Patents

Literature

157results about "Nitric acid ester preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

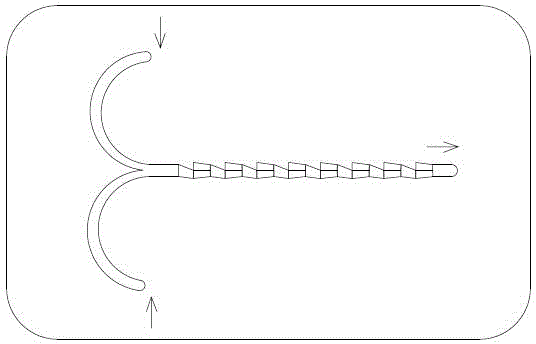

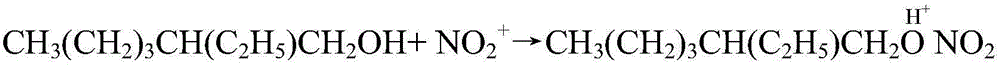

Method for synthesizing isooctyl nitrate and microchannel reactor

ActiveCN101462962AAvoid production accidentsLow costNitric acid ester preparationSynthesis methodsSolvent

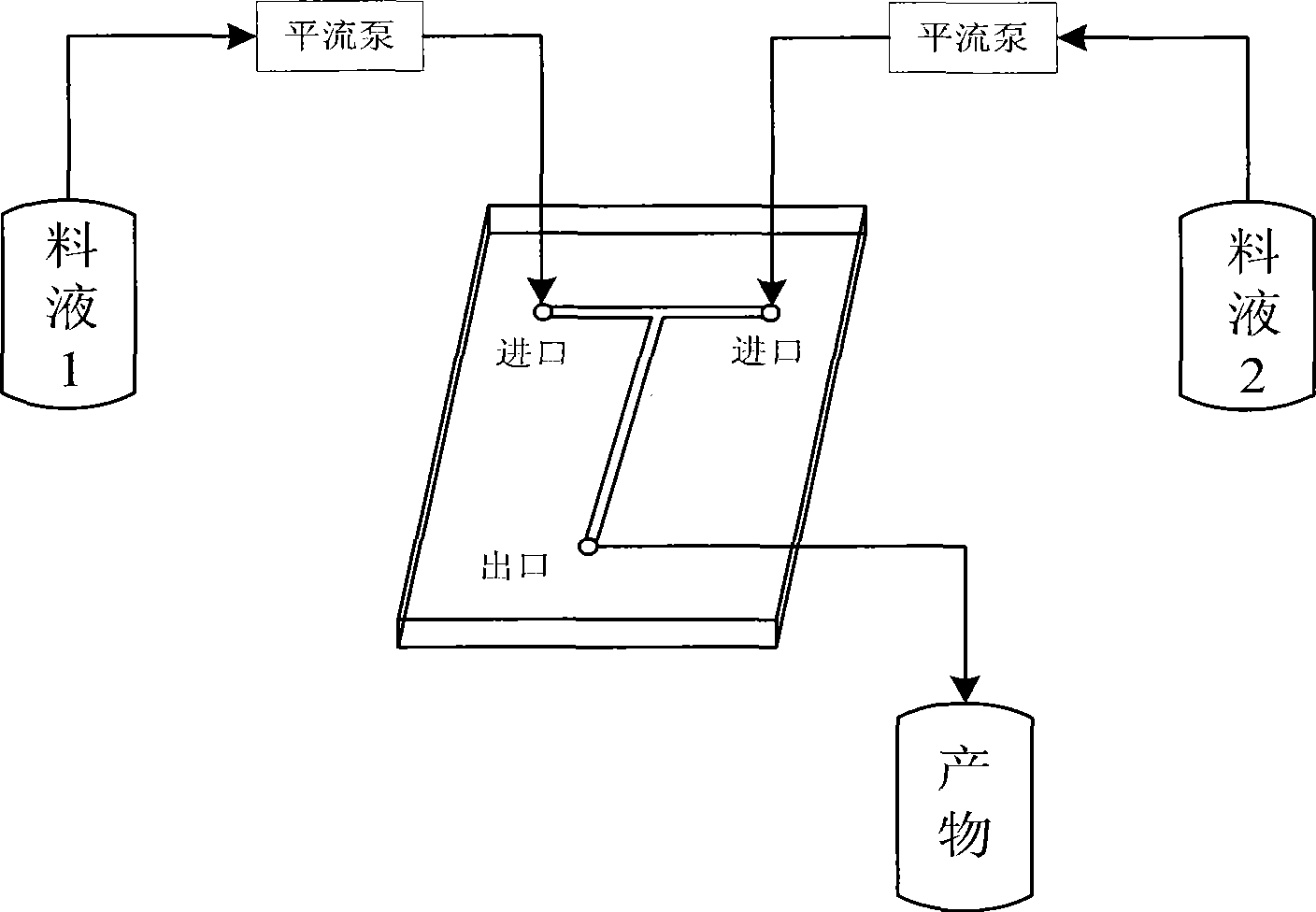

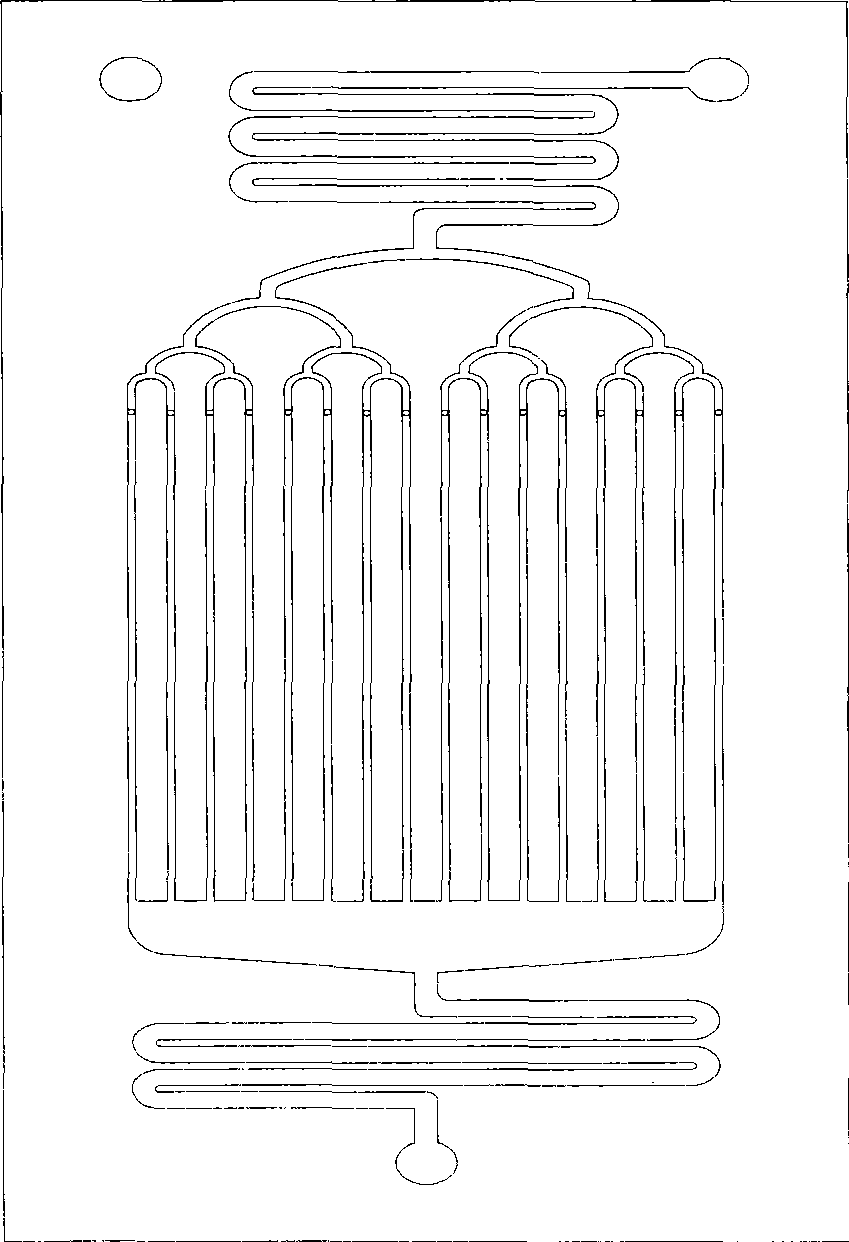

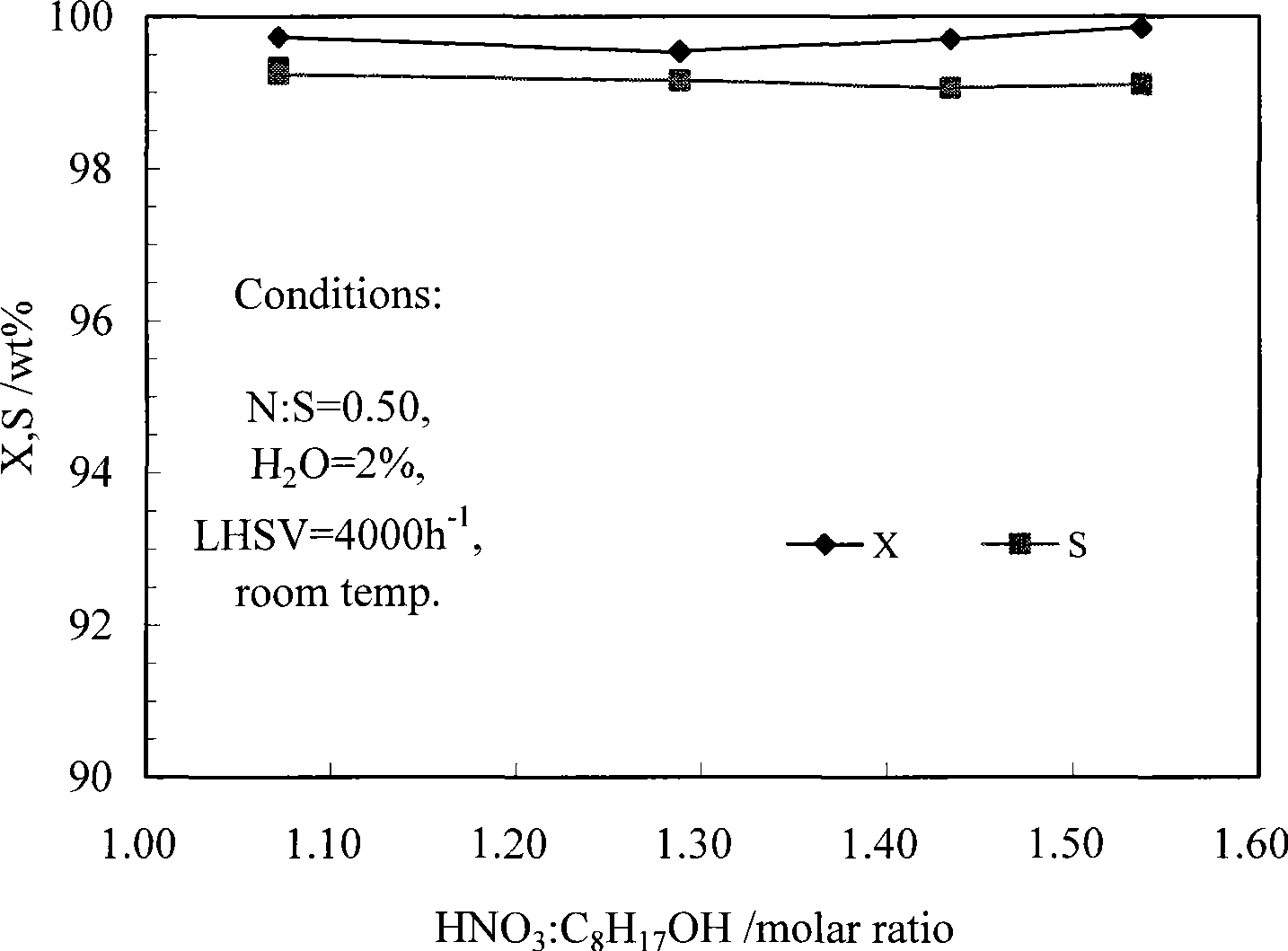

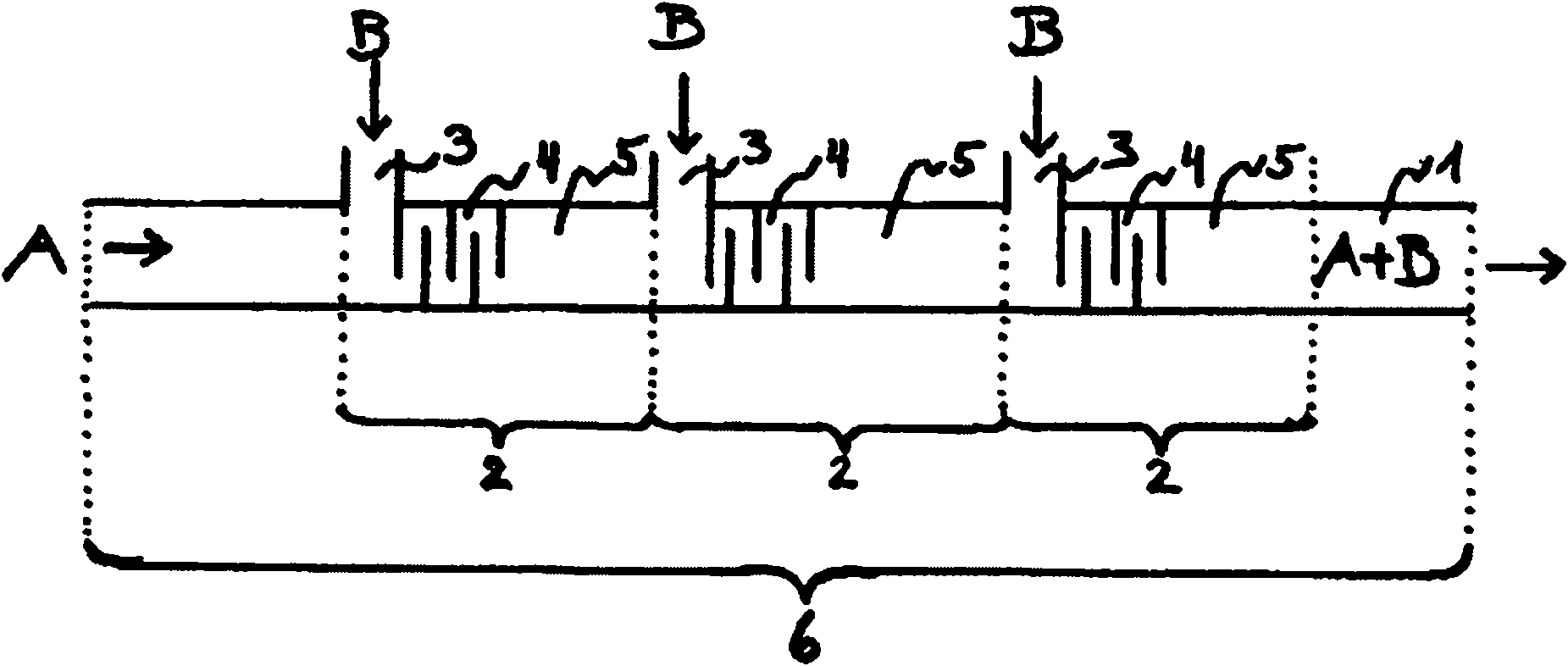

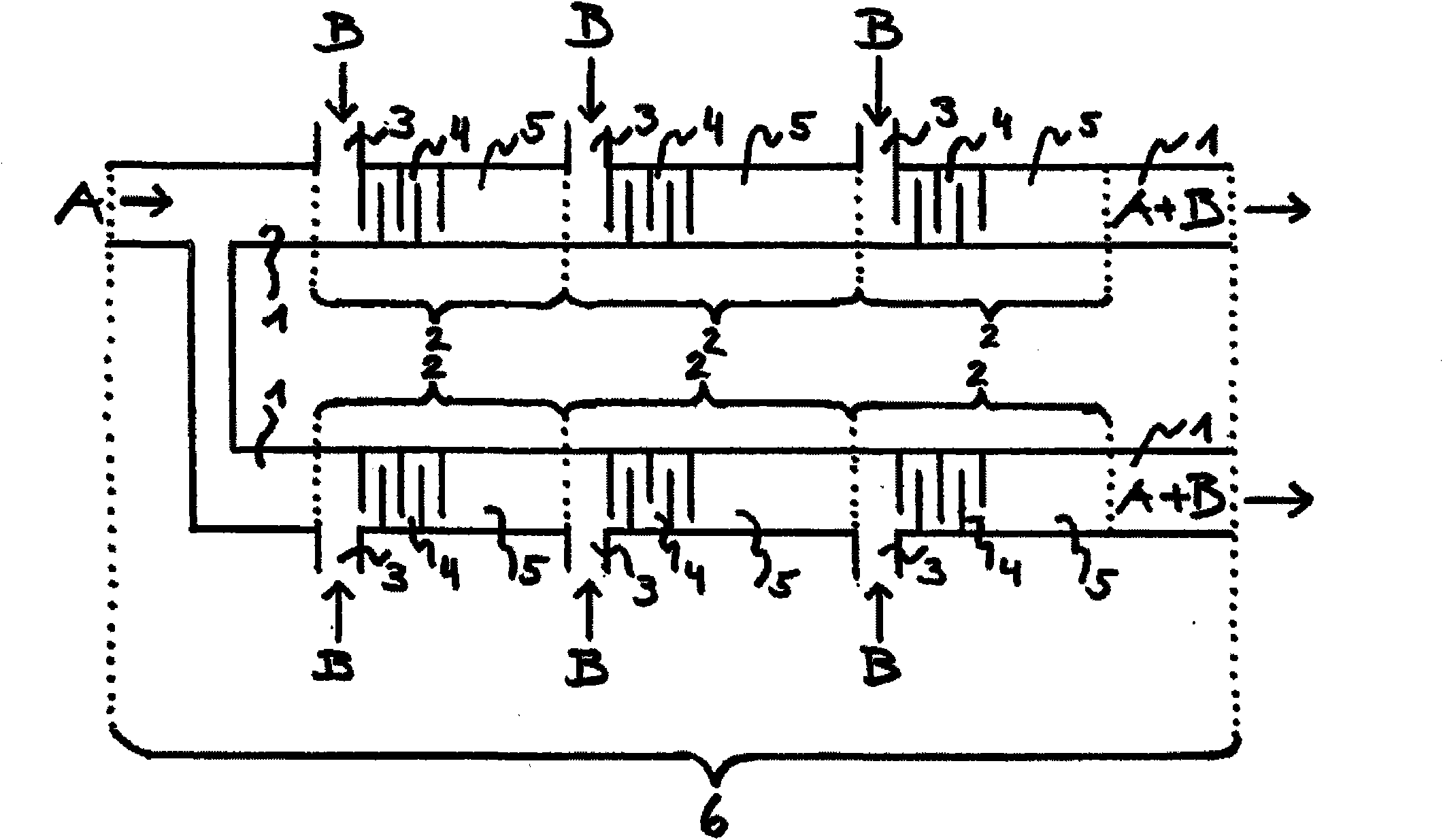

The invention relates to the synthesis of isooctyl nitrate; in particular to a synthesis method of isooctyl nitrate and a microchannel reactor. Isooctyl alcohol is taken as raw material and an acid mixture of nitric acid and sulphuric acid is taken as nitrating agent, and the raw material and the nitrating agent are pumped into the microchannel reactor at normal temperature and pressure to carry out direct esterification. The process needs no catalyst or solvent, makes full use of the efficient heat and mass transfer capability of the microchannel as well as the characteristic of direct amplification and adopts two microreactors, of which one is a single-channel microreactor and the other is a multichannel microreactor; liquid hourly space velocity in the microreactor is 3000-10000h<-1>, the once-through conversion ratio of isooctyl alcohol is higher than 99% and the yield coefficient of isooctyl nitrate is higher than 98%. The process has high operation safety and high selectivity and can realize approximate isothermal operation in the reaction. The reactor is small in volume, is easy to integrate and amplify and space-time productive rate is high, thus being significant for strengthening and guaranteeing the safe production of isooctyl nitrate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

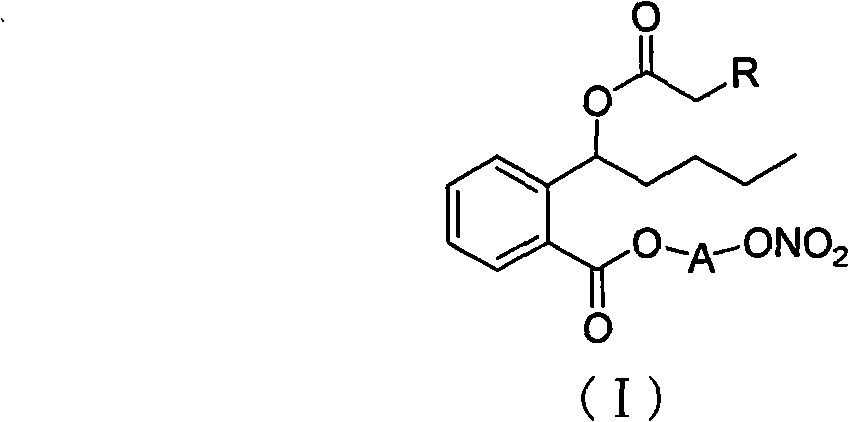

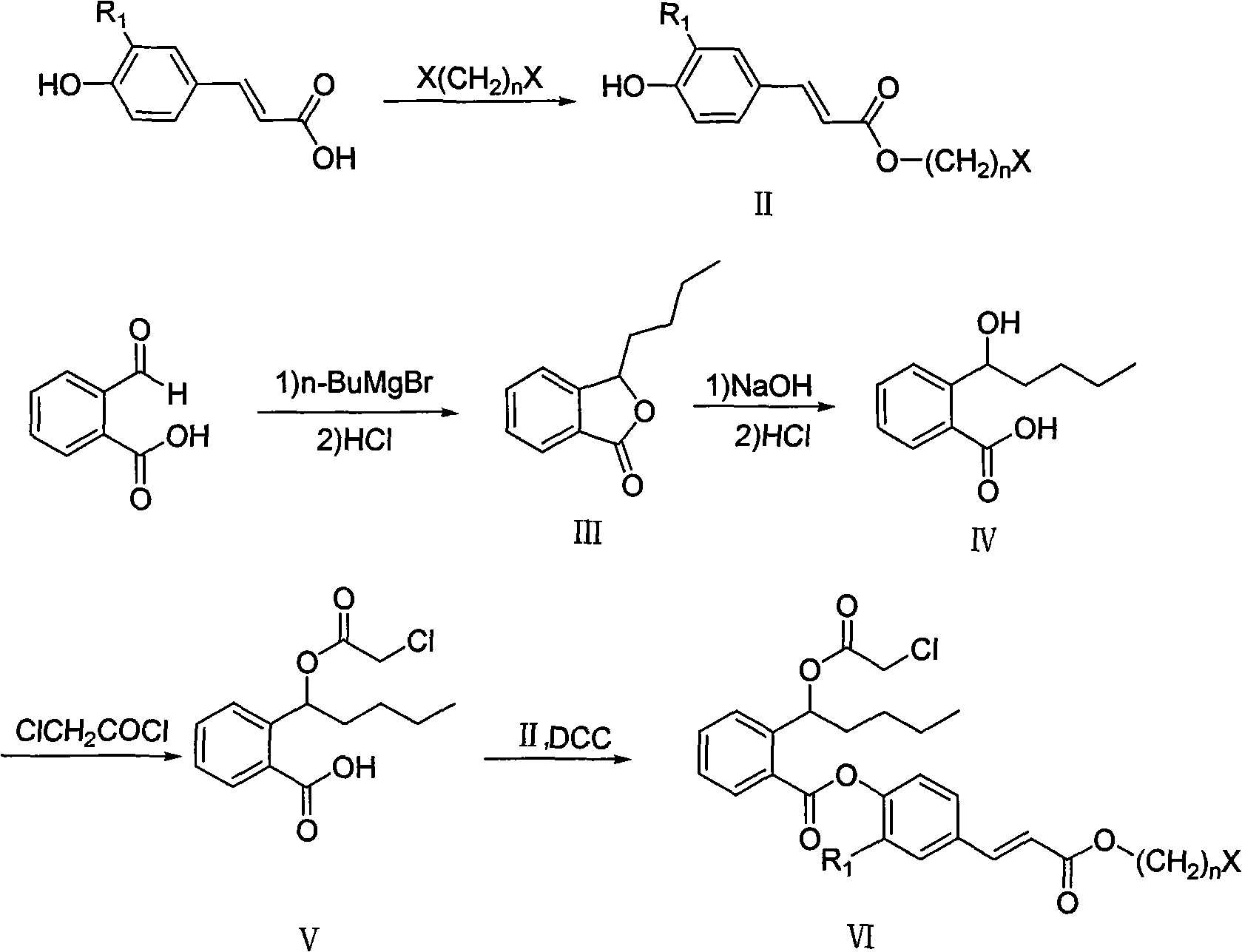

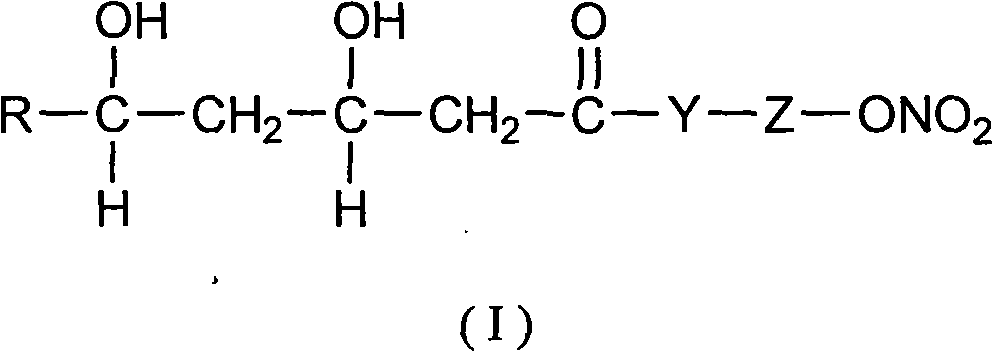

Nitric oxide donor type 3-butylphthalide derivates, method for preparing same and pharmaceutical use

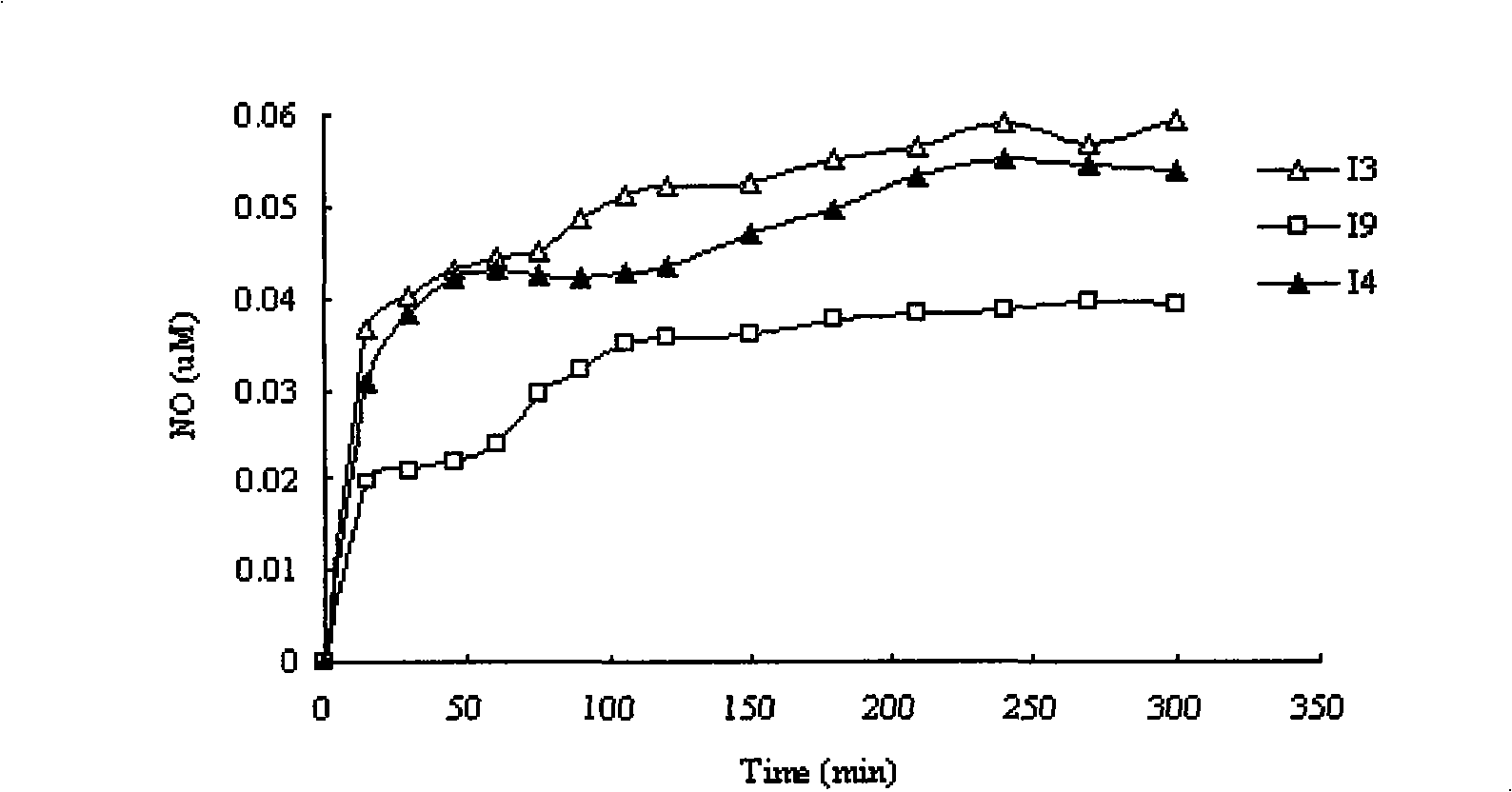

InactiveCN101337891AGood antithromboticEnhance anti-ischemic effectEster active ingredientsBlood disorder3-BUTYLPHTHALIDEDrugs preparations

The invention relates to the pharmaceutical chemistry filed, and particularly relates to novel nitric oxide donor butyl phthalide derivatives (I), the preparation method thereof, a drug preparation containing the derivatives (I) and the application as a drug for resisting thrombosis and cerebral ischemia. Wherein, the definitions of R and A are shown in the instruction.

Owner:CHINA PHARM UNIV

Method of synthesizing isooctyl nitrate

InactiveCN105566120AHigh mixing mass transfer effectImprove thermal conductivityNitric acid ester preparationIsooctyl alcoholNitrate

The invention relates to a method of synthesizing isooctyl nitrate. The method comprises the steps that mixed acid obtained by mixing concentrated nitric acid and concentrated sulfuric acid and isooctyl alcohol are conveyed into a micro-channel reactor through conveying equipment for a reaction for 5-60 seconds in the reactor at the temperature of 5-50 DEG C, the reaction product stands for skimming, and the organic phase is washed and dried to obtain the isooctyl nitrate. According to the method, the reaction is performed in a triangular three-layer structure reaction plate, mass and heat transfer is quick, the reaction can be performed at constant temperature, and operation safety is high. In the process, the single-pass conversion rate of the isooctyl alcohol is 99% or above, and the yield is also 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

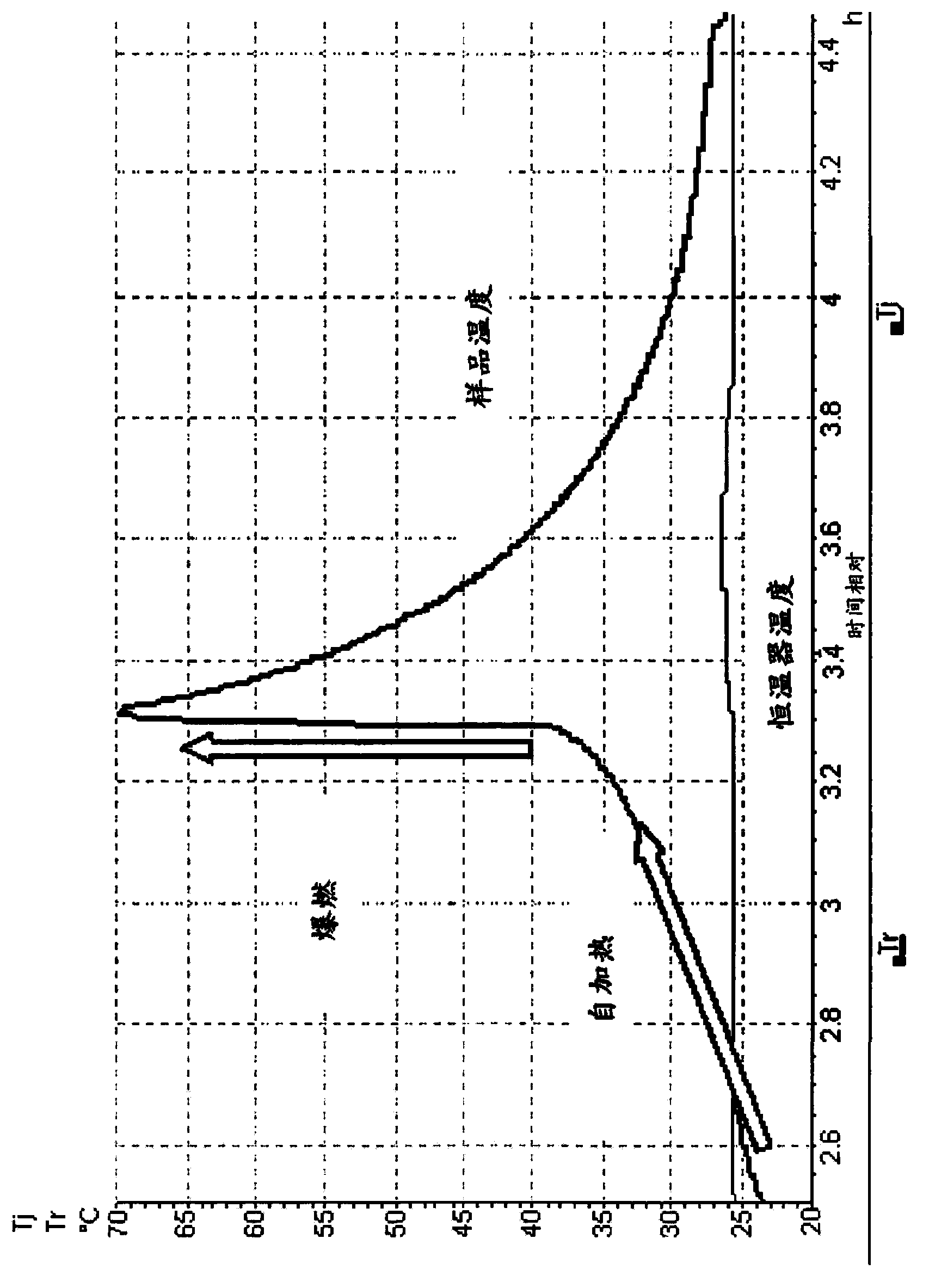

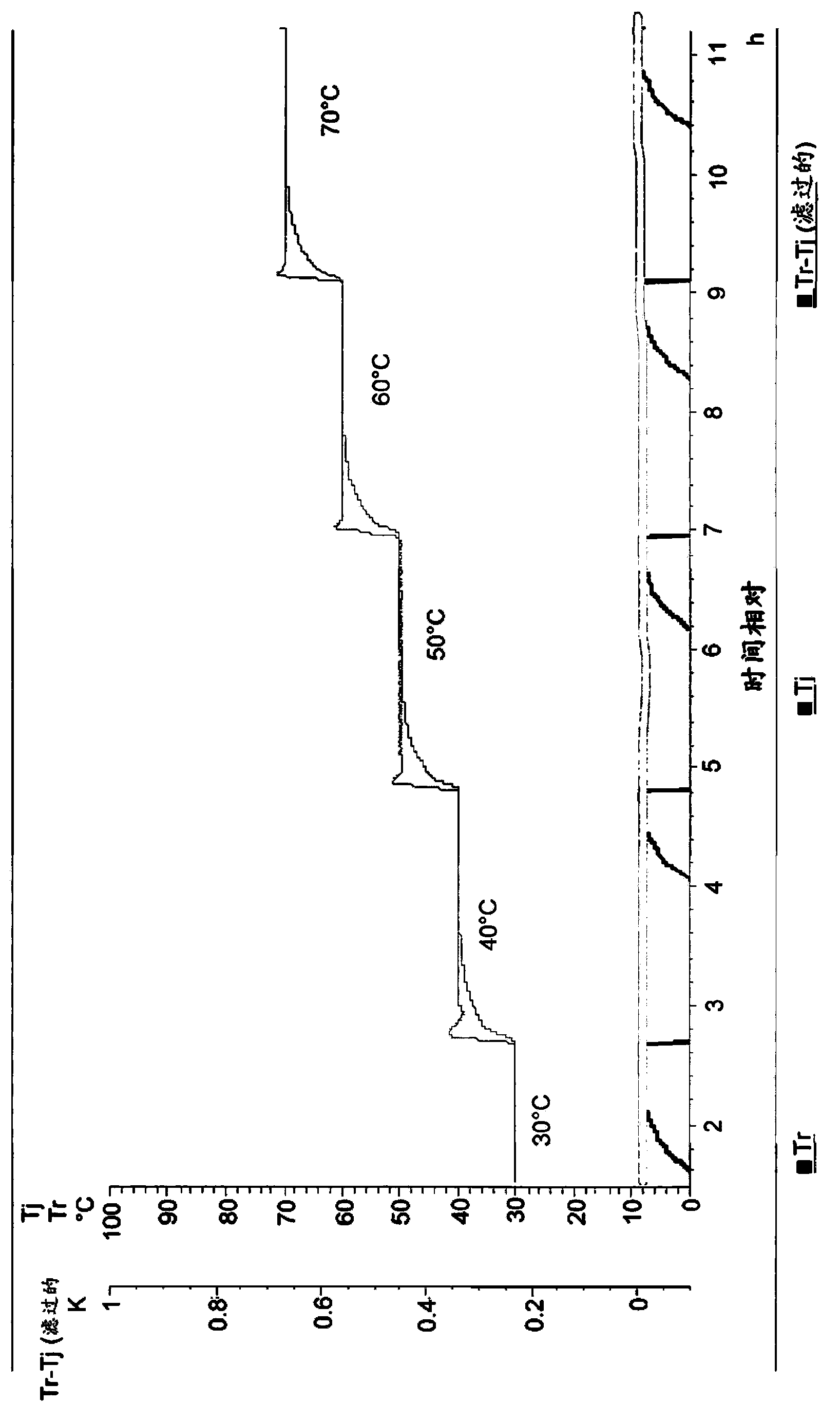

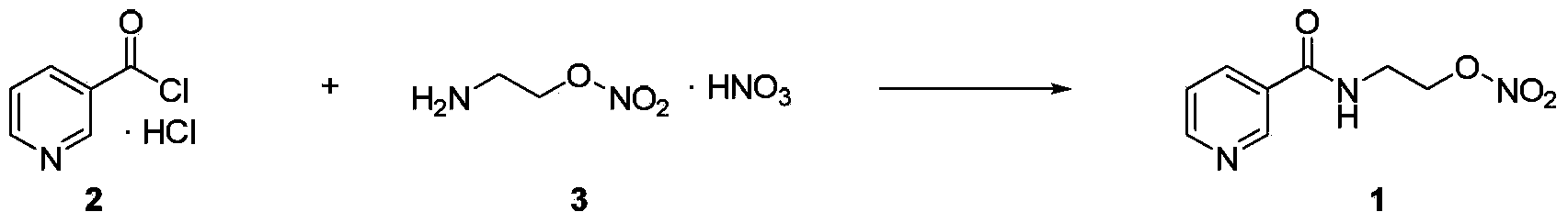

Process for the manufacture of nicorandil

Disclosed is a process for the synthesis of Nicorandil (1), 2-(nicotinamide)ethyl nitrate, starting from N-(2-hydroxyethyl)nicotinamide (15), using nitration with nitric acid in the presence of acetic anhydride Said synthesis method is particularly advantageous because it solves the safety problems involved in the use of nitric acid as nitrating agent, and allows a product with excellent yields and quality to be isolated.

Owner:PROCOS

Method for synthesizing isooctyl nitrate

InactiveCN1814581AThe synthesis process is smooth and safeProcess safety and stabilityNitric acid ester preparationIsooctyl alcoholNitrate

The invention discloses Isooctyl nitrate compounding method. It includes the following steps: mixing nitric acid and sulfuric acid with mol ratio 1:1-5; adding latent solvent with 10-50% volume ratio to the mixed acid or isooctyl alcohol; adding isooctyl alcohol into mixed acid or adding the mixture of isooctyl alcohol and latent solvent into the mixed acid; reacting for 0.5-1h; static layering; discharging acid liquor; water washing; alkali washing; water washing to neutrality; separating ester from latent solvent; and drying by dryer. The latent solvent can be cycling using.

Owner:CHINA PETROCHEMICAL CORP +1

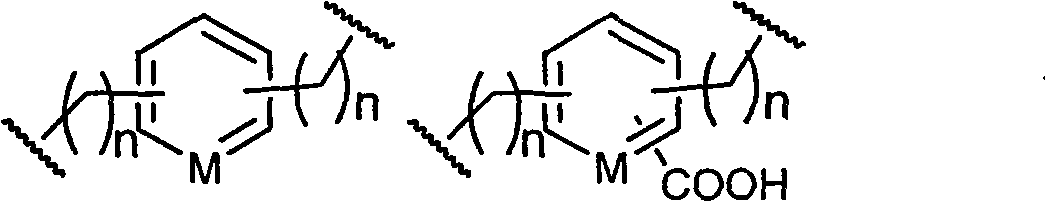

Production of fatty olefin derivatives via olefin metathesis

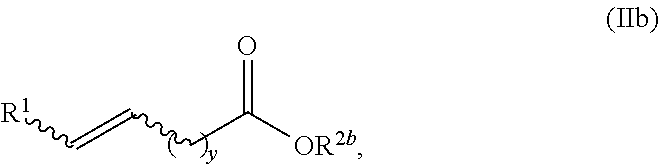

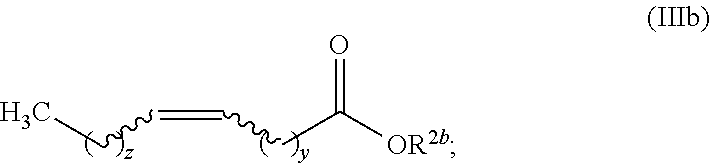

In one aspect, the invention provides a method for synthesizing a fatty olefin derivative. The method includes: a) contacting an olefin according to Formula Iwith a metathesis reaction partner according to Formula IIbin the presence of a metathesis catalyst under conditions sufficient to form a metathesis product according to Formula IIIb:andb) converting the metathesis product to the fatty olefin derivative. Each R1 is independently selected from H, C1-18 alkyl, and C2-18 alkenyl; R2b is C1-8 alkyl; subscript y is an integer ranging from 0 to 17; and subscript z is an integer ranging from 0 to 17. In certain embodiments, the metathesis catalyst is a tungsten catalyst or a molybdenum catalyst. In various embodiments, the fatty olefin derivative is a pheromone. Pheromone compositions and methods of using them are also described.

Owner:PROVIVI

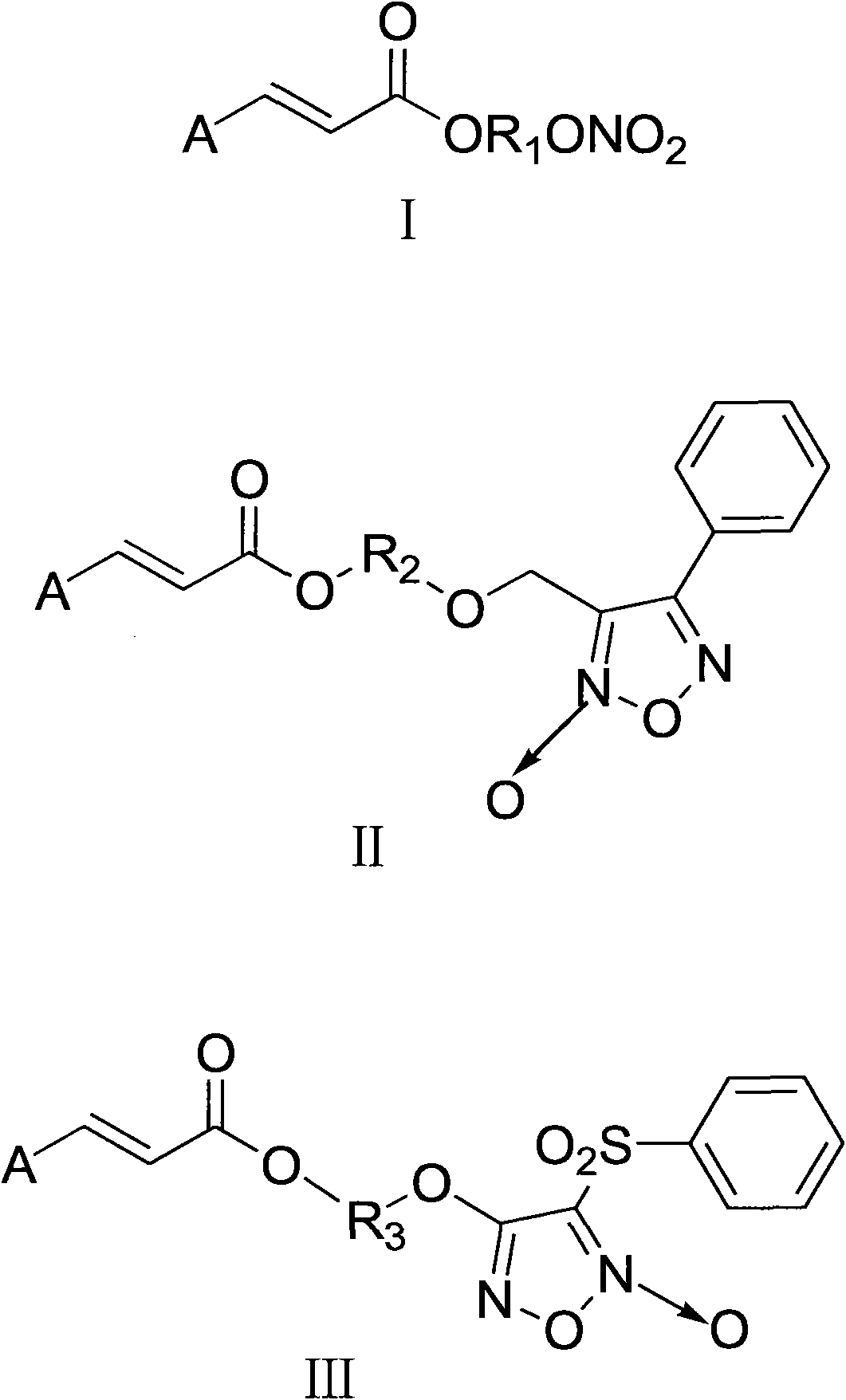

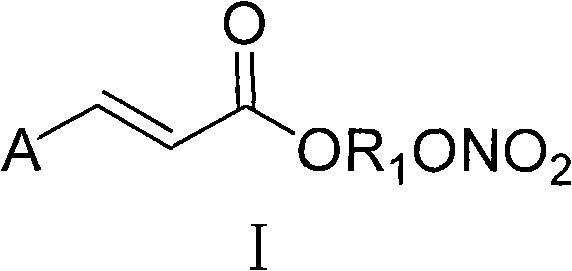

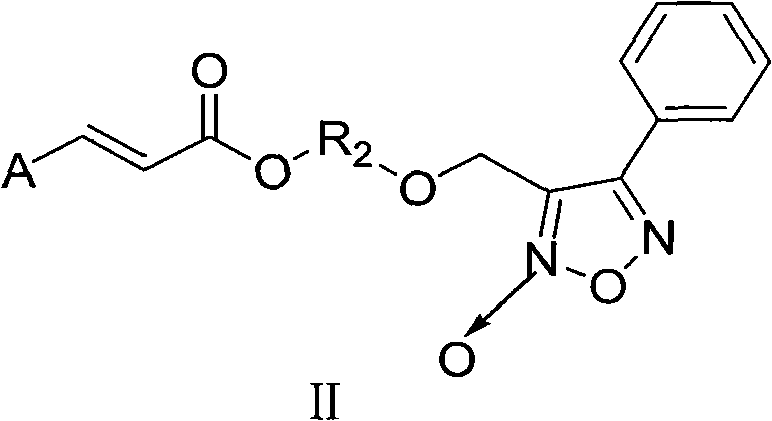

Aromatic acid pro-drug with nitrogen monoxide donor, and preparation method and application thereof

InactiveCN101885684AImprove solubilityReduce adverse reactionsOrganic active ingredientsBlood disorderDiseaseLipid formation

The invention relates to the field of research into pharmaceutical chemistry, and particularly discloses a novel aromatic acid pro-drug with nitrogen monoxide donor, and a preparation method and application thereof in preventing and treating thrombotic diseases. In the invention, natural aromatic acid compounds with strong antithrombotic actions are structurally modified, and the carboxylic acid groups are incorporated with nitrogen monoxide donor to obtain the nitrogen monoxide donor type aromatic acid pro-drug with favorable liposolubility. The aromatic acid pro-drug with nitrogen monoxide donor has favorable solubility, can effectively permeate into the biomembrane lipid bimolecular layer, and can enhance the bioavailability after the human body takes the pro-drug. The pro-drug can be resolved into aromatic acid compounds and release nitrogen monoxide, and the aromatic acid compounds and nitrogen monoxide can cooperate to perform the pharmacological activities of resisting thrombi, resisting platelet aggregation and the like. The aromatic acid pro-drug with nitrogen monoxide donor can be used for preventing and treating thrombotic diseases and cerebral ischemia diseases.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

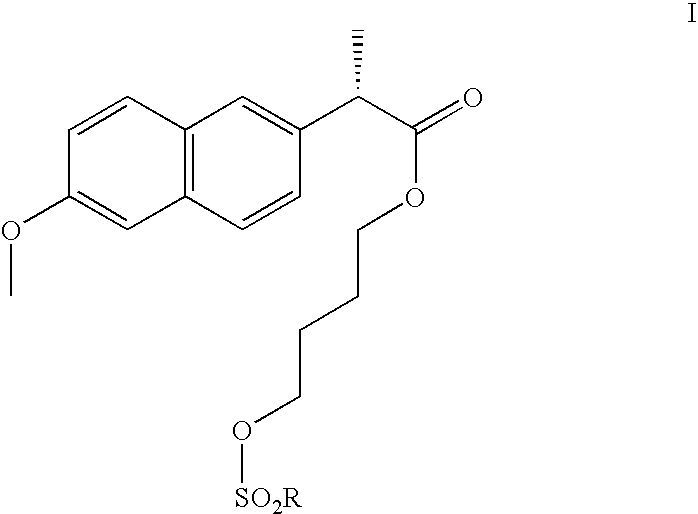

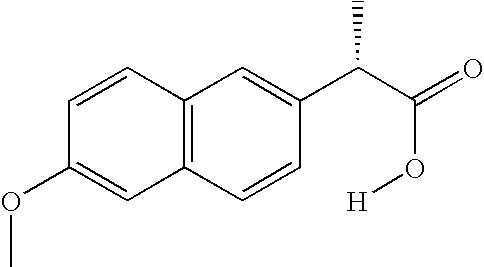

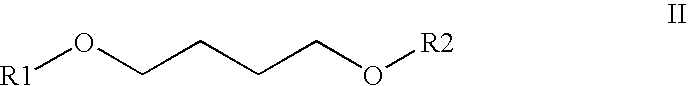

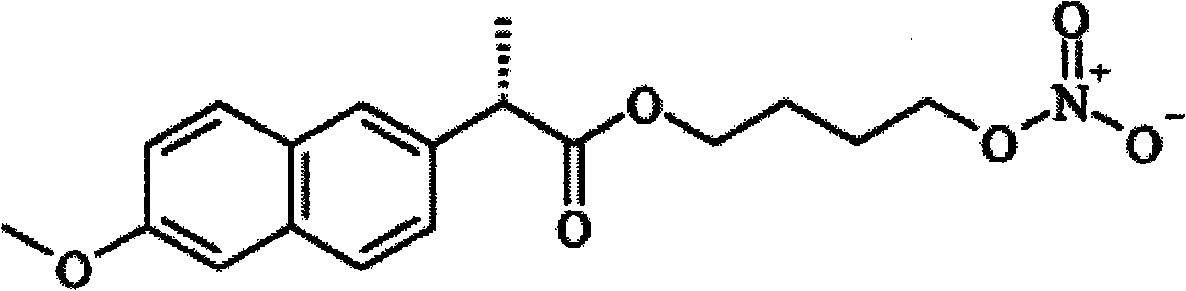

Process

At the present invention relates to a new process for the preparation of the (S)-naproxen 4-nitrooxybutyl ester and to new intermediates obtained and used therein. The invention further relates to the use of the new intermediates for the manufacturing of pharmaceutically active compounds such as (S)-naproxen 4-nitrooxybutyl ester. The invention also relates to the use of (S)-naproxen 4-nitrooxybutyl ester prepared according to the process of the present invention for the manufacturing of a medicament for the treatment of pain.

Owner:NICOX SA

Method for the preparation of organic nitrates

The present invention relates to a process for the preparation of organic nitrates having at least one nitryloxy and at least one hydroxy group, wherein the at least one hydroxy group may be present in form of an esterified hydroxy residue, the latter being esterified with an acid other than nitric acid.

Owner:LONZA LTD +1

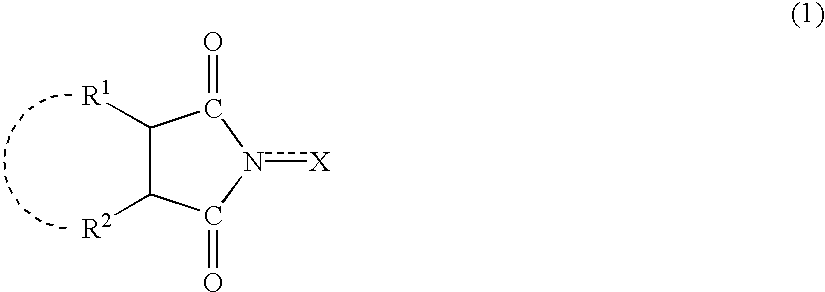

Catalyst comprising a cyclic imide compound and process for producing organic compounds using the catalyst

InactiveUS20020128149A1High yieldSmoothly introducedPreparation by oxidation reactionsOrganic compound preparationSimple Organic CompoundsImide

A catalyst includes a cyclic imide compound having an N-substituted cyclic imide skeleton represented by following Formula (I): 1 wherein X is an oxygen atom or a hydroxyl group, and having a solubility parameter of less than or equal to 26 [(MPa).sup.1 / 2] as determined by Fedors method. The catalyst may further comprise a metallic compound. By allowing (A) a compound capable of forming a radical to react with (B) a radical scavenging compound in the presence of the catalyst, an addition or substitution reaction product between the compound (A) and the compound (B) or a derivative thereof can be obtained.

Owner:DAICEL CHEM IND LTD

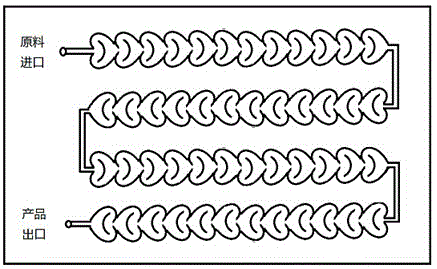

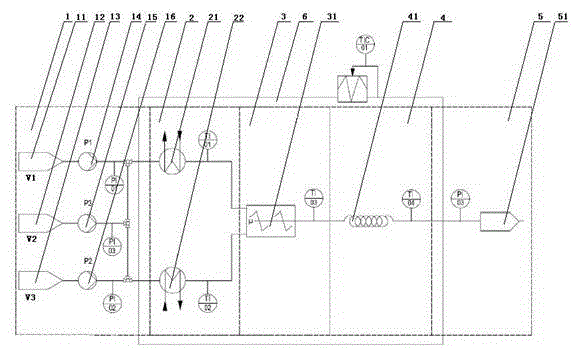

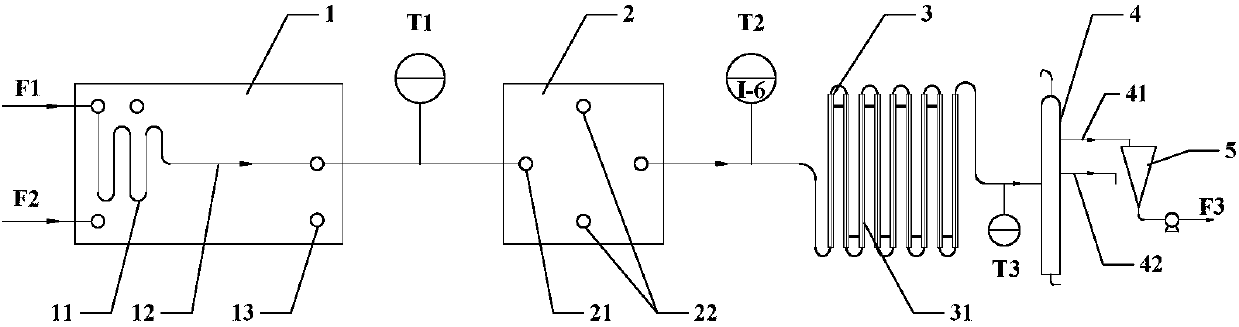

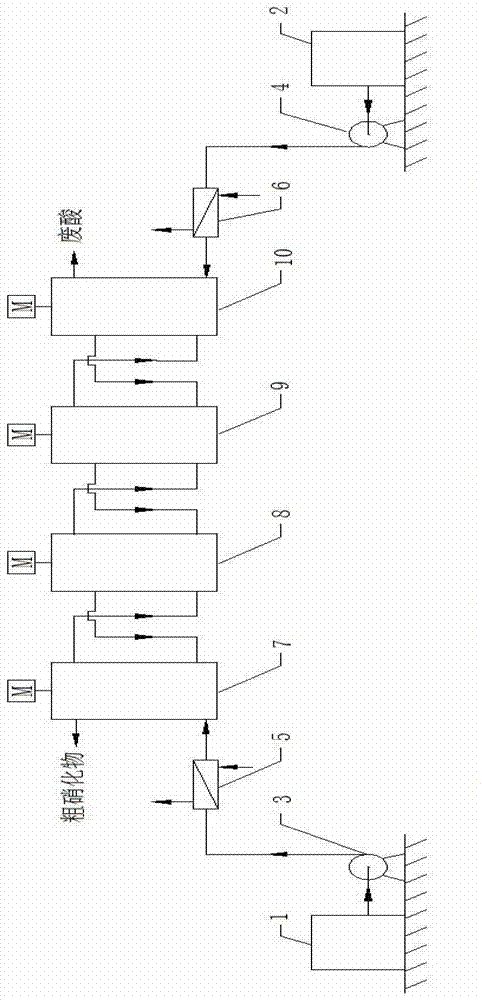

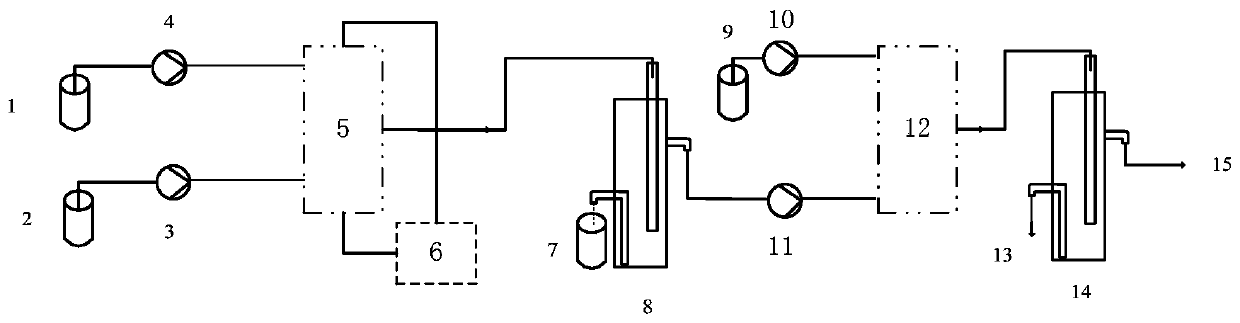

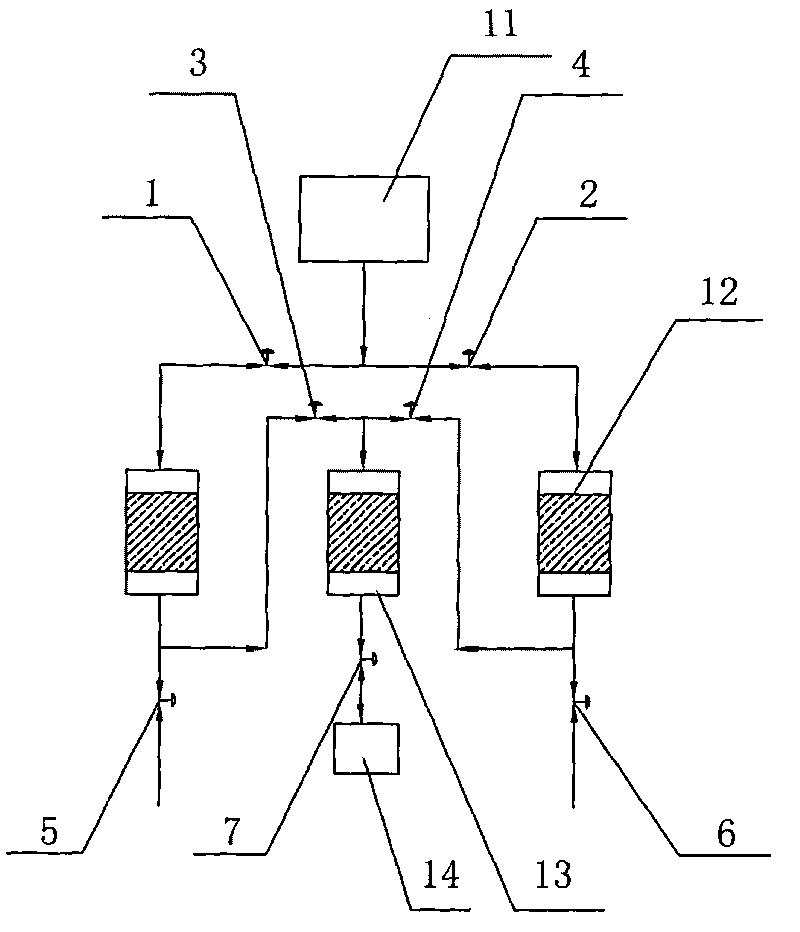

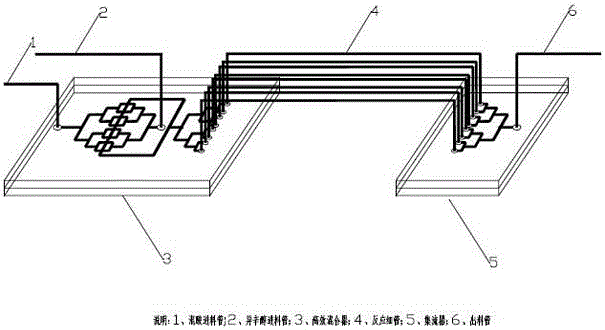

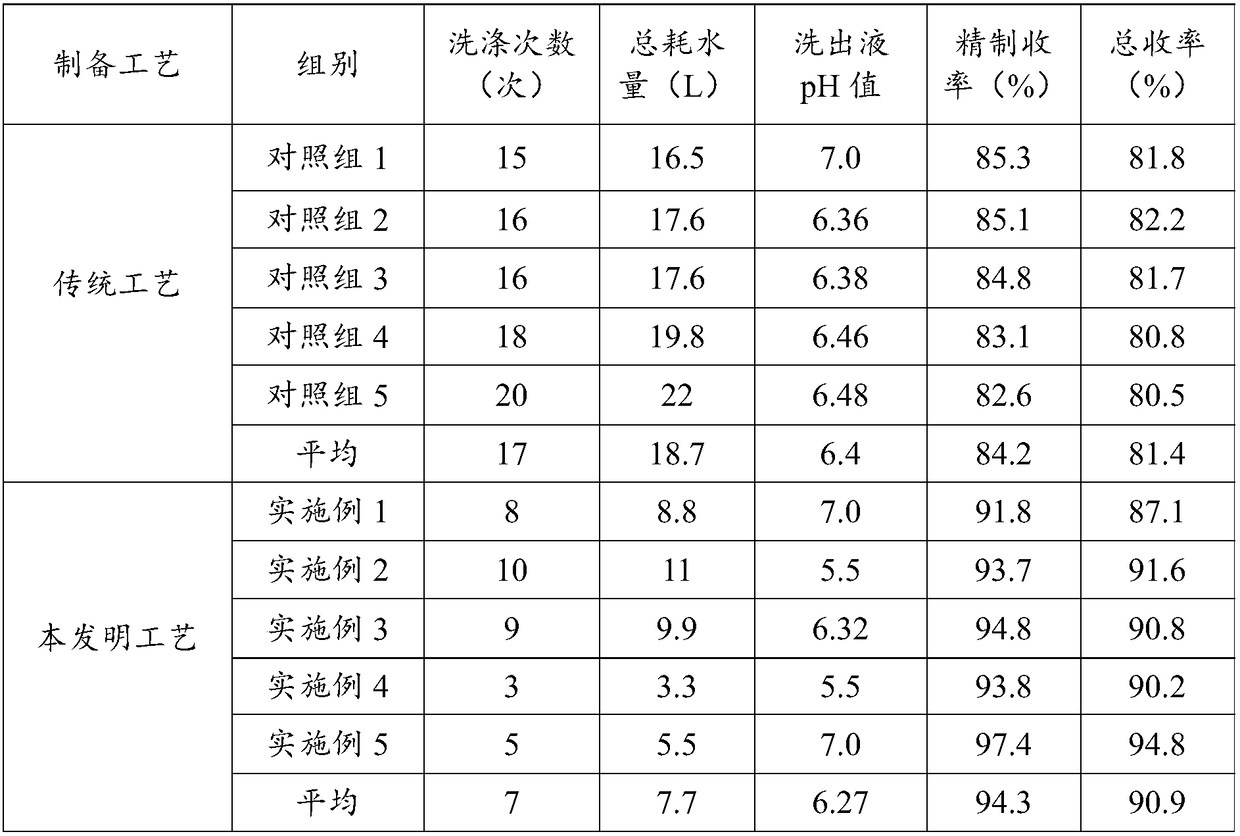

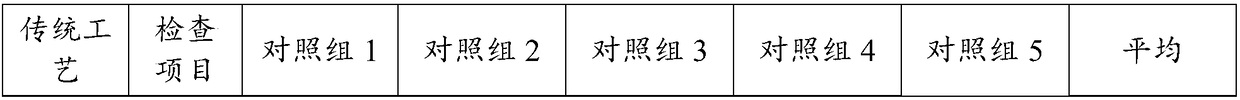

Device and process method for producing isooctyl nitrate

ActiveCN104557556ARealize industrial mass productionAvoid security risksChemical industryMixersIsooctyl alcoholProcess engineering

The invention discloses a device for producing isooctyl nitrate and a process method for producing isooctyl nitrate by using the device. The device comprises a feed system, a precooling system, a mixing system, a reaction system, a receiving system and a circulating bath system, and particularly is an industrial device capable of being used for efficiently and safely producing isooctyl nitrate. The invention mainly aims to solve the problems of potential safety hazards and low production efficiency of the prior art, a connecting device for a micro mixer and an alloy tube array reactor is adopted, and the characteristics of efficient heat and mass transferring capacity and easiness for direct amplification of the device are utilized to ensure that the conversion rate of isooctyl alcohol reaches more than or equal to 99% and the yield of isooctyl nitrate reaches more than or equal to 98%. The device and the method disclosed by the invention have relatively high operational safety and reaction selectivity, can be used for realizing continuous reaction, and are of great significance for strengthening and guaranteeing efficient and safe production of isooctyl nitrate.

Owner:大连微凯化学有限公司

Method for preparing isooctyl nitrate in micro-channel reactor

InactiveCN105330549ASolve the problem of local reaction overheatingReduce energy consumptionNitric acid ester preparationMicroreactorNitrate

The invention discloses a method for preparing isooctyl nitrate in a micro-channel reactor. Isooctanol and nitric-sulfuric acid are taken as raw materials, no inert solvents or additives are used, and the reaction raw materials have a reaction in the micro-channel reactor. The problem of overheating of local parts during the reaction is solved through superhigh heat exchange capacity of the micro-channel reactor, a large-scale cooling system is not required to be used, and accordingly, the energy consumption is reduced; nitric-sulfuric acid obtained after the reaction can be treated simply and recycled; the problems of addition of the inert solvents or stabilizers and the like during the reaction and separation after the reaction are avoided, the production process is simplified, raw materials are saved, the energy consumption problem caused by separation is further solved, and the purity of the prepared isooctyl nitrate products can reach more than 99.0% under the condition that no purification means such as evaporation is adopted.

Owner:NANJING UNIV OF SCI & TECH

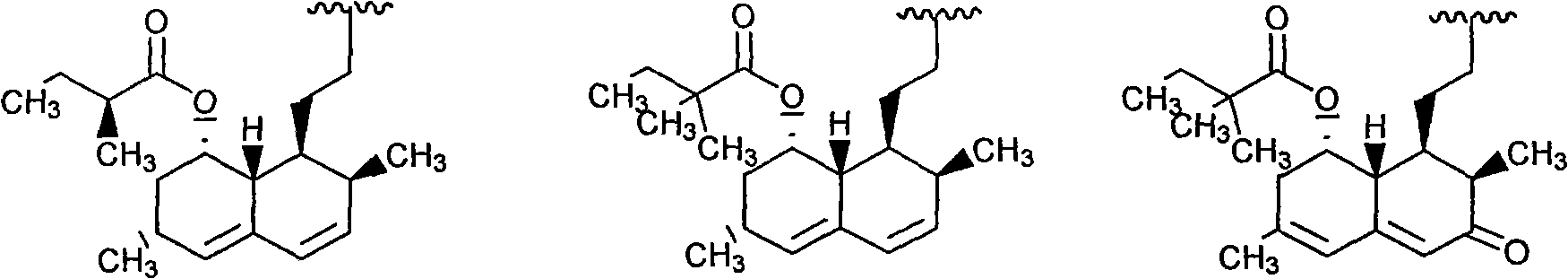

Lovastatin, simvastatin and simvastatin-6-oxide nitro-oxo-derivative and preparation method thereof

The invention describes lovastatin, simvastatin and simvastatin-6-oxide (L-669262) nitro-oxo-derivative of which the general formula is shown in formula (I) and the drugs can increase the non-lipid activity of statins such as anti-inflammatory and the like. The invention also relates to a preparation method of the drugs.

Owner:四川抗菌素工业研究所有限公司

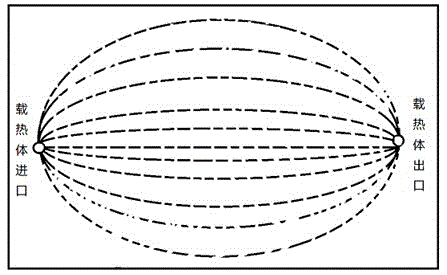

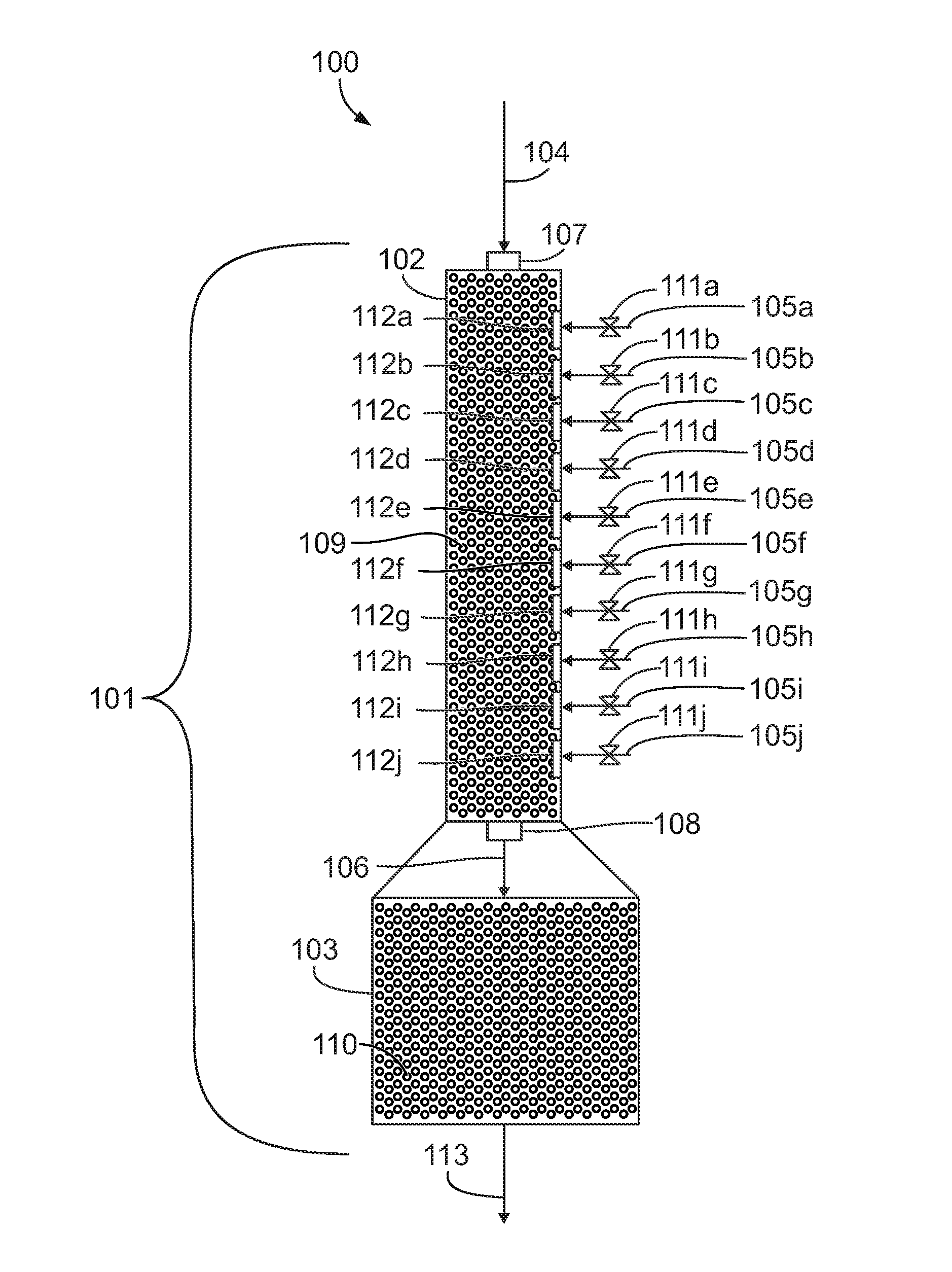

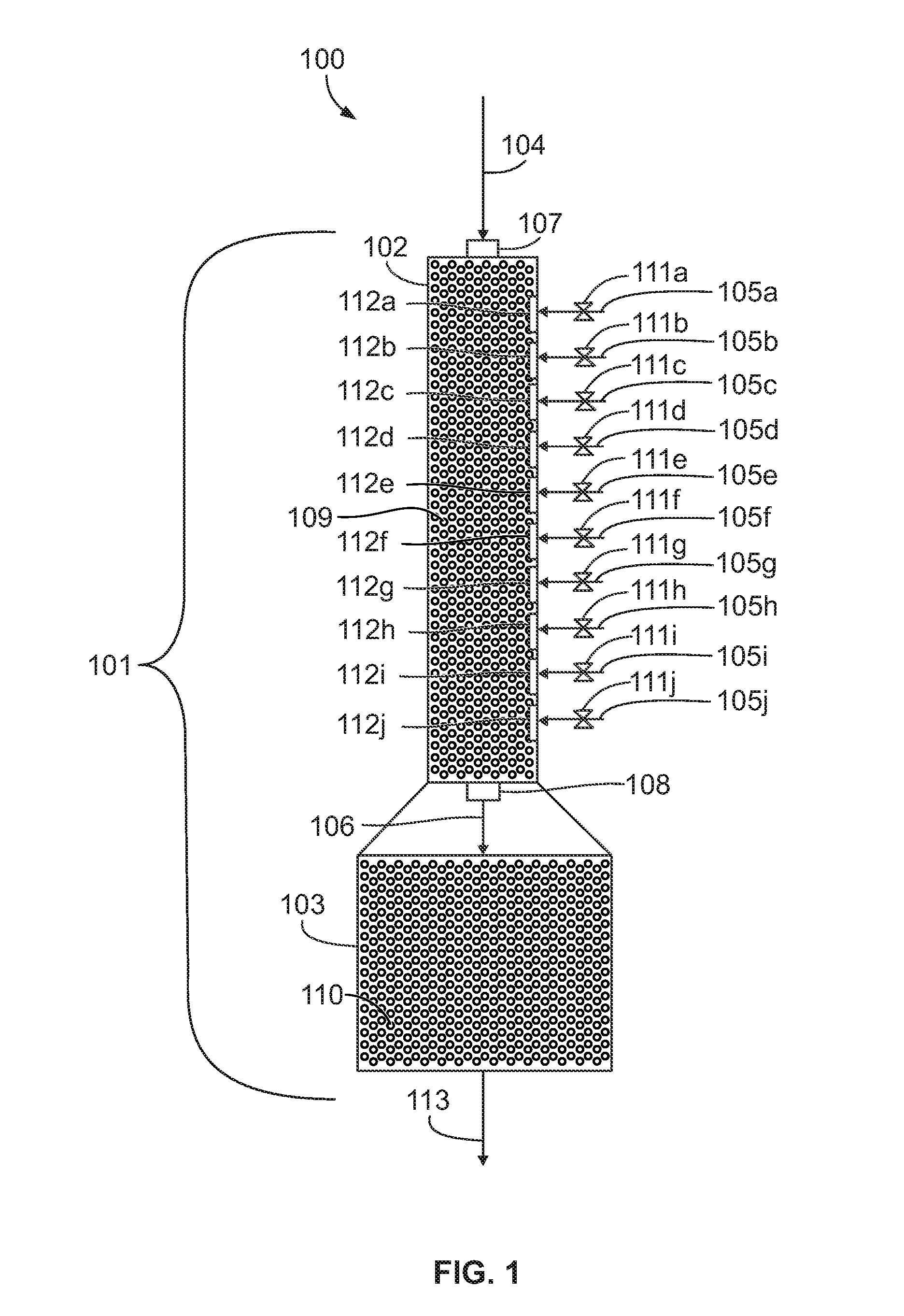

Isothermal reactor for hydrocarbon nitration

ActiveUS20110092737A1Chemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesNitroalkaneNitration

Disclosed are a process and an apparatus for synthesizing nitroalkanes by reaction of a hydrocarbon feedstock with aqueous nitric acid. By using an isothermal reactor with multiple input ports for aqueous nitric acid, a hydrocarbon feedstock may be sequentially exposed to a plurality of flows of aqueous nitric acid as it flows through the reactor.

Owner:ANGUS CHEM CO

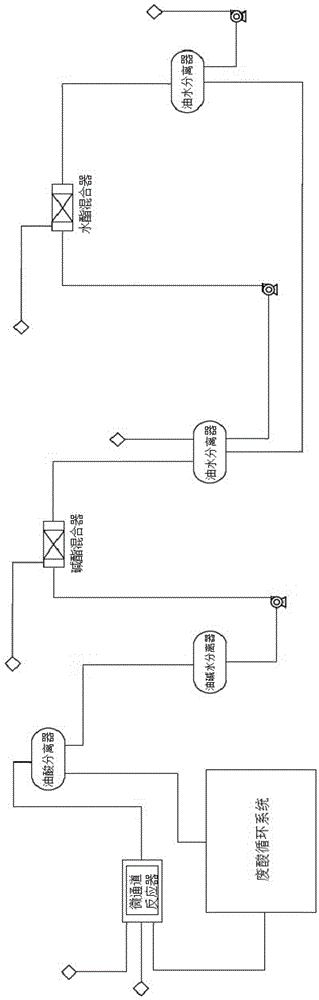

Production method of isooctyl nitrate

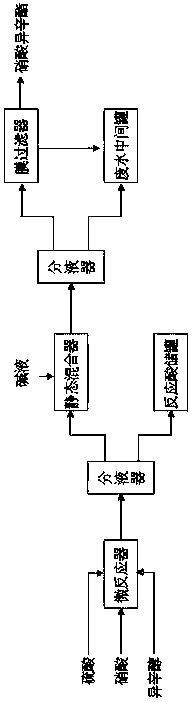

PendingCN107935857AIncrease the nitrification reaction timeEfficient nitrification reactionTransportation and packagingMixersNitrationMixed materials

The invention provides a production method of isooctyl nitrate. The method mainly comprises the following steps that metered conveyance of nitro-sulfuric acid and isooctanol raw materials is performedthrough reliable and stable feeding equipment; the two strands of raw materials are mixed for reaction in a micro mixer; the mixed materials are subjected to heat exchange in a micro heat exchanger and enter a single pipe reactor for further reaction; acidic isooctyl nitrate and waste acid are separated out from a reaction product in an automatic separator; the acidic isooctyl nitrate is fast treated by a conventional water washing, alkali washing and water washing process in a series of micro mixers, and is finally dried or subjected to still standing to remove moisture to obtain a product of isooctyl nitrate. The method has the advantages that the nitration process is safe and efficient; the raw material isooctanol conversion rate and the product selectivity are higher than 99.5 percent; the product acidity value can reach 0.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Synthetic method of isooctyl nitrate

InactiveCN103980125ASimple crafting systemReduce manufacturing costNitric acid ester preparationProcess systemsNitrate

The invention provides a synthetic method of isooctyl nitrate. The method includes preparing a mixed acid solution and keeping for further use, wherein a concentrated sulfuric acid solution having a mass concentration of 90% and a concentrated nitric acid solution having a mass concentration of 98% are mixed to obtain the mixed acid solution, and the mole ratio of the sulfuric acid to the nitric acid in the mixed acid solution is 1.5-2.5:1. The synthetic method achieves efficient utilization of resources by a waste acid circulating system. The reaction temperature is low and the application zone is wide. The method can be widely used in cities in northern China. In low-temperature reactions, the selectivity of reactants is good and byproducts are less, thus facilitating waste water treatment in the later period and easily meeting the state standard of second level for discharging. The yield of a finished product of the isooctyl nitrate is high, the process system is simple, and the production cost is low, so that the synthetic method is prone to achievement.

Owner:CHANGZHOU UNIV

Normal-temperature continuous production technology for cetane number improver

InactiveCN101633620AReduce consumptionReduce energy consumptionLiquid carbonaceous fuelsNitric acid ester preparationHigh energyReaction rate

The invention discloses normal-temperature continuous production technology for a cetane number improver, which belongs to the technical field of the preparation of organic nitrate ester compounds, and comprises the steps of using nitramine or nitric acid and isooctanol to react under the action of a catalyst. The normal-temperature continuous production technology for the cetane number improver is characterized by changing concentrated sulfuric acid as the catalyst, using different proportions of the concentrated sulfuric acid, concentrated nitric acid and water to control different reaction temperatures and realize continuous production, returning waste acid to an acid distribution post for acid mixing according to the content of the acid, then circularly utilizing the waste acid, finally selecting a normal reaction temperature of between 8 DEG C below zero and 40 DEG C in order to the safety and the control of the purity and the yield of energy consumption and the like, and utilizing the proportion of acid mixing to control reaction rate to achieve optimum process conditions such as continuous recycling of the waste acid, continuous feeding nitrification and the like. The technology overcomes the disadvantages of unsteady quality of products, large potential safety hazard, high energy consumption and material consumption and the like, improves the yield, ensures that the quality of the products entirely and steadily reaches that of high-class products, and greatly improves the utilization efficiency of equipment.

Owner:SHANDONG LIANHE CHEM

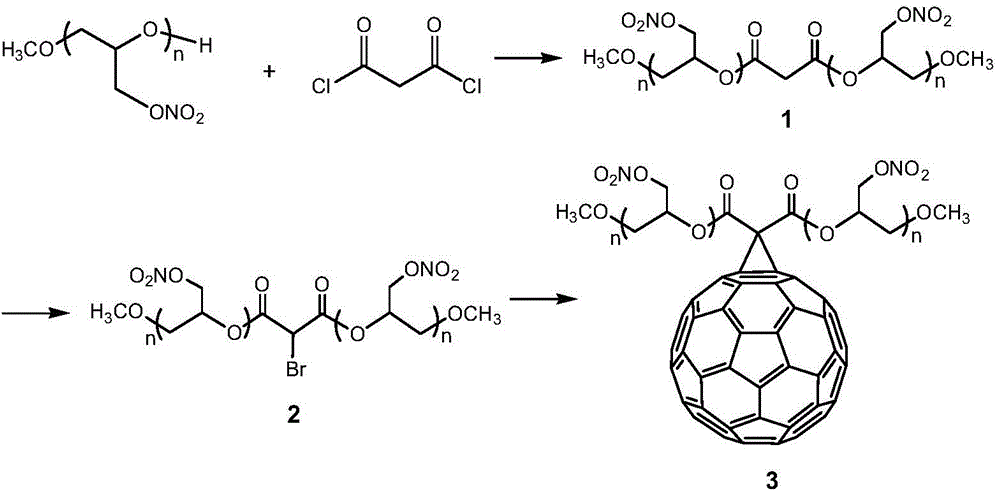

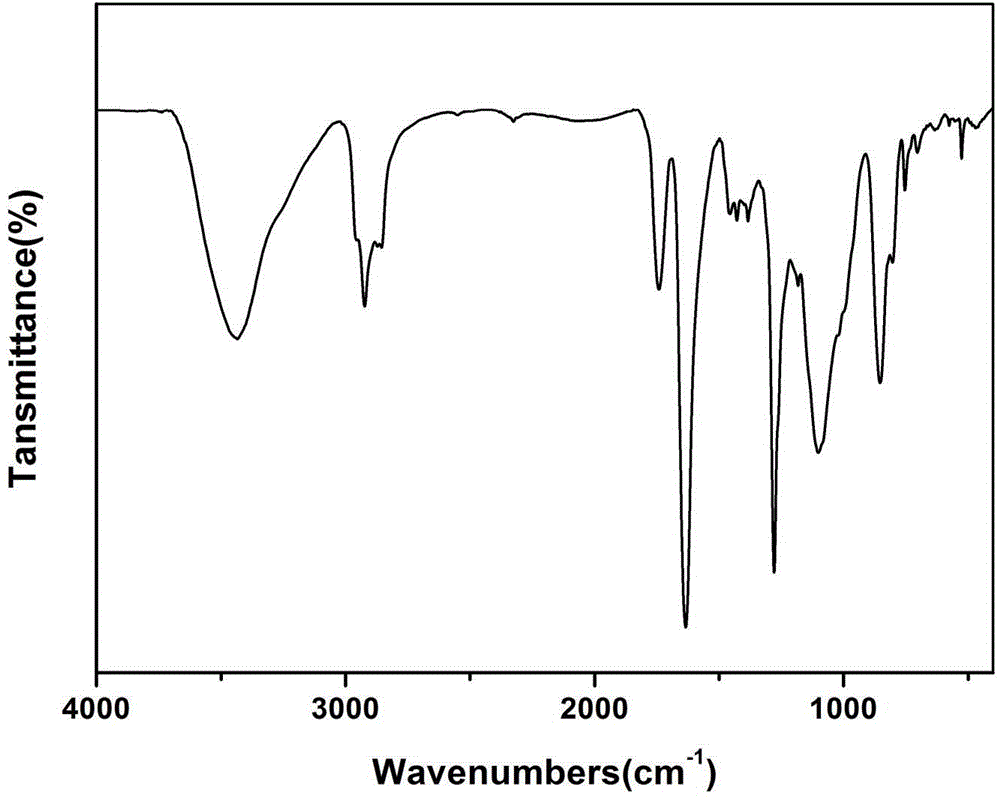

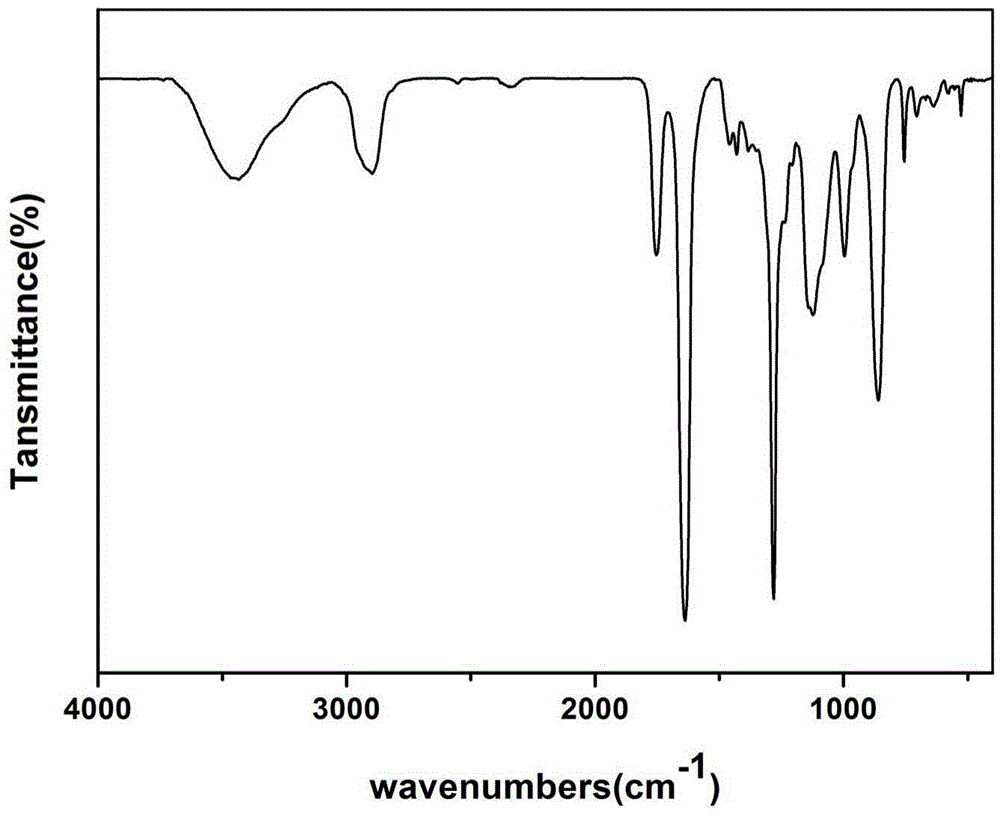

Fullerene poly(glycidyl nitrate), preparation method and application thereof

InactiveCN104311427AGreat development potentialGood market prospectNitric acid ester preparationPressure gas generationChemical structureCombustion

The invention relates to fullerene poly(glycidyl nitrate), a preparation method and an application thereof, wherein the fullerene poly(glycidyl nitrate) has the chemical structure formula represented by a formula (I). The invention further relates to the preparation method, which comprises: adopting monomethyl-terminated poly(glycidyl nitrate) (PGN) and malonyl chloride as raw materials, carrying out the esterification and bromination two-step reaction to prepare bromomalonate dipoly(glycidyl nitrate), and reacting with fullerene to prepare the fullerene poly(glycidyl nitrate). According to the present invention, the fullerene derivative can be used in the solid rocket propellant as a novel energetic combustion catalyst; and experiment results prove that the product yield can be 82%, and the platform combustion rate can be increased by 65% while the pressure index is reduced to 0.21 when the product of the present invention is applied in the solid propellant as the novel combustion catalyst. The formula I is defined in the instruction, wherein n is 2-20.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Production method for isooctyl nitrate

InactiveCN105418432AReduce generation costThe response is stable and easy to controlNitric acid ester preparationIsooctyl alcoholNitrate

The invention discloses a production method for isooctyl nitrate. The production method comprises steps: firstly, an acid mixture of sulfuric acid and nitric acid with a mol ratio of 1.5-2.5:1 is prepared as a nitrating agent; secondly, a mixed solution of isooctyl nitrate and isooctyl alcohol with a mass ratio of 0.8-2:1 is prepared; thirdly, the mixed solution of isooctyl nitrate and isooctyl alcohol is added in the acid mixture of sulfuric acid and nitric acid at a temperature of 10-30 DEG C, the reaction is carried out for 0.5-1h, the mixture is allowed to stand for separation, organic phase alkali washing is carried out, water washing is carried out, and an isooctyl nitrate product is prepared. The production method is advantaged by simple technology, low cost and easy industrialization.

Owner:JIANGXI SILINCO

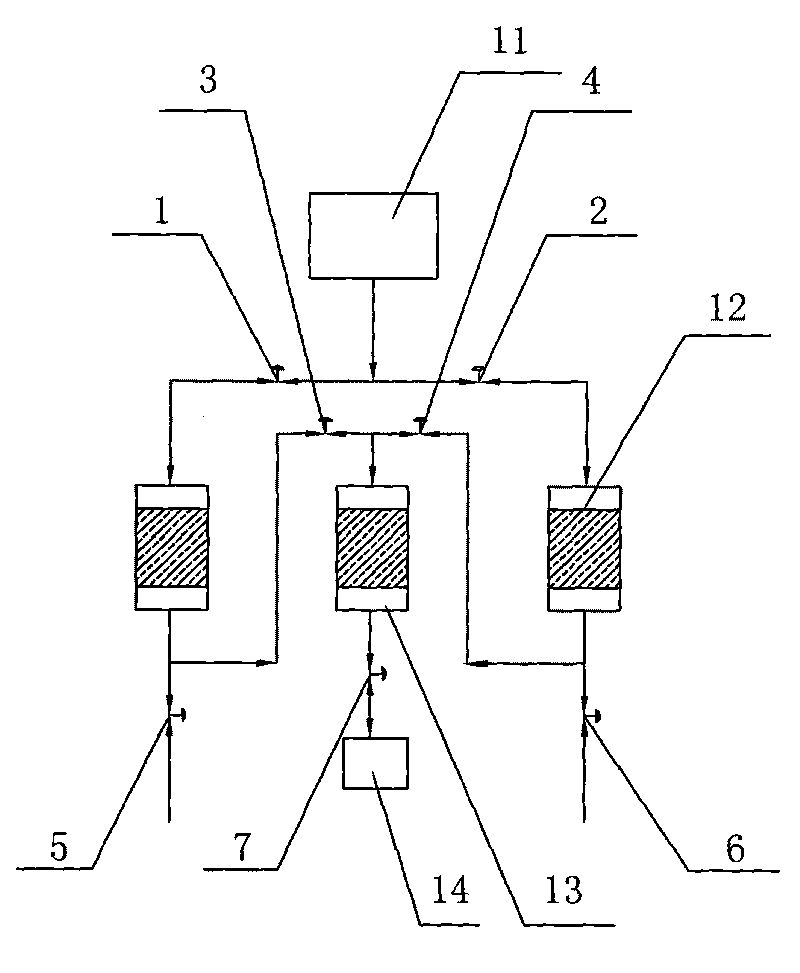

Safe production method of nitro-compound

ActiveCN103044261AHigh yieldLow costNitric acid ester preparationNitro compound preparationNitro compoundAutomatic control

The invention provides a production method of nitro-compound. The production method comprises the steps of: continuously feeding a mixed acid solution from a heavy-phase inlet of a first centrifugal extraction separation device of a nitration separation system disclosed by the invention, and continuously feeding a raw material to be nitrified from a light-phase inlet of a final centrifugal extraction separation device at the same time, wherein the reaction temperature inside each centrifugal extraction separation device is controlled at 10-160 DEG C, and the rotating speed of each centrifugal extraction separation device is controlled at 800-2000 r / min; after multi-stage continuous nitration reaction, discharging final coarse nitride from a light-phase outlet of the first centrifugal extraction separation device, and discharging final waste acid from a heavy-phase outlet of the final centrifugal extraction separation device; and carrying out common alkali washing and water washing on the coarse nitride, and distilling the coarse nitride to obtain the refined nitro-compound product. According to the method disclosed by the invention, the nitration reaction is continuously carried out; the device is compact, easy to achieve automatic control, large in operation elasticity, and high in production efficiency; and as the reaction product and the waste acid are separated from each other at the same time inside the same reactor, the contact time of the reaction product and the waste acid is greatly shortened, side reaction is effectively avoided, energy consumption and material consumption are greatly reduced, and the security of the nitration reaction process is fundamentally ensured.

Owner:徐德良 +1

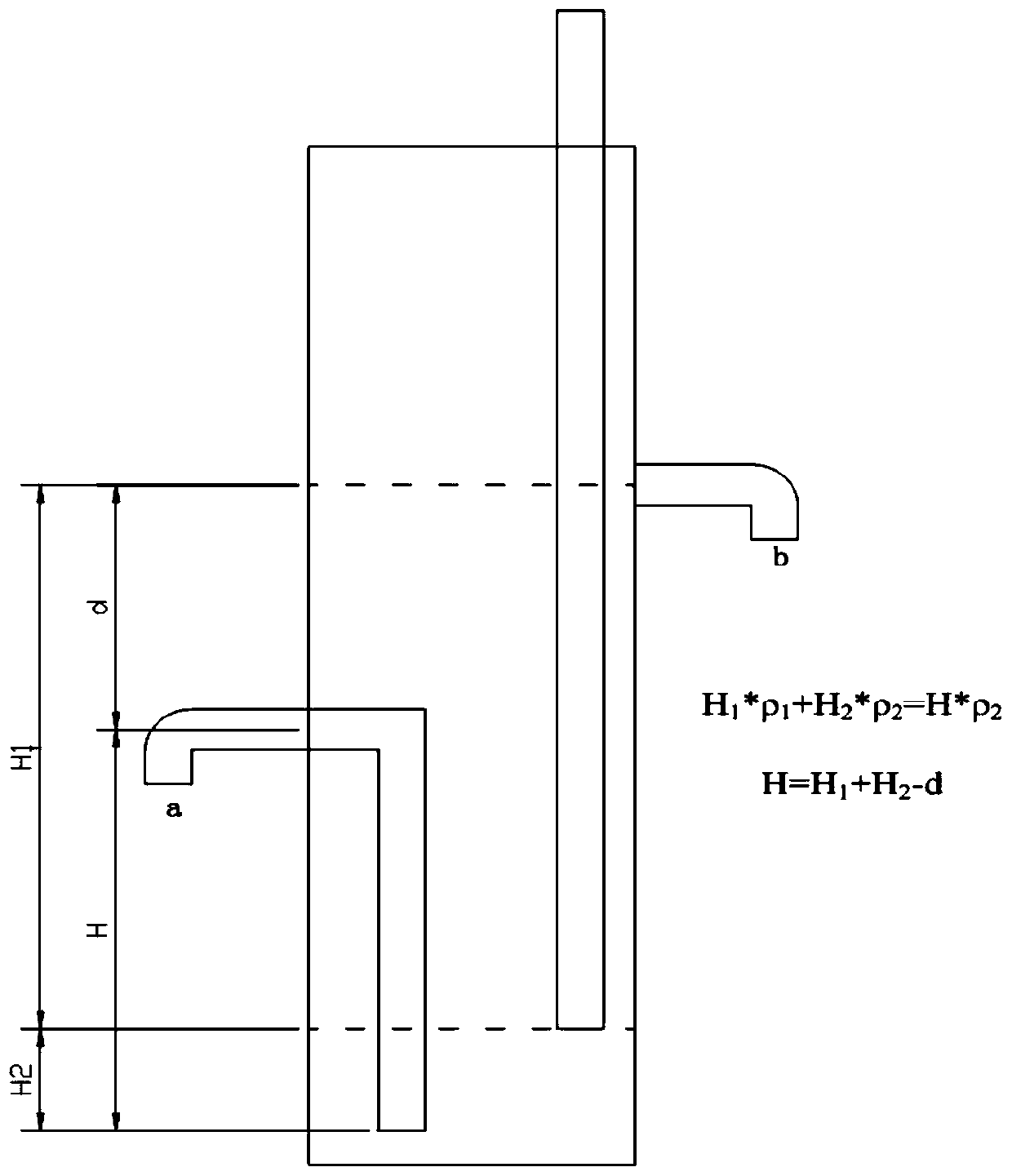

Dewater technology of isooctyl nitrate

The present invention relates to a dehydration process of isooctyl nitrate, belonging to the field of carbon and nitrogen bearing compound technology whose carbon frame is further connected by single bond and is substituted by oxygen atom. It includes dehydration procedure, utilizes sedimentation separation to remove most of water content, and further utilizes anhydrous sodium sulfate to remove micro water content. Said invention can stably control water content in the product and make it be below 0.01%.

Owner:SHANDONG LIANHE CHEM

Isooctyl nitrate crude product deacidification method

InactiveCN105566117AProne to partial emulsificationPromote stratificationNitric acid ester preparationAcid valueRoom temperature

The present invention discloses an isooctyl nitrate crude product deacidification process, which is characterized that: sodium hydroxide is selected as a deacidification agent, and specifically, a saturated sodium chloride solution of sodium hydroxide is selected. Process steps are as follows: at room temperature, 2.5-10% of saturated sodium chloride solution of sodium hydroxide is added into an isooctyl nitrate crude product for reaction while stirring for 0.5 to 2 hours, the solution is statically stratified, an organic phase is an isooctyl nitrate product, and after an aqueous phase is analyzed, the aqueous phase is recycled by addition of sodium hydroxide. According to the isooctyl nitrate crude product deacidification process, the organic phase and the aqueous phase are quick to separate, the organic phase isooctyl nitrate residue is extremely less in the aqueous phase, and the final product acid number is below 2mg / KOH / 100ml. The isooctyl nitrate crude product deacidification process is simple in operation and low in cost, and the acid value of the product is very ideal.

Owner:JIANGXI SILINCO

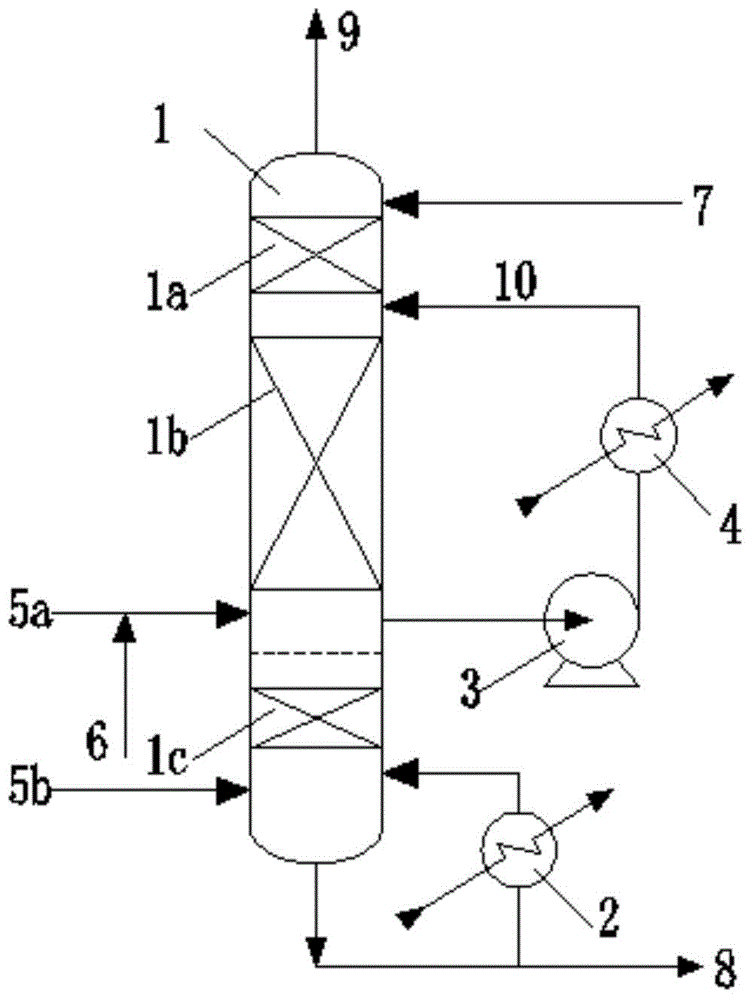

Production method for alkyl nitrite

The invention relates to a production method for alkyl nitrite. The method mainly solves the technical problems of low yield of alkyl nitrite or high energy consumption of equipment in the prior art. A technical scheme of the invention adopts a reactor which is divided into three sections, i.e., an upper section, a middle section and a lower section, wherein the middle section is a reaction section, and reaction temperature is controlled through outside-cycled cooling; the upper section is an absorption section which absorbs nitric acid and water in gaseous reaction products; and the lower section is a rectification section which recovers alkyl nitrite in liquid reaction products; thus, the problem is well solved, and the production method for alkyl nitrite can be applied in industrial production of alkyl nitrite.

Owner:CHINA PETROLEUM & CHEM CORP +1

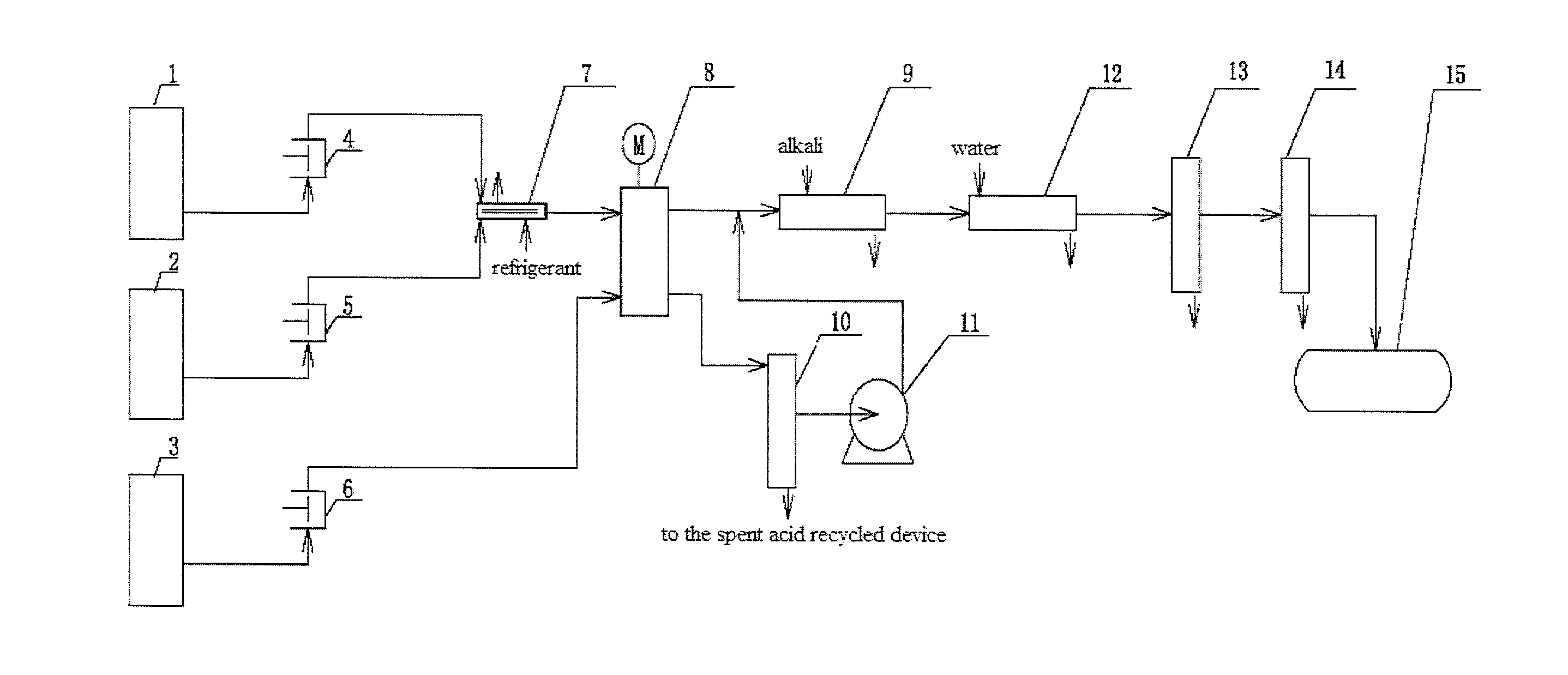

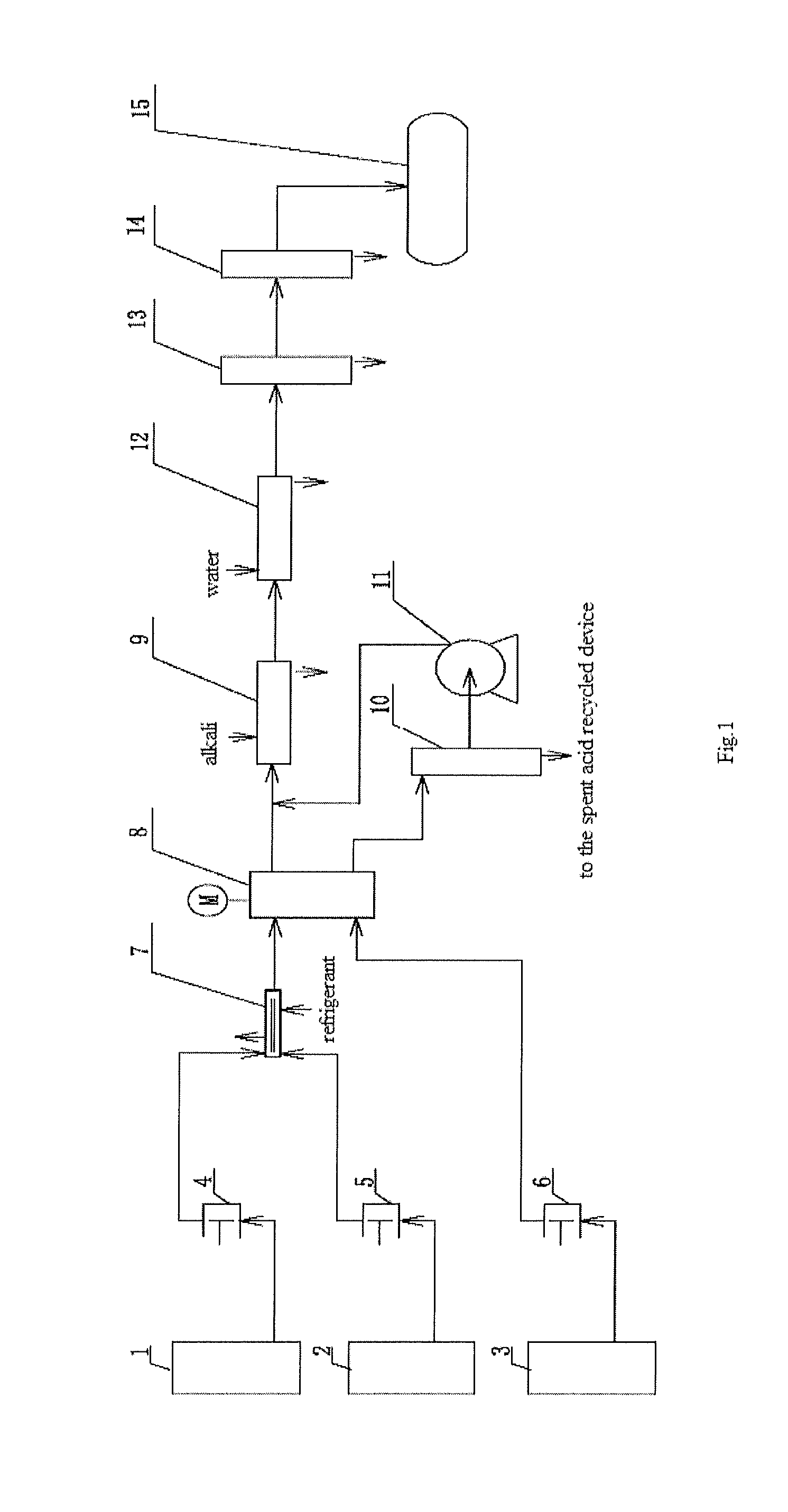

Method for continuously synthesizing 2-ethylhexyl nitrate in micro-reactors and extracting residual acid in 2-ethylhexyl nitrate

ActiveCN110683953AHigh purityAvoid deacidification difficultiesNitric acid ester preparationMicroreactorNitrate

The invention relates to a method for continuously synthesizing 2-ethylhexyl nitrate in micro-reactors and extracting residual acid in the 2-ethylhexyl nitrate. The method for continuously synthesizing the 2-ethylhexyl nitrate in the micro-reactors and extracting the residual acid in the 2-ethylhexyl nitrate comprises the following steps: with isooctanol and a mixed acid, with a molar ratio of sulfuric acid to nitric acid ranging from 1.5 to 2.5, as raw materials, carrying out a nitration reaction in a first micro-reactor to generate 2-ethylhexyl nitrate and a waste acid, and separating out anacid-containing 2-ethylhexyl nitrate crude product through a liquid-liquid automatic separator; and mixing the crude product and a NaOH aqueous solution in a second micro-reactor, then carrying out areaction to extract the residual acid in the 2-ethylhexyl nitratecrude product, and conducting water-oil separation to obtain the 2-ethylhexyl nitrate with an ultra low acid content. The extraction efficiency is higher than 96%. By means of the method for continuously synthesizing the 2-ethylhexyl nitrate in the micro-reactors and extracting the residual acid in the 2-ethylhexyl nitrate, continuous operation of synthesis of the 2-ethylhexyl nitrate and acid removal is achieved, the danger level is lowered, and the consumed time of acid removal is shortened, so that the production efficiency is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

System and process for dehydrating and drying isooctyl nitrate crude product

ActiveCN101696168AReal-time adjustabilityReal-time controlSolid sorbent liquid separationNitric acid ester preparationMolecular sieveState of art

The invention belongs to the technical field of producing petrochemicals such as nitrates, and specifically relates to a system and a process for dehydrating and drying an isooctyl nitrate crude product. The system and the process are to overcome the defect of low production efficiency in the prior art and adopt the following technical scheme: the system for drying the isooctyl nitrate crude product comprises a crude product tank, a rough-removing component, a fine-removing component and a product tank which are connected with a pump in turn, wherein the rough-removing component comprises two silica gel rough-removing devices connected in parallel, and the fine-removing component comprises one molecular sieve fine-removing device. The system and the process have the following advantages that: 1, the processing and the operation are simple and convenient; 2, the water content can be conveniently adjusted and controlled in real time as requested; 3, the used adsorbents are particles and have no problems of a sodium sulfate adsorbent which is easy to agglomerate after absorbing water and then increases the operational complexity; 4, the system and the process are stable and reliable; and 5, the production efficiency is greatly improved.

Owner:西安万德能源化学股份有限公司

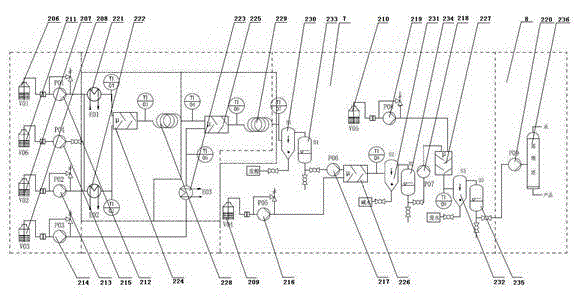

Continuous synthesis method for 2-ethylhexyl nitrate

InactiveCN109280007AFast mass and heat transferEliminate the risk of overheating explosionChemical/physical/physico-chemical microreactorsNitric acid ester preparationChemistryResidence time

The invention provides a continuous synthesis method for 2-ethylhexyl nitrate. 2-ethylhexanol, sulfuric acid, and nitric acid are sent to a microchannel reactor by utilizing pumps; during a reaction,the flow rate of the two pumps is controlled, the molar ratio of the sulfuric acid to the nitric acid is maintained to be 3.5-2.5:1, the molar ratio of the nitric acid to the 2-ethylhexanol is 1.5-1.0:1, the residence time is 1-5 s, the reaction temperature is 0-5 DEG C; and a reaction liquid is subjected to continuous liquid separation, neutralization, and membrane filtration to obtain a productof the 2-ethylhexyl nitrate. The method has the following characteristics of utilizing a microreactor as an esterification reactor, utilizing a static mixer as a neutralization reactor, and utilizinga membrane filter as a desalination dehydration reactor. The method is continuous in operation and stable in process, is high in safety and high in production efficiency, is free of solid waste and isless in amount of waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Safe method for producing alkyl nitrate

ActiveUS20150031909A1Prevent water dropletOutflow smoothlyNitric acid ester preparationSide reactionCentrifugal extractor

The present invention provides a method for producing alkyl nitrate. The centrifugal extraction equipment acts as the esterification separator; a mixed acid solution containing sulfuric acid and nitric acid enters from the heavy phase inlet of the centrifugal extraction equipment; alkyl alcohol enters from the light phase inlet of the centrifugal extraction equipment; the feeding molar ratio of alkyl alcohol and nitric acid equals to 1:1.0-3.0; esterification reaction occurs with the mixed acid and alkyl alcohol at a temperature of 10˜60° C. under the rotating speed of 800-2000 r / min; under the action of centrifugal force, the generated coarse ester as a light phase and the spent acid as a heavy phase are separated; coarse ester as a light phase is discharged through the light-phase outlet of the centrifugal extractor; the spent acid as a heavy phase is discharged through the heavy-phase outlet of the centrifugal extractor; after alkali washing and water washing conventionally, coarse ester is dehydrated for drying and purified, then the refining products of alkyl nitrate is obtained. In the method of the present invention, esterification reaction, the separation of reaction products and the spent acid are finished in the same reactor simultaneously, which reduces the contact time of reaction products with the spent acid greatly, avoids the side reaction effectively, and ensures the safety of esterification process.

Owner:SHANDONG LIBAODE CHEM

Process for the preparation of nitric esters of monohydric alcohols

The present invention relates to a process for the preparation of nitric esters of monohydric alcohols wherein a monohydric alcohol or a mixture of monohydric alcohols is converted with nitric acid to the corresponding nitric esters under adiabatic reaction conditions in the presence of sulfuric acid.

Owner:JOSEF MEISSNER

Continuous production process of isooctyl nitrate

InactiveCN106699569AControl responseGuaranteed mass transfer rateNitric acid ester preparationIsooctyl alcoholNitrate

The invention provides a continuous production process of isooctyl nitrate. The continuous production process comprises the following steps: metering concentrated sulfuric acid and concentrated nitric acid via a metering tank, adding the concentrated sulfuric acid and the concentrated nitric acid into a stirring kettle for uniformly stirring and mixing; respectively injecting mixed acid and isooctanol into two coolers for cooling, injecting the mixed acid and the isooctanol into a reactor assembly for mixing and reacting after the mixed acid and isooctanol are cooled to be lower than or equal to 15 DEG C, and firstly mixing in an efficient mixer in the reactor assembly; adding the uniformly-mixed material into a reaction thin tube through a distribution tank for reacting, and filling the periphery of the fine tube with cooling water; collecting reaction products via a collector, then adding the reaction products into a centrifugal machine for separating acid ester, and removing waste acid; refining and deacidifying coarse products via a 10wt% sodium hydroxide solution in an alkaline washing tower; enabling deacidified products to continuously flow into a settling tank from the alkaline washing tower for settling and dewatering, and adding the deacidified products into a drying tower for drying to obtain a product. Through the production process, the problem about safety in the existing process is solved; the production efficiency is improved; the production stability is improved; the cost is reduced.

Owner:庄晓东

Preparation method of glycerin trinitrate

ActiveCN108084031AAvoid decompositionAvoid removalInorganic non-active ingredientsPharmaceutical delivery mechanismActivated carbonAlcohol

The invention discloses a preparation method of glycerin trinitrate. The preparation method comprises the following steps: (1) nitration reaction; and (2) refining: A, purified water washing; B, waterremoval by using a drying agent; and C, activated carbon adsorption. The invention further provides glycerin trinitrate prepared by using the preparation method and an absolute ethyl alcohol solutionof glycerin trinitrate. The preparation method provided by the invention is high in yield, few in produced impurities and capable of effectively avoiding decomposition effects of reaction temperature, residual water and acids to glycerin trinitrate, reducing decomposition products of glycerin trinitrate and controlling the content of related substances in a storage process of glycerin trinitrateand the absolute ethyl alcohol solution thereof to make a glycerin trinitrate product more stable and ensure that the quality of the glycerin trinitrate product conforms to relevant regulations in a validity period.

Owner:GUANGZHOU BAIYUNSHAN MINGXING PHARM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com