Patents

Literature

99results about How to "High continuity of operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Predictive Method for Managing Logging or Replaying Non-Deterministic Operations within the Execution of an Application Process

InactiveUS20080086730A1Monitor progressProtection worksElectronic circuit testingError detection/correctionComparative testPredictive methods

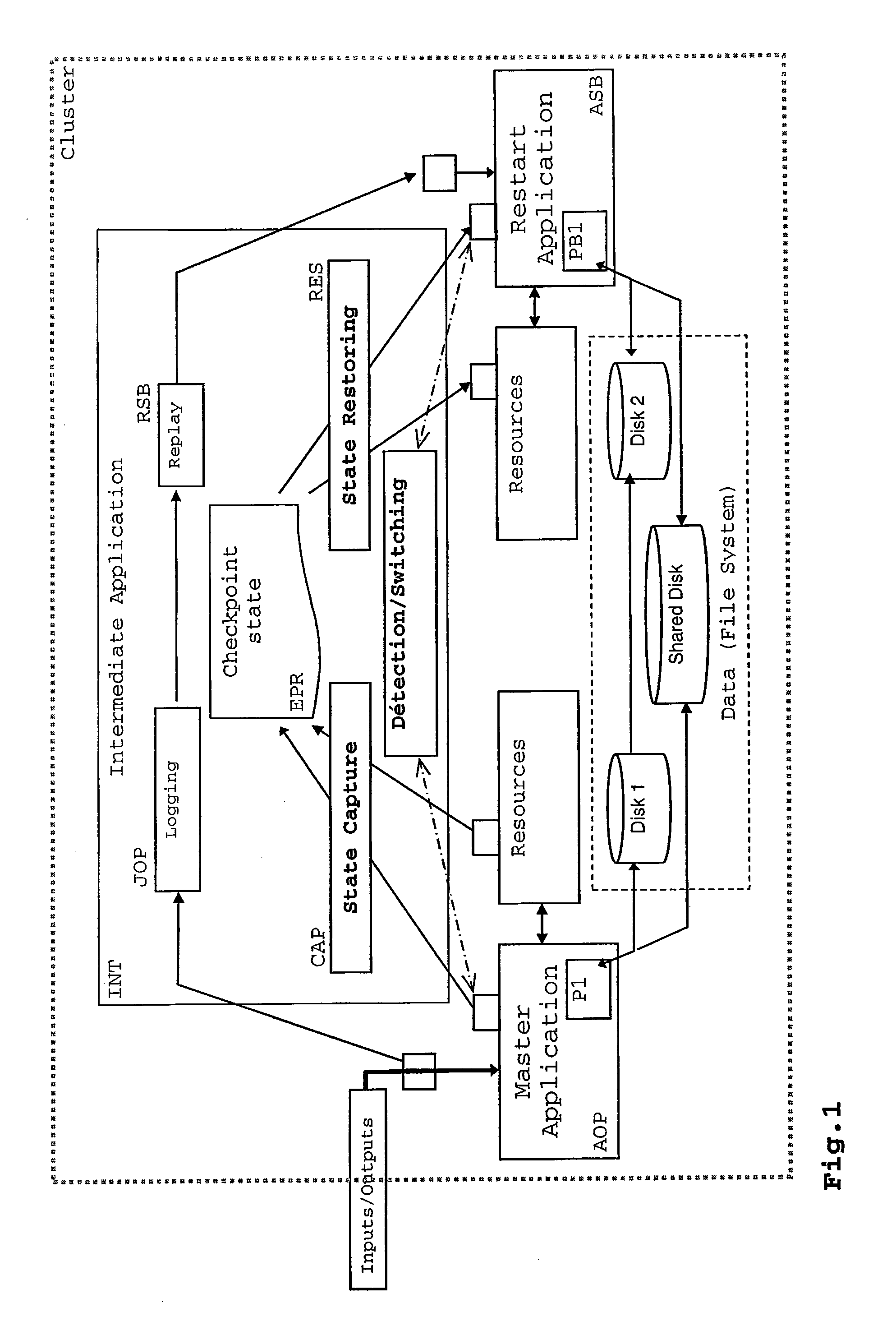

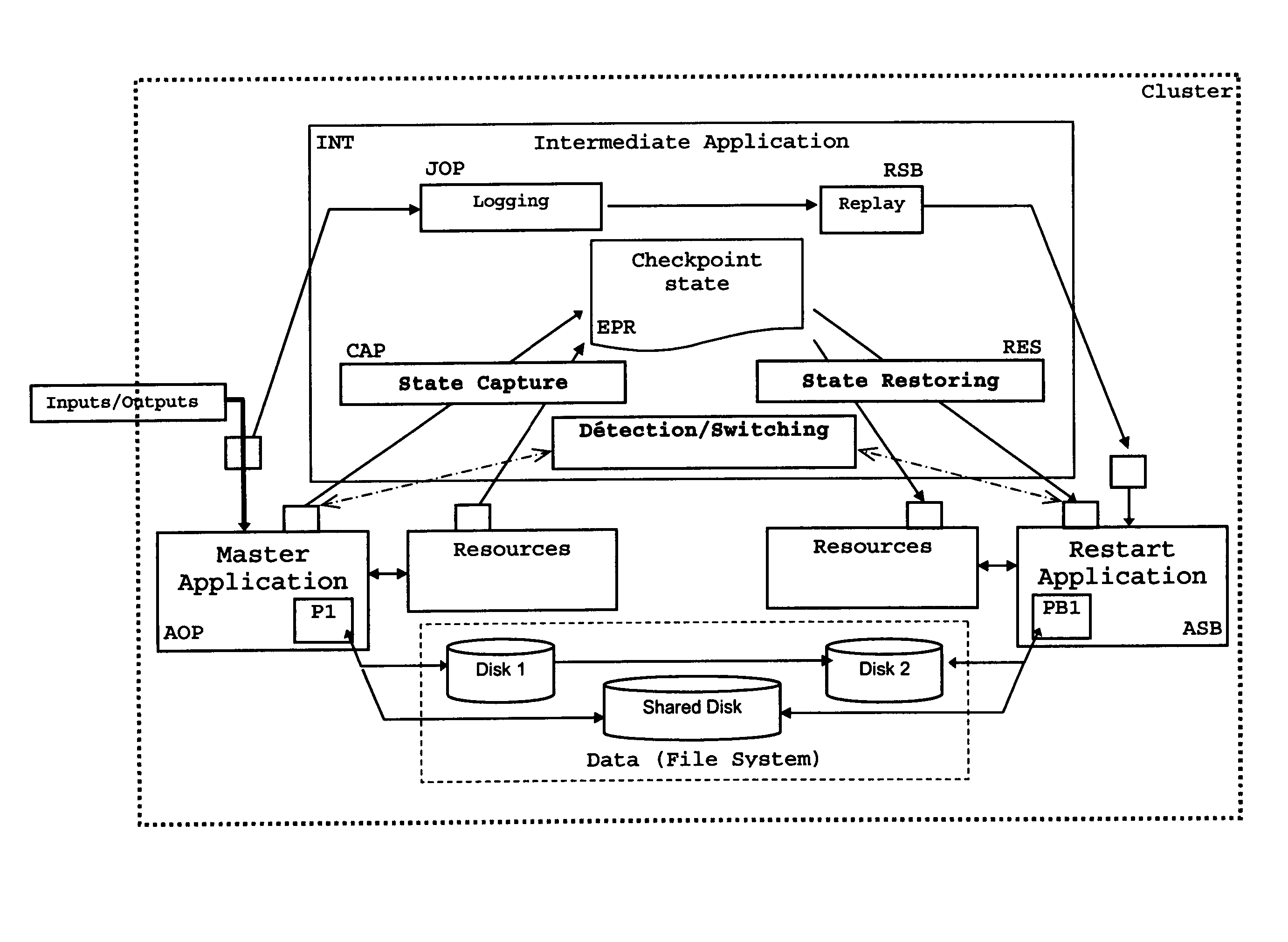

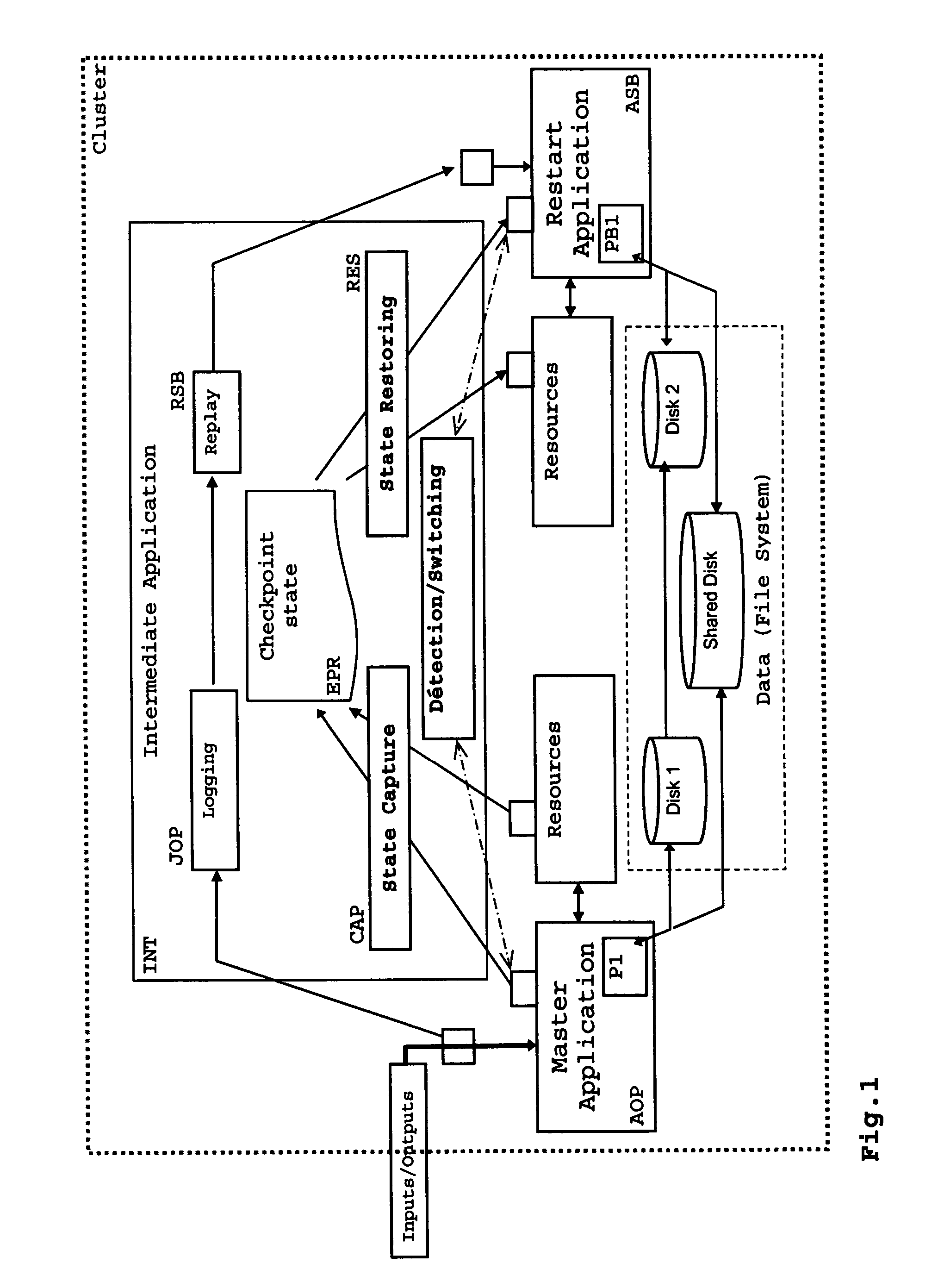

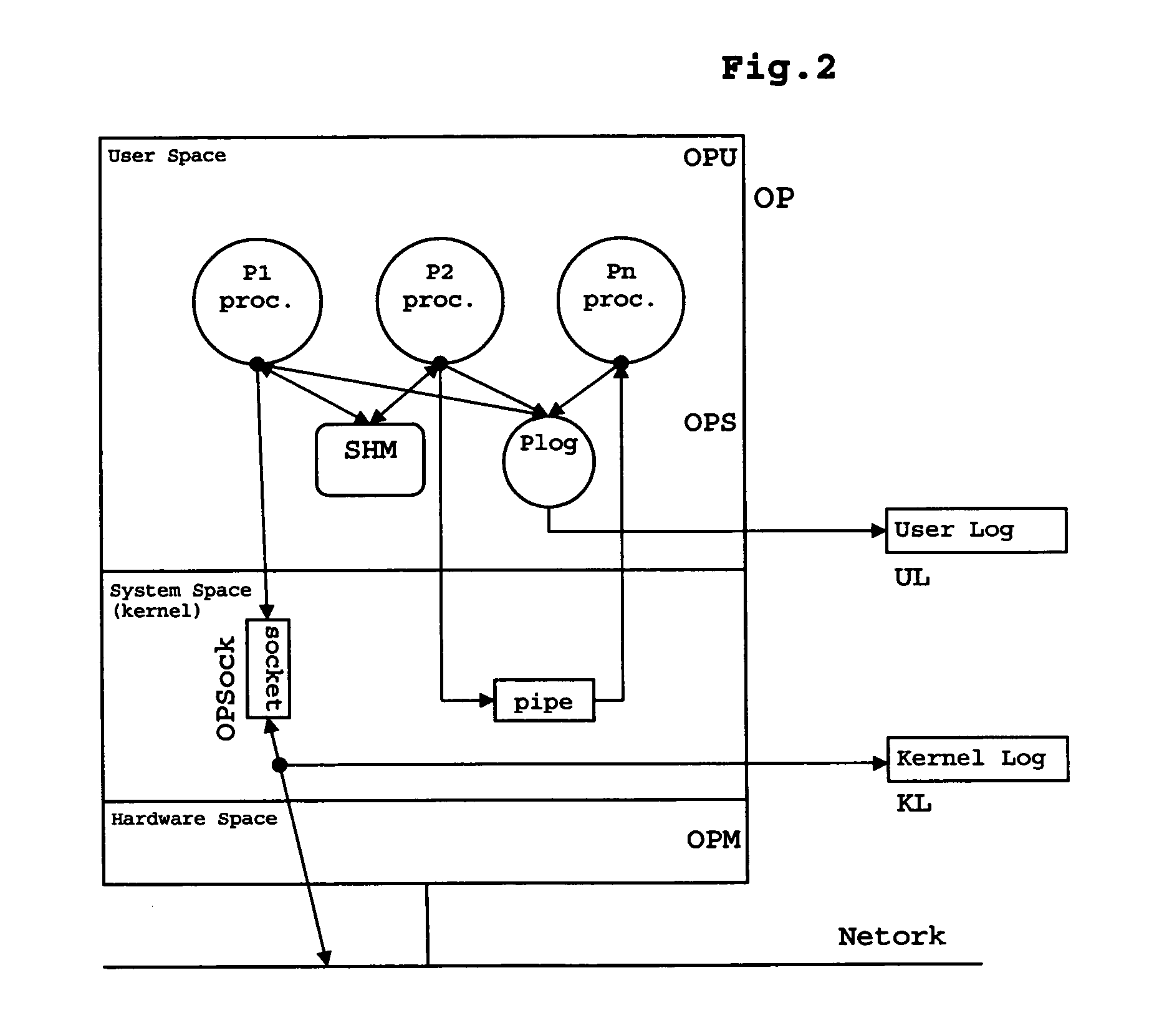

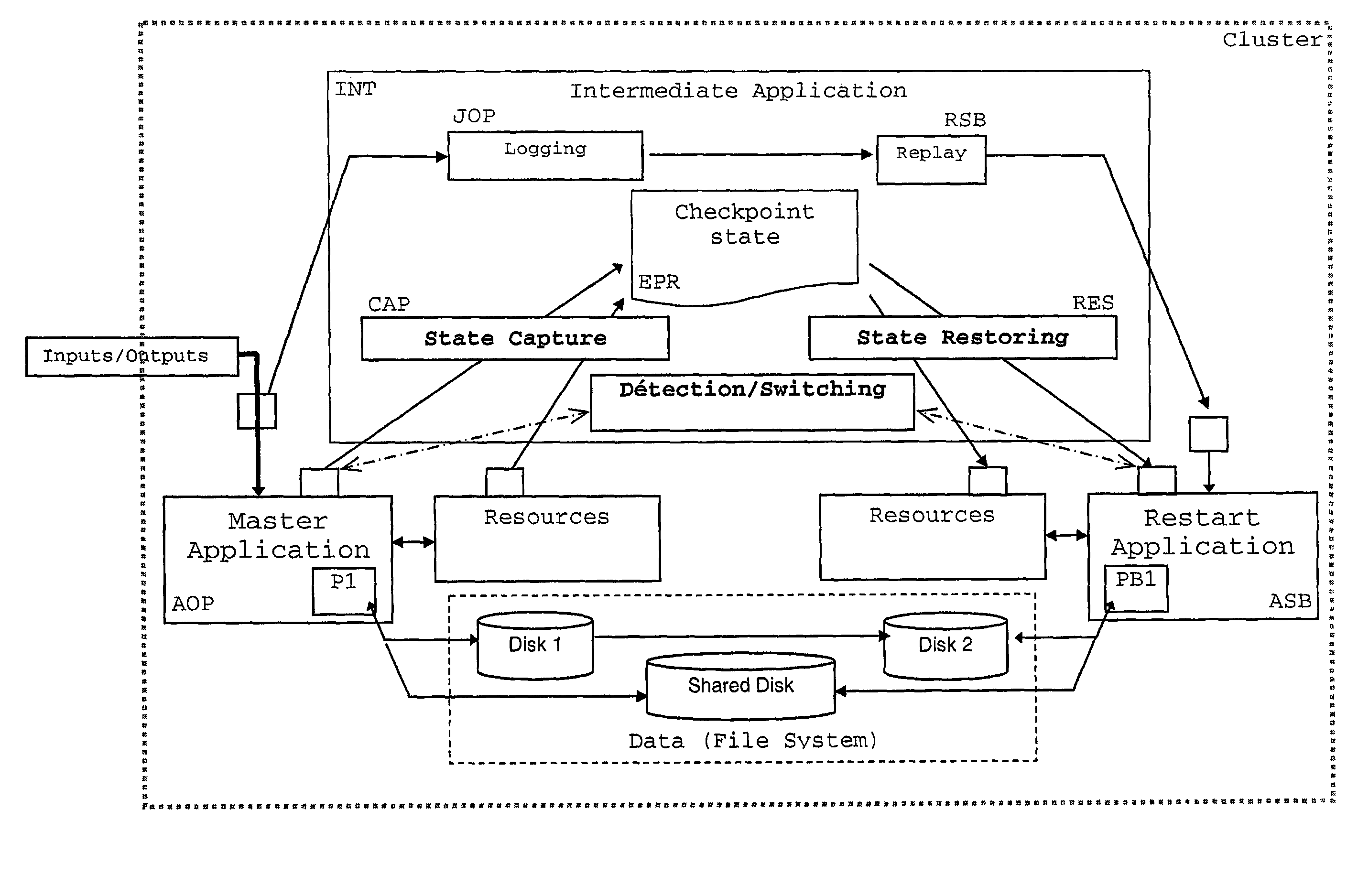

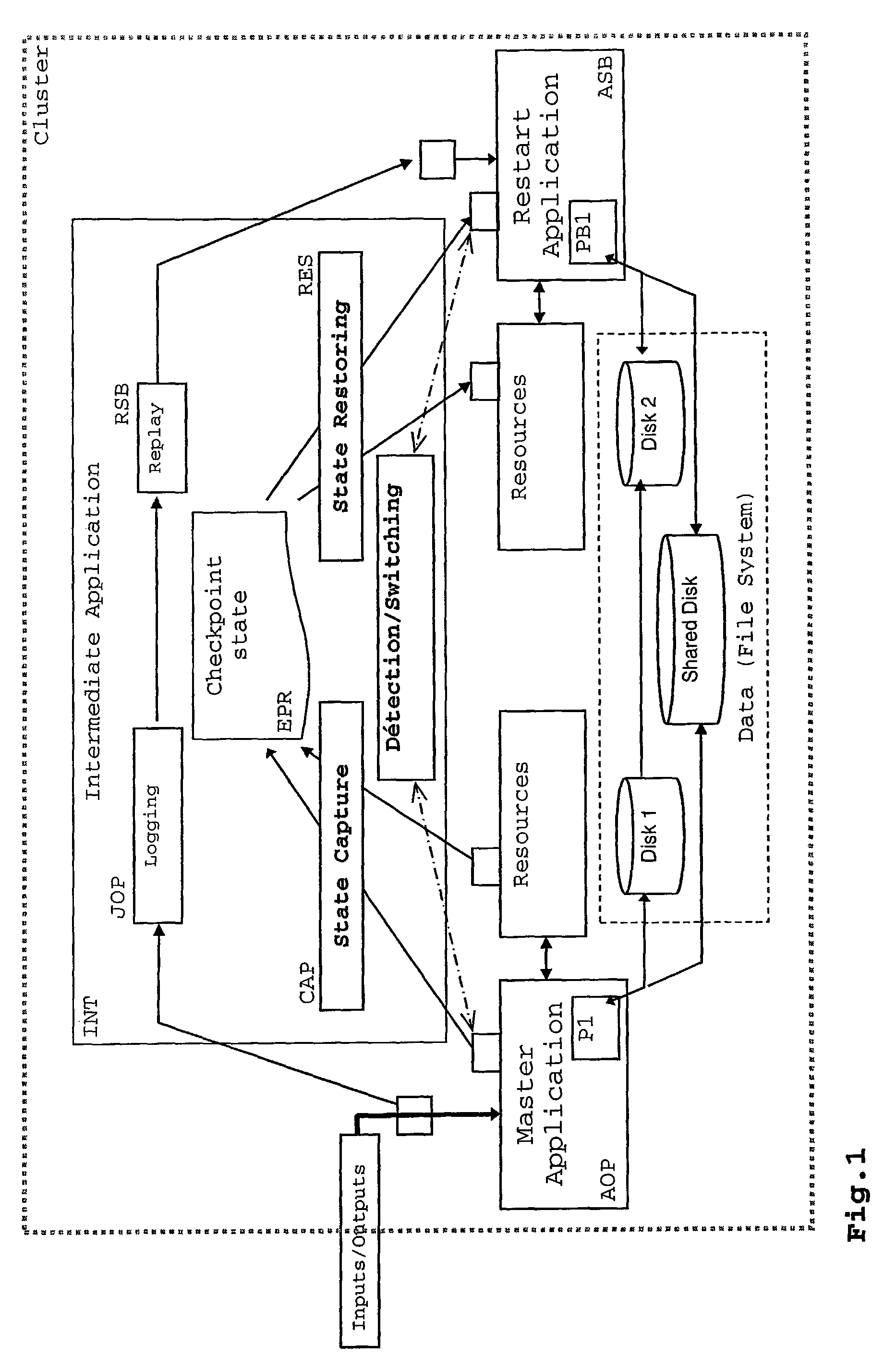

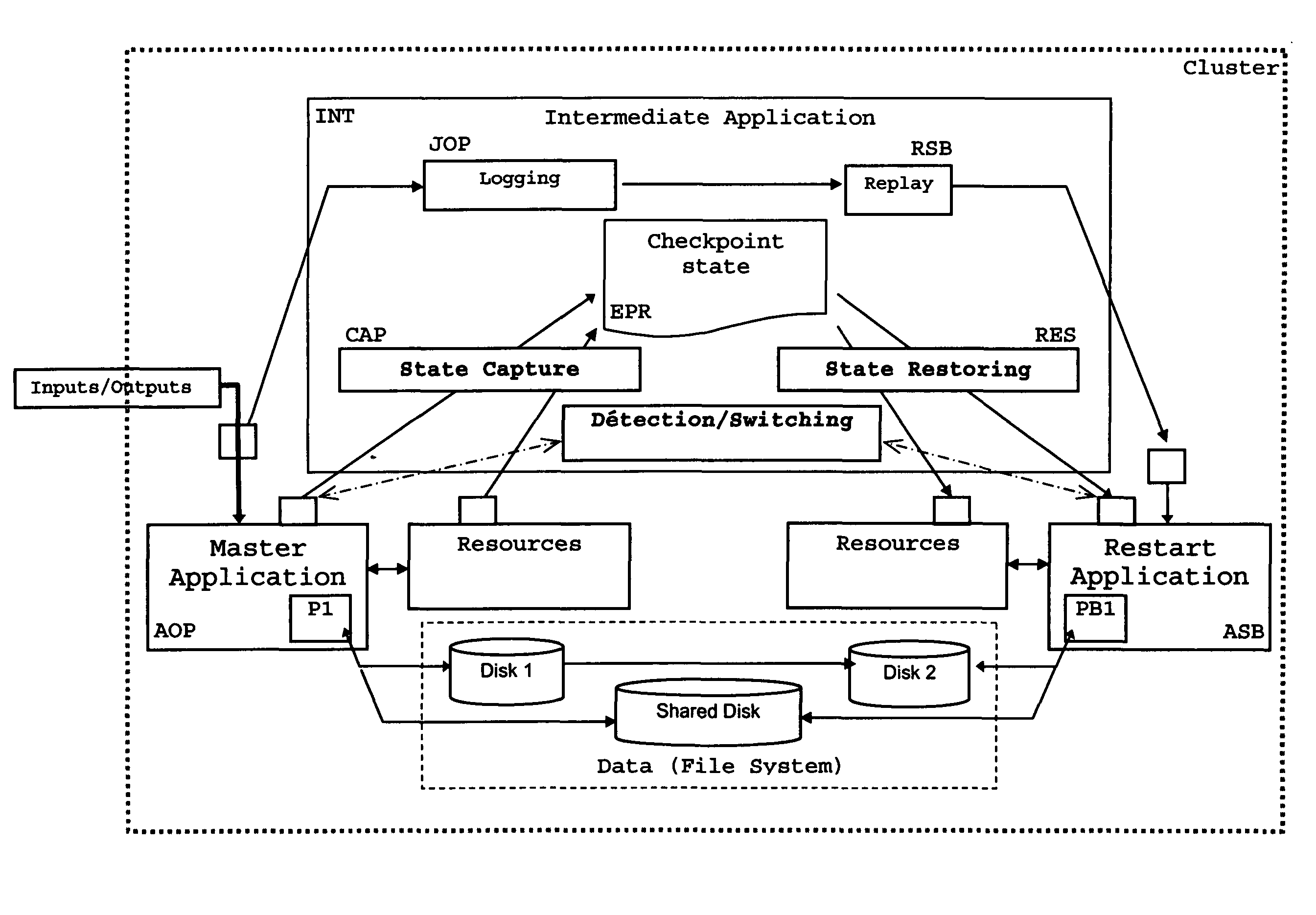

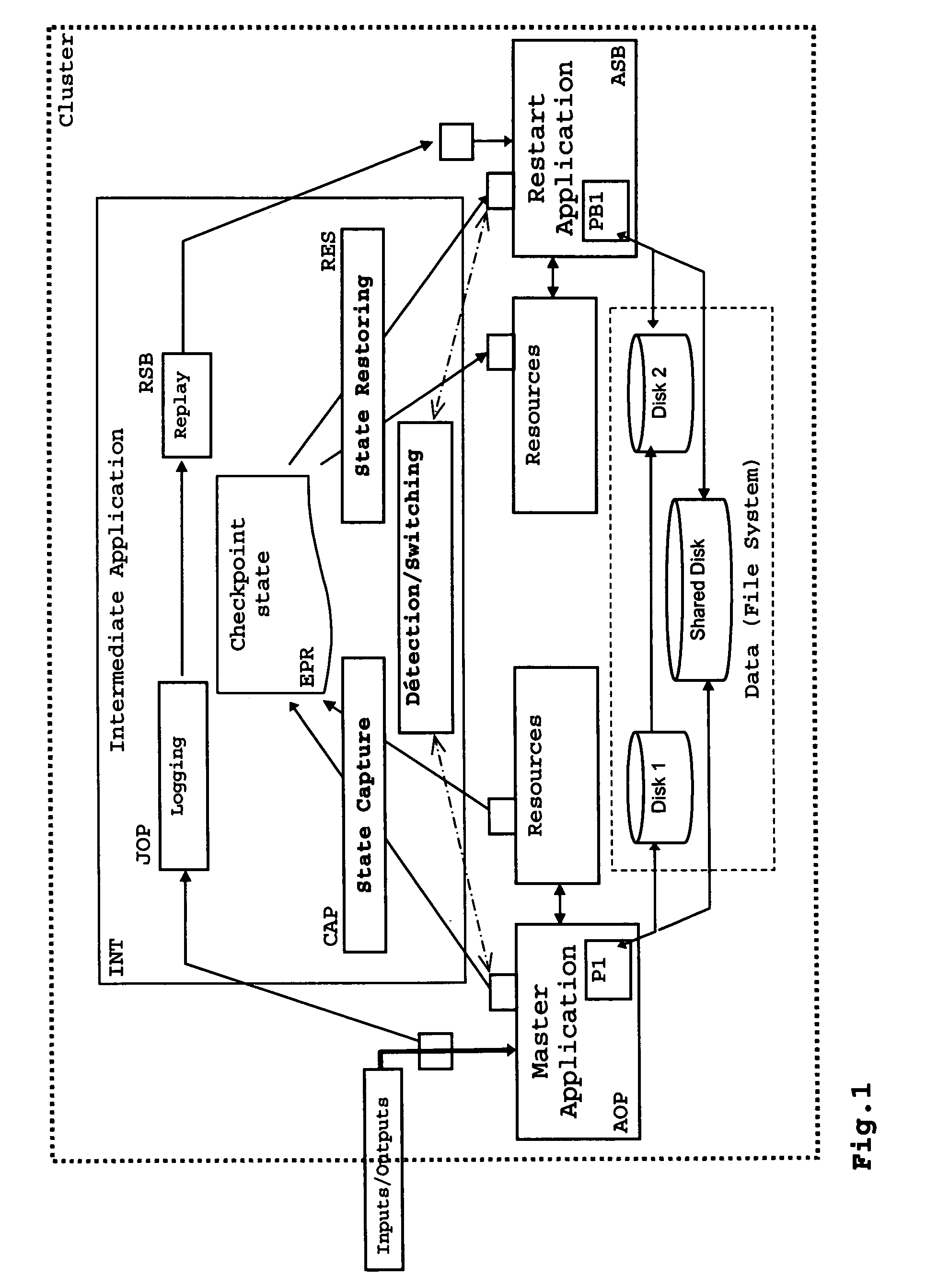

This invention relates to a management method, more particularly by logging and replay, for software operations performed during the execution of an application process executed on a computer. This method applies in particular to internal operations sending a result datum to the managed process, and comprises the following steps: carrying out a deterministic software processing, termed prediction function (FH), based on the state of a managed process or of the application (AOP, ASB), to provide a predicted result (RP) for said operation; comparative test to establish whether the value of the predicted result (RP) corresponds or does not correspond to the value of the actual result (DR, RRJ); performance of a complementary management phase (CH, DH) of said managed operation, this complementary management depending on the result of the preceding test.

Owner:IBM CORP

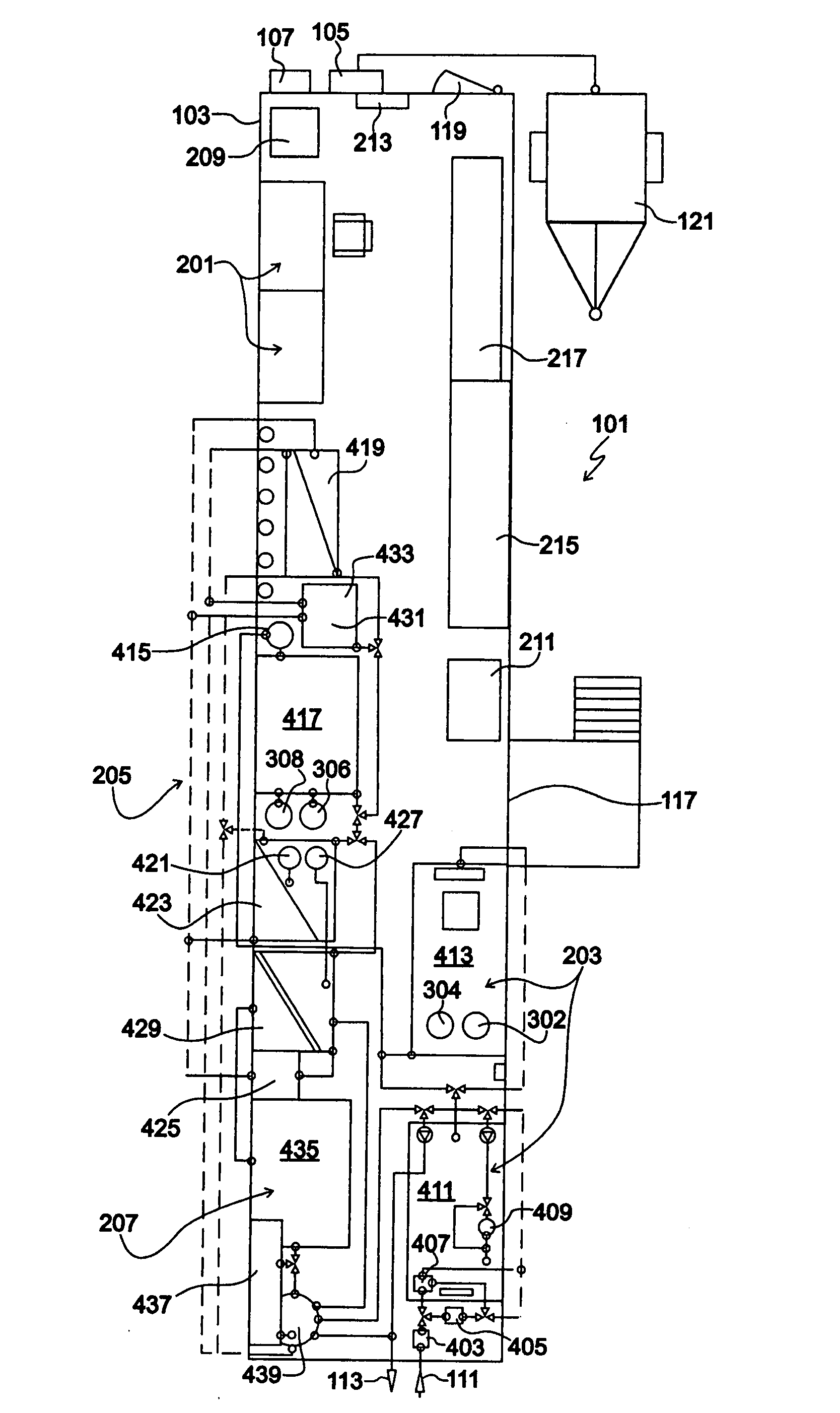

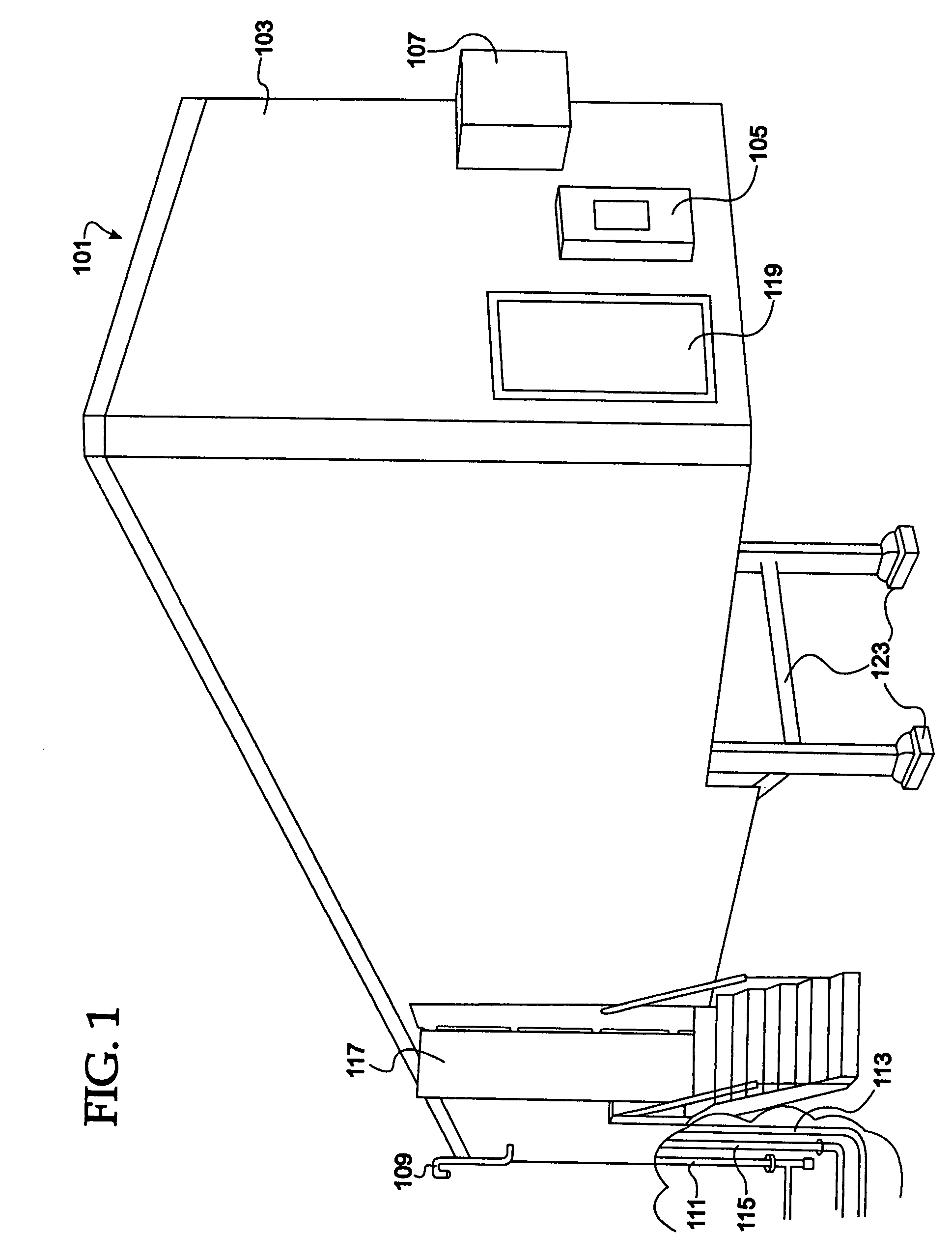

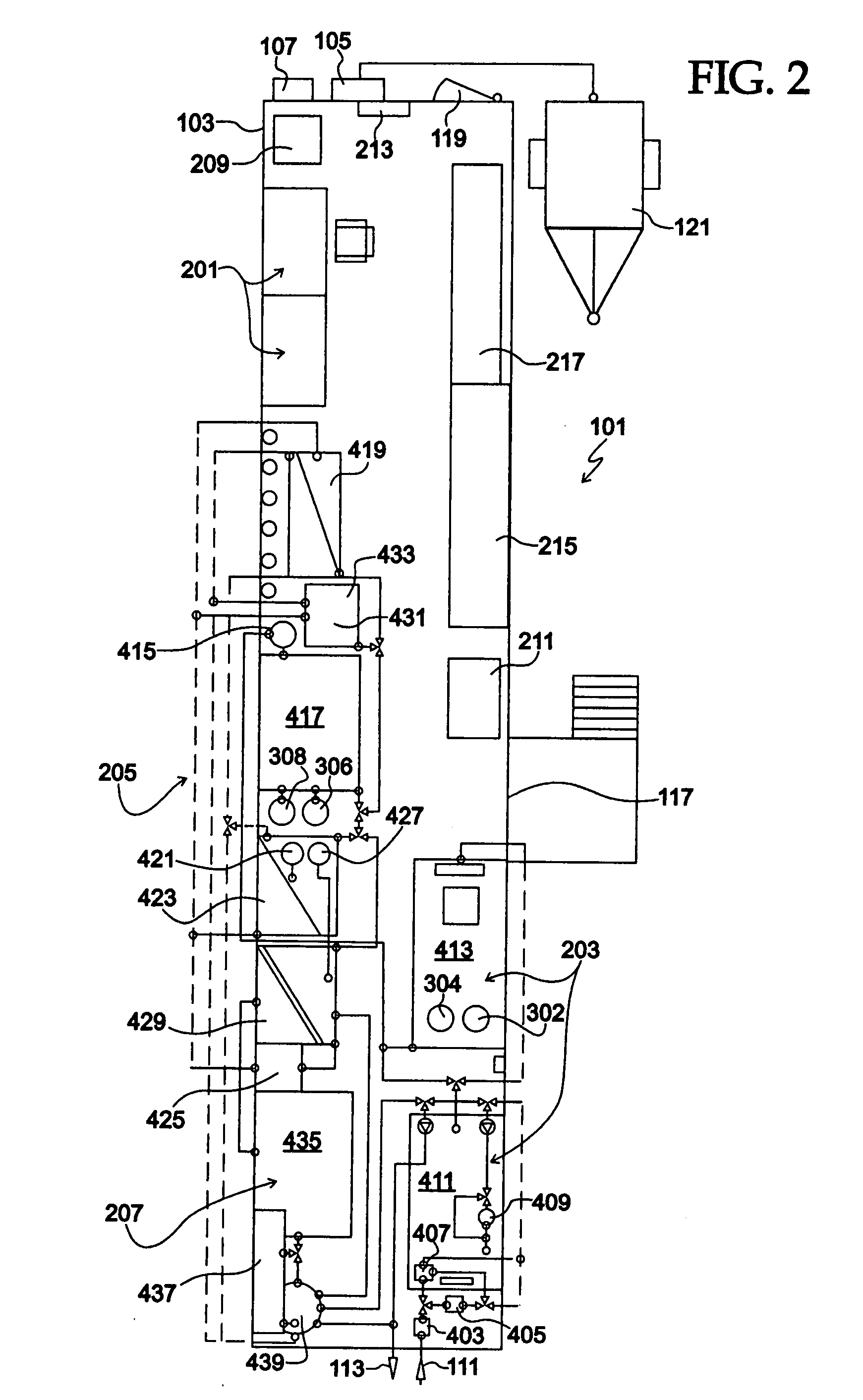

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

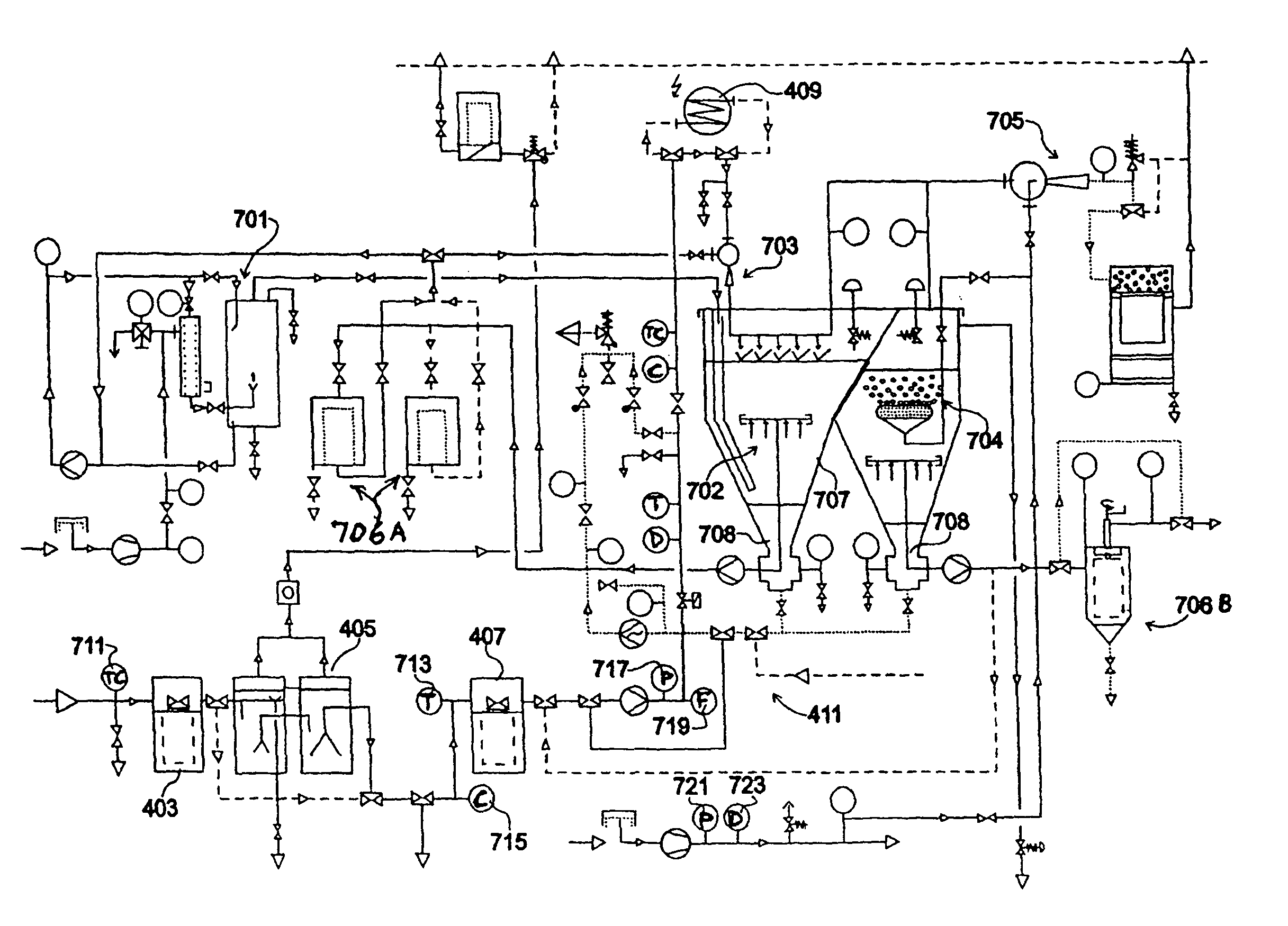

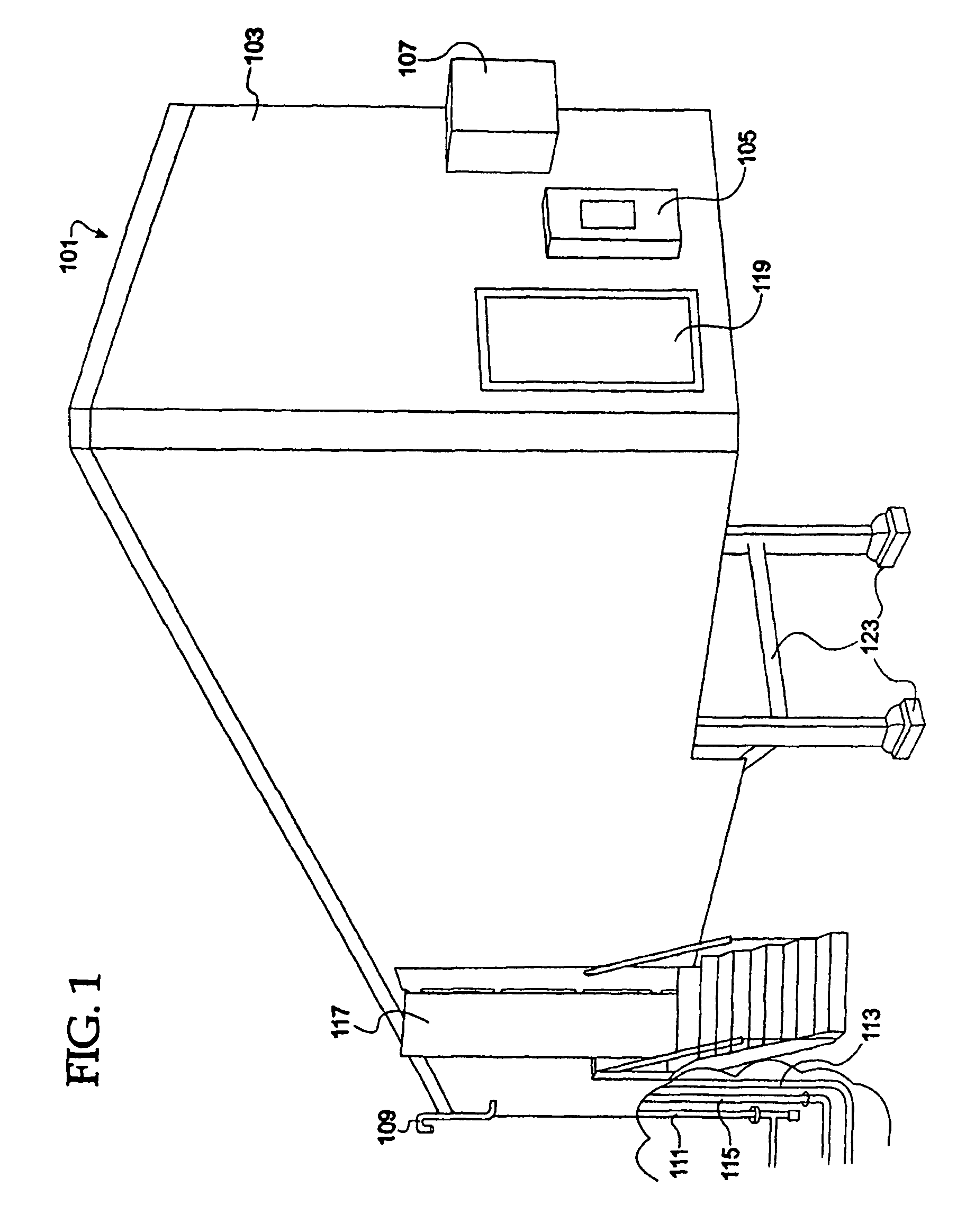

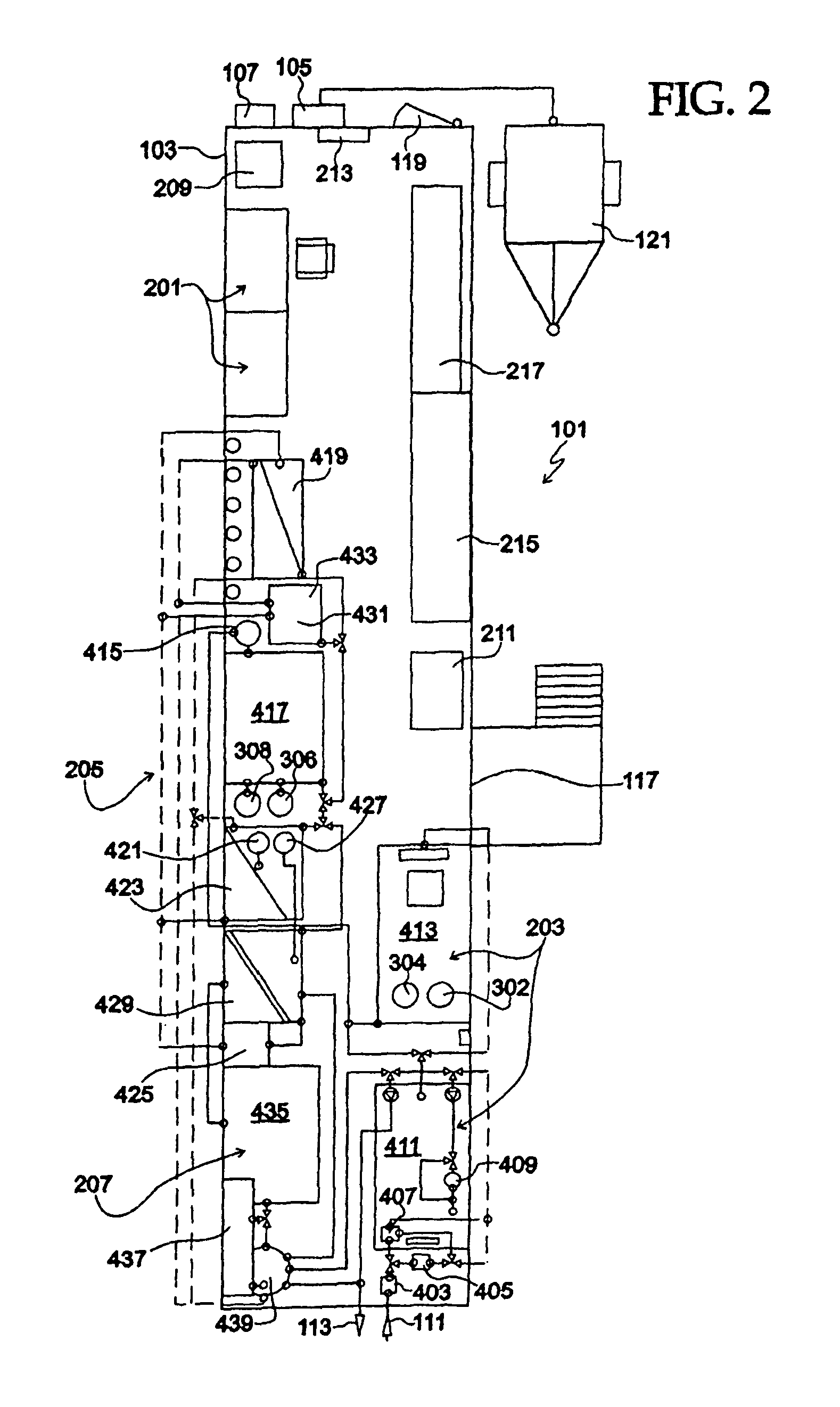

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

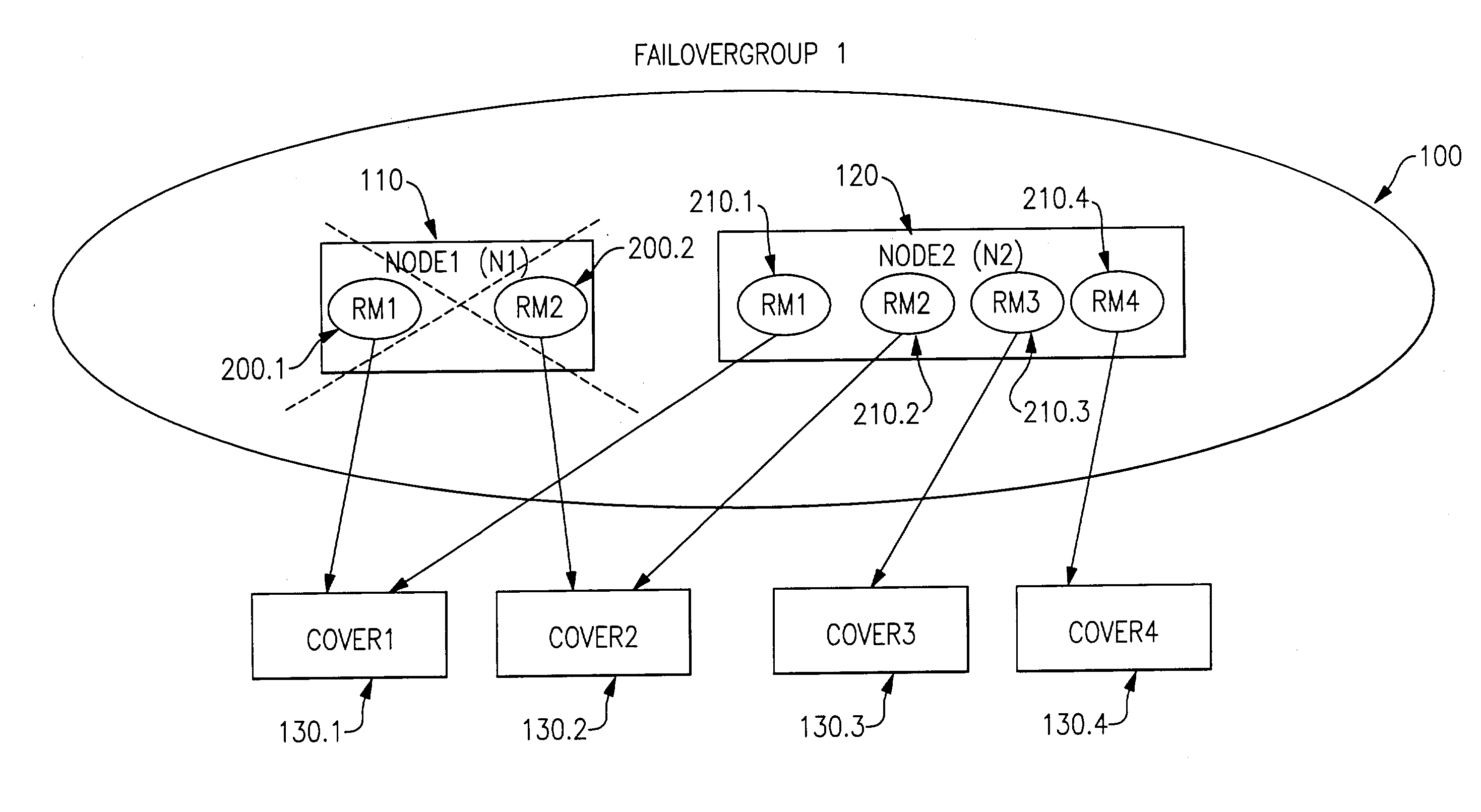

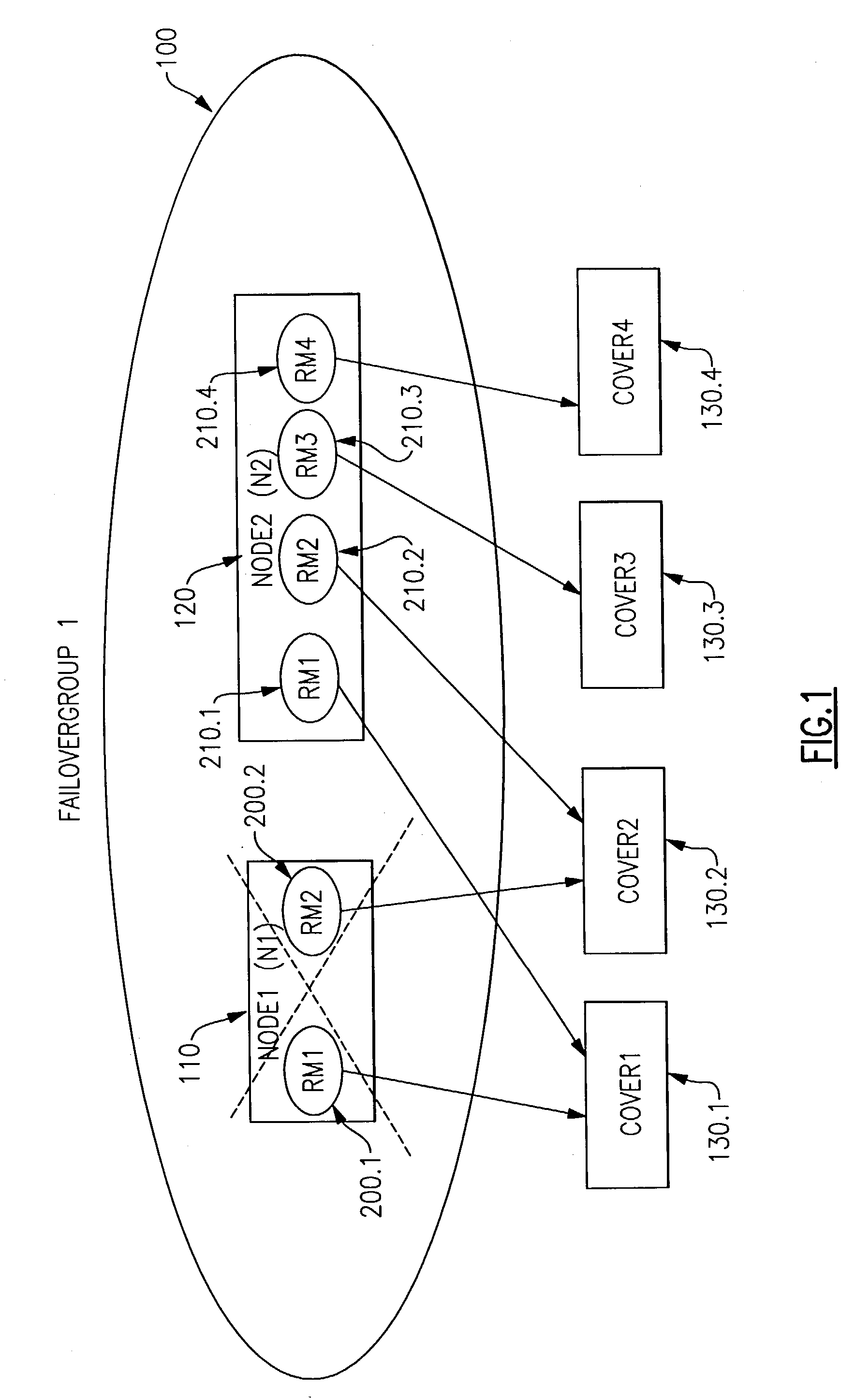

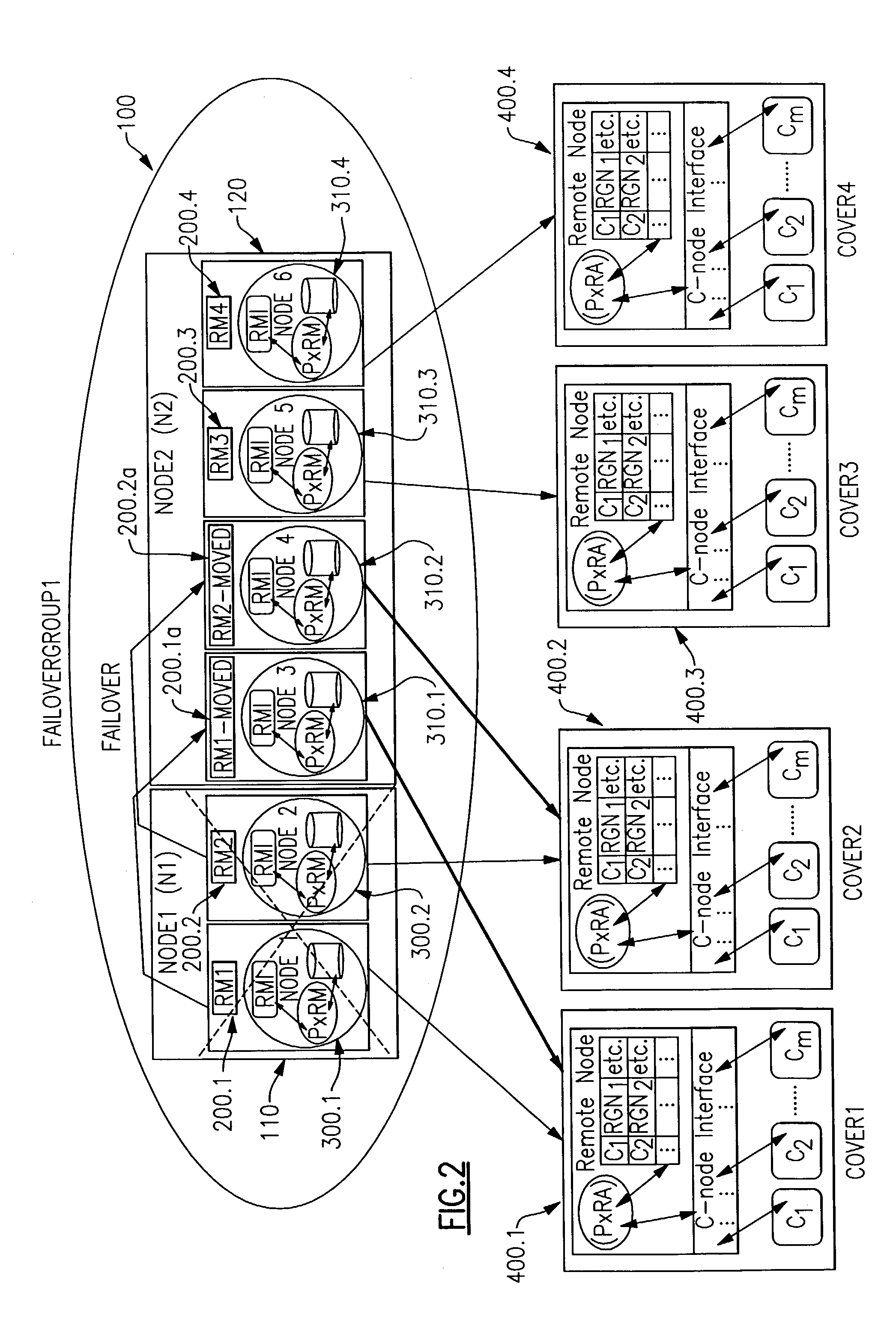

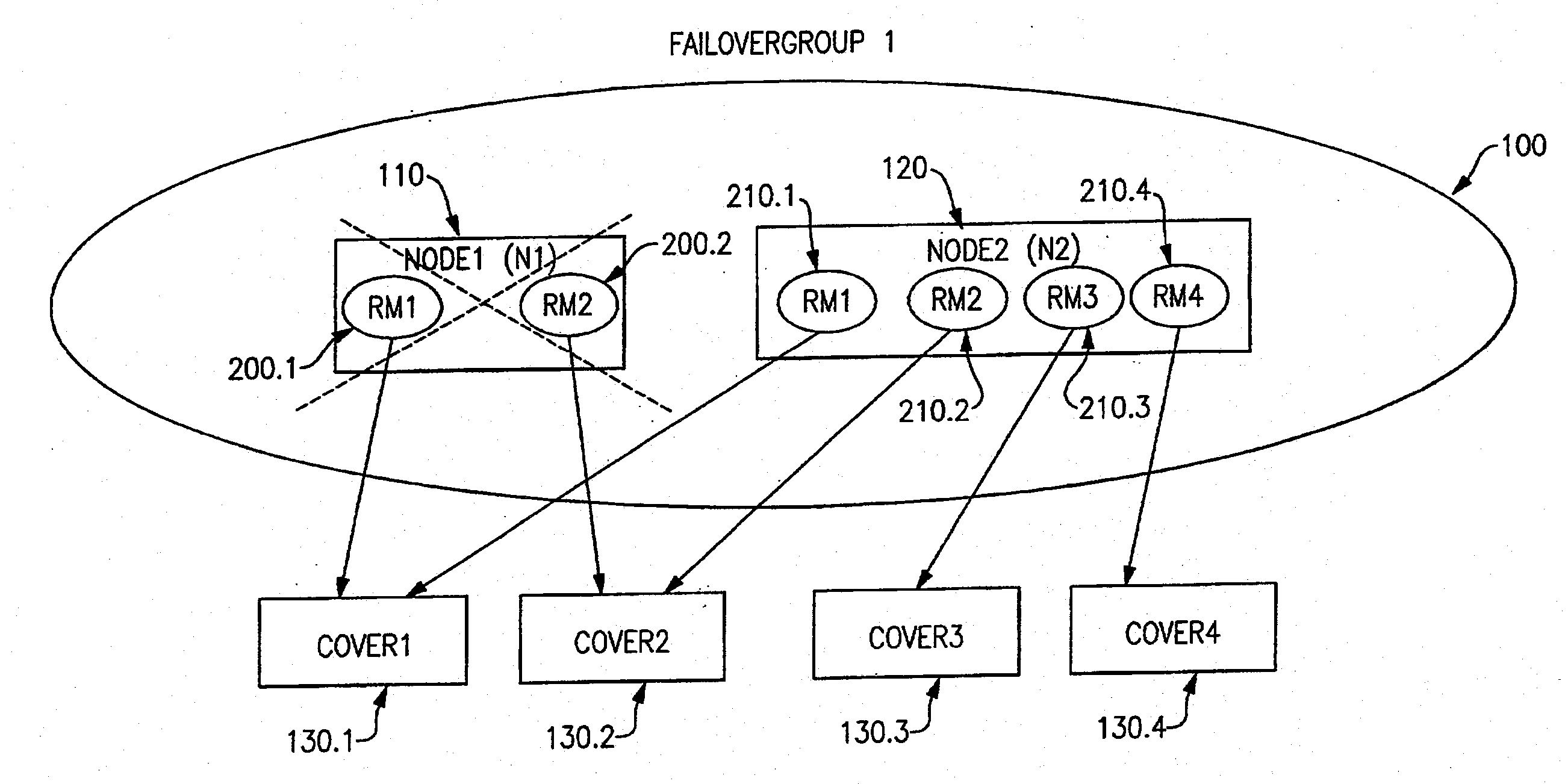

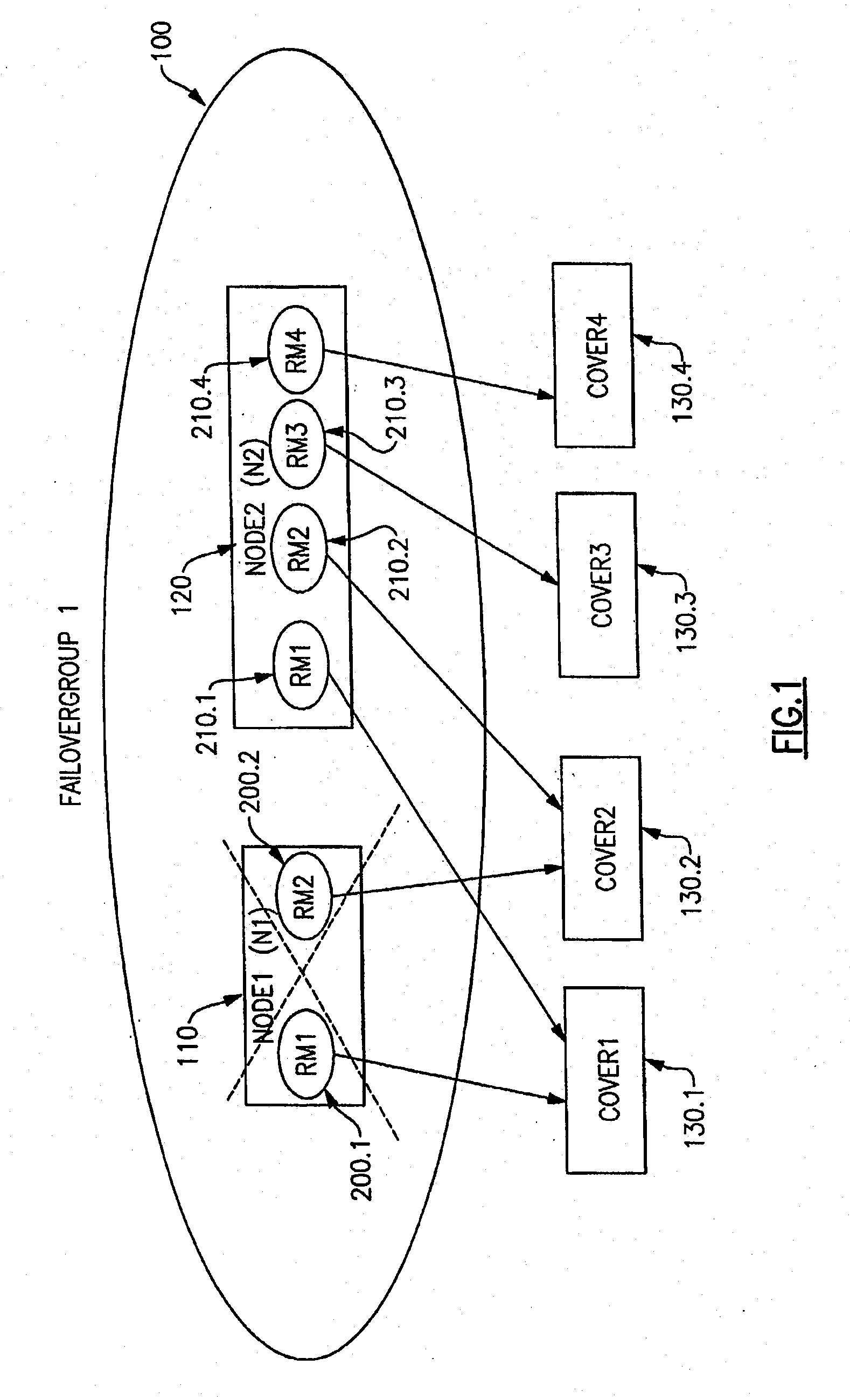

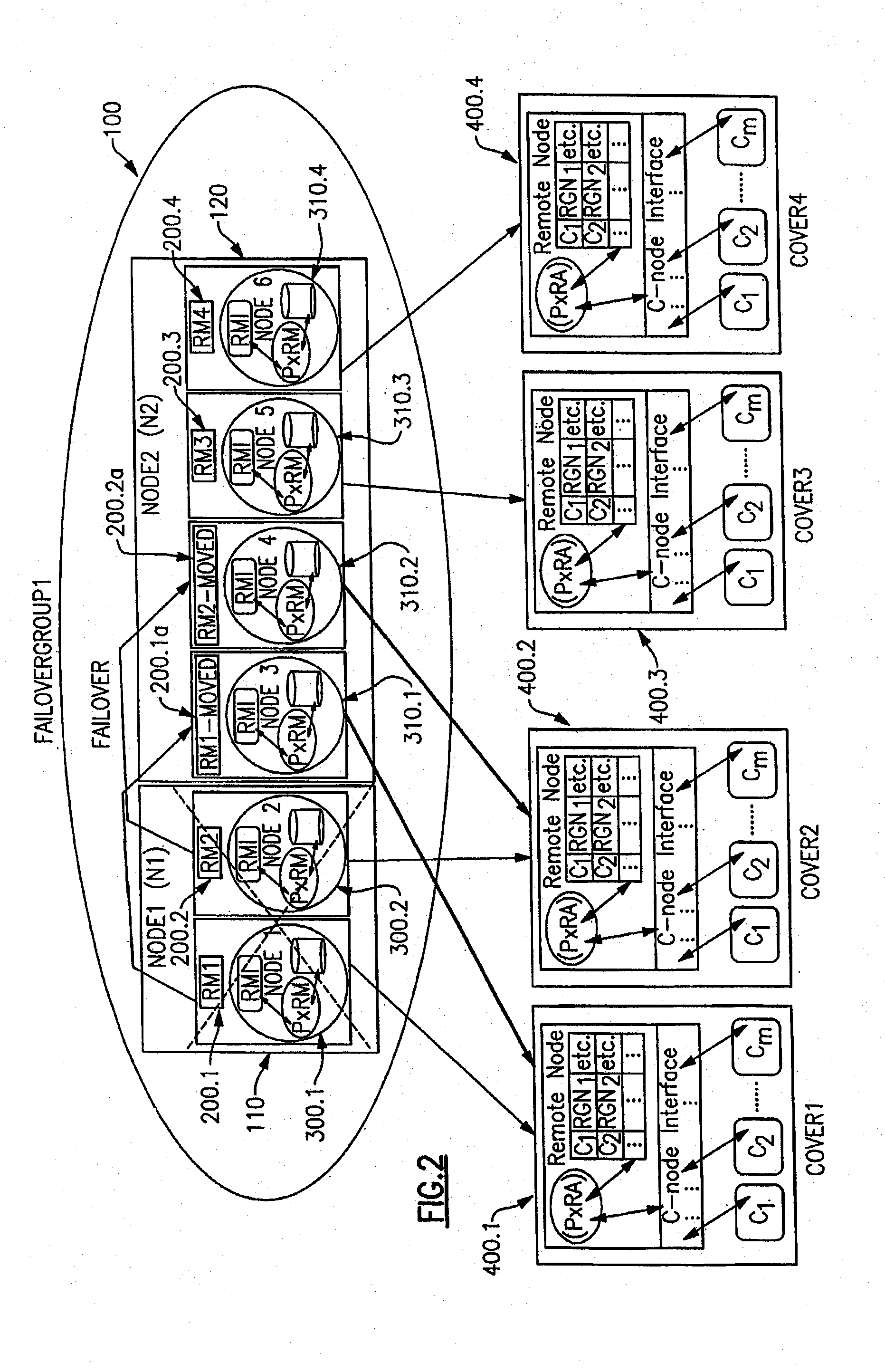

Scalable method of continuous monitoring the remotely accessible resources against the node failures for very large clusters

ActiveUS7137040B2High continuity of operationError preventionDigital computer detailsData processing systemFailover

The notion of controlling, using and monitoring remote resources in a distributed data processing system through the use of proxy resource managers and agents is extended to provide failover capability so that resource coverage is preserved and maintained even in the event of either temporary or longer duration node failure. Mechanisms are provided for consistent determination of resource status. Mechanisms are also provided which facilitate the joining of nodes to a group of nodes while still preserving remote resource operations. Additional mechanisms are also provided for the return of remote resource management to the control of a previously failed, but now recovered node, even if the failure had resulted in a node reset.

Owner:GOOGLE LLC

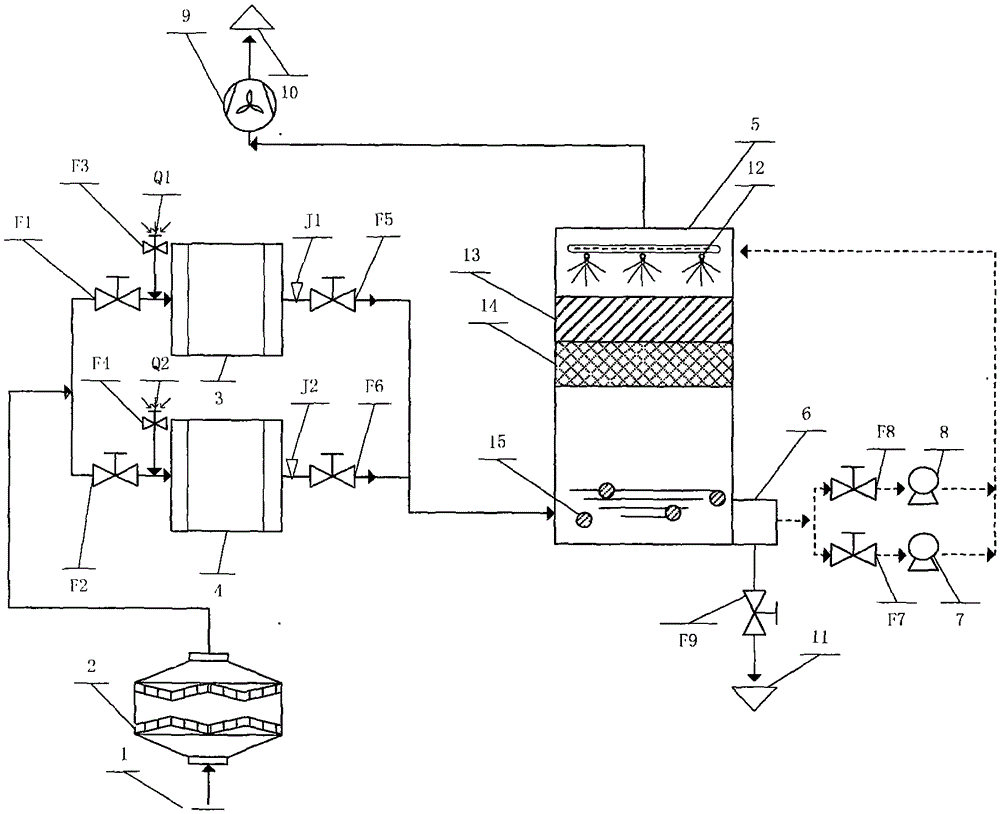

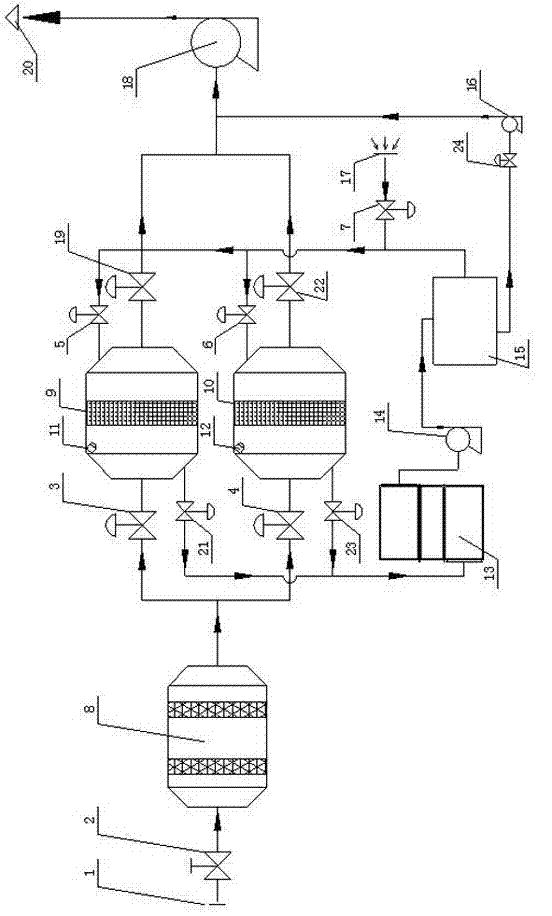

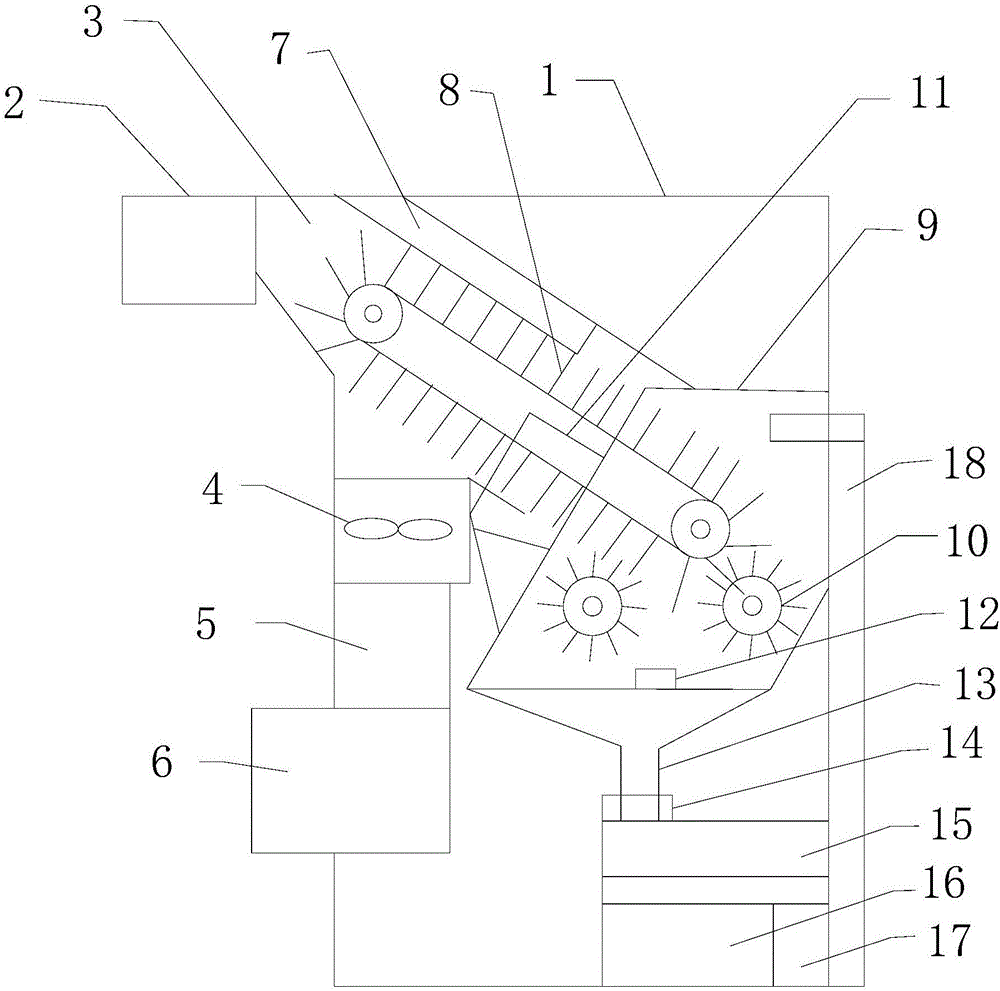

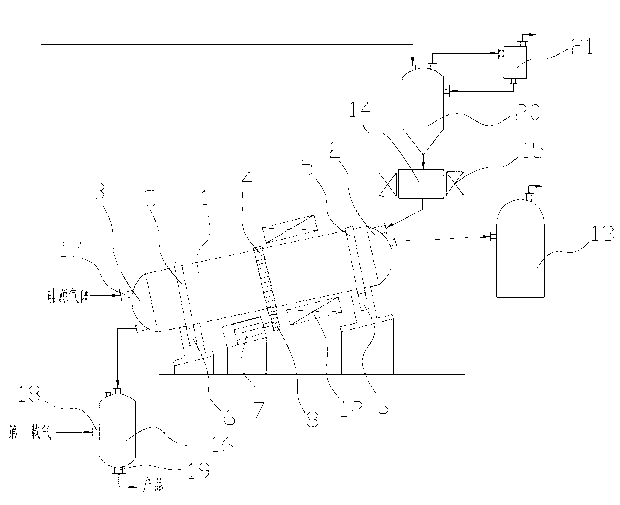

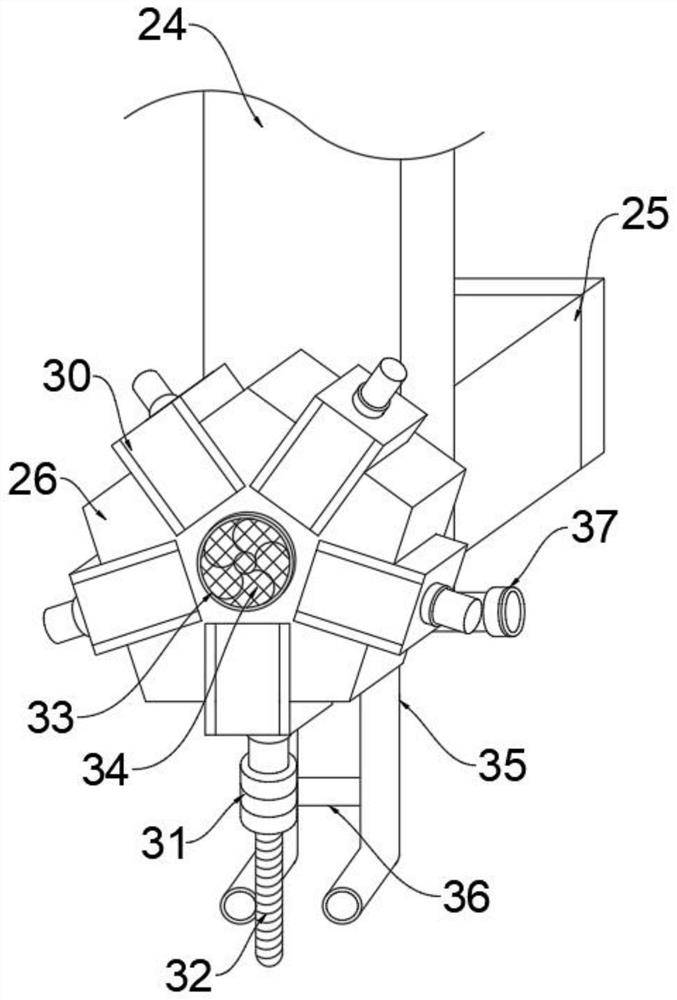

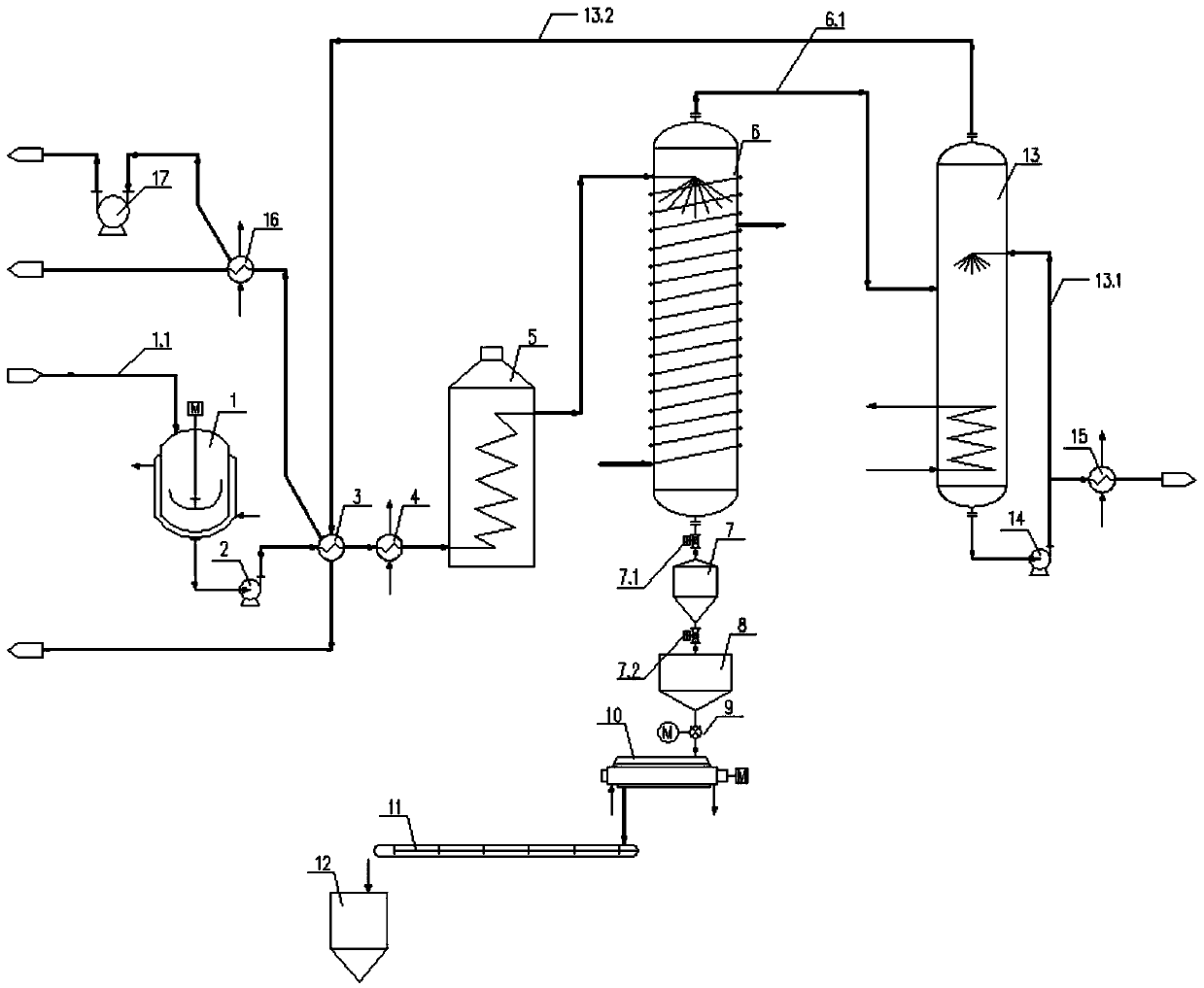

System for purifying volatile organic compounds exhaust gas through plasma synergistic biological technology

InactiveCN105233640AImprove biodegradabilityEquipment is safe and reliableDispersed particle separationAir quality improvementExhaust gasVolatile organic compound

The invention relates to a system and method for purifying volatile organic compounds VOCs exhaust gas through a plasma synergistic biological technology, and belongs to the organic waste gas pollution control field. The device includes a gas inlet, a dry type filter, a plasma purification device, a biological filter pool purification device, an air supplement port, a detection port, an exhaust blower, and an exhaust cylinder; the gas inlet collects the VOCs exhaust gas, the exhaust gas is filtered by the dry type filter and then is transported to the plasma purifying device, organic molecules are decomposed into small-molecular substances by the plasma purification device, gas after decomposition is transported to the biological filter pool purification device, the small-molecular organic matters are decomposed into CO2 and H2O by microorganisms, and finally, CO2 and H2O are discharged to upper air through the exhaust cylinder by the exhaust blower.

Owner:CHONGQING KELAN ENVIRONMENTAL PROTECTION IND CO LTD

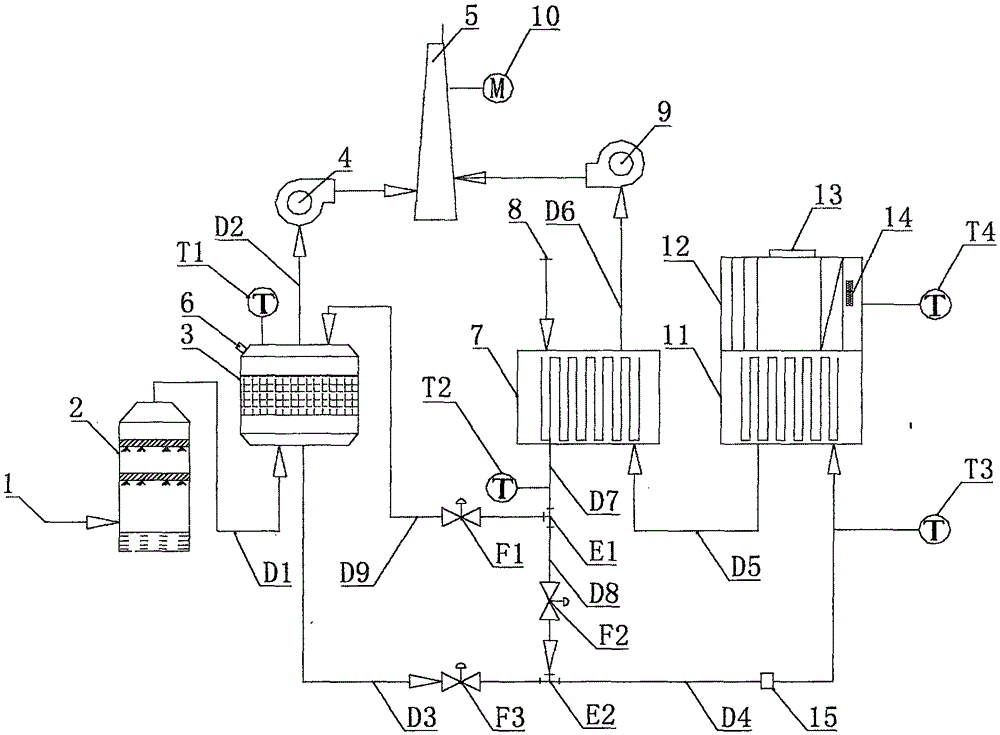

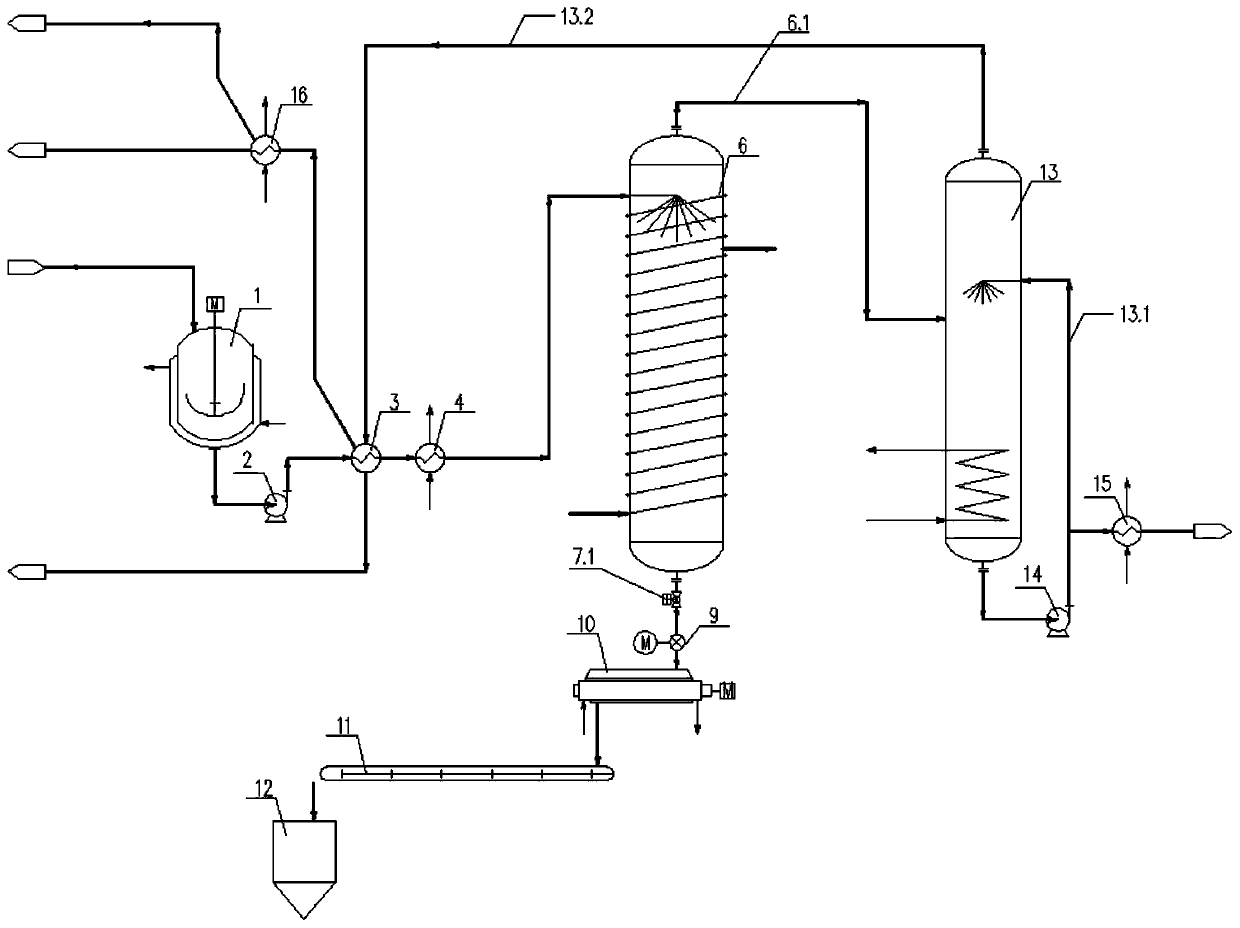

Adsorption concentration-preheating type catalytic combustion system for purifying automobiles and coating exhaust gas in related fields and purifying method thereof

ActiveCN105605593AEfficient and stable purificationBurn fullyGas treatmentDispersed particle separationSimple Organic CompoundsActivated carbon

The invention relates to an adsorption concentration-preheating type catalytic combustion system for purifying automobiles and coating exhaust gas in related fields and a purifying method thereof. The adsorption concentration-preheating type catalytic combustion system comprises an exhaust gas inlet, a wet-type filter, an activated carbon adsorption device, a heat exchanger, a catalytic combustion device, an air inlet, an air supplement port, a sampling port, a temperature detector, an on-line monitor, a frequency conversion draught fan and an exhaust funnel. A gas collecting port collects volatile organic exhaust gas, the volatile organic exhaust gas enters the activated carbon adsorption device after being filtered by the wet-type filter, and exhaust gas obtained after adsorption purification reaches the standard and is discharged by an exhaust blower to high altitude through the exhaust funnel; after the catalytic combustion system is preheated, volatile organic compounds adsorbed by the activated carbon are heated by hot air and desorbed and then are conveyed to a catalytic combustor for low-temperature catalytic oxygenolysis; after sufficient burning, the organic compounds are decomposed into harmless CO2, H2O and other matter to be discharged to high altitude.

Owner:CHONGQING KELAN ENVIRONMENTAL PROTECTION IND CO LTD

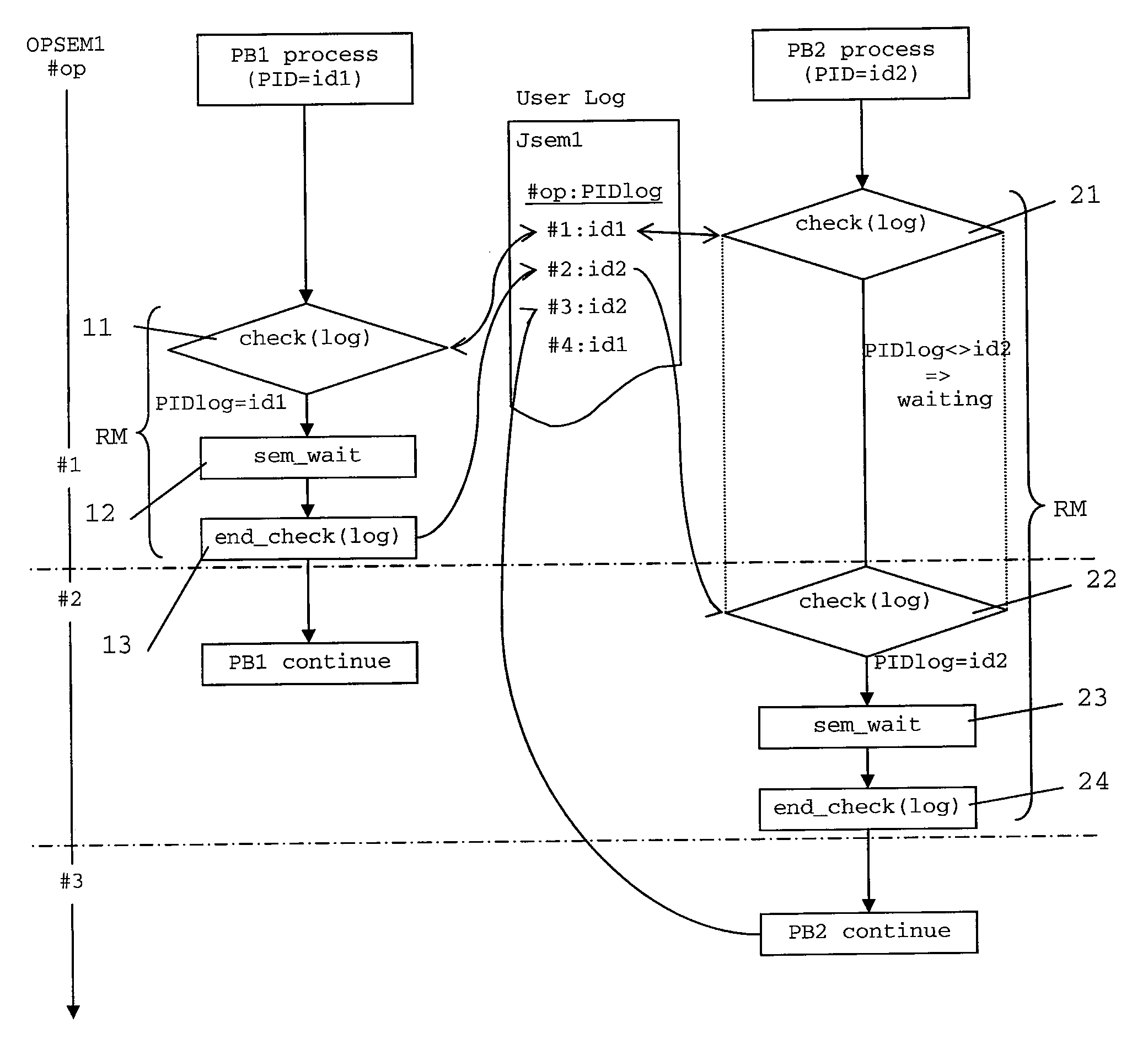

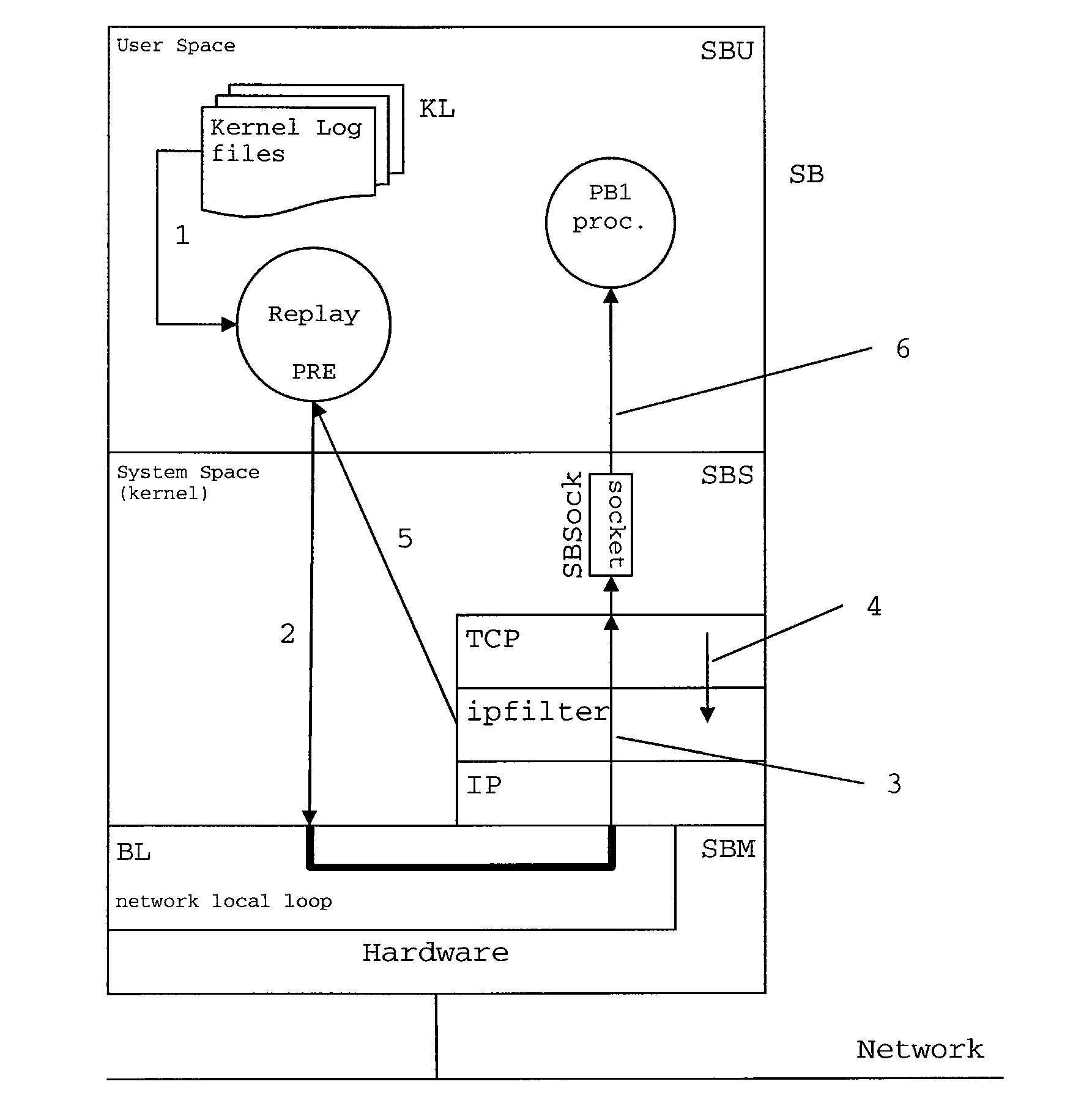

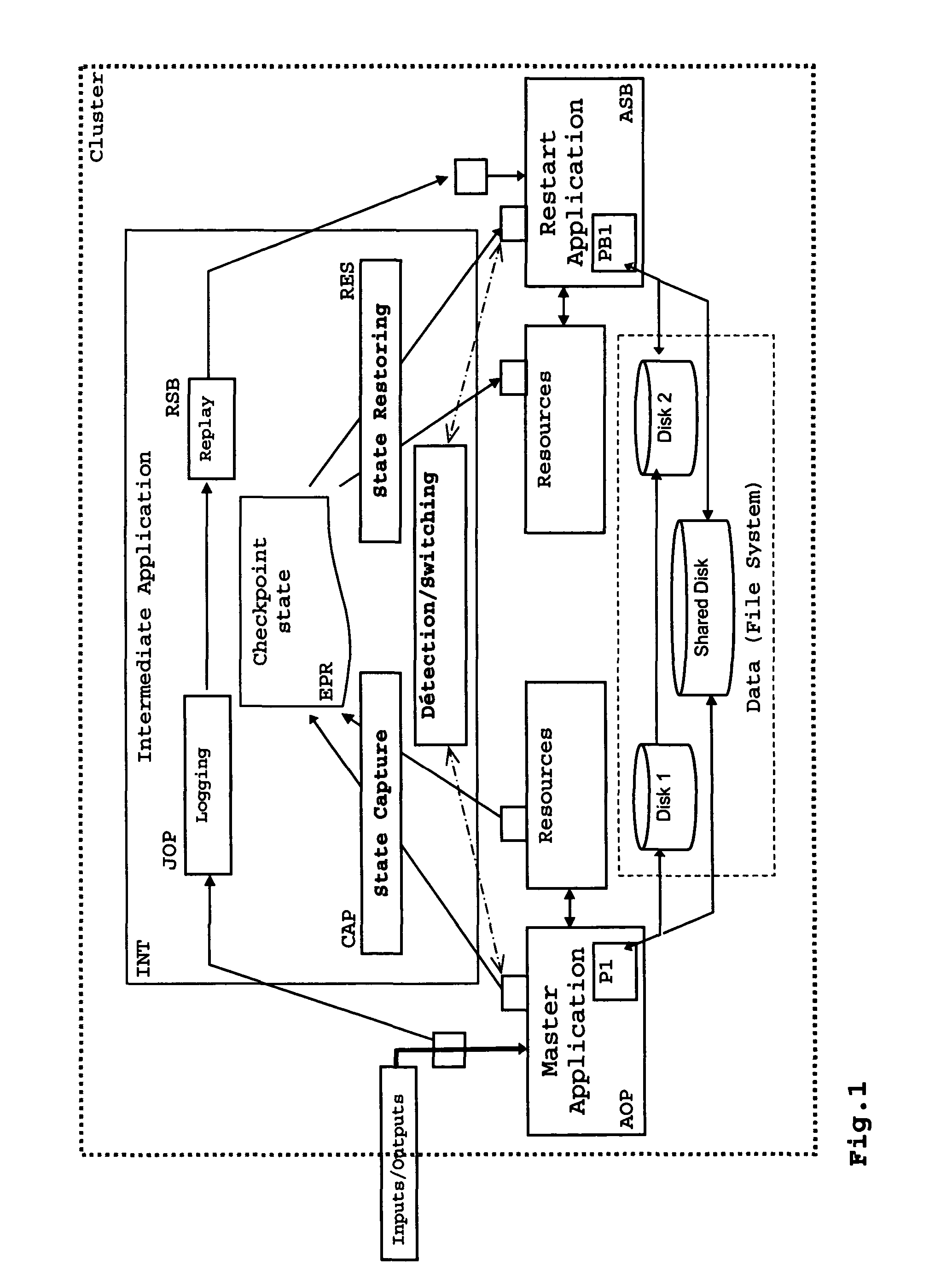

Non-Intrusive Method for Replaying Internal Events In An Application Process, And System Implementing This Method

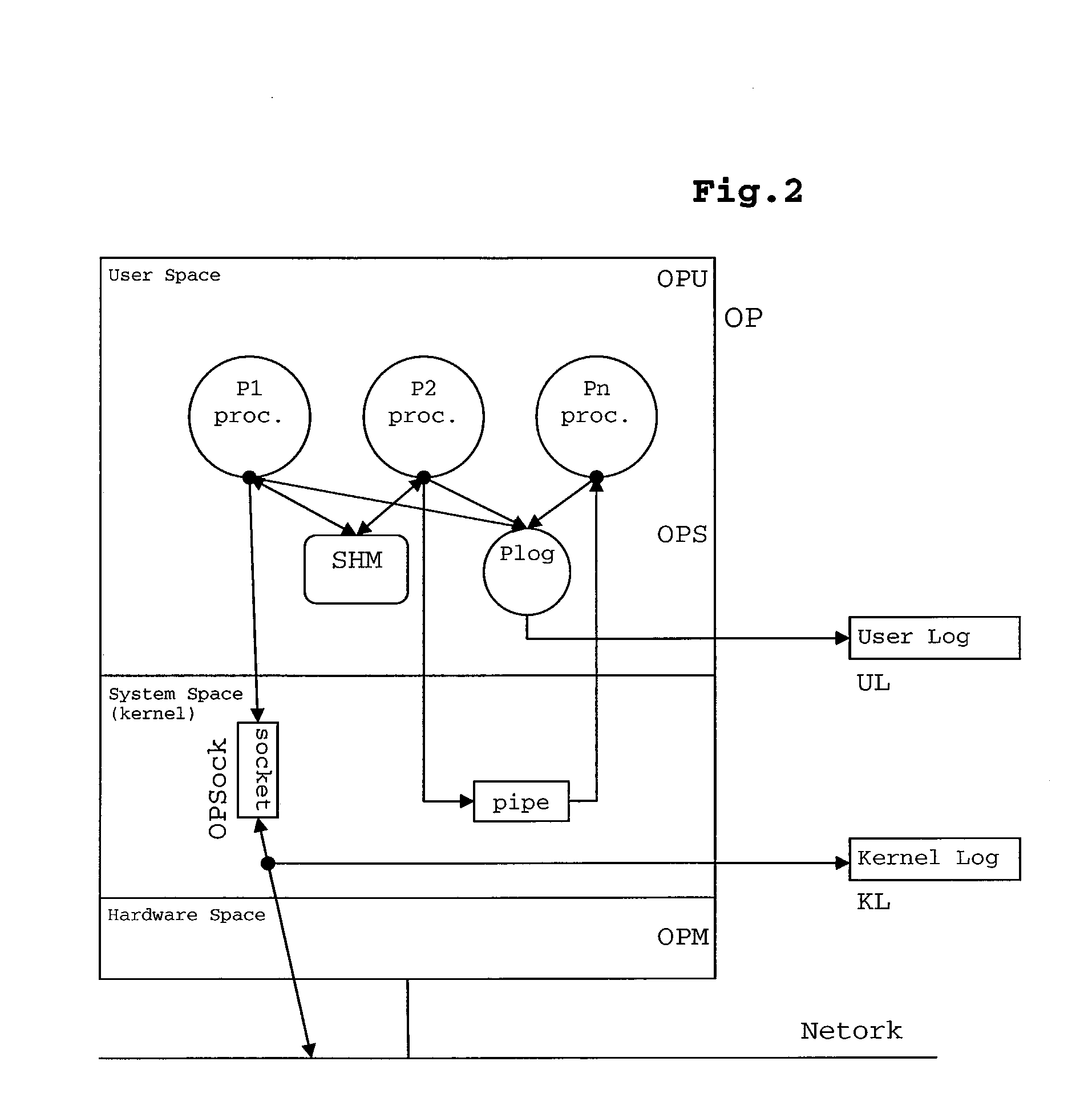

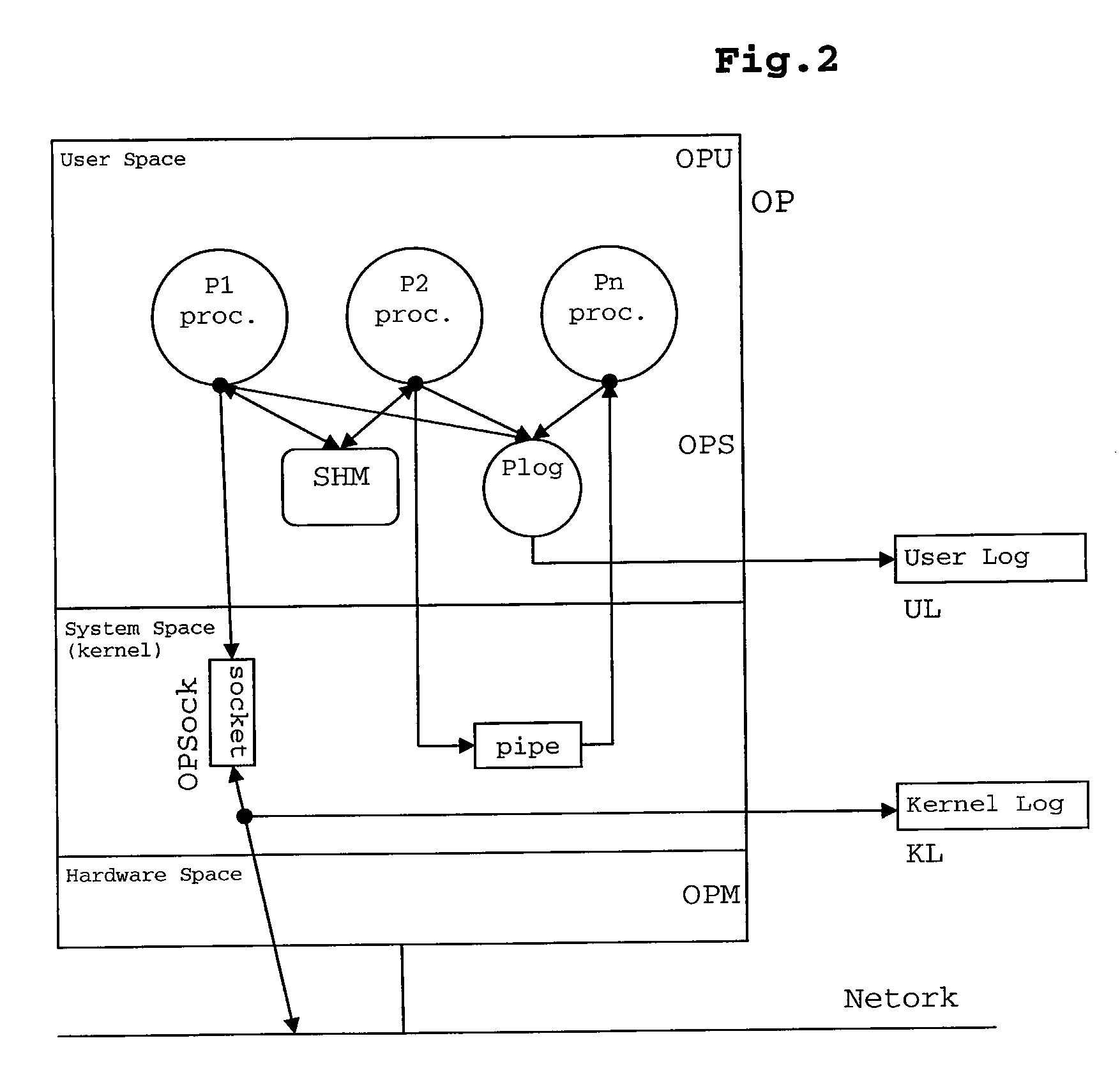

InactiveUS20080046696A1High continuity of operationReduce intrusionDigital computer detailsHardware monitoringSoftware agentSoftware

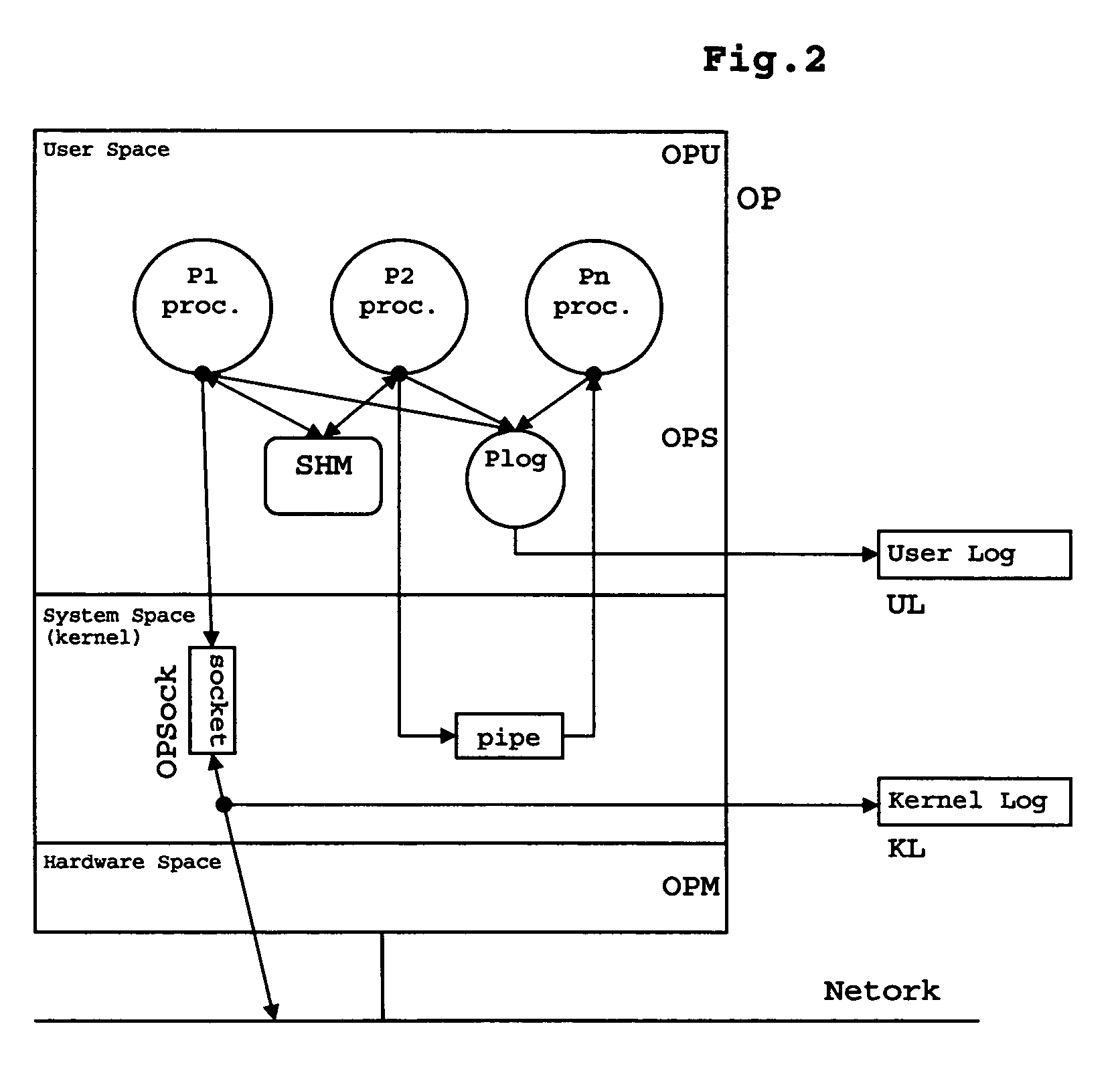

This invention relates to a method for replaying, from a log file, internal events within a process belonging to a software application in a network. This method comprising the following steps: executing at least one replay instruction by the target process, initiating a replayed operation (EVI) that returns, to this target process (PB1), at least one result datum obtained (RRJ) by this replayed operation; performing, by a software agent (PRI) external to the restart process, a forcing process (7) comprising a forcing operation upon the target process, instead and in place of the replay result datum (RRJ), of a forced datum, (RLi), extracted from logging data. Advantageously, the target process (PB1) executes the replay instruction of its own initiative from its executable file (EXE; FIG.7).

Owner:IBM CORP

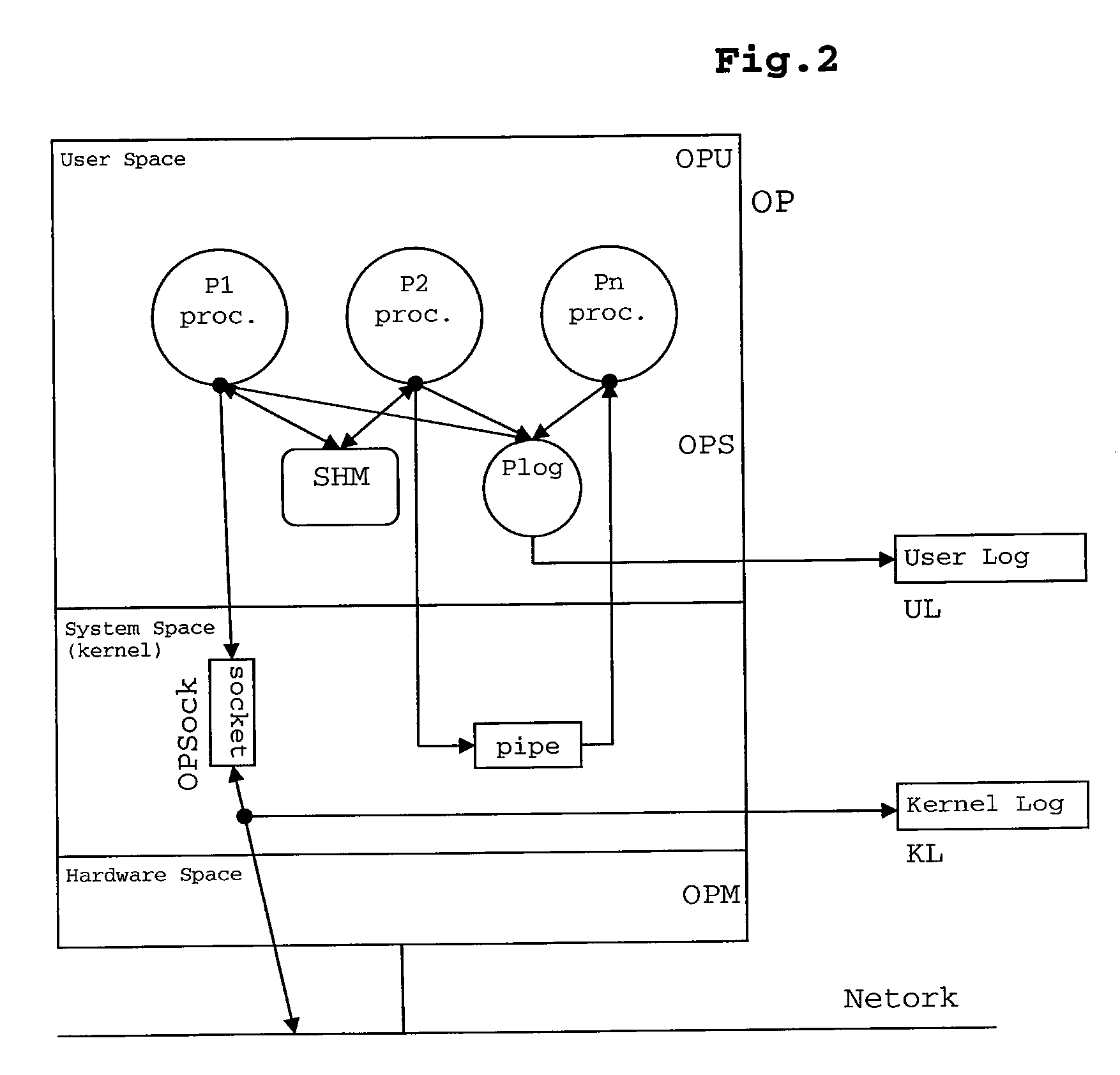

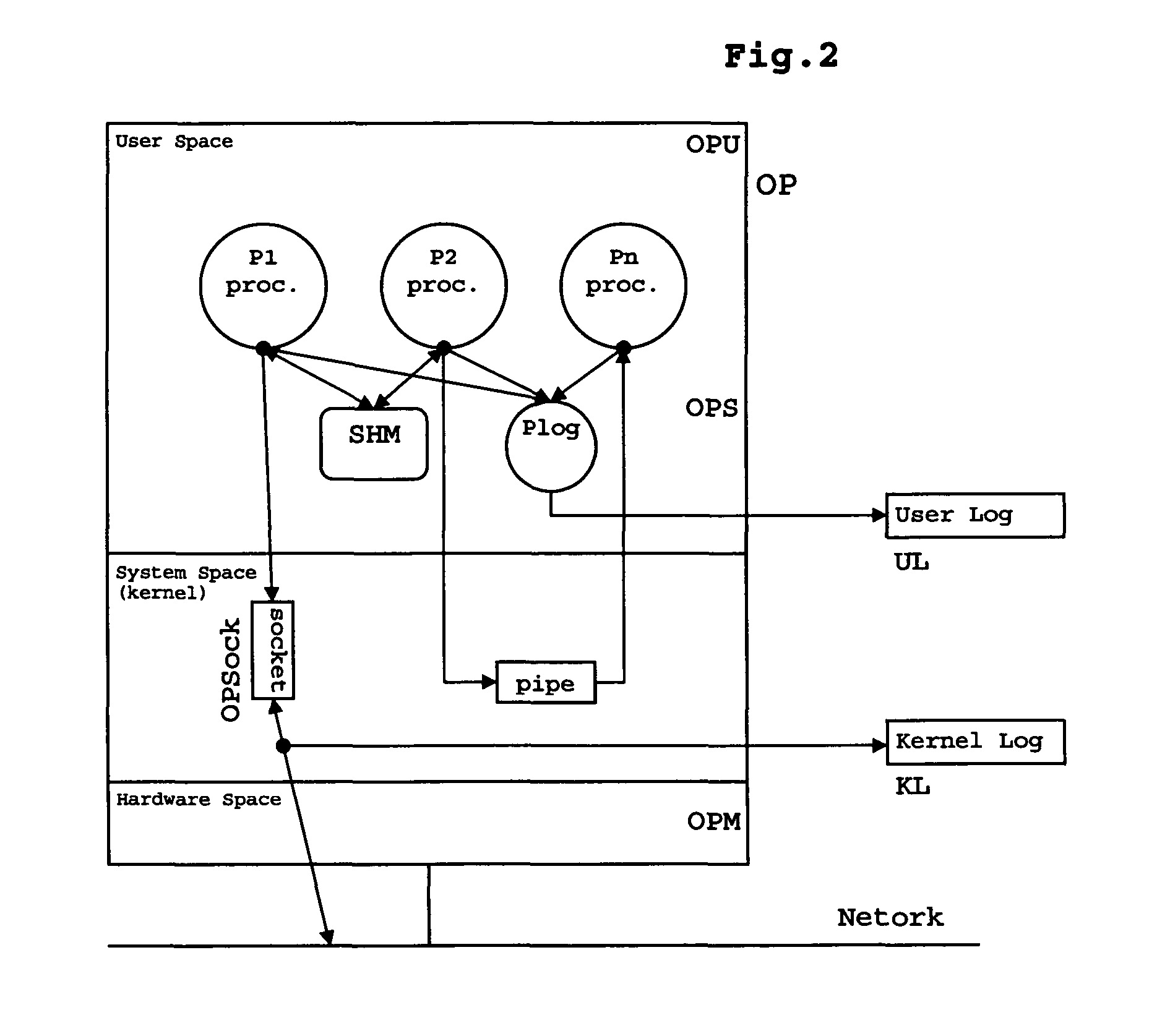

Non-intrusive method for logging external events related to an application process, and a system implementing said method

InactiveUS7568131B2Slow downEasy to manageError detection/correctionSpecific program execution arrangementsApplication softwareLogging

This invention relates to a method for logging events, in particular external, occurring in an application in a multi-computer environment, operating non-intrusively and transparently vis-à-vis said application.Said method comprises the following steps:reception (1) by the system software of a message addressed to said process and initiating for this process an external event;interception, by an interception agent, of message data representing said message or the event which it initiates;logging said event, by storing or sending (2) for storage logging data representing said message or the event which it initiates;transmission (4, 5) by the system software of said message data to said process.

Owner:INT BUSINESS MASCH CORP

Device and method for purifying total volatile organic compounds

ActiveCN102814099AEfficient and stable purificationWill not cause secondary pollutionCombination devicesCombustion chamberDesorption

The invention discloses a device and a method for purifying total volatile organic compounds (TVOCs). The device comprises a gas inlet, an active carbon adsorption apparatus, an supersonic desorption emitter, a cold combustion chamber, a gas supply port, a desorption fan and a gas discharge port, wherein the gas inlet collects a TVOC exhaust gas and inputs the TVOC exhaust gas to the active carbon adsorption apparatus, the active carbon adsorption apparatus adsorbs the TVOC exhaust gas, and a gas reaching a discharge standard is directly discharged through the gas discharge port; the supersonic desorption emitter is started after a certain degree of the adsorption to desorb the TVOCs, and inputs the TVOCs to the cold combustion chamber; and the desorbed TVOCs are conveyed to the cold combustion chamber together with supplied oxygen, the TVOCs are decomposed by the vacuum ultraviolet (VUV) rays of the cold combustion chamber and reacts with ozone and oxygen to generate H2O and CO2, and the TVOCs are discharged into the gas discharge port through the desorption fan after the VUV cold combustion to generate H2O and CO2 to discharge a purified gas.

Owner:深圳市科德环保科技有限公司

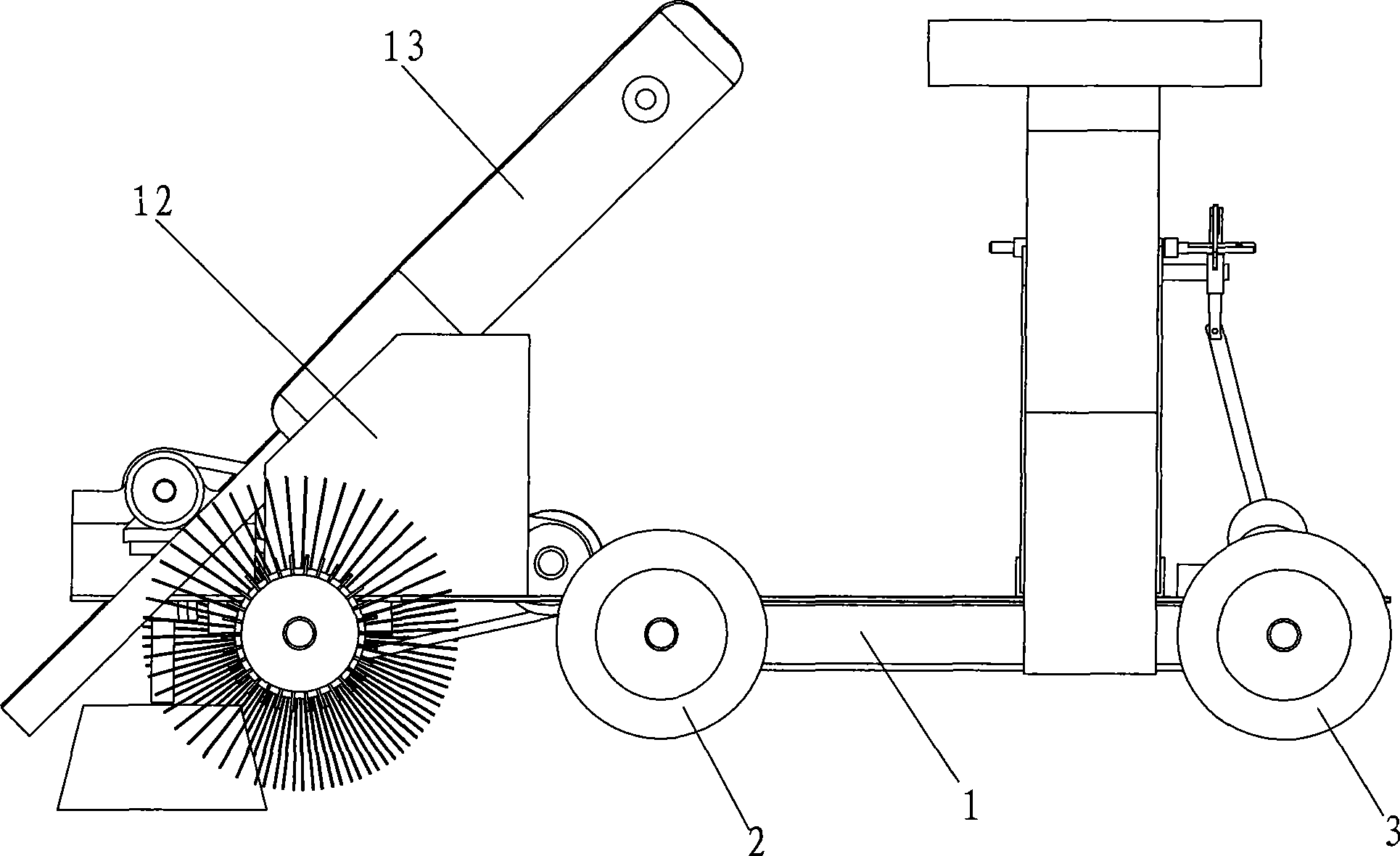

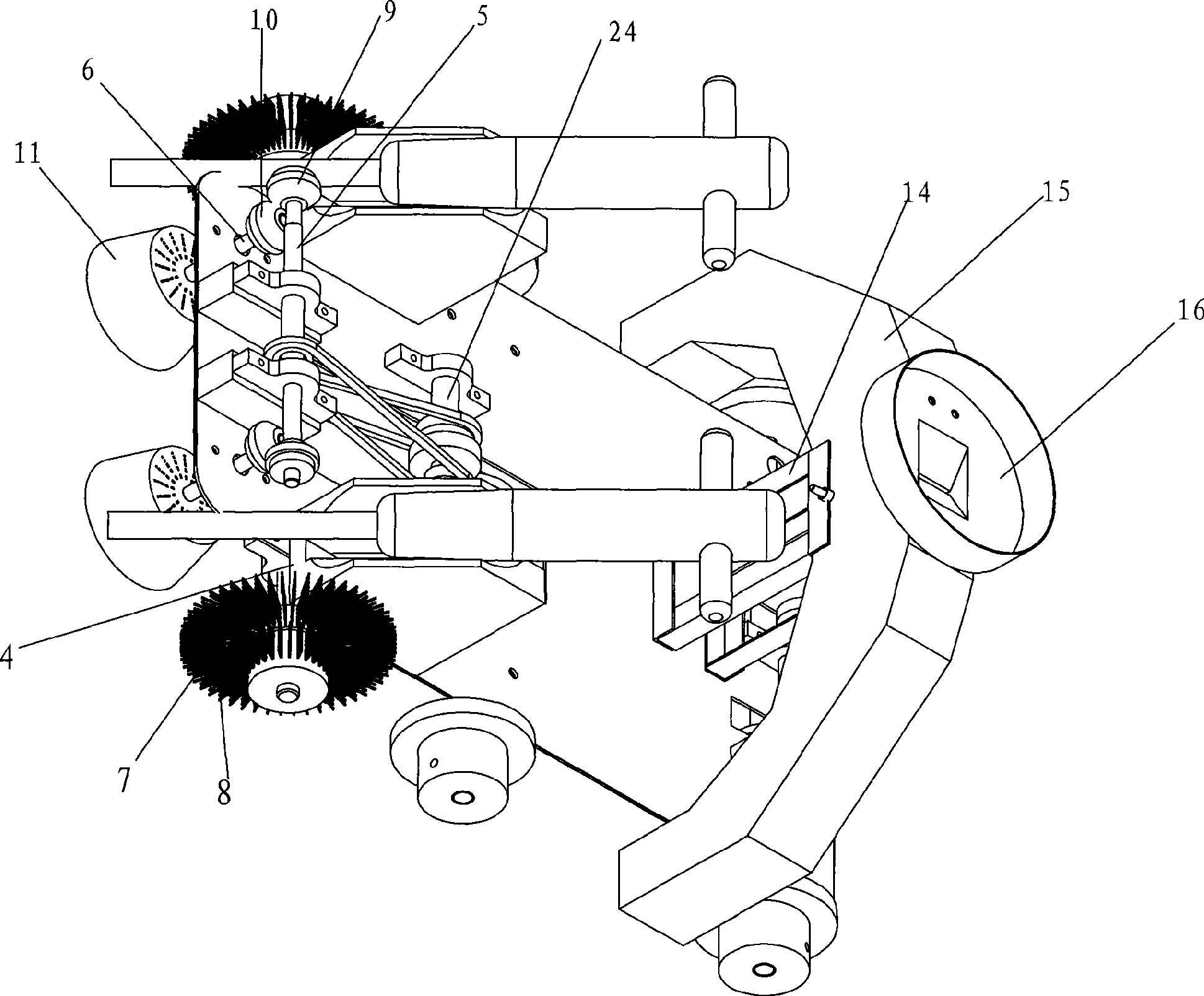

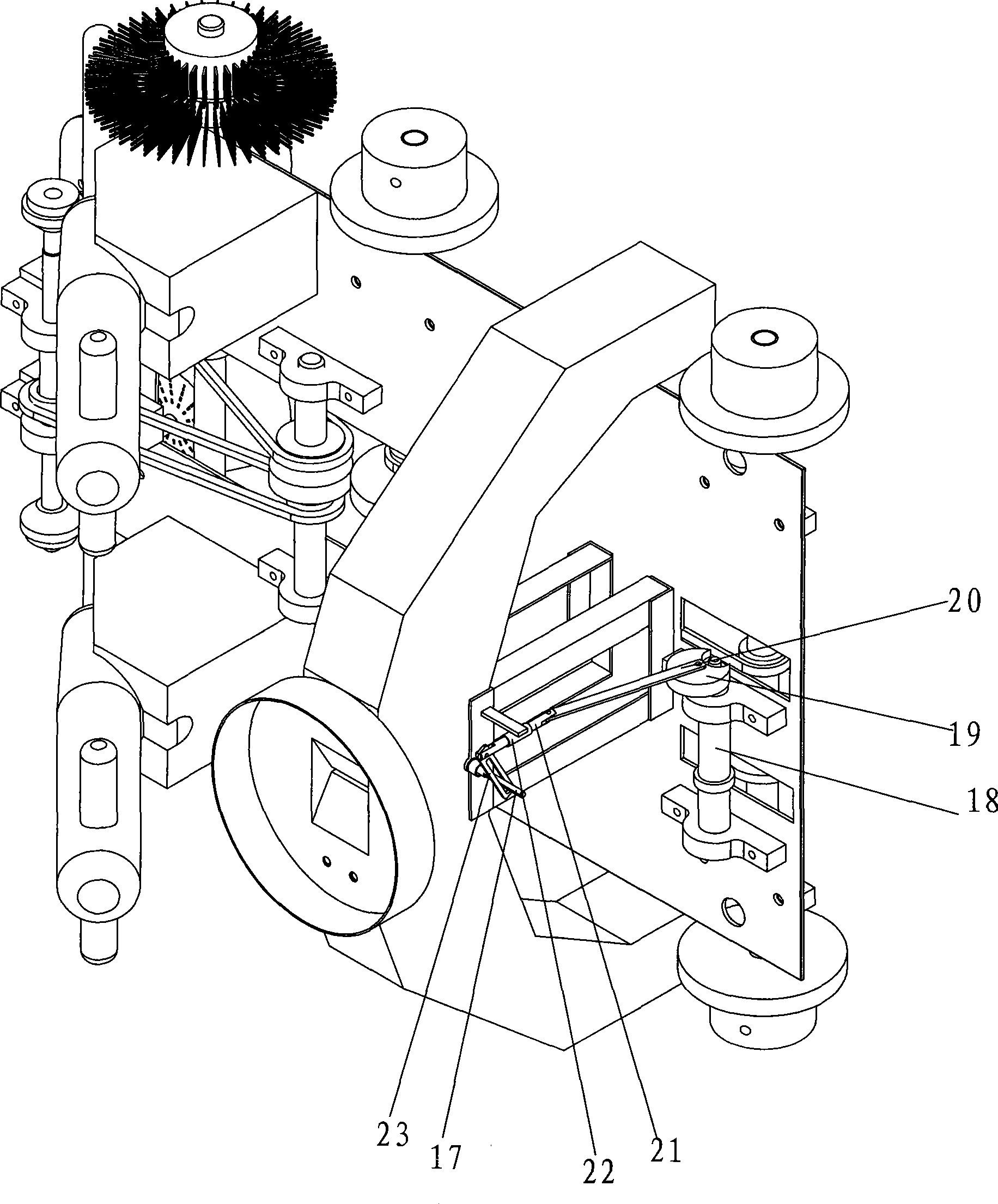

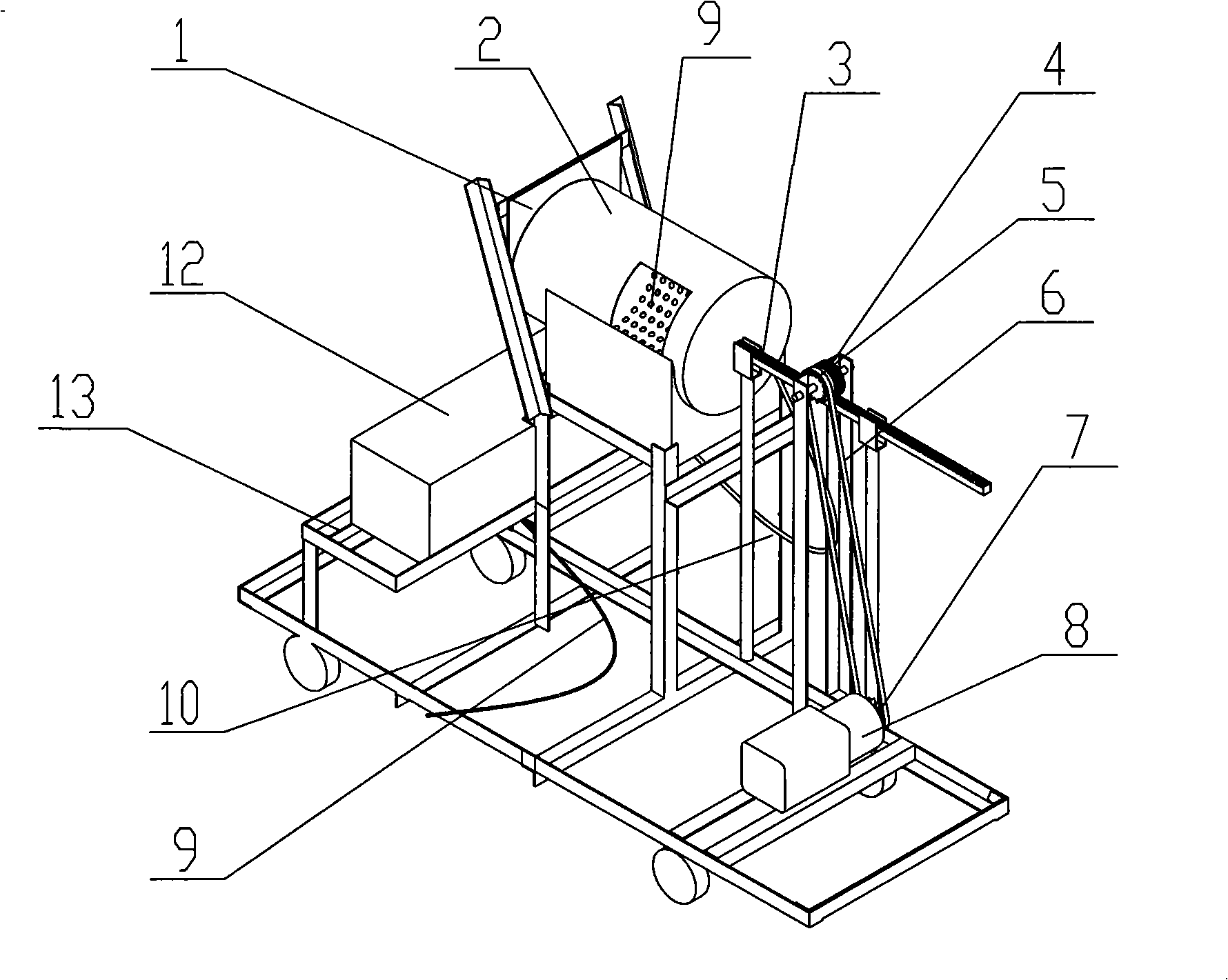

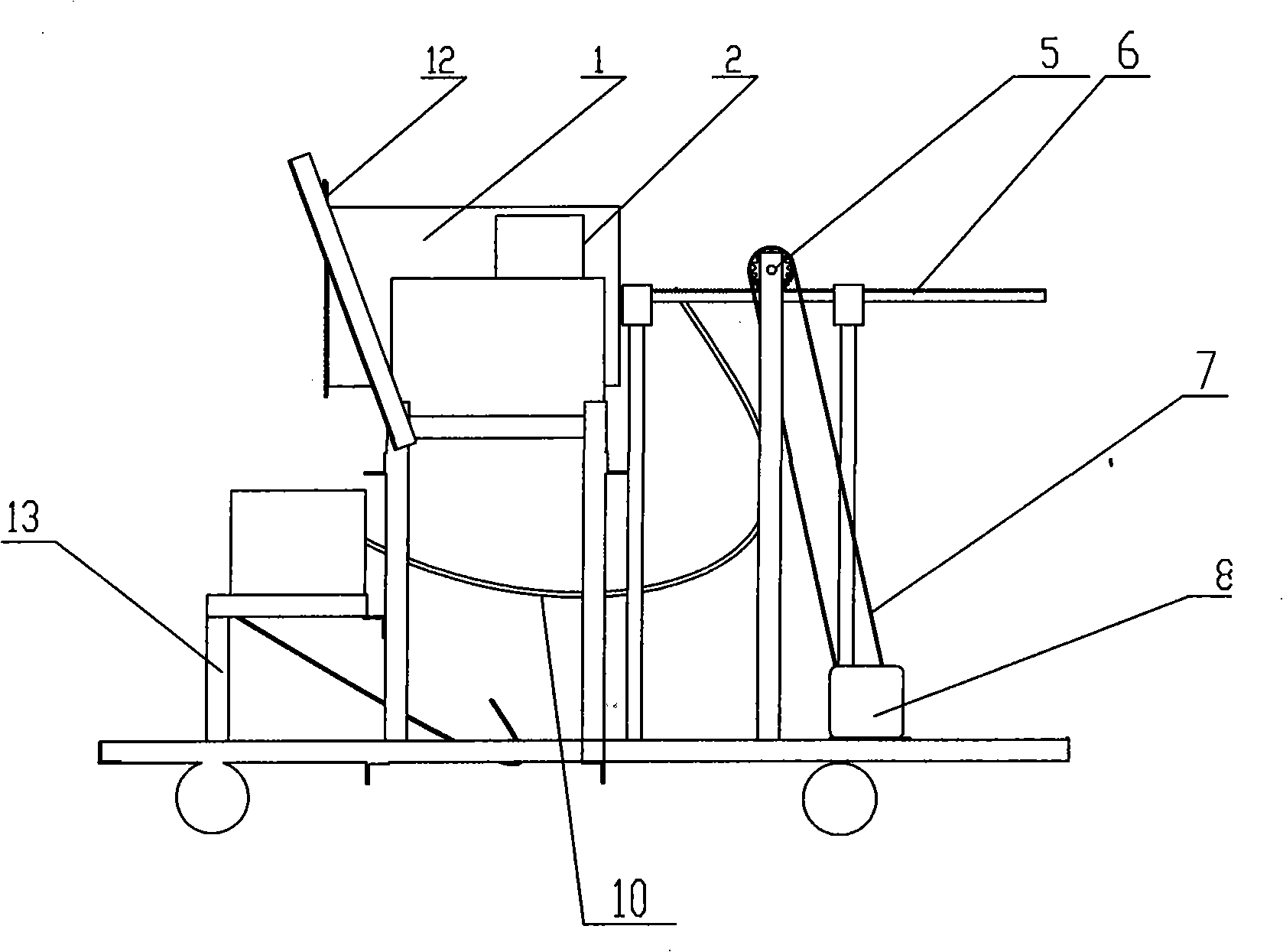

Snow ice clear away car for railway

The invention relates to a railroad ice and snow cleaning vehicle. The vehicle comprises a vehicle frame, front wheels and rear wheels, wherein the front wheels and the rear wheels are arranged on the vehicle frame through a front wheel shaft and a rear wheel shaft, respectively; an ice and snow cleaning device, a symmetric salt scattering device and a power device are also arranged on the vehicle frame; in operation, a solar wheel does backhoe circular motion; a perching knife scoops up ice and snow of the outer side of the rail; industrial salt is scattered in a region where the ice and snow is scooped up through the symmetric salt scattering device so as to prevent the ice and snow from coagulating; thick ice in a turnout zone of the inner side of the rail is smashed through an air pick; and ice blocks shattered by the air pick are swept to the middle of the rail by a sweeping wheels brush. The invention provides the railroad ice and snow cleaning vehicle, can realize integrated treatment of ice breaking, cleaning and slat scattering, has complete function of ice and snow cleaning, saves energy, can prevent the ice and snow from coagulating and has high automation degree.

Owner:ZHEJIANG UNIV OF TECH

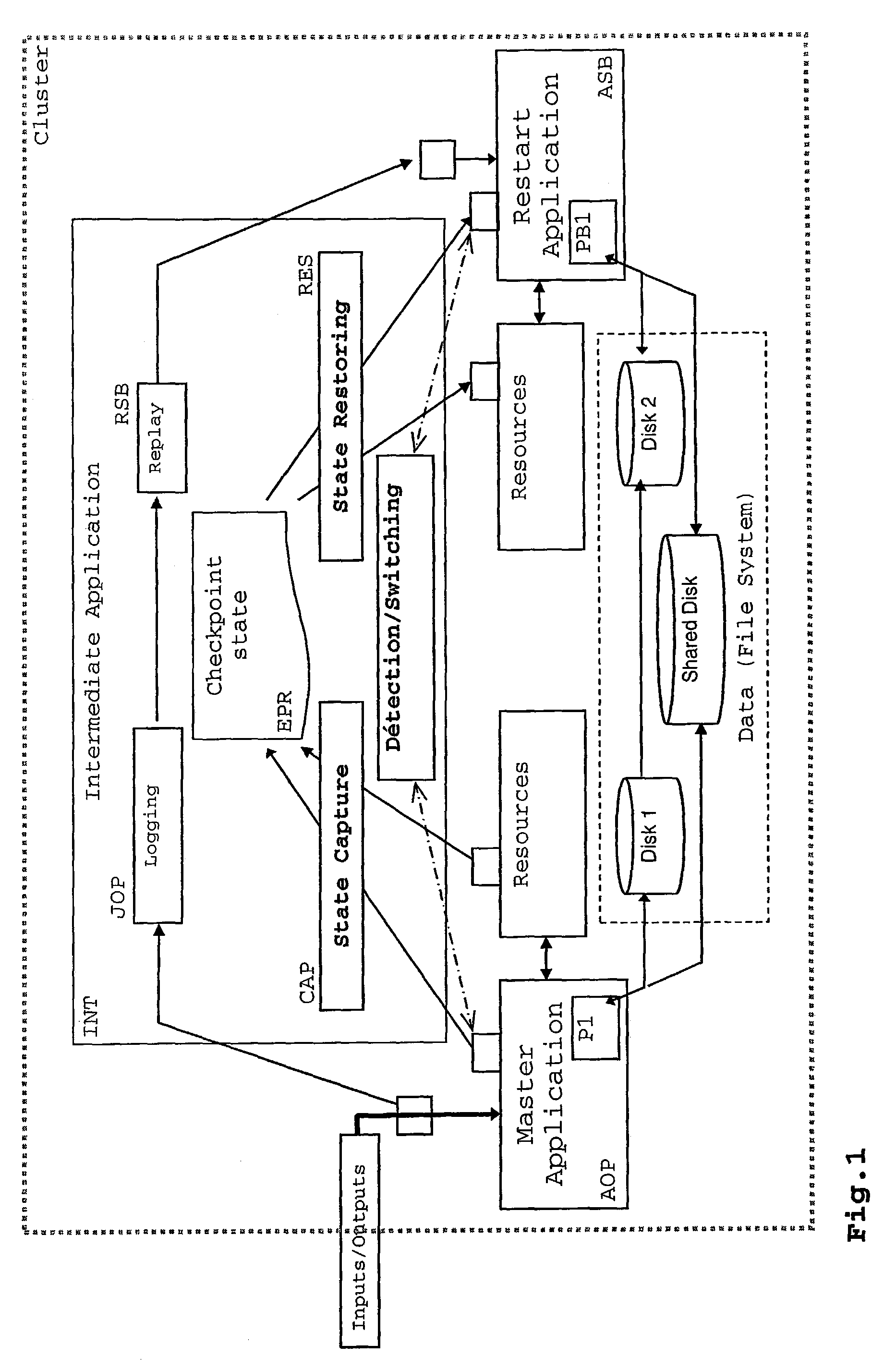

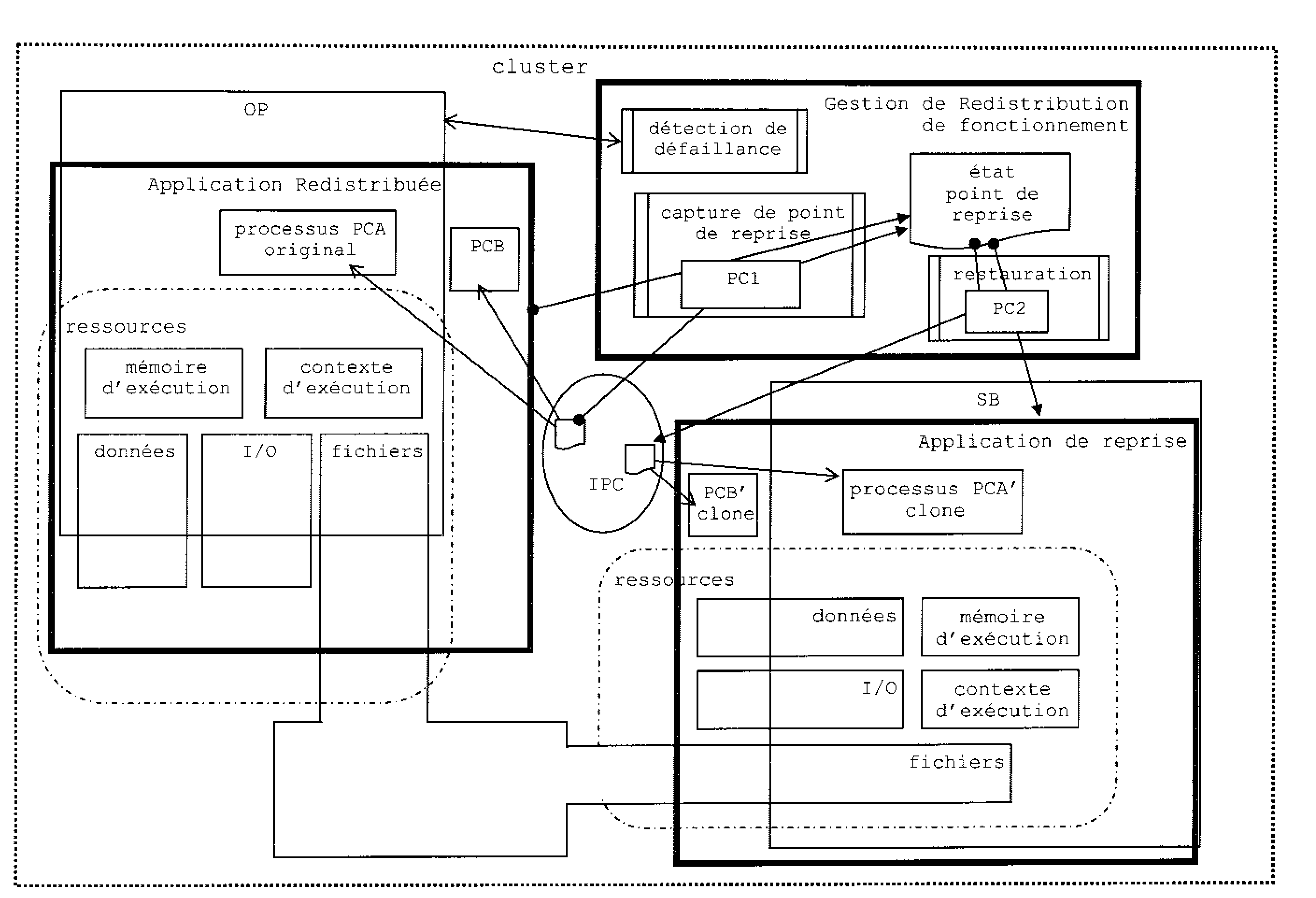

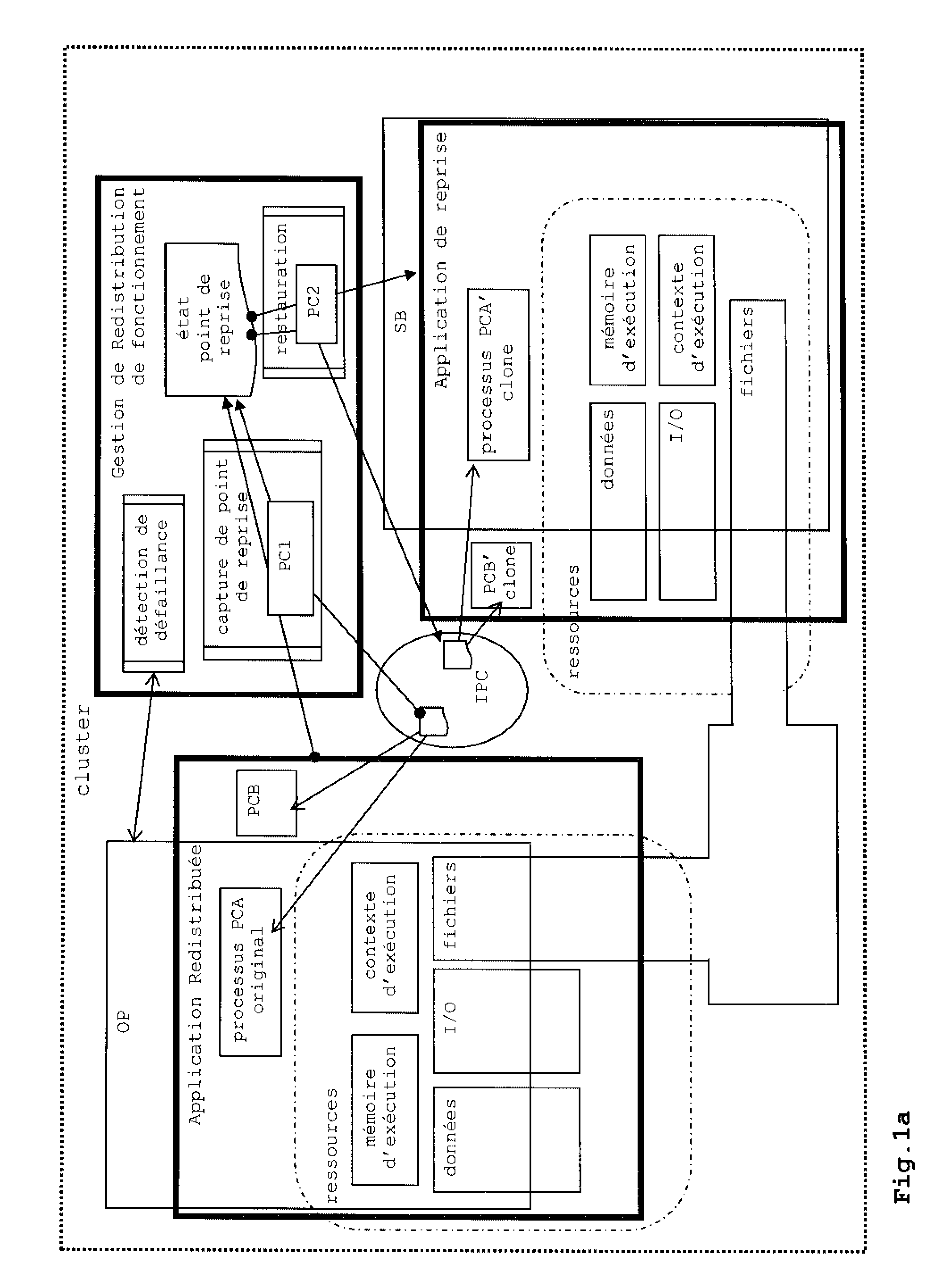

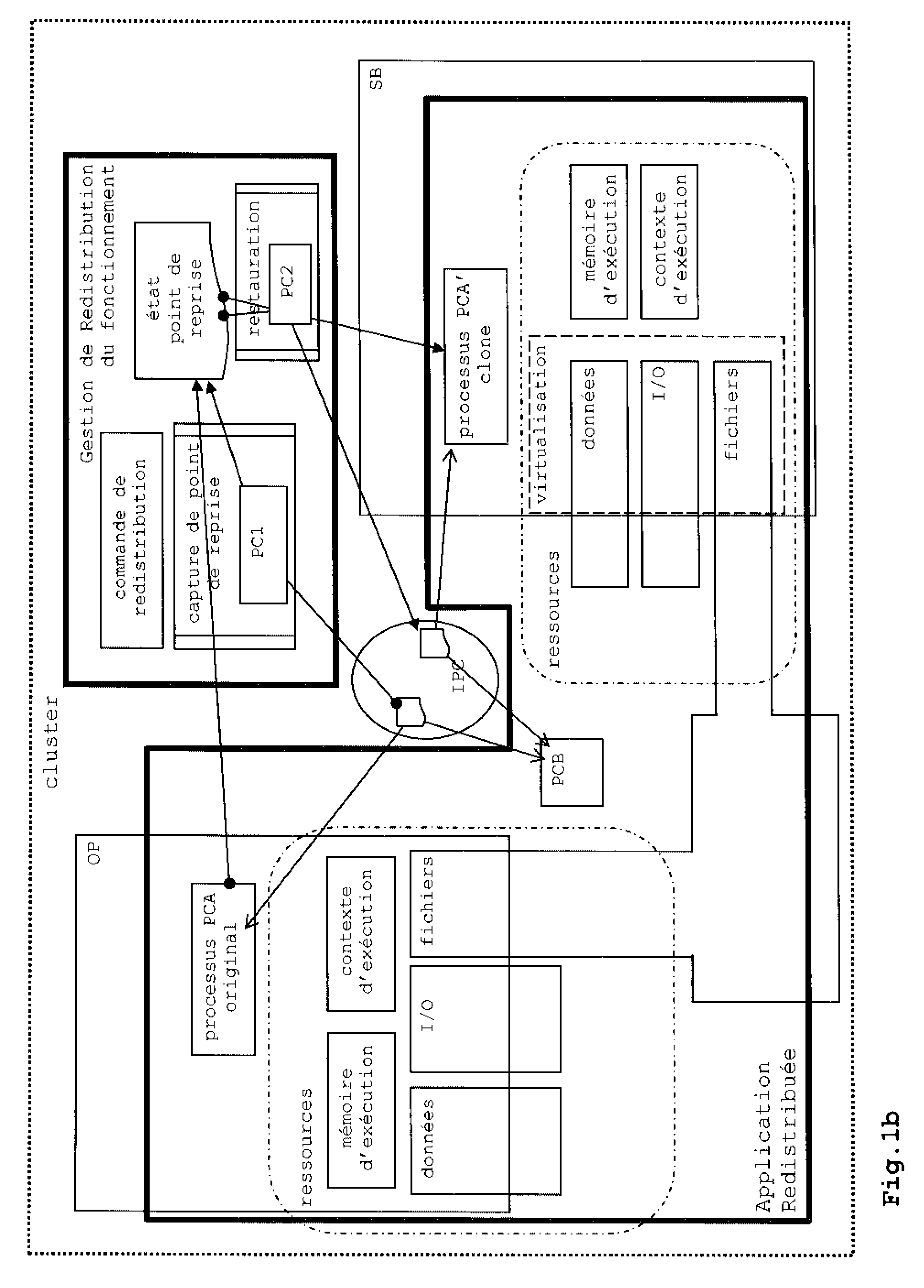

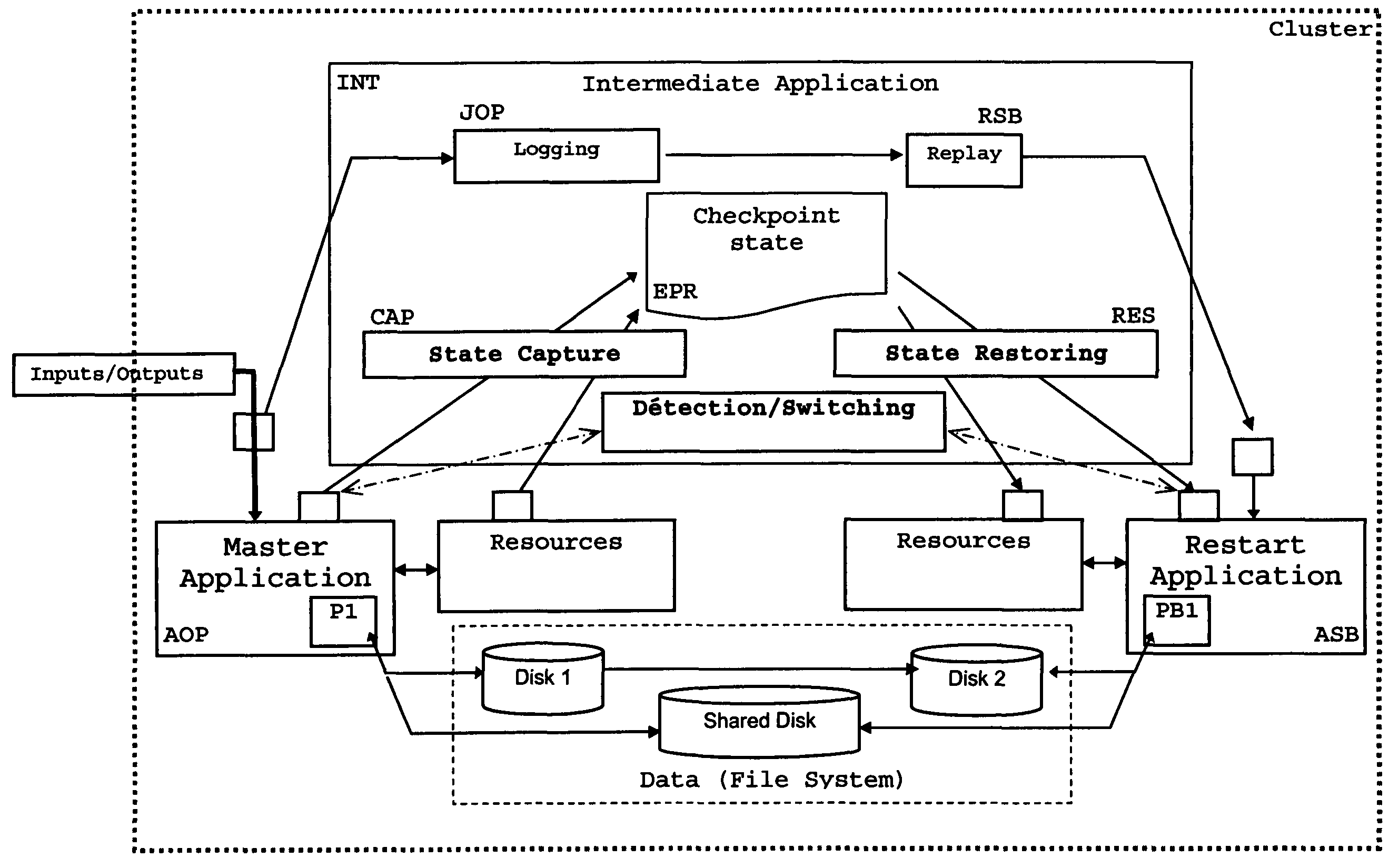

Method for Managing a Software Process, Method and System for Redistribution or for Continuity of Operation in a Multi-Computer Architecture

InactiveUS20080307265A1Reliably madeHigh continuity of operationRedundant operation error correctionWork memoryContinuous operation

This invention relates to a method for managing a software application functioning in a multi-computer architecture (cluster). This management is applied, for example, to the analysis or modification of its execution environment, in as transparent a manner as possible vis-à-vis this application. This management is applied to operations of analysis, capture and restoration of the state of one or more processes of the application.These operations use a controller external to the application which carries out an injection of system call instructions inside the working memory of the process(es) to be managed.

Owner:IBM CORP

Method for solid-liquid separation of waste incineration fly ash water washing slurry

ActiveCN104478122AFacilitate solid-liquid separationImprove continuityWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentLitterSlurry

The invention discloses a method for solid-liquid separation of a waste incineration fly ash water washing slurry. The method comprises the following steps: 1, adding water to waste incineration fly ash to be processed, and carrying out stirring water washing to obtain a primary fly ash water washing slurry to be processed by adopting two horizontal screw discharge decanter centrifuges; 2, carrying out primary centrifuge separation on the primary fly ash water washing slurry by adopting a first horizontal screw discharge decanter centrifuge to obtain solid fly ash and a secondary fly ash water washing slurry; 3, simultaneously pumping a flocculating agent and the secondary fly ash water washing slurry into a second horizontal screw discharge decanter centrifuge; and 4, carrying out secondary centrifuge separation on the flocculated secondary fly ash water washing slurry by adopting a second horizontal screw discharge decanter centrifuge to obtain a solid phase and a liquid phase. The method can effectively remove salt substances in the waste incineration fly ash water washing slurry, and controls the fly ash loss amount of the waste incineration fly ash water washing slurry in an allowed loss amount range.

Owner:BEIJING LIULIHE CEMENT +1

Semantic management method for logging or replaying non-deterministic operations within the execution of an application process

InactiveUS7840940B2Reduce workloadHigh continuity of operationSpecific program execution arrangementsMemory systemsProgram instructionApplication software

Owner:LINKEDIN

Adsorption dust-extraction device for textile equipment

ActiveCN106540944ANot easy to accumulateImprove dust removal effectElectrostatic cleaningDirt cleaningWater storageSolenoid valve

The invention discloses an adsorption dust-extraction device for textile equipment. The adsorption dust-extraction device comprises a rack, an exhaust inlet, an air inlet duct, an air draft motor, a filter bellows, an exhaust outlet, an electrostatic dust-absorbing plate, a hair brush conveying belt, a dust-extraction brushing trough, cleaning brushing rollers, a filtering and drying case, a smudginess detector, a drain pipe, a drain solenoid valve, a filter case, a water storage case, a water-delivery pump and a water-delivery pipe. The adsorption dust-extraction device for textile equipment has the beneficial effects that the dust-extraction device can conduct active adsorption and collection on the dust produced in the textile process, the collected dust is subjected to synchronous processing, dust-extraction effect is good, device operation continuity is strong, dust-extraction efficiency is high, faults such as dust accumulation is not liable to occur, and the adsorption dust-extraction device for textile equipment is beneficial to application and popularization in production.

Owner:江苏品之杰纺织实业有限公司

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

InactiveUS8790517B2Reduce financial riskHigh continuity of operationSolid sorbent liquid separationAnalogue computers for chemical processesInitial treatmentIon exchange

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

Predictive method for managing logging or replaying non-deterministic operations within the execution of an application process

InactiveUS8132190B2Reduce workloadHigh continuity of operationElectronic circuit testingError detection/correctionComparative testPredictive function

This invention relates to a management method, more particularly by logging and replay, for software operations performed during the execution of an application process executed on a computer. The method applies in particular to internal operations sending a result datum to the managed process, and comprises the following steps: —carrying out a deterministic software processing, termed prediction function (FH), based on the state of a managed process or of the application (AOP, ASB), to provide a predict result (RP) for said operation; —comparative test to establish whether the value of the predict result (RP) corresponds or does not correspond to the value of the actual result (DR, RRJ); —performance of a complementary management depending on the result of the preceding test.

Owner:IBM CORP

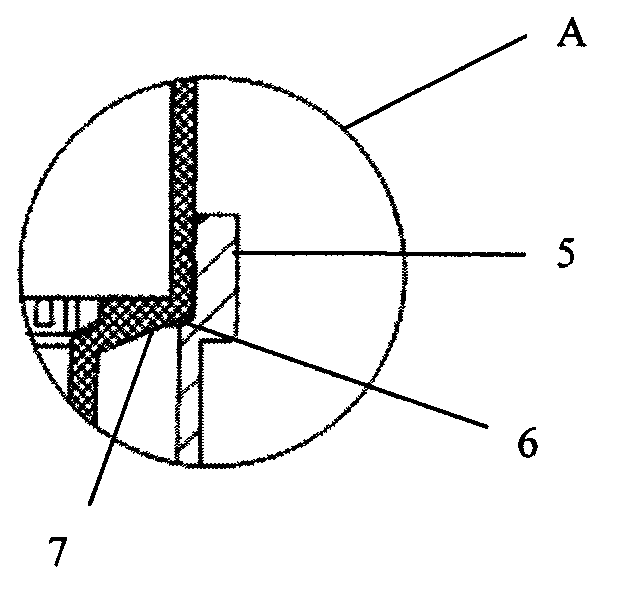

Polysilicon granule preparation system and preparation method

ActiveCN103213989AInhibit adhesion depositionProduce uniformEnergy inputSilicon compoundsCycloneFluidized bed

The invention discloses a polysilicon granule preparation system, and solves the problems of the polysilicon particles in prior art, such as easy deposition on wall of a fluidized bed reactor, nonuniform particle size, low utilization rate of the polysilicon seed crystal and large loss rate of polycrystalline silicon fine powder. The system comprises an aslant arranged rotating fluidized bed, a first stage cyclone separator, a second stage cyclone separator, a carrier gas filter, a material preheating tank and a tail gas buffer tank. The reaction cylinder in the middle of the rotating fluidized bed can rotate relatively to end sockets at the two ends; and the rotating fluidized bed is provided with a baffle plate. The invention can effectively restrain deposition of the polycrystalline silicon particles in the fluidized bed reactor wall, improve utilization rate of polycrystalline silicon and reduce the loss rate of polycrystalline silicon fine powder. The invention also discloses a preparation method of polycrystalline silicon particles. The preparation method has advantages of stable process, good continuity of operations, high utilization rate of polycrystalline silicon, high efficiency of polycrystalline production and uniform size of the obtained polysilicon granules.

Owner:ZHEJIANG JINGGONG NEW MATERIAL TECH

Method for the management, logging or replay of the execution of an application process

InactiveUS8539434B2Reduce workloadHigh continuity of operationError detection/correctionSoftware simulation/interpretation/emulationOperating systemSoftware

This invention relates to a management method, more particularly by recording or external control, of software operations performed within the execution of an application process executed on a computer. This management applies in particular to the recording of operations in the form of logging data, or to a replay of operations according to a given execution corresponding to a running previously logged running This method applies in particular to operations returning at least one result datum to the managed process, and comprises the carrying out of at least one complementary management phase for the managed operation, this complementary management depending on the deterministic or non deterministic nature of the managed operation or of its result.

Owner:IBM CORP

Steel wire drawing method

ActiveCN107497868AGuaranteed surface finishReduce frictionFurnace typesHeat treatment furnacesEpoxyCarbon nanotube

The invention provides a steel wire drawing method. The steel wire drawing method comprises the following steps of: applying a lubricating cooling agent to the surfaces of raw metal wires, and then carrying out first-stage drawing, annealing treatment, second-stage drawing and heat treatment in sequence to obtain steel wires, wherein the lubricating cooling agent is prepared from carbon nanotubes, epoxy resin, an aminosilane coupling agent, an emulsifying agent and water. The lubricating cooling agent adopted by the steel wire drawing method has the effects of lubrication and cooling in a drawing process, ensures the smooth finish of steel wires in the drawing process, reduces friction and prevents tensile failure. As the lubricating cooling agent contains the carbon nanotubes, the lubricating cooling agent prevents the steel wires from being oxidized at a high temperature. The steel wire drawing method has the beneficial effects that the preparation method has good operation continuity; the surfaces of prepared steel wires have good smoothness, and the prepared steel wires have relatively good toughness, relatively thin diameter and relatively high strength; the internal stress is reduced through intermediate annealing treatment, so that the steel wires are less likely to suffer tensile failure during secondary drawing; and the quench tempering after drawing ensures that the steel wire finished products have higher hardness than existing steel wires.

Owner:SHANGHAI NETUREN

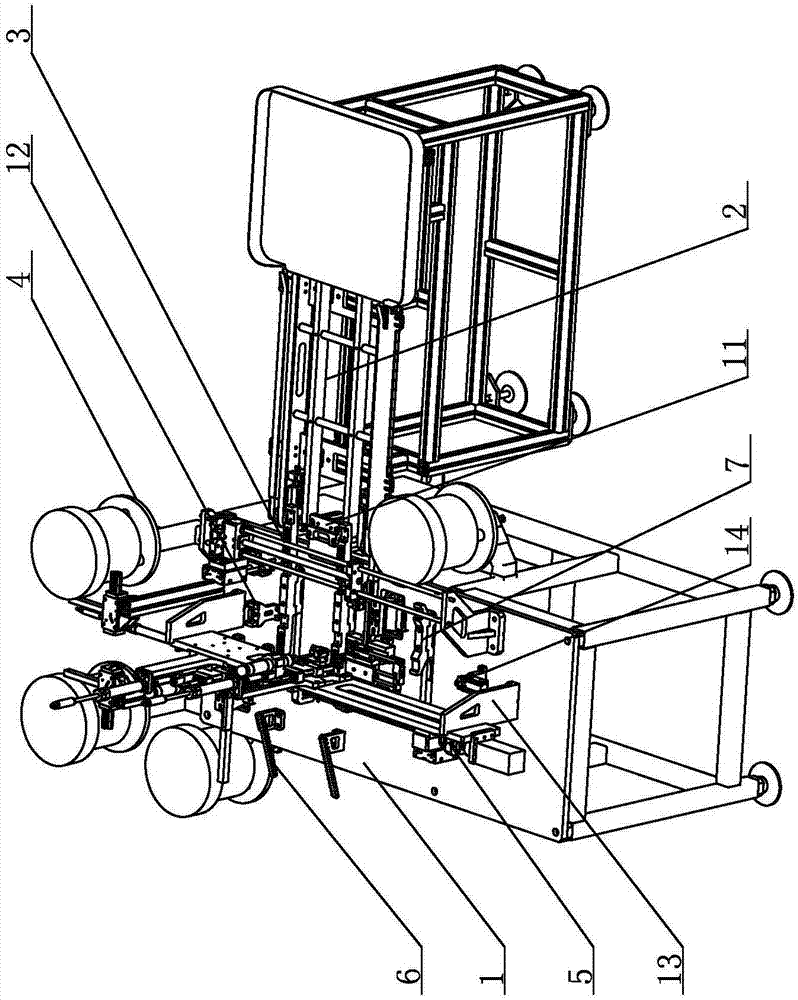

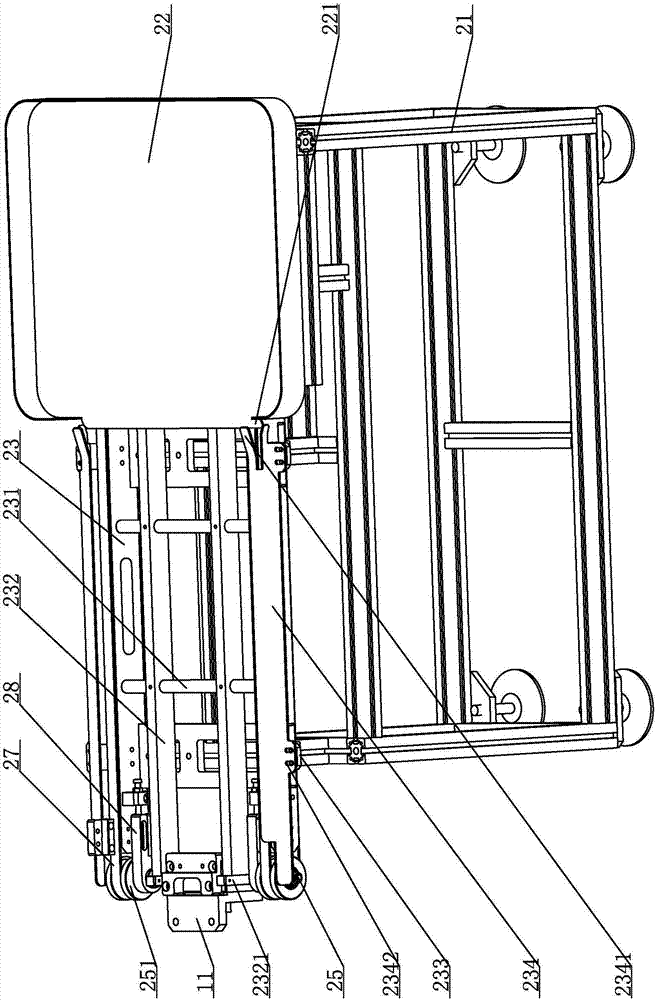

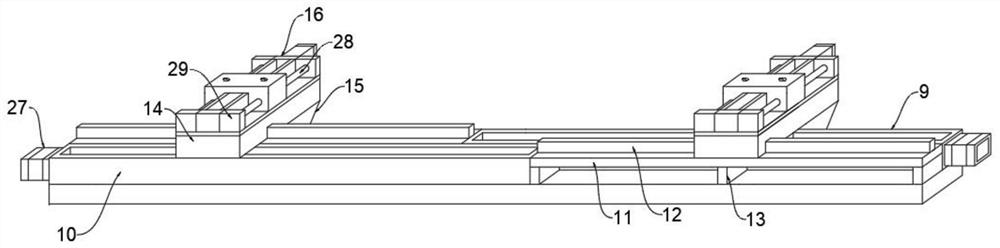

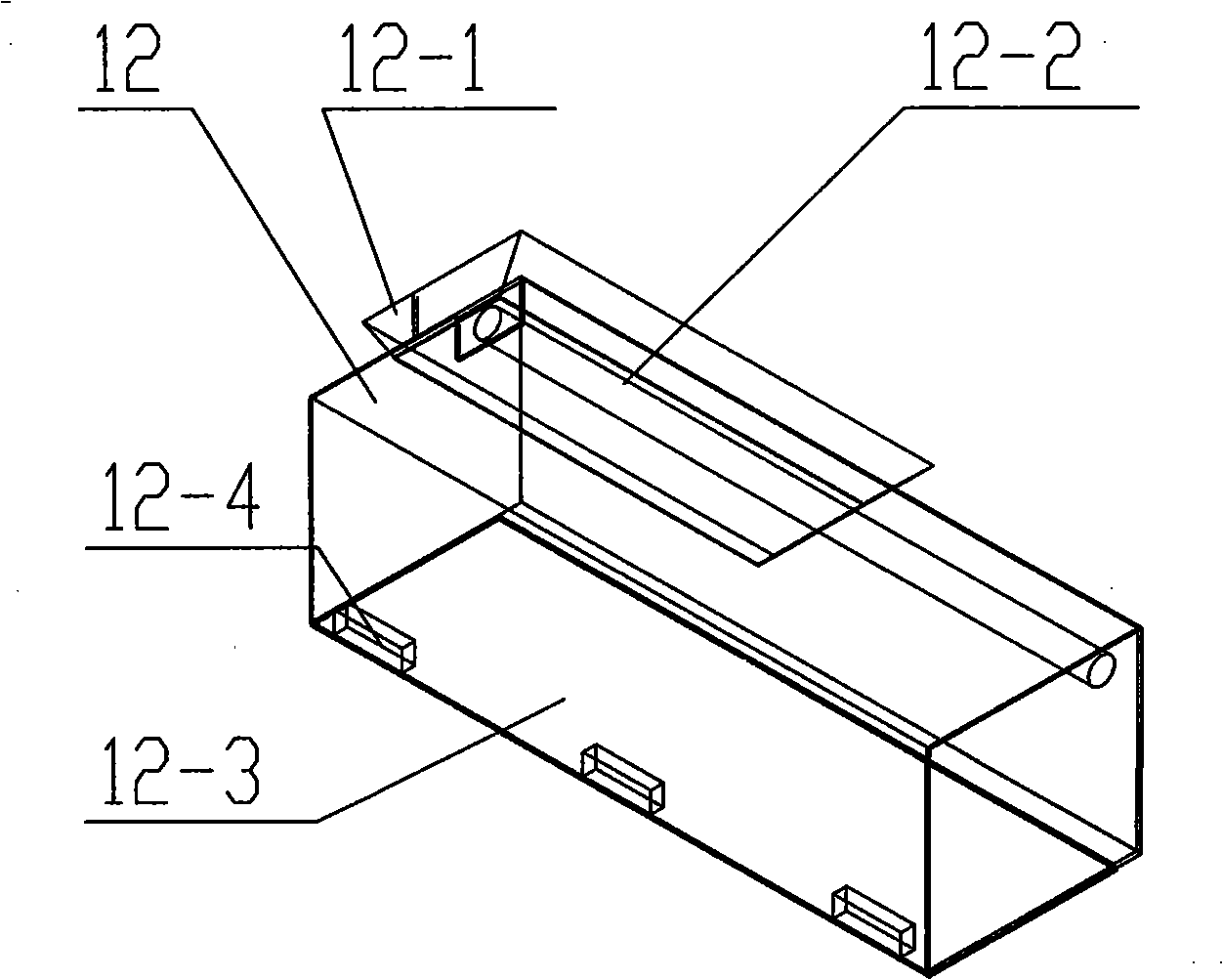

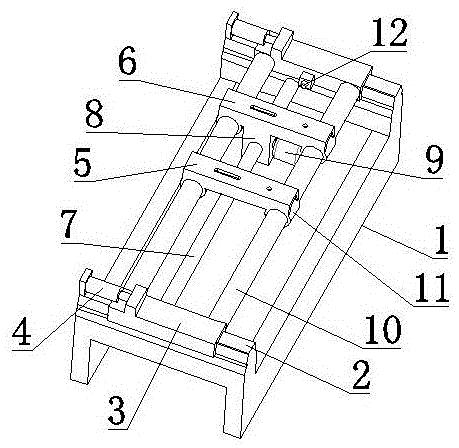

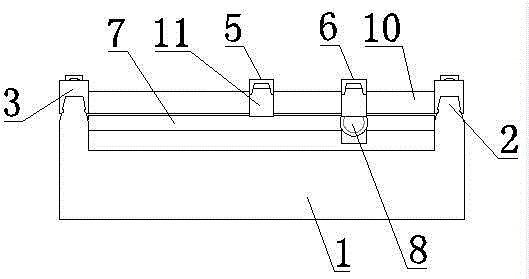

Equipment for sliding rail assembly nut locking screws

ActiveCN107336002ACompact structureHigh continuity of operationMetal working apparatusStructural engineeringControl theory

The invention discloses equipment for sliding rail assembly nut locking screws. The equipment comprises a circuit controller, a rack, a sliding rail assembly feeding mechanism connected with the rack through a lifting device, a sliding rail supporting part, a sliding rail unfolding mechanism, a nut locking screw mechanism, a sliding rail assembly folding mechanism, a sliding rail assembly output mechanism, and a carrying mechanism arranged below the rack, wherein the sliding rail supporting part, the sliding rail unfolding mechanism, the nut locking screw mechanism, the sliding rail assembly folding mechanism and the sliding rail assembly output mechanism are arranged on the rack. The sliding rail assembly feeding mechanism, the sliding rail assembly unfolding mechanism, the nut locking screw mechanism, the sliding rail assembly folding mechanism and the sliding rail assembly output mechanism are arranged in the assembling and conveying direction. The sliding rail assembly feeding mechanism, the lifting device, the sliding rail assembly unfolding mechanism, the nut locking screw mechanism, the sliding rail assembly folding mechanism and the carrying mechanism are connected with the circuit controller. Compared with the prior art, before a nut is installed, a sliding rail assembly is unfolded, after the nut is installed on the sliding rail assembly, the sliding rail assembly is folded and output along the sliding rail assembly output mechanism, and the equipment is compact in structure, coherent in operation and high in production efficiency.

Owner:QINGYUAN SACA PRECISION MFG CO LTD

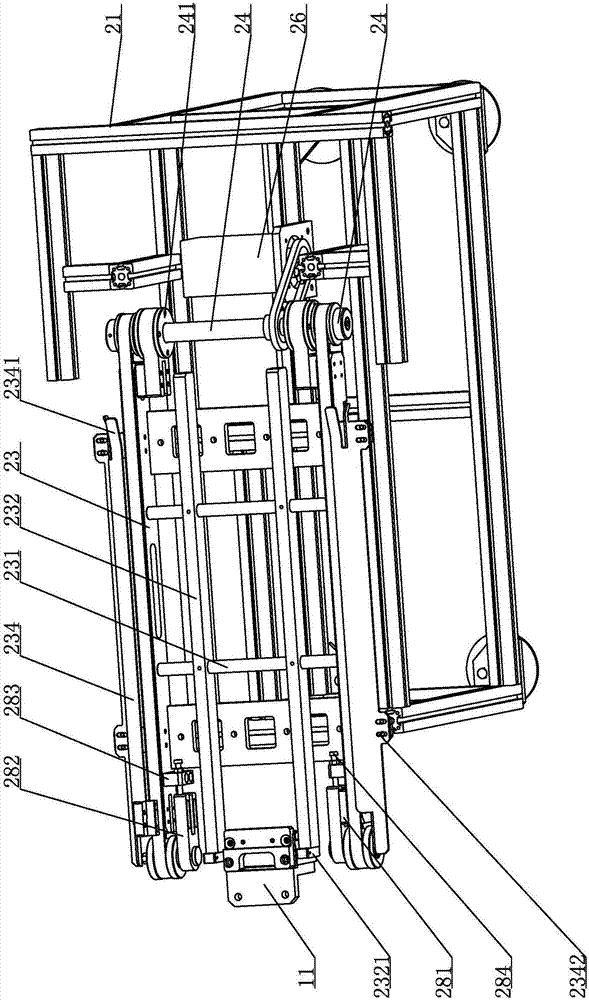

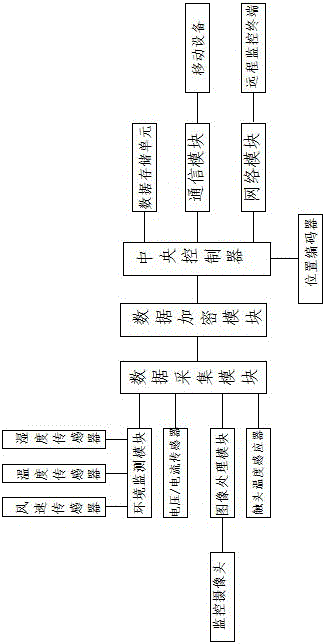

Internet of things based area isolating switch state monitoring system

InactiveCN106093773AReduce risky operationsHigh continuity of operationCircuit interrupters testingThe InternetCurrent sensor

The invention relates to an internet of things based area isolating switch state monitoring system, which comprises a central controller, and is characterized in that the central controller is connected to a data storage unit, a communication module, a network module, a data encryption module and a position encoder, the communication module is connected to a mobile device, the network module is connected to a remote monitoring terminal, the data encryption module is connected to a data acquisition module, the data acquisition module is connected to an environment monitoring module, a voltage / current sensor, an image processing module and a contact temperature inductor, the environment monitoring module is connected to a wind speed sensor, a temperature sensor and a temperature sensor, and the image processing module is connected to a monitoring camera. The internet of things based area isolating switch state monitoring system is safe, reliable, convenient to be managed, and capable of monitoring in real time.

Owner:张振堂

Minced euphausia superba extruded instant product and production method thereof

InactiveCN105285782AObvious fibrous textured appearanceFull of nutritionFood mechanical treatmentFood ingredient as taste affecting agentAdditive ingredientAquatic product

The invention belongs to the technical field of aquatic food processing and particularly relates to a minced euphausia superba extruded instant product and a production method thereof. The product is prepared by taking low-fluorine frozen minced euphausia superba phospholipid as main material, premixing the main material with soybean protein isolate, corn starch and other ingredients according to proper proportion, and extruding by a double-screw extruder. The minced euphausia superba prepared by the production process can efficiently utilize excellent protein and lipid formed by euphausia superba, and provide protein, phospholipid and unsaturated fatty acid with rich nutrition for an eater. Through the double-screw extrusion method, the product has good chewing mouthfeeling and digestive performance, good operation continuity, high production efficiency, and easiness in industrialization.

Owner:OCEAN UNIV OF CHINA

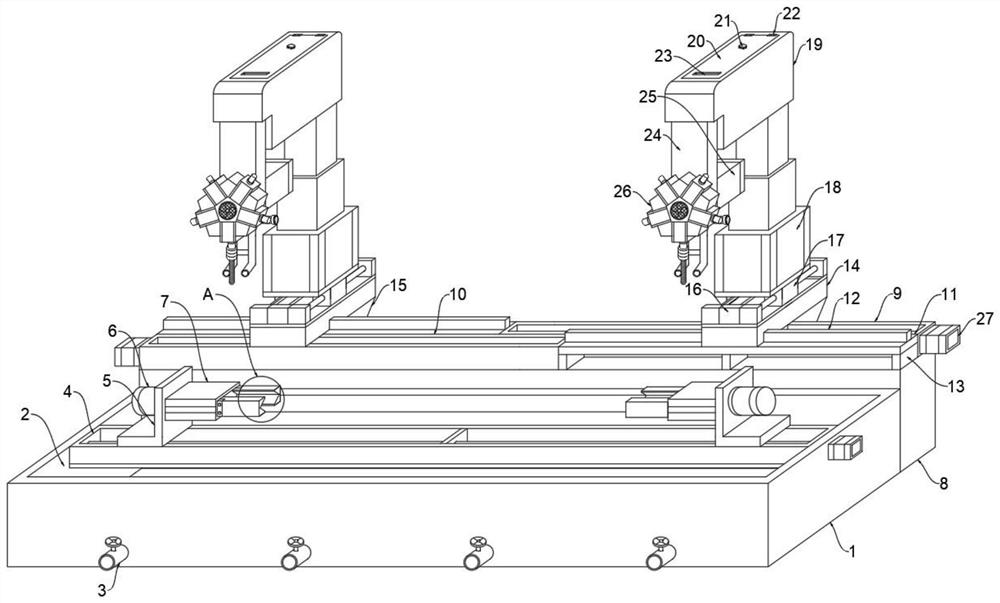

Punching device for colored aluminum sectional material machining and punching method of punching device

ActiveCN113579285AHigh continuity of operationImprove stabilityFeeding apparatusDriving apparatusPunchingWater storage tank

The invention discloses a punching device for colored aluminum sectional material machining and a punching method of the punching device, and relates to the technical field of colored aluminum sectional material machining. The punching device and the punching method aim at solving the problems that an existing punching device for colored aluminum sectional material machining cannot flexibly adjust the size of a drilled hole in the machining process, only one specification of hole site can be formed in an aluminum sectional material through one-time machining, and if a plurality of through holes with different specifications need to be formed in the same sectional material, a drill rod on the punching device needs to be replaced many times, and the process is tedious. A water storage tank is arranged in a clamping table, a bidirectional lead screw guide rail is installed in the water storage tank, L-shaped sliding blocks are installed on the two sides of the upper surface of the bidirectional lead screw guide rail correspondingly, a pneumatic clamping jaw is installed on one sides of each L-shaped sliding block, and a first stepping motor is installed on the other side of each L-shaped sliding block. The output end of each first stepping motor is in transmission connection with the corresponding pneumatic clamping jaw, two clamping arms are installed at the output end of each pneumatic clamping jaw, and a V-shaped groove is formed in the inner side of each clamping arm.

Owner:HUBEI SHIMEI TECH

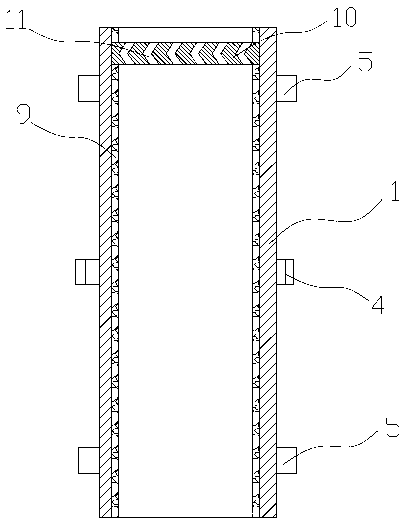

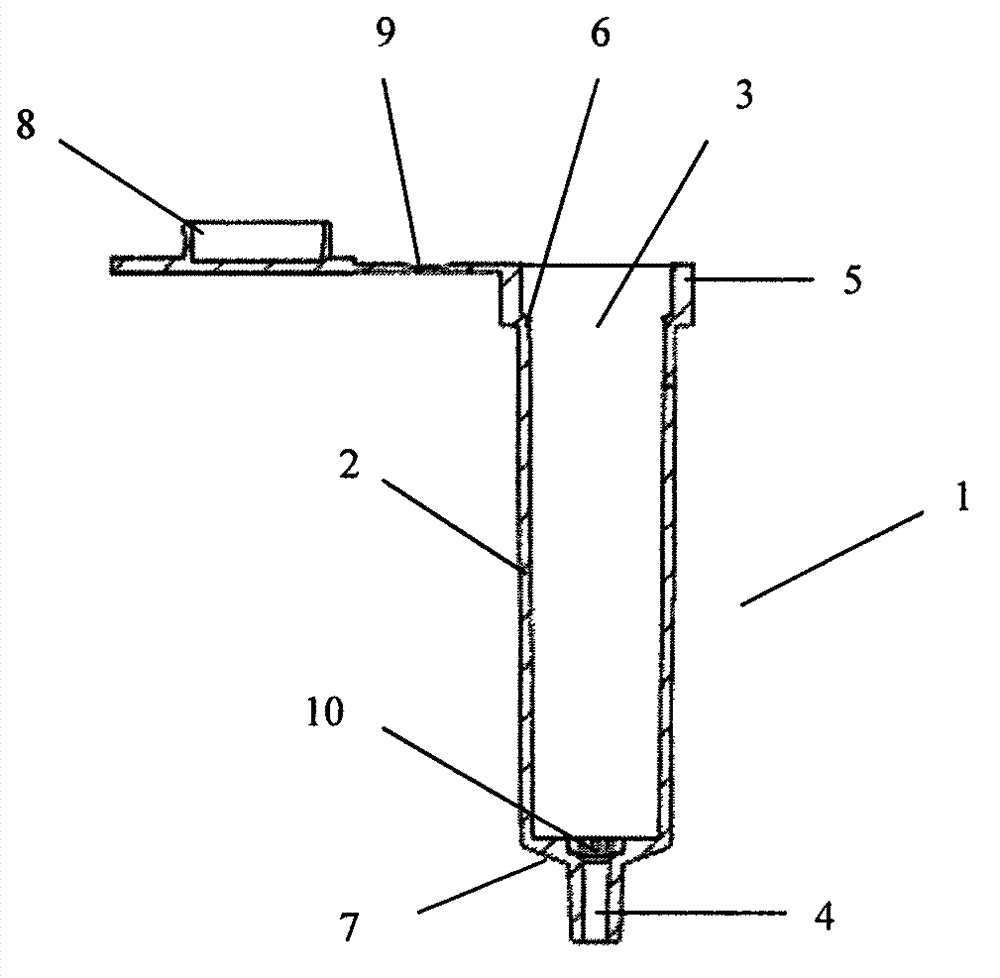

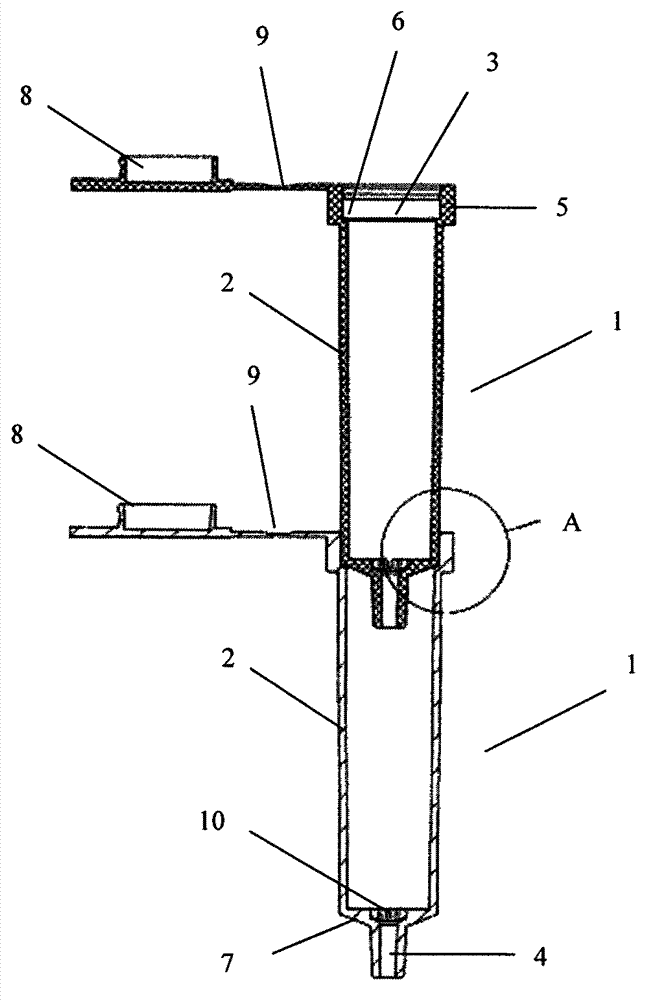

Nucleic acid purifying column system and its application in nucleic acid extraction

ActiveCN103087903AEnsure stabilityMeet continuous operation requirementsApparatus sterilizationDNA preparationInjection portContinuous operation

The invention provides a nucleic acid purifying column system and its application in nucleic acid extraction. The nucleic acid purifying column system comprises two mutually-independent biological sample preparation columns which can be overlapped up and down, each of the biological sample preparation columns comprises a body, the upper portion of the body has a sample injection port, the lower portion of the body has a sample outlet mouthpiece, the portion of each of the biological sample preparation columns above the sample injection ports is provided with a retaining component, and the lower preparation of the upper preparation column is tightly buckled in the retaining component of lower preparation column. The adoption of the mutually-overlapped purifying column system satisfies the continuous operation of experiments and the conversion between / among different samples.

Owner:HANGZHOU KMB BIOTECH

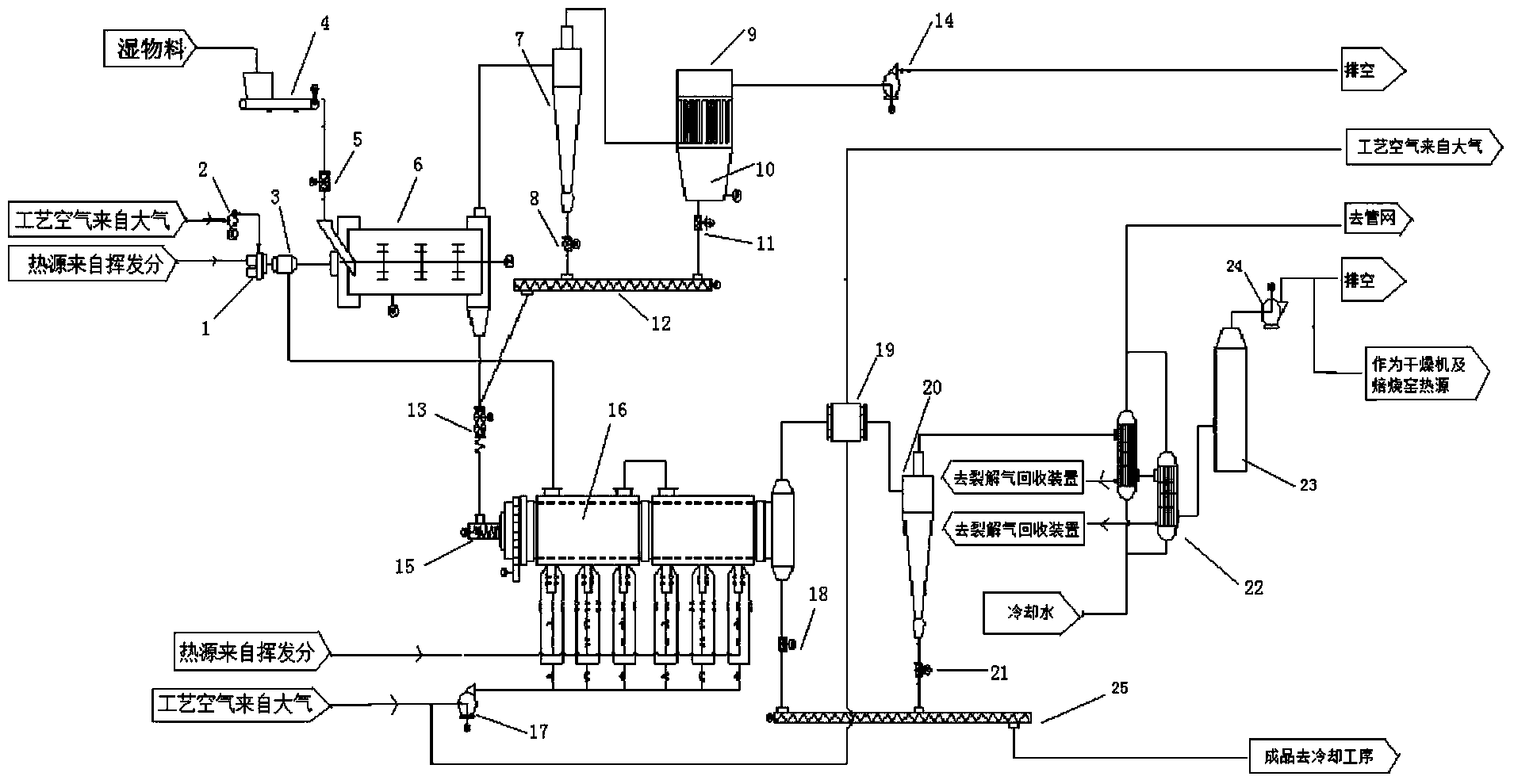

Oil sand calcining device and an oil sand calcining process

ActiveCN103450919AGuaranteed uptimeImprove thermal efficiencyLiquid hydrocarbon mixture productionAir preheaterAutomatic control

The invention discloses an oil sand calcining device and an oil sand calcining process. The oil sand calcining device comprises a rotary dryer, a cyclone dust collector I, a cyclone dust collector II, a bag-type dust collector, a spiral conveyer I, a spiral conveyer II, a drying induced fan, a combustor, a combustor combustion fan, a hot-blast furnace, a feeding machine, a calcining kiln, a combustion fan, an air preheater, a shell and tube condenser, an absorbing tower and a system induced fan. A system which adopts the process has the advantages of continuity in operation, stability in operation, high heat efficiency and convenience for operation, can realize the automatic control, is suitable for larger-scale production, is reduced in occupied area and low in investment and operation and maintenance cost and successfully solves the problem of wall adhesion of oil sand. According to the oil sand calcining device and the oil sand calcining process disclosed by the invention, a calcined product is more incompact and can meet the requirements of building materials; the waste heat recovery rate of the system is greatly increased, and the energy is saved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP +1

Food garbage solid-liquid separation and sterilization integrated device

The invention relates a solid-liquid separation and disinfection integrated plant for food waste. The invention includes a solid-liquid separation mechanism and a solid waste disinfection mechanism, wherein the solid-liquid separation mechanism includes a compressed barrel, a piston and a linear reciprocating mechanism; a waste inlet is formed on the compressed barrel; the executive element of the linear reciprocating mechanism passes through one end of the compressed barrel, the front end of the executive element is connected with the piston capable of sliding in the compressed barrel; an liquid outlet is opened on the compressed barrel; a waste outlet is formed on the other end of the compressed barrel; an openable constant pressure door is arranged on the waste outlet and is connected with a spring with preset elasticity; and the waste outlet is connected with the inlet of the solid waste disinfection mechanism. The solid-liquid separation and disinfection integrated plant for food waste has the advantages of reasonable connection, good operational continuity and improved production efficiency.

Owner:ZHEJIANG UNIV OF TECH

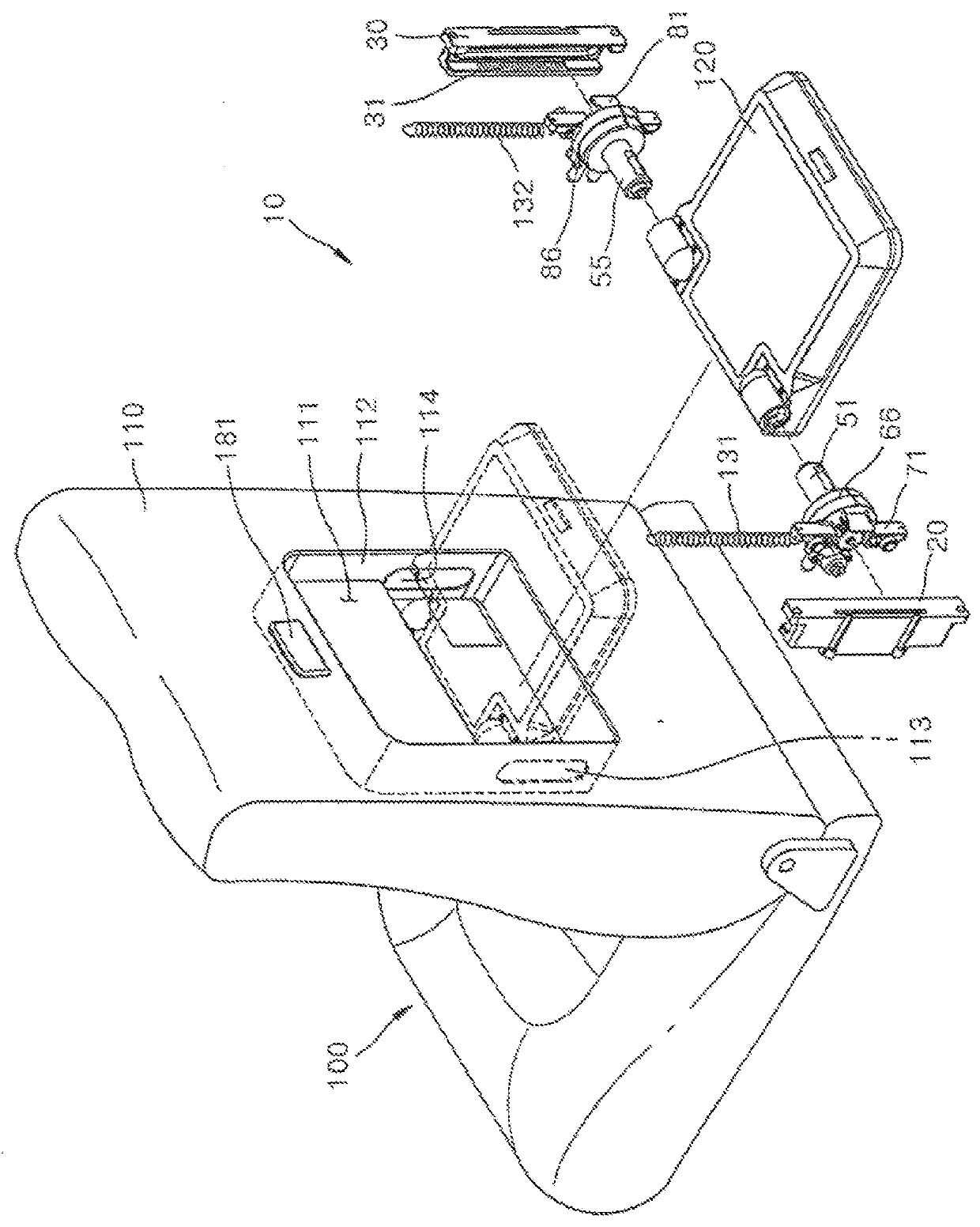

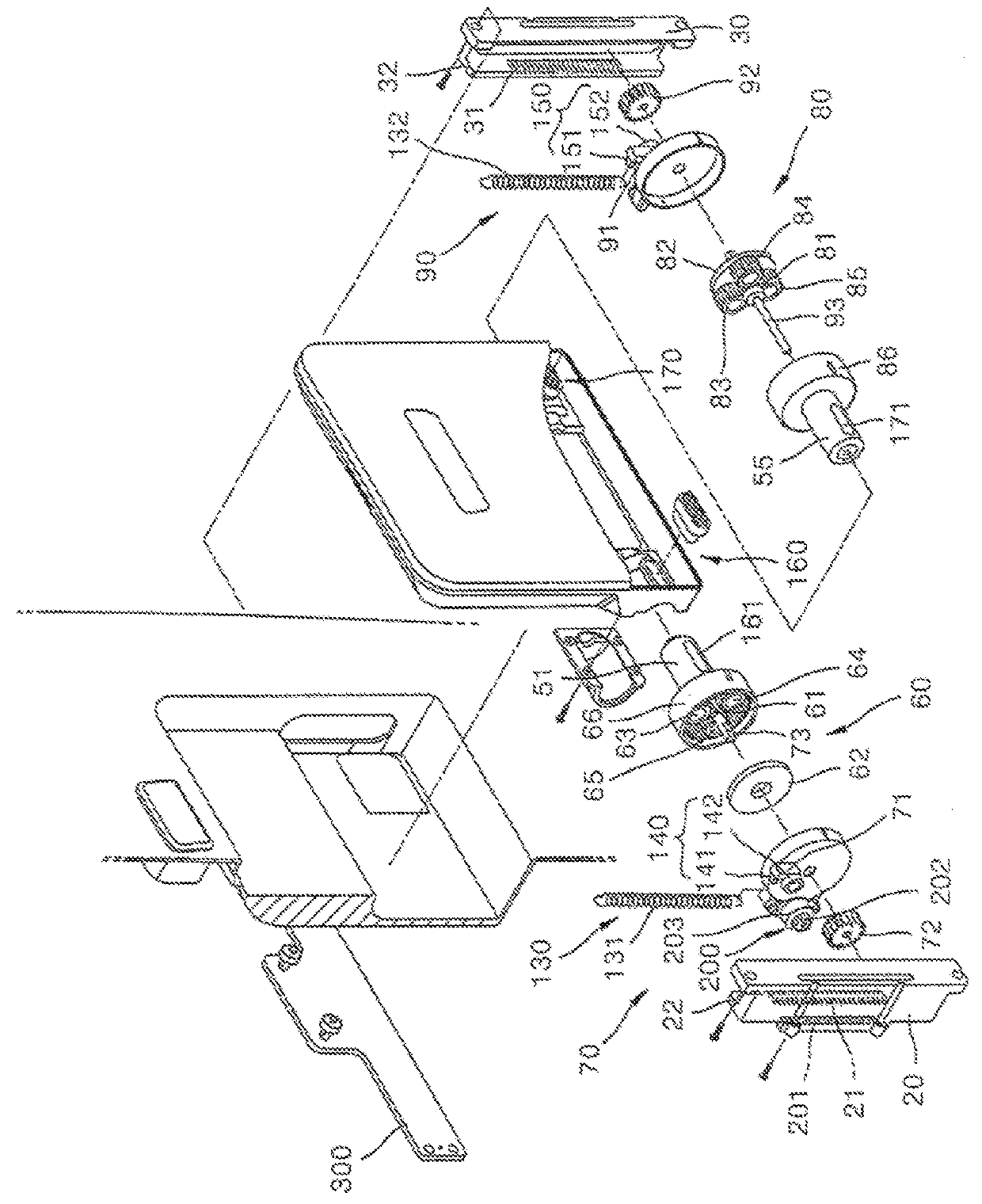

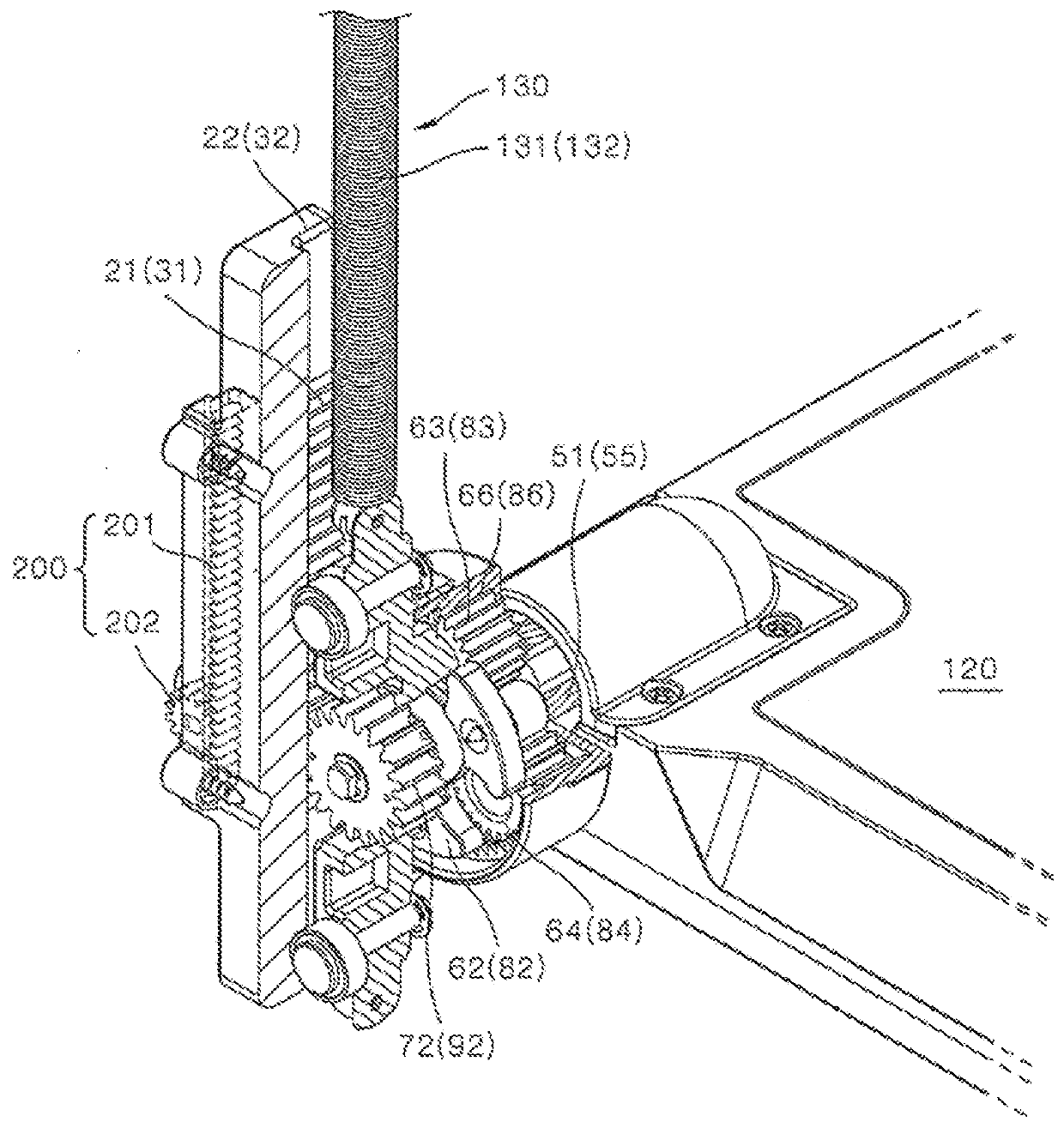

Vehicular seat back table

Disclosed herein is a vehicular seat back table apparatus including: a guide member installed at each of both sides of a table installation space of a backrest and including a rack gear portion; a driving shaft at which a pinion rotatably, which is installed at a guide frame and engaged with the rack gear portion of the guide member, is installed; a driving unit rotated by a rotation varying unit connected to the driving shaft, installed at a side surface of a table, and including a rotating hinge shaft member configured to provide a rotational force to rotate the table when the pinion is moved along the rack gear portion; and an elastic bias portion configured to support the guide frame to move upwardly along the guide member.

Owner:OH HYUNG JONG

Device for recycling oil or solvent from solid-containing oil through spray flash evaporation drying and recycling method

ActiveCN110229688AVolatileLower evaporation temperatureLiquid hydrocarbon mixture productionBuffer tankGas phase

The invention discloses a device for recycling oil or a solvent from solid-containing oil through spray flash evaporation drying and a recycling method. The device comprises a feeding buffer tank, a preheater, a heater, a spray flash evaporation drying tower, a dry gas phase scrubbing tower and a solvent condenser, wherein the feeding hole of the feeding buffer tank communicates with a raw material conveying pipeline; the discharge hole of the feeding buffer tank communicates with the feeding hole of the preheater; the discharge hole of the preheater communicates with the feeding hole of the heater; the discharge hole of the heater communicates with the spray flash evaporation drying tower; a gas phase discharge pipeline is arranged at the upper end of the spray flash evaporation drying tower; the gas phase discharge pipeline is connected with the dry gas phase scrubbing tower; a dry phase cooling machine is arranged at the bottom of the gas phase discharge pipeline; a conveyer is connected with the outlet of the dry phase cooling machine; a powder cabin is connected with the outlet of the conveyer; a condensation device is arranged at the lower half section of the dry gas phase scrubbing tower; a circulation pipeline is arranged at the bottom of the dry gas phase scrubbing tower; a gas phase flowing pipeline is arranged at the upper end of the dry gas phase scrubbing tower; the outlet end of the gas phase flowing pipeline is connected with the preheater to achieve heat exchange cooling; and an uncondensed gas which is not cooled is conveyed into the solvent condenser for secondary condensation through an uncondensed gas conveying pipeline.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +2

Intelligent adjustment device for transmission system of oil pumping unit

ActiveCN106015480AExtended service lifeReduce labor intensityGearingStructural associationEngineeringWorkload

The invention discloses an intelligent adjustment device for a transmission system of an oil pumping unit. The intelligent adjustment device comprises a fixed base, a transversal adjustment device installed on the fixed base, and a longitudinal adjustment device installed on the transversal adjustment device, wherein the transversal adjustment device comprises guide rails, slide seats and hydraulic devices; the guide rails are fixedly installed on the fixed base; one slide seat is slidably arranged on each guide rail; one hydraulic device used for pushing each slide seat to slide relative to the corresponding guide rail is arranged between the slide seat and the corresponding guide rail; two slide rails which are arranged in parallel are arranged between the two corresponding slide seats; and the longitudinal adjustment device comprises a drive base, a driven base, the slide rails, a lead screw, nuts and motors. The adjustment device is capable of realizing automatic tensioning of a belt of the oil pumping unit, thus reducing the workload of an operator, and increasing the working efficiency; and moreover, stalling and alarming of an oil pumping motor are realized after the belt is broken, the operation is intelligent and convenient, and energy waste is reduced.

Owner:大庆宏升石油机械设备制造有限公司

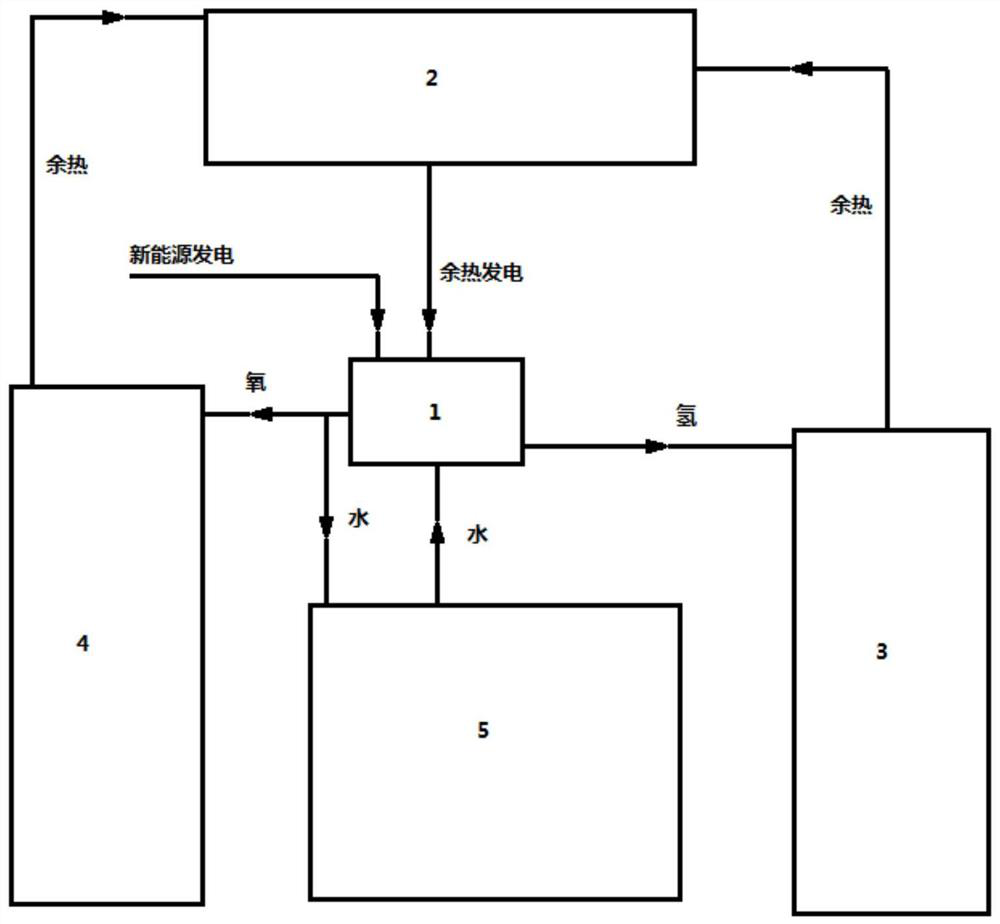

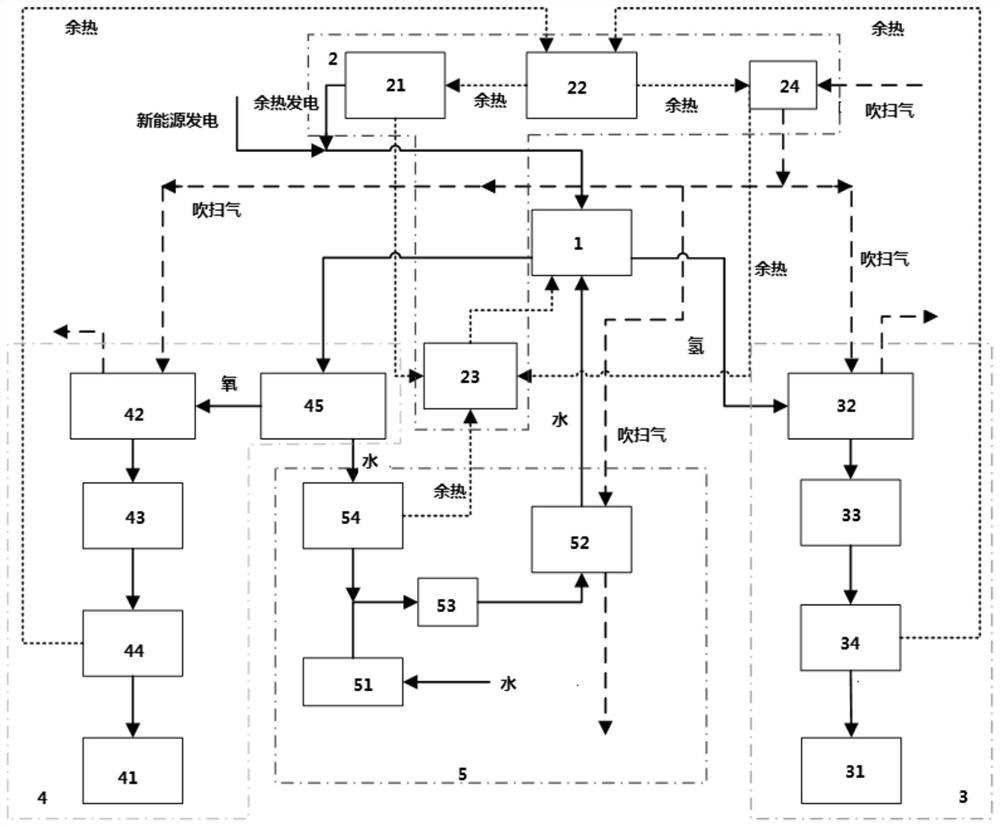

Hydrogen production and storage system and multi-mode circulating hydrogen production method

ActiveCN113846338AAvoid variable conditionsAvoid the problem of frequent start and stopCellsEnergy inputOrganic Rankine cycleHydrogen storage system

The invention discloses a hydrogen production and storage system, which comprises an electrolytic bath and a hydrogen storage device, and further comprises a heat storage power generation device, an oxygen storage device and a water storage device. The invention further discloses a multi-mode circulating hydrogen production method, which adopts the hydrogen production and storage system. According to the invention, a heat storage power generation device is introduced into a hydrogen production system and cooperates with renewable energy power generation to electrolyze water to produce hydrogen in an electrolytic cell, so that the problems of variable working conditions and frequent start and stop caused by the use of renewable energy in the hydrogen production process are avoided, and the adaptability of the PEM electrolytic hydrogen production system to the fluctuation characteristic of new energy is improved; according to the multi-mode circulating hydrogen production method provided by the invention, a method of coupling organic Rankine cycle power generation with renewable energy power generation is adopted, so that the power shortage of the input end caused by fluctuating renewable energy is filled up, and the productivity of a hydrogen production system is ensured; and the method and the system provided by the invention are simple and easy to implement, energy generated in the whole hydrogen production and storage system can be fully utilized, the economical efficiency of the whole system is improved, and the energy consumption is reduced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Scalable method of continuous monitoring the remotely accessible resources against the node failures for very large clusters

InactiveUS20060242454A1Enhance reliability and availabilityImprove performance and efficiencyError preventionDigital computer detailsDistributive data processingResource management

The notion of controlling, using and monitoring remote resources in a distributed data processing system through the use of proxy resource managers and agents is extended to provide failover capability so that resource coverage is preserved and maintained even in the event of either temporary or longer duration node failure. Mechanisms are provided for consistent determination of resource status. Mechanisms are also provided which facilitate the joining of nodes to a group of nodes while still preserving remote resource operations. Additional mechanisms are also provided for the return of remote resource management to the control of a previously failed, but now recovered node, even if the failure had resulted in a node reset.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com