Patents

Literature

3428 results about "Anhydrous ethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gasoline sold in Brazil contains at least 25% anhydrous ethanol. Hydrous ethanol (about 95% ethanol and 5% water) can be used as fuel in more than 90% of new gasoline fueled cars sold in the country. Brazilian ethanol is produced from sugar cane and noted for high carbon sequestration.

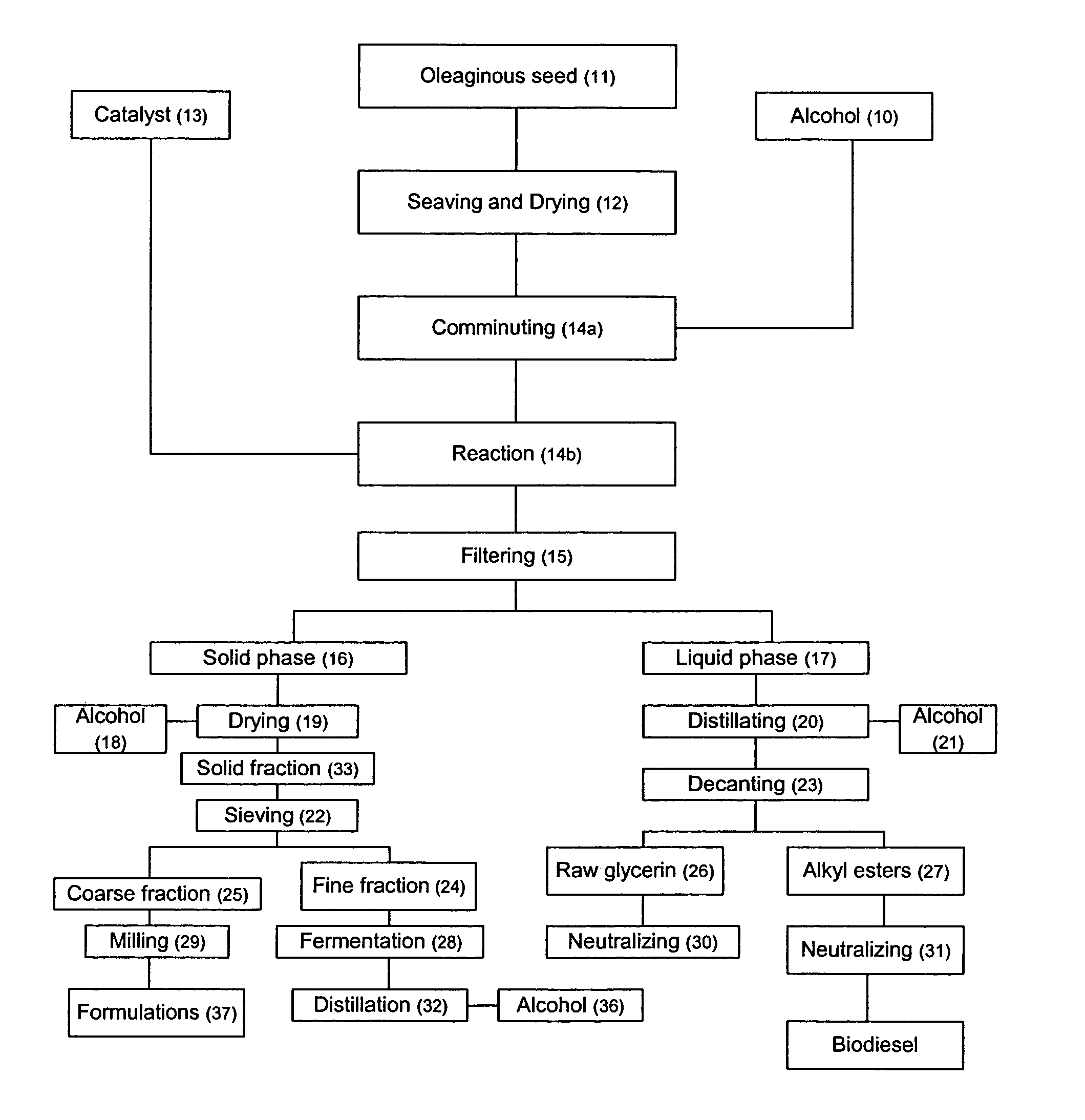

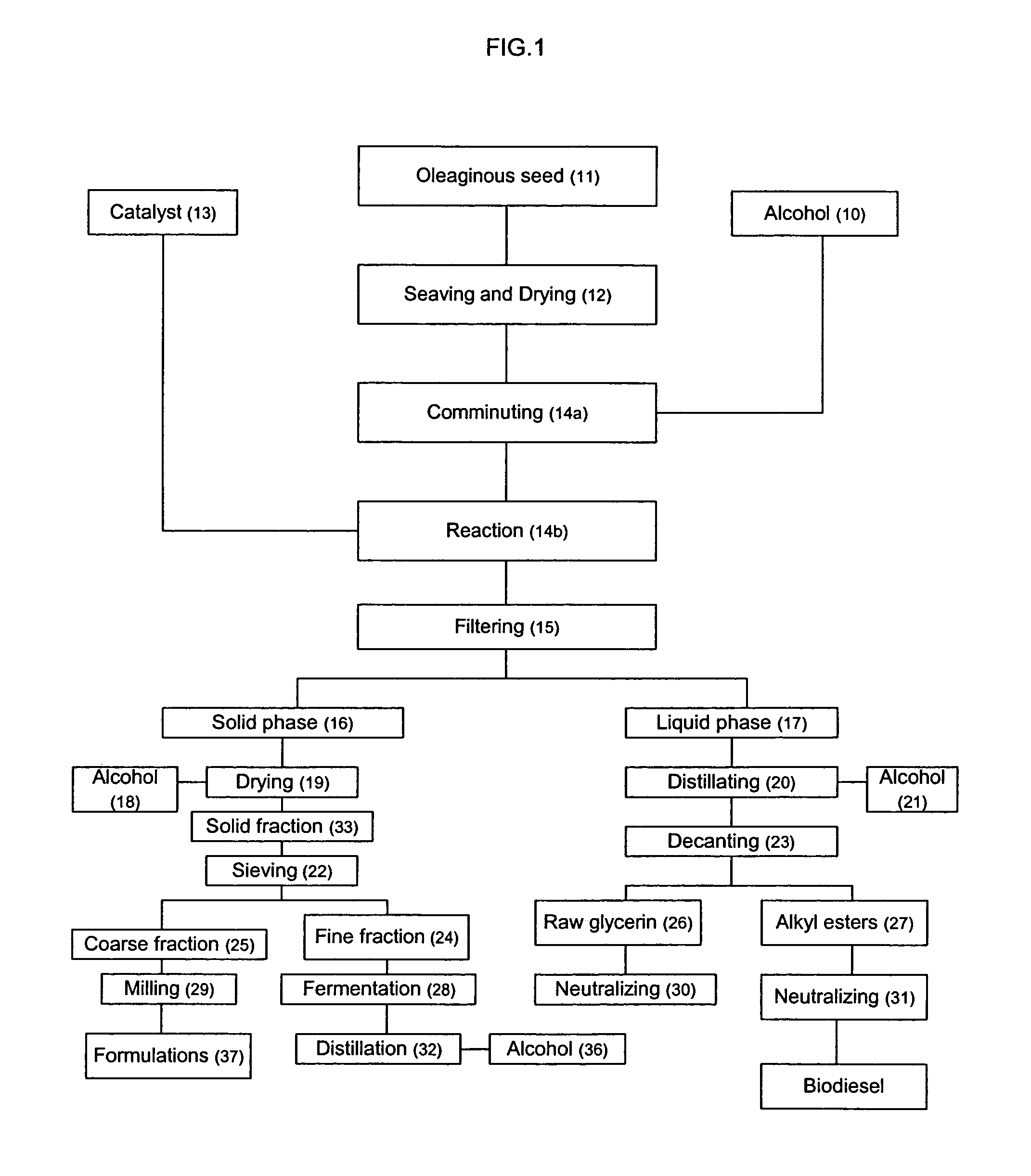

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

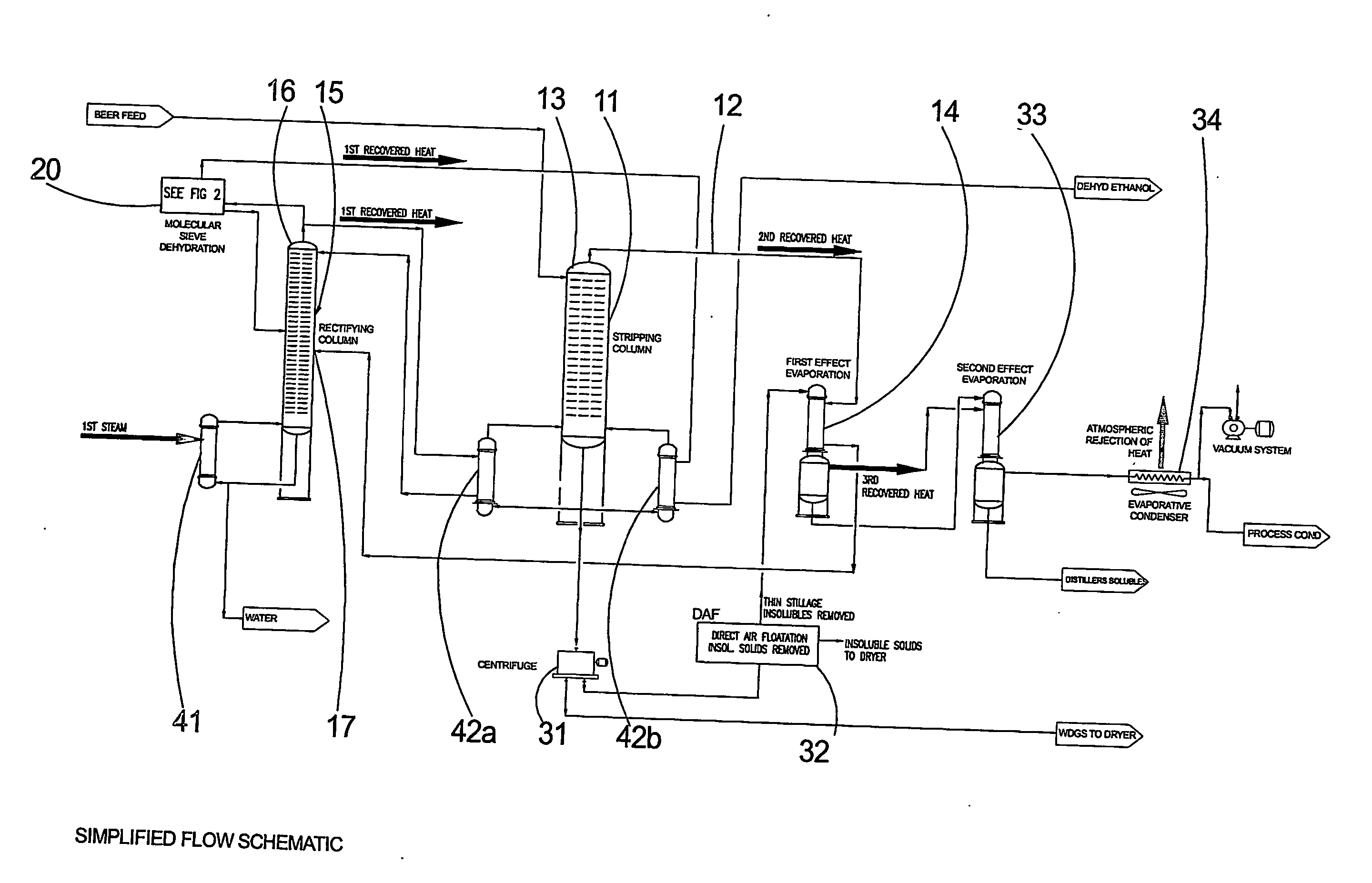

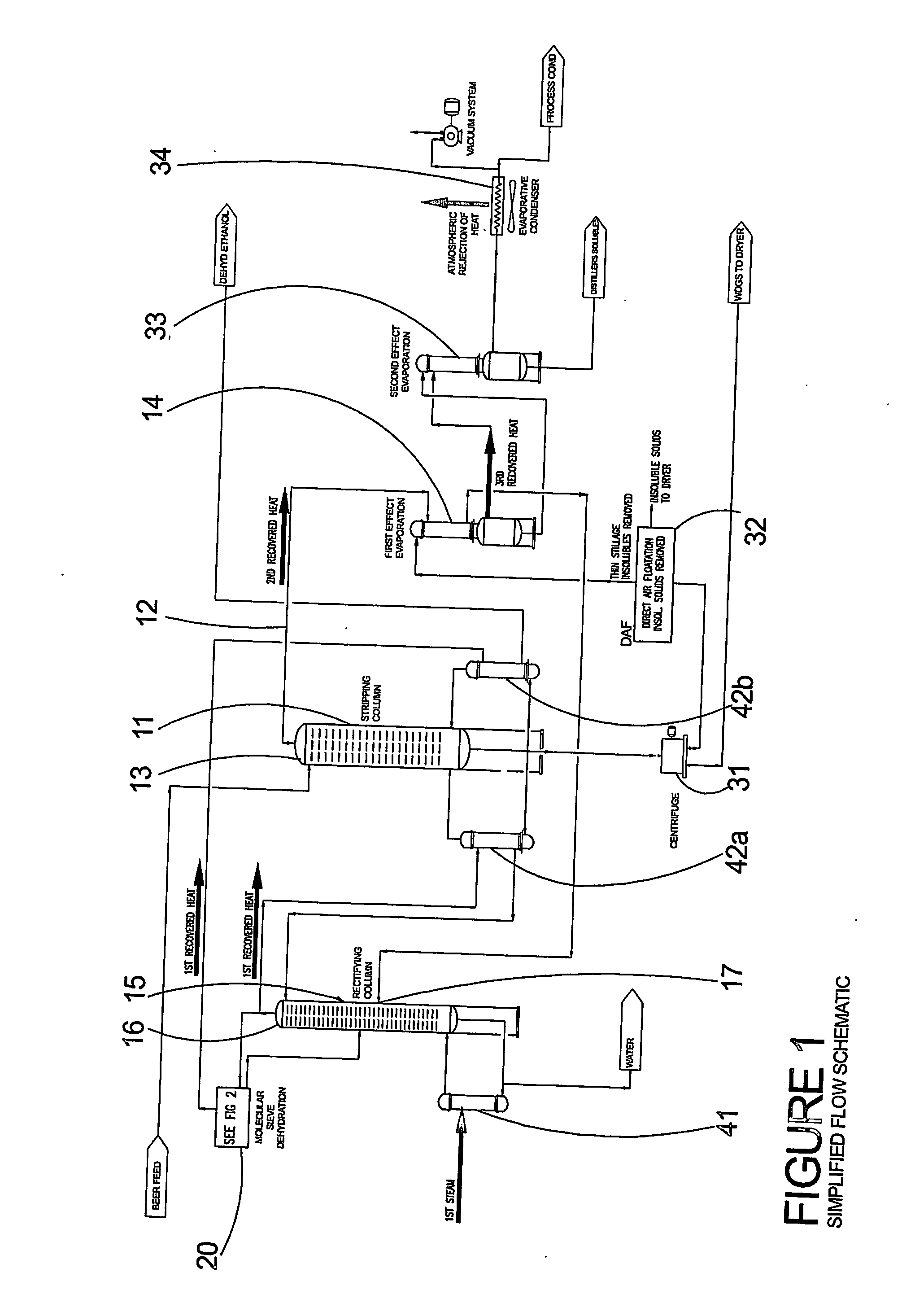

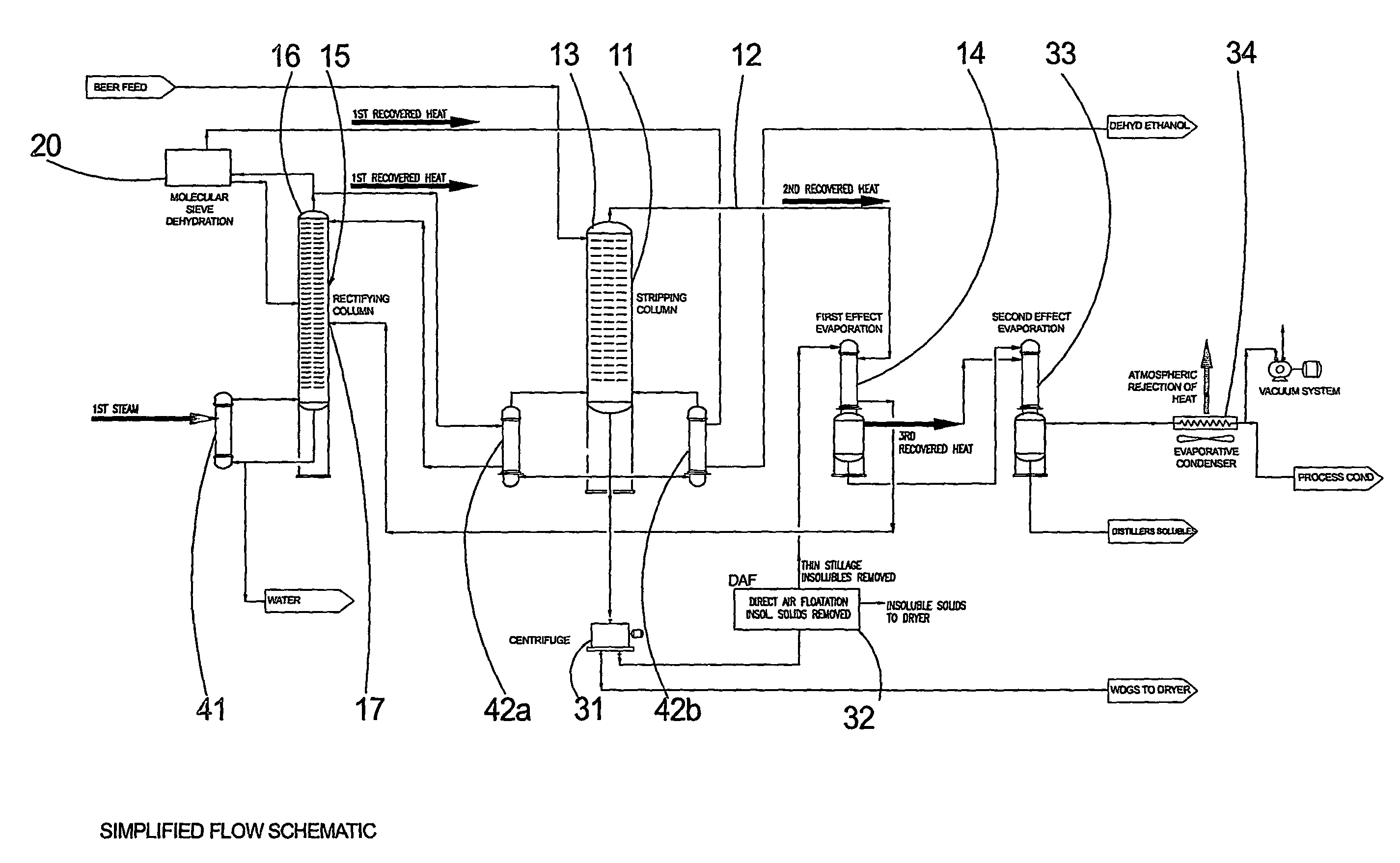

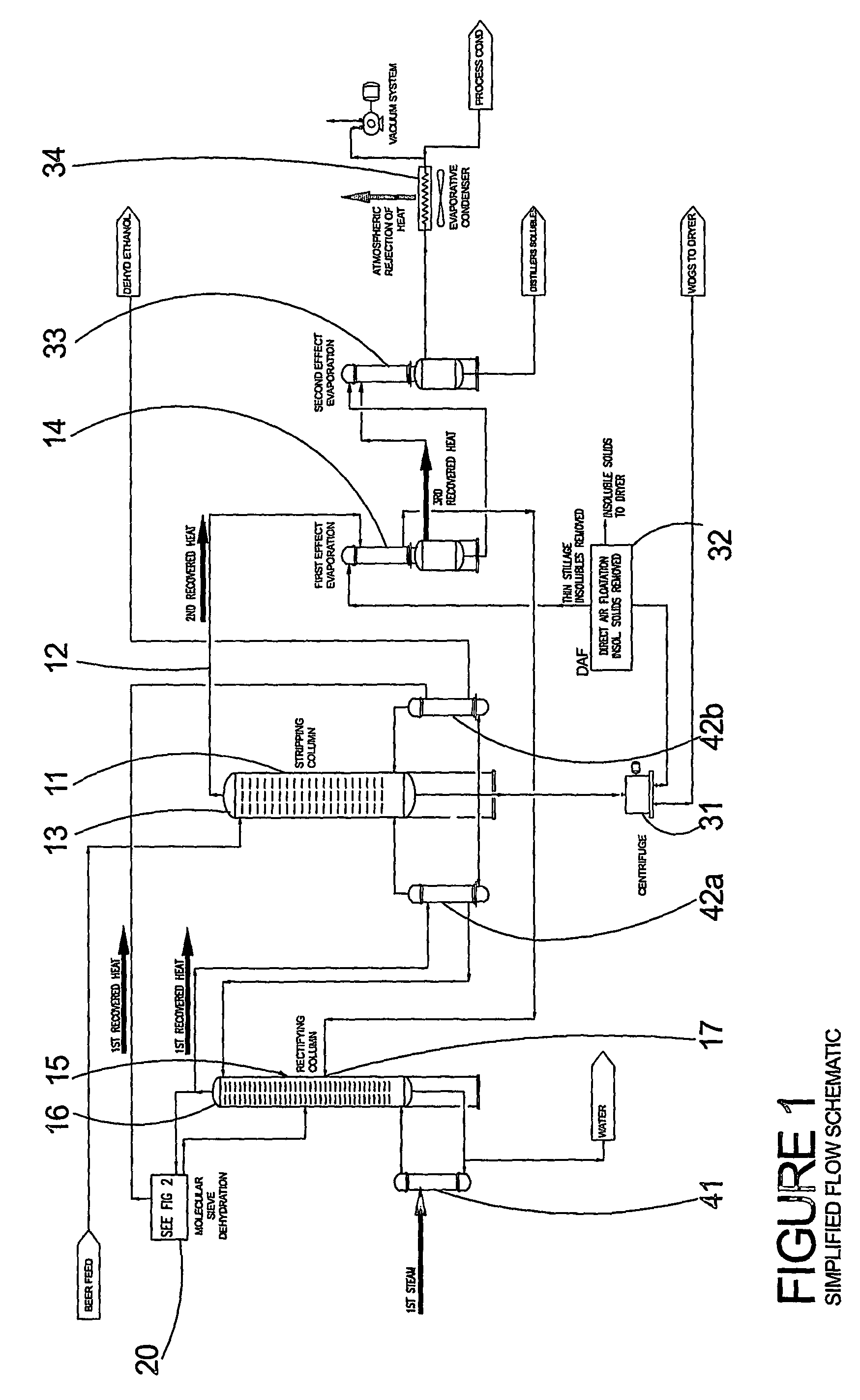

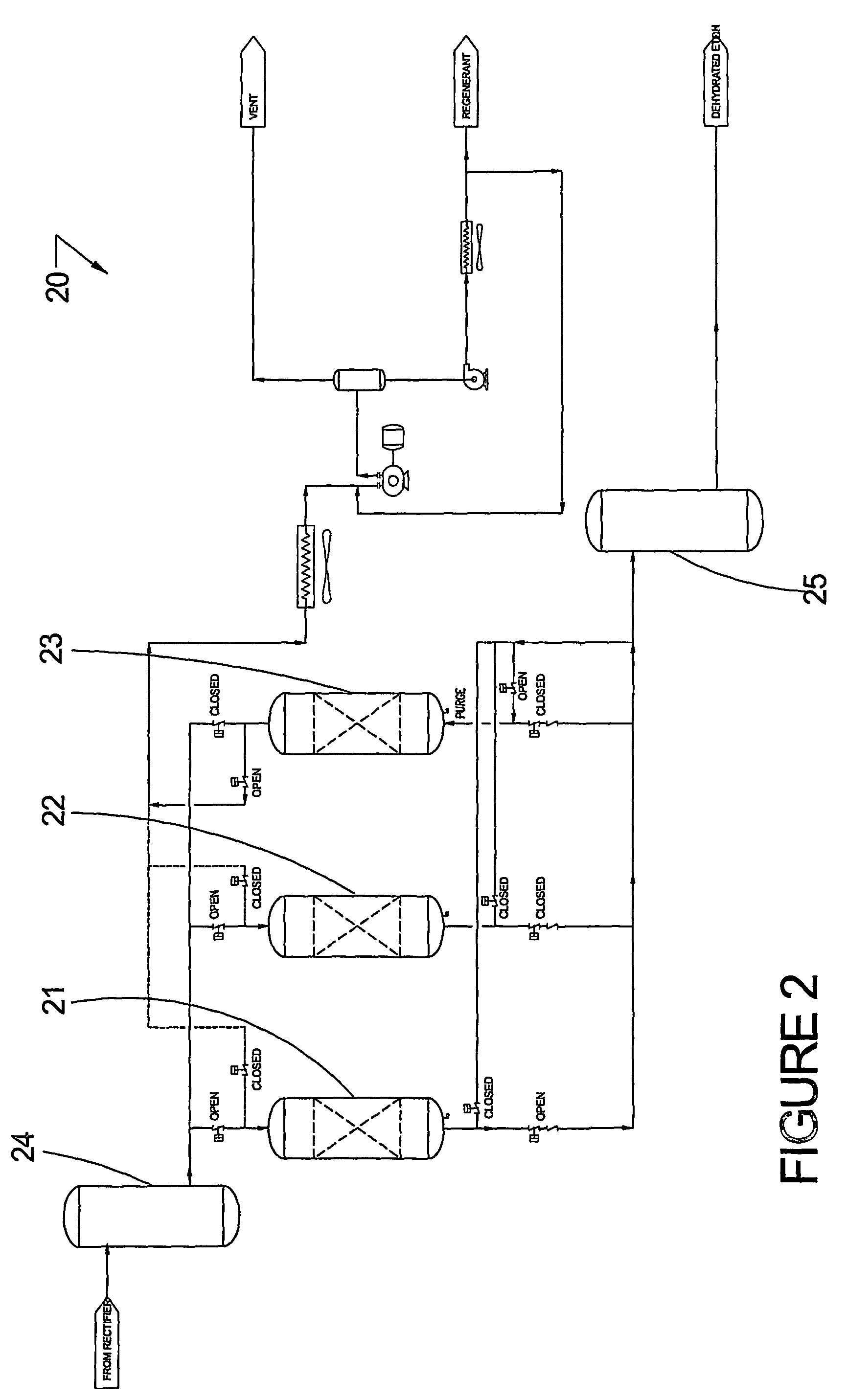

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS20070000769A1High operating temperatureReduce drying loadDistillation regulation/controlBiofuelsMolecular sieveAnhydrous ethanol

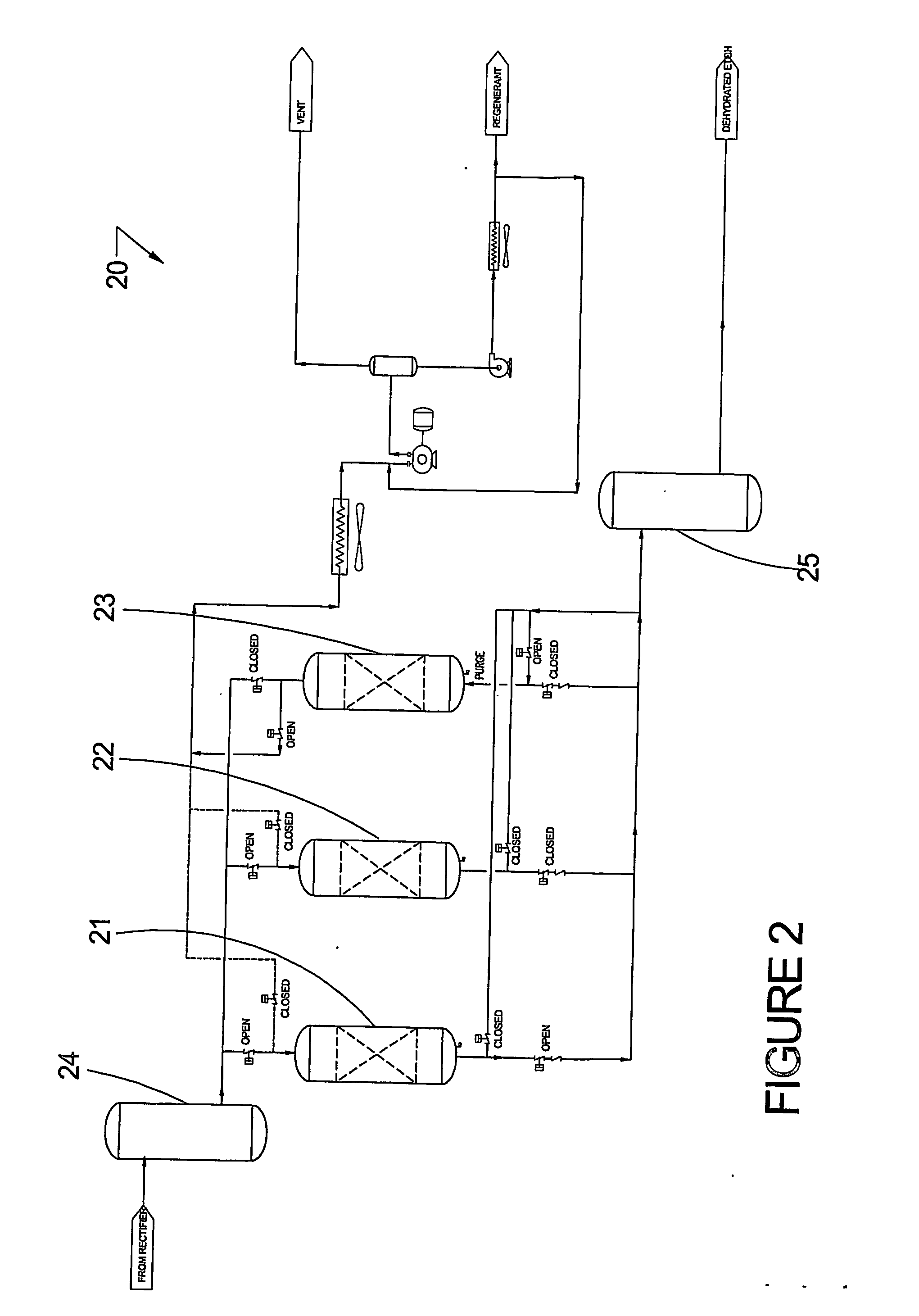

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column that operates between 160 to 220 degrees F.; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column; and (d) an energy control means.

Owner:RCM TECH USA INC

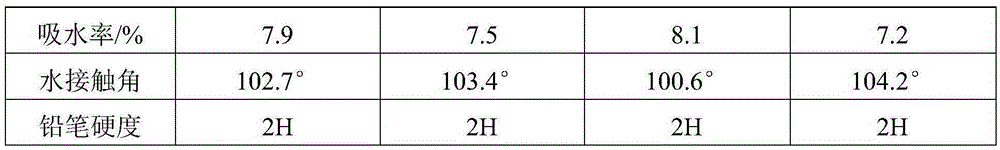

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

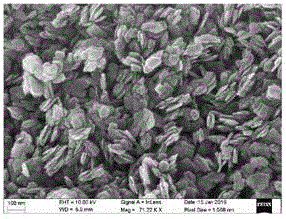

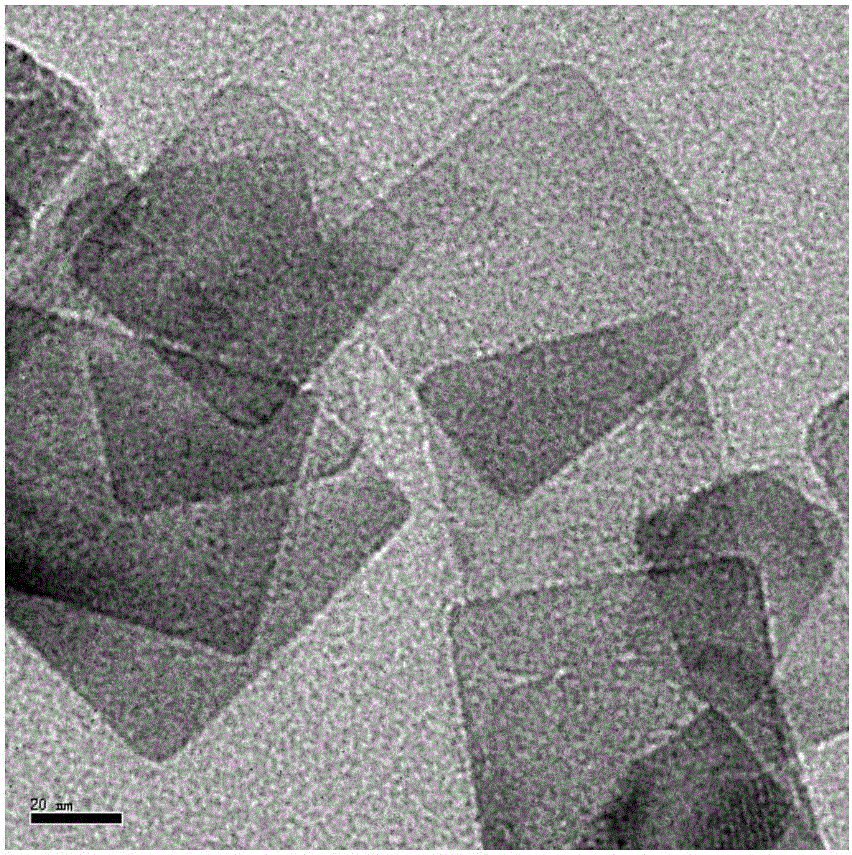

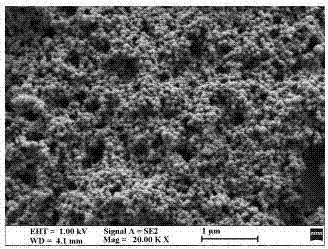

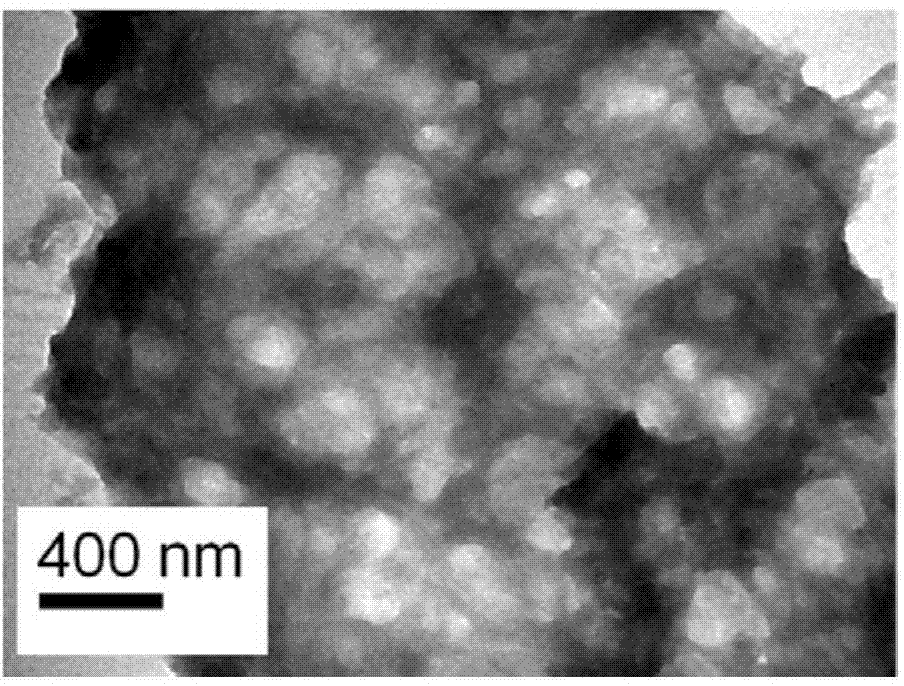

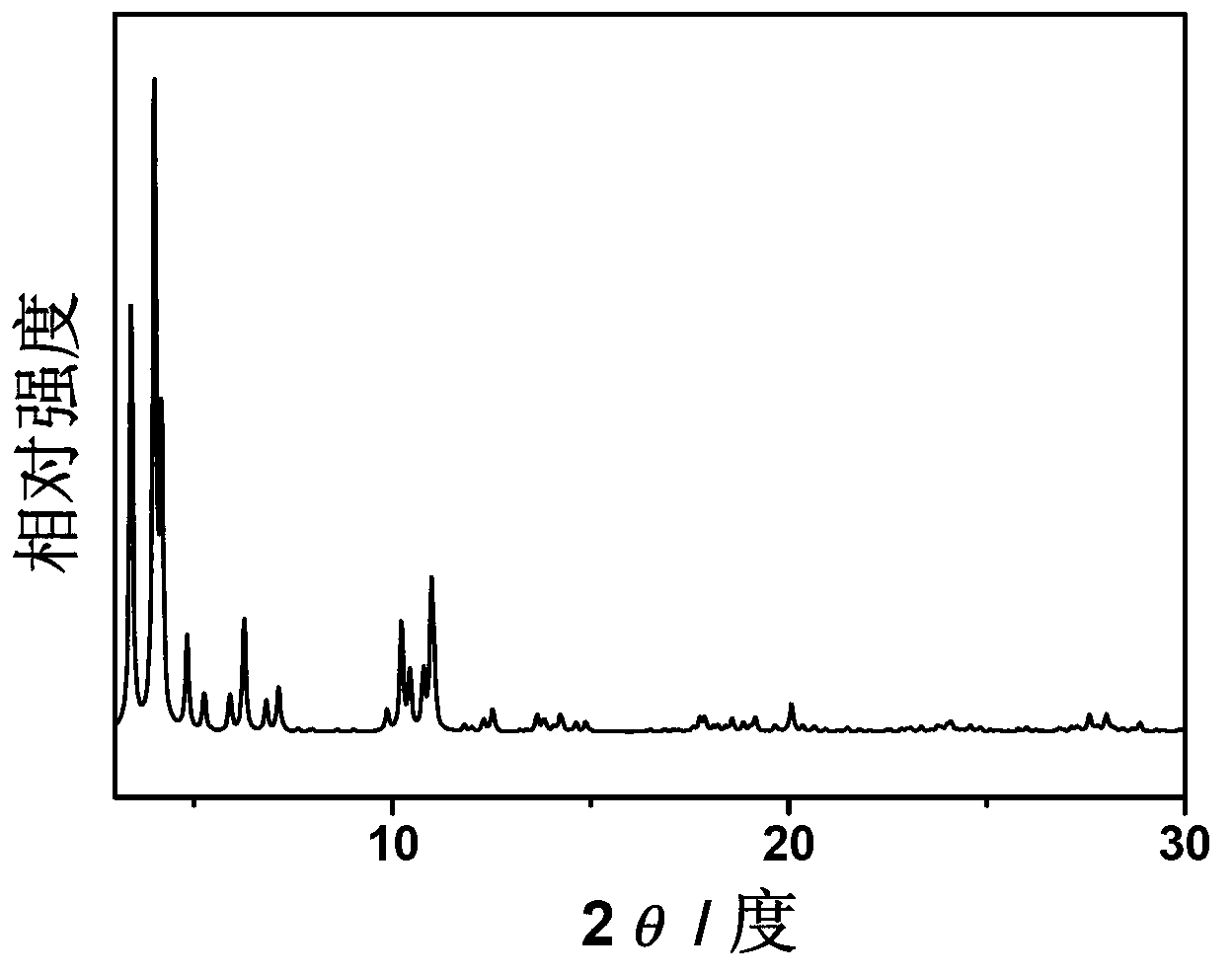

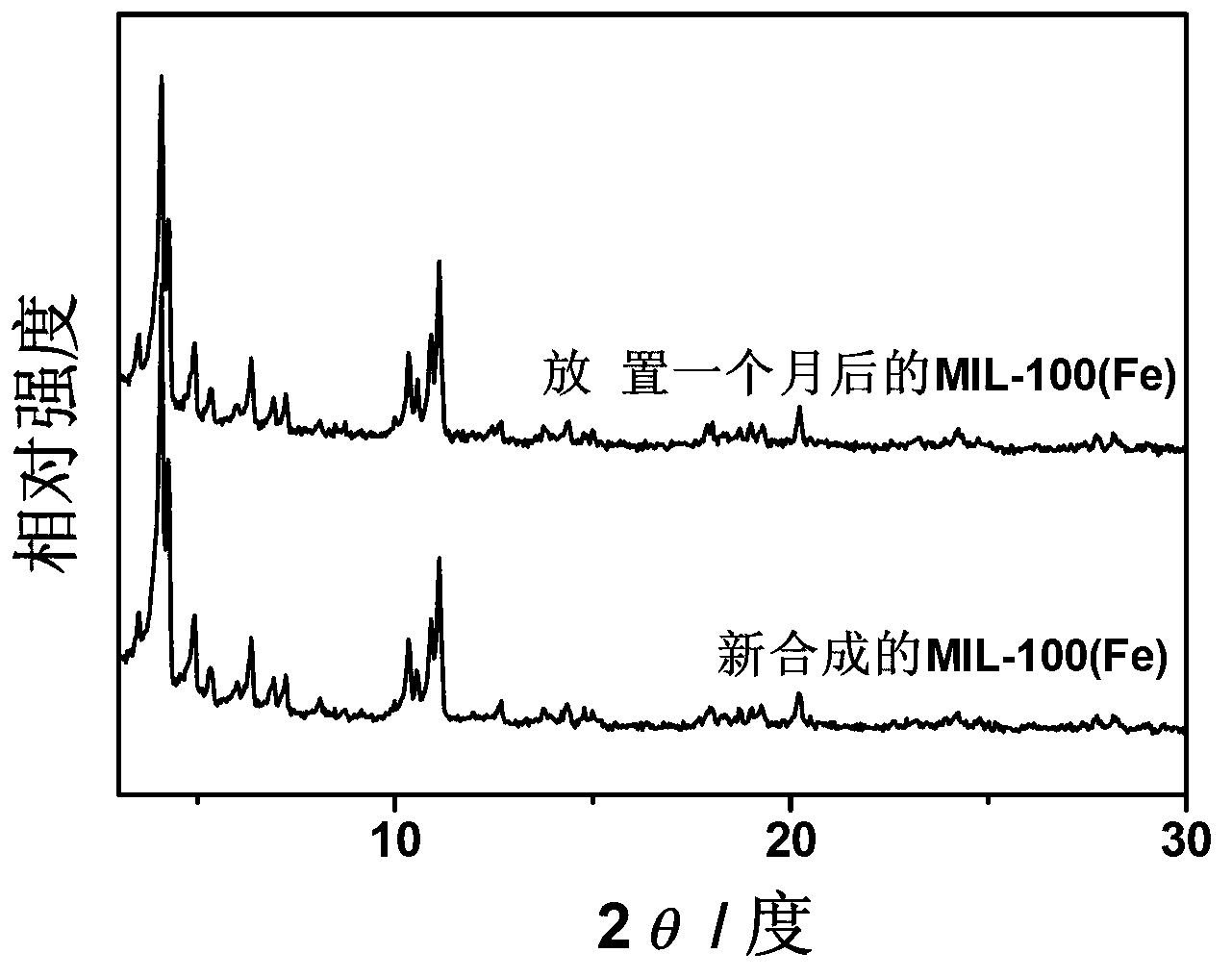

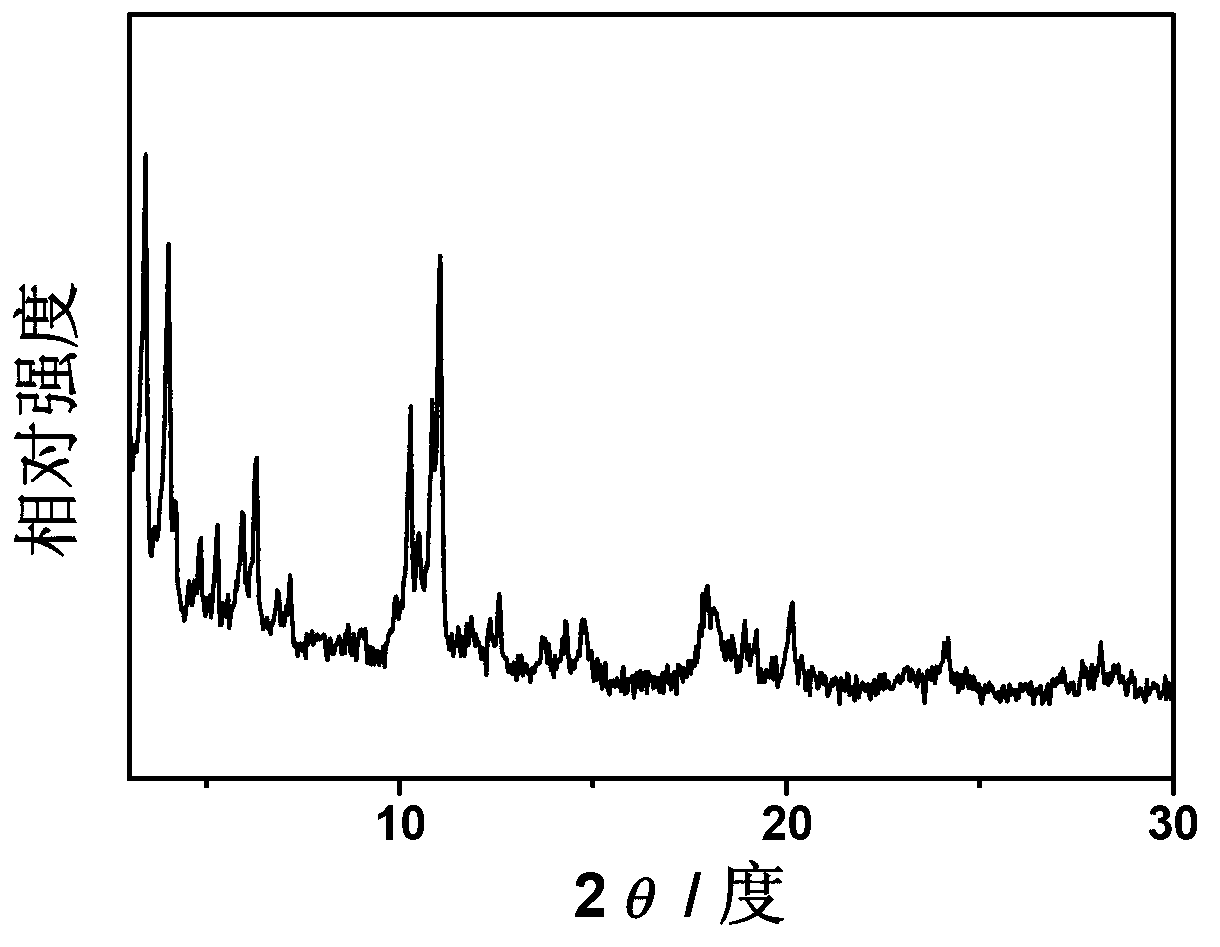

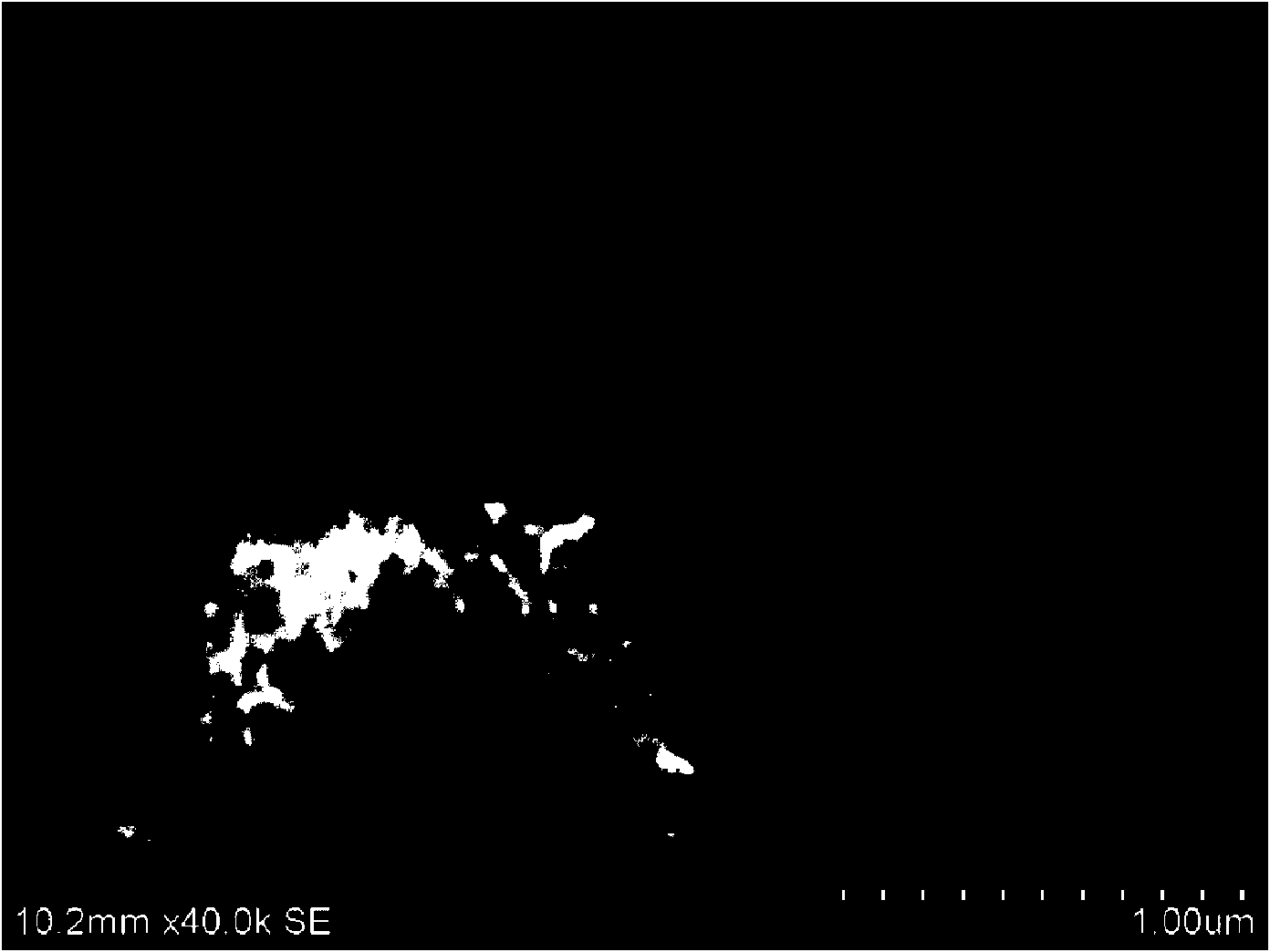

Preparation method and application method of titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material

ActiveCN106238100AShape is easy to controlImprove adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationWater baths

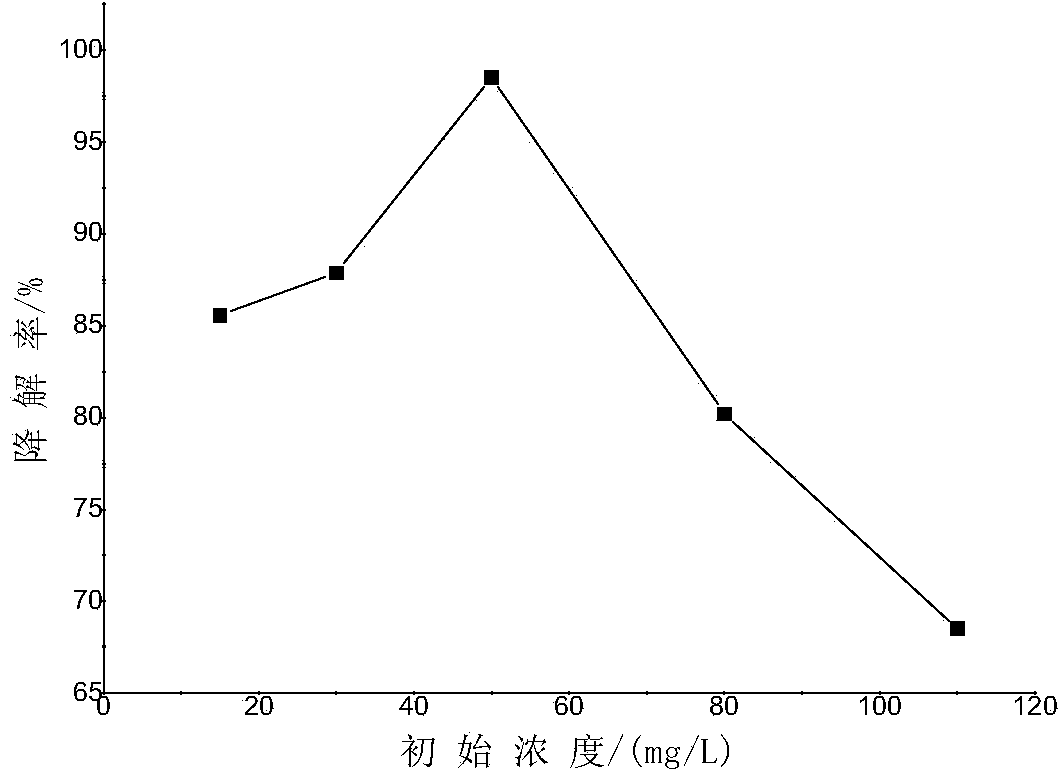

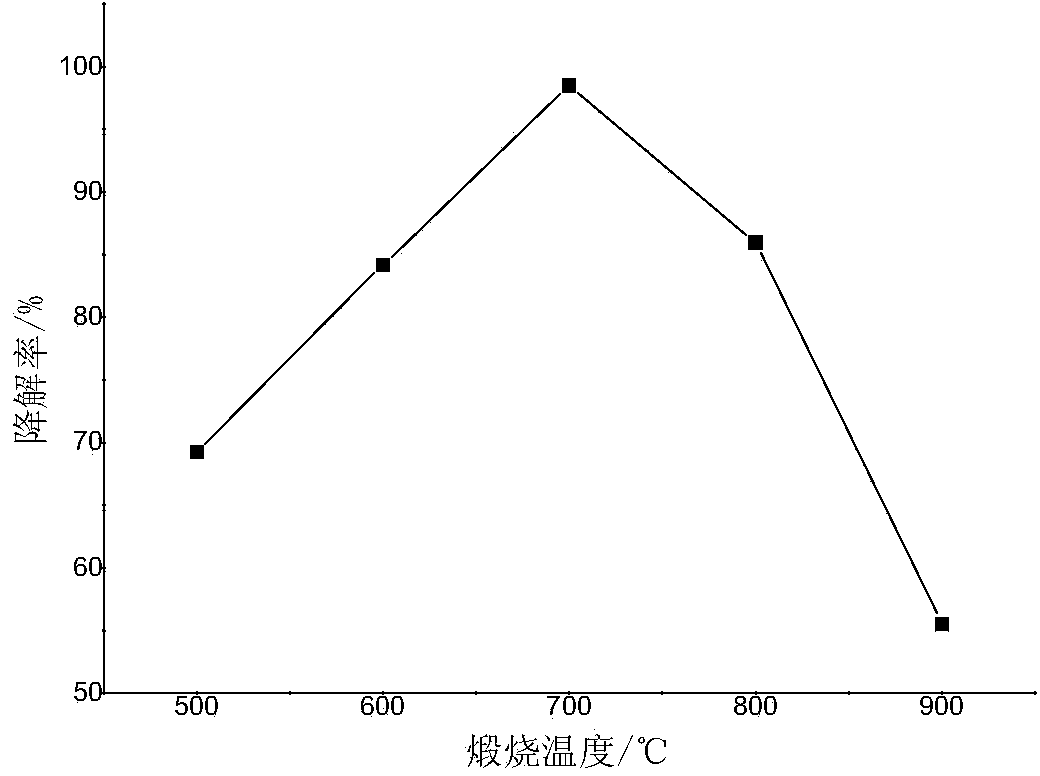

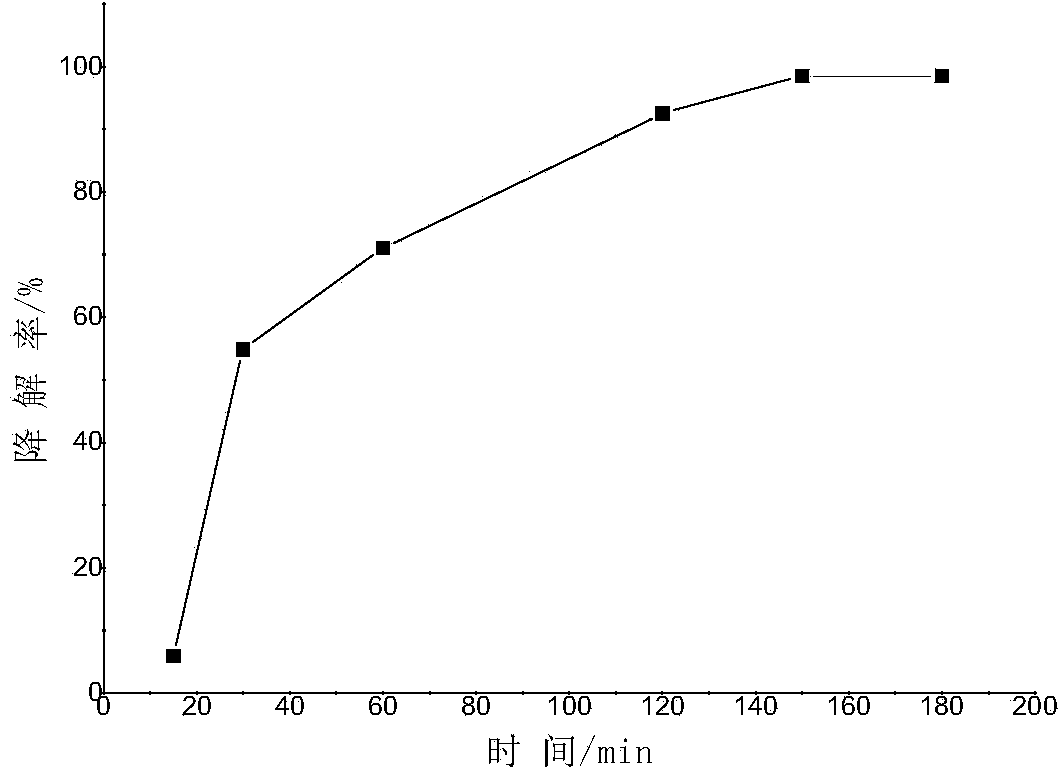

The invention relates to a preparation method and application method of a titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material, belongs to the field of titanium dioxide photocatalysis, and especially relates to the field of titanium dioxide nanosheet supported porous metal organic skeleton (MOFs) composite materials. The preparation method comprises the following steps: 1, uniformly stirring tetrabutyl titanate and hydrofluoric acid at normal temperature, putting the obtained mixture in a hydrothermal reaction kettle, carrying out a reaction, separating the obtained material, washing the separated material, and drying the washed material to obtain titanium dioxide nanosheets; and 2, uniformly dispersing the titanium dioxide nanosheets in an anhydrous ethanol solution of iron trichloride, carrying out magnetic stirring at normal temperature for 15 min, carrying out suction filtration separation to obtain a product, dispersing the product in an anhydrous ethanol solution of trimesic acid, carrying out a 50-80 DEG C water bath reaction for 20-50 min, carrying out suction filtration separation to obtain a product, and repeating above processes in step 2 2-50 times to obtain the titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material. The catalyst prepared through the method is especially suitable for catalytic degradation of high-concentration organic dyes (such as methylene blue) under visible light irritation) to reach a very high degradation rate.

Owner:UNIV OF SCI & TECH BEIJING

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS7867365B2Reduce energy useIncrease concentrationDrying using combination processesDistillation regulation/controlMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column. Heat from the overhead of the second distillation rectifying column and the molecular sieve dehydration are used to heat the first distillation stripping column.

Owner:RCM TECH USA INC

Preparation method of flexible silica aerogel

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Method for preparation of superhydrophobic timber on the basis of sol-gel method

InactiveCN105599077AHas a superhydrophobic surfaceEasy to operateWood treatment detailsPretreated surfacesSilica nanoparticlesSilanes

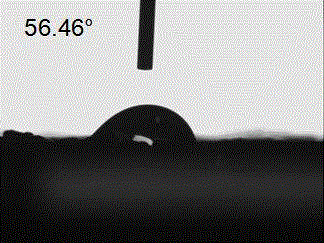

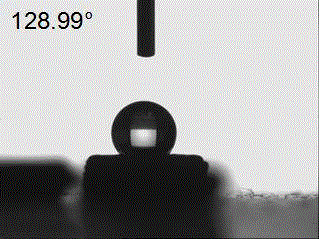

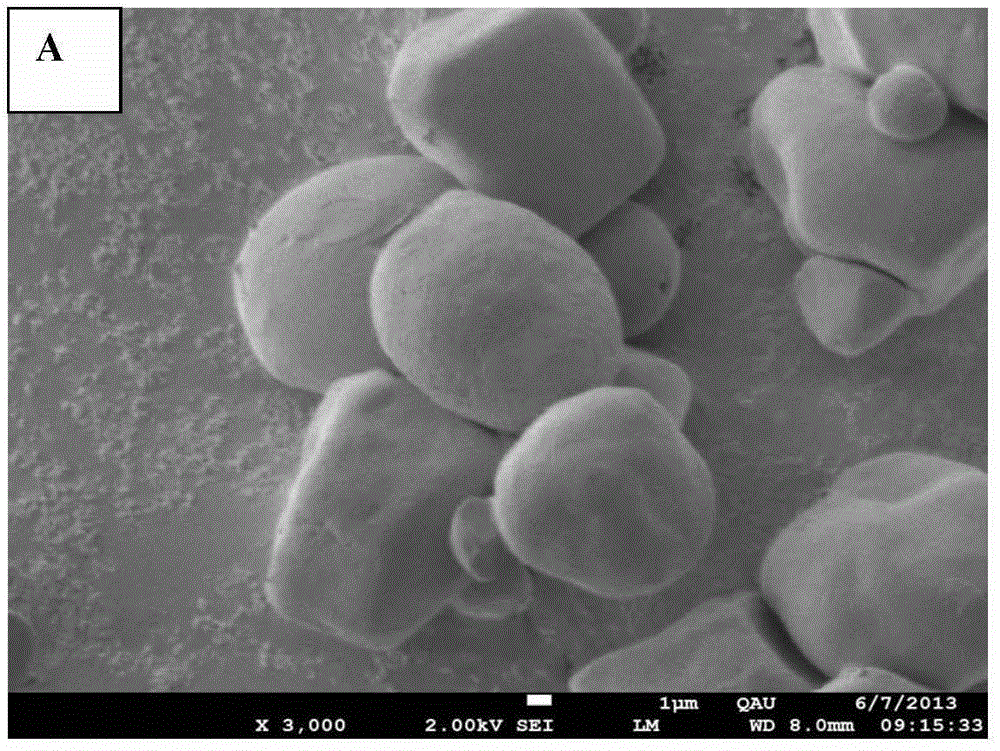

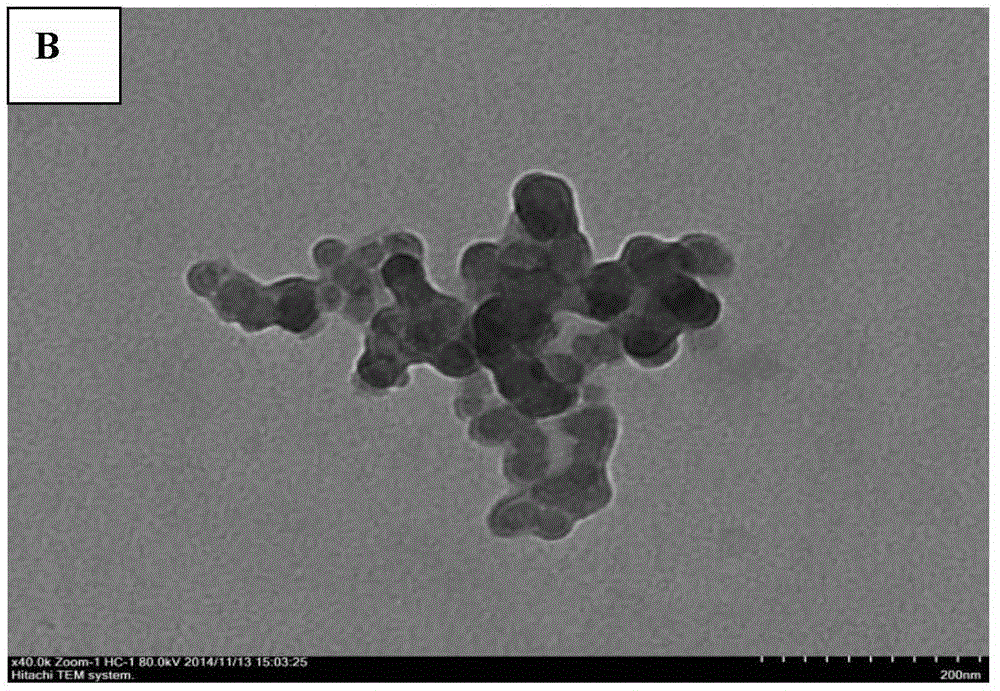

The present invention pertains to a method for preparation of superhydrophobic timber on the basis of a sol-gel method, and the method is as follows: (1), silica sol synthesis, to be more specific, materials are prepared in the volume ratio of ammonia to anhydrous ethanol to ethyl orthosilicate of 1:15 to 17:1; (2), hydrophobic modification of monodispersed nano silica sol, to be more specific, hexadecyl trimethoxysilane, or triethoxysilane-1H, 1H, 2H, 2H-heptadecafluorodecyl silane is used for hydrophobic modification of the synthesized monodispersed nano silica sol, and the hydrophobic agent promotes mutual aggregation of nanoparticles to promote the formation of aggregates of silica nanoparticles; and (3) timber coating processing, to be more specific, the timber surface is coated with the hydrophobically modified silica sol solution by dipping or spraying process. Contact angles of the processed timber surface and water droplets are greater than 150 degrees, roll angles are less than 10 degrees, and a superhydrophobic film has good resistance to acid and alkali erosion and stability in high-humidity environment. The method is simple in operation, less demanding on equipment, and capable of scale production, and has wide market prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

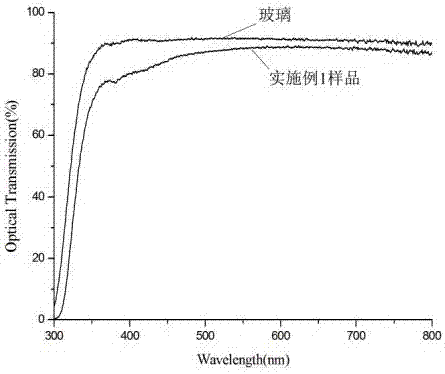

Preparation method of highly transparent wear-resistant superhydrophobic composite coating

ActiveCN107022279AEasy to prepareWide applicabilityEpoxy resin coatingsWear resistantSuperhydrophobic coating

The invention belongs to the technical field of superhydrophobic materials, and particularly relates to a preparation method of a highly transparent wear-resistant superhydrophobic composite coating. Surface-modified nano-silica powder prepared by a sol-gel method is dispersed in anhydrous ethanol to obtain a superhydrophobic coating solution. The surface of a substrate of stone, metal, glass and the like is coated with reactive-diluent-modified E-51 epoxy resin glue, standing is carried out for 1 to 2 hours at room temperature, the superhydrophobic coating solution is used for brushing to obtain the highly transparent wear-resistant superhydrophobic coating. The contact angle between the coating and water is 165 to 175 DEG, a rolling angle is 2 to 5 DEG, the light transmittance of coating glass in the 500 to 650nm is greater than 84%, and at pressure intensity of 2500 Pa, the contact angle between the coating and water is greater than 90 DEG after the coating is rubbed with 320-mesh sandpaper along a line. The preparation method of the coating is simple, environmentally friendly and low in cost, is suitable for the surface of glass, stone, ceramics, wood, metal and the like, and has a wide application prospect.

Owner:FUZHOU UNIV

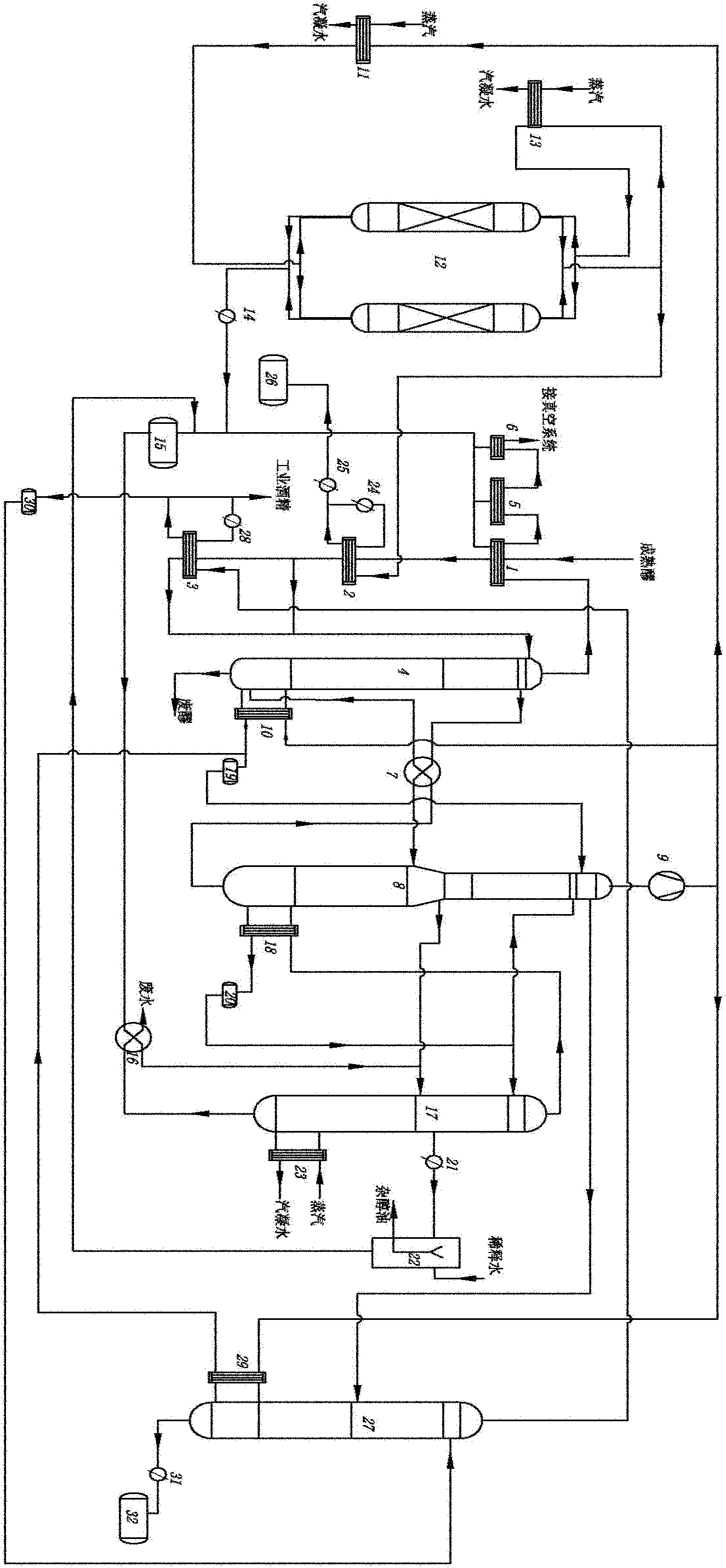

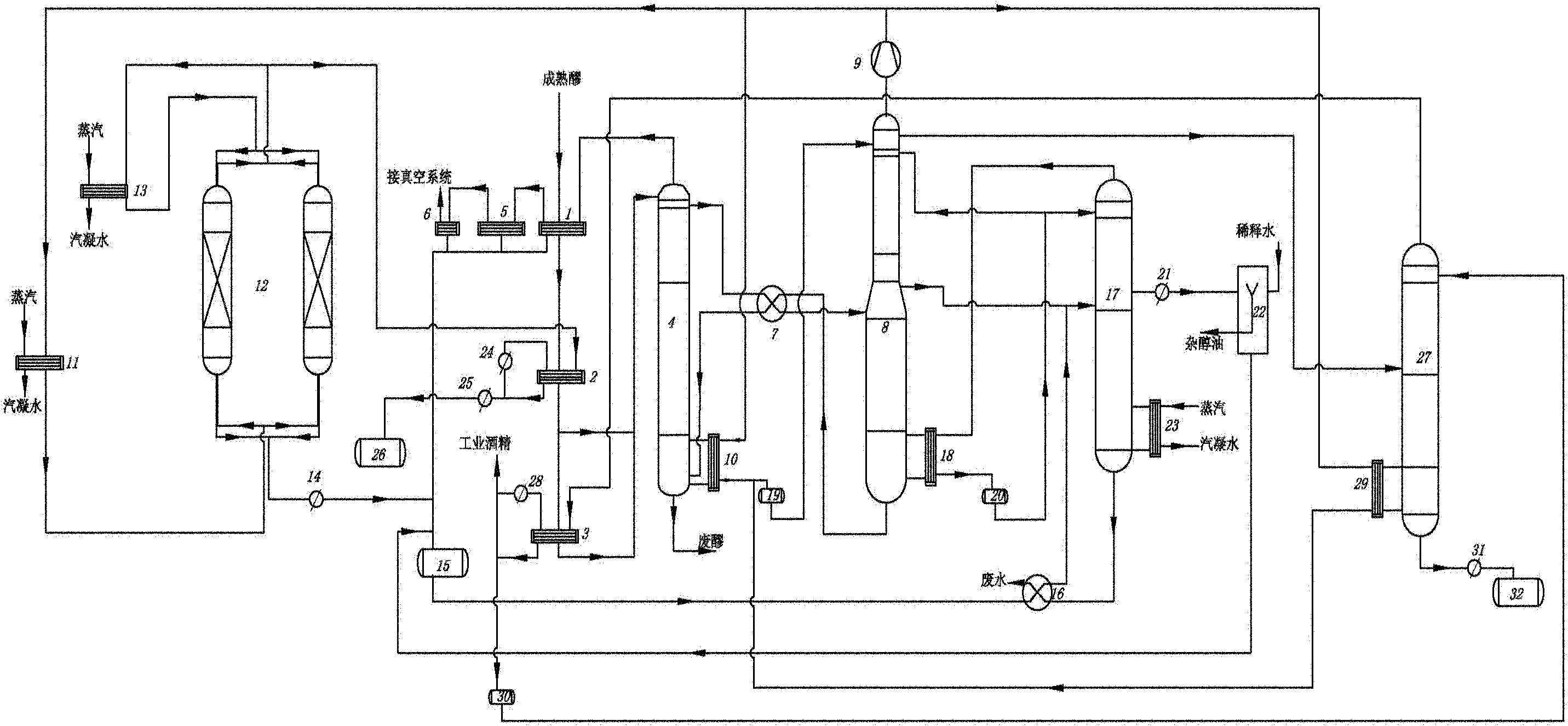

Distillation dehydration device and process for co-producing ethanol fuels and custom grade edible alcohols

ActiveCN102040471ALow operating pressureLess investmentOrganic compound preparationHydroxy compound separation/purificationDesorptionDistillation

The invention discloses a distillation dehydration device and a distillation dehydration process for co-producing ethanol fuels and custom grade edible alcohols. The device comprises a molecular sieve adsorption / desorption tower, a coarse fractionating tower, an assembled tower, a rectifying tower, a methanol tower and mash pre-heaters, wherein the wine steam of the assembled tower, after compressed by an ethanol steam compressor, is used as the heat sources and raw material wine steams of the coarse fractionating tower and the methanol tower; the wine steam of the rectifying tower is used asthe heat source of the assembled tower; and the wine steam of the coarse fractionating tower, the anhydrous alcohol steam and the wine steam of the methanol tower are respectively used as the heat sources of the first, second and third mash pre-heaters. The device can simultaneously produce ethanol fuels and custom gradeedible alcohols, and can separately produce ethanol fuels or custom grade edible alcohols. The device and the process of the invention have the advantages that, because a multi-effect energy coupling mode is adopted, compared with an original process, the energy consumption ofthe process of the invention is greatly reduced, and the steam consumption of the ethanol fuel per metric ton is reduced to 1.1 to 1.5 t / t, compared with the steam consumption of 1.5 to 2.0 t / t in the original process, the steam consumption is down by 25 to 35 percent without consuming high-grade steams (more than 0.7 MPag); and the steam consumption of the custom grade edible alcohol per metric ton is reduced to 1.2 to 1.4 t / t, compared with the steam consumption of 1.9 to 2.5 t / t in the original process, the steam consumption is down by 35 to 50 percent.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

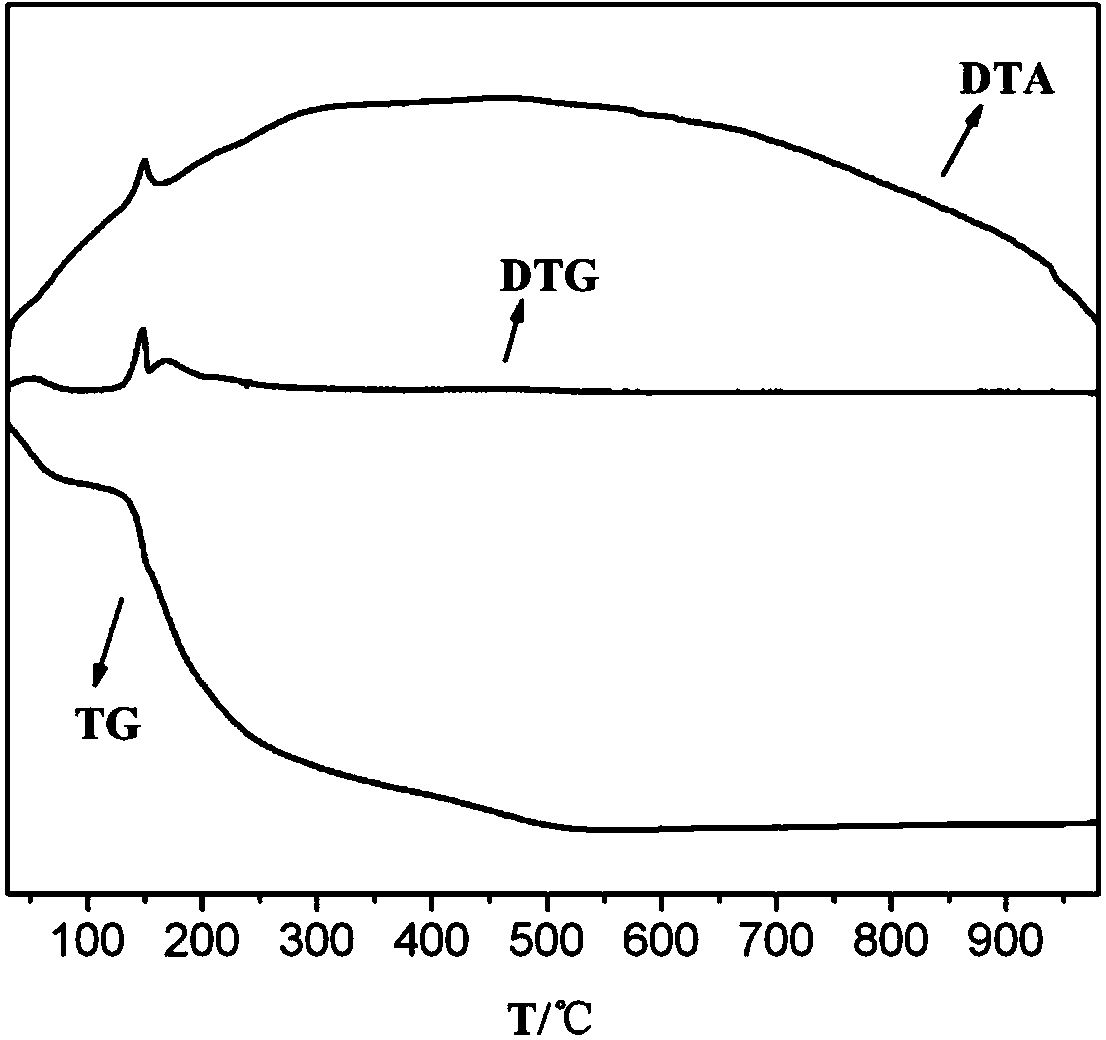

Preparation method of NASICON-type lithium ion solid electrolyte

ActiveCN103825052AOvercome purityOvercome the cycleFinal product manufactureElectrolyte accumulators manufactureSaturated aqueous solutionElectrolyte

The invention discloses a preparation method of an NASICON-type lithium ion solid electrolyte. The method comprises the following steps: dissolving lithium nitrate and aluminum nitrate in a citric acid solution, and stirring to form a transparent and uniform nitrate mixed solution; dissolving tetrabutyl titanate in anhydrous ethanol, and stirring to form an alcoholic solution of tetrabutyl titanate; slowly adding the alcoholic solution of tetrabutyl titanate to the nitrate mixed solution, and stirring to a transparent mixed solution; dissolving ammonium biphosphate in water to obtain a saturated aqueous solution of ammonium biphosphate, adding the saturated aqueous solution of ammonium biphosphate to the transparent mixed solution in a dropwise manner, and stirring to obtain an emulsion; adjusting the pH value of the emulsion, and drying the emulsion to obtain an xerogel; carrying out heat treatment of the xerogel, and grinding the obtained xerogel to form fine powder which is precursor powder; and compacting the precursor powder to form a green body, and sintering to obtain NASICON-type lithium ion solid electrolyte slices. The method has the advantages of low energy consumption, simplicity, easy implementation, and convenience for large-scale industrialized production, and the obtained solid electrolyte has a high conductivity.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing hexagonal boron nitride nanosheets by chemical stripping

InactiveCN103626141AEasy to operateLow costMaterial nanotechnologyNitrogen compoundsAnhydrous ethanolHexagonal boron nitride

The invention provides a method for preparing hexagonal boron nitride nanosheets by chemical stripping, which comprises the following steps: (1) uniformly mixing and stirring every 0.5-5g of hexagonal boron nitride powder with 100ml of acid, adding potassium permanganate according to the potassium permanganate / hexagonal boron nitride powder mass ratio of 1:10:10:1, and continuing stirring to prepare a mixture; (2) stirring the mixture in an ice bath to react for 1-24 hours; dropwisely adding oxydol to remove the residual potassium permanganate; and (3) finally, washing the reaction product with water until the pH value is 6-8, dissolving in anhydrous ethanol for separation, and removing unstripped boron nitride powder to obtain the boron nitride nanosheets. The acid, potassium permanganate, oxydol and hexagonal boron nitride react together to prepare the boron nitride nanosheets; and thus, the method is simple to operate and low in cost, does not need complex or expensive equipment, and is beneficial to large-scale production.

Owner:SHANDONG UNIV

Preparation of methyl vinyl MQ resin for LED encapsulated strengthening

The invention discloses a preparation method of organic resin, in particular to a preparation method of a methyl vinyl MQ resin used for LED encapsulation and reinforcement. The method is that a soluble glass aqueous solution is added into concentrated hydrochloric acid (36.5 percent); after the reaction, the anhydrous ethanol solution of phenyl alkoxy silicane, vinyl alkoxy silicane and methyl alkoxy silicane is added; an extraction is carried out after cohydrolysis; the upper oil layer is removed; the reactants are washed to be neutral and dried; the low-boiling substances are removed; the colorless and transparent product of MQ resin is obtained. The preparation method of the invention has the advantages of accessible and cheap raw materials, simple and easy operation, and is convenient to industrialized with good effect. The products of the invention are especially suitable to be used as reinforcement materials in the LED encapsulation materials, also be expected as a reinforcing agent for other organosilicon materials and used in aspects of anchoring agent, surface treating agent, mold discharging agent, anti-blowing agent, adhesion preventives, brightening agent and other additives, etc.

Owner:HANGZHOU NORMAL UNIVERSITY

Gingko leaf slow-releasing table and preparation process thereof

InactiveCN1371744AReduce the number of dosesStable blood concentrationUnknown materialsPill deliveryDiseaseAnhydrous ethanol

The preparation method of ginkgo leaf slow-released tablet mainly for curing cerebrovascular disease includes the following steps: 1. preparing gingko leaf extract; and 2. preparing slow-released tablet: using gingko leaf extract 120 portions, hydroxypropyl methyl cellulose 80-100 portions, lactose 50-80 portions and starch 30-80 portions, mixing them uniformly, adding anhydrous ethanol 0.8-1.2 portions to make granulation, then adding magnesium stearate 2-5 portions, uniformly mixing them and tabletting to obtain said invented product.

Owner:YABAO PHARMA GRP CO LTD

Preparation method of phenolic resin aerogel

ActiveCN103709346AStructural regulationControl mechanical propertiesOther chemical processesCarbon preparation/purificationAnhydrous ethanolOrganic solvent

The invention discloses a preparation method of phenolic resin aerogel. The preparation method is characterized in that chitosan, one or more acid, one or more filling materials, one or more phenols, one or more aldehydes, and water or a water-anhydrous ethanol mixture are mixed; the mixture undergoes a hydrothermal reaction to produce phenolic resin organogel; the phenolic resin organogel is immersed in an organic solvent for replacement; and the replacement product is subjected to supercritical CO2 drying so that the phenolic resin aerogel is obtained. The preparation method has simple processes and safe and reliable reactions and realizes adjustment of a structure and mechanical properties of the phenolic resin organogel. The structure and density of the phenolic resin aerogel obtained by drying and porosity and a specific surface area of the derivative porous carbon material obtained by carbonization of the phenolic resin aerogel are adjusted and controlled well.

Owner:UNIV OF SCI & TECH OF CHINA

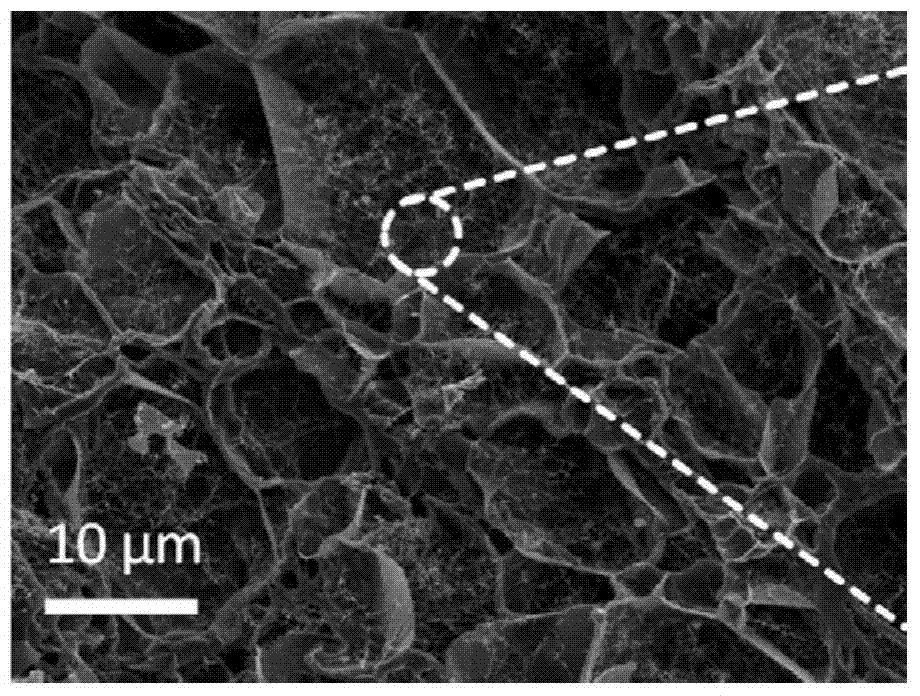

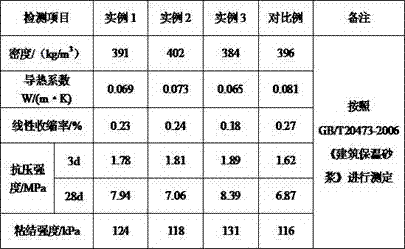

Inorganic thermal-insulation mortar and production method thereof

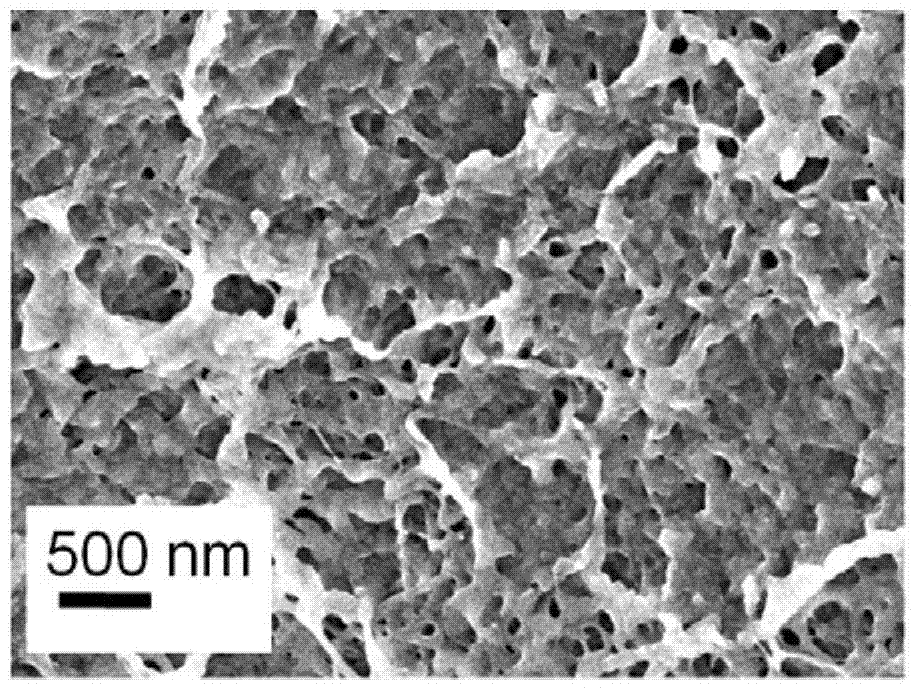

The invention belongs to the technical field of building materials and particularly relates to inorganic thermal-insulation mortar and a production method thereof. The production method includes: using rice husks as the raw material, performing pickling preprocessing, calcining, using alkali dissolution to extract sodium silicate, removing impurities to obtain silicic acid, adding aluminum silicate fibers and tetraethyl silicate to serve as the framework of gel, performing condensation polymerization to deposit silicon dioxide composite hydrogel on the framework, cleaning with anhydrous ethanol and normal hexane, using trimethylchlorosilane to perform hydrophobic modification to obtain silicon dioxide aerogel, using the capillary force of the silicon dioxide aerogel adsorb paraffin, serving as the phase change thermal storage material, into pores to compact the aerogel, mixing the prepared silicon dioxide composite aerogel phase change material with expanded and vitrified small balls, silica fume and the like, and discharging to obtain the inorganic thermal-insulation mortar. The prepared inorganic mortar is small in heat conductivity coefficient, low in contractibility rate, high in strength, capable of effectively increasing the crack resistance and seepage resistance of the mortar and capable of prolonging building service life.

Owner:常州市天宁区鑫发织造有限公司

Composite TiO2-SiO2 aerogel and application thereof

InactiveCN103706348AImprove degradation ratePhysical/chemical process catalystsWater/sewage treatment by irradiationSupercritical dryingAnhydrous ethanol

The invention provides composite TiO2-SiO2 aerogel and an application thereof. The aerogel material has the adsorption performance of SiO2 and the photocatalytic performance of TiO2. A preparation method for the composite TiO2-SiO2 aerogel comprises the following steps of 1, preparing SiO2 sol; 2, preparing TiO2 sol; 3, dropping the SiO2 sol into the TiO2 sol, uniformly stirring the SiO2 sol and the TiO2 sol, standing the sol under room temperature until the sol is condensed, aging the sol mixture through anhydrous ethanol for multiple days, and performing supercritical drying through ethyl alcohol. The preparation technology for the TiO2-SiO2 aerogel is simple; the composite TiO2-SiO2 aerogel has an extremely good effect of degrading explosive powder wastewater.

Owner:NANJING TECH UNIV

Preparation method of hydrophobic activated carbon modified material

ActiveCN104437444AImprove hydrophobicityRestore hydrophobicityOther chemical processesActivated carbonAnhydrous ethanol

The invention relates to a preparation method of a hydrophobic activated carbon modified material. The hydrophobic activated carbon modified material is prepared by taking ethyl orthosilicate as an additive, hexadecyltrimethoxysilane as a modifier, and anhydrous ethanol as a solvent, and carrying out liquid-phase impregnation, suction filtration and drying on activated carbon. The preparation method provided by the invention has the advantages of being simple in process and mild in conditions, and the hydrophobic activated carbon modified material can be prepared under the condition of room temperature; and the modified activated carbon is good in hydrophobic effect, stable in property and good in repeatability, the hydrophobic property can be restored only by simply drying, especially the defects that porous activated carbon produces bacteria and mildews in a humidity environment and has reduced absorption capability for target pollutants due to moisture absorption are overcome, and economic and technical effects are remarkable.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

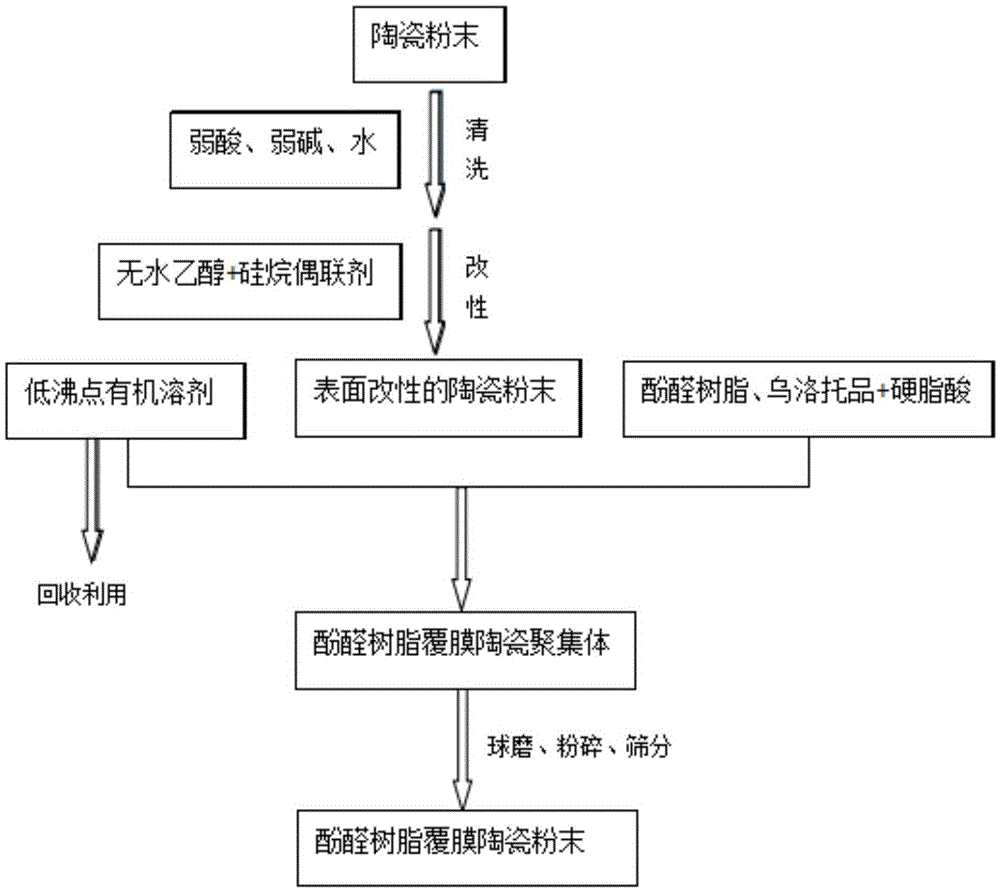

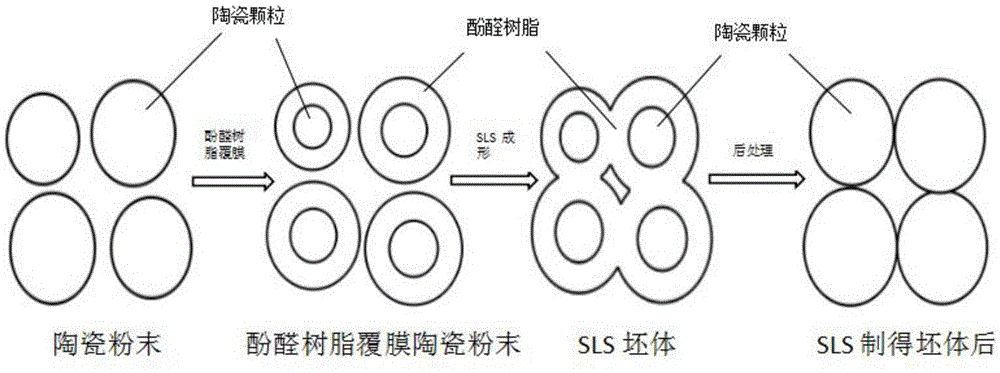

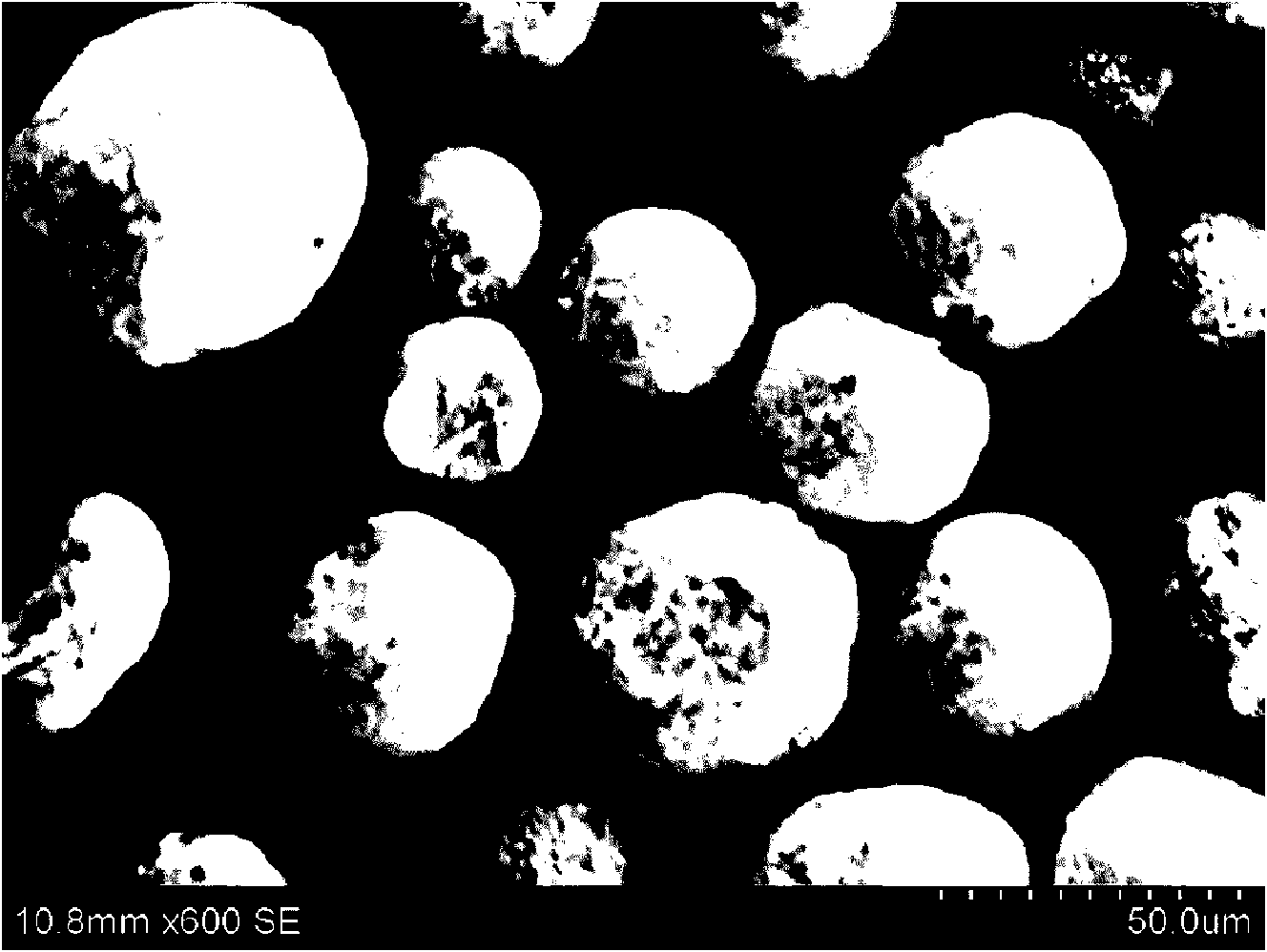

Phenolic resin coated ceramic powder for laser 3D printing and preparation method thereof

InactiveCN105669208AReduce hydrophilicityImprove efficiencyAdditive manufacturing apparatusAnhydrous ethanolAdhesive

The invention provides a phenolic resin coated ceramic powder for laser 3D printing. The particle size of the ceramic powder is 10-50 mu m. The ceramic powder comprises 10-30 wt% of phenolic resin, 1-2.5 wt% of urotropine, 0.5-1.5 wt% of stearic acid and the balance of silane coupling agent surface-modified ceramic powder. The preparation method comprises the following steps: a) modifying the surface of the ceramic powder with anhydrous ethanol and a silane coupling agent; b) carrying out reaction on the surface-modified ceramic powder, phenolic resin, urotropine and stearic acid in a closed vessel to obtain an aggregate; and c) pulverizing the aggregate by ball milling, and screening. The ceramic powder is subjected to impurity removal and surface modification, thereby lowering the hydrophilicity, improving the wettability with the adhesive, and enhancing the efficiency of the adhesive and the strength of the initial mold blank. The phenolic resin has the advantages of higher absorptivity for laser and favorable adhesive effect, thereby being beneficial to enhancing the quality of the ceramic part. By using the urotropine as the curing agent and the stearic acid as the lubricant, the strength and plasticity of the SLS blank formed by the phenolic resin coated ceramic powder can be enhanced.

Owner:WUHAN UNIV OF TECH +1

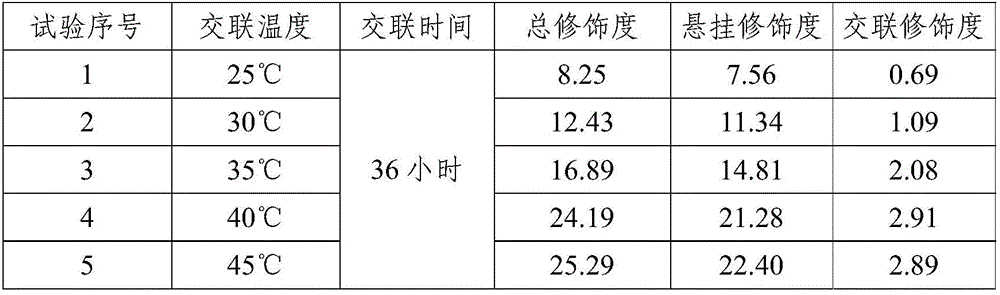

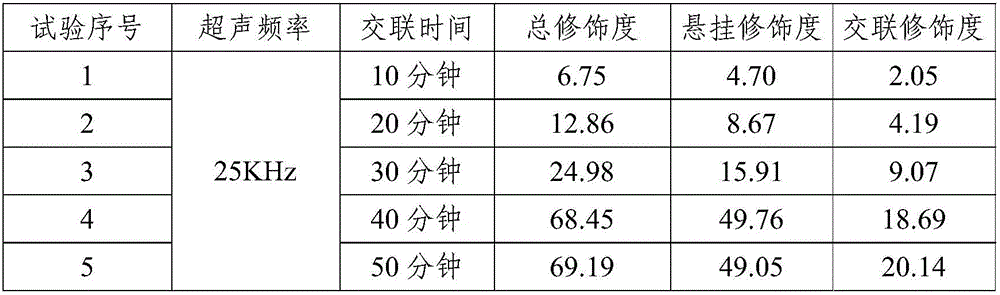

Crosslinking sodium hyaluronate gel and preparation method thereof

ActiveCN106279726ASolve the problem of low proportion of cross-linking modification (about 10%)Controllable ratioPharmaceutical delivery mechanismProsthesisAnhydrous ethanolAqueous solution

The invention provides crosslinking sodium hyaluronate gel and a preparation method thereof. The preparation method comprises the following steps: dropwise adding a crosslinking agent in an aqueous alkaline solution of sodium hyaluronate and carrying out crosslinking reaction; after reaction is finished, adjusting pH value of a system to be 7.1-7.5 with acid; stirring for 1-2 hours; and then precipitating with anhydrous ethanol to obtain the crosslinking sodium hyaluronate gel. The shortcoming that the proportion of crosslinking modification degree in a traditional crosslinking technology is lower (about 10%) is overcome effectively, and the proportion of the crosslinking modification degree is increased to be about 60% and is controllable. An ultrasonic crosslinking technology is introduced, the proportion of the crosslinking modification degree in crosslinking hyaluronic acid can be increased effectively, the proportion of suspension modification degree is reduced, and degradation time of a material is prolonged.

Owner:BEIJING DATSING BIO TECH

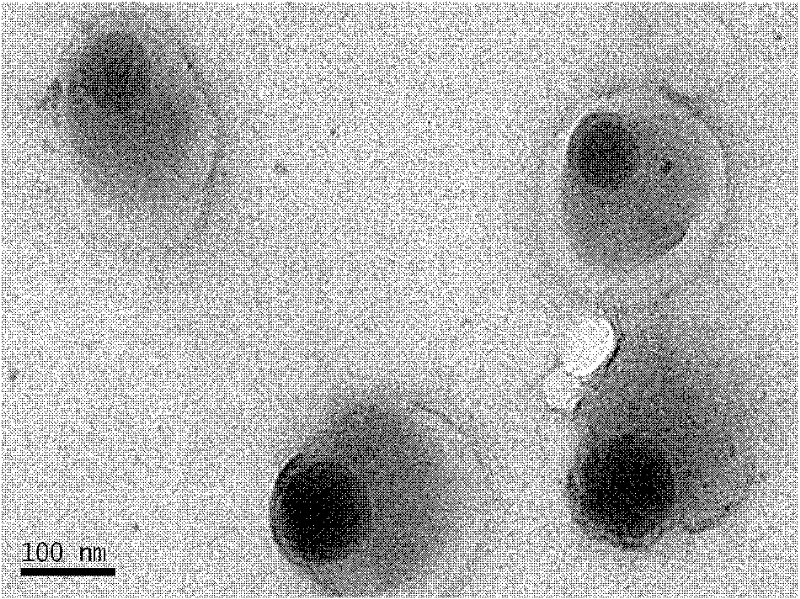

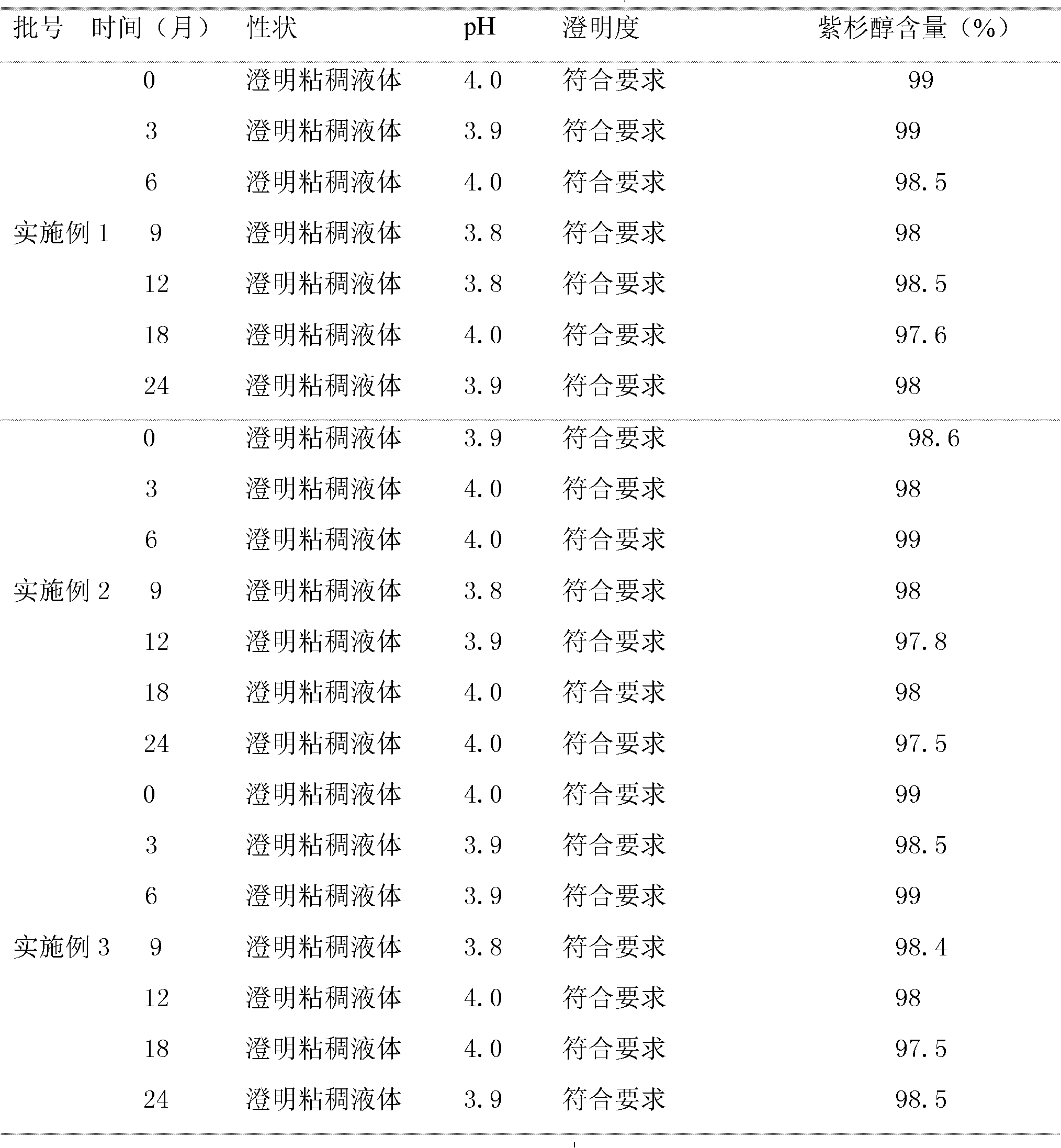

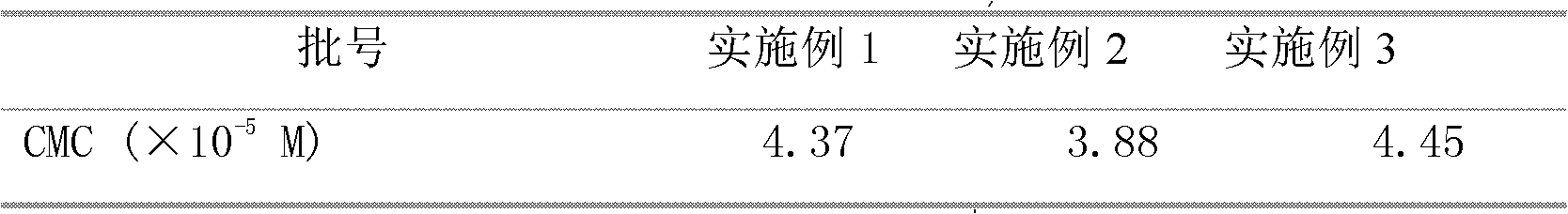

Paclitaxel mixed micelle preparation, and preparation method thereof

InactiveCN102198084AReduce toxic and side effectsImprove securityOrganic active ingredientsPharmaceutical delivery mechanismSolubilityPolyoxyethylene castor oil

The invention discloses a paclitaxel mixed micelle preparation, comprising 100 to 300 milligram of tocopherol polyethylene glycol succinate 1000 (TPGS), 0 to 50 milligram of phosphatide, 0.5 milliliter of anhydrous ethanol and 6 milligram of paclitaxel. The preparation method is as follows: the TPGS is dissolved in the anhydrous ethanol, or the TPGS and the phosphatide are dissolved in the anhydrous ethanol; the paclitaxel is added and dissolved under stirring; the mixture is filtered with a millipore filtration of 0.22 micrometer so as to obtain the paclitaxel mixed micelle preparation. In the invention, the TPGS and the phosphatide are used to form mixed micelles which have good stability and little toxic and side effects; the preparation method is simple and practicable, having a good application prospect. Compared to the prior art, polyoxyethylene castor oil in conventional prescription is substituted in the invention, thereby reducing toxic side effects of paclitaxel injections and greatly enhancing the safety of the injections on condition that solubility is guaranteed.

Owner:SHANDONG UNIV

Preparation method of polyacrylate/nano silicon dioxide composite emulsion coating material

The invention discloses a preparation method of a polyacrylate / nano silicon dioxide composite emulsion coating material. The preparation method comprises the following steps: adding tetraethoxysilane, anhydrous ethanol, ammonium hydroxide and silane coupling agent into deionized water, mixing and heating to obtain modified nano silicon dioxide sol; then adding an emulsifier, an acrylate monomer and an initiator, and preparing a composite emulsion by virtue of an in-situ hydrolysis method; and uniformly mixing the composite emulsion with a dispersing agent, a filler, deionized water, a tackifier and a defoaming agent to prepare the polyacrylate / nano silicon dioxide composite emulsion coating material. The method is simple in process, raw materials are likely to get, the clustering problem of nano silicon dioxide is avoided, and the heat resistance, washing resistance, water and contamination resistance and cohesive force to a basic material of the coating material can be improved.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

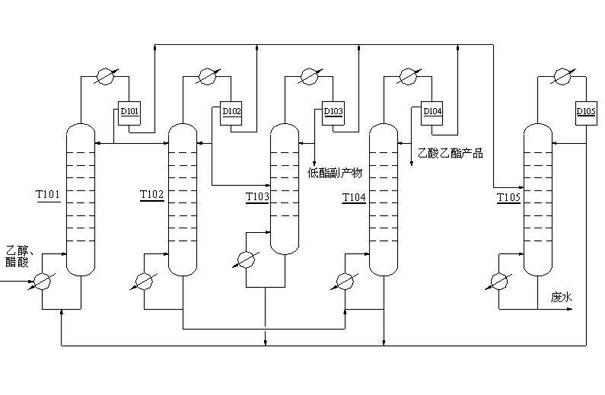

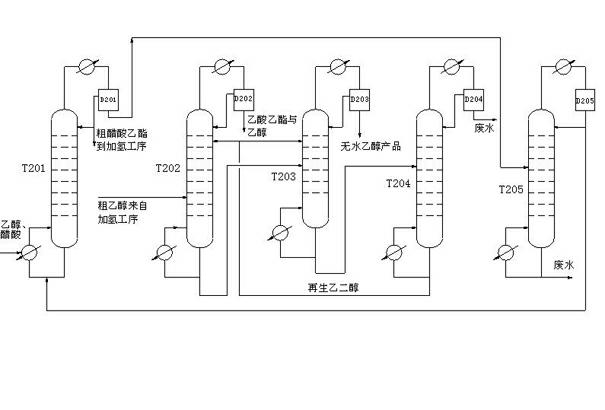

Method for simplifying rectification process for preparing ethanol through hydrogenation of acetic acid

ActiveCN102399130AMeet separation requirementsLess investmentOrganic compound preparationHydroxy compound preparationAnhydrous ethanolAcetic acid

The invention discloses a method for simplifying a rectification process for preparing ethanol through hydrogenation of acetic acid. An extractive distillation mode is adopted, and an ethanol product with higher purity can be obtained; a rectifying device can meet the separation requirement on an acetic ether product and an ethanol product; in addition, the acetic ether and the ethanol are separated by the same separation equipment; when the ethanol is produced, crude acetic ether and absolute ethanol products are obtained in the device, and when the ethanol is not produced, the device can produce the qualified acetic ether product, so that the device investment is saved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

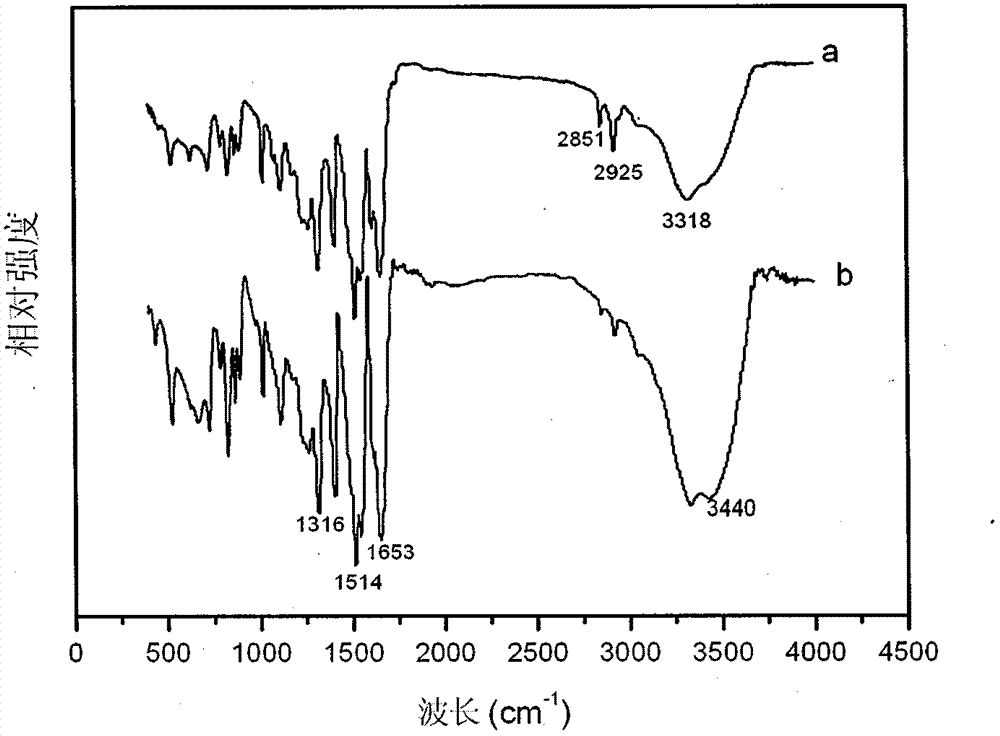

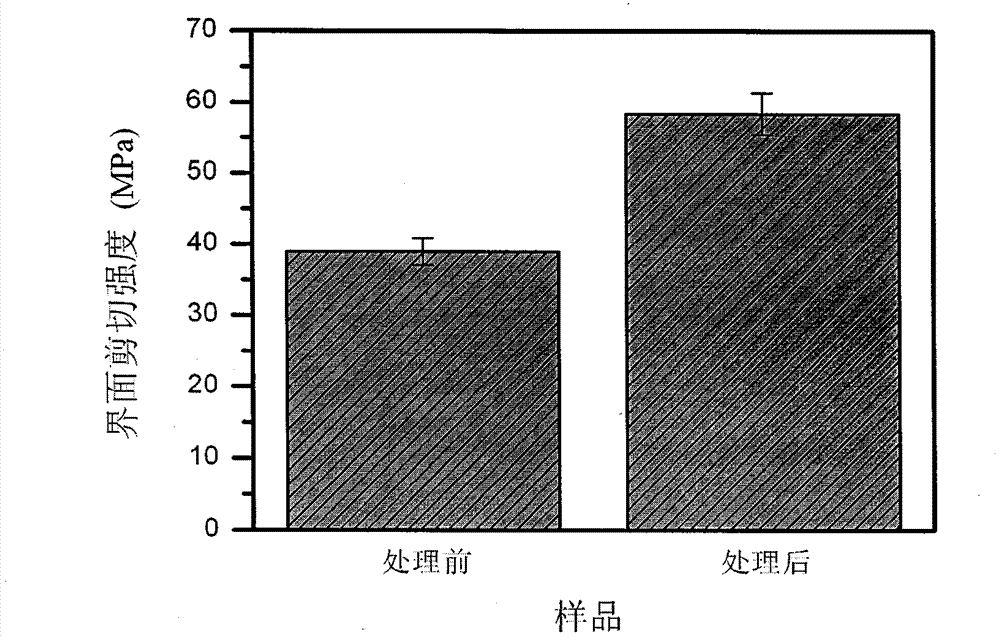

Method for improving surface activity of aramid fiber

InactiveCN103031708AImprove surface activityImprove interfacial bond strengthFibre typesFiber-reinforced compositeBiological activation

The invention discloses a method for improving the surface activity of aramid fiber. The method comprises the following steps of: (1) immersing the aramid fiber in acetone, heating and boiling for 1 hour, further immersing into anhydrous ethanol, and heating and boiling for 1 hour; and then placing into deionized water for washing, and drying for 2 hours after the treatment; and (2) performing surface activation treatment on the aramid fiber: (a) preparing a hydrogen peroxide solution with the concentration of 20%-60%; (b) cutting the aramid fiber after pretreatment into samples of 20cm, and placing into the hydrogen peroxide solution for performing treatment at the temperature of 0 DEG C-80 DEG C for 30min-90min; (c) washing with the deionized water till the pH value of a washing solution is 7; and (d) drying after washing to obtain the aramid fiber with surface modification. The treatment method disclosed by the invention is simple, the interfacial binding strength of an aramid fiber-reinforced composite material can be greatly improved, the mechanical strength of the aramid fiber can be also kept unchanged, the equipment is simple, the operation is convenient, and the industrial continuous treatment is convenient to realize.

Owner:SHANDONG UNIV OF TECH

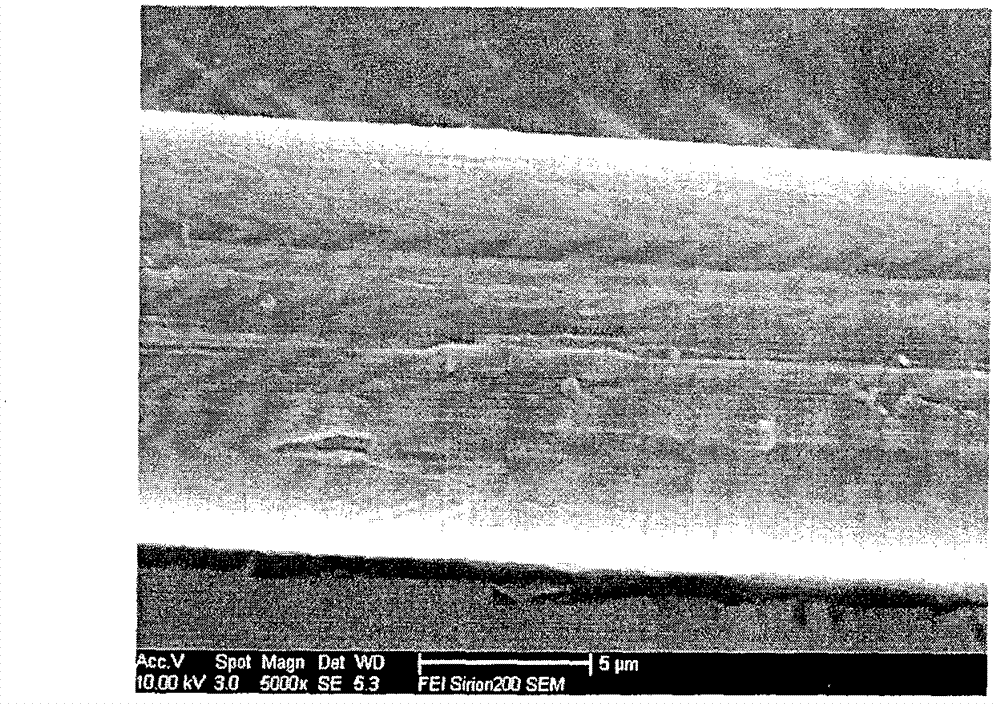

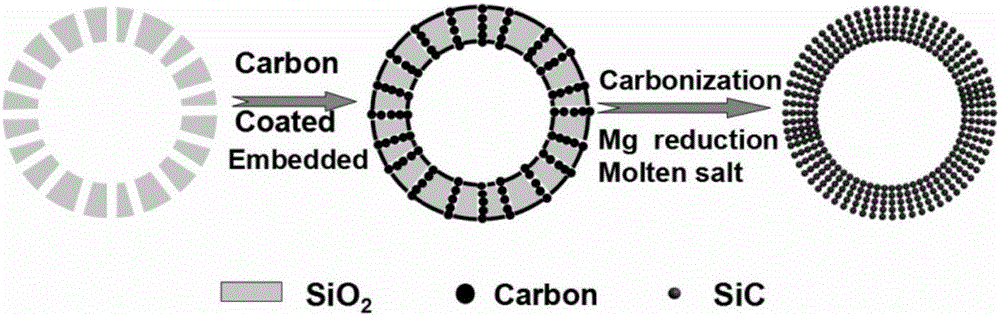

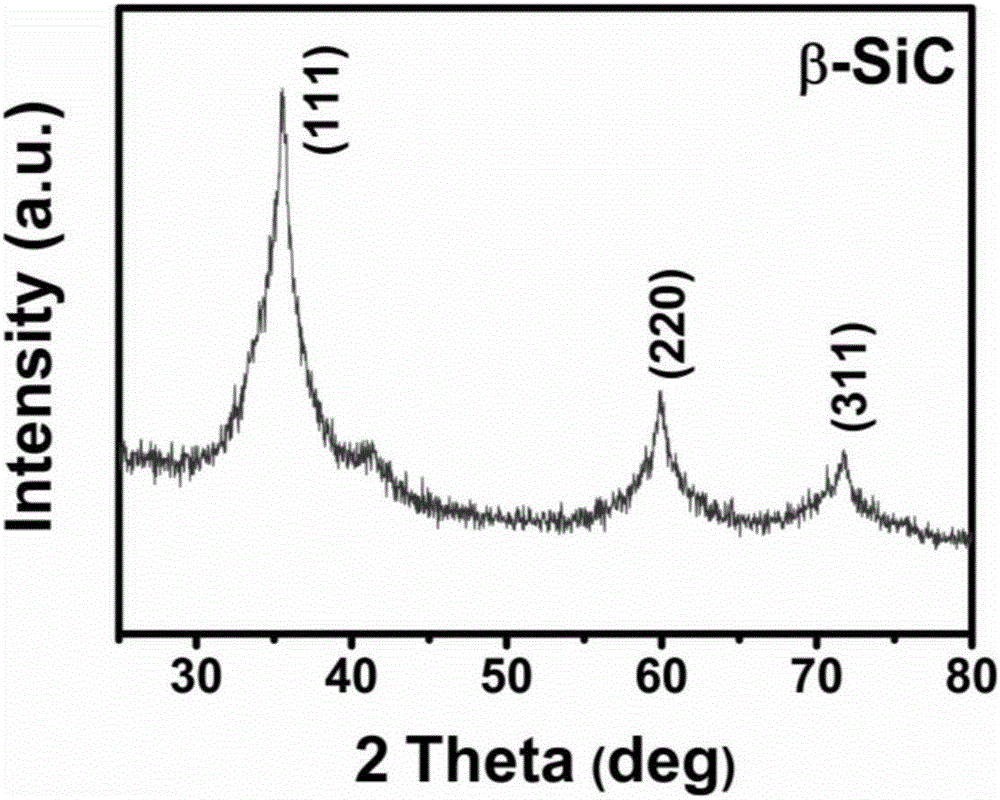

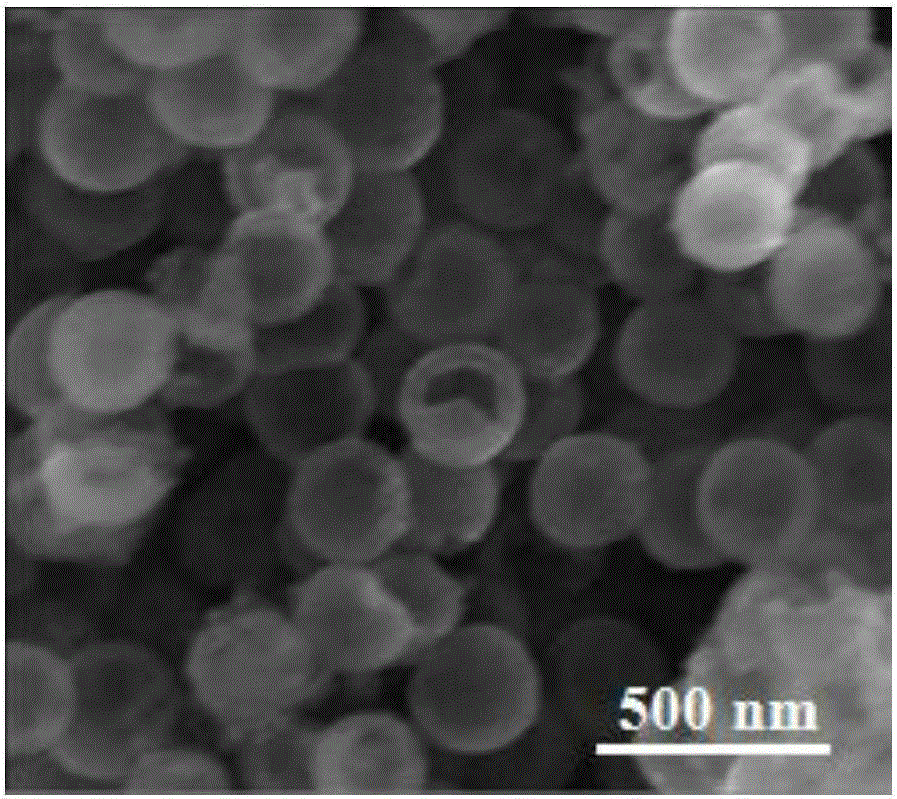

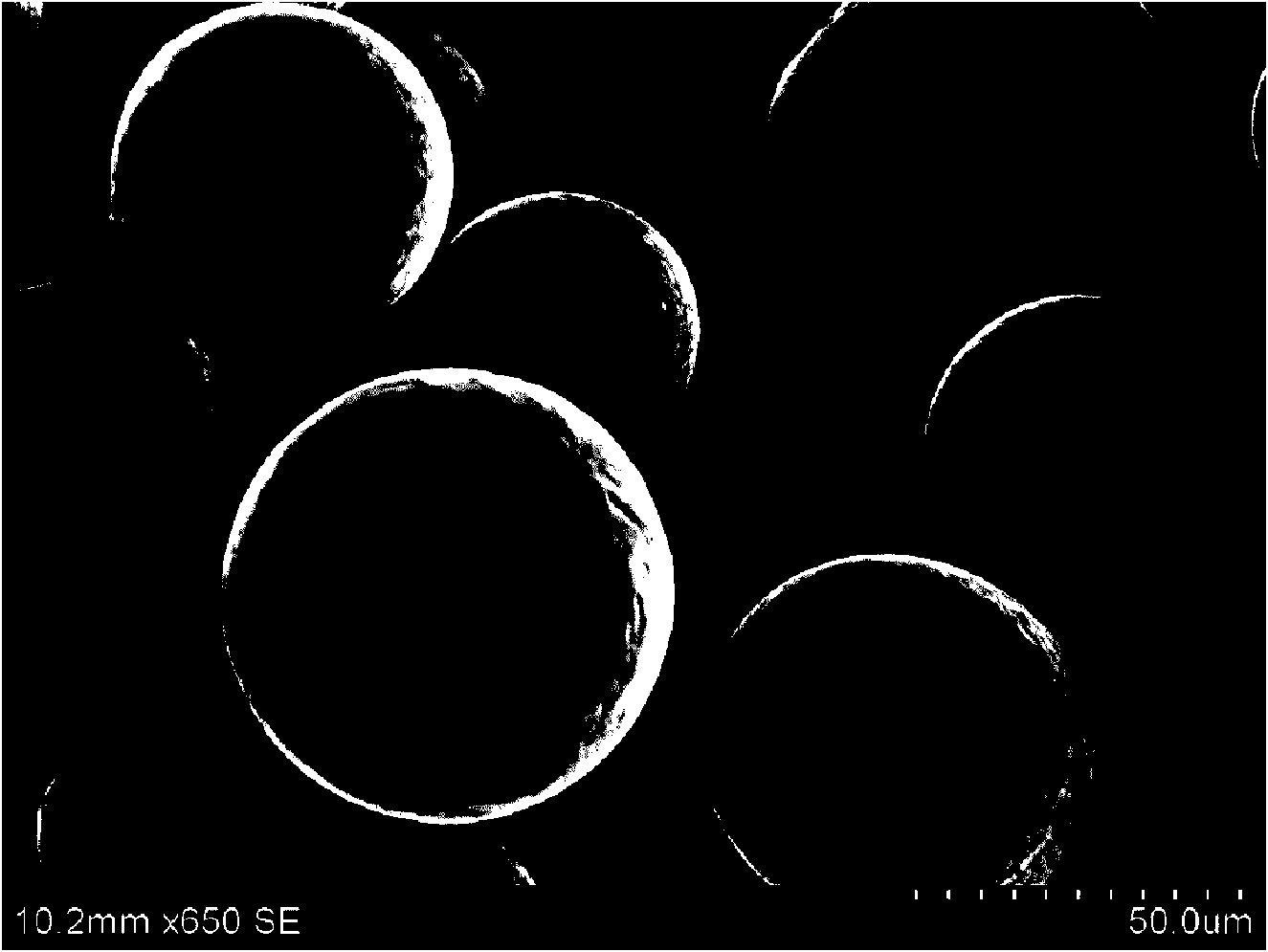

High-specific surface area nanometer mesoporous silicon carbide hollow ball and preparation method thereof

InactiveCN105236411ALarge specific surface areaUniform structureMaterial nanotechnologyThermal insulationReaction temperature

The invention relates to a high-specific surface area nanometer mesoporous silicon carbide hollow ball and a preparation method thereof. The preparation method comprises dropwisely adding different amounts of silica precursor tetraethoxysilane into water-anhydrous ethanol mixed solutions with different ratios so that the silica precursor tetraethoxysilane is hydrolyzed into silica solid nanospheres with different diameters, dispersing the silica solid nanospheres in distilled water with different volumes, carrying out thermal insulation for a certain time to obtain nanometer mesoporous silicon carbide hollow balls with different diameters are obtained, coating the inner and outer shells of the nanometer mesoporous silicon carbide hollow ball with an organic matter layer so that the organic matter is insert into the shell walls, carrying out carbonization, mixing the reaction product, magnesium powder and a metal salt to obtain a uniform mixture, and carrying out thermal insulation in an inert atmosphere for some hours to obtain nanometer mesoporous silicon carbide hollow balls with uniform structures and adjustable sizes. The preparation method has a low reaction temperature and a low cost. The obtained hollow silicon carbide has the advantages of uniform structure, adjustable sizes, superhigh specific surface area of 648m<2> / g and excellent mesoporous structure.

Owner:湖北朗驰新型材料有限公司

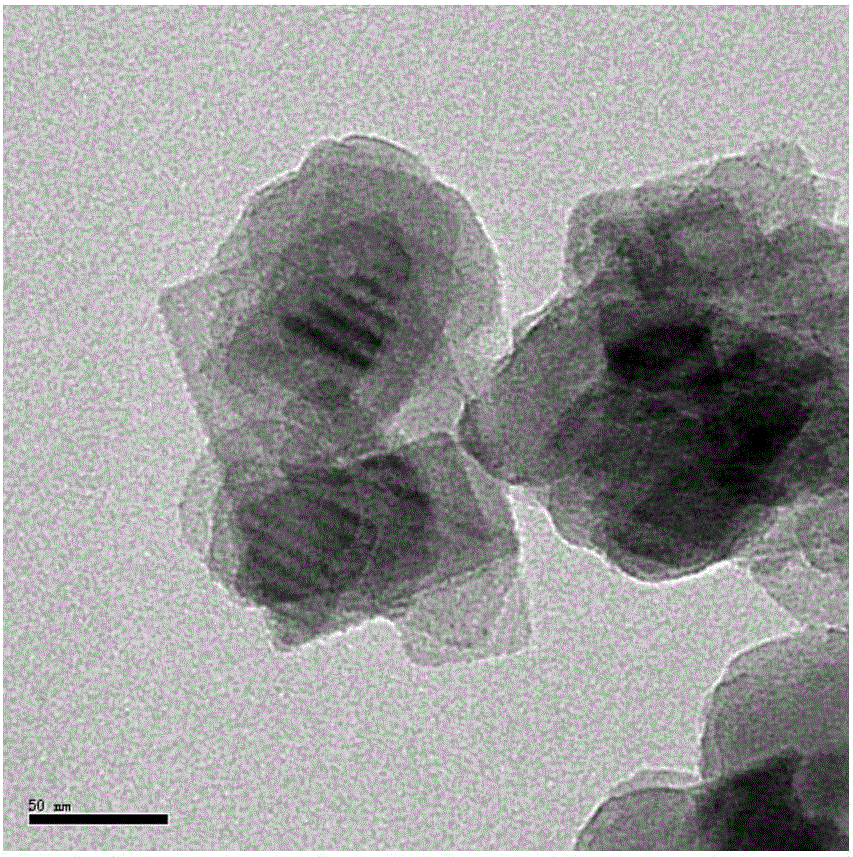

Preparation method of metal organic framework material MIL-100 (Fe)

ActiveCN103242374AImprove qualityOvercome the disadvantage of low yieldIron organic compoundsAnhydrous ethanolMetal-organic framework

The invention relates to a preparation method of a metal organic framework material MIL-100 (Fe), which comprises the following steps: proportionally adding an organic ligand and an iron source into a certain amount of deionized water, and mixing for 30 minutes; mixing the mixture obtained in the step (1) at 80-95 DEG C under atmospheric pressure to react for 5-20 hours; and filtering the solid obtained in the step (2), washing with anhydrous ethanol at 60-80 DEG C for 10-20 hours, treating with a 30-60 mmol / L ammonium fluoride solution at 60-80 DEG C for 10-20 hours, sufficiently washing with deionized water, and finally, drying at 100-200 DEG C for 5-10 hours to obtain the pure MIL-100 (Fe). The method has the advantages of mild synthesis conditions, high product yield and high product quality.

Owner:湖州优研知识产权服务有限公司

Composite oxide photocatalyst Li2ZnM3O8 and its preparation method

InactiveCN102228828AImprove catalytic performanceEasy to prepareWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processAnhydrous ethanolRoom temperature

The invention discloses a composite oxide photocatalyst Li2ZnM3O8 and its preparation method. The chemical general formula of the composite oxide photocatalyst is Li2ZnM3O8, wherein M is one element from the group consisting of Sn, Zr and Ti. The preparation method comprises the following steps of: weighing and proportioning 99.9% analytically pure chemical raw materials Li2CO3, ZnO and MO2 according to the chemical formula of Li2ZnM3O8, wherein M is one element from the group consisting of Sn, Zr and Ti; placing the proportioned raw materials into a ball-milling tank, adding zirconia balls and anhydrous ethanol, carrying out ball milling for 8-10 hours, mixing, grinding, taking out to dry, and sieving through a 200-mesh sieve; pre-burning the above uniformly mixed powders at the temperature of 850-950 DEG C, keeping warm for 4-8 hours, naturally cooling to room temperature, making the diameter of the particles small by ball milling until the diameter reaches below 2 microns to obtainthe composite oxide photocatalyst Li2ZnM3O8 powder. The preparation method provided by the invention is simple and has low cost; and the photocatalyst prepared by the method has excellent catalytic performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Nano-enhanced leadless solder and preparation method thereof

The invention relates to a nano-enhanced leadless solder and a preparation method thereof, solving the problems of poor wettability, low tensile strength and low yield strength of 0.2% of the joint soldered by the existing Sn-58Bi solder. The method comprises the following steps: washing precipitate obtained by ultrasonically and centrifugally treating a carbon nano-tube in the mixed acid solutionby de-ionized water until the pH of the lotion is 7, filtering, adding anhydrous ethanol into filter residue, drying; adding the Sn-58Bi solder according to the predetermined weight percentage, ballmilling and pressing to obtain a blank, sintering the blank to obtain the leadless solder. The leadless solder for soldering obtained by the method has wetting angle of 24.6-26.2 DEG, 0.2% yield strength of 39.1-47.1MPa of the soldered joint, tensile strength of 51.5-57.5MPa and extensibility of 55.90-57.24% of the joint.

Owner:YIK SHING TAT INDUSTRIALCO LTD +1

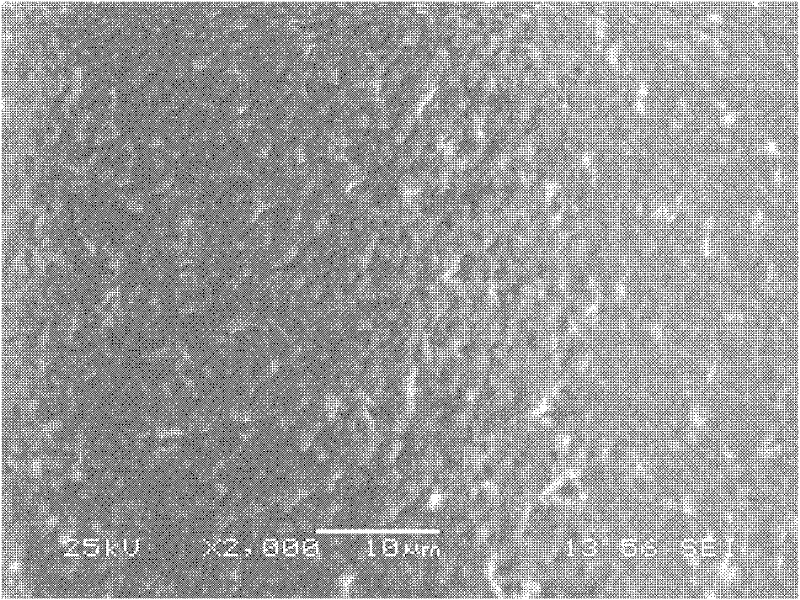

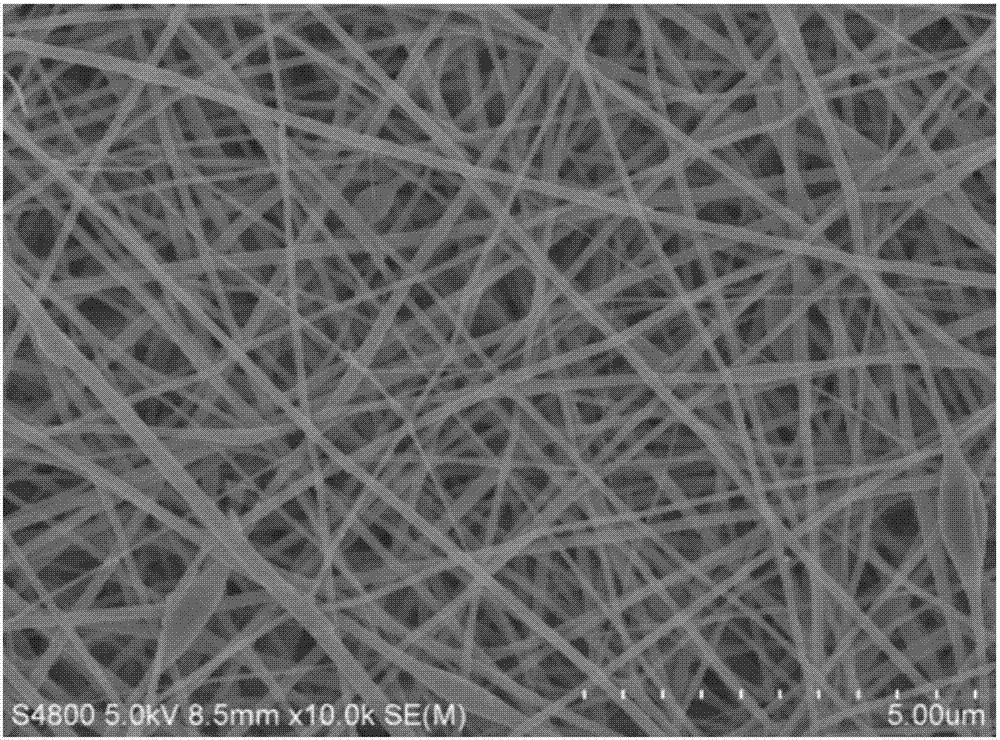

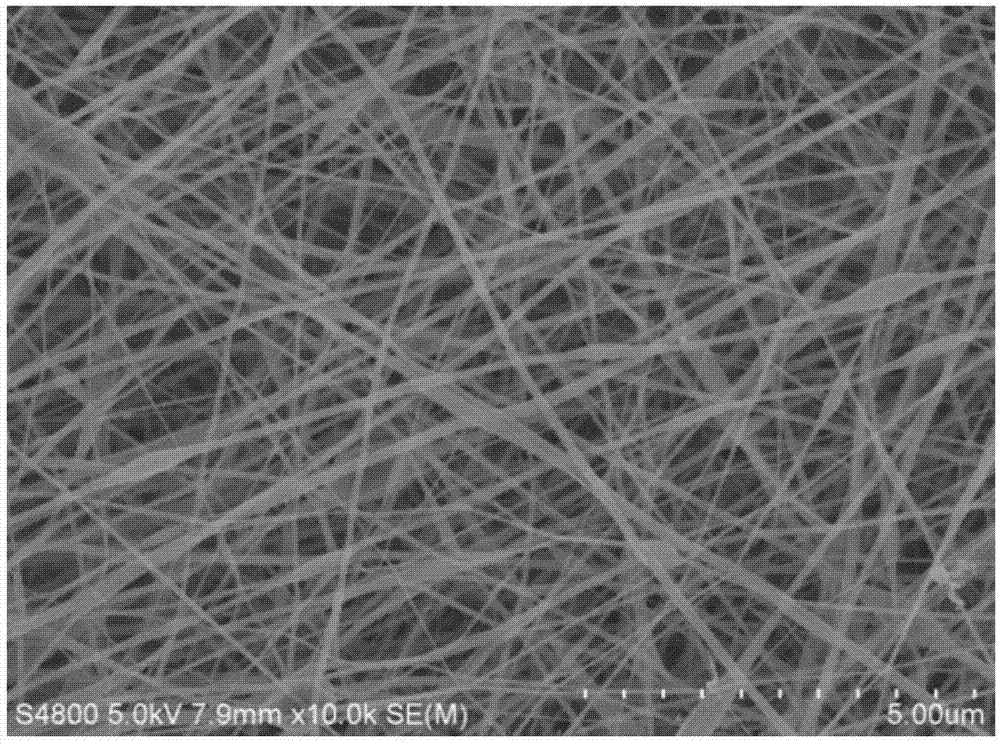

Preparation method of silk fibroin/graphene composite nano fiber support material

InactiveCN106913910AGood biocompatibilityImprove mechanical propertiesTissue regenerationNon-woven fabricsFiberBiocompatibility Testing

The invention provides a preparation method of a silk fibroin / graphene composite nano fiber support material. The preparation method comprises the following steps: preparing a silk fibroin sample, subjecting a graphene ethanol dispersion liquid to high speed centrifugation to obtain graphene; adding obtained silk fibroin sample into hexafluoroisopropanol, stirring to completely dissolve the silk fibroin sample so as to obtain a solution A; transferring the obtained graphene into the solution A by using hexafluoroisopropanol, dispersing the graphene by ultrasonic waves to obtain a solution B; transferring the solution B to an injection syringe, carrying out electrostatic spinning by controlling the technical parameters of electrostatic spinning; carrying out a post treatment namely soaking obtained electrostatic spun films into anhydrous ethanol for four hours, and naturally drying to obtain the silk fibroin / graphene composite nano fiber support material. The preparation method is simple and feasible, the raw materials are abundant, and the industrial production can be realized easily. Micro / nano meter level composite fibers can be prepared; and the composite fiber preserves the good biocompatibility of silk fibroin and excellent biological activity and mechanical properties of graphene.

Owner:WUHAN UNIV OF TECH

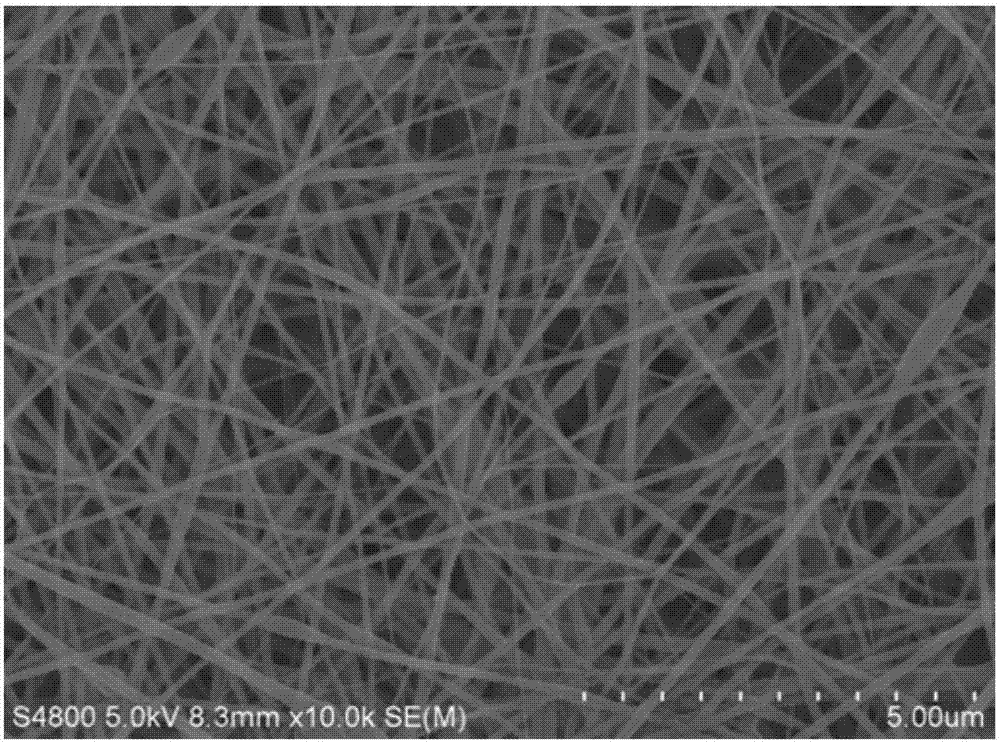

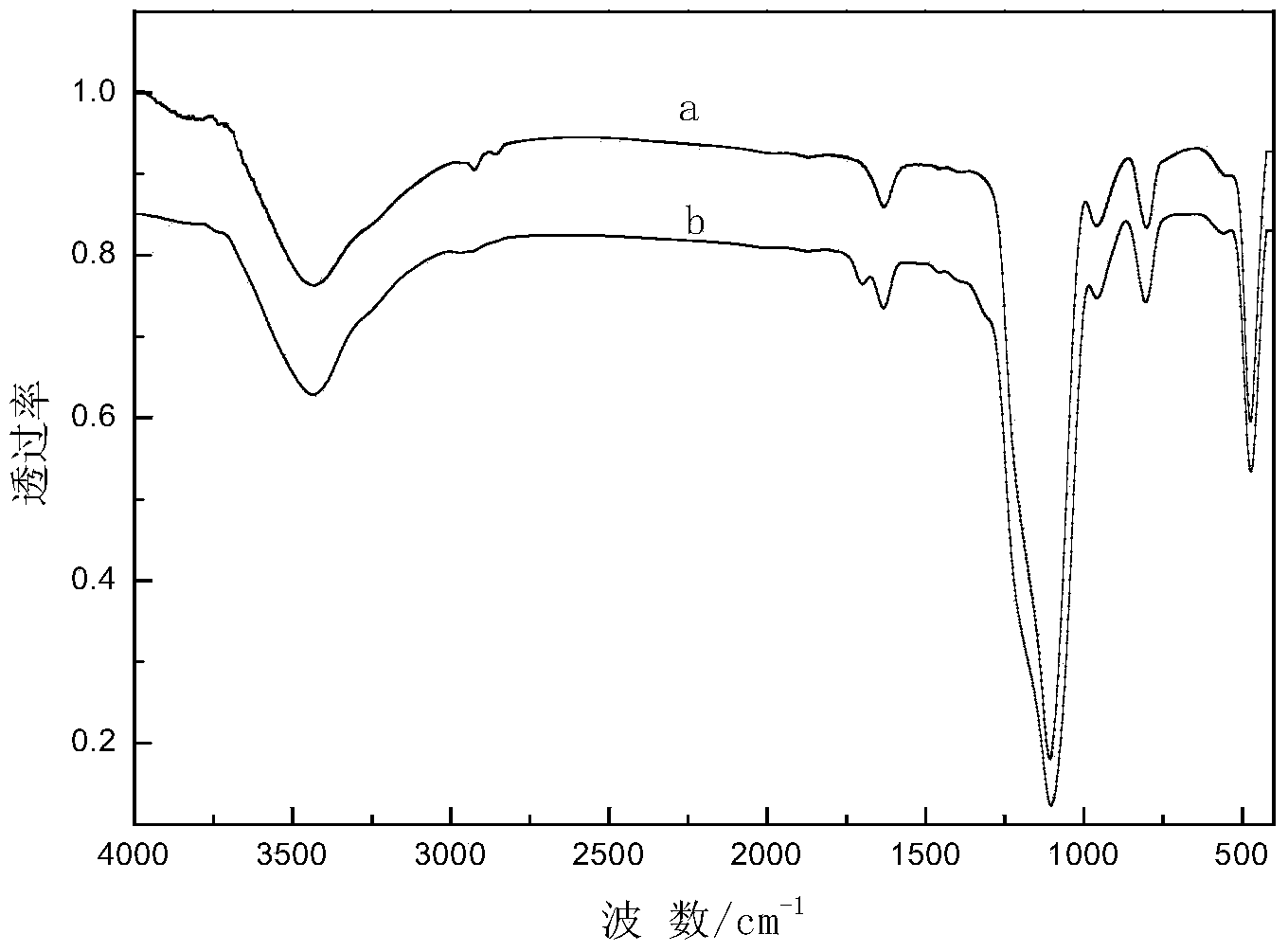

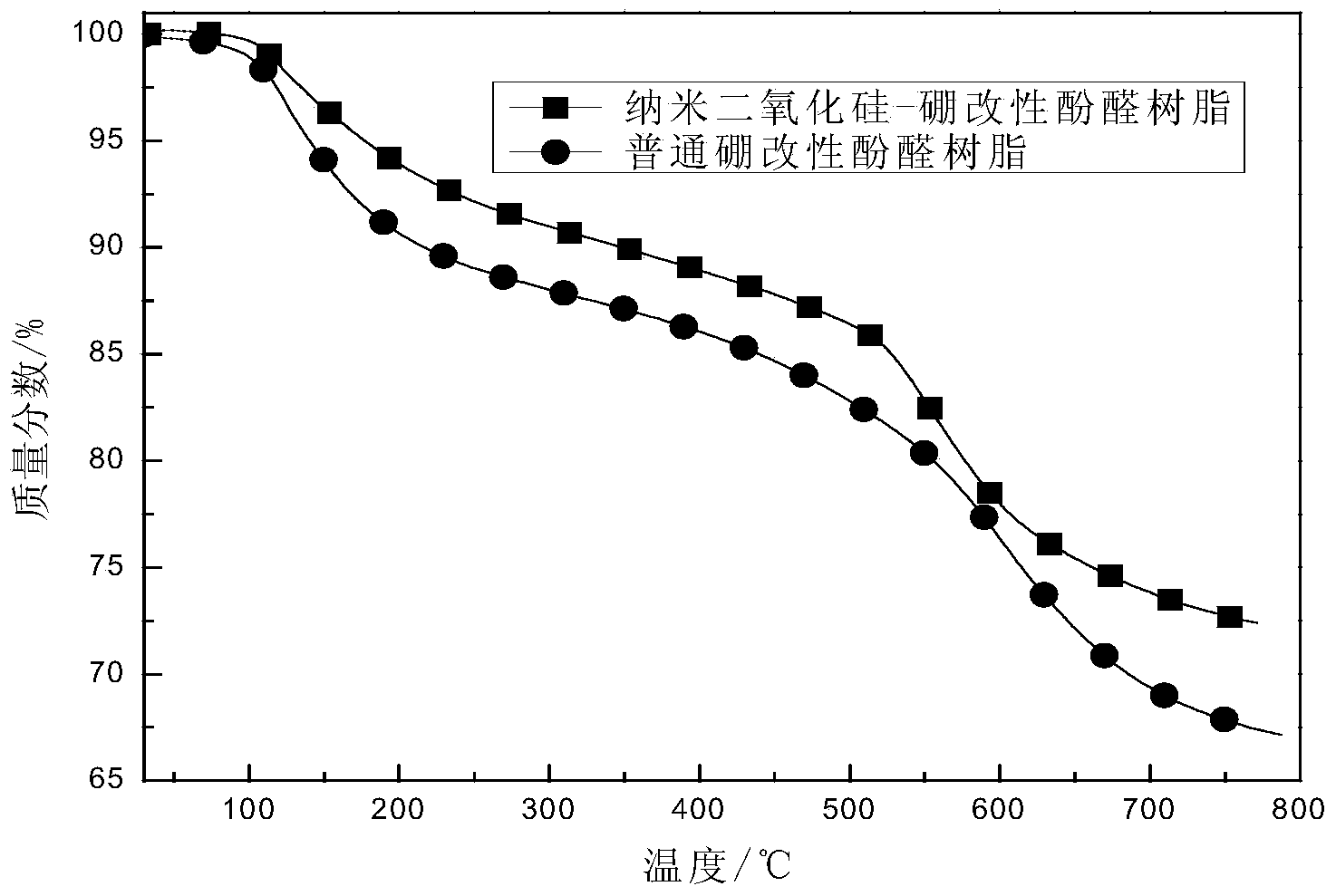

Method for preparing nano-silica-boron modified phenolic resin

The invention discloses a method for preparing nano-silica-boron modified phenolic resin, and relates to phenolic resin. Firstly, a silane coupling agent gamma-methylacryloyl acyloxy propyl group trimethoxy silane is adopted to modify hydrophilic nano-silicon to obtain hydrophobic nano-silica. Secondly, reaction is carried out on phenol and formaldehyde under the condition that sodium hydroxide serves as catalyst to obtain phenolic resin emulsion, and the modified nano-silicon which is dispersed by anhydrous ethanol solution in an ultrasonic mode is added to the phenolic resin emulsion to be reacted. Lastly, boric acid is added, polymerization reaction is carried out on the phenolic resin micromolecule and the boric acid, and the nano-silica-boron modified phenolic resin is prepared. The nano-silica is added with part organo-functional groups through silane coupling agent gamma-methylacryloyl acyloxy propyl group trimethoxy silane so that the problems that the nano-silica is poor in dispersity, solubleness and machinability can be solved. The carbon yield of the prepared nano-silica-boron modified phenolic resin is 72.40%, and the thermal performance is improved by about 5% compared with the thermal performance of ordinary boron modified phenolic resin.

Owner:XIAMEN UNIV

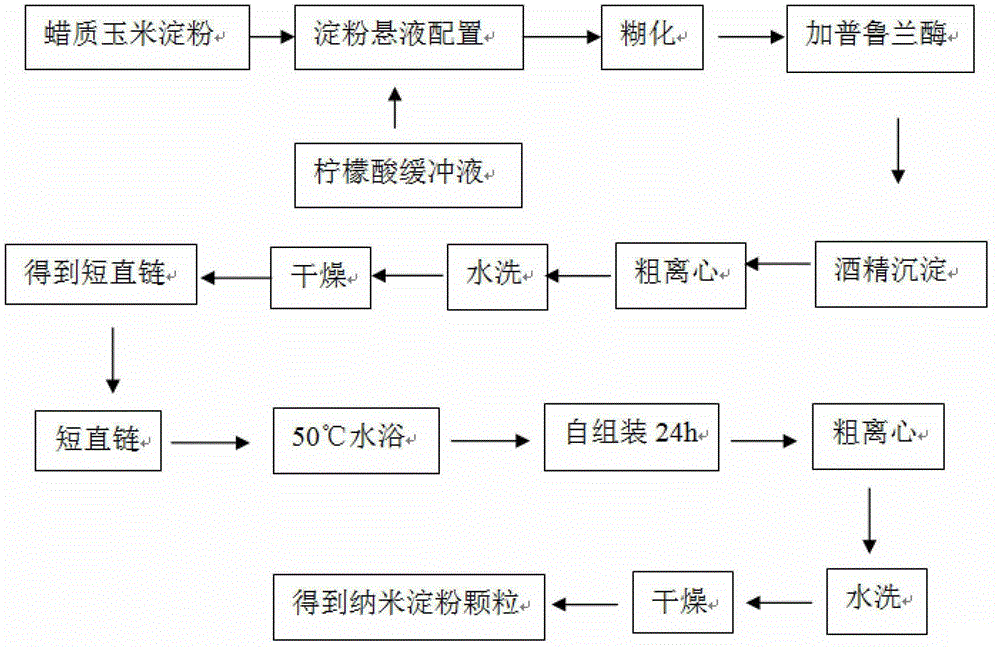

Process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose

The invention discloses a process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose. The process particularly comprises the following steps: (1) preparing a buffer solution; (2) preparing a starch water solution; (3) past-forming; (4) enzymolyzing, and then using anhydrous ethanol to precipitate the degreased starch solution; (5) preparing short amylose; (6) preparing nano starch. According to the process, enzyme hydrolysis starch is adopted to prepare nano starch at 30-70 DEG C in an anabiosis manner, the nano starch prepared by the method is high in productivity, low in cost, safer and more environment-friendly, and can serve as embedding materials of medicines, active ingredients and the like, and the application field of the process in the food industry is widened.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com