Waterborne metal baking varnish with flexibility and hardness and low temperature reactivity, and preparation method and application thereof

A metal baking paint, water-based technology, applied in coatings, polyester coatings, etc., can solve problems such as adhesion, salt spray resistance, chemical resistance, baking temperature, baking time, and flexibility and hardness. , to achieve the effect of improving operability and controllability, comprehensive improvement and balance of flexibility and hardness, and reducing baking temperature and baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

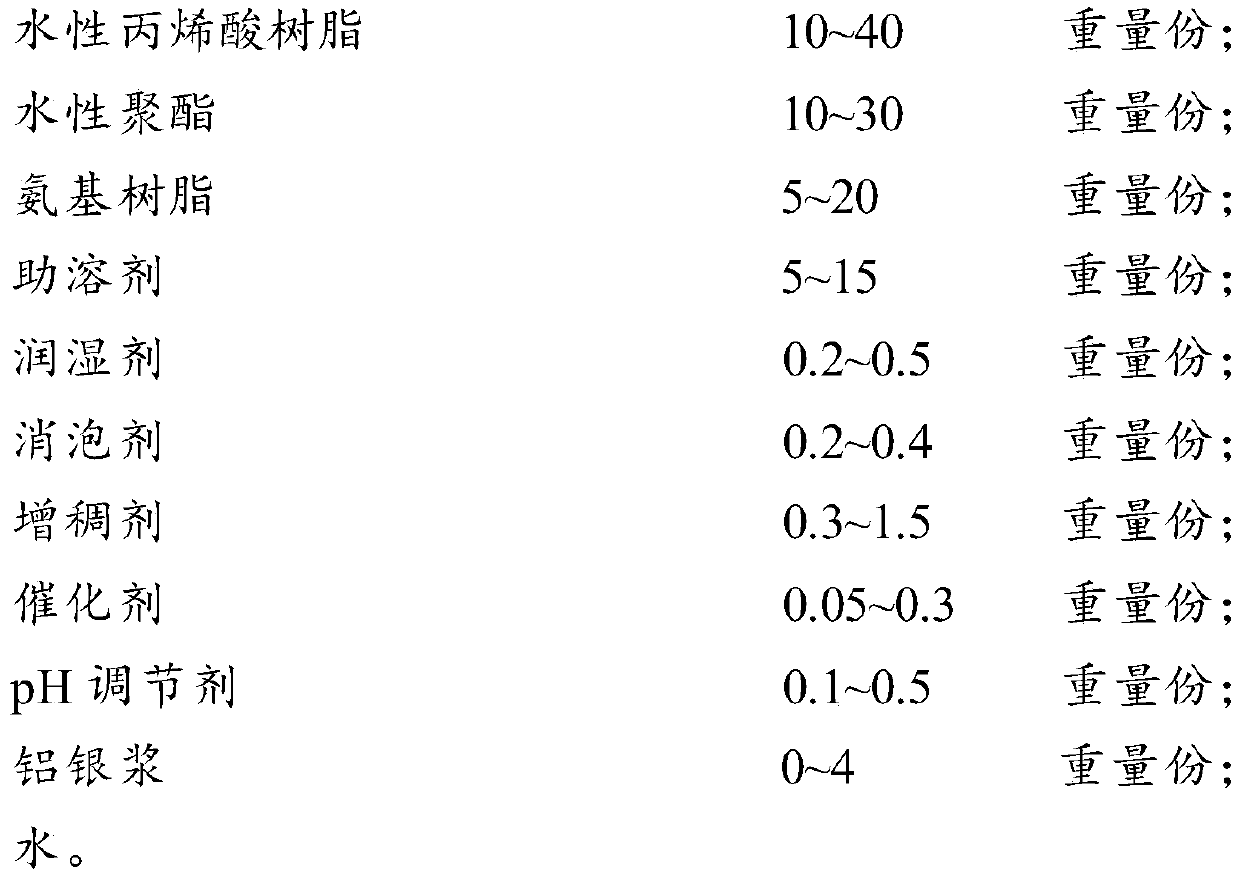

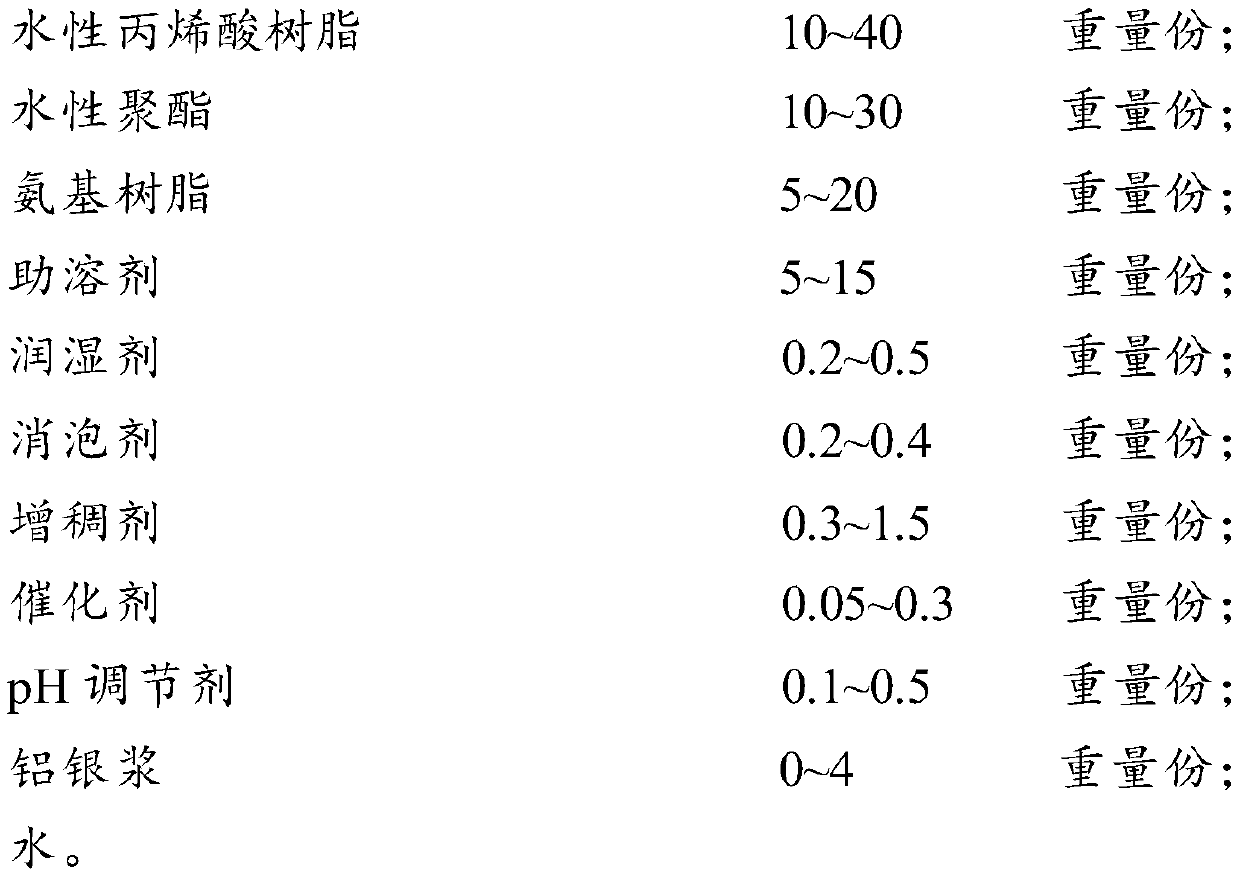

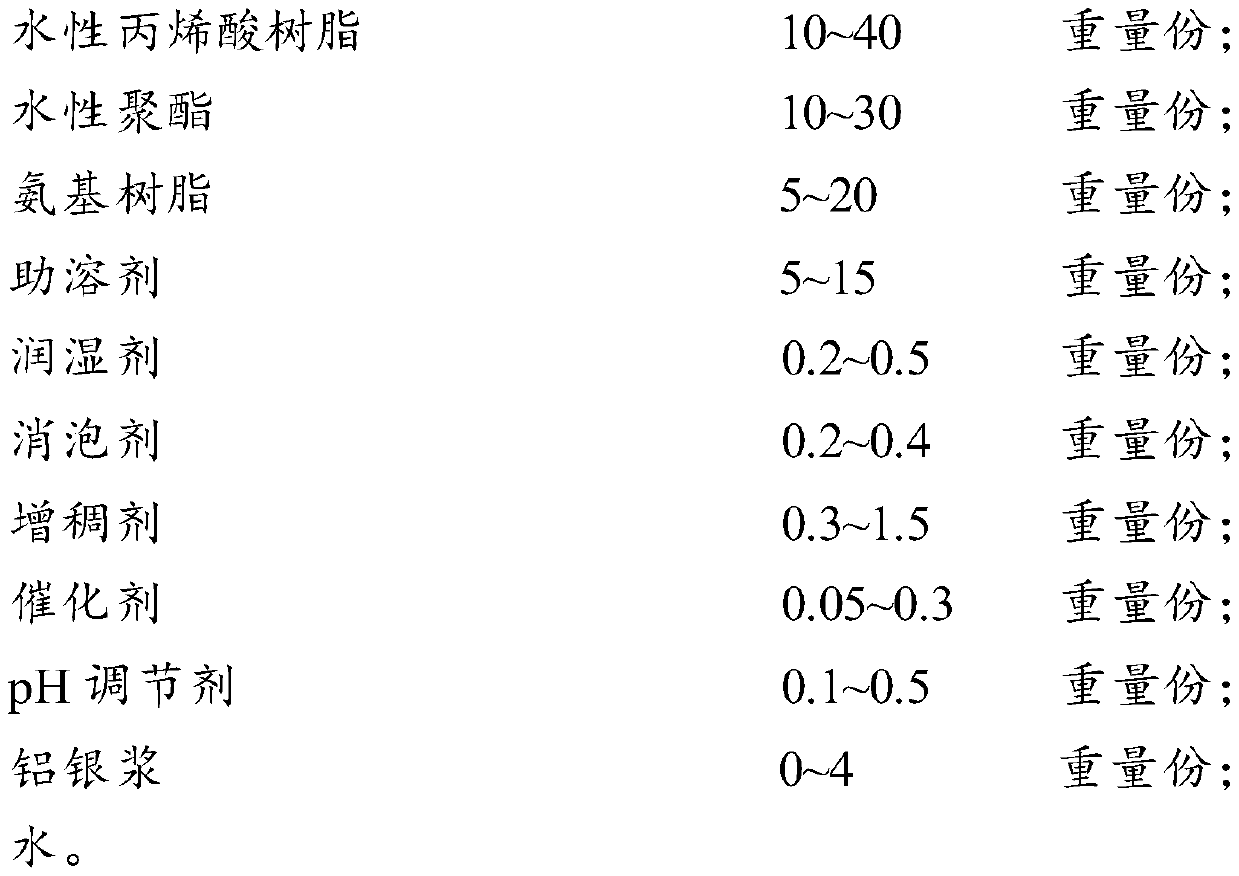

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides a kind of preparation method of water-based metal baking varnish as described in any one of above-mentioned technical scheme, comprises the following steps:

[0070] 1) After mixing water-based polyester and water, mixture A is obtained; after premixing defoamer, wetting agent, cosolvent, catalyst and pH regulator, mixture B is obtained;

[0071] 2) After continuing to mix the mixture A, mixture B, acrylic resin and amino resin obtained in the above steps, mixture C is obtained;

[0072] 3) The mixture C obtained in the above steps, the thickener and the water-based aluminum silver paste are finally mixed to obtain a water-based metallic baking paint.

[0073] In the preparation method of the present invention, the specific preferred scheme of the raw material, and the preferred numerical value of the number of added parts are consistent with the specific preferred scheme of the components in the aforementioned water-based metal bakin...

Embodiment 1

[0100] A kind of water-based metallic baking varnish comprises the following components according to mass percentage:

[0101] KT6031: 40%, WX194: 30%, CYMEL303: 5%, CYMEL325: 5%, butyl glycol ether: 10%, DMEA: 0.5%, tego wet 4100: 0.2%, BYK 028: 0.3%, OS6050: 0.6%, BD7744: 0.2%, water-based aluminum silver paste: 3%, deionized water: 5.2%.

[0102] The preparation steps of water-based metal baking paint are as follows:

[0103] (1) According to the above mass fraction, first mix WX194 with deionized water to obtain mixture A, then pre-mix ethylene glycol butyl ether, BYK028, tego wet4100, DMEA, and BD7744 to obtain mixture B. At 400-500rpm, the mixture Add B slowly to mixture A;

[0104] (2) After the addition of mixture B, slowly add KT6031, CYMEL303, and CYMEL325, and disperse at 1000 rpm for 20 minutes after the addition to obtain mixture C;

[0105] (3) Finally, add OS6050 and water-based aluminum silver paste to mixture C, and disperse at 1500rpm for 20 minutes to obt...

Embodiment 2

[0110] A kind of water-based metallic baking varnish comprises the following components according to mass percentage:

[0111] KT6031: 30%, WX194: 40%, CYMEL303: 3%, CYMEL325: 5%, butyl glycol ether: 8%, DMEA: 0.6%, tego wet 4100: 0.3%, BYK 028: 0.3%, OS6050: 0.8%, BD7744: 0.2%, deionized water: 11.8%.

[0112]The preparation steps of water-based metal baking paint are as follows:

[0113] (1) According to the above mass fraction, first mix WX194 with deionized water to obtain mixture A, then pre-mix ethylene glycol butyl ether, BYK028, tego wet4100, DMEA, and BD7744 to obtain mixture B. At 400-500rpm, the mixture Add B slowly to mixture A;

[0114] (2) After the addition of mixture B, slowly add KT6031, CYMEL303, and CYMEL325, and disperse at 1000 rpm for 20 minutes after the addition to obtain mixture C;

[0115] (3) Finally, add OS6050 to the mixture C and disperse at 1500rpm for 20 minutes to obtain a water-based metallic baking paint.

[0116] The water-based metal ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com