Patents

Literature

949 results about "Isobutane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isobutane, also known as i-butane, 2-methylpropane or methylpropane, is a chemical compound with molecular formula HC(CH₃)₃. It is an isomer of butane. It is the simplest alkane with a tertiary carbon. Isobutane is used as a precursor molecule in the petrochemical industry, for example in the synthesis of isooctane.

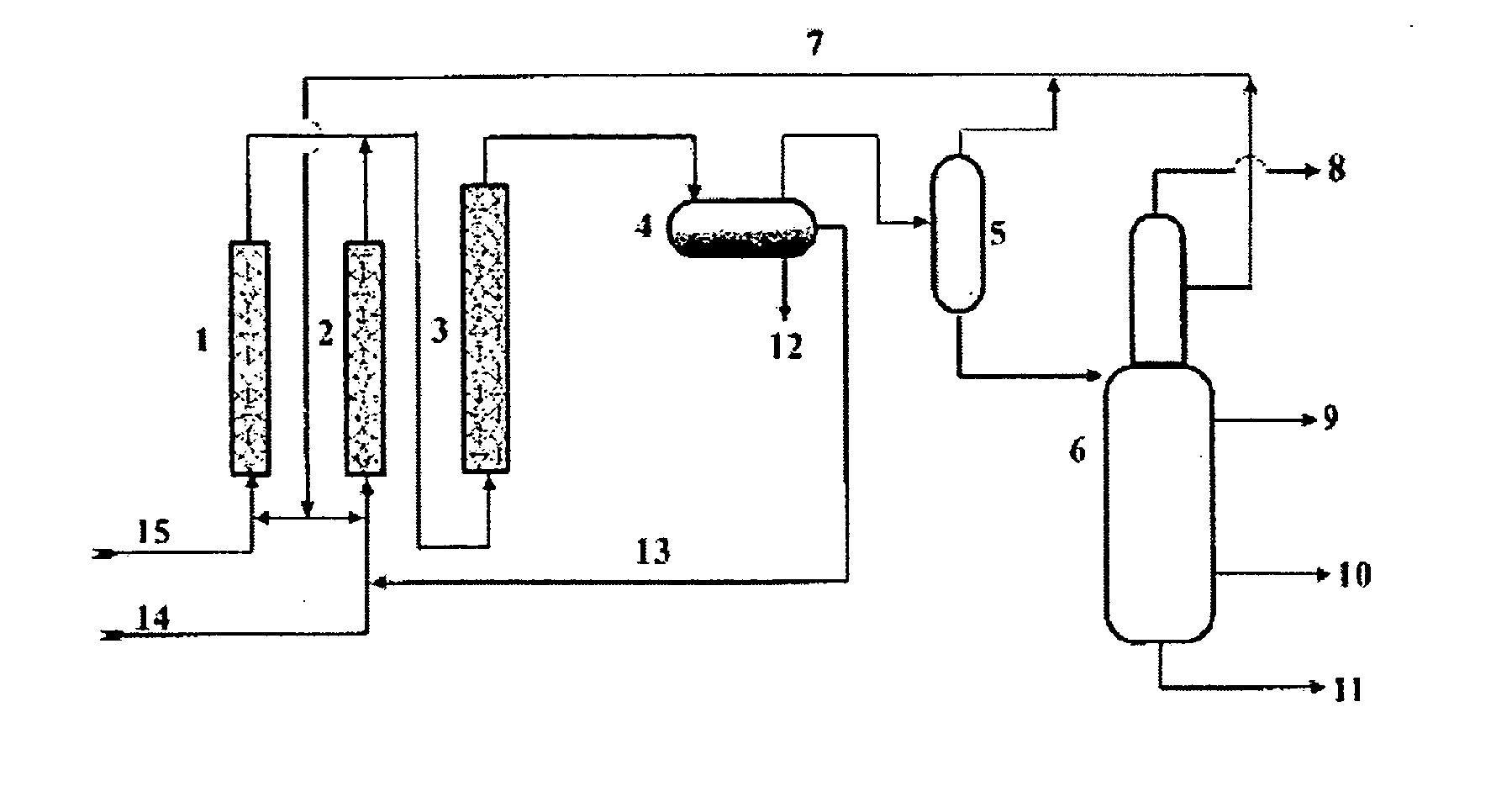

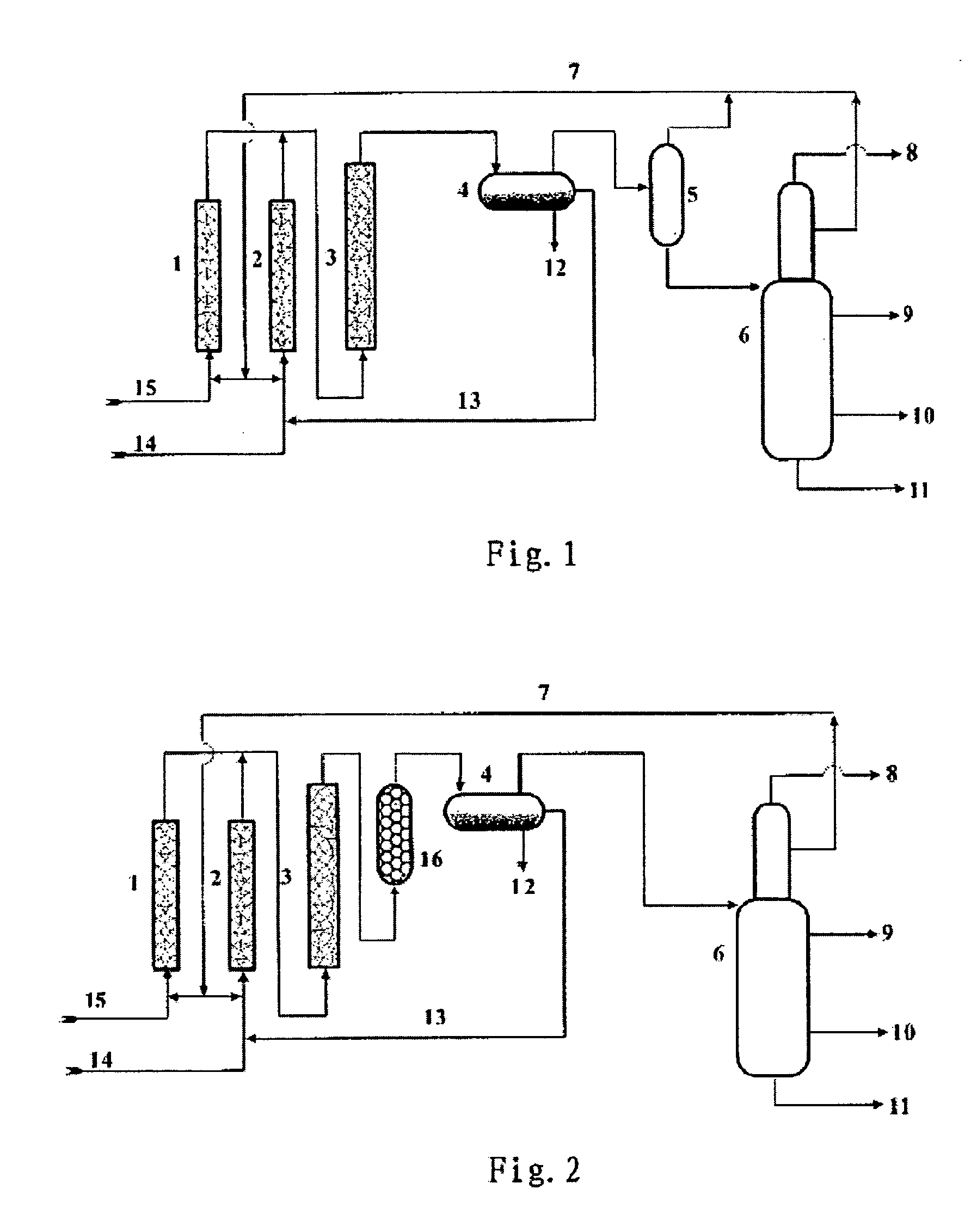

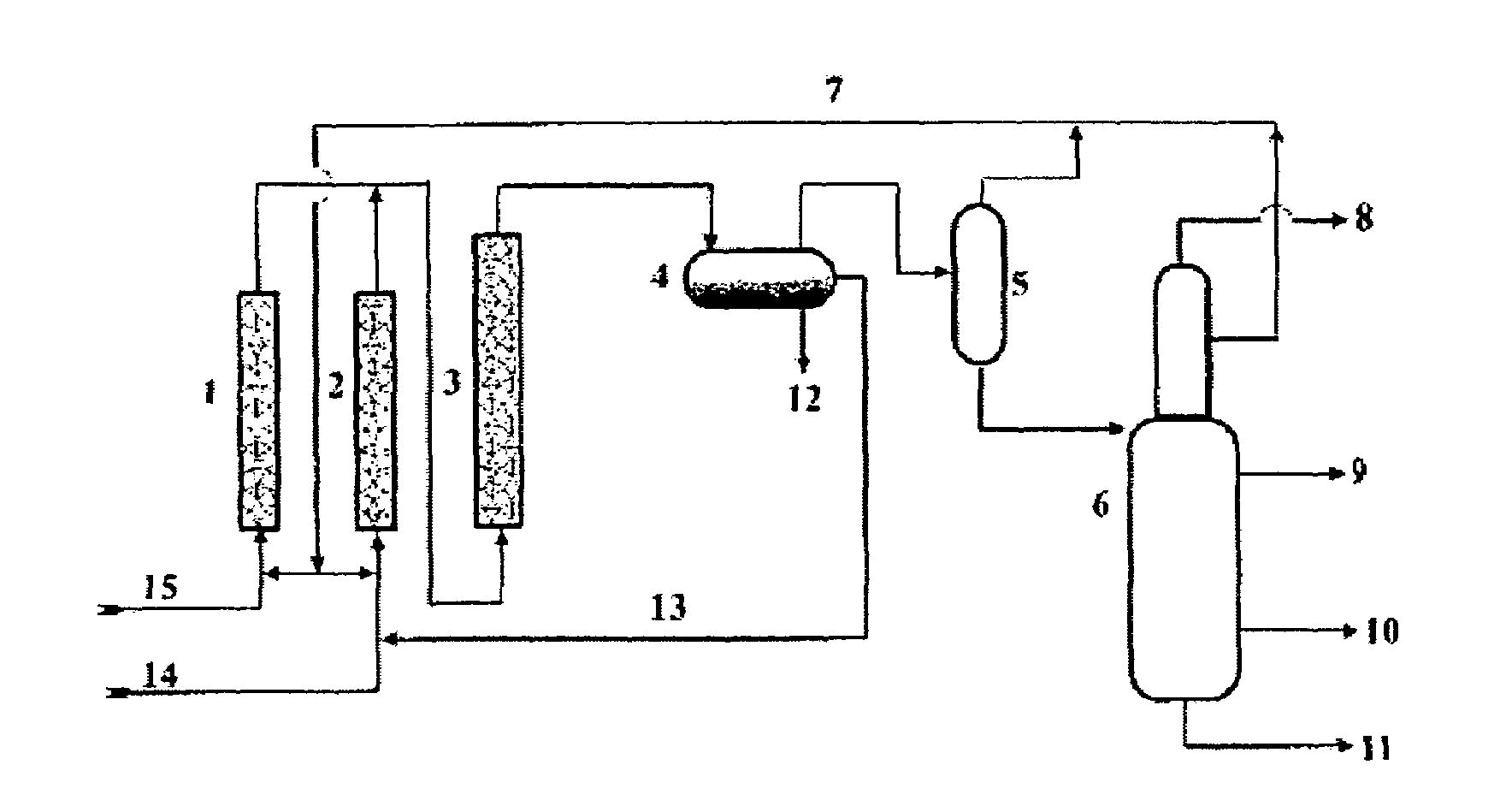

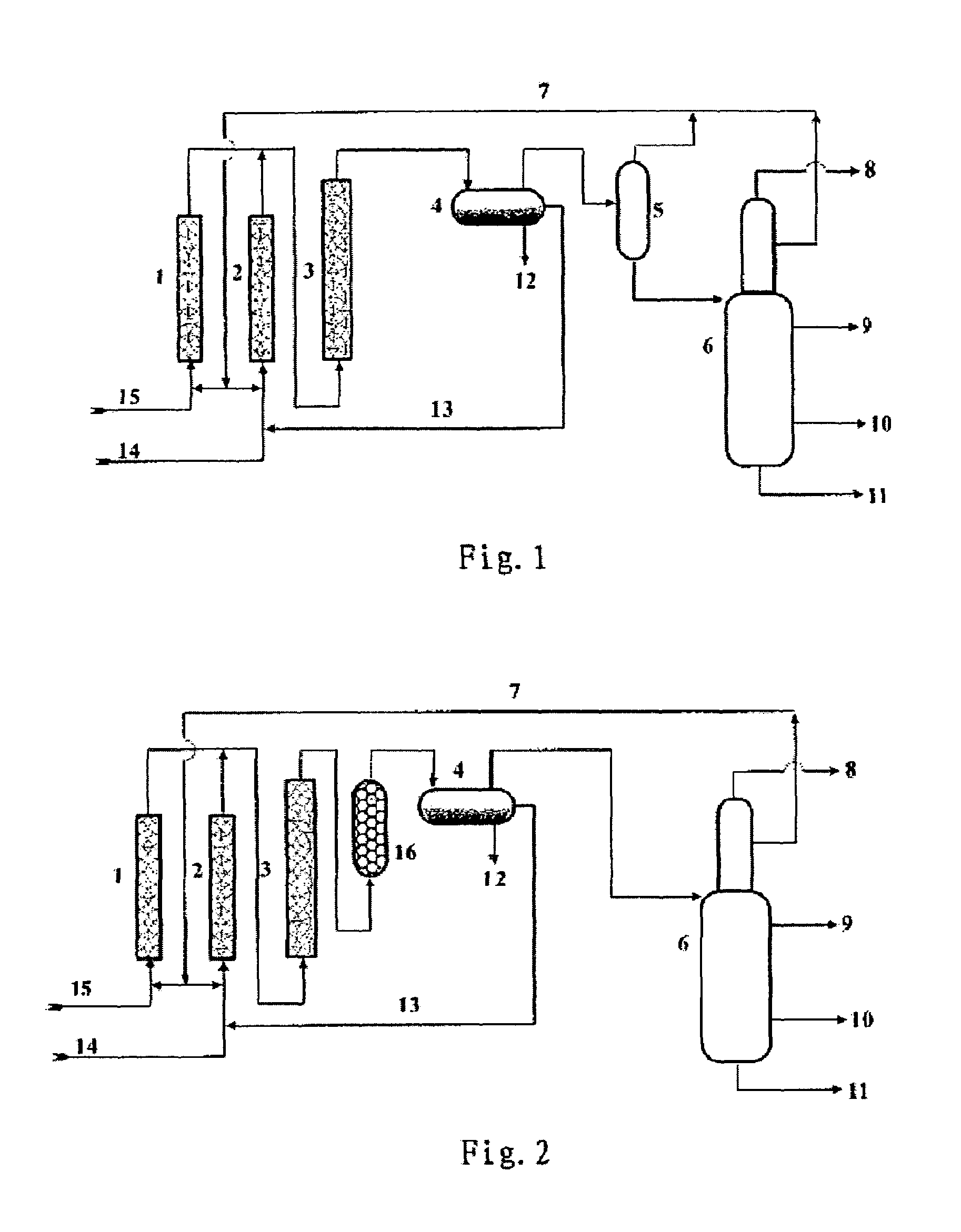

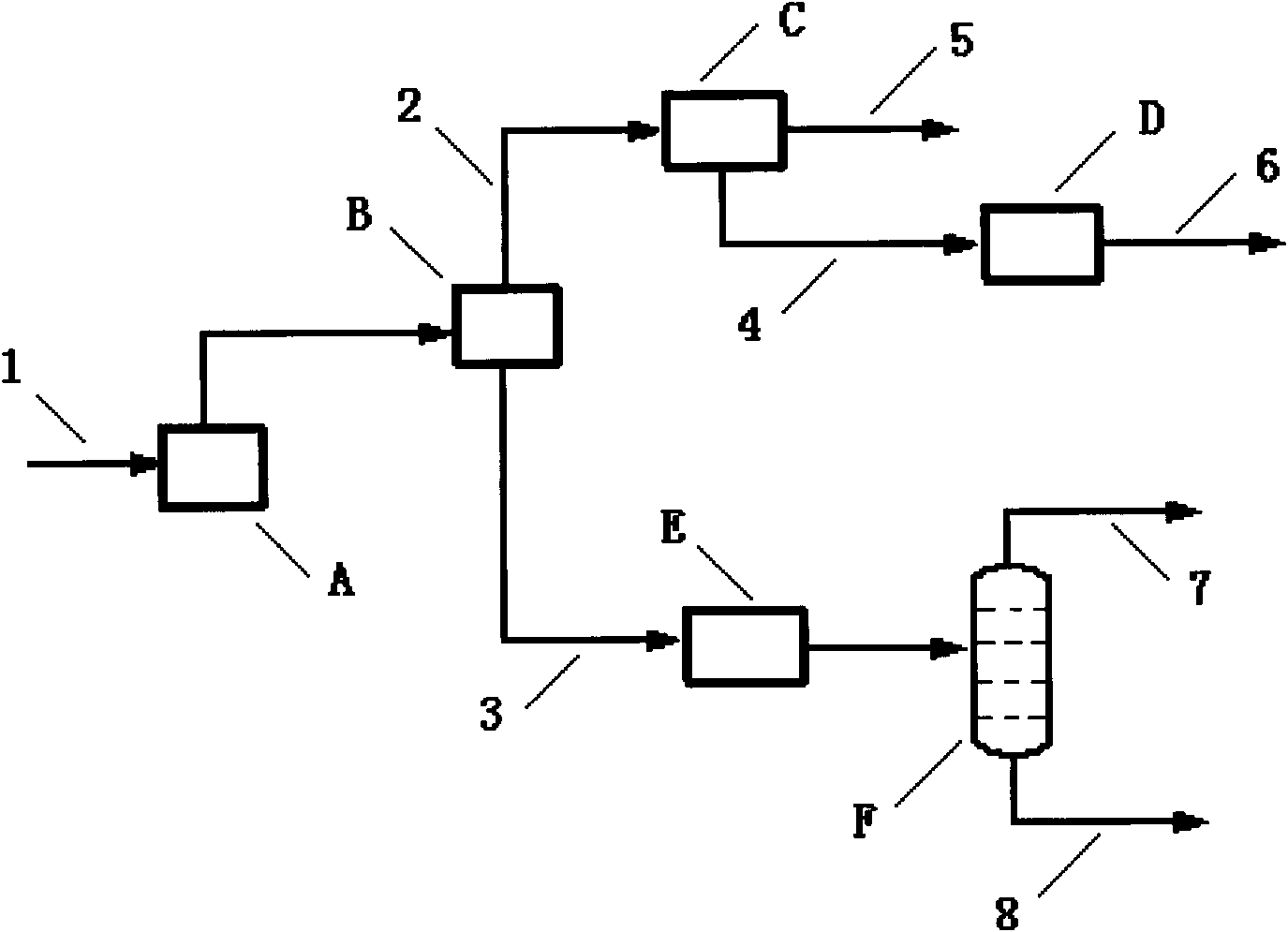

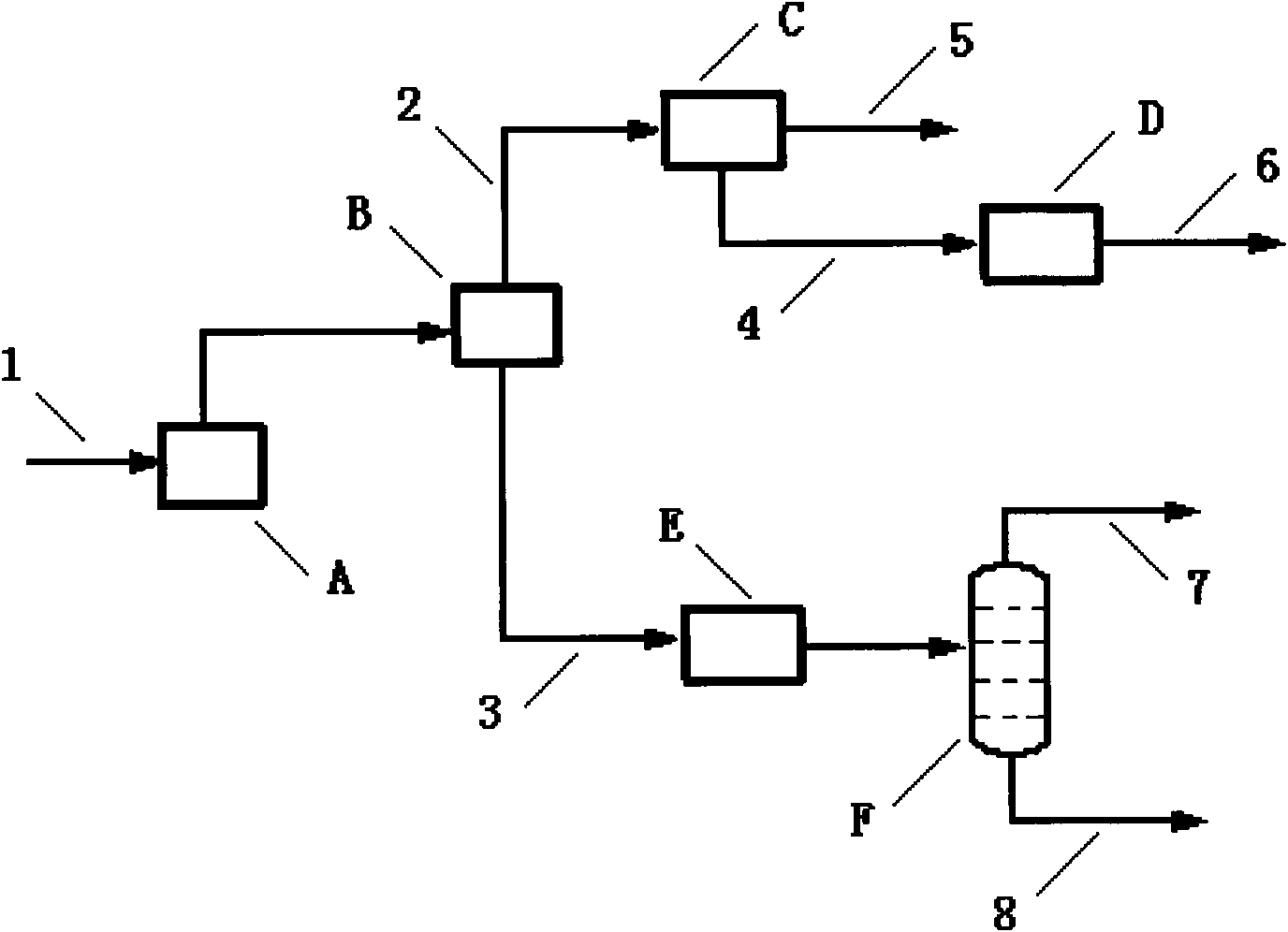

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

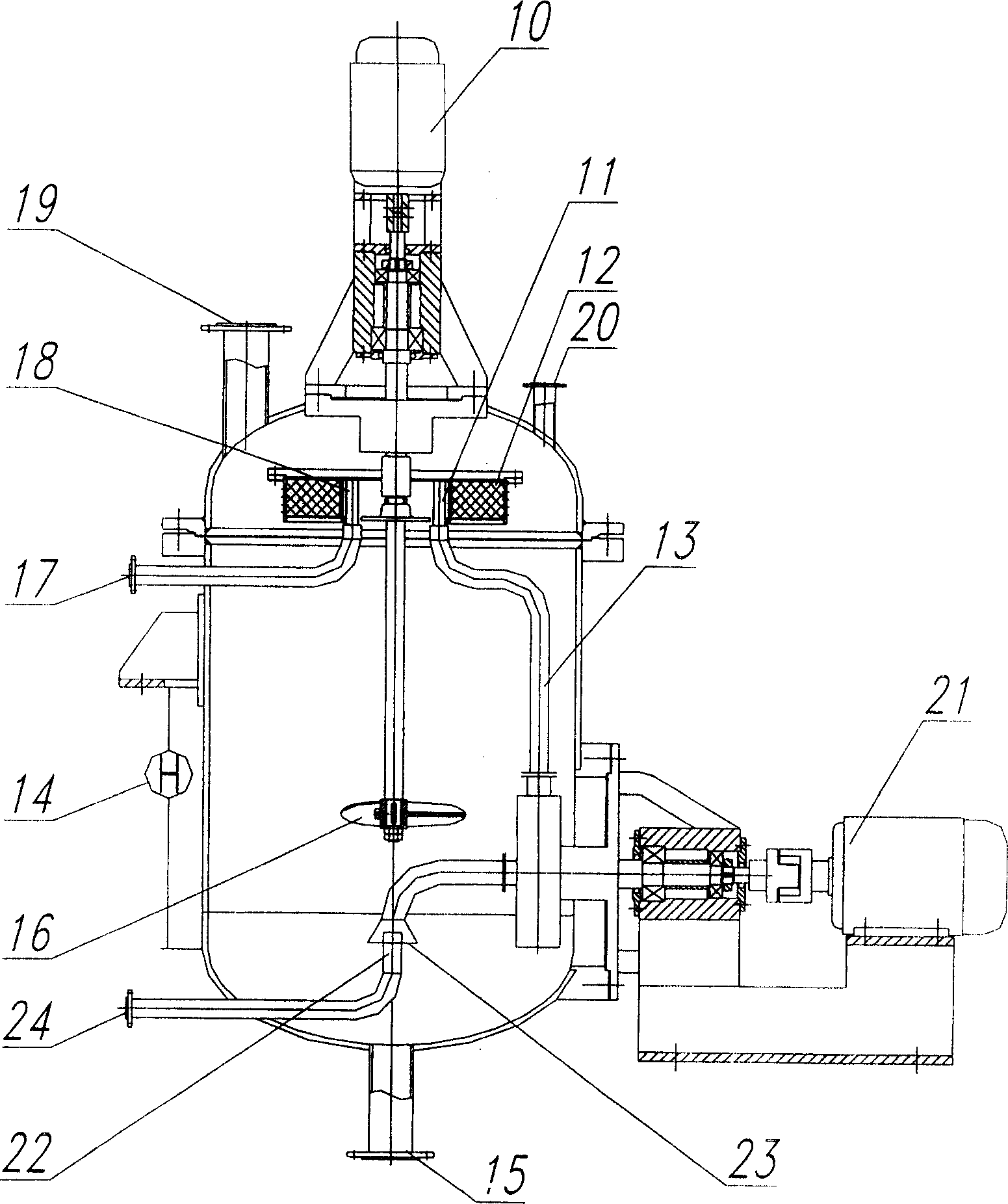

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

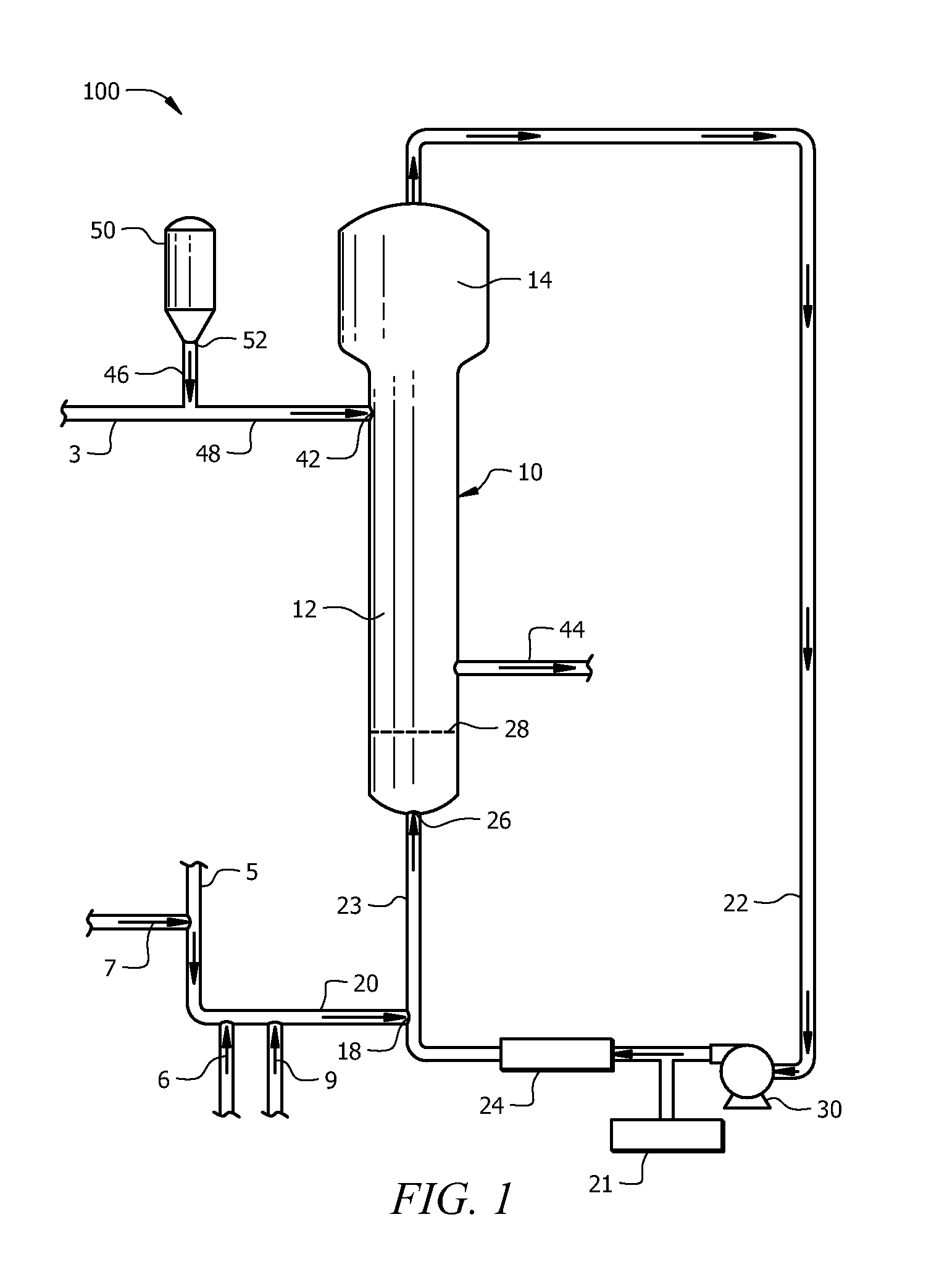

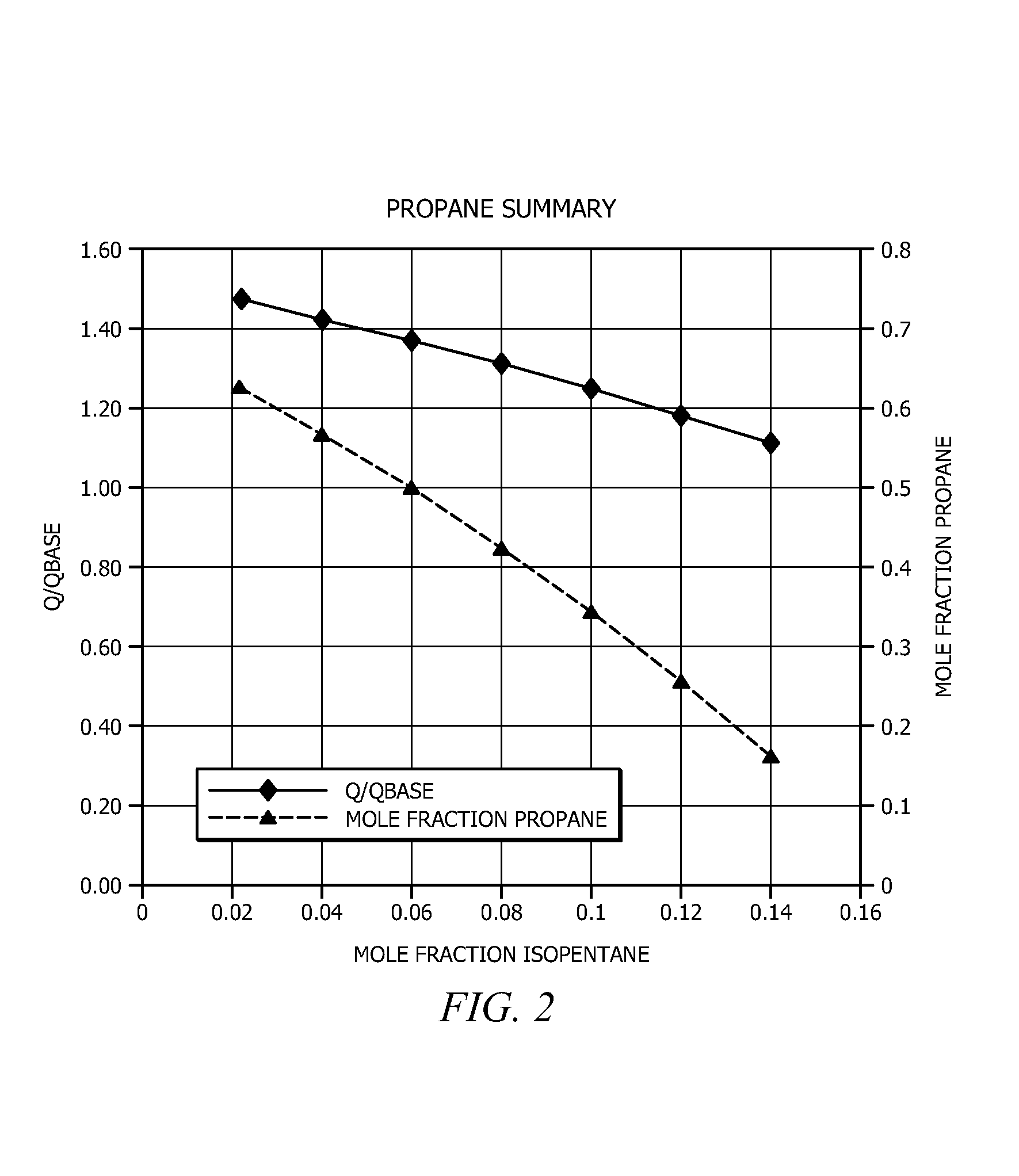

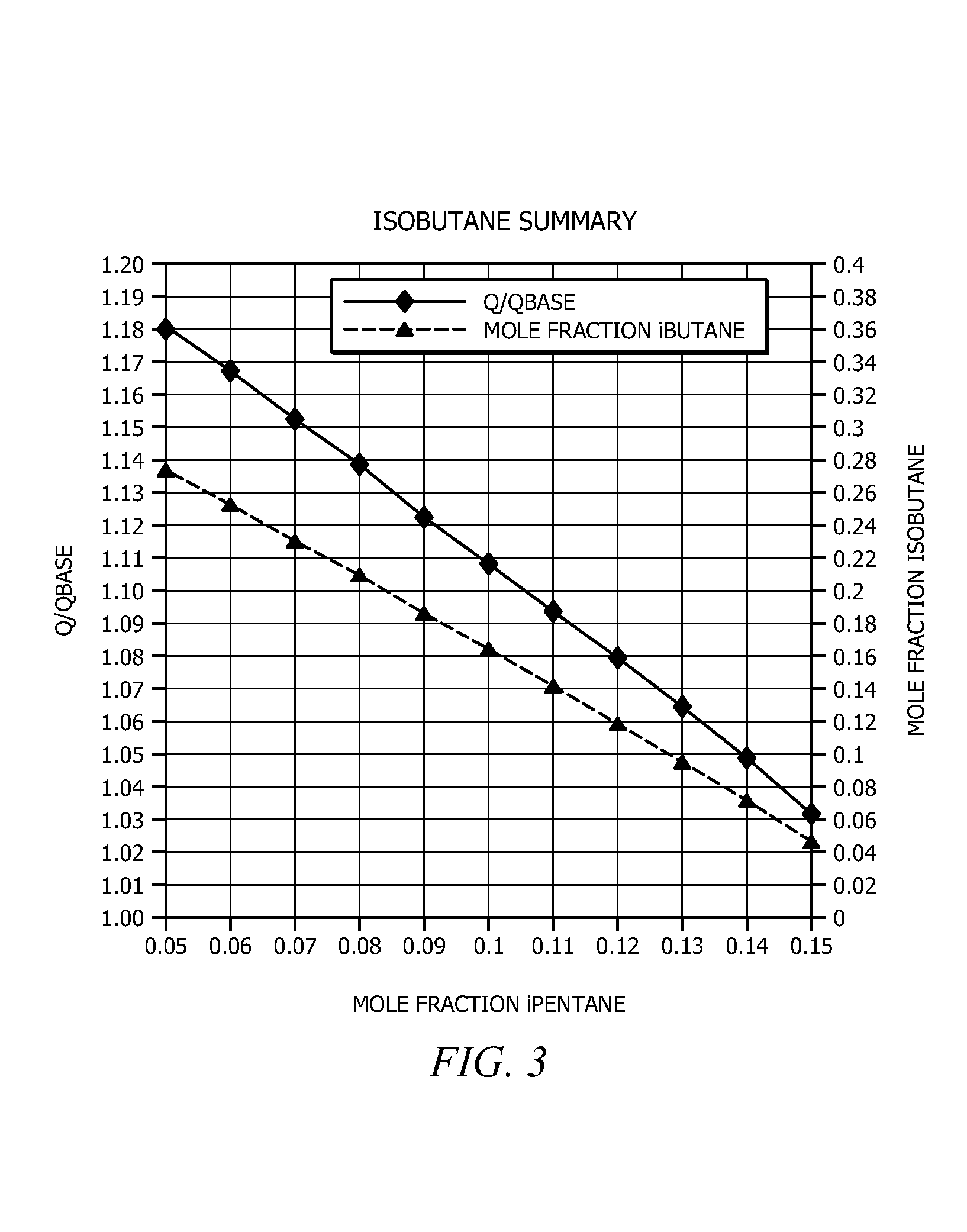

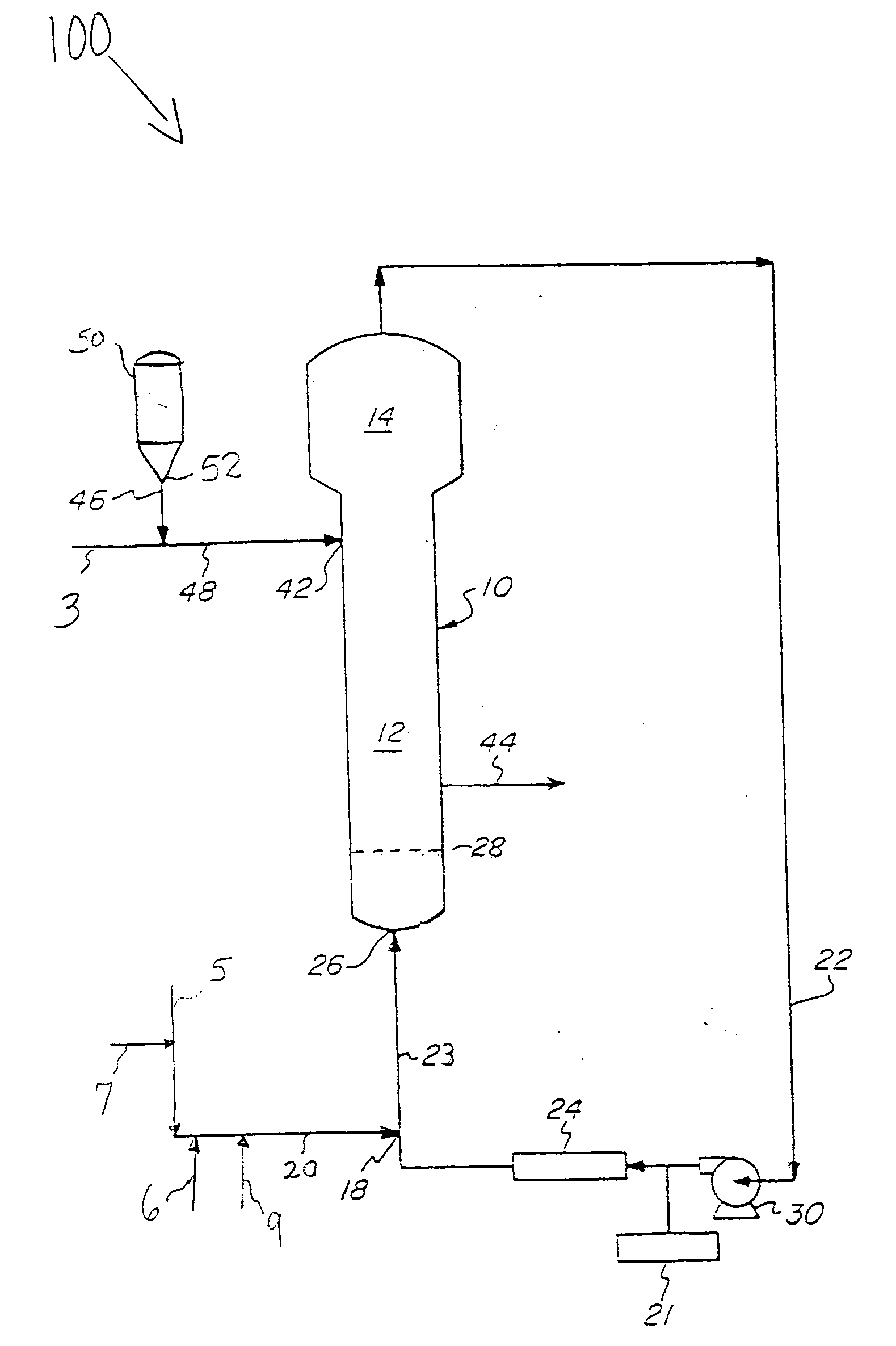

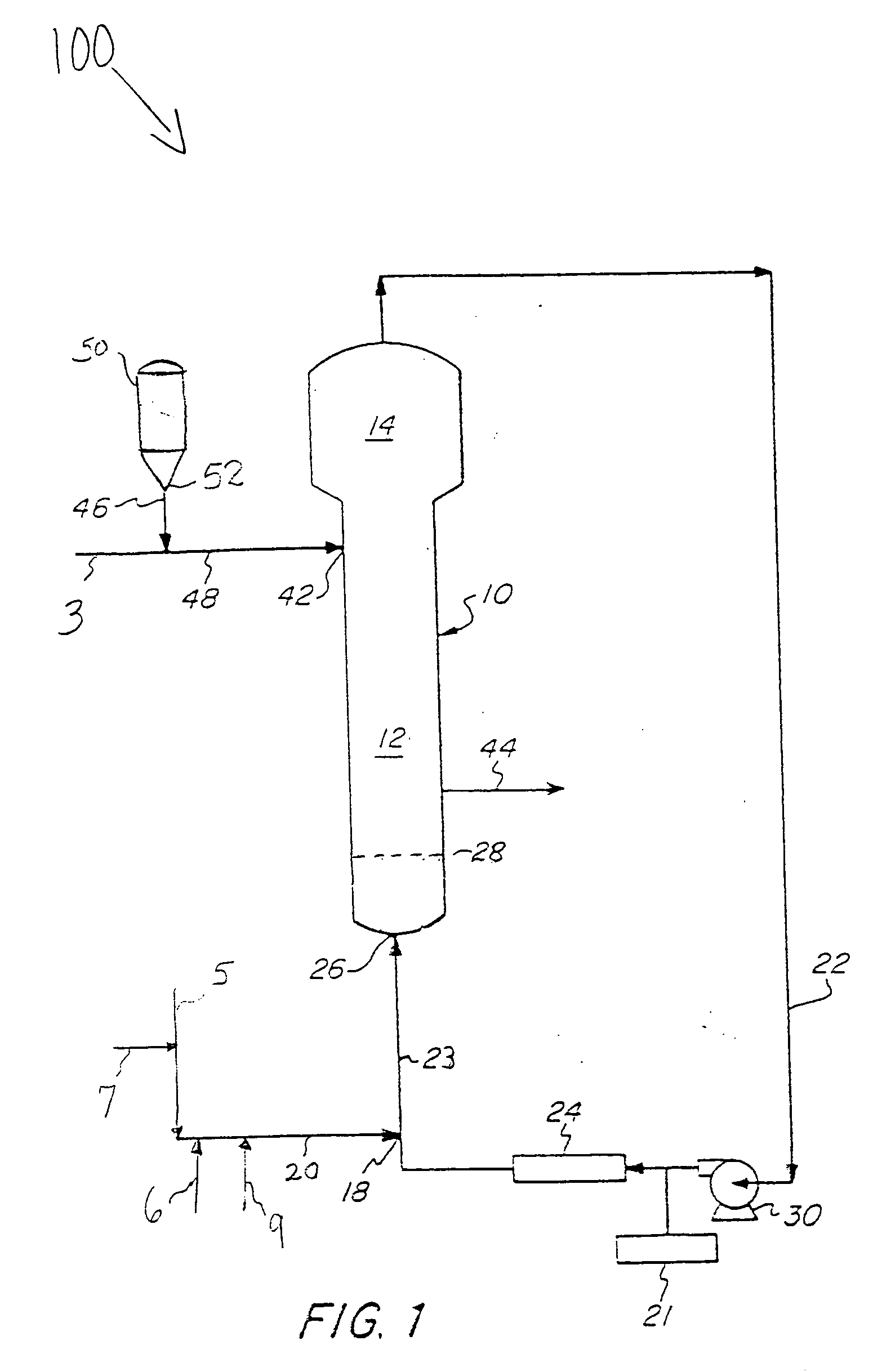

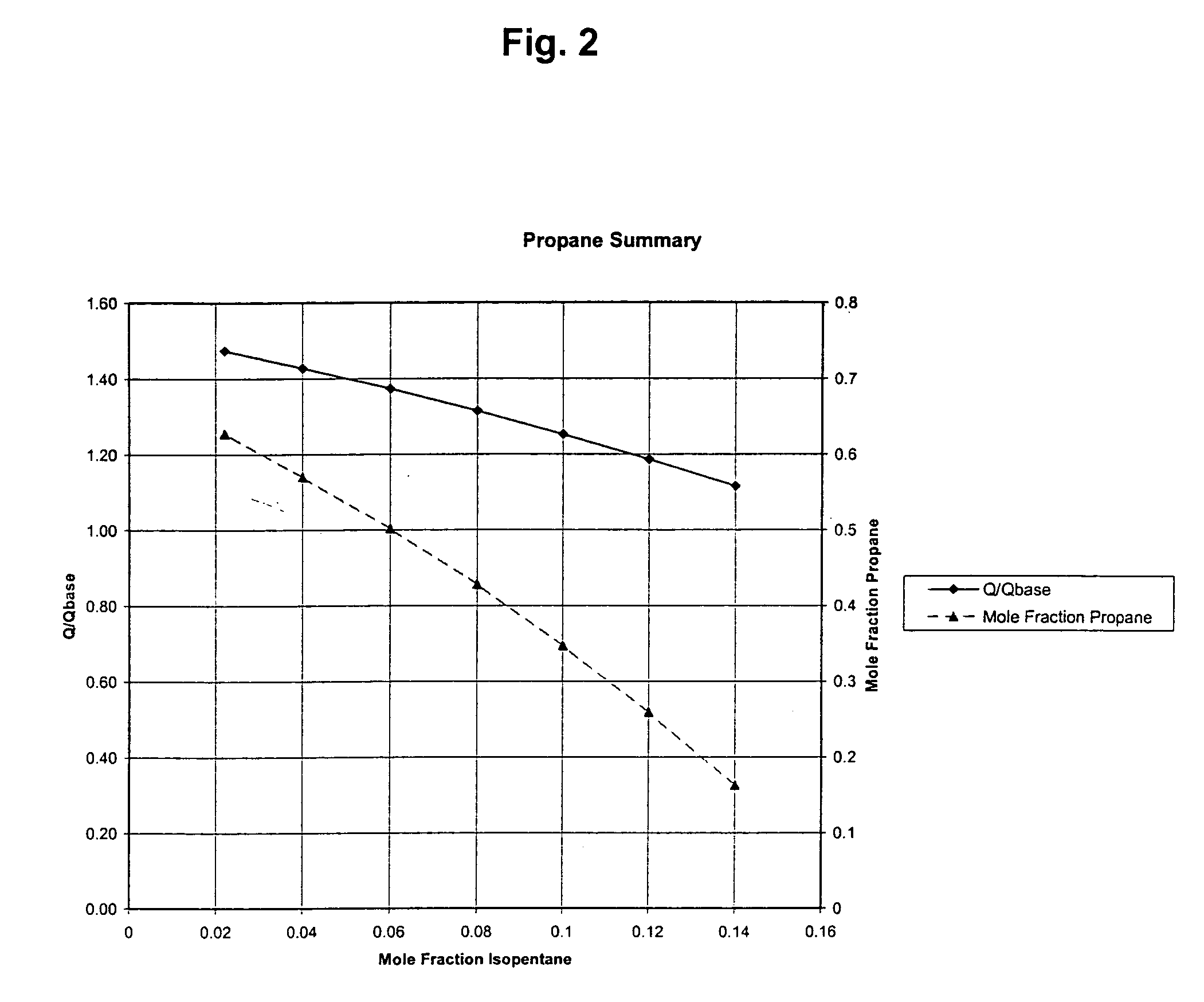

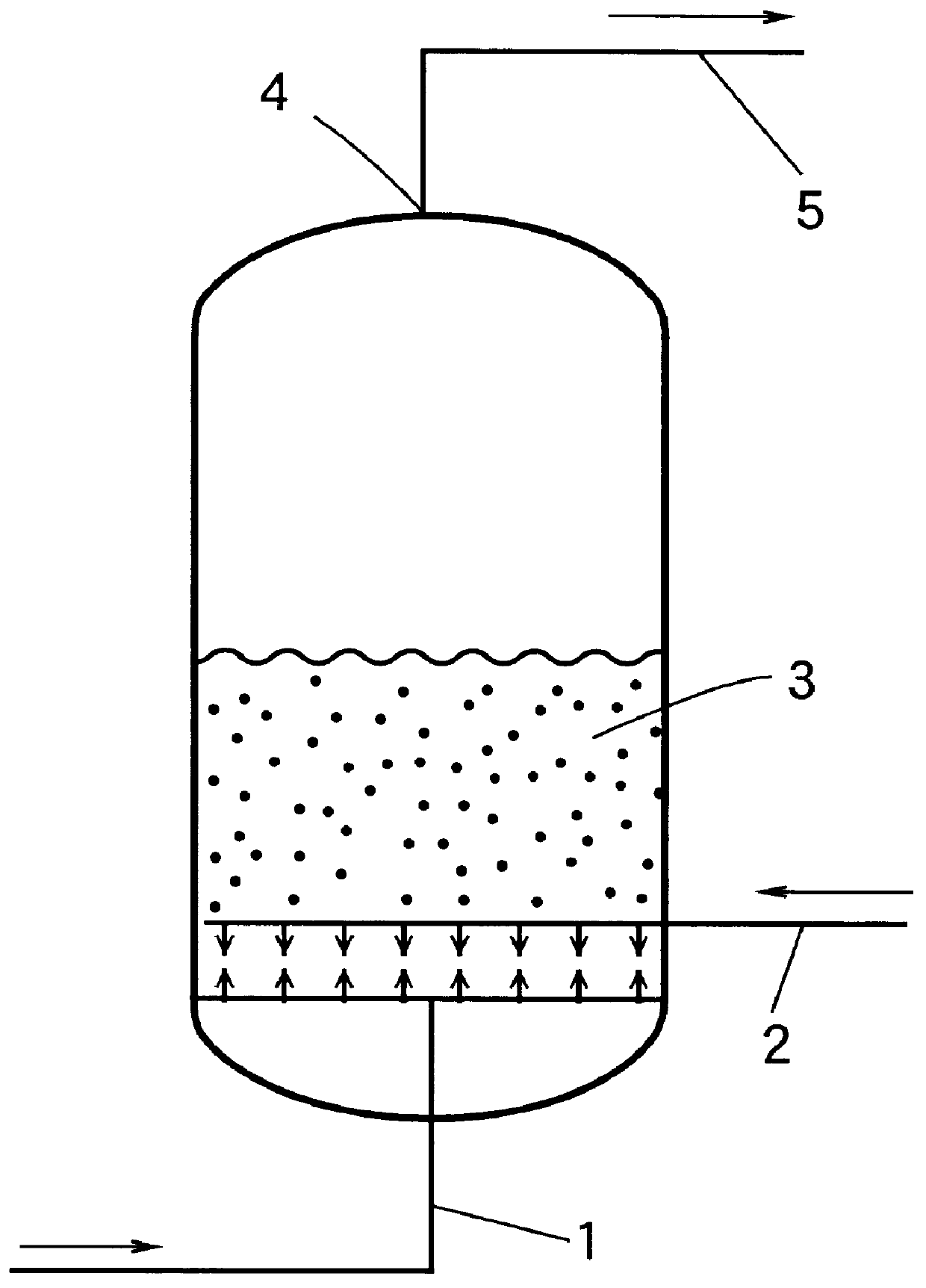

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

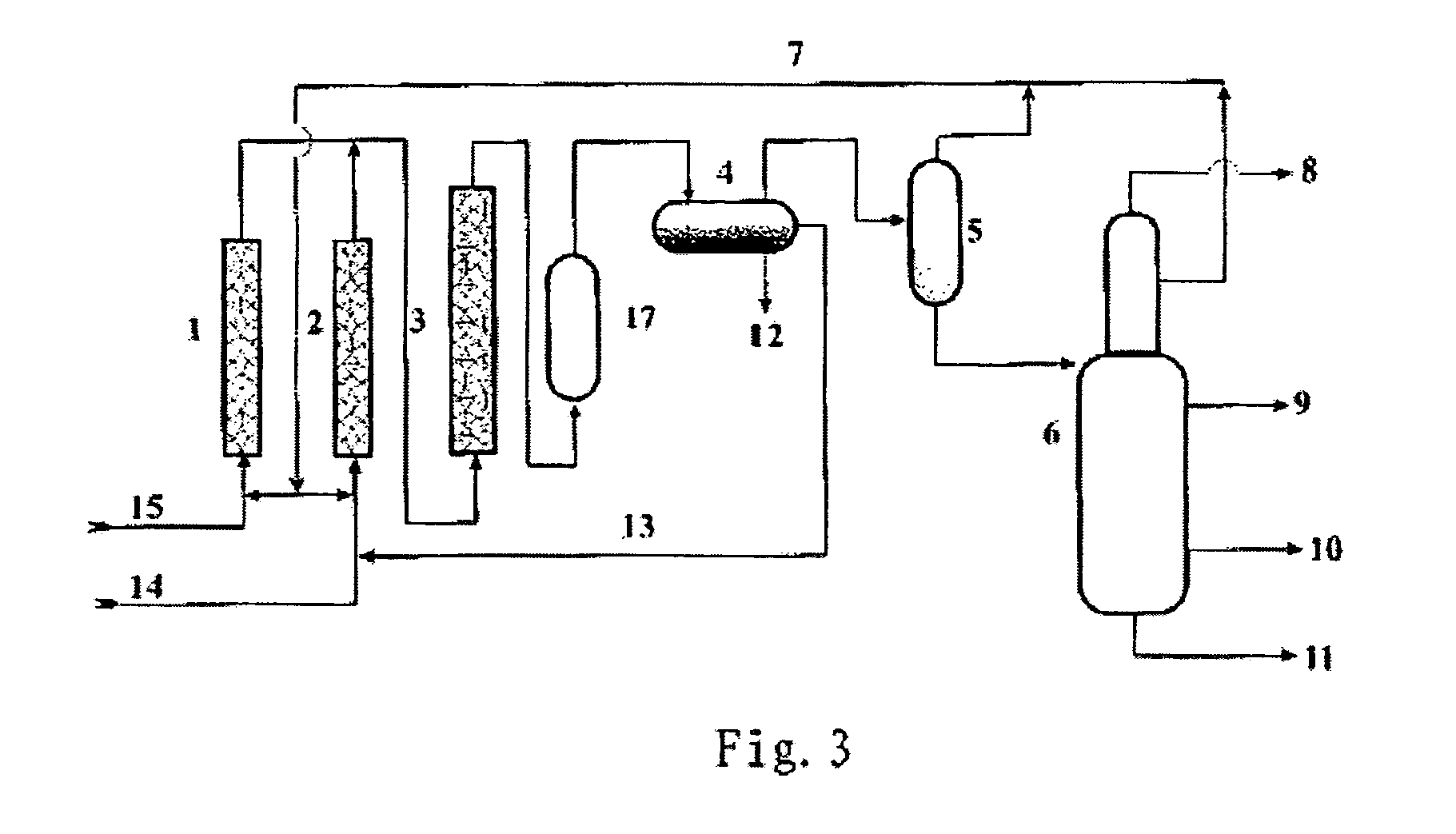

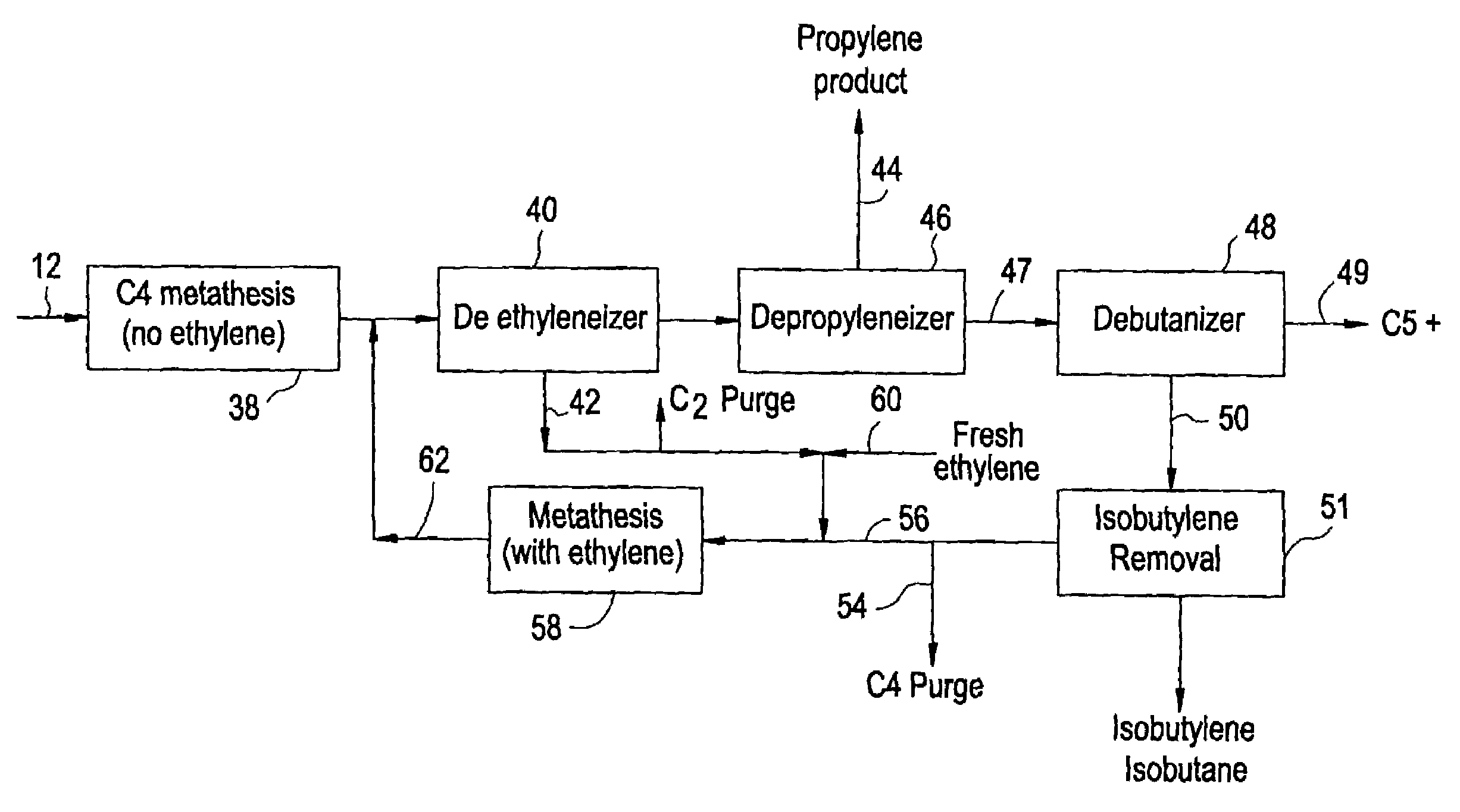

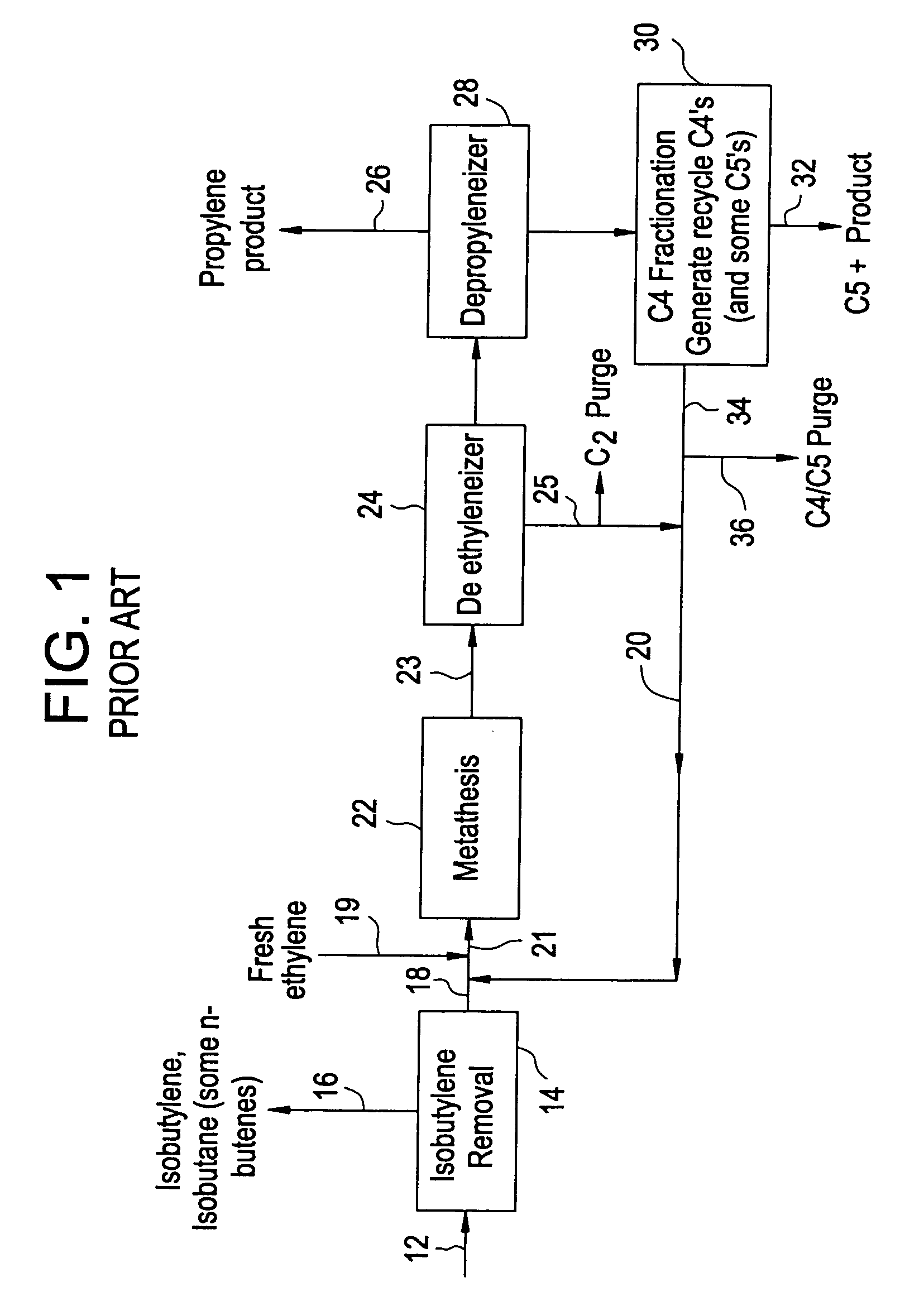

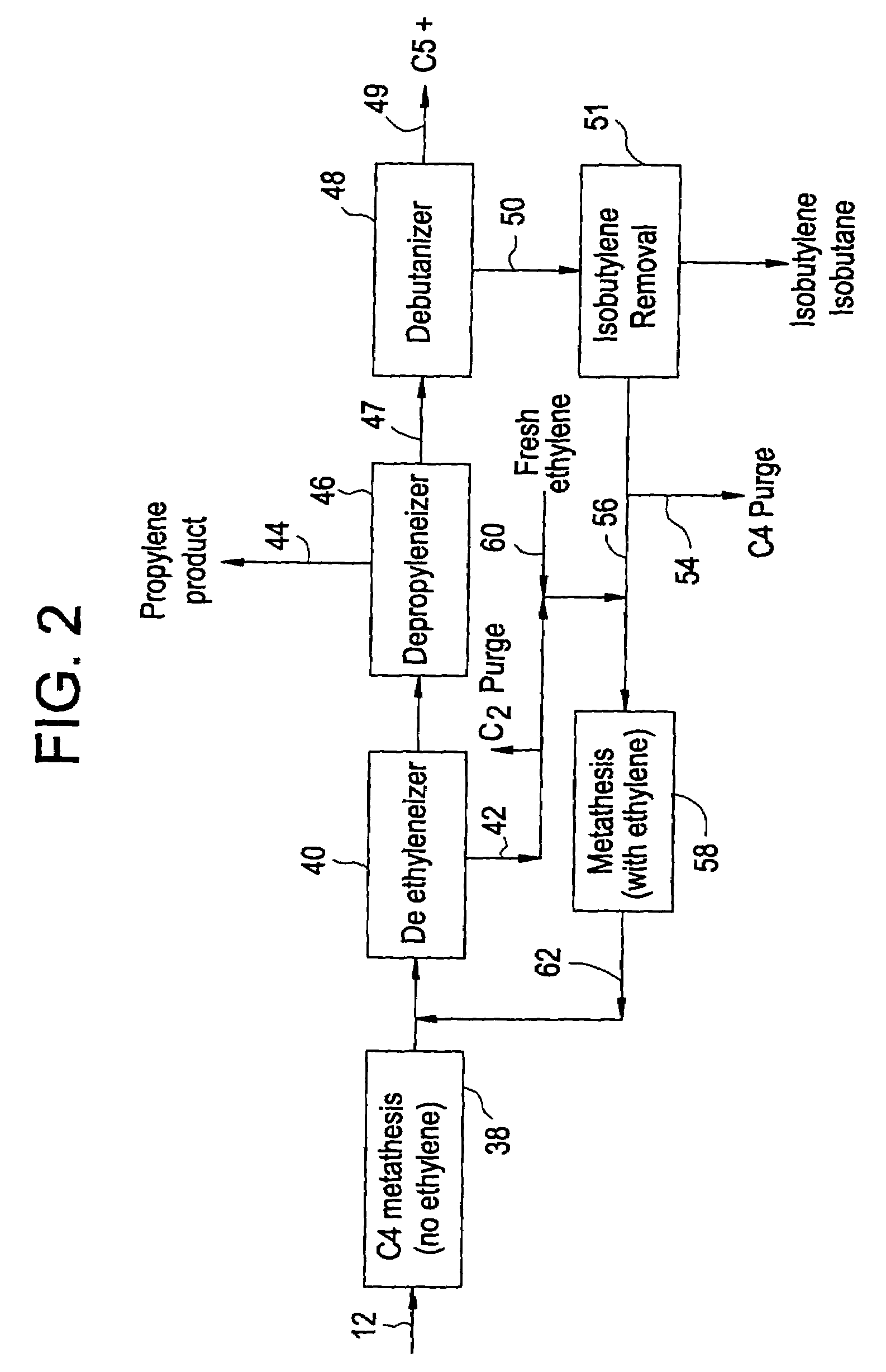

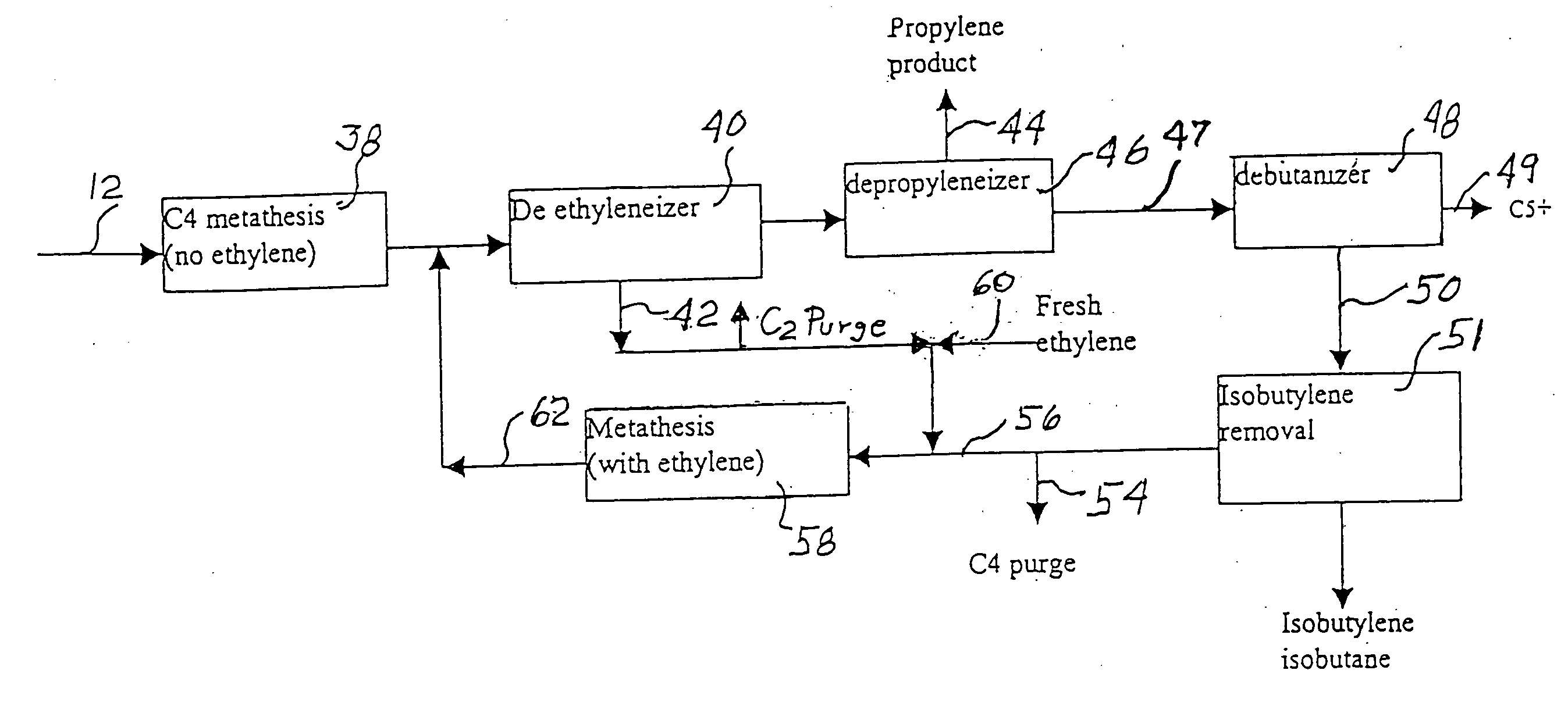

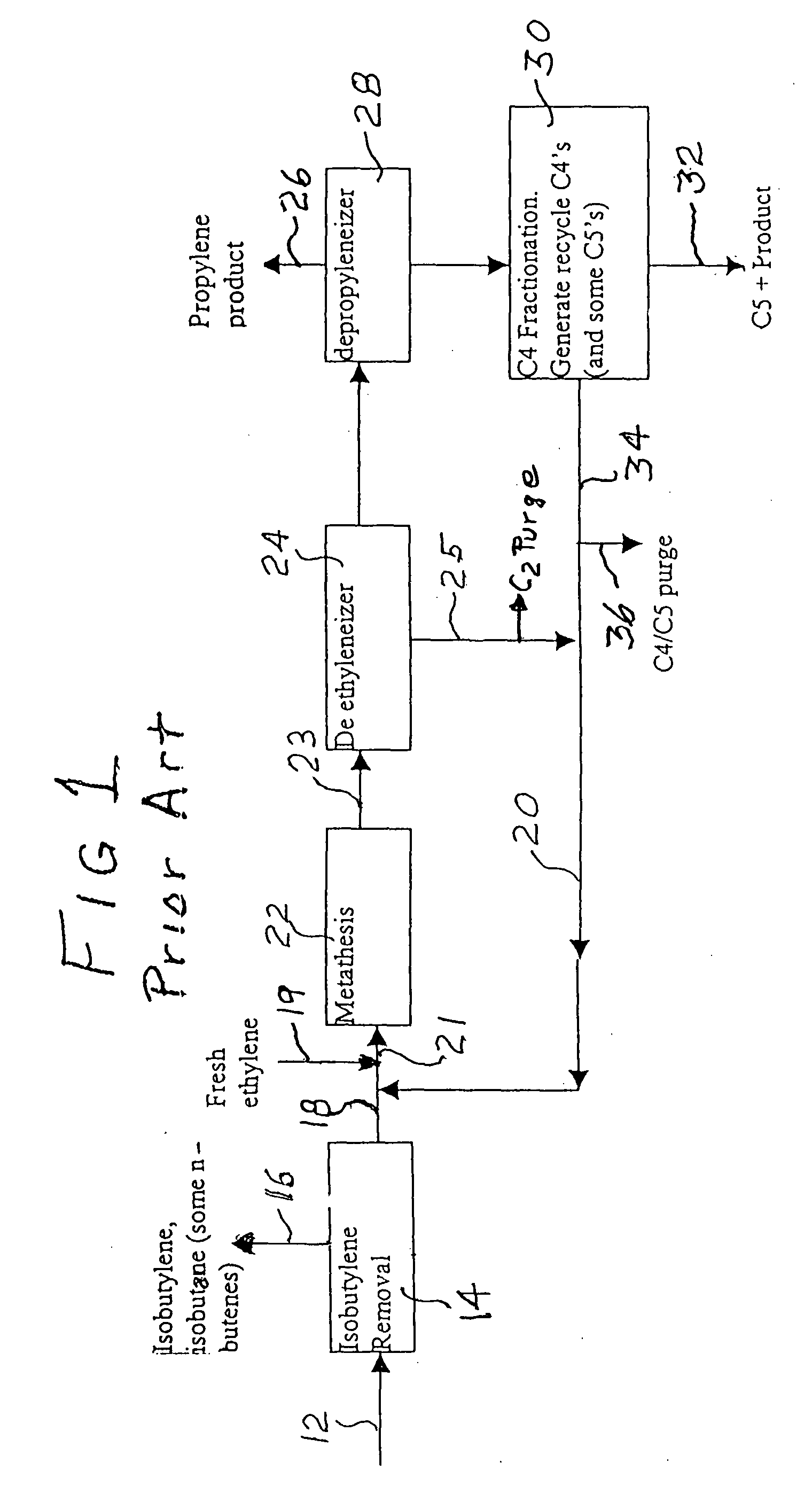

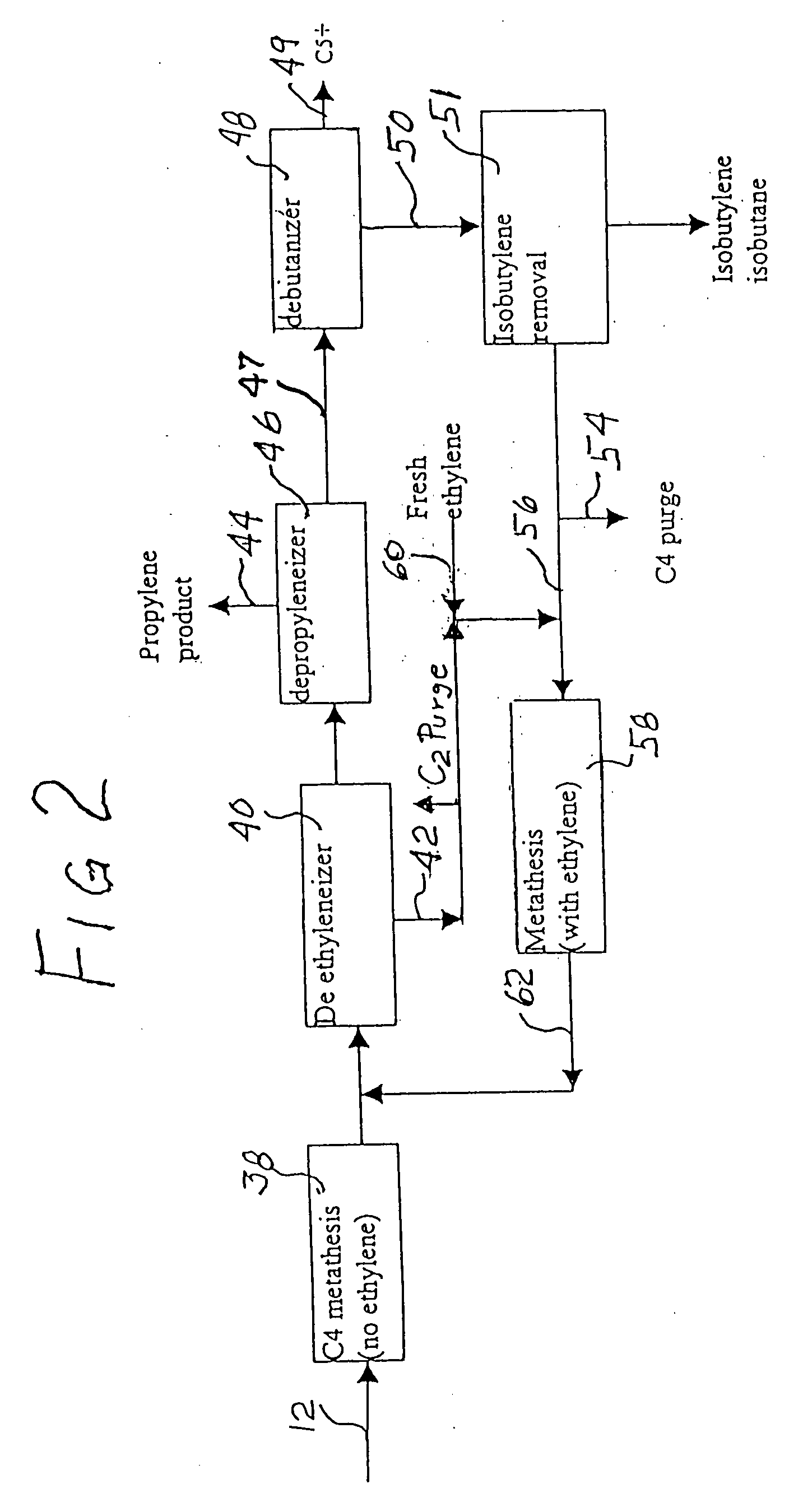

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

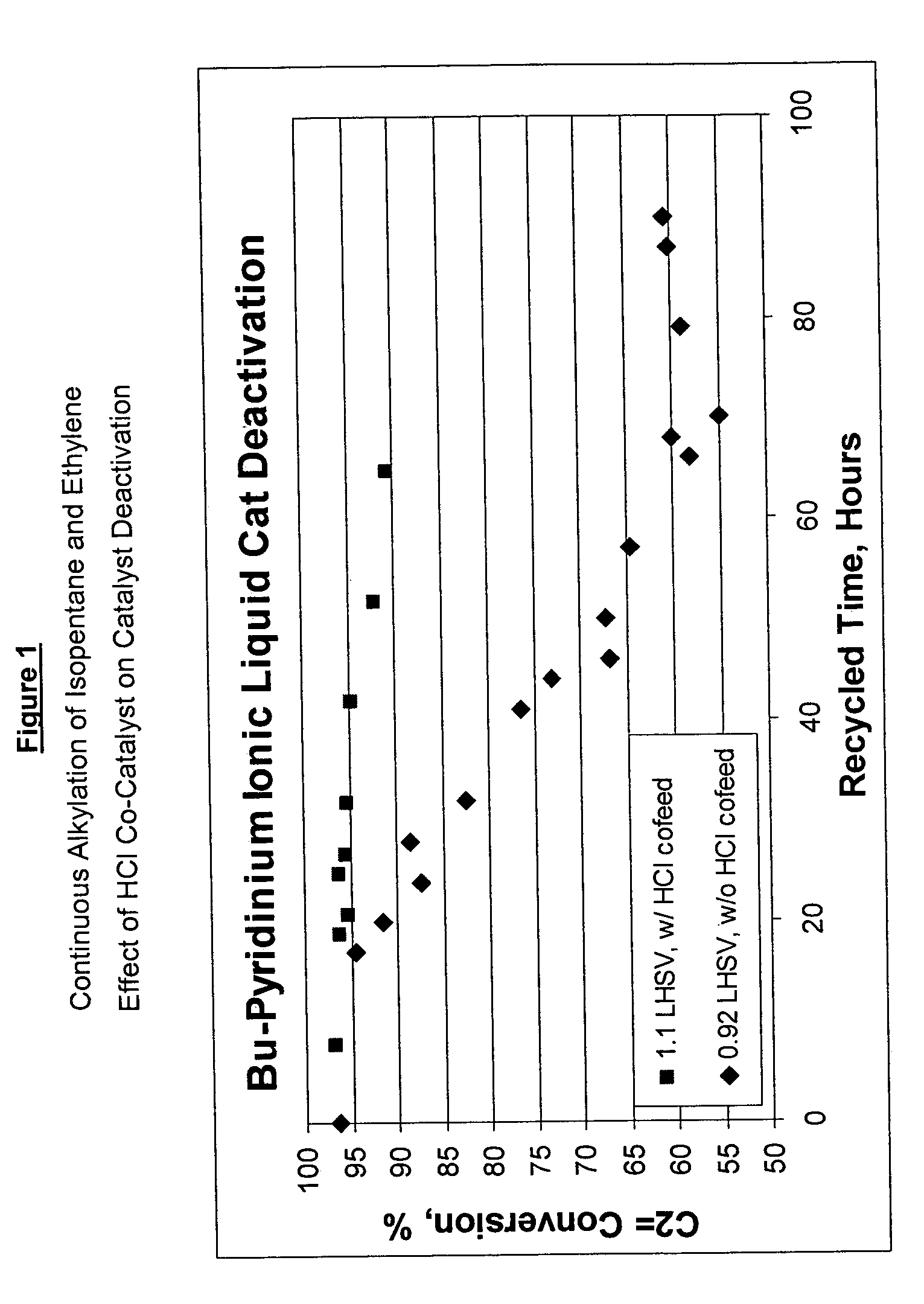

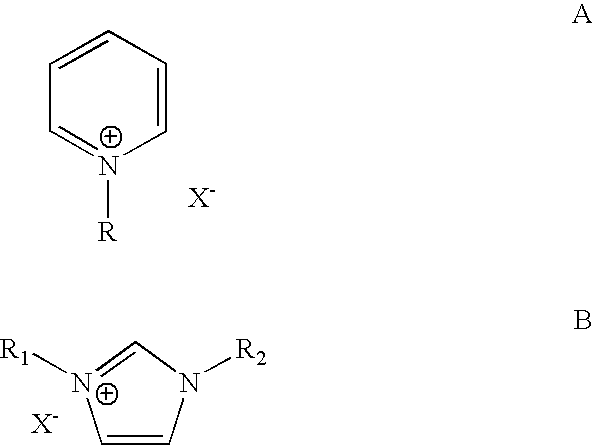

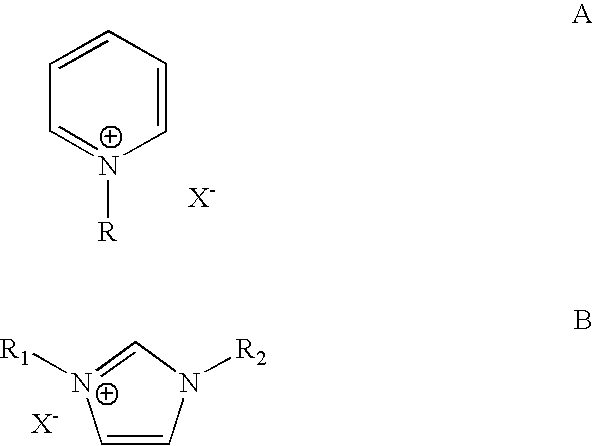

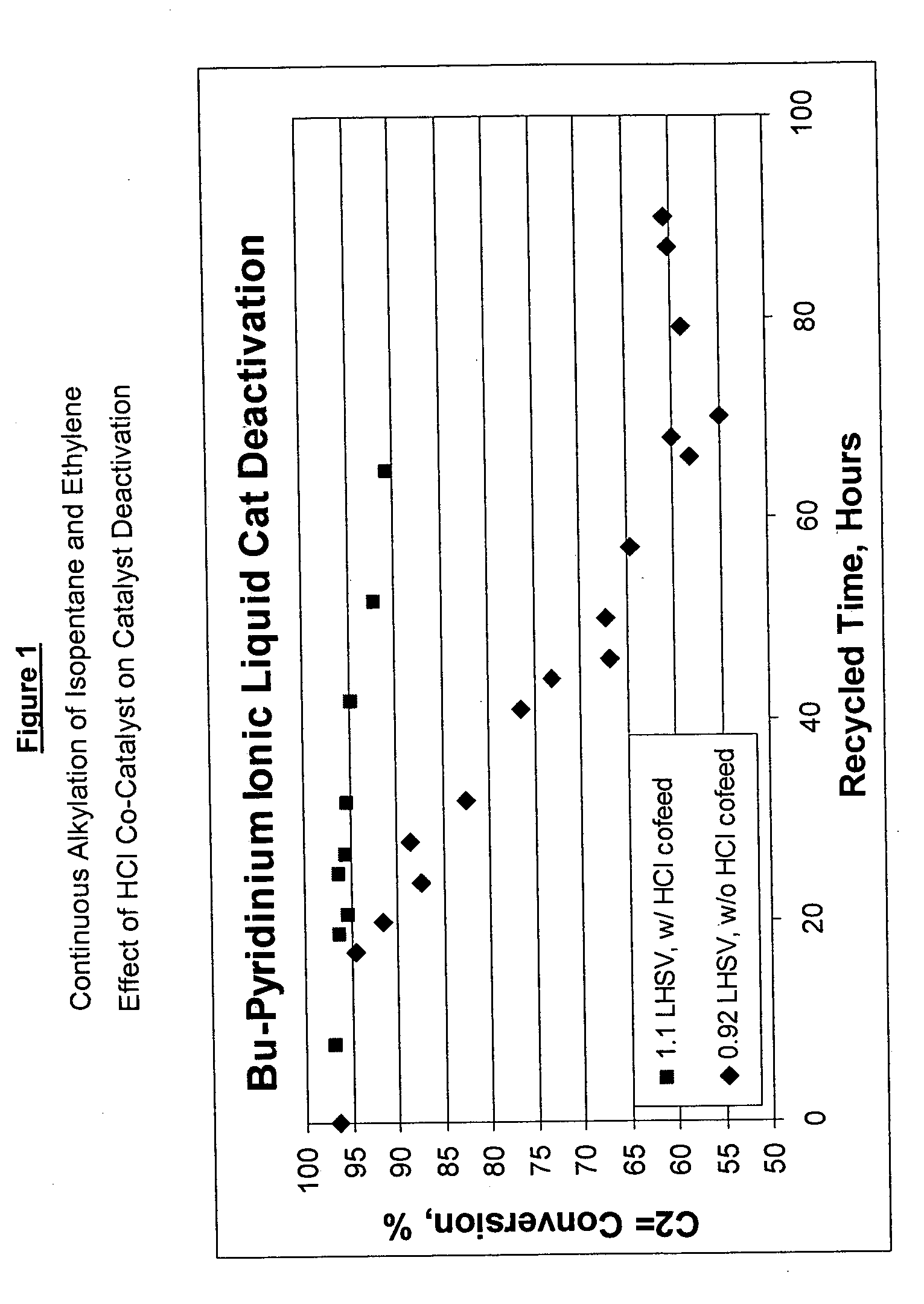

Alkylation process using chloroaluminate ionic liquid catalysts

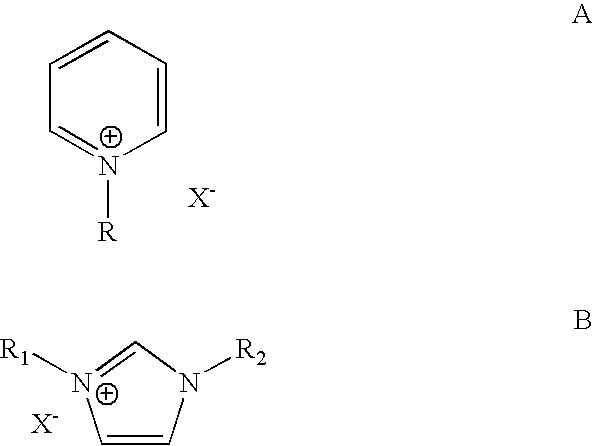

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium chloroaluminate or a hydrocarbyl substituted imidazolium chloroaluminate of the general formulas A and B, respectively.Where R═H, methlyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a chloroaluminate, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

Alkylation process using chloroaluminate ionic liquid catalysts

ActiveUS20060135839A1Quality improvementLiquid hydrocarbon mixtures productionHydrocarbons2-methylbutanePyridinium

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium halide or a hydrocarbyl substituted imidazolium halide of the general formulas A and B, respectively. Where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

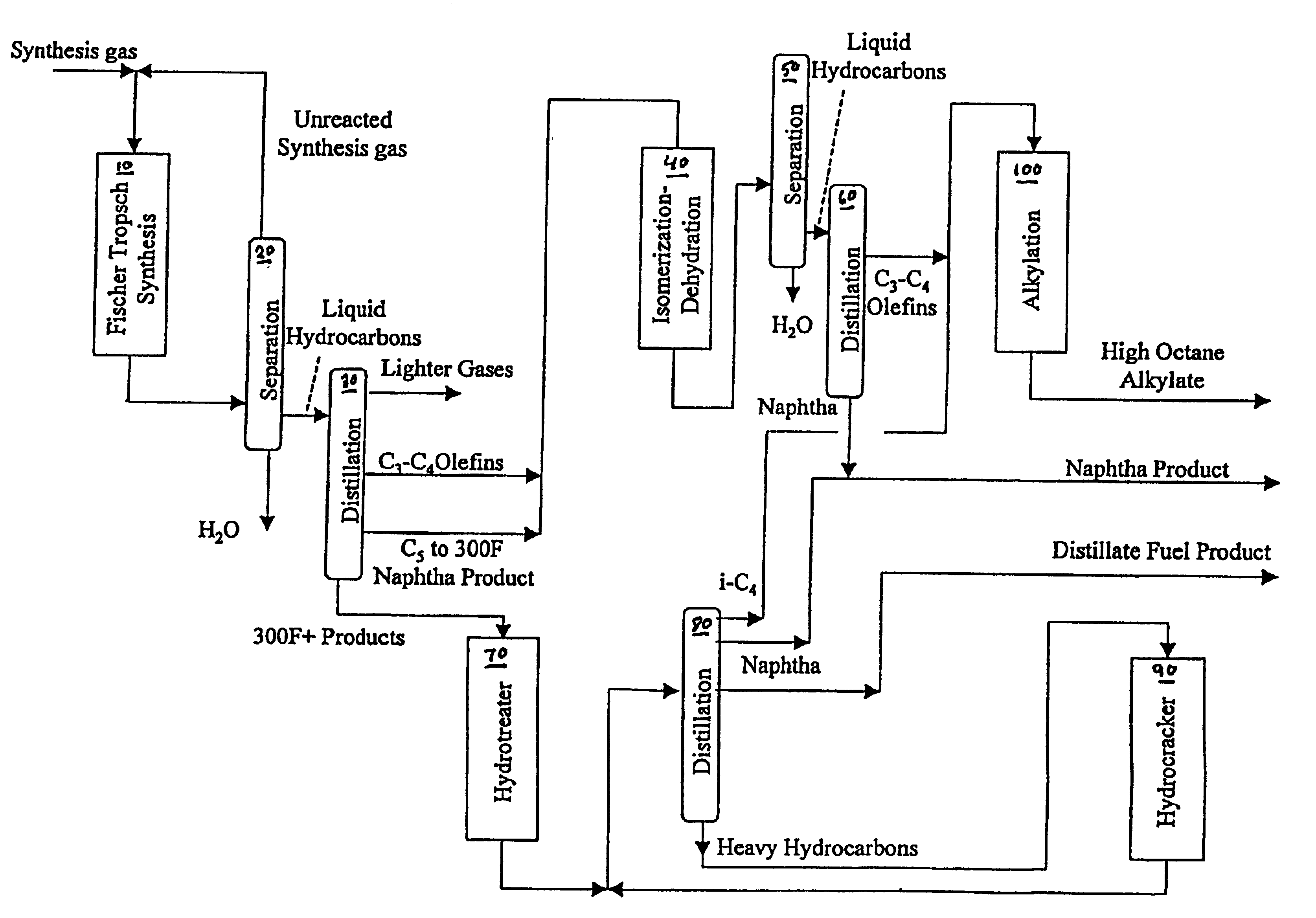

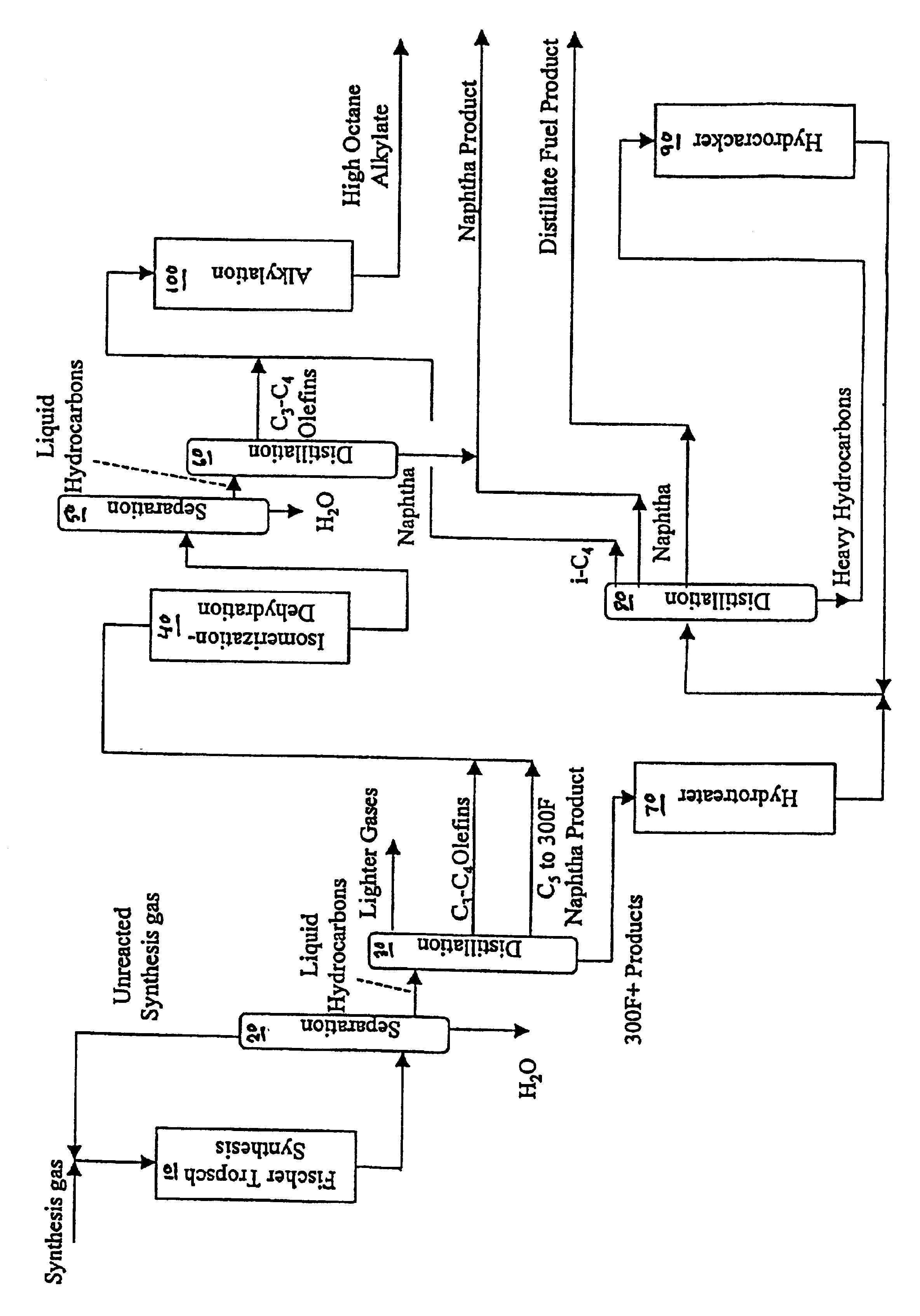

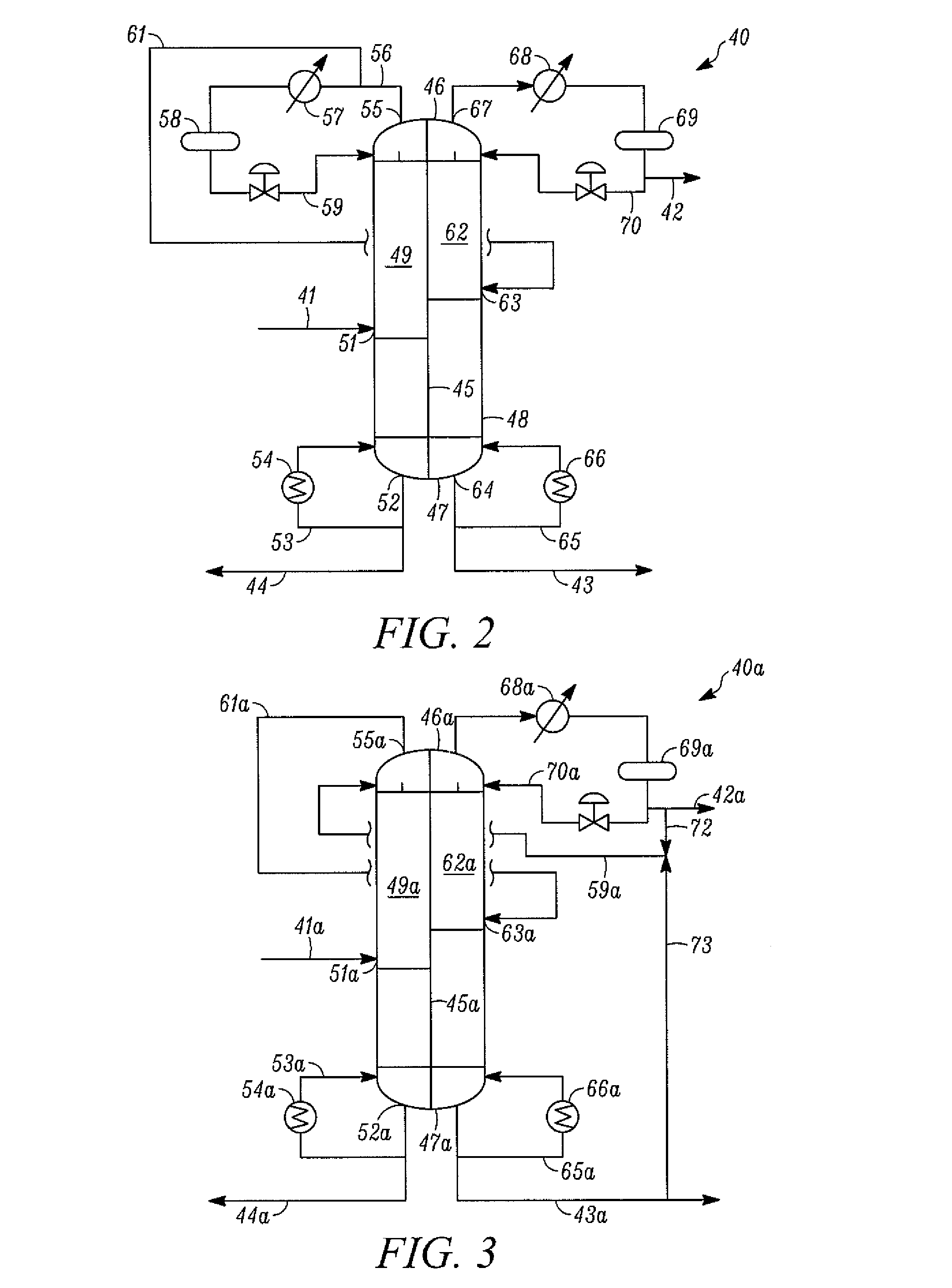

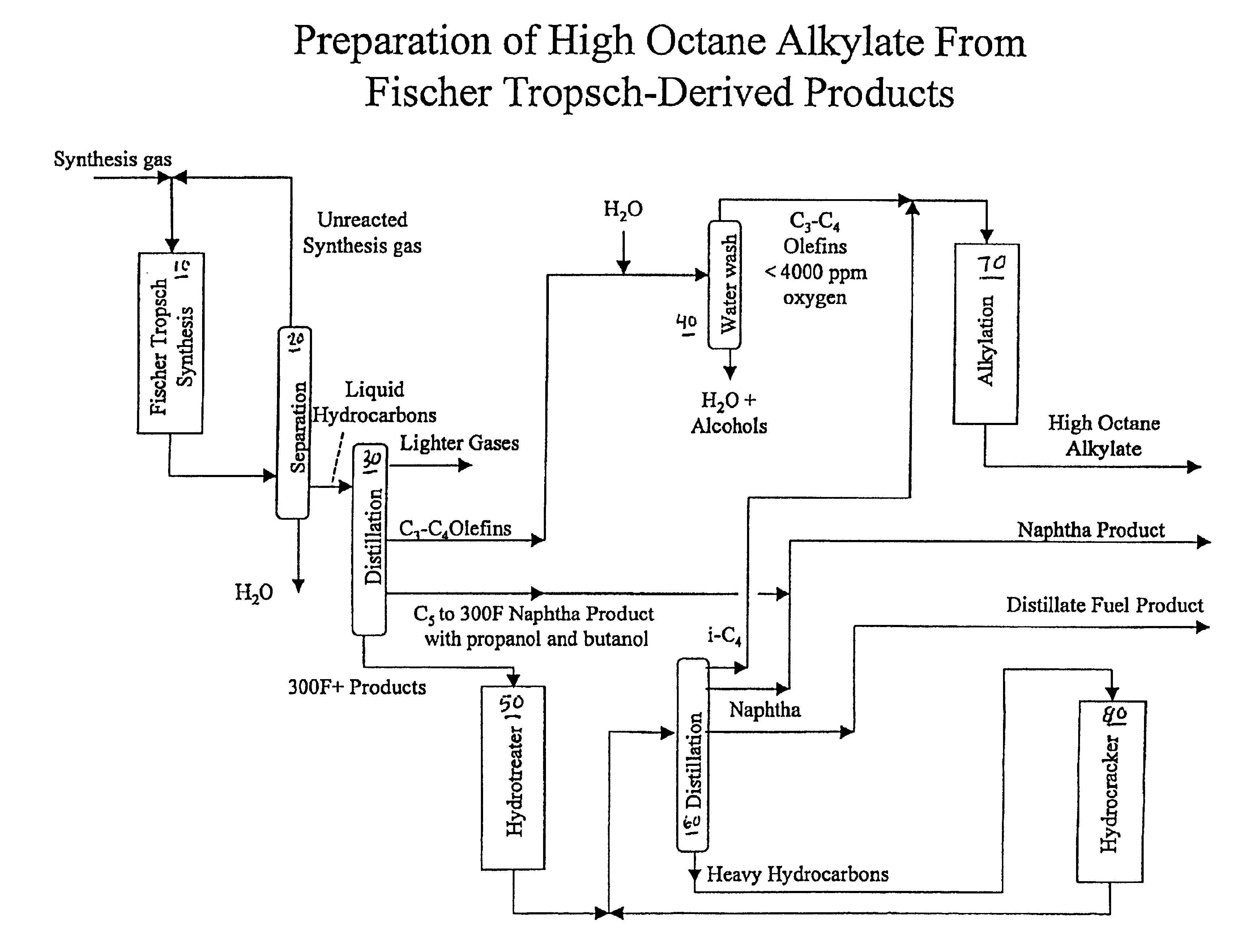

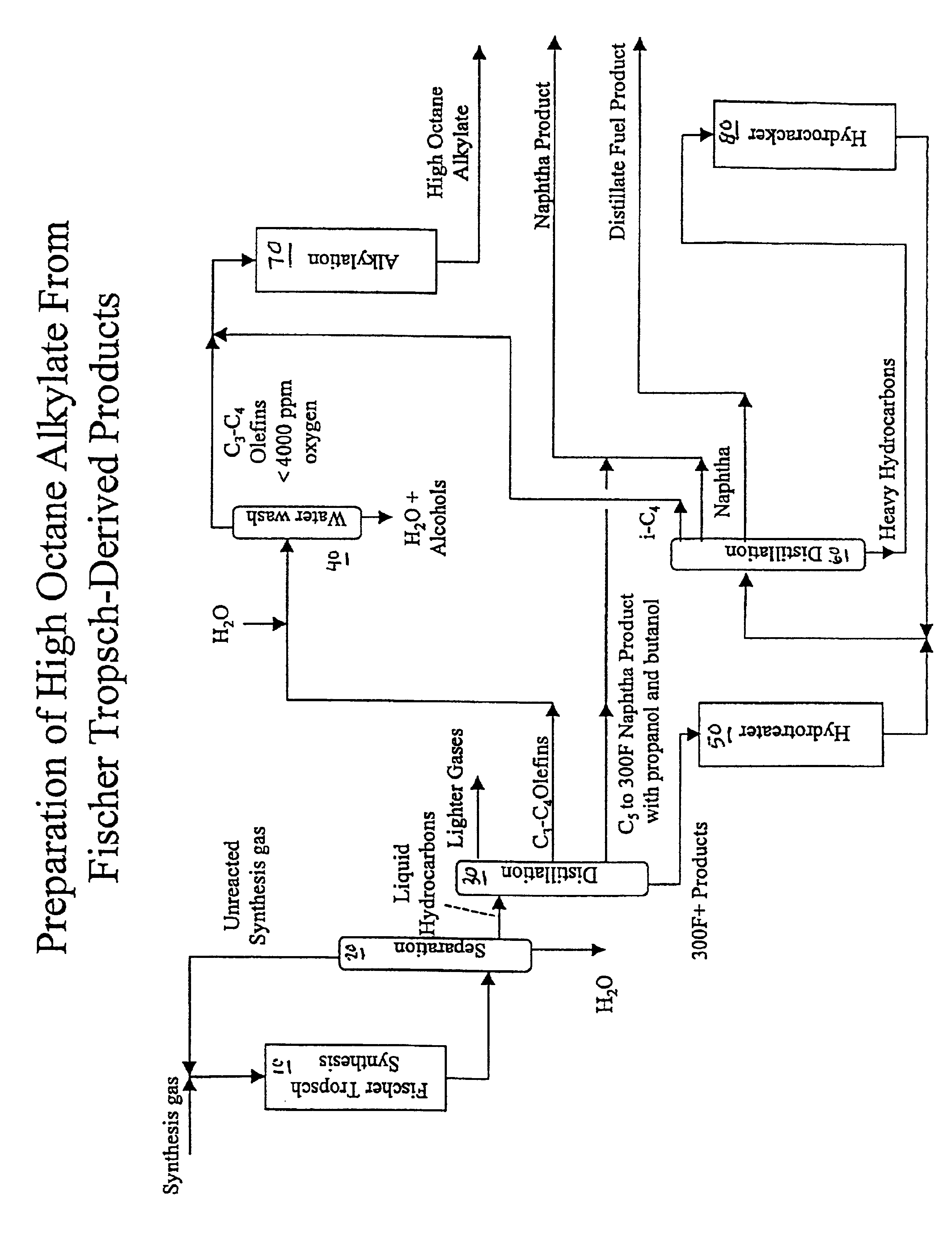

Manufacture of high octane alkylate

InactiveUS6768035B2Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

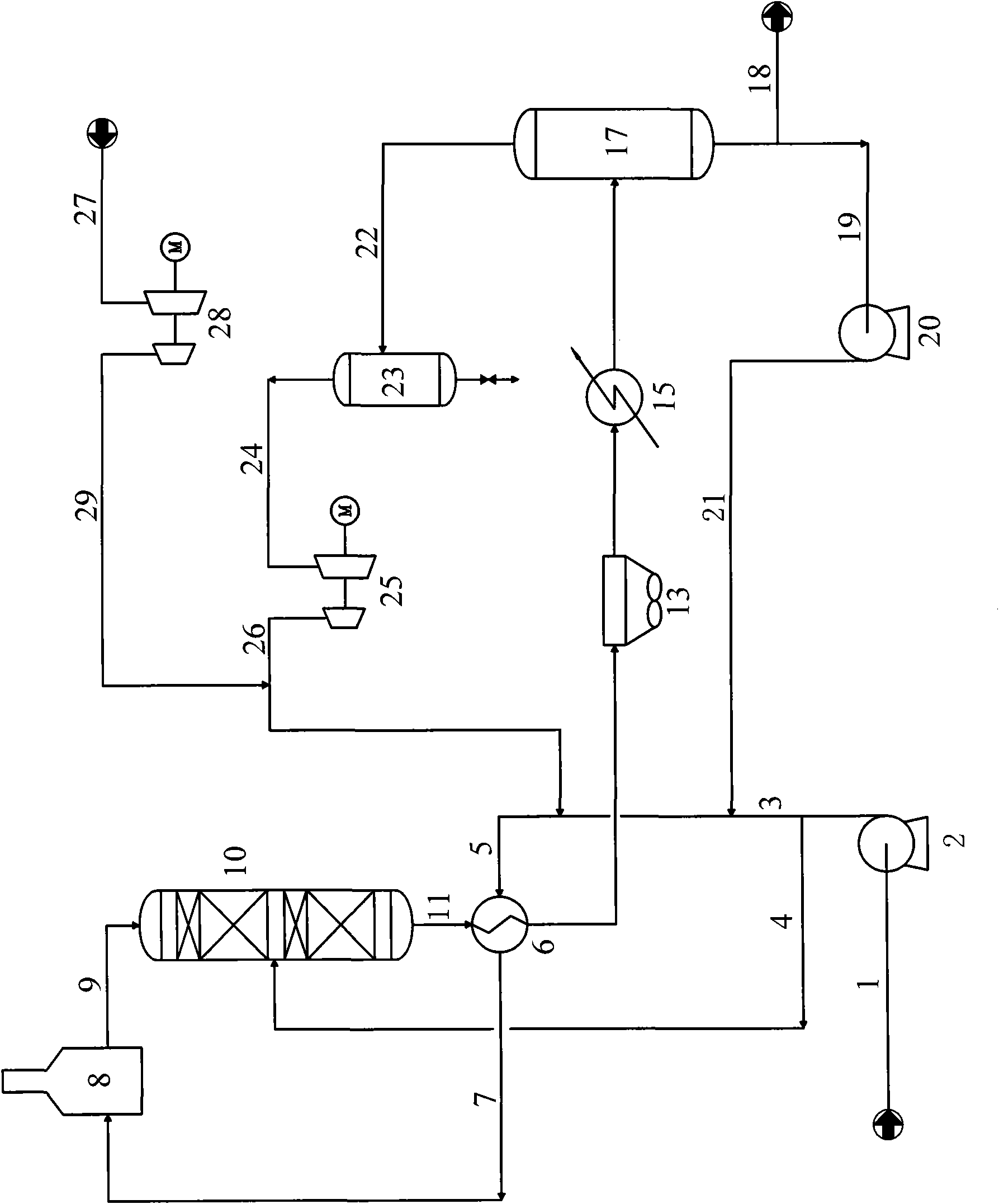

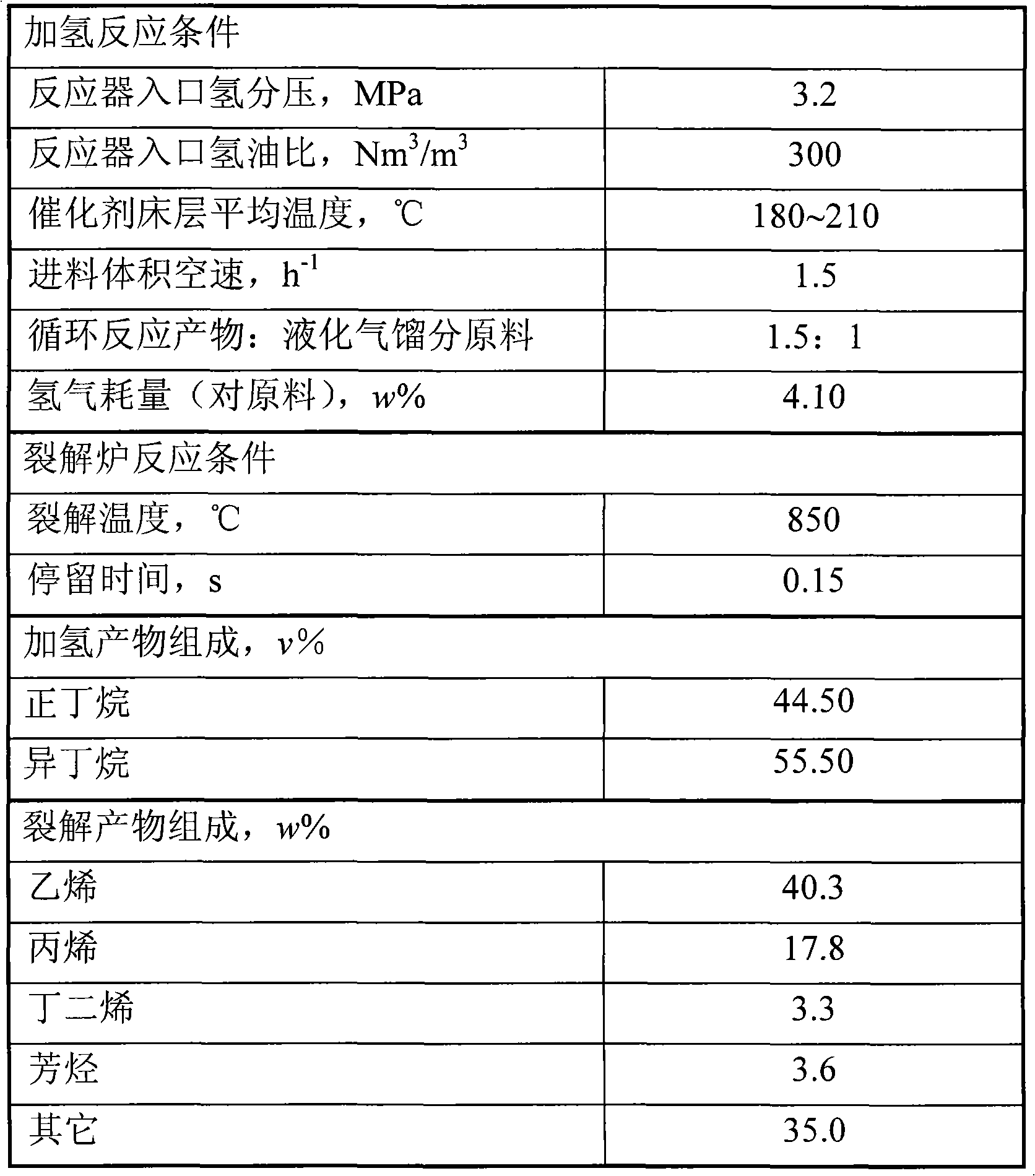

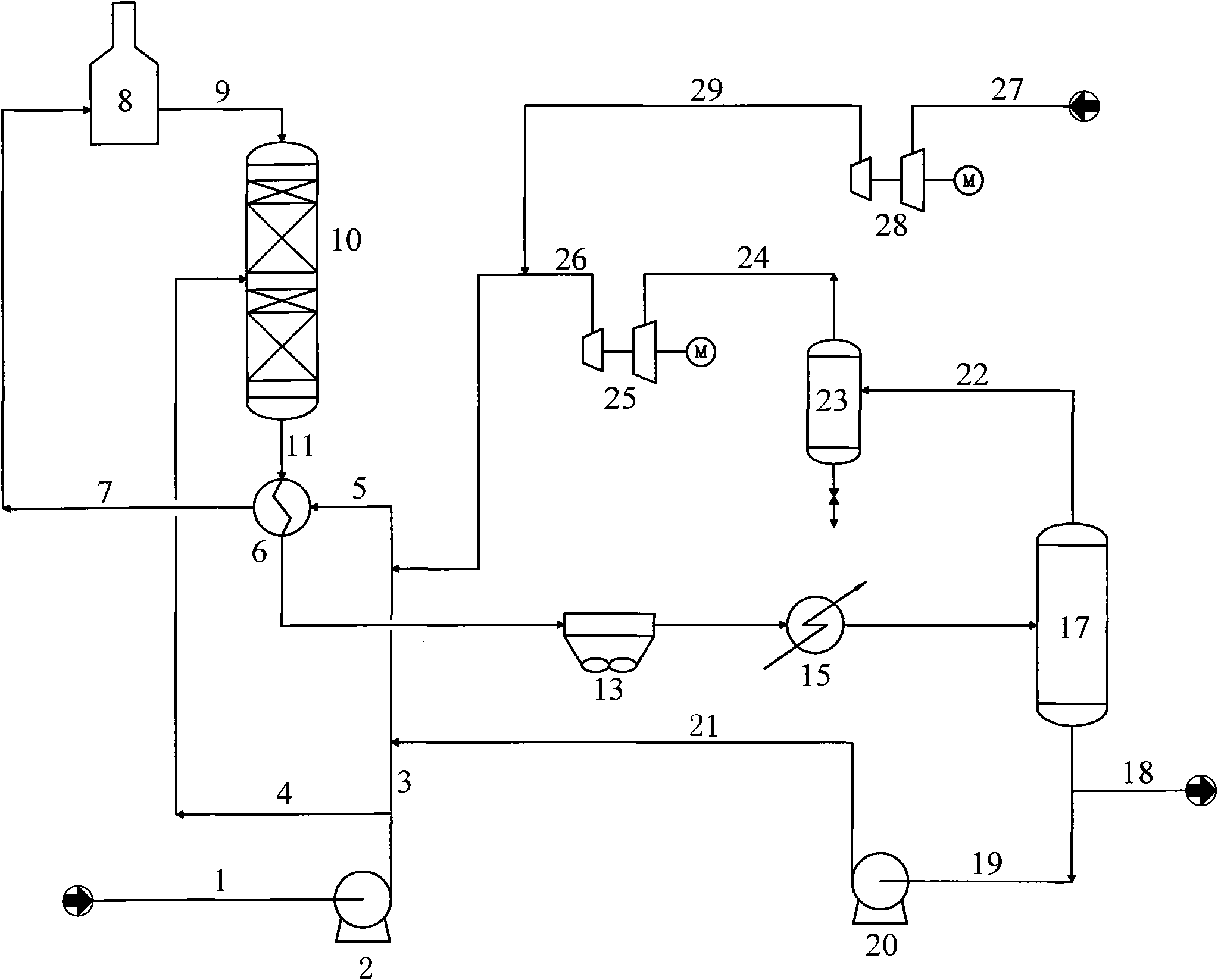

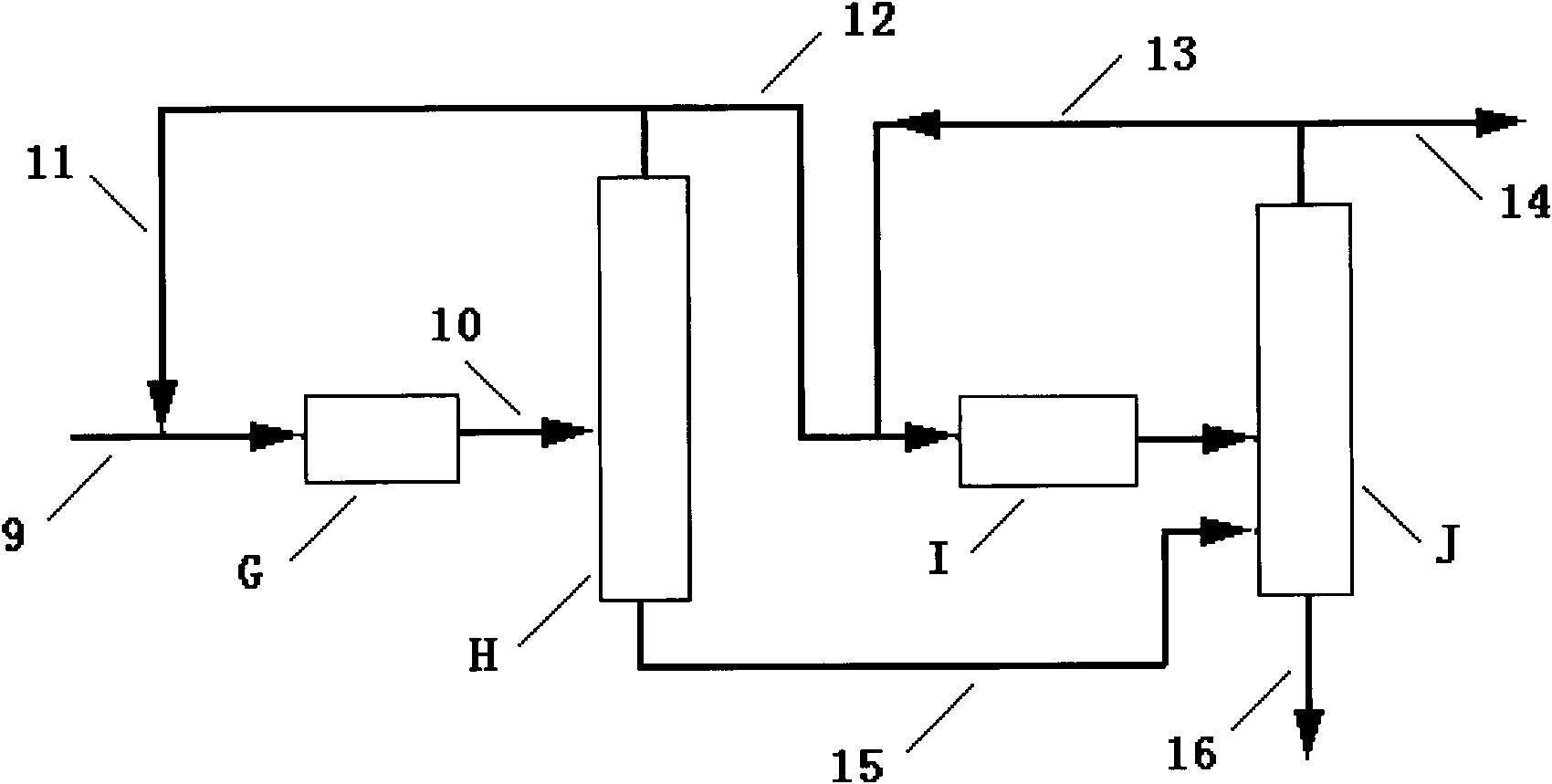

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

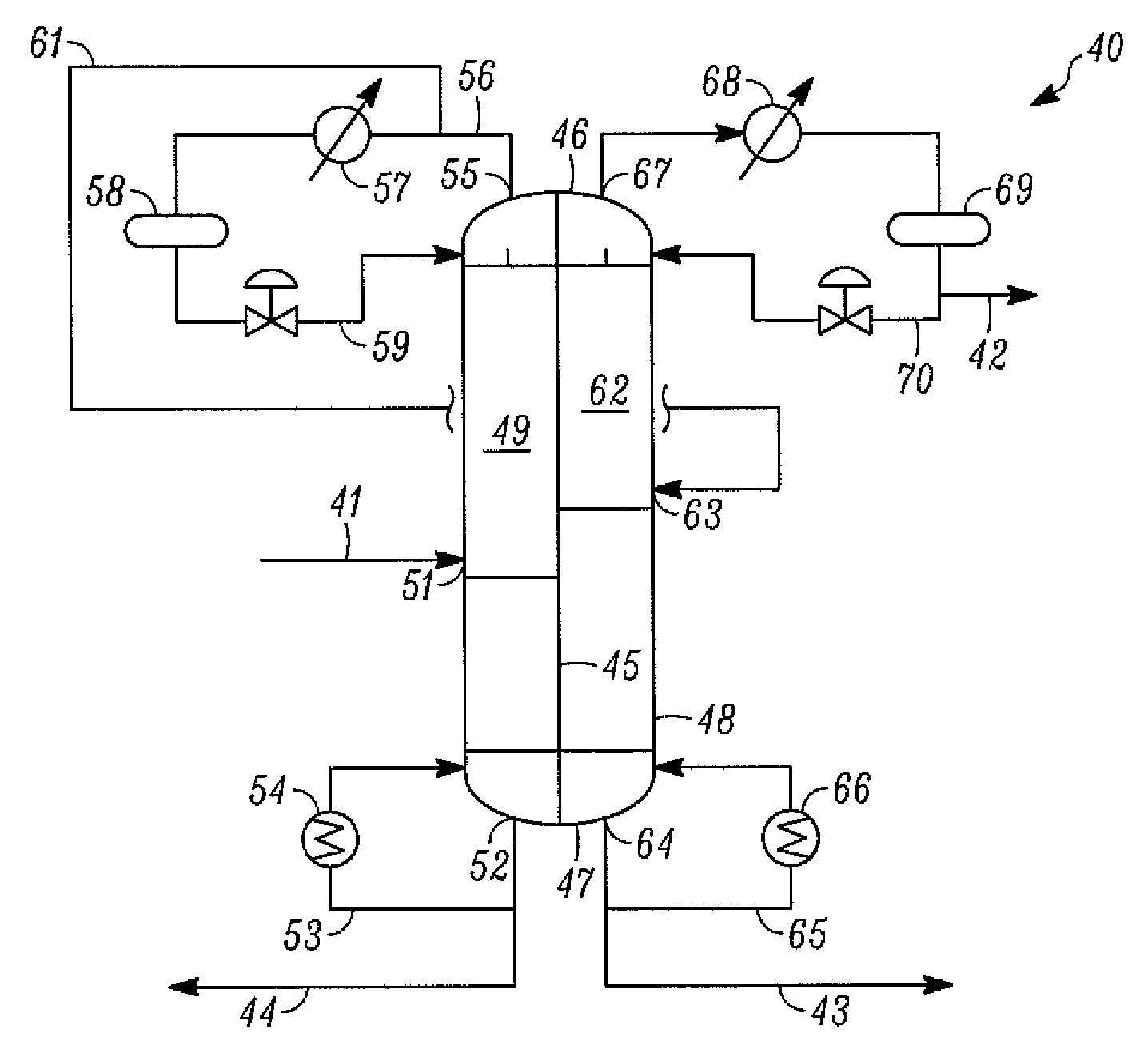

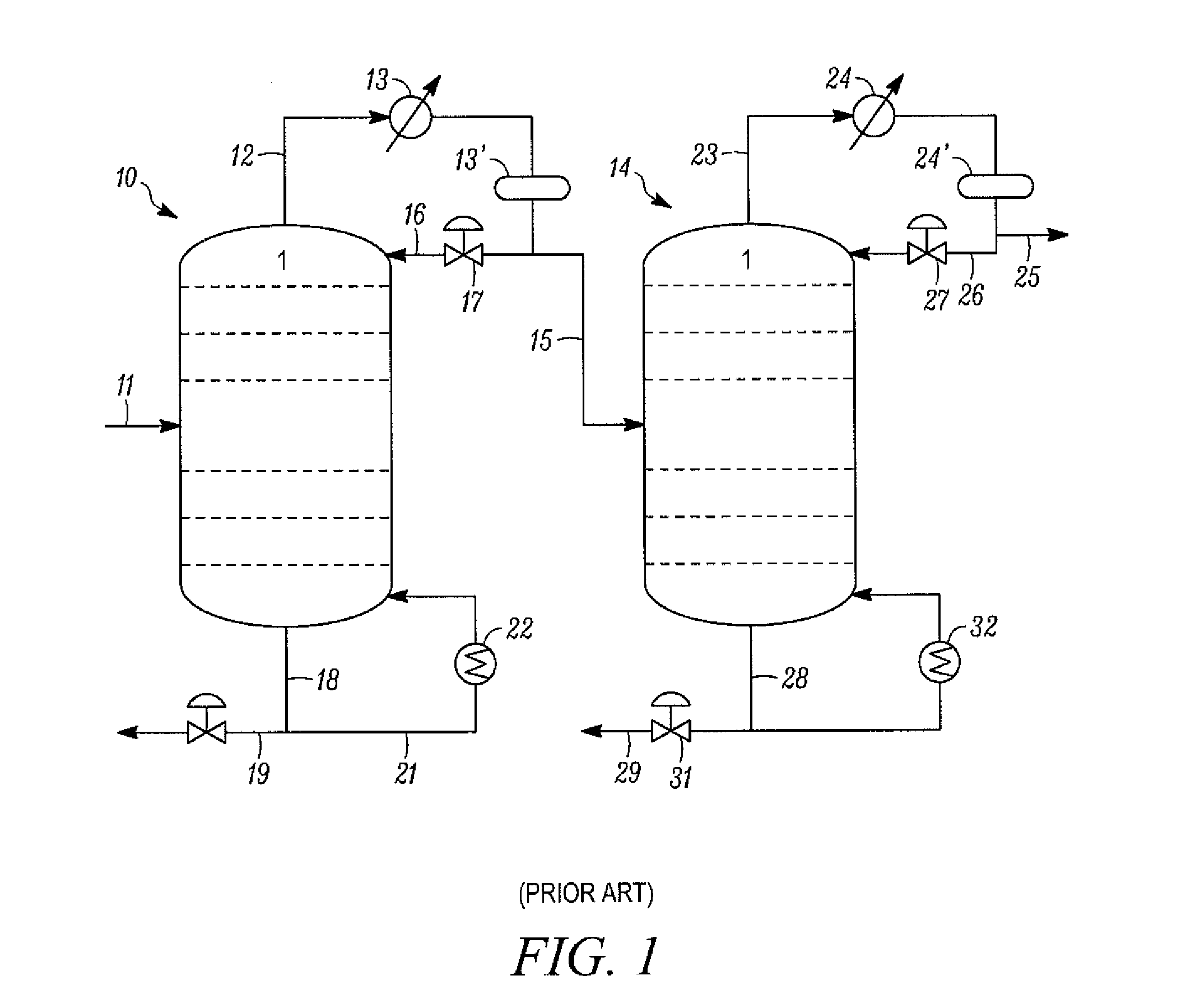

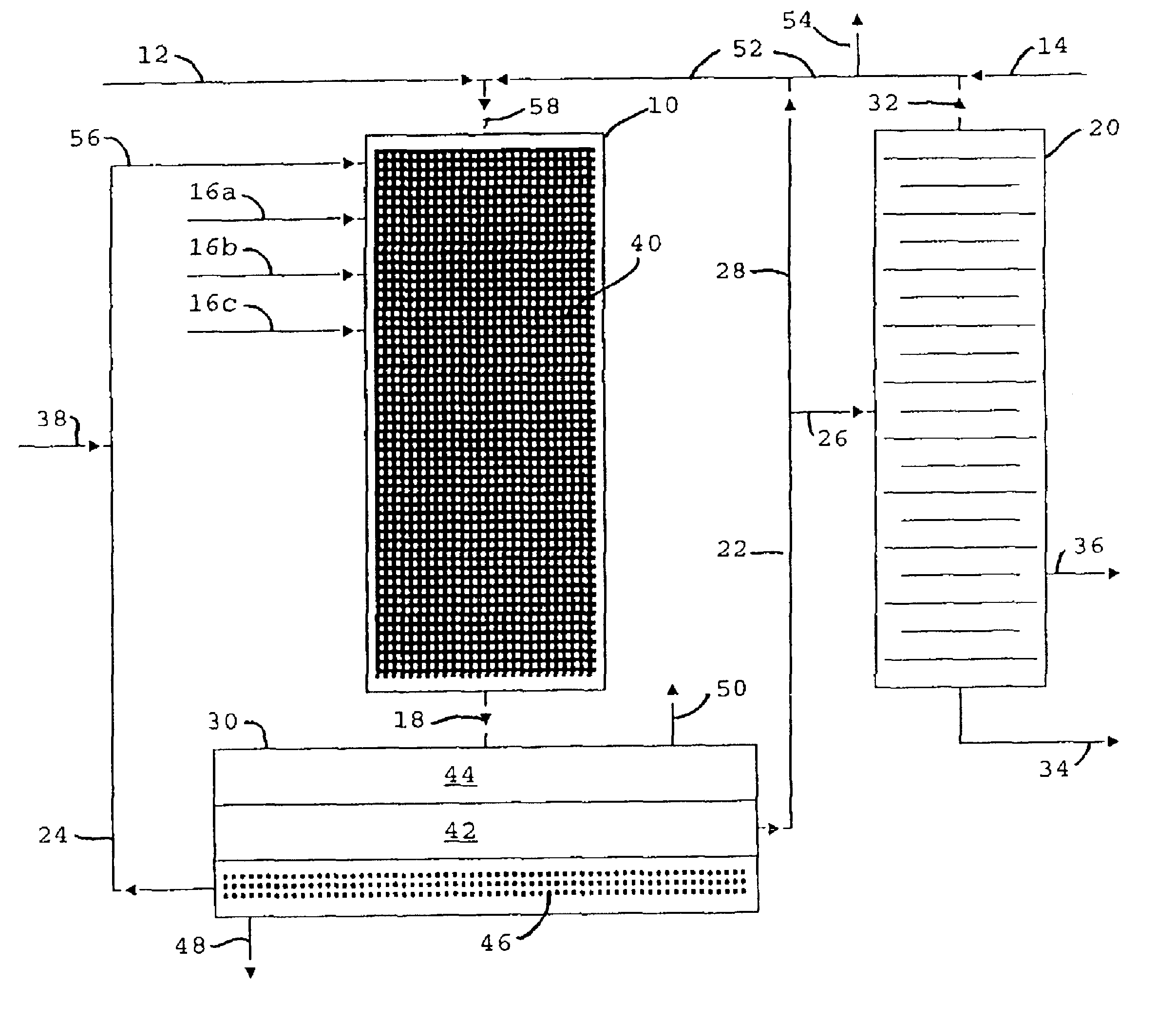

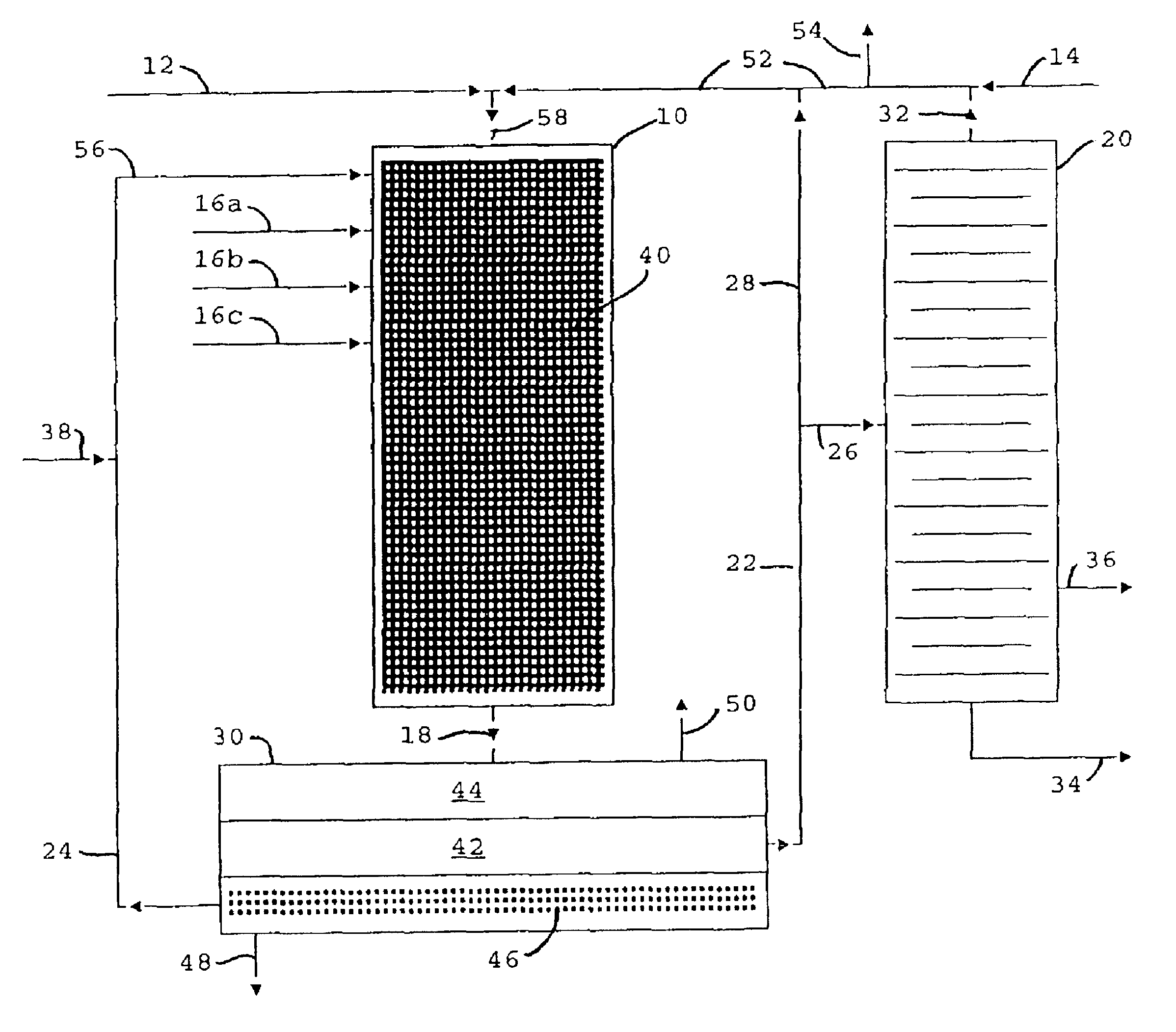

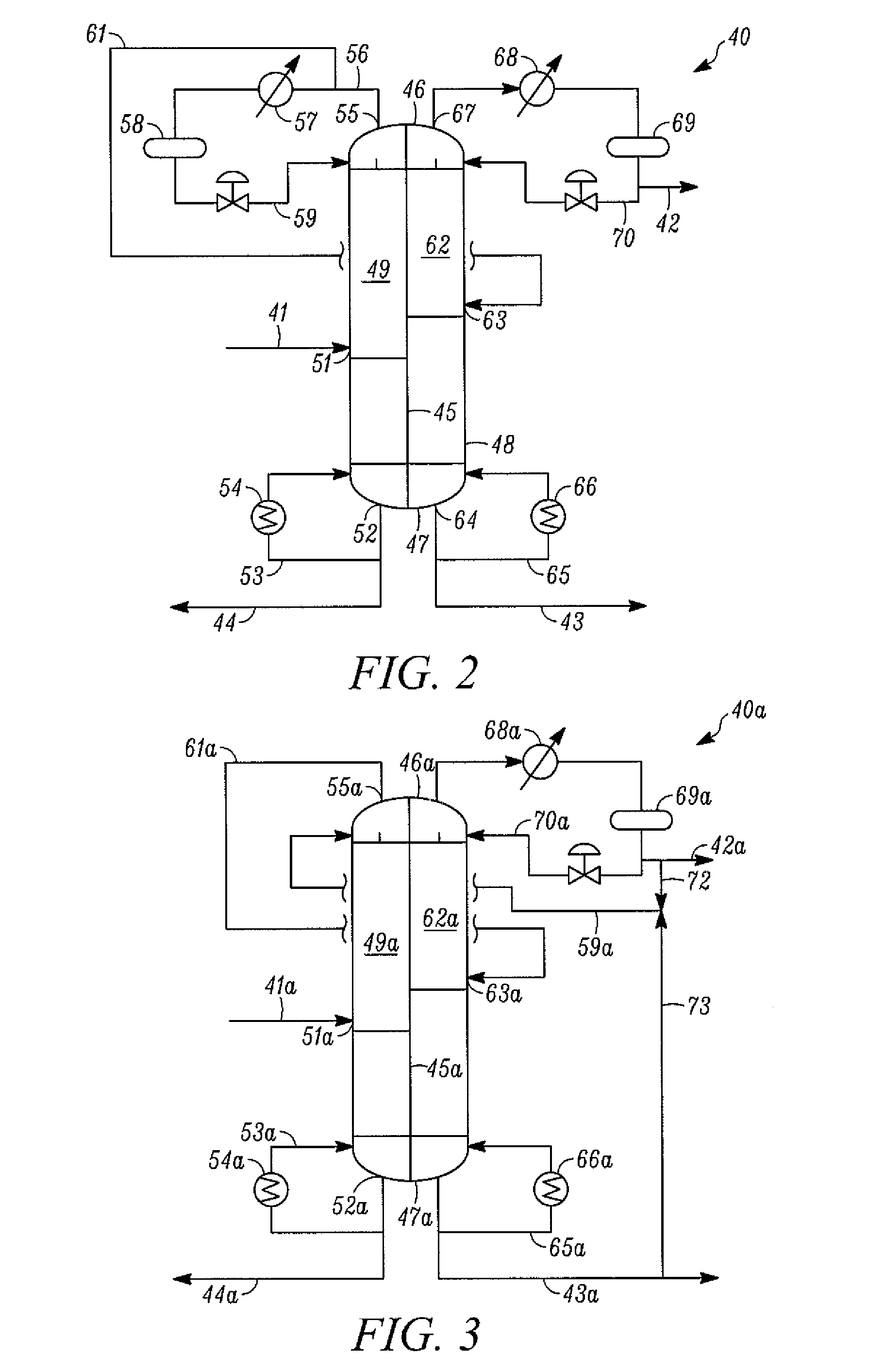

Apparatus and Methods for Separating Butene-1 from a Mixed C4 Feed

ActiveUS20080161618A1Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneFractionating column

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

Preparation of high octane alkylate from Fischer-Tropsch olefins

InactiveUS6743962B2Refining to change hydrocarbon structural skeletonOrganic chemistry methodsAlkyl transferGasoline

A Fischer-Tropsch C3-C4 olefin stream is treated to lower the oxygenate content to below 4000 ppm. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane-containing stream. The treated C3-C4 olefin stream is reacted with the isobutane stream in an alkylation reactor to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

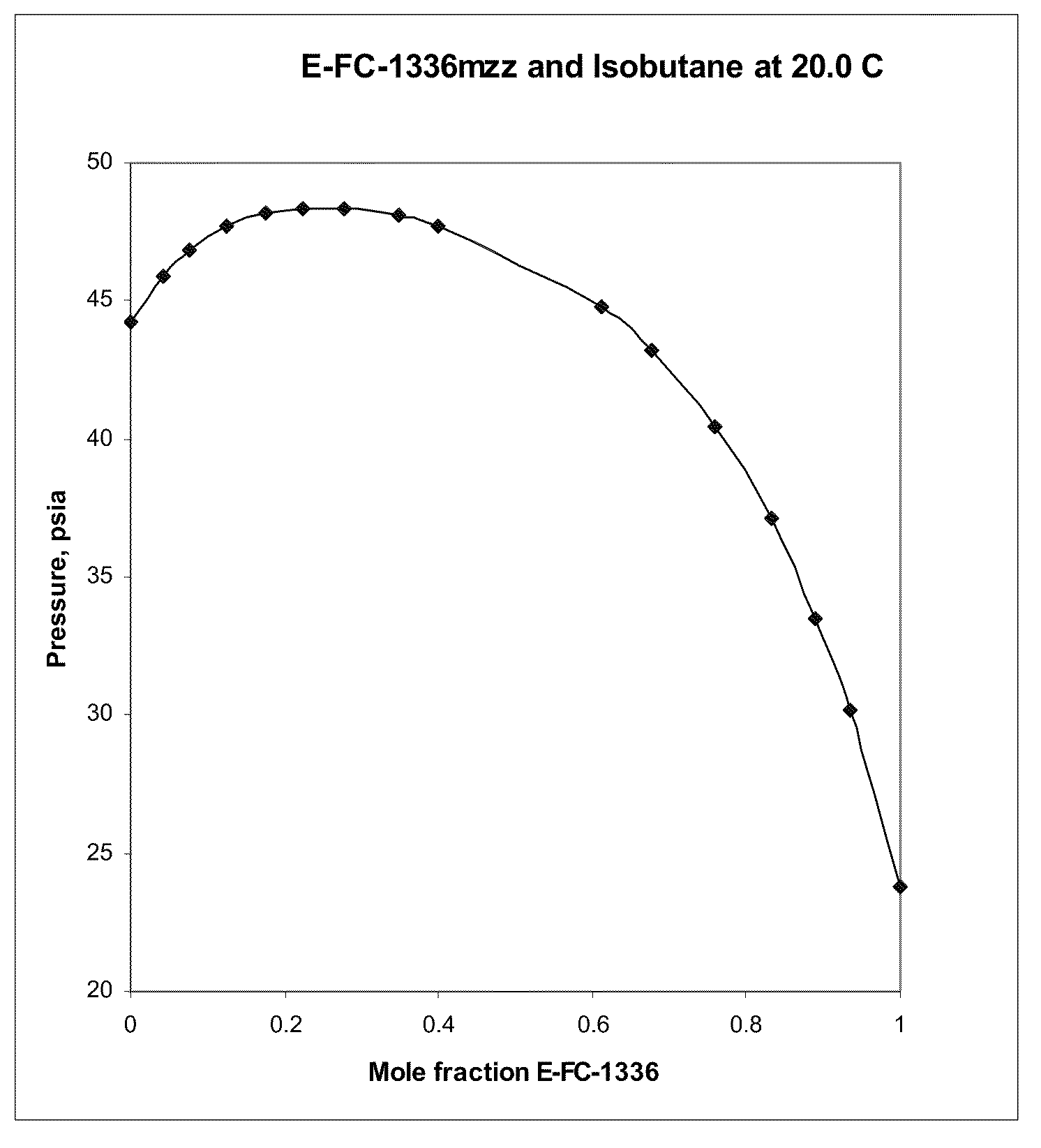

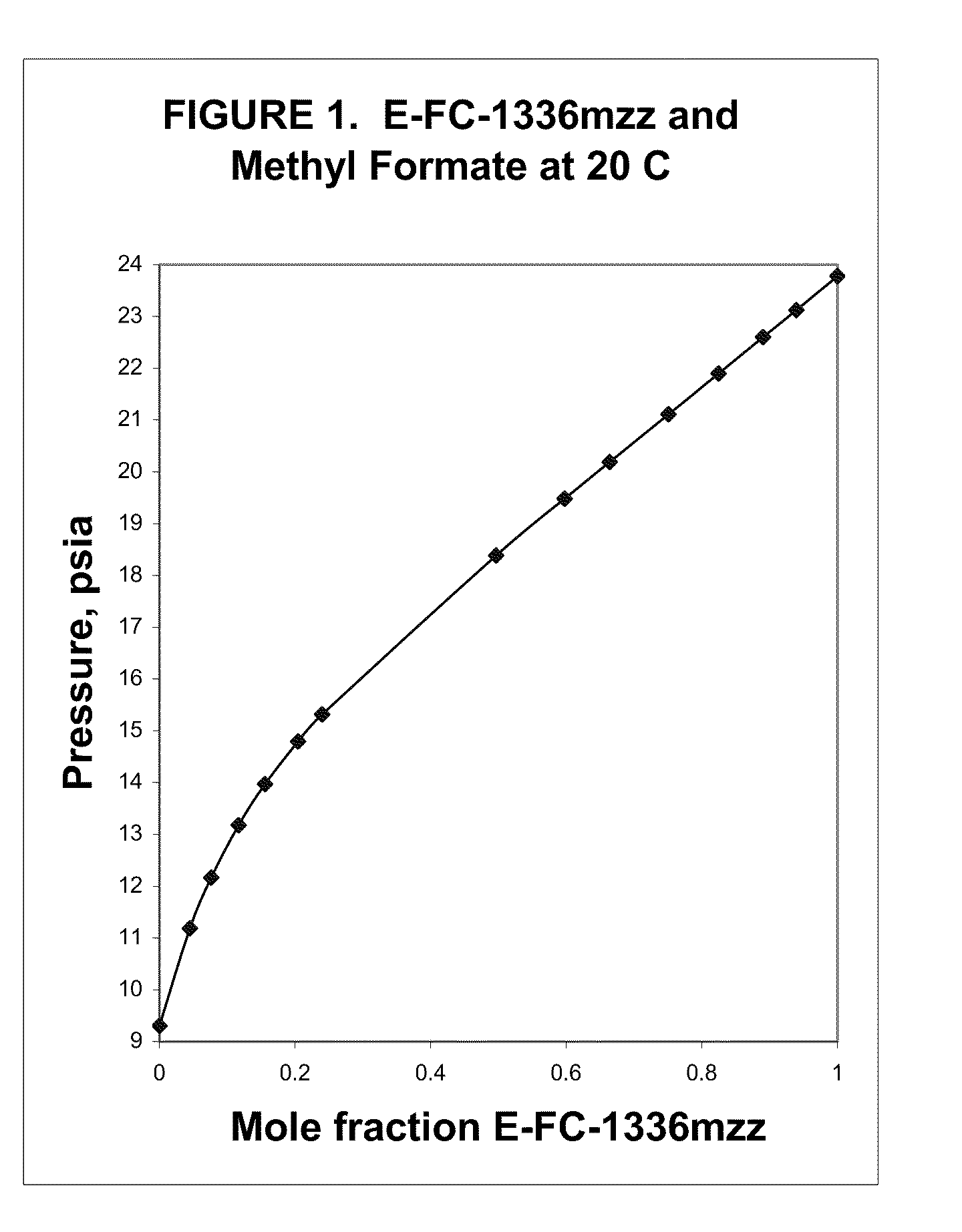

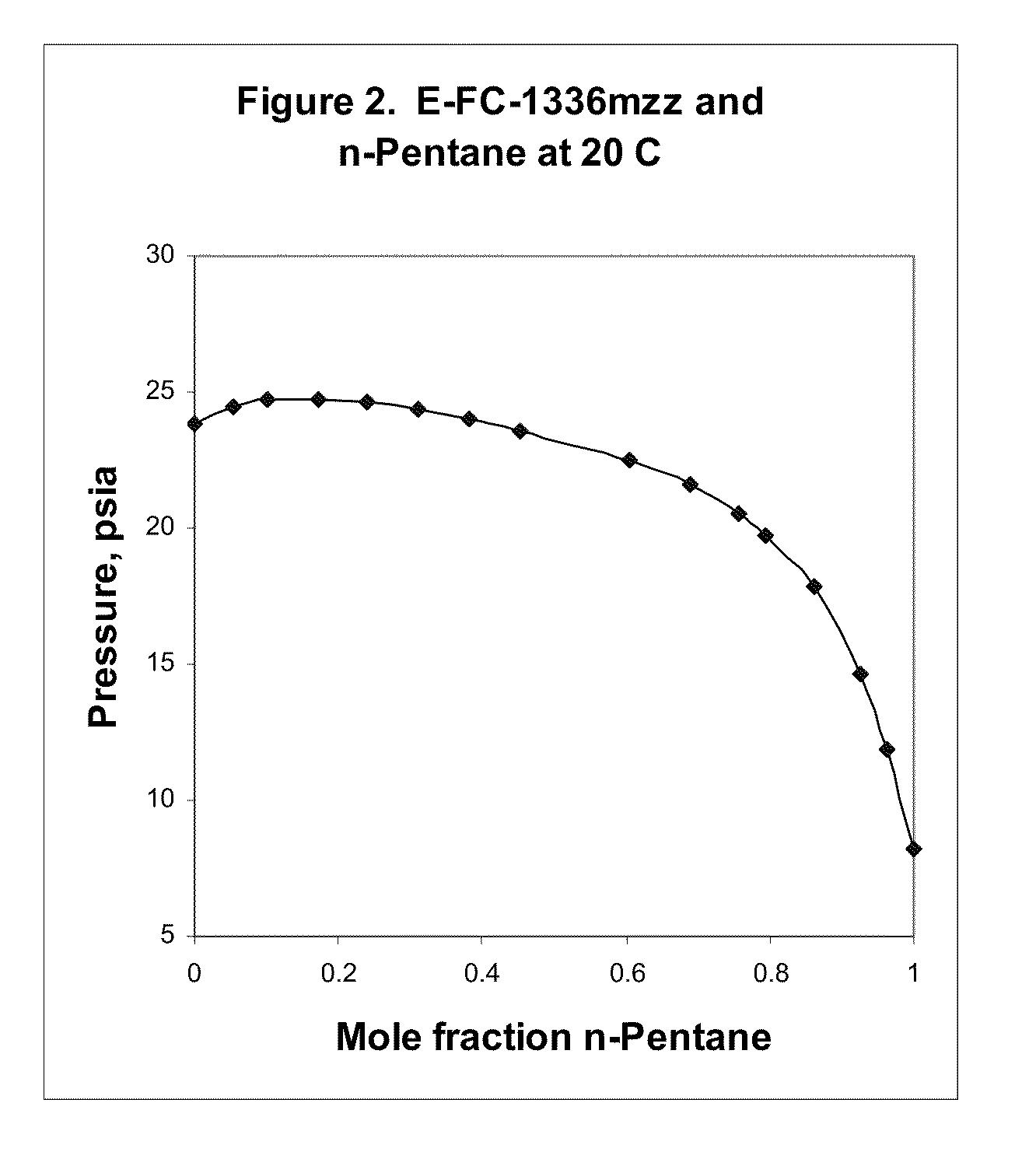

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

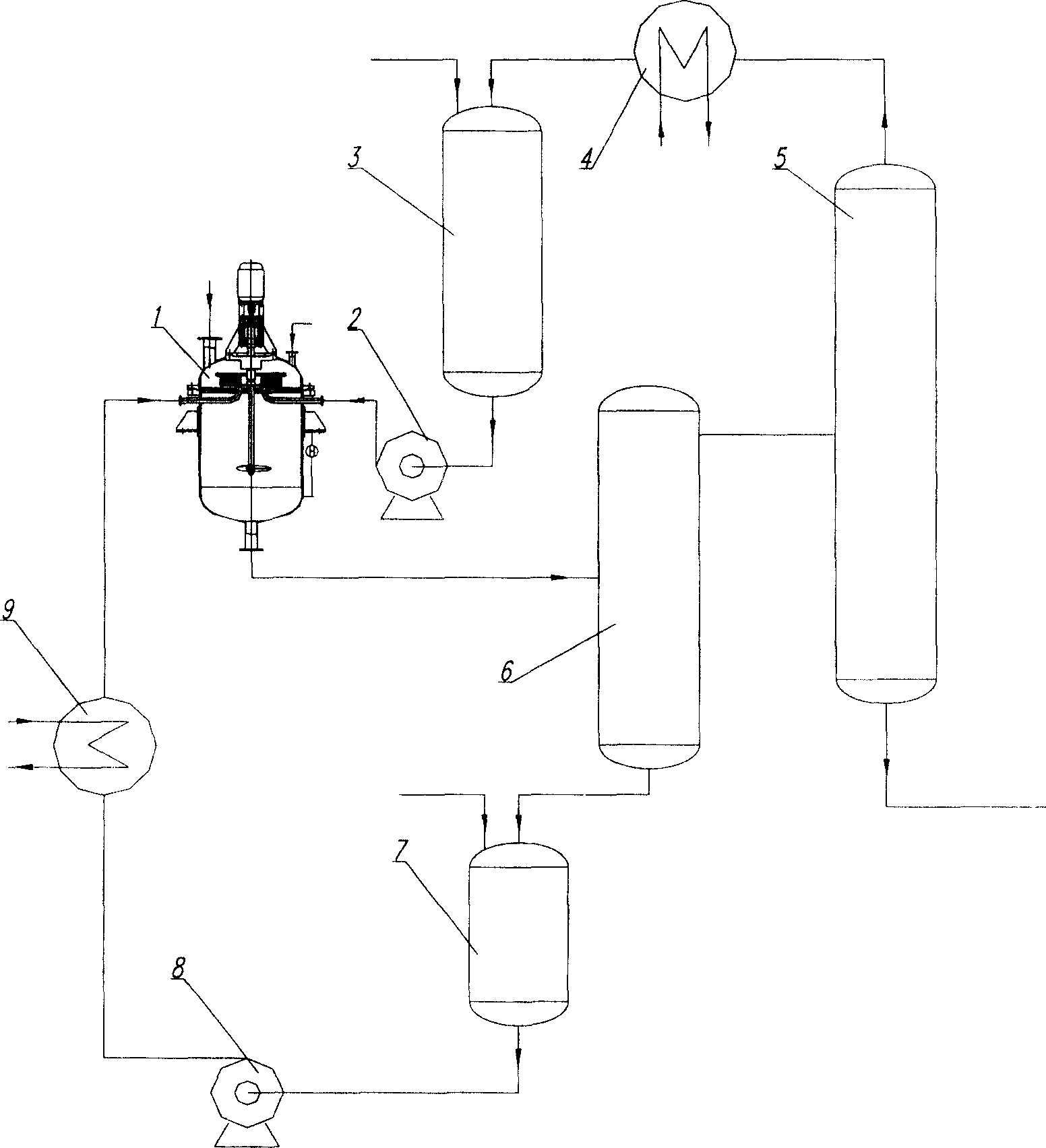

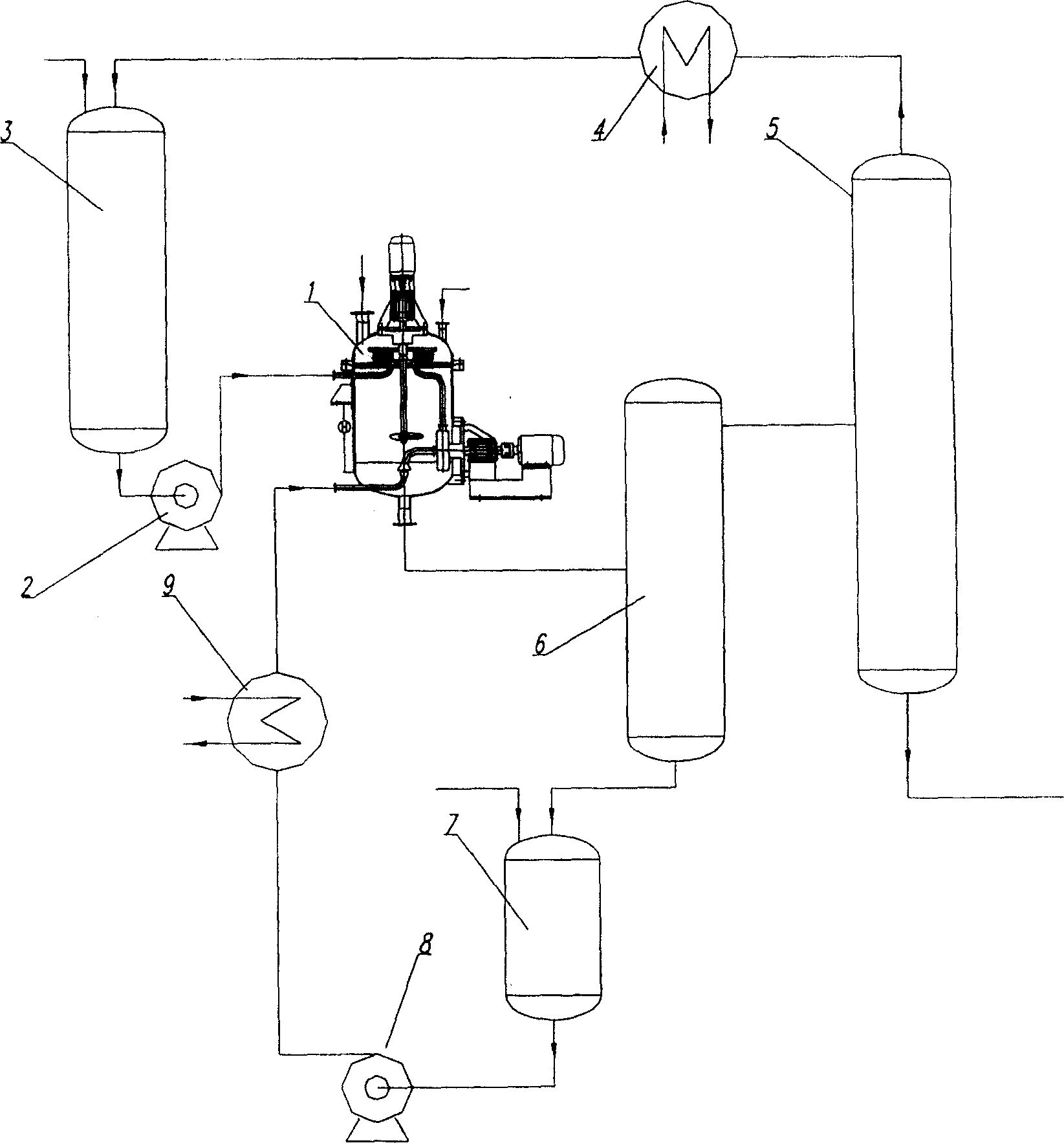

Alkylation reaction technique catalyzed by ion liquid and reactor apparatus

InactiveCN1907924AEasy to separateRestore catalytic activityHydrocarbon from saturated and unsaturated hydrocarbon additionHydrocarbon oils refiningIonAlkane

This invention involves an ion liquid catalytic alkylation process and a responsing reactor. The process comprises carrying out a reaction of isobutene, C3-C5 olefins and ionic liquid catalyst in a rotating bed reactor with reaction temperature of 8~40DEG C, pressure of 0.3~1.0 MPa and rotor speed of 100~2500 rpm, wherein the volume ratio of ion liquid feed to alkanes-olefins is 0.1~1.5:1 and the molar ratio of alkanes to olefins is 10~300, and controlling the reaction time less than 1~10min. The invention improved alkylation reaction selectivity, and the octane value of alkylation product can reach to 94-100. The operation is simple and low-cost, and has no pollution to environment and beneficial to environment protection.

Owner:BEIJING UNIV OF CHEM TECH

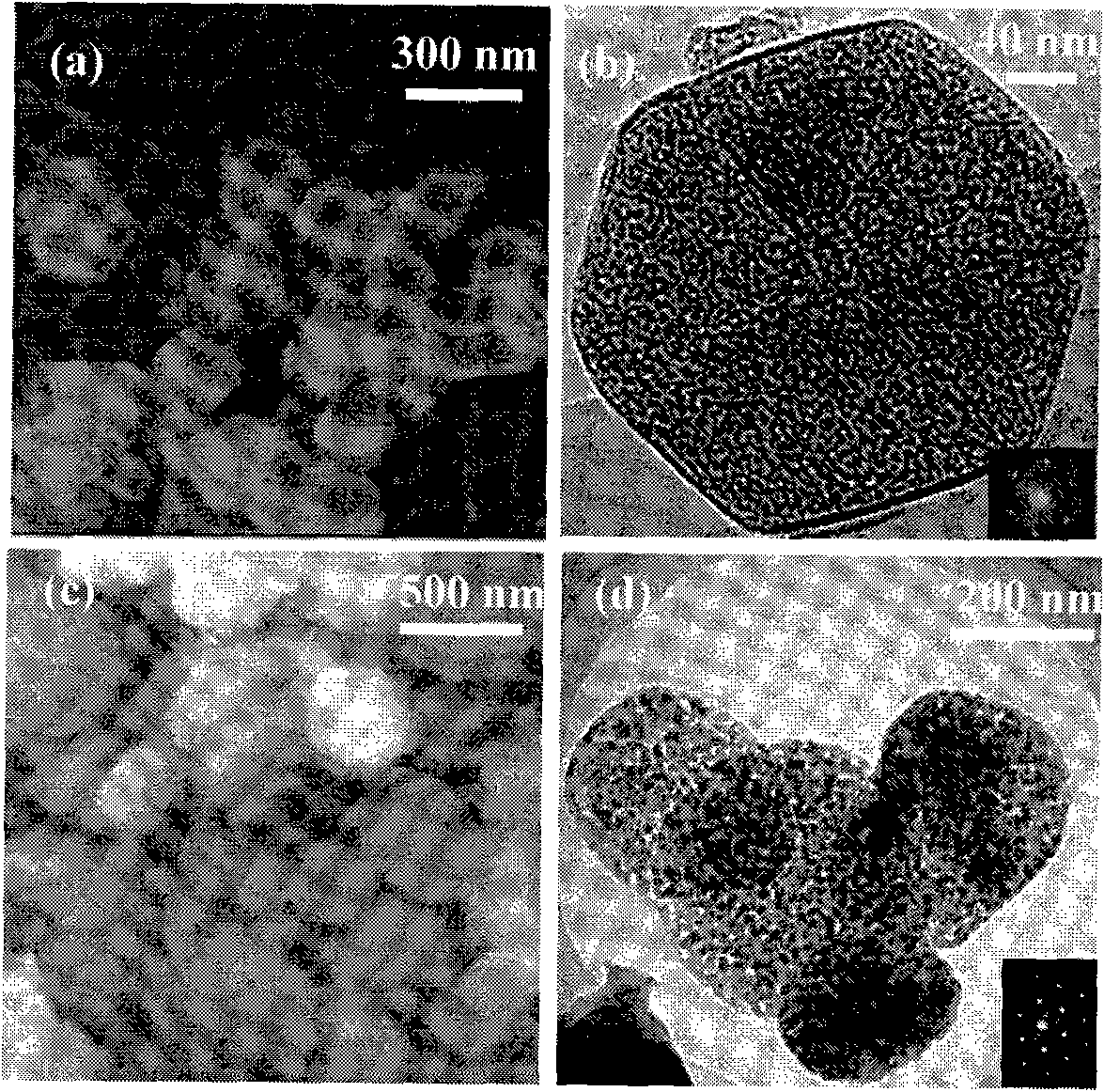

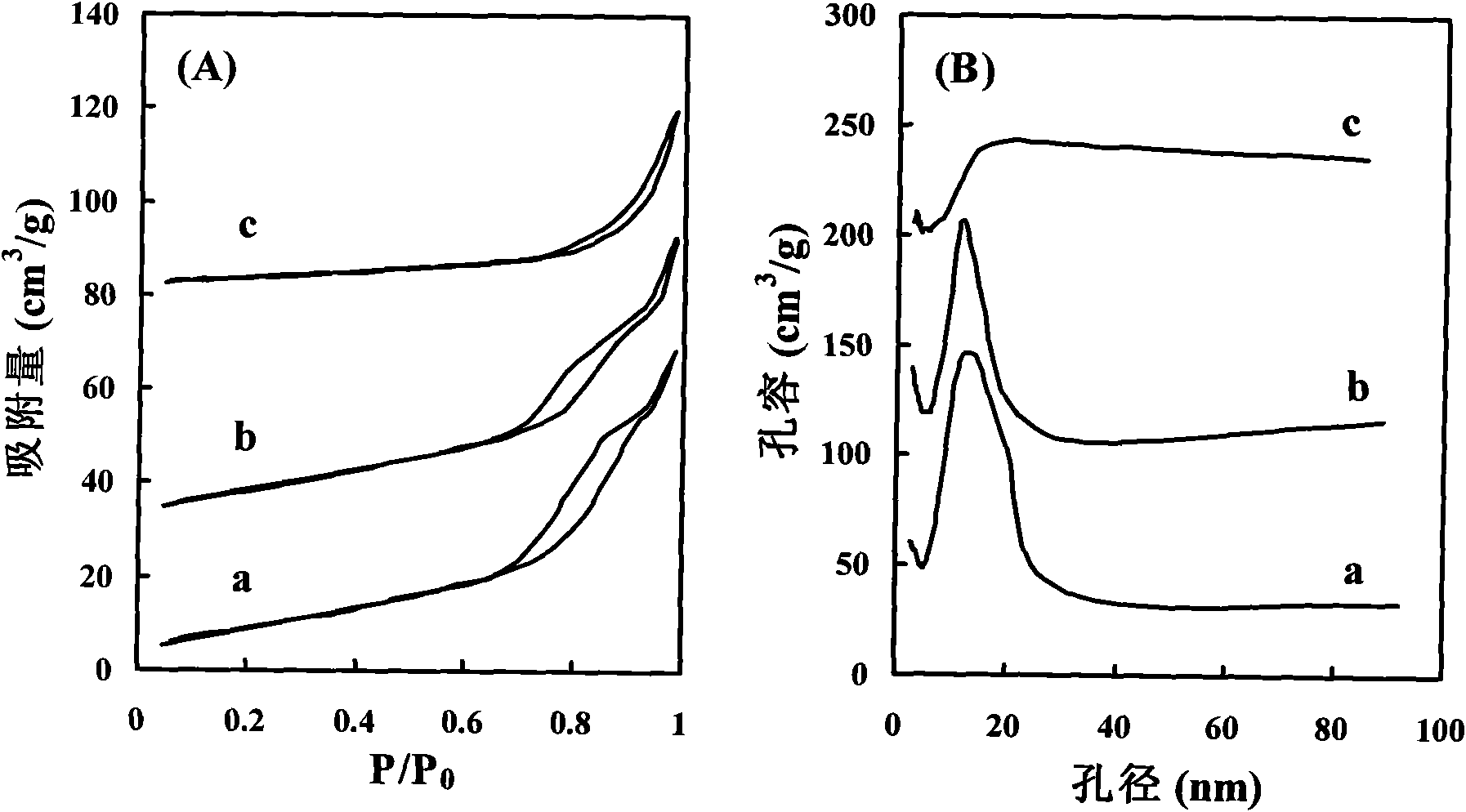

Catalyst for preparing isobutene through dehydrogenation of iso-butane and preparation method thereof

InactiveCN101862669AHigh selectivityImprove reaction stabilityMolecular sieve catalystsHydrocarbonsPlatinumMolecular sieve

The invention discloses a catalyst for preparing isobutene through dehydrogenation of iso-butane and a preparation method thereof. The catalyst is prepared by the following steps of: co-dipping a carrier mesoporous alumina based molecular sieve of which the skeleton contains tin and a carrier modifier basic metal aid in a mixed aqueous solution of HaPtCl6 and SnCl4; and performing drying and reducing activation, wherein the basic metal is one or a mixture of several of IV and IIA elements and rare earth metals; based on the mesoporous alumina based molecular sieve, the skeleton tin metal accounts for 0.01 to 20 weight percent of the carrier; based on the mesoporous alumina based molecular sieve of which the skeleton contains tin, the active metal platinum accounts for 0.01 to 10 weight percent of the carrier, the aid metal tin accounts for 0.01 to 10 weight percent of the carrier and the aid basic metal accounts for 0.01 to 5 weight percent of the carrier. The catalyst has high iso-butane conversion rate, isobutene selectivity and reaction stability under the conditions of high temperature and low pressure.

Owner:SOUTHEAST UNIV

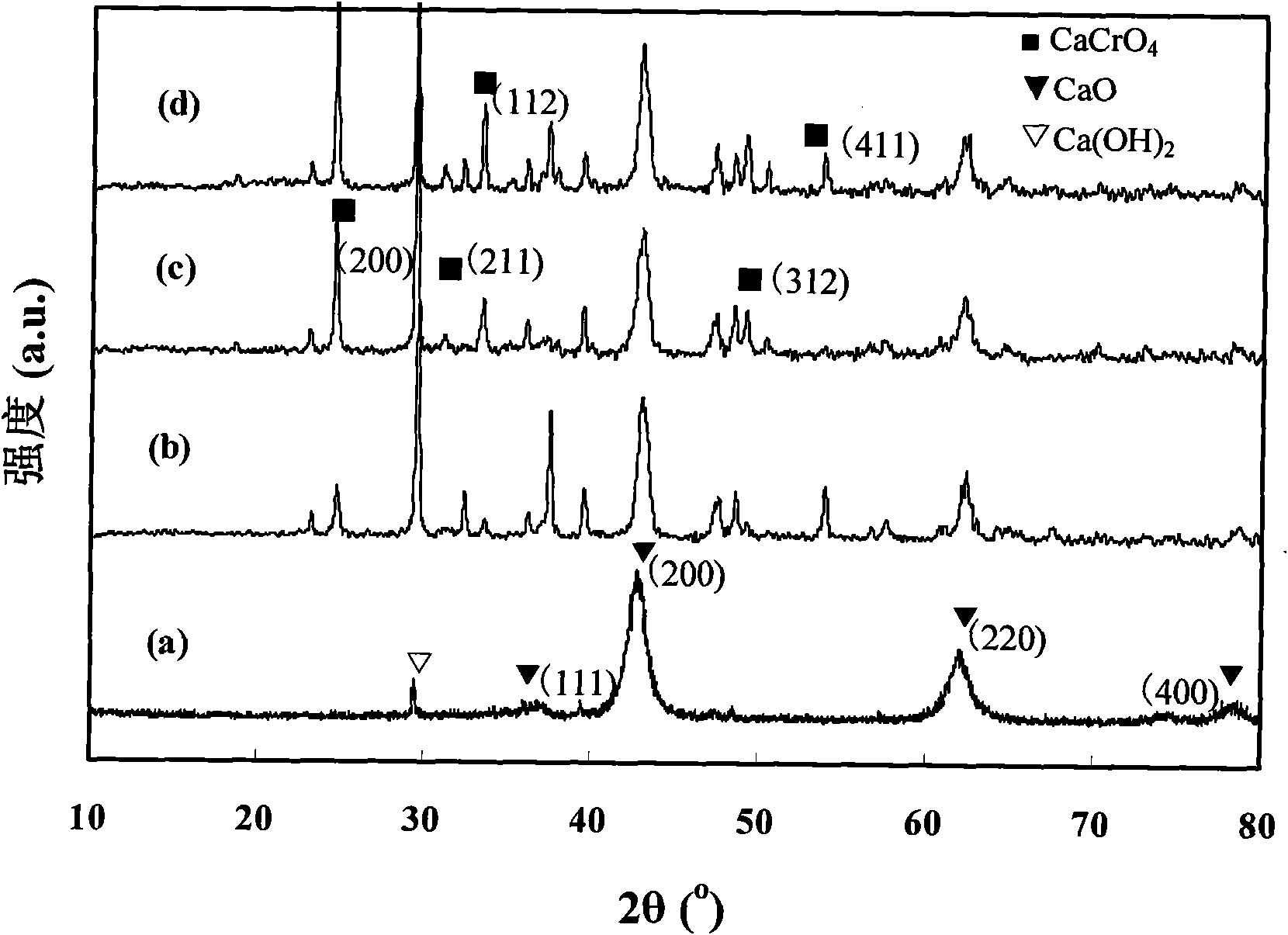

Efficient CrOx/mesoporous CaO catalyst for preparing isobutene by oxidative dehydrogenation of iso-butane and preparation method thereof

InactiveCN101618319AGood oxidation-reduction performanceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereActive component

The invention discloses an efficient CrOx / mesoporous CaO catalyst for preparing isobutene by oxidative dehydrogenation of iso-butane and a preparation method thereof, and belongs to the field of catalysis. The prior catalyst for preparing the isobutene by the oxidative dehydrogenation of the iso-butane has the problems of low isobutene selectivity and the like. The catalyst provided by the invention uses mesoporous CaO as a carrier and uses CrOx as an active component, wherein x is 1 to 3; and the loading capacity of the CrOx active component is 4 to 12 percent in percentage by mass of Cr2O3. The preparation method comprises the following steps: dissolving soluble chromium salt into anhydrous ethanol, then adding the solution into the mesoporous CaO carrier, stirring the mixture evenly, and drying the mixture for 12 hours at 120 DEG C to obtain white solid powder; and heating the white solid powder to 550 DEG C at the rate of 1 DEG C per minute in air atmosphere in a muffle furnace, and firing the heated white solid powder for 3 hours at constant temperature to obtain the CrOx / mesoporous CaO catalyst. The CrOx / mesoporous CaO catalyst prepared by the method has high isobutene selectivity and high activity, and the preparation method has low cost and simple and convenient operation.

Owner:BEIJING UNIV OF TECH

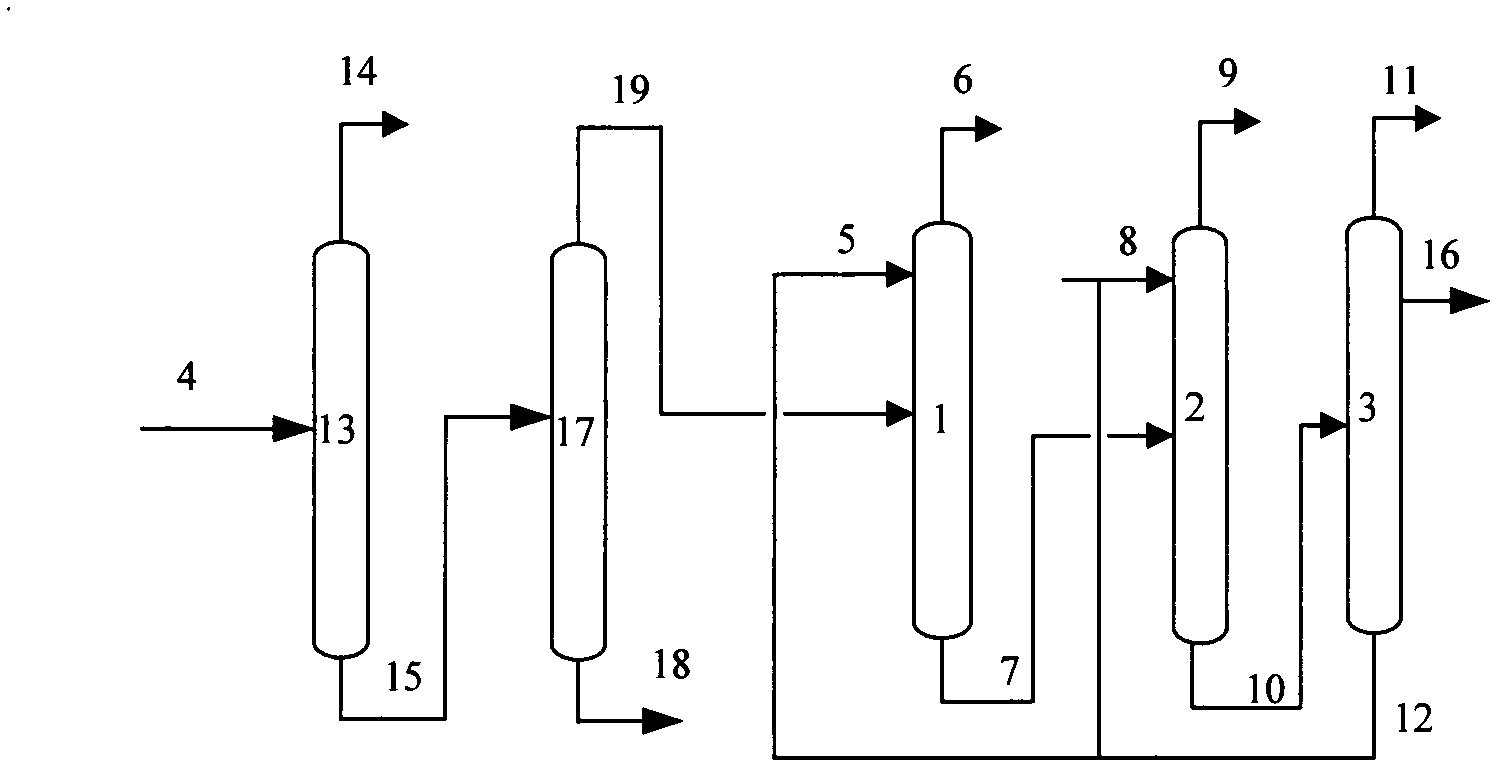

Method for preparing isobutylene by comprehensively using mixed C4

InactiveCN102070391AHigh purityIncrease added valueHydrocarbon by isomerisationChemical industryButeneHigh concentration

The invention provides a method for preparing isobutylene by comprehensively using mixed C4 and mainly solves the problems of low overall utilization efficiency and low additional value of the mixed C4 byproduct of a refinery or a steam cracking device. An aim is fulfilled by adopting a technical scheme which comprises the following steps of: (1) selectively hydrogenating to remove butadiene in the mixed C4; (2) isomerizing butylenes-1 in the mixed C4 obtained in the first step into butylenes-2 by using catalytic distillation technology, and simultaneously dividing the mixed C4 into two strands of materials, namely the first material comprising isobutylene and iso-butane, and the second material comprising n-butane and butylenes-2; (3) separating the first material through an etherifying device to obtain high-purity isobutylene and high-concentration iso-butane; (4) dehydrogenating the iso-butane to obtain the high-purity isobutylene; and (5) isomerizing the butylenes-2 of the second material into the isobutylene by using isomerizing technology, and simultaneously separating to obtain higher-purity n-butane. The method can be applied to the industrial field of producing the high-purity isobutylene.

Owner:王伟跃

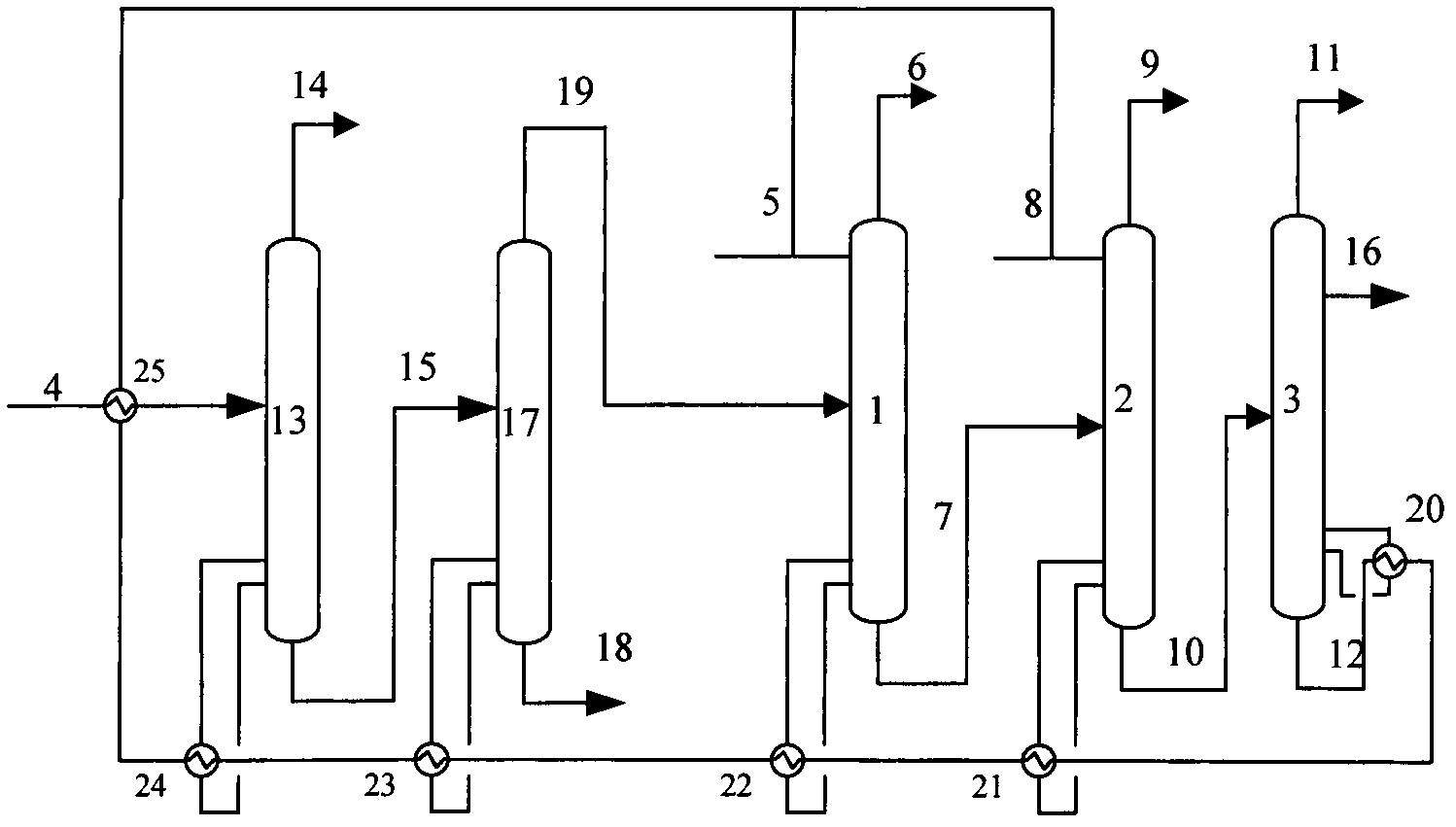

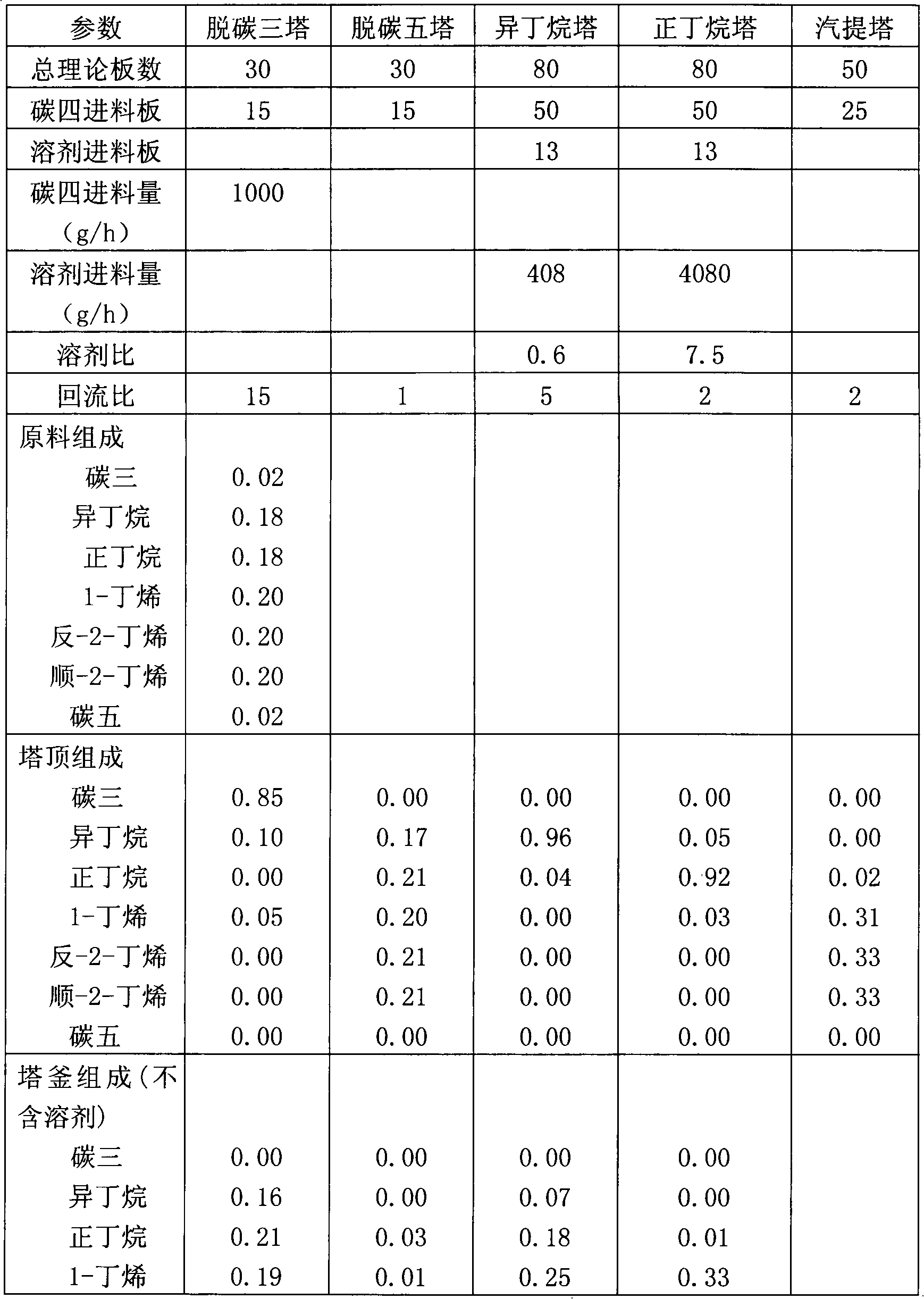

Iso-butane, n-butane and butylene separation and purification method

InactiveCN102603454ALess investmentReduce energy consumptionDistillation purification/separationButenePurification methods

The invention provides an iso-butane, n-butane and butylene separation and purification method. C4 raw materials are successively put into a C3 decarburization tower, a C5 decarburization tower, an iso-butane tower, an n-butane tower and a stripping tower to obtain high-purity iso-butane, n-butane and butylene. Solvents are cyclically utilized. The iso-butane, n-butane and butylene separation and purification method has the technical advantages that not only can equipment investment be reduced, but also the advantages of extractive distillation are used and the energy consumption is reduced.

Owner:YANTAI UNIV

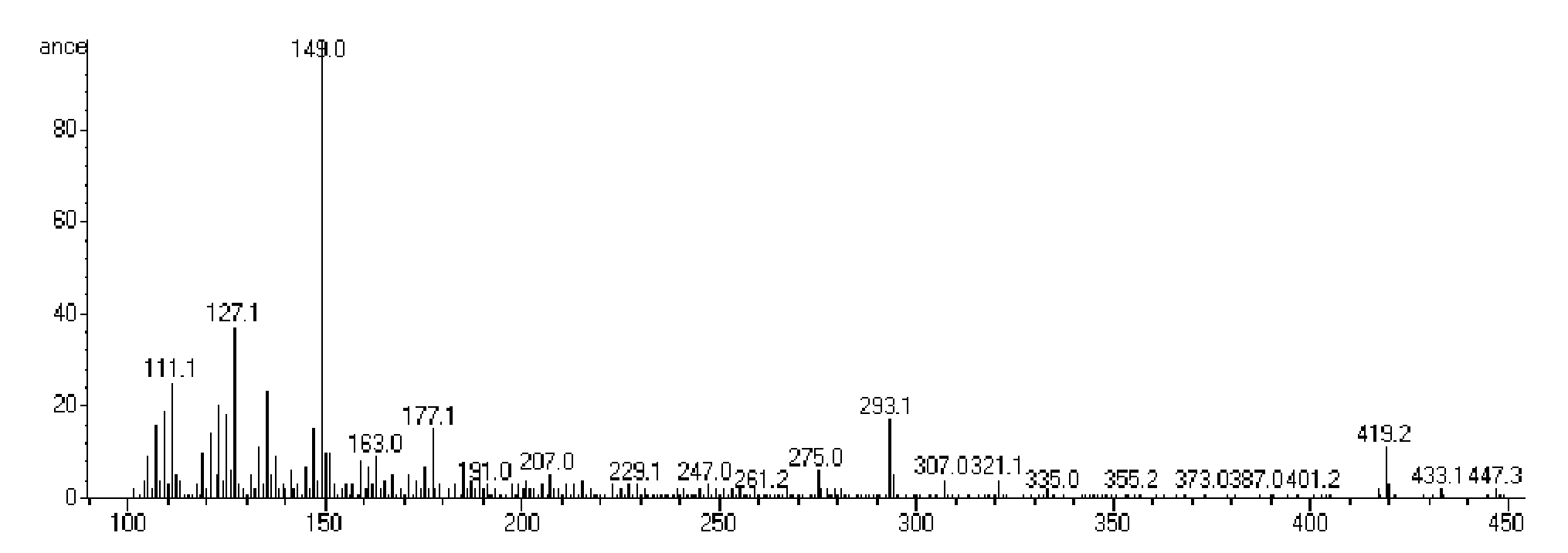

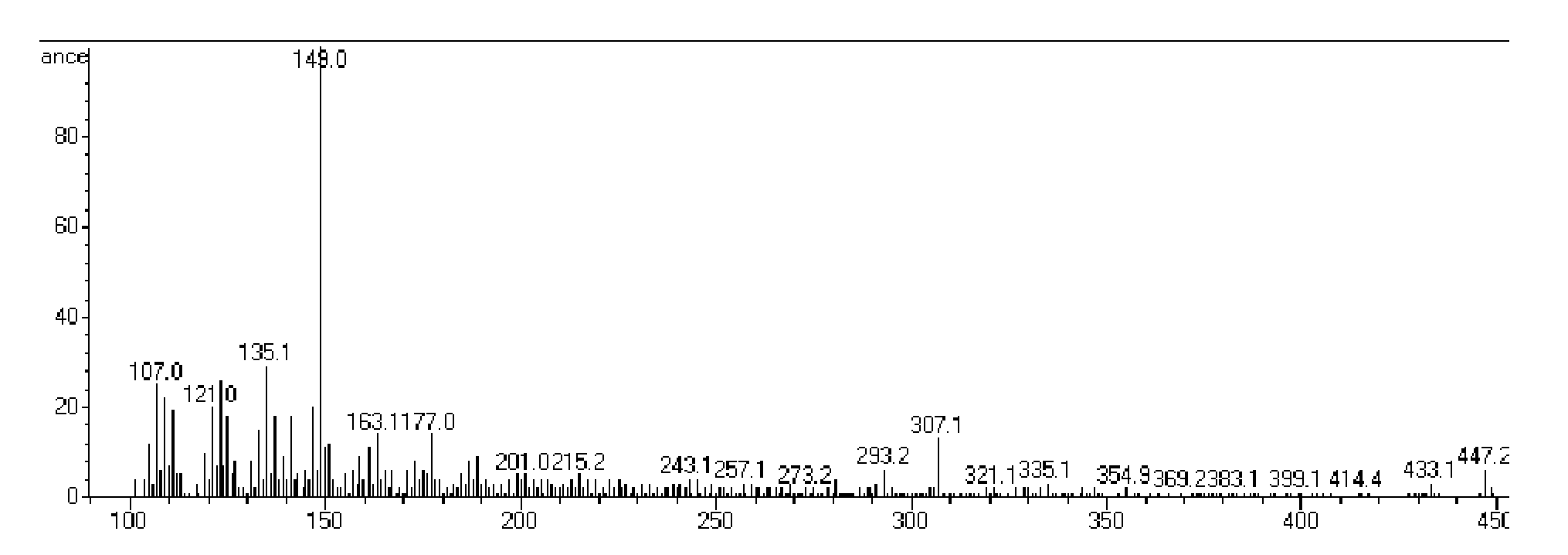

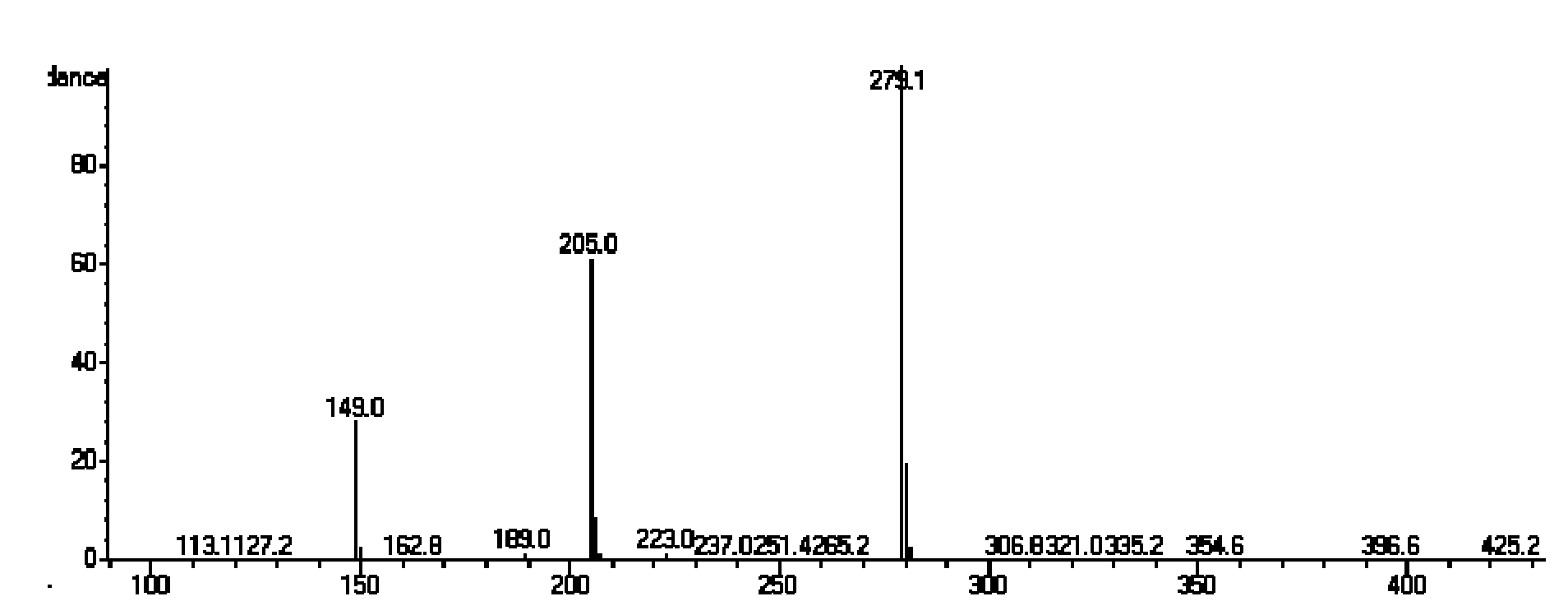

Detection method of phthalate plasticizer

InactiveCN101858897AImprove accuracySolve problems that cannot be accurately qualitative and quantitativeComponent separationPreparing sample for investigationOrganic solventThermal ionization mass spectrometry

The invention discloses a detection method of a phthalate plasticizer, comprising the following steps: 1. pretreatment: putting a sample to be detected into an organic solvent, and then dissolving and treating to obtain the solution to be detected in which the plasticizer is dissolved; and 2. content determination of the plasticizer: utilizing a gas chromatogram method and a chemical ionization mass spectrometry method to detect the type and the content of the plasticizer in the detected solution, wherein, the chemical ionization reagent used in the chemical ionization mass spectrometry method is composed of isobutane, methane or ammonia. The detection method of the phthalate plasticizer provided by the invention has high qualitative and quantitative accuracy and high quantitative detection sensitivity.

Owner:深圳出入境检验检疫局玩具检测技术中心

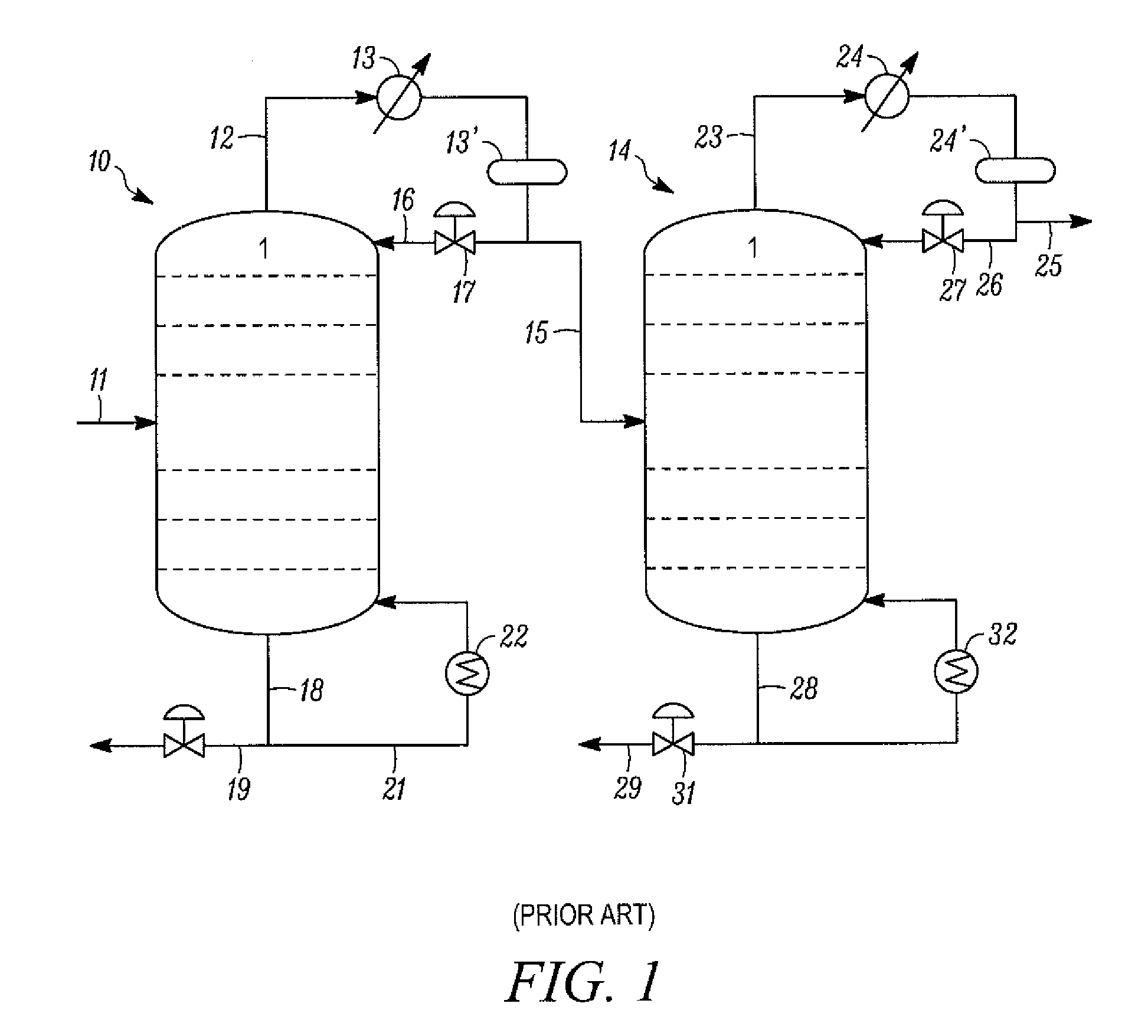

Paraffin alkylation

InactiveUS6858770B2Inhibit side effectsEasy to convertPhysical/chemical process catalystsCatalytic naphtha reformingParaffin waxAlkane

A process for the alkylation of alkane with olefin or olefin precursor such as an oligomer of tertiary olefin comprising contacting a liquid system comprising acid catalyst, isoparaffin and olefin in concurrent downflow into contact in a reaction zone with a disperser mesh under conditions of temperature and pressure to react said isoparaffin and said olefin to produce an alkylate product is disclosed. Preferably, the liquid system is maintained at about its boiling point in the reaction zone. Unexpectedly, the olefin oligomers have been found to function as olefin precursors and not as olefins in the reaction. Thus, for example, a cold acid alkylation using an oligomer of isobutene (principally dimer and trimer) with isobutane produces isooctane with the isobutane reacting with the constituent isobutene units of the oligomers on a molar basis. The product isooctane is essentially the same as that produced in the conventional cold acid process.

Owner:CHEM RES & LICENSING CO

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

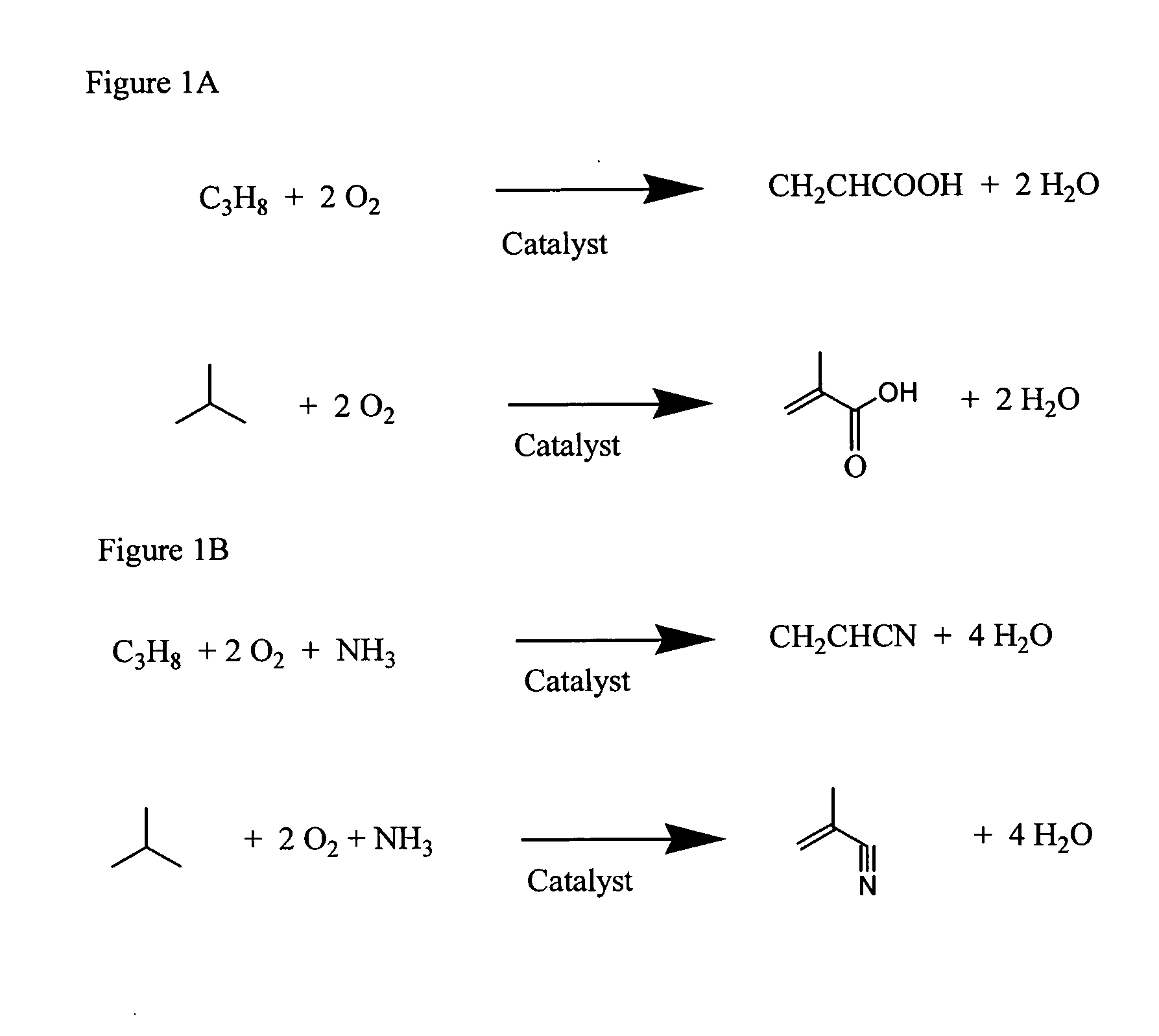

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

Mixed metal oxide catalysts for propane and isobutane oxidation and ammoxidation, and methods of preparing same

InactiveUS20050054869A1Increase productionOrganic compound preparationHeterogenous catalyst chemical elementsNiobiumGas phase

Compositions of matter and catalyst compositions effective for gas-phase conversion of propane to acrylic acid (via oxidation) or to acrylonitrile (via ammoxidation) and isobutane to methacrylic acid (via oxidation) and isobutane to methacrylonitrile (via ammoxidation) are disclosed. Preferred catalyst compositions comprise molybdenum, vanadium, niobium, antimony and germanium and molybdenum, vanadium, tantalum, antimony, and germanium. Methods of preparing such compositions and related compositions, including hydrothermal synthesis methods are also disclosed. The preferred catalysts convert propane to acrylic acid and / or to acrylonitrile and isobutane to methacrylic acid / methacrylonitrile with a yield of at least about 50%.

Owner:INEOS USA LLC

Ni catalysts and methods for alkane dehydrogenation

Owner:CELANESE INT CORP

Apparatuses and methods for separating butene-1 from a mixed C4 feed

ActiveUS7528290B2Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneDistillation

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

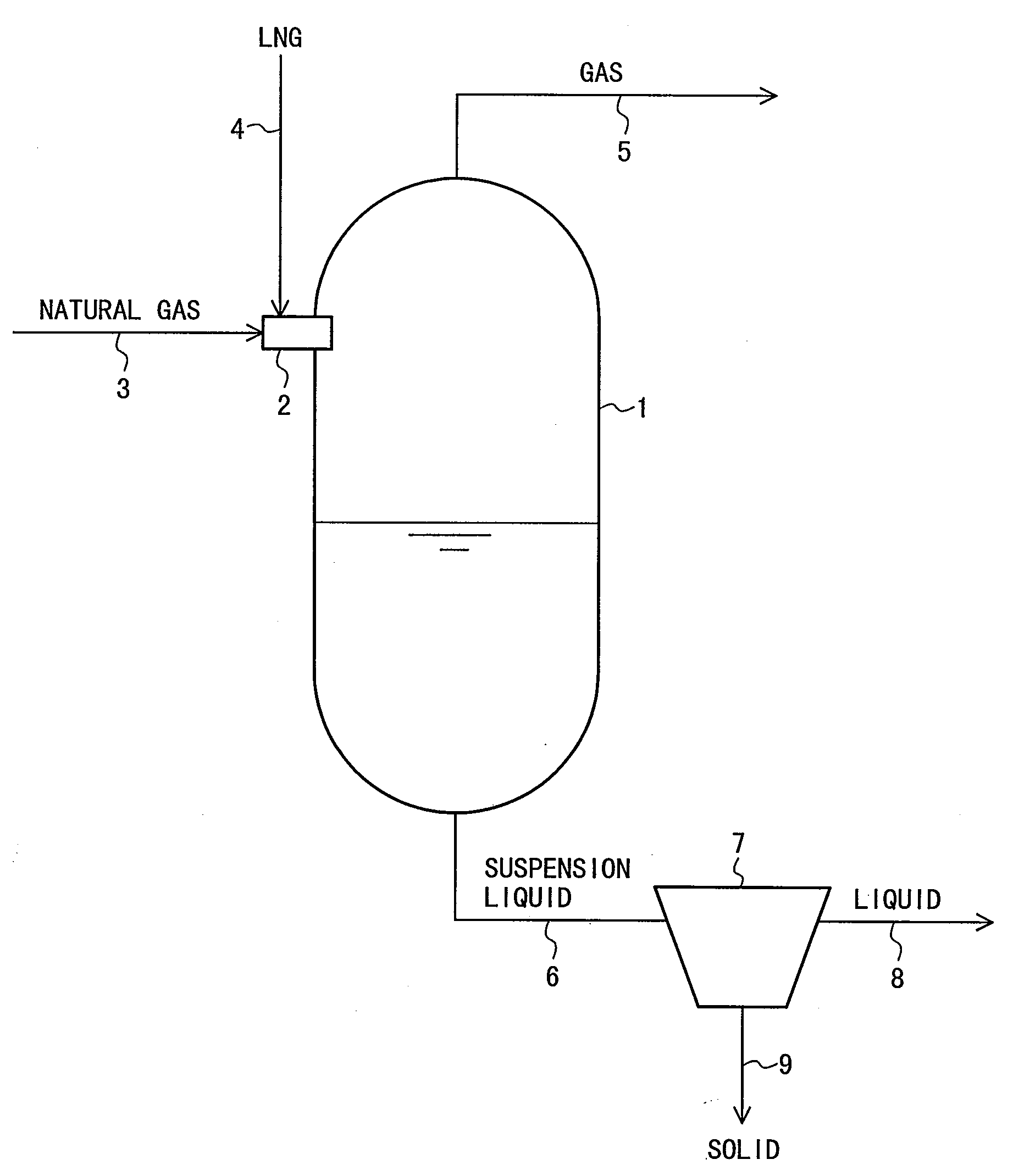

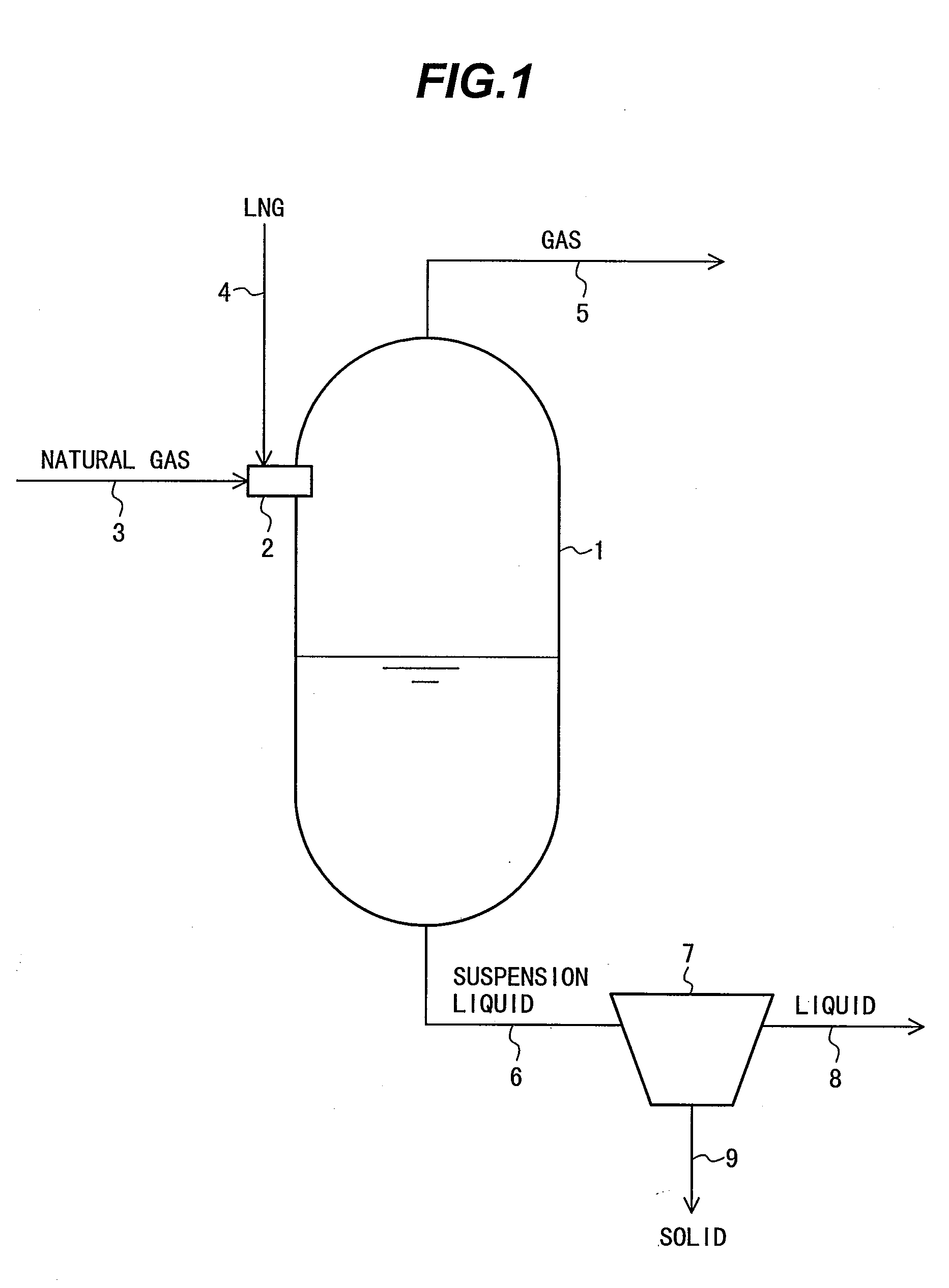

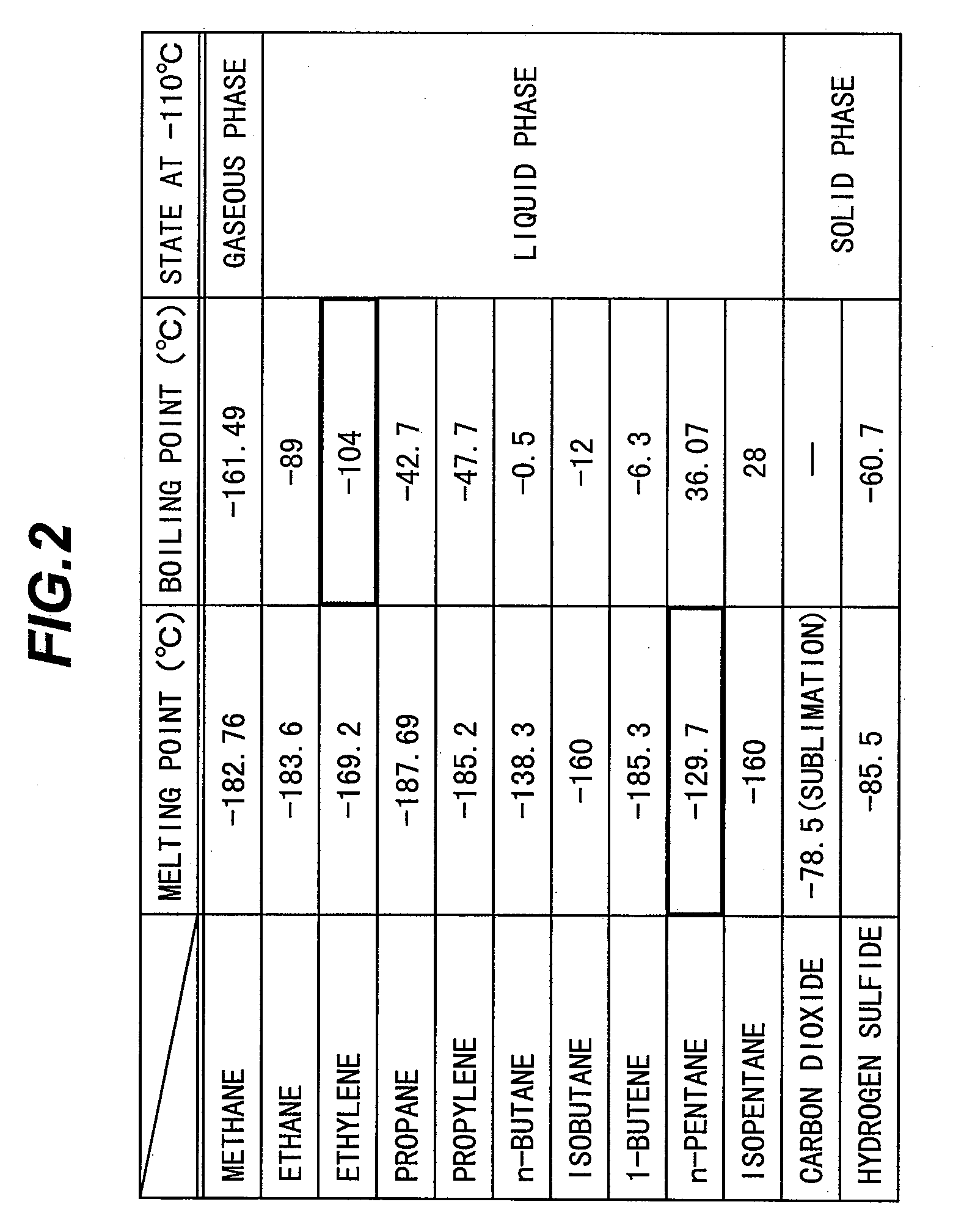

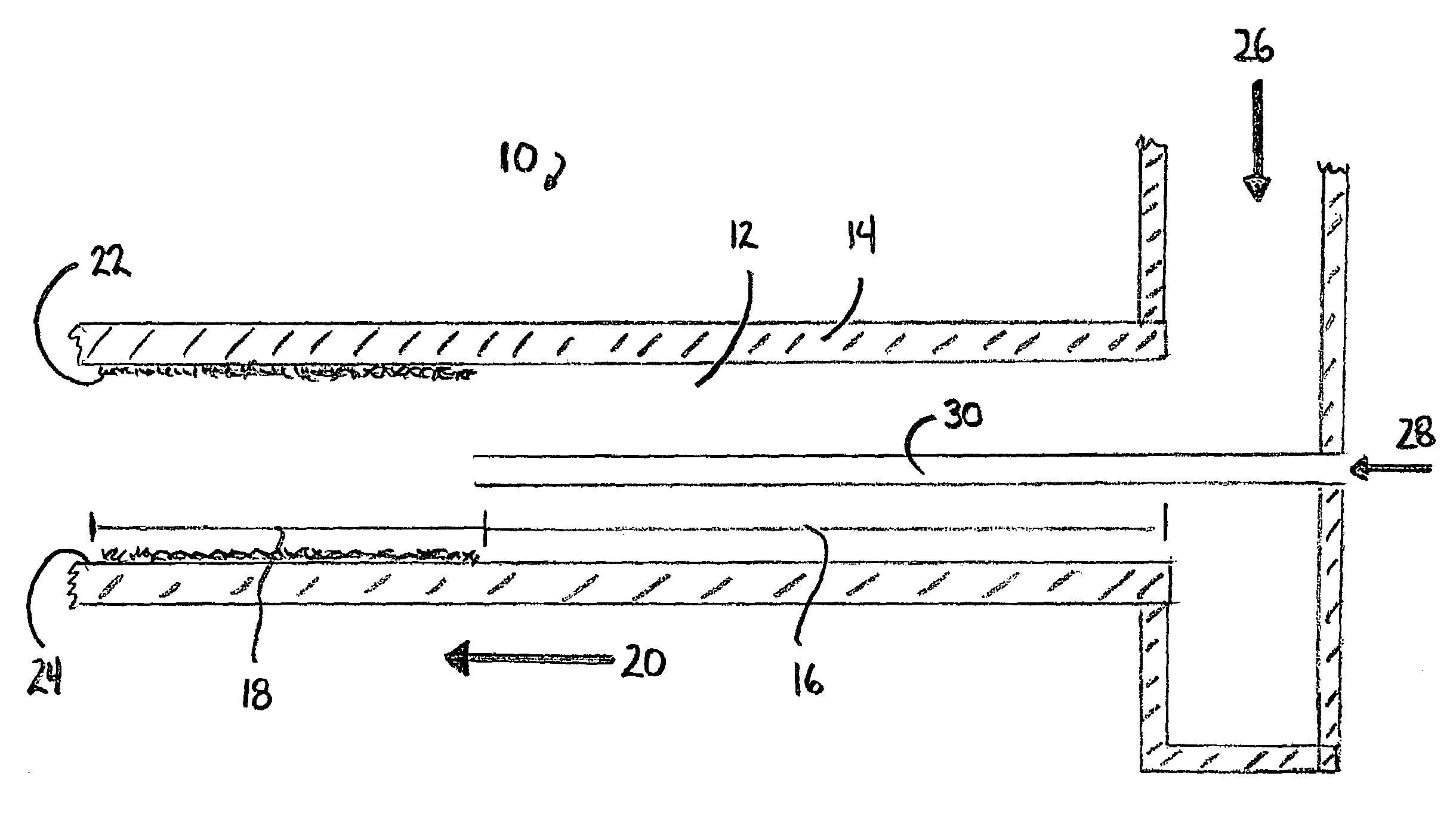

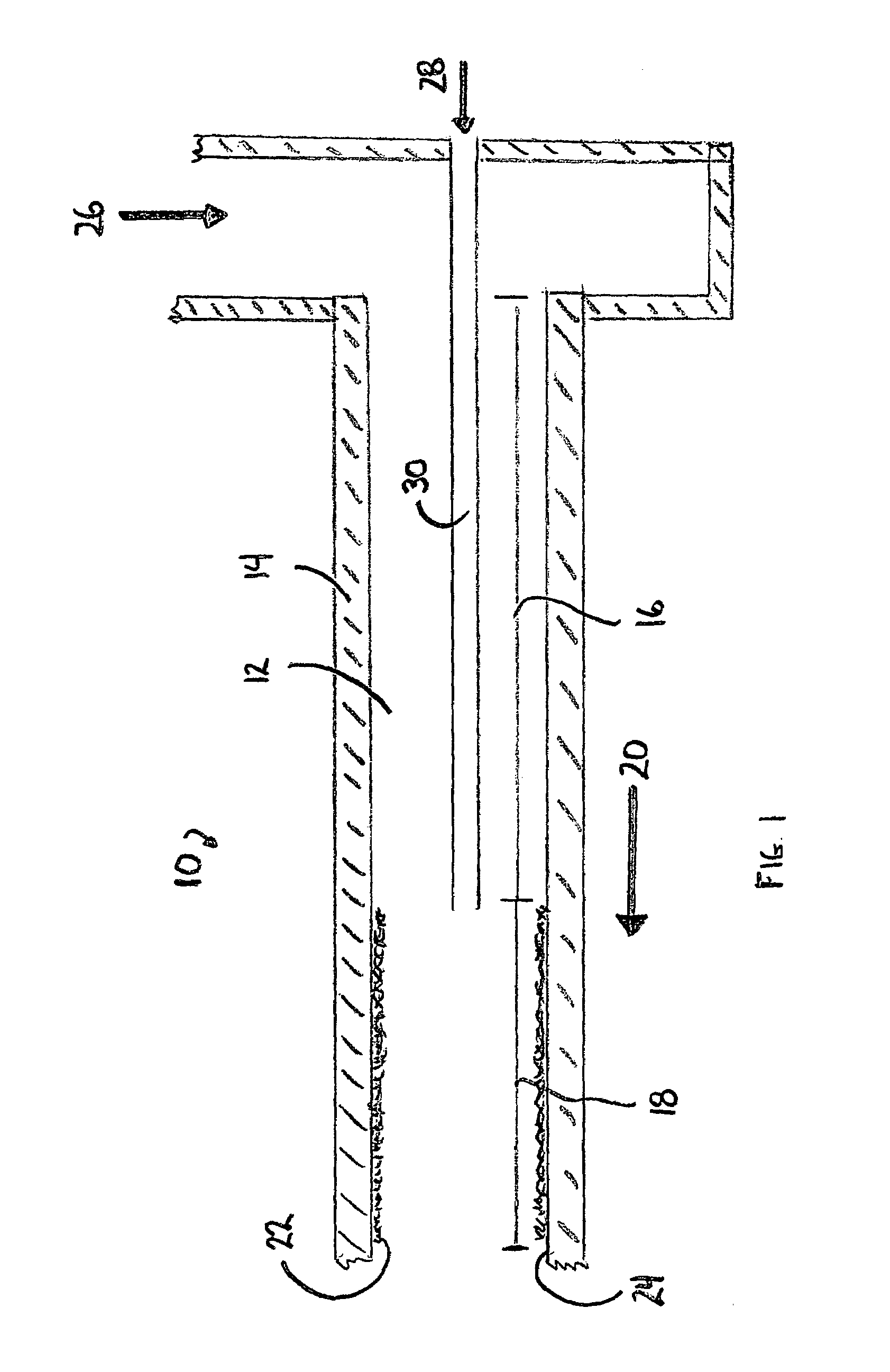

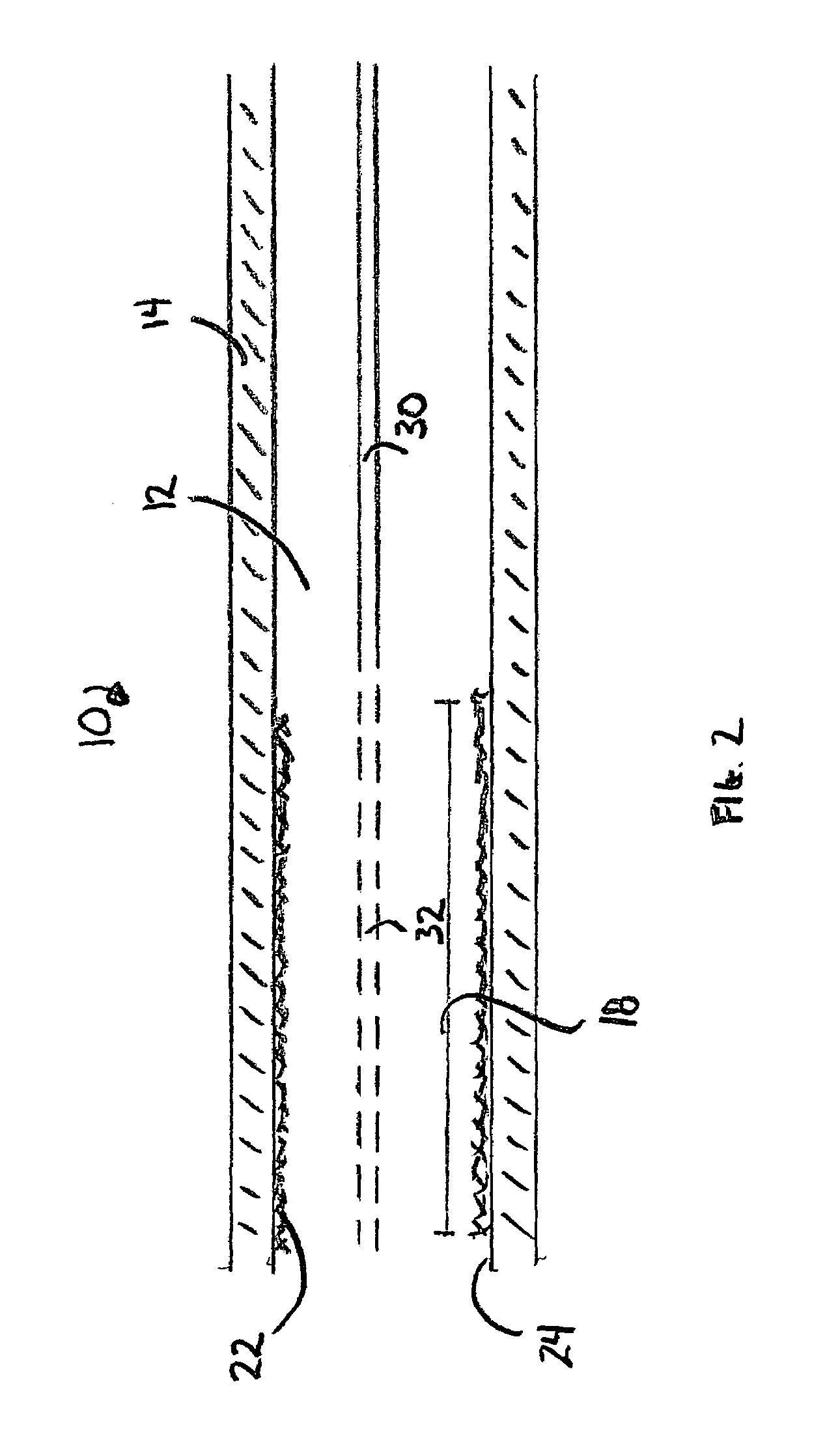

Method of refining natural gas and natural gas refining system

InactiveUS20080307827A1Improve product qualityQuality improvementSolidificationLiquefaction2-methylbutaneGas phase

A method and system of refining natural gas that improves the quality of liquefied natural gas and enables separation and recovery of hydrocarbons other than methane. The method of refining natural gas containing methane; any other hydrocarbon selected from the group consisting of ethane, ethylene, propane, propylene, n-butane, isobutane, 1-butene, n-pentane, and isopentane; carbon dioxide; and hydrogen sulfide, includes adjusting a pressure and temperature of the natural gas so that the methane is in the gas phase, the other hydrocarbon in the liquid phase, and the carbon dioxide and the hydrogen sulfide in the solid phase, respectively; separating the natural gas, of which the pressure and temperature has been adjusted, into a gas containing the methane and a suspension liquid; and separating the separated suspension liquid into a liquid containing the other hydrocarbon and a solid containing the carbon dioxide and the hydrogen sulfide.

Owner:HITACHI LTD

Isobutane alkylation

InactiveUS7550644B2Promotes an economically feasible use of fixed bed catalystsRate of diffusion of olefin to the catalyst surface is maintained sufficiently lowCatalyst activation/preparationHydrocarbonsAlkyl transferFixed bed

A method for isobutane alkylation is provided using a fixed-bed catalytic alkylation reactor comprises at least one catalytic flow channel. A feed stream comprising a compound to be alkylated is passed into a flow channel having an alkylation catalyst positioned on at least a portion of the flow channel inner surface in the flow channel downstream region. Olefin is injected into the feed stream at a point beyond a flow channel entrance region whereby the olefin contacts the alkylation catalyst by diffusion to the flow channel inner surface thereby reacting the compound with the olefin and produces an alkylate product.

Owner:PRECISION COMBUSTION

Process for para-xylene production from light aliphatics

InactiveUS7439409B1Hydrocarbon by isomerisationHydrocarbon by hydrogenationIsomerizationDehydrogenation

Low-value mixed butanes are processed to obtain a high yield of high-purity para-xylene. Processing steps may comprise fractionation to recover isobutane, dehydrogenation of the isobutane to isobutene, dimerization of the isobutene to obtain C8 iso-olefins and isoparaffins, aromatization of the dimerized C8 product, and recovery of high-purity para-xylene from the dimerized product by low-intensity crystallization. The availability of isobutane may be increased by isomerization of normal butane. Each of the processing steps may be tailored to the overall objective of high para-xylene yield from a relatively inexpensive feedstock.

Owner:UOP LLC

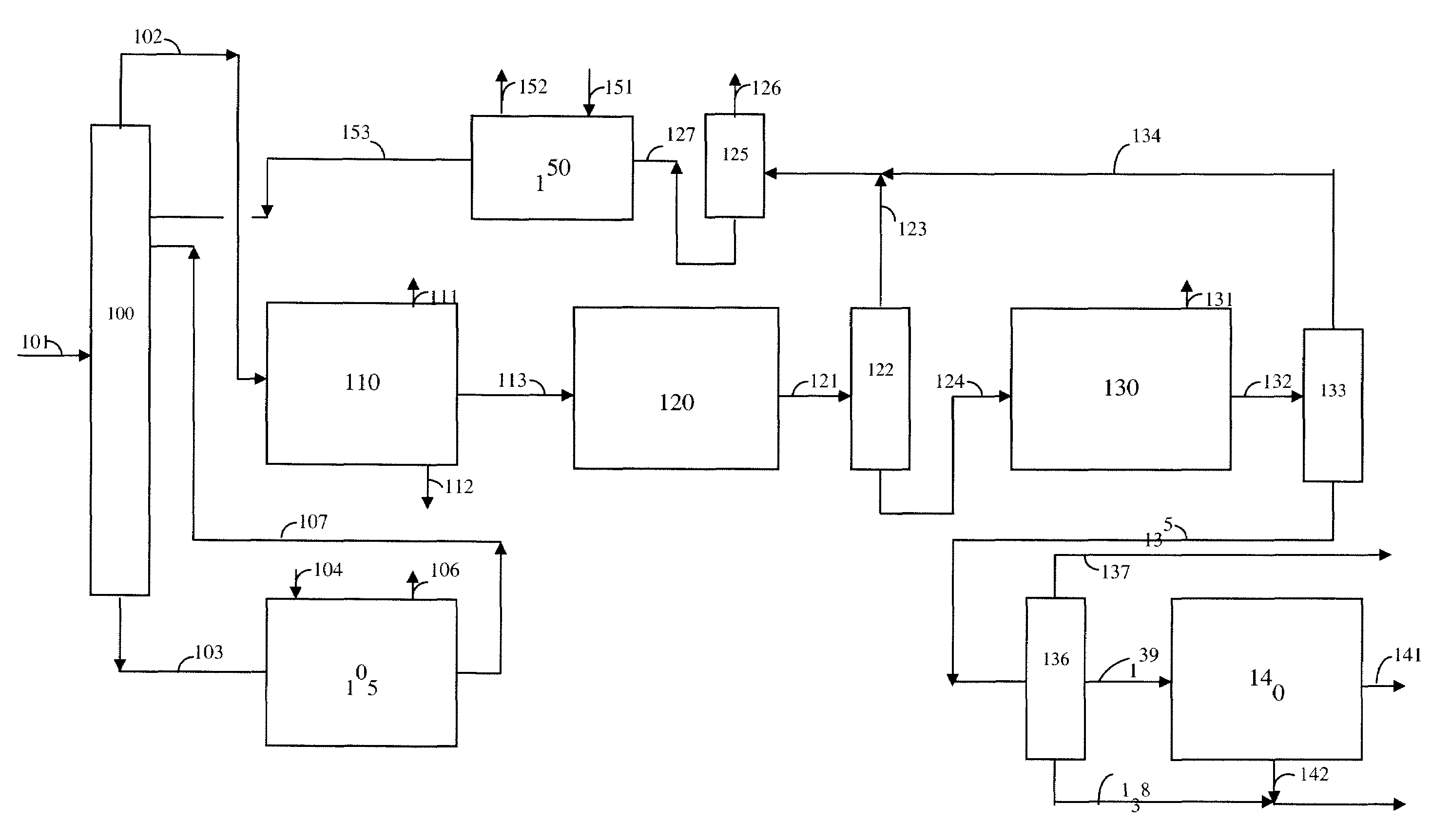

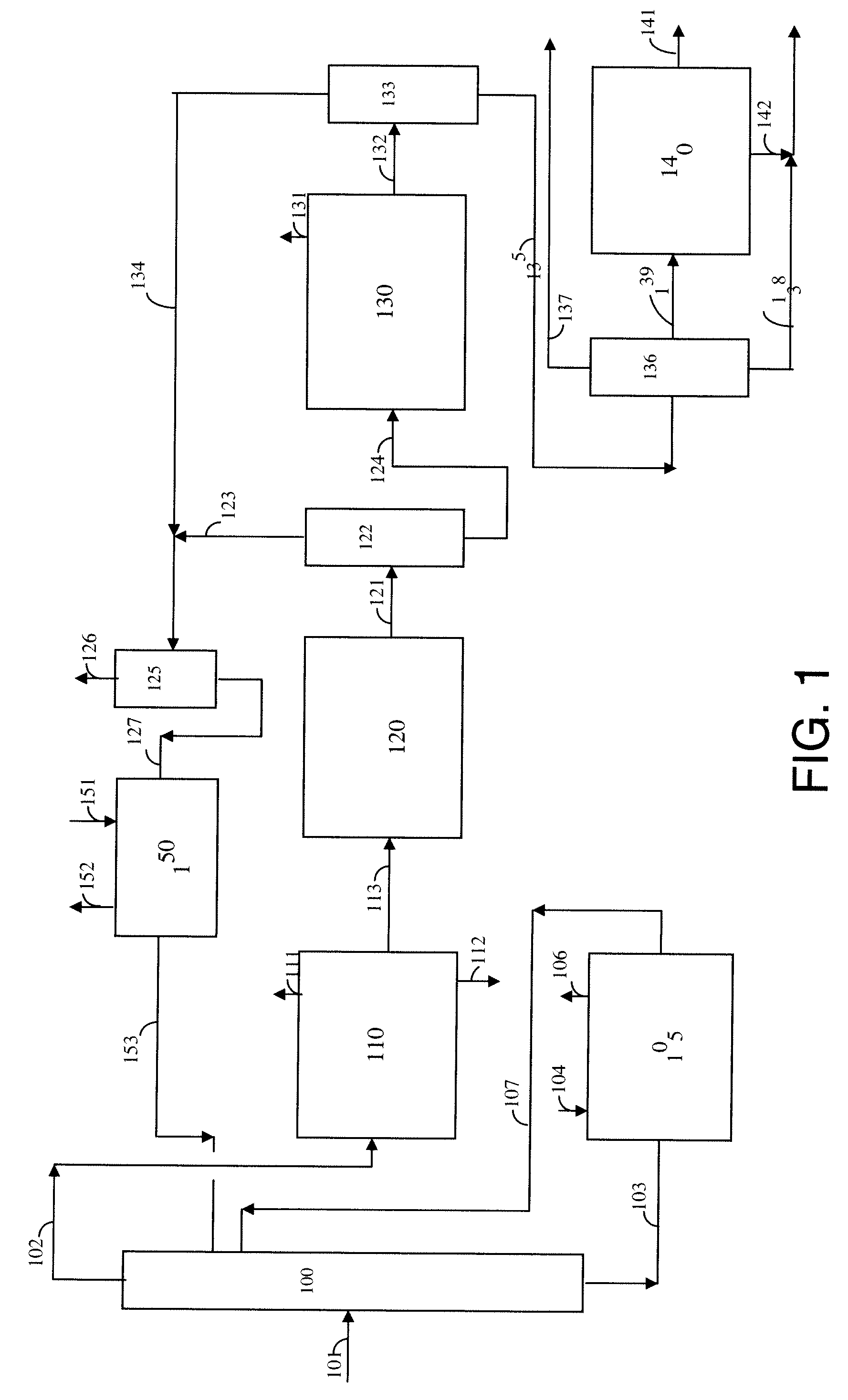

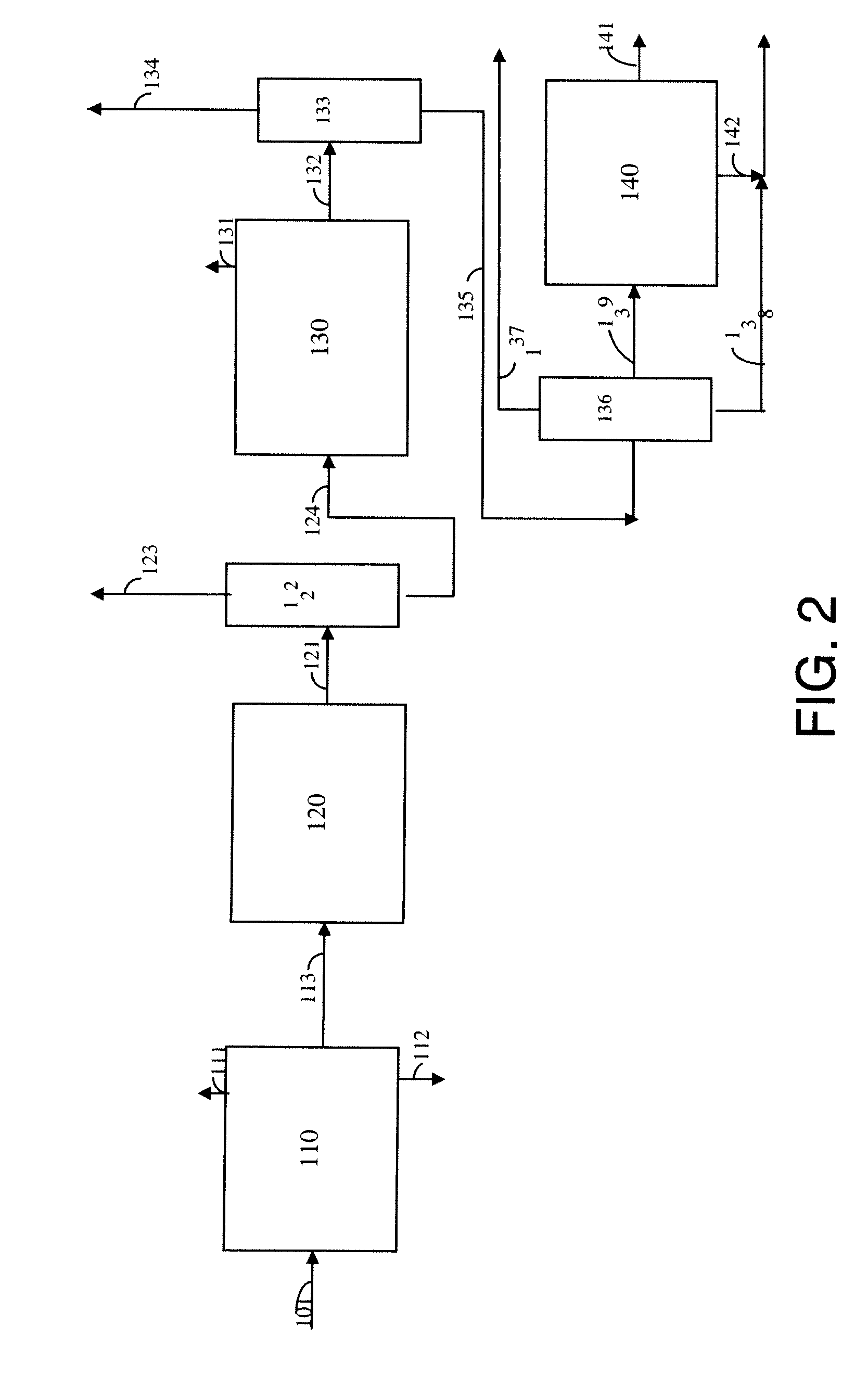

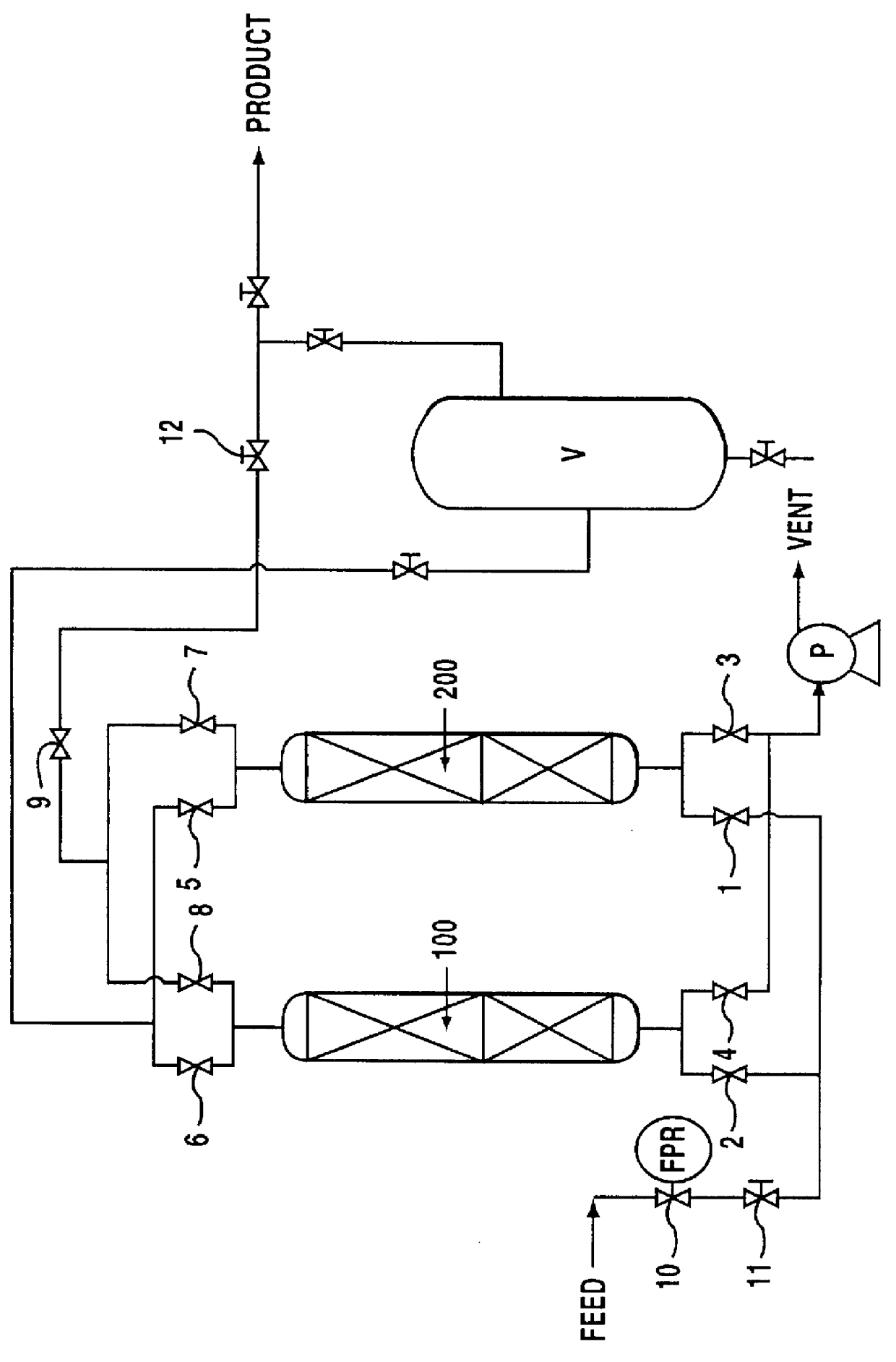

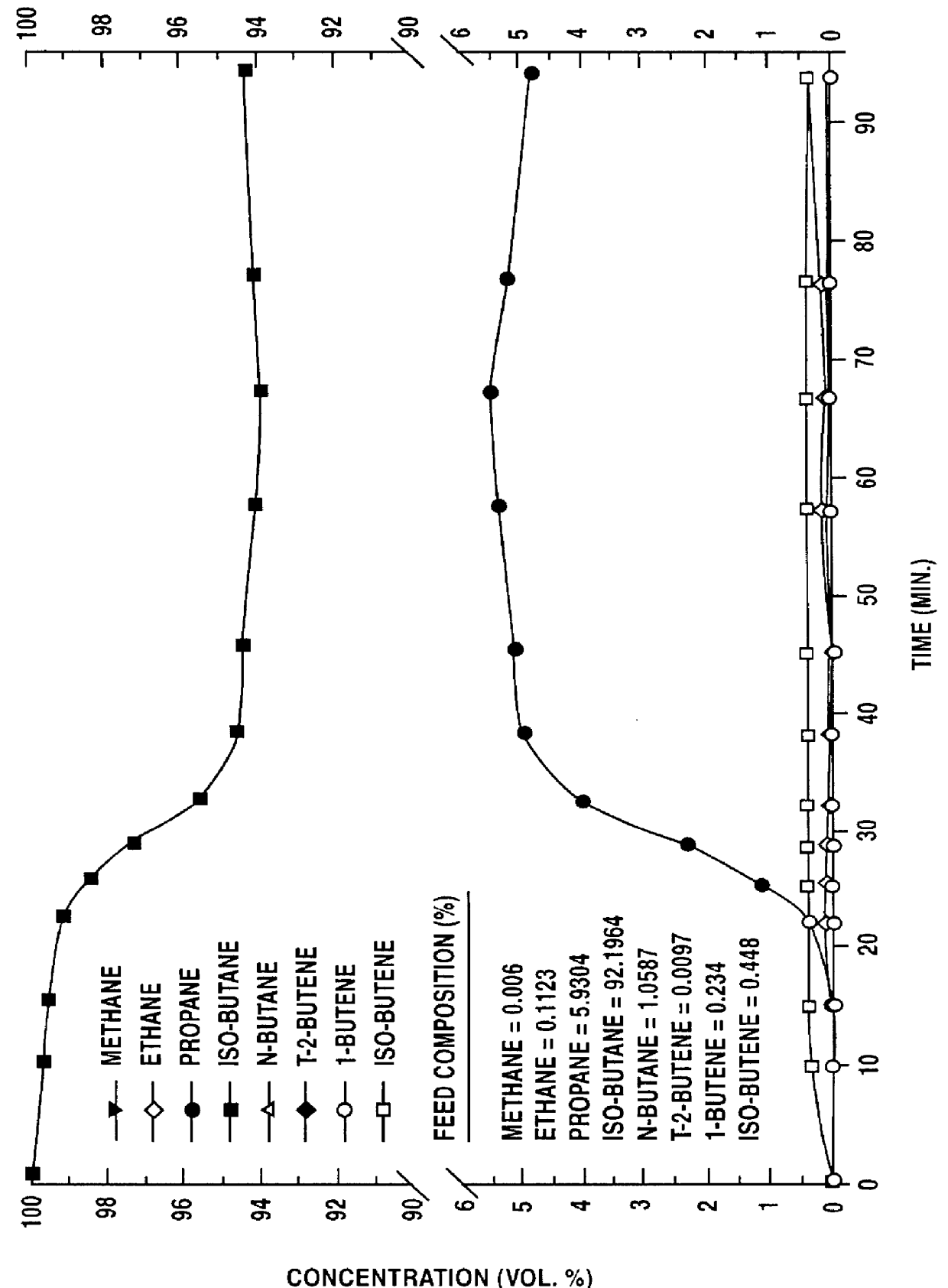

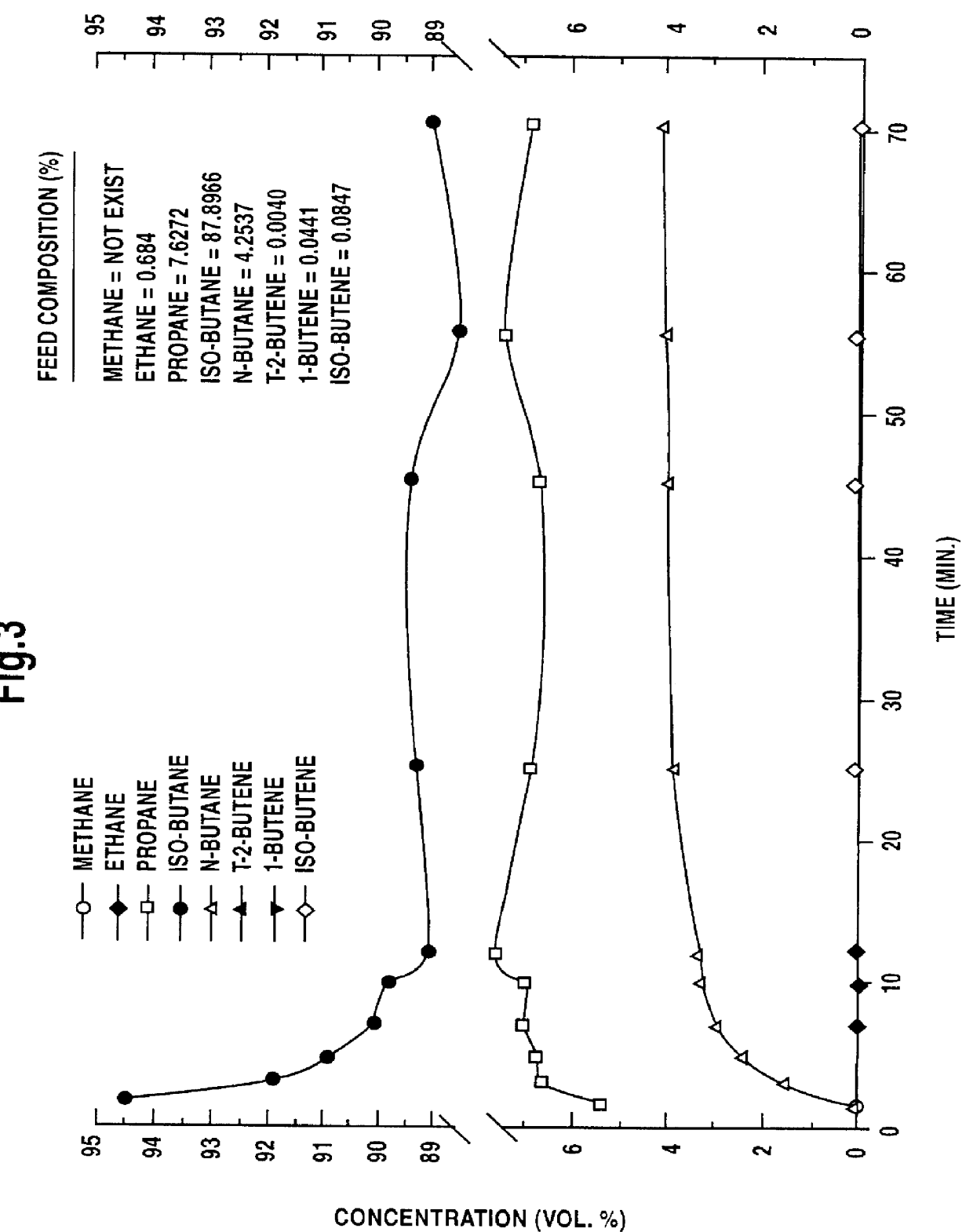

Adsorption separation and purification apparatus and process for high purity isobutane production

A high purity isobutane adsorption separation and purification apparatus is provided including a pressure regulator which regulates the pressure of an isobutane-containing gas; the at least one adsorption bed packed with zeolite 5A and carbon molecular sieve arranged downstream of and operatively associated with the pressure regulator; a flow control valve disposed between the pressure regulator and the at least one adsorption bed; a surge tank operatively associated with and for receiving a purified isobutane product from the at least one adsorption bed; a vacuum pump operatively associated with and for removal of impurities from the at least one adsorption bed; and valves disposed between the pressure regulator and the at least one adsorption bed, between the at least one adsorption bed and the surge tank, and between the at least one adsorption bed and the vacuum pump. An adsorptive separation and isobutane purification process is also provided which may be used with the apparatus of the invention.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

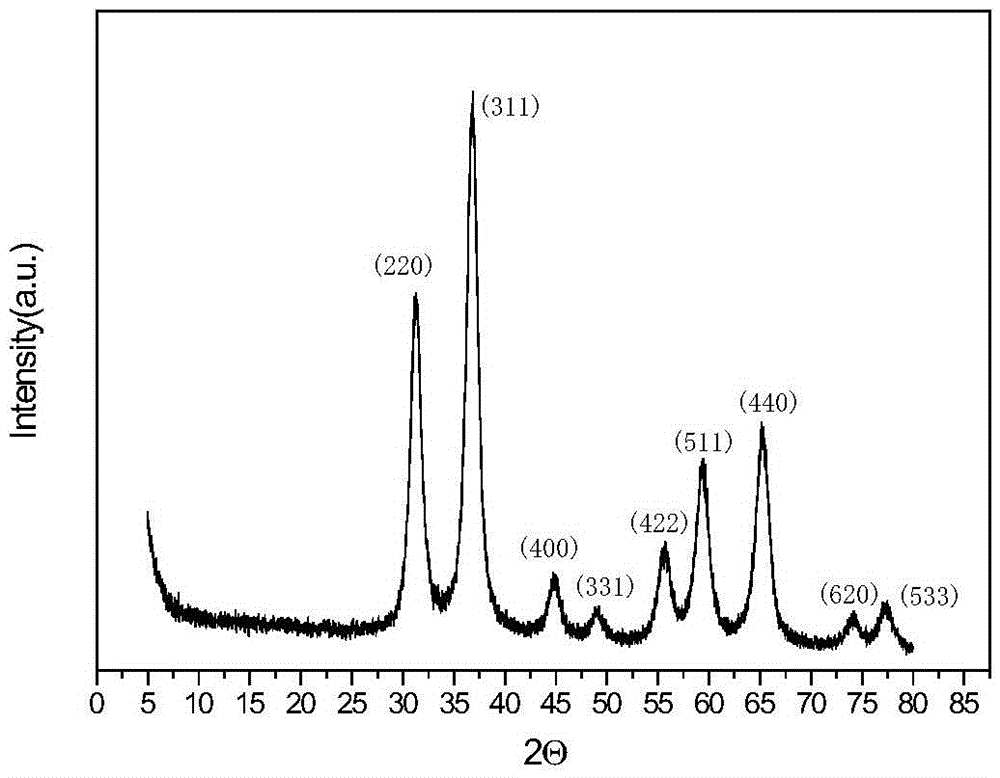

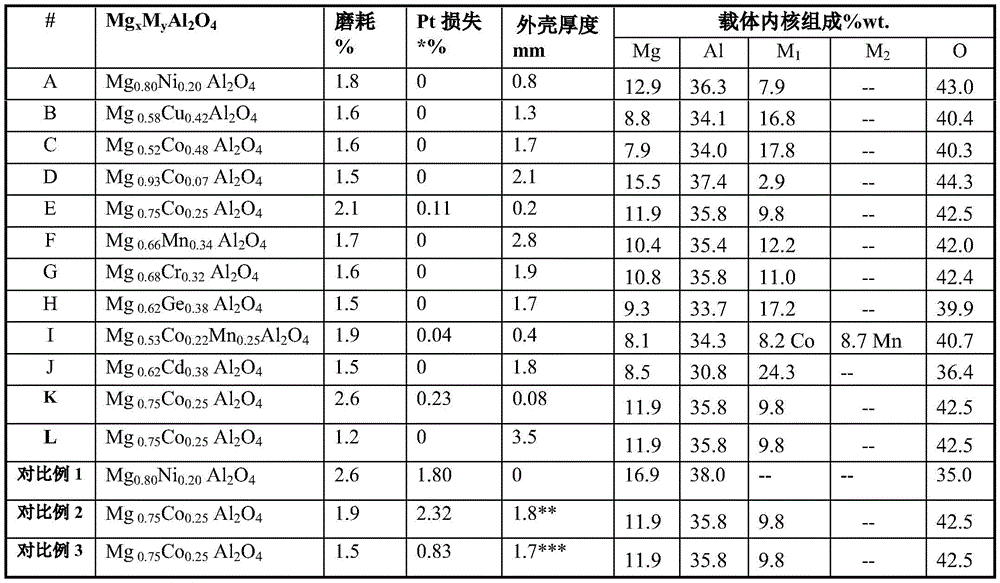

Carrier of catalyst for light alkane dehydrogenation preparation of light olefin and use thereof

ActiveCN106607100AImprove wear resistanceReduce catalysisCatalyst carriersHydrocarbonsAlkaneReaction temperature

The invention relates to a carrier of a platinum catalyst for light alkane dehydrogenation and a use thereof. The carrier mainly solves the problem that the existing catalyst has poor wear resistance and the precious metal is easy to lose along with the carrier wear during the use. A preparation method of the platinum catalyst comprises coating the surface of a magnesium aluminate carrier with alumina or pseudo-boehmite sol through a spraying or rolling method to obtain an alumina housing, carrying out drying and high temperature calcination to obtain a compound metal oxide carrier having the inert housing, loading platinum and tin components through an impregnation method through impregnation of a soluble salt aqueous solution of platinum, and carrying out drying, roasting and vapor treatment to obtain the platinum catalyst. Propane / isobutane as a raw material contacts with the catalyst and undergoes a reaction under conditions of a reaction temperature of 520 to 620 DEG C, reaction pressure of 0 to 0.4MPa, an alkane mass space velocity of 0.1 to 8.0h<-1> and a H2O / CnH2n+2 volume ratio of 1 to 18 to produce propylene / isobutene so that the problem is solved. The platinum catalyst carrier can be used in industrial preparation of a catalyst for light alkane dehydrogenation preparation of a light olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

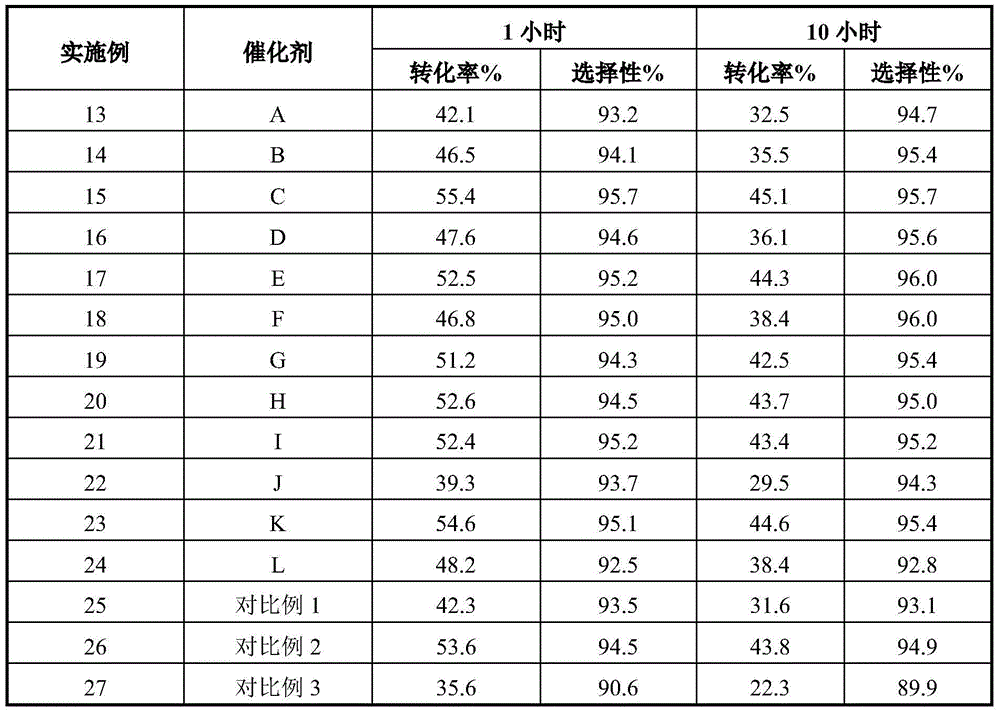

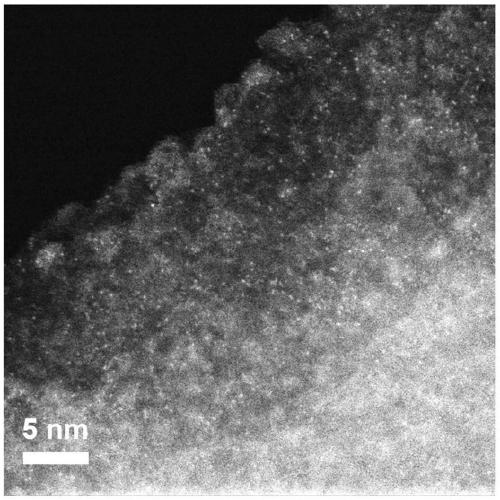

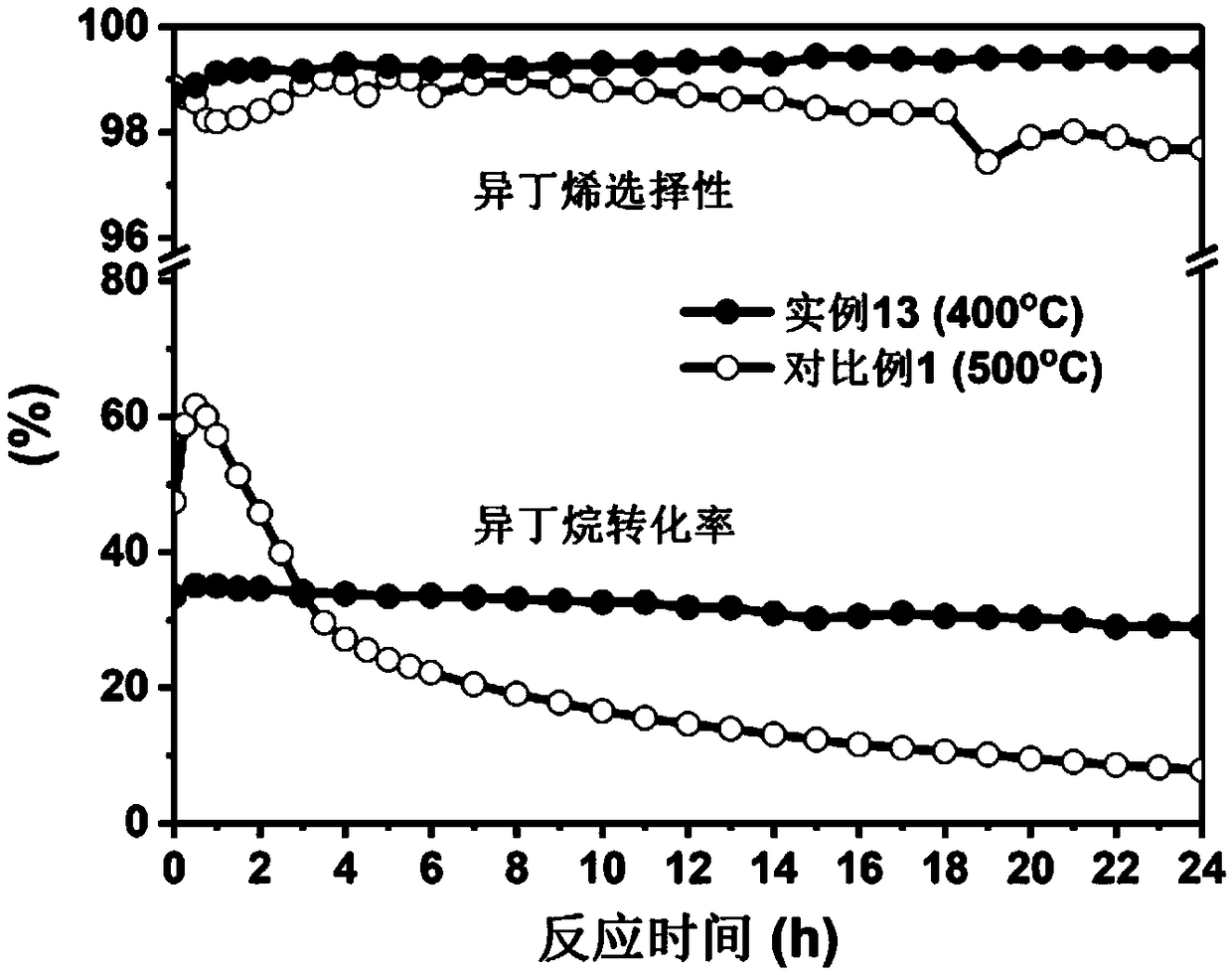

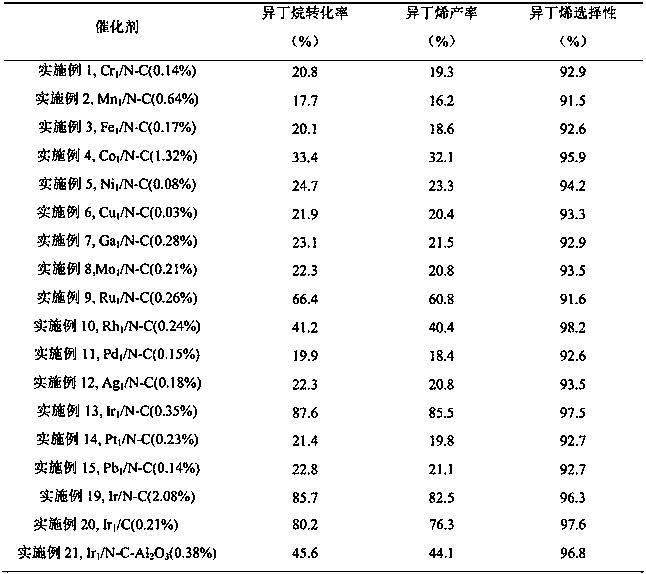

Monoatomic catalyst for preparation of low-carbon olefin by means of dehydrogenation of lower low-carbon hydrocarbons, and catalytic method

ActiveCN109225306ALow costReduce pollutionPhysical/chemical process catalystsCatalystsReaction temperatureDehydrogenation

The invention relates to a monoatomic catalyst for preparation of low-carbon olefin by means of dehydrogenation of low-carbon hydrocarbons, and a catalytic method. The catalyst is obtained by supporting metal active components, dispersed in an isolated monoatomic form, on a carrier, or supporting the metal active components on the carrier in a form in which single atoms and metal nanoparticles coexist. The metals in the metal active components are preferably selected from at least one of chromium, manganese, iron, cobalt, nickel, copper, gallium, molybdenum, ruthenium, rhodium, palladium, silver, iridium, platinum and lead; the carrier is prepared from one or more of a carbon-nitrogen material, a carbon material or oxides. The catalyst provided by the invention can realize the reduction ofmetal consumption and has very good stability; the catalyst can significantly reduce the reaction temperature while guaranteeing high catalytic performance, reduces the energy consumption, effectively avoids the formation of carbon deposit, and increases the production efficiency. The catalyst can catalyze a dehydrogenation reaction of the multiple low-carbon hydrocarbons such as isobutane, n-butane, butene, propane and ethane so as to produce corresponding low-carbon olefin products, thus being wide in application range; the monoatomic catalyst is multiple in preparation methods, wide in rawmaterials, low in cost and suitable for mass industrial production.

Owner:北京博思福催化科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com