Yttria-stabilized zirconia powder and preparation method thereof

A technology for stabilizing zirconia and yttrium oxide, applied in the field of ZrO2 composite ceramic materials, can solve the problems of difficult raw material source of organic alkoxide hydrolysis method, no industrialized production, harsh conditions of hydrothermal method, etc. Aging ability, the effect of avoiding hard agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Prepare Zr in a stirred mill 4+ Concentration is the zirconium oxychloride solution of 2mol / L, adds the yttrium oxide of 2mol% (accounting for Zr4+ total amount) and the third component, heating and stirring to dissolve the yttrium oxide, the third component is 1wt% of alumina, 0.2wt% of cerium oxide, 0.2wt% of lanthanum oxide, 0.5wt% of magnesium oxide, and 0.1% of calcium oxide;

[0041] (2) Then add 3wt% polyethylene glycol relative to the mass of zirconia, and stir evenly;

[0042] (3) Finally, slowly add the precipitating agent solution to the uniformly stirred solution, and the precipitating agent is ammonium bicarbonate and urea.

[0043] (4) Until the zirconium ions and yttrium ions are completely precipitated, the reaction is completed, and the final pH value is controlled at 8;

[0044] (5) Afterwards, wash with water, filter, and dry in an oven. When drying, set the temperature at 120°C and dry for 3 hours. Calcining the obtained nano-zirconia composit...

Embodiment 2

[0048] (1) Put a certain amount of zirconia balls in the stirring mill in advance, and prepare Zr 4+ Concentration is the zirconium oxychloride solution of 2mol / L, adds the yttrium oxide of 8mol% (accounting for Zr 4+ total amount) and the third component, heating and stirring to dissolve the yttrium oxide, the third component is 0.5wt% of alumina, 0.2wt% of cerium oxide, 0.5wt% of magnesium oxide, and 0.3% of calcium oxide;

[0049] (2) Then add 3wt% polyacrylic acid relative to the mass of zirconia, and stir evenly;

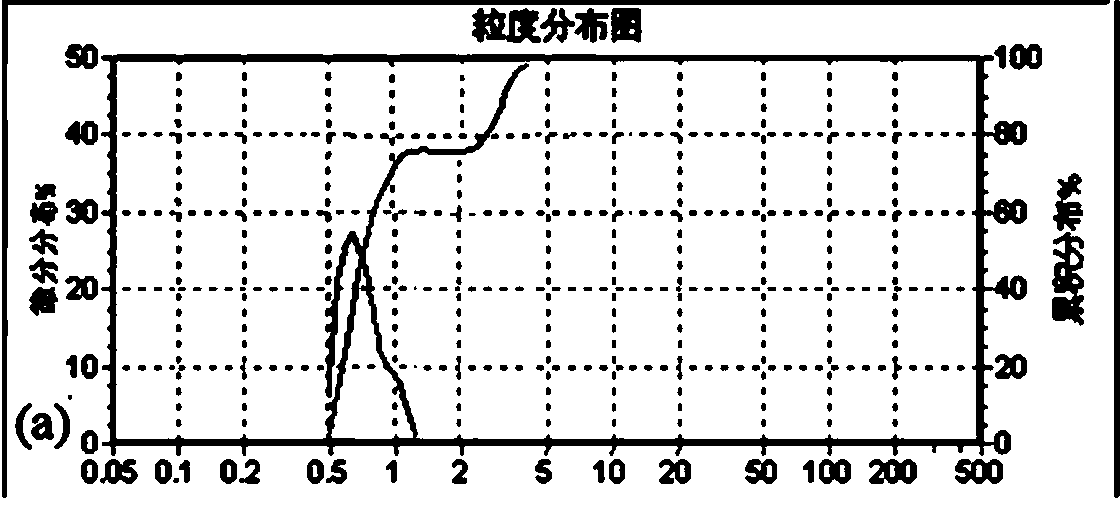

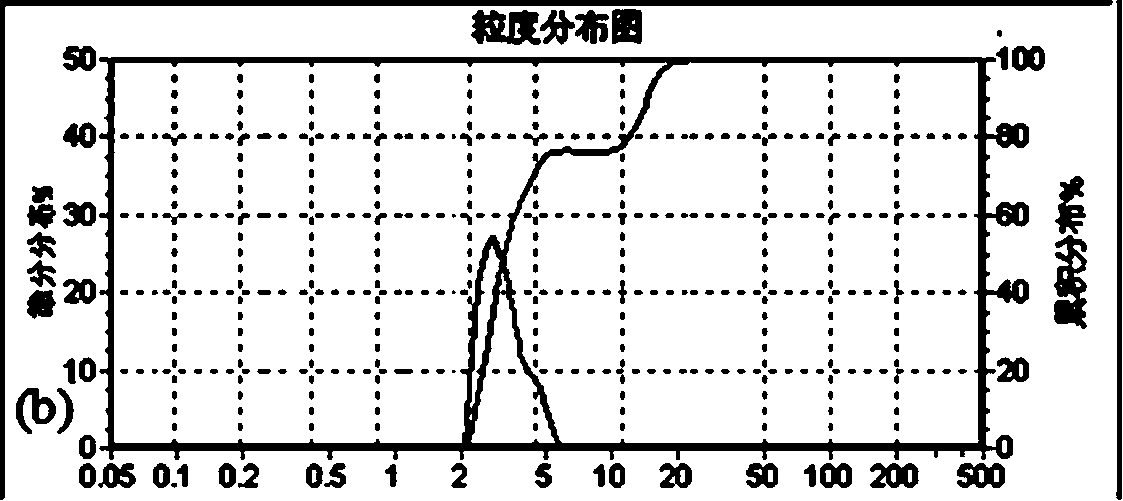

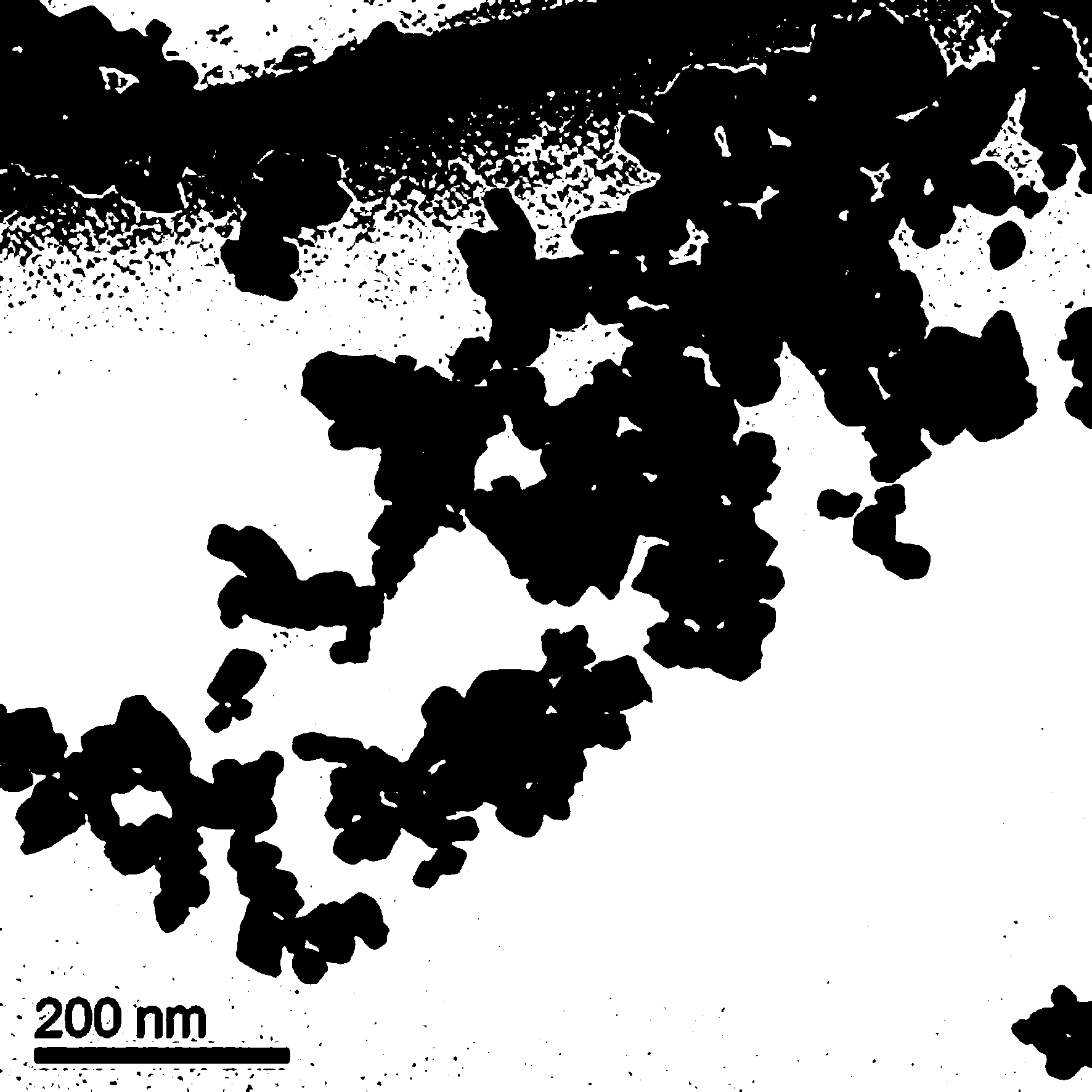

[0050] (3) Finally, slowly add a solid-phase precipitant to the uniformly stirred solution. The precipitant is ammonium bicarbonate and ammonium carbonate, and mix with ball milling for 8 hours; the obtained particle size is D 50 Colloid aggregates <0.8 μm. Using solid-liquid reaction, the generation of waste water is greatly reduced, and the agglomeration of micelles is destroyed by ball mill stirring. Compared with traditional mechanical agitation, ball mi...

Embodiment 3

[0056] (1) Pre-place a certain ratio of zirconia balls in the stirring mill, and prepare Zr 4+ Zirconium oxychloride solution with a concentration of 2mol / L, adding 2-8mol% yttrium oxide (accounting for Zr 4+ total amount) and the third component, heating and stirring to dissolve the yttrium oxide, the third component is 0.5wt% of alumina, 0.2wt% of cerium oxide, 0.5wt% of magnesium oxide, and 0.3% of calcium oxide;

[0057] (2) Then add 3wt% polyacrylic acid relative to the mass of zirconia, and stir evenly;

[0058] (3) Finally, slowly add a solid-phase precipitant to the uniformly stirred solution. The precipitant is ammonium bicarbonate and ammonium carbonate, and mix with ball milling for 4 hours; the obtained particle size is D 50 Colloid aggregates <0.8 μm.

[0059] (4) Until the zirconium ions and yttrium ions are completely precipitated, the reaction is completed, and the final pH value is controlled at 7;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com