Ceramic stacked abrasive material, method for preparing same, and grinding tool

A technology for accumulating abrasives and ceramics, used in abrasives, manufacturing tools, grinding/polishing equipment, etc., to solve the problems of decreased durability and sharpness of abrasives, low porosity of abrasives, and clogging of abrasive surfaces. Achieve good self-sharpening effect and durability, stabilize surface quality and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

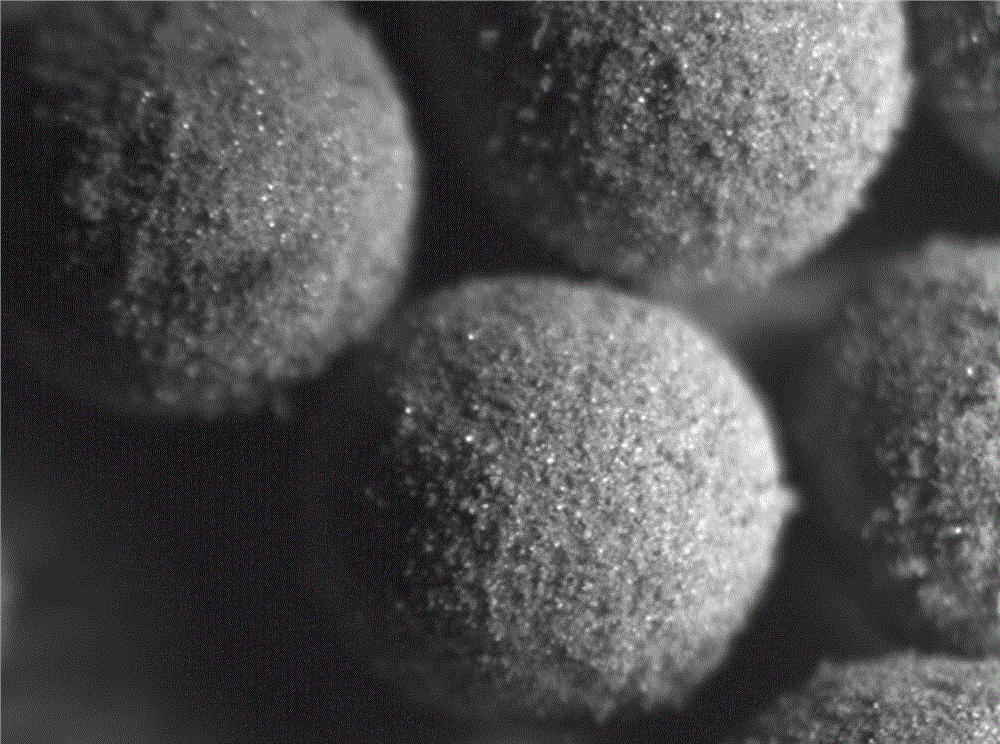

[0029] Embodiment 1 of the present invention provides a silicon carbide ceramic stacked abrasive, a preparation method thereof, and a coated abrasive using the silicon carbide ceramic stacked abrasive. details as follows:

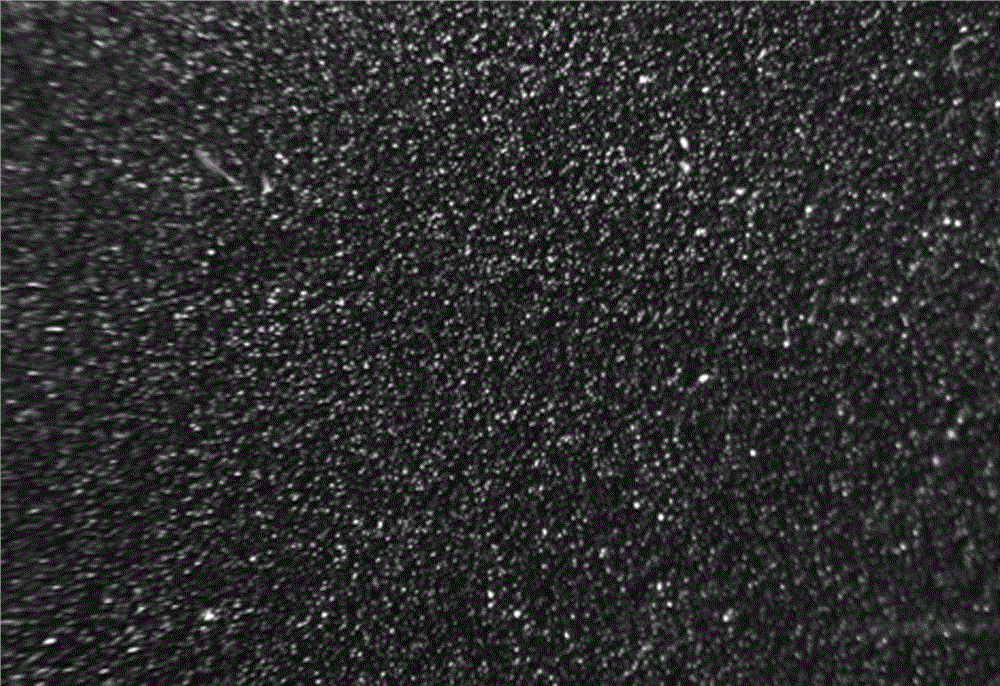

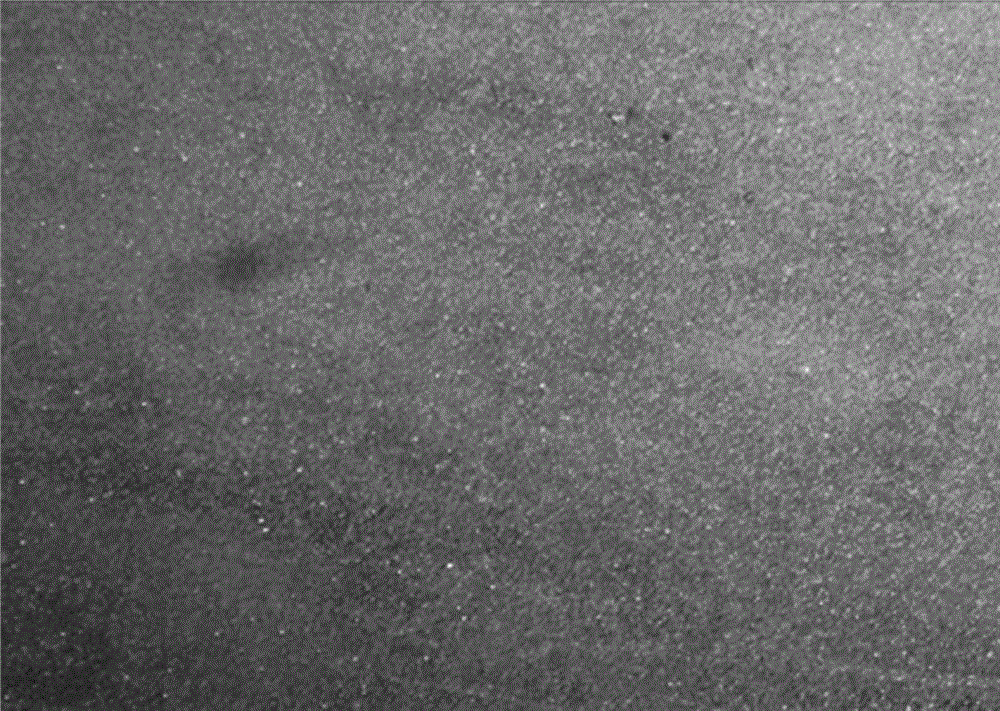

[0030] Get 45 mesh sieves under 40 mesh sieves, 1.5kg hollow microspheres with a wall thickness of 1 to 2 microns, 240# silicon carbide micropowder 6kg, 1kg vitrified bond powder, 1kg temporary binder water glass, wherein , the vitrified bond powder passes through a 200-mesh sieve, and consists of the following mass percentage components: ZnO7%, SiO 2 34%, Al 2 o 3 8%, H 3 BO 3 32%, Na 2 CO 3 3%, Li 2 CO 3 16%. Pour the hollow microspheres into the mixing device, start the mixing device, and then spray the temporary binder water glass on the surface of the microspheres in the form of mist. The silicon micropowder abrasive is sieved with a 100-mesh sieve, and 1 / 5 of the total amount is taken each time to make it evenly cover the surface of the micr...

Embodiment 2

[0036] Embodiment 2 of the present invention provides a corundum ceramic stacked abrasive, a preparation method thereof, and a coated abrasive using the corundum ceramic stacked abrasive. details as follows:

[0037] Take 1.7kg of hollow microspheres with a wall thickness of 3-4 microns on the 35-mesh sieve under the 25-mesh sieve, 6.5kg of brown corundum micropowder with a particle size of 180#, 1.2kg of vitrified bond powder, and 1.2kg of temporary binder paste Semen, wherein the vitrified powder passes through a 200-mesh sieve and consists of the following mass percentage components: ZnO6%, SiO 2 35%, Al 2 o 3 9%, H 3 BO 3 30%, Na 2 CO 3 4%, Li 2 CO 3 16%. Pour the hollow microspheres into the mixing device, start the mixing device, and then spray the temporary binder water glass on the surface of the microspheres in the form of mist. The silicon micropowder abrasive is sieved with a 100-mesh sieve, and 1 / 4 of the total amount is taken each time to make it evenly ...

Embodiment 3

[0042] Embodiment 3 of the present invention provides a silicon carbide ceramic stacked abrasive, a preparation method thereof, and a coated abrasive using the silicon carbide ceramic stacked abrasive. details as follows:

[0043] Get 55 mesh sieves under 50 mesh sieves, 1.4kg hollow microspheres with a wall thickness of 1 to 2 microns, 6.6kg of diamond micropowder of W7, 1.3kg vitrified bond powder, 1.3kg temporary binder water glass, Wherein, the vitrified bond powder passes through a 200-mesh sieve, and is composed of the following mass percentage components: ZnO10%, SiO 2 33%, Al 2 o 3 8%, H 3 BO 3 30%, Na 2 CO 3 3%, Li 2 CO 3 16%. Pour the hollow microspheres into the mixing device, start the mixing device, and then spray the temporary binder water glass on the surface of the microspheres in the form of mist. The silicon micropowder abrasive is sieved with a 100-mesh sieve, and 1 / 5 of the total amount is taken each time to make it evenly cover the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com