Patents

Literature

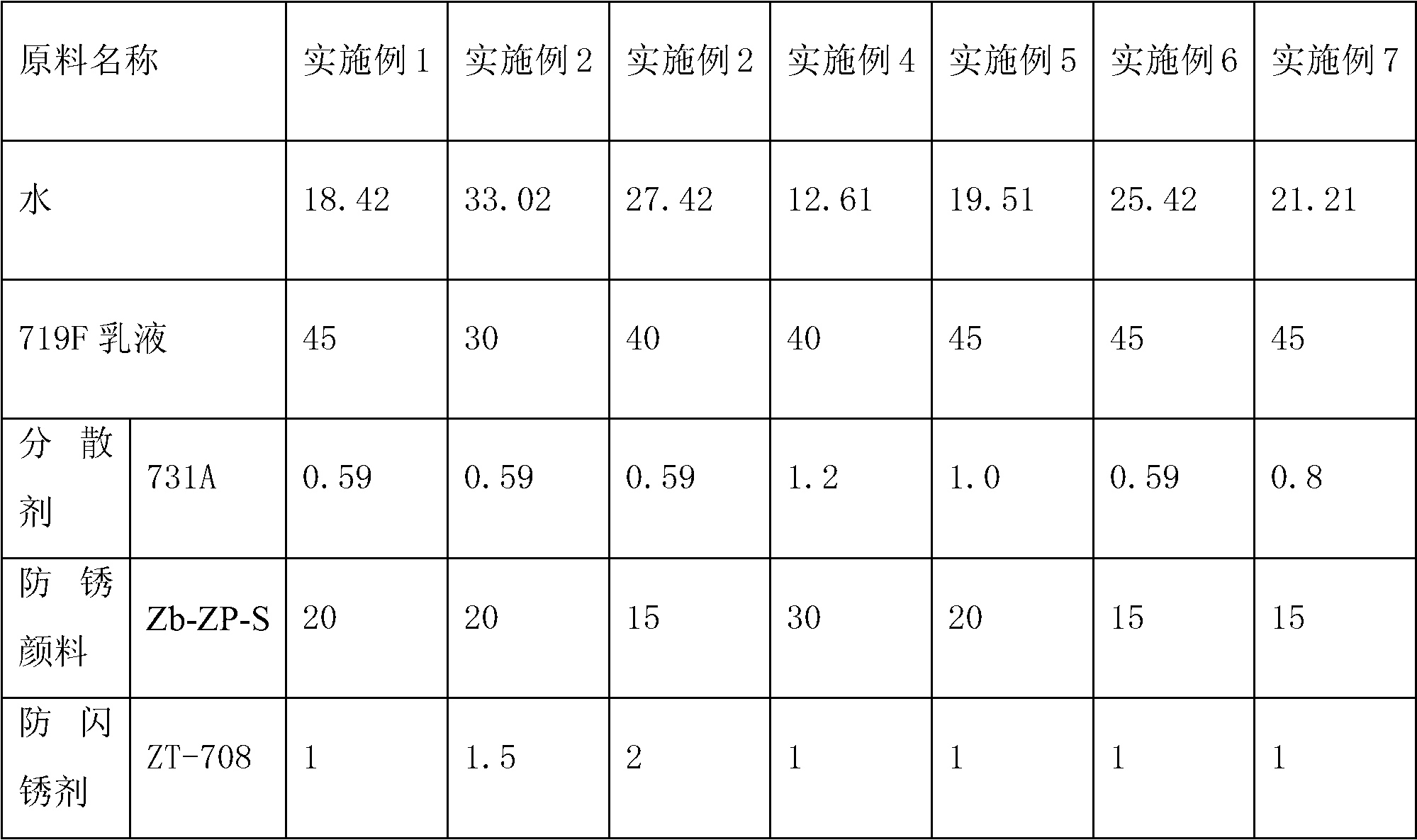

62results about How to "Strong resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

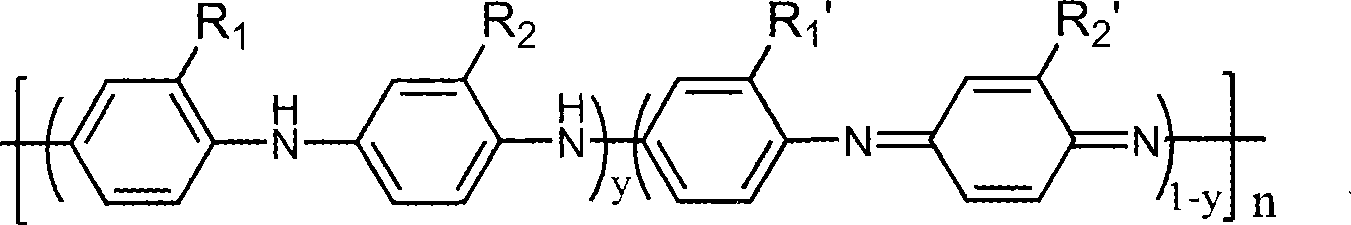

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

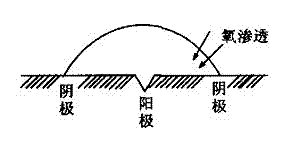

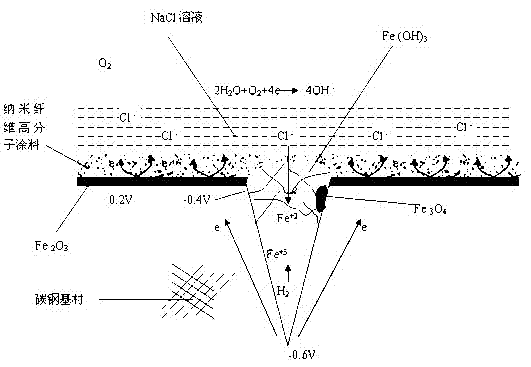

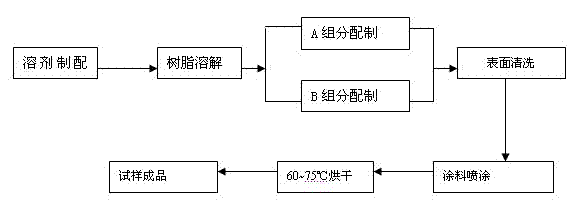

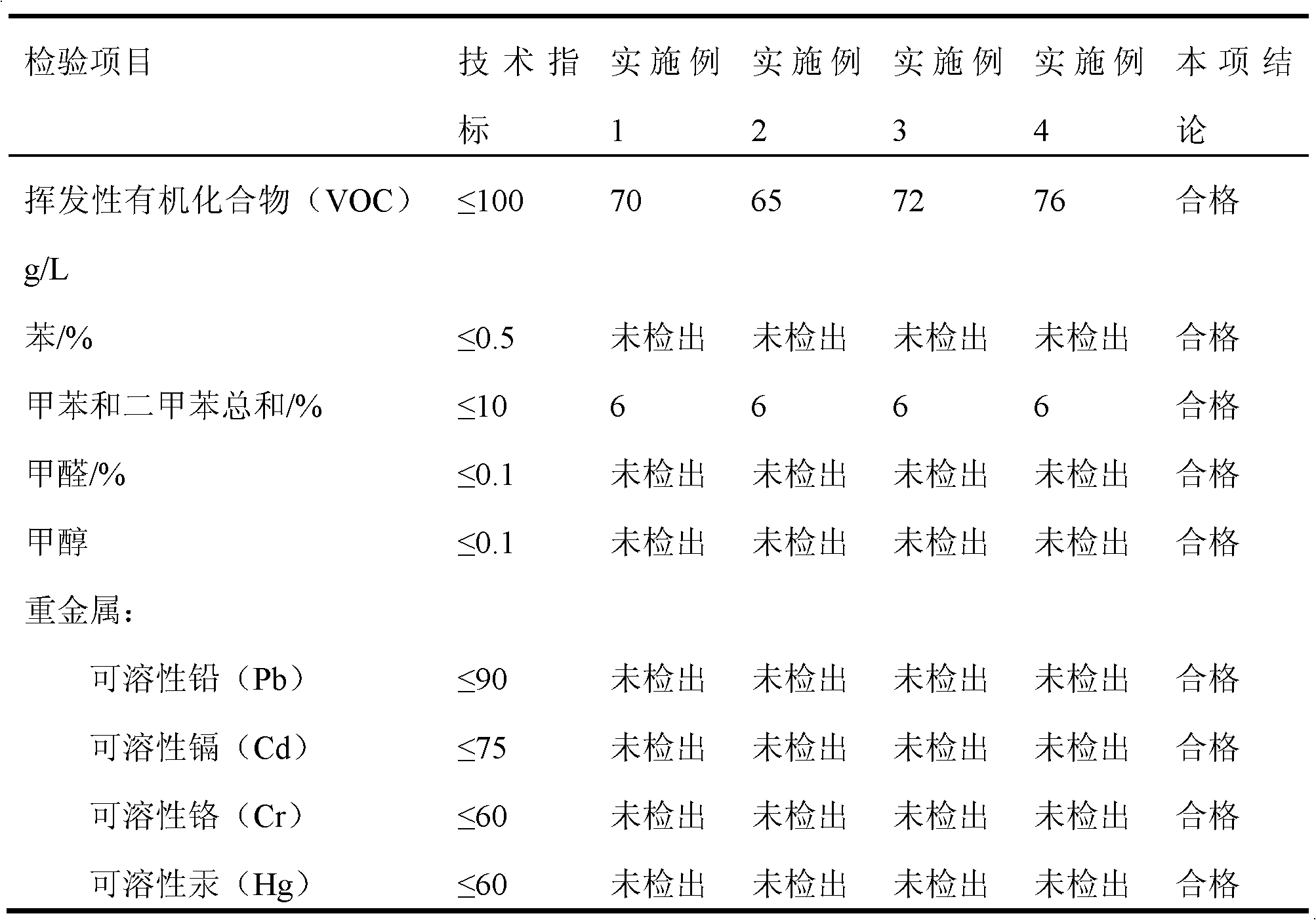

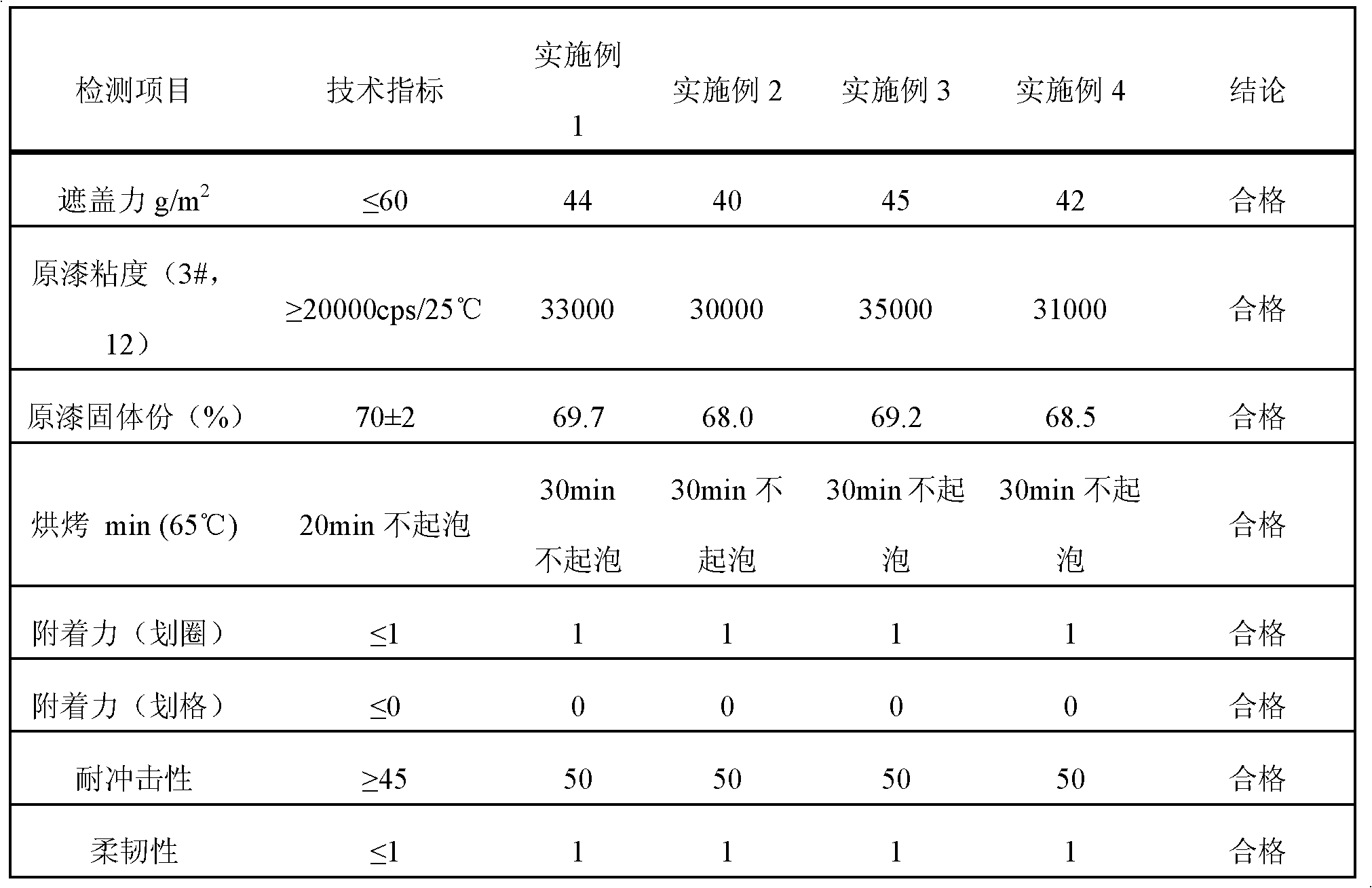

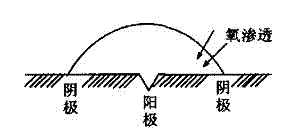

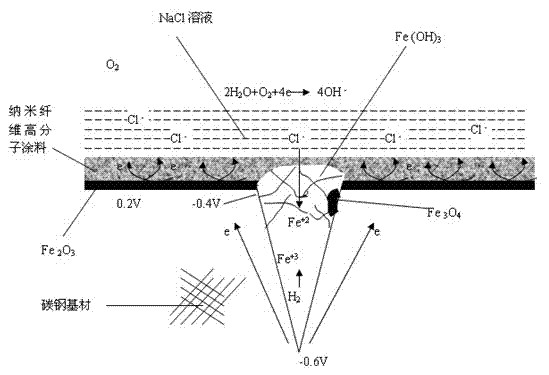

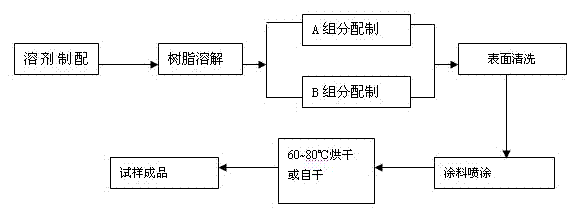

Nanofiber heavy-duty anti-corrosive coating, preparation method and spraying method of nanofiber heavy-duty anti-corrosive coating

ActiveCN102604509AStrong resistance to salt sprayStrong resistance to salt waterAnti-corrosive paintsPolyurea/polyurethane coatingsNanofiberPetrochemical

The invention discloses nanofiber heavy-duty anti-corrosive coating, a preparation method and a spraying method of the nanofiber heavy-duty anti-corrosive coating. The anti-corrosive coating comprises components C, A and B by mass ratio. The preparation method comprises the steps of preparing mixed solvent C, dissolving resin and preparing resin solution, pouring the dissolved resin solution into a ball mill for stirring and refluxing, then pouring the component A into the ball mill, uniformly stirring with a glass rod initially, performing ball milling and filtering, pouring the component B into the ball mill, uniformly stirring, adding the component B into the component A, and then uniformly stirring to obtain the nanofiber heavy-duty anti-corrosive coating. The spraying method comprises the steps of cleaning up the surface of an object to be sprayed, uniformly spraying the coating onto the surface of the object to be sprayed with a spray gun, and drying or naturally drying the sprayed surface. The nanofiber heavy-duty anti-corrosive coating has super-normal acid resistant, alkali resistant, salt resistant, water vapor corrosion resistant and harmful substances corrosion resistant capabilities, is non toxic, harmless, tasteless and environmentally friendly, and is applicable to the fields of ocean vessels, submarines, ocean engineering, drilling platforms, wharfs, water conservancy facilities, petrochemical equipment, bridge buildings, concrete facilities and the like.

Owner:西安华捷奥海新材料有限公司

Special primer for heavy-duty machinery

InactiveCN102618144AAvoid interferenceEnsure quality stabilityAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistanceEpoxy

The invention relates to a special primer for heavy-duty machinery, which consists of A components and B components, wherein the A components include, by weight percentage (amount to 100%), 40-50% of epoxy resin, 8-12% of diluents, 1-5% of auxiliary, 7-15% of paint and 28-37% of fillers, and the B components include modified polyamide curing agent. The primer made by resin with proper epoxy equivalent, functional paint and fillers and high-performance curing agent is stable in quality, dry, quick, excellent in corrosion resistance, applicable to various coating manners, excellent in construction compatibility, low in price, non-toxic and environment-friendly and can be applied to the heavy-duty machinery having high requirement for corrosion resistance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Antirust oil for engine seal

ActiveCN104004573AHumidity and heat resistanceImprove corrosion resistanceLubricant compositionKerosenePolyethylene glycol

The invention discloses an antirust oil for engine seal. The antirust oil comprises, by weight, 81-90 parts of aviation kerosene, 2-3 parts of polyisobutylene, 3-5 parts of lanolin magnesium soap, 2-3 parts of barium stearate, 2-3 parts of allyl polyethylene glycol, 1-2 parts of tert-butyl chromate, 0.6-1 part of N-lauroyl sarcosine sodium, 1-2 parts of polyoxyethylene stearate, 0.8-2 parts of N,N-bis(2-cyanoethyl)formamide, 0.1-0.2 parts of sodium silicate, and 4-6 parts of an antirust aid. The antirust oil has the characteristics of moist heat resistance, corrosion resistance and strong salt spray resistance, is especially suitable for the engine seal, has a long antirust life, can well protect the engine, and prolongs the service life of the engine.

Owner:BENGBU HONGAN PRECISION MACHINERY

Water-based modified pure acrylic acid anticorrosive paint

ActiveCN102702899ACorrosion protectionImprove anti-corrosion performanceAnti-corrosive paintsWater basedEmulsion

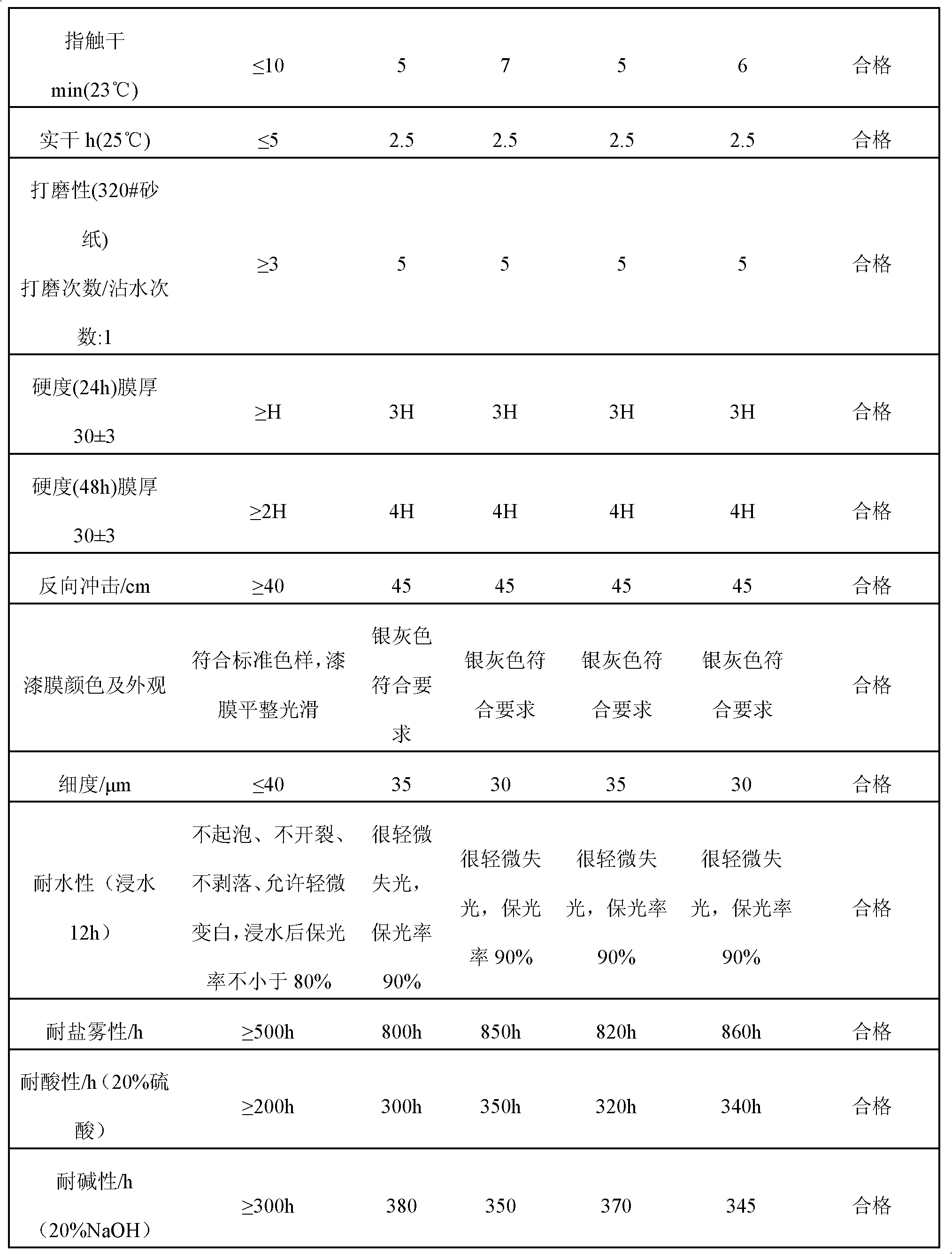

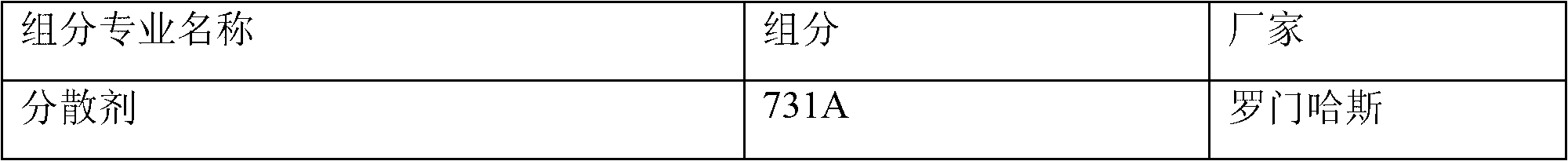

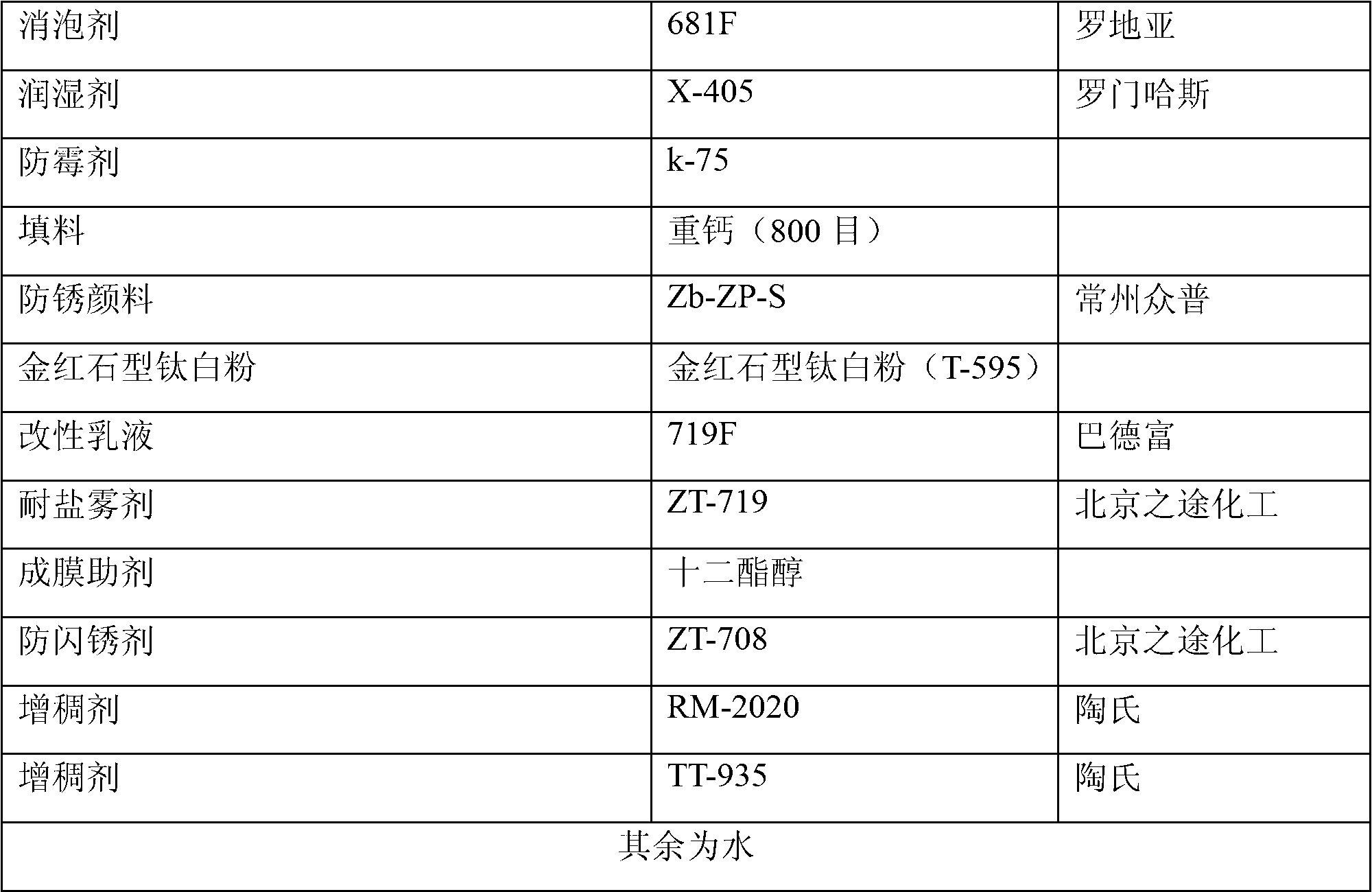

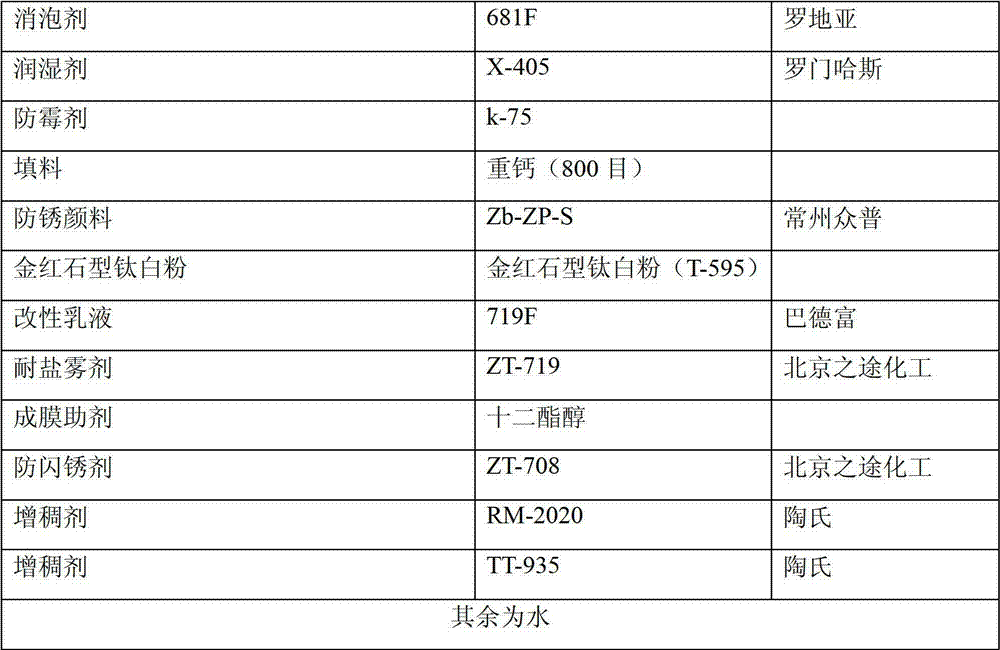

The invention relates to a water-based modified pure acrylic acid anticorrosive paint which is prepared from the following components in percentage by mass: 30-45% of modified acrylic acid emulsion, 3-5% of film-forming assistant, 0.6-1.2% of dispersant, 0.1-1.0% of defoaming agent, 0.1-0.2% of wetting agent, 0.05-0.10% of mold preventive, 1-2% of flash-rust inhibitor, 2-5% of pigment, 15-30% of antirust pigment and filler, 2-5% of filler, 2-5% of thickening agent, 1-2.5% of salt-fog inhibitor and the balance of water. The pH value is regulated to 8-9. The anticorrosive paint provided by the invention has the advantages of combined primer and precoat functions, single component and self drying, is water-based, and satisfies the requirement for environmental protection. The invention has the advantages of simple production technique, accessible raw materials, low cost, low VOC (volatile organic compound), environmental protection and high safety, can easily implement industrialization, and is simple and convenient for construction.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

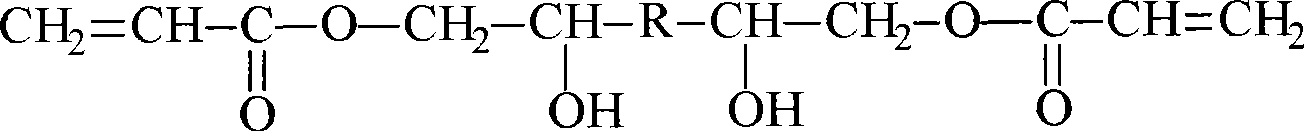

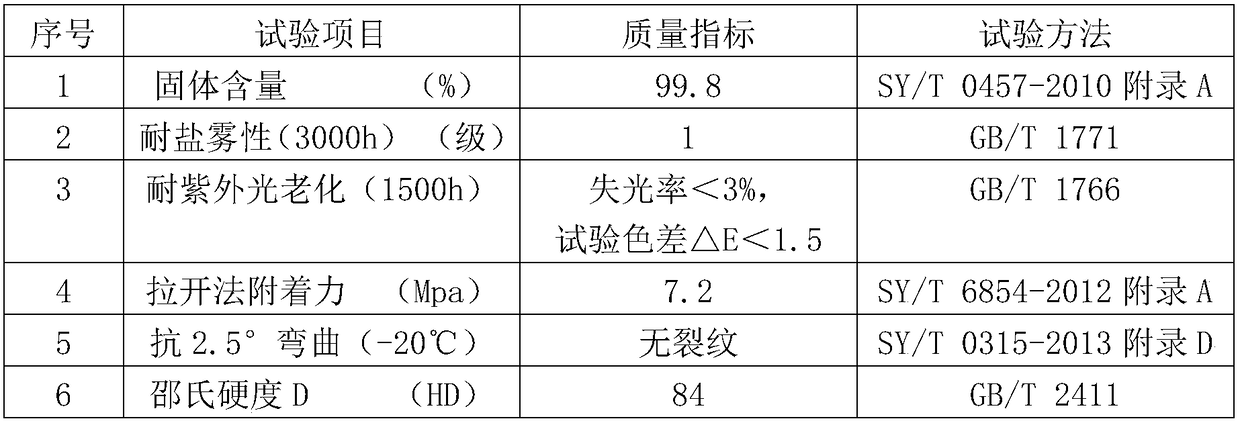

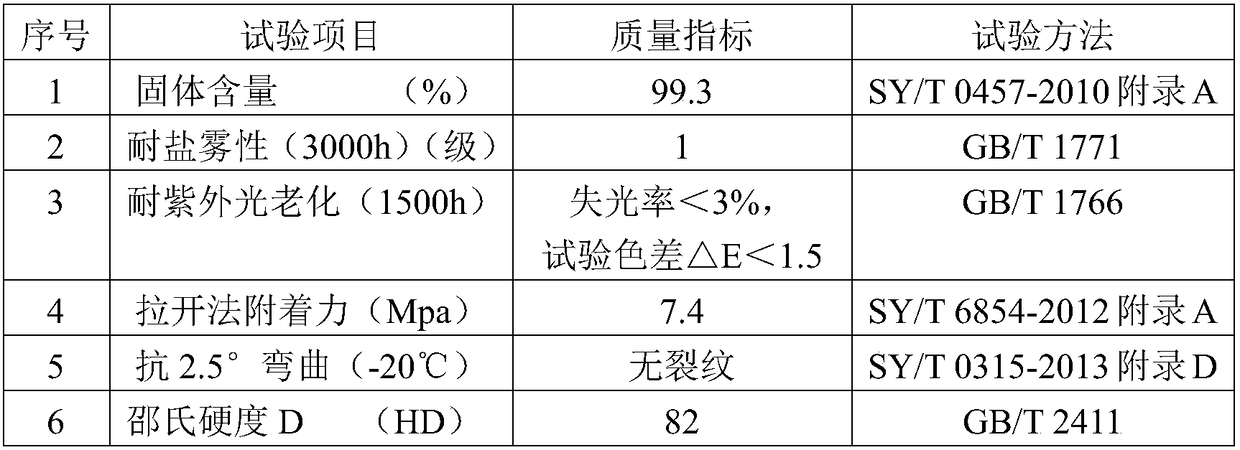

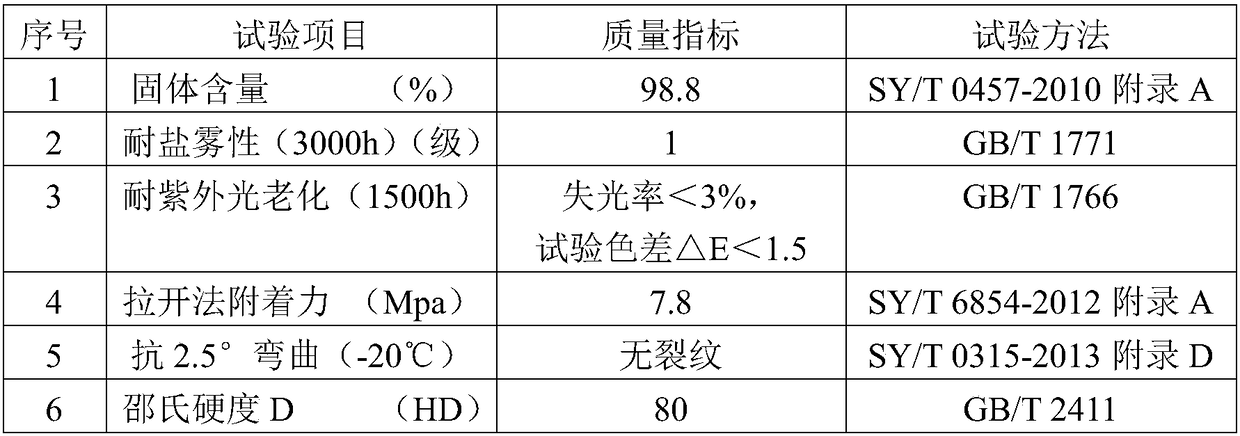

Solvent-free polyurea weather-resistant anticorrosion coating and method for preparing same

InactiveCN109439158AGood flexibility at low temperatureImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsAbove groundSolvent free

The invention discloses solvent-free polyurea weather-resistant anticorrosion coating. The solvent-free polyurea weather-resistant anticorrosion coating comprises components A and component B. The components A are hexamethylene diisocyanate curing agents with the solid contents of 100% by weight; the components B comprise, by weight, 40-50 parts of parahelium polymers, 0.3-0.5 part of dispersing agents, 0.3-0.5 part of defoaming agents, 0.8-1 part of thixotropic agents, 3-5 parts of coupling agents, 7-10 parts of titanium dioxide, 7-10 parts of sericite and 23-42 parts of glass powder; a weight ratio of the components A to the components B is 27:100-34:100. The solvent-free polyurea weather-resistant anticorrosion coating has the advantages that the solvent-free polyurea weather-resistantanticorrosion coating can be used for the outer walls of above-ground steel storage tanks and the outer surfaces of non-heat-insulation steel overhead pipelines; the solvent-free polyurea weather-resistant anticorrosion coating is good in low-temperature flexibility and is ultrahigh in bond force with the surfaces of coated objects; the solvent-free polyurea weather-resistant anticorrosion coatingis sufficient in abrasion-resistant hardness and ultrahigh in ultraviolet aging resistance and salt spray resistance; the solid content of the solvent-free polyurea weather-resistant anticorrosion coating can reach 98% at least, and the solvent-free polyurea weather-resistant anticorrosion coating is wide in curing reactive environmental temperature interval; curing reaction can be quickly carried out without curing agents or accelerators; the solvent-free polyurea weather-resistant anticorrosion coating is free of sagging when thickly coated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

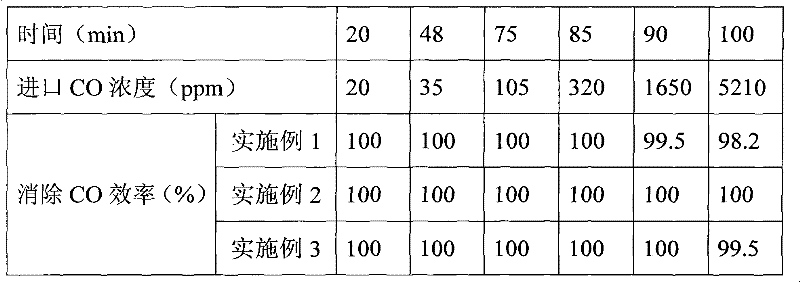

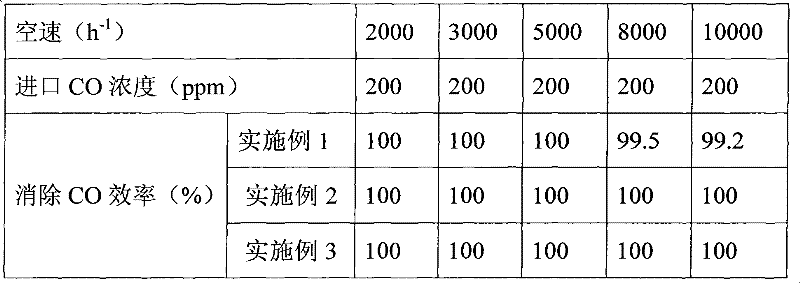

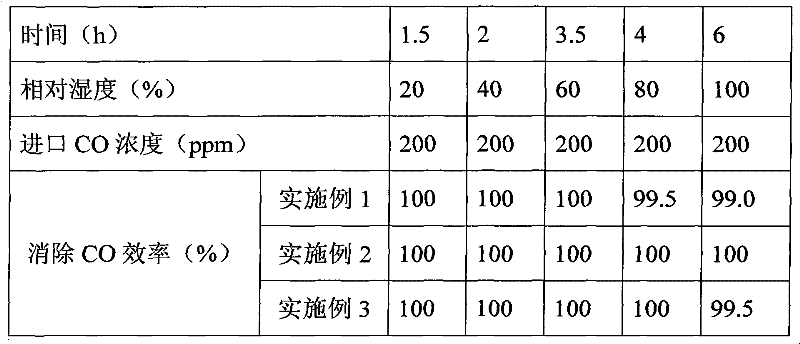

Salt mist-resistant moisture-resistant catalyst for removing carbon monoxide at low temperature

ActiveCN102211025AExtend your lifeReduce usageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioAdhesive

The invention discloses a salt mist-resistant moisture-resistant catalyst for removing carbon monoxide at low temperature, in particular a catalyst and a preparation method thereof, and belongs to the technical field of chemical engineering. The catalyst is characterized by consisting of a carrier and active metals, wherein the carrier is a mixture of alumina, manganese oxide, cerium zirconium composite oxide of CexZr1-xO2 and a small amount of adhesive; a mass ratio of the alumina to the manganese oxide is (1-5):1; the cerium zirconium composite oxide is 1 to 10 mass percent of the carrier, and x is more than or equal to 0.5 and less than or equal to 1; the adhesive is 0.5 to 5 mass percent of the carrier; and the active metals are Pt and Pb, wherein the Pt is 0.1 to 1 mass percent of the carrier, and the Pd is 0.3 to 2 mass percent of the carrier. The invention has the advantage that: the prepared catalyst is low in cost, high in low temperature catalytic activity, high salt mist resistance and moisture resistance, and high stability.

Owner:DALIAN SAMAT NEW MATERIAL CO LTD

Rare earth compound epoxy zinc-rich paint for preventing microorganism attachment and preparation method thereof

InactiveCN101831232AGood storage stabilityNo crackAntifouling/underwater paintsPaints with biocidesMicroorganismSulfate-reducing bacteria

The invention provides a rare earth compound epoxy zinc-rich paint for preventing microorganism attachment and a preparation method thereof. The rare earth compound epoxy zinc-rich paint consists of a component A, a component B and rare earth chloride, wherein the component A comprises the following components in parts by weight: 20-32 parts of bisphenol A type epoxy resin, 10-35 parts of flaky zinc powder, 3-5 parts of auxiliary filler, 15-25 parts of first solvent and 1-3 parts of assistant; the component B comprises the following components in parts by weight: 10-15 parts of neutral polyamide curing agent and 10-20 parts of second solvent; and the weight percentage of rare earth chloride is 1-3 parts. The rare earth compound epoxy zinc-rich paint for preventing microorganism attachment has the advantages of better function for resisting SRB (Sulfate-Reducing Bacteria) and strong capability of preventing organism attachment and preventing corrosion.

Owner:HARBIN ENG UNIV

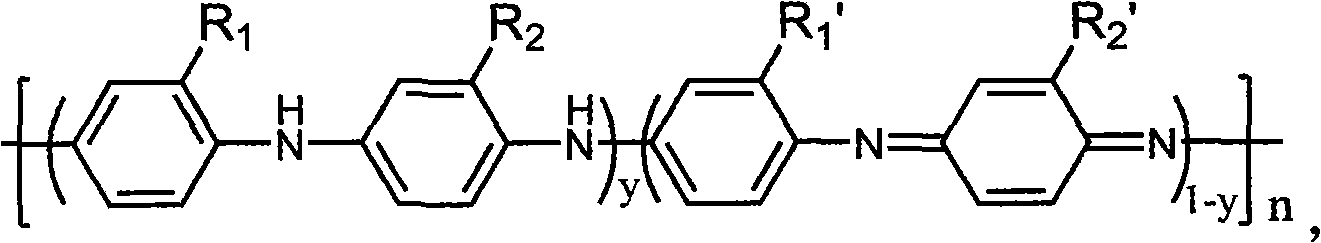

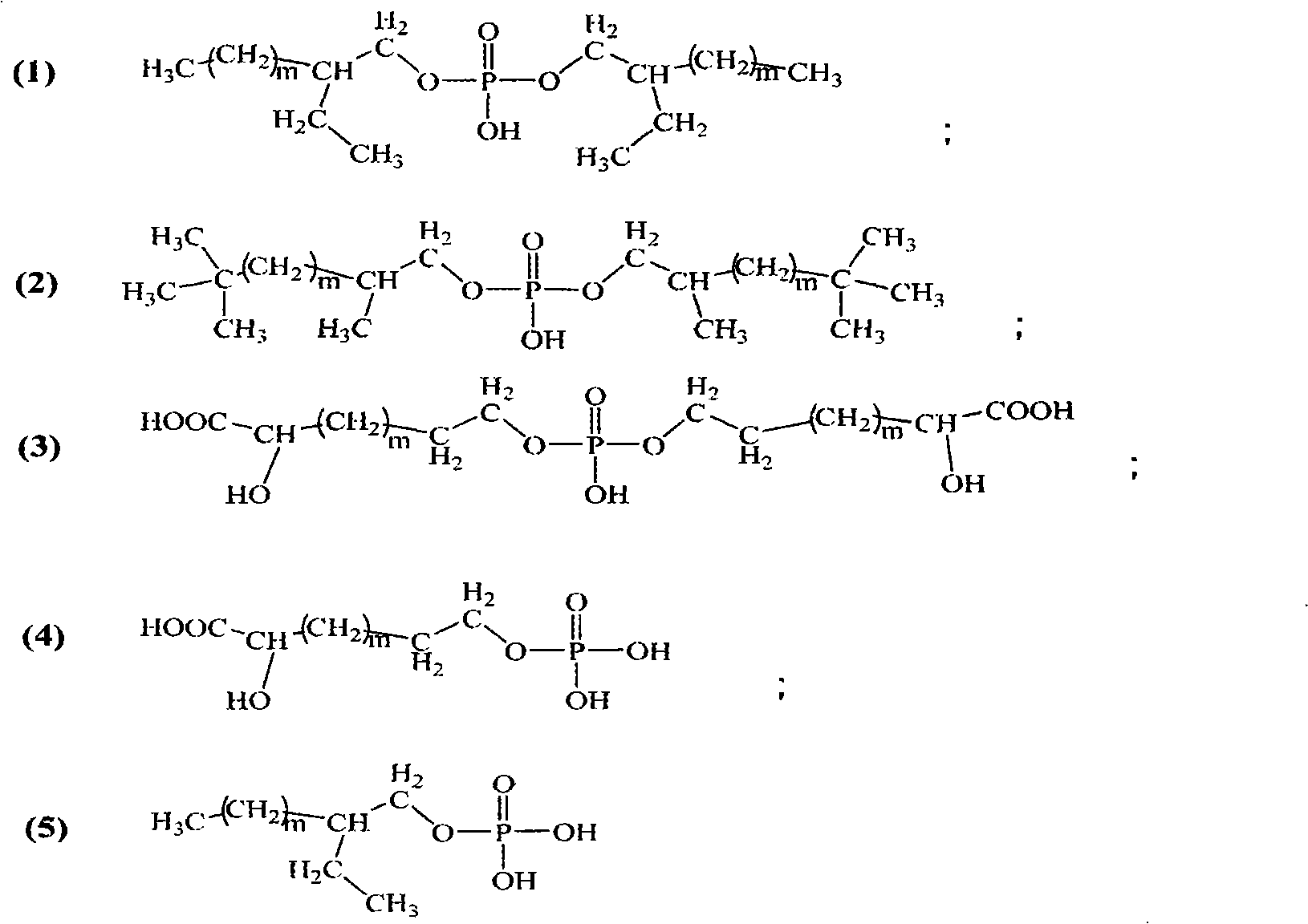

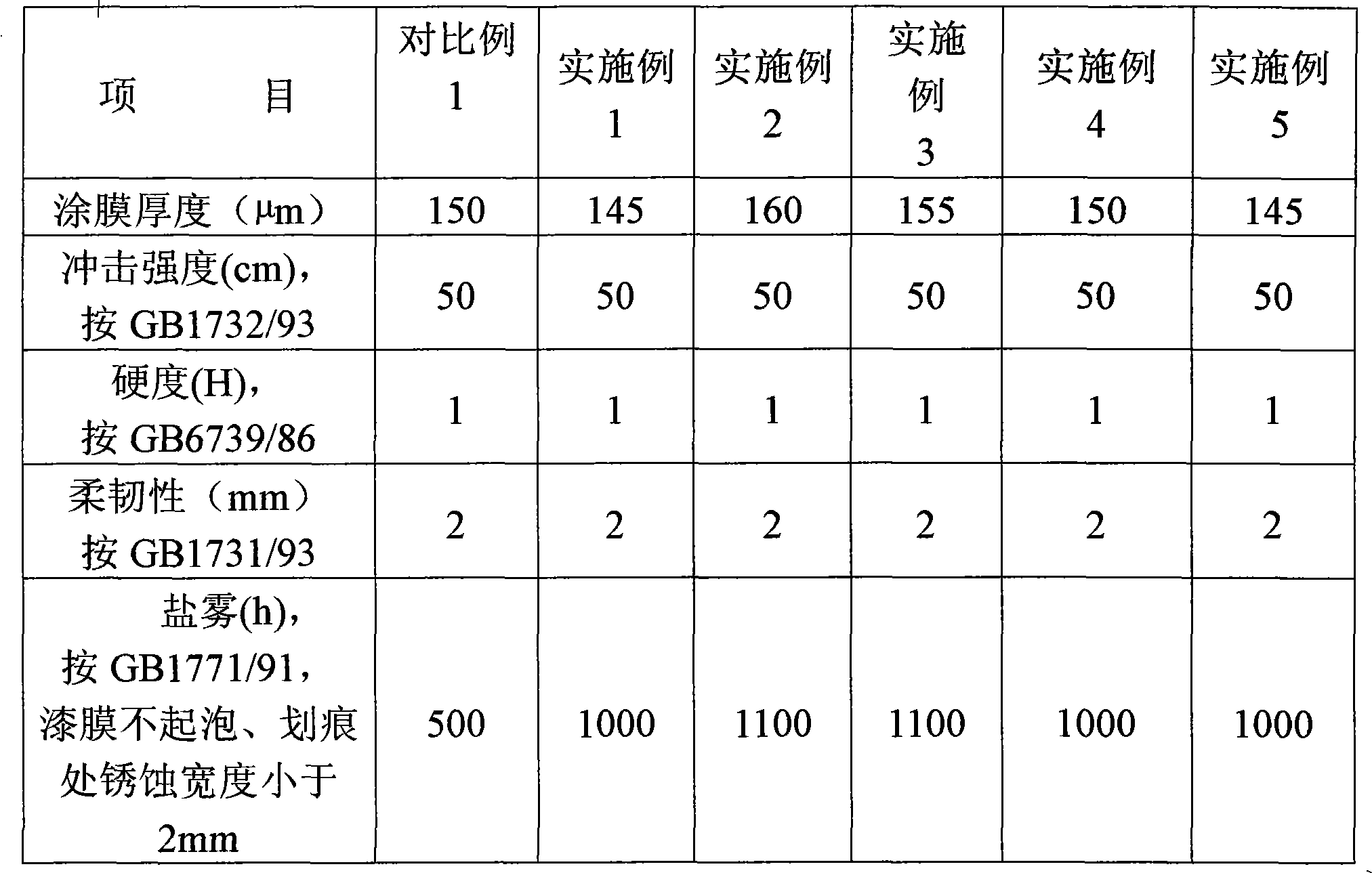

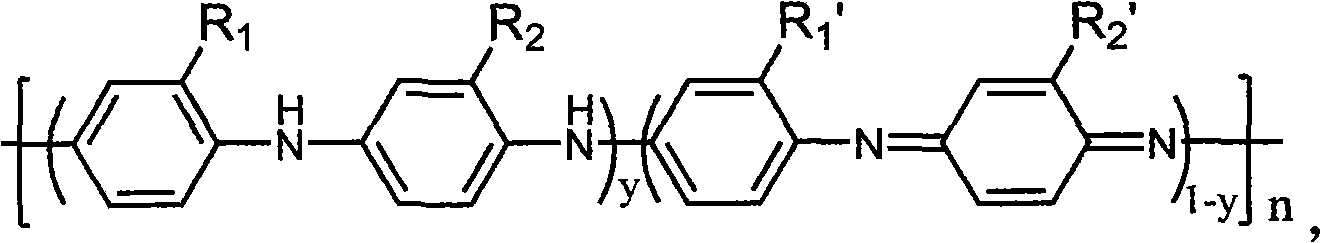

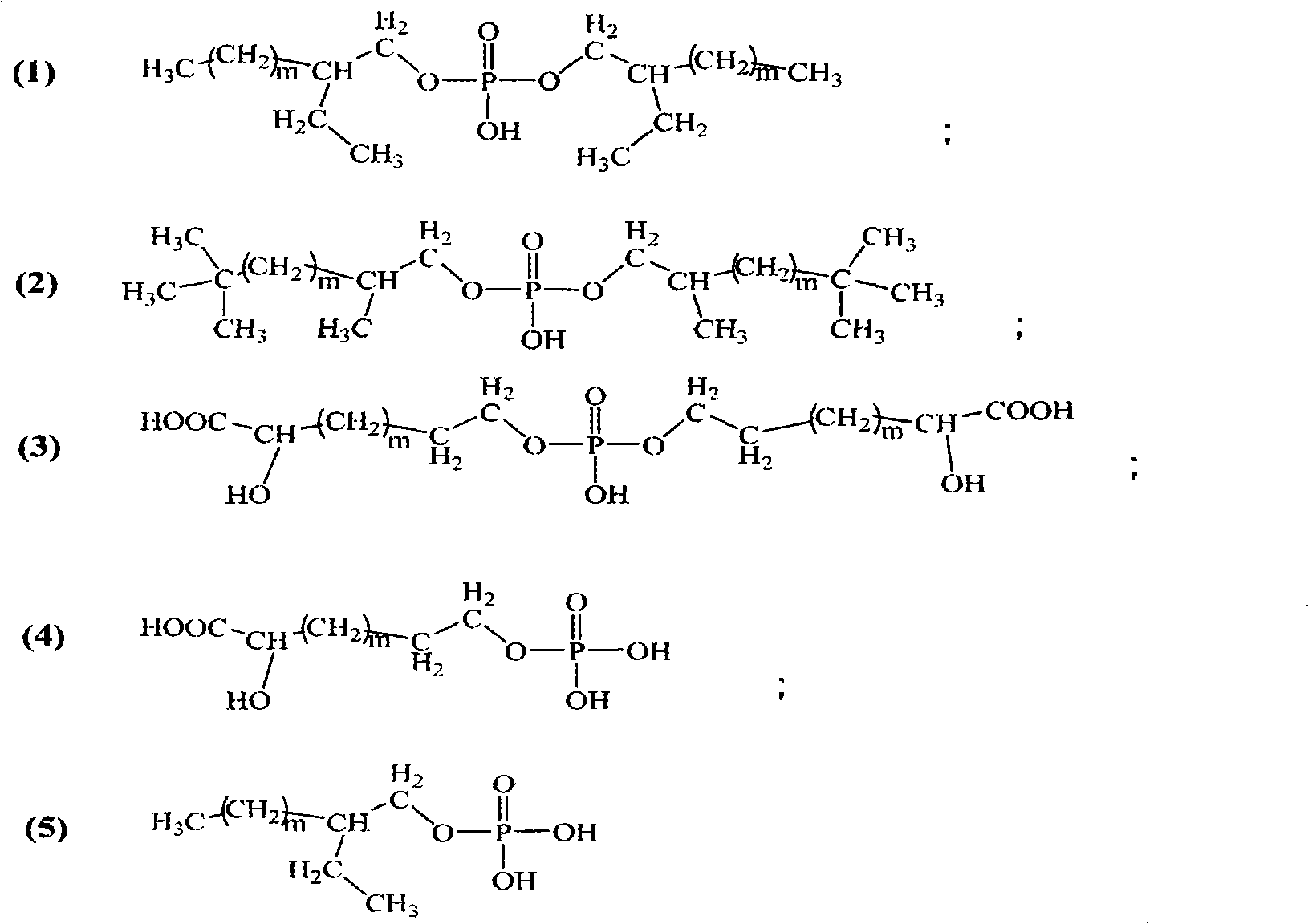

Phosphate doped polyaniline anticorrosive paint and preparation method thereof

ActiveCN102108241AStrong resistance to salt sprayImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOrganic solventPhosphate

The invention provides a phosphate doped polyaniline anticorrosive paint and a preparation method thereof. In the preparation method, polyaniline is well dispersed in an organic solvent on the basis of 'countra-ion induction workability' in the presence of special phosphate used as a doping agent of the polyaniline, so that a good anticorrosive effect can be obtained by adding little conductive polyaniline in the formula of the anticorrosive paint, thereby greatly reducing the cost of polyaniline anticorrosive paint. The anticorrosive paint has strong resistance to corrosion of media (salt mist, acid, alkali and the like) and atmosphere environment, and has good anticorrosive effect on different metals such as steel, copper, aluminum and the like, thereby widening the application range of the anticorrosive paint. The synthesis process is simple with low preparation cost. After a 1000-hour scratch-resistant experiment, the anticorrosive paint can reach the technical indexes of non-propagating rusting and no blister on a board surface, which is twice more than that of the traditional polyaniline anticorrosive paint, thereby solving the defects such as blistering, happening commonly when the traditional polyaniline anticorrosive paint is subjected to scratch-resistant experiment.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Nanomaterial-modified chromium-free Dacromet treatment liquid, and preparation method and application thereof

InactiveCN109971325AUniform compositionDoes not affect pollutionPretreated surfacesAnti-corrosive paintsChromium freeFilm-forming agent

The invention relates to the field of environmentally-friendly functional Dacromet treatment liquids, and especially relates to a nanomaterial-modified chromium-free Dacromet treatment liquid, and a preparation method and an application thereof. The nanomaterial-modified chromium-free Dacromet treatment liquid comprises, by weight, 23-49 parts of metal powder, 0.5-1.5 parts of a nanometer conductive agent, 20-40 parts of a dispersant, 6-12 parts of a film-forming agent and 15-50 parts of an aqueous binder. The nanomaterial-modified chromium-free Dacromet treatment liquid has the advantages ofuniform composition, no need to be used in the field, no pollution to the production environment, reduction of weighing and operating errors, and stable product quality; the introduction of the aqueous binder makes a coating layer have good wear resistance; and the surface coating layer of an anticorrosion part, obtained after processing using the nanomaterial-modified chromium-free Dacromet treatment liquid, has good adhesion and strong salt spray resistance.

Owner:广州艾可罗高新材料有限公司

Stable high-adhesive aluminum alloy surface conditioning agent

InactiveCN104109849AImprove stabilityStrong weather resistanceMetallic material coating processesPhosphoric Acid EstersAdhesive

The invention discloses a stable high-adhesive aluminum alloy surface conditioning agent. The agent is composed of the following raw materials in parts by weight: 0.4 to 1 part of calcium hexafluoroacetylacetonate, 0.7 to 1 part of lauryl alcohol phosphoric acid ester potassium, 1 to 2 parts of formamide, 0.5 to 1 part of polyisobutenyl succinimide, 1 to 2 parts of itaconic acid, 0.4 to 1 part of magnesium hydroxide, 1 to 2 parts of N-methylolacrylamide, 0.2 to 0.4 part of mica powder, 0.1 to 0.2 part of tung oil, 0.1 to 0.3 part of triethanolamine borate, 2 to 4 parts of film-forming auxiliary agent, 13 to 20 parts of (3-Aminopropyl)trimethoxysilane, and 120 to 140 parts of deionized water. The added calcium hexafluoroacetylacetonate can effectively improve the stability of the coating, and furthermore, the raw materials are reasonably compounded, so the prepared coating has the advantages of weatherability, acid and alkali resistance, strong salt fog resistant performance, good anti-peeling property, and enduring protection effect on metal tools.

Owner:RUIZHAN TONGLING TECH

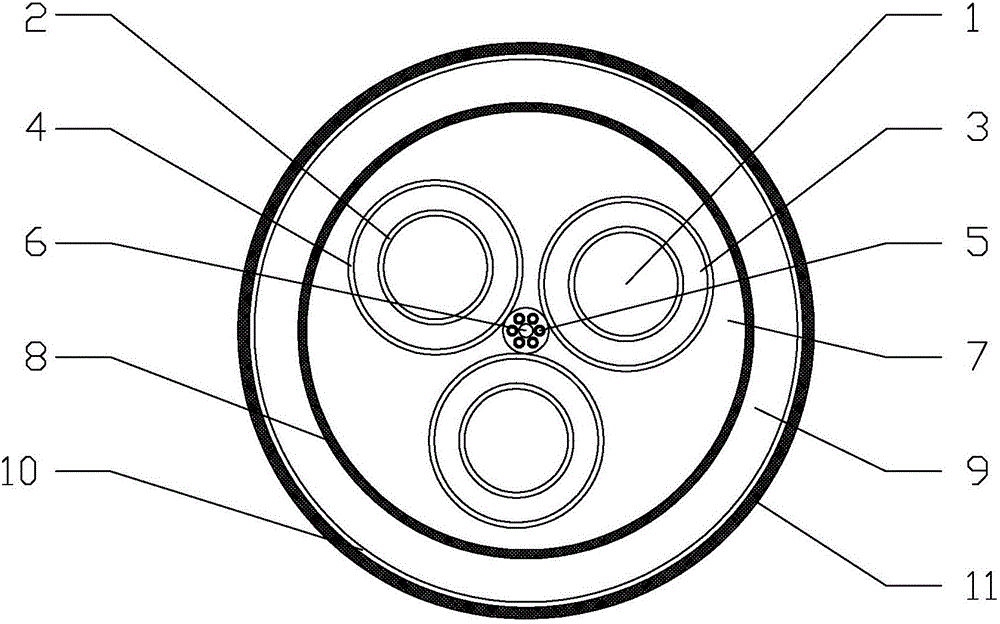

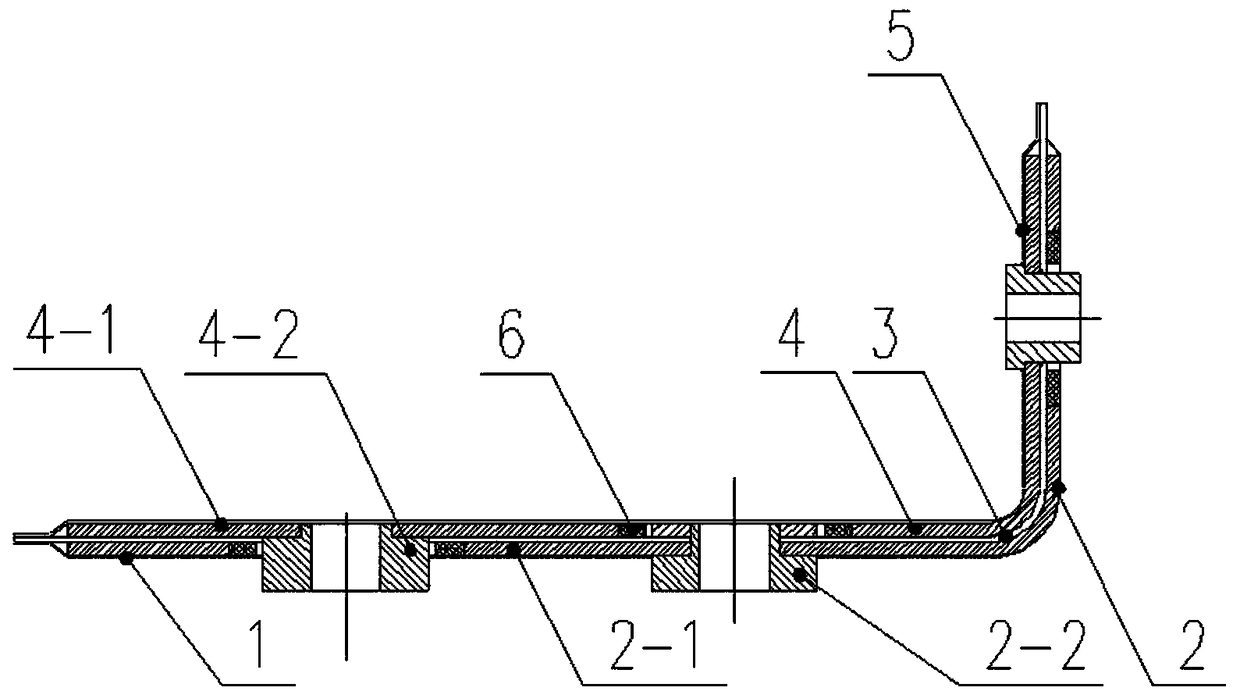

Flexible tensile optical fiber composite shore connection cable

InactiveCN106158138AGood waterproof effectSmall footprintNon-insulated conductorsCommunication cablesCorrosionHigh intensity

The invention relates to a flexible tensile optical fiber composite shore connection cable which comprises a cable core formed by mutually stranding a plurality of wire cores, wherein the wire cores comprise conductors; isolation layers are arranged outside the conductors; insulation layers are used for wrapping the isolation layers in a pressing manner; the insulation layers are provided with semi-conductive wrapping layers; a combination body comprising a plurality of control wire cores and an optical communication unit is arranged in the center of the cable core; an inner sheath is used for wrapping the cable core in a pressing manner; an aramid yarn inner reinforcing layer is woven outside the inner sheath; a high-intensity chlorinated polyethylene outer protection layer is used for wrapping the reinforcing layer in a pressing manner; a wrapping layer and an outer reinforcing layer are arranged outside the outer protection layer. The flexible tensile optical fiber composite shore connection cable has good comprehensive performance of easiness in bending, torsion resistance, tear resistance, wave resistance, salt mist resistance, high corrosion resistance, excellent long-term water soaking electrical property, easiness in stripping and portability.

Owner:YUANCHENG CABLE CO LTD

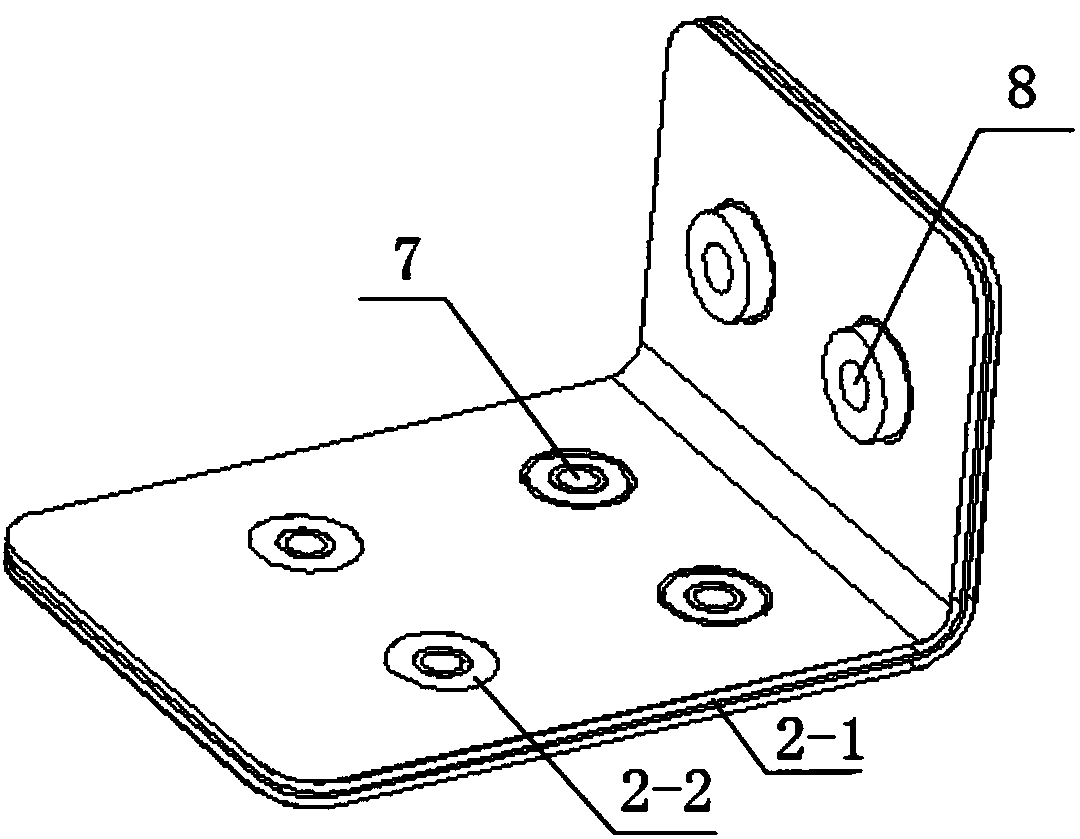

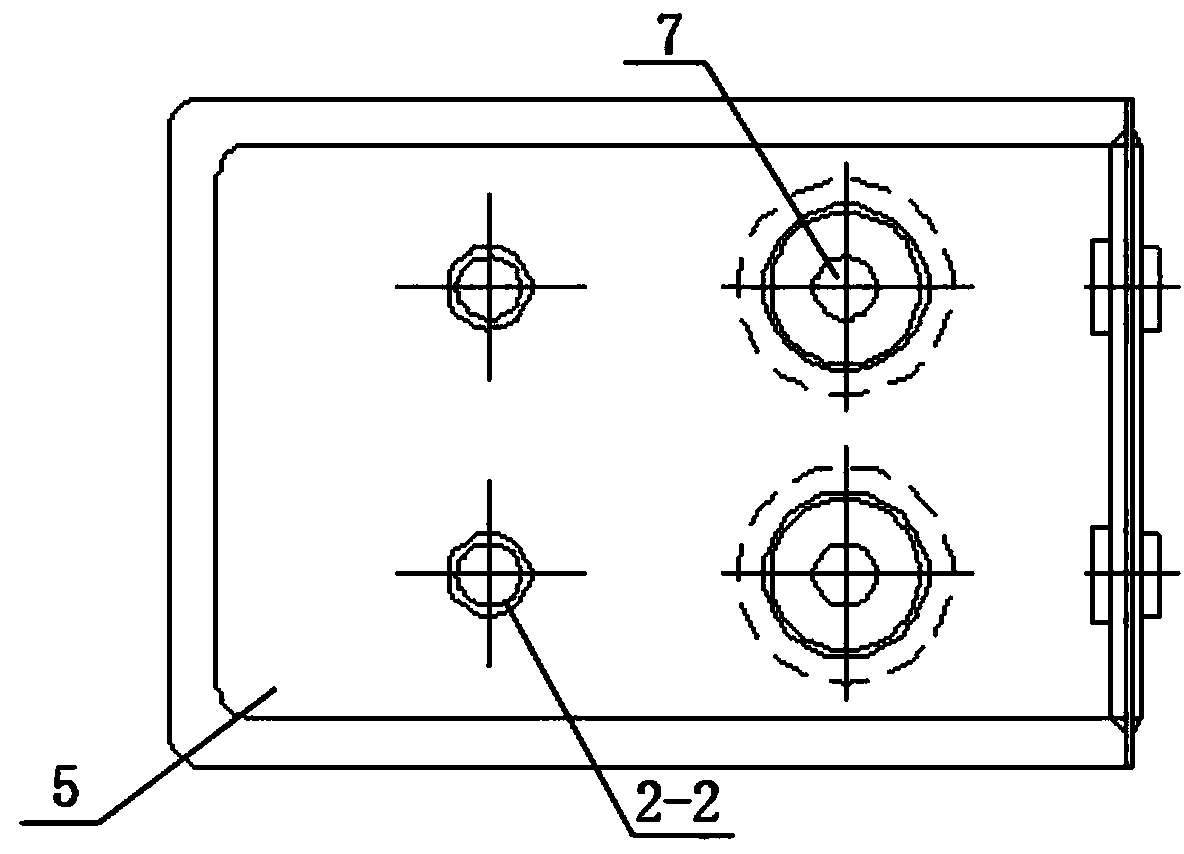

Copper-aluminum composite low-sensitive busbar and manufacturing method thereof

InactiveCN109427437AImprove conductivityReduce weightInsulated cablesMetal/alloy conductorsBusbarEngineering

The invention discloses a copper-aluminum composite low-sensitive busbar. The copper-aluminum composite low-sensitive busbar comprises a plurality of conductor layers, and a plurality of insulating layers, wherein the conductor layers are made of copper-aluminum composite boards; each insulating layer is arranged on an upper surface and / or lower surface of the conductor layer through a bonding layer in a fitting layer, so that the conductor layers are mutually insulated and the conductor layers are insulated from the external; through holes are formed on corresponding locations of the conductor layers and the insulating layers; the through holes are used for arranging guide pillars penetrating the conductor layers and the insulating layers; the conductor layers and the external circuit canform the conductive channel through the guide pillars; the manufacturing method of the copper-aluminum composite low-sensitive busbar comprises the following steps: copper-aluminum composite board processing, the guide pillar fixing, the surface electroplating, laminating and molding. The copper-aluminum composite low-sensitive busbar disclosed by the invention is good in corrosion resistance, light in weight, and good in conductivity, the problems that the existing aluminum busbar is bad in conductivity and the existing pure-copper busbar is high in cost and large in weight are solved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Aqueous anti-rusting paint and preparation method therefor

ActiveCN105219239AUnparalleled environmental friendlinessGood resistance to salt sprayAnti-corrosive paintsPolyester coatingsSolubilityLacquer

An aqueous anti-rusting paint and a preparation method therefor. The paint is characterized in that: the raw materials in a formula in parts by mass are as follow: 600-700 parts of an acrylate modified alkyd resin emulsion, 100-120 parts of deionized water, 90-110 parts of pigments and fillers, 5-10 parts of a rheological agent, 5-10 parts of a dispersant, 1-5 parts of a defoamer, 1-3 parts of a bactericide, 70-90 parts of film forming auxiliaries, 15-25 parts of a co-solvent, 3-8 parts of a flash-rust agent, 5-10 parts of a multi-functional agent and 4-10 parts of a thickener solution. The process steps comprises: dispersing, milling, paint mixing, thickening, filtering and packaging. According to the present invention, water is used as a dispersion medium, multiple anti-rusting mechanism of physical, chemical and the like are used to prepare and produce the anti-rusting industrial paint. The paint combines an undercoat and a finishing coat and is constructed at one-time, so that the mode that the undercoat and the finishing coat of the conventional paint are constructed separately is broken. The paint is unequalled in environmental protection performance, good in salt-spray resistance and weather resistance and strong in anti-rusting function, and is an excellent product of a new generation that can replace the traditional anti-rusting paint. The paint has water solubility and non-flammable property, and is safe in use, and the paint is good in water resistance and good in thermal stability, and has a good anti-rusting function even in a high-temperature state.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

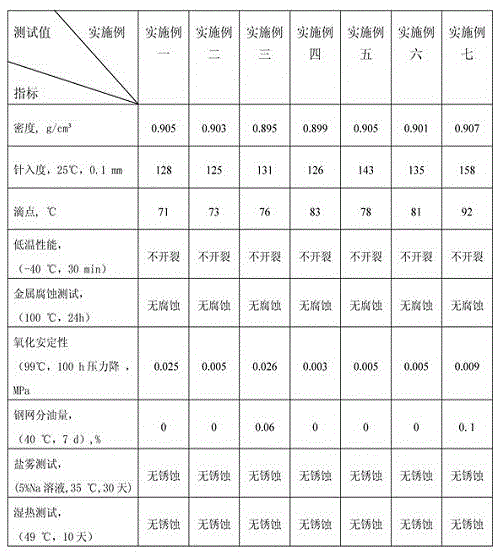

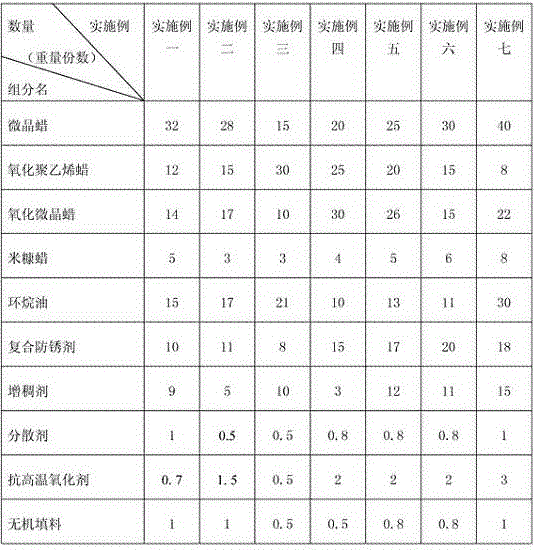

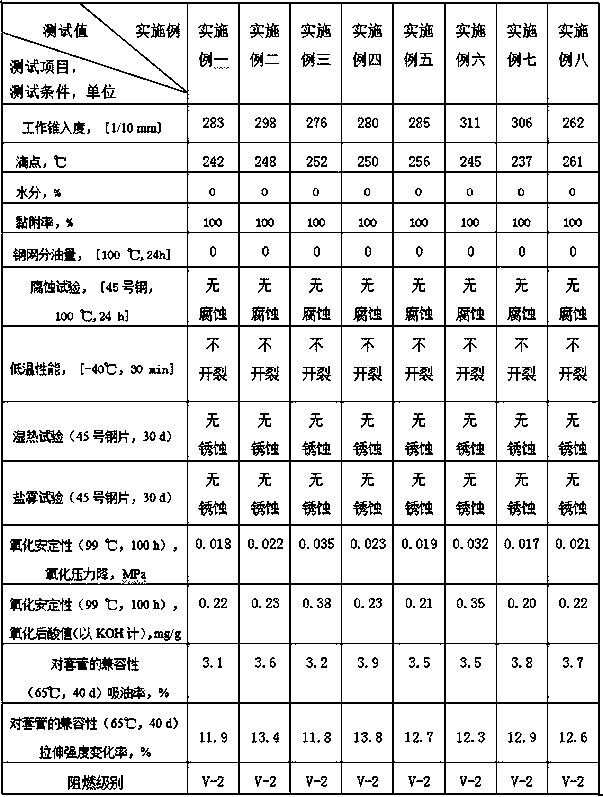

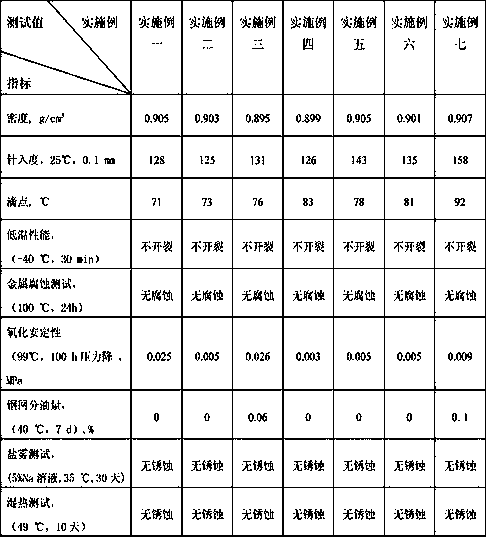

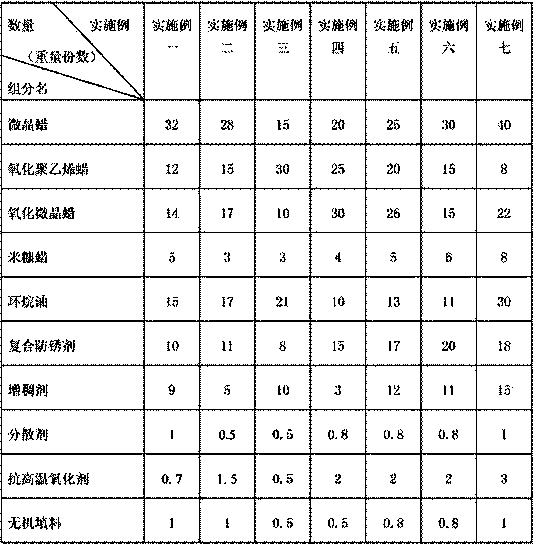

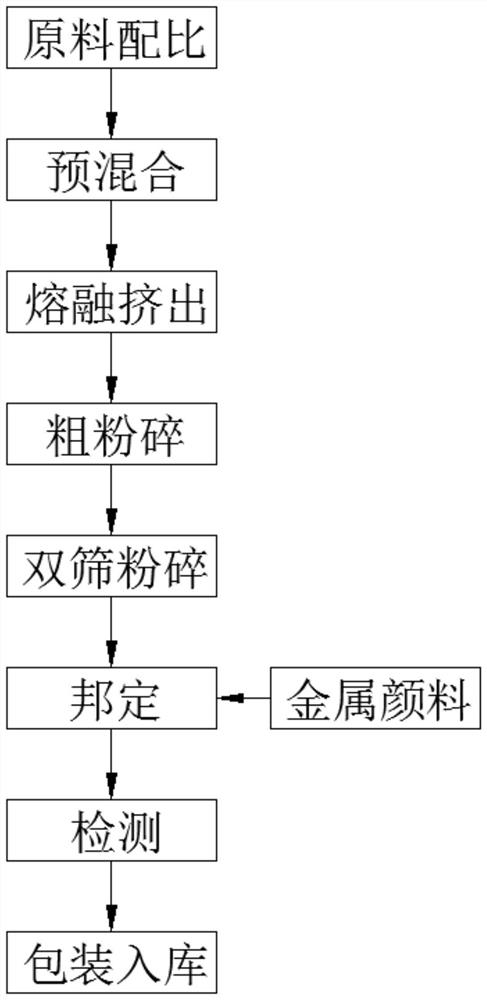

Anticorrosion sealing wax for bridge cables and anchor heads and preparation method thereof

The invention discloses anticorrosion sealing wax for bridge cables and anchor heads. The anticorrosion sealing wax is a mixture composed of, by weight, 15-40 parts of microcrystalline wax, 8-30 parts of oxidized polyethylene wax, 10-30 parts of oxidized microcrystalline wax, 3-8 parts of rice bran wax, 10-30 parts of naphthenic oil, 8-20 parts of composite antirust agent, 3-15 parts of thickening agent, 0.5-1 part of dispersing agent, 0.5-3 parts of high temperature resistance oxidizing agent and 0.5-1 part of inorganic filler. According to a preparation method of the anticorrosion sealing wax, all the components are sequentially put in a heating container, a certain temperature is maintained, stirring is performed, and then the anticorrosion sealing wax is prepared. The anticorrosion sealing wax for the bridge cables and anchor heads has the advantages of being high in compactness and sealing performance, low in shrinking rate, high in adhesive force, free of losses, high in dampness and heat resistance, salt mist resistance and oxidation resistance and long in anticorrosion period, and has long-term protective properties on the bridge cables and anchor heads and other steel components.

Owner:LIUZHOU OVM MASCH CO LTD

Phosphate doped polyaniline anticorrosive paint and preparation method thereof

ActiveCN102108241BStrong resistance to salt sprayImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOrganic solventPhosphate

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

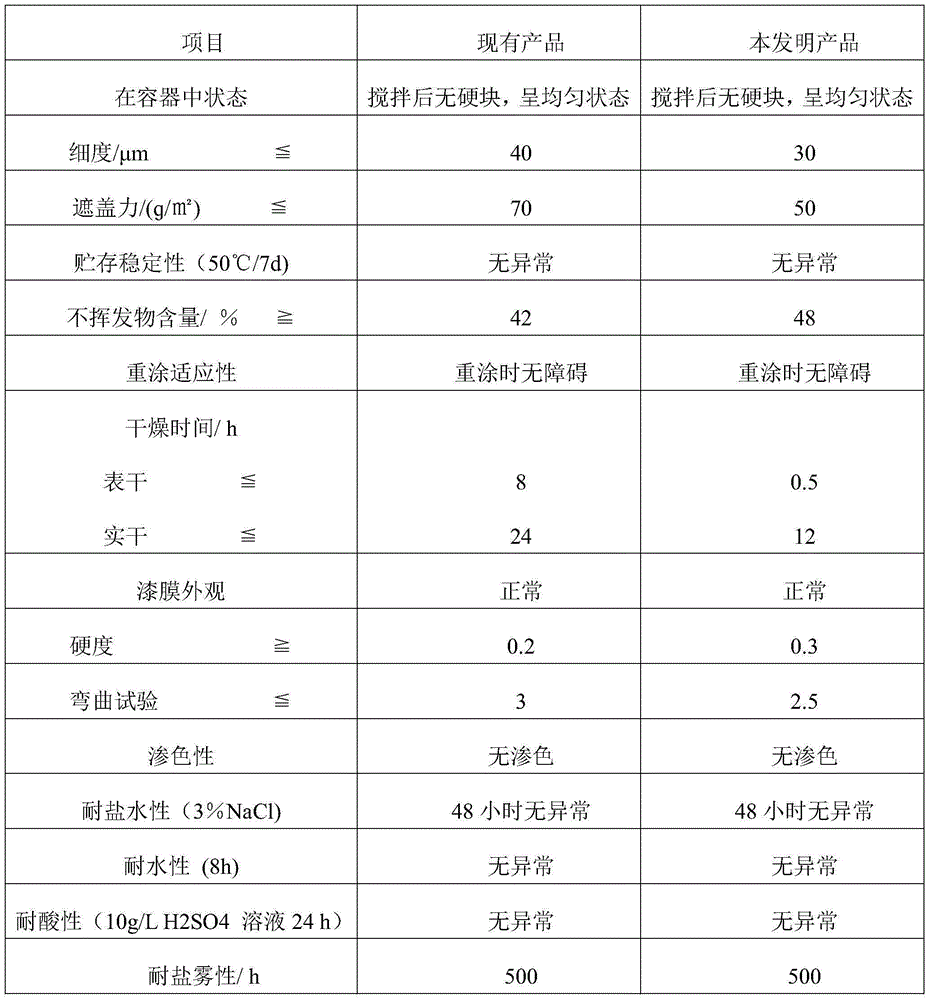

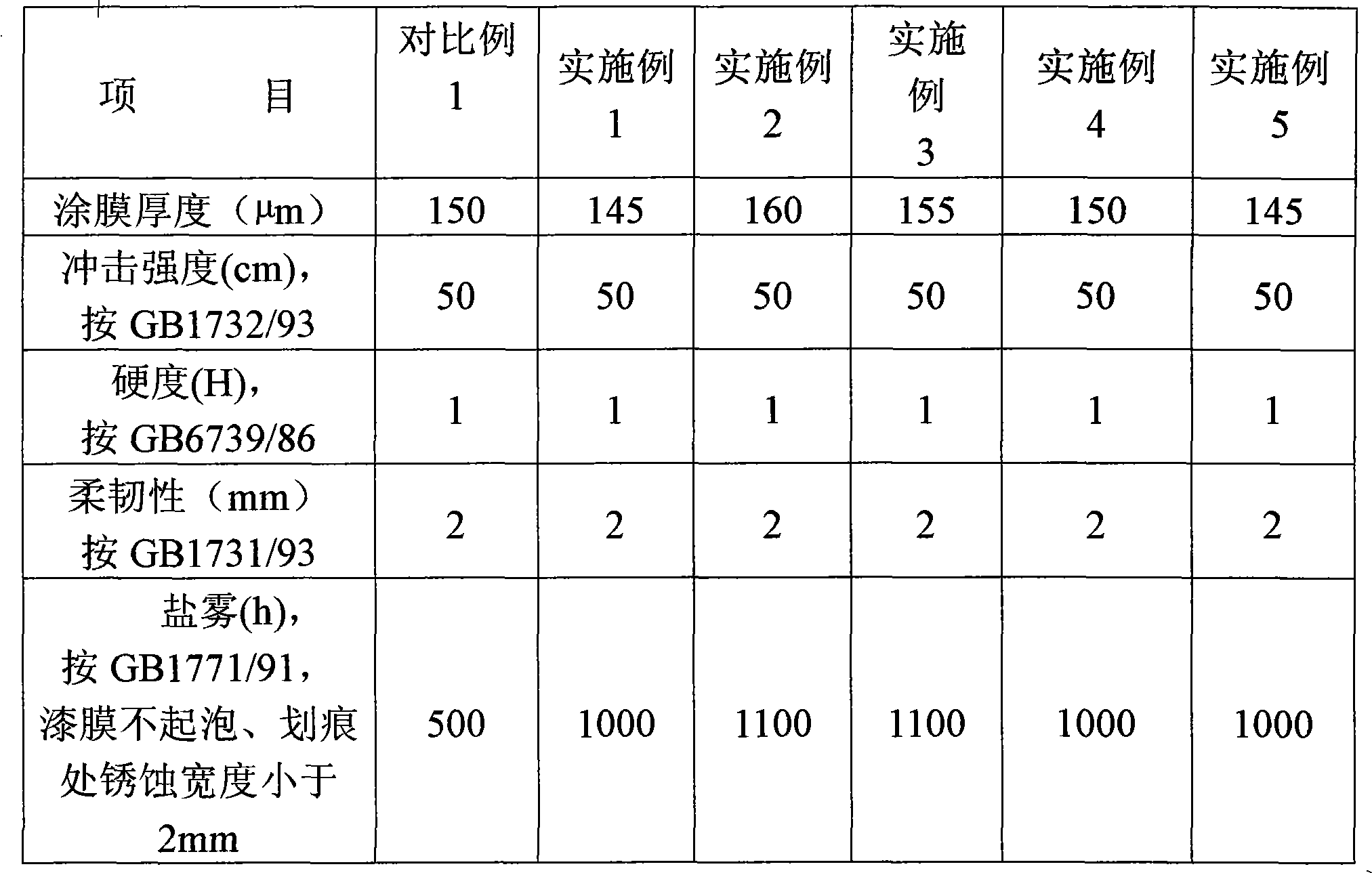

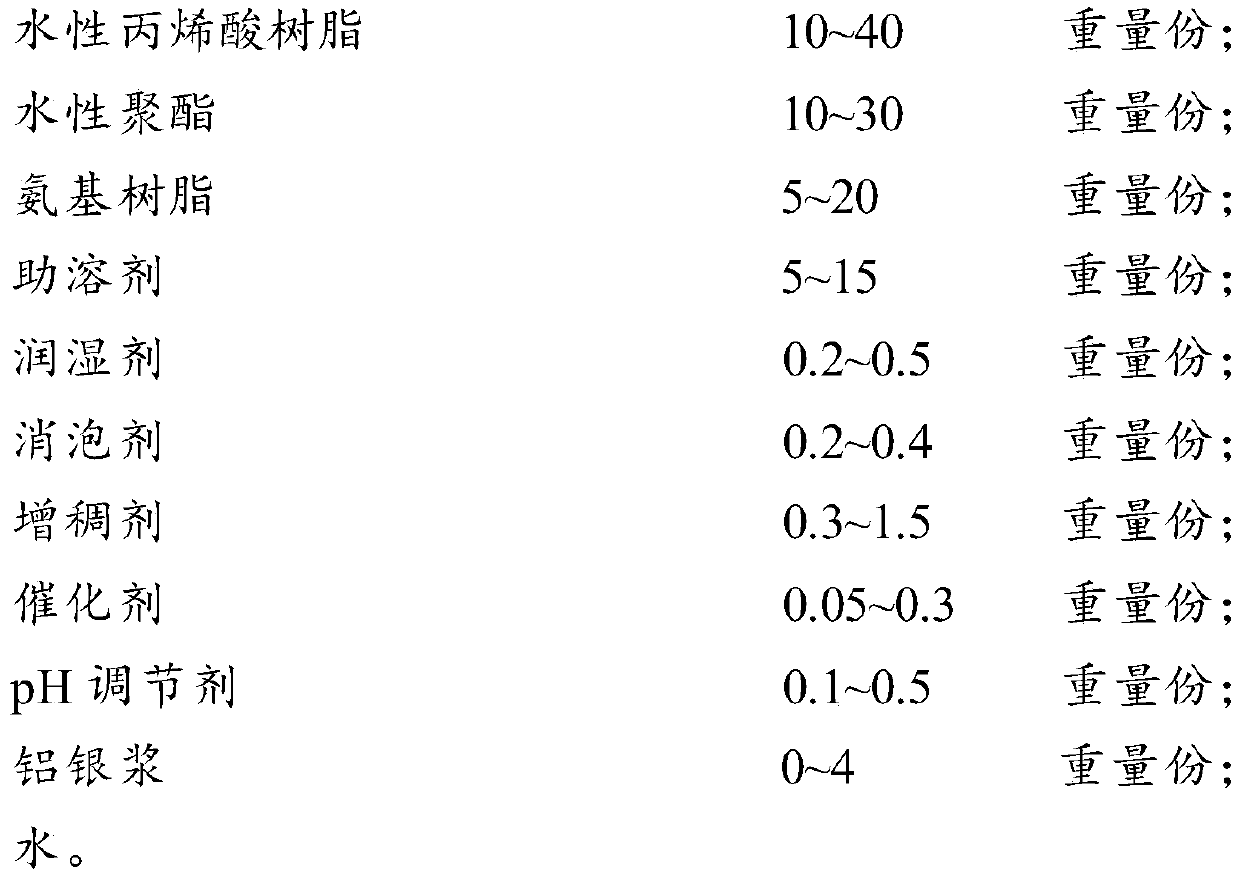

Waterborne metal baking varnish with flexibility and hardness and low temperature reactivity, and preparation method and application thereof

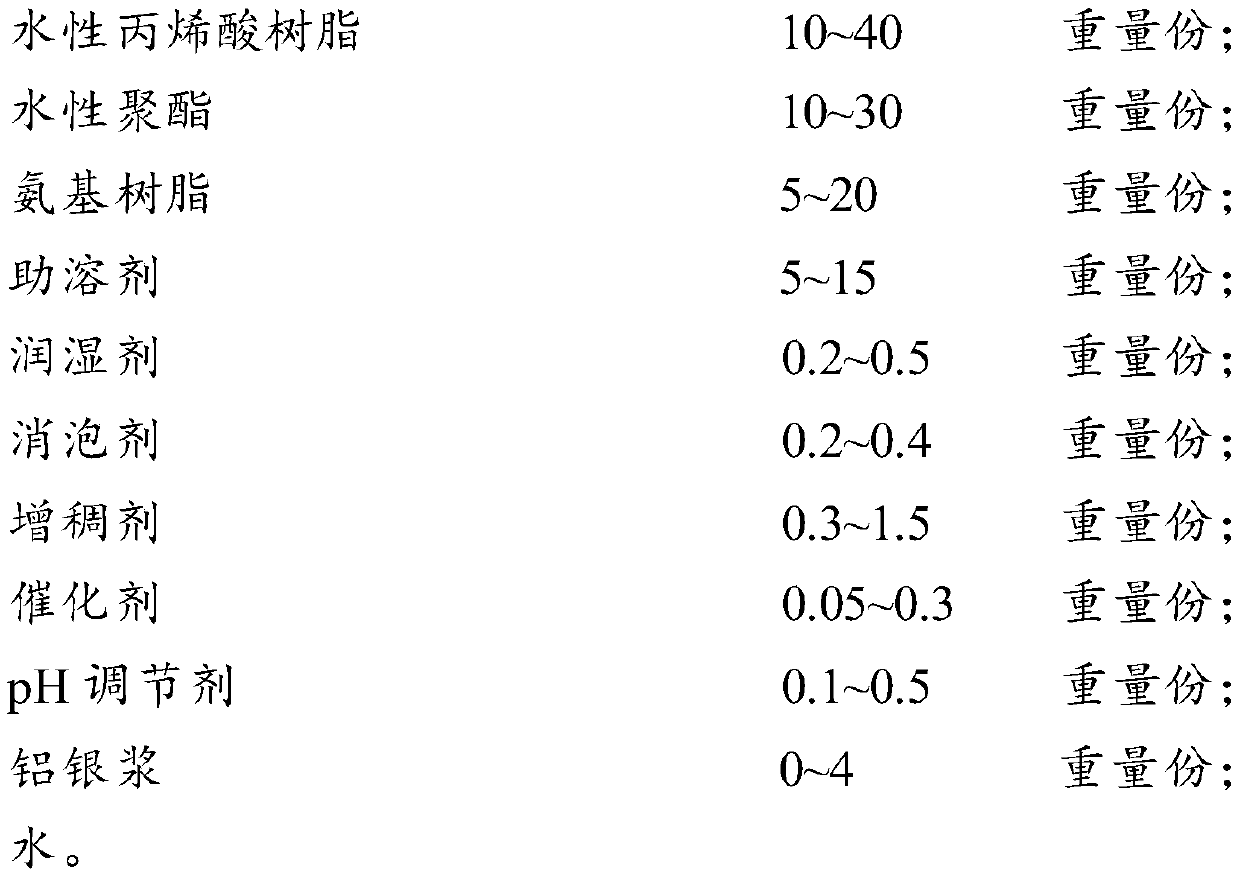

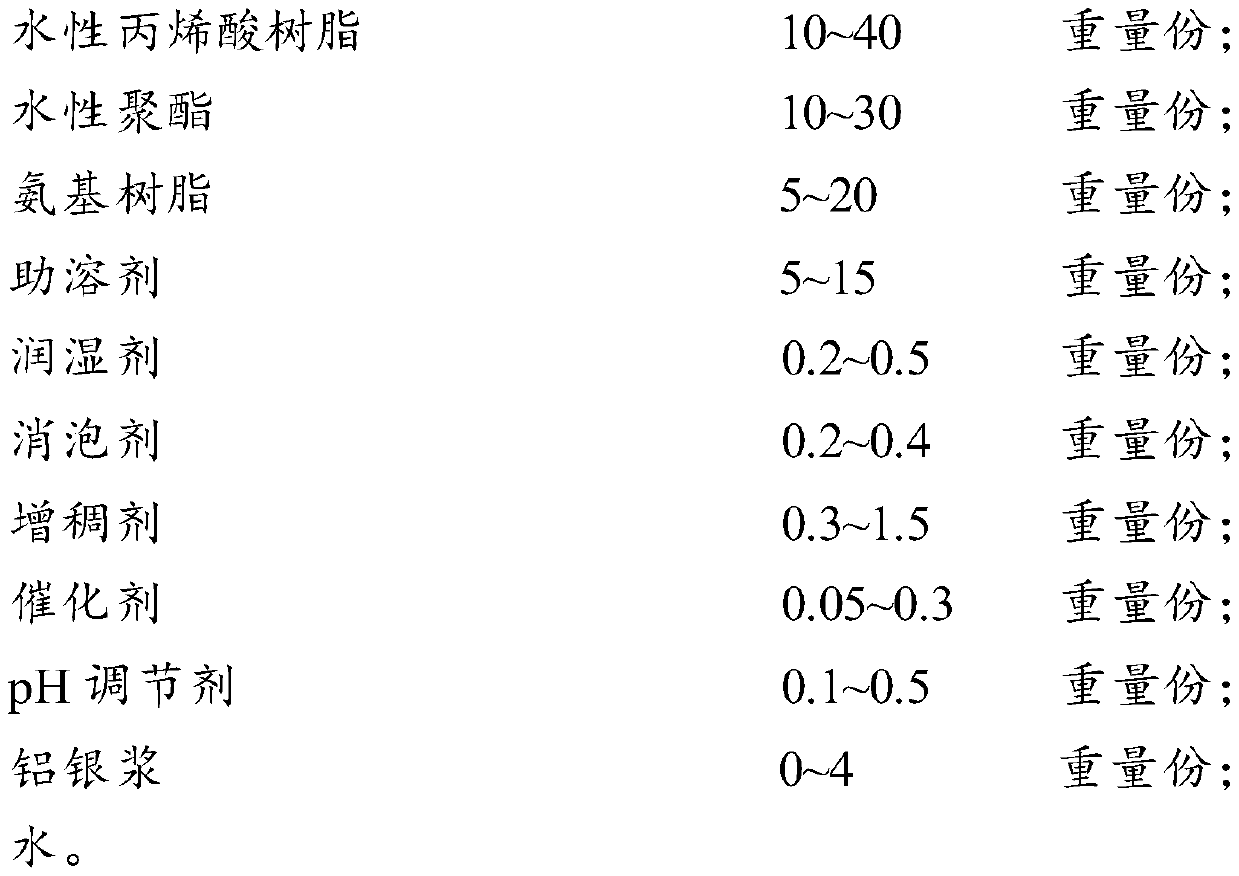

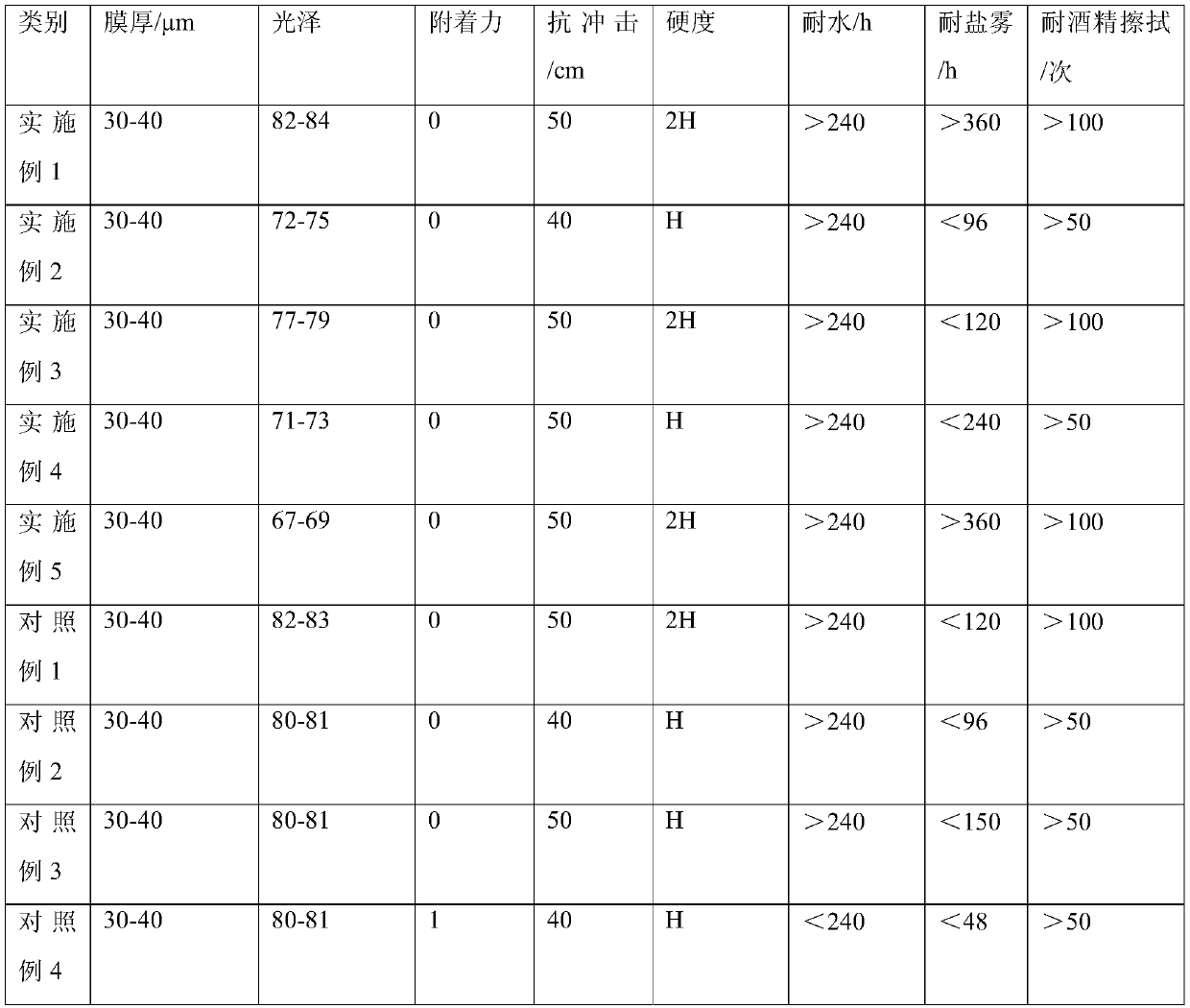

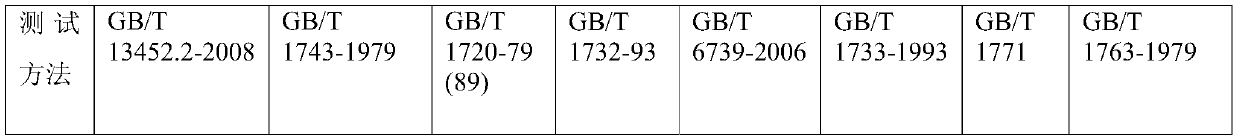

The invention provides a waterborne metal baking varnish. The metal baking varnish comprises, in parts by weight, 10-40 parts of a waterborne acrylic resin, 10-30 parts of a waterborne polyester, 5-20parts -of an amino resin, 5-15 parts of a co-solvent, 0.2-0.5 part of a wetting agent, 0.2-0.4 part of an anti-foaming agent, 0.3-1.5 parts of a thickener, 0.05-0.3 part of a catalyst, 0.1-0.5 part of a pH adjuster, 0-4 parts of an aluminum silver paste, and water. Compared with an oil paint, the provided waterborne metal baking varnish is more environment-friendly and yellowing-resistant, and has relatively strong hardness, water resistance, chemical resistance and other properties. Compared with an ordinary waterborne metal baking varnish, the waterborne metal baking varnish has a lower baking temperature, and has relatively strong tolerance at baking temperature and baking time. At the same time, a paint film has high hardness, strong flexibility, and strong adhesion and salt fog resistance, operability and controllability in use are greatly improved, and popularization and use are easier.

Owner:深圳市雷巴环保材料有限公司

Amino baking varnish for galvanized pipe and preparation method of amino baking varnish

InactiveCN110387175AIncrease crosslink densityImprove adhesionAnti-corrosive paintsVarnishIsocyanate compound

The invention relates to an amino baking varnish, in particular to an amino baking varnish for a galvanized pipe and a preparation method of the amino baking varnish. The amino baking varnish comprises resin, a conventional auxiliary agent, a film forming auxiliary agent, an anti-settling agent, a thickener, deionized water, a functional auxiliary agent, a dispersing agent, a coloring pigment, ananti-rust material, methyl etherified amino resin, an amine neutralizing agent, a leveling agent and a wetting agent. According the amino baking varnish, adhesion is excellent, the crosslink density of the amino resin can be enhanced by adding enclosed isocyanate, the adhesion with a base material is enhanced, oxidation and rust of the galvanized pipe are prevented, the preparation process is simple, the operation is convenient, the production cost is saved, and manpower and material resources are saved.

Owner:山东七维新材料有限公司

High-weather-resistance natural rubber material and preparation method thereof

The invention discloses a high-weather-resistance natural rubber material. The high-weather-resistance natural rubber material is prepared from, by weight, 1-2 parts of casein, 4-6 parts of diethylene glycol dibenzoate, 100-140 parts of natural rubber, 20-30 parts of kaolinite, 400-500 parts of dimethyl sulfoxide, 900-1000 parts of methanol, 70-80 parts of N-methyl imidazole, 100-120 parts of bromoethane, 4-6 parts of nano silicon oxide, 1-2 parts of an anti-aging agent tnp, 1-1.6 parts of sulfur, 1-2 parts of alkanolamide, 1-2 parts of a promoter CZ and 3-4 parts of poly butyl acrylate. The high-weather-resistance natural rubber material has good weatherability, is resistant to heat, cold, acid and alkali corrosion and salt fog and has strong ozone resistance and superior comprehensive performance.

Owner:HEFEI JIEMING NEW MATERIAL TECH CO LTD

High-strength wear-resistant aluminum alloy for electric power fittings

The invention provides high-strength wear-resistant aluminum alloy for electric power fittings. The high-strength wear-resistant aluminum alloy comprises an aluminum alloy body and an electroplating layer. The aluminum alloy body is prepared from Si-Mg-Nb-Ce-Co-Al alloy materials. The electroplating layer is an Al-Zn-Ni-Cu plating layer. The prepared aluminum alloy has excellent conductivity, wear resistance, corrosion resistance and oxidation resistance, the mechanical strength is remarkably improved, the machining performance is good, and the combining force between the electroplating layer and the body is high. By means of the appropriately-added complexing agent, brightening agent and the like, the electroplating effect is effectively improved, and the service life of the aluminum alloy is prolonged.

Owner:安徽固齐线路器材有限公司

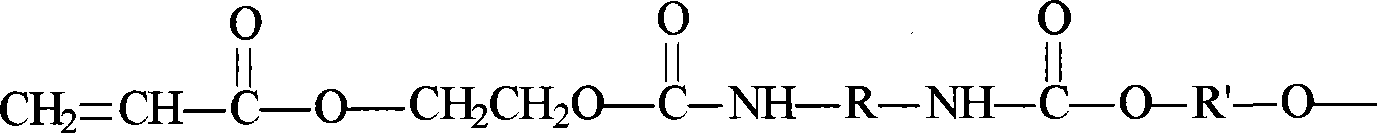

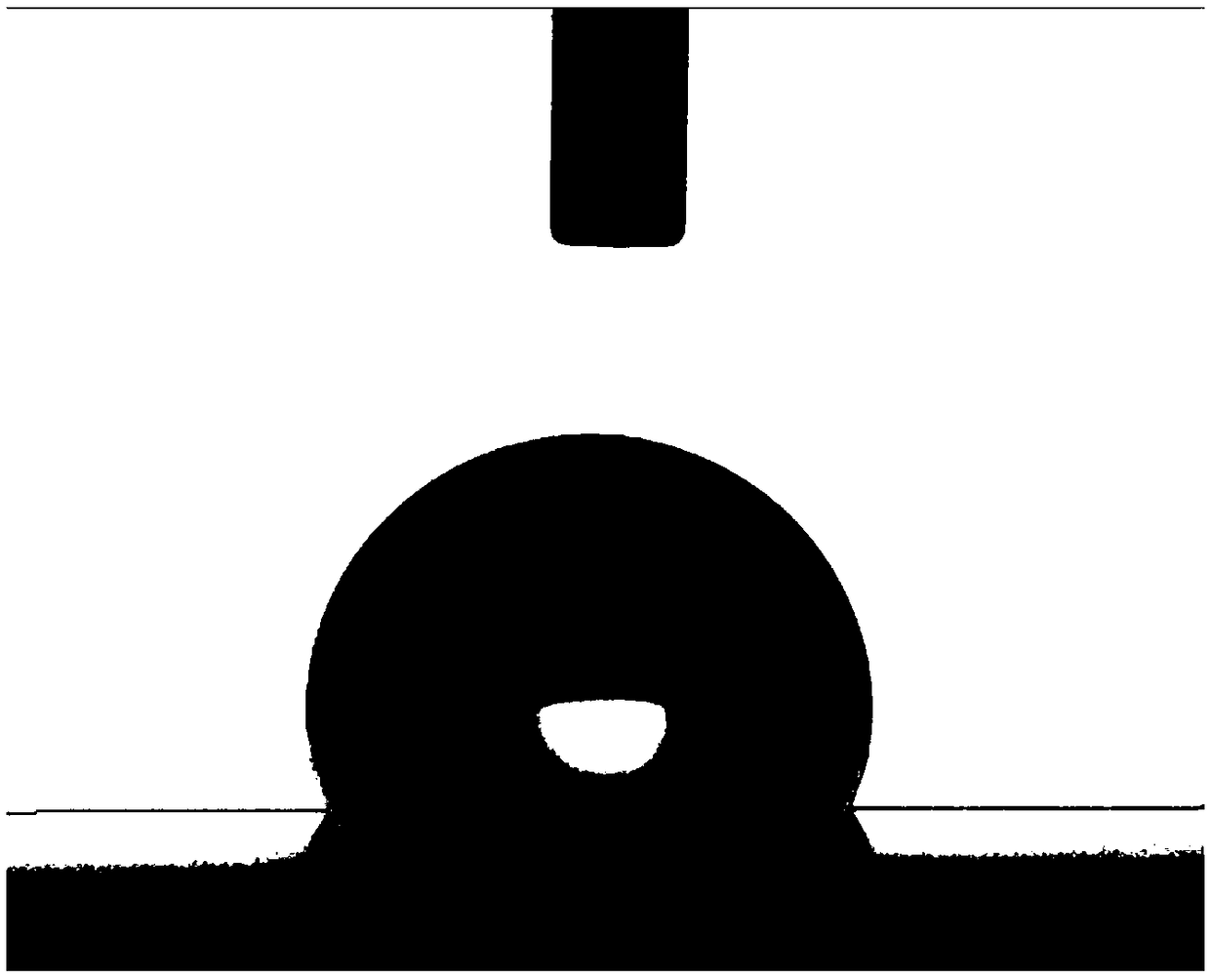

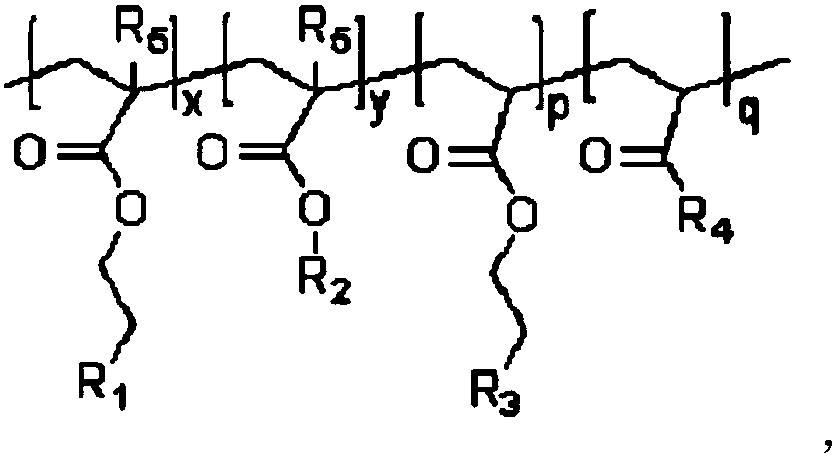

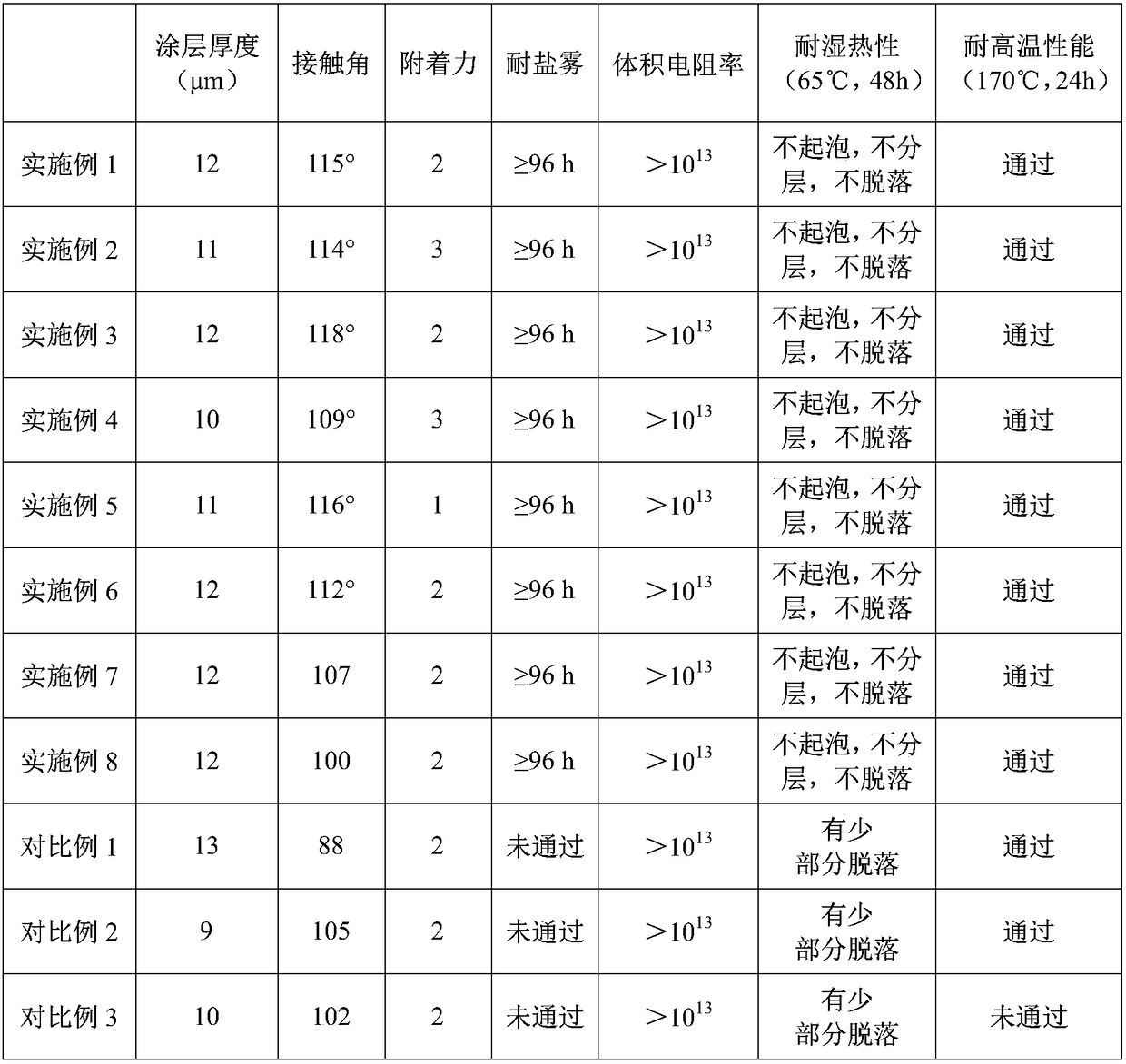

Micron-scale strong salt mist resistant and water repellent three-proof paint for circuit boards

ActiveCN108610868AStrong resistance to salt sprayHigh temperature resistanceFireproof paintsAlkaneMicron scale

The invention relates to a micron-scale strong salt mist resistant and water repellent three-proof paint for circuit boards, wherein the paint comprises a perfluoropolyether modified acrylate polymer.The perfluoropolyether modified acrylate polymer comprises the following structural units: (A) a structural unit provided by a perfluoropolyether derivative monomer and represented by the general formula I, (B) a structural unit provided by a fluorine atom-free acrylate derivative monomer, (C) a structural unit with a cyclic structure and (D) a structural unit with a polar group, wherein CF3CF2CF2O[CF(CF3)CF2O]nCF(CF3)-Y-C(R1)=CH2 (I), in the formula I, n is 5-50, R1 is hydrogen or 1-4 carbon saturated alkanes, and Y is a connecting group. According to the perfluoropolyether modified acrylatepolymer used for preparing the three-proof paint, a side chain as a perfluoropolyether-based chain is introduced to a polymer chain, a polar group, a cyclic group and other groups are introduced intothe polymer, and the prepared three-proof paint has strong salt mist resistance, high temperature resistance, moisture and heat resistance and excellent water repellency.

Owner:太仓中化环保化工有限公司

Protective grease for bridge inhaul cables, and preparation method thereof

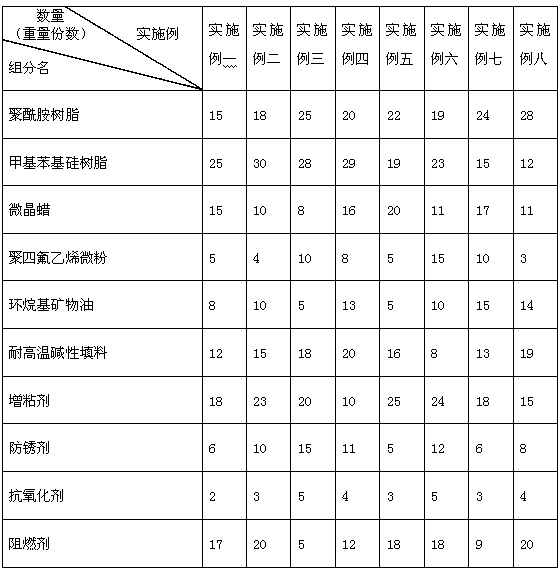

ActiveCN111117730AGood stabilityStrong resistance to salt sprayLubricant compositionSilicone resinPolyamide

A protective grease for bridge inhaul cables is a mixture comprising 15-28 parts by weight of polyamide resin, 12-30 parts by weight of methyl phenyl silicone resin, 8-20 parts by weight of microcrystalline wax, 3-15 parts by weight of polytetrafluoroethylene micro-powder, 5-15 parts by weight of naphthenic mineral oil, 8-20 parts by weight of a high-temperature-resistant alkaline filler, 10-25 parts by weight of a tackifier, 5-15 parts by weight of an antirust agent, 2-5 parts by weight of an antioxidant and 5-20 parts by weight of a flame retardant. A preparation method of the protective grease comprises the following steps: sequentially adding the components into a heating container, keeping a certain temperature, and stirring. The protective grease for bridge inhaul cables has the advantages of being good in stability, strong in adhesive force, strong in salt spray resistance, long in corrosion inhibition period, strong in lubricating property, not prone to combustion, good in flame retardant effect and the like, and is particularly suitable for sealing protection of the bridge inhaul cables with high requirements for flame retardant property and lubricating property.

Owner:LIUZHOU OVM STRUCTURE INSPECTION TECH

Water-based electroplating antirust agent and preparation method thereof

InactiveCN104313592AStrong anti-corrosion, anti-tarnishStrong anti-rustWater basedPolyethylene glycol

The invention discloses a water-based electroplating antirust agent. The water-based electroplating antirust agent is characterized by being prepared from the following raw materials in part by weight: 0.5-1 part of amino silicon oil, 2-4 parts of sodium carboxymethyl starch, 0.5-1 part of ethylmaltol, 1-2 parts of polyethylene glycol monolaurate, 6-8parts of a modifying additive, 0.2-0.4 part of L-cysteine, 4-6 parts of water-based wax emulsion, 1-2 parts of octenylsuccinate starch, 0.3-0.5 part of lauramidopropyl hydroxyl sulphobetaine, 0.3-0.5 part of pentaerythritol oleate, 1-2 parts of sodium thiosulfate, 0.1-0.2 part of disodium etidronate and 30-40 parts of water. A film layer formed by the water-based electroplating antirust agent on the surface of metal has very strong corrosion-resistant, discoloration-resistant, anti-static, rust-proof and salt fog-resistant capabilities, is nonflammable, environment-friendly and nontoxic; the water-based electroplating antirust agent is convenient to use and easy to operate; a processed workpiece is good in gloss.

Anticorrosive and antirust nanometer fiber paint for containers, method for preparing and spraying paint

ActiveCN102786861AGood acid and alkali resistanceGood oil resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsCarbide siliconSolvent

The invention discloses an anticorrosive and antirust nanometer fiber paint for containers, and a method for preparing and spraying the paint, wherein a component A is composed of a resin solution, talcum powder, silicon carbide, lithopone and nanometer fiber; and a component B is composed of polyamide and a mixed solvent; the resin solution is composed of a solvent and resin; the component A is mixed with the component B on ratio of 100:10-15 to form the paint. The method comprises steps as follows: preparing the solvent, dissolving the resin, preparing the component A and the component B, and then preparing the paint; and the spraying method comprises steps as follows: uniformly spraying the paint onto the surface of a sprayed object by an ejection gun, spraying 1-5 surface layers with each layer being 30 mu m thick, drying the sprayed sample for 60 minutes at 60-80 DEG C, or naturally drying the sprayed sample. The paint has strong salt mist resistance which is 10 times that of a traditional paint; the paint is soaked for 8 years in a 5% NaCl solution in the salt water resistance, the paint film is not changed; the acid resistance is more than 80 times that of the traditional anticorrosive paint; the alkali resistance is more than 40 times that of the traditional anticorrosive paint; and the paint film is not changed in oil resistance for 3 years later. The paint provided by the invention is applied to the containers and ship submarines.

Owner:西安华捷奥海新材料有限公司

Corrosion-resistant sealing wax for bridge cables and anchor heads and preparation method thereof

Owner:LIUZHOU OVM MASCH CO LTD

Novel high-grade powder coating and preparation method thereof

InactiveCN111635691AHigh impact strengthAcid resistantPowdery paintsGrain treatmentsCoated surfaceWeather resistance

The invention discloses a novel high-grade powder coating and a preparation method thereof. The problems that the existing powder coating is poor in impact strength and acid and alkali resistance, thelubricity of the powder coating cannot meet the use requirements, in addition, in the powder coating production process, the problem of oxidative decomposition of body resin is easily caused due to the problems of an agent discharging method, the quality of the powder coating is further influenced are solved. The matching of the powder coating and the synthesis method of the powder coating are improved and optimized, so the powder coating has high impact strength, strong acid resistance, alkali resistance, salt spray resistance and weather resistance, and flat and smooth coating surface, thecuring time can be shortened, the purposes of energy conservation, low carbon and environmental protection are achieved, and the use performance of the powder coating is improved; and matrix resin oxygenolysis can be avoided by adopting a deep thread low-temperature extrusion method in the production process of the powder coating. Double-screening fine grinding is adopted to guarantee that matrixresin particles are small and uniform, so thin coating can be conducted, and the coating effect is better.

Owner:ANHUI MEIJIA NEW MATERIAL

Hardware salt-spray-resistant antirust liquid and preparation method thereof

ActiveCN103695924AStrong resistance to salt sprayStrong oxidation resistanceDiethylene glycol monobutyl etherHexanediol diacrylate

The invention discloses a hardware salt-spray-resistant antirust liquid which is prepared from the following raw materials in parts by weight: 2-3 parts of polyoxyethylenated castor oil, 1-2 parts of sodium benzoate, 12-14 parts of diethylene glycol monobutyl ether, 8-10 parts of 6-hexanediol diacrylate, 2-4 parts of propyl gallate, 3-5 parts of citric acid, 1-2 parts of rosin amine, 6-8 parts of melamine, 6-8 parts of butyl methacrylate, 1-2 parts of EDTA disodium, 4-5 parts of an auxiliary agent, and 300 parts of water. The hardware antirust liquid has strong salt spray resistance ability, can form a layer of dense protective film on the surface of copper, iron, stainless steel or other metals, effectively prevents outside matters from corroding the metals, does not affect conductive welding, and allows the protective film to be easy to clean up. The antirust liquid allows a workpiece and a workpiece to be not stuck together, has strong anti-fingerprint, anti-discoloration and anti-oxidation abilities, can be operated with the original liquid under the normal temperature, and saves energy. The antirust liquid is applicable to surface rust prevention of copper, iron, stainless steel and other metals and electroplating metals.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Single-component water-based automobile chassis paint as well as preparation method and use method thereof

ActiveCN114806318AStrong adhesionImprove water resistanceAnti-corrosive paintsPolyester coatingsEpoxySilicon oxide

The invention belongs to the technical field of coating production, and particularly relates to single-component water-based automobile chassis paint. The water-based automobile chassis paint provided by the invention is prepared from 30 to 50 parts of water-based epoxy ester dispersion resin, 5 to 15 parts of deionized water, 1 to 8 parts of butyl cellosolve, 0.5 to 5 parts of dispersing agent, 0.1 to 1 part of defoaming agent, 0.1 to 1 part of wetting agent, 0.1 to 1 part of flash rust inhibitor, 0.5 to 1.5 parts of adhesion promoter, 5 to 15 parts of modified zinc phosphate pigment, 1 to 5 parts of superfine calcium phosphate antirust pigment, 1 to 10 parts of superfine talcum powder, 5 to 18 parts of superfine barium sulfate and 0.1 to 1 part of fumed silica. 0.8-5 parts of carbon black and 0.1-1 part of iron oxide yellow. The water-based automobile chassis paint provided by the invention has high resistance, salt mist resistance of 420 hours or more, excellent adhesive force and chemical resistance to various metals, good flexibility and good impact resistance.

Owner:GUANGDONG YATU CHEM

Water-based modified pure acrylic acid anticorrosive paint

ActiveCN102702899BCorrosion protectionImprove anti-corrosion performanceAnti-corrosive paintsWater basedEmulsion

The invention relates to a water-based modified pure acrylic acid anticorrosive paint which is prepared from the following components in percentage by mass: 30-45% of modified acrylic acid emulsion, 3-5% of film-forming assistant, 0.6-1.2% of dispersant, 0.1-1.0% of defoaming agent, 0.1-0.2% of wetting agent, 0.05-0.10% of mold preventive, 1-2% of flash-rust inhibitor, 2-5% of pigment, 15-30% of antirust pigment and filler, 2-5% of filler, 2-5% of thickening agent, 1-2.5% of salt-fog inhibitor and the balance of water. The PH value is regulated to 8-9. The anticorrosive paint provided by the invention has the advantages of combined primer and precoat functions, single component and self drying, is water-based, and satisfies the requirement for environmental protection. The invention has the advantages of simple production technique, accessible raw materials, low cost, low VOC (volatile organic compound), environmental protection and high safety, can easily implement industrialization, and is simple and convenient for construction.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Environment-friendly fluorine-free aluminum alloy surface treating agent

InactiveCN104109467AStrong resistance to salt sprayGood coating adhesionAnti-corrosive paintsZinc Acetate DihydrateFluorine free

The invention discloses an environment-friendly fluorine-free aluminum alloy surface treating agent. The surface treating agent is composed of the following raw materials in parts by weight: 2.3 to 3 parts of sodium borate, 1 to 1.7 parts of zinc acetate, 0.1 to 0.2 part of calcined gypsum powder, 0.8 to 1 part of glucolactone, 0.03 to 0.1 part of resorcinol monobenzoate, 0.1 to 0.3 part of N,N-diethylaniline, 1 to 2.4 parts of sodium methylenebisnaphthalenesulphonate, 2 to 3 part of polyethylene glycol 400, 0.8 to 1 part of potassium tungstate, 2 to 2.6 parts of myristyl binary acid, 2 to 3 parts of film-forming auxiliary agent, 14 to 20 parts of silane coupling agent KH570, and 130 to 150 parts of deionized water. The surface treating agent can form a layer of conversion membrane on the aluminum alloy surface, and the conversion film has the advantages of compactness, uniformity, corrosion resistance, acid and alkali resistance, strong salt fog resistant performance, and very good coating adhesivity. Moreover the processing method is simple, the requirement on temperature is low, and the energy consumption is low.

Owner:RUIZHAN TONGLING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com