Patents

Literature

441 results about "Hydrodenitrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodenitrogenation (HDN) is an industrial process for the removal of nitrogen from petroleum. Organonitrogen compounds, even though they occur at low levels, are undesirable because they cause poisoning of downstream catalysts. Furthermore, upon combustion, organonitrogen compounds generate NOx, a pollutant. HDN is effected as general hydroprocessing, which traditionally focuses on hydrodesulfurization (HDS) because sulfur compounds are even more problematic. To some extent, hydrodeoxygenation (HDO) is also effected.

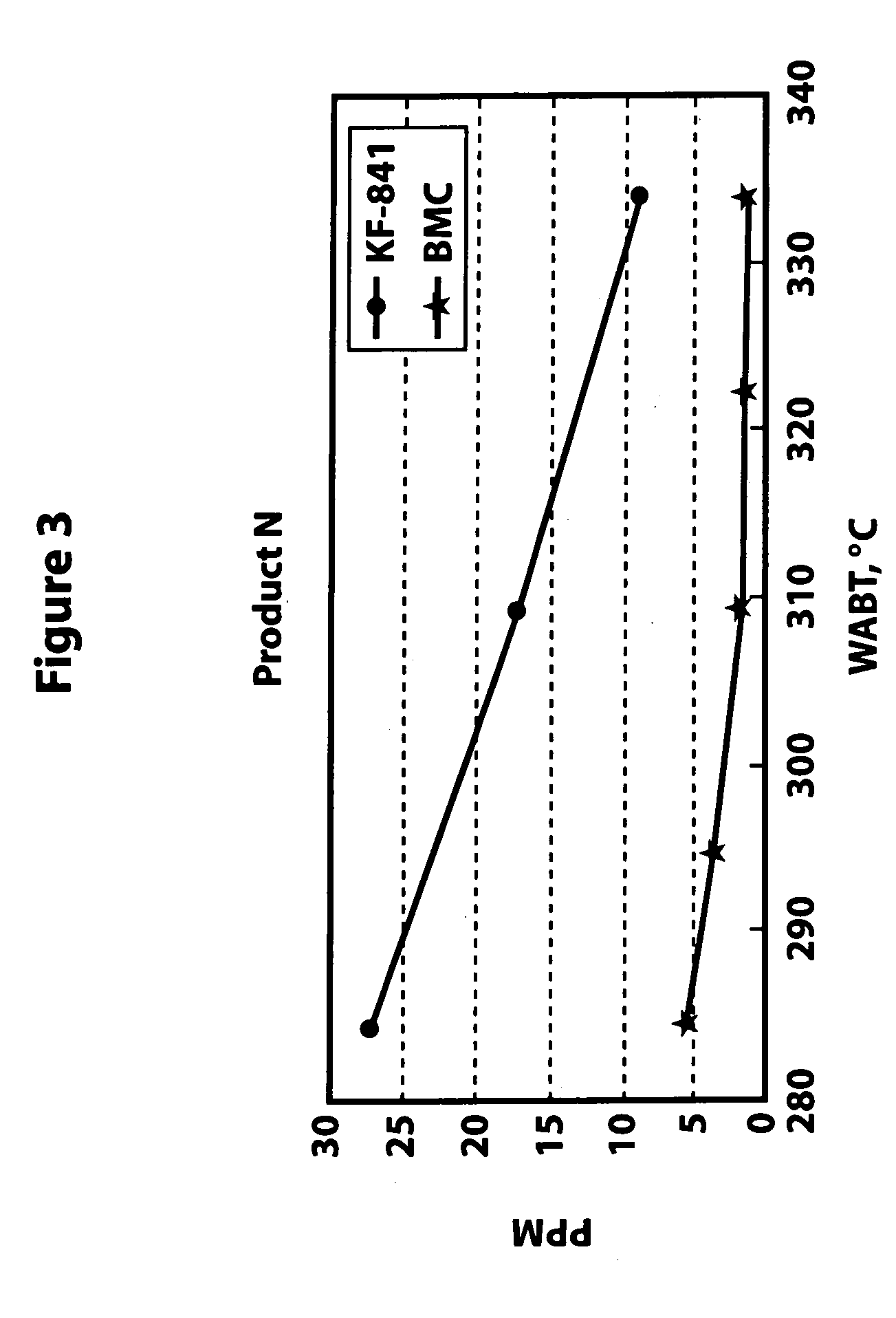

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Process for sulfiding a hydrotreating catalyst comprising an organic compound comprising n and carbonyl

InactiveUS6540908B1Inorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenSulfidation

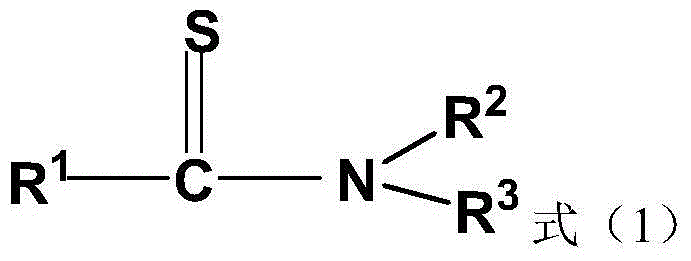

The invention pertains to a process for preparing a sulfided hydrotreating catalyst in which a hydrotreating catalyst is subjected to a sulfidation step, wherein the hydrotreating catalyst comprises a carrier comprising at least 50 wt % of alumina, the catalyst comprising at least one hydrogenation metal component and an organic compound comprising at least one covalently bonded nitrogen atom and at least one carbonyl moiety, the molar ratio between the organic compound and the total hydrogenation metal content being at least 0.01:1. The invention further pertains to the use of said hydrotreating catalyst in hydrotreating a hydrocarbon feed, in particular to achieve hydrodenitrogenation, (deep) hydrodesulfurization, or hydrodearomatization.

Owner:ALBEMARLE NETHERLANDS BV

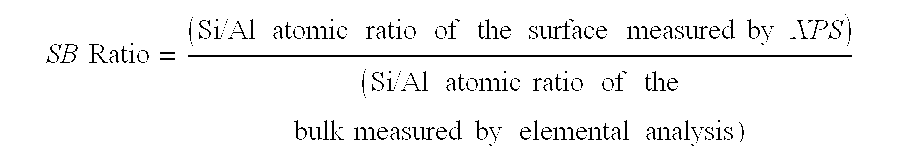

Extremely low acidity USY and homogeneous, amorphous silica-alumina hydrocracking catalyst and process

InactiveUS6902664B2High catalytic activityLow pollution rateMolecular sieve catalystsRefining to change hydrocarbon structural skeletonSingle stageAmorphous silica-alumina

A catalyst composition comprising a minor amount of a low acidity, highly dealuminated ultra stable Y zeolite having an Alpha value of less than about 5, preferable less than about 3 and Broensted acidity measured by FT-IR from about 1 to about 20, preferably from about 1-10, micro mole / g of, a homogeneous, amorphous silica-alumina cracking component having an SB ratio of from about 0.7 to about 1.3, wherein a crystalline alumina phase is present in an amount of no greater than about 10%, preferably no greater than 5% and a catalytic amount of hydrogenation component selected from the group consisting of a Group VI metal, a Group VIII metal, and mixtures thereof is disclosed. The present invention provides for a process for converting hydrocarbonaceous oils comprising contacting the hydrocarbonaceous oils with the catalyst under suitable hydrocarbon conversion conditions. Such processes in include, but are not limited to, single stage hydrocracking, two-stage hydrocracking, series-flow hydrocracking, mild hydrocracking, lube hydrocracking, hydrotreating, lube hydrofinishing, hydrodesulphurization, hydrodenitrification, catalytic dewaxing and catalytic cracking.

Owner:CHEVROU USA INC

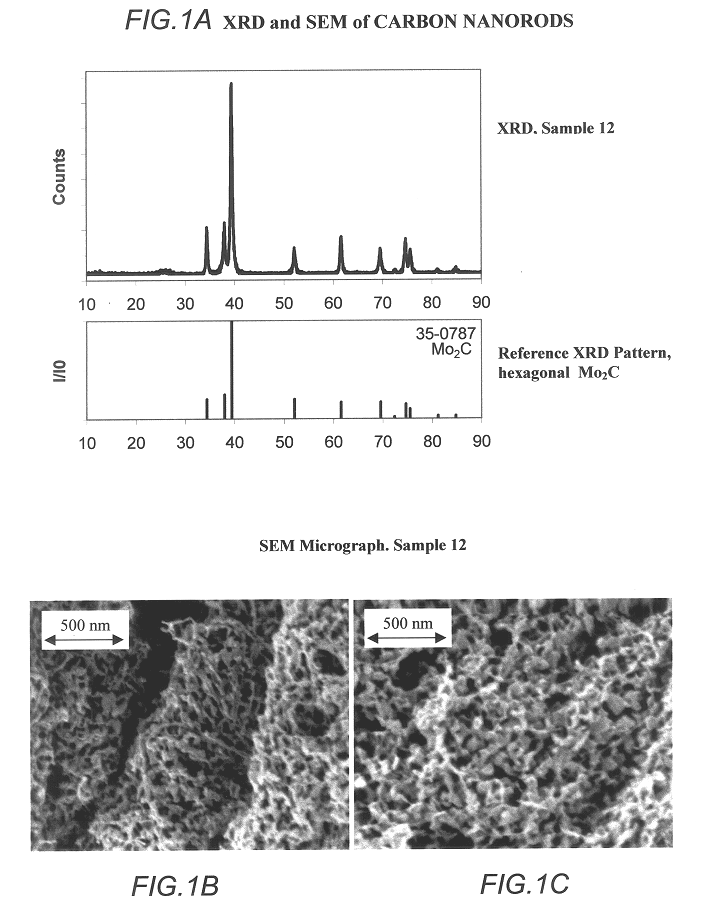

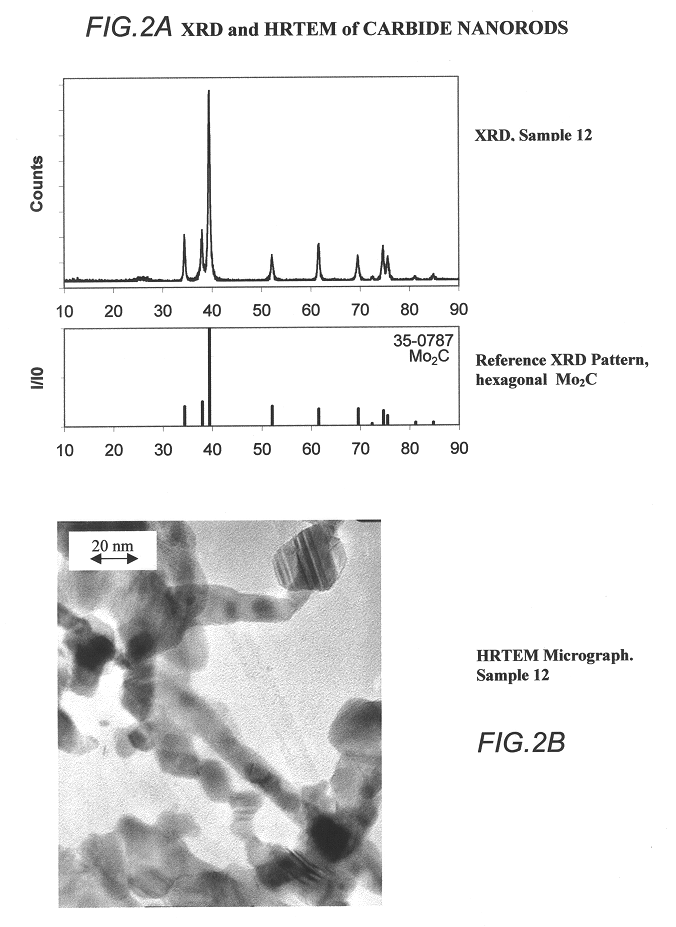

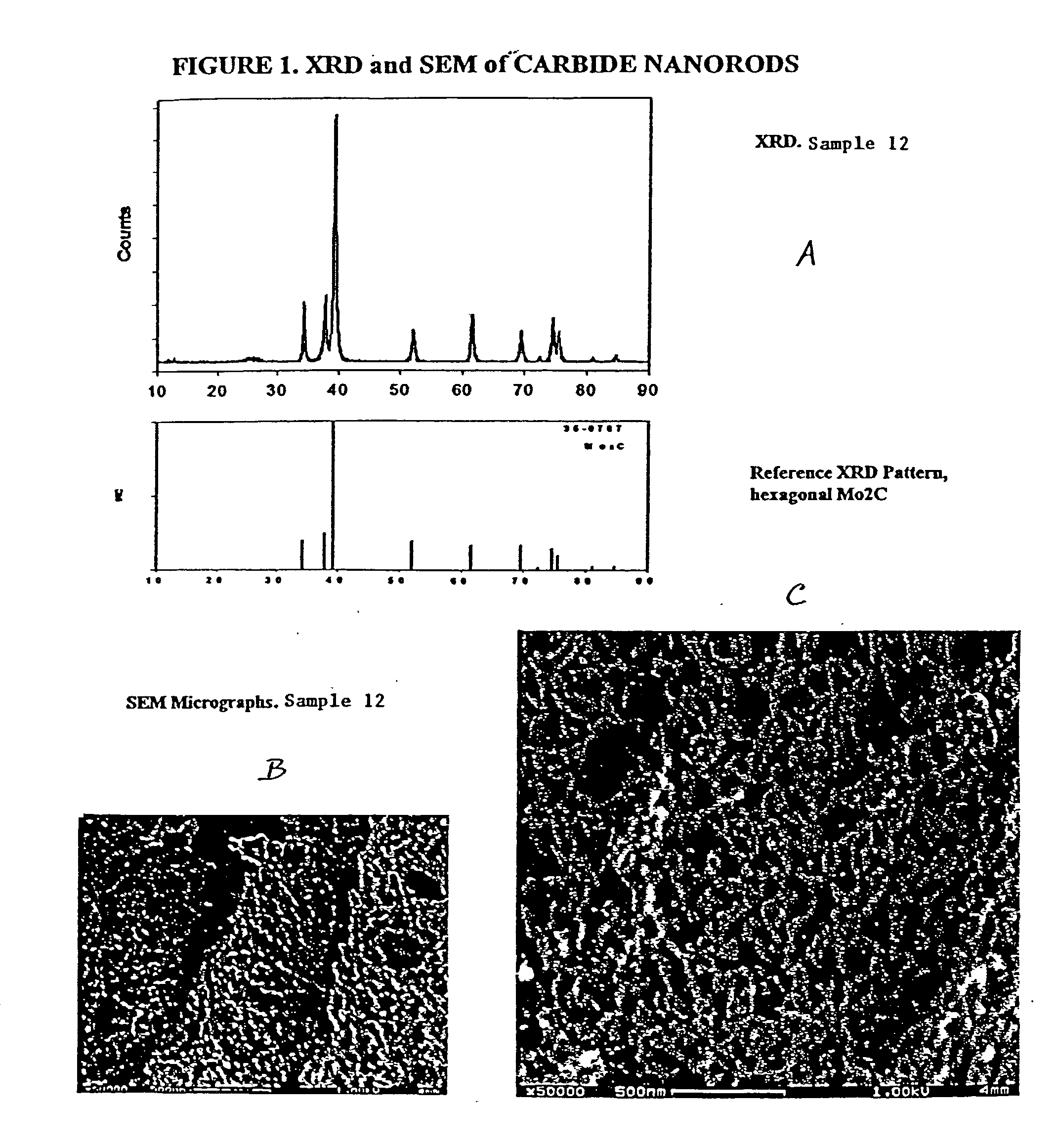

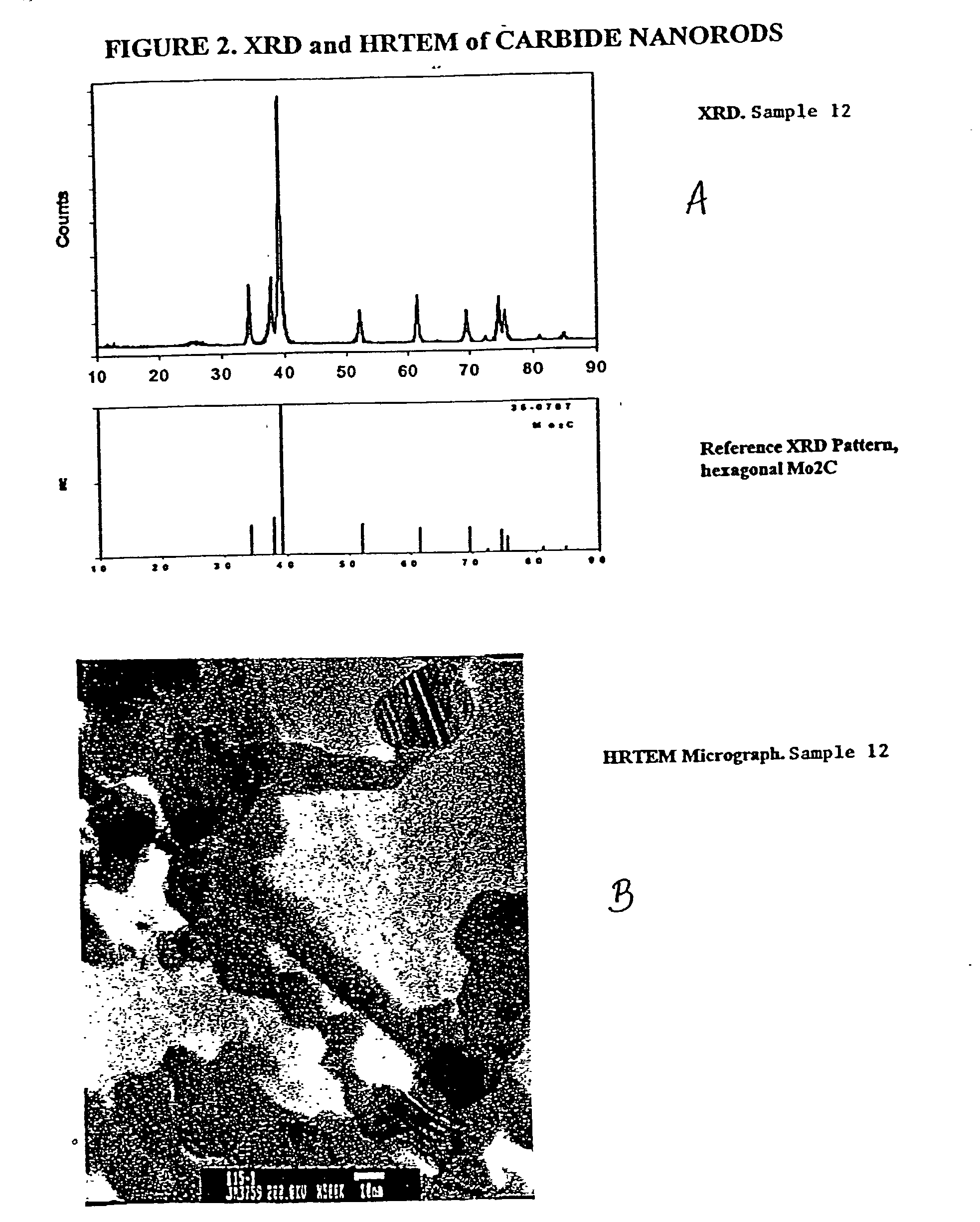

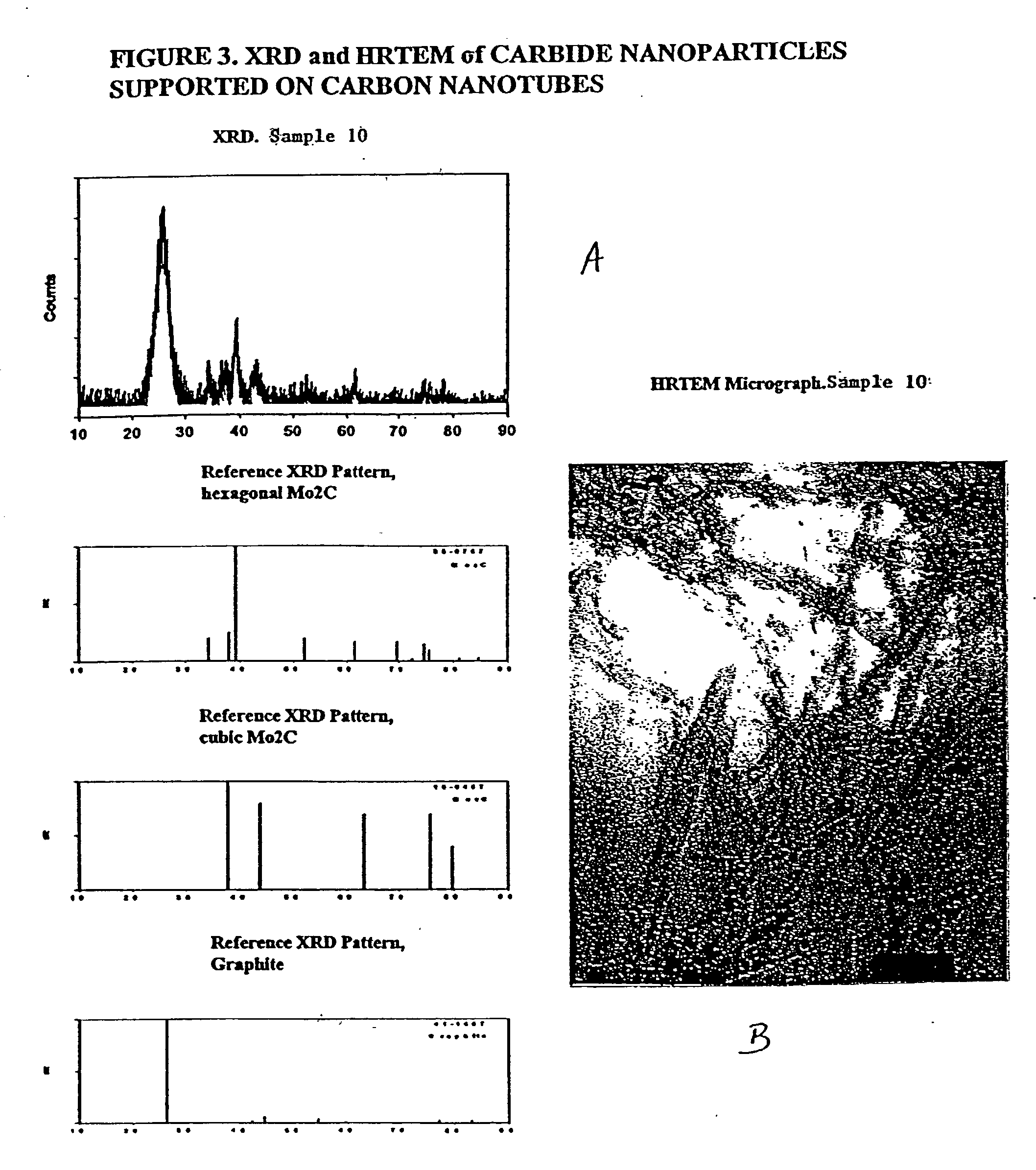

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

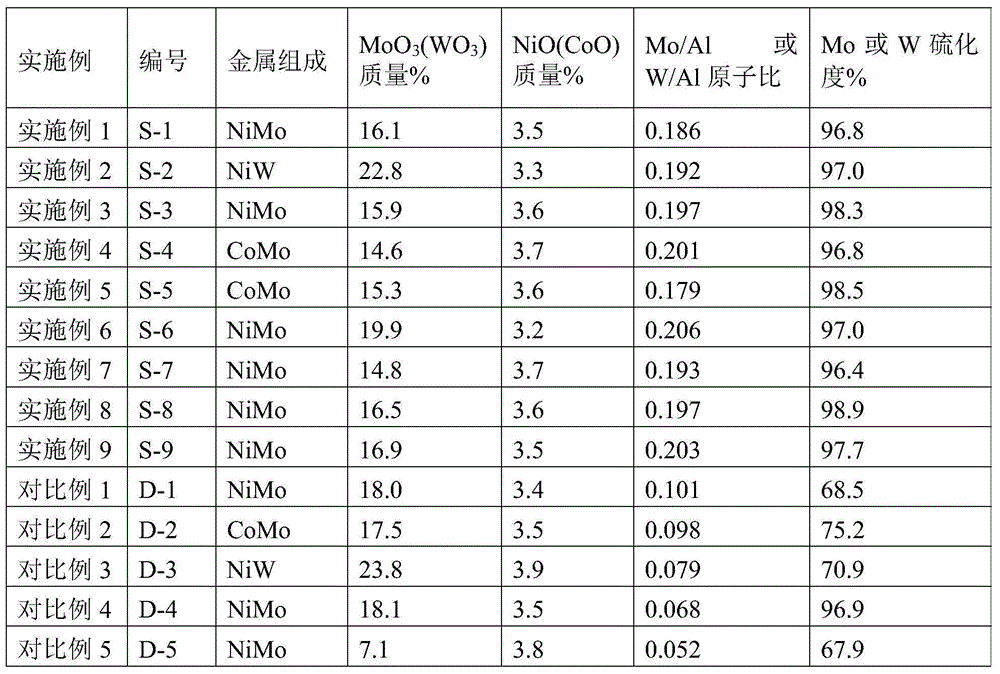

Preparation method of hydro-treatment catalyst

ActiveCN103769125AModerate decrease in viscosityImprove permeabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystUltrasonic cavitation

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

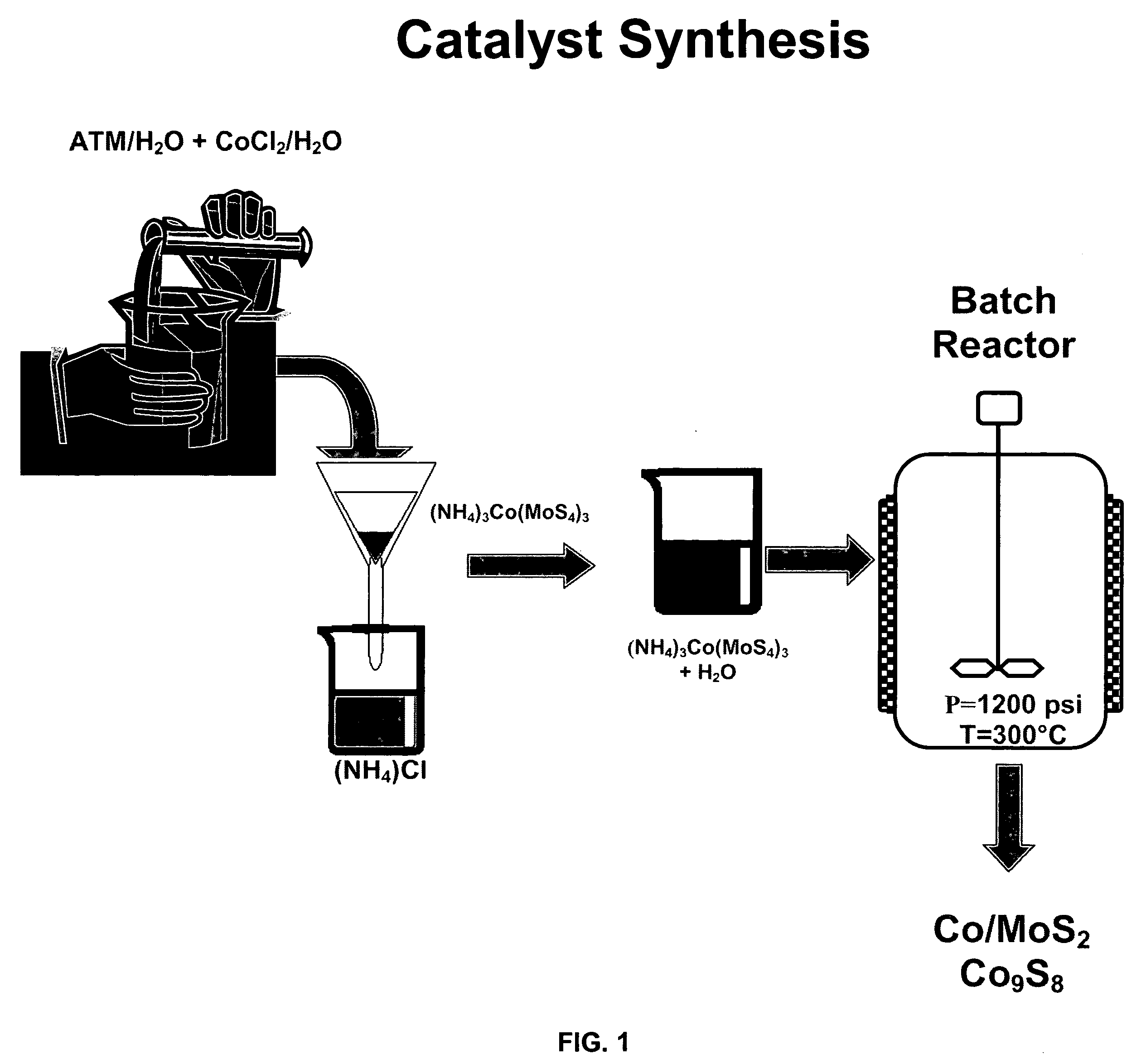

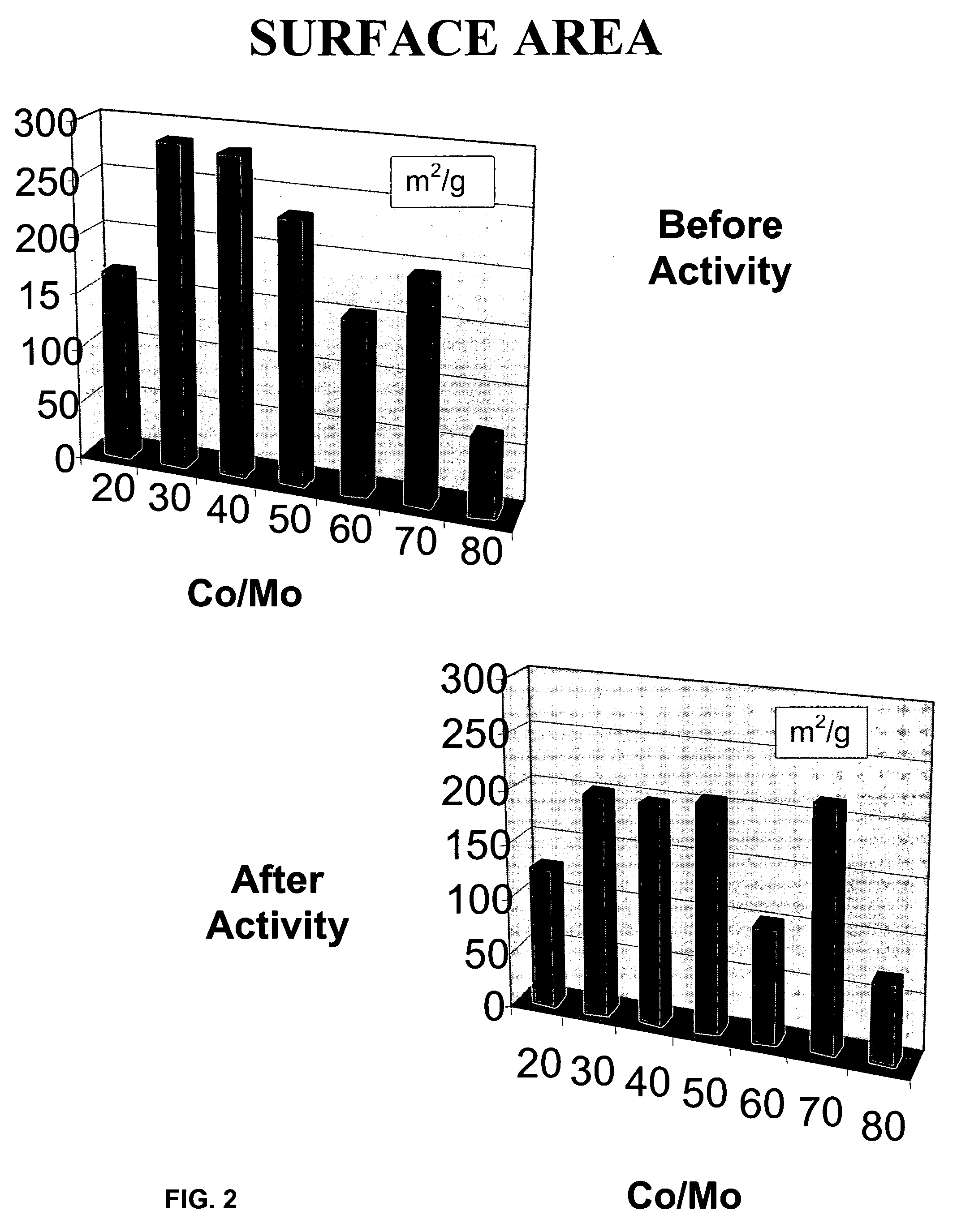

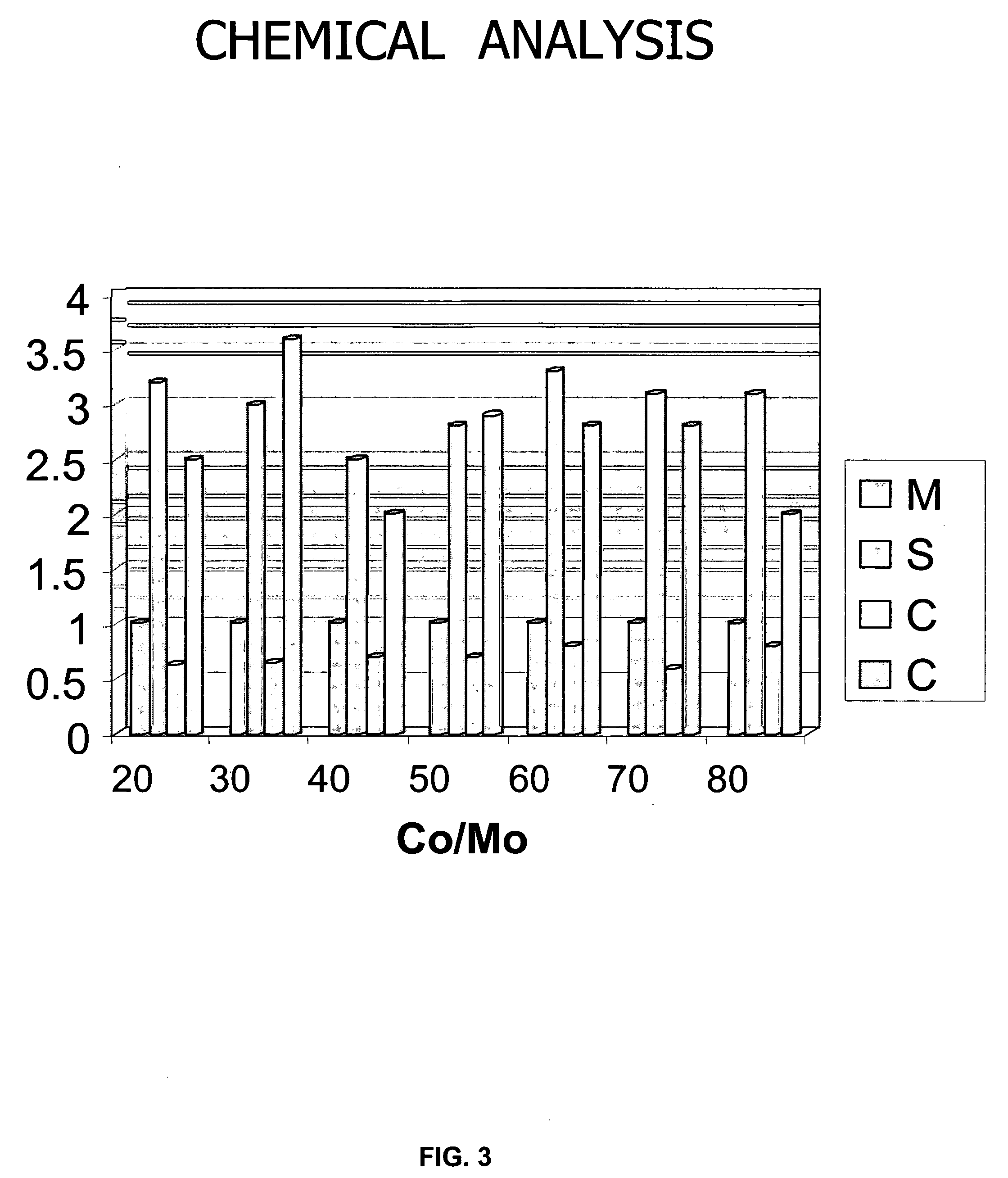

Molybdenum sulfide/carbide catalysts

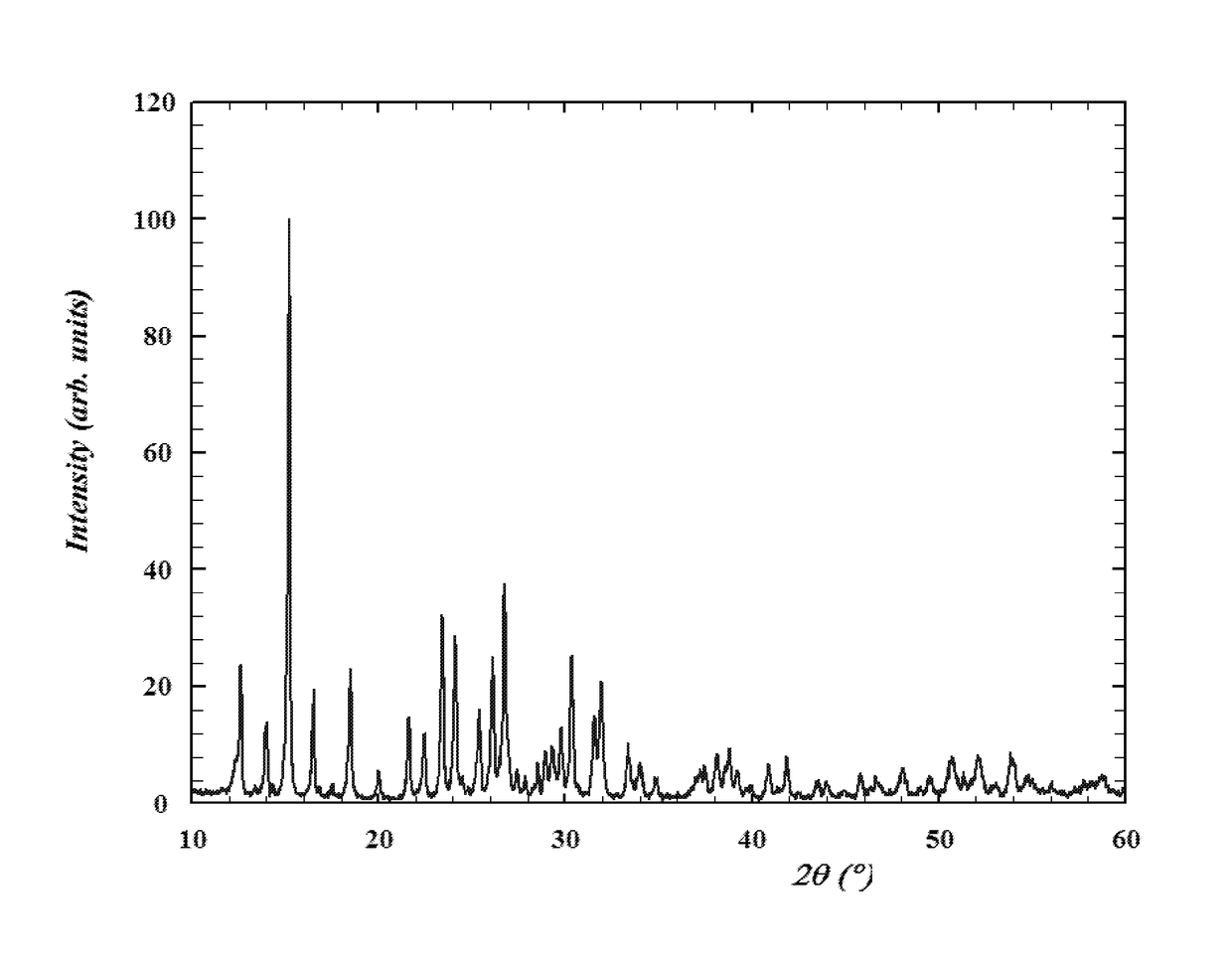

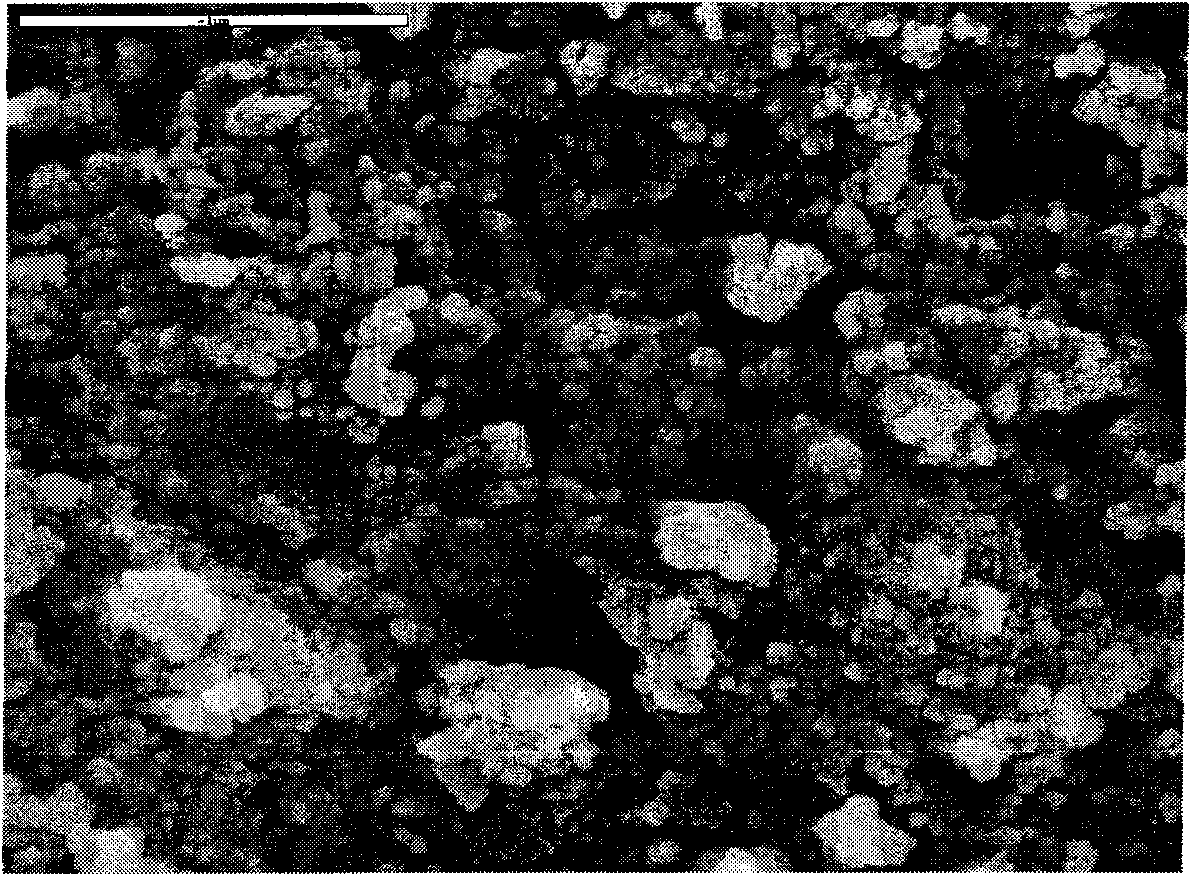

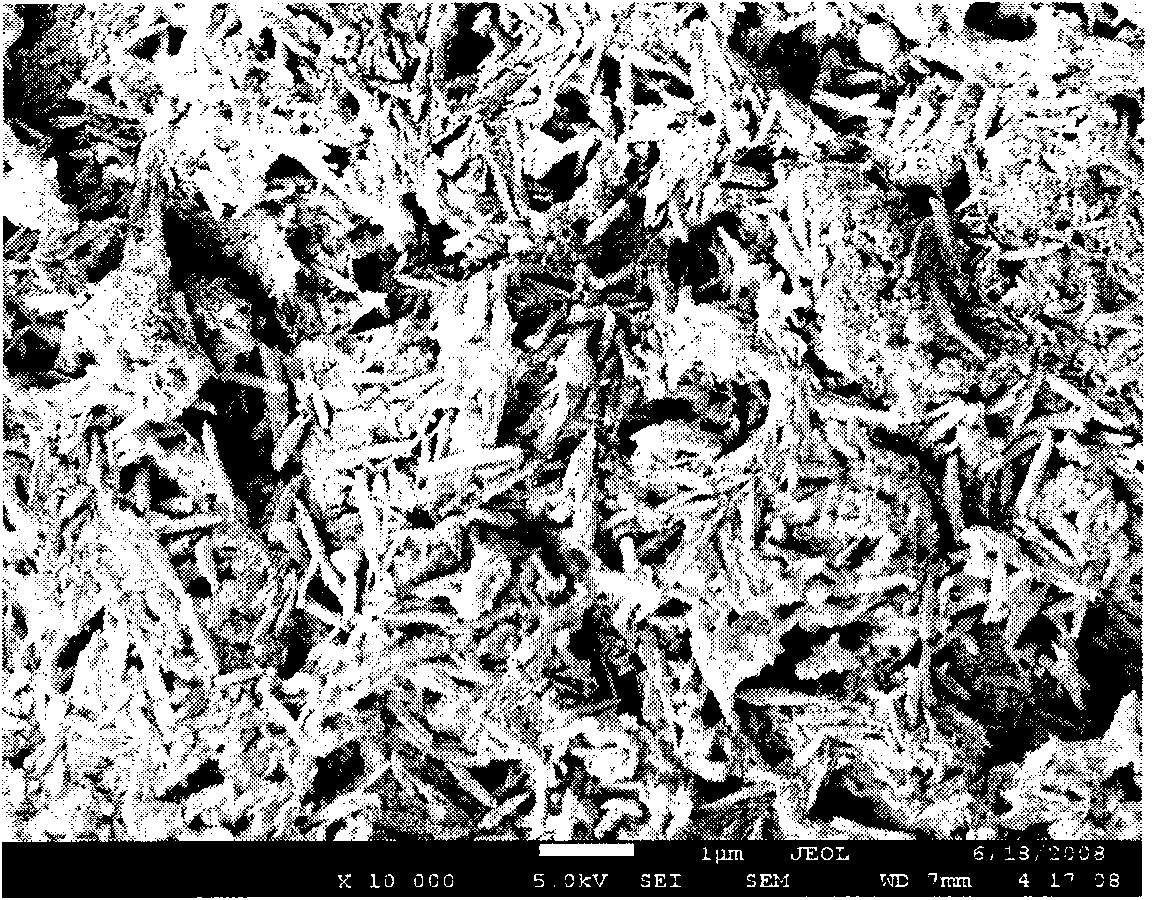

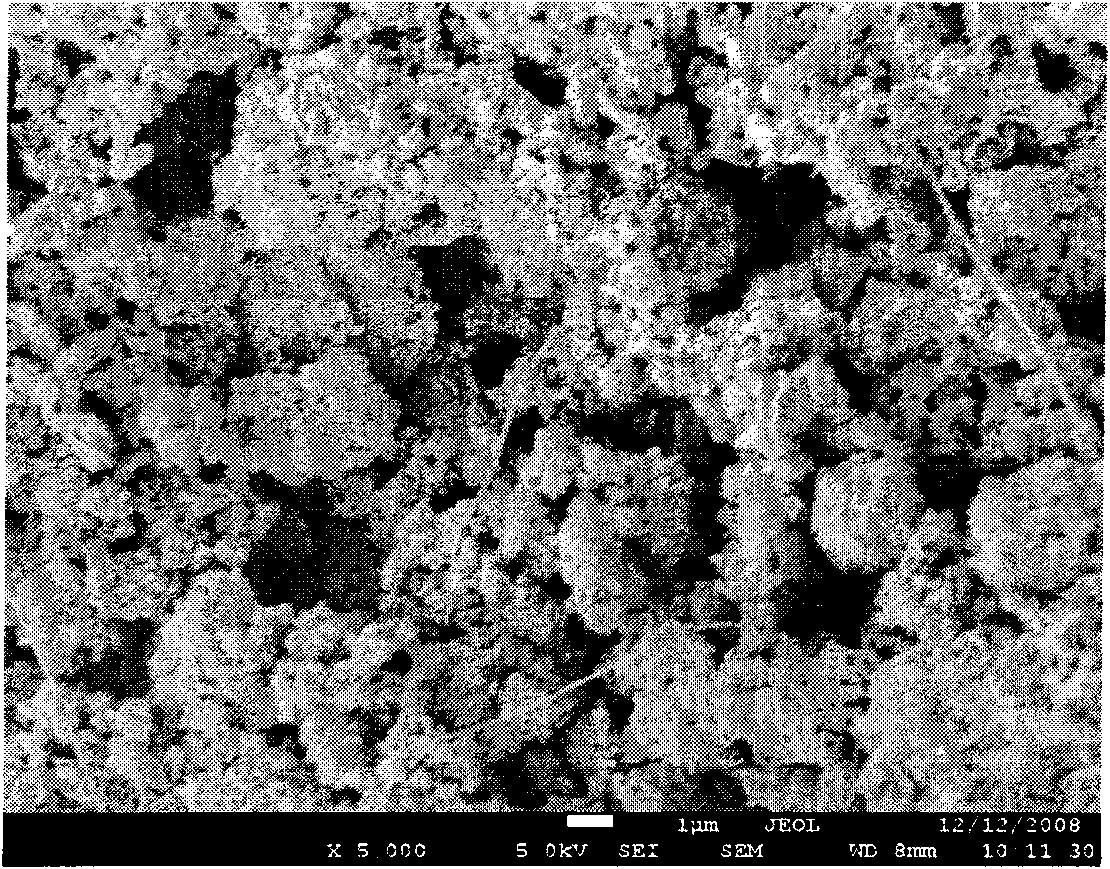

InactiveUS7223713B2High activityImprove stabilityCell electrodesCatalyst activation/preparationMolybdateNitrogen

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

High activity supported distillate hydroprocessing catalysts

InactiveUS20080146438A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHigh activityCatalyst support

Supported metallic catalysts comprised of a Group VIII metal, a Group VIB metal, and an organic additive, and methods for synthesizing supported metallic catalysts are provided. The catalysts are prepared by a method wherein precursors of both metals are mixed and interacted with at least one organic additive, dried, calcined, and sulfided. The catalysts are used for hydroprocessing, particularly hydrodesulfurization and hydrodenitrogenation, of hydrocarbon feedstocks.

Owner:EXXON RES & ENG CO

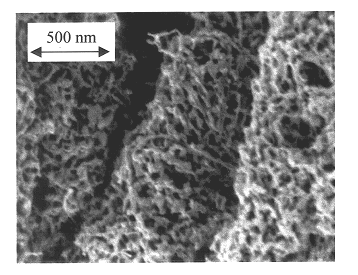

Hydrotreating catalyst and processes for hydrotreating hydrocarbon oil with the same

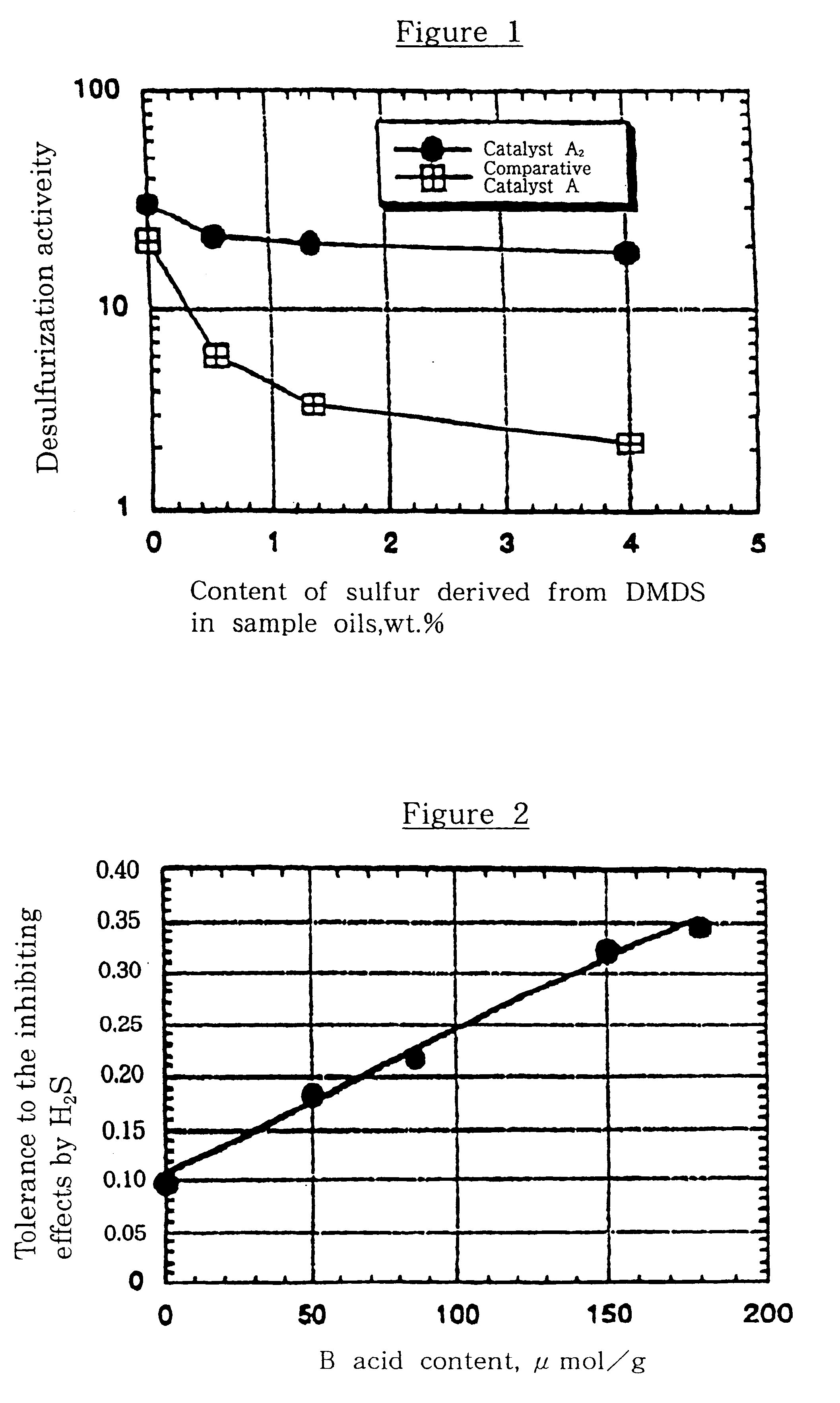

InactiveUS6267874B1Improve toleranceEfficient removalHydrocarbon oil crackingTreatment with hydrotreatment processesActive componentSilicon dioxide

The present invention relates to a hydrotreating catalyst composed of a carrier having a Brønsted acid content of at least 50 mumol / g such as a silica-alumina carrier or a silica-alumina-third component carrier, in which the silica is dispersed to high degree and a Brønsted acid content is at least 50 mumol / g, and at least one active component (A) selected from the elements of Group 8 of the Periodic Table and at least one active component (B) selected from the elements of Group 6 of the Periodic Table, supported on said carrier. The present invention also relates to a method for hydrotreating hydrocarbon oils using the same. The hydrotreating catalyst of the present invention provides excellent tolerance to the inhibiting effect of hydrogen sulfide, high desulfurization activity, and exhibits notable effects for deep desulfurization of hydrocarbon oils containing high contents of sulfur, in particular gas oil fractions containing difficult-to-remove sulfur compounds. The hydrotreating catalyst of the present invention is also very effective for hydrodenitrogenation, hydrocracking, hydrodearomatization, hydroisomerization, hydrofining and the like of hydrocarbon oils.

Owner:TONENGENERAL SEKIYU

Prepn process of vulcanized hydrogenation catalyst

ActiveCN101088619AFull and even contactEvenly mixedCatalyst activation/preparationRefining by selective hydrogenationSulfurNitrogen

The present invention relates to one kind of vulcanized hydrocarbon oil hydrogenating catalyst and its preparation process. The preparation process includes the first supporting certain amount of VI and VIII metal precursor oxide, the subsequent introducing sulfur and heat treatment in dynamic heating equipment, and final adding the residual VI and VIII metal precursor oxide and drying treatment. The present invention combines the pre-vulcanizing into the preparation process of catalyst, and the catalyst has raised reaction performance, and is suitable for hydrocarbon oil hydroprocessing, especially light fraction oil desulfurizing reaction, hydrodenitrogenation reaction, arene hydrogenating saturation and other catalytic reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

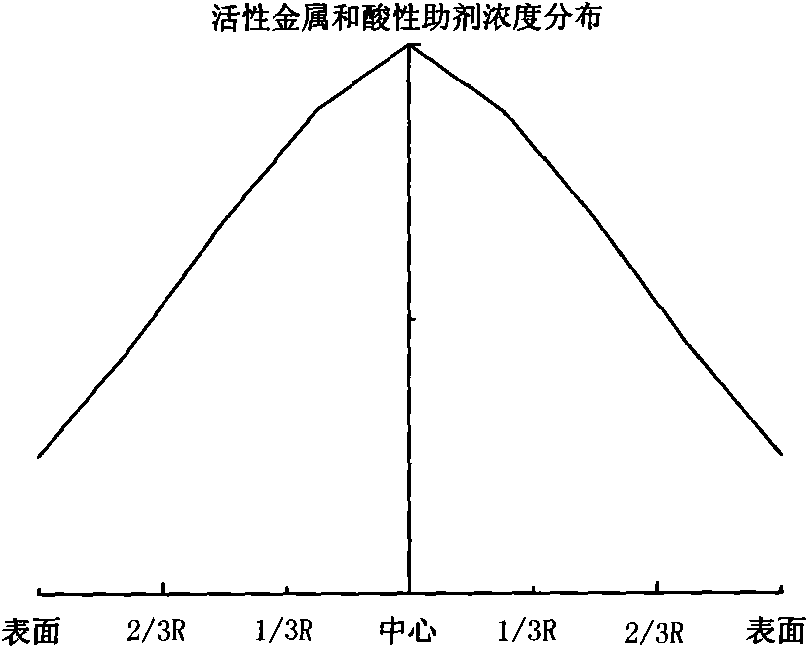

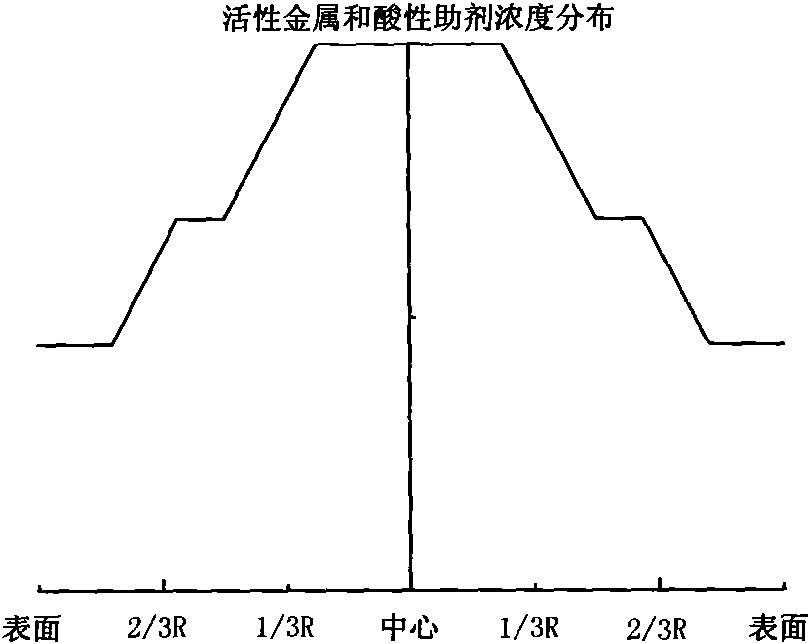

Graded composition of heavy oil hydrogenation catalysts

ActiveCN101928593ASlow down inactivationExtended operating cycleRefining to eliminate hetero atomsPorosityGranularity

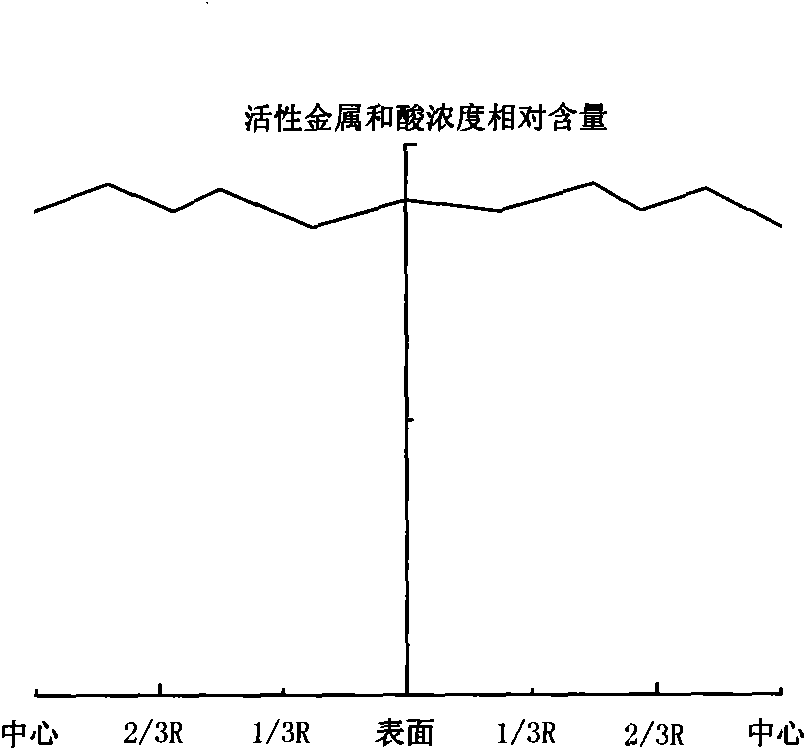

The invention relates to a graded composition of heavy oil hydrogenation catalysts. 5 to 55 percent of hydrodemetallization catalyst, 5 to 55 percent of hydrodesulfurization catalyst and 5 to 55 percent of hydrodenitrogenation catalyst are filled into a reactor from the top to the bottom respectively; along the flow direction, the activity of the catalysts is gradually increased, the aperture is gradually reduced, the granularity is gradually reduced and the porosity is gradually reduced; the active metal ingredients and the acid aid concentrations of the demetallization catalyst and the desulfurization catalyst are in non-uniform distribution, the active metal ingredient and the acid aid concentration of the demetallization catalyst are in gradient reduction, and the active metal ingredient and the acid aid concentration of the denitrogenation catalyst are in gradient increment; the active metal ingredient and the acid aid concentration of the desulfurization catalyst are in uniform distribution; the demetallization catalyst, the desulfurization catalyst and the denitrogenation catalyst consist of one or more catalysts respectively; and the demetallization, carbon residue removal, desulfurization and denitrogenation activities and stability of the catalyst graded composition system are high, and the service life is long.

Owner:PETROCHINA CO LTD

Vulcanized hydrogenation catalyst, and preparation method and application thereof

InactiveCN105521799AReduce manufacturing costImprove hydrogenation performancePhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityHydrodesulfurization

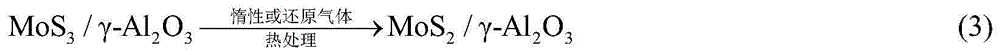

The invention provides a single-metal vulcanized hydrogenation catalyst and a double-metal vulcanized hydrogenation catalyst, and a preparation method and application thereof. The preparation method for the single-metal vulcanized hydrogenation catalyst comprises the following steps: (1) subjecting a dispersant and a solution A containing group-VIB metal salt and a sulfur source to contacting, wherein the solution A is acidic; the dispersant is a water-soluble organic solvent with a boiling point of 15 DEG to 90 DEG C; and the sulfur source is a sulfur-contained substance capable of hydrolyzing at 50 to 100 DEG C under the condition of acidity; (2) subjecting the product obtained by contacting in the step (1) and a catalyst carrier to contacting at 60 to 150 DEG C under a sealed condition for 5 to 30 hours; and (3) subjecting a solid material obtained by contacting in the step (2) to calcinating in an inert or reducing atmosphere. The invention also provides the single-metal vulcanized hydrogenation catalyst prepared by using the above-mentioned method, and application of the single-metal vulcanized hydrogenation catalyst in hydrodesulfurization and / or hydrodenitrification. Compared with the prior art, the hydrogenation catalyst provided by the invention has the characteristics of high metal activation grade, high active metal dispersity, high activity, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

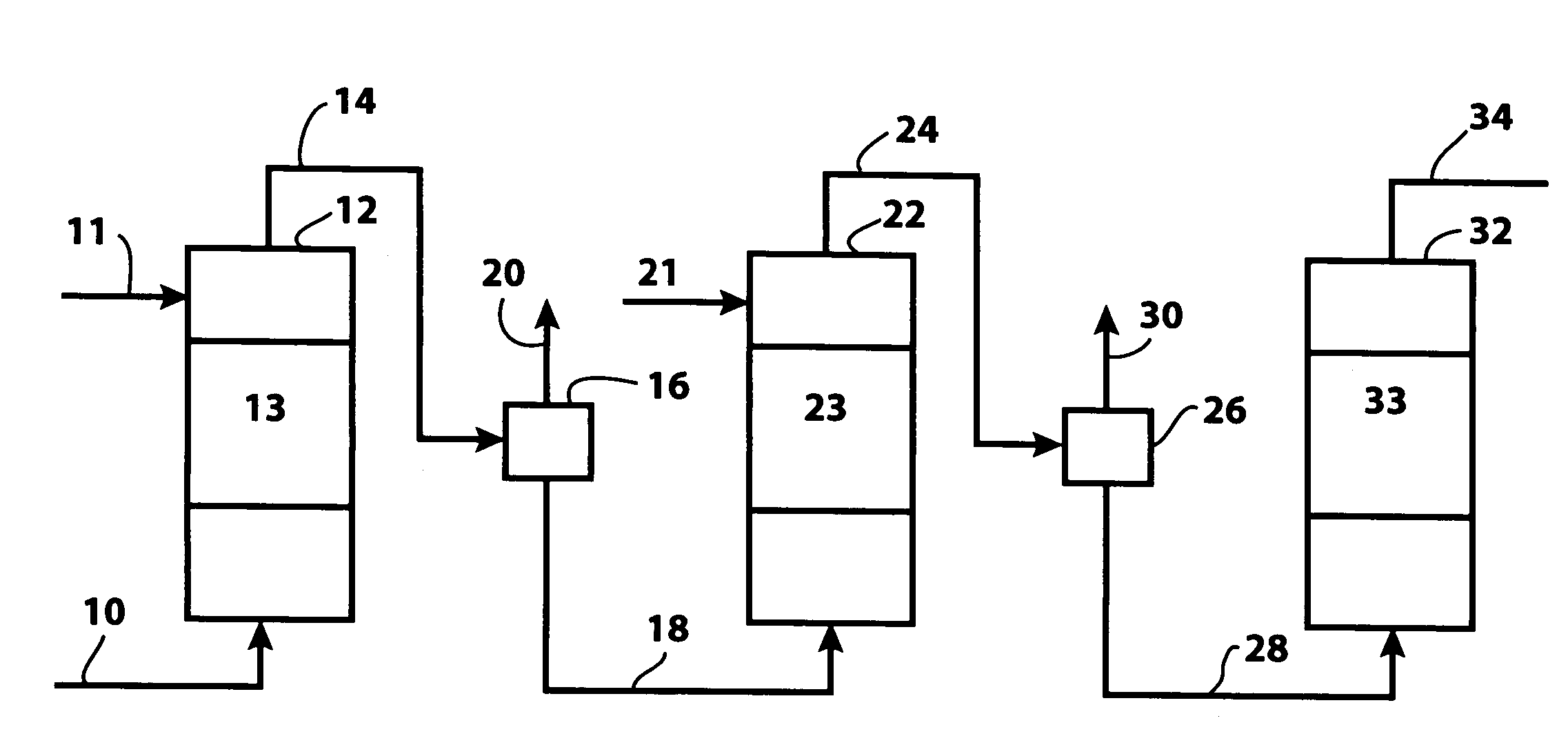

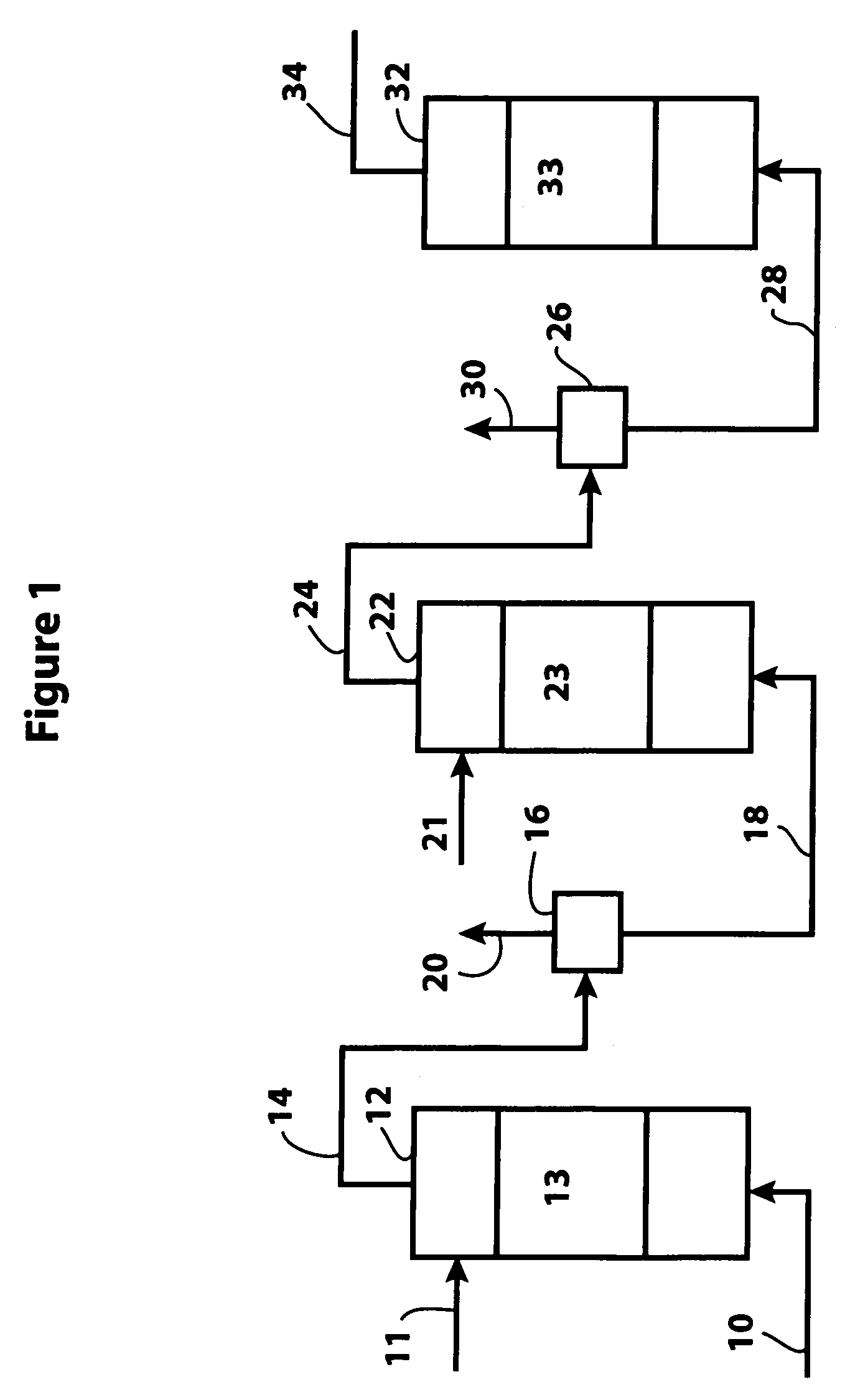

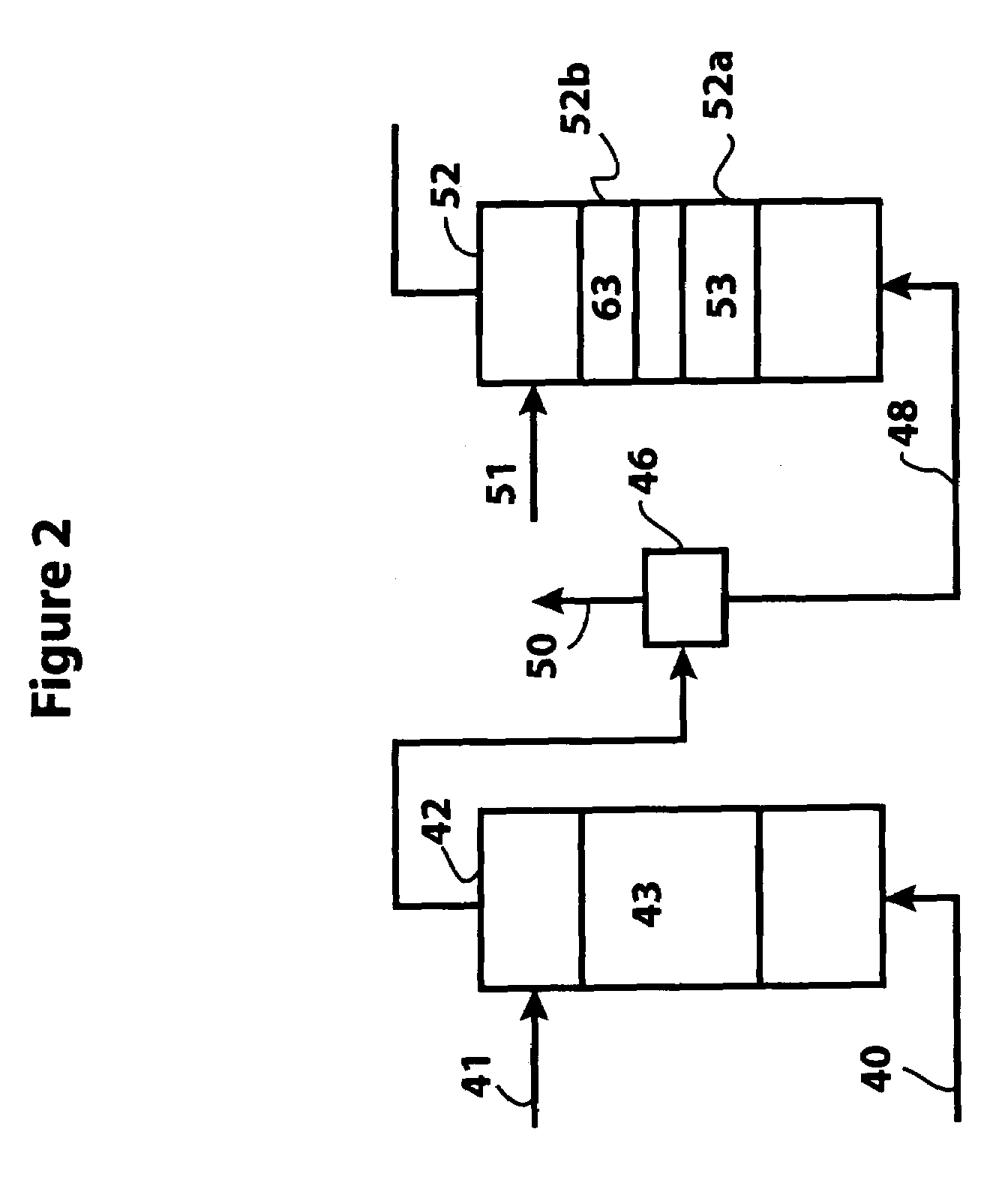

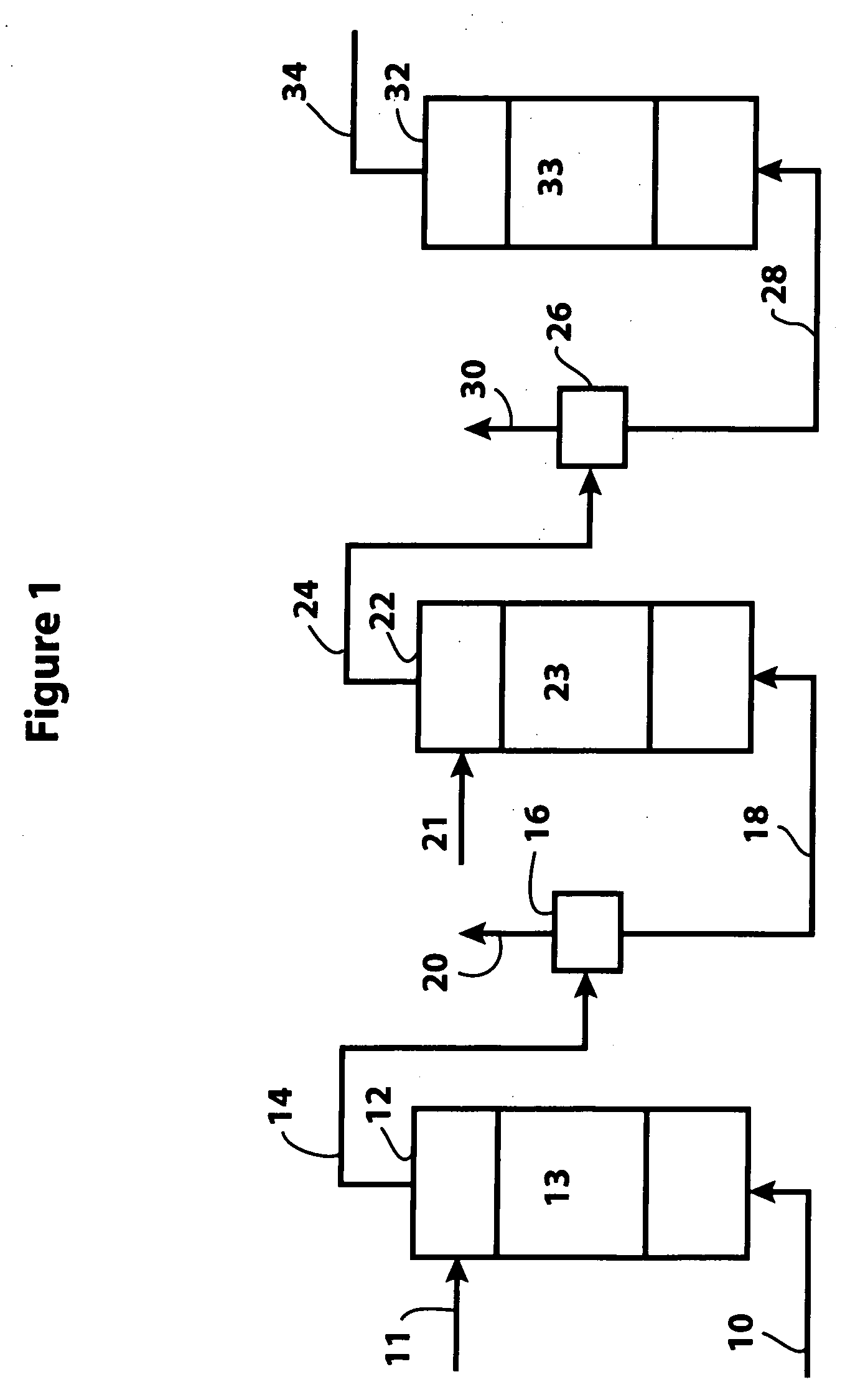

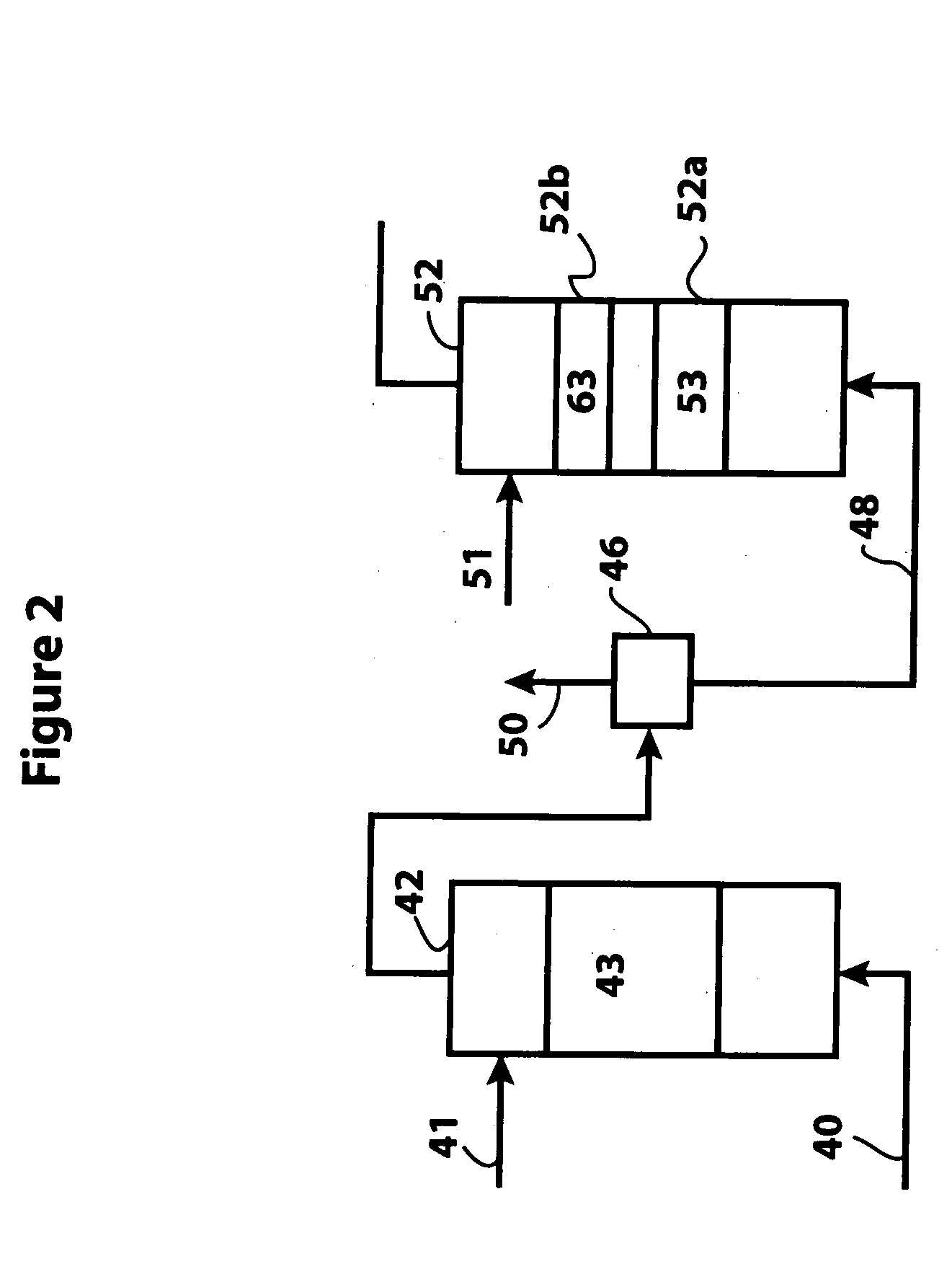

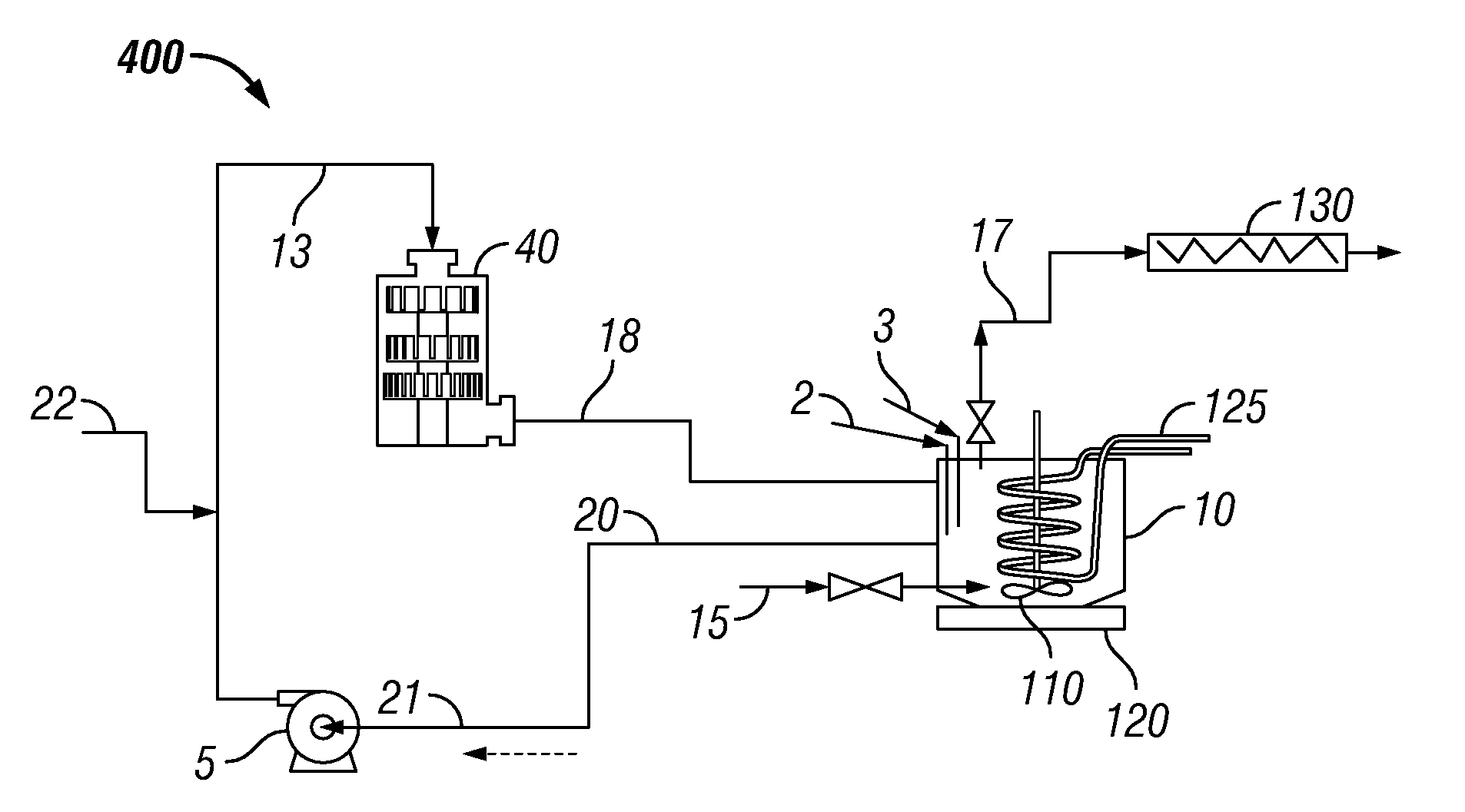

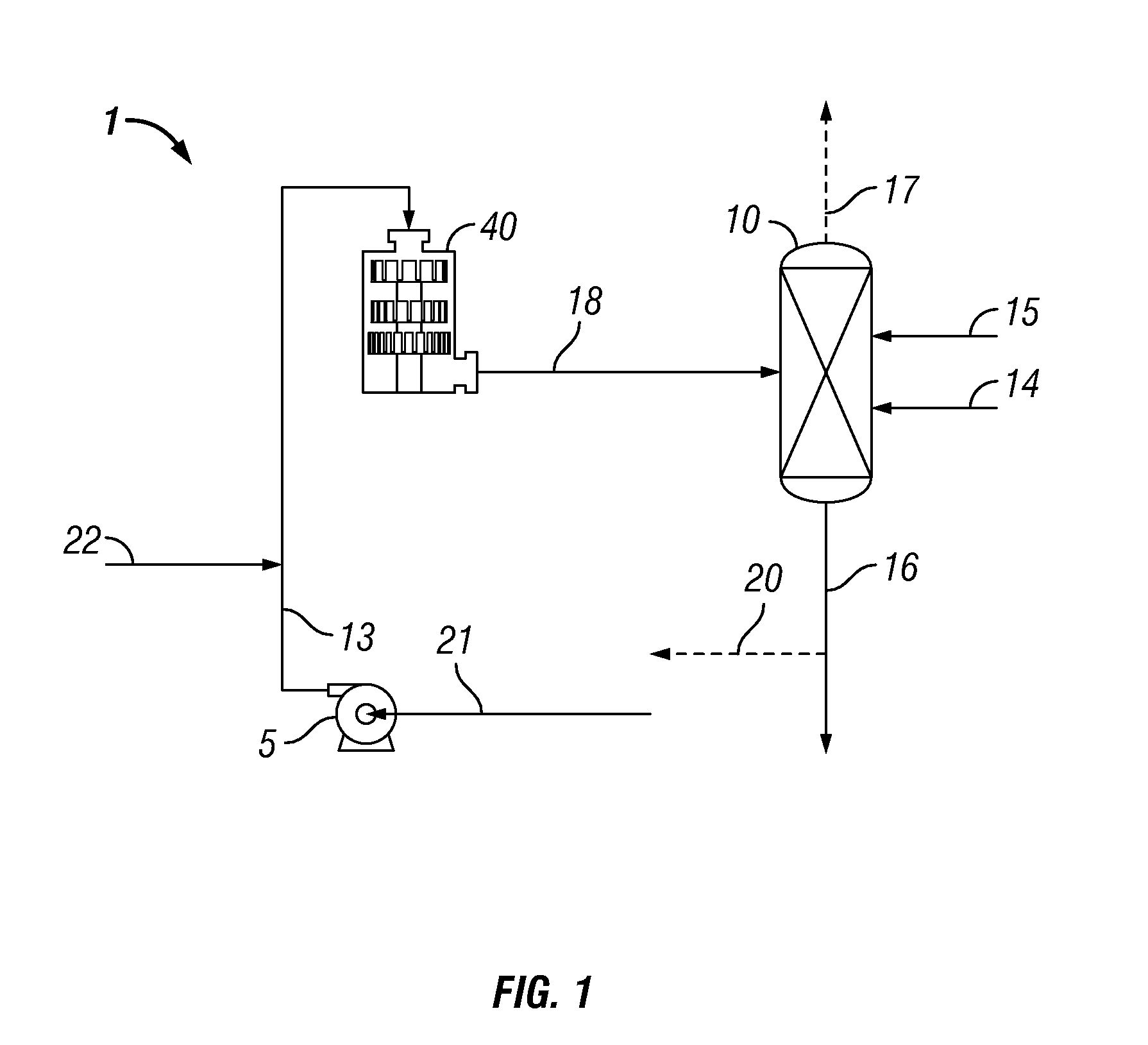

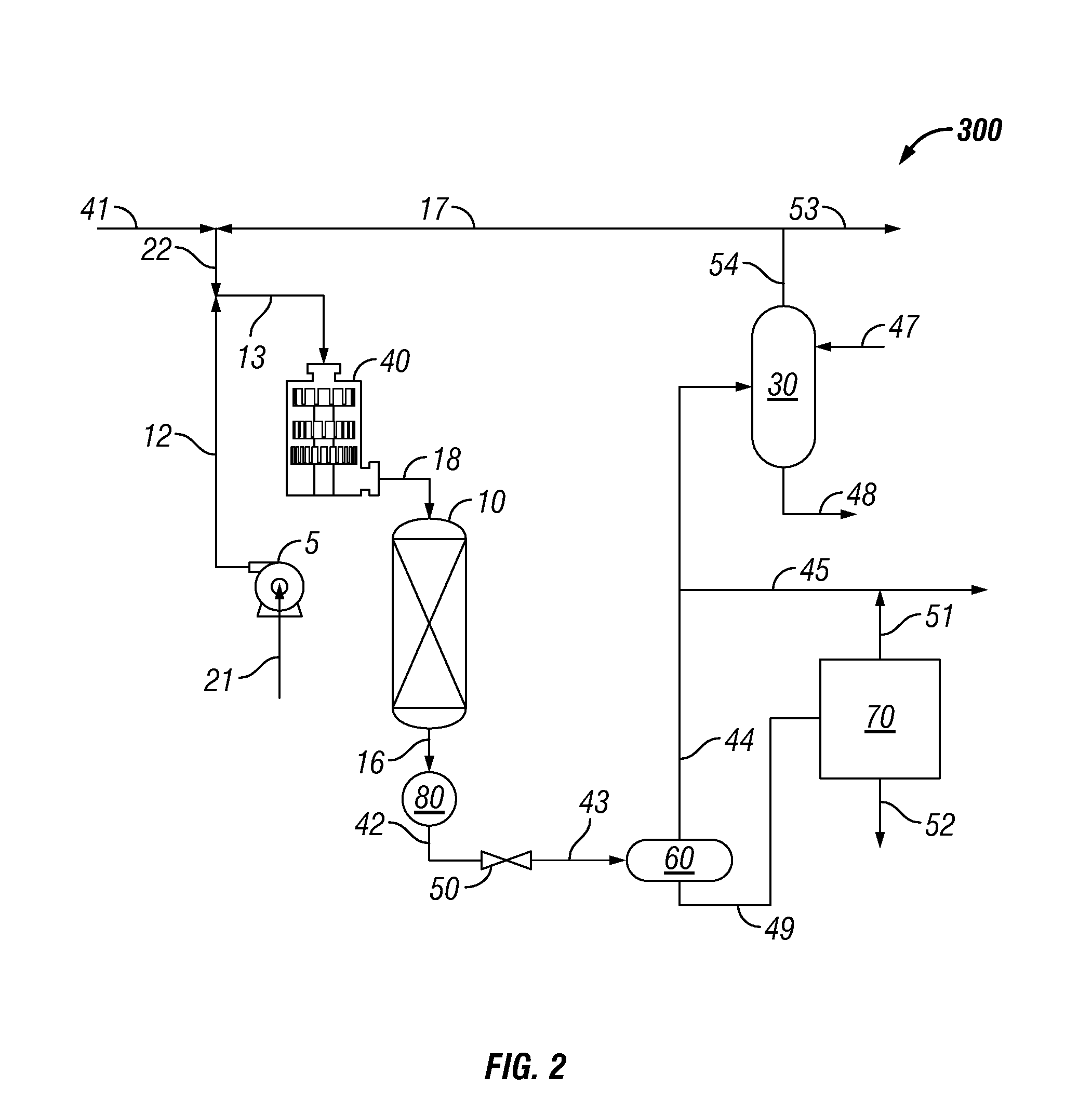

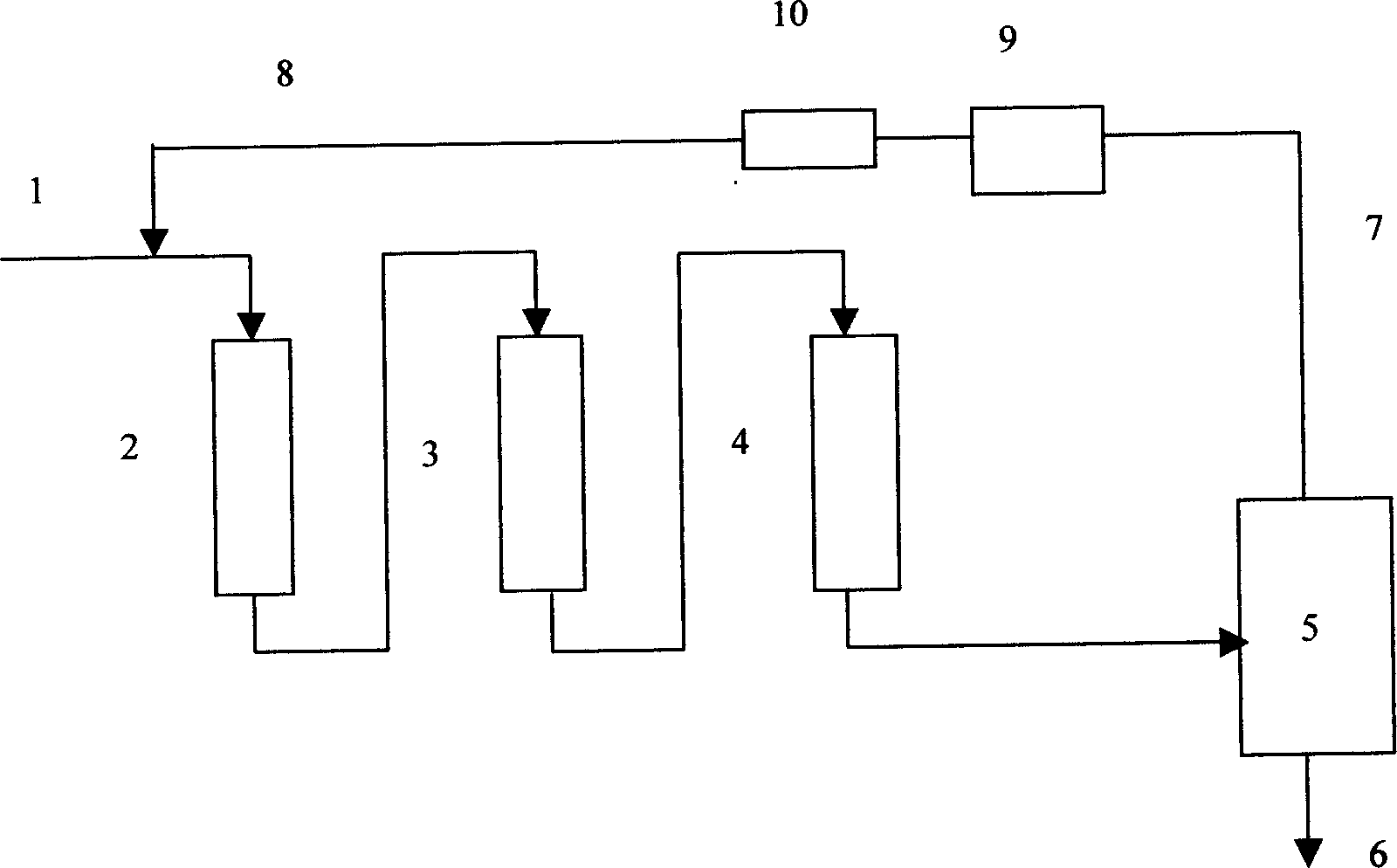

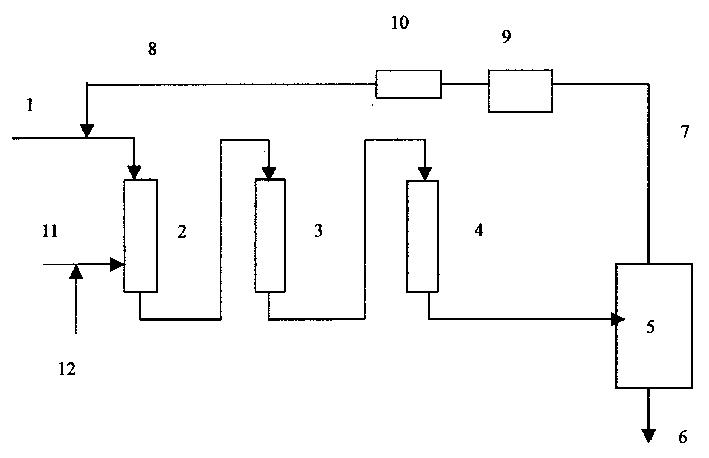

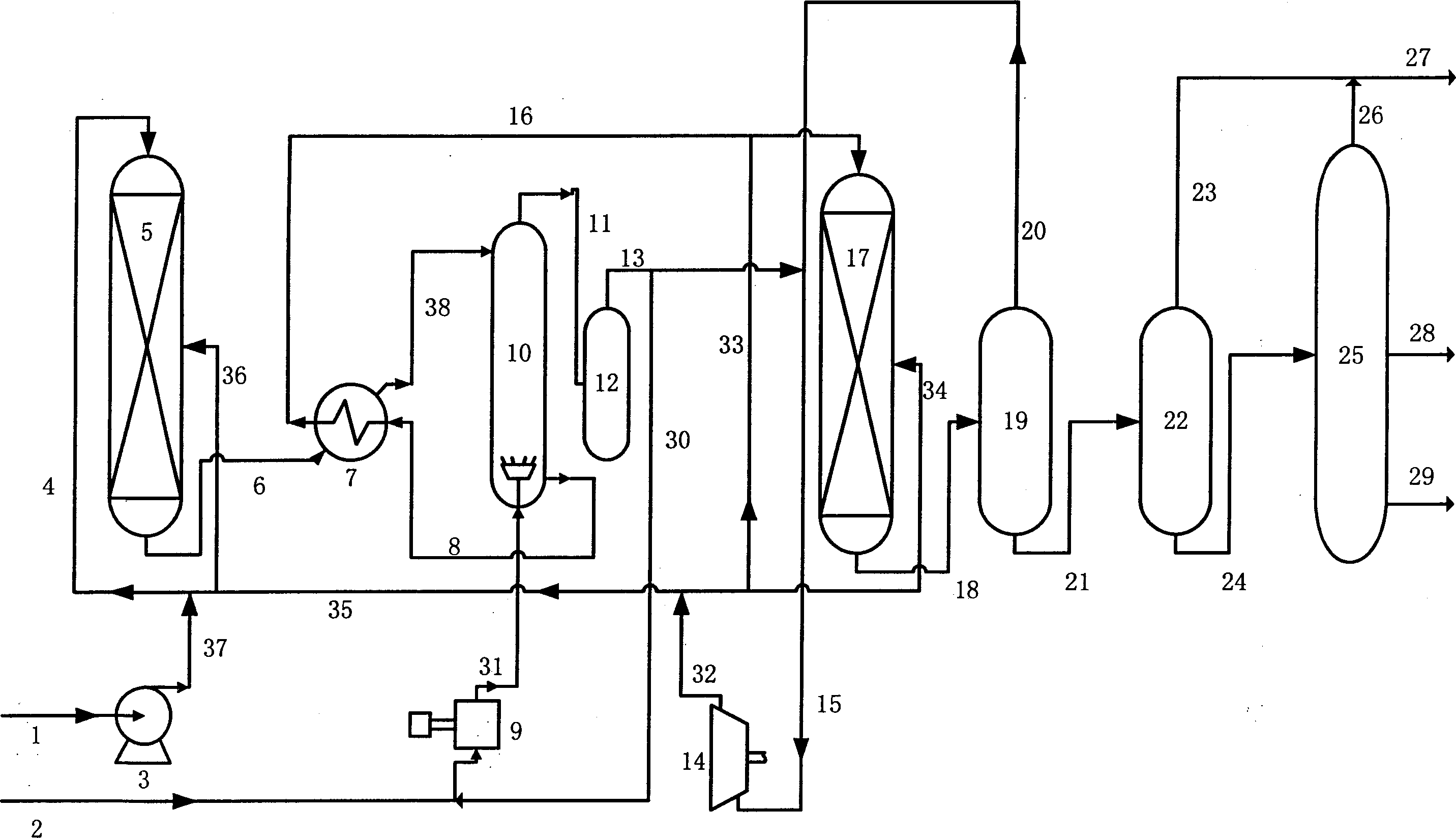

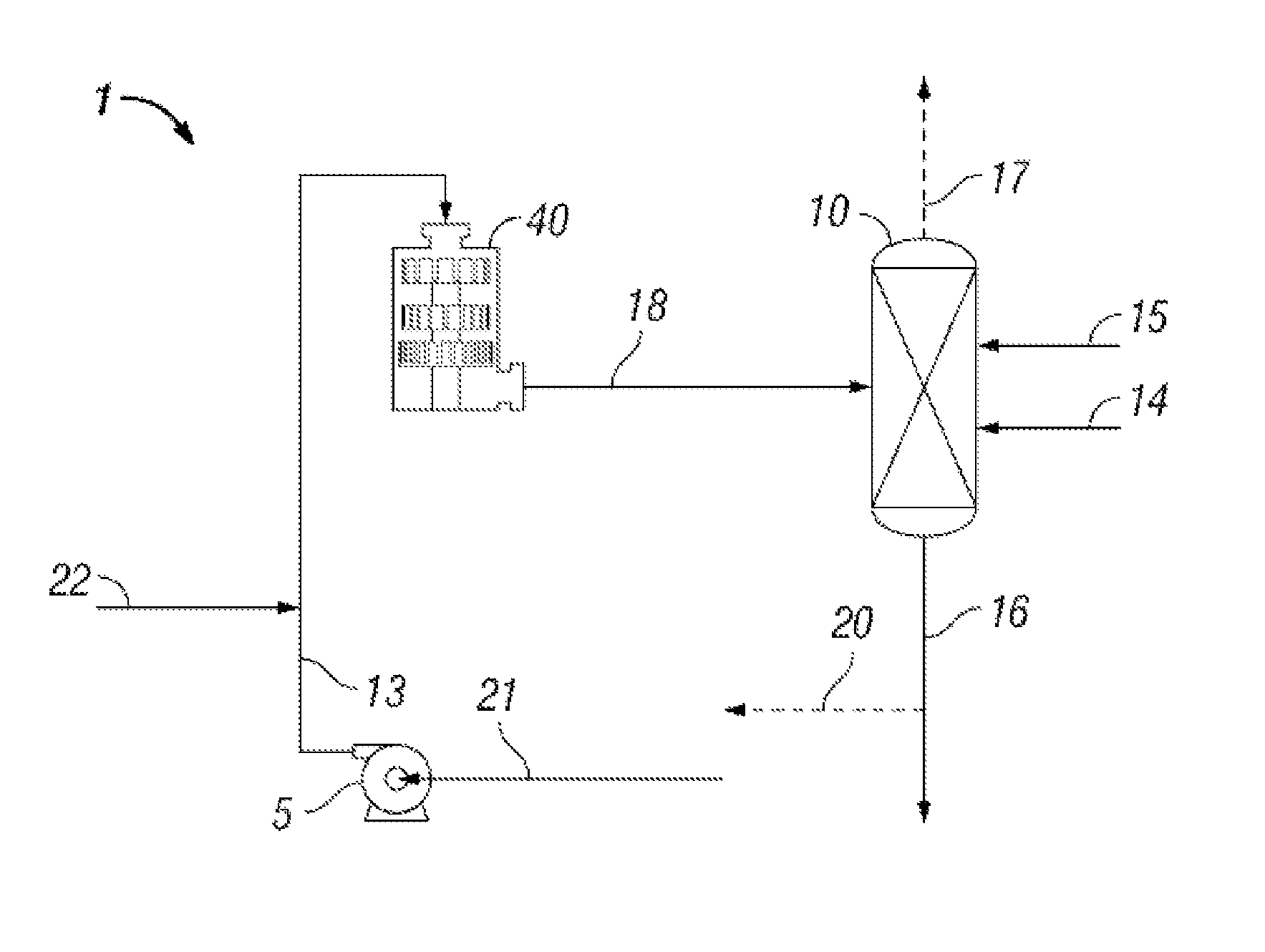

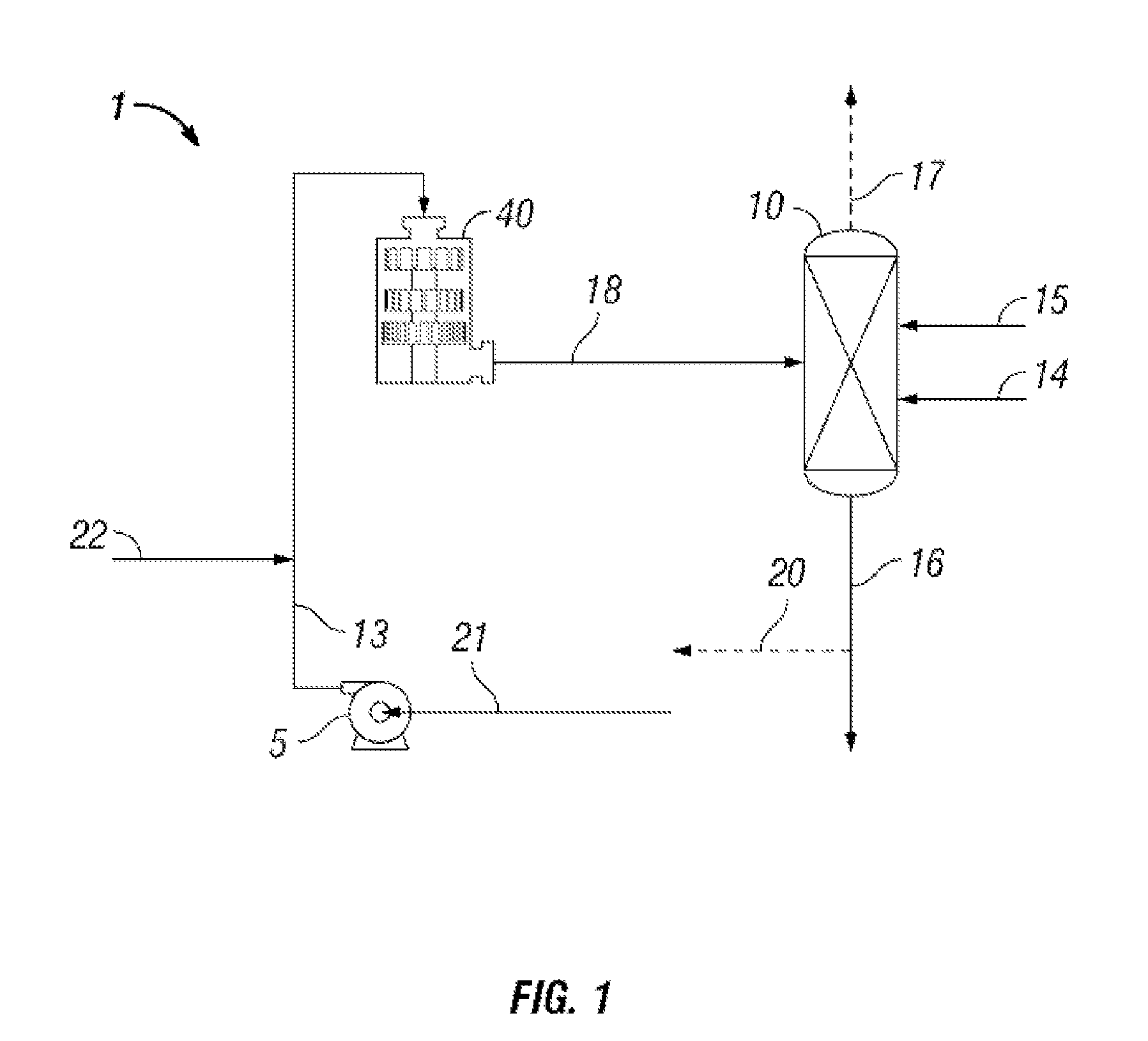

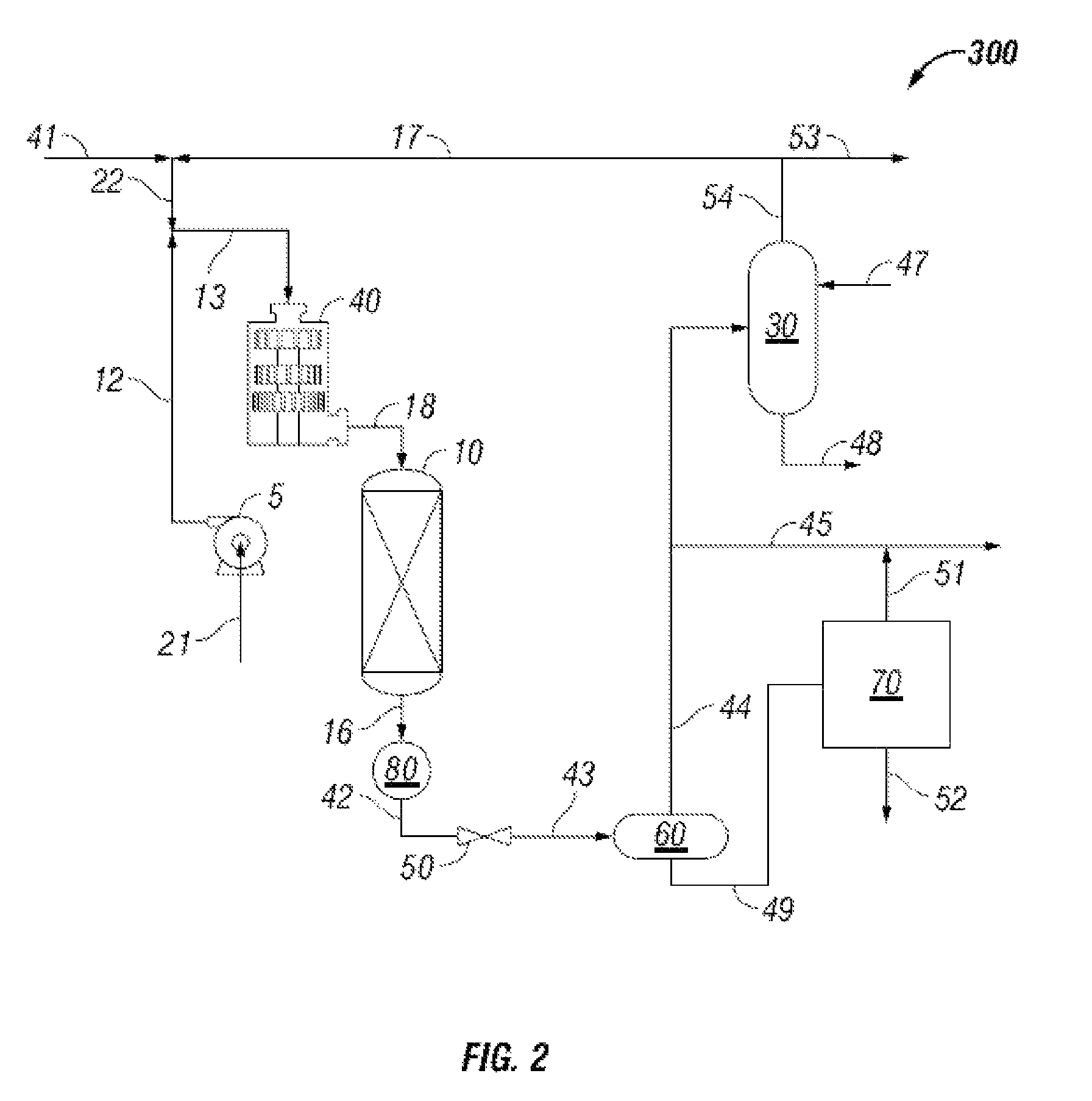

System and process for hydrodesulfurization, hydrodenitrogenation, or hydrofinishing

ActiveUS20090000989A1Increase ratingsLow costShaking/oscillating/vibrating mixersFlow mixersHydrogenFixed bed

A method for hydrodesulfurization by forming a dispersion comprising hydrogen-containing gas bubbles with a mean diameter of less than 1 micron dispersed in a liquid phase comprising sulfur-containing compounds. Desulfurizing a liquid stream comprising sulfur-containing compounds by subjecting a fluid mixture comprising hydrogen-containing gas and the liquid to a shear rate greater than 20,000 s−1 to produce a dispersion of hydrogen in a continuous phase of the liquid and introducing the dispersion into a fixed bed hydrodesulfurization reactor from which a reactor product is removed. Systems of apparatus for hydrodesulfurization are also presented.

Owner:HRD CORP

Extremely low acidity ultrastable Y zeolite catalyst composition and process

InactiveUS6860986B2High selectivityMolecular sieve catalystsHydrocarbon oil crackingSingle stageMetal

A catalyst composition comprising a low acidity, highly dealuminated ultra stable Y zeolite having an Alpha value of less than about 3 and Broensted acidity measured by FT-IR from about 1 to about 20, preferably from about 1-10, micro mole / g of, an amorphous cracking component and a catalytic amount of hydrogenation component selected from the group consisting of a Group VI metal, a Group VIII metal, and mixtures thereof is disclosed. The present invention provides for a process for converting hydrocarbonaceous oils comprising contacting the hydrocarbonaceous oils with the catalyst under suitable hydrocarbon conversion conditions. Such processes in include, but are not limited to, single stage hydrocracking, two-stage hydrocracking, series-flow hydrocracking, mild hydrocracking, lube hydrocracking, hydrotreating, lube hydrofinishing, hydrodesulphurization, hydrodenitrification, catalytic dewaxing and catalytic cracking.

Owner:CHEVROU USA INC

Hydroprocessing using rejuvenated supported hydroprocessing catalysts

ActiveUS20090261019A1Catalytic naphtha reformingRefining by aromatic hydrocarbon hydrogenationOrganic compoundHydrocarbon

Methods for hydroprocessing of hydrocarbon feedstocks, including hydrodesulfurization and hydrodenitrogenation, using rejuvenated supported metallic catalysts are provided. The supported metallic catalysts comprised of a Group VIII metal, a Group VIB metal, are rejuvenated by a process making use of these metals, an organic complexing agent, and optionally an organic additive. The rejuvenation includes stripping and regeneration of a spent or partially spent catalyst, followed by impregnation with metals and at least one organic compound. The impregnated, regenerated catalysts are dried, calcined, and sulfided.

Owner:EXXON RES & ENG CO

Regeneration and rejuvenation of supported hydroprocessing catalysts

InactiveUS7906447B2Other chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsOrganic compoundHydrodenitrogenation

Methods for rejuvenation of supported metallic catalysts comprised of a Group VIII metal, a Group VIB metal, making use of these metals, an organic complexing agent, and optionally an organic additive, are provided. The rejuvenation includes stripping and regeneration of a spent or partially spent catalyst, followed by impregnation with metals and at least one organic compound. The impregnated, regenerated catalysts are dried, calcined, and sulfided. The catalysts are used for hydroprocessing, particularly hydrodesulfurization and hydrodenitrogenation, of hydrocarbon feedstocks.

Owner:EXXON RES & ENG CO

Heavy hydrocarbon hydroprocessing method

InactiveCN1488719AReduce operating costsReduce recyclingRefining to eliminate hetero atomsWaxHydrodenitrogenation

The present invention discloses a heavy hydrocarbon hydrogenation treatment method, and is characterized by that the residuum raw material is successively passed through protecting agent bed layer, hydrodematalization catalyst bed layer, hydro-desulfurization catalyst bed layer and hydro-denitro-genation (cracking) catalyst bed layer, and after protecting agent bed layer and before hydro-denitro-genation (cracking) catalyst bed layer, and after protecting agent bed layer and before hydro-desulfurization catalyst bed layer the deasphalted oil and / or coker wax oil can be introduced. Said invented method mainly is used for making common hydrogenation treatment of residuum deasphalted oil and coker wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation purification method for siliceous distillate

ActiveCN101343565AIncrease capacityFast inactivationTreatment with hydrotreatment processesPurification methodsHydrogen

The invention relates to a silicon-containing distillate oil hydrofining method, which adopts the method that the silicon-containing distillate oil raw material and hydrogen pass through at least two hydrofining catalyst beds under the hydrofining condition, the silicon-containing distillate oil raw material first passes through a hydrogenising catalyst bed with the silicon catching function, and then passes through a conventional hydrofining catalyst bed; wherein the hydrogenising catalyst with the silicon catching function has a greater pore volume and a specific surface area and a relatively lower metal content. Compared with the prior art, the method has the advantages that the process is simple, the good hydrodesulfurization and hydrodedenitrification performance is kept on the premise of enhancing the silicon-containing ability, and the running period of the device is effectively prolonged. The method can be applied to various silicon-containing distillate oil hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

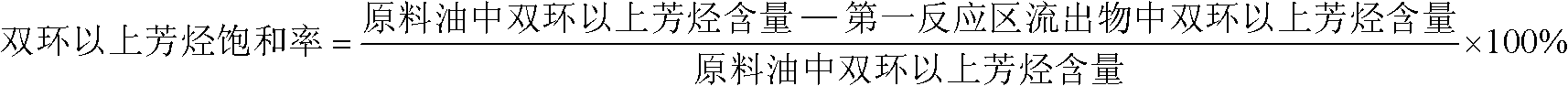

Hydrocracking method for producing gasoline blending component with high octane value

ActiveCN103184073ASimple processEasy to operateHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineReaction zone

The invention relates to a hyfrocracking method for producing a gasoline blending component with a high octane value. The hyfrocracking method controls aromatic saturation depth in a first reaction zone, that is, compared with a diesel oil raw oil, a saturation rate of aromatics with two or more aromatic rings in reaction effluent in the first reaction zone is over 60%, the content of monocyclic aromatics is increased to over 40 mass% on basis of liquid components of the reaction effluent in the first reaction zone; and at the same time, organic nitrogen content in feeding materials of a second reaction zone is no higher than 10 [mu]g.g<-1>. The method for controlling the aromatic saturation depth of a hydrofining section and reinforcing hydro-denitrification activity of a hydrofining catalyst, gasoline fractions with sulfur content less than 50 [mu]g / g and a research octane number higher than 90 can be produced from inferior diesel fractions with high content of the aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

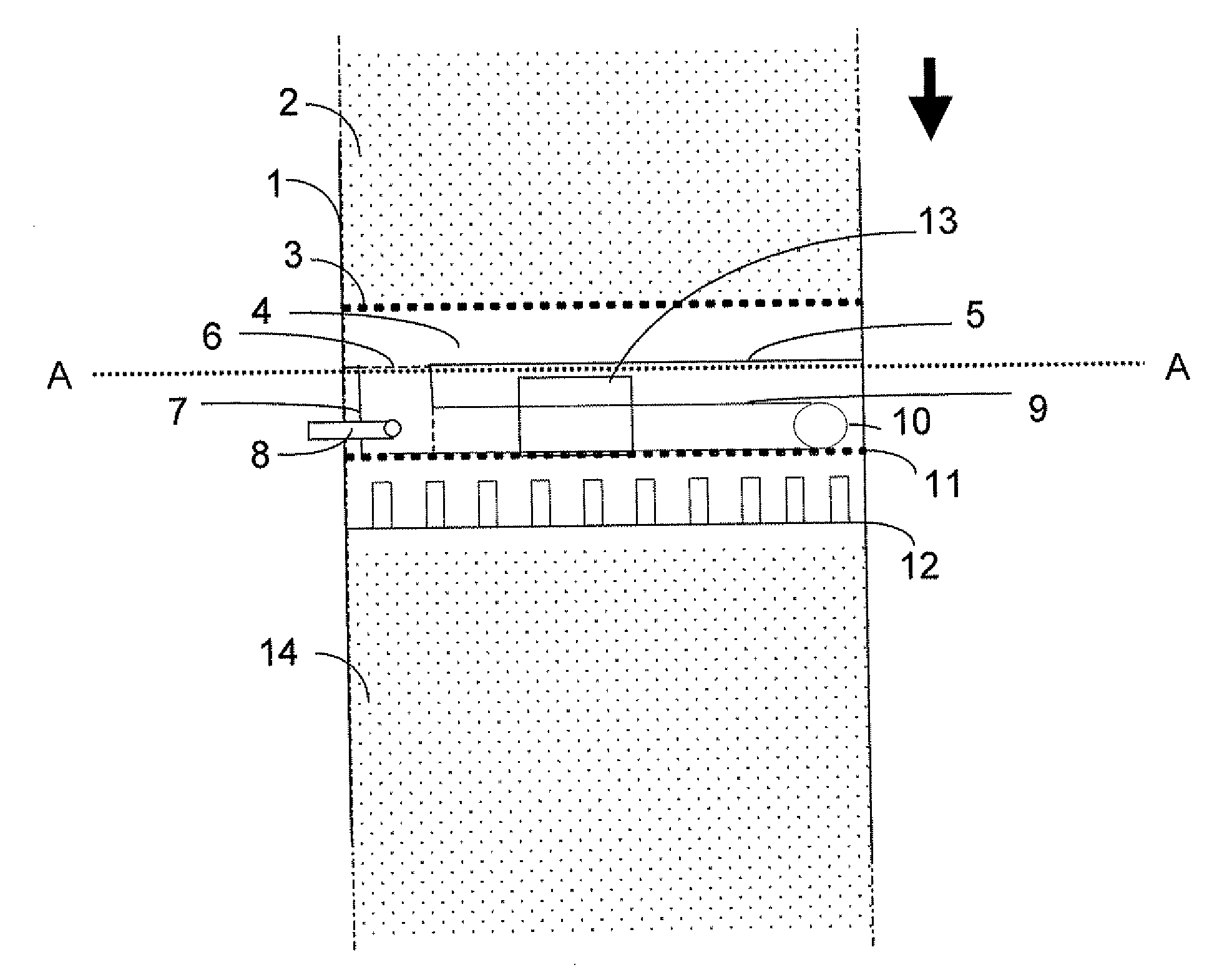

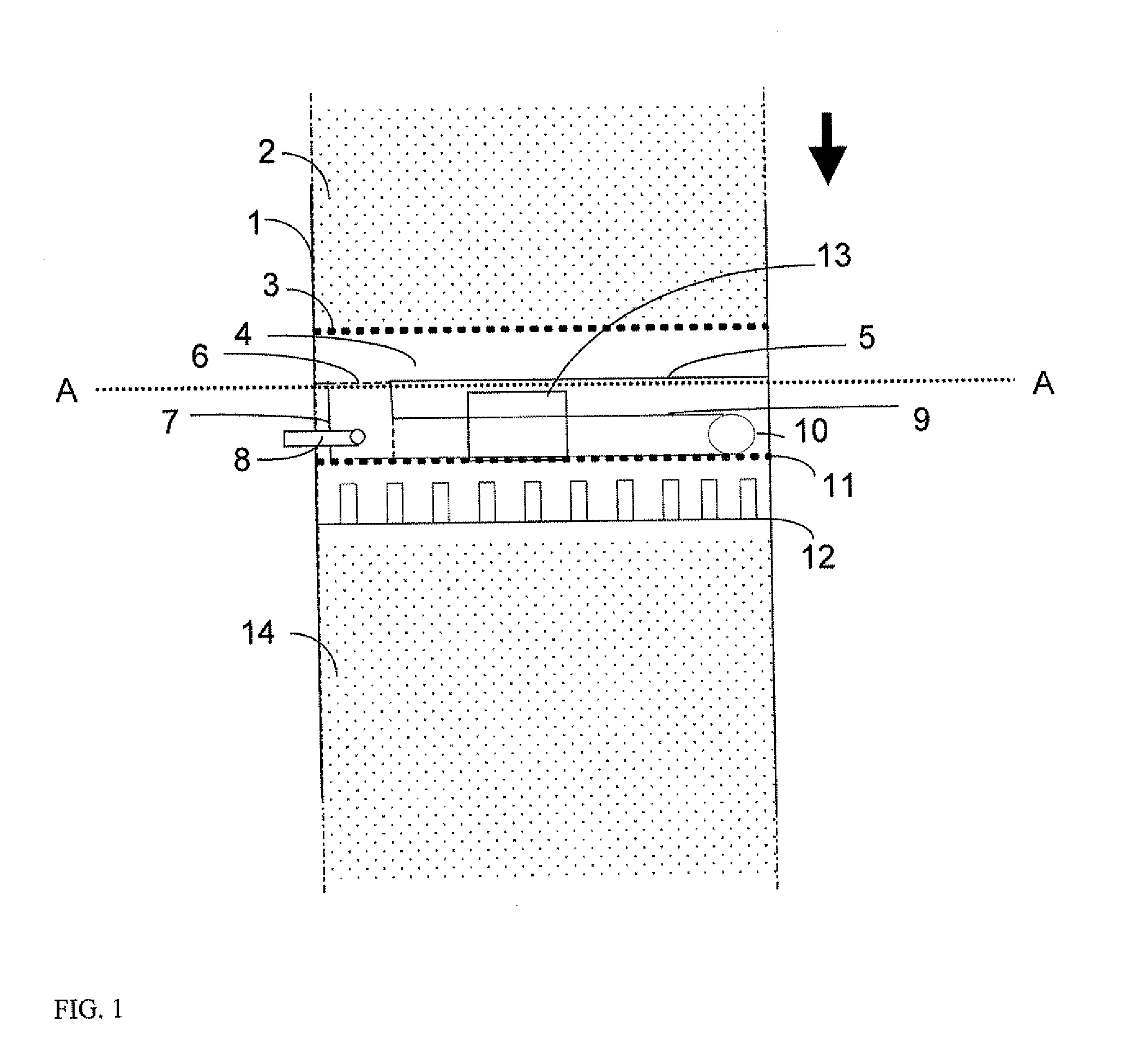

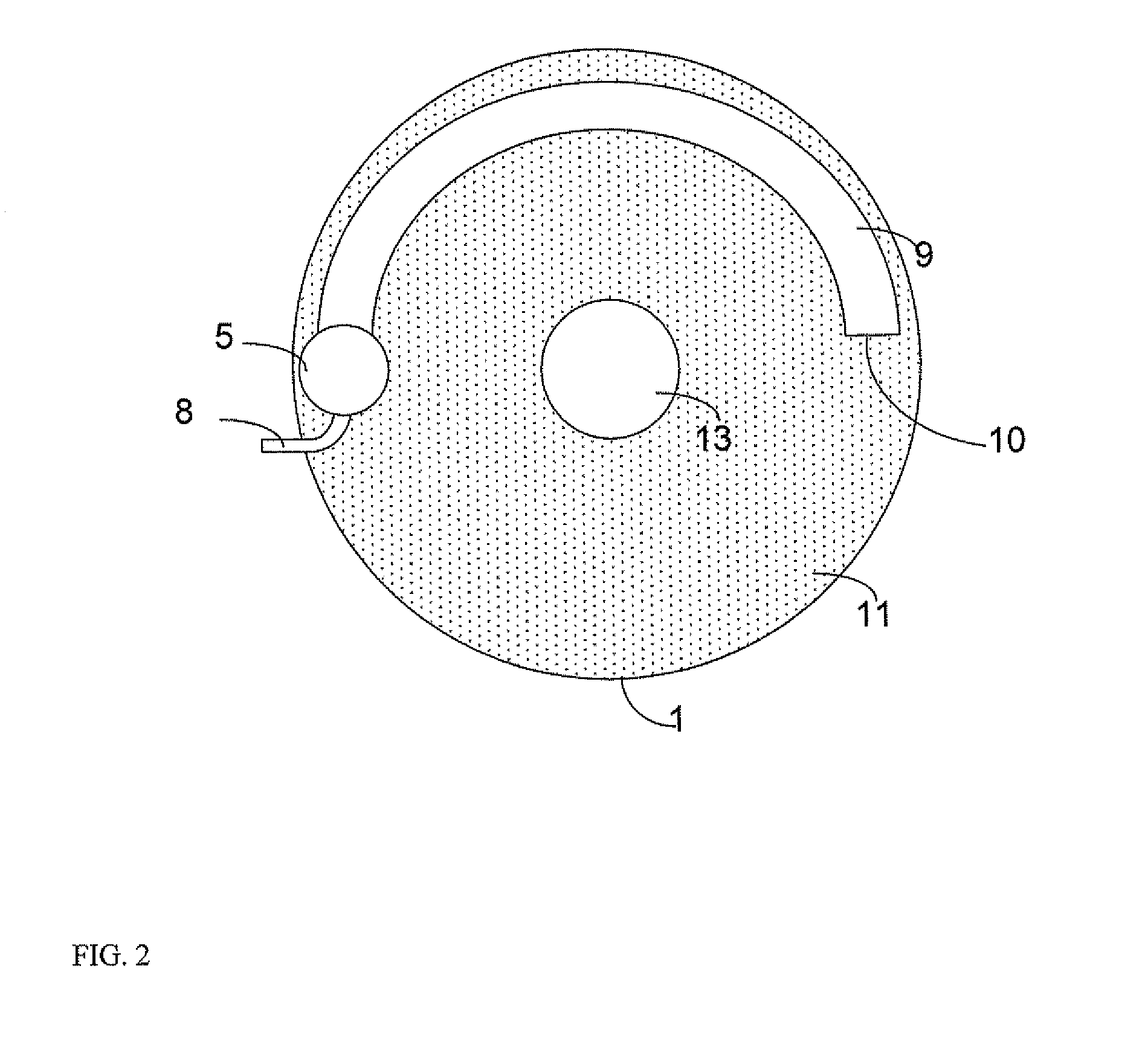

Compact device for mixing fluids in a downflow reactor

ActiveUS20110123410A1Device compactPhysical/chemical process catalystsFlow mixersEngineeringHydrogen treatment

A compact device for mixing fluids in a downflow reactor comprising at least one substantially horizontal gathering device provided with a vertical gathering line intended to receive the fluids, at least one injection device arranged in the gathering line, an annular mixing chamber located downstream from the gathering means in the direction of circulation of the fluids, the mixing chamber comprising an inlet end directly connected to the gathering line and an outlet end for passage of the fluids, and a horizontal predistribution plate comprising at least one chimney, the plate being located downstream from the mixing chamber at a distance d2, in the direction of circulation of the fluids. The reactor is especially useful for exothermic reactions, e.g. hydrotreatment, hydrodesulfurization, hydrodenitrogenation, hydrocracking, hydrogenation and hydrodearomatization reactions.

Owner:INST FR DU PETROLE

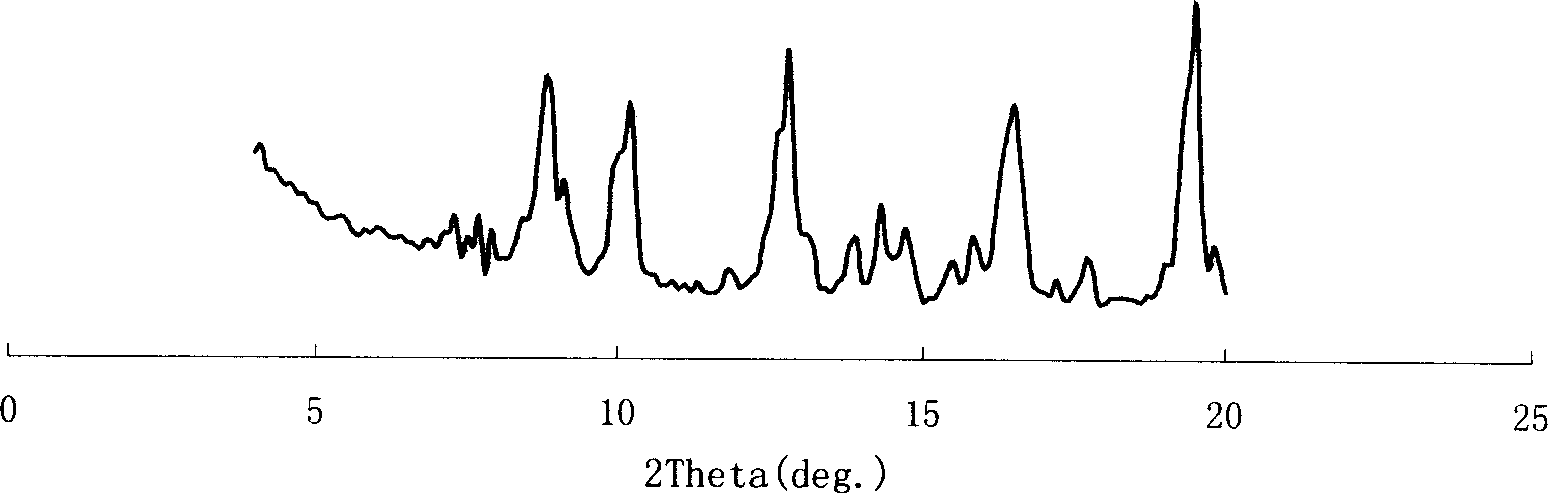

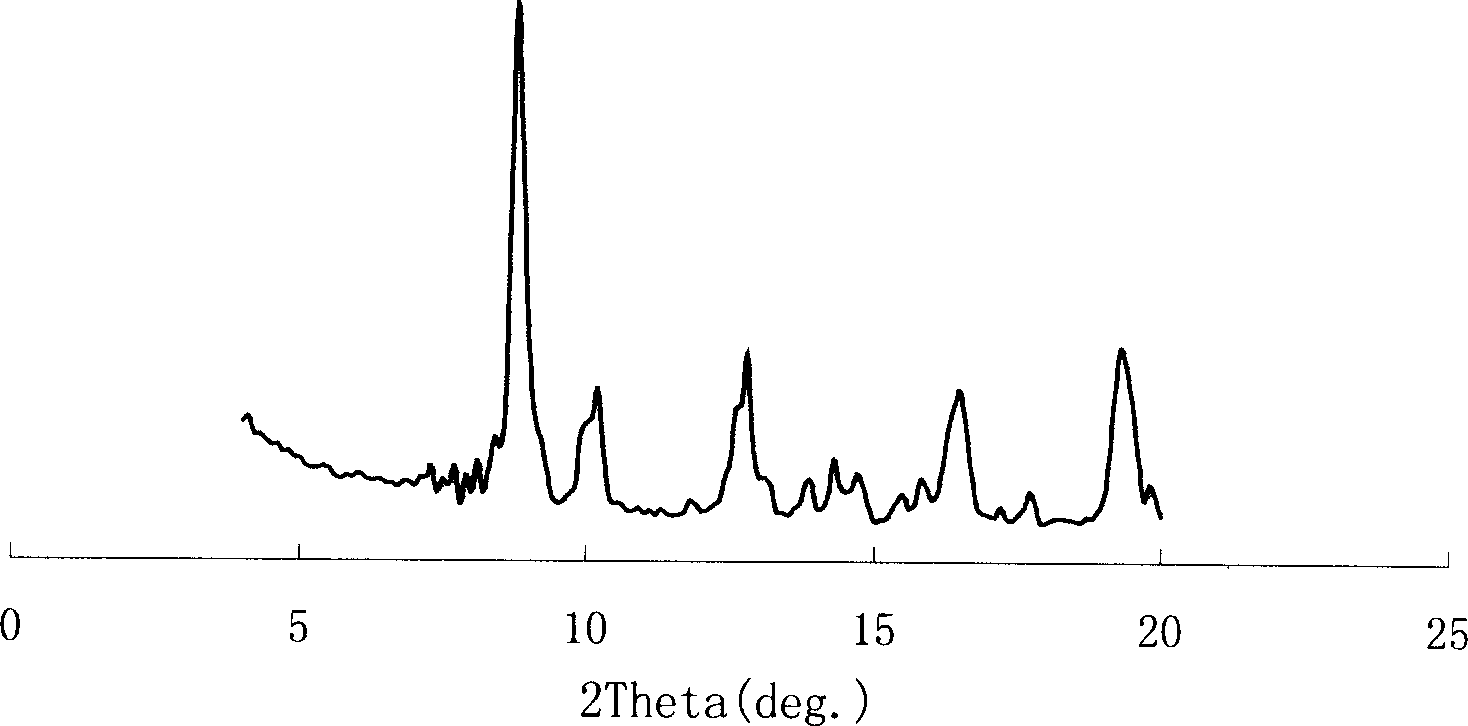

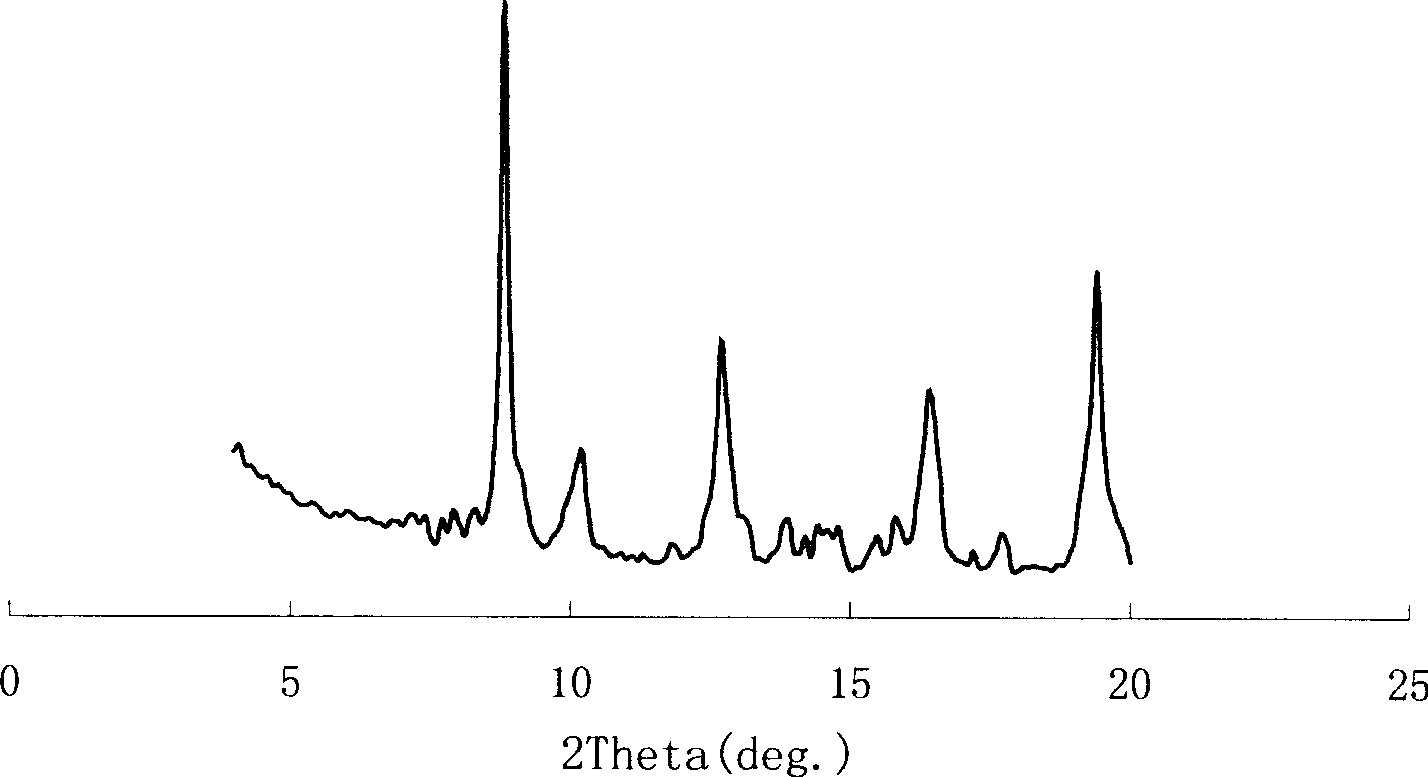

Crystalline ammonia transition metal molybdate

ActiveUS20170165649A1Catalyst activation/preparationHydrocarbon oil crackingMolybdateHydrodesulfurization

A hydroprocessing catalyst has been developed. The catalyst is a unique crystalline ammonia transition metal molybdate material. The hydroprocessing using the crystalline ammonia transition metal molybdate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Hydrodenitrogenation of hydrocarbons utilizing a carbon-supported catalyst

InactiveUS6162351ATreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsNaphthaNitrogen

A naphtha or a middle distillate hydrocarbon is hydrodenitrogenized by hydrotreating in the presence of a catalyst containing a carbon support bearing (i) molybdenum or tungsten, (ii) a metal of non-noble Group VIII, and (iii) chromium.

Owner:TEXACO INC

Hydrodenitrogenation catalyst and application thereof

ActiveCN101890383AExtended operating cycleIncrease depositionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPorosityHydrogen

The invention discloses a hydrodenitrogenation catalyst and application thereof. The catalyst has the characteristics of large pore volume, large pore diameter, reasonable pore size distribution, high porosity, large outer surface orifice and high pore canal penetrability. The catalyst is applied to a residual oil fixed bed hydrogenation method so that the nitrogen impurity content of treated oil is less than 100 mu g / g, separated metal can be uniformly deposited on an entire catalyst bed layer, long-period running is kept, very high denitrogenation rate is achieved and treated residual oil can be fed into a hydrogen cracking device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment catalyst and its preparation method

ActiveCN1769376AHDSHighHigh activityCatalyst carriersRefining to eliminate hetero atomsNitrogenTitanium

The invention discloses the hydrotreatment catalyst and preparing method. The catalyst contains the 1wt%-20wt% organic auxiliary agent, using the aluminum oxide modified by titanium and silicon as carrier, and using the metals in the VIB and VIII as active metal componemt. The method comprises the following steps: using the modified aluminum oxide as carrier, after soaking the catalyst carrier in the active metal and organic auxiliary agent, drying at the 200íµ, and getting the catalyst. The said catalyst can be used for hydrotreating process of fraction of petroleum, especially for hydrodesulphurization and hydrodenitrification process of middle distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

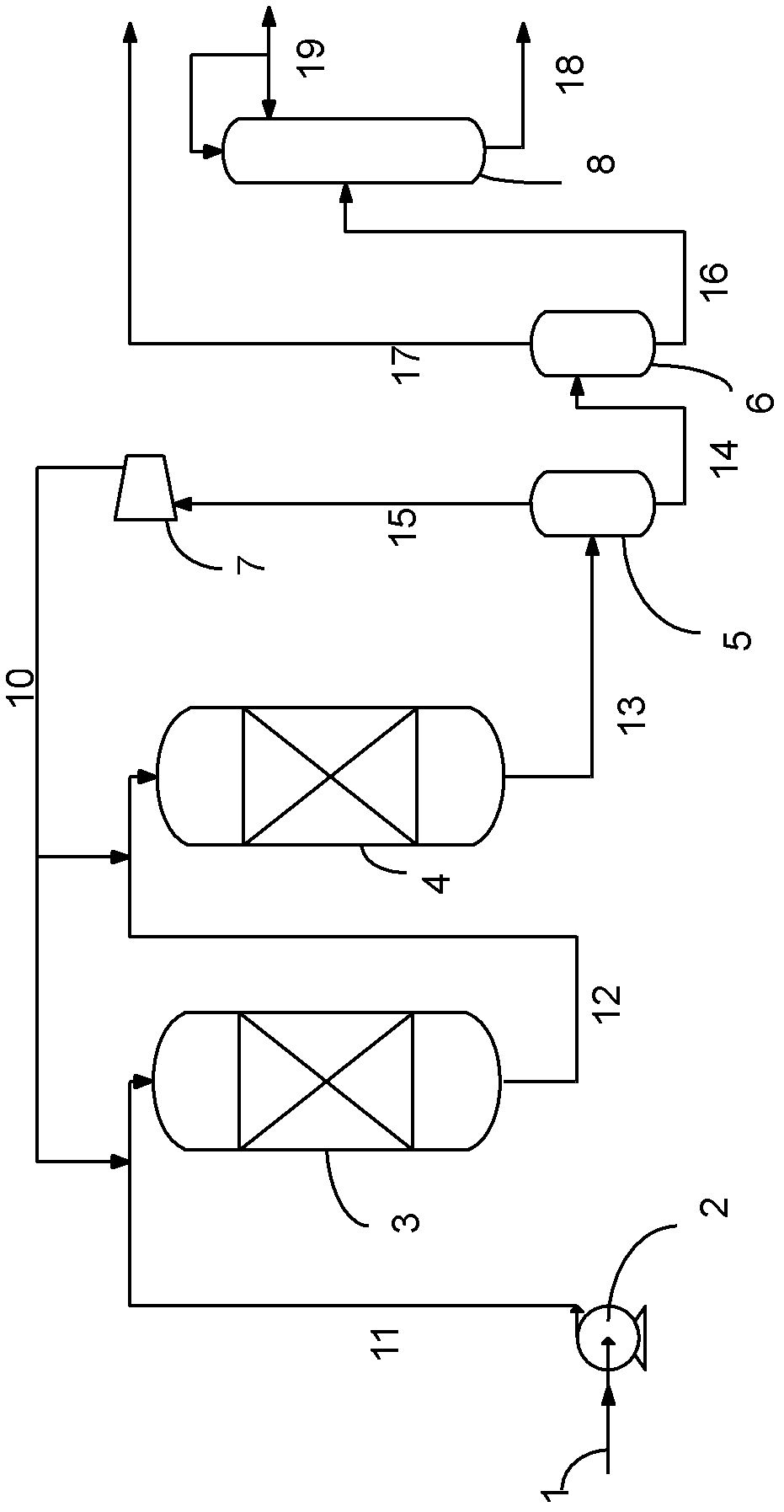

Process of desulfurizing and eliminating aromatic hydrocarbons deeply for diesel oil

InactiveCN1485413AReduced sulfur and aromatic contentReduce severityTreatment with hydrotreatment processesHigh pressureImpurity

A process of removing sulfur and aromatic hydrocarbons from diesel oil. It comprises, mixing diesel oil and circulating hydrogen, and entering the first reactor for hydrogenating and removing sulfur and nitrogen, hydrogenating and saturating olefins and aromatic hydrocarbons, the effluent entering a high-temperature high-pressure gas stripping tower for gas stripping to remove H2S and NH3, then mixing the effluent and circulating hydrogen, entering the second hydrogenation refining reactor; the effluent of the reactor entering in sequence a high-pressure separator, a low-pressure separator and a fractionating tower, the fractionating tower separating naphtha and diesel fractions; gas enriched in hydrogen from the high-temperature high-pressure gas stripping tower entering a water-washing tank, to remove H2S and NH3, then mixing with gas enriched in hydrogen from the high-pressure separator, compressing and circulating to the first and the second reactor. The method could greatly reduce impurities in diesel oil, such as sulfur and nitrogen.

Owner:CHINA PETROLEUM & CHEM CORP +1

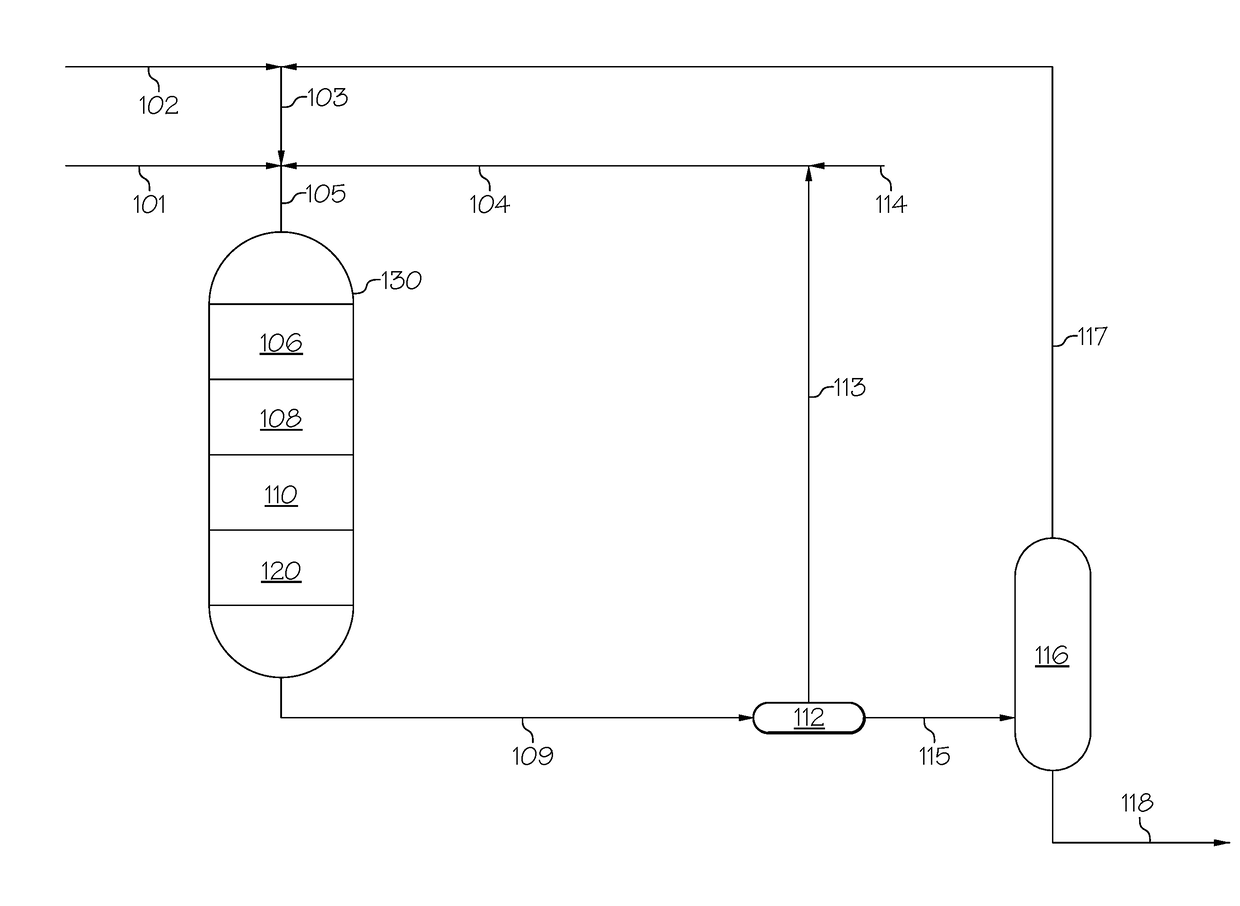

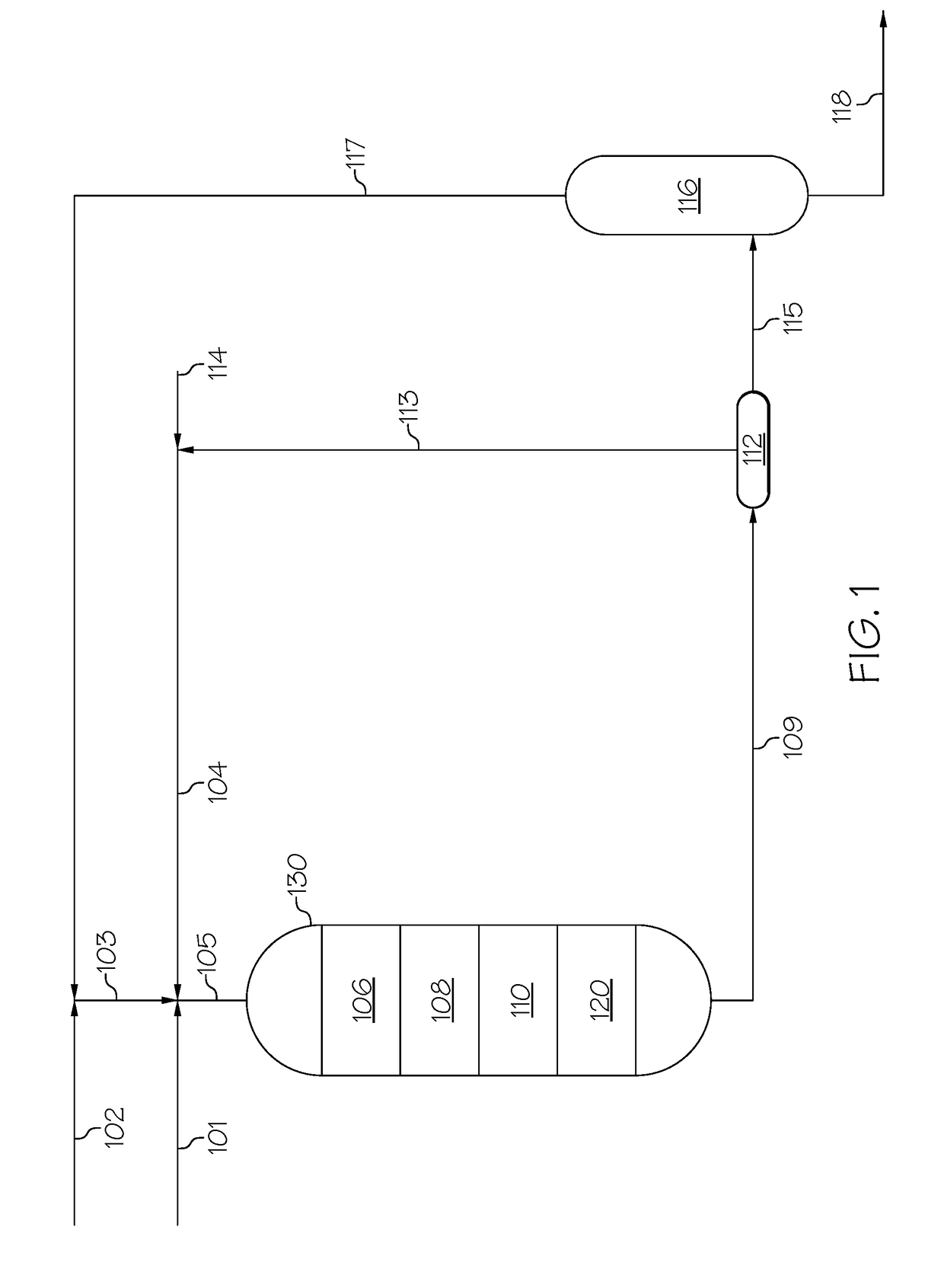

Process for hydrodesulfurization, hydrodenitrogenation, hydrofinishing, or amine production

InactiveUS8128808B2Increase ratingsLow costShaking/oscillating/vibrating mixersFlow mixersMean diameterKerosene

Herein disclosed is a method for hydrodesulfurization, hydrodenitrogenation, hydrofinishing, amine production or a combination thereof. The method comprises forming a dispersion comprising hydrogen-containing gas bubbles dispersed in a liquid feedstock, wherein the bubbles have a mean diameter of less than about 5 μm and wherein the feedstock comprises a mixture of petroleum-derived hydrocarbons and a naturally derived renewable oil. The feedstock comprises hydrocarbons selected from the group consisting of liquid natural gas, crude oil, crude oil fractions, gasoline, diesel, naphtha, kerosene, jet fuel, fuel oils, and combinations thereof. The method further comprises contacting the dispersion with a catalyst that is active for hydrodesulfurization, hydrodenitrogenation, hydrofinishing, amine production, or a combination thereof. The catalyst comprises homogeneous catalysts and heterogeneous catalysts. The catalyst may be utilized in fixed-bed or slurry applications.

Owner:HRD CORP

Method of producing catalytic reforming raw material

The invention is a method for producing catalytic reforming raw material, cutting secondary gasoline raw material into light gasoline fraction, medium gasoline fraction and heavy gasoline fraction, where the medium gasoline fraction, optional virgin naphtha and hydrogen gas contact with first hydrofining catalyst to make alkene saturated reaction, the resultant effluent is not separated but directly contacts with second hydrofining catalyst to make hydrodesulfurization and hydro- denitrogenation reactions, and the extracted hydrogen-enriched gas is recycled and the extracted liquid enters a distillation dehydrating tower and is purified to obtain naphtha. And it can process secondary gasoline with high sulfur, nitrogen and alkene contents, and provides qualified raw material with sulfur and nitrogen contents both less than 0.5 mug / g for catalytic reforming.

Owner:CHINA PETROLEUM & CHEM CORP

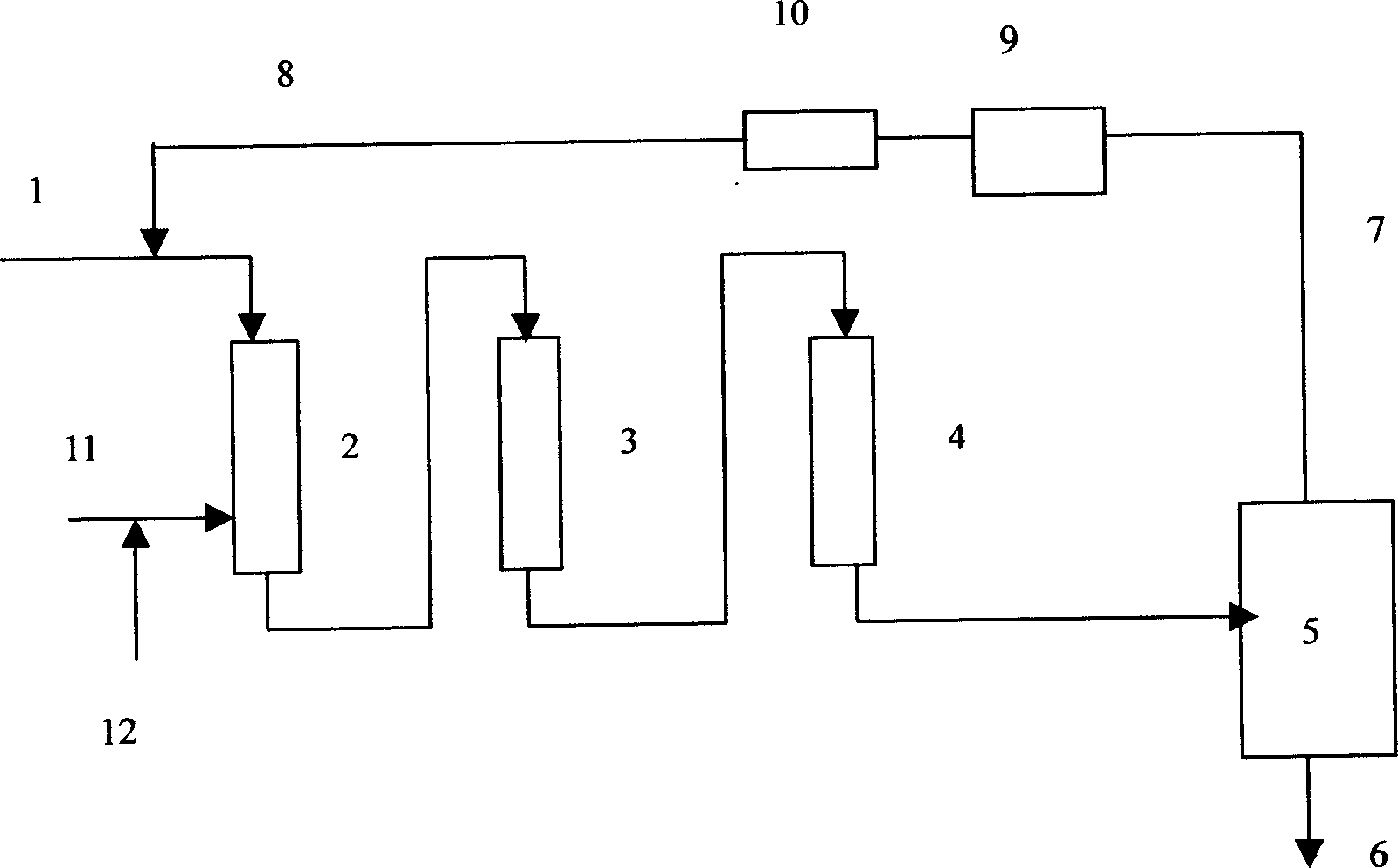

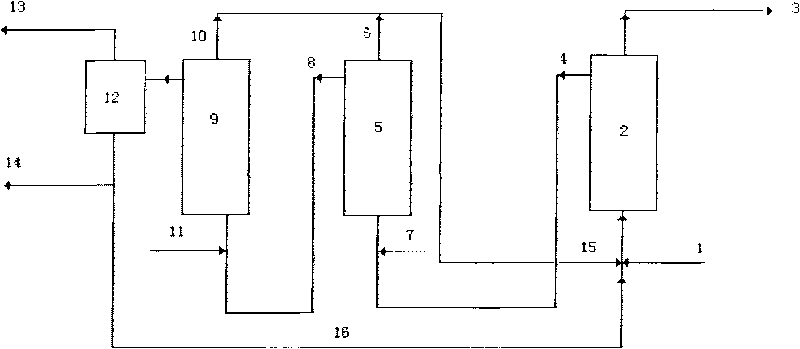

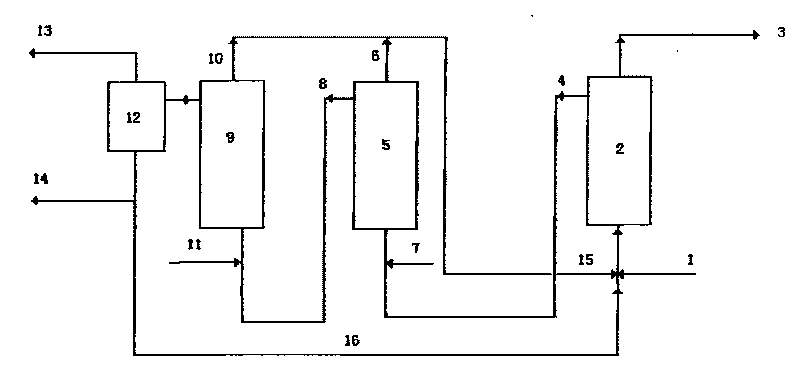

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

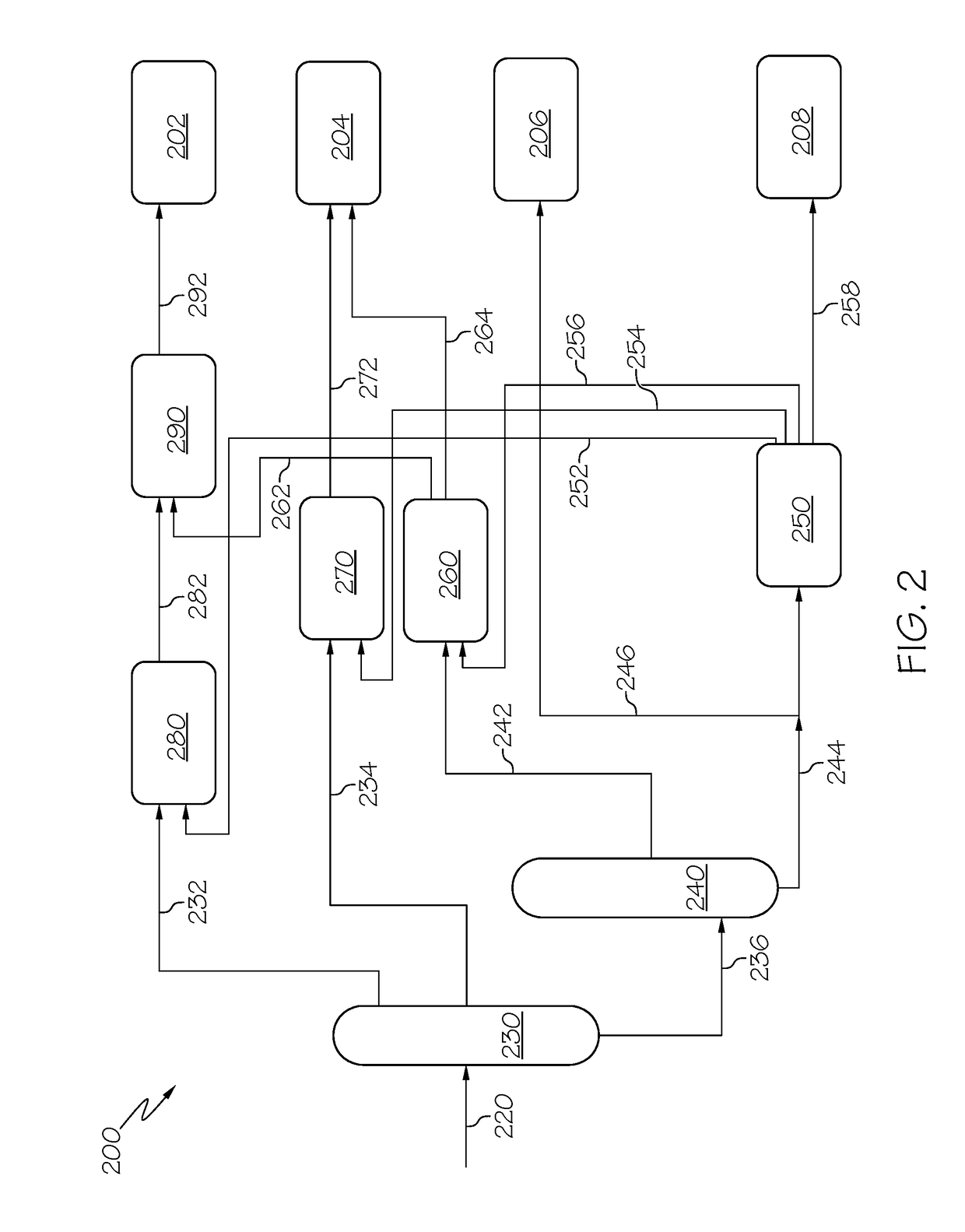

Systems and methods for upgrading heavy oils

ActiveUS20170349846A1Improve functionalityFunction increaseTreatment with hydrotreatment processesRefining to eliminate hetero atomsNitrogenFuel oil

In accordance with one embodiment of the present disclosure, a heavy oil may be upgraded by a process that may include removing at least a portion of metals from the heavy oil in a hydrodemetalization reaction zone to form a hydrodemetalization reaction effluent, removing at least a portion of metals and at least a portion of nitrogen from the hydrodemetalization reaction effluent in a transition reaction zone to form a transition reaction effluent, removing at least a portion of nitrogen from the transition reaction effluent in a hydrodenitrogenation reaction zone to form a hydrodenitrogenation reaction effluent, and reducing aromatics content in the hydrodenitrogenation reaction effluent in a hydrocracking reaction zone by contacting the hydrodenitrogenation reaction effluent to form an upgraded fuel.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com