Phenolic resin coated ceramic powder for laser 3D printing and preparation method thereof

A technology of ceramic powder and phenolic resin, which is applied in the field of laser 3D printing powder material preparation, can solve the problems of lack of preparation methods, high cost, and few types of organic binders, and achieves good dissolution effect, high absorption rate and volatile. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

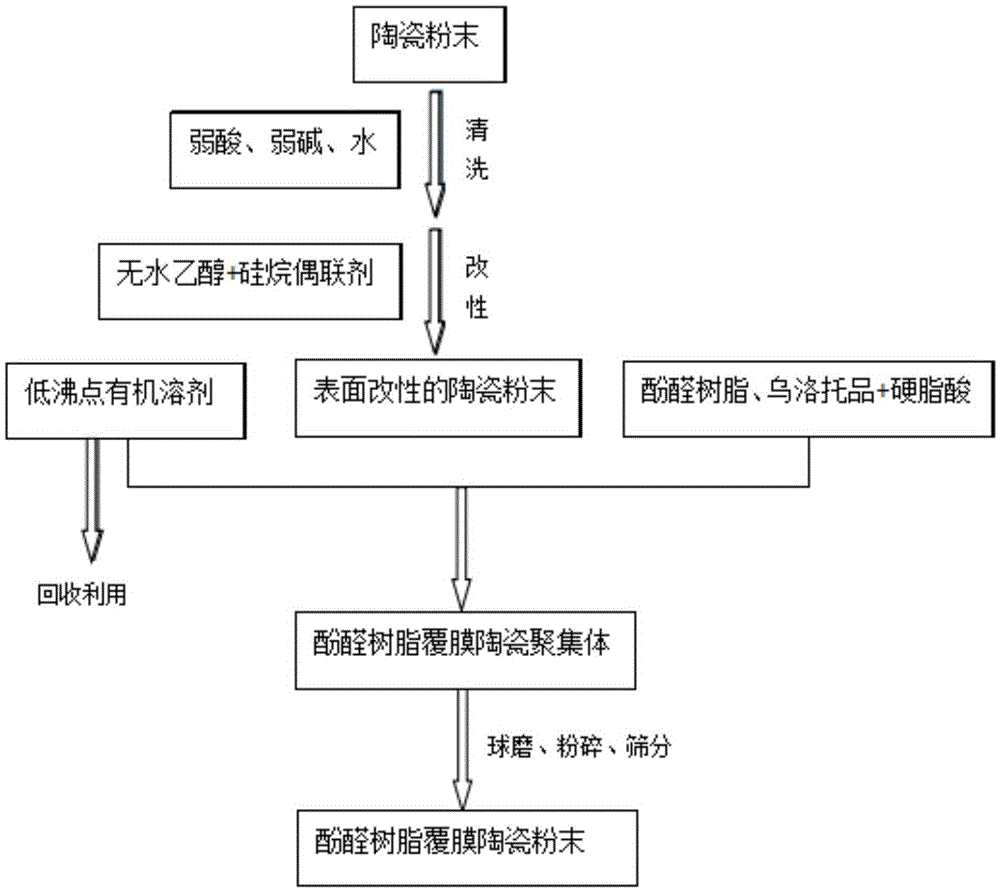

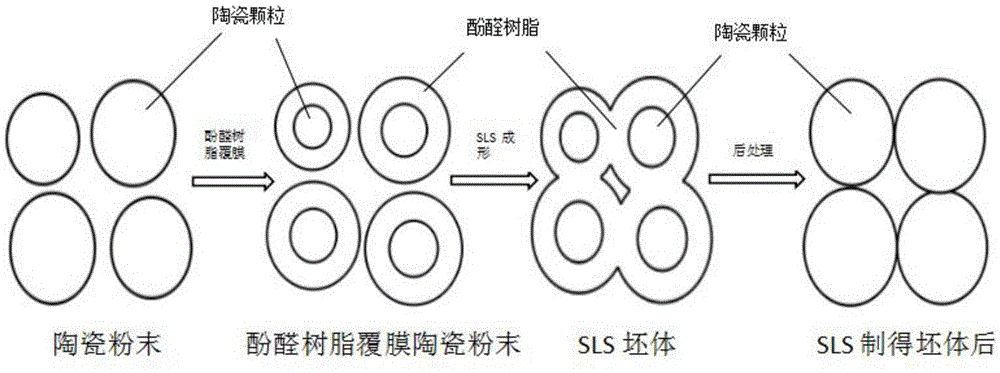

[0031] A phenolic resin coated silicon carbide ceramic powder includes 20-30wt% phenolic resin, 1.5-2.5wt% urotropine, 1-1.5wt% stearic acid, and the balance is surface-modified silicon carbide. The preparation process and principle of the phenolic resin coated silicon carbide ceramic powder are as follows Figure 1-2 As shown, it specifically includes the following steps:

[0032] (1) Preparation of surface-modified silicon carbide ceramic powder: Take 1000g of silicon carbide ceramic powder, wash them with dilute hydrochloric acid, dilute sodium hydroxide and water, and put them in a vacuum drying oven for drying. Then, a mixture of 30 g of absolute ethanol and 10 g of vinyl silane is uniformly mixed with the aforementioned silicon carbide ceramic powder, and at the same time, a stirring device is used to fully stir the mixture for surface modification treatment. After the reaction is completed, the mixture is vacuum dried and sieved to obtain surface-modified silicon carbide ...

Embodiment 2

[0036] A phenolic resin coated titanium carbide ceramic powder includes 15-25wt% phenolic resin, 1-2wt% urotropine, 0.5-1wt% stearic acid, and the balance is surface-modified titanium carbide. The preparation method of the phenolic resin coated titanium carbide ceramic powder is as follows:

[0037] (1) Preparation of surface-modified titanium carbide ceramic powder: Take 1000g of titanium carbide ceramic powder, wash them with dilute sulfuric acid, dilute sodium carbonate and water, and put them in a vacuum drying oven for drying. Then, a mixture of 60 g of absolute ethanol and 15 g of aminosilane is uniformly mixed with the aforementioned titanium carbide ceramic powder, and at the same time, a stirring device is used to fully stir the mixture for surface modification treatment. After the reaction is completed, the mixture is vacuum dried and sieved to obtain surface-modified titanium carbide ceramic powder with a particle size of 30 microns.

[0038] (2) Preparation of phenolic...

Embodiment 3

[0041] A phenolic resin coated zirconia ceramic powder includes 10-20wt% phenolic resin, 1-2wt% urotropine, 0.5-1wt% stearic acid, and the balance is surface-modified zirconia. The preparation method of the phenolic resin coated zirconia ceramic powder is as follows:

[0042] (1) Preparation of surface-modified zirconia ceramic powder: Take 1000g of zirconia ceramic powder, wash them with dilute nitric acid, dilute calcium sulfate and water, and put them in a vacuum drying oven for drying. Then, a mixture of 50 g of absolute ethanol and 10 g of methacryloxy silane is uniformly mixed with the aforementioned zirconia ceramic powder, and at the same time, the mixture is fully stirred by a stirring device for surface modification treatment. After the reaction is completed, the mixture is vacuum dried and sieved to obtain surface-modified zirconia ceramic powder with a particle size of 50 microns.

[0043] (2) Preparation of phenolic resin-coated zirconia ceramic aggregates: adding sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com