Patents

Literature

2310results about "Hydrocarbon by isomerisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

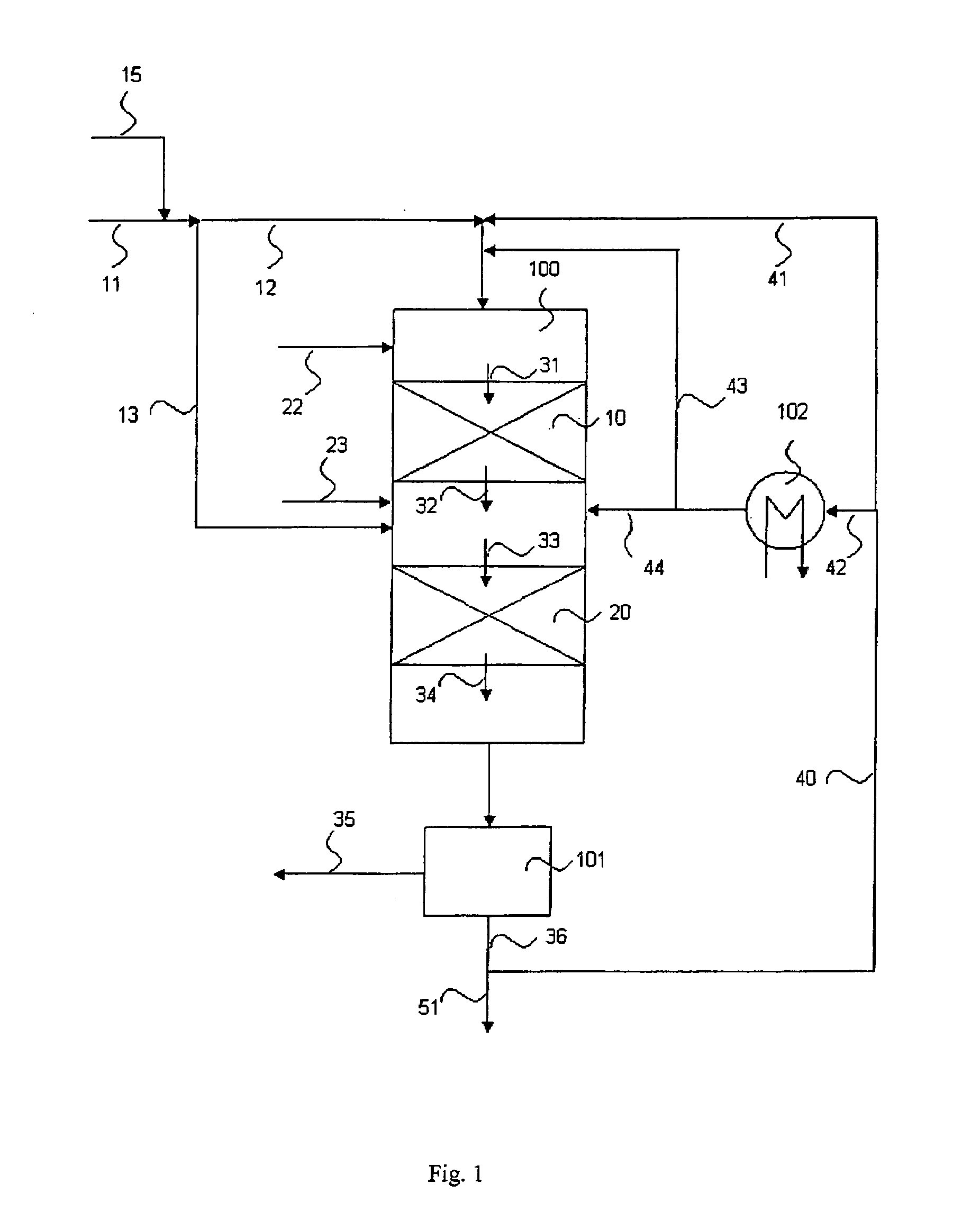

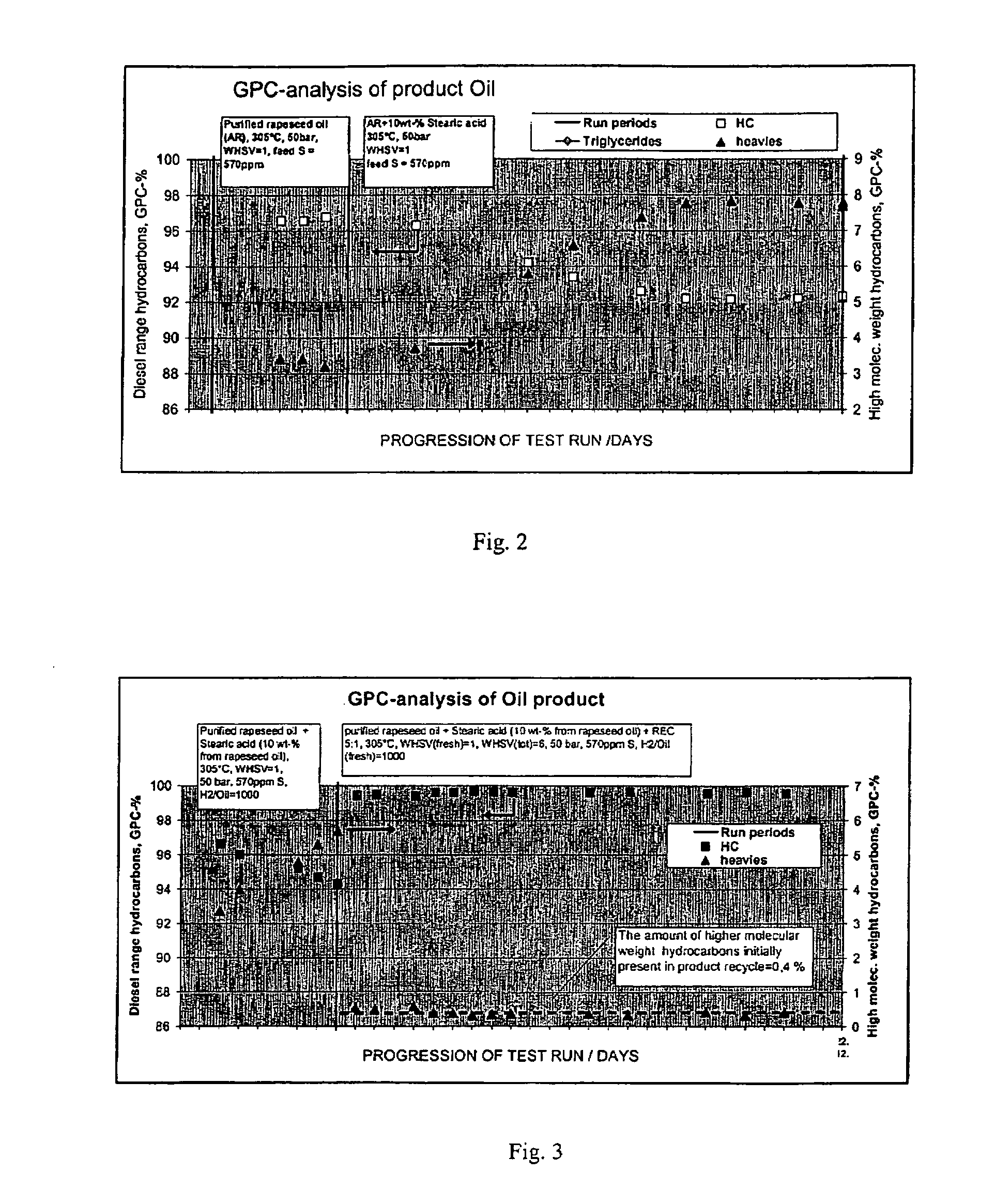

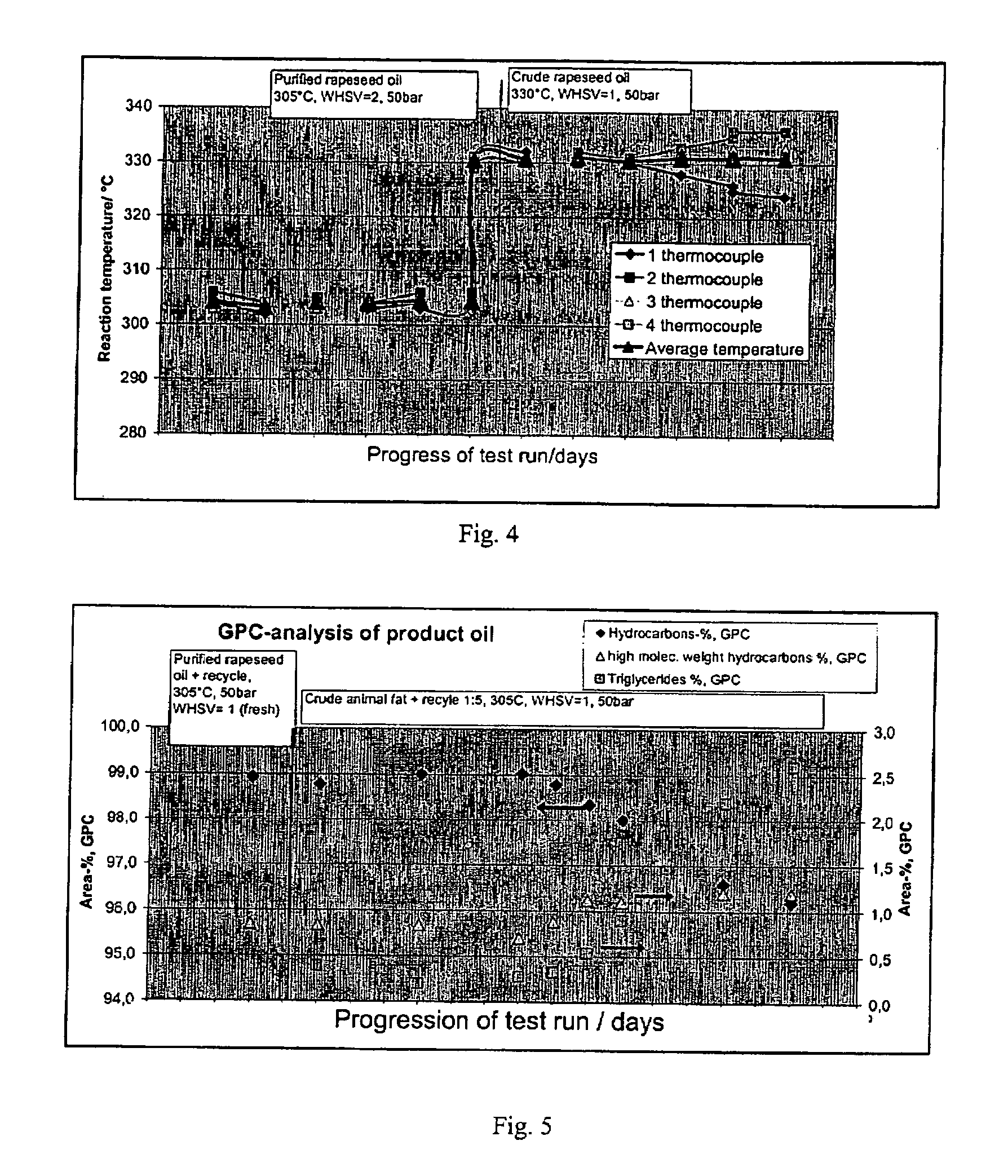

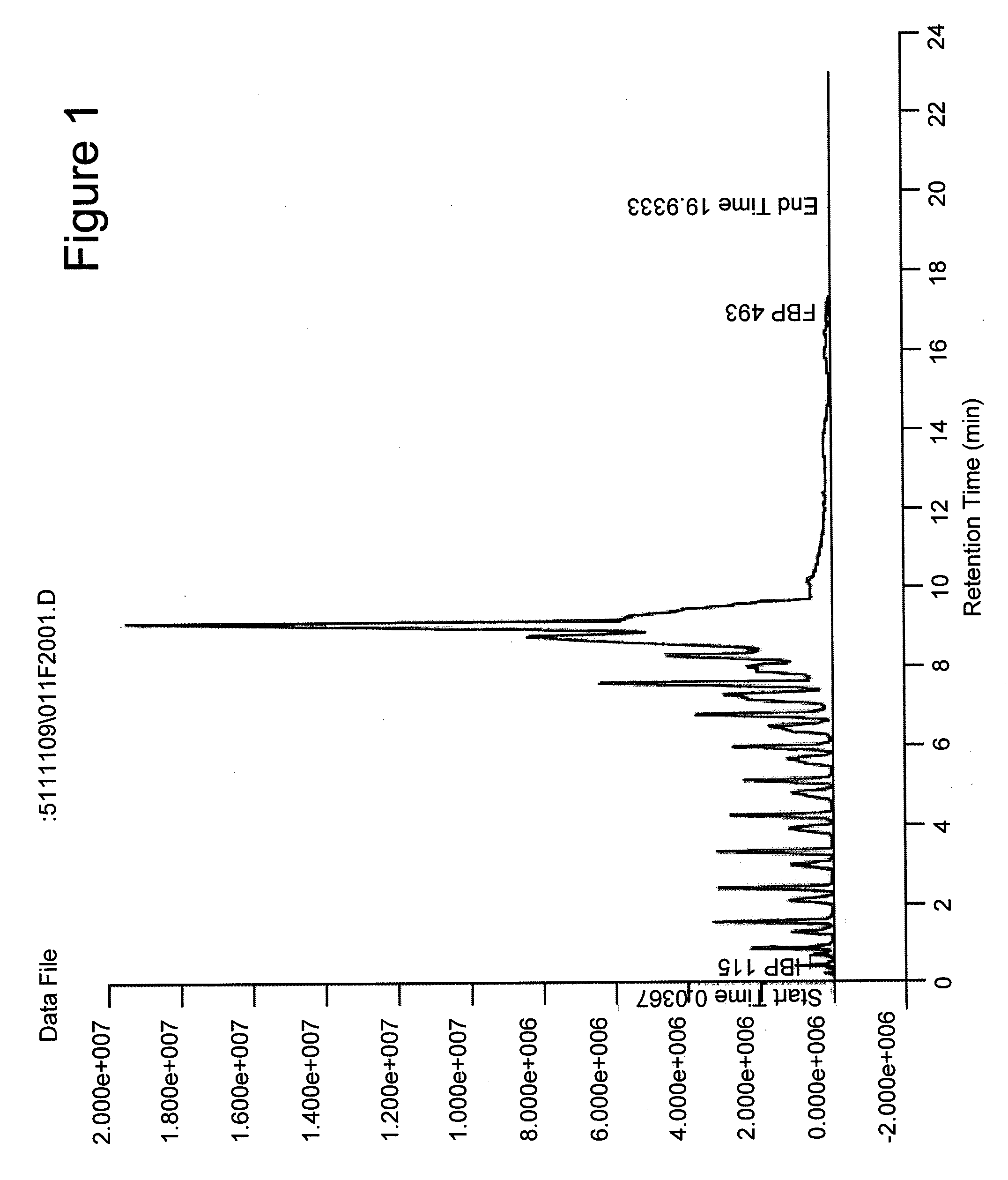

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

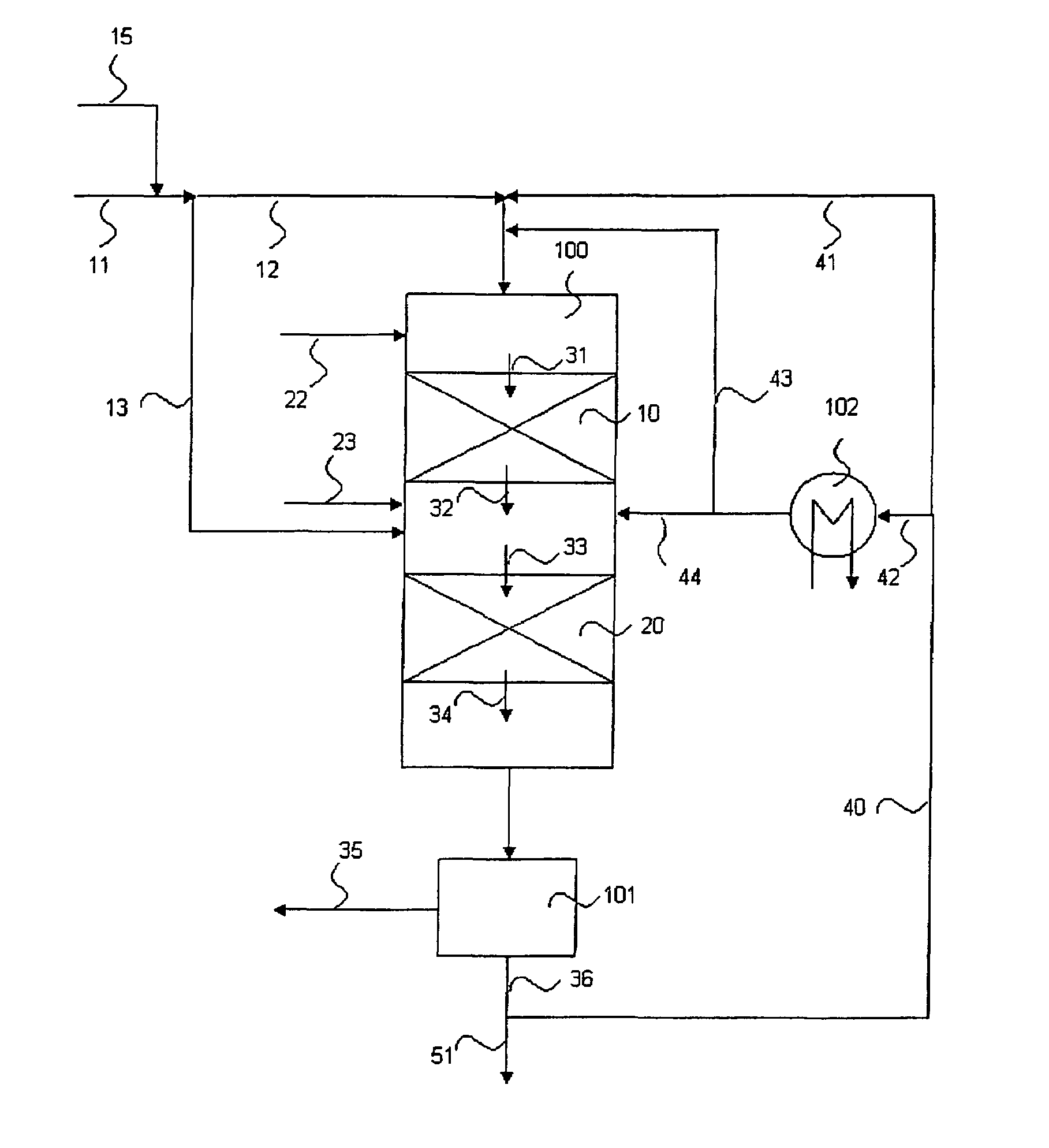

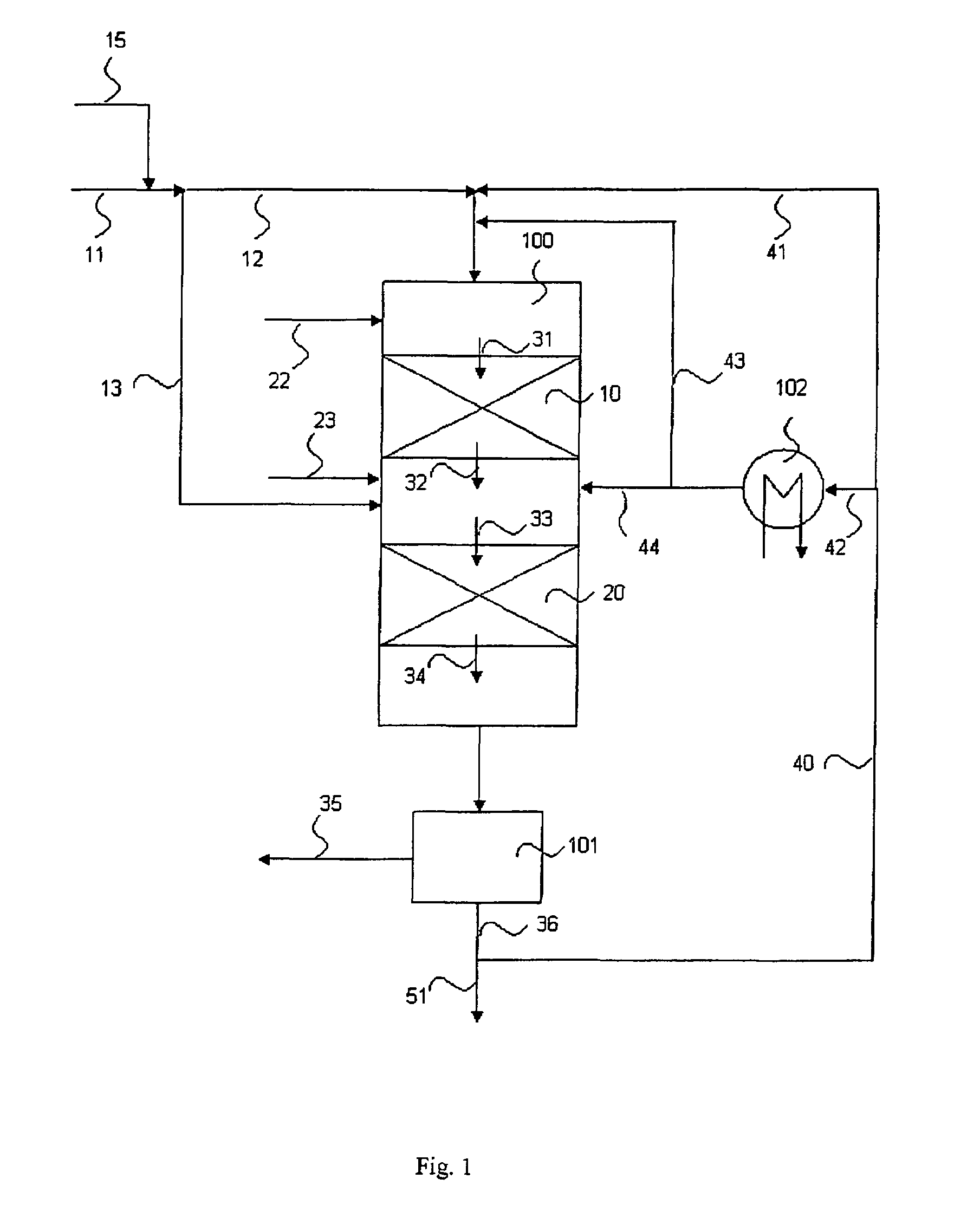

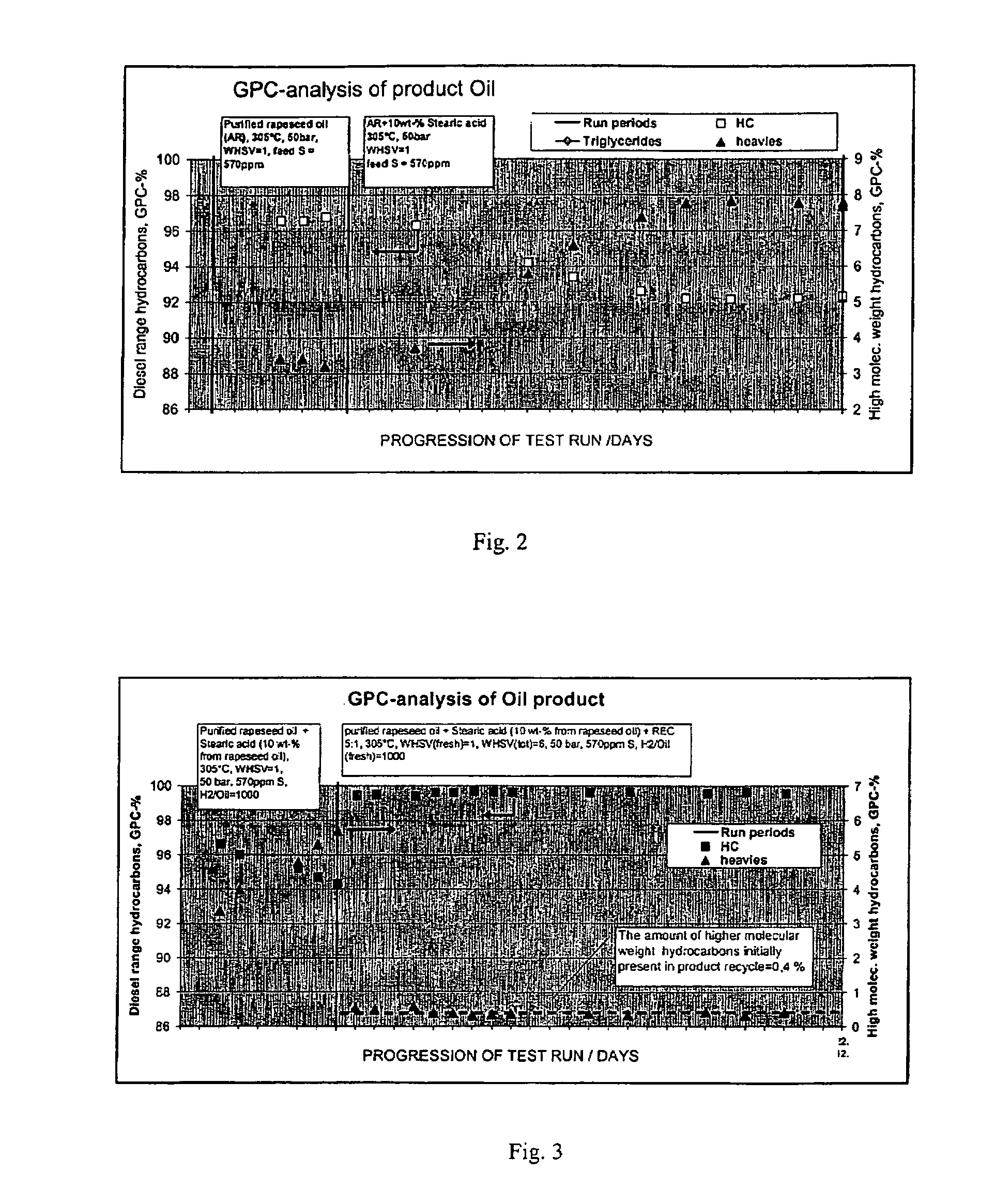

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Hydroprocessing Microalgal Oils

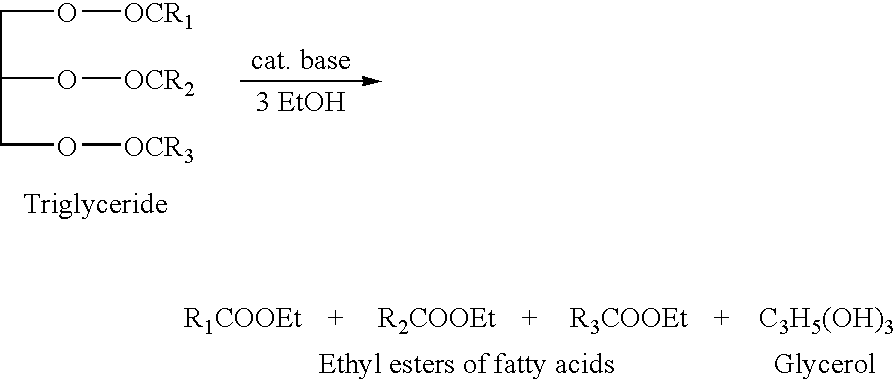

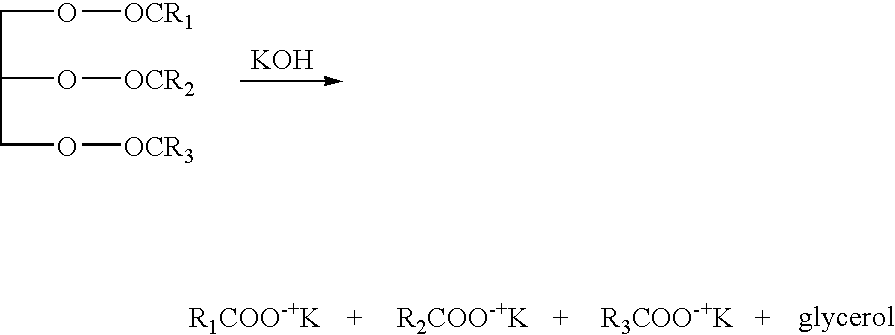

InactiveUS20100170144A1Improve efficiencyLow costHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

Fuels and other valuable compositions and compounds can be made from oil extracted from microbial biomass and from oil-bearing microbial biomass via hydroprocessing and / or other chemical treatments, including the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts.

Owner:TERRAVIA HLDG INC

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst and process of paraffin hydrocarbon conversion

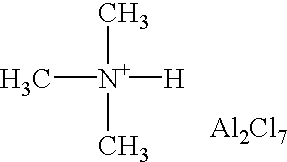

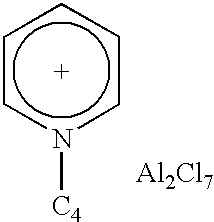

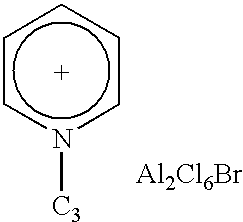

InactiveUS20040077914A1Improve solubilityEasy to useHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkanePtru catalyst

A catalyst composition and process for the conversion of linear and / or branched paraffin hydrocarbons based on the use of an ionic liquid catalyst in combination with a Brønsted Acid, which provides a catalytic composition with an increased activity compared with said ionic liquid. Under suitable reaction conditions this conversion is leading to paraffin hydrocarbon fraction with higher octane number.

Owner:HALDOR TOPSOE AS

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon additive

InactiveUS6797853B2High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingAlkaneIonic liquid

Owner:HALDOR TOPSOE AS

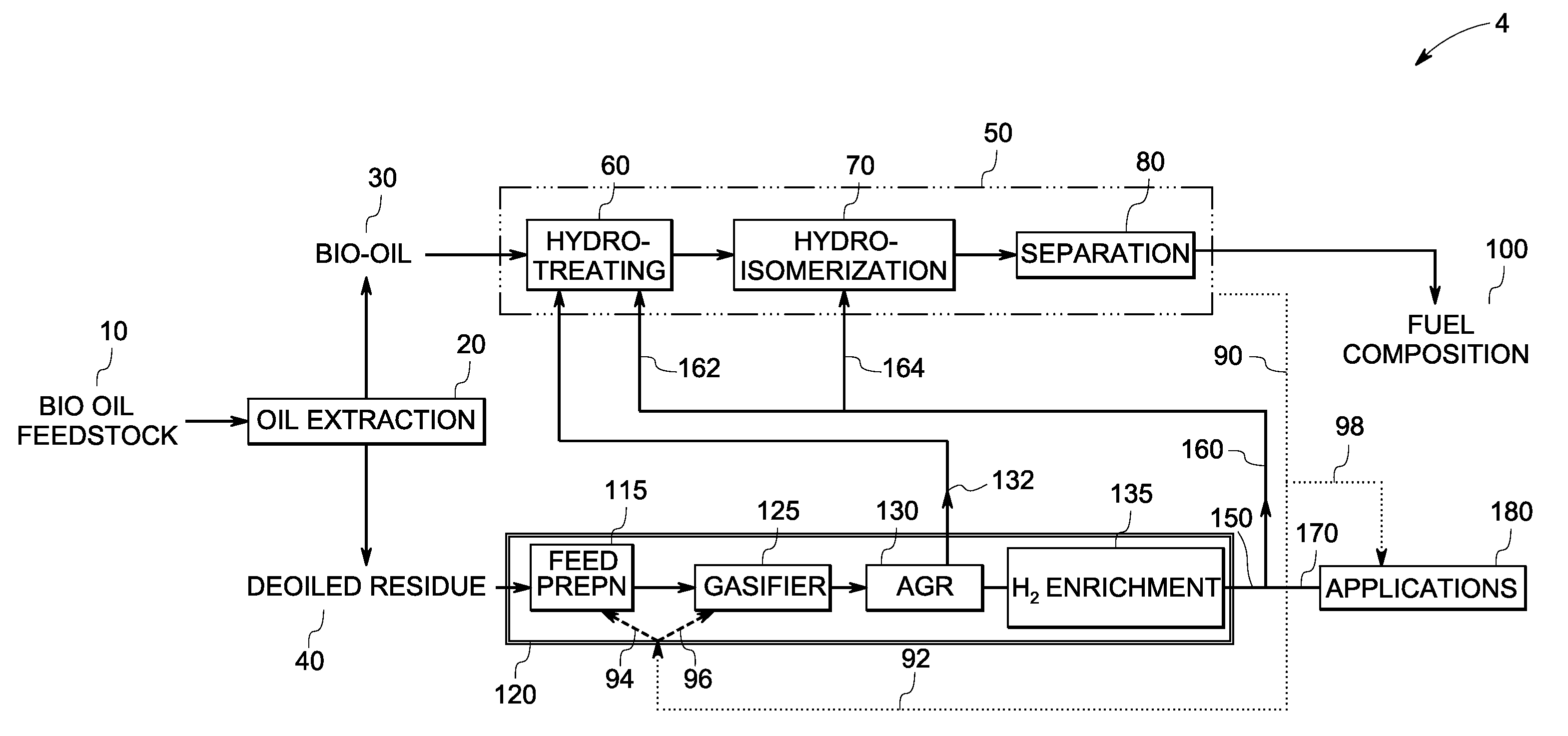

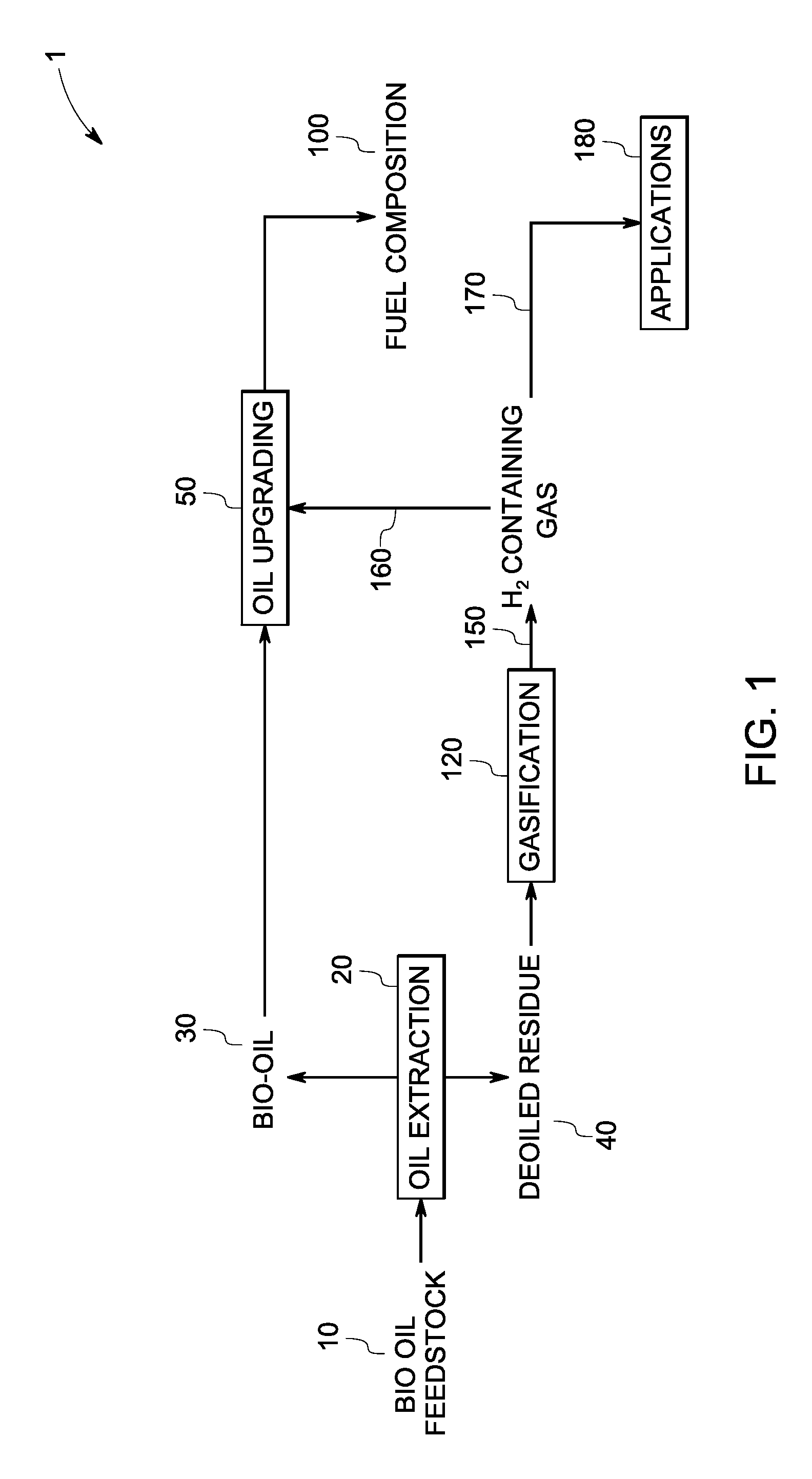

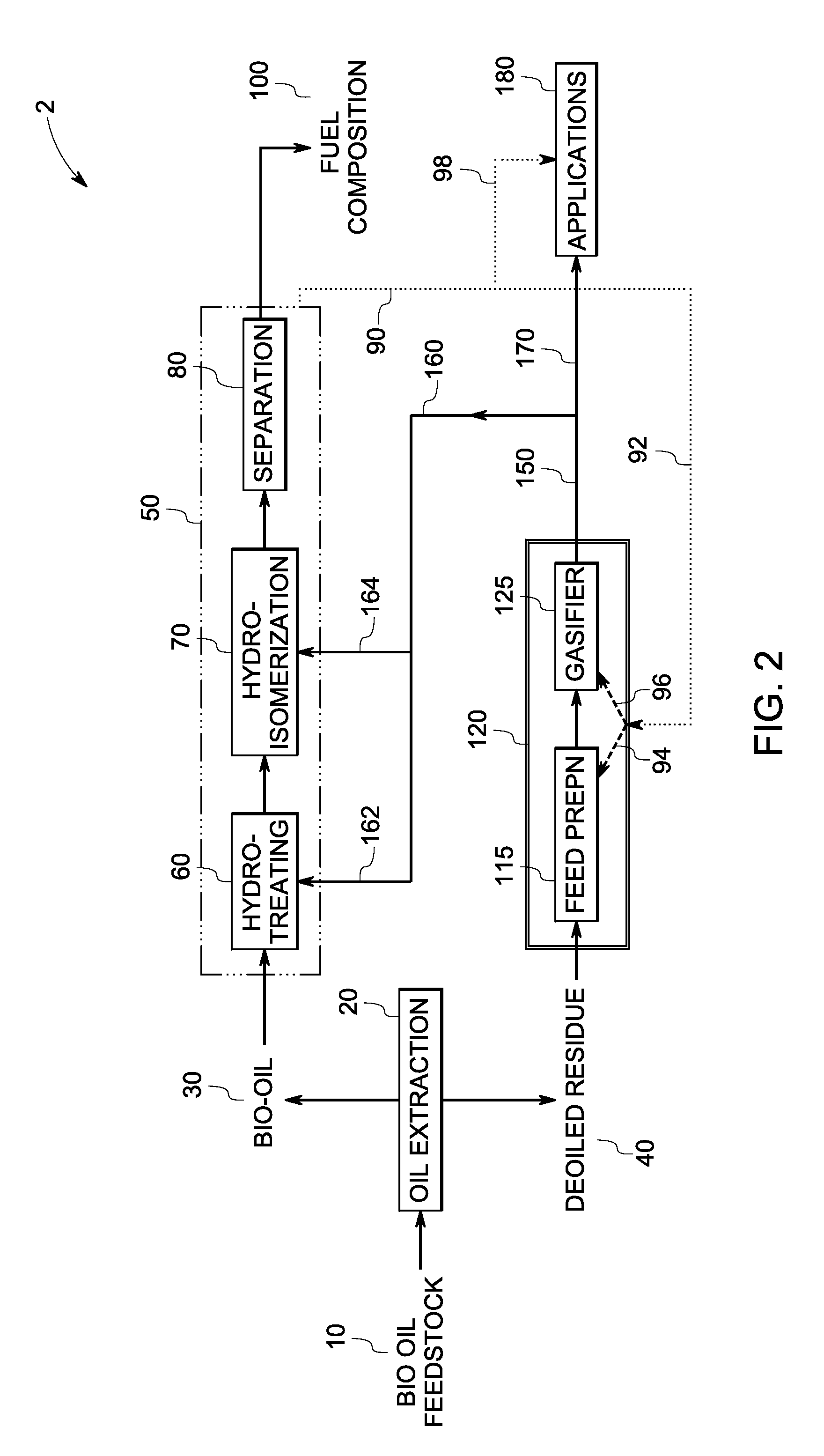

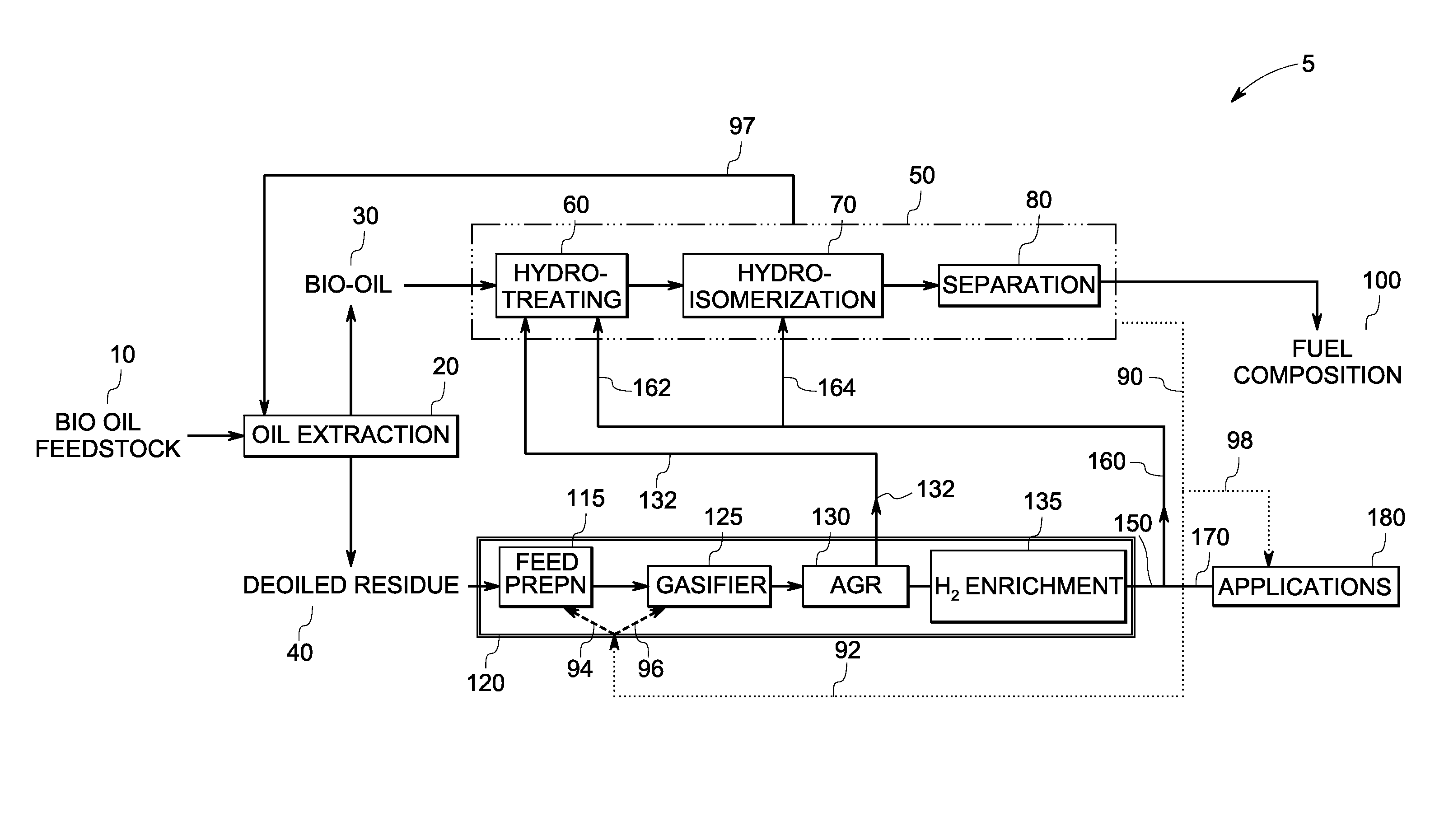

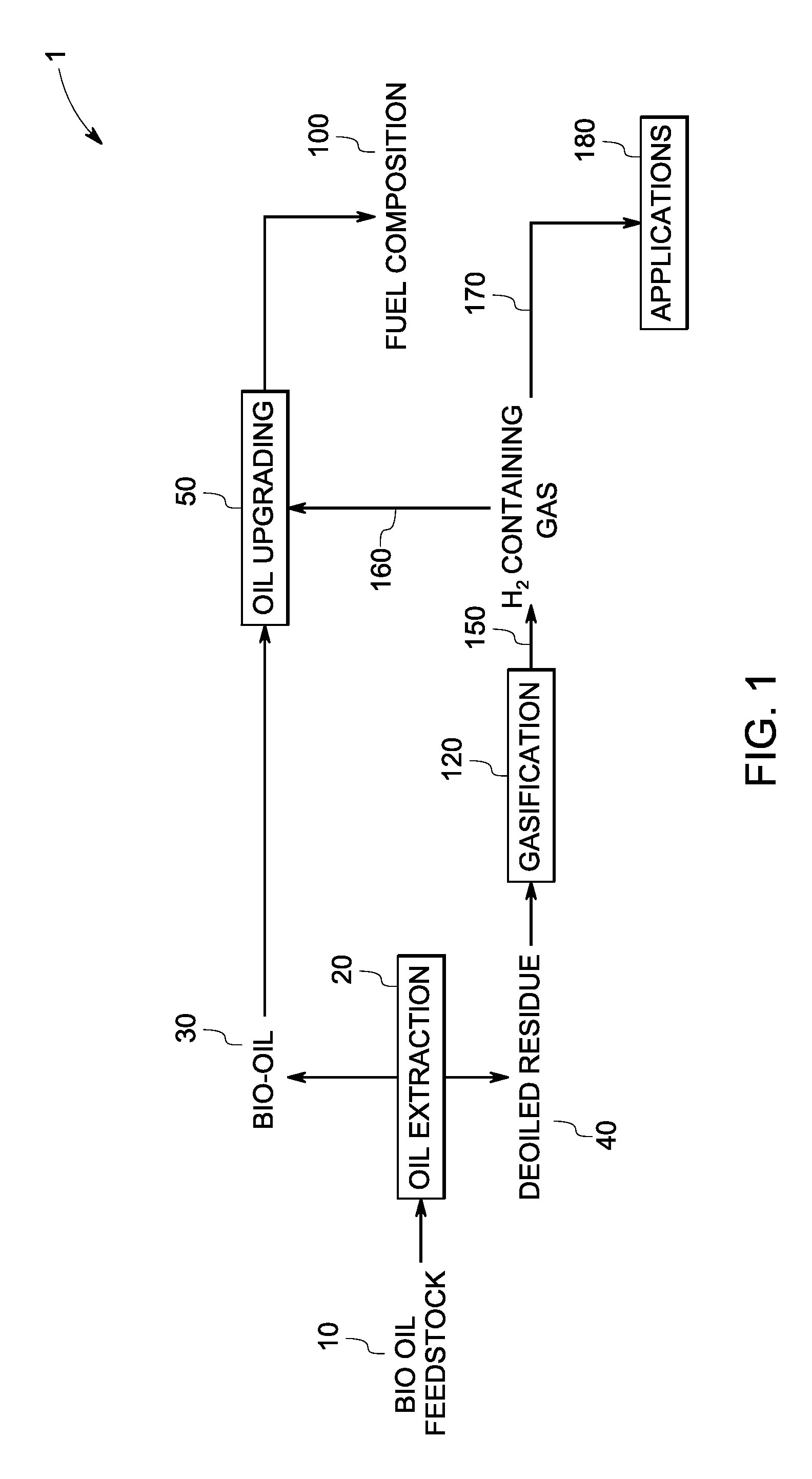

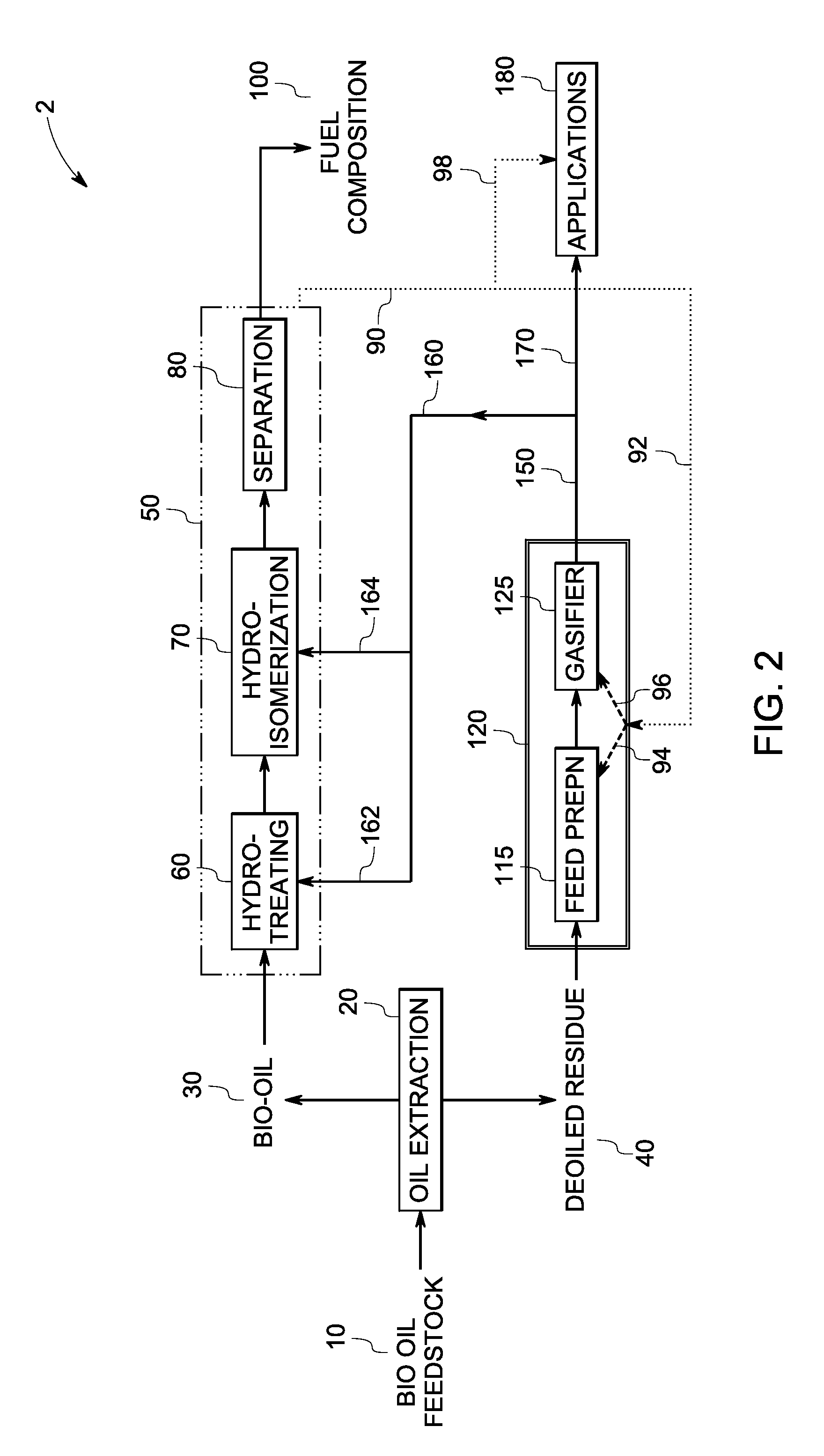

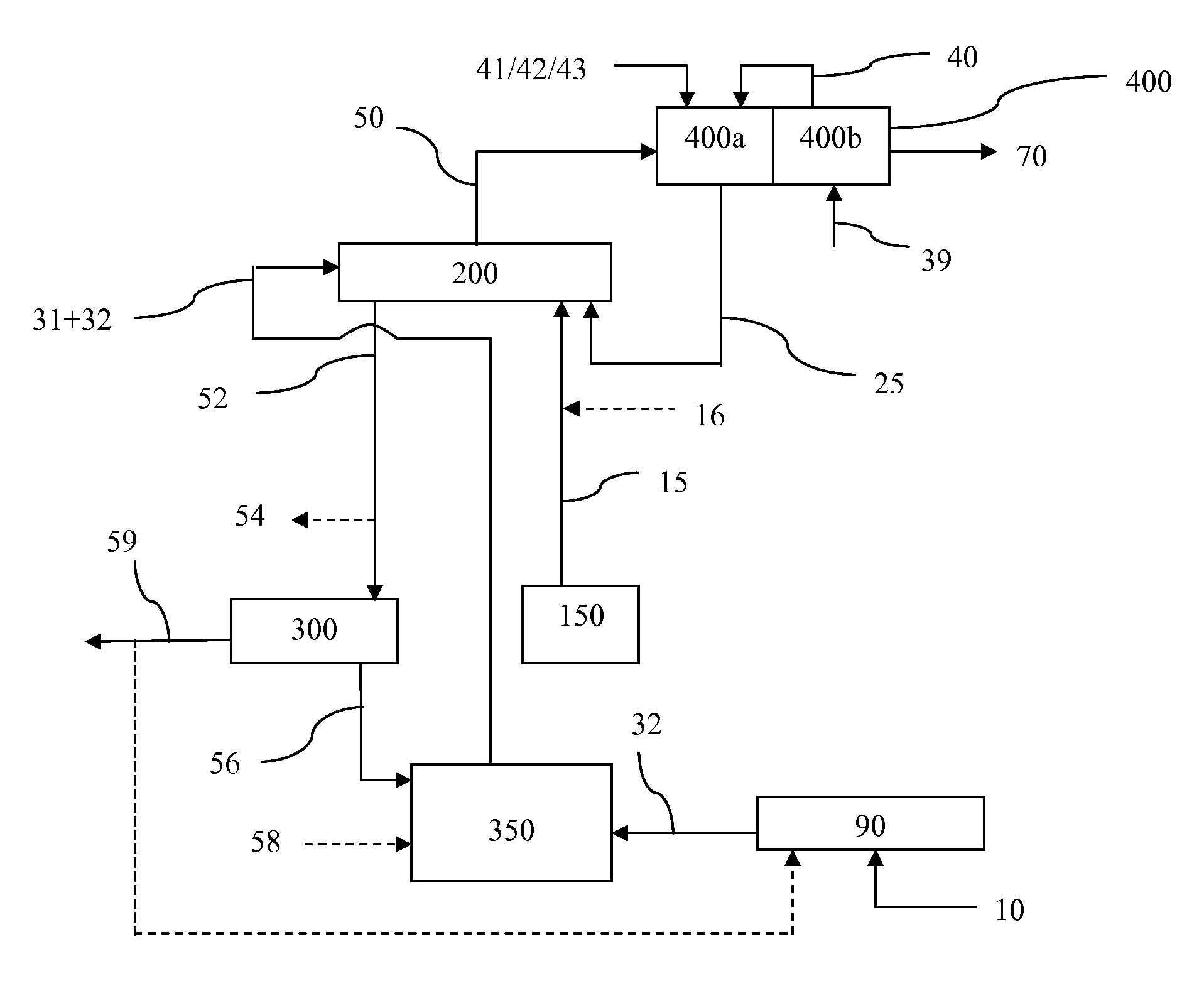

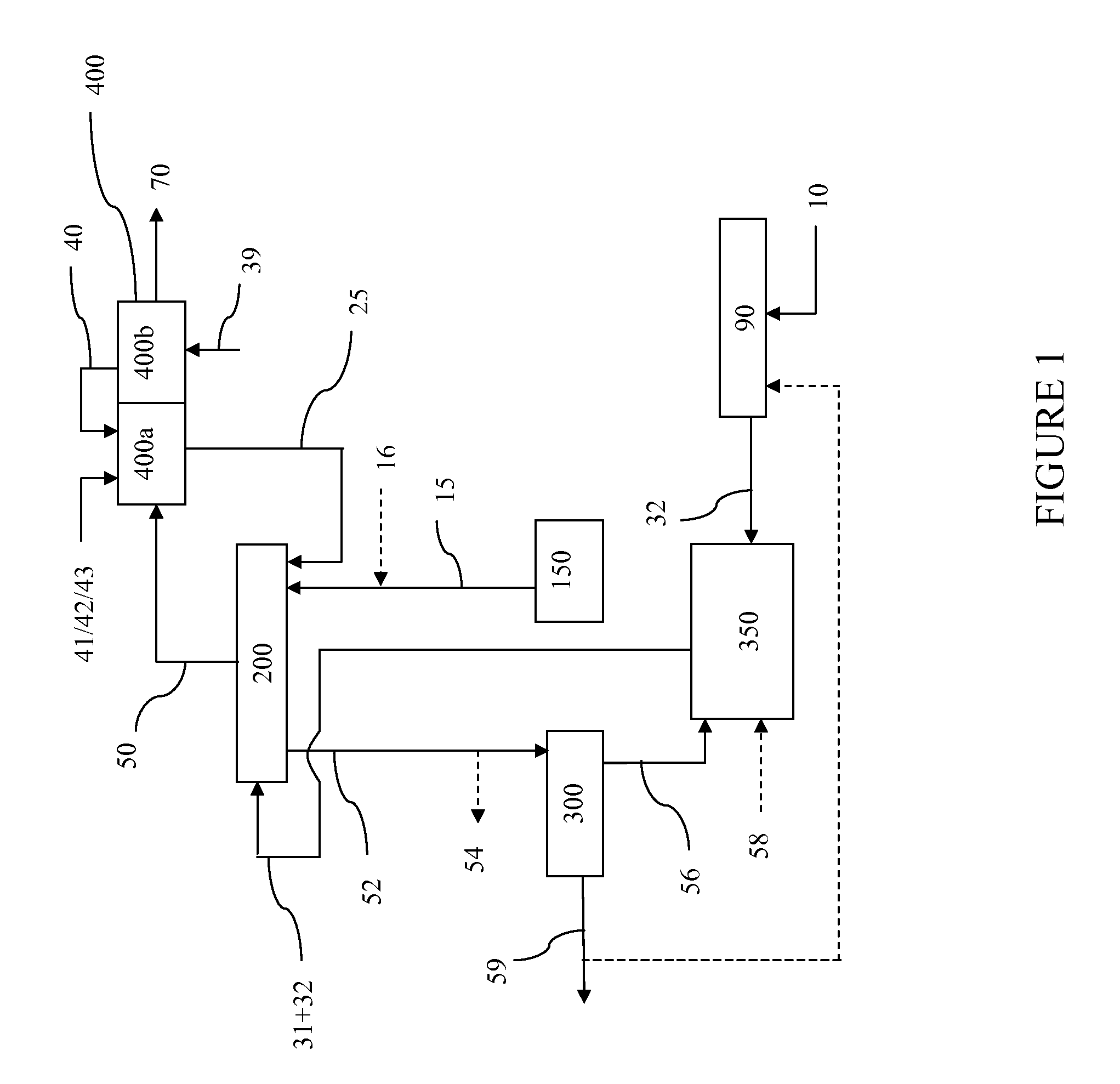

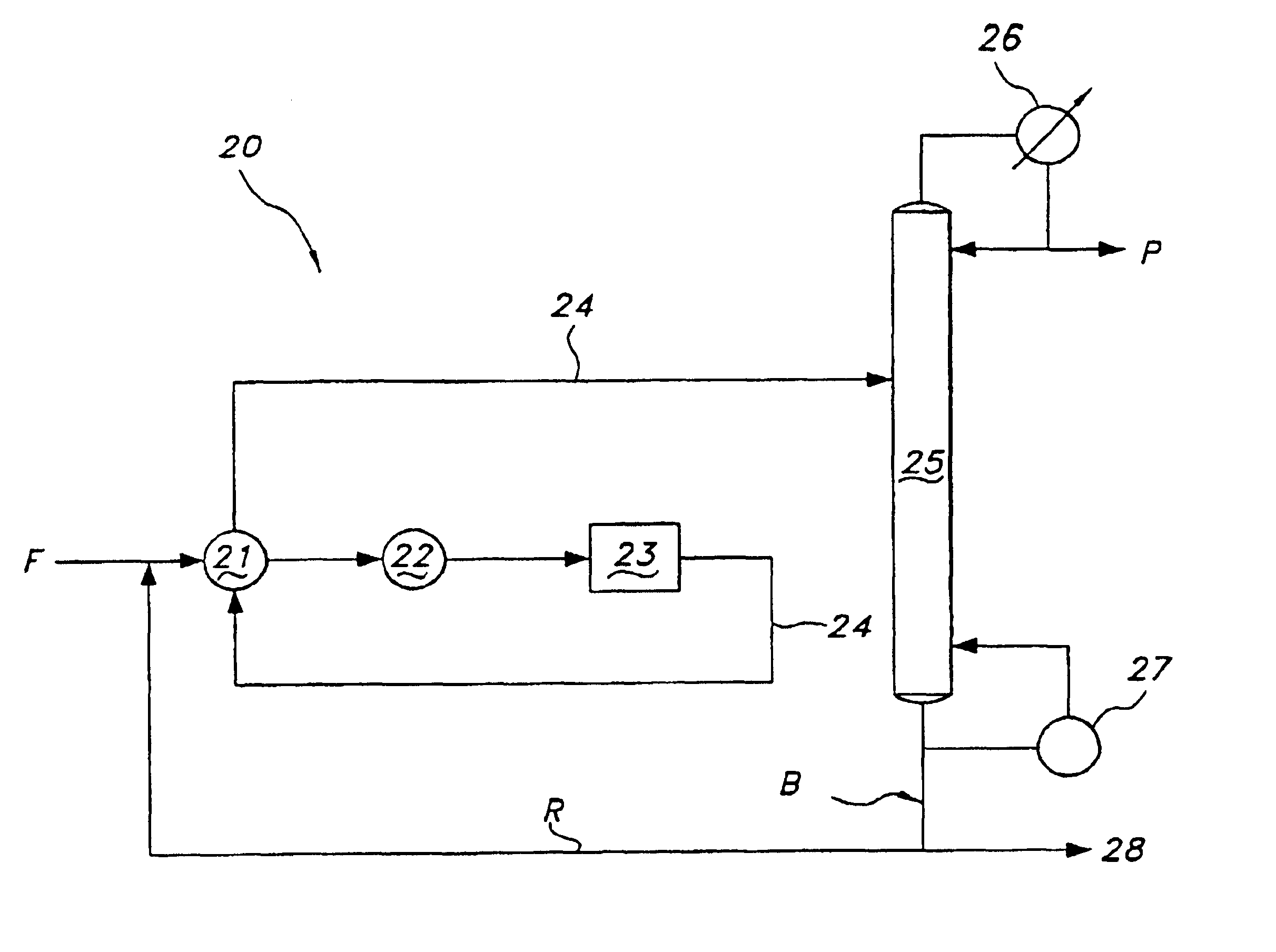

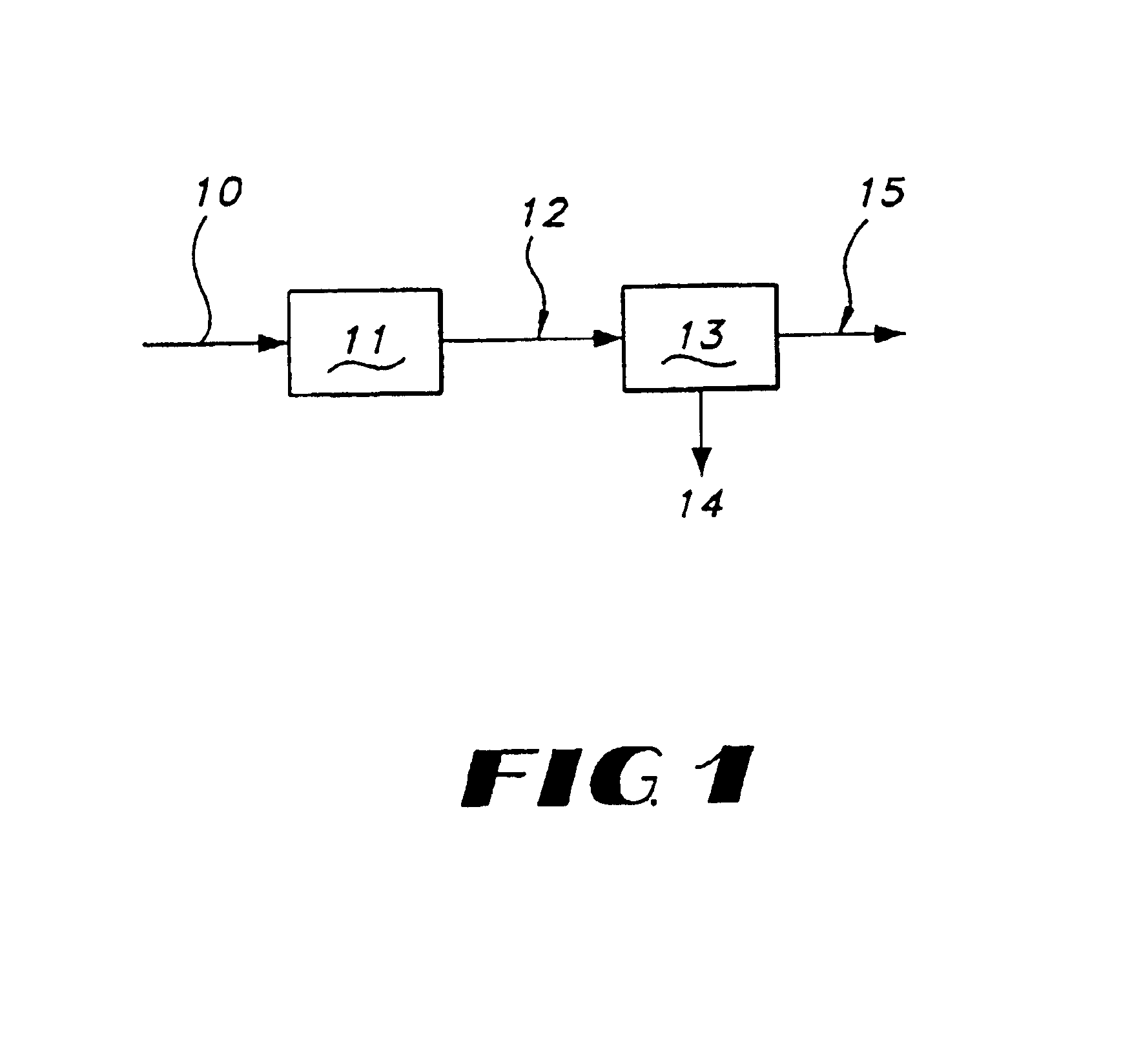

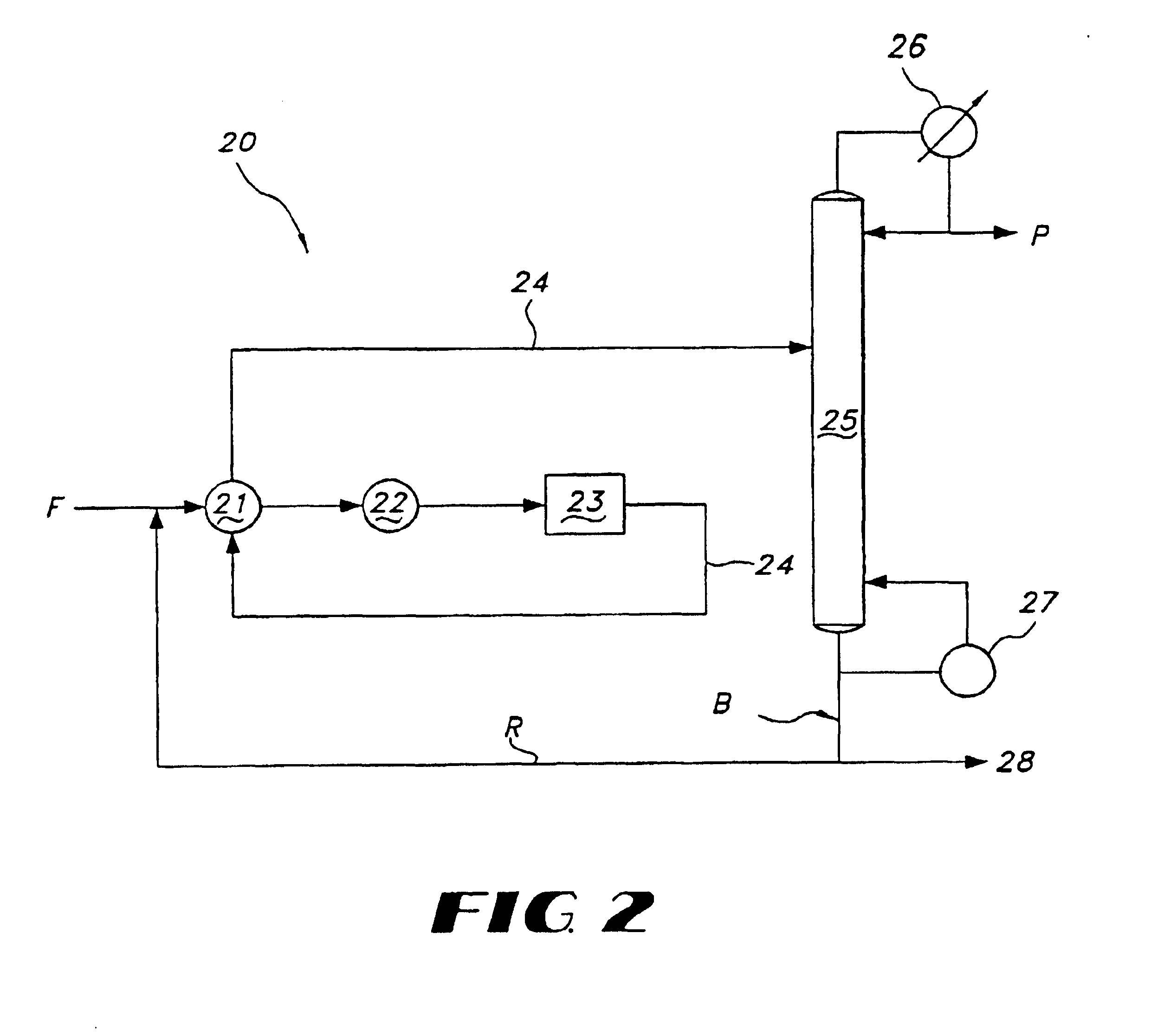

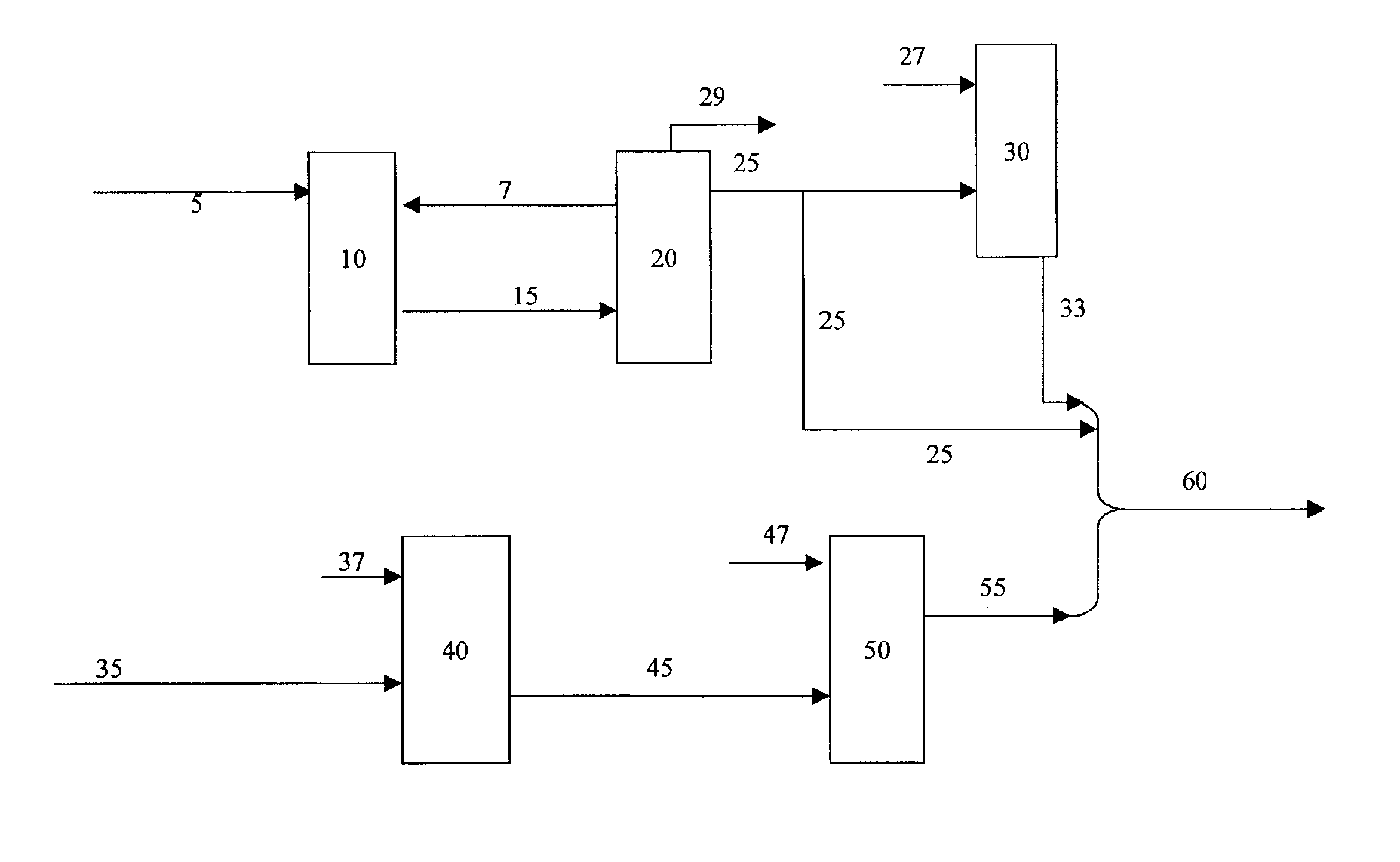

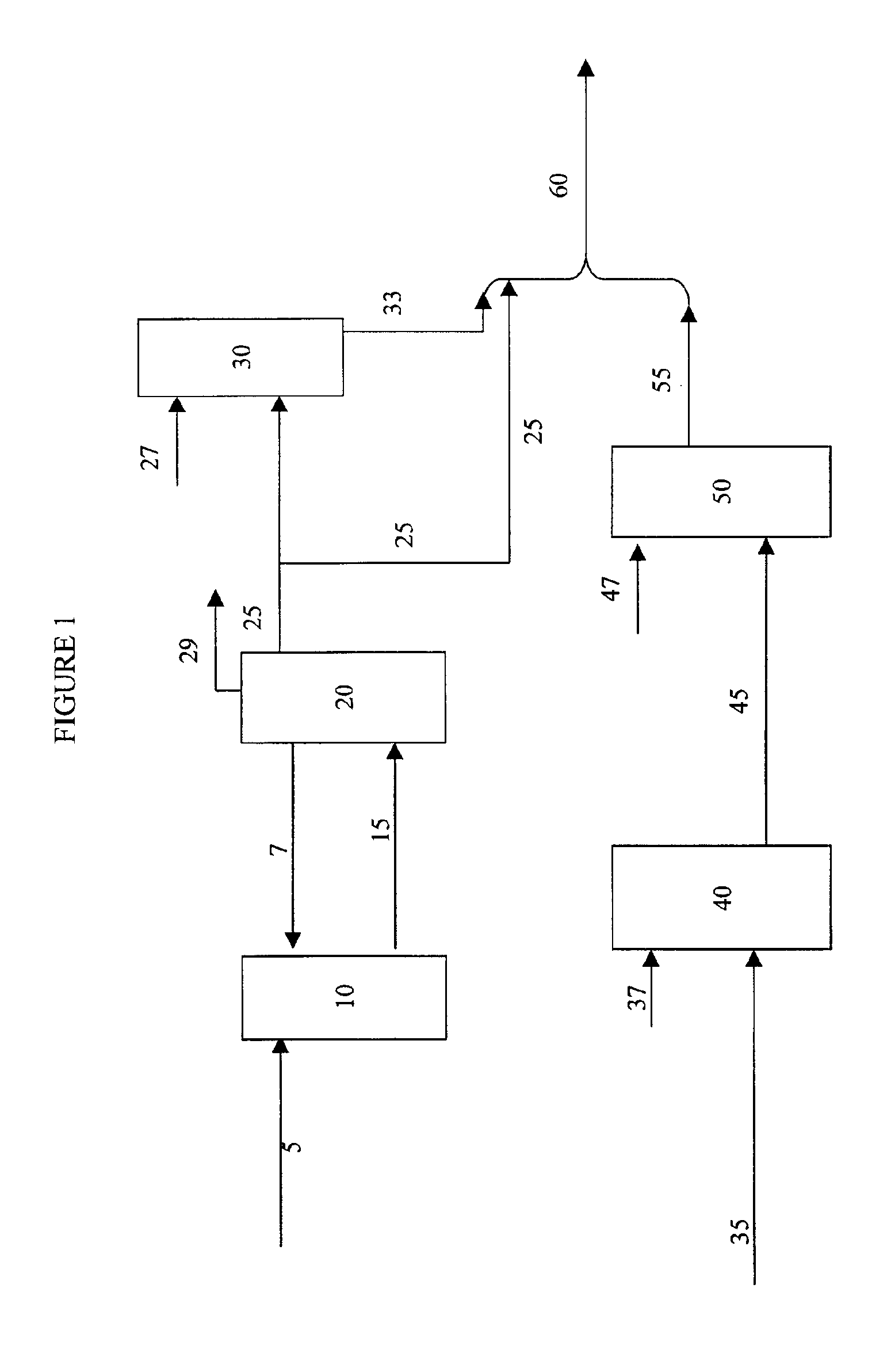

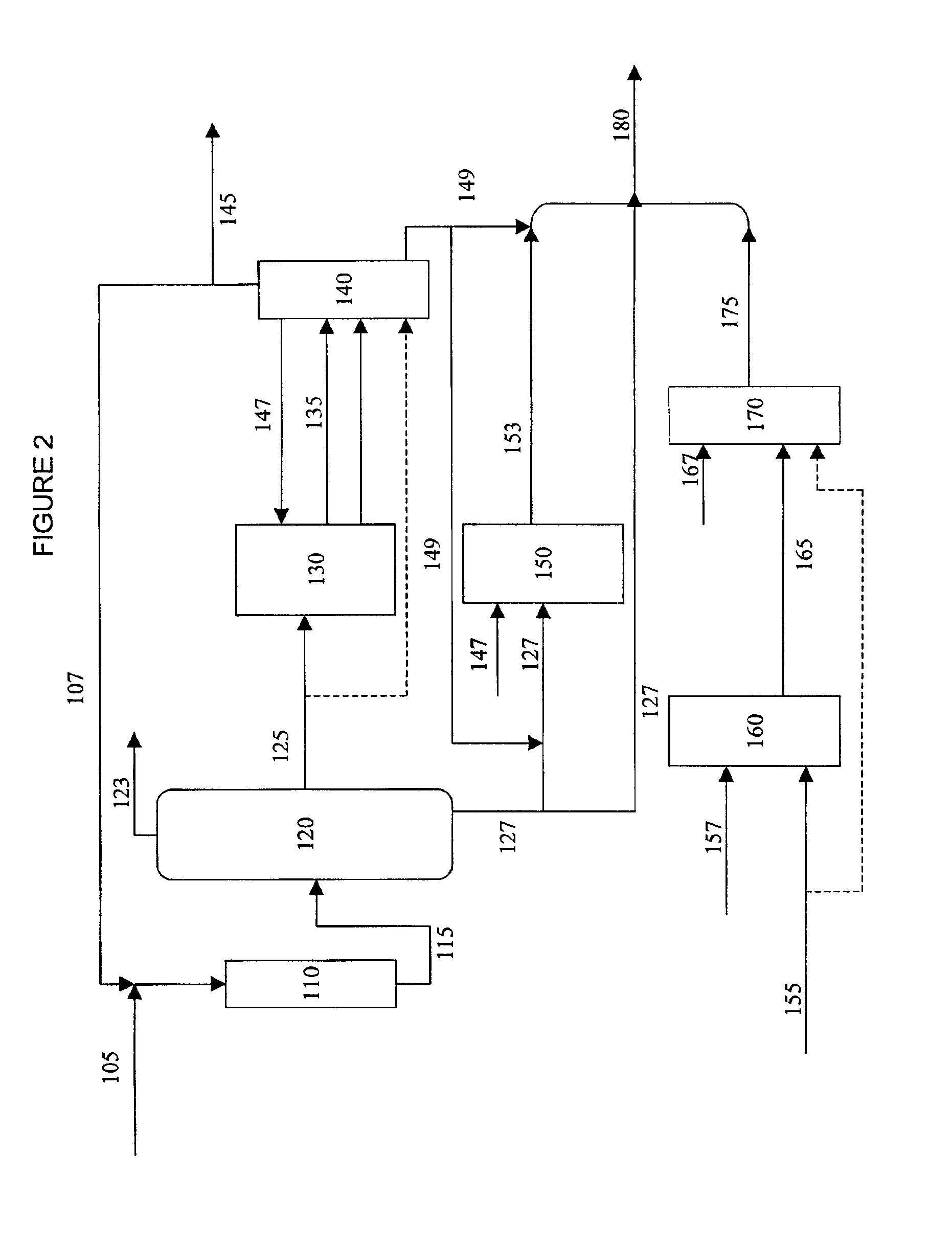

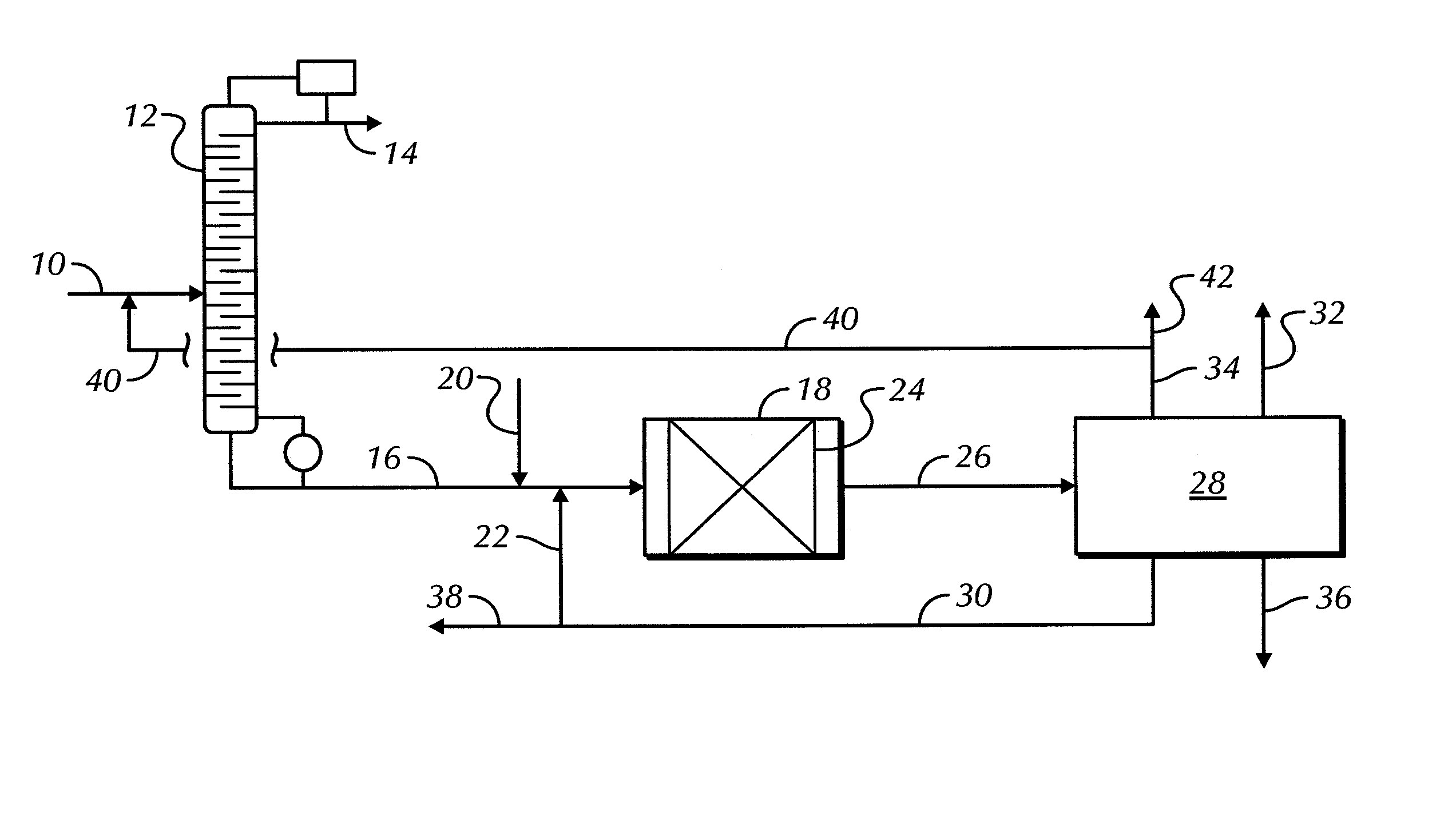

Integrated system and method for producing fuel composition from biomass

InactiveUS7888540B2Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentHydrogenTar

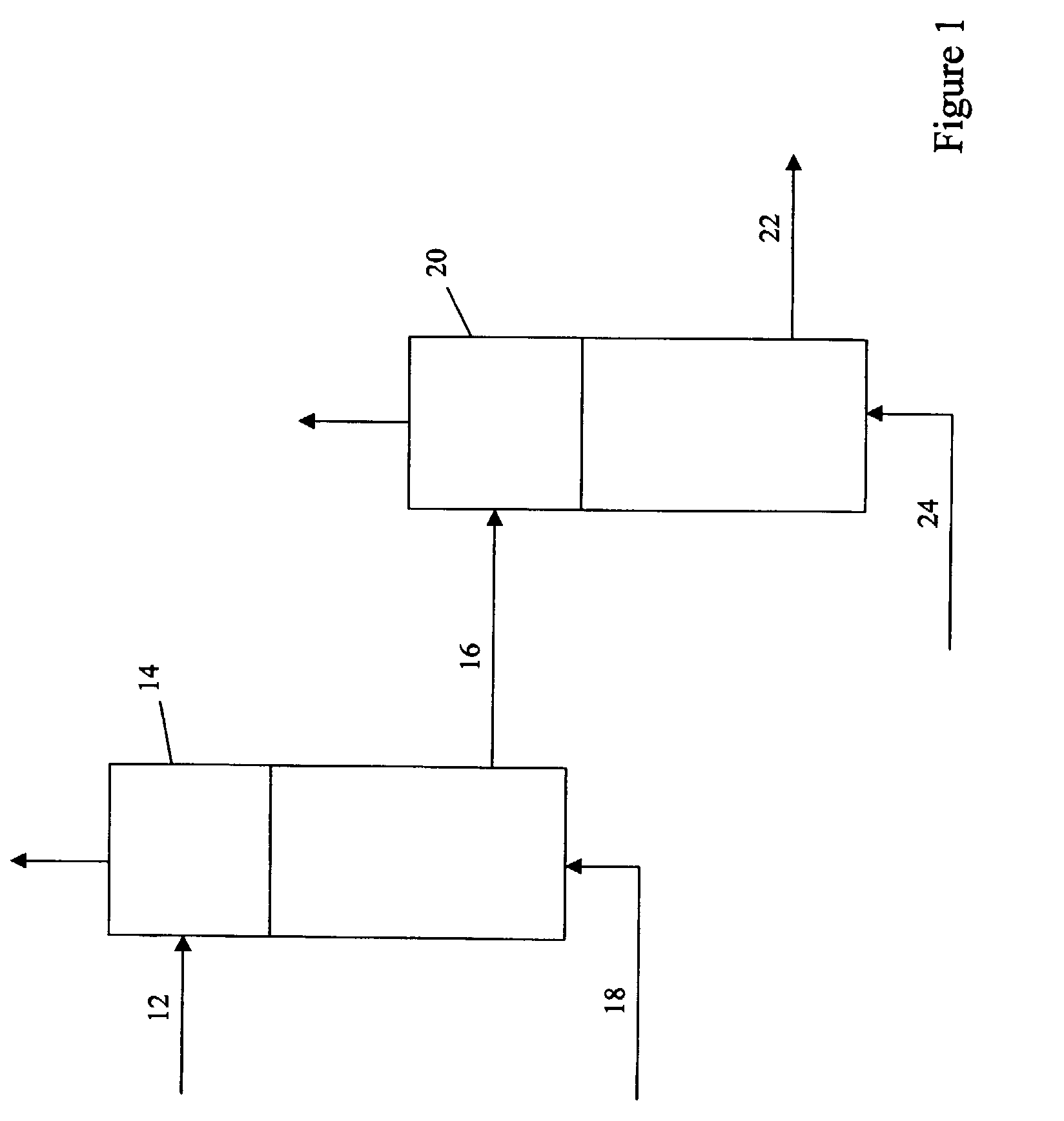

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

Integrated system and method for producing fuel composition from biomass

InactiveUS20090259082A1Reduce formationHydrocarbon by isomerisationCombustible gas catalytic treatmentThermodynamicsProcess engineering

A method of producing a fuel composition from a bio-oil feedstock is provided, wherein the bio-oil feedstock is subjected to a step of oil extraction to produce a bio-oil and deoiled residue. At least a portion of the deoiled residue is gasified to produce a hydrogen-containing gas. The bio-oil is subjected to an upgrading process to ultimately produce a fuel composition. At least a part of the hydrogen-containing gas produced in the gasification of deoiled residue is used in the upgrading process of producing a fuel composition. The upgrading process, which can involve hydro-treating, hydroisomerization and at least one separation step, produces light hydrocarbons in addition to the product fuel composition. The light hydrocarbons can be used in the gasification operation, e.g., to reduce tar formation.

Owner:GENERAL ELECTRIC CO

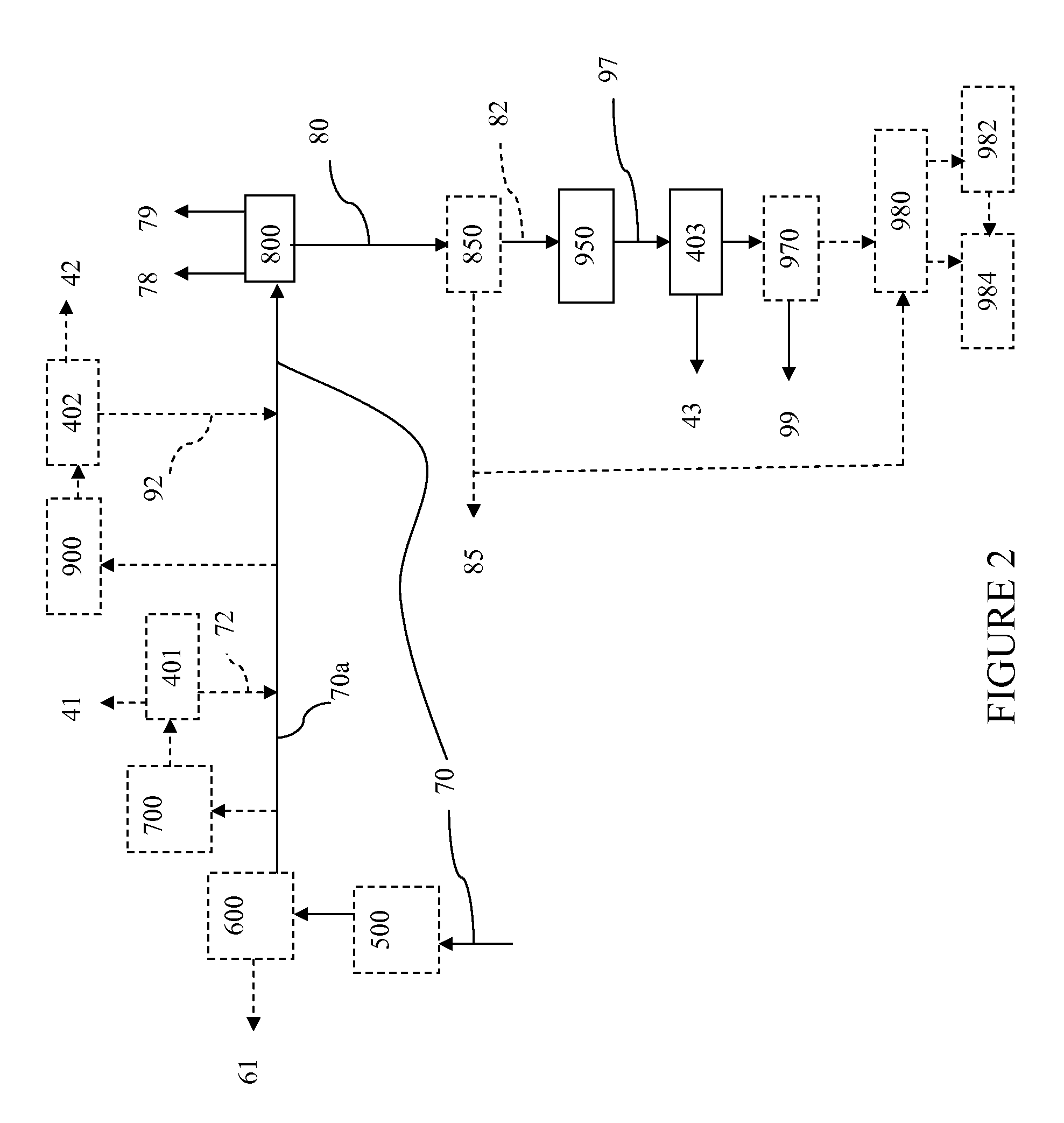

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287835A1Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationMethanationOrganic chemistry

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

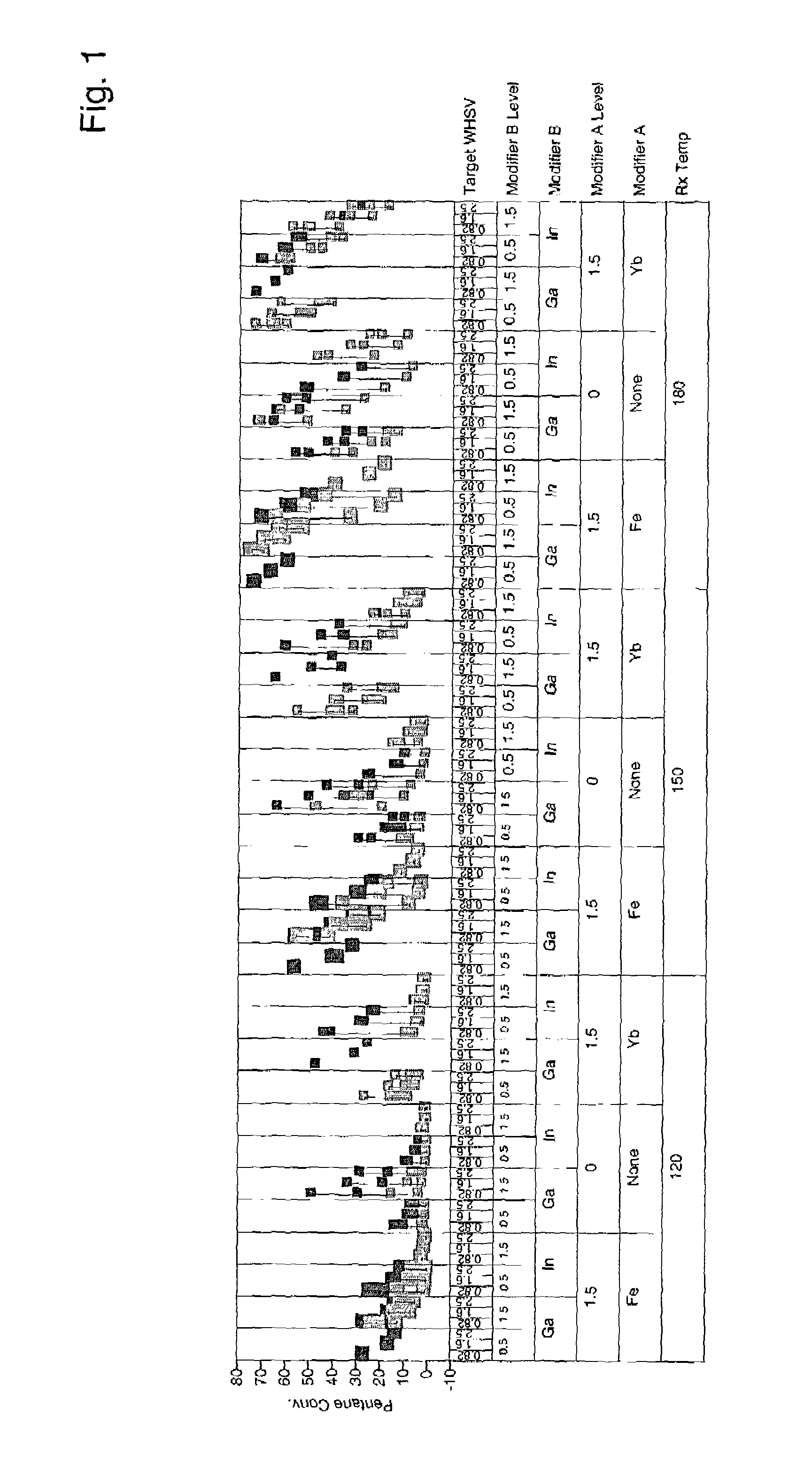

Solid-acid isomerization catalyst and process

ActiveUS7041866B1Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component comprising at least one Group III A (IUPAC 13) component, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

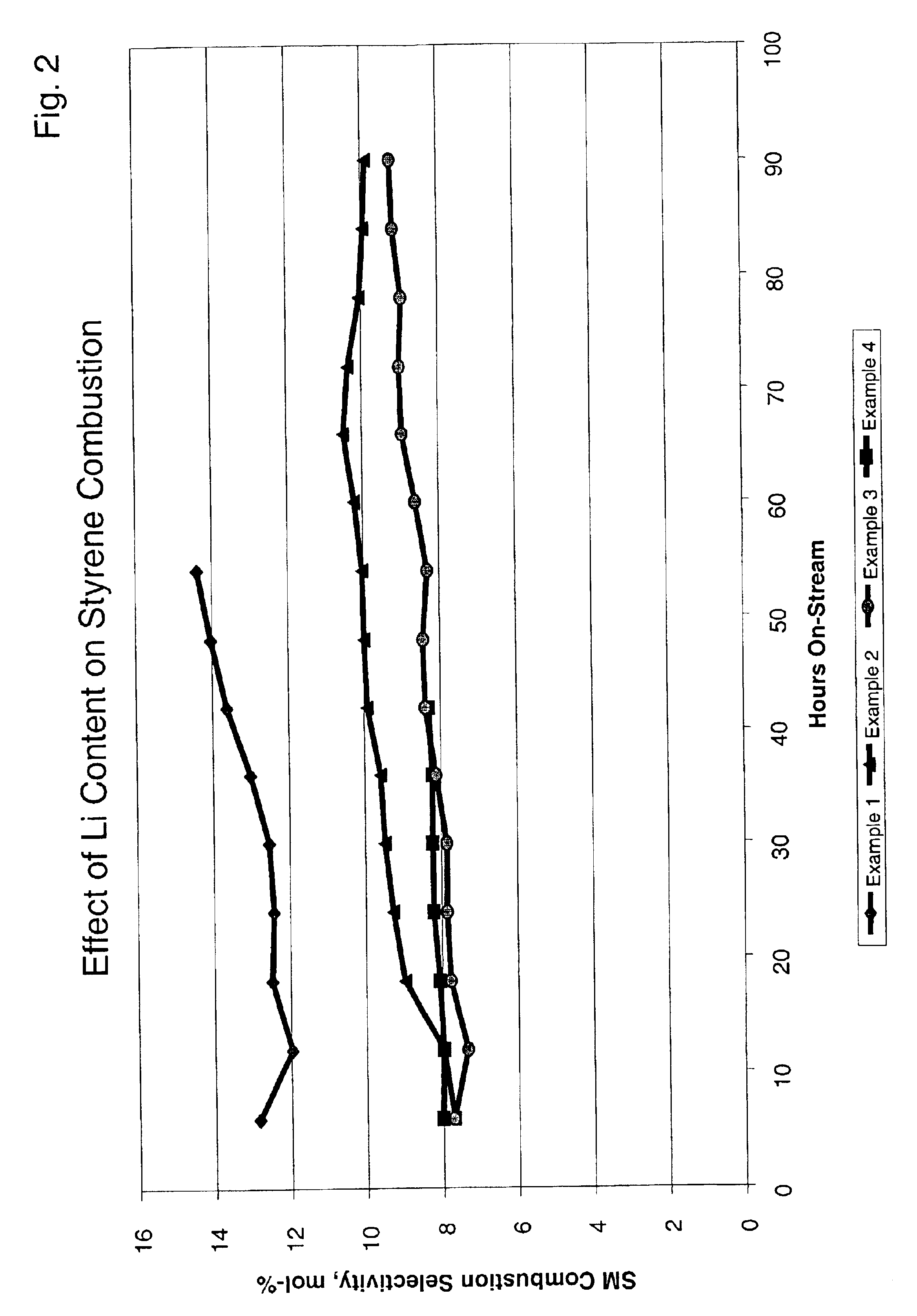

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

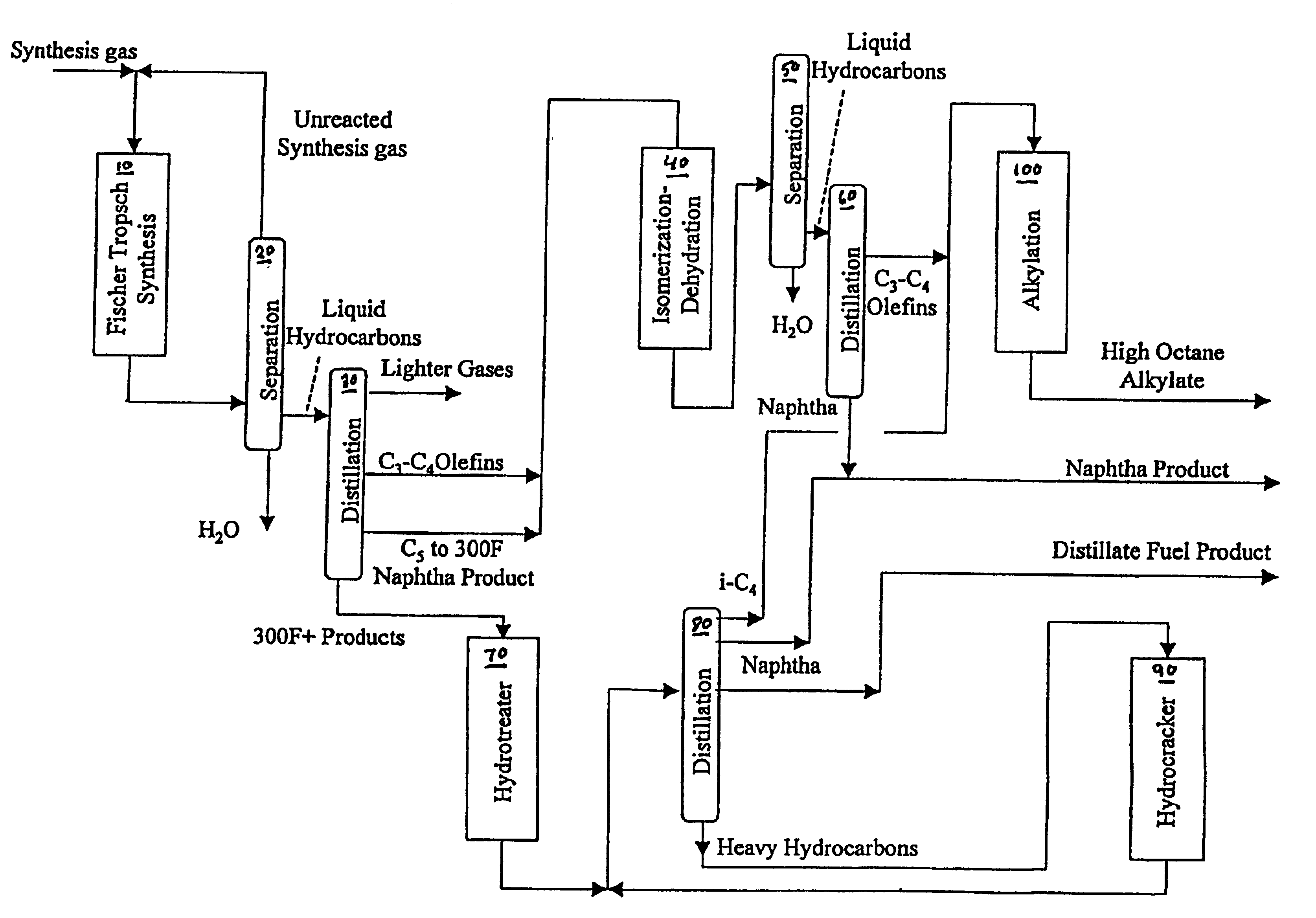

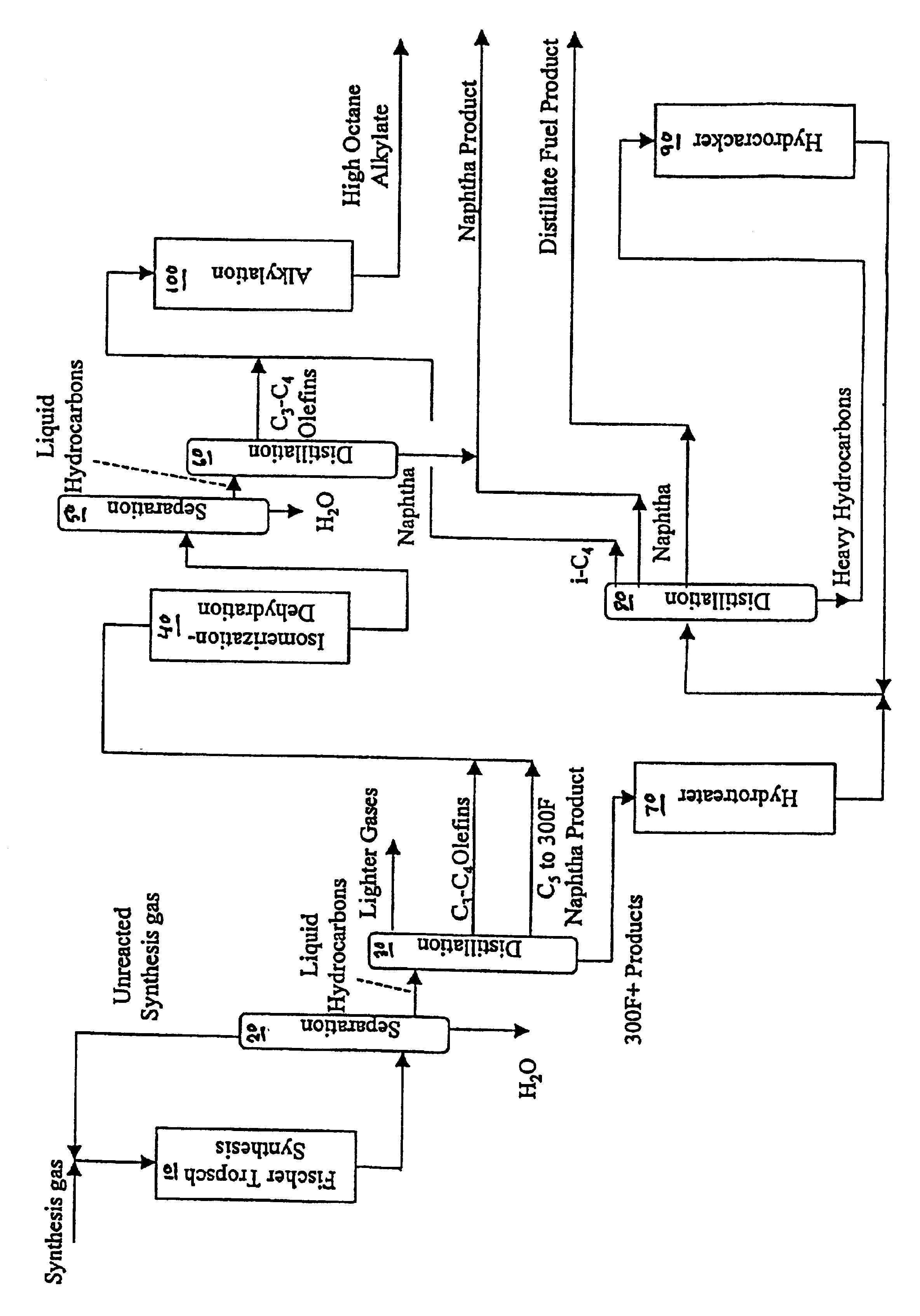

Manufacture of high octane alkylate

InactiveUS6768035B2Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

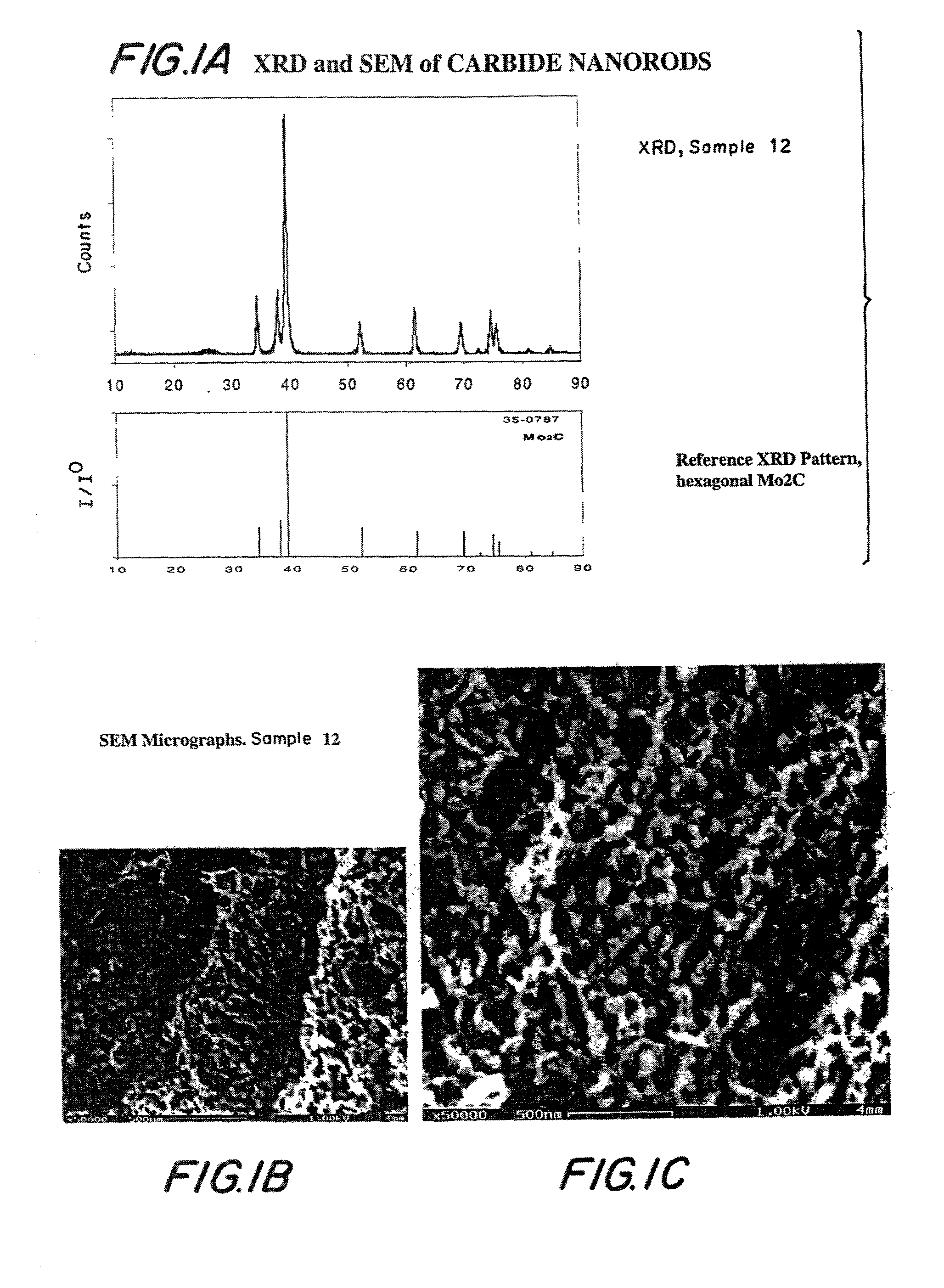

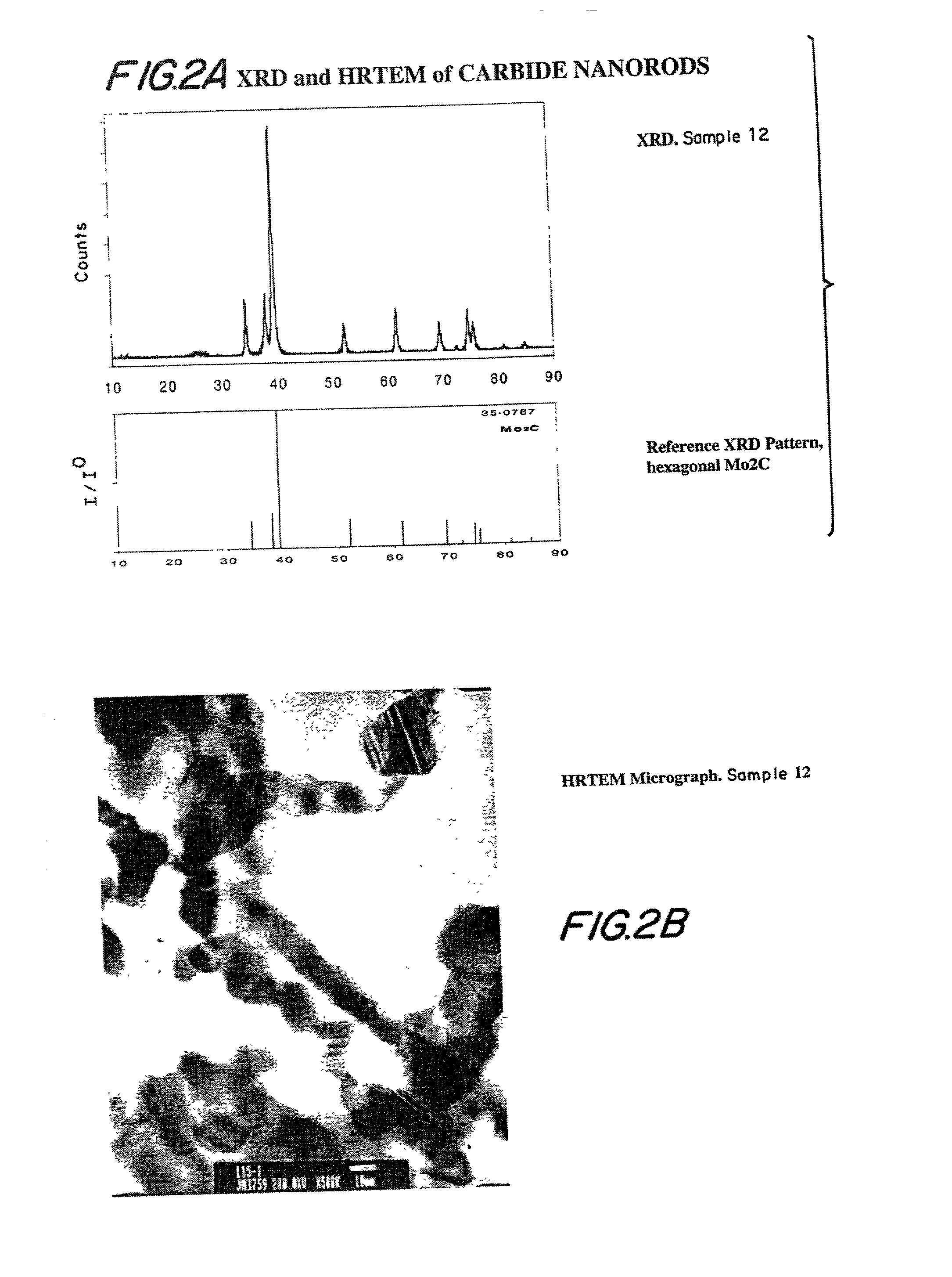

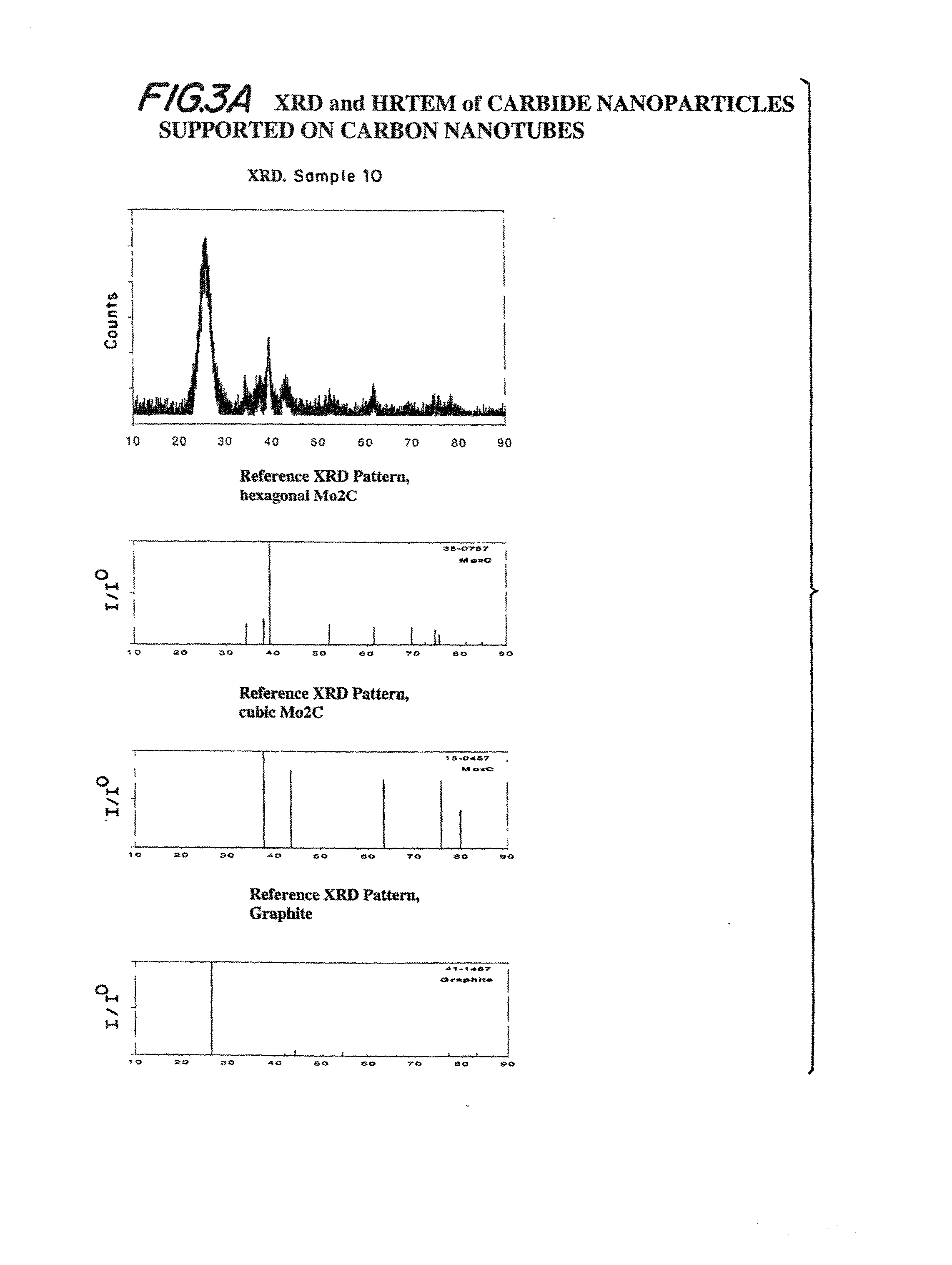

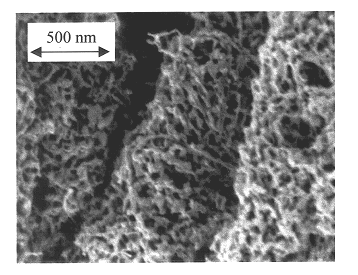

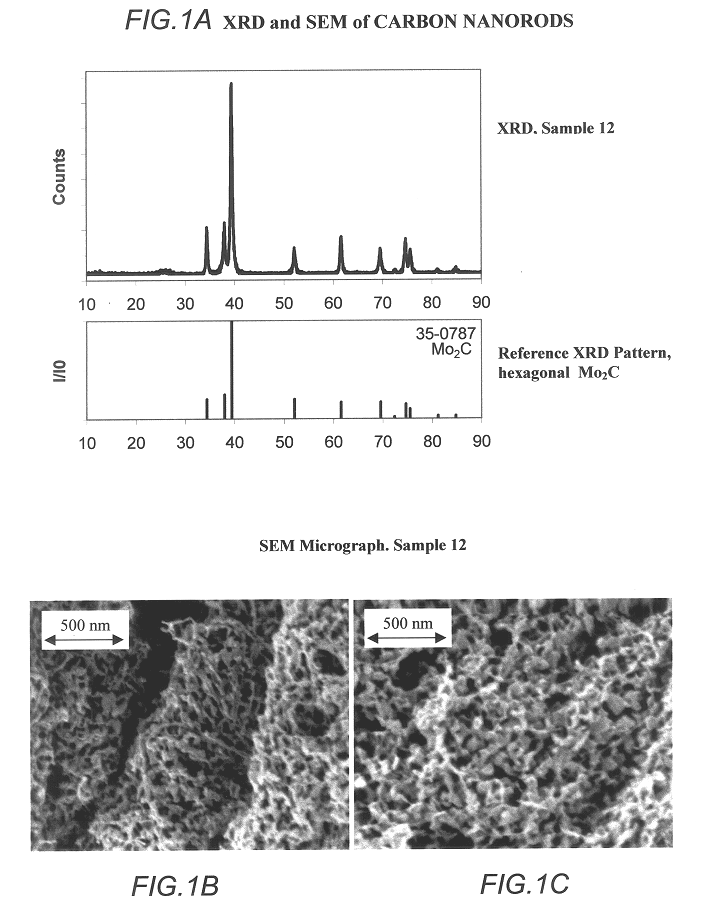

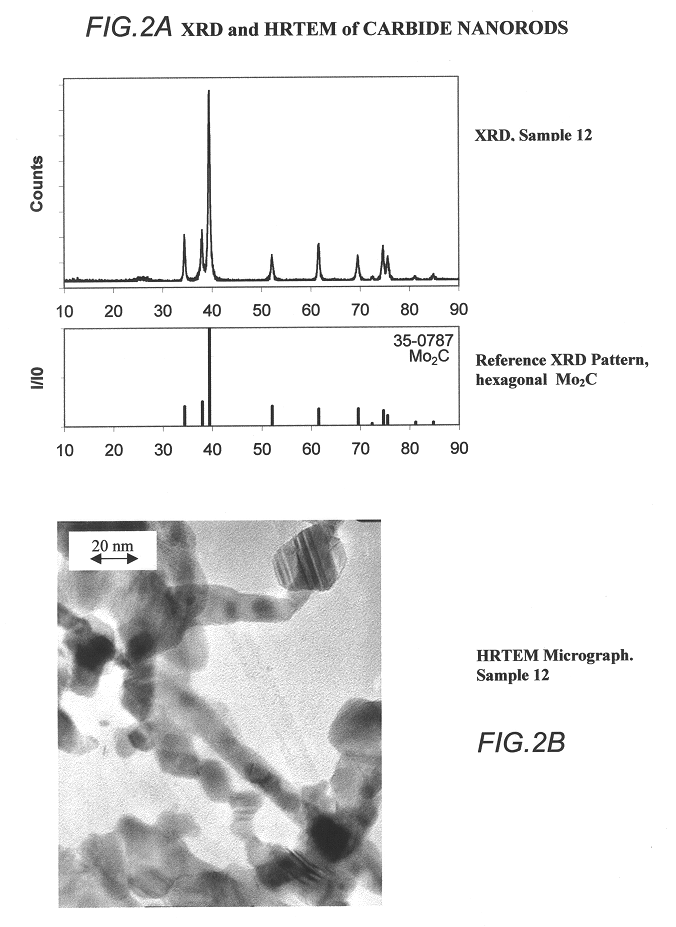

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

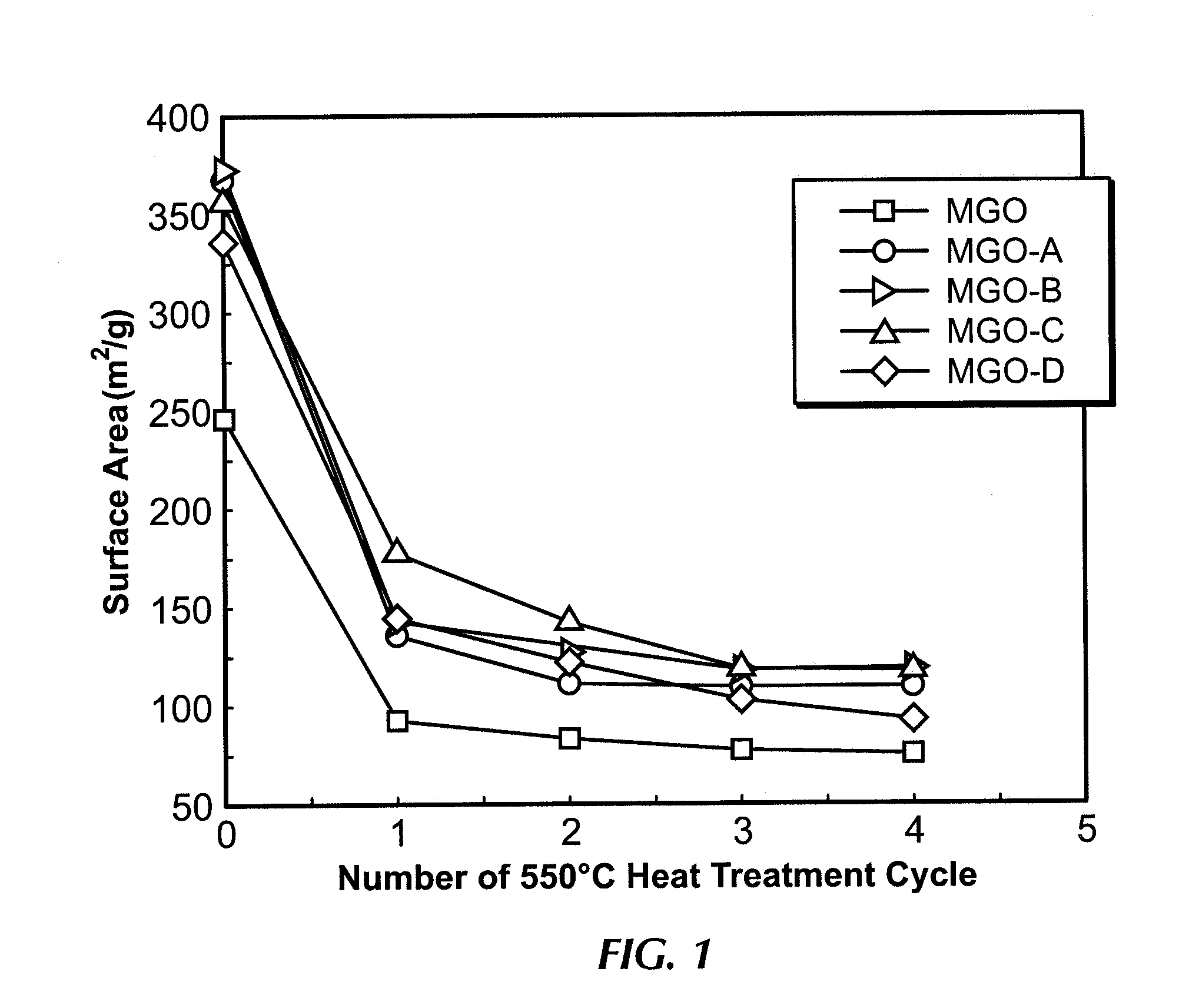

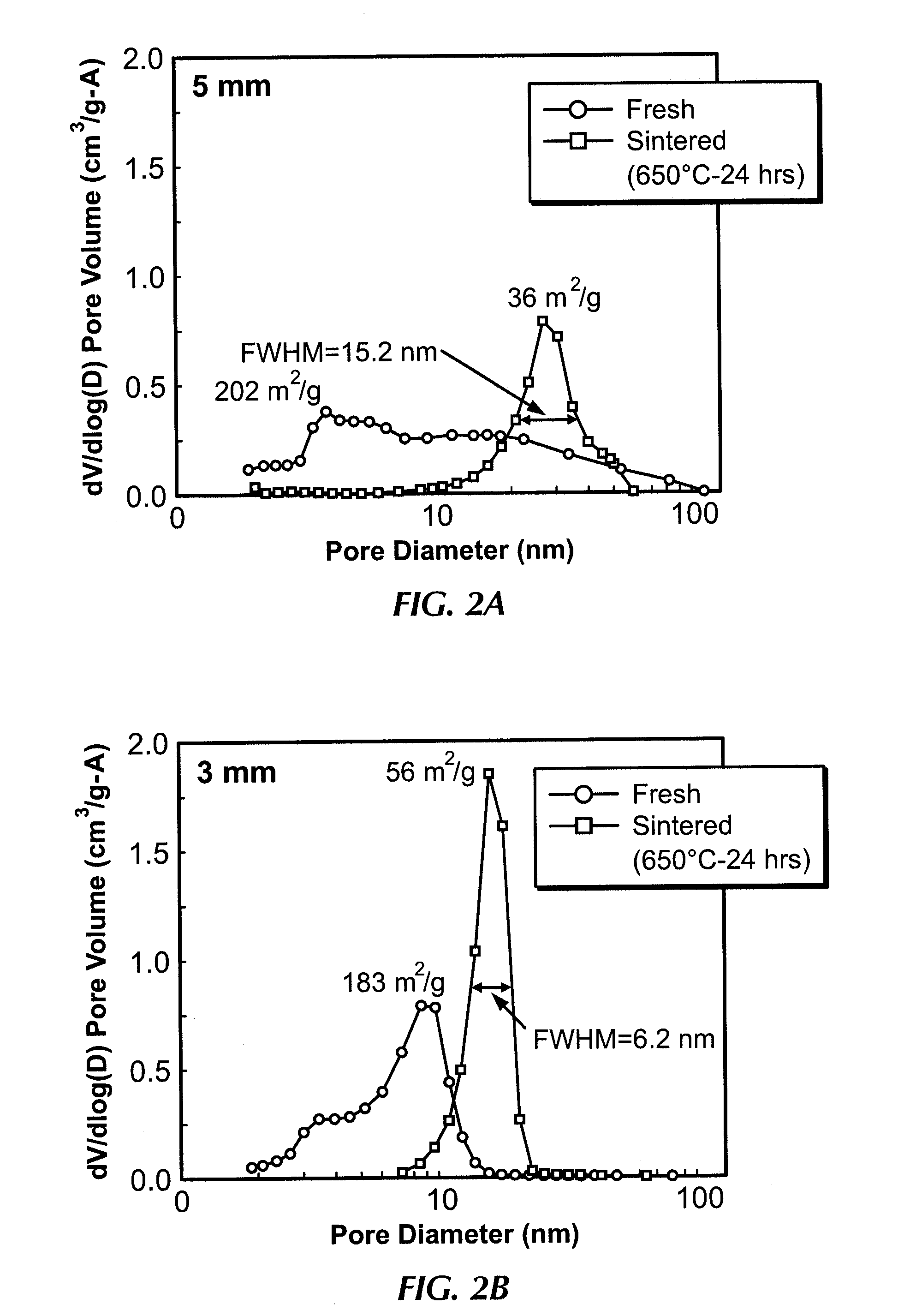

Olefin isomerization process

InactiveUS6875901B2High catalytic activityHydrocarbon by isomerisationPhysical/chemical process catalystsButeneIsomerization

An olefin isomerization process employs a basic metal oxide catalyst, such as magnesium oxide, which retains at least about 85 percent of its initial activity for at least about 168 hours of on-stream time. The catalyst is preferably a high purity magnesium oxide. The olefin isomerization process and catalyst described herein are advantageously used for the production of a terminal olefin such as 1-butene from an internal olefin such as 2-butene.

Owner:ABB LUMMUS GLOBAL INC

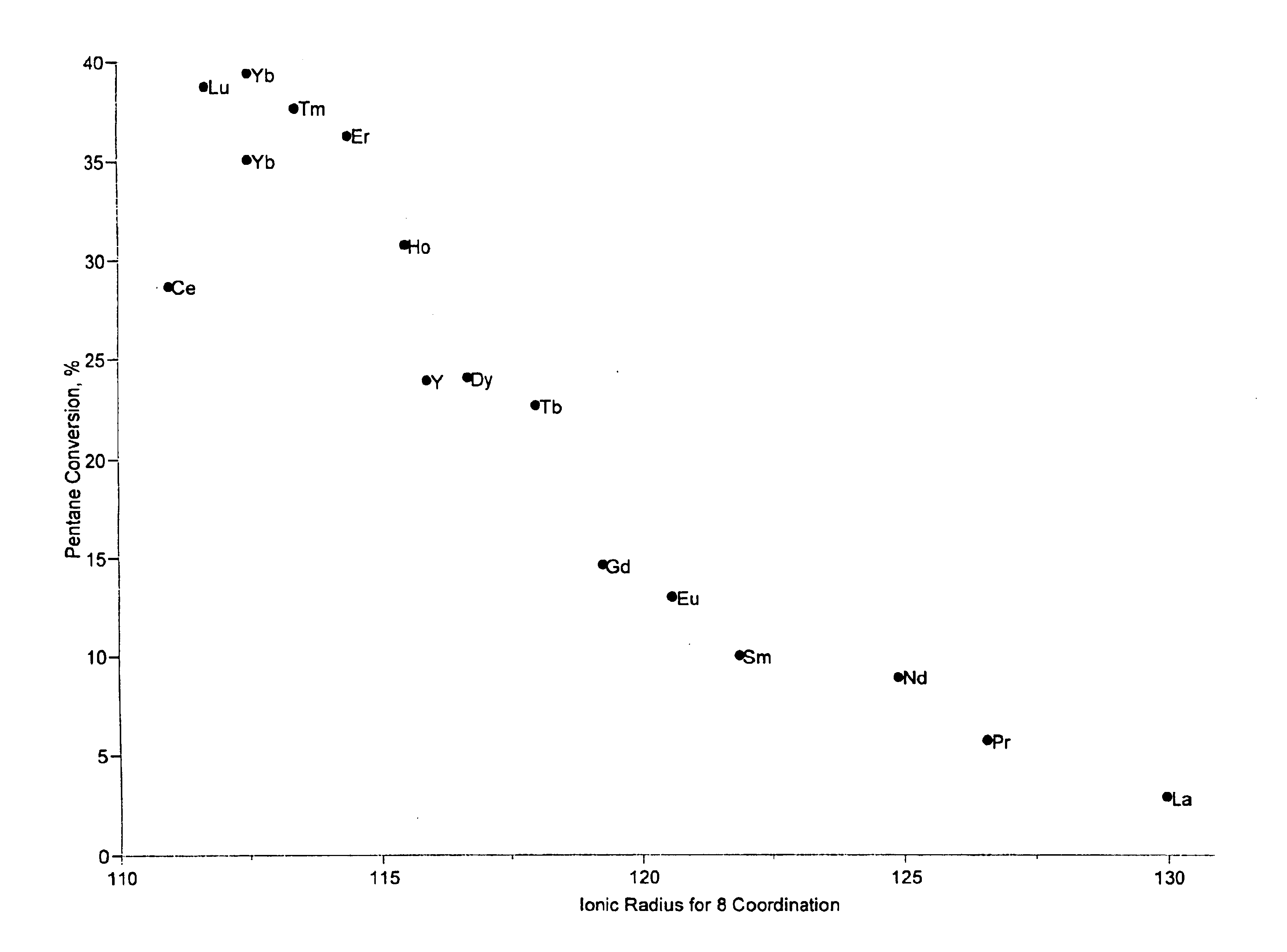

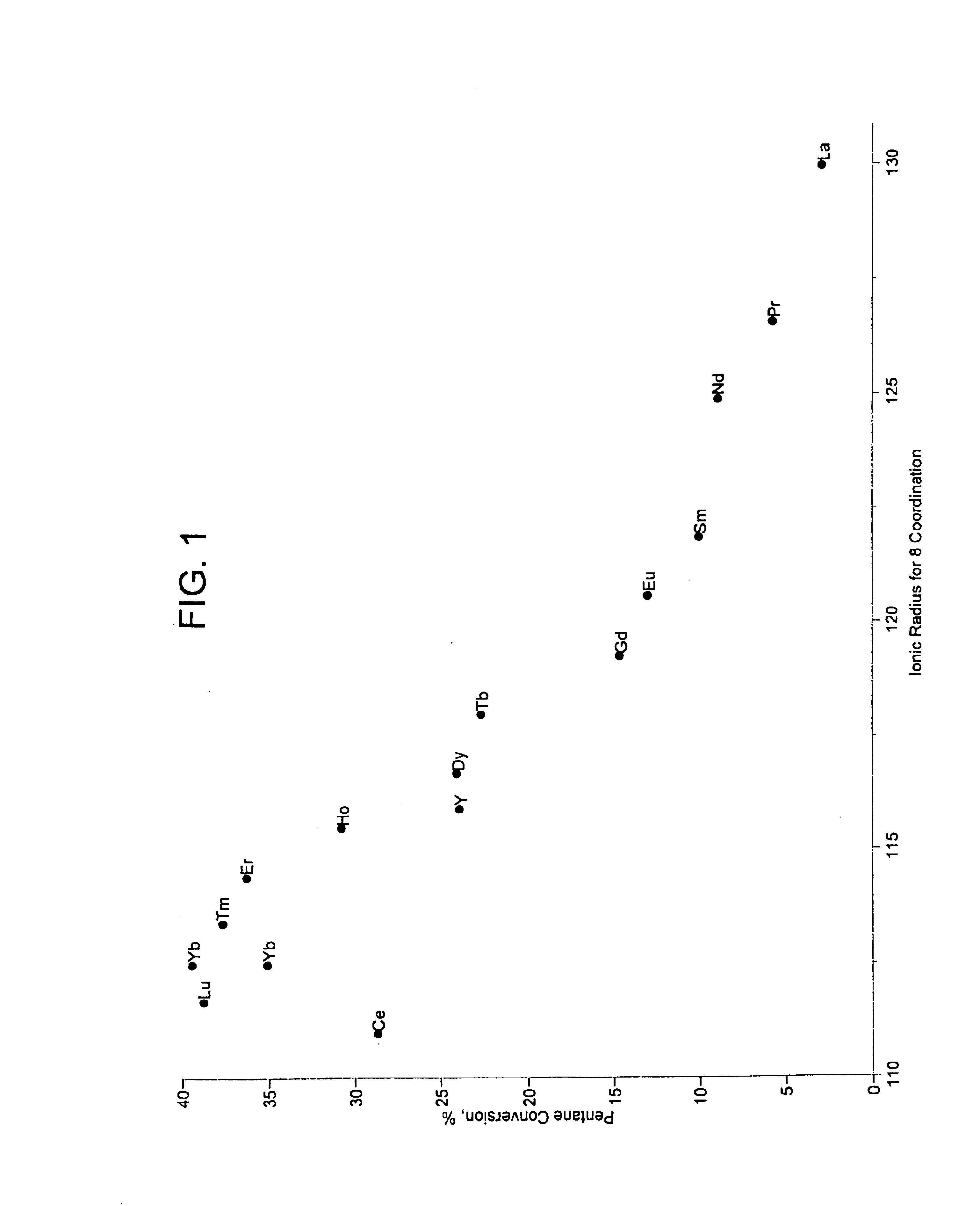

Isomerization catalyst and processes

InactiveUS6977322B2Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneIsomerization

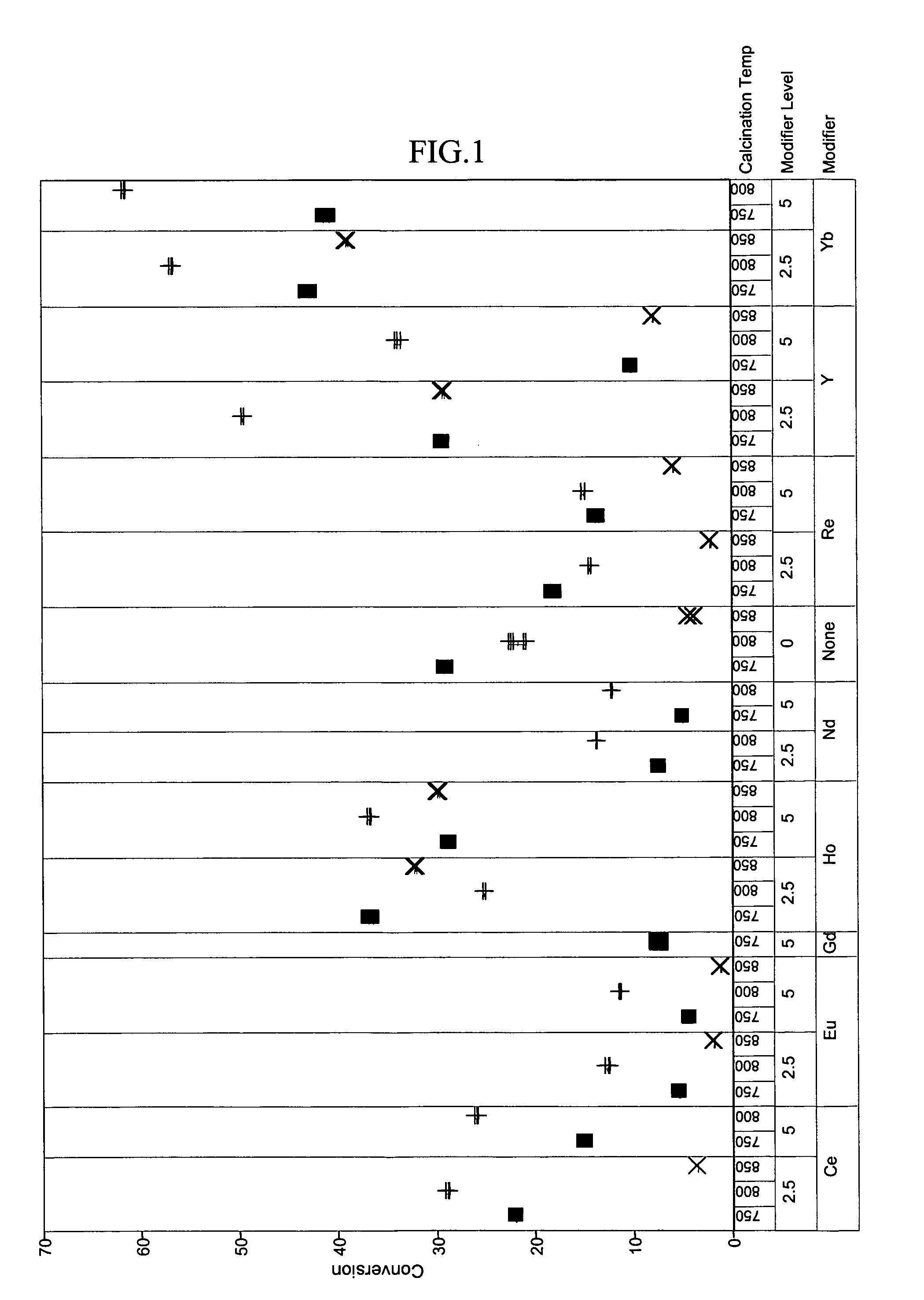

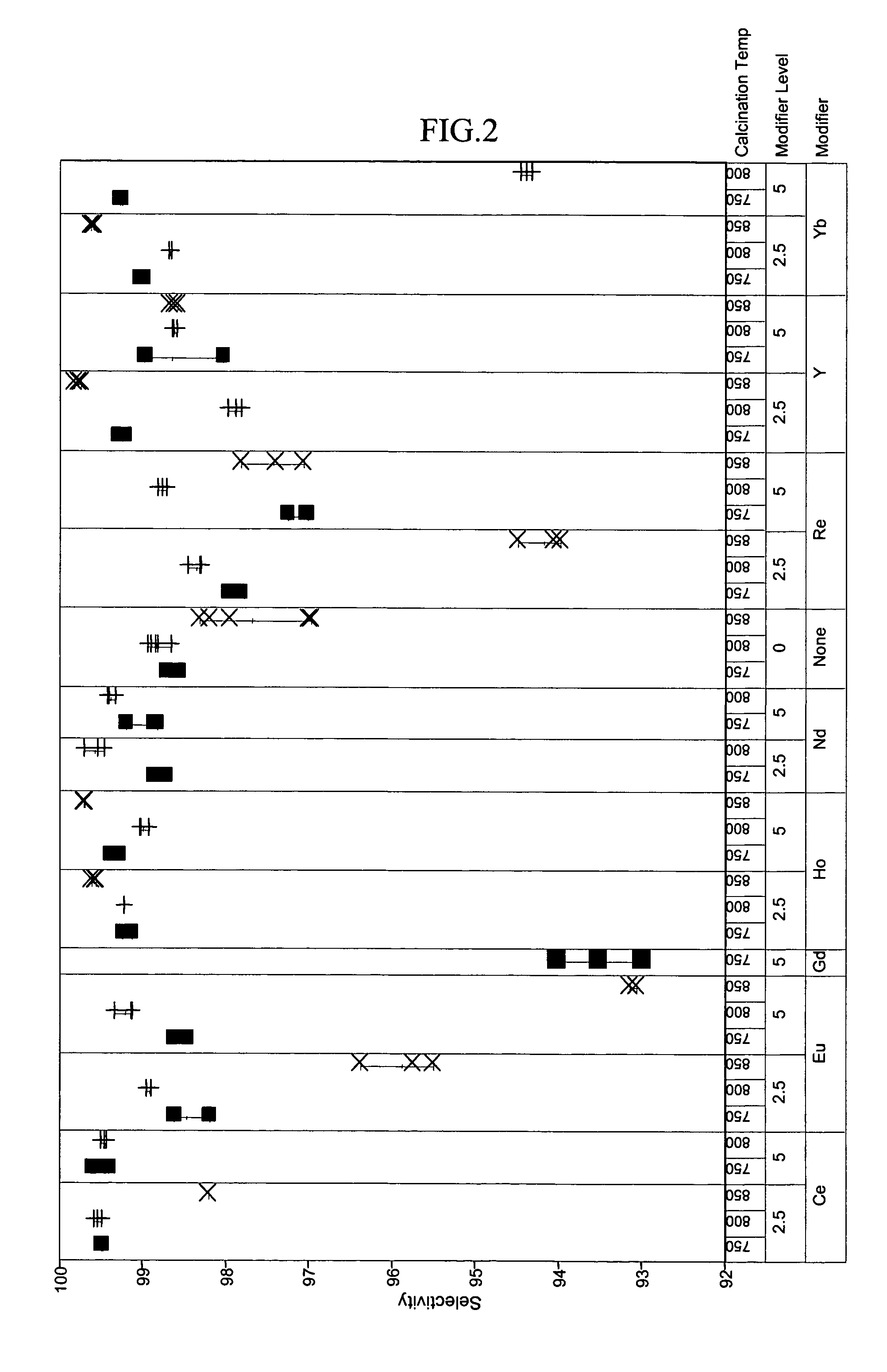

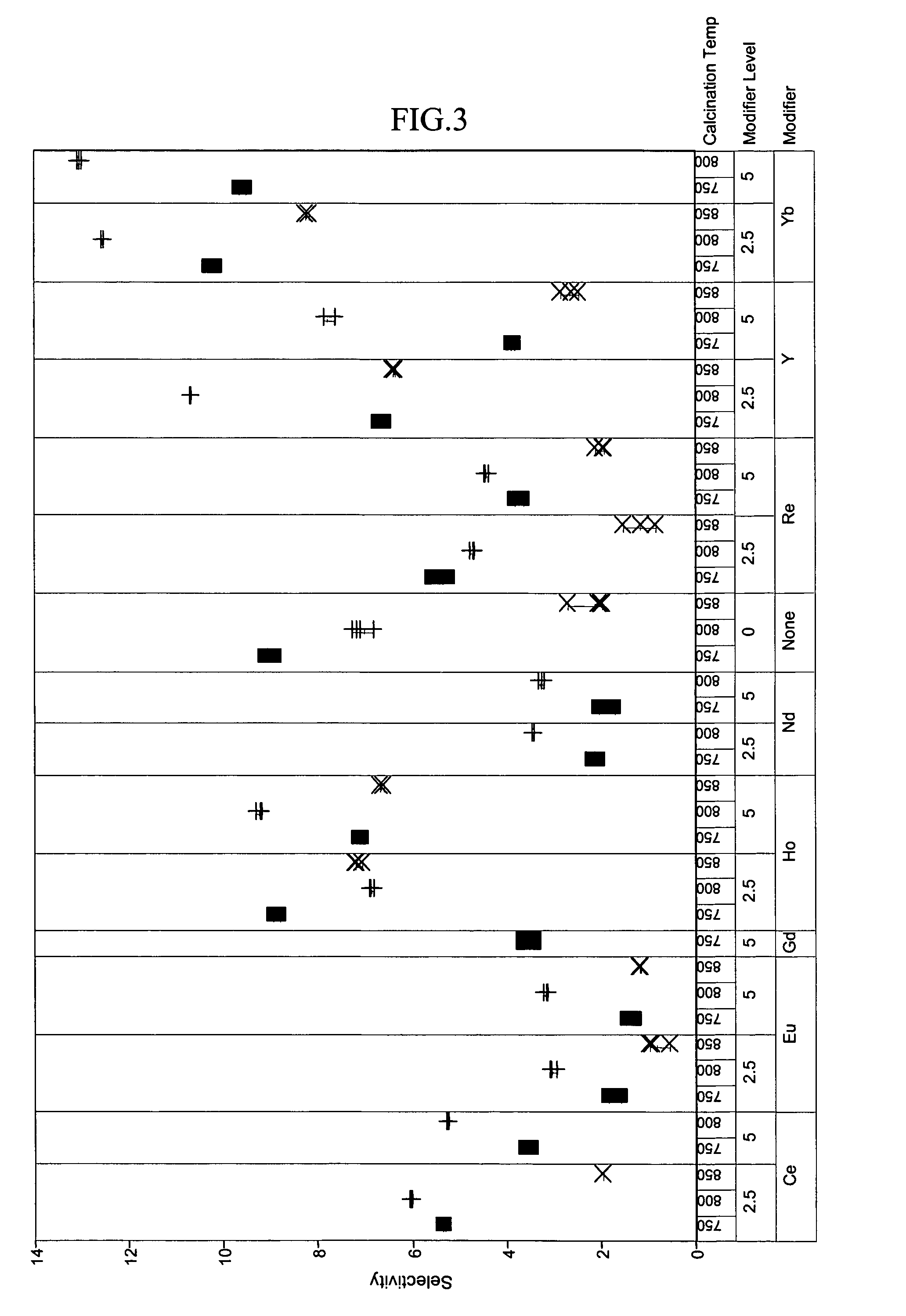

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a tungstated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element, yttrium or mixtures thereof, which is preferably ytterbium or holmium, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

Selective xylenes isomerization and ethylbenzene conversion

This invention is drawn to a process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene using an oil-dropped catalyst comprising a zeolite, a platinum-group metal and an aluminophosphate binder, resulting in a greater yield of para-xylene at favorable conditions compared to processes of the known art.

Owner:UOP LLC

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

High-activity isomerization catalyst and process

InactiveUS6881873B2Improve performanceImprove stabilityThermal non-catalytic crackingHydrocarbon by isomerisationAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element or yttrium component, which is preferably ytterbium, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

Distillate fuel blends from Fischer Tropsch products with improved seal swell properties

InactiveUS6890423B2Hydrocarbon by isomerisationCatalytic naphtha reformingPolymer scienceEngineering

The invention provides distillate fuel blend components with improved seal swell and lubricity properties obtained from Fischer Tropsch products. The blends contain a highly paraffinic distillate fuel component and distillate-boiling alkylcycloparaffins and / or distillate-boiling alkylaromatics. The invention further provides processes for obtaining such blends using the products of Fischer Tropsch processes. Finally, the invention provides methods for improving seal swell and lubricity properties for distillate fuels.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Process for producing cumene

InactiveUS6888037B2Hydrocarbon by isomerisationMolecular sieve catalystMolecular sieveAlkyl transfer

A process for producing cumene is provided which comprises the step of contacting benzene and propylene under at least partial liquid phase alkylating conditions with a particulate molecular sieve alkylation catalyst, wherein the particles of said alkylation catalyst have a surface to volume ratio of about 80 to less than 200 inch−1.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for metathesis of ethylene and 2-butene and/or double bond isomerization

ActiveUS20110021858A1Hydrocarbon by isomerisationHydrocarbon purification/separationDouble bondChemistry

A process for the double-bond isomerization of olefins is disclosed. The process may include contacting a fluid stream comprising olefins with a fixed bed comprising an activated basic metal oxide isomerization catalyst to convert at least a portion of the olefin to its isomer. The isomerization catalysts disclosed herein may have a reduced cycle to cycle deactivation as compared to conventional catalysts, thus maintaining higher activity over the complete catalyst life cycle.

Owner:LUMMUS TECH INC

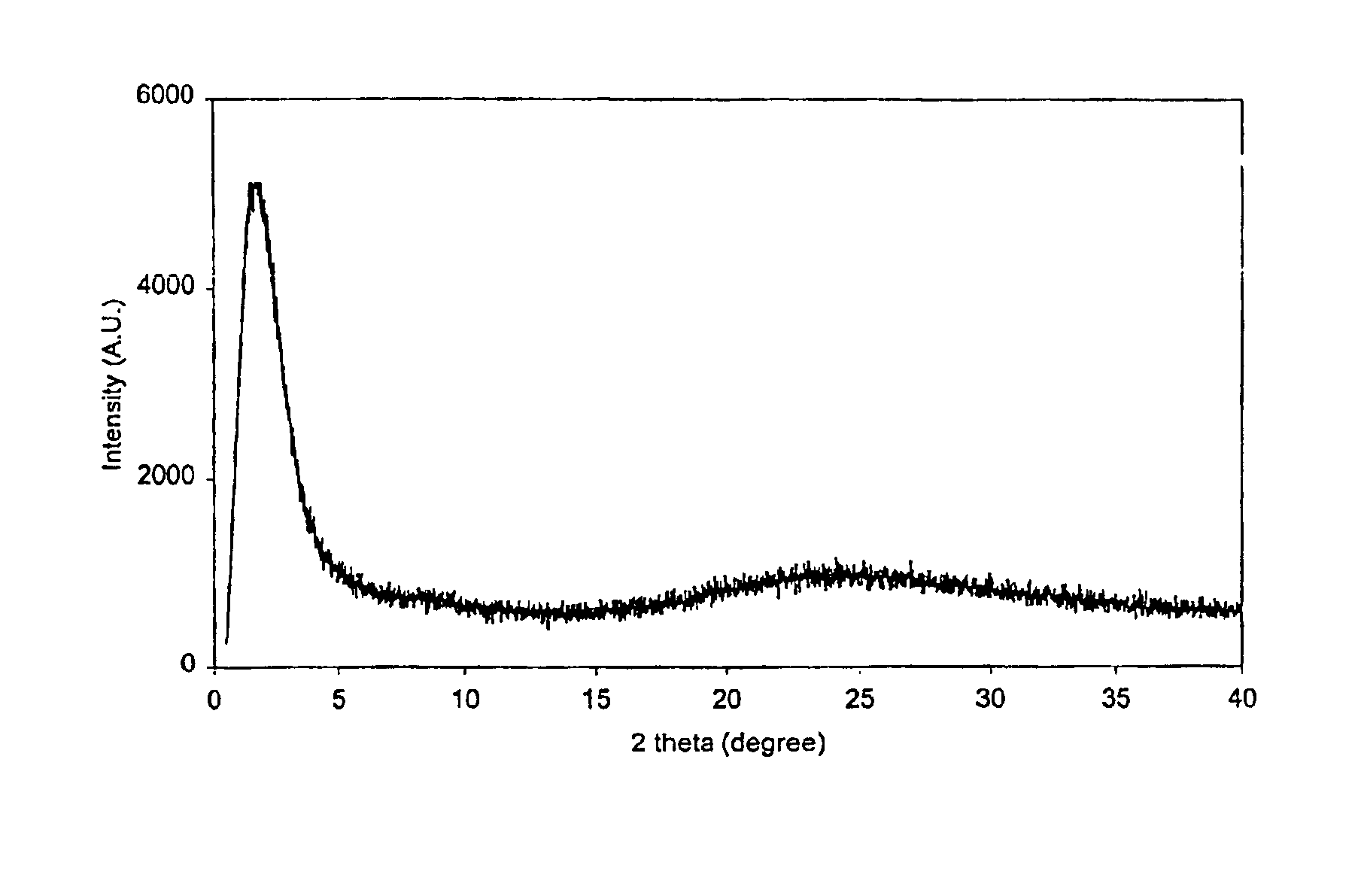

Mesoporous material with active metals

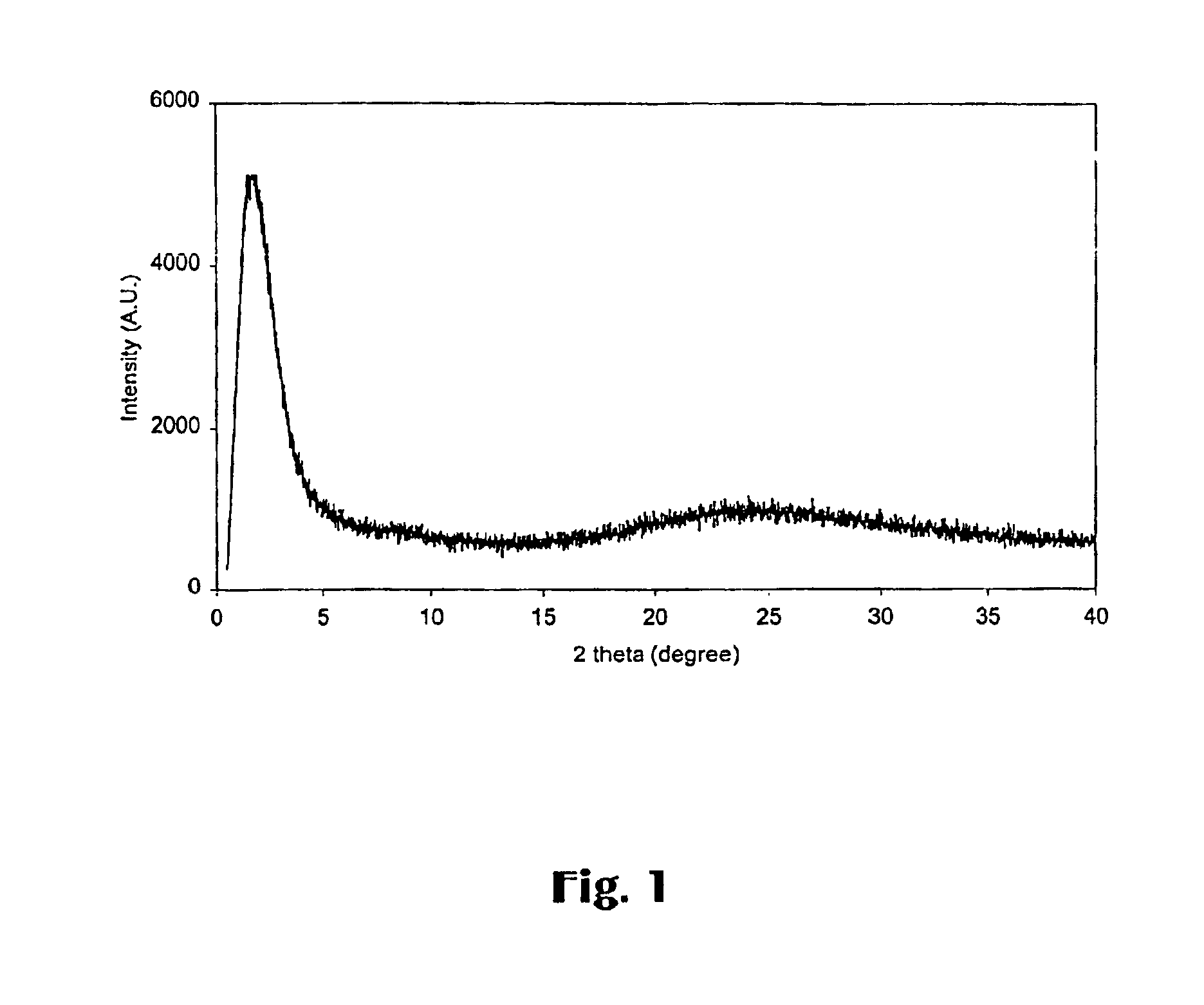

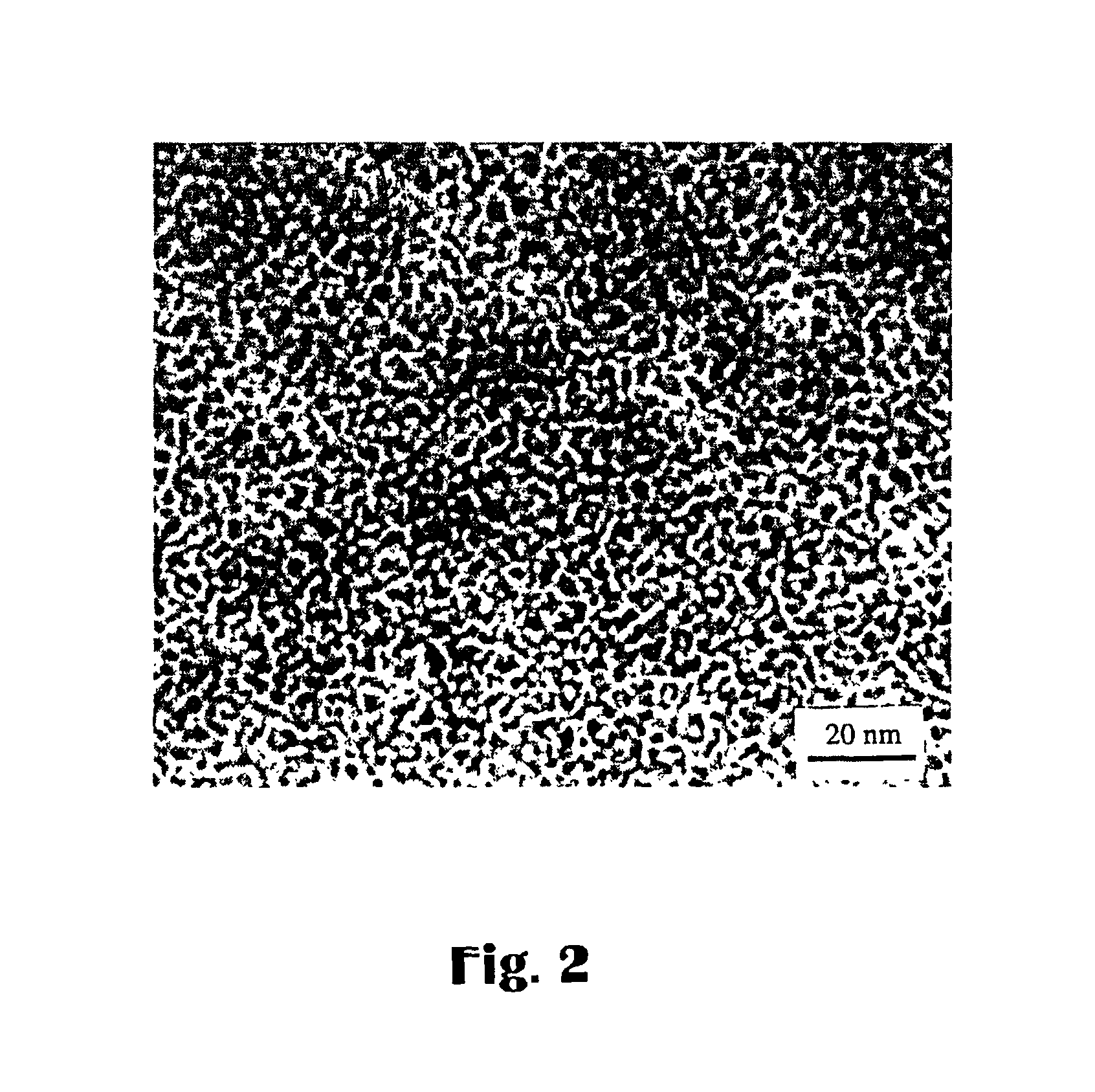

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

Hydrocarbon conversion processes using non-zeolitic molecular sieve catalysts

Hydrocarbon or oxygenate conversion process in which a feedstock is contacted with a non zeolitic molecular sieve which has been treated to remove most, if not all, of the halogen contained in the catalyst. The halogen may be removed by one of several methods. One method includes heating the catalyst in a low moisture environment, followed by contacting the heated catalyst with air and / or steam. Another method includes steam-treating the catalyst at a temperature from 400° C. to 1000° C. The hydrocarbon or oxygenate conversion processes include the conversion of oxygenates to olefins, the conversion of oxygenates and ammonia to alkylamines, the conversion of oxygenates and aromatic compounds to alkylated aromatic compounds, cracking and dewaxing.

Owner:EXXONMOBIL CHEM PAT INC

Production of monocycloalkyl aromatic compounds

There is described a process for the transalkylation of a polycycloalkyl aromatic compound, particularly the transalkylation of dicyclohexylbenzene to produce monocyclohexylbenzene. The process comprises contacting the polycycloalkyl aromatic compound with benzene in the presence of a catalyst selected from the group consisting of an acidic solid comprising a Group IVB metal oxide modified with an oxyanion of a Group VIBA metal oxide, TEA-mordenite, zeolite beta and a porous crystalline material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom. Preferably the catalyst is a WOx / ZrO2 material.

Owner:EXXONMOBIL CORP (US)

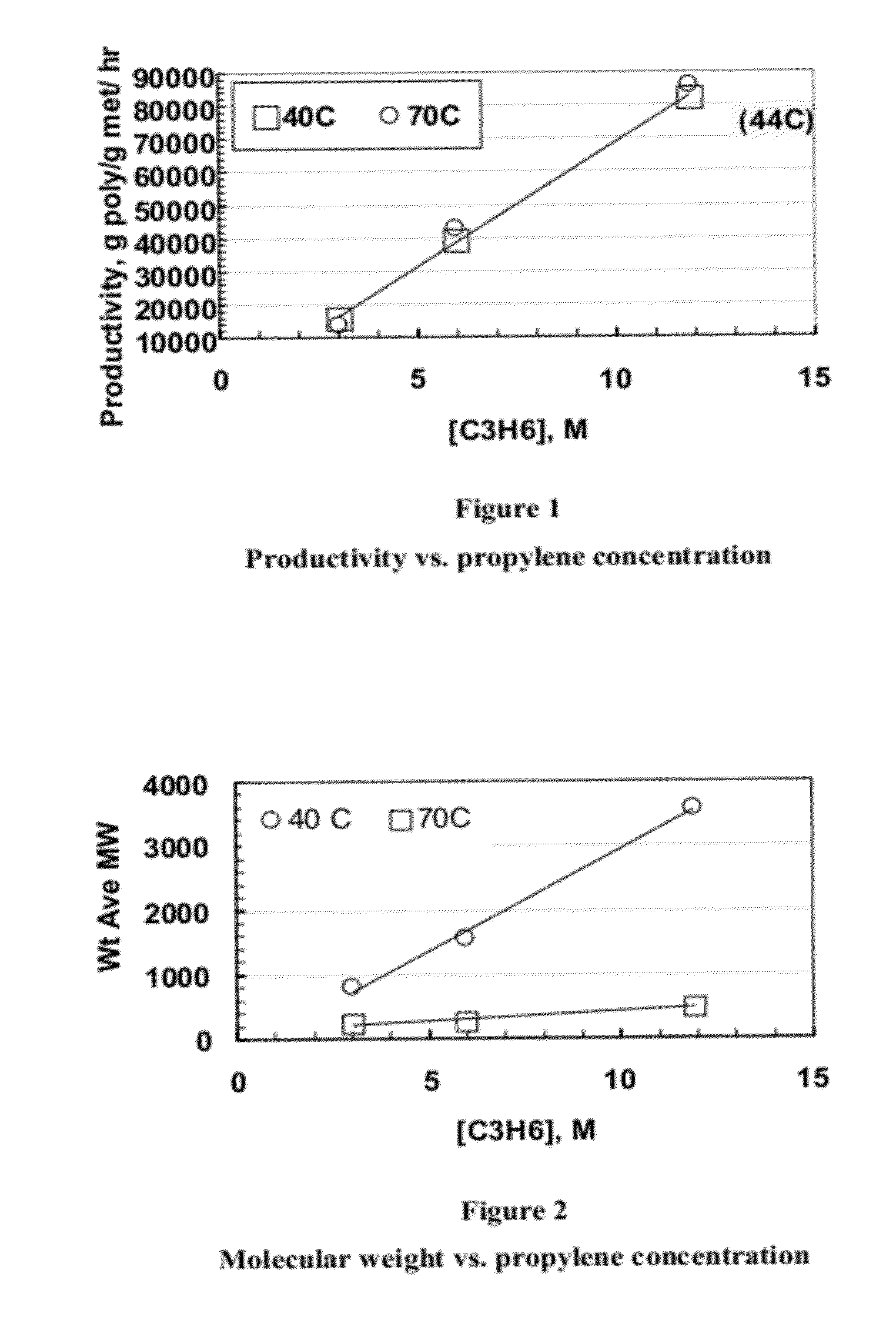

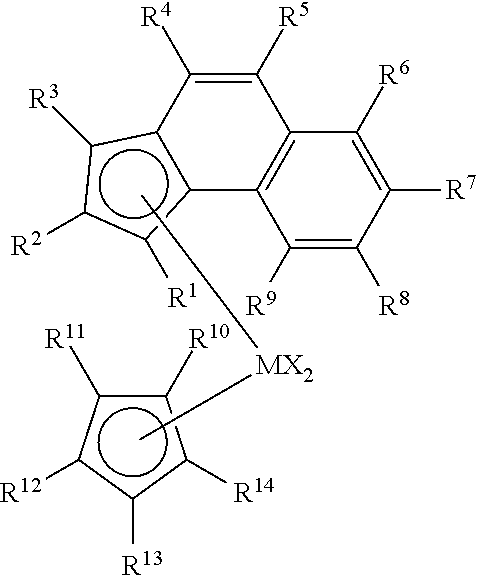

Enhanced catalyst performance for production of vinyl terminated propylene and ethylene/propylene macromers

ActiveUS8318998B2Hydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

This invention relates to a transition metal catalyst compound represented by the structure:whereinM is hafnium or zirconium;each X is, independently, selected from the group consisting of hydrocarbyl radicals having from 1 to 20 carbon atoms, hydrides, amides, alkoxides, sulfides, phosphides, halogens, dienes, amines, phosphines, ethers, or a combination thereof;each R1 and R3 are, independently, a C1 to C8 alkyl group; andeach R2, R4, R5, R6, R7, R8, R9, R10, R11, R12, R13, and R14 are, independently, hydrogen, or a substituted or unsubstituted hydrocarbyl group having from 1 to 8 carbon atoms, provided however that at least three of the R10-R14 groups are not hydrogen, compositions thereof and methods of use thereof to prepare polymers.

Owner:EXXONMOBIL CHEM PAT INC

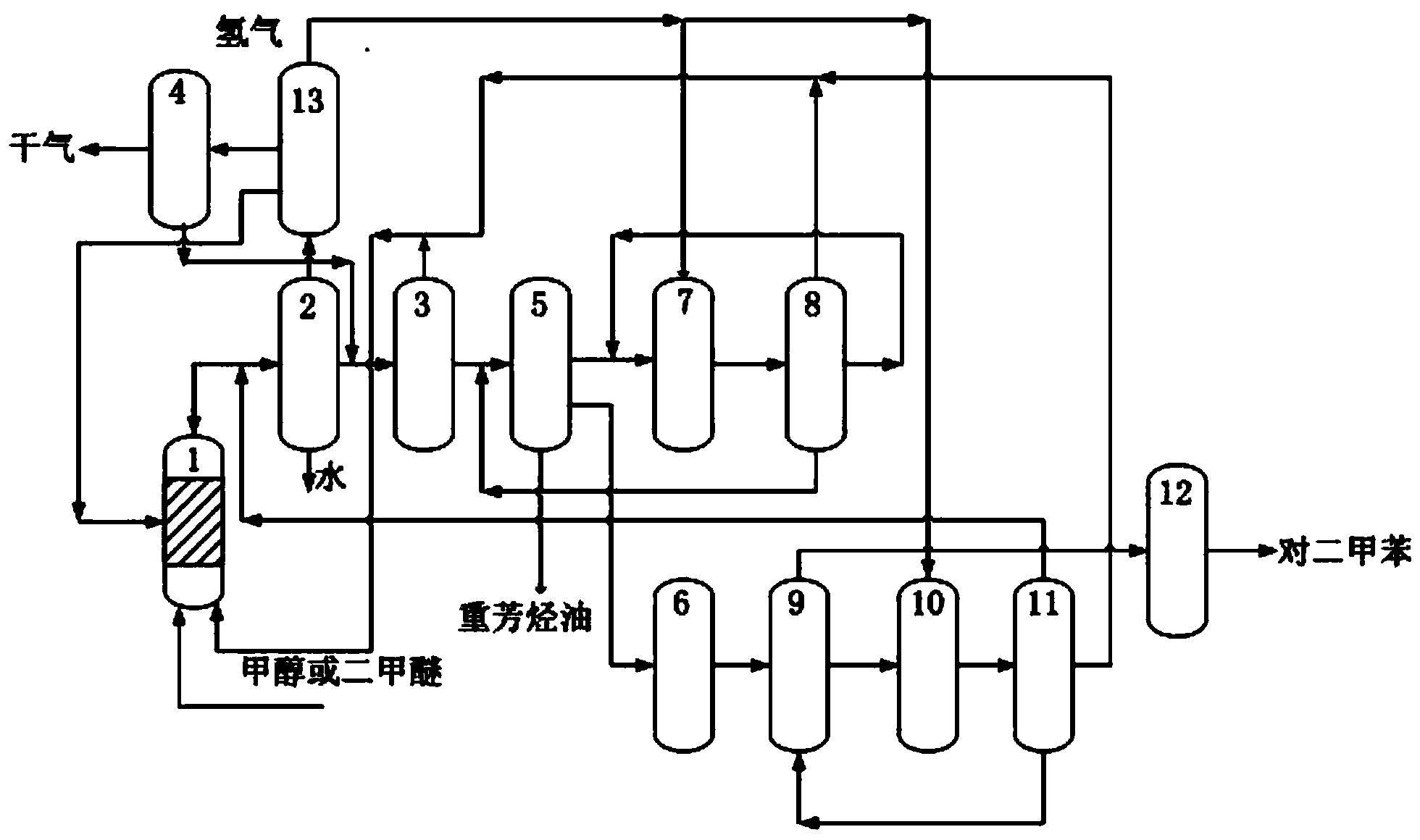

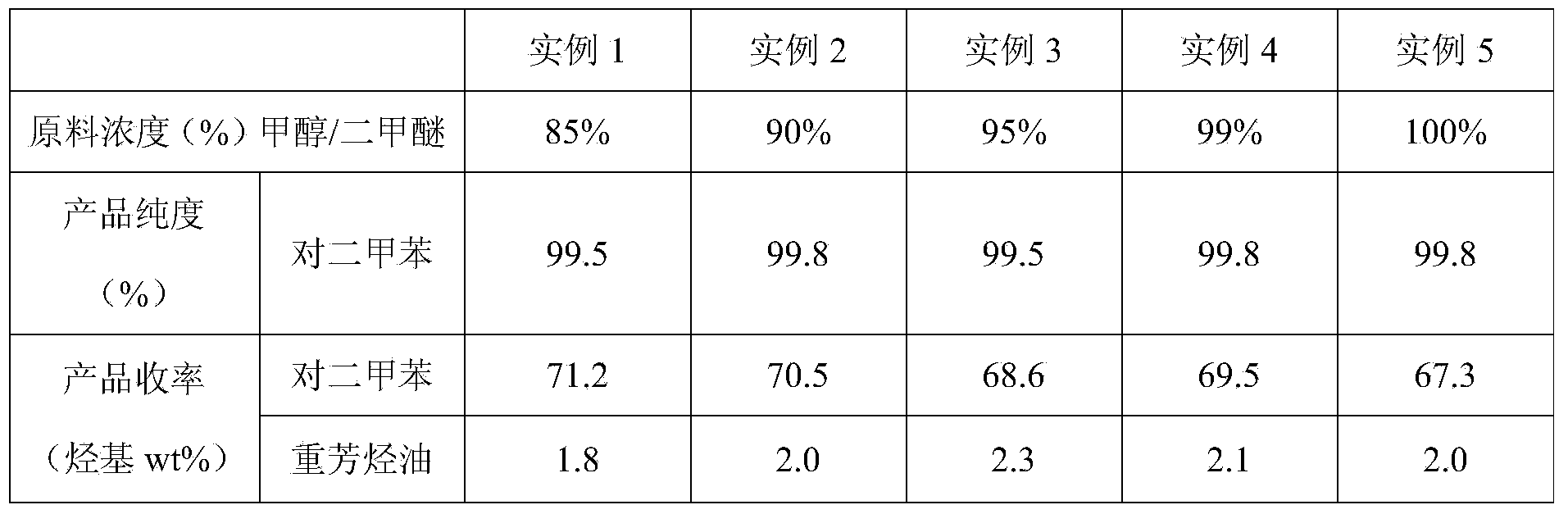

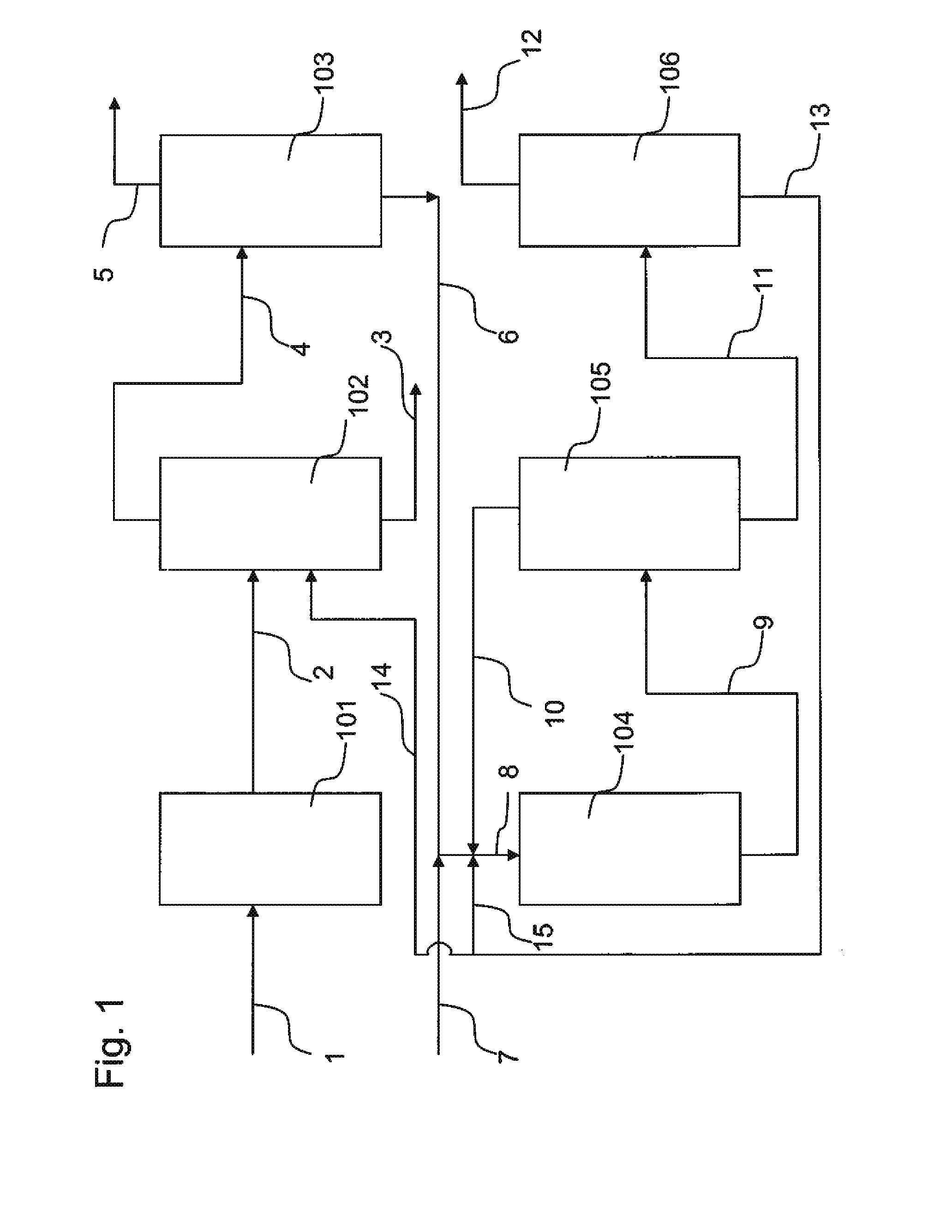

System and method of preparing paraxylene by alcohol/ether conversion

ActiveCN103864565AHigh yieldRaise the ratioHydrocarbon by isomerisationHydrocarbon from oxygen organic compoundsEtherThree-phase

The invention belongs to the field of craft processes of arene production devices, and particularly relates to a system and method of preparing paraxylene by alcohol / ether conversion. The system provided by the invention mainly consists of an alcohol / ether aromatization reaction device, a gas-liquid-liquid three phase separating device, a benzene fractional device, a paraxylene fractional device, an olefin-removing device, a paraxylene separating device and a paraxylene product tower. The yield of the paraxylene is increased by means of aromatization reaction of non-arene, alkylation reaction of benzene and disproportionated reaction of xylene and arene with more than 9 carbon atoms. By adopting an unclear separation technology of a product with less than 7 carbon atoms, an arene extraction system is canceled, the investment and energy consumption are greatly reduced, and gaseous phase hydrocarbon with more than 2 carbon atoms is fully utilized as a raw material of an alcohol / ether aromatization system. Hydrogen generated is used for disproportionation of C9 methyl arene and C10 methyl arene and isomerization reaction of C8 arene. The system and method have the advantages of self supply of raw materials, less investment, low energy consumption, short flow and high yield of paraxylene.

Owner:HUADIAN COAL IND GRP +1

Process of paraffin hydrocarbon isomerization catalysed by ionic liquids

InactiveUS20030109767A1Complicated processingComplicates technologyHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkaneIsomerization

A process for the conversion of paraffin hydrocarbon feed stock via skeletal isomerisation by contacting this feed with a catalyst comprised of an ionic liquid formed from an N-containing heterocyclic and / or N-containing aliphatic organic cation and an inorganic anion derived from metal halides.

Owner:HALDOR TOPSOE AS

Production of 1-Butene and Propylene From Ethylene

ActiveUS20120095275A1Reduce the amount requiredIncrease productionHydrocarbon by isomerisationHydrocarbons from unsaturated hydrocarbon additionEthylenePropene

A process for producing propylene and 1-butene is disclosed. The process comprises dimerizing ethylene in the presence of a dimerization catalyst to produce a dimerization mixture comprising 1-butene and 2-butenes. The dimerization mixture is distilled to produce a 1-butene stream containing 1-butene and ethylene, a 2-butenes stream, and a heavy stream. The 2-butenes stream is reacted with ethylene in the presence of a metathesis catalyst to produce a metathesis mixture comprising propylene, ethylene, and 2-butenes. Propylene is separated from the metathesis mixture.

Owner:EQUSR CHEM LP +1

Process for the manufacture of diesel range hydrocarbons

ActiveUS8022258B2Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationHydrocotyle bowlesioides

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com