Patents

Literature

2514results about How to "Reduce reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6129933AReduce reunionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

Powder-layered oral dosage forms

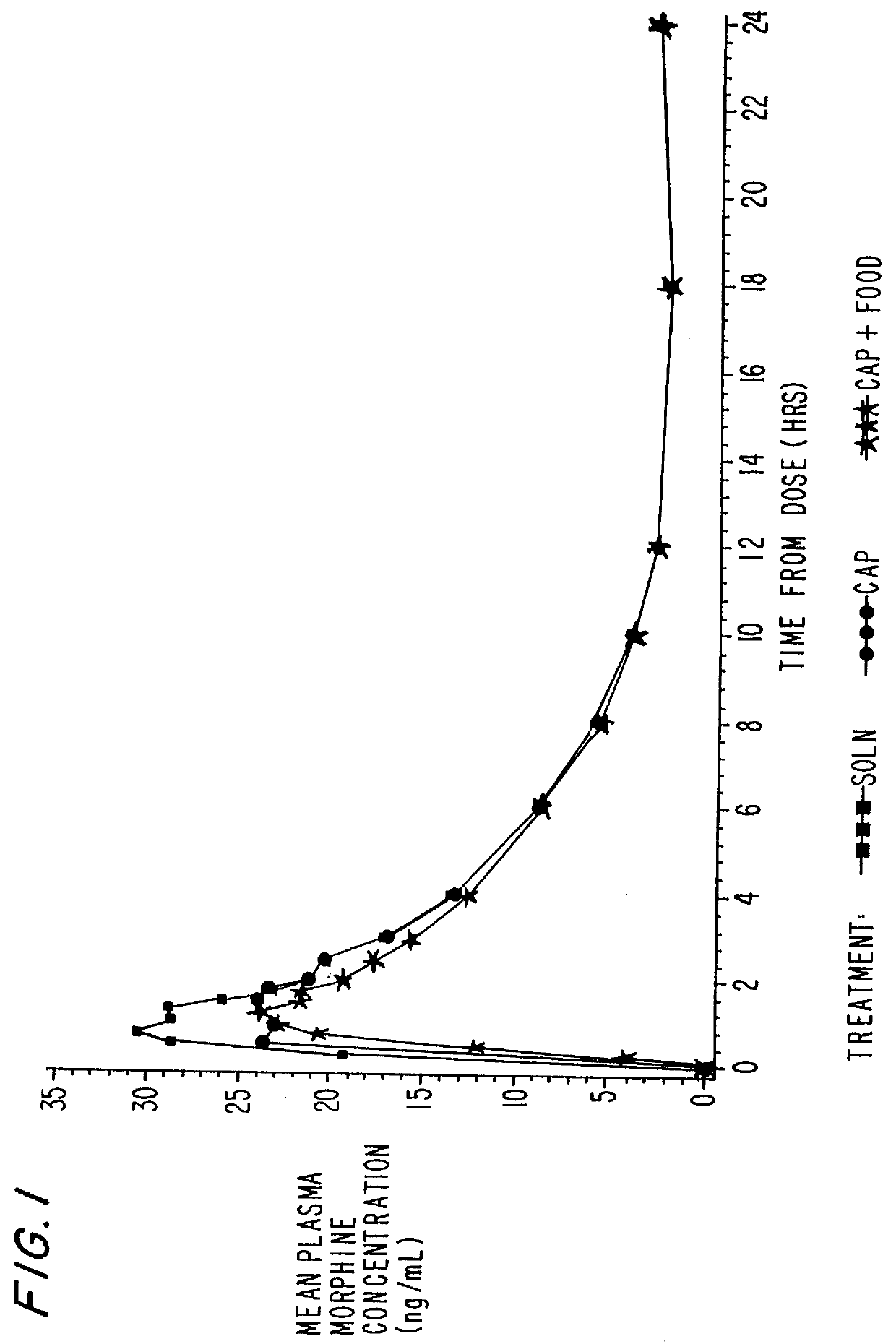

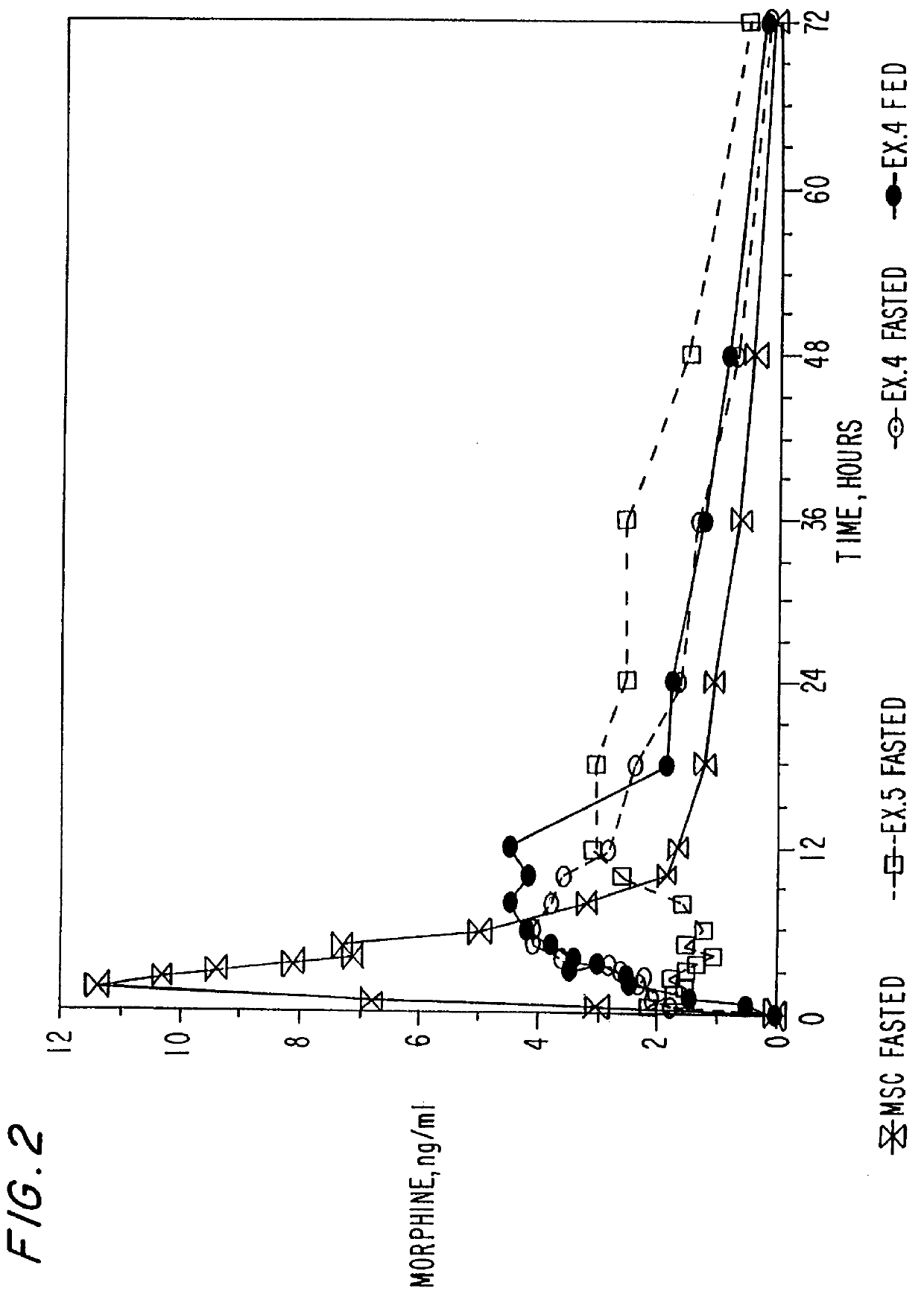

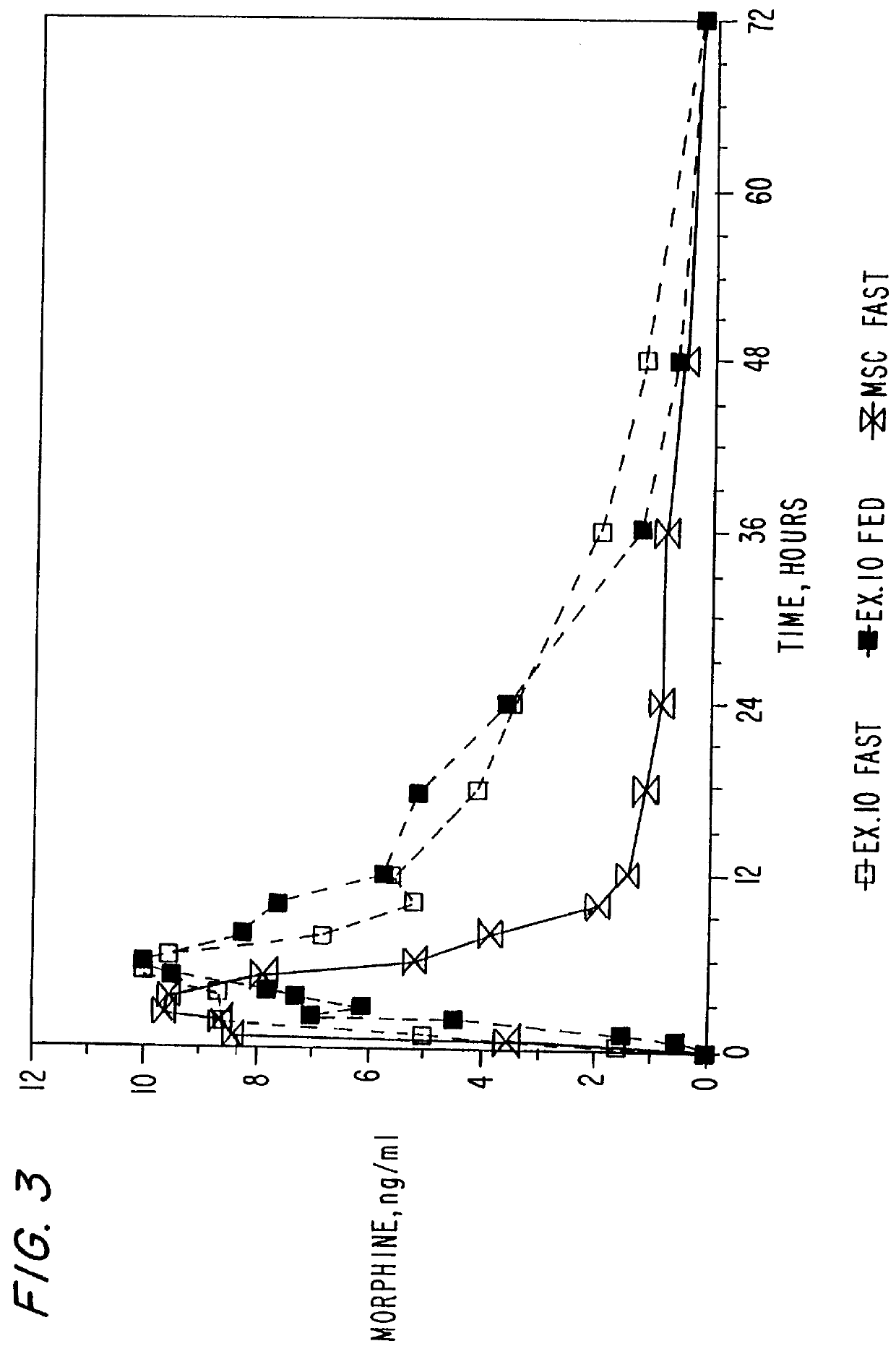

InactiveUS6077533AFacilitated releaseMinimize impactPretreated surfacesGranular deliveryImmediate releaseLactose

An oral dosage form of morphine is formulated by powder-layering an homogeneous mixture of morphine sulfate and hydrous lactose impalpable onto inert beads to obtain a multiparticulate product. A plurality of the powder-layered beads may be administered either in immediate release form or in an extended release form by coating with a hydrophobic material. In addition, multi-particulate oral dosage forms containing therapeutically effective agents containing a plurality of pharmaceutically acceptable inert beads powder-layered with homogeneous mixture of a therapeutically effective agent and hydrous lactose impalpable are also disclosed. A method of preparing the dosage forms as well as a method preparing spheroids containing the homogeneous mixture of therapeutically effective agent and hydrous lactose impalpable are also disclosed.

Owner:PURDUE PHARMA LP

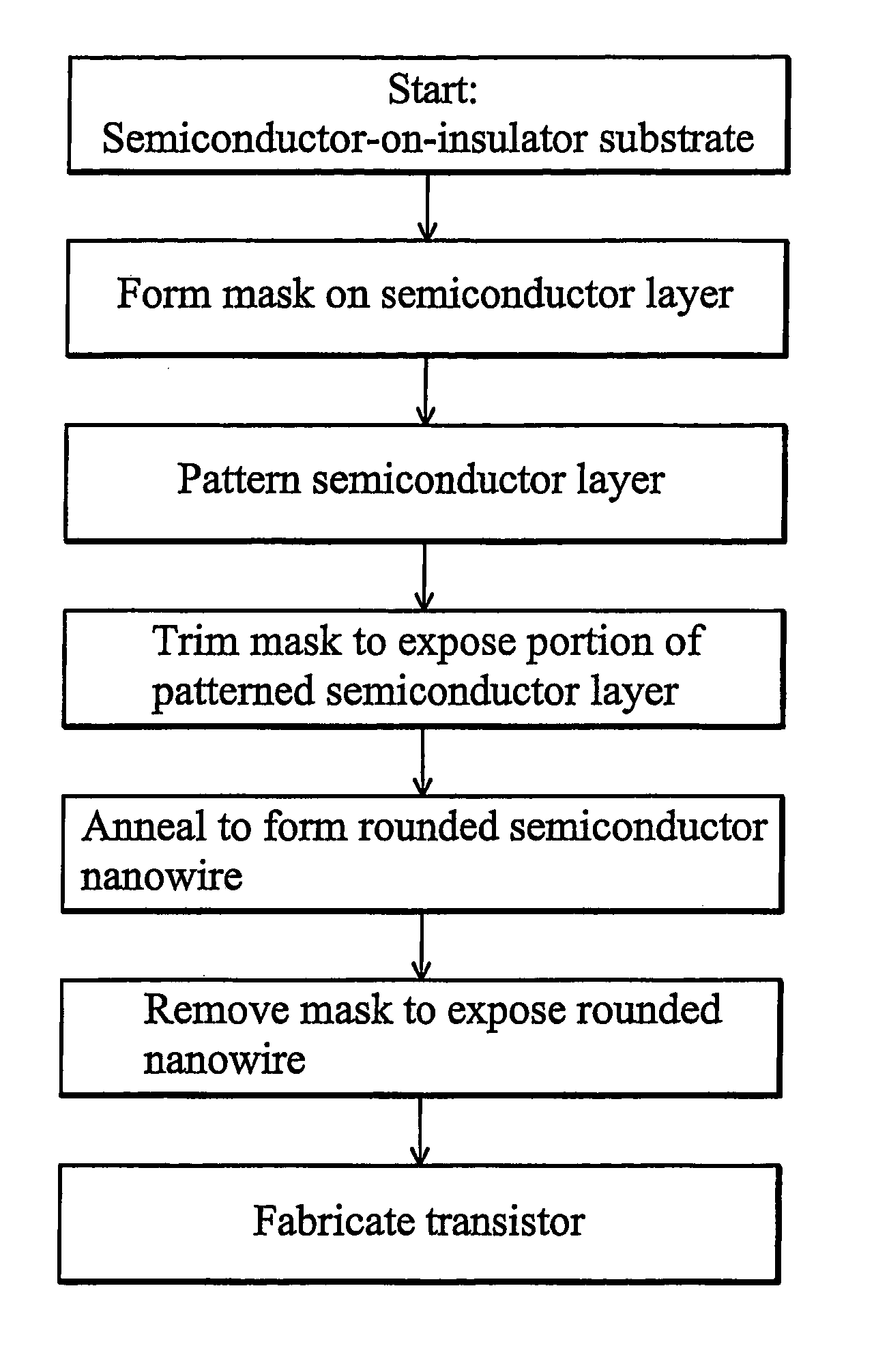

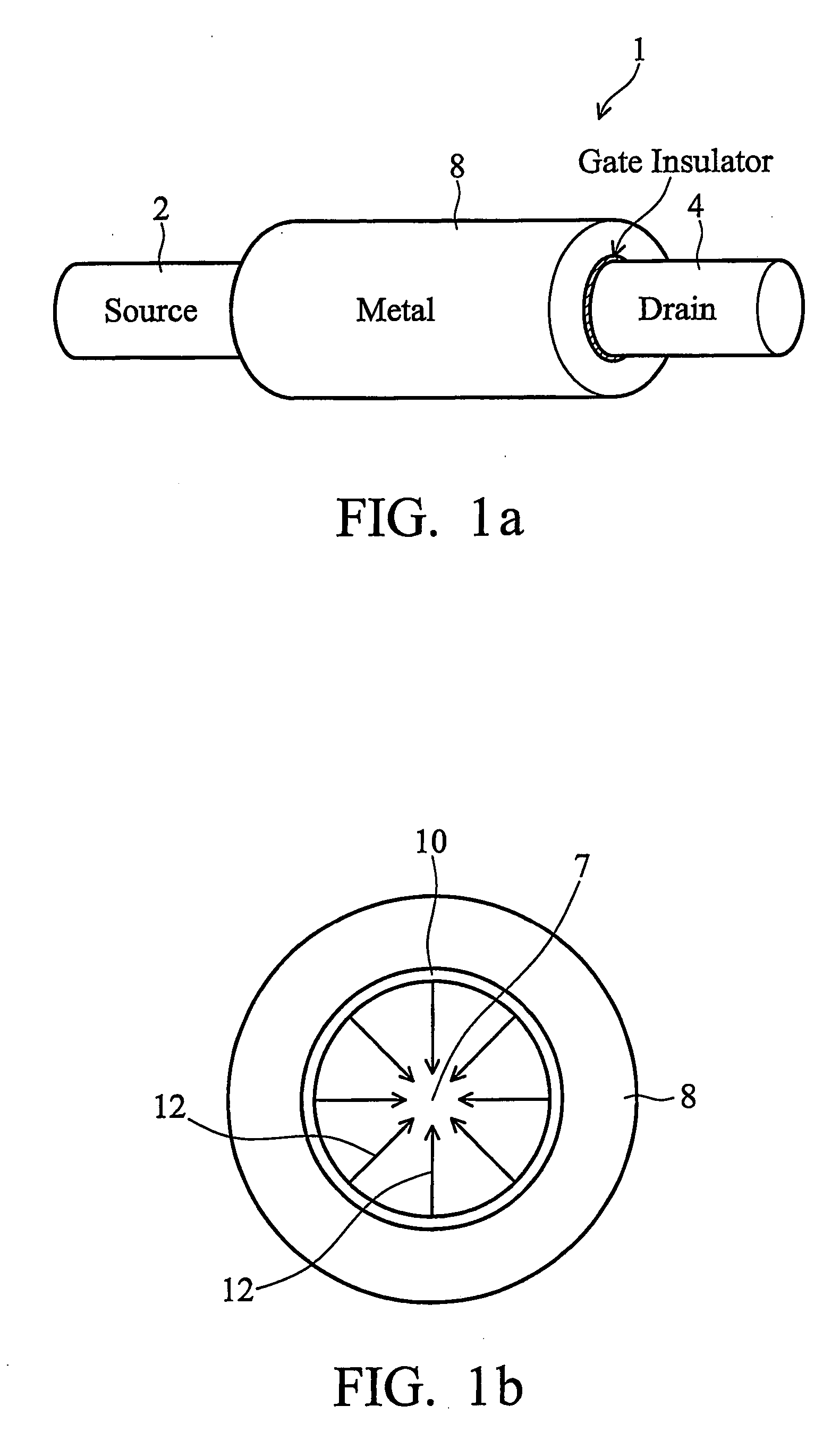

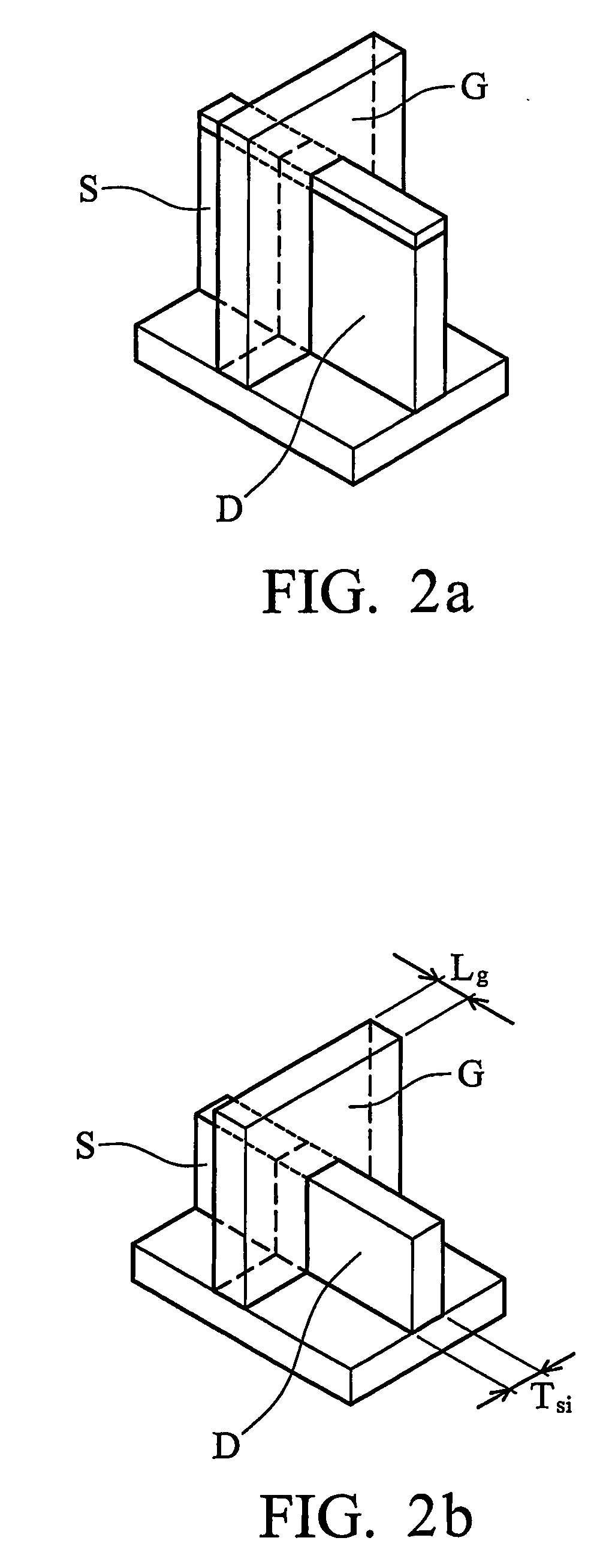

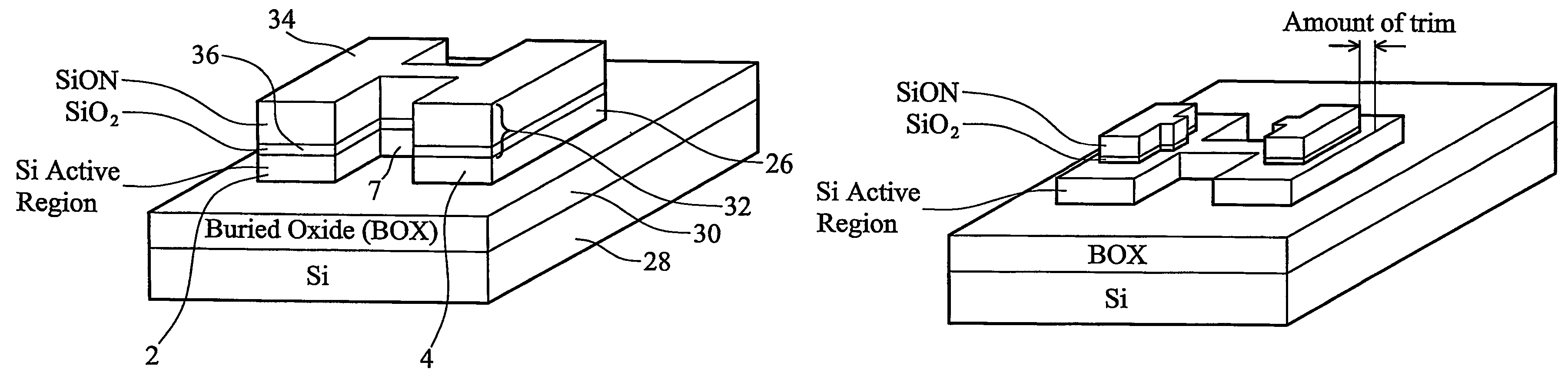

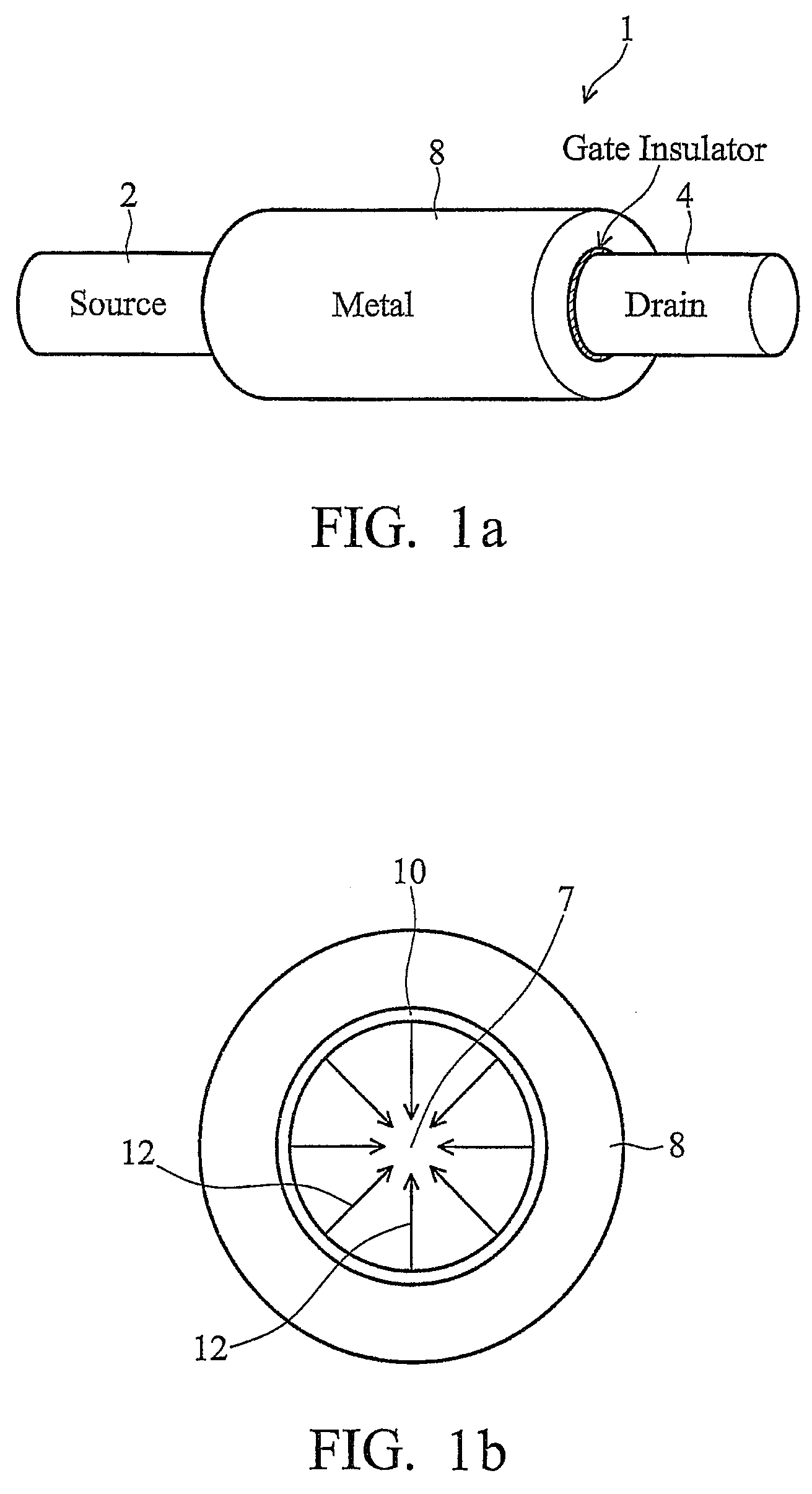

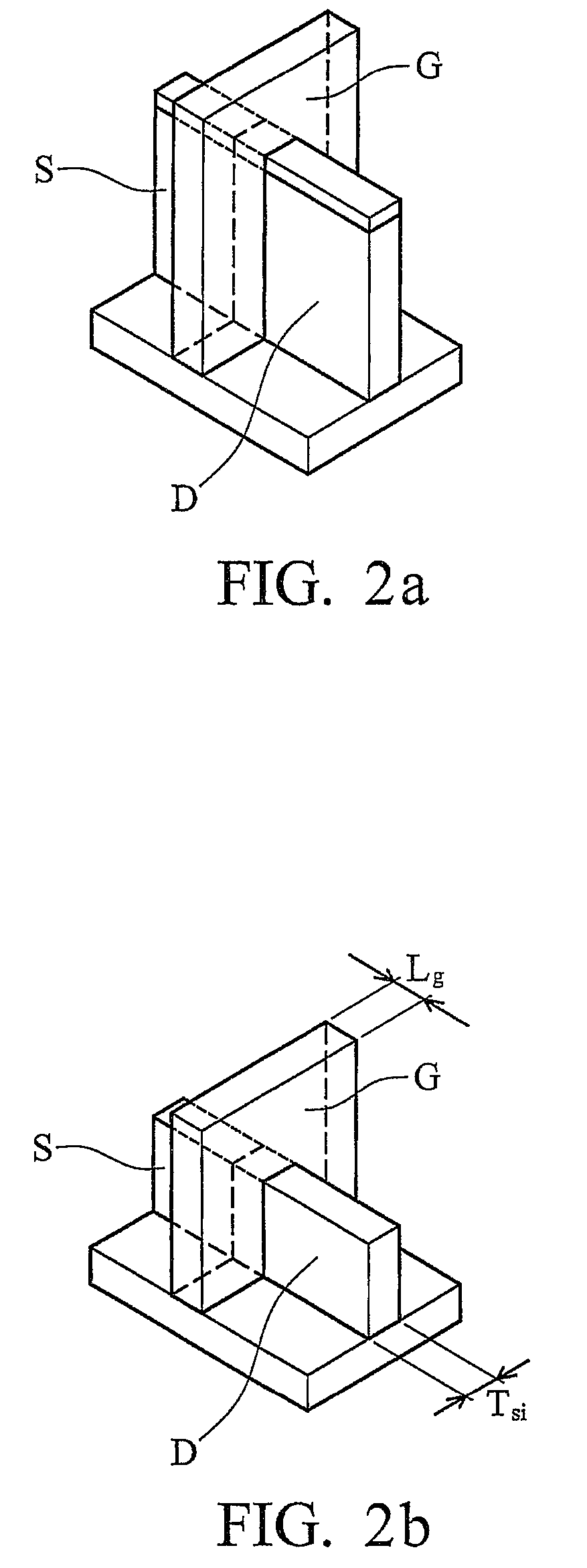

Semiconductor nano-wire devices and methods of fabrication

InactiveUS20050275010A1Rule out the possibilityReduce agglomerationTransistorNanoinformaticsDielectricNanowire

Nano-wires, preferably of less than 20 nm diameter, can be formed with minimized risk of narrowing and breaking that results from silicon atom migration during an annealing process step. This is accomplished by masking portion of the active layer where silicon atomer would otherwise agglomerate with a material such as silicon dioxide, silicon nitride, or other dielectric that eliminates or substantially reduces the silicon atom migration. Nano-wires, nanotubes, nano-rods, and other features can be formed and can optionally be incorporated into devices, such as by use as a channel region in a transistor device.

Owner:TAIWAN SEMICON MFG CO LTD

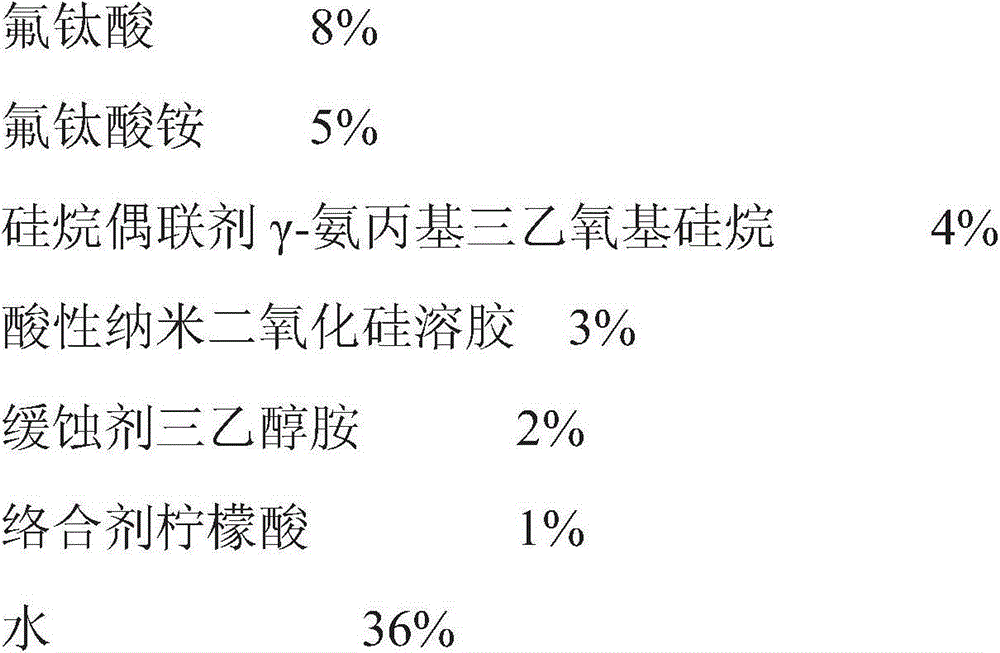

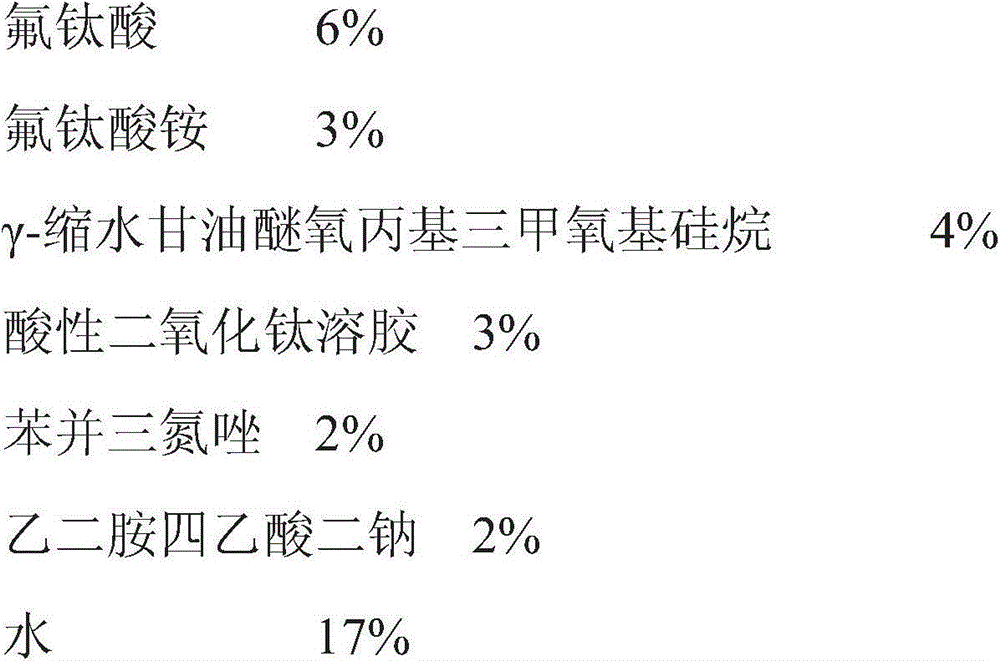

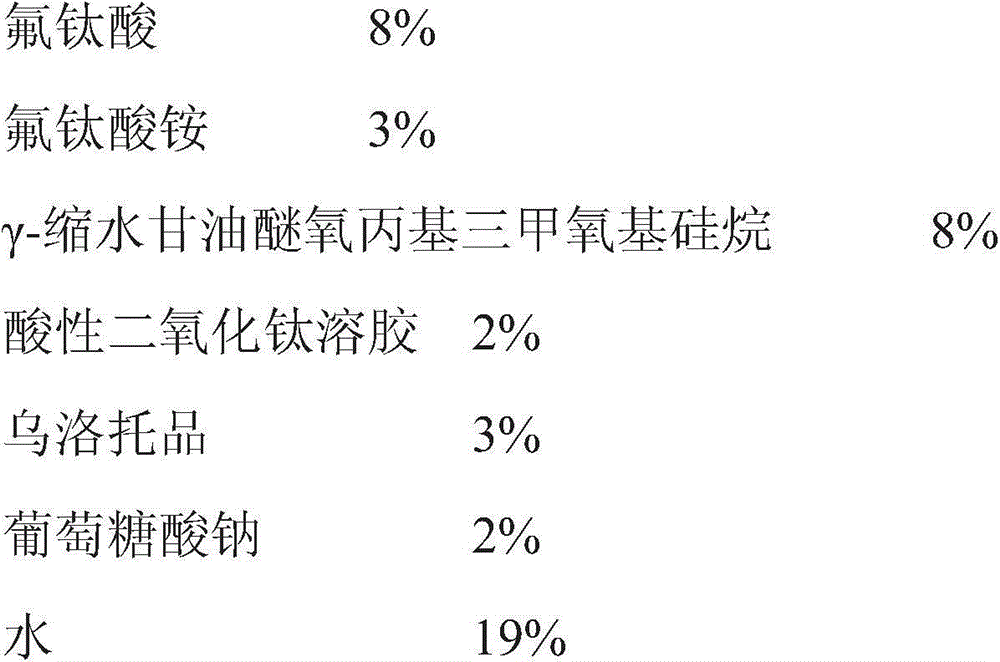

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Polymer compositions containing colloids of silver salts

The present invention relates to antimicrobial compositions, methods for the production of these compositions, and use of these compositions with medical devices, such as catheters, and implants. The compositions of the present invention advantageously provide varying release kinetics for the active ions in the compositions due to the different water solubilities of the ions, allowing antimicrobial release profiles to be tailored for a given application and providing for sustained antimicrobial activity over time. More particularly, the invention relates to polymer compositions containing colloids comprised of salts of one or more oligodynamic metal, such as silver. The process of the invention includes mixing a solution of one or more oligodynamic metal salts with a polymer solution or dispersion and precipitating a colloid of the salts by addition of other salts to the solution which react with some or all of the first metal salts. The compositions can be incorporated into articles or can be employed as a coating on articles such as medical devices.

Owner:CR BARD INC

Semiconductor nano-wire devices and methods of fabrication

InactiveUS7452778B2Rule out the possibilityReduce agglomerationTransistorNanoinformaticsDielectricNanowire

Nano-wires, preferably of less than 20 nm diameter, can be formed with minimized risk of narrowing and breaking that results from silicon atom migration during an annealing process step. This is accomplished by masking portion of the active layer where silicon atomer would otherwise agglomerate with a material such as silicon dioxide, silicon nitride, or other dielectric that eliminates or substantially reduces the silicon atom migration. Nano-wires, nanotubes, nano-rods, and other features can be formed and can optionally be incorporated into devices, such as by use as a channel region in a transistor device.

Owner:TAIWAN SEMICON MFG CO LTD

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6316031B1Reduce reunionStable productionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

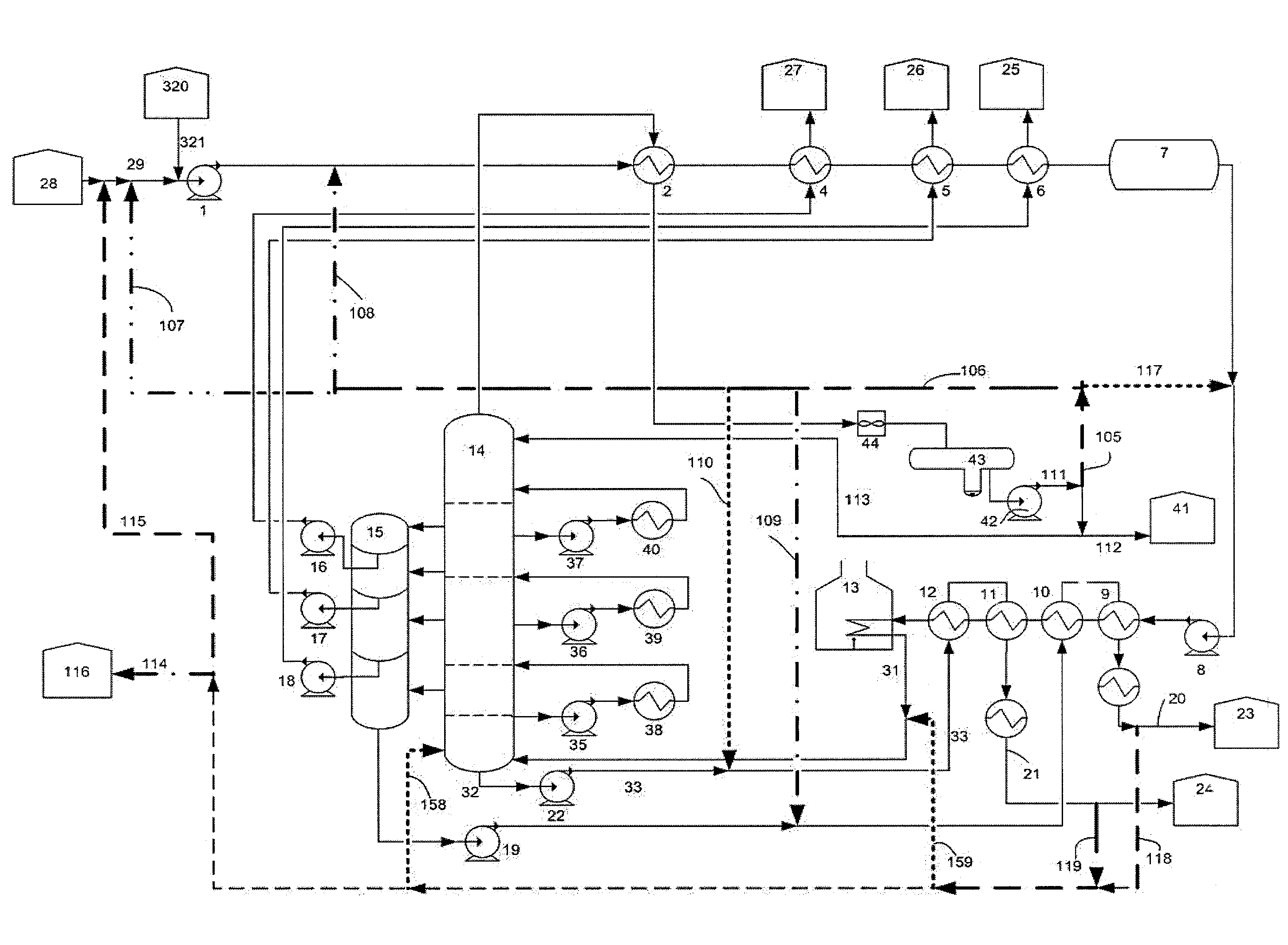

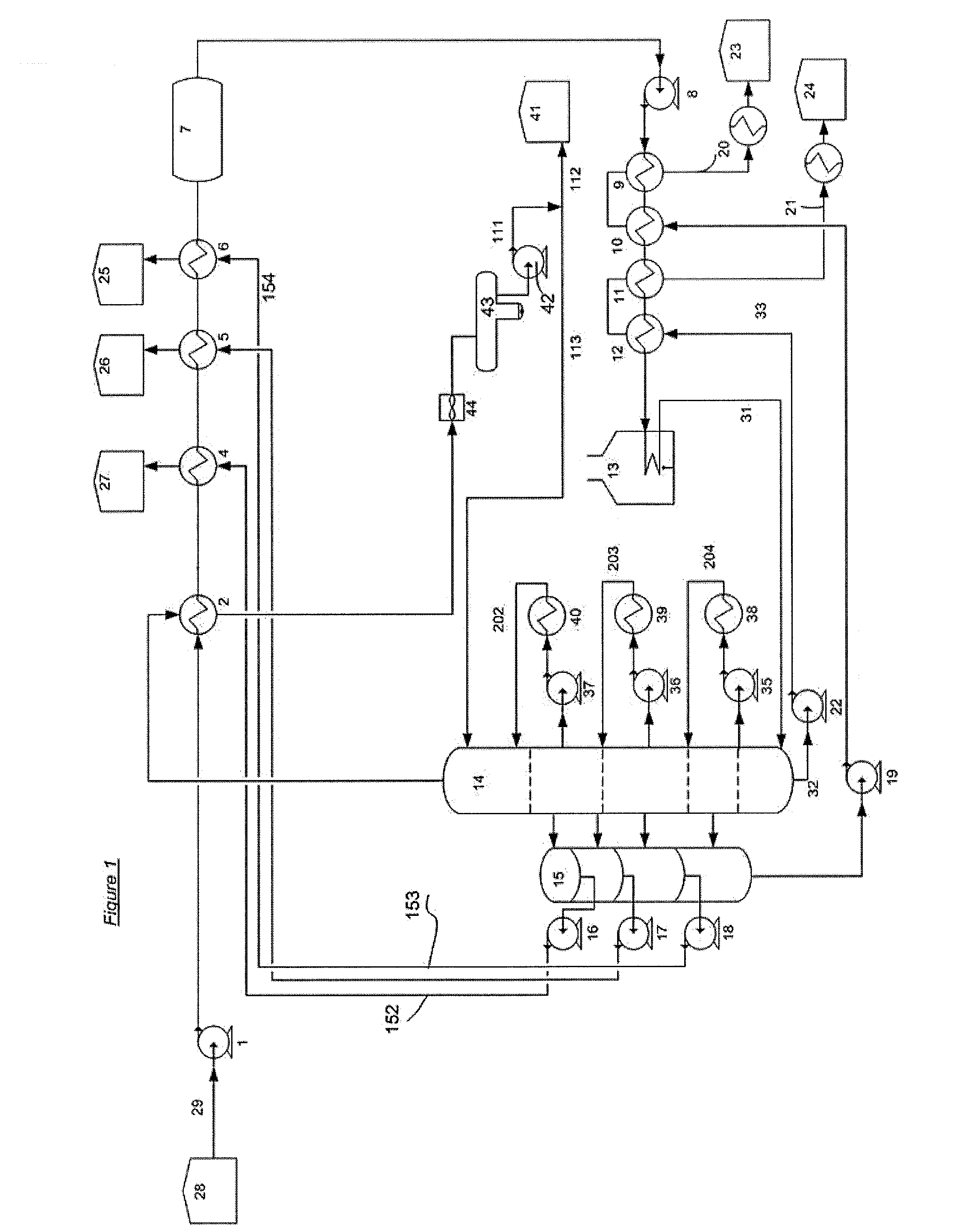

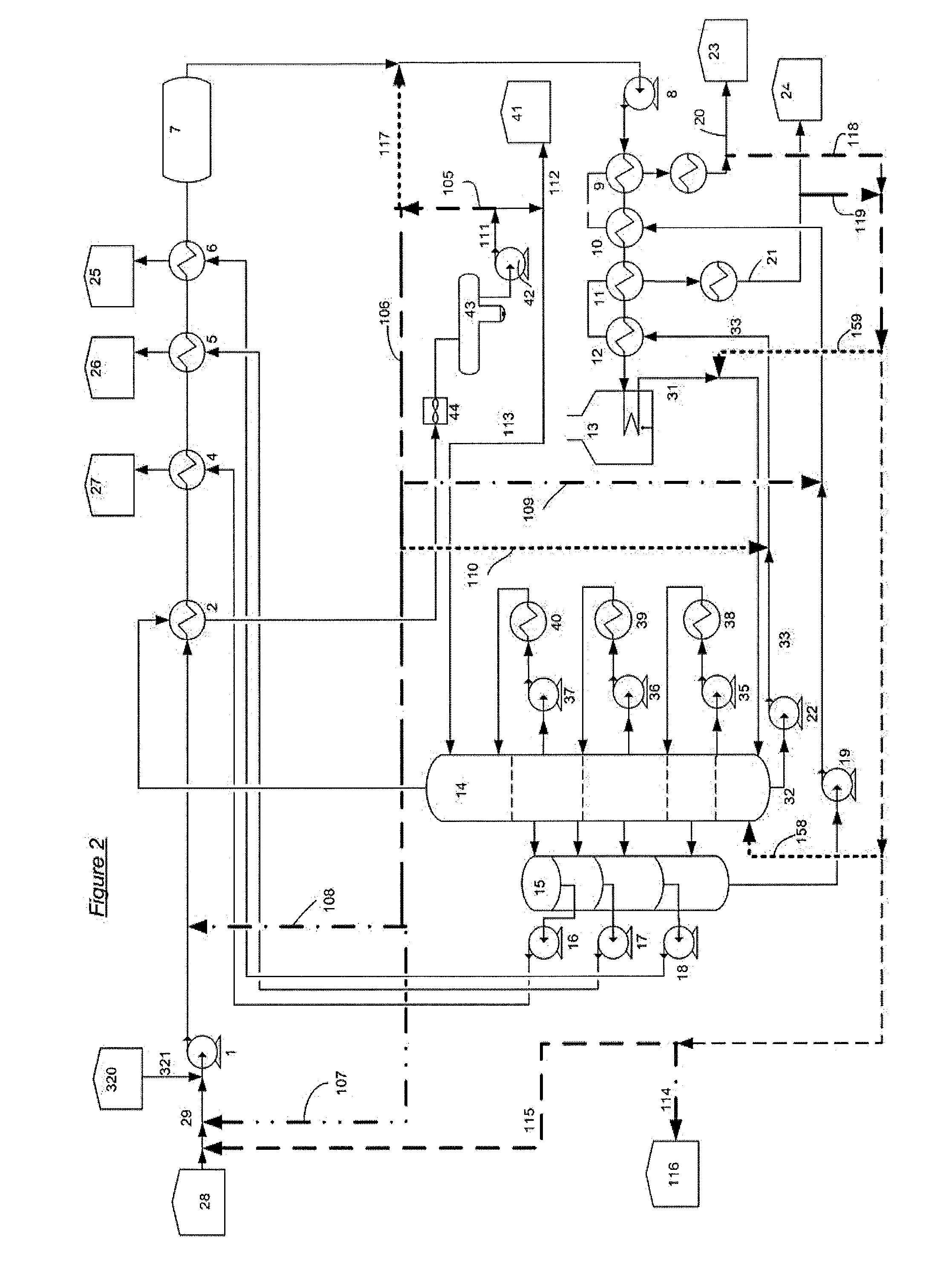

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

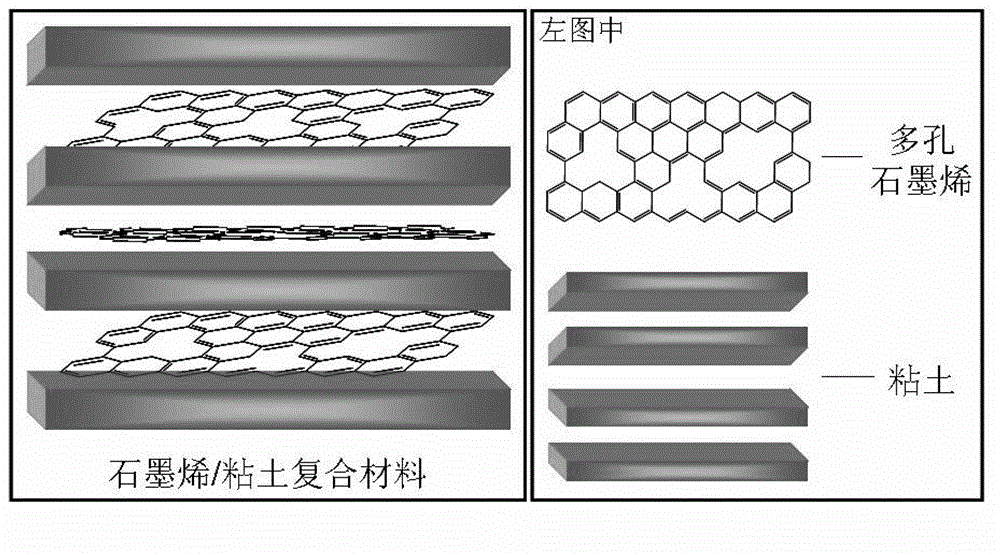

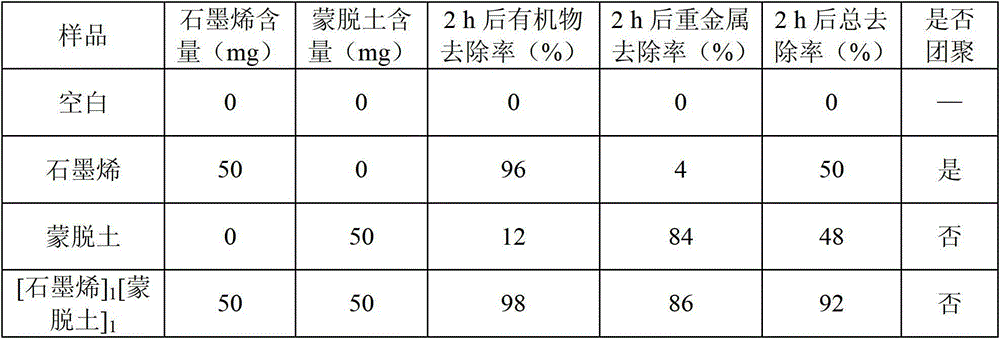

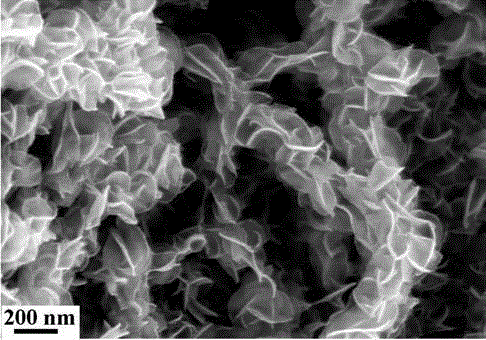

Graphene/clay composite material, and preparation method and application thereof

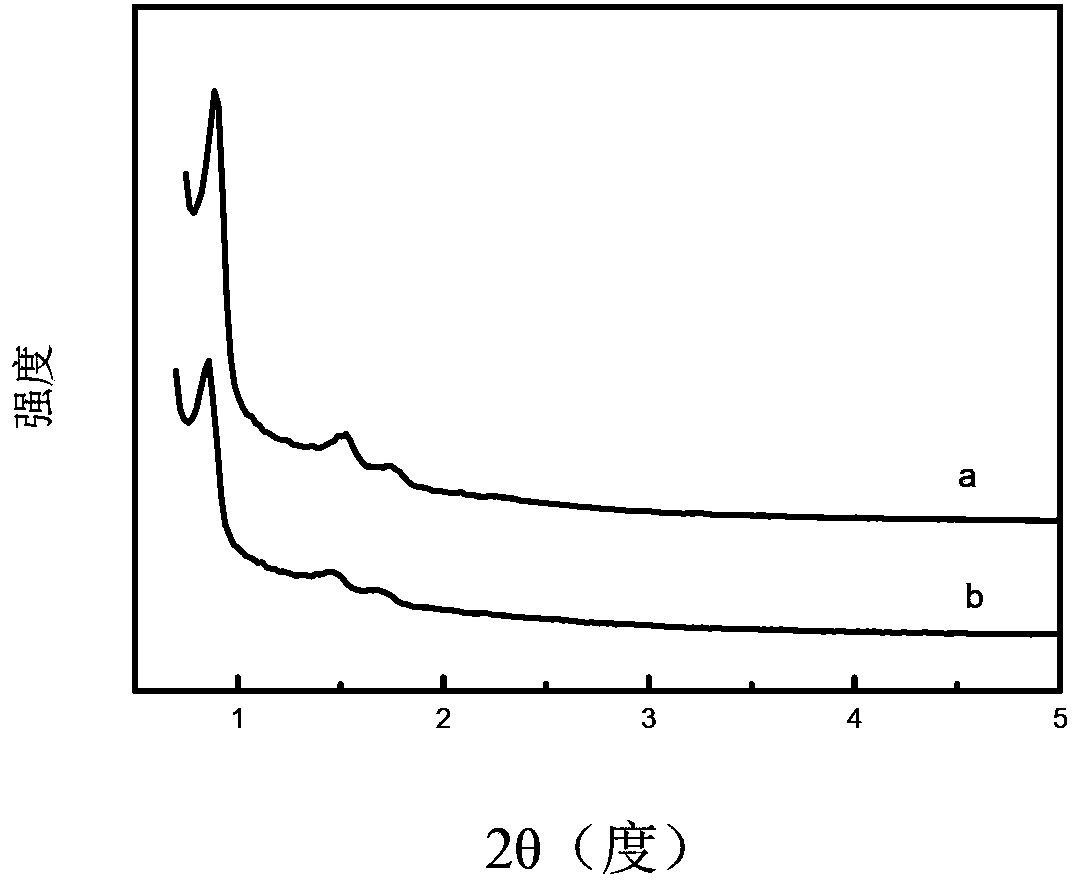

ActiveCN103143319AGood dispersionReduce reunionOther chemical processesWater/sewage treatment by sorptionIntercalation reactionDispersity

The invention belongs to the field of adsorbing materials, and relates to an inorganic-inorganic hybrid material, particularly a graphene / clay composite material. The composite material is powdery, is compounded from porous graphene and clay, and has a porous structure; the porous graphene is inserted among clay layers through intercalation reaction; the mass ratio of the porous graphene to the clay is 1:(0.1-10); the specific area of the graphene / clay composite material is 200-250 m<2> / g, and the weight loss within 900 DEG C is 3-6 wt%; and the clay is montmorillonite, vermiculite, illite, kaolin or rectorite. The graphene / clay composite material can be easily dispersed, can be used for comprehensively and efficiently adsorbing heavy metals and organic substances, and has the characteristics of high dispersity and efficient and selective adsorbability for heavy metals and organic substances; the maximum comprehensive removal rate can reach 99%; and thus, the invention has wide prospects in industrialized application.

Owner:JINAN UNIVERSITY

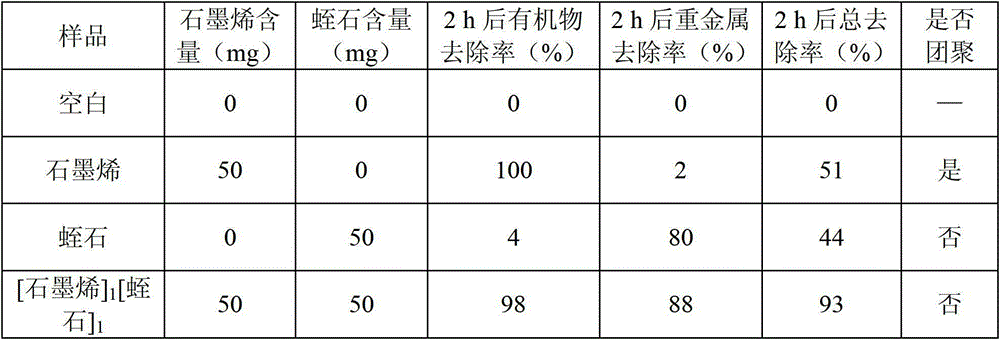

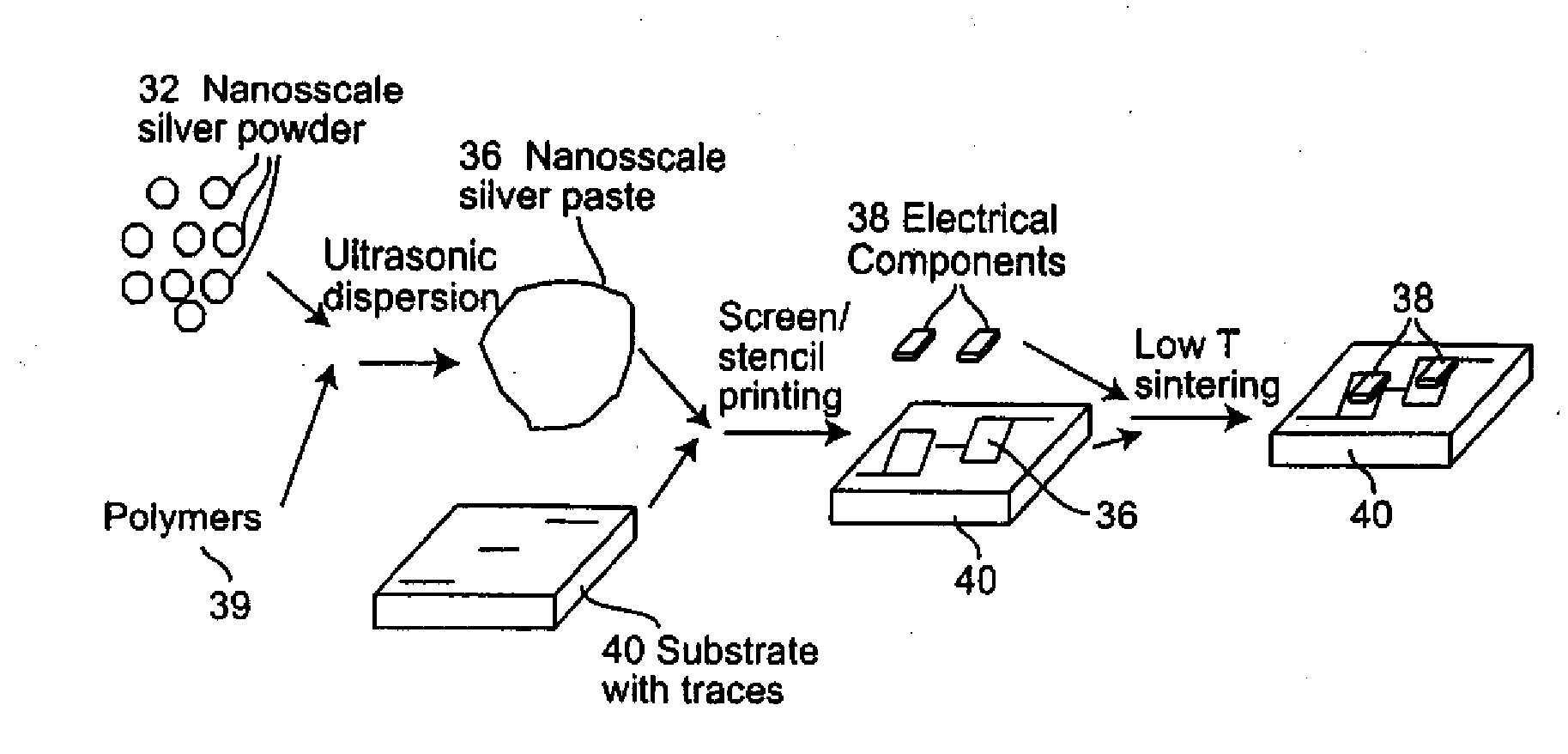

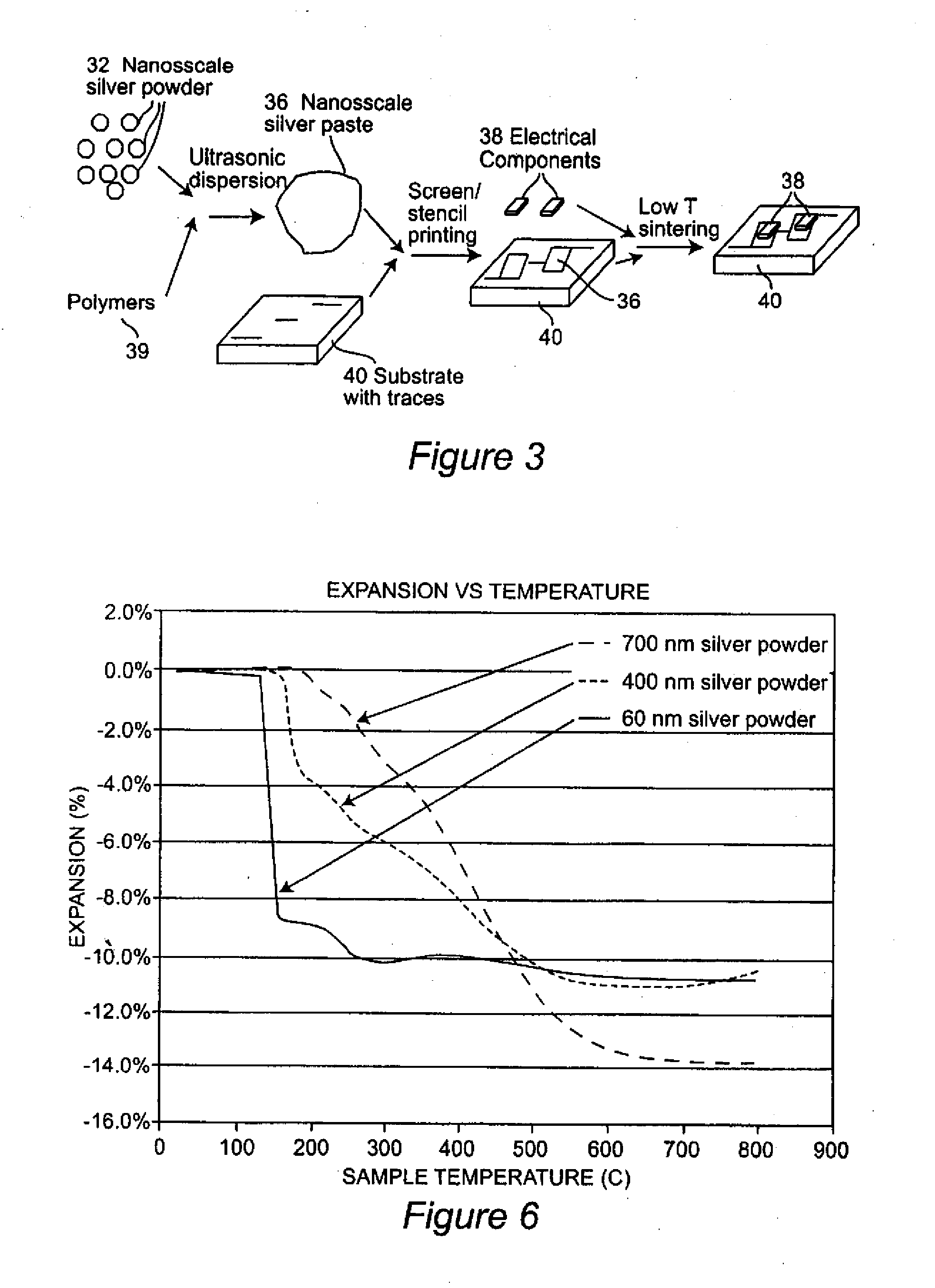

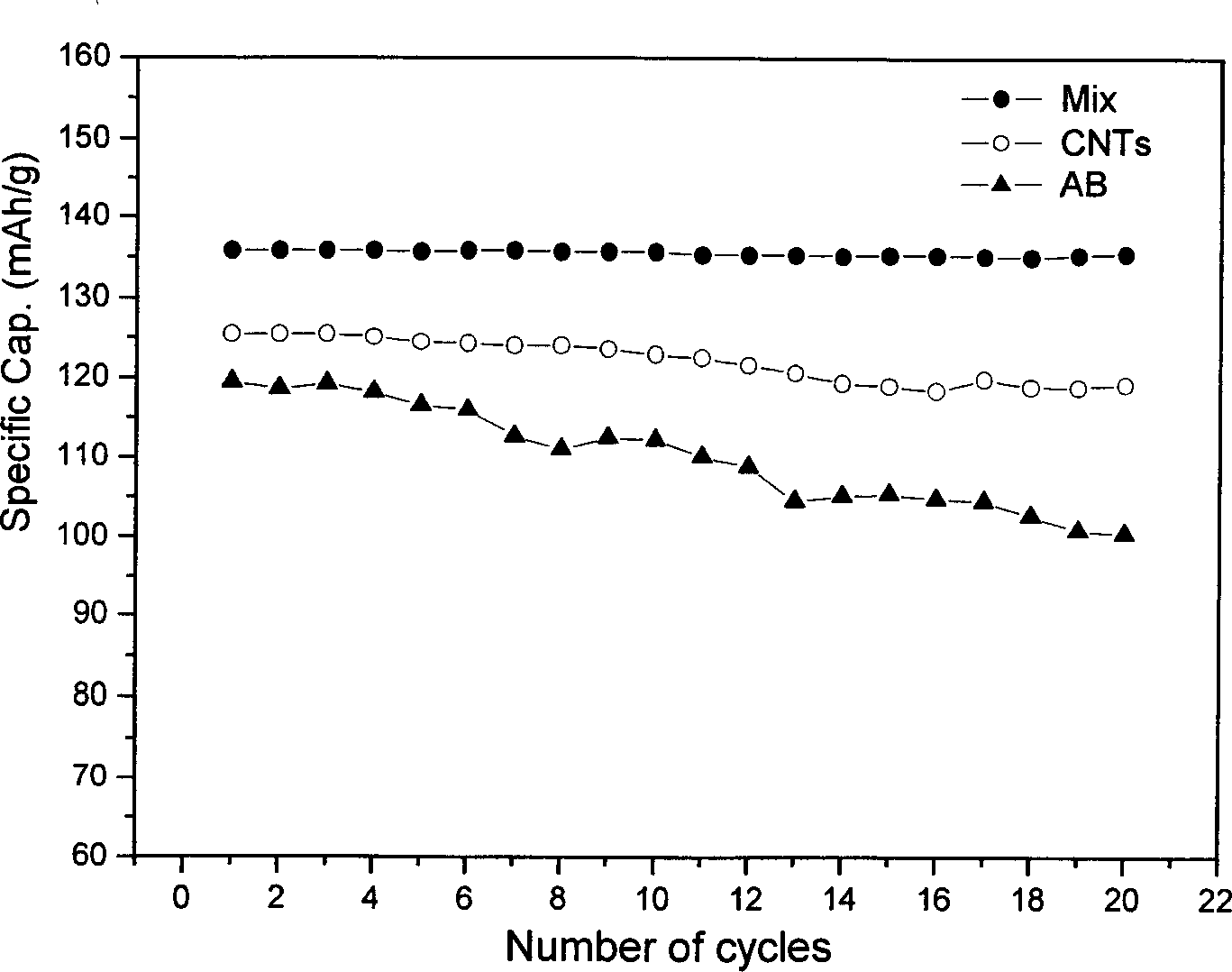

Nanoscale metal paste for interconnect and method of use

ActiveUS20090162557A1Broaden applicationEasy to handleTransportation and packagingPrinted circuit aspectsMicrometerMetal particle

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

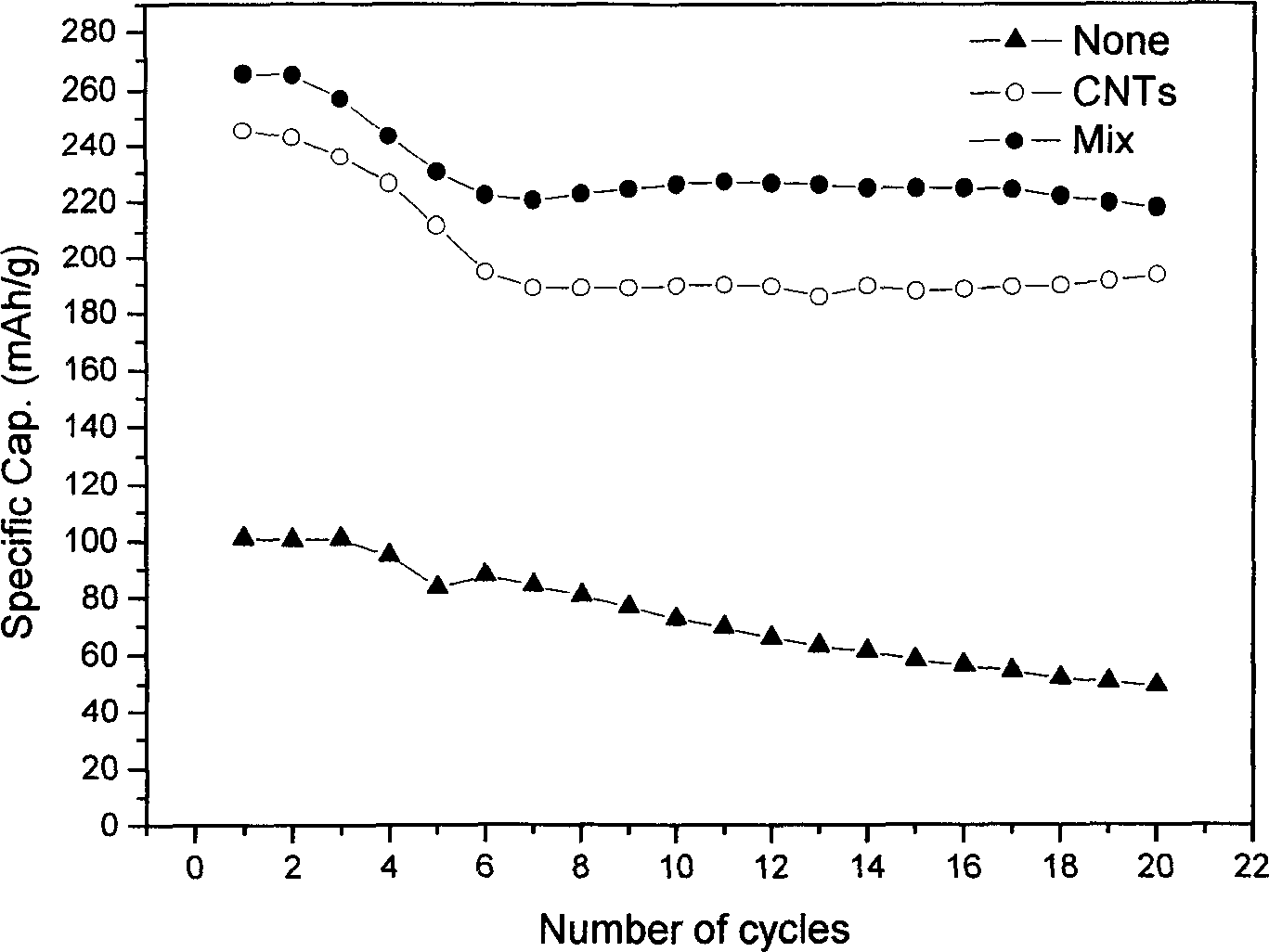

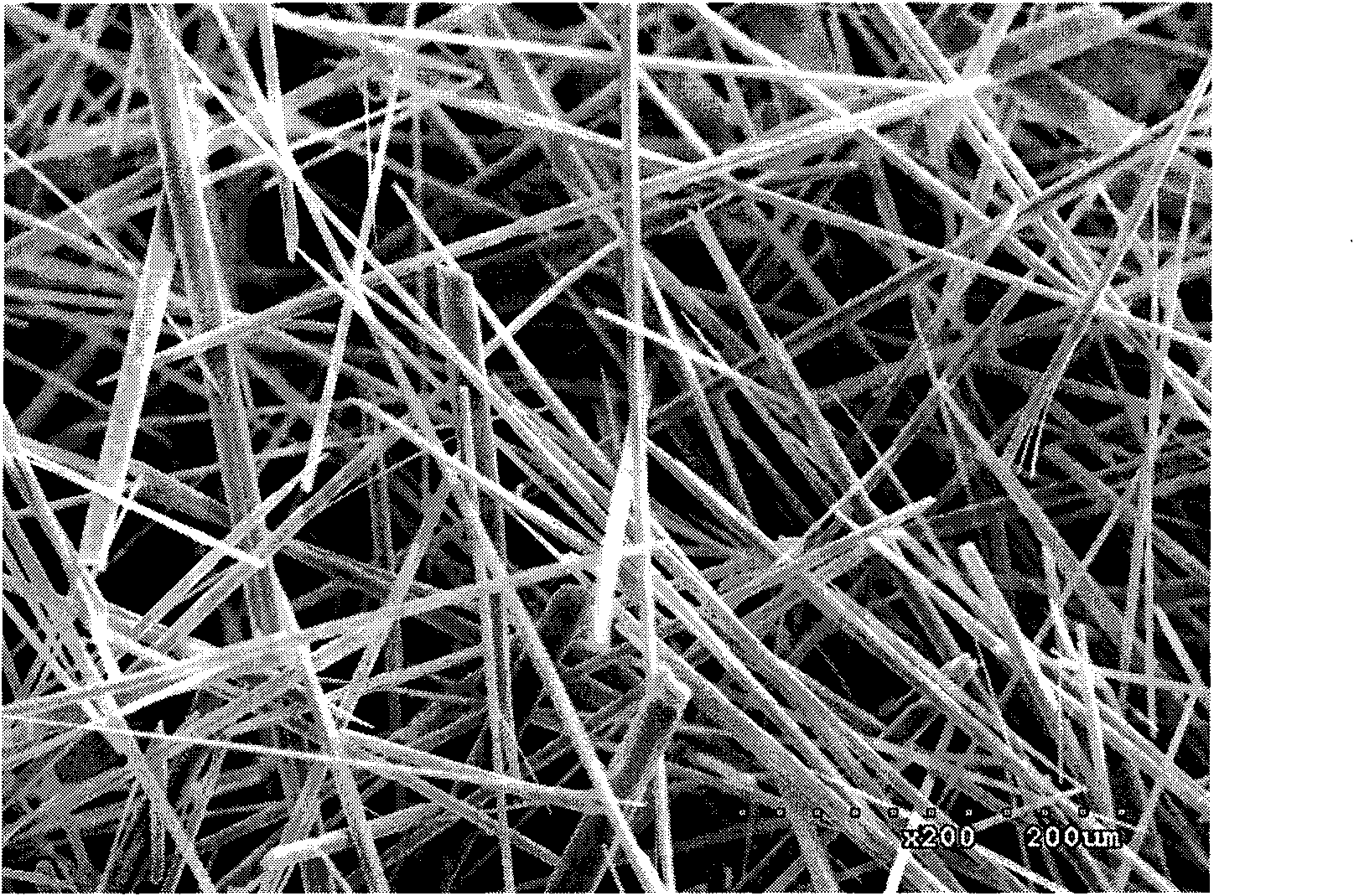

Anode, cathode material conductive agent for lithium-ion secondary battery and preparation method thereof

This invention discloses one second battery anode and negative conductive agent and its process method by use of carbon nanometer tube and acetylene black compound, wherein, the method comprises the following steps: Processing the mother liquid with concentration of 0.5 to 8 percent by adding the carbon nanometer tube and acetylene black compound into dispersion agent; or after adding the dispersion agent water or organic agent to dissipate the nanometer tube to process the low concentration mother liquid with 0.5 to 8 by adding acetylene black; The mother liquid passes filter or pressing to process compound conductive agent with dry weight of 6 to 60 percent. Comparing with conductive carbon or fiber, the nanometer tube has high capacity with high charging efficiency,

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

Method for preparing cyclodextrin-polyolefin blends and products made therefrom

InactiveUS20050043482A1Reduce reunionMaximize reactionPharmaceutical non-active ingredientsPolyolefinAntimicrobial polymer

The present invention discloses a method of dispersing cyclodextrins into a base polymer. The method of the invention comprises reacting grafted microfine polymer powder with a cyclodextrin to form a cyclodextrin-attached grafted polymer, and mixing the cyclodextrin-attached grafted polymer and the base polymer for a sufficient time that the cyclodextrin-attached grafted polymer is dispersed within the base polymer. The present invention also provides several cyclodextrin-inclusion complex products formed by the method of the invention. This products include an antimicrobial polymer blend, a fragrant polymer blend, and a dyed polymer blend.

Owner:EQUSR CHEM LP

Preparation method of graphene-containing water-based electrothermal film

ActiveCN105906832AHigh viscosityImprove conductivityPolyurea/polyurethane coatingsHeating element materialsWater basedHydrophilization

The invention discloses a preparation method of graphene-containing water-based electrothermal film. The method comprises the following steps of: (1) carrying out hydrophilization treatment on graphene, then adding solutions of cellulose derivatives as a dispersing agent and a thickening agent, and carrying out pre-dispersion; (2) adding an auxiliary agent into the pre-dispersed graphene, and dispersing to obtain homogeneous dispersion liquid; (3) adding an adhesive into the homogeneous dispersion liquid, and mixing to obtain graphene-containing electrothermal film slurry; and (4) coating a film formation carrier with the graphene-containing electrothermal film slurry to form a graphene conducting layer, and drying to obtain the graphene-containing electrothermal film formed by the graphene conducting layer and the film formation carrier. After the preparation method is adopted, a heating body having excellent heat conduction and electric conduction properties can be prepared.

Owner:四川烯材科技有限公司

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

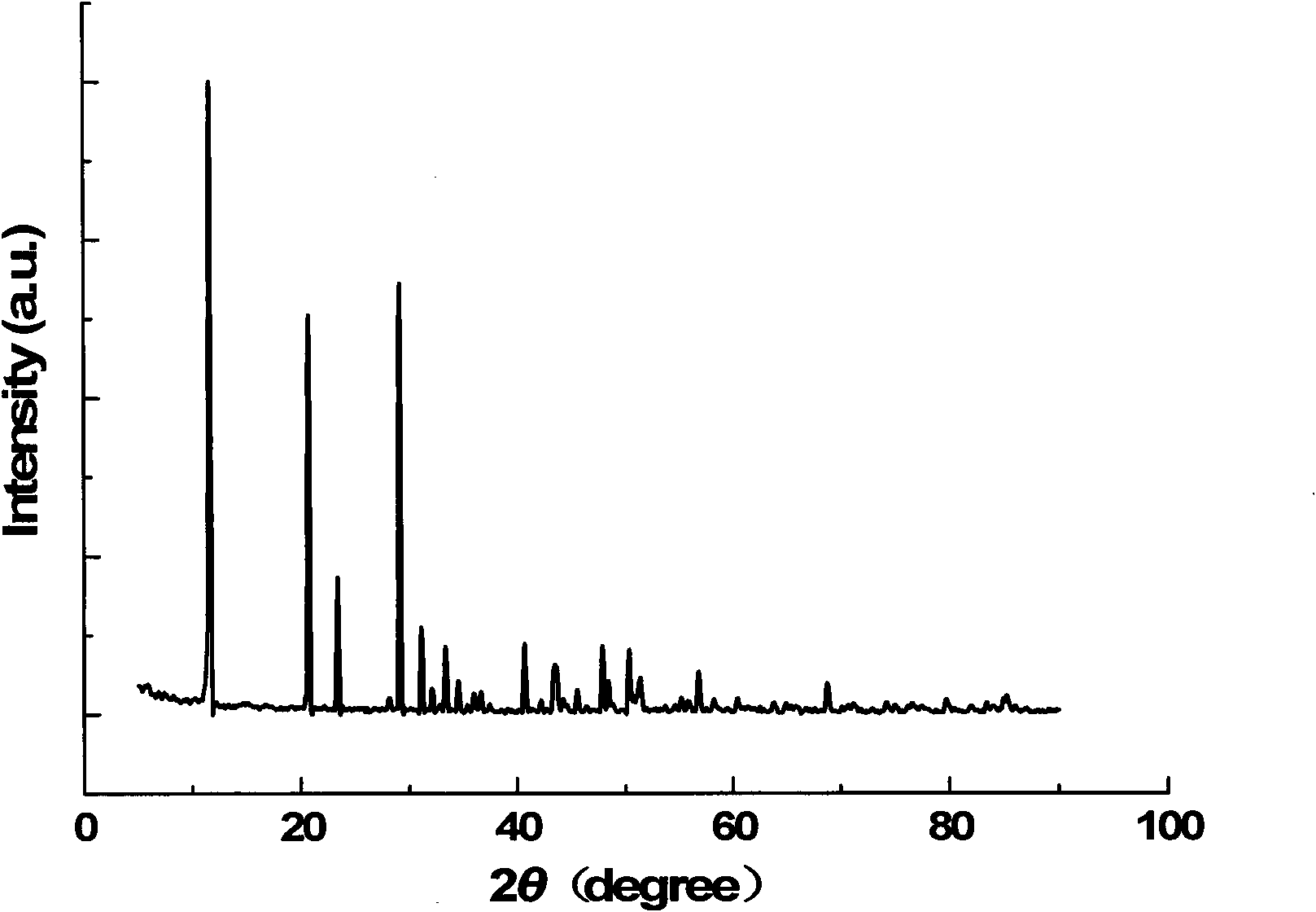

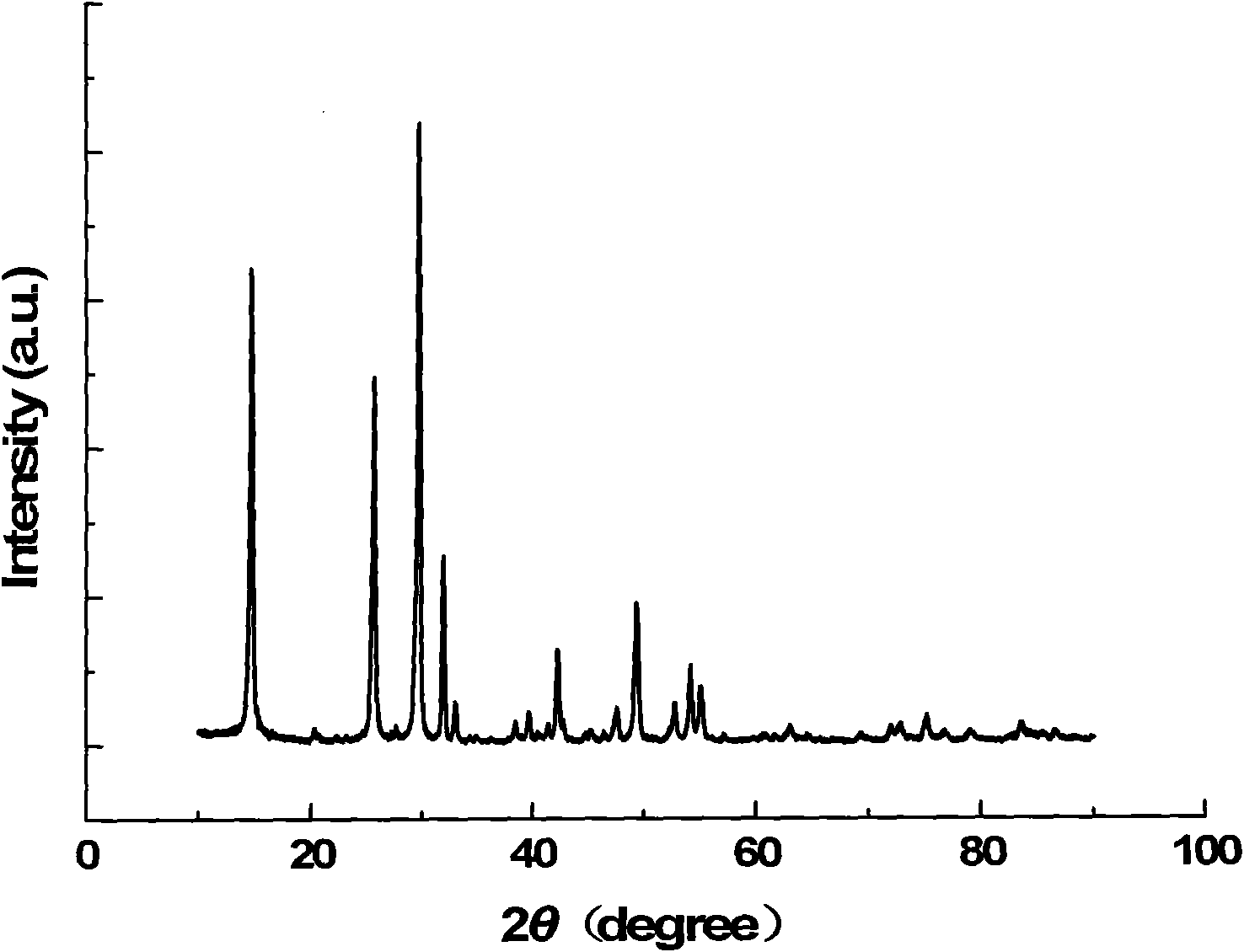

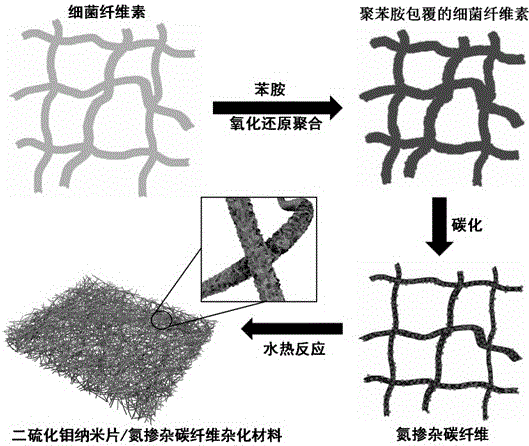

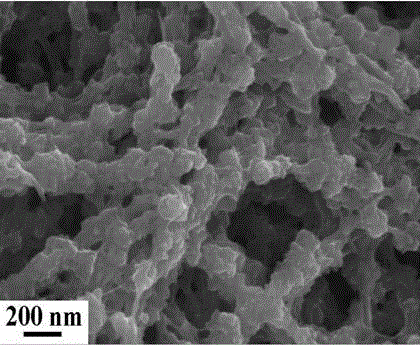

Molybdenum disulfide nanosheet/nitrogen-doped carbon fiber hybrid material and preparation method therefor

InactiveCN105056983AHigh electrical conductivityReduce reunionPhysical/chemical process catalystsElectrodesFiberCarbon fibers

The invention belongs to the technical field of carbon fiber materials, and particularly discloses a molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material and a preparation method therefor. The molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material is prepared by growing a molybdenum disulfide nanosheet on a nitrogen-doped carbon fiber with a three-dimensional network structure in situ by taking molybdenum salt and sulfosalt as precursors; A preparation process for the molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material comprises: preparing the nitrogen-doped carbon fiber through in-situ oxidization-reduction reaction, freeze-drying and high-temperature carbonization; and growing the molybdenum disulfide nanosheet on the nitrogen-doped carbon fiber in situ through a one-step solvothermal method. According to the nitrogen-doped carbon fiber prepared by the preparation method, the wettability of the carbon fiber and a solvent is improved, and more active sites are provided for growth of inorganic particles; and moreover, the electrical conductivity of the carbon fiber is greatly improved, so that the migration rate for electrons in an electro-catalysis hydrogen-evolution process is increased. The molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material prepared by the preparation method can be used as an ideal high-performance catalyst material and can be used for the electro-catalysis hydrogen-evolution field.

Owner:FUDAN UNIV

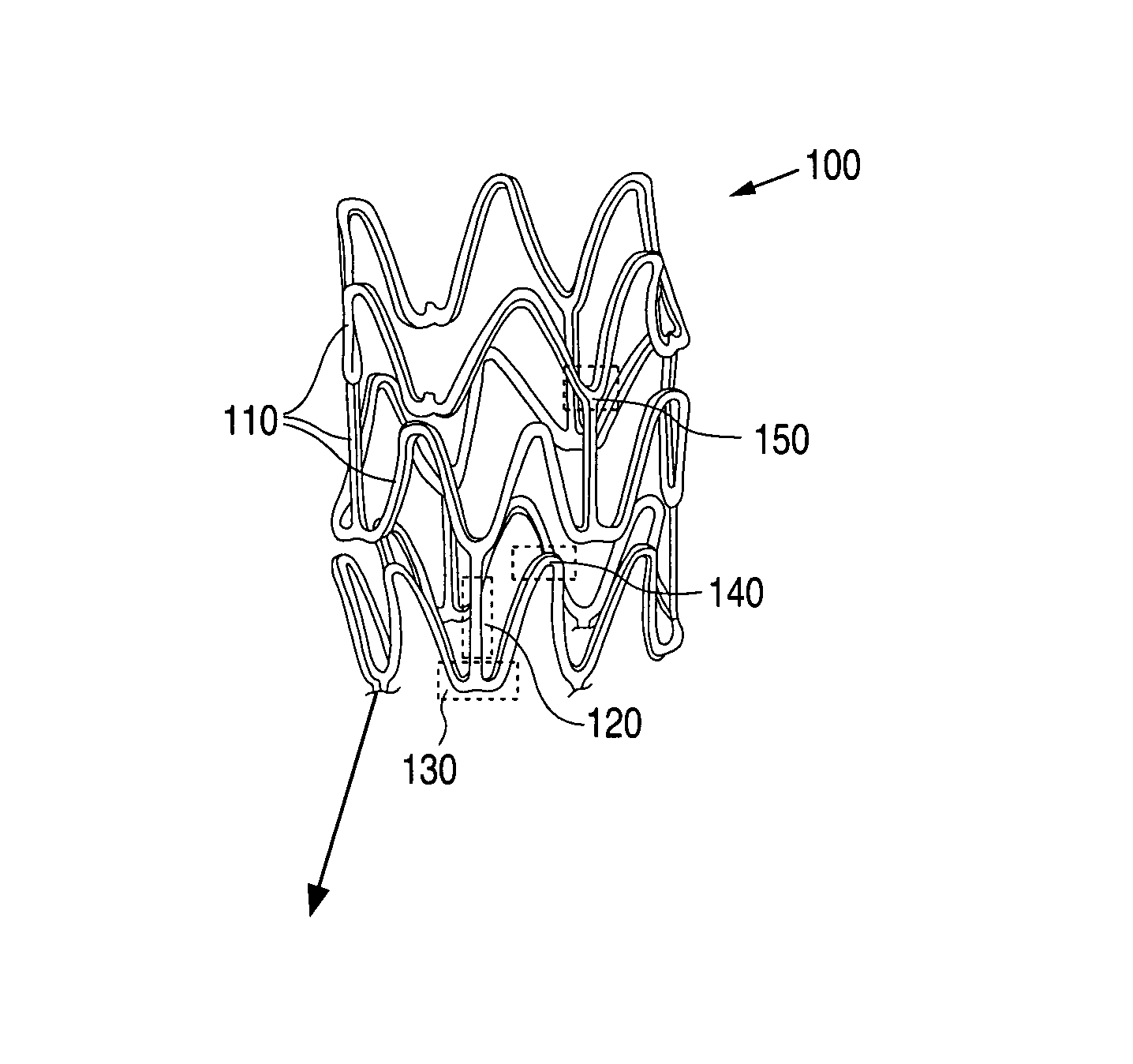

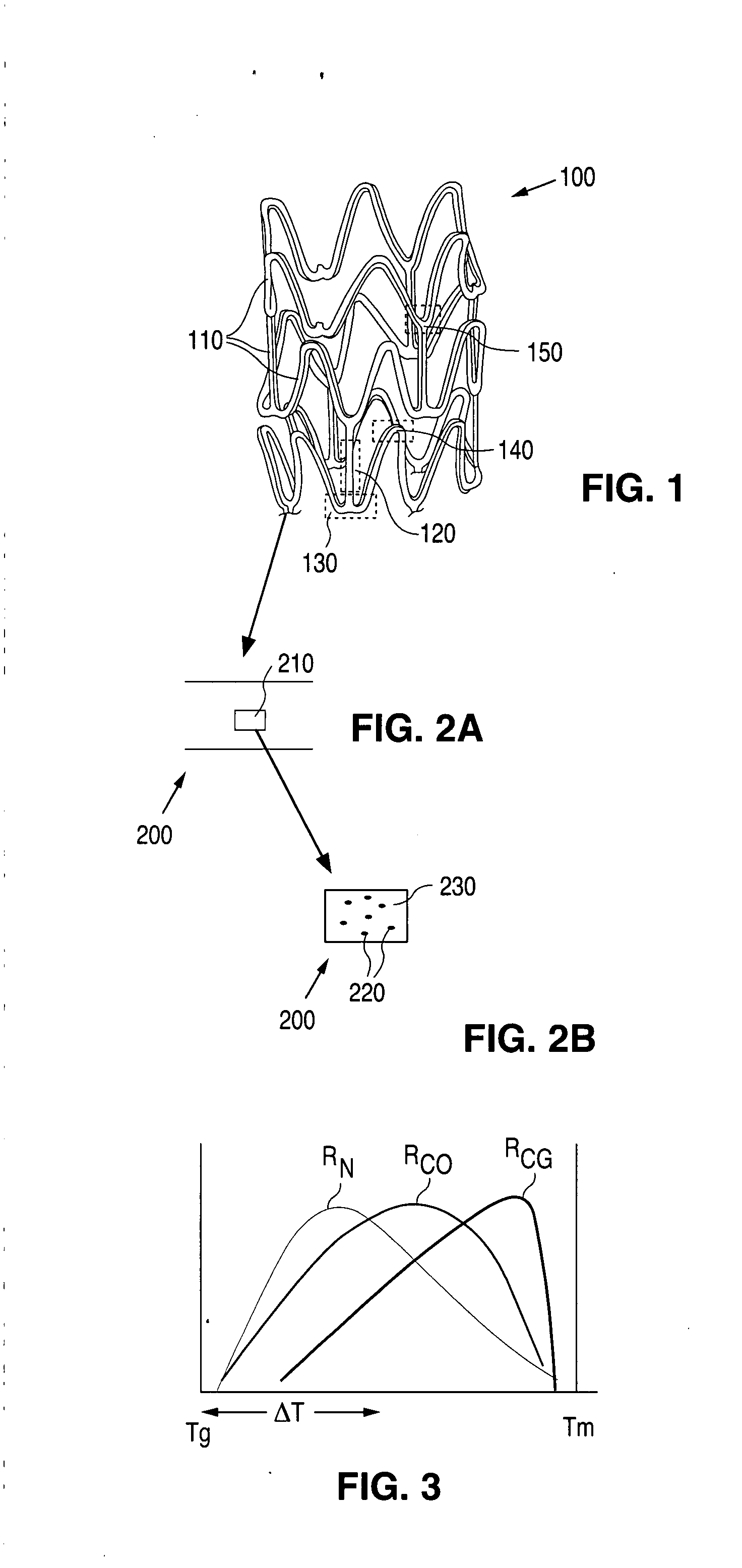

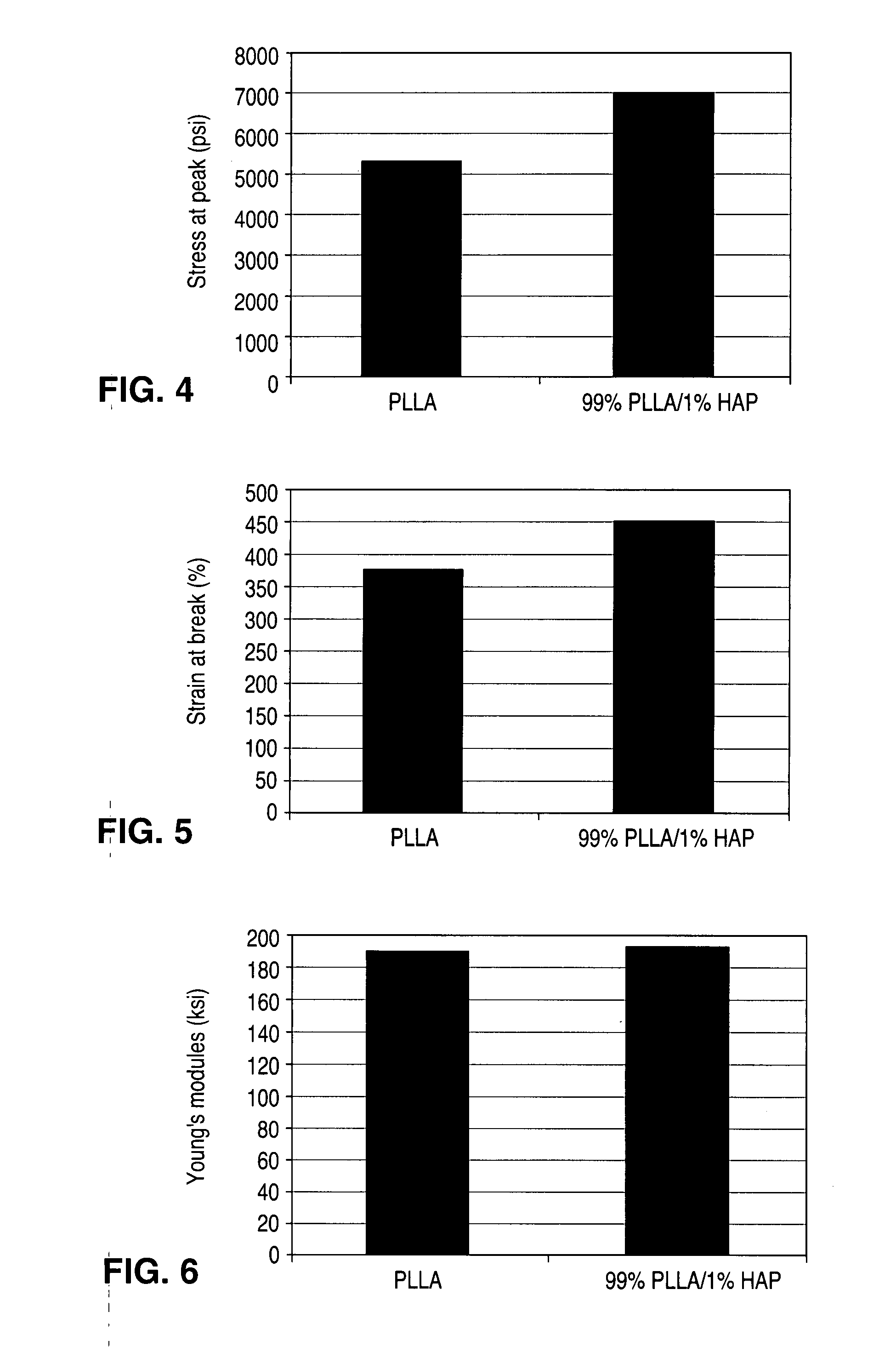

Implantable medical devices made from polymer-bioceramic composite

InactiveUS20070278720A1Reduce reunionIncrease shear stressStentsNanotechBioceramicBiomedical engineering

Methods and devices relating to polymer-bioceramic composite implantable medical devices are disclosed.

Owner:ABBOTT CARDIOVASCULAR

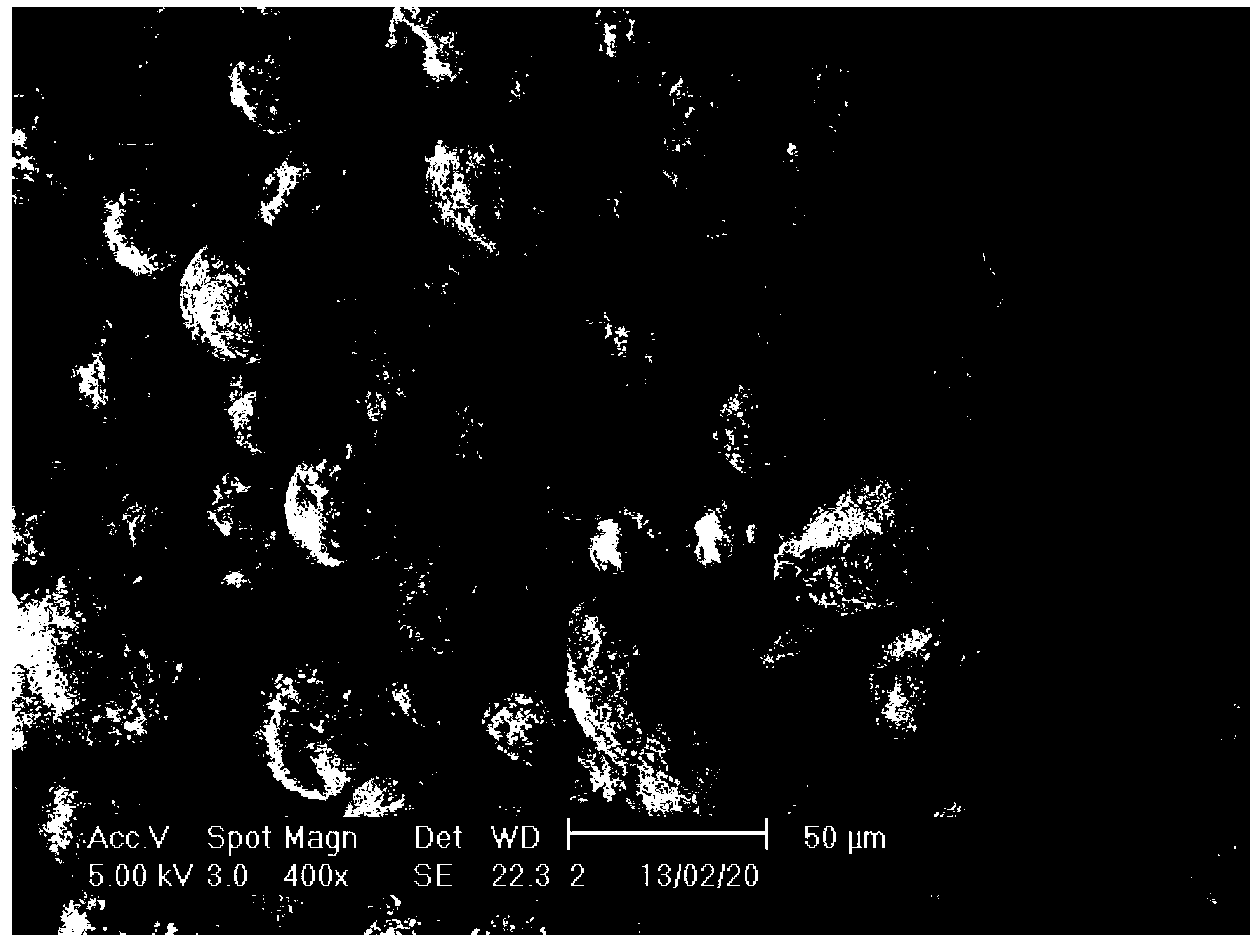

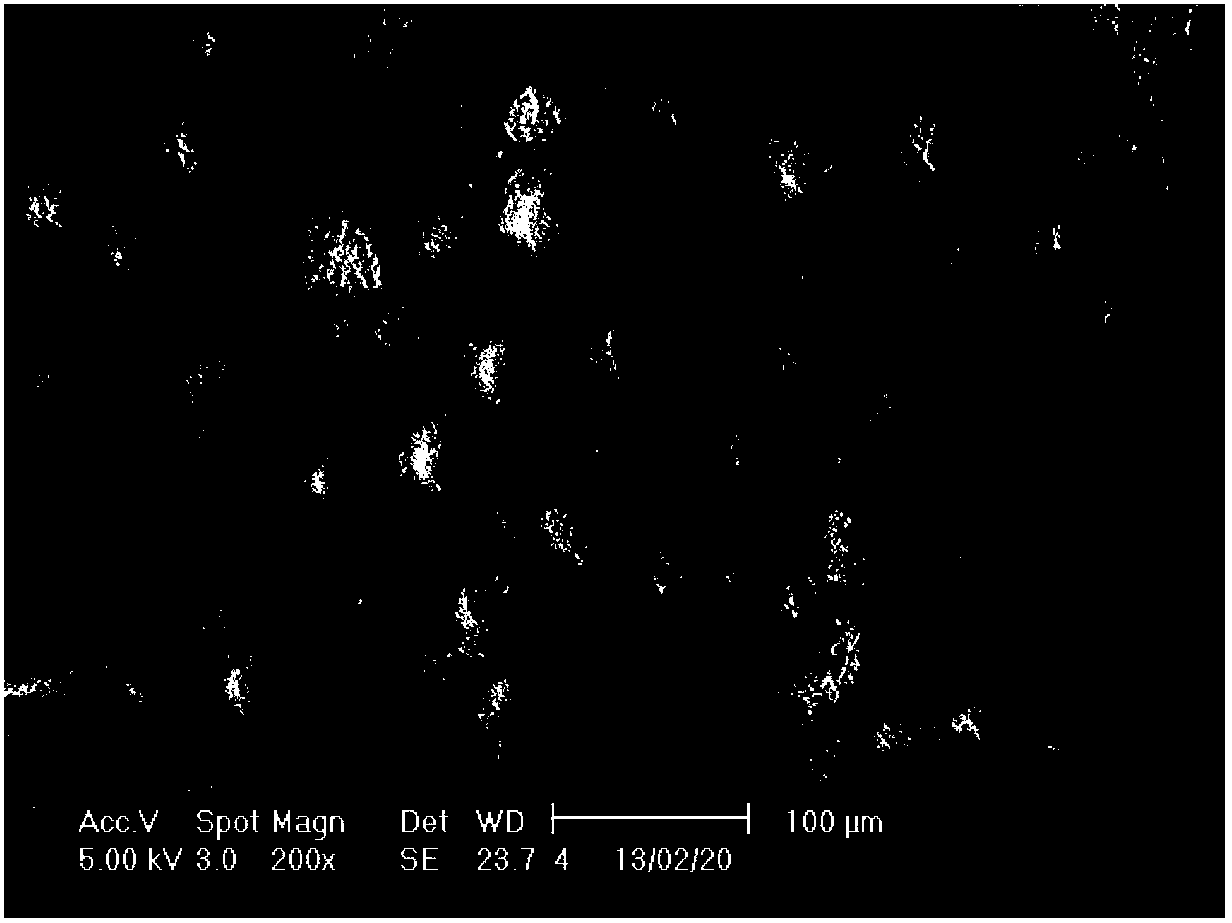

Spherical montmorillonite mesoporous composite carrier, supported catalyst and preparation method and application thereof, and ethyl acetate preparation method

ActiveCN104248985AReduce manufacturing costGood platformCatalyst carriersOrganic compound preparationMolecular sieveAcetic acid

The invention discloses a spherical montmorillonite mesoporous composite carrier and a preparation method thereof, a supported benzenesulfonic acid catalyst and a preparation method thereof, an application of the catalyst in an esterification reaction, and a preparation method of ethyl acetate. The spherical montmorillonite mesoporous composite carrier contains montmorillonite and a mesoporous molecular sieve material, average particle size of the spherical montmorillonite mesoporous composite carrier is 30-60 micrometers, the specific surface area is 150-600 square meters / gram, pore volume is 0.5-1.5 milliliters / gram, aperture distribution is trimodal distribution, most probable apertures corresponding to three peaks are 2-4 nanometers, 5-15 nanometers and 10-40 nanometers respectively. The provided supported benzenesulfonic acid catalyst has the advantages of high catalytic activity and repeated usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing active calcium carbonate

InactiveCN101967309AImprove hydrophobicityReduce reunionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsAdhesiveFatty acid

The invention discloses a method for preparing active calcium carbonate, which comprises the following steps of: adding 1 to 10 weight parts of one or a mixture of more of fatty acid and fatty acid salt and 0.05 to 5 weight parts of coupling agent into suspension containing 100 weight parts of calcium carbonate, and modifying at the temperature of between 60 and 90 DEG C for 0.5 to 5 hours to prepare the active calcium carbonate. The method has a simple preparation process and is stable in performance; and the surface of the prepared active calcium carbonate has the good hydrophobicity, is easy to disperse in rubber and resin, improves the combination property of polymers, and can be used in fields of the rubber, adhesives and the like.

Owner:山东海泽纳米材料有限公司

Polyvinyl butyral granular material for 3-D binder printing, production method and uses therefor

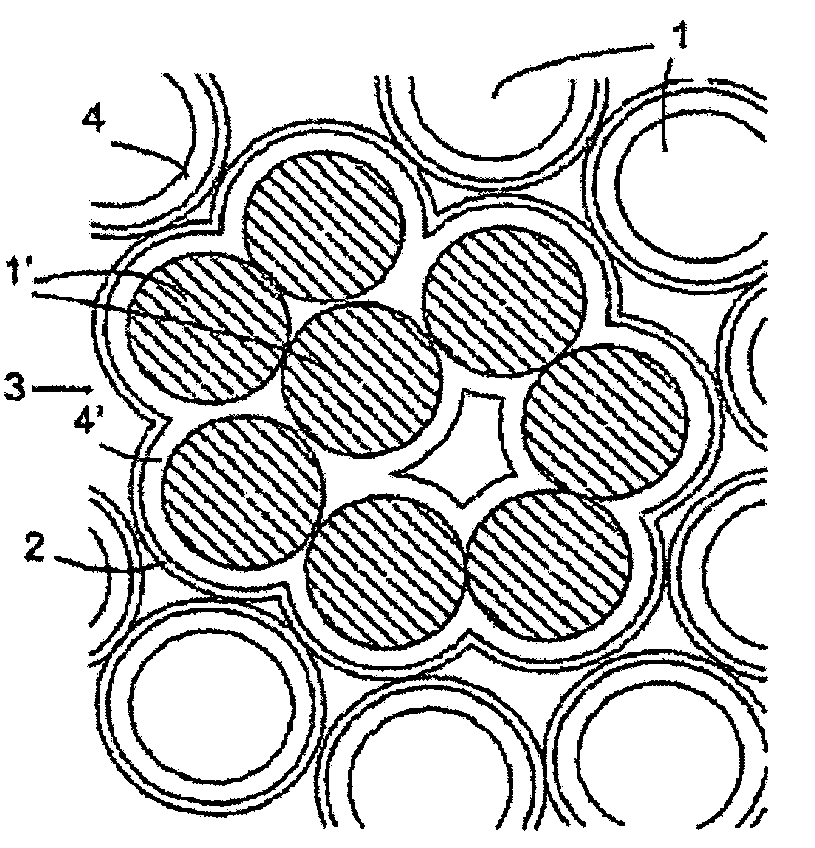

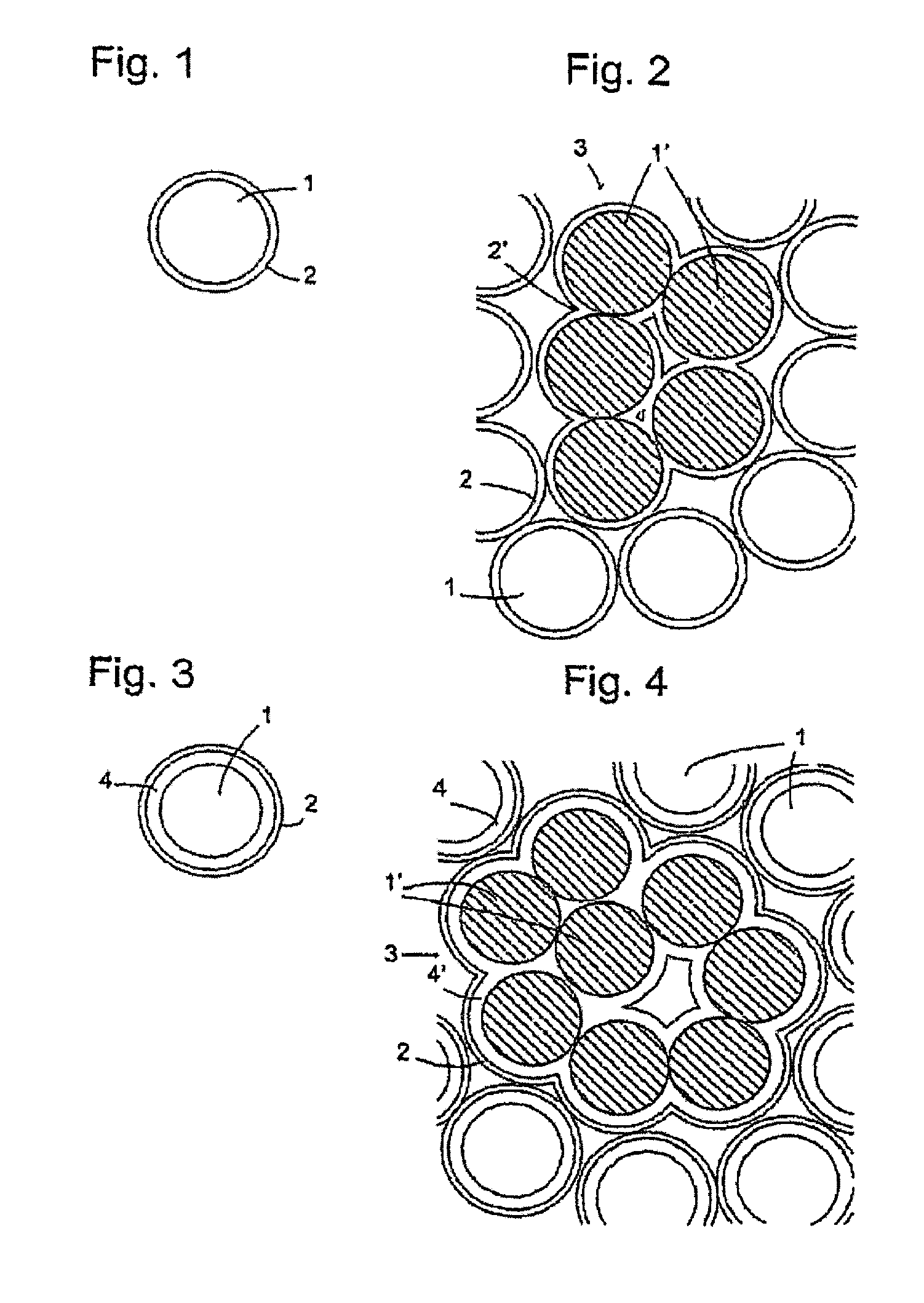

InactiveUS7402330B2Flat surfaceFiner and more detailed structureGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

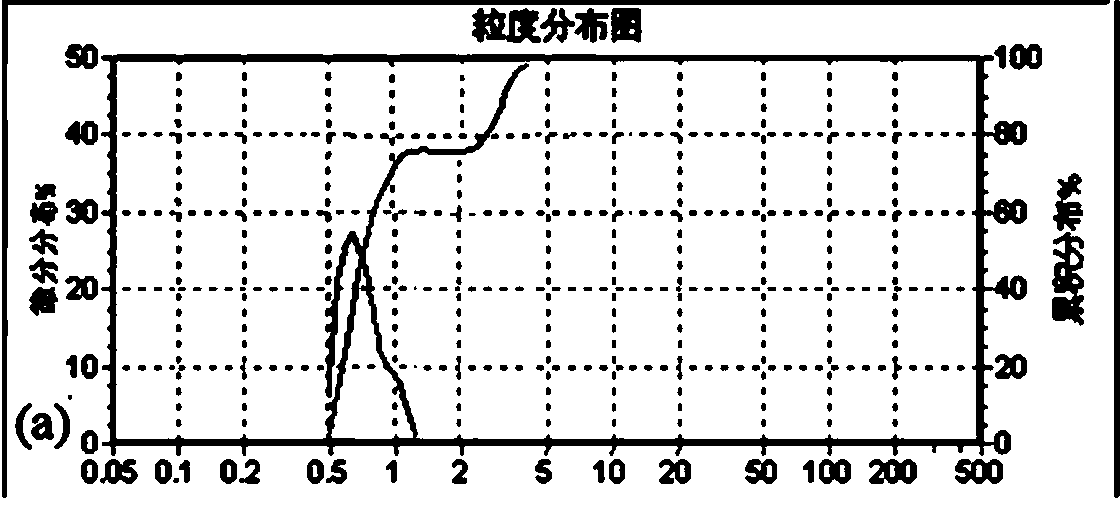

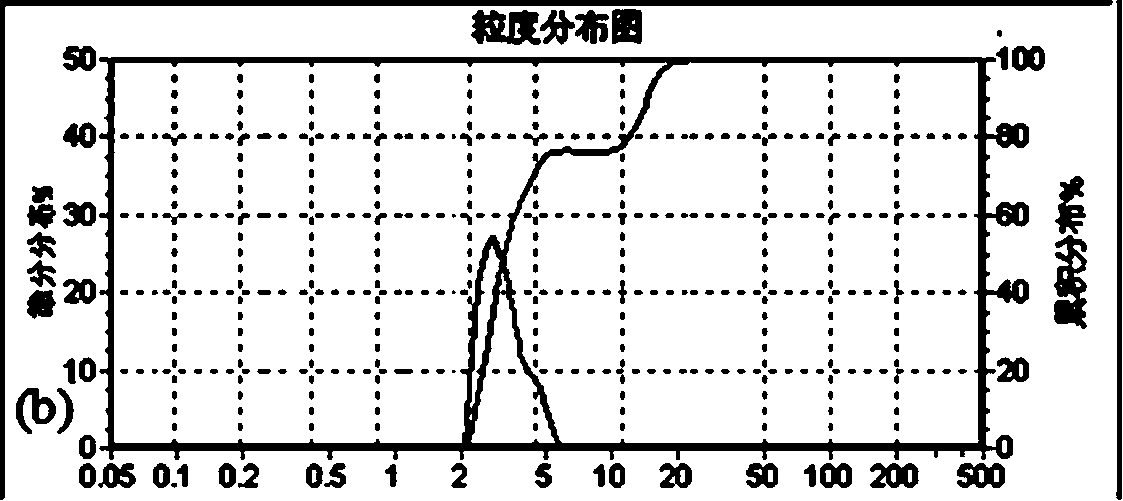

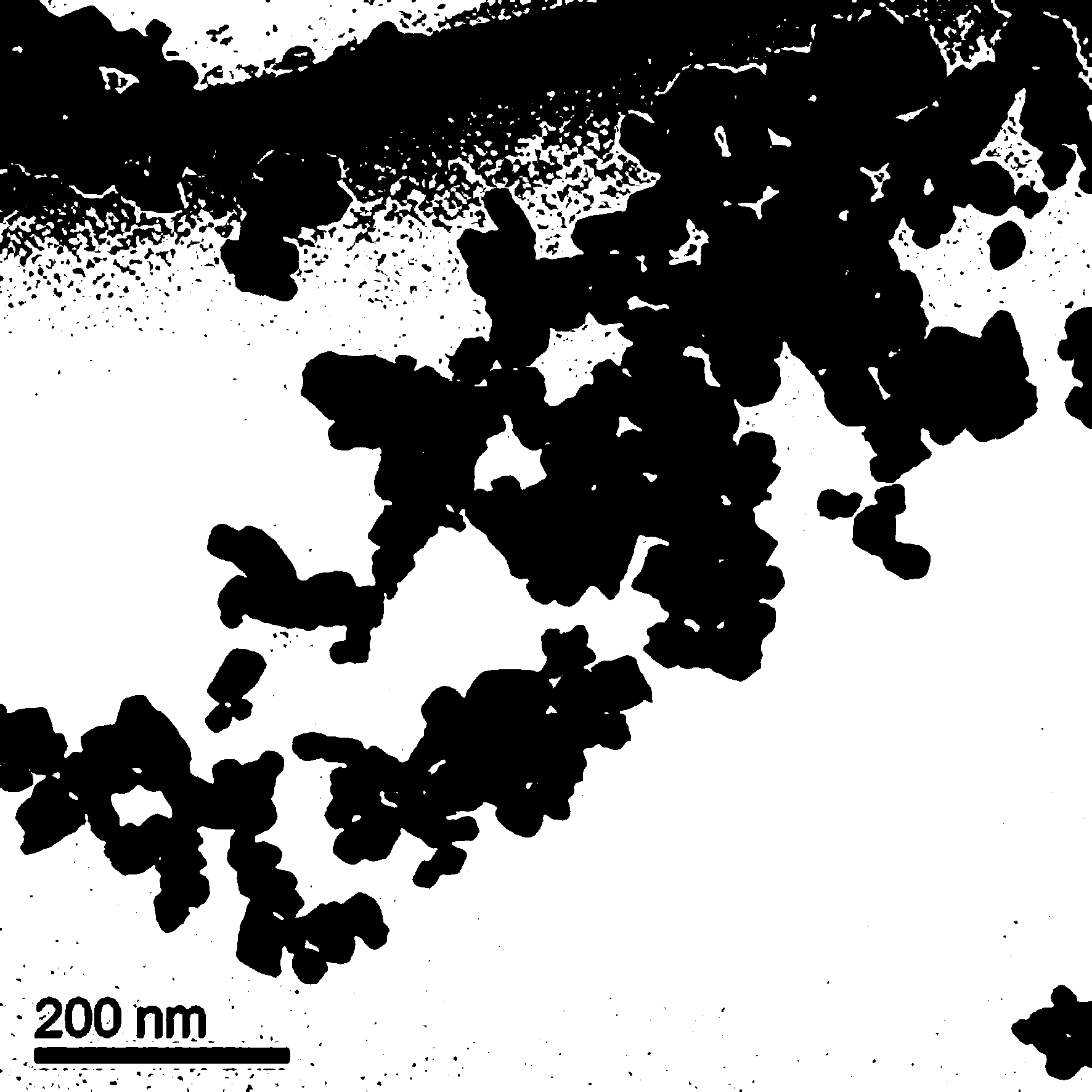

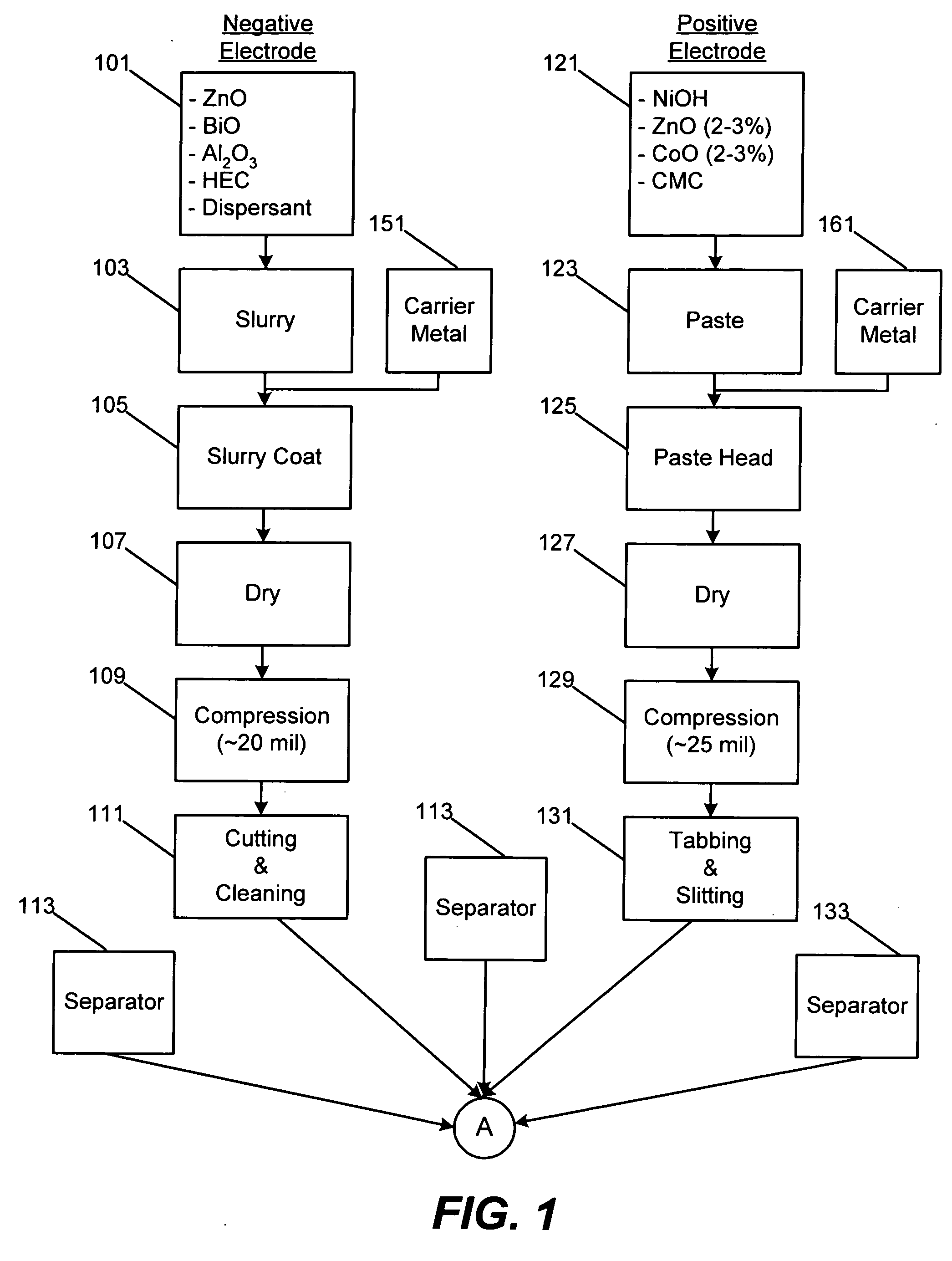

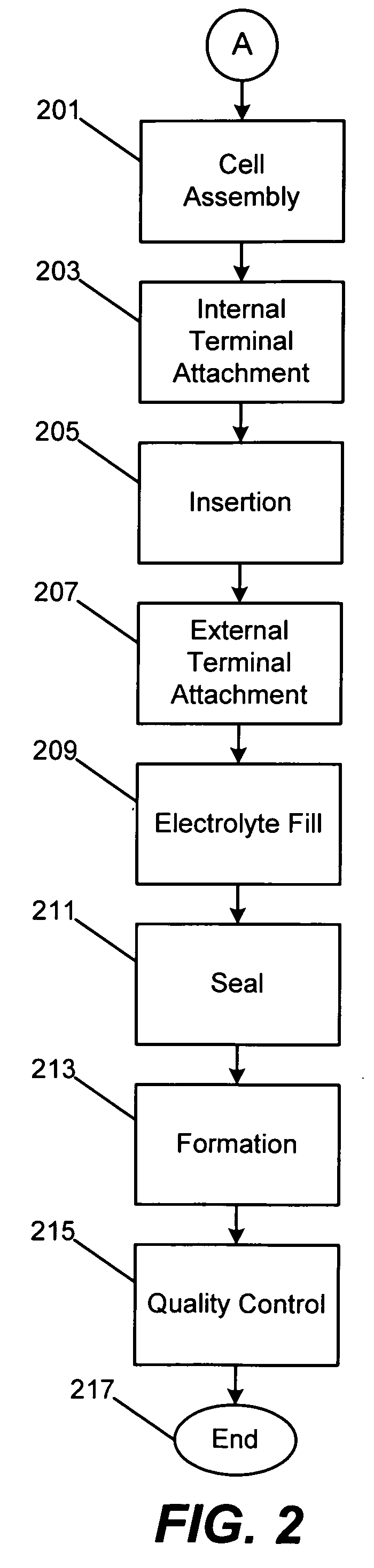

Method of manufacturing nickel zinc batteries

InactiveUS20060207084A1Reduce reunionImprove efficiencyFinal product manufacturePrimary cellsZinc compoundsNickel cadmium

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry, paste, or dry mixture of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in nickel cadmium batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:POWERGENIX SYST

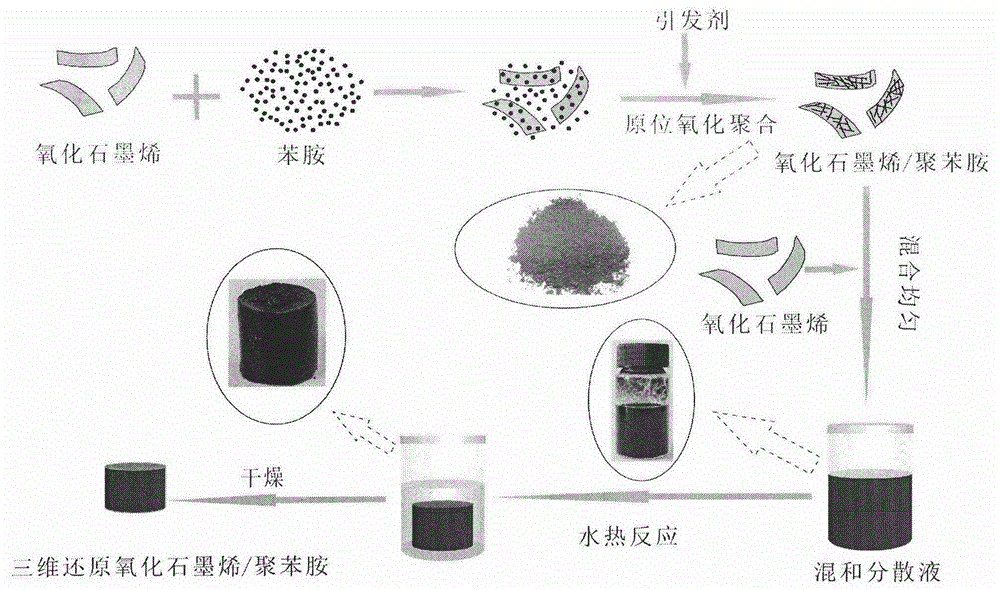

Preparation method of three-dimensional reduced graphene oxide/polyaniline composite material

InactiveCN104559176AReduce reunionEvenly dispersedHybrid capacitor electrodesNetwork structurePolyaniline composite

The invention discloses a preparation method of a three-dimensional reduced graphene oxide / polyaniline composite material, which comprises the following steps: 1) uniformly stirring a graphene oxide raw material and deionized water in a reactor to obtain a graphene oxide dispersion solution; 2) adding aniline, stirring uniformly, adding medium acid, stirring uniformly under ice bath conditions, and adding an initiator; filtering the reaction product, washing the filter residue, and drying to obtain a graphene oxide / polyaniline composite material; and 3) uniformly mixing the graphene oxide / polyaniline composite material with the graphene oxide dispersion solution, putting in a closed reactor, carrying out hydrothermal reaction to form a three-dimensional reduced graphene oxide polyaniline / composite material aquagel, and drying to obtain the three-dimensional reduced graphene oxide / polyaniline composite material. The polyaniline nano particles are uniformly dispersed among the reduced graphene oxide sheets to form the three-dimensional network-structure composite material. The composite material has the advantages of large specific area, high electric conductivity and high structural stability of polyaniline.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing nanometer tungsten combined powder by collosoling, spraying and desiccating and hot reducing

The invention relates to a powder preparation process, especially for preparing a nano composite powder, which belongs to the field of powder metallurgical technique. The preparation process is characterized by: weighing the different metal salts in proportion for preparing a salt solution and a mixed salt solution; adding a few acid or alkali for controlling the pH value in a range of less than 4 or more than 10, adding 0.1% to 5% of surfactant, spray drying at the temperature of between 300 C. and 350 C. for preparing the nano oxide composite powder or composite salt powder precursor; obtaining the nano tungsten base composite powder by first reduction at 400 C. to 600 C. and second reduction at 650 C. to 1000 C. . The nano tungsten base composite powder prepared by the process has superfine granularity, uniform distribution, high purity, and good sintering activity.

Owner:CENT SOUTH UNIV

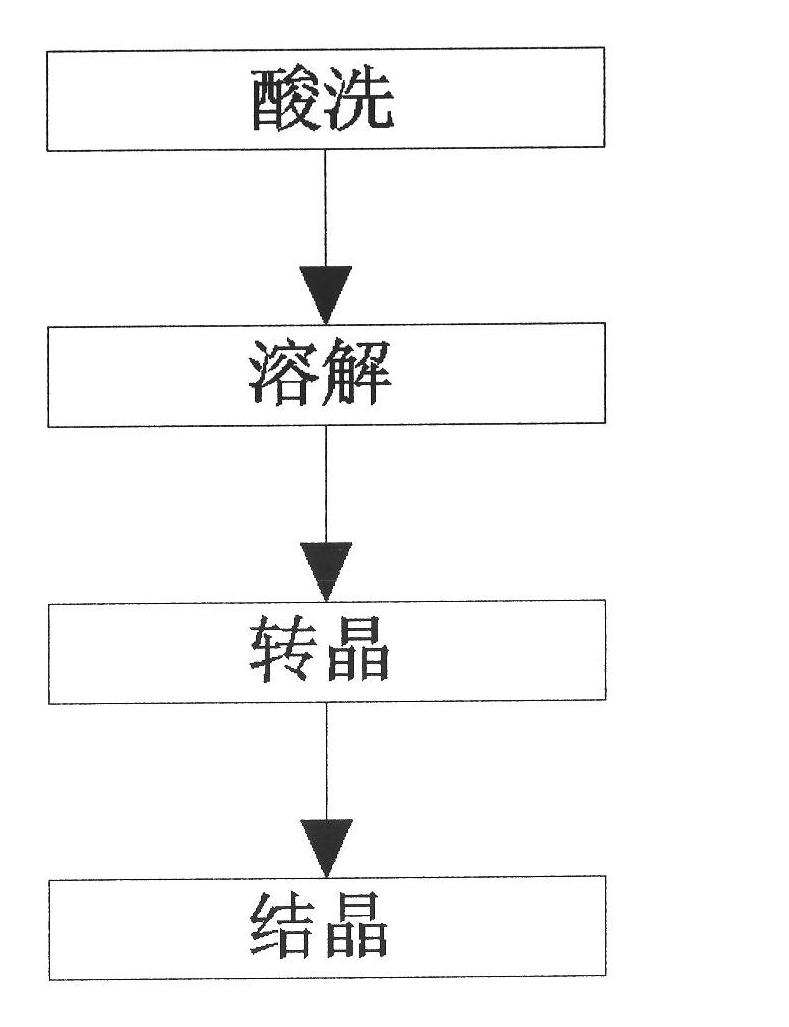

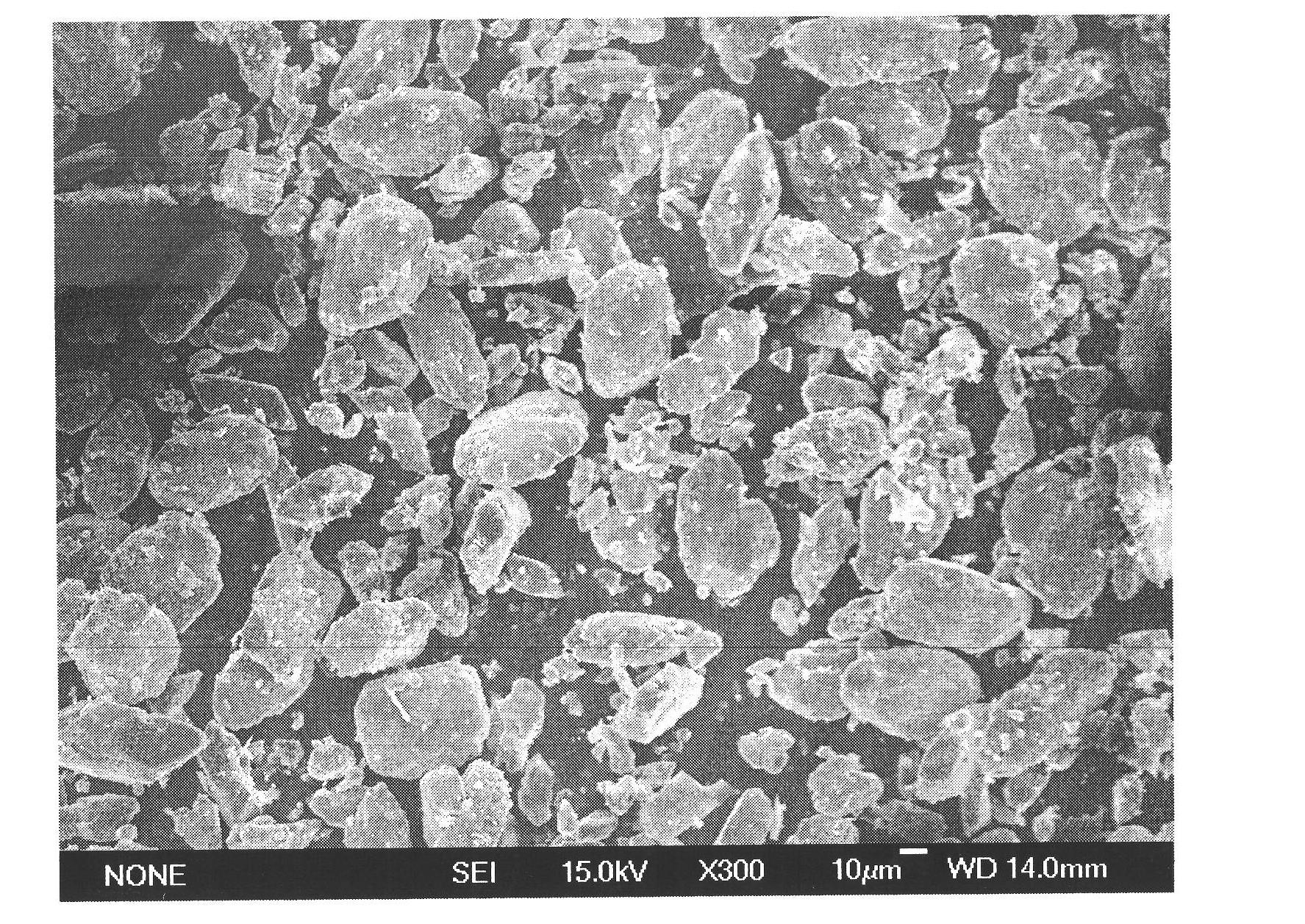

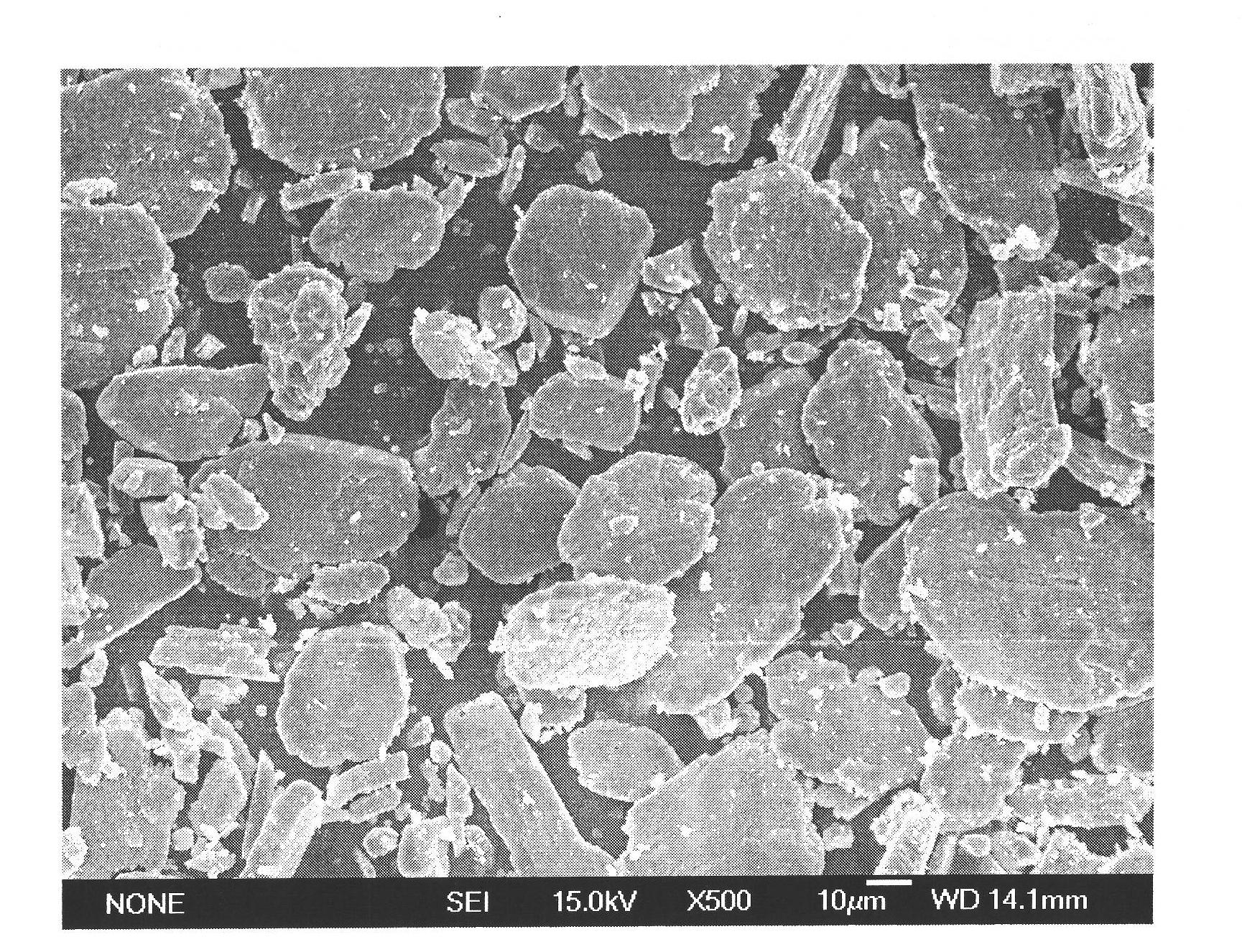

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

Method for preparing cyclodextrin-polyolefin blends and products made therefrom

InactiveUS7019073B2Reduce reunionMaximize reactionPharmaceutical non-active ingredientsPolymer sciencePolyolefin

The present invention discloses a method of dispersing cyclodextrins into a base polymer. The method of the invention comprises reacting grafted microfine polymer powder with a cyclodextrin to form a cyclodextrin-attached grafted polymer, and mixing the cyclodextrin-attached grafted polymer and the base polymer for a sufficient time that the cyclodextrin-attached grafted polymer is dispersed within the base polymer. The present invention also provides several cyclodextrin-inclusion complex products formed by the method of the invention. This products include an antimicrobial polymer blend, a fragrant polymer blend, and a dyed polymer blend.

Owner:EQUSR CHEM LP

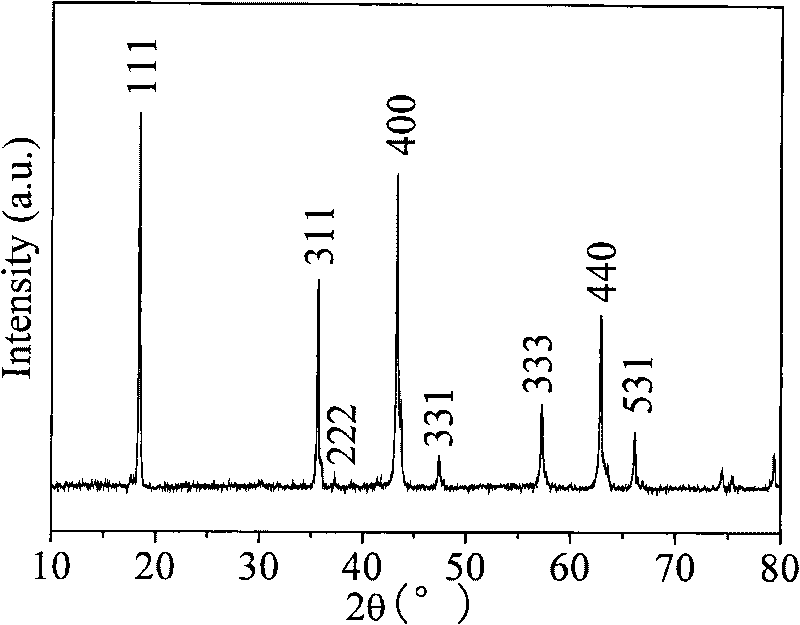

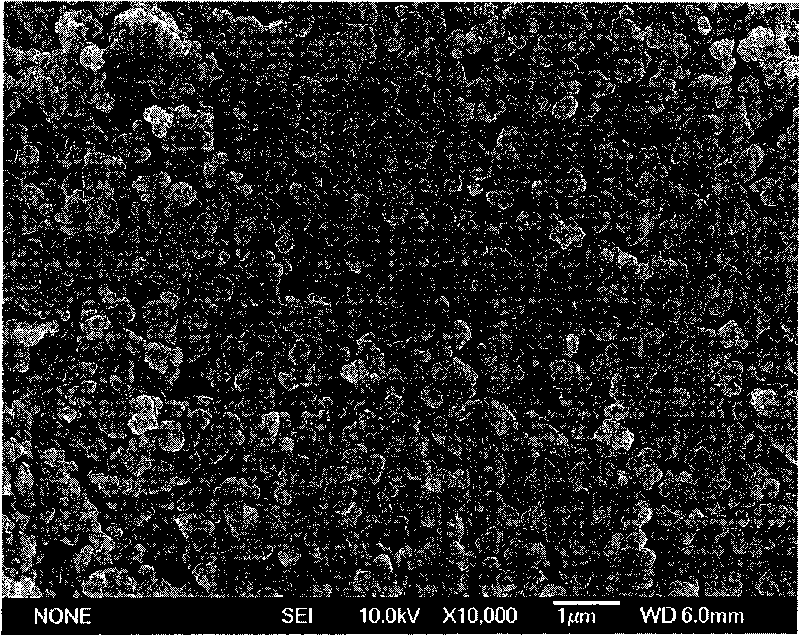

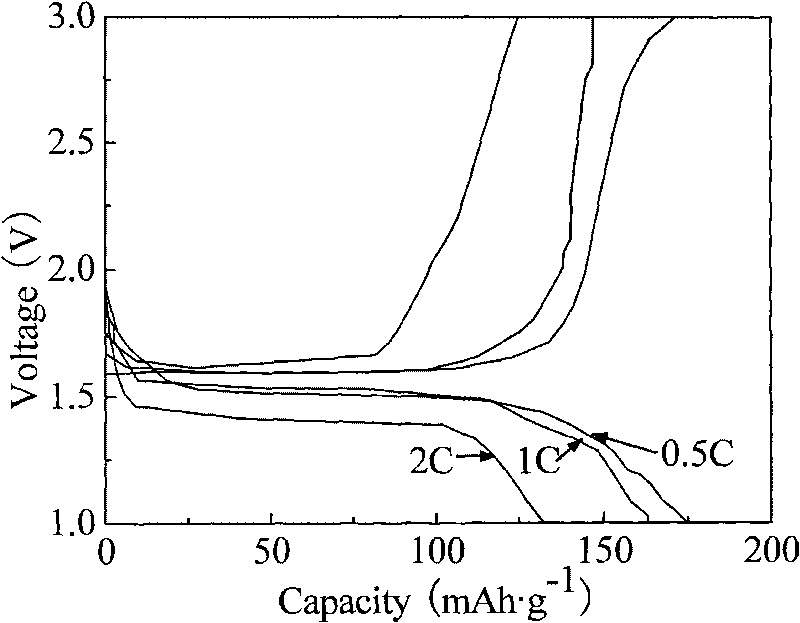

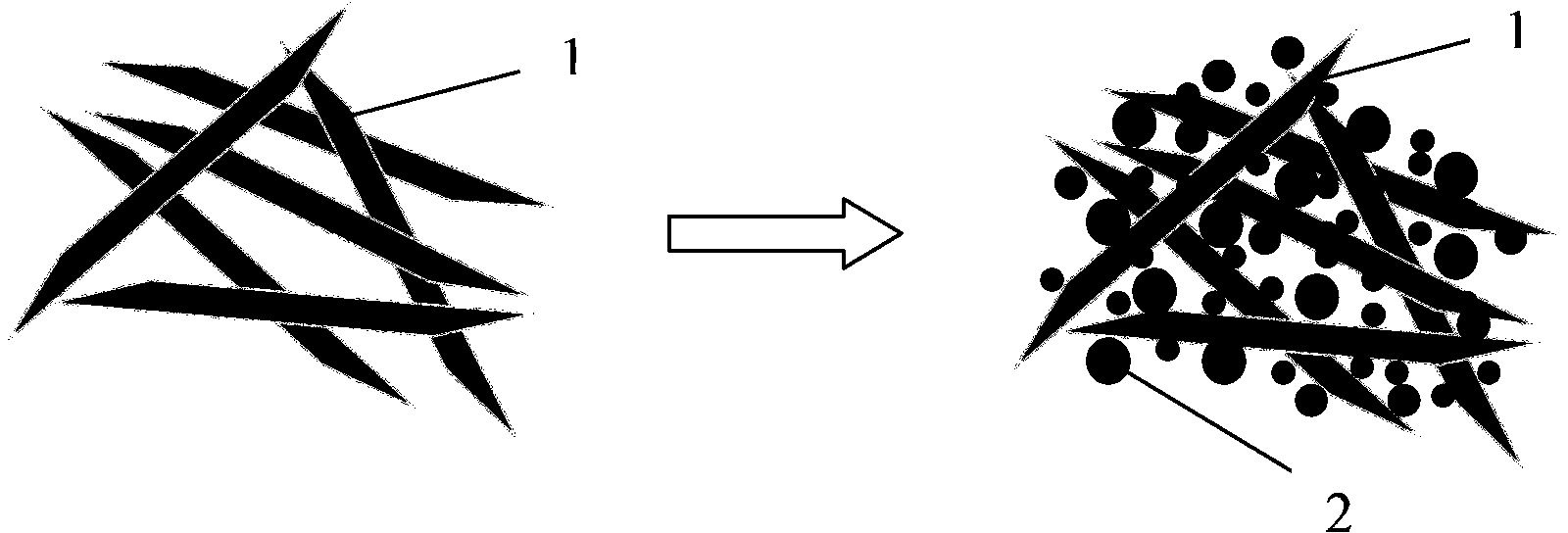

Preparation method of lithium titanium negative electrode composite material for lithium ion battery

The invention relates to a preparation method of lithium titanium negative electrode composite material for lithium ion battery. In the invention, Li soluble compound and Ti soluble compound are taken as lithium source and titanium source, high polymer compound is added, reaction is carried out by sol-gel method, sintering atmosphere is controlled, and sintering is carried out to obtain the composite material. The method not only can prepare nano crystalline with favourable dispersity and can prepare pyrolytic carbon evenly distributed at the periphery or on the surface of granules and obviously improves conductivity of product. The lithium titanium negative electrode material prepared by the method shows excellent multiplying power performance and is applicable to power battery.

Owner:NANJING UNIV OF TECH

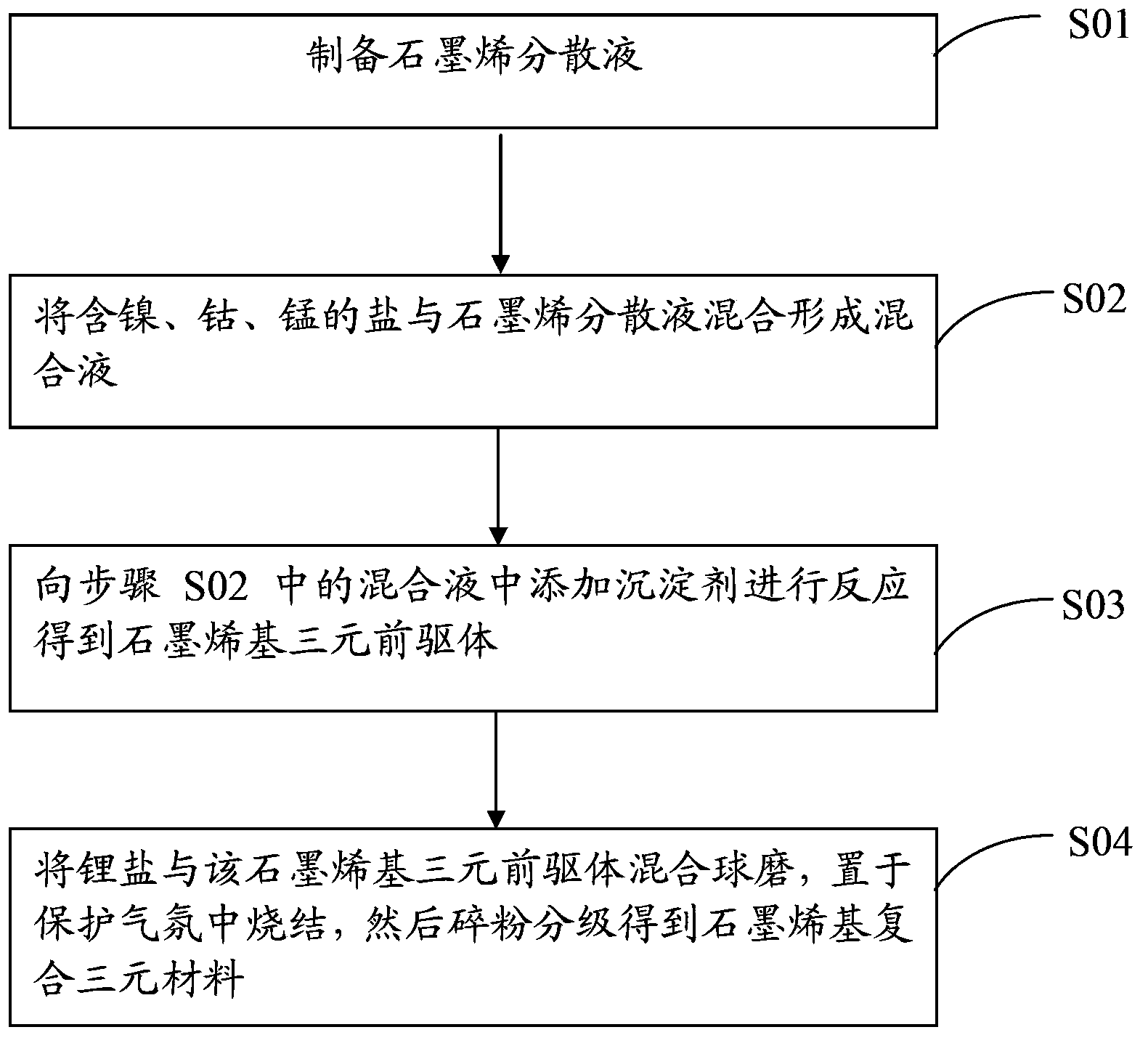

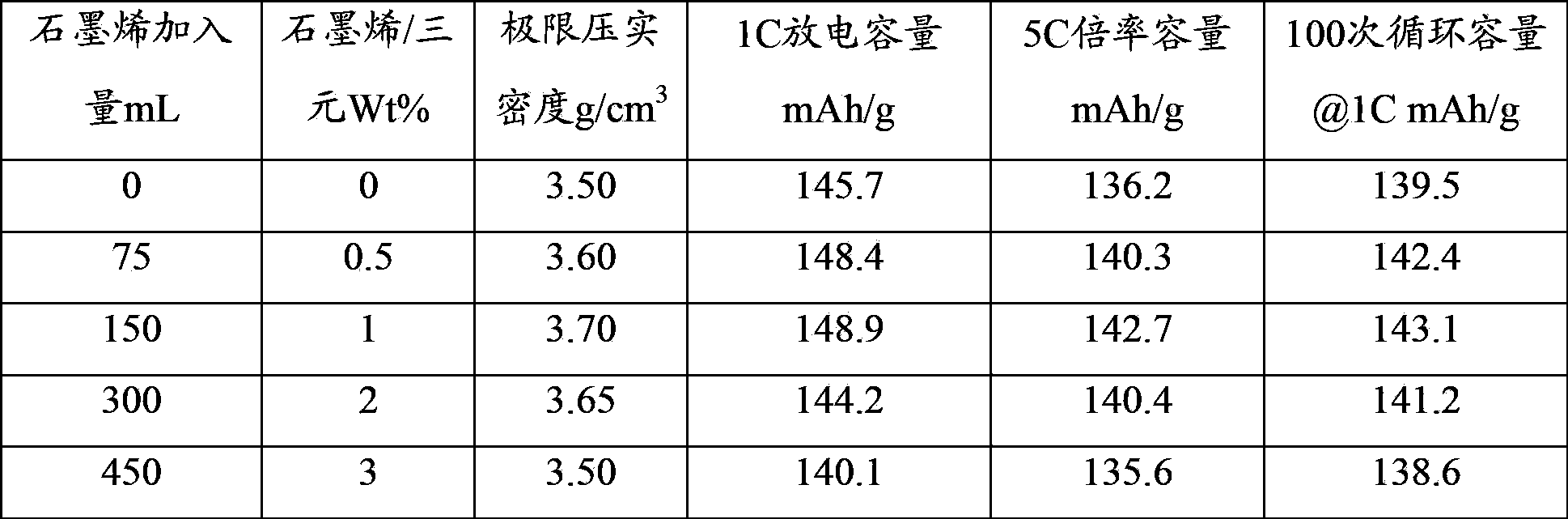

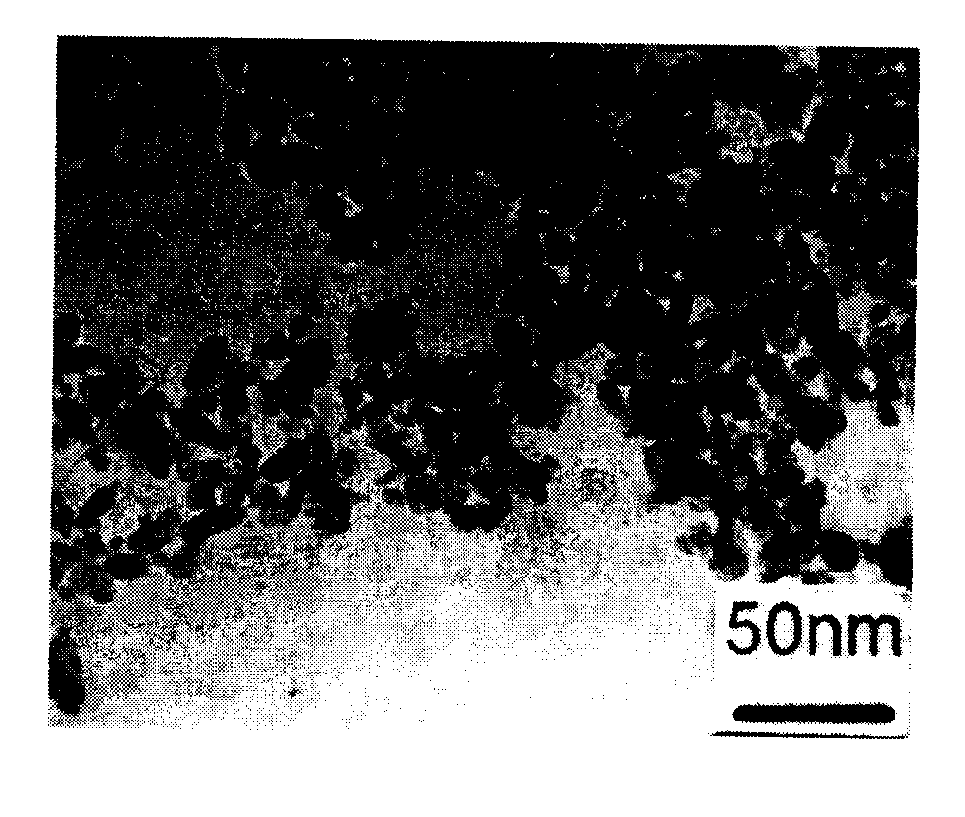

Graphene-based composite ternary material, preparation method thereof, and lithium ion battery

ActiveCN103904330AIncrease compaction densityReduce breakageMaterial nanotechnologyCell electrodesManganeseCobalt

The invention provides a graphene-based composite ternary material. The ternary material comprises graphene and a nickel-cobalt-manganese ternary material, wherein the graphene is prepared by sintering oxidized graphene, is composed of single-layered graphene slices or multi-layered graphene slices whose layer number is less than 10, and accounts for 0.1% to 10.0% of the total weight of the composite ternary material; and the nickel-cobalt-manganese ternary material has a primary particle structure or a secondary particle structure, has a molecular formula of Li(Ni<x>Co<y>Mn<z>)O2, wherein the sum of x, y, and z is equal to 1, and x, y, and z are all in a range of 0 to 1, and accounts for 90.0% to 99.9% of the total weight of the composite ternary material. The graphene slices are freely stacked in the graphene, thus conductive nets and cavities are formed, and the nickel-cobalt-manganese ternary material particles are embedded into the cavities between the nano graphene layers through a chemical precipitation method. The invention also provides a preparation method of the graphene-based composite ternary material.

Owner:HUAWEI TECH CO LTD

Process for prepairng granularity controllable nm-class zirconium oxide

A process for preparing nm-class zirconium oxide with controllable size (less than 30 nm) includes preparing two portions of microsuspension containing non-ionic surfactant, n-hexanol, cyclohexane and zirconium salt solution or amminia water, mixing, hydrolysis reaction, centrifuging or filtering, washing with alclohol and water several times, drying and calcining. It features that its size can be controlled by controlling the content of zirconium solution or ammonia water, the ratio of water to surfactant and reaction temp.

Owner:TSINGHUA UNIV

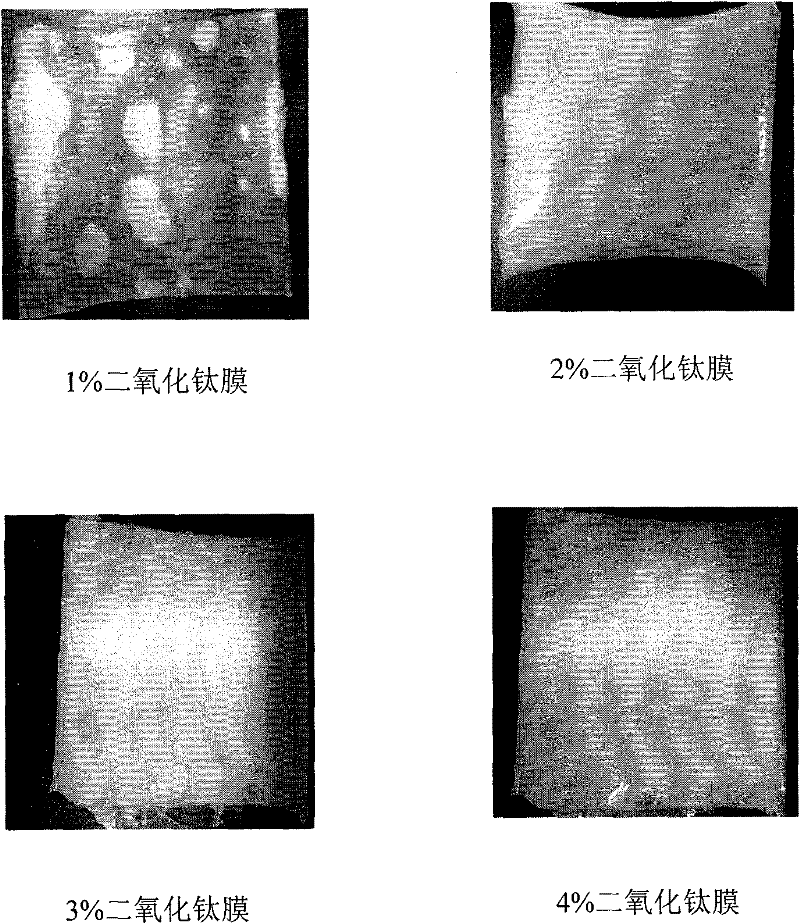

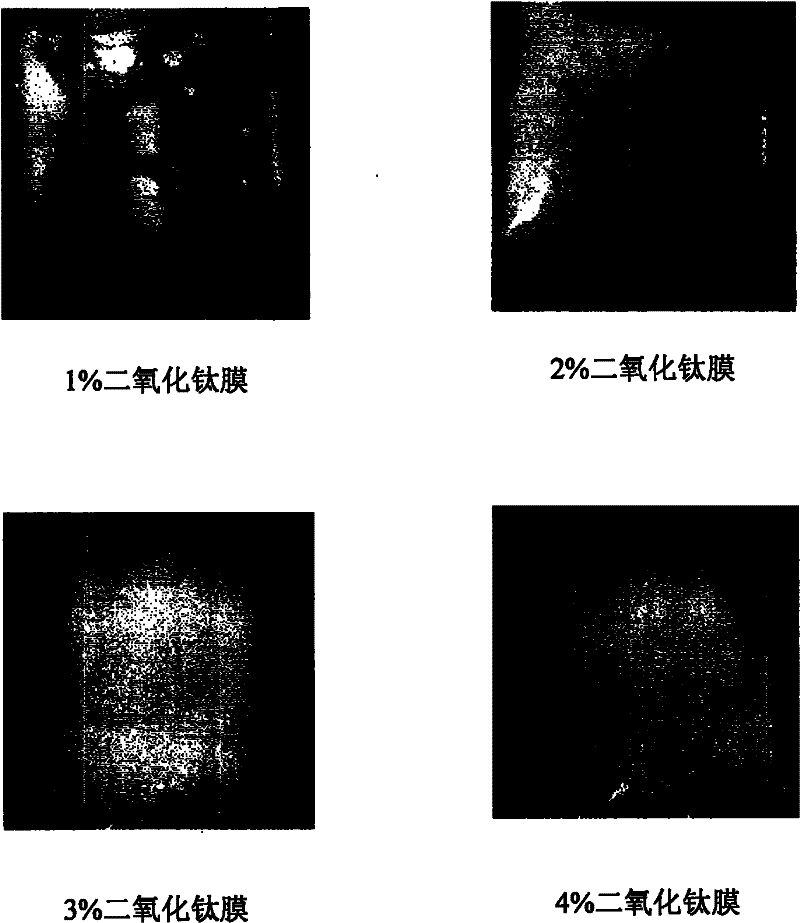

Preparation method of nano tio2 modified pvdf ultrafiltration membrane

InactiveCN102294180AImprove hydrophilicityExtended service lifeSemi-permeable membranesHydrophilic monomerUltrafiltration

The invention relates to a preparation method of a nano TiO2-modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane. The preparation method comprises the following steps of: preparing a membrane making liquid from 15-20 percent by mass of PVDF, 1-3 percent of pore-foaming agent, 1-4 percent of nano TiO2, 3-5 percent of surfactant and 70-80 percent of solvent, ultrasonically oscillating the membrane making liquid for 5-10 minutes, leaching and defoaming; scraping with a membrane scraping machine to form a liquid membrane, standing in the air for 20-60 seconds, soaking into a coagulation bath and coagulating the liquid membrane into an ultrafiltration membrane; and after the ultrafiltration membrane falls off, taking the ultrafiltration membrane out, soaking into distilled water and cutting according to required size for later use. A nano TiO2 hydrophilic monomer is arranged on the surface of the PVDF ultrafiltration membrane, sodium dodecyl sulfate serving as a surfactant is used simultaneously, and dispersion is performed by ultrasonically oscillating, so that agglomeration of nano TiO2 is reduced, nano TiO2 is quickly and uniformly distributed into the membrane making liquid, the hydrophilicity of the PVDF ultrafiltration membrane is enhanced effectively, the energy consumption is enhanced greatly, the anti-pollution capacity and pollutant intercepting performance of the membrane are enhanced, and the service life of the membrane is prolonged.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com