Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31999results about "Water/sewage treatment by flocculation/precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

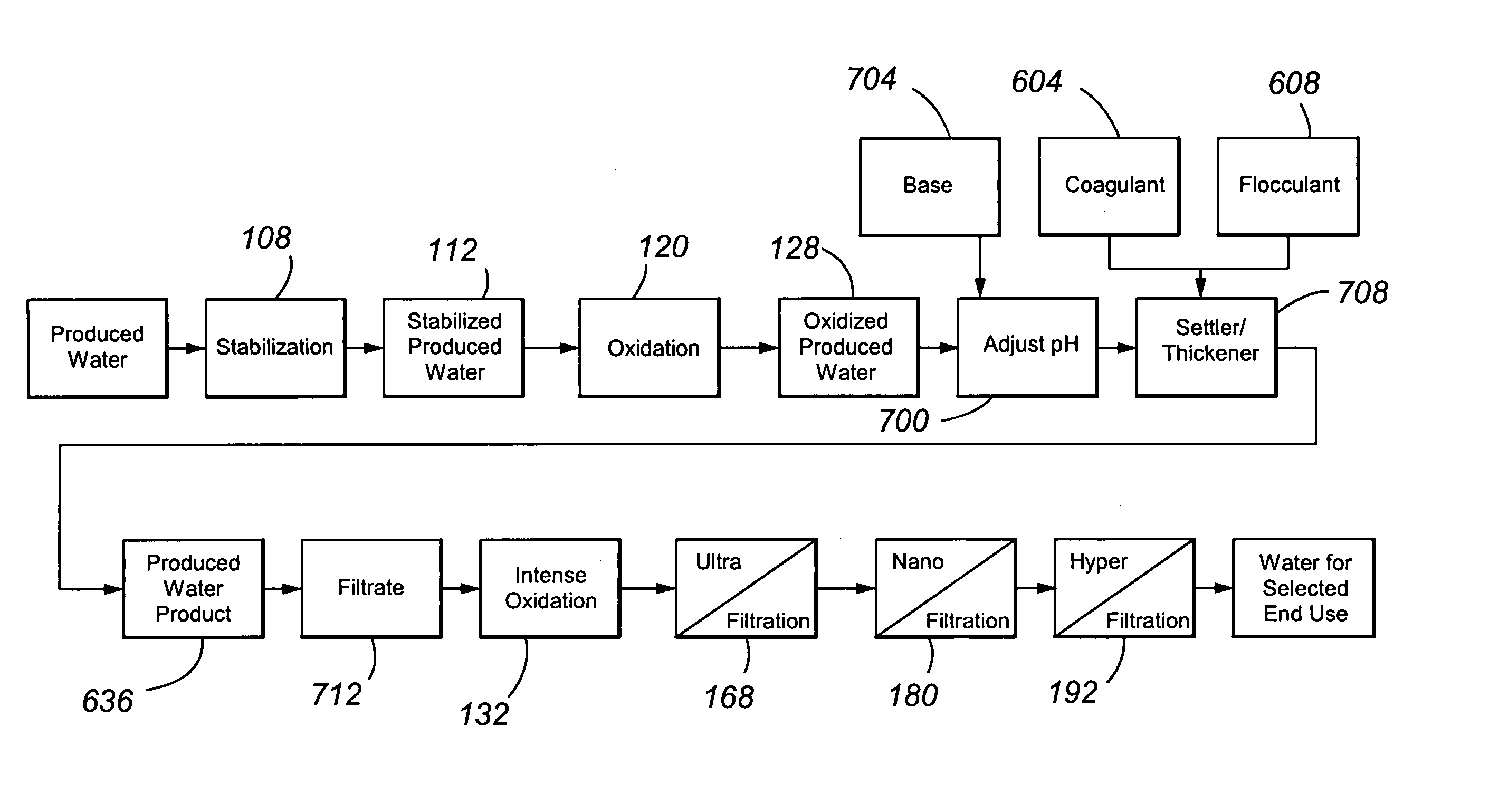

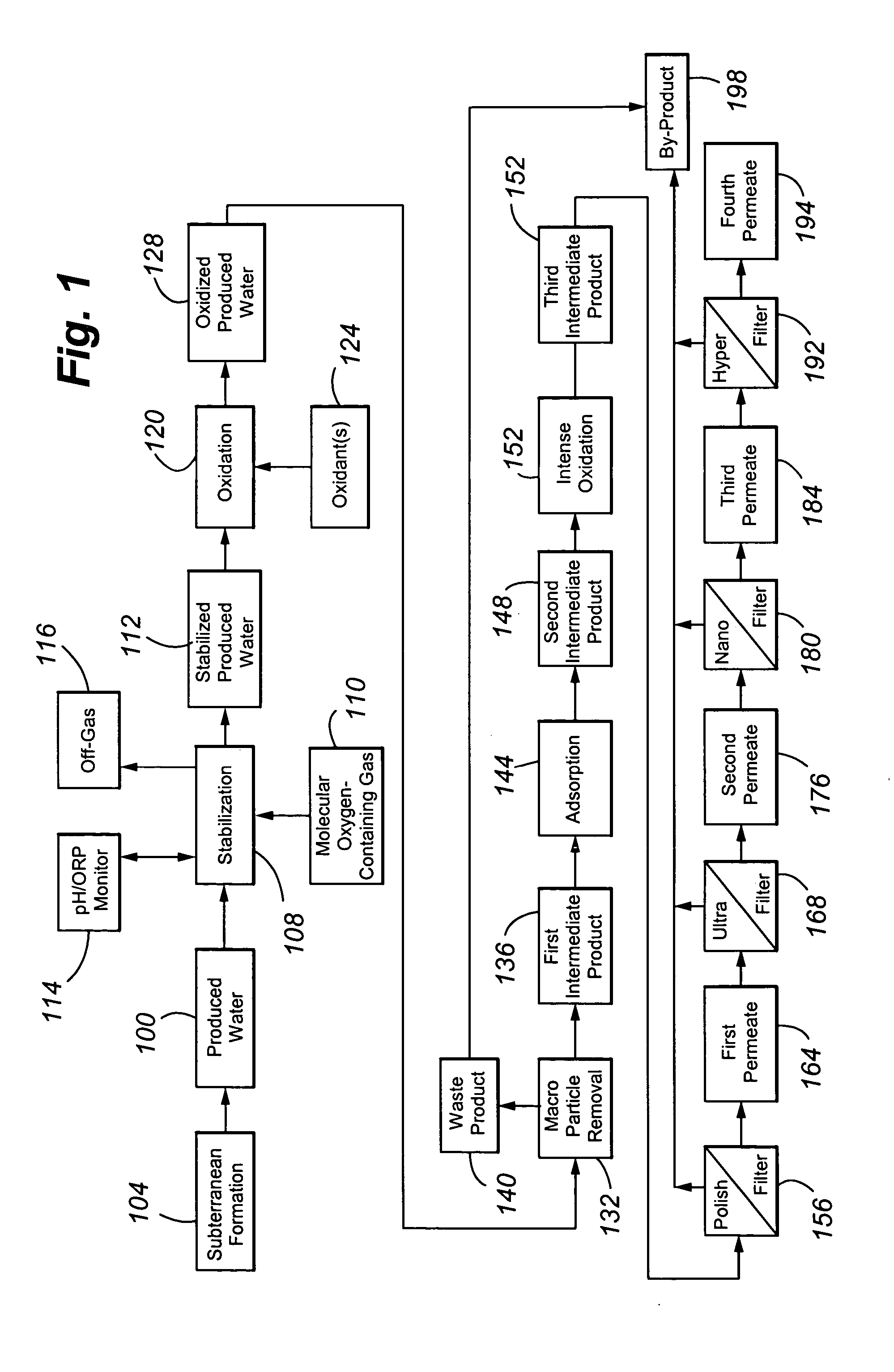

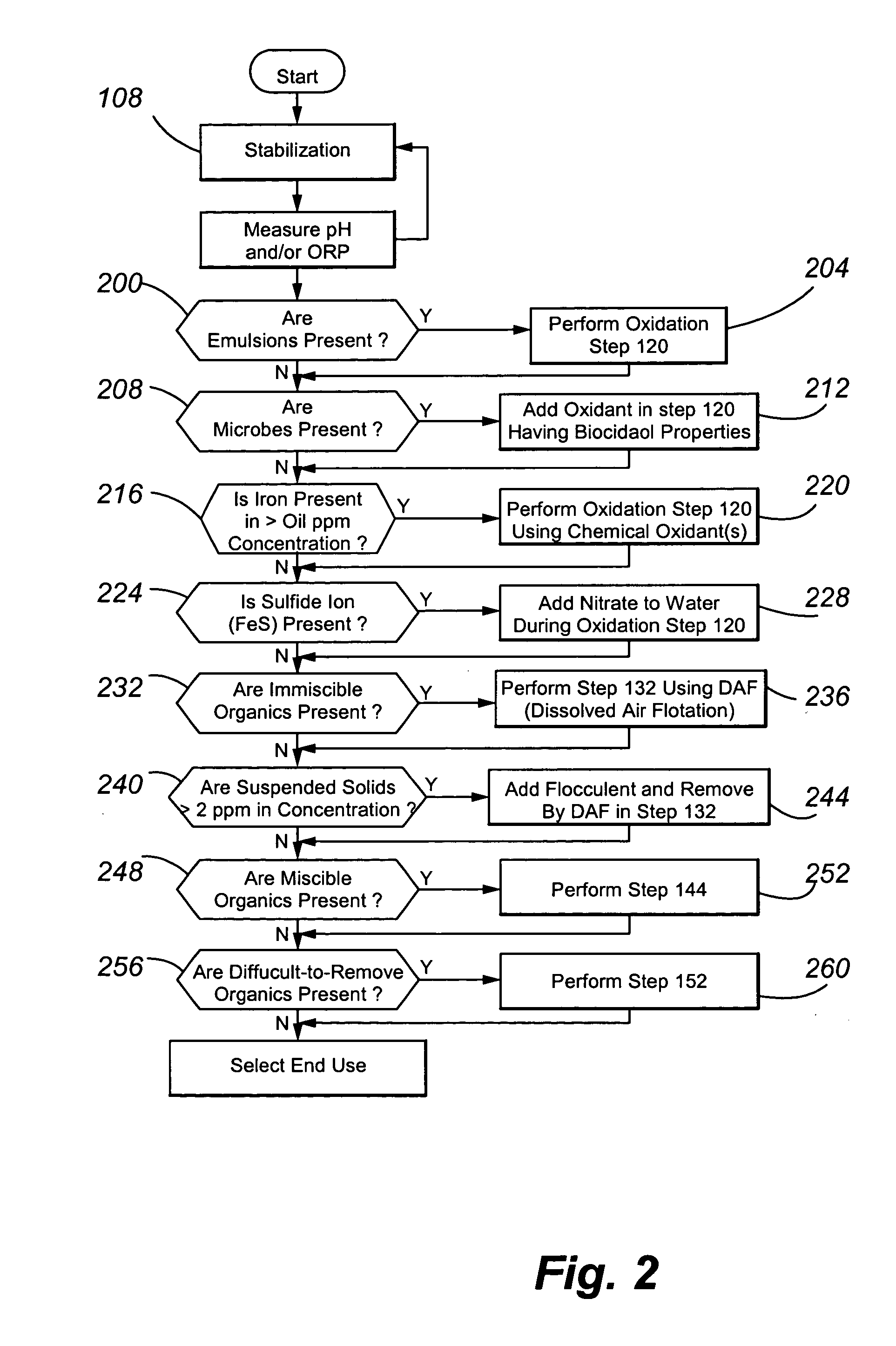

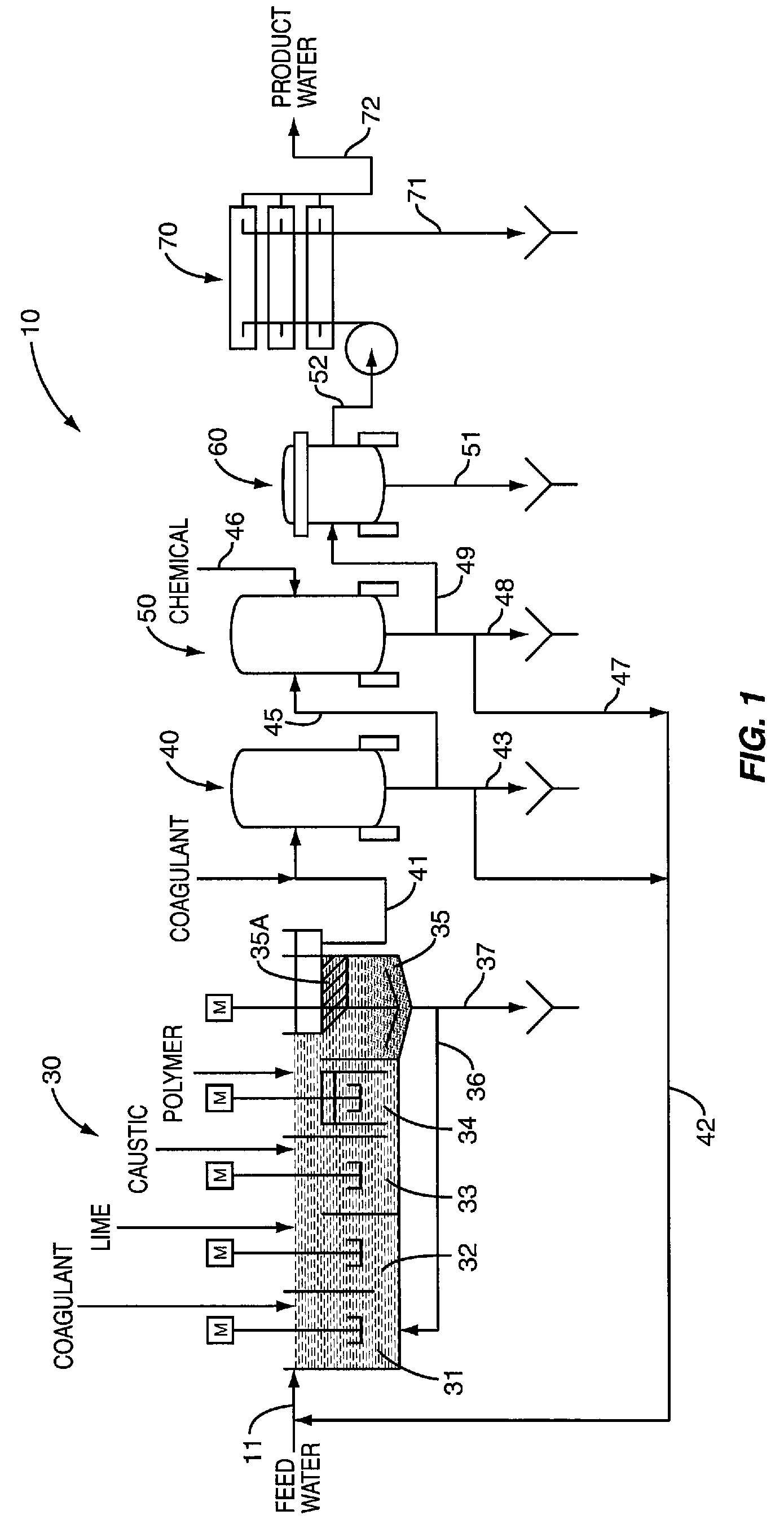

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

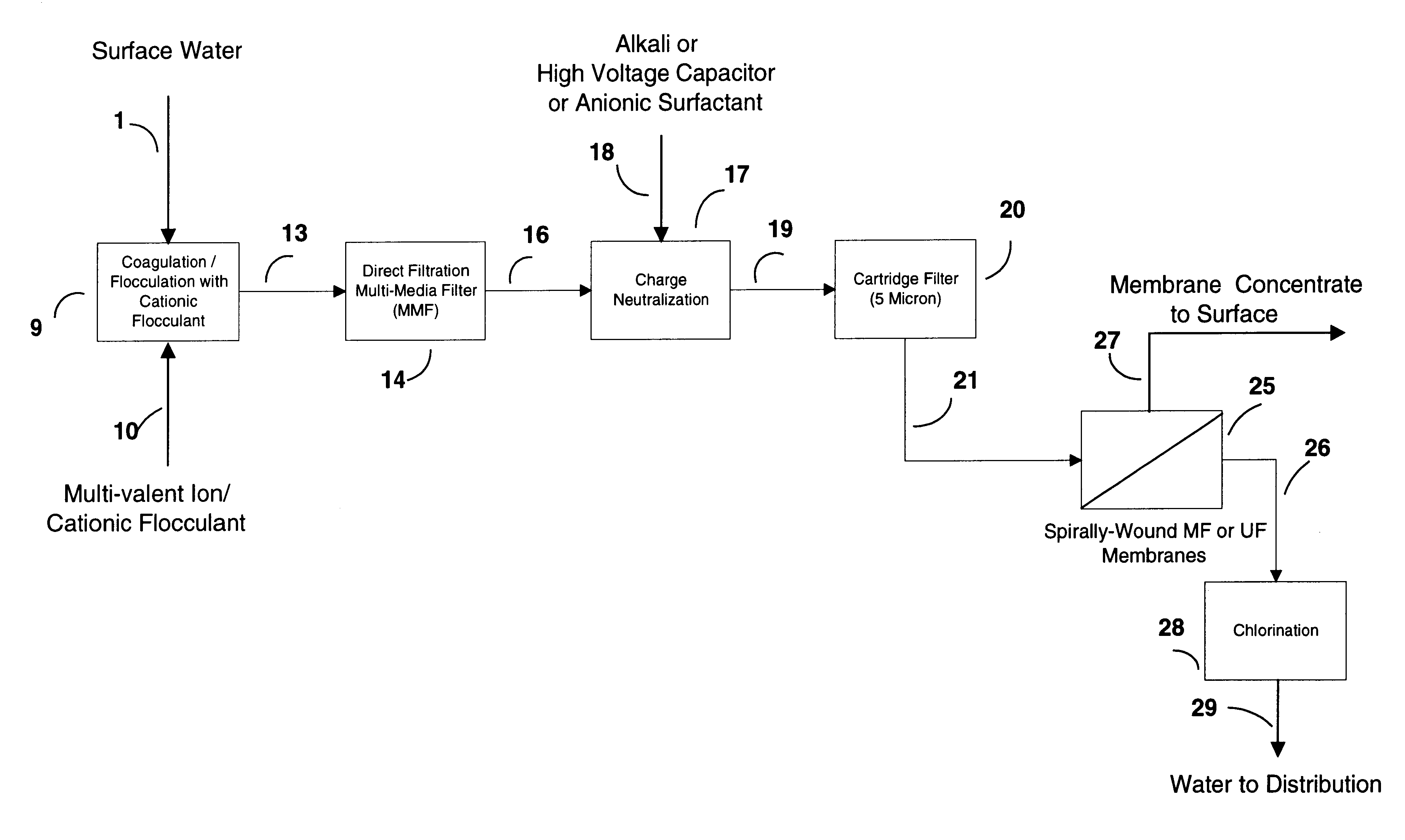

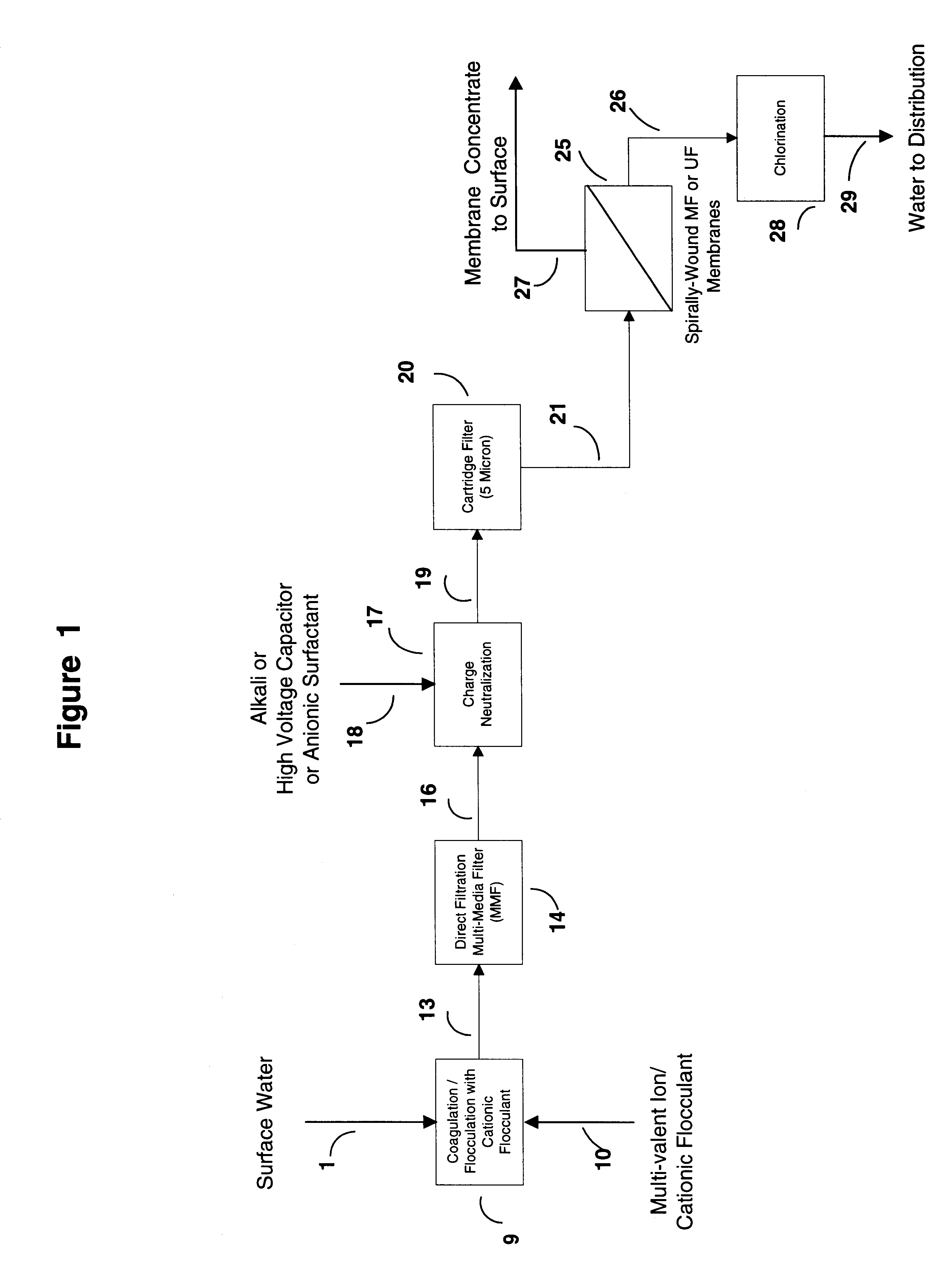

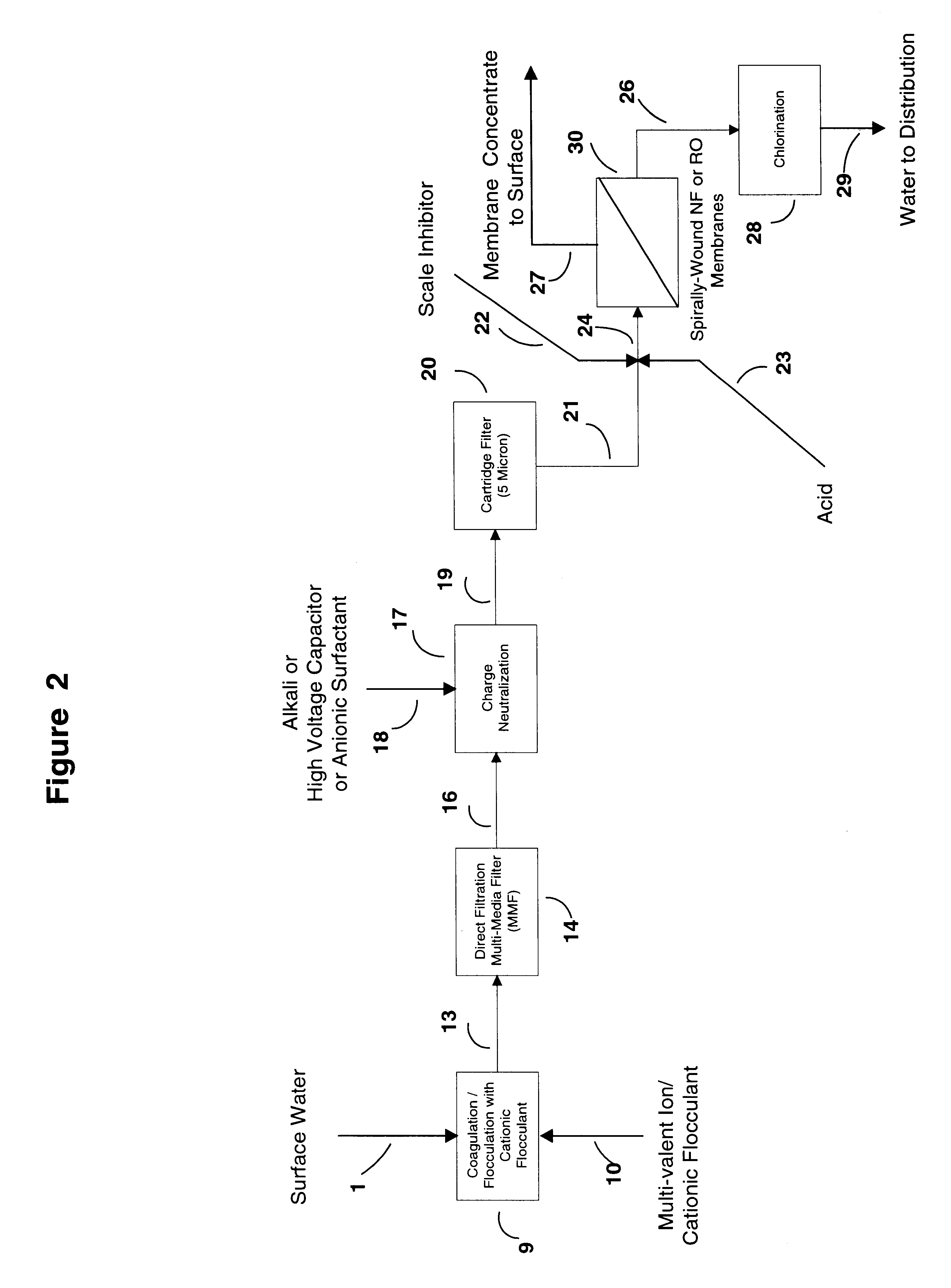

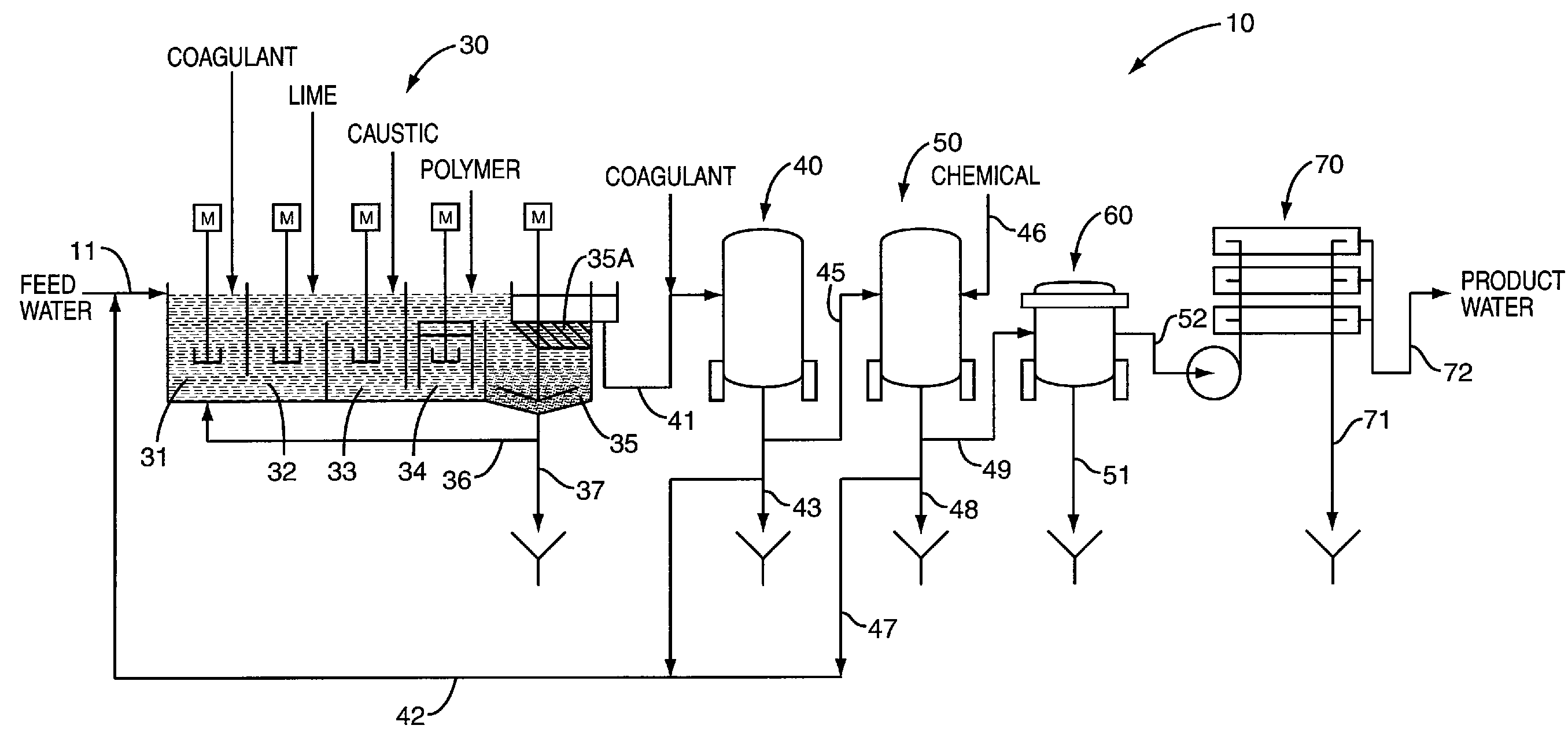

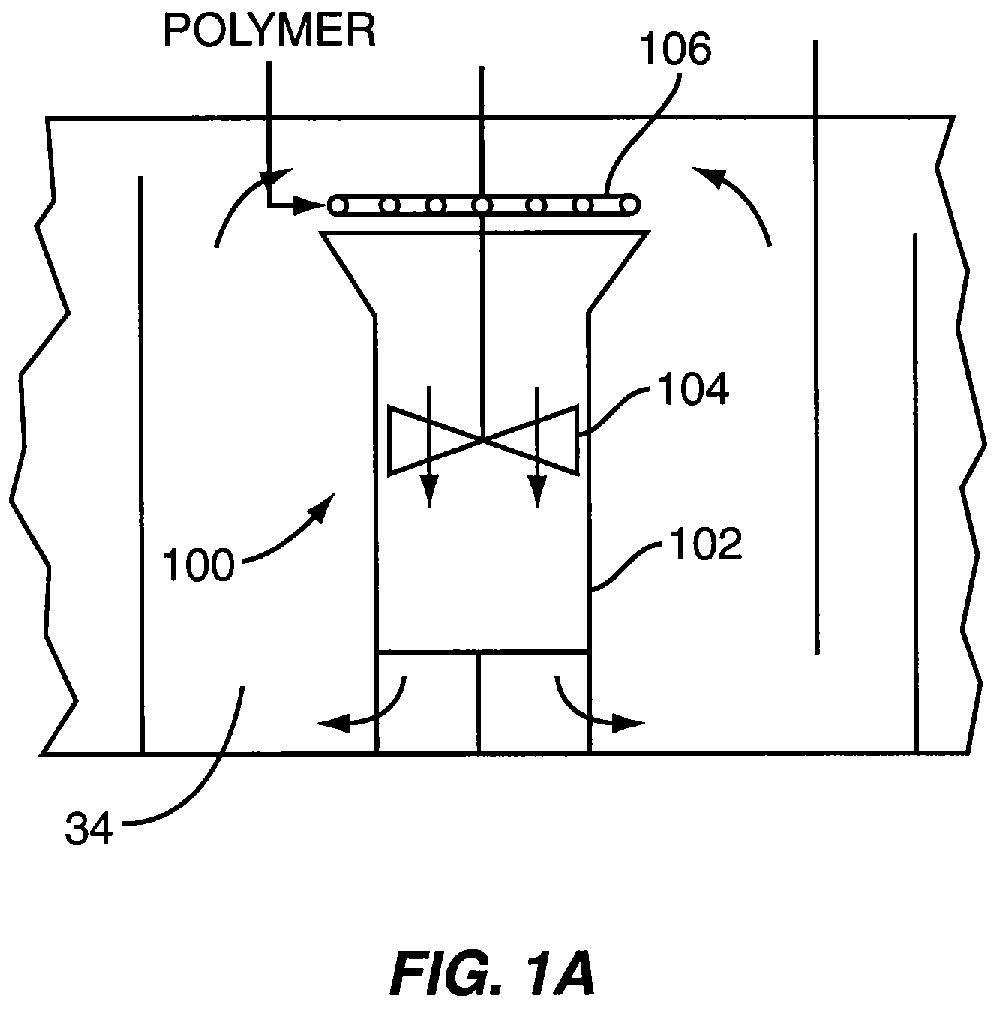

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

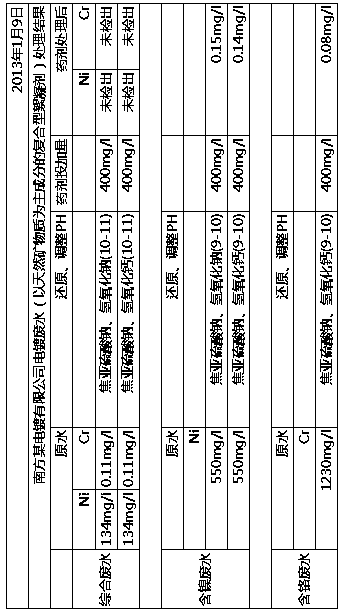

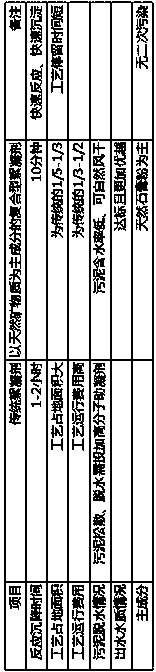

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

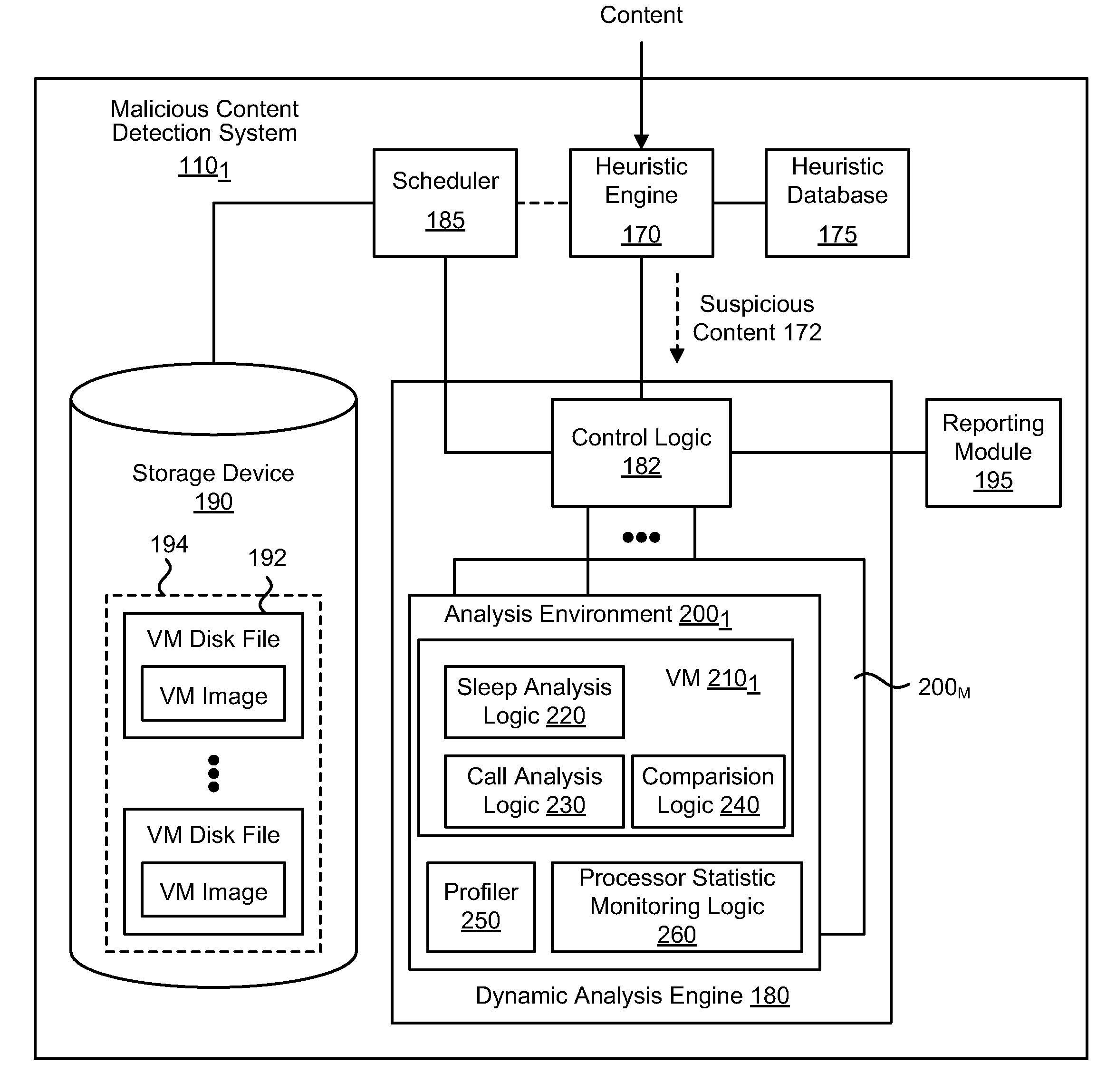

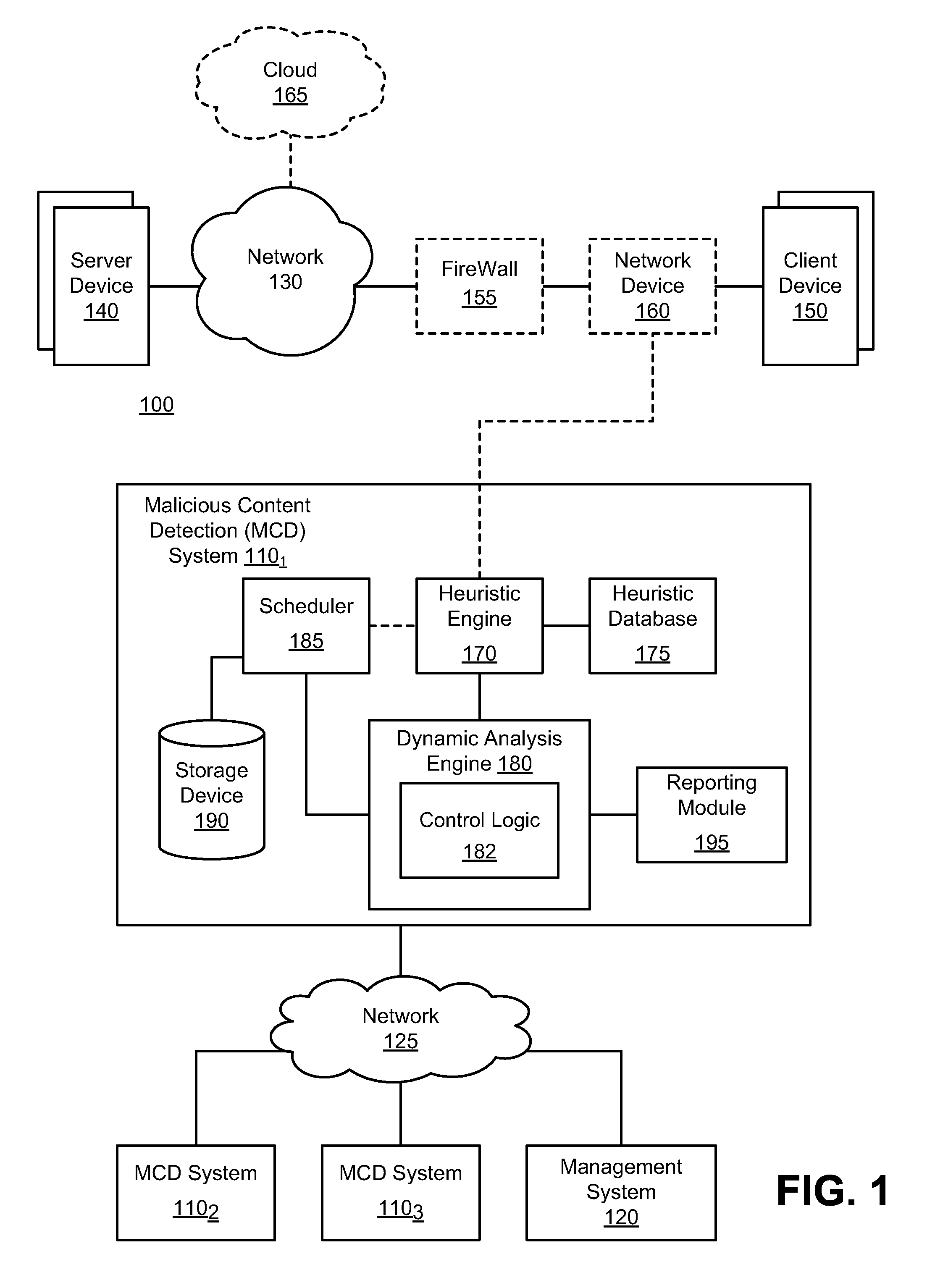

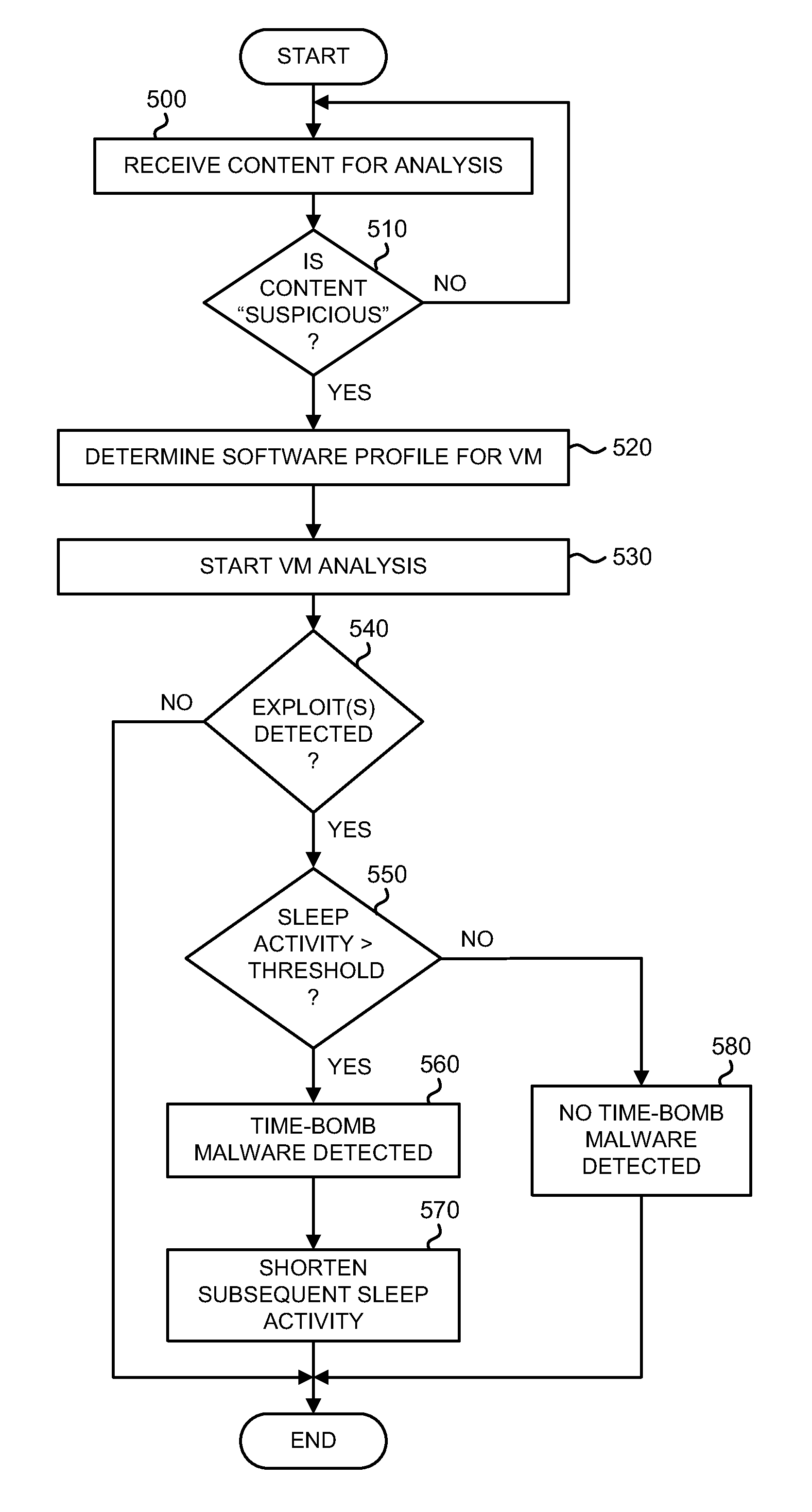

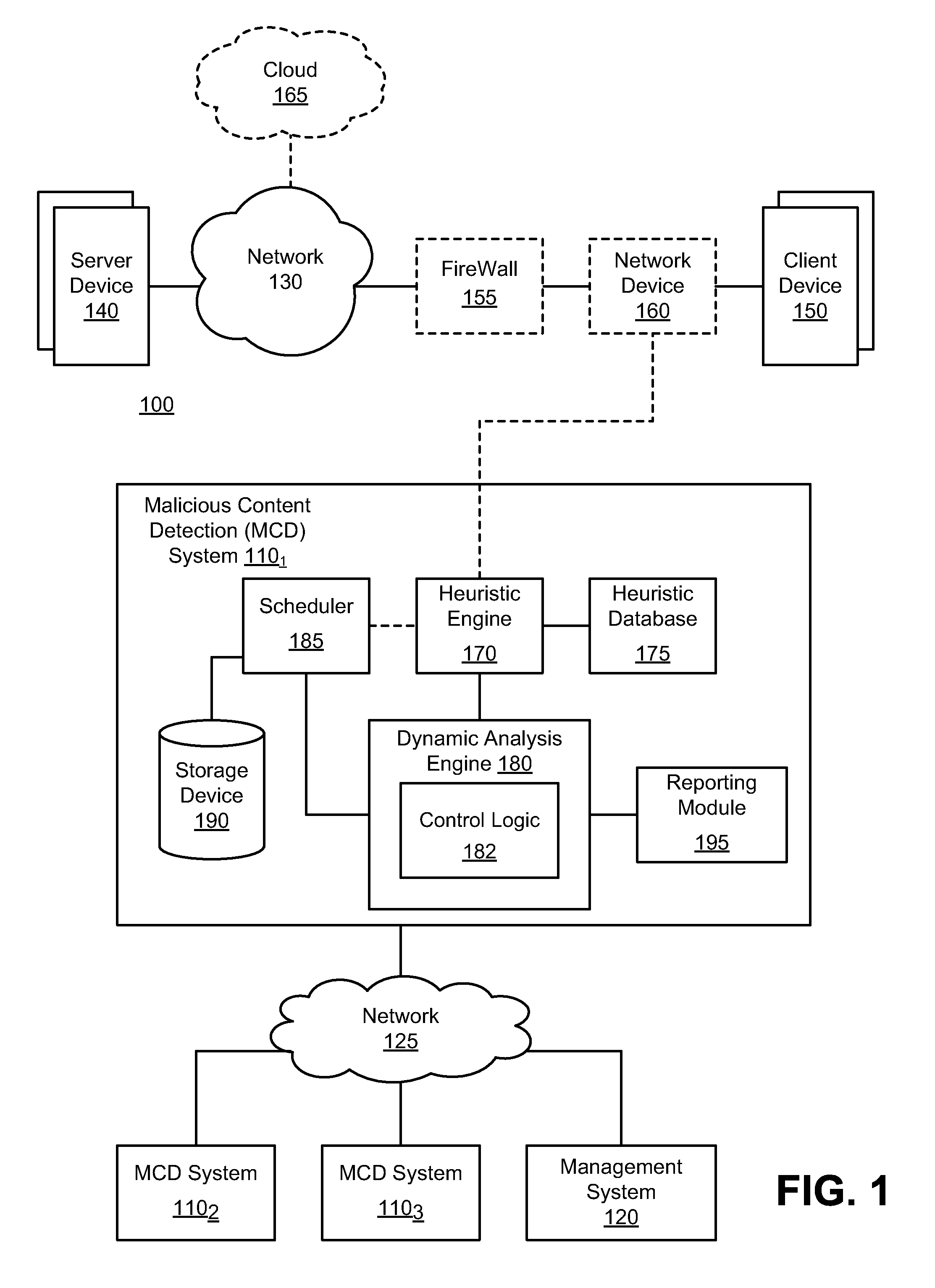

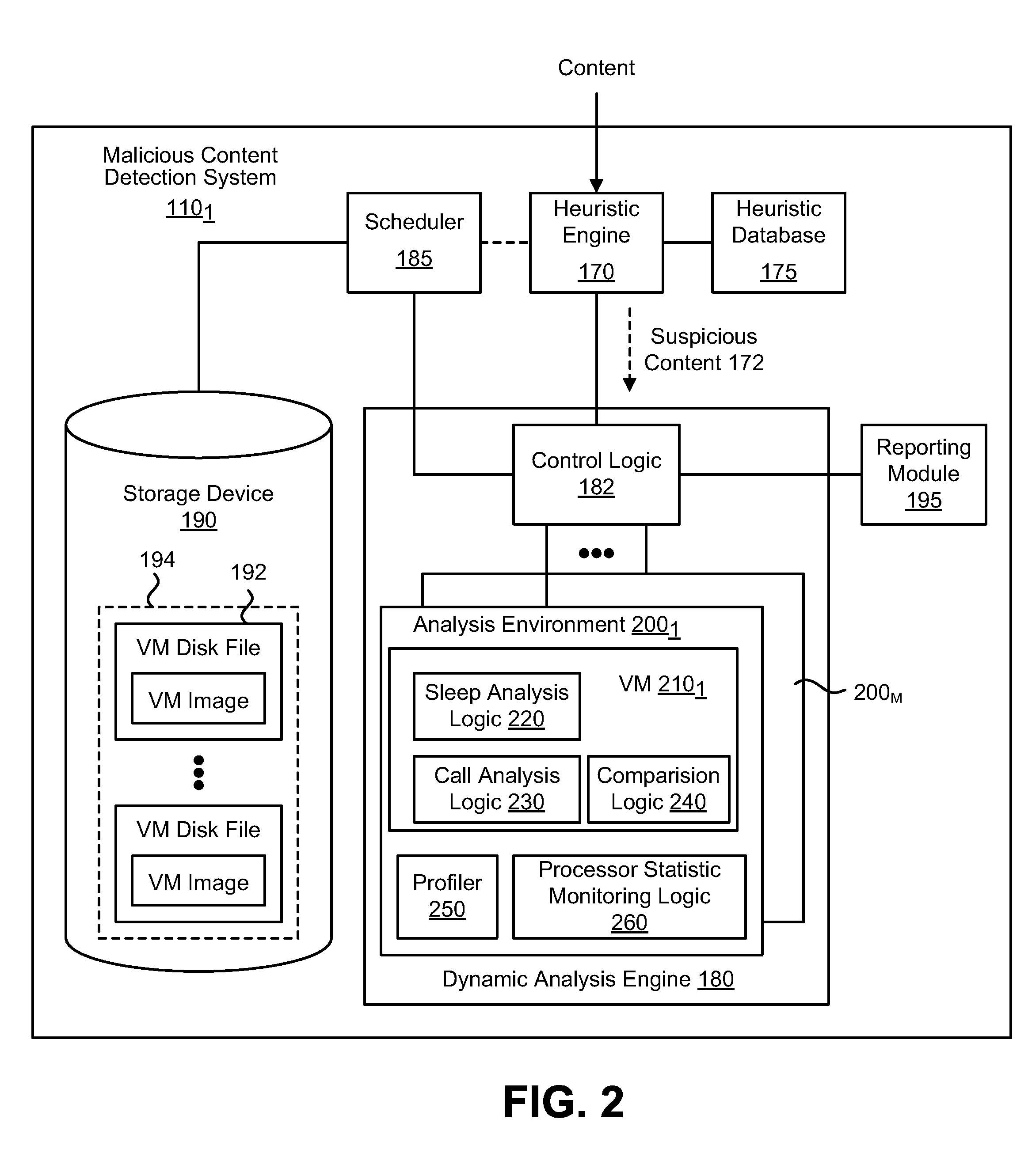

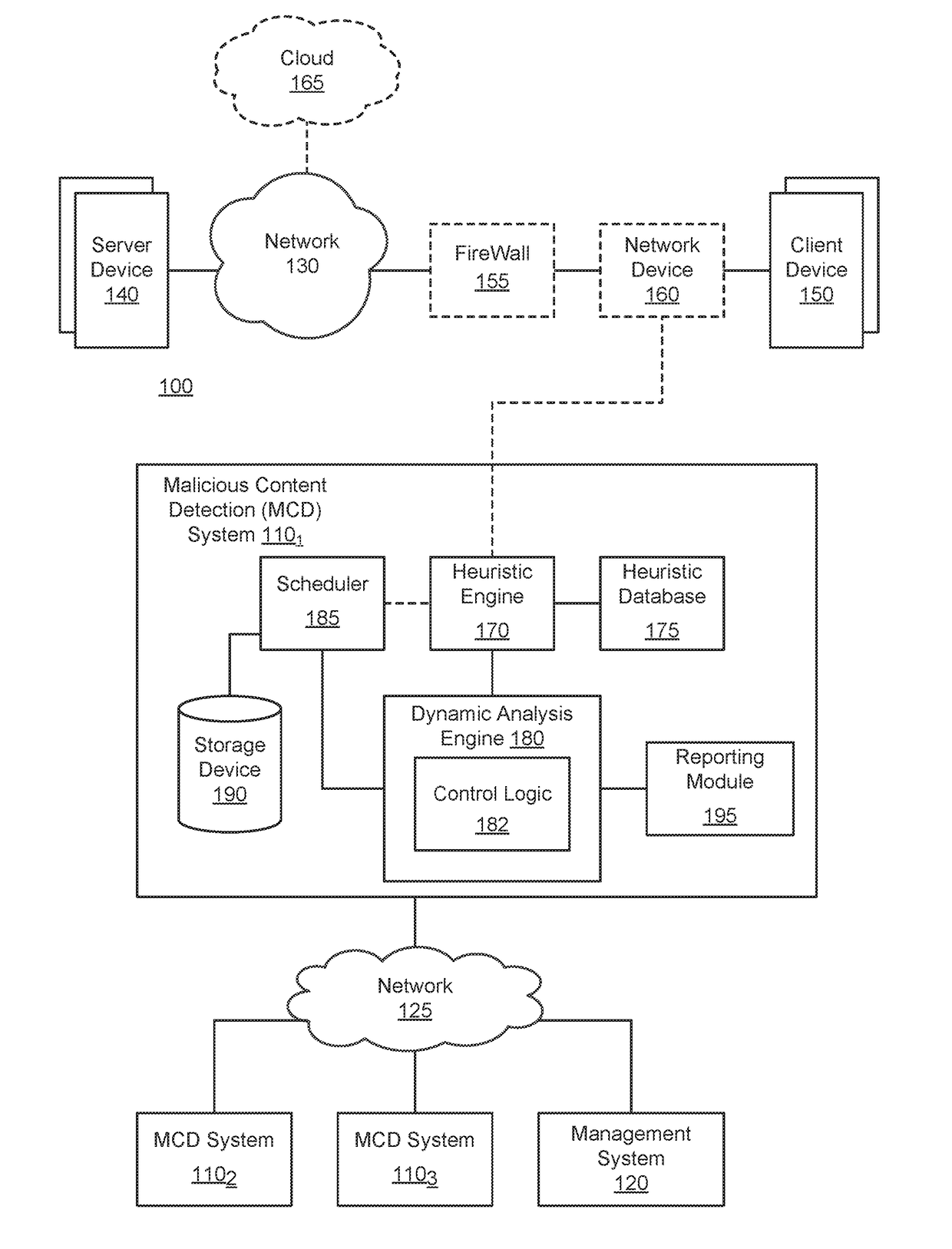

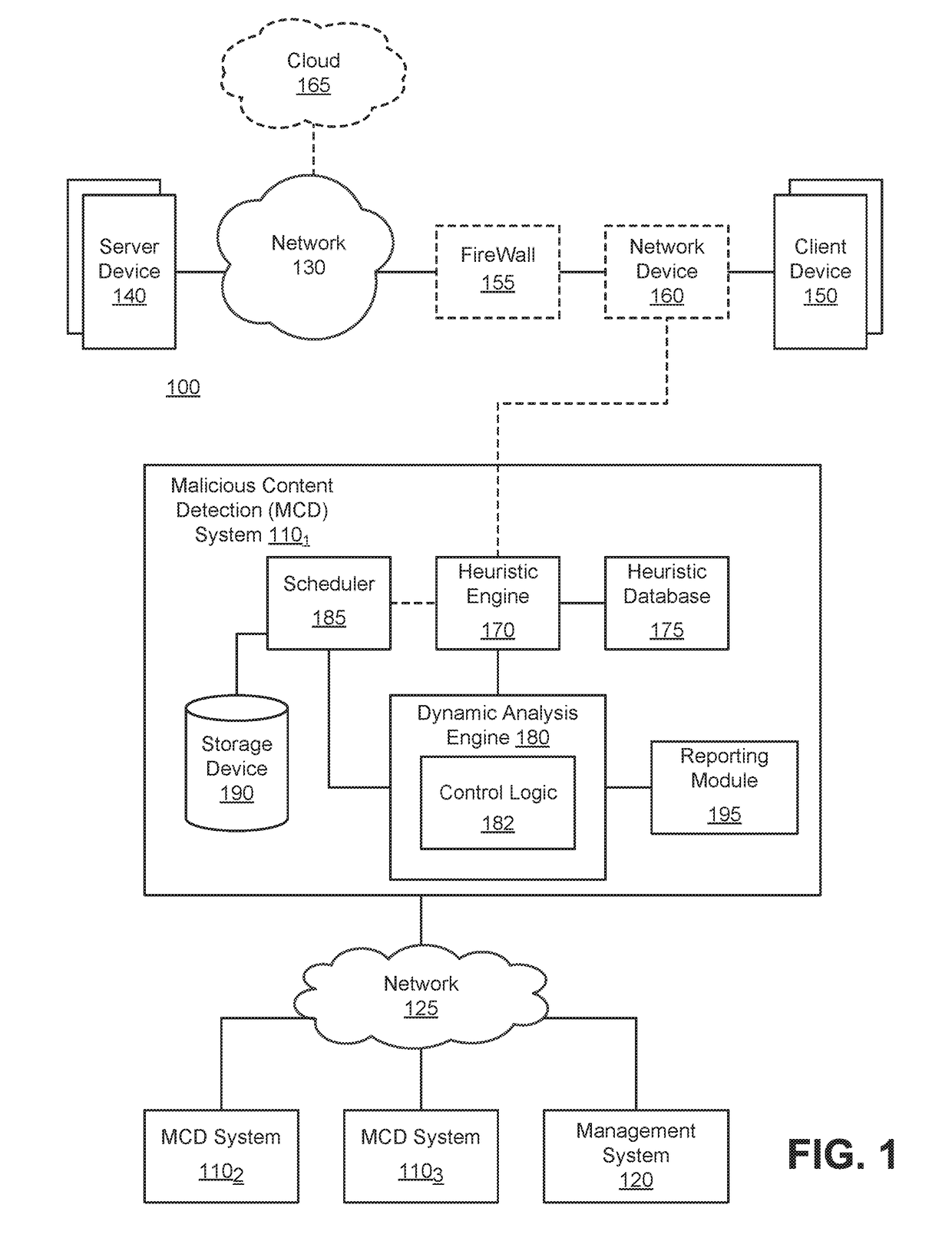

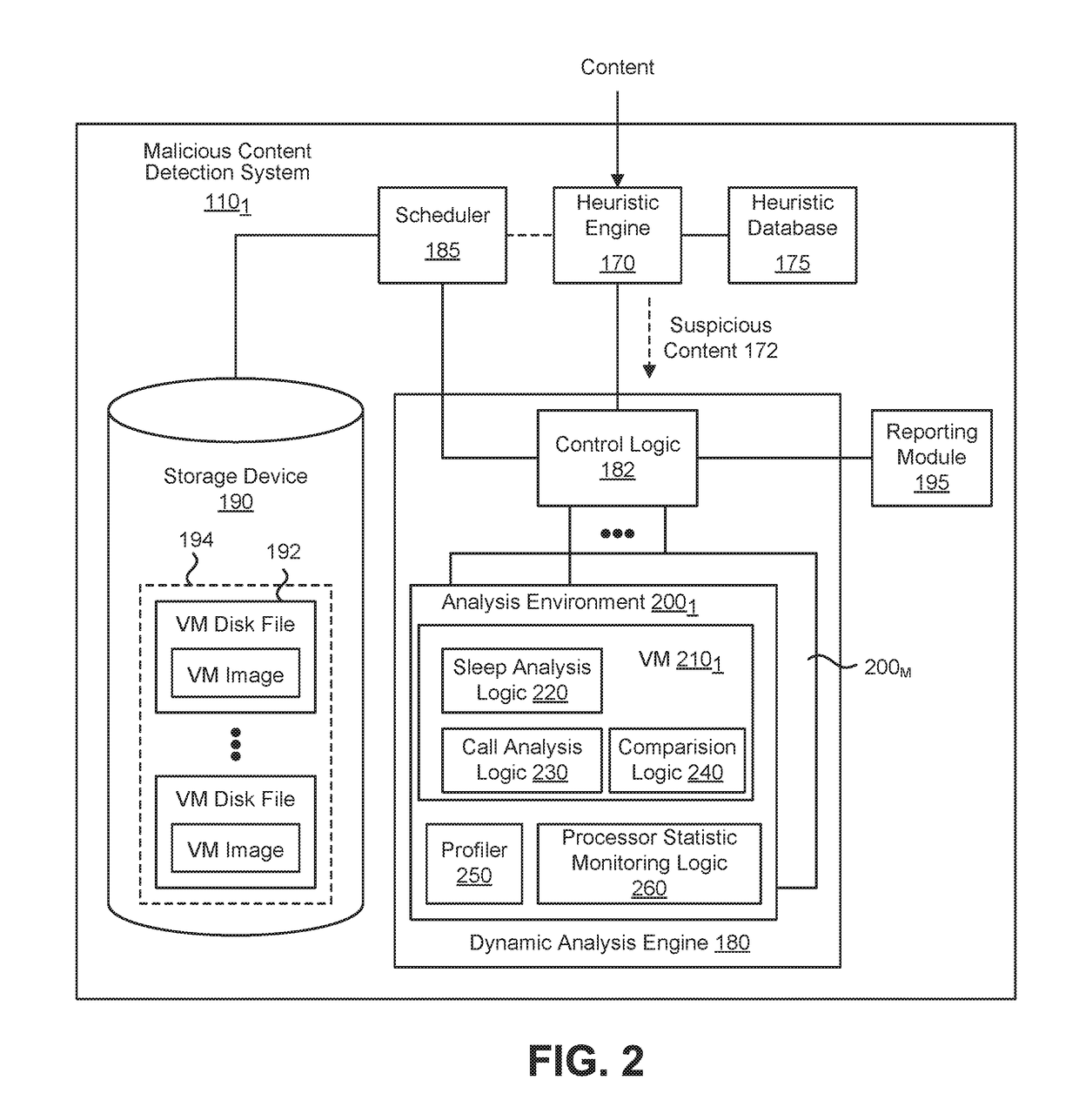

System and Method for Detecting Time-Bomb Malware

According to one embodiment, a system comprises one or more counters; comparison logic; and one or more hardware processors communicatively coupled to the one or more counters and the comparison logic. The one or more hardware processors are configured to instantiate one or more virtual machines that are adapted to analyze received content, where the one or more virtual machines are configured to monitor a delay caused by one or more events conducted during processing of the content and identify the content as including malware if the delay exceed a first time period.

Owner:FIREEYE SECURITY HLDG US LLC

Efficient water treatment flocculant

InactiveCN101327976AEfficient purificationPromote generationWater/sewage treatment by flocculation/precipitationWater qualityHigh intensity

The invention relates to a high efficiency water treatment flocculant for drinking water and water treatment comprising a metal cation flocculant which is characterized in that the high efficiency water treatment flocculant also comprises a high efficiency adsorption component and an assistant medicament to be remixed, inwhich the weight ratio is: the high efficiency adsorption component 5-15%, the metal cation flocculant 50-85%, the assistant medicament 5-15%. The obvious characteristics of the invention are that each component can play the advantages of high intensity of the flocs of the inorganic flocculant and large flocs of the polymeric flocculant, overcomes the drawback of small flocs of the inorganic flocculant and low intensity of the flocs of the organic flocculant. The existence of the high adsorption component plays the action of adsorption of the organic compounds and heavy metal ion which are difficult to flocculat and precipitate, also plays the role of aid-coagulation, decoloration and deflavour. Thus the flocculant of the invention has advantages of good coagulation effect, large alum blossom, rapid settling velocity, good effluent quality and few dosage or the like.

Owner:郭振岳 +1

Water purifier and method of making and using the same

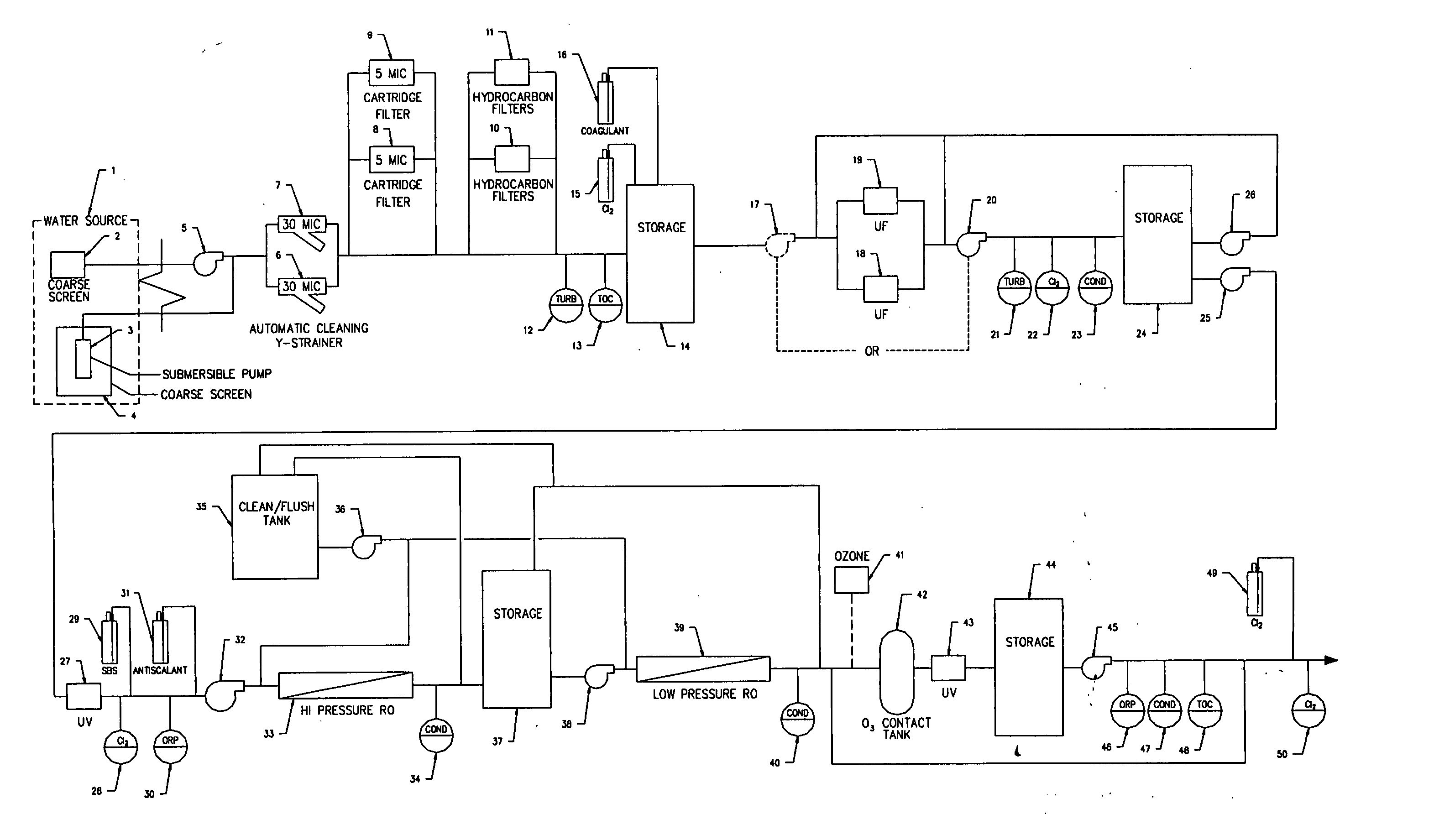

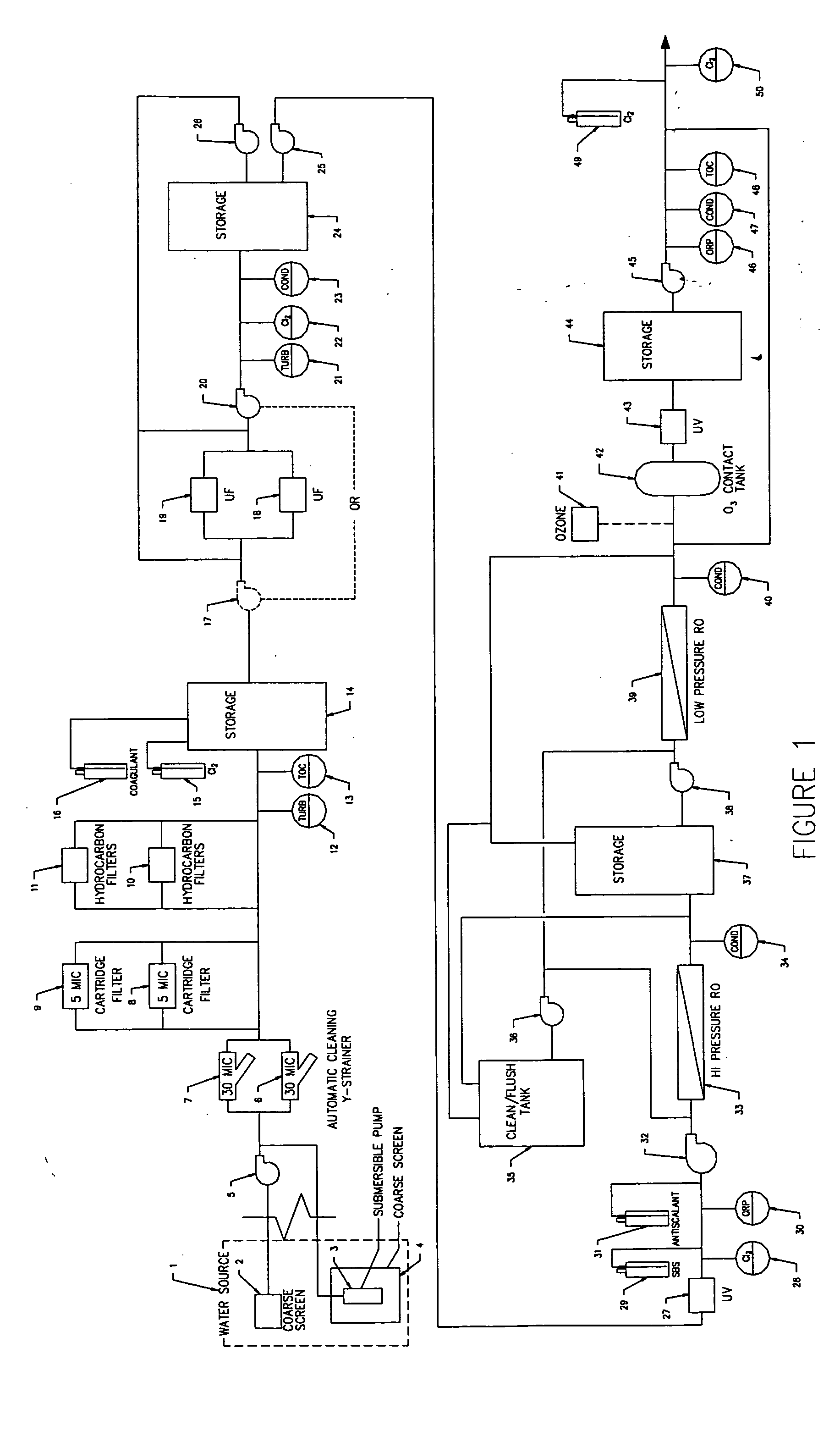

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

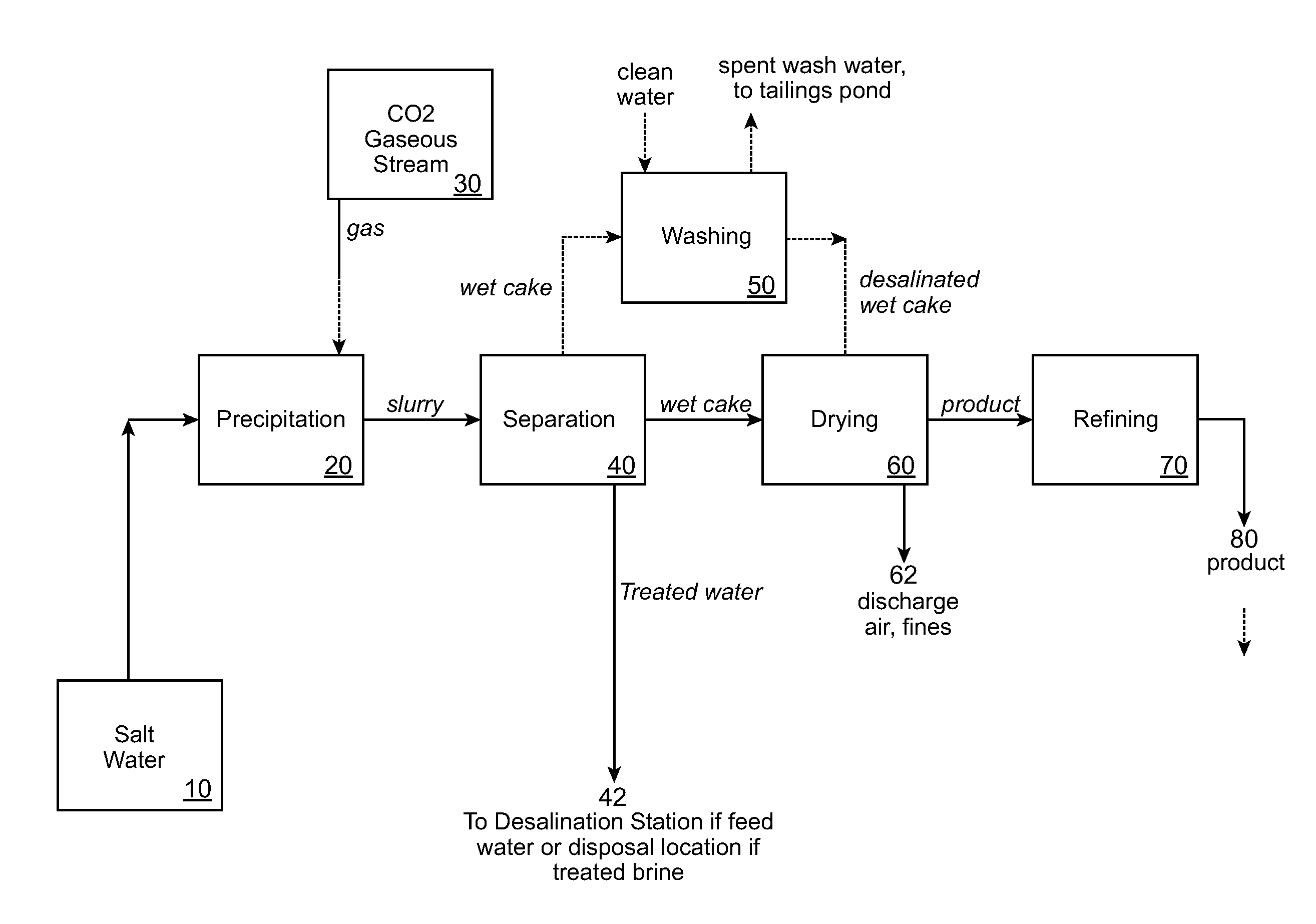

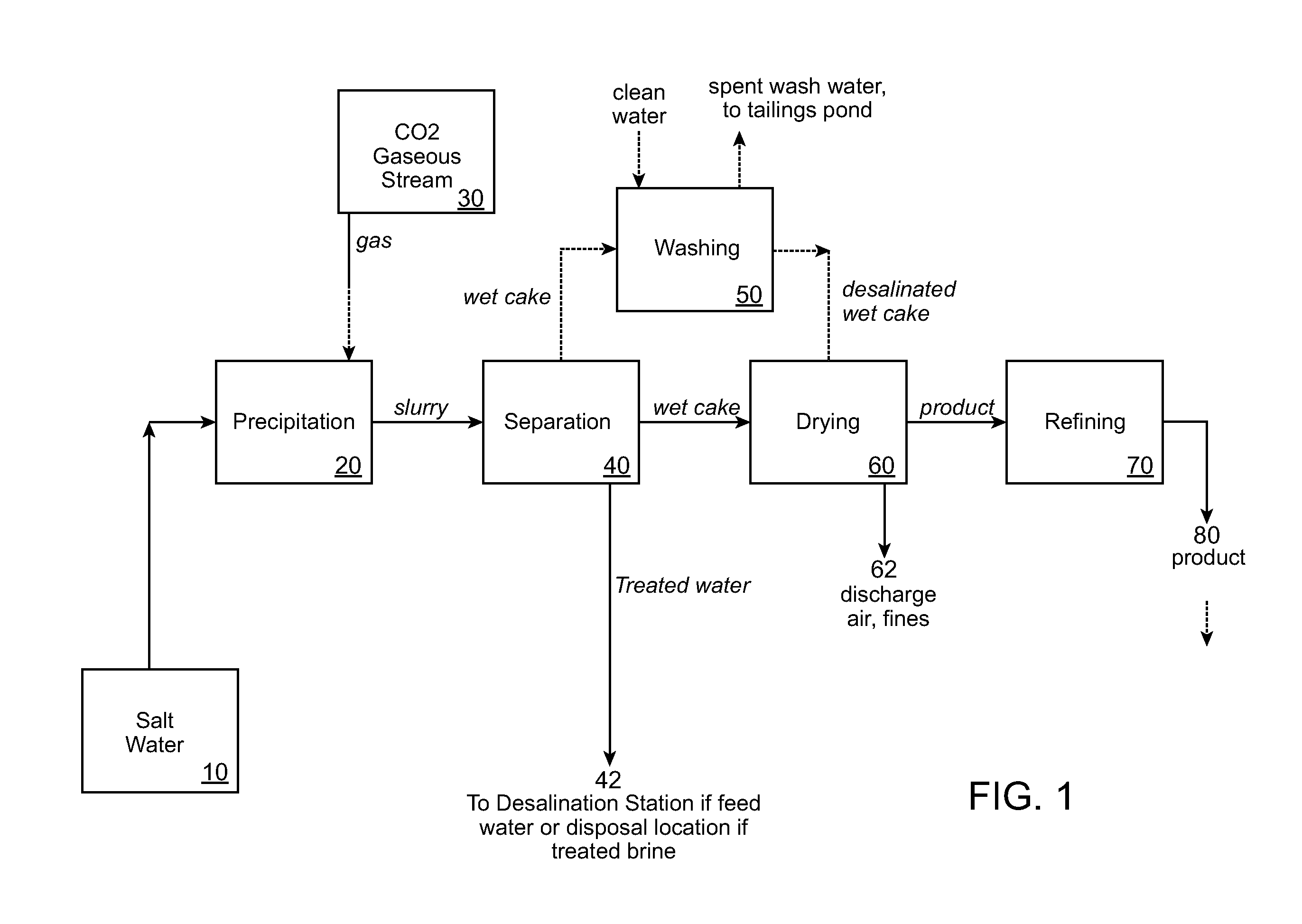

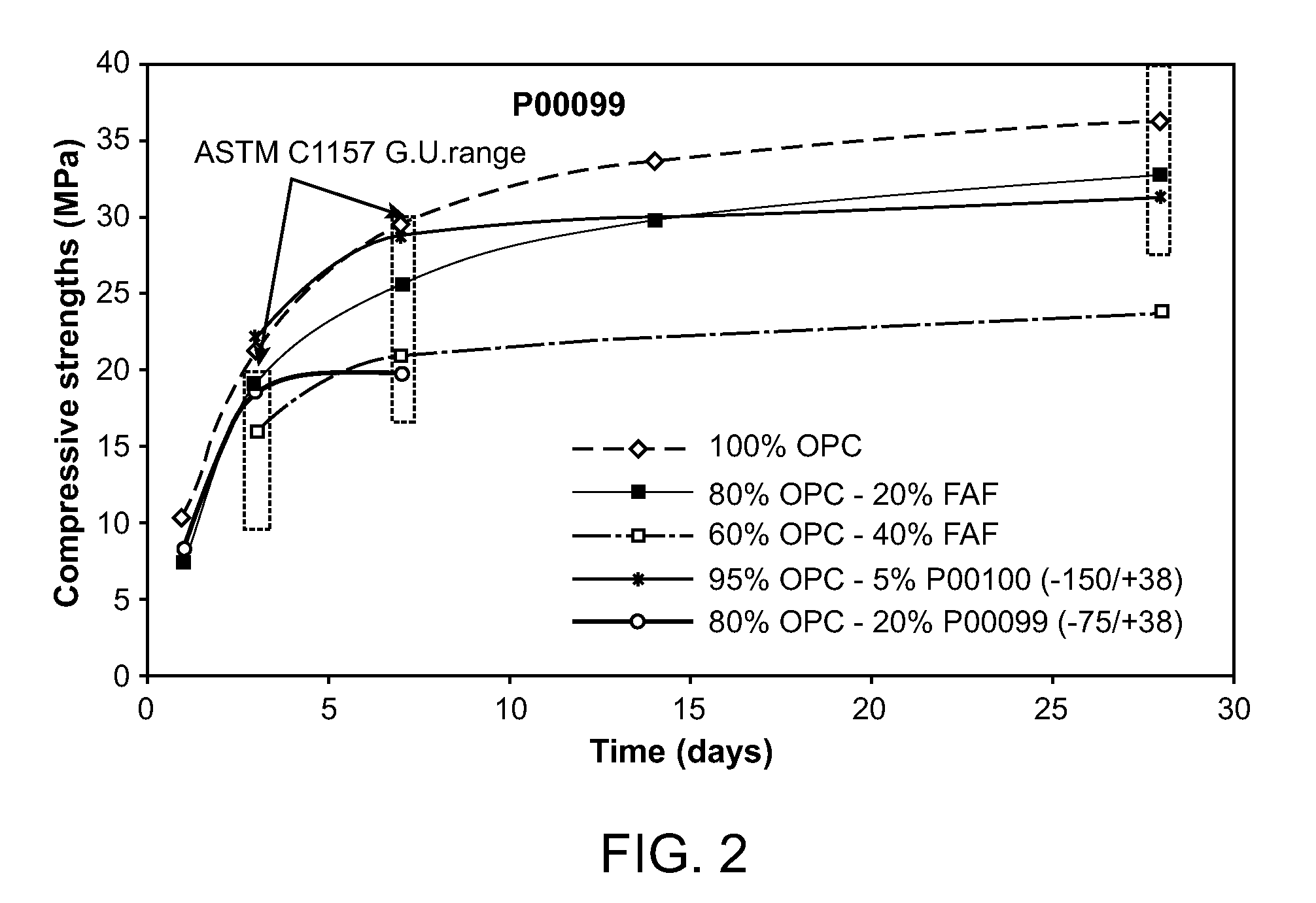

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

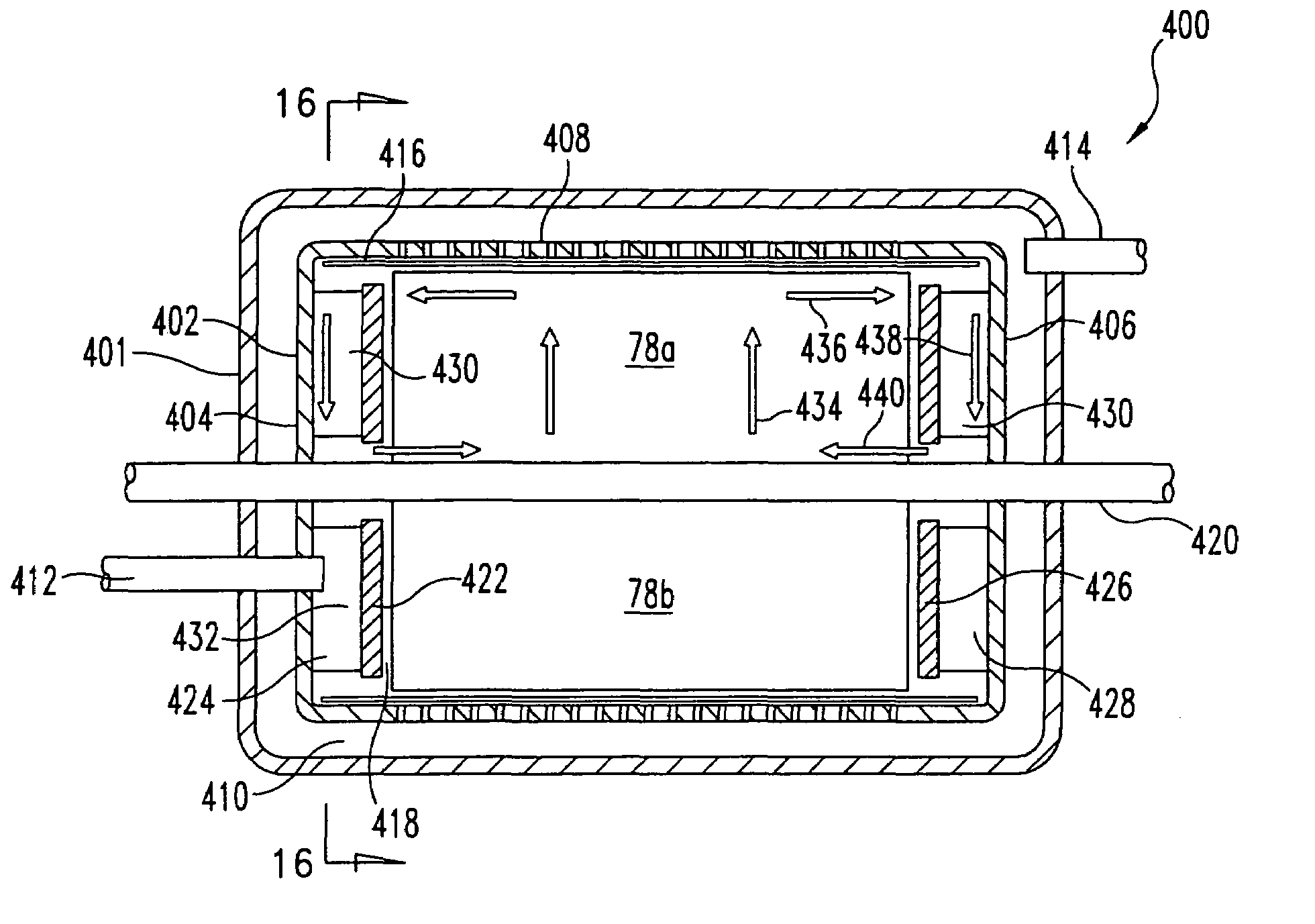

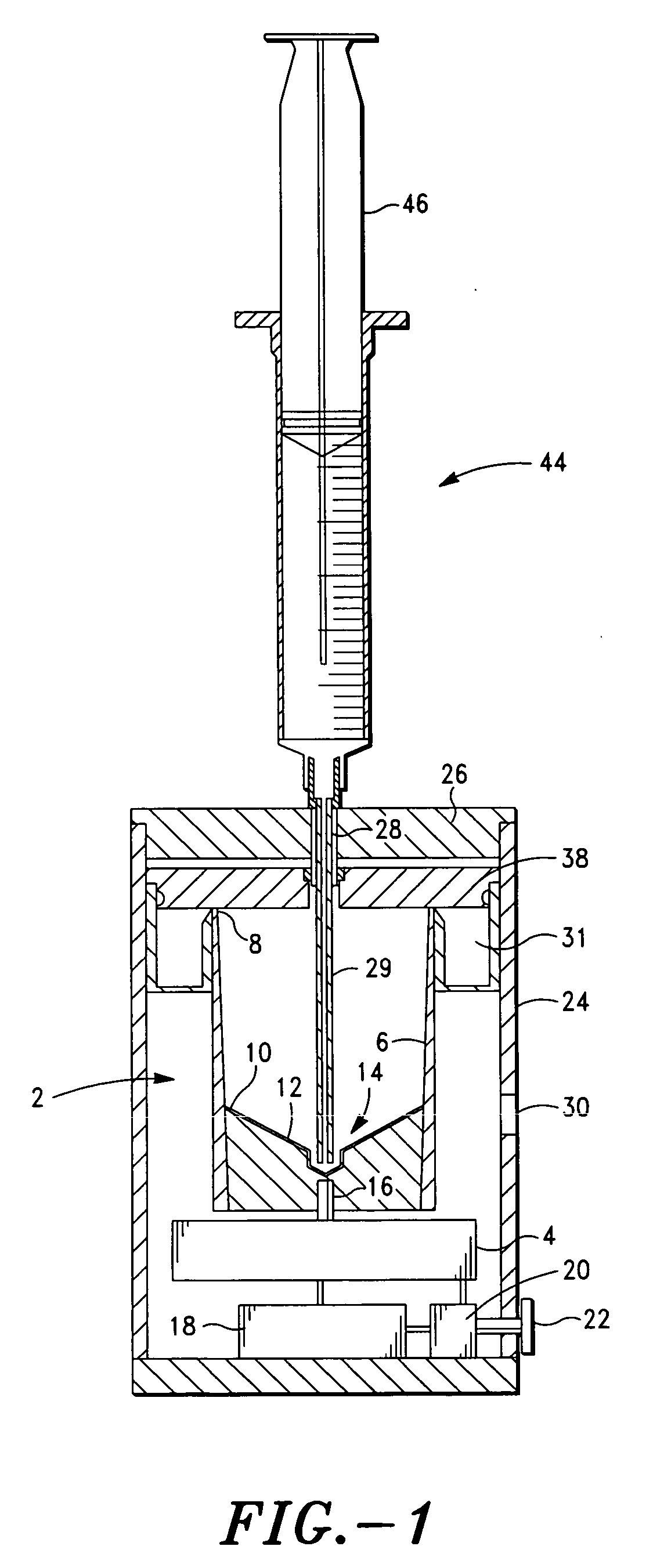

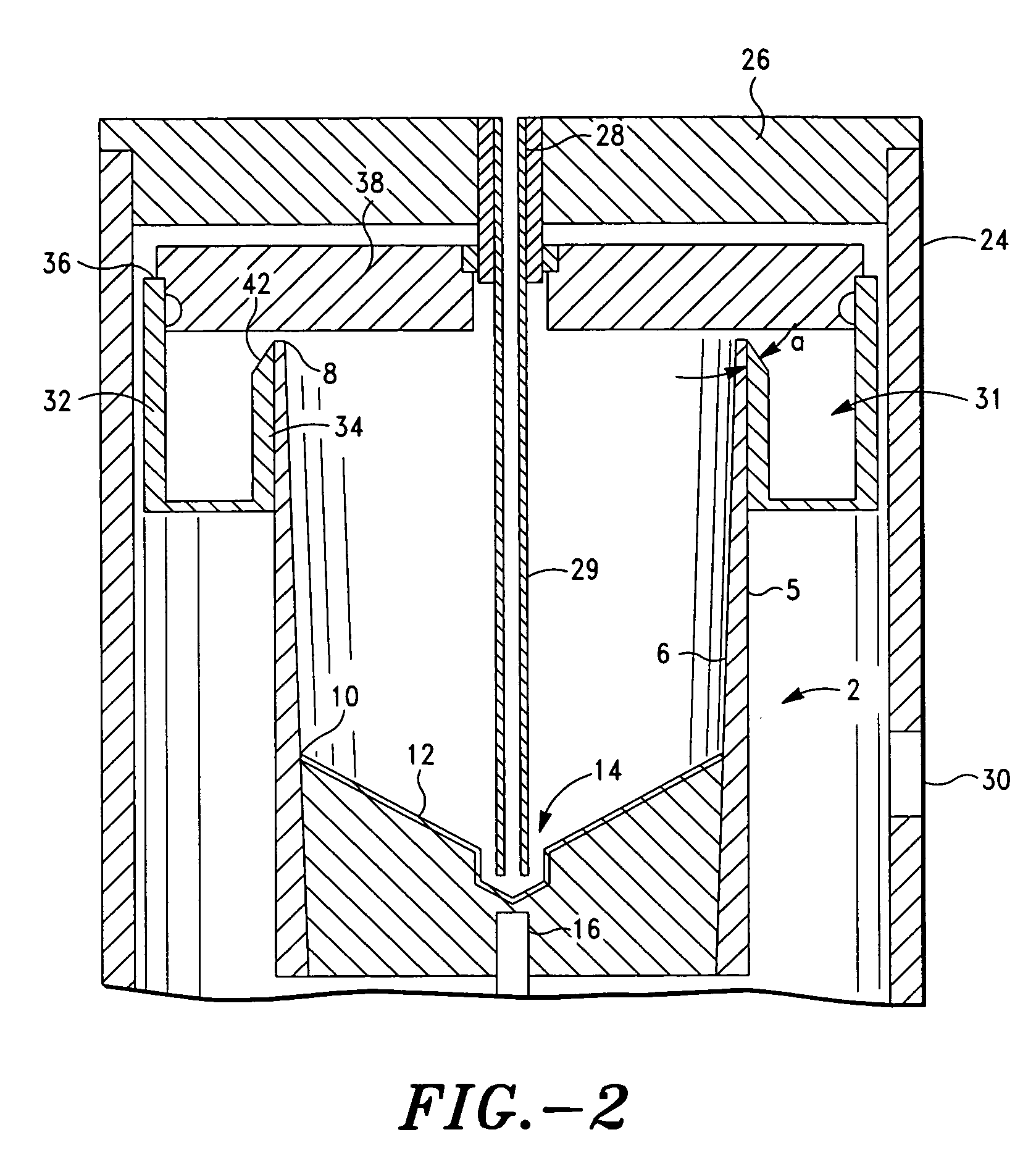

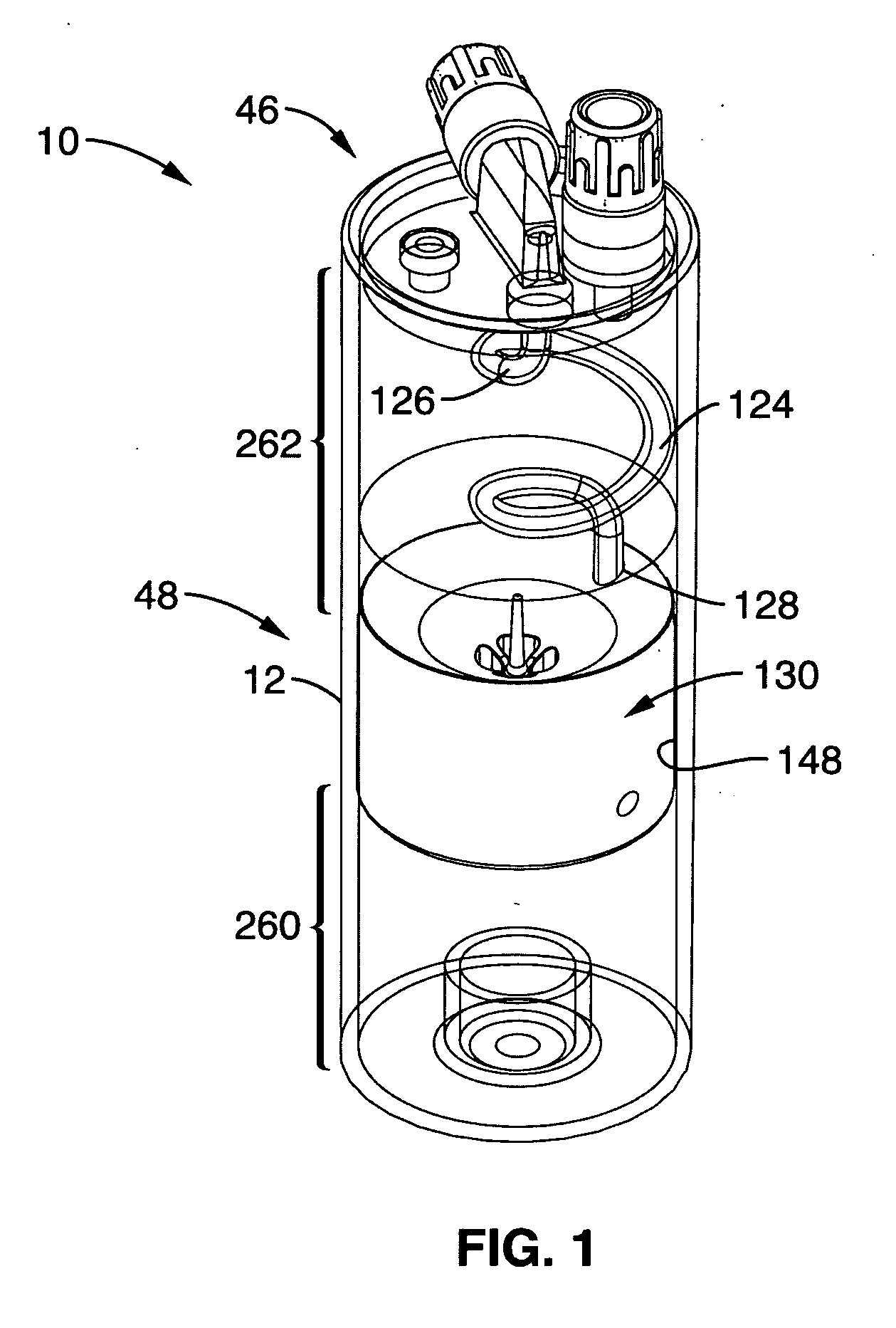

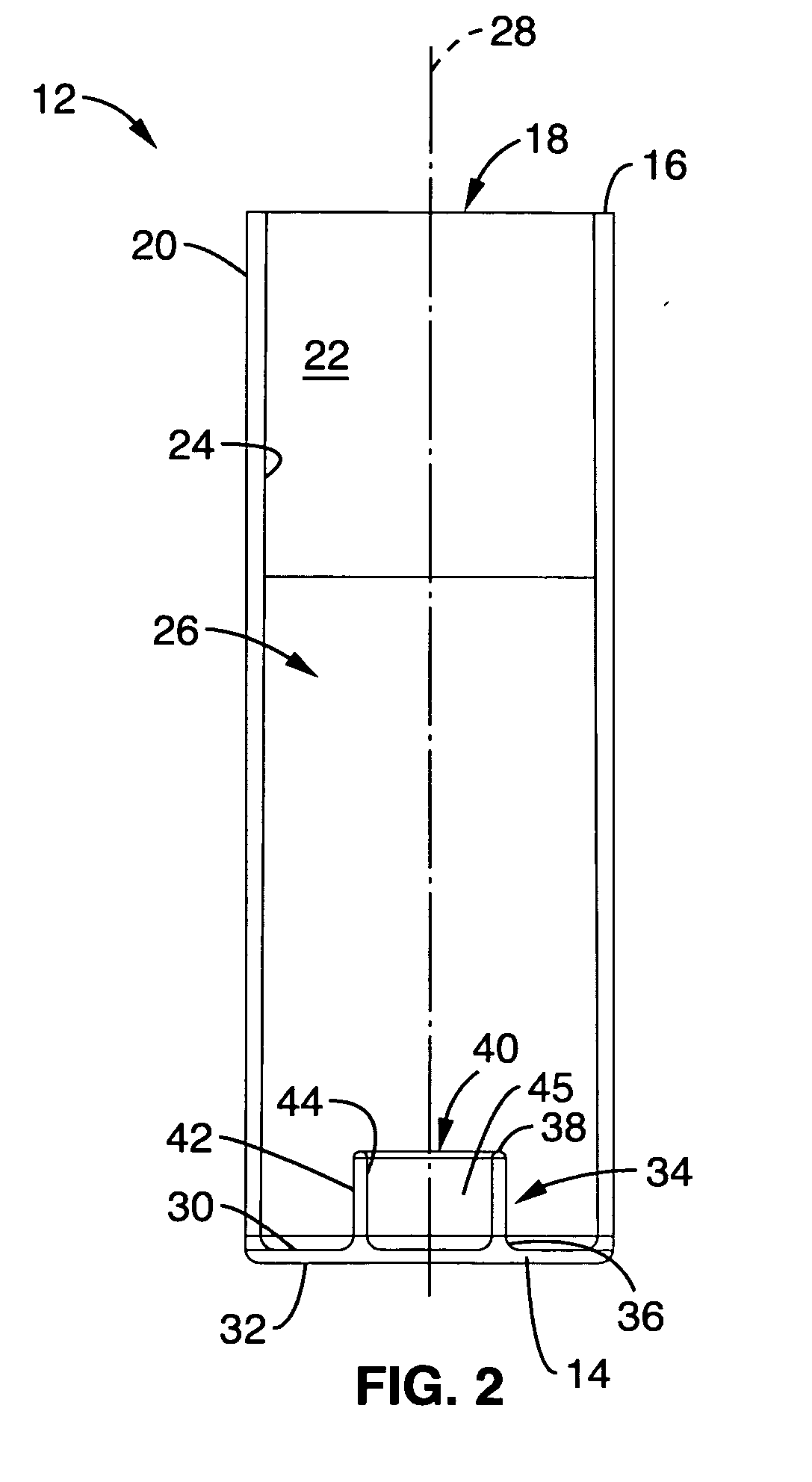

Sorbent reactor for extracorporeal blood treatment systems, peritoneal dialysis systems, and other body fluid treatment systems

InactiveUS7169303B2Facilitate homogeneous suspensionReduce probabilitySolvent extractionHaemofiltrationFluid balancePeritoneal dialysis

Systems and methods for extracorporeal processing of blood or other body fluid for the treatment of conditions, such as sepsis, autoimmune disease, or toxemia related to kidney failure, liver failure, or drug overdose are provided. In an extracorporeal treatment system, a fraction of a body fluid is passed into a treatment fluid, at least a portion of which is then passed through a sorbent suspension reactor for treatment by a sorbent suspension. The treatment fluid circuit can be maintained at a fixed volume, which enables accurate fluid balance between the patient and the extracorporeal circuit. Some or all of the treatment fluid, optionally also containing nutrients and / or therapeutic agents, is returned to the patient. In a peritoneal dialysis system, dialysate is passed into a patient's peritoneal cavity, recovered from the cavity, passed through a sorbent suspension reactor in accordance with the invention, and returned to the cavity.

Owner:HEMOCLEANSE TECH

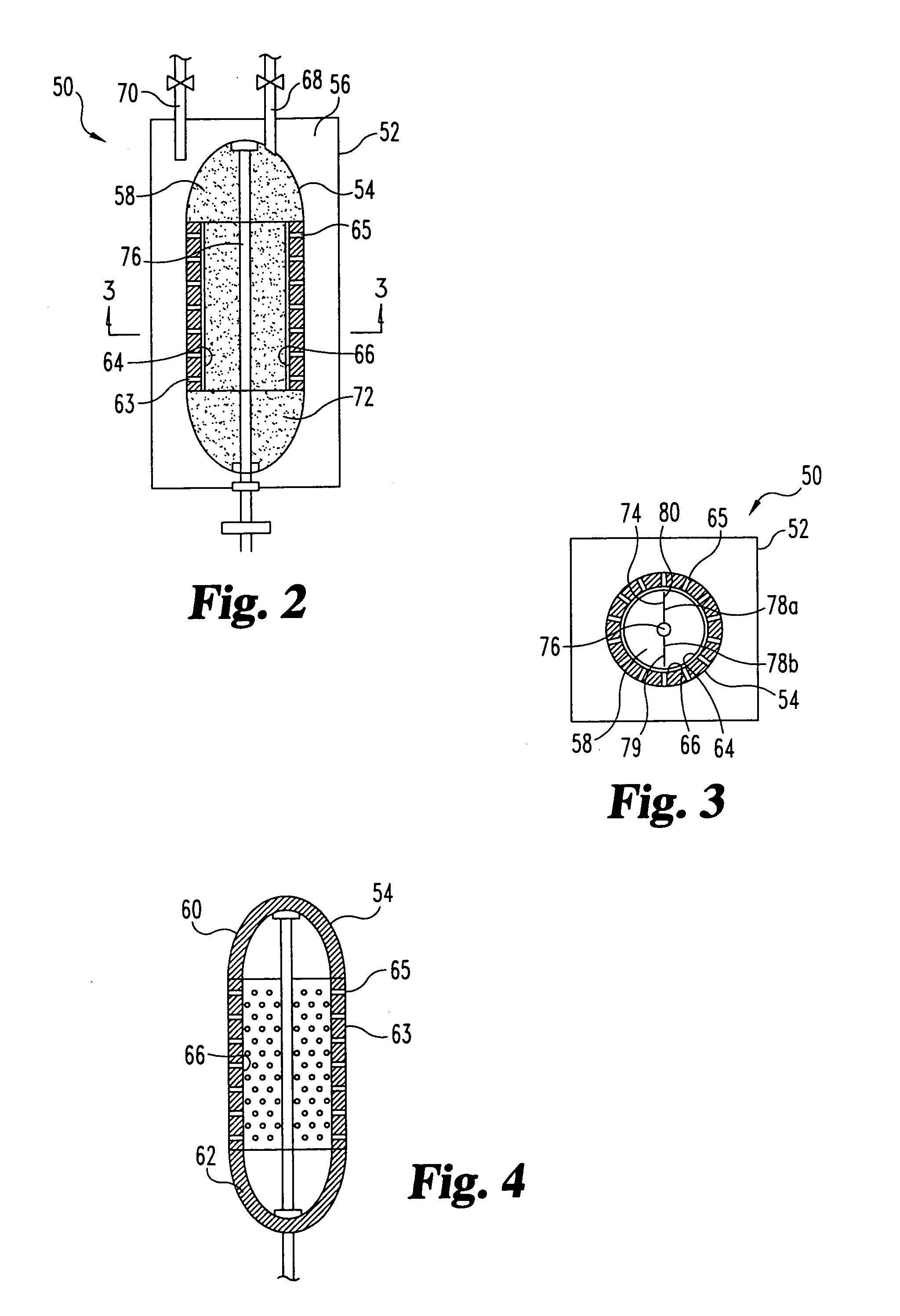

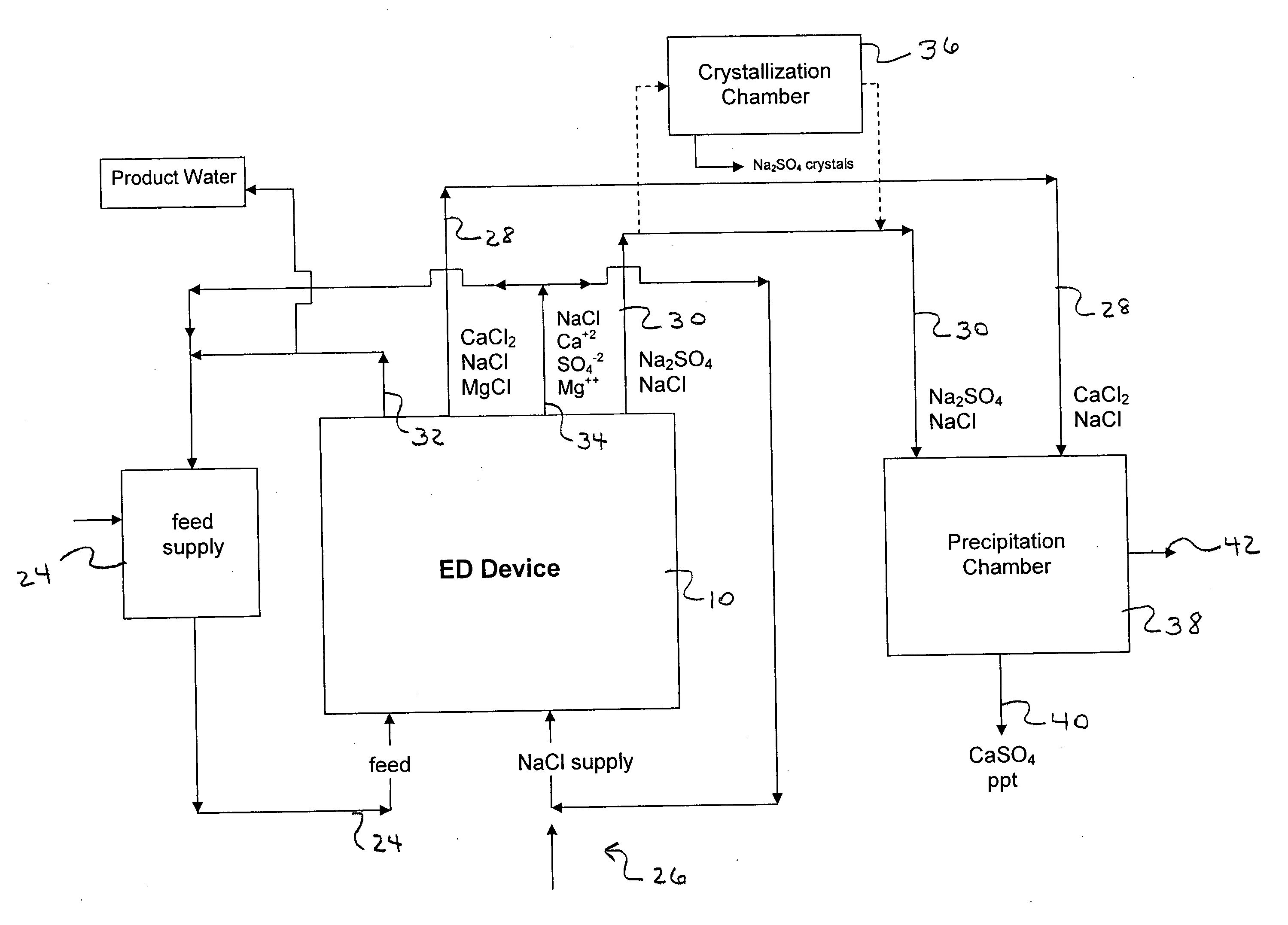

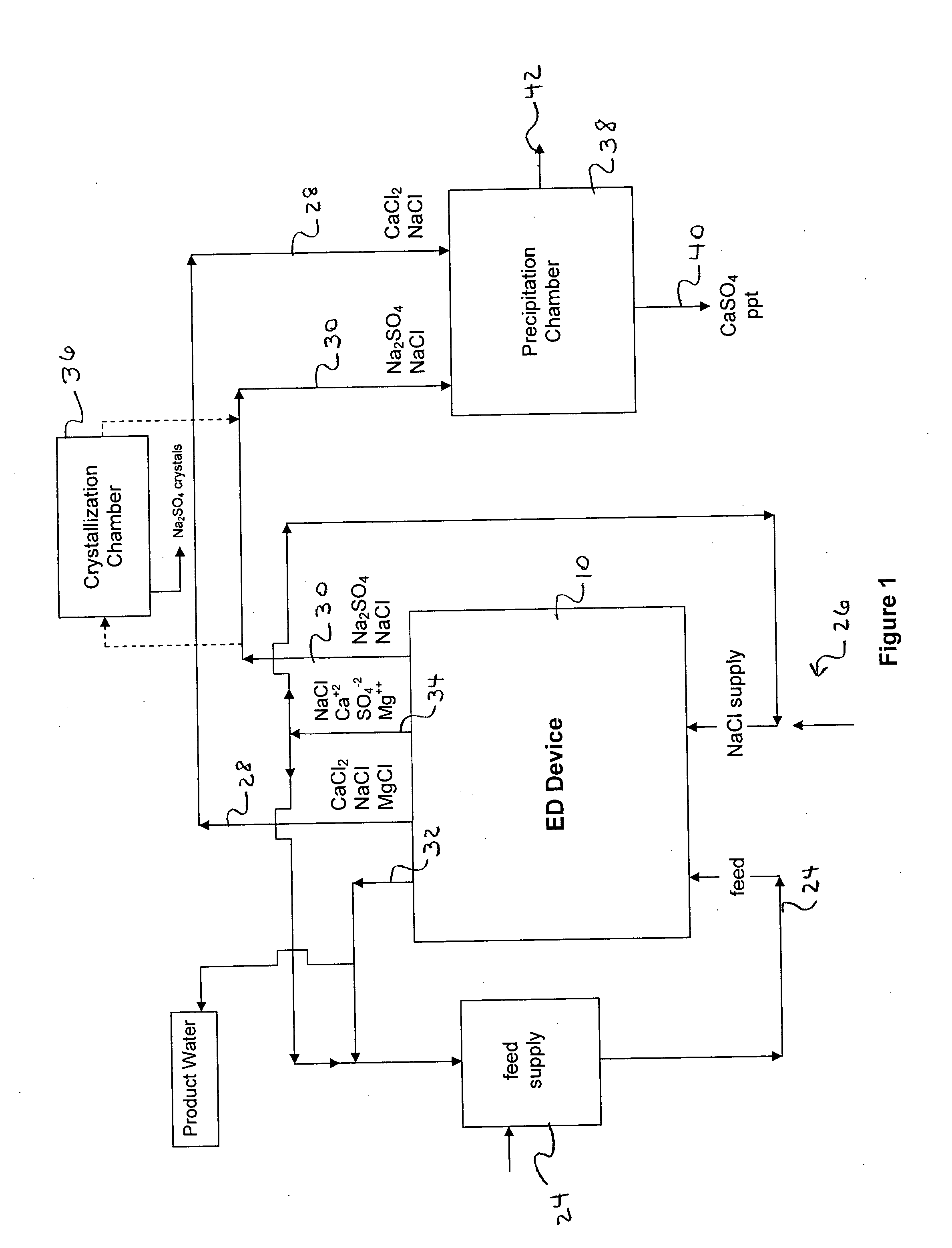

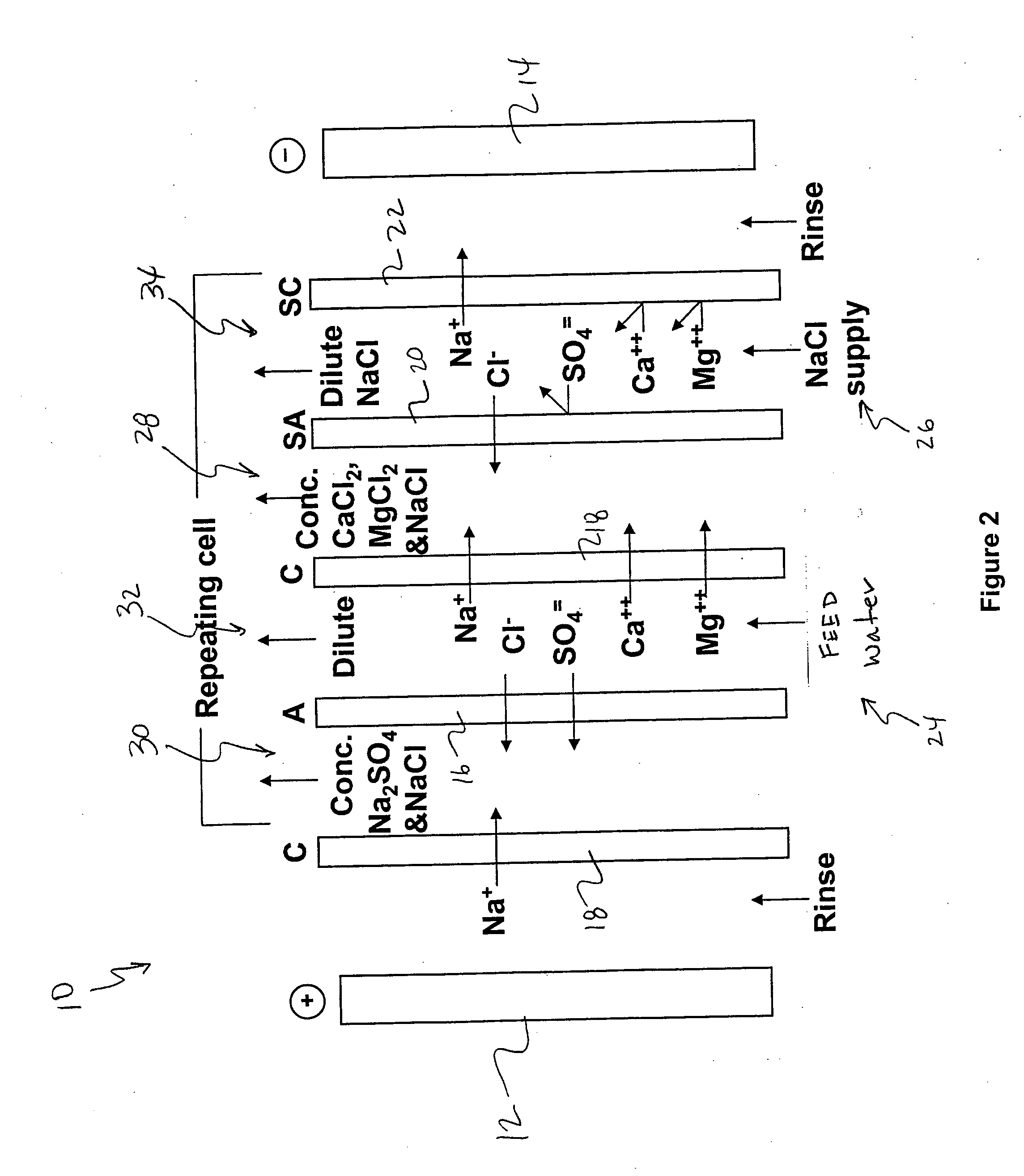

Water desalination process and apparatus

ActiveUS20060060532A1Electrolysis componentsGeneral water supply conservationSolubilityWater desalination

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

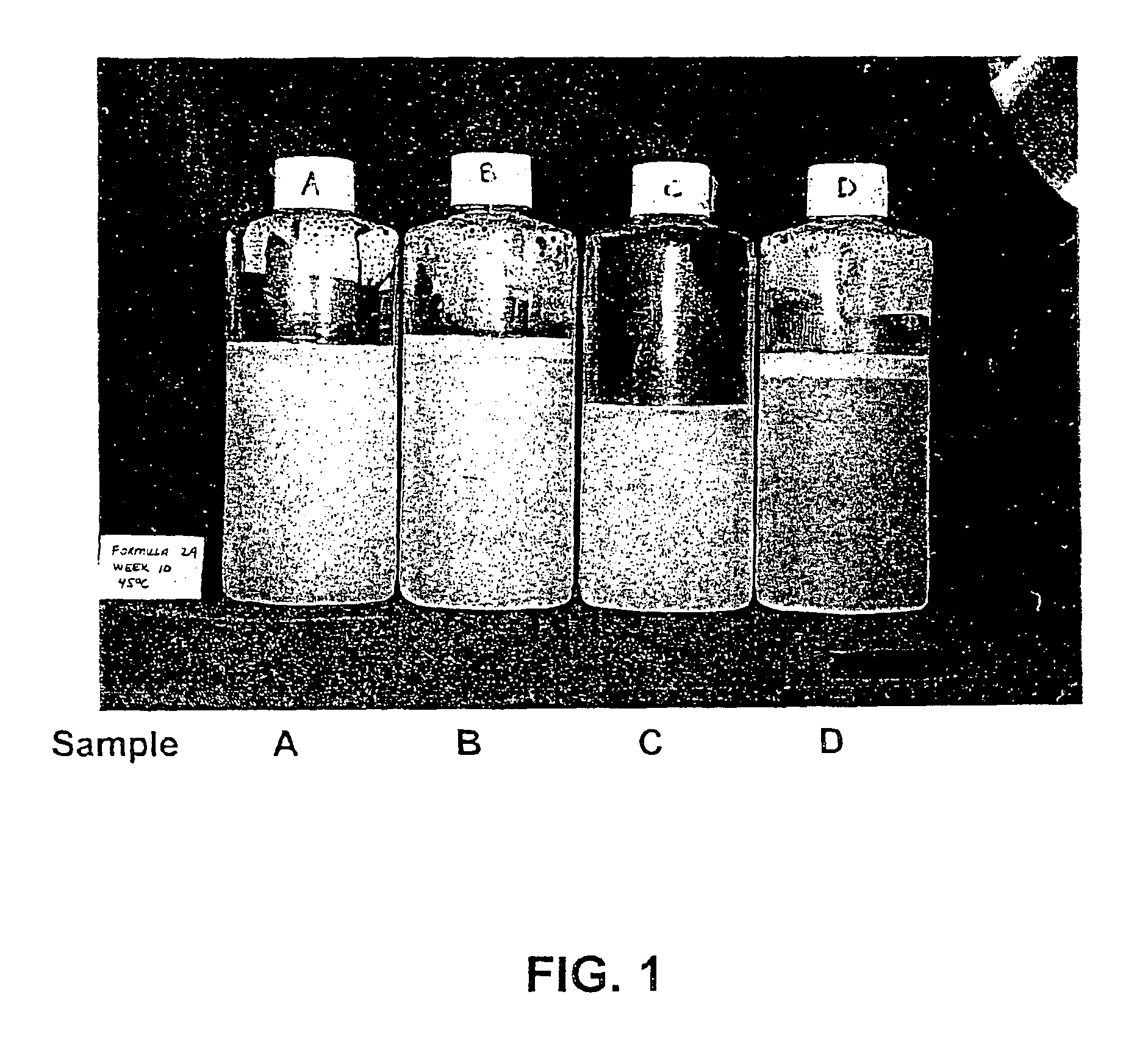

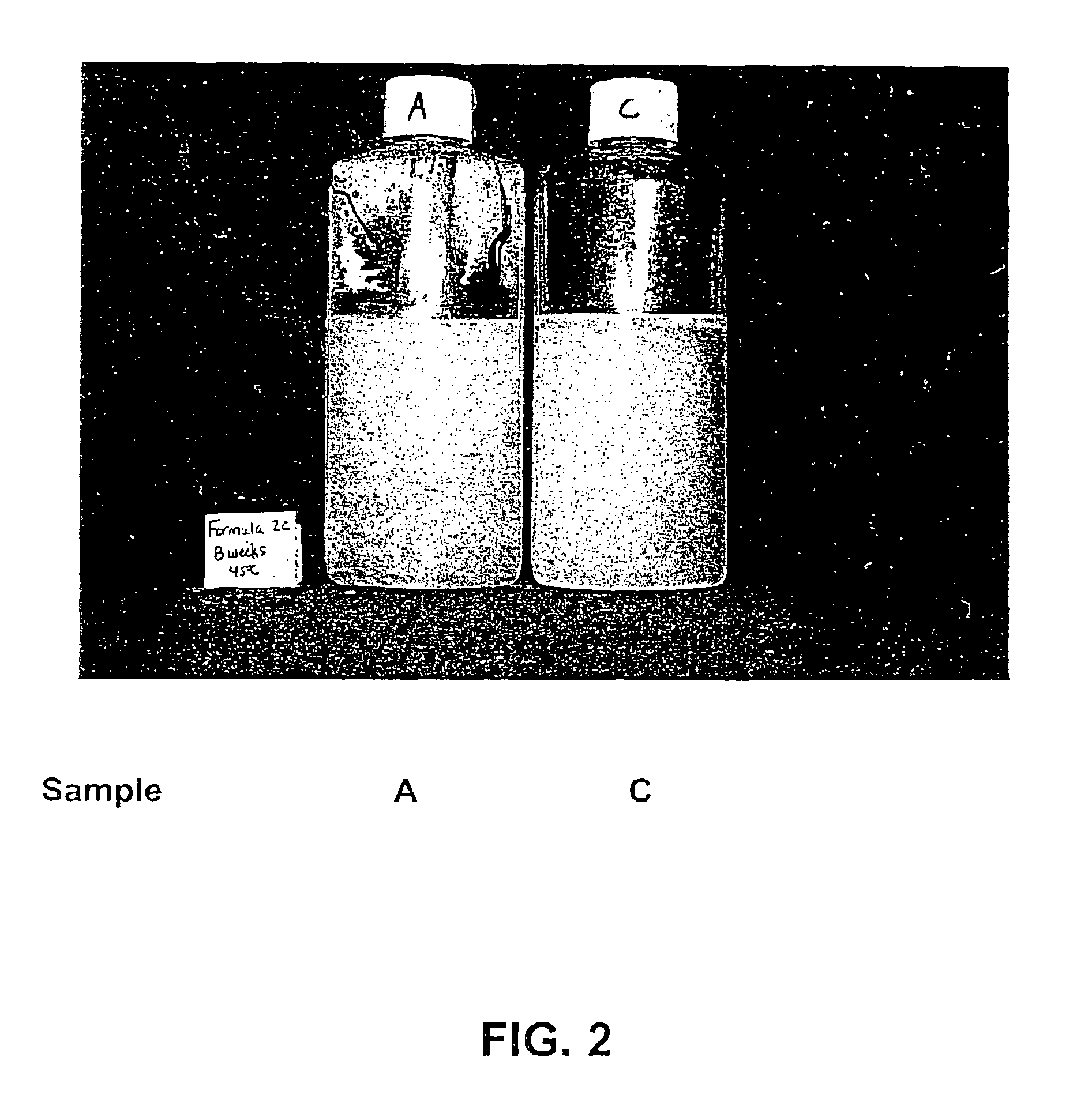

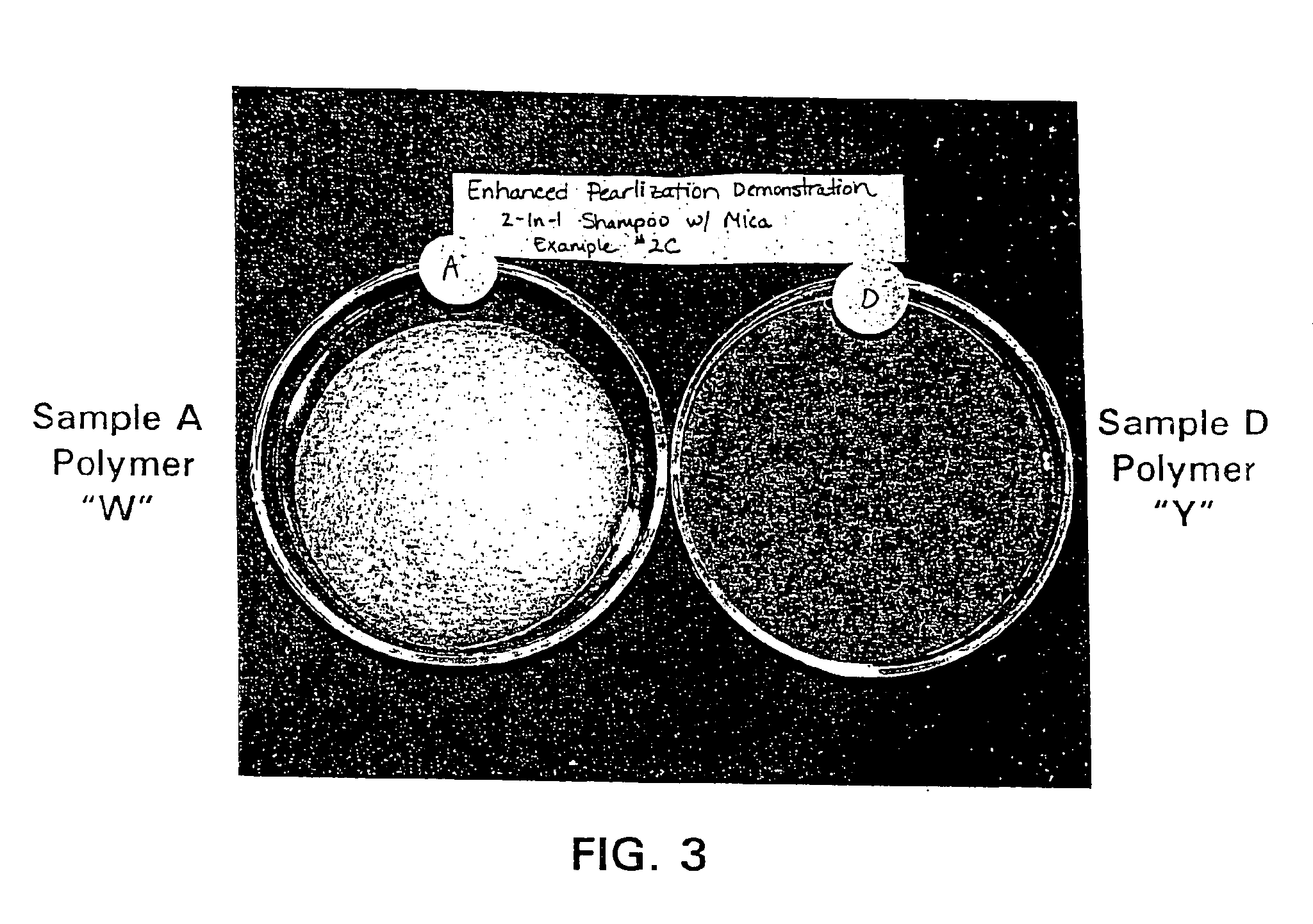

Stable aqueous surfactant compositions

InactiveUS6897253B2Enhanced pearlescent appearanceLow compositionInorganic/elemental detergent compounding agentsBiocideHair dyesAcid substances

A stable, aqueous composition containing a substantially crosslinked alkali-swellable acrylate copolymer rheology modifier, a surfactant, an alkaline material, and various compounds therein, as for example substantially insoluble materials requiring suspension or stabilization, such as a silicone, an oily material, or a pearlescent material. Additionally, this invention also relates to the formation of a rheologically and phase stable cationic hair dye composition. The invention further relates to the incorporation of an acidic material after the addition of an alkaline material to reduce the pH of the composition without negatively impacting the viscosity of the composition.

Owner:LUBRIZOL ADVANCED MATERIALS INC

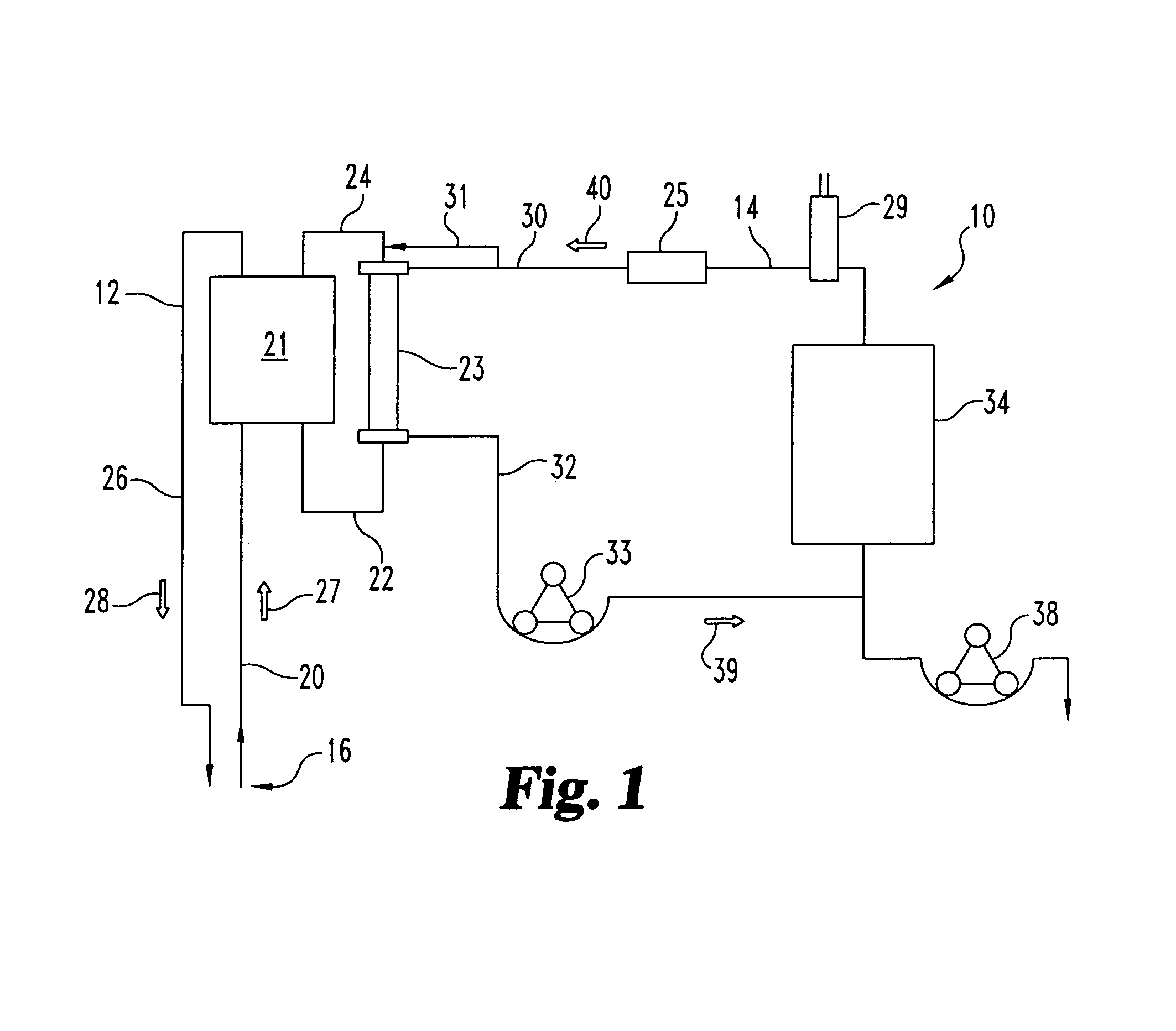

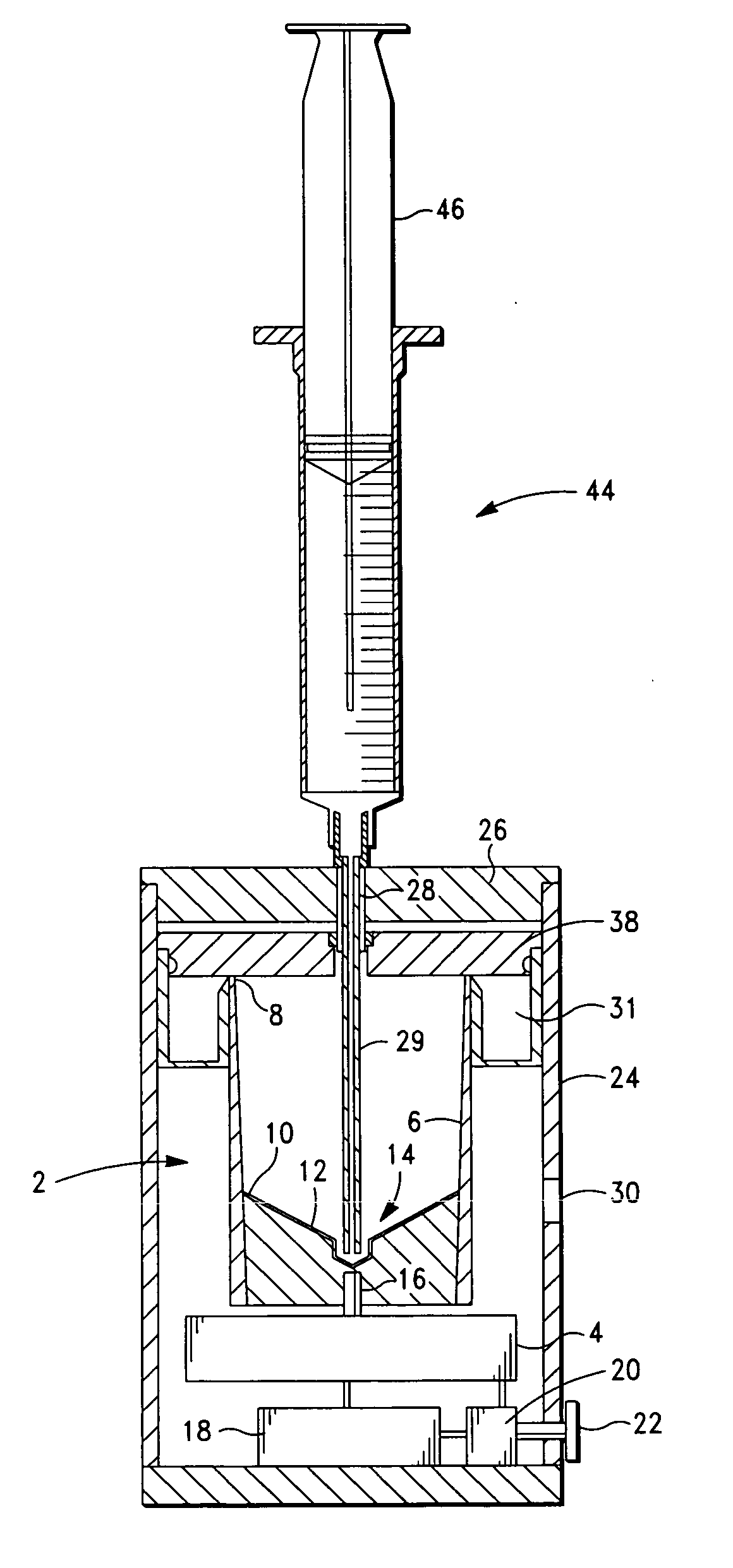

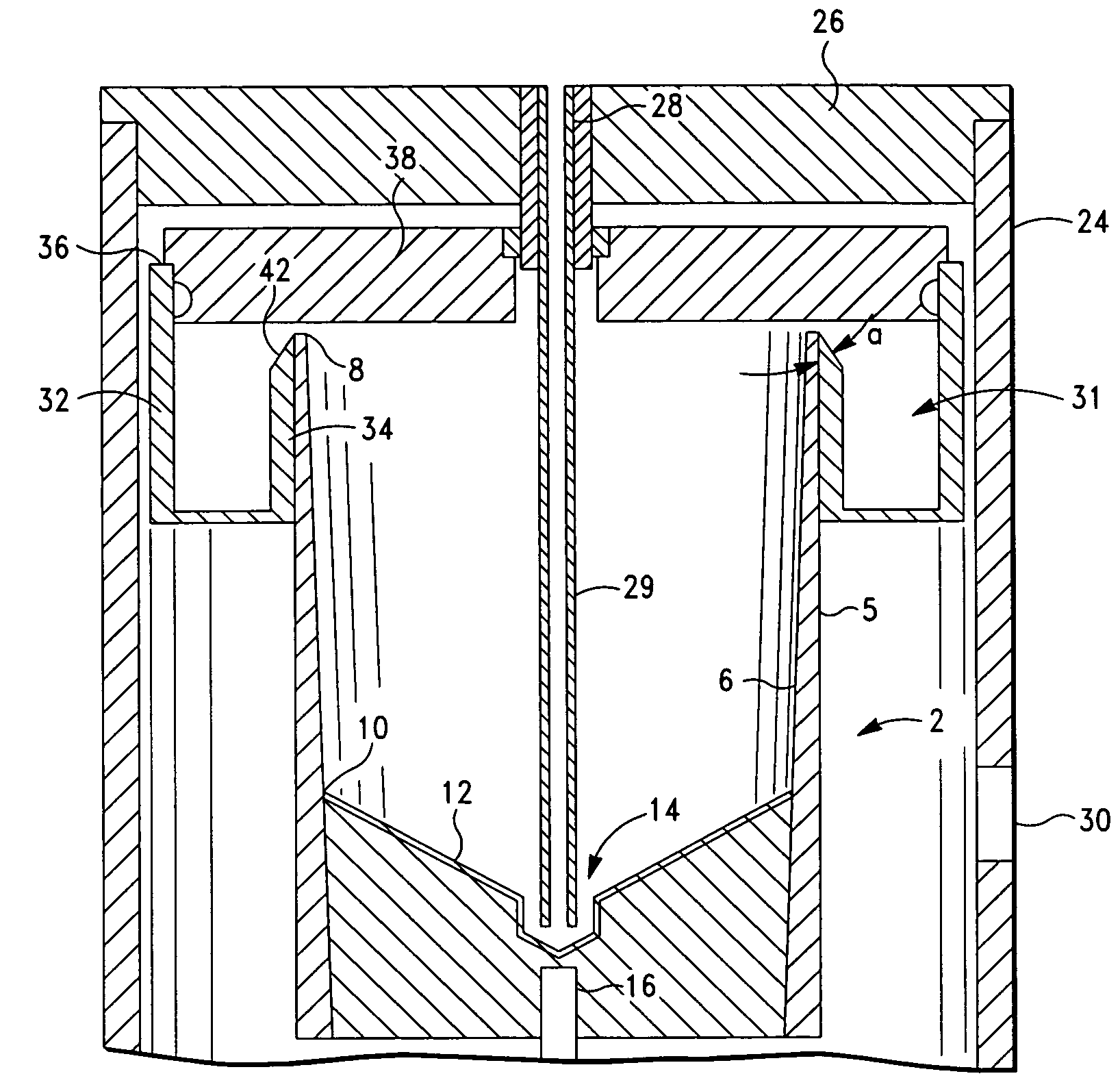

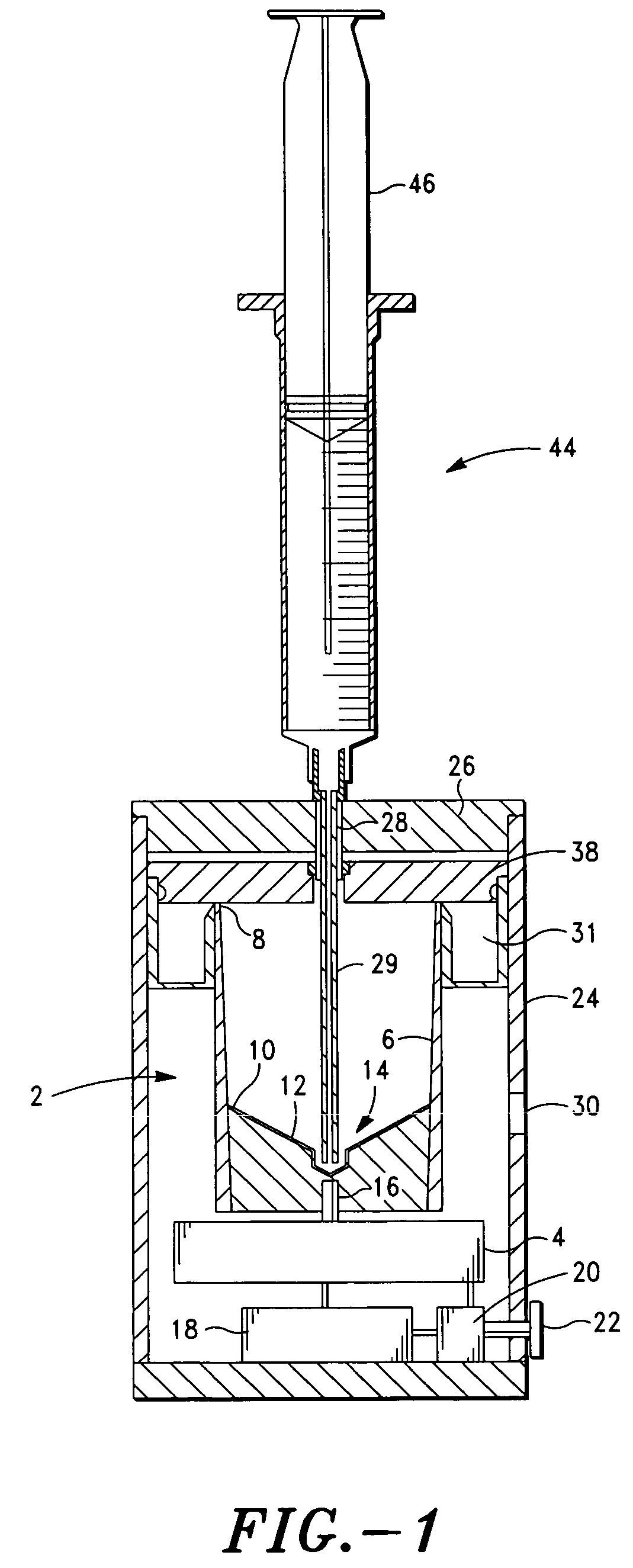

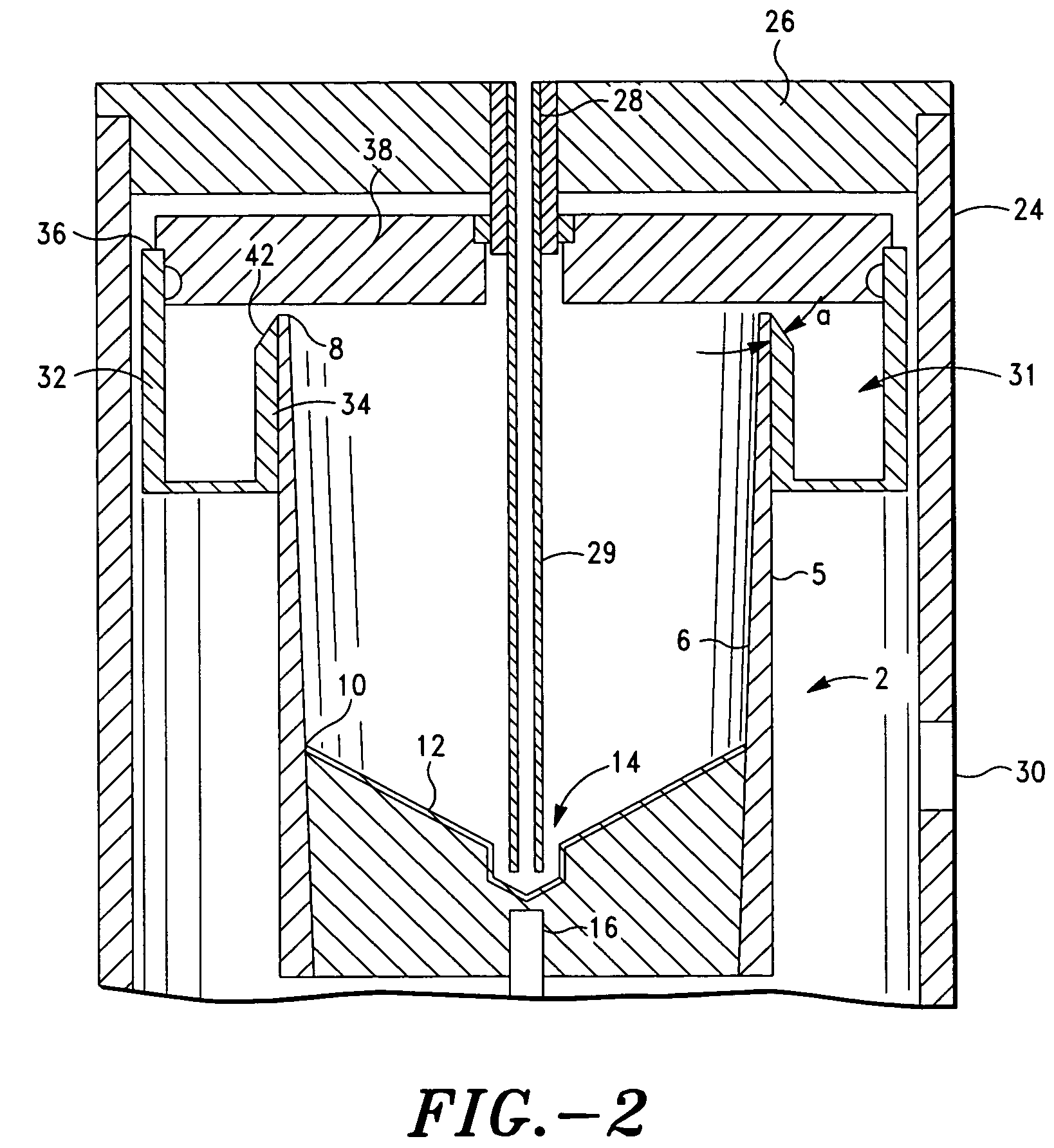

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS20060175242A1Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

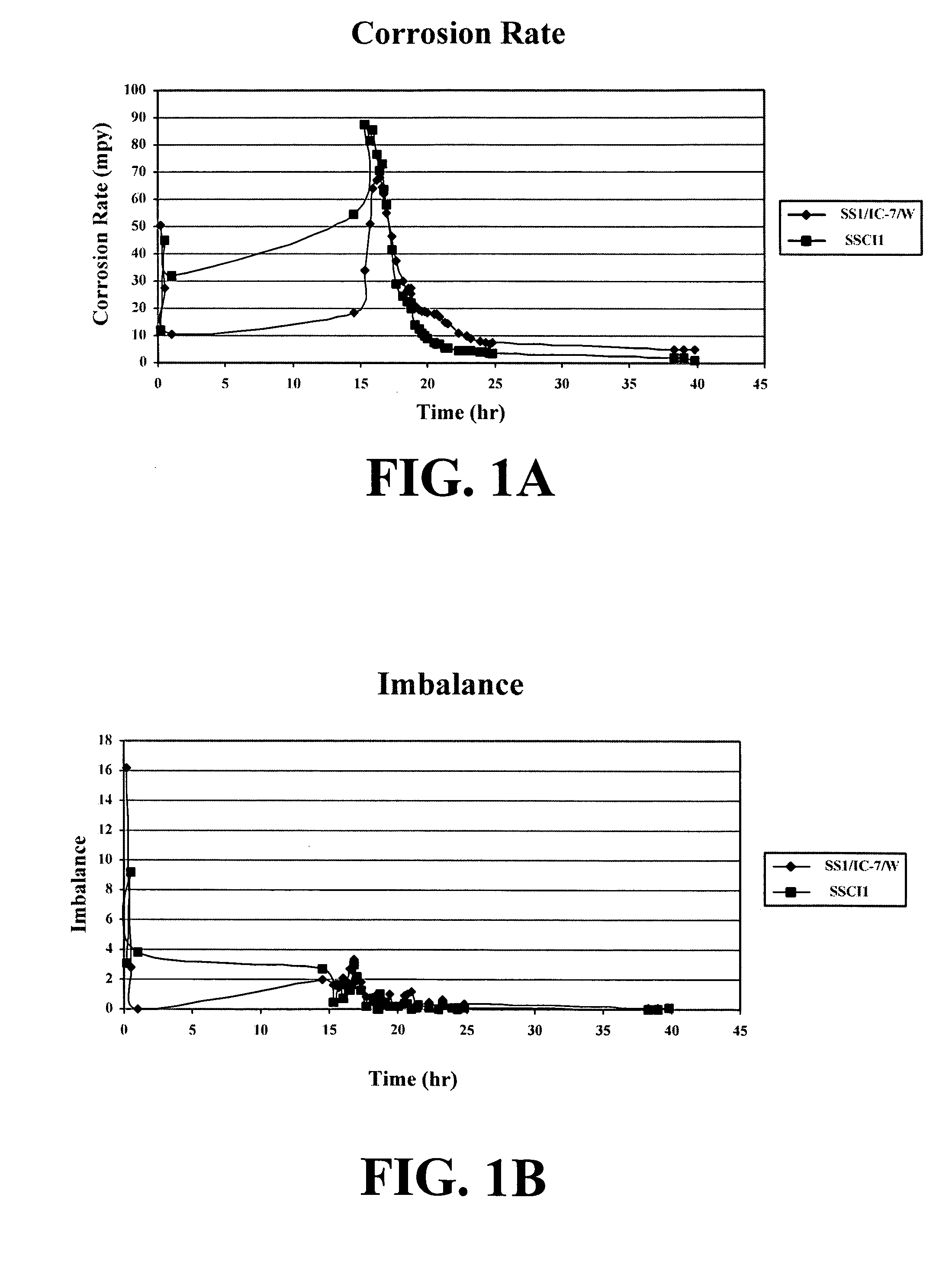

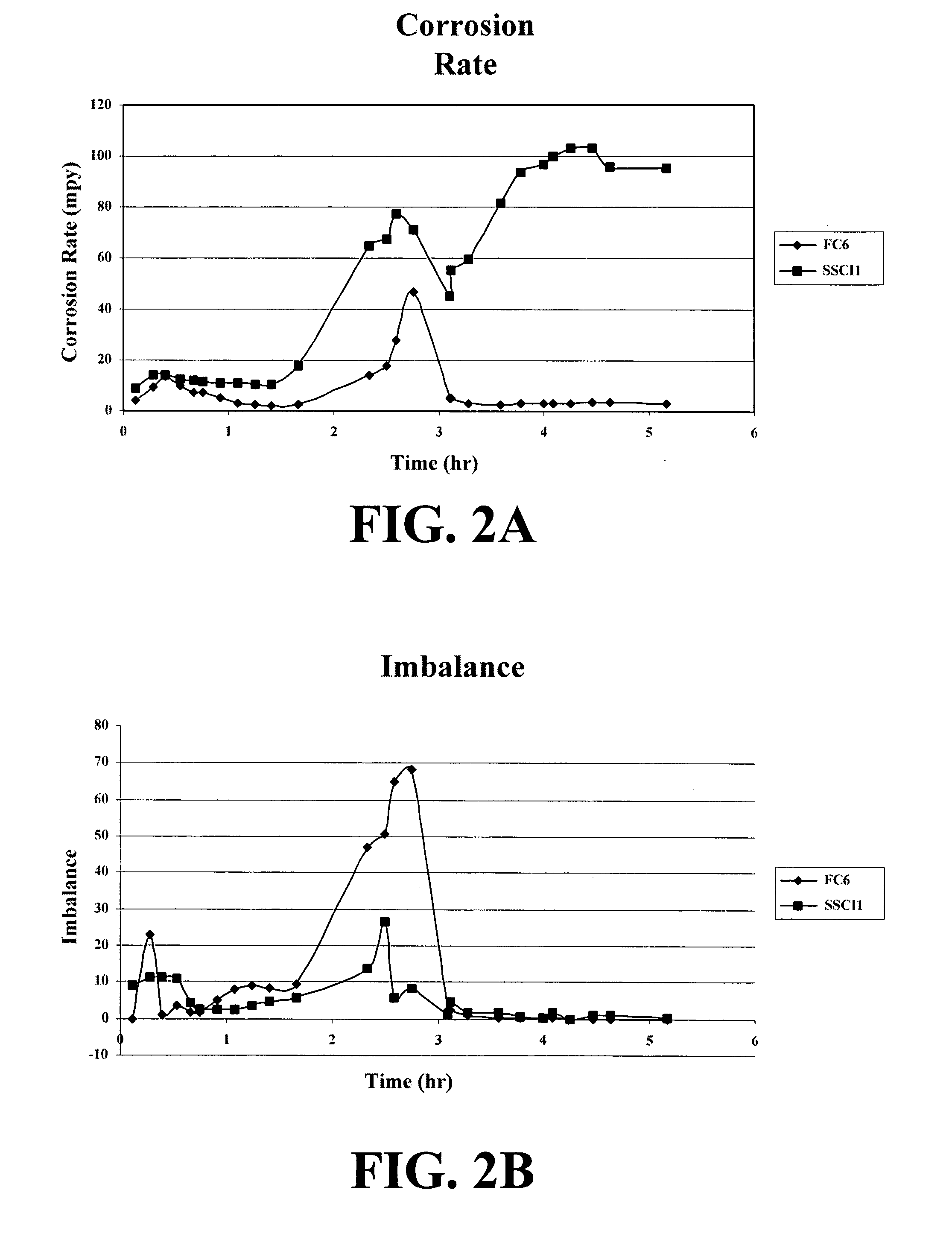

Foamer/sulfur scavenger composition and methods for making and using same

InactiveUS20050250666A1High activityImprove featuresOrganic chemistryConstructionsFoaming agentDisposal waste

A new multi-purpose foaming composition having applications in oil field application, industrial applications, waste management applications, or other applications that can be benefitted by a foam, is disclosed, where the composition includes a surfactant, a sulfur scavenger and optionally an additive, where the sulfur scavenger and / or additive improve foam characteristics and / or the foam improves an activity of the sulfur scavenger and / or the additives. Method for using and making the foaming compositions are also disclosed, especially, coiled and capillary coiled tubing downhole applications.

Owner:LUBRIZOL OILFIELD SOLUTIONS

Apparatus and method for separating and isolating components of a biological fluid

A device for separating and isolating components of a biological fluid comprising a container for containing the fluid to be processed, a tube cap assembly for closing the container while providing filling and extraction communication therewith, a float assembly disposed within the container for funneling and controlling biological fluid flow into an inverted domed shaped isolation chamber within the float and controlling the biological fluid flow out of the isolation chamber for effecting an encapsulation or a sealed isolation of at least one component or fraction of the biological fluid flow within the isolation chamber during a centrifugation process. The device further comprising a flexible tube for connecting an extraction passageway disposed within the float assembly and an extraction valve of the tube cap assembly for allowing extraction of at least the one component or fraction encapsulated or isolated within the chamber.

Owner:THERMOGENESIS HLDG INC

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

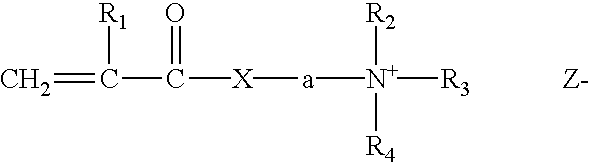

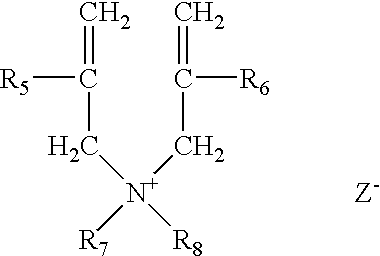

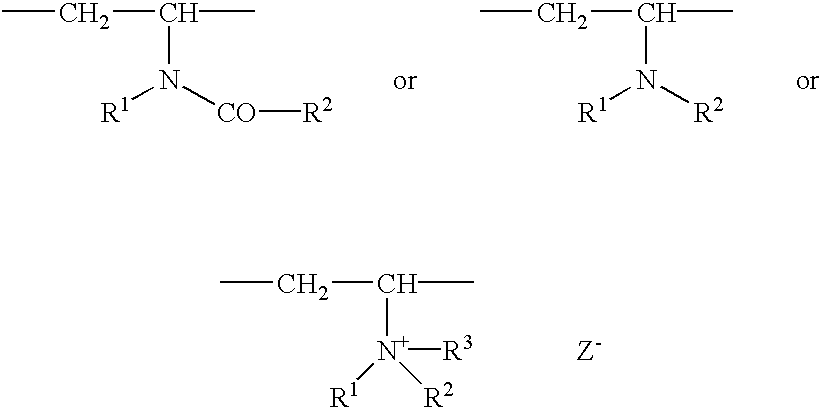

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS7708152B2Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

System and method for detecting time-bomb malware

According to one embodiment, a system comprises one or more counters; comparison logic; and one or more hardware processors communicatively coupled to the one or more counters and the comparison logic. The one or more hardware processors are configured to instantiate one or more virtual machines that are adapted to analyze received content, where the one or more virtual machines are configured to monitor a delay caused by one or more events conducted during processing of the content and identify the content as including malware if the delay exceed a first time period.

Owner:FIREEYE SECURITY HLDG US LLC

System and method for detecting time-bomb malware

Owner:FIREEYE SECURITY HLDG US LLC +1

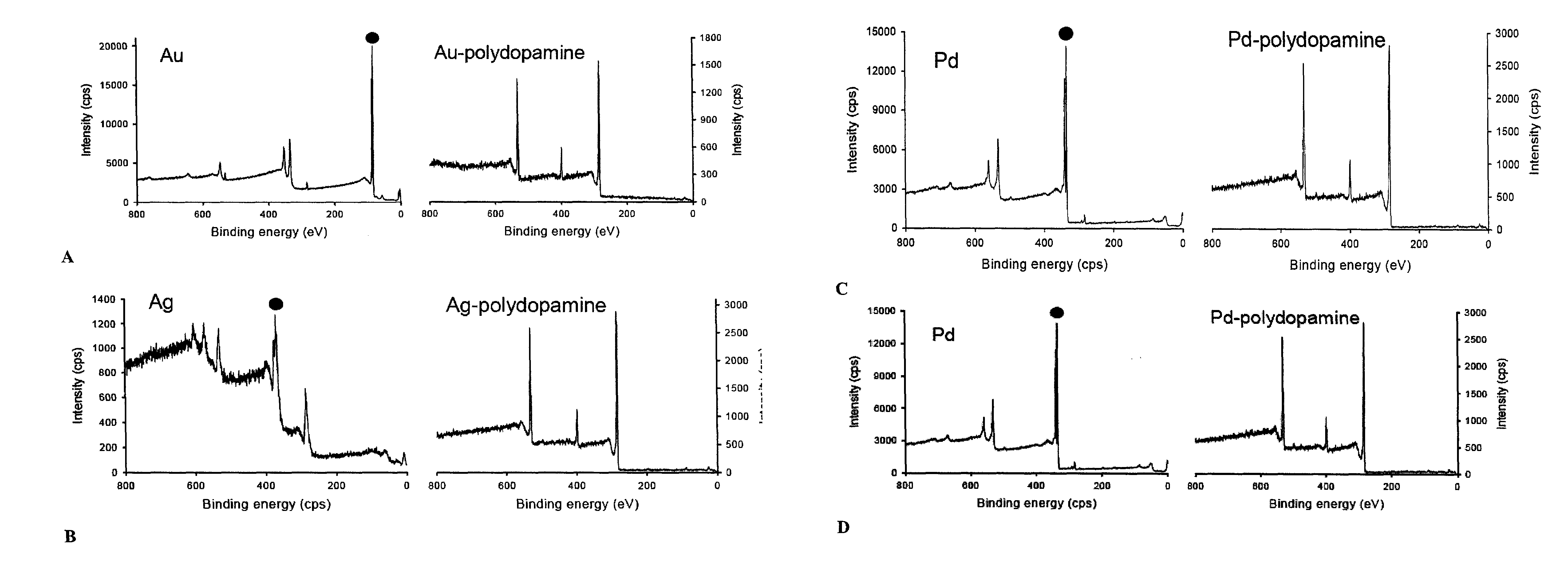

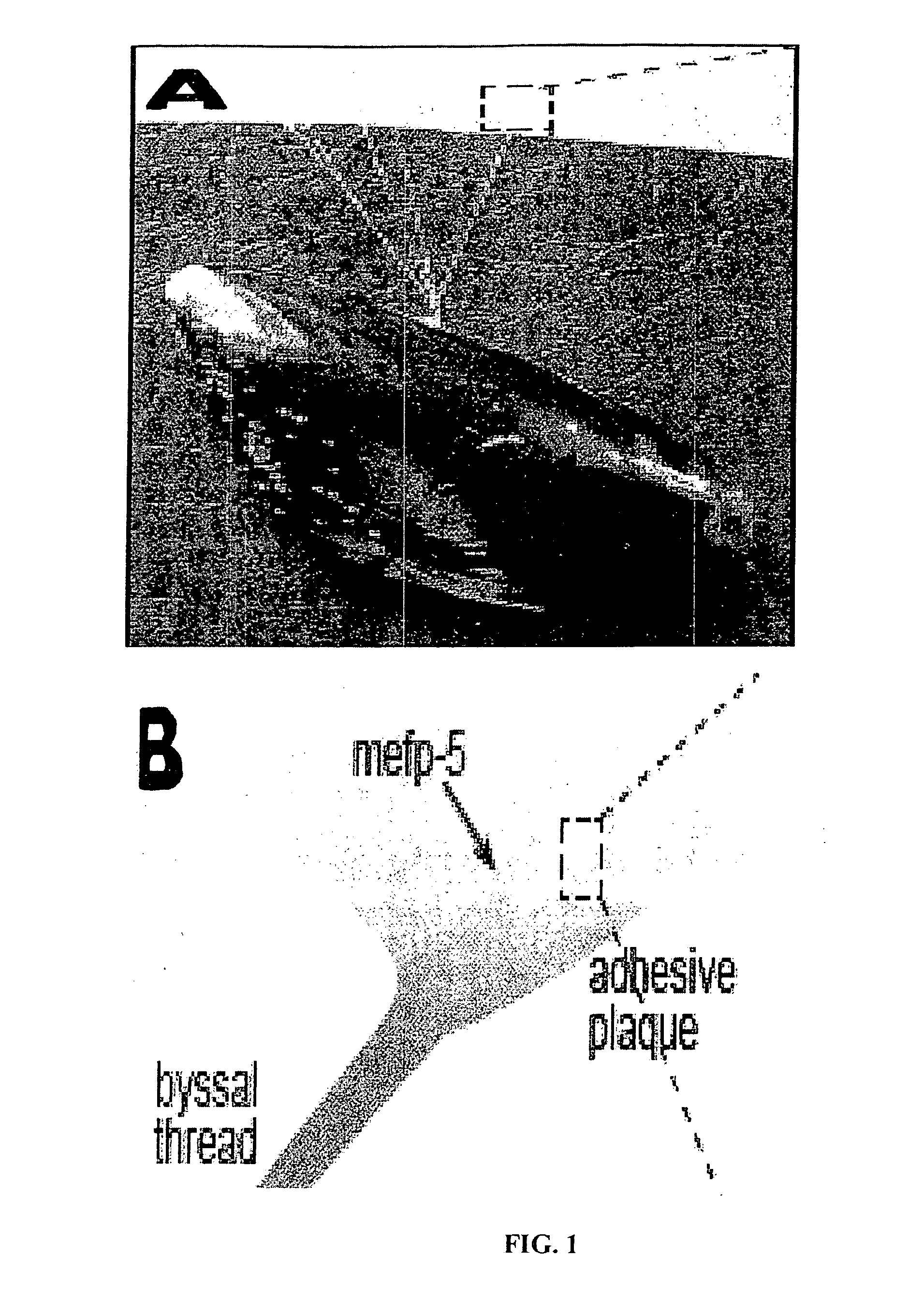

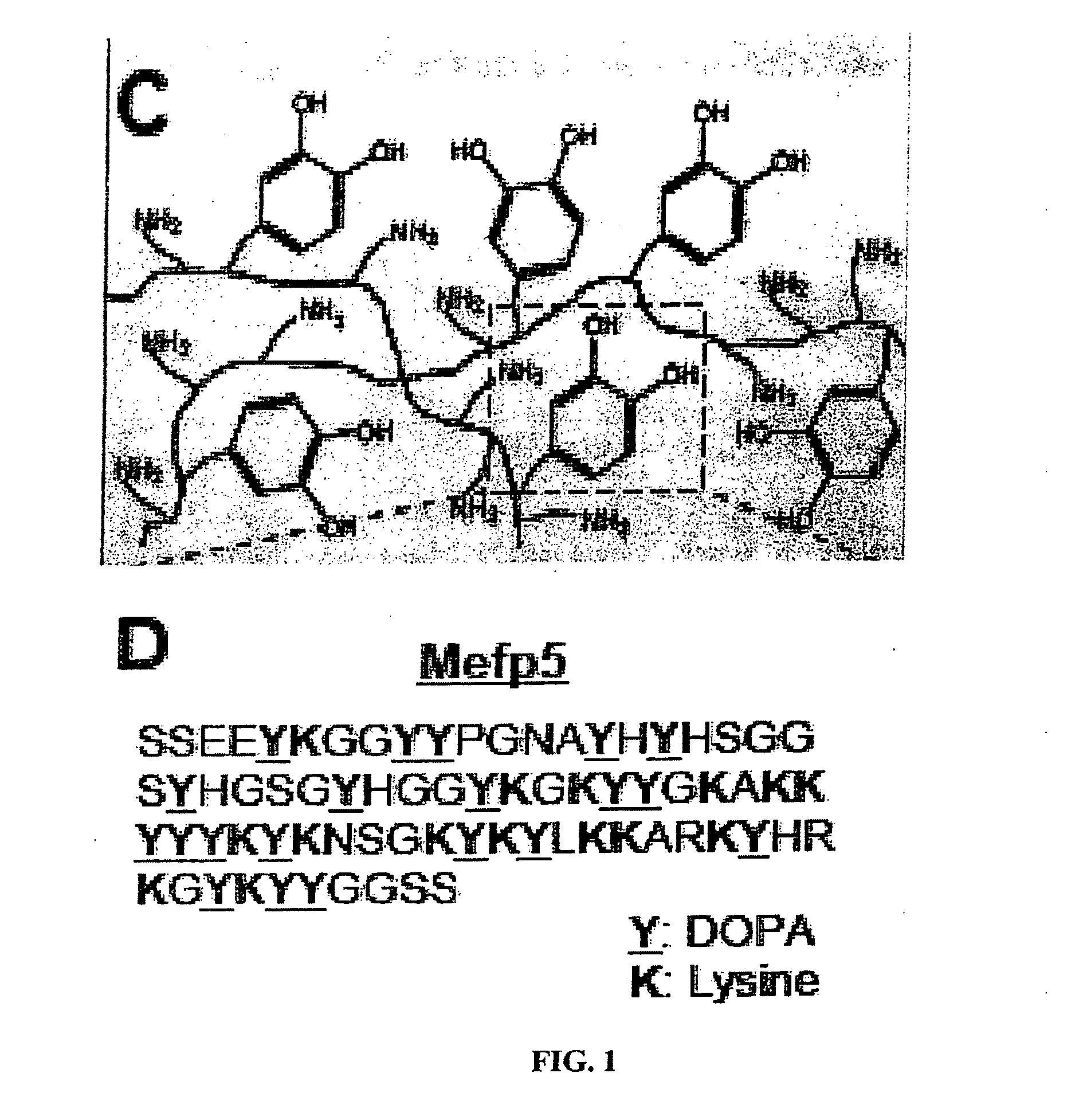

Surface-Independent, Surface-Modifying, Multifunctional Coatings and Applications Thereof

ActiveUS20080149566A1Prevent buildupOrganic chemistryWater contaminantsSubstrate surfaceSurface modified

The present invention provides a surface-independent surface-modifying multifunctional biocoating and methods of application thereof. The method comprises contacting at least a portion of a substrate with an alkaline solution comprising a surface-modifying agent (SMA) such as dopamine so as to modify the substrate surface to include at least one reactive moiety. In another version of the invention, a secondary reactive moiety is applied to the SMA-treated substrate to yield a surface-modified substrate having a specific functionality.

Owner:NORTHWESTERN UNIV

Method of using hydroxycarboxylic acids or related compounds for treating skin changes associated with intrinsic and extrinsic aging

A composition comprising an amphoteric or pseudo-amphoteric agent and a polyhydroxy alpha hydroxyacid existing as a free acid, lactone, or salt, and isomeric or non-isomeric forms thereof is provided. The amphoteric or pseudo-amphoteric agent can be selected from amino acids, dipeptides, aminoaldonic acid, aminouronic acid, lauryl aminoproplyglycine, aminoaldaric acid, neuraminic acid desulfated heparin, deacetylated hyaluronic acid, hyalobiuronic acid, chondrosine, deacetylated chondroitin, creatine, creatinine, hydroxyproline, homocysteine, homocystine, homoserine, ornithine, citrulline, phosphatidylserine, and sphingomyelin. The composition may contain other additives, including cosmetic or pharmaceutical agents for topical treatment of dermatological disorders.

Owner:TRISTRATA TECH

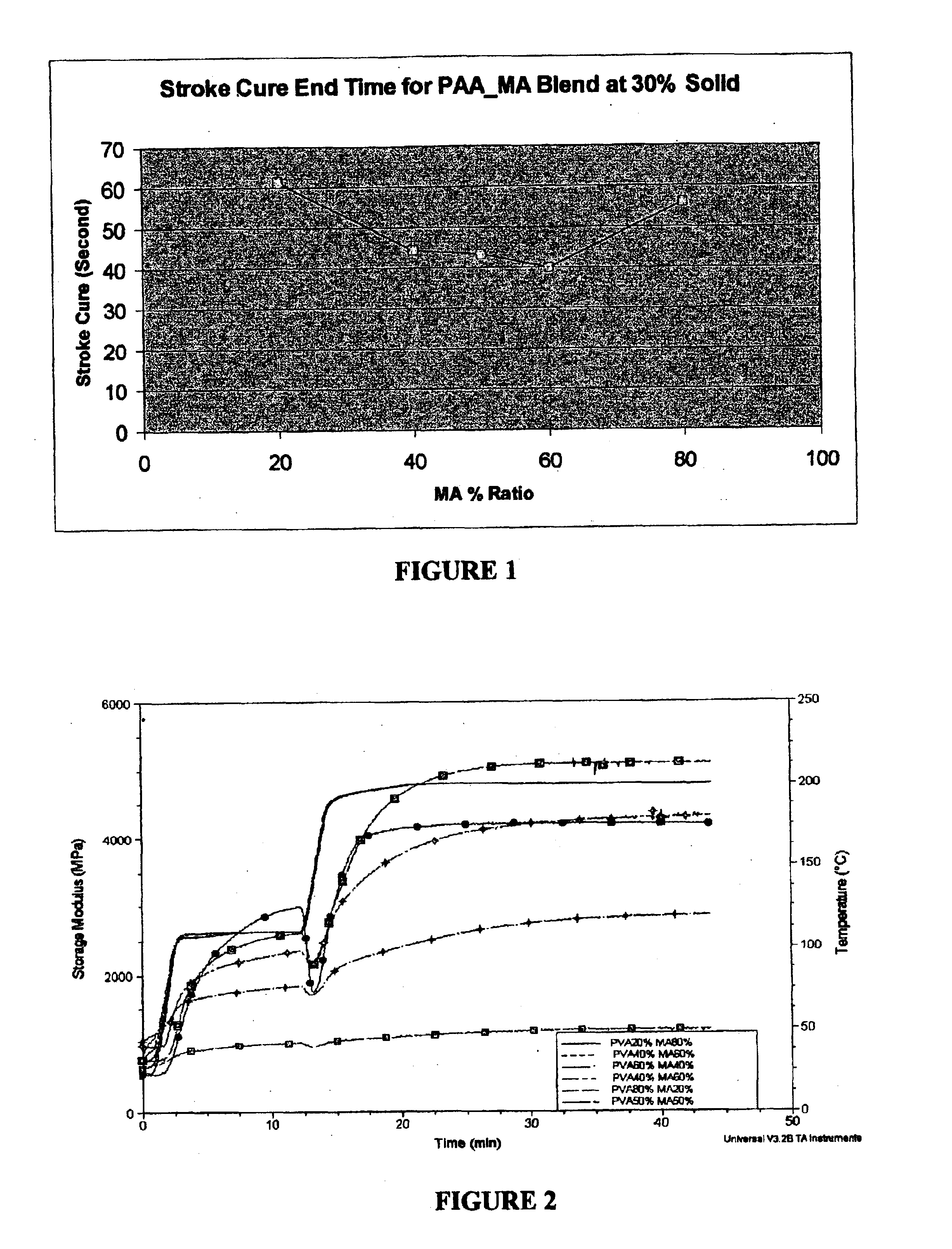

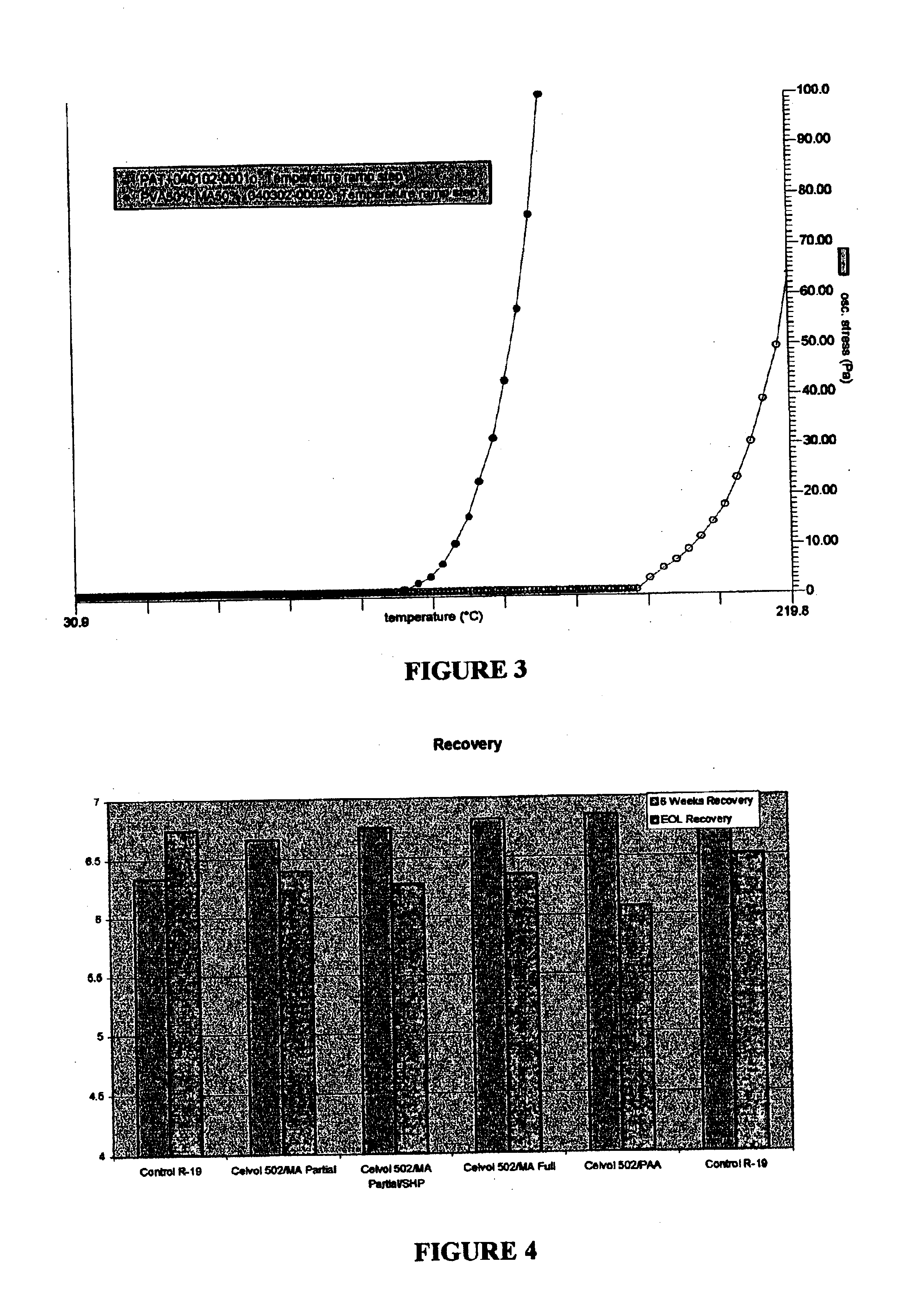

Poly alcohol-based binder composition

InactiveUS6884849B2Improve curing effectEmission reductionNon-fibrous pulp additionSynthetic resin layered productsAlcoholCarboxylic acid

The present invention provides a binder composition comprising a low molecular weight polycarboxylic acid, such as maleic anhydride, and a low molecular weight poly alcohol, such as polyvinyl alcohol, that exhibits improved cure performance with reduced emissions without sacrificing the performance of the final product or complication the manufacturing process. The binder composition may also incorporate a cure catalyst or accelerant such as sodium hypophosphite.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

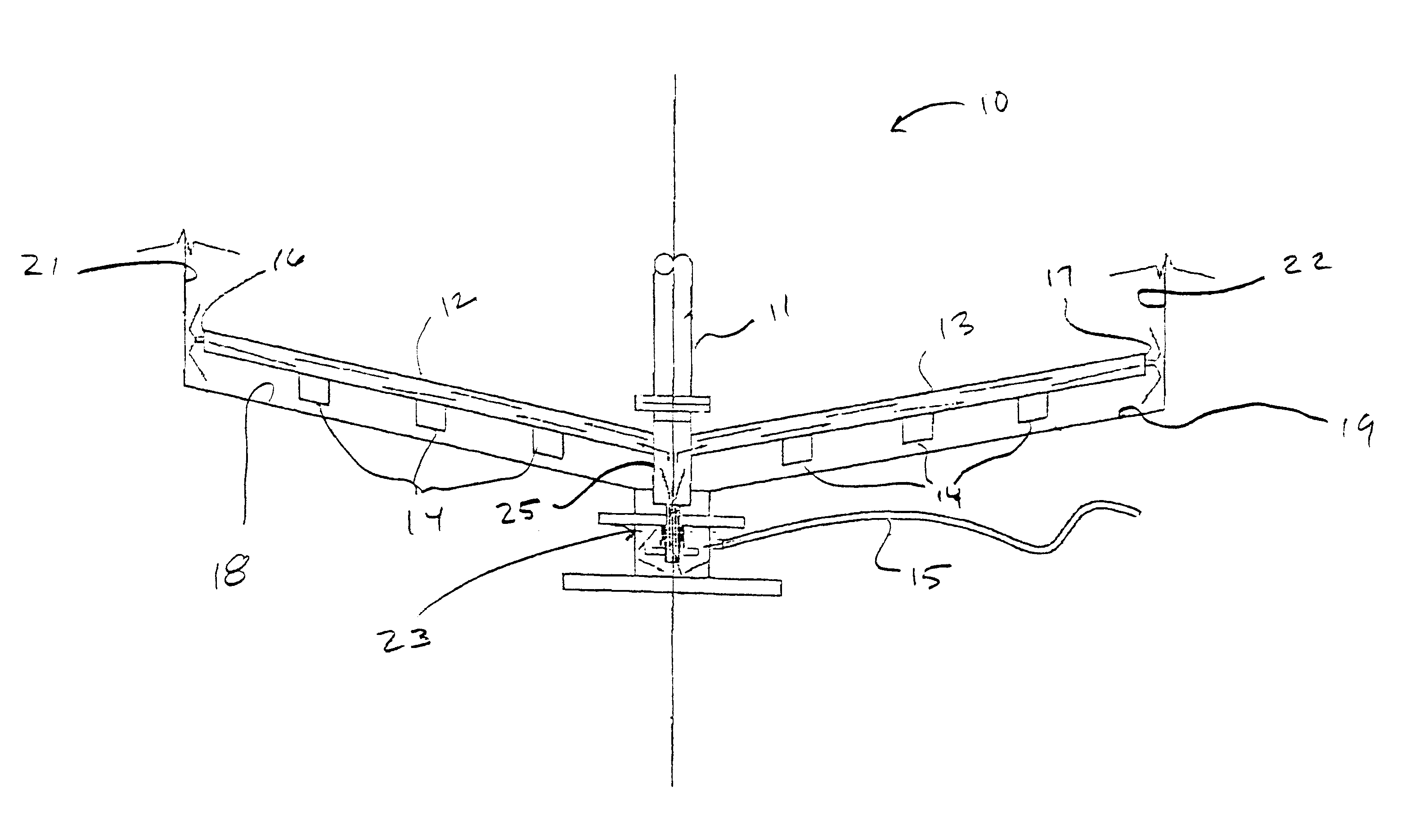

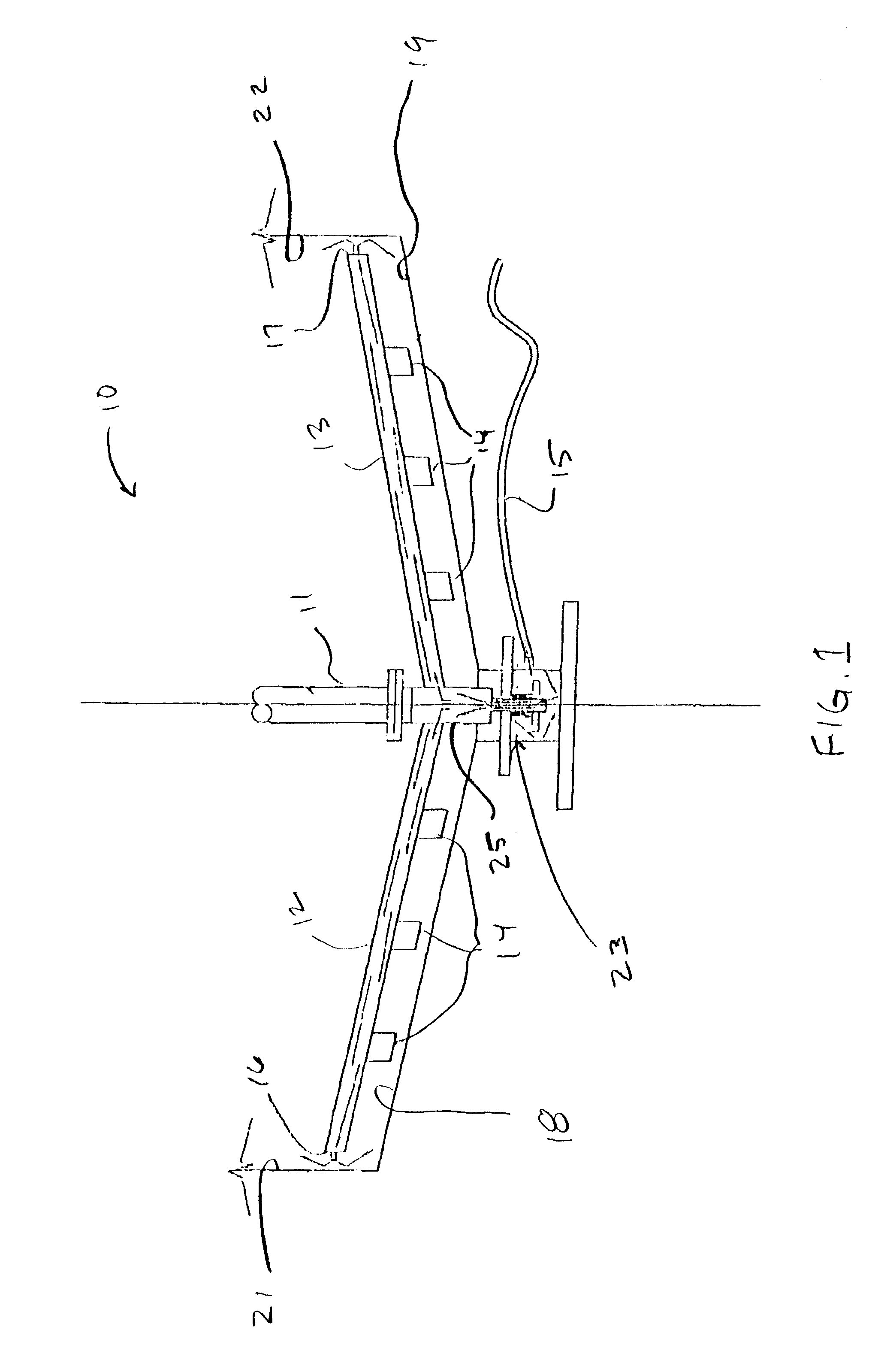

Rheology modification of settled solids in mineral processing

InactiveUS6365116B1Low viscosityIncrease speedRotary stirring mixersTransportation and packagingEngineeringSlurry

The present invention comprises a method for reducing the viscosity of the settled mud or underflow of a raked thickener thereby reducing the torque necessary to move the rake blade through the settled mud. The method includes the step of delivering a viscosity modifier to the settled mud and in front of the rake blade by pumping the viscosity modifier down the rake arm to an area in front of the rake blade. The method also includes an improved rake mechanism that includes a means for delivering viscosity modifier to the settled mud and in front of the rake blade. The present invention also includes a method for increasing the rate of consolidation of flocculated solids in a slurry.

Owner:ECOLAB USA INC

Method for treating wastewater or produced water

ActiveUS7815804B2Reduce hardnessReduce dissolved solidWaste water treatment from quariesGeneral water supply conservationWastewaterIon exchange

A method or process for treating wastewater containing high organics, silica, boron, hardness, and suspended and dissolved solids. The method includes degasifying the wastewater for the removal of dissolved gases and thereafter chemically softening the wastewater. After the chemical softening step, the wastewater is directed through a media filter or membrane which removes additional solids and precipitants. Thereafter the wastewater is directed through a sodium ion exchange that further softens the wastewater. The effluent from the ion exchange is directed through a cartridge filter and the effluent from the cartridge filter is directed through one or more reverse osmosis units. At a selected phase of the process, prior to the wastewater reaching the reverse osmosis unit or units, the pH of the wastewater is raised and maintained such that the pH of the wastewater reaching a reverse osmosis unit is at a pH greater than 10.5.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

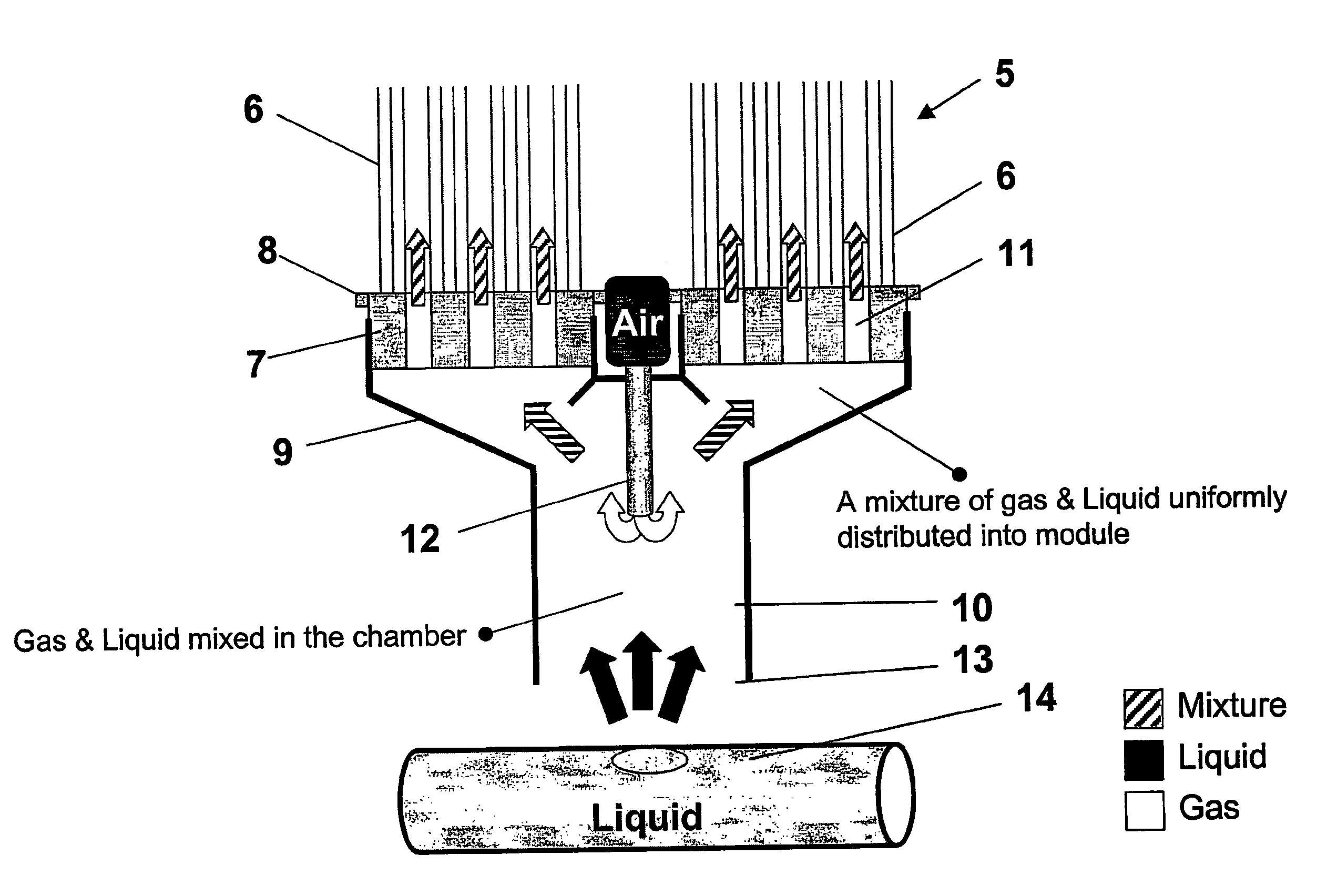

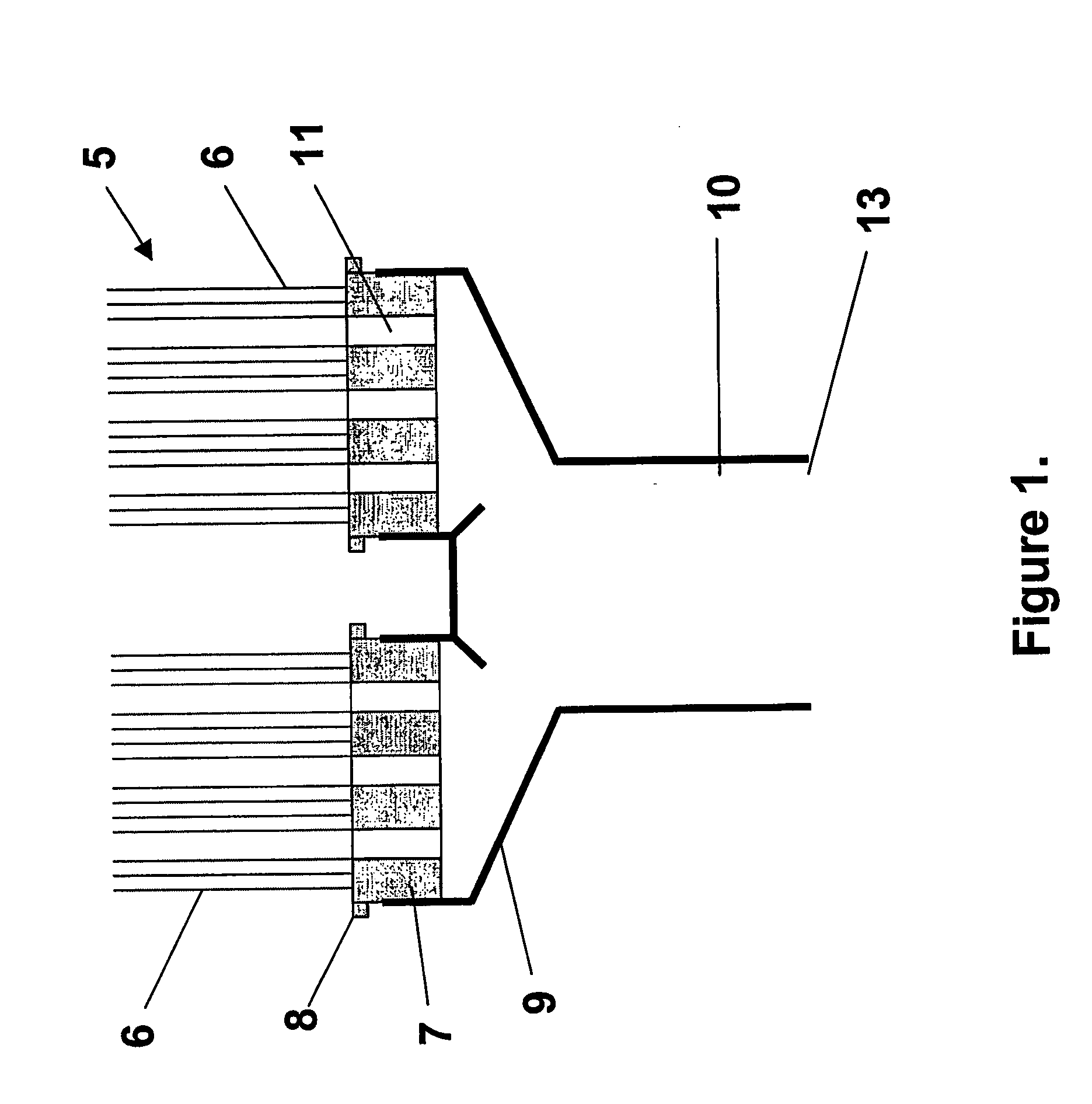

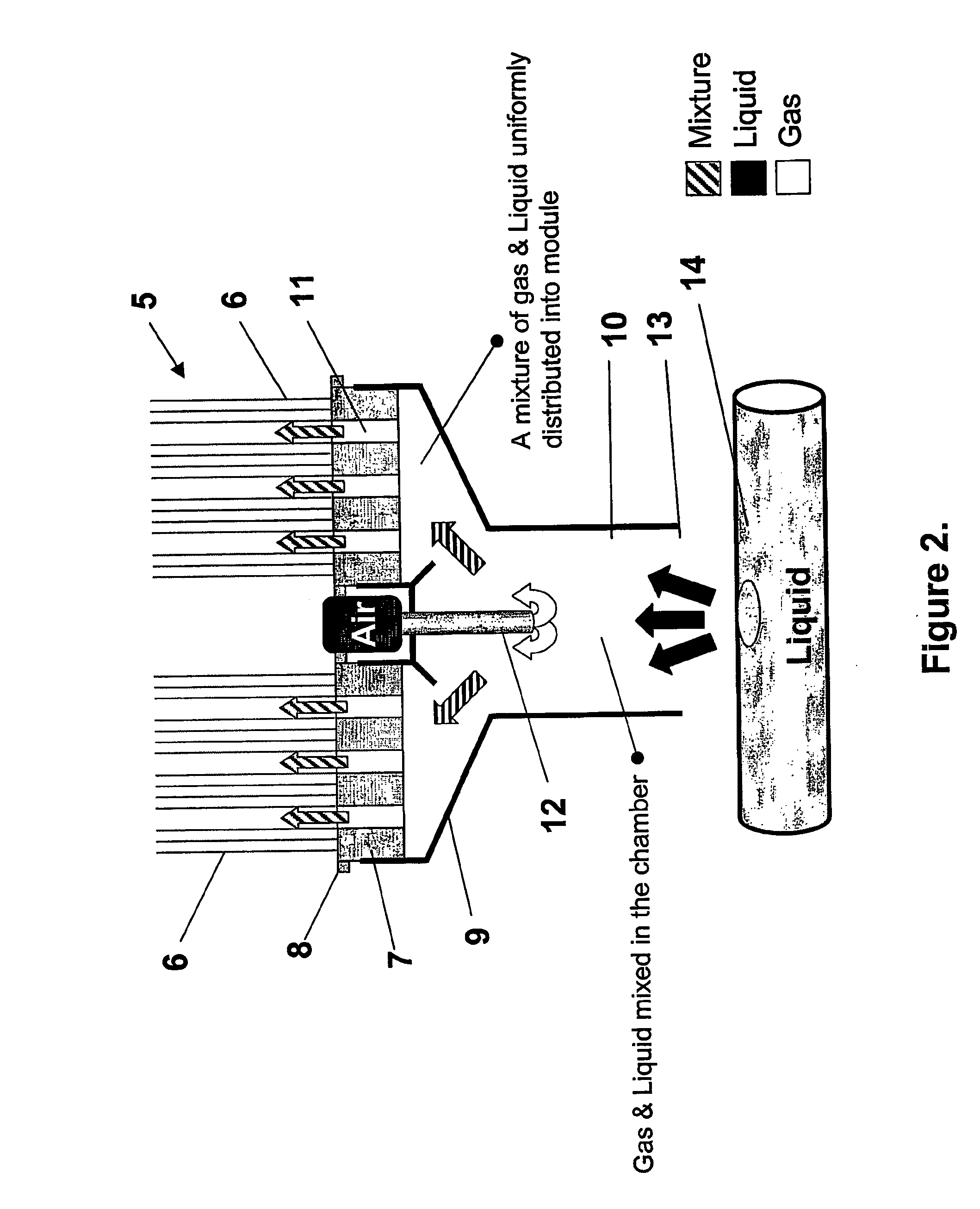

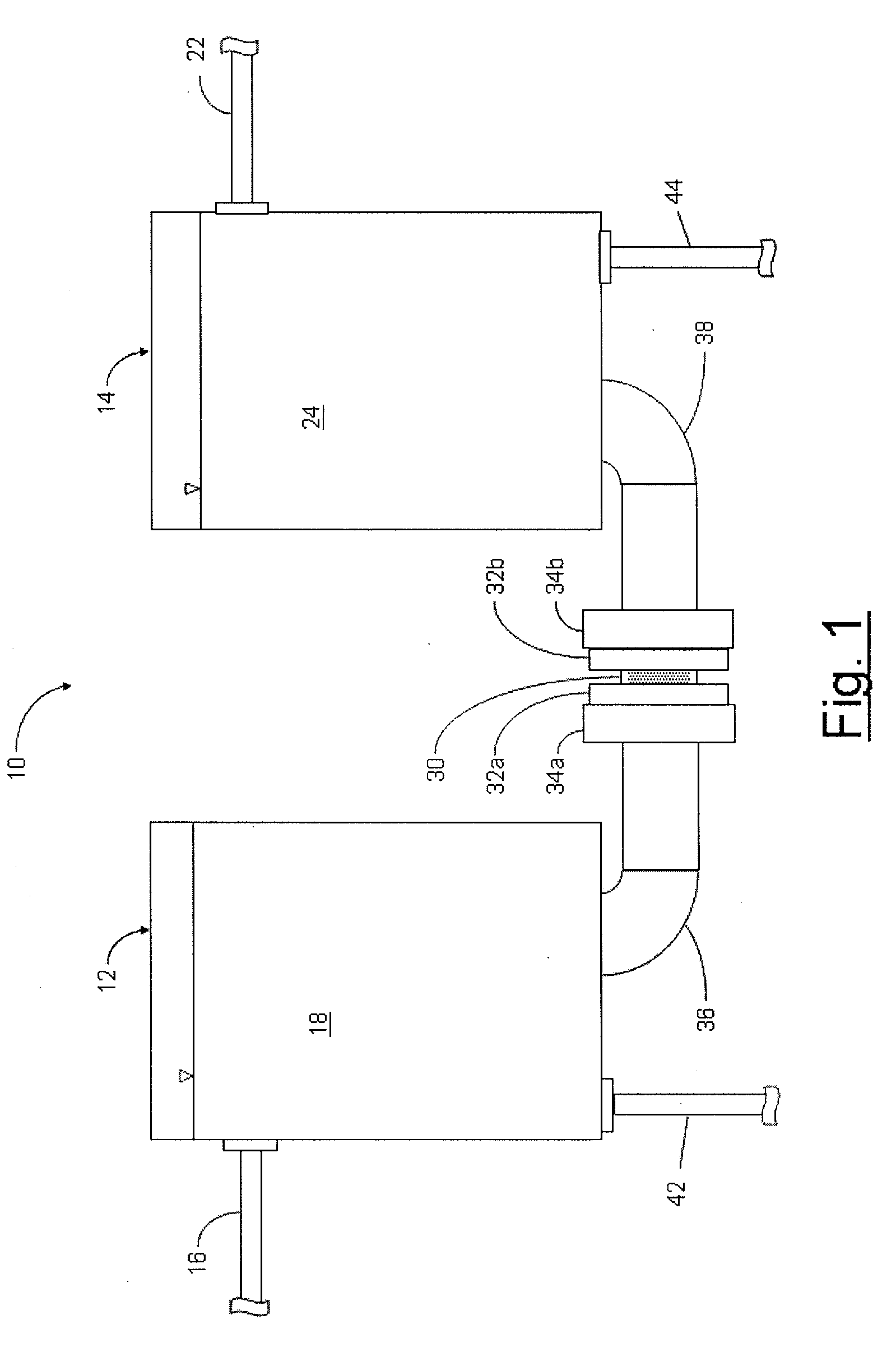

Mixing chamber

ActiveUS20070007214A1Reduce anoxic zoneImprove filtrate qualityMembranesLiquid degasificationPorous membraneBiomedical engineering

Owner:EVOQUA WATER TECH LLC

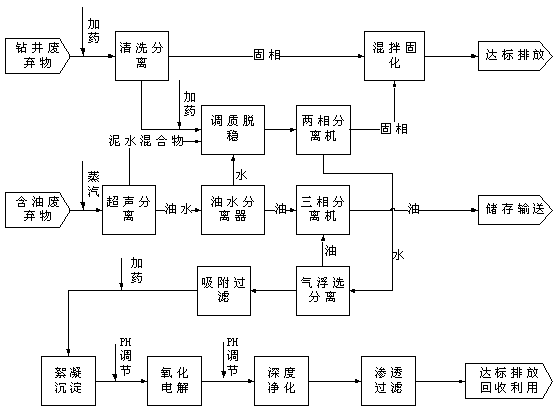

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

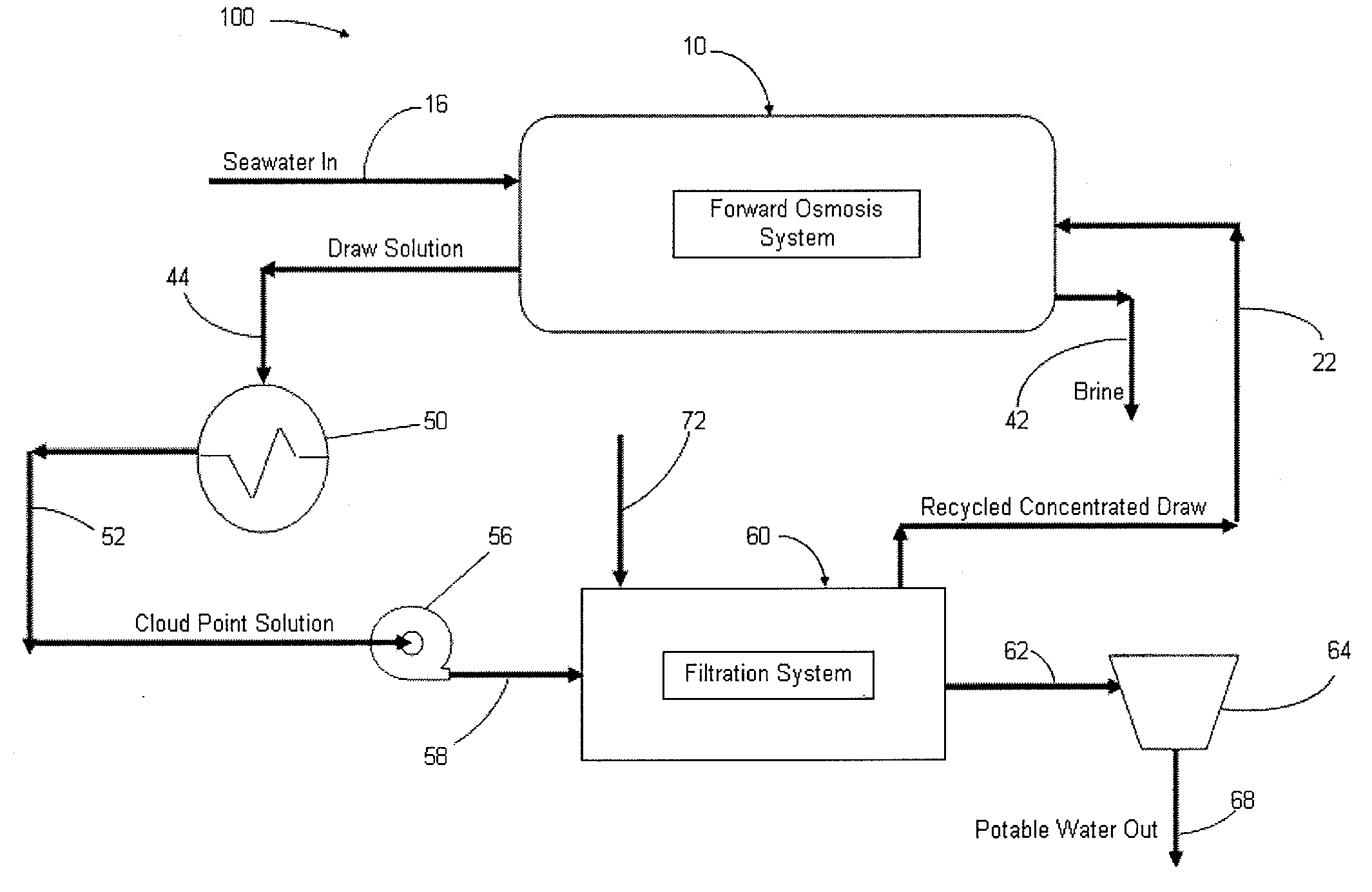

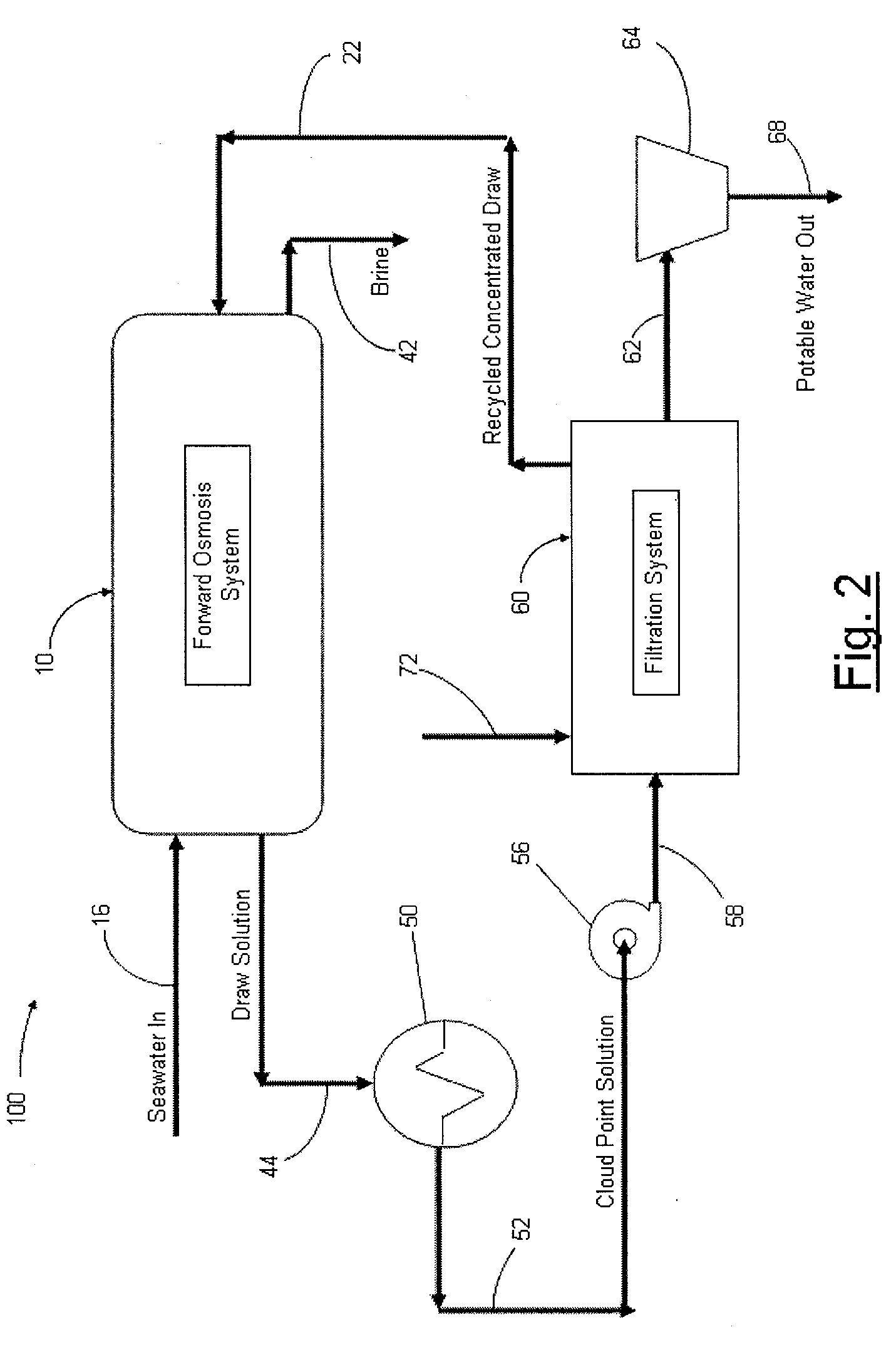

Systems and methods for forward osmosis fluid purification

ActiveUS20100155329A1Improve efficiencyFunction increaseGeneral water supply conservationSeawater treatmentSaline waterDesalination

A process for purification of fluids, for example, desalination of seawater or brackish water, using organic solutes in a concentrated water solution for use in a forward osmosis process, to extract fresh water out of salt water through the forward osmosis membrane, and subsequently separating the organic solutes out of the diluted forward osmosis permeate by cloud point extraction, thereby regenerating a concentrated organic solution for recycling to the forward osmosis process, and fresh water for potable water use.

Owner:JFEENG CORP

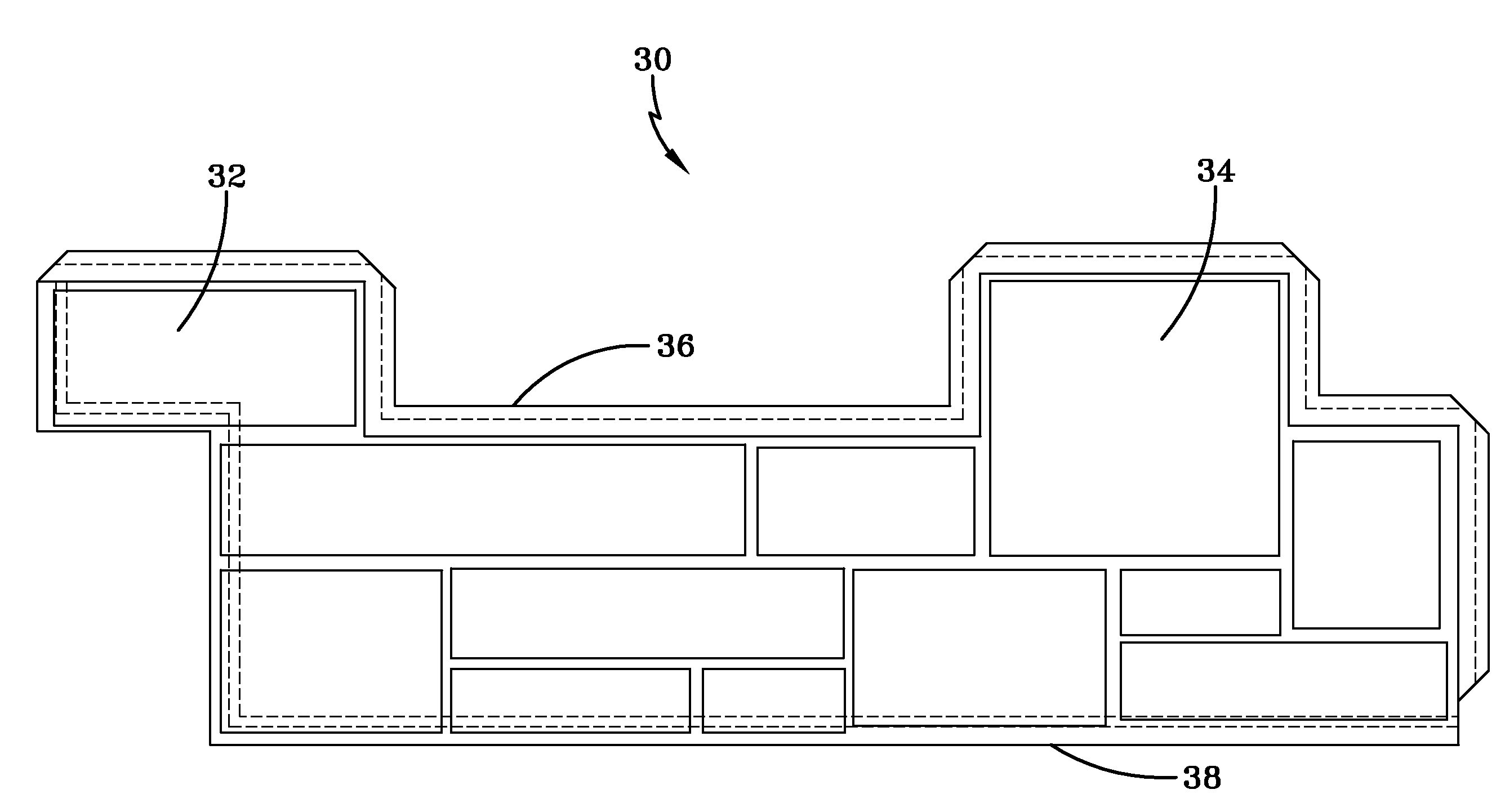

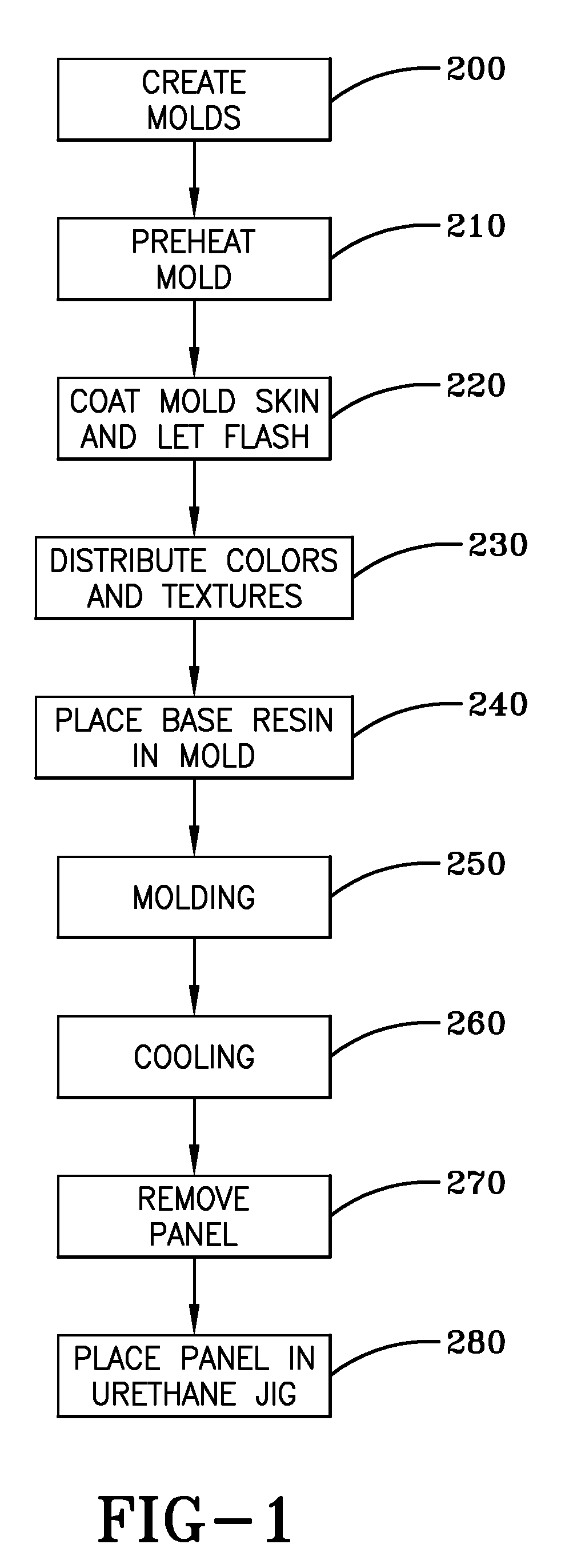

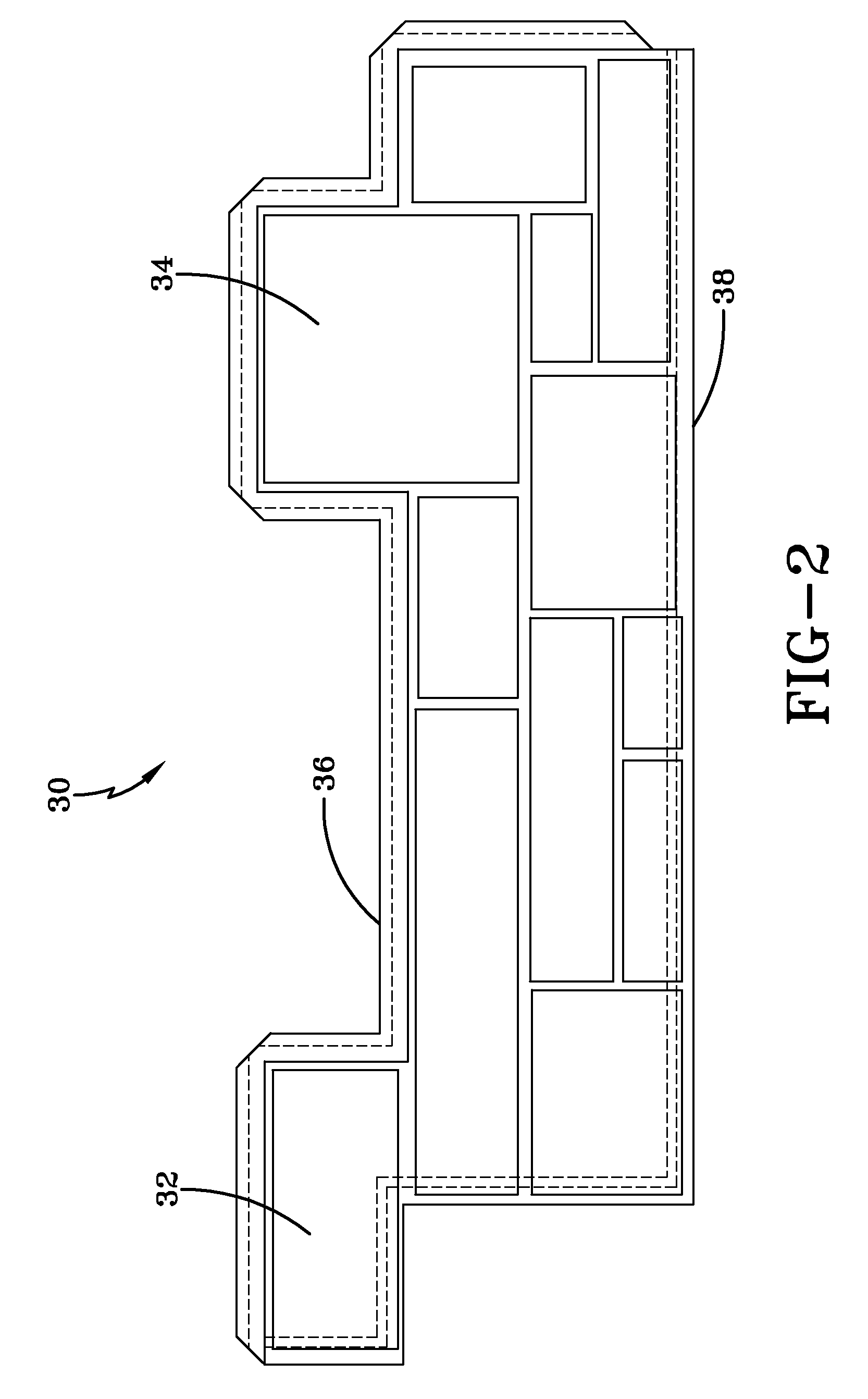

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

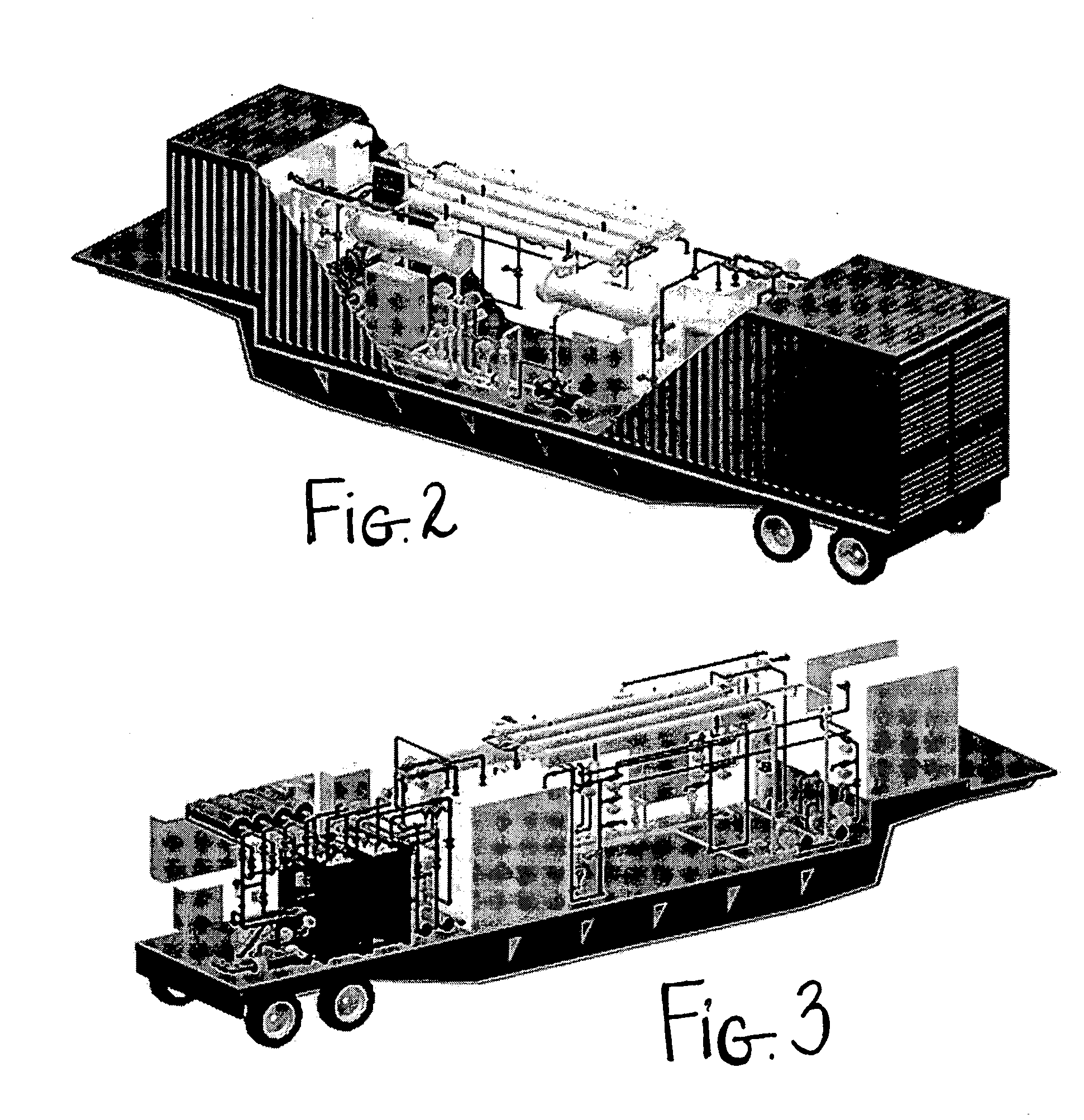

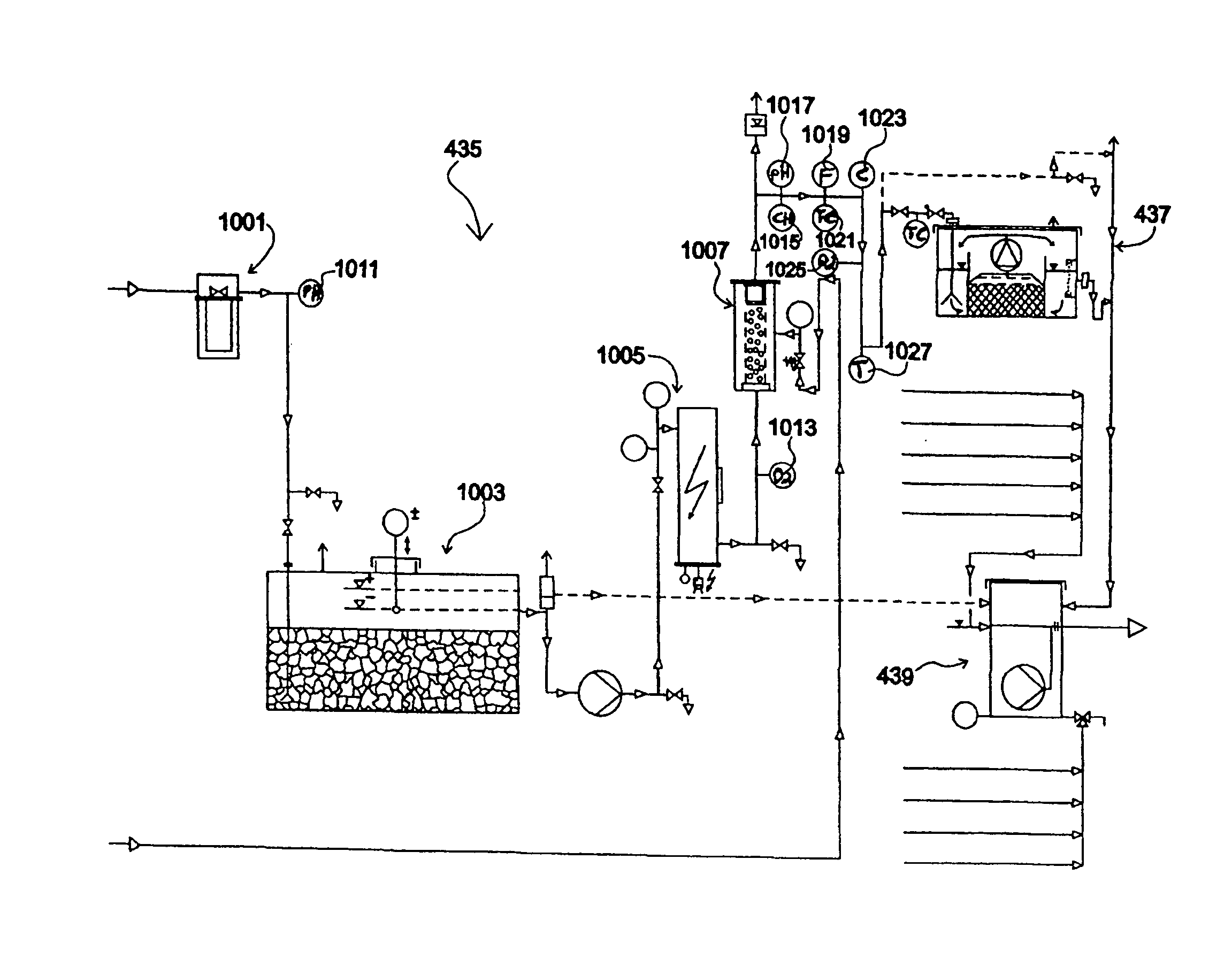

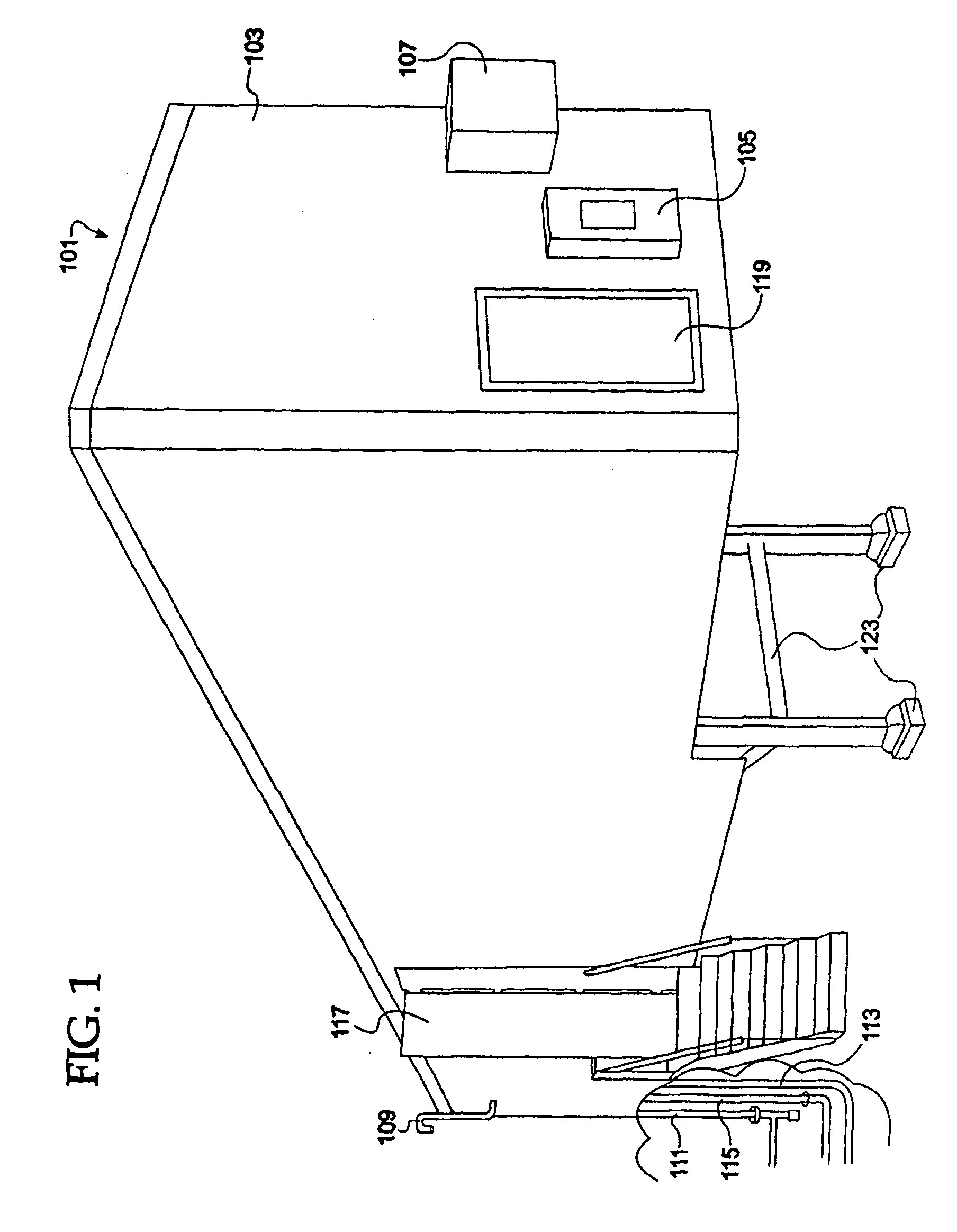

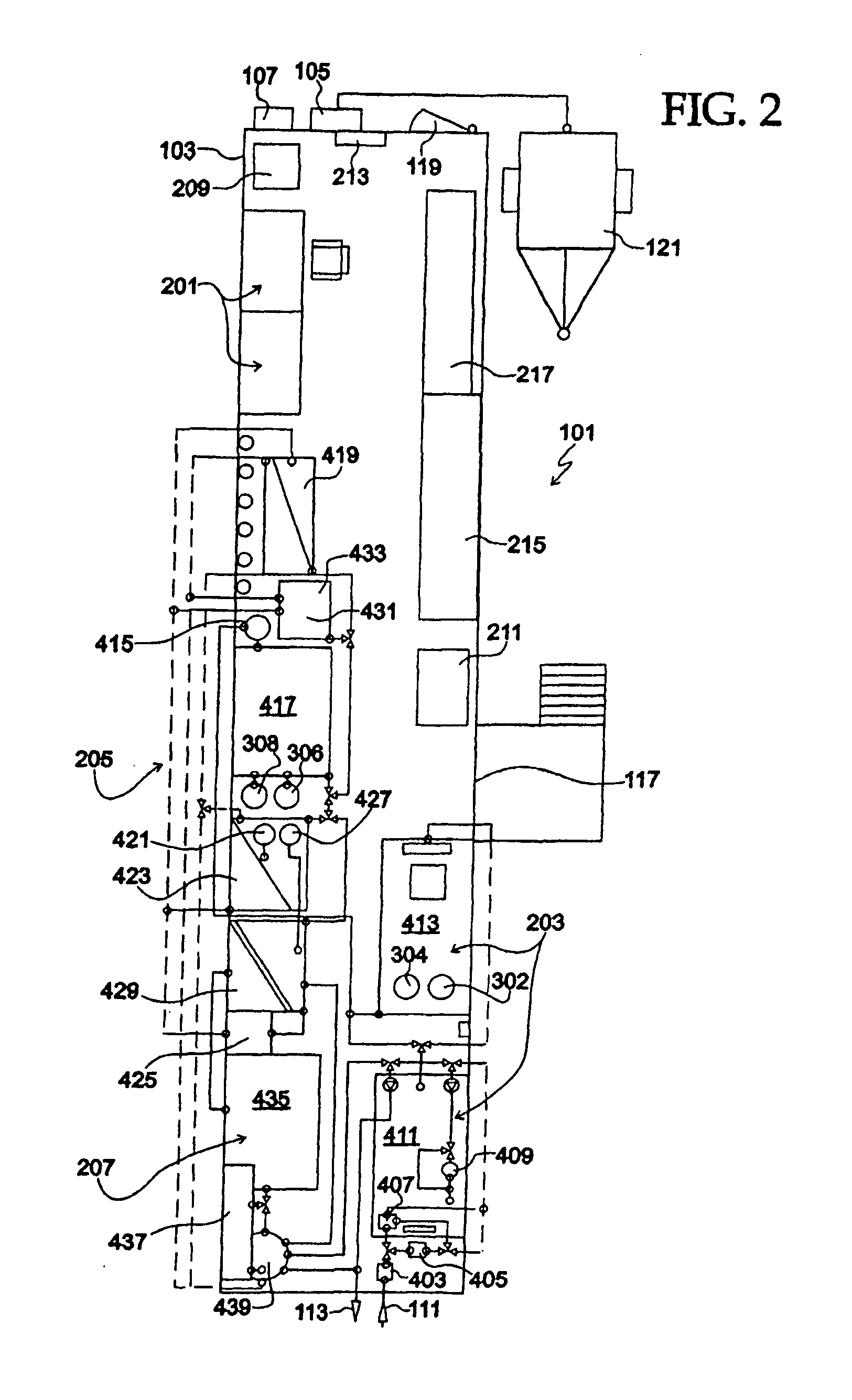

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

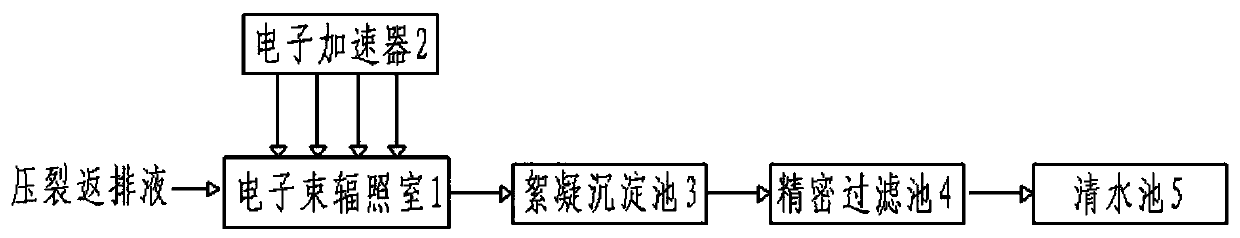

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

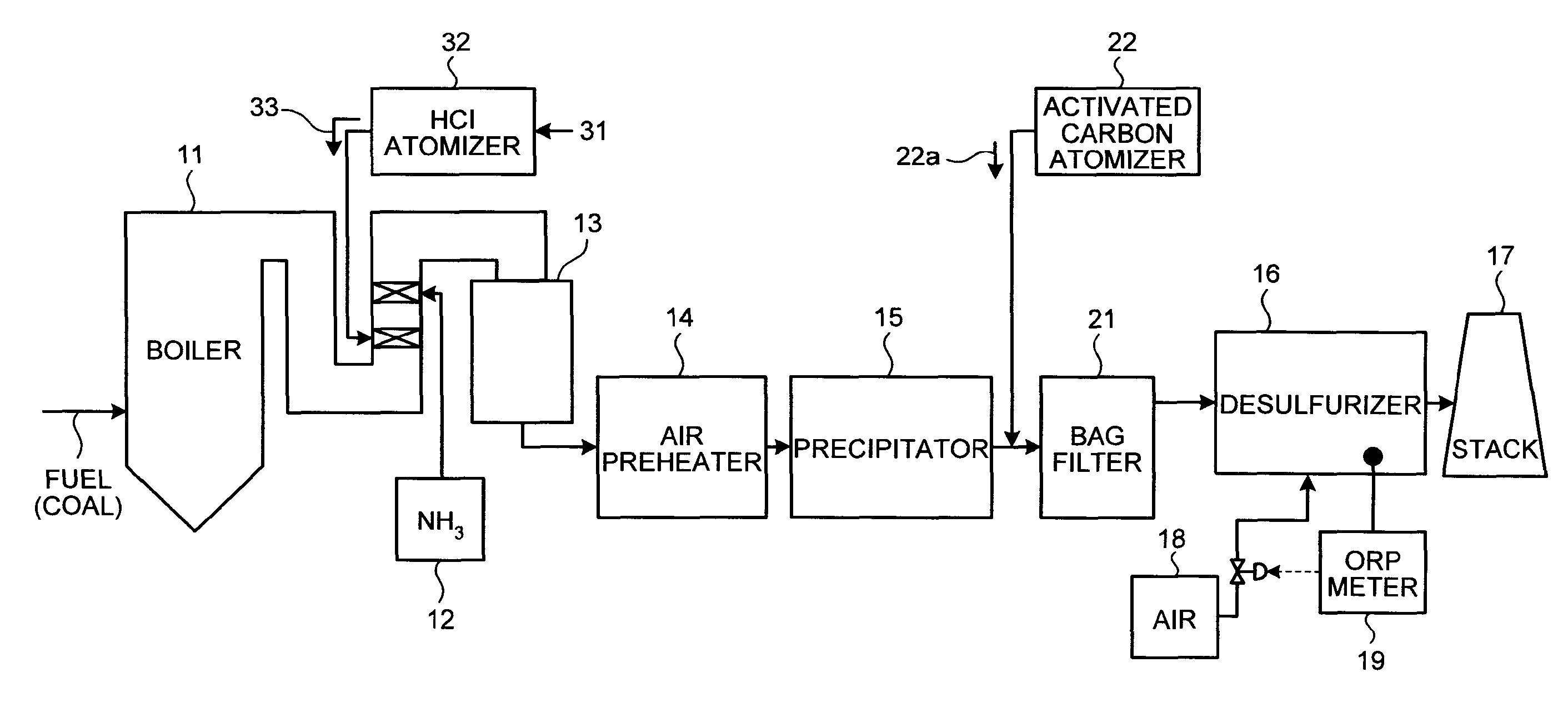

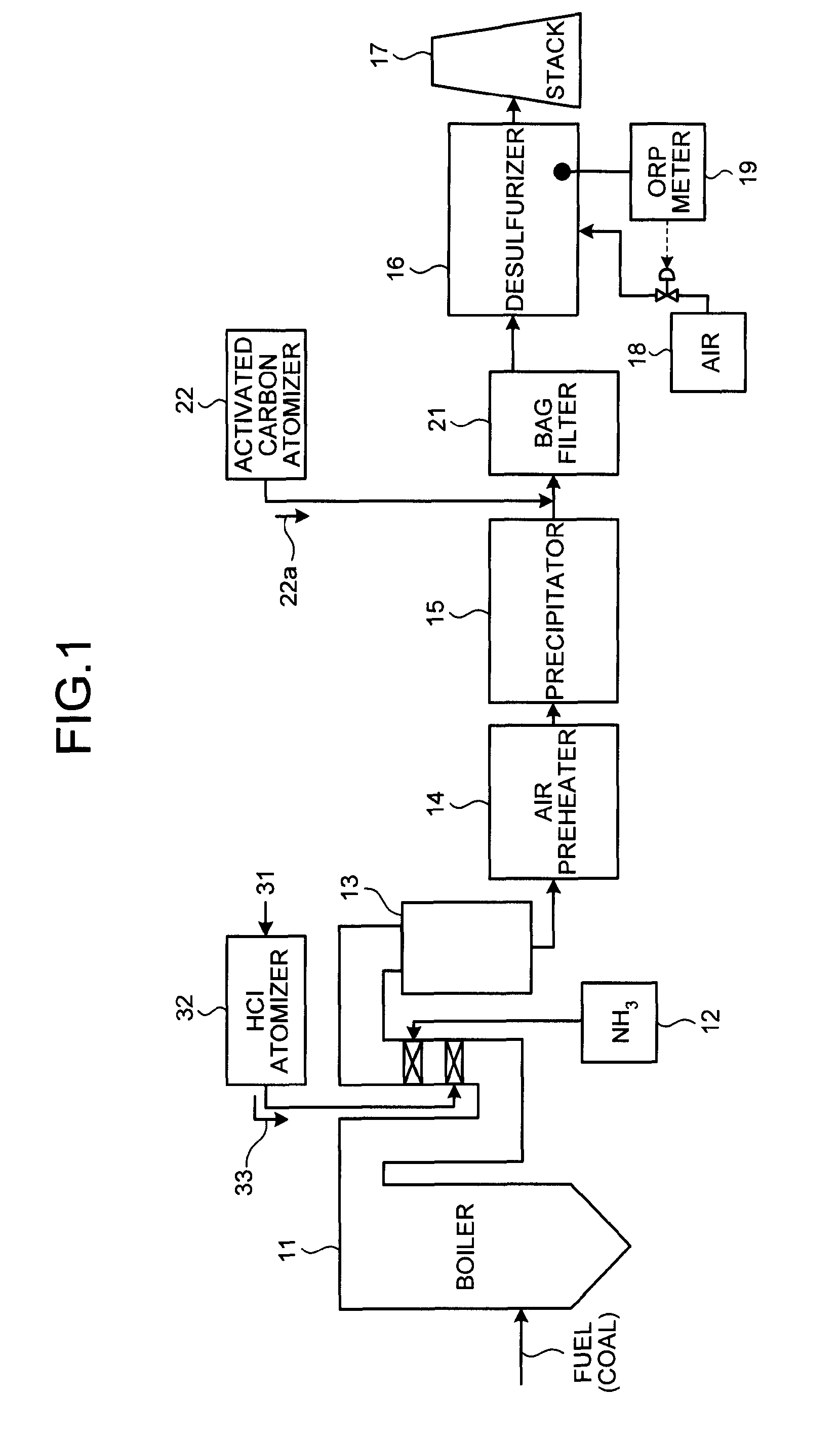

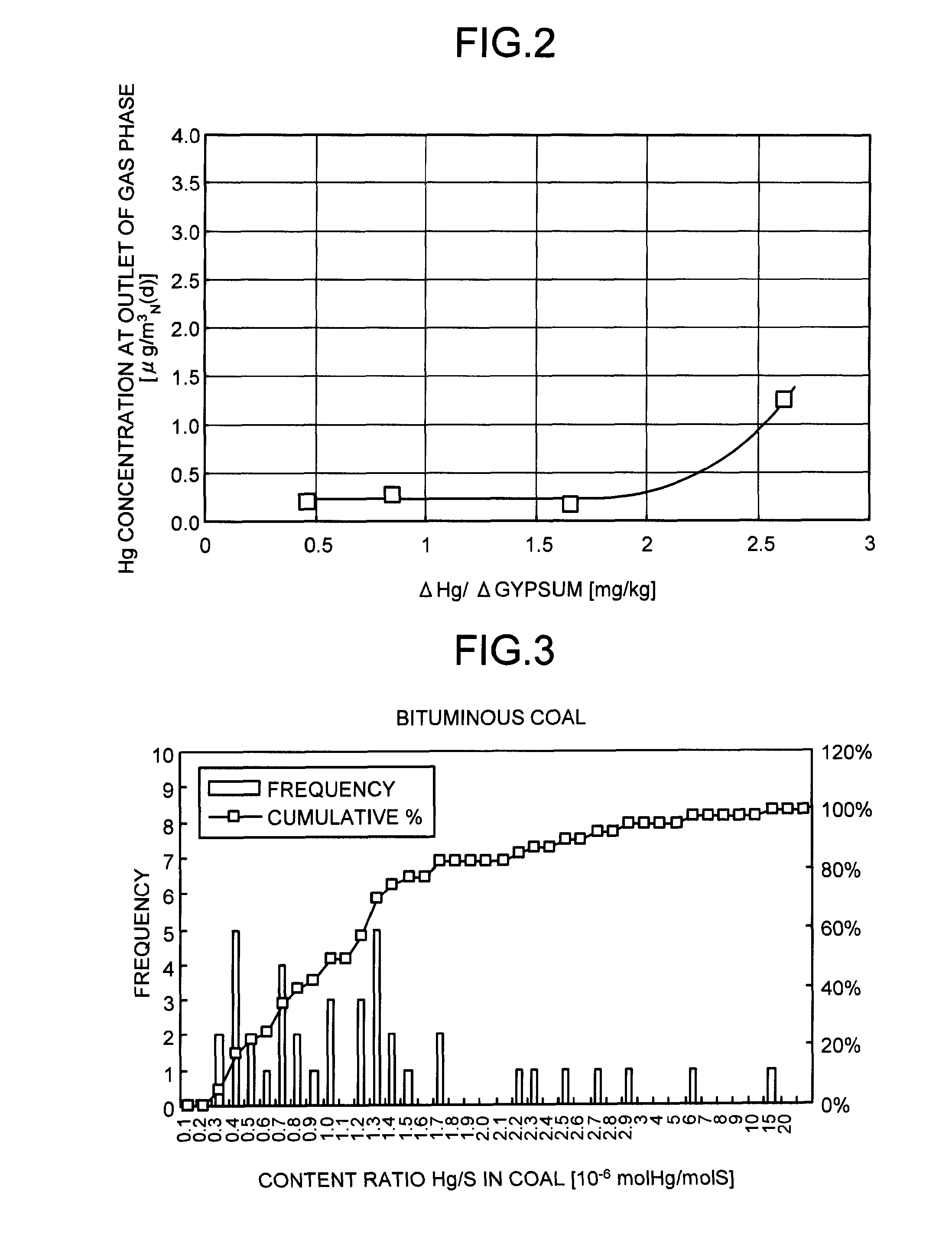

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

Popular searches

Solid sorbent liquid separation Water/sewage treatment by substance addition Liquid separation Contaminated groundwater/leachate treatment Water/sewage treatment by oxidation Water treatment parameter control Water/sewage treatment by irradiation Other chemical processes Water treatment compounds Water/sewage treatment by ion-exchange

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com