Patents

Literature

3658 results about "Octane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Octane is a hydrocarbon and an alkane with the chemical formula C₈H₁₈, and the condensed structural formula CH₃(CH₂)₆CH₃. Octane has many structural isomers that differ by the amount and location of branching in the carbon chain. One of these isomers, 2,2,4-trimethylpentane (isooctane) is used as one of the standard values in the octane rating scale.

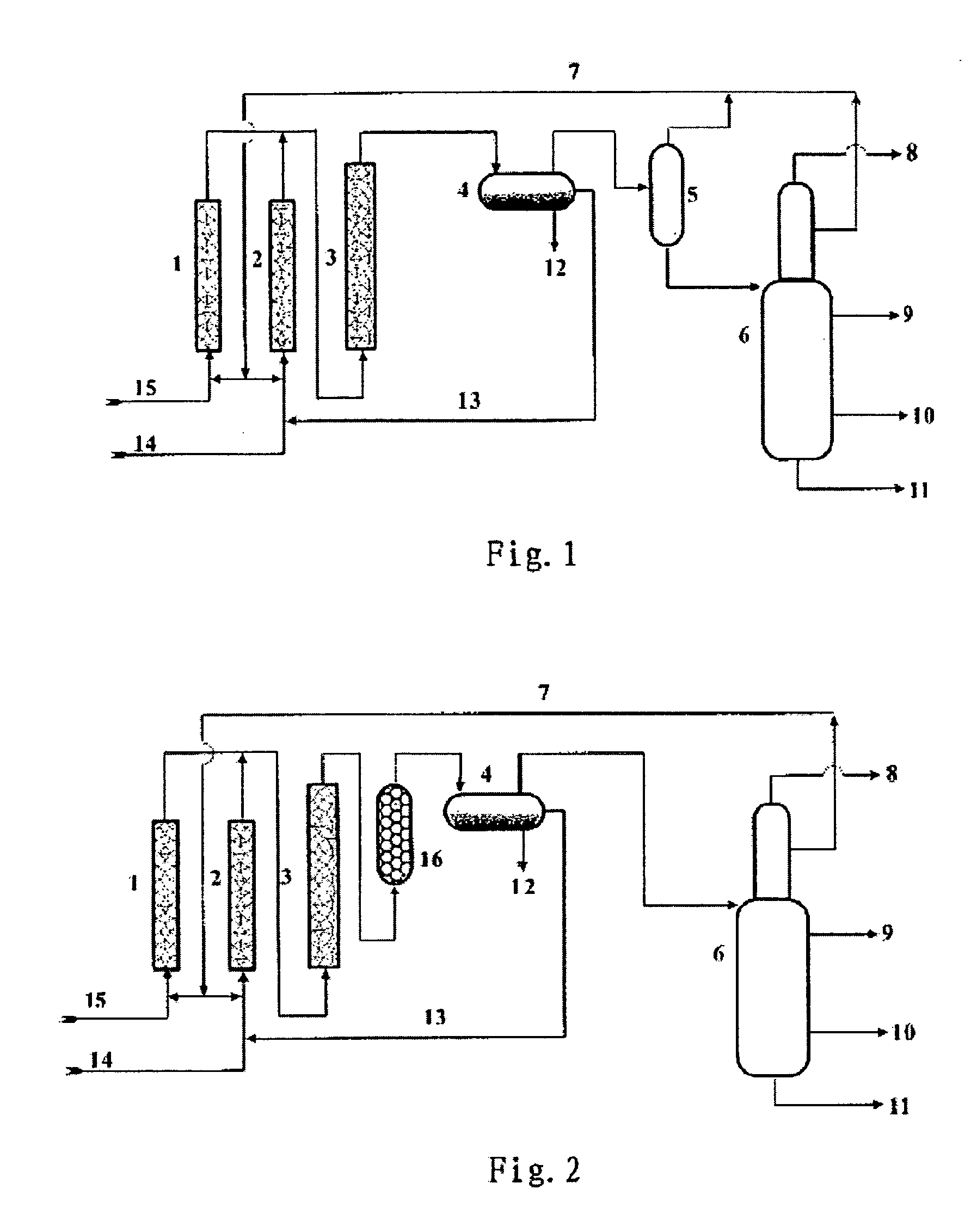

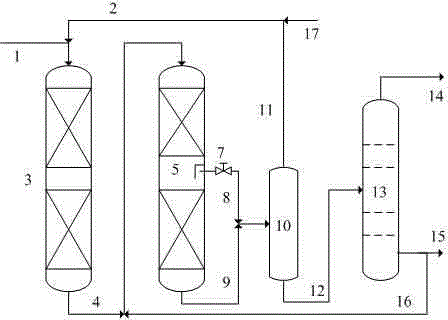

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

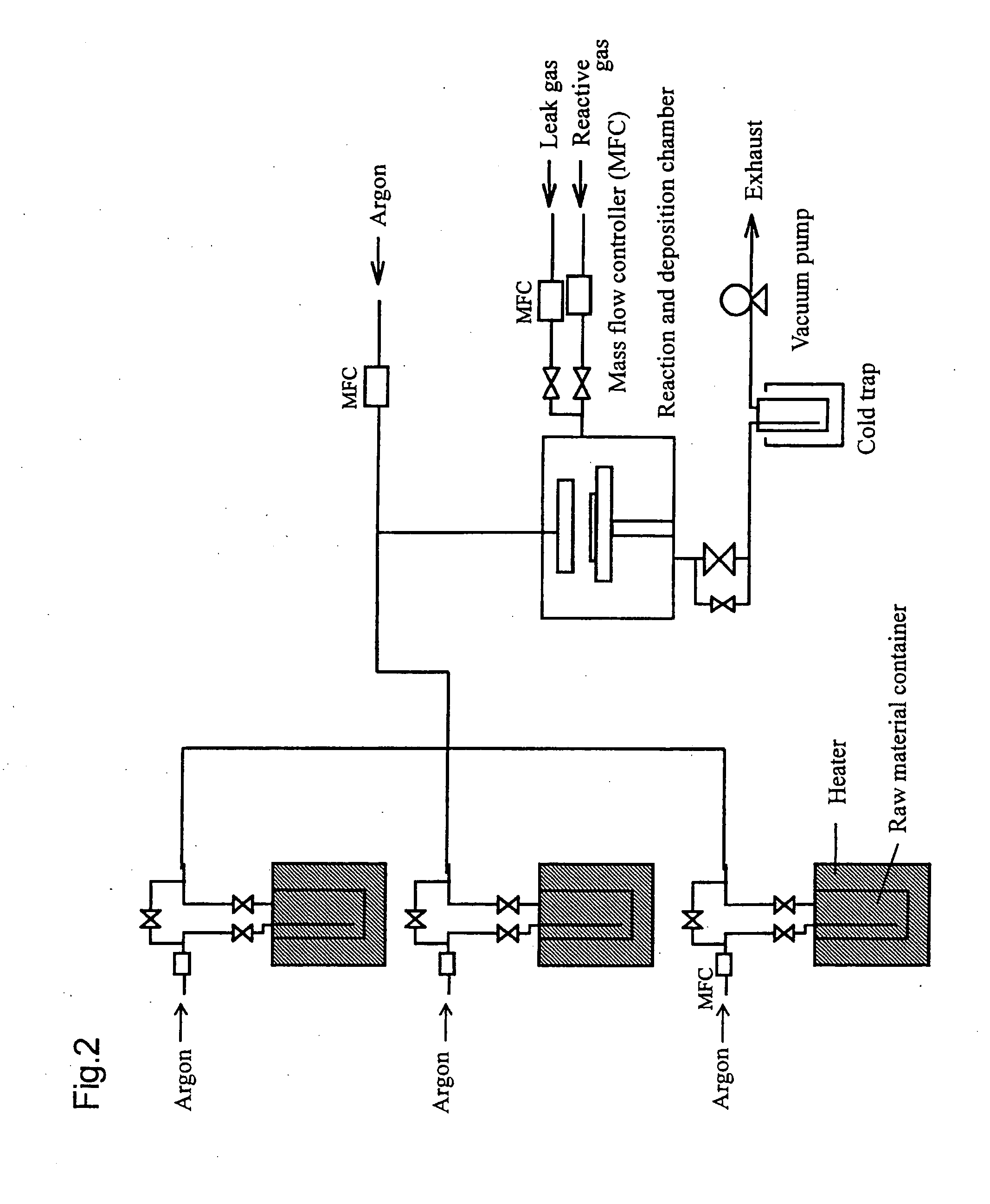

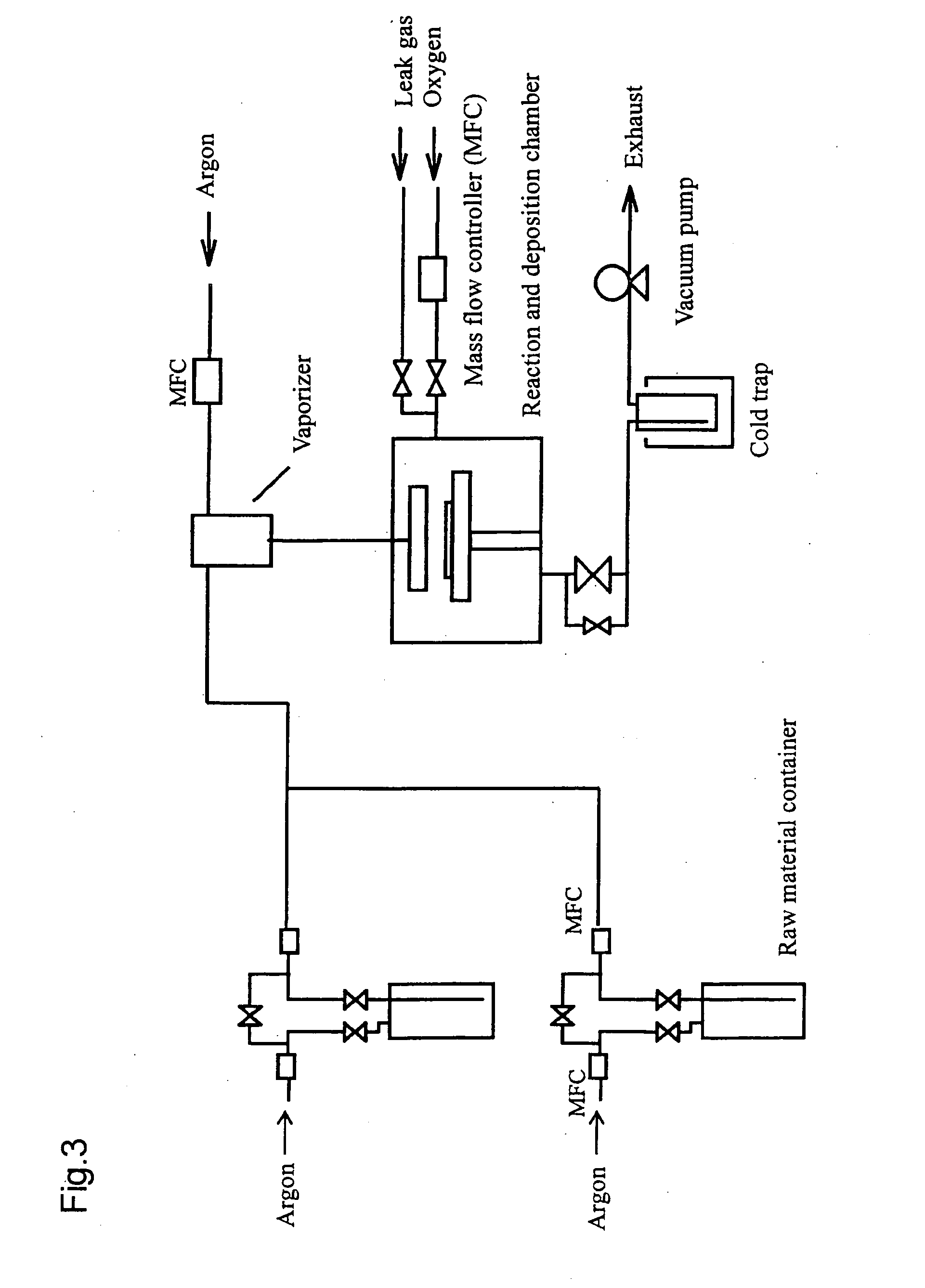

Thin film-forming material and method for producing thin film

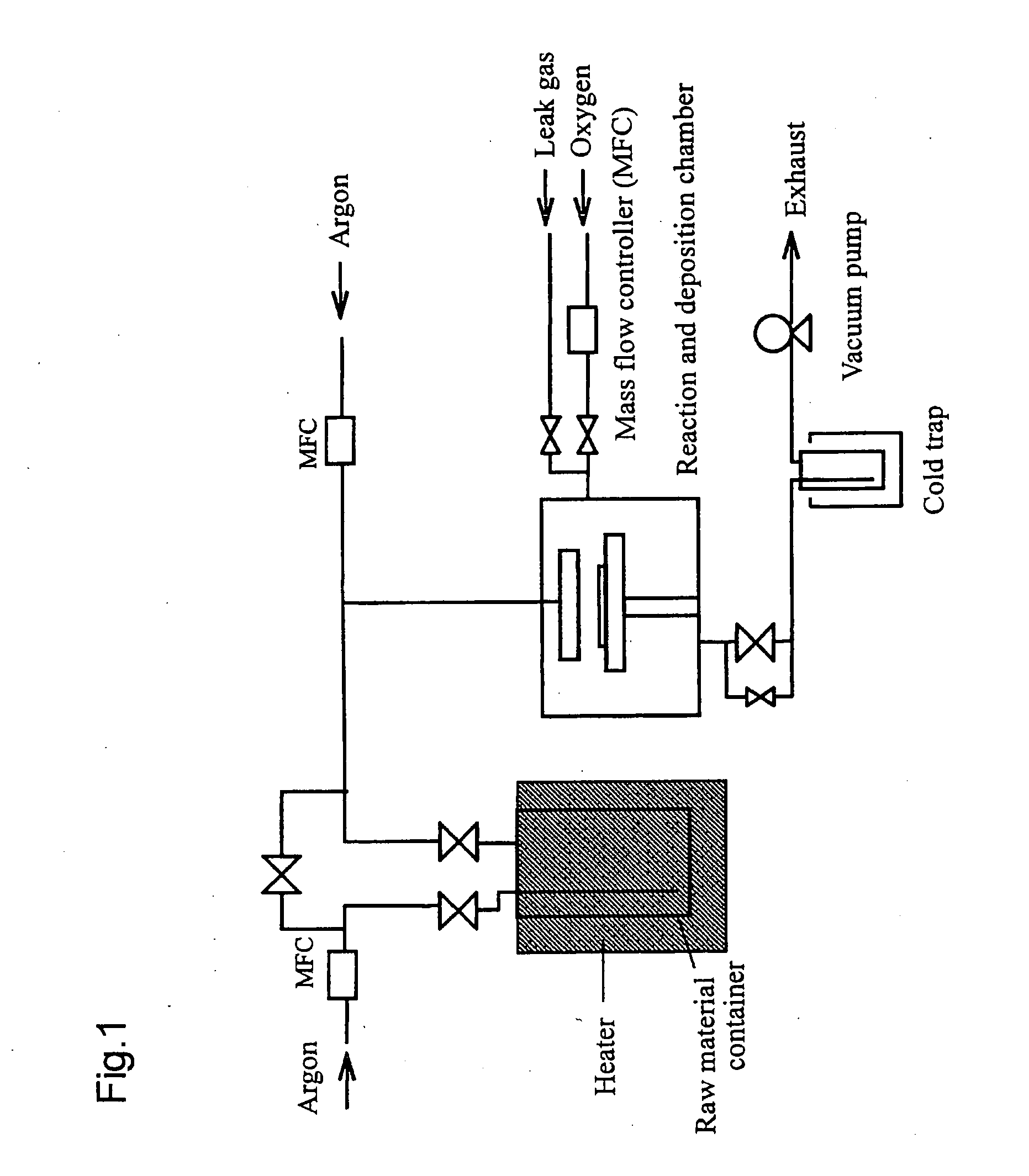

InactiveUS20070178235A1Chemical vapor deposition coatingZinc organic compoundsZinc compoundsMaterials science

The thin film-forming material of the present invention comprises a bis(β-diketonato)zinc compound that is liquid at 25° C. and is suitable for forming a zinc-containing thin film. By using the thin film-forming material, a thin film can be produced with stable film-forming rate or stable film composition control without suffering from problems of raw material gas suppliability and in-line raw material transport. Preferred (β-diketonato)zinc compounds include, for example, bis(octane-2,4-dionato)zinc and bis(2,2-dimethyl-6-ethyldecane-3,5-dionato)zinc.

Owner:ADEKA CORP

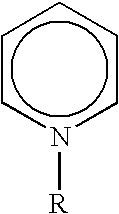

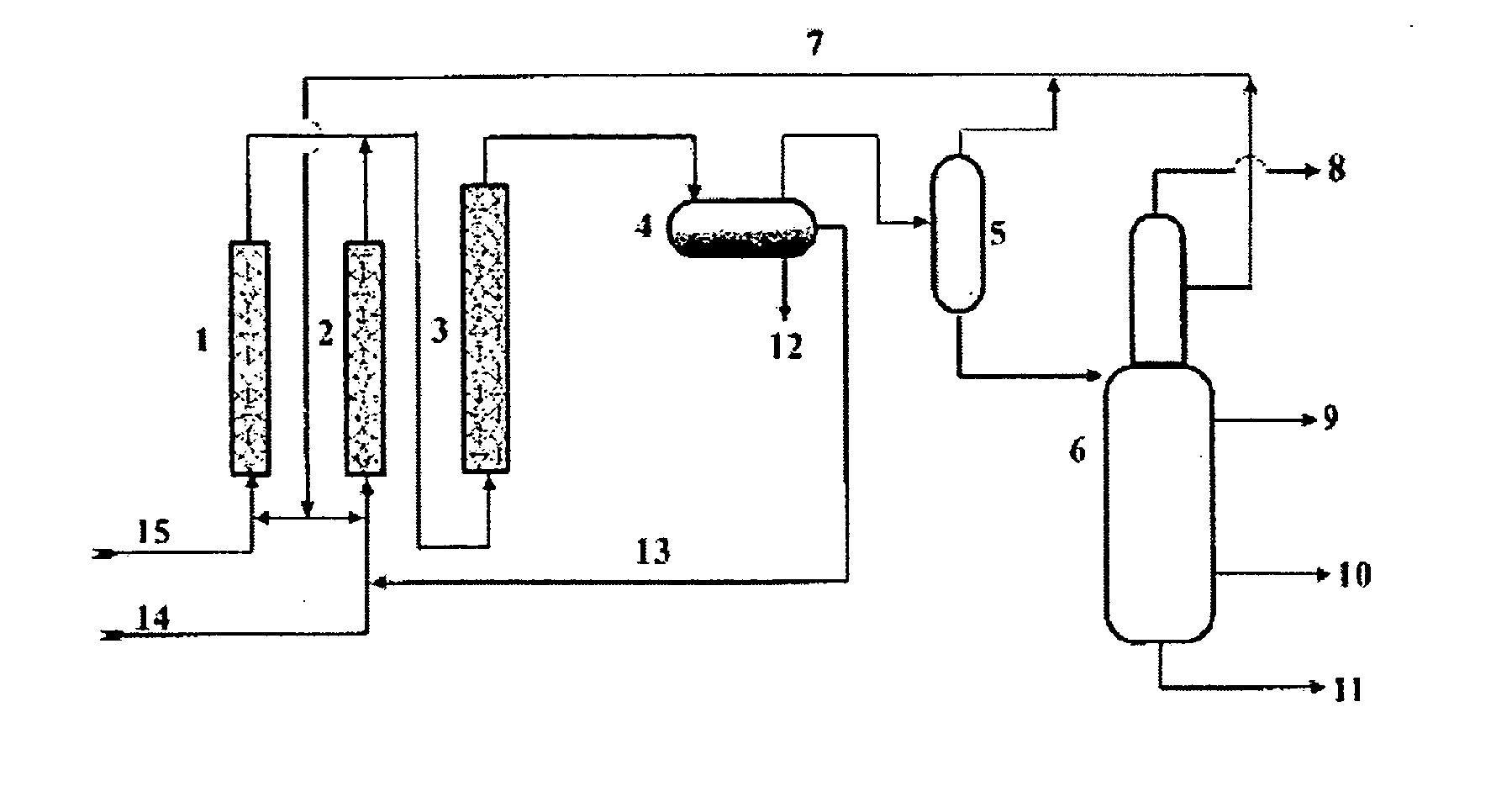

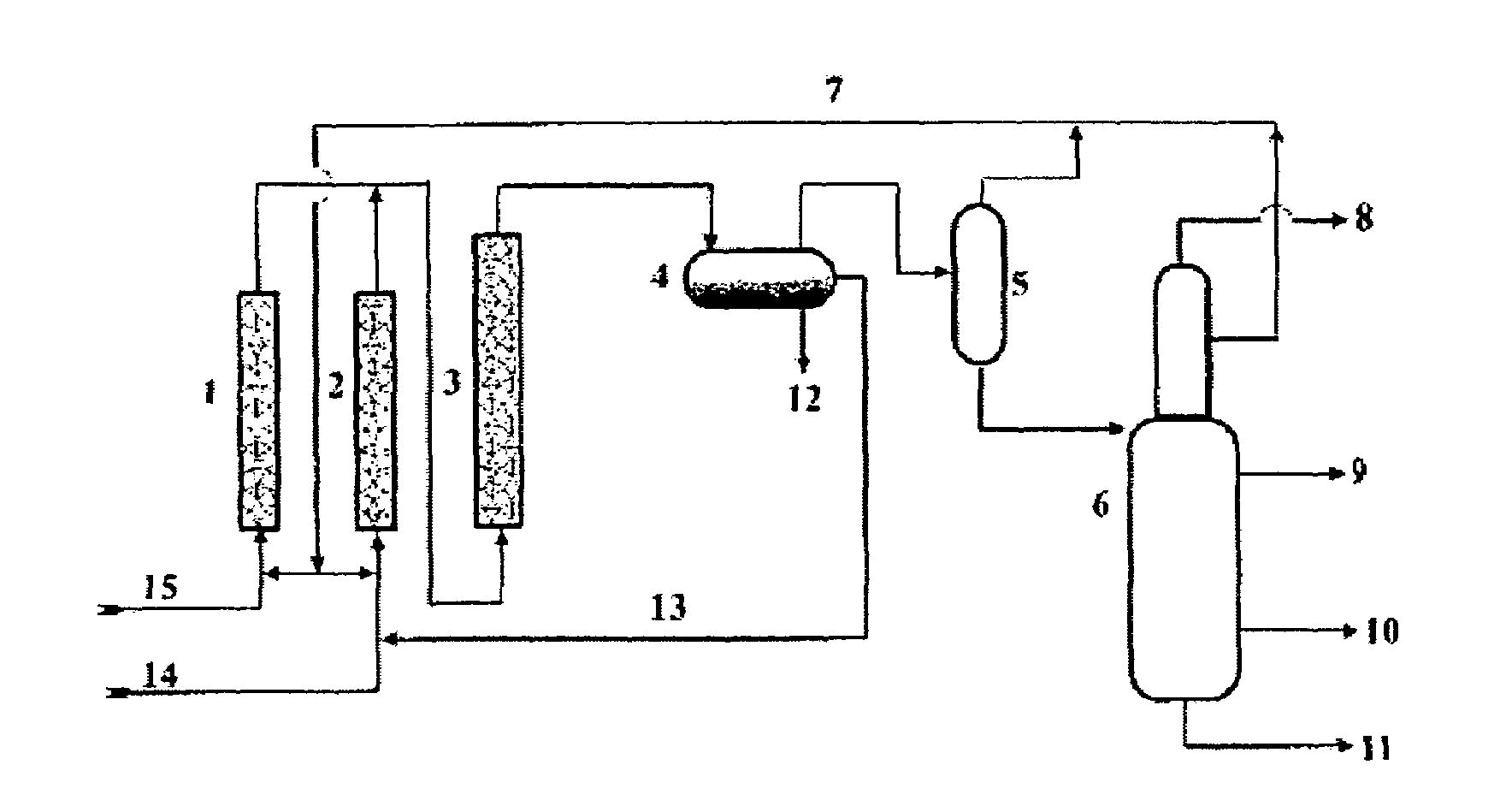

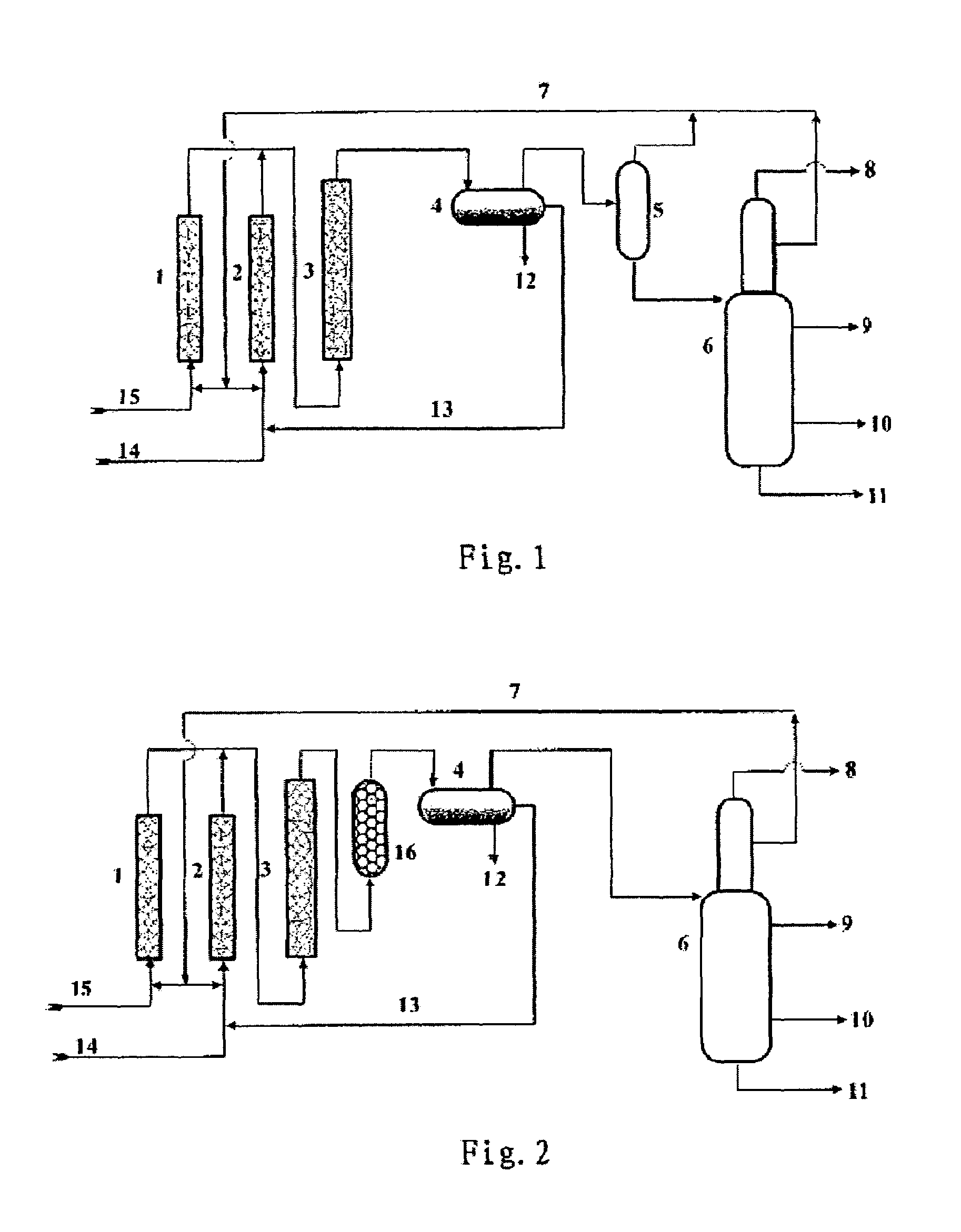

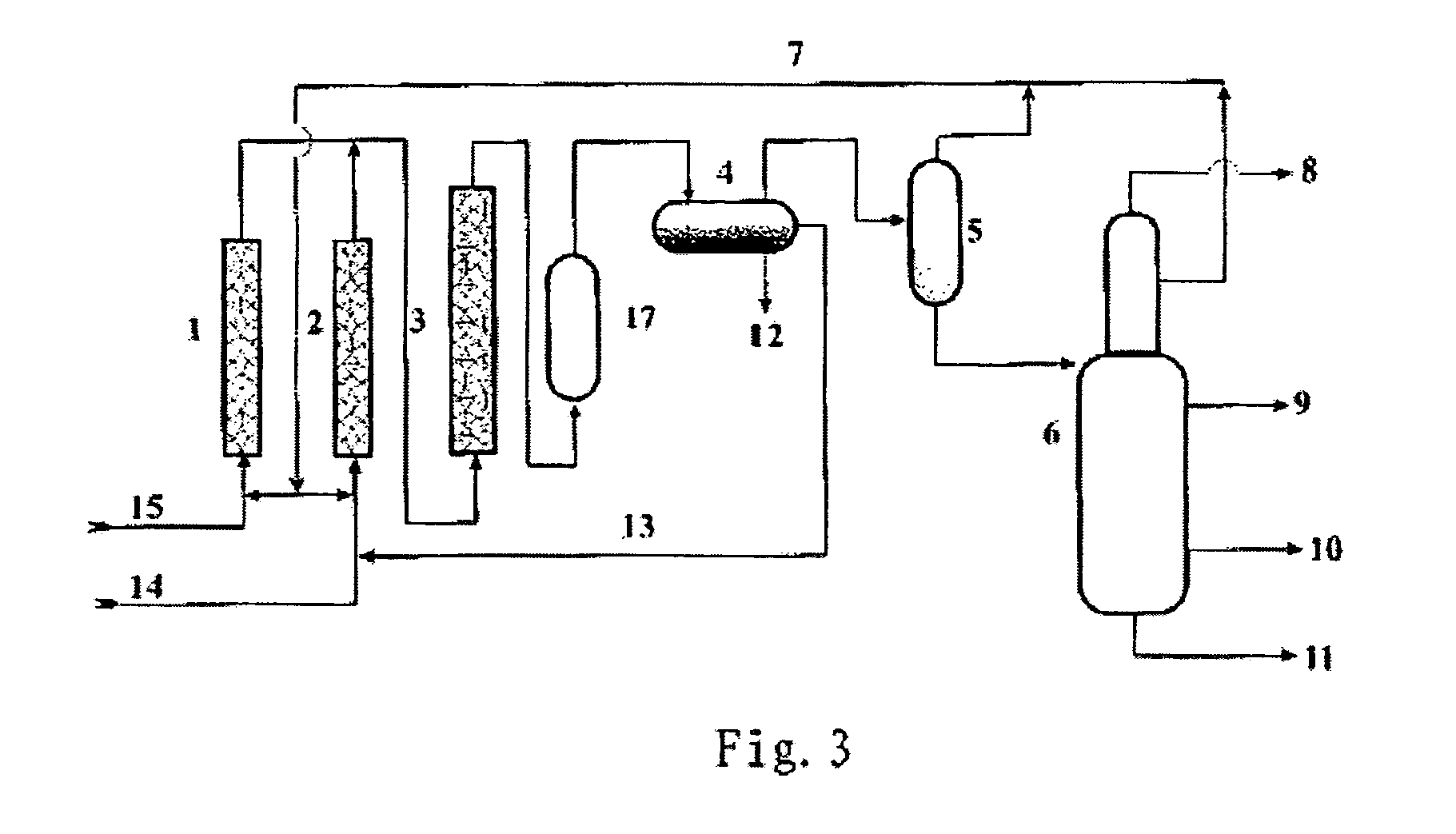

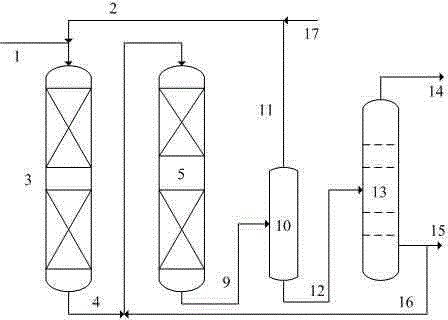

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

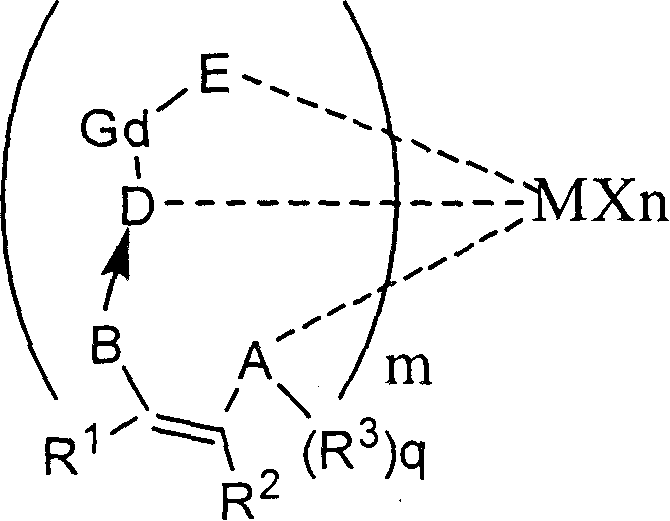

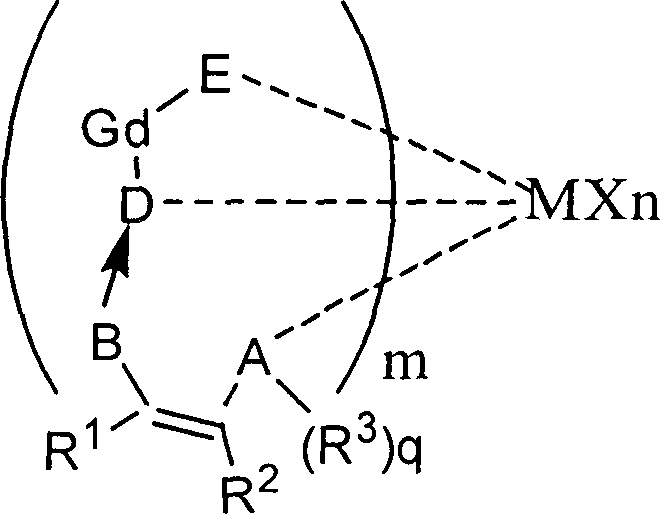

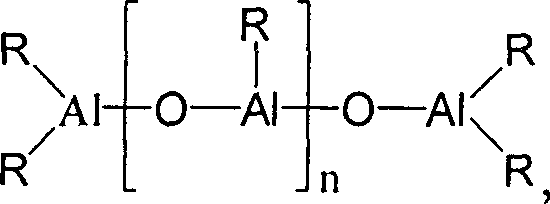

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

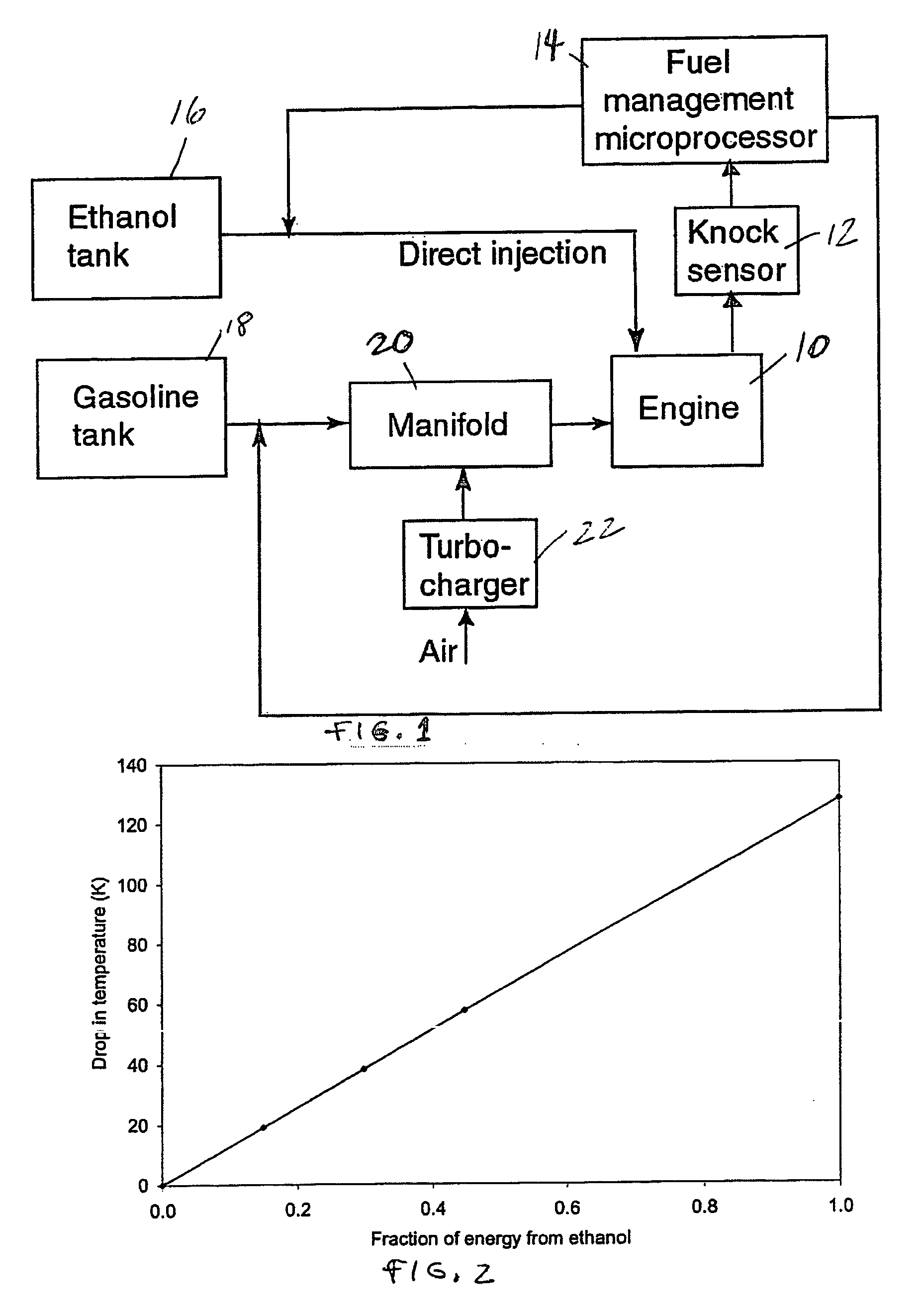

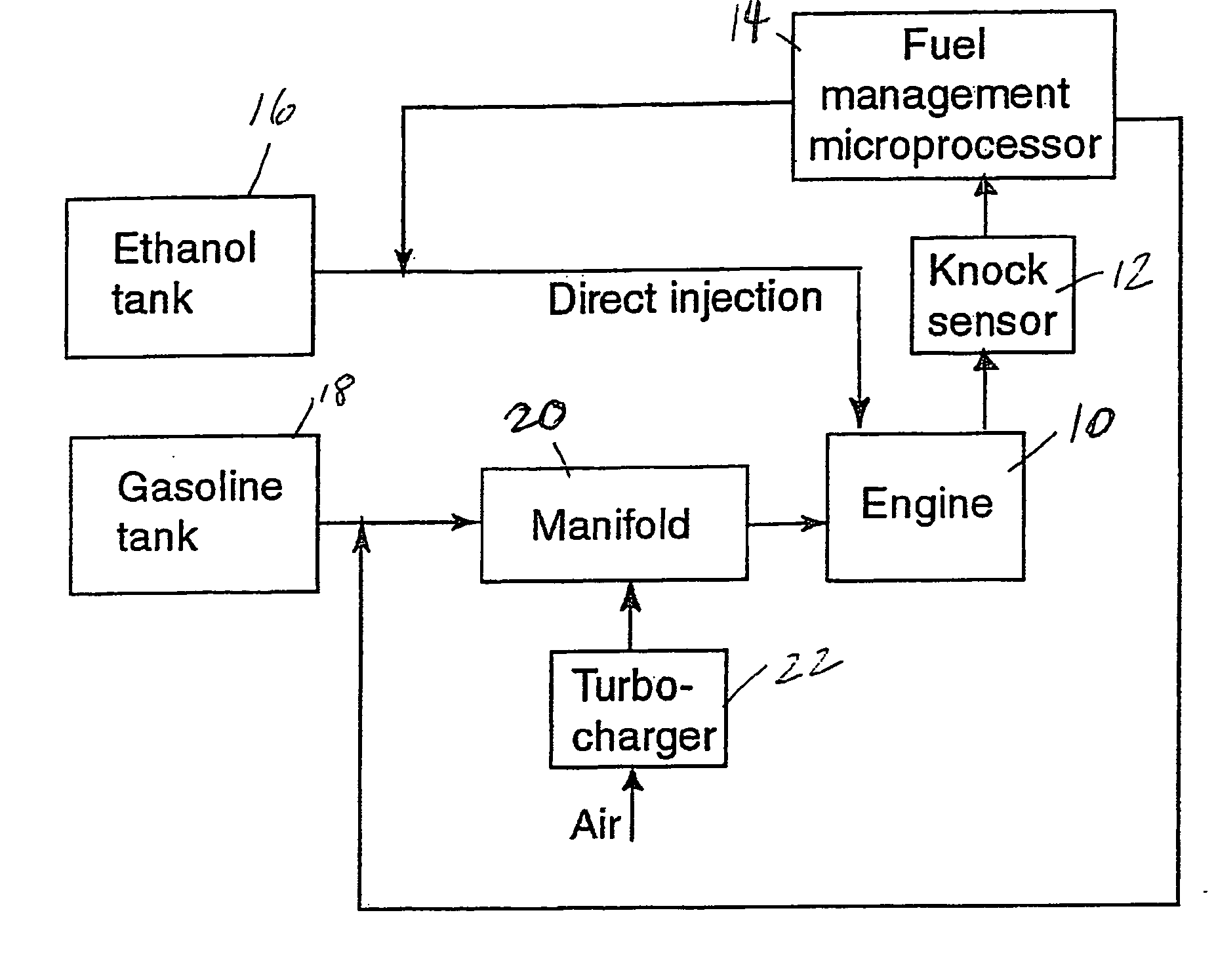

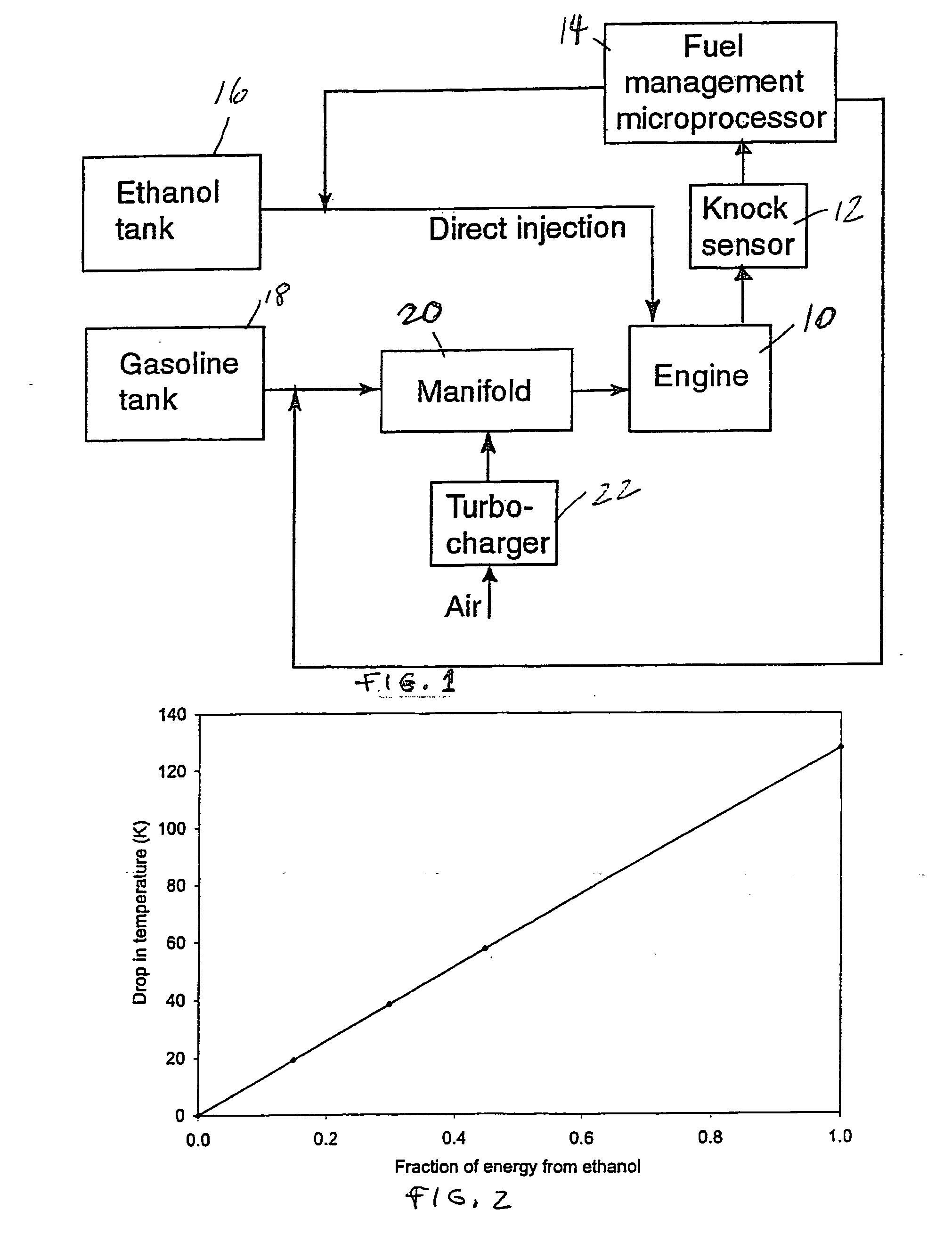

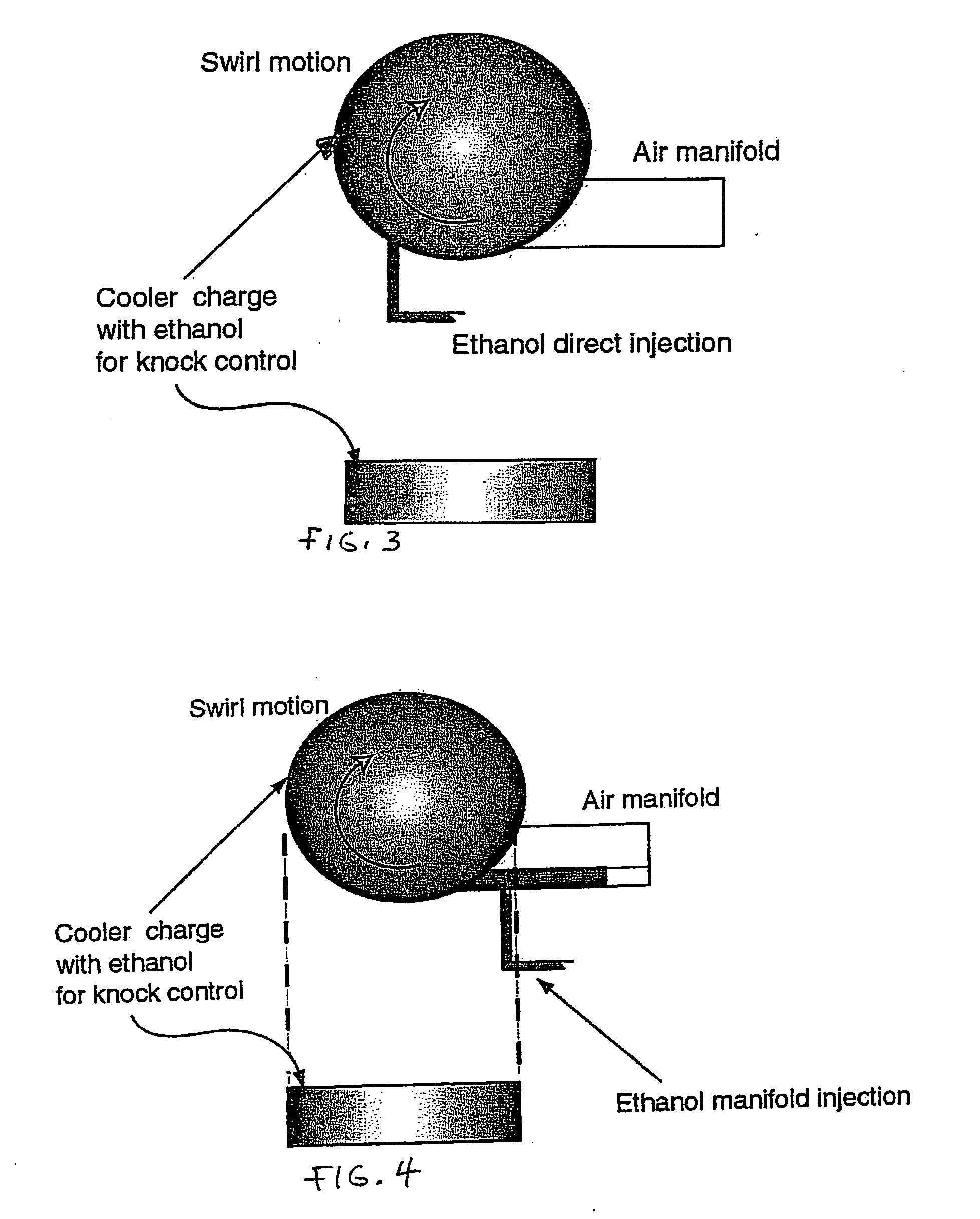

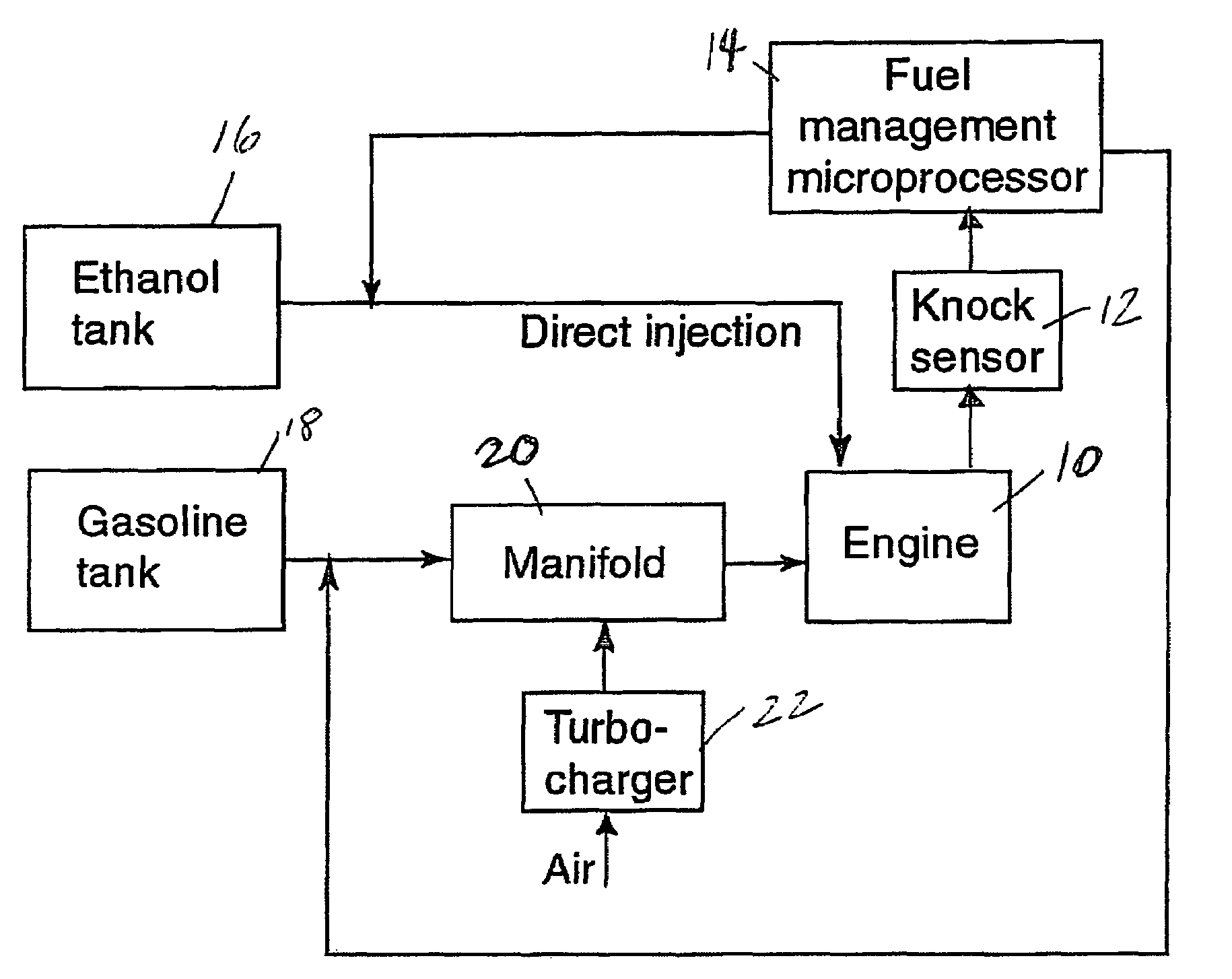

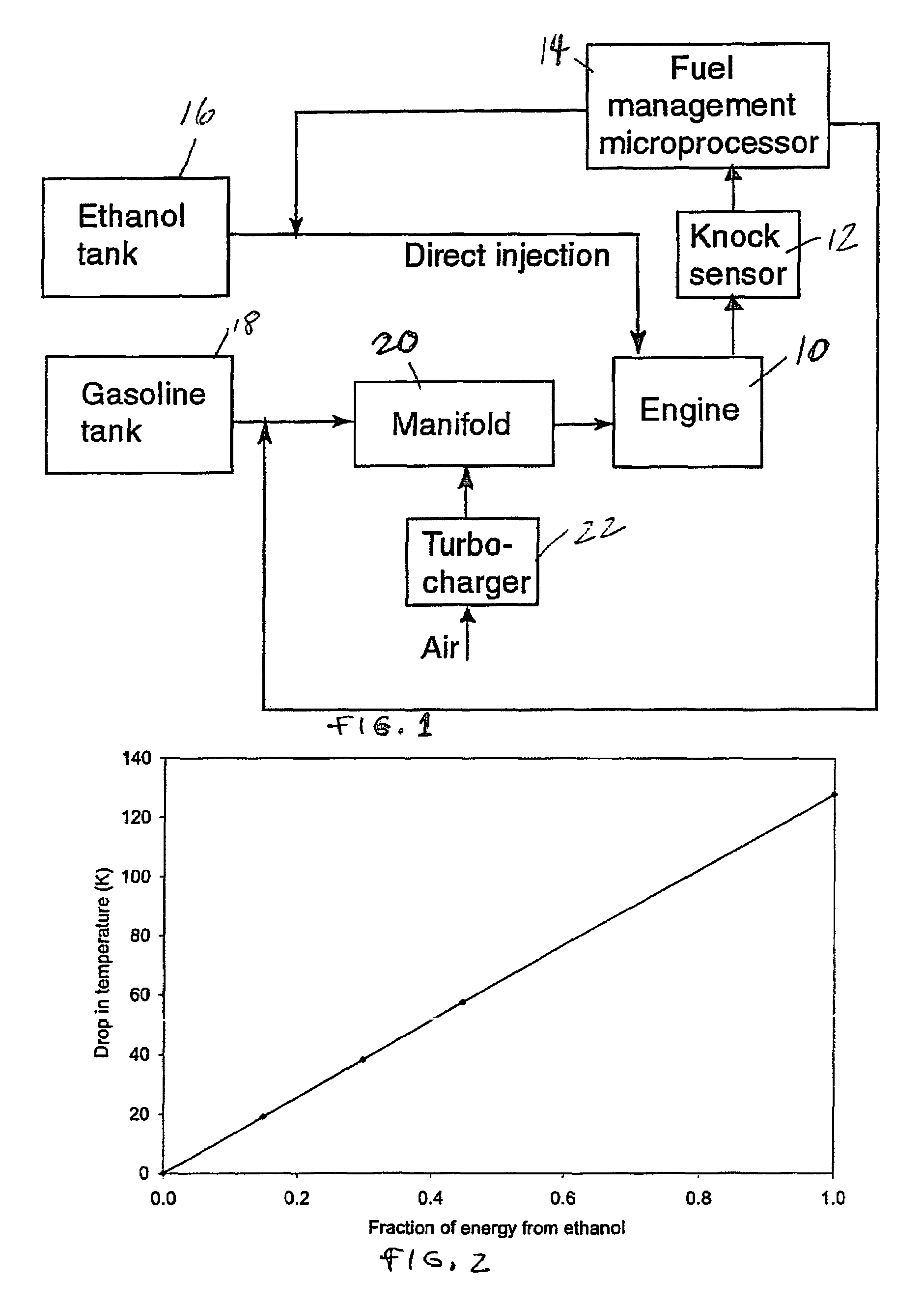

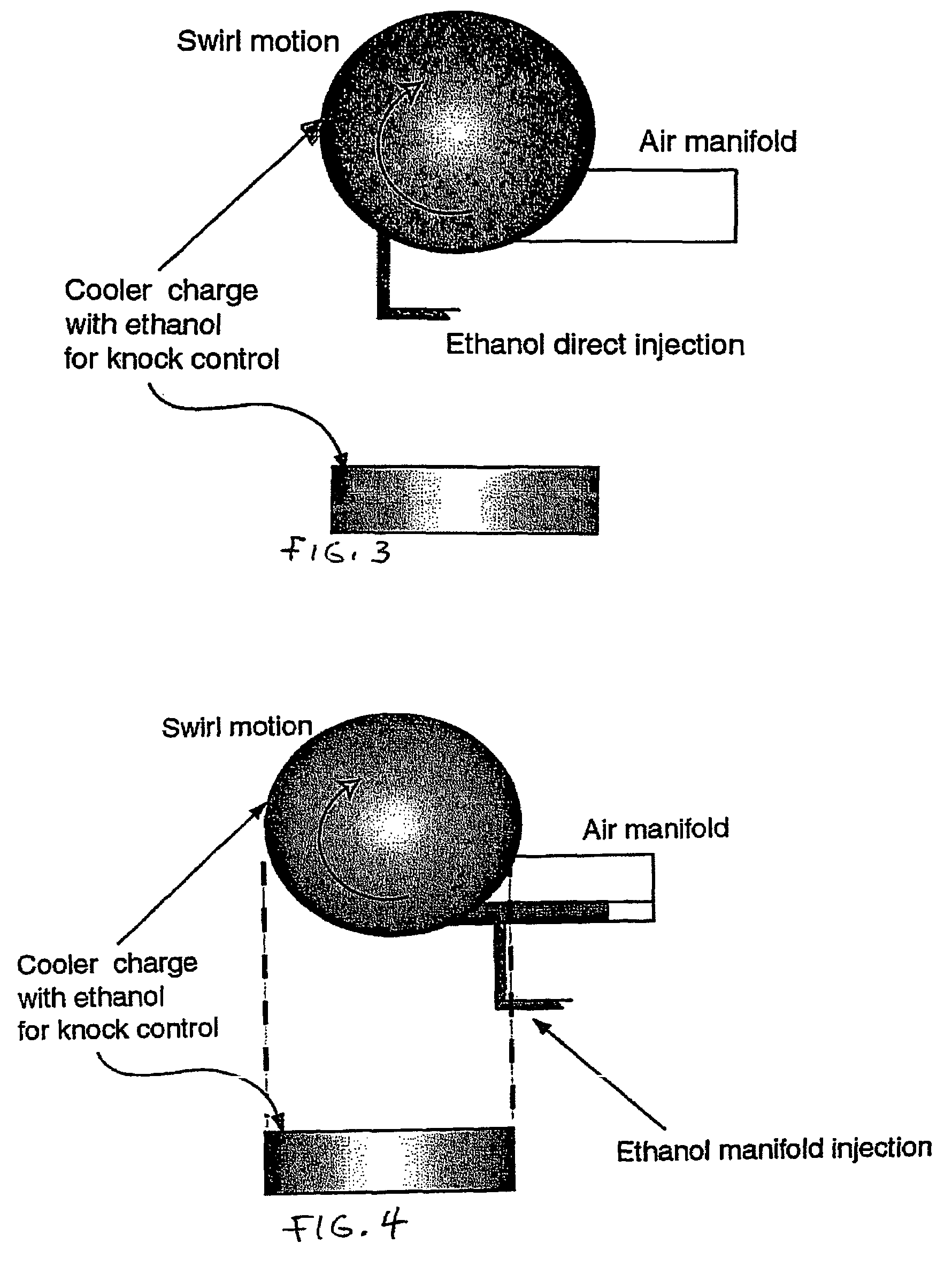

Fuel management system for variable ethanol octane enhancehment of gasoline engines

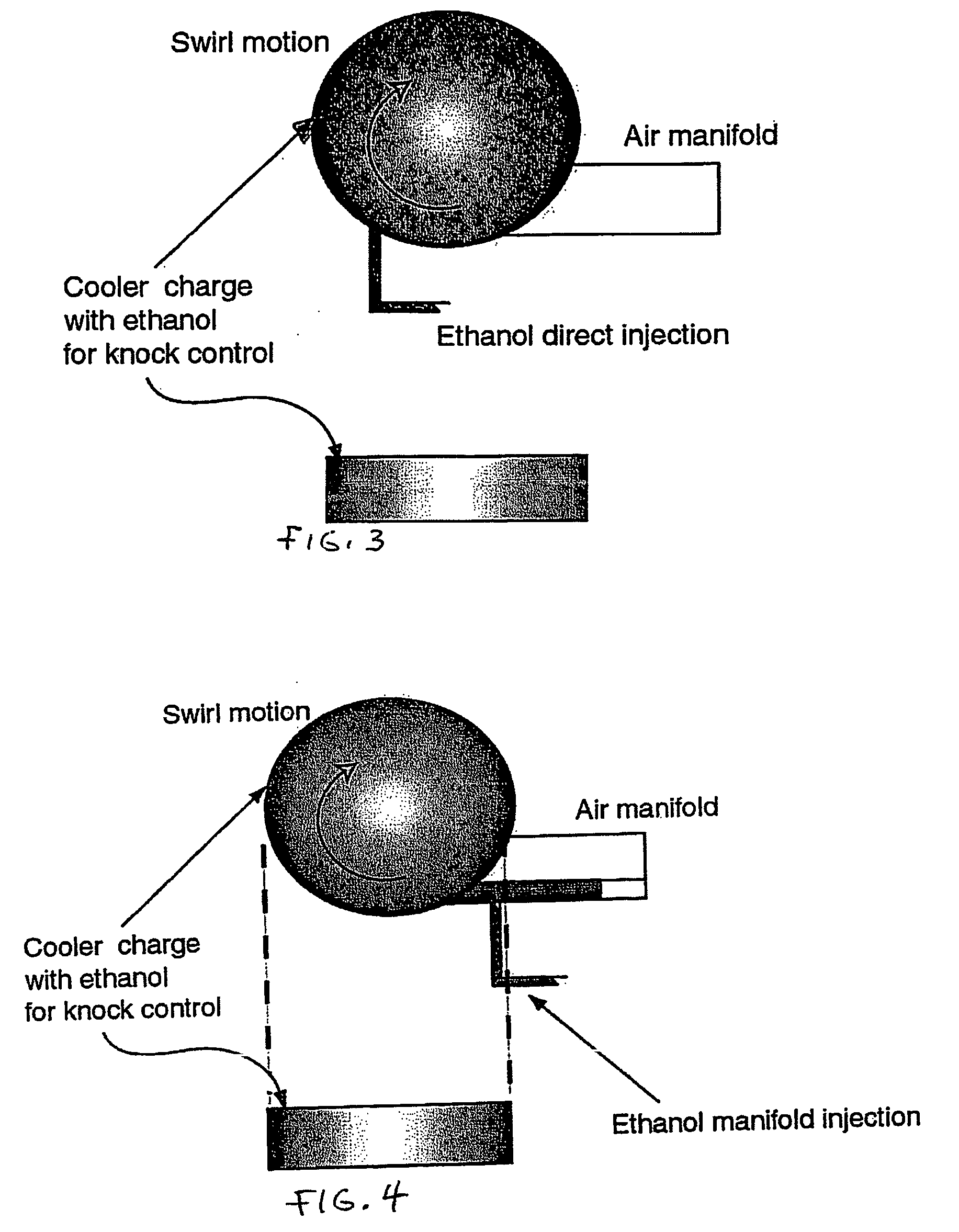

InactiveUS20060102145A1Increase heatMeet cutting requirementsElectrical controlInternal combustion piston enginesEthanol InjectionEngineering

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

Catalyst and process of paraffin hydrocarbon conversion

InactiveUS20040077914A1Improve solubilityEasy to useHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkanePtru catalyst

A catalyst composition and process for the conversion of linear and / or branched paraffin hydrocarbons based on the use of an ionic liquid catalyst in combination with a Brønsted Acid, which provides a catalytic composition with an increased activity compared with said ionic liquid. Under suitable reaction conditions this conversion is leading to paraffin hydrocarbon fraction with higher octane number.

Owner:HALDOR TOPSOE AS

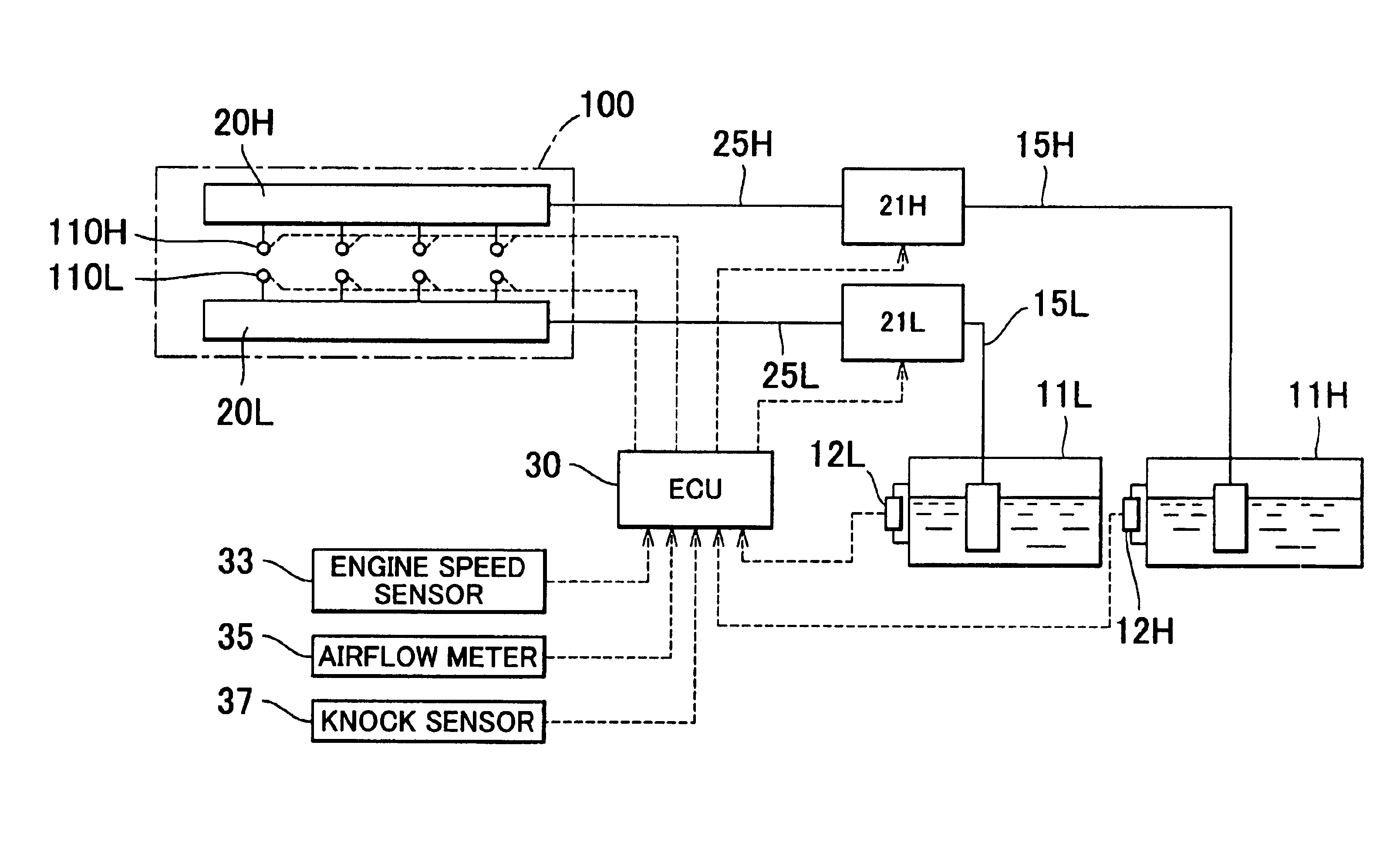

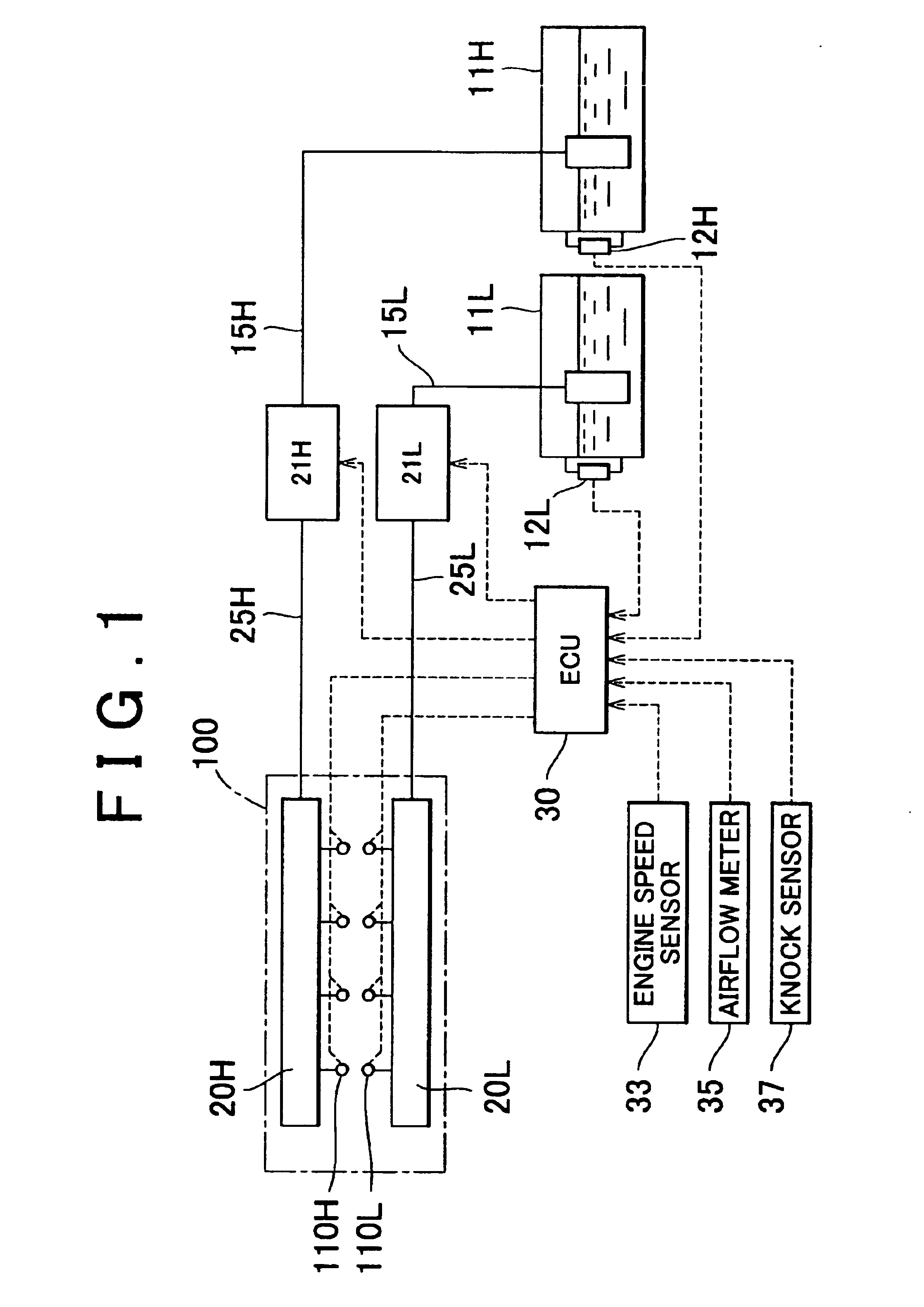

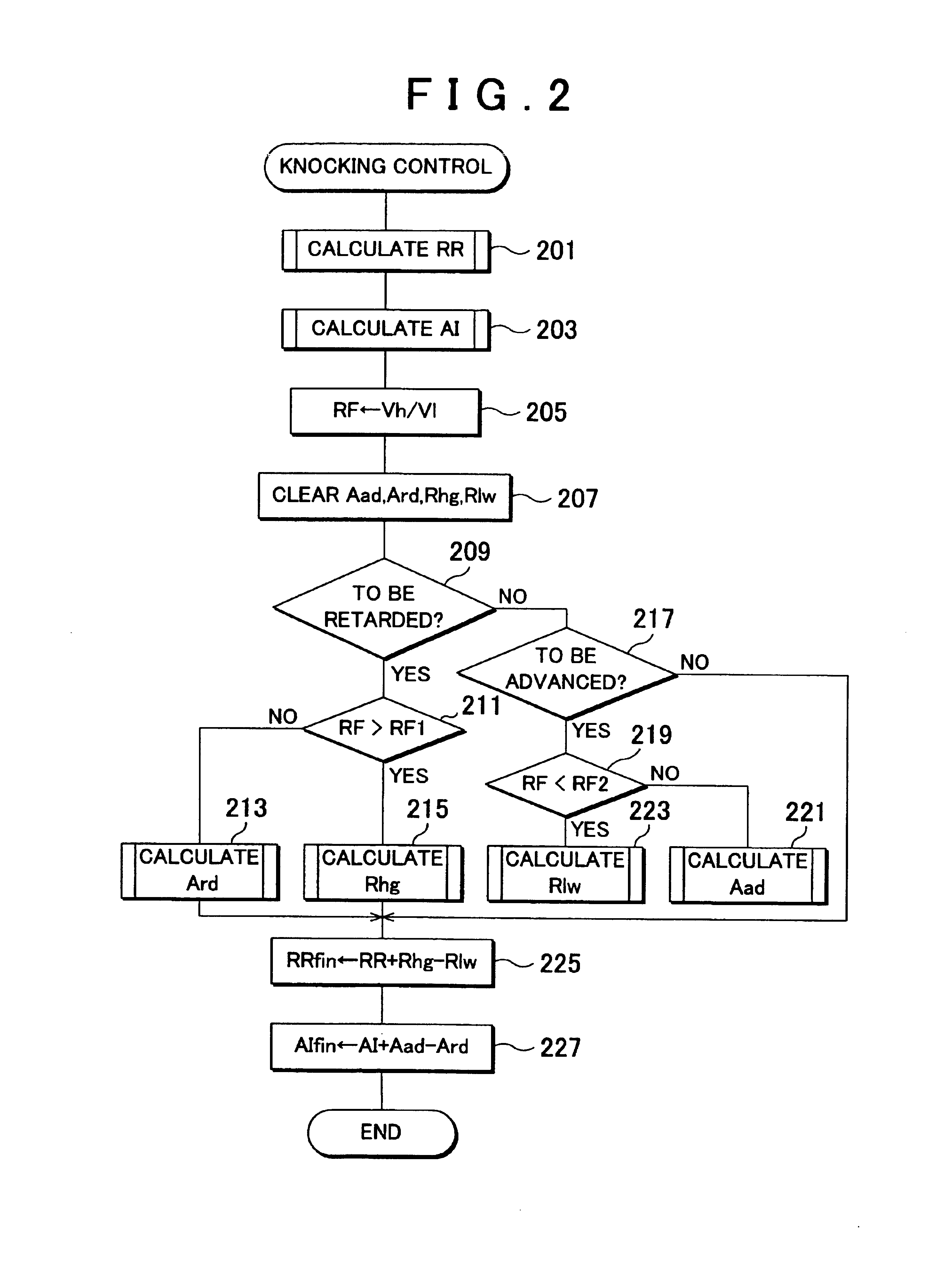

Knocking control system and method for internal combustion engine using multiple fuels

InactiveUS6951202B2Maintain balanceImprove balanceElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

High octane fuel and low octane fuel are supplied into the combustion chamber of an engine from high-octane fuel tank and low octane fuel tank via a high octane fuel injector and a low octane fuel injector. During a knocking control, if the quantity of high and low octane fuels in the respective tanks has been unbalanced, the supply ratio between high octane fuel and low octane fuel is changed 1 to control a knocking occurring in the engine without changing the ignition timing.

Owner:TOYOTA JIDOSHA KK

Fuel management system for variable anti-knock agent octane enhancement of gasoline engines

InactiveUS20060102146A1Increase heatReduces octane requirementElectrical controlNon-fuel substance addition to fuelEthanol InjectionEngineering

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

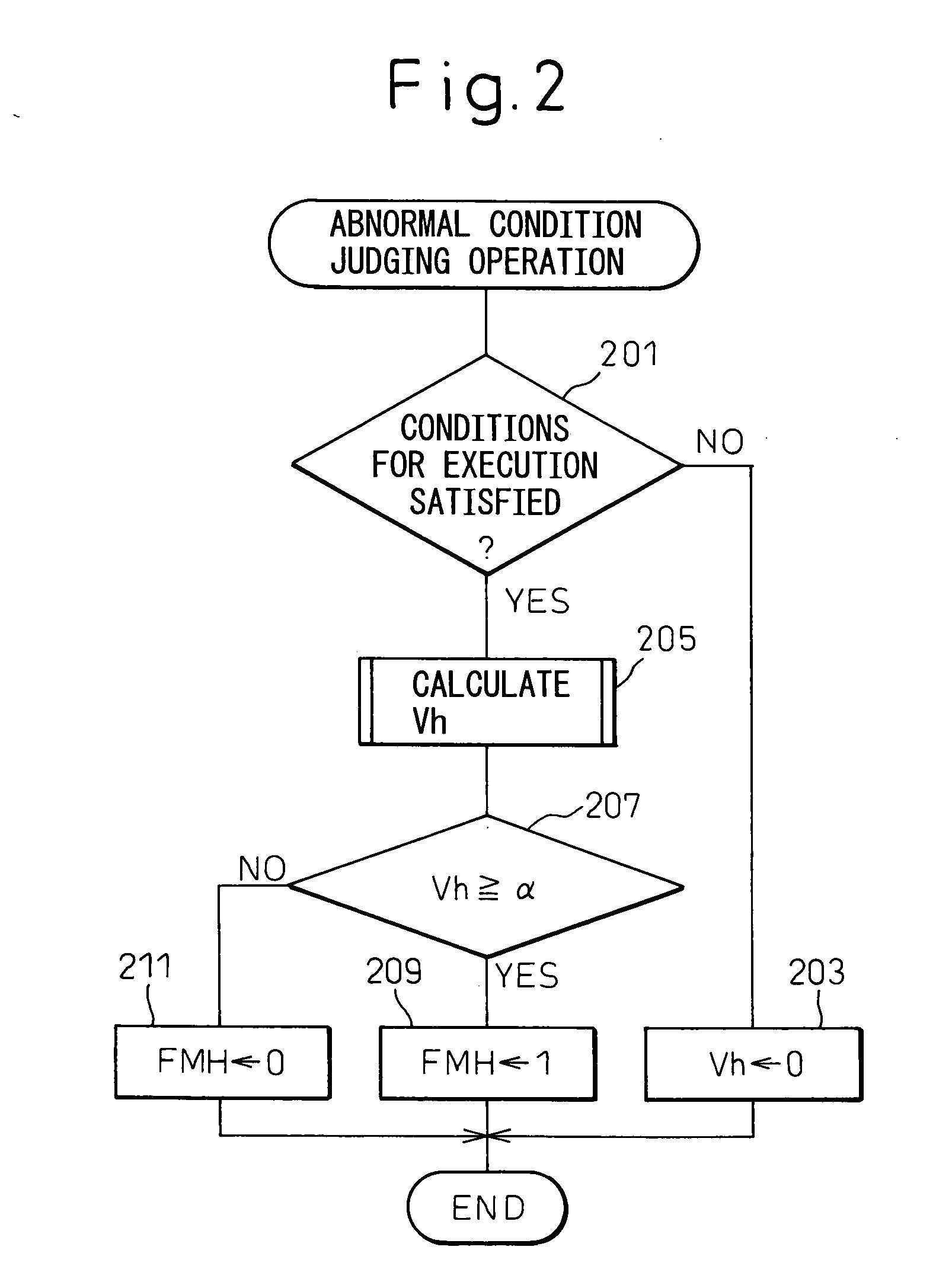

Onboard fuel separation apparatus for an automobile

A fuel separation apparatus includes a fuel tank storing the material fuel fed to a separation membrane, a fuel tank storing a separated low-octane fuel, and a fuel tank storing a separated high-octane fuel. An electronic control unit of the separation apparatus calculates the flow rate (amount of formation) of the high-octane fuel flowing into the high-octane fuel tank based on a change in the liquid level in the tank and on the amount of fuel fed to an engine from the tank, and so judges that an abnormal condition is occurring due to the breakage of the separation membrane when the amount of forming the high-octane fuel is larger than a predetermined upper limit value and that an abnormal condition is occurring due to a drop in the function of the separation membrane when the amount of formation is smaller than a predetermined lower limit value.

Owner:TOYOTA JIDOSHA KK

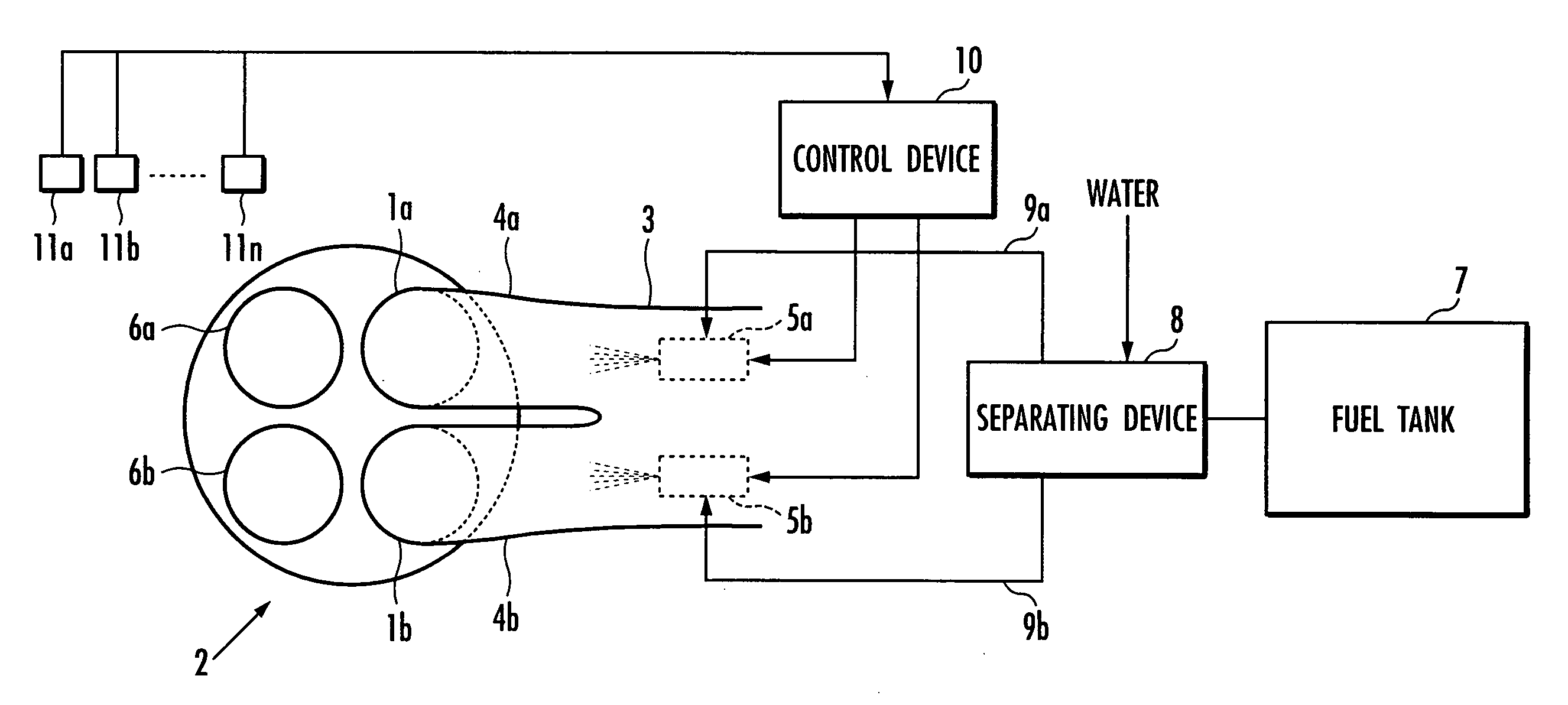

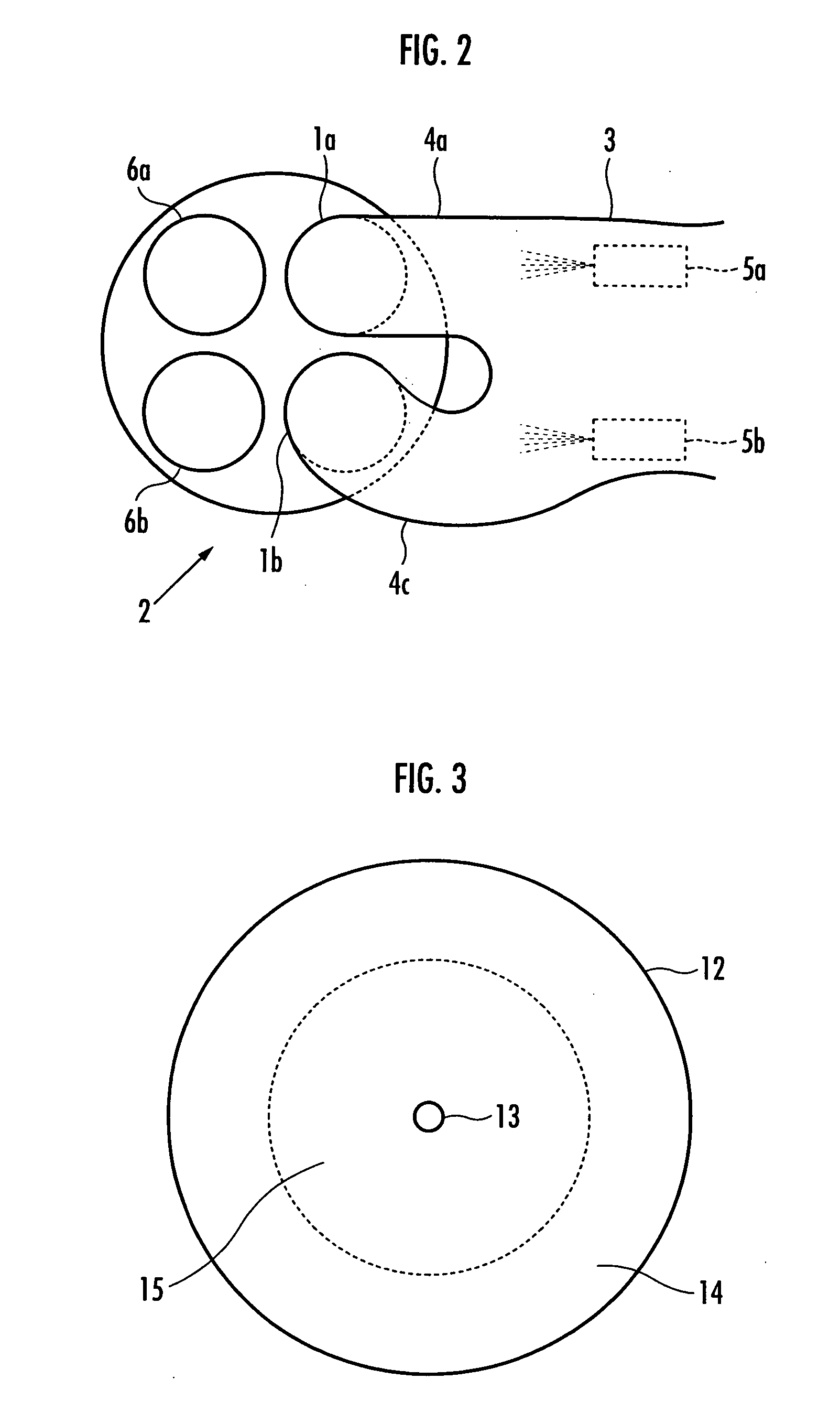

Internal combustion engine

InactiveUS20070034192A1Proportionally largeEasy to getInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberAlcohol

There is provided an internal combustion engine that uses a blended fuel consisting of hydrocarbon and alcohol, and can efficiently operate relative to a wide range of required load. The internal combustion engine includes: intake ports 4a and 4b and two injectors 5a and 5b. The injectors include a first injector 5a that injects a hydrocarbon fuel and a second injector 5b that injects an alcohol fuel. An optimum combustion mode is selected according to an operation state, and the ratio of the alcohol is properly adjusted according to the combustion mode. The intake ports includes a first intake port 4a that guides the hydrocarbon fuel to an inner peripheral portion of a combustion chamber, and a second intake port 4c that guides the alcohol fuel to an outer peripheral portion of the combustion chamber to control octane number distribution in a cylinder. The internal combustion engine further includes separating means 8 for adding water to a blended fuel consisting of alcohol and hydrocarbon to separate into the alcohol fuel consisting of the alcohol and the water and the hydrocarbon fuel.

Owner:HONDA MOTOR CO LTD

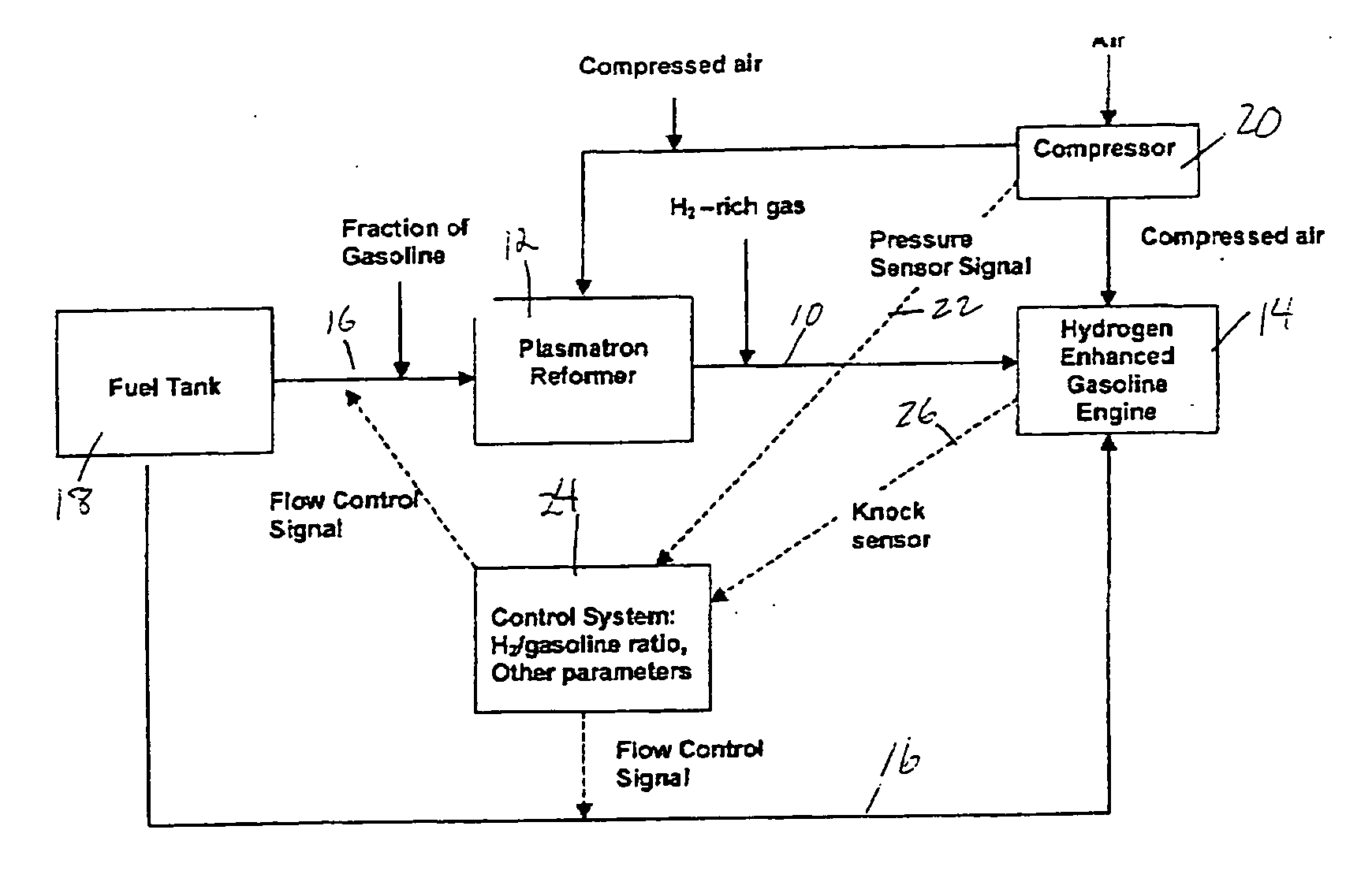

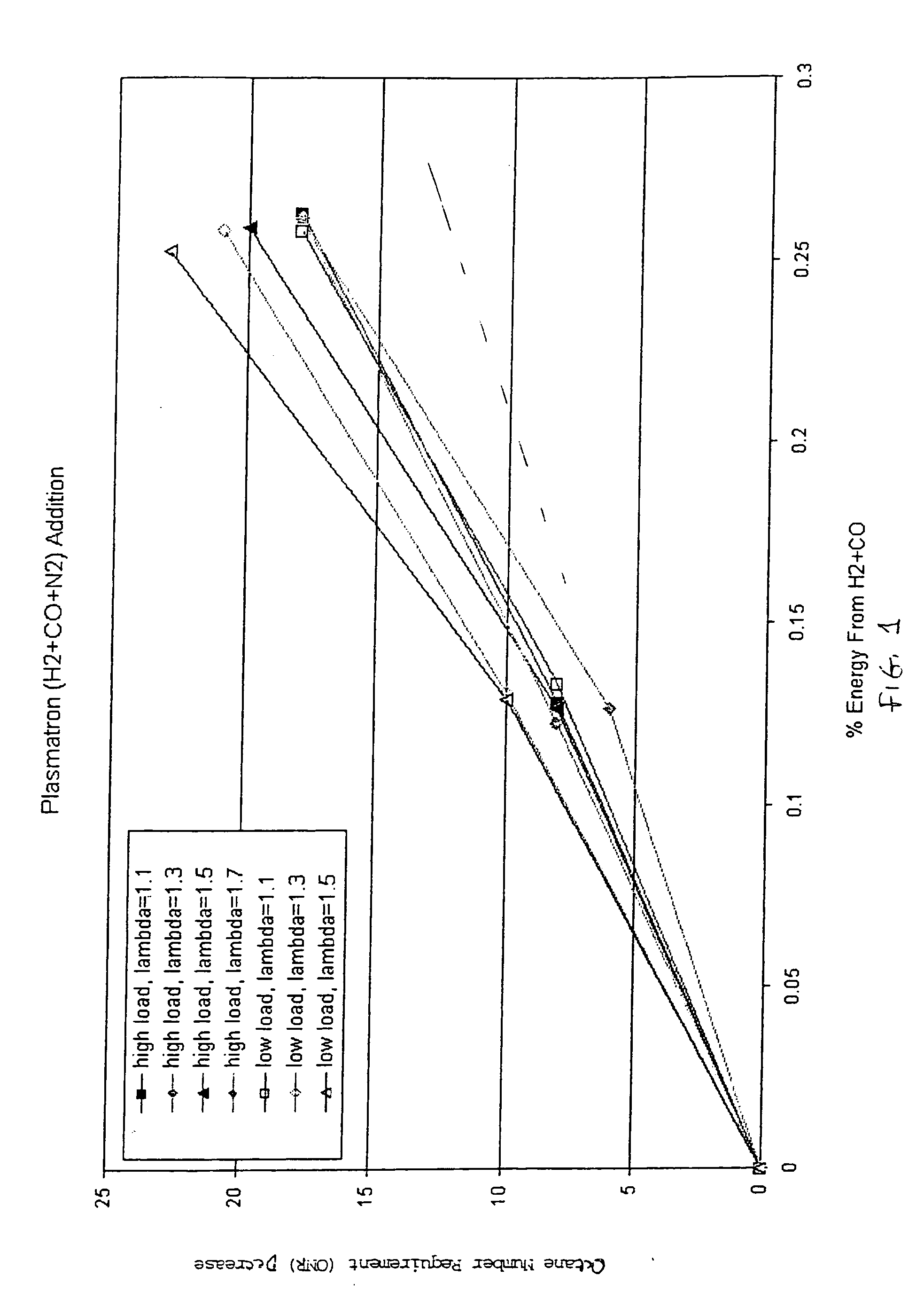

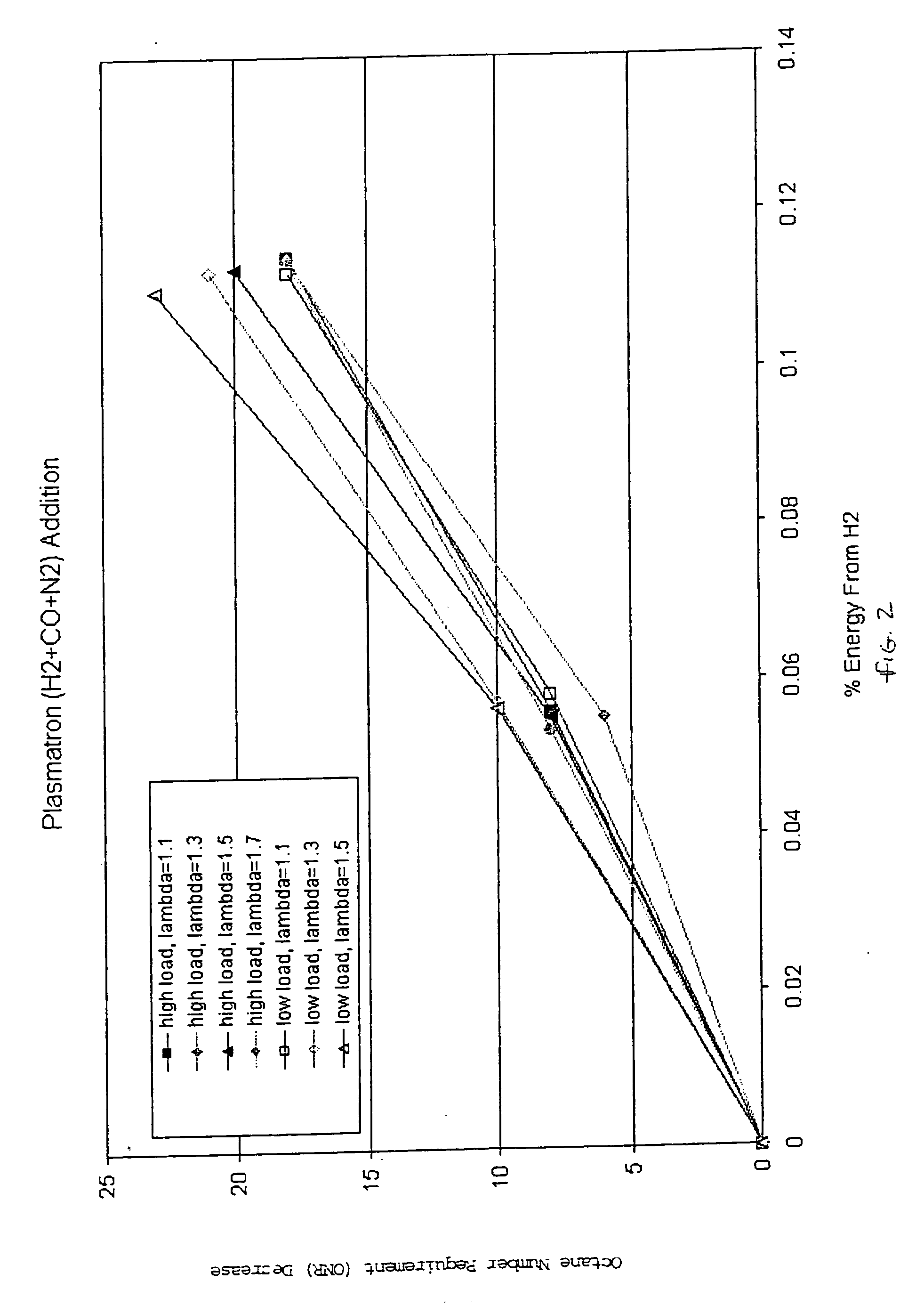

Hydrogen and carbon monoxide enhanced knock resistance in spark ignition gasoline engines

InactiveUS20060075991A1Good anti-knock performanceGreater spark retardElectrical controlNon-fuel substance addition to fuelHydrogenCombustion

A method for reducing required octane number and a spark ignition gasoline engine system with hydrogen-enhanced knock resistance. The method for reducing required octane number of gasoline needed to prevent knock includes the addition of hydrogen or hydrogen-rich gas containing carbon monoxide to gasoline. Octane number can be improved by 5 or more for a hydrogen energy fraction of 10%. The spark ignition gasoline engine system includes a spark ignition gasoline engine and a source of gasoline and hydrogen or hydrogen-rich gas. Apparatus is provided to supply the gasoline and the hydrogen or hydrogen-rich gas to the engine at a varying hydrogen or hydrogen-rich gas to gasoline ratio selected both to prevent knock and to ensure a desired level of combustion stability throughout a full range of engine operation. The engine system may be normally aspirated or boosted; the compression ratio may be high such as greater than 11 or below 11, and EGR may be added. The hydrogen or hydrogen-rich gas to gasoline ratio may be controlled as a function of boost pressure, torque, engine speed, or air / fuel mixture ratio.

Owner:HEYWOOD JOHN B +4

Onboard fuel separation apparatus for an automobile

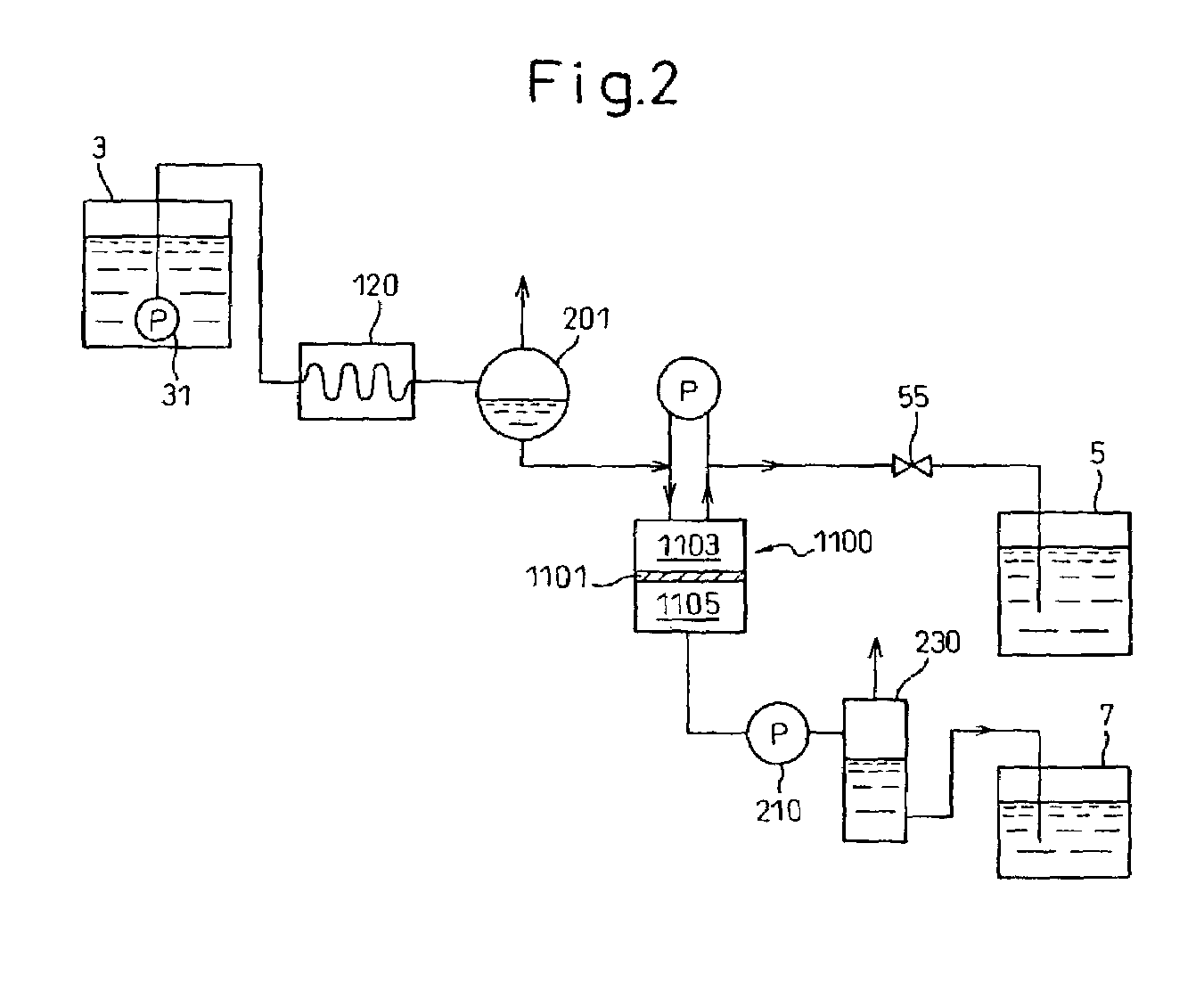

InactiveUS6972093B2Increase volumeBoost octaneInternal combustion piston enginesUsing liquid separation agentVolatilesEngineering

An onboard fuel separation apparatus separates a material fuel (gasoline) into a high-octane fuel having a higher octane value than the material fuel and a low-octane fuel having a lower octane value than the material fuel using a separation membrane which selectively allows high-octane value components (such as aromatic components) permeate through the membrane. The apparatus increases the ratio of the amount of the high-octane value components permeating through the membrane to the amount of the high-octane value components contained in the material fuel by, (A) Controlling the temperature of the material fuel supplied to the membrane (B) Increasing partial pressure of the low-octane value components on the high-octane fuel side of the membrane and removing volatiles from the permeate, and (C) Bypassing volatiles in the material feed around the membrane.

Owner:EXXON RES & ENG CO +1

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Liquid phase aromatics alkylation process

InactiveUS7476774B2Improve overall utilizationEasy to useLiquid carbonaceous fuelsHydrocarbonsAlkylationChemistry

A process for the production of high octane number gasoline from light refinery olefins and benzene-containing aromatic streams such as reformate. Light olefins including ethylene and propylene are extracted from refinery off-gases, typically from the catalytic cracking unit, into a light aromatic stream such as reformate containing benzene and other single ring aromatic compounds which is then reacted with the light olefins to form a gasoline boiling range product containing akylaromatics. The alkylation reaction is carried out in the liquid phase with a catalyst which preferably comprises a member of the MWW family of zeolites such as MCM-22 using a fixed catalyst bed.

Owner:EXXON RES & ENG CO

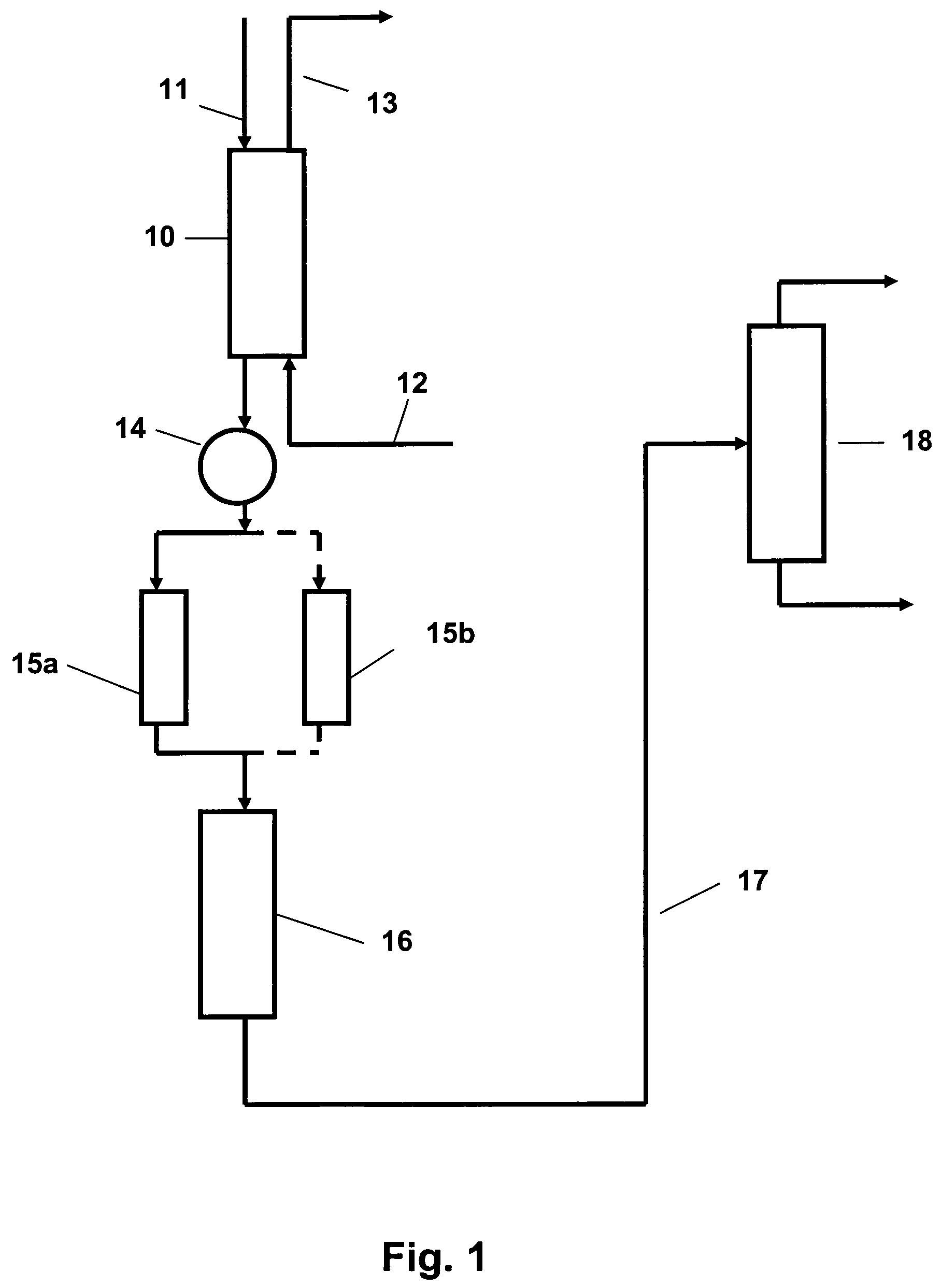

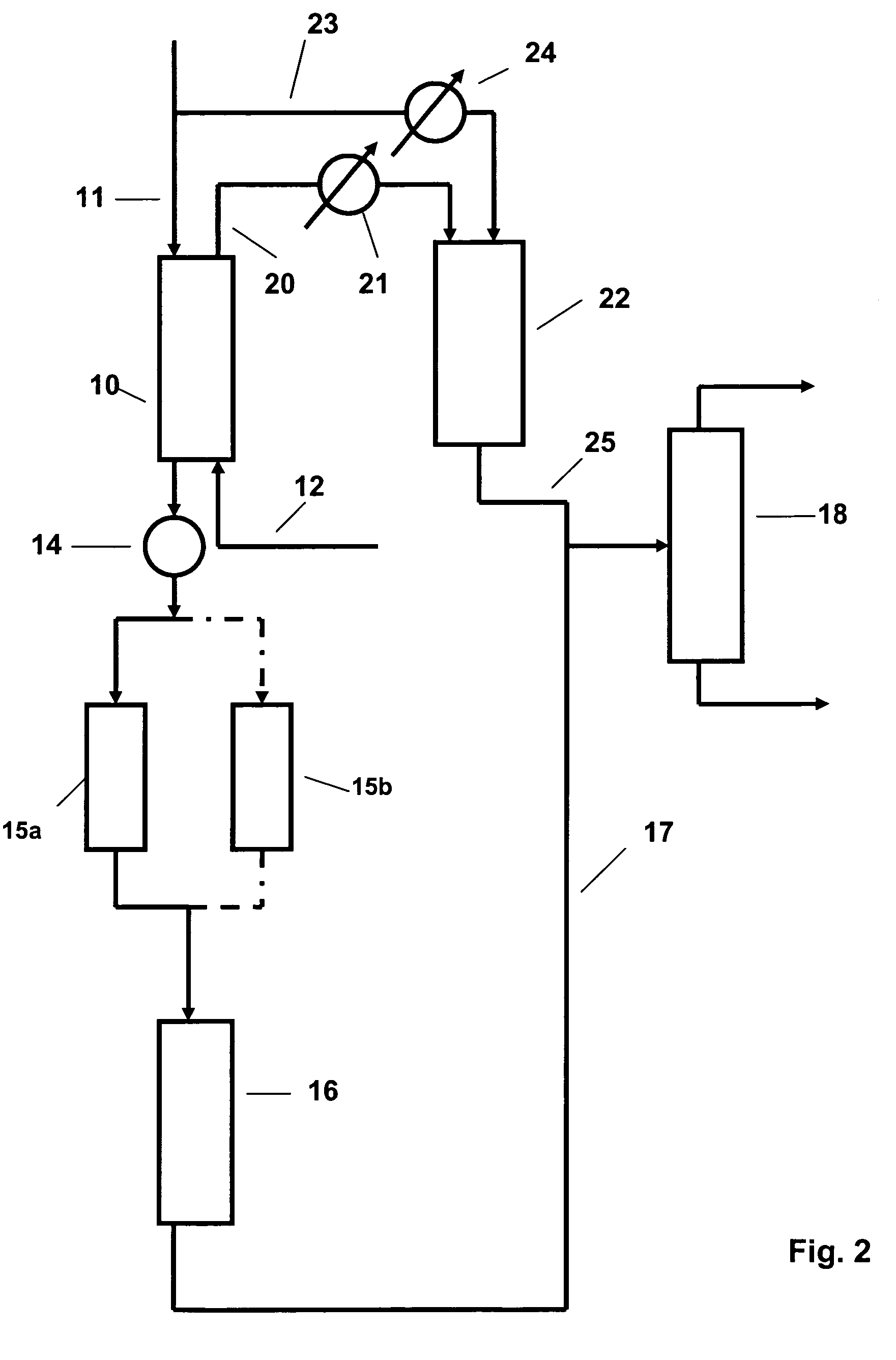

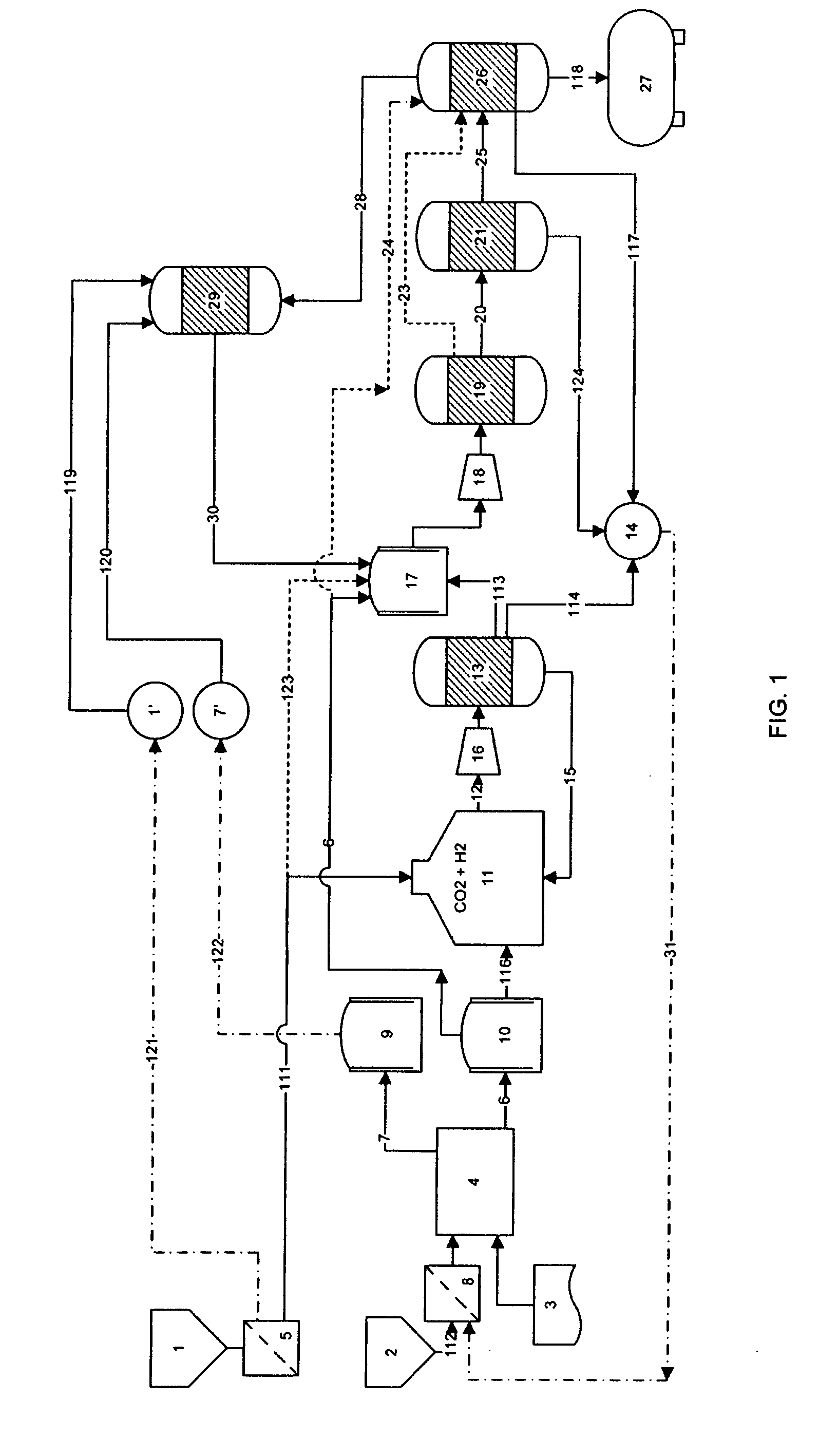

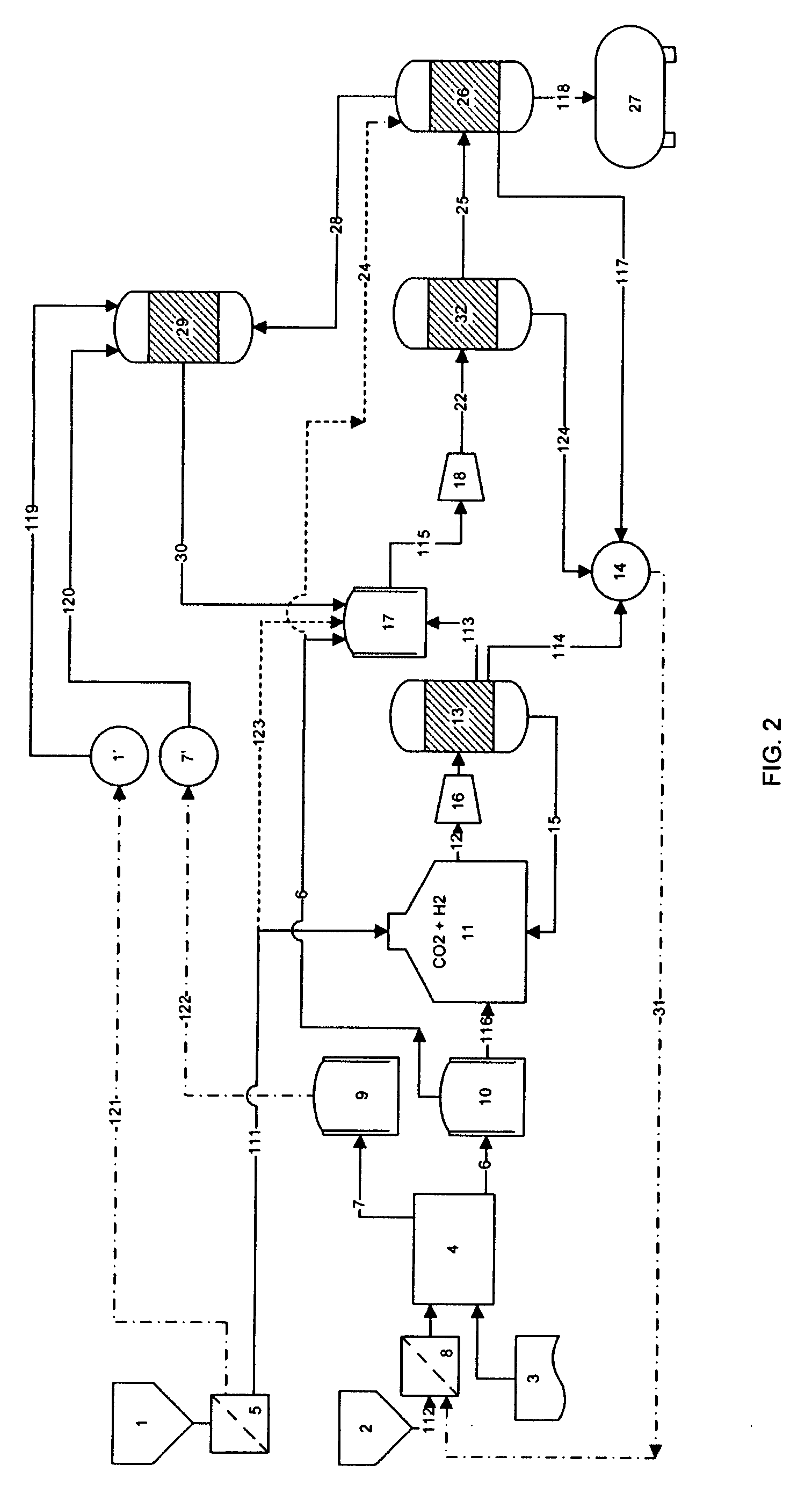

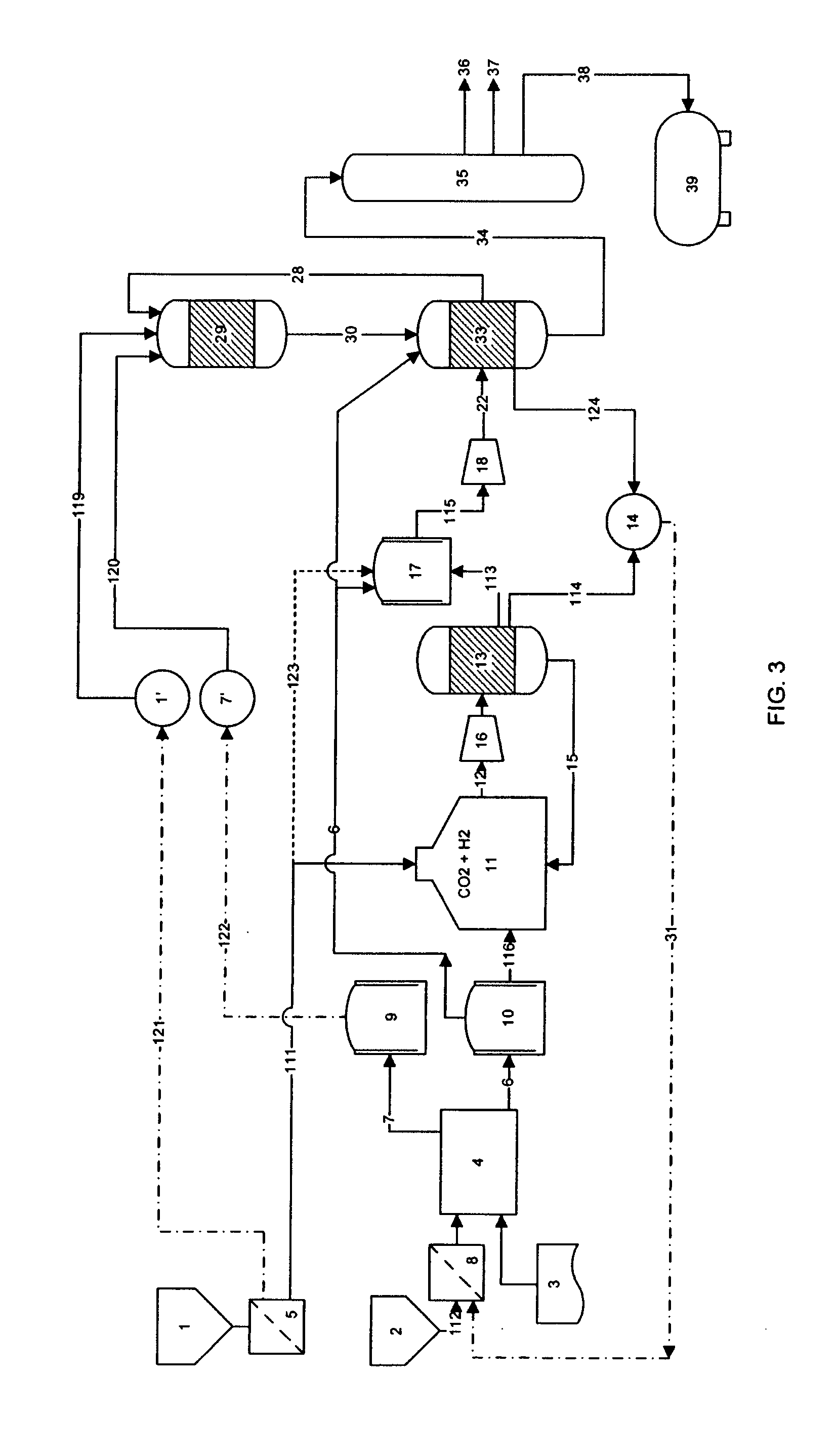

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

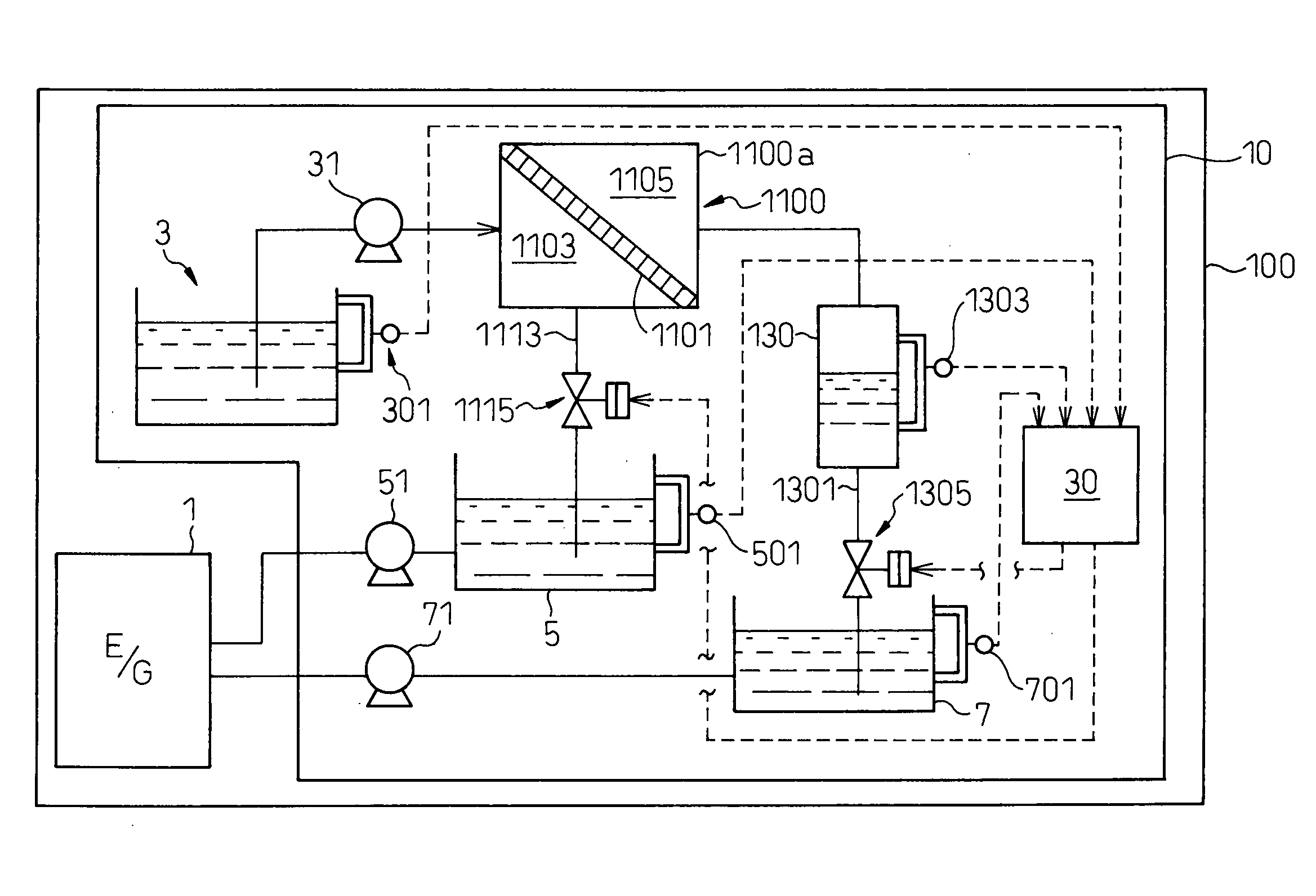

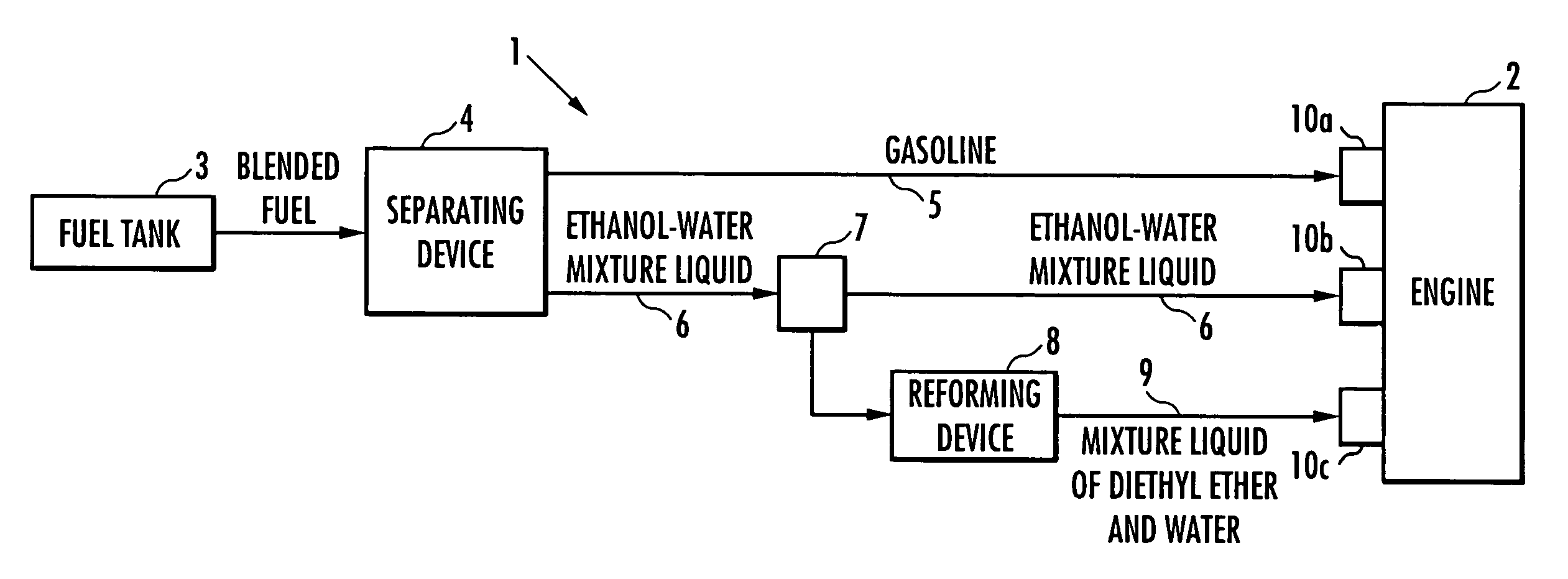

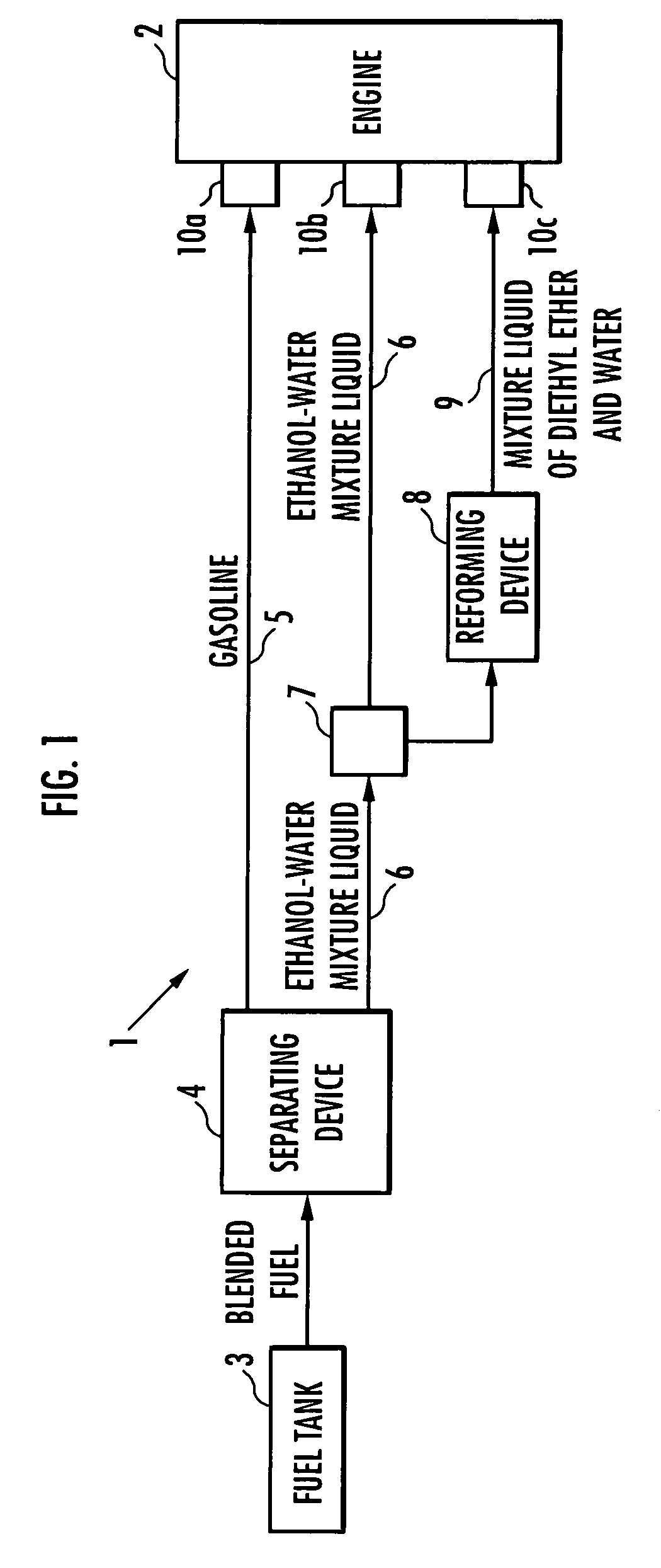

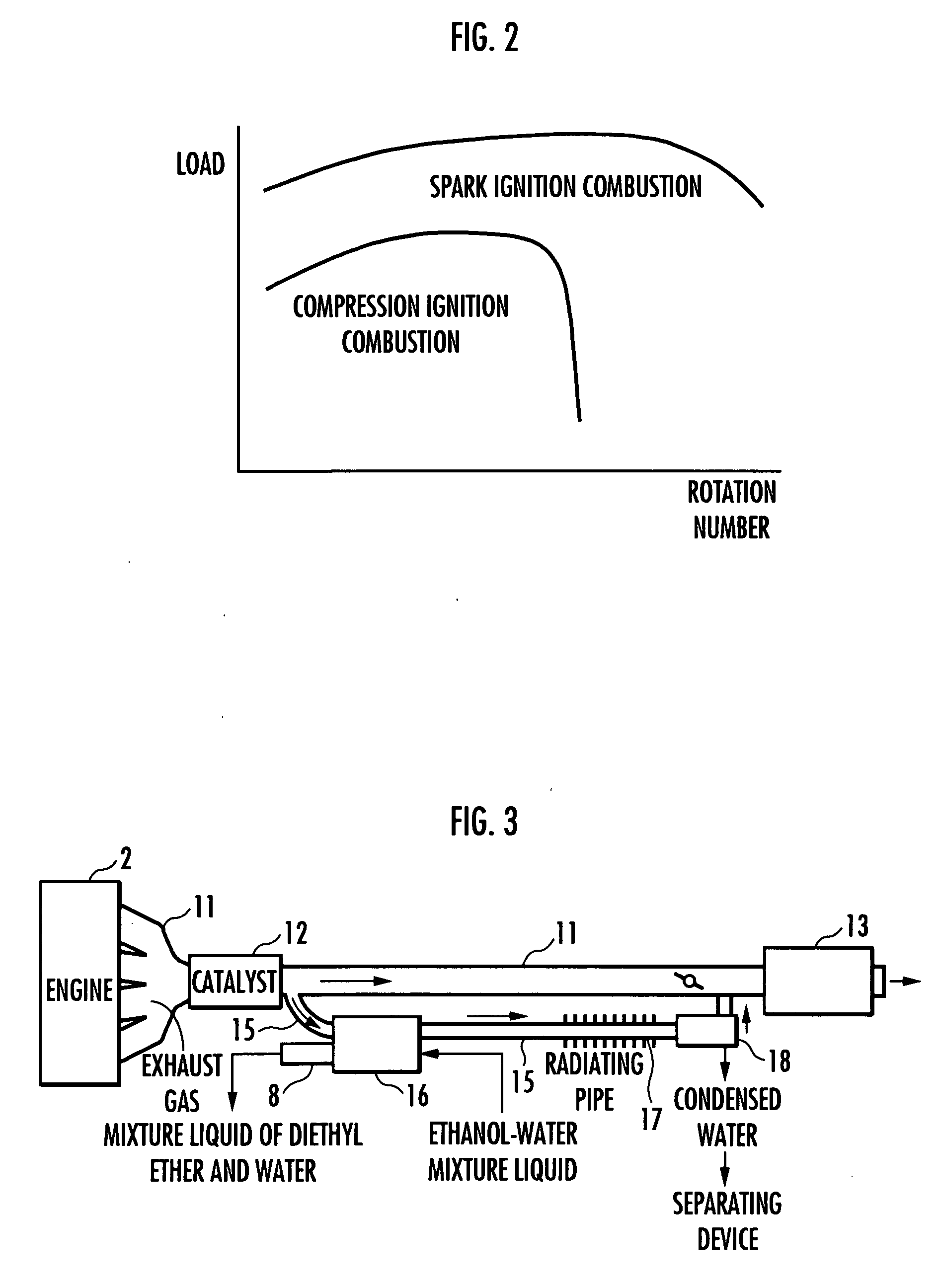

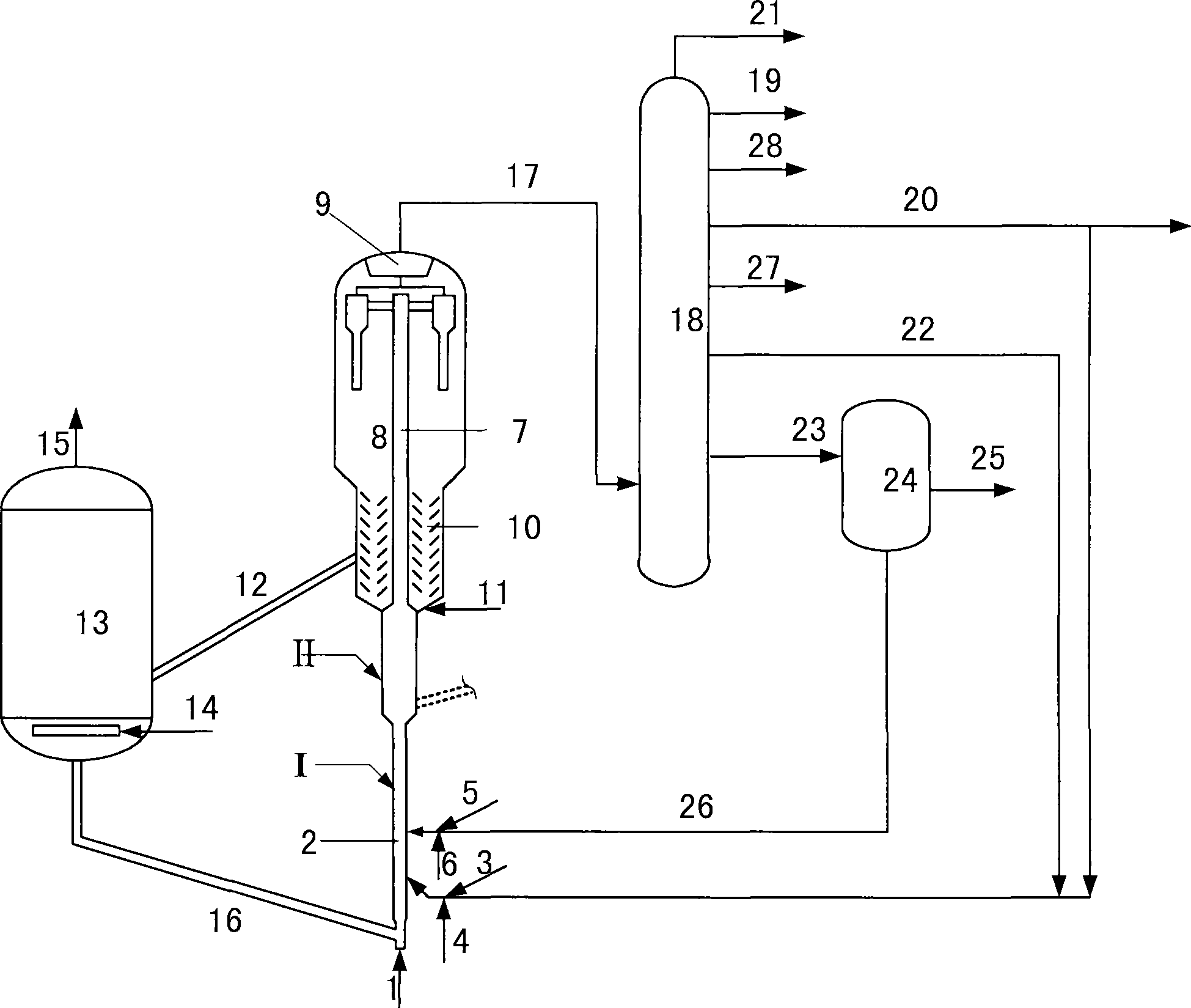

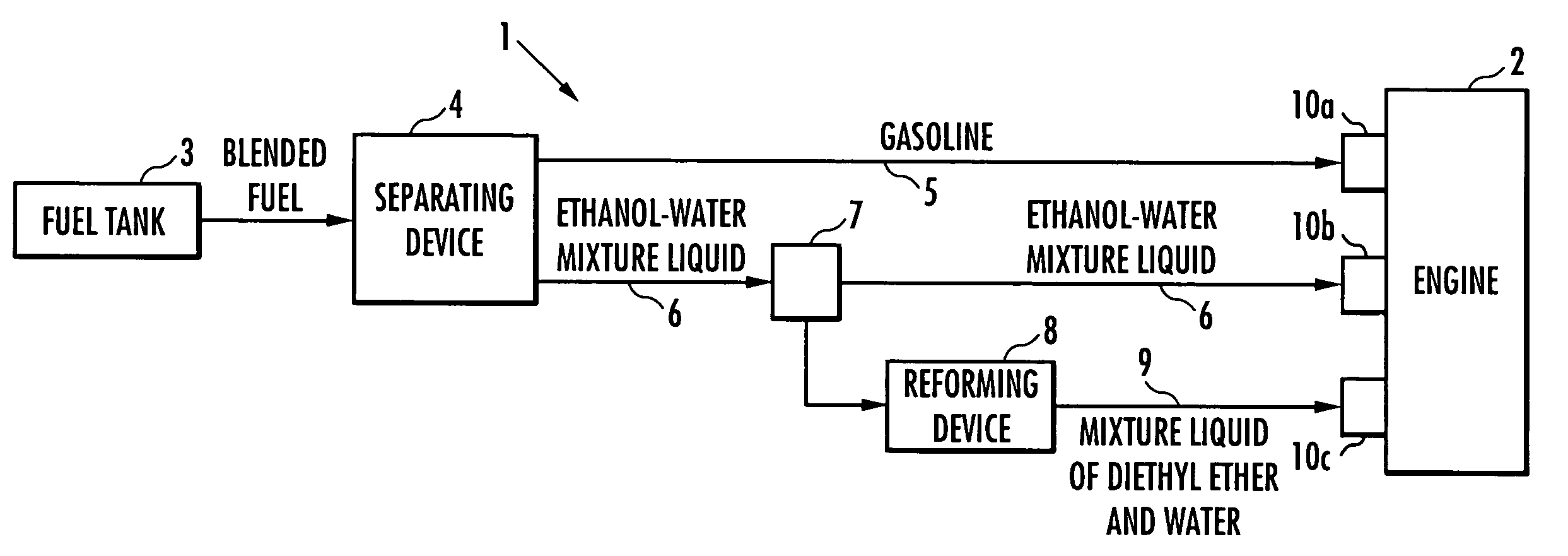

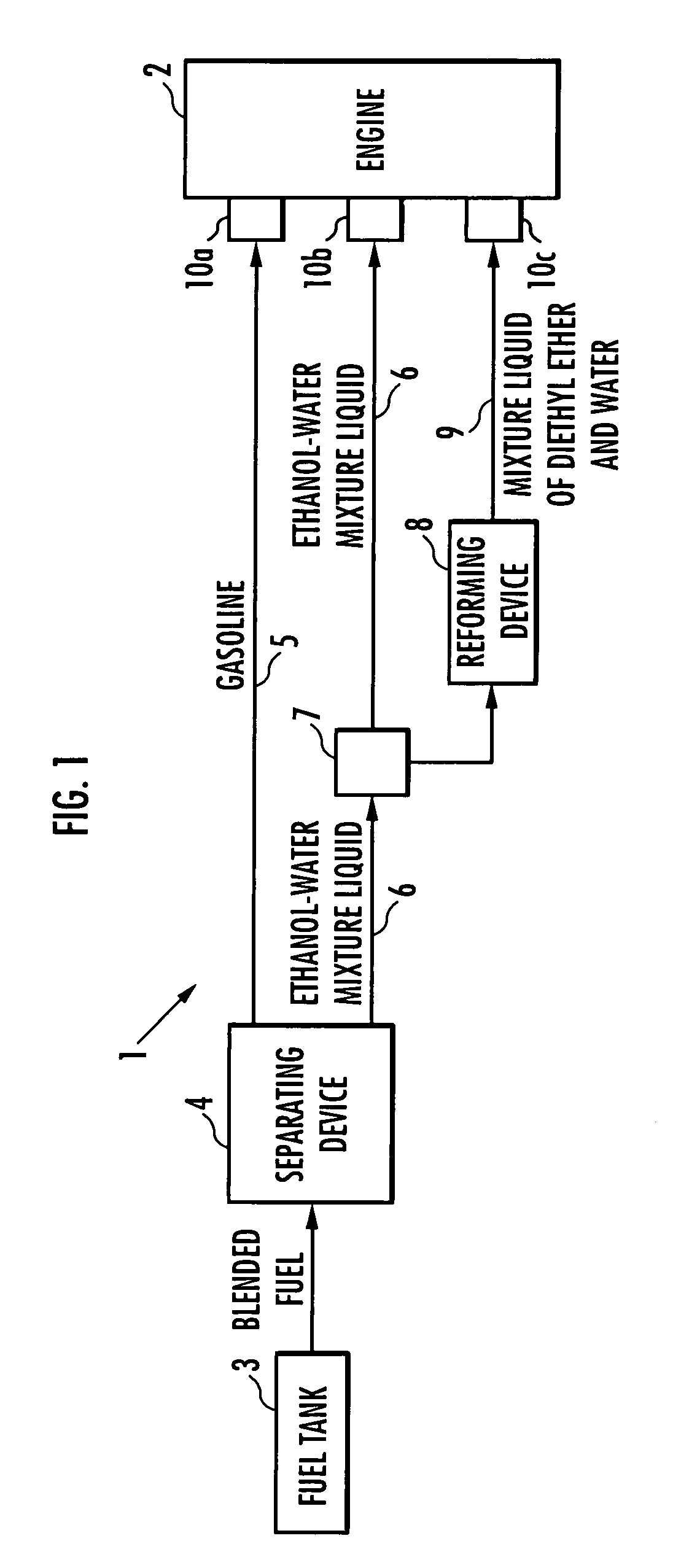

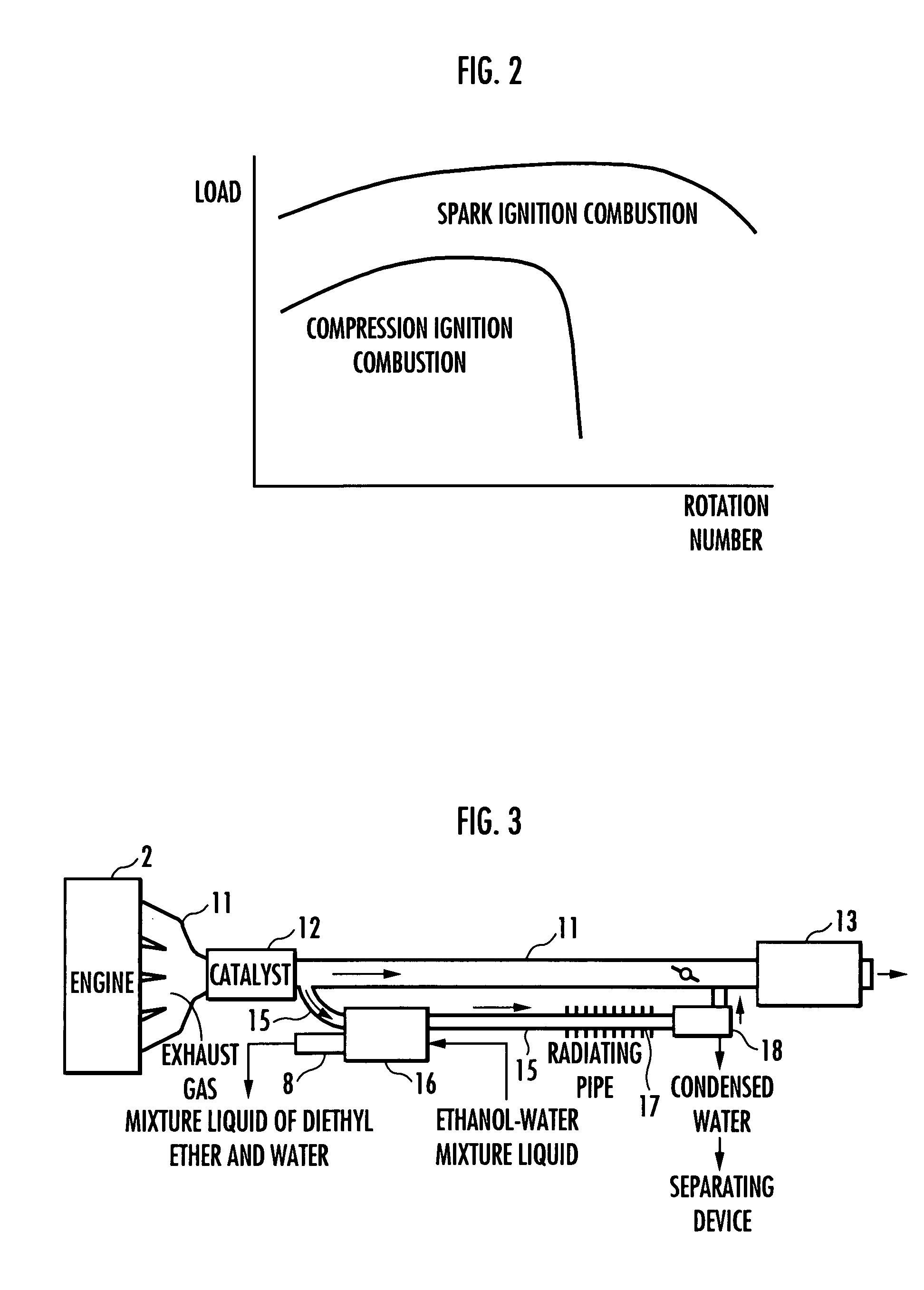

Internal combustion engine system

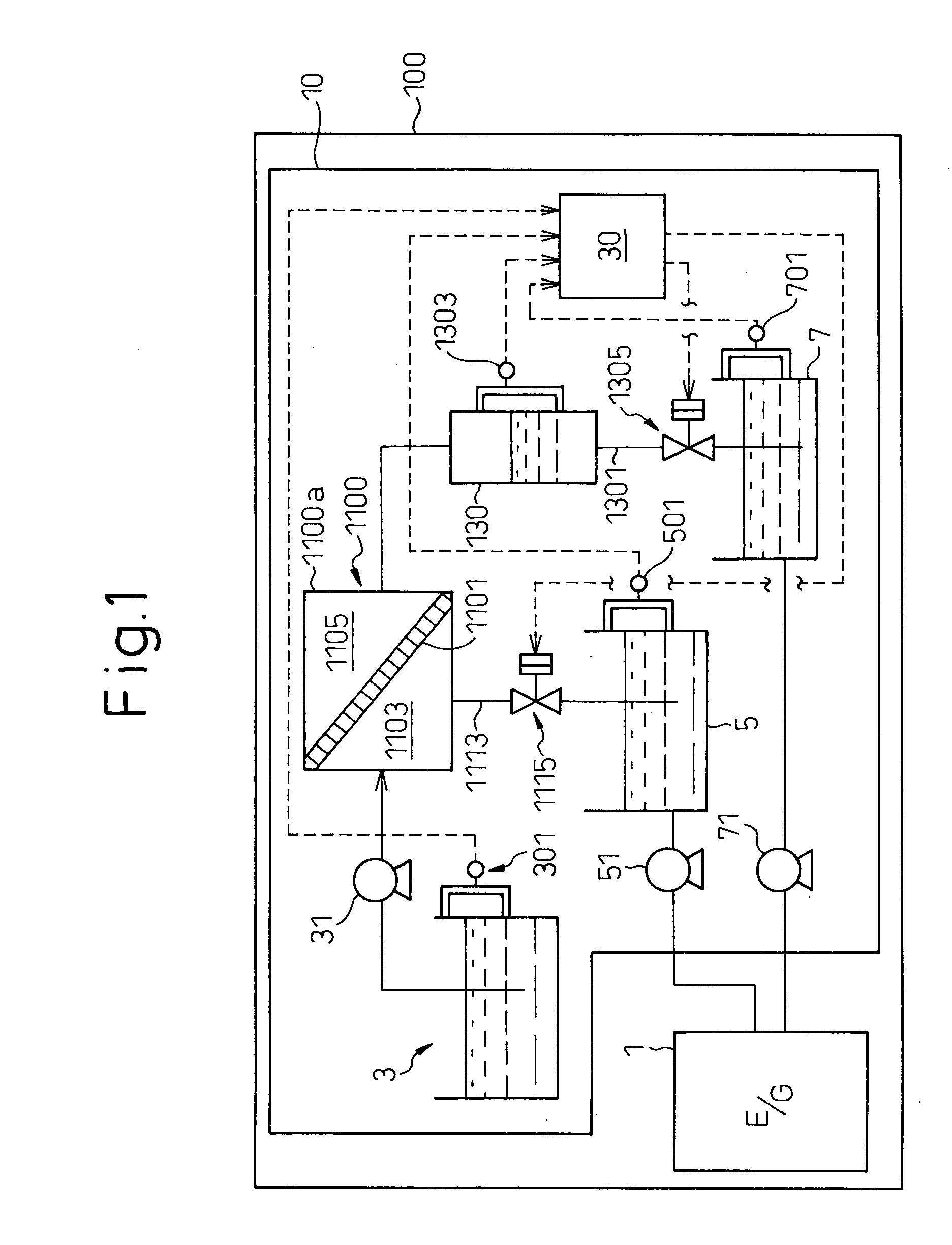

InactiveUS20070221163A1Improve efficiencyEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionFuel tank

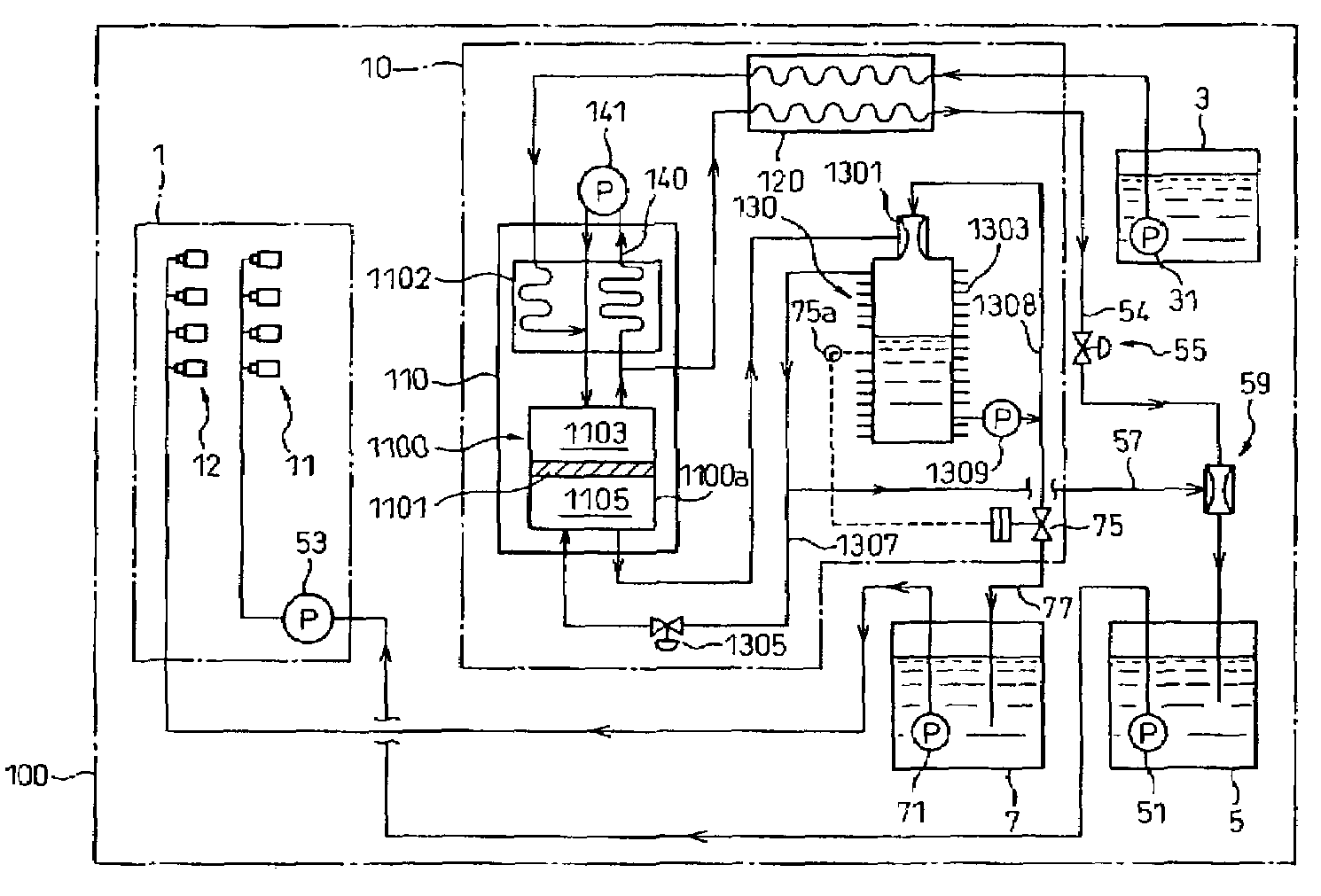

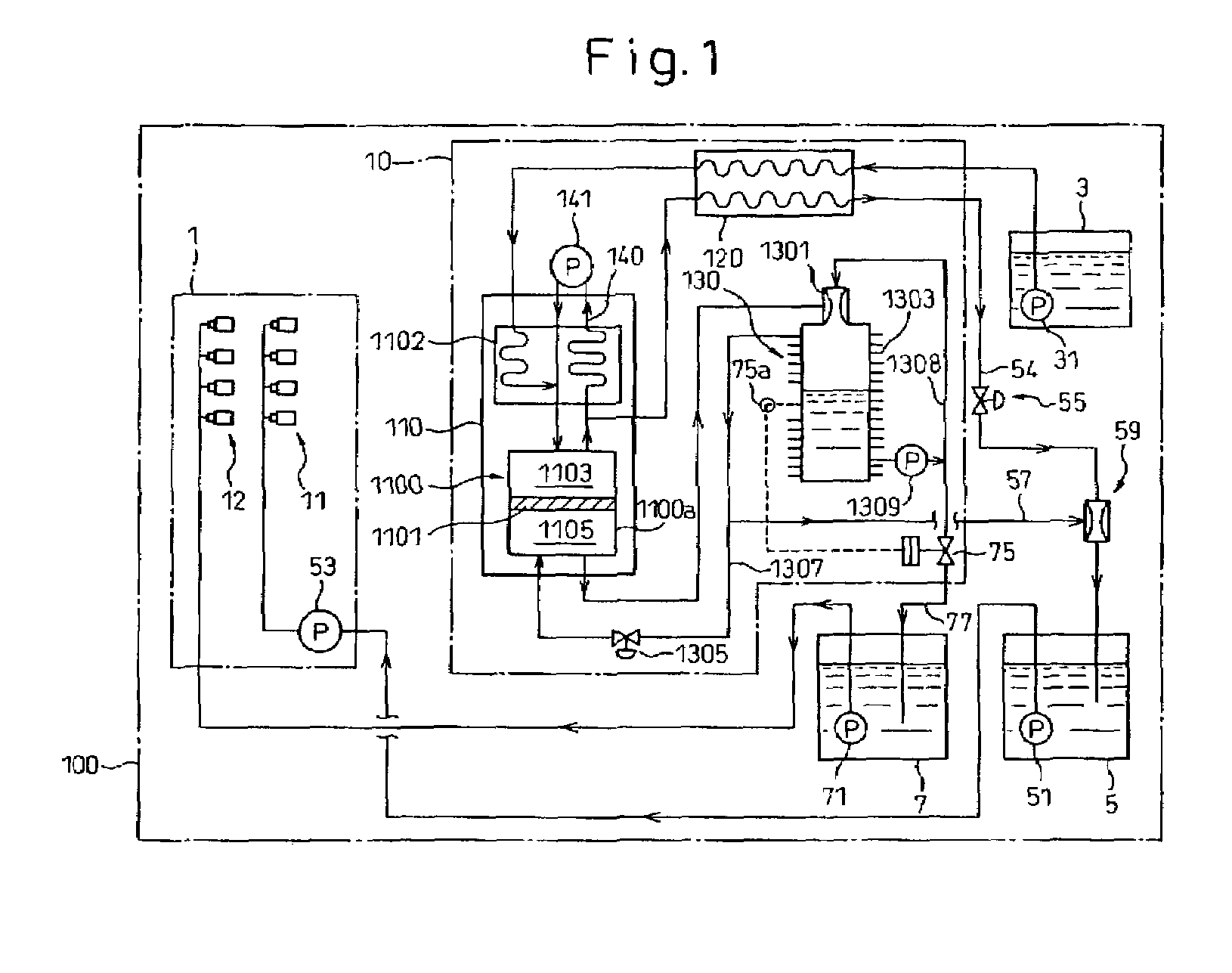

The present invention provides an internal combustion engine system which uses a blended fuel of gasoline and ethanol, operates with high efficiency, and can inhibit nitrogen oxide and the like from being discharged. The internal combustion engine system comprises: a fuel tank 3 that accommodates a blended fuel having an octane number of 80 to 100, which has been prepared by blending gasoline having the octane number of 30 to 85 and ethanol into a weight ratio between 9:1 and 6:4; separating means 4 for adding water to the blended fuel to separate the blended fuel into the gasoline and an ethanol-water mixture liquid; reforming means 8 for reforming one part of the ethanol-water mixture liquid to produce a mixture liquid of diethyl ether and water; and fuel injectors 10a, 10b and 10c which independently inject each of the gasoline, the ethanol-water mixture liquid and the mixture liquid of diethyl ether and water. The internal combustion engine system conducts spark ignition combustion when a load is high, and conducts homogeneous charge compression ignition combustion when the load is low.

Owner:HONDA MOTOR CO LTD

Hydrocracking method for producing high-octane petrol

ActiveCN101724454AWide applicabilitySimple methodTreatment with hydrotreatment processesHydrogenGasoline

The invention discloses a hydrocracking method for producing high-octane petrol, which comprises the following steps that: raw oil and hydrogen gas are mixed and then enter a first reactor for impurity removal reaction; and reaction effluent enters a second reactor for hydrocracking reaction which uses an appropriate catalyst and is performed under a certain content of nitrogen. Compared with the prior art, the method has the characteristics of machining poorer raw materials and having long running period of the catalyst, good quality of a hydrocracking product and the like. The method is mainly used for the hydrocracking technological process for producing the high-octane petrol by using diesel fractions with various high arene contents as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

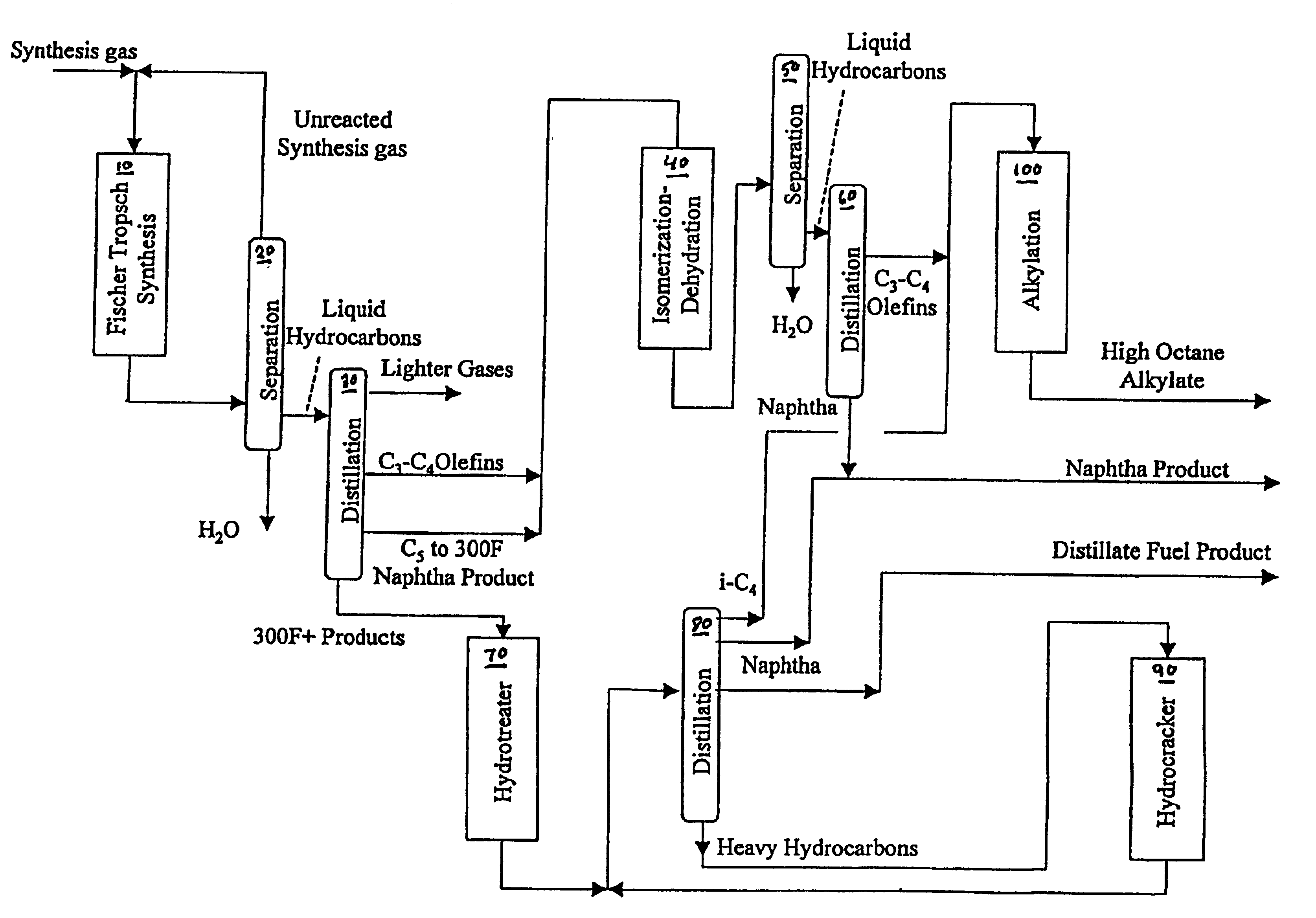

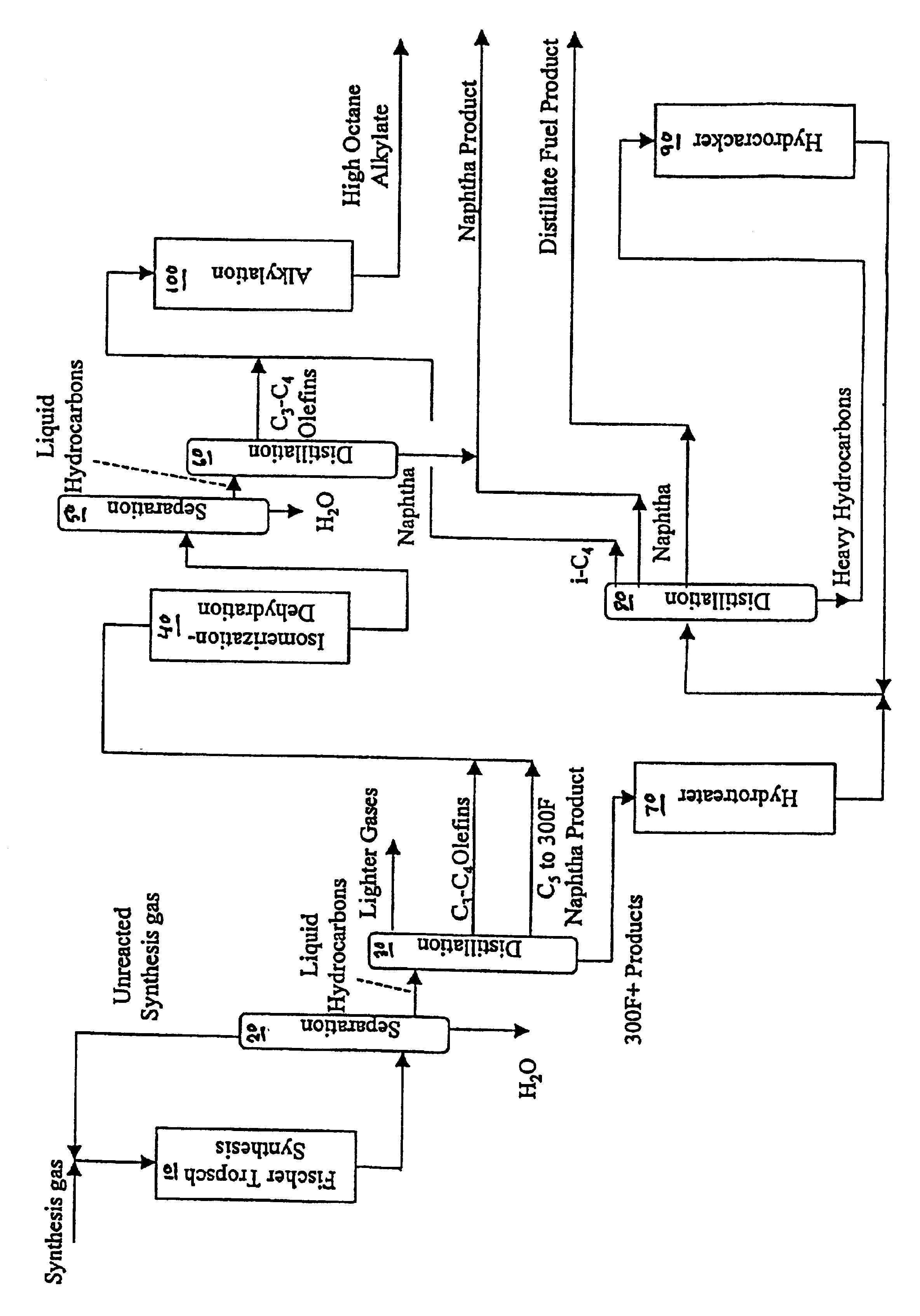

Manufacture of high octane alkylate

InactiveUS6768035B2Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

Fuel management system for variable ethanol octane enhancement of gasoline engines

InactiveUS7314033B2Increase heatMeet cutting requirementsElectrical controlNon-fuel substance addition to fuelEngineeringAntiknock agent

Fuel management system for efficient operation of a spark ignition gasoline engine. Injectors inject an anti-knock agent such as ethanol directly into a cylinder of the engine. A fuel management microprocessor system controls injection of the anti-knock agent so as to control knock and minimize that amount of the anti-knock agent that is used in a drive cycle. It is preferred that the anti-knock agent is ethanol. The use of ethanol can be further minimized by injection in a non-uniform manner within a cylinder. The ethanol injection suppresses knock so that higher compression ratio and / or engine downsizing from increased turbocharging or supercharging can be used to increase the efficiency of the engine.

Owner:MASSACHUSETTS INST OF TECH

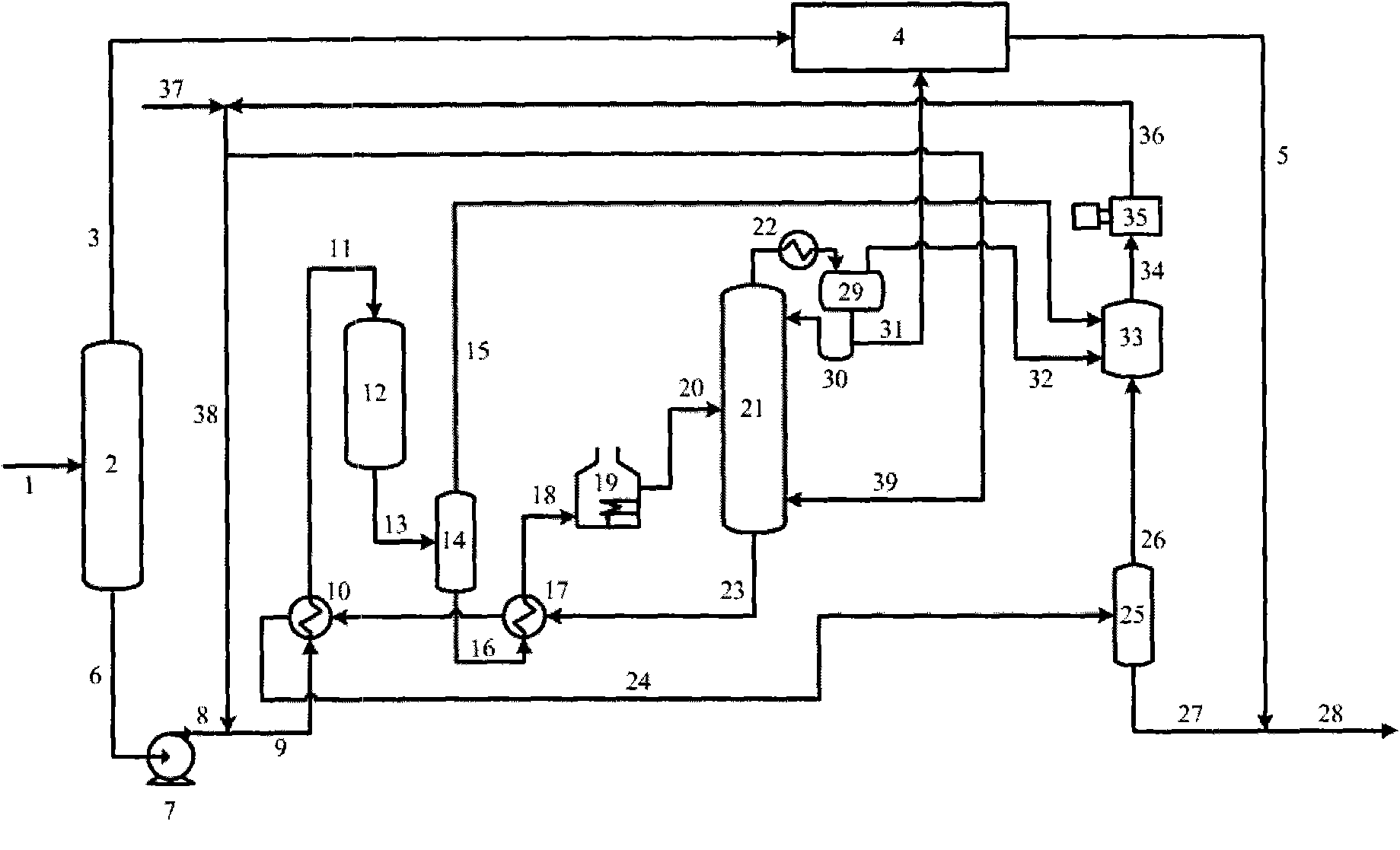

Catalytic cracking diesel fuel hydroconversion method

ActiveCN104611029AReduce hydrogenationHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The present invention discloses a catalytic cracking diesel fuel hydroconversion method. According to the method, catalytic diesel fuel and hydrogen are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and then is subjected to a contact reaction with the grading catalyst bed layer inside the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the naphtha and the diesel fuel. With the method of the present invention, the diesel fuel hydrocracking effect can be ensured while the excessive hydrogenation and the secondary cracking of the naphtha can be reduced and the chemical hydrogen consumption can be reduced so as to increase the octane number and the liquid yield of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatization catalyst, its preparation method and application

ActiveCN1651141ALipophilicHigh aromatization activityMolecular sieve catalystsHydrocarbonsMolecular sieveAdhesive

An aromatizing catalyst for molifying poor gasoline to prepare high-octane gaseline component or arylhydrocarbon is prepared from the Zn, P and RE metal modified HZSM-5 molecular sieve, Y-type molecular sieve, carrier and adhesive proportionally.

Owner:CHINA PETROCHEMICAL CORP +1

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Catalytic conversion method for preparing propylene and high-octane gasoline

ActiveCN101531923AHigh selectivityHigh yieldOrganic chemistryTreatment with hydrotreatment processesGasolineReaction temperature

A catalytic conversion method for preparing propylene and high-octane gasoline comprises the following steps: raw materials which are difficult to be cracked are firstly contacted with a thermal regeneration catalytic cracking catalyst to carry out cracking reaction under the conditions that the reaction temperature is 600-750 DEG C and the weight hourly space velocity is 100-800h<-1>, the reactant flow is mixed with raw oil which is easy to be cracked to carry out the cracking reaction under the conditions that the reaction temperature is 450-620 DEG C and the weight hourly space velocity is 0.1-100h<-1>; the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to a reactor after regeneration, the reaction oil and gas are separated to obtain propylene and gasoline, and hydrogenated heavy oil obtained by hydrotreating fractions above 260 DEG C is taken as raw oil of the catalytic cracking device or a conventional catalytic cracking device. The method improves the yield and the selectivity of the propylene, increases the yield of the high-octane gasoline, reduces the yield of dry gas, greatly increases the yield of liquid and realizes the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

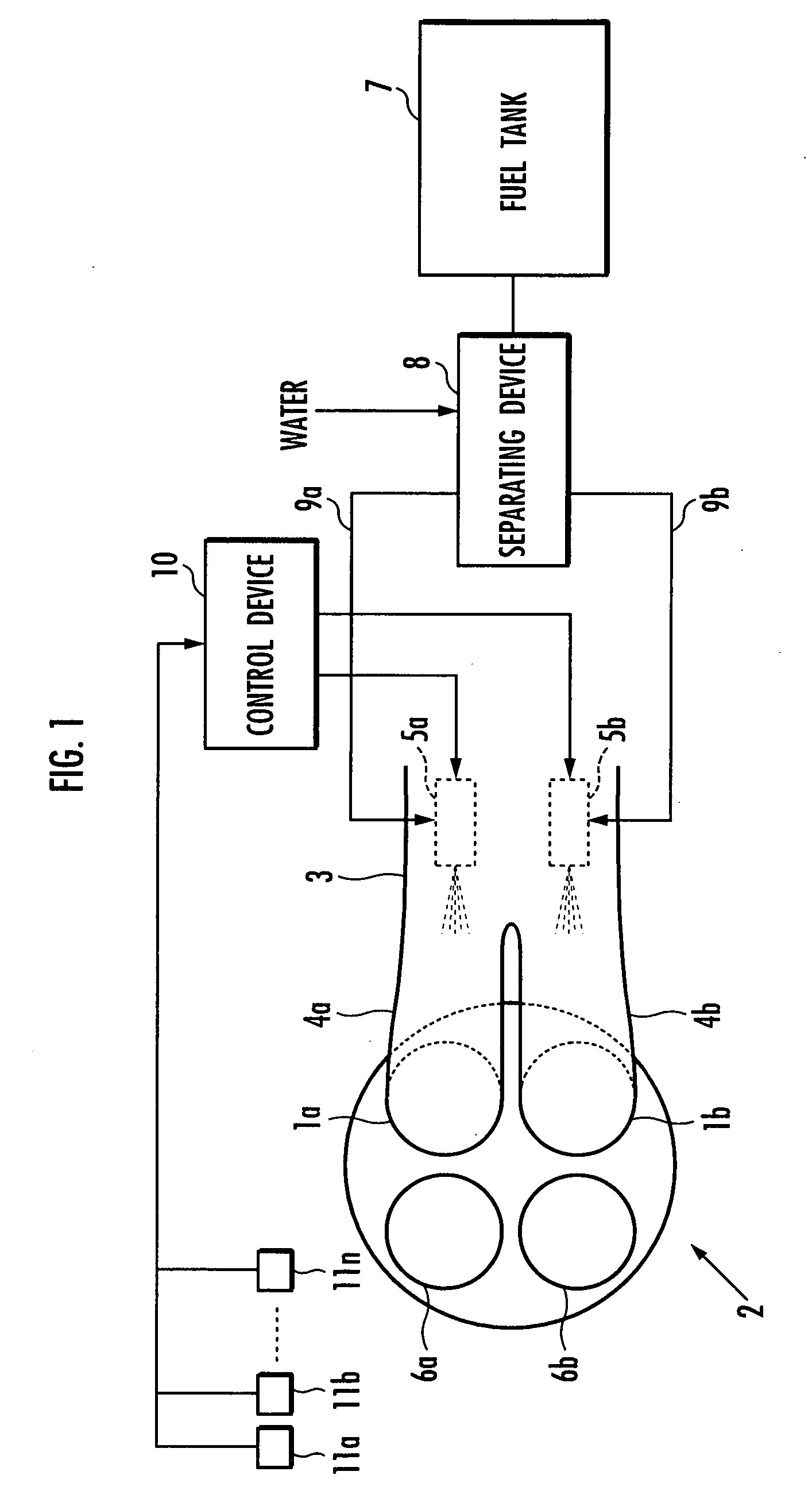

Internal combustion engine system

InactiveUS7370609B2Improve efficiencyEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesFuel tankNitrogen oxide

An internal combustion engine system uses a blended fuel of gasoline and ethanol, operates with high efficiency, and can inhibit nitrogen oxide and the like from being discharged. The internal combustion engine system includes: a fuel tank 3 that accommodates a blended fuel having an octane number of 80 to 100, which has been prepared by blending gasoline having the octane number of 30 to 85 and ethanol into a weight ratio between 9:1 and 6:4; A separating device for adding water to the blended fuel to separate the blended fuel into the gasoline and an ethanol-water mixture liquid; A reforming device for reforming one part of the ethanol-water mixture liquid to produce a mixture liquid of diethyl ether and water; and fuel injectors which independently inject each of the gasoline, the ethanol-water mixture liquid and the mixture liquid of diethyl ether and water.

Owner:HONDA MOTOR CO LTD

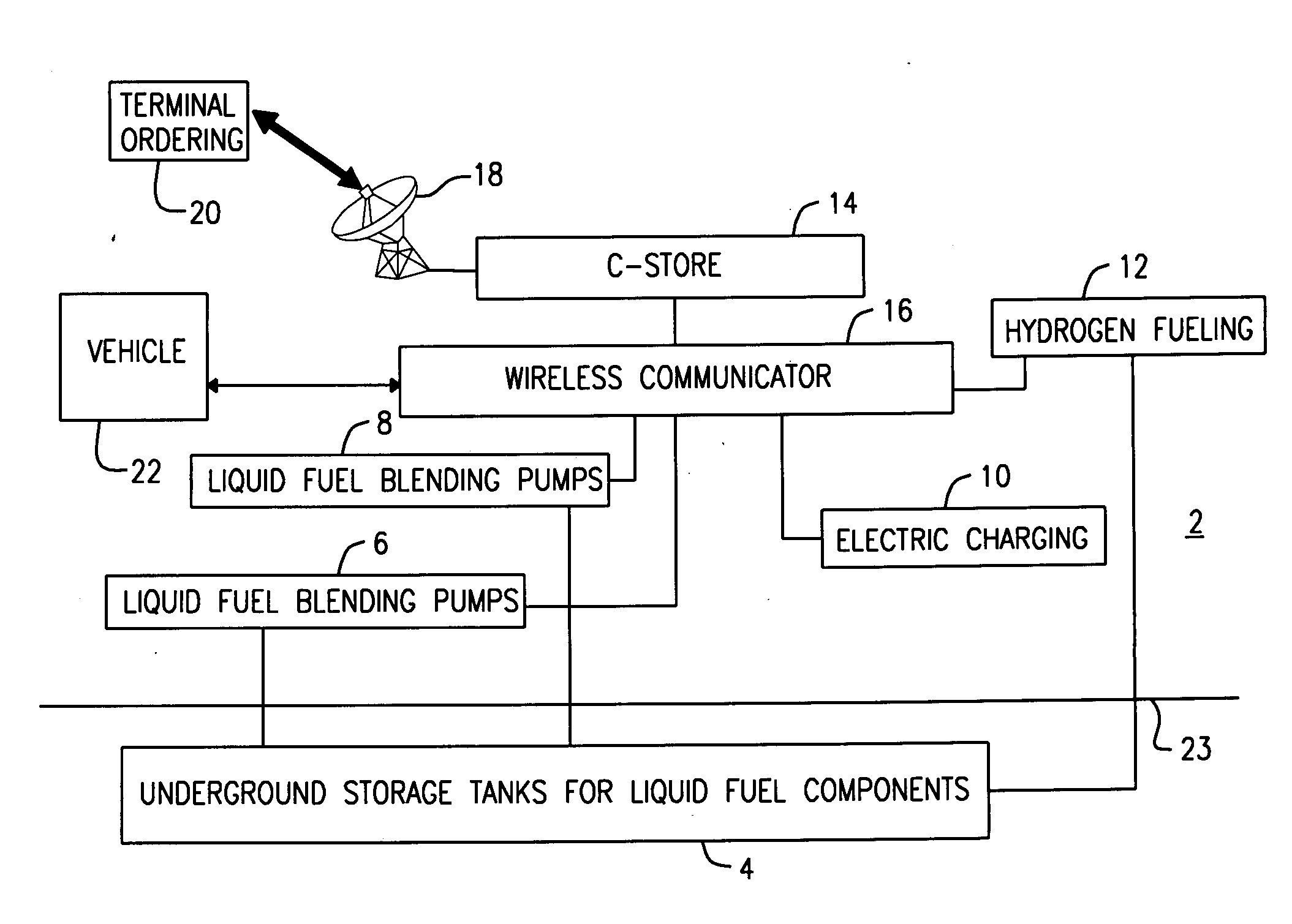

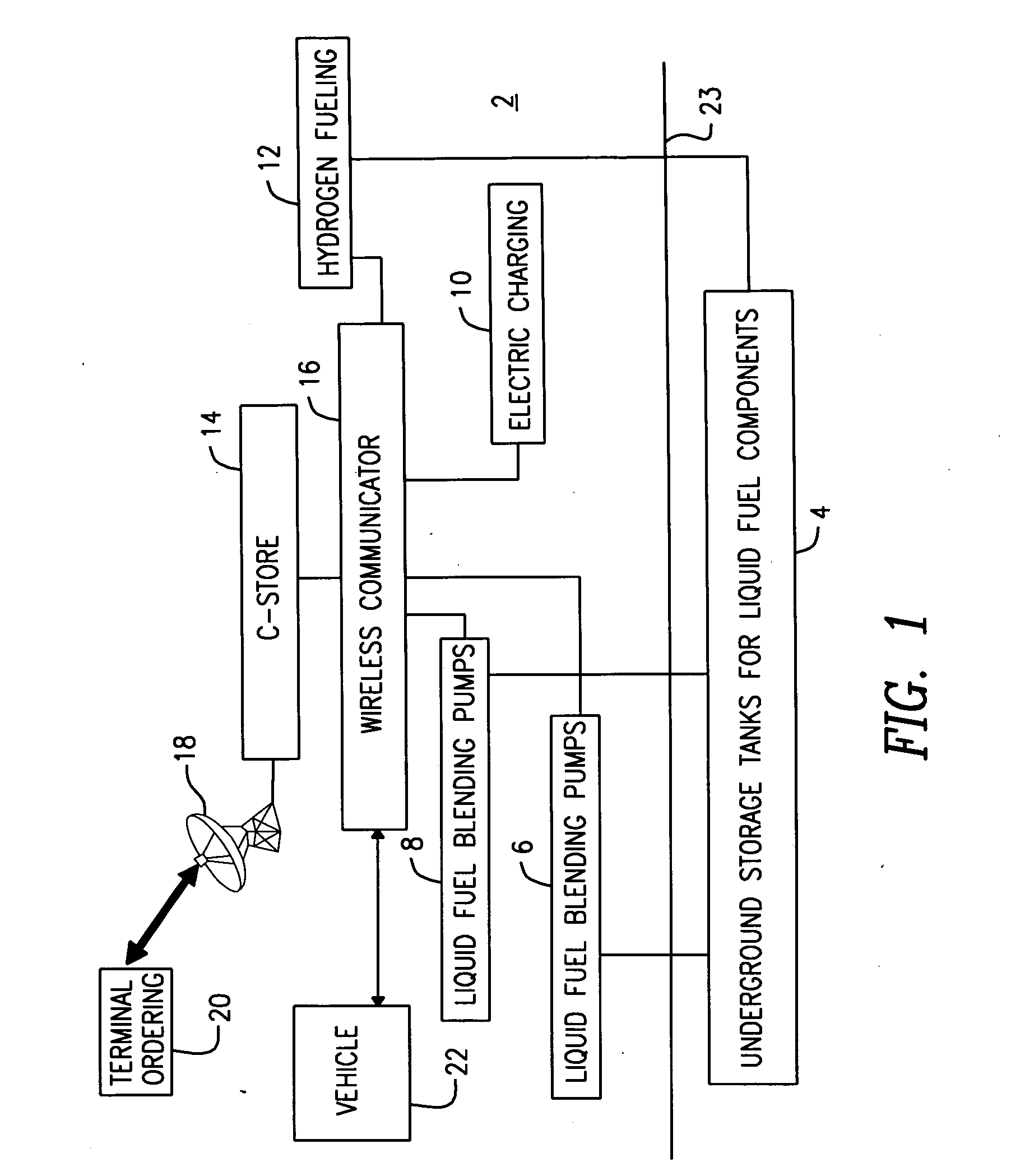

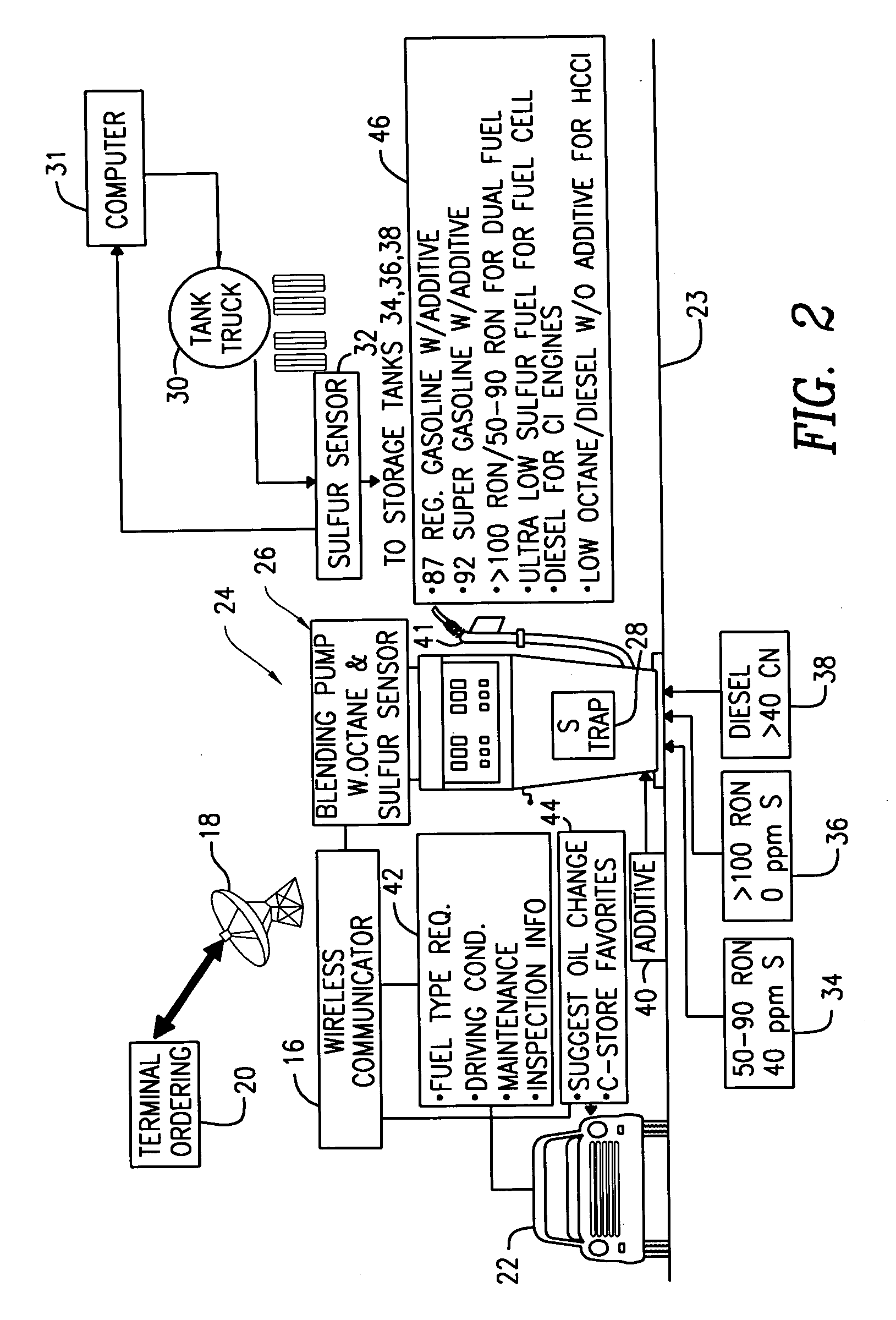

Service station for serving requirements of multiple vehicle technologies

InactiveUS20070144605A1Prevent fueling errorAvoid mistakesLiquid fillingData processing applicationsFuel cellsGasoline

A service station is provided with a plurality of vehicle servicing islands including liquid fuel blending pumps for dispensing and blending fuel components from underground tanks for refueling standard gasoline engine driven vehicles, standard diesel engine vehicles, vehicles with engines requiring dual fuels, vehicles with HCCI engines requiring low octane gasoline blended with standard diesel fuel, and fuel cell powered vehicles having onboard reformers. Other service islands include pumps for dispensing compressed hydrogen to fuel cell powered vehicles that do not include onboard reformers. In addition, service islands are provided for recharging the batteries of pure electric powered vehicles.

Owner:EXXON RES & ENG CO

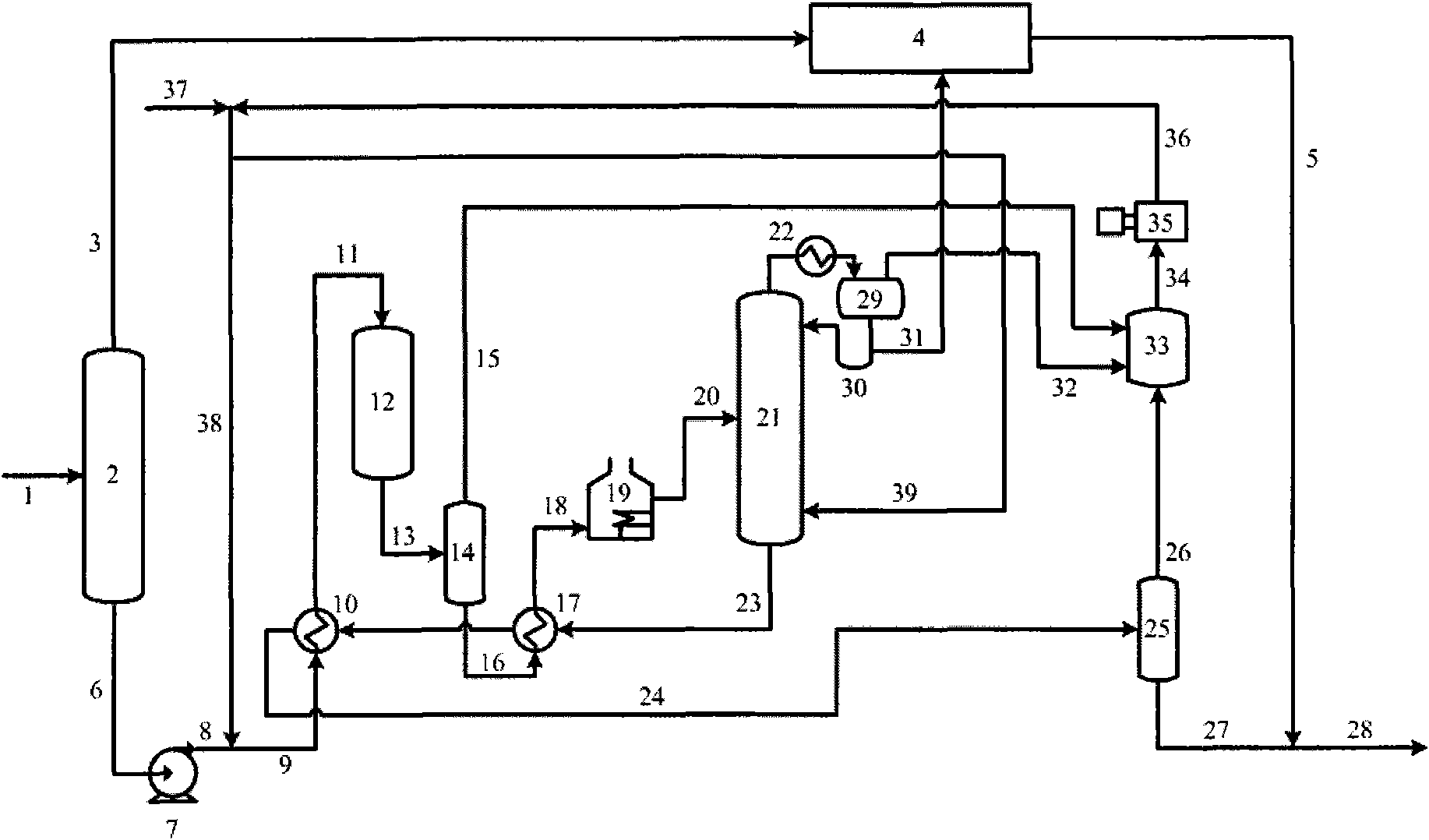

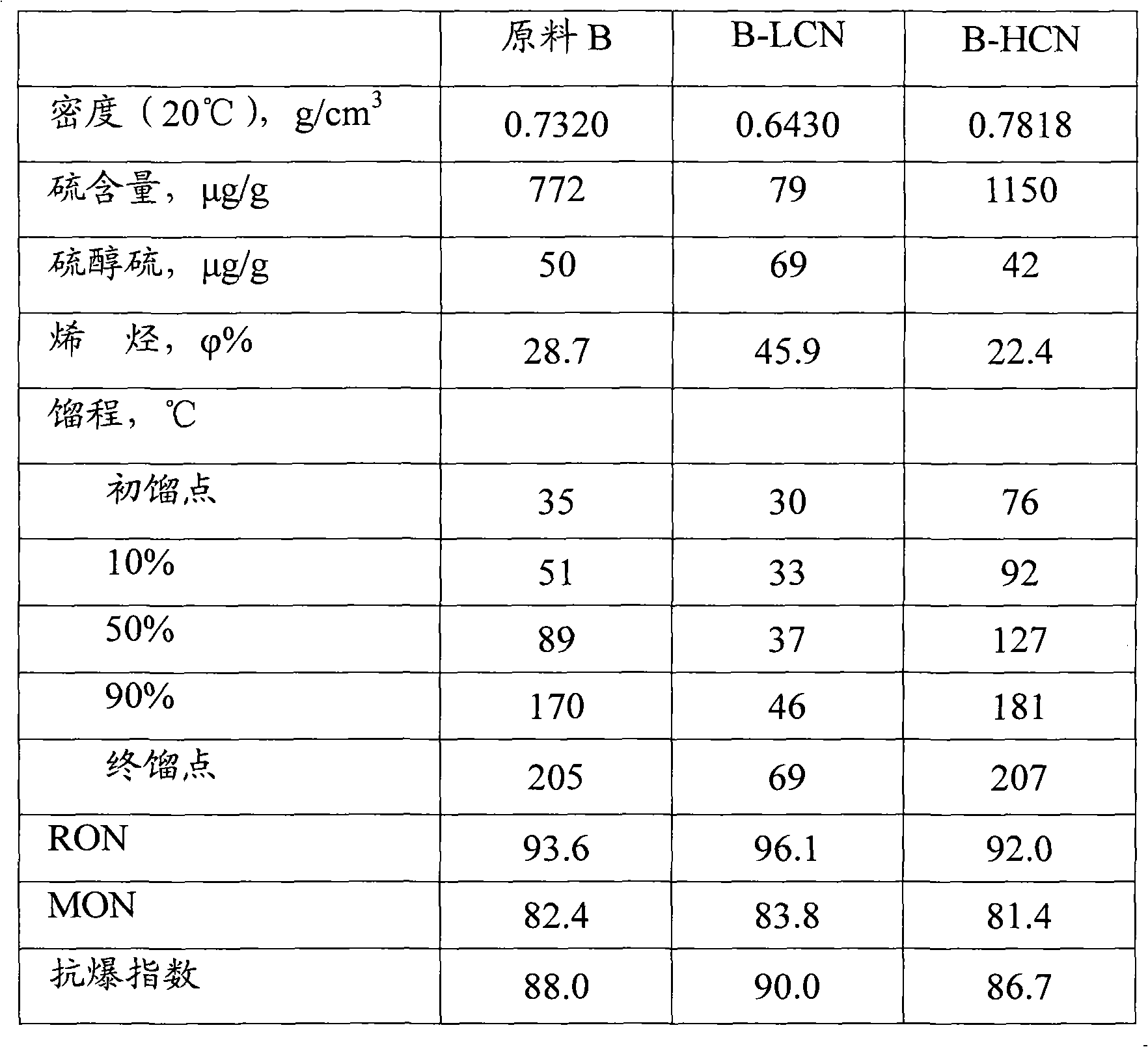

Gasoline hydrodesulfurization method

ActiveCN101787307ASmall mercaptan sulfur contentReduce lossesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention relates to a gasoline hydrodesulfurization method, which comprises the following steps that: gasoline raw materials are fractionated into light fraction gasoline and heavy fraction gasoline, wherein the light fraction gasoline is removed mercaptan sulfer through caustic washing refining, the heavy fraction gasoline carries out a hydrogenation diene-removal reaction, a selective hydrodesulfurization reaction and a selective hydrogenation mercaptan sulfer-removal reaction respectively through two hydrogenation reactors, and the obtained hydrogenation heavy fraction gasoline and the refined light fraction gasoline are mixed to obtain full fraction gasoline with ultra-low sulfur. According to the method provided by the invention, under the condition that the desulfurization degree reaches a target, the full fraction gasoline product have small mercaptan sulfur content, less olefin saturation and small octane value loss. The mercaptan sulfur content of the obtained dull fraction gasoline product is less than 10Mug / g, the total sulfur content is reduced under 50Mug / g, and the octane value RON loss is less than 1.0 unit, particularly, the total sulfur content of the full fraction gasoline product is reduced under 10 Mug / g, and the octane value RON loss is less than 1.5 units.

Owner:CHINA PETROLEUM & CHEM CORP +1

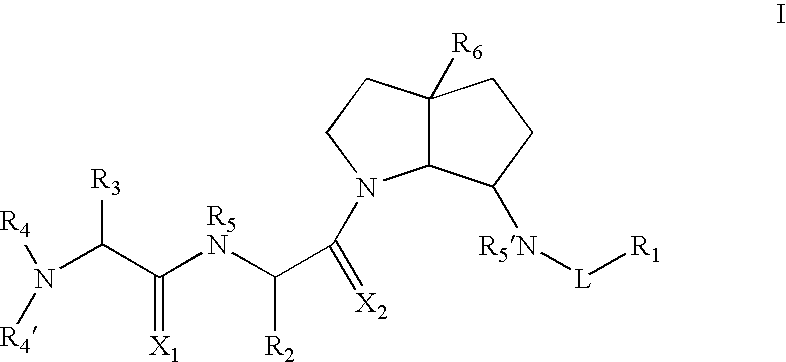

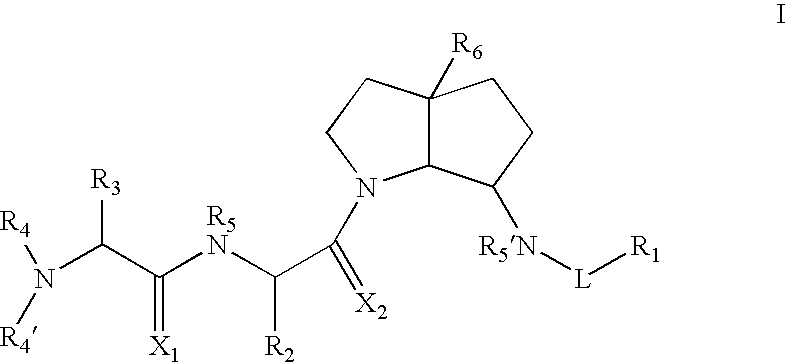

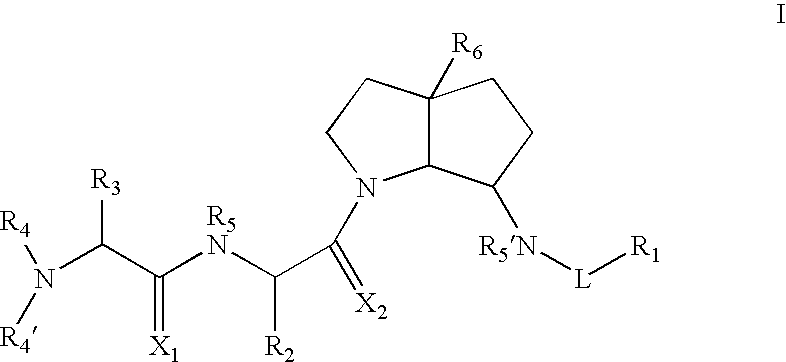

Azabicyclo-octane inhibitors of IAP

Owner:GENENTECH INC

Hydrogenation catalyst, its process and use

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com