Patents

Literature

17599 results about "Wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wetting is the ability of a liquid to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. The degree of wetting (wettability) is determined by a force balance between adhesive and cohesive forces. Wetting deals with the three phases of materials: gas, liquid, and solid. It is now a center of attention in nanotechnology and nanoscience studies due to the advent of many nanomaterials in the past two decades (e.g. graphene, carbon nanotube, boron nitride nanomesh).

Electro-wetting displays

Owner:E INK CORPORATION

Nonwoven Having Durable Hydrophilic Coating

InactiveUS20110268932A1Promote migrationLamination ancillary operationsDecorative surface effectsHydrophilic coatingTrace Amounts

A nonwoven material coated with an amine-polyether silicone. The coating composition may include a wetting agent, an acid, and / or a defoamer. The nonwoven may be incorporated into a disposable absorbent article. The disposable absorbent article may include at least trace amounts of a mineral oil. The coating of the nonwoven may be durable even in the presence of mineral oil.

Owner:THE PROCTER & GAMBLE COMPANY

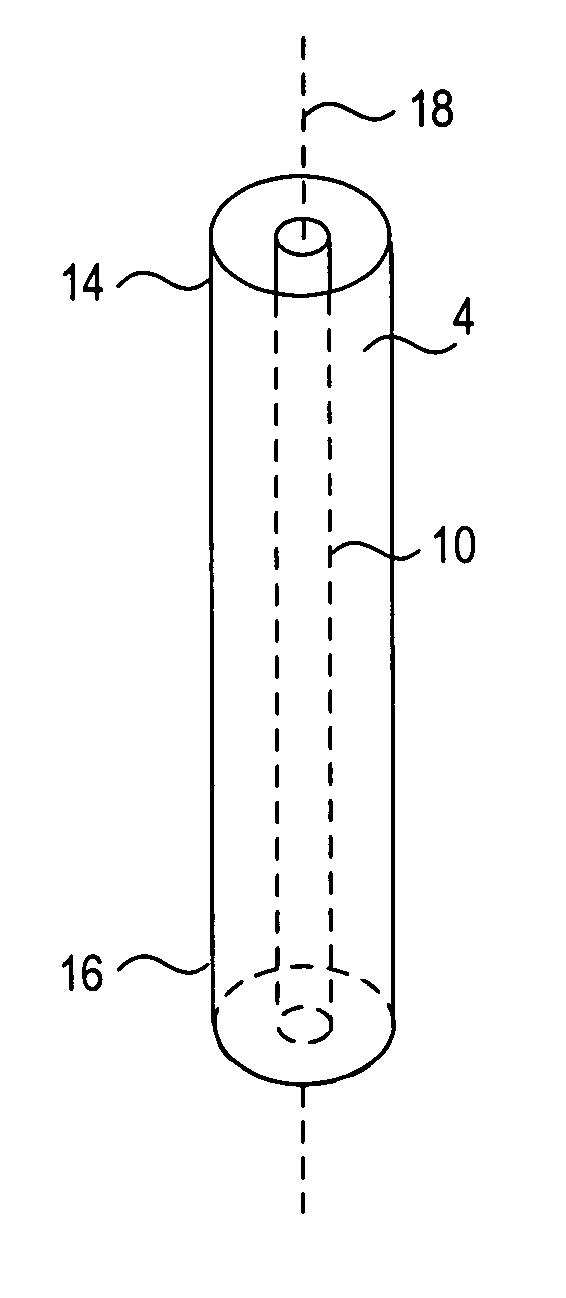

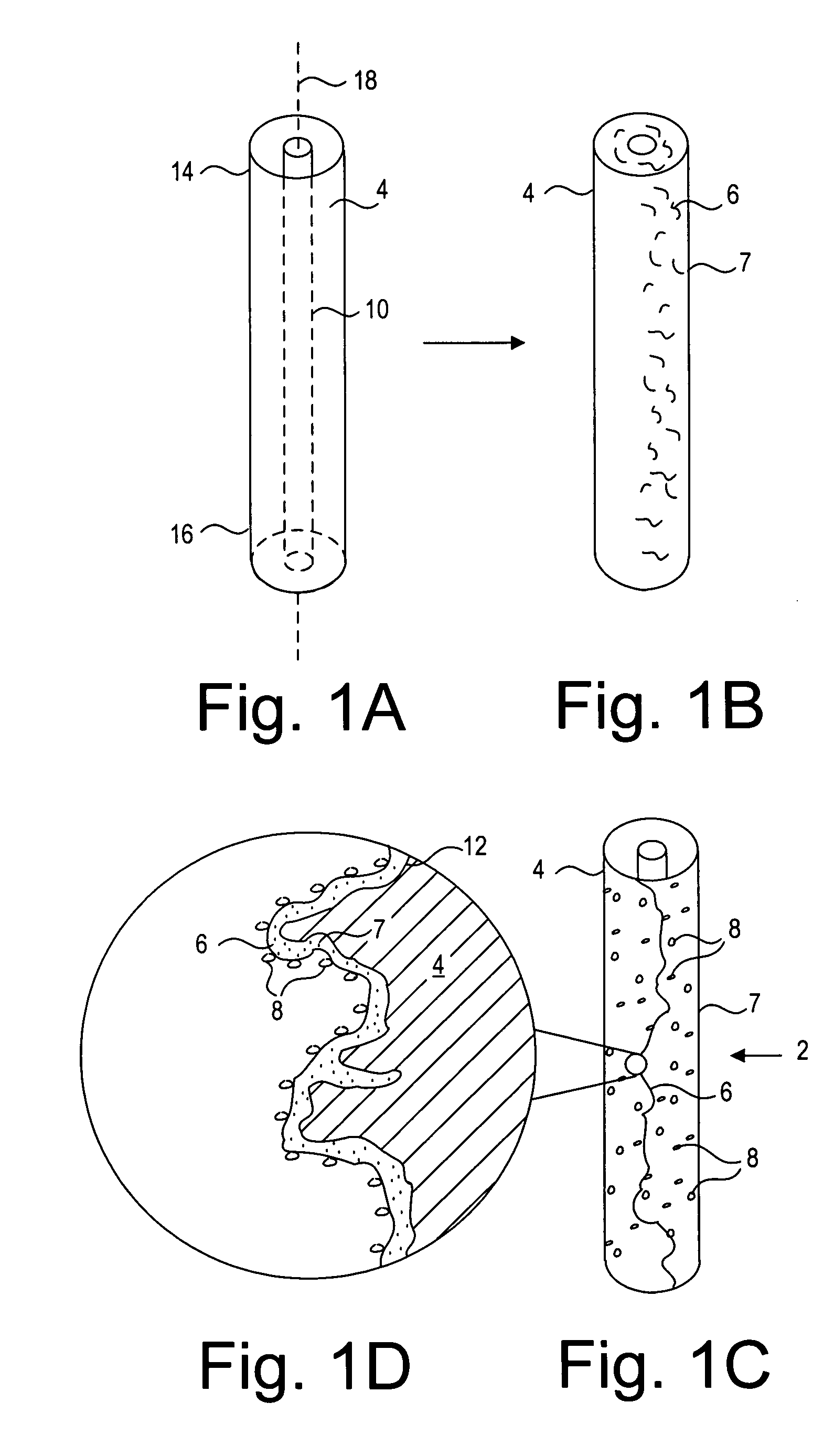

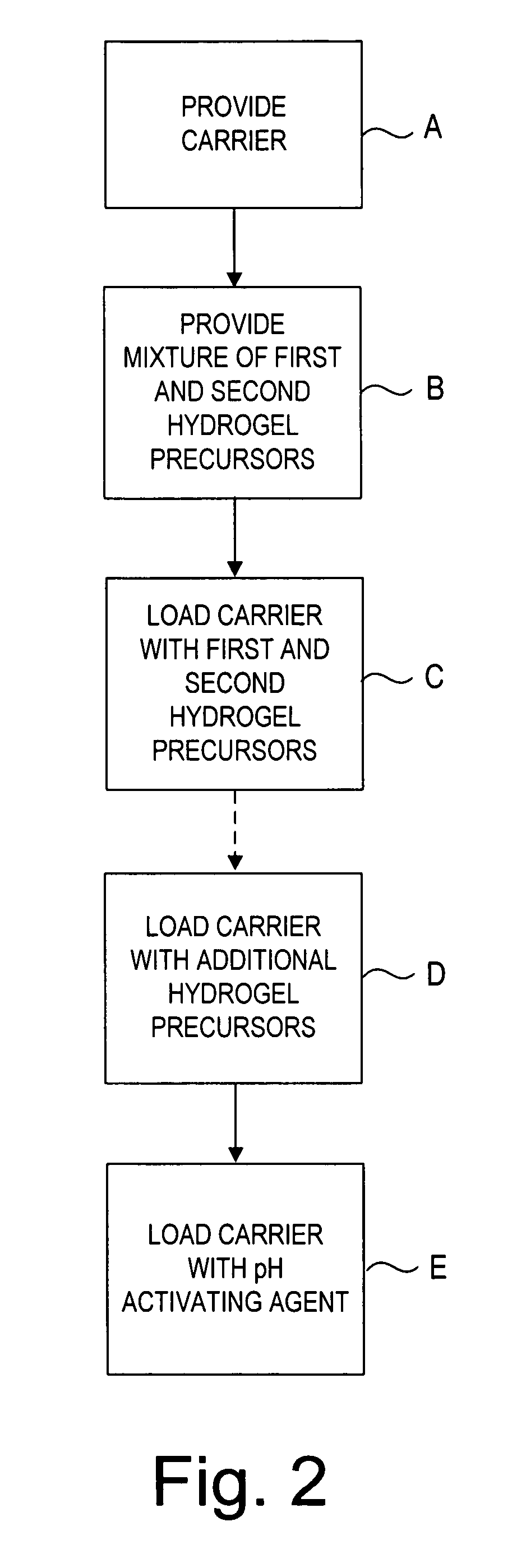

Apparatus and methods for sealing a vascular puncture

Apparatus for sealing a puncture communicating with a blood vessel includes a porous carrier formed from lyophilized hydrogel or other material. The plug may include at least first and second hydrogel precursors and a pH adjusting agent carried by the porous carrier in an unreactive state prior to exposure to an aqueous physiological environment. Once exposed to bodily fluids, the carrier expands as the lyophilized material hydrates to enhance and facilitate rapid hemostasis of the puncture. When the plug is placed into the puncture, the natural wetting of the plug by bodily fluids (e.g., blood) causes the first and second precursors to react and cross-link into an adhesive or “sticky” hydrogel that aids in retaining the plug in place within the puncture.

Owner:INCEPT LLC

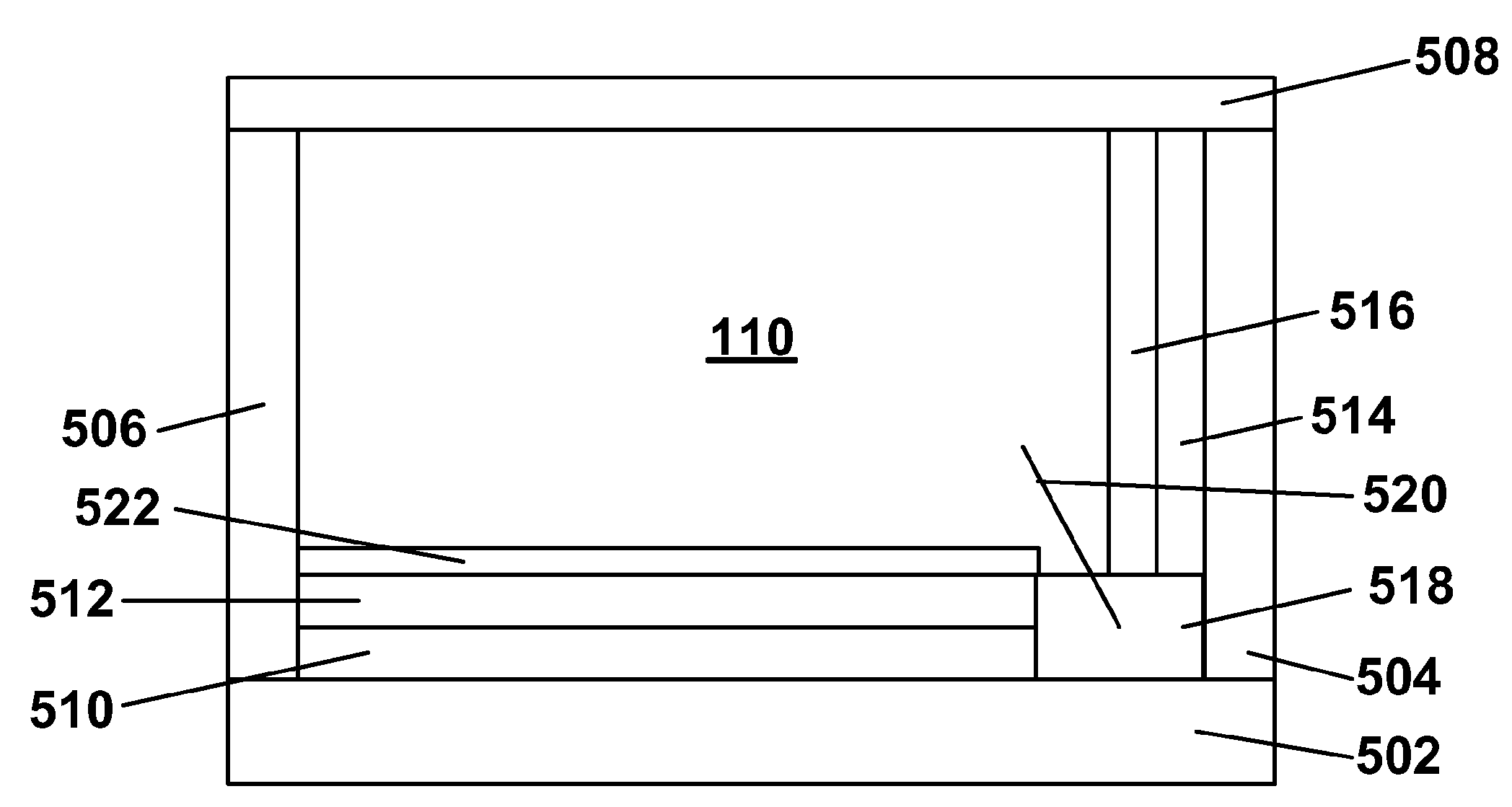

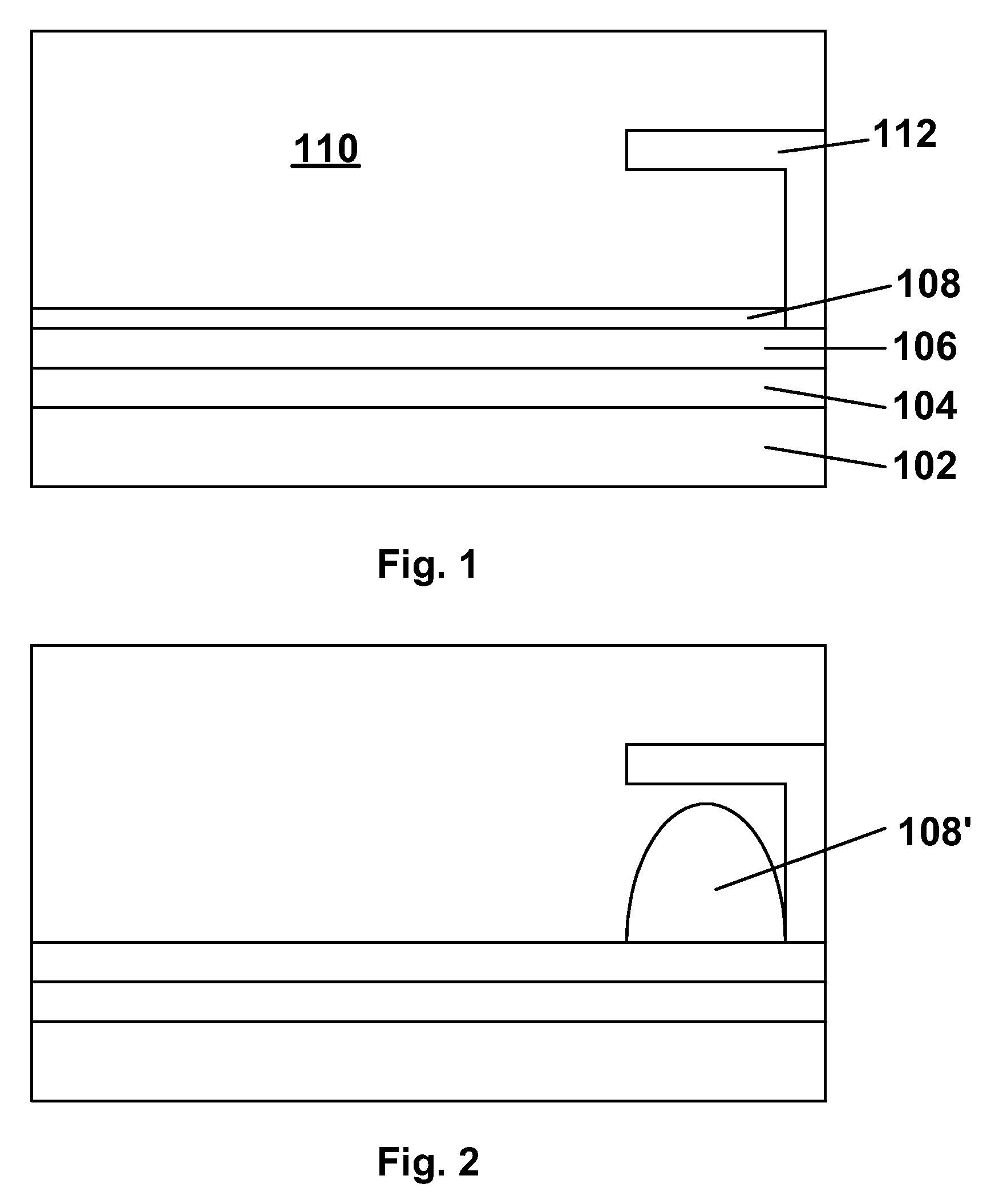

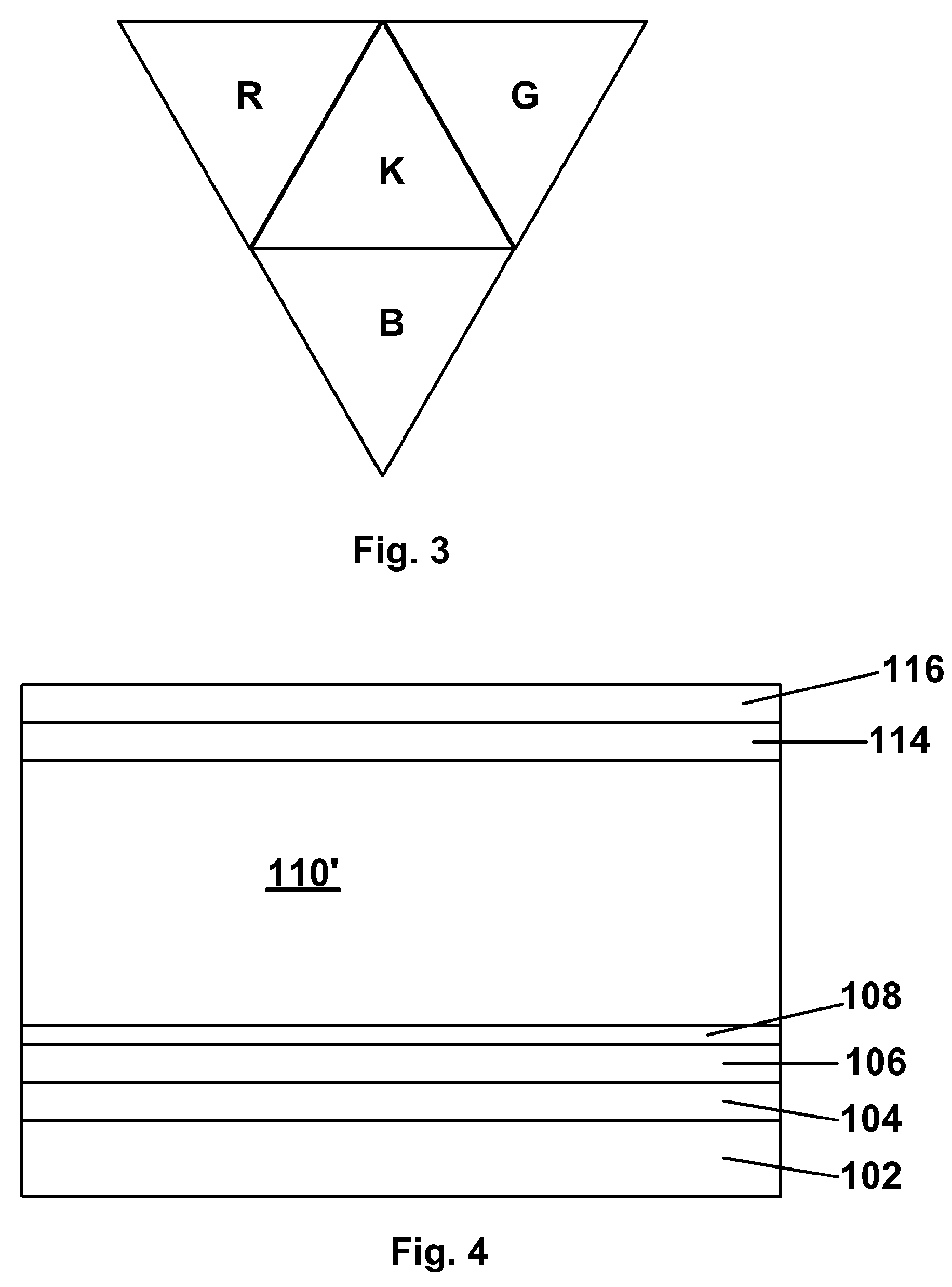

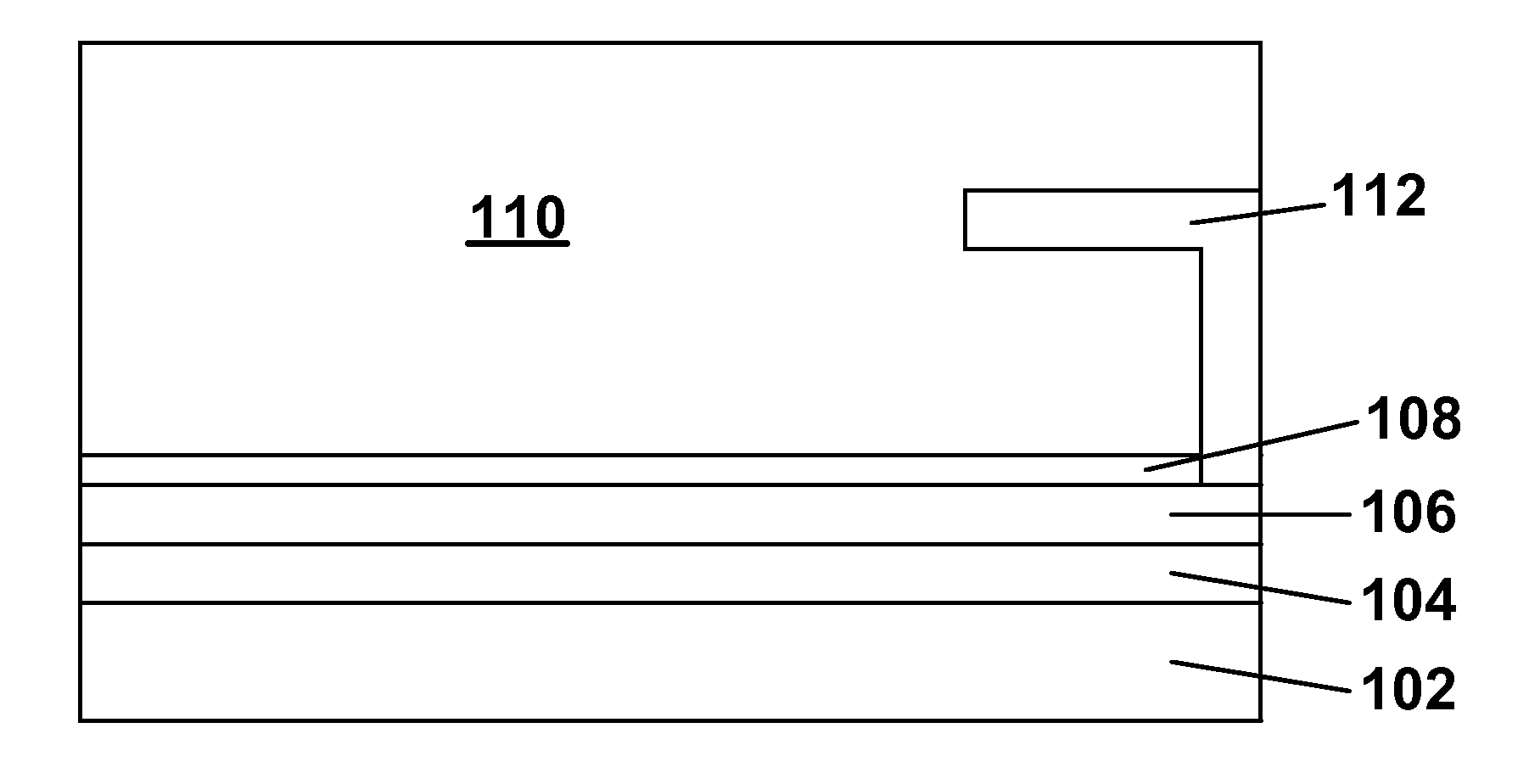

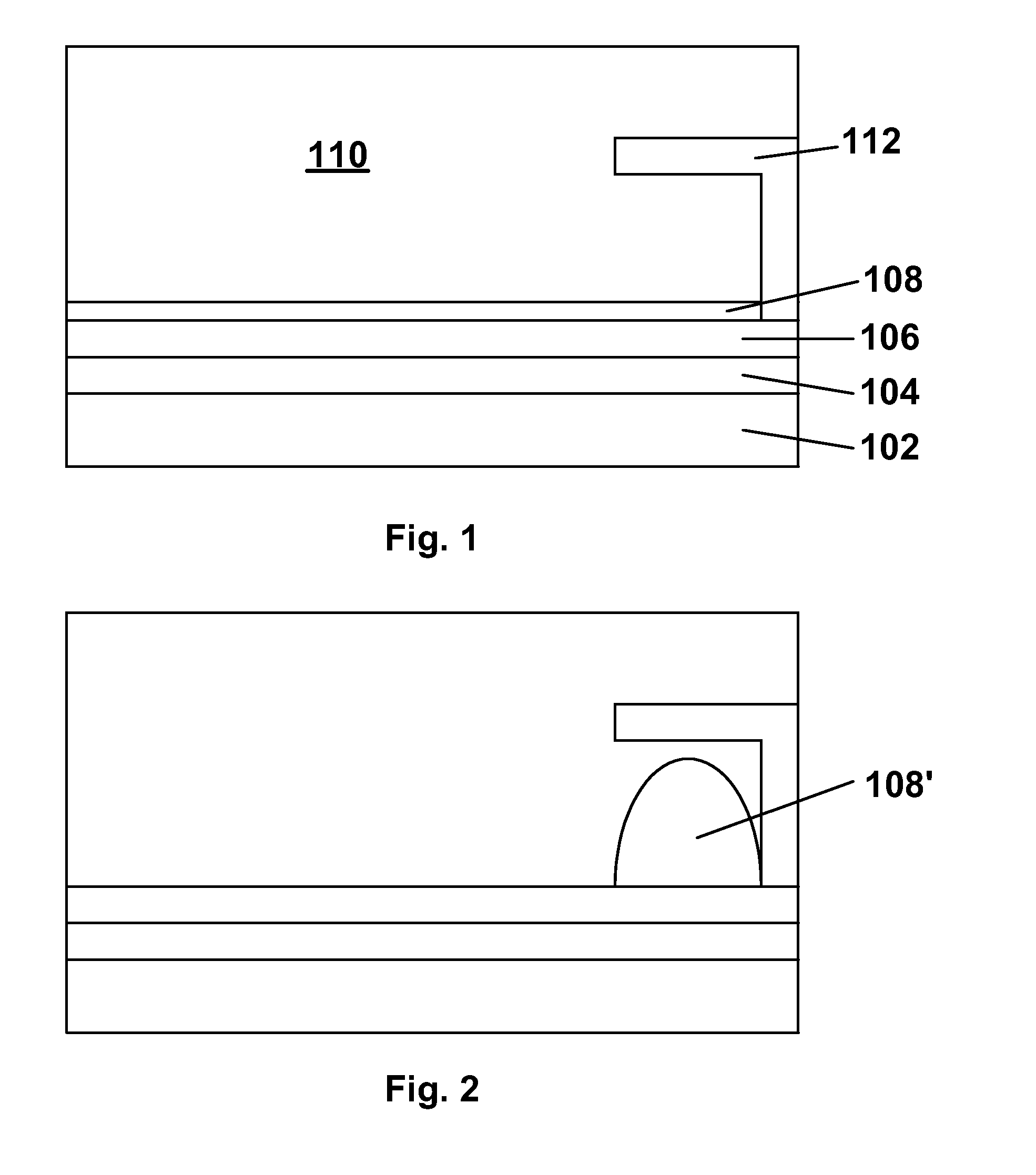

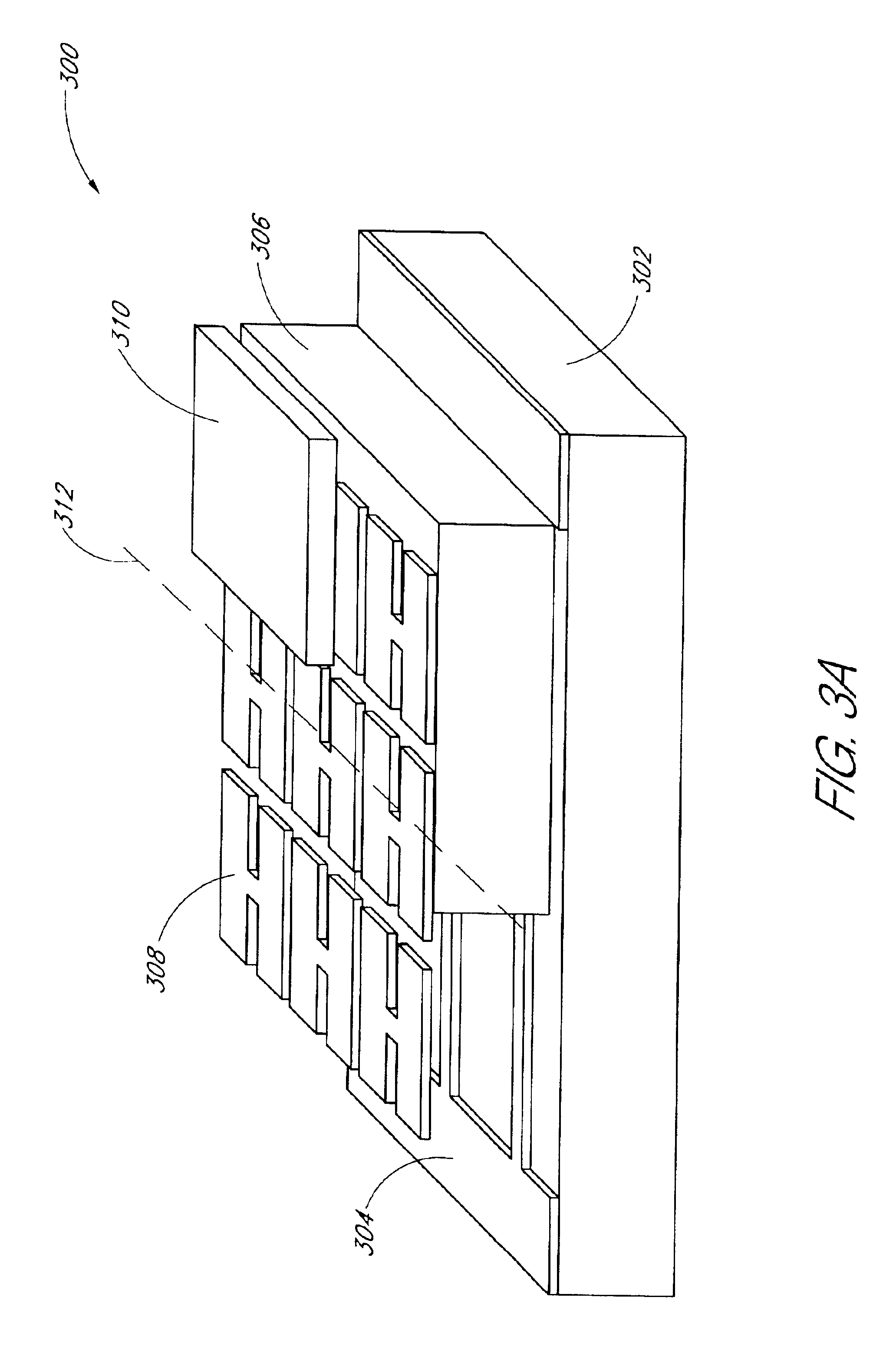

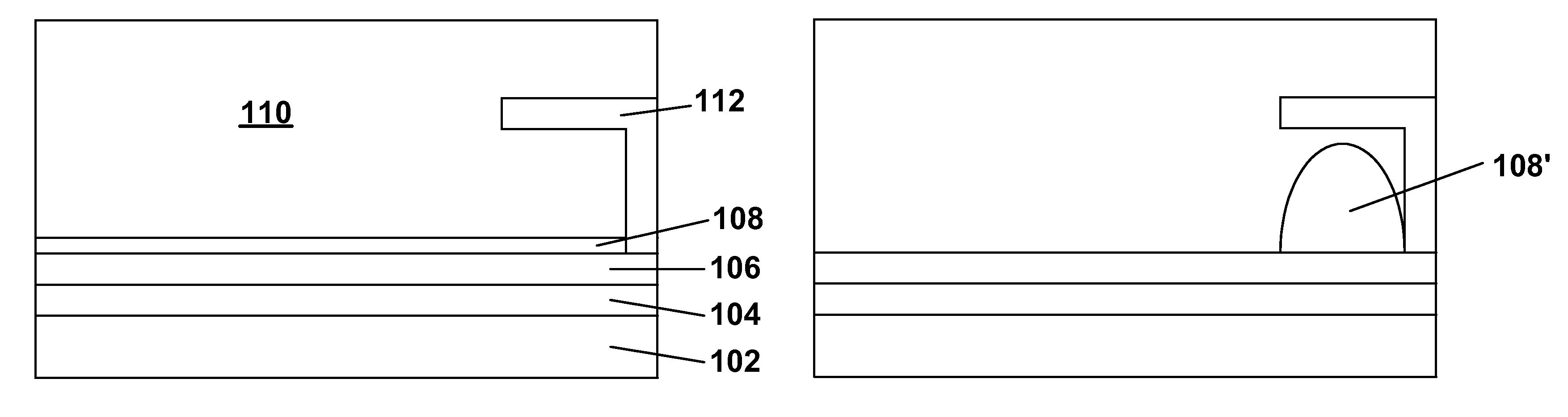

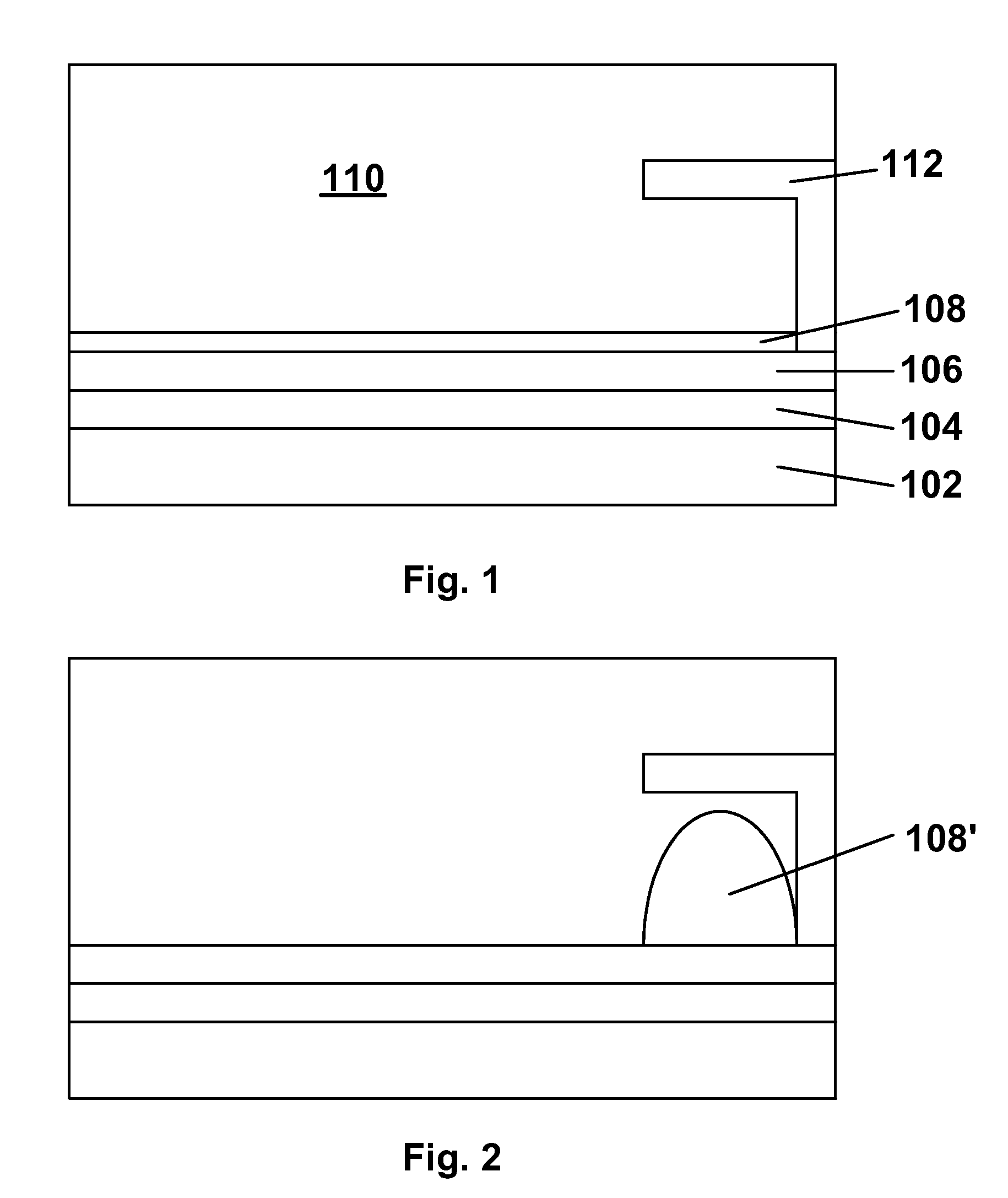

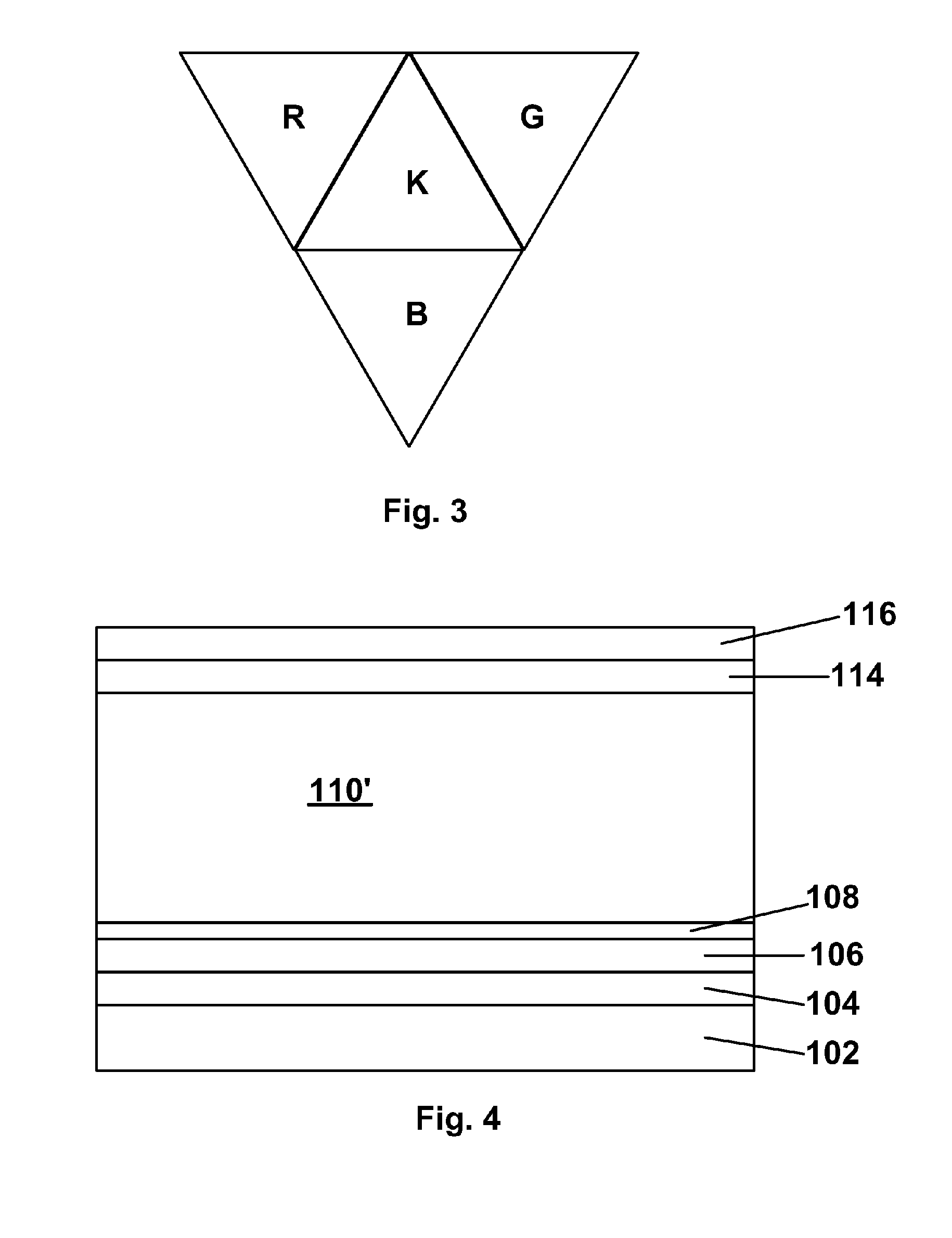

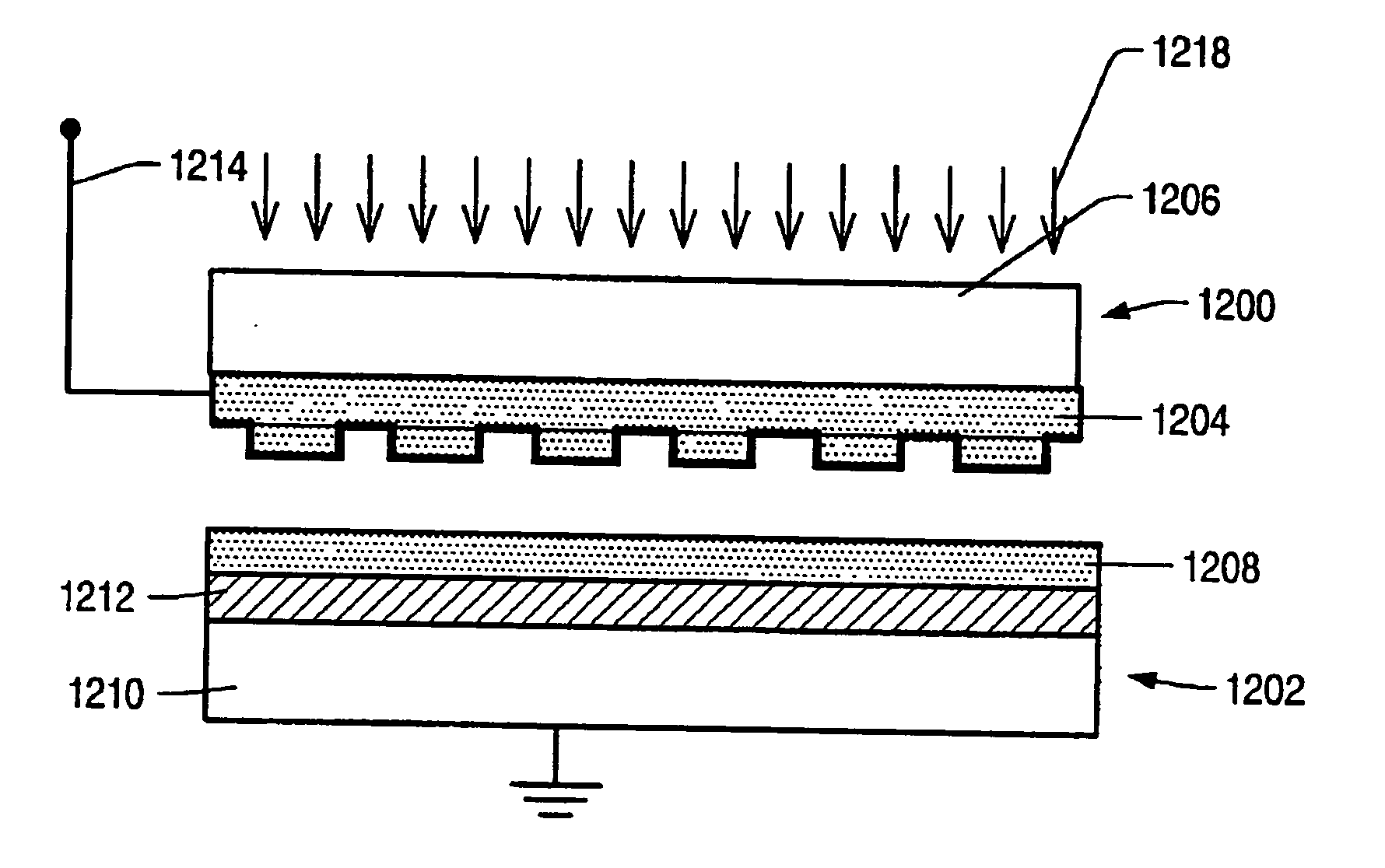

Electro-wetting displays

The performance of electro-wetting displays can be improved by: (a) providing a concealment member (112) which conceals the moving fluid (108) when that fluid (108) is confined to a small area; (b) using the moving fluid to cover one or more sections of a filter or reflector having differently-colored sections; (c) moving the moving fluid between the rear surface and a side surface of a microcell; (d) using as a substrate for a moving fluid a substrate resistant to wetting by the fluid but pierced by multiple conductive vias capped with a material wetted by the fluid; and (e) coloring the moving fluid with pigments or nanoparticles.

Owner:E INK CORPORATION

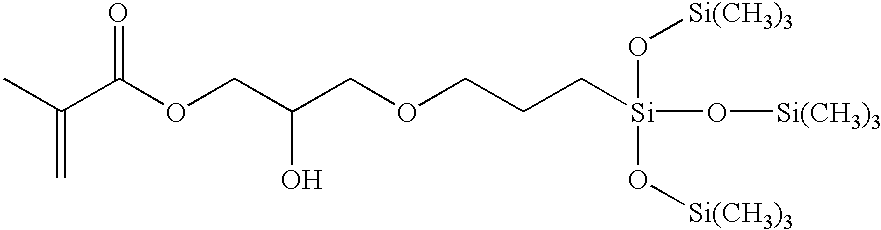

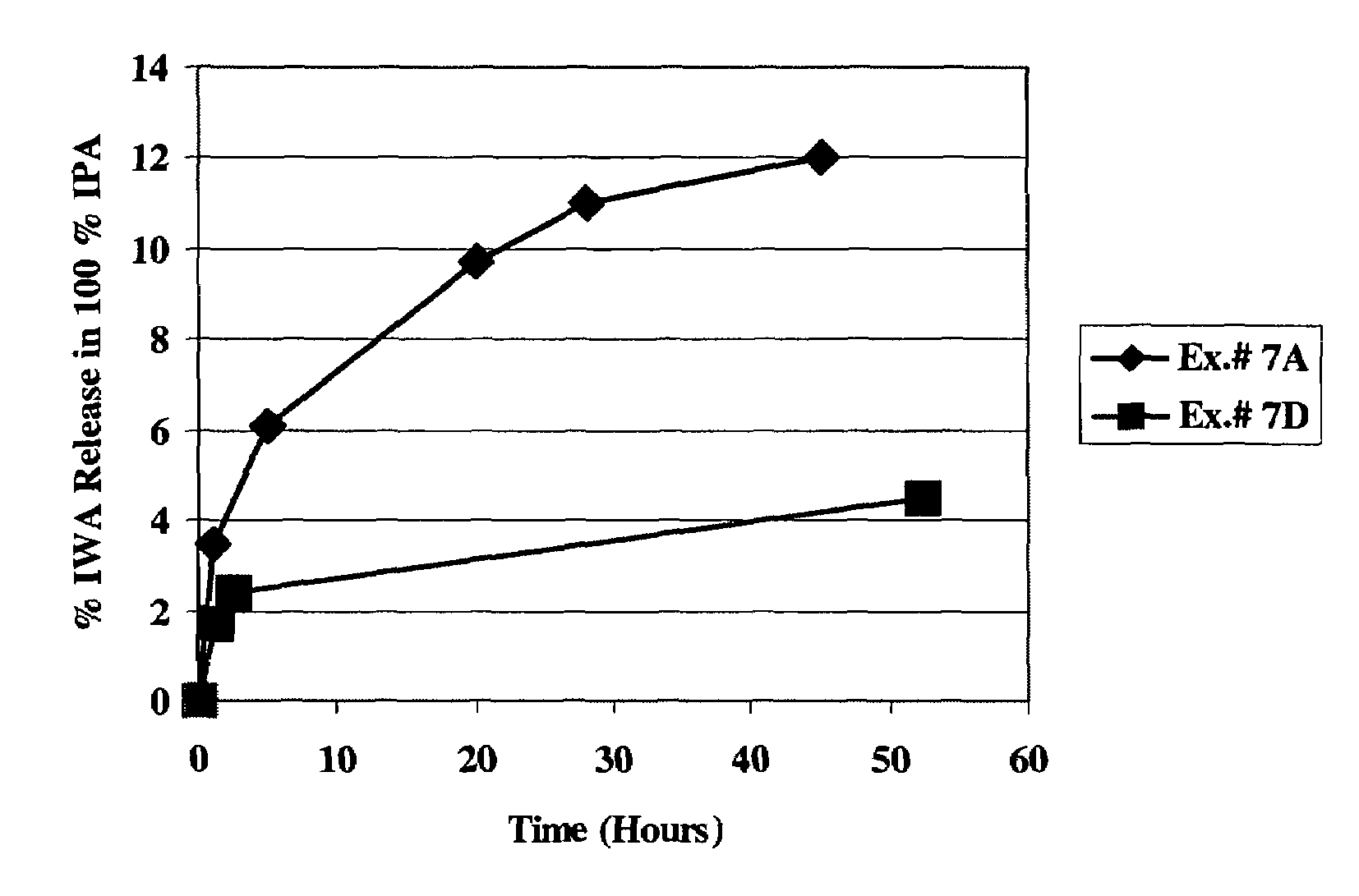

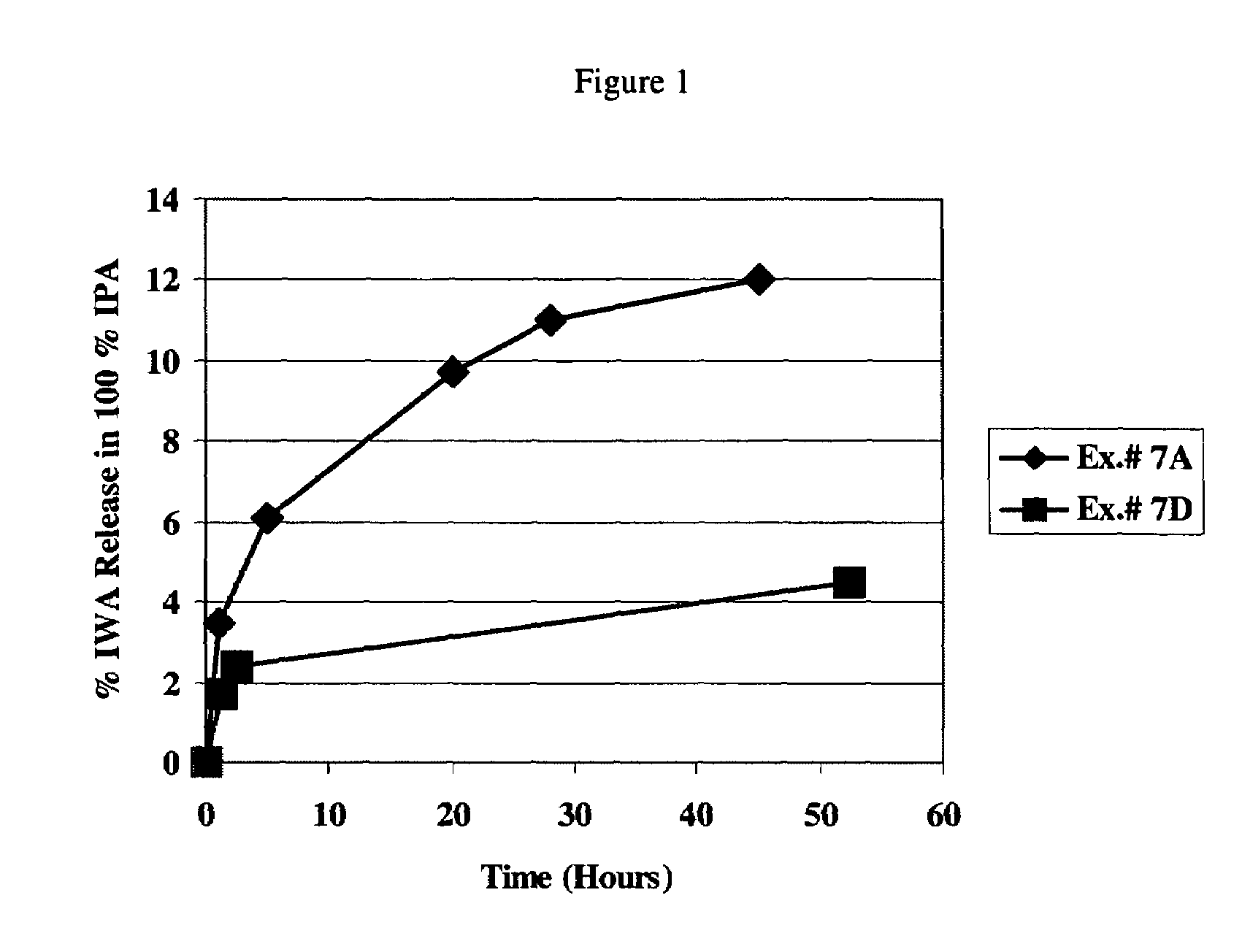

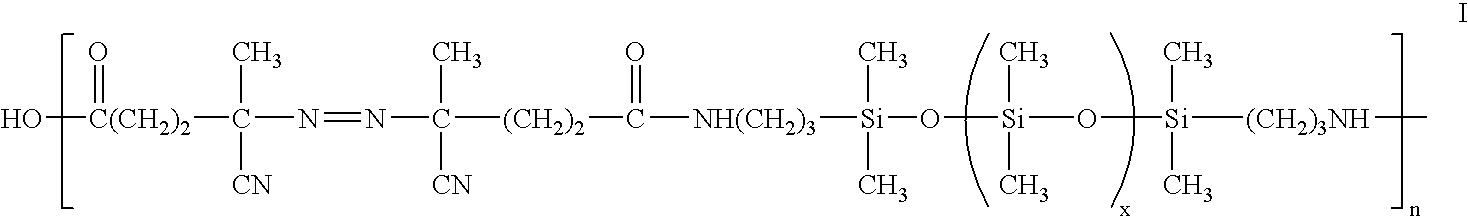

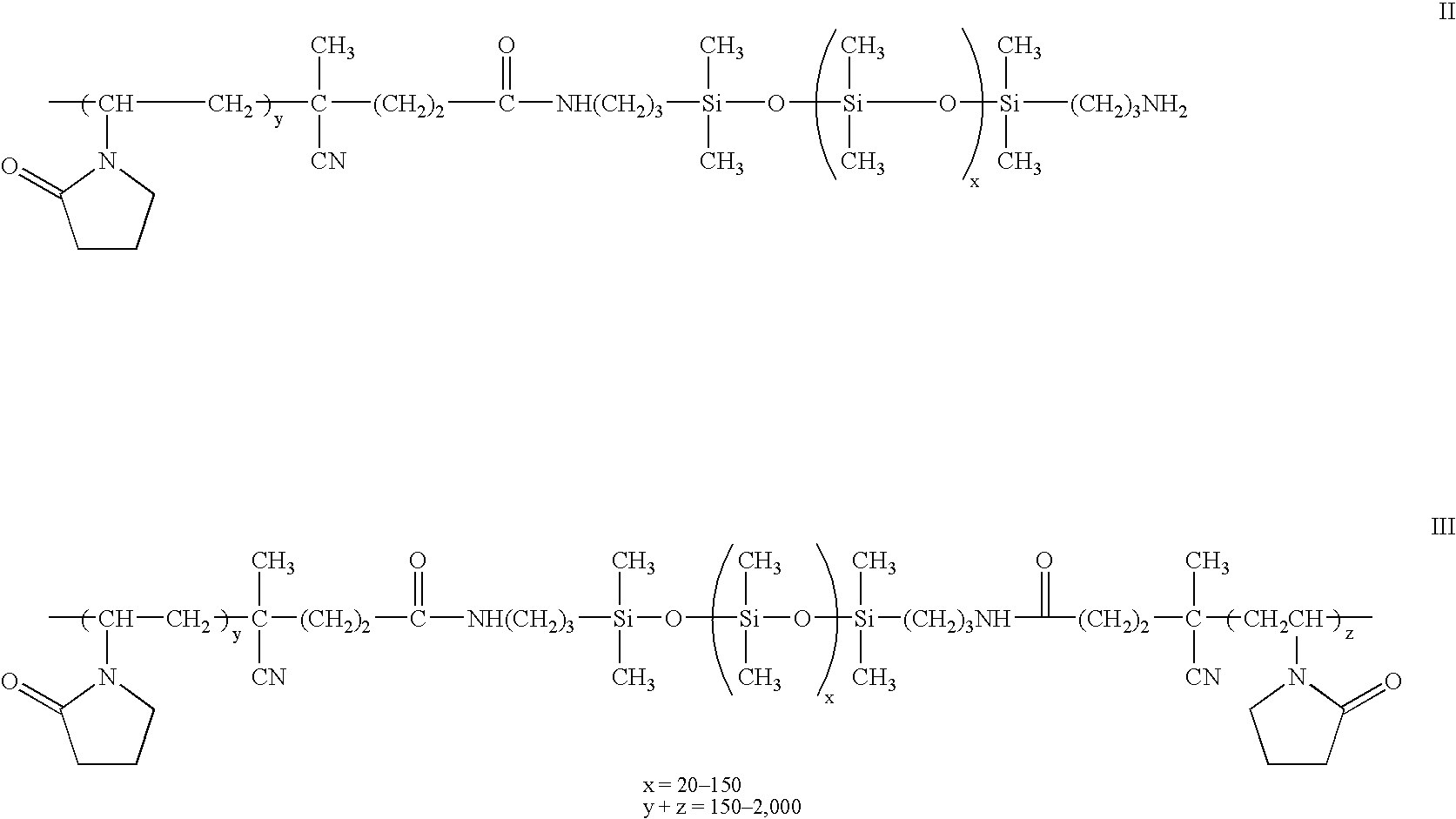

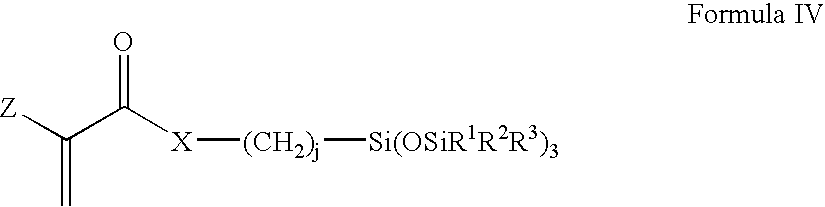

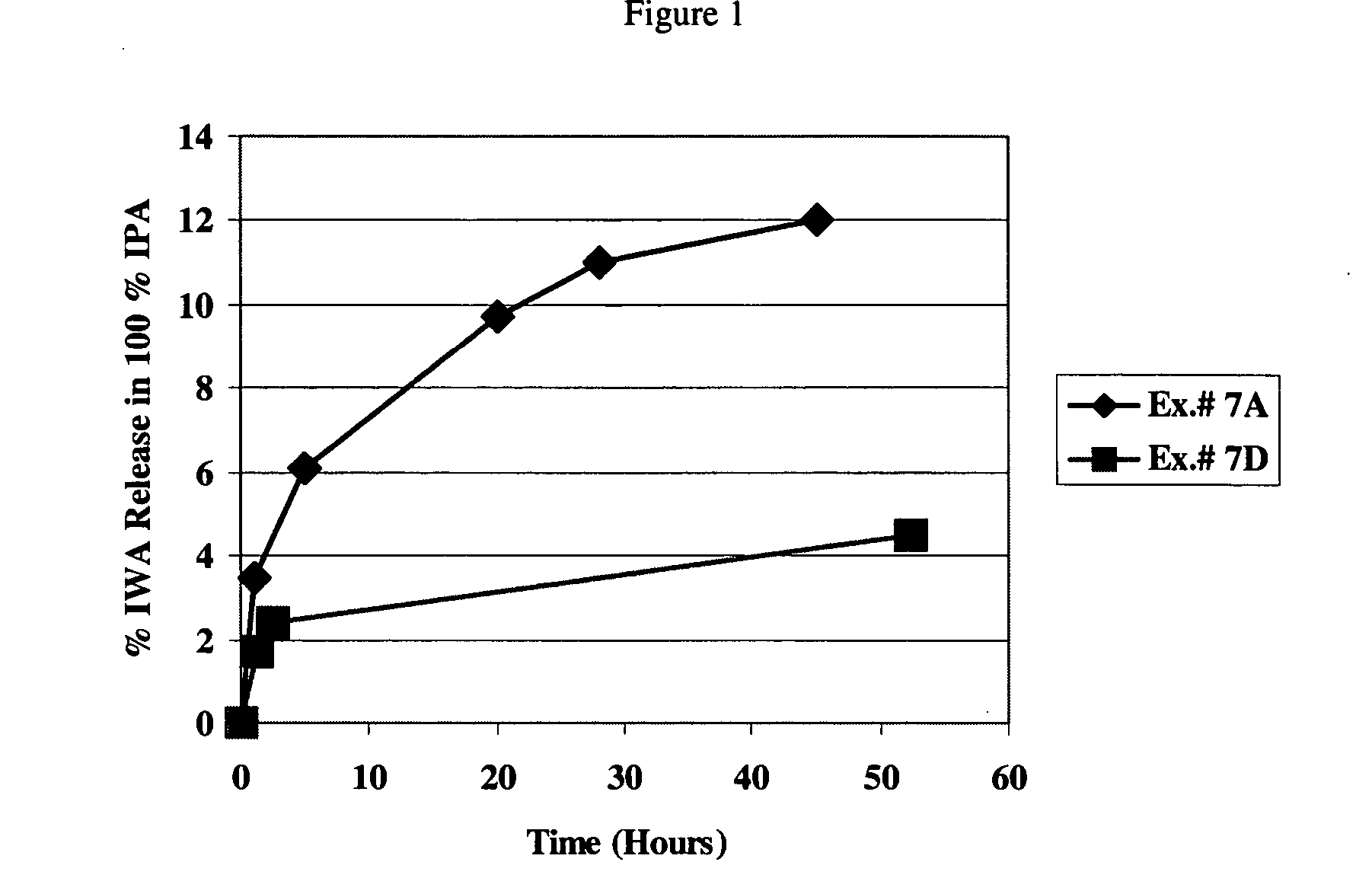

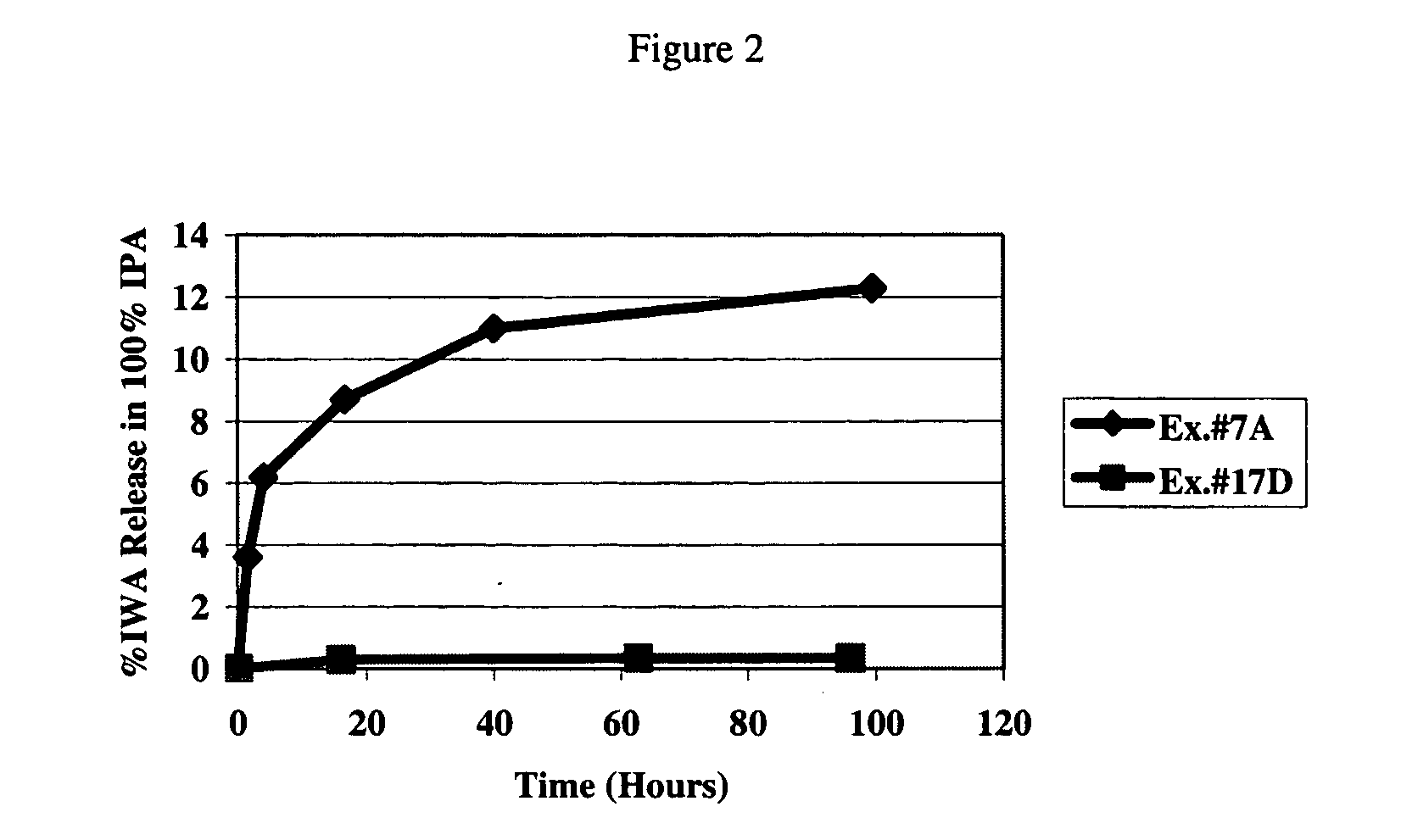

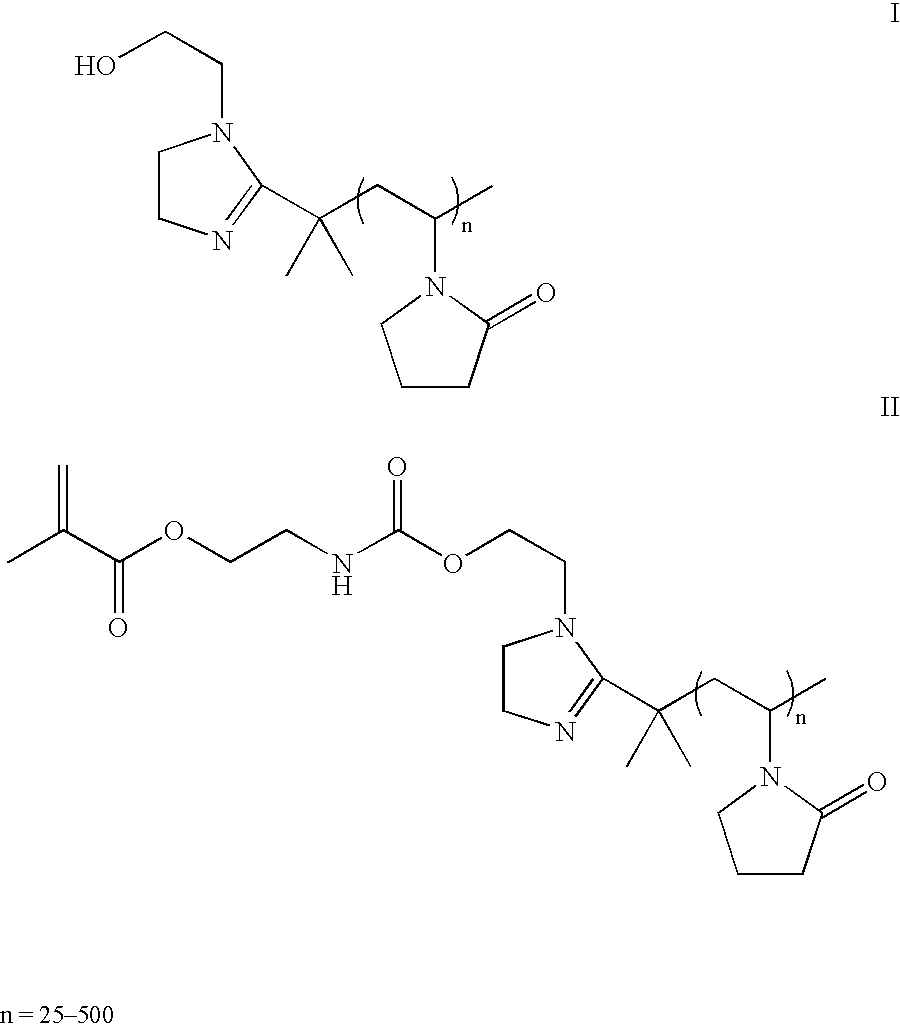

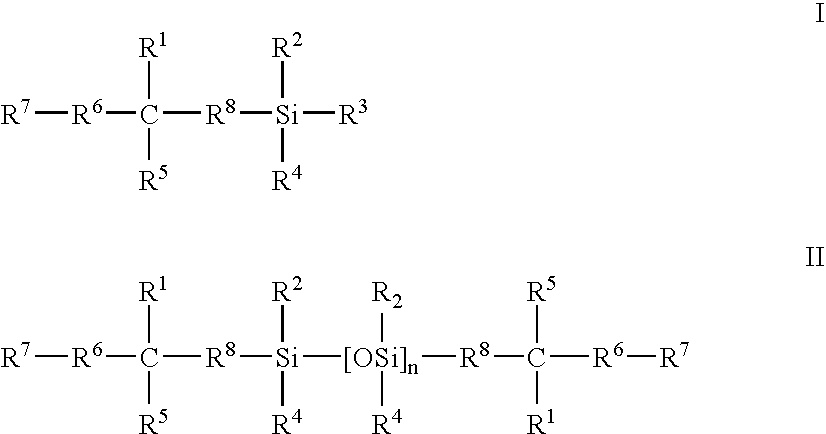

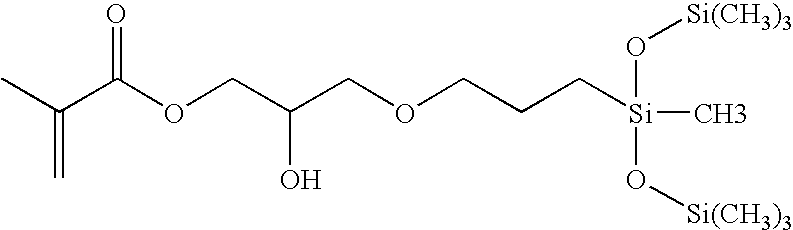

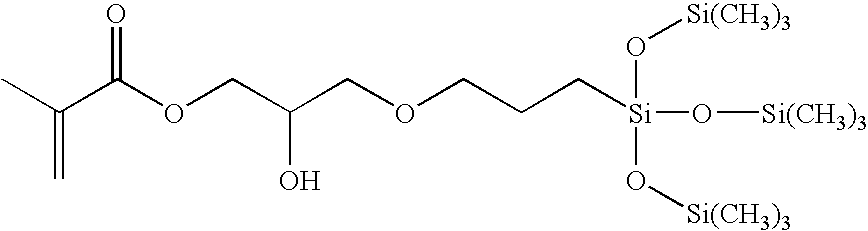

Wettable hydrogels comprising reactive, hydrophilic, polymeric internal wetting agents

The present invention relates to wettable silicone hydrogels comprising the reaction product of at least one siloxane containing component and at least one reactive, hydrophilic polymeric internal wetting agent. The present invention further relates to silicone hydrogel contact lenses comprising at least one oxygen permeable component, and an amount of reactive, hydrophilic polymeric internal wetting agent sufficient to impart wettability to said device.

Owner:JOHNSON & JOHNSON VISION CARE INC

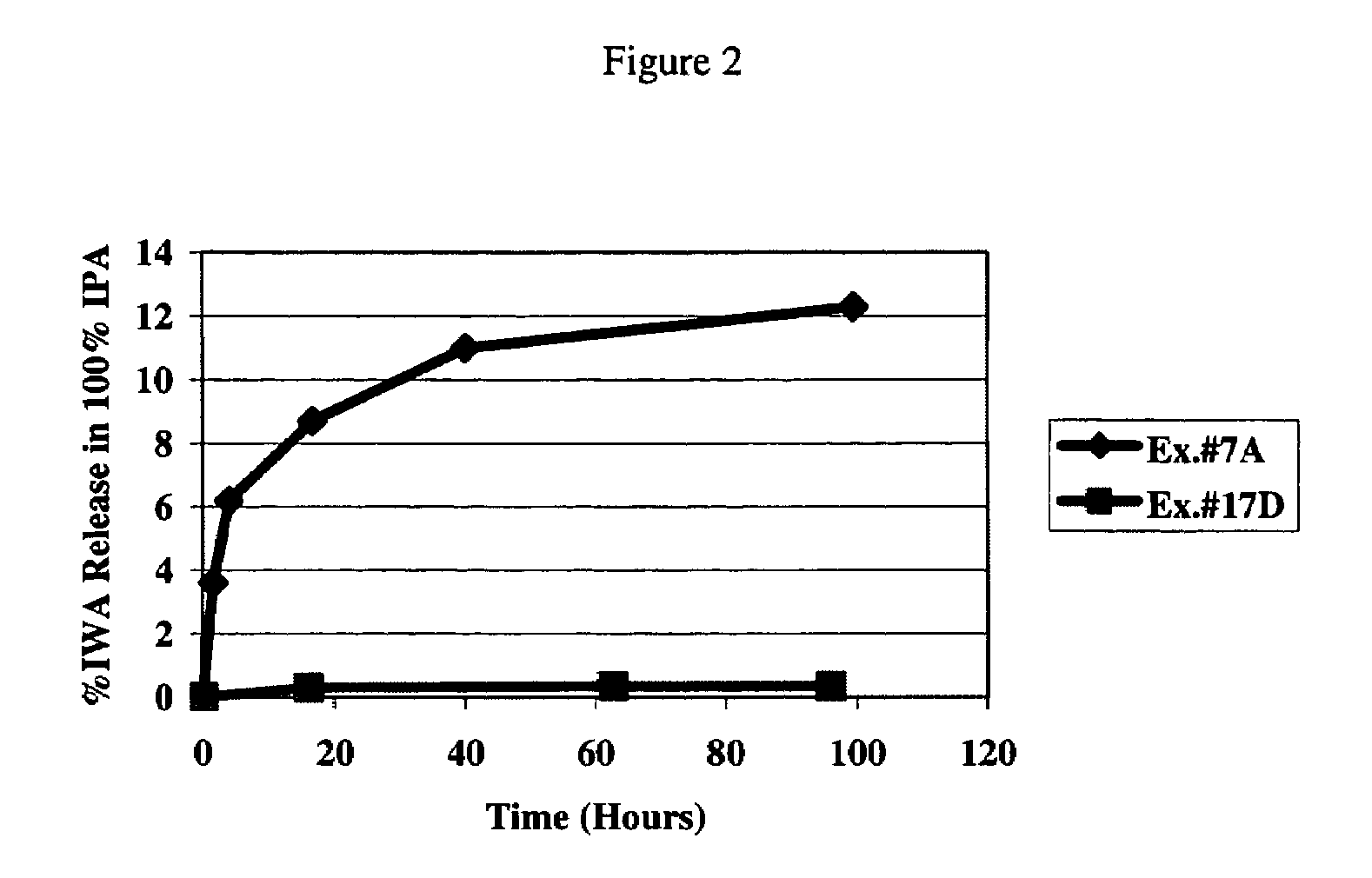

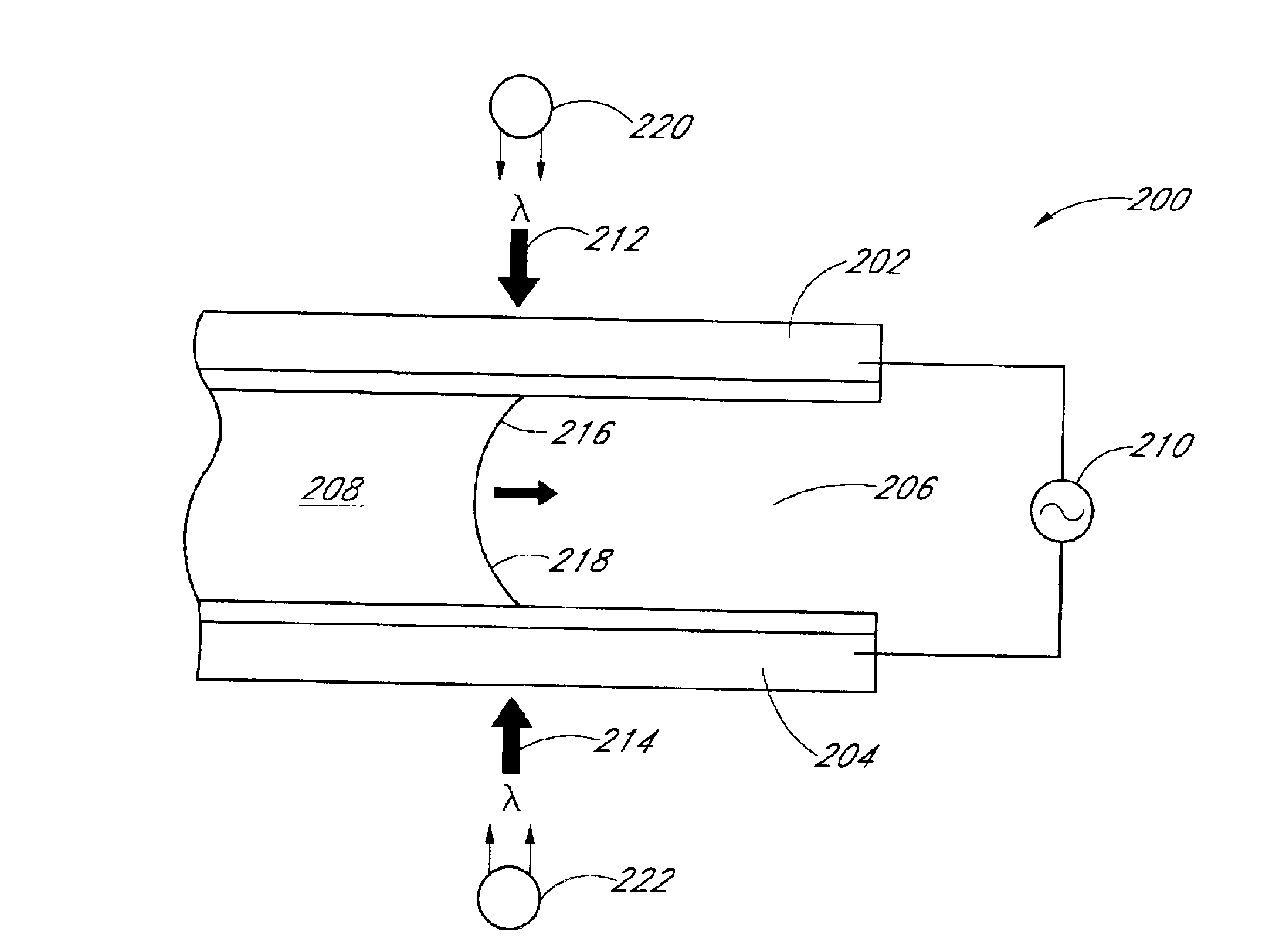

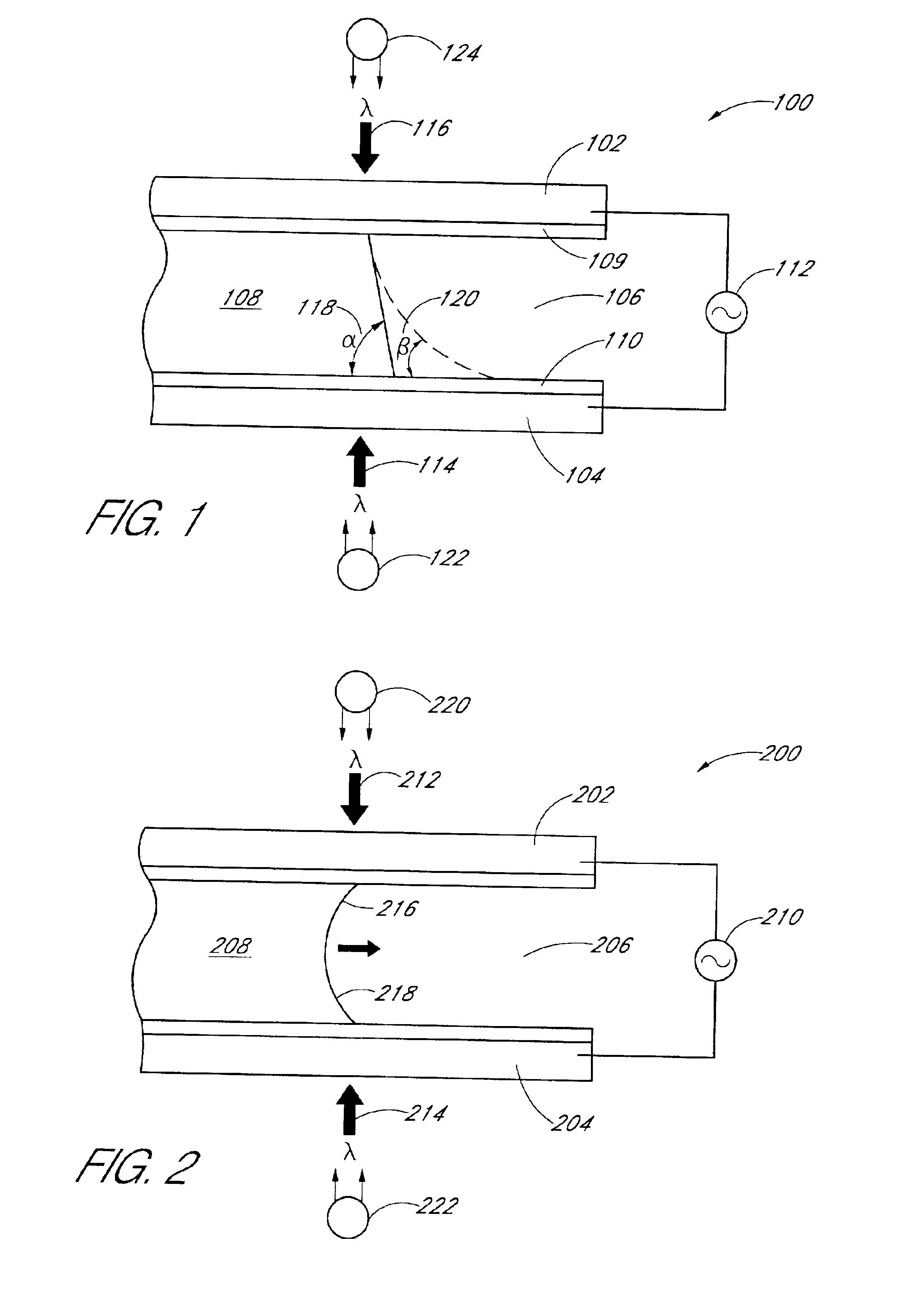

Systems and methods for optical actuation of microfluidics based on opto-electrowetting

InactiveUS6958132B2Improve performanceSludge treatmentMaterial analysis by electric/magnetic meansElectricityMicrofluidics

Owner:RGT UNIV OF CALIFORNIA

Electrowetting displays

ActiveUS8319759B2Cathode-ray tube indicatorsInput/output processes for data processingNanoparticleDisplay device

The performance of electro-wetting displays can be improved by: (a) providing a concealment member (112) which conceals the moving fluid (108) when that fluid (108) is confined to a small area; (b) using the moving fluid to cover one or more sections of a filter or reflector having differently-colored sections; (c) moving the moving fluid between the rear surface and a side surface of a microcell; (d) using as a substrate for a moving fluid a substrate resistant to wetting by the fluid but pierced by multiple conductive vias capped with a material wetted by the fluid; and (e) coloring the moving fluid with pigments or nanoparticles.

Owner:E INK CORPORATION

Biomedical devices containing amphiphilic block copolymers

This invention relates to wettable biomedical devices comprising amphiphilic block copolymers. The amphiphilic block copolymers are useful as internal wetting agents for biomedical applications, such as implantable devices, ophthalmic devices and in one embodiment, contact lenses.

Owner:JOHNSON & JOHNSON VISION CARE INC

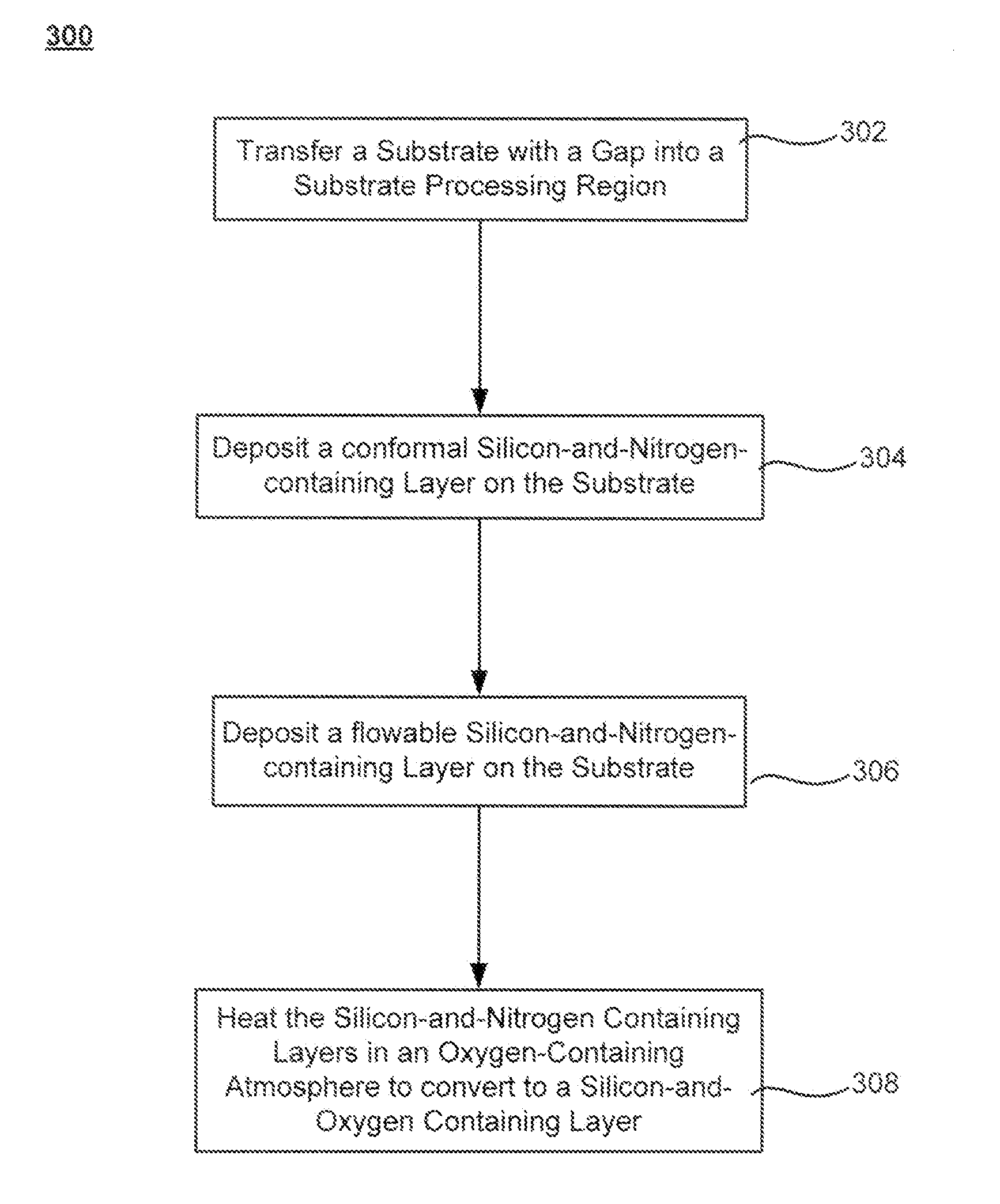

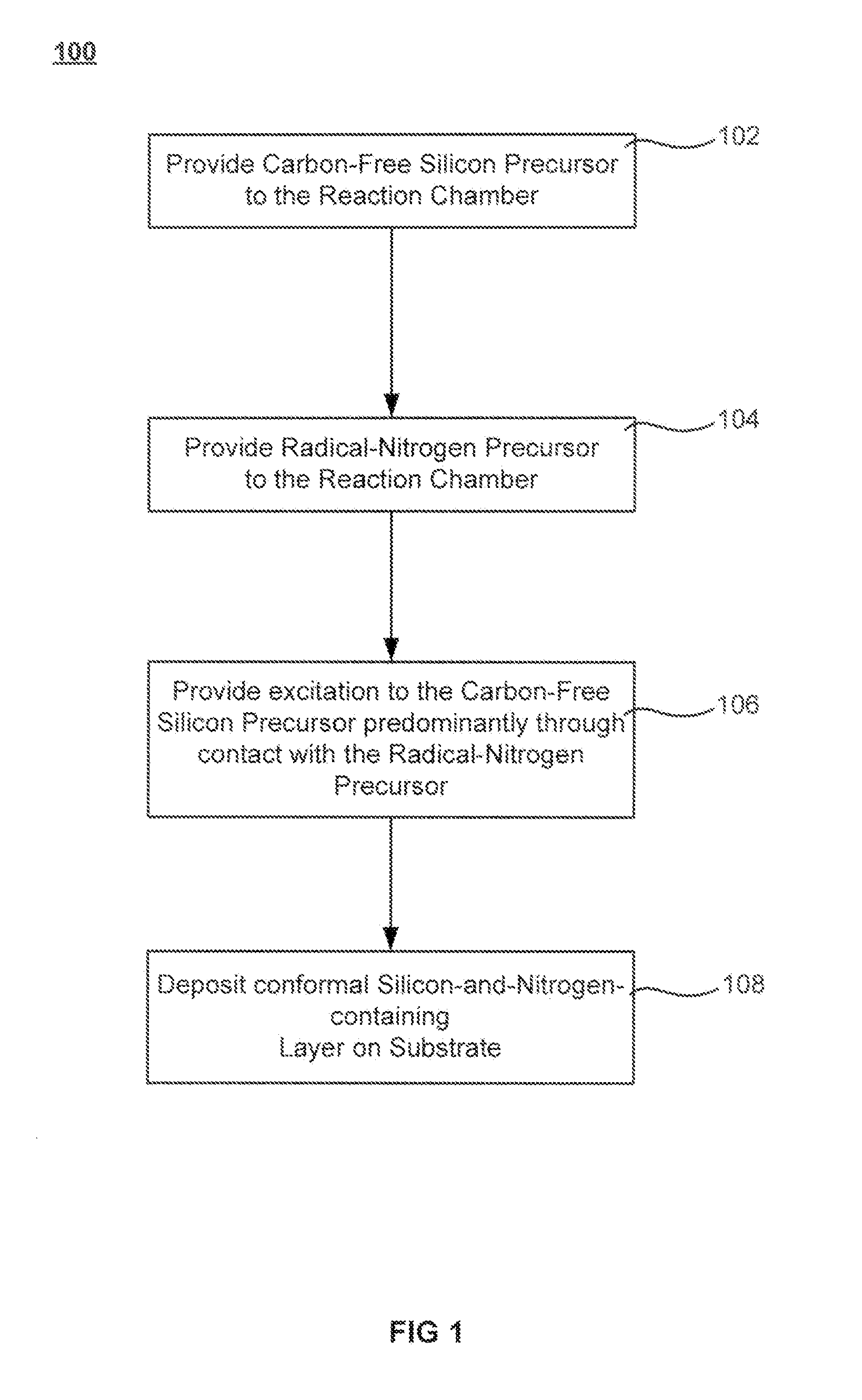

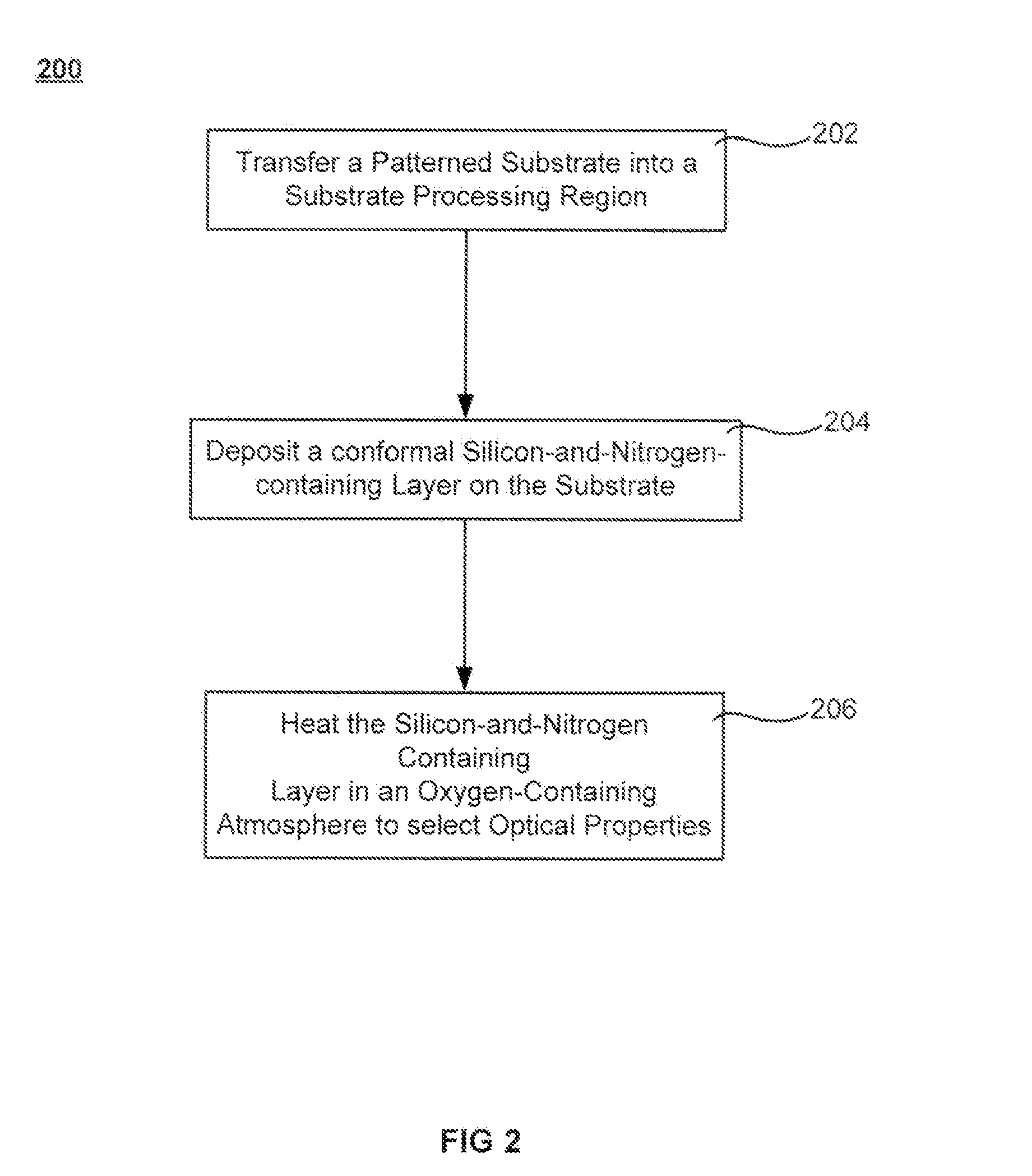

Conformal layers by radical-component CVD

ActiveUS20110217851A1Less volume shrinkageImprove wettabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptical propertyHydrogen

Methods, materials, and systems are described for forming conformal dielectric layers containing silicon and nitrogen (e.g., a silicon-nitrogen-hydrogen (Si—N—H) film) from a carbon-free silicon-and-nitrogen precursor and radical-nitrogen precursor. The carbon-free silicon-and-nitrogen precursor is predominantly excited by contact with the radical-nitrogen precursor. Because the silicon-and-nitrogen film is formed without carbon, the conversion of the film into hardened silicon oxide is done with less pore formation and less volume shrinkage. The deposited silicon-and-nitrogen-containing film may be wholly or partially converted to silicon oxide which allows the optical properties of the conformal dielectric layer to be selectable. The deposition of a thin silicon-and-nitrogen-containing film may be performed at low temperature to form a liner layer in a substrate trench. The low temperature liner layer has been found to improve the wetting properties and allows flowable films to more completely fill the trench.

Owner:APPLIED MATERIALS INC

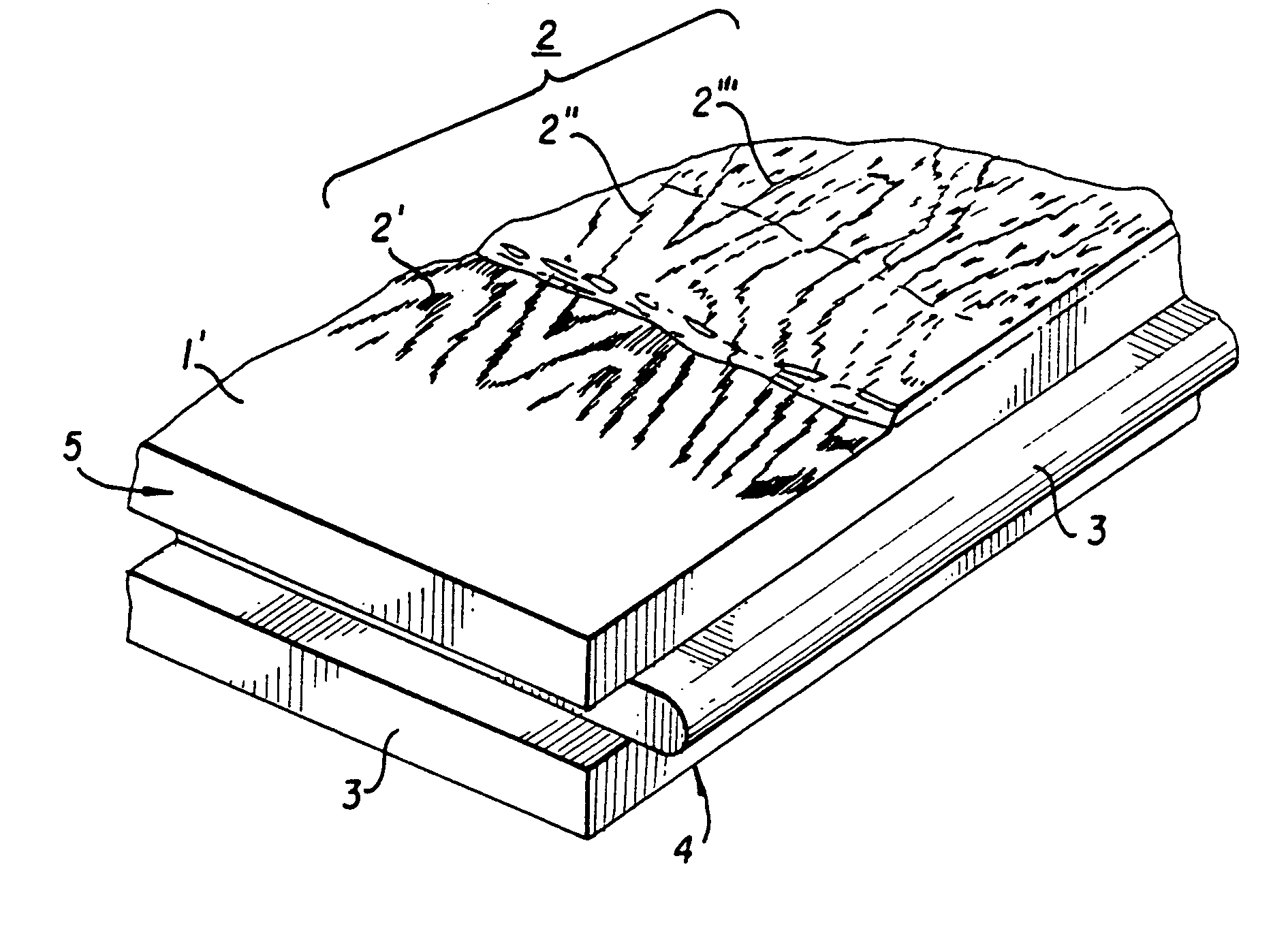

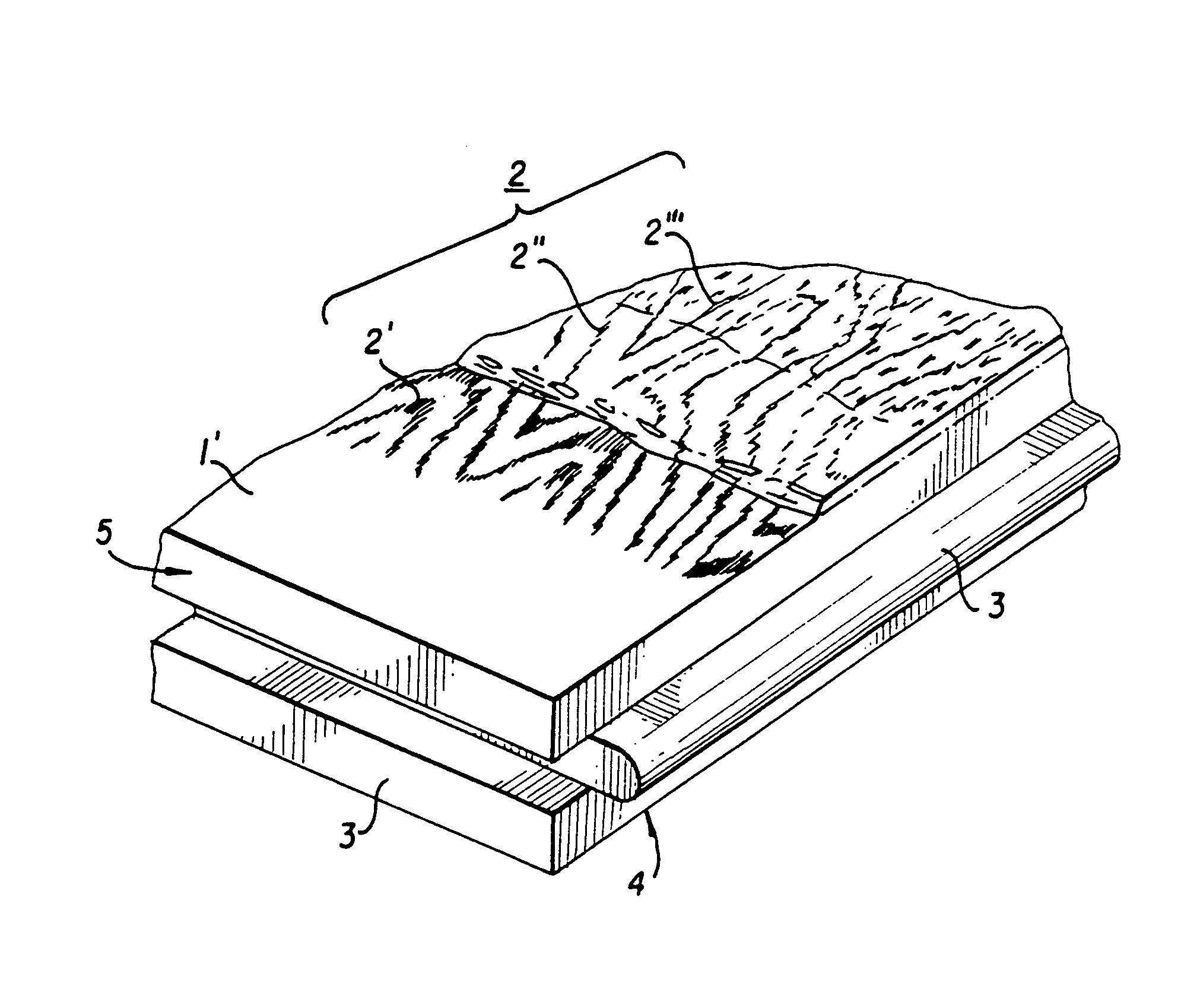

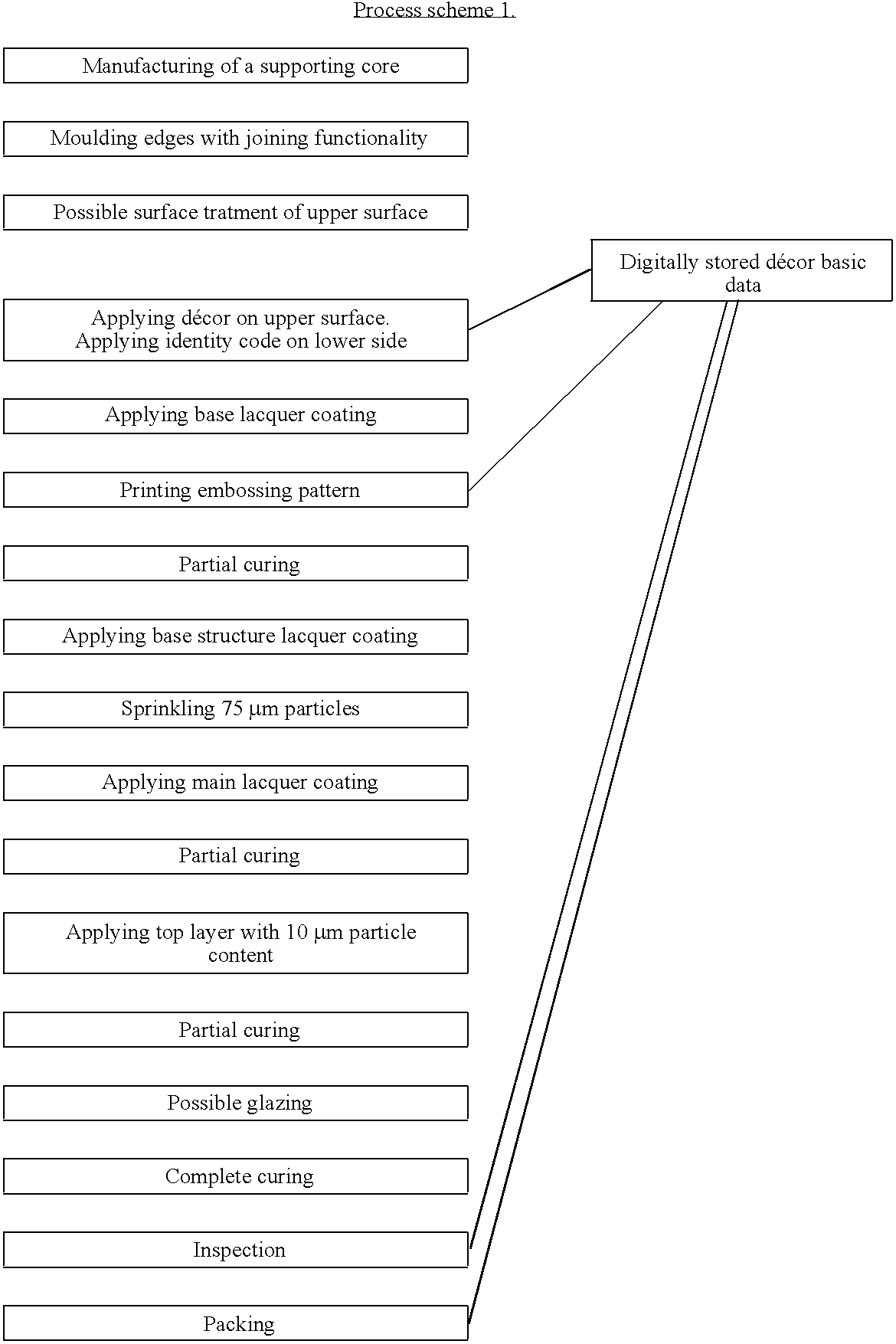

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

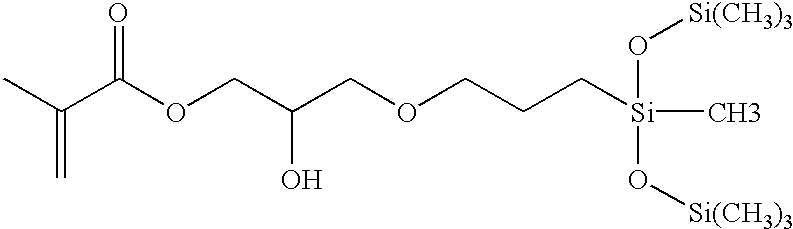

Wettable hydrogels comprising reactive, hydrophilic, polymeric internal wetting agents

The present invention relates to wettable silicone hydrogels comprising the reaction product of at least one siloxane containing component and at least one reactive, hydrophilic polymeric internal wetting agent. The present invention further relates to silicone hydrogel contact lenses comprising at least one oxygen permeable component, and an amount of reactive, hydrophilic polymeric internal wetting agent sufficient to impart wettability to said device.

Owner:JOHNSON & JOHNSON VISION CARE INC

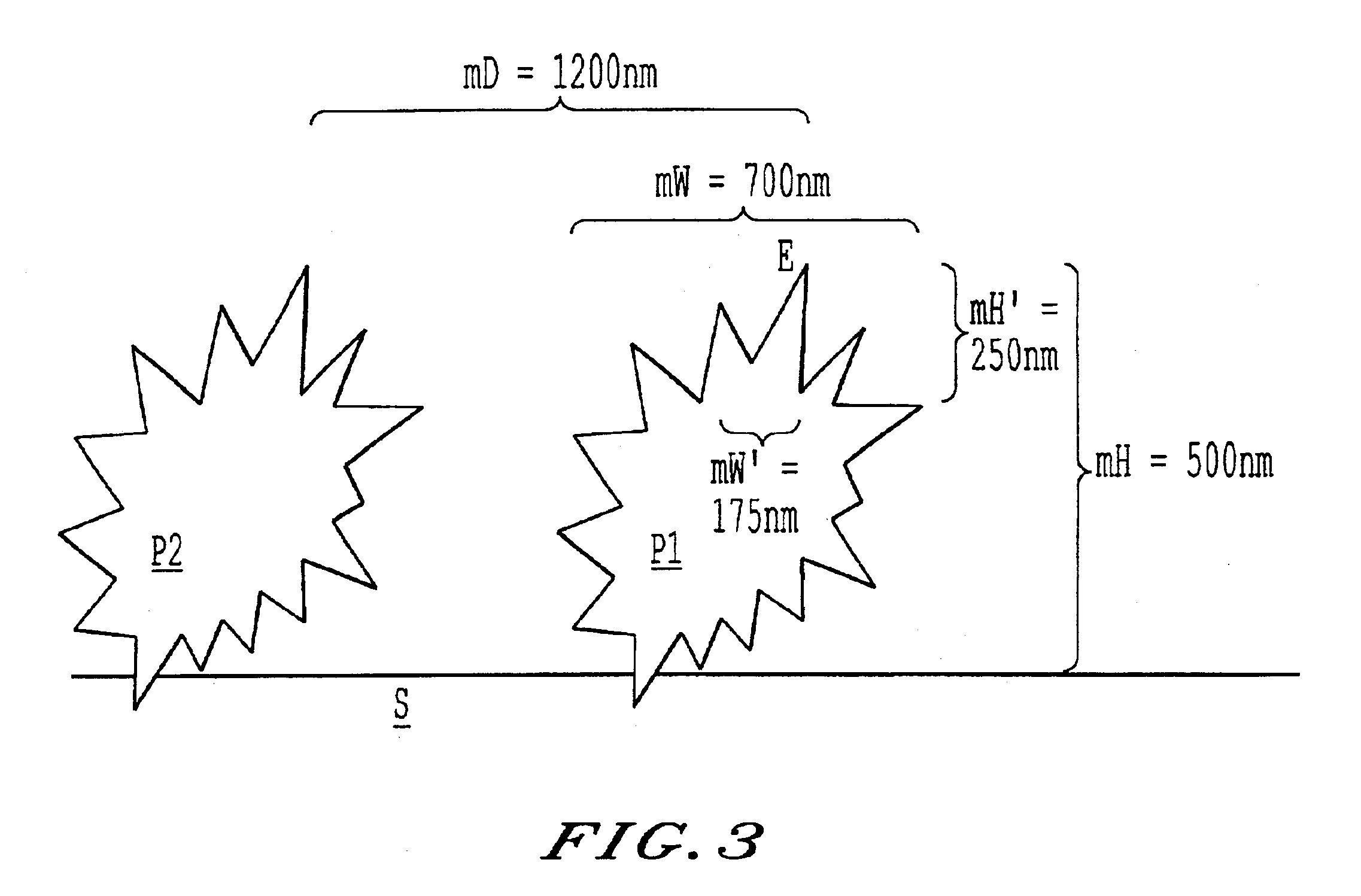

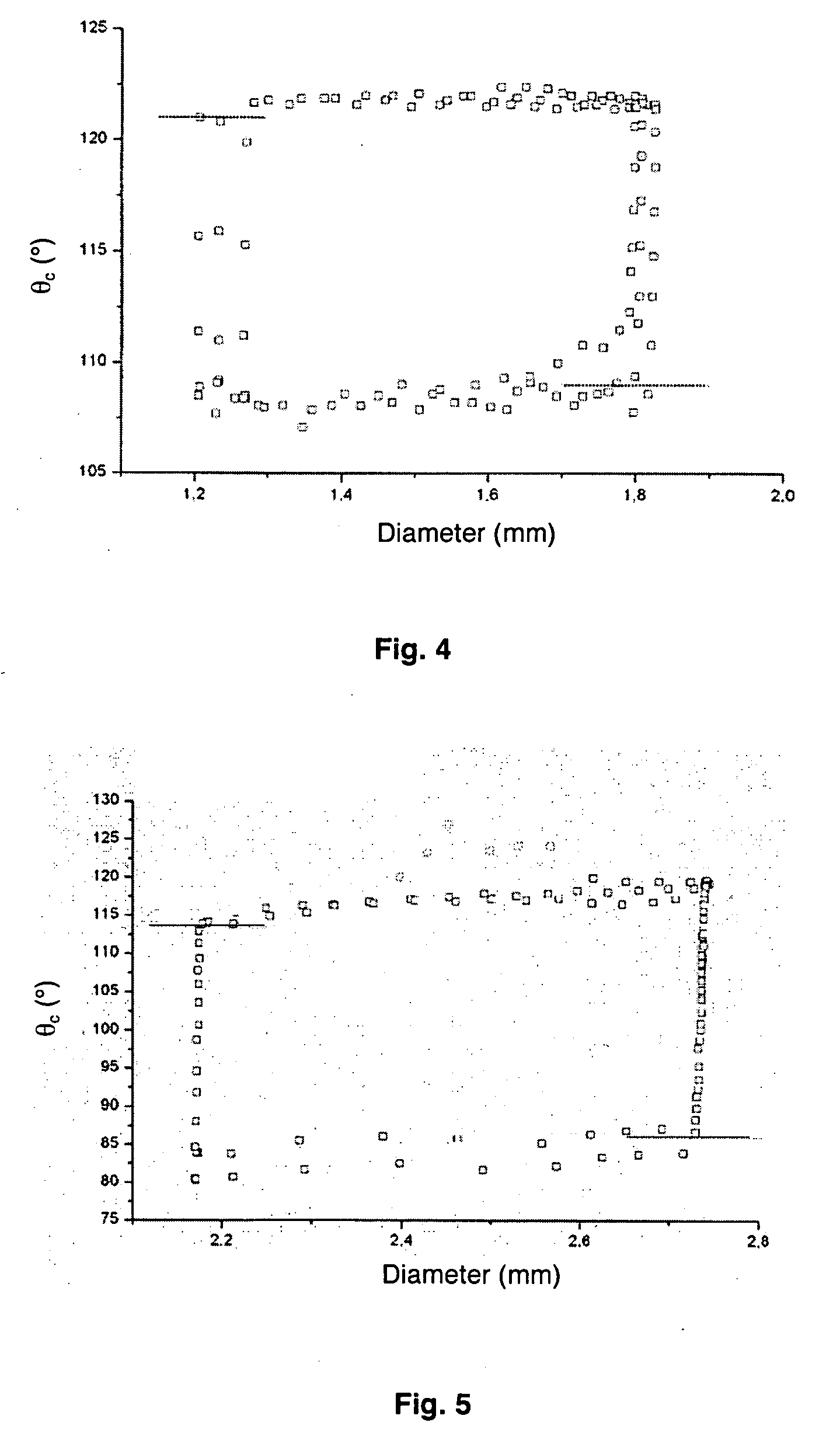

Formation of discontinuous films during an imprint lithography process

The present invention is directed to a template having a body including a surface with first and second regions. The first region has first wetting characteristics for a given material and the second region has second wetting characteristics for the given material. The first wetting characteristics differ from the second wetting characteristics. Specifically, the first region is formed from a surface treatment layer with a first surface energy to provide the first wetting characteristics. The second region is exposed portions of the body, typically quartz of fused silica, having a second surface energy associated therewith. The second surface energy is greater than the first surface energy to provide the second region with the second wetting characteristics.

Owner:CANON KK +1

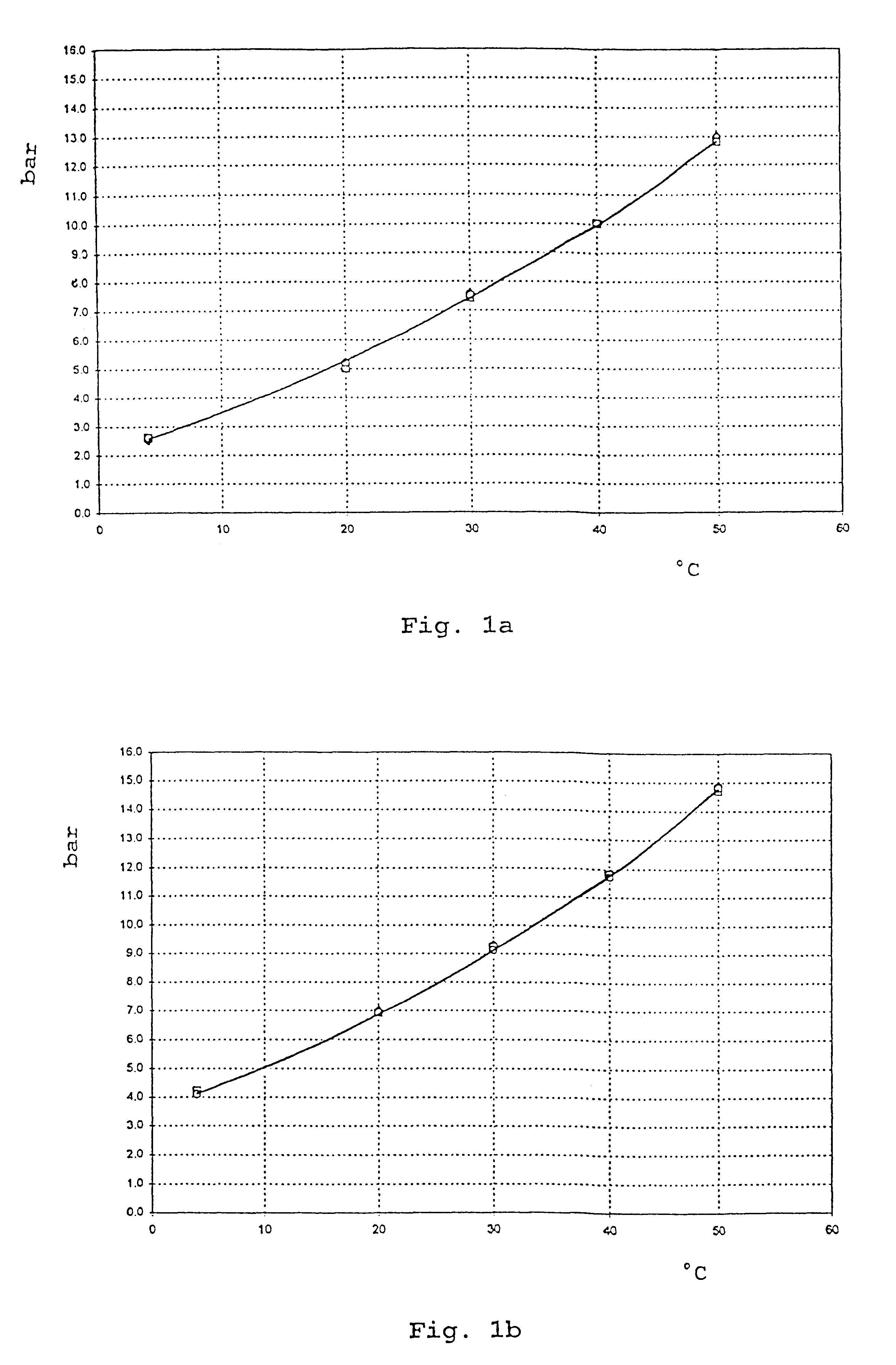

Medical aerosol formulations

InactiveUS6461591B1Improve dosage accuracyIncrease doseBiocideDispersion deliveryAlkaneAerosol spray

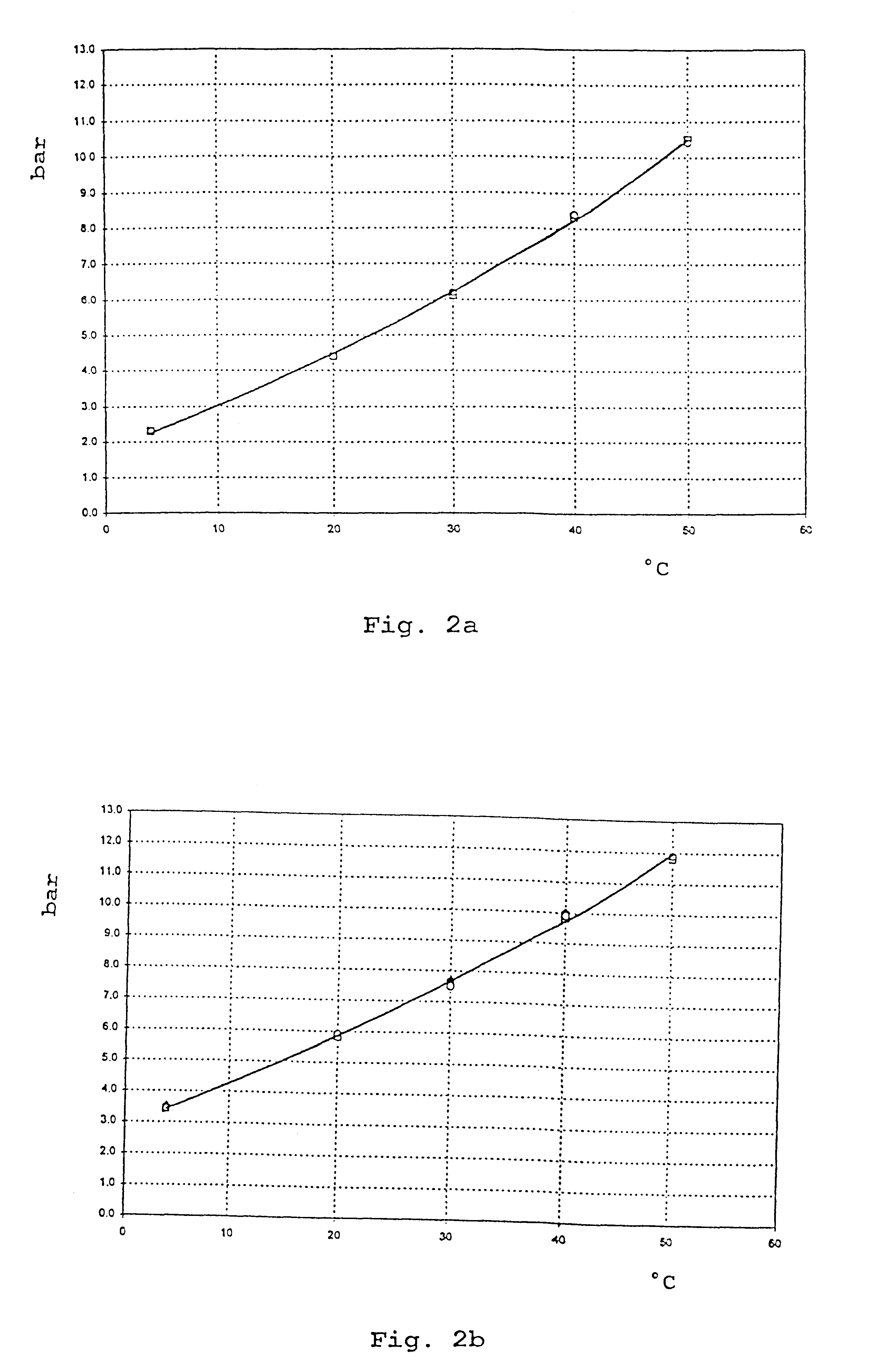

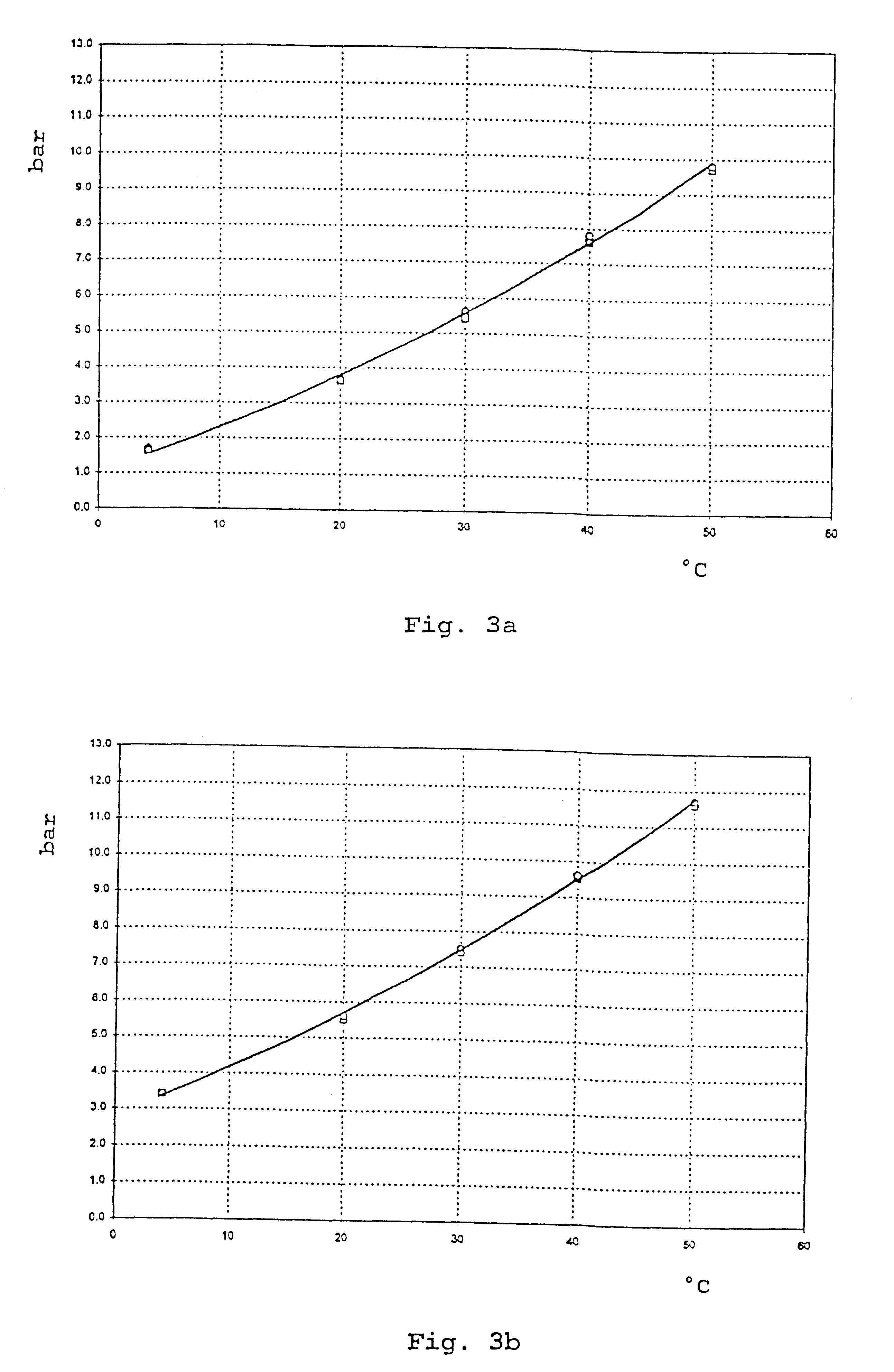

A pressure-liquefied propellant mixture for aerosols, comprising a fluorinated alkane, in particular 1,1,1,2-tetrafluoroethane and / or 1,1,1,2,3,3,3-heptafluoropropane, and carbon dioxide, makes possible an improvement of the wetting properties of pharmaceutically active compounds, with which the formulation problems existing with hydrofluoroalkanes in relation to suspension as well as solution aerosols can be overcome and thus improved medicinal aerosol formulations can be obtained. With the aid of carbon dioxide, it is also possible to specifically influence the pressure and thus the particle size distribution and also by displacement of oxygen from the hydrofluoroalkanes to improve the storage stability of oxidation-sensitive active compounds.

Owner:JAGOTEC AG

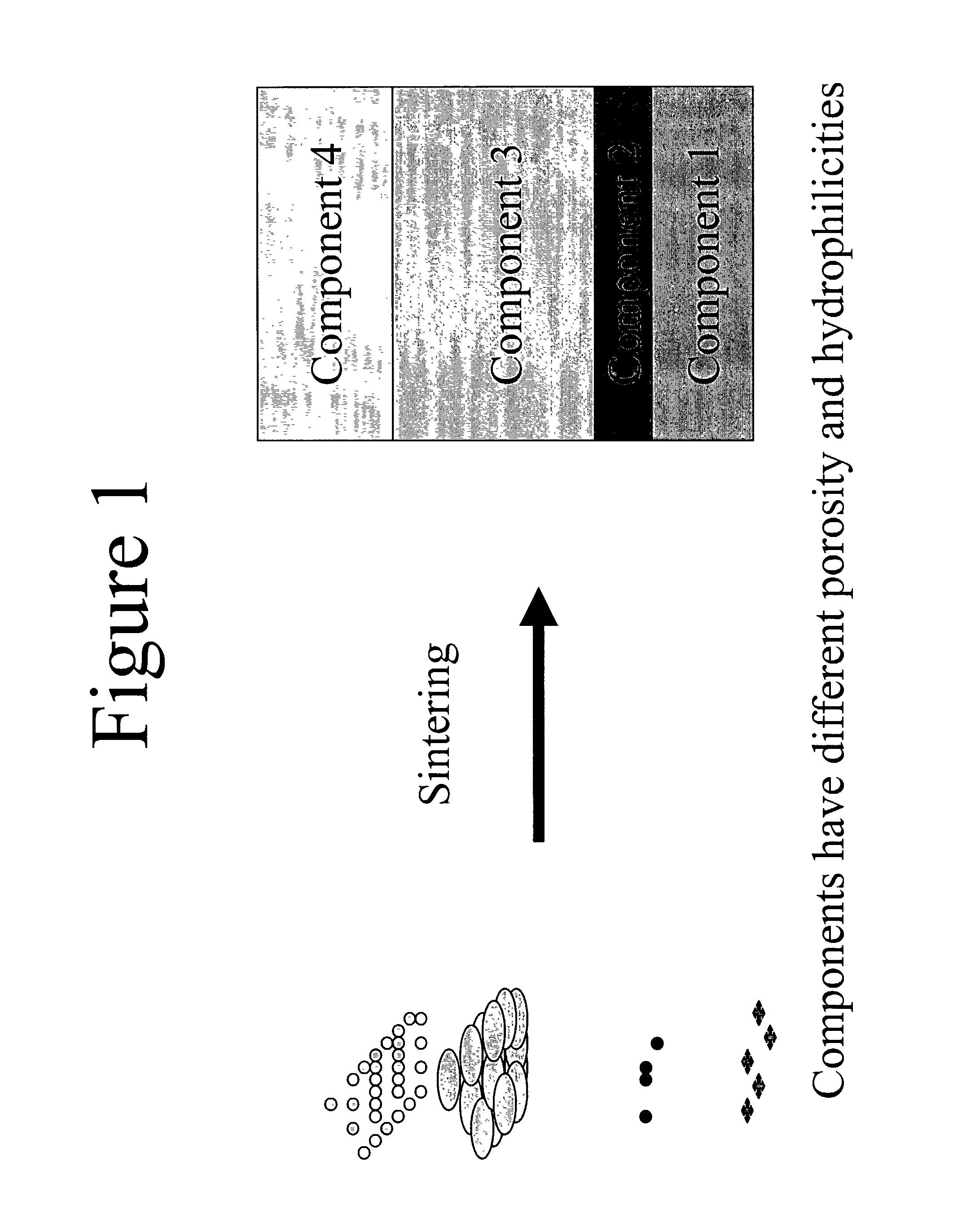

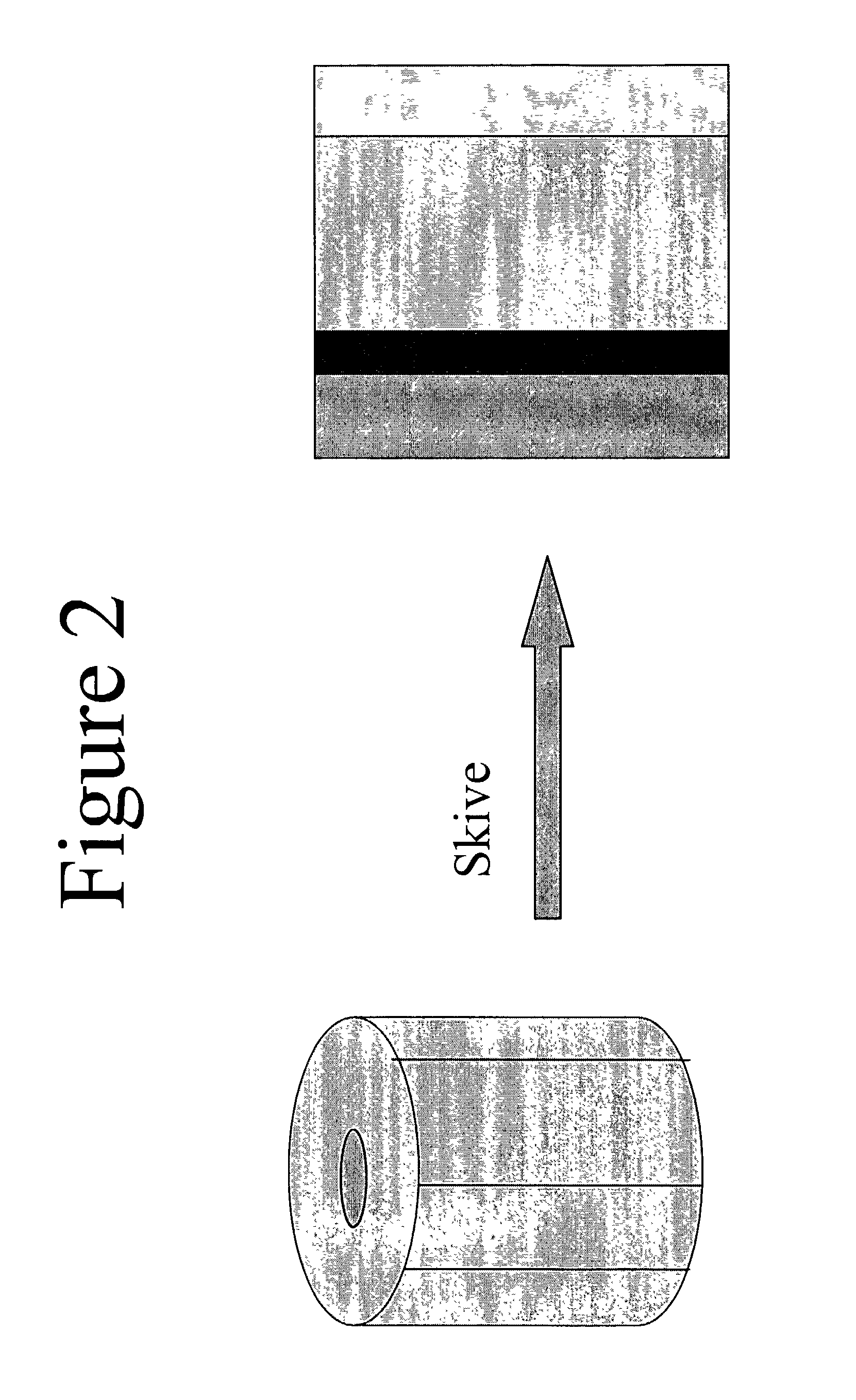

Discrete hydrophilic-hydrophobic porous materials and methods for making the same

This invention relates to porous polymeric materials having discrete regions that exhibit distinct surface properties. The invention also relates to methods of making such porous polymeric materials and their applications. The geography of the discrete regions can be determined in a selective and controlled manner. Porous materials having discrete regions of distinct hydrophilicity, hydrophobicity, oleophobicity, biological molecules binding capability, wetting and wicking property, presence or density of functional groups, chemical reactivity, electric charges, porosity and pore sizes can be manufactured using this invention.

Owner:POREX CORP

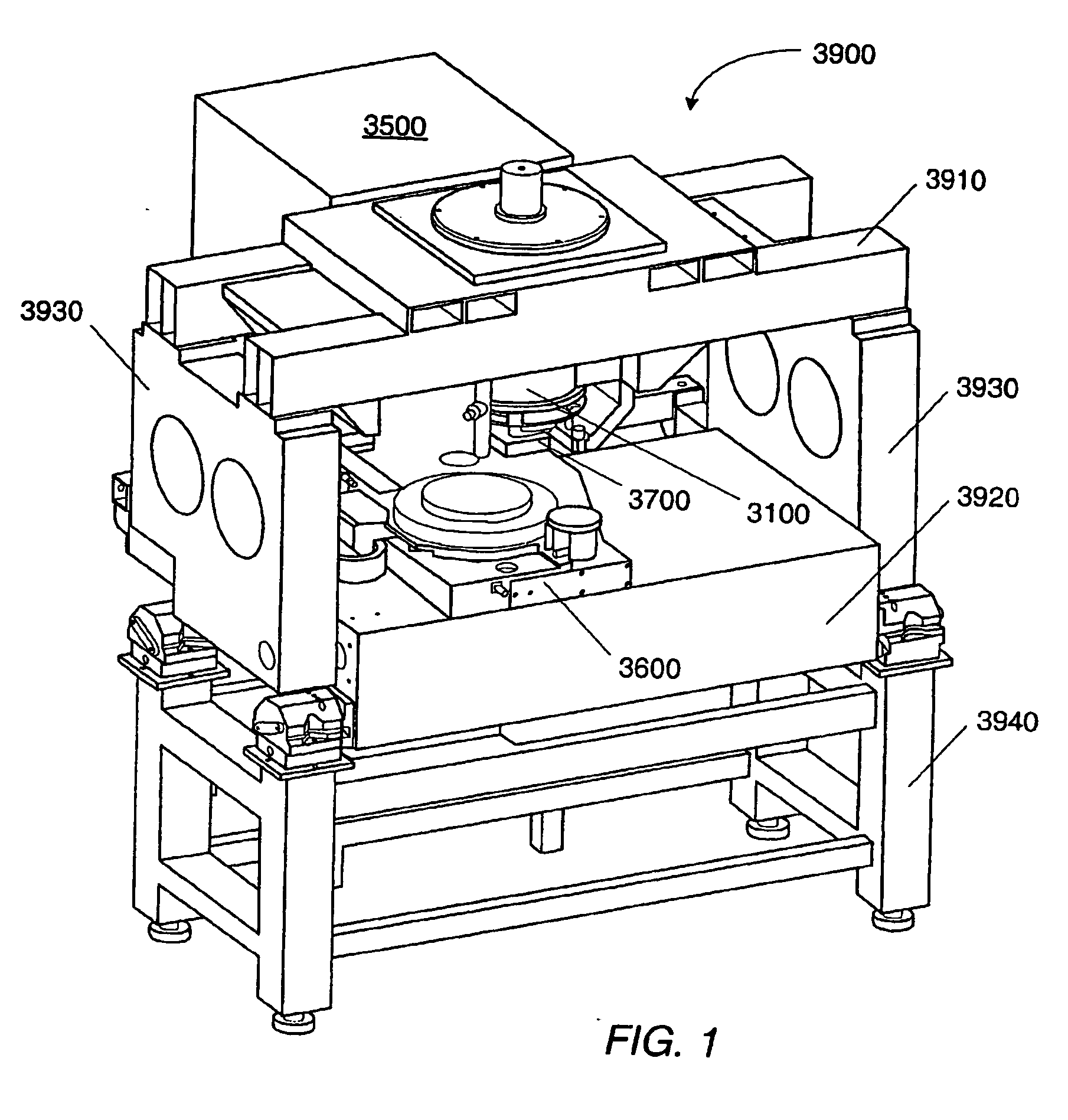

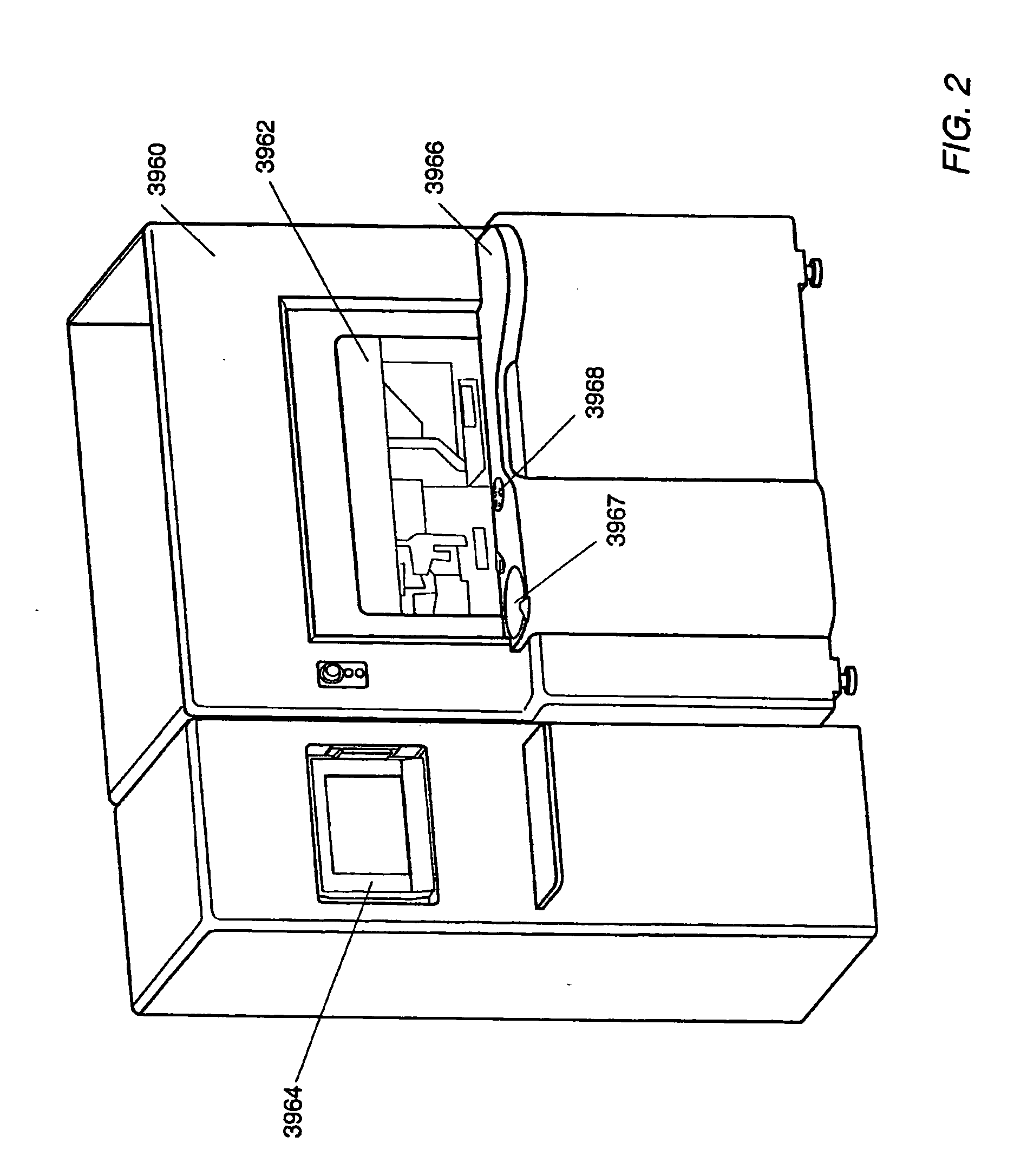

Digital microfluidics based apparatus for heat-exchanging chemical processes

ActiveUS20110048951A1Low costEasy to detectTelevision system detailsSludge treatmentElectricityEngineering

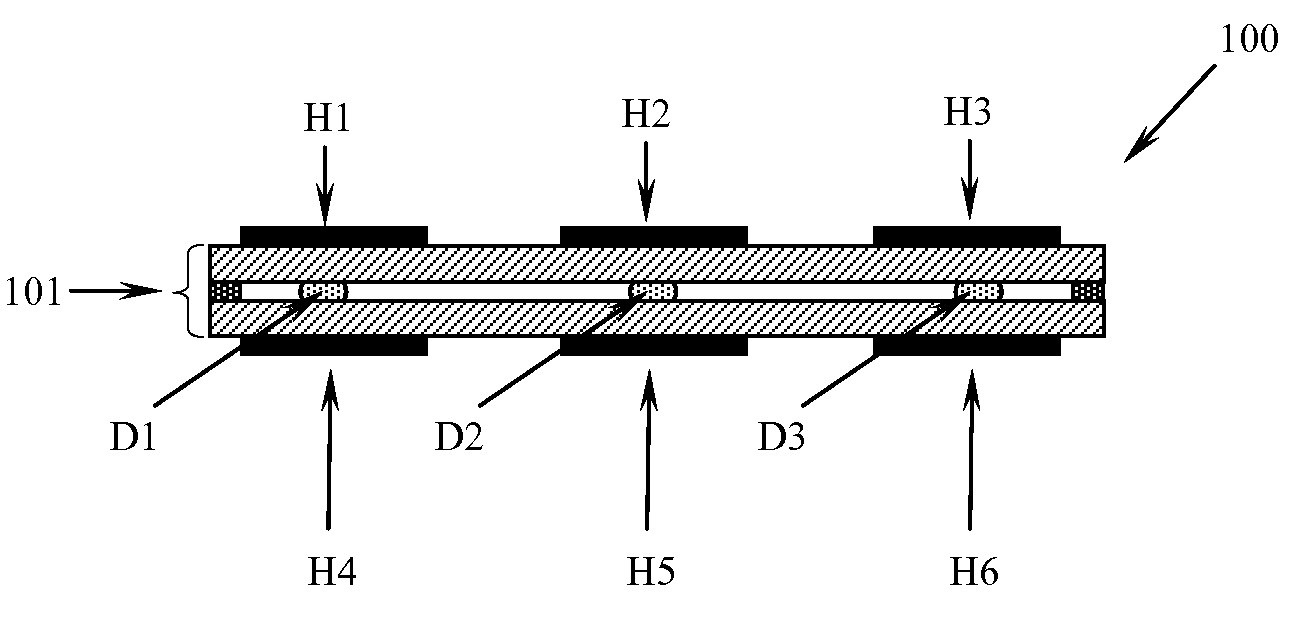

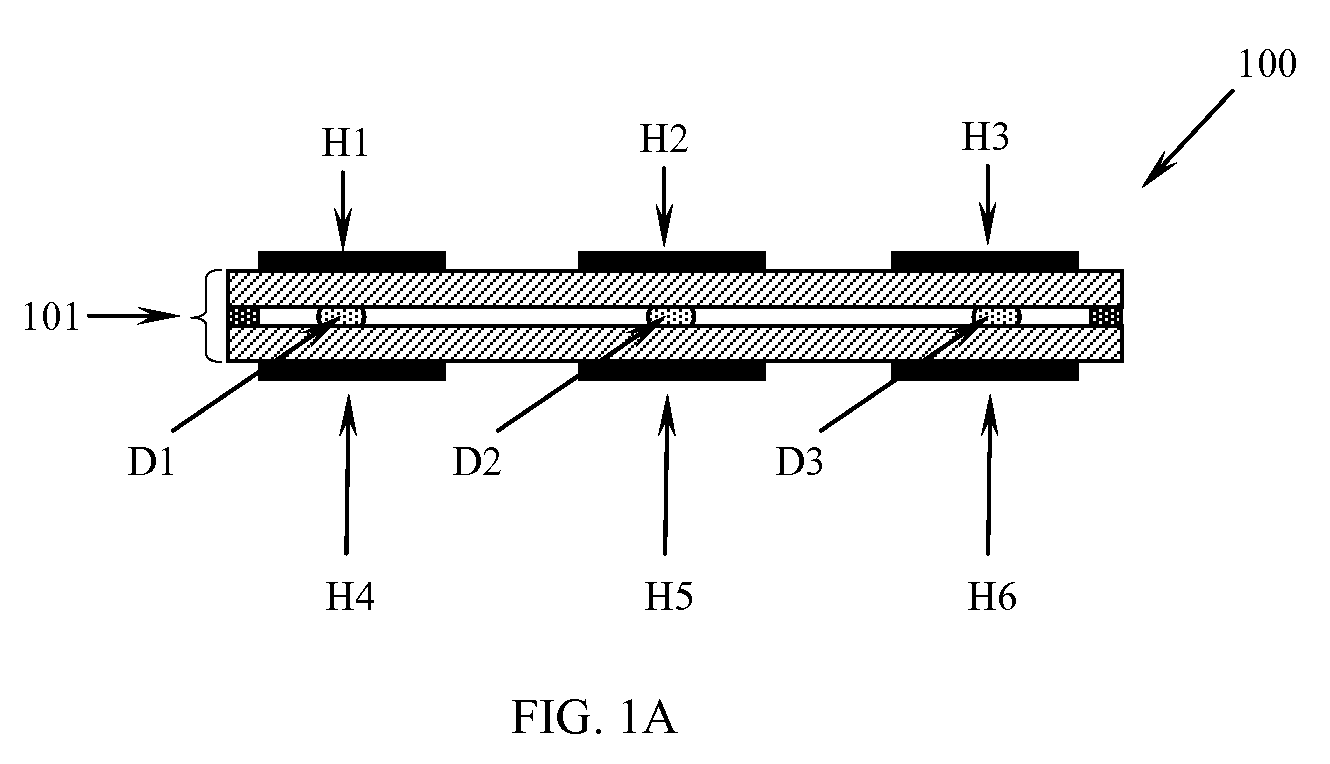

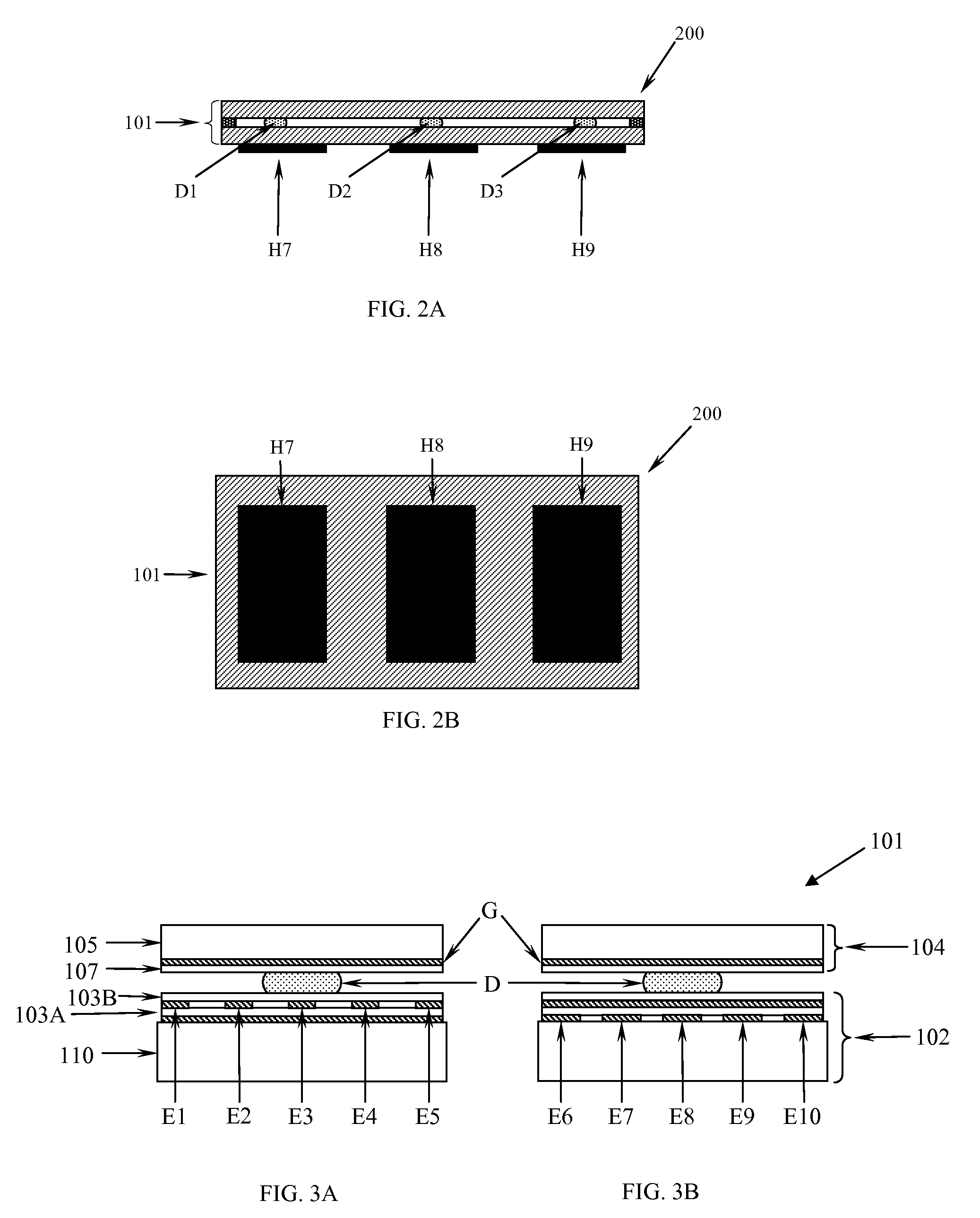

The present invention provides an apparatus and method for performing heat-exchanging reactions on an electro wetting-based micro fluidic device. The apparatus provides one or multiple thermal contacts to an electro wetting-based device, where each thermal contact controls the part of the electro wetting-based device it communicates with to a designed temperature. The electrowetting-based device can be used to create, merge and mix liquids in the format of droplets and transport them to different temperature zones on the micro fluidic device. The apparatus and methods of the invention can be used for heat-exchanging chemical processes such as polymerase chain reaction (PCR) and other DNA reactions, such as ligase chain reactions, for DNA amplification and synthesis, and for real-time PCR.

Owner:DIGITAL BIOSYST

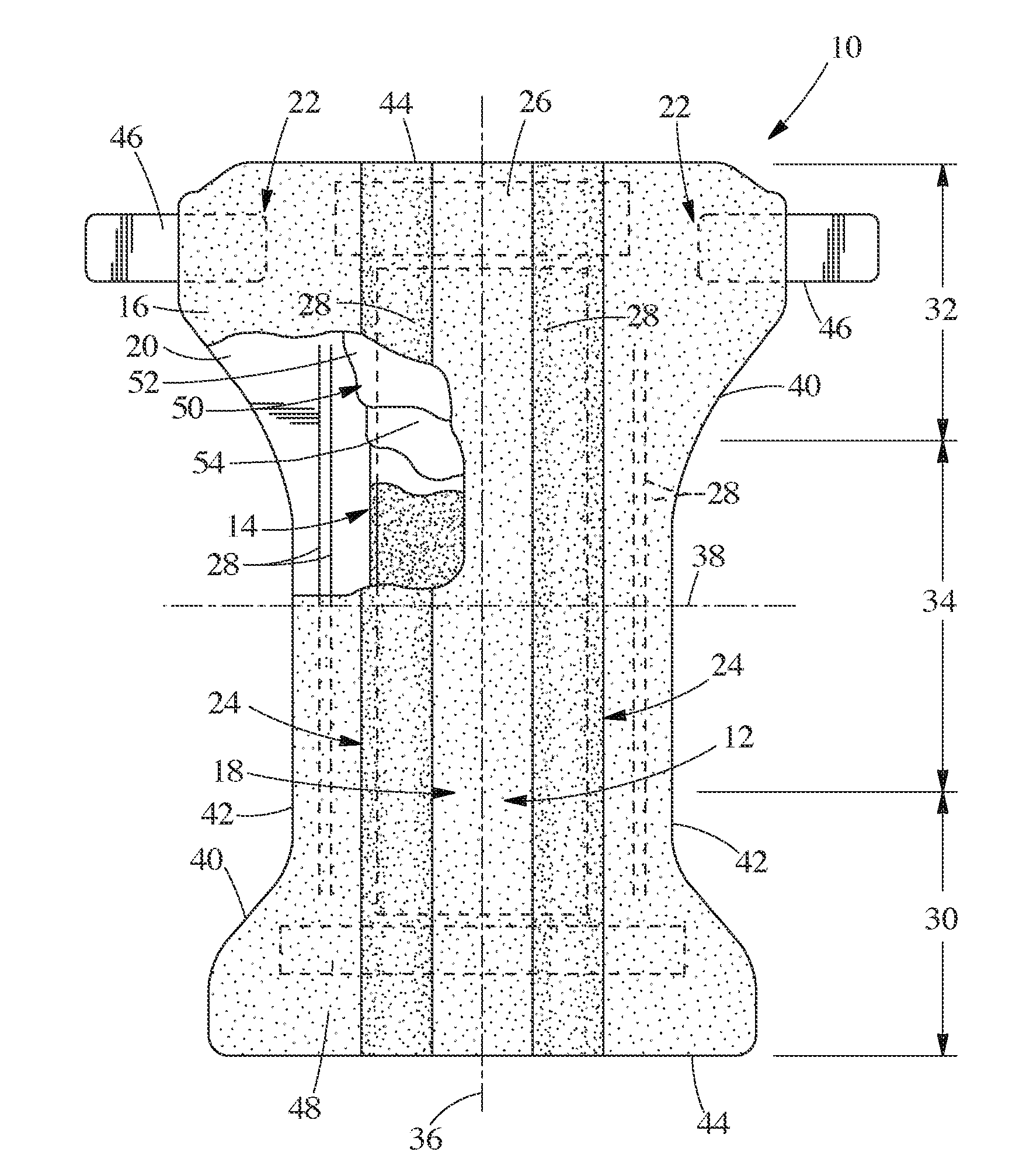

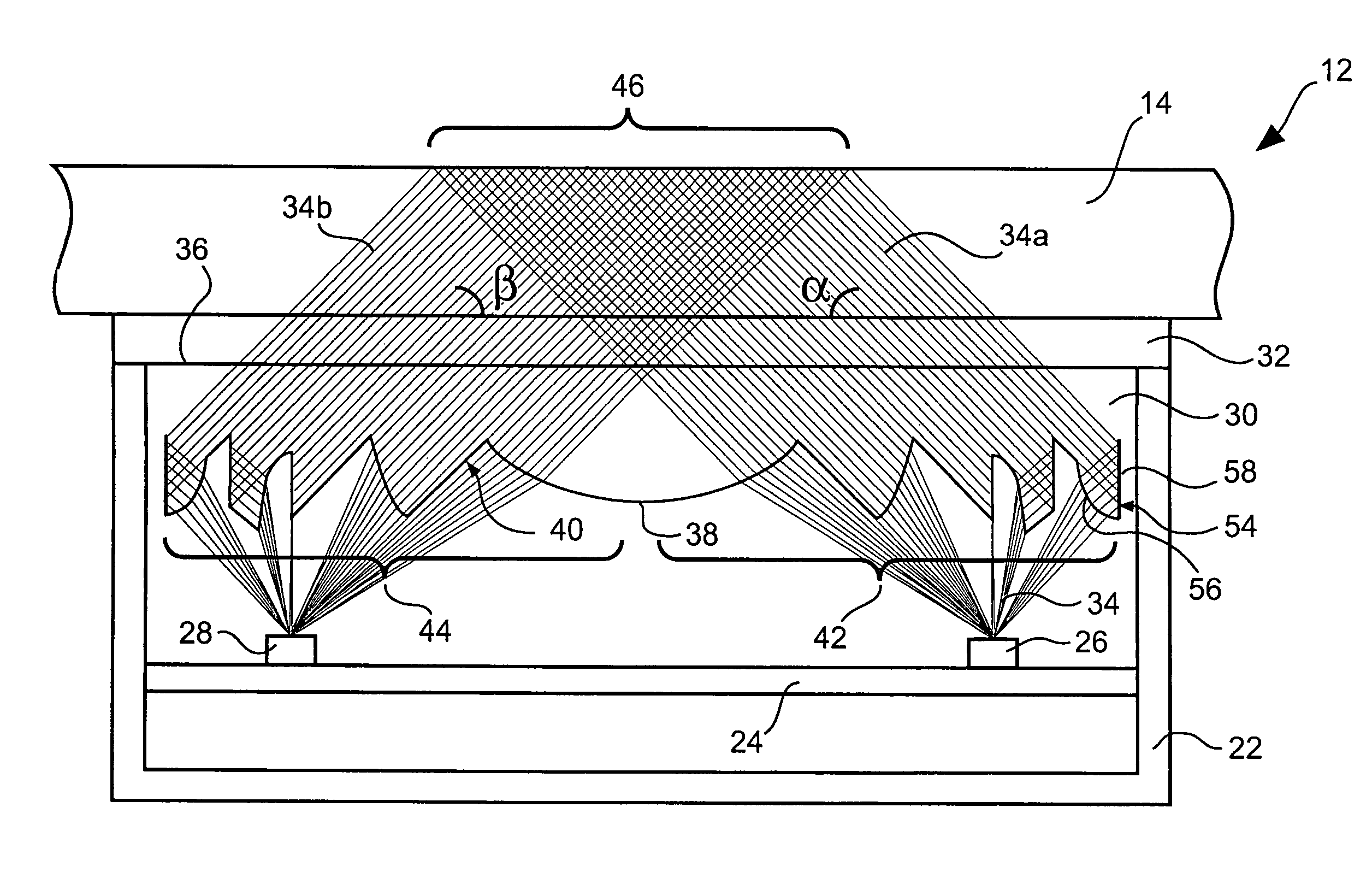

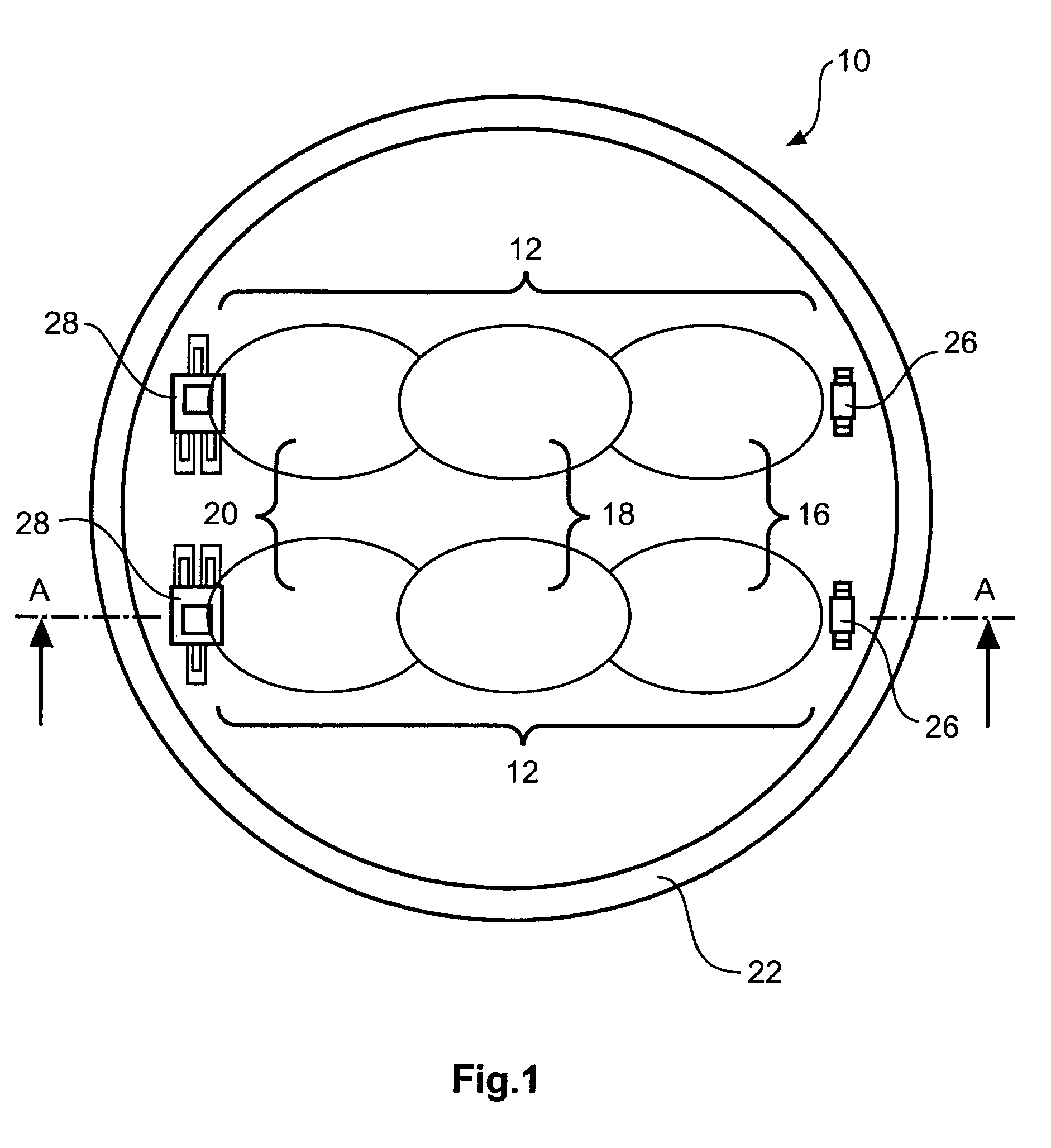

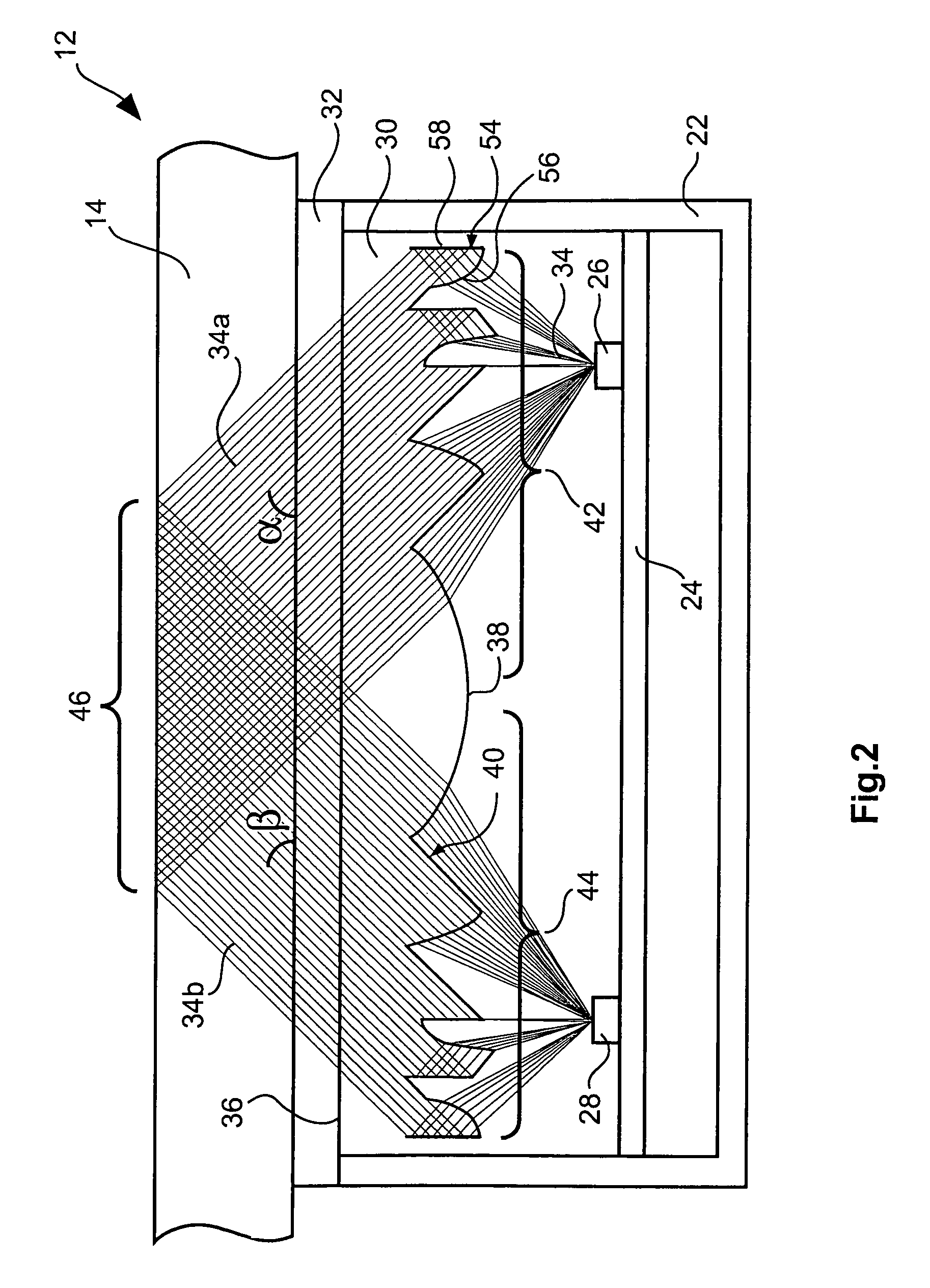

Optical sensor device for detecting wetting

InactiveUS7751054B2Small thicknessIncrease the areaScattering properties measurementsPhotoelectric discharge tubesFresnel lensElectrical conductor

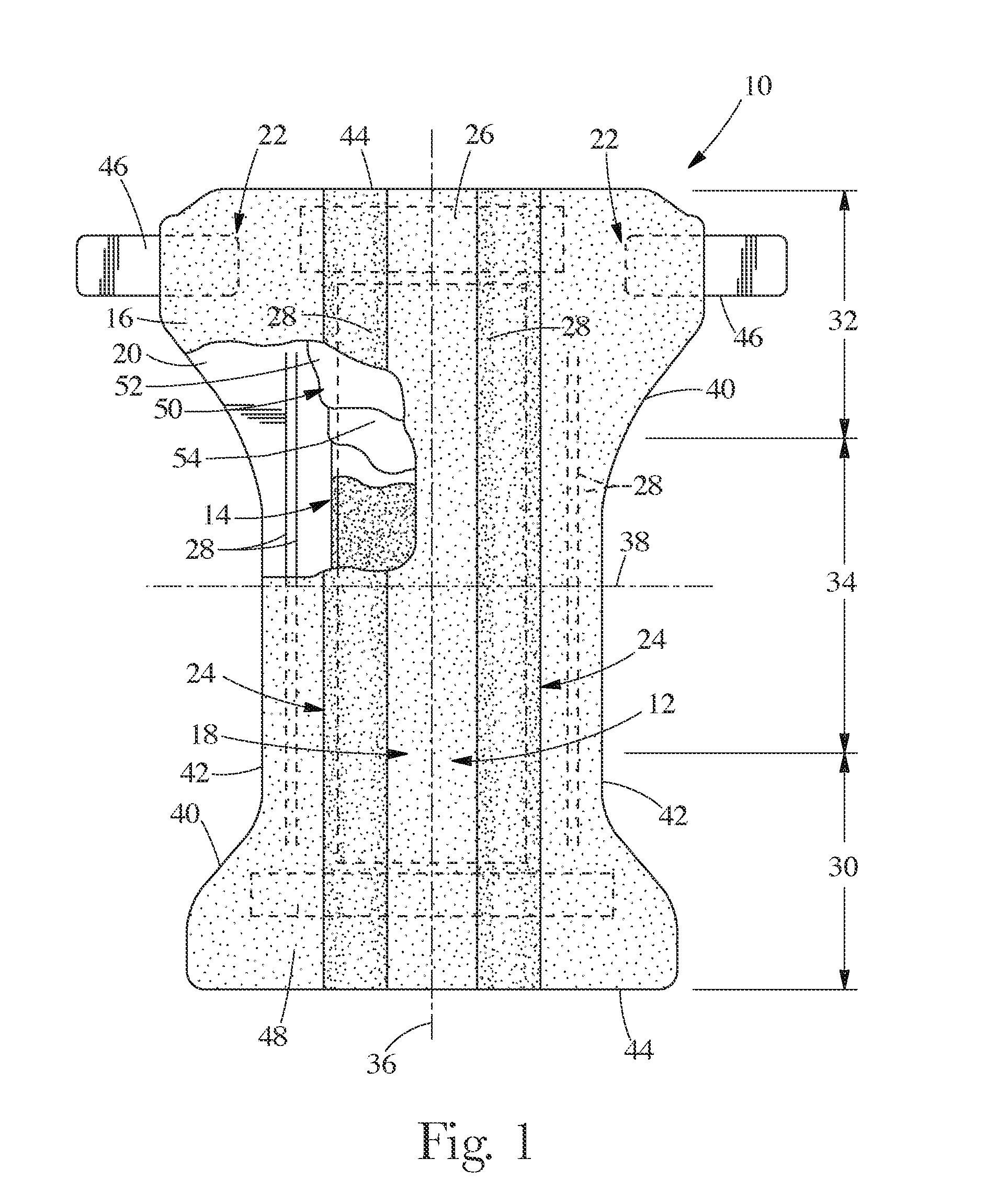

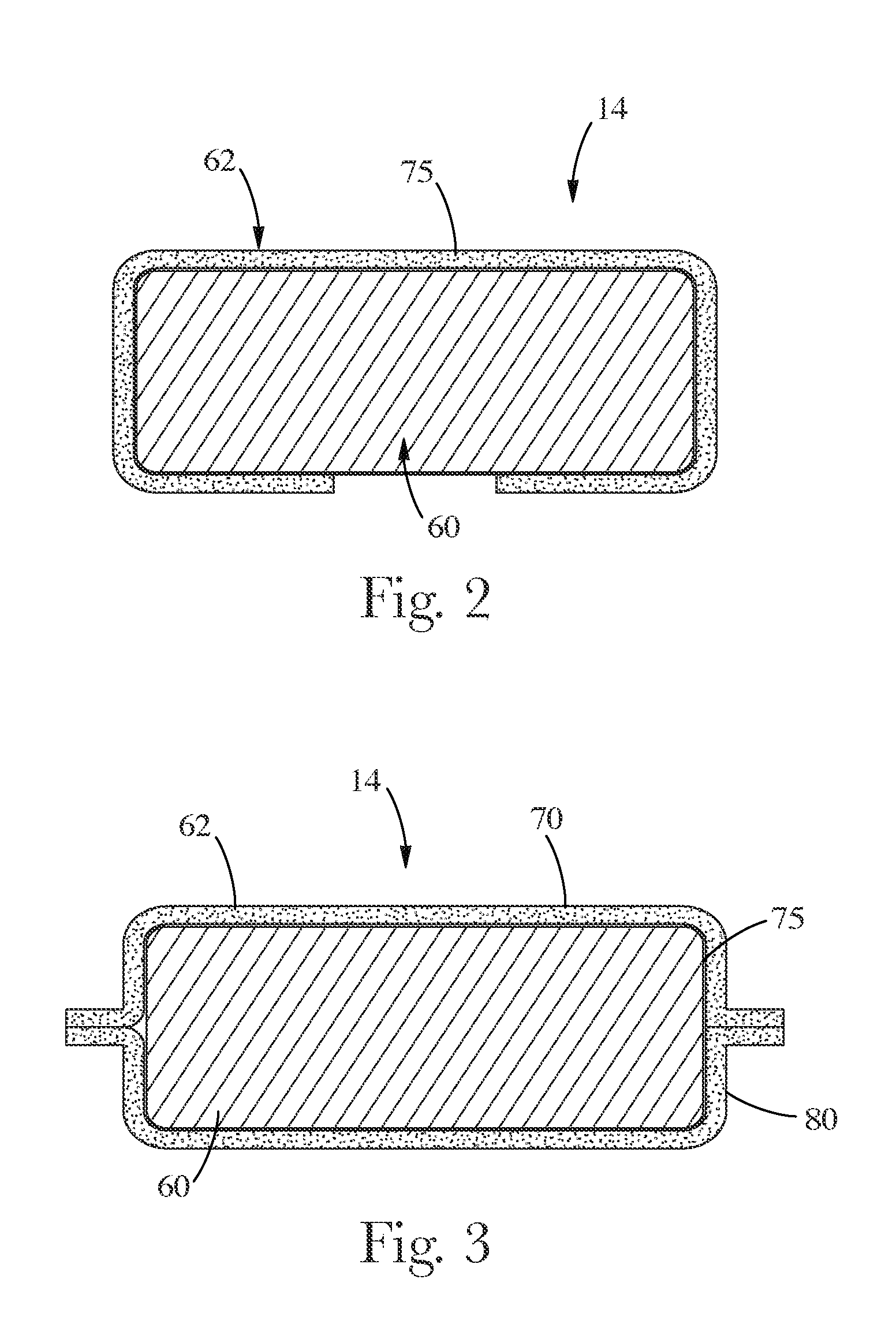

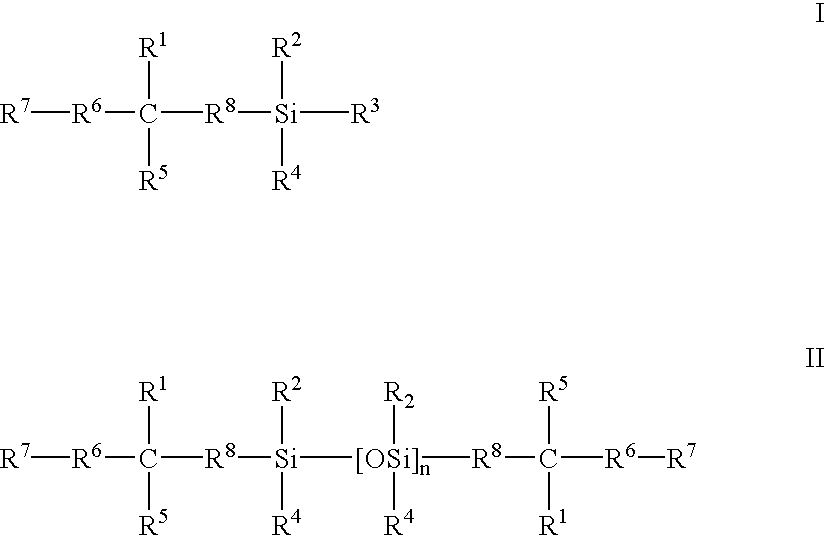

An optical sensor device (10) is able to be coupled to a window (14), in particular to a windscreen of a motor vehicle. The optical sensor device (10) comprises a sensor unit (12), which includes a emitter (26), a receiver (28) and a light conductor unit (30). By the light conductor unit (30), a light beam (34) emitted by the emitter (26) is coupled into the window (14), coupled out of the window (14) and directed onto the receiver (28). The light conductor unit (30) includes Fresnel lens regions and associated reflecting regions.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

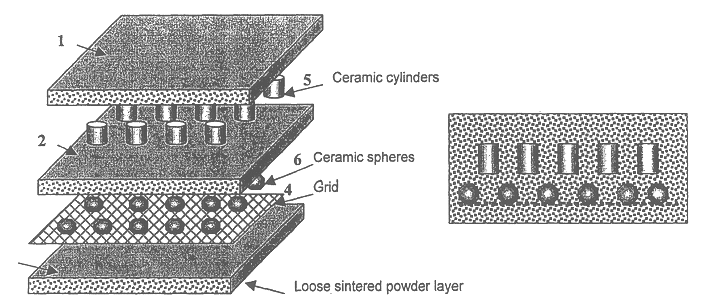

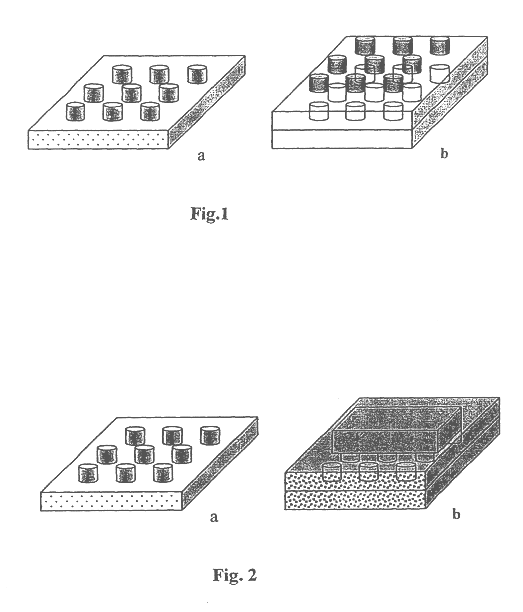

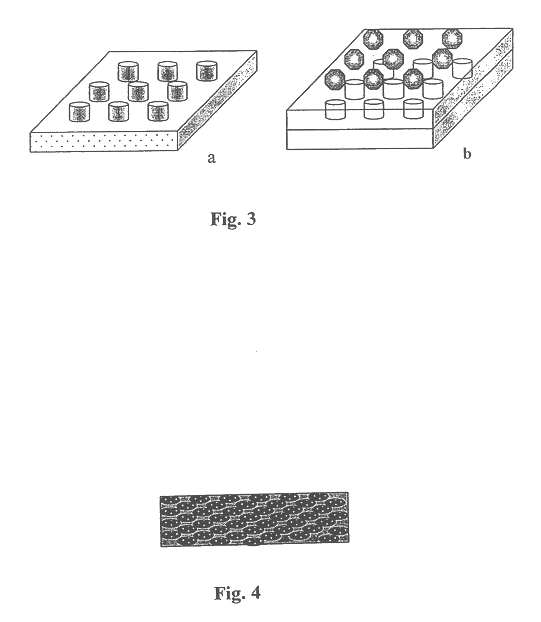

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

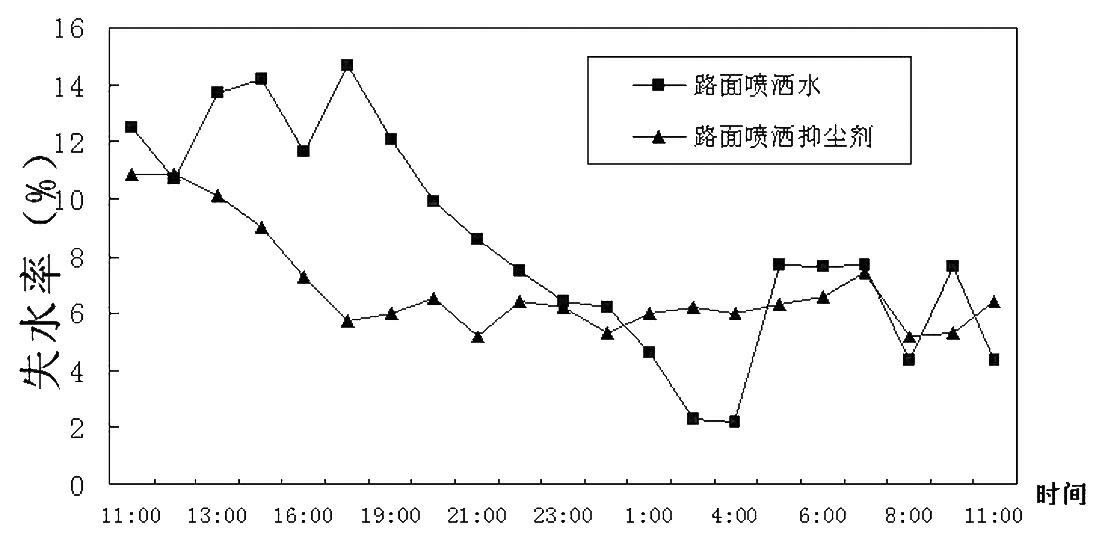

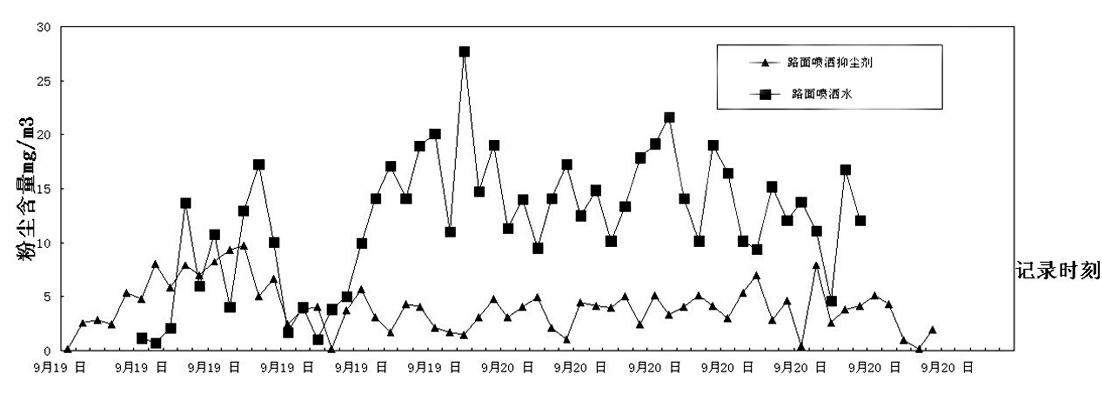

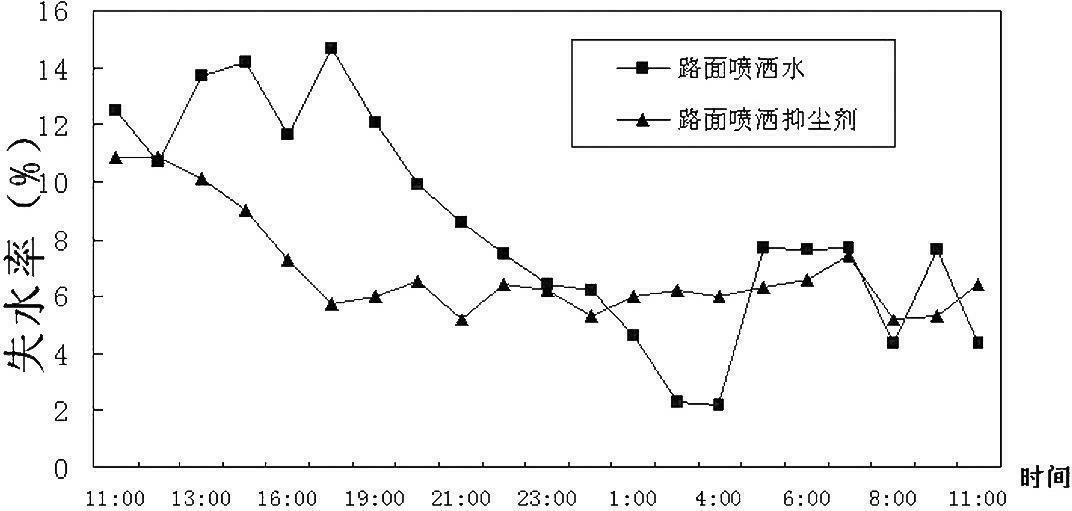

Road dust suppressant

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

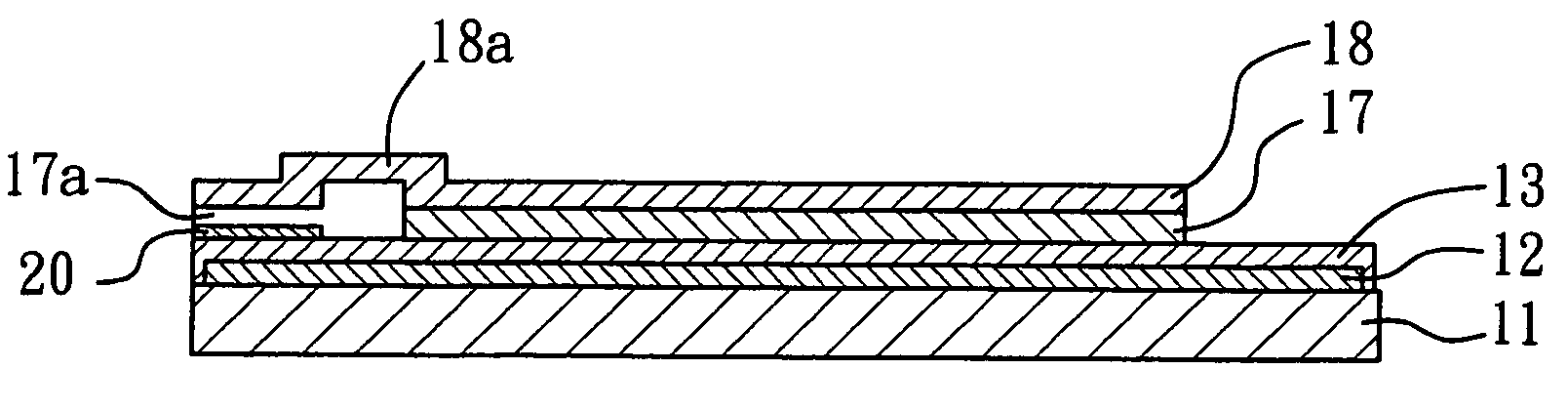

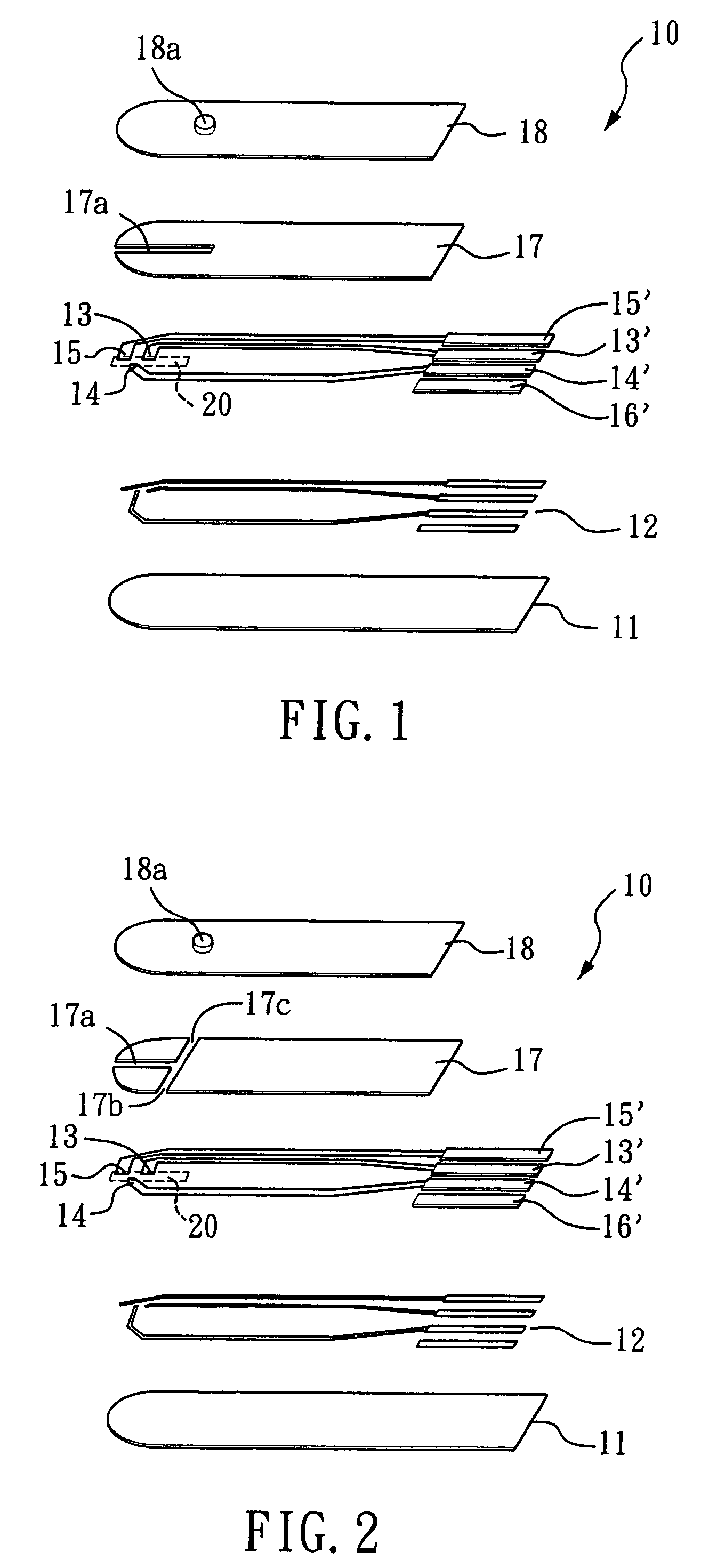

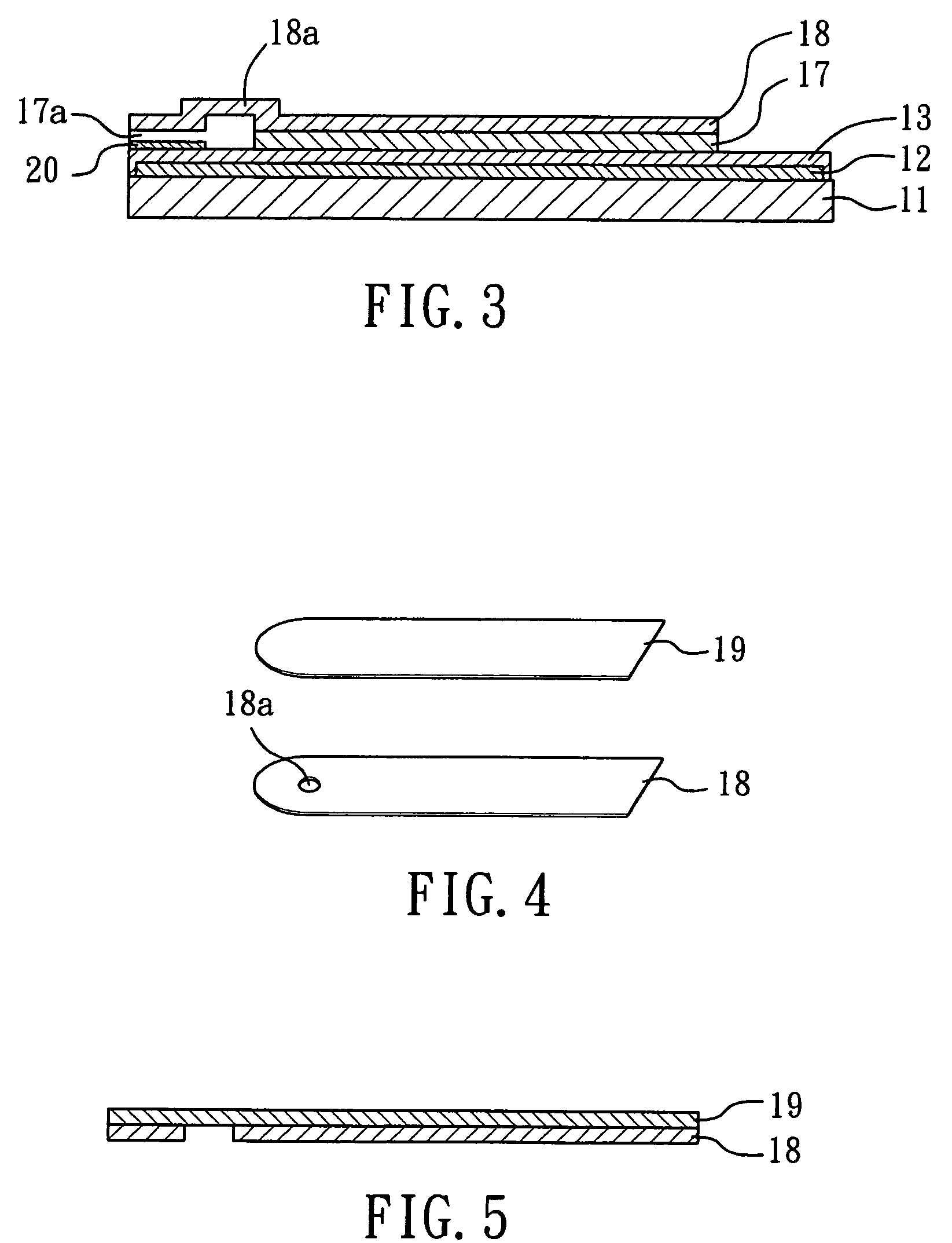

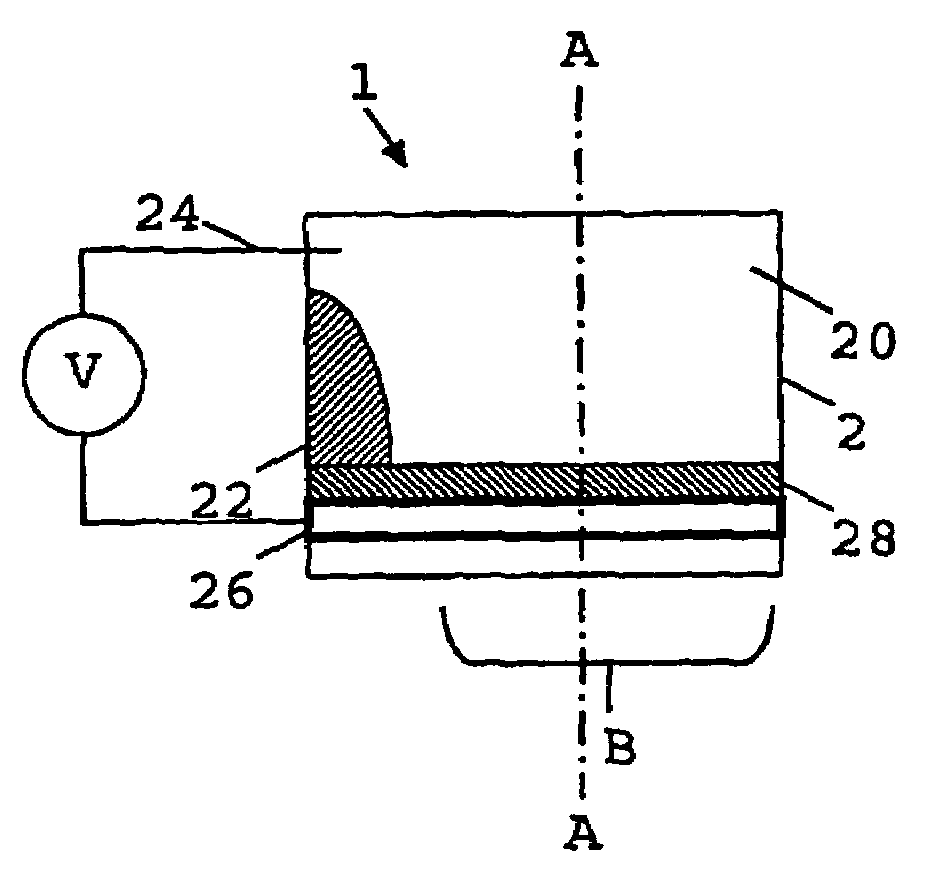

Electrochemical biosensor by screen printing and method of fabricating same

ActiveUS7138041B2Rapid sample inflowSmall volumeImmobilised enzymesBioreactor/fermenter combinationsReaction layerSiphon

An electrochemical biosensor formed by screen printing and method of fabricating such biosensor is disclosed in the present invention. The biosensor can quickly absorb a sample to be measured therein, effectively control volume of the sample fed and “fill-and-position” the sample therein. The biosensor includes an electrode layer (electrode area) comprising two or three electrodes, which are a working electrode, a reference electrode and an auxiliary electrode (tri-electrode) on an insulating substrate. An active reaction layer containing reactant, reaction catalyst, mediator, wetting agent and surfactant is spread on the surface of the electrode layer. A sample inflow area is formed above the electrode area by adding an upper cover on top of a middle insulating layer with a U-shaped opening formed therein. Sample solution with a minute amount about 0.8 to 1 μl can be rapidly introduced into the electrode area and the active reaction layer via the inflow area by siphon or capillary, where the ingredient of the sample can be analysed by measuring reaction between the sample, reaction catalyst and mediator in the reaction layer using electrochemical potentiometric or amperometric method. An upwardly extended closed space formed within the upper cover above the electrode area adjacent to the front of conductive wires can be effectively used to control sample volume and “fill-and-position” the sample.

Owner:GENERAL LIFE BIOTECHNOLGOY

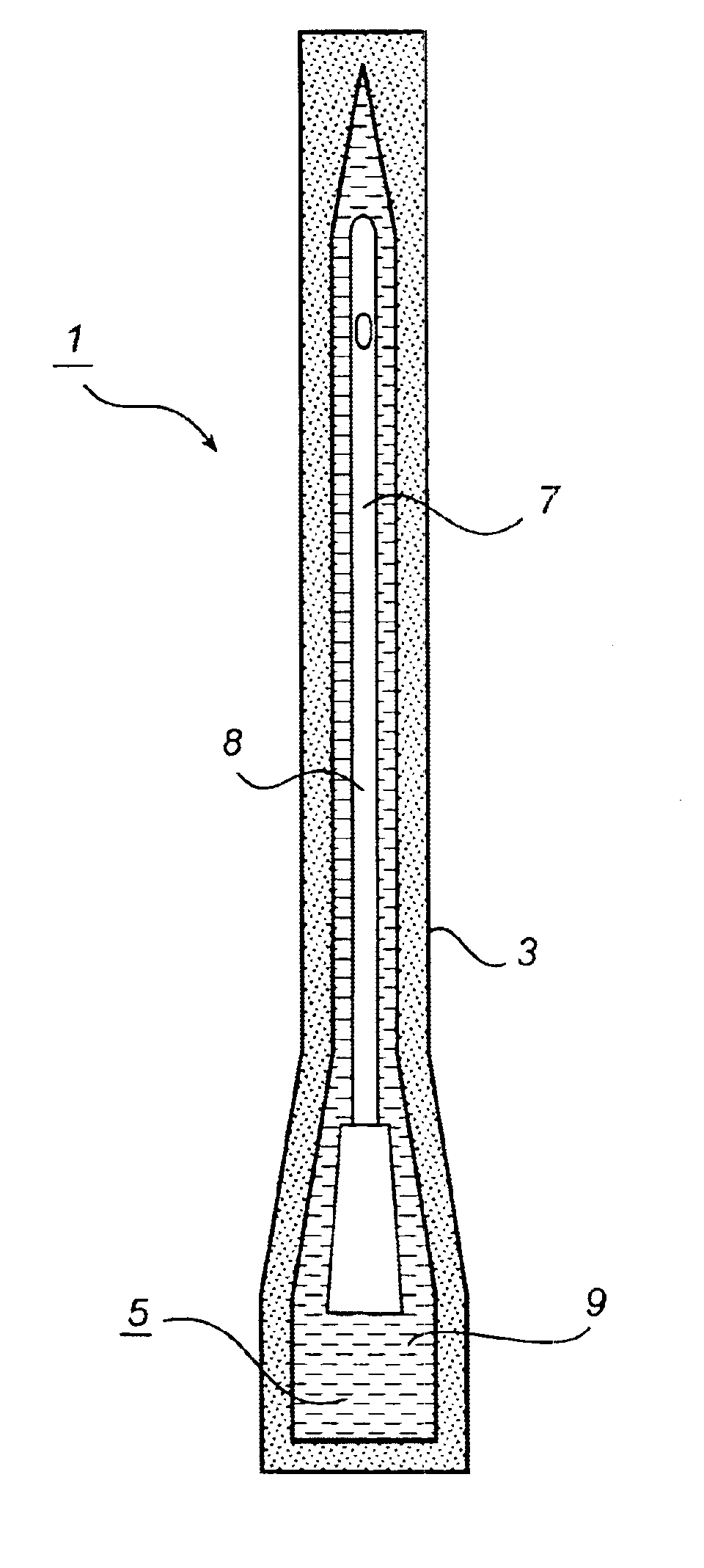

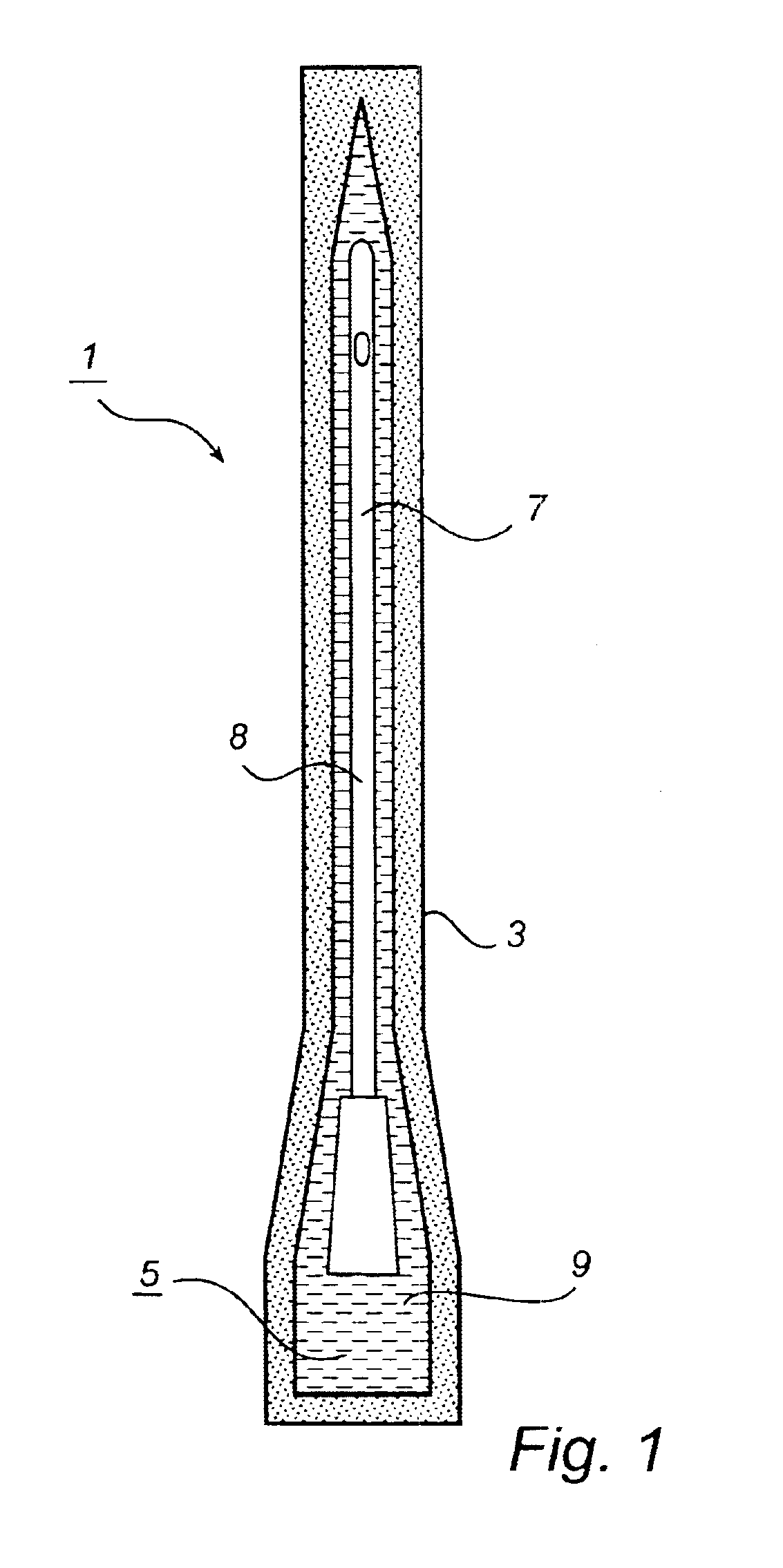

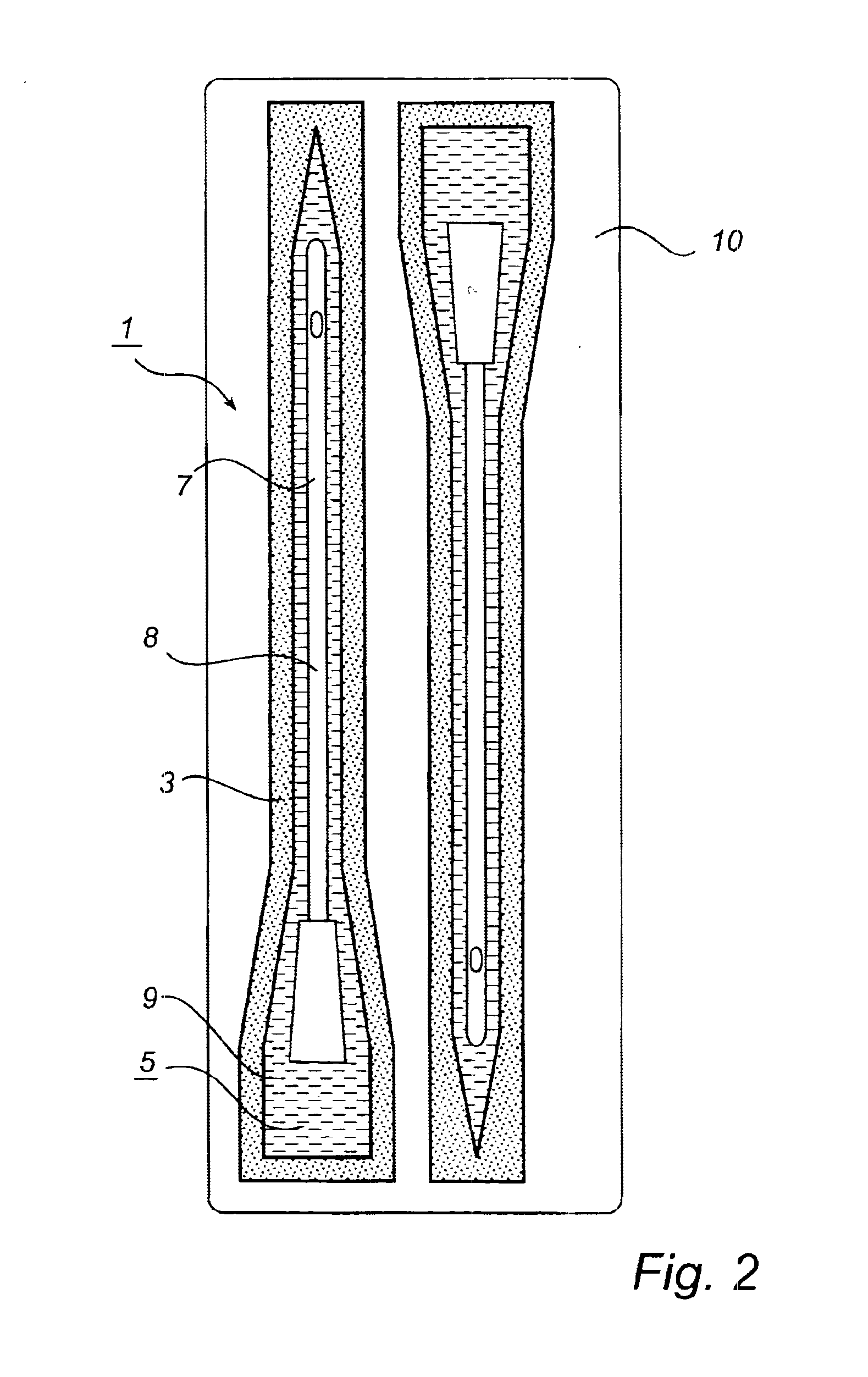

Storage package and a method for packaging

InactiveUS6848574B1Long shelf lifeExtended shelf lifeWrappersDispensing apparatusCoated surfaceUrethral catheter

A storage package (1) contains a medical device (7) having a coated surface (8 ) which exhibits a reduced friction when wetted with a wetting liquid and a supply of the wetting liquid (9). The package is adapted such that the coated surface of the medical device is maintained contact with the supply of wetting liquid during storage. A good shelf-life for the medical device is achieved an where the medical device is a urethral catheter the catheter is immediately “ready-for-use” after the package has been opened.

Owner:ASTRA TECH SE

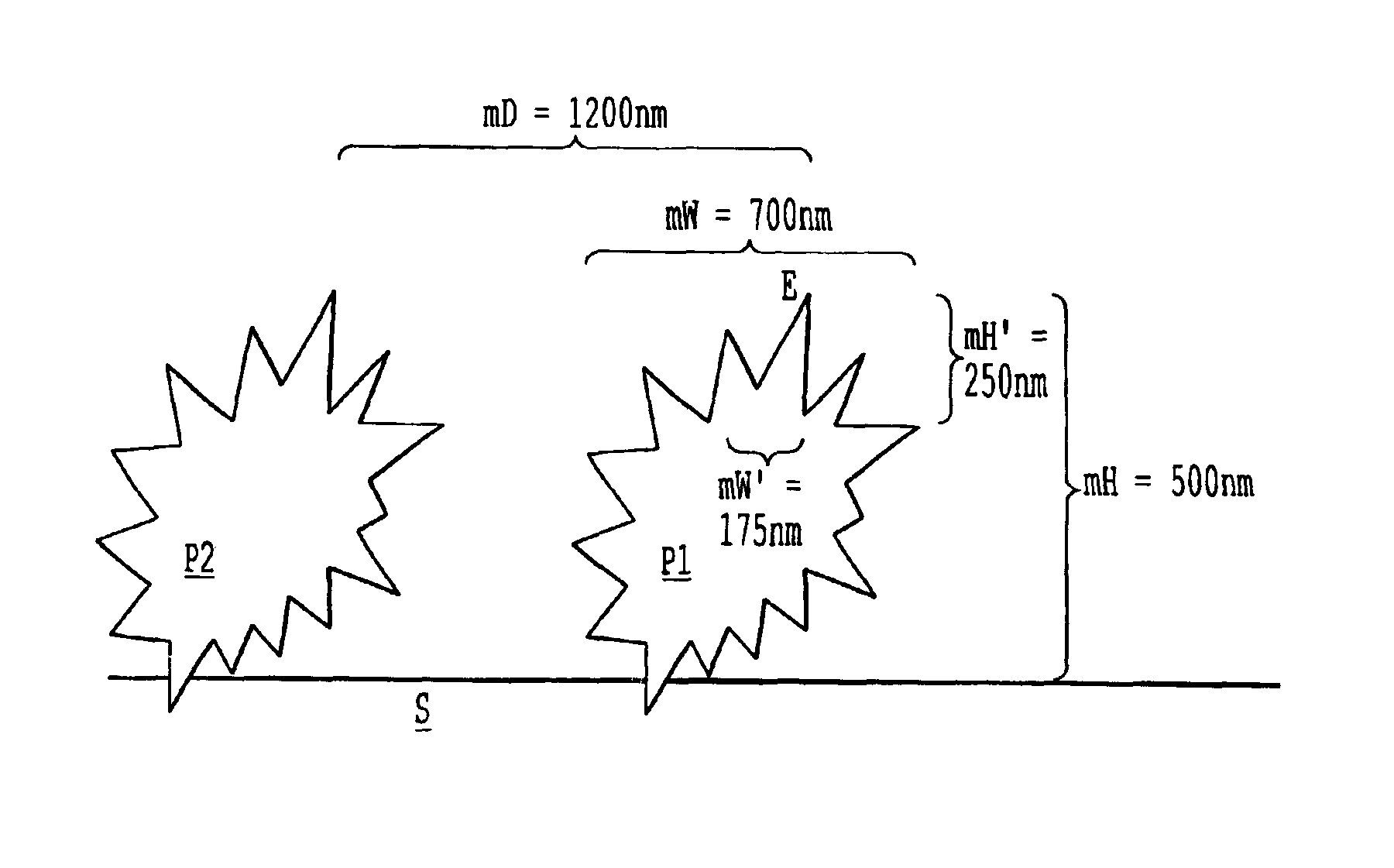

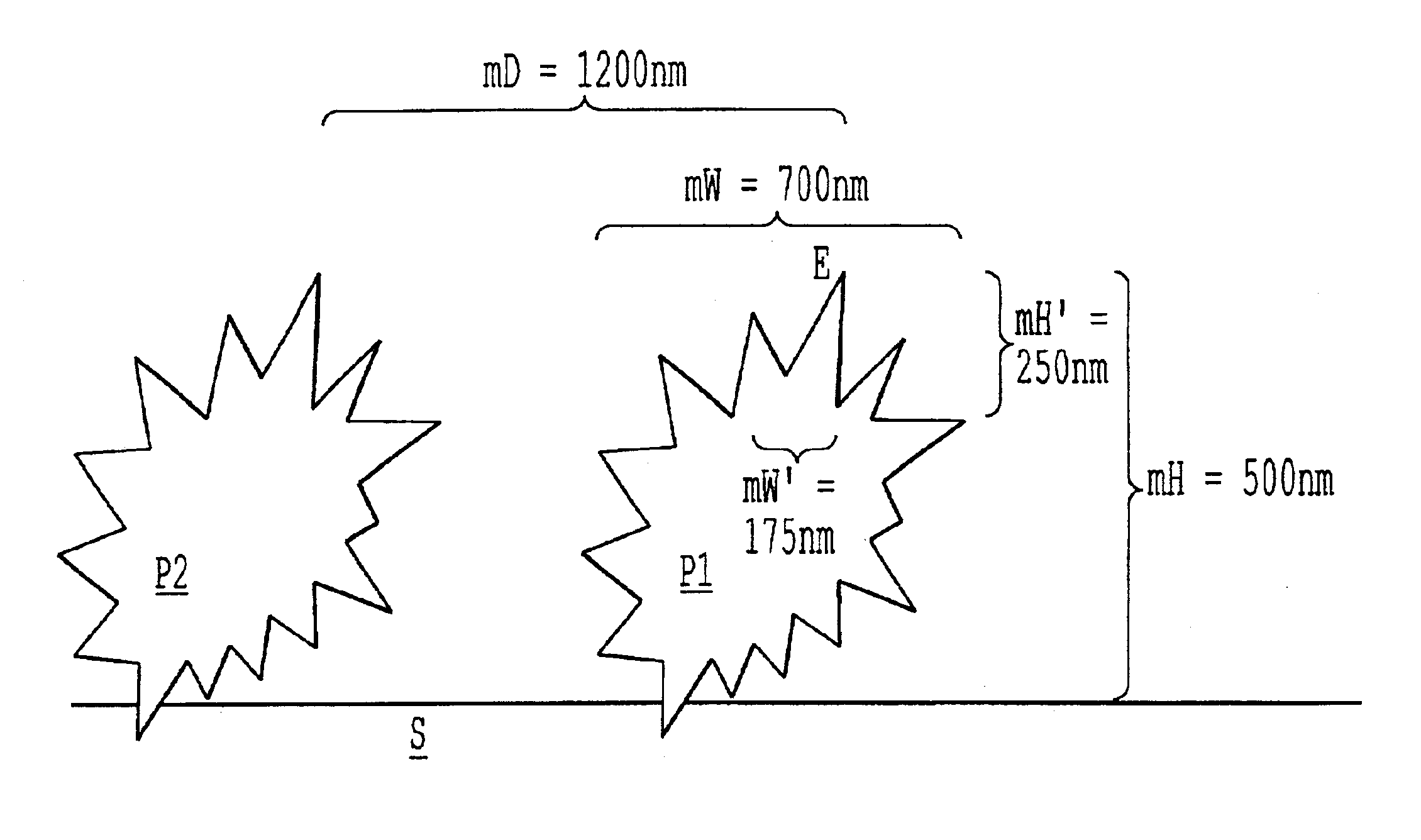

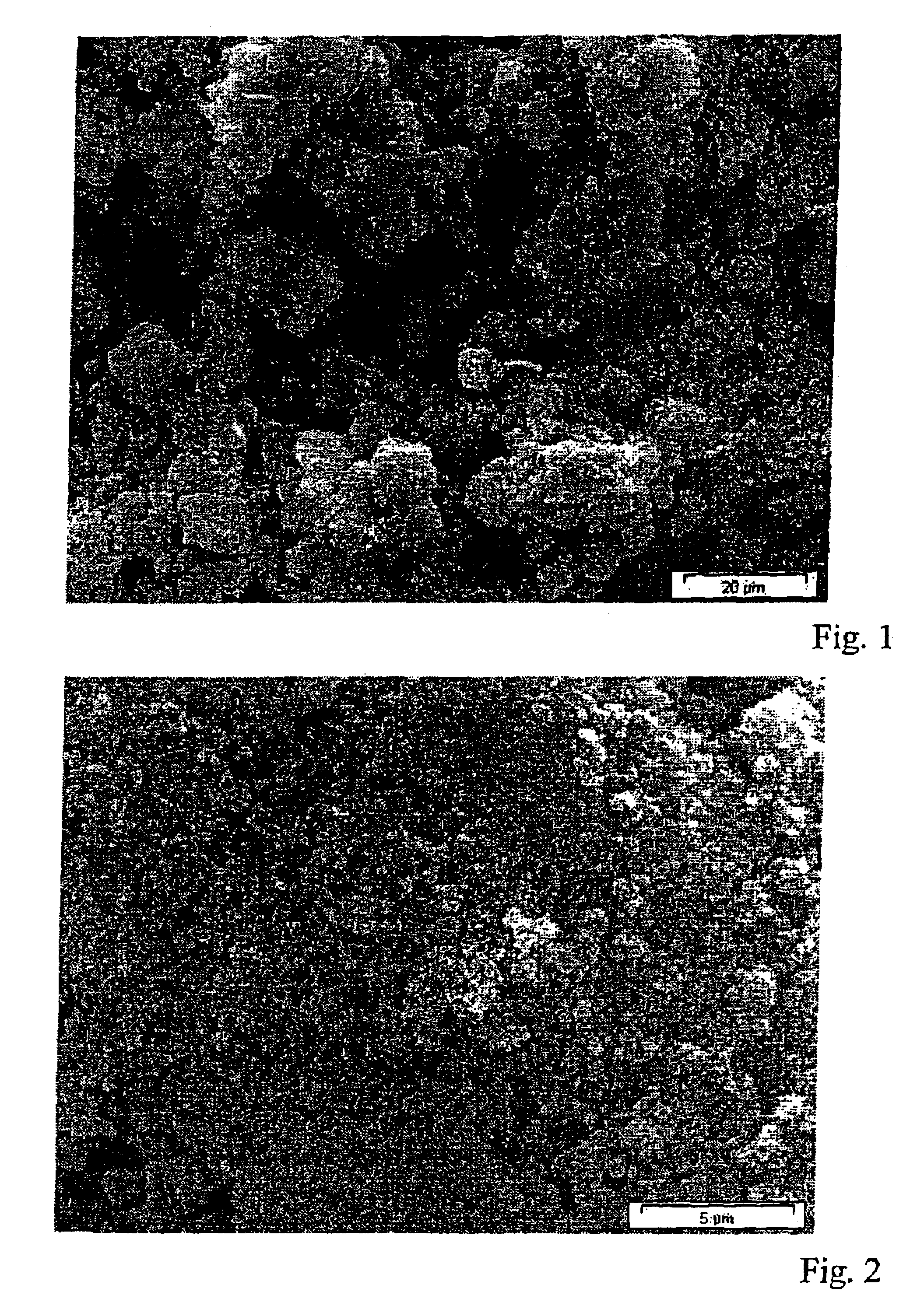

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

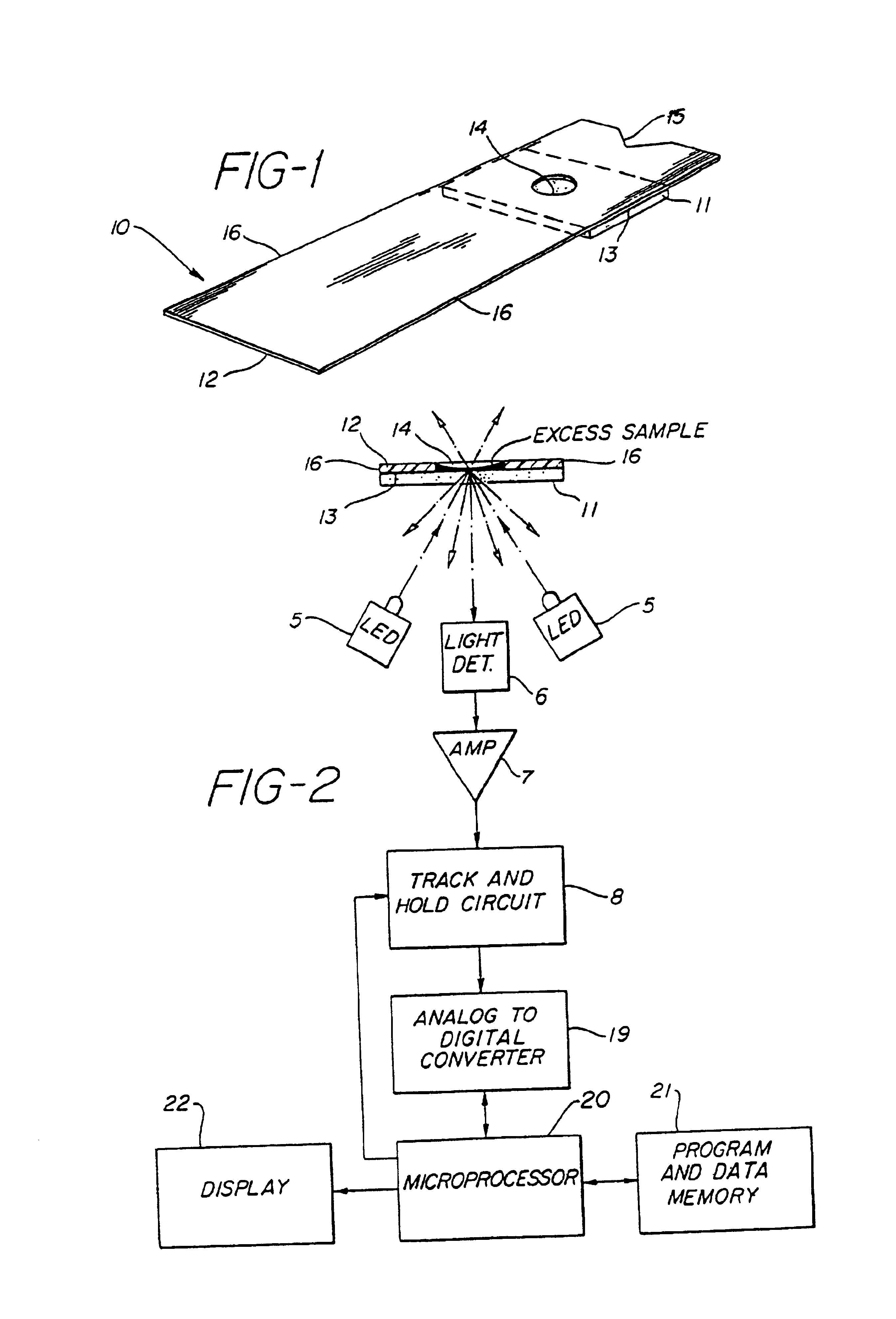

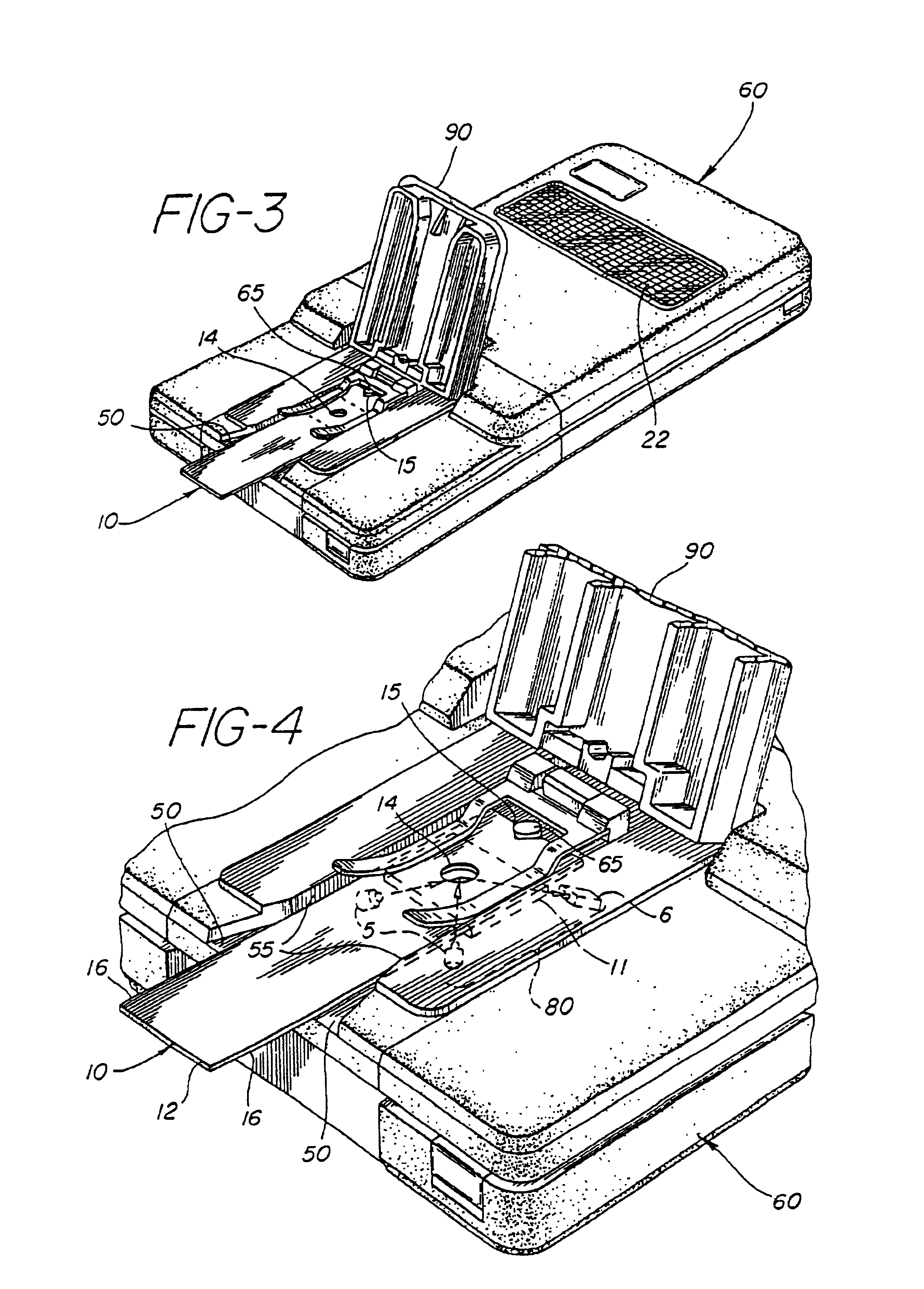

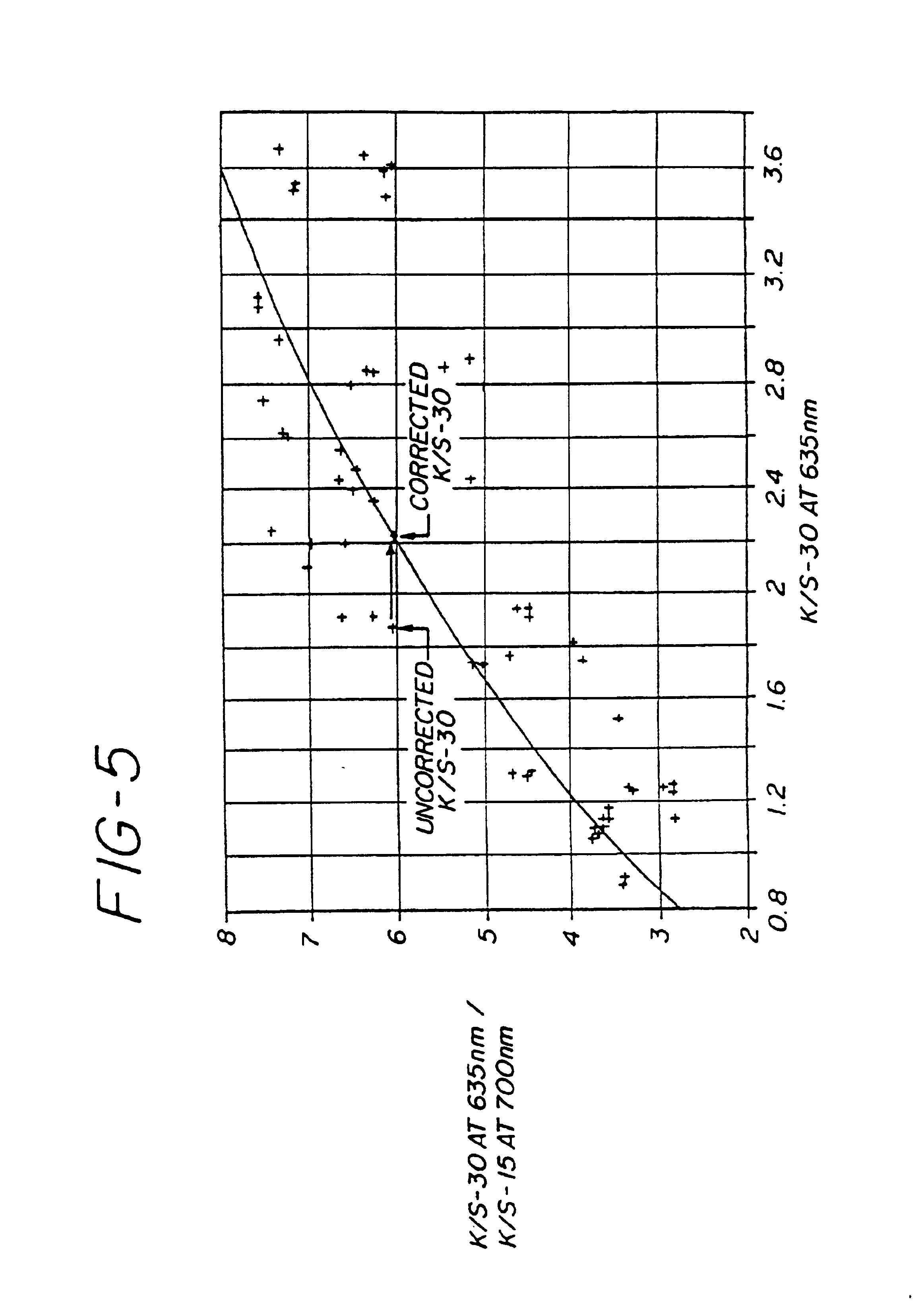

Method for the determination of glucose employing an apparatus emplaced matrix

InactiveUS6881550B2Minimization of actionBioreactor/fermenter combinationsBiological substance pretreatmentsReagent stripFluorescence

Owner:LIFESCAN INC

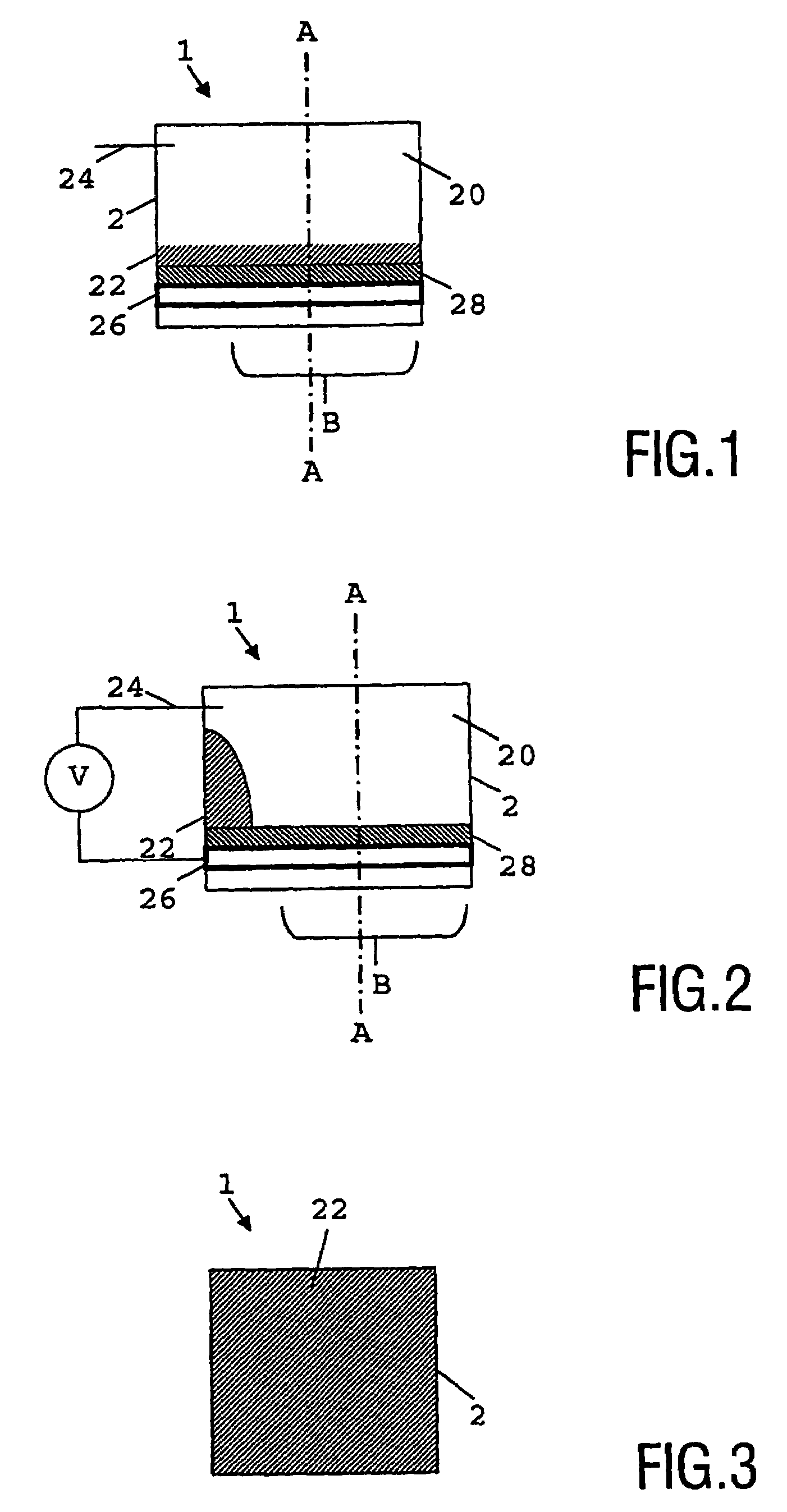

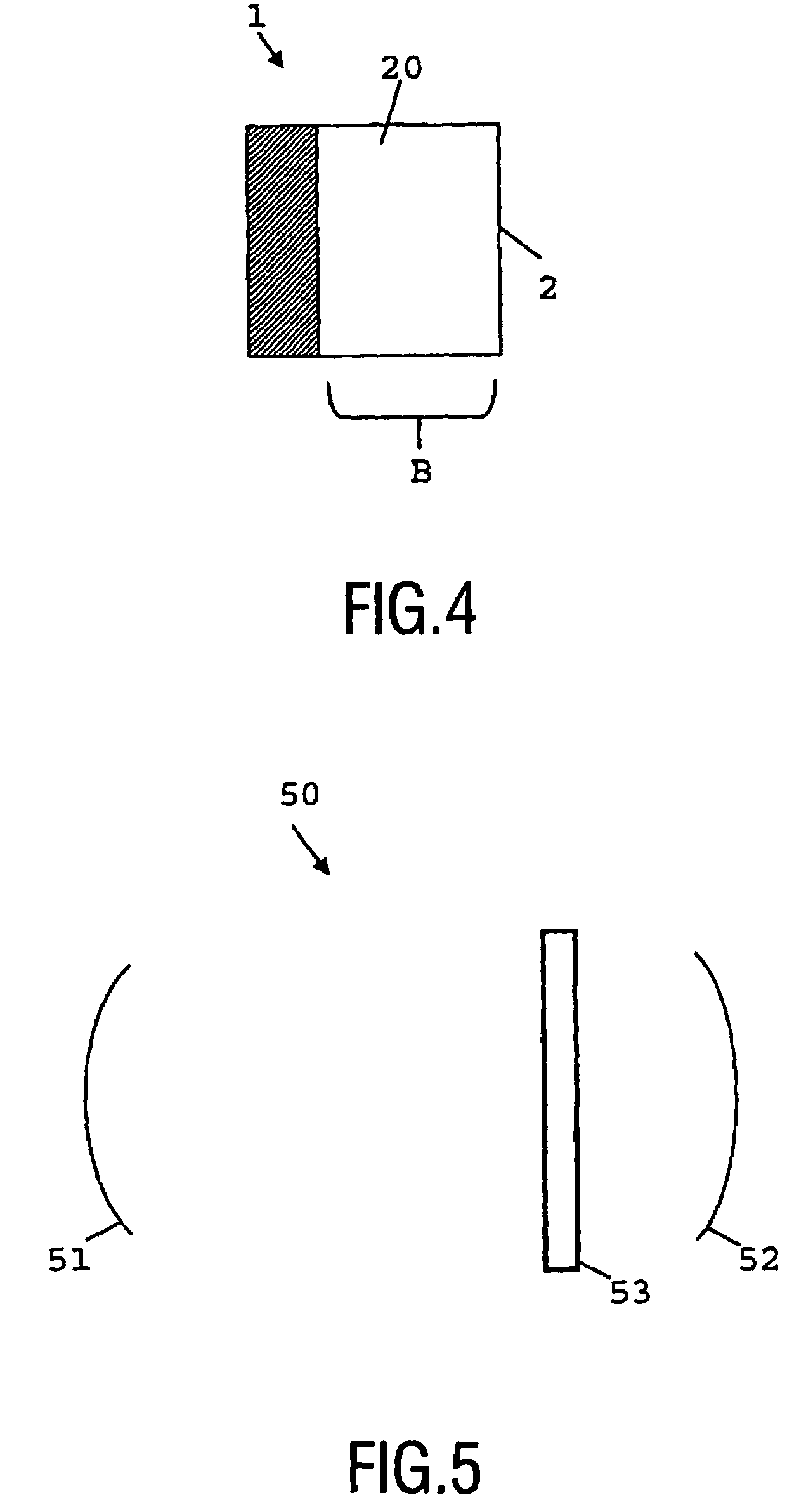

Switchable optical element

ActiveUS7508566B2Improve evenlyAvoid introducingRecord information storageOptical beam guiding meansOptical axisClassical mechanics

A switchable optical element has a fluid chamber including immiscible first and second bodies of fluid disposed relative to one another along an optical axis of the element. The second body of fluid is movable in a direction away from the optical axis (A) by electro-wetting action, giving the switchable optical element a changeable transmissivity along the optical axis.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

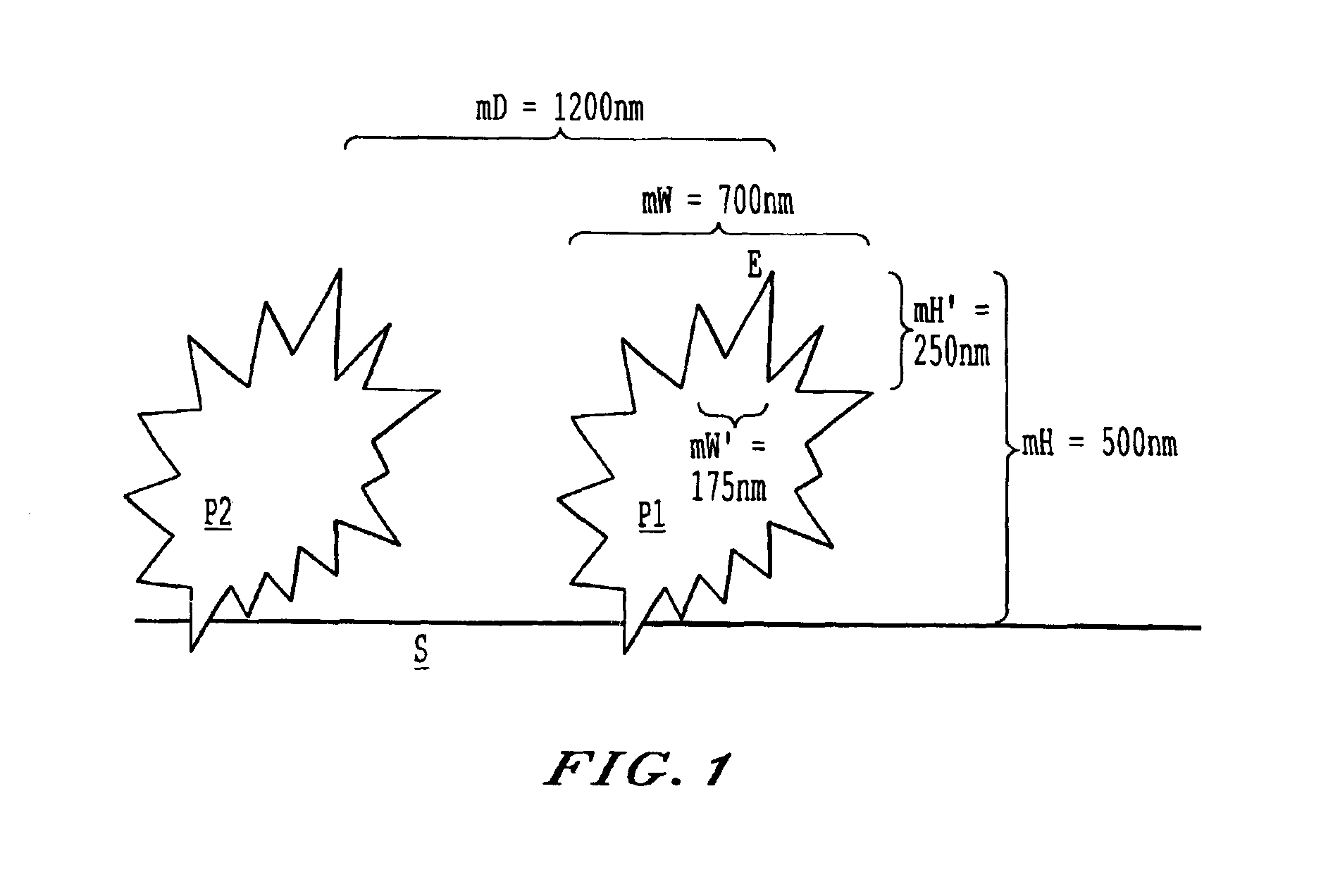

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

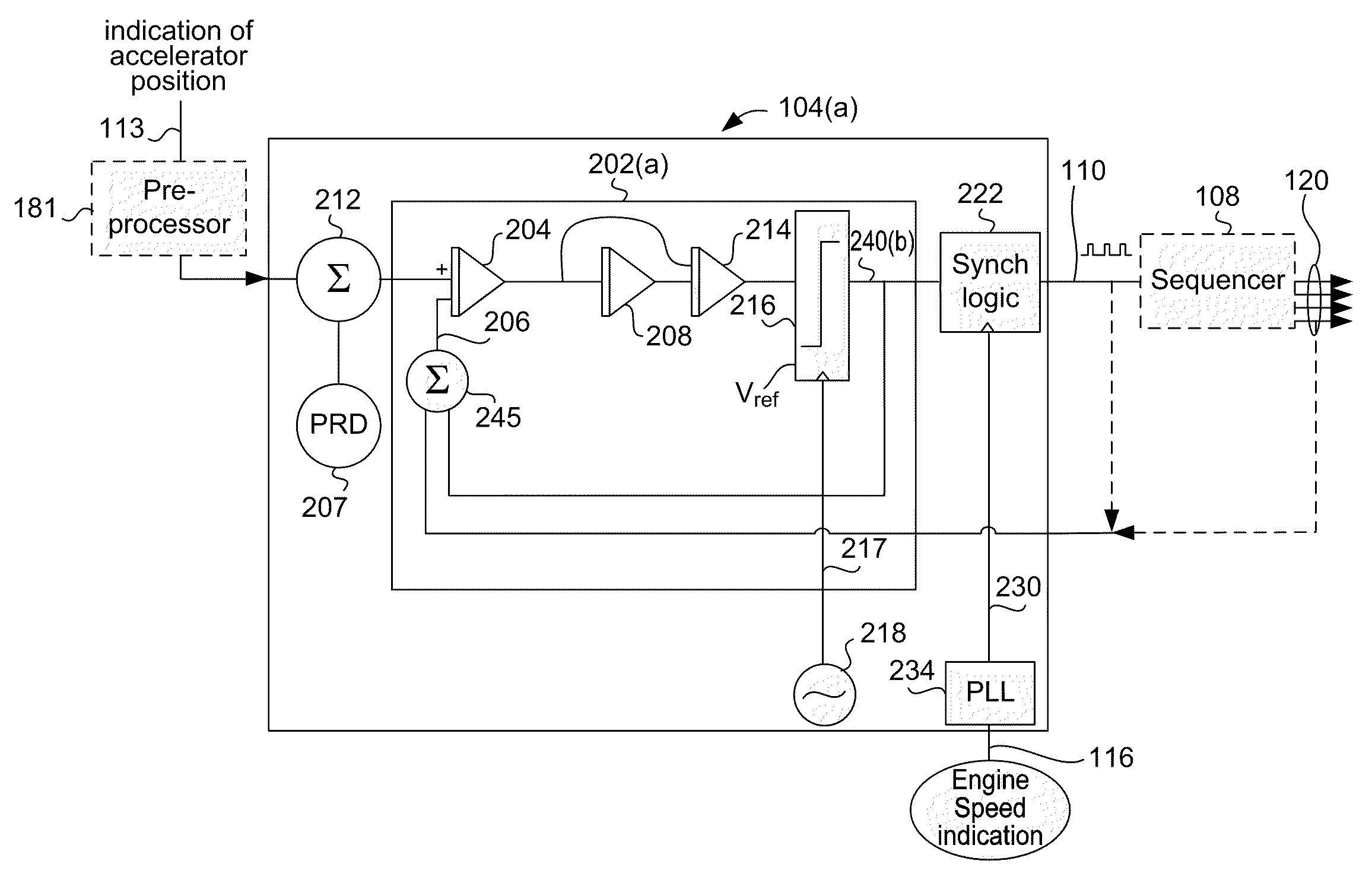

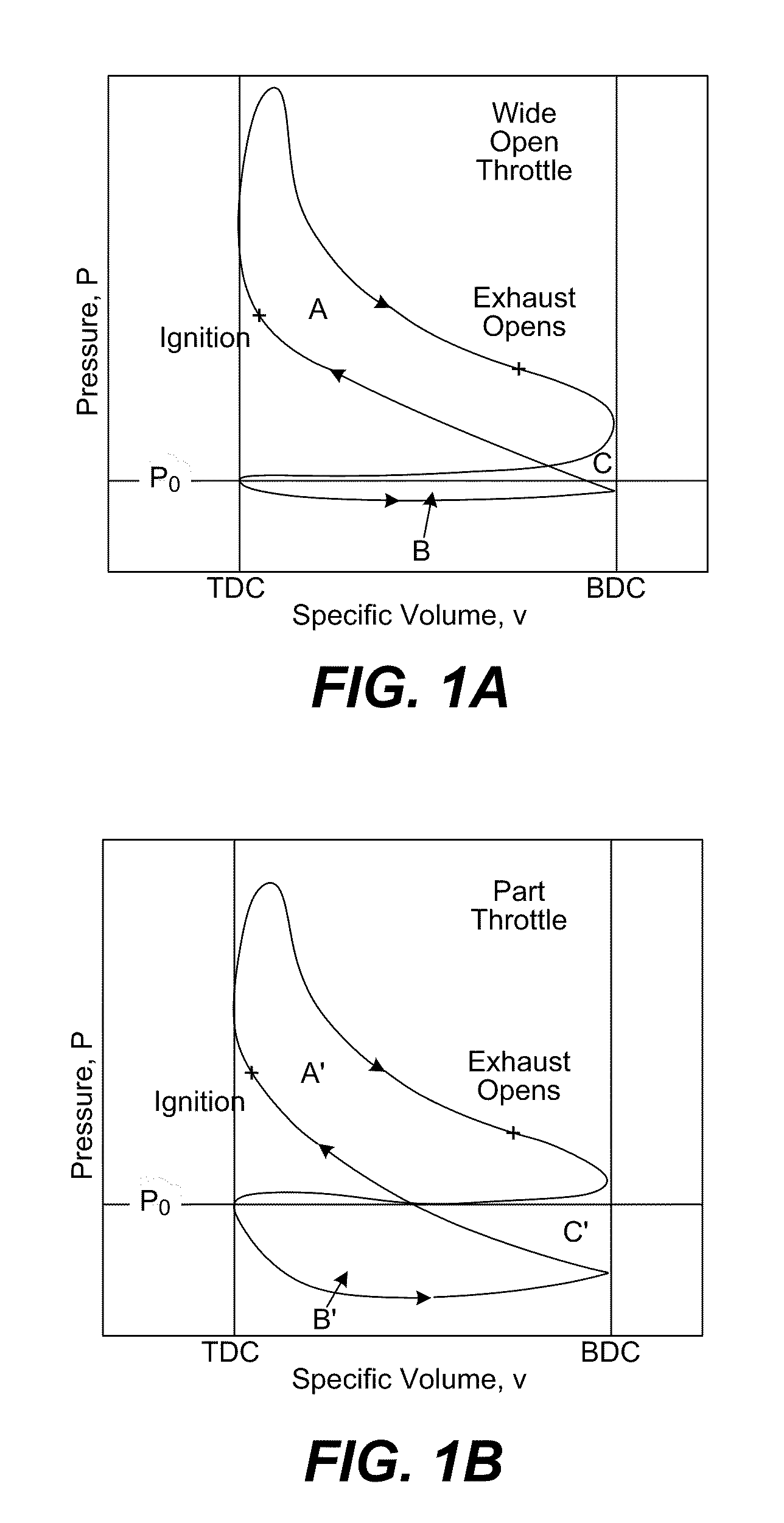

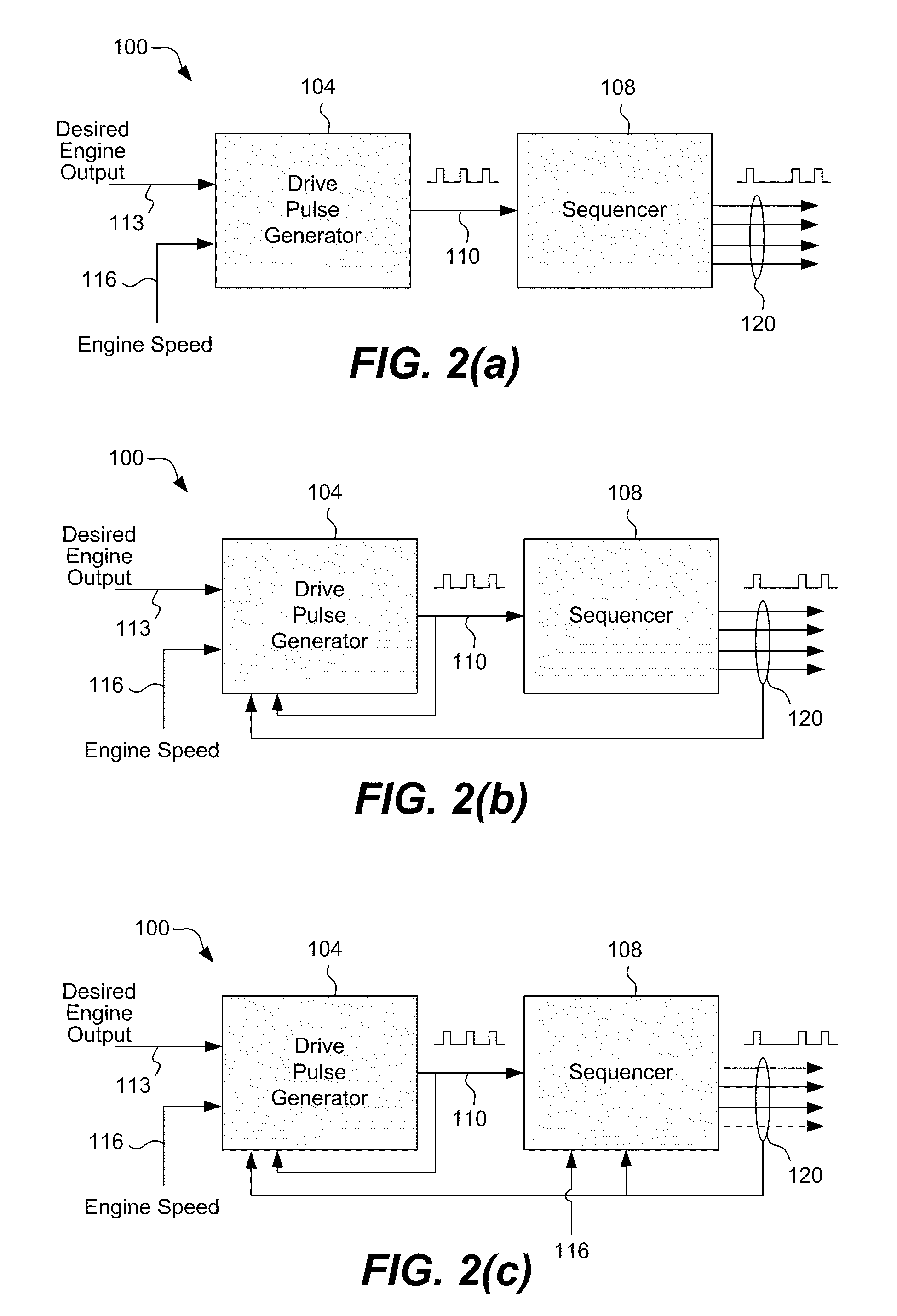

Skip fire engine control

ActiveUS20110030657A1Improve thermodynamic efficiencyReduce wall wetting lossElectrical controlMachines/enginesCombustionMode control

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. Generally, an engine is controlled to operate in a skip fire variable displacement mode. In the variable displacement mode, selected combustion events are skipped so that other working cycles can operate at better thermodynamic efficiency. More specifically, selected “skipped” working cycles are not fired while other “active” working cycles are fired. Typically, fuel is not delivered to the working chambers during skipped working cycles. In one aspect of the invention, a firing pattern is determined that is not fixed but the active working cycles are selected to favor the firing of working chambers that have recently been fired at least in part to reduce wall wetting losses. In another aspect of the invention, when an active working cycle follows a skipped working cycle in the same working chamber, the quanta of fuel injected for delivery to the working chamber is increased relative to the quanta of fuel that would be delivered to the working chamber when the active working cycle follows another active working cycle in the same working chamber in order to compensate for wall wetting losses that occur during skipped working cycles.

Owner:TULA TECH INC

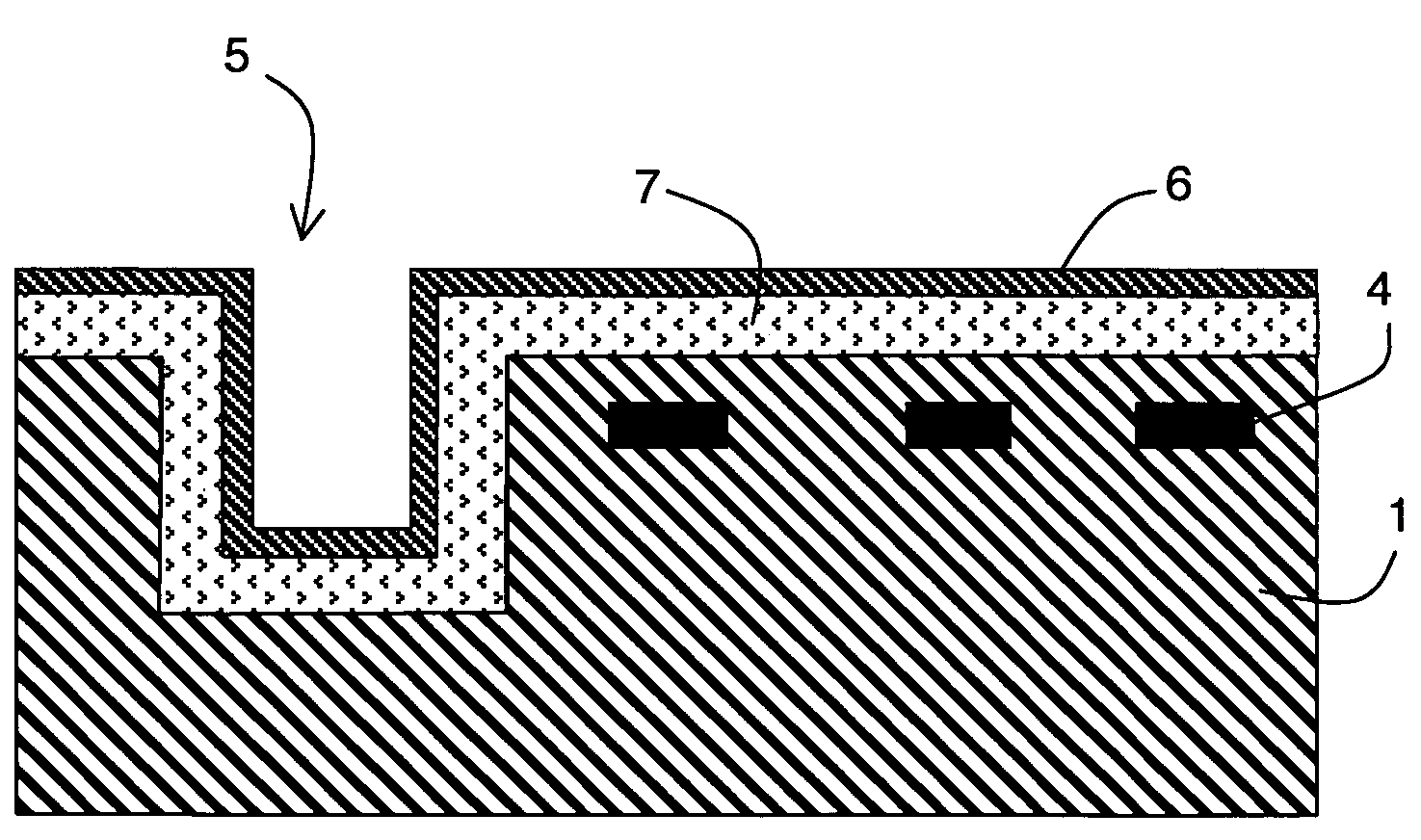

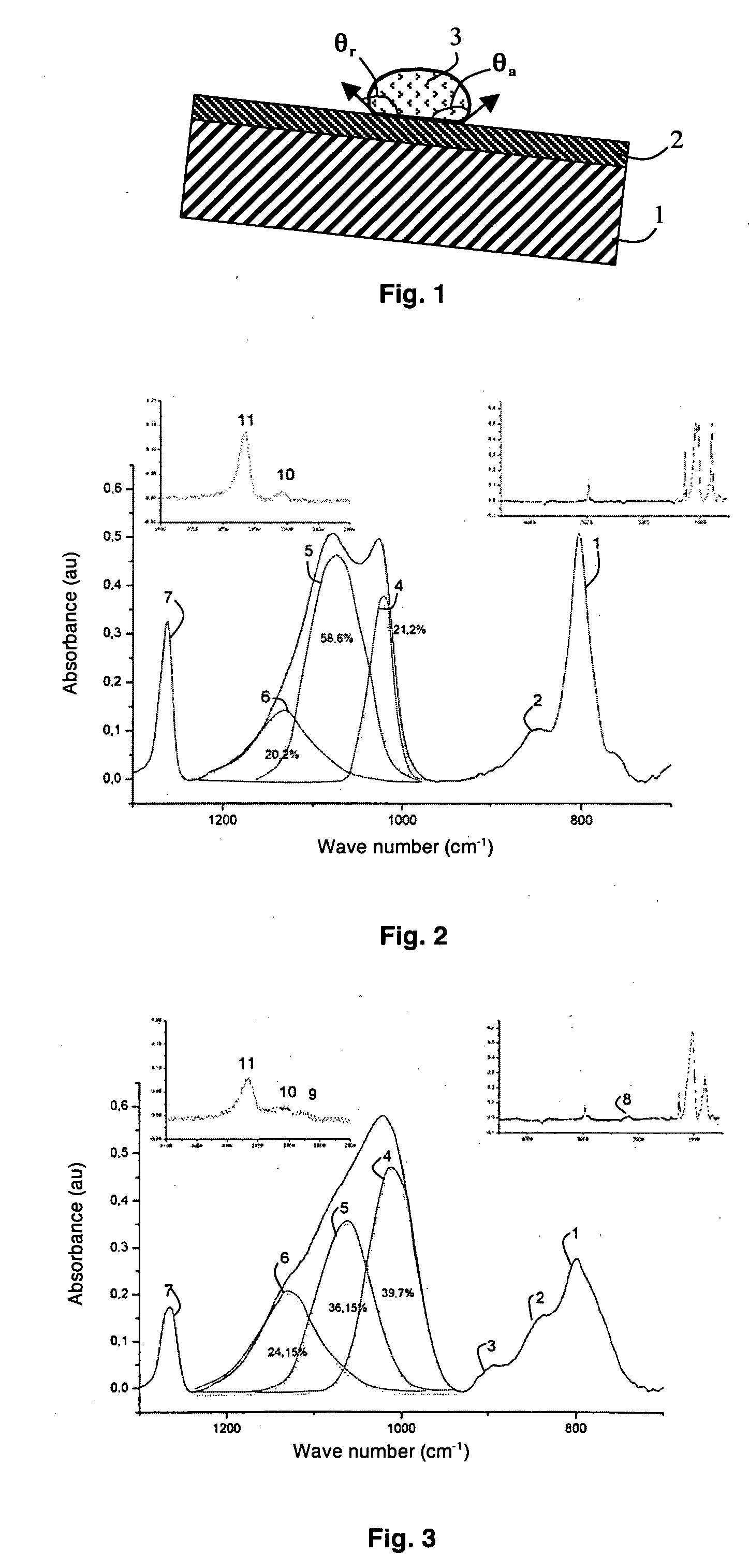

Hydrophobic Surface Coating With Low Wetting Hysteresis, Method for Depositing Same, Microcomponent and Use

ActiveUS20090142564A1Improve hydrophobicityHigh dielectric constantGroup 4/14 element organic compoundsSynthetic resin layered productsHysteresisDielectric

A hydrophobic surface coating, preferably obtained by chemical vapor deposition, comprises at least an upper thin layer formed by a compound selected from the group consisting of SiCxOy:H with x comprised between 1.4 and 2 and y comprised between 0.8 and 1.4 and SiCx′Ny′:H with x′ comprised between 1.2 and 1.4 and y′ comprised between 0.6 and 0.8, so as to obtain a free surface with a low wetting hysteresis. Such a hydrophobic surface coating can be arranged on the free surface of a microcomponent comprising at least one substrate provided with, an electrode array and particularly suitable for moving drops of liquid by electrowetting on dielectric.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Formation of discontinuous films during an imprint lithography process

The present invention is directed to a template having a body including a surface with first and second regions. The first region has first wetting characteristics for a given material and the second region has second wetting characteristics for the given material. The first wetting characteristics differ from the second wetting characteristics. Specifically, the first region is formed from a surface treatment layer with a first surface energy to provide the first wetting characteristics. The second region is exposed portions of the body, typically quartz of fused silica, having a second surface energy associated therewith. The second surface energy is greater than the first surface energy to provide the second region with the second wetting characteristics.

Owner:CANON KK +1

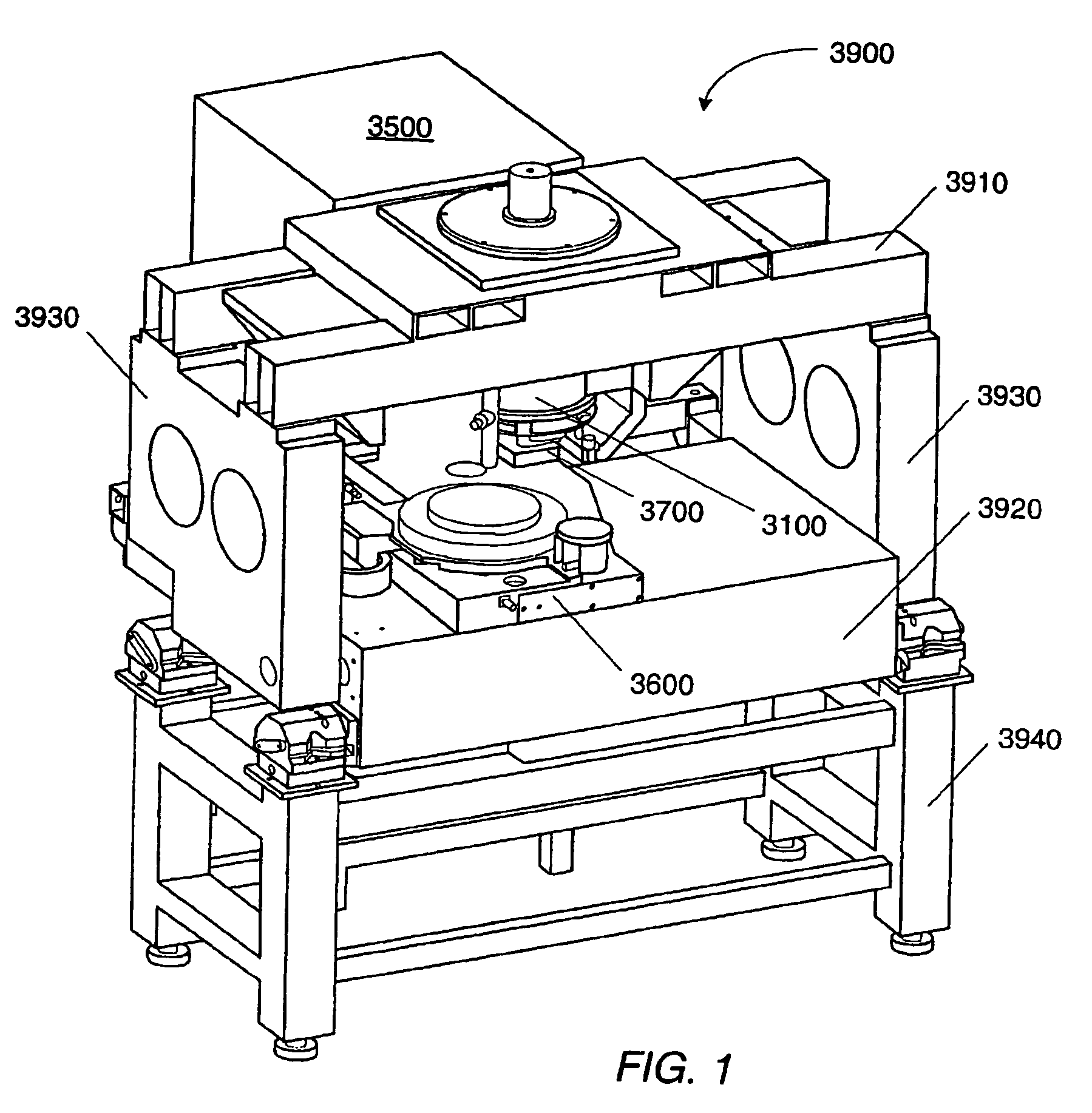

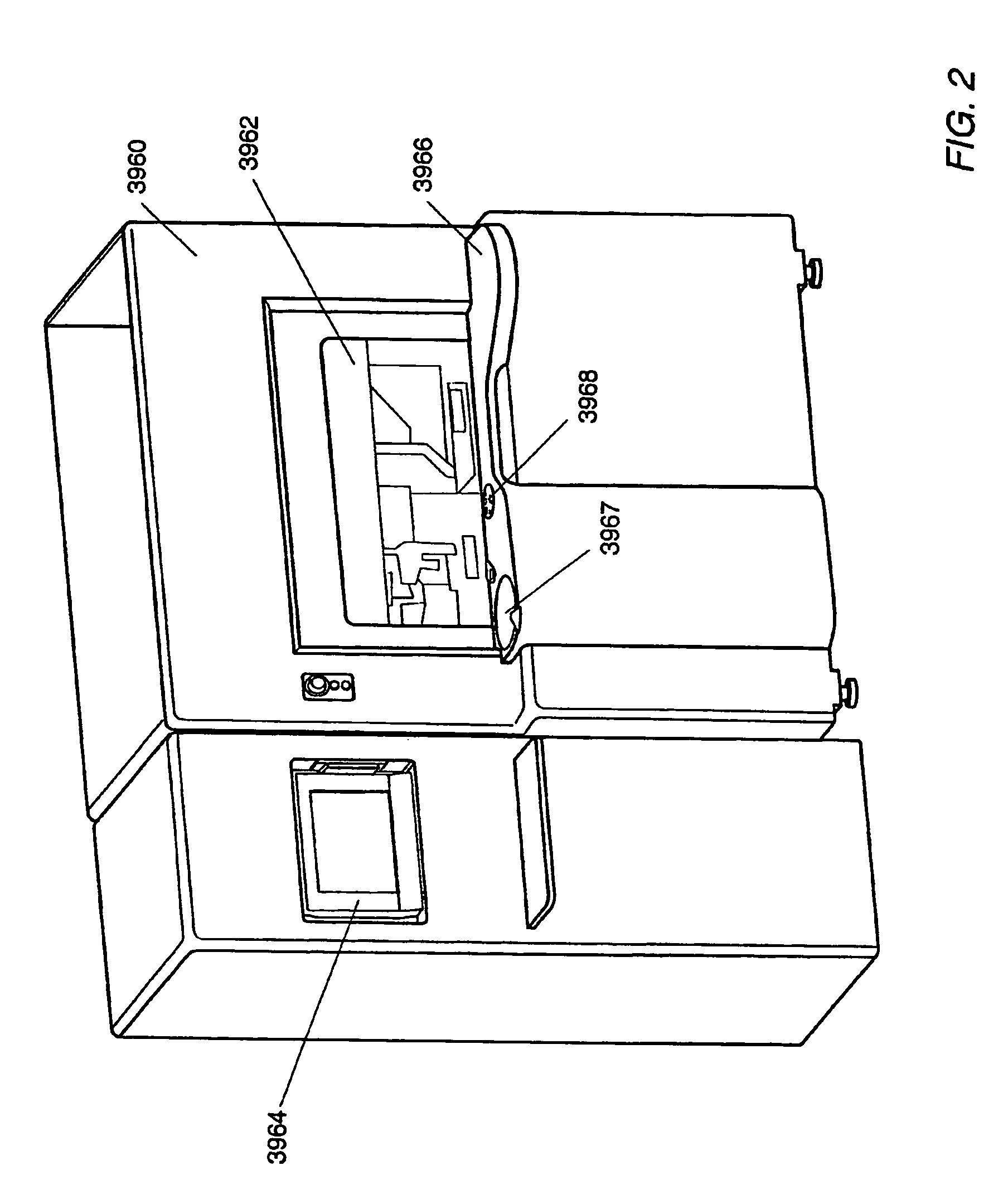

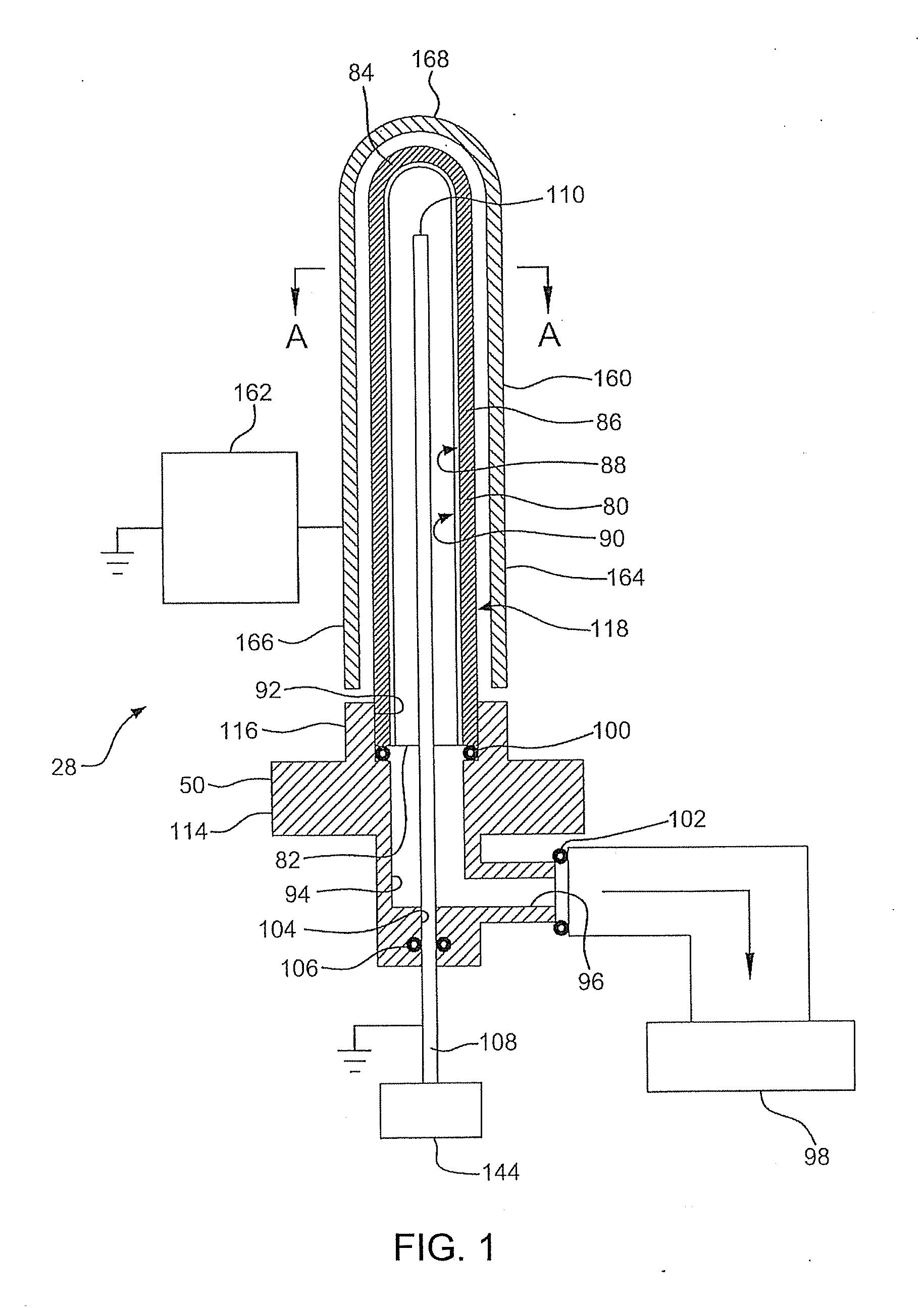

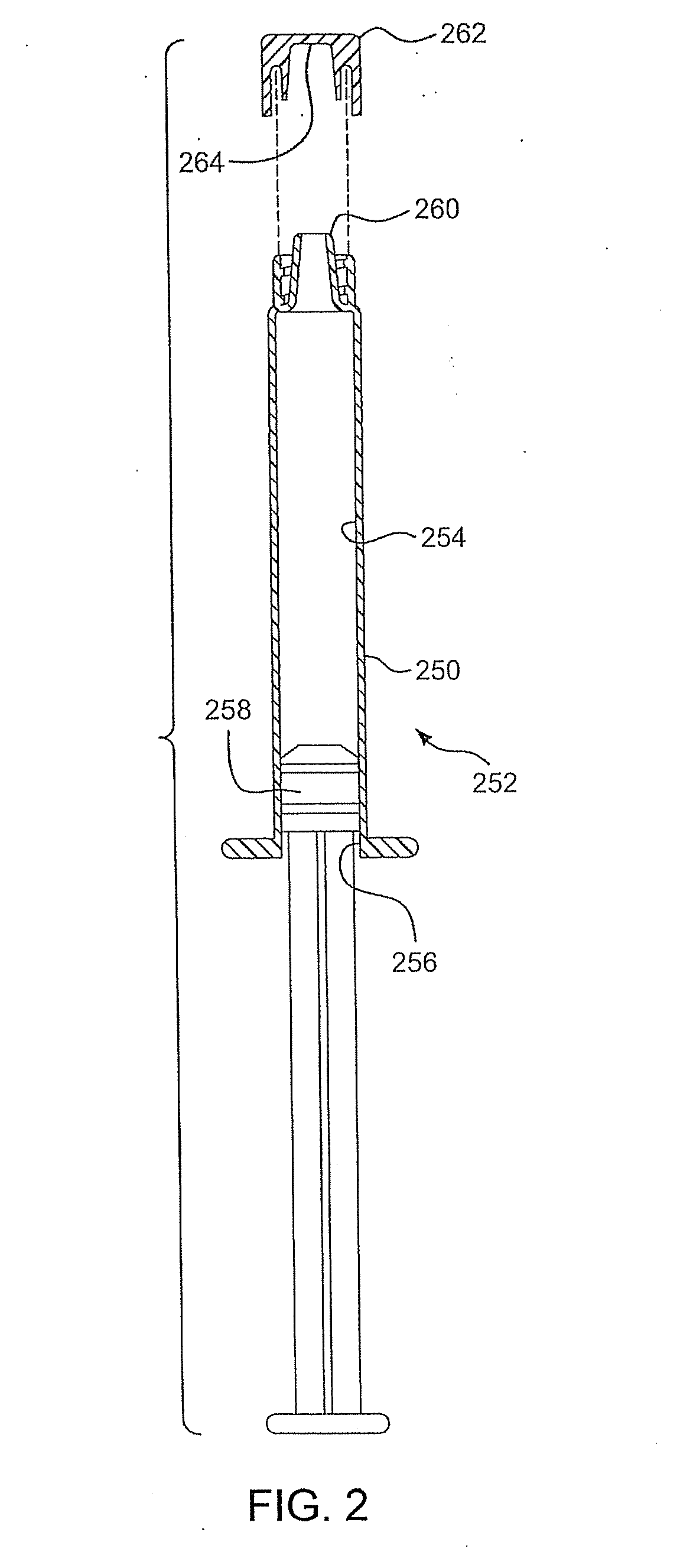

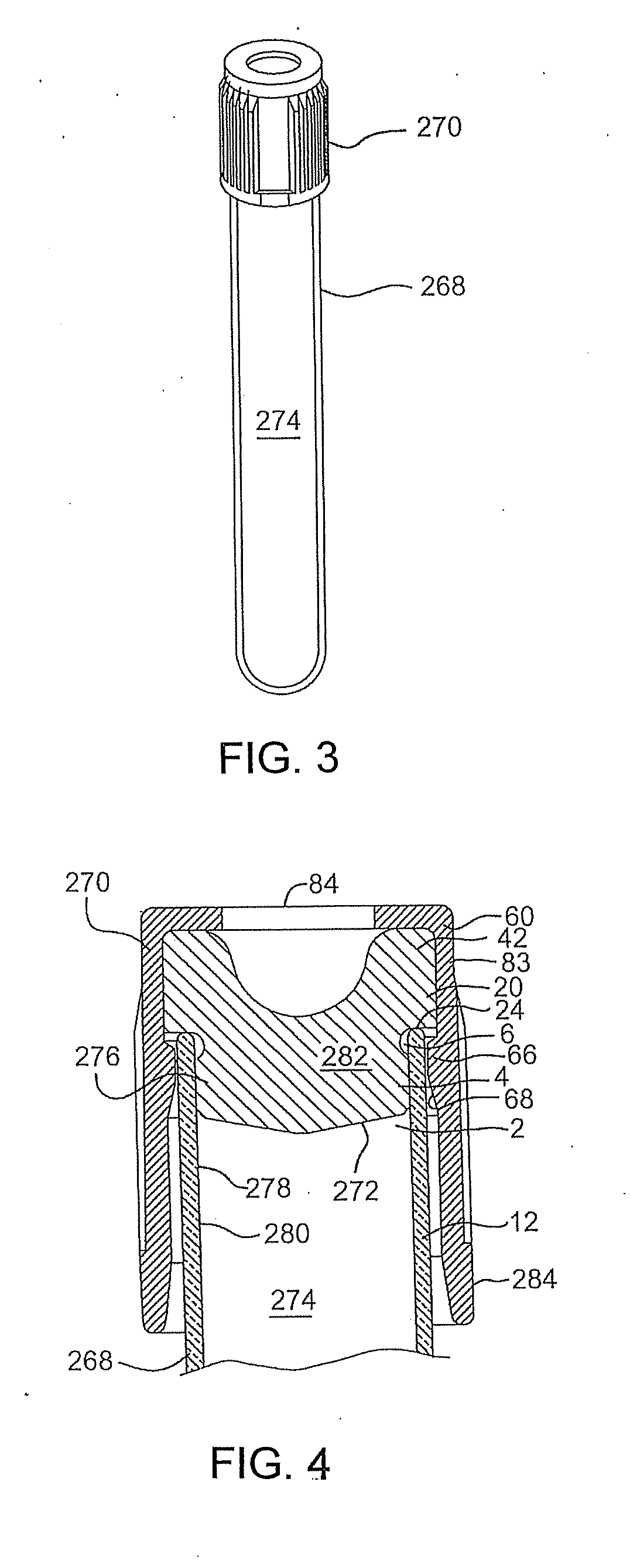

Vessels, contact surfaces, and coating and inspection apparatus and methods

ActiveUS20120252709A1Reduce transmission of fluidReduce transmissionInfusion syringesBearing componentsProduct gasSurface barrier

Methods for processing a contact surface, for example to provide a gas barrier or lubricity or to modify the wetting properties on a medical device, are disclosed. First and second PECVD or other contact surface processing stations or devices and a contact surface holder comprising a contact surface port are provided. An opening of the contact surface can be seated on the contact surface port. The interior contact surface of the seated contact surface can be processed via the contact surface port by the first and second processing stations or devices. contact surface barrier, lubricity and hydrophobic coatings and coated contact surfaces, for example syringes and medical sample collection tubes are disclosed. A contact surface processing system and contact surface inspection apparatus and methods are also disclosed.

Owner:SI02 MEDICAL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com