Synthesis of iodized plant ethyl oleate for injection

A synthesis method and technology of ethyl oil, applied in the synthesis field of iodinated vegetable oil ethyl ester for injection, can solve the problems of enzyme toxicity, high price, high price and the like, and achieve mild reaction conditions, good product stability and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

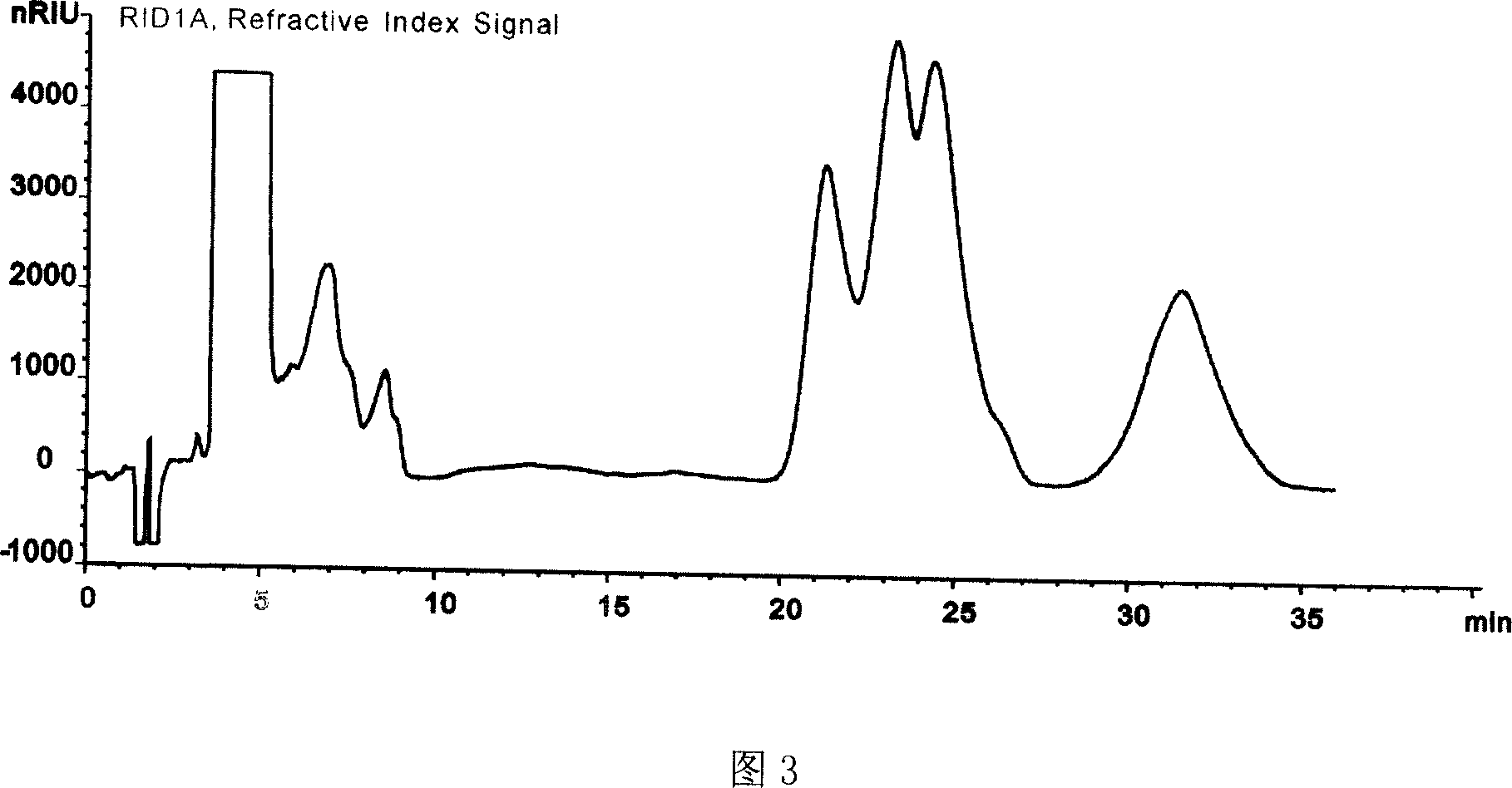

[0020] Embodiment 1 (synthesis of iodized poppy seed oil ethyl ester):

[0021] 1. Synthesis of poppy seed oil ethyl ester

[0022] Raw material and source:

[0023] Poppy Seed Oil 【Gansu Nongken Medicine Station Vegetable Oil Factory】

[0024] Absolute ethanol [Shanghai Zhenxing Chemical No. 1 Plant Analytical Pure]

[0025] Potassium hydroxide [Shanghai Experimental Reagent Co., Ltd. analytically pure]

[0026] Add 1.3g of potassium hydroxide to 30ml of absolute ethanol, then add 100g of poppy seed oil, heat the reaction mixture to 80°C, stir and react at this temperature for 5 hours, then recycle the absolute ethanol under reduced pressure to obtain the phase preparation Poppy seed oil ethyl ester, the crude poppy seed oil ethyl ester was washed with distilled water to remove potassium hydroxide and by-product glycerol, and then dried at a vacuum of 400 Pa and 80°C to obtain 81g poppy seed oil ethyl ester.

[0027] 2. Synthesis of iodinated poppy seed oil ethyl ester

...

Embodiment 2

[0035] Embodiment 2 (the synthesis of iodized walnut kernel oil ethyl ester)

[0036] Raw material and source:

[0037] 1. Synthesis of walnut kernel oil ethyl ester

[0038] Walnut Kernel Oil 【Dalian Ruifang Biochemical Products Co., Ltd.】

[0039] Absolute ethanol [Shanghai Zhenxing Chemical No. 1 Plant Analytical Pure]

[0040] Sodium ethylate [Zibo Fuxier Chemical Co., Ltd. analytically pure]

[0041] Add 3.5g of sodium ethylate to 30ml of absolute ethanol, then add 100g of walnut kernel oil, heat the reaction mixture to 80°C, stir and react at this temperature for 6 hours, then recover the absolute ethanol under reduced pressure to obtain crude walnuts Kernel oil ethyl ester, wash the crude walnut kernel oil ethyl ester with distilled water, to remove sodium ethylate and by-product glycerin, dry at vacuum degree 300Pa, 80 ℃ again, obtain 78g walnut kernel oil ethyl ester.

[0042] 2. Synthesis of ethyl iodide walnut kernel oil

[0043] Raw material and source:

[0044...

Embodiment 3

[0049] Embodiment 3 (synthesis of iodized peanut oil ethyl ester):

[0050] 1. Synthesis of peanut oil ethyl ester,

[0051] Raw material and source:

[0052] Peanut oil 【Luhua Peanut Oil Co., Ltd.】

[0053] Absolute ethanol [Shanghai Zhenxing Chemical No. 1 Plant Analytical Pure]

[0054] Sodium [Sinopharm Chemical Reagent Co., Ltd. analytically pure]

[0055] Add 2.2g of sodium to 30ml of absolute ethanol, the sodium ethoxide produced by the reaction of sodium and ethanol is the catalyst, then add 100g of peanut oil, heat the reaction mixture to 30°C, stir and react at this temperature for 8 hours, and then recover under reduced pressure Dehydrated ethanol to obtain crude peanut oil ethyl ester, wash the crude peanut oil ethyl ester with distilled water to remove the catalyst sodium ethoxide and by-product glycerin, and then dry at a vacuum degree of 267Pa and 70°C to obtain peanut oil ethyl ester.

[0056] 2. Synthesis of iodized peanut oil ethyl ester

[0057] Raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com