Patents

Literature

945 results about "Spark-ignition engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

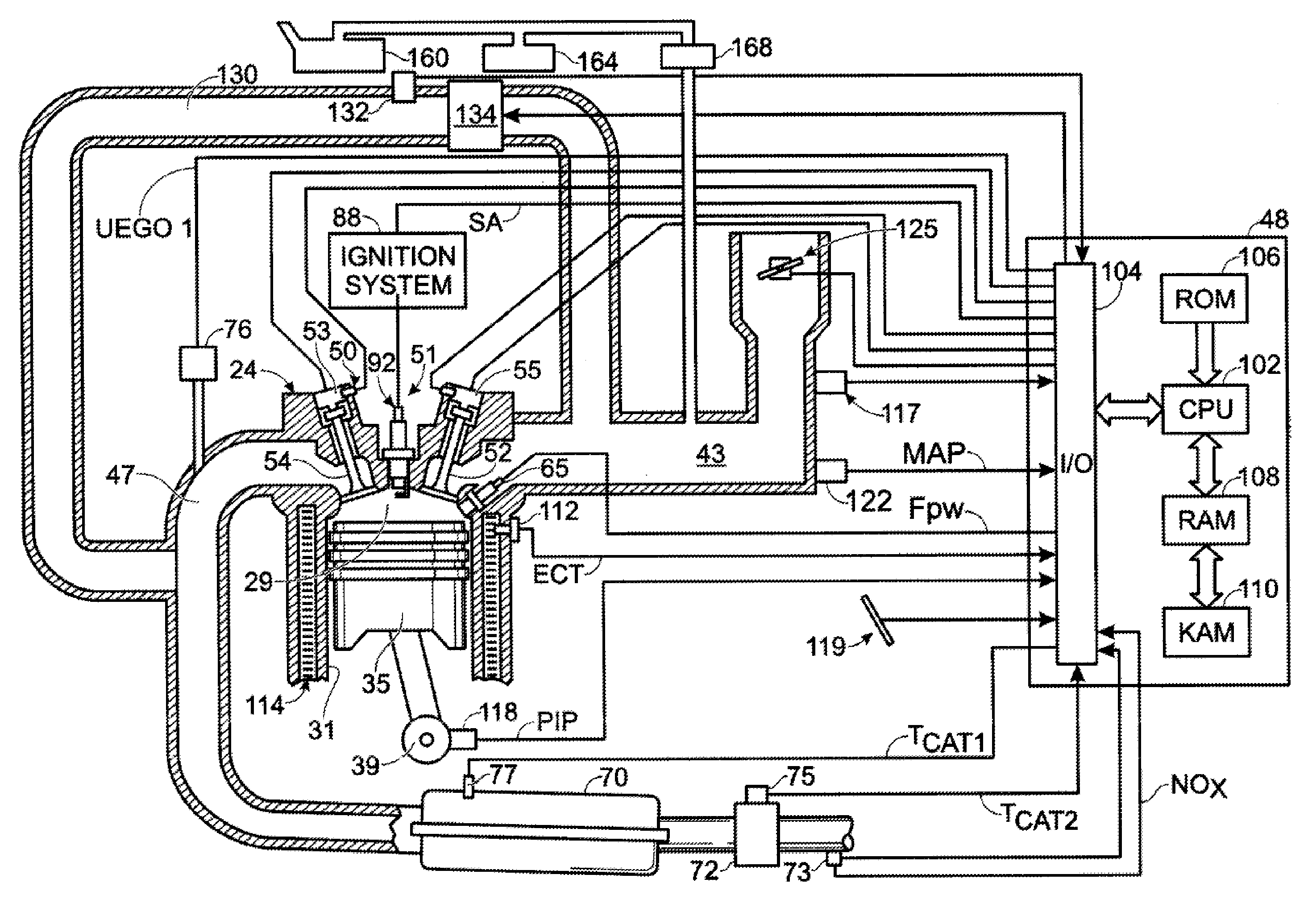

A spark-ignition engine (SI engine) is an internal combustion engine, generally a petrol engine, where the combustion process of the air-fuel mixture is ignited by a spark from a spark plug. This is in contrast to compression-ignition engines, typically diesel engines, where the heat generated from compression together with the injection of fuel is enough to initiate the combustion process, without needing any external spark.

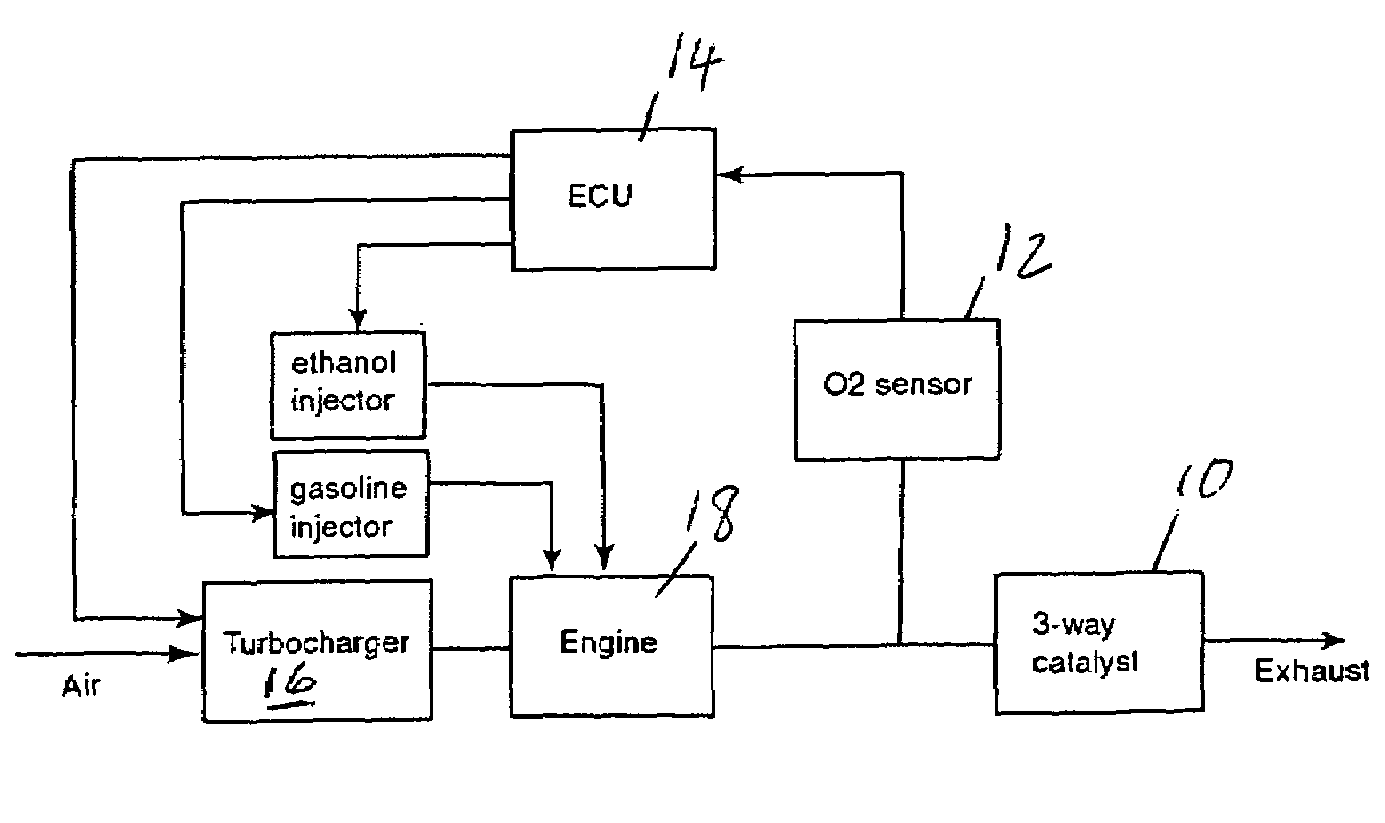

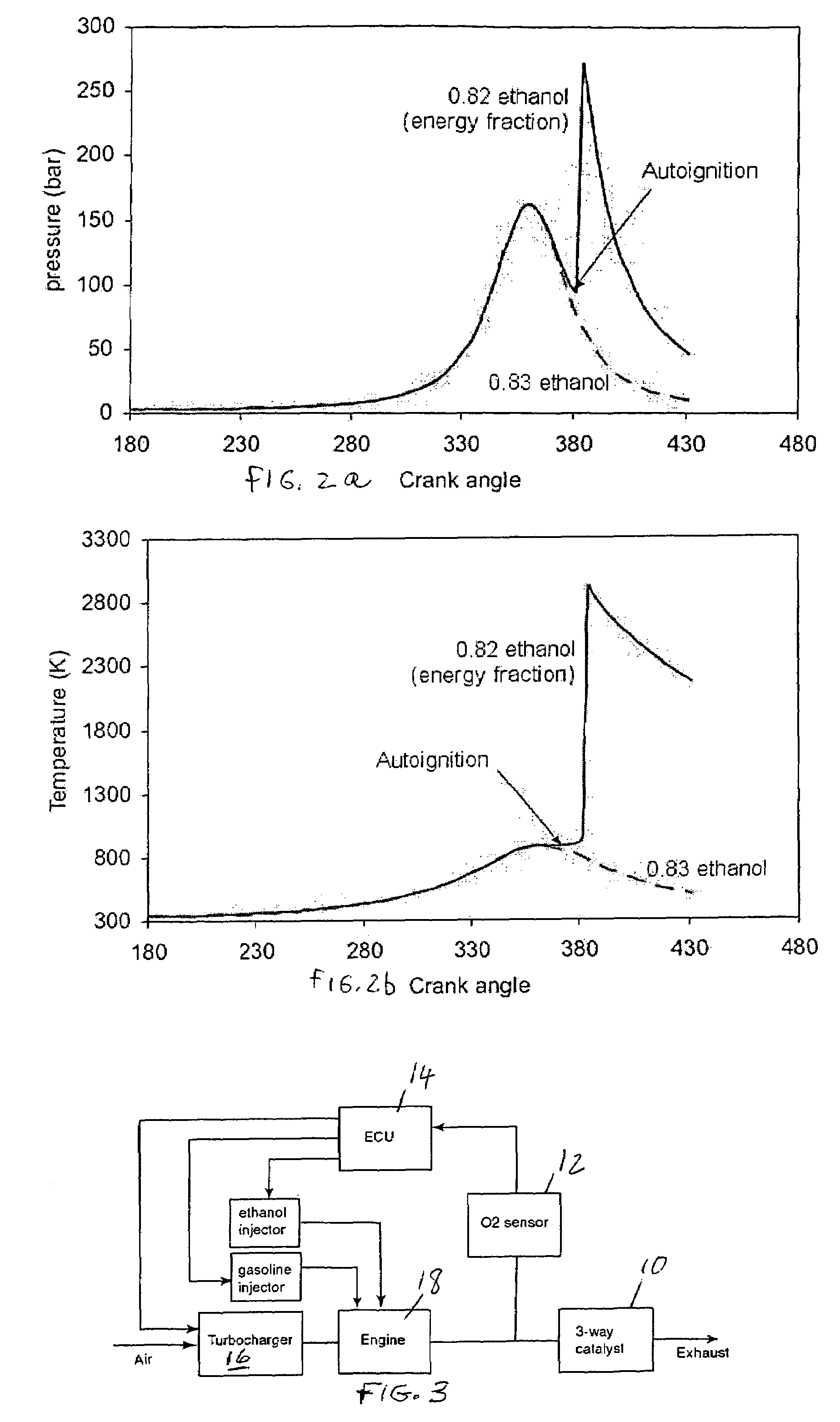

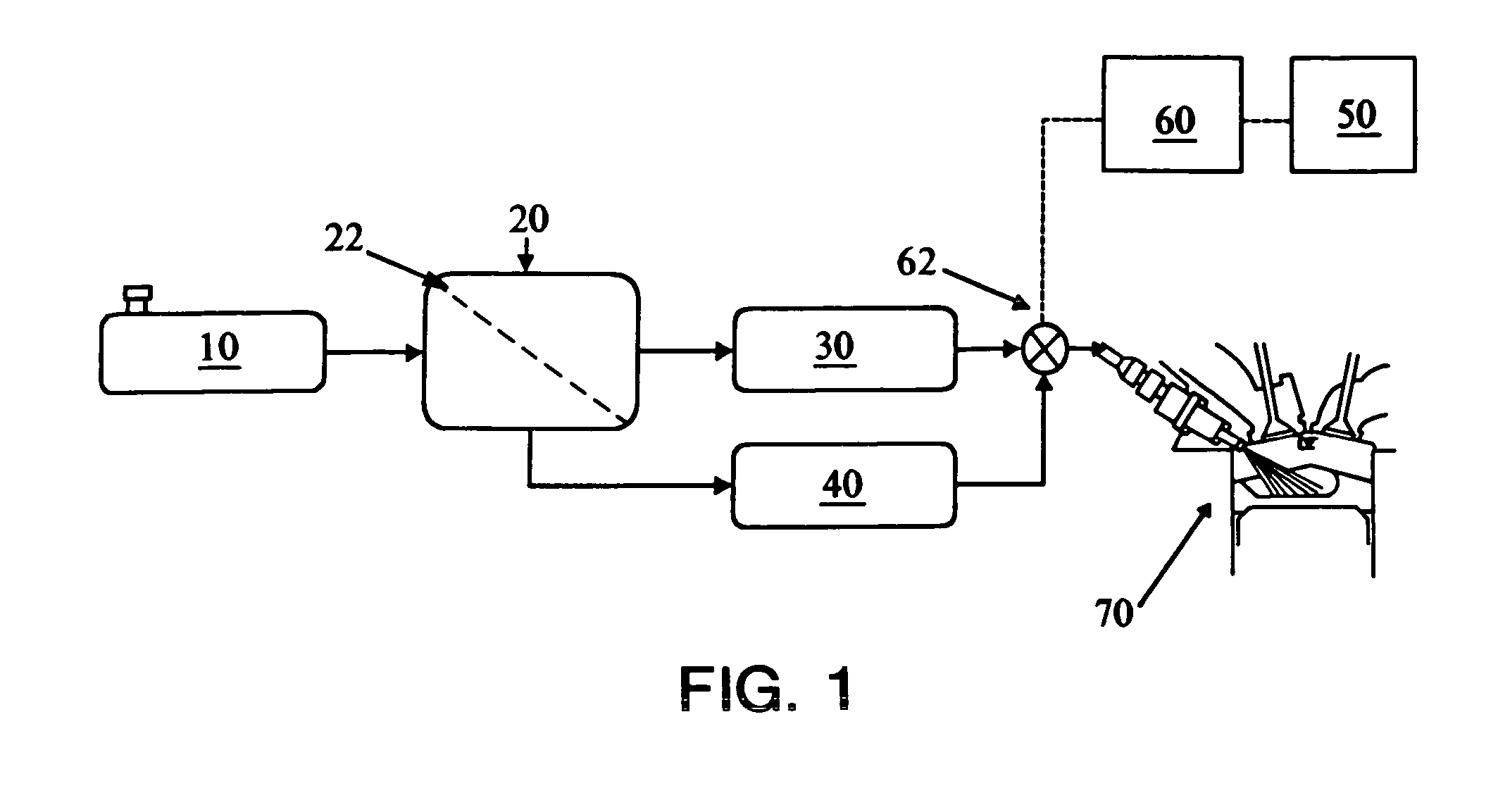

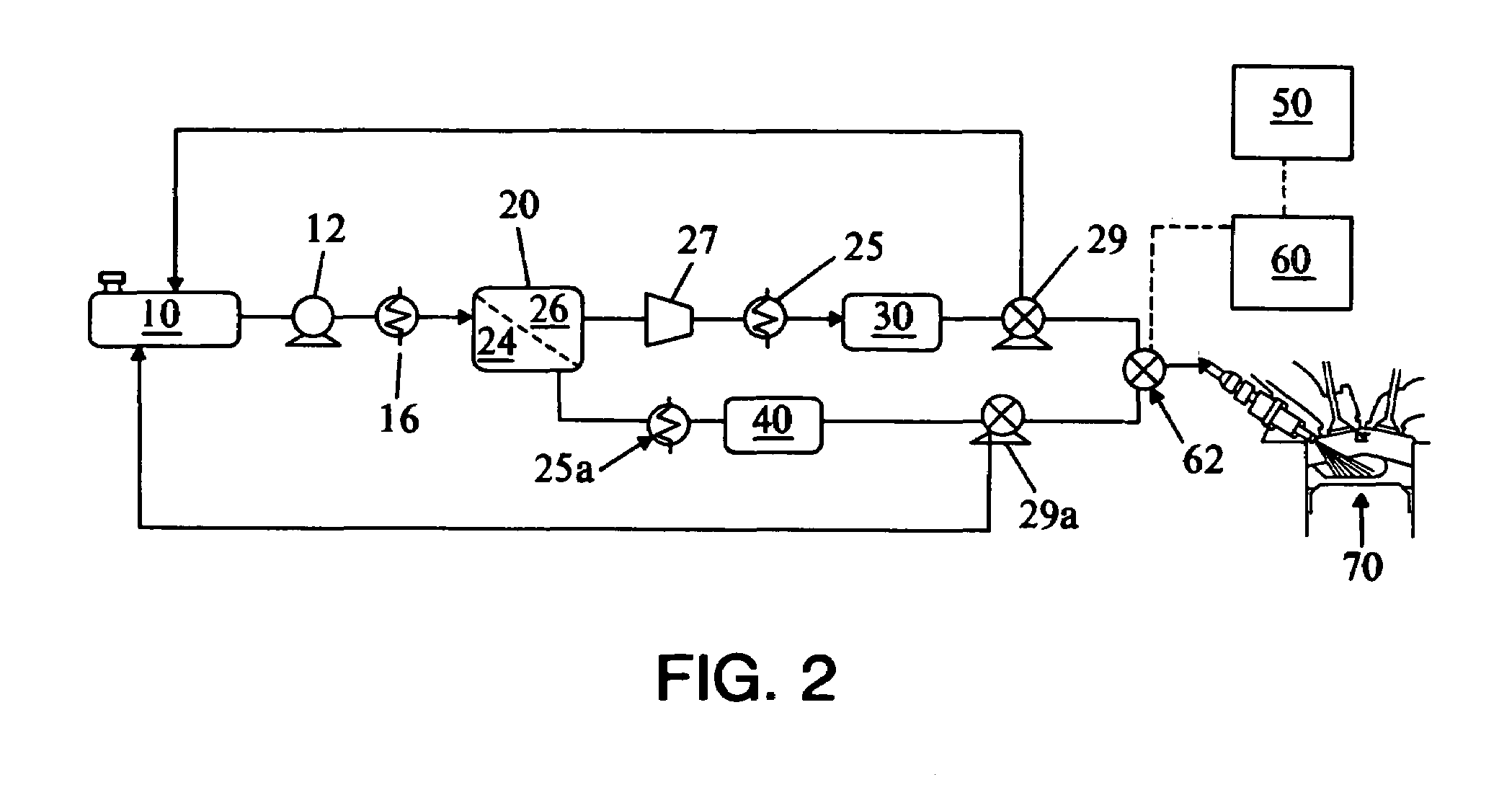

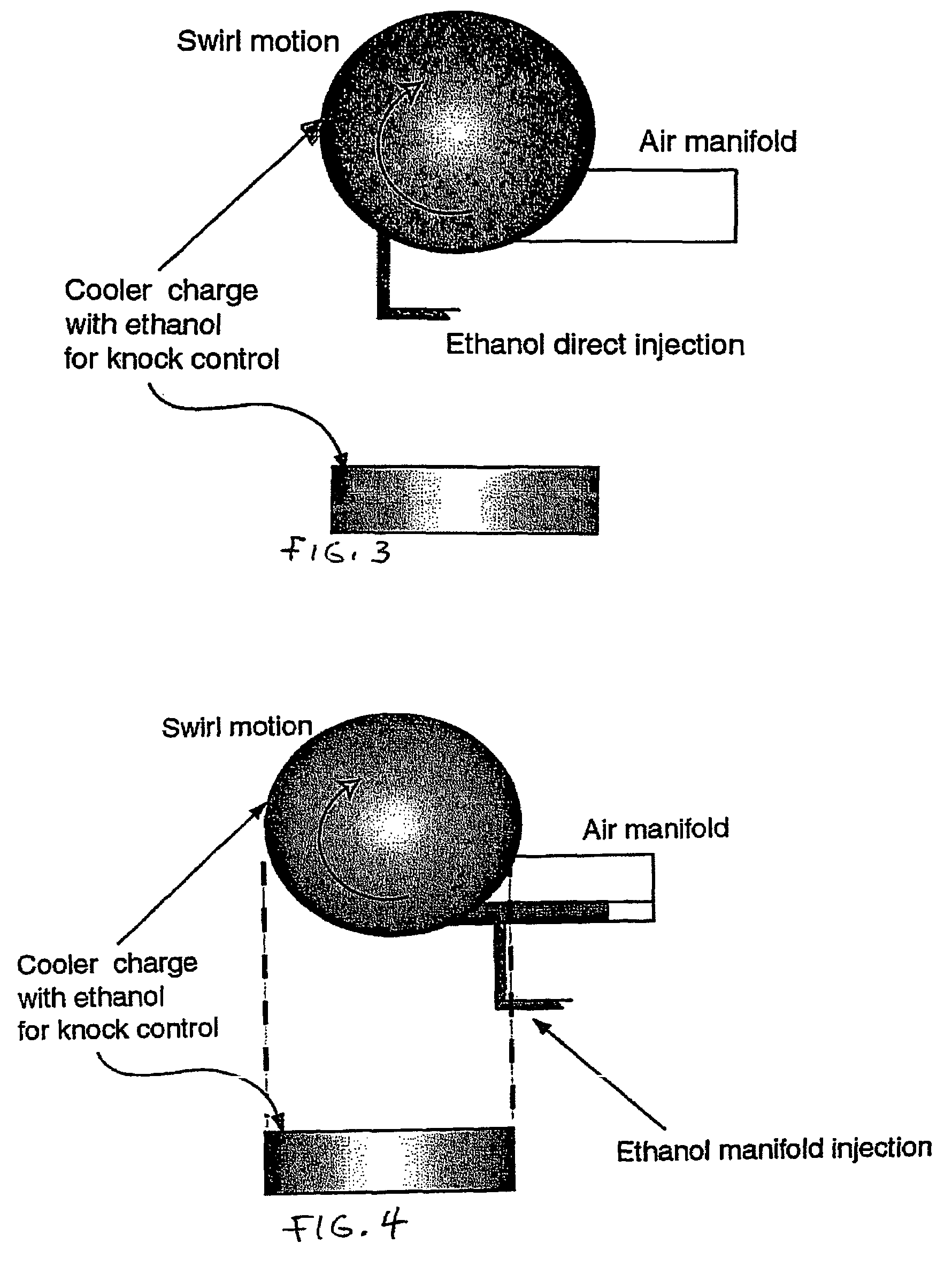

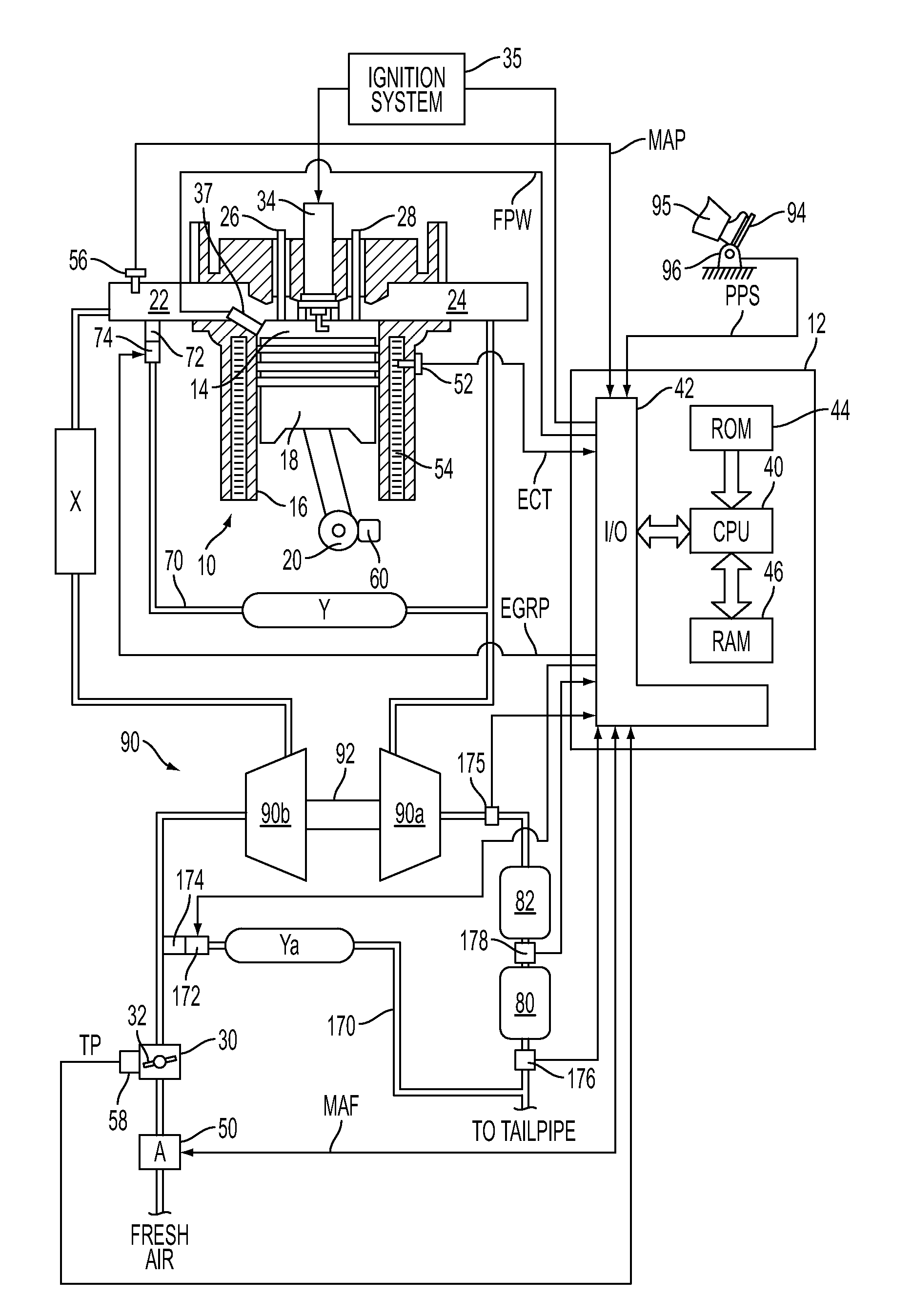

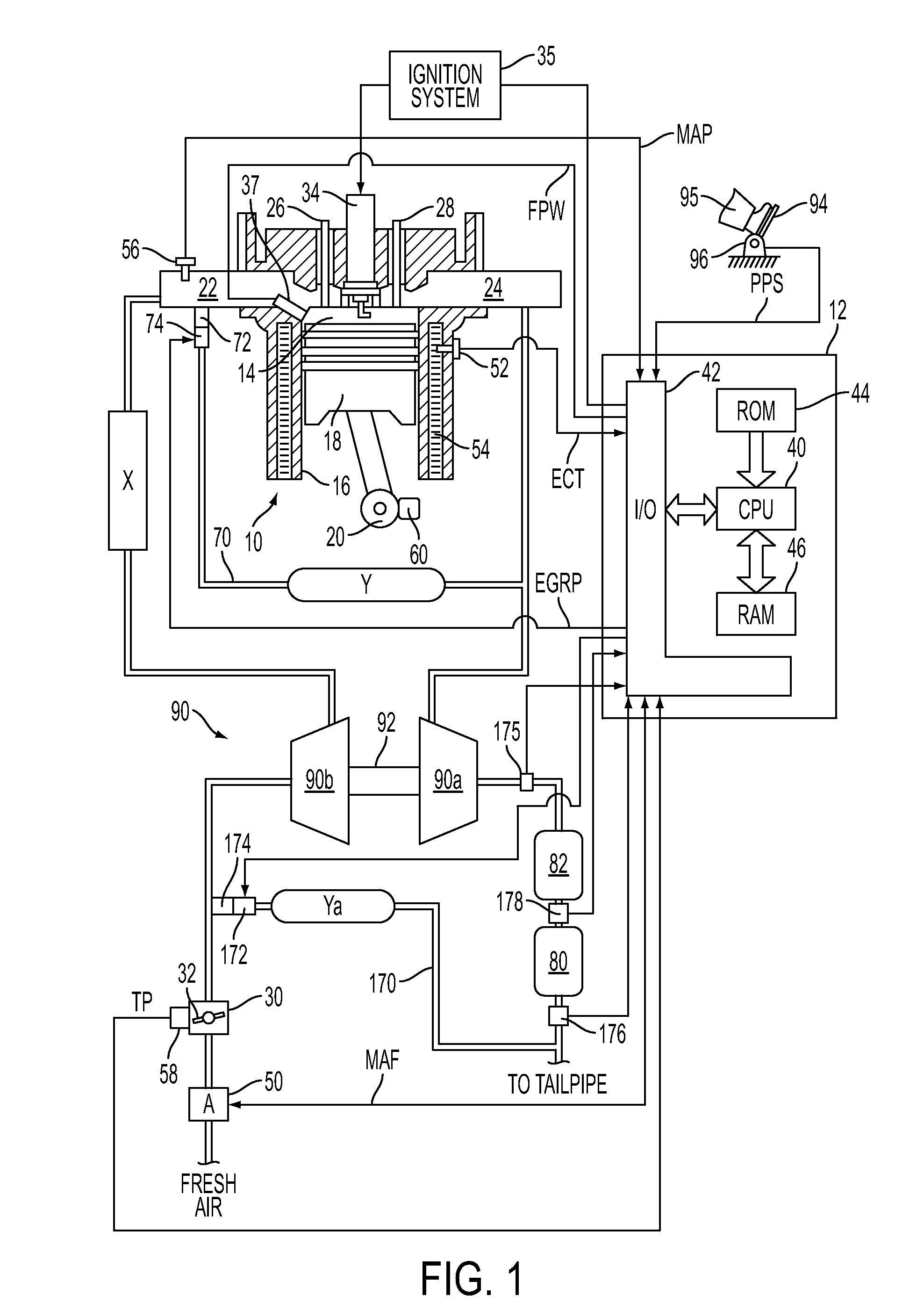

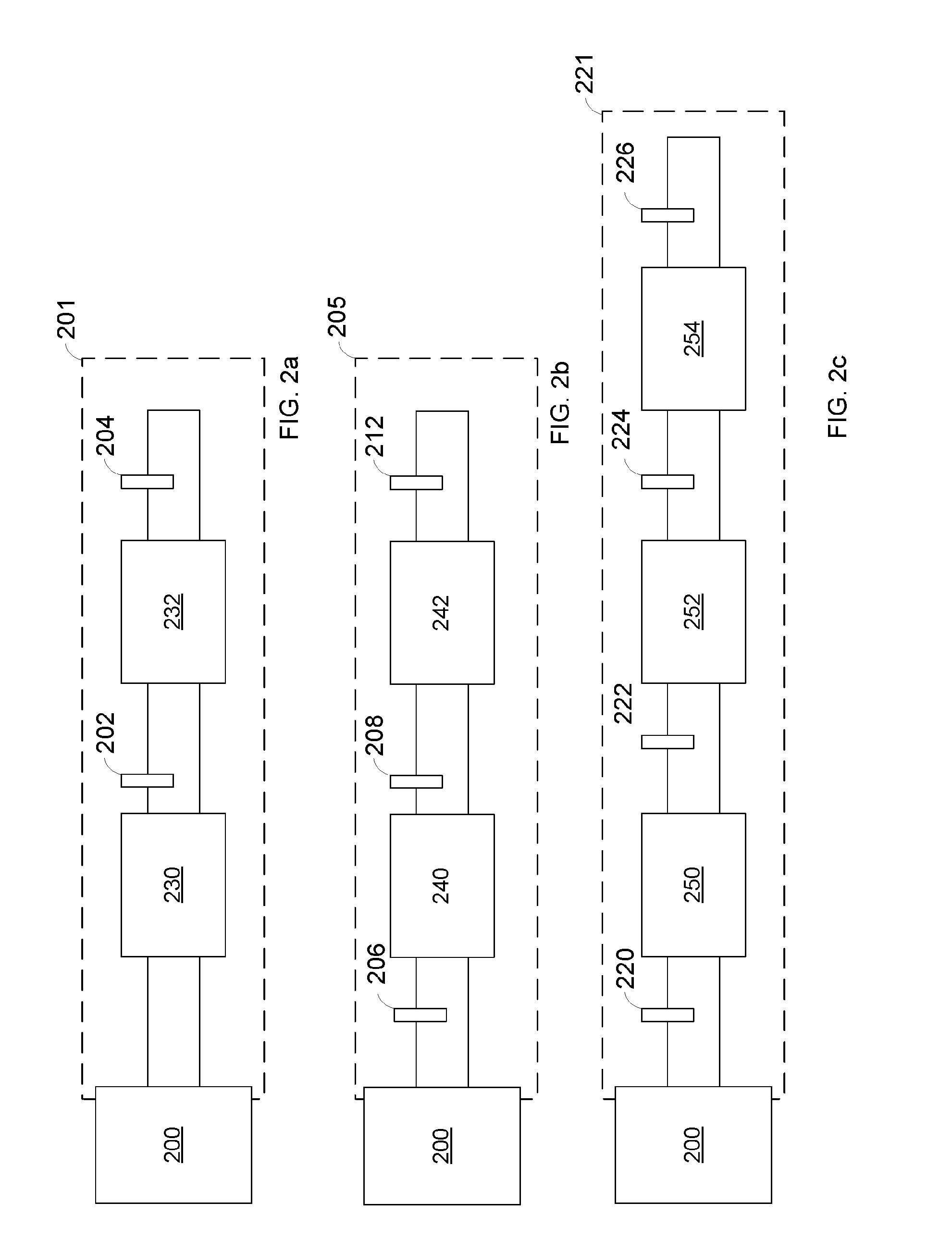

Optimized fuel management system for direct injection ethanol enhancement of gasoline engines

InactiveUS7225787B2Save gasImprove engine efficiencyElectrical controlNon-fuel substance addition to fuelEngineeringProcess engineering

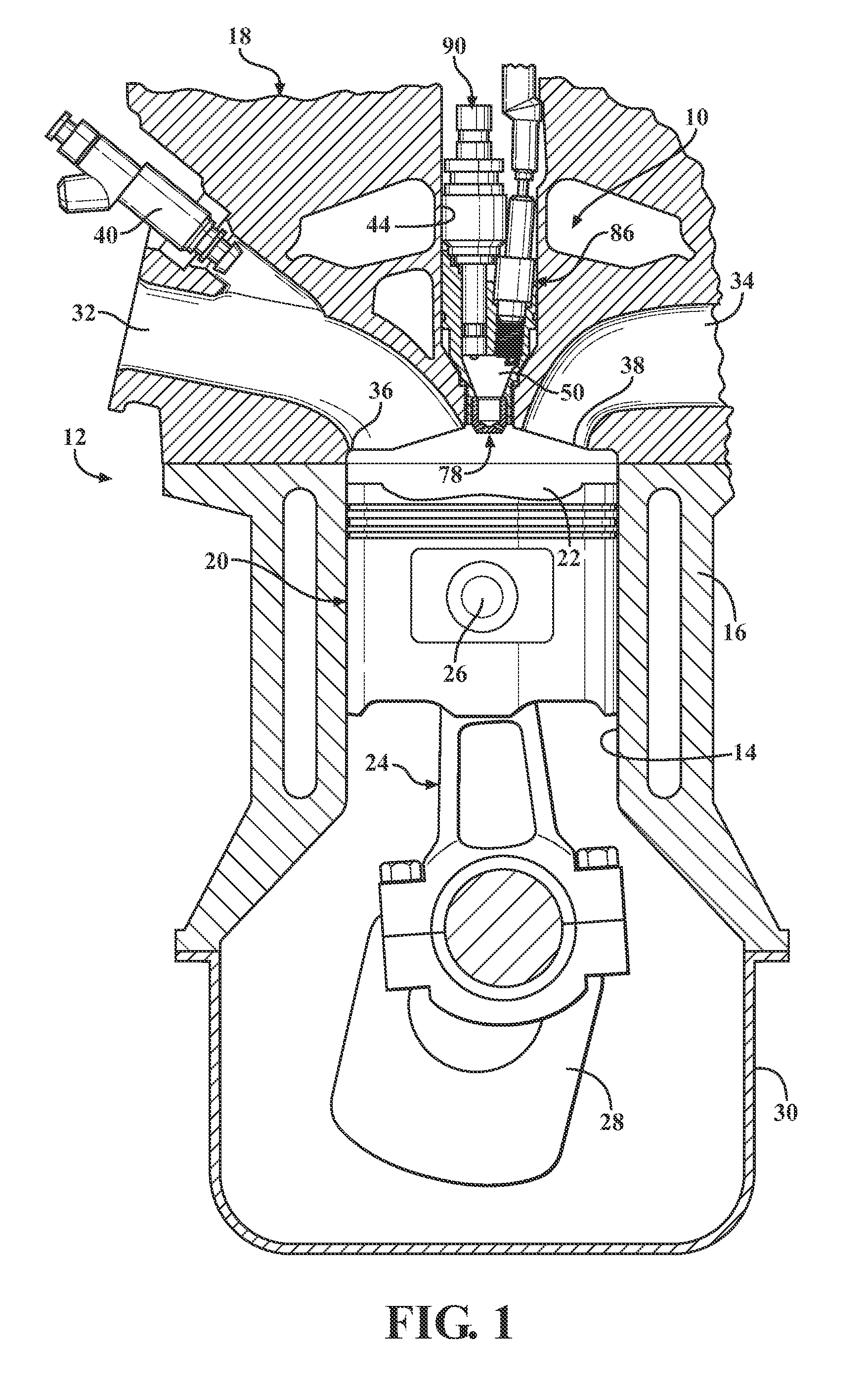

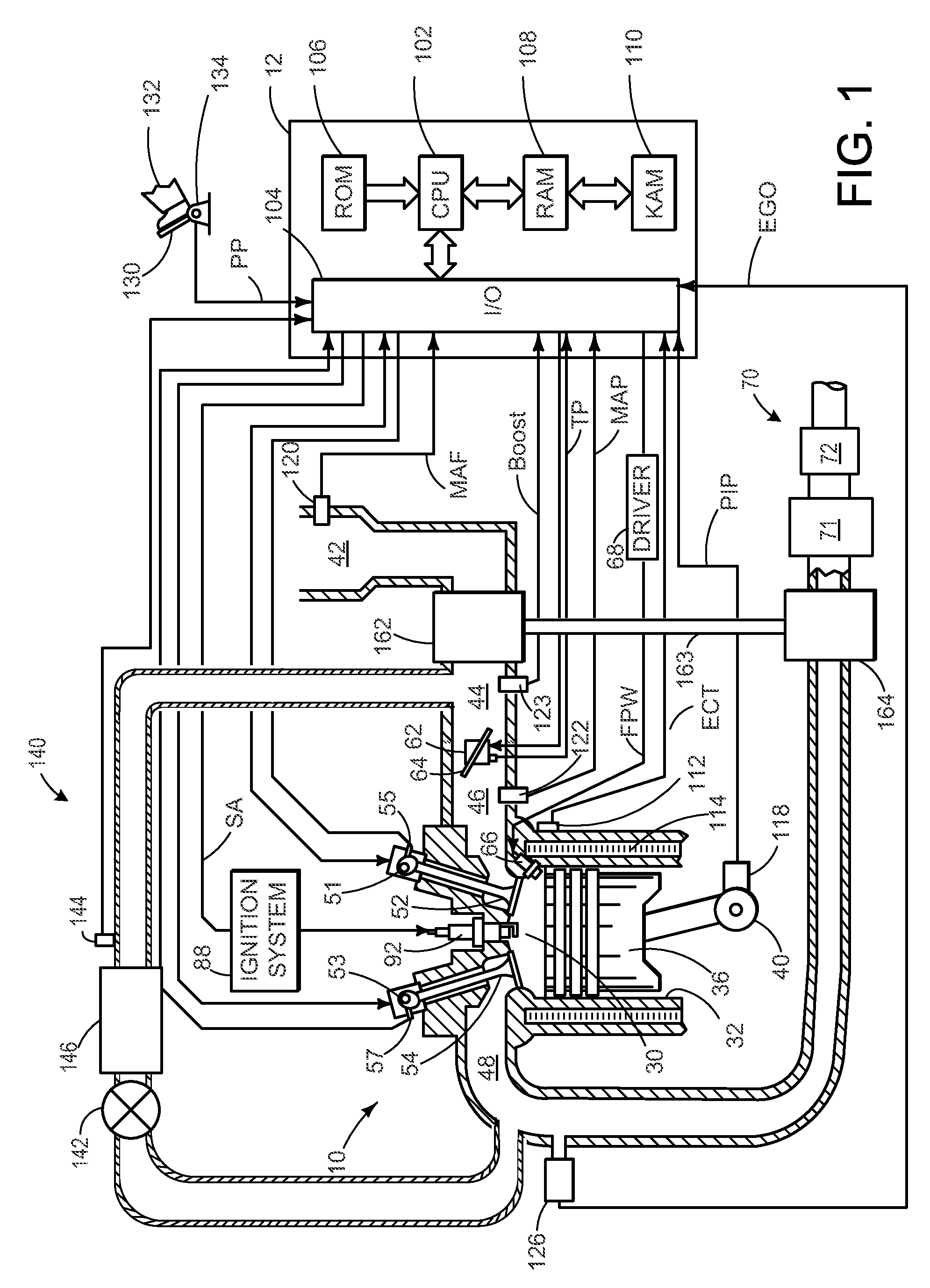

Fuel management system for enhanced operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder. It is preferred that the direct injection occur after the inlet valve is closed. It is also preferred that stoichiometric operation with a three way catalyst be used to minimize emissions. In addition, it is also preferred that the anti-knock agents have a heat of vaporization per unit of combustion energy that is at least three times that of gasoline.

Owner:MASSACHUSETTS INST OF TECH

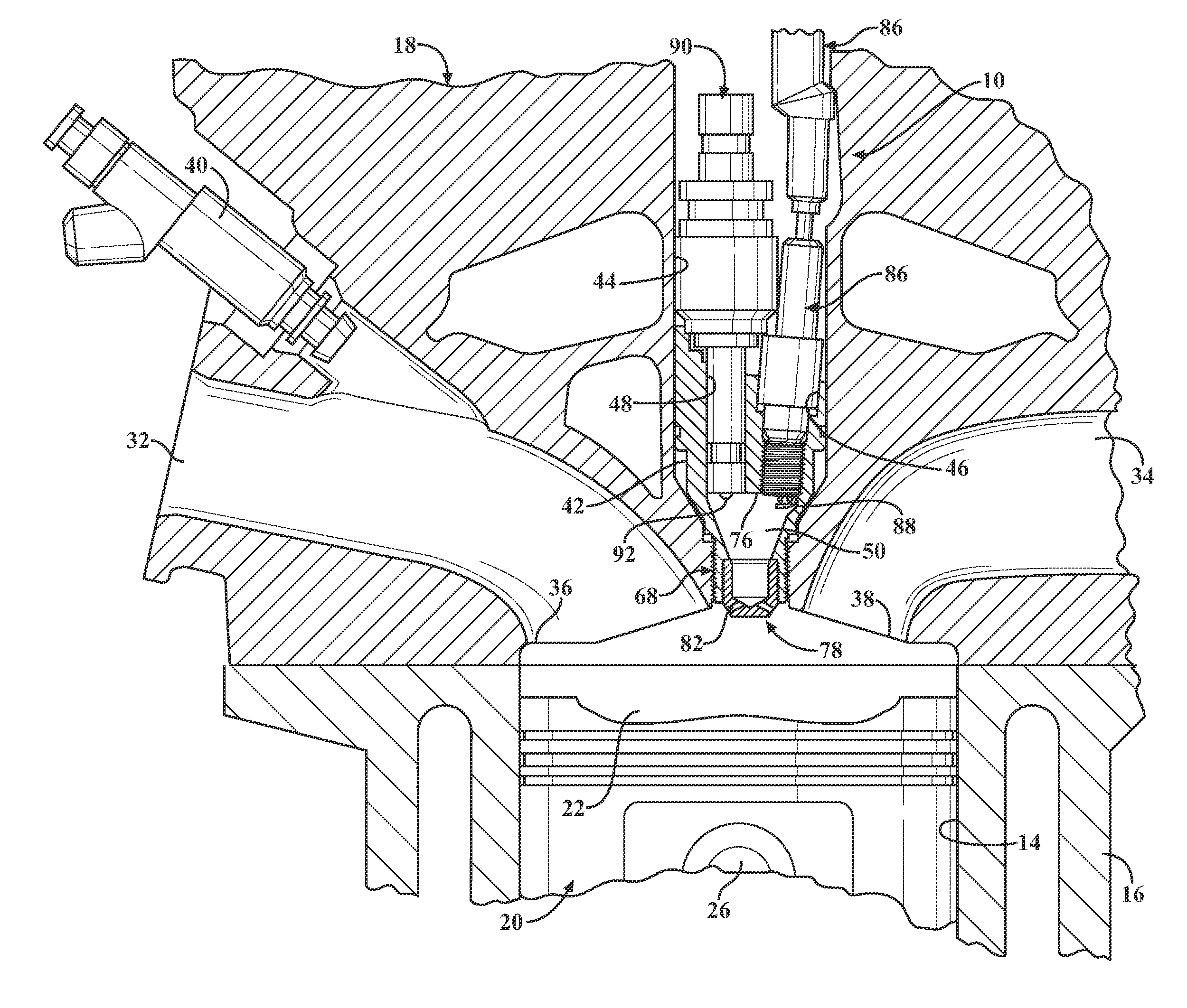

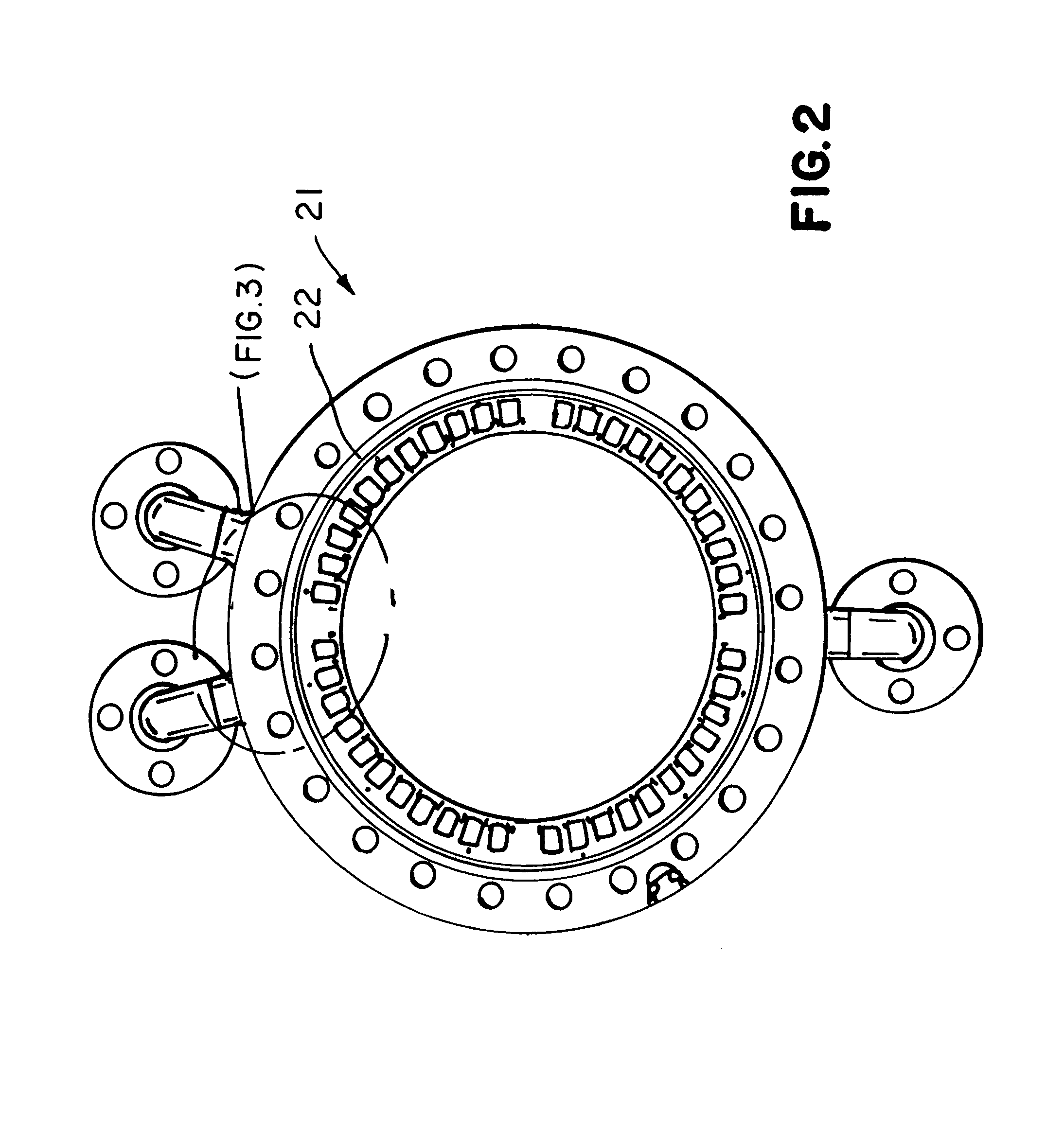

Turbulent jet ignition pre-chamber combustion system for spark ignition engines

ActiveUS20120103302A1Promote flame quenchingHigh-drive cycle (part load) fuel economyElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

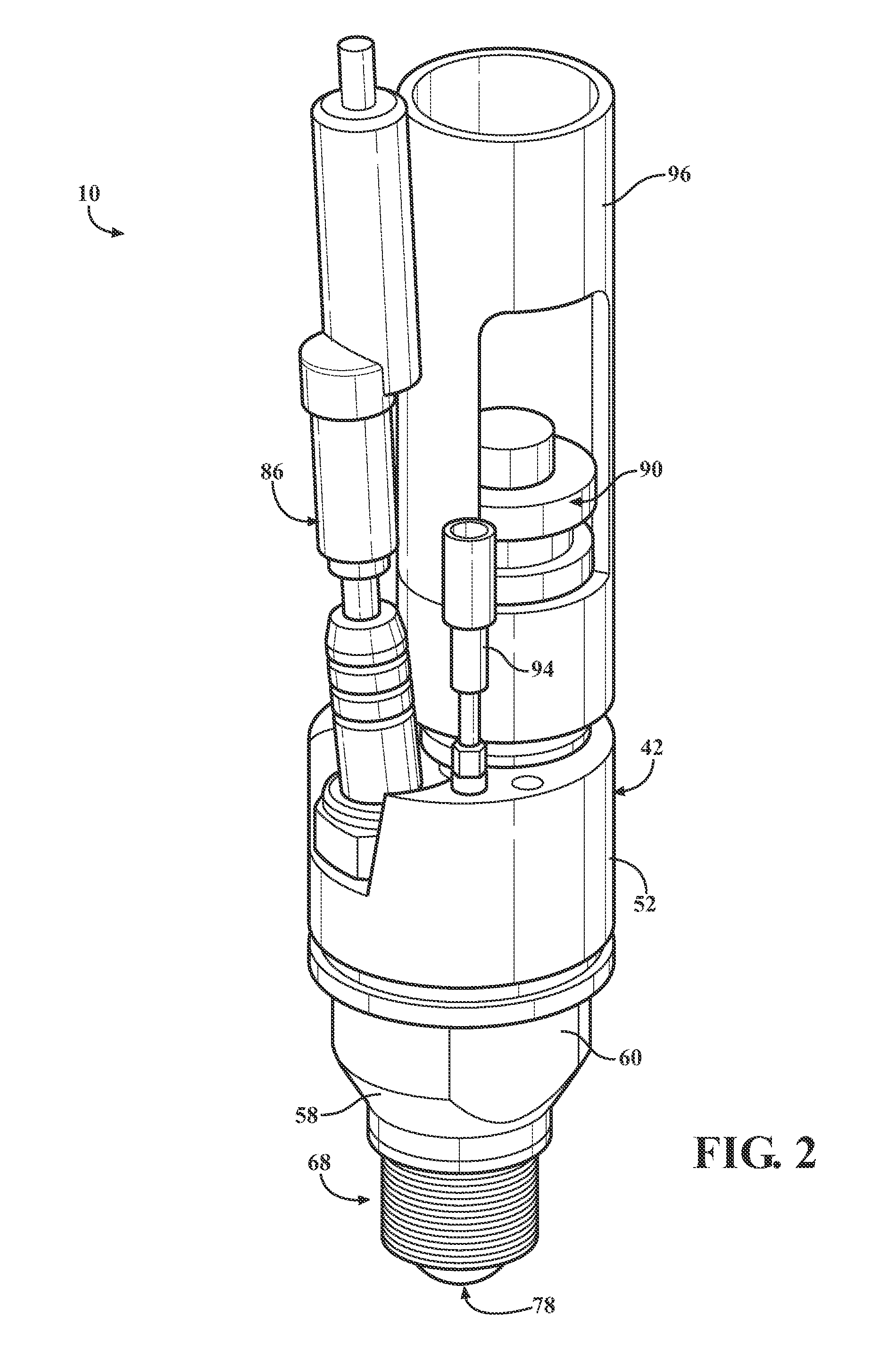

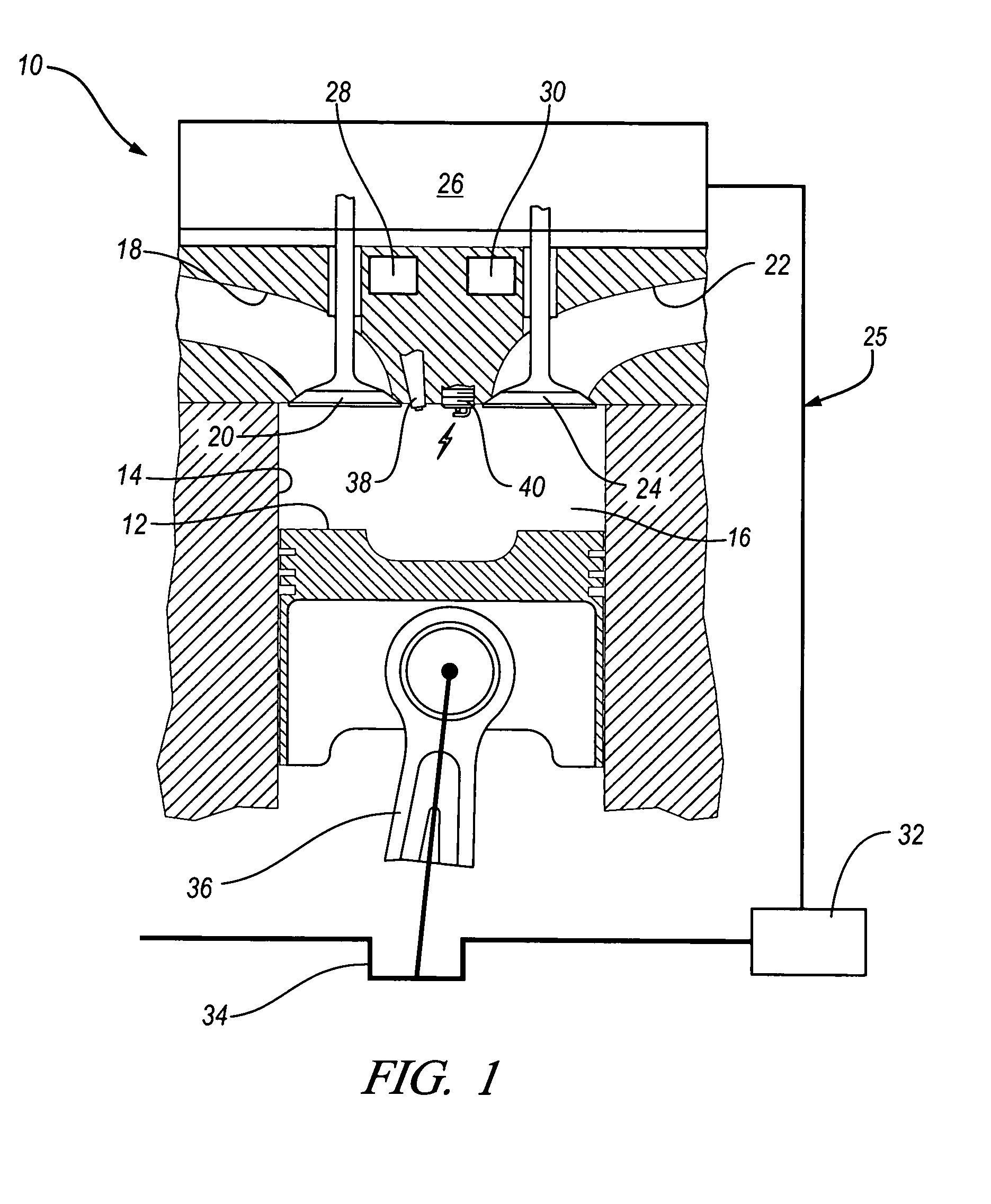

An ignition system for an internal combustion engine having at least one combustion chamber where the ignition system includes a housing, an ignition device, an injector, and a pre-chamber having a nozzle disposed spaced from the proximal portion of the pre-chamber. The igniter portion of the ignition device and the nozzle of the injector are operatively supported in the proximal portion of the pre-chamber and disposed flush therewith. The igniter portion ignites the fuel in pre-chamber such that partially combusted pre-chamber products are forced through orifices in the pre-chamber nozzle and extinguish, but dispersed through the combustion chamber so as to ignite the main fuel charge therein.

Owner:MAHLE POWERTRAIN

Method of operating a combustion system for increased turndown capability

ActiveUS7137256B1Emission reductionStable combustionContinuous combustion chamberGas turbine plantsCombustion systemLow load

A method of operating a gas turbine engine combustion system at lower load conditions while maintaining required emissions levels is disclosed. The present invention includes multiple embodiments of axial, radial, and circumferential fuel staging within a can-type combustor having alternate ignition techniques of spark ignition or torch ignition.

Owner:ANSALDO ENERGIA SWITZERLAND AG

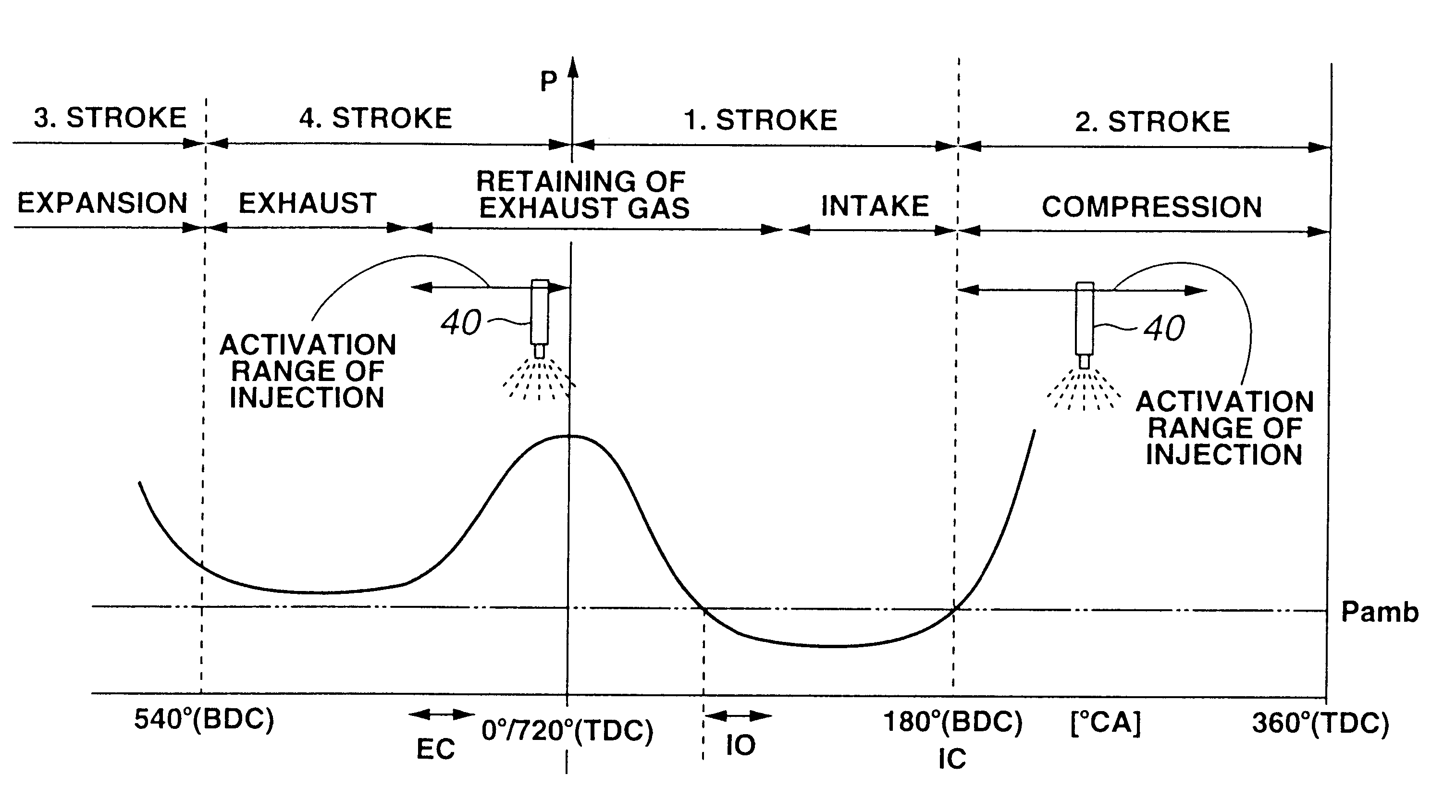

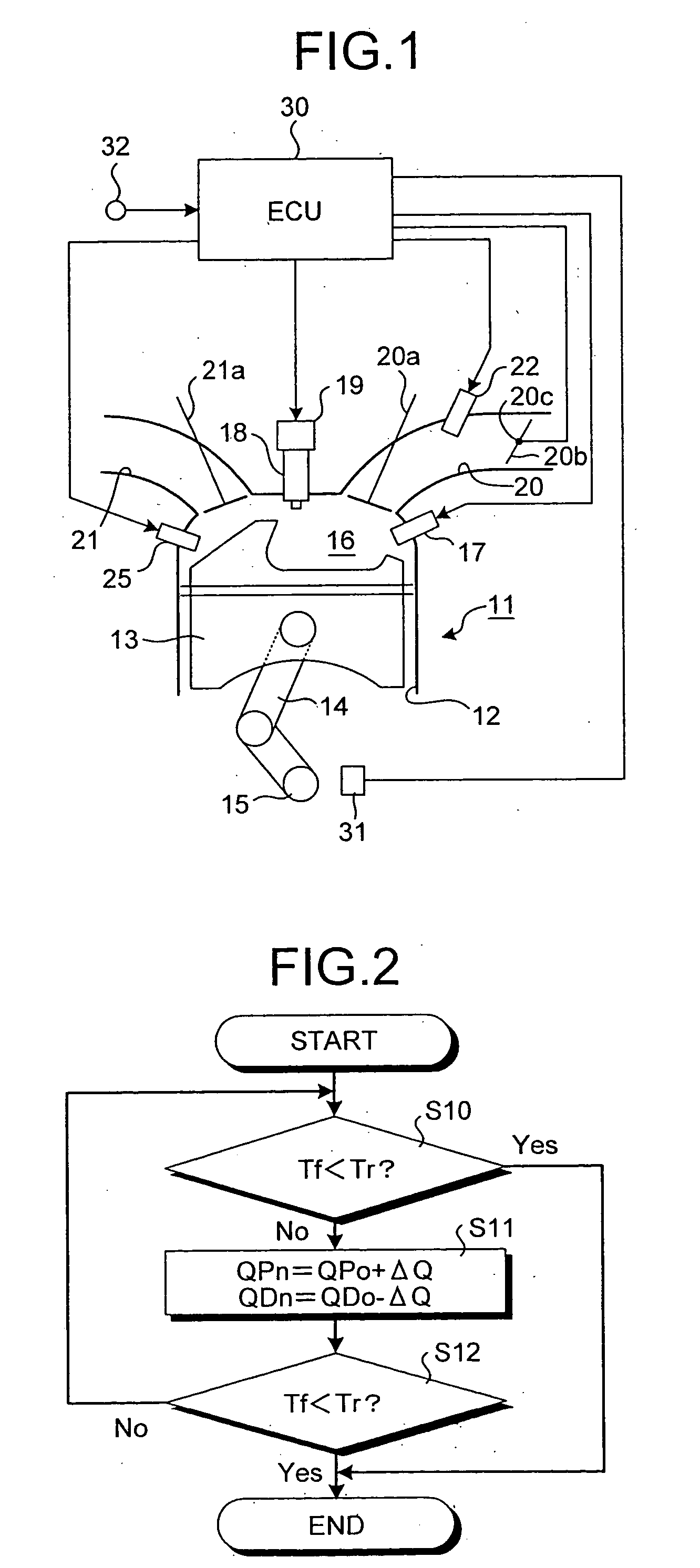

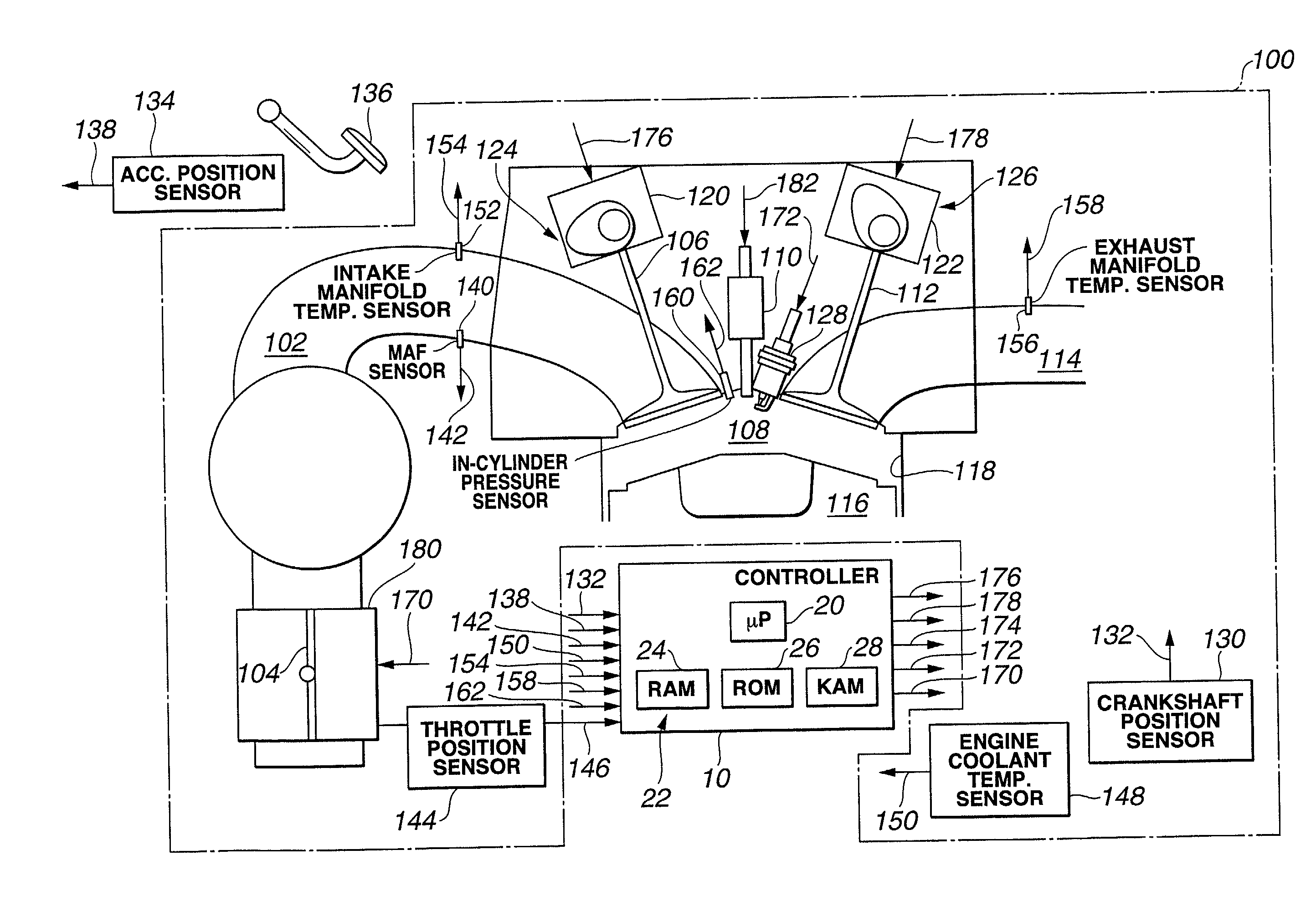

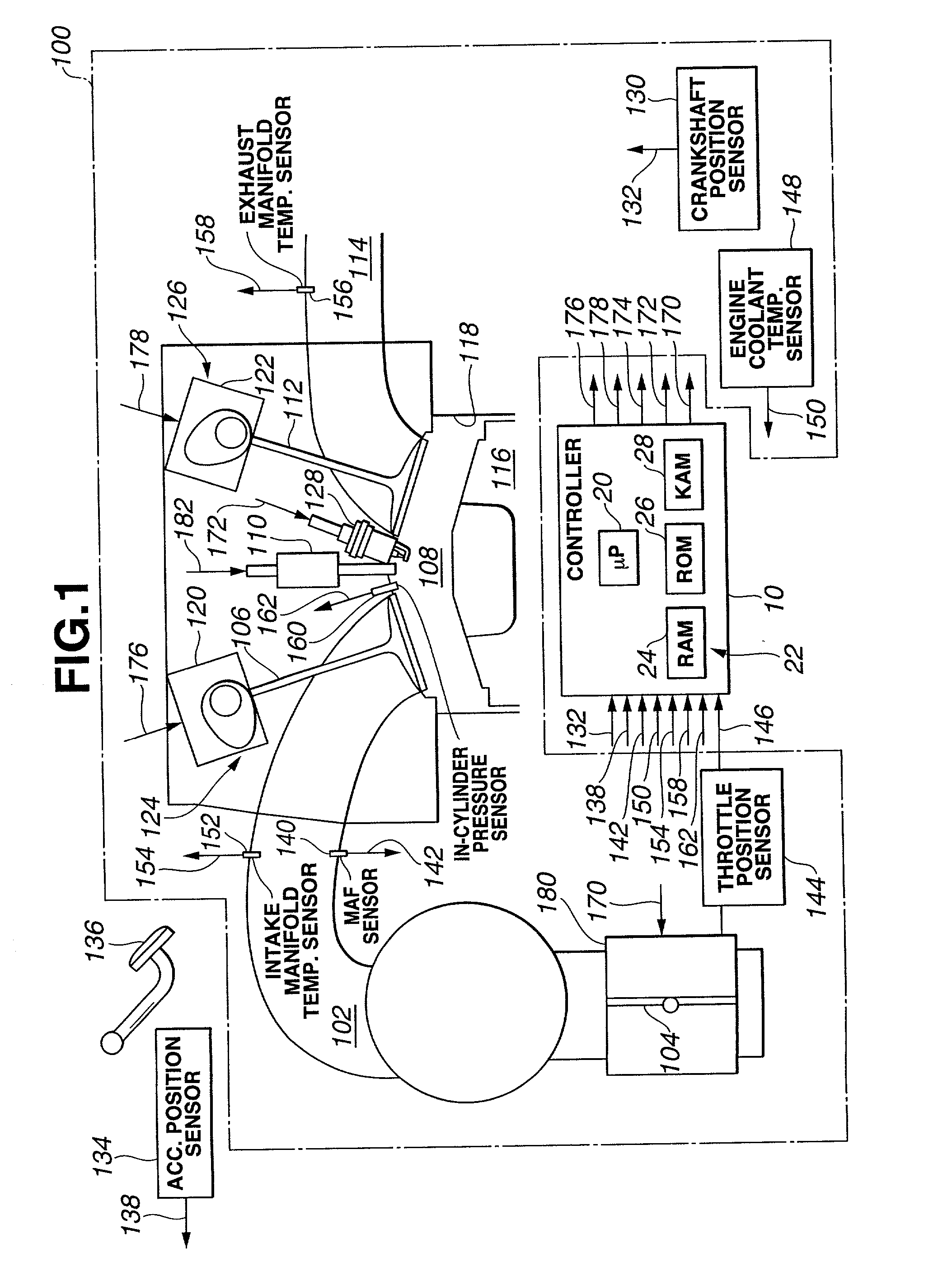

System and method for auto-ignition of gasoline internal combustion engine

During operation with part load, a gasoline internal combustion engine is operated with a lean air / fuel mixture by auto-ignition. During operation with full load, spark-ignition is used to operate the engine. The internal combustion engine is operated in three auto-ignition combustion modes depending upon magnitude of a predetermined operating parameter. The operating parameter is indicative of the engine load or the engine speed. The three auto-ignition combustion modes are a gasoline reform auto-ignition combustion mode, an auto-ignition stratified charge combustion mode, and an auto-ignition homogeneous charge combustion mode. In the gasoline reform auto-ignition combustion mode that may be selected during operation with low part load, a first fuel injection during an exhaust gas retaining phase produces sufficient amount of active fuel radicals for promotion of auto-ignition of air / fuel mixture produced by a second fuel injection during the subsequent compression phase. In the auto-ignition stratified charge combustion mode that may be selected during operation with intermediate part load, a fuel injection during compression phase supports auto-ignition. In the auto-ignition homogeneous charge combustion mode that may be selected during operation with high part load, a fuel injection during intake phase supports auto-ignition.

Owner:NISSAN MOTOR CO LTD

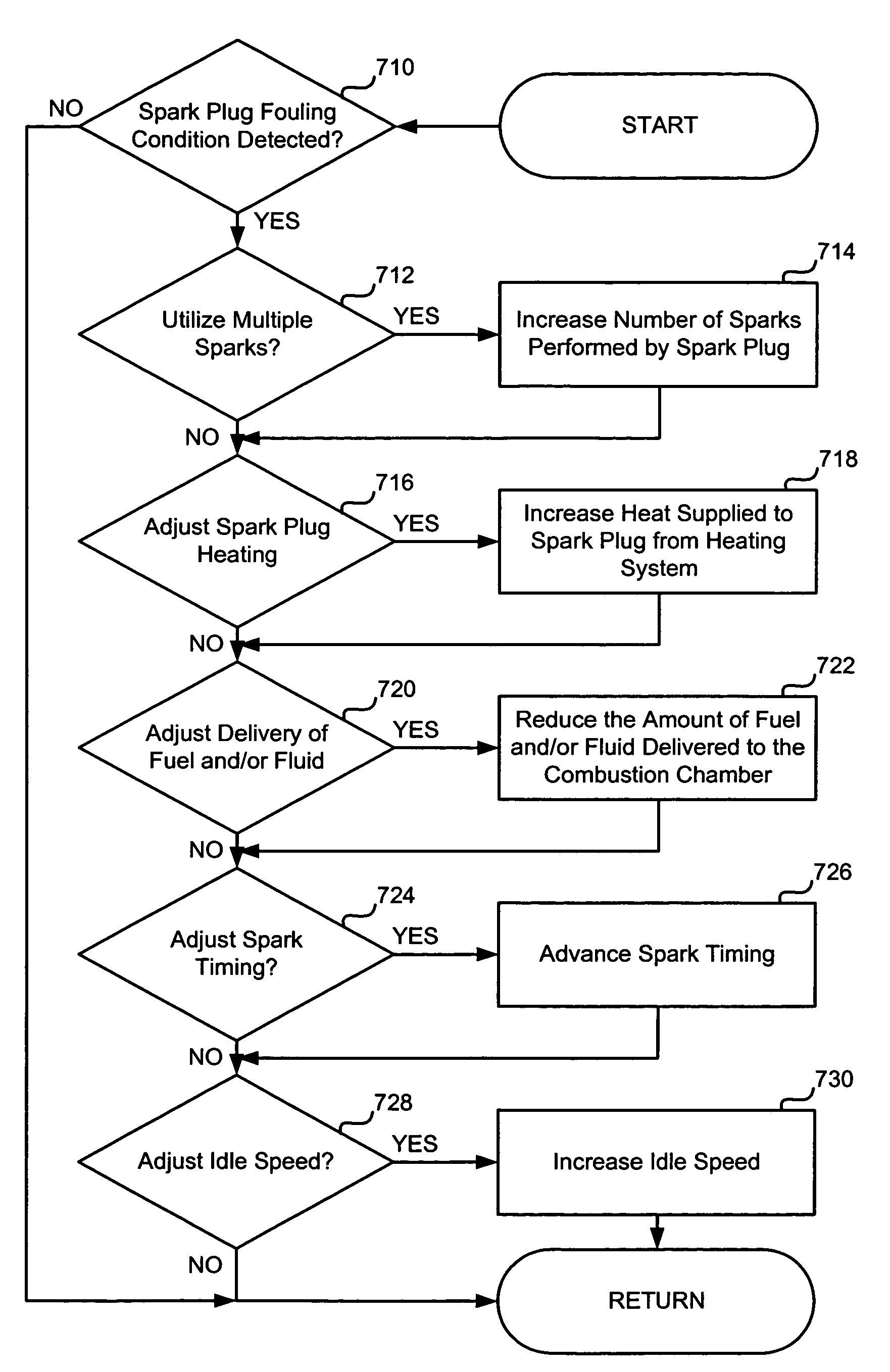

Spark plug heating for a spark ignited engine

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, a spark plug heating system configured to supply heat to the spark plug, and a control system configured to vary an amount of heat supplied to the spark plug by the spark plug heating system responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

Fuel composition supply means for spark ignition engines

ActiveUS7107942B2More of efficiencyMore of emissionsNon-fuel substance addition to fuelInternal combustion piston enginesMotor fuelDriving cycle

A fuel system for on-board vehicle fuel separation to supply engine fuel compositions formulated as a function of driving cycle conditions. The invention results in improvements in one or more of feed efficiency and combustion emissions.

Owner:TOYOTA JIDOSHA KK +1

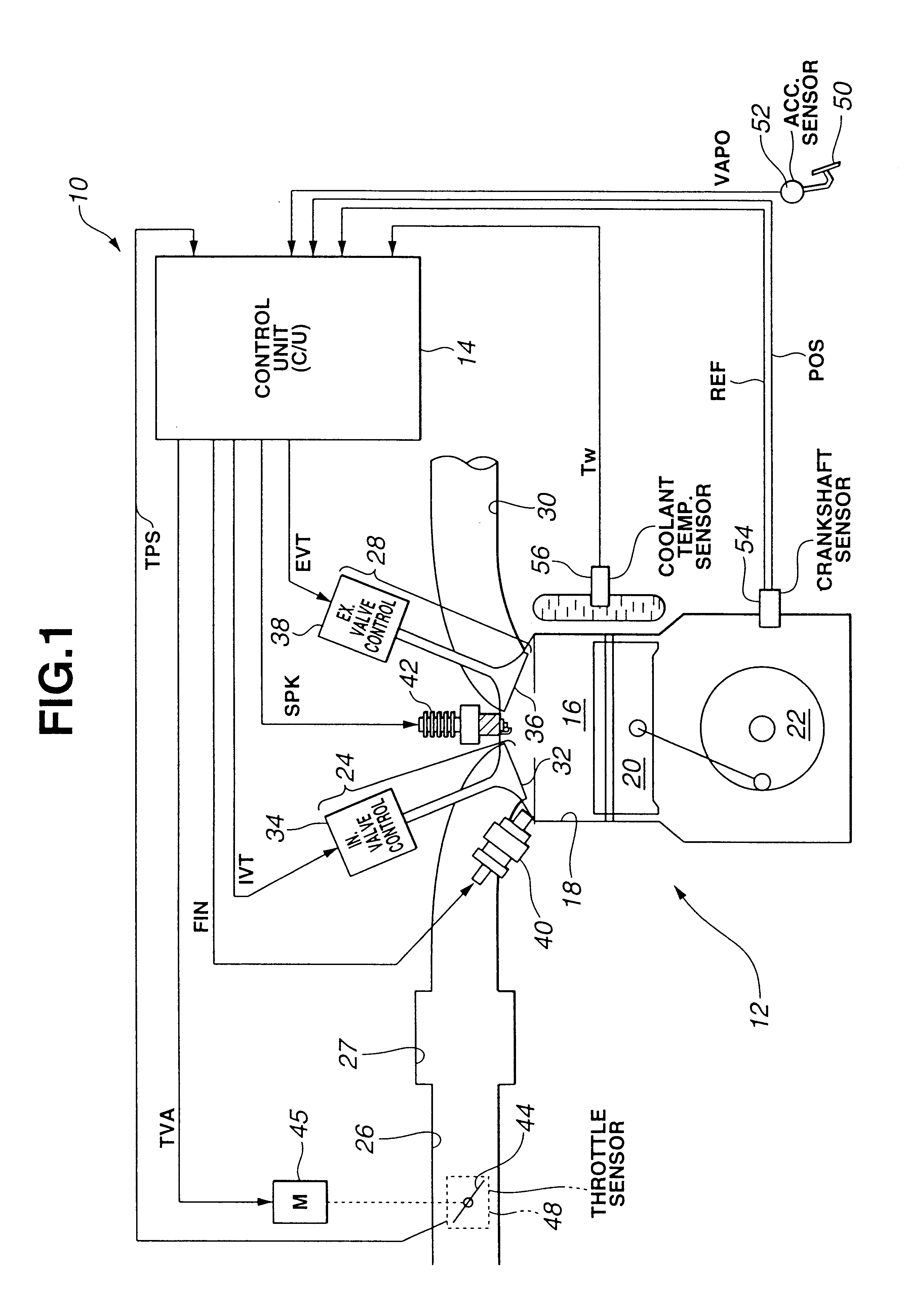

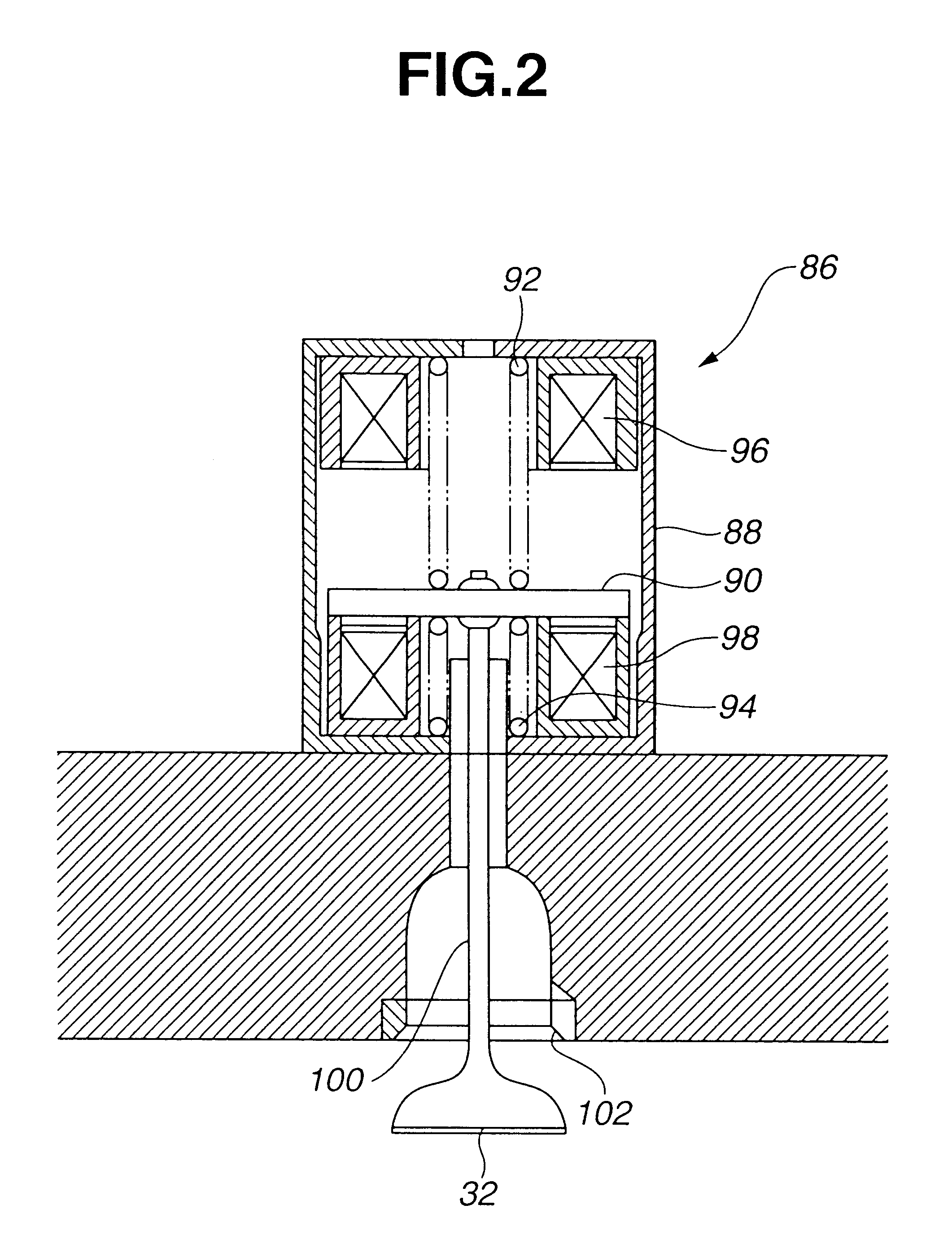

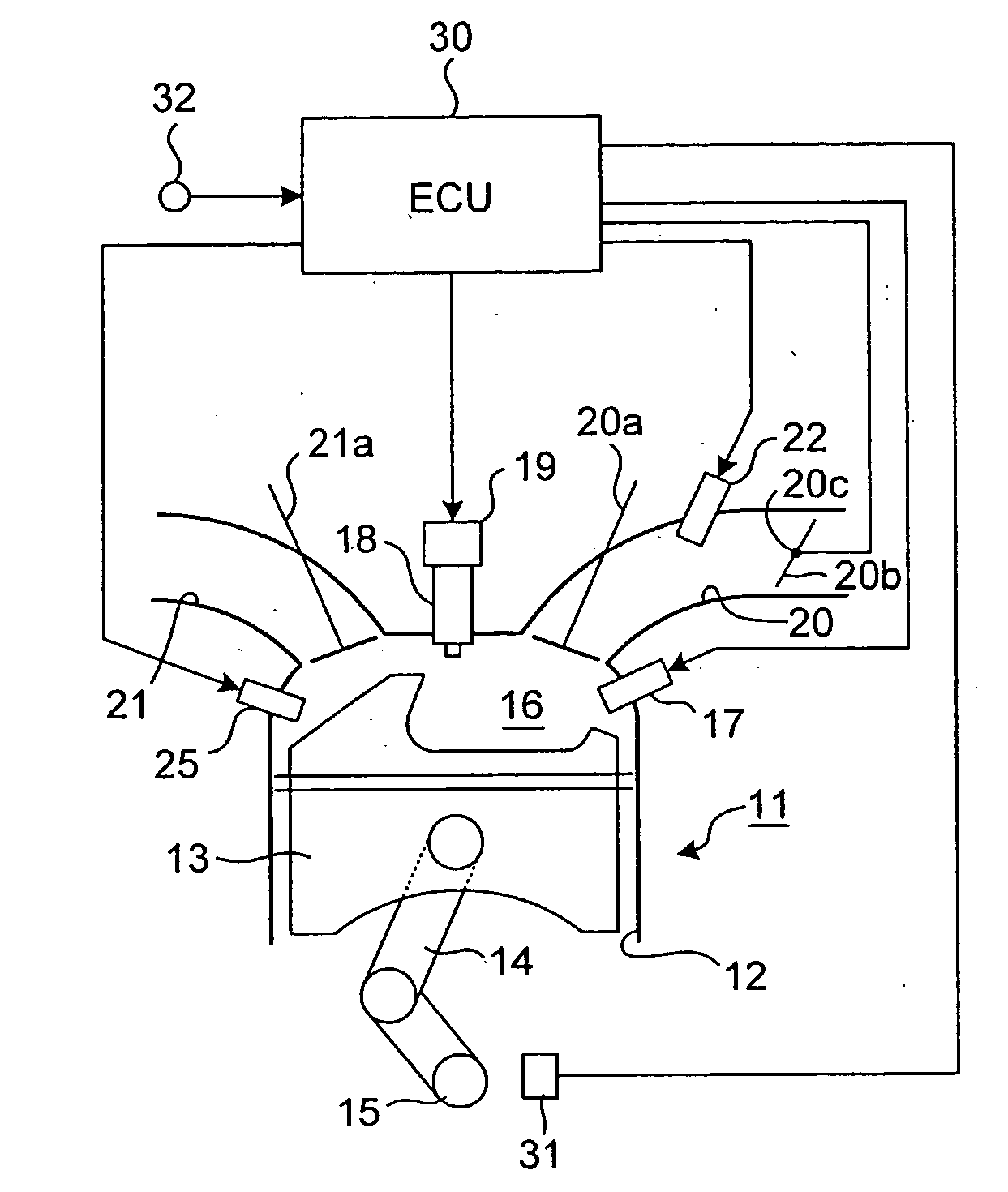

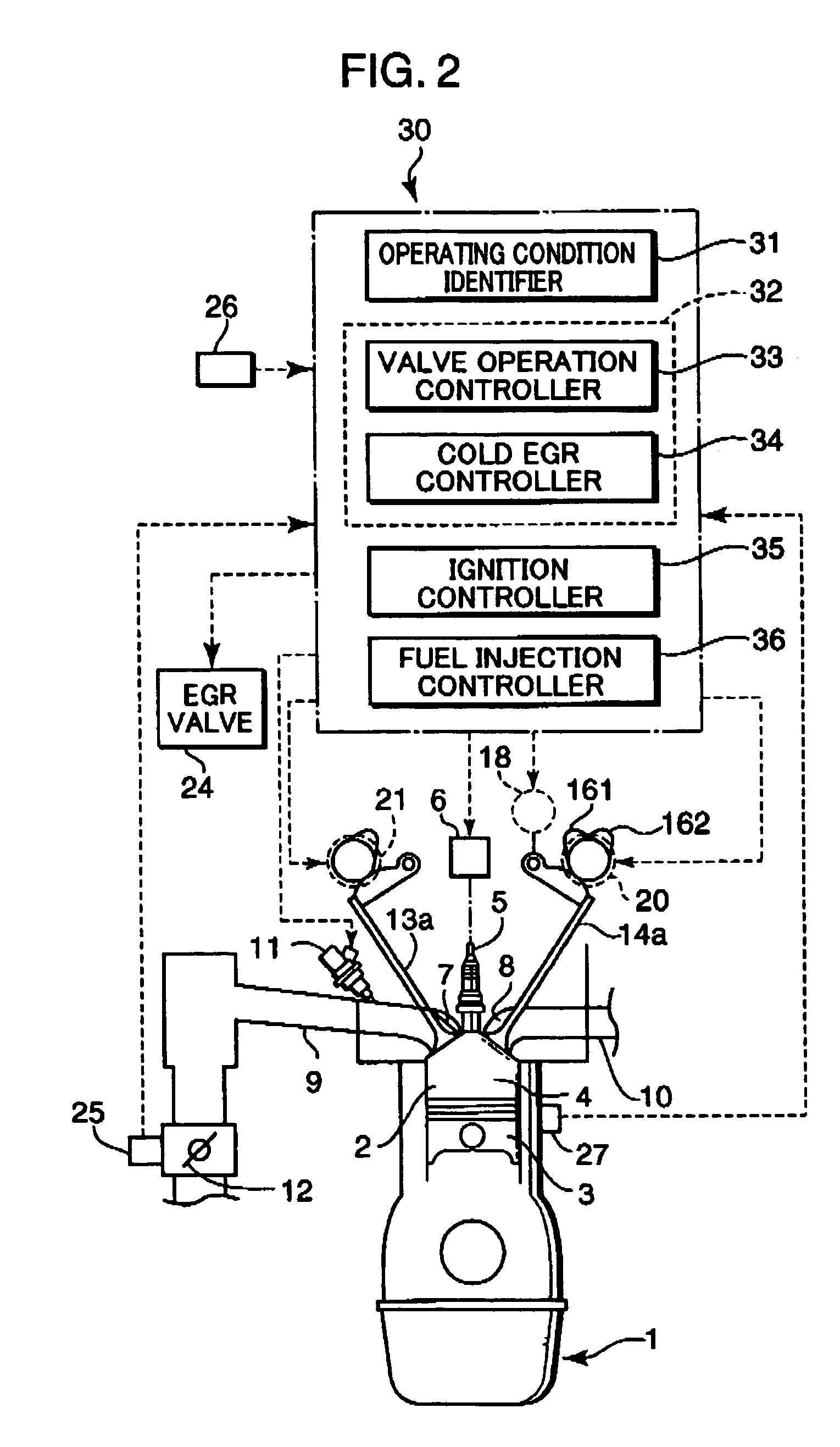

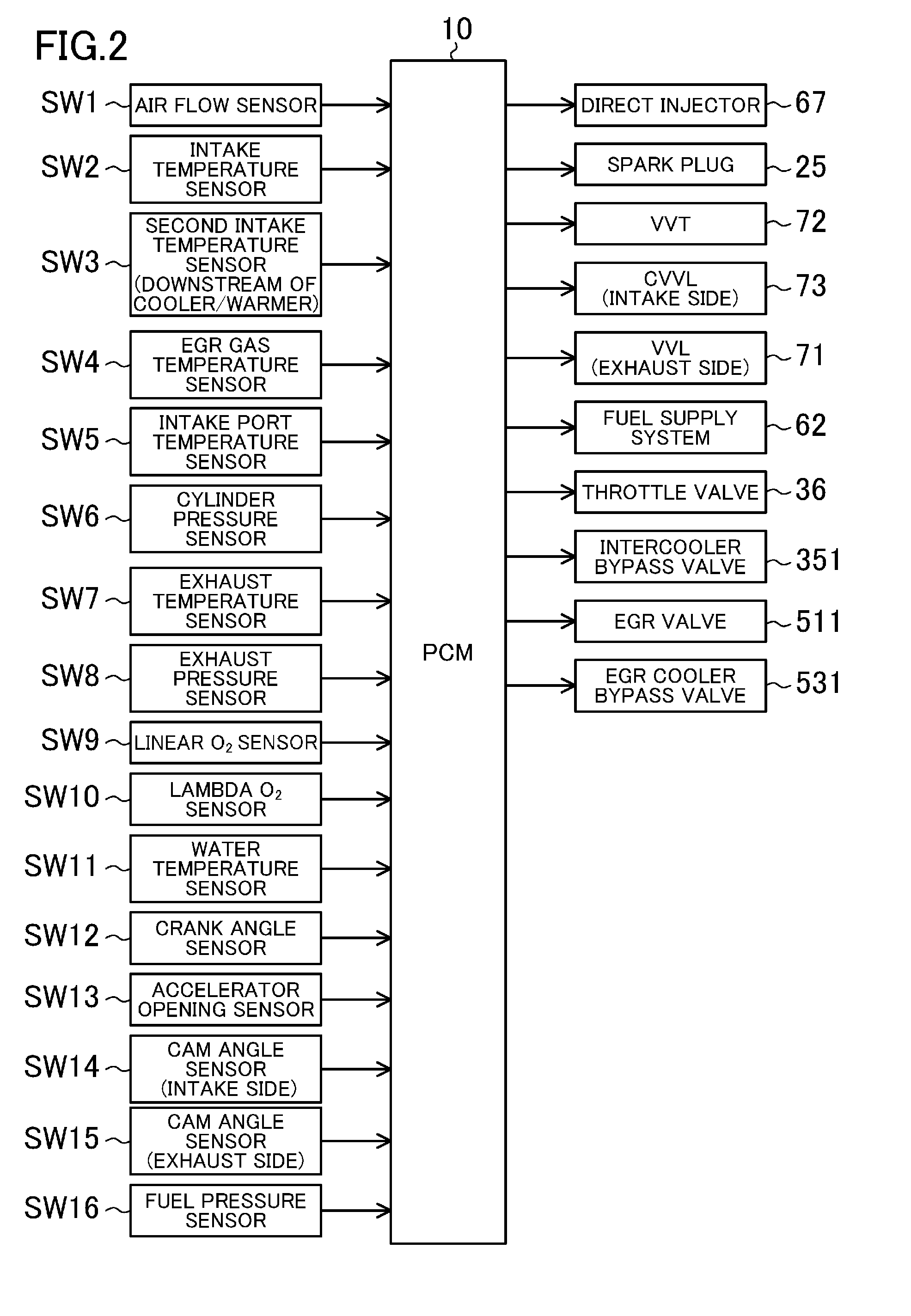

System and method for controlling spark-ignition internal combustion engine

ActiveUS20050051135A1Reduce openingElectrical controlNon-fuel substance addition to fuelControl systemFuel injection

A control system controls a spark-ignition internal combustion engine. The spark-ignition internal combustion engine includes a cylinder, and a fuel injection valve arranged in the cylinder; and an intake port that communicates with the cylinder, and a fuel injection valve arranged in the intake port. Fuel is injected from both the fuel injection valves in at least a part of an operating range. If combustion fluctuations exceed a predetermined amount, in consideration of a preset proportion of fuels to be injected into the cylinder and the intake port, a proportion of fuel to be injected into the cylinder is decreased and a proportion of fuel to be injected into the intake port is increased.

Owner:TOYOTA JIDOSHA KK

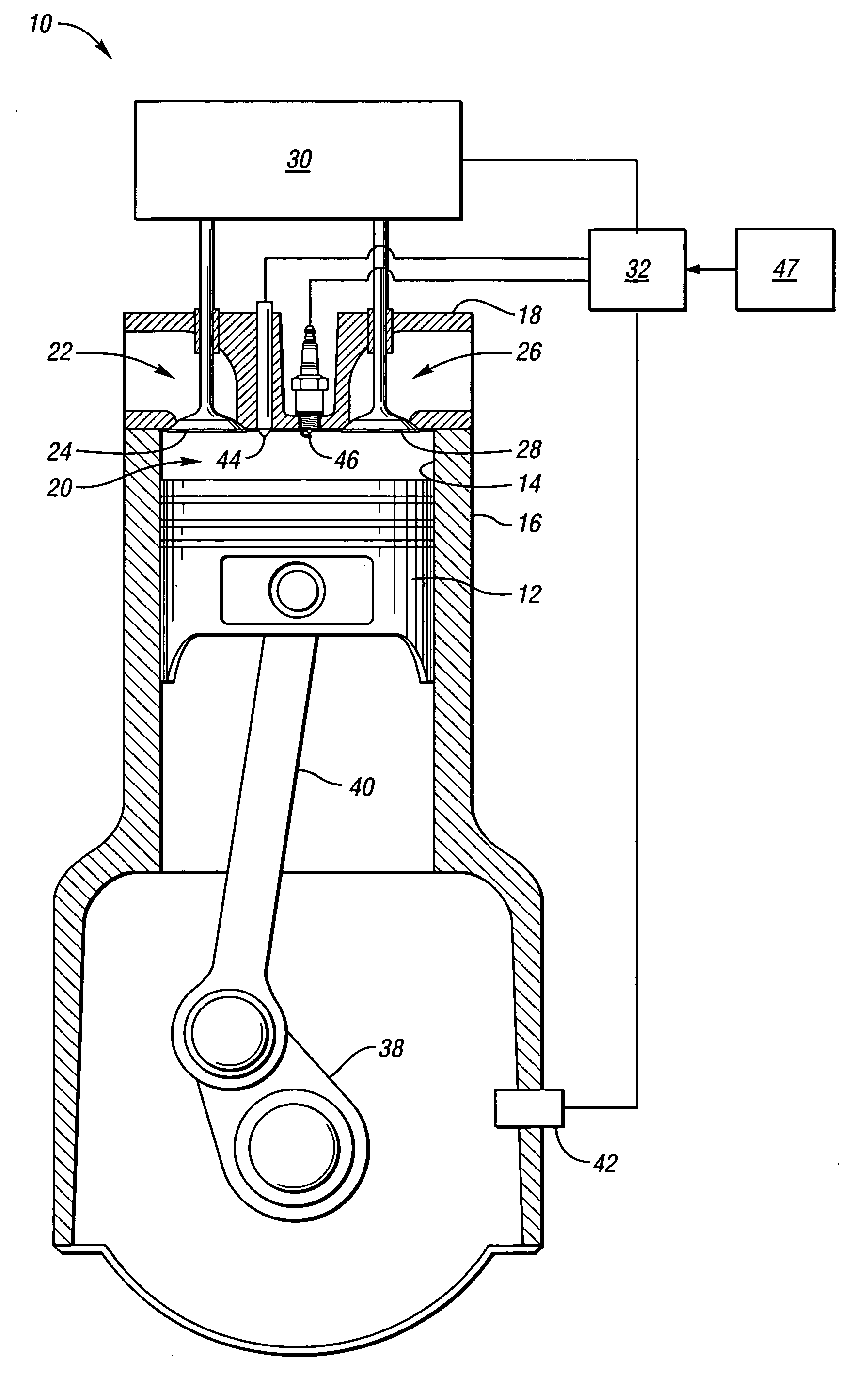

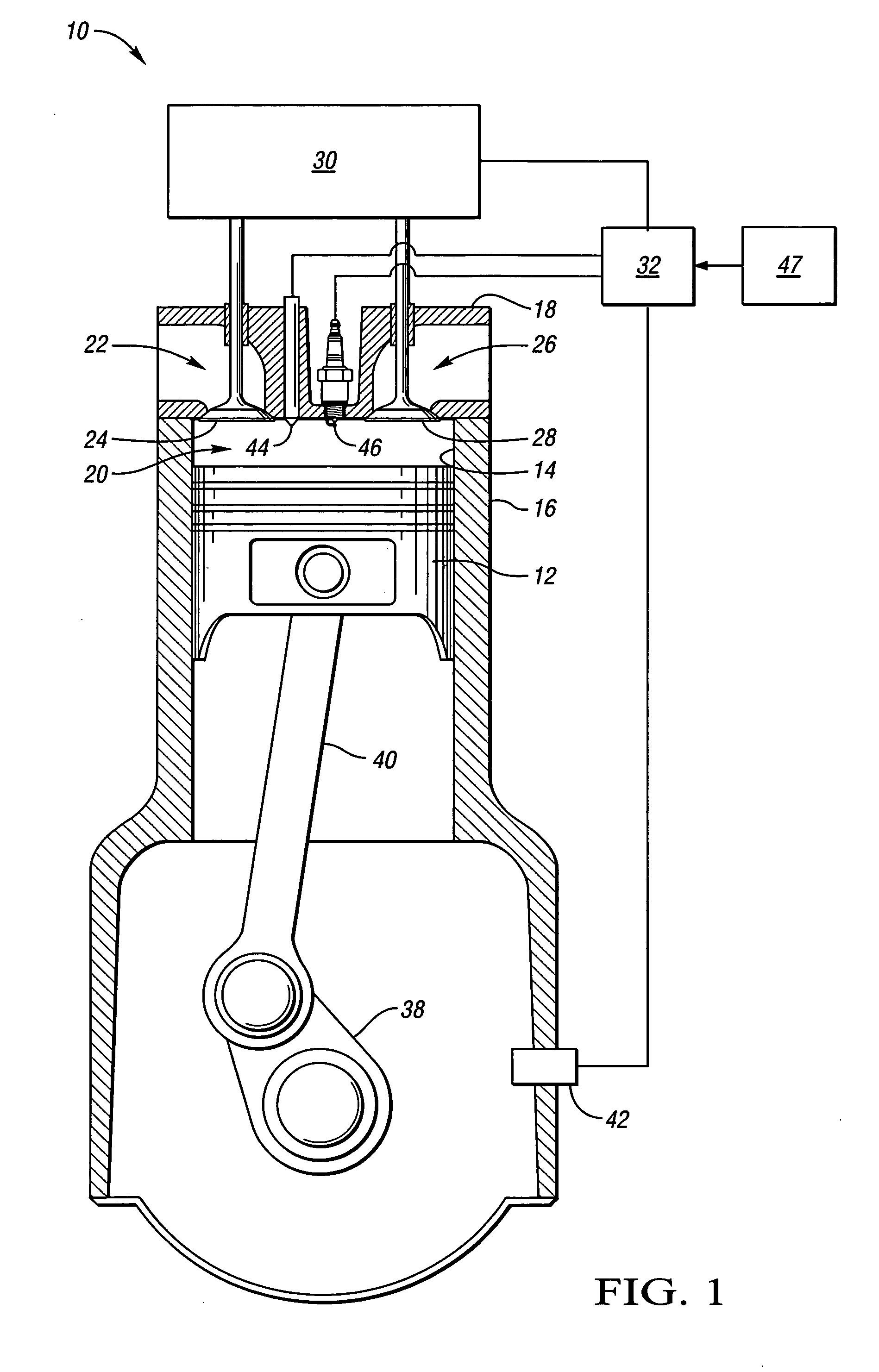

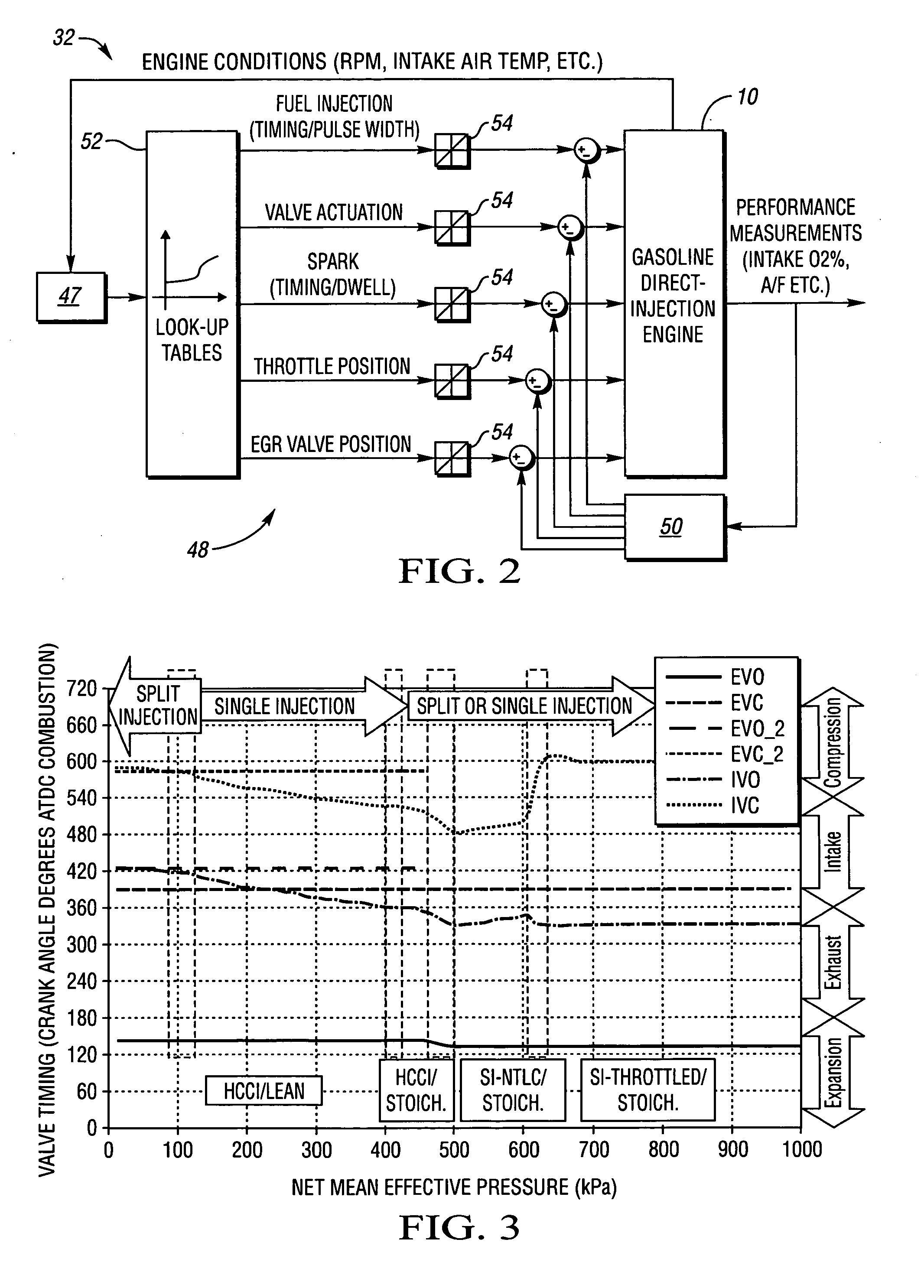

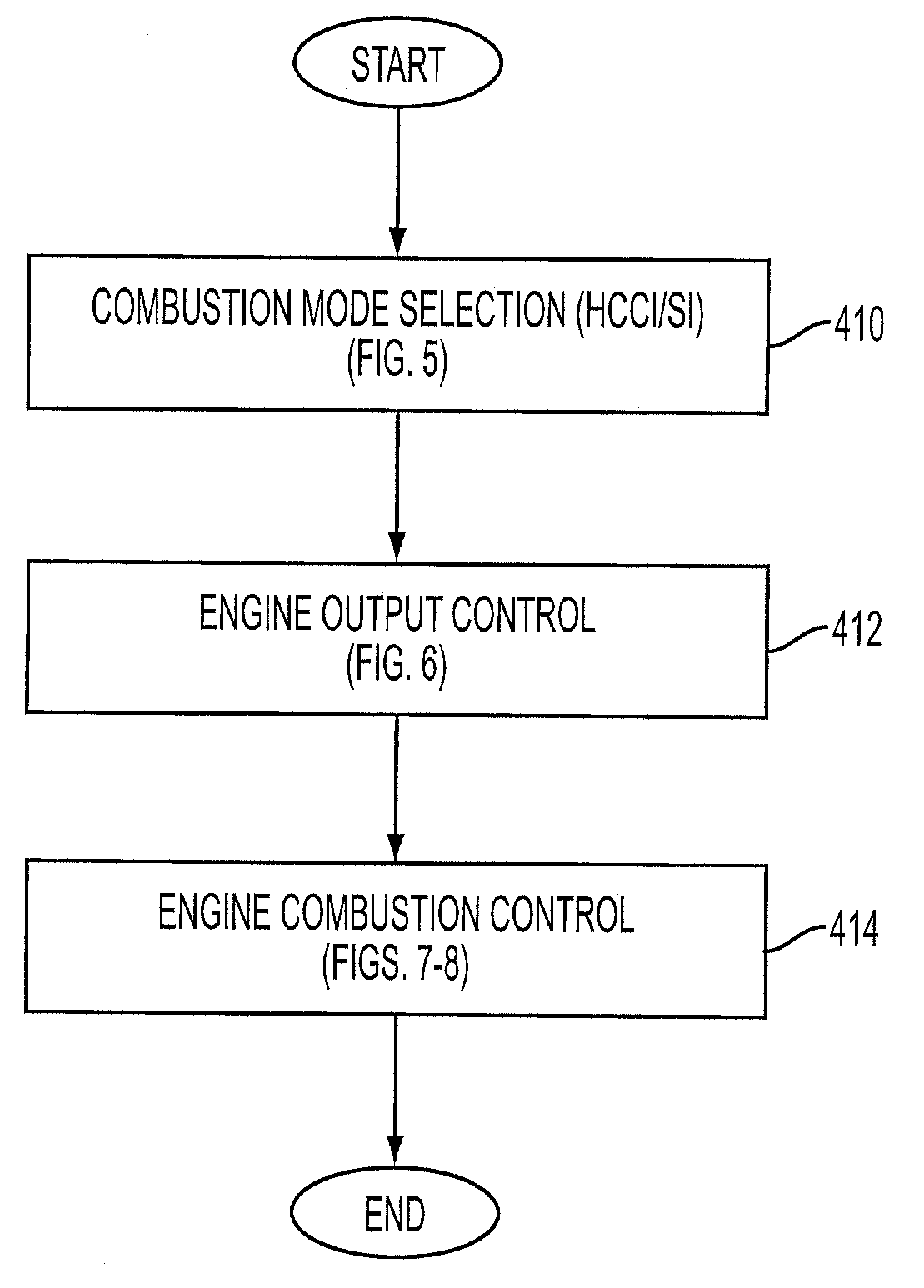

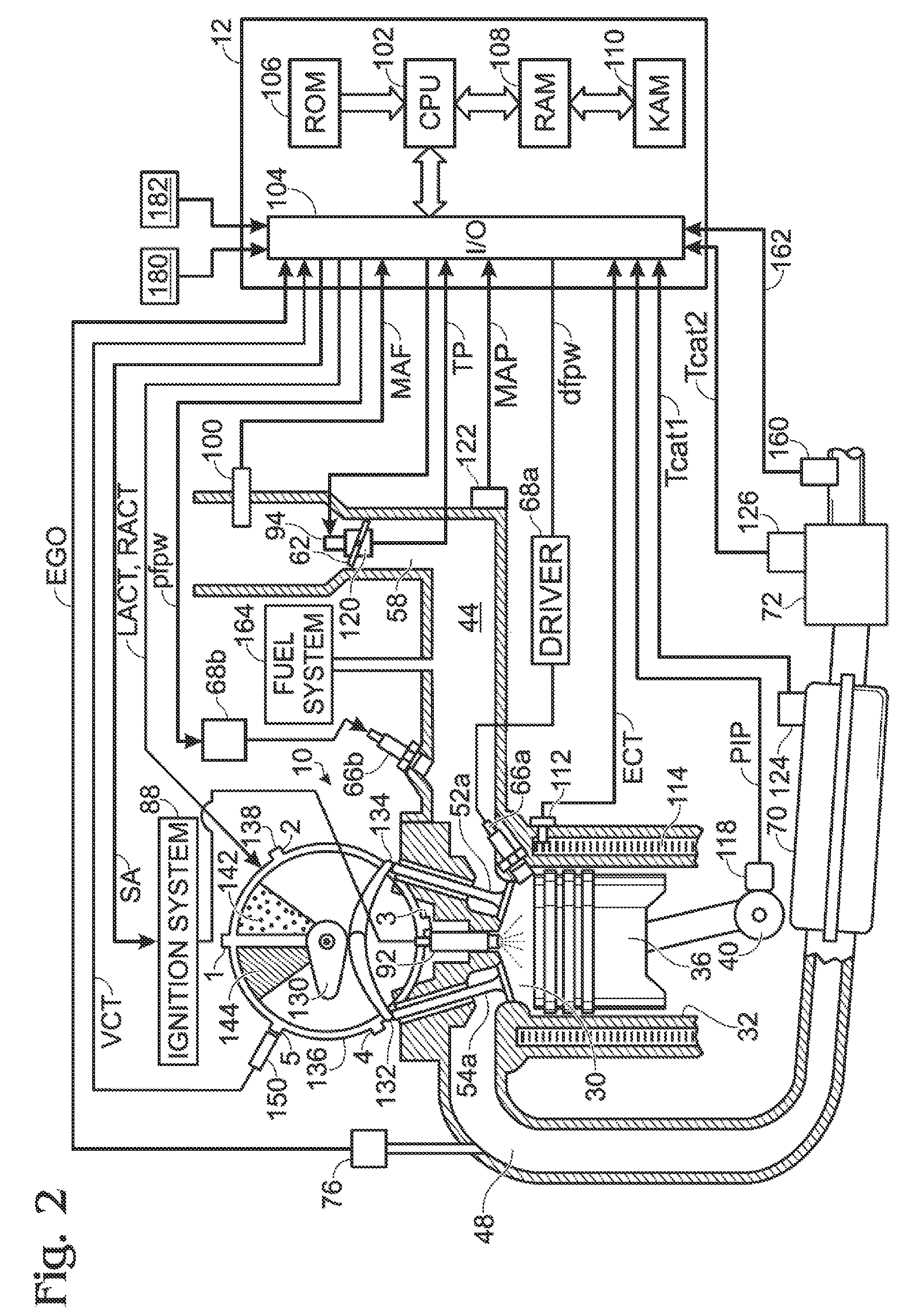

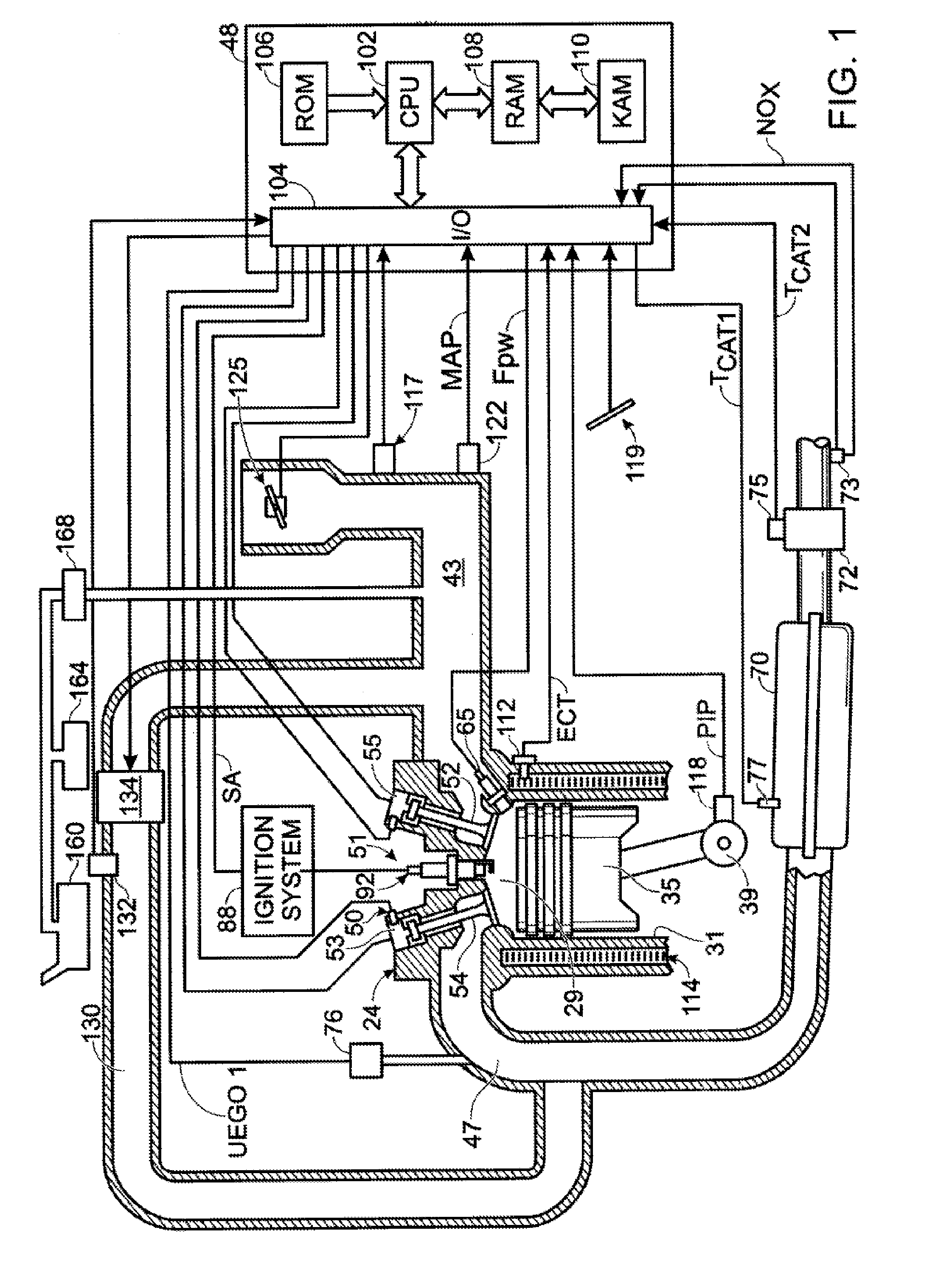

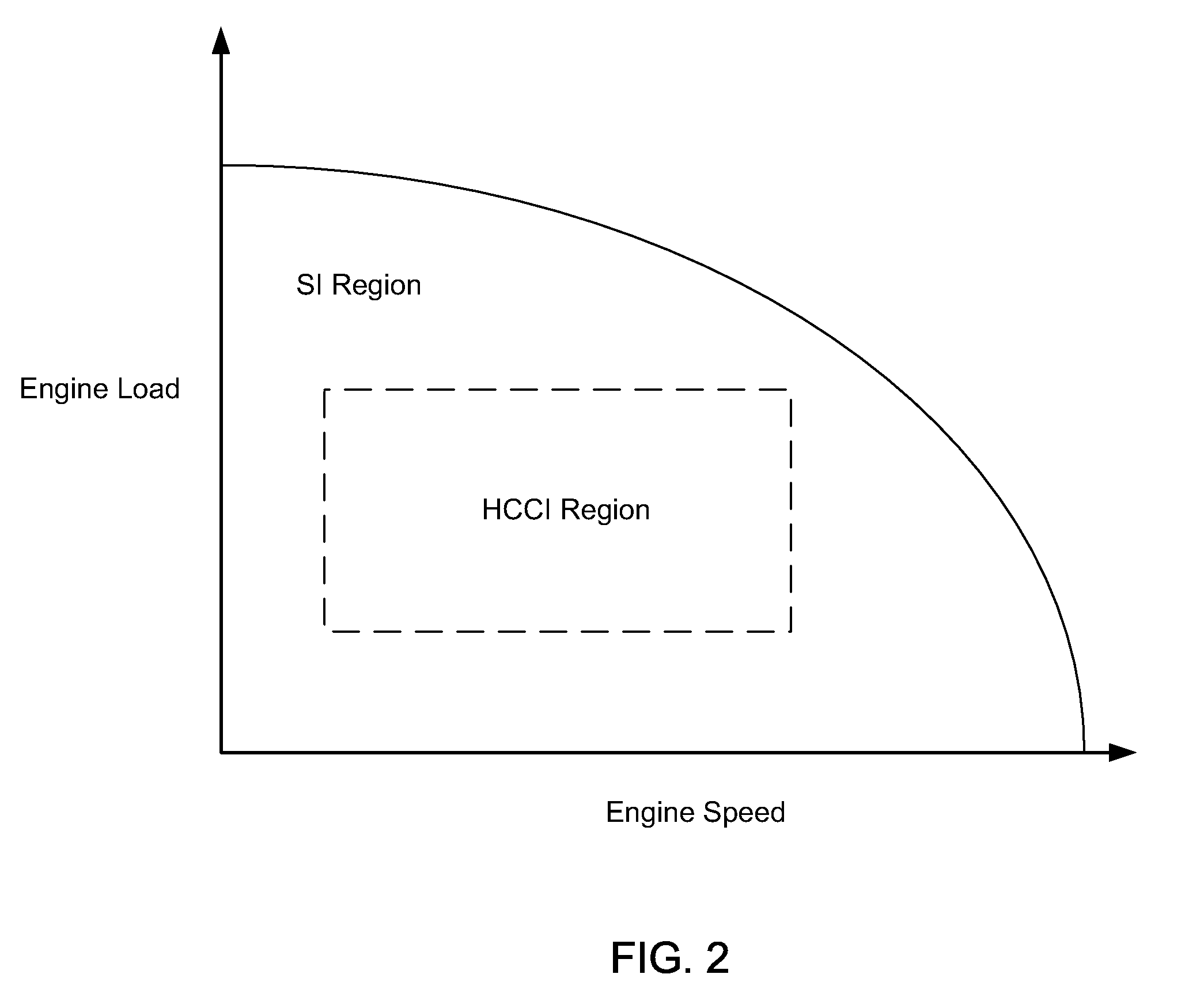

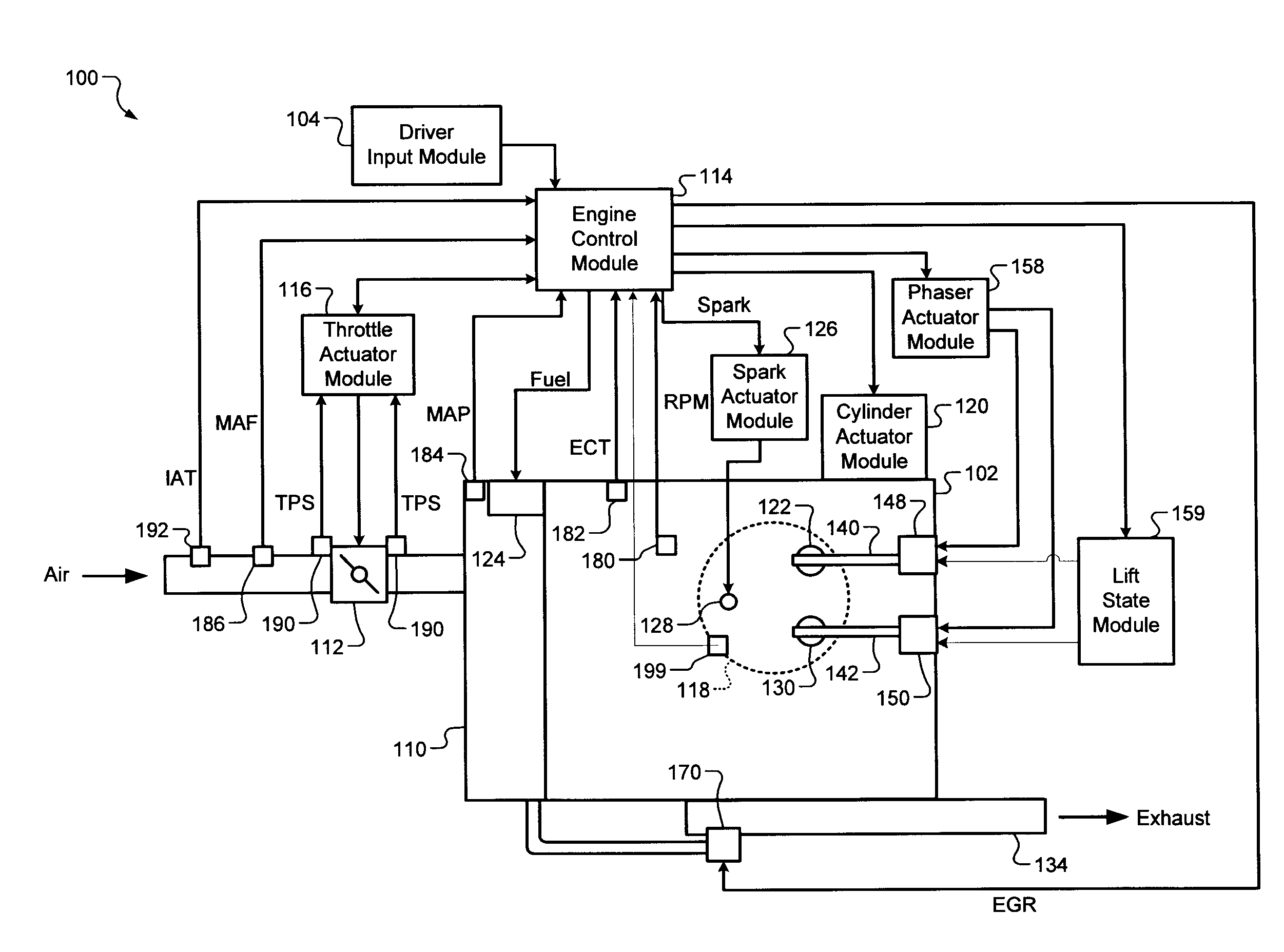

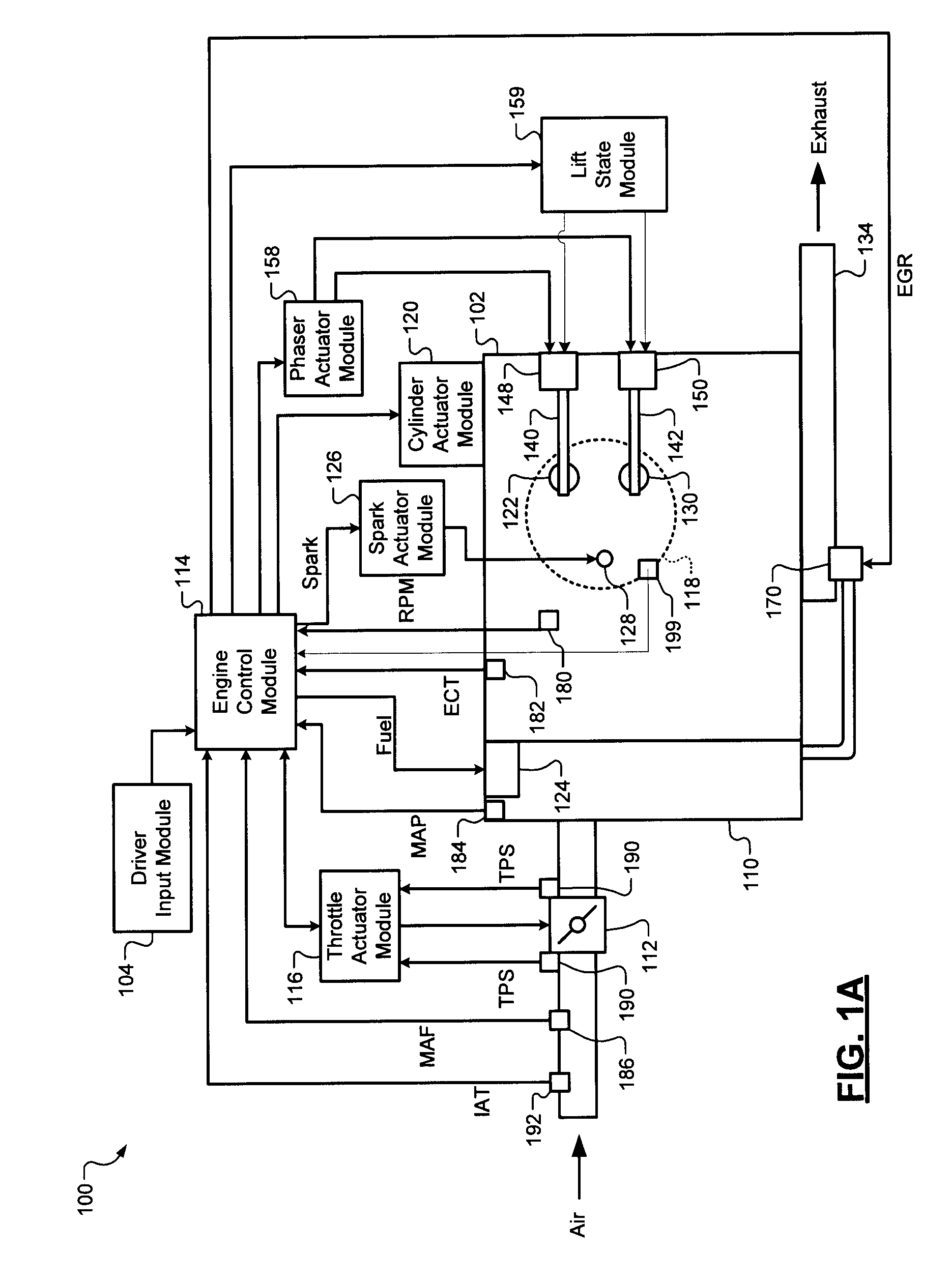

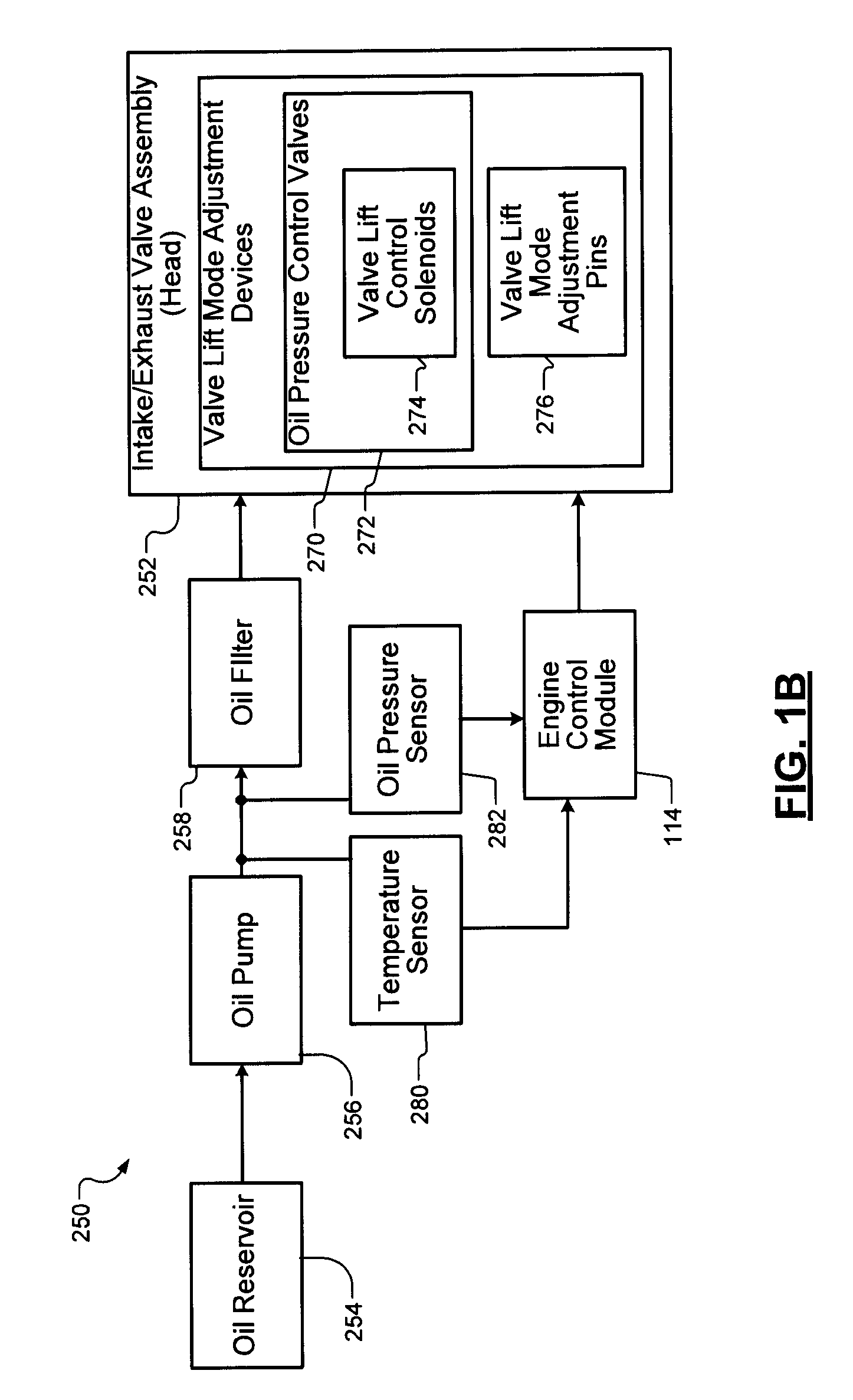

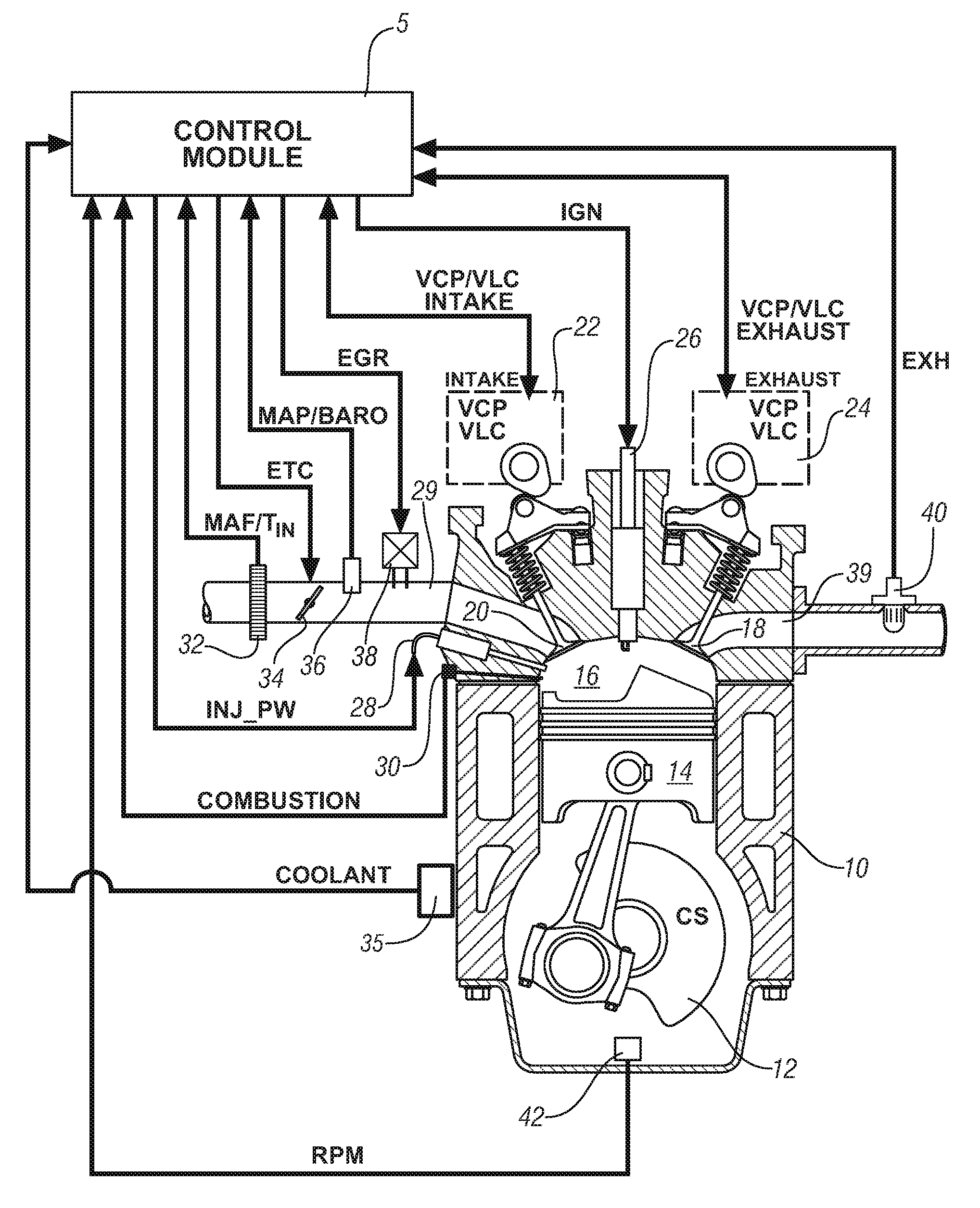

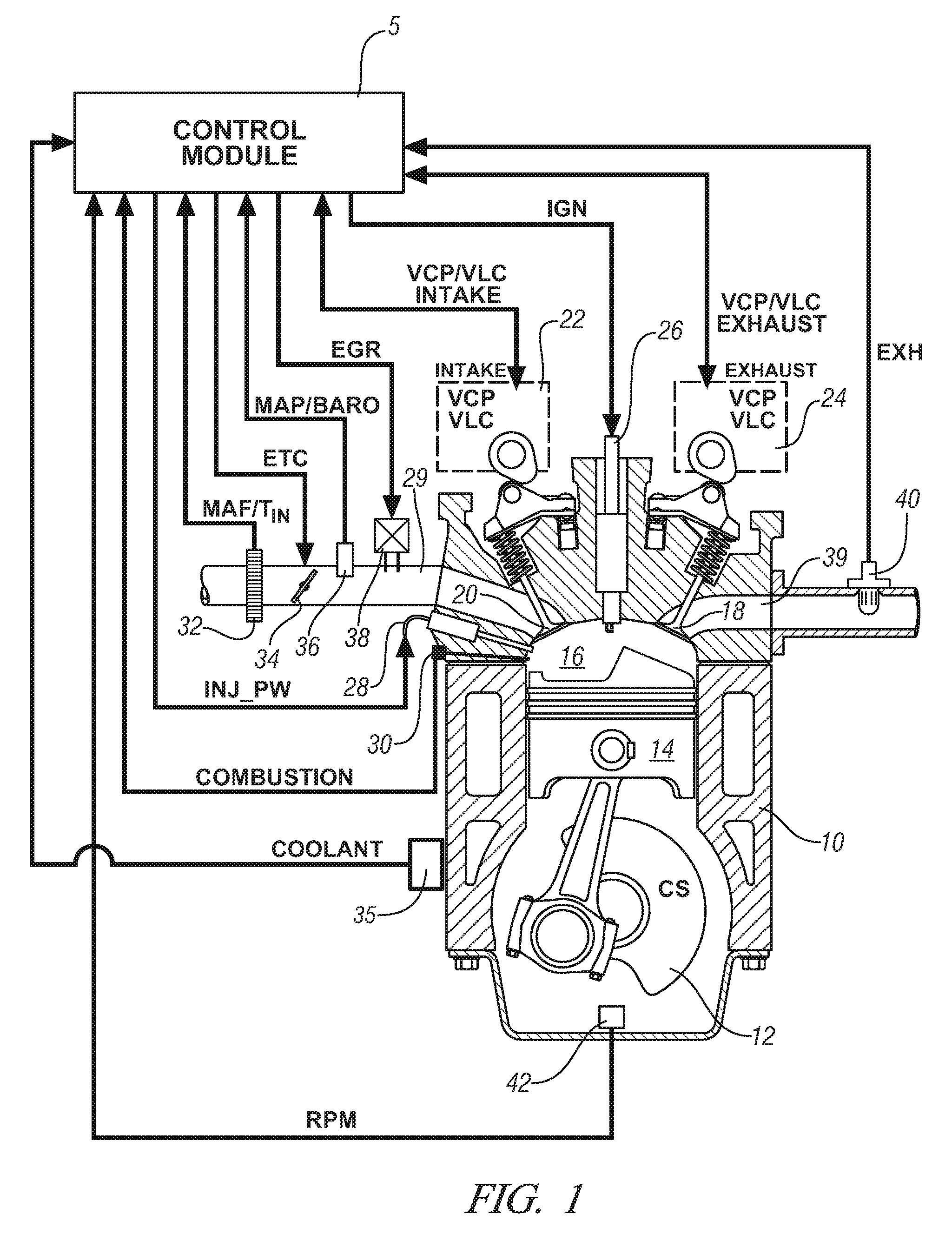

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

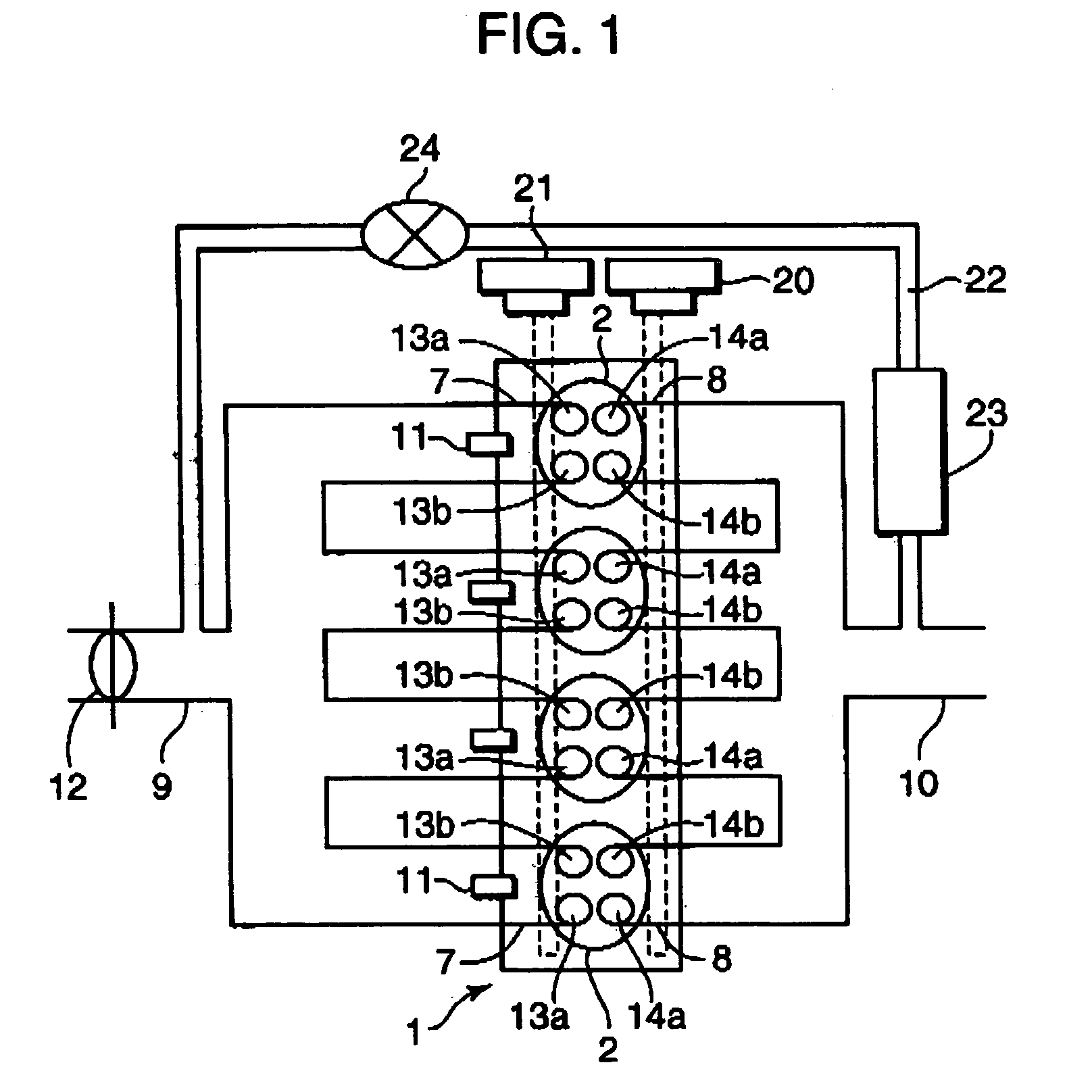

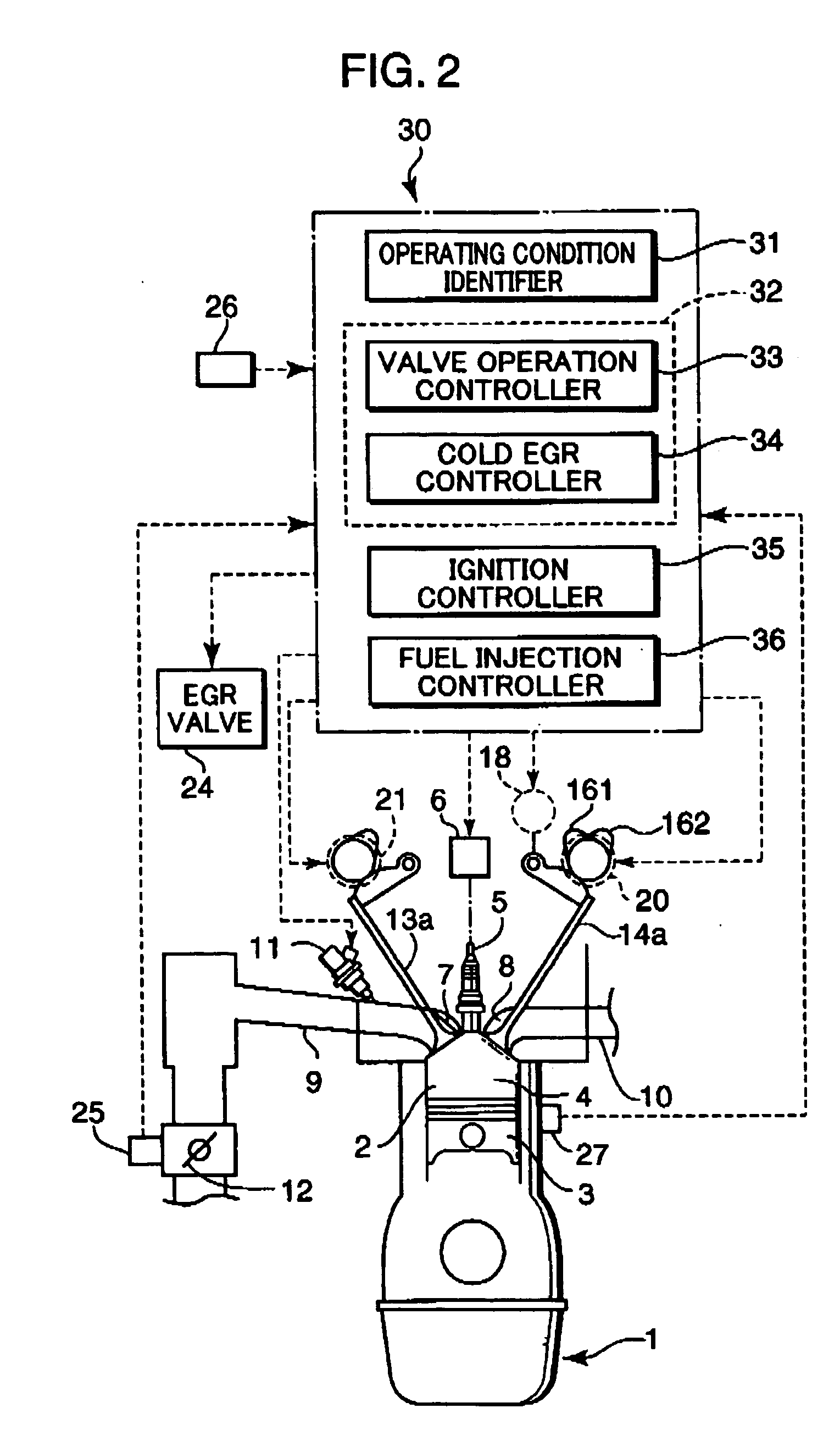

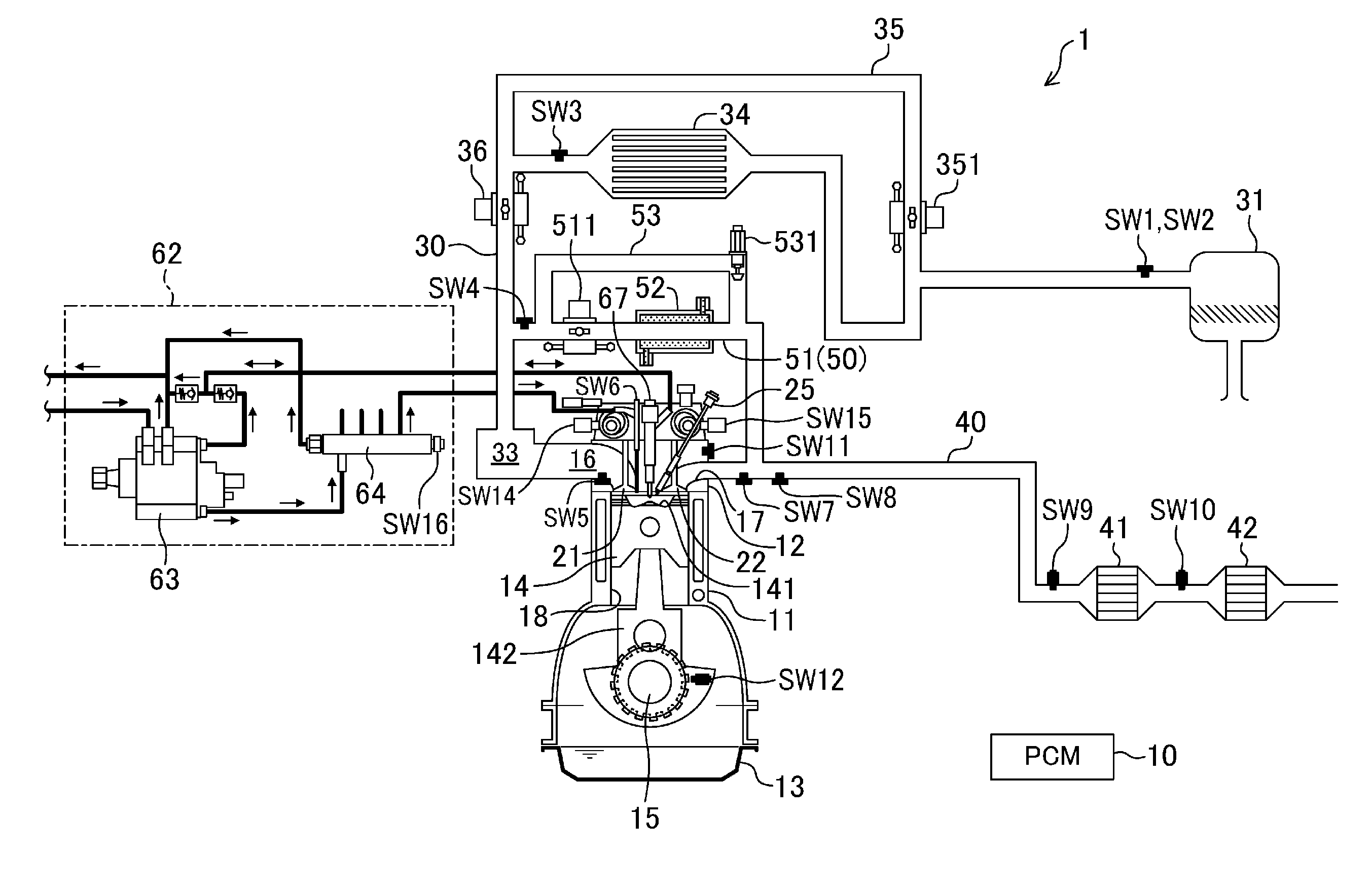

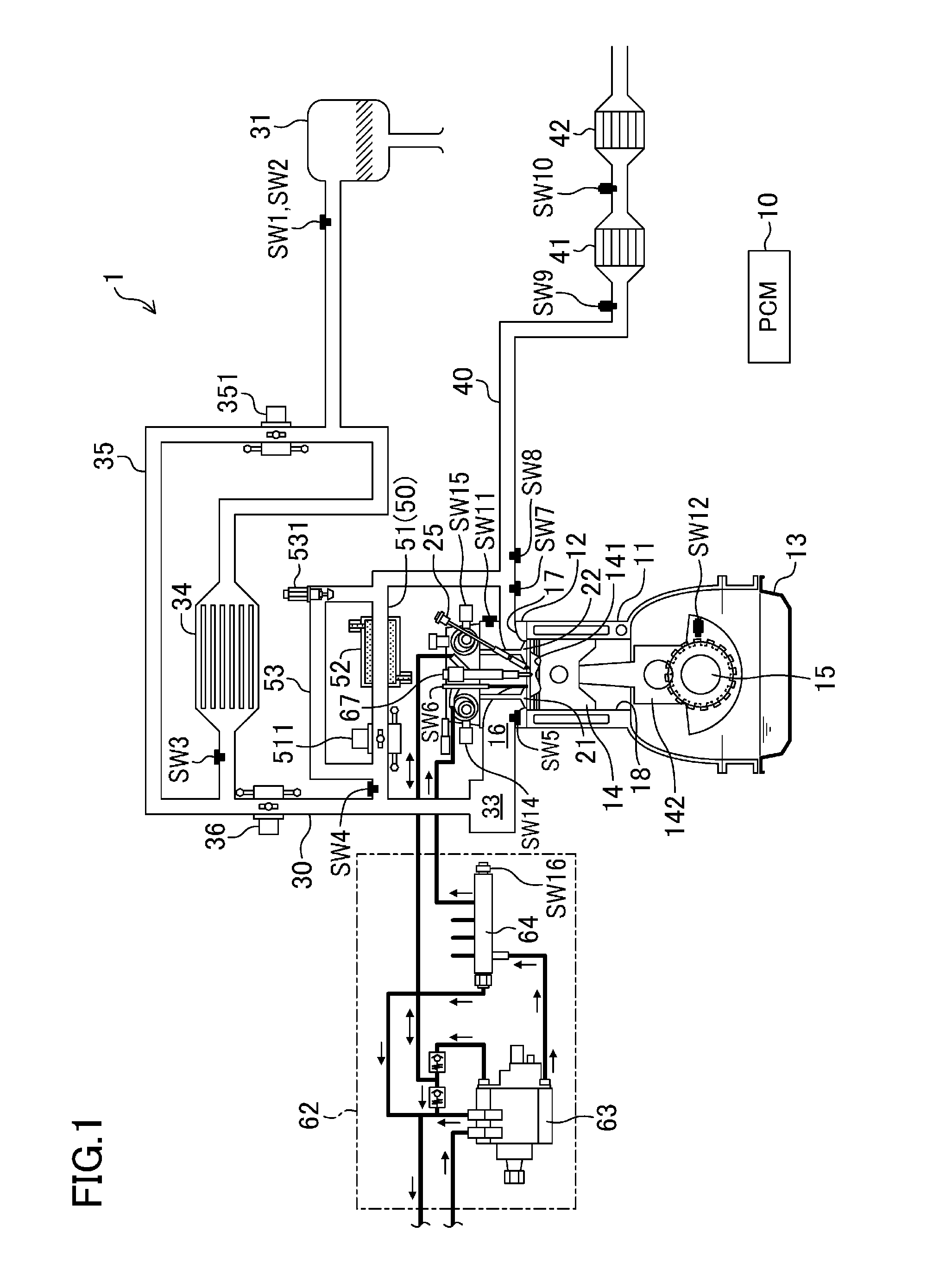

Control device for spark-ignition engine

InactiveUS20050016496A1Increase rangeEfficiently prevent knockingValve arrangementsElectrical controlCombustion chamberLow speed

A control device for a spark-ignition engine, in which a mixture in a combustion chamber is fired by compression ignition in a part-load range under warm-running conditions, includes an EGR controller incorporating a valve operation controller for controlling internal EGR of hot burned gas and a cold EGR controller for controlling external EGR of cold burned gas. The EGR controller performs EGR control operation to leave the hot EGR gas in the combustion chamber in a lower-load, lower-speed region within a compression ignition combustion range and to introduce the cold EGR gas into the combustion chamber in a higher-load, higher-speed region within the compression ignition combustion range. The control device further includes a firing assist unit for inducing the compression ignition at least when ignitability of the mixture decreases due to introduction of the cold EGR gas in the compression ignition combustion range.

Owner:MAZDA MOTOR CORP

Fuel composition supply means for driving cycle conditions in spark ignition engines

InactiveUS6622663B2More of efficiencyMore of emissionsInternal combustion piston enginesNon-fuel substance addition to fuelOn boardMotor fuel

A fuel system for on-board vehicle fuel separation to supply engine fuel compositions formulated as a function of driving cycle conditions. The invention results in improvements in one or more of feed efficiency and combustion emissions.

Owner:EXXON RES & ENG CO

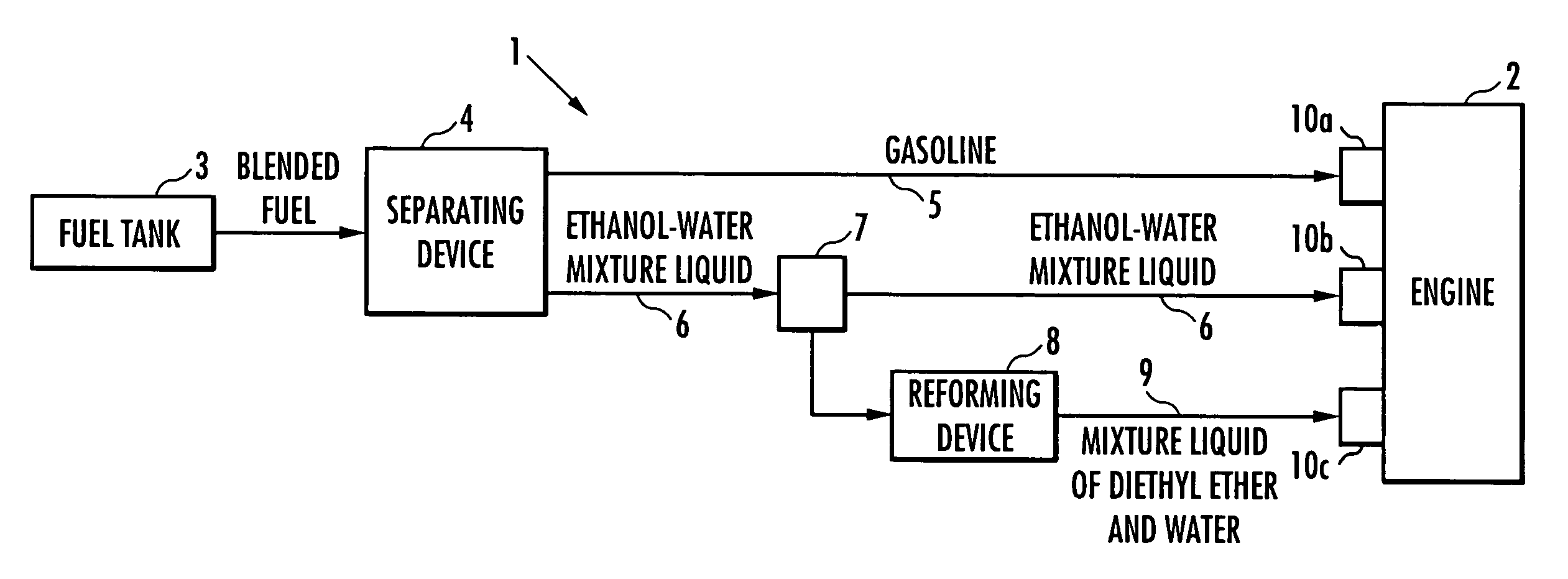

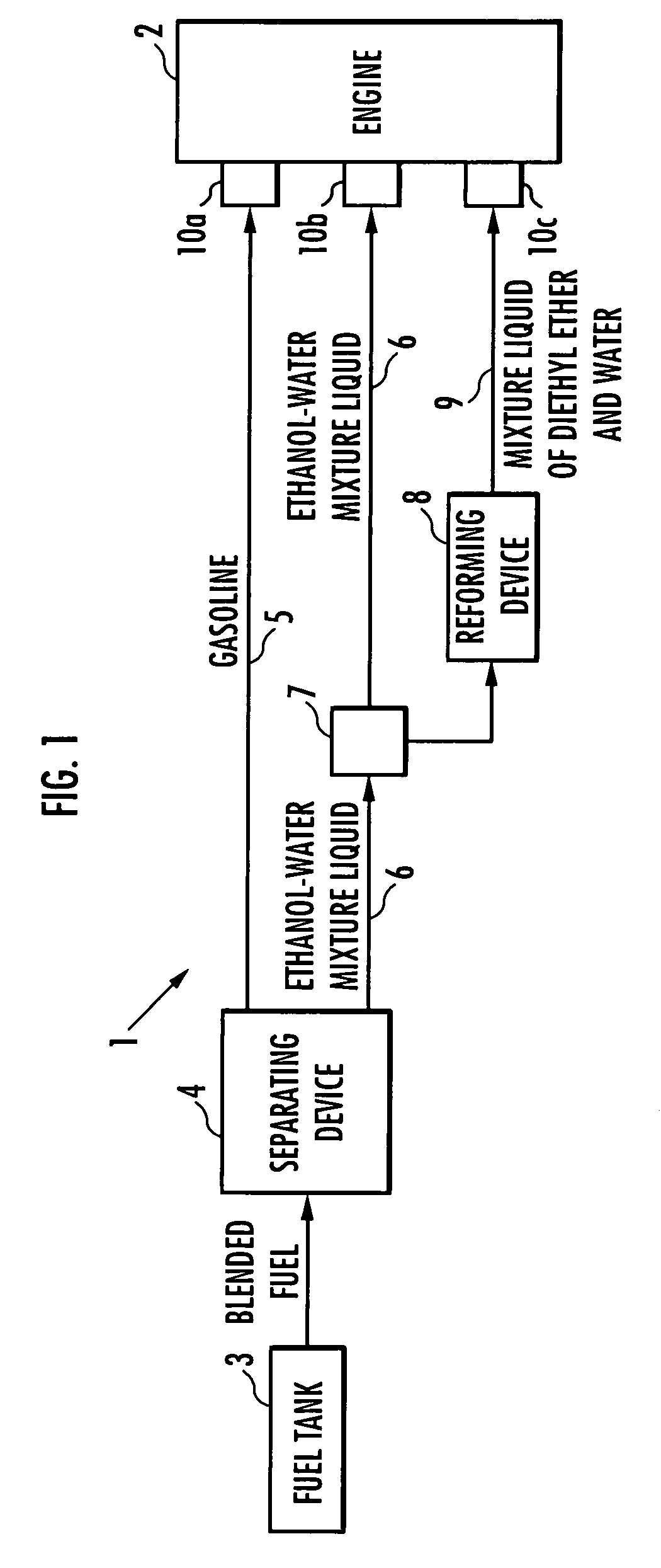

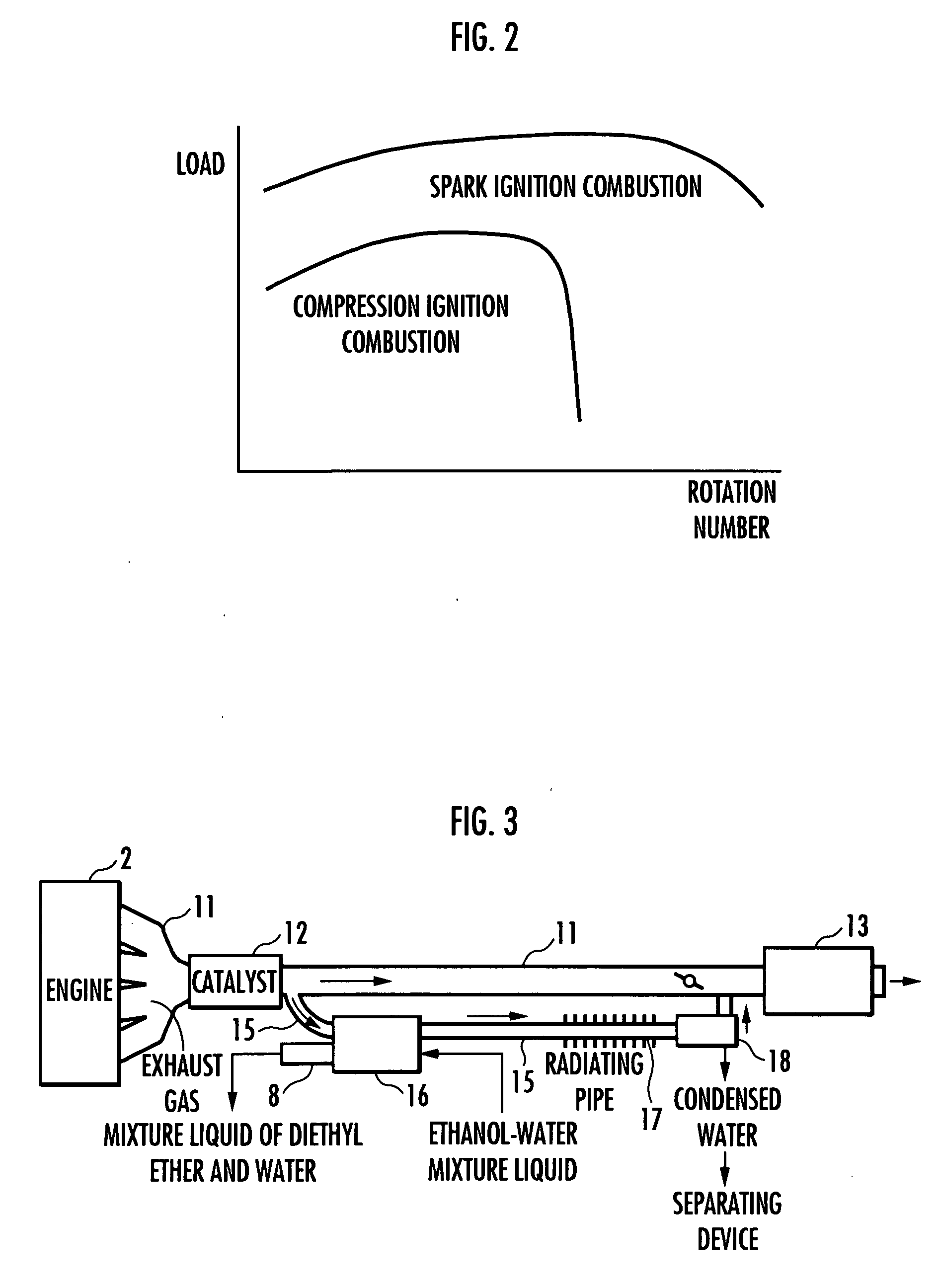

Internal combustion engine system

InactiveUS20070221163A1Improve efficiencyEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionFuel tank

The present invention provides an internal combustion engine system which uses a blended fuel of gasoline and ethanol, operates with high efficiency, and can inhibit nitrogen oxide and the like from being discharged. The internal combustion engine system comprises: a fuel tank 3 that accommodates a blended fuel having an octane number of 80 to 100, which has been prepared by blending gasoline having the octane number of 30 to 85 and ethanol into a weight ratio between 9:1 and 6:4; separating means 4 for adding water to the blended fuel to separate the blended fuel into the gasoline and an ethanol-water mixture liquid; reforming means 8 for reforming one part of the ethanol-water mixture liquid to produce a mixture liquid of diethyl ether and water; and fuel injectors 10a, 10b and 10c which independently inject each of the gasoline, the ethanol-water mixture liquid and the mixture liquid of diethyl ether and water. The internal combustion engine system conducts spark ignition combustion when a load is high, and conducts homogeneous charge compression ignition combustion when the load is low.

Owner:HONDA MOTOR CO LTD

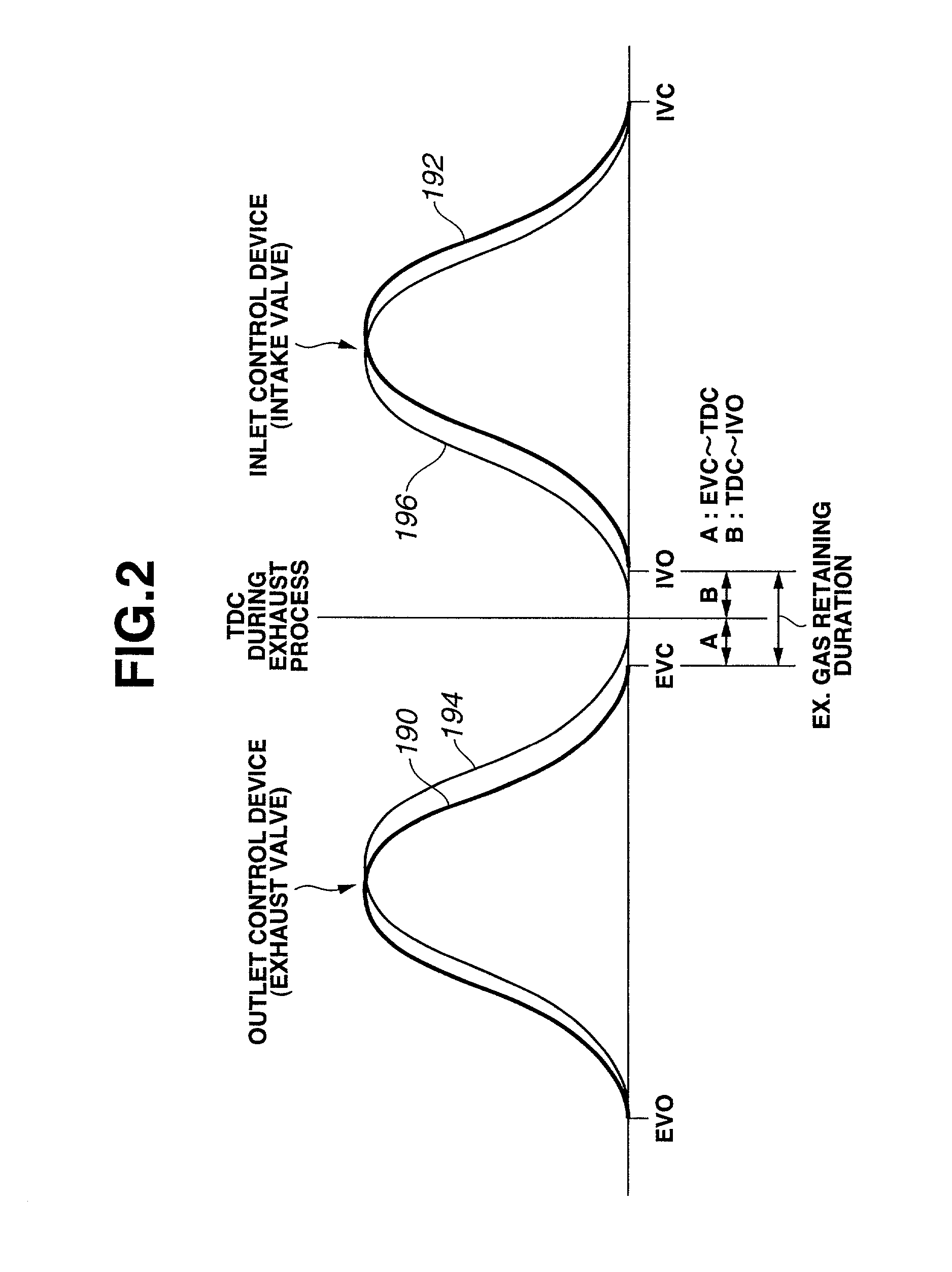

Intelligent control to stabilize auto-ignition combustion without rapid pressure increase

InactiveUS20020046741A1Combustion of suppressedIgnition of suppressedValve arrangementsElectrical controlEngineeringIntelligent control

The present invention concerns a method and a system for operating an internal combustion engine capable of performing auto-ignition combustion as well as spark-ignition combustion. In auto-ignition combustion mode, inlet and outlet control devices are adjusted to retain a portion of exhaust gas for subjecting the retained exhaust gas to compression. In one preferred embodiment, a parameter indicative of engine-surrounding environment is monitored. Closing timing of the outlet control device is adjusted in response to the monitored parameter, thereby to vary an exhaust gas retaining duration when there is a change in the monitored parameter.

Owner:NISSAN MOTOR CO LTD

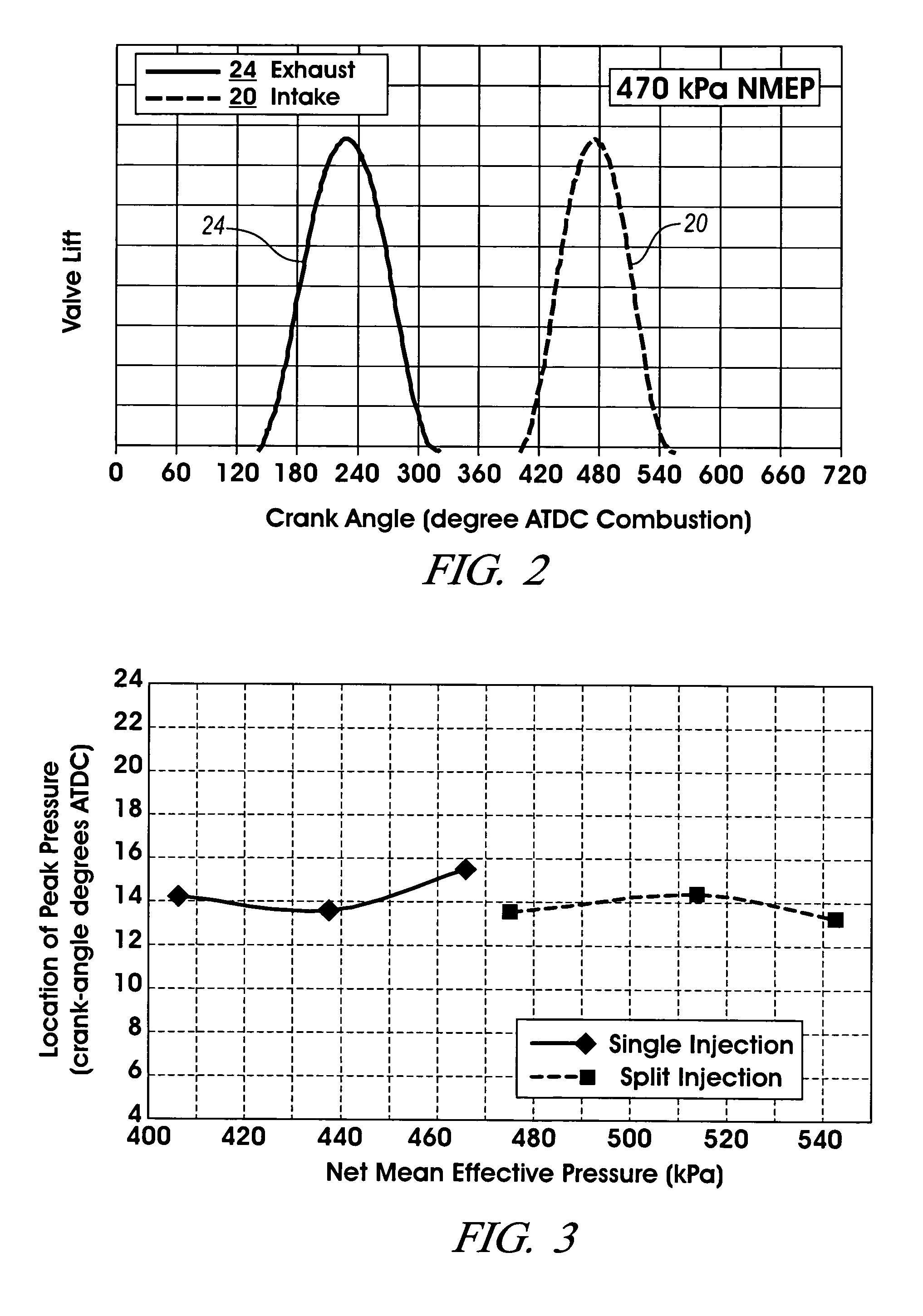

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

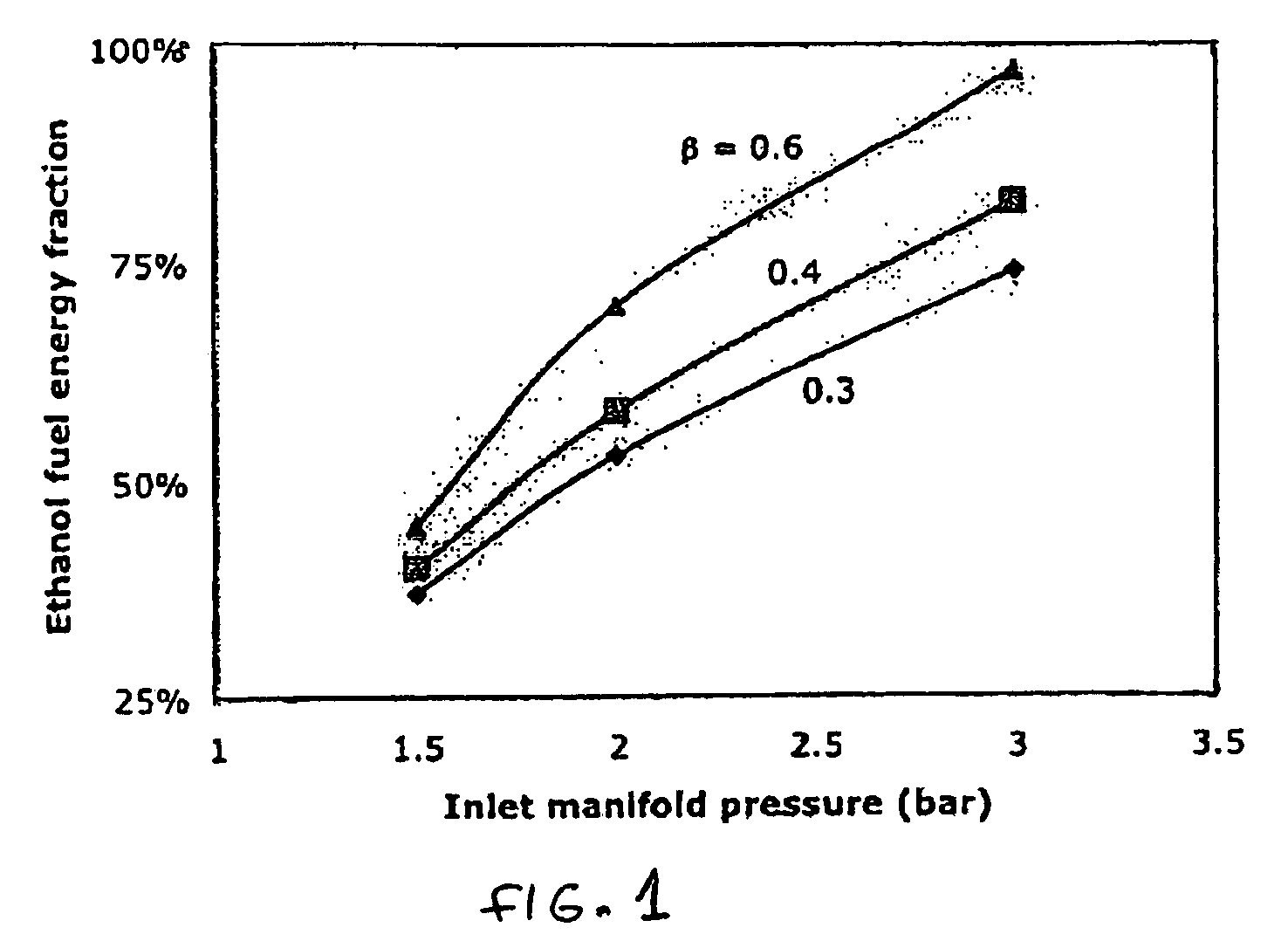

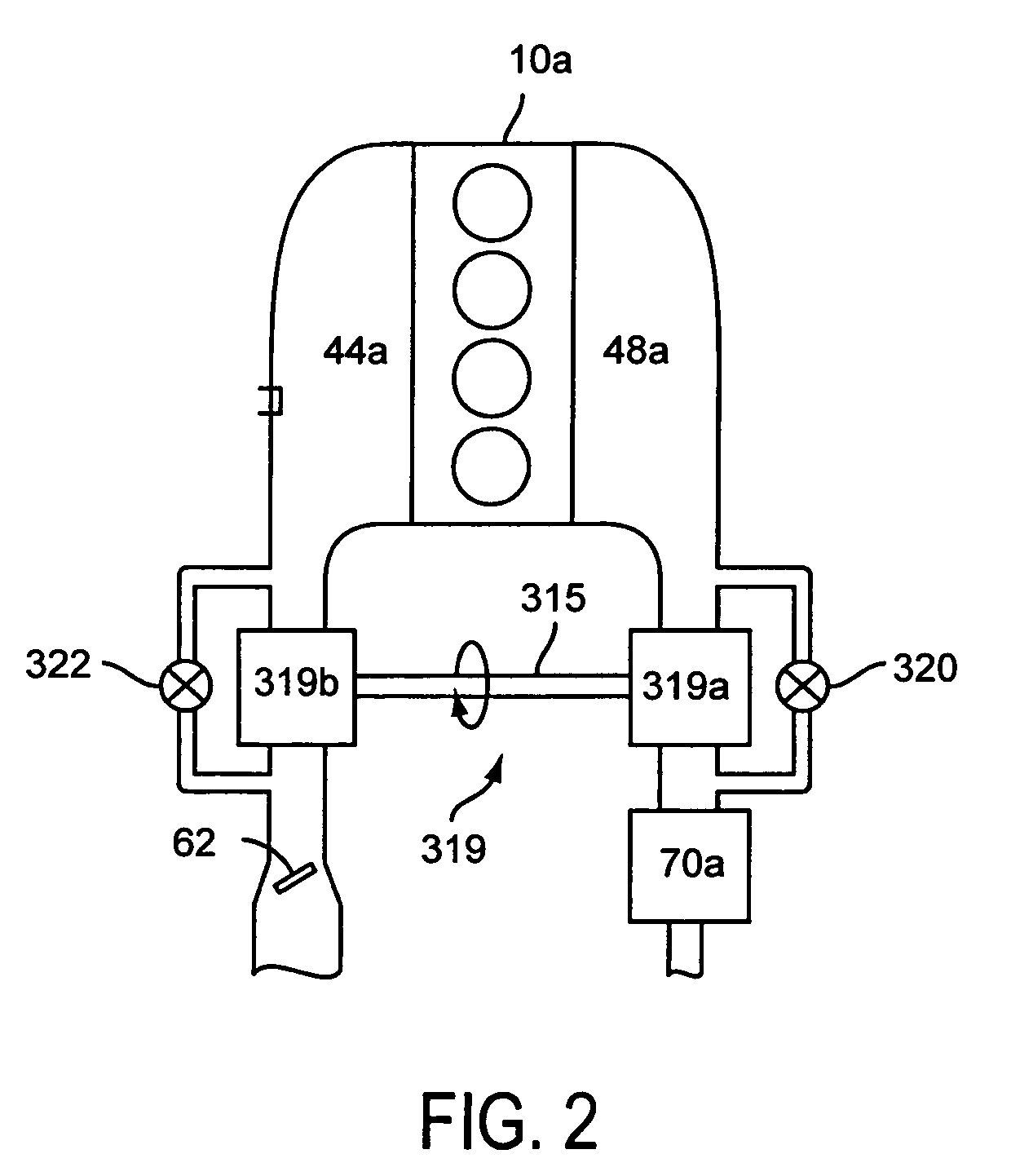

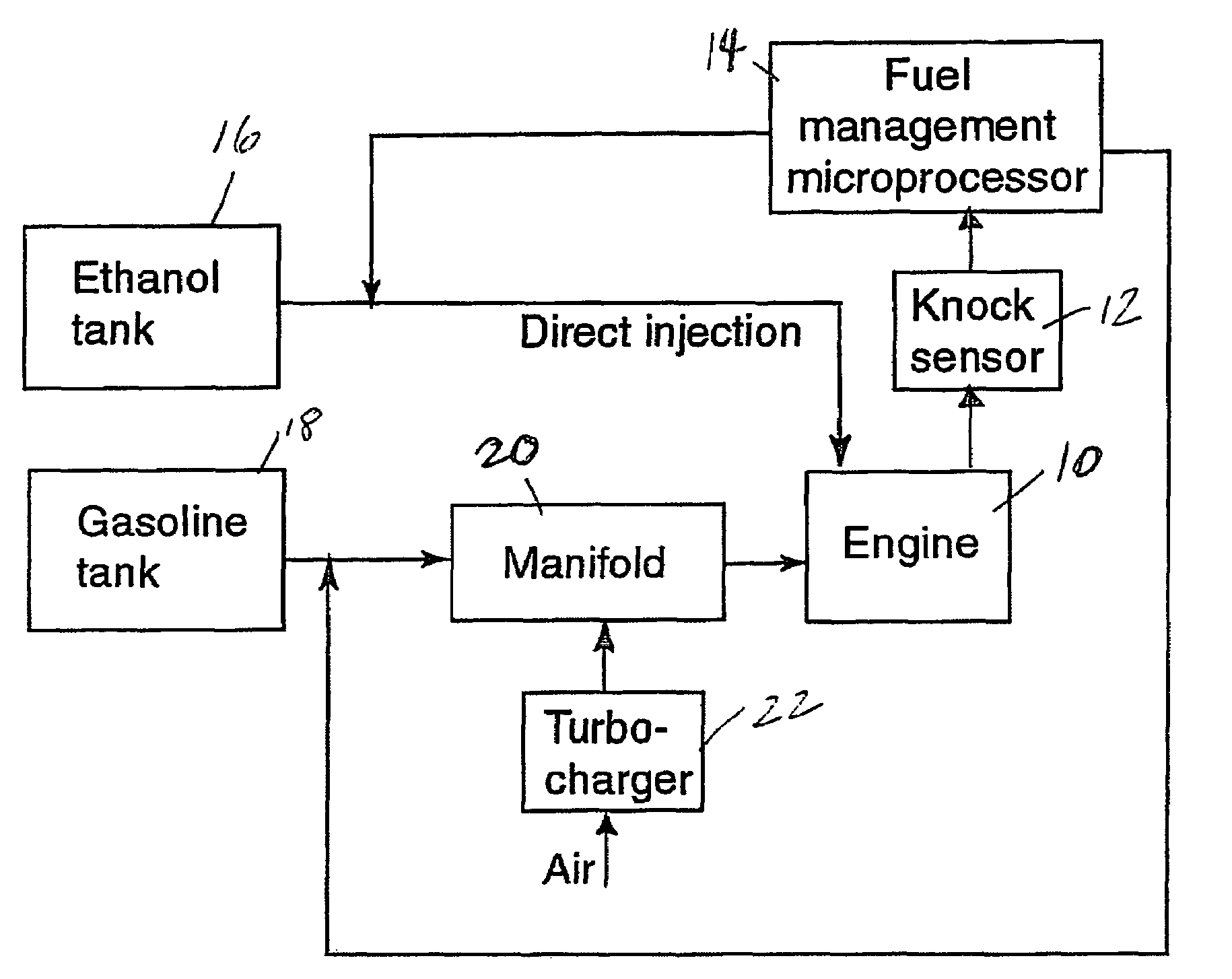

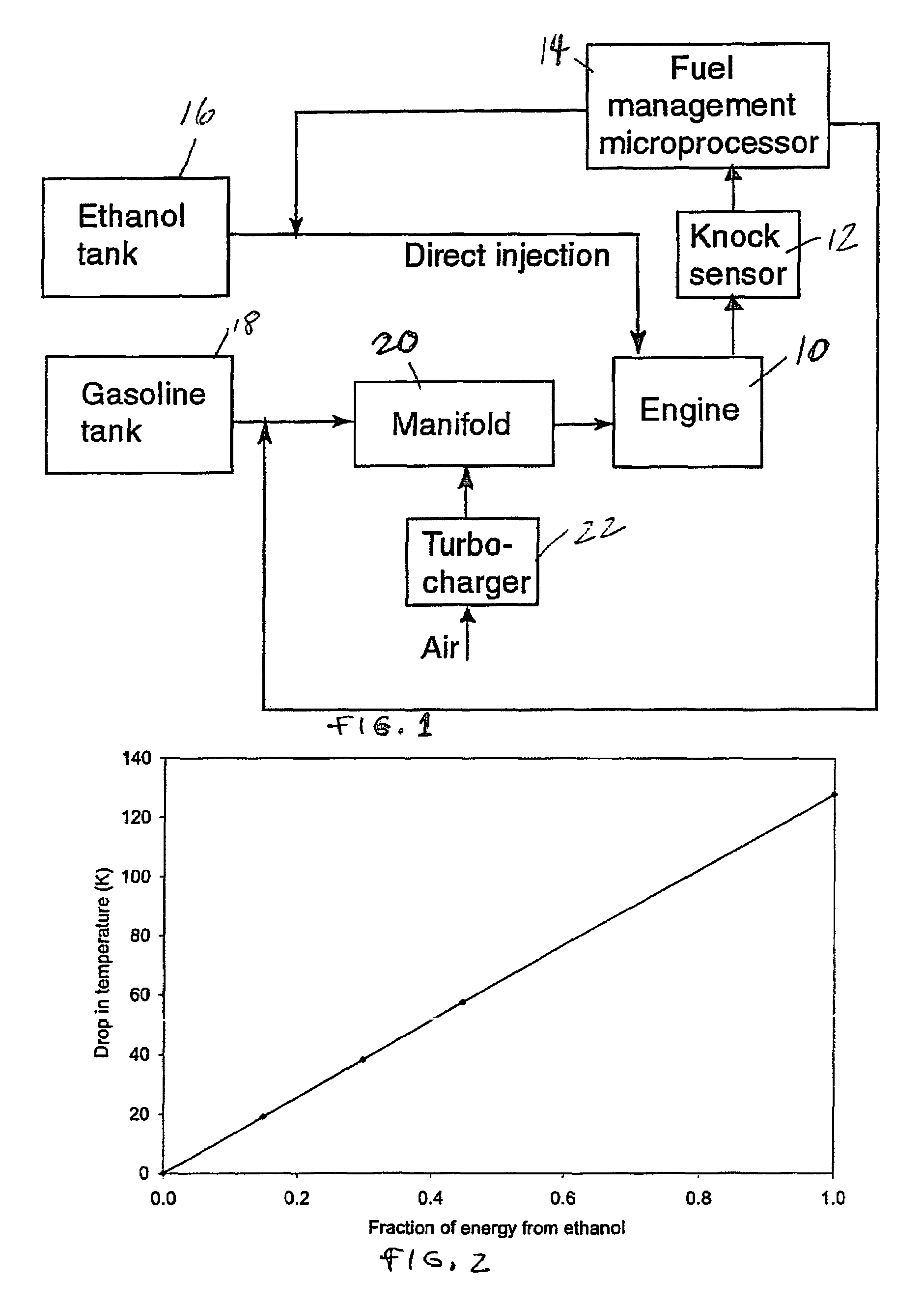

Fuel management system for variable ethanol octane enhancement of gasoline engines

InactiveUS7314033B2Increase heatMeet cutting requirementsElectrical controlNon-fuel substance addition to fuelEngineeringAntiknock agent

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

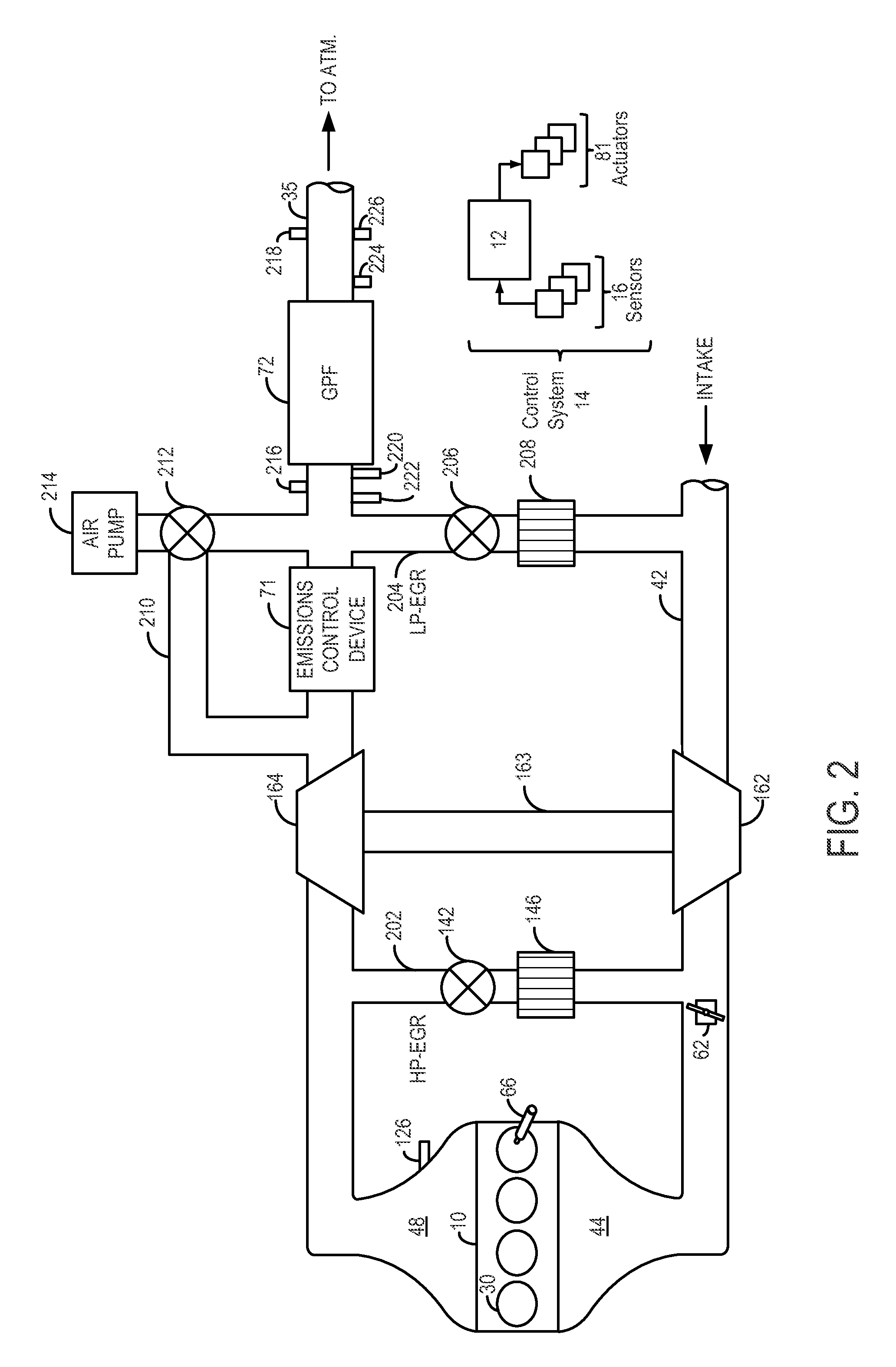

Method for controlling fuel of a spark ignited engine while regenerating a particulate filter

ActiveUS20110073088A1Improve efficiencyLower charging temperatureElectrical controlInternal combustion piston enginesGasoline direct injectionExhaust fumes

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

Multiple combustion mode engine using direct alcohol injection

ActiveUS7461628B2Improve efficiencyReduce the production of nitrogen oxidesAnalogue computers for vehiclesElectrical controlHomogeneous charge compression ignitionAlcohol

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

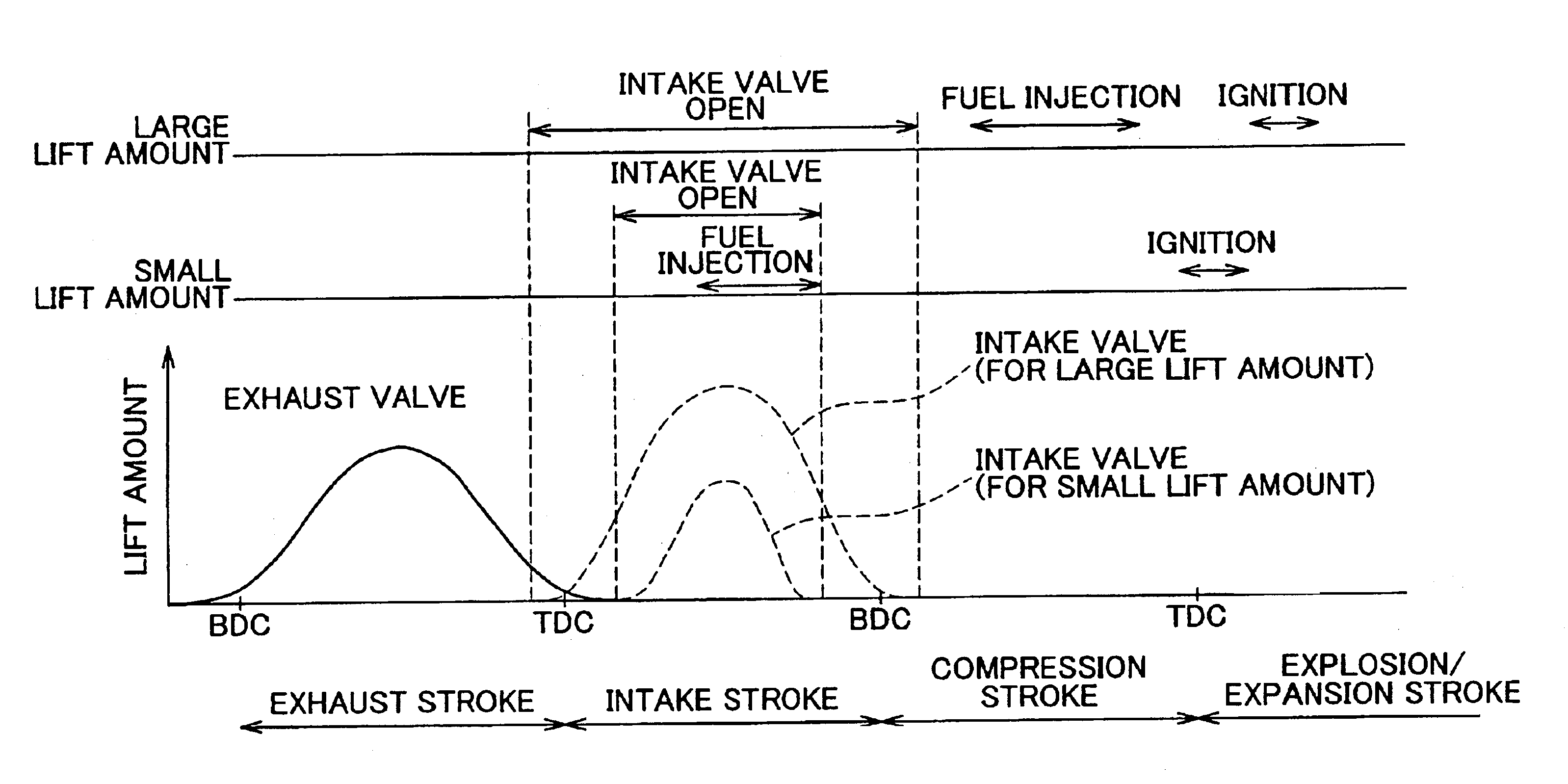

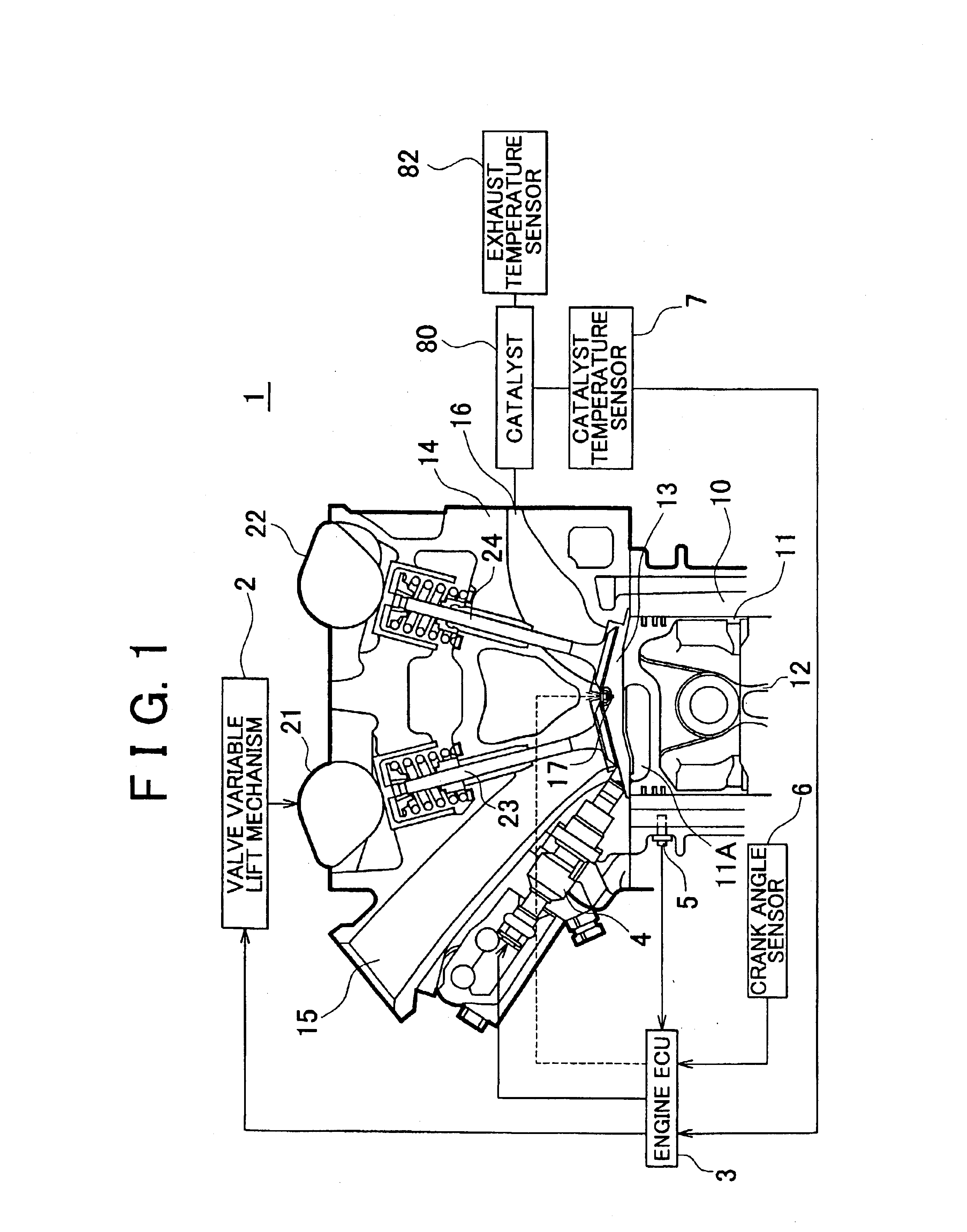

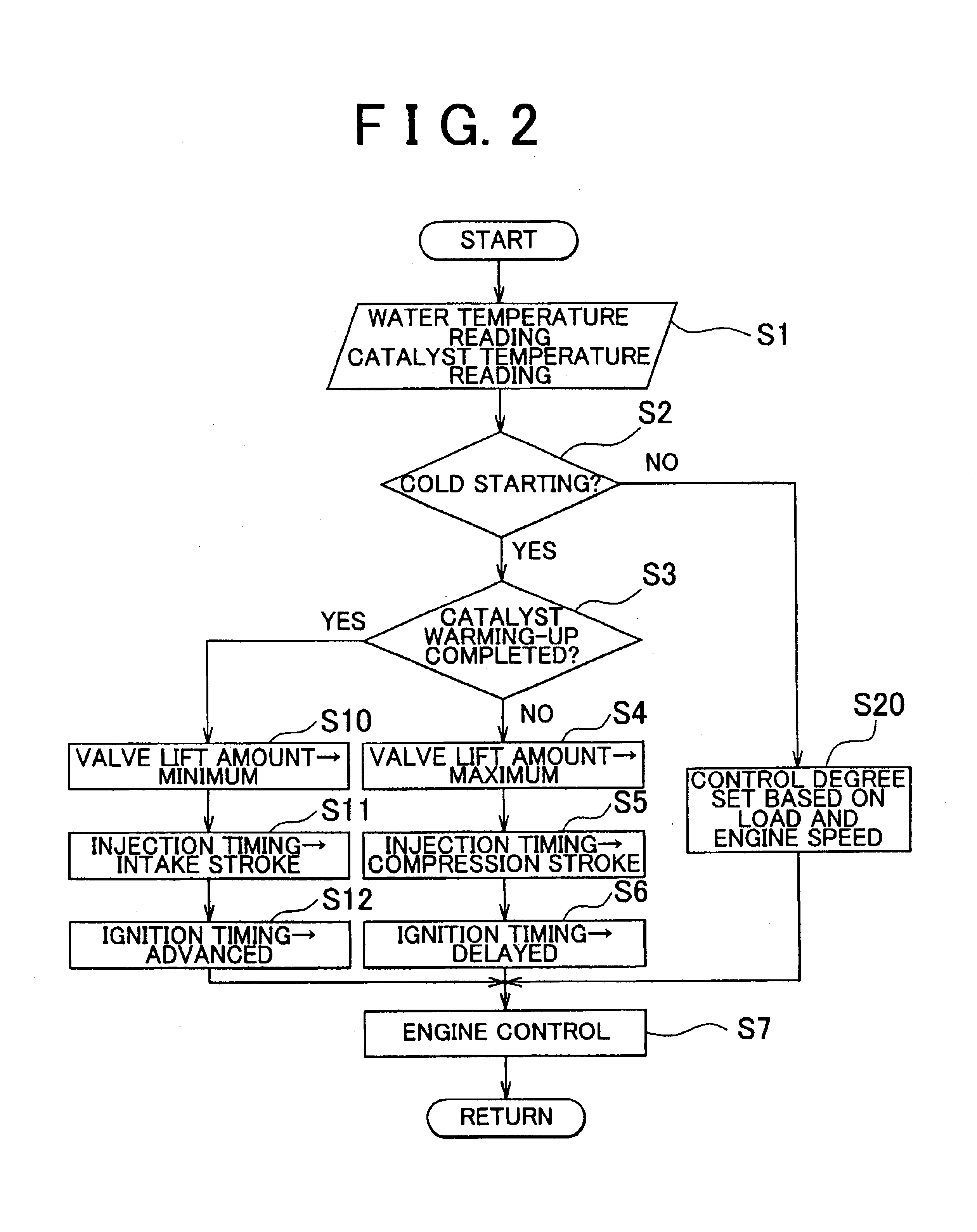

In-cylinder injection type spark-ignition internal combustion engine and control method thereof

InactiveUS6837040B2Improve fuel efficiencyValve arrangementsElectrical controlInlet valveIgnition timing

An in-cylinder injection type spark-ignition internal combustion engine and a control method thereof realize a stabilized stratified-charge combustion by setting a large lift amount to an intake valve when the engine is cold-started and by executing a compression stroke injection. At this time, warming-up capability of a catalyst is improved by delaying an ignition timing.

Owner:TOYOTA JIDOSHA KK

Control device for spark-ignition engine

InactiveUS6968825B2Increase rangeEfficiently prevent knockingValve arrangementsElectrical controlCombustion chamberLow speed

A control device for a spark-ignition engine, in which a mixture in a combustion chamber is fired by compression ignition in a part-load range under warm-running conditions, includes an EGR controller incorporating a valve operation controller for controlling internal EGR of hot burned gas and a cold EGR controller for controlling external EGR of cold burned gas. The EGR controller performs EGR control operation to leave the hot EGR gas in the combustion chamber in a lower-load, lower-speed region within a compression ignition combustion range and to introduce the cold EGR gas into the combustion chamber in a higher-load, higher-speed region within the compression ignition combustion range. The control device further includes a firing assist unit for inducing the compression ignition at least when ignitability of the mixture decreases due to introduction of the cold EGR gas in the compression ignition combustion range.

Owner:MAZDA MOTOR CORP

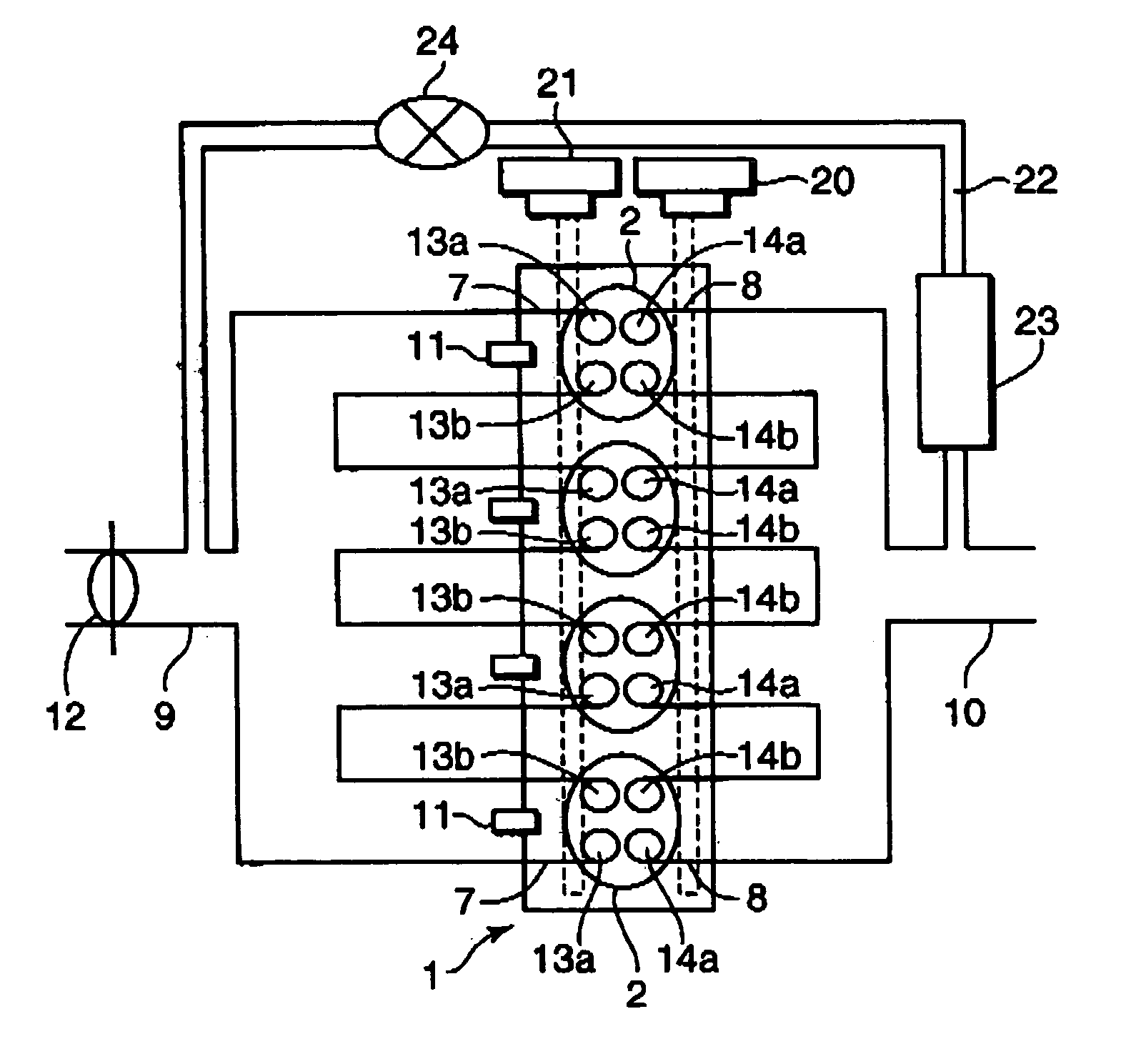

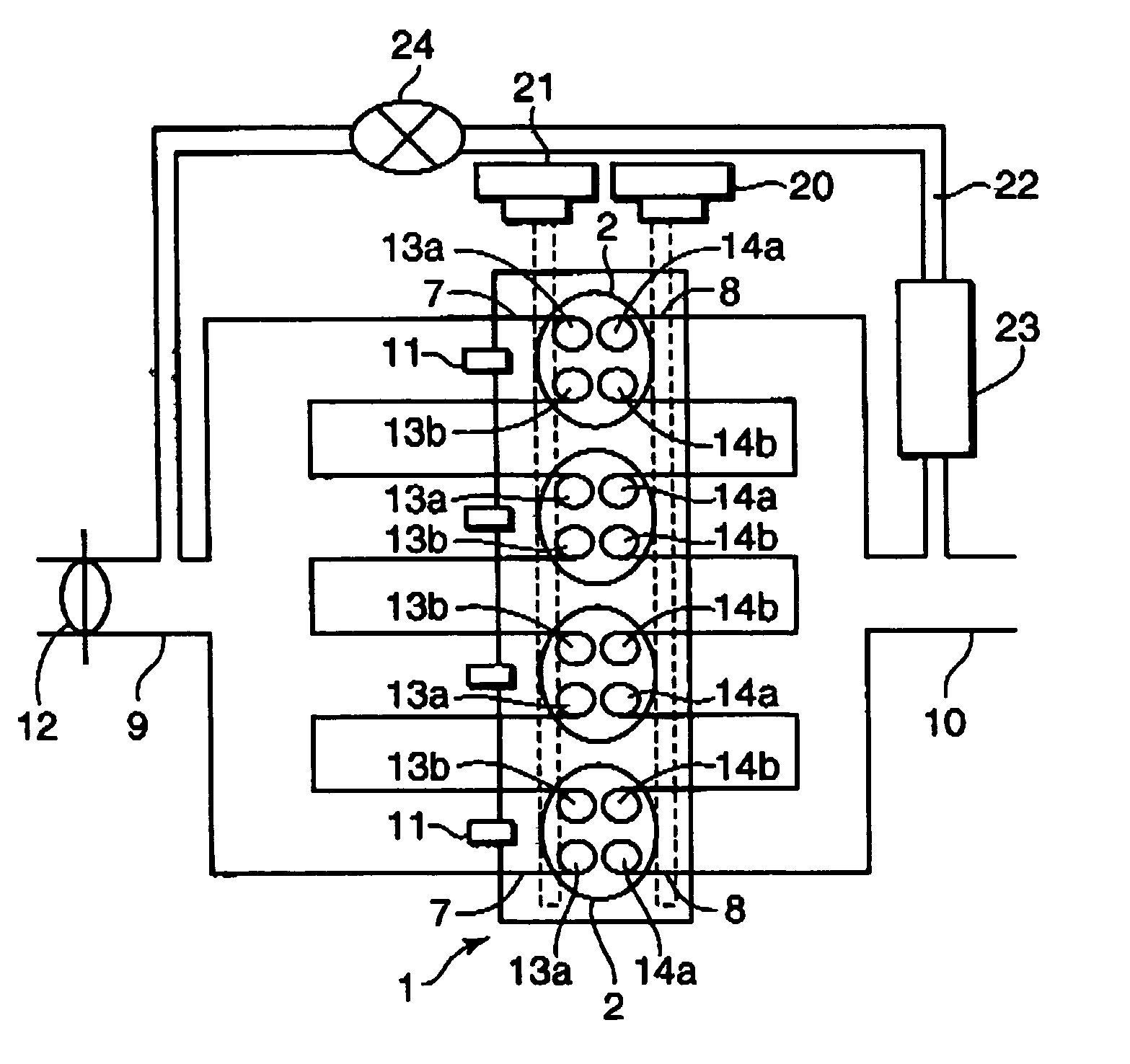

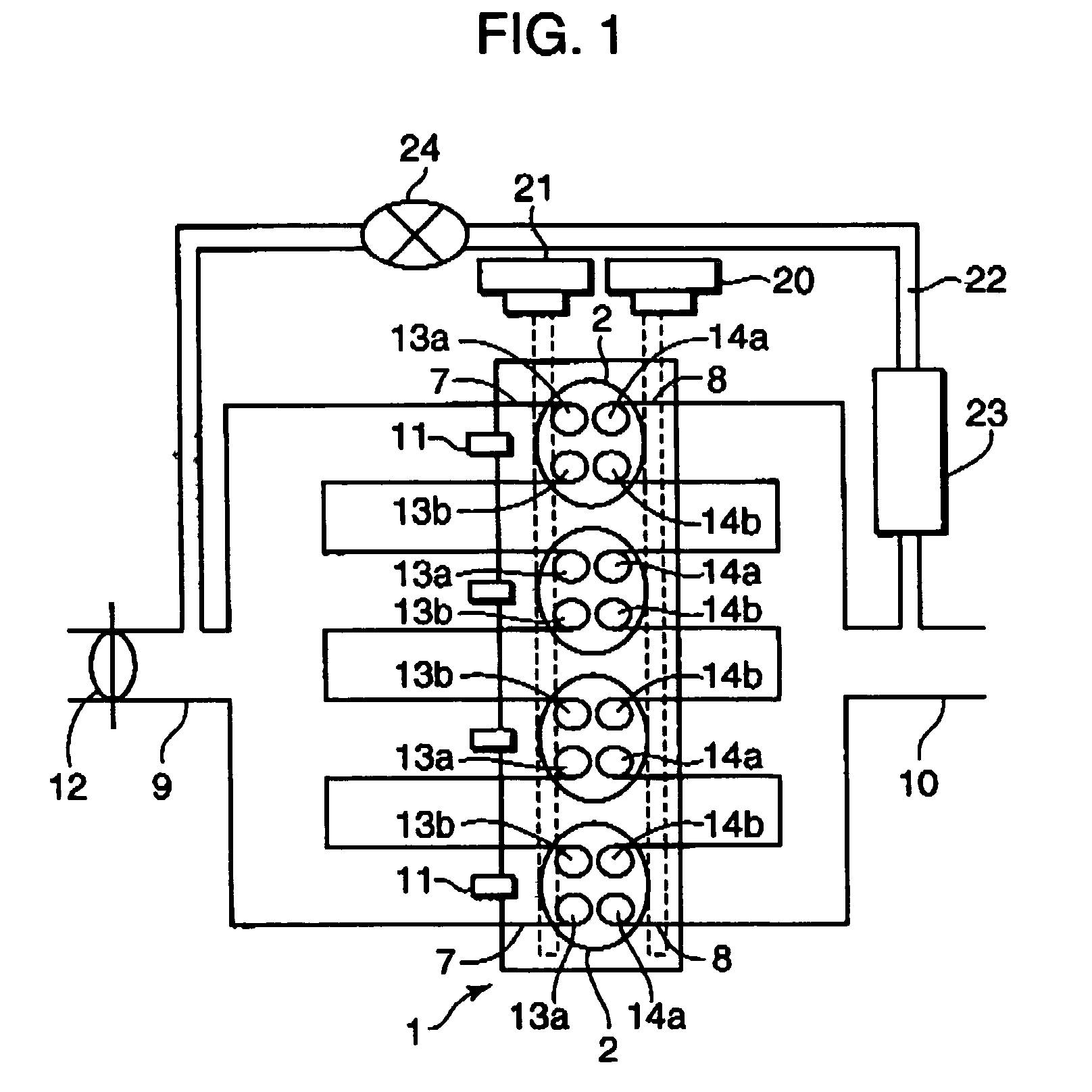

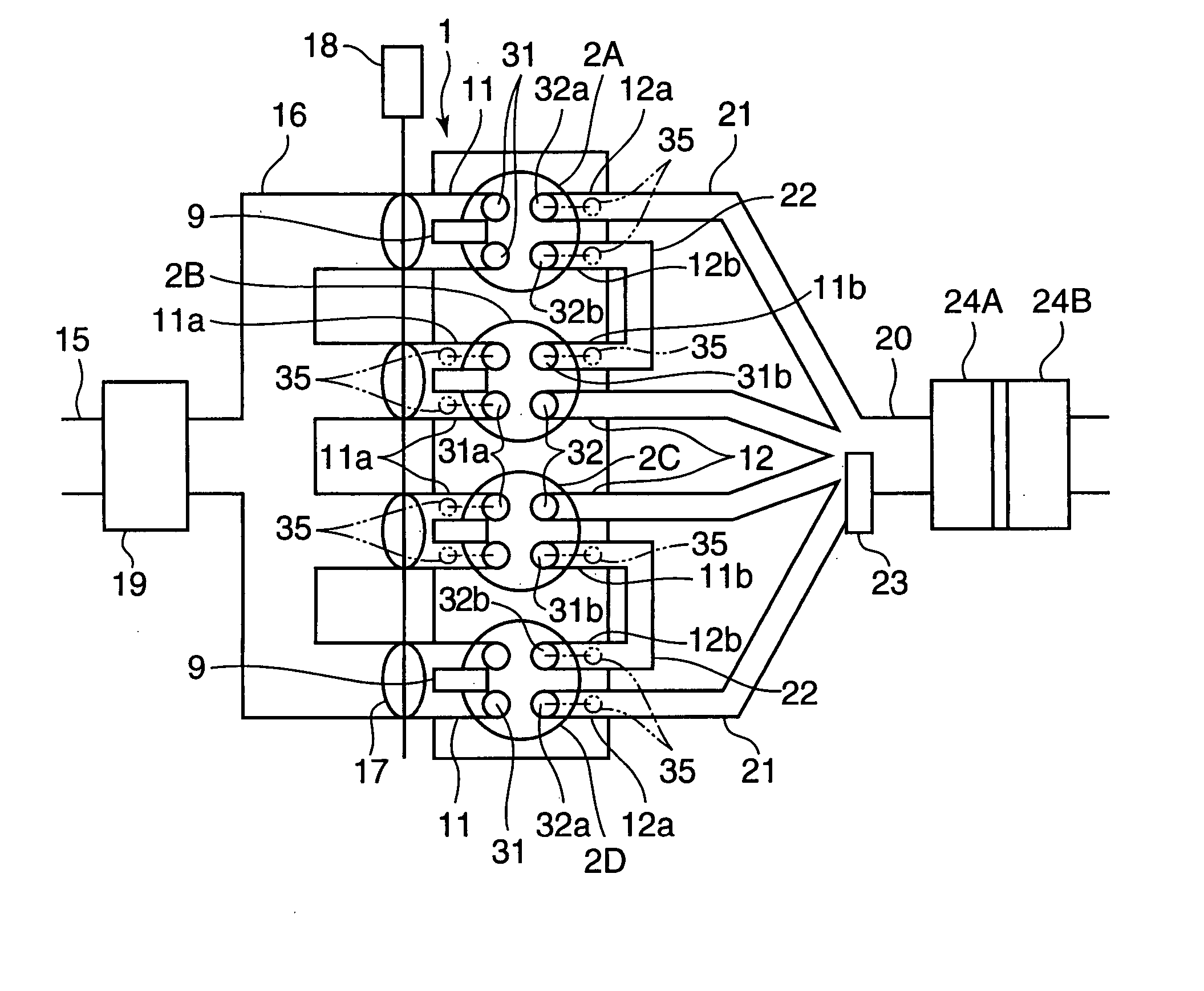

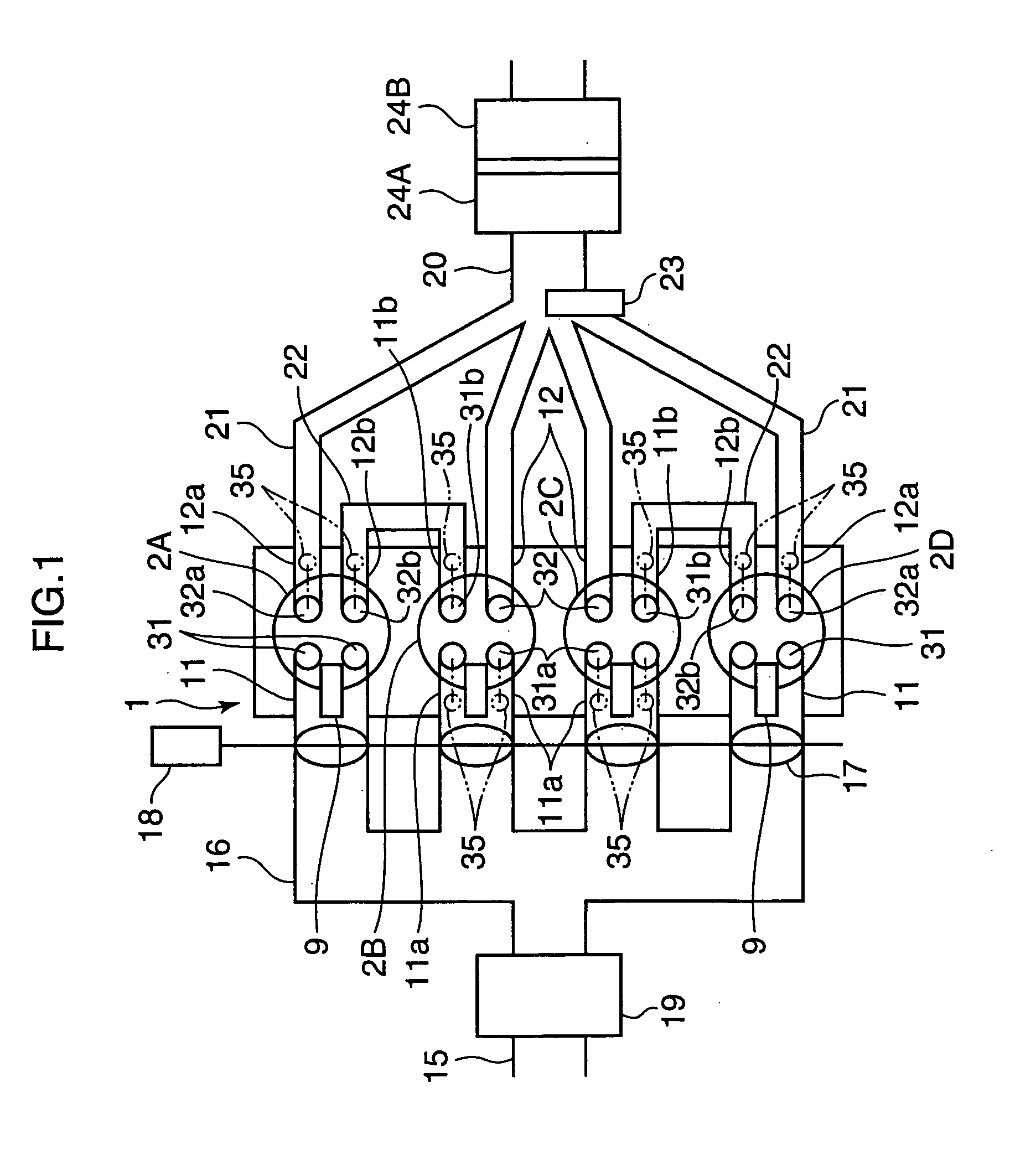

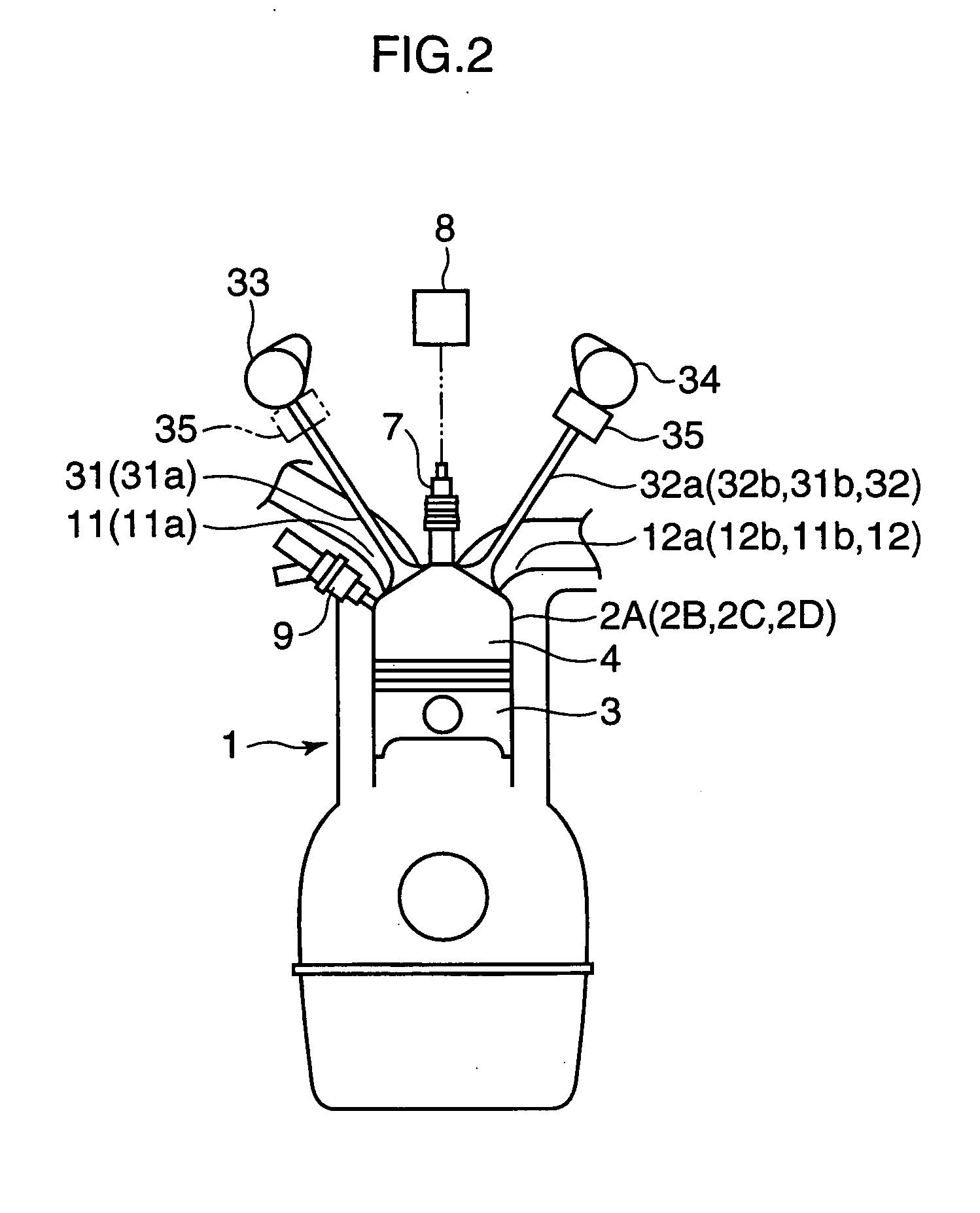

Spark ignition engine control device

InactiveUS20050022755A1Expand operating regionIncreased fuel costValve arrangementsElectrical controlLean combustionSpark-ignition engine

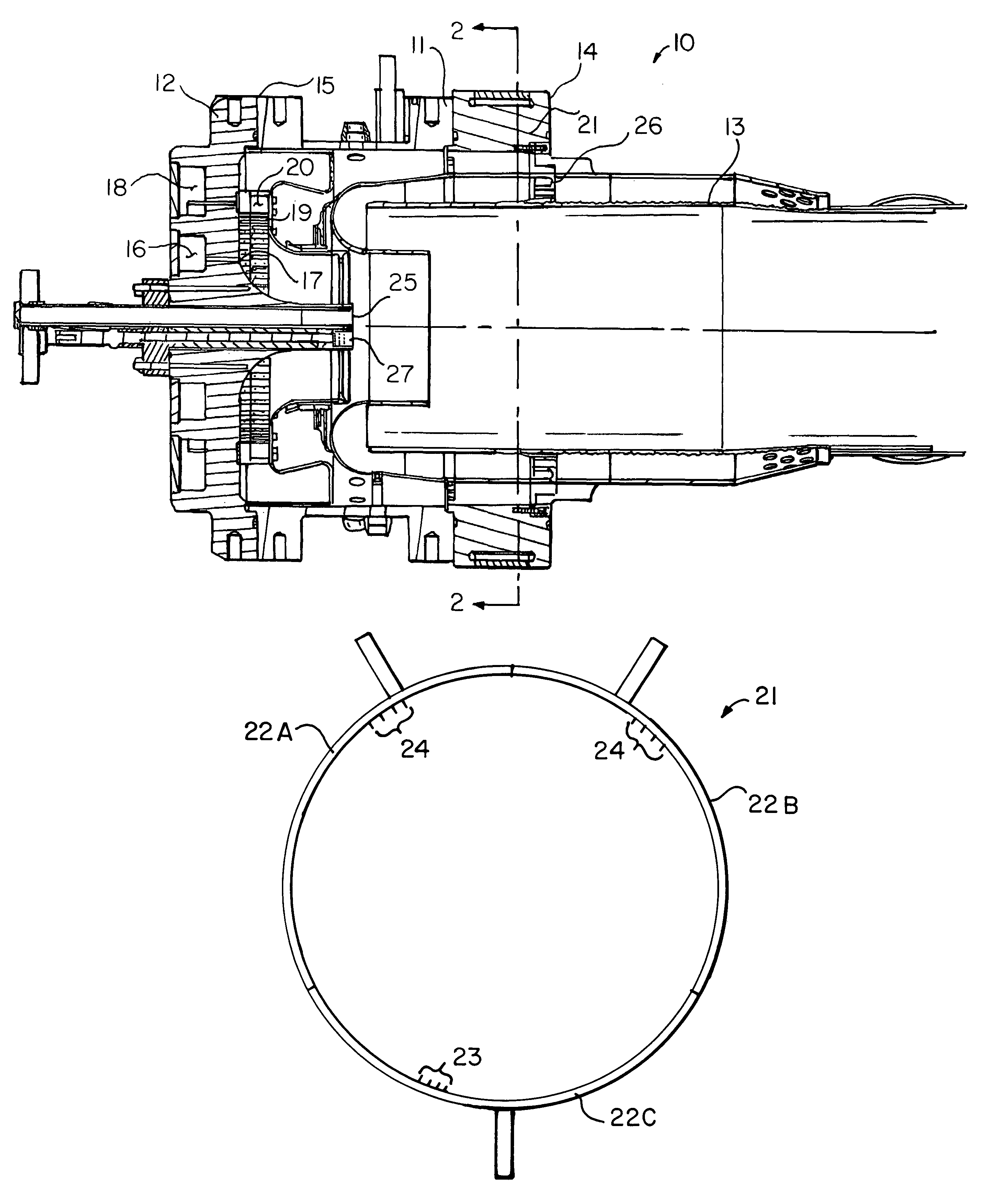

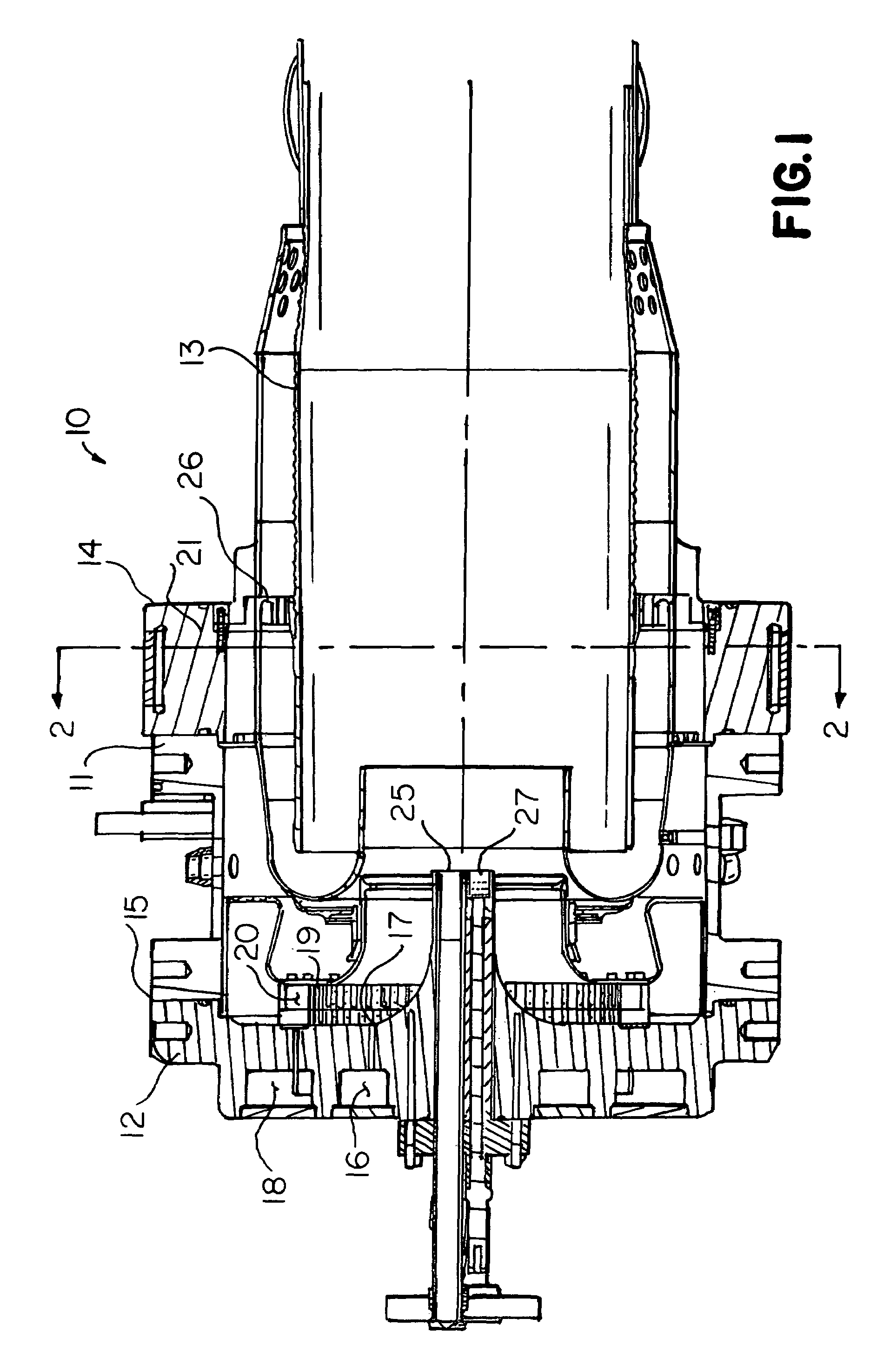

For the purpose of improving the fuel efficiency by lean combustion and enhancing the fuel efficiency improvement effects by performing compression ignition efficiently in some cylinders, a multi-cylinder spark ignition engine is constructed such that exhaust gas, that is exhausted from preceding cylinders 2A, 2D on the exhaust stroke side among pairs of cylinders whose exhaust stroke and intake stroke overlap in a low load, low rotational speed region, is directly introduced through an inter-cylinder gas passage 22 into following cylinders 2B, 2C on the intake stroke side and only gas exhausted from the following cylinders 2B, 2C is fed to an exhaust passage 20, which is provided with a three-way catalyst 24. Combustion controller is provided that controls the combustion of each of the cylinders such that combustion is conducted by forced ignition in a condition in which the air / fuel ratio is a lean air / fuel ratio which is larger by a prescribed amount than the stoichiometric air / fuel ratio in the preceding cylinders 2A, 2D and, in the following cylinders 2B, 2C, fuel is supplied to burnt gas of lean air / fuel ratio introduced from the preceding cylinders 2A, 2D and combustion is conducted by compression ignition.

Owner:MAZDA MOTOR CORP

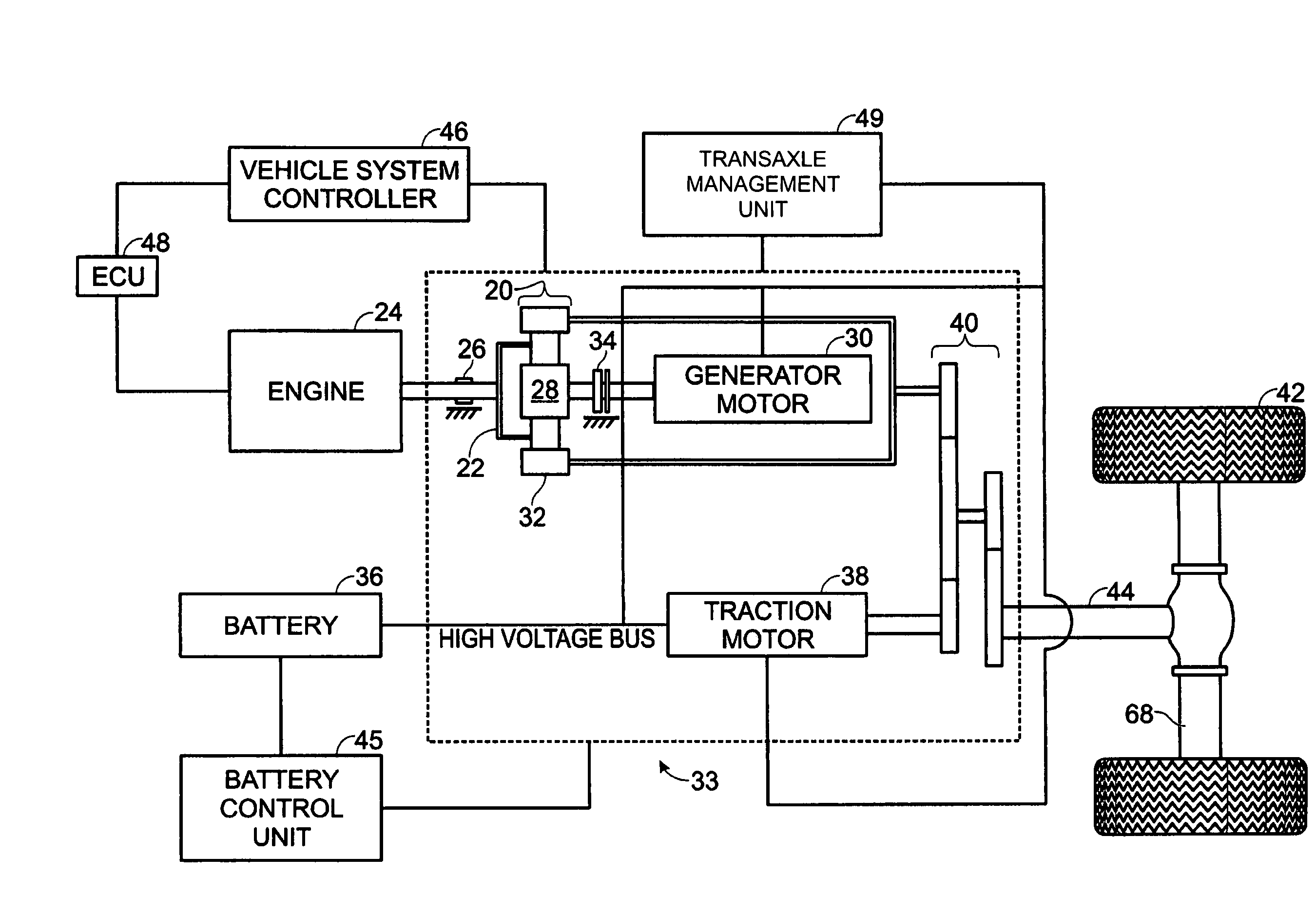

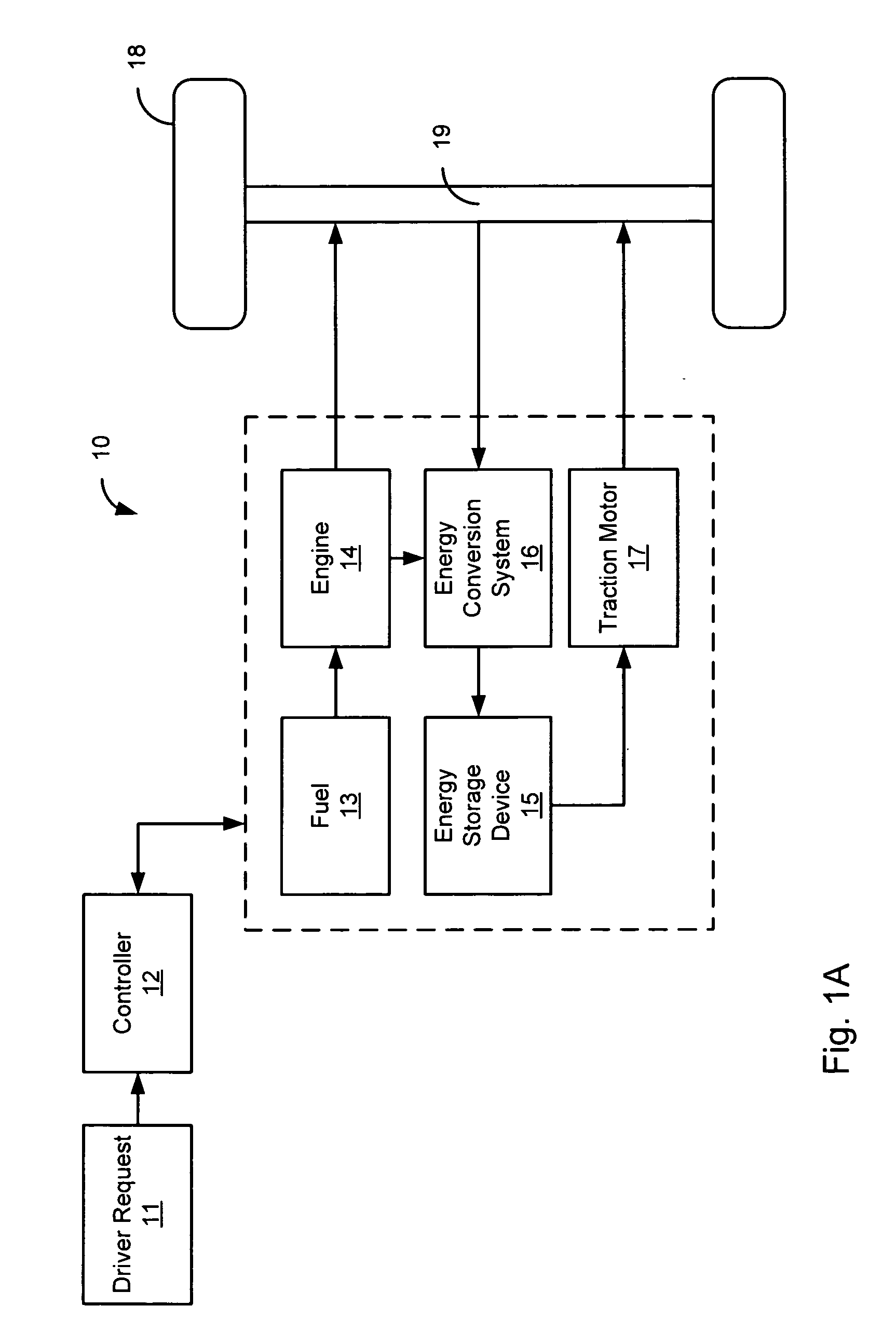

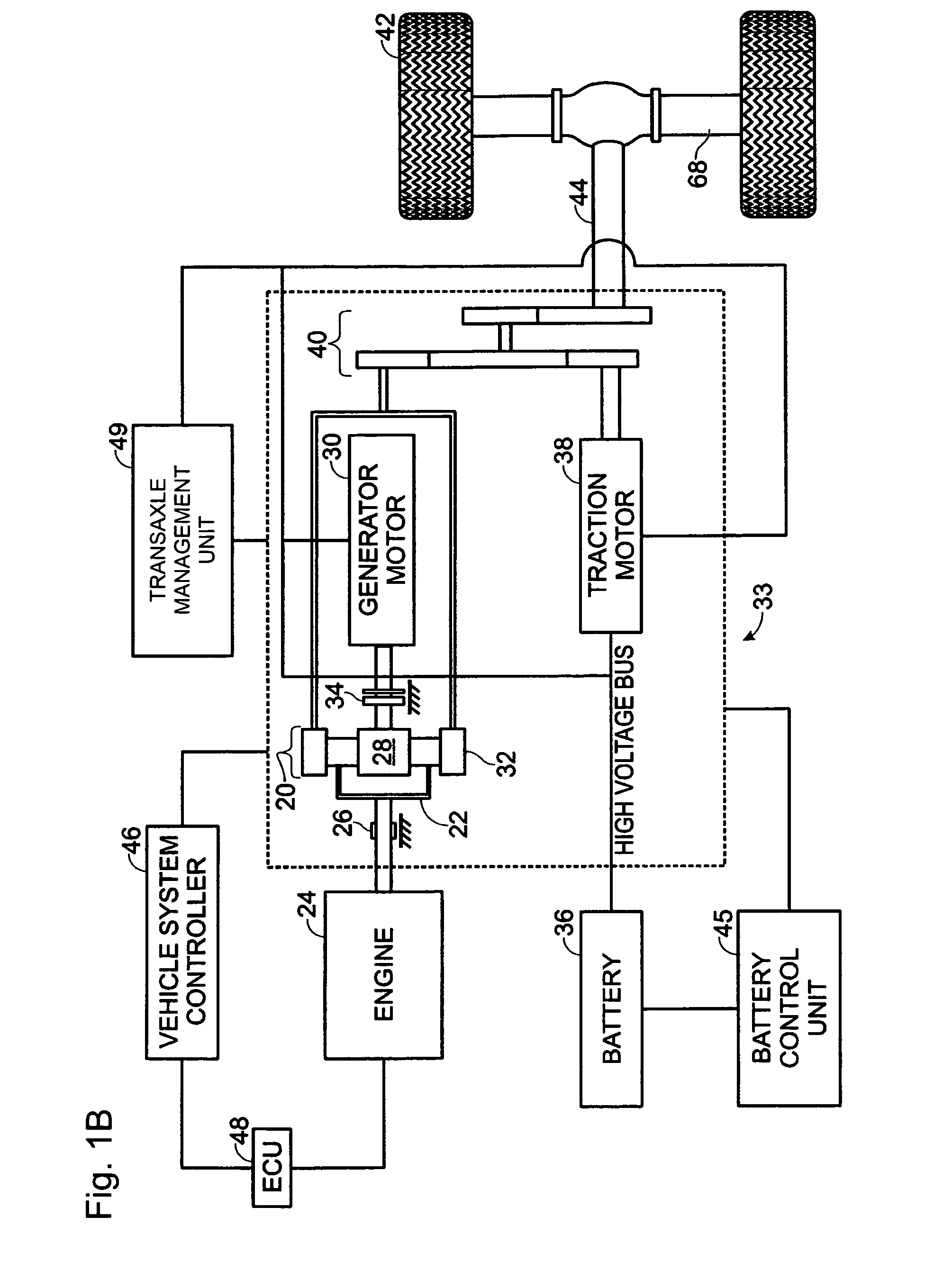

System and method for controlling vehicle operation

InactiveUS20070205029A1Improve fuel efficiencyReduce the production of nitrogen oxidesHybrid vehiclesAuxillary drivesHybrid vehicleEnergy storage

A hybrid vehicle propulsion system is disclosed comprising an engine having at least one combustion cylinder configured to operate in a first and a second combustion mode, wherein the first combustion mode is a spark ignition mode and the second combustion mode is a compression ignition mode, wherein the engine is configured to supply an engine output; a motor configured to selectively supply or absorb a secondary output; an energy storage device configured to selectively store at least a portion of the engine output and selectively supply energy to the vehicle; a lean NOx trap configured to store NOx produced by the engine; and a controller configured to control at least the engine, the motor, and the energy storage device, wherein the controller is configured to selectively operate said at least one combustion cylinder in one of the spark ignition mode and the compression ignition mode based on a condition of the lean NOx trap.

Owner:FORD GLOBAL TECH LLC

Approach for Facilitating Engine Mode Transitions

ActiveUS20080066713A1Increasing negative overlapElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A method of transitioning a cylinder of an engine from a spark ignition mode to a homogeneous charge compression ignition mode, the cylinder having at least one electrically actuated intake valve and at least one exhaust valve, the method comprising of before a transition, operating the cylinder with at least some overlap between an opening event of the intake valve and an opening event of the exhaust valve in the spark ignition mode; in response to a transition request, operating the cylinder with at least some negative overlap between an opening event of the intake valve and an opening event of the exhaust valve, retarding the intake valve opening and closing timing by different amounts and retarding ignition timing; and further increasing negative overlap and performing the homogeneous charge compression ignition mode.

Owner:FORD GLOBAL TECH LLC

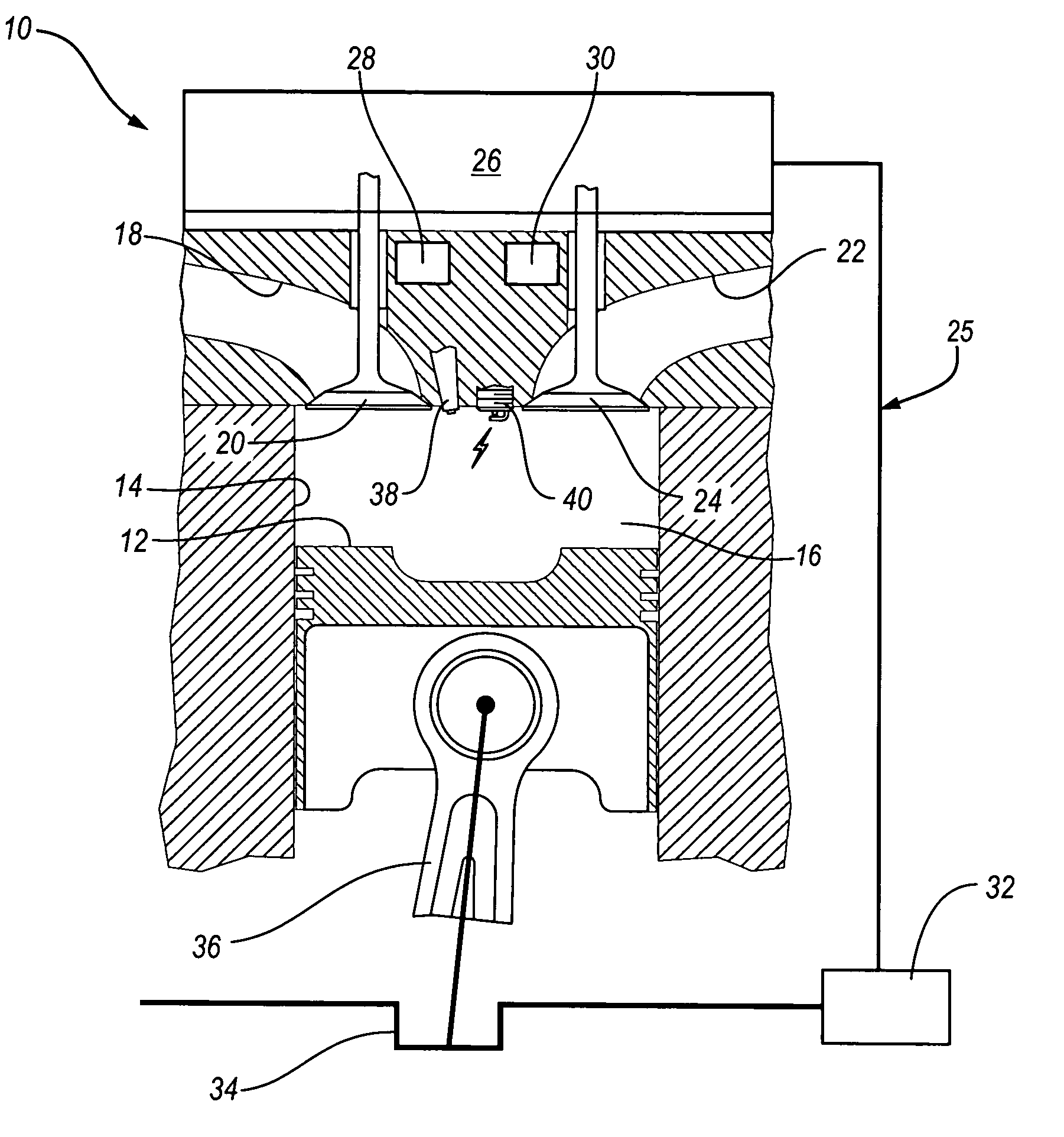

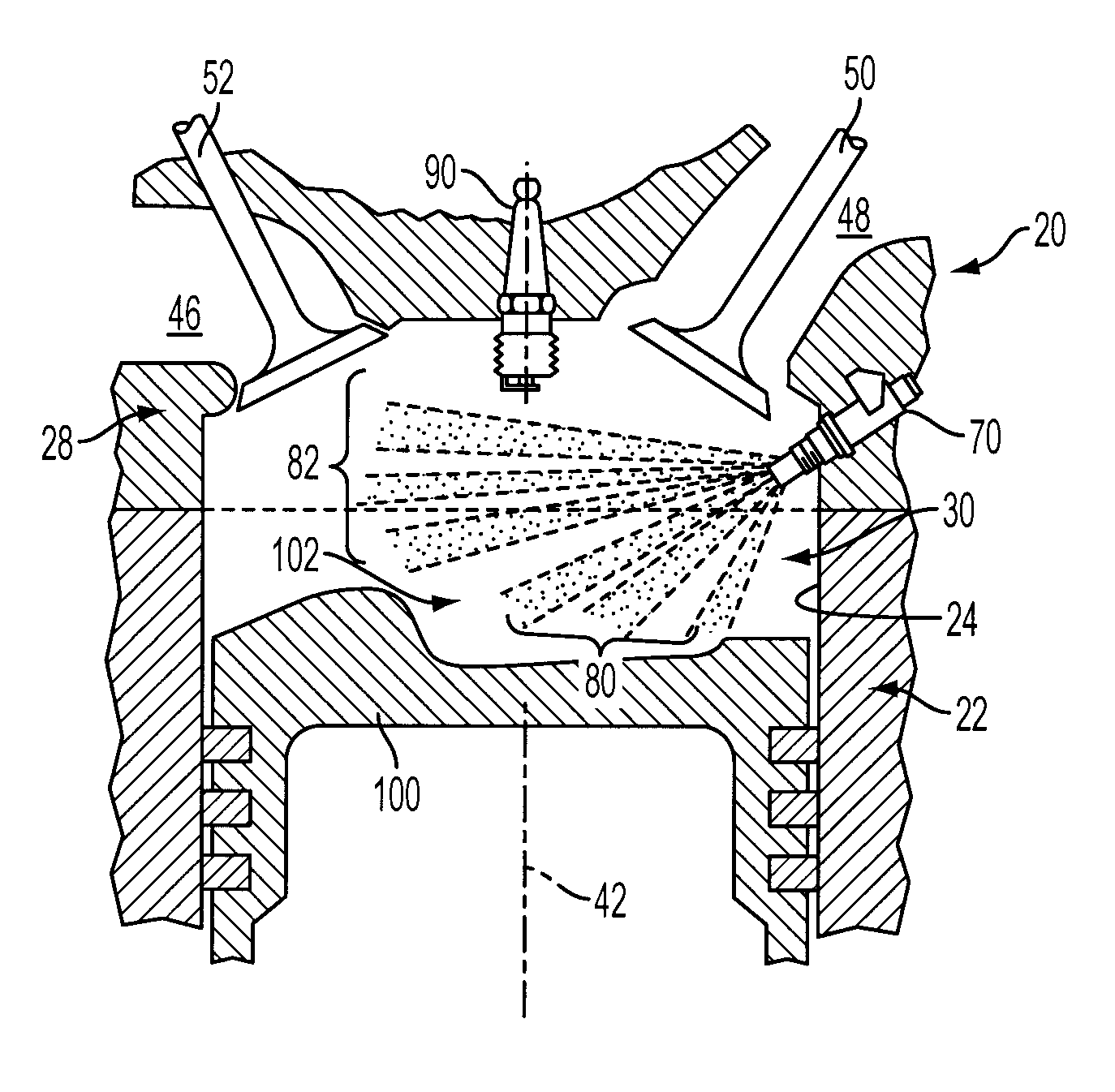

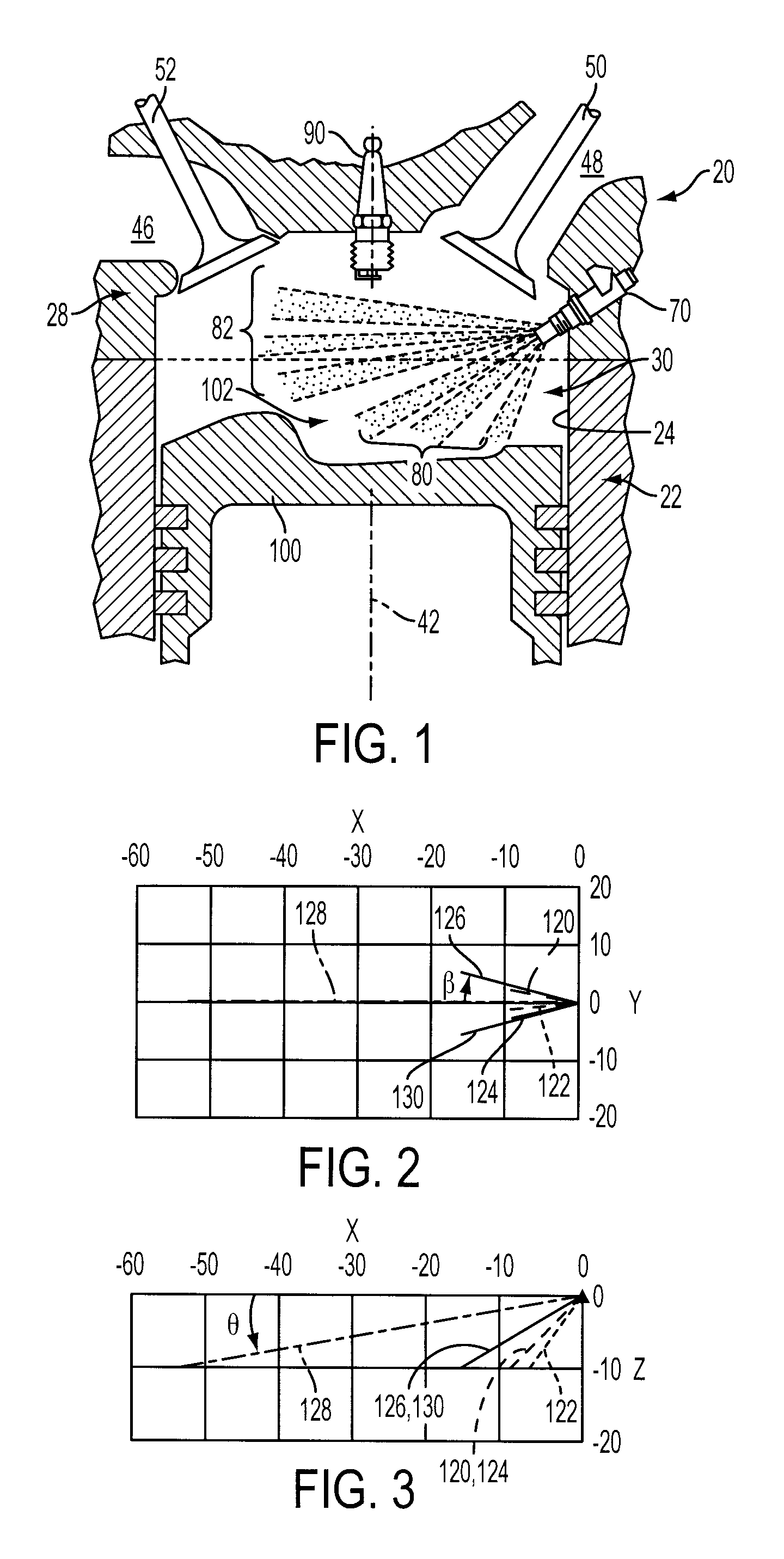

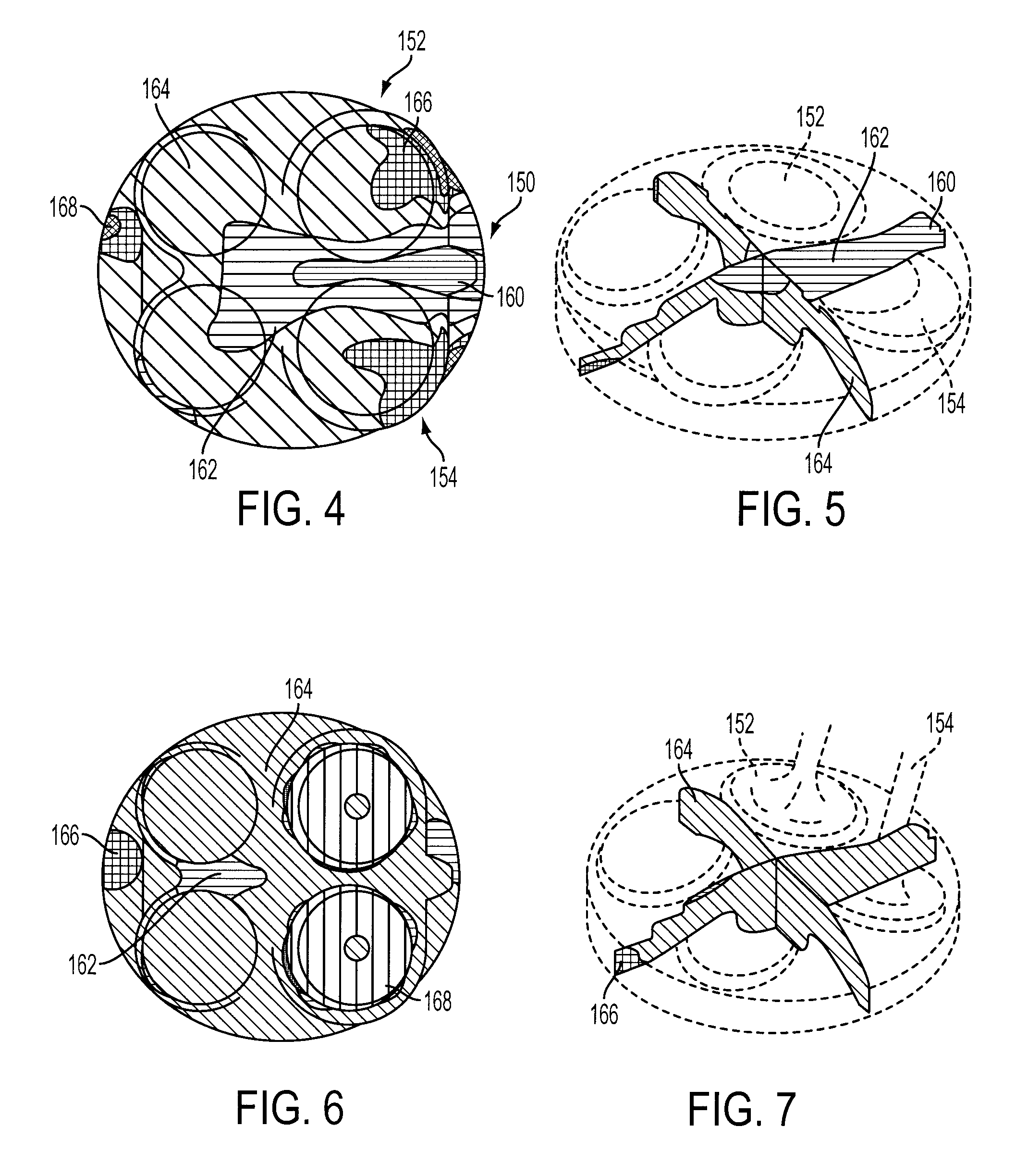

Fuel injector spray pattern for direct injection spark ignition engines

ActiveUS7418940B1Enhanced cold start combustion stabilityReduced cylinder wall wettingInternal combustion piston enginesExhaust valvePiston

A system and method for operating an internal combustion engine include injecting fuel through a plurality of fuel jets of a fuel injector directly into a corresponding cylinder with at least a first plurality jets oriented to primarily support operation in a stratified mode and a second plurality of jets oriented to primarily support operation in a homogeneous mode. The first plurality of jets is oriented to spray fuel generally downward toward the piston bowl and the second plurality of jets is oriented to spray fuel generally across the cylinder toward the exhaust valves. The spray jets reduce or eliminate valve, liner, and piston wetting while providing good mixing in homogeneous mode and good combustion stability for light stratified charge during cold starts to achieve desired targets for feedgas emissions and combustion efficiency.

Owner:FORD GLOBAL TECH LLC

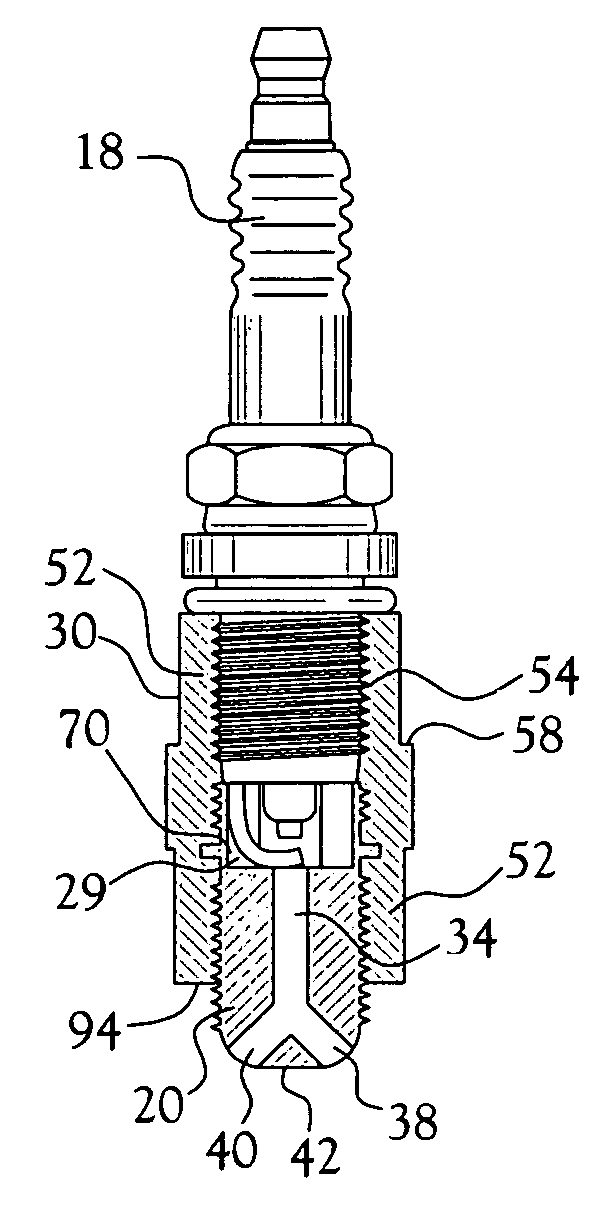

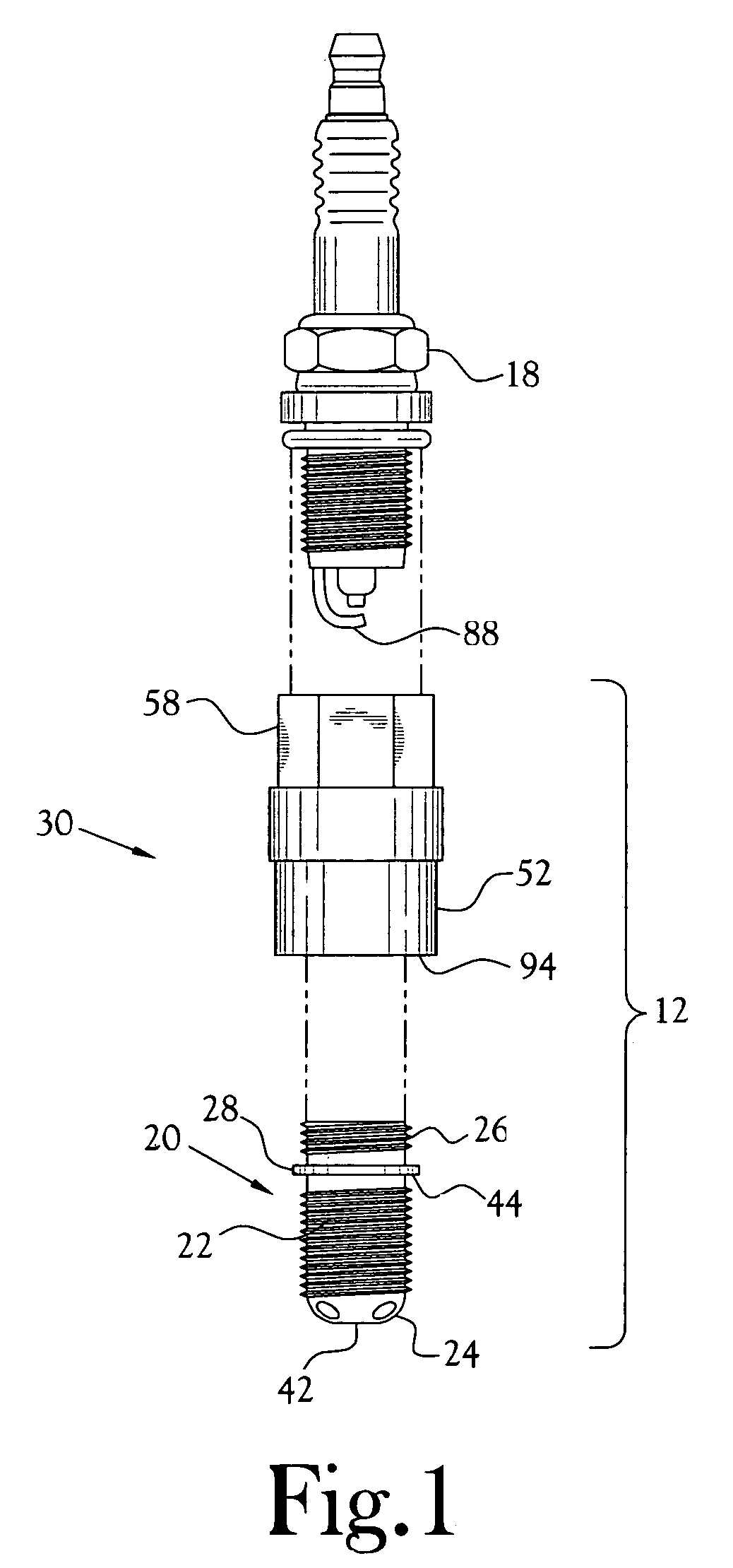

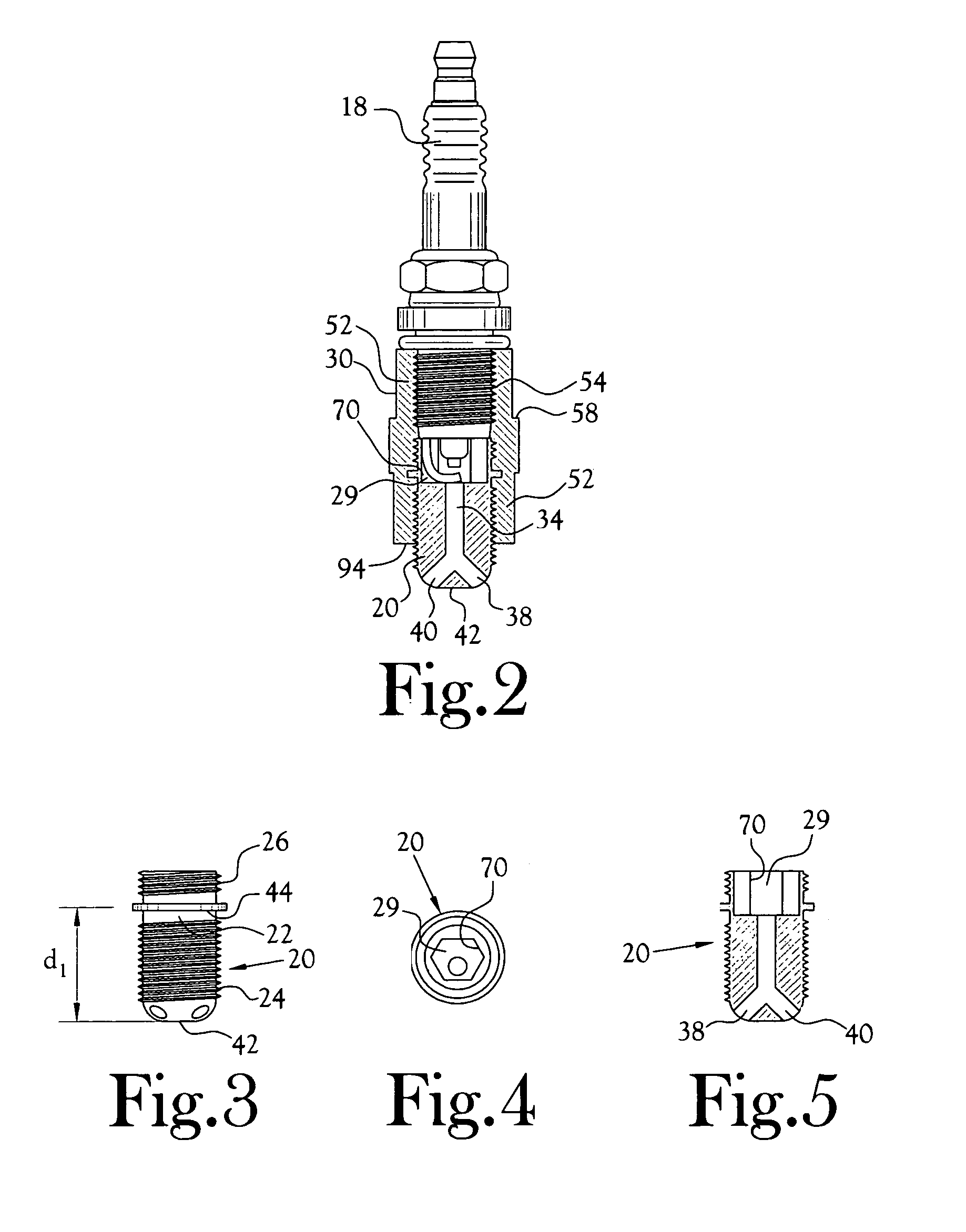

Spark ignition modifier module and method

InactiveUS7104246B1Easy to operateSparking plugsInternal combustion piston enginesCylinder blockSpark plug

A multi-part module including a flame cone and a connector adapted to be interposed between the normal spark plug port in an internal combustion engine block and a spark plug suitable for use with the engine in question. In the method, a quantity of fuel / air mixture is captured in a chamber which also houses the electrode of a spark plug. Upon generation of a spark from the spark plug, this quantity of fuel / air mixture ignites, generating a flame which propagates through one or more channels in a flame cone interposed between the spark plug and the cylinder of the engine and exits into the cylinder through multiple directionally oriented ports, whereupon the flame fronts rapidly ignite substantially all the fuel / air mixture held within the cylinder.

Owner:SMARTPLUG

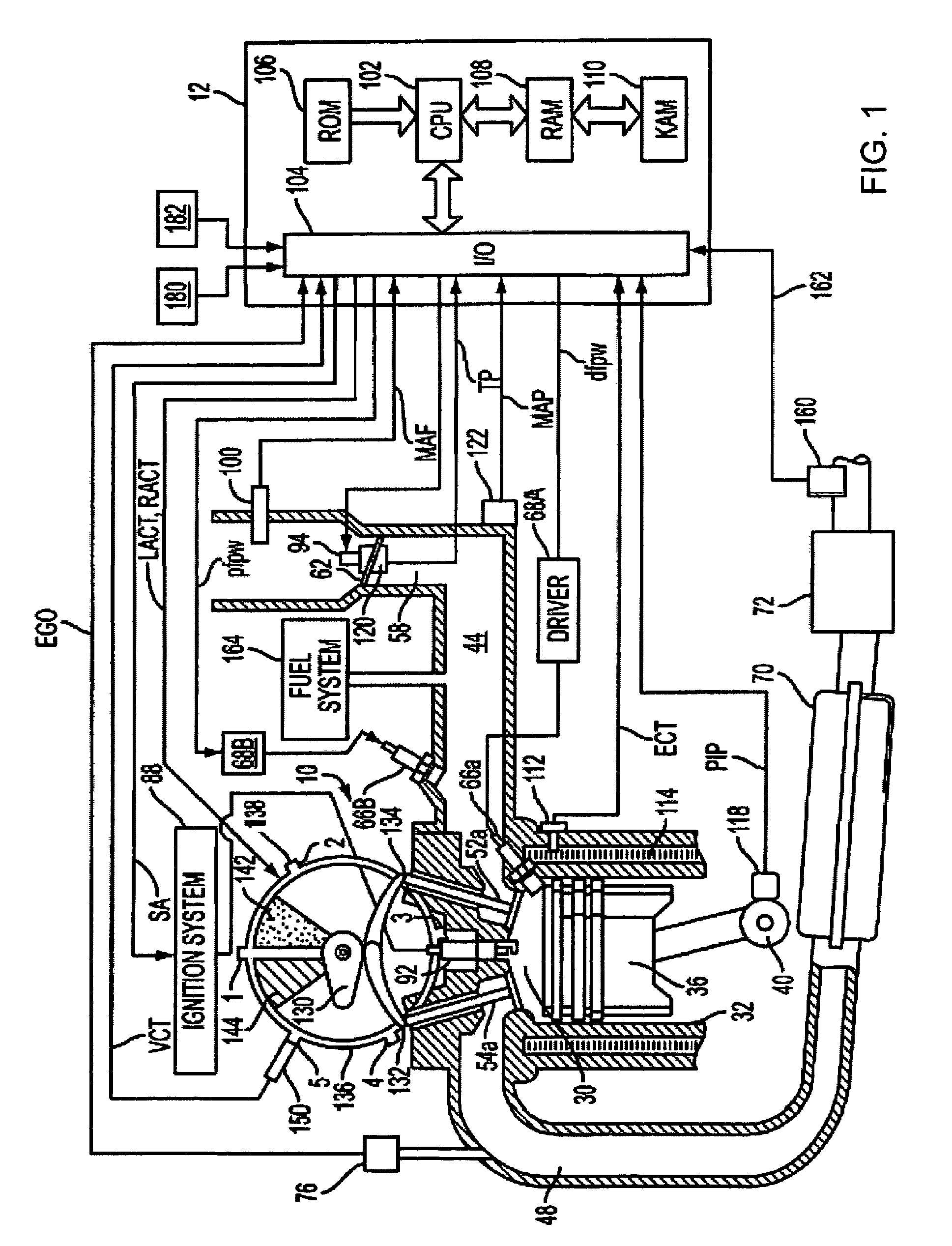

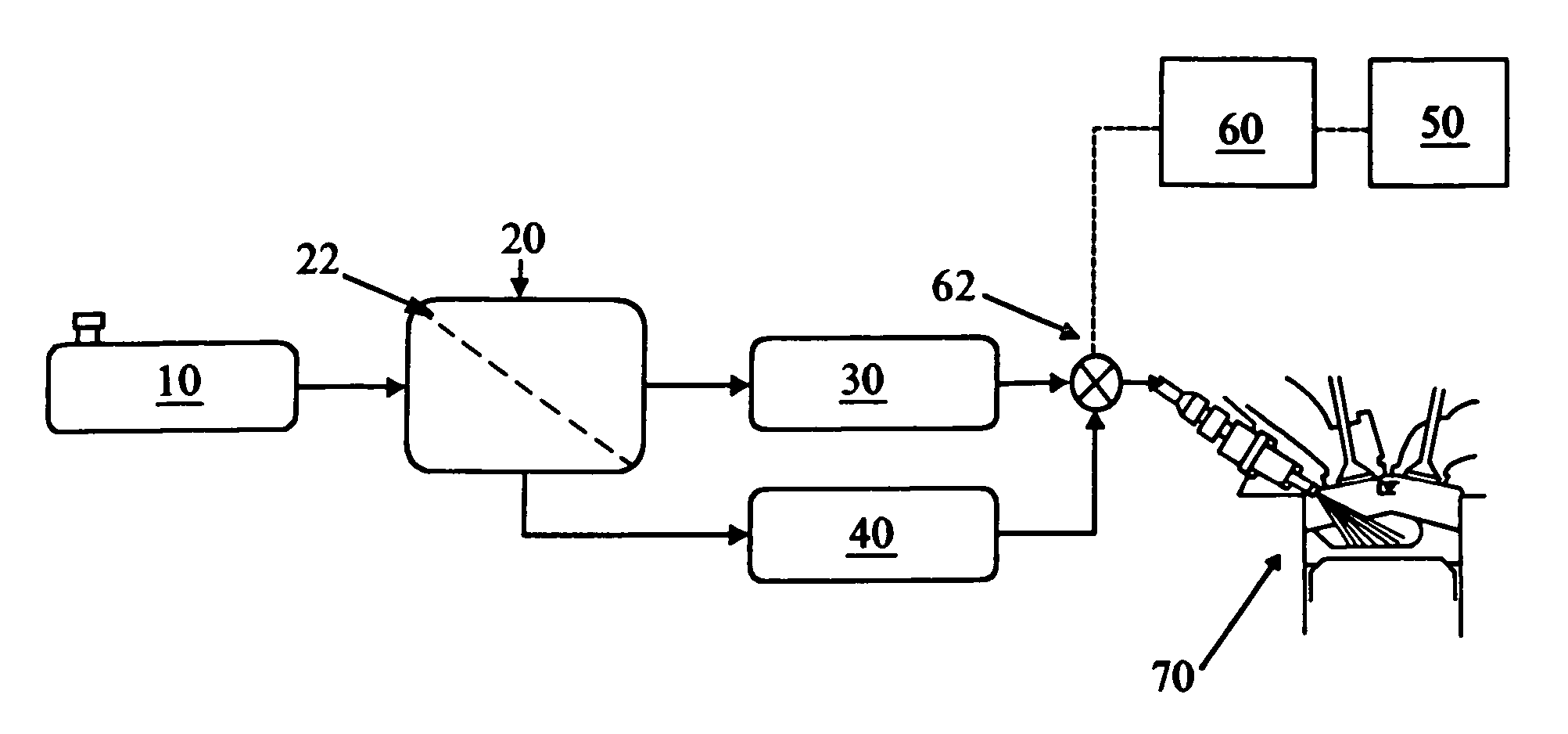

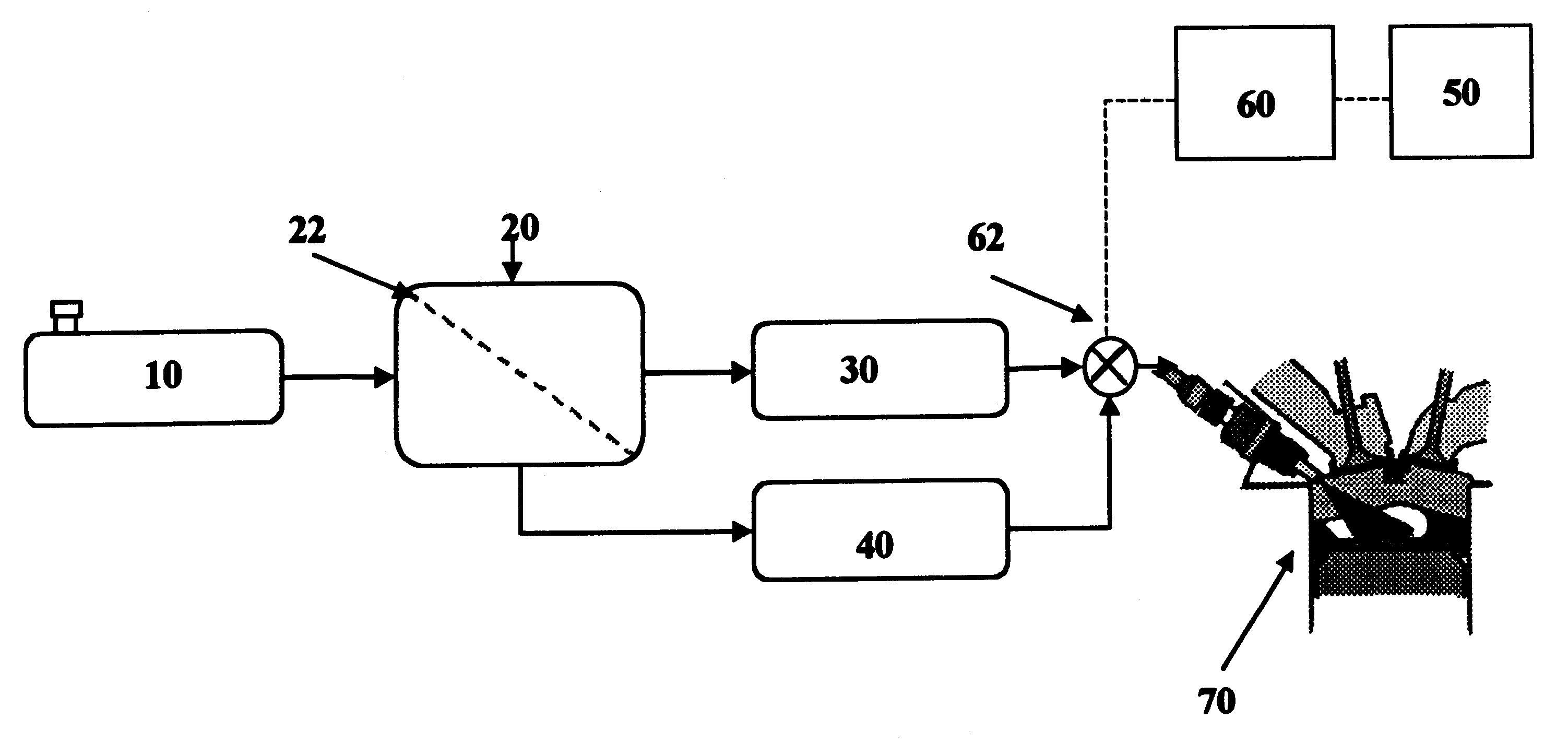

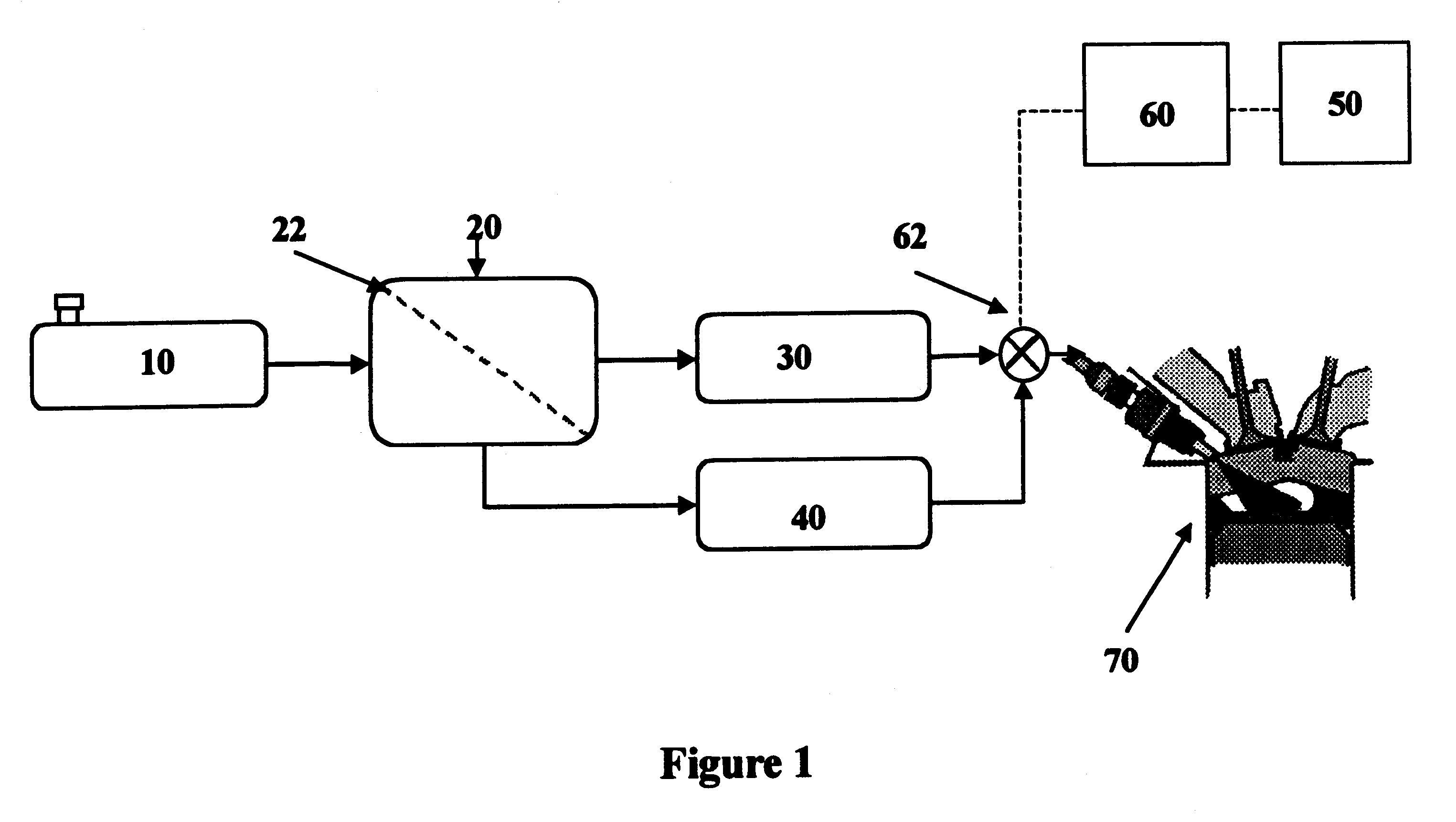

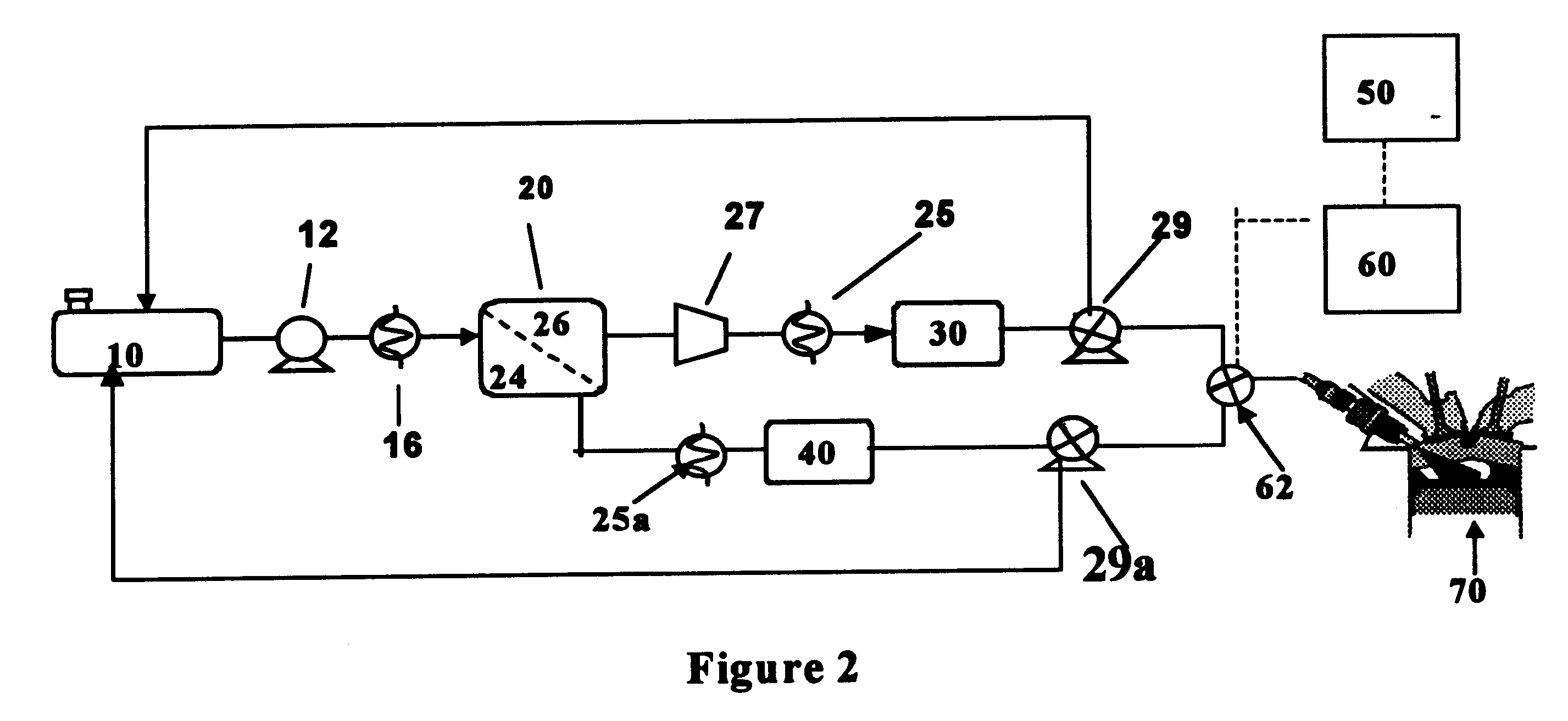

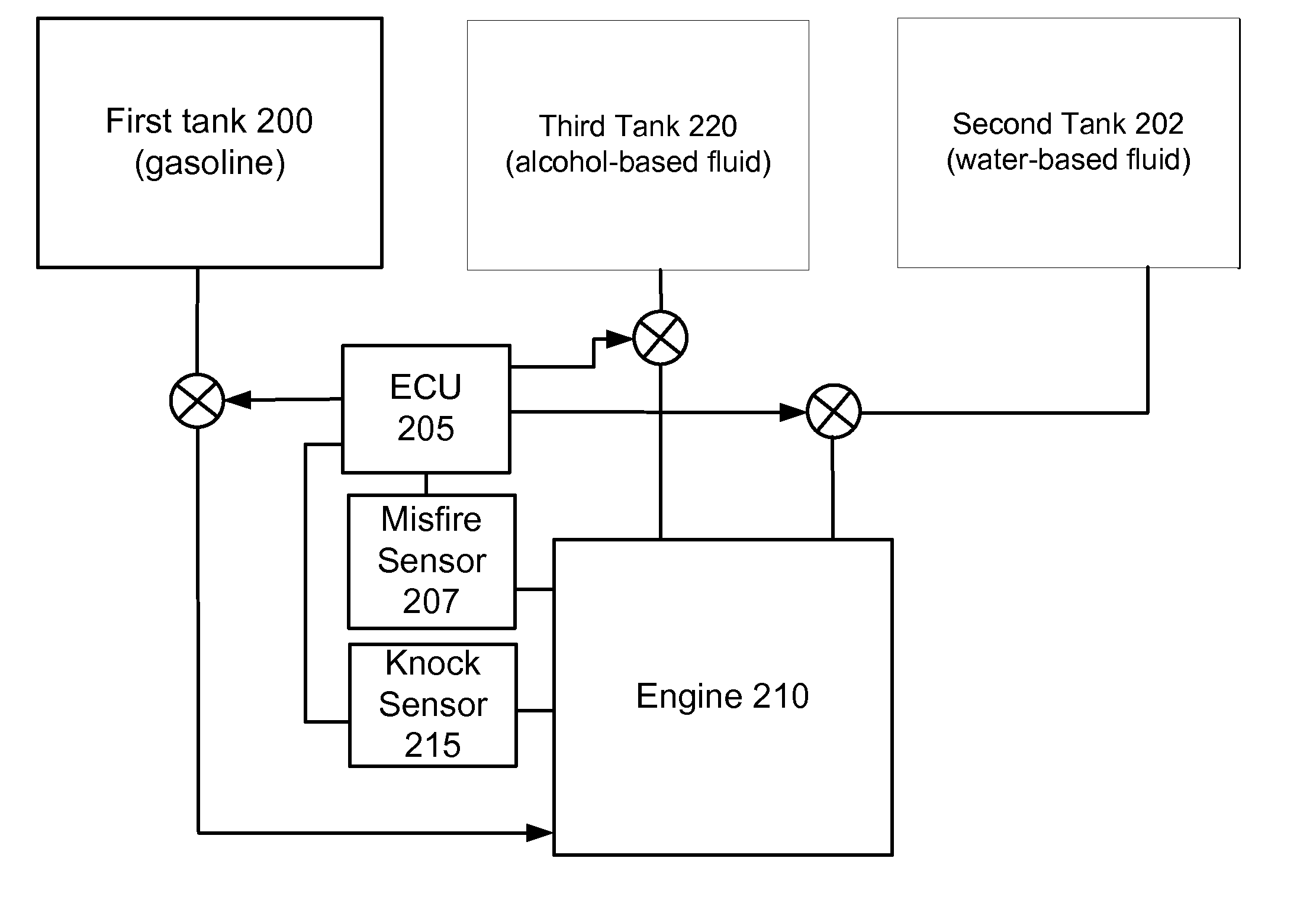

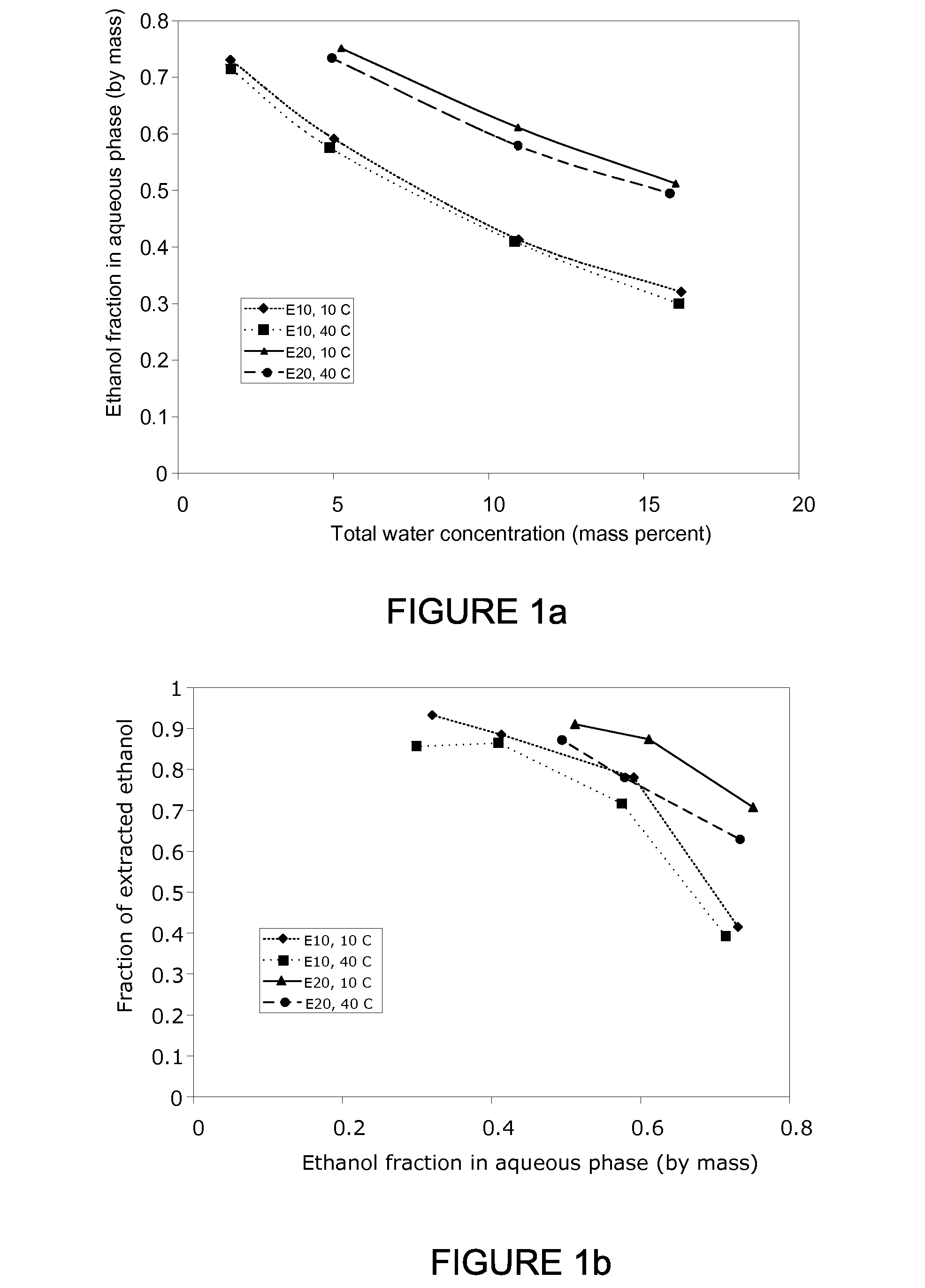

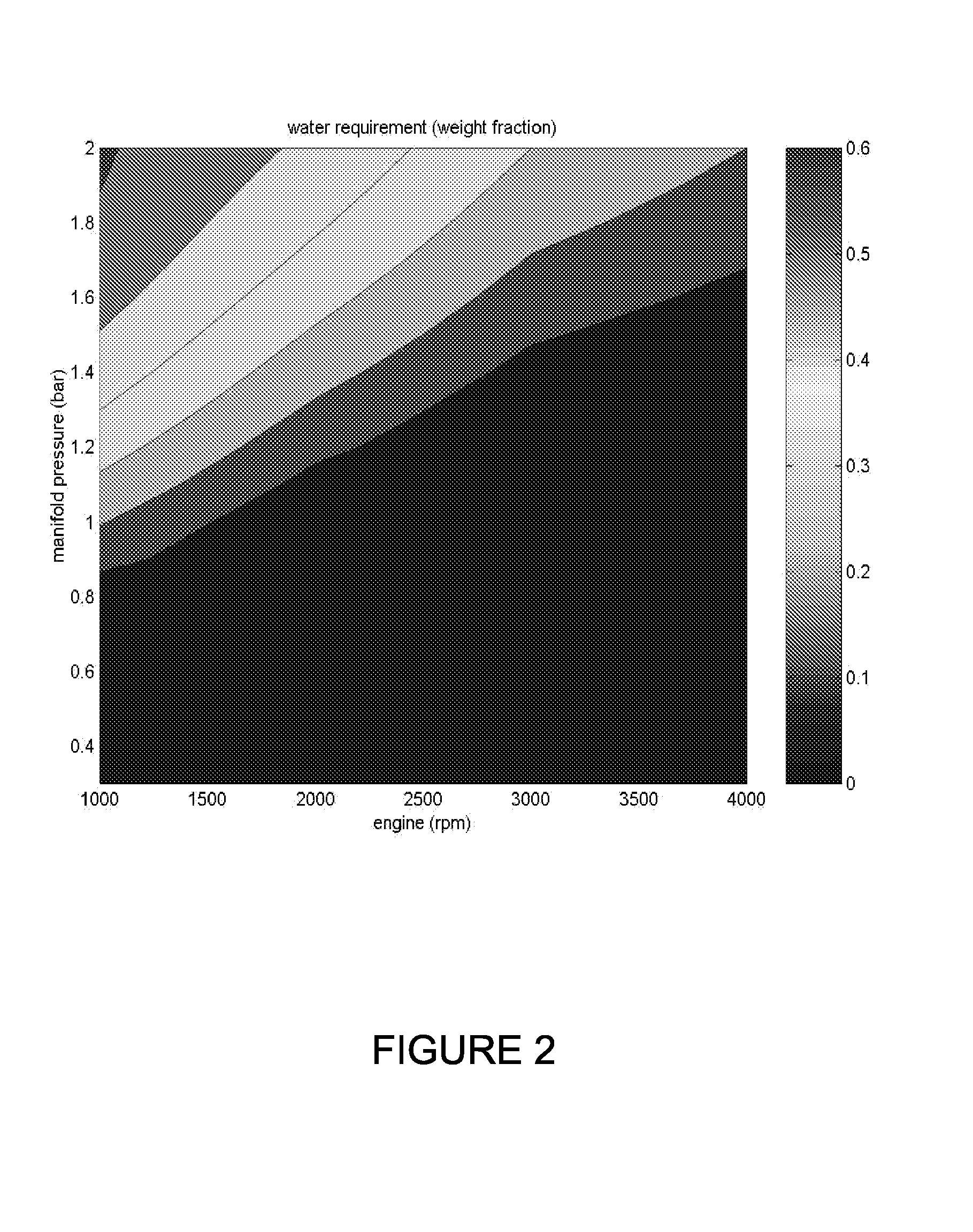

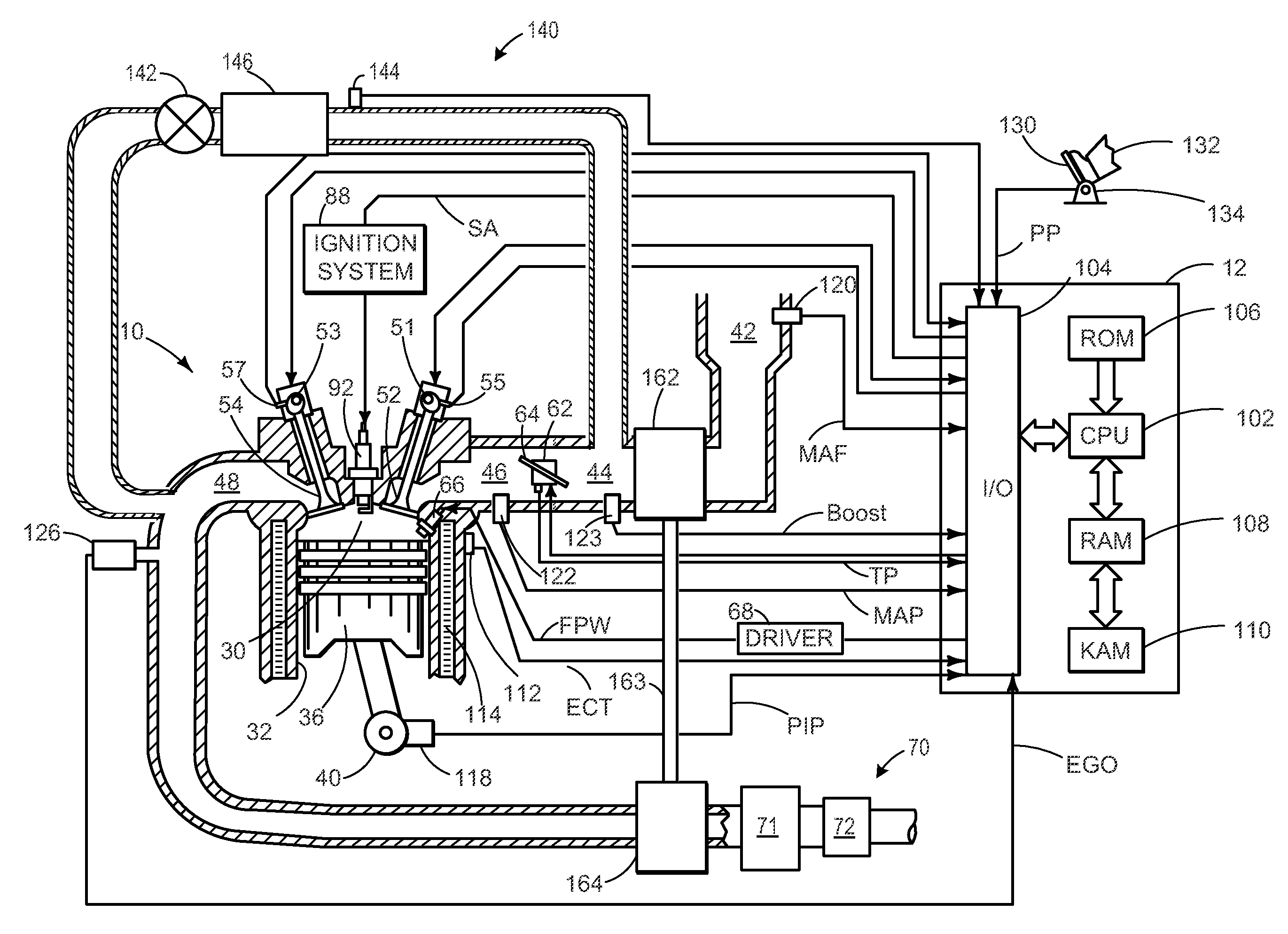

Water Based Systems for Direct Injection Knock Prevention in Spark Ignition Engines

InactiveUS20100121559A1Minimizing and eliminating misfiringLiquid separation auxillary apparatusInternal combustion piston enginesWater basedAlcohol

A fuel management system for using water for on-board vehicular separation of ethanol from ethanol-gasoline blends is described. Water or a water-alcohol mixture from a secondary tank is mixed with the ethanol-gasoline blend resulting in separation of the ethanol. By using on-board vehicular separation, the consumption of the externally supplied liquid from a secondary tank can be decreased to less than 1% of the gasoline consumption. This allows for long refilling periods for the externally supplied fluid. In another embodiment, a water-based fluid is directly injected into the cylinders of a spark ignition engine to eliminate knocking without causing misfire. In a further embodiment, an alcohol-based fluid is also used in those circumstances where injection of the water-based fluid may cause misfire.

Owner:ETHANOL BOOSTING SYST LLC

Gasoline particulate filter regeneration and diagnostics

ActiveUS20110072788A1Improve engine performanceReduce transient air-fuel disturbanceElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

Spark-ignition direct-injection engine

ActiveUS20150114342A1Promote atomizationShorten the overall cycleElectrical controlInternal combustion piston enginesLow loadHigh load

A controller injects fuel into a cylinder at a high fuel pressure of 30 MPa or higher, at least in a period between a terminal stage of a compression stroke and an initial stage of an expansion stroke when an operating mode of an engine body is at least in a first specified sub-range of a low load range, and at least in a second specified sub-range of a high load range. The controller sets an EGR ratio in the first specified sub-range to be higher than an EGR ratio in the second specified sub-range, and advances start of fuel injection in the first specified sub-range to start of fuel injection in the second specified sub-range.

Owner:MAZDA MOTOR CORP

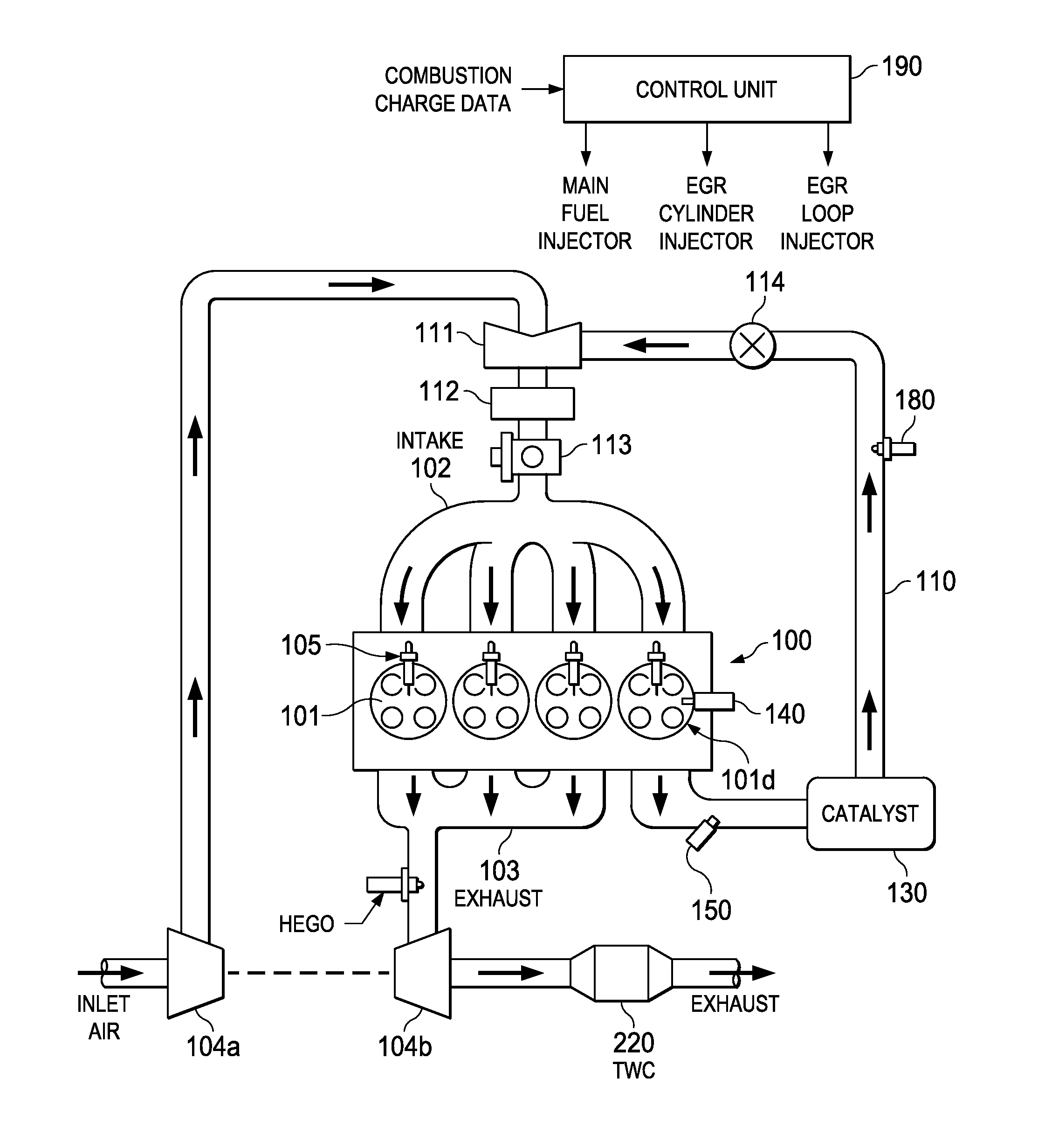

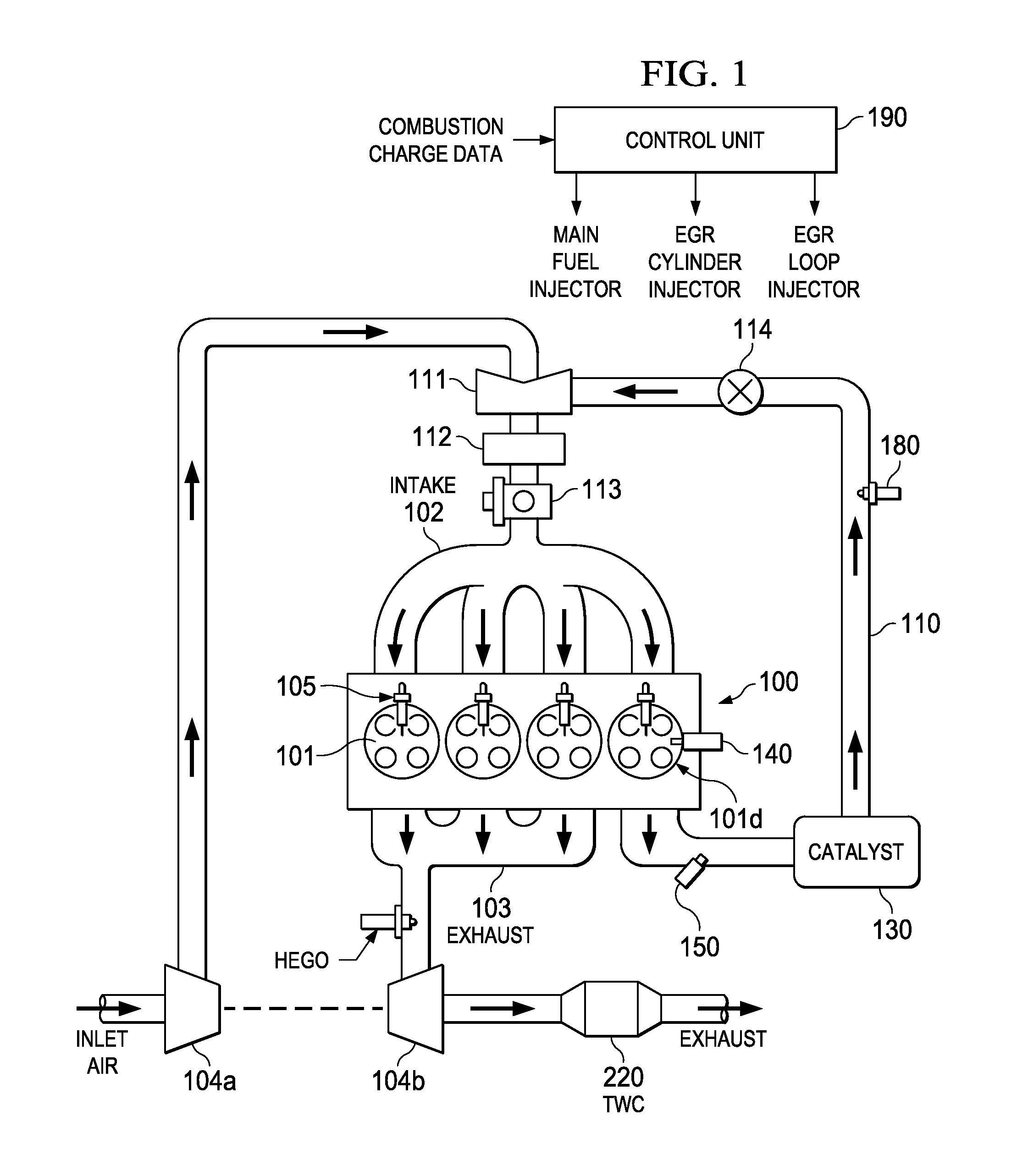

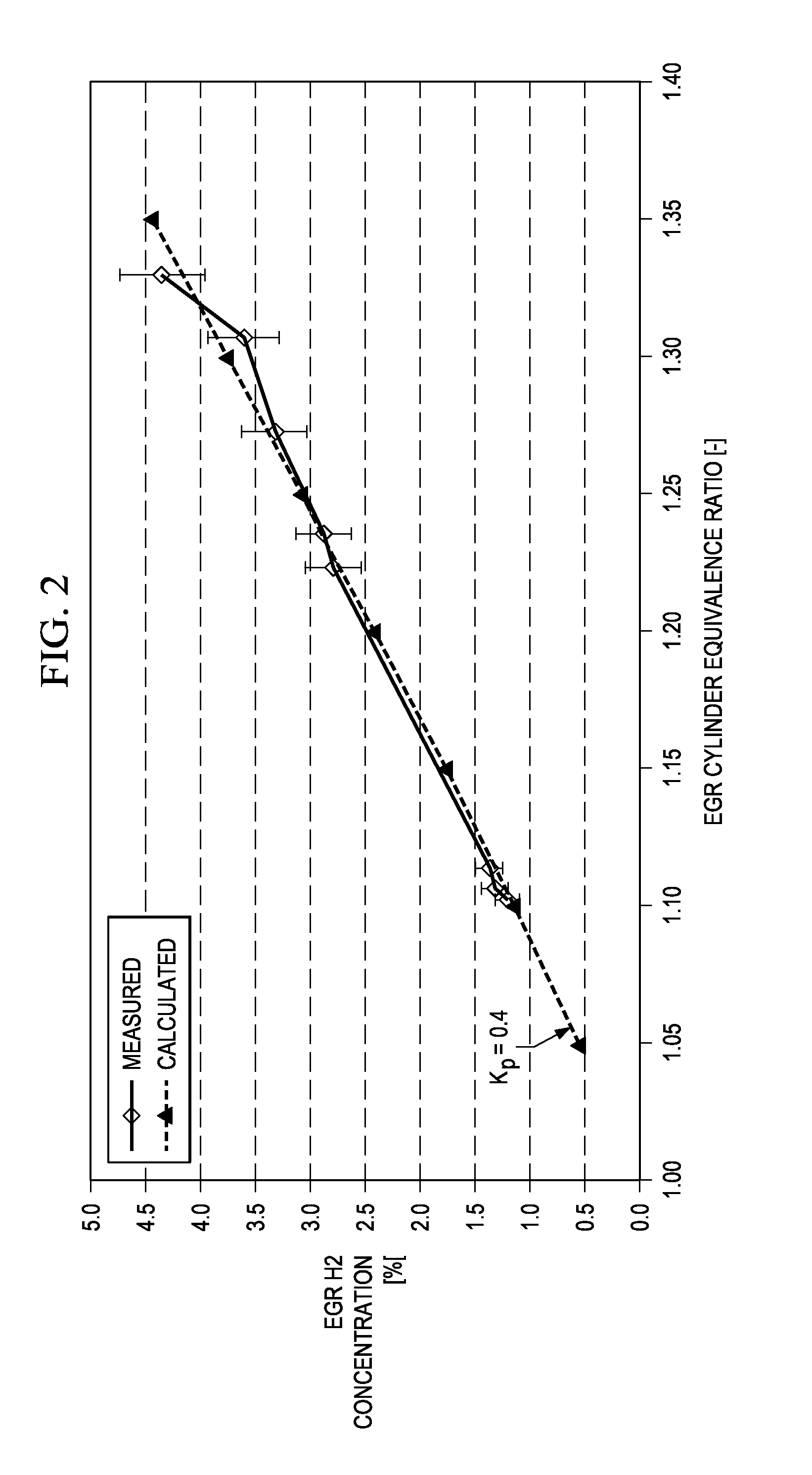

Ignition and Knock Tolerance in Internal Combustion Engine by Controlling EGR Composition

ActiveUS20140196702A1Improve efficiencyElectrical controlNon-fuel substance addition to fuelHydrogenExhaust gas recirculation

A method for improving ignition of a spark ignited internal combustion engine by controlling the composition of recirculated exhaust gas. It is assumed that the engine has a spark ignition system and an exhaust gas recirculation (EGR) loop such that at least one of the combustion cylinders is an EGR cylinder that generates an EGR stream carried by the EGR loop. Thus, the combustion charge is a mixture of air, fuel and recirculated exhaust. A first step is receiving combustibility data representing the current ignitability of the charge. It is then determined whether the energy of the ignition system is sufficient to ignite the charge. If not, the amount of hydrogen in the EGR stream is increased, which increases the ignitability of the charge.

Owner:SOUTHWEST RES INST

Spark timing and control during transitions between spark ignited combustion and homogenous charge compression ignition

InactiveUS20090229562A1Electrical controlInternal combustion piston enginesHcci combustionControl system

A control system for an engine comprises an air per cylinder (APC) generating module that generates measured and desired APC values. A combustion transition module selectively transitions the engine from spark ignition (SI) combustion to homogeneous charge compression ignition (HCCI) combustion and from HCCI combustion to SI combustion. A spark control module selectively retards spark during the transitions based on a ratio of the measured APC value and the desired APC value. Alternately, spark retard can be based on measured and desired engine torque representing values (ETRVs).

Owner:GM GLOBAL TECH OPERATIONS LLC

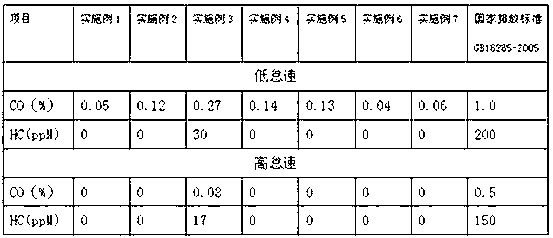

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

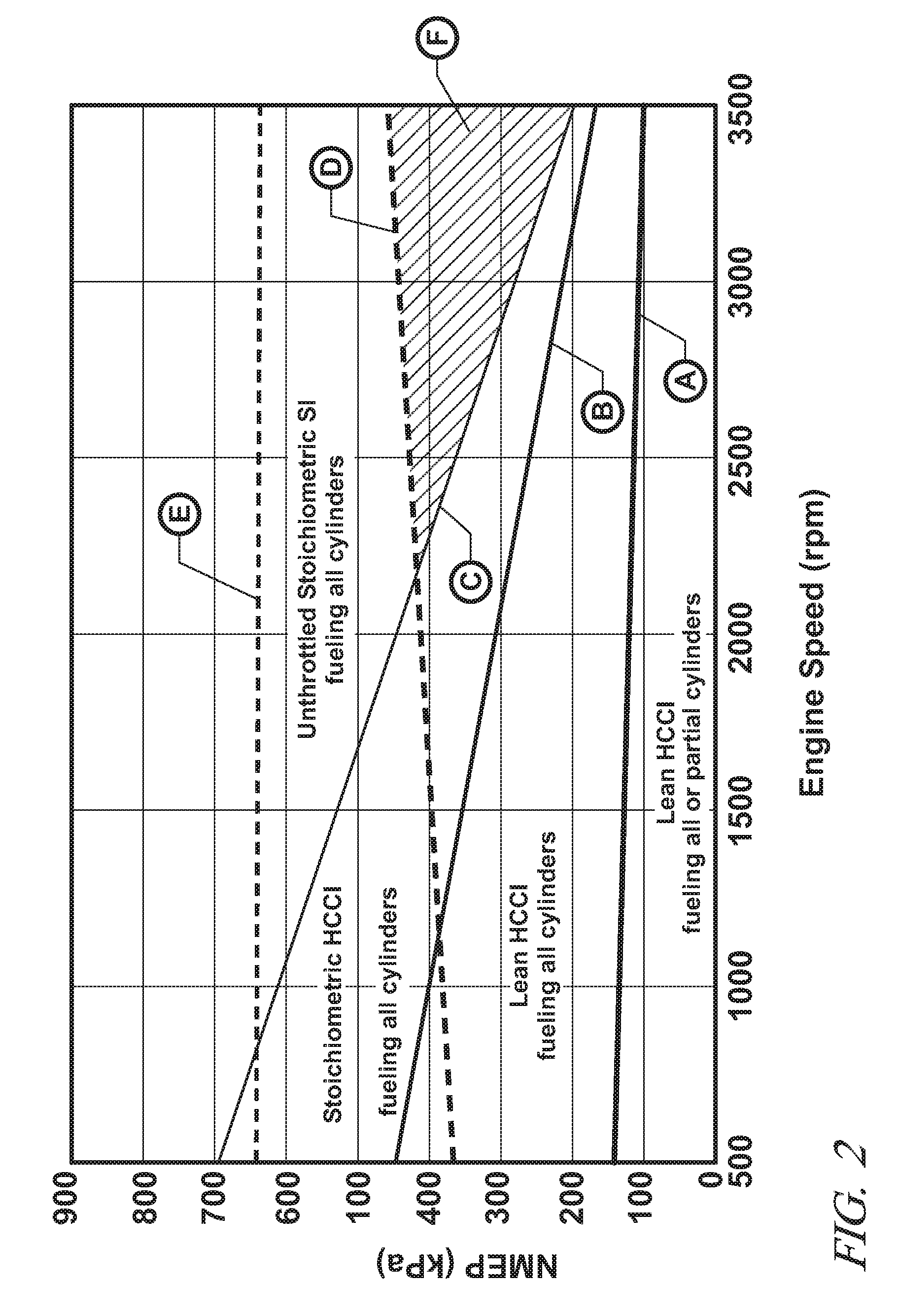

Method and apparatus to control a transition between HCCI and SI combustion in a direct-injection gasoline engine

InactiveUS20070272202A1Increased torque outputValve arrangementsElectrical controlOperating pointGasoline

A method to operate a multi-cylinder direct-injection engine in one of a controlled auto-ignition and a spark-ignition combustion mode is described. Engine operation and an operator torque request are monitored. Fuel delivery to a portion of the cylinders is selectively deactivated and torque output from non-deactivated cylinders is selectively increased to achieve the operator torque request when the monitored engine operation is above a predetermined threshold. An engine operating point at which an engine load demand exceeds an operating capability of the engine in a stoichiometric HCCI mode is identified. The engine is selectively operated in an unthrottled spark-ignition mode with at least one cylinder unfueled and torque output from the remaining cylinders is selectively increased.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com