Patents

Literature

171results about How to "Improve thermodynamic efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

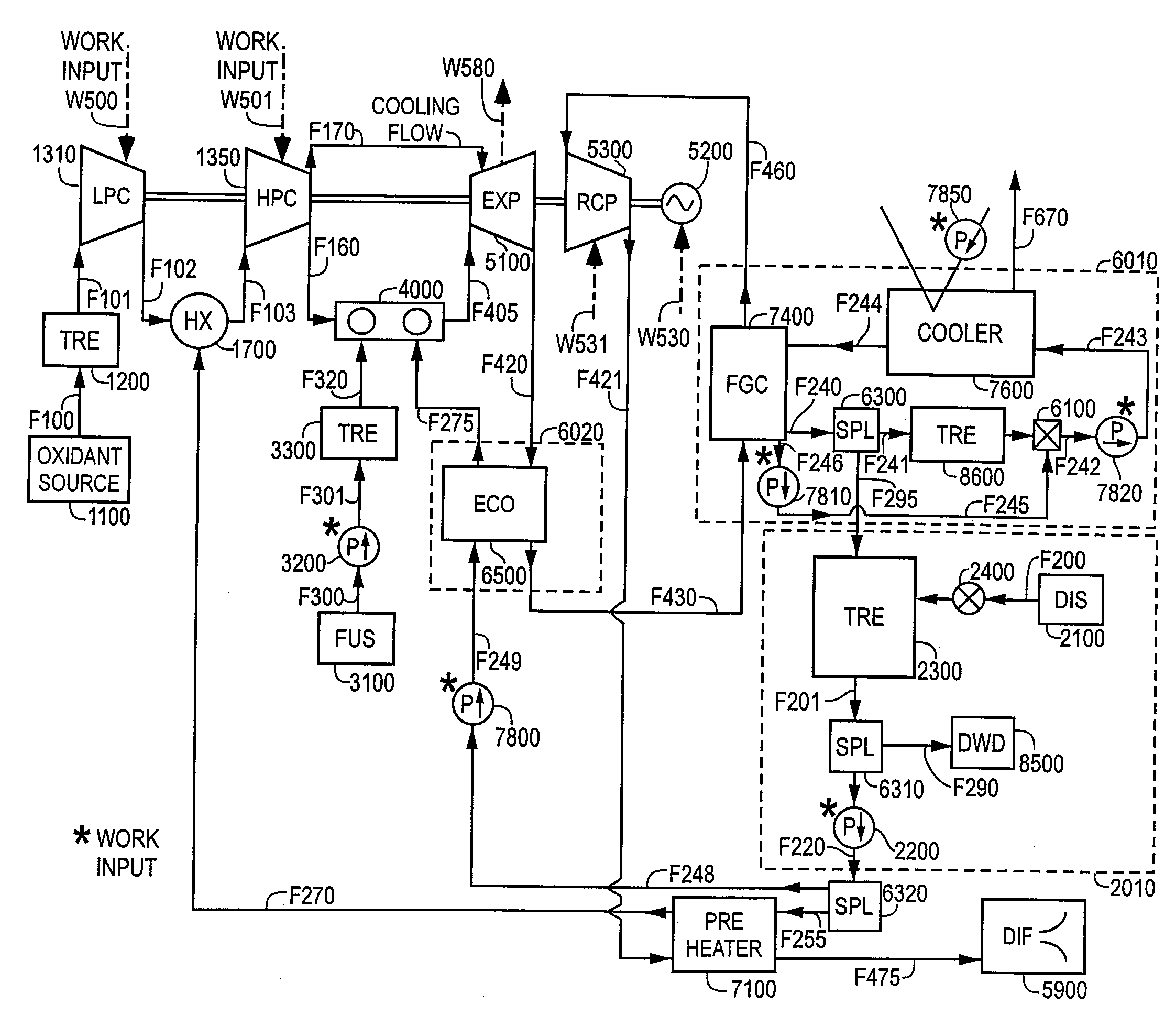

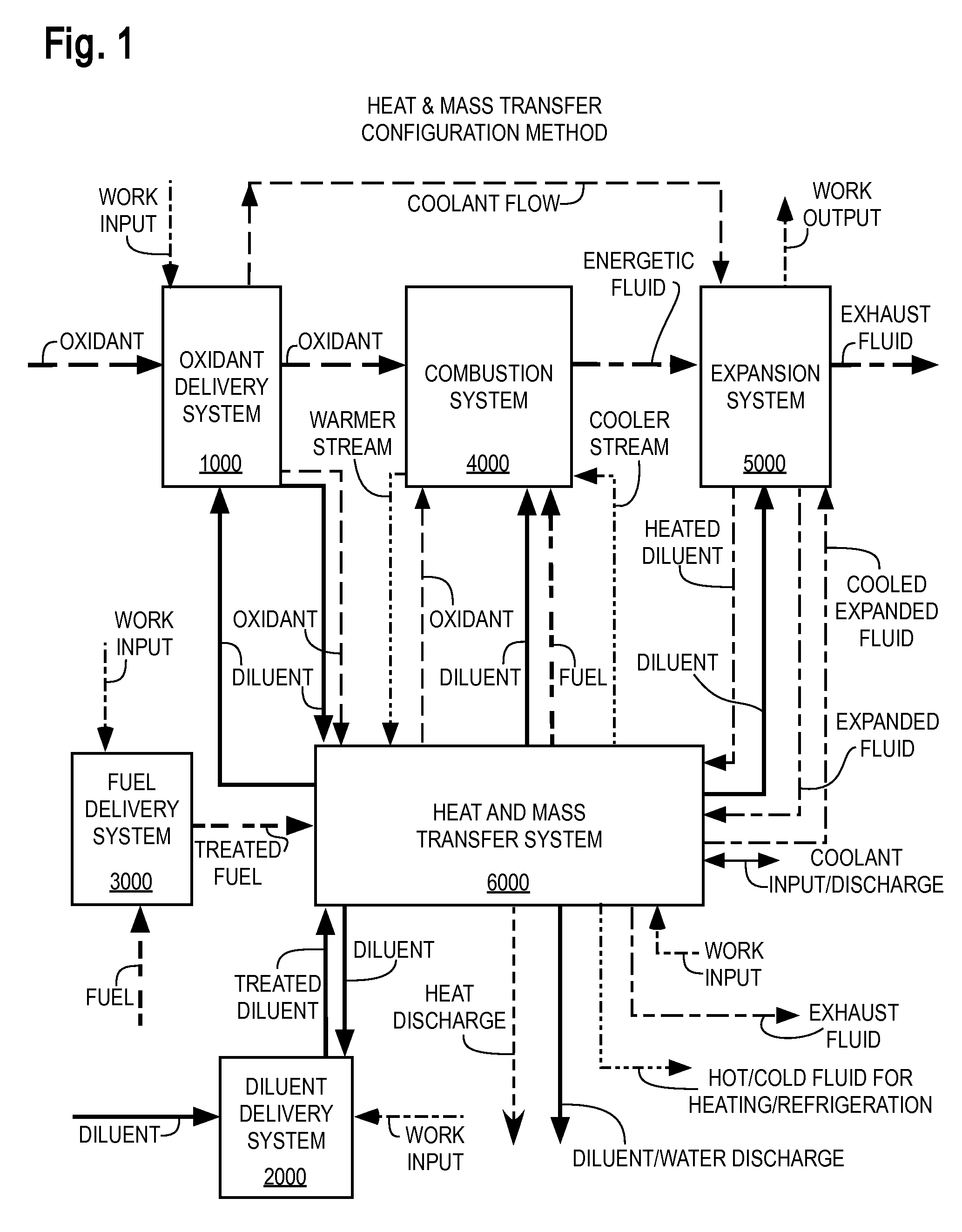

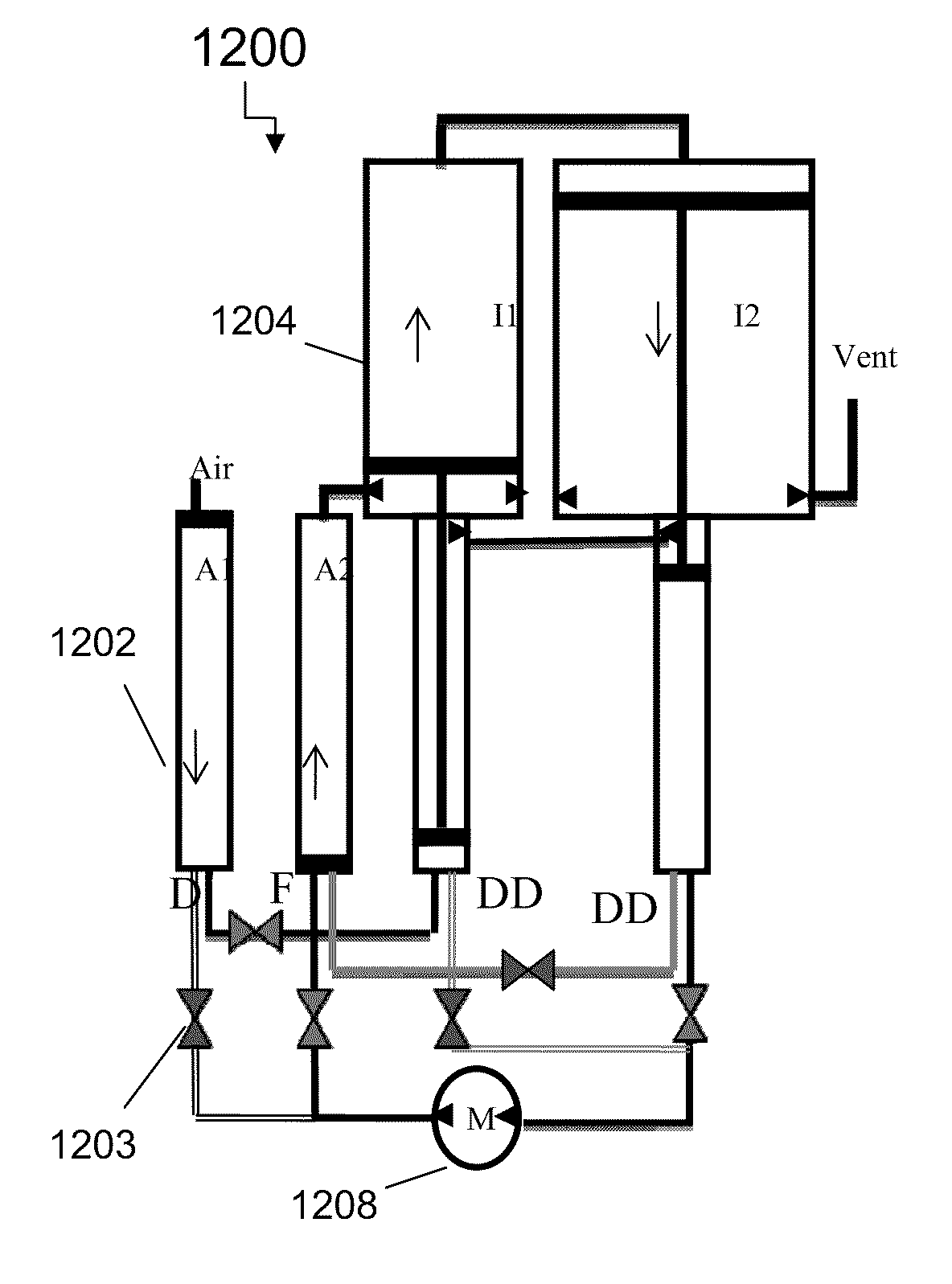

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

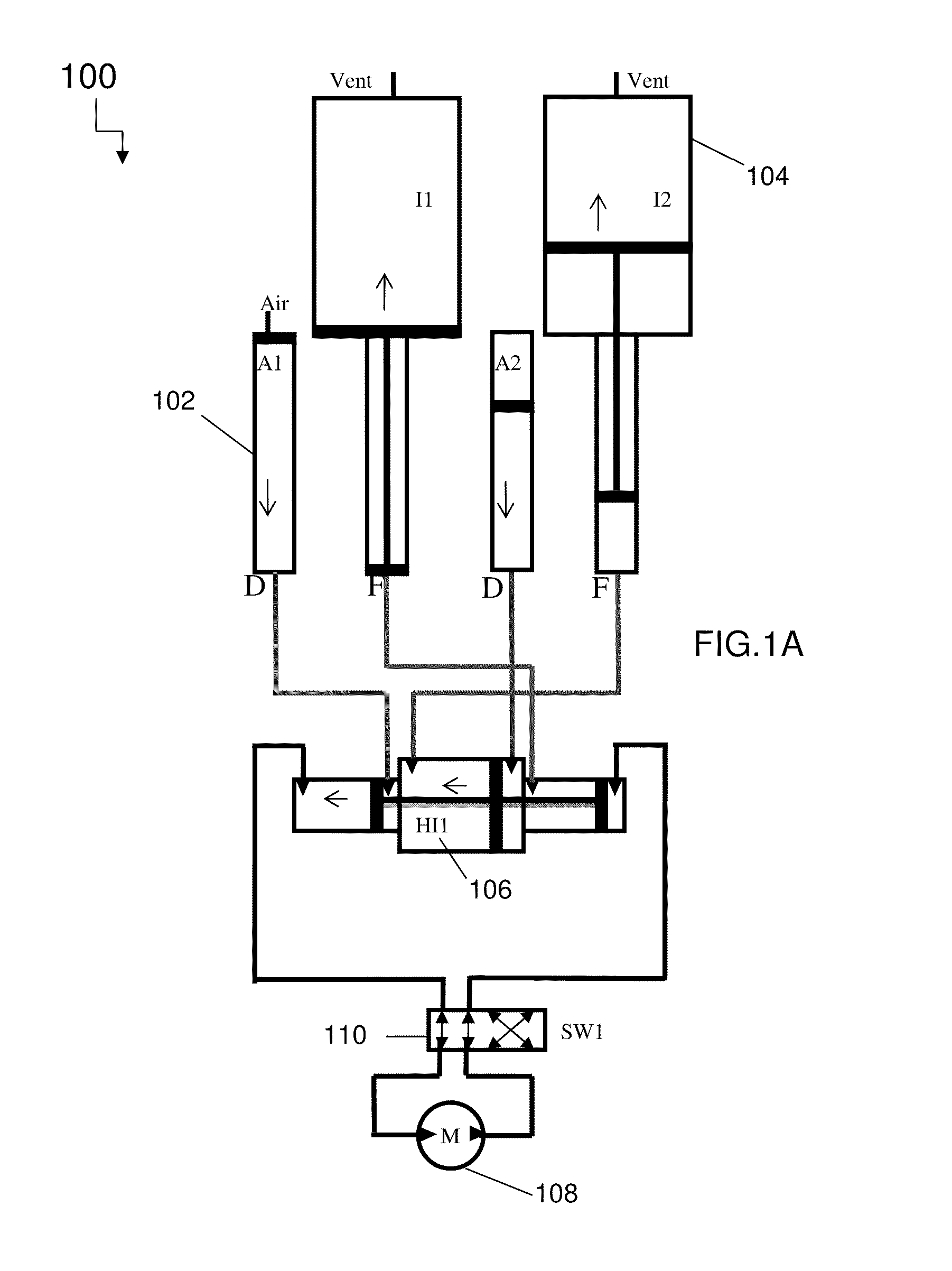

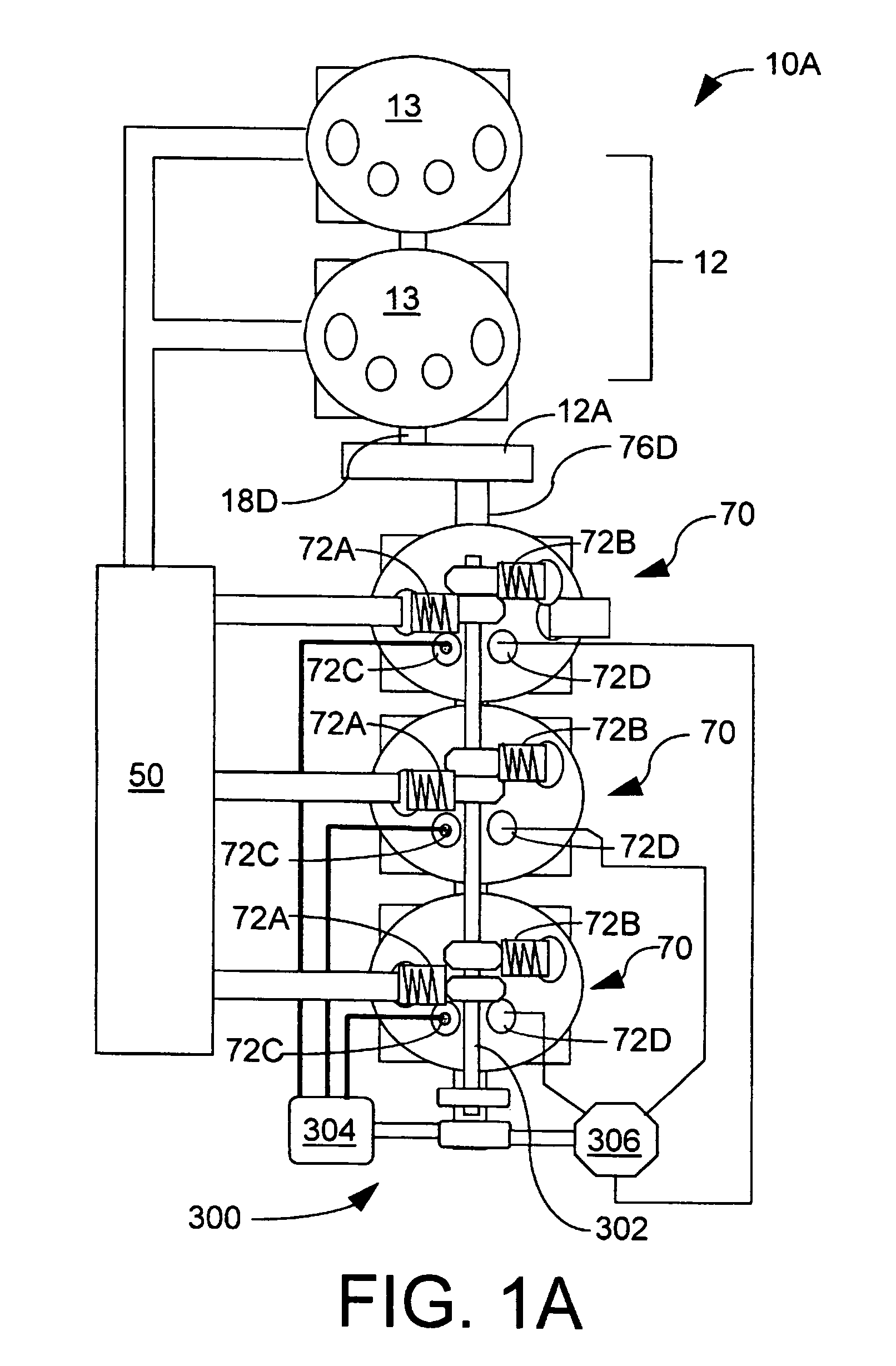

Systems and Methods for Improving Drivetrain Efficiency for Compressed Gas Energy Storage and Recovery Systems

InactiveUS20100307156A1Easy to testLow costElectrical storage systemGas turbine plantsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

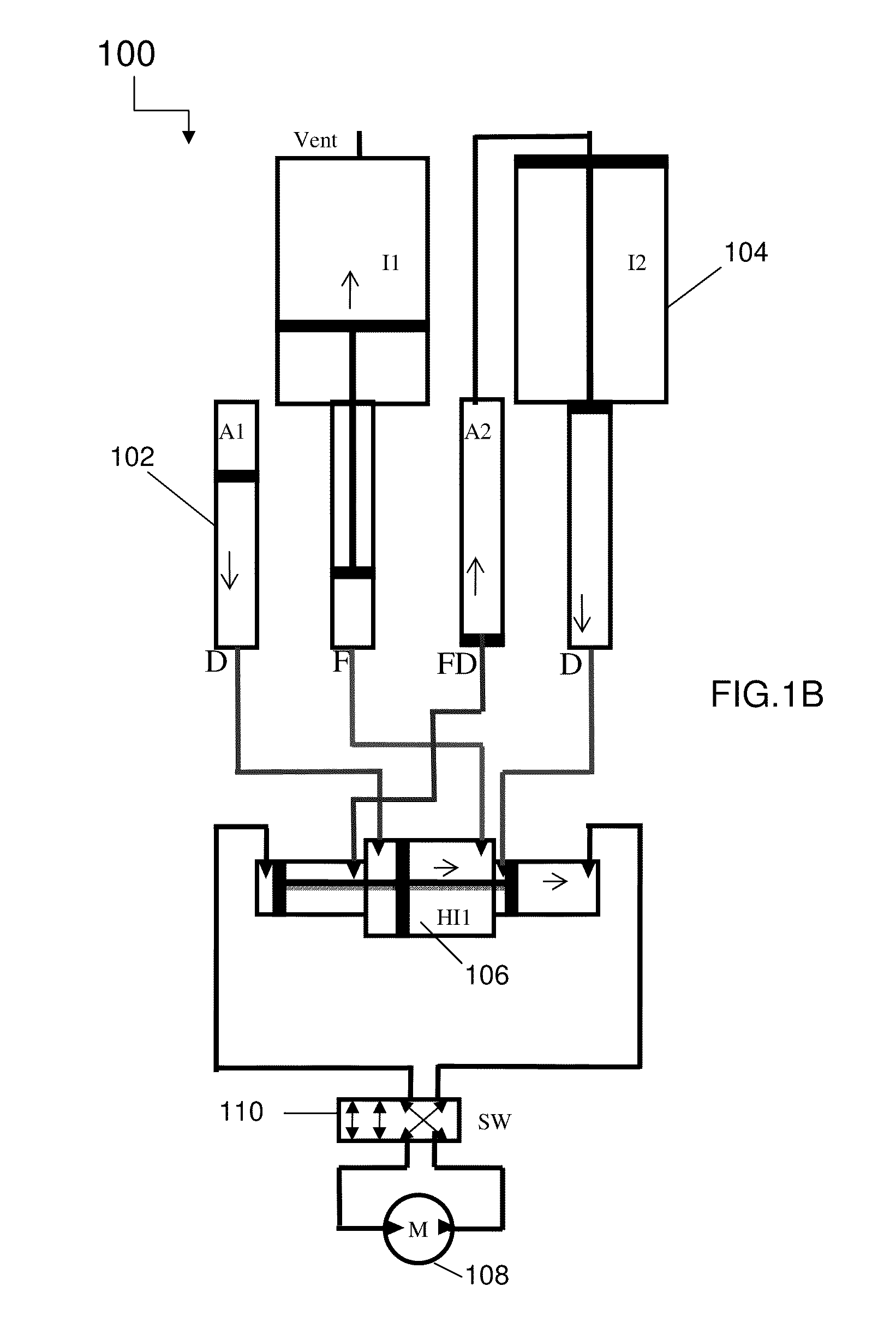

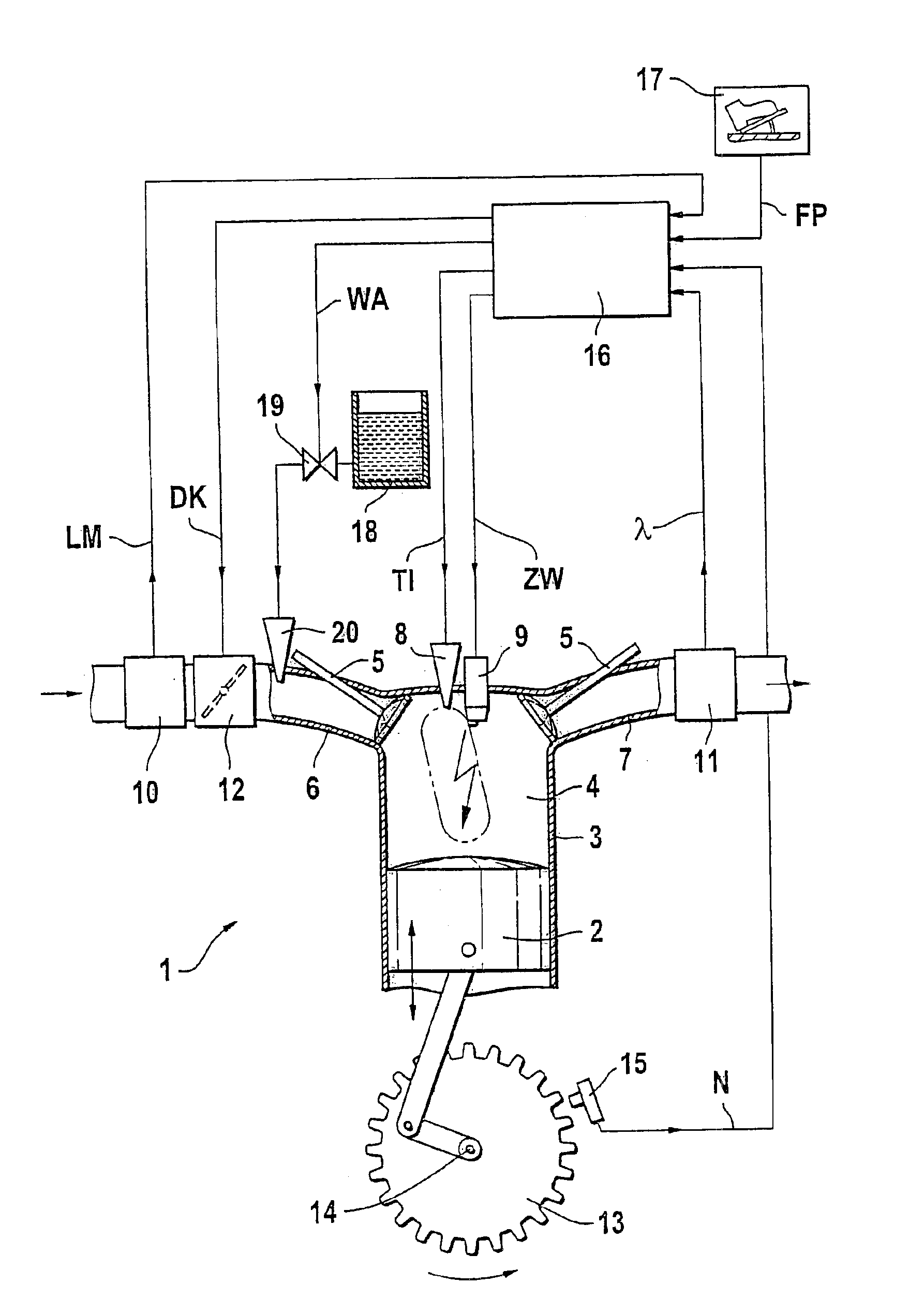

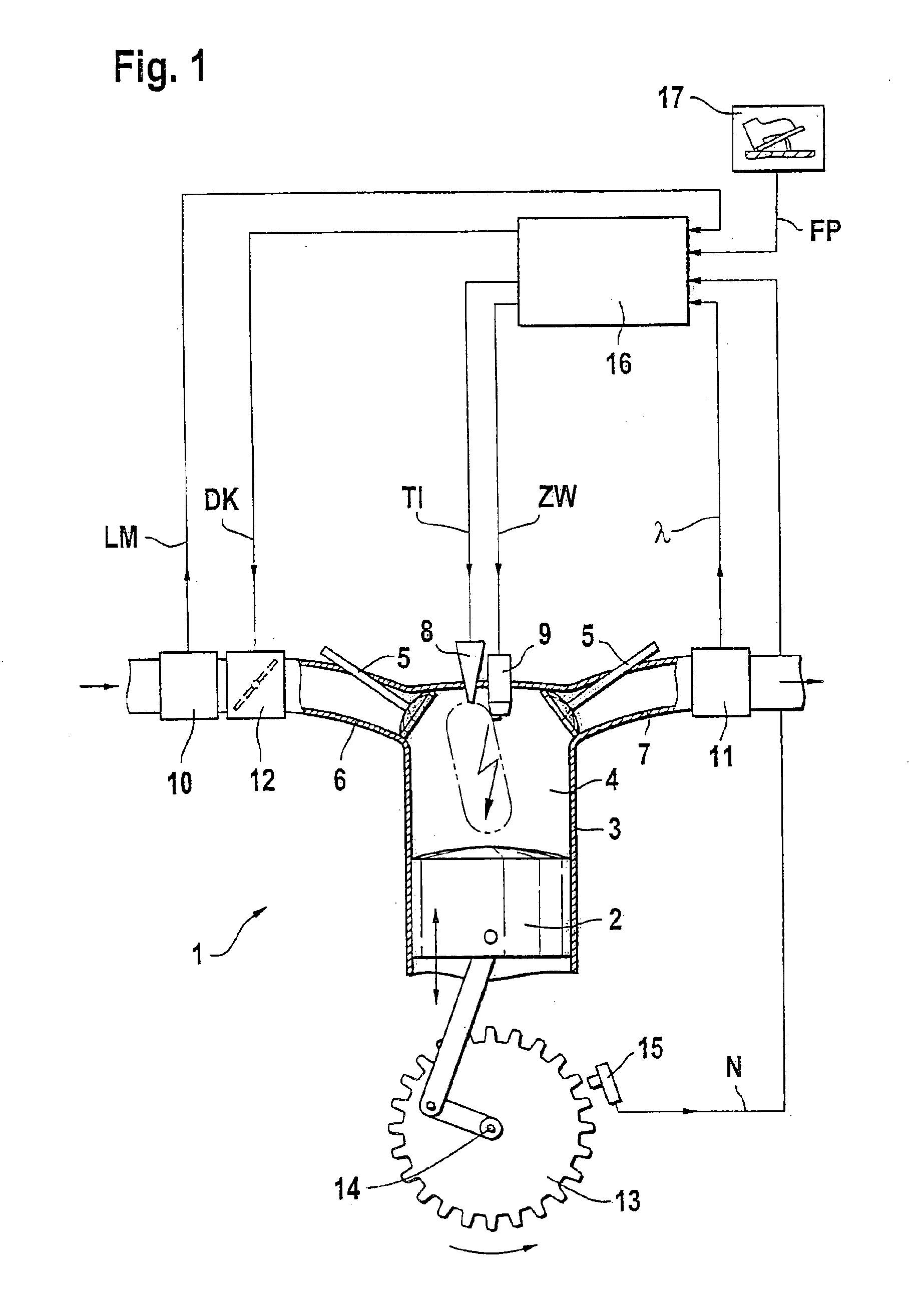

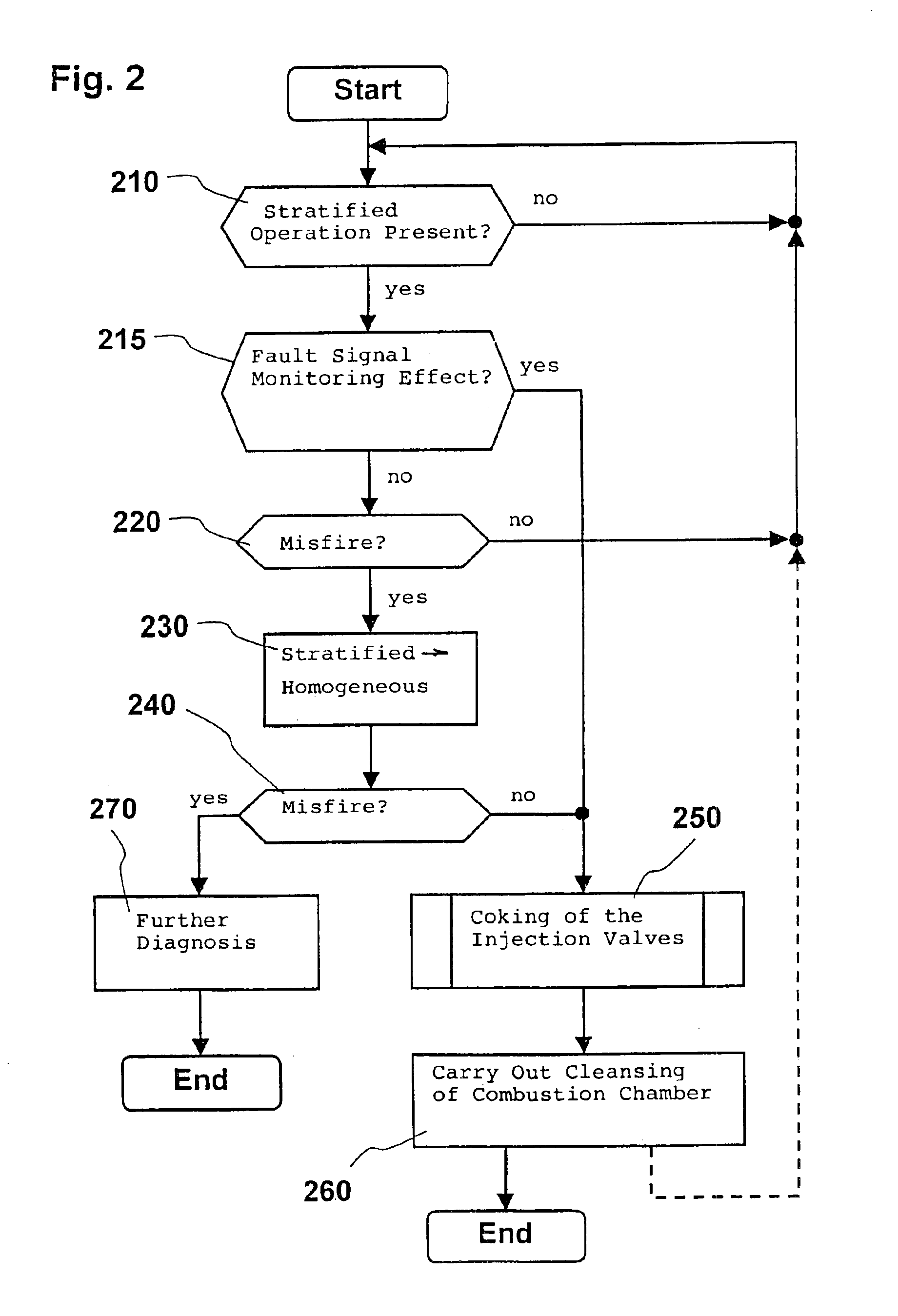

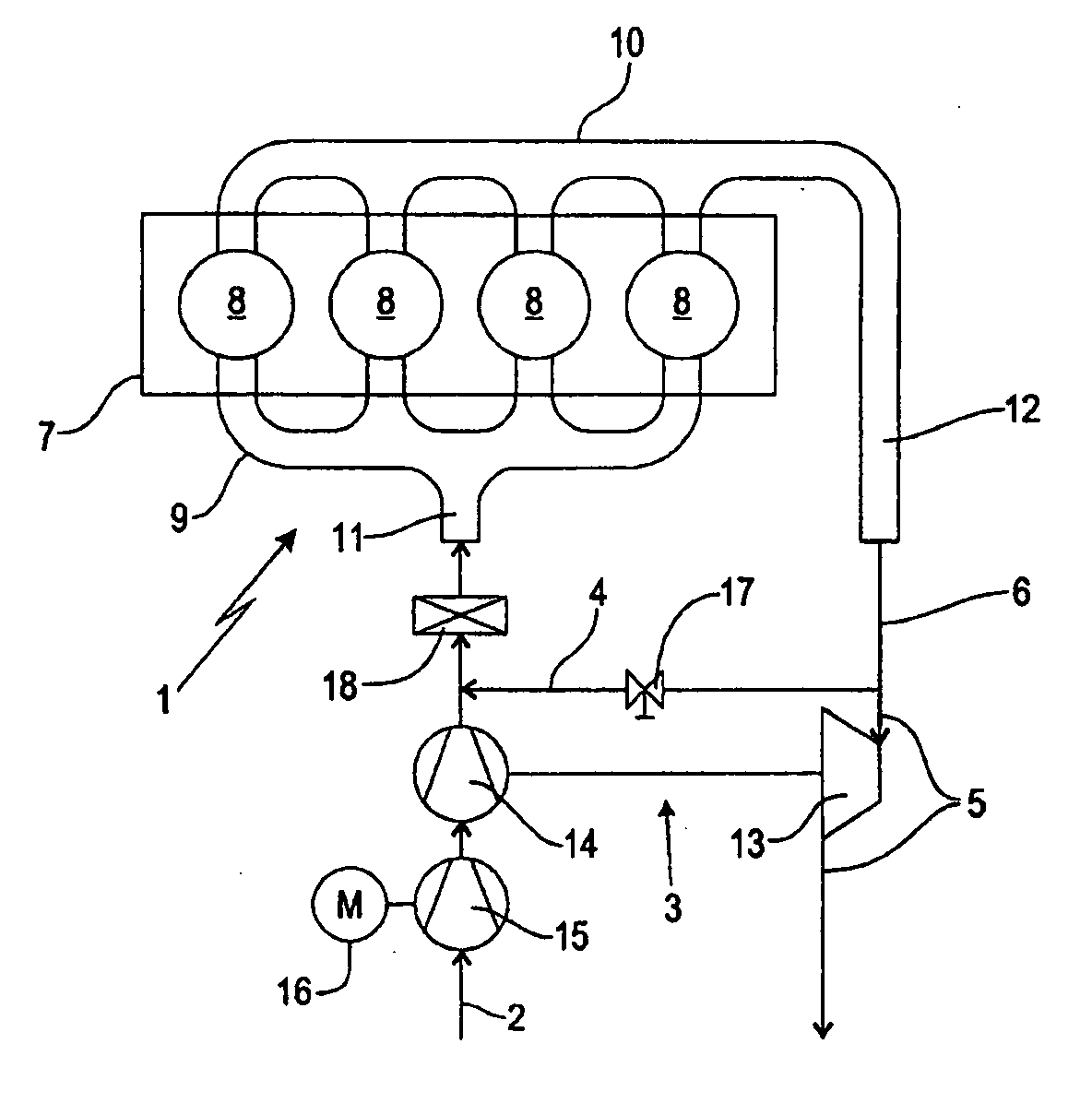

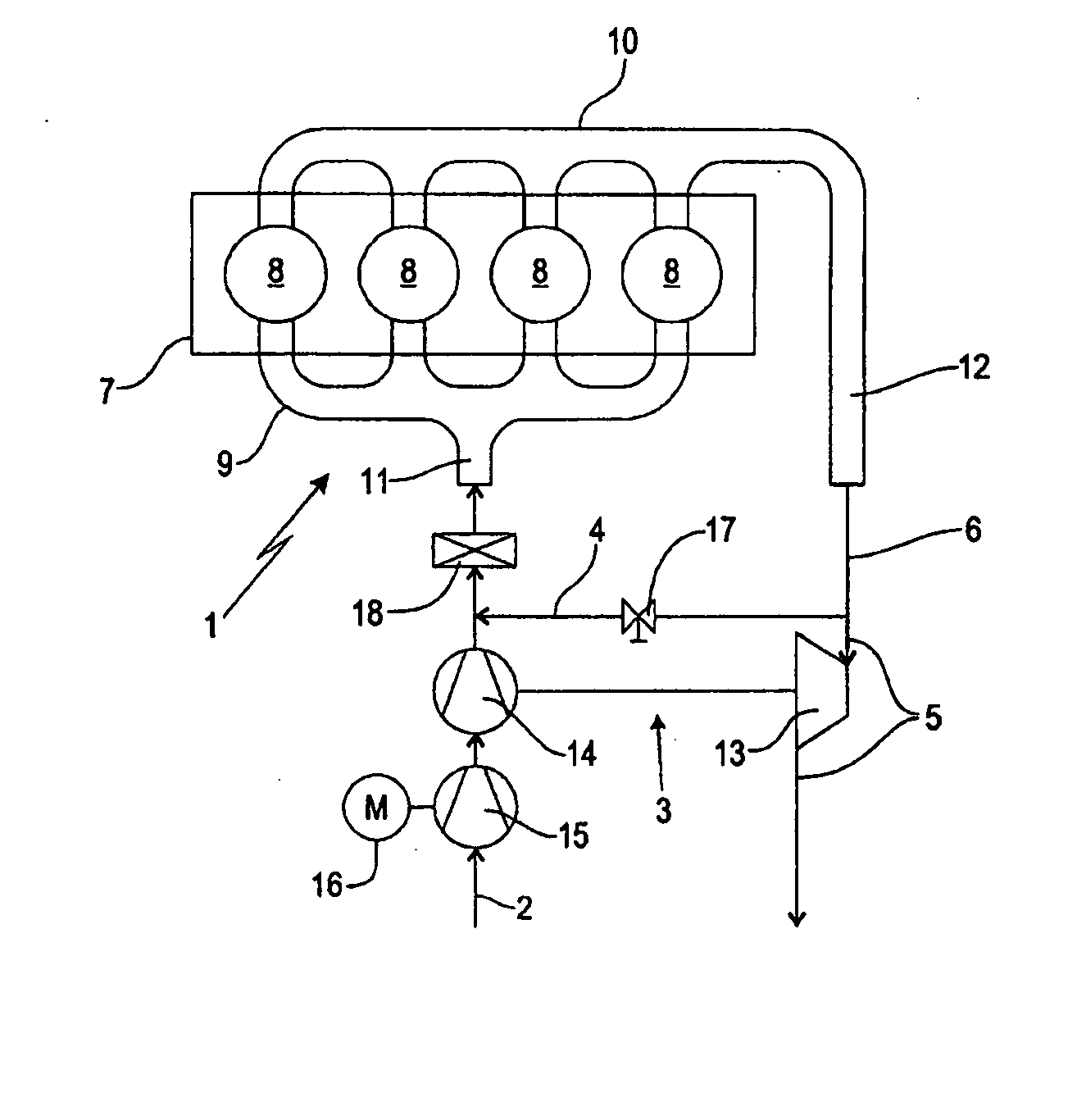

Method for operating an internal combustion engine

InactiveUS6892691B1Simple meansPromote combustionAnalogue computers for vehiclesElectrical controlExternal combustion engineInternal combustion engine

The operation of an internal combustion engine under unfavorable operating conditions can lead to the formation of deposits in the combustion chamber (4). A method and an arrangement for operating an internal combustion engine (1), especially of a motor vehicle, is suggested, wherein fuel is conducted into a combustion chamber (4) and is there combusted. When deposits are detected in the combustion chamber (4), measures are initiated in a targeted manner for cleansing the combustion chamber (4). A knocking combustion is especially introduced and / or a cleansing liquid is added to the inducted combustion air.

Owner:ROBERT BOSCH GMBH

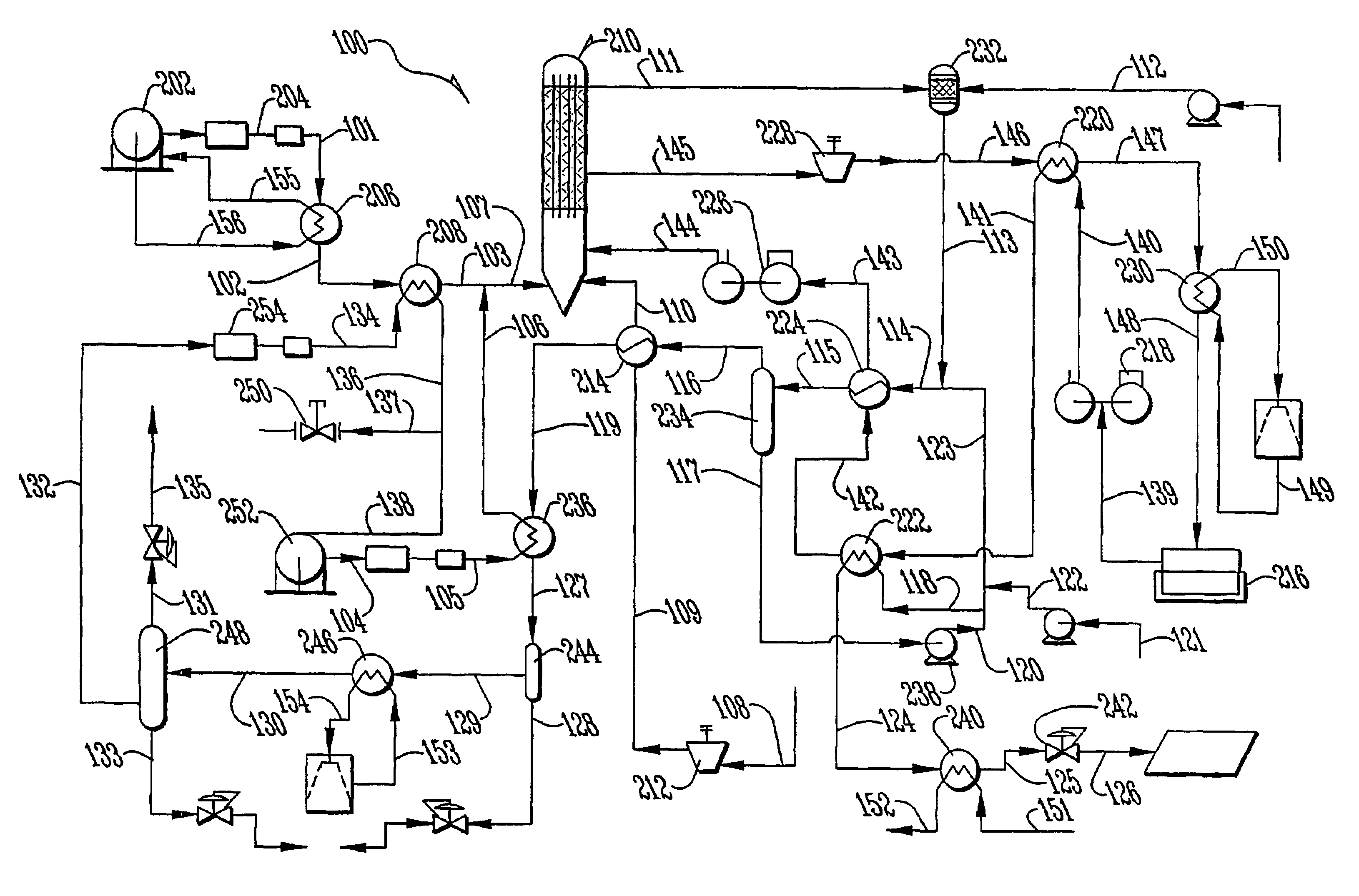

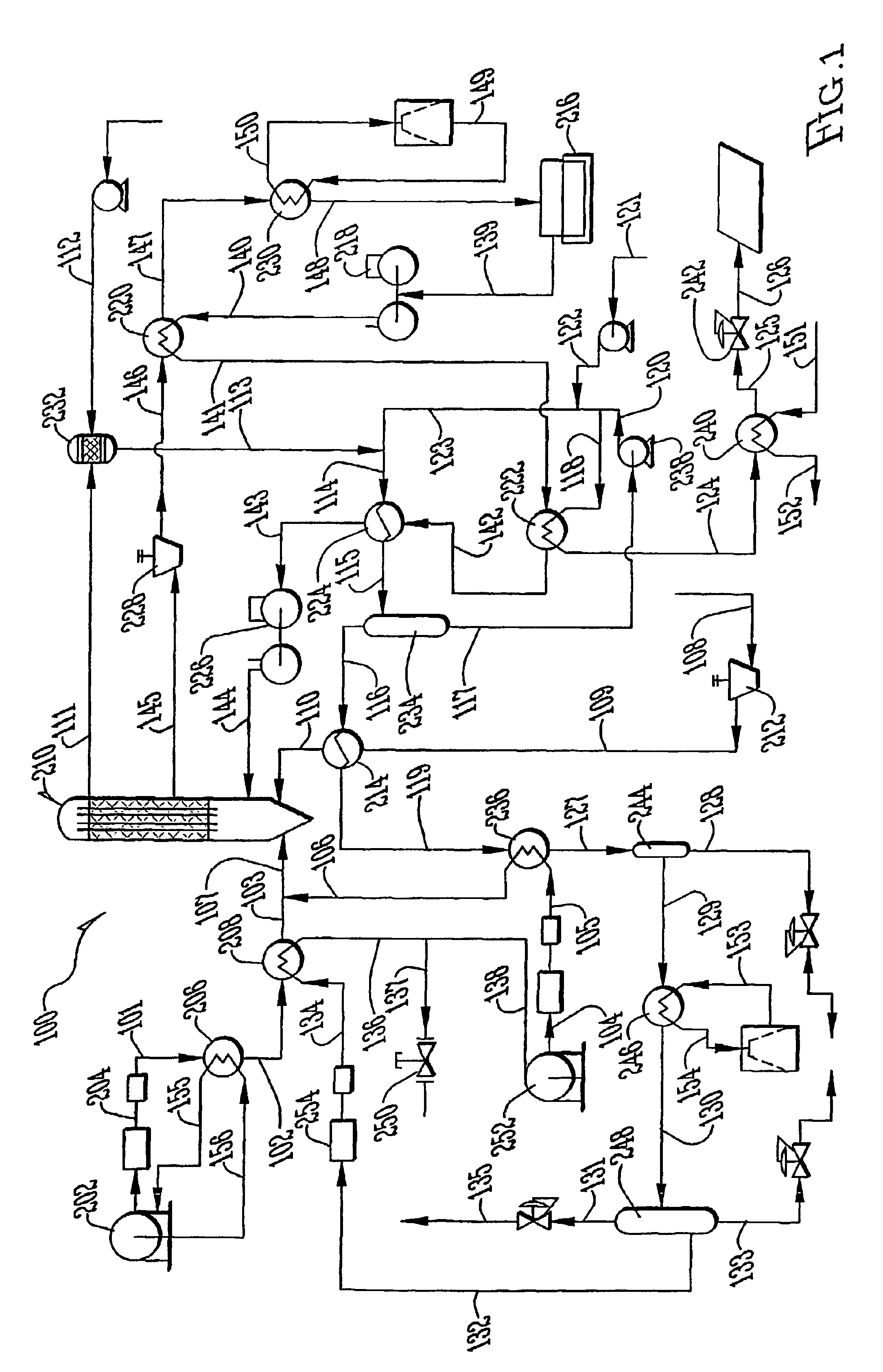

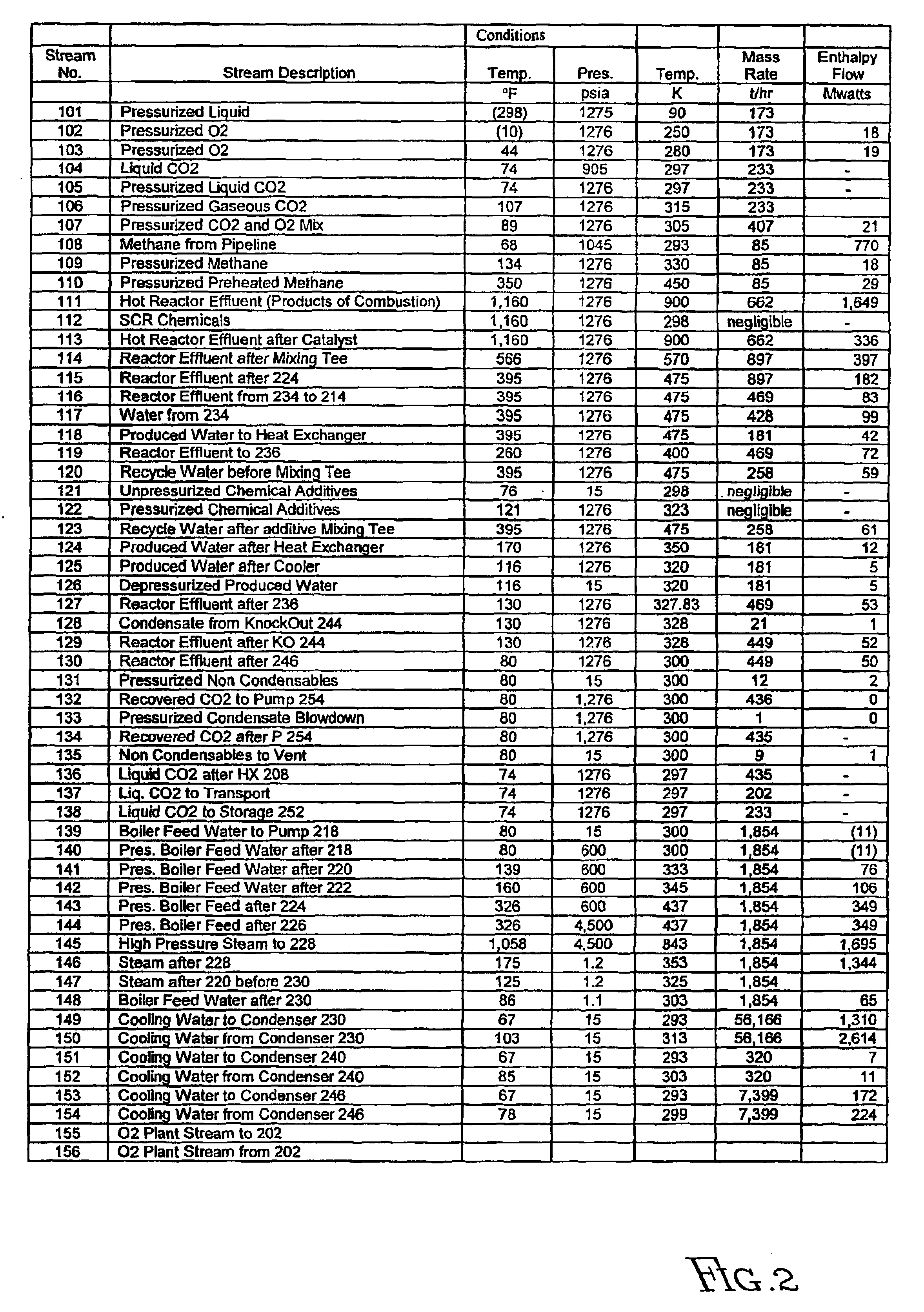

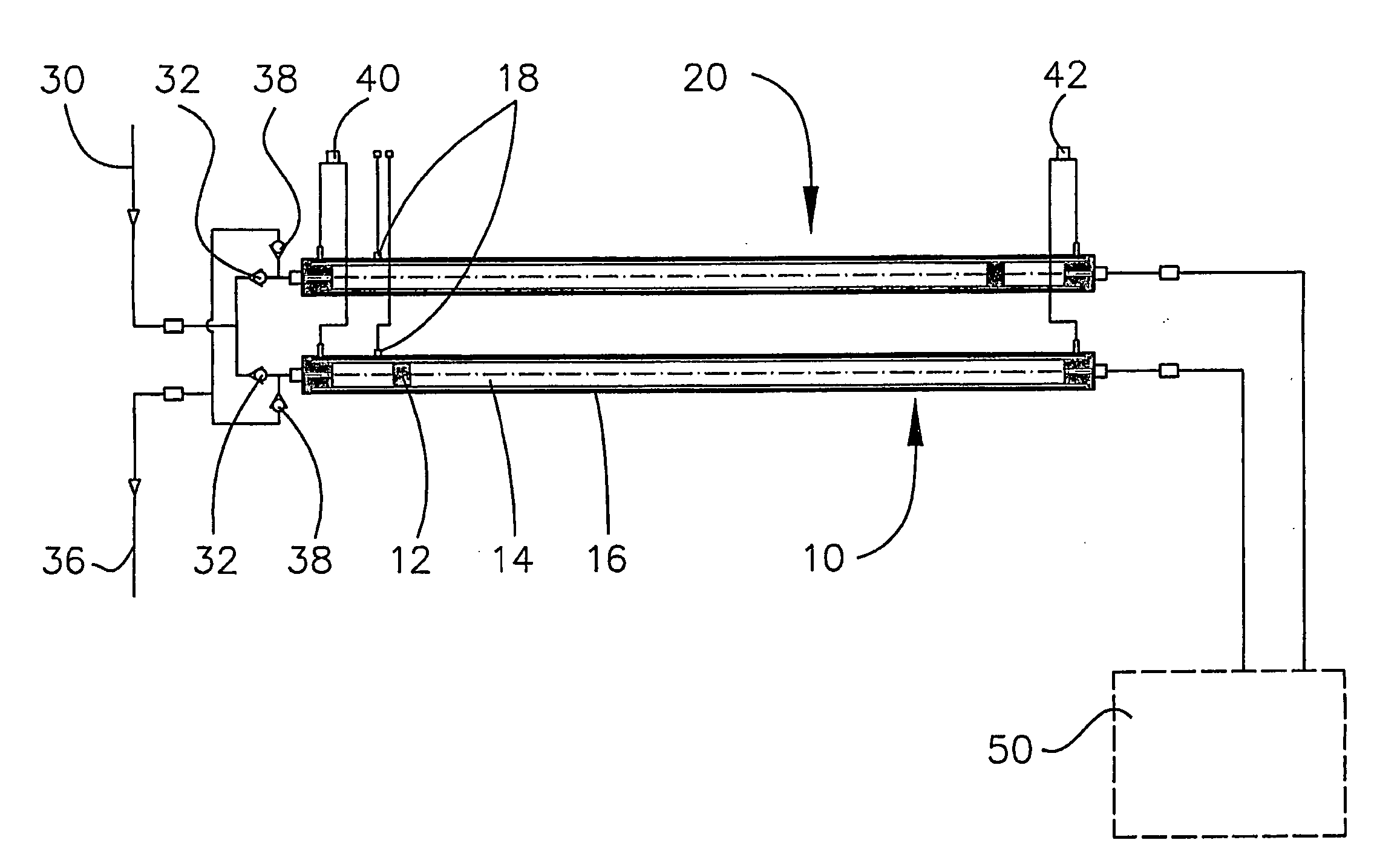

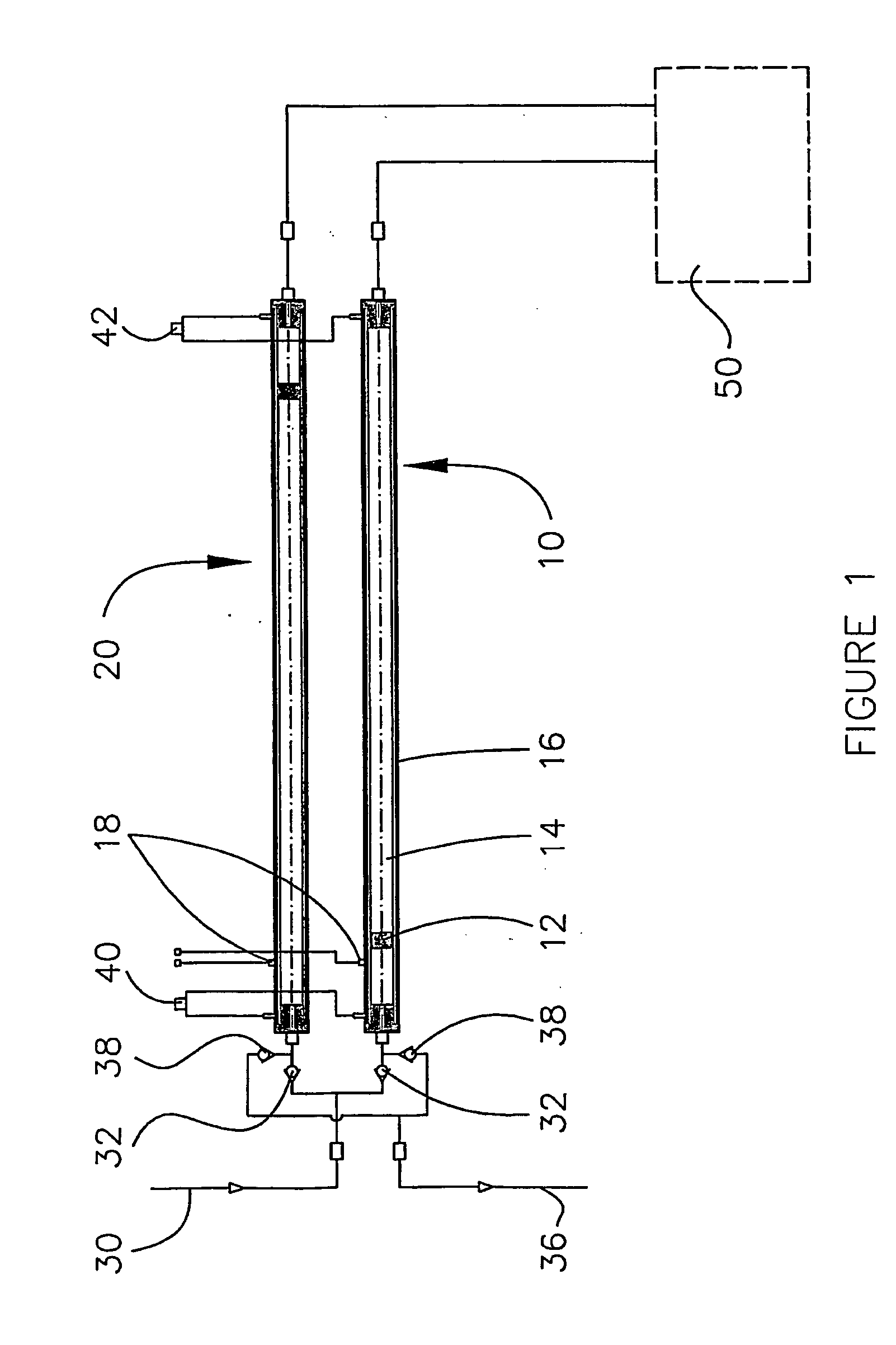

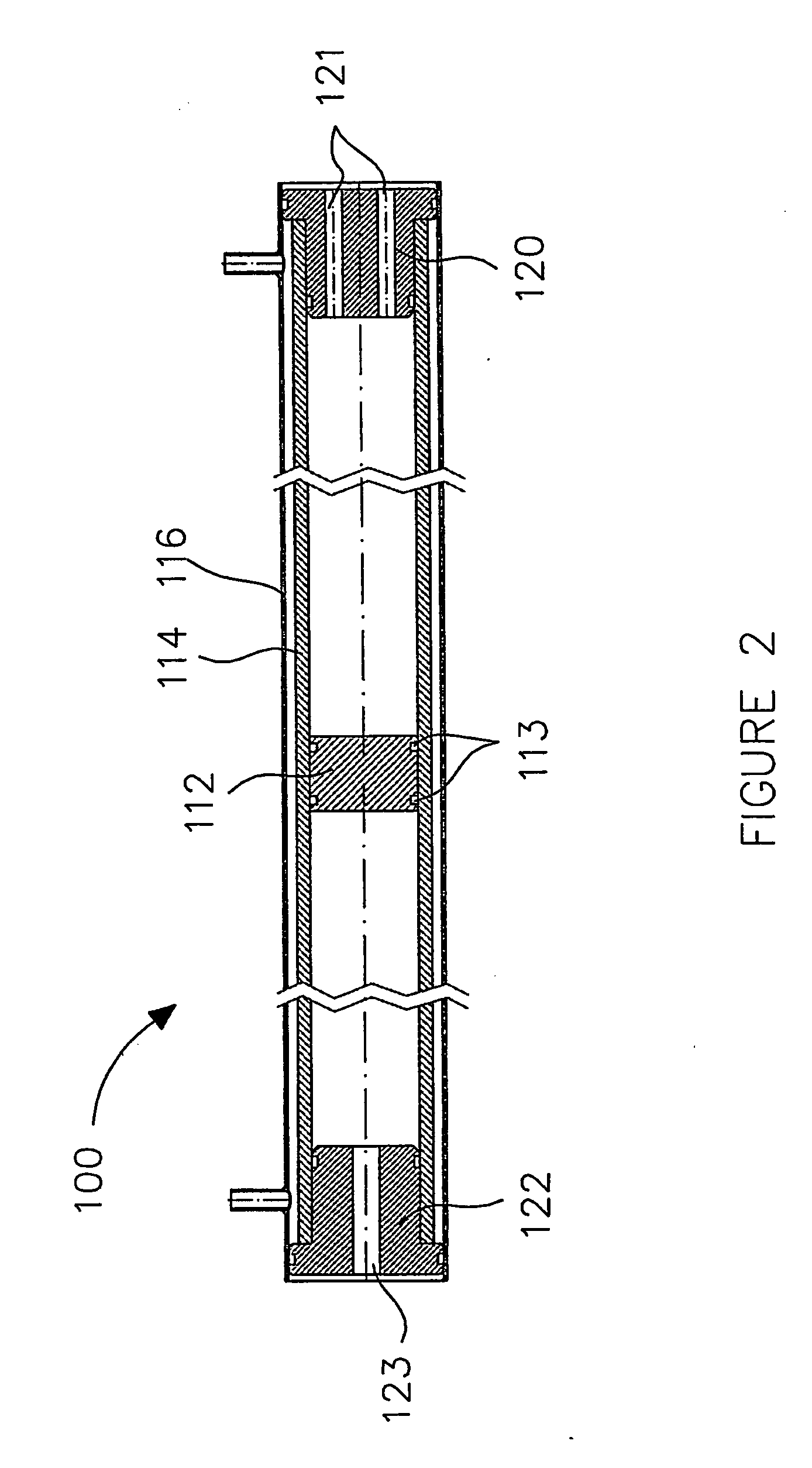

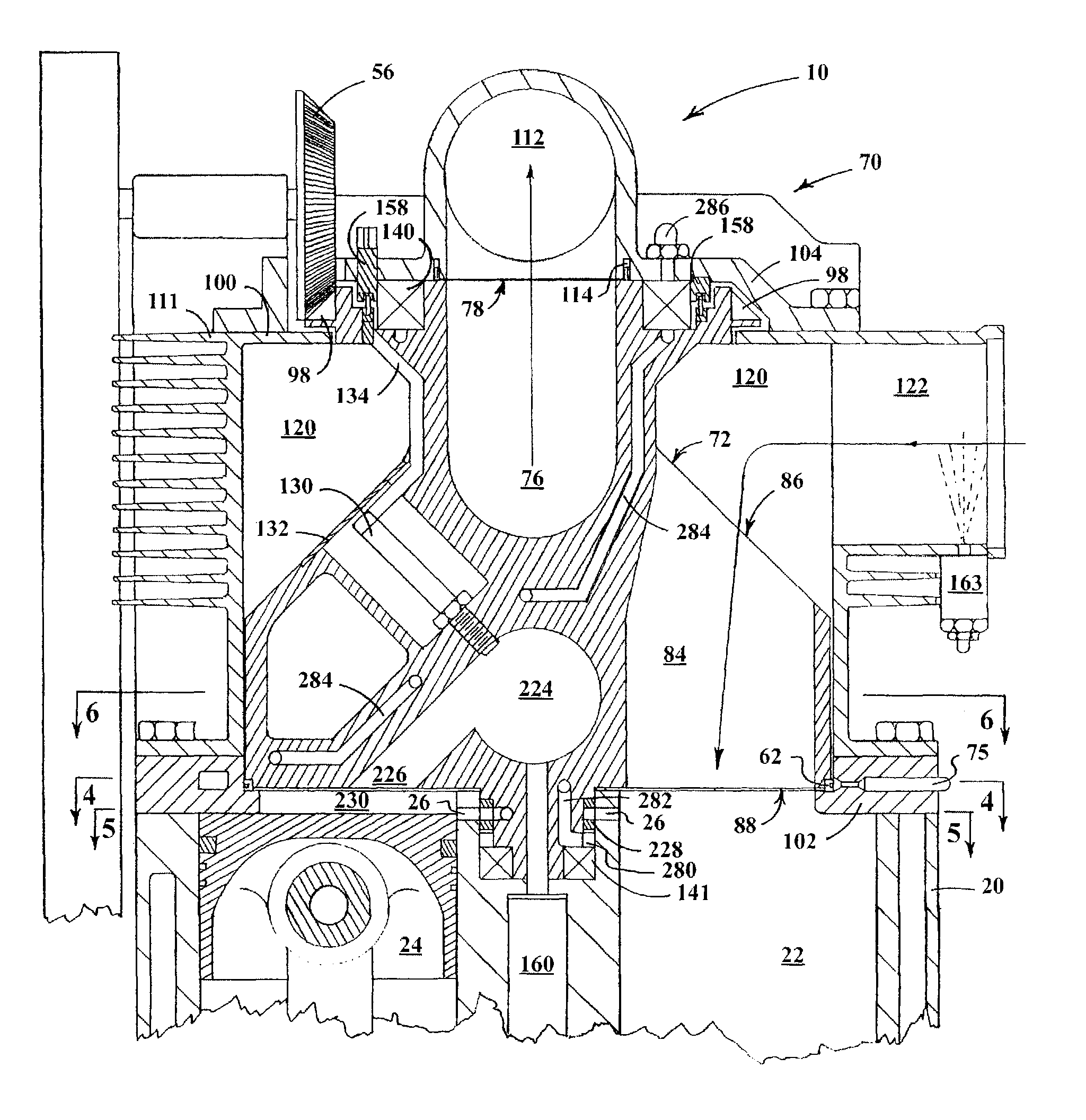

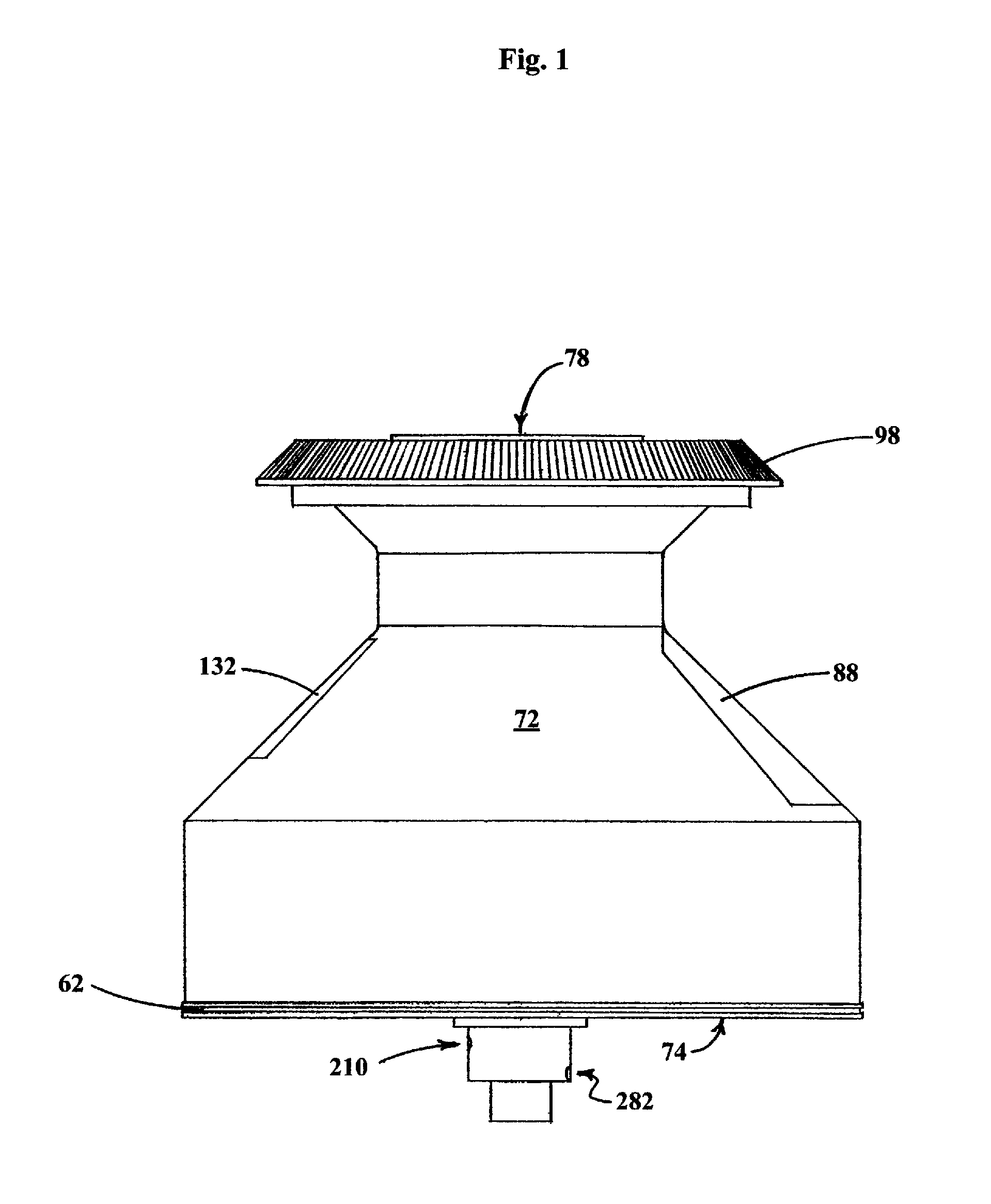

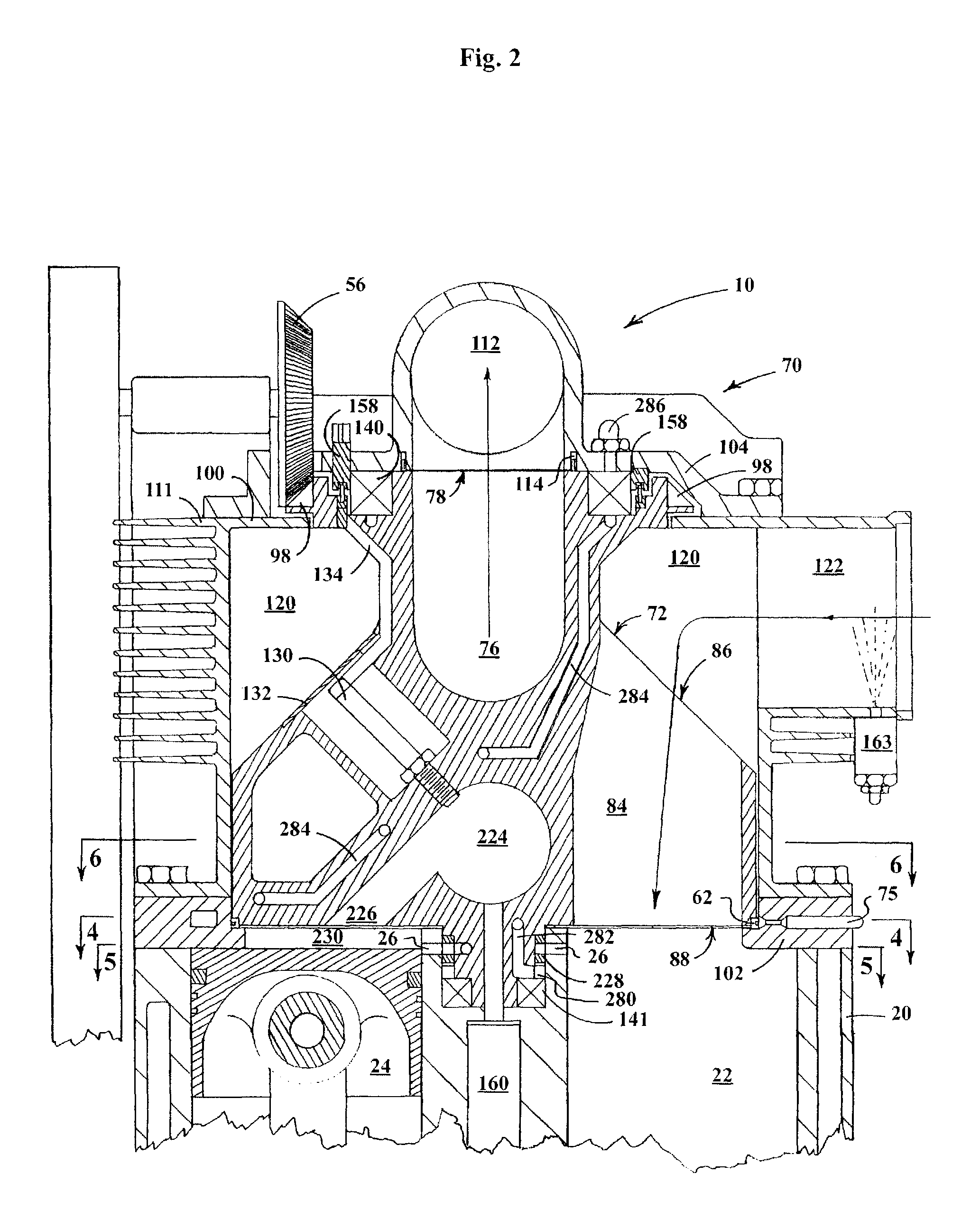

Power system with enhanced thermodynamic efficiency and pollution control

InactiveUS6918253B2Reduce equipment costsReduce wearSteam generation using pressureSteam useCondensed waterPressure range

An elevated pressure power plant (100) for cleanly and efficiently oxidizing, gasifying or combusting a fuel. The fuel is oxidized or gasified in a reaction chamber (210) at a pressure range from approximately 700 psia to 2000 psia, or from approximately 850 psia to 1276 psia. Products of combustion from the chamber may be passed to a heat exchanger (224). A portion of the condensed water may be recycled to the products of combustion upstream of the heat exchanger. Also, before being passed to the reaction chamber, the coolant may be routed through the heat exchanger in a two-step pressure fashion.

Owner:THERMOENERGY POWER SYST

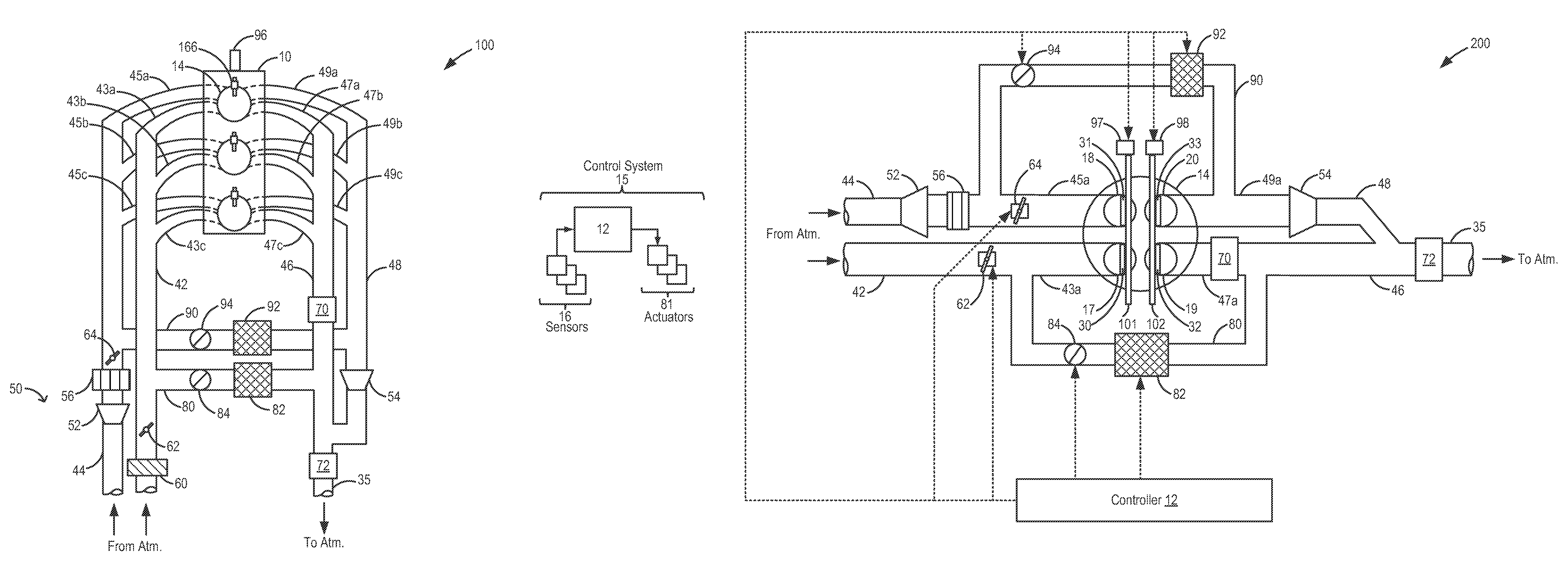

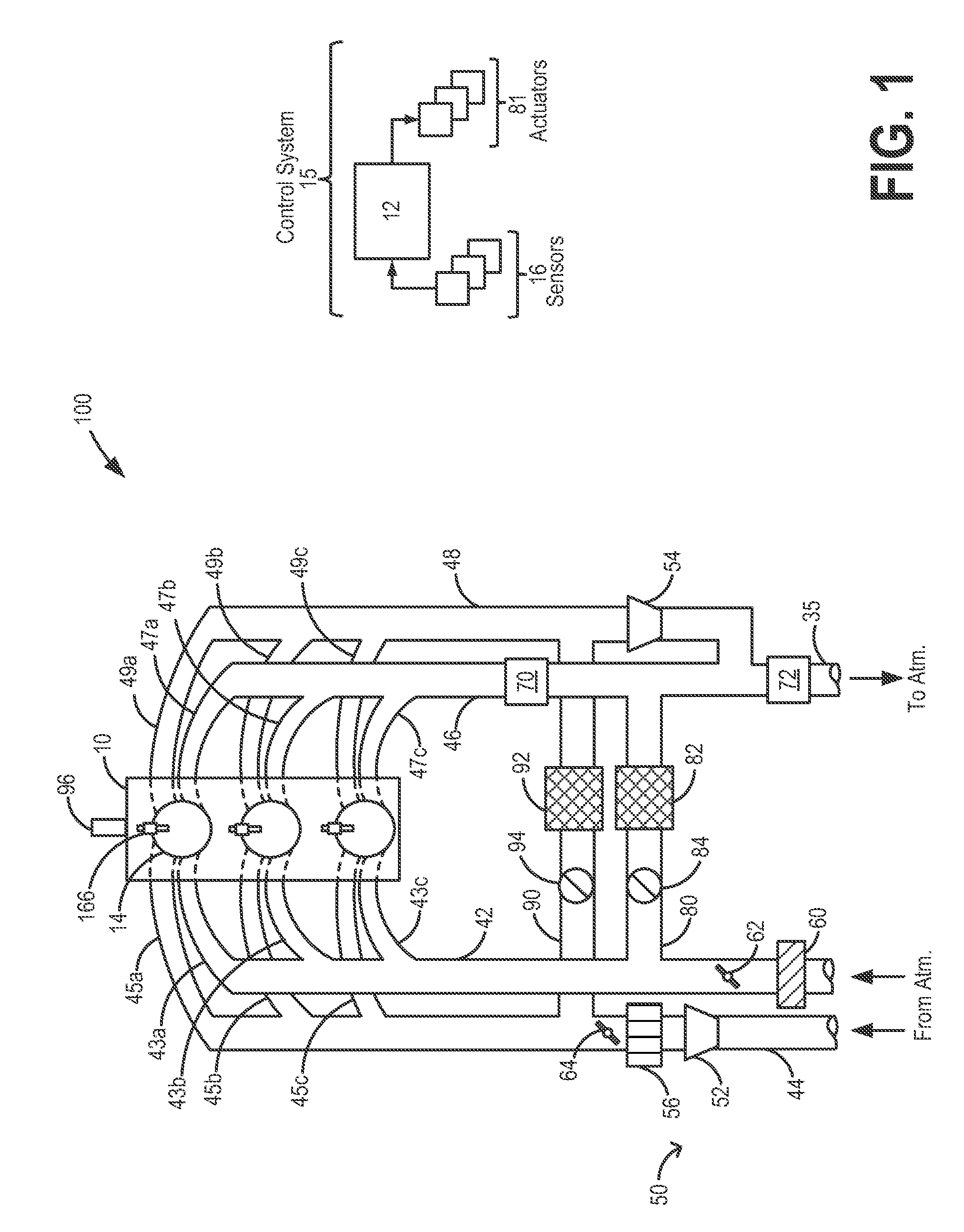

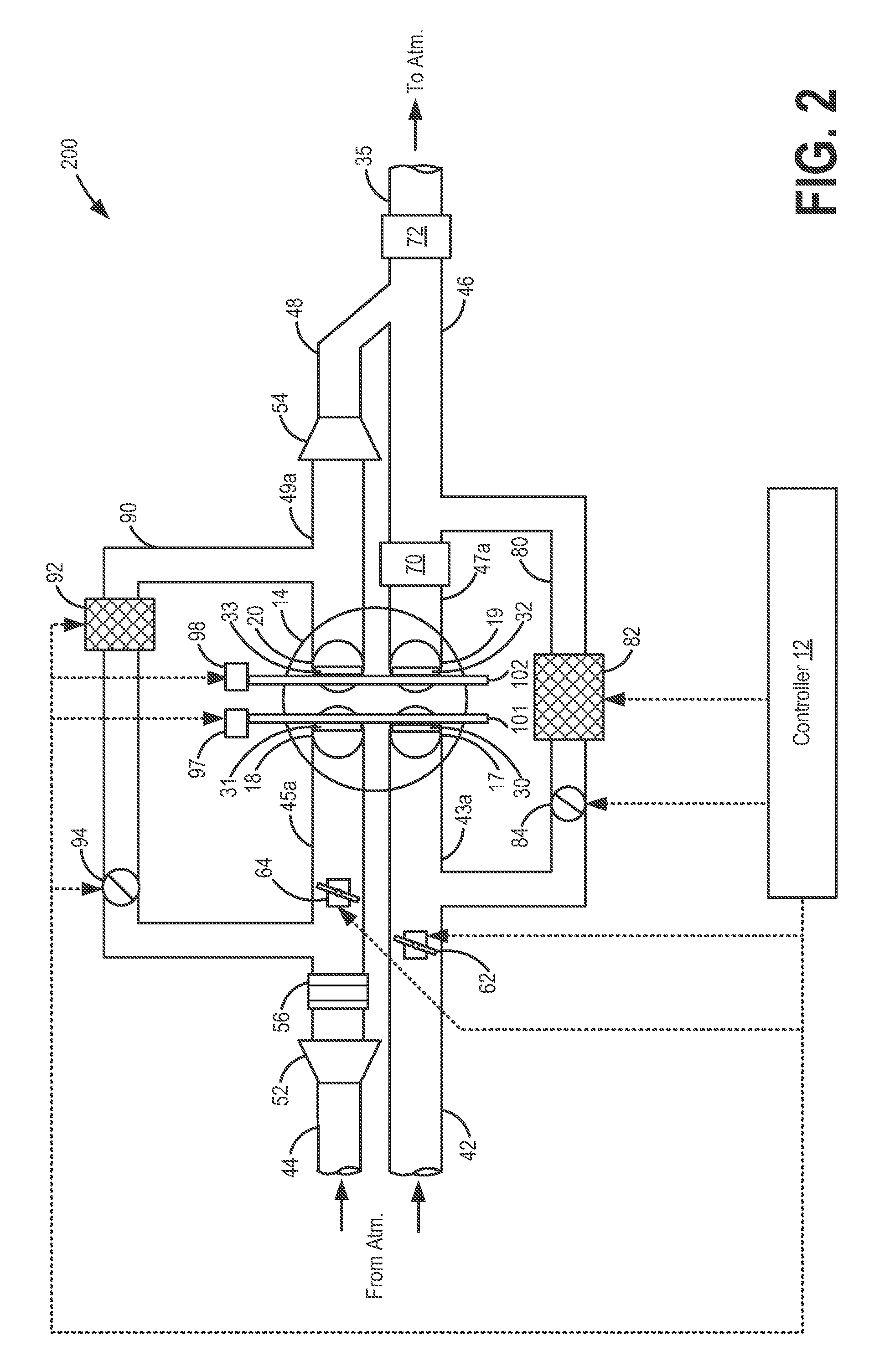

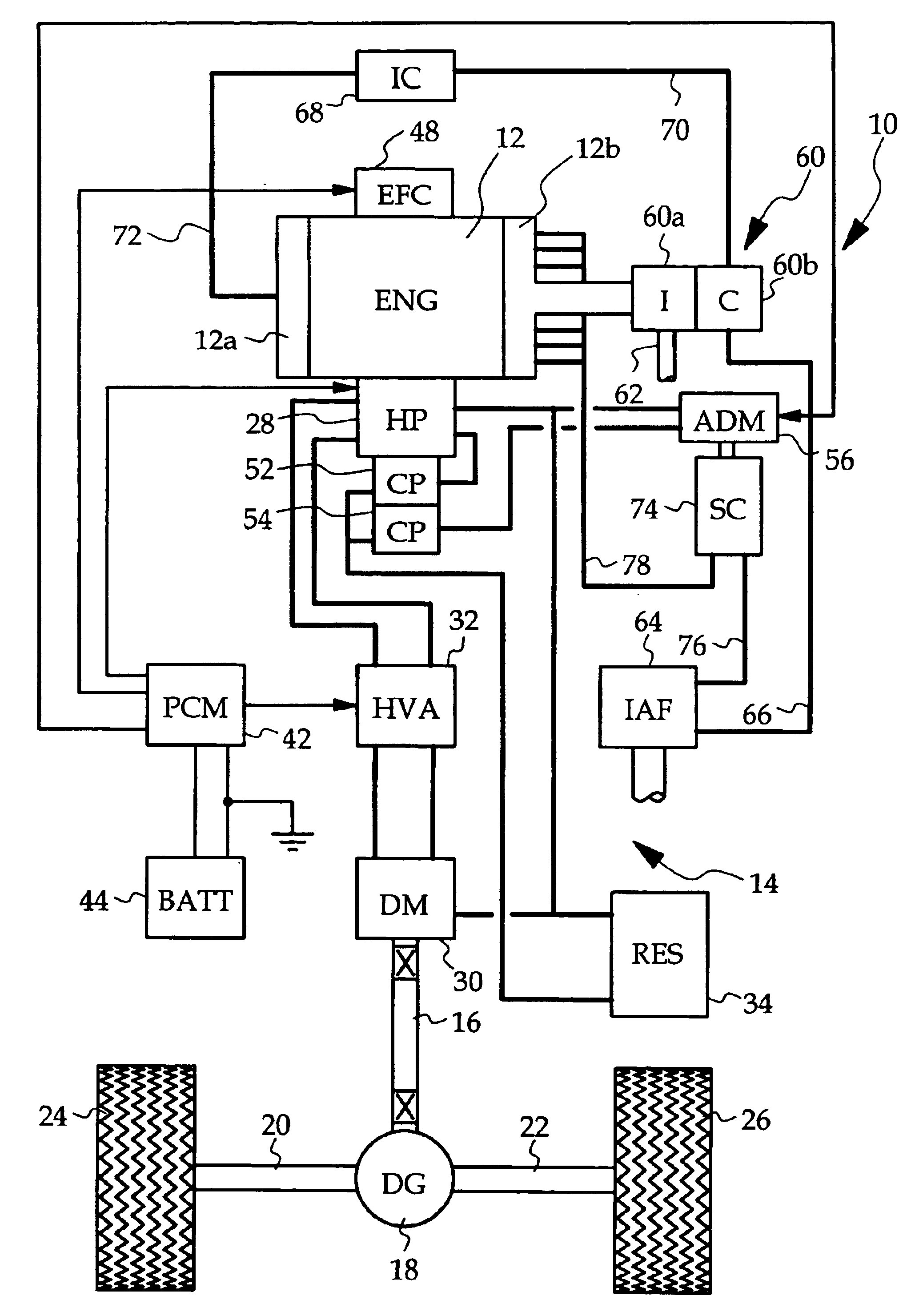

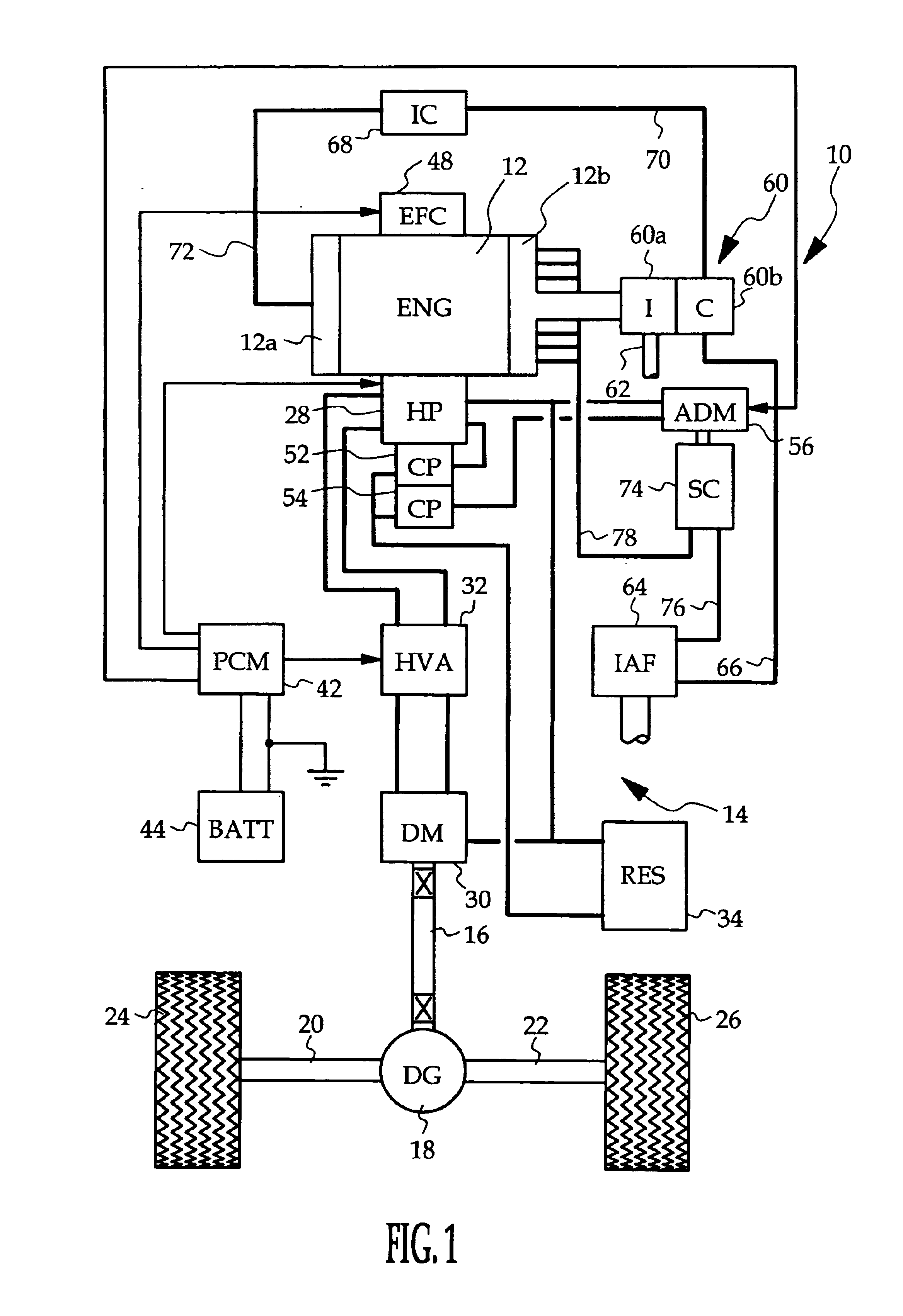

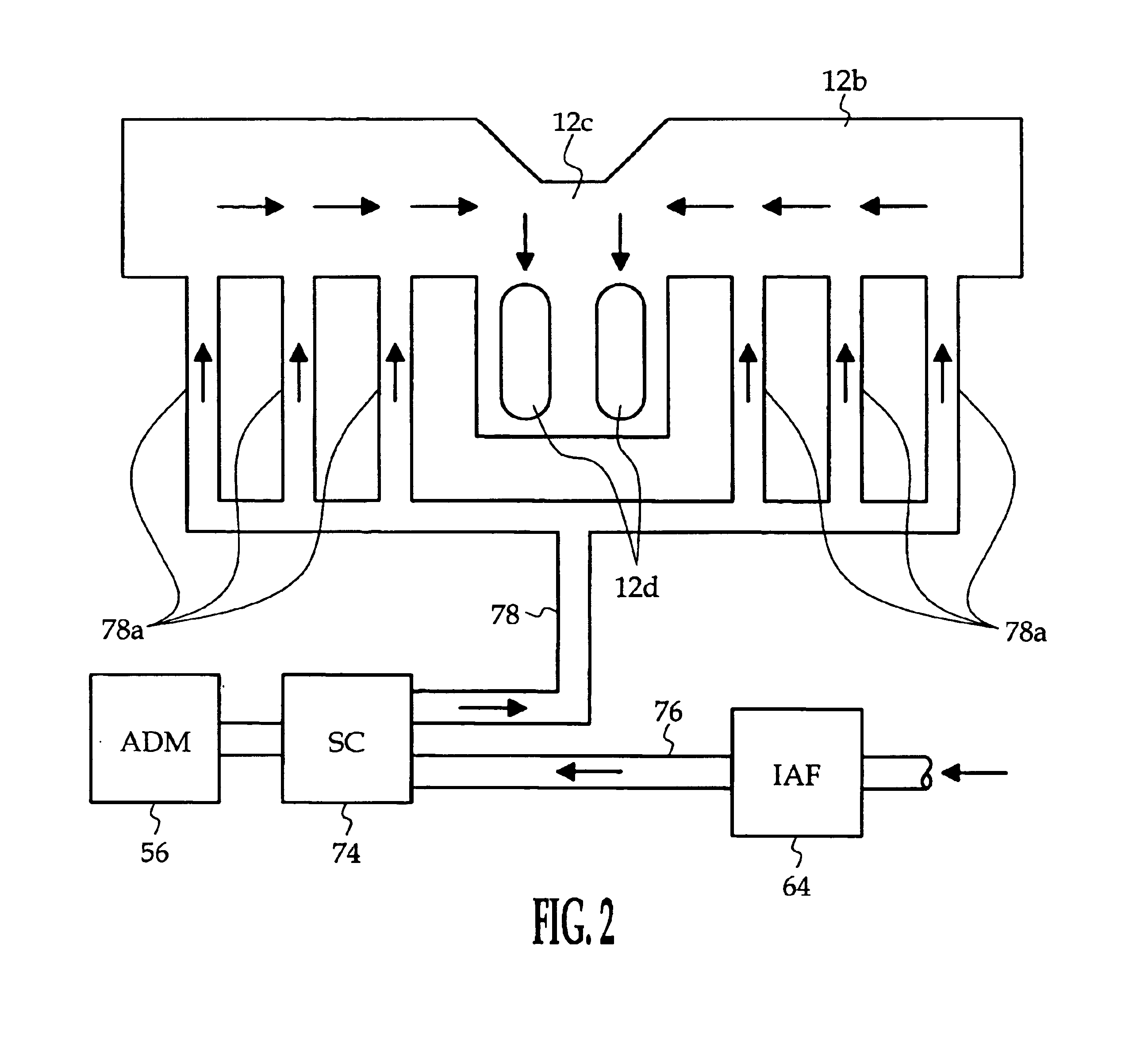

Method and system for a turbocharged engine

ActiveUS8479511B2Without compromising boost performanceBoosted airchargeValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

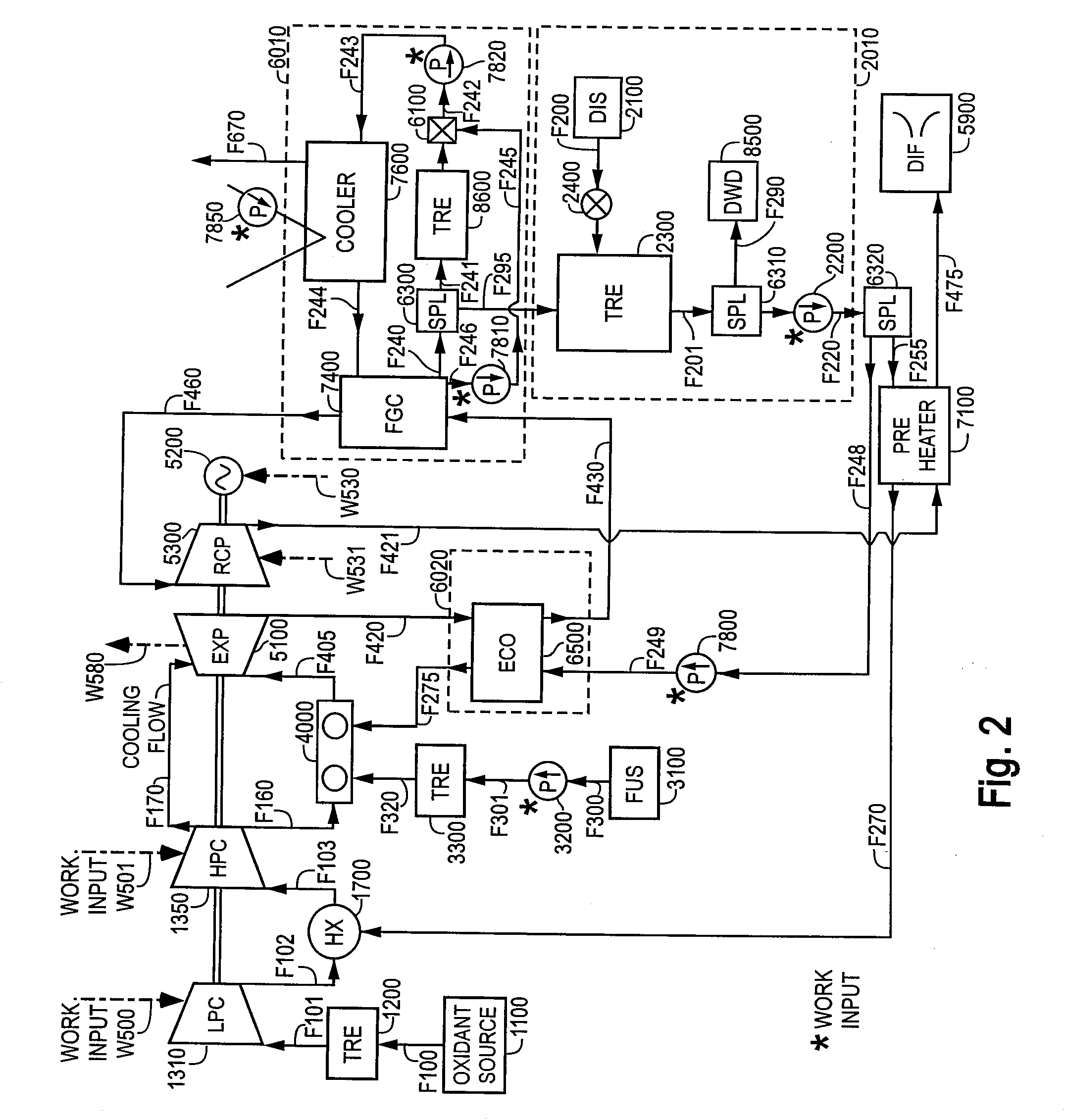

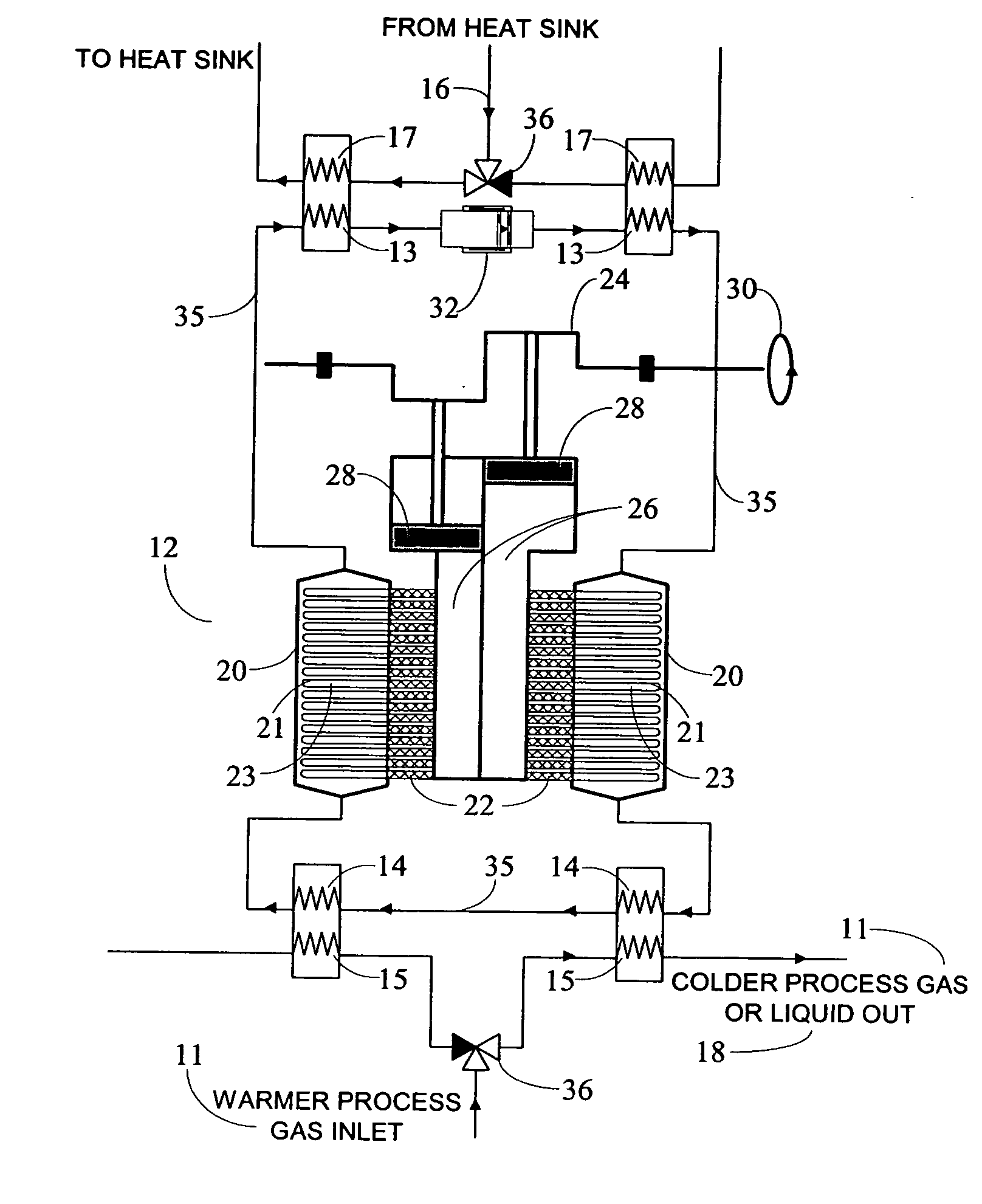

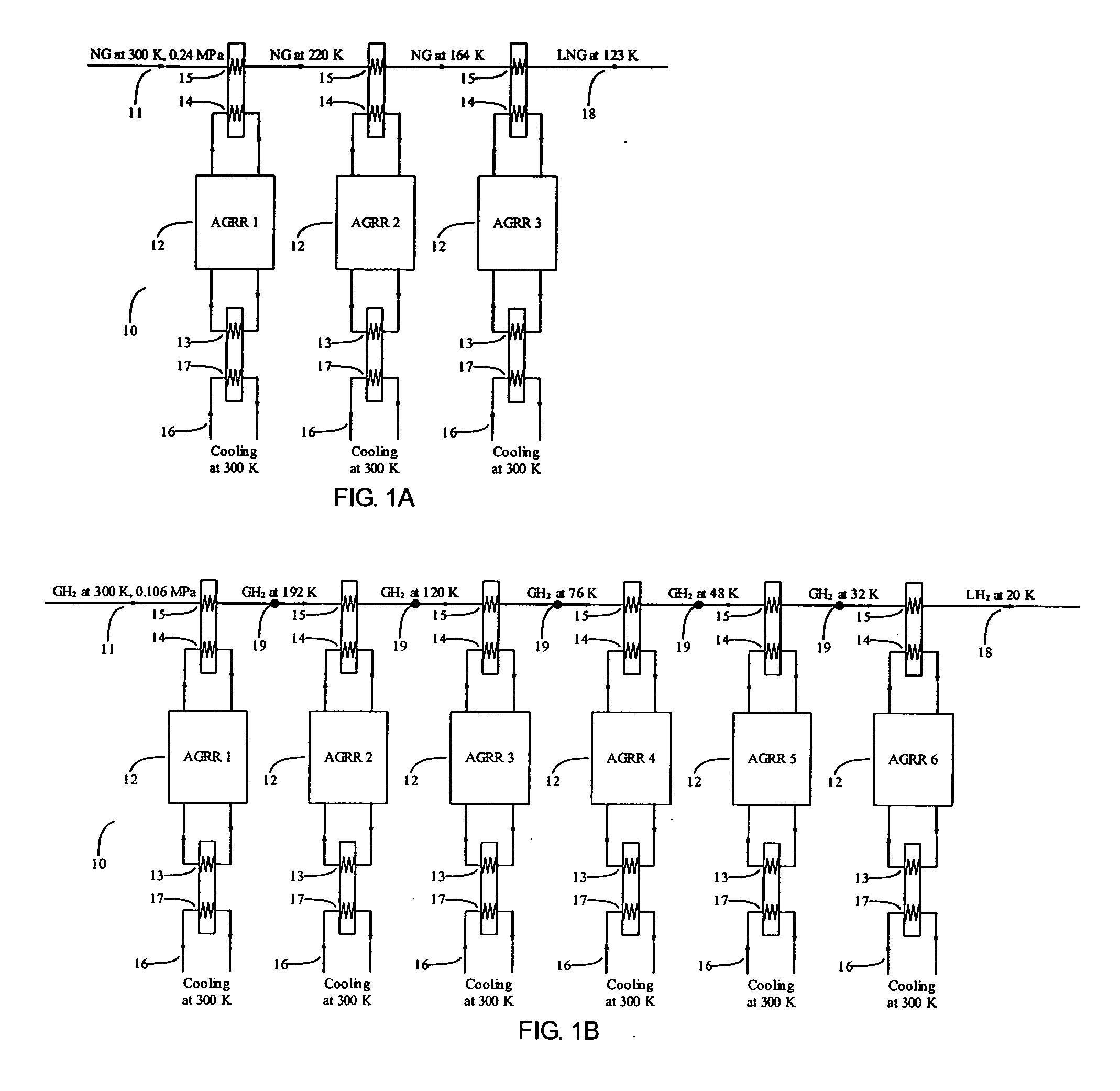

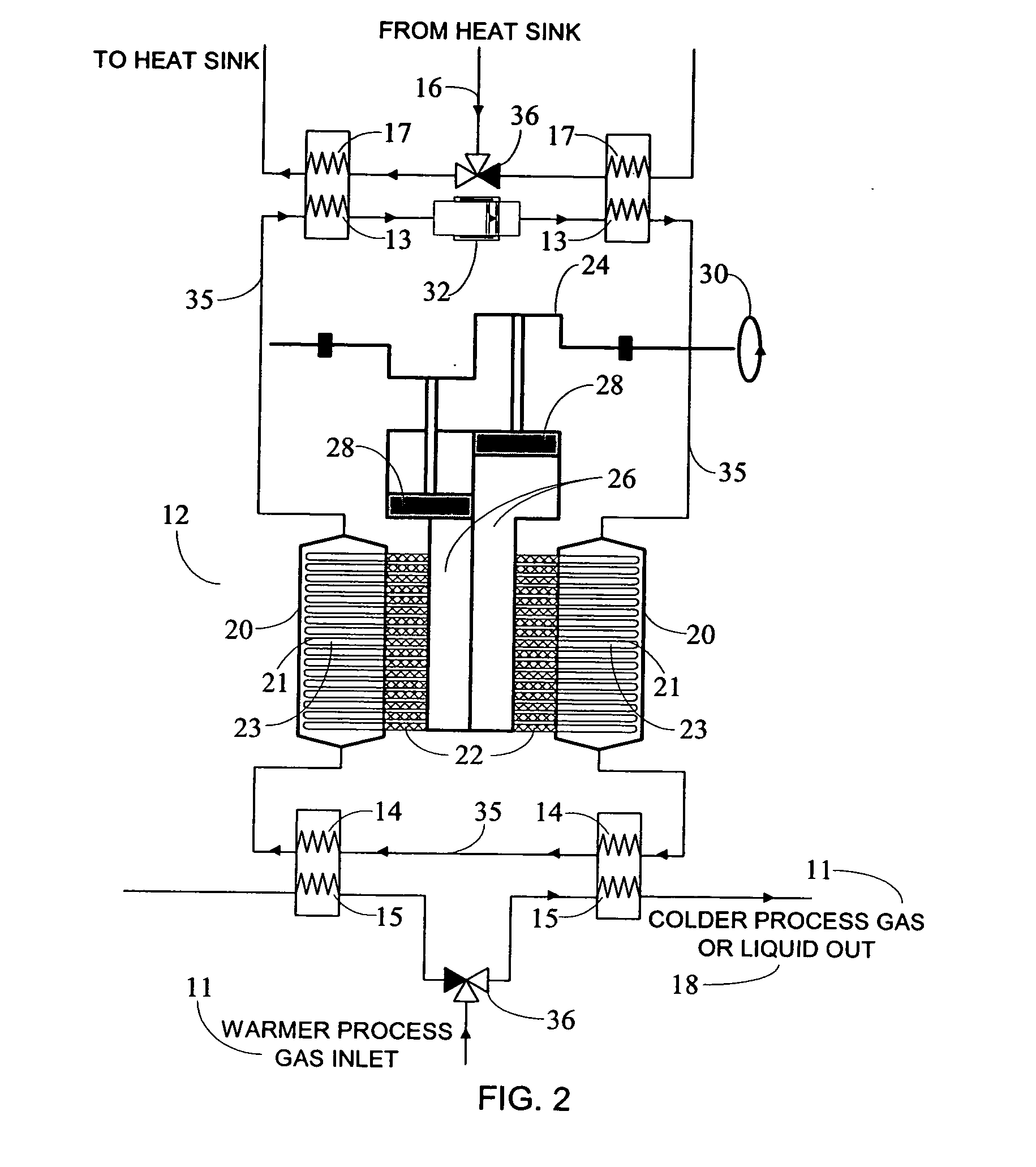

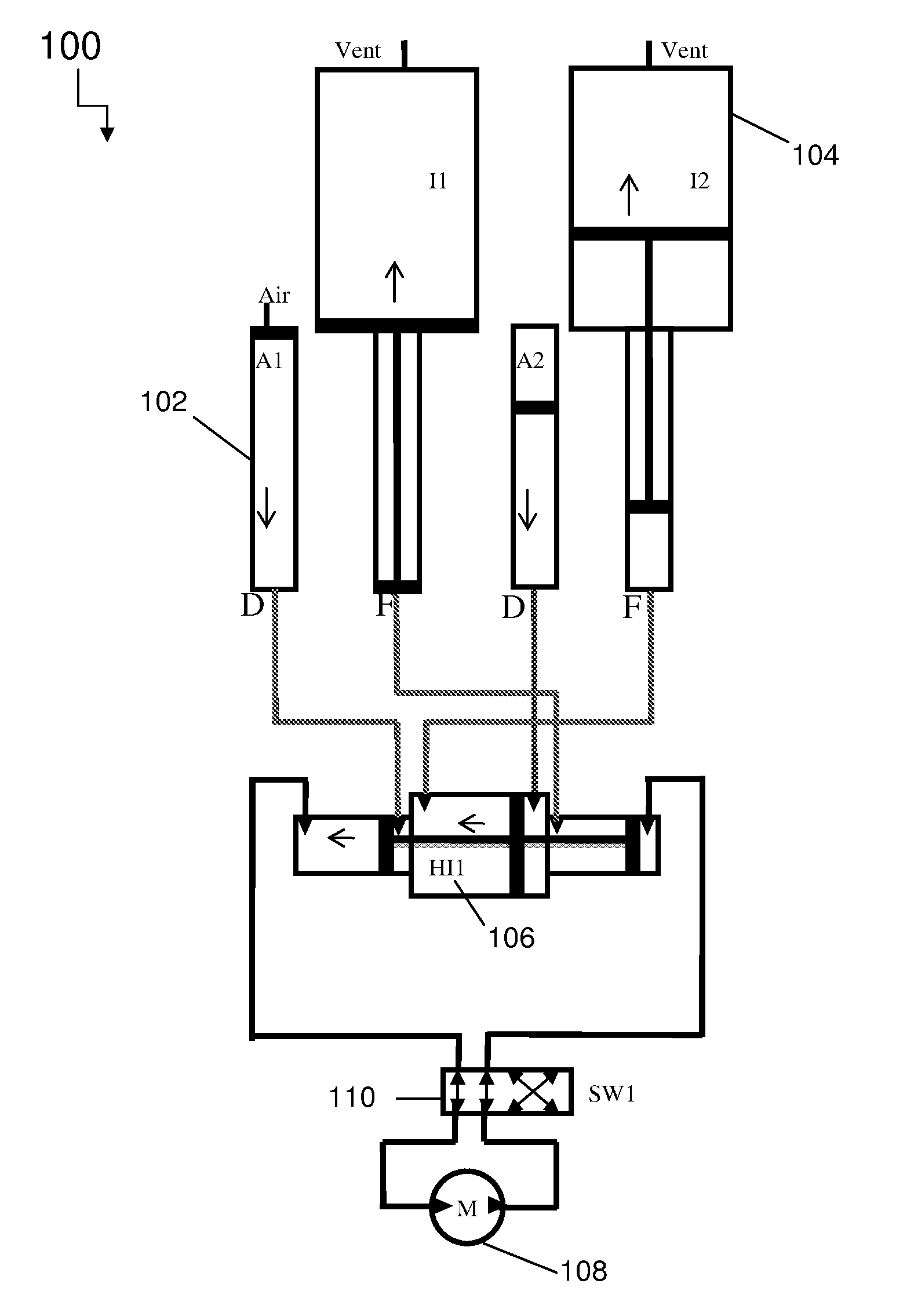

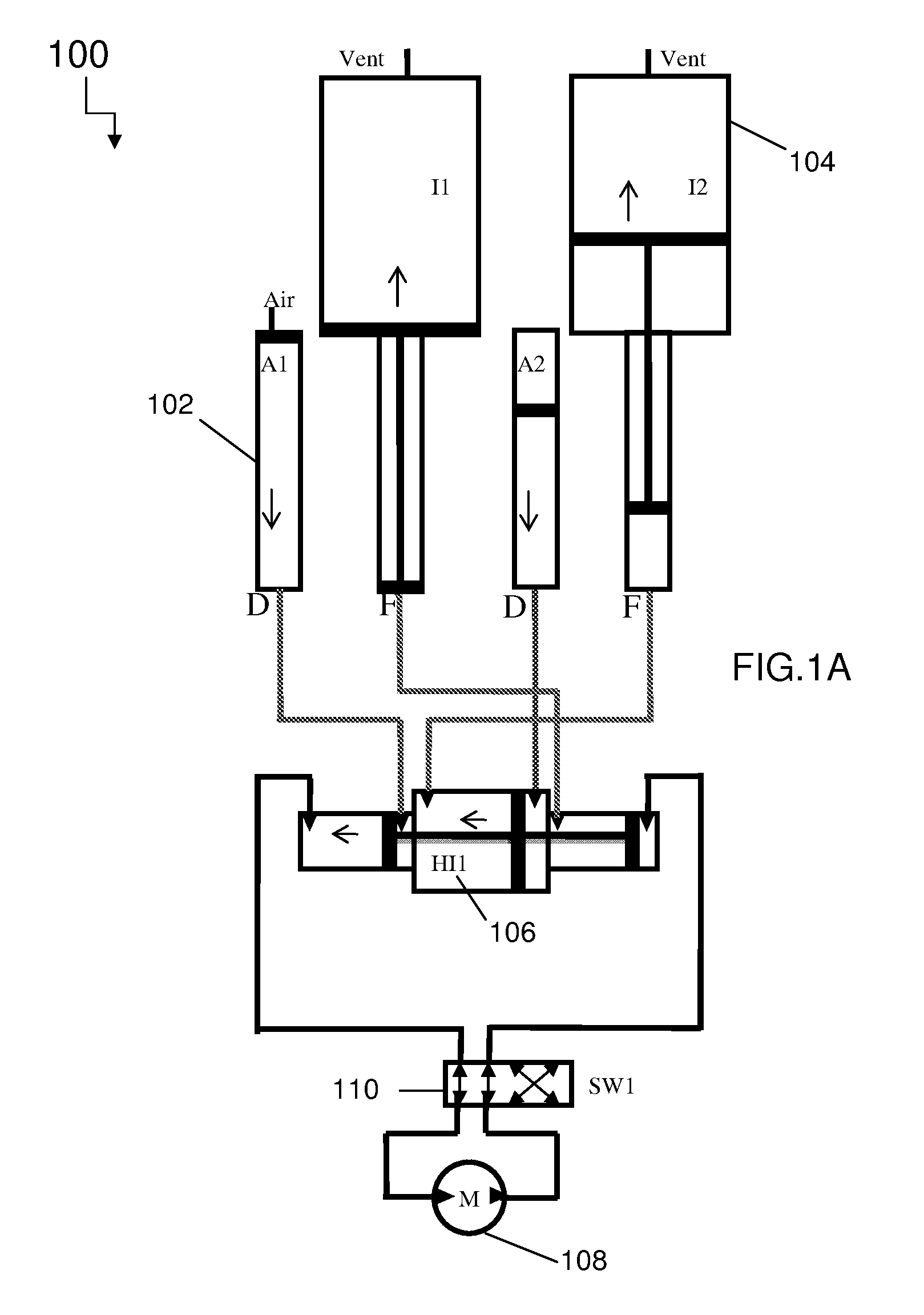

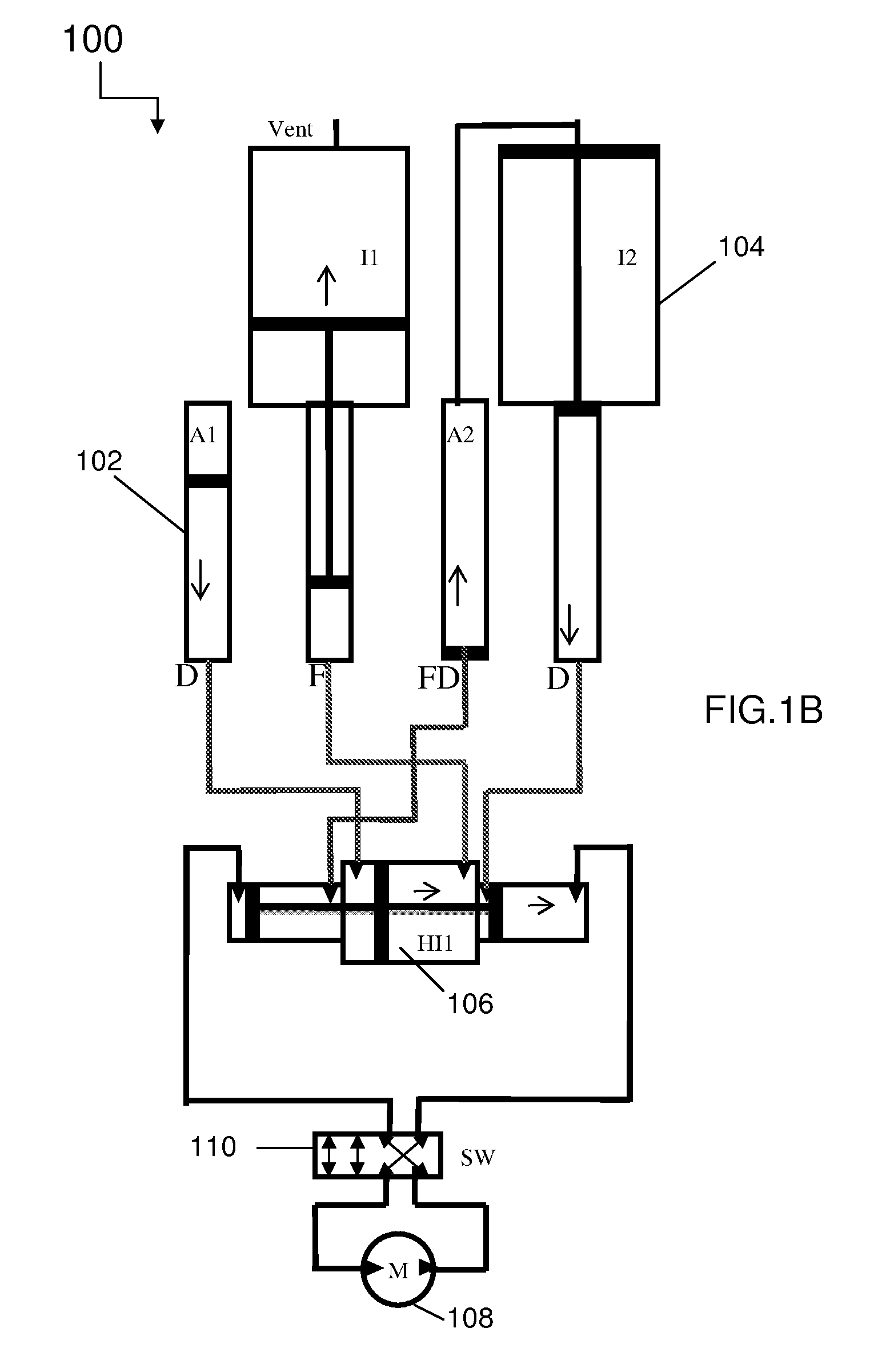

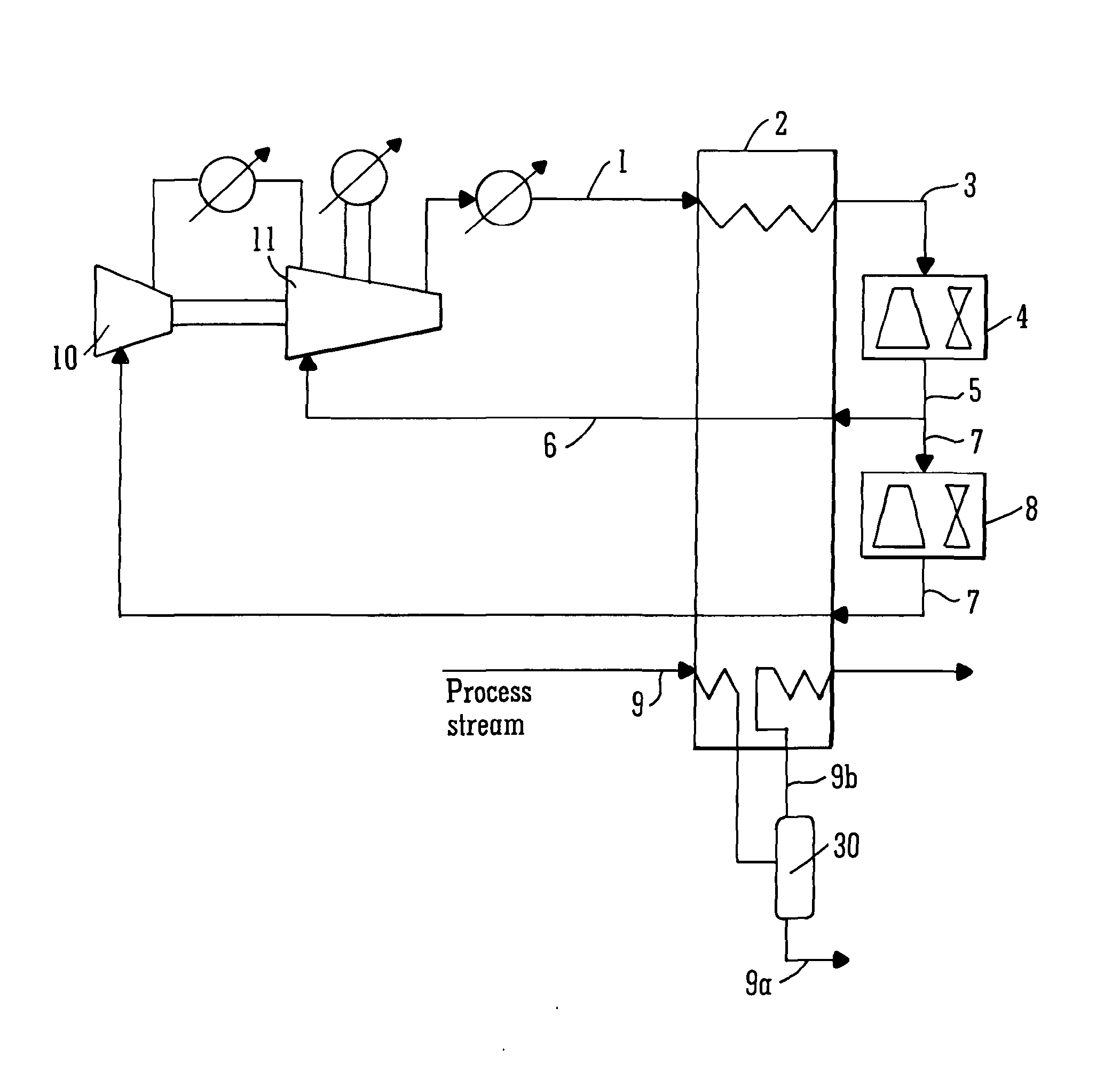

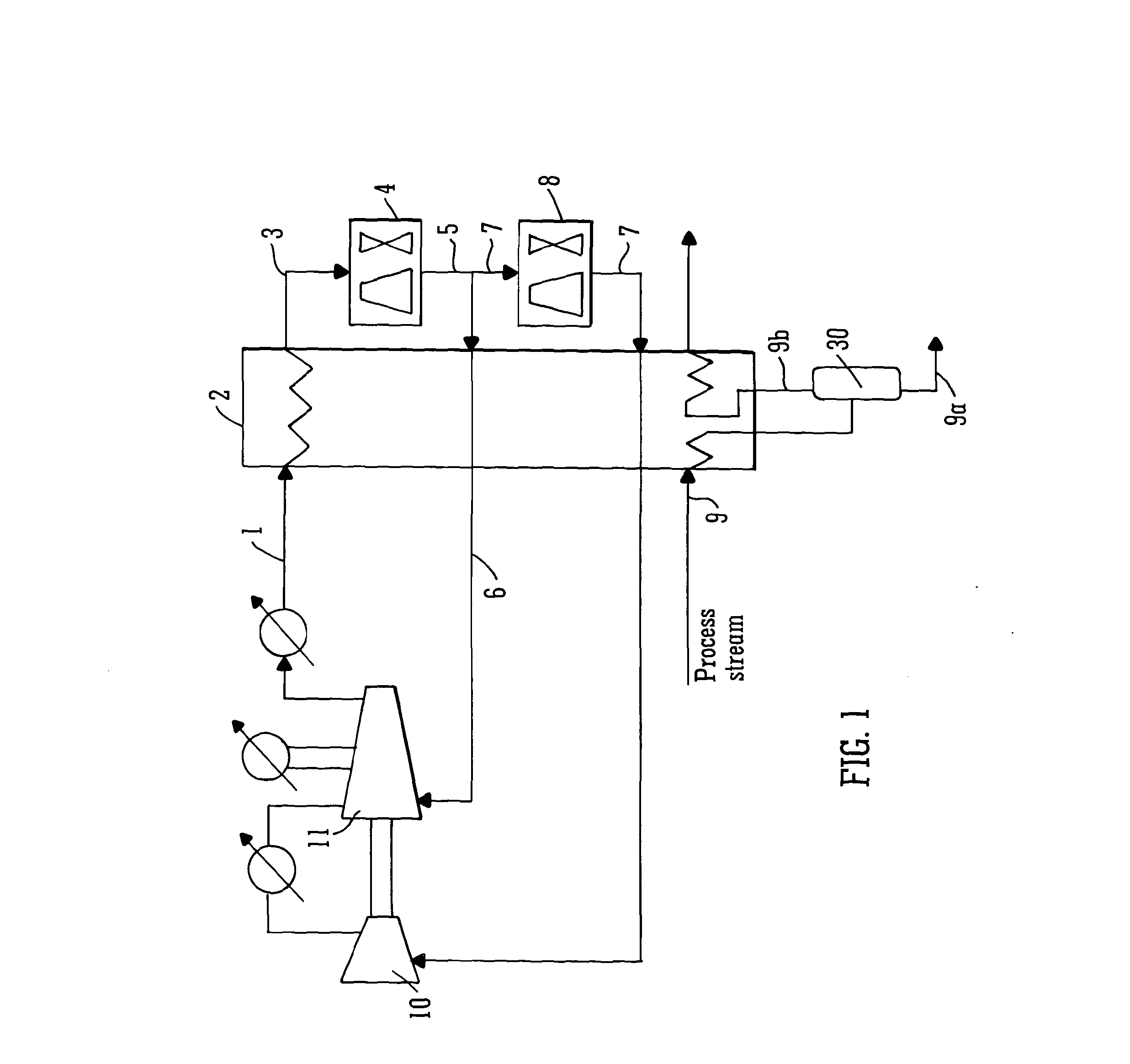

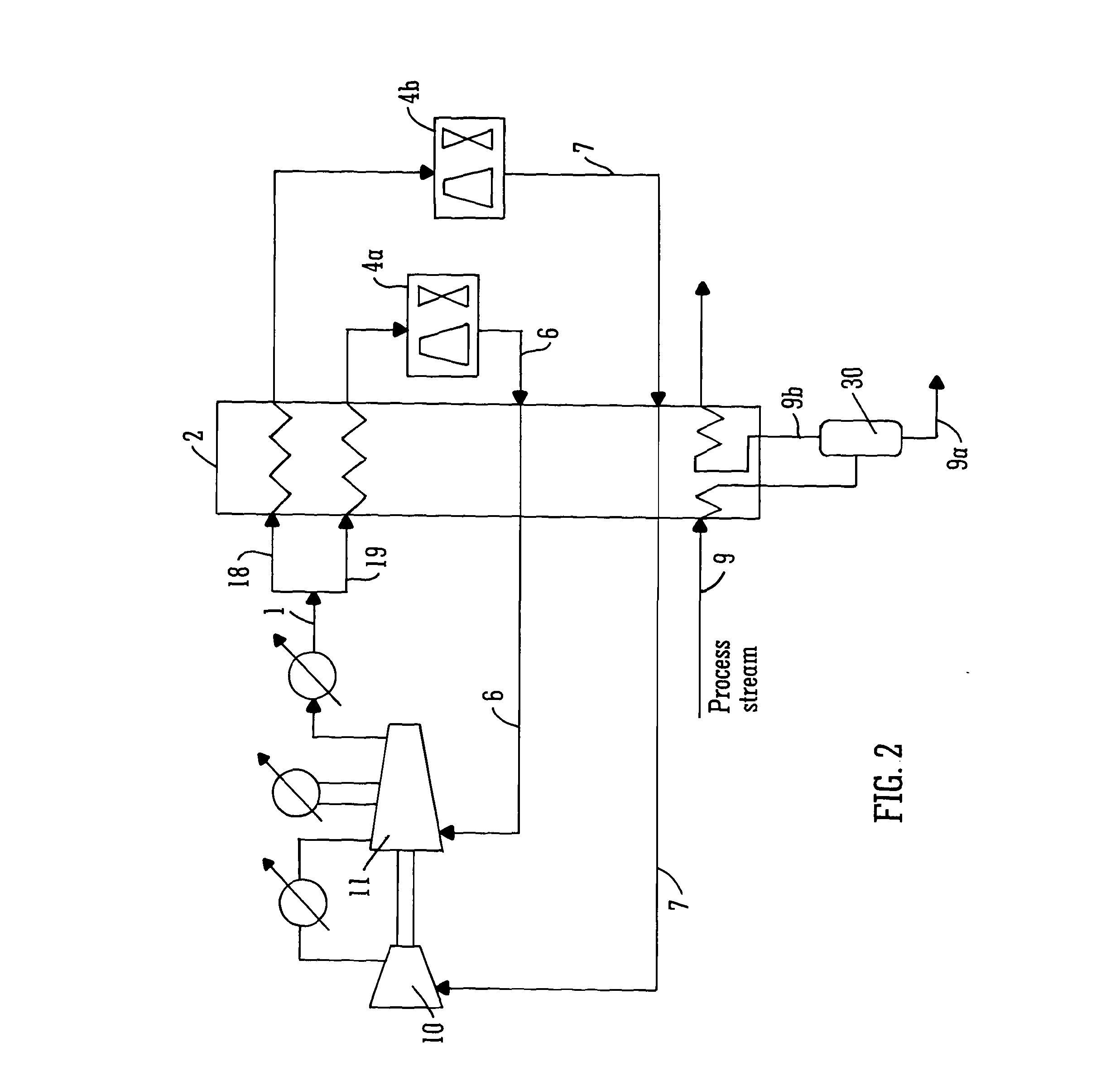

Active gas regenerative liquefier system and method

InactiveUS20080016907A1Improve efficiencyMinimize irreversible entropy creationSolidificationLiquefactionHydrogenProduct gas

The present invention provides an active gas regenerative liquefier (AGRL) for efficiently cooling and liquefying a process stream based on the combination of several active gas regenerative refrigerator (AGRR) stages configured to sequentially cool and liquefy the process stream, e.g. natural gas or hydrogen. In specific embodiments, the individual AGRR stages include heat exchangers, dual active regenerators, and a compressor / expander assembly, configured to recover a portion of the work of compression of a refrigerant by simultaneously expanding a refrigerant in one portion of the device while compressing the refrigerant in another portion to effect cooling of a heat transfer fluid, and ultimately the process stream.

Owner:PROMETHEUS TECH

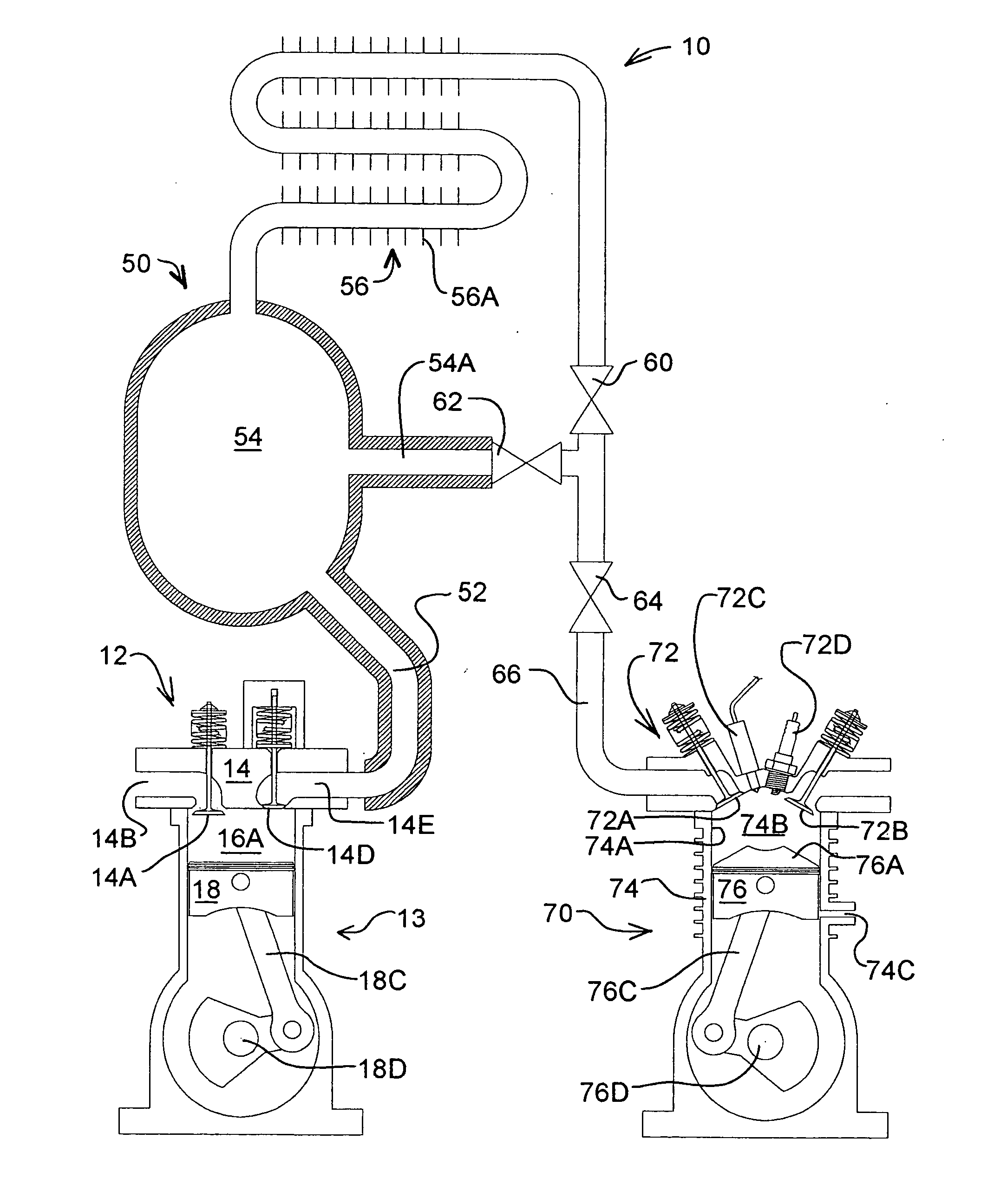

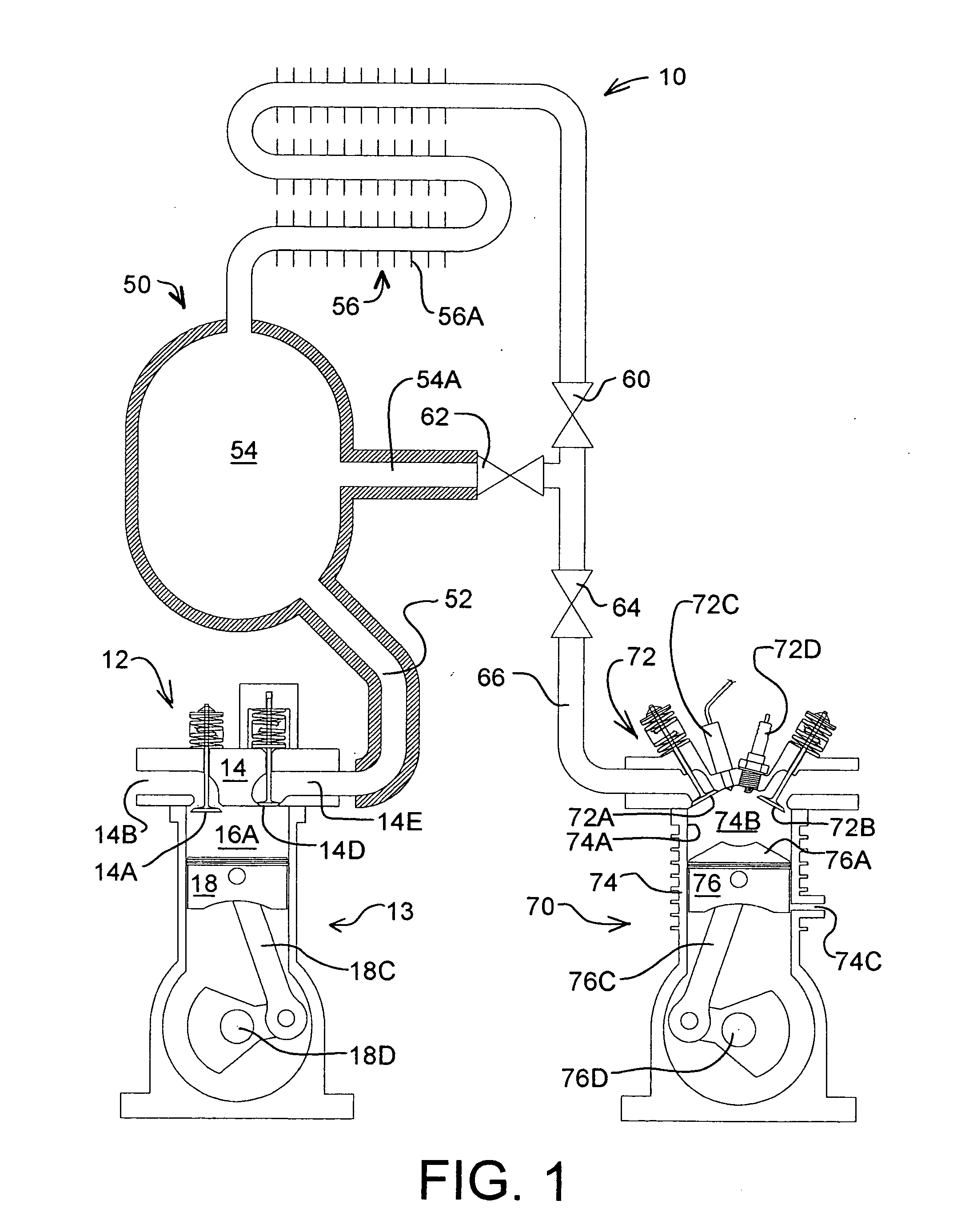

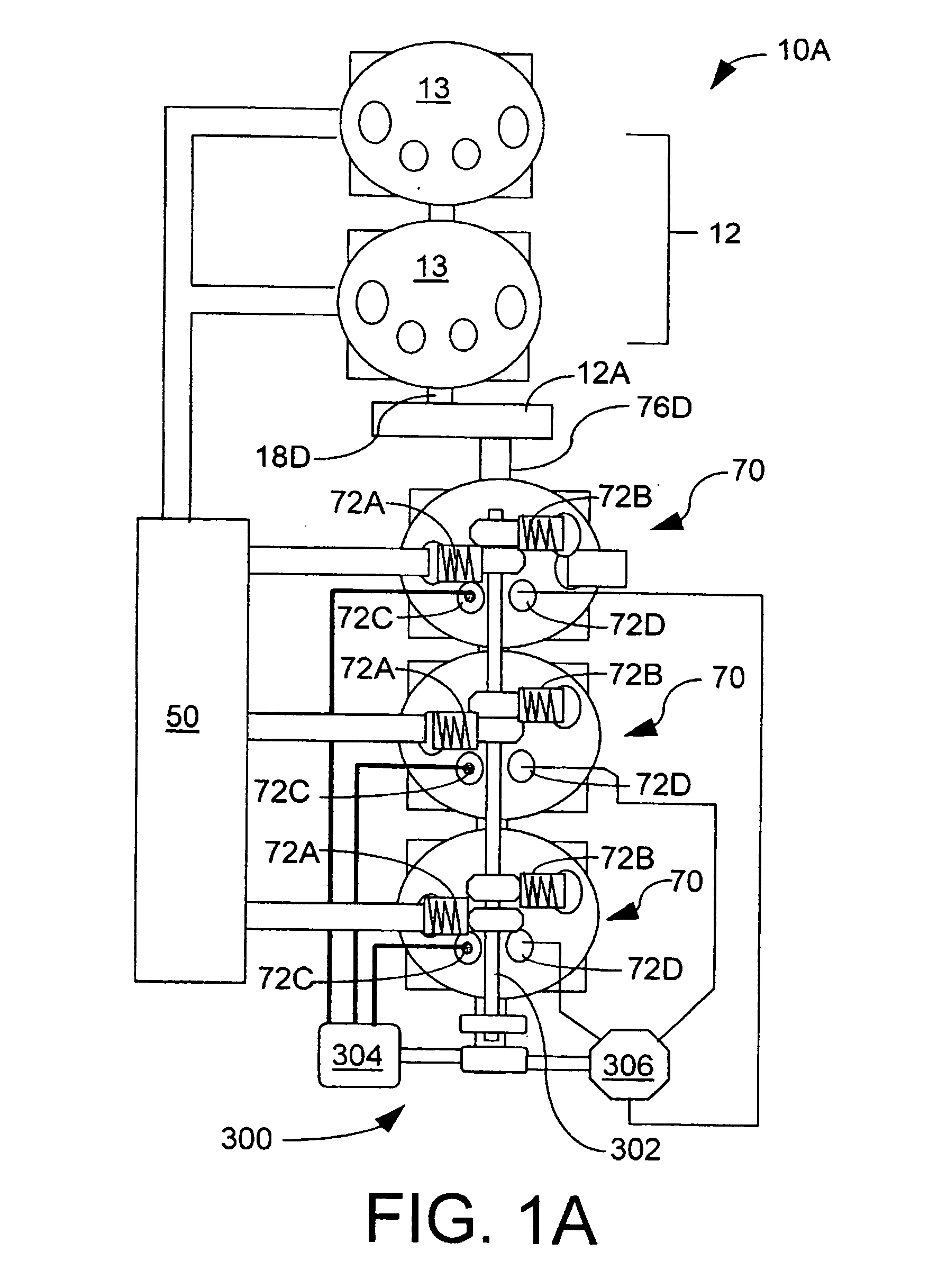

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Systems and methods for improving drivetrain efficiency for compressed gas energy storage and recovery systems

InactiveUS20110138797A1Easy to testLong lastingElectrical storage systemFluid couplingsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

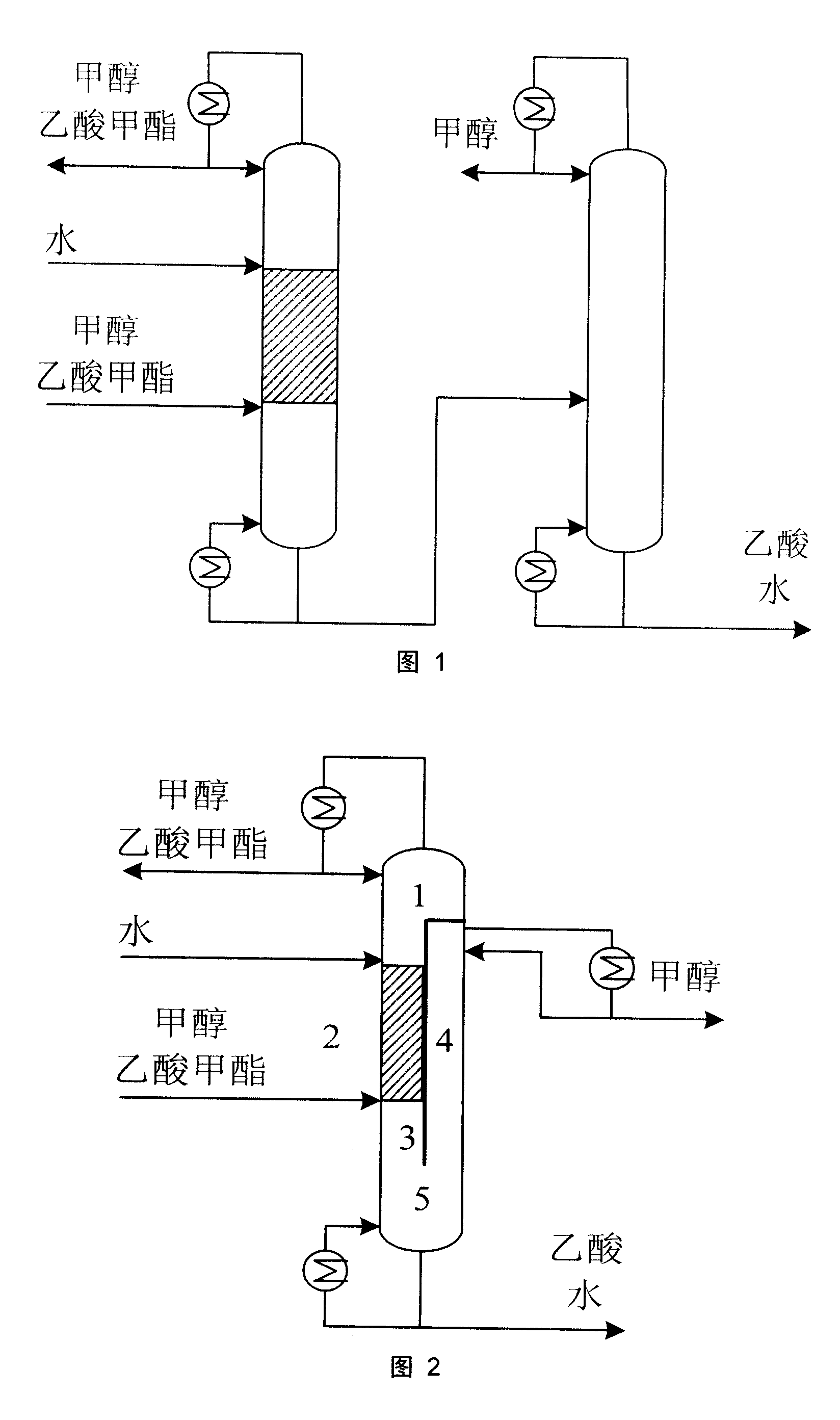

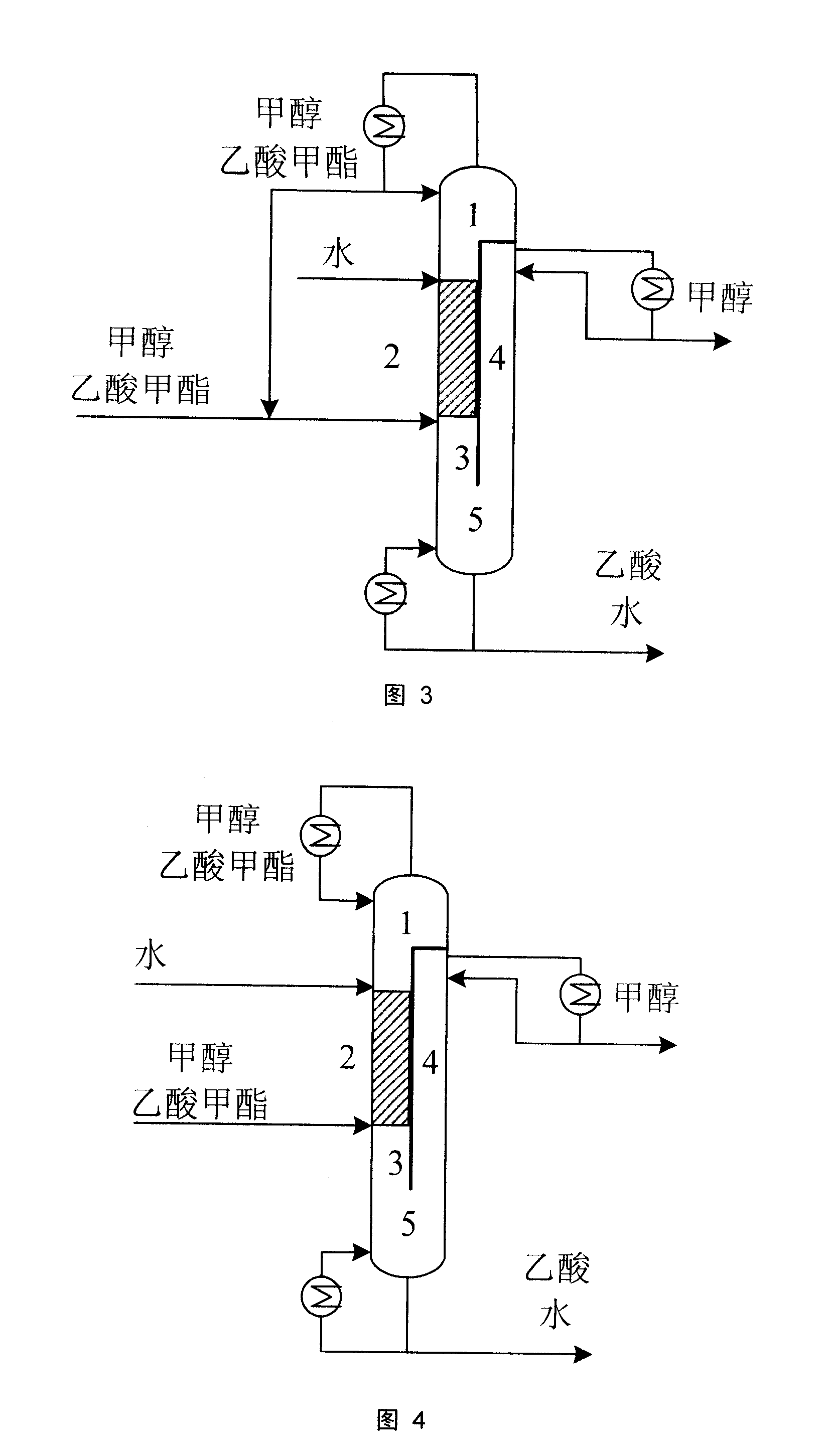

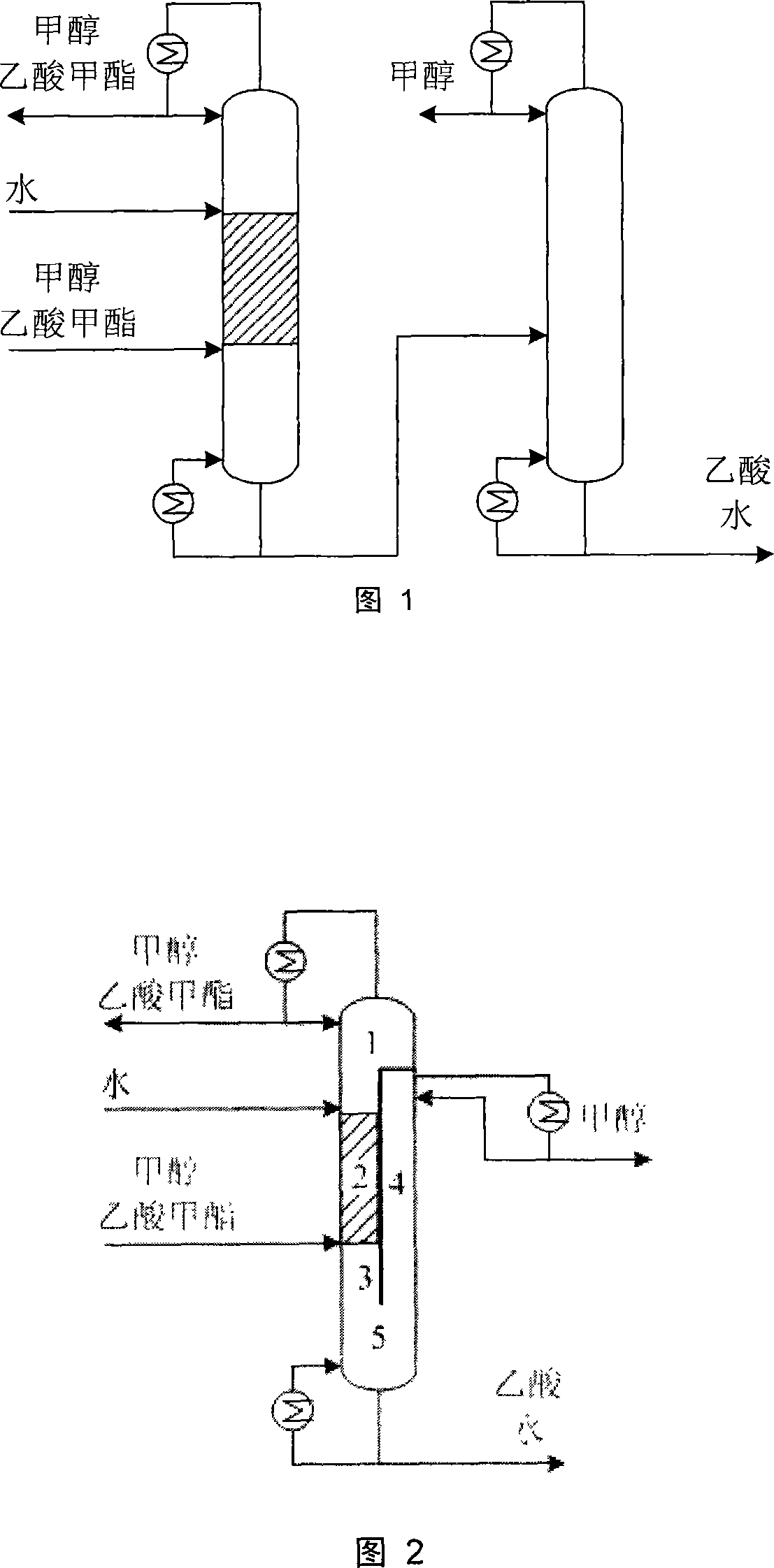

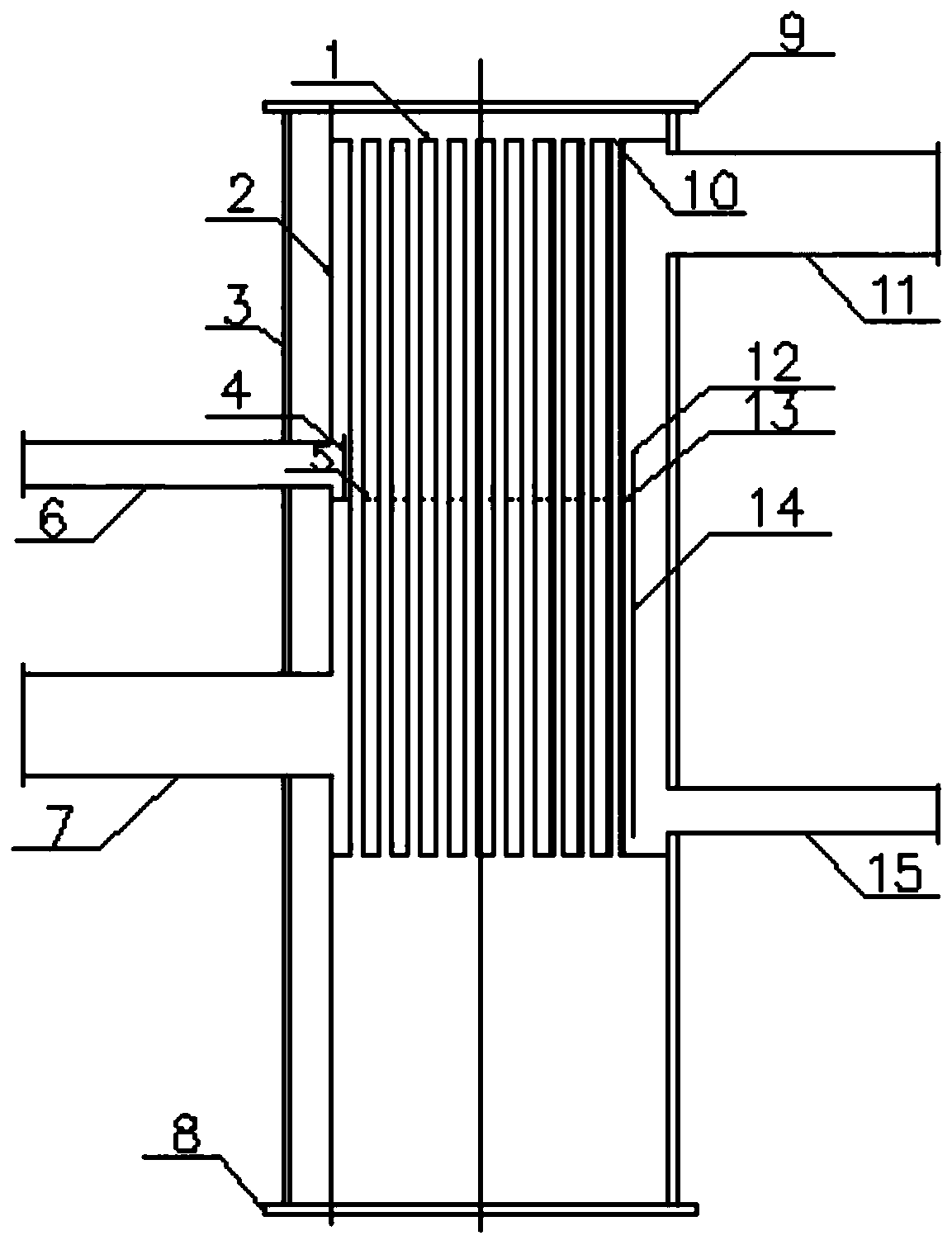

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

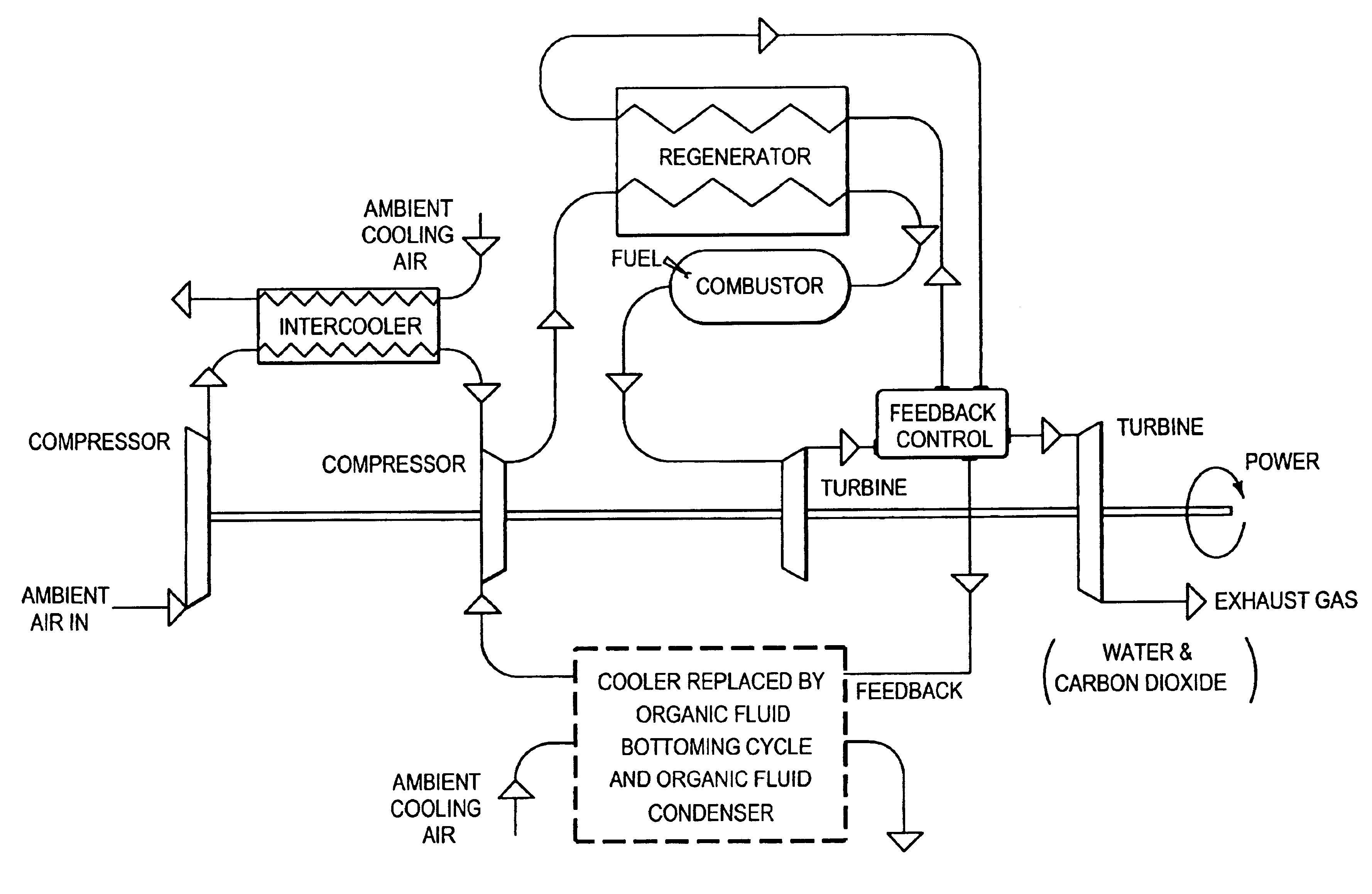

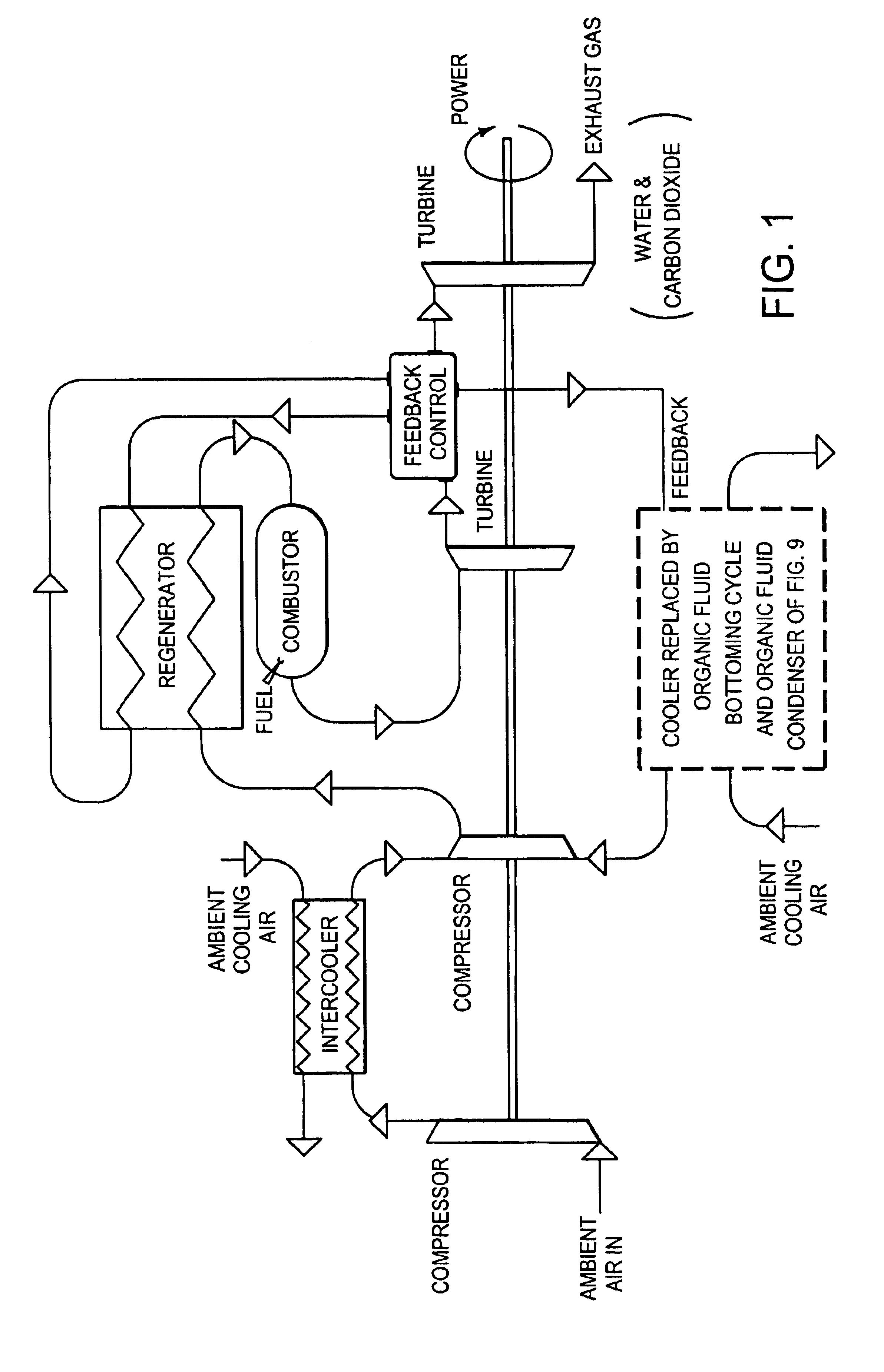

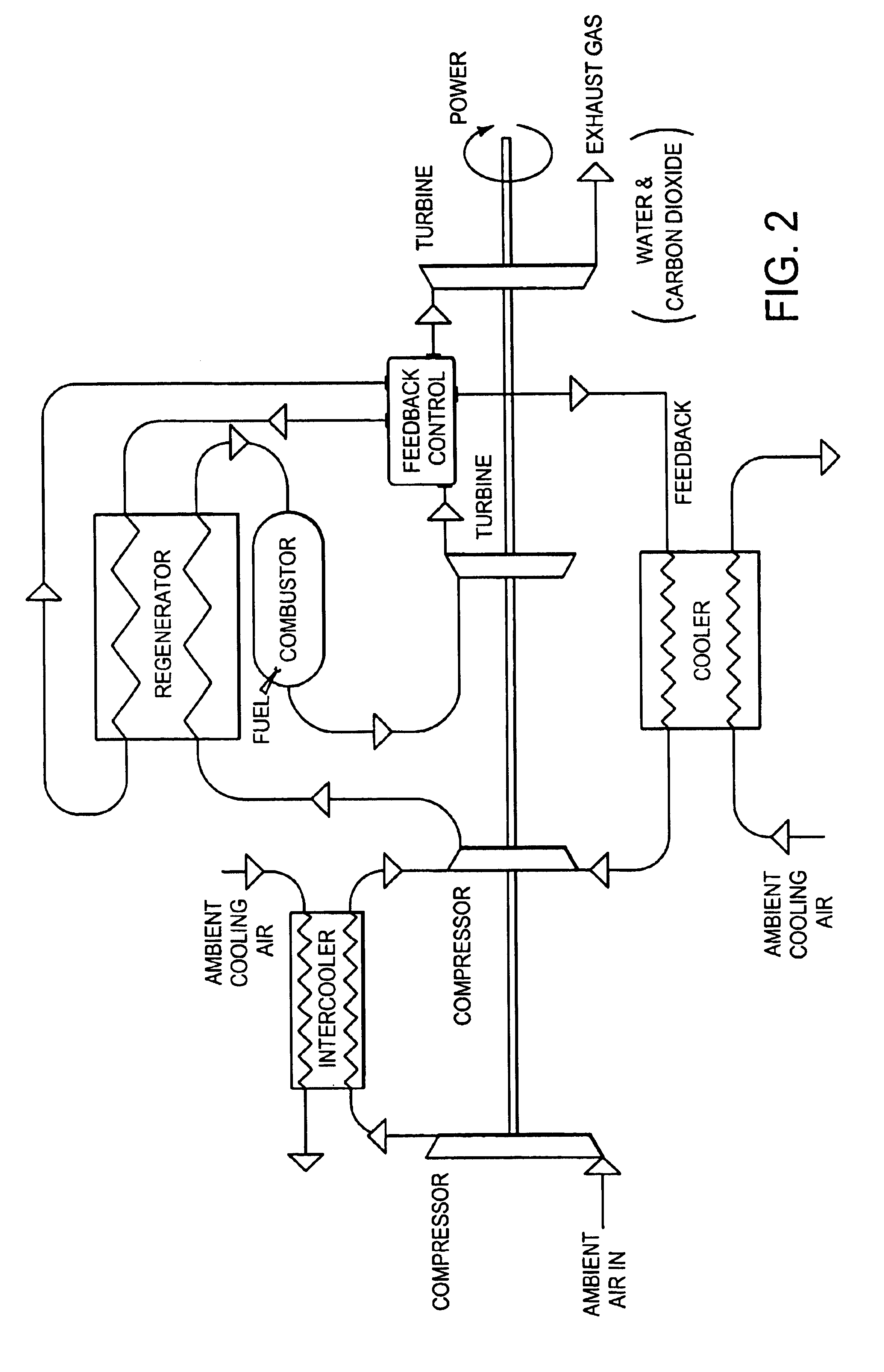

Coleman regenerative engine with exhaust gas water extraction

InactiveUS6848249B2Improve thermodynamic efficiencyEfficient powerTurbine/propulsion engine coolingEngine fuctionsFeedback controllerExhaust fumes

An improved turbine engine topology, wherein the improvement comprises a repositioning, with respect to a conventional intercooled regenerative turbine engine topology, of exhaust gas output from a low pressure turbine stage to a regenerator, to an exhaust gas output from a high pressure turbine stage to the regenerator. The engine topology may additionally employ, as an intermediate stage between the high pressure turbine and the low pressure turbine, a feedback control system, whereby the exhaust gas output from the high pressure turbine stage to the regenerator flows through the feedback control. The engine topology may advantageously also employ an additional cooler and an additional exhaust gas output in the feedback control, whereby exhaust gas flows from the feedback control through the additional cooler to a high pressure compressor stage, or the exhaust gas can flow from the feedback control through a bottoming cycle to the high pressure compressor stage. An exhaust gas condenser may advantageously be placed into the bottoming cycle system. The bottoming cycle / condenser improvements may alternatively be effected an other wise conventional intercooled regenerative turbine engine topology.

Owner:COLEMAN RICHARD R +1

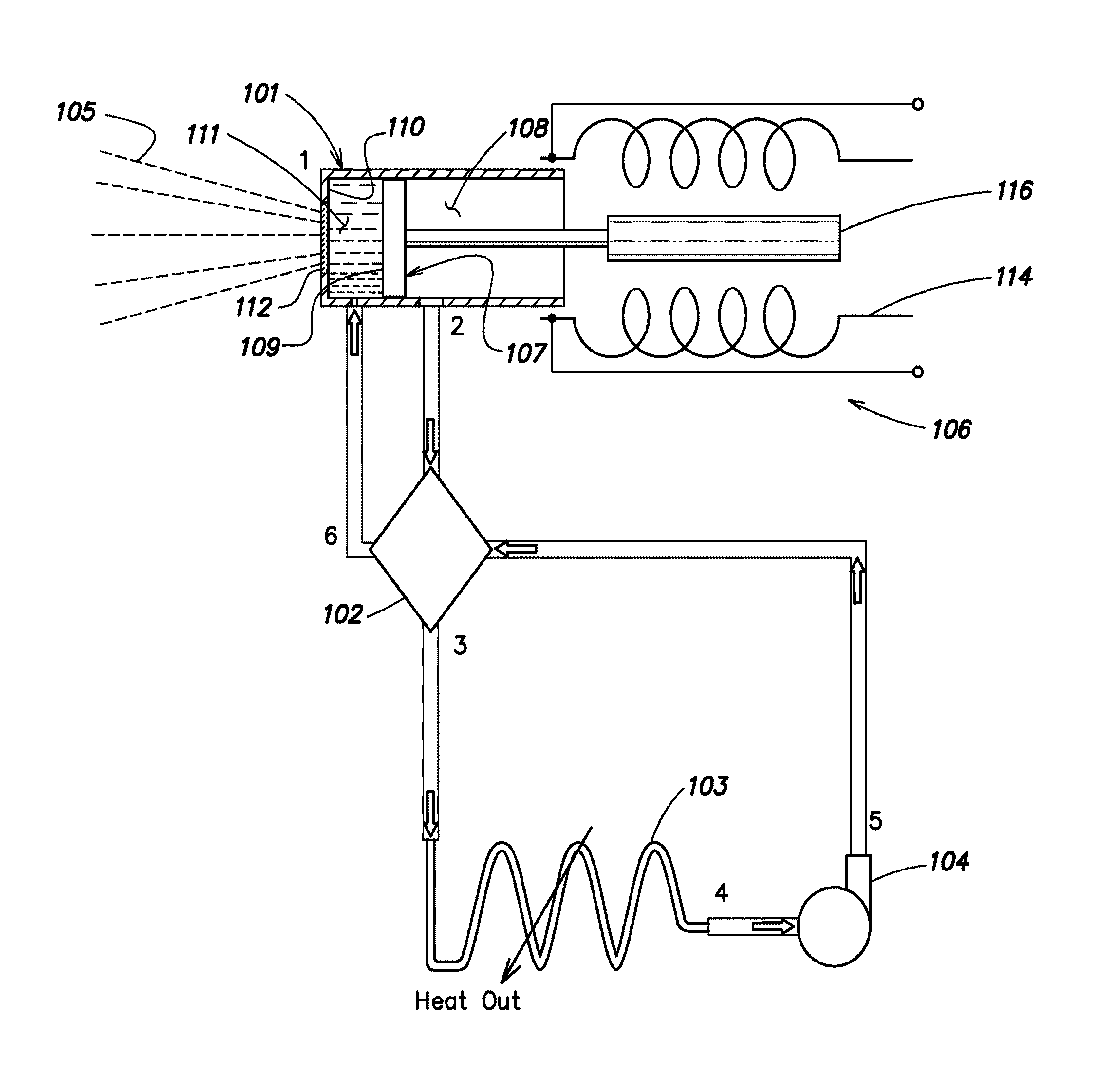

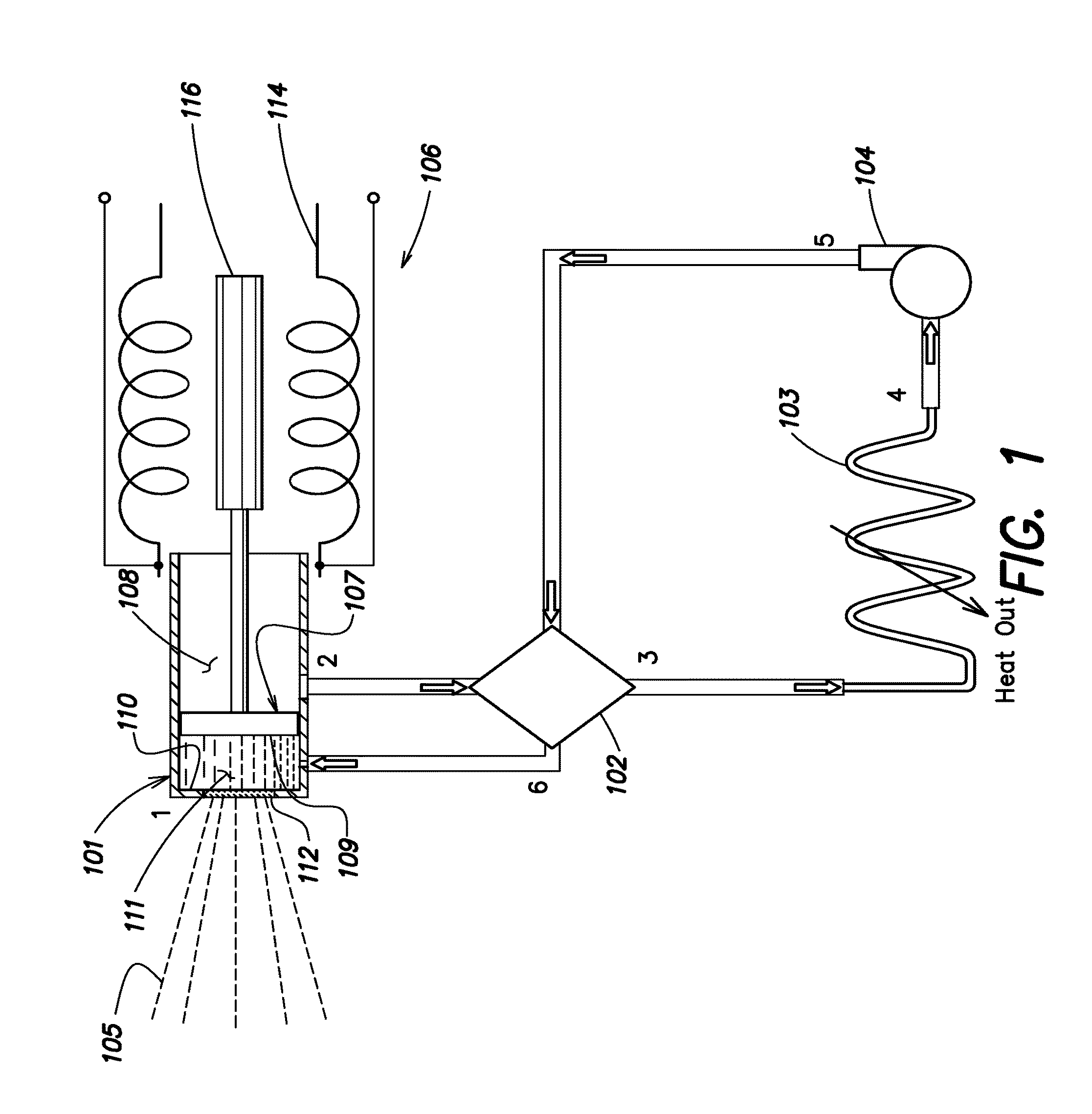

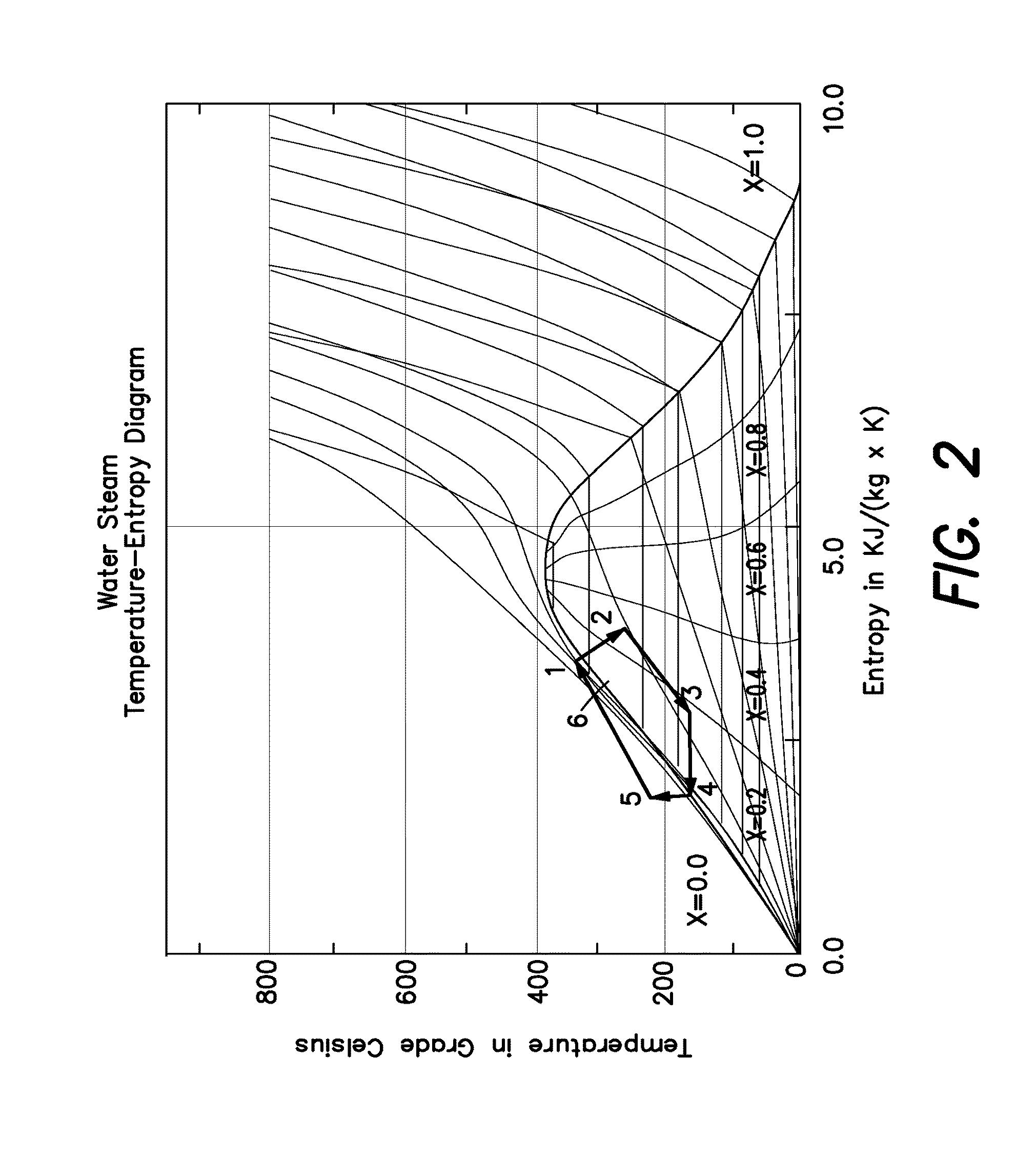

Heat engine with cascaded cycles

InactiveUS20110271676A1Low emissivityImprove absorption rateSteam engine plantsSolar thermal energy generationThermal energyWorking fluid

A method of converting thermal energy into another energy form using a thermodynamic cycle is disclosed, the method including the steps of: pressurizing a working fluid; supplying thermal energy to heat the working fluid from a liquid or substantially liquid state to a supercritical fluid state; in a first expander, substantially isentropically expanding the working fluid to yield energy in the other energy form; separating the expanded working fluid to form a first portion of the fluid diverted to a second expander and a second portion of the working fluid diverted to bypass the second expander; in the second expander, substantially isentropically expanding the first portion of the working fluid to yield energy in the other energy form; condensing the expanded first portion of the working fluid to a liquid or substantially liquid state; and recombining the first and second portions of the working fluid to be recirculated in the cycle.

Owner:SOLARTREC

Method and apparatus for compressing a gas to a high pressure

ActiveUS20050180864A1Improve compressor efficiencyHigh aspect ratioPositive displacement pump componentsFlexible member pumpsElectronic controllerHydraulic pump

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

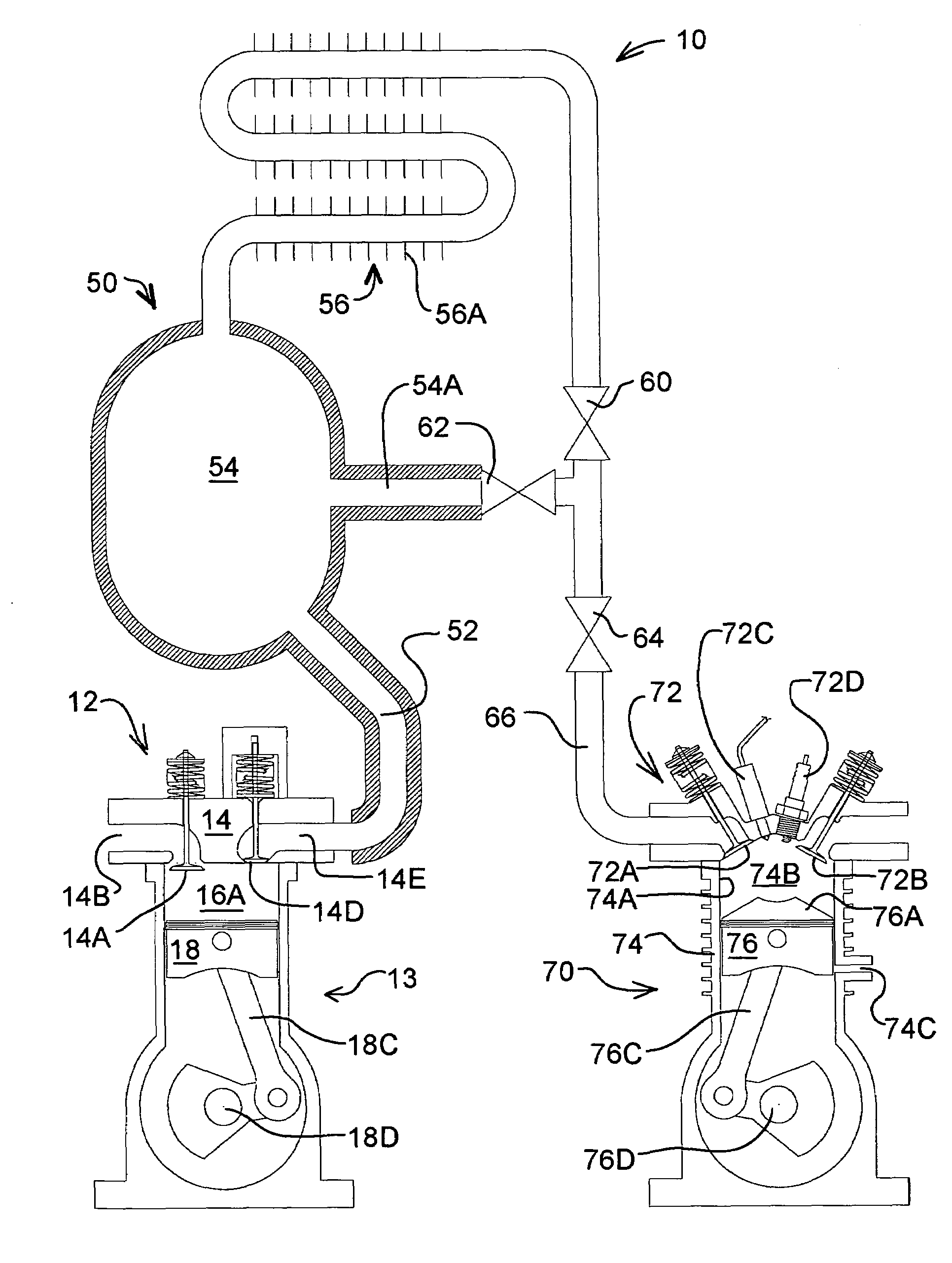

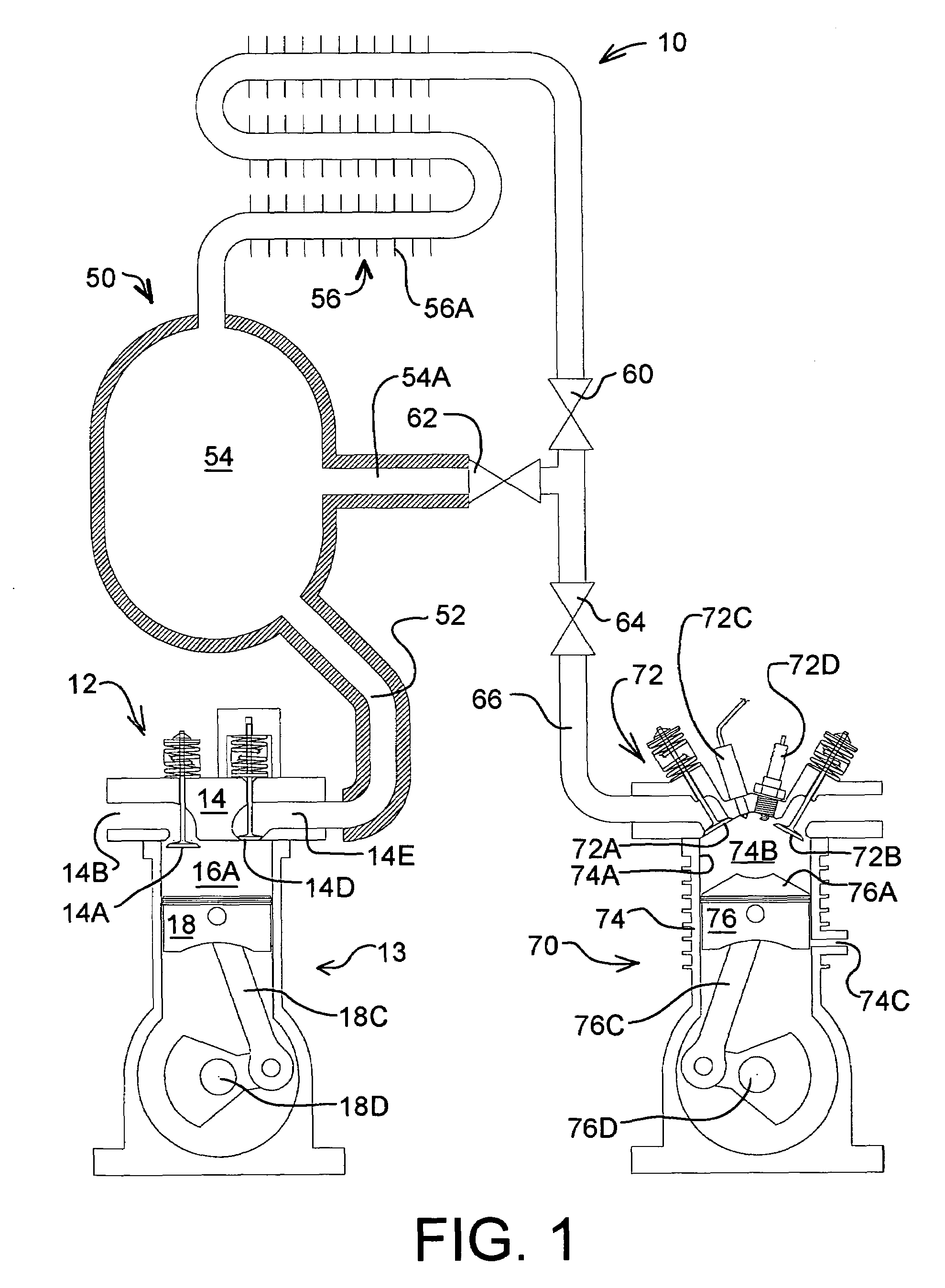

Air injection engine

InactiveUS20060124085A1Ratio of compression can be significantly higher or lowerHigh expansion rateInternal combustion piston enginesOutput powerInjection airCylinder (engine)

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

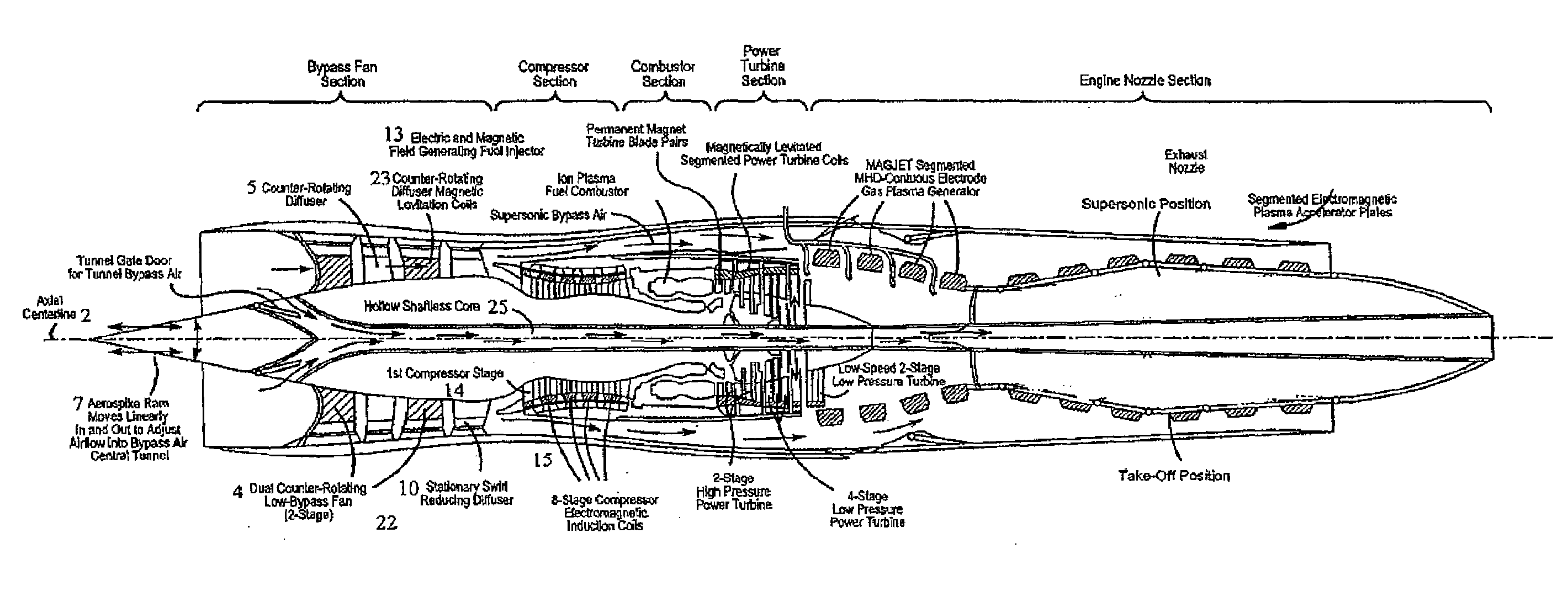

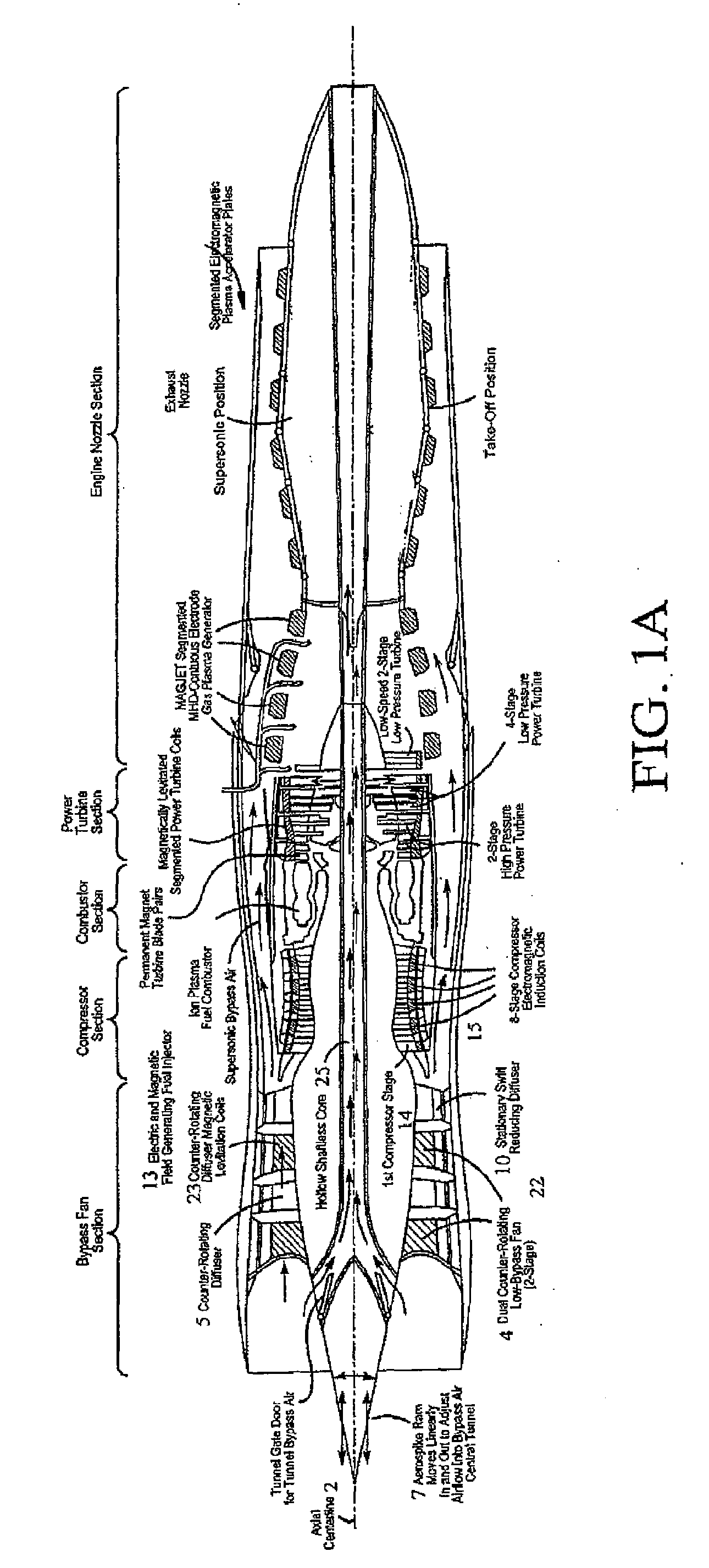

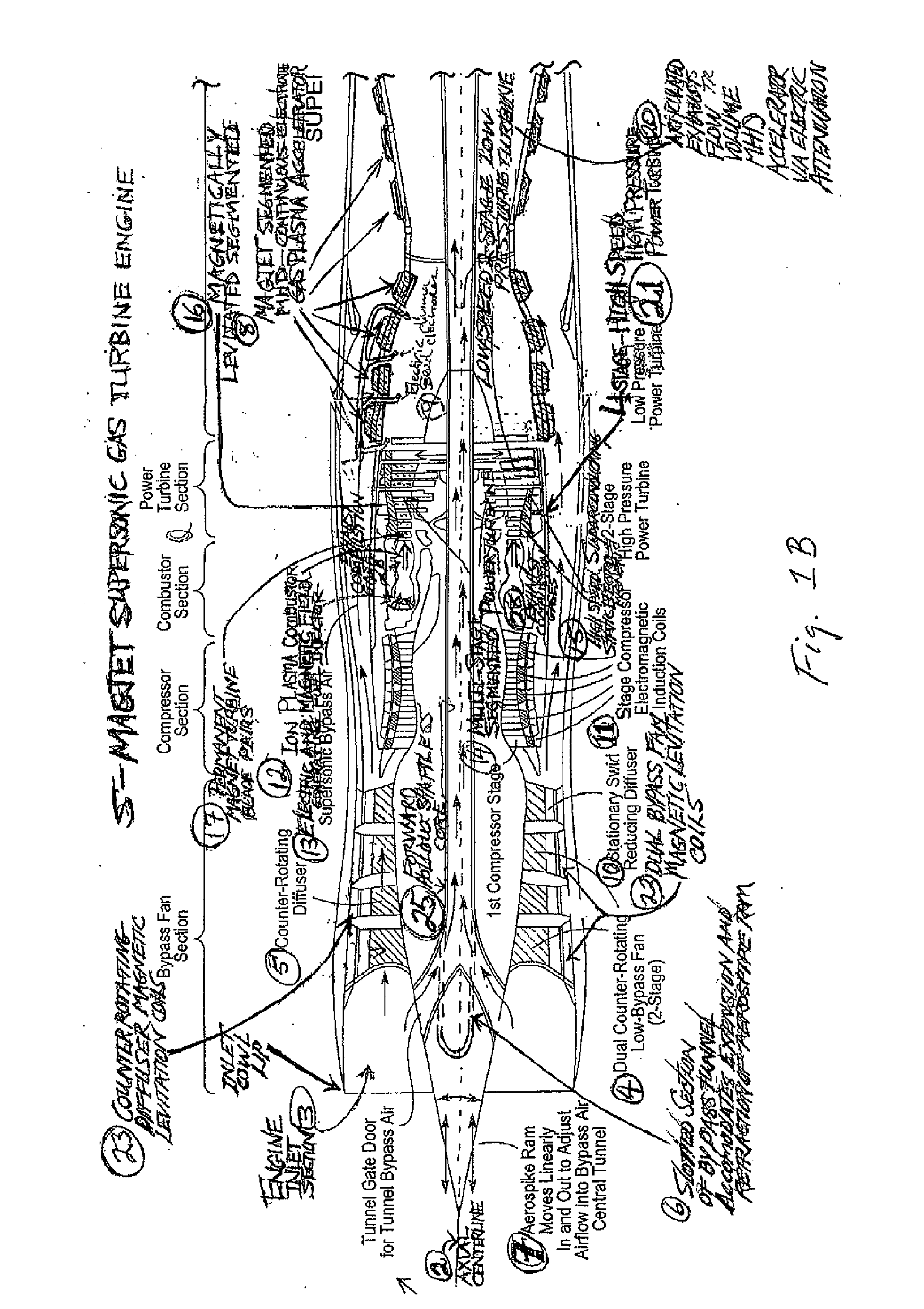

Magnetic advanced generation jet electric turbine

ActiveUS20110138765A1Improve combustion efficiencyImprove propulsion efficiencyGas turbine plantsEnergy production using magneto-hydrodynamic generatorsAviationFuel efficiency

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exo-skeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation over traditional gas turbine technology today. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions. With bypass fan(s), compressor stages and turbine segments controlled electrically in a shaftless turbine design, the S-MAGJET maximizes the propulsion efficiencies over a broader range of operating conditions compared to current art of turbine technology and at much higher thermodynamic and aerodynamic efficiencies.

Owner:SONIC BLUE AEROSPACE

Refrigeration process

InactiveUS20130008204A1Thermodynamic efficiency can be optimisedIncrease flexibilitySolidificationLiquefactionEngineeringRefrigeration

The present invention relates to a single cycle mixed refrigerant process for industrial cooling applications, for example, the liquefaction of natural gas. The present invention also relates to a refrigeration assembly configured to implement the processes defined herein and a mixed refrigerant composition usable in such processes.

Owner:UNIV OF MANCHESTER

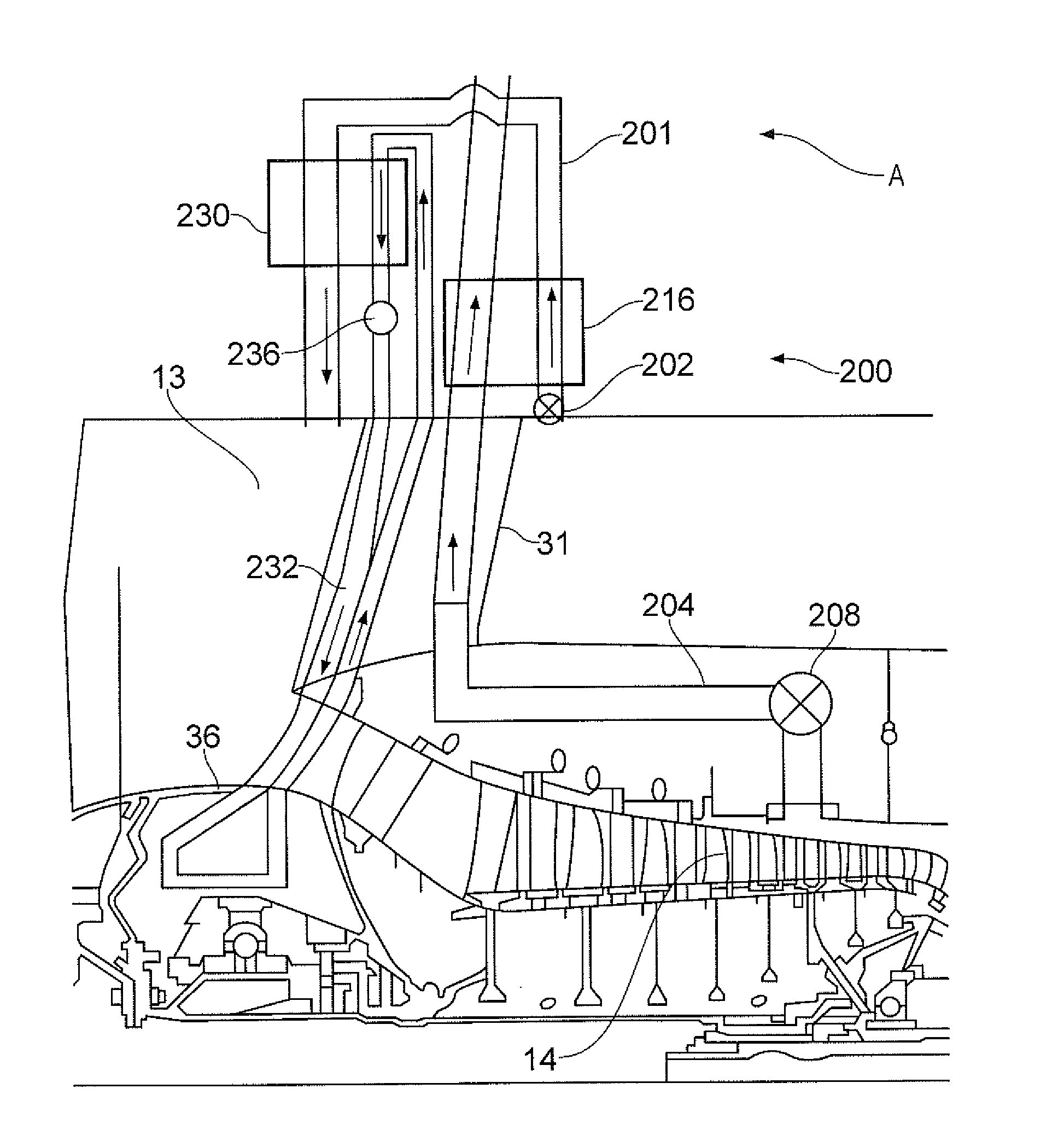

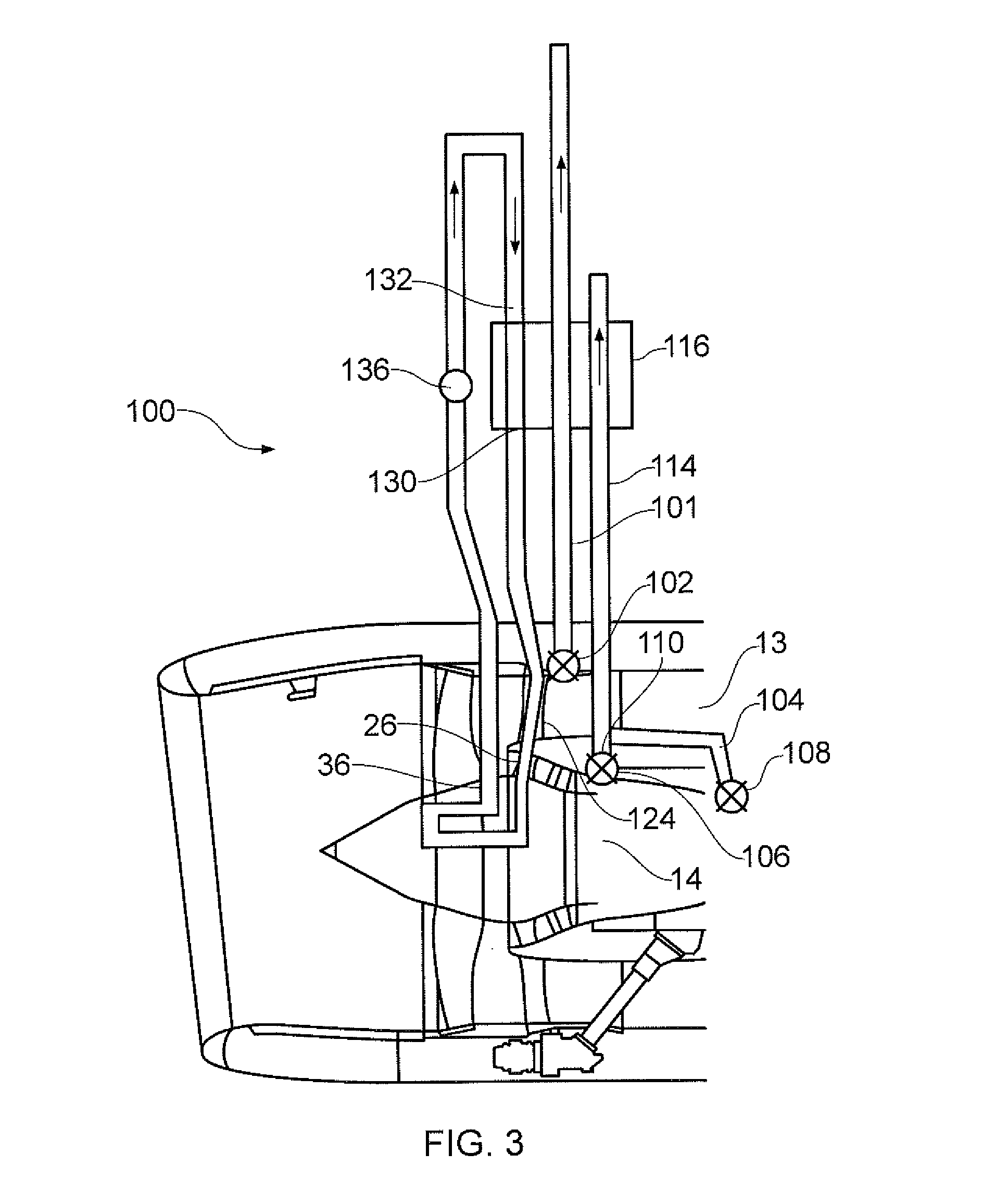

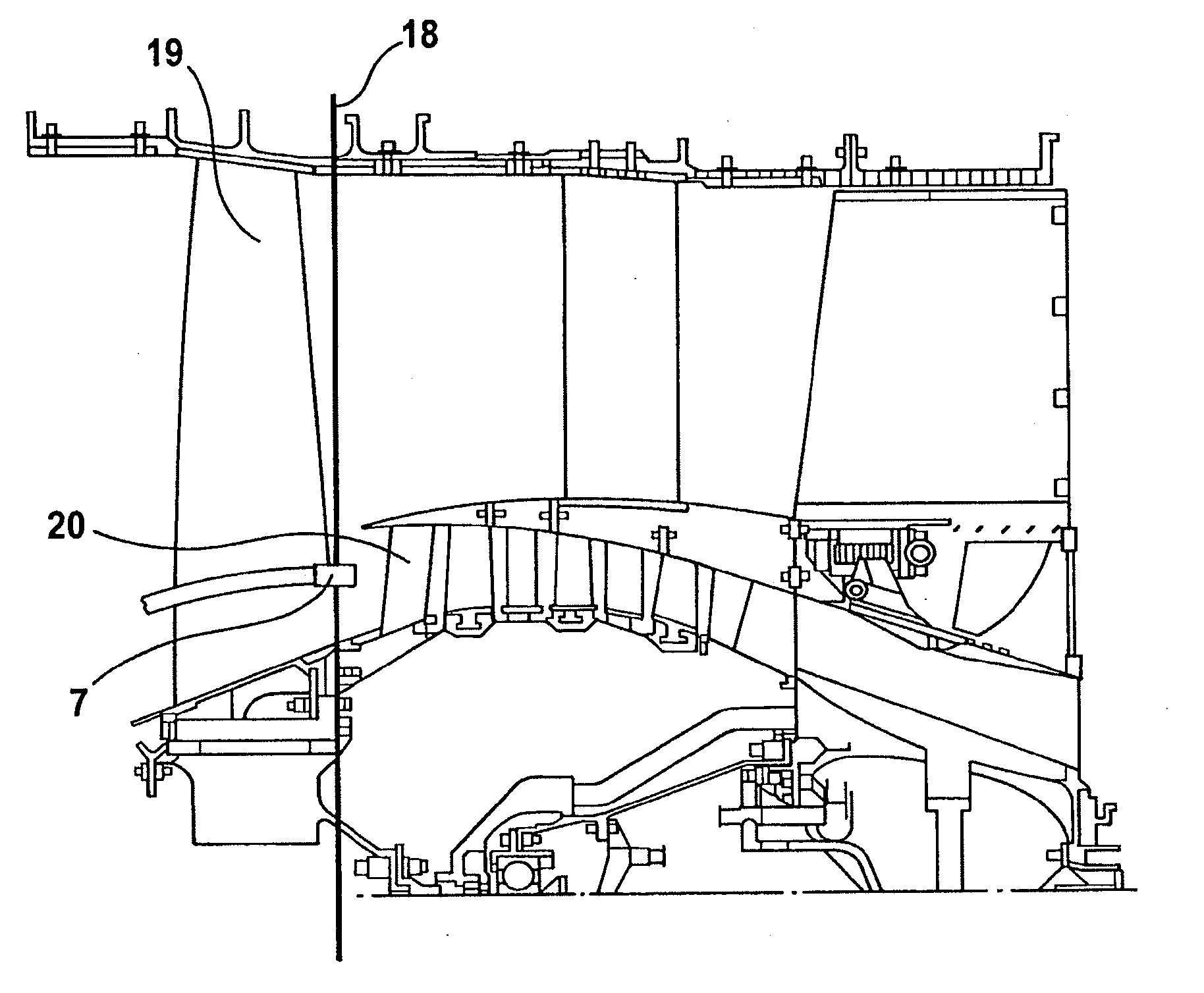

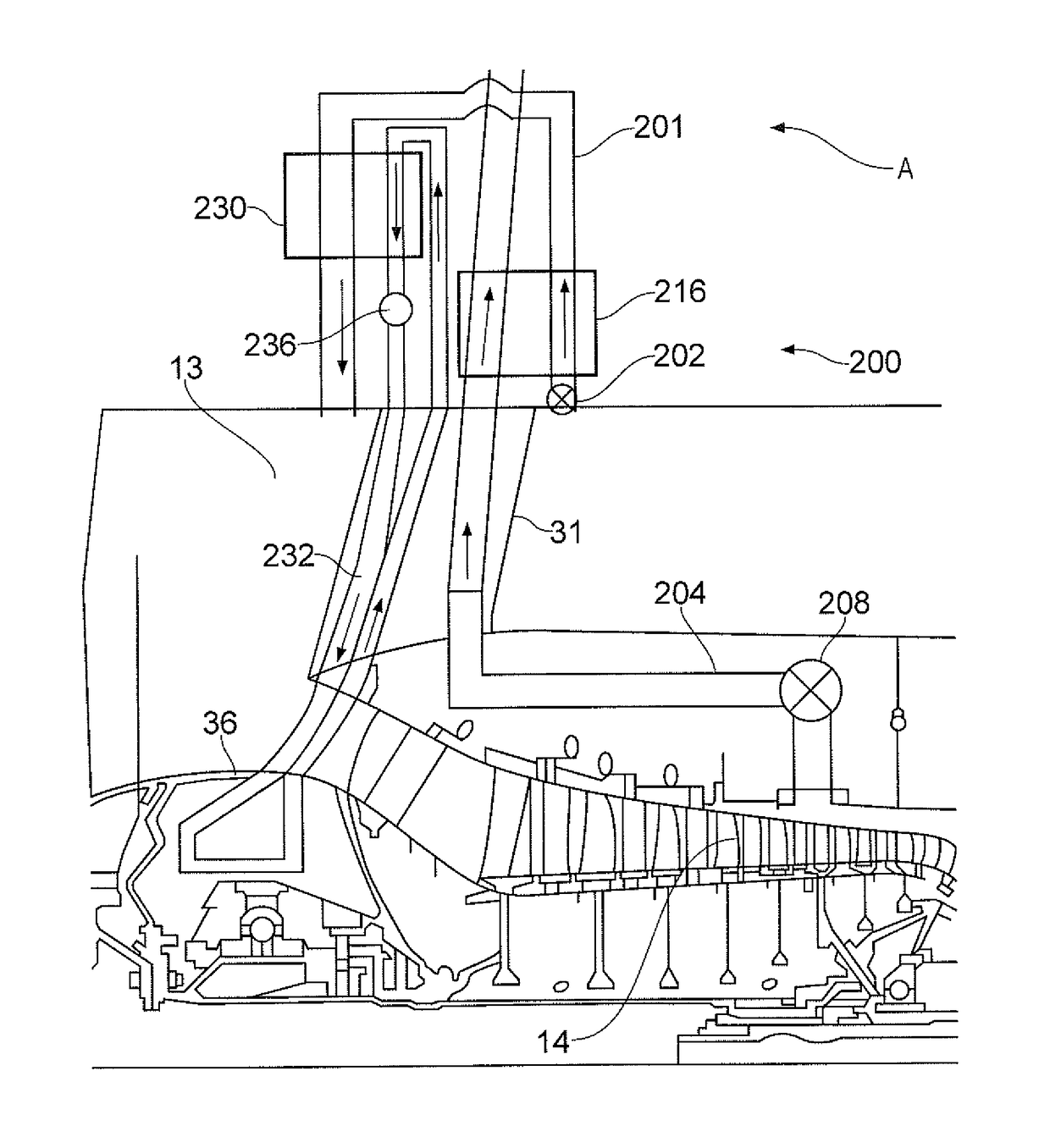

Gas turbine engine Anti-icing system

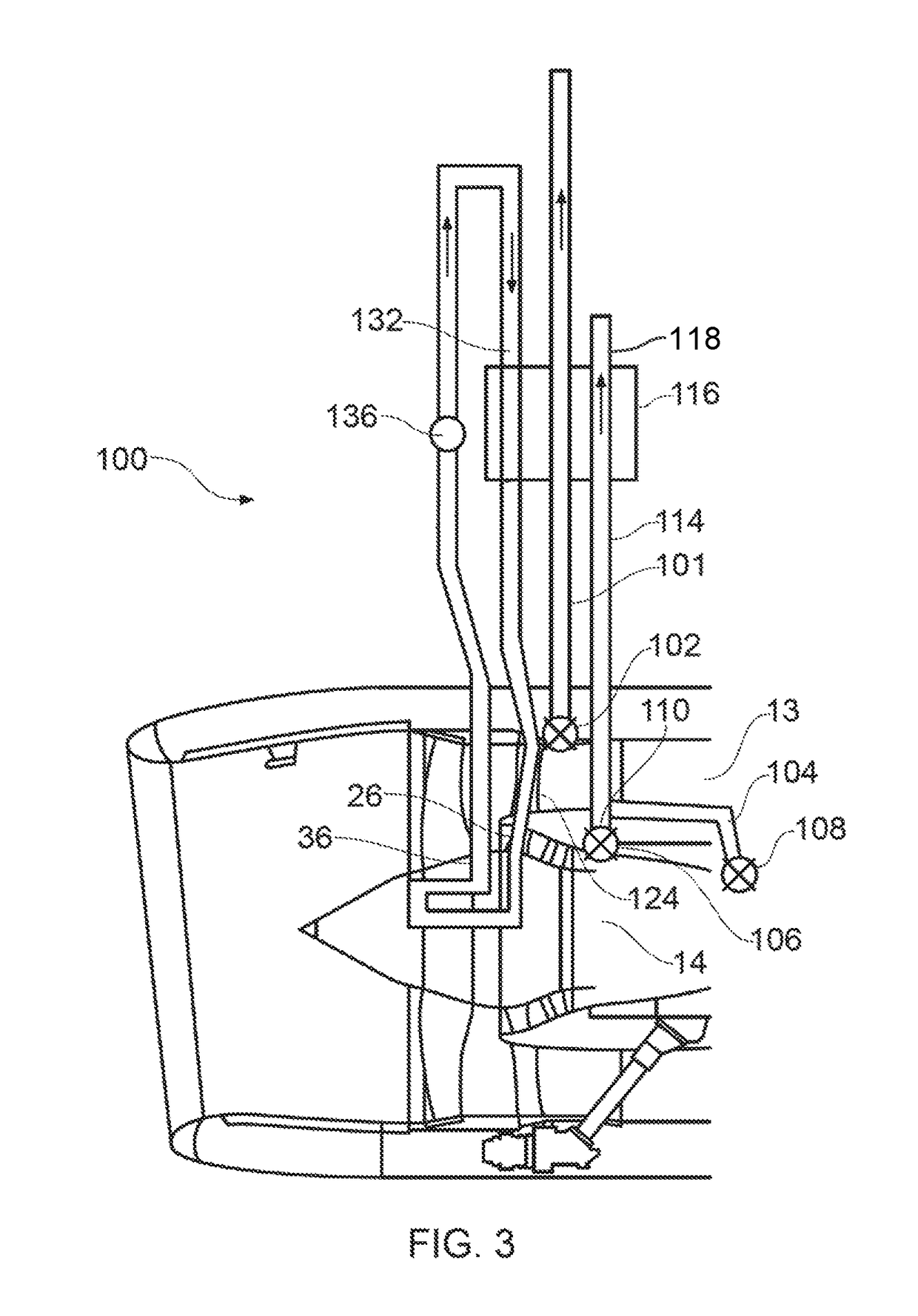

ActiveUS20160061056A1Sufficient energyImprove thermodynamic efficiencyWind motor controlEngine fuctionsStatorGas turbines

An anti-icing system (100) for an engine section stator (26) of a gas turbine engine (10), the system (100) comprising:an environmental control system pre-cooler heat exchange system (116) configured to exchange heat between air bled from a compressor (14, 16) of the engine (10) and bypass duct air; anda conduit (132) configured to exchange heat from the pre-cooler heat exchange system (116) to a further a heat transfer medium, the conduit (132) being configured to transfer the heat from the heat transfer medium to the engine section stator (26).

Owner:ROLLS ROYCE PLC

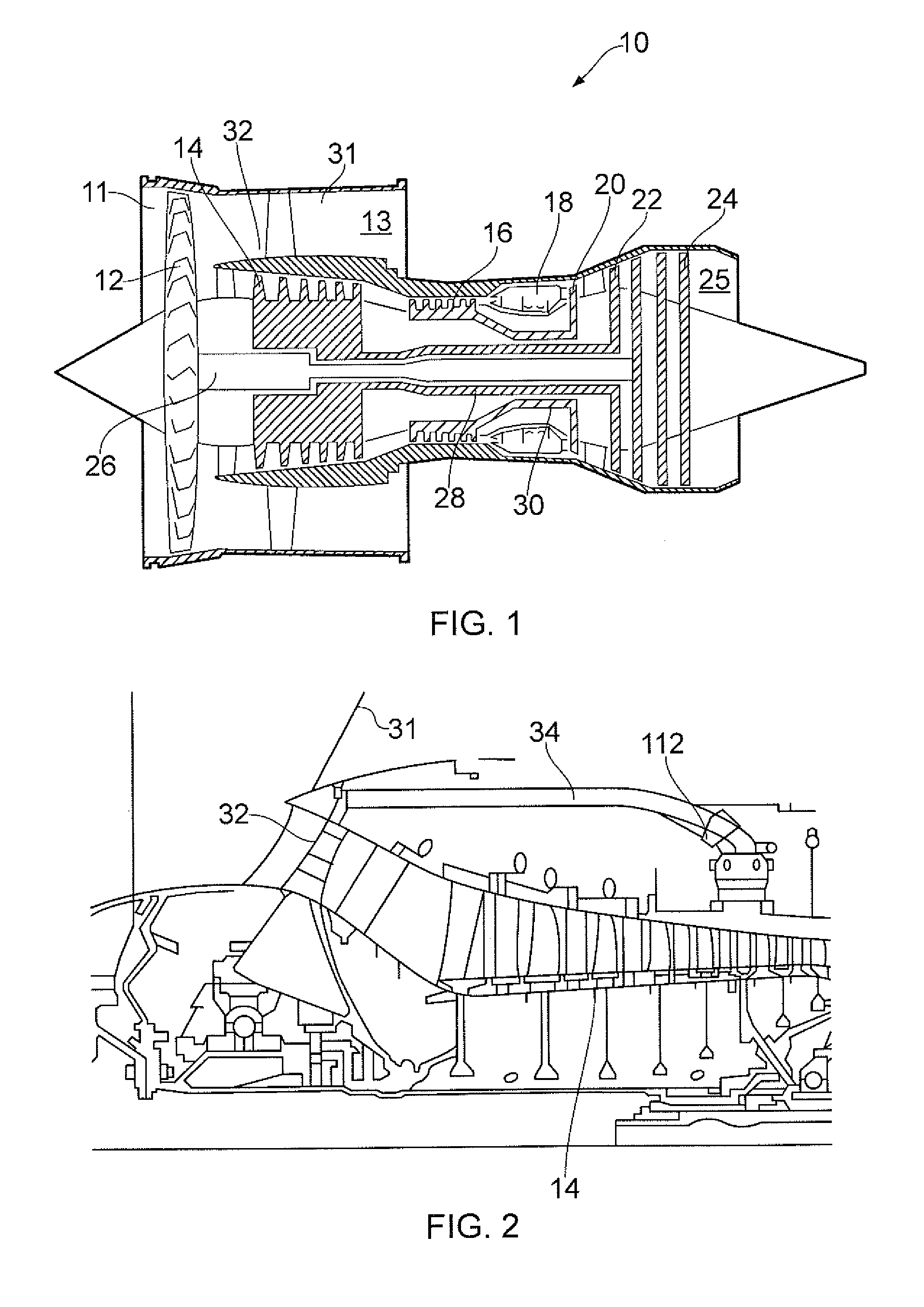

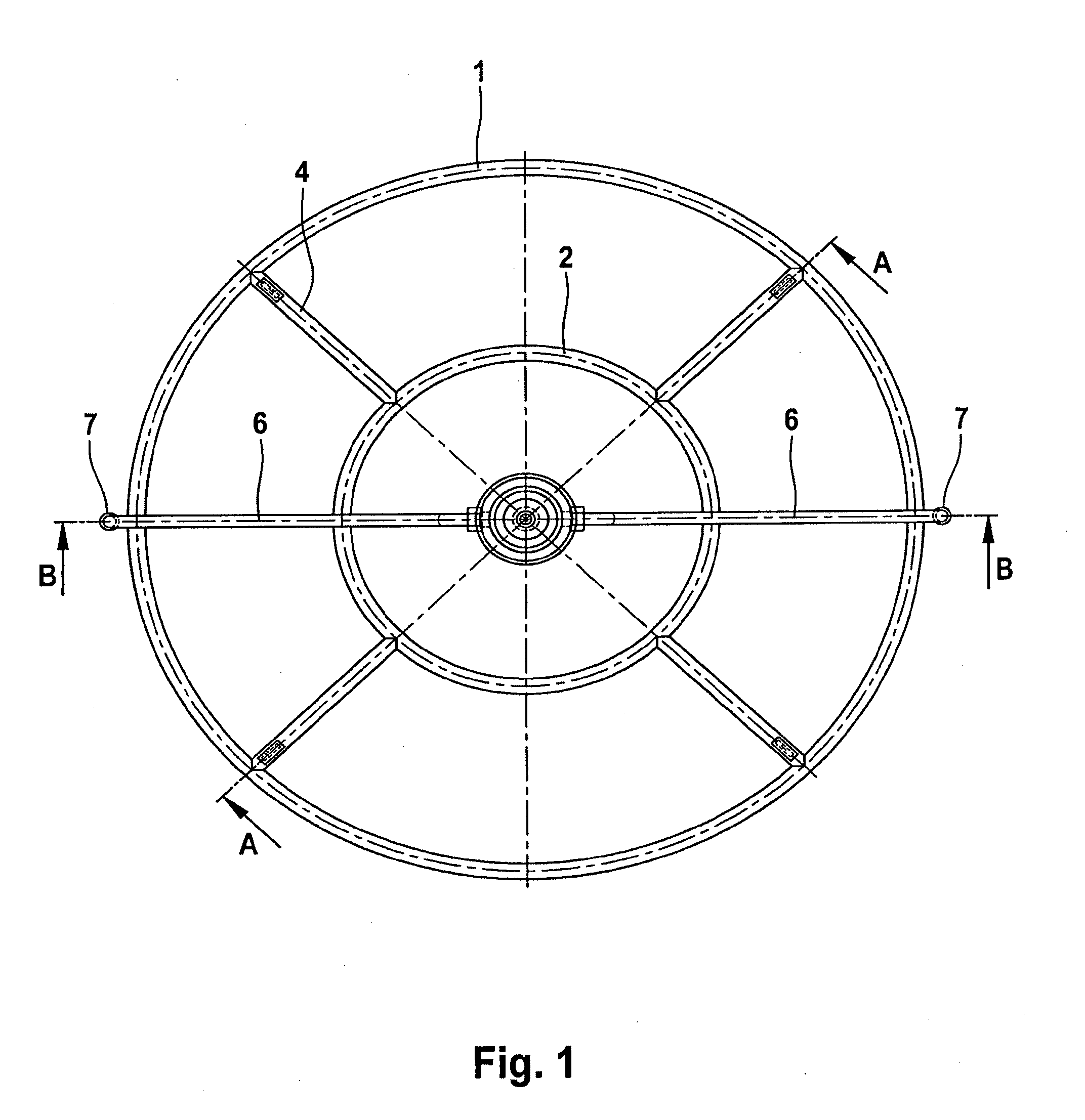

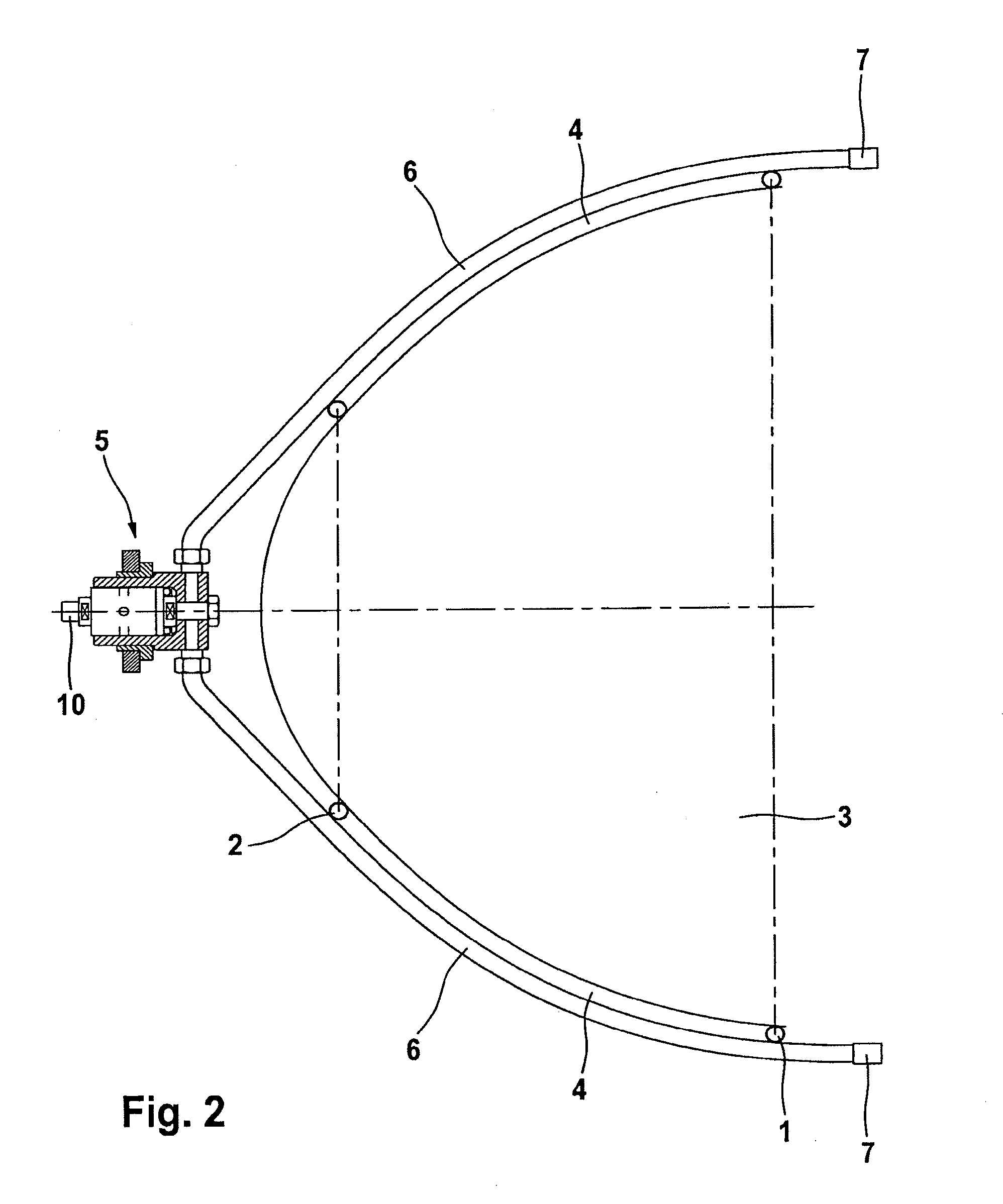

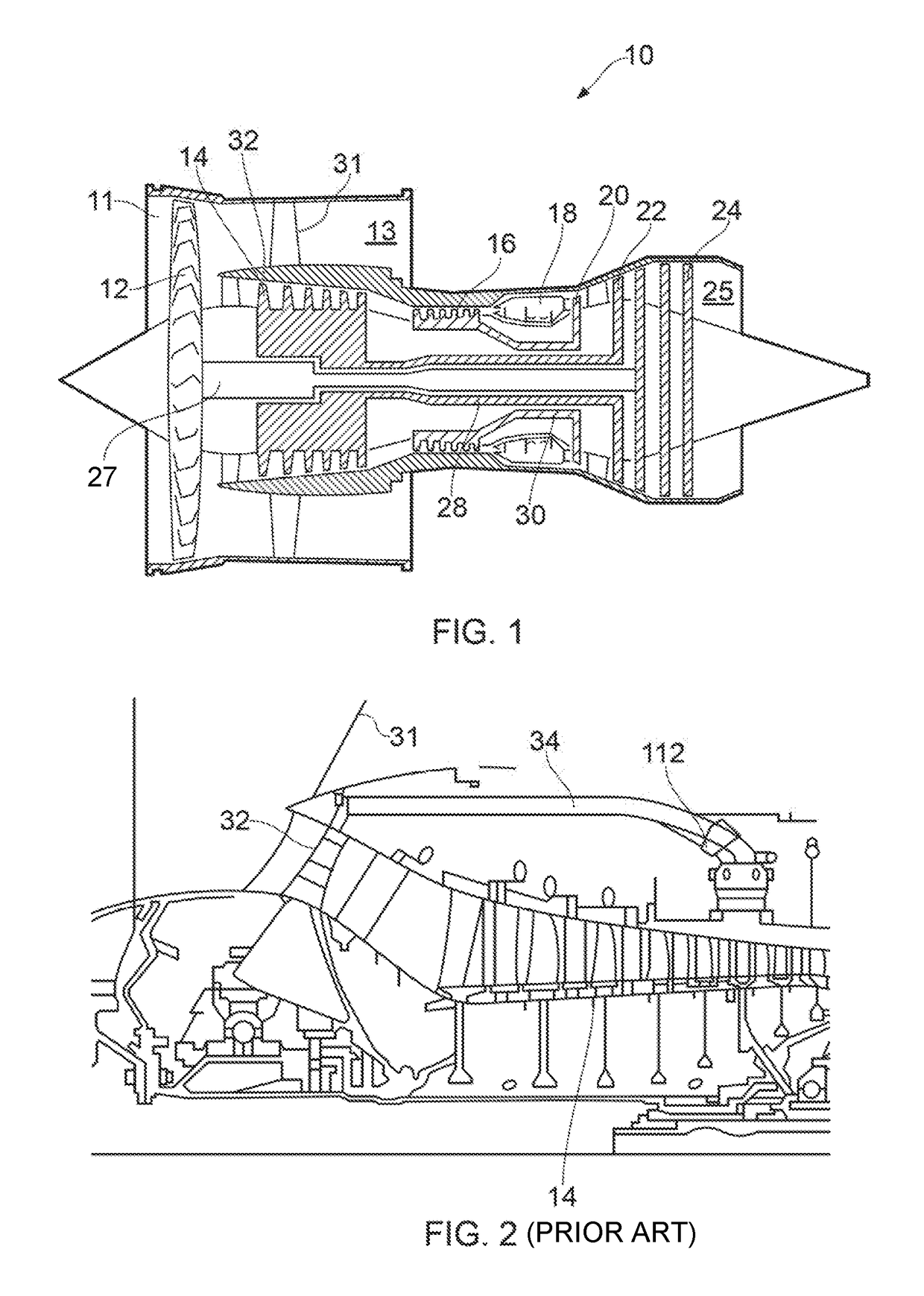

Device and method for cleaning the core engine of a jet engine

ActiveUS20100200023A1Easy to cleanImprove thermodynamic efficiencyHollow article cleaningElectrostatic cleaningJet engineCoupling

The object of the invention is a device for cleaning the core engine of a jet engine, having a supply unit, which provides the cleaning medium, a nozzle unit, which is configured for feeding the cleaning medium into the core engine, and a line connection between the supply unit and the nozzle unit. The invention provides that the nozzle unit has a means for the rotationally fixed connection to the fan shaft of the jet engine, and that a rotary coupling is provided between the nozzle unit and the line connection. The object of the invention is further an arrangement of such a device and a turbo fan jet engine, and a method for cleaning the core engine of a jet engine using the device.

Owner:LUFTHANSA TECH AG

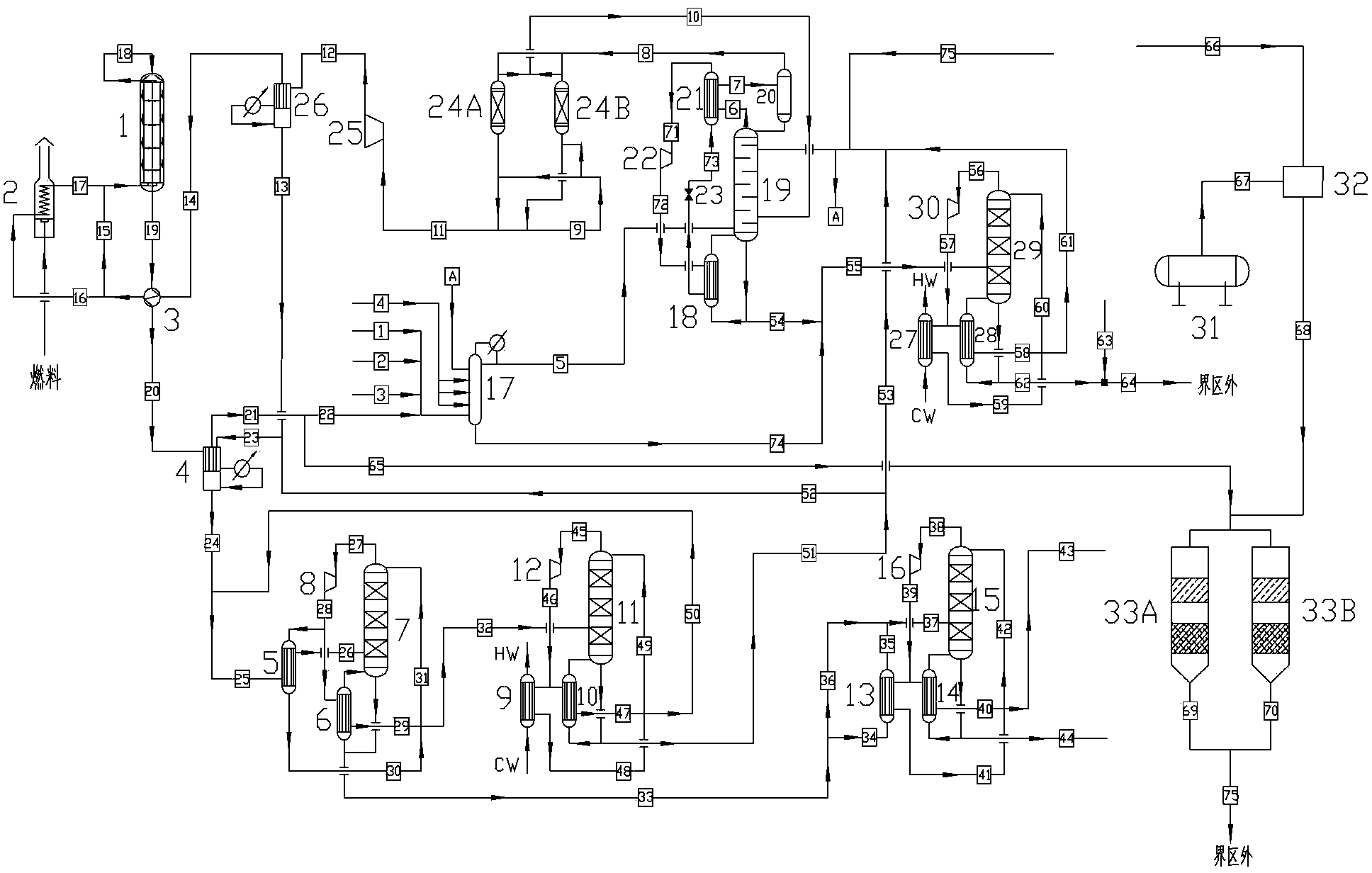

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

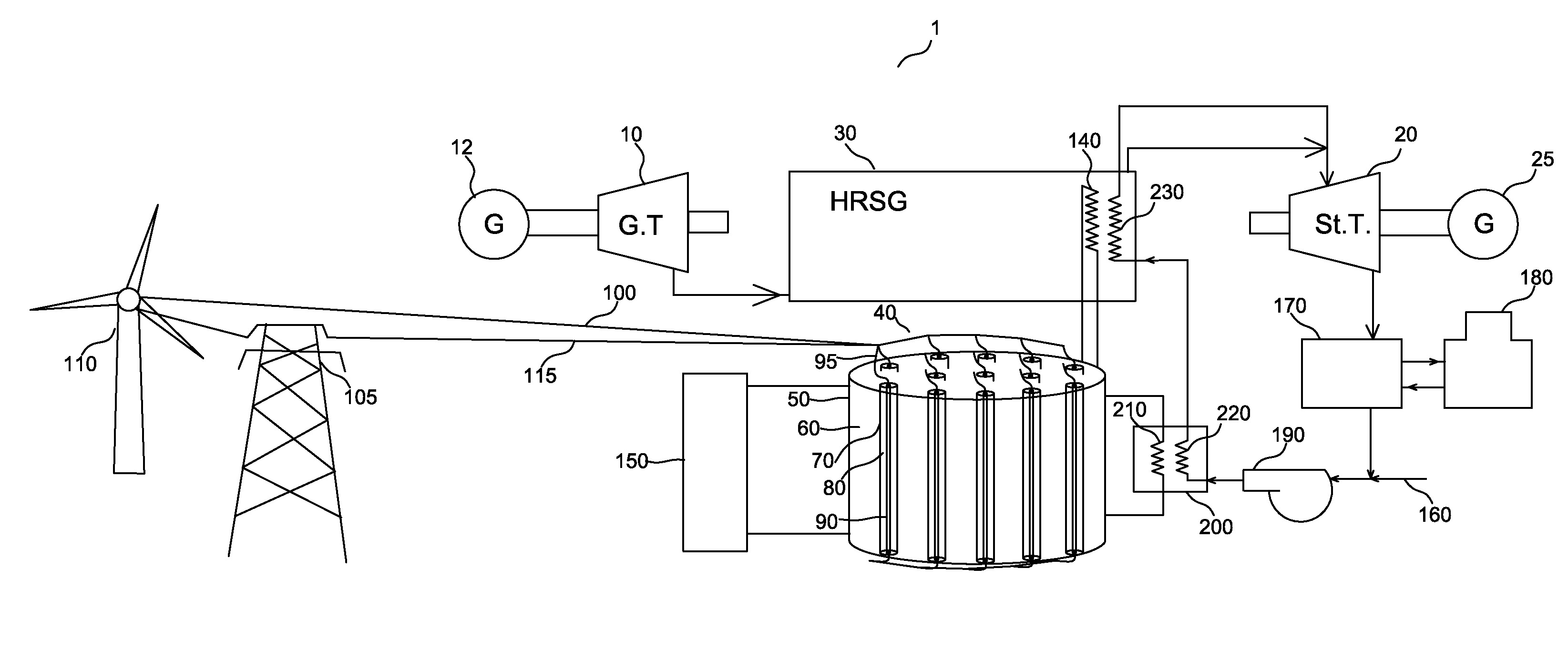

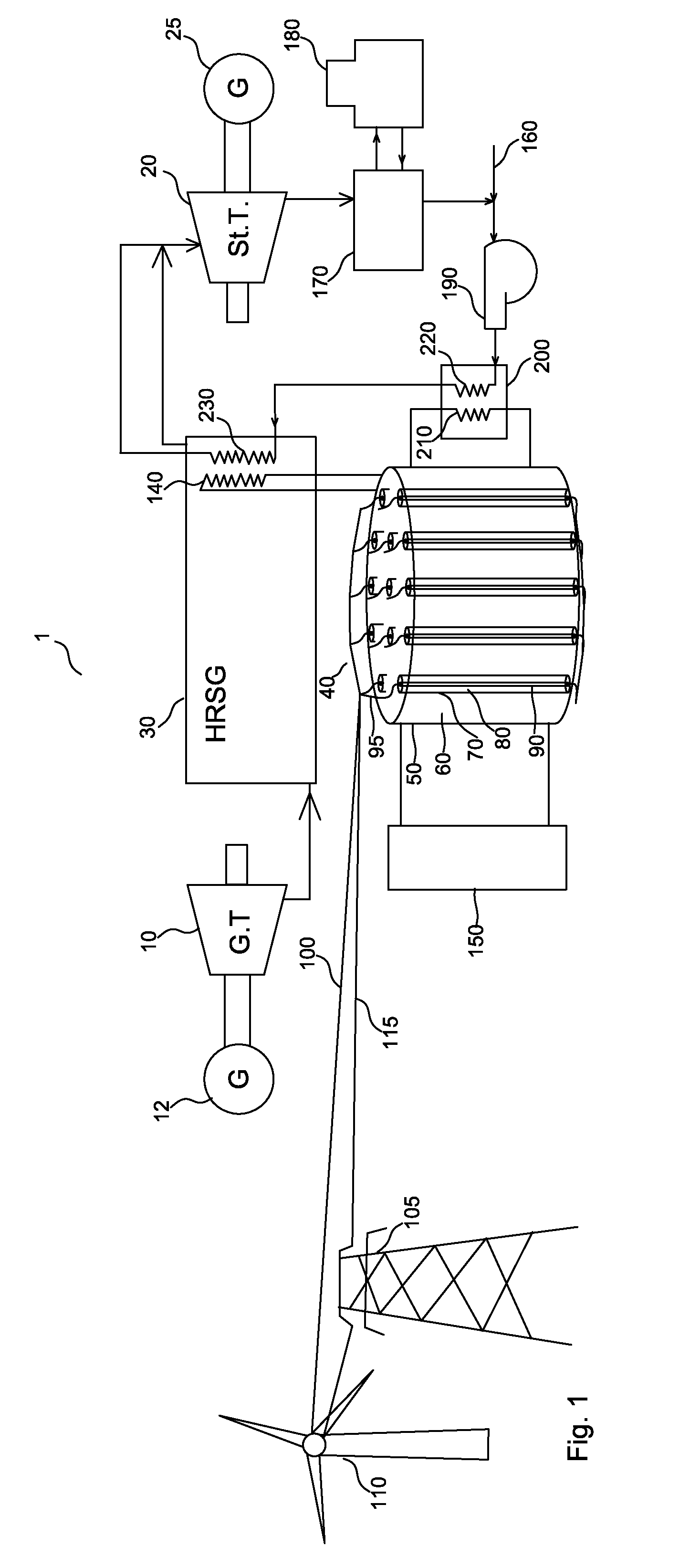

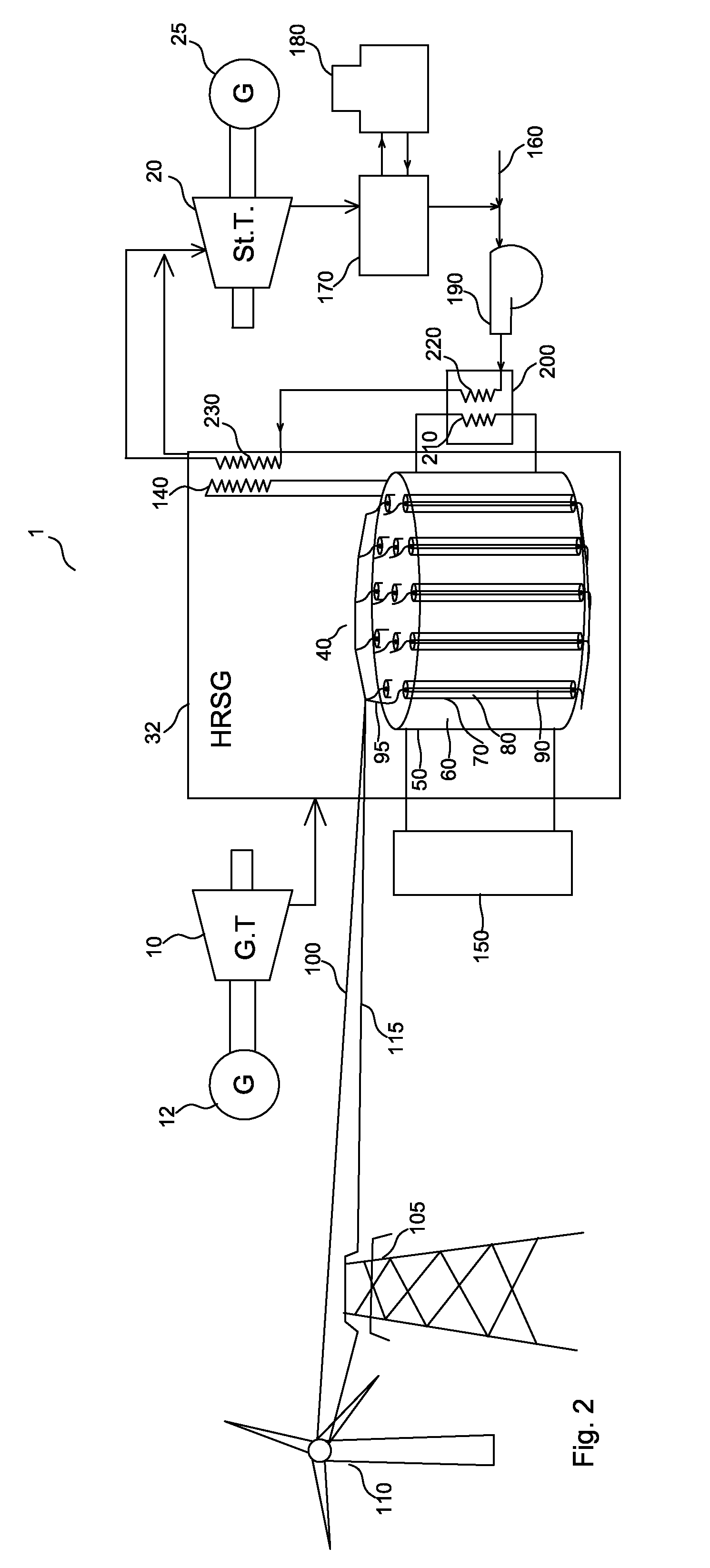

Combined Cycle Plant With Thermal Energy Storage

InactiveUS20150267566A1Maximum flexibilityGrowth of renewable energyHeat storage plantsTurbine/propulsion engine ignitionSeasonal thermal energy storagePower station

A combined cycle power plant for frequent stops and startups comprises at least one gas turbine, a heat recovery steam generator, at least one steam turbine and a thermal energy storage and retrieval system utilizing latent heat of fusion. Phase change materials receive thermal charge from two sources: (a) renewable energy generation plants, when their production exceeds demand and (b) gas turbine exhaust heat. The thermal energy storage and retrieval system, discharges efficiently thermal energy for steam production, which keeps the at least one steam turbine preheated and ready for fast startups, thus increasing the plant's flexibility and efficiency.A novel two stage latent thermal energy storage system provides at least supercritical steam.

Owner:VAMVAS VASSILIOS

Air injection apparatus for a turbocharged diesel engine

InactiveUS6862885B1Improves turbocharger boostReduce the formation of nitrogen oxidesInternal combustion piston enginesExhaust apparatusLow speedCombustion

A supercharger injects air into the engine exhaust manifold of an engine to dramatically improve turbocharger boost at low engine speeds, while cooling the gases in the exhaust manifold to reduce NOx formation. The injected air additionally reduces other exhaust emissions through secondary combustion, allowing the air / fuel ratio to be controlled closer to the stoichiometric ratio for improved thermodynamic efficiency. The engine is particularly well suited to high torque, low speed applications, such as a vehicle hydrostatic drive in which the engine is connected to drive a variable capacity hydrostatic pump at a low and substantially constant speed.

Owner:SUPERDRIVE

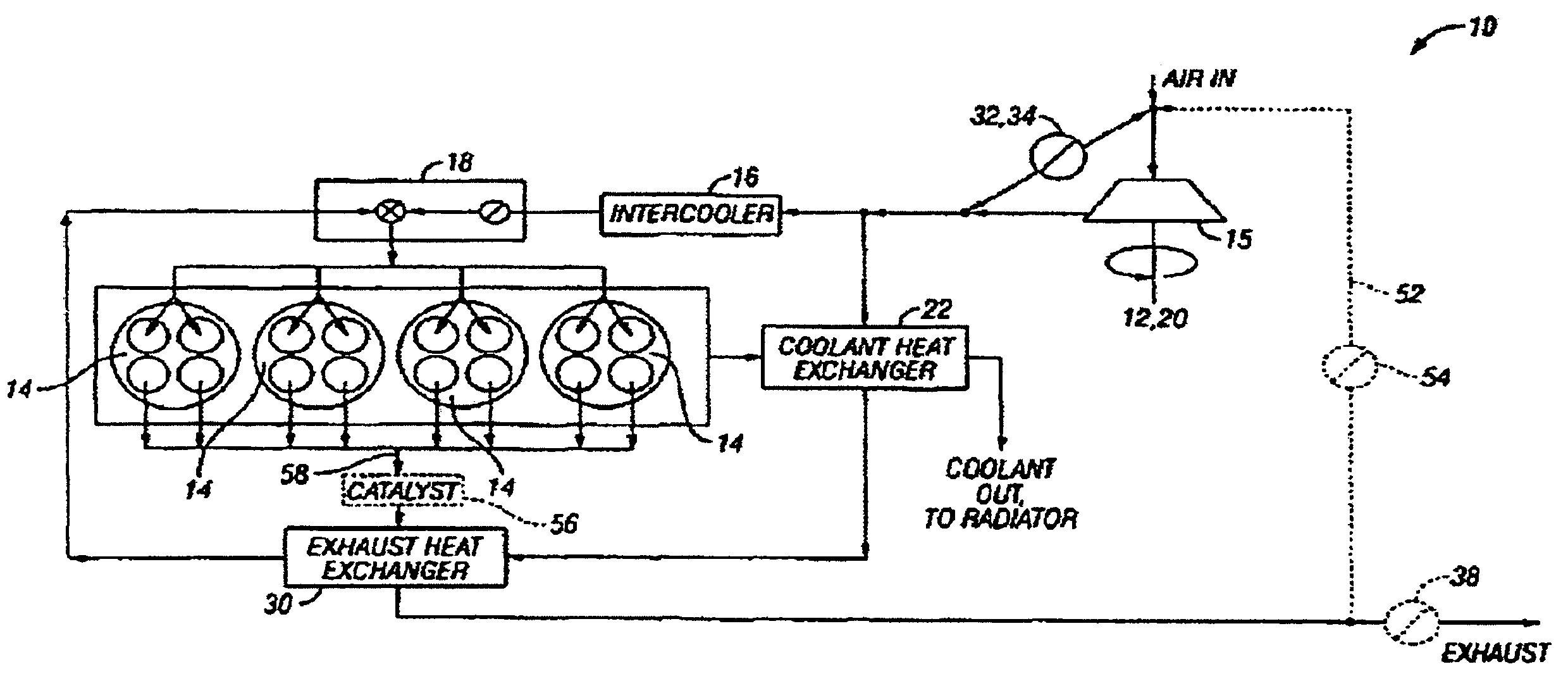

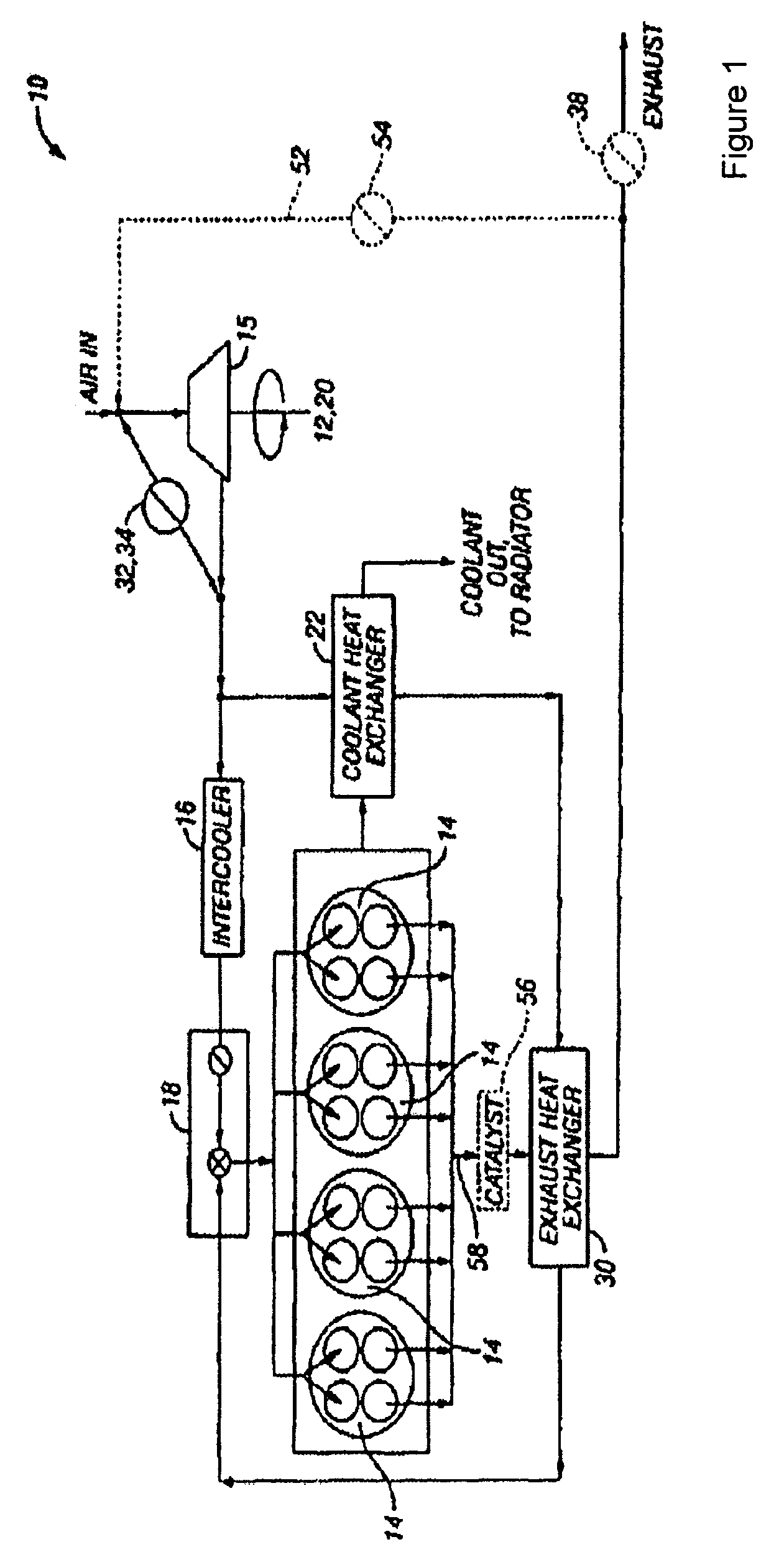

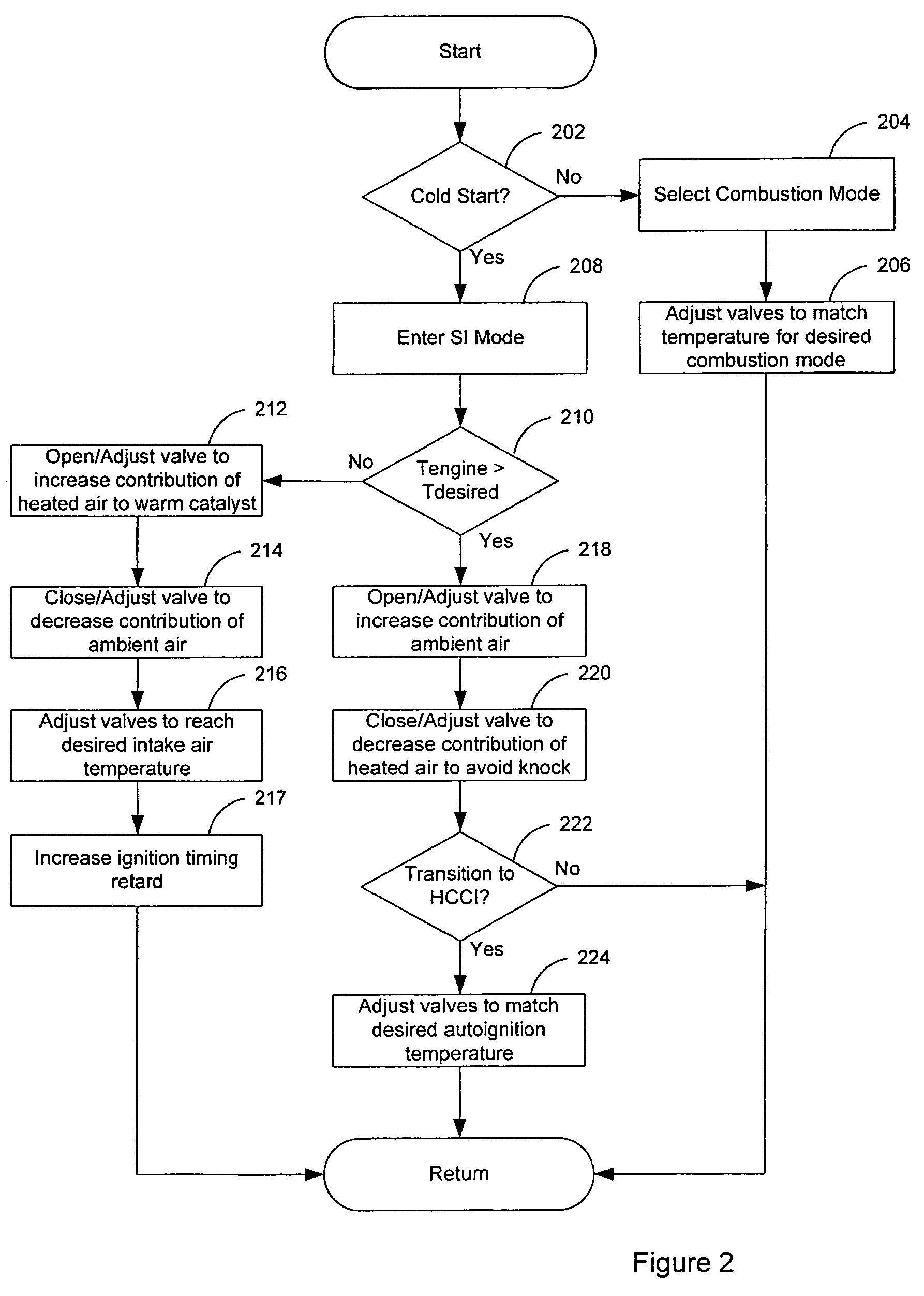

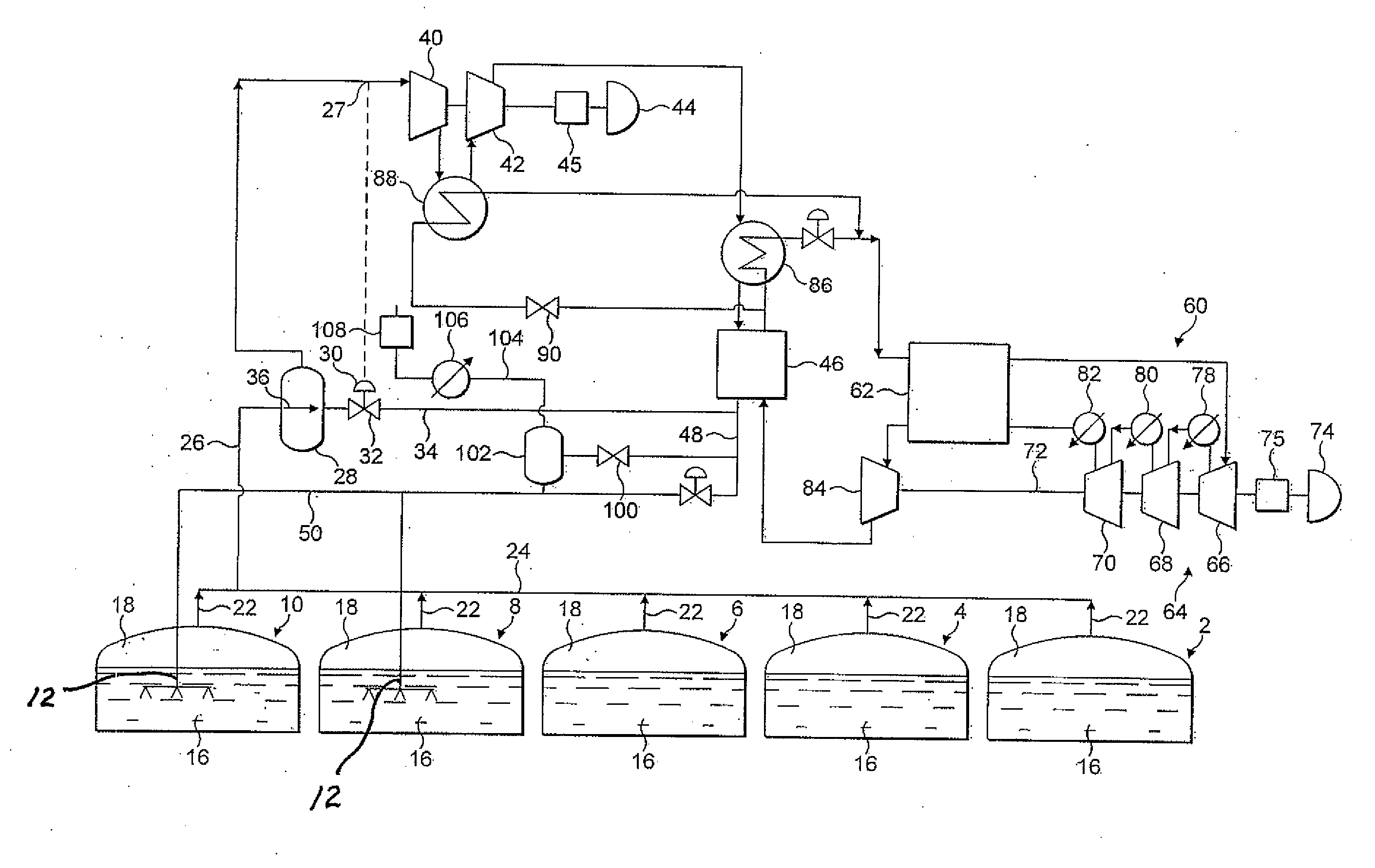

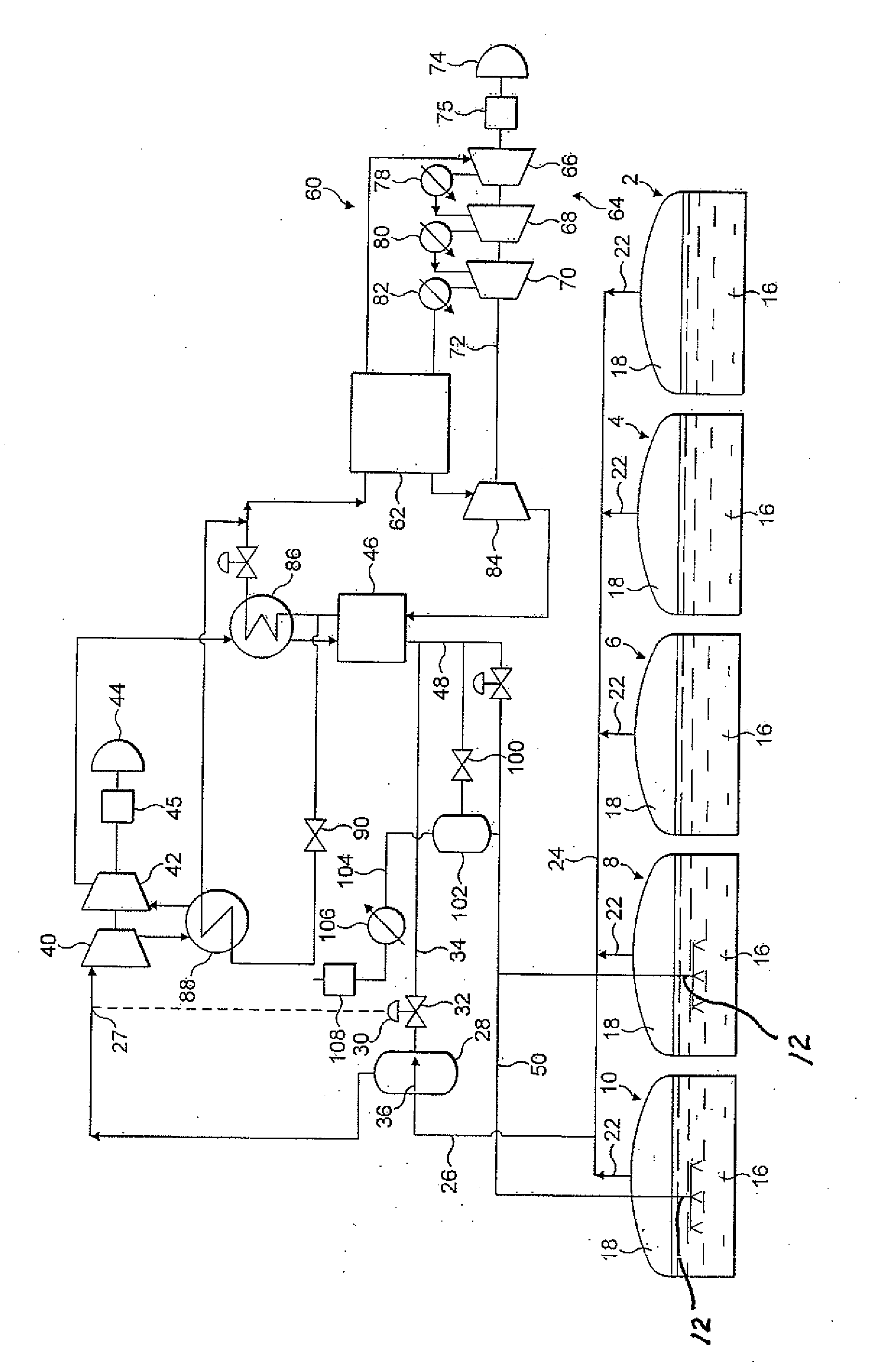

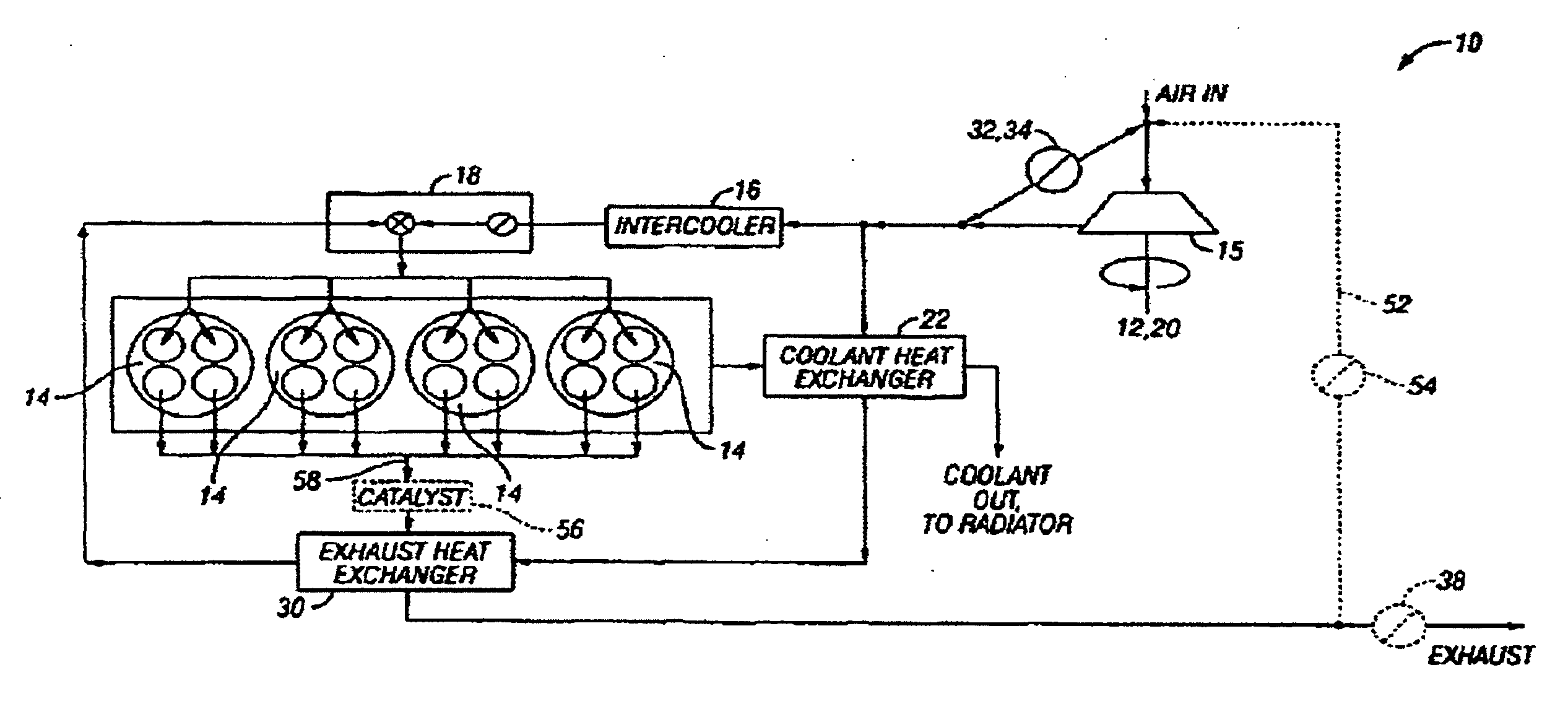

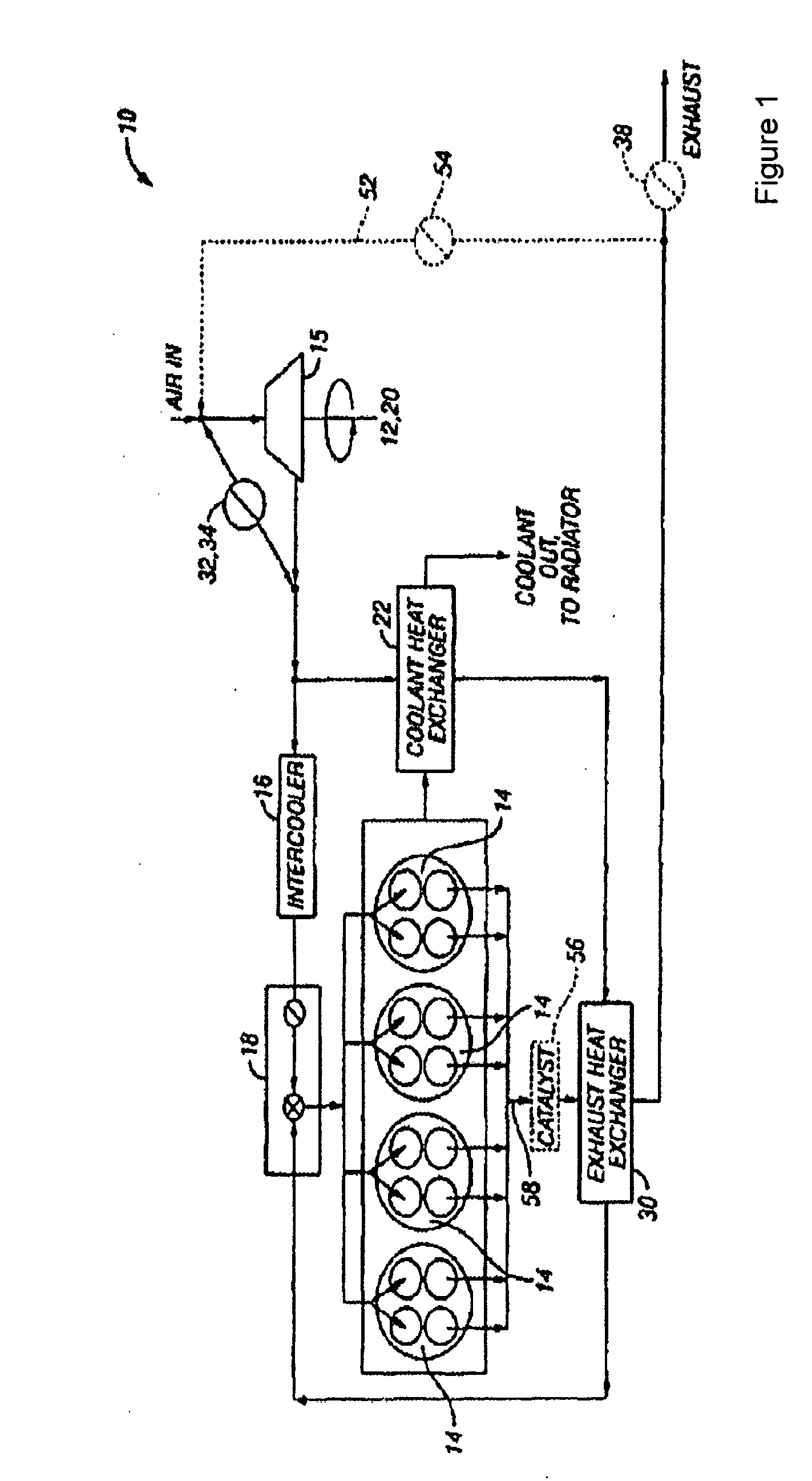

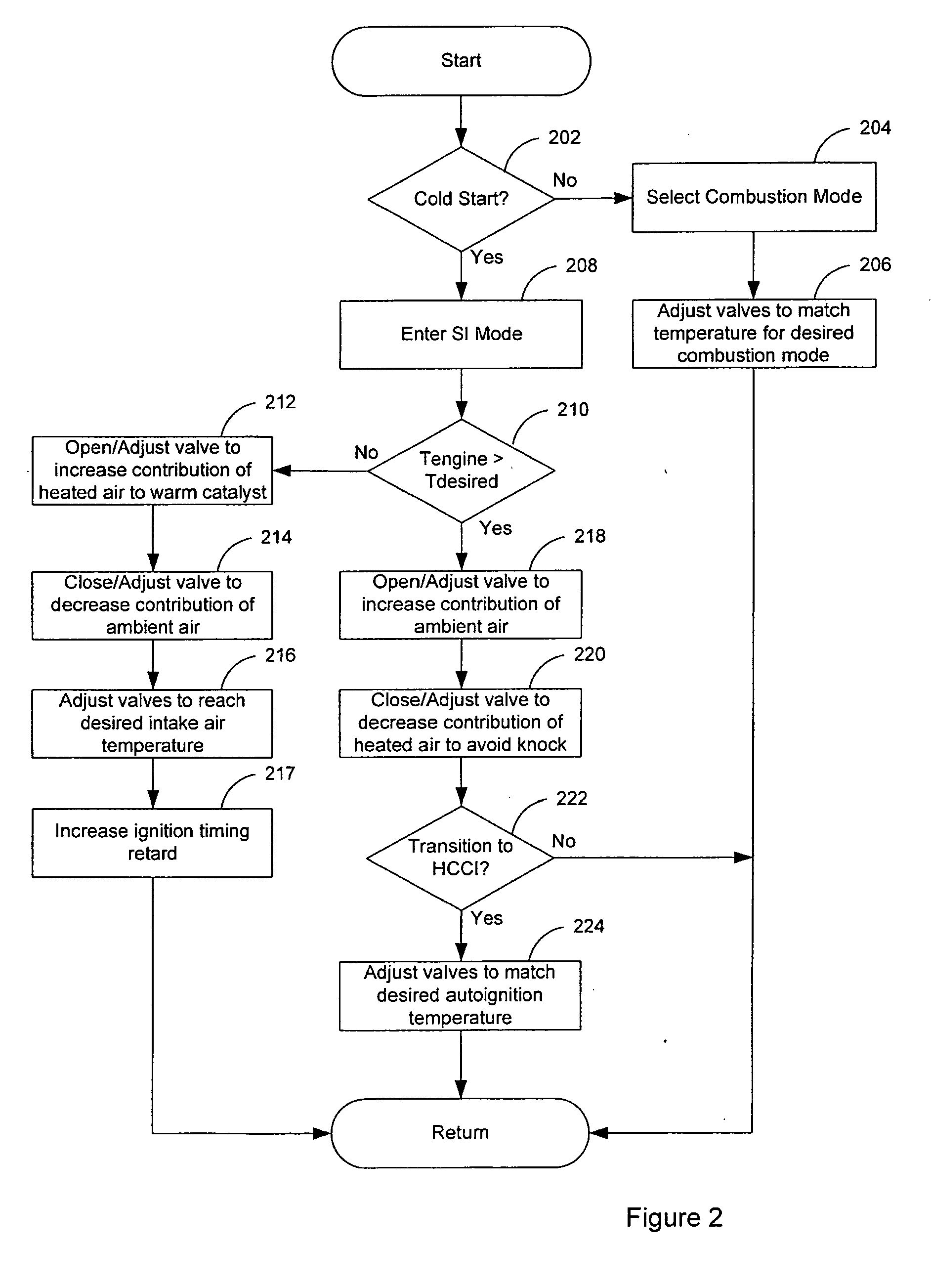

System and method for improved engine starting using heated intake air

InactiveUS7287521B2Improve efficiencyReduce the production of nitrogen oxidesElectrical controlInternal combustion piston enginesHeat exchangerSpark plug

A system for an internal combustion engine, the engine having an intake and exhaust manifold, the system comprising of a heat exchanger configured to extract energy from engine exhaust gases; a catalyst coupled between said heat exchanger and the exhaust manifold of the engine; a spark plug in a cylinder of the engine; and a controller to operate the engine to perform spark ignition of a mixture of air and fuel in said cylinder during an engine cold start, where said air is heated with the energy before being inducted into said cylinder.

Owner:FORD GLOBAL TECH LLC

Method and apparatus for the reliquefaction of a vapour

Boiled off liquefied natural gas flows from a storage tank and is compressed in vapour compression stages. The resulting compressed vapour is condensed in a condenser and the condensate returned to the tank. The condenser is cooled by a working fluid, for example nitrogen, flowing in a Brayton cycle. The Brayton cycle includes a heat exchanger which removes heat of compression from the compressed natural gas vapour upstream of its passage through the condenser. In addition a part of the working fluid is withdrawn from a region of the Brayton cycle intermediate the working fluid outlet from the condenser and the working fluid inlet to the heat exchanger and the withdrawn working fluid flows through another heat exchanger in which it removes heat of compression from the natural gas vapour intermediate the compression stages. The withdrawn working fluid is returned to the Brayton cycle.

Owner:CRYOSTAR

Combined cycle engine

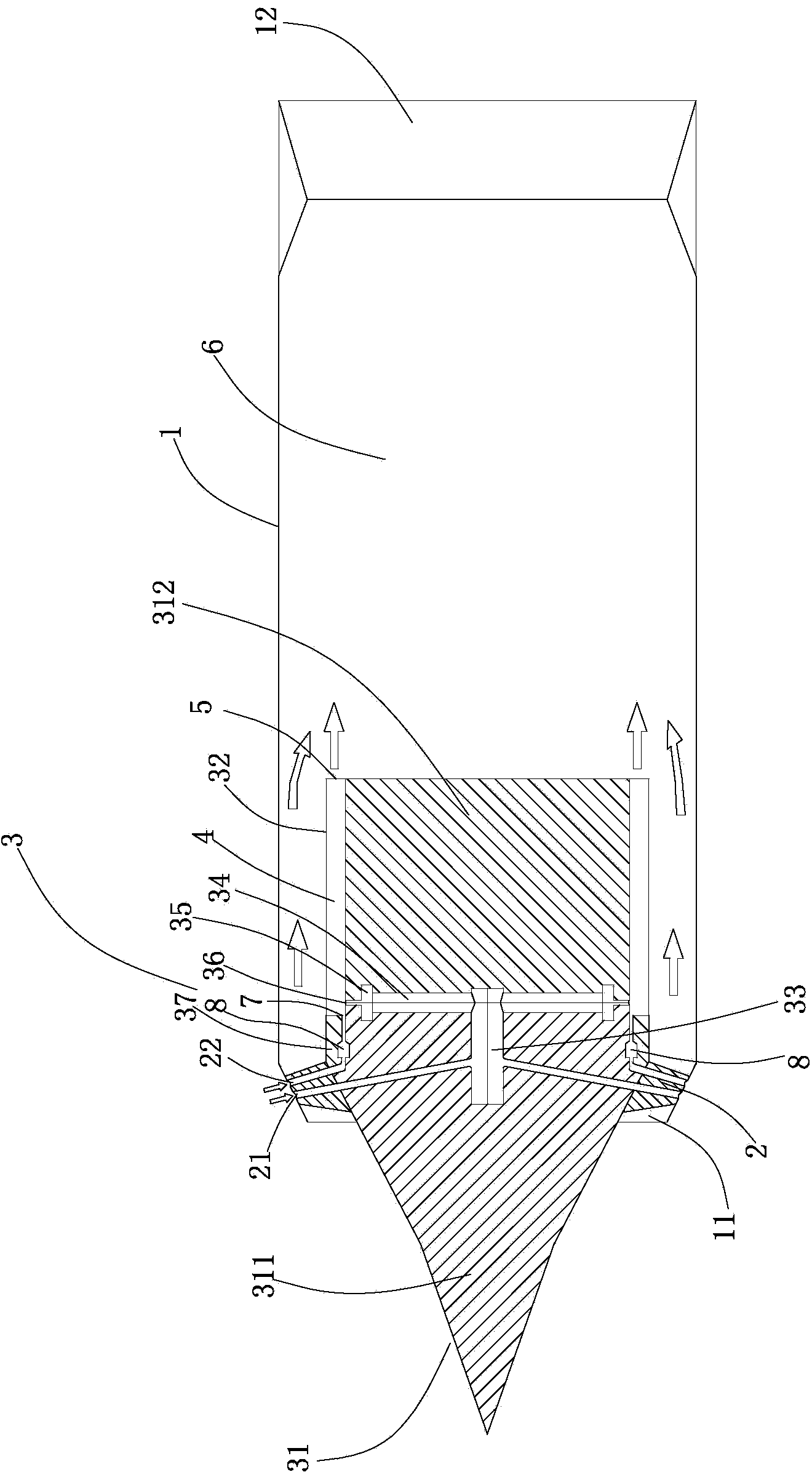

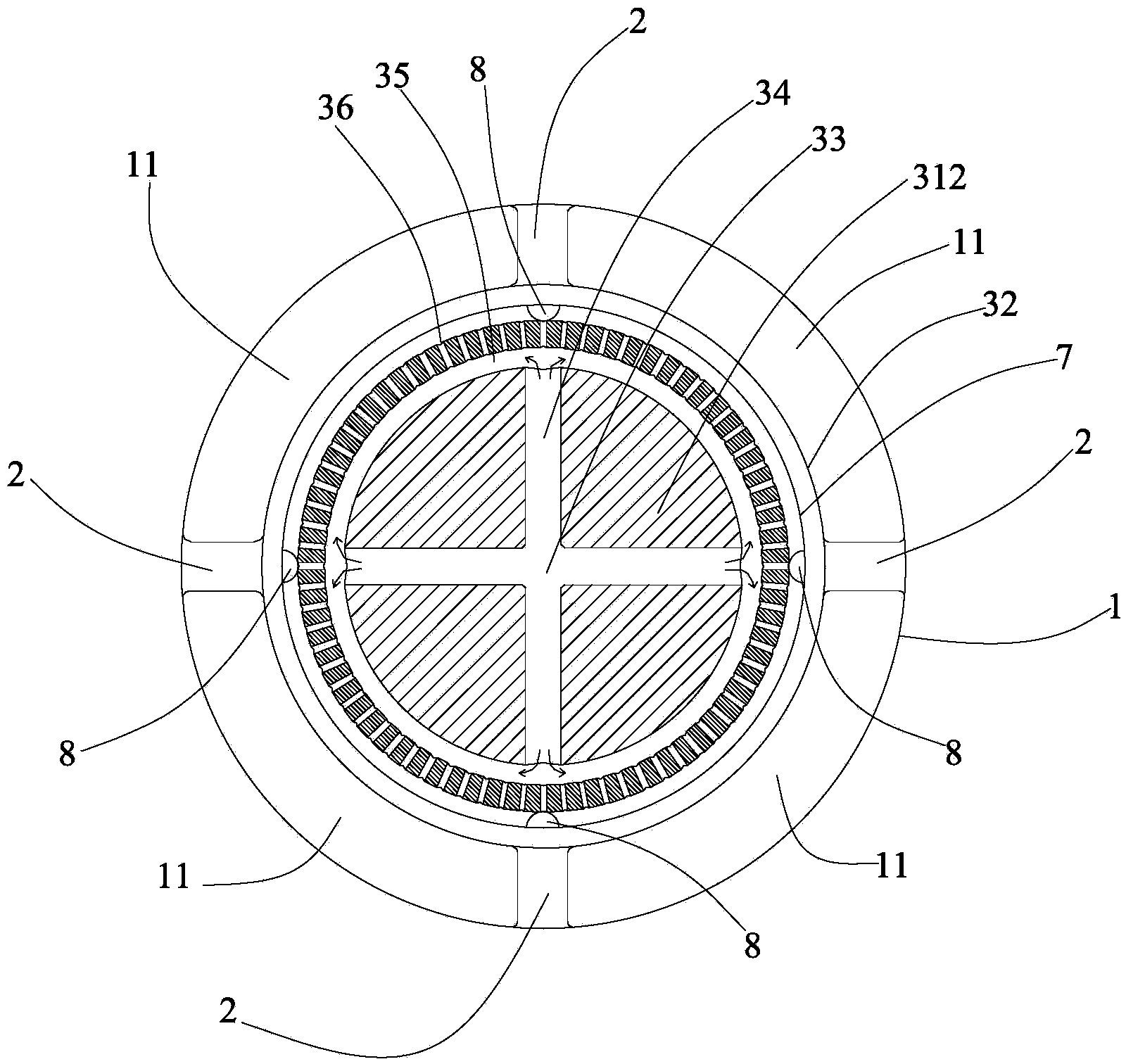

ActiveCN104110325AImprove combustion efficiencyImprove thermodynamic efficiencyJet propulsion plantsCombustion chamberContinuous rotation

The invention provides a combined cycle engine. The combined cycle engine comprises a casing, a fixing guide column and a continuous rotation knock engine as an ejecting device. The casing is provided with an air inlet and a supersonic nozzle. The fixing guide column is provided with a fuel inlet and an oxidant inlet. The continuous rotation knock engine comprises a central conical body, a fuel collecting pipe, a plurality of fuel conveying channels, a fuel inlet pipe, a plurality of fuel nozzles and a ring-shaped body. The central conical body comprises a front body and a rear body, the casing is fixedly arranged by surrounding the outer surface of the whole rear body and part of the front body, a first combustion chamber extends axially and is defined by the casing, the outer surface of the whole rear body and part of the front body, the tail end of the first combustion chamber, which is in an axial direction, is an outlet, space between the casing and the portion behind the rear body of the central conical body inside the casing forms a second combustion chamber, the first combustion chamber is communicated with the second combustion chamber through the outlet, and the second combustion chamber is communicated with the air inlet. Therefore, the combined cycle engine can improve the ejecting efficiency of the ejecting device and simplify the structure of the ejecting device.

Owner:清航空天(浙江)科技有限公司

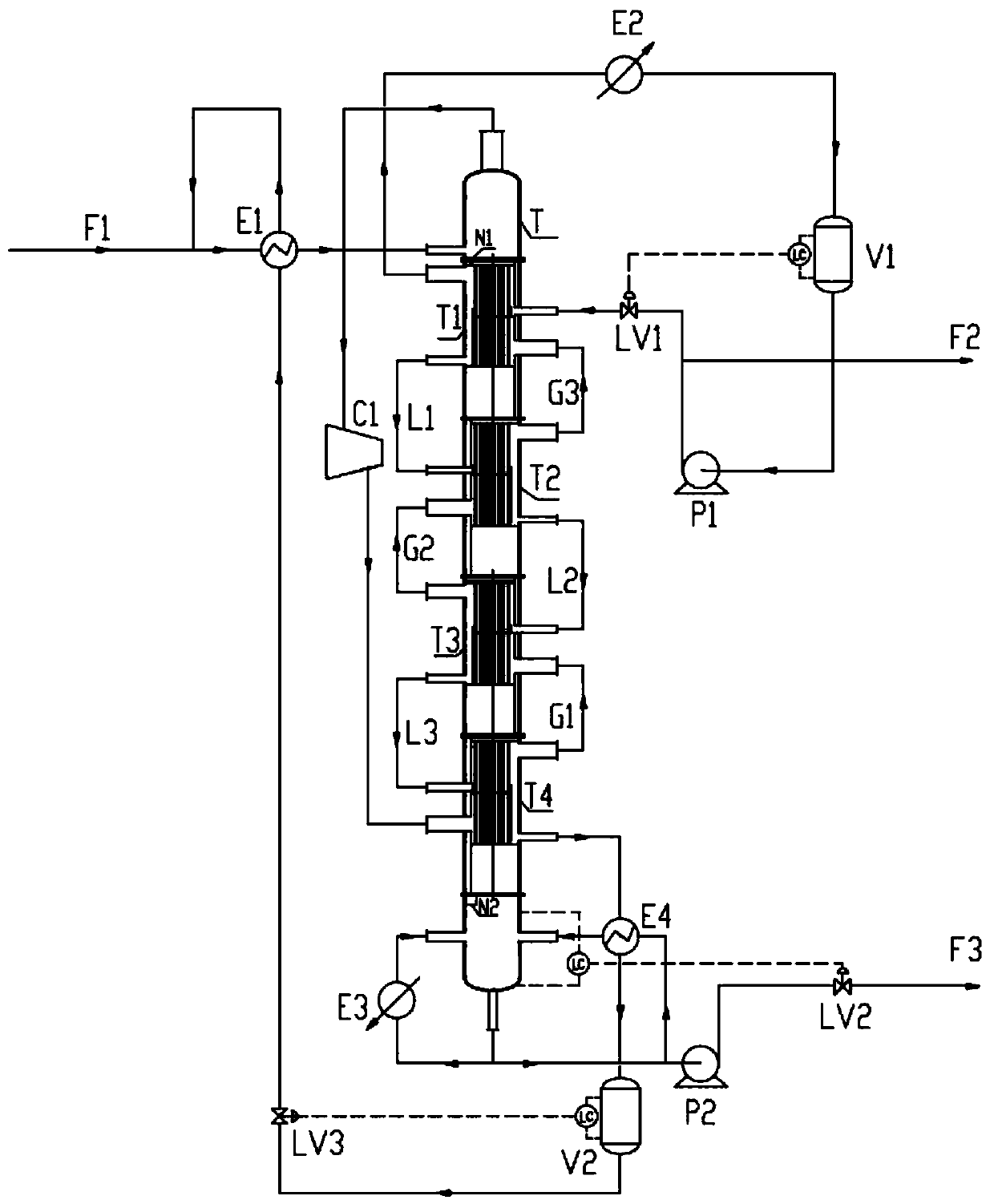

Matching device and method of novel rectifying tower system with internal energy integration

ActiveCN110180205AImprove mass and heat transferLower the altitudeDistillation regulation/controlChemical industryInternal energyMass transfer

The invention relates to a novel rectifying tower system with internal energy integration. The rectifying tower system comprises a raw material preheater, a tower top condenser, a starting heater, a tower bottom heat exchanger, a rectifying tower, a compressor, a tower top reflux tank, a tower bottom buffer tank, a reflux pump, a tower bottom extraction pump and a tower bottom throttling valve; the energy integration rectifying tower is formed by coaxially connecting N tower sections in a sealing mode, wherein N is larger than or equal to 1; and a stripping section and a rectifying section which are in airtight separation with each other are formed in each tower section. The rectifying tower device is of a composite coupling structure, and then the rectifying sections and the stripping sections are coupled together, so that the effects of mass transfer and heat transfer are enhanced, the theoretically designed rectifying tower height is reduced, and cost is saved. The heat exchange area of the rectifying sections and the stripping sections is increased between a liquid descending pipe and a pipe bundle, the heat exchange effect is enhanced, energy consumption is saved, operation issimple, and safety and reliability are achieved.

Owner:TIANJIN UNIV

Method for operating a spark ignition engine

ActiveUS20090173319A1Lower temperature levelAdequate power levelValve arrangementsElectrical controlBattery chargerExhaust gas

In a method for operating a spark ignition engine, wherein the inlet valves of the spark ignition engine are closed very early or very late, and a combustion air flow which is supplied to the spark ignition engine is compressed by means of a charger, and, under full load operation, the inlet valves are closed either early or late to avoid knocking of the engine, a partial flow of re-circulated exhaust gas is supplied to the combustion air flow supplied to the engine also during full load engine operation.

Owner:DAIMLER AG

System and method for improved engine starting using heated intake air

InactiveUS20070062178A1Improve fuel efficiencyReduce the production of nitrogen oxidesElectrical controlNon-fuel substance addition to fuelInlet manifoldCylinder (engine)

A system for an internal combustion engine, the engine having an intake and exhaust manifold, the system comprising of a heat exchanger configured to extract energy from engine exhaust gases; a catalyst coupled between said heat exchanger and the exhaust manifold of the engine; a spark plug in a cylinder of the engine; and a controller to operate the engine to perform spark ignition of a mixture of air and fuel in said cylinder during an engine cold start, where said air is heated with the energy before being inducted into said cylinder.

Owner:FORD GLOBAL TECH LLC

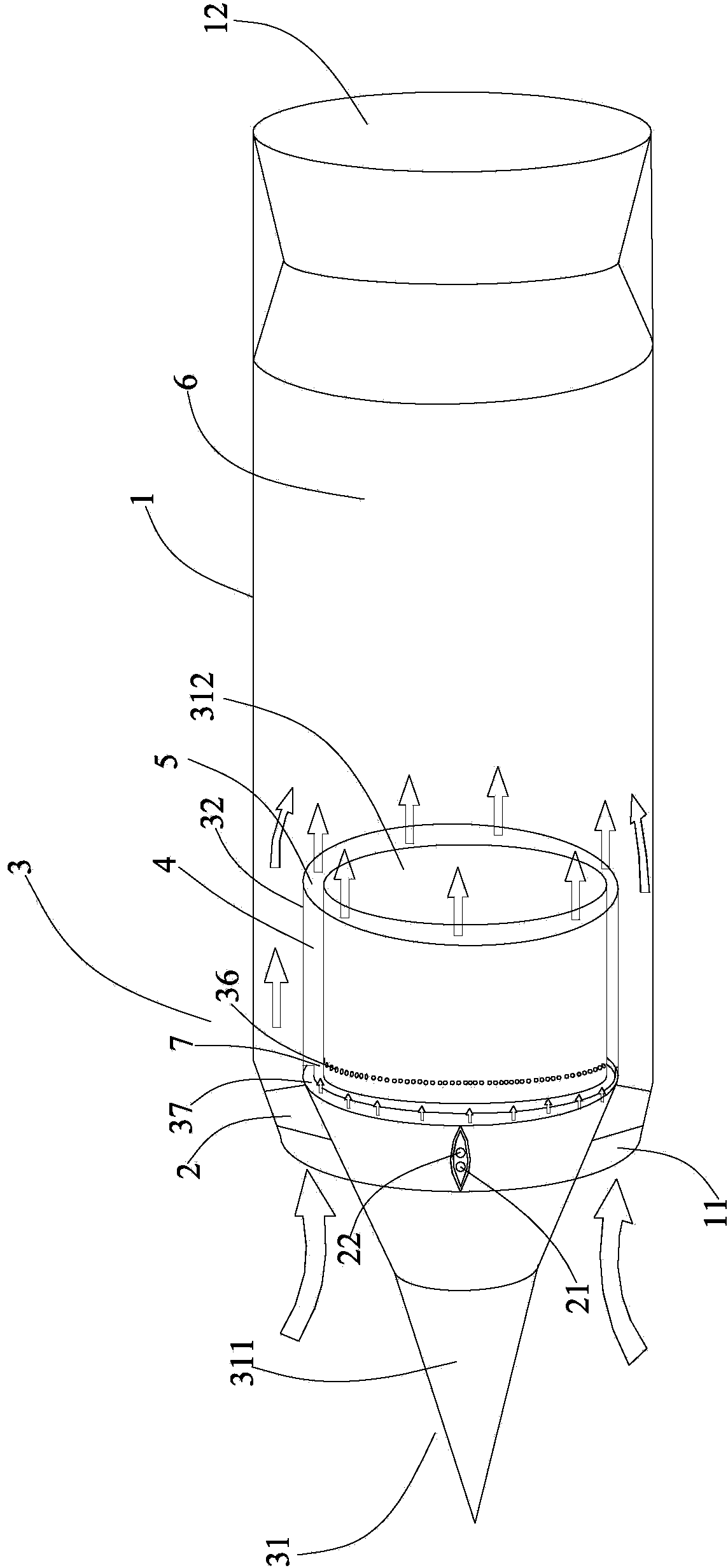

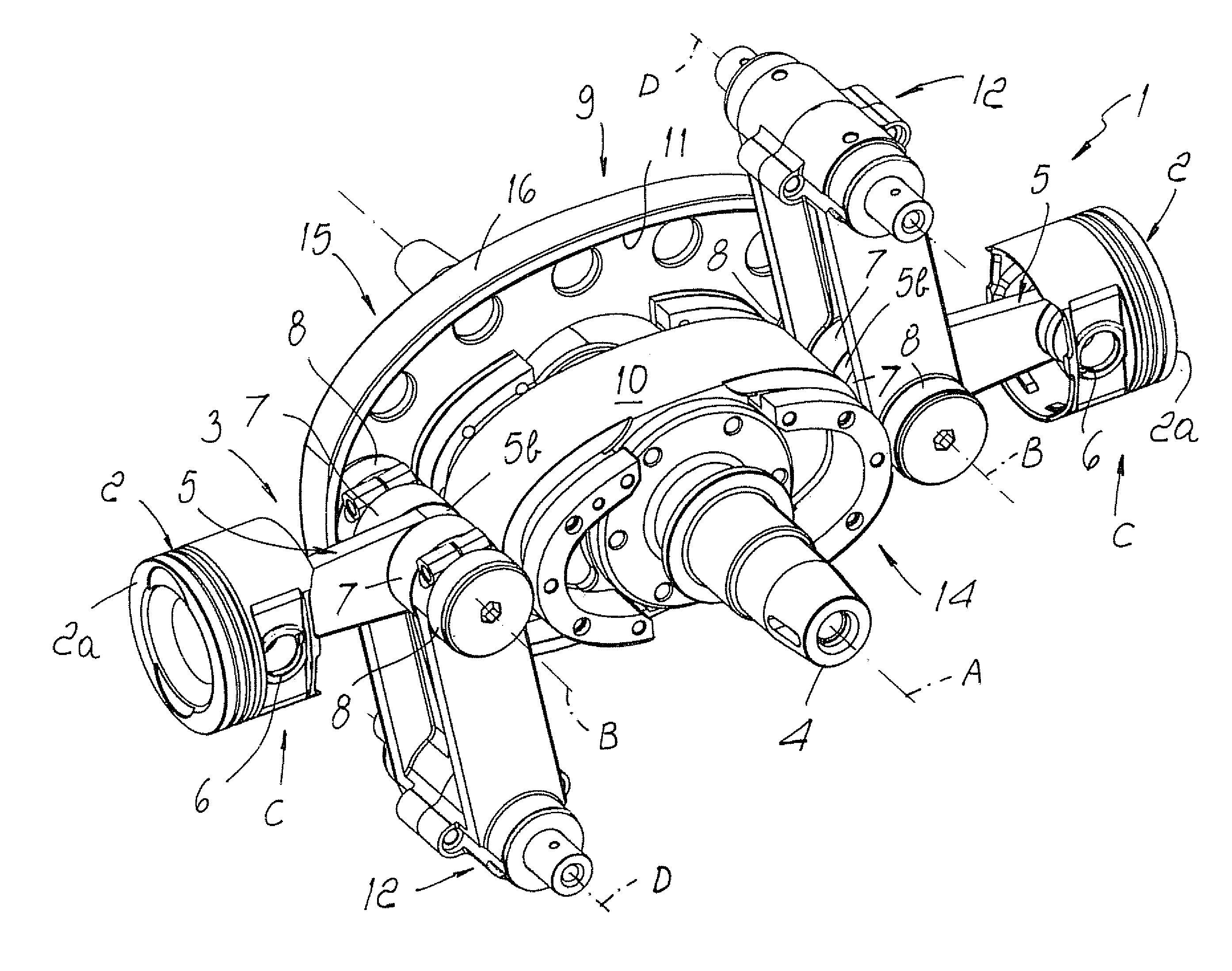

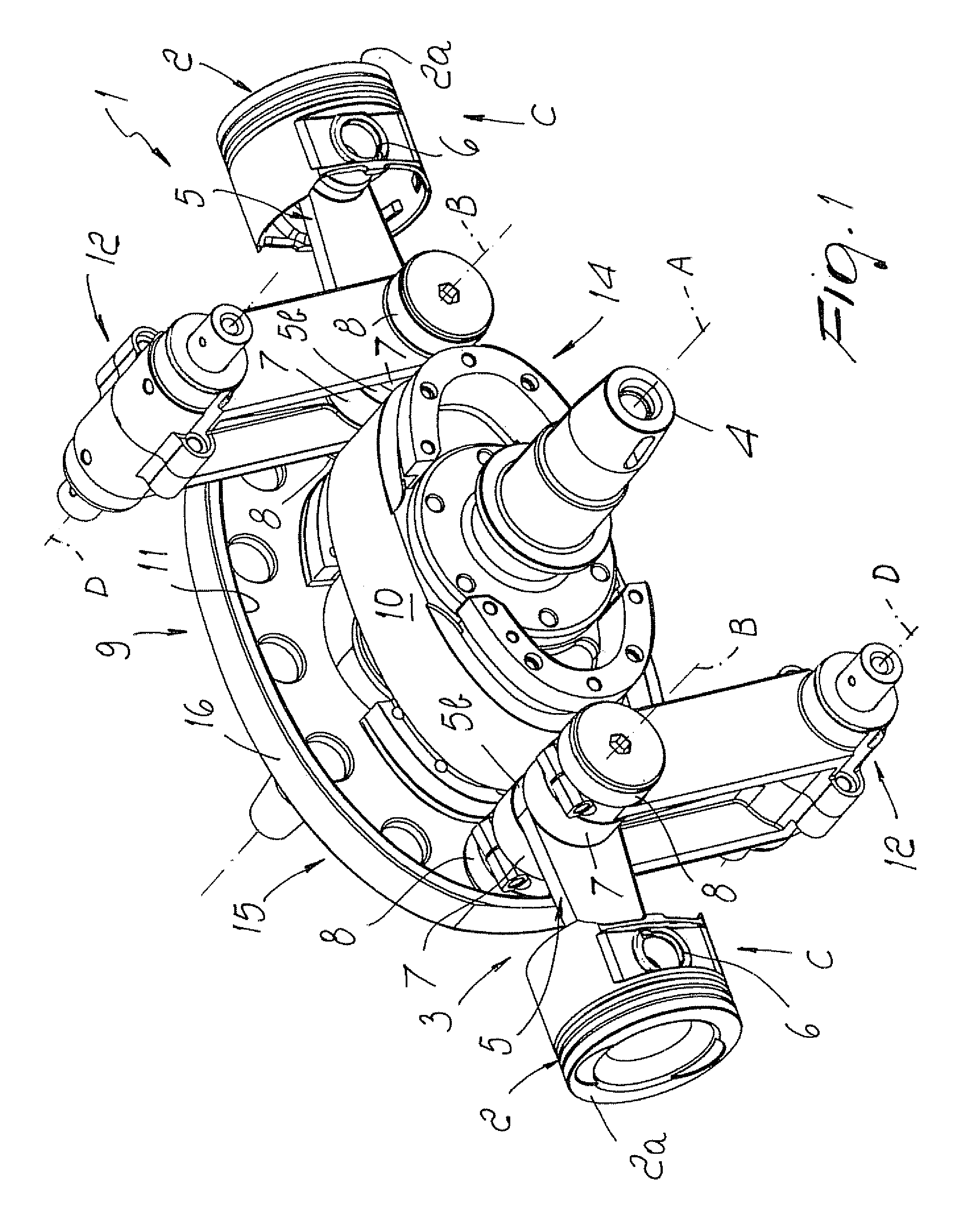

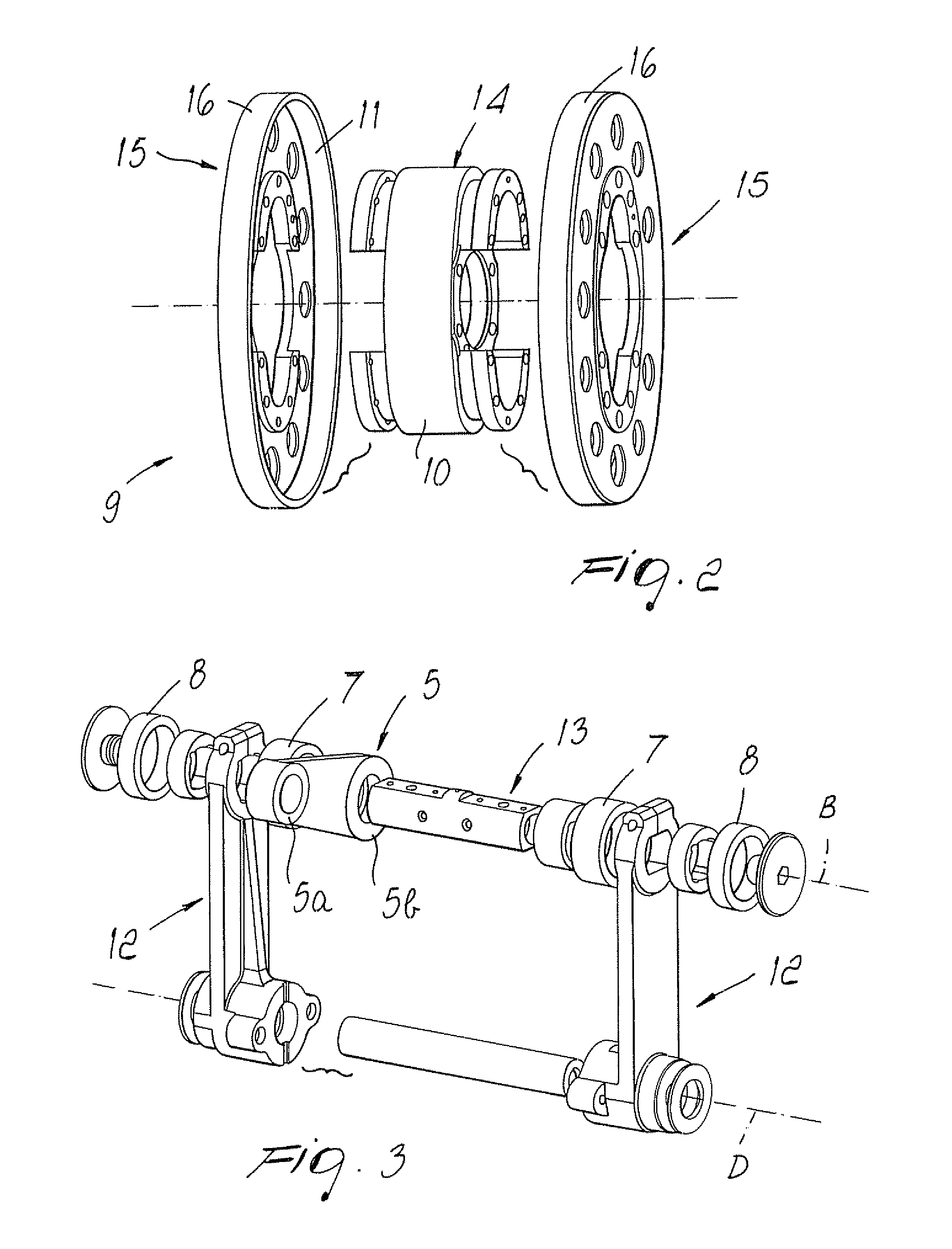

Internal-Combustion Engine With Guided Roller Piston Drive

InactiveUS20080121196A1Improve efficiencyEasy to operateConnecting rodsReciprocating piston enginesWorking fluidTop dead center

An internal-combustion engine (1) with improved reciprocating operation comprises at least one hollow cylinder (C), which contains a chamber for the evolution of a working fluid and has one end closed by a head and the opposite end closed by a piston (2) which can slide with a reciprocating rectilinear motion between a bottom dead center (BDC) and a top dead center (TDC), and a device (3) for converting the reciprocating rectilinear motion of the piston (2) into a rotary motion of an engine shaft (4) which comprises a push rod (5), which is substantially perpendicular to the engine shaft (4) and in which a first end (5a) is connected to the piston (2) and a second end (5b) is connected to at least one pin (13) for supporting at least one pusher roller (7) and at least one return roller (8), which rotate in mutually opposite directions, a rotating contoured body (9), which is fixed to the engine shaft (4) and is provided with at least one pusher circuit (10) and at least one return circuit (11), along which the respective rollers (8) travel, at least one guiding arm (12), in which one end is associated with the roller supporting pin (13) and the opposite end is articulated so that it can move about a fixed axis (D); the pusher and return circuits (10, 11) comprise respective circular arcs for the sliding of the pusher and return rollers (7, 8) which, when the piston (2) is proximate to the top dead center, are suitable to keep the push rod (5) and the piston (2) in a substantially stationary configuration over a predefined space or angle of rotation of the rotating contoured body, the volume of the chamber remaining substantially constant until explosion has occurred.

Owner:KEY PARTNER HLDG

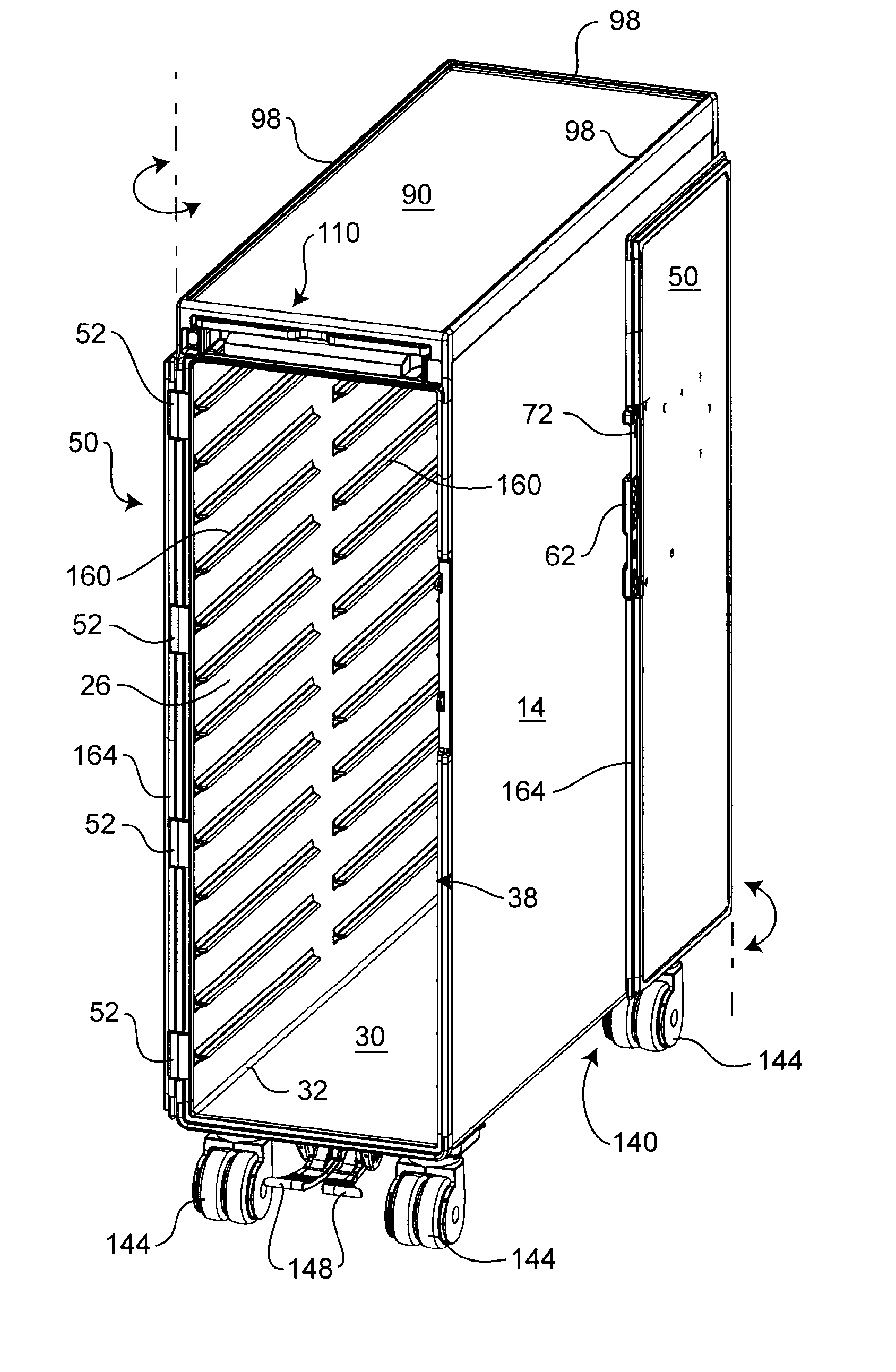

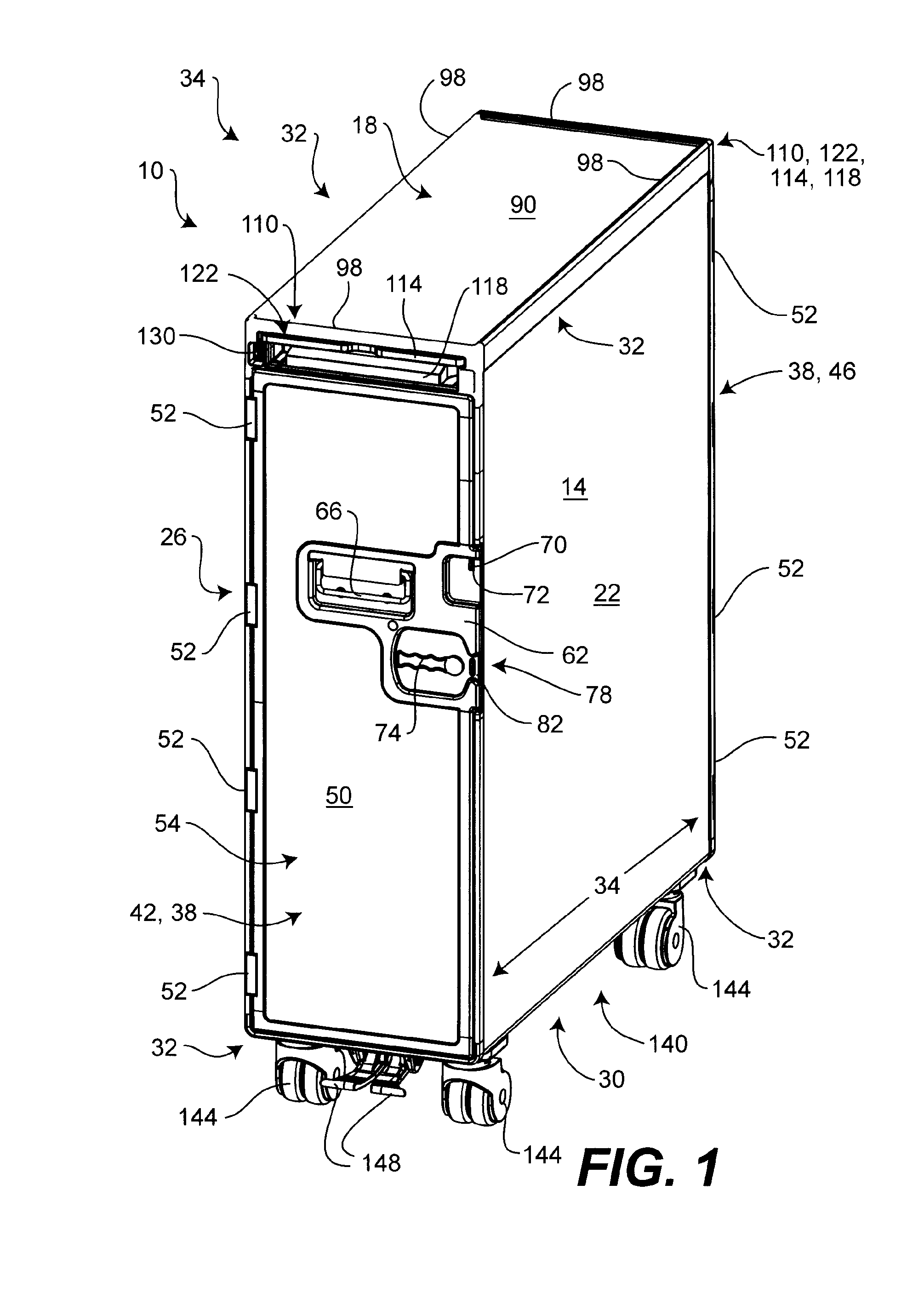

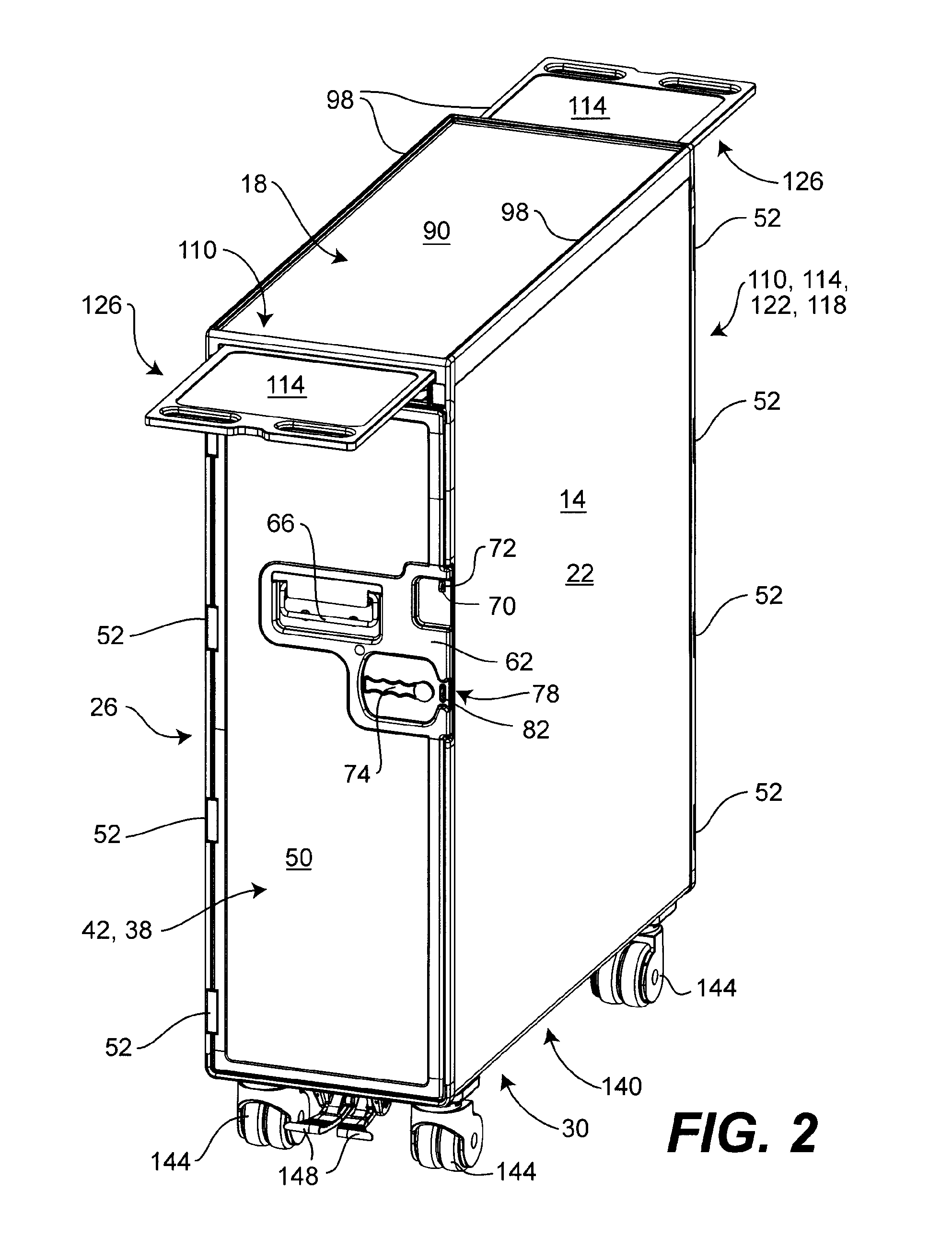

Service cart

A service cart adapted to be moved along an aisle is provided, the service cart comprising a body defining an upper portion, a lower portion and two opposed lateral portions respectively disposed between the upper and the bottom portions, the portions being interconnected with intervening curved portions to form a continuous wall thereof and at least one longitudinal opening; wheels attached to a lower portion of the body for supporting the body; and a closing device for substantially closing the longitudinal opening. A method of manufacturing a service cart and a service cart kit are also provided.

Owner:NORDUYN

Rotary valve in an internal combustion engine

InactiveUS7841308B1Increase volumeImprove fuel economyNon-fuel substance addition to fuelEngine operationsThermal energyCombustion chamber

A rotary valve engine using a single rotary valve serving multiple cylinders significantly increases both volumetric and thermodynamic efficiencies. A novel stratified three stage low temperature combustion system reduces both heat transfer loss and combustion process irreversibility. Using large intake and exhaust valves and passages to reduce throttling losses, the rotary valve also contains a combustion valve and passage connected to a central combustion chamber. Combustion is initiated for all cylinders by a fuel injector in this central chamber which then sequentially ignites a second combustion chamber charge located in each cylinder head. A passage in the rotary valve shaft transfers gas from the combustion cycle to the compression cycle varying the compression ratio of the engine, producing EGR, and transferring radical species for combustion to the next cycle. A compounding element on the rotary valve extracts additional thermal energy derived from reduced heat transfer loss and increased energy.

Owner:MUTH BARRY A

Gas turbine engine anti-icing system

ActiveUS9945247B2Sufficient energyImprove thermodynamic efficiencyEngine fuctionsAir-treatment apparatus arrangementsControl systemEngineering

An anti-icing system for an engine section stator of a gas turbine engine. The system includes an environmental control system pre-cooler heat exchange system and a conduit. The environmental control system pre-cooler heat exchange system is configured to exchange heat between air bled from a compressor of the engine and bypass duct air. The conduit is configured to exchange heat from the pre-cooler heat exchange system to a heat transfer medium. The conduit is also configured to transfer the heat from the heat transfer medium to the engine section stator.

Owner:ROLLS ROYCE PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com