Prepn process of vulcanized hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as not being combined, so as to avoid inhomogeneity of product properties and uneven mixing of materials average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Hydrogenation catalyst A: With γ-alumina as the carrier, the active metal composition is as follows: Mo content is expressed as MoO 3 The weight percentage is 23.7%, the Co content is 4.5% by weight in CoO, and the P content is in P 2 o 5 The weight percentage is 3.1%. (excluding the composition of vulcanizing agent)

[0027] Contain the preparation process of the above-mentioned composition catalyst of vulcanizing agent:

[0028] Take 1000 grams of gamma-alumina carrier, the specific surface area of the carrier is 296m 2 / g, pore volume 0.87ml / g, use 129 grams of molybdenum trioxide, 56 grams of cobalt carbonate, 30.6 grams of 85% phosphoric acid and appropriate amount of water to prepare 900ml aqueous solution, impregnate the above carrier, and dry the impregnated sample at 340°C for 4 hours , to prepare the catalyst intermediate, the Mo content is expressed as MoO 3 The weight percentage is 10%, the Co content is 2% by weight of CoO, and the P content is P 2 o ...

Embodiment 2

[0030] Hydrogenation catalyst A: With γ-alumina as the carrier, the active metal composition is as follows: Mo content is expressed as MoO 3 The weight percentage is 25.8%, the Co content is 4.9% by weight in CoO, and the P content is in P 2 o 5 The weight percentage is 3.5%. (excluding the composition of vulcanizing agent)

[0031] Contain the preparation process of the above-mentioned composition catalyst of vulcanizing agent:

[0032] Take 1000 grams of gamma-alumina carrier, the specific surface area of the carrier is 296m 2 / g, pore volume 0.87ml / g, use 129 grams of molybdenum trioxide, 56 grams of cobalt carbonate, 30.6 grams of 85% phosphoric acid and appropriate amount of water to prepare 1300ml aqueous solution, impregnate the above carrier, and dry the impregnated sample at 340°C for 4 hours , to prepare the catalyst intermediate, the Mo content is expressed as MoO 3 The weight percentage is 8.9%, the Co content is 1.7% by weight in CoO, and the P content is P...

Embodiment 3

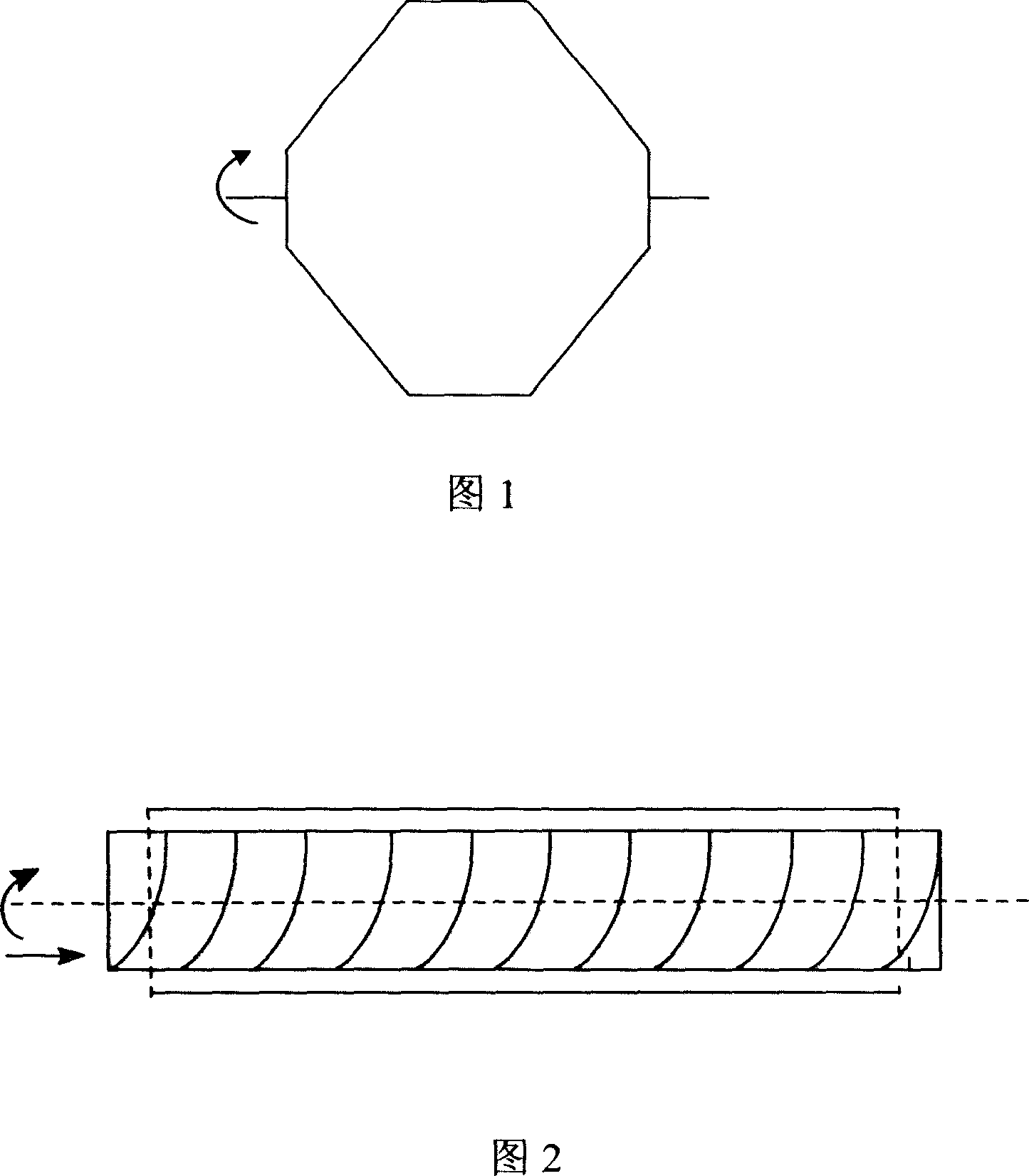

[0034] According to the method for embodiment 1, reducing the active metal content in the catalyst intermediate is 15% (weight) of the final catalyst active metal content, and the elemental sulfur consumption is 80% of theoretical requirement, and heat treatment temperature is 150 ℃, and heat treatment time is 20 Hours, the heat treatment equipment adopts the biconical rotary heat processor described in Figure 1, and the speed is 3 rpm. Other according to the method of embodiment 1, obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com