Patents

Literature

344results about How to "Full and even contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

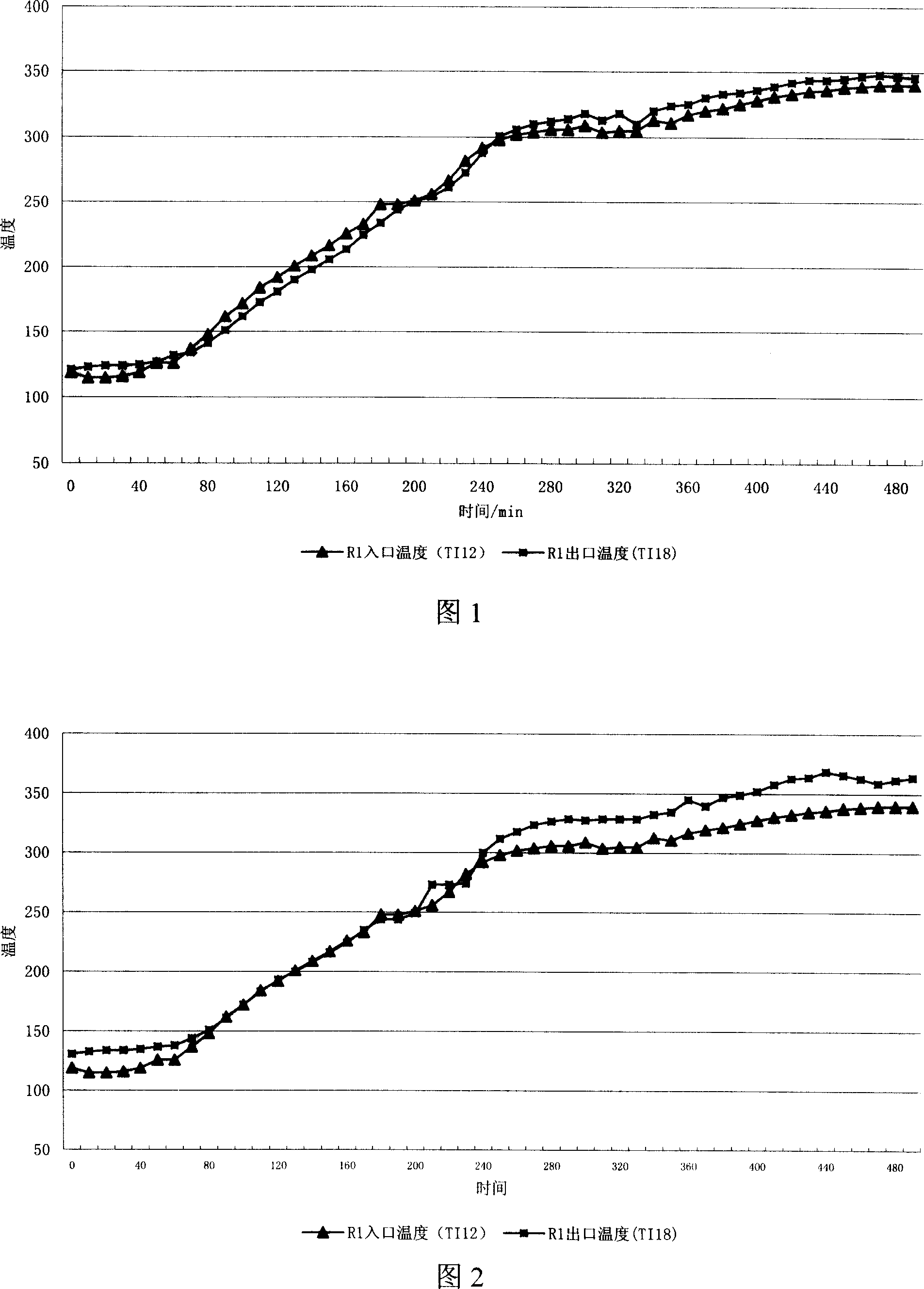

Prepn process of vulcanized hydrogenation catalyst

ActiveCN101088619AFull and even contactEvenly mixedCatalyst activation/preparationRefining by selective hydrogenationSulfurNitrogen

The present invention relates to one kind of vulcanized hydrocarbon oil hydrogenating catalyst and its preparation process. The preparation process includes the first supporting certain amount of VI and VIII metal precursor oxide, the subsequent introducing sulfur and heat treatment in dynamic heating equipment, and final adding the residual VI and VIII metal precursor oxide and drying treatment. The present invention combines the pre-vulcanizing into the preparation process of catalyst, and the catalyst has raised reaction performance, and is suitable for hydrocarbon oil hydroprocessing, especially light fraction oil desulfurizing reaction, hydrodenitrogenation reaction, arene hydrogenating saturation and other catalytic reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

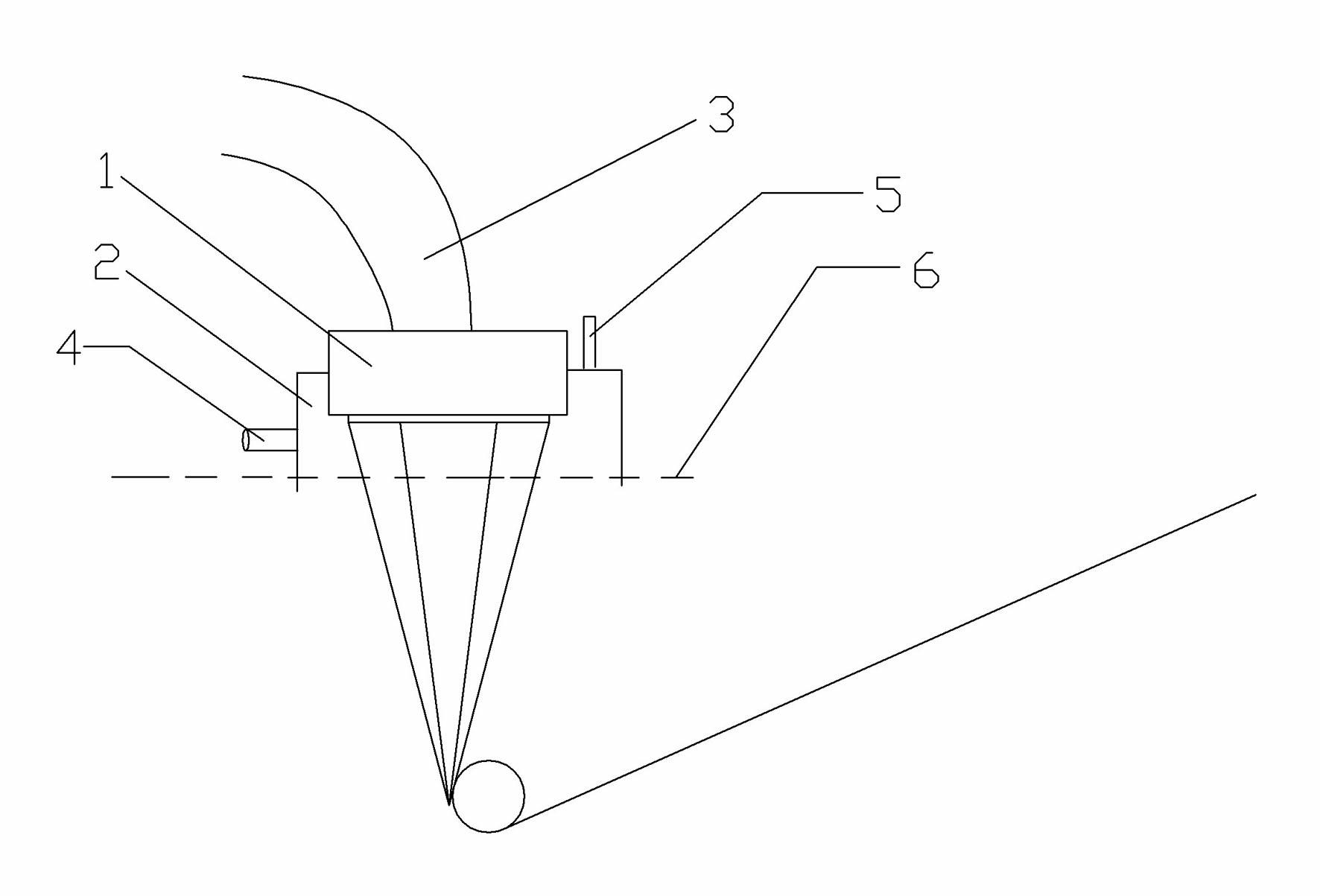

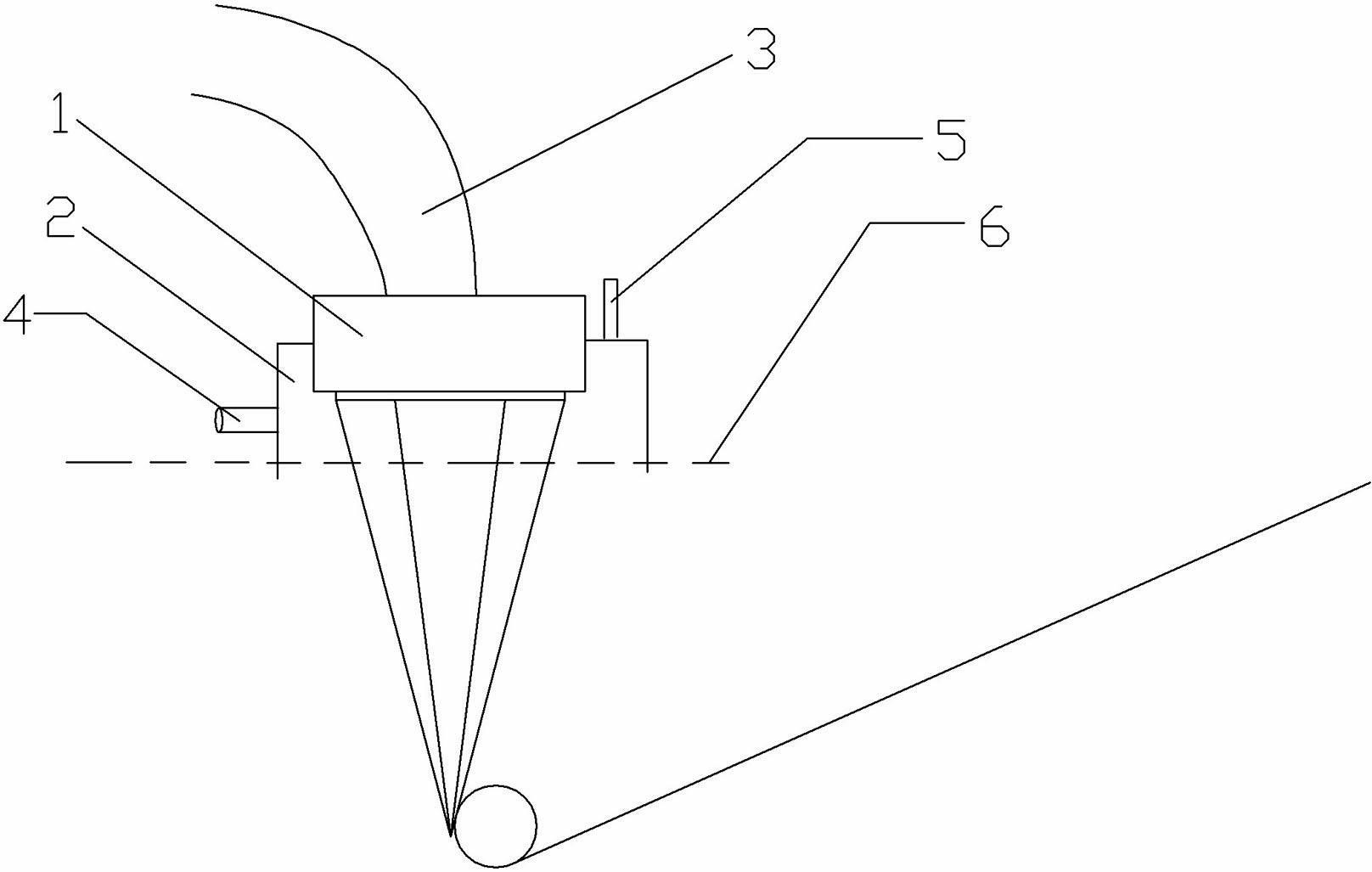

A method for preparing polyacrylonitrile carbon fiber precursors by dry jet wet spinning

ActiveCN102277629AFull and even contactInhibition formationArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentYarnGas liquid reaction

The invention relates to a method for preparing a polyacrylonitrile carbon fiber precursor. The method comprises the following steps of: copolymerizing acrylonitrile and copolymerization components in multicomponent solution so as to form polymer spinning stock solution which has a relatively uniform and controllable molecular structure, performing demonomerization on the spinning stock solution,defoaming, filtering, and preparing the polyacrylonitrile carbon fiber precursor by a dry-jet wet-spinning process. The key technology of the method is that: a gas storage box is arranged on a dry wet spinning pack, the gas storage box and the liquid level of coagulating bath fluid form a dry-jet wet-spinning air layer into a confined space, and ammonia is persistently aerated into the space to carry out gas-liquid reaction with spinning solution trickle in the air layer. The polyacrylonitrile precursor prepared by the method has regular sections and few defects, the density is not less than 1.187g / cm<3>, the density after carbonization is not less than 1.79g / cm<3>, the strength is not less than 5.1GPa, and the modulus of elasticity is 280 to 300GPa.

Owner:KINGFA SCI & TECH CO LTD +1

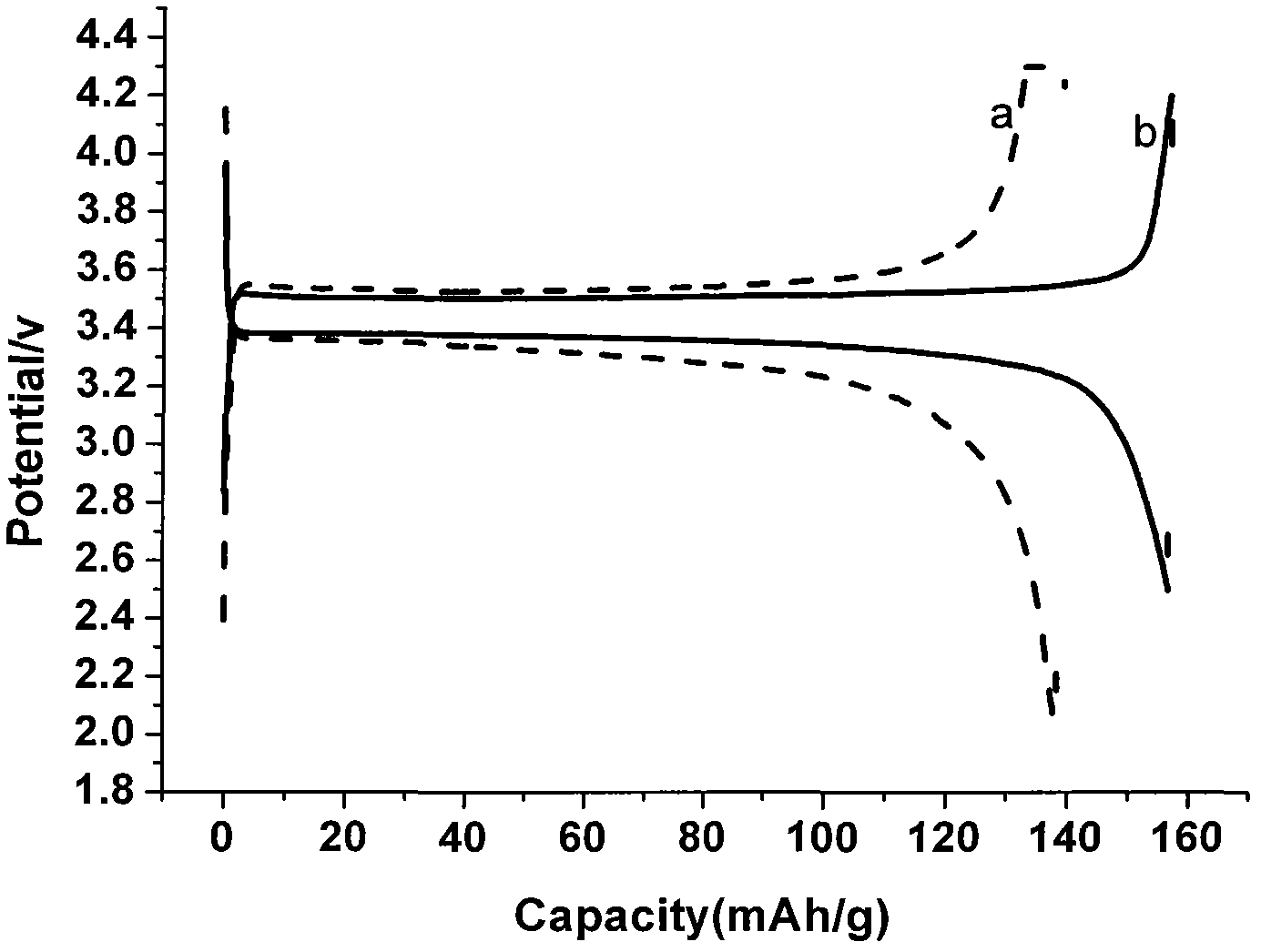

A kind of preparation method of the lithium-ion battery of conductive polymer coating positive electrode

InactiveCN102280656AImprove adhesionImprove conductivityCell electrodesSecondary cellsConductive polymerSlurry

The invention discloses a preparation method of a lithium-ion battery with a conductive polymer coated positive electrode. The positive electrode sheet is a positive electrode slurry made of a positive electrode material, a conductive agent, a positive electrode binder, a conductive polymer or a conductive polymer monomer, and a solvent. The negative electrode sheet is composed of negative electrode material, thickener, negative electrode binder, and solvent mixed into negative electrode slurry and negative electrode current collector. The specific capacity of the battery is increased by 10-20% by adding a conductive polymer or a conductive polymer monomer to the slurry for coating. The invention effectively improves the performance of the prepared positive electrode material, and because the method is simple, the product cost is reduced, the process is simplified, and the method is suitable for large-scale production.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

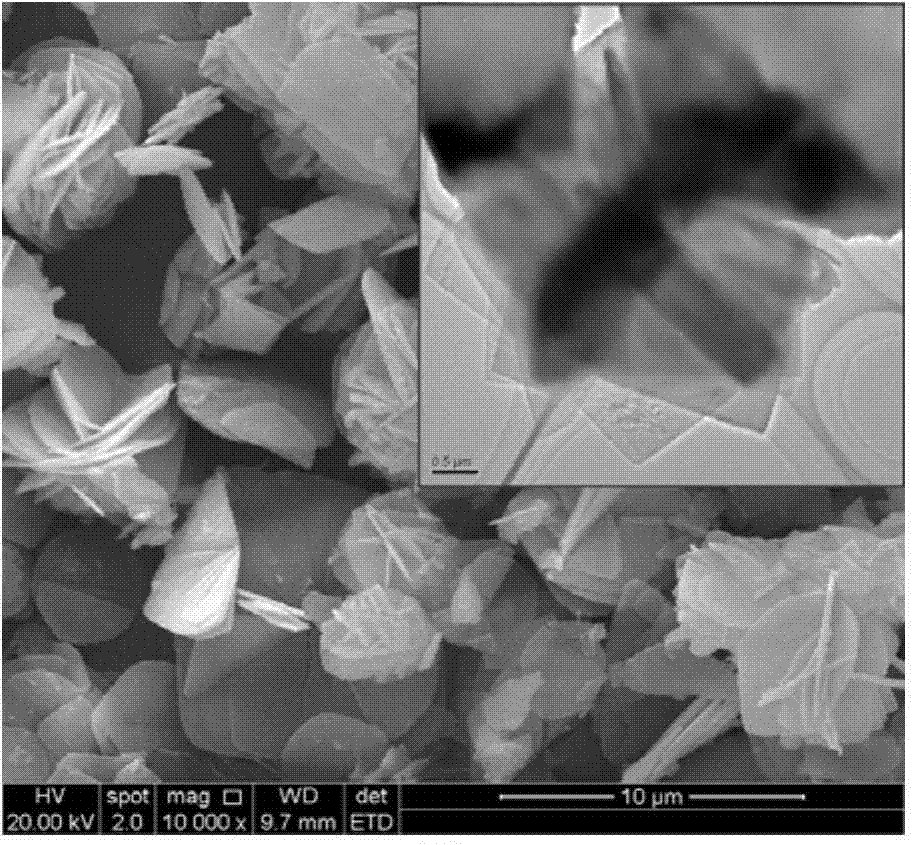

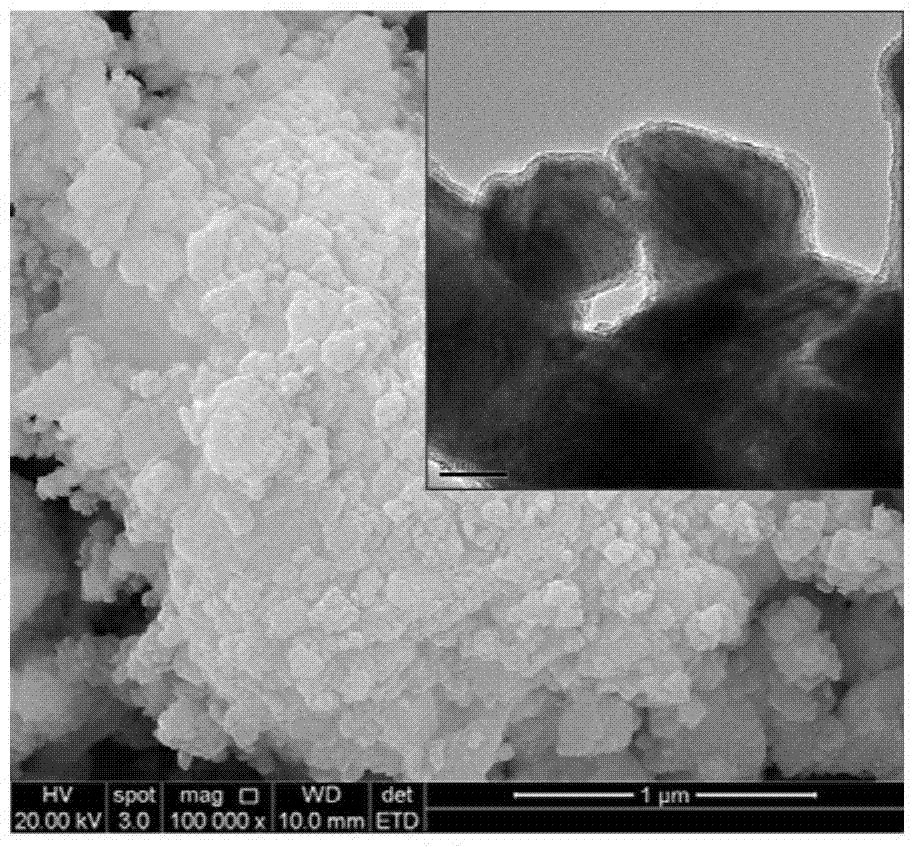

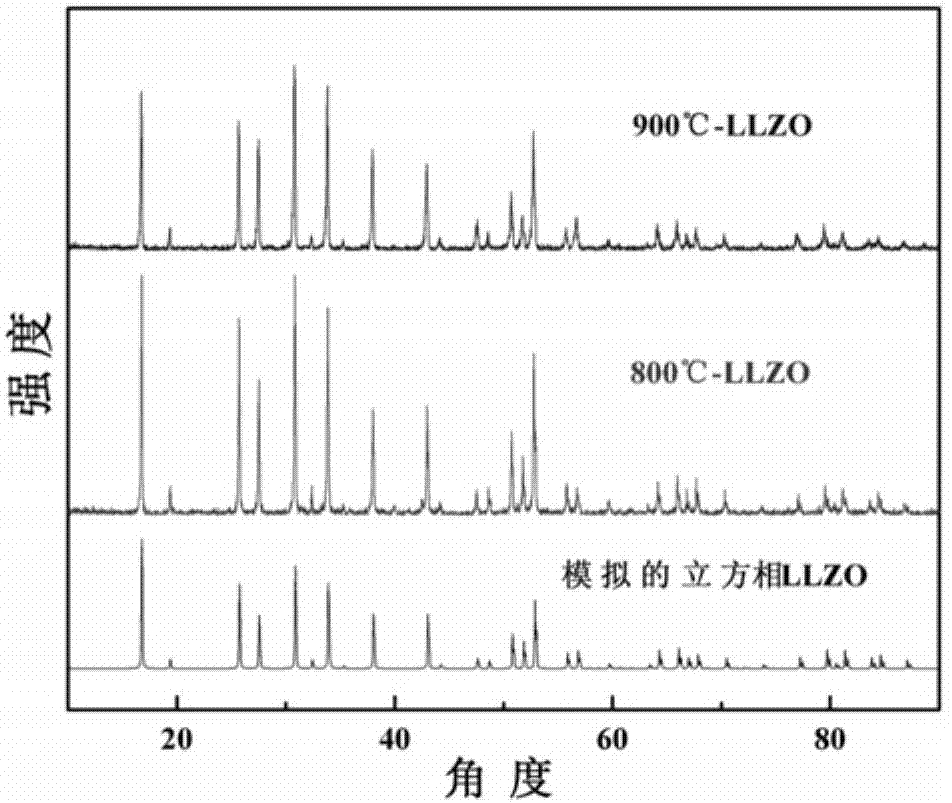

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

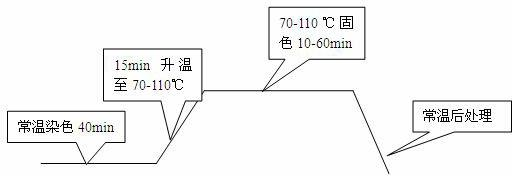

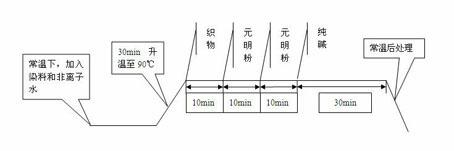

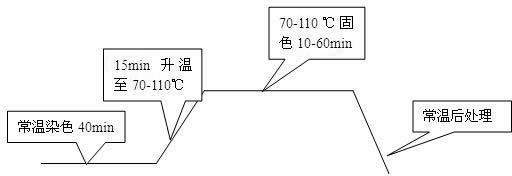

Dyeing process of pure cotton fabric

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

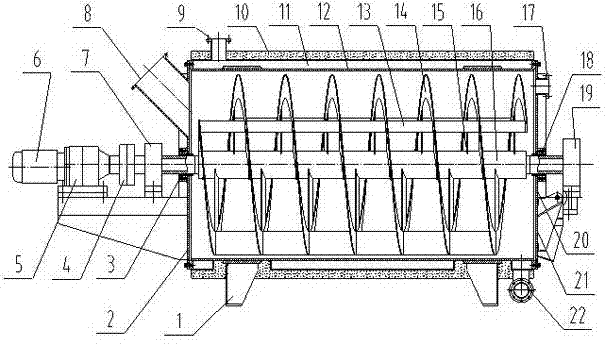

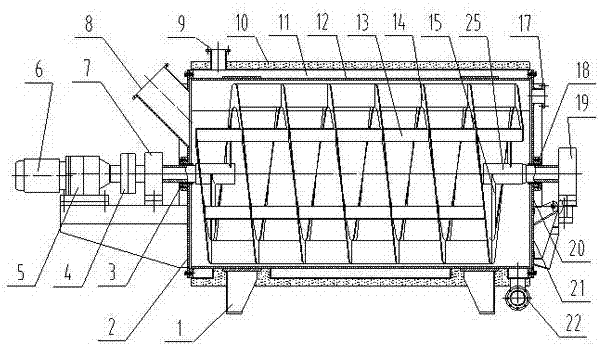

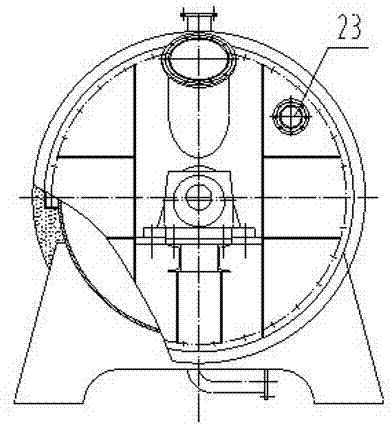

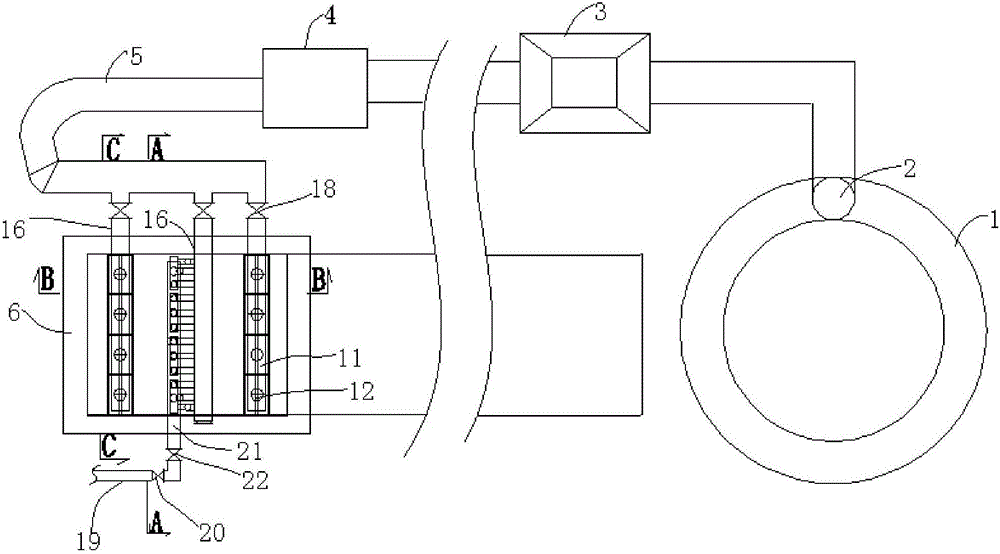

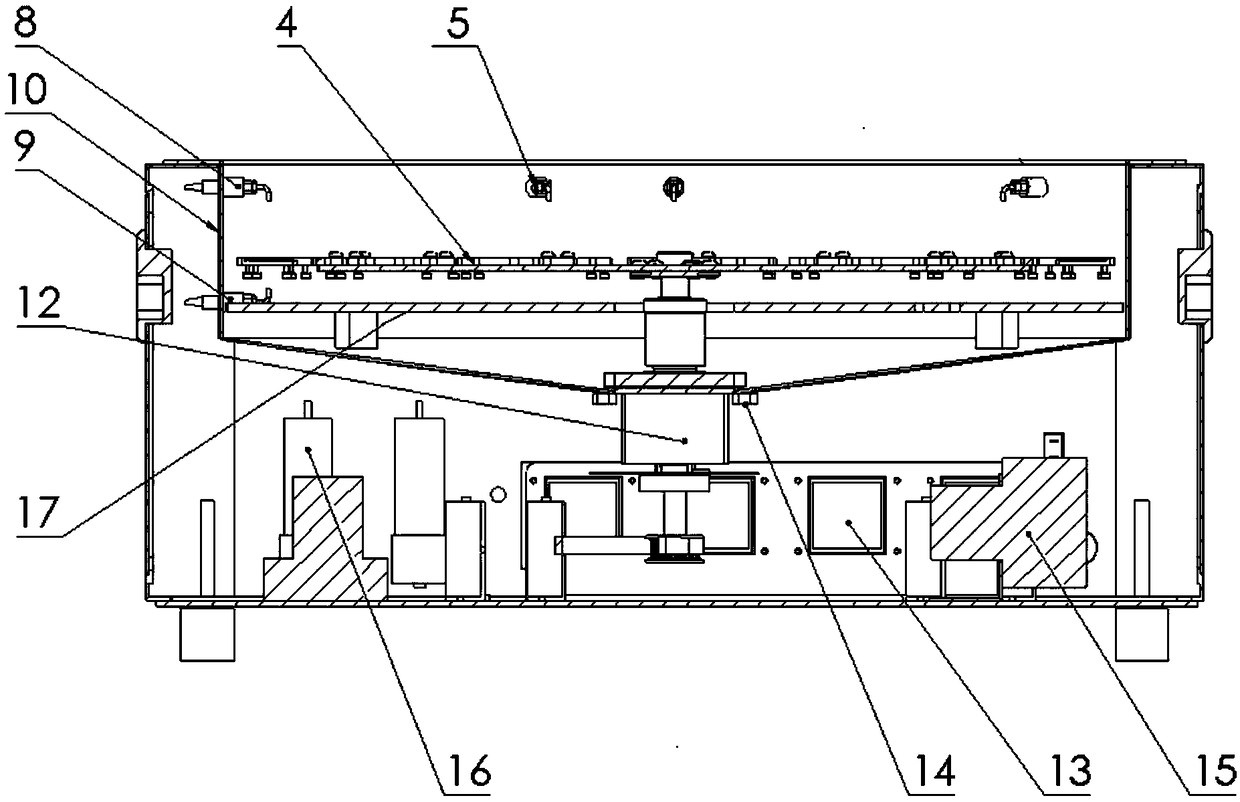

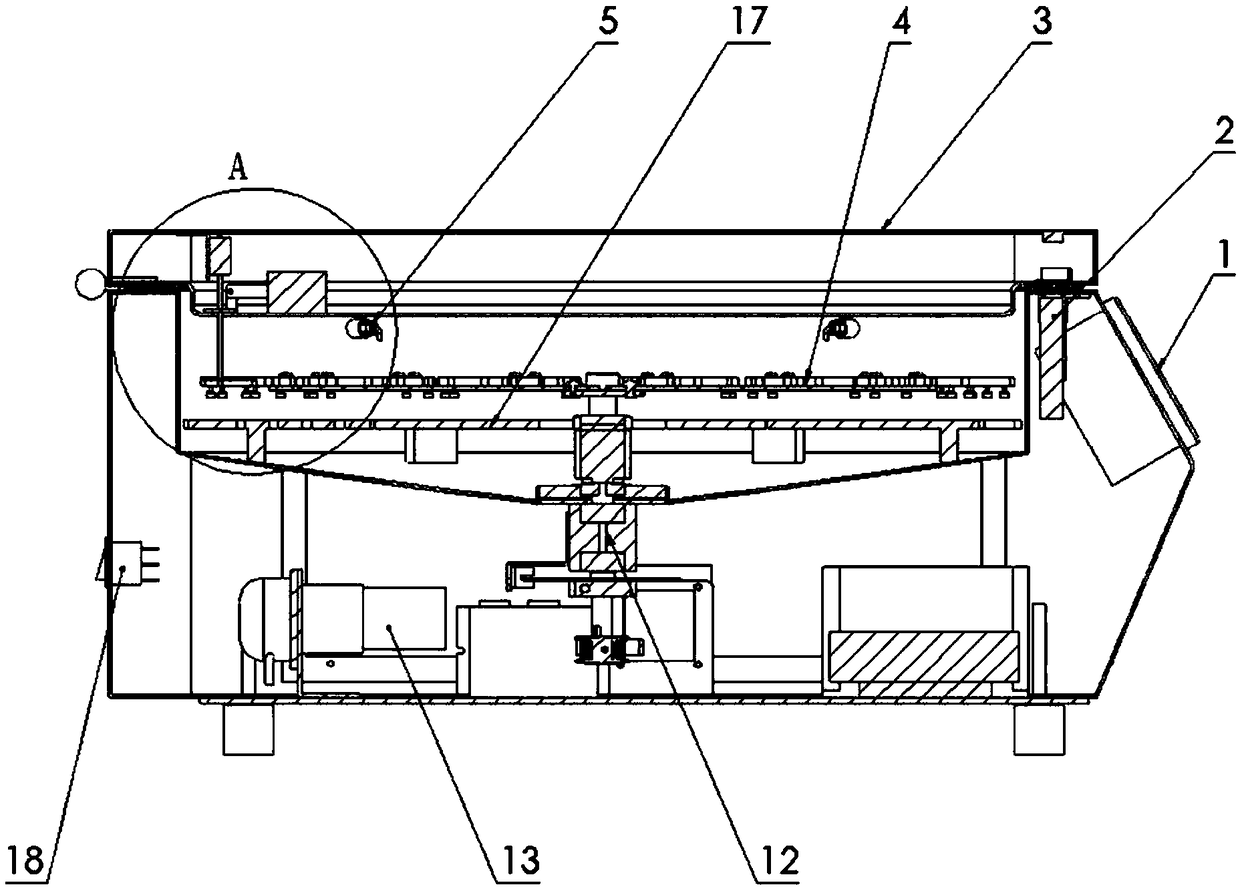

Horizontal aerobic fermentation reactor and aerobic fermentation reaction method

InactiveCN102924131AIncrease contact areaReduce energy consumptionClimate change adaptationOrganic fertiliser preparationBiologySmall footprint

The invention discloses a horizontal aerobic fermentation reactor and an aerobic fermentation reaction method. The horizontal aerobic fermentation reactor comprises a horizontal cylinder, wherein a stirring device is arranged in the horizontal cylinder. Through a jacket connected with an external connecting pipe, a fermentation material is rapidly heated and an aerobic fermentation reaction is controlled to be carried out at a proper temperature, death and dormancy of aerobic microorganisms due to overhigh fermentation temperature are avoided; through driving the stirring device with a helical blade to rotate, the fermentation material is in full and uniform contact with oxygen to generate a high-speed aerobic reaction; through a ventilating flange connected with an external ventilating system, waste gas generated by the reaction is intensively treated and then exhausted; and heat generated by the reaction is recycled. The horizontal aerobic fermentation reactor has the advantages of small occupation area, lower drive power and good environmental protection and energy saving effect.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

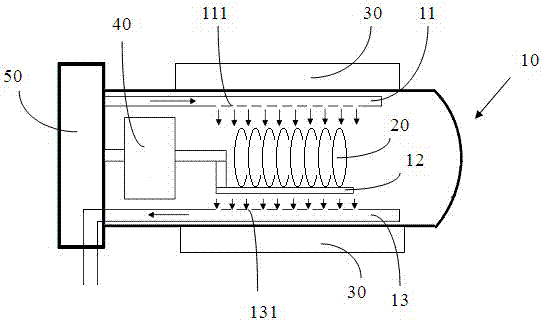

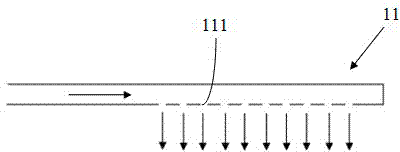

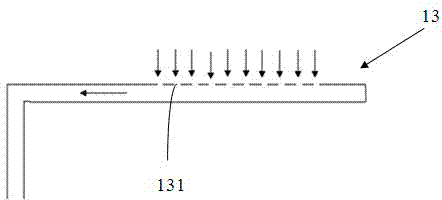

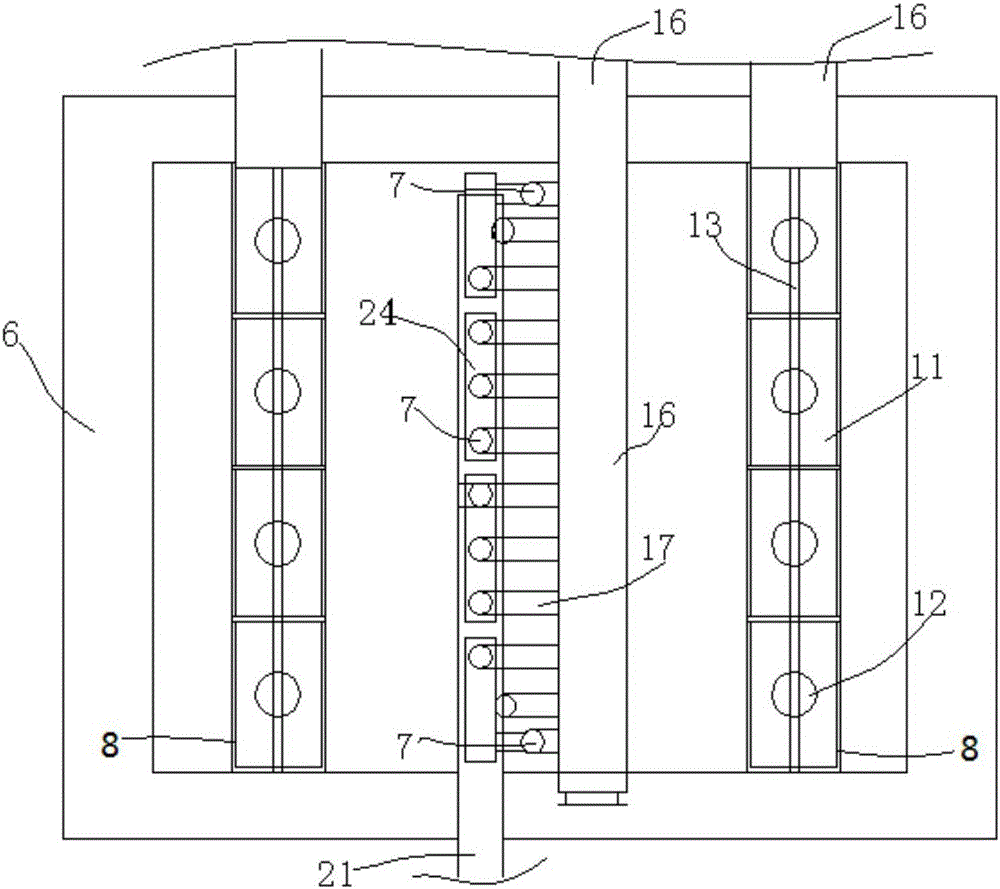

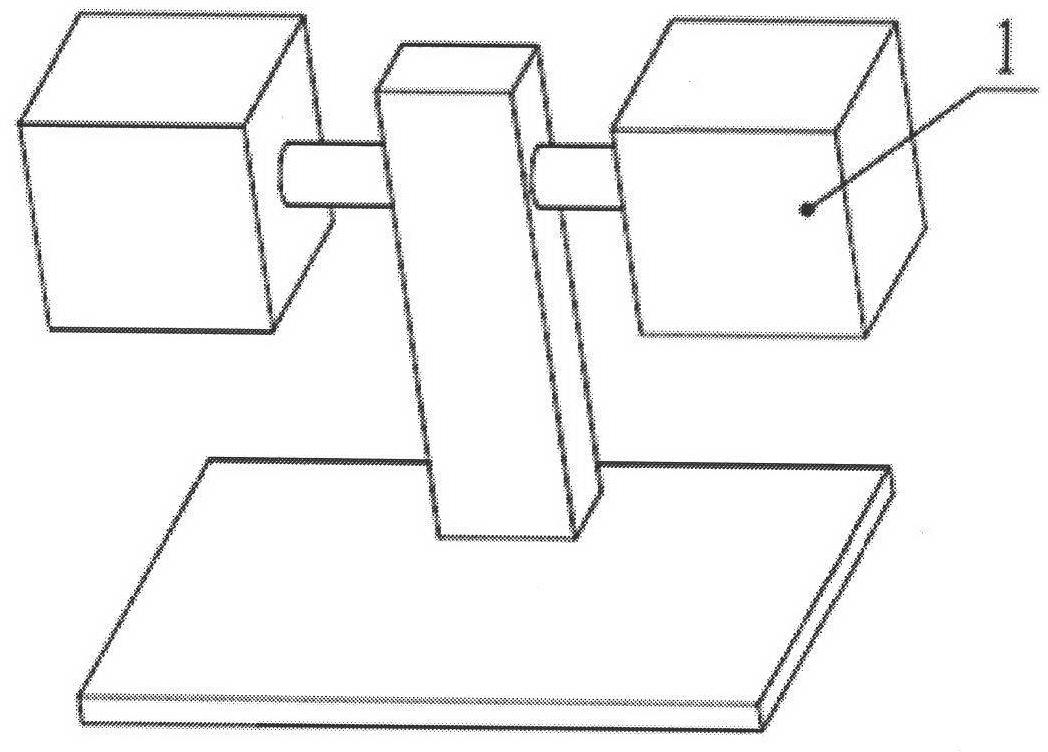

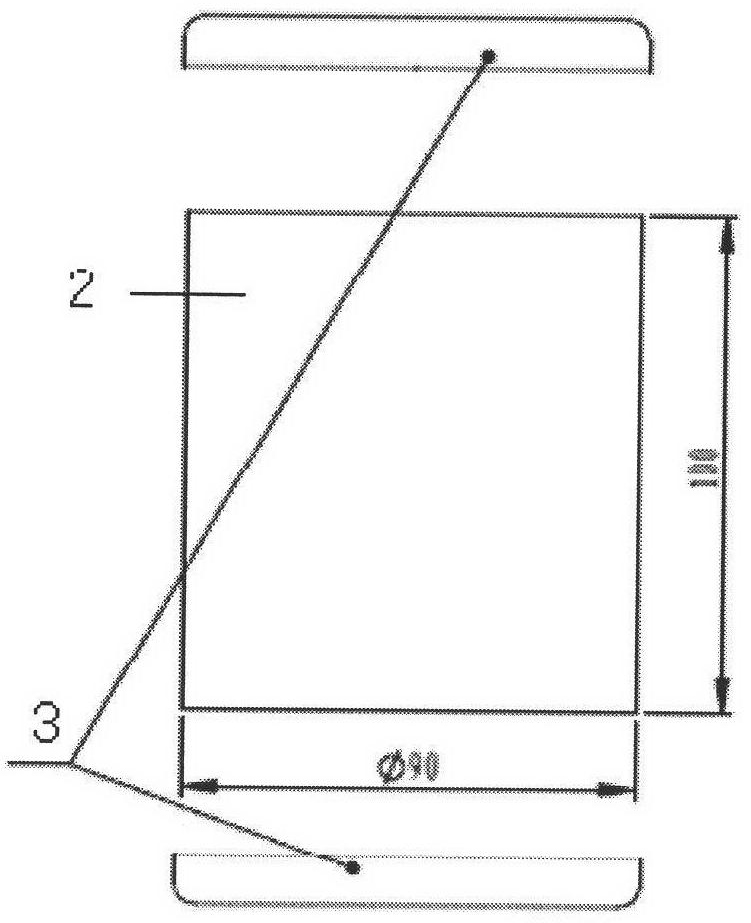

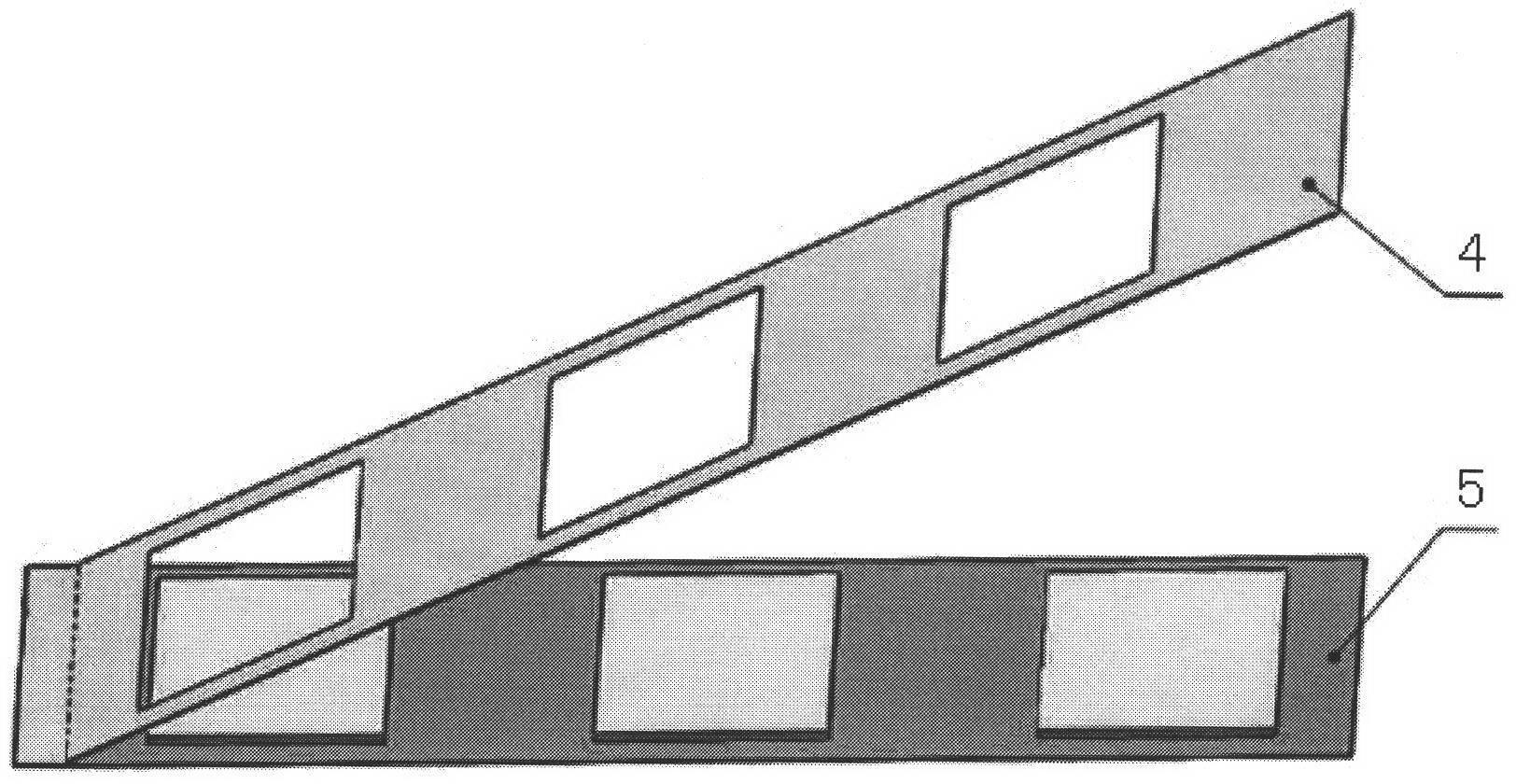

Device and method for preparing carbon nanotube

ActiveCN103569998AUniform growthImprove spatial distribution uniformityMaterial nanotechnologyCarbon nanotubesCarbon nanotubeProduct gas

The invention provides a device for preparing a carbon nanotube. The device comprises a reaction chamber, wherein one or more gas inlet tubes, a substrate bearing disc and one or more gas outlet tubes are arranged in the reaction chamber; a plurality of gas inlets are formed in each gas inlet tube; a plurality of gas outlets are formed in each gas outlet tube; the substrate bearing disc is positioned between the gas inlet tube and the gas outlet tube; each gas inlet tube and each gas outlet tube are detachably mounted in the reaction chamber. The gas inlet tube and the gas outlet tube in a chemical vapor deposition (CVD) reaction chamber for growth of the traditional carbon nanotube array are improved, so that the space distribution uniformity of a carbon source gas in the reaction chamber is greatly improved; a substrate is vertically or slantways placed on the substrate bearing disc in the reaction chamber of the device, so that the substrate is in contact with the carbon source gas in the growth process of the carbon nanotube array completely, and uniform growth of a plurality of carbon nanotube arrays is promoted. The device for preparing the carbon nanotube has an important promoting effect on batched preparation of the carbon nanotube arrays.

Owner:SUZHOU CREATIVE CARBON NANOTECH

Building cement stirring mixing system and method

InactiveCN110065164AAvoid accumulationImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusEngineeringGravity center

The invention relates to a mixing system and method, in particular to a building cement stirring mixing system and method. The system comprises a whole support, a mixing support, a pushing mechanism,a mixing cylinder, a swing support, a power mechanism, a planetary mechanism, a stirring mechanism, a lifting screw, a water inlet mechanism and a sliding support; through the power mechanism, the mixing support and the stirring mechanism are driven at the same time to rotate at the same time, the mixing support and the stirring mechanism are opposite in rotation direction to mix and stir the cement raw material in the mixing cylinder, the pushing mechanism is combined for pushing the mixing support to swing, due to the fact that centrifugal force generated by rotating of the mixing support and the stirring mechanism has the tendency of pushing a cement raw material mixture to the outer side, when the pushing mechanism pushes the mixing support to swing, the gravity center of the cement raw material mixture is repeatedly changed, the cement raw material mixture is prevented from being stacked on the outer ring in the mixing cylinder, and the mixing and stirring effect is improved.

Owner:陈常

Method for preparing chicken essence with control oxidization--Maillard Reaction of chicken fat raw material

InactiveCN101317648AOutstanding meat flavorRich and harmonious fragranceFood preparationFood additiveMaillard reaction

The invention provides a method for preparing chicken essence by controlling oxidation-Maillard reaction of chicken fat raw material, which belongs to the technical field of food additive. The method of the invention uses the chicken fat as the raw material; at the reaction temperature of 120-170 DEG C, air is pumped into the chicken fat by a type of bottom bubbling ventilation, with the air flowing speed of 2-10m<3> / kg.h and the oxidation time of 1-6 hours; xylose, glucose, L-cysteine and water with a certain quantity are added into the oxidation chicken fat to carry out the Maillard reaction at the temperature of 110-120 DEG C so as to prepare the chicken essence. The chicken essence prepared by the method of the invention can be widely applied to seasonings such as instant noodle seasoning, chicken essence, and the like; the selected raw material is natural without harms, the meat taste is real and delicious, the fragrance is strong and harmonic; as the chicken essence is characterized in that meat fragrance is strong, therefore, the method of the invention is a good way for preparing natural chicken essence. The method of the invention uses the air as the oxidant and carries out the reaction at high temperature; furthermore, the operation is easy and the cost of product is low.

Owner:JIANGNAN UNIV

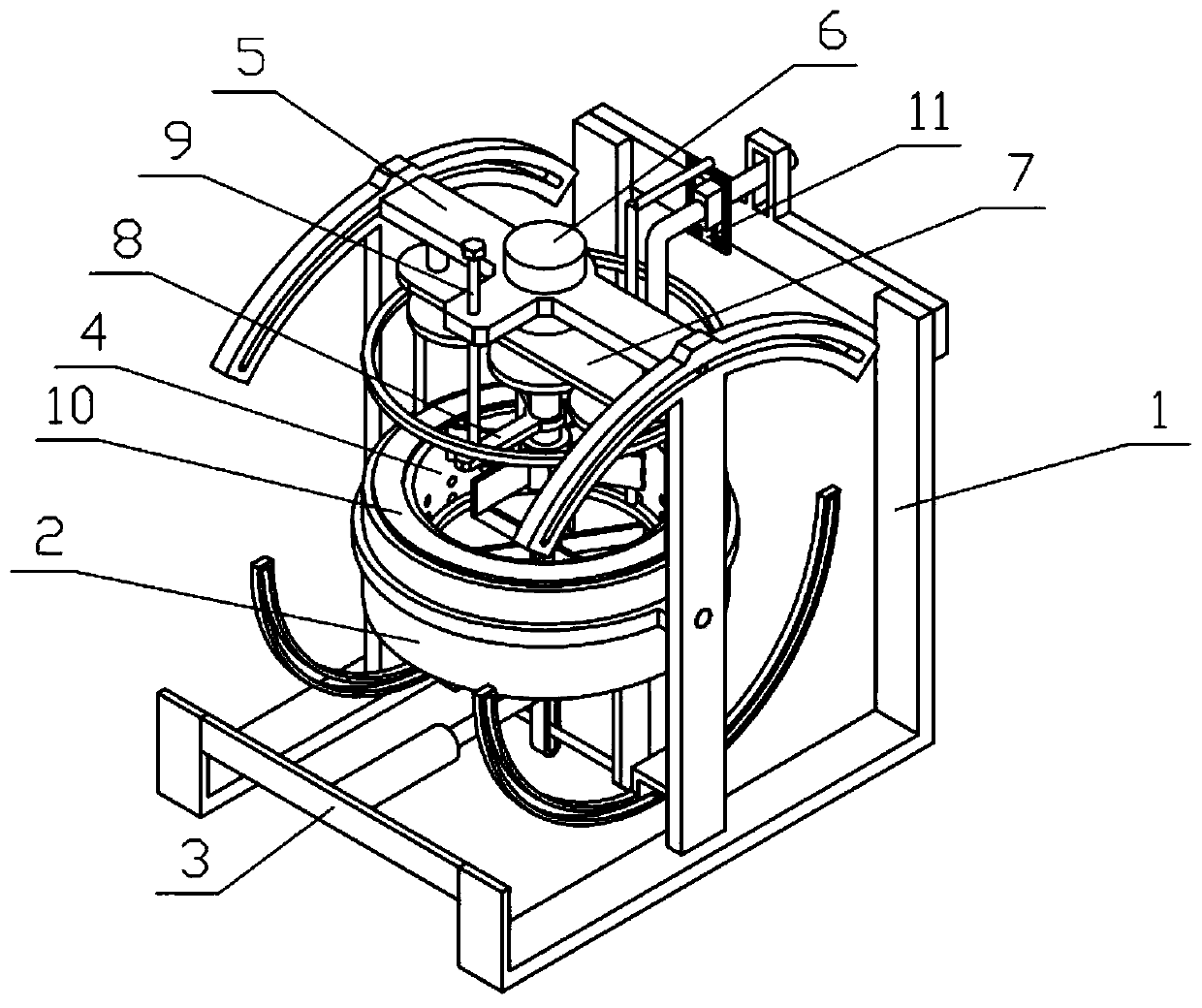

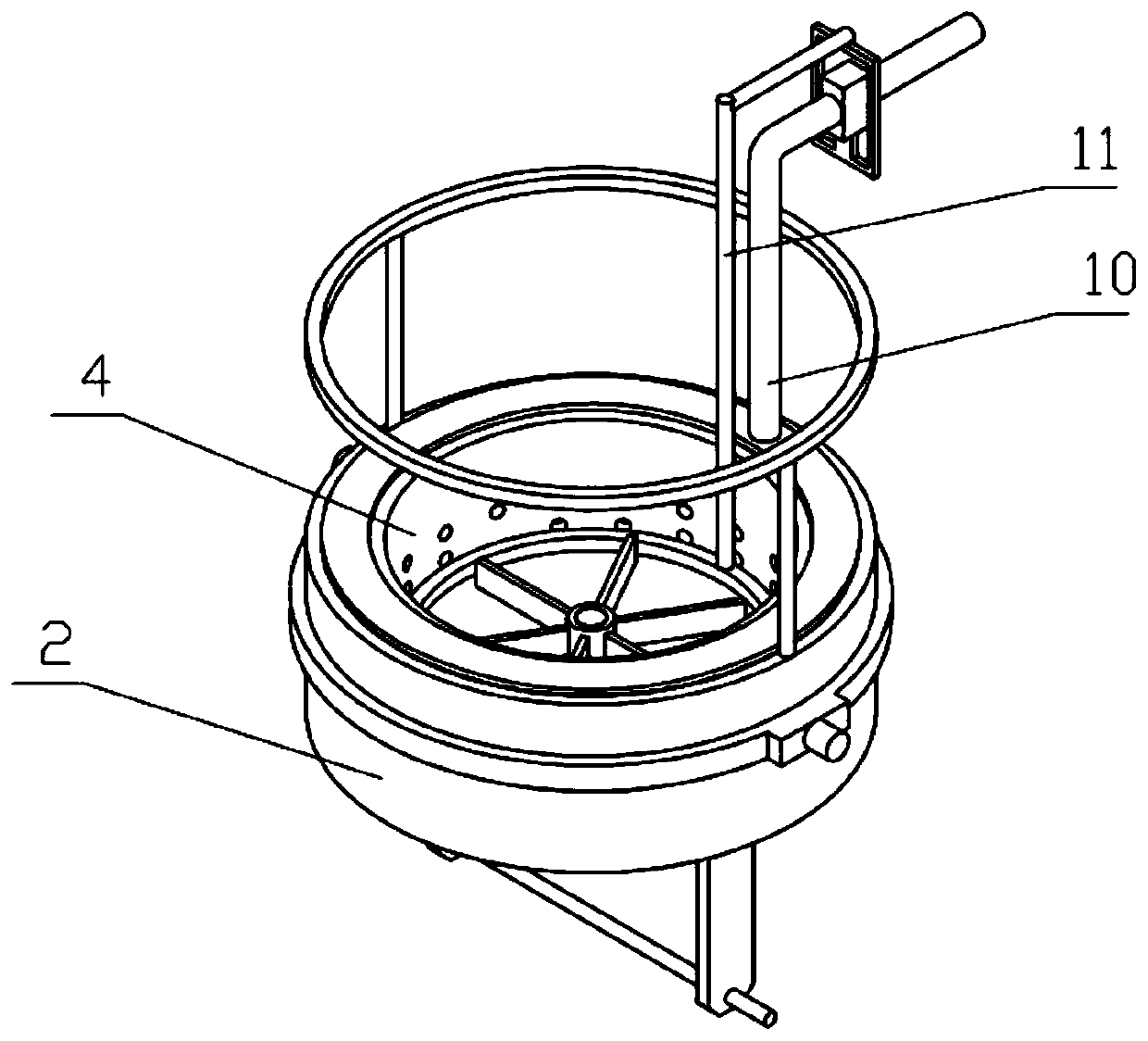

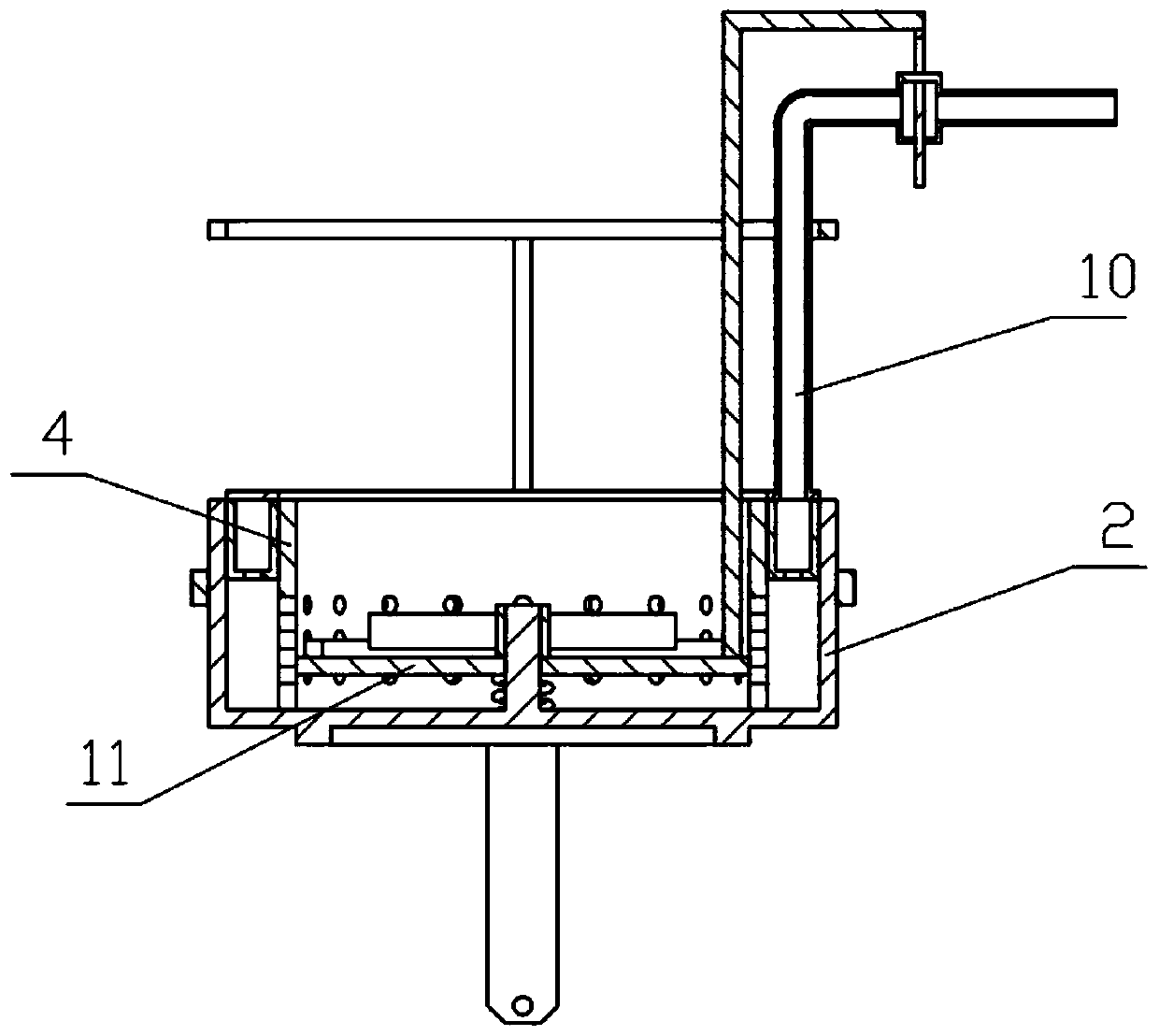

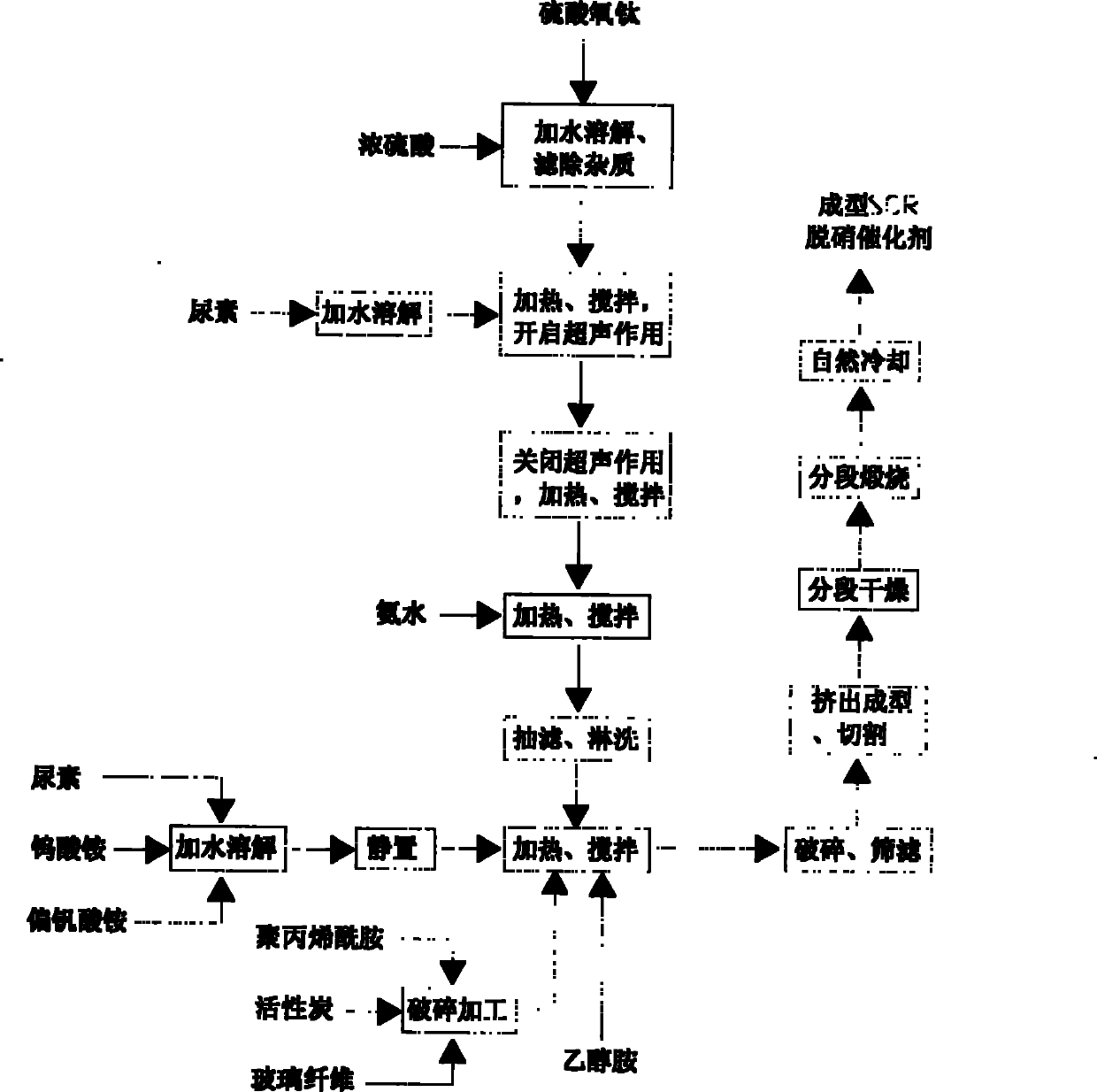

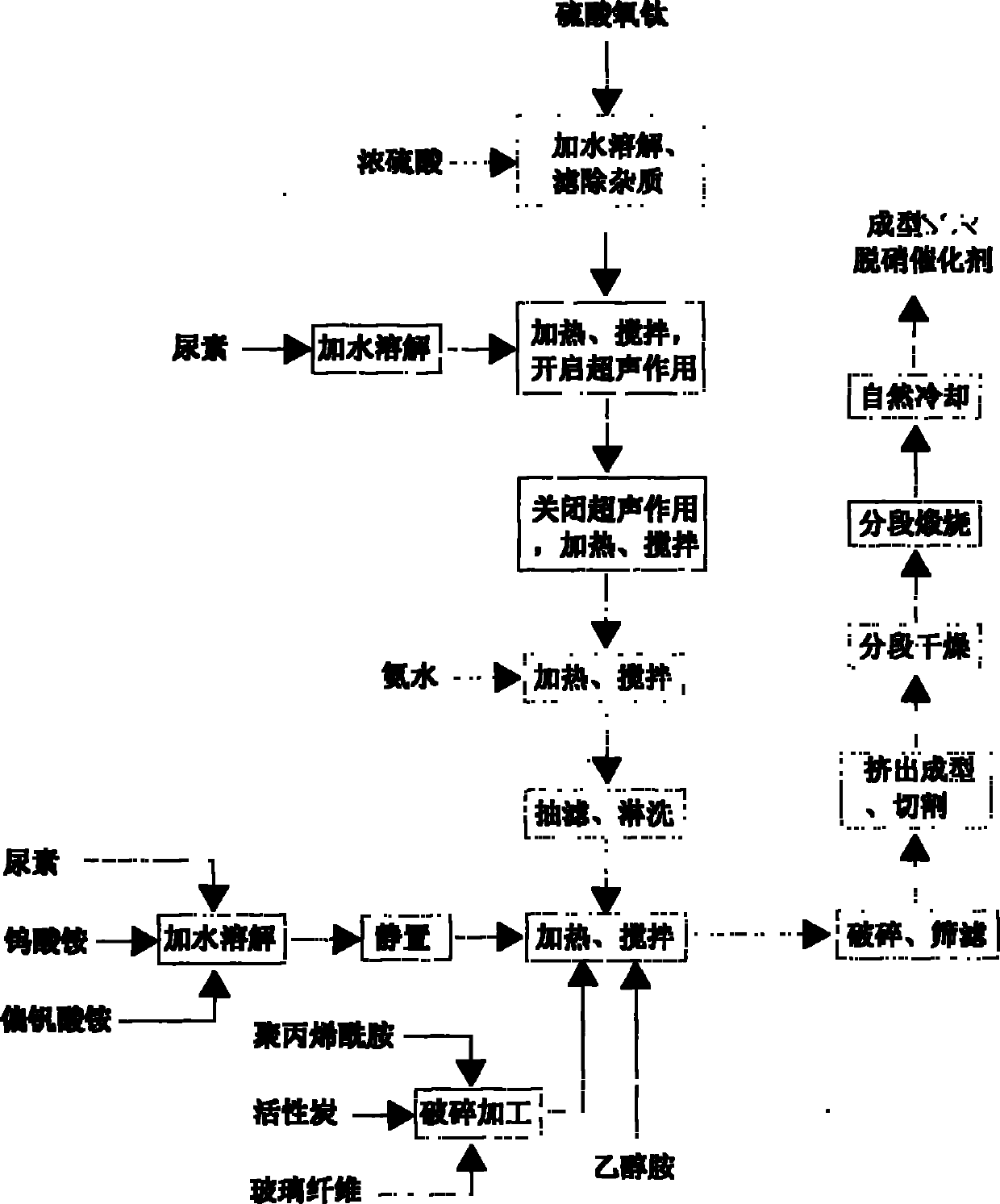

Method for preparing formed selective catalytic reduction denitration catalyst by using ultrasonic mixing sedimentation method

InactiveCN101791549ASmall particle sizeGood dispersionDispersed particle separationCatalyst activation/preparationTungstateAmmonium metavanadate

The invention discloses a method for preparing a formed selective catalytic reduction (SCR) denitration catalyst by using an ultrasonic mixing sedimentation method, comprising the following steps of: preparing metatitanic acid as a dipping carrier by using the processes of uniform sedimentation and direct sedimentation sequentially and being assisted by an ultrasonic strengthened reaction process by taking industry titanyl sulfate as a raw material; then mixing with an ammonium metavanadate-ammonium tungstate-oxalate solution, a flocculating agent comprising polyacrylamide and glass fibre, a structure promoter, and the like, and stirring to finish the processes of active component dipping and loading and plastic pasty master batch preparation synchronously. The prepared master batch is processed by a vacuum-extruder after finely crushed to obtain a formed catalyst green body, and finally the preparation process of the formed SCR denitration catalyst is finished through drying and sintering operations. Compared with the traditional preparation process of the SCR denitration catalyst, the method has simple and clear process and high production efficiency, and the raw materials for preparing the carrier of the catalyst have wide sources and low cost, thereby lowering the production cost to a certain extent.

Owner:SOUTHEAST UNIV

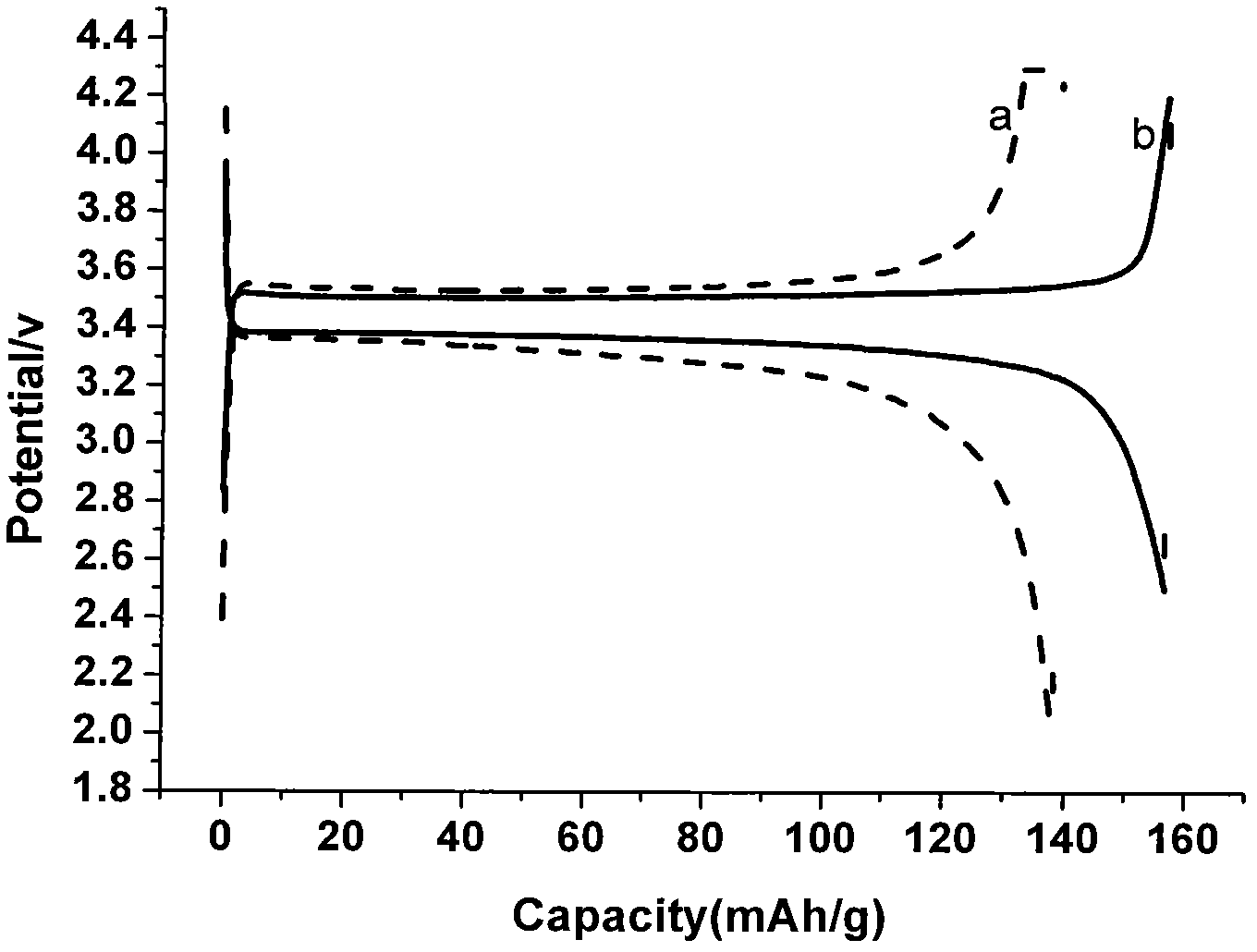

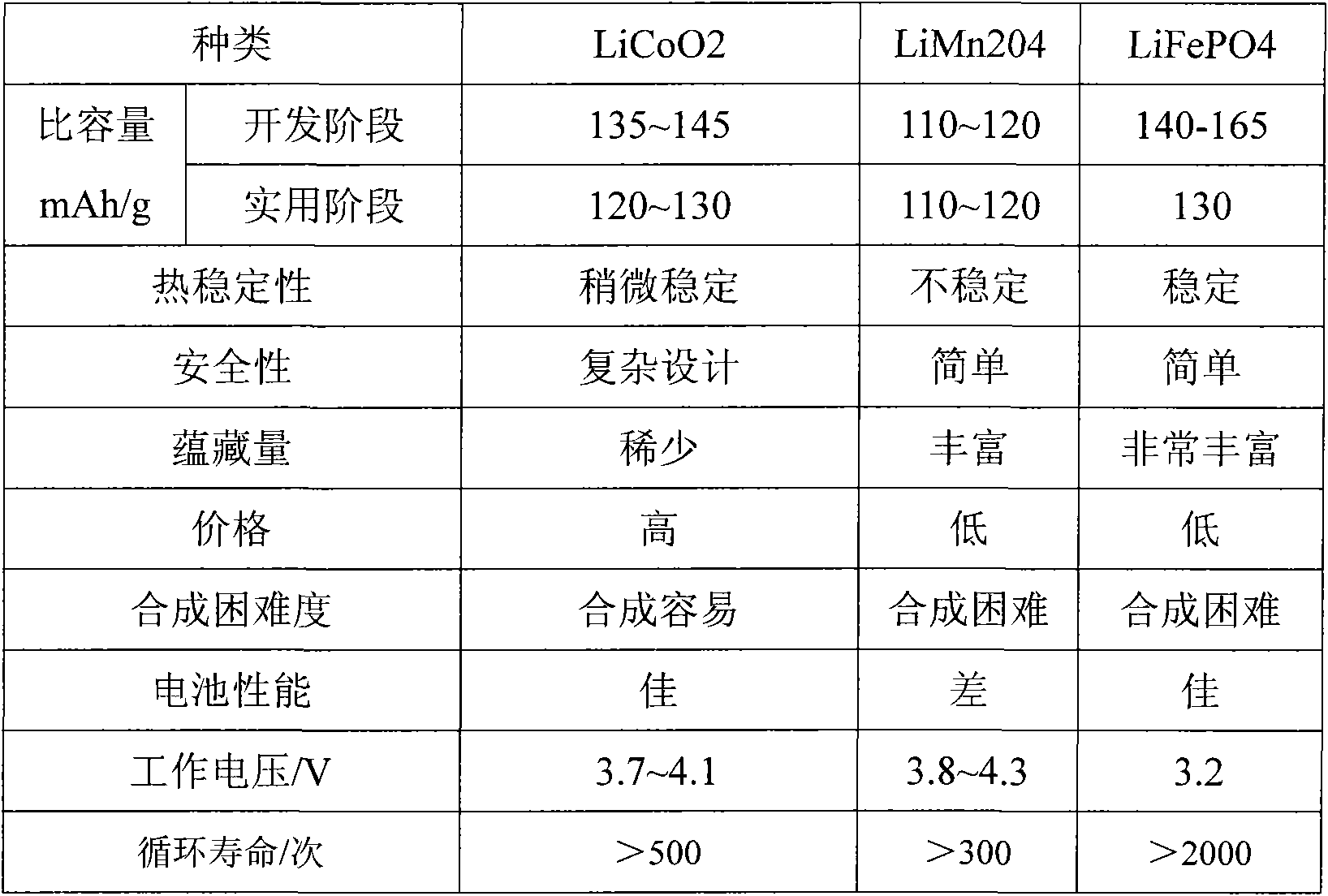

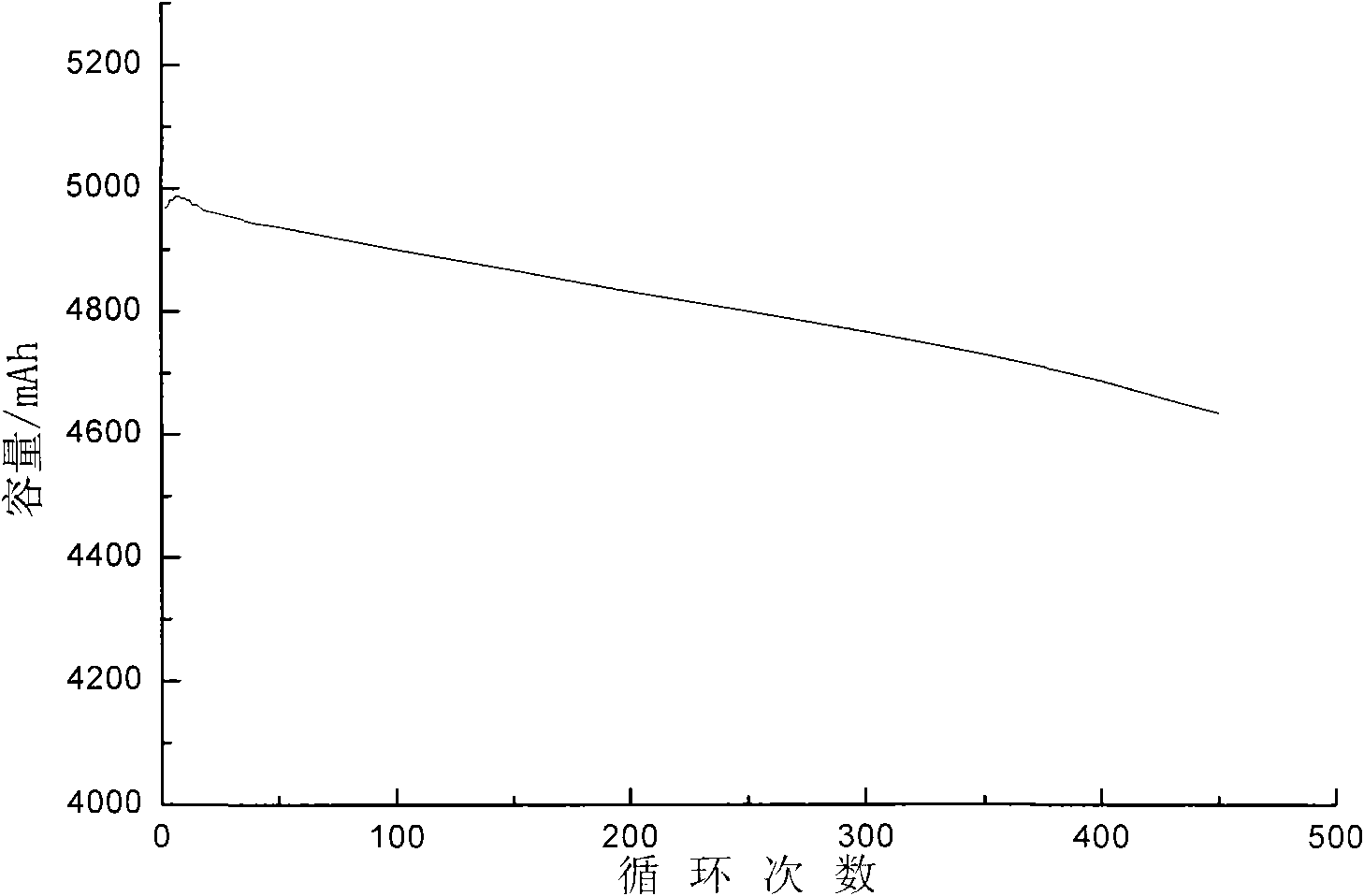

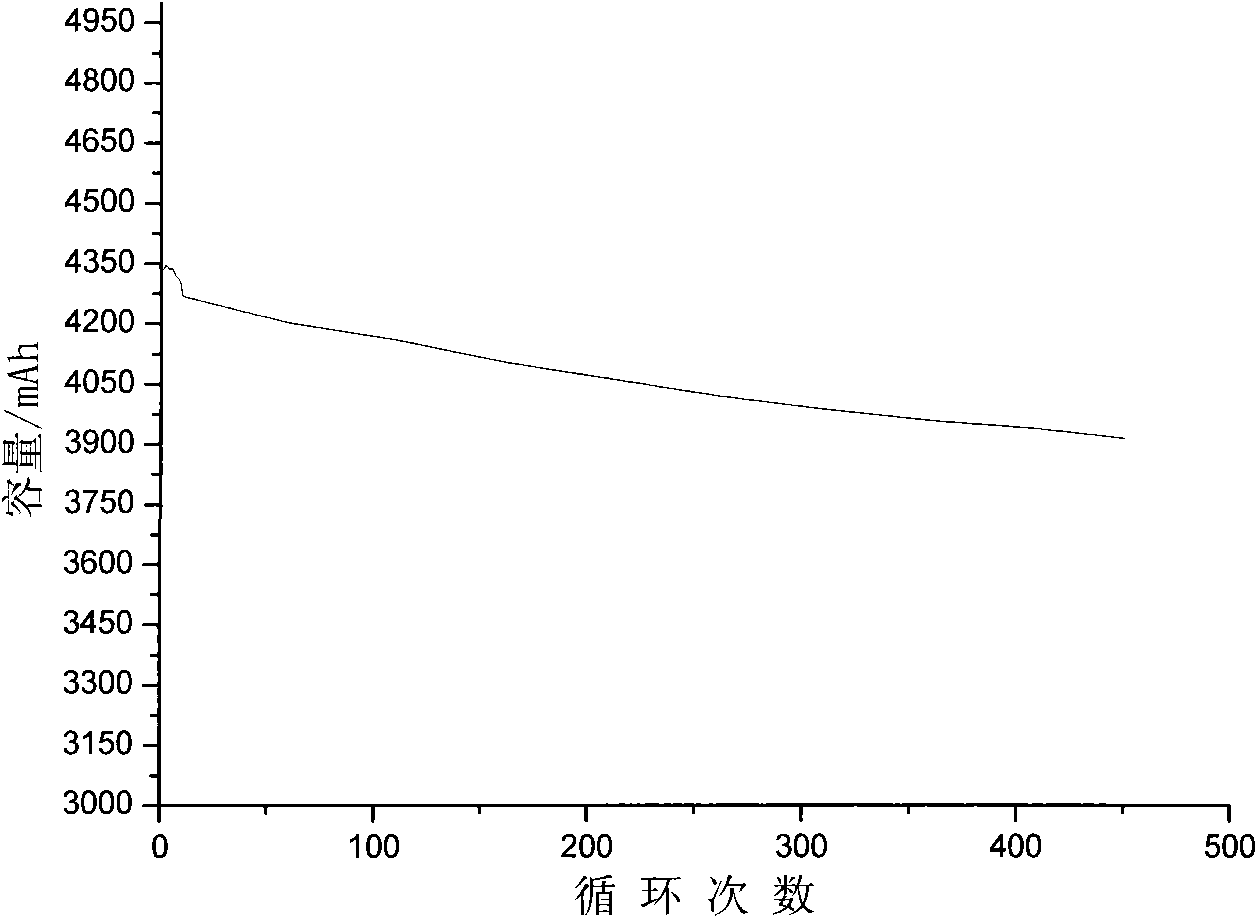

Power polymer lithium ion battery and fabricating process thereof

InactiveCN101567469AImprove electronic conductivityImprove high-magnification performanceElectrode manufacturing processesElectrode carriers/collectorsHigh ratePositive current

The invention discloses a power polymer lithium ion battery and a fabricating process thereof. A positive plate comprises modified lithium iron phosphate, conductive agent, positive adhering agent, dispersant and positive current collector. A negative plate comprises graphite, conductive agent, negative adhering agent and negative current collector. The fabricating process comprises the following steps: firstly, dispersing the conductive agent; secondly, dispersing the modified lithium iron phosphate; thirdly, adding the efficient organic adhering agent so as to increase the adhering property among grains of the conductive agent, between the conductive agent and the positive material, and between the conductive agent and the positive material and the current collector, and to increase the electrode contact conductivity and electron conductivity, thereby greatly improving the battery high-rate charge and discharge property. The invention has the advantages of simple process, easy control, good product safety and long circulation service life.

Owner:ZHEJIANG ZHENLONG BATTERY

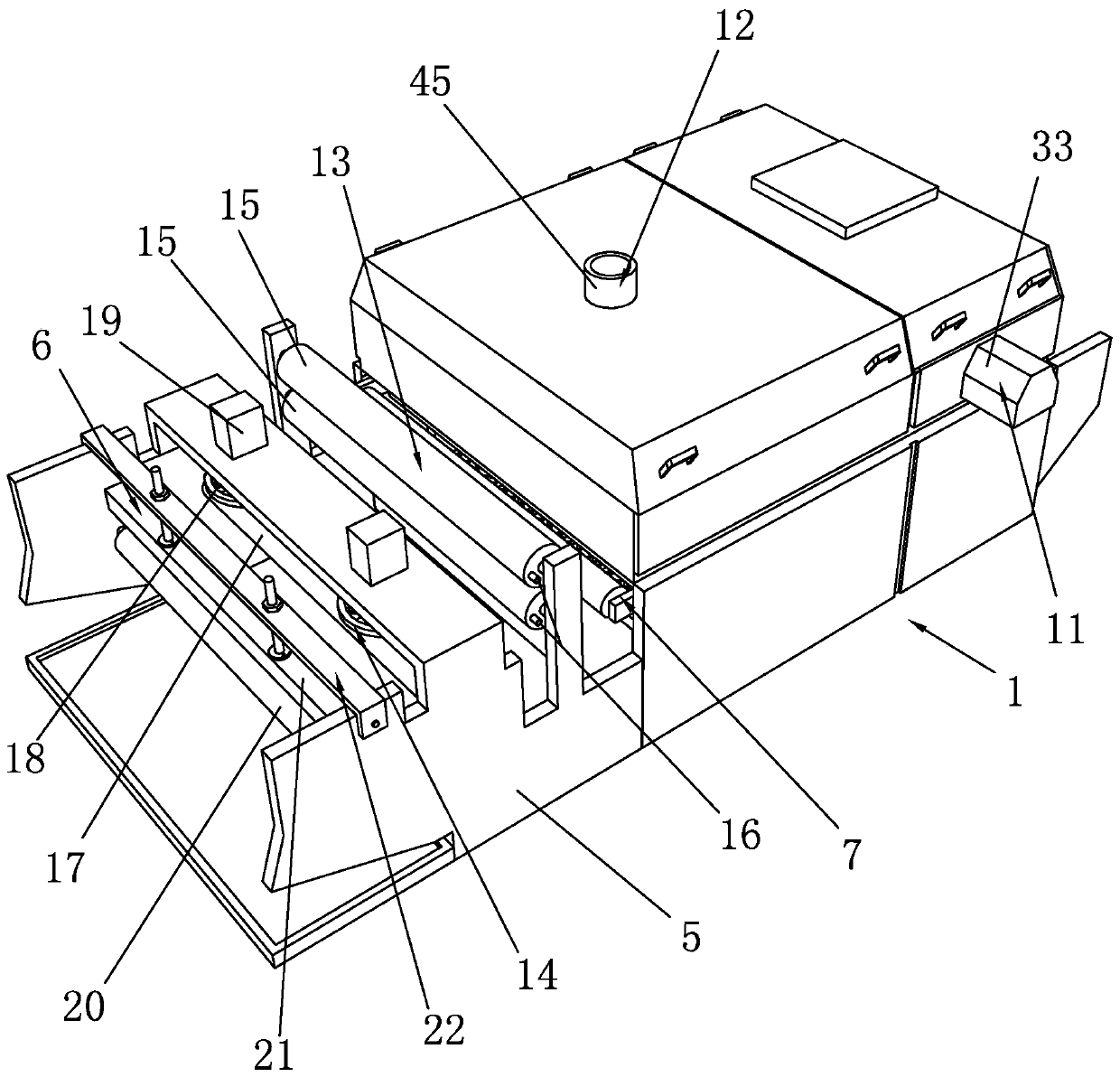

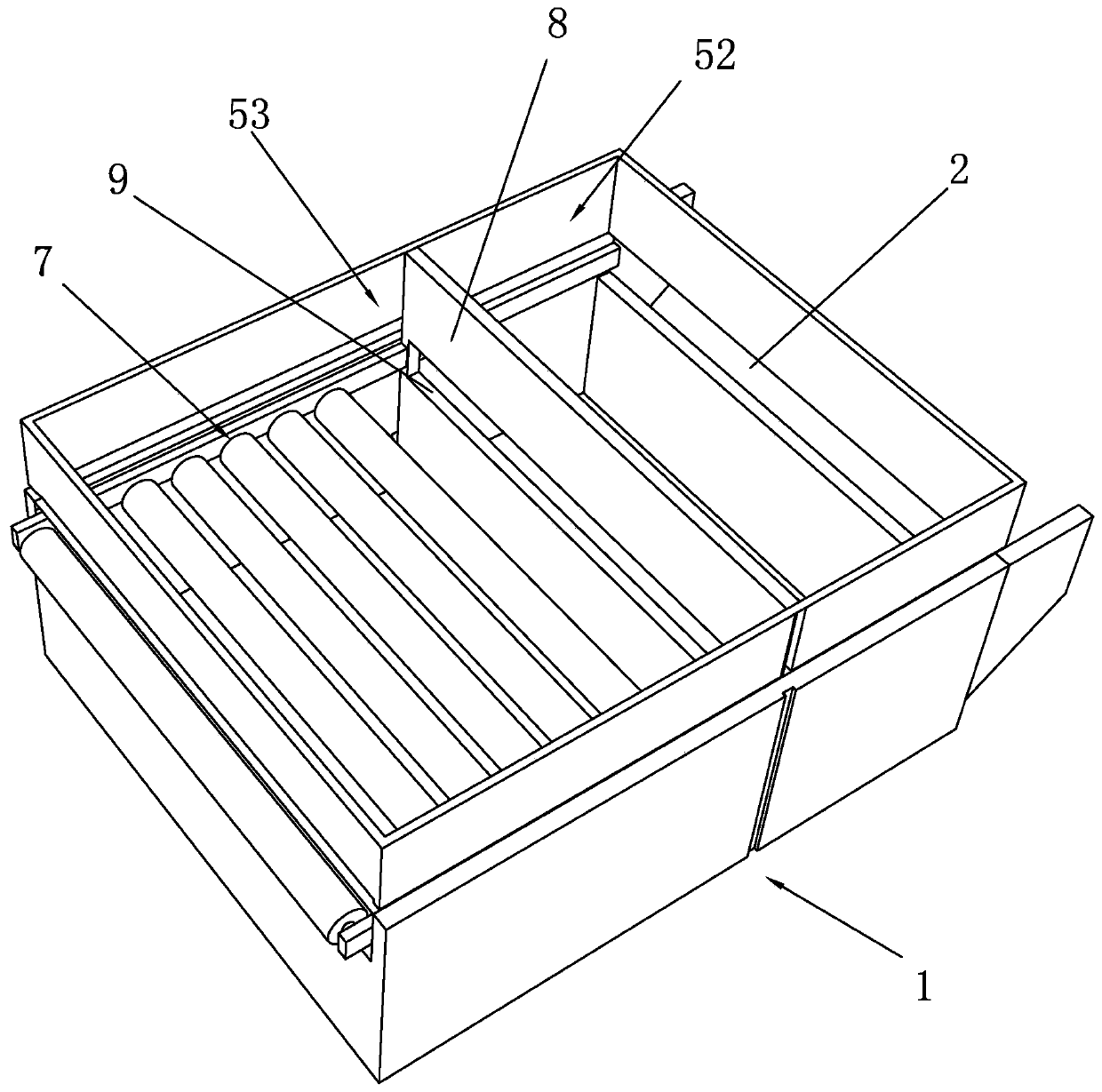

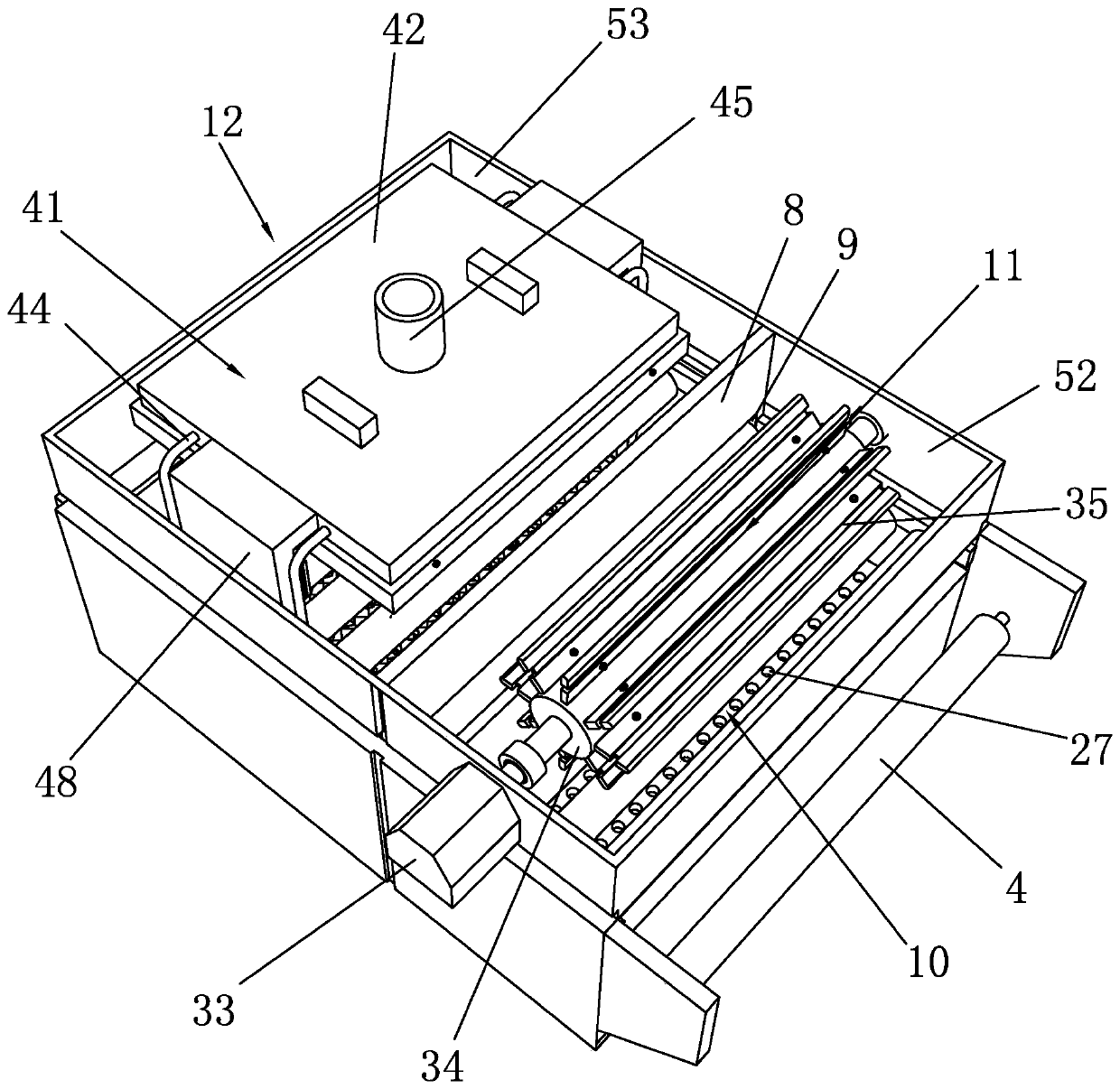

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

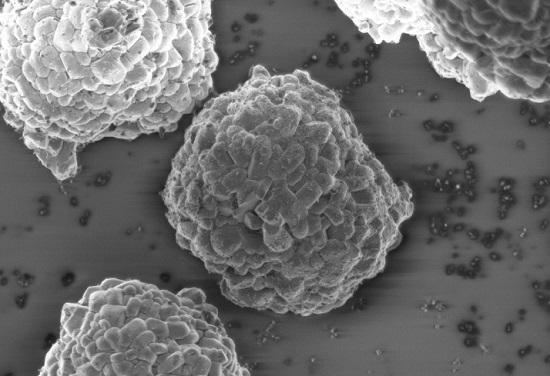

Lithium nickel cobalt manganese aluminate positive electrode material with shell-core-shell structure and preparation method of lithium nickel cobalt manganese aluminate positive electrode material

ActiveCN113955809APromote fragmentationShorten the diffusion pathSecondary cellsPositive electrodesPhysical chemistryManganese

The invention discloses a lithium nickel cobalt manganese aluminate positive electrode material with a shell-core-shell structure and a preparation method of the lithium nickel cobalt manganese aluminate positive electrode material. The preparation method comprises the steps of taking Co-based MOF (zif-67) as a crystal nucleus for nickel, cobalt, manganese and aluminum coprecipitation reaction, generating a high-nickel quaternary component precursor with a core-shell structure, evenly mixing the precursor, lithium salt and an additive according to a certain proportion, calcining in an oxygen atmosphere furnace, and obtaining a primary sintered matrix; crushing, washing, filter-pressing and dehydrating the primary sintered matrix to obtain a filter cake containing certain moisture, uniformly mixing the filter cake and a coating material, drying at a low temperature, and carrying out secondary sintering in an oxygen atmosphere furnace to obtain the high-nickel quaternary component positive electrode material with a 'shell-core-shell' sandwich hollow structure. The positive electrode material not only has relatively high initial discharge specific capacity, relatively low internal resistance and relatively good rate capability, but also has good cycling stability and safety performance.

Owner:HENAN KELONG NEW ENERGY CO LTD

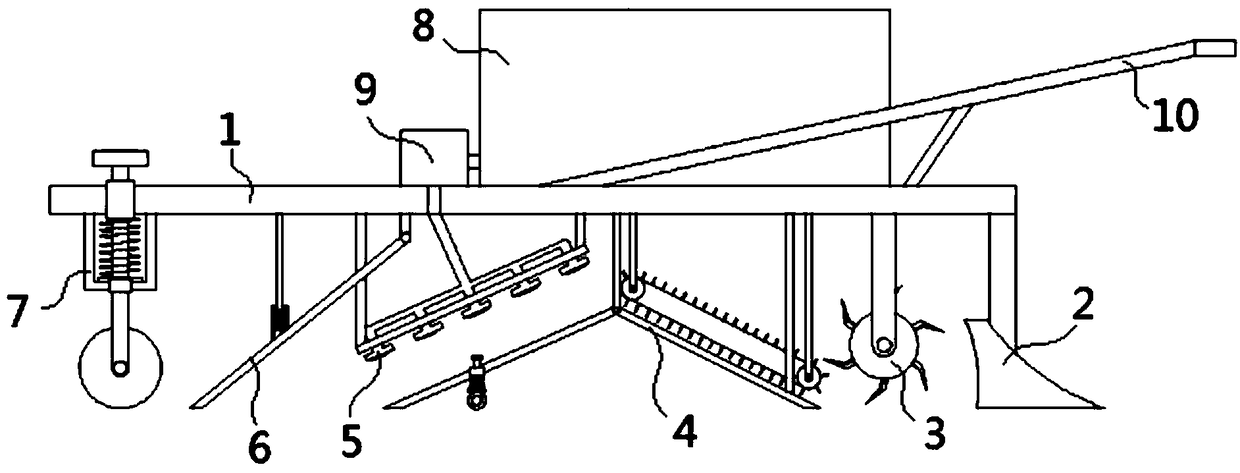

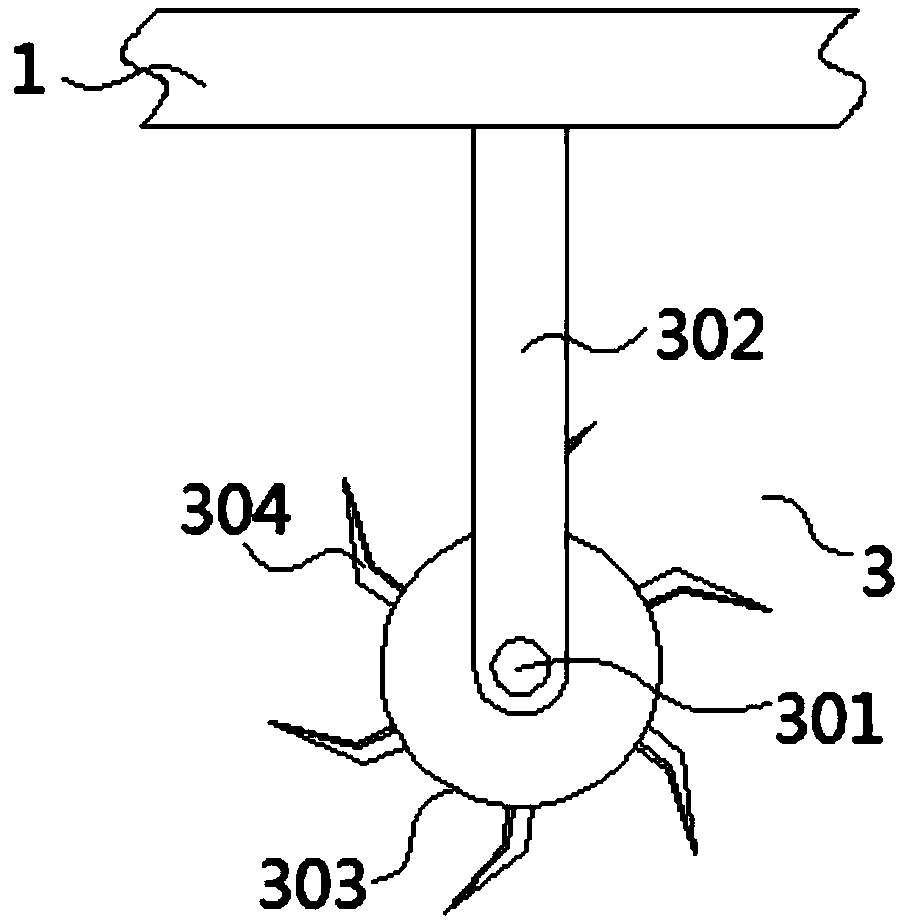

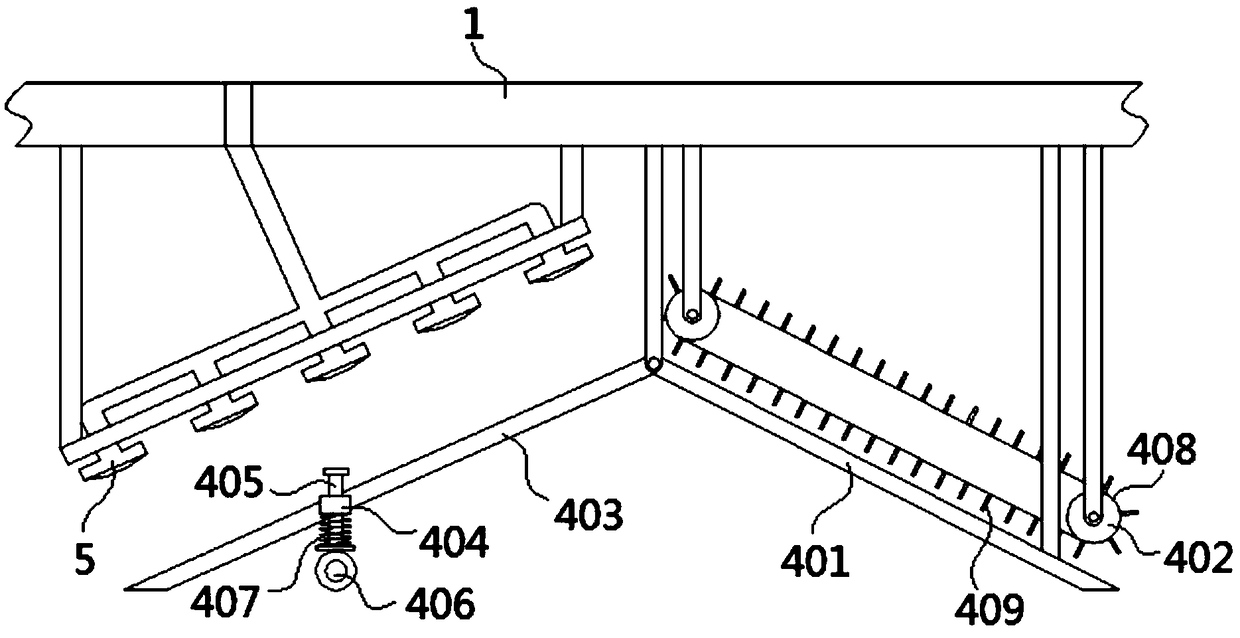

Agricultural equipment for agricultural soil improvement

InactiveCN108856276AIncrease profitFull and even contactSoil lifting machinesSpadesAgricultural engineeringMechanical equipment

The invention discloses agricultural equipment for agricultural soil improvement, and relates to the technical field of agricultural mechanical equipment. The agricultural equipment comprises a frame;a soil loosening shovel, a crushing mechanism, a conveying mechanism, a nozzle, a planar plate and a compaction mechanism are fixed at the bottom of the frame in sequence from right to left; a watertank and a water pump are fixed at the top of the frame; and the water tank and the water pump communicate through a water pipe. Through cooperative use of the frame, the soil loosening shovel, the crushing mechanism, the conveying mechanism, the nozzle, the water tank and the water pump, the agricultural equipment can crush overturned soil, so that the uniform-crushed soil can be fully and uniformly contacted with an improvement agent, the utilization rate of the improvement agent is improved, and the improvement effect is more ideal.

Owner:广西银木农业科技开发有限公司

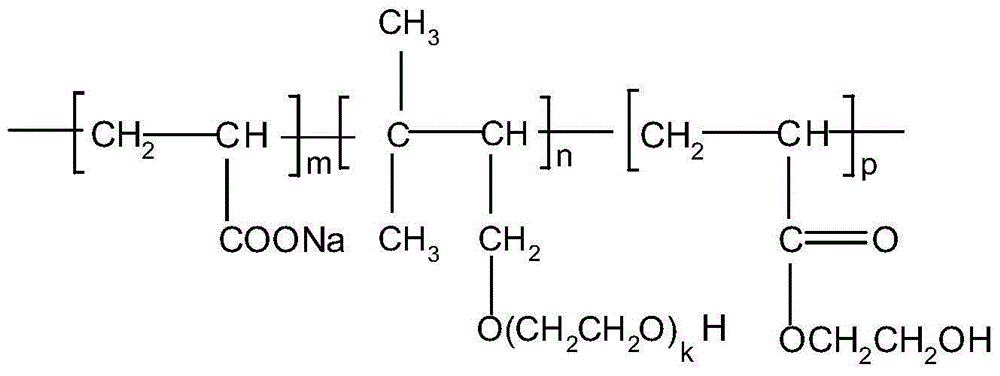

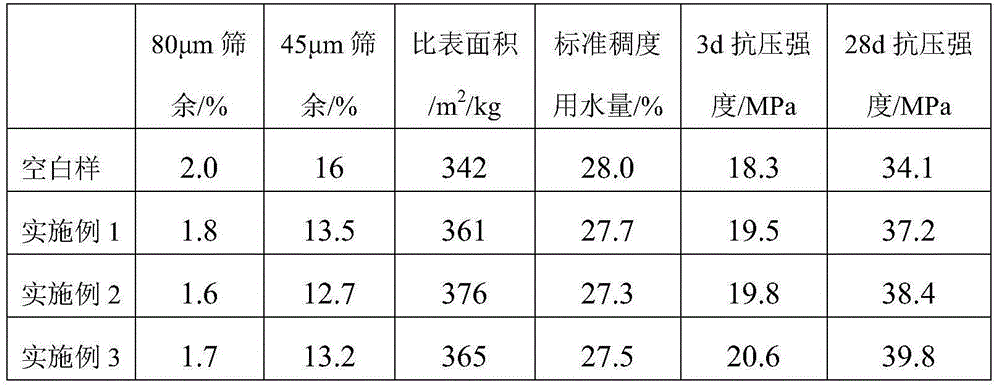

High-limestone-flour-adulterate-amount composite enhanced grinding aid for cement and preparation method of high-limestone flour-adulterate amount composite enhanced grinding aid

The invention relates to a high-limestone-flour-adulterate-amount composite enhanced grinding aid for cement and a preparation method of the high-limestone-flour-adulterate-amount composite enhanced grinding aid. The preparation method comprises the following steps that 1, materials including 18%-25% of triethanolamine, 8%-15% of triisopropanolamine, 20%-28% of ethanediol, 8%-12% of molasses, 4%-8% of polycarboxylate superplasticizer, 6%-10% of sodium sulfate, 5%-8% of glacial acetic acid and 2%-24% of water are taken; 2, the water is poured into an agitator kettle, and sodium sulfate is added to be stirred till sodium sulfate is completely dissolved; 3, glacial acetic acid is added to be completely dissolved, triethanolamine, triisopropanolamine, ethanediol, molasses and polycarboxylate superplasticizer are sequentially added after glacial acetic acid is dissolved, stirring continues to be carried out for 20-30 minutes, and the high-limestone flour-adulterate amount composite enhanced grinding aid is obtained. The high-limestone-flour-adulterate-amount composite enhanced grinding aid has the advantages that cement particles are prevented from clustering, and the cement particles are kept in a high homodisperse state; the strength of an interfacial transition zone is increased, and the strength of the cement is further increased; the grinding aiding efficiency of the grinding aid is improved.

Owner:WUHAN UNIV OF TECH

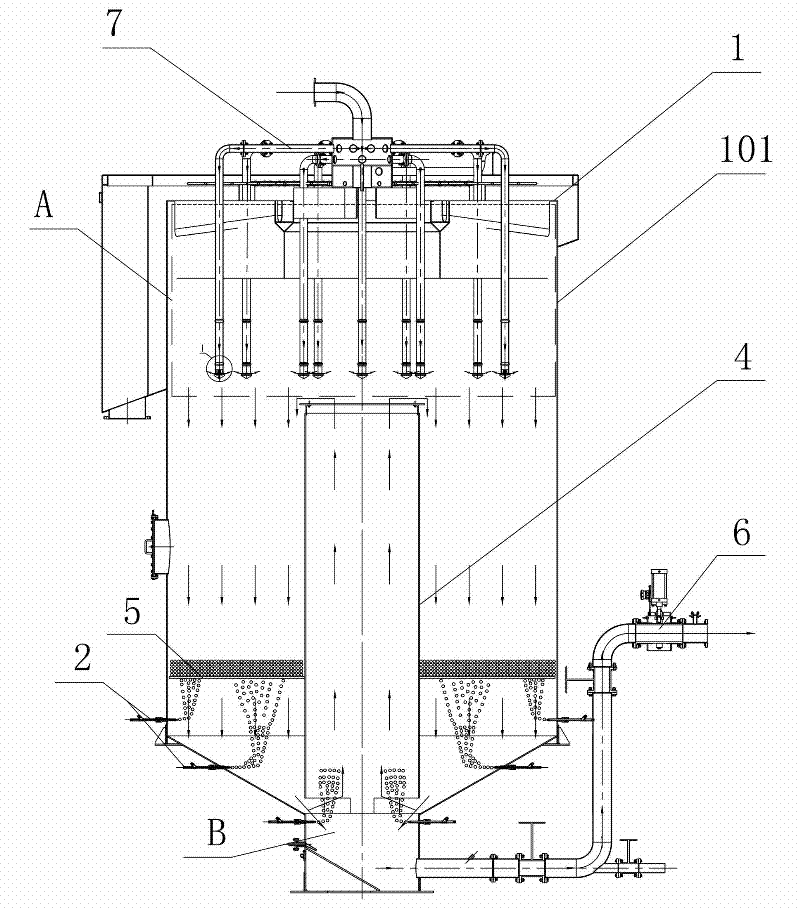

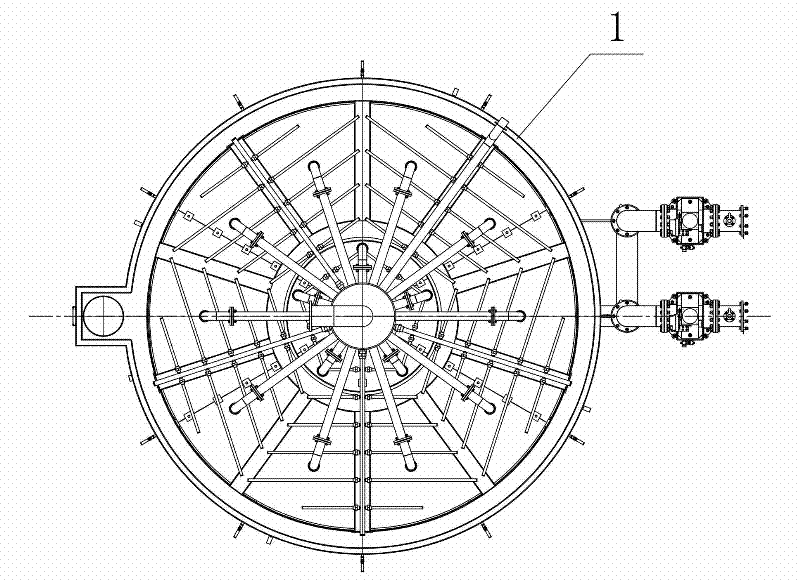

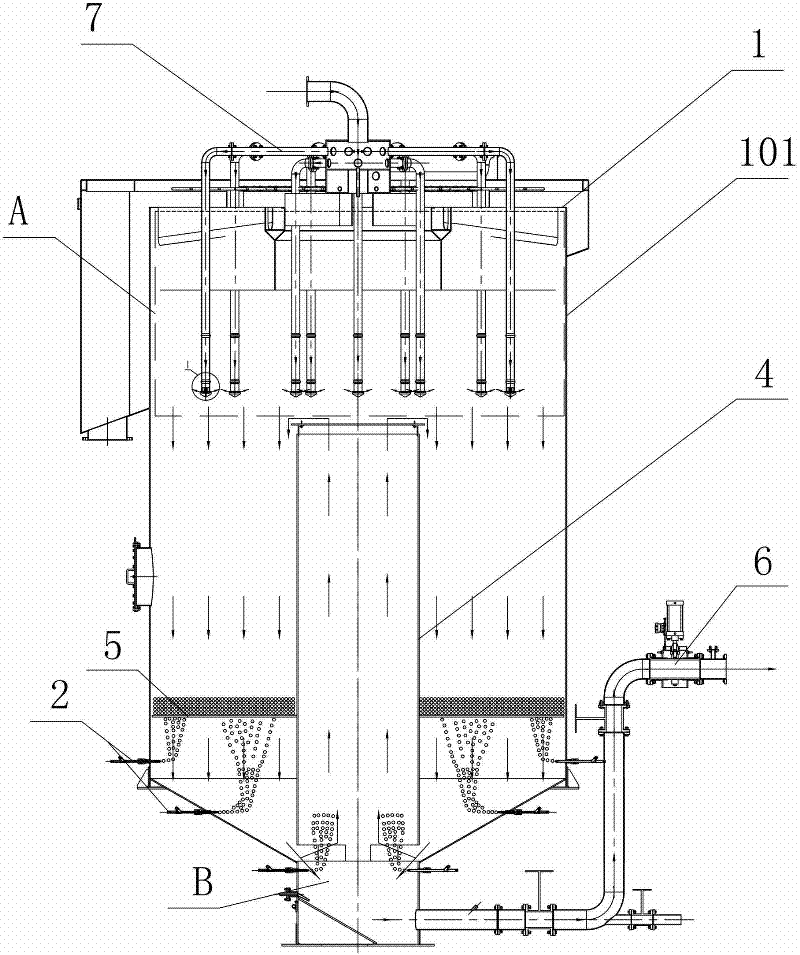

Floatation device

The invention discloses a flotation device, which comprises a flotation column, a feeding component and more than one inflation ejection gun which is installed in the flotation column. A scavenging channel is arranged in a column body of the flotation column; the scavenging channel is pipe-shaped, is located at the middle part of the column body and is distributed along a vertical direction; the lower end of the scavenging channel is an inlet end and the upper end of the scavenging channel is an outlet end. The flotation device has the advantages of simple and compact structure, low cost, stable and reliable work, low operation cost, convenience in maintenance, simplicity in operation, good flotation effect, wide application range and the like.

Owner:CHANGGAO ELECTRIC GROUP CO LTD

Method for preparing high-specific-surface-area macroporous-mesoporous carbon by using salt template, and applications of high-specific-surface-area macroporous-mesoporous carbon

ActiveCN109553098ALow pricePlay the role of nano confinementCarbon compoundsArgon atmosphereFiltration

The invention discloses a method for preparing a high-specific-surface-area macroporous-mesoporous carbon material by using a salt template. The method comprises: dissolving biomass gelatin in hot water to form a sol, adding an inorganic salt as a templating agent, cooling to a room temperature, placing in a 4 DEG C constant-temperature box to form a hydrogel, and continuously placing at a temperature of -20 DEG C to form a frozen gel; carrying out freeze drying on the frozen gel to obtain an aerogel, and calcining at a temperature of 400-1000 DEG C under an argon atmosphere to obtain a blackcarbonized product; and carrying out water washing, suction filtration and drying to obtain the final product. According to the present invention, by using the soluble biomass carbon source and the inorganic salt as the raw materials, the method is simple, the cost is low, the poorly soluble metal template is not used, the acid washing is not required, no residual metal impurity exists, and the method is environmentally friendly; the prepared carbon material has characteristics of high specific surface area (2872 cm<2> / g), three-dimensional continuous property, rich macropores (50-150 nm) andmesopores (2-4 nm), nitrogen atom doping and the like; and with the application of the material in 4V ionic liquid supercapacitors, the energy density of 92 Wh / kg and the excellent power density can be provided.

Owner:SICHUAN UNIV

Method for sterilizing oral artificial tooth, die, and gypsum model

InactiveCN1775293ASolve the problem that it cannot be directly used for disinfection of oral denture modelsEfficient killingChemicalsPathogenic microorganismRedox

The present invention relates to a disinfection method of oral artificial tooth, impression and plaster model. Said disinfection method includes the following steps: electrolyzing sodium chloride or potassium chloride solution to produce acidic redox potential water; utilizing ultrasonic oscillation process to atomize the acidic redox potential water to form acidic redox electrolytic vapour saturated space; in said saturated space disinfecting oral artificial tooth, impression and plaster model for 25-90 min, then drying for 30-60 min. so as to complete said disinfection operation.

Owner:THE STOMATOLOGIAL HOSPITAL OF ZHEJIANG UNIV SCHOOL OF MEDICINE

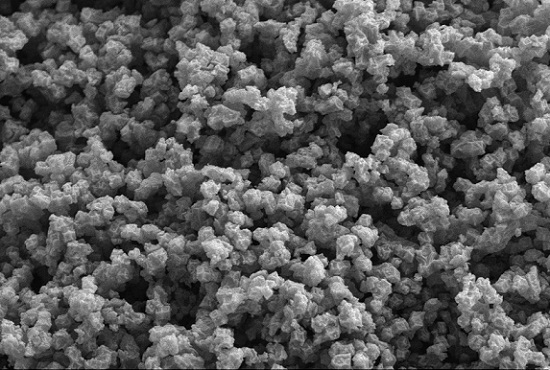

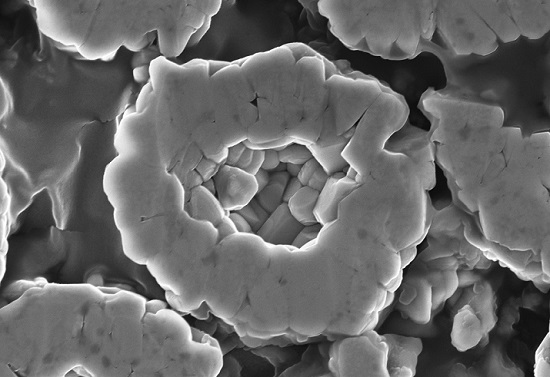

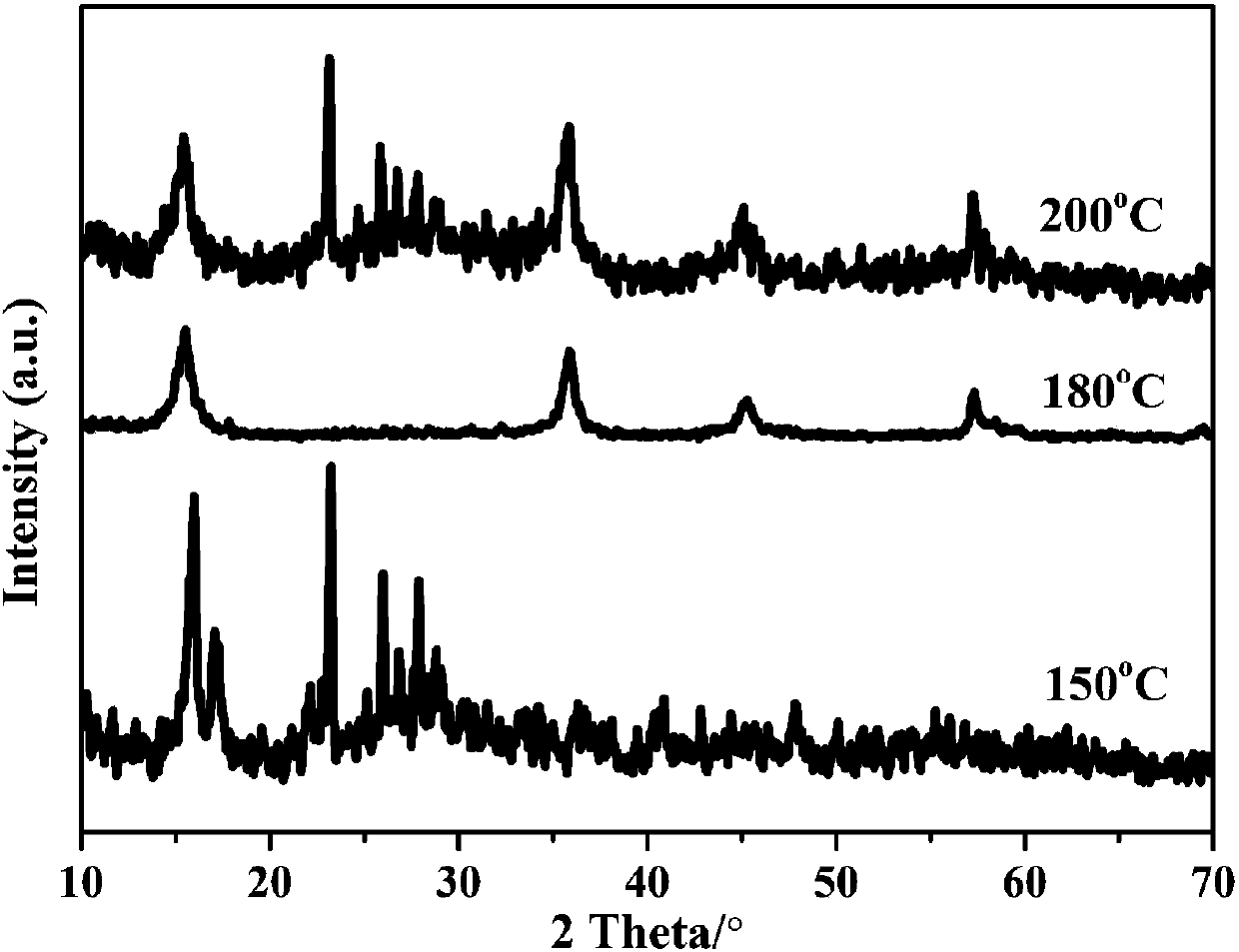

(001)-oriented nanosheet self-assembled three-dimensional VS2 microrod and preparation method thereof

ActiveCN107902697ASynthesis temperature is lowLow costMaterial nanotechnologyVanadium compoundsSingle crystalSolvent

A preparation method of a (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod comprises the following steps: simultaneously adding sodium metavanadate and thioacetamide into anhydrous ethanol to obtain a solution A; and pouring the solution A into a reaction liner, sealing the reaction liner, carrying out a hydrothermal reaction in a homogeneous reactor, naturally cooling the obtained reaction product to room temperature, taking out the obtained cooled reaction product, alternately cleaning the product with water and alcohol, collecting the product, and drying the product toobtain the (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod. The center of the microrod is obtained through mutually interlacing large VS2 nanosheets in a radial form, the edgeof the microrod is formed by small flaky VS2 nanosheets, the nanosheets are monocrystalline structures and grow along the (001) crystal face orientation, the diameter of the microrod is 2-15 [mu]m, and the thickness of the nanosheets is 5-20 nm. The highly-pure three-dimensional self-assembled VS2 is synthesized through a one-step solvothermal technology. The method has the advantages of simple reaction process, low temperature, easiness in control, and no large devices or strict reaction conditions.

Owner:SHAANXI UNIV OF SCI & TECH

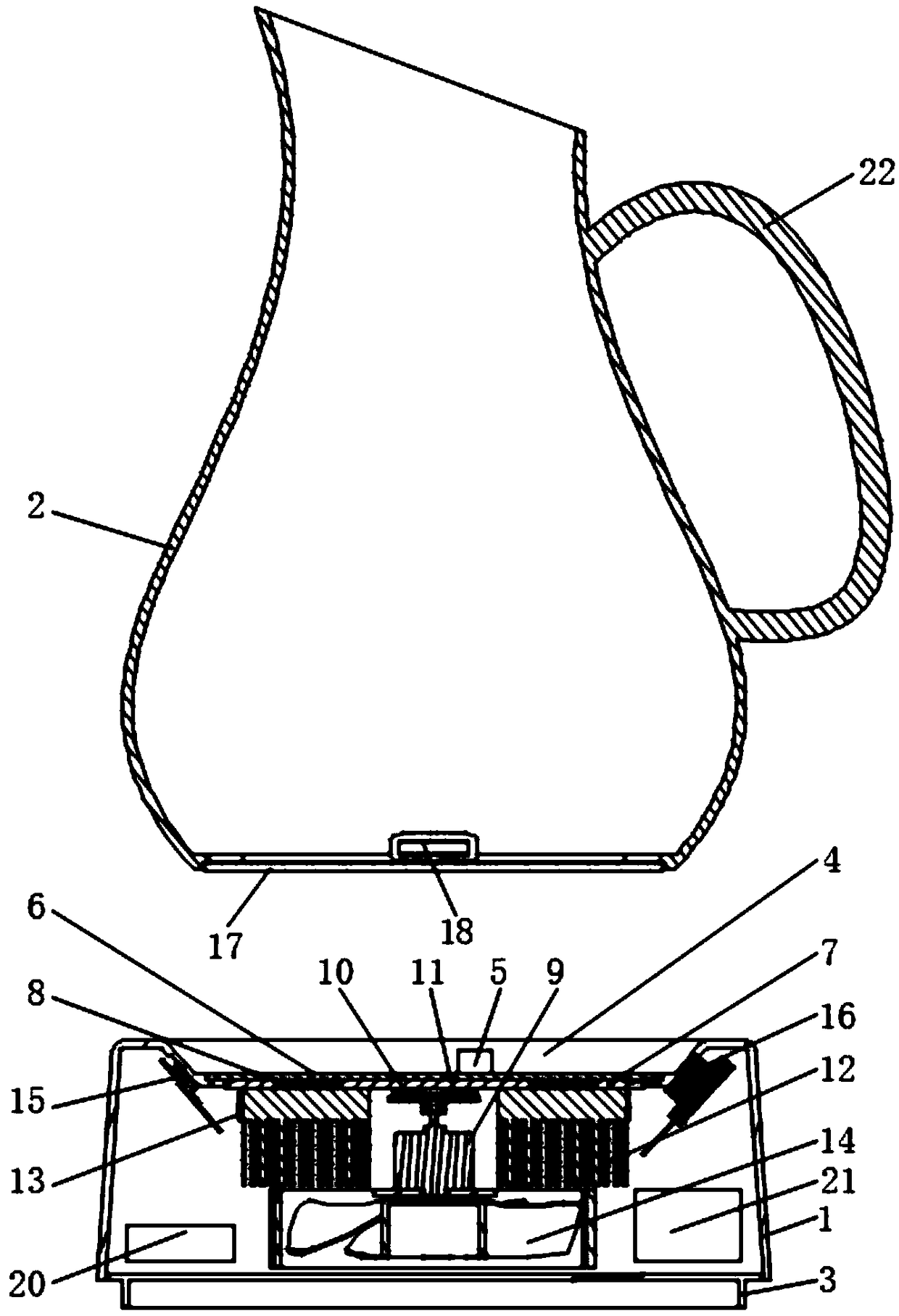

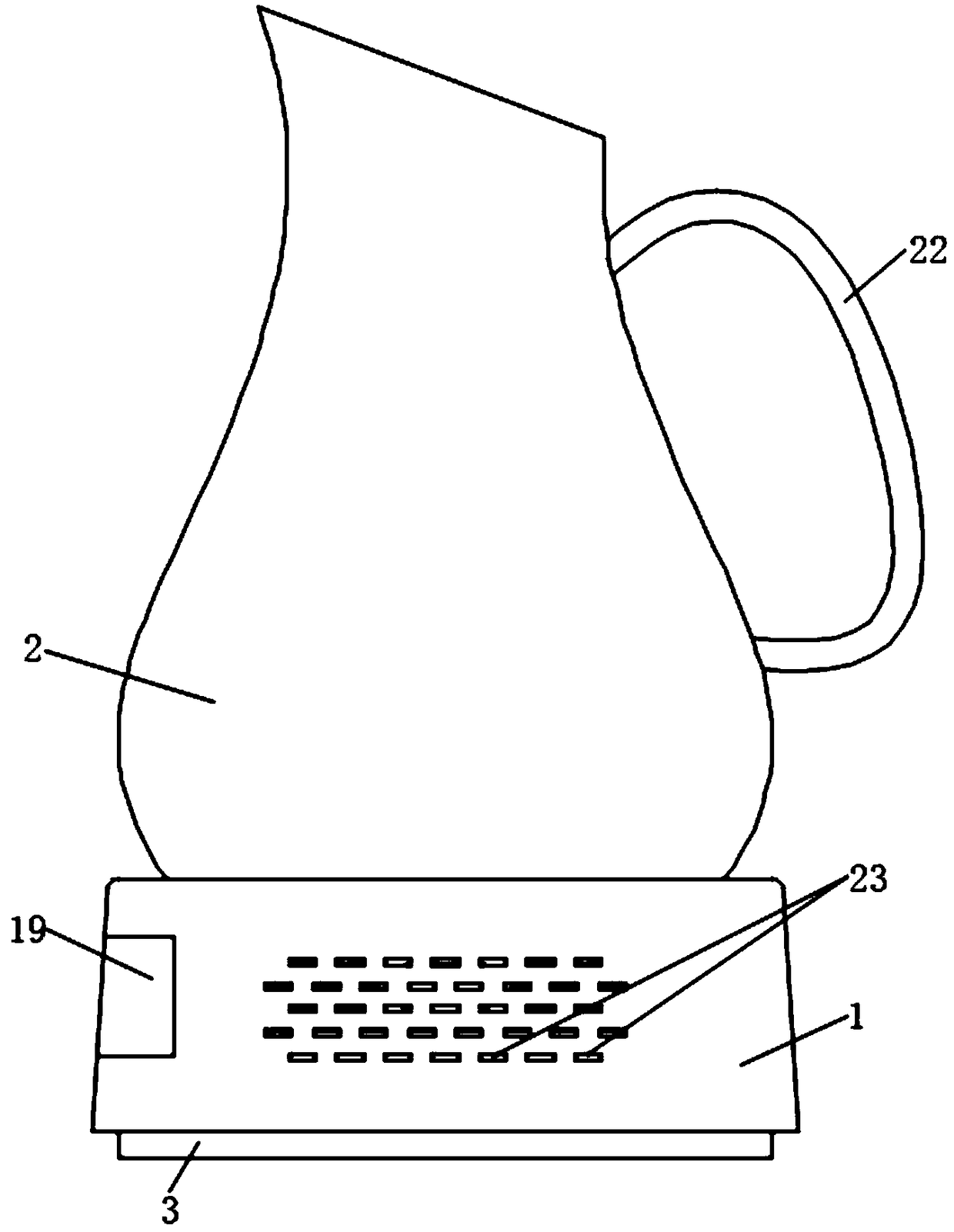

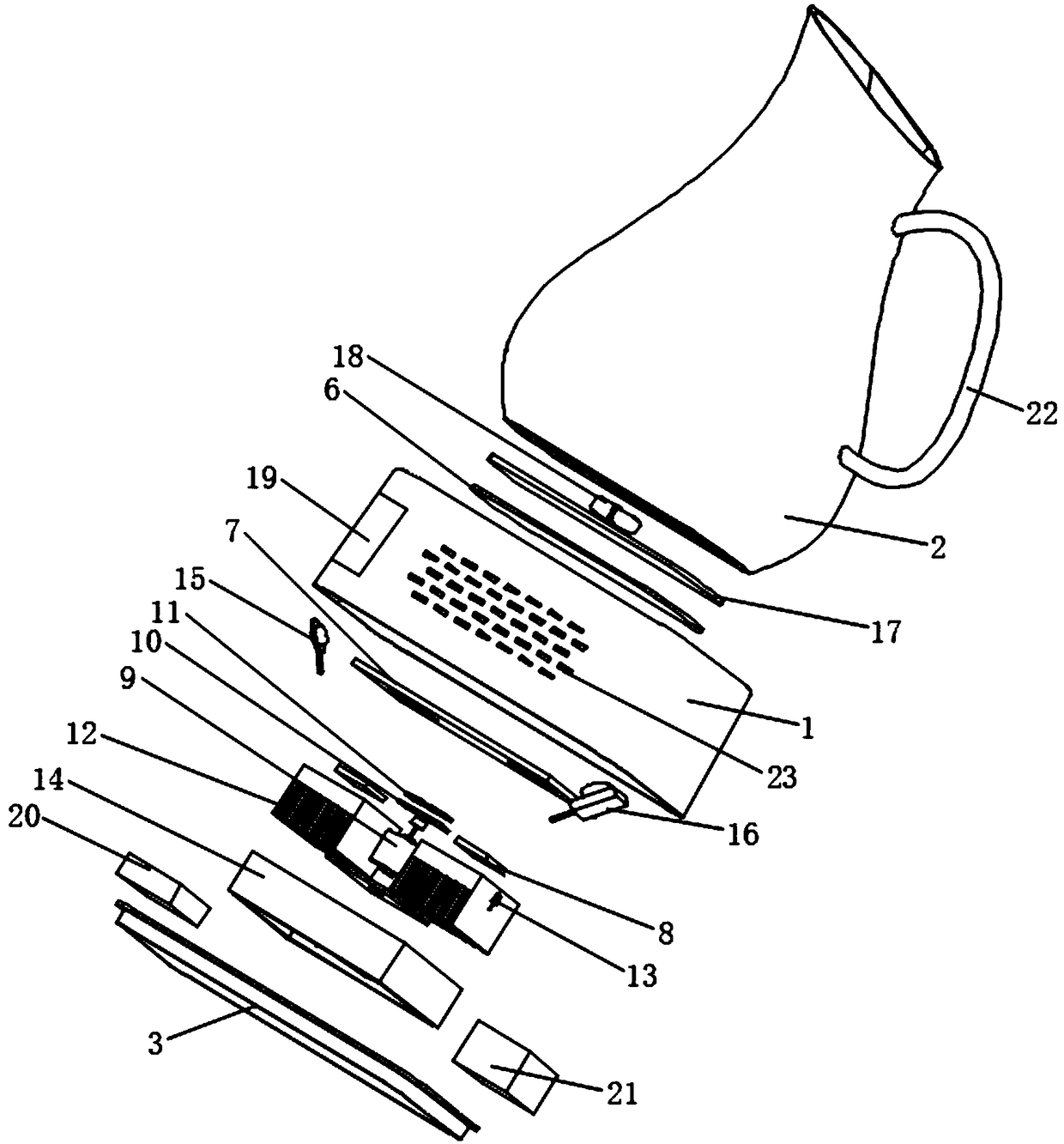

All-purpose wine decanter

InactiveCN109171502APrecise and controllable temperature curveFull and even contactKitchen equipmentEngineeringDrive motor

The invention discloses an all-purpose wine decanter, comprising an upper shell of the base and a transparent wine container, wherein a lower shell of the base is arranged at the bottom end of the upper shell of the base; an upper end surface of the upper shell of the base is integrally for with a groove, and the groove engages with a bottom shape of a transparent wine container and the groove engages with a bottom shape of a transparent wine container; a light effect lamp is symmetrically arrange on the outer side wall of the groove; the groove bottom of the groove is provided with a step through groove; the upper part of the step through groove is provided with a cooling conducting sheet; the lower part of the step through groove is provided with a heat insulating fin; a semiconductor cooling fin is symmetrically embedded through the heat insulating fin; a driving motor is arranged in the middle of the lower end face of the heat insulating fin; and a magnet fin is symmetrically arranged on the upper end face of the rotating table, and a heat dissipating fin is uniformly arranged on the lower end face of the heat insulating fin corresponding to the position of the semiconductor cooling fin. The all-purpose wine decanter has the advantages of effectively improving the wine after decanting, being convenient, being adapted to the common liquor, red wine, rice wine and other typesof drinking liquor, and being easy to clean and hygienic.

Owner:厦门尼金自动化设备有限公司

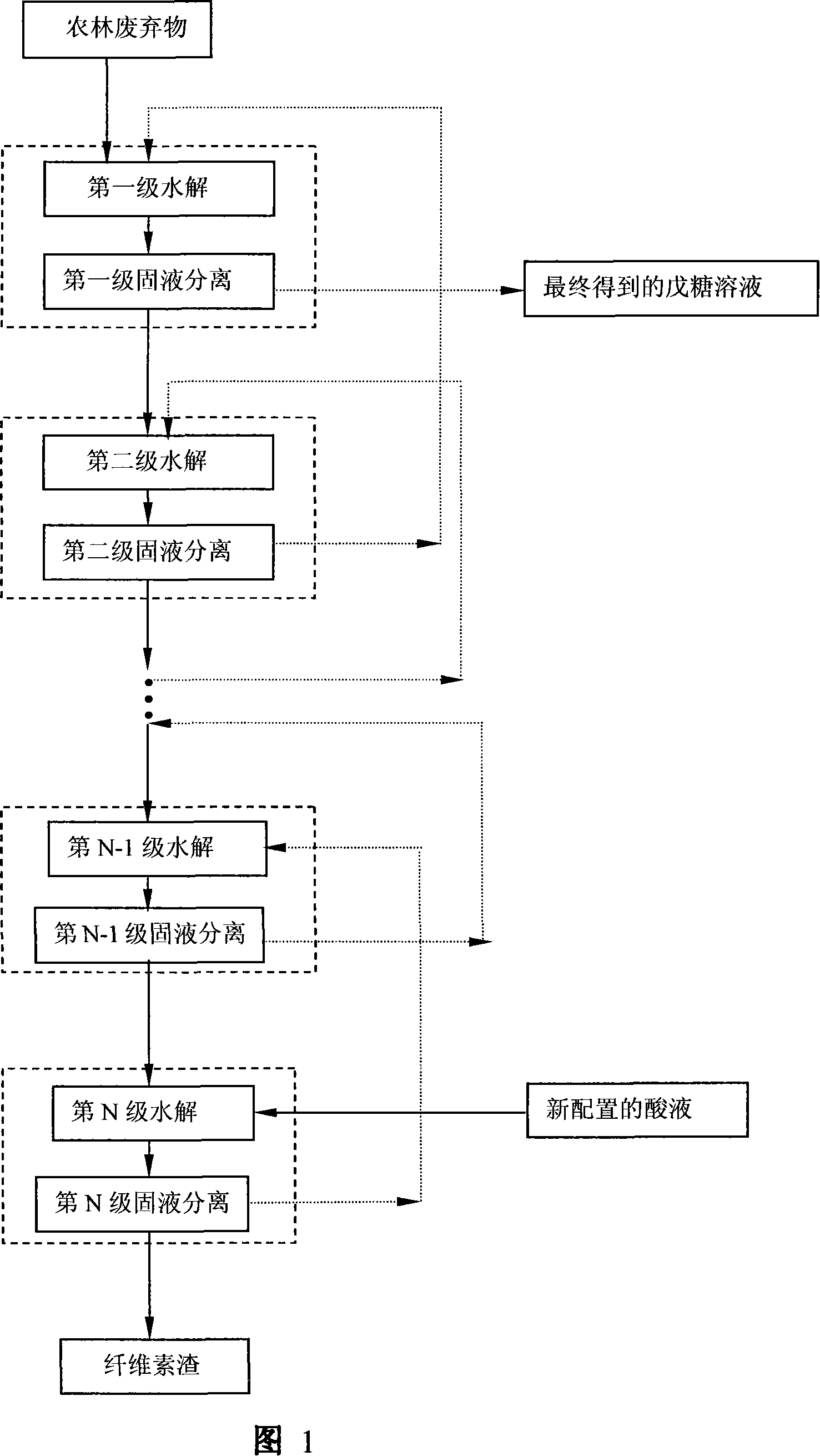

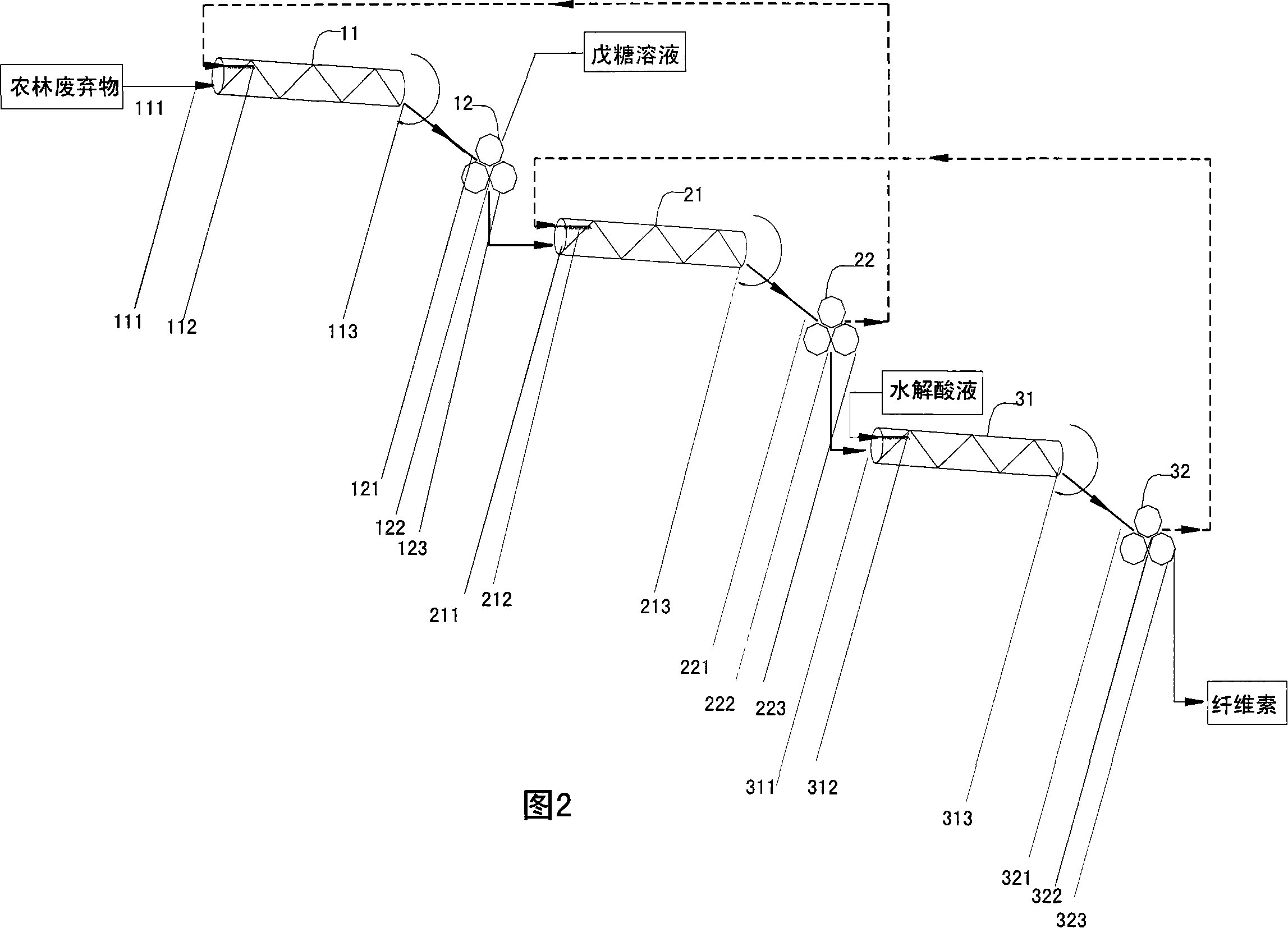

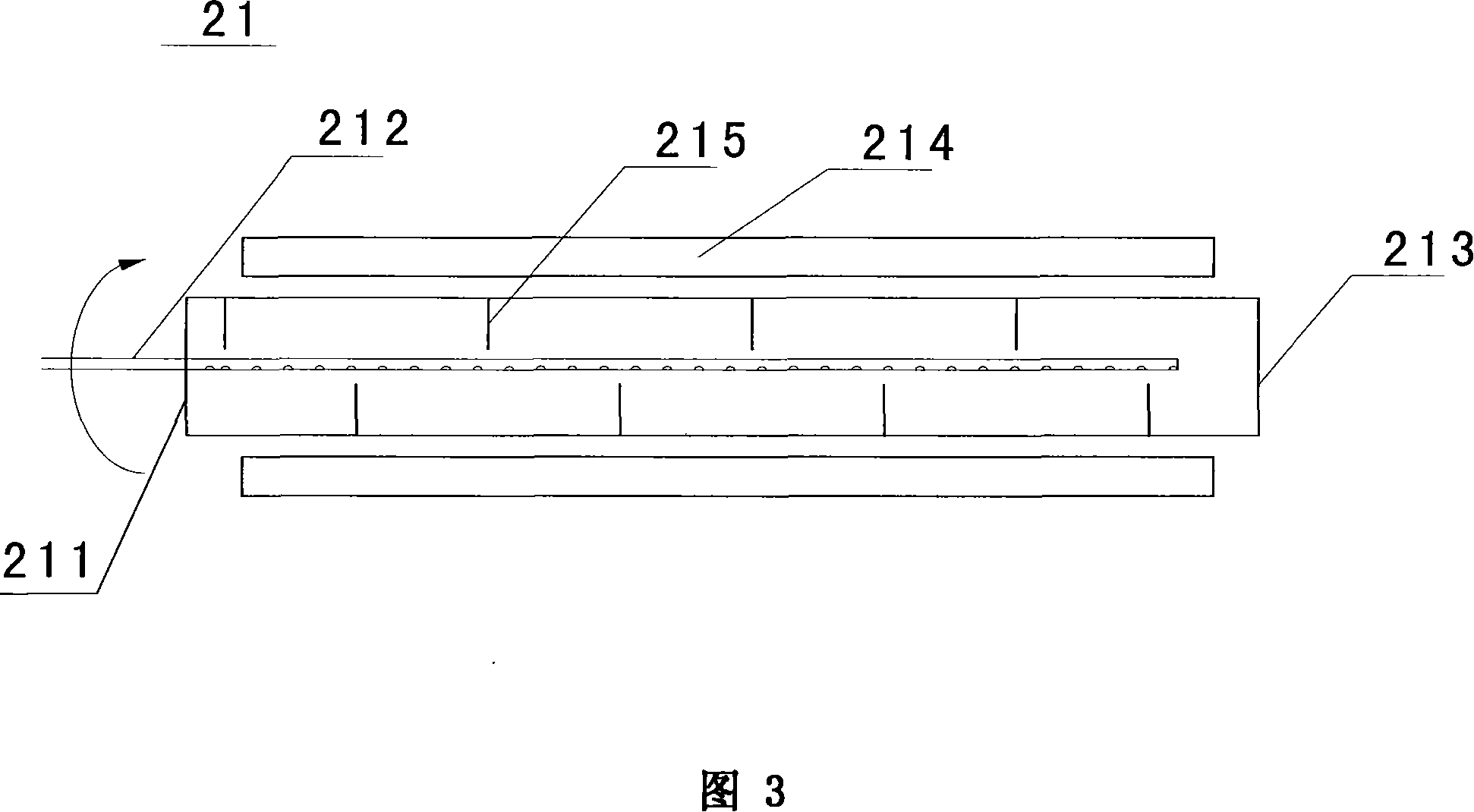

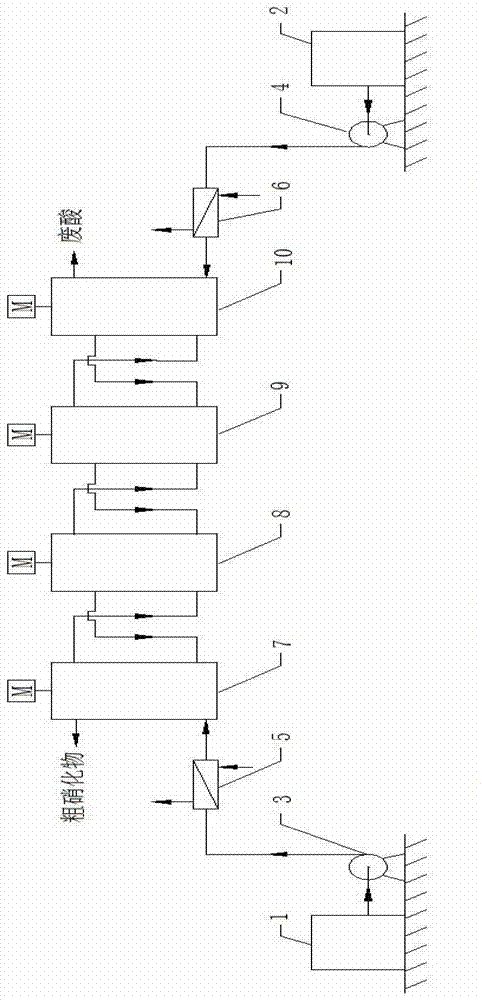

System and method for producing pentose solution by series continuous hydrolyzation

ActiveCN101130558AIncrease concentrationHigh in celluloseSugar derivativesSugar derivatives preparationCelluloseEnvironmental engineering

The invention discloses a system to make pentose solution through serially continuing hydrolysis for agricultural and forestry chemical waste, which contains N-grade of mutually serial hydrolytic units, wherein N is integral, which is not less than 2; each grade of hydrolytic unit includes mutually serial hydrolytic device and solid-liquid separating device to hydrolyze the agricultural and forestry chemical waste and separate liquid and solid of the hydrolyzed mixture to generate the hydrolytic acid liquid and solid with pentose. The system makes the entire technique realize automation with high conversion rate of agricultural and forestry chemical waste and high pentose solution density, which produces the solid material as raw material cellulose of alcohol.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Igniting device and ignition method for sintering

ActiveCN106440811AImprove distributionBalanced sinter ignition qualityFuel lightersFurnace typesEngineeringEnergy conservation

The invention discloses an igniting device and an ignition method for sintering and belongs to the field of iron smelting of a blast furnace. The igniting device disclosed by the invention comprises an ignition furnace, a gas charging pipe and a hot air charging pipe; a row of burner nozzles are arranged on a part, at an ignition section of the ignition furnace, of the furnace top; the middle burner nozzles are arranged linearly; the burner nozzles close to the two sides of a sintering machine trolley are arranged in an arc shape; each burner nozzle communicates with the gas charging pipe and the hot air charging pipe respectively; the parts, at the front end and the rear end of the ignition section, of the furnace top are each provided with an isolation chamber; each isolation chamber communicates with the hot air charging pipe; an air box is arranged at the bottom of the ignition furnace, wherein a retarder is arranged inside the air tank under the burner nozzles. The igniting device disclosed by the invention has the advantages of optimizing distribution of an igniting fuel on an overall sintering material surface, balancing the ignition quality of sintering materials at all positions of a sintering machine, improving the quality of sintered ore products, also enhancing the ignition effect, reducing consumption of the igniting fuel and satisfying the production process requirements on energy conservation and environmental protection.

Owner:MAANSHAN IRON & STEEL CO LTD

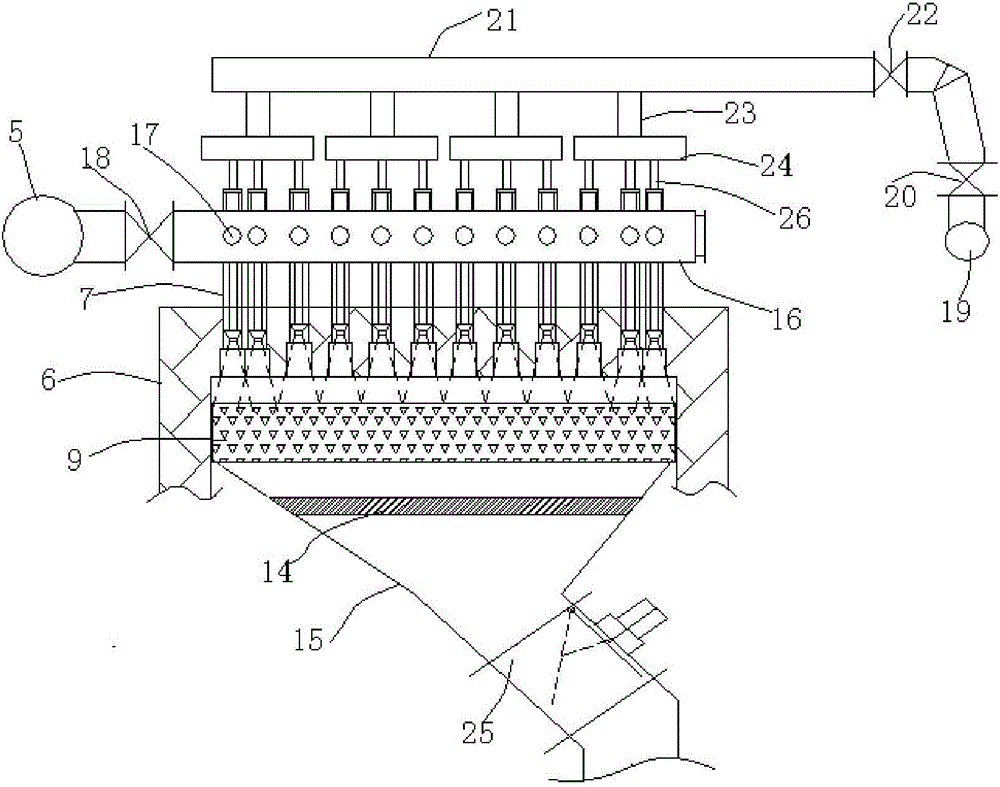

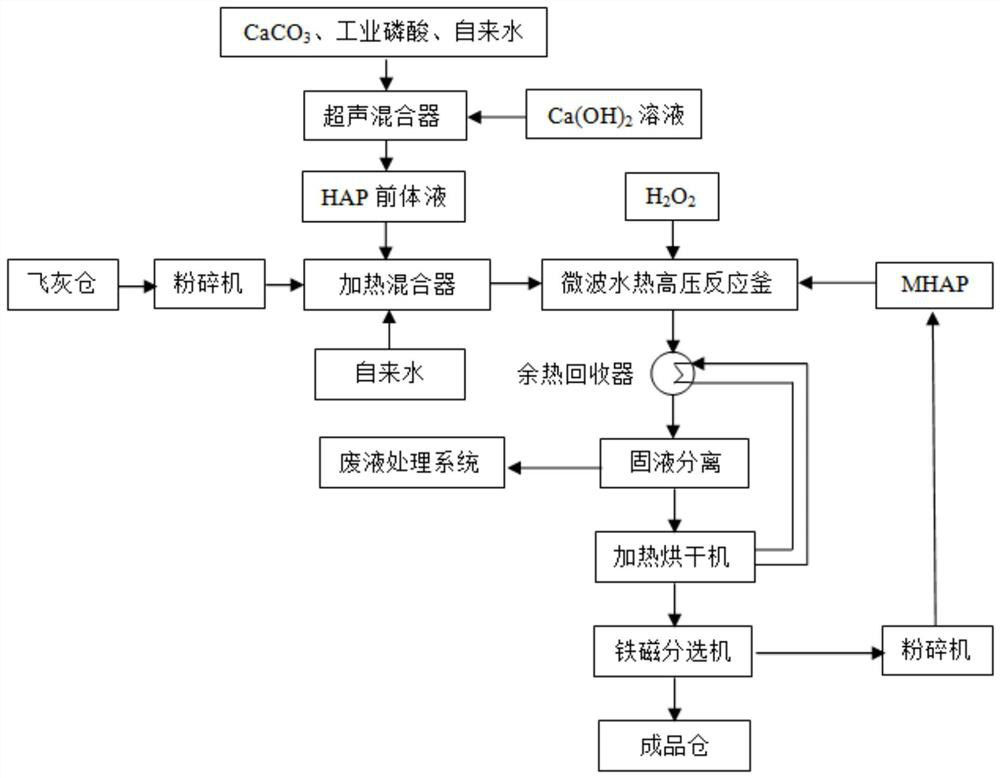

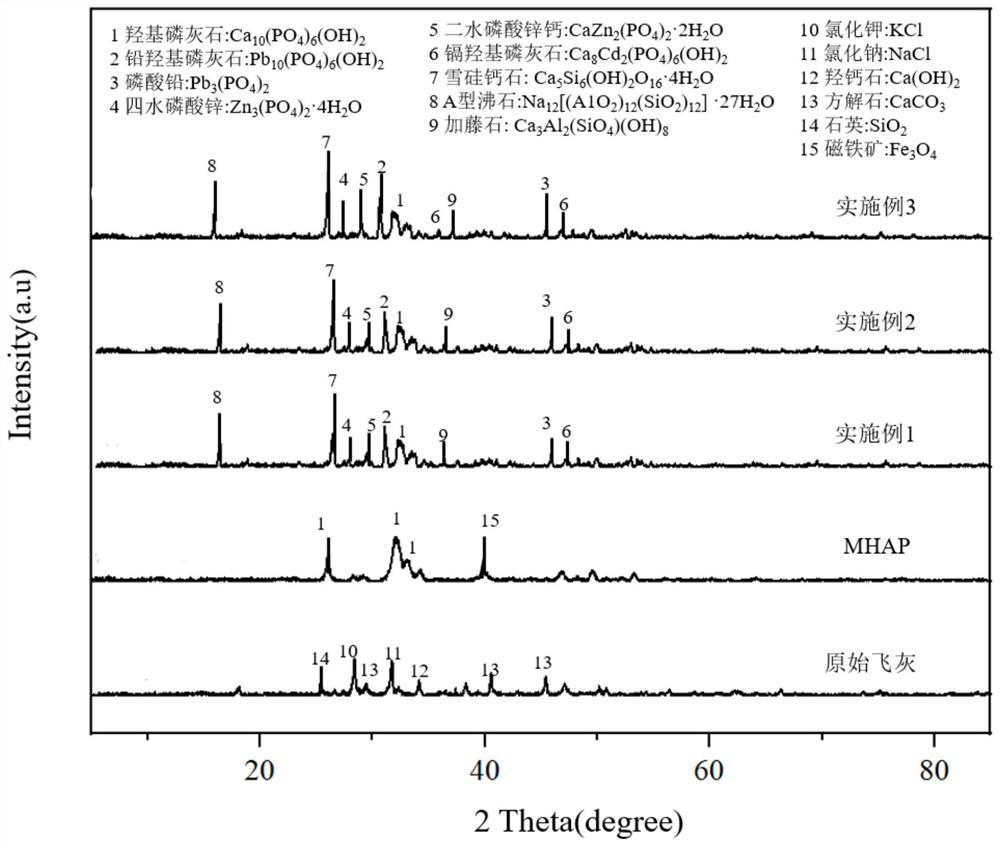

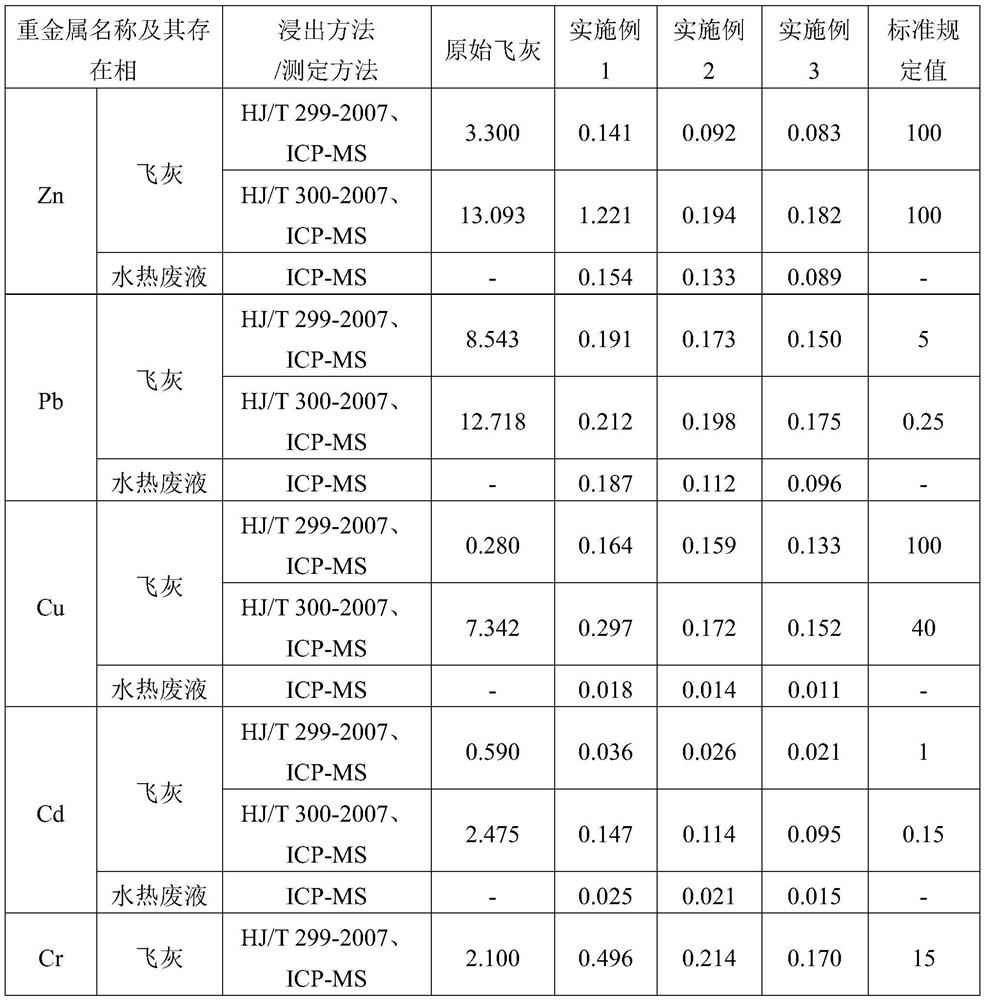

Method for harmless treatment of waste incineration fly ash through hydrothermal technology

ActiveCN111672876AStable and efficientImprove adsorption capacitySolid waste disposalTransportation and packagingEngineeringPolyaromatic hydrocarbon

The invention discloses a method for harmless treatment of waste incineration fly ash through a hydrothermal technology. The method comprises the following steps of (1) adding a hydroxyapatite precursor liquid into fly ash, and then performing first-step hydrothermal reaction under normal pressure at 40 to 50 DEG C to stabilize heavy metals in the fly ash; and (2) adding magnetic hydroxyapatite powder and hydrogen peroxide into a mixture obtained by the reaction of the step (1), and then performing second-step microwave hydrothermal reaction under a high pressure at 20 to 150 DEG C to furtherstabilize the heavy metals in the fly ash and degrade polyaromatic hydrocarbons. According to the method, stabilization of the heavy metals and degradation and detoxification of the polyaromatic hydrocarbons in the waste incineration fly ash can be realized efficiently and synchronously; the leaching toxicity of the heavy metals is lower than identification standards for hazardous wastes and can meet domestic waste landfill pollution control standards; the heavy metals are actually stabilized in the fly ash rather than being transferred to a hydrothermal waste liquid on a large scale; the toxic equivalent degradation rate of sixteen polyaromatic hydrocarbons is up to 95.06 percent; and secondary pollution is prevented.

Owner:CHONGQING UNIV

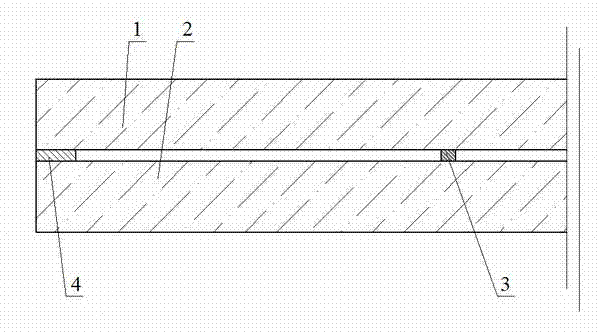

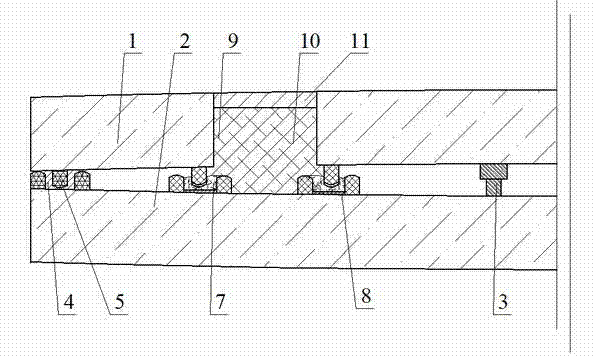

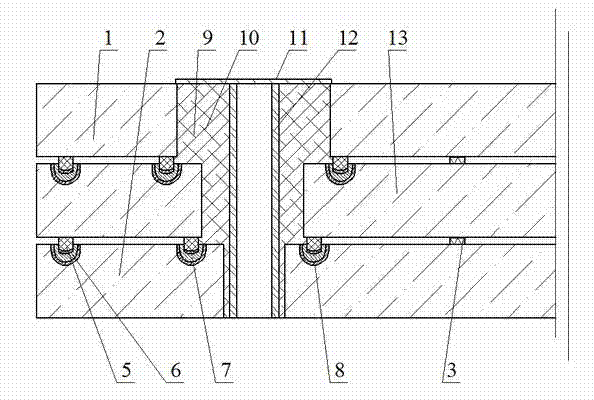

Vacuum glass laminated at high temperature and production method thereof

InactiveCN104743842AShorten the timeGuaranteed timeGlass reforming apparatusGlass productionHigh volume manufacturingHeating furnace

The invention relates to a vacuum glass laminated at high temperature, which comprises an upper glass and a lower glass, the upper glass and the lower glass are plane glass or convex glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder or a metal solder in a vacuum furnace, an enclosing vacuum layer is formed between the upper glass and the lower glass, and the supporters with lattice arrangement are arranged in the vacuum layer. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

Safe production method of nitro-compound

ActiveCN103044261AHigh yieldLow costNitric acid ester preparationNitro compound preparationNitro compoundAutomatic control

The invention provides a production method of nitro-compound. The production method comprises the steps of: continuously feeding a mixed acid solution from a heavy-phase inlet of a first centrifugal extraction separation device of a nitration separation system disclosed by the invention, and continuously feeding a raw material to be nitrified from a light-phase inlet of a final centrifugal extraction separation device at the same time, wherein the reaction temperature inside each centrifugal extraction separation device is controlled at 10-160 DEG C, and the rotating speed of each centrifugal extraction separation device is controlled at 800-2000 r / min; after multi-stage continuous nitration reaction, discharging final coarse nitride from a light-phase outlet of the first centrifugal extraction separation device, and discharging final waste acid from a heavy-phase outlet of the final centrifugal extraction separation device; and carrying out common alkali washing and water washing on the coarse nitride, and distilling the coarse nitride to obtain the refined nitro-compound product. According to the method disclosed by the invention, the nitration reaction is continuously carried out; the device is compact, easy to achieve automatic control, large in operation elasticity, and high in production efficiency; and as the reaction product and the waste acid are separated from each other at the same time inside the same reactor, the contact time of the reaction product and the waste acid is greatly shortened, side reaction is effectively avoided, energy consumption and material consumption are greatly reduced, and the security of the nitration reaction process is fundamentally ensured.

Owner:徐德良 +1

Testing apparatus and testing method for textile resistance of solid state dirt contamination

InactiveCN102305765AEffective driveIncrease elasticityUsing mechanical meansMaterial analysisBiochemical engineeringTest fixture

The invention relates to a testing apparatus and a testing method for textile resistance of solid state dirt contamination. The apparatus is characterized in that: the textile is positioned in a sample fixture; an upper fixture piece and a lower fixture piece are used for holding the textile through the interlocking of a rectangular hole and an elastic gasket; the sample fixture is positioned in a cylinder, and solid state dirt is added into the cylinder; and the cylinder is rotated in a cubic tumbling box. Through the impacting of the cylinder and the cubic tumbling box, a solid state dirt contamination process of the textile during application can be simulated and accelerated.

Owner:中纺标检验认证股份有限公司

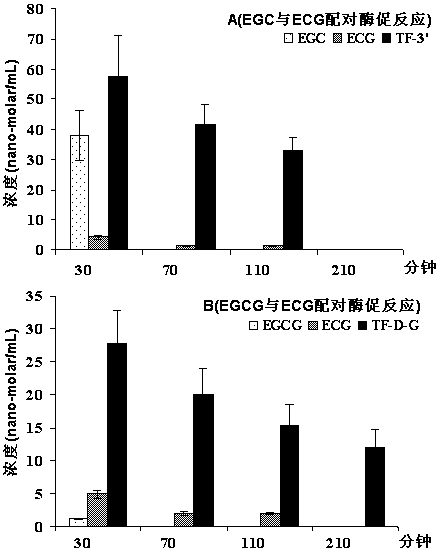

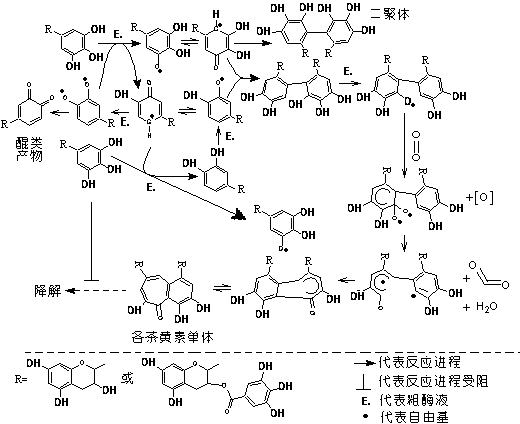

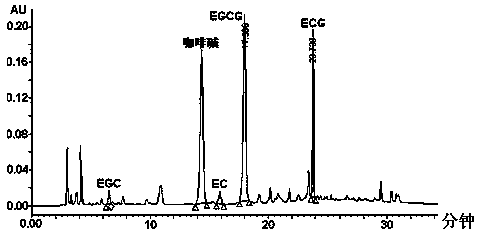

Method for increasing fresh tealeaves enzymatic-synthesized theaflavin productive rate

ActiveCN103749751AEasy to storeEasy to standardize operationPre-extraction tea treatmentCatechinic acidBlack tea

The invention relates to the field of tealeaves processing, in particular to a method for increasing the productive rate of theaflavoin formed by converting catechinic acid in fresh tealeaves. The adopted scheme is as follows: storing harvested fresh tealeaves into a soft sealed bag, carrying out vacuum sealing on the bag (controlling the vacuum degree at minus 0.1MPa to minus 0.01MPa), adequately freezing the fresh tealeaves, warming the tealeaves under an ambient temperature which is more than zero (about 4 to 37 DEG C) for 2 to 15h, and promoting the catechinic acid to be enzymatically synthesized into theaflavin. After the reaction is ended, the high-temperature withered fresh tealeaves can be directly processed into bar-shaped red tea, flat red tea or twisted into coiled red tea; the mass percent of four theaflavin monomers (theaflavin, theaflavin-3-gallate, theaflavin-3'-gallate and theaflavin-3,3'-bi-gallate) in a dry sample of the prepared read tea is more than or equal to 2 percent of the total mass percent.

Owner:HANGZHOU TEA RES INST CHINA COOP

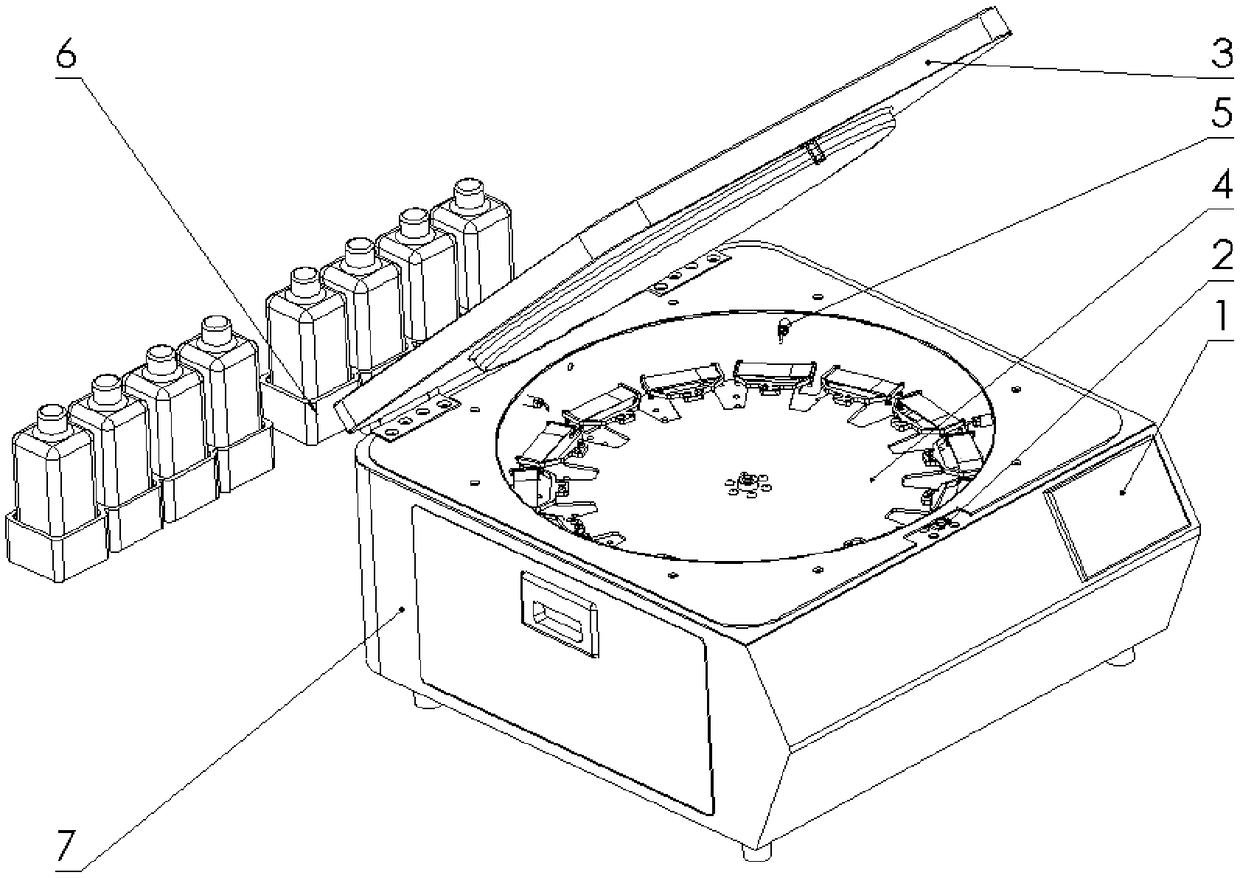

Automatic dyeing device and control method thereof

PendingCN109238812AControlled drippingReduce wastePreparing sample for investigationEngineeringGlass slide

The invention discloses an automatic dyeing device. The device comprises: a shell body; a cover plate; a dripping dyeing mechanism, which is installed in the shell body, and is used for dyeing on samples; a detecting mechanism, which is used for detecting positions and the number of the samples; a cleaning mechanism, which is used for cleaning the inside of the device; a rotating mechanism, whichis used for centrifuging on the samples; and a reagent detecting mechanism, which is installed outside the shell body, and is used for detecting the use amount of a reagent. The detecting mechanism includes a sensor support seat installed on the cover plate, a sensor, a protection baffle and a pushing component. The sensor support seat is installed on the cover plate. The sensor is installed on the sensor support seat. A light transmission hole corresponding to a position of the sensor is disposed on the cover plate. The protection baffle is disposed on the light transmission hole. The devicehas the advantages that positions and the number of glass slides are detected through the sensor, positions where dyeing liquid droplets fall on the glass slides are effectively controlled, waste of the reagent is reduced, the light transmission hole is completely blocked through the protection baffle after detection completion, and a case where the reagent in experiment contaminates the sensor, and thus impacts accuracy of detecting is avoided.

Owner:TIANJIN YUANTIANSHENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com