Patents

Literature

162results about How to "Guaranteed surface finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

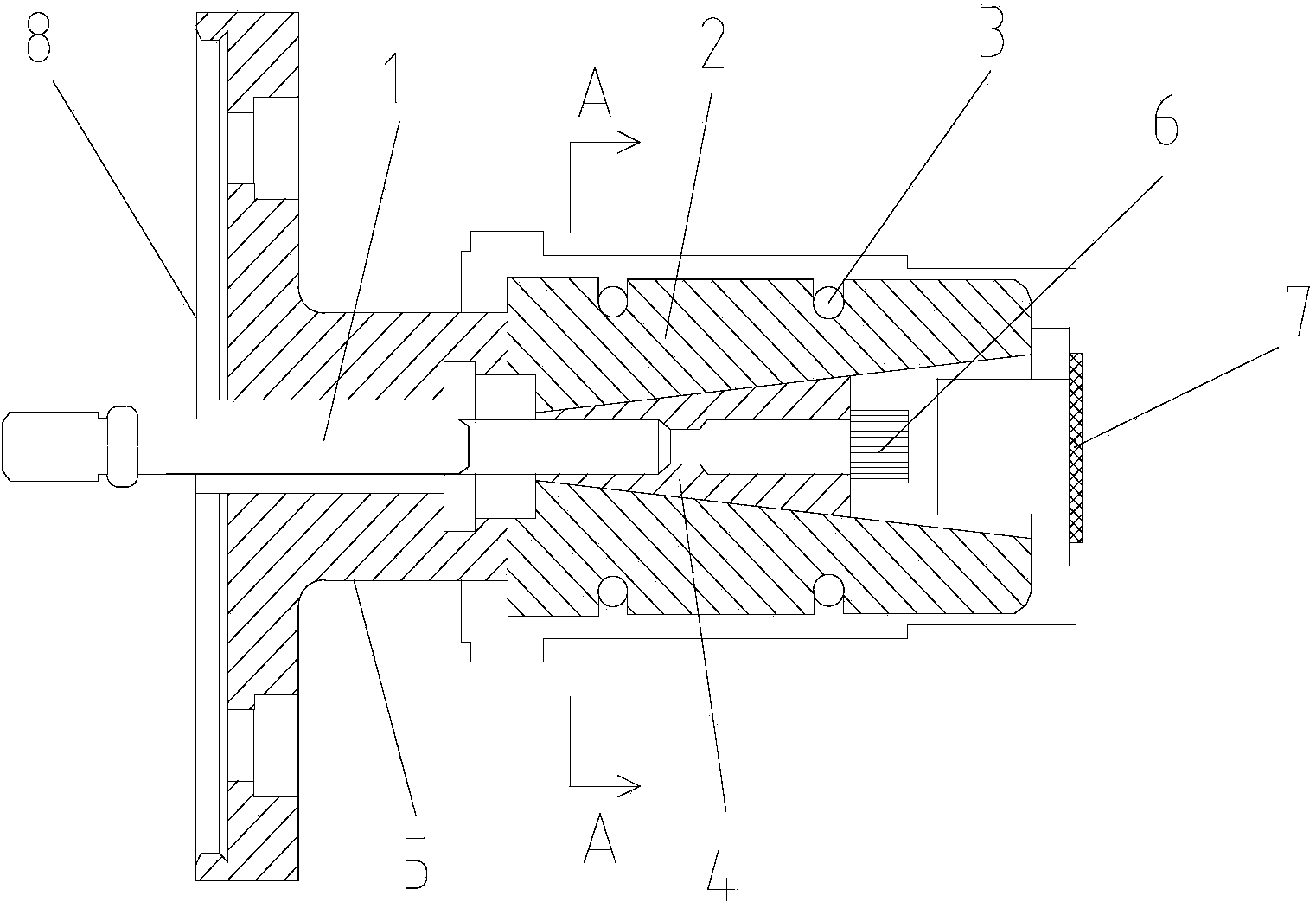

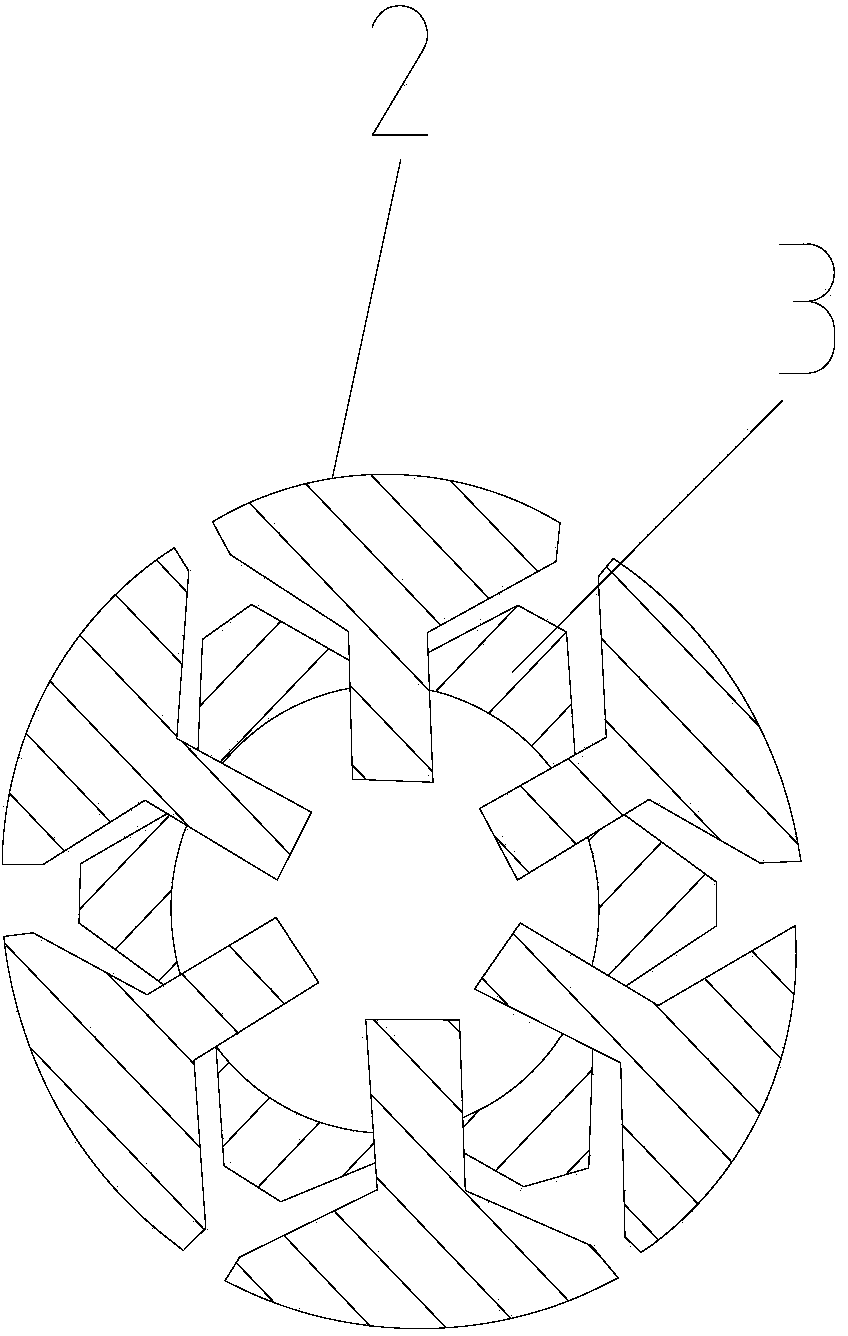

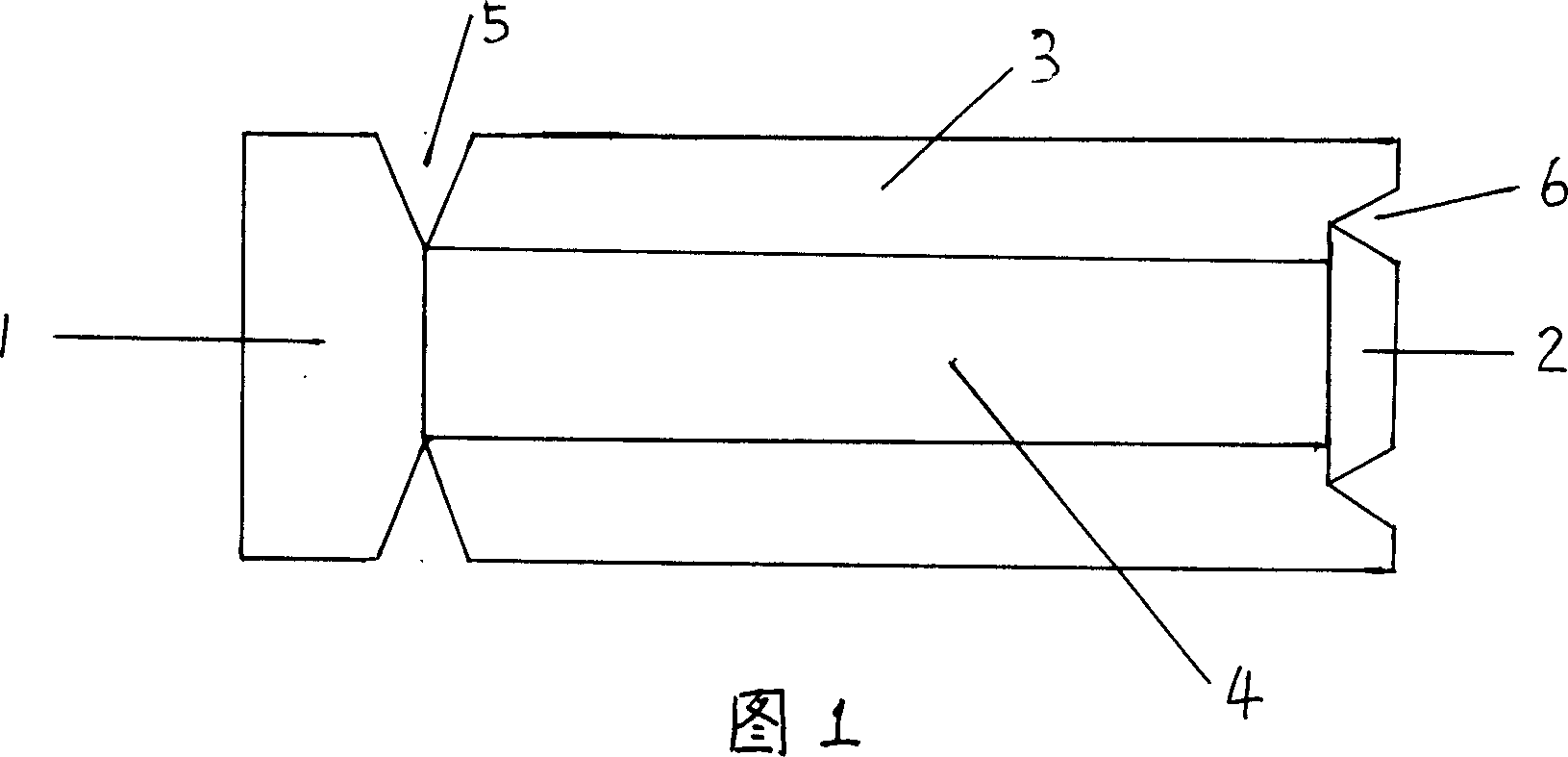

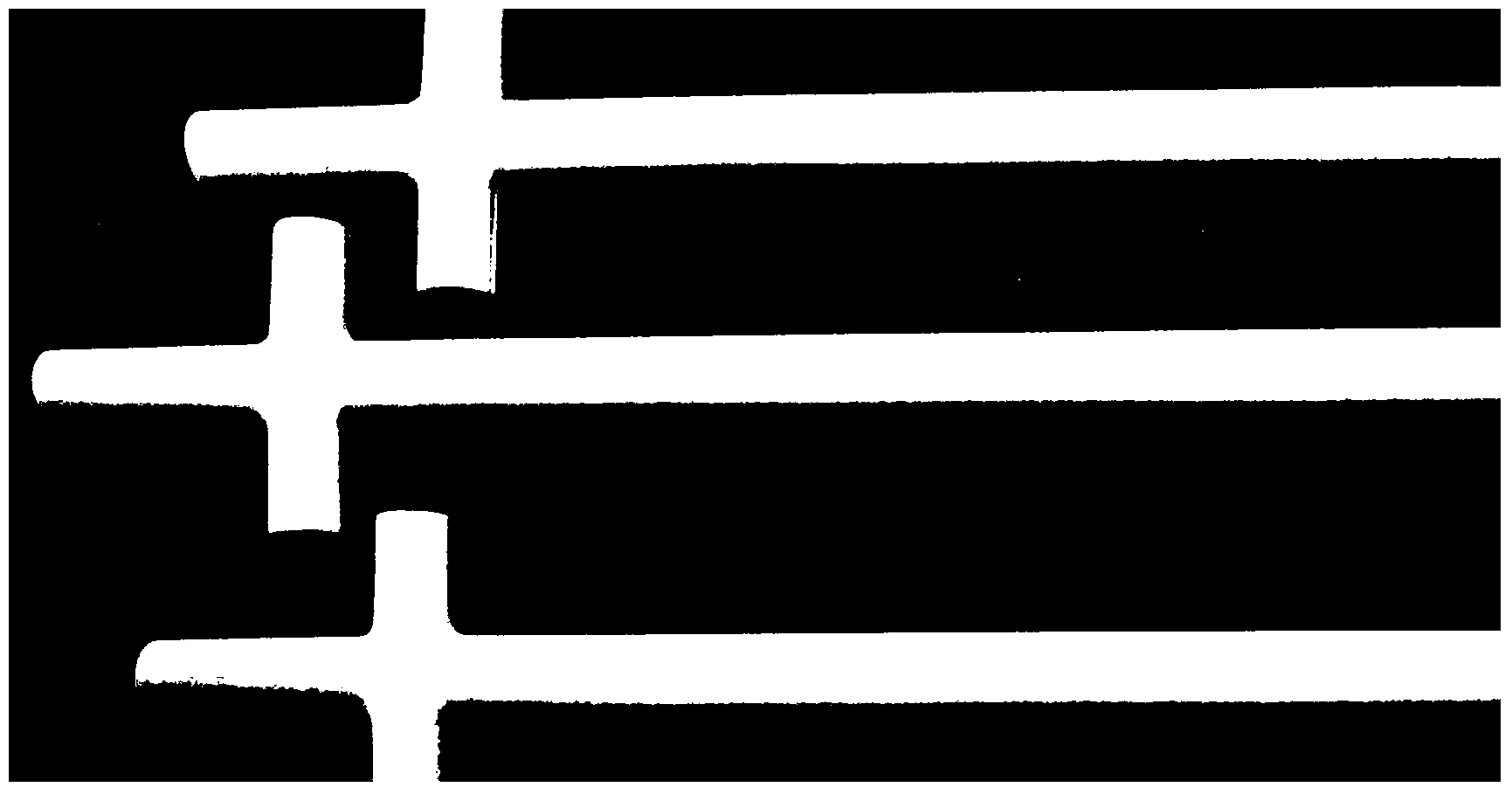

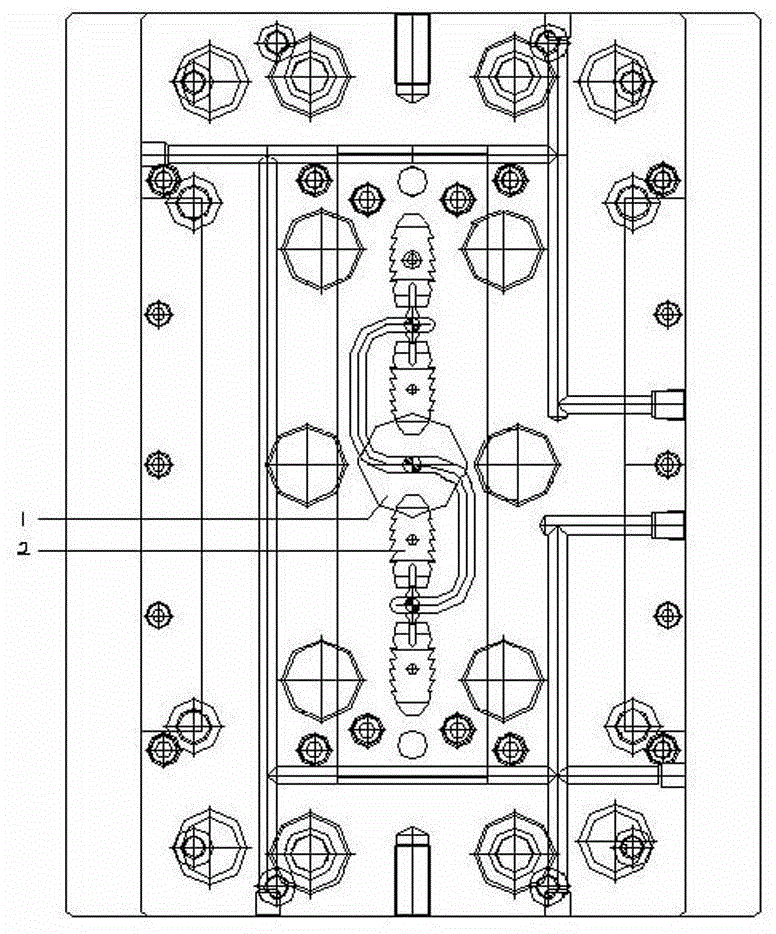

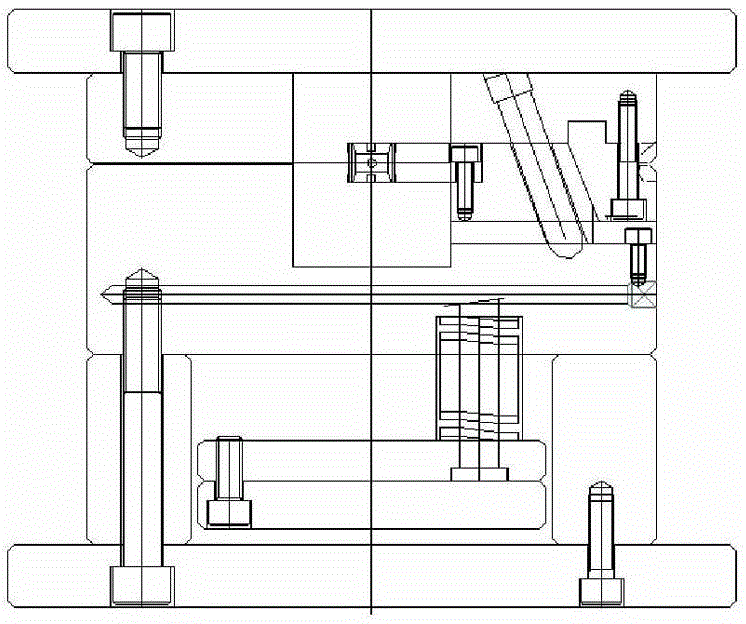

Expansion fixture device

The invention relates to the technical field of fixtures, in particular to an expansion fixture device. The expansion fixture device is characterized by being composed of a pull rod, flat section bodies, extension springs, a wedge block and a fixture body. A center through hole is formed inside the fixture body, and the pull rod is arranged inside the center through hole. The outer surface of the right side of the fixture body is provided with six evenly-distributed axial long grooves in a milling mode, and the six flat section bodies capable of forming a complete circle are arranged in the axial long grooves. The exterior of each flat section body is provided with a groove, and the extension springs are arranged in the grooves in a sleeved mode. The lower surface of each flat section body is provided with a conical surface. The wedge block is arranged in the center hole of the fixture body, connected with the pull rod through threads and provided with six evenly-distributed inclined grooves which are matched with the conical surfaces of the lower portions of the flat section bodies respectively, and a hexagon screw head is welded to the right end face of the wedge block. The expansion fixture device is simple in structure, and the wedge block is of a complete circle type.

Owner:CHANGZHOU CHANGOU METAL PROD

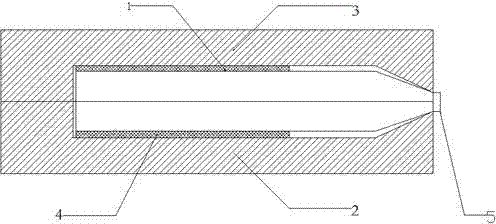

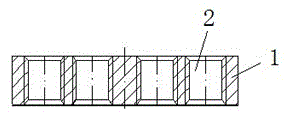

Manufacturing method of carbon fiber composite material rectangular hollow pipe for mechanical arm

The invention provides a manufacturing method of a carbon fiber composite material rectangular hollow pipe for a mechanical arm, and the obtained rectangular hollow pipe. A carbon fiber composite material serves as a raw material and is carbon fiber prepreg; the prepreg comprises one-way and fabric prepregs and the rectangular hollow pipe is manufactured by a mould pressing inflation forming method. According to the manufacturing method of the carbon fiber composite material rectangular hollow pipe, a rectangular thin-walled hollow pipe is manufactured by performing mould pressing inflation combined forming on the carbon fiber prepreg serving as the raw material. Compared with the prior art, the invention has the advantages that the carbon fiber composite material rectangular hollow pipe has high bearing capacity, high rigidity and light weight; during operation, the arm is more stable in action and moves and stops more quickly; the arm can be quickly positioned by the vibration damping characteristic of the carbon fiber composite material; the carbon fiber composite material is applicable to precision equipment due to the zero thermal expansion coefficient; equipment investment is small; a mould is simple to manufacture; production energy consumption is low; production period is short; automatic production is realized.

Owner:HENGSHEN

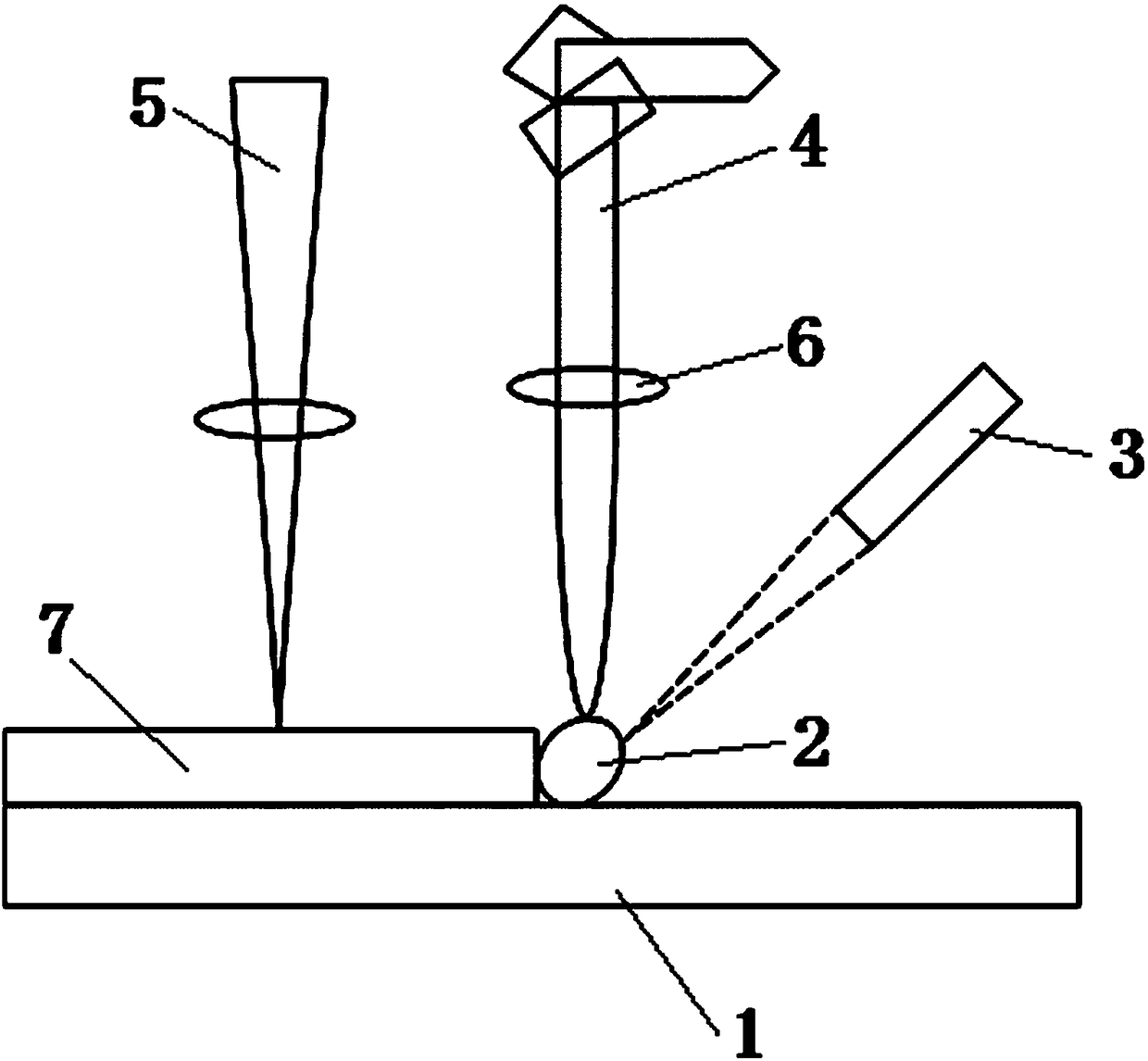

Manufacturing method of double-high-energy-beam metal additive material

InactiveCN108115137AQuality improvementImprove surface topographyAdditive manufacturing apparatusIncreasing energy efficiencyMathematical modelControl system

The invention discloses a manufacturing method of a double-high-energy-beam metal additive material. The manufacturing method comprises the following steps: (a) determining a three-dimensional entitymodel of a forming component, and modeling; and (b) manufacturing an additive material of the forming component: carrying out slicing and layering on a mathematical model in the step (a), so as to obtain two-dimensional outline information of a section of each layer and generate a machining route, inputting information into a control system of additive material manufacturing equipment, and manufacturing the double-high-energy-beam metal additive material by taking metal powder as the raw material according to a preset machining route. According to the manufacturing method, the internal defectsof pores, incomplete fusion, cracks and the like of a formed part are avoided, the system error of the formed part and an original design is small, and the formed part is relatively high in dimensional accuracy, small in residual stress, low in surface roughness and high in comprehensive quality; and compared with the prior art, the manufacturing method has significant progress and industrial application values.

Owner:SHANGHAI UNIV OF ENG SCI

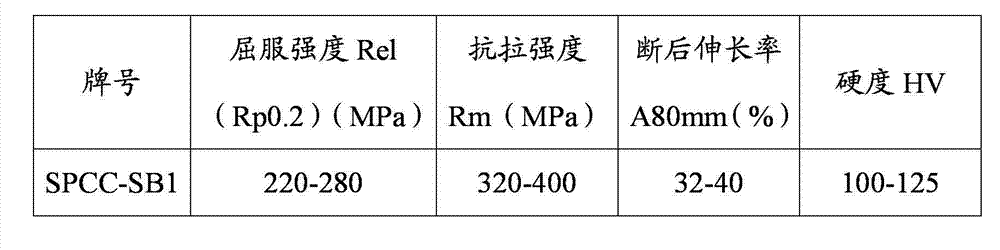

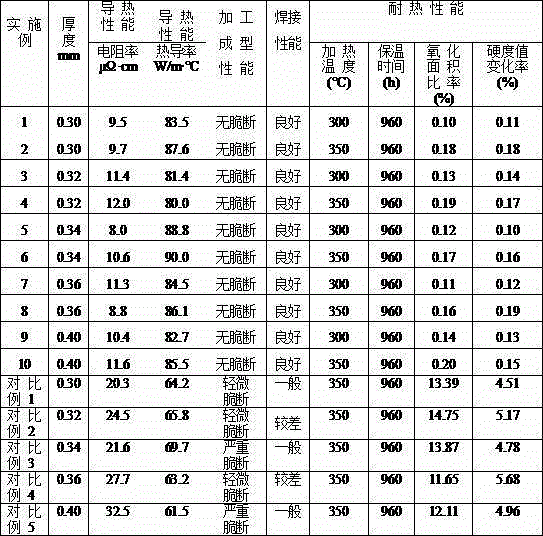

Steel strip for LED bracket and manufacturing method thereof

The invention provides a steel strip for an LED bracket and a manufacturing method thereof. The steel strip comprises the following chemical compositions by mass percent: 0.03%<=C<=0.07%, 0.01%<=Si<=0.03%, 0.2%<=Mn<=0.3%, 0%<P<0.02%, 0%<S<0.02%, 0.01%<=Al<=0.035% and the balance of Fe, as well as a trace of inevitable impurities. Repeated tests and trials show that the LED steel strip completely satisfies the quality requirements on the strength, the rigidity and the extensibility, which ensure that the LED bracket is free from cracks after being punched and bent for 6 times, and at present, the LED steel strip gains popularity of customers; and as the LED new material cold-rolled strip has a very wide development prospect, the popularization and application values are extremely high and the prospect is very wide.

Owner:浙江龙盛薄板有限公司

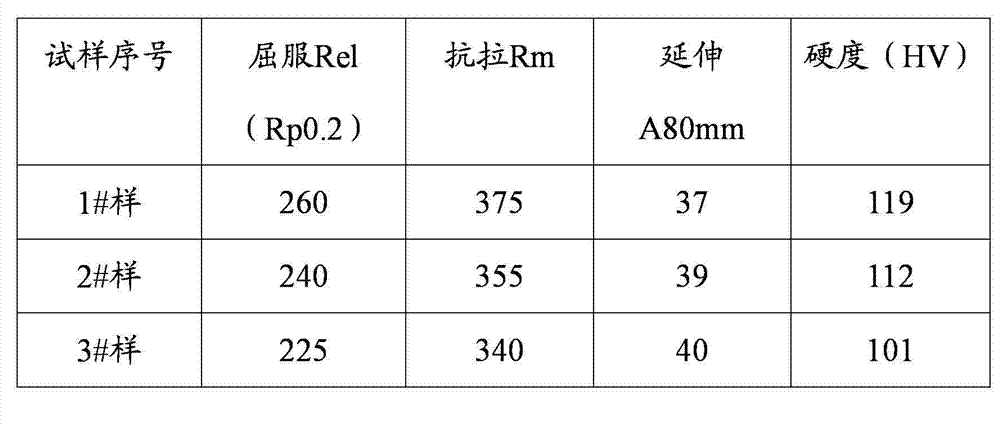

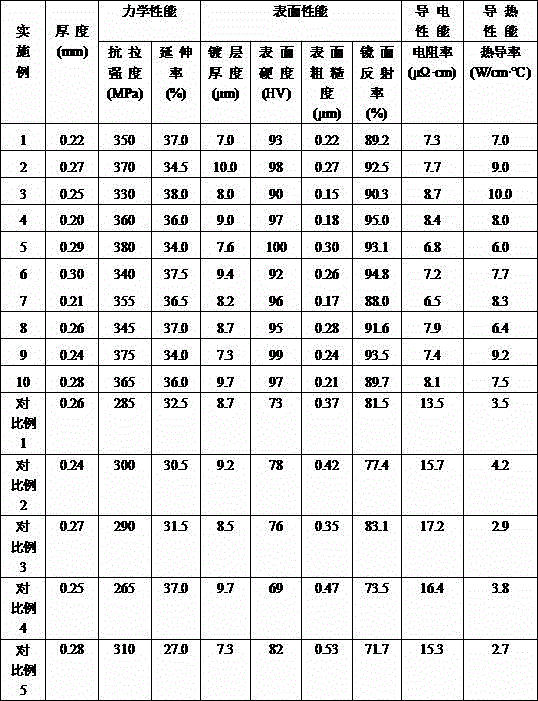

Production method for Cu-Ni/Ni-Ag double-composite coating extra-thin steel strip

InactiveCN104805484ALow costGuaranteed thicknessMolten spray coatingThermal sprayingRoom temperature

The invention discloses a production method for a Cu-Ni / Ni-Ag double-composite coating extra-thin steel strip. The production method comprises the following steps of performing primary cold rolling on an SPHC hot rolled coil subjected to acid pickling; after conventional degreasing is finished, performing primary annealing; performing secondary cold rolling; performing conventional degreasing and coiling; preparing a strip; uncoiling, striping and removing burrs; electroplating Cu-Ni; performing primary conventional washing and drying; performing thermal spraying on Ni-Ag; performing secondary conventional washing and drying; performing secondary annealing; naturally cooling to room temperature and then coiling. According to the product disclosed by the production method disclosed by the invention, the tensile strength is 330 to 380MPa, and the elongation is 34 to 38 percent; a layer of Cu-Ni / Ni-Ag double-composite coating with uniformity, compactness and high adhesive force is generated on the surface of the product; the surface hardness of the coating is 90 to 100HV, the roughness of the coating is 0.15 to 0.30 mu m, the mirror reflectivity is 88 to 95 percent, the resistivity is 6.5 to 8.7 mu omega cm, and the thermal conductivity is 6 to 10W / cm DEG C. The problems of high cost, great waste, serious pollution and low efficiency caused by a traditional process are solved.

Owner:武钢集团有限公司

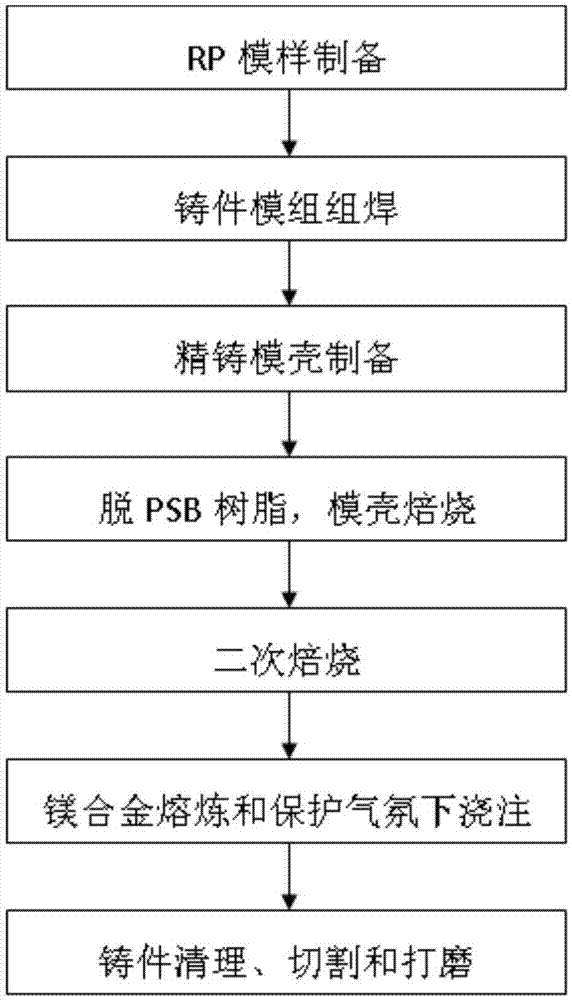

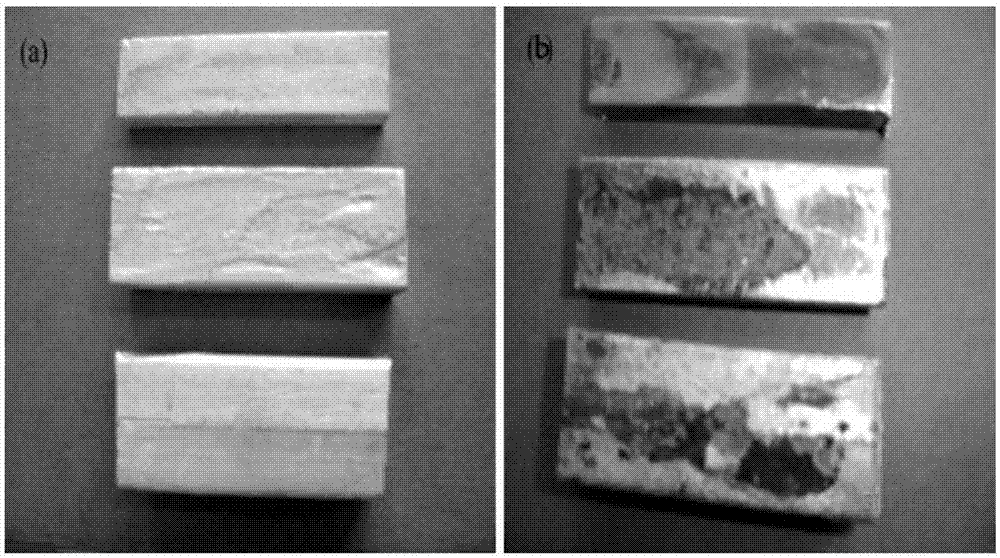

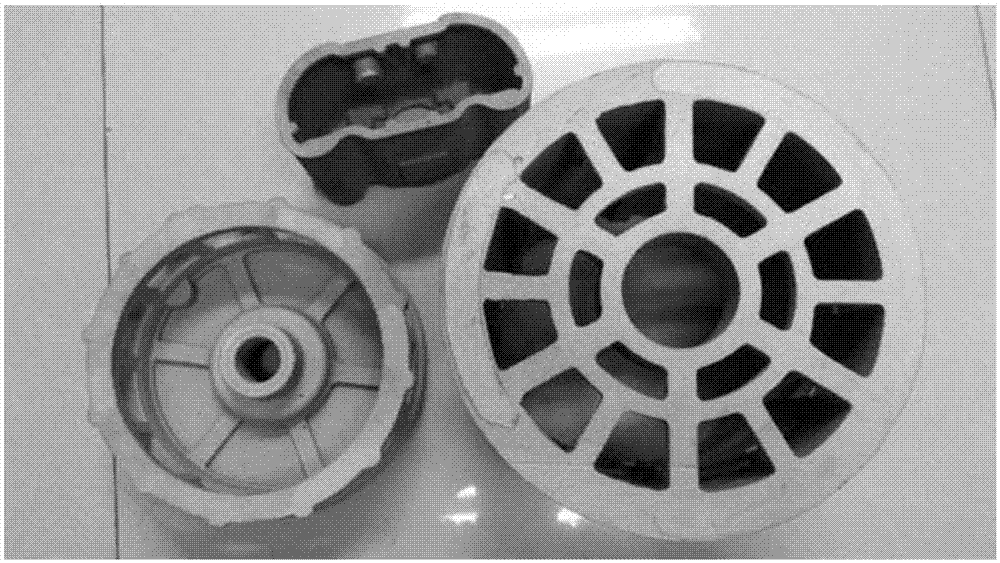

Precision investment casting method for magnesium alloy

The invention discloses a precision investment casting method for magnesium alloy, which is used for solving the technical problem that the conventional investment casting method is poor in oxidization prevention measures. According to the technical scheme, the method comprises the following steps: preparing a wax mould by adopting 3D laser printing, using ZrO2 as a surface layer and second layer sand material, and desorbing resin by using a roasting method to be sufficiently burned; after roasting, immersing a mould shell cavity in a hot saturated boric acid aqueous solution with the temperature being 90-100 DEG C; before pouring, introducing mixed protection gas with the volume fraction ratio of HFC134a to Ar being 30 to 70; in the pouring process, uninterruptedly sprinkling appropriate sulfur to the magnesium alloy ladle pouring liquid level and a riser, and thus effectively preventing magnesium alloy oxidation and burning. As the wax mould is prepared by adopting 3D laser printing, the dimensional precision and the surface smoothness of magnesium alloy casts are ensured. ZrO2 is used to prevent magnesium alloy melt from reacting with a casting mould. The resin is desorbed by using the roasting method to be sufficiently burned, ash content and slag are not left, and the surface smoothness and the internal quality of the magnesium alloy casts are ensured.

Owner:宝鸡金航华颢新材料技术研究院有限公司

Preparaton method of iron nickel alloy/copper composite wire material

A composite FeNi alloy / Cu wire 4J50 / Cu is made of the copper rod cored FeNI alloy ingot through vacuum high-temp treating, squeezing at 900-950 deg.C, cold drawing and heat treating. Its advantages are high electric and thermal conductivities, better weldability, and good sealing performance to glass and ceramics.

Owner:SINO PLATINUM METALS CO LTD

Water-soluble and oil-soluble diamond grinding liquid and preparation method thereof

The invention discloses water-soluble and oil-soluble diamond grinding liquid, and belongs to the field of precise finishing and polishing processing. The liquid is prepared by the following raw materials in percentages by weight: 54-87% of base oil, 5-15% of an emulsifier, 5-10% of a co-emulsifier, 0.1-1% of an anti-aging agent of oil products, 0.05-5% of a diamond abrasive, and the balance being water. The invention also discloses a preparation method of the water-soluble and oil-soluble diamond grinding liquid, and the method comprises the following steps: (1) the base oil, the emulsifier, the co-emulsifier and the anti-aging agent of oil products are mixed and poured into a reaction vessel, and heating is carried out with stirring at 70 DEG C for 10-20 minutes; (2) the diamond abrasive is added into water and placed in supersonic wave with stirring for 10 minutes, and mixed liquor is obtained; (3) the mixed liquor with dispersed diamond abrasive is slowly added into a reaction vessel, temperature is raised to 70 DEG C with stirring for 30 minutes, temperature is reduced to room temperature with stirring, and the water-soluble and oil-soluble diamond grinding liquid is obtained.

Owner:HENAN UNION ABRASIVES

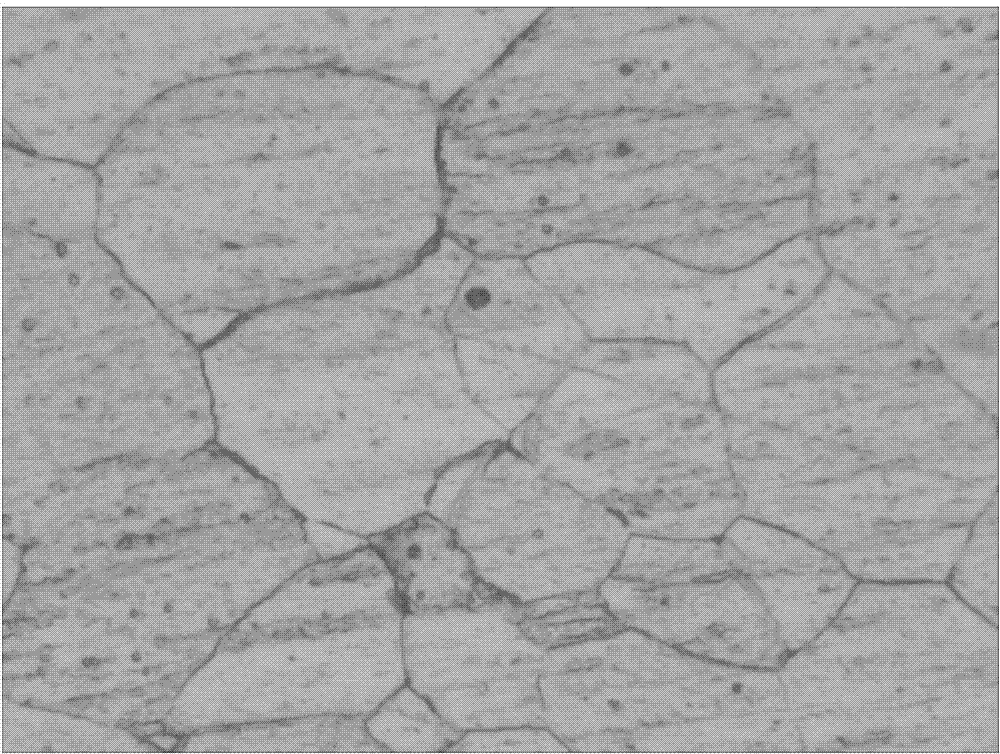

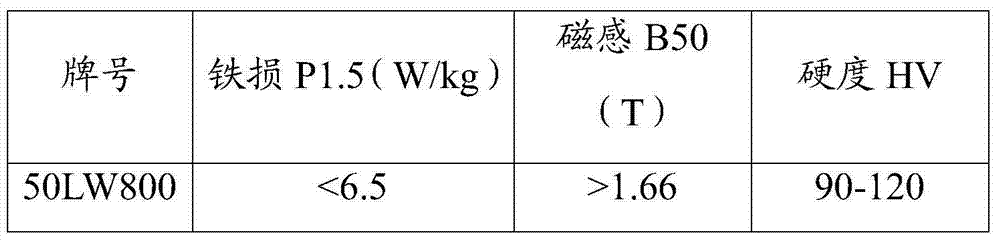

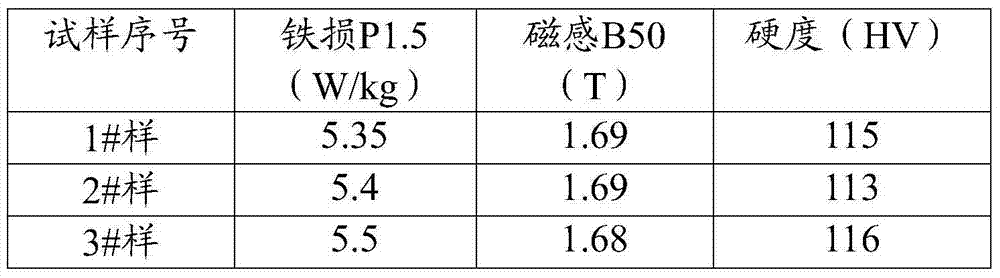

Semi-processed non-oriented silicon steel and manufacturing method thereof

ActiveCN104195426AGuaranteed plasticityGuaranteed surface finishChemical compositionSurface roughness

The invention provides semi-processed non-oriented silicon steel. The silicon steel comprises following chemical components by mass: not more than 0.005% and not less than 0 of C, not more than 0.8% and not less than 0.15% of Si, not more than 0.4% and not less than 0.2% of Mn, more than 0.02% and less than 0.1% of P, more than 0% and less than 0.01% of S and not more than 0.1% and not less than 0.03% of Al, with the balance being Fe. The thickness of the silicon steel is 0.35-0.65 mm, the width is 1000-1250 mm, and the surface roughness Ra is 0.4-1.0 [mu]m. Through a plurality of tests and trials, the silicon steel fully meets quality requirements on iron loss and magnetic induction for motors. After secondary annealing and blueing, the performance can be improved by two levels. The silicon steel is favored by users at present. As the development prospect of the motor industry is wide, the silicon steel is high in popularization and application value and has a wide prospect.

Owner:浙江龙盛薄板有限公司

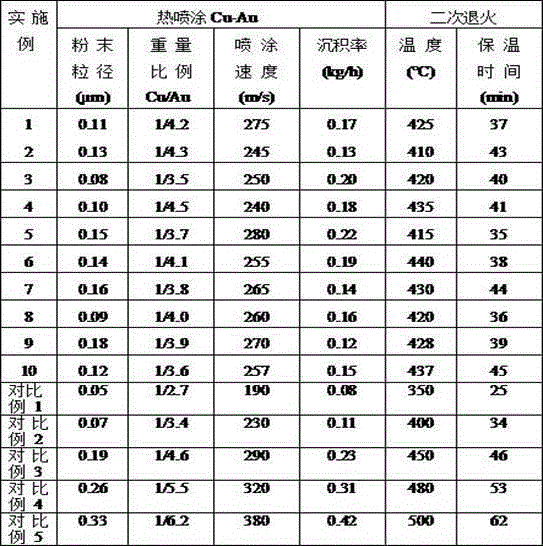

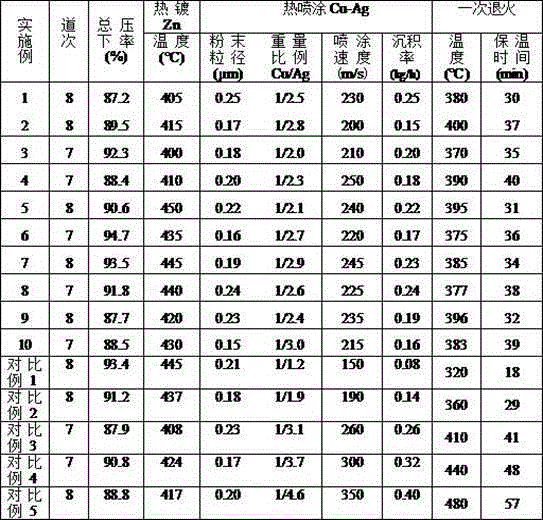

Production method of Zn/Cu-Ag/Cu-Au composite coating steel band for photoelectric material

ActiveCN105063620AReduce internal stressGuaranteed surface finishSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

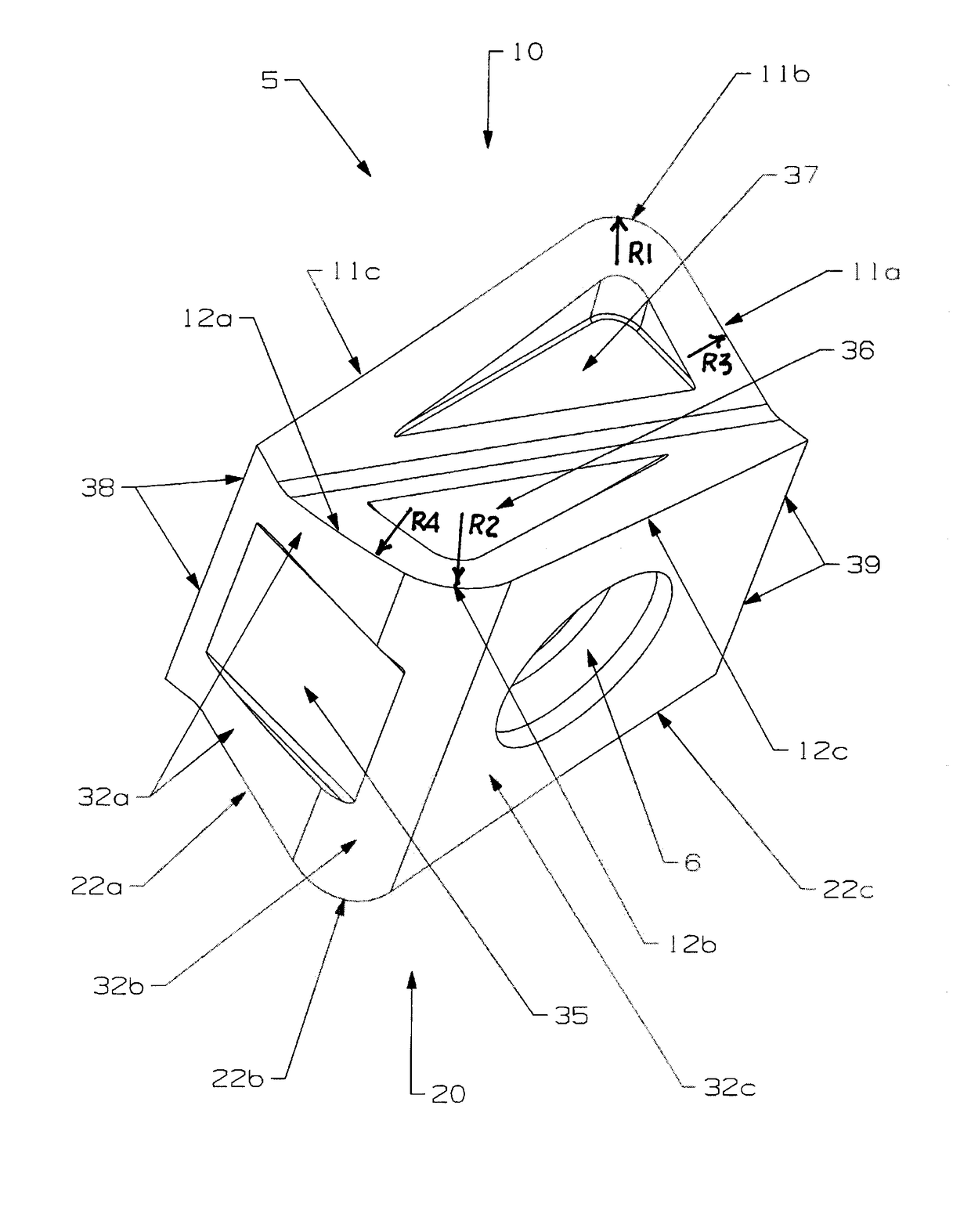

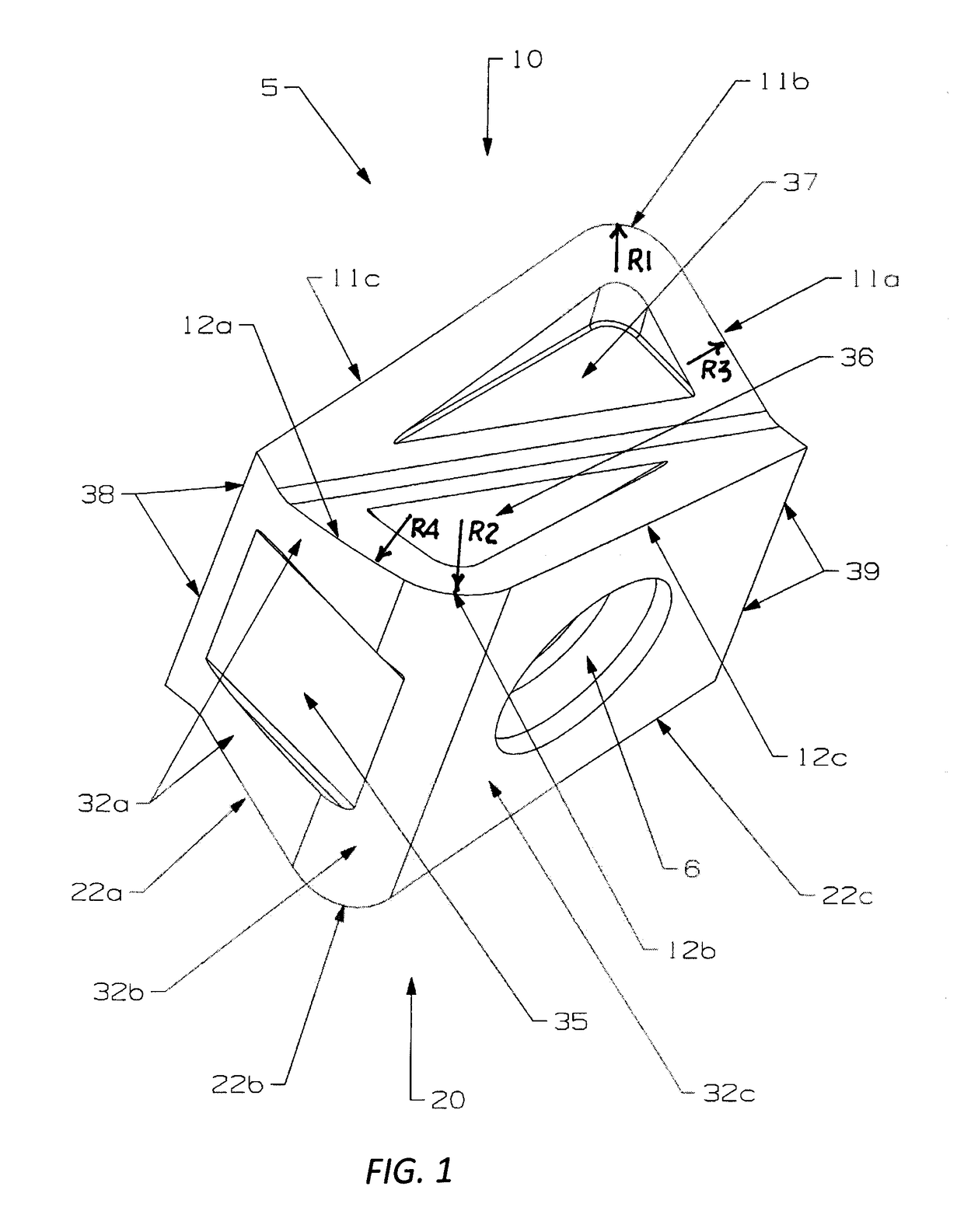

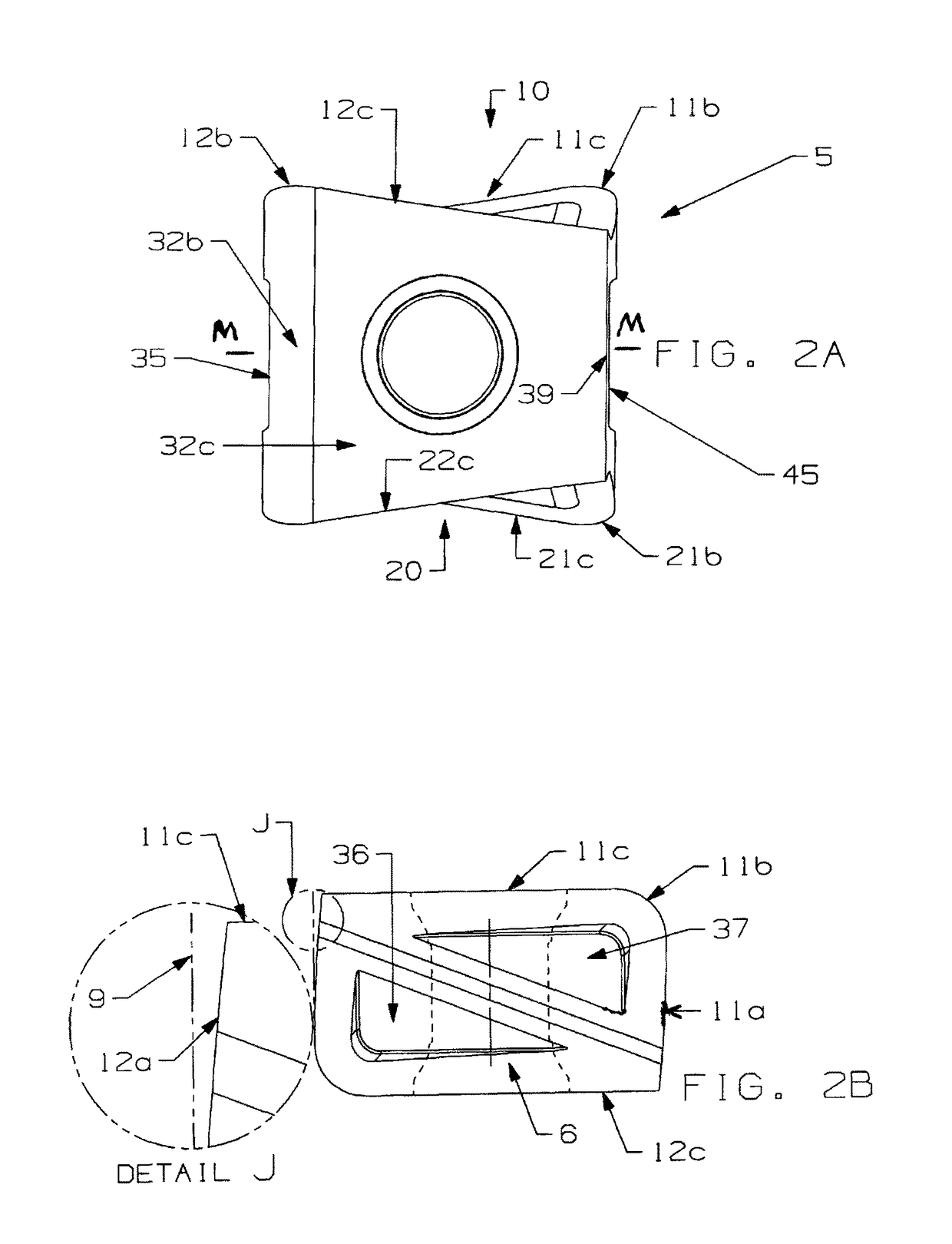

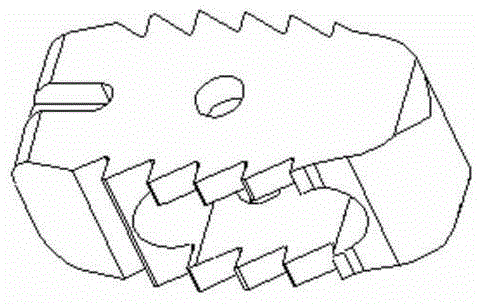

Double-sided tangential cutting insert and cutting tool system using the same

A double-sided tangential cutting insert, as well as a tool holder system that carries a plurality of the double-sided tangential cutting inserts, that has a peripheral side shape, as viewed from one of said cutting rake faces, that includes a pair of generally identical opposing main cutting edges wherein each of the main cutting edge comprises a substantially straight main cutting edge portion and an adjoining convex main cutting edge portion. The convex main cutting edge portion is truncated by an adjacent convex minor side face so as to define a generally sharp edge and a point of truncation. The peripheral side shape further includes a pair of opposing full nose cutting edges with a nose cutting radius; and a pair of opposing convex minor cutting edges with a minor cutting edge radius. The minor cutting edge radius is at least about four times greater than the nose cutting radius.

Owner:KENNAMETAL INC

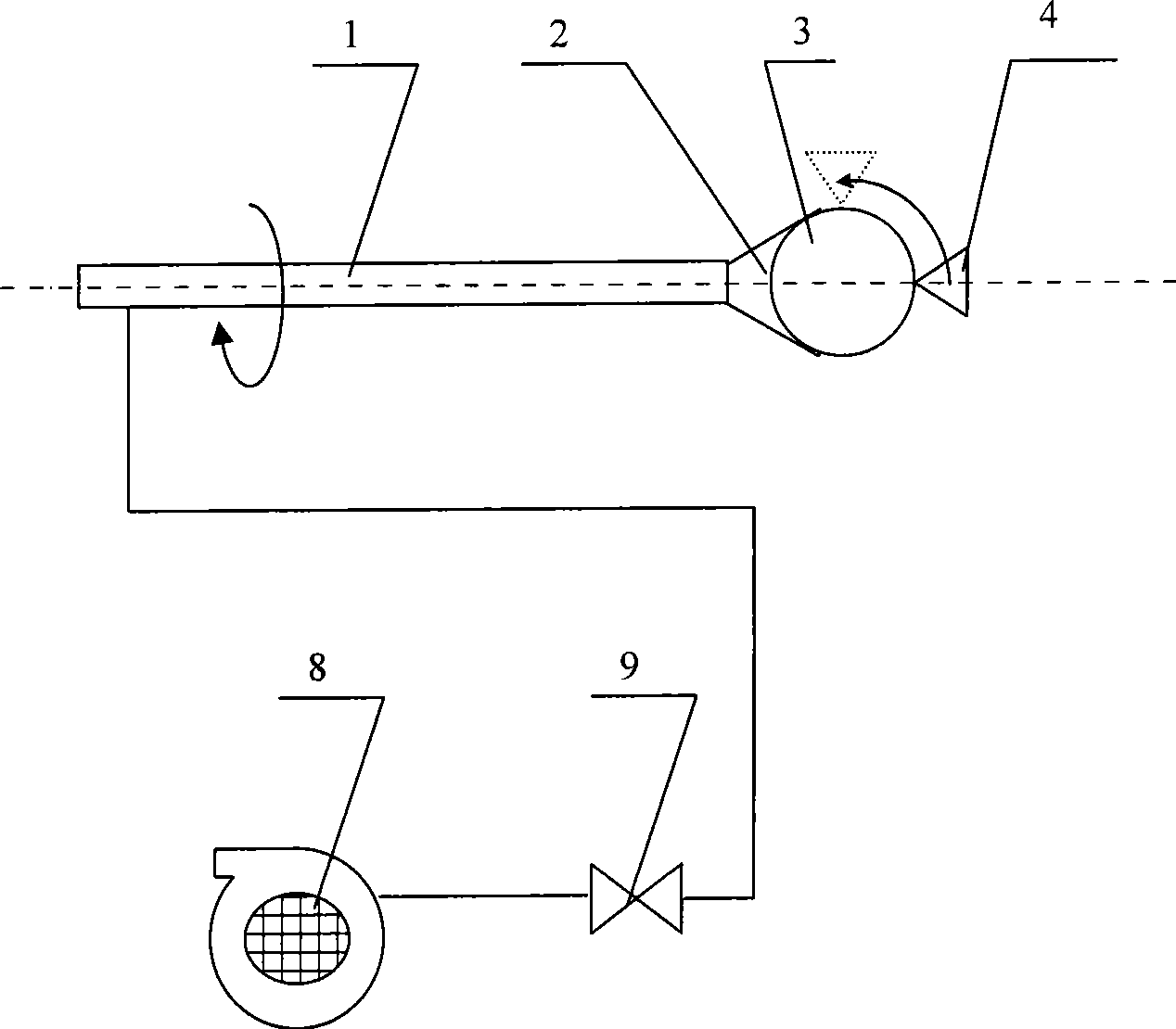

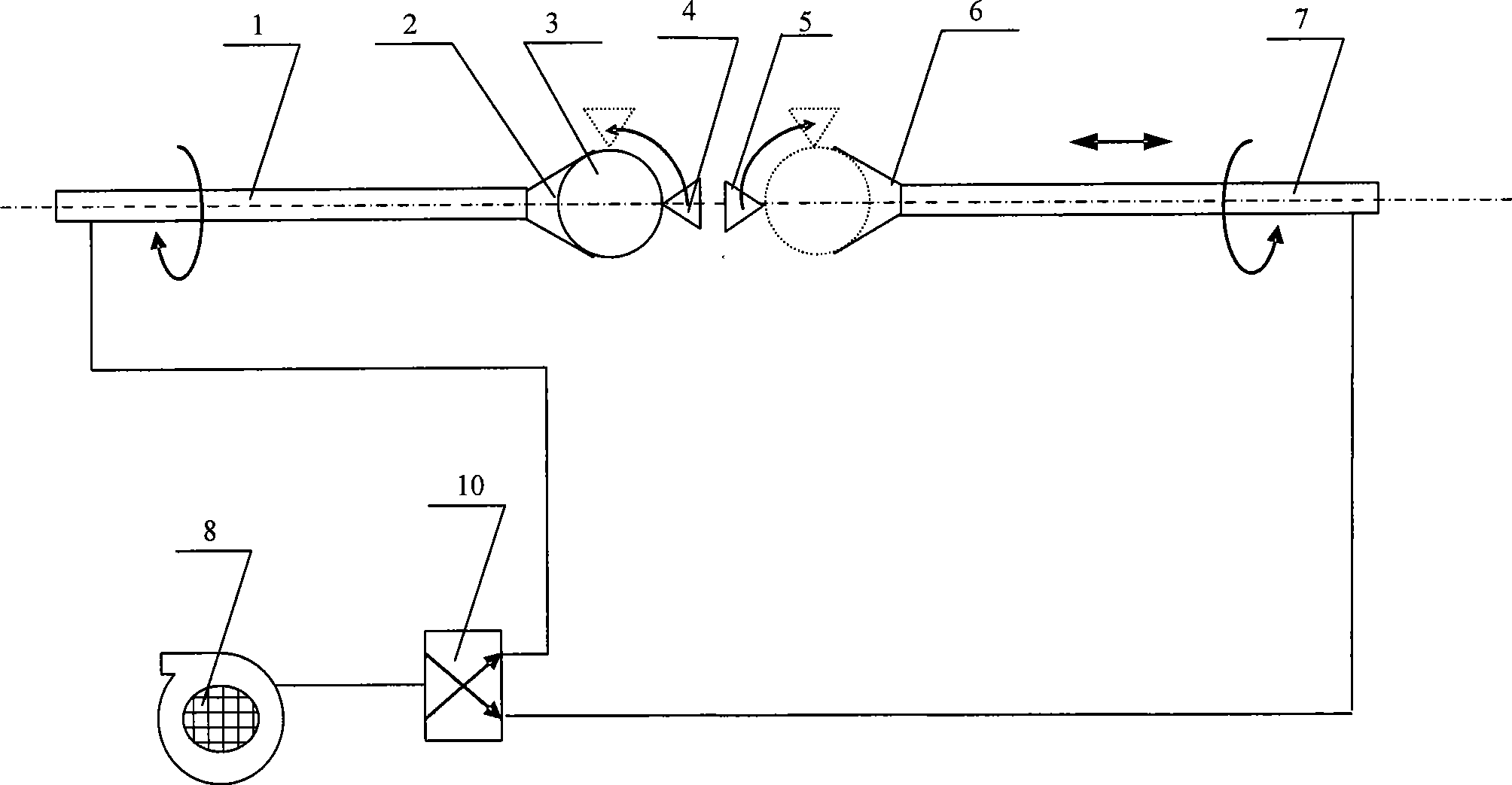

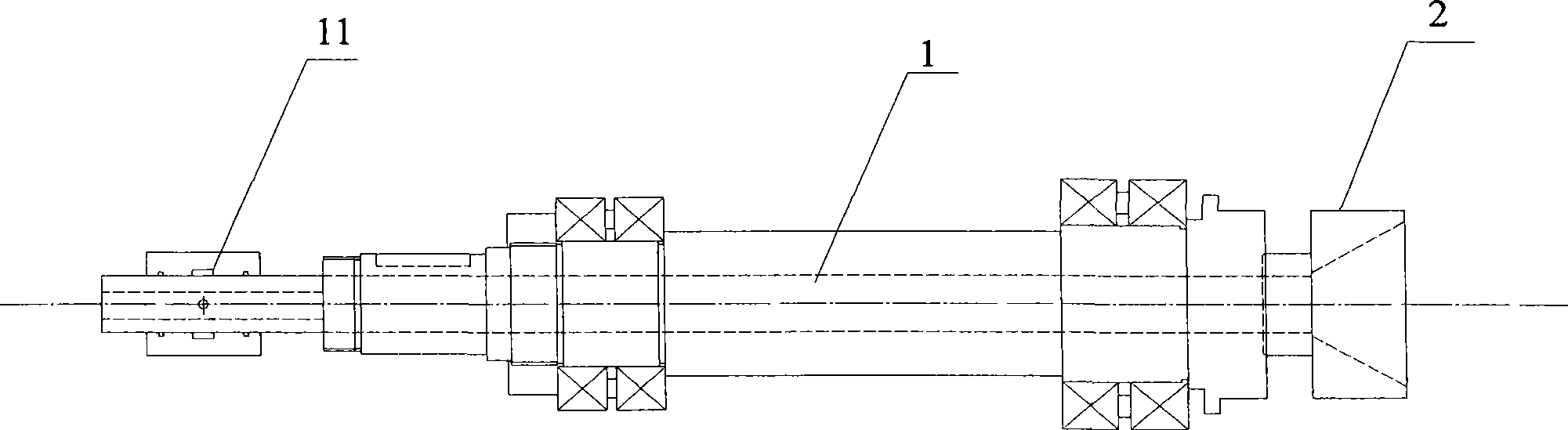

Method and device for finish-machining spherical ingot

InactiveCN101456080ACut evenlyEnsure eccentricityFeeding apparatusTurning machinesSurface finishAutomatic control

The invention relates to the technical field of ball blank processing, in particular to a method and a device for mechanically processing a high-temperature gas-cooled reactor fuel element ball blank or graphite ball blank. A main shaft holds the ball blank to rotate along an axial lead, a cutter is fed and reaches in place to move in a plane of the main shaft using a ball center of the ball blank as a circle center in an arc shape of 90 degrees, so as to finish semi-ball processing, and finishing of the whole ball blank can be finished through twice semi-ball processing. The device system can ensure even cutting of the whole ball blank, so as to ensure that a fuel-free area of fuel element produces eccentricity due to machining; in addition, when the method and the device are used for processing, surface finish can be ensured by feeding speed; the whole operating process is easy to realize automatic control, particularly when a double-shaft mechanism with the characteristics is adopted, the processing of two semi-balls can be finished continuously; and compared with the prior machine tool, precision of work pieces and working efficiency are improved greatly.

Owner:TSINGHUA UNIV +1

Packing powder for sintering ceramic core

ActiveCN104043770AGood wax removal ability and surface finishGood supportFoundry mouldsFoundry coresSurface smoothnessMass ratio

The invention aims to provide packing powder for sintering a ceramic core. The packing powder is characterized by being formed by mixing fine particle powder and ceramic balls, wherein the mass ratio of the fine particle powder to the ceramic balls ranges from (3:1) to (10:1). The packing powder has certain de-waxing capability in a biscuit de-waxing phase, has high supporting capability in a sintering process and guarantees that the finished product ceramic core has no gravity deformation and has certain surface smoothness; the yield in a production process of the ceramic core can be improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Durable silicon steel furnace bottom roller sleeve and preparation method thereof

The invention relates to a silicon steel furnace bottom roller sleeve and a preparation method thereof. The technical scheme of the invention is as follows: 2-10wt% of dense carbon material large particles, 2-10wt% of dense carbon material small particles, 80-95wt% of dense carbon material fine powder and 0.3-2.0wt% of Si micro powder are mixed together and are then ground for 20 to 30 minutes with the addition of 8-20wt% of bonding agent of the above materials; a silicon steel furnace bottom roller sleeve blank is manufactured after the mixed grinding and is baked for 4 to 8 hours after heat preservation under the temperature of 1,400 to 1,450 DEG C; then the silicon steel furnace bottom roller sleeve blank is placed in a pressure vessel and is maintained for 15 to 30 minutes under the pressure of 10,000 to 20,000Pa, tar is filled until the sleeve blank is completely soaked, and then the sleeve blank is pumped to the vacuum degree of 10,000 to 20,000Pa and is maintained for 15 to 30 minutes; finally, the sleeve blank is heat-preserved for 8 to 12 hours under the high temperature of 1,950 to 2,150 DEG C and is processed by machinery until the surface roughness is smaller than or equal to 12.5. The durable silicon steel furnace bottom roller sleeve has the characteristics of long service life, good oxidation resisting performance, high strength, good wear-resisting property, low porosity, no accretion and high quality of silicon steel plates.

Owner:WUHAN UNIV OF SCI & TECH

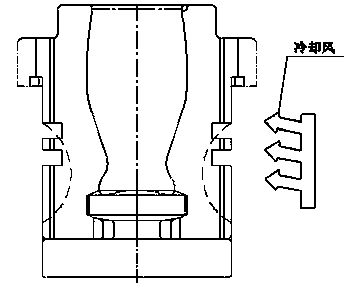

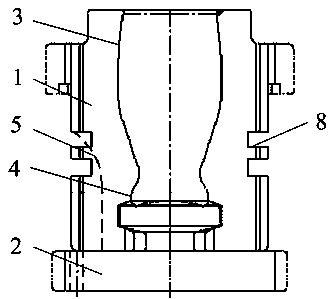

Glass forming mold

ActiveCN103803778ALow molding temperatureGuaranteed surface finishGlass blowing apparatusSurface finishBottle

The invention discloses a glass forming mold. The glass forming mold comprises a formed mold and a mold base matched with the bottom part of the formed mold, wherein the formed mold is provided with a bottle body forming cavity; a bottle bottom forming cavity is arranged on the mold base; the formed mold is provided with a cooling channel which penetrates through the bottom part of the mold base to the side wall of the formed mold and extends to the middle part of the formed mold to be communicated with the outside. The temperature of the upper part of the formed mold is higher during forming to guarantee the surface smoothness of a glass product; the temperature of the lower part of the formed mold is lower to be beneficial for the forming of the bottom part of the glass product and to prevent depressing.

Owner:DAYE HUAXING GLASS

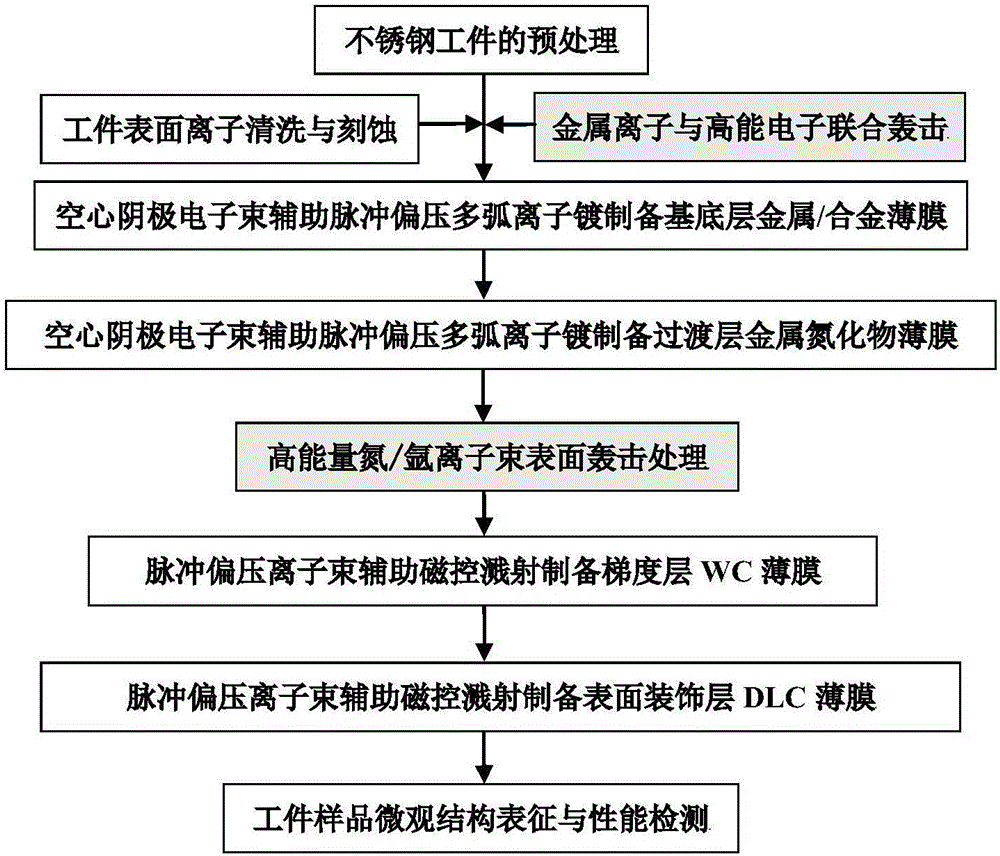

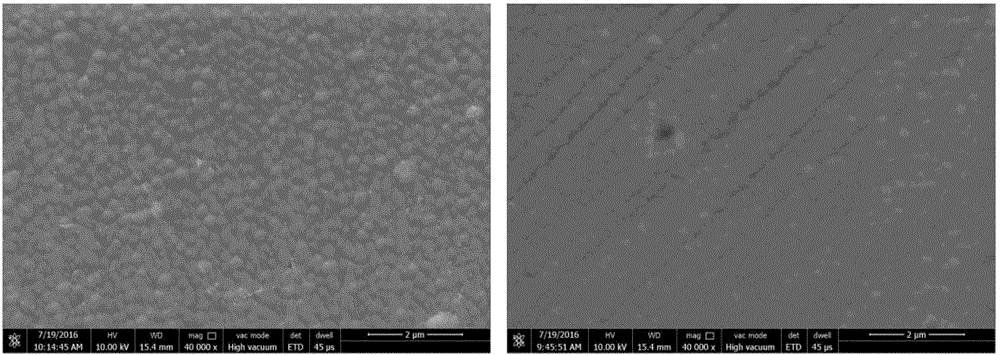

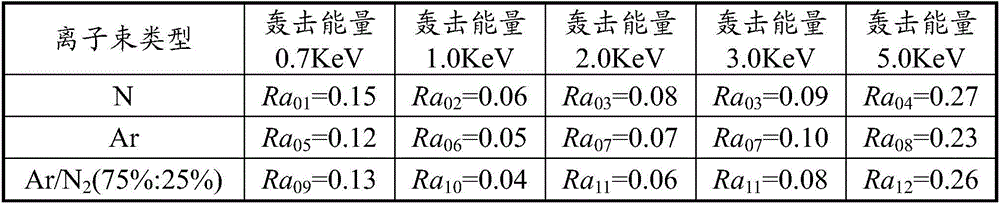

Functionally-graded diamond-like carbon film as well as preparation method and product of functionally-graded diamond-like carbon film

ActiveCN106244986AReduce manufacturing costImprove defectsVacuum evaporation coatingSputtering coatingCarbon filmCorrosion

The invention relates to a functionally-graded diamond-like carbon film as well as a preparation method and a product of the functionally-graded diamond-like carbon film. The preparation method of the functionally-graded diamond-like carbon film comprises the following steps: (1) depositing a metal base layer on the surface of a work piece by virtue of hollow cathode electron beams secondarily combined with pulsed-bias multi-arc ion plating; (2) depositing a metal nitride transition layer on the surface of the metal base layer by virtue of hollow cathode electron beams accompanied with pulsed-bias multi-arc ion plating; (3) depositing a tungsten carbide gradient layer on the surface of the metal nitride transition layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering; (4) depositing a diamond-like carbon decorative layer on the surface of the tungsten carbide gradient layer by virtue of pulsed-bias multi-arc ion plating accompanied with magnetron sputtering. The functionally-graded diamond-like carbon film prepared by the preparation method provided by the invention has the advantages of high glossiness, high interface bonding strength and high surface hardness and is also excellent in wear resistance, corrosion resistance and scratching resistance.

Owner:ZHUHAI ROSSINI WATCH IND +1

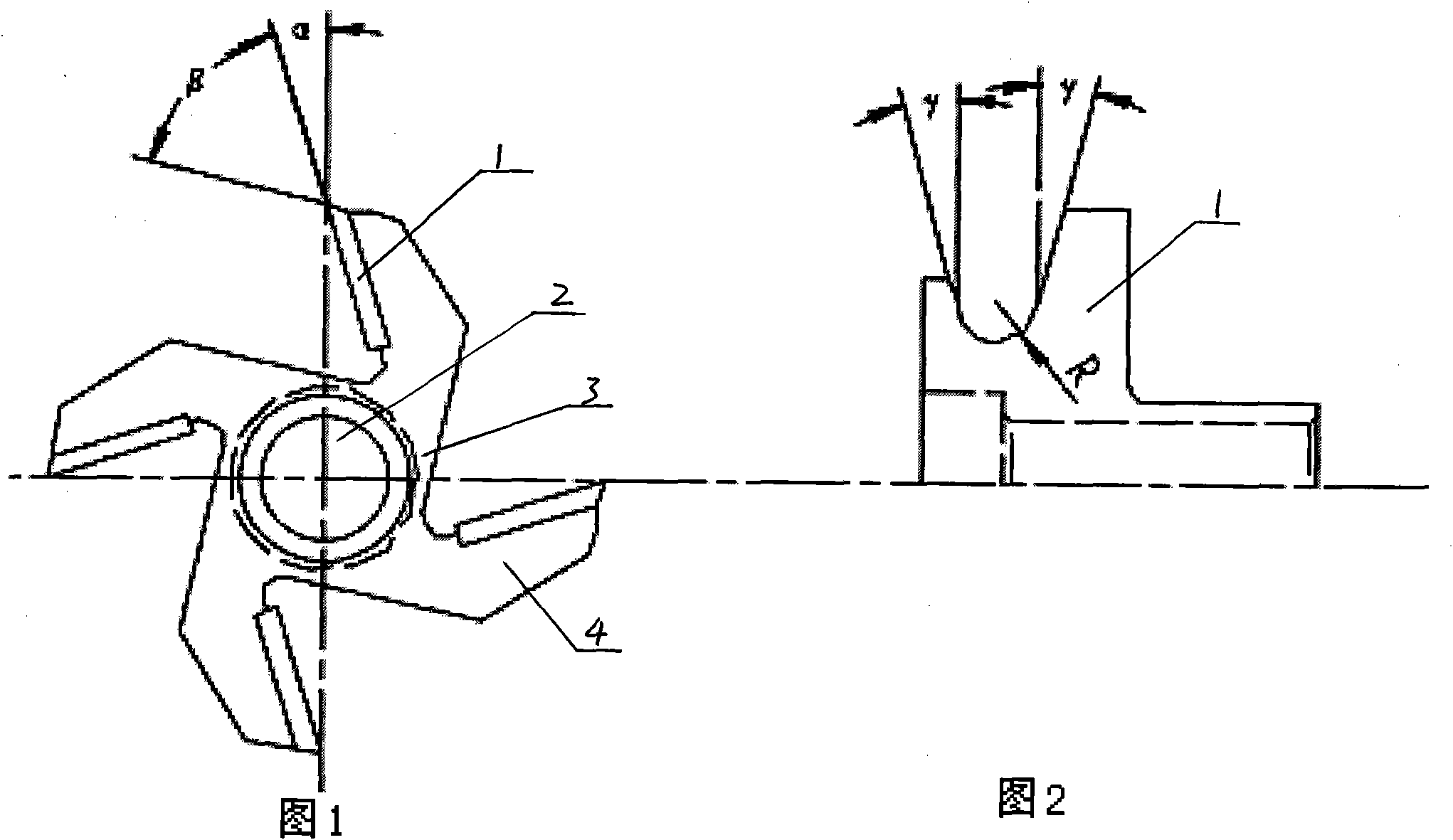

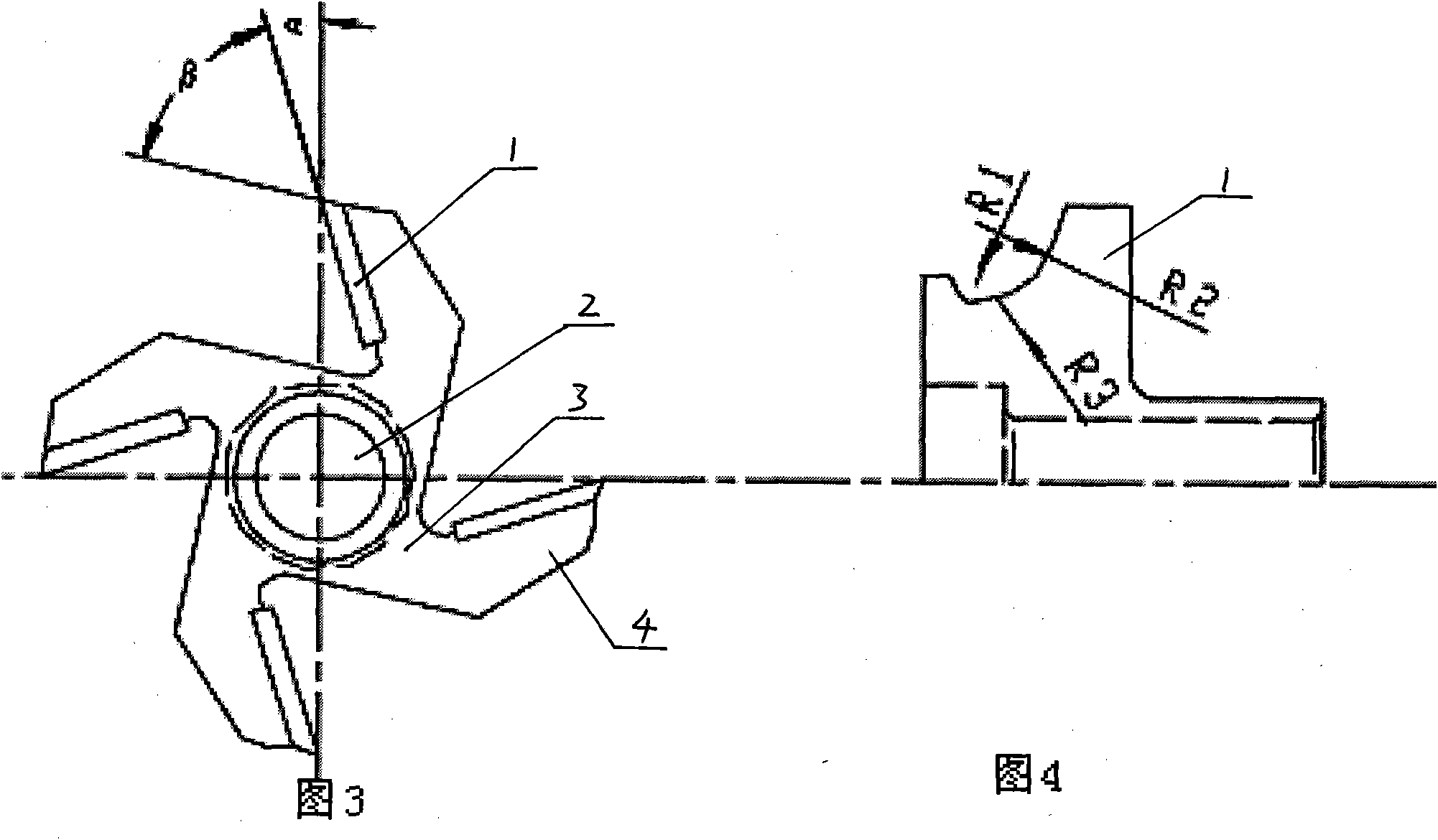

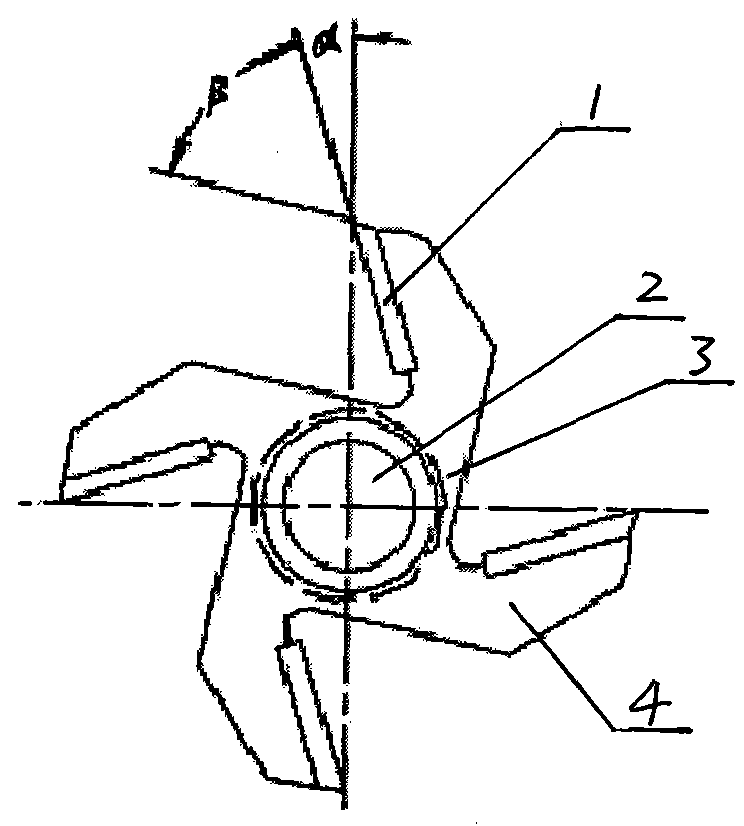

Moulding milling cutter

ActiveCN102029421AReduce processing timeGuaranteed machining accuracyMilling cuttersSurface finishMilling cutter

The invention discloses a moulding milling cutter. A cutter body is in a circular truncated cone shape; four inclined planes are evenly distributed at the outer edge of the end surface of one end part of the cutter body; a cutting tool is respectively fixed on concave platforms of the four inclined planes; the cutting edge of the cutting tool is in an arc shape matched with a cut arc shape of a cut workpiece; both ends of the cutting edge of the cutting tool respectively form an angle gamma (gamma is not greater than 15 degrees) with the tangent lines of two end circular arcs; the front end surface of the cutting edge of the cutting tool and a radial shaft of the end surface of the cutter body form an angle alpha (alpha is equal to 5-8 degrees); the middle part of the cutter body is provided with a penetrated counter bore; and a cutter shaft assorted with a machine tool is arranged in the counter bore. The invention ensures the processing precision and the surface finishment; the cutter body is in a counter bore structure of which the middle part is penetrated, can be clamped with a milling machine through the cutter shaft and is convenient to clamp; the arc processing of the workpiece can be completely finished by the milling machine of the milling cutter without manual operation, thereby shortening the processing time of the workpiece and improving the production efficiency.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

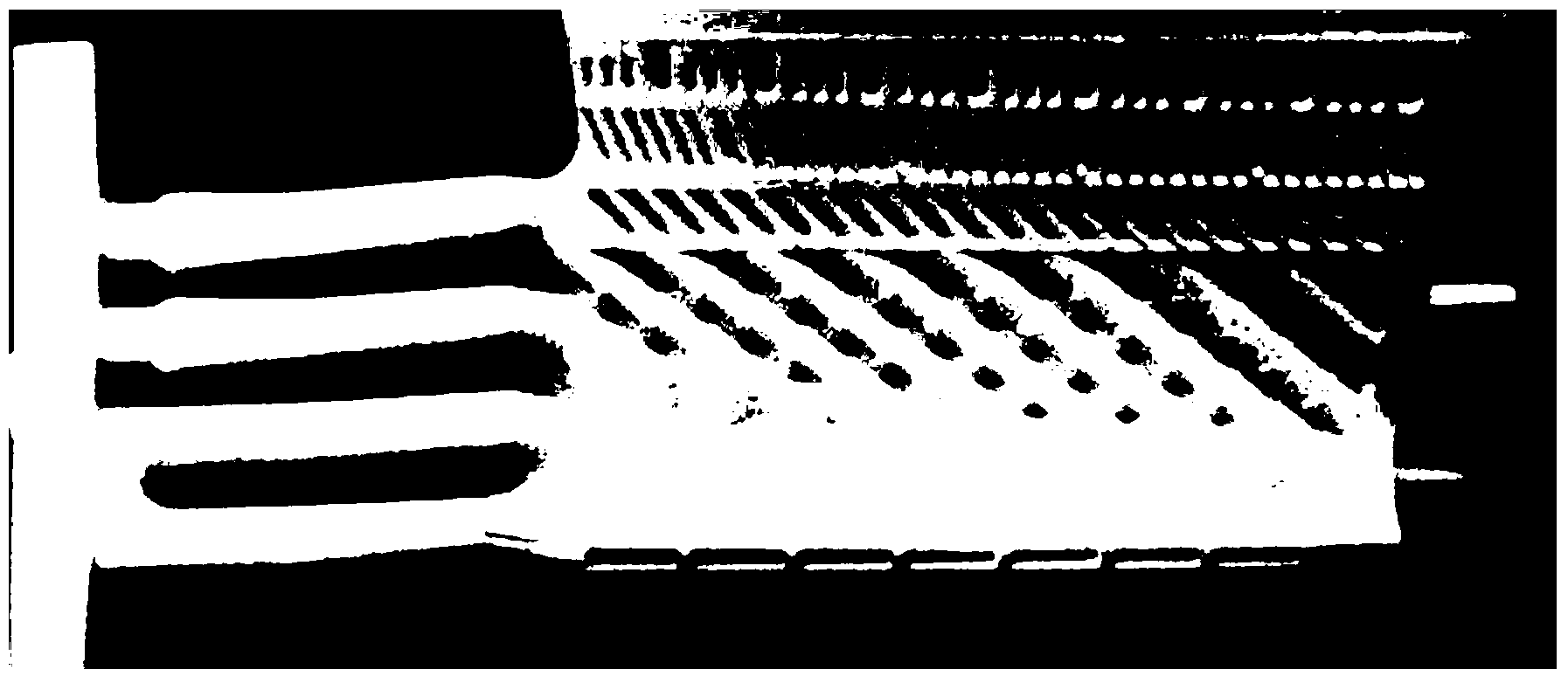

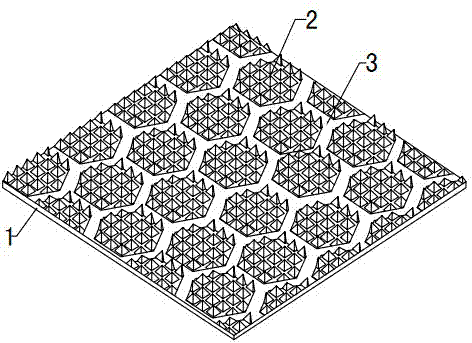

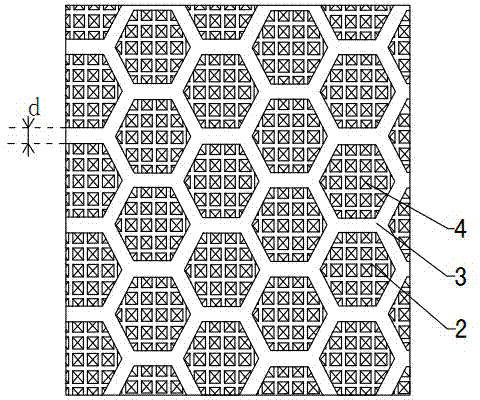

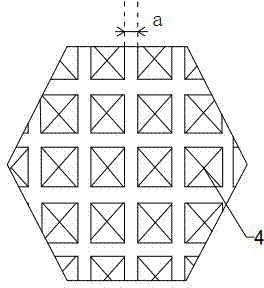

Anti-clogging stereoscopic structure grinding tool and preparation method thereof

ActiveCN104493737AImprove adhesionGuaranteed surface finishAbrasion apparatusGrinding devicesManufacturing technologyEngineering

The invention discloses an anti-clogging stereoscopic structure grinding tool and a preparation method thereof, and belongs to the technical field of grinding tool manufacture. The grinding tool is characterized in that a grinding material layer is divided into a plurality of staggered hexagonal large unit structures (2) by meshed chip removal channels (3), the width (d) of each chip removal channel is 200-450 micrometers, micro-tooth units (4) are densely distributed on the large unit structures (2), and the distance (a) between every two micro-tooth units is 80-120 micrometers. The preparation method is characterized in that the large unit structures (2) are printed by the aid of flexible nets after a pretreatment glue layer and a resin coating are coated, and the micro-tooth units (4) formed on each large unit structure (2) by grinding materials are flattened in a cold-pressed manner. By the aid of the chip removal channels among the large unit structures, grinded parts cannot generate dark fringes or micro-scratches, grinding chips can be timely removed, and the micro-tooth units can be firmly adhered by the aid of the distance between every two micro-tooth units.

Owner:ZIBO RIKEN MT COATED ABRASIVES

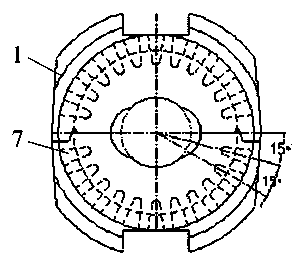

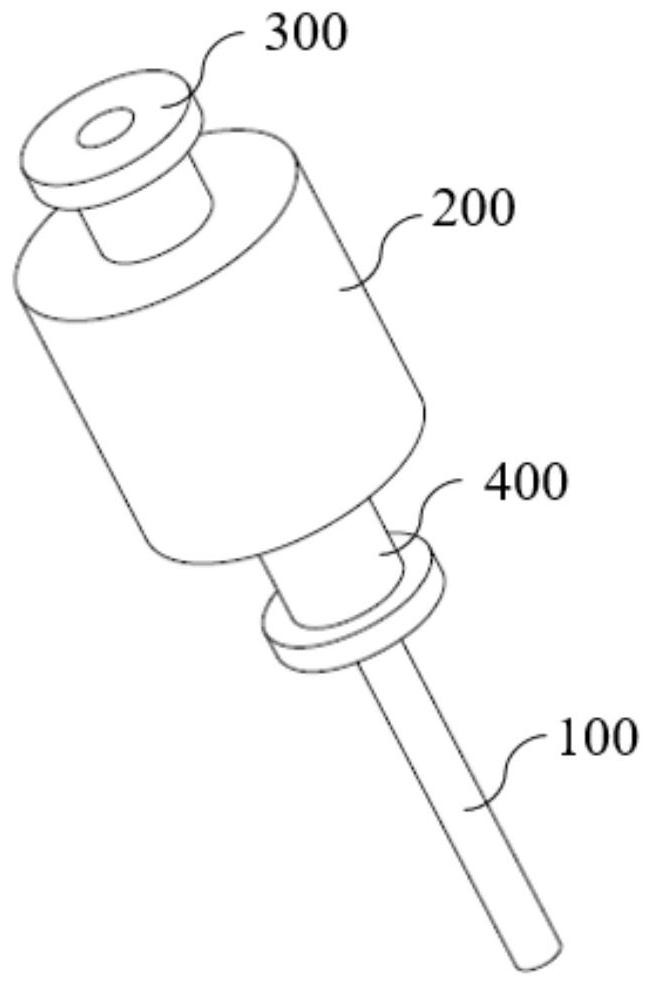

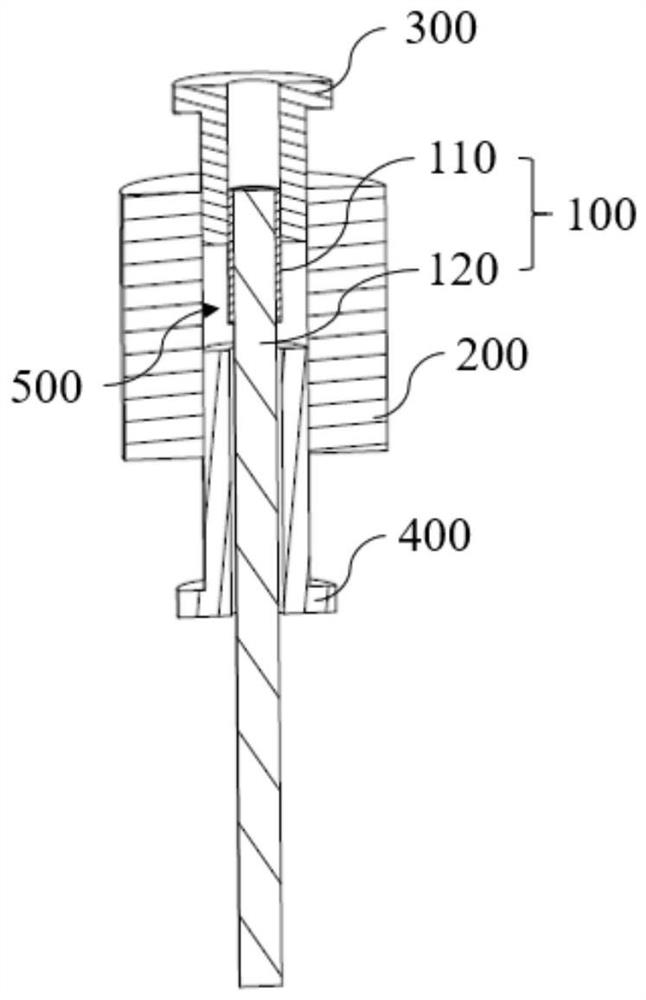

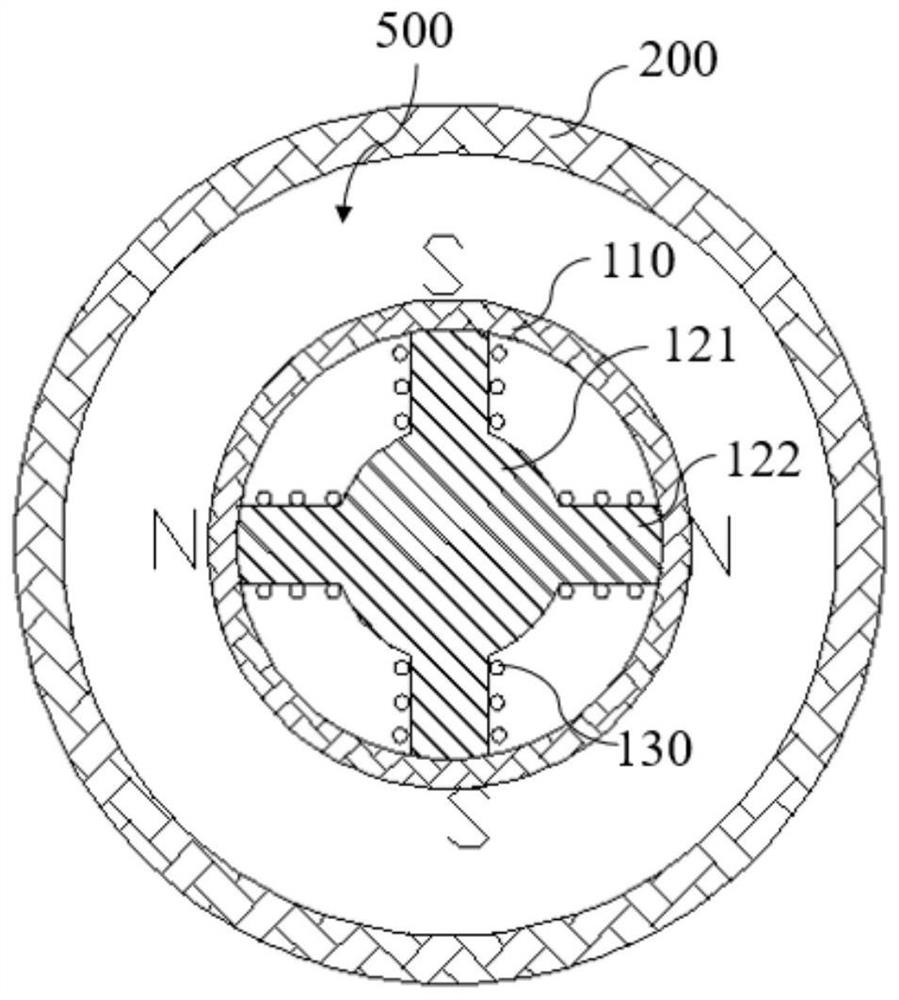

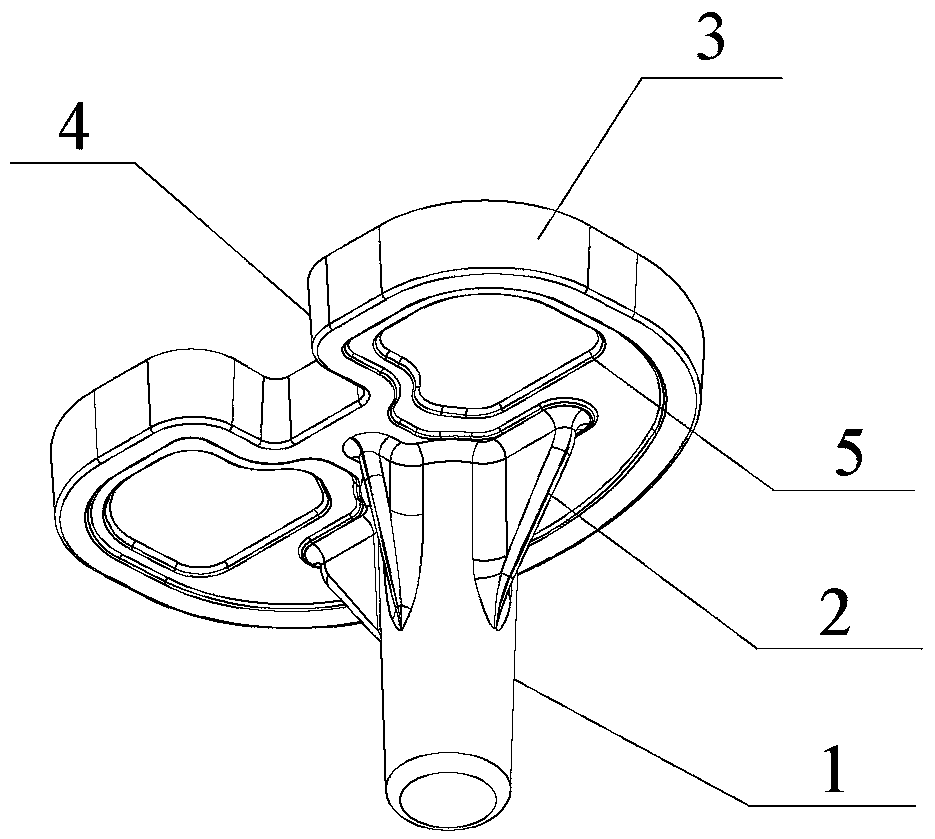

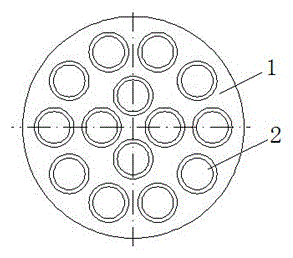

Anisotropic inner circle orientation multi-pole magnetic ring and mold and preparation method thereof

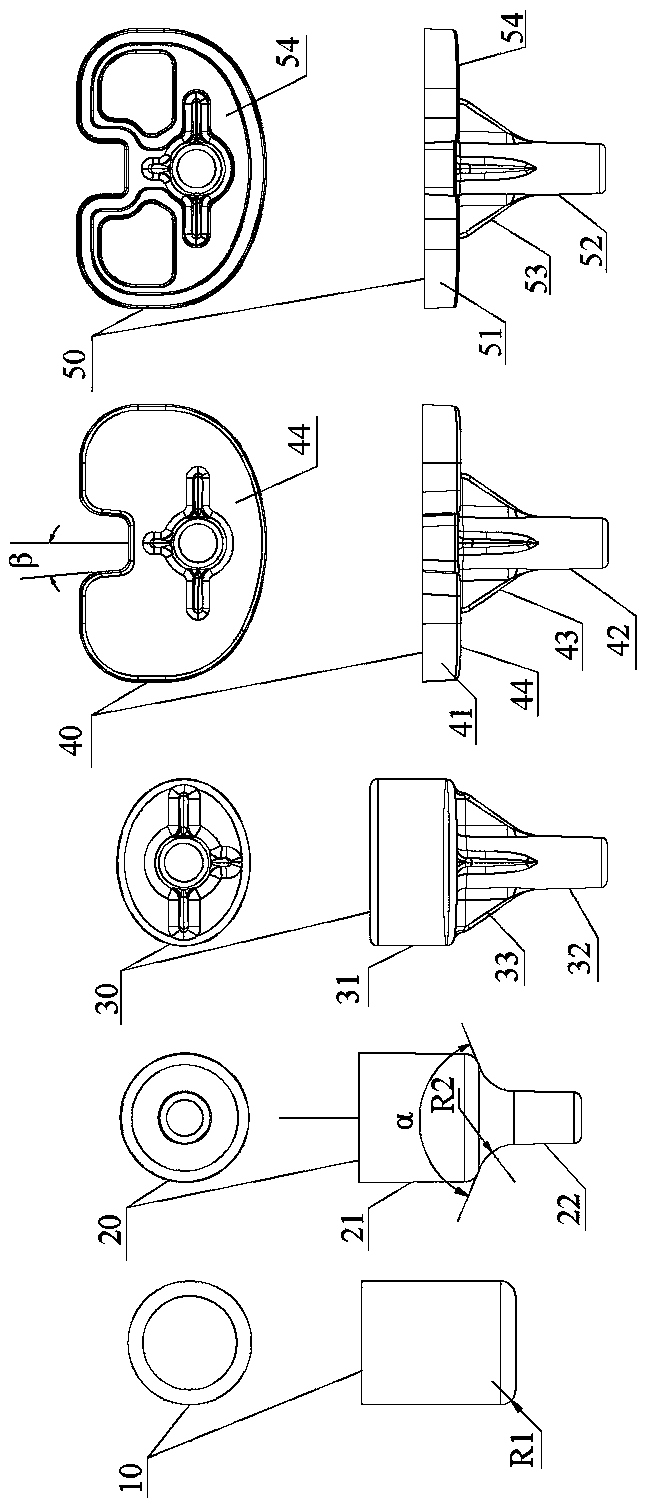

InactiveCN112086259ANo flux leakageQuiet and smooth operationPermanent magnetsInductances/transformers/magnets manufactureCopper wireElectric machinery

The invention discloses an anisotropic inner circle orientation multi-pole magnetic ring and a mold and a preparation method thereof, and belongs to the field of magnetic ring manufacturing. The multi-pole magnetic ring is an anisotropic 2n-pole magnetic ring with an oriented inner circle, n is a natural number, and the waveform of a magnetic circuit on the surface of the inner circle of the magnetic ring is a sinusoidal waveform; the mold comprises a core rod, an outer cylinder, an upper pressing head and a lower pressing head, and the core rod, the upper pressing head, the lower pressing head and the outer cylinder are matched and sleeved to form a mold cavity. The core rod comprises a sleeve and a magnet yoke, the magnet yoke comprises a base body and protruding parts, 2n protruding parts are distributed on the side face of the end, stretching into the upper pressing head, of the base body in the circumferential direction, copper wires are wound around the protruding parts respectively, and the protruding parts are sleeved with the sleeve in a matched mode. The preparation method comprises the following steps of: filling magnetic powder into the mold cavity, pressing the magnetic powder, electrifying a copper wire, applying a direct-current or pulsed magnetic field to the magnetic powder, orienting the magnetic powder, sintering, grinding and magnetizing to obtain the anisotropic inner circle orientation multi-pole magnetic ring. The multi-pole magnetic ring is directly manufactured into an integral stator magnetic ring, and stable and quiet operation of a motor is facilitated.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Forging method for CoCrMo tibial plateau artificial joint implant

ActiveCN110369655AImprove mechanical propertiesReduce the amount of processingMetal-working apparatusTibiaArtificial joints

The invention provides a forging method for a CoCrMo tibial plateau artificial joint implant. The problem that CoCrMo tibial plateaus cannot be produced through existing conventional forging method, and CoCrMo tibial plateaus produced through precision casting methods are low in finish degree, poor in mechanical property and dimensional accuracy can be solved. The method comprises the steps of blanking, surface treatment, spray coating, primary extrusion, surface treatment, spray coating, secondary extrusion, surface treatment, spray coating, pre-forging, surface treatment and final forging.

Owner:无锡航亚科技股份有限公司

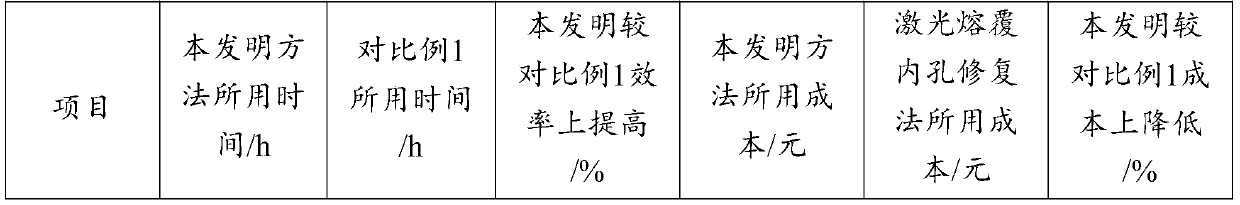

Hydraulic support oil cylinder refabrication method based on CMT (Cold Metal Transition)

The invention provides a hydraulic support oil cylinder refabrication method based on CMT and belongs to the technical field of metal surface engineering. The hydraulic support oil cylinder refabrication method comprises the steps that mechanical machining and cleaning are firstly performed on the oil cylinder inner wall to be repaired in sequence, then CMT welding is performed on the hydraulic support oil cylinder inner wall, finally, the mechanical machining is performed on a CMT weld layer, and a refabricated hydraulic support oil cylinder is obtained. According to the hydraulic support oilcylinder refabrication method based on the CMT, the cold metal transition welding technology is utilized to weld the hydraulic support oil cylinder inner wall, heat input and spatter are less in thewelding peocess, the fact that the refabricated oil cylinder will not lose efficacy due to heat deformation can be guaranteed, and the service life of the oil cylinder is prolonged; by means of the manner that the mechanical machining is performed on the oil cylinder inner wall before and after the welding, the surface smoothness, the size and the tolerance of the oil cylinder all can be guaranteed to meet the drawing requirements; and meanwhile, the refabrication method provided by the invention is low in cost and high in efficiency, and full-automatic production can be realized.

Owner:YANSHAN UNIV

Titanium alloy powder, and preparation method and application thereof

The invention discloses a titanium alloy powder, and a preparation method and application thereof. The titanium alloy powder is mainly prepared by mixing the following components in percentage by weight: 2-7% of aluminum powder, 2-8% of molybdenum powder, 2-6% iron powder and the balance of titanium powder. The titanium alloy powder is mainly applied to the field of preparation for orthopedic implant special-shaped parts for spinal internal fixation. The titanium alloy powder has low cytotoxicity and production cost, and can achieve complex three-dimensional structure formation once and mass production of the orthopedic implant special-shaped parts with high raw material utilization rate, low cost and excellent mechanical property.

Owner:长沙瑞泰医学科技有限公司

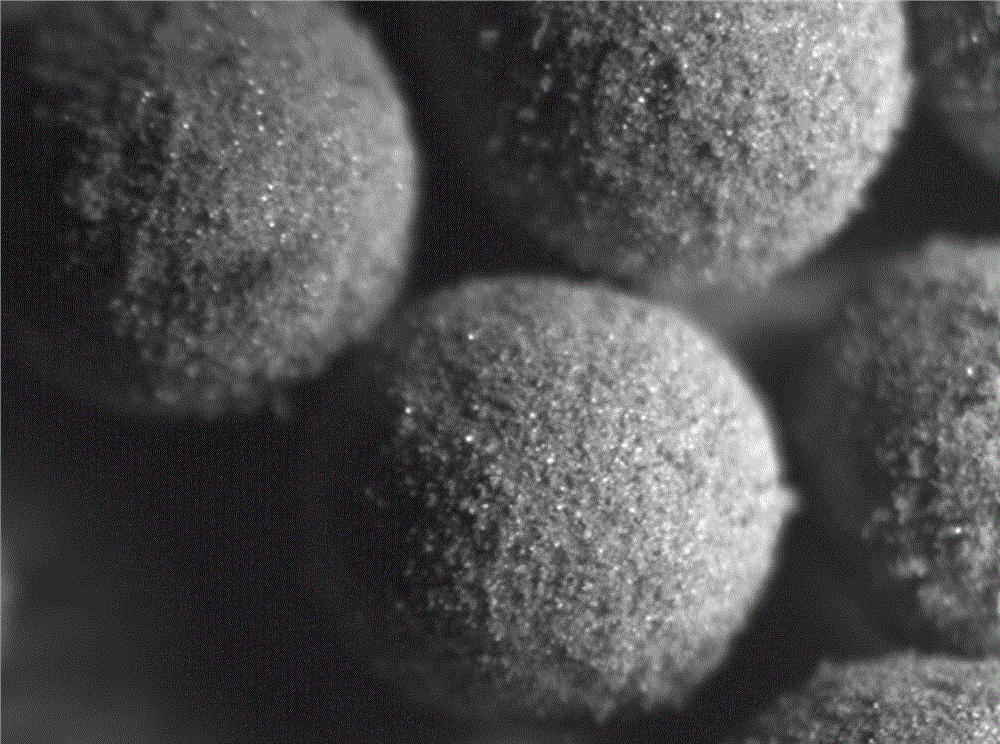

Ceramic stacked abrasive material, method for preparing same, and grinding tool

InactiveCN105666347AIncreased durabilityImprove grinding performanceAbrasion apparatusGrinding devicesMicrosphereCeramic

The invention provides a ceramic stacked abrasive material. Hollow microspheres are mainly taken as the base body, and the surfaces of the hollow microspheres are evenly wrapped in a fugitive binder and a micro powder-level abrasive material and ceramic bond powder which adhere to the fugitive binder; then calcination is conducted to form the hollow spherical ceramic stacked abrasive material. The invention further provides a method for preparing the ceramic stacked abrasive material and a grinding tool using the ceramic stacked abrasive material. By the adoption of the ceramic stacked abrasive material, the thickness of a working layer of the grinding tool can be made large, so that the durability of the grinding tool is improved greatly; furthermore, large gaps exist between particles during grinding and polishing, so that blocking is effectively prevented and grinding efficiency is improved, high flatness of the surface of the working layer can be guaranteed, and surface smoothness can be guaranteed during grinding and polishing. The grinding tool also has the properties of resin binders, so that the sharpness and durability of the grinding tool are improved.

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

Measurement method of small hardness sample and clamping fixture

InactiveCN105277432AReduce work intensityGuaranteed parallelismInvestigating material hardnessEngineeringHardness

The invention discloses a measurement method of small hardness sample and clamping fixture. The method comprises: first placing a clamping fixture full with positioning and mounting holes on a backing plate, clamping the hardness samples separately in the positioning and mounting holes, fixing every hardness sample on the clamping fixture on basis of the upper surface of the backing plate, clamping and fixing the clamping fixture on a polish-grinding machine and polishing and grinding the end surface to be measured of the hardness sample, placing the clamping fixture on the table of the hardness test machine, and then measuring one by one the end surface of the hardness sample to be measured on the clamping fixture and recording results. In the invention, the hardness samples are made and measured together, while the original method for hardness measurement is only in a single measurement style, measurement efficiency is largely promoted, work intensity of the personnel is lowered, and defects of slow speed, trivial steps and low efficiency for the measurement and preparation of hardness samples in the prior art is solved.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

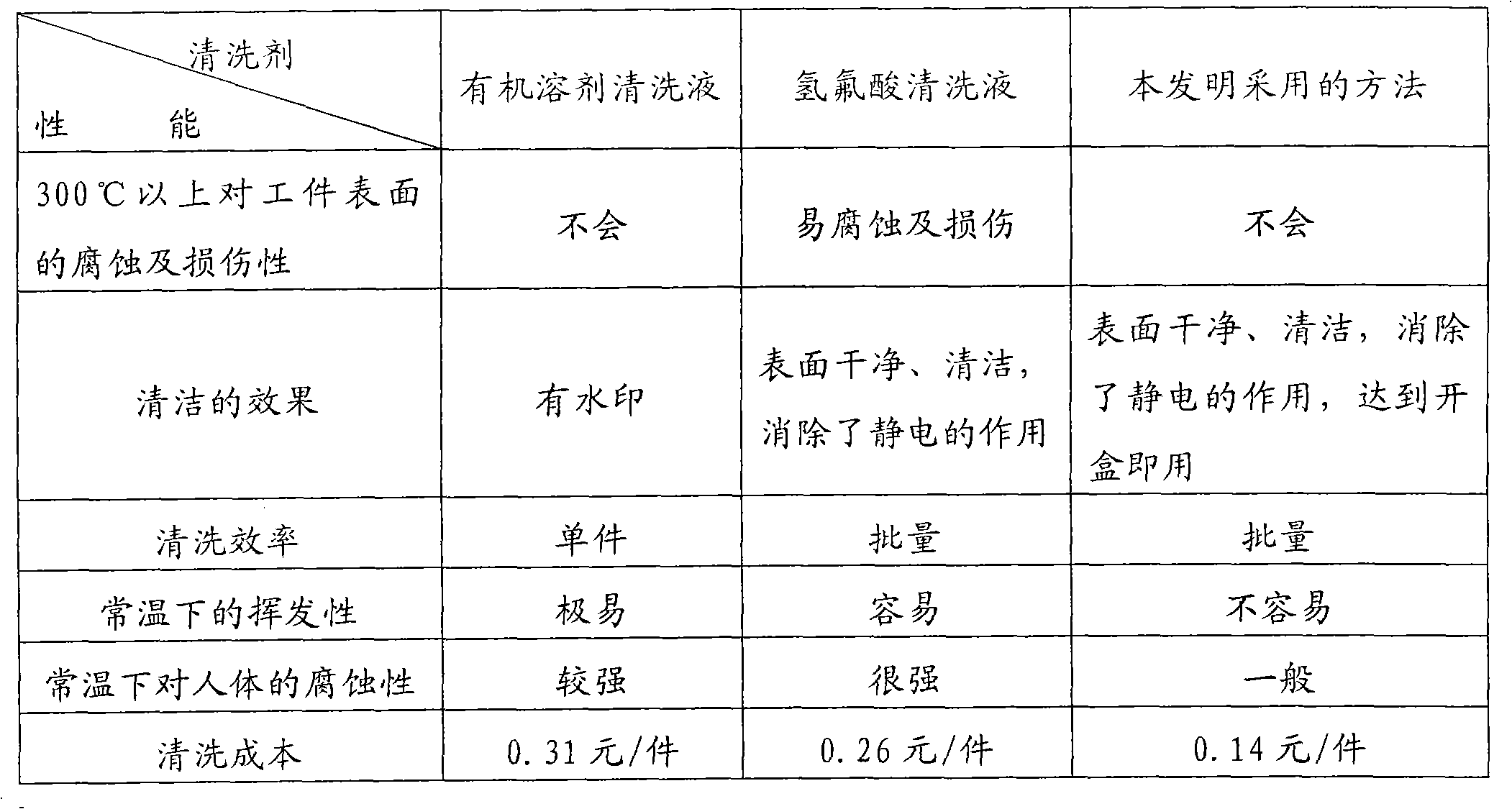

Sapphire infrared window cleaning agent and preparation method

InactiveCN101875886AQuality assuranceGuaranteed surface finishInorganic non-surface-active detergent compositionsSapphire windowSurface finish

The invention relates to a sapphire infrared window cleaning agent and a preparation method. The sapphire infrared window cleaning agent is characterized by comprising 1472-1840 parts by weight of concentrated sulfuric acid, 300-500 parts by weight of potassium dichromate and 4000-5500 parts by weight of water. When used to clean a sapphire window, the cleaning agent is non-corrosive on human body at normal temperature because the cleaning agent is not volatile easily, thus the cleaning agent has safe and convenient use without corroding and damaging polishing surfaces in the cleaning process and can ensure that the surface quality and the surface finish quality of the sapphire infrared window are not damaged.

Owner:CHONGQING CHUANYI AUTOMATION

Steel wire drawing method

ActiveCN107497868AGuaranteed surface finishReduce frictionFurnace typesHeat treatment furnacesEpoxyCarbon nanotube

The invention provides a steel wire drawing method. The steel wire drawing method comprises the following steps of: applying a lubricating cooling agent to the surfaces of raw metal wires, and then carrying out first-stage drawing, annealing treatment, second-stage drawing and heat treatment in sequence to obtain steel wires, wherein the lubricating cooling agent is prepared from carbon nanotubes, epoxy resin, an aminosilane coupling agent, an emulsifying agent and water. The lubricating cooling agent adopted by the steel wire drawing method has the effects of lubrication and cooling in a drawing process, ensures the smooth finish of steel wires in the drawing process, reduces friction and prevents tensile failure. As the lubricating cooling agent contains the carbon nanotubes, the lubricating cooling agent prevents the steel wires from being oxidized at a high temperature. The steel wire drawing method has the beneficial effects that the preparation method has good operation continuity; the surfaces of prepared steel wires have good smoothness, and the prepared steel wires have relatively good toughness, relatively thin diameter and relatively high strength; the internal stress is reduced through intermediate annealing treatment, so that the steel wires are less likely to suffer tensile failure during secondary drawing; and the quench tempering after drawing ensures that the steel wire finished products have higher hardness than existing steel wires.

Owner:SHANGHAI NETUREN

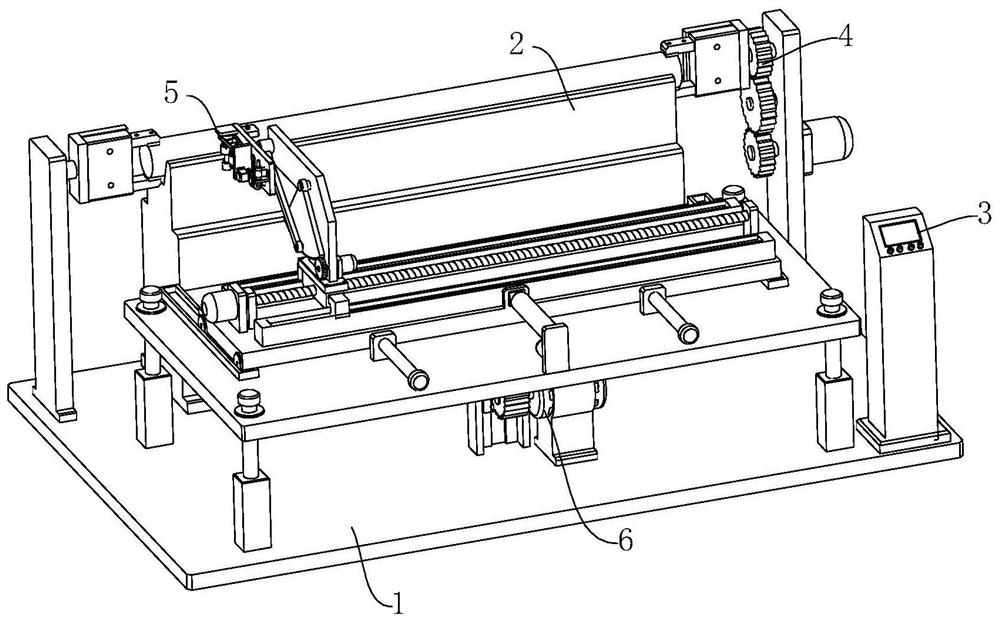

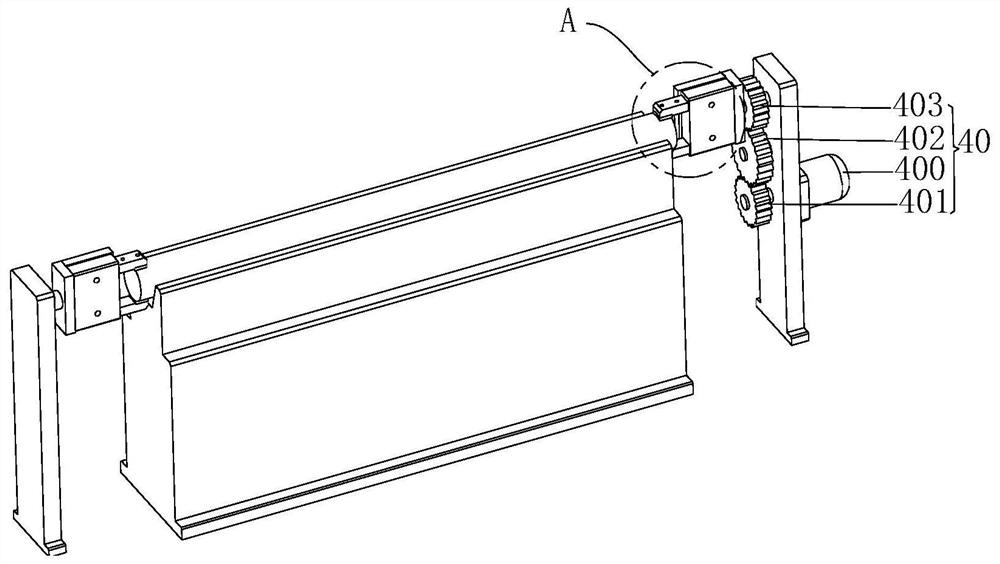

Shaft mold surface flaw detection repairing device and using method

ActiveCN111633519AGuaranteed surface finishImprove processing qualityEdge grinding machinesGrinding carriagesStructural engineeringMachining

The invention relates to the field of machining, and particularly relates to a shaft mold surface flaw detection repairing device and a using method. The shaft mold surface flaw detection repairing device comprises a base and a supporting table, and further comprises a controller, a rotating mechanism, a repairing mechanism and a lifting mechanism, wherein the rotating mechanism comprises a driving assembly and two pneumatic claws; the lifting mechanism comprises a lifting plate and a jacking assembly; the repairing mechanism comprises an ultrasonic probe, a polishing assembly and a filling assembly; a camera is mounted at the end, close to the bottom of the supporting table, of a rotating plate; and the camera, the ultrasonic probe, the driving assembly, the jacking assembly, the polishing assembly, the filling assembly and the two pneumatic claws are all electrically connected with the controller. According to the shaft mold surface flaw detection repairing device and the using method, burrs can be removed, cracks and pits can be filled at the same time, manual intervention is not needed in the repairing process, and the repairing efficiency and yield can be improved.

Owner:盐城金刚星精密锻造有限公司

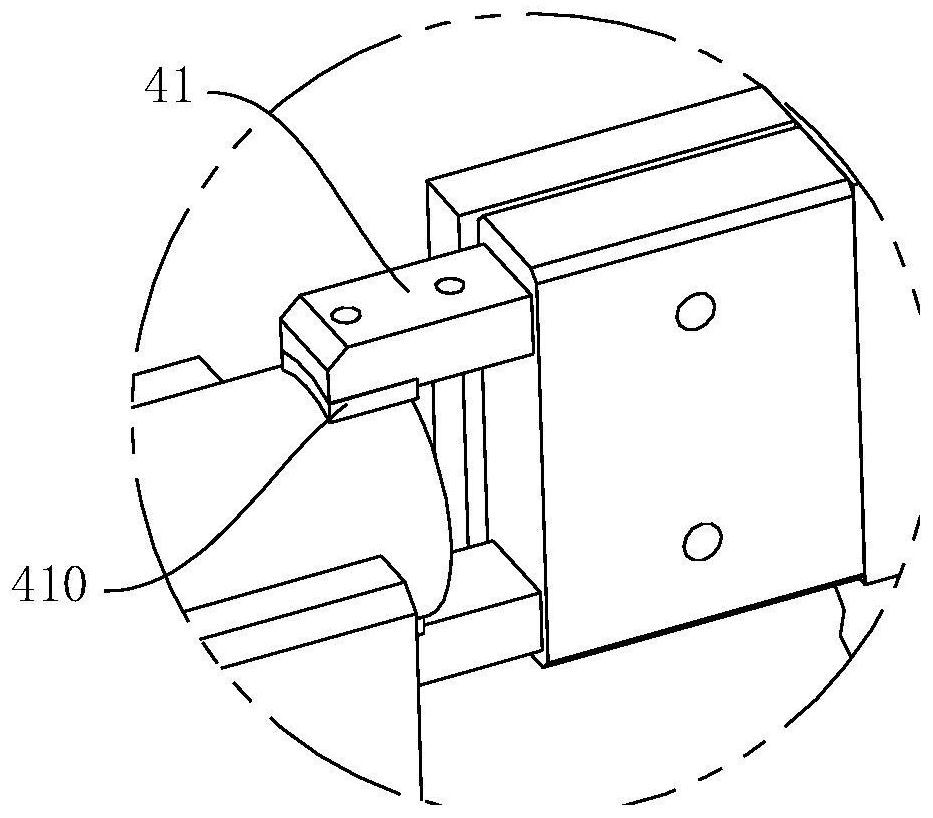

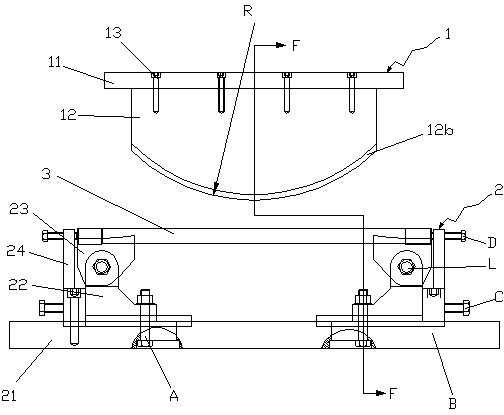

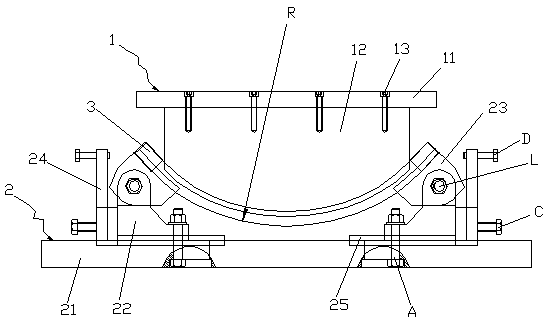

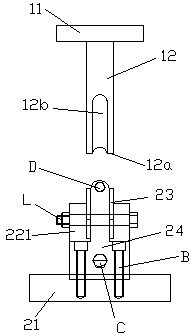

Stamping die structure for circumferential bolts and longitudinal bolts for rail transit

ActiveCN103394590AIncrease contact areaReduce labor intensityShaping toolsEngineeringMechanical engineering

The invention discloses a stamping die structure for circumferential bolts and longitudinal bolts for rail transit. The stamping die structure comprises an upper stamping die and a lower stamping die which are arranged in an up-down manner. A stamping contact surface of the upper stamping die is an arc-shaped surface with the radius R, and an upper stamping groove arc which is matched with a peripheral arc of a stamped product is formed in the stamping contact surface along the integral arc length of the stamping contact surface; the lower stamping die comprises a stamping die bottom plate and two stamping movable block supports, the distance between the two stamping movable block supports is adjustable, the two stamping movable block supports are bilaterally arranged on the stamping die bottom plate, a stamping movable block is rotationally pivotally connected onto each stamping movable block support in a hole and shaft matching manner, a lower stamping groove arc which is correspondingly matched with the upper stamping groove arc is formed in a stamping supporting surface of each stamping movable block, and two ends of the stamped product are respectively supported in the lower stamping groove arcs of the two stamping movable blocks in an erected manner. The stamping die structure has the advantages that the upper stamping die and the lower stamping die move up and down and are matched with each other to squeeze the stamped product, so that a rod of the stamped product is forced to deform and is bent to form an arc with the radius R.

Owner:盐城诚创铸造有限公司

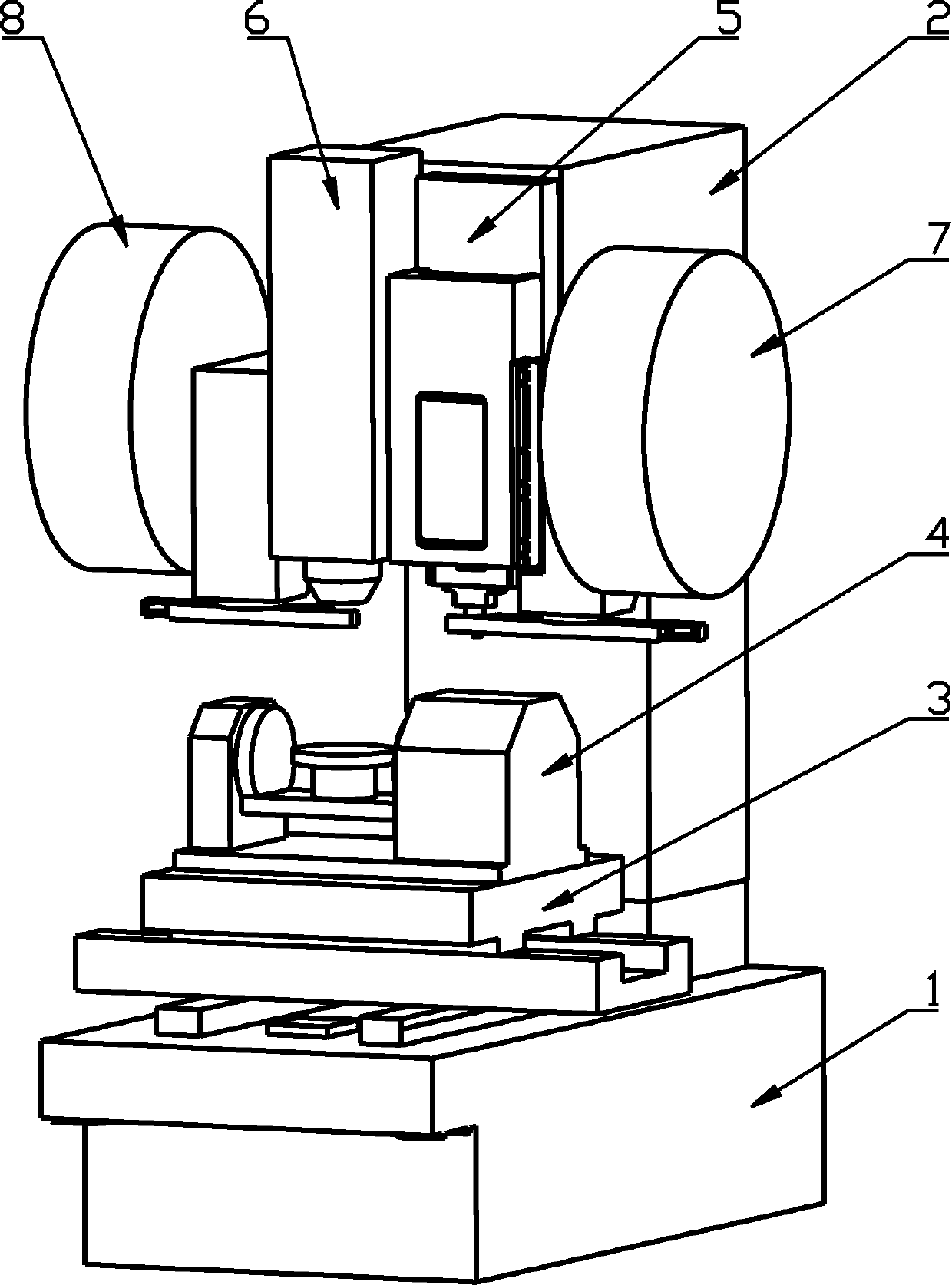

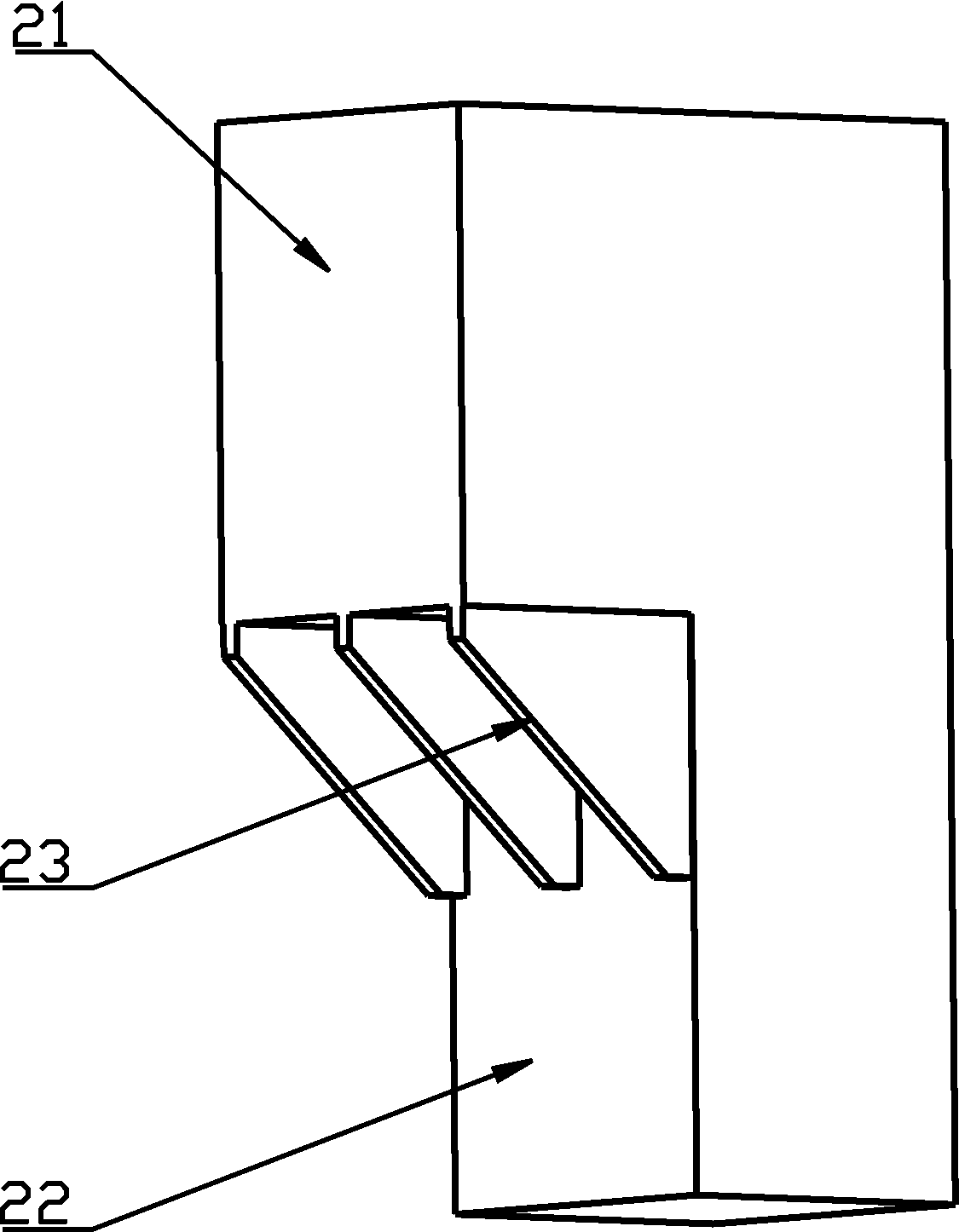

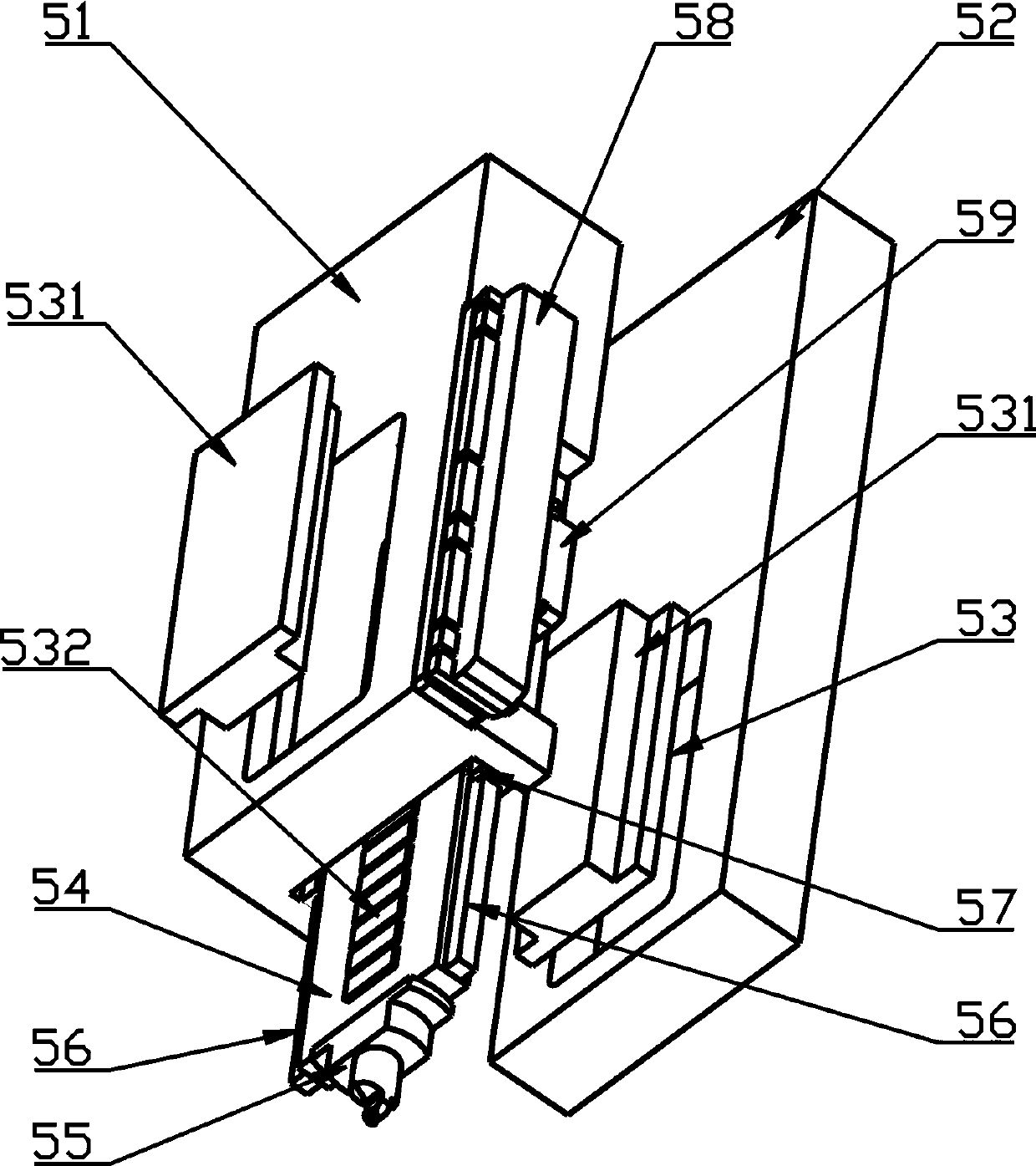

Numerical-control machine tool capable of realizing non-rotary curved-surface turning and milling combined machining

PendingCN110814754ASimple structureReduce the number of clampingOther manufacturing equipments/toolsNumerical controlMilling cutter

The invention relates to a numerical-control machine tool capable of realizing non-rotary curved-surface turning and milling combined machining. The numerical-control machine tool comprises a machinetool bed, a suspension wall column, a cross sliding table workbench, a double-shaft rotary workbench, a turning machine head, a milling machine head, a turning tool magazine and a milling tool magazine, wherein the suspension wall column is of an inverted L-shaped structure composed of a cantilever end and an upright post end, and the upright post end is fixed on the machine tool bed; the cross sliding table workbench is mounted on the machine tool bed, and the double-shaft rotary workbench is mounted on the cross sliding table workbench and can perform reciprocating feeding along the X-axis and the Y-axis under the action of an X-axis driving system and a Y-axis driving system along with the cross sliding table workbench; the turning machine head and the milling machine head are arrangedon the front end face of the cantilever end side by side, and can reciprocate up and down along the Z axis respectively; and the turning tool magazine and the milling tool magazine are respectively arranged on the left side and the right side of the suspension wall column corresponding to the turning machine head and the milling machine head. The numerical-control machine tool is simple in structure and high in response speed, and five-axis curved surface turning and five-axis linkage milling machining can be achieved.

Owner:BEIJING JINGDIAO GRP CO LTD

Glass glaze and manufacturing technology thereof

The invention relates to glass glaze and the manufacturing process thereof. The invention is characterized in that the ingredient of the glass glaze mainly comprises by weight percentage: quartz powder is 5 to 18 percent, boric acid is 9 to 23 percent, red lead is 40 to 65 percent, and expansion stabilizing agent is 8 to 17 percent. The manufacturing process is realized by that: (a) the materials are mixed fully according to the weight percentage; (b) the mixture is fused to be thick and sticky at the temperature of 1000 to 1200 DEG C; (c) the fused mixture is cooled to be the glass base glaze block with original color; (d) the glaze block is crashed into powder to be fully mixed with paint to form colored glaze. The glass glaze and the manufacturing process thereof of the invention provide the glass glaze which keeps the designs and characters on the surface of a glass product having embossing effect and high ornamental value.

Owner:冯庆铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com