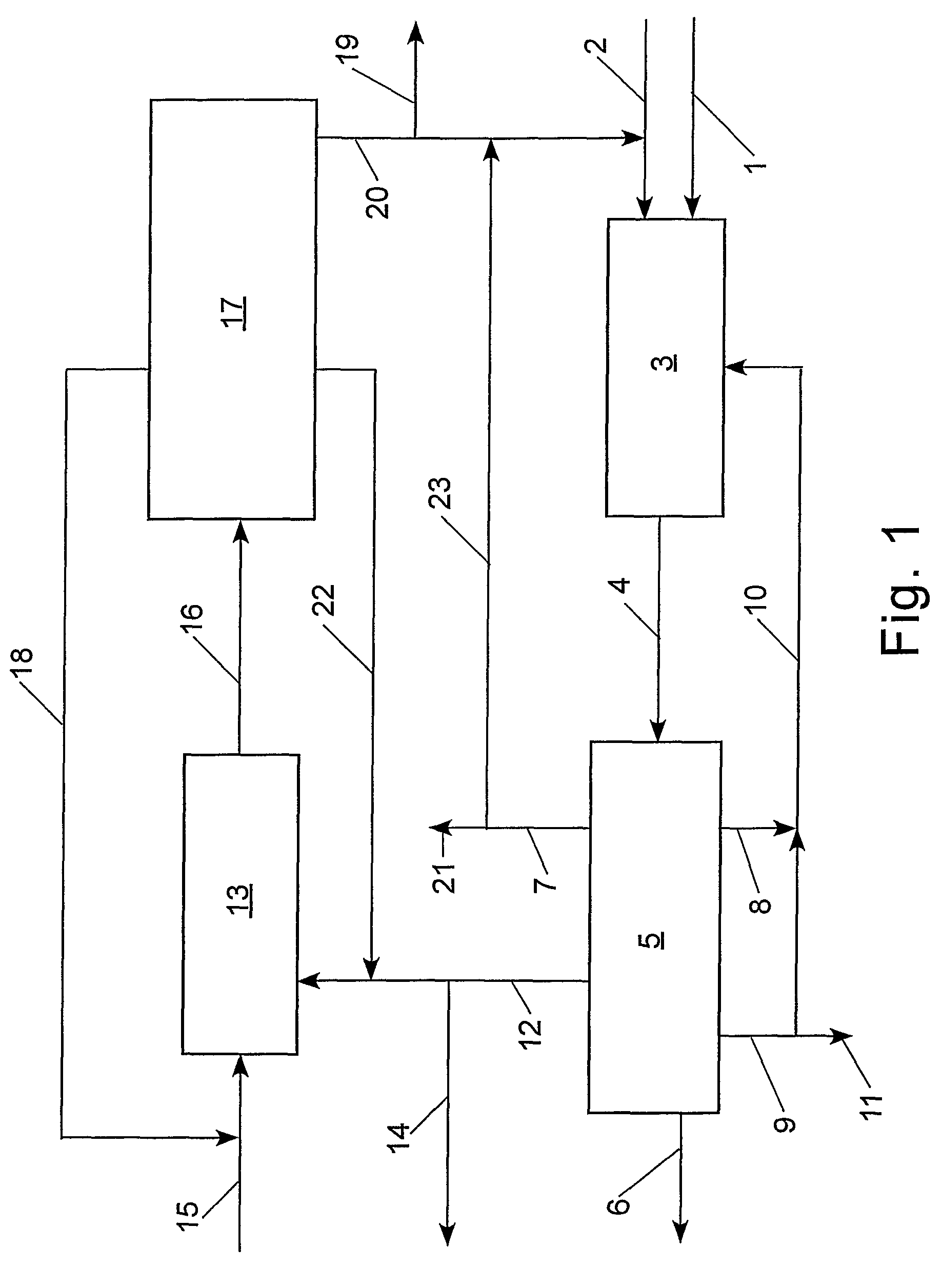

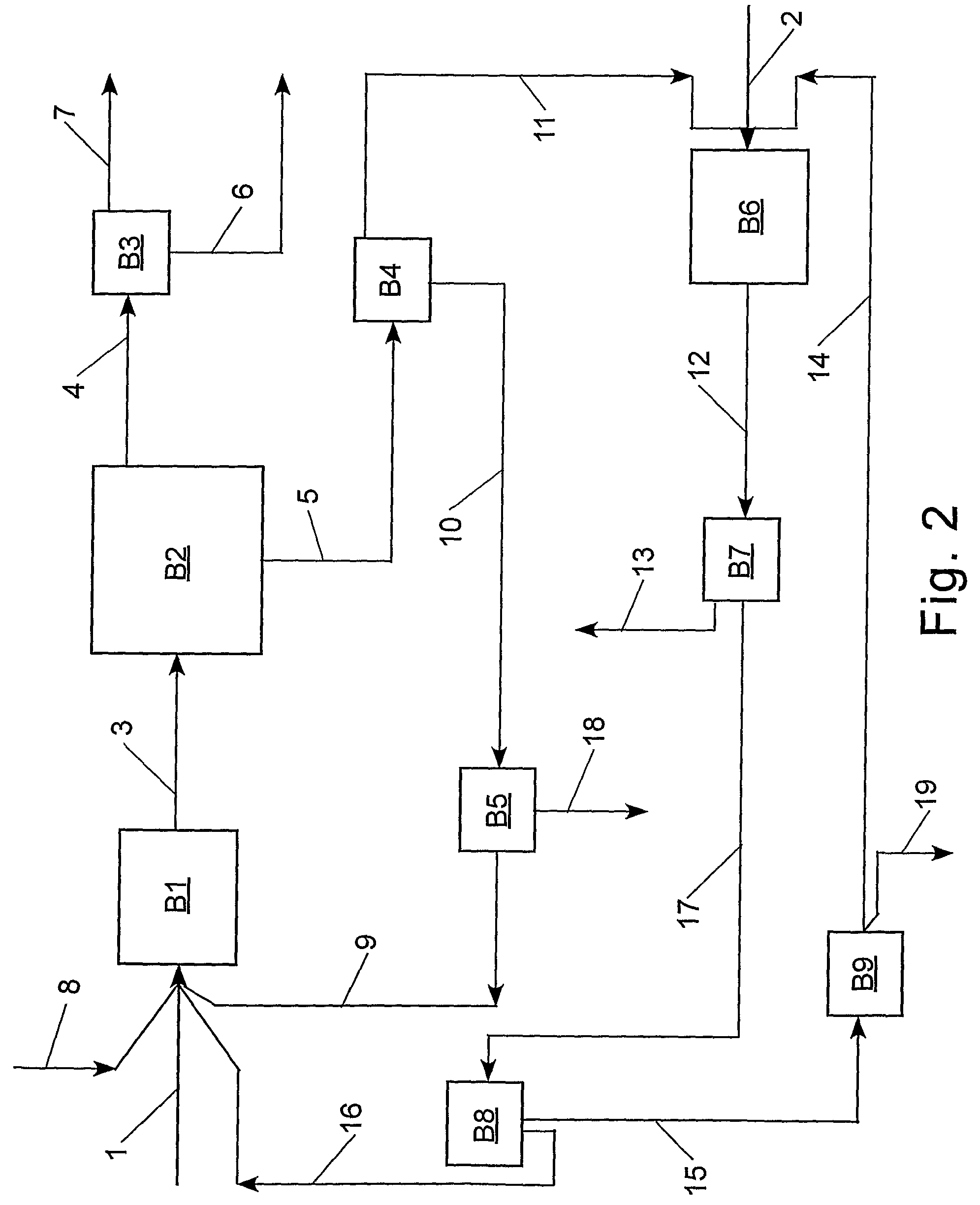

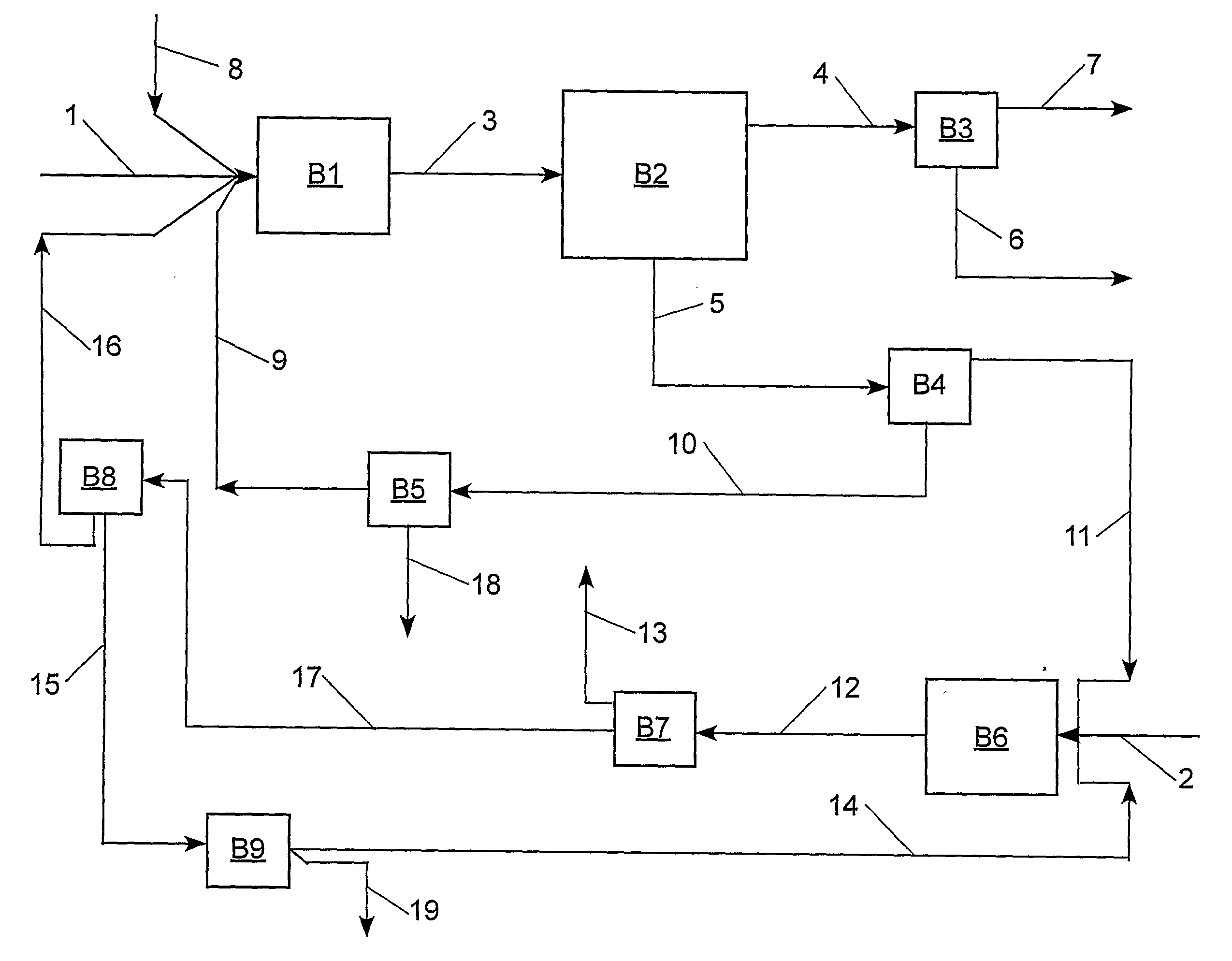

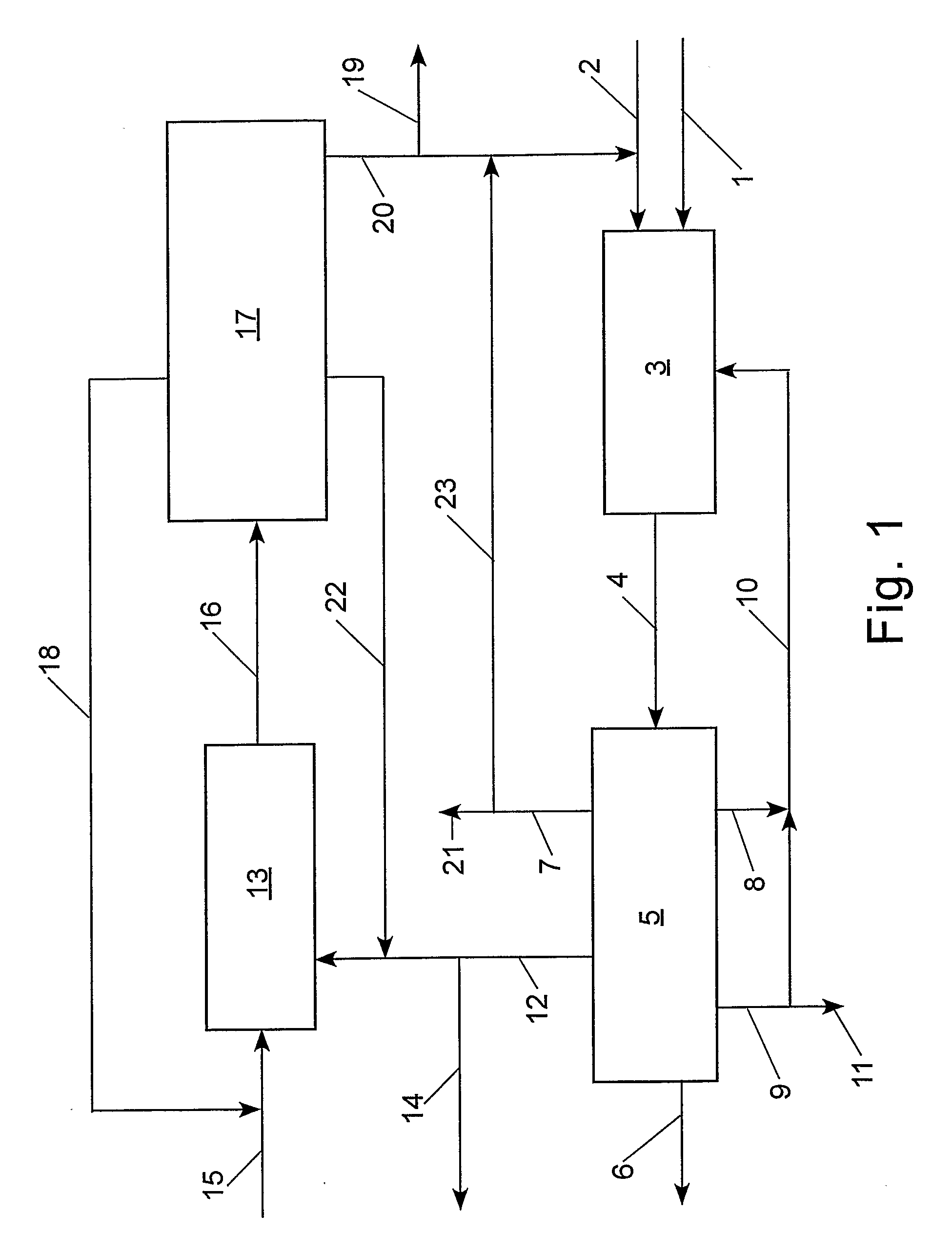

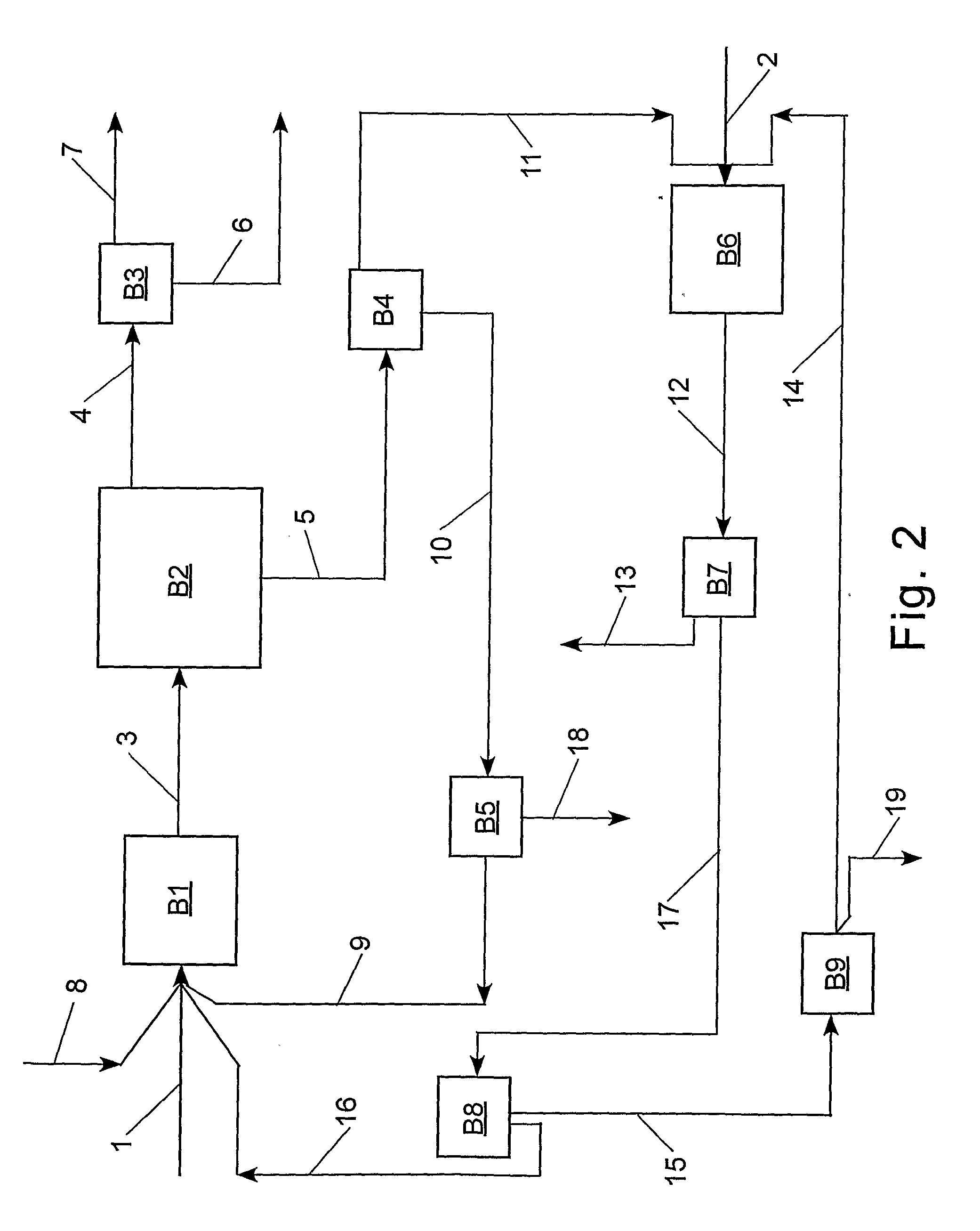

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

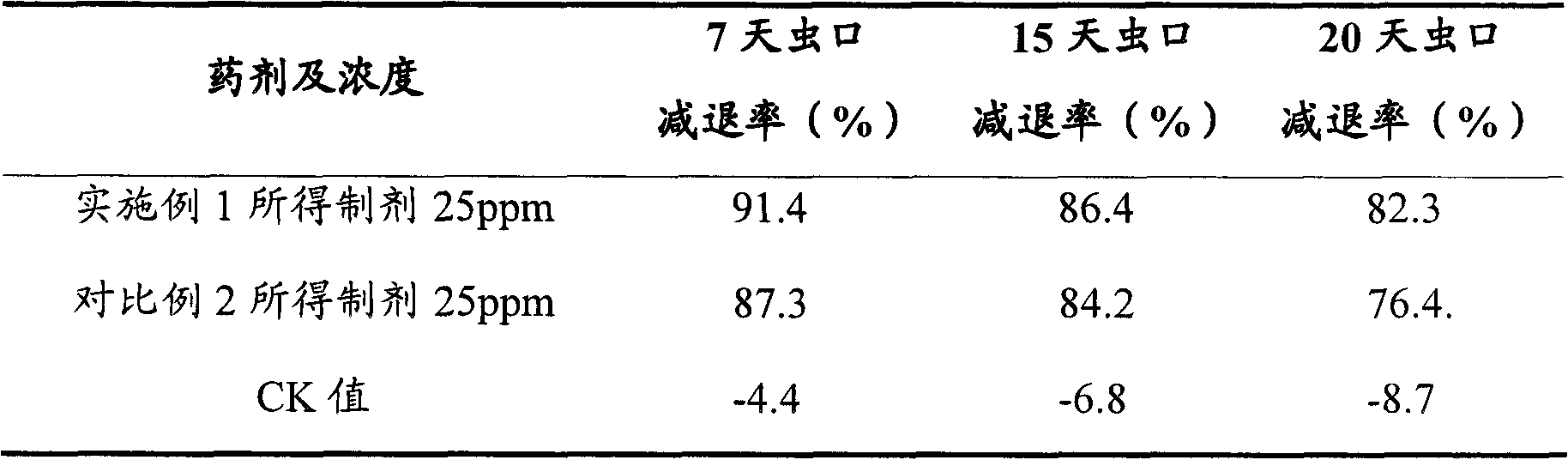

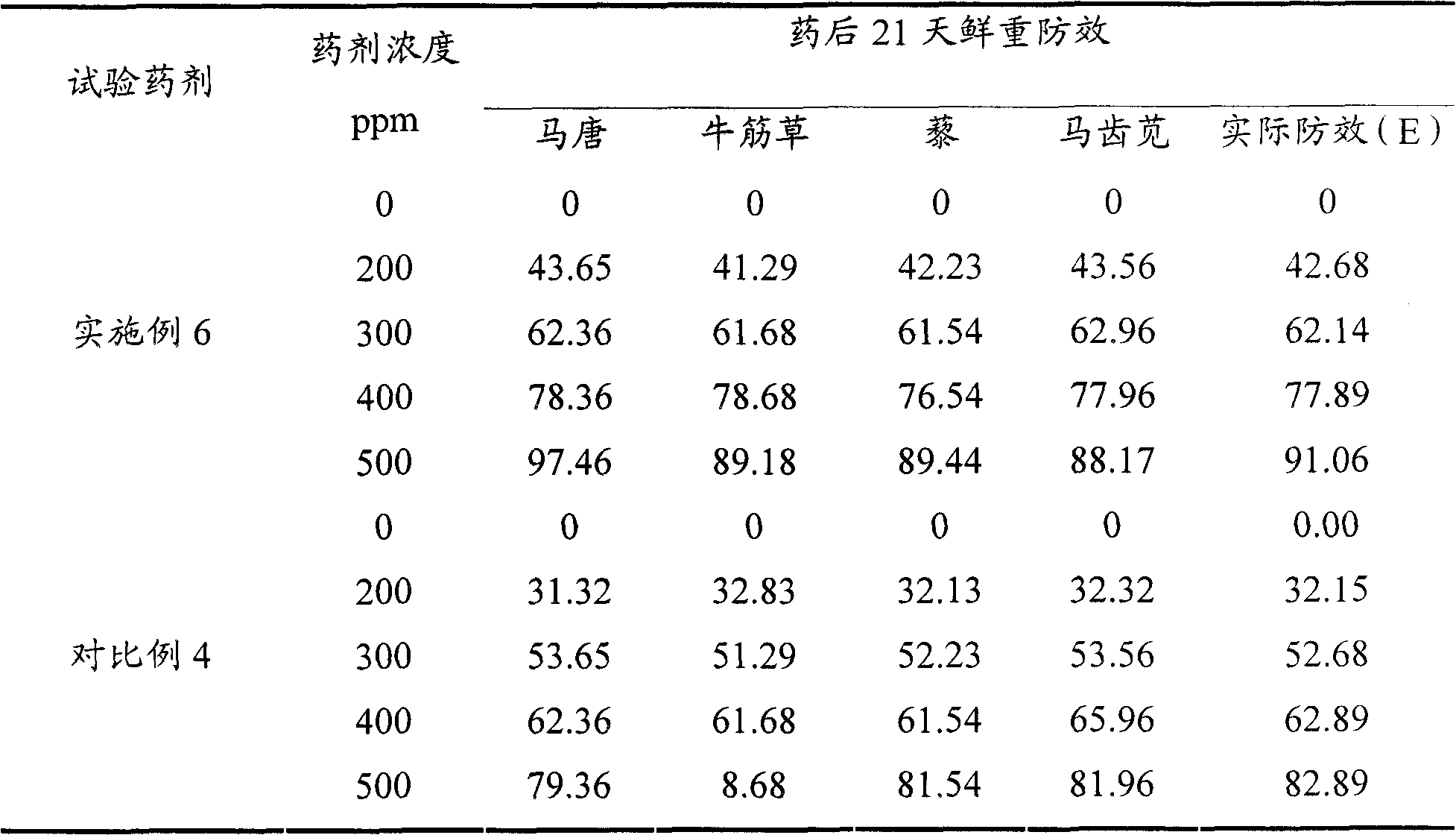

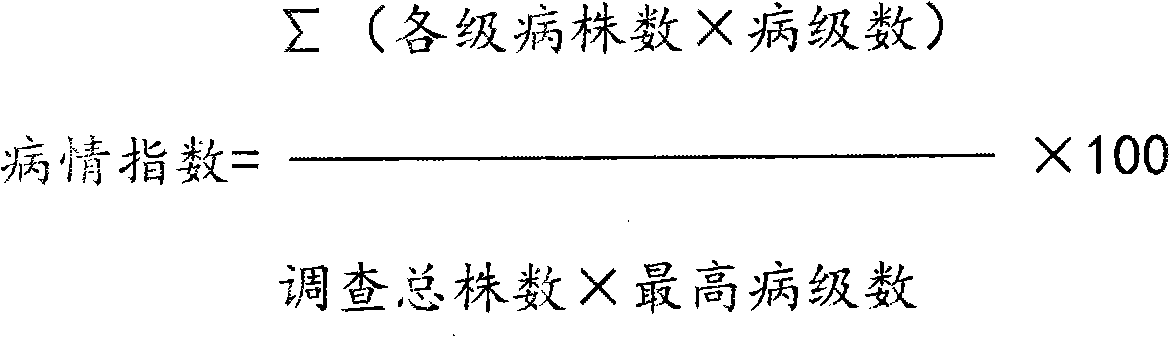

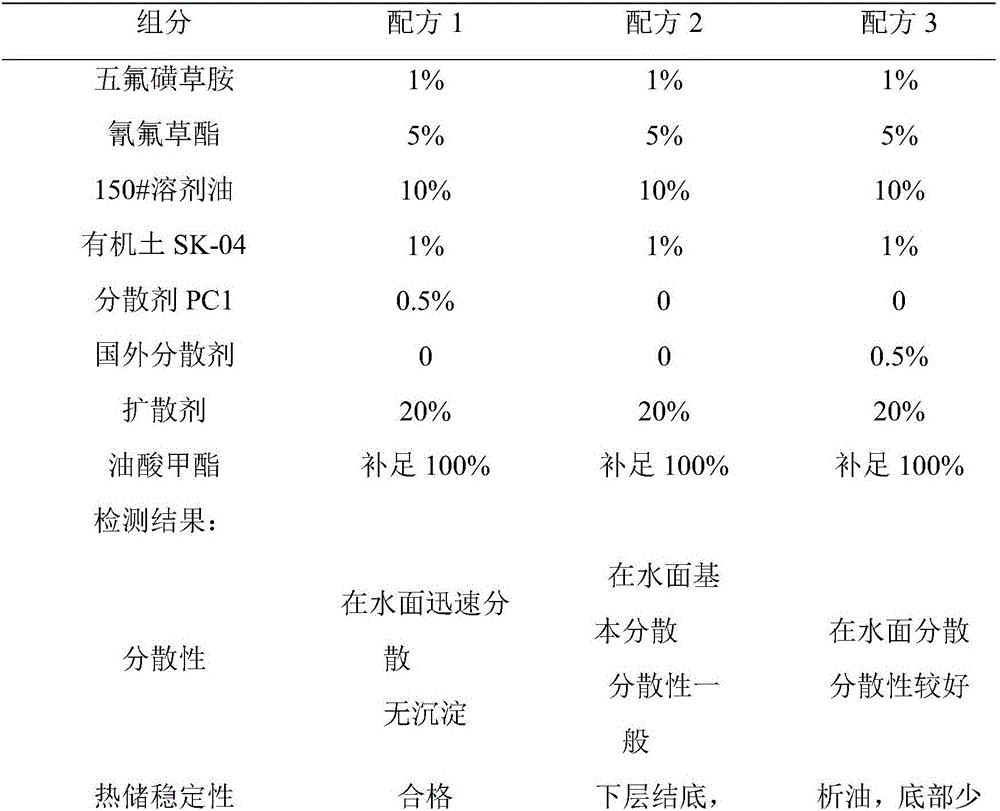

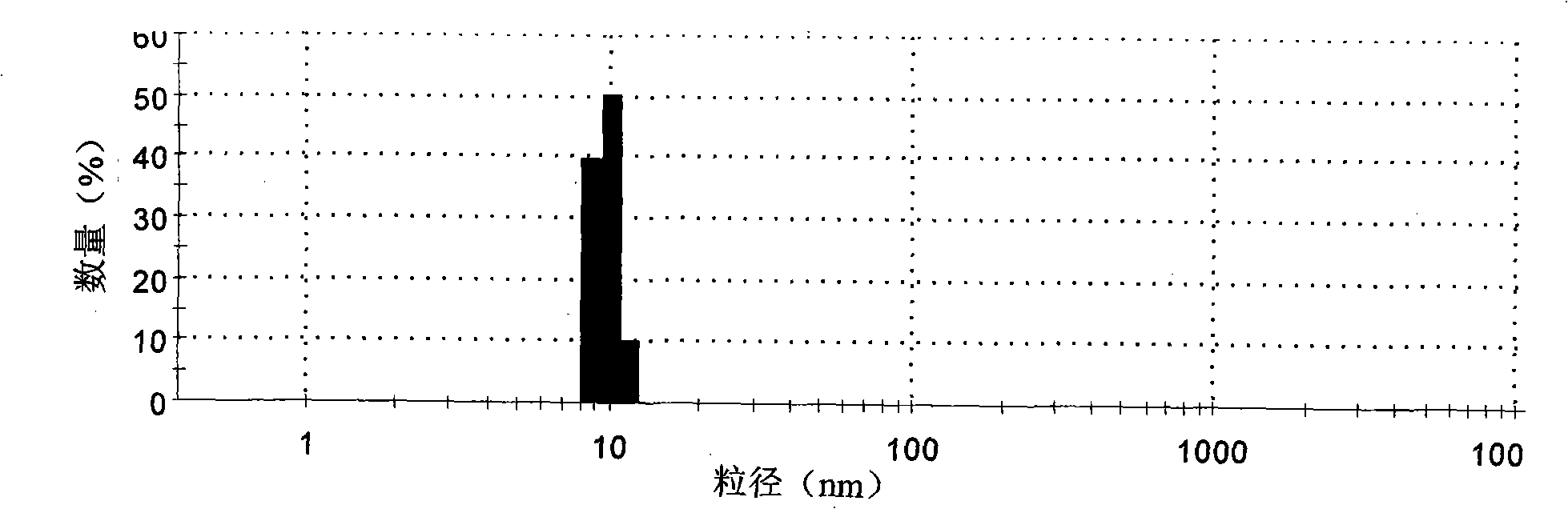

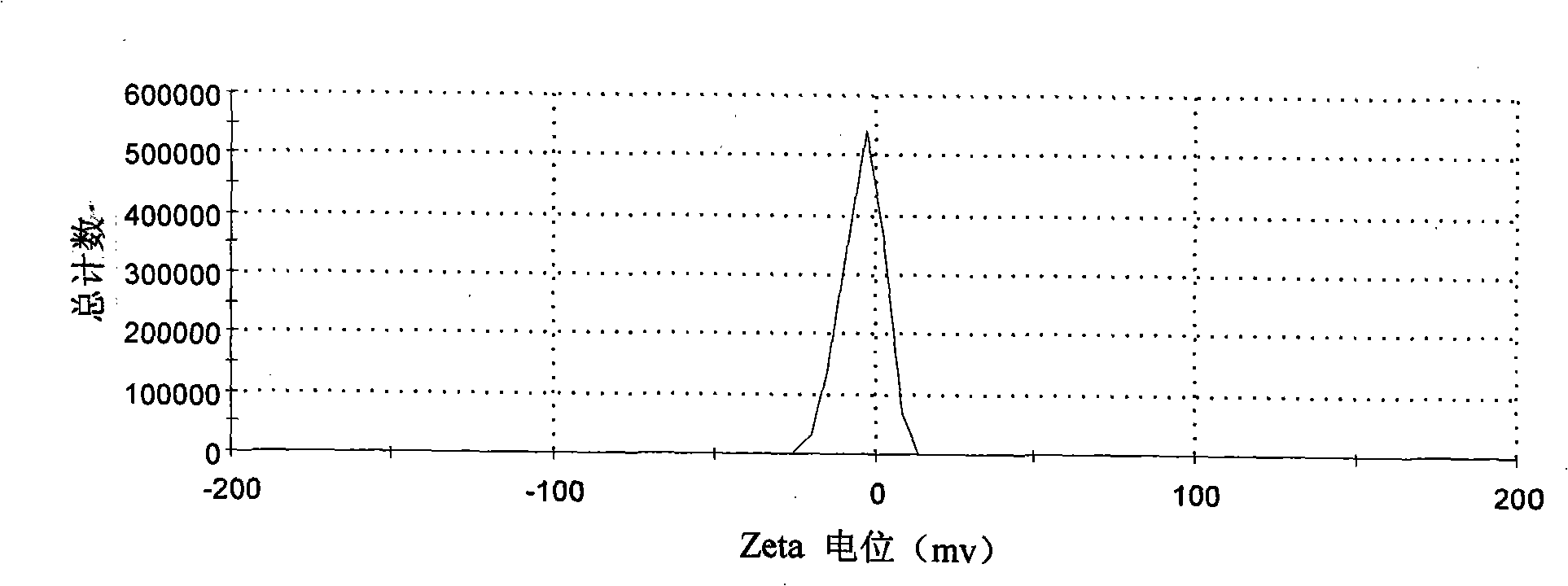

Pesticide oil suspension agent and preparation method thereof

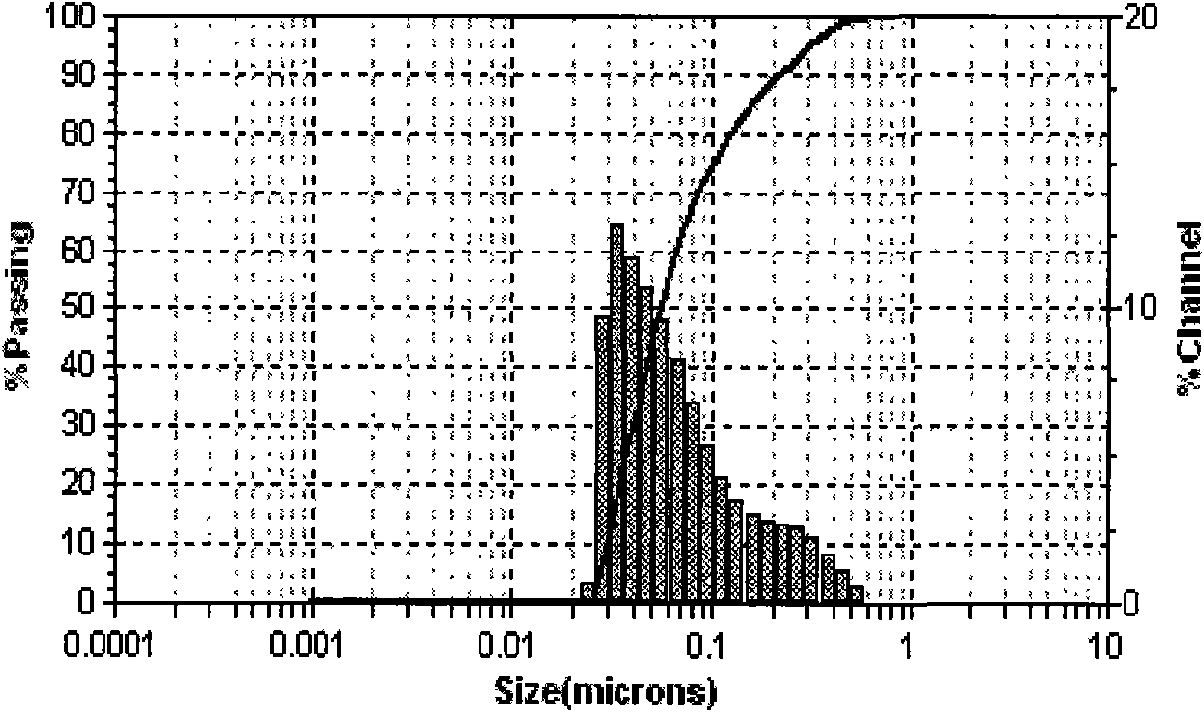

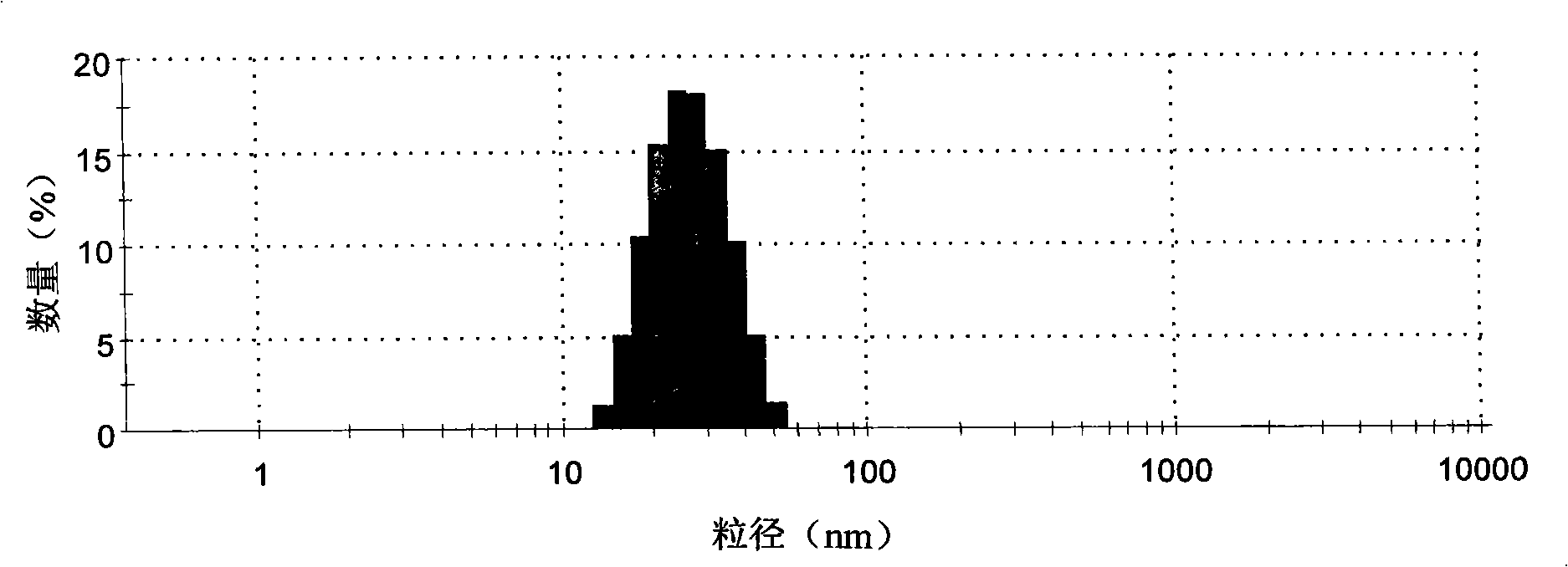

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

Metathesis Process For Preparing An Alpha, Omega-Functionalized Olefin

InactiveUS20080228017A1Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

Highly-efficient lubricant for drilling fluid

InactiveCN101735778AImprove the lubrication effectIncrease the extreme pressure valueDrilling compositionPolyesterPhosphate

The invention discloses a highly-efficient lubricant for a drilling fluid. The highly-efficient lubricant comprises the following components in percentage by weight: 10 to 40 percent of white oil, 30 to 70 percent of fatty acid methyl ester or methyl oleate, 5 to 20 percent of polyester, 2 to 8 percent of organic phosphate, 1 to 6 percent of oilness extreme-pressure additive, 0.5 to 2 percent of emulsifier OP-10 and 0.5 to 2 percent of span-80. The invention also discloses a method and steps for preparing the highly-efficient lubricant for the drilling fluid. The highly-efficient lubricant can enhance the lubricating property of the drilling fluid and increase an extreme pressure value of the drilling fluid, and is suitable for the demand of ordinary drilling and use in a high-difficulty highly deviated directional well and a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Nematoid-killing composition containing abamectin and paecilomyces lilacinus

InactiveCN102077846AAvoid infectionIncrease parasitic rateBiocideNematocidesPaecilomyces lilacinusAbamectin

The invention relates to a nematoid-killing composition containing abamectin and paecilomyces lilacinus, which is characterized by comprising abamectin and paecilomyces lilacinus; 100g of nematoid-killing composition is prepared by the following components of 0.1-5g of abamectin, 0.1-1 billion live spores / g of paecilomyces lilacinus, 1-10g of stabilizing agent, 1-90g of solvent and 10-90g of assistant, wherein the assistant is any one or the combination of any two of attapulgite, kaoline, sepiolite, light calcium and kieselguhr and is prepared into a granular formulation or suspending agent or wettable powder; the stabilizing agent is any one or the combination of any two of castor oil, soybean oil, epoxidized soybean oil, propylene glycol, methyl oleate, ethylene glycol, butylated hydroxytoluene (BHT) and butylated hydroxyanisole (BHA); and the solvent is any one of dimethylbenzene, trimethylbenzene and dimethylformamide. The nematoid-killing composition is used for controlling the knot nematode and has better control effect on the knot nematode.

Owner:佛山市盈辉作物科学有限公司

Load type acidic ionic liquid catalyst and preparation method and application thereof and preparation method of ethyl acetate and methyl oleate

ActiveCN102814195AReduce dosageEasy to prepareOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMesoporous silicaEthyl acetate

The invention provides a load type acidic ionic liquid catalyst and a preparation method and an application thereof, wherein the catalyst comprises hollow spherical mesoporous silica carriers and an acidic ionic liquid loaded on the hollow spherical mesoporous silica carriers, the average particle diameter of the hollow spherical mesoporous silica carriers is 3 micrometers to 20 micrometers, the specific surface area is 200 square meters per gram, the pore volume is 0.5 to 1.5 milliliters per gram, and the most probable pore size is 3 micrometers to 20 micrometers. Esterification reaction of acetic acid and ethanol and oleic acid and methanol can be effectively catalyzed by using the load type acidic ionic liquid catalyst; and the catalyst can be recycled through simple recovery processing, and a high catalytic efficiency is maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

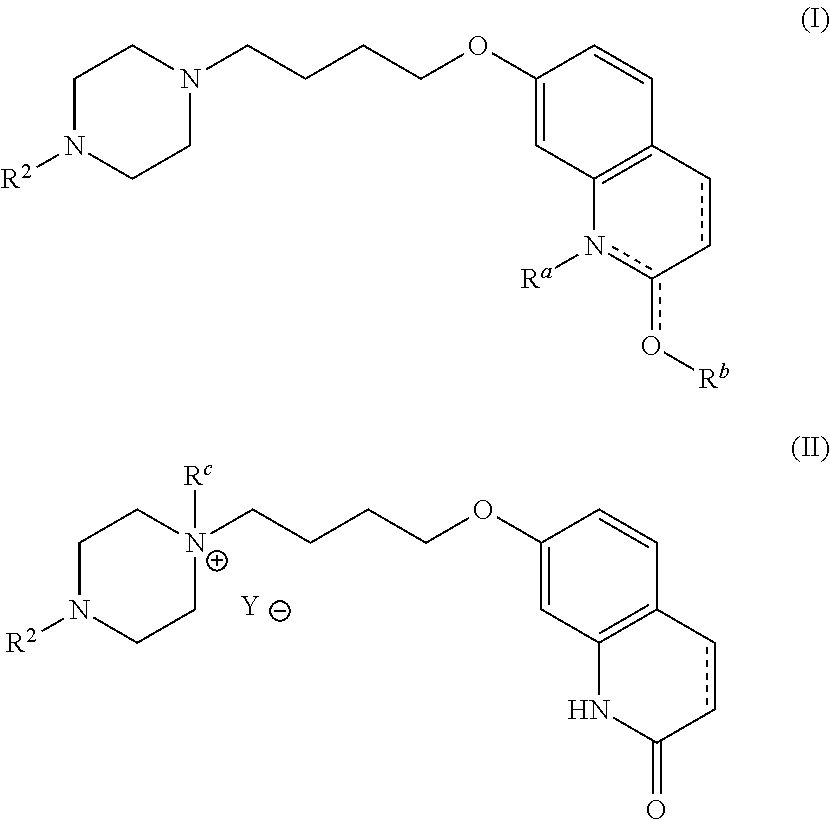

Pharmaceutical compositions comprising fatty acid esters

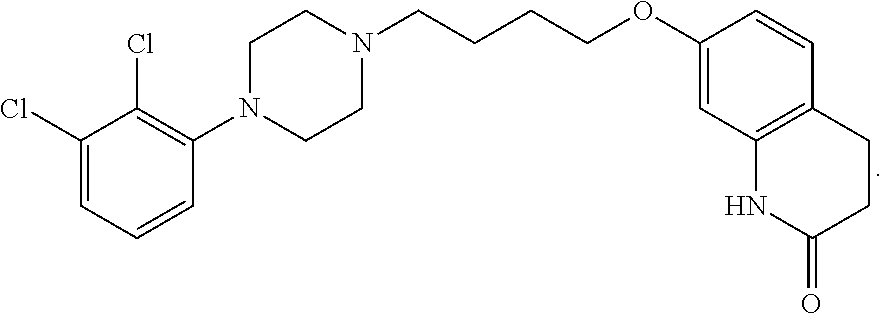

ActiveUS20130267503A1Patient compliance is goodOptimizing pharmacological profileBiocideNervous disorderPsychosis drugEthyl ester

The present invention relates to an injectable, pharmaceutical composition comprising a C1-6 alkyl ester of a C10-20 fatty acid. In an embodiment, the fatty acid is ethyl oleate, isopropyl oleate, ethyl myristate, or isopropyl myristate. These compositions are useful for the delivery of anti-psychotic drugs.

Owner:ALKERMES PHARMA IRELAND LTD

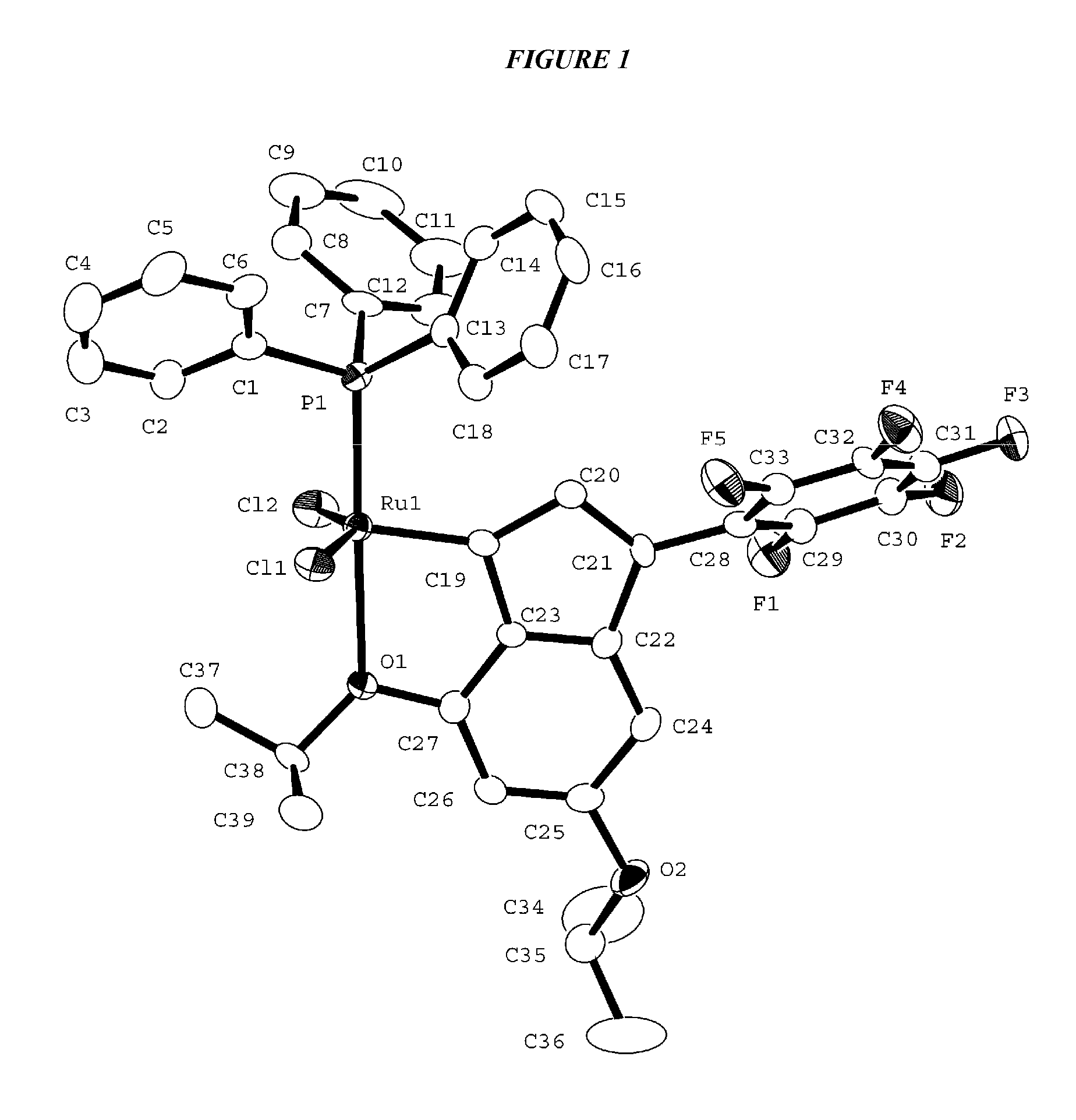

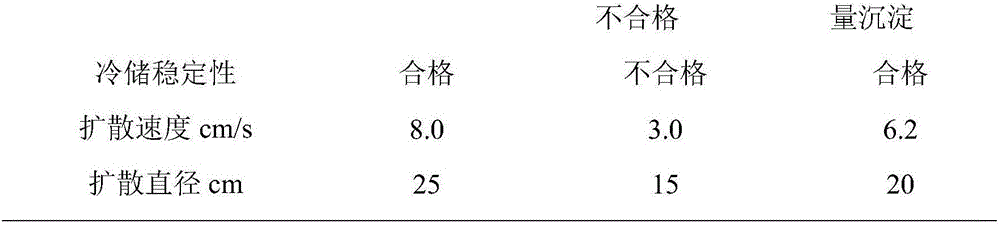

Metathesis Catalyst and Process for Use Thereof

ActiveUS20120289729A1Ruthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlpha-olefinAlkene

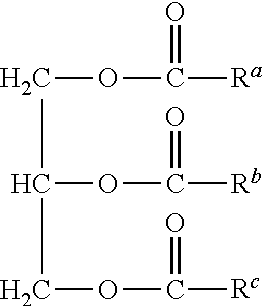

This invention relates to a Group 8 catalyst compound for the metathesis ofThis invention also relates to process to make alphaolefins comprising contacting an olefin, such as ethylene, with a feed oil containing a triacylglyceride (typically a fatty acid ester (such as methyl oleate)) with a Group 8 catalyst compound. The fatty acid ester may be a fatty acid methyl ester derived from biodiesel.

Owner:EXXONMOBIL CHEM PAT INC

Ivermectin nanoemulsion drug combination and preparation method thereof

ActiveCN101623256AHigh thermodynamic stabilityGood storage stabilityOrganic active ingredientsPharmaceutical non-active ingredientsDistilled waterBioavailability

The invention discloses an ivermectin nanoemulsion drug combination. Oil-in-water type nanoemulsion consisting of ethyl oleate, Tween-80, 1,2- propylene glycol and ivermectin is prepared from being diluted by double distilled water. The ivermectin nanoemulsion drug combination greatly improves the effect of ivermectin in resisting parazoon, enhances the dissolubility, safety and bioavailability and is a high-efficiency antiparasitic nano level medicinal preparation with convenient use and wide ways of administration.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Tanshinone IIA microemulsions and preparing method thereof

InactiveCN101224203AHave affinityReduce releaseOrganic active ingredientsPharmaceutical non-active ingredientsFiltration membraneTanshinone IIA

The invention discloses a tanshinone II A microemulsion preparation which has targeting and comparatively high entrapment efficiency and drug-loading rate, is not haemolytic and mainly applied to the treatment of tumor and a preparation method thereof. The invention comprises the following raw materials by weight percentage: 0.6-0.8 percent of tanshinone II A, 0.6-1.8 percent of phosphotide for injection, 2.5-3 percent of glycerin for injection, 1.5-3 percent of F68 for injection, 11-15 percent of ethyl oleate and water for injection. The preparation method of the invention is that first the tanshinone II A is dissolved in the ethyl oleate to prepare the oil phase mixture solution; next the phosphotide for injection, the glycerin for injection and the F68 for injection are dissolved in the water for injection which accounts for 60-70percent of the total water for injection to prepare the water phase solution; then the oil phase solution and the water phase solution are respectively preheated to 60-70DEG C and the oil phase solution is slowly dropped to the water phase solution when the water phase solution is blended; the mixed solution is then sheared for 1-2minutes in a high shearing dispersing emulsification machine and filtrated with a 0.8Mum filtration membrane when the solution is still hot and the rest water for injection is added to the filtrate; the liquid obtained from step d is homogenized by a high pressure emulsification machine and next filtrated with the 0.8 Mum filtration membrane; finally the filtrate obtained from step e is packaged, filled with nitrogen, sealed and disinfected.

Owner:THE SECOND HOSPITAL OF DALIAN MEDICAL UNIV

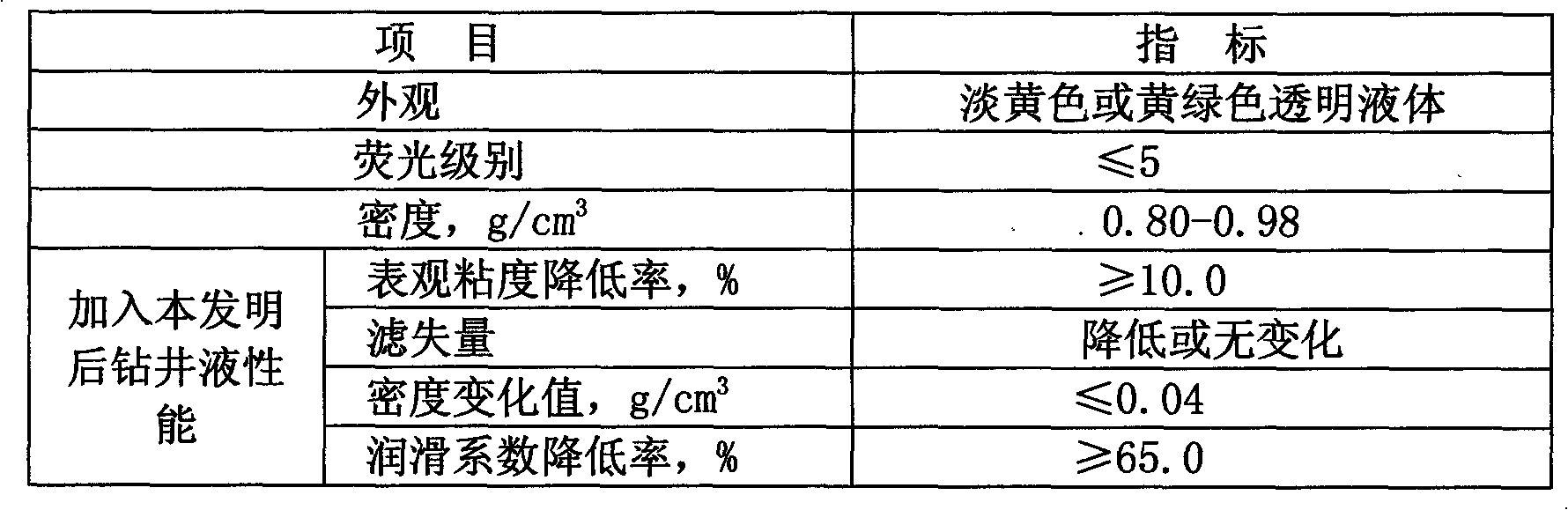

High-efficient antisticking lubricant for drilling fluid

ActiveCN102344783APlay a lubricating roleLow fluorescence levelDrilling compositionPolymer scienceFluorescence

A high-efficient antisticking lubricant for drilling fluid has a technical scheme that the lubricant is obtained by mixing five components of white oil which is used as a main raw material, oleic acid and methyl oleate which are used as auxiliary materials, a defoamer and an extreme pressure agent which are used as regulators, wherein the weight percent ranges of the components are 30%-70% of white oil, 18%-30% of oleic acid, 10%-20% of methyl oleate, 1%-10% of defoamer and 1%-10% of extreme pressure agents. The lubricant of the invention has the advantages of extreme pressure lubrication, sticking resistance, less fluorescence grade, and the like, does not cause index change of drilling fluid, has lubrication effect on hard surface to soft surface (drilling tool to mud cake) and hard surface to hard surface (drilling tool to rock), has good lubrication effect, and thus is a good lubricant for polymer drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

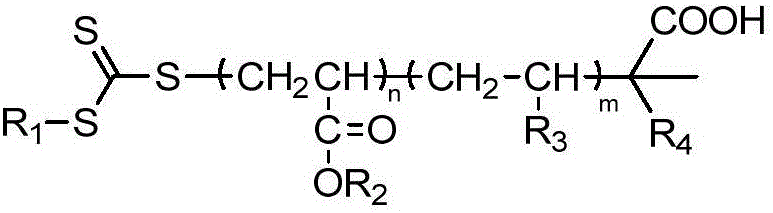

Comb type polymeric dispersant and preparation method and application thereof

InactiveCN106492706AImprove the lubrication effectReduce the chance of collisionBiocideTransportation and packagingPropanoic acidCarboxylic acid

The invention discloses a comb type polymeric dispersant and a preparation method and application thereof. The structural formula of the polymeric dispersant is defined in the specification. The preparation method comprises the steps that the RAFT living polymerization technology is adopted, dodecane sulfenyl sulfo-carbonyl sulfenyl propionic acid serves as a chain transfer agent, azodiisobutyronitrile serves as an initiator, and the comb type polymeric dispersant is obtained through graft copolymerization between unsaturated monomers. According to the application, the dispersant is applied to a spreading oil system, methyl oleate and other environment-friendly solvents are adopted as an organic carrier, an oil-dispersible system is obtained through a wet sanding process, a dispersing agent is added, and spreading oil of different conventional processes is obtained. According to the structure of the comb type polymeric dispersant, polyoxyethylene ether, benzene rings, carboxylic acid groups and other group repetitive units are contained, multipoint adsorption is achieved in the wet sanding process, the dispersant has good compatibility with an oil phase, the lubricating function among particles is improved, the collision probability among the particles is reduced through a macromolecular main chain steric hindrance, and sanding efficiency is improved.

Owner:NANJING UNIV OF TECH +1

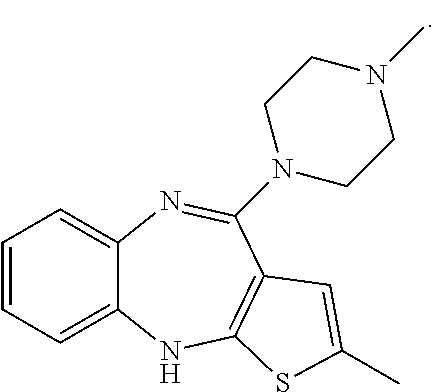

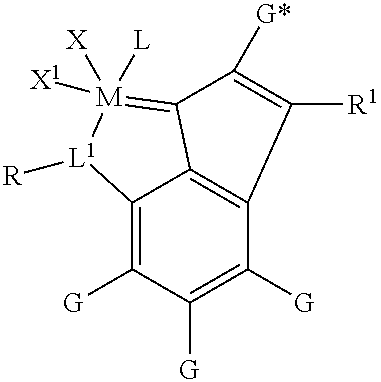

Metathesis Catalyst and Process for Use Thereof

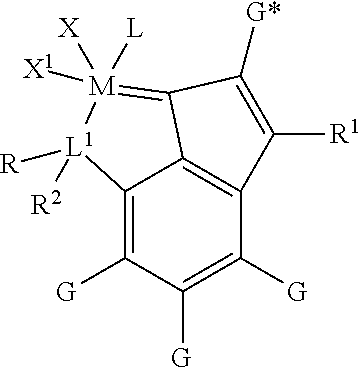

InactiveUS20110112349A1Ruthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsElectron donorAlpha-olefin

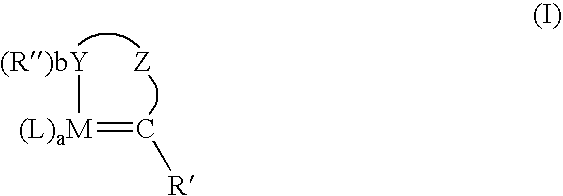

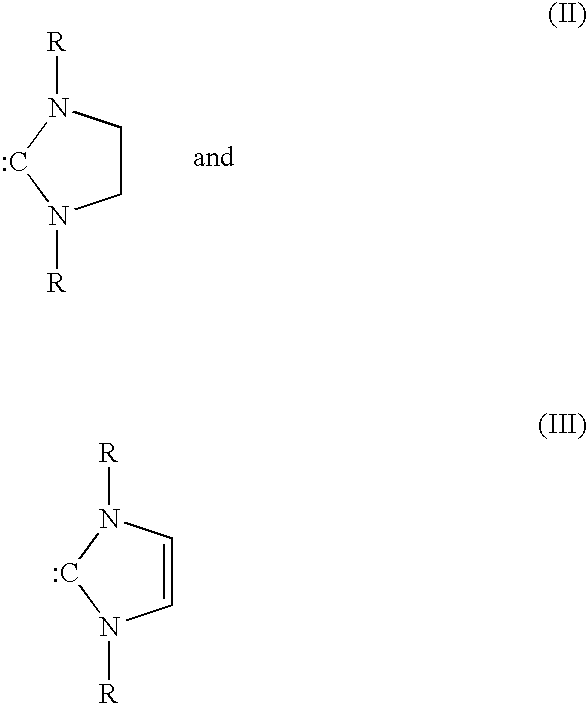

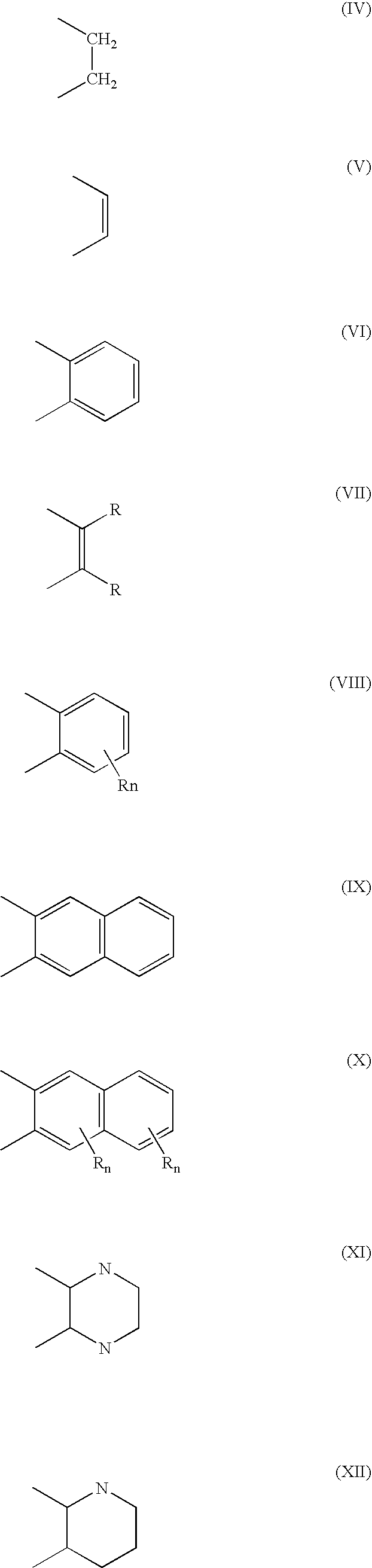

This invention relates to a catalyst compound for the metathesis of olefins represented by the formula:wherein M is a Group 8 metal; X and X1 are anionic ligands; L is a neutral two electron donor; L1 is N, O, P, or S, preferably N or O; R is a C1 to C30 hydrocarbyl or a C1 to C30 substituted hydrocarbyl; G* is selected from the group consisting of hydrogen, a C1 to C30 hydrocarbyl, and a C1 to C30 substituted hydrocarbyl; R1 is selected from the group consisting of hydrogen, a C1 to C30 hydrocarbyl, and a C1 to C30 substituted hydrocarbyl; and G is independently selected from the group consisting of hydrogen, halogen, C1 to C30 hydrocarbyls and C1 to C30 substituted hydrocarbyls.This invention also relates to process to make alphaolefins comprising contacting an olefin, such as ethylene, with a feed oil containing a triacylglyceride (typically a fatty acid ester (such as methyl oleate)) with the catalyst compound described above. The fatty acid ester may be a fatty acid methyl ester derived from biodiesel.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of nonanal and methyl formylcaprylate

InactiveCN102126953AHigh yieldSlow reaction rateMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of nonanal and methyl formylcaprylate. The method comprises the following steps: epoxidized methyl oleate is used as a raw material to react under the action of catalyst and generate nonanal and methyl formylcaprylate, wherein the reaction temperature is 40-100 DEG C, the pressure is atmospheric pressure; the mesoporous molecular sieve which is treated with 10-35% hydrogen peroxide is taken as a carrier for the catalyst, the weight ratio of tungsten used as main catalyst to the weight of the carrier is 0.005-0.1, and the weight ratio of one of titanium and molybdenum, used as cocatalyst to the weight of the carrier is 0-0.1. The invention has the following beneficial effects: by adopting the technical scheme that the reaction temperature is 40-100 DEG C, the pressure is atmospheric pressure; the mesoporous molecular sieve is taken as a carrier for the catalyst, tungsten is used as a main catalyst and titanium or molybdenum used as cocatalyst is added or not, the problem can be solved well. The preparation method provided by the invention has mild reaction conditions, low cost and higher product yield and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

Icariin microemulsion and preparation method thereof

InactiveCN101513388ASimple mixing processIncreased penetration through the cell layerOrganic active ingredientsSkeletal disorderBULK ACTIVE INGREDIENTMethyl oleate

The invention relates to an icariin microemulsion which takes icariin as active ingredient; the icariin is dissolved in oil and then added with emulsifying agent, assistant emulsifier and water to prepare microemulsion with the micro emulsion grain diameter of 10-100nm, wherein, the oil can be one or more in oleic acid, ethyl oleate, isopropyl myristate or castor oil; the icariin microemulsion has the components with the mass percent: 0.66-6.02% of saturated solution of oil of icariin, 10-50% of emulsifying agent, 10-38% of assistant emulsifier and the balance water, Hank's balanced salt solution (HBSS), PBS buffer solution or normal saline. The icariin microemulsion can be kept clear, transparent, stable and uniform when being placed at room temperature for a year, thus good stability is verified evidently. The experiments of cells and animals prove that the icariin microemulsion can strengthen the icariin to penetrate cell layers, promote the medicine to be ingested and absorbed and enhance the healing effect of the medicine. The invention also discloses a preparation method of the icariin microemulsion.

Owner:贾晓斌

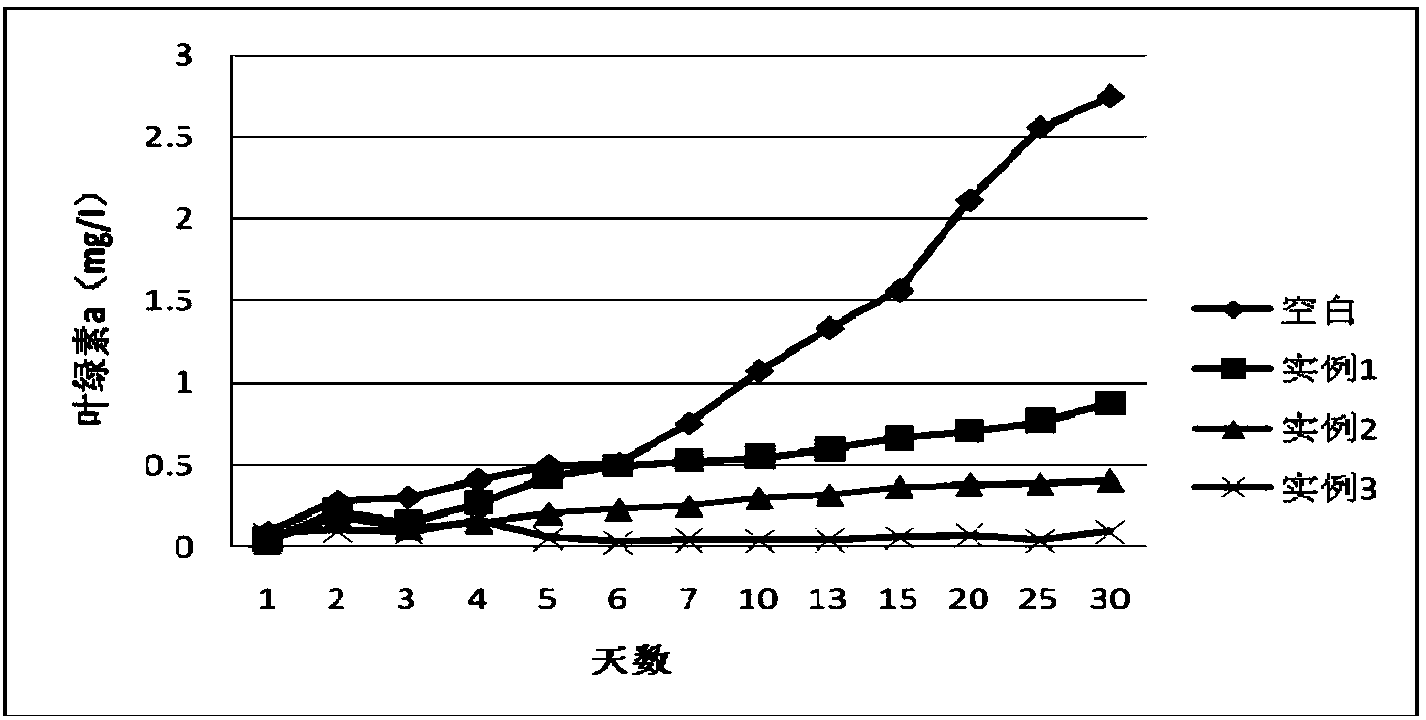

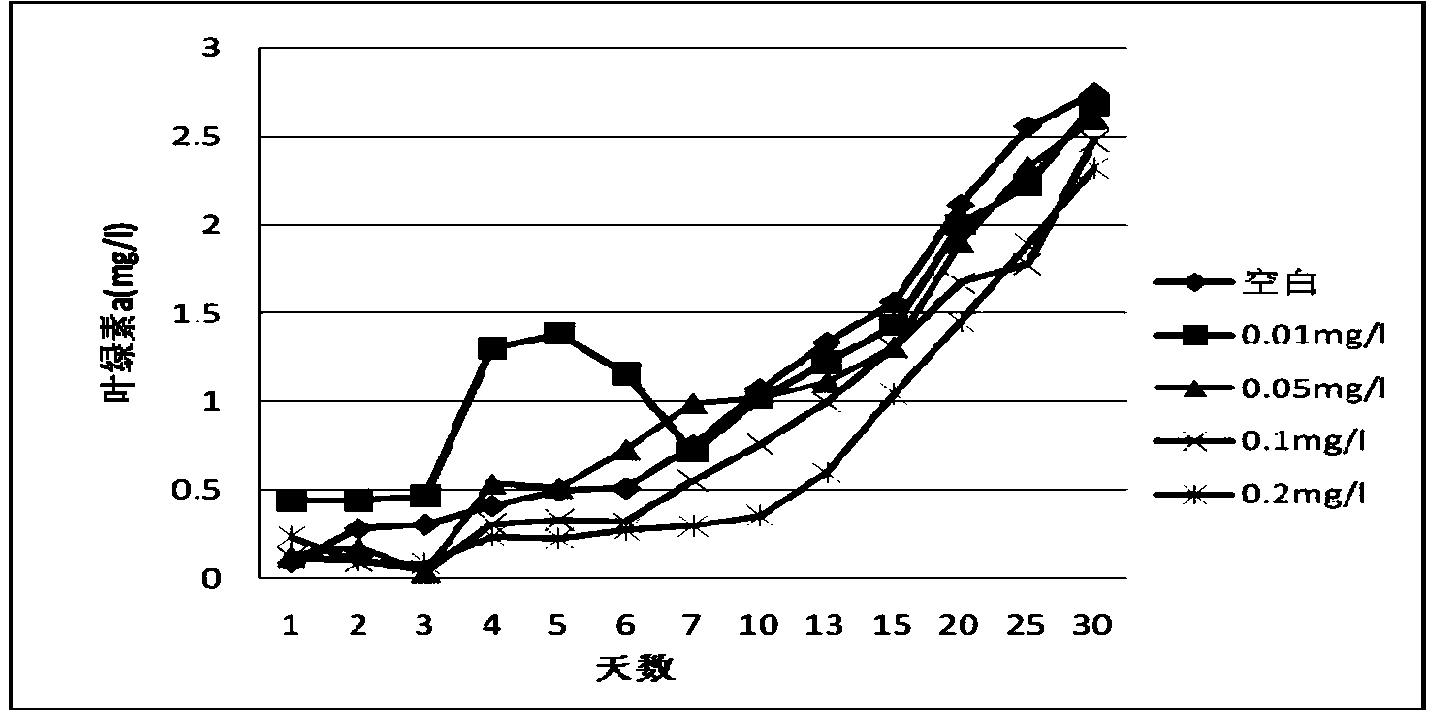

Method for preparing linoleic acid sustained-release algal inhibiting agent

InactiveCN103478125AReduce releaseGood biocompatibilityBiocideAnimal repellantsMicrosphereCross linker

A method for preparing a linoleic acid sustained-release algal inhibiting agent comprises the following steps that firstly, linoleic acid is dissolved through ethyl oleate, emulgator is added into the linoleic acid, and the emulsified linoleic acid is added into a solution of sodium alginate tech grade; secondly, the solution obtained in the first step is dropwise added into a glacial acetic acid solution containing chitosan and calcium chloride to form microspheres; thirdly, after the microspheres are cooled to the indoor temperature, a cross-linking agent is added into the cooled microspheres; fourthly, the process of suction filtration is carried out, and the microspheres to which the cross-linking agent is added are washed by petroleum ether and distilled water; fifthly, the linoleic acid sustained-release algal inhibiting agent is obtained after drying. Algal inhibition effective time is prolonged, the algal inhibition effect is improved, and cost is reduced. All adopted preparing materials are natural polymer materials which are non-toxic, good in biocompatibility and biodegradable, and the problems of secondary pollution caused by chemical algal removing and bio-concentration and biological amplification caused by chemical medicines can be effectively avoided.

Owner:HOHAI UNIV

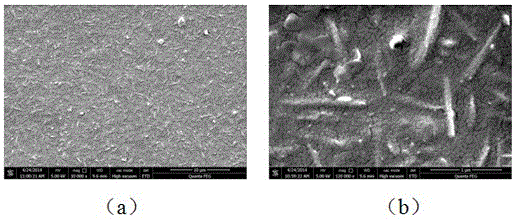

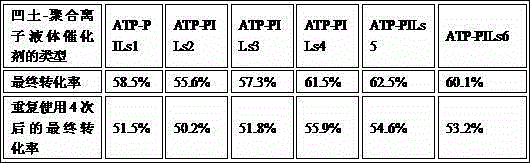

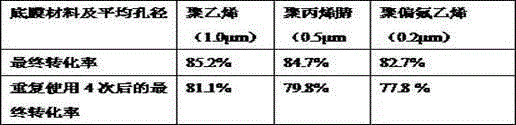

Preparation method for polyvinyl alcohol/attapulgite-polyion liquid catalytic esterification composite membrane

ActiveCN105056772AEnhanced mechanical strength and thermalGood chemical stabilitySemi-permeable membranesPtru catalystPolyvinyl alcohol

The invention discloses a preparation method for a polyvinyl alcohol / attapulgite-polyion liquid catalytic esterification composite membrane. The preparation method comprises the following steps: adding an attapulgite clay / polyion liquid composite catalyst (ATP-PILs) immobilized with a high-density acidic site into a polyvinyl alcohol (PVA) solution for alloying to form a membrane casting solution, and stewing for defoaming; then coating a smooth and clean glass plate or a microhole basement membrane with the defoamed membrane casting solution; then performing drying, heating and crosslinking after-treatment to form a per-vaporized compact catalytic esterification membrane with a catalysis function. The PVA dense membrane is filled with attapulgite immobilized with the high-density acidic site, so that the mechanical strength and the thermal and chemical stability of the membrane are improved; furthermore, the surface of the catalysis membrane has the high-density acidic catalysis site, and an efficient integrated membrane reaction-separator is constructed; in the catalytic esterification reaction of oleic acid and methyl alcohol, the oleic acid methyl alcohol conversion rate is up to about 90 percent; after the polyvinyl alcohol / attapulgite-polyion liquid catalytic esterification composite membrane is repeatedly used for 4 times, the oleic acid methyl alcohol conversion rate is reduced by about 5 percent or less.

Owner:HUAIYIN TEACHERS COLLEGE

Prepn process of iodized plant ethyl oleate

ActiveCN101020633AImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationVegetable oilEthyl ester

The present invention relates to preparation process of iodized vegetable oil ethyl ester. Iodized vegetable oil is first produced with vegetable oil and hydrogen iodide gas through addition reaction, and iodized vegetable oil and ethanol then produce ester exchange reaction under the action of alkali catalyst to produce iodized vegetable oil ethyl ester, with the hydrogen iodide gas being produced through reaction of iodine, red phosphorus and water. The present invention has facile cheap materials and high conversion rate of ester exchange reaction, and the product has low viscosity.

Owner:季珉

Gas-phase rust-preventing aerosol and preparation process thereof

ActiveCN103232883AExtended service lifeImprove rust resistanceLubricant compositionGas phaseMethyl oleate

The invention discloses a gas-phase rust-preventing aerosol and a preparation process thereof. The formula of the gas-phase rust-preventing aerosol comprises the following components in parts by mass: 0.5-1.5 parts of caprylic acid tributylamine, 1-3 parts of benzotriazole tributylamine, 2.5-3.5 parts of oleic acid, 1-3 parts of laurinol, 0.2-0.8 part of amino silicon oil, 2.5-3.5 parts of methyl oleate, 0.2-0.8 part of sodium petroleum sulfonate, 0.2-0.8 part of barium petroleum sulfonate, 0.5-1.5 parts of capric acid tributylamine, 51.5-61.5 parts of 20# machine oil and 27-33 parts of liquefied petroleum gas. The process comprises the following steps: mixing and stirring the raw materials; filling the obtained liquid into a spray can; inserting a capillary valve; filling the liquefied petroleum gas; performing leak detection, and blowing-dry; and boxing, and warehousing. The invention has the characteristics of small aerosol particle diameter and high aerosol particle uniformity DR, and can effectively enhance the corrosion inhibition effect of a metal component.

Owner:ZHEJIANG LUDAO TECH CO LTD

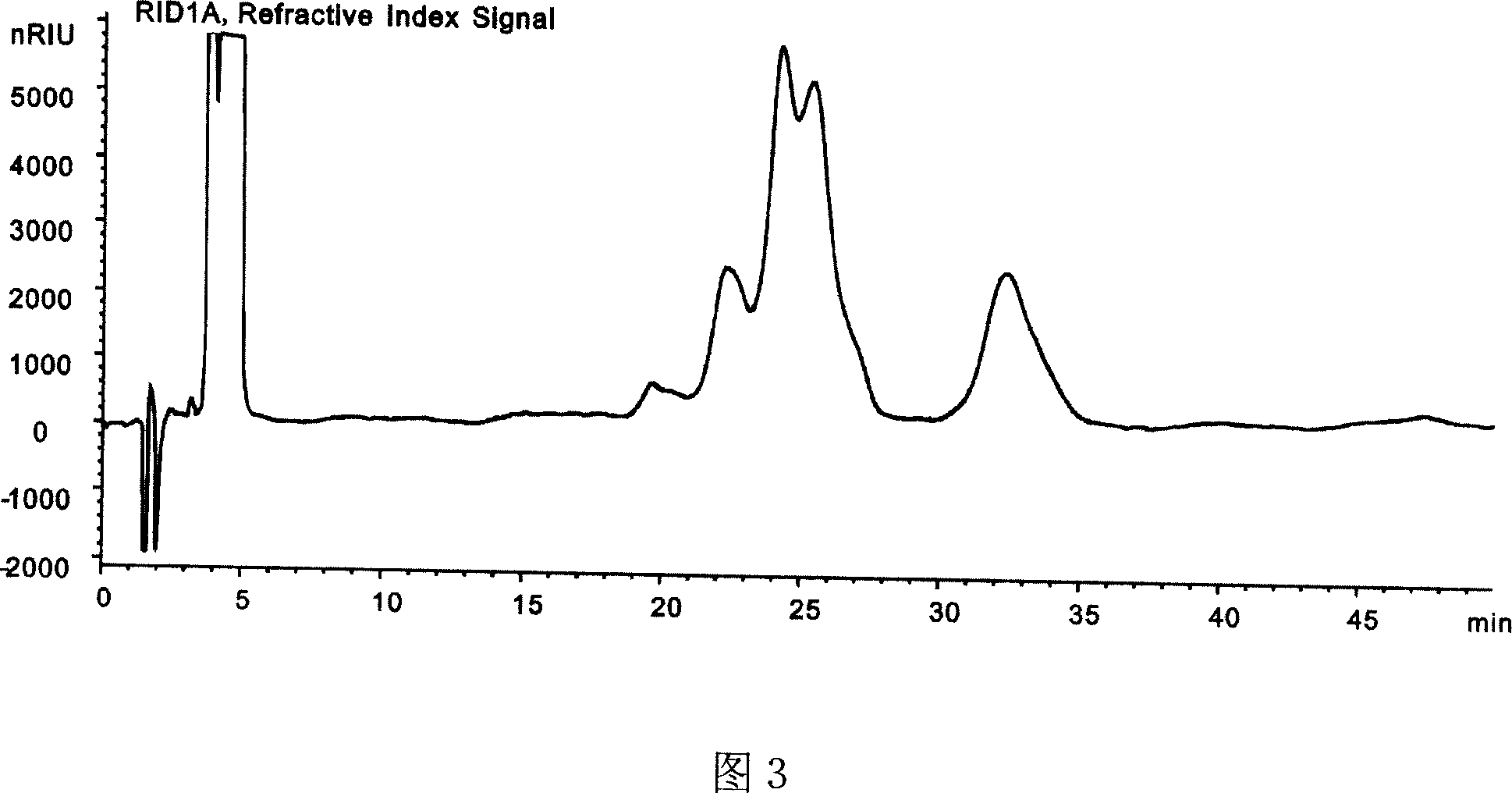

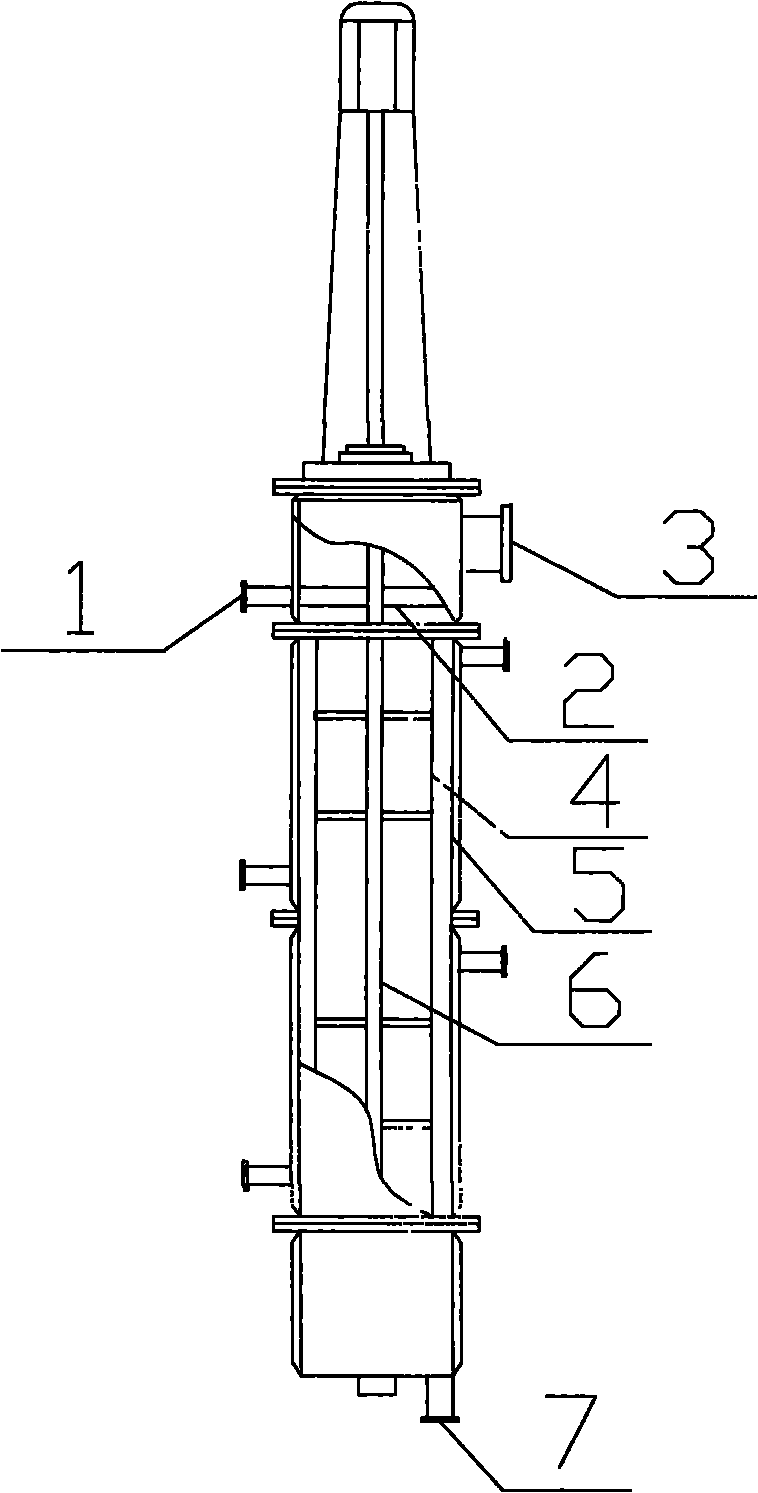

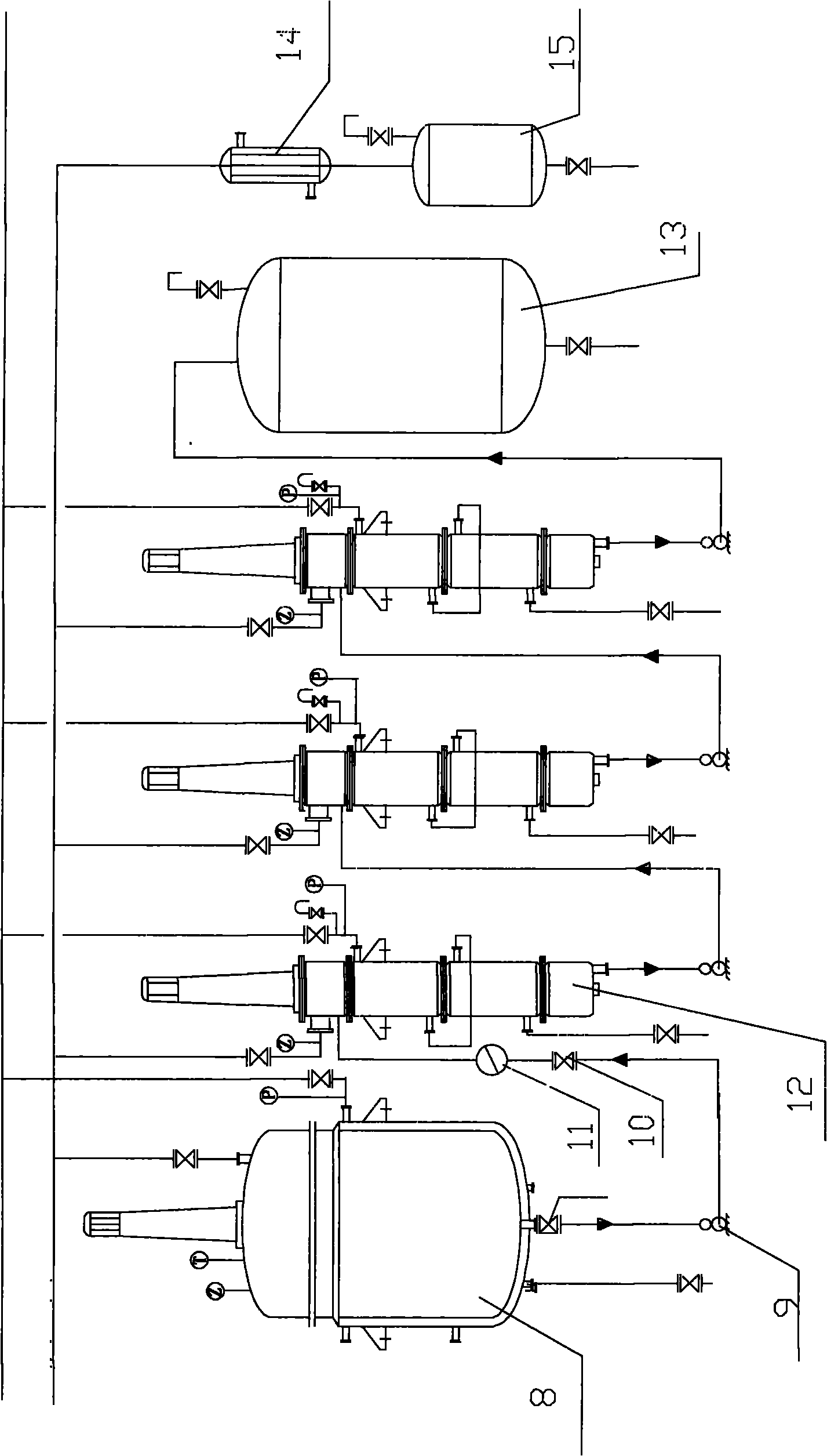

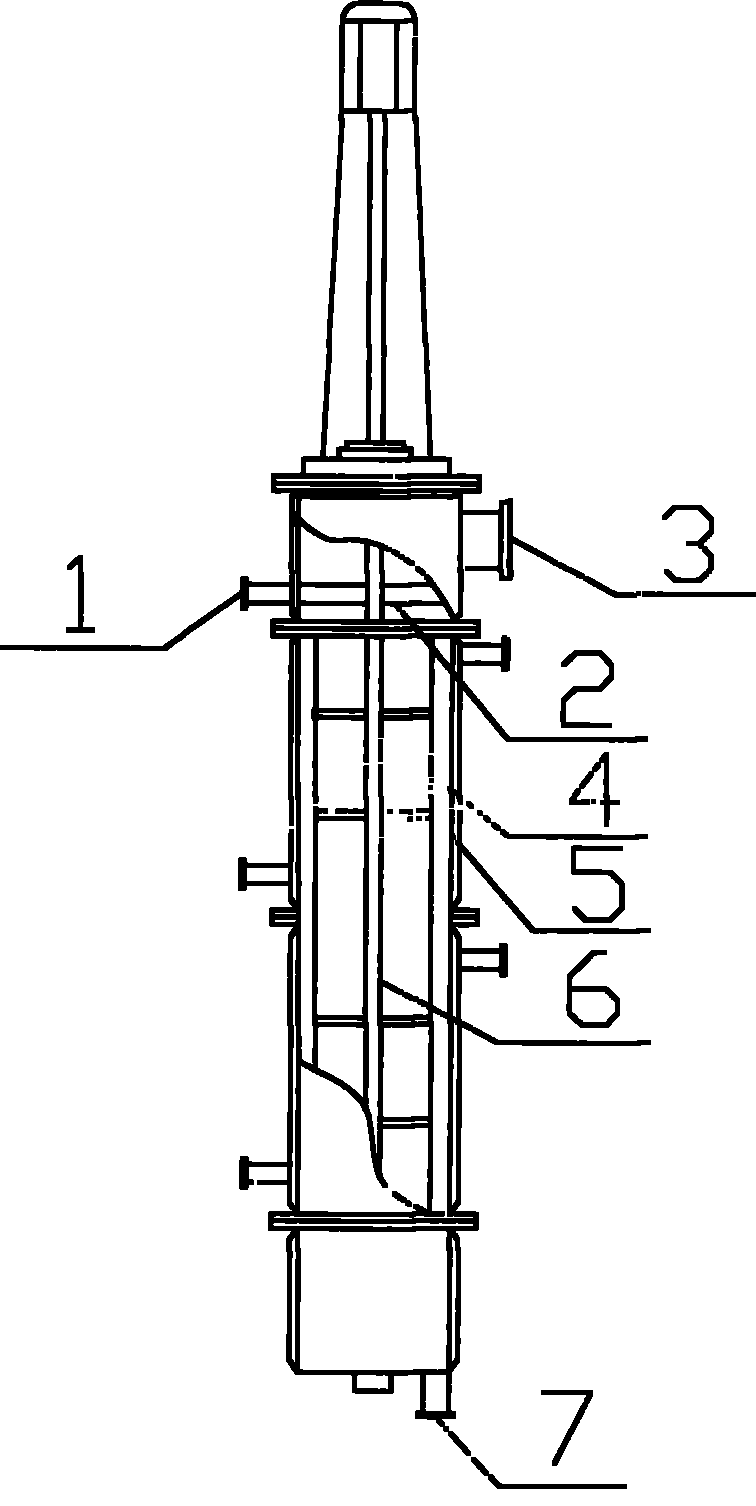

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

InactiveCN102093438AIncrease contact areaSimple interfaceEsterified saccharide compoundsSugar derivativesResource utilizationPOTASSIUM STEARATE

The invention discloses a process for synthesizing sucrose polyester, particularly a process for synthesizing sucrose polyester by using a rotating film transesterification flow reactor. The process comprises the following steps: methyl oleate, sucrose powder, potassium stearate and potassium carbonate are added into a mixing kettle, and heated while stirring; the materials enter the rotating film transesterification flow reactor to react; the crude fatty acid sucrose polyester product obtained after the reaction enters a product storage tank, and the reaction product methanol enters a methanol receiver after being cooled by a condenser; and the crude product in the product storage tank is neutralized with acetic acid, washed and dried to obtain the sucrose polyester product. The low-boiling-point substances generated in the process provided by the invention are quickly removed out of the reaction system, thereby being beneficial to the generation of the product, greatly increasing the reaction speed and enhancing the product quality. The process can be used for continuous-feeding production, is beneficial to large-scale production, enhances the production efficiency, has the advantages of high yield and simple process, lowers the production cost and raises the resource utilization ratio.

Owner:ADANA FOOD TECH LIUZHOU

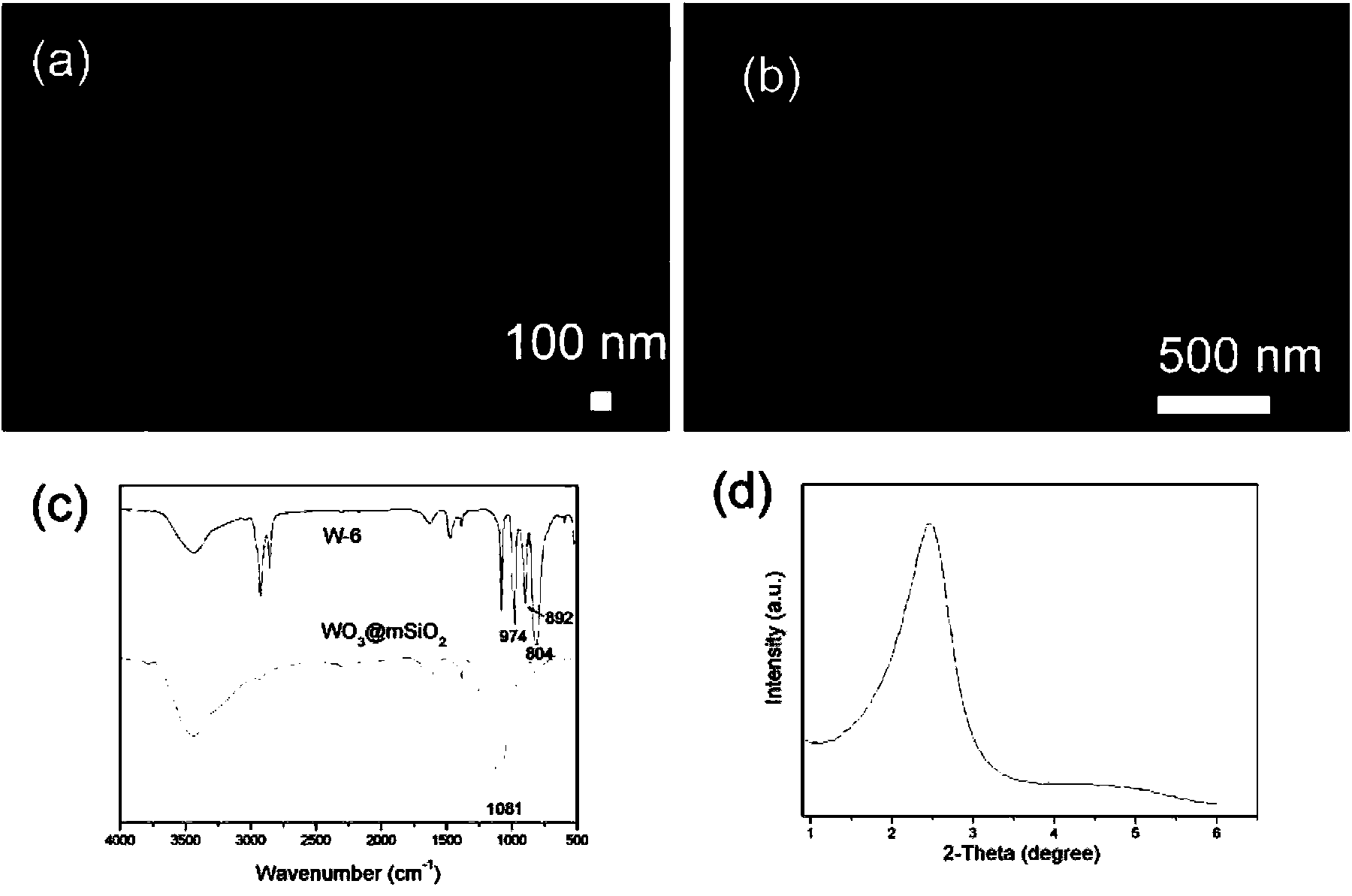

WO3@mSiO2 microballoon sphere with nuclear shell hollow structure as well as preparation method and application thereof

ActiveCN103433032AHigh esterification rateInhibit aggregationFatty acid esterificationOrganic compound preparationDispersityBiodiesel

The invention discloses a prepared WO3@mSiO2 microballoon sphere as well as a preparation method and an application thereof, belonging to the technical field of preparation of nano materials. The preparation method comprises the steps of utilizing hexadecyl trimethyl ammonium phosphotungstate as a nucleus and covering one layer of SiO2 by adopting a sol-gel method; then calcining to obtain the WO3@mSiO2 microballoon sphere with a nuclear shell hollow structure. The WO3@mSiO2 microballoon sphere is good in dispersity, has a grain diameter of 500nm-600nm and has the nuclear shell hollow structure; the nucleus is WO3 and the shell is porous SiO2. The microballoon sphere has a very good catalytic effect on an esterification reaction for synthesizing methyl oleate (biodiesel) by taking oleic acid and methanol as raw materials; the reaction temperature is 90 DEG C and the reaction time is 8 hours; the mass ratio of the oleic acid to the methanol is 1 to 5.2; the esterification rate of the oleic acid can be up to 97.6% under the condition that the use amount of a catalyst is 36% of the mass of the oleic acid.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Abiraterone oral spray and use and preparation methods thereof

InactiveCN105055314ACorrectly designedTake a small doseOrganic active ingredientsAerosol deliveryPolyoxyethylene castor oilMetabolite

The invention relates to the technical field of pharmaceutical preparations and particularly relates to an abiraterone oral spray. The abiraterone oral spray comprises the following components in percent by weight: abiraterone acetate, an oil phase, a surfactant, a co-surfactant and the balance of water, wherein the oil phase is used as a carrier for prompting system micro-emulsification, and the oil phase is medium chain triglyceride, ethyl oleate or oleic acid; the surfactant is used for improving the performance of the abiraterone oral spray, expanding the range of application and realizing solubilization, and the surfactant is polyoxyethylene 40 hydrogenated castor oil or polyoxyethylene 35 castor oil; and the co-surfactant is used for reducing the surface tension of liquid and enhancing the emulsifying, moistening and blistering effects, and the co-surfactant is ethanol, n-butyl alcohol or propylene glycol. The spray has the advantages that the taking dose is reduced, so that the manufacturing cost is lowered; the formation of invalid metabolites is reduced, so that adverse reactions are effectively reduced; and the drug effect of the spray is longer than that of an oral drug.

Owner:HANGZHOU ANDE TECH CO LTD

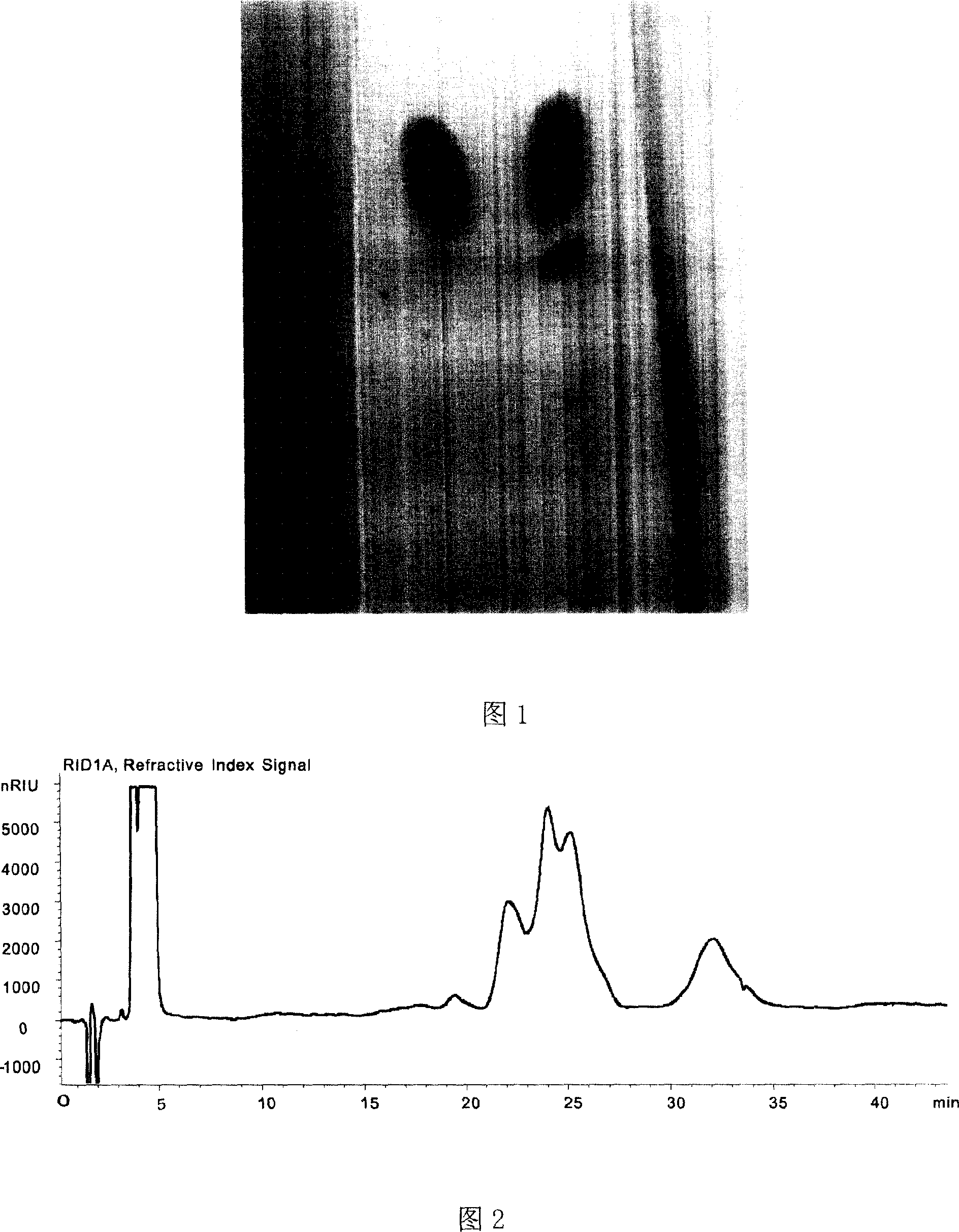

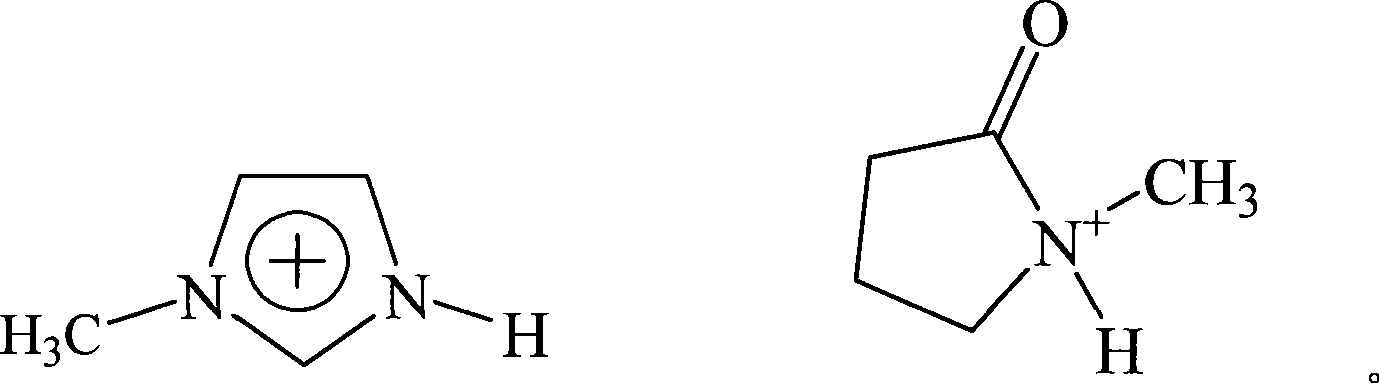

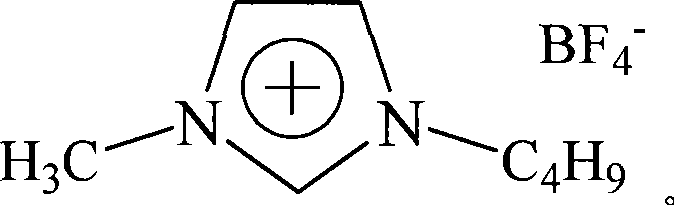

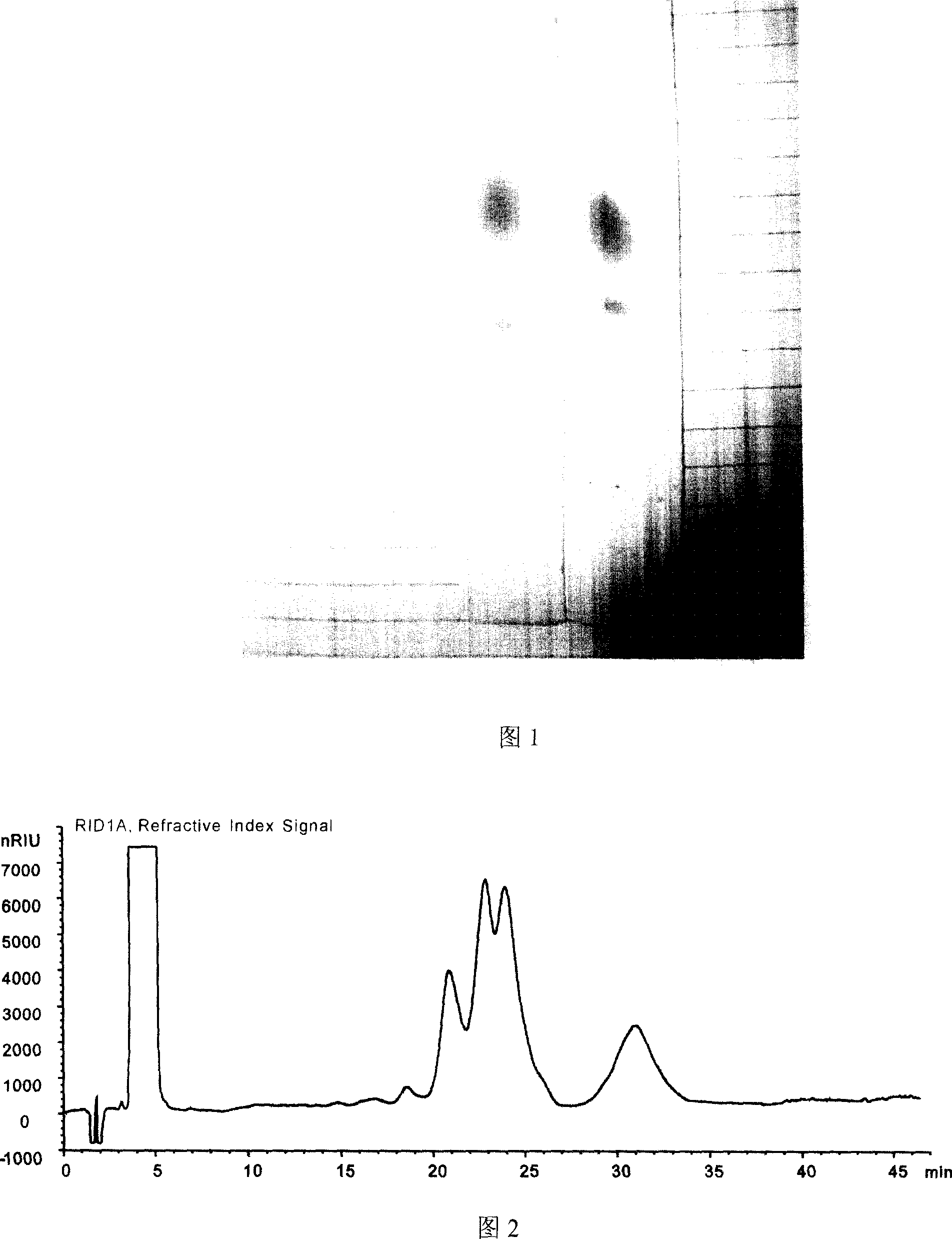

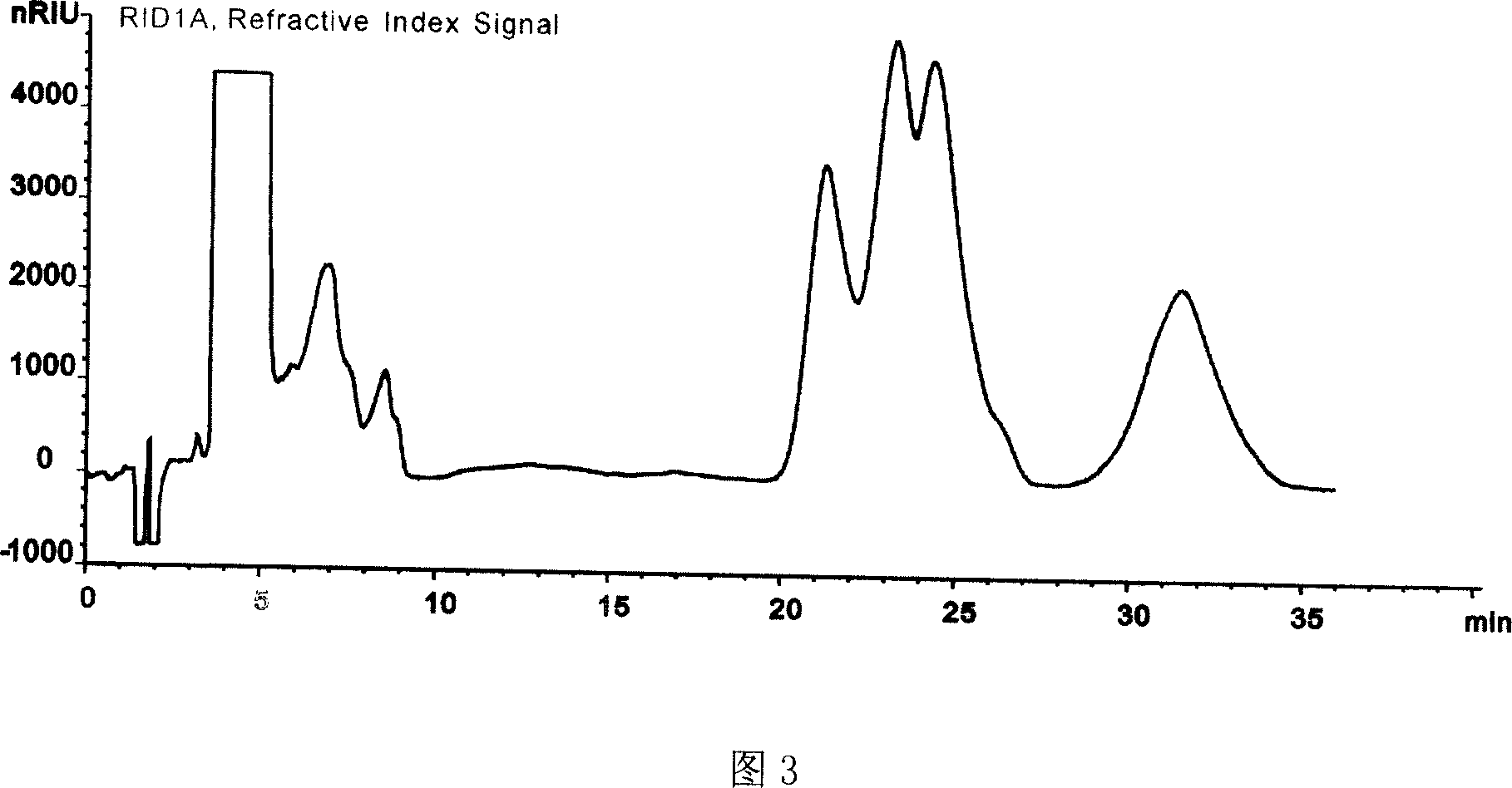

Method for synthesizing methyl oleate and epoxy methyl oleate in ion liquid medium

InactiveCN101391956ACan be used repeatedlyTo achieve the effect of energy saving and emission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateLiquid medium

The invention discloses a method for synthesizing methyl oleate and epoxy methyl oleate in ionic liquid medium, which pertains to the technical field of fine chemical synthesis. The invention adopts N-methylimidazole positive ion or ionic liquid composed of N-methyl-2-ketopyrrolidine positive ion liquid and inorganic anions as the catalyst and the medium for reaction; under normal atmosphere, oleic acid and methanol are catalyzed to react for generating methyl oleate; and the invention also adopts 1-methyl-3-n-butylimidazolium chloride ionic liquid as the reaction medium and [Bmim]W10O23 as the catalyst, and under normal atmosphere, uses the synthesized methyl oleate to carry out epoxidation reaction by being dropped with oxyful of 30 percent, thus generating the epoxy methyl oleate. Compared with the traditional catalyzing method, the invention has the advantages that: 1. the reaction temperature is low, the reaction time is short and the energy consumption is low without pollution; 2. the separation process is easier; and 3. the ionic liquid medium used in the reaction can be reused after being simply processed.

Owner:JIANGNAN UNIV

Synthesis of iodized plant ethyl oleate for injection

ActiveCN101020634AMild reaction conditionsRaw materials are easy to getOrganic compound preparationCarboxylic acid esters preparationAnhydrous ethanolVegetable oil

The present invention is process of synthesizing iodized vegetable oil ethyl ester. Vegetable oil ethyl ester is first produced through the ester exchange reaction of vegetable oil and anhydrous ethanol under the action of alkali catalyst, and then addition reacted with hydrogen iodide gas to produce iodized vegetable oil ethyl ester, with the hydrogen iodide gas being produced through reaction of iodine, red phosphorus and water. The present invention has facile cheap materials, and the product has high stability, low viscosity, light color and other features.

Owner:季珉

Matrine type alkaloid microemulsion and preparation method thereof

InactiveCN101548679APlay a preventive roleIncrease contactBiocideArthropodicidesDispersitySolubility

The invention relates to matrine microemulsion and a preparation method thereof, which overcomes the defects of low solubility and low bioavailability of matrine and improves the stability of matrine microemulsion. The invention adopts microemulsion as a pharmaceutical carrier to prepare matrine O / W type microemulsion with liquid drop of 1 to 100nm particle size so as to improve the dispersity of enveloped medicaments, promote the percutaneous absorption of plant surface cuticle and strengthen the effect of eliminiting insect injury, thereby providing scientific basis for theory and application study. The invention also relates to a method of forming stable O / W emulsion by doping matrine into oil. The compound comprises matrine, oil phase, water and surfactant. In a preferred embodiment, the oil is tween 80, an emulgator is ethyl oleate, and an emulgator assistant is absolute ethyl alcohol. The medicament content of soluble water aqua of matrine type alkaloid microemulsion is improved,the medicament effect is strengthened, the cost is saved and the medicament is more effectively to be absorbed by crops by forming matrine type alkaloid O / W microemulsion.

Owner:SHENYANG PHARMA UNIVERSITY

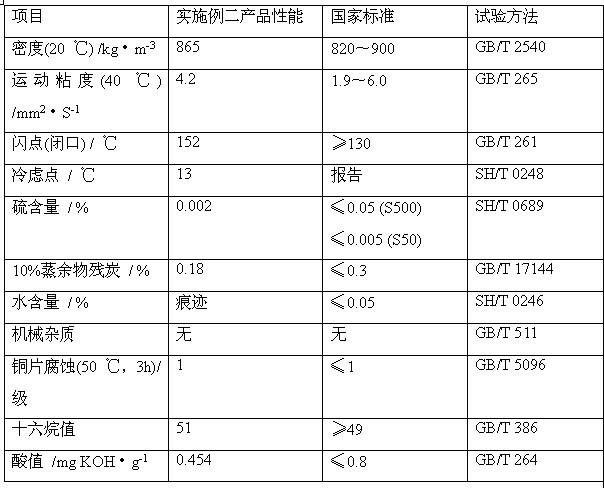

Biodiesel prepared by non-edible vegetable oil and method thereof

InactiveCN102585927AExcellent cetane numberExcellent flash pointFatty acid esterificationBiofuelsMethyl linoleateVegetable oil

The invention relates to biodiesel prepared by non-edible vegetable oil and a method thereof, which belong to the biodiesel field. By-product milk thistle oil produced during the production process of Silibinin serves as a raw material for preparing the biodiesel. The biodiesel is obtained by transesterification of the milk thistle oil and methyl alcohol under the condition of a catalyst. Gas chromatography-mass spectrometry analysis results show that main components of the biodiesel prepared by the milk thistle oil serving as the raw material are methyl oleate and methyl linoleate. The biodiesel is high in cetane number, excellent in performance and capable of meeting China current biodiesel standard. In addition, the biodiesel is simple in process, mild in reaction condition, low in cost and capable of achieving large-scale production.

Owner:JIANGSU UNIV

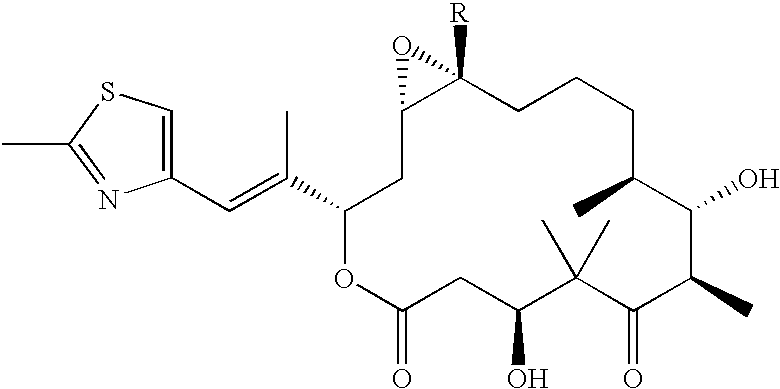

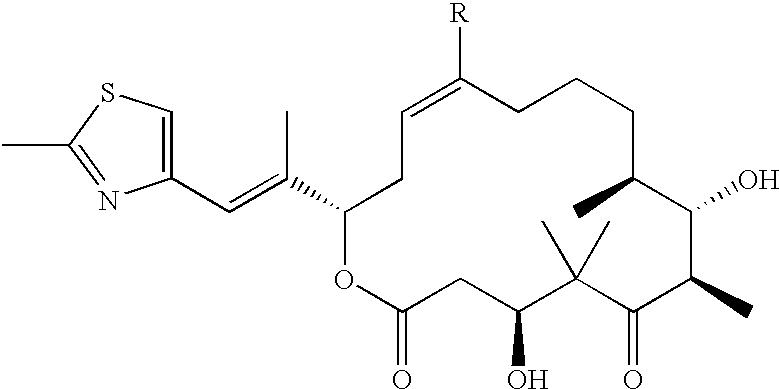

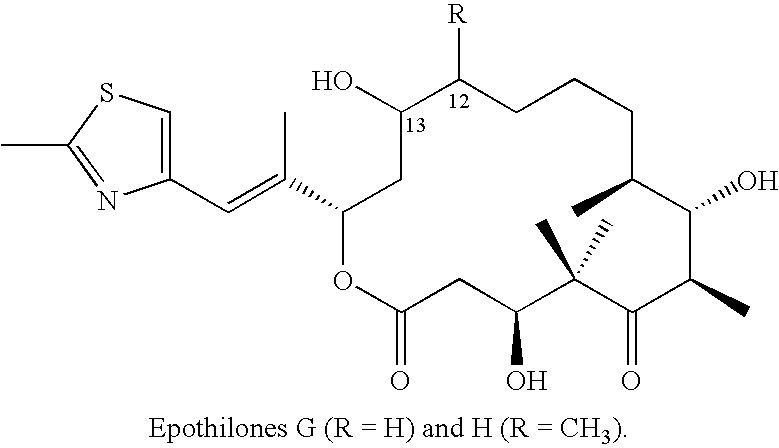

Methods of obtaining epothilone D using crystallization and /or by the culture of cells in the presence of methyl oleate

InactiveUS6998256B2Useful in treatmentProduce epothilonesOrganic chemistryBacteriaMyxococcus xanthusMethyl oleate

Methods are provided for purification of epothilone D and epothilone D analogs from epothilone producing cells such as, for example, Sorangium cellulosum and Myxococcus xanthus (recombinant). Epothilone can be purified from fermentation broth, for example by using resins, chromatography, and crystallization. Epothilone D can be crystallized from a binary solvent system in which water is the forcing solvent.

Owner:KOSAN BIOSCI

Method for epoxidating methyl oleate

InactiveCN101928267AMild reaction conditionsShort reaction timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventOrganic layer

The invention discloses a method for epoxidating methyl oleate, which comprises the following steps of: adding the methyl oleate into a reactor, adding a catalyst and an organic solvent, heating the mixture to the required reaction temperature of 50 to 70 DEG C, keeping constant the temperature, adding dropwise hydrogen peroxide with the concentration of 30 weight percent according to the mass ratio of the hydrogen peroxide to the methyl oleate of 1-2:1 in a way of ensuring that the dropwise addition of the hydrogen peroxide is finished within 2 to 2.5 hours, and continuing to preserve the heat for 2 to 6 hours after the dropwise addition is finished, wherein the mass ratio of the organic solvent to the methyl oleate is 2.0-5.0:1, and the mass ratio of the catalyst to the methyl oleate is 5-25:1,000; standing the reacted mixed solution in an environment of 5 to 10 DEG C for 3 to 5 hours to slowly separate the catalyst out and filtering the mixed solution to remove the catalyst; and standing and demixing filtrate, and distilling an organic layer under reduced pressure to remove the organic solvent to obtain the product epoxy methyl oleate. The method has the advantages of easy post-treatment, no environmental pollution, and high percent conversion and selectivity.

Owner:CHINA RES INST OF DAILY CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com