Patents

Literature

6147 results about "Mole ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mole ratio is the ratio between the amounts in moles of any two compounds involved in a chemical reaction. Mole ratios are used as conversion factors between products and reactants in many chemistry problems.

Binding agent for solid block functional material

InactiveUS6258765B1Fit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBULK ACTIVE INGREDIENTActive ingredient

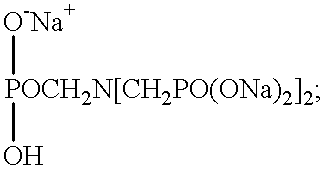

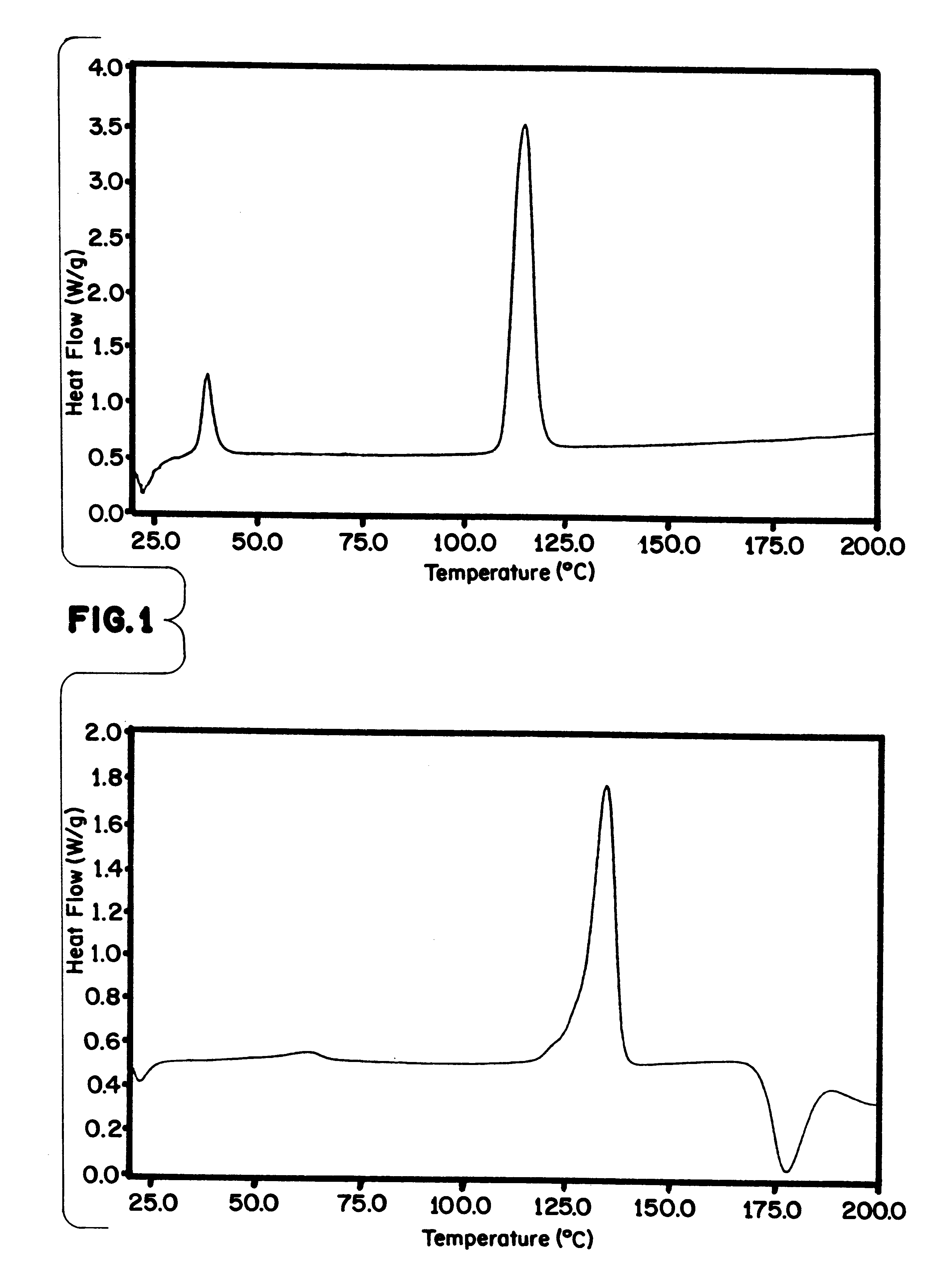

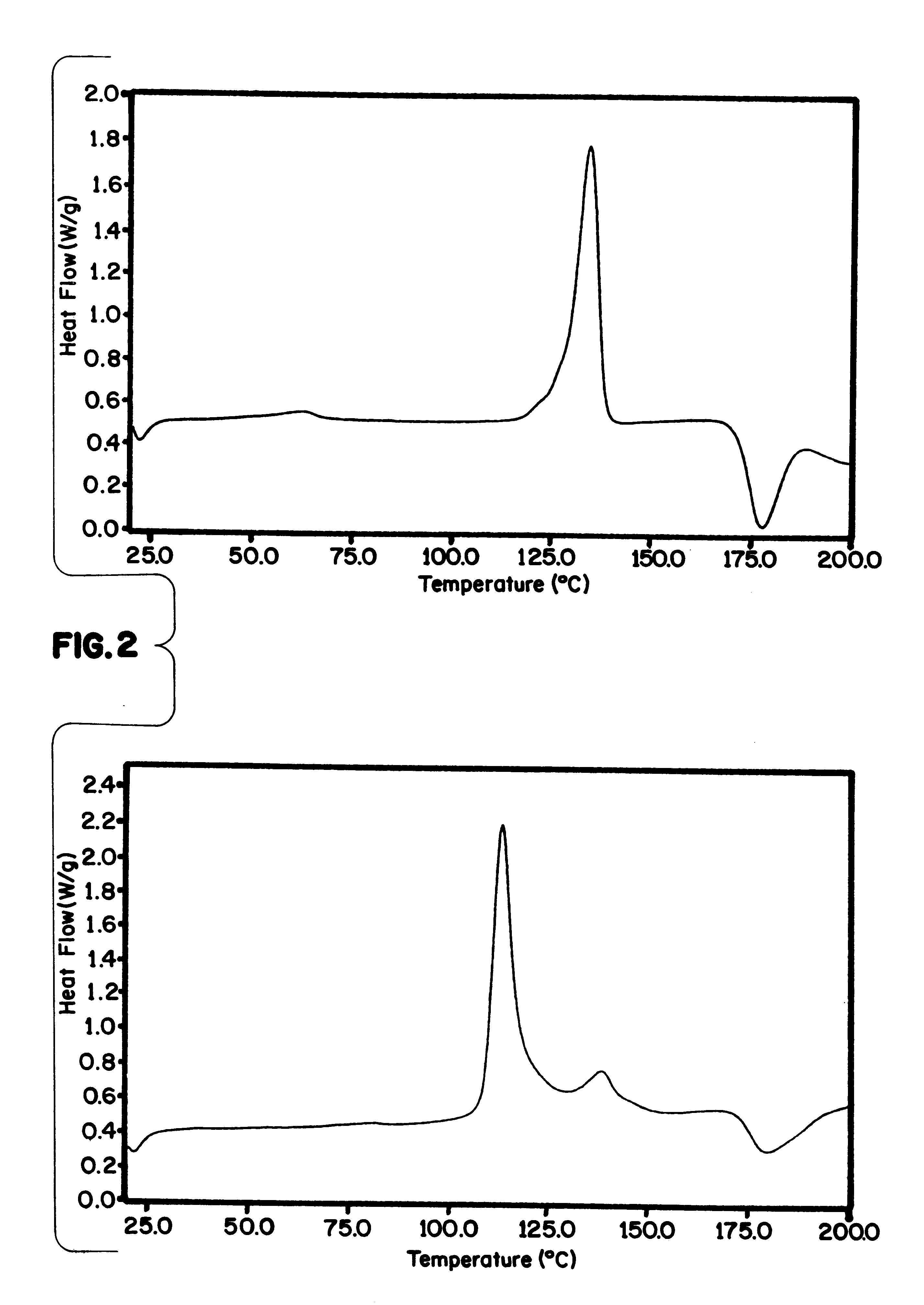

A solid functional material comprises a functional agent such as a cleaning composition, a sanitizing agent, where a rinse agent, etc. in a solid block format. The solid block is formed by a binding agent that forms the active ingredients into a solid block. The binding agent comprises a phosphonate or amino acetate sequestrant, a carbonate salt and water in an E-Form hydrate. These materials at a specific mole ratio form a novel binding agent that can form functional materials into a solid matrix form.

Owner:ECOLAB USA INC

Wound healing polymer compositions and methods for use thereof

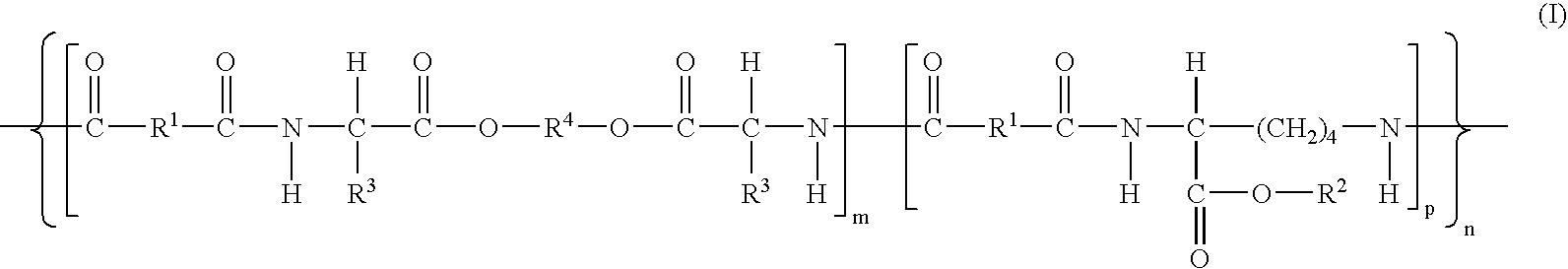

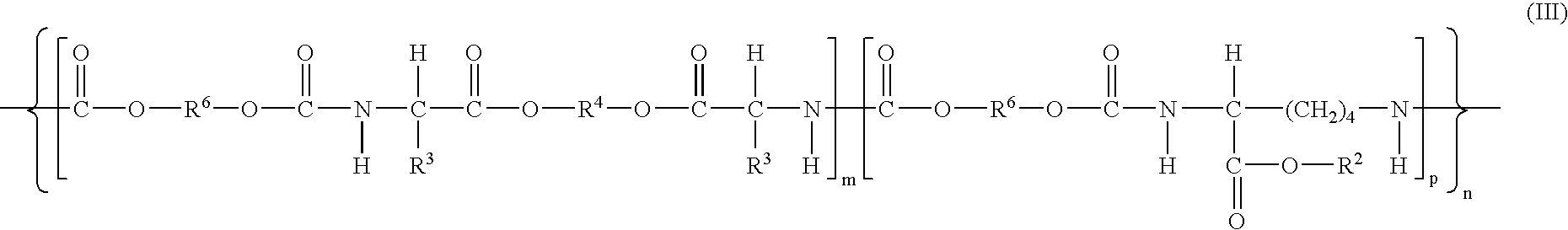

The present invention provides bioactive polymer compositions that can be formulated to release a wound healing agent at a controlled rate by adjusting the various components of the composition. The composition can be used in an external wound dressing, as a polymer implant for delivery of the wound healing agent to an internal body site, or as a coating on the surface of an implantable surgical device to deliver wound healing agents that are covalently attached to a biocompatible, biodegradable polymer and / or embedded within a hydrogel. Methods of using the invention bioactive polymer compositions to promote natural healing of wounds, especially chronic wounds, are also provided. Examples of biodegradable copolymer polyesters useful in forming the blood-compatible, hydrophilic layer or coating include copolyester amides, copolyester urethanes, glycolide-lactide copolymers, glycolide-caprolactone copolymers, poly-3-hydroxy butyrate-valerate copolymers, and copolymers of the cyclic diester monomer, 3-(S)[(alkyloxycarbonyl)methyl]-1,4-dioxane-2,5-dione, with L-lactide. The glycolide-lactide copolymers include poly(glycolide-L-lactide) copolymers formed utilizing a monomer mole ratio of glycolic acid to L-lactic acid ranging from 5:95 to 95:5 and preferably a monomer mole ratio of glycolic acid to L-lactic acid ranging from 45:65 to 95:5. The glycolide-caprolactone copolymers include glycolide and ε-caprolactone block copolymer, e.g., Monocryl or Poliglecaprone.

Owner:MEDIVAS LLC

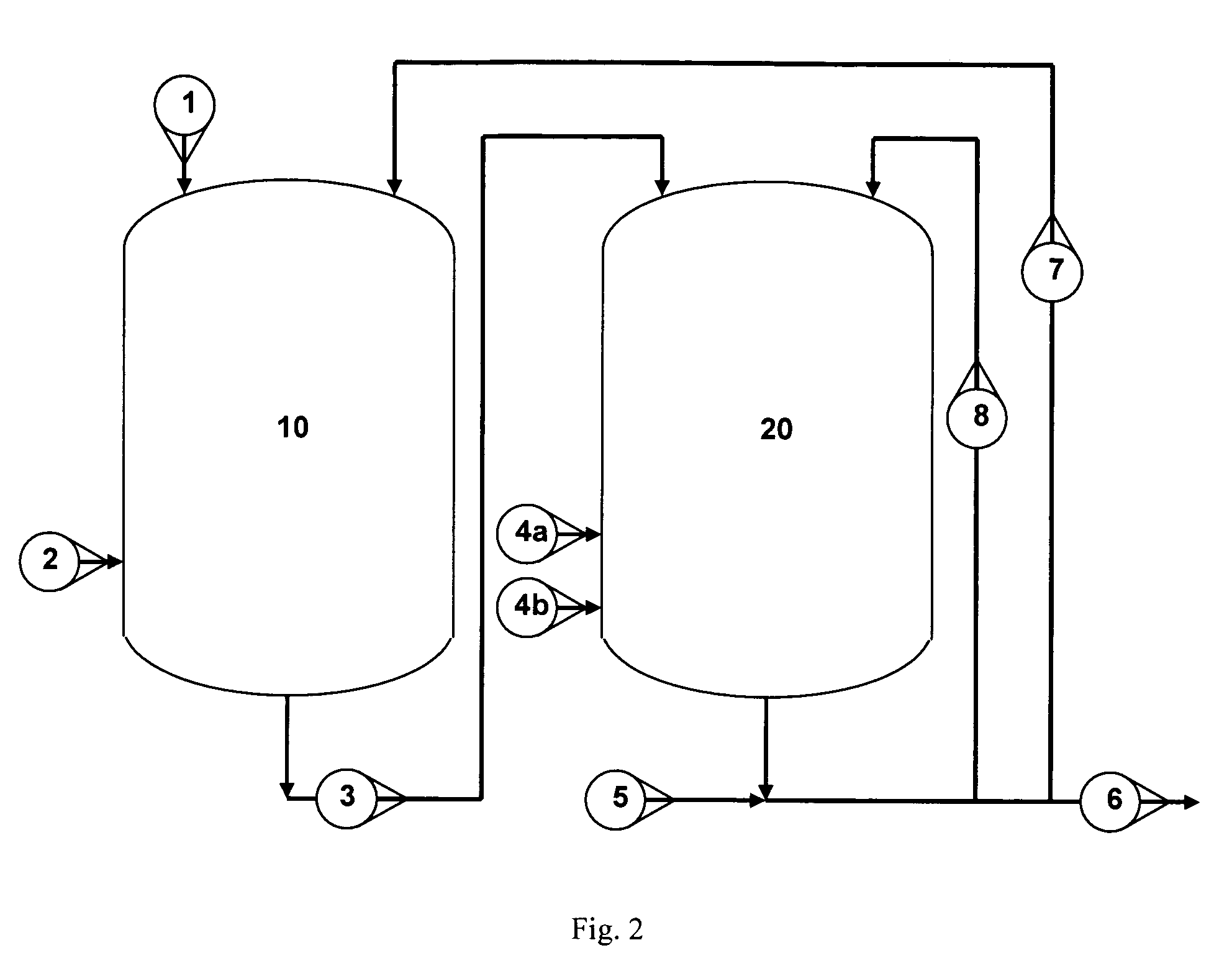

Staged reactor process

In a process for the in situ blending of polymers comprising contacting ethylene and one or more comonomers in two or more fluidized bed reactors with a catalyst system comprising (i) a magnesium / titanium based precursor containing an electron donor and (ii) a hydrocarbyl aluminum cocatalyst, the improvement comprising (A) increasing or decreasing the melt flow ratio and / or molecular weight of the blend by, respectively, decreasing or increasing the mole ratio of a precursor activator compound to the electron donor or (B) increasing or decreasing the bulk density of the blend by, respectively, increasing or decreasing the mole ratio of a precursor activator compound to the electron donor, both (A) and (B) subject to defined provisos including partial pre-activation of the precursor.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Liposomal products

InactiveUS6060080AHigh encapsulation efficiencyEasy to packLiposomal deliveryCholesterolWater soluble drug

A liposomal aqueous dispersion and method of making the liposomal aqueous dispersion is useful for encapsulation of drugs. The liposomal aqueous dispersion comprises: an aqueous suspension medium; multilamellar liposomes comprising an anionic phospholipid and cholesterol as essential components; neutral phospholipid in a mole ratio of 0 to 40% based on the total amount of said multilamellar liposomes; and a cation moiety-containing water-soluble drug, wherein the electrolyte concentration of said aqueous suspension medium is not more than 40 mM.

Owner:DAIICHI PHARMA CO LTD

Method of preparing an aliphatic polyurea spray elastomer system

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is less than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention also concerns a a polyurea elastomer, comprising the reaction product of (a) a resin blend containing one or more polyoxyalkyleneamine and an aspartic ester and (b) an isocyanate, wherein the aspartic ester in the resin blend comprises a reaction product of an amine chain extender and a dialkyl maleate, wherein the mole ratio of amine functionality in the amine chain extender to dialkyl maleate or fumarate is greater than 1:1.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

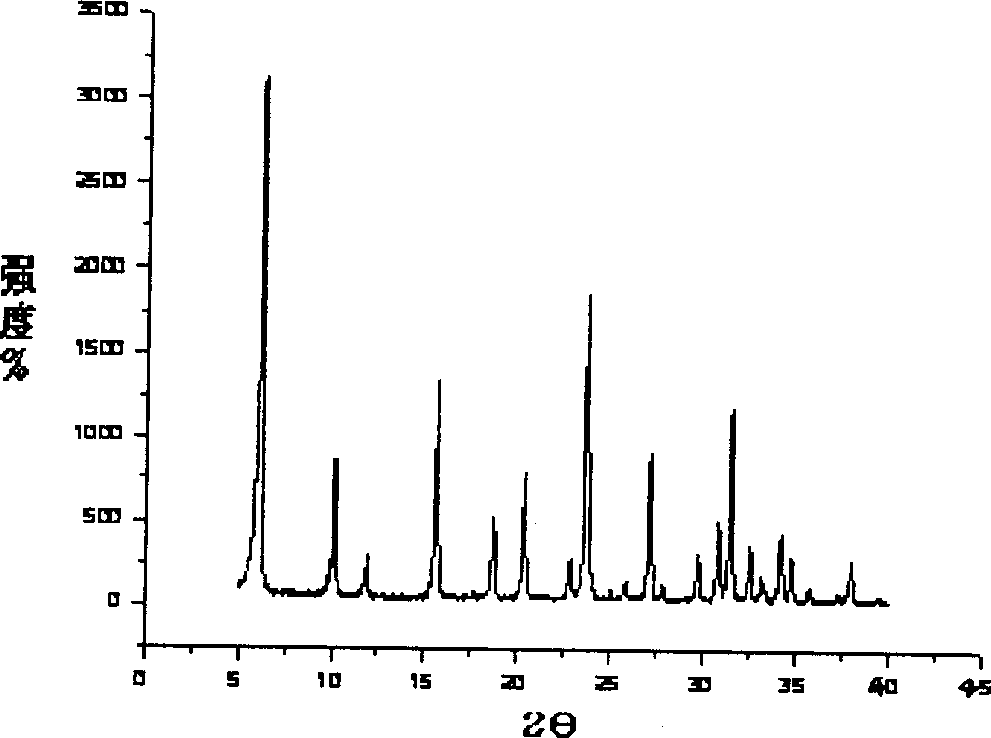

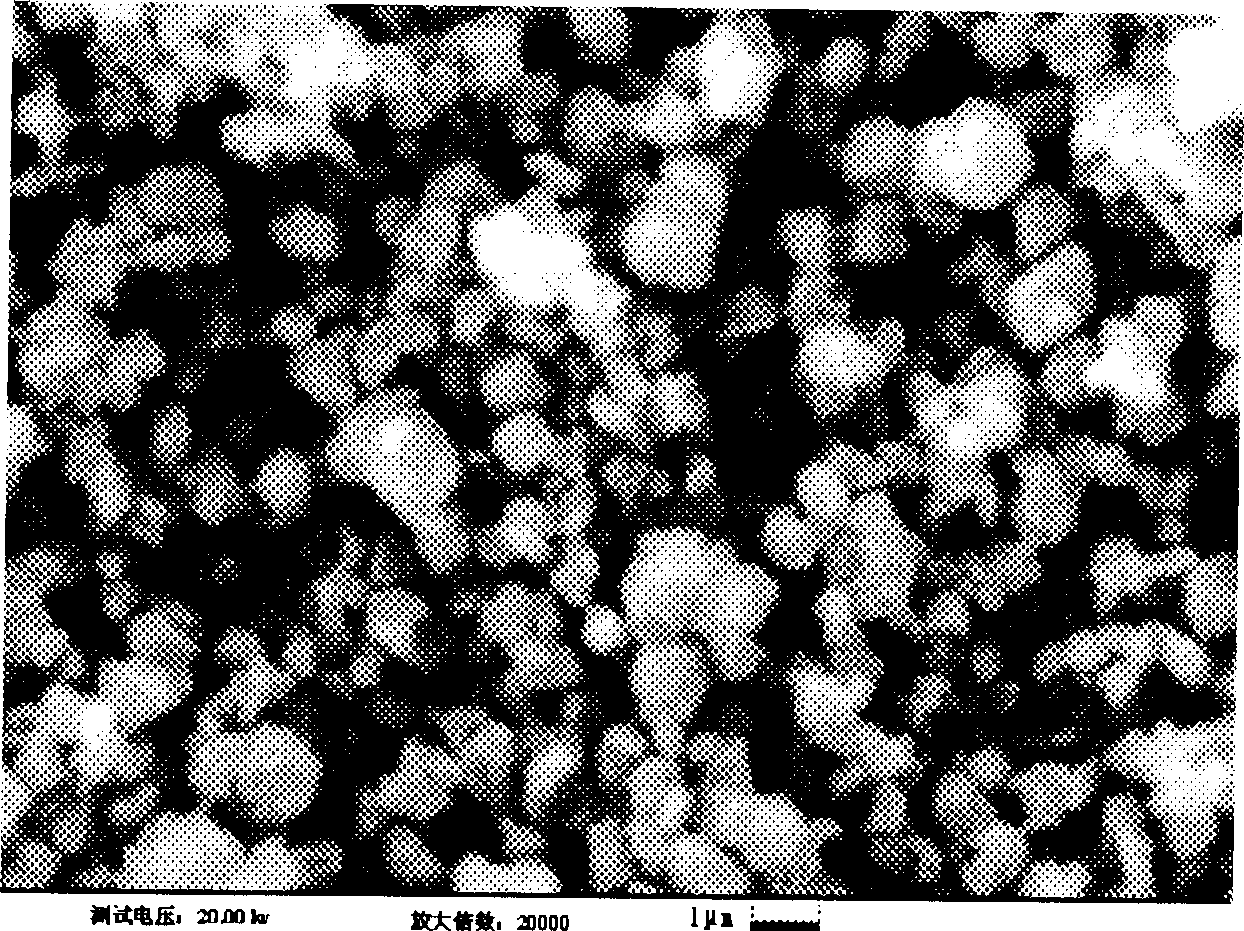

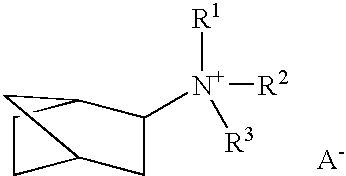

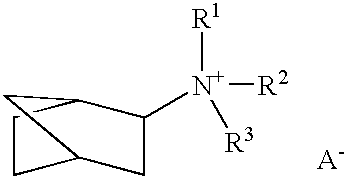

High silicon aluminium ratio small crystal NaY molecular sieve

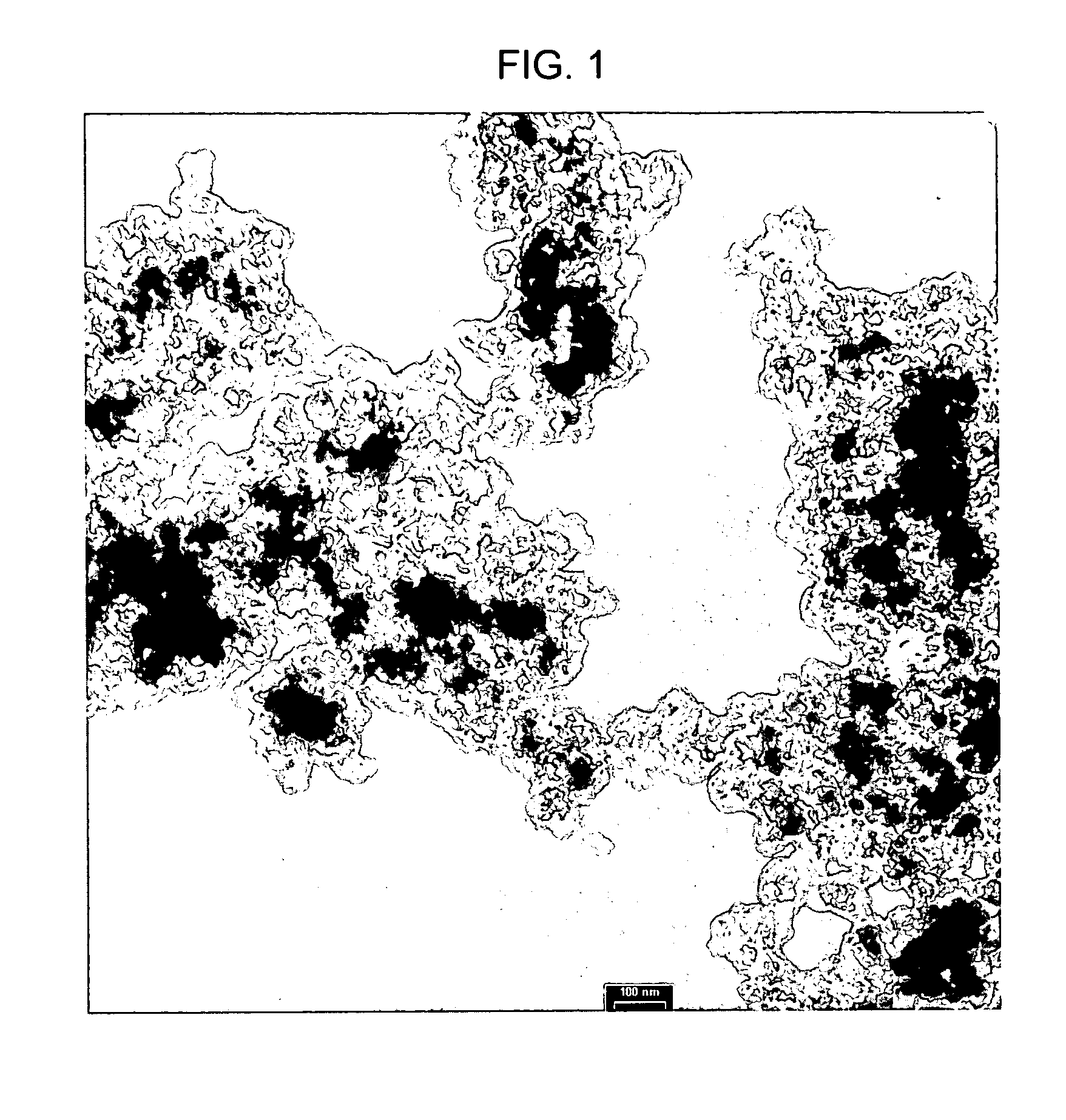

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

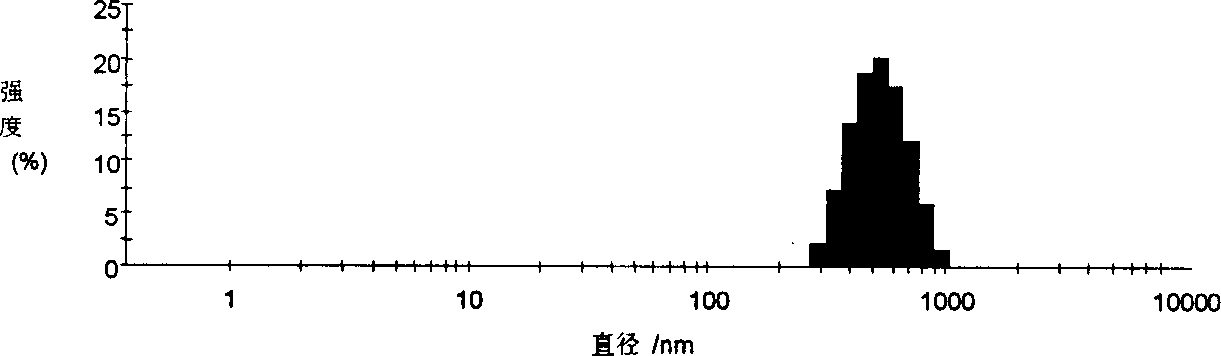

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

Catalyst system and process for the polymerization of olefins

InactiveUS7141527B1High activityIncrease temperatureOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

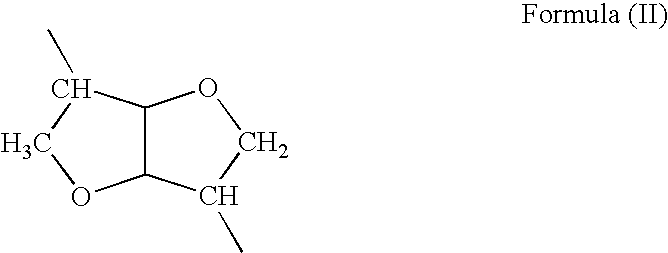

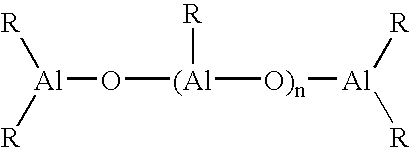

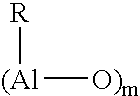

A catalyst system for the polymerization of olefins comprising the product obtained by contacting:(A) a metallocene complex;(B) an organometallic aluminium compound of formula (II):Al[CH2—C(Ar)R4R5]xHy (II)wherein Ar is a substituted or unsubstituted aryl group having from 6 to 20 carbon atoms; R4 is a linear or branched, saturated or unsaturated, C1–C10 alkyl, C6–C20 aryl, C7–C20 arylalkyl or C7–C20 alkylaryl; R5 is hydrogen or a linear or branched, saturated or unsaturated, C1–C10 alkyl, C6–C20 aryl, C7–C20 arylalkyl or C7–C13 alkylaryl group;x=2 or 3; y=3-x; andwater;the molar ratio (B) / (C) being between 1:1 and 100:1. These catalysts show an improved activity with respect to known catalysts, wherein different aluminium compounds are used.

Owner:BASELL POLYOLEFINE GMBH

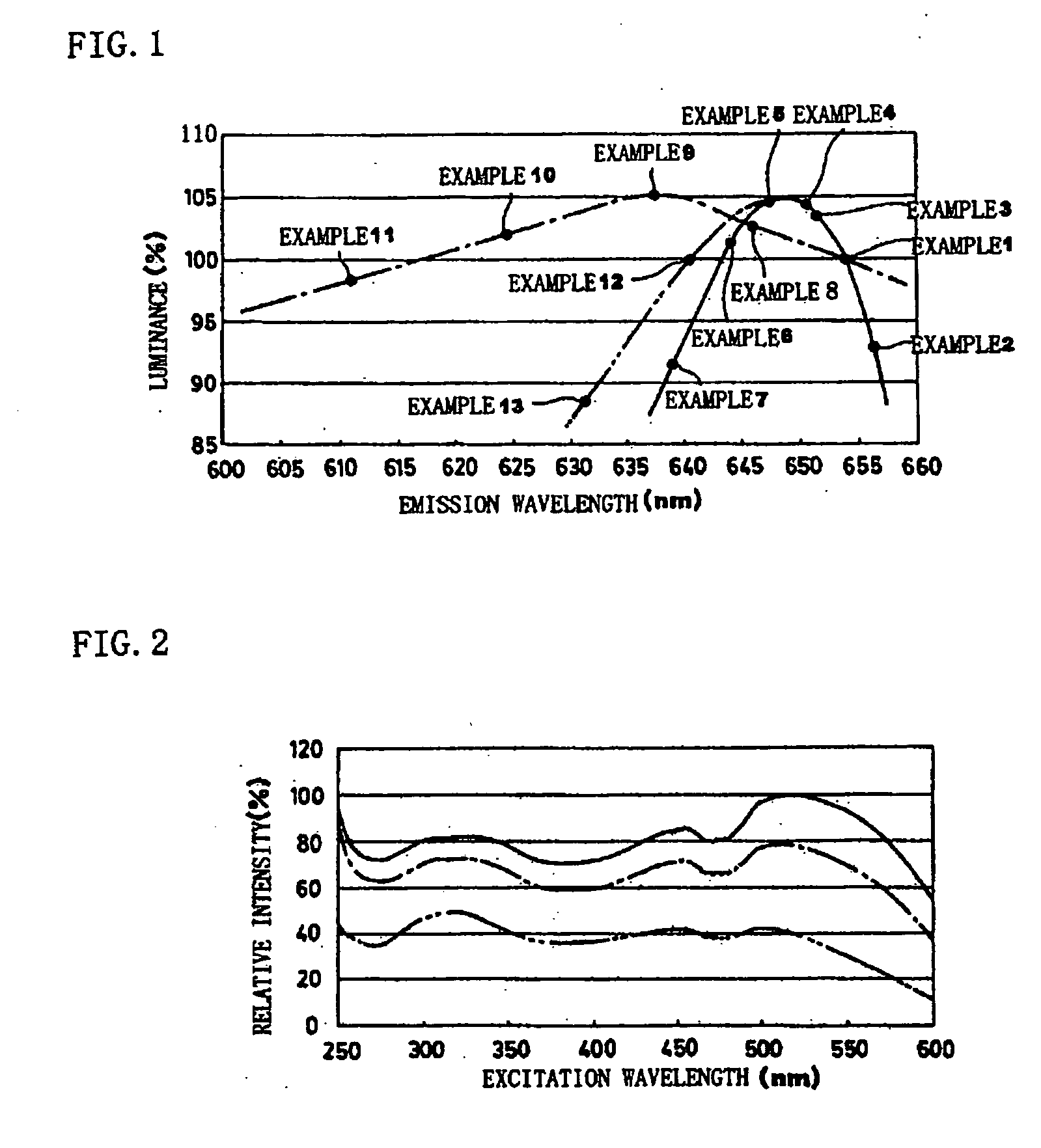

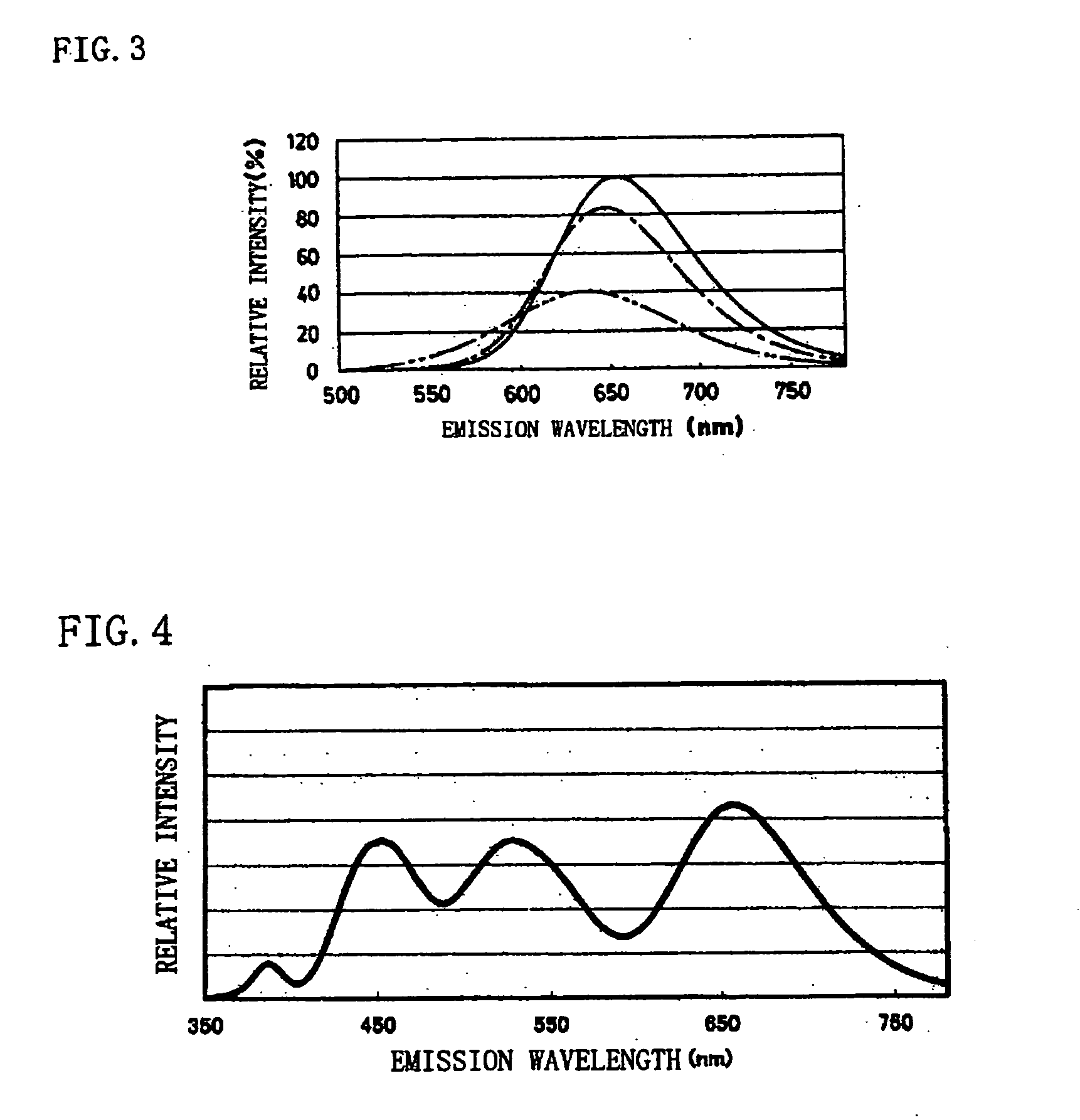

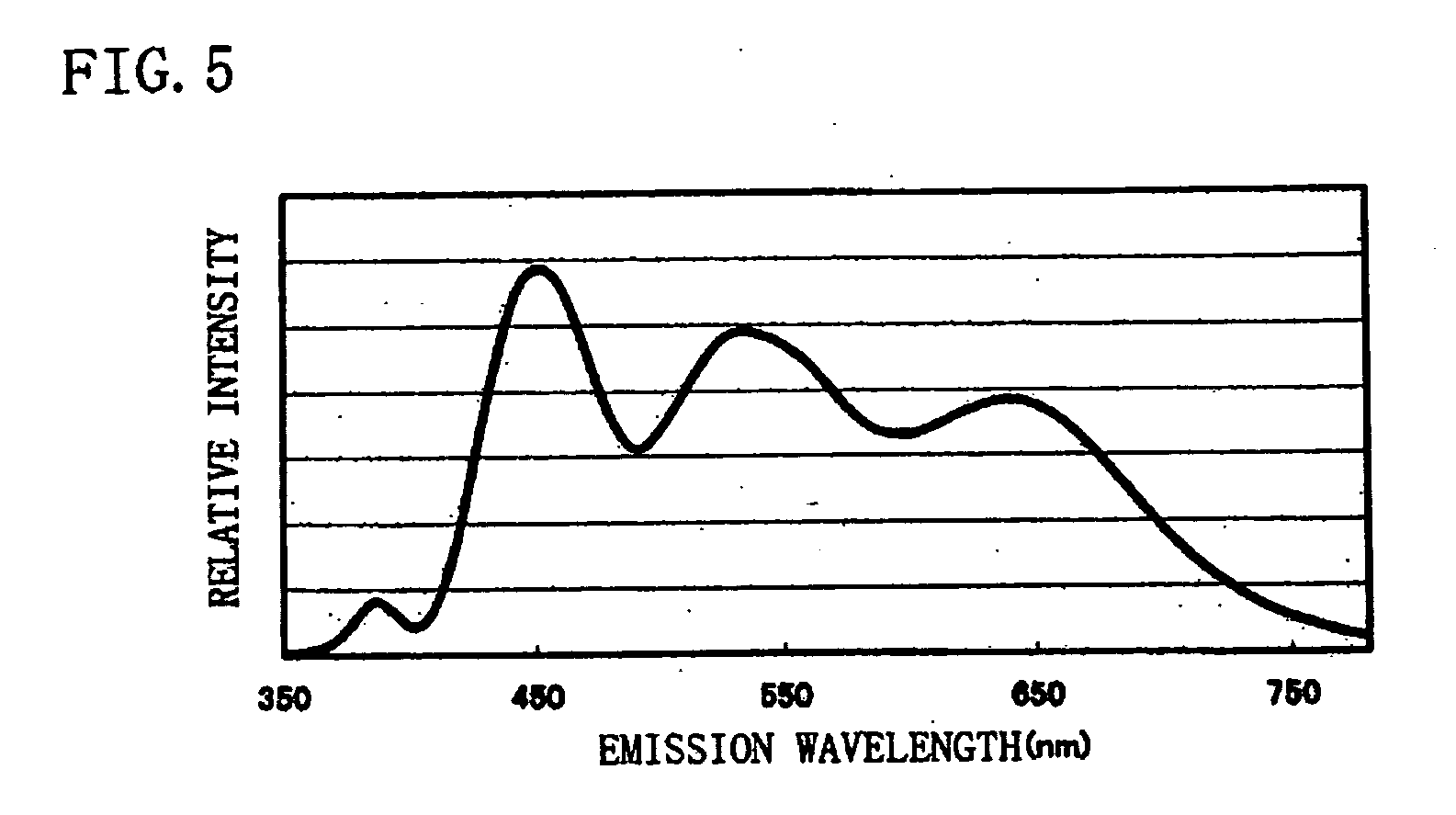

Phosphor and production method of the same, method of shifting emission wavelength of phosphor, and light source and LED

ActiveUS20060017365A1High sensitivityImprove luminous performanceDischarge tube luminescnet screensLamp detailsPhosphorNitrogen atmosphere

A phosphor of which emission wavelength can be optionally set in a region with high human visual sensitivity to make it possible to enhance lumlinance in the region, and which has an excitation band for light in a wavelength region emitted from the aforesaid light emitting portion, a production method of the same, illumination and an LED using the aforesaid phosphor are provided. As raw materials, for example, Ca3N2, CaO, Al2O3, AlN, Si3N4, and SiO2 an Eu2O3 are prepared, and each of the raw material is weighed so that a mole ratio of each element is, for example, (Ca, Eu): Al: Si=1:1:1, mixed and prepared under a nitrogen atmosphere, fired at 1500° C. under the nitrogen atmosphere to obtain a main production phase of a phosphor expressed by CaAlSiN3:Eu, and by controlling a compounding amount of each raw material at the time of raw material preparation, the oxygen concentration in the constitution of the production phase and mol concentration of Eu doping are controlled to optionally set the emission wavelength of the production phase.

Owner:NICHIA CORP

Method for preparing salvianolic acid A by catalytically converting salvianolic acid B

InactiveCN102212004AShorten the timeHigh yieldOrganic compound preparationCarboxylic acid esters preparationSalvianolic acid KSalvianolic acid B

The invention discloses a method for preparing salvianolic acid A by catalytically converting salvianolic acid B. The method is characterized in that the converted raw material is a salvia miltiorrhiza aqueous extract (salvianolic acid B=>50%) primarily purified through combined chromatography; the concentration of the raw material salvianolic acid B is 0.5-2%; urea is taken as the catalyst; the mole ratio of urea to the salvianolic acid B is 0.3-0.7; the conversion reaction temperature is 100-125 DEG C; and the reaction time is 3-6 hours. The method has the following beneficial effects: urea is taken as the catalyst, thus greatly shortening the time for which the salvianolic acid B is in easily destroyed state and remarkably increasing the yield of the salvianolic acid A; the primarily purified salvia miltiorrhiza extract is taken as the converted raw material, thus not only removing the metal ions which are not beneficial to conversion but also removing most colloid-like impurities and frontal impurities which are not beneficial to following separation of the salvianolic acid; and the directional conversion rate of the salvianolic acid B to the salvianolic acid A prepared by the method is not less than 10% and even reaches 60%.

Owner:SUZHOU LEINA PHARMA RES DEV +1

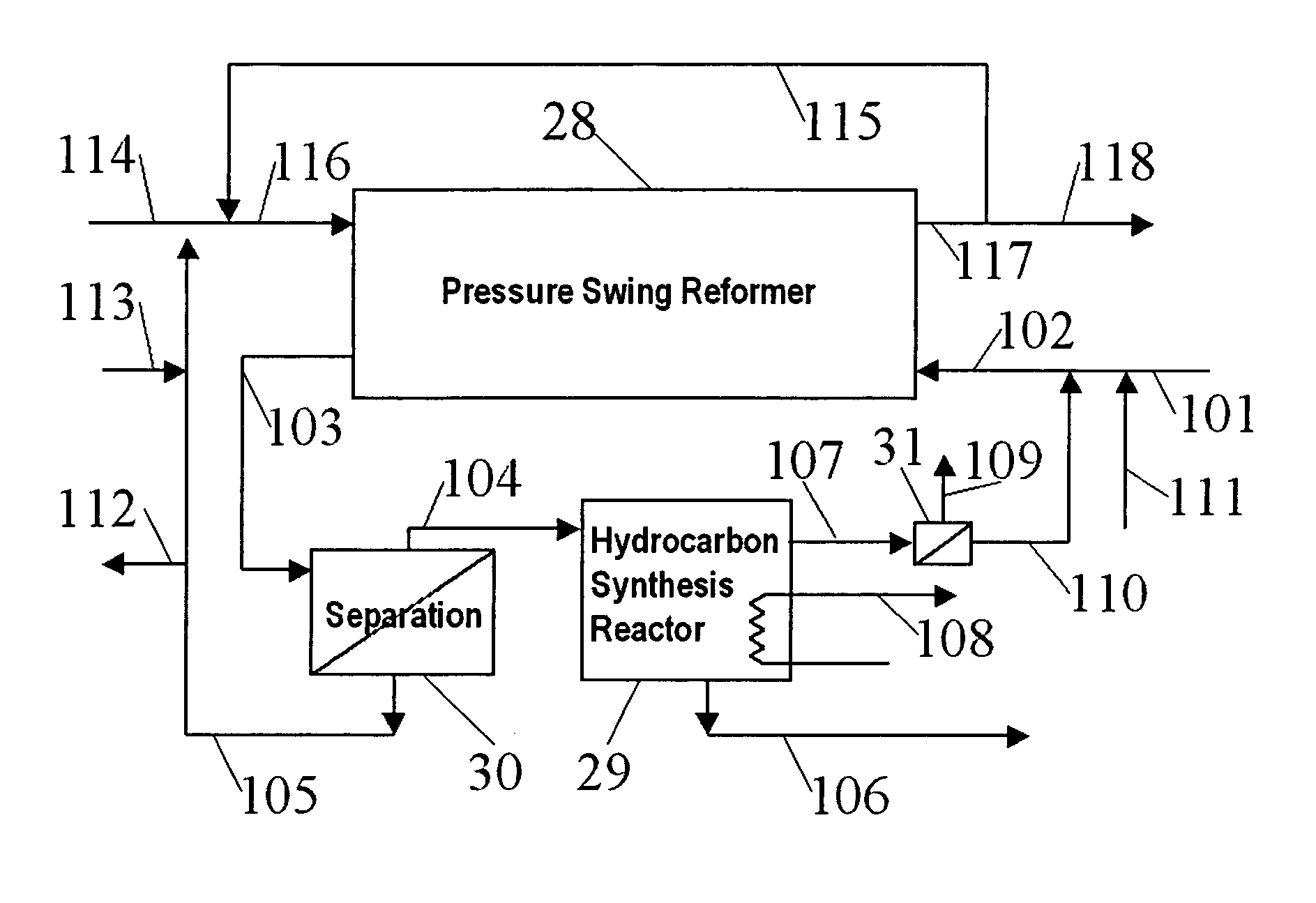

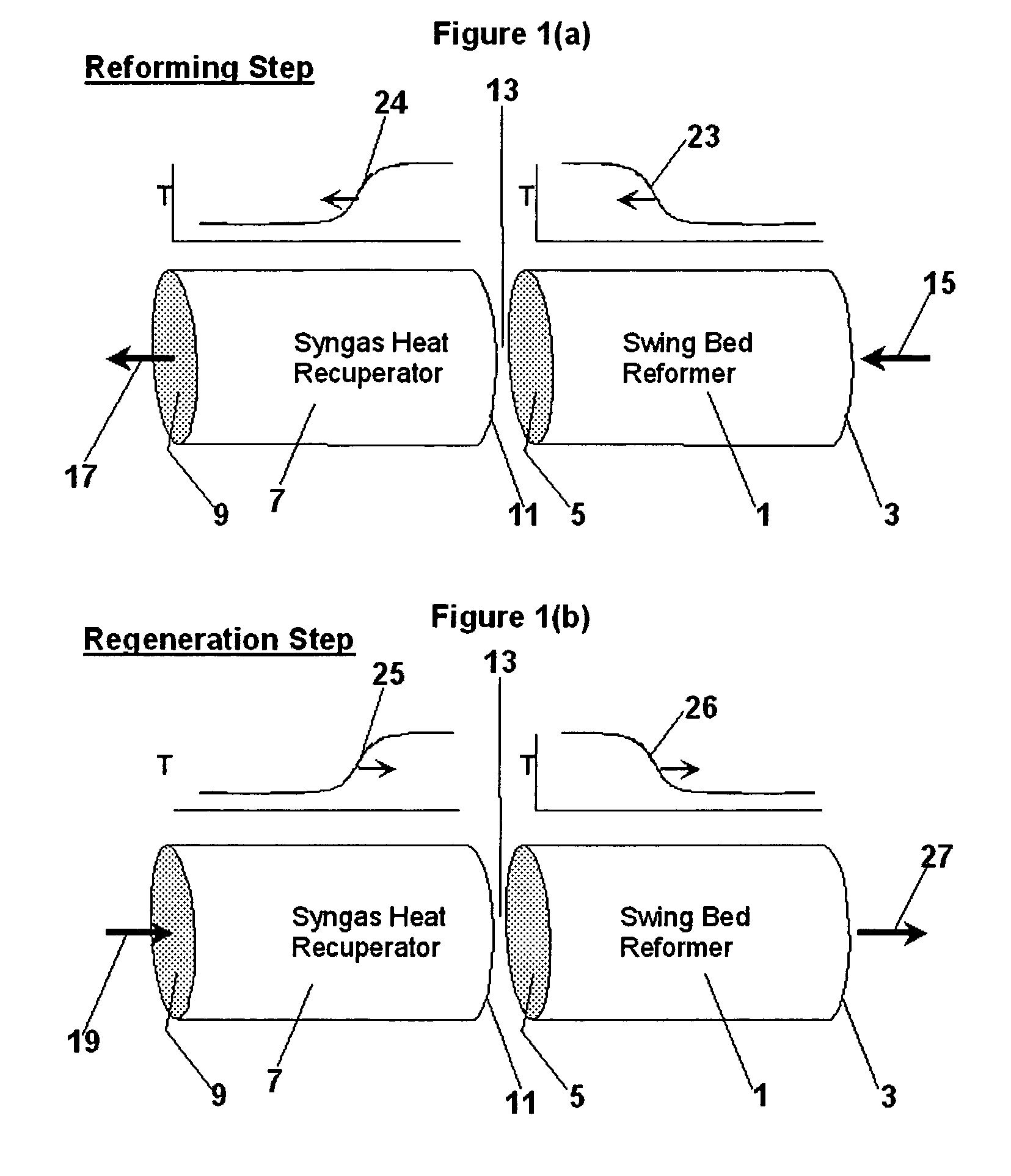

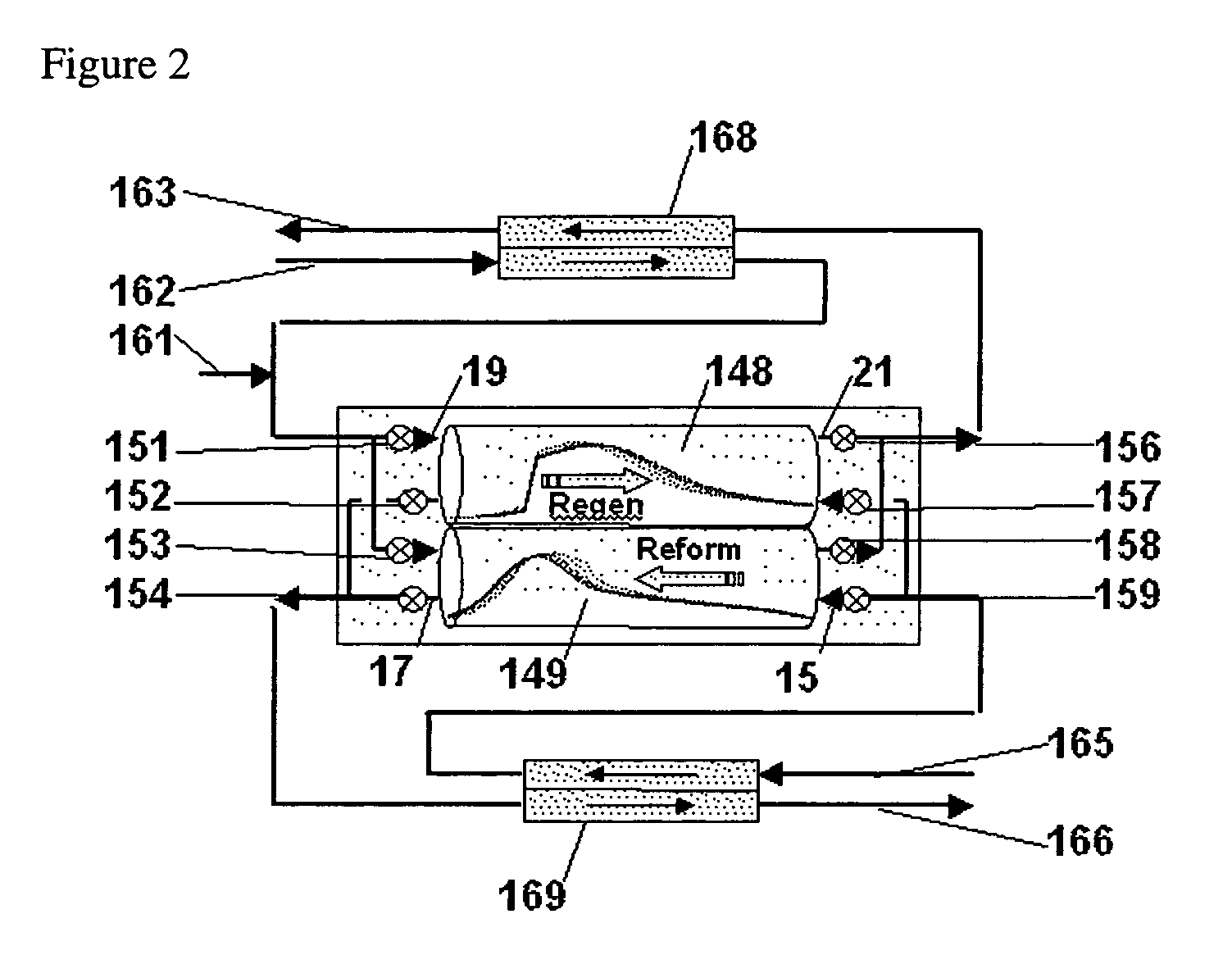

Hydrocarbon synthesis process using pressure swing reforming

ActiveUS7053128B2HydrogenOrganic compounds purification/separation/stabilisationLiquid productHydrogen

The invention provides a method for producing liquid hydrocarbons by first generating in a pressure swing reformer a synthesis gas stream having a mole ratio of H2:CO greater than 2:1. Then, a portion of the hydrogen is separated to produce a synthesis gas stream having a mole ratio of H2:CO of about 2:1 which steam is then introduced into a hydrocarbon synthesis reactor for conversion to liquid products.

Owner:EXXON RES & ENG CO

Adhesion-Preventive Film

InactiveUS20080090936A1Good flexibilityProvide effectSuture equipmentsCosmetic preparationsLactideCaprolactone

An adhesion-preventive film is provided that is excellent in flexibility and can prevent cracks from occurring. The adhesion-preventive film contains a copolymer of lactide and caprolactone. The lactide and the caprolactone of the copolymer has a mole ratio in the range of 65:35 to 80:20. Even when this adhesion-preventive film is used in a curved state in vivo or is wound around an affected part such as a tendon, for example, it can provide an adhesion-preventive function for a sufficiently long period without cracking.

Owner:JMS CO LTD

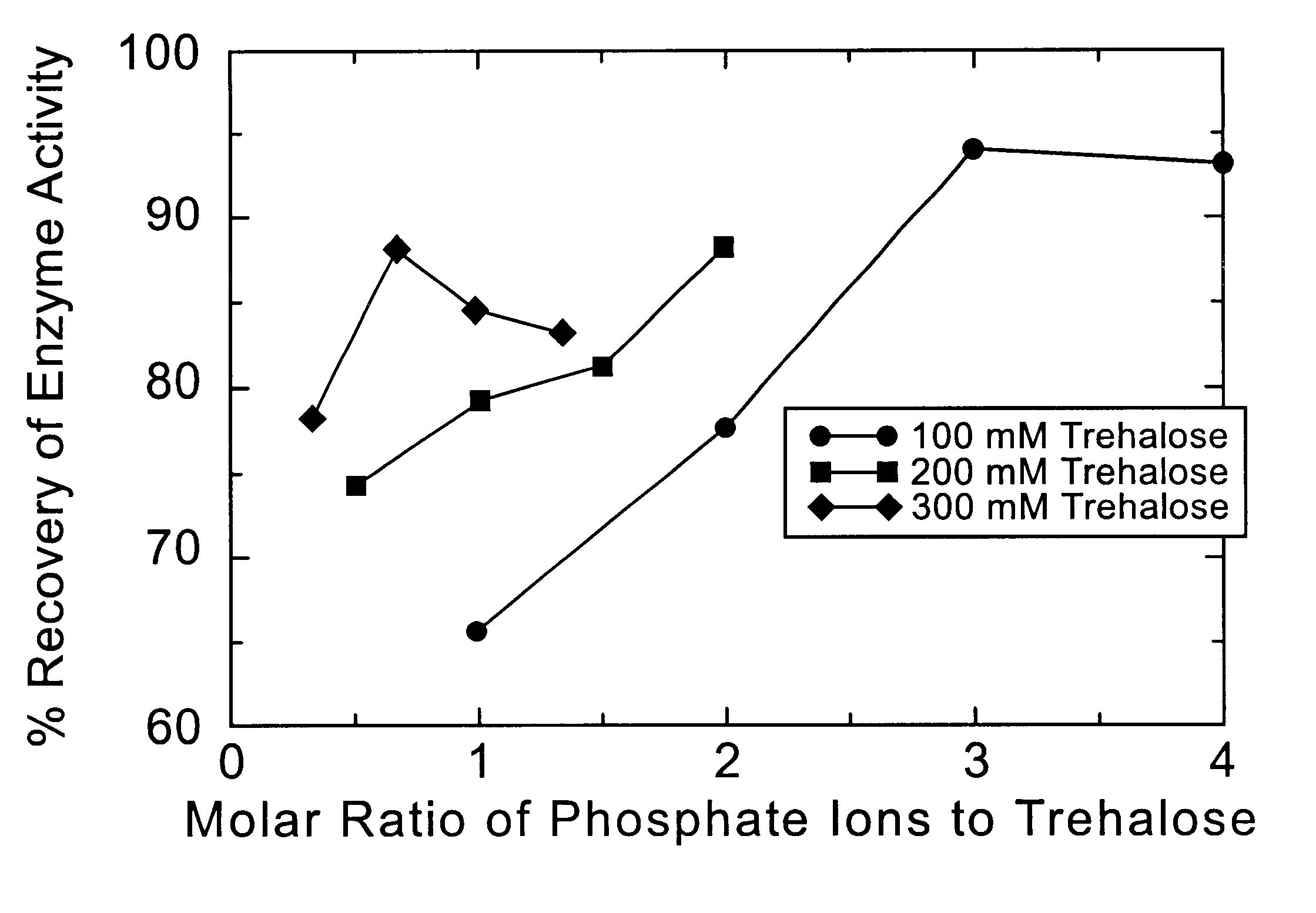

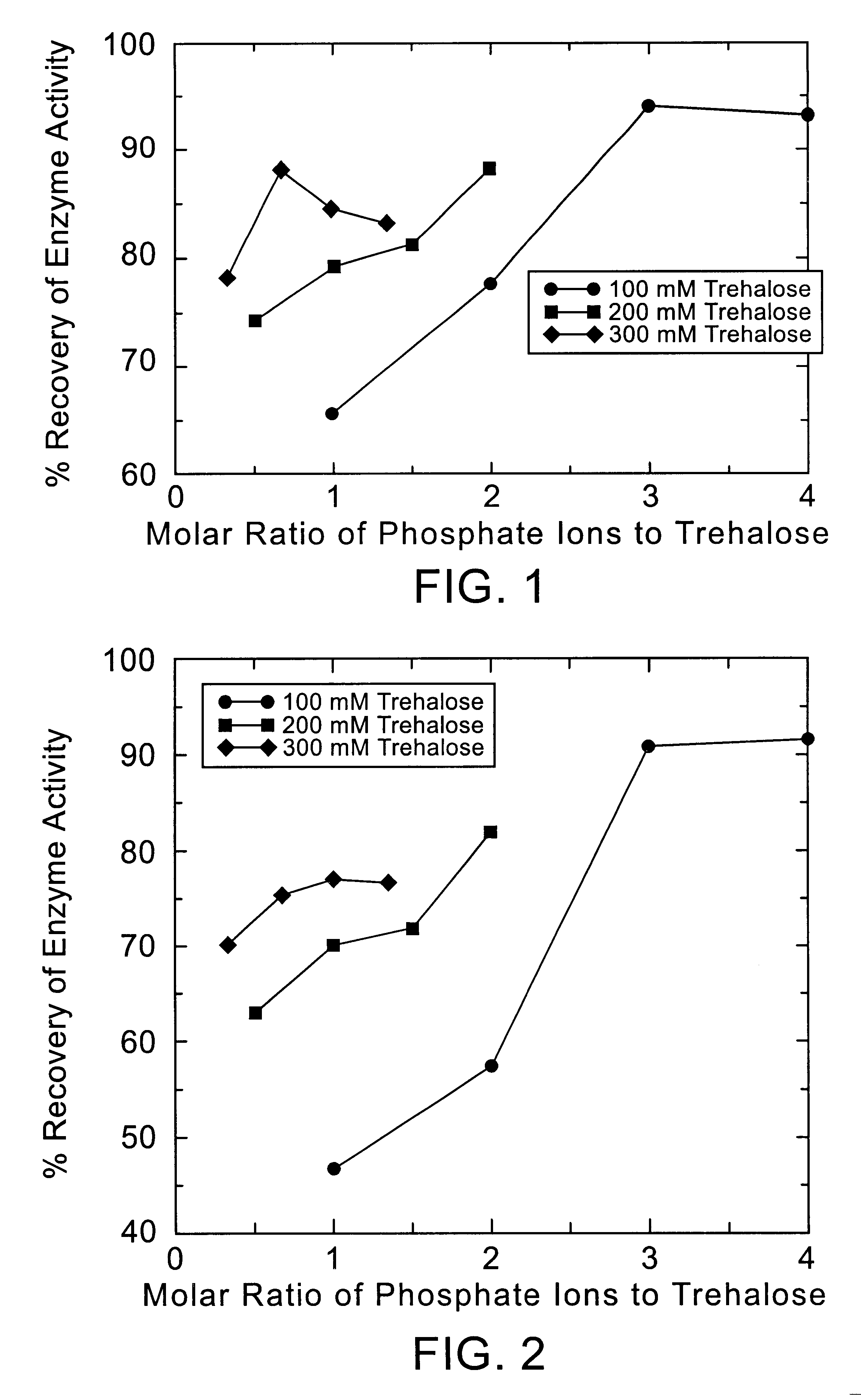

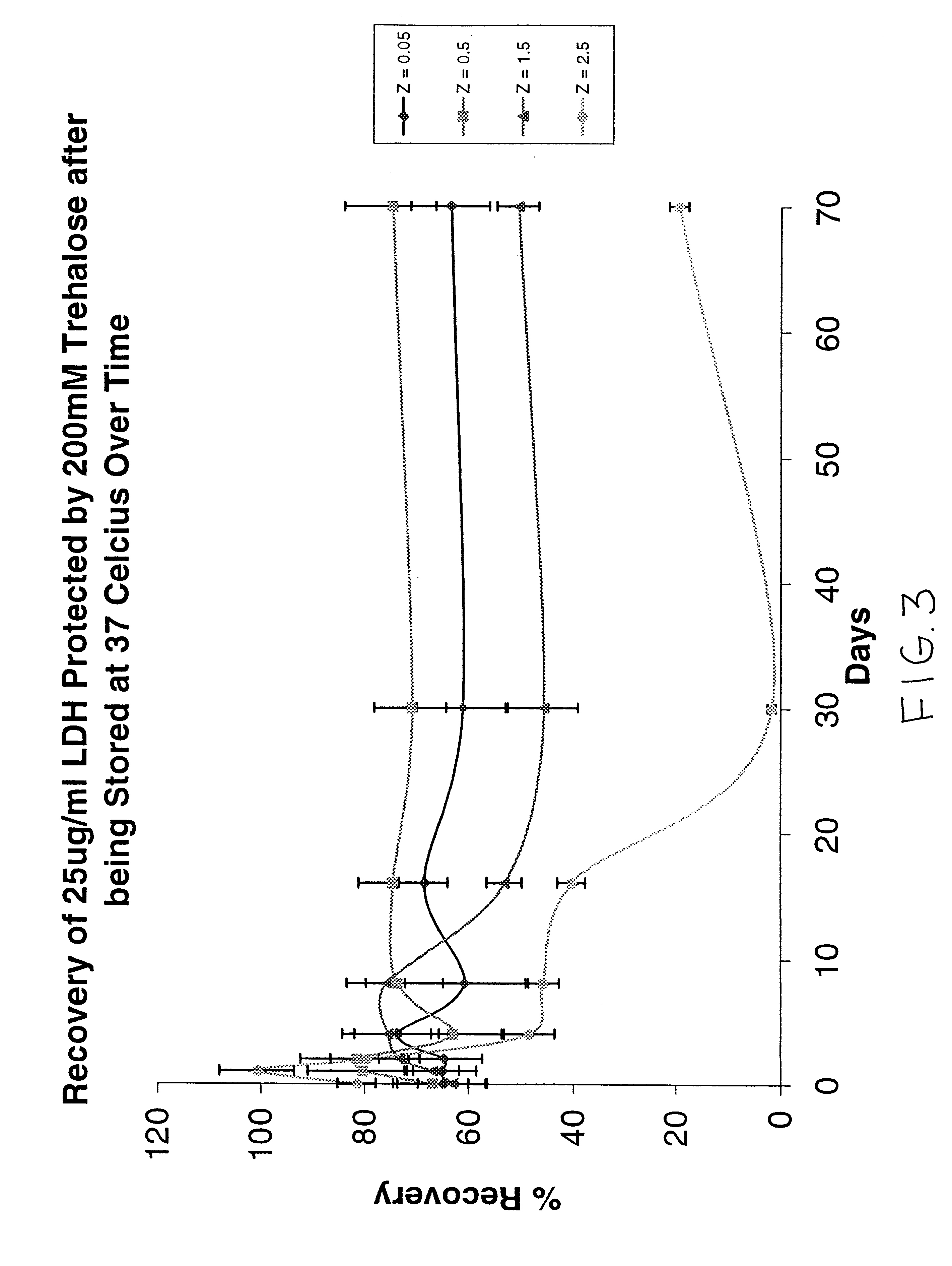

Preservation and storage medium for biological materials

A protectant mixture for use in preserving biological materials comprising (1) at least one polyhydroxy compound, where the total amount of polyhydroxy compound in the mixture is from about 5% to about 60% by weight of the mixture where the mixture is an aqueous solution and is from about 10% to about 95% where the mixture is in solid form, and (2) phosphate ions, where the total amount of phosphate ions in the mixture is such that the molar ratio of phosphate ions to hydroxy groups in the polyhydroxy compound is from about 0.025 to about 0.625; a preservation medium comprising (1) a biological material, (2) at least one polyhydroxy compound, where the total amount of polyhydroxy compound in the medium is from about 5% to about 60% by weight of the medium, and (3) phosphate ions, where the total amount of phosphate ions in the mixture is such that the molar ratio of phosphate ions to hydroxy groups in the polyhydroxy compound is from about 0.025 to about 0.625; methods of preserving the preservation medium; and the resulting preserved biological material composition.

Owner:WISCONSIN ALUMNI RES FOUND

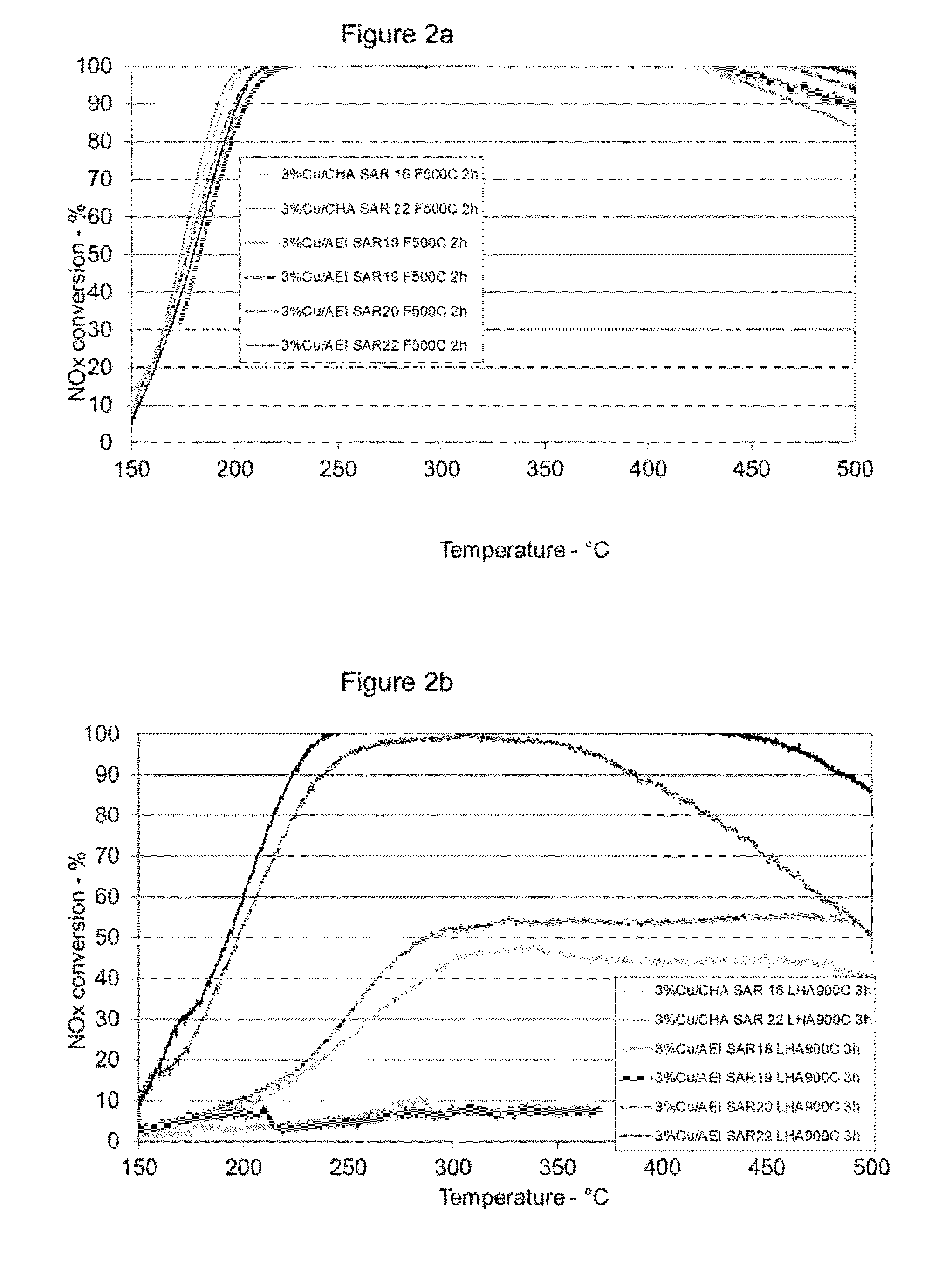

Catalyst for treating exhaust gas

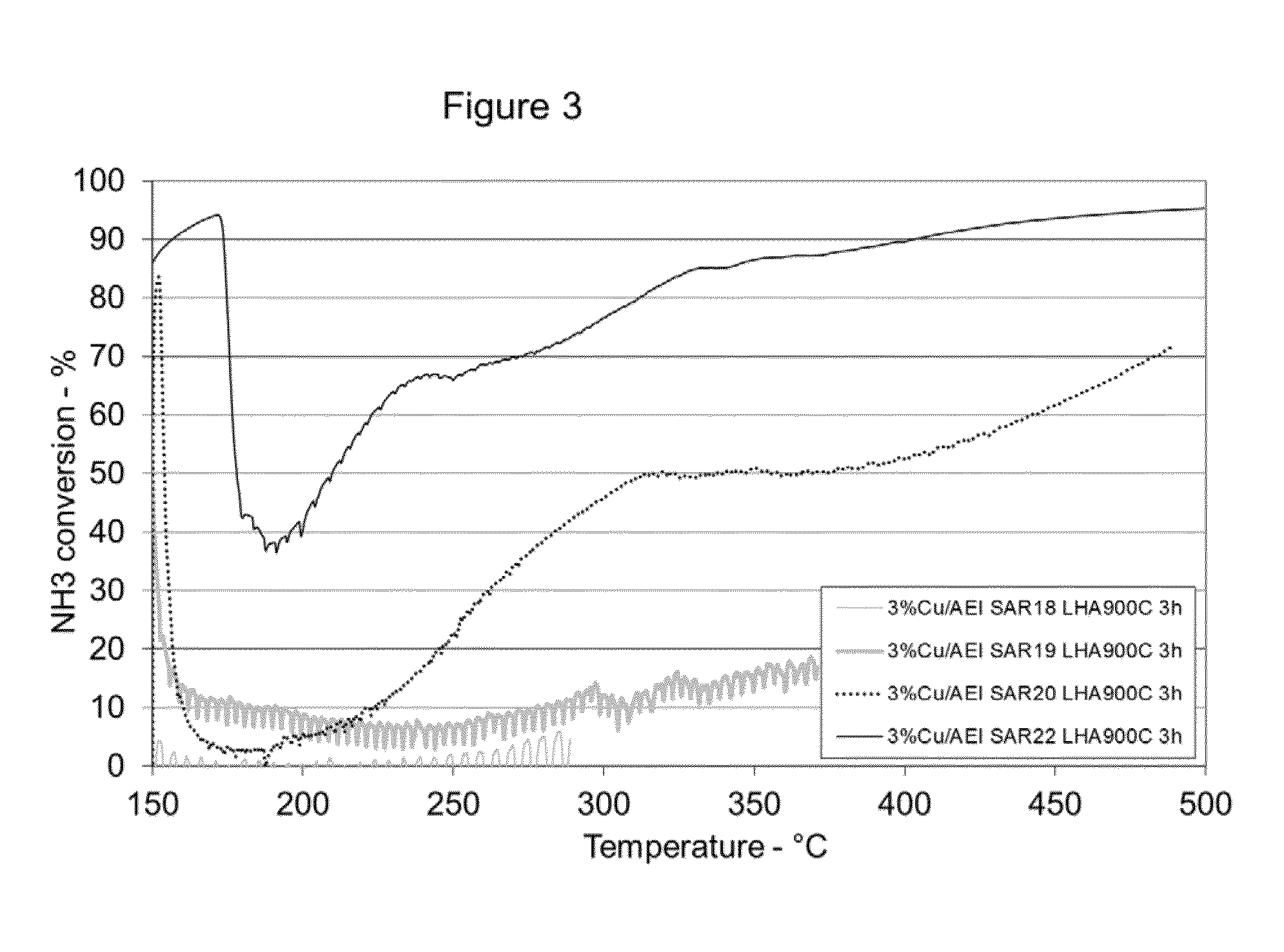

ActiveUS20140271426A1Improve catalytic performanceCombination devicesNitrogen compoundsMolecular sieveSilicon dioxide

Provided is a catalyst composition having an aluminosilicate molecular sieve having an AEI structure and a mole ratio of silica-to-alumina of about 20 to about 30 loaded with about 1 to about 5 weight percent of a promoter metal, based on the total weight of the molecular sieve material. Also provided are method, articles, and systems utilizing the catalyst composition.

Owner:JOHNSON MATTHEY PLC

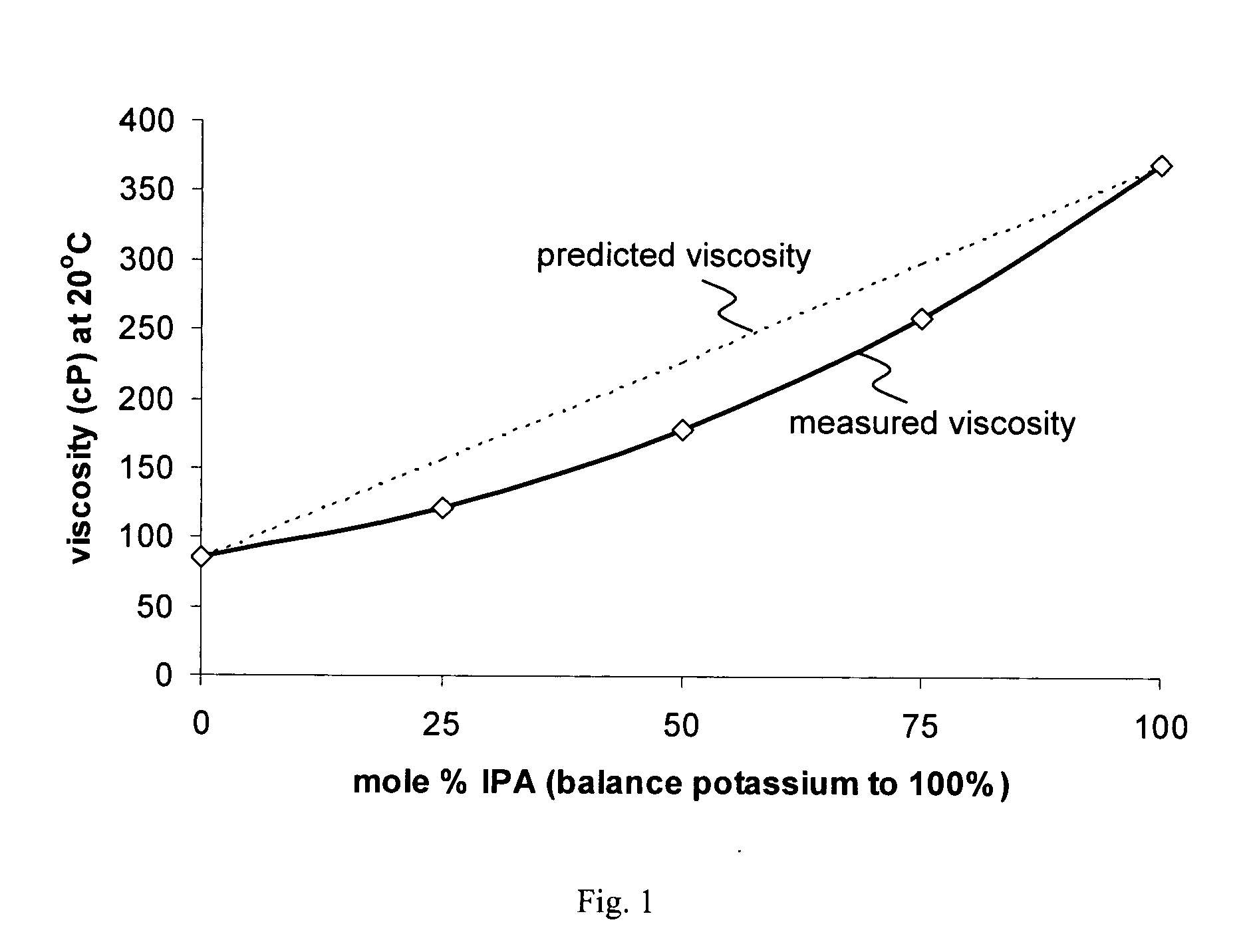

Glyphosate salt herbicidal composition

ActiveUS20060040826A1Improve compatibilityAcceptable surfactant compatibilityBiocideDead animal preservationPotassiumAqueous solution

A herbicidal composition comprises in aqueous solution a mixture of salts of glyphosate at a total glyphosate a.e. concentration not less than about 360 g / l, wherein (a) said glyphosate is in anionic form accompanied by low molecular weight non-amphiphilic cations in a total molar amount of about 100% to about 120% of the molar amount of said glyphosate; (b) said cations comprise potassium and propylammonium (e.g., isopropylammonium) cations in a mole ratio of about 70:30 to about 90:10; and (c) said potassium and propylammonium cations together constitute about 90 to 100 molar percent of all of said low molecular weight non-amphiphilic cations in the composition.

Owner:MONSANTO TECH LLC

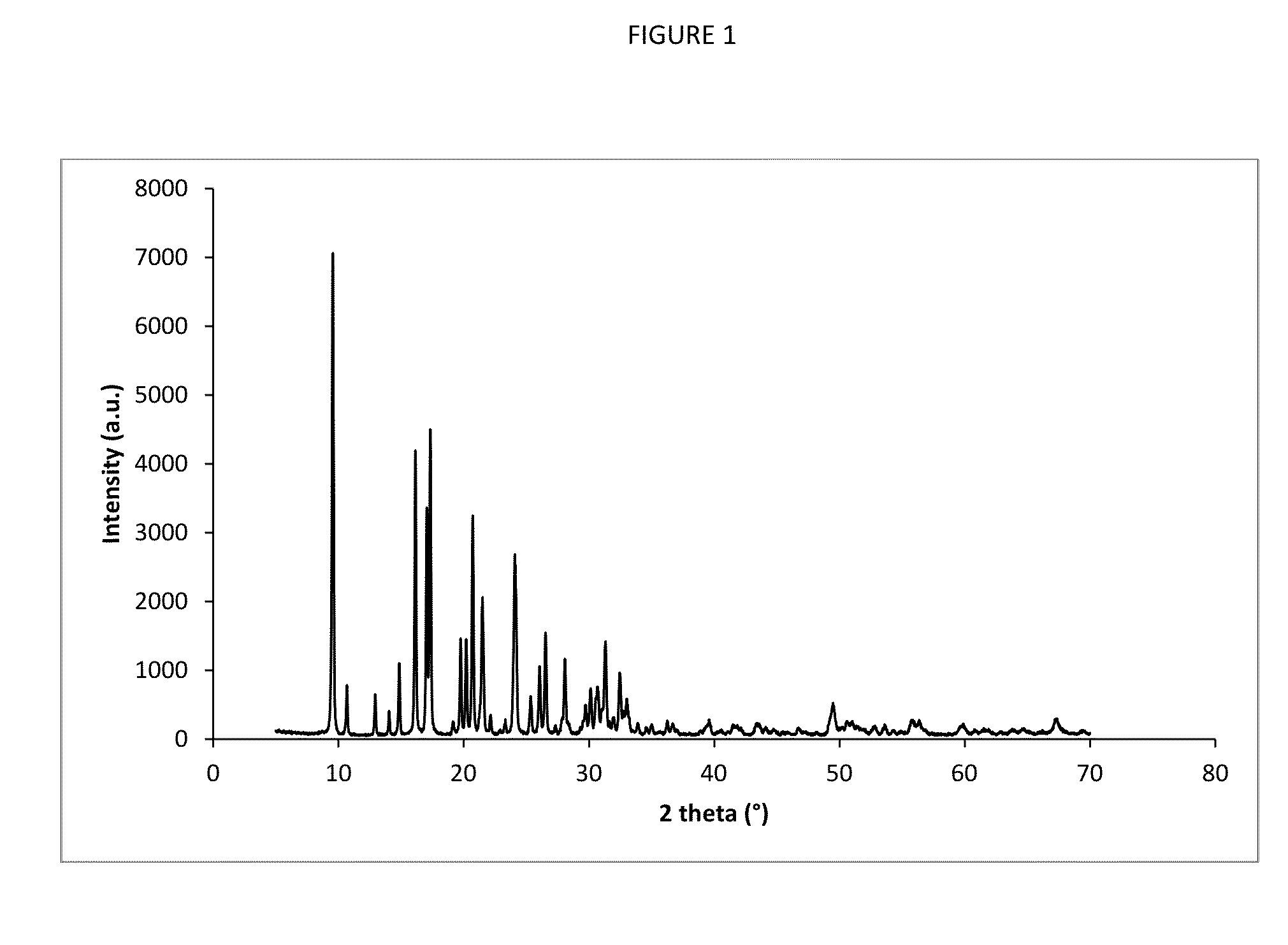

Aluminum phosphate or polyphosphate particles for use as pigments in paints and method of making same

InactiveUS20060045831A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAluminium sulfateOrganic acid

An aluminum phosphate or polyphosphate-based pigment product is made by a process comprising contacting phosphoric acid with aluminum sulfate and an alkaline solution to produce an aluminum phosphate based product; and optionally calcining the aluminum phosphate based product at an elevated temperature, wherein the process is substantially free of an organic acid. The aluminum phosphate or polyphosphate-based pigment is amorphous. The amorphous aluminum phosphate or polyphosphate characterized by a bulk density of less than 2.30 grams per cubic centimeter and a phosphorus to aluminum mole ratio of greater than 0.8. The composition is useful in paints and as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Reduction of oxides of nitrogen in a gas stream using high-silics molecular sieve CHA

A process for the reduction of oxides in a gas stream (e.g., automotive exhaust) uses a catalyst comprising a molecular sieve having the CHA crystal structure and having a mole ratio of greater than 50 to 1500 of (1) an oxide selected from silicon oxide, germanium oxide or mixtures thereof to (2) an oxide selected from aluminum oxide, iron oxide, titanium oxide, gallium oxide or mixtures thereof.

Owner:CHEVROU USA INC

Process for the preparation of polyethylene

InactiveUS6617405B1Avoid experimentationDisperse thoroughlyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorSlurry

A process of polymerizing ethylene or ethylene and one or more comonomers in one or more fluidized bed reactors with a catalyst system comprising (i) a supported or unsupported magnesium / titanium based precursor in slurry form, said precursor containing an electron donor; and (ii) an activator containing aluminum in an amount sufficient to essentially complete the activation of the precursor is disclosed. In the process, the precursor and the activator are mixed prior to introduction into the reactor in at least one mixing procedure, and then the mixture is contacted again with additional activator to essentially complete activation of the precursor. In the method, the atomic ratio of aluminum to titanium is in the range of about 1:1 to about 15:1 and the mole ratio of activator to electron donor is about 1:1 to about 2:1, and no additional activator is introduced into the reactor(s).

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

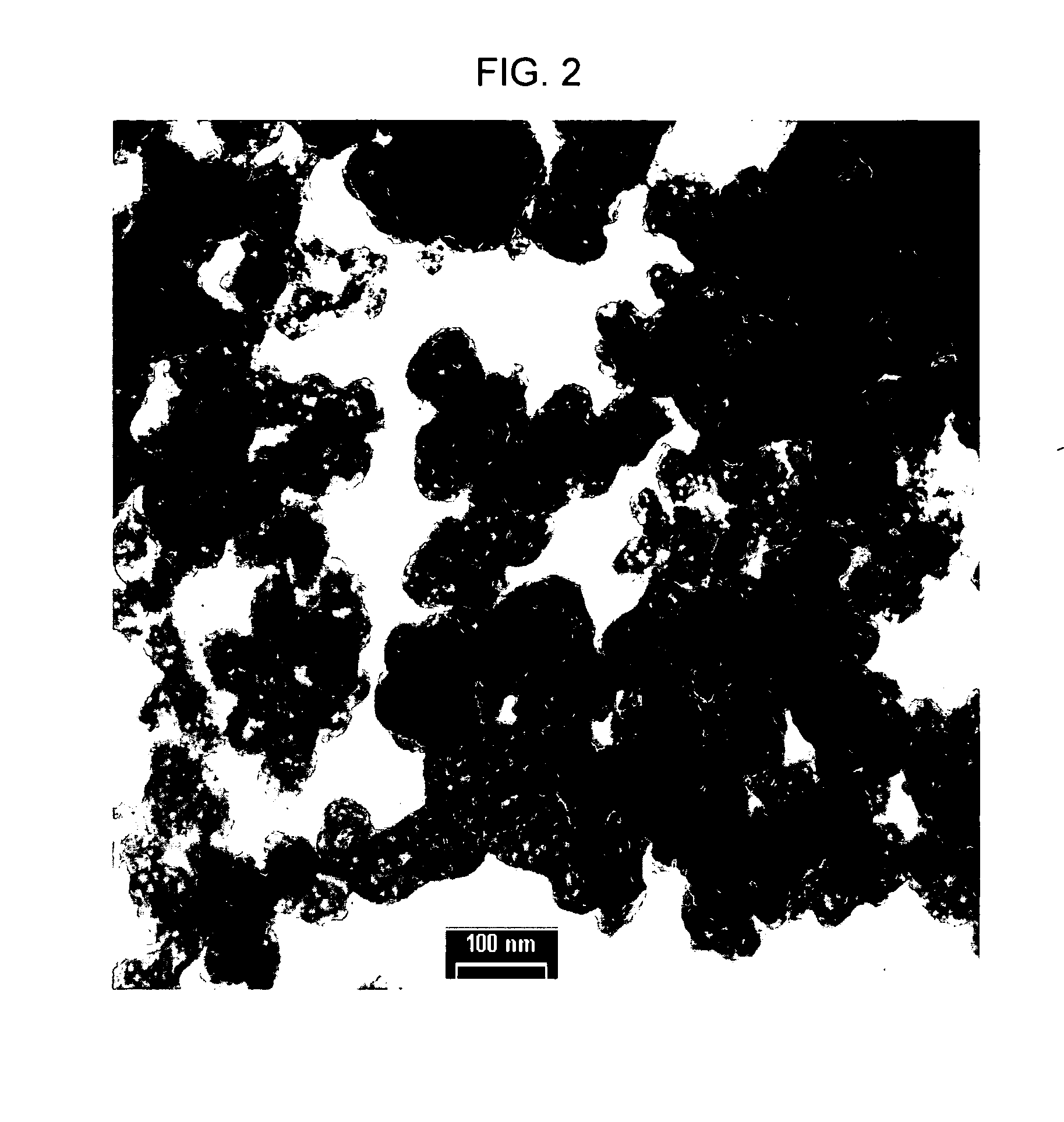

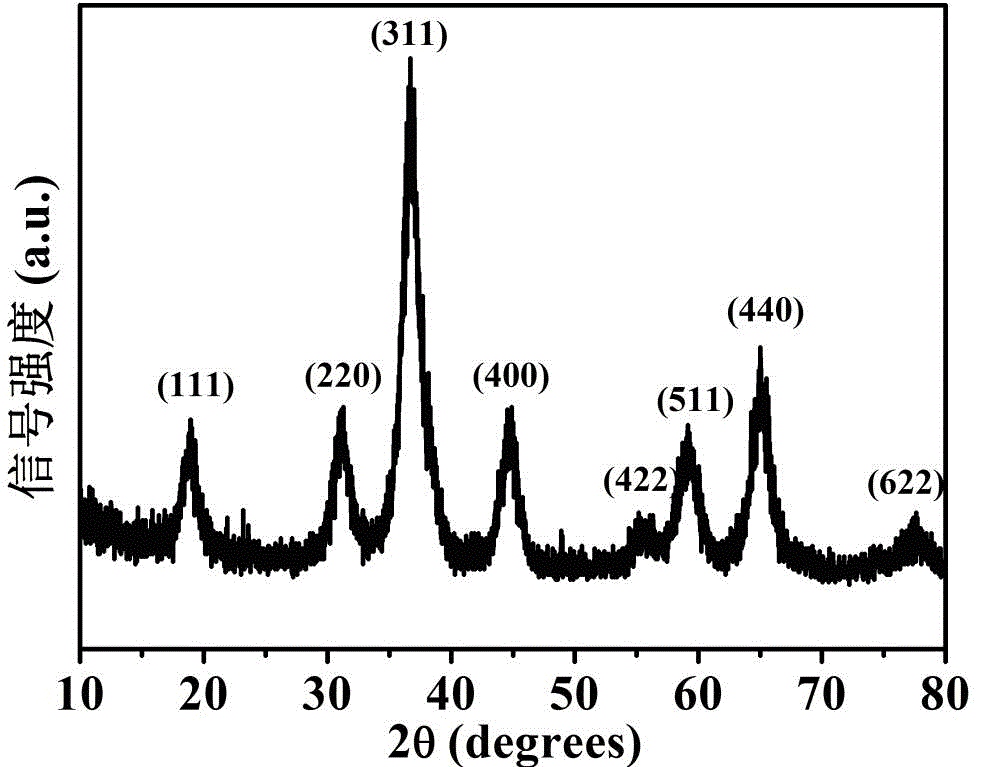

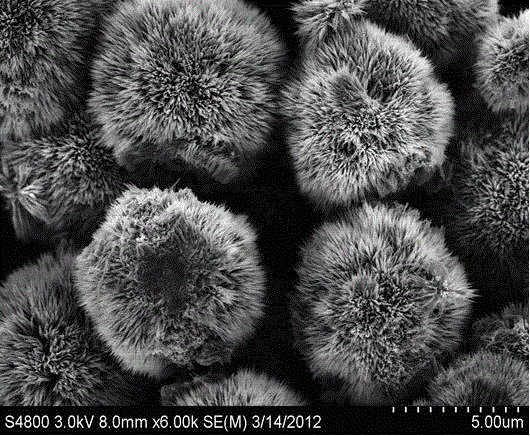

Method of synthesizing mesoporous nickel cobalt oxide nanowire using hydrothermal method and application thereof

InactiveCN102745752AHigh purityLarge specific surface areaMaterial nanotechnologyElectrolytic capacitorsCapacitanceAir atmosphere

The invention relates to a method of synthesizing nickel cobalt oxide electrode material using a hydrothermal method and an application thereof. The method comprises dissolving CoCl2.6H2O, NiCl2.6H2O and CO(NH2)2 into an appropriate amount of deionized water, wherein the mole ratio of CoCl2.6H2O to NiCl2.6H2O is 1 : 2; uniformly stirring the mixed solution by using a magnetic stirrer, transferring the solution into an autoclave, heating the solution to 100 DEG C and keeping the temperature constant for 10 hours; cooling the solution to room temperature, filtering, washing and drying reactants, and then annealing the reactants for 2 hours in an air atmosphere of 250 DEG C. The method is simple to operate and environmental-friendly. The prepared nickel cobalt oxide nanowire is a spinel-type cubic phase and porous, has high purity and relatively high specific surface area, and can be used as electrode materials for super capacitors, with specific capacitance thereof being 722 F / g.

Owner:TONGJI UNIV

Composite catalyst flue gas denitrating under low-temperature condition and method of preparing the same

InactiveCN101254464ALarge specific surface areaImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention relates to a composite catalyst used for denitrification of flue gases under low-temperature conditions. The catalyst contains a Ti / Zr composite oxide as carrier, an oxide of manganese as catalytically-active component, and at least one oxide of vanadium, chromium, iron, copper, nickel and cerium as auxiliary agent. The Ti / Zr composite oxide is prepared by coprecipitation method and loads the catalytically-active component and the auxiliary agent by immersion method, wherein the mole ratio of Ti / Zr in the composite oxide is controlled in a range from 0.25 to 4, the oxide of manganese accounts for 1-15% of the weight of the Ti / Zr composite oxide, and the auxiliary agent accounts for 1-5% of the weight of the Ti / Zr composite oxide. The catalyst has good catalytic activity at low temperature and high NO conversion rate up to 100% at 100-300 DEG C, and has good prospect in industrial application.

Owner:NANJING UNIV OF TECH

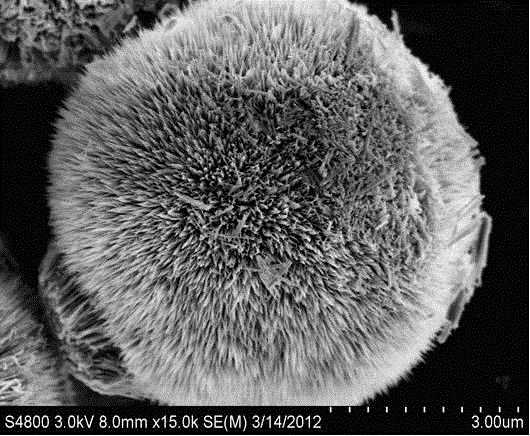

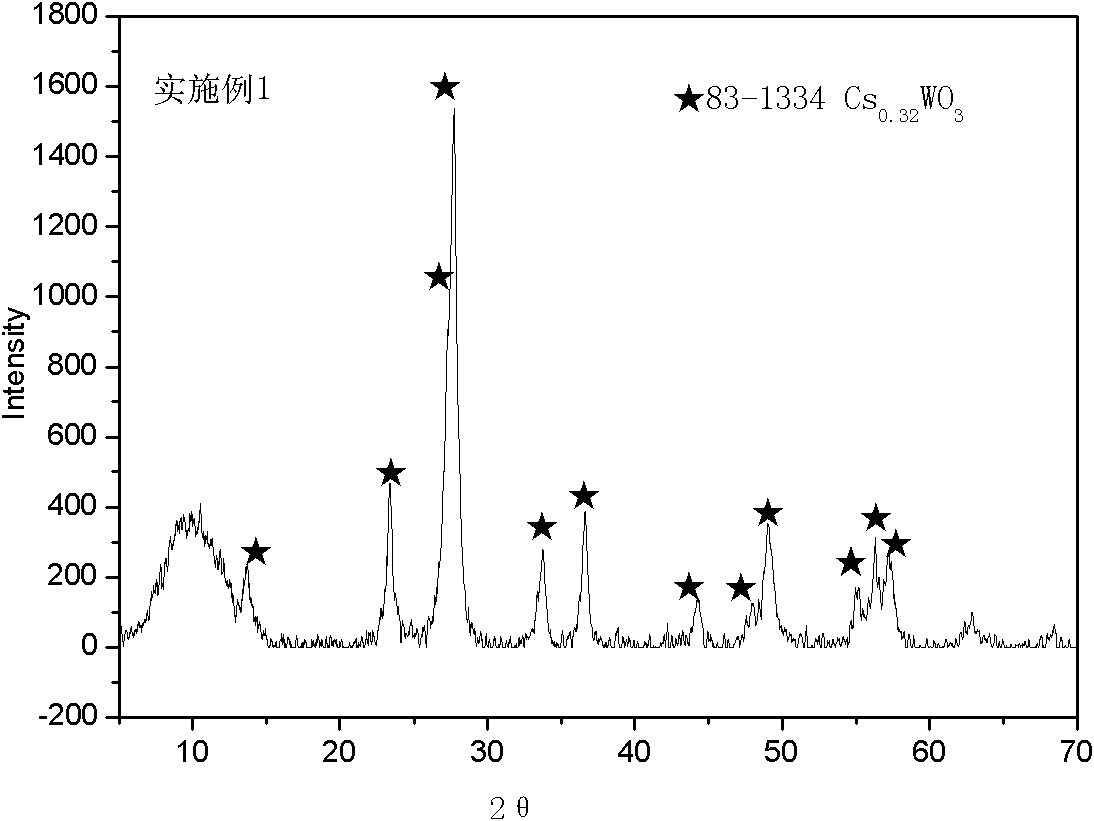

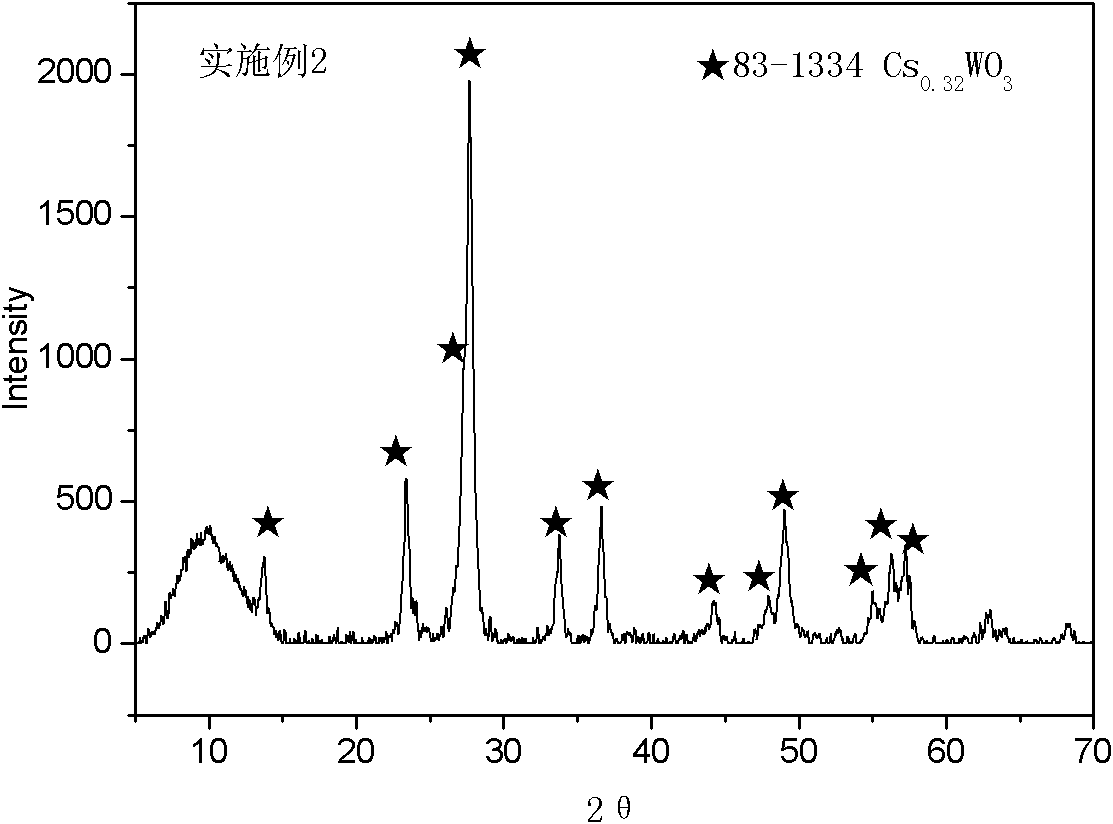

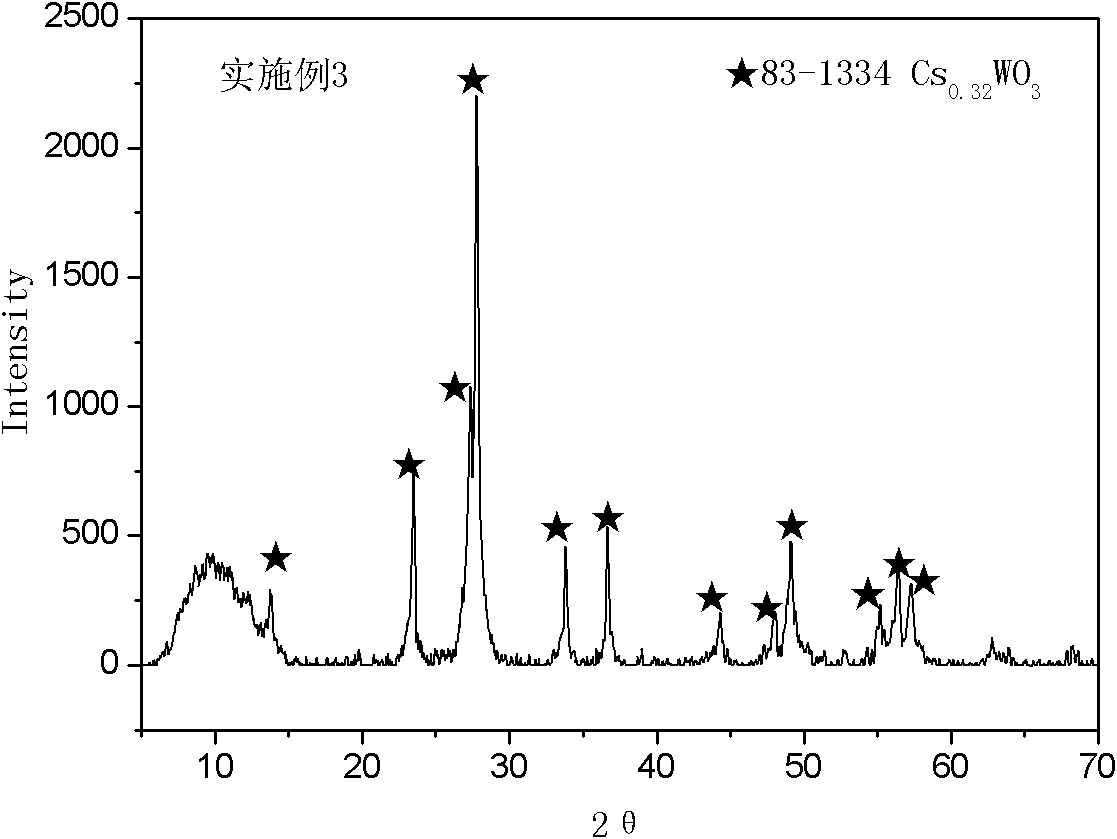

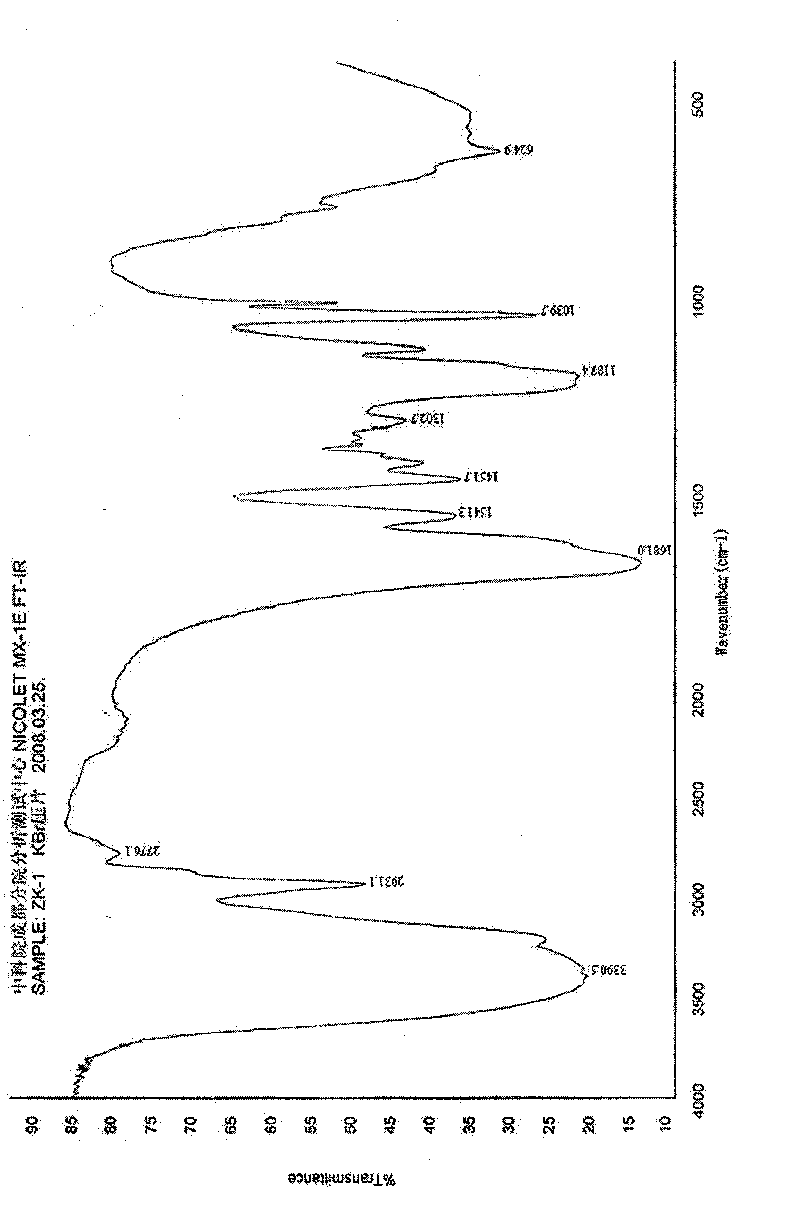

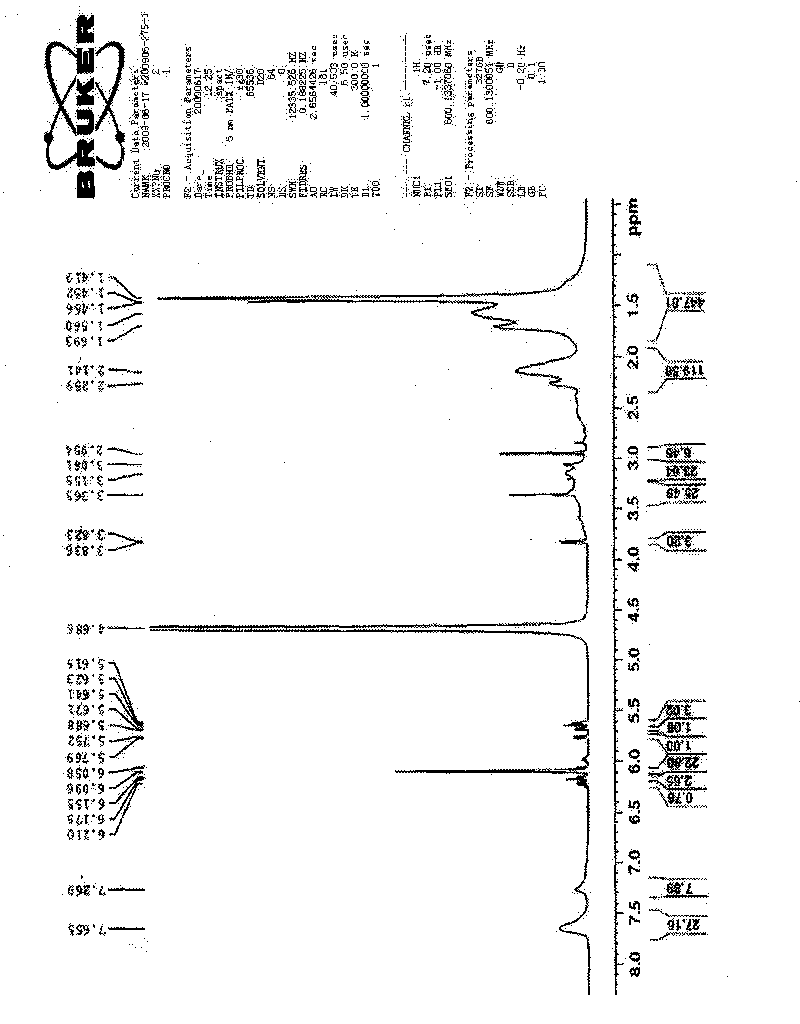

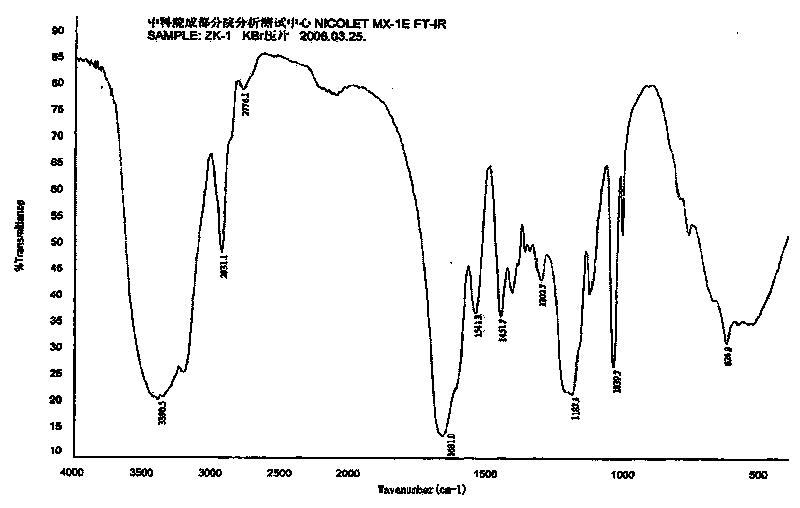

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Cyanide-free pyrophosphoric acid bath for use in copper-tin alloy plating

InactiveUS6416571B1Changeable colorEasy to separateAnti-corrosive paintsLiquid/solution decomposition chemical coatingAlloyAmine derivatives

The present invention provides a pyrophosphoric acid bath for use in Cu-Sn alloy plating without containing a cyanic ion comprising a reaction product (A) of an amine derivative and an epihalohydrin in a 1:1 mole ratio and a cationic surfactant (B) and, when necessary, further comprising a surface tension adjusting agent (C), a bath stabilizer (D) and an N-benzylpyridinium derivative (E) as additives. According to the bath of the present invention, by changing a bath composition of copper and tin or by employing a characteristic additive, a stable film with a silver-white, gold, copper or light black color can be obtained. By increasing tin contents in the bath, the bath can be used for lead-free solder plating. The bath is safe in handling and hygienic and, moreover, has no sewage process and environmental problems since it contains neither cyanic compound nor formaldehyde derivative.

Owner:NIHON NEW CHROME

Preparation method of transition element doped iron lithium phosphate powder

InactiveCN1785799AIncrease capacityImprove capacity cycling performancePhosphorus compoundsMaterials preparationLithium iron phosphate

The present invention discloses a preparation method of transition element Mn, Co and Ni doped iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. Its molecular formula is Li1-x TRxFePO4, and its preparation method includes the following steps: weighting lithium salt, ferrous salt, phosphate and adulterant according to mole ratio, mixing them, drying, low-temperature prebaking and high-temperature secondary calcining so as to obtain the invented product which can be used as positive electrode material of lithium ion cell.

Owner:TSINGHUA UNIV

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

Compound metal oxide de-fluorine sorbent

ActiveCN1954906AImprove adsorption capacityWide pH rangeOther chemical processesWater/sewage treatment by sorptionSorbentRare earth

A complex metal oxide used as an adsorbent for removing fluorine from water is prepared from the transition metal chosen from Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn, aluminum and RE metal chosen from Ce and La in the mole ratio of (0.5-1.5): (2-6): (0.5-1.5) through dissolving them in water to become aqueous solution, dropping alkali solution to make its pH=9.0-9.5, laying aside, centrifugal washing and separating by deionized water, drying, and grinding.

Owner:北京国中科创环境科技有限责任公司

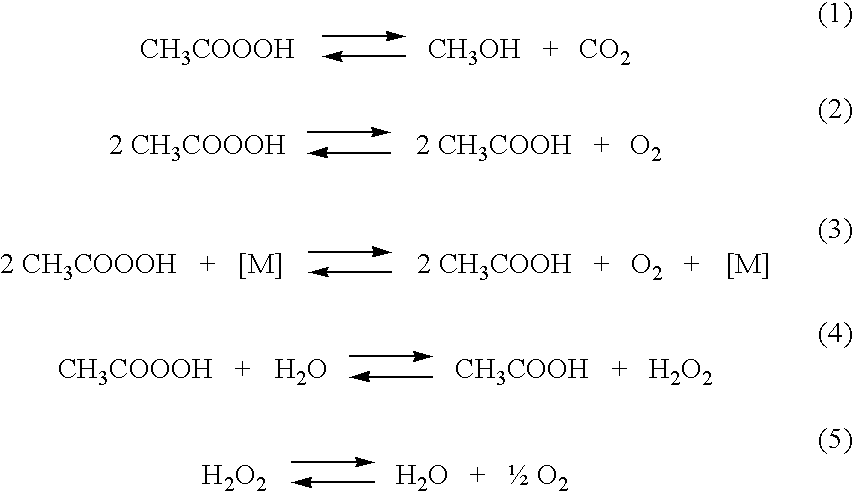

Dilute Aqueous Peracid Solutions and Stabilization Method

A method for stabilizing a dilute peracetic acid solution containing less than about 5 wt % peracetic acid by controlling the concentration of hydrogen peroxide and the mole ratio of hydrogen peroxide to acetic acid and by introducing a stabilizer to provide sequestering activity. The method is particularly useful for the long-term stabilization of dilute peracetic acid solutions. Stabilized dilute peracetic acid solutions are also within the scope of this invention.

Owner:FMC CORP

Primer composition for a fluorinated elastomer or a fluorinated gel

A primer composition for a fluorinated elastomer or a fluorinated gel, said primer composition comprising:100 parts by weight of (a) a linear perfluoro polyether compound having at least two alkenyl groups per molecule, a perfluoro polyether backbone having repeating units represented by the formula, —CaF2aO—, wherein a is an integer of from 1 to 6, and a weight average molecular weight of from 5,000 to 100,000,(b) an organosiloxane compound having one or more fluorine atom and at least two SiH bonds per molecule, in such an amount that a molar ratio of the SiH bond in the organosiloxane compound to the alkenyl group in Component (a) ranges from 0.8 to 5.0,a catalytic amount of (c) a hydrosilylation catalyst,5 to 100 parts by weight of (d) an organosiloxane compound having, per molecule, at least one SiH bond and at least one epoxy group and / or trialkoxysilyl group bonded to a silicon atom of said organosiloxane via an organic group which may have an oxygen atom, and100 to 10000 parts by weight, per total 100 parts by weight of said components (a), (b), (c) and (d), of (e) an organic solvent having a fluorine atom and a boiling point of not higher than 150° C. at atmospheric pressure.

Owner:SHIN ETSU CHEM CO LTD

Process for direct synthesis of diesel distillates with high quality from synthesis gas through Fischer-Tropsch synthesis

InactiveUS6765025B2Organic compound preparationOxygen compounds preparation by reductionActivated carbonSyngas

Diesel fuels or blending stocks having excellent lubricity, oxidative stability and high cetane number are directly produced from synthesis gas over activated carbon supported cobalt based Fischer-Tropsch catalyst under the condition of temperature within the range of 120 to 400° C., reaction pressure within the range of 0.5 to 10.0 MPa, volume hourly space velocity of a mixture of hydrogen and carbon monoxide within the range of 100 to 5000, the mole ratio of hydrogen to carbon monoxide within the range of 1 to 4. Diesel fuels containing at least 95 wt % paraffins with an iso to normal ratio of about 0.03 to 0.3, <50 ppm (wt) of sulfur and nitrogen, less than about 2 wt % unsaturates, and about 0.001 to less than 0.3 wt % oxygen were obtained by separating the Fischer-Tropsch product into a lighter (180 to 245 ° C. fraction) and heavier fractions (245 to 380° C. fraction) utilizing a rough flash, and combining the 180 to 245° C. portion of the lighter product with the 245 to 380° C. fraction in desired ratios.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Synthetic method and application of covalent organic framework (COF) material

ActiveCN103755588AOrganic-compounds/hydrides/coordination-complexes catalystsHydrazide preparationMetal-organic frameworkNitromethane

The invention discloses a synthetic method of a covalent organic framework (COF) material. The method comprises the following steps: after mixing 1,3,5-benzenetricarboxaldehyde with 2,5-di(N,N-dimethyl)amino-1,4-benzdihydrazide uniformly in an organic solvent, reacting in the presence of a catalyst acetic acid to obtain the COF material, wherein the mole ratio of 1,3,5-benzenetricarboxaldehyde to 2,5-di(N,N-dimethyl)amino-1,4-benzdihydrazide is 1:(0.5-3). The COF material obtained by adopting the method has relatively large specific surface area and regular open framework structure with adjustable diameter, thus being beneficial for mass transfer of reactants and products in photoabsorption and catalytic processes; the material can serve as a photocatalyst and can increase the yield of the dehydrogenative coupling reaction between 2-phenyl-1,2,3,4-tetrahydroisoquinoline and nitromethane from 39% in the absence of catalysts to 89%.

Owner:LANZHOU UNIVERSITY

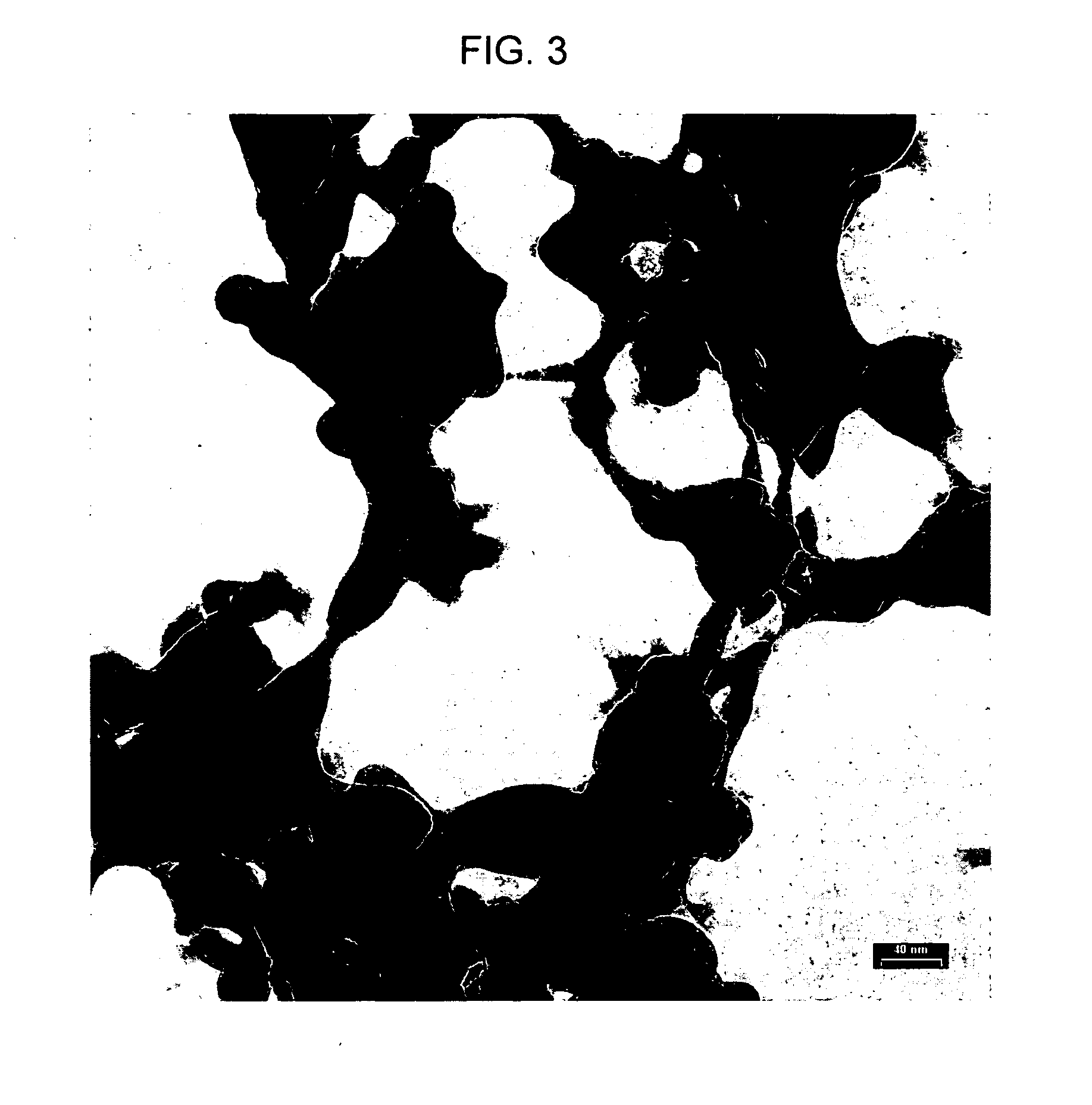

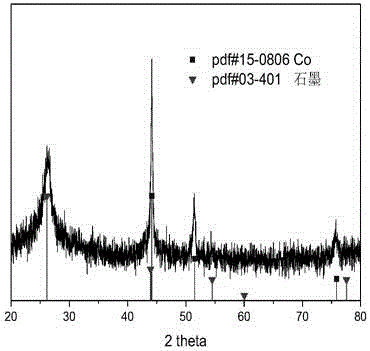

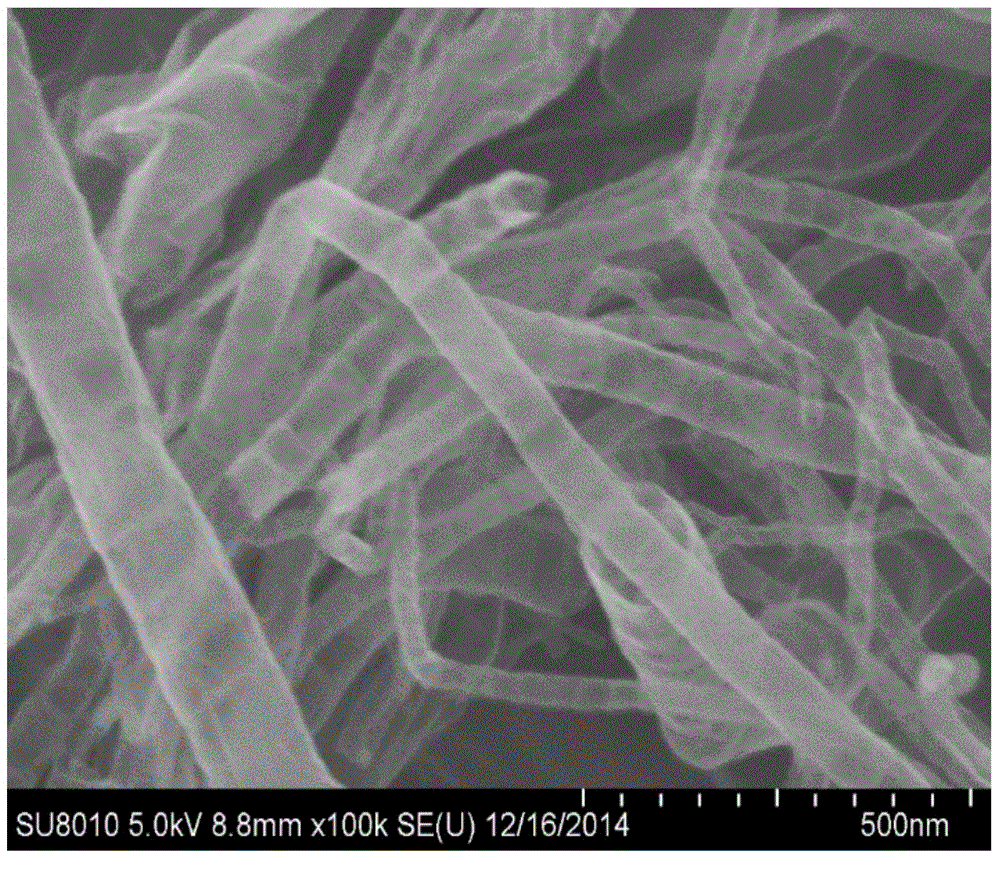

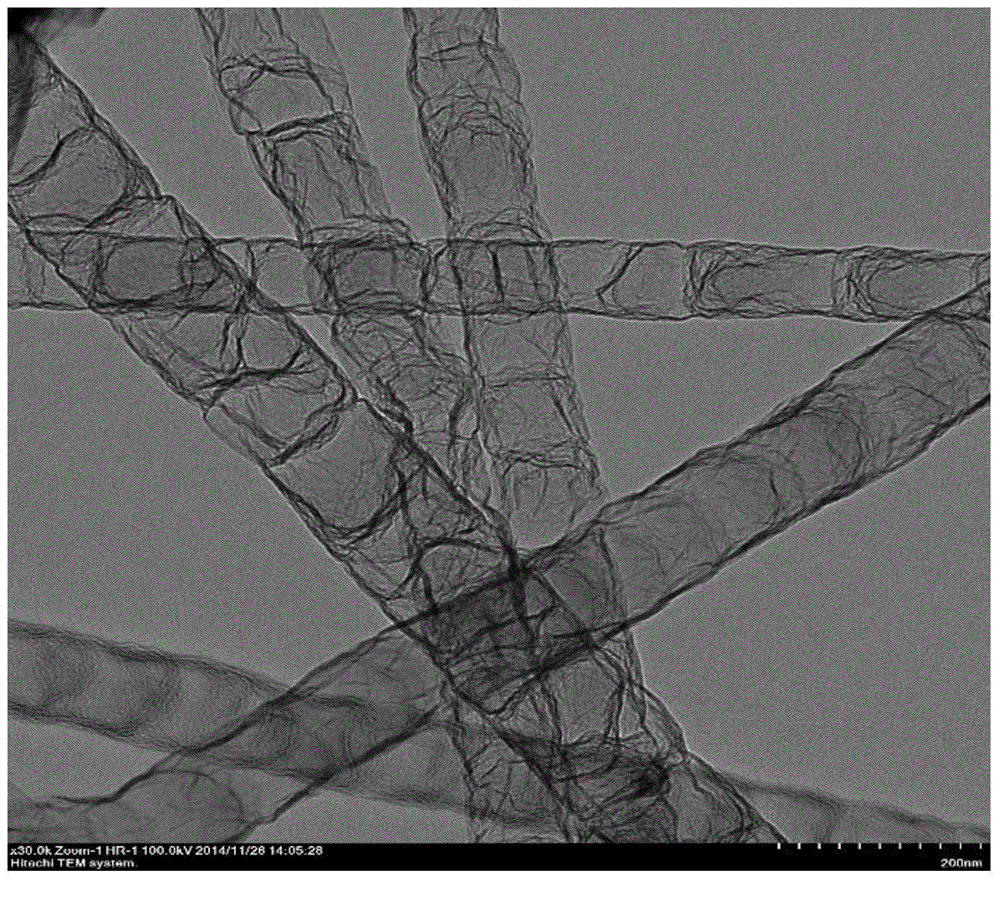

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

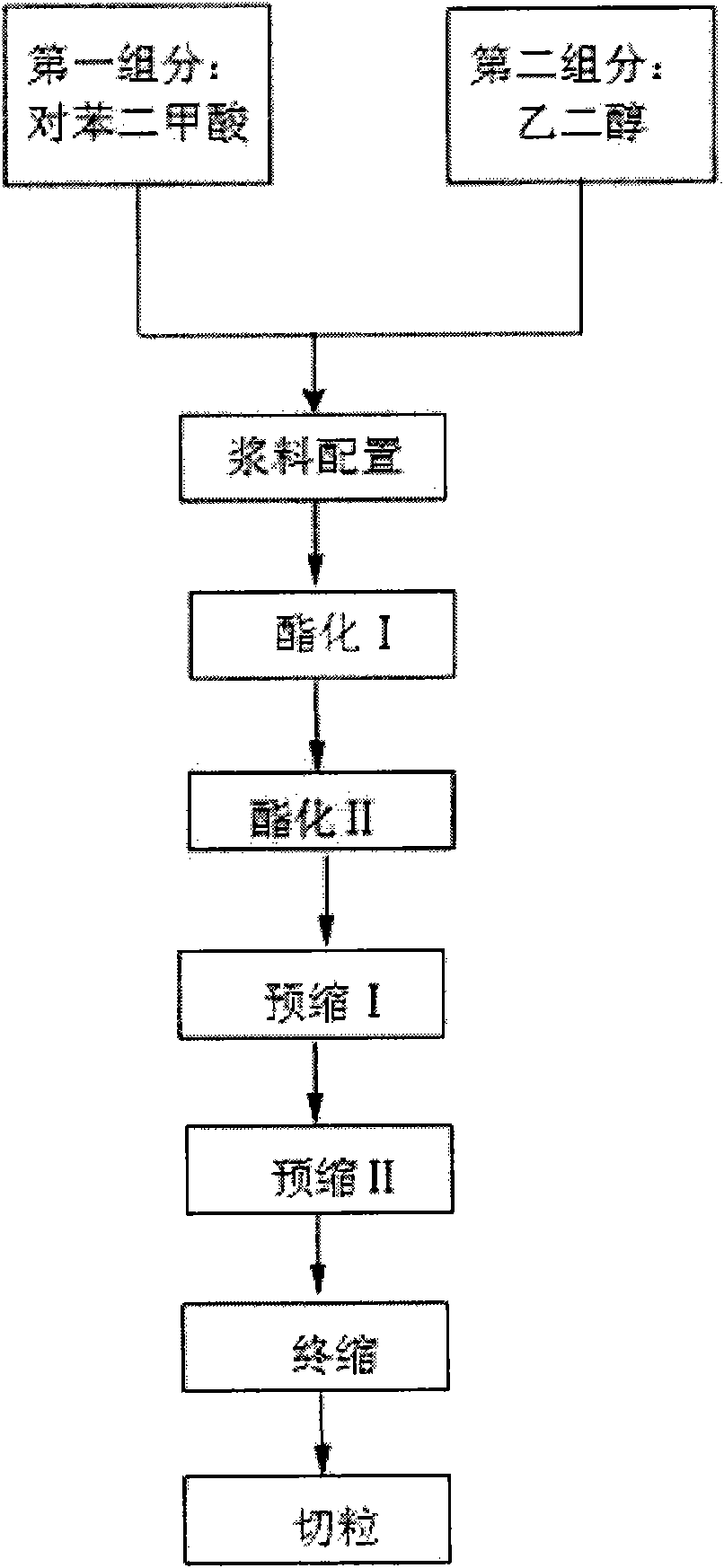

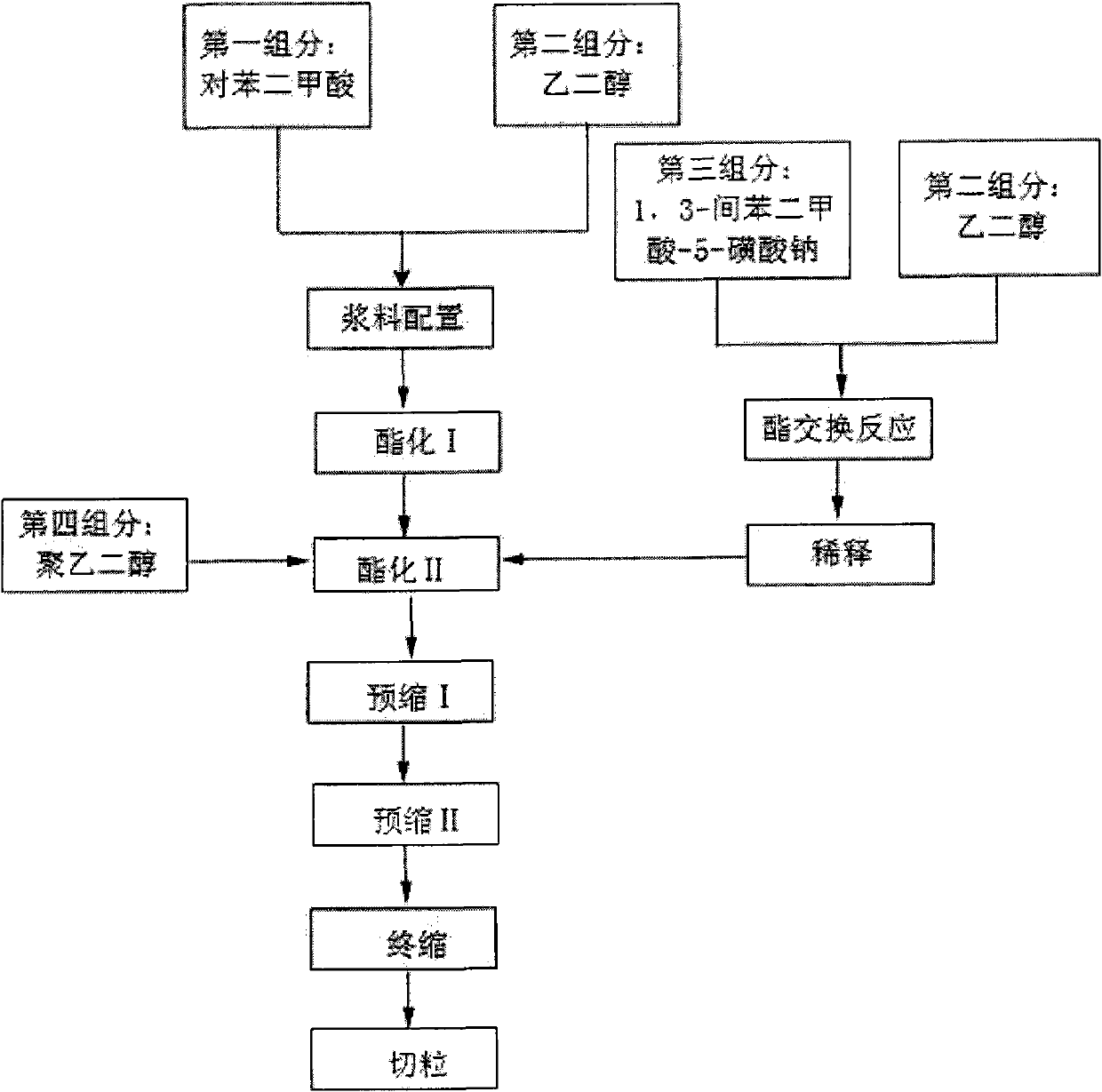

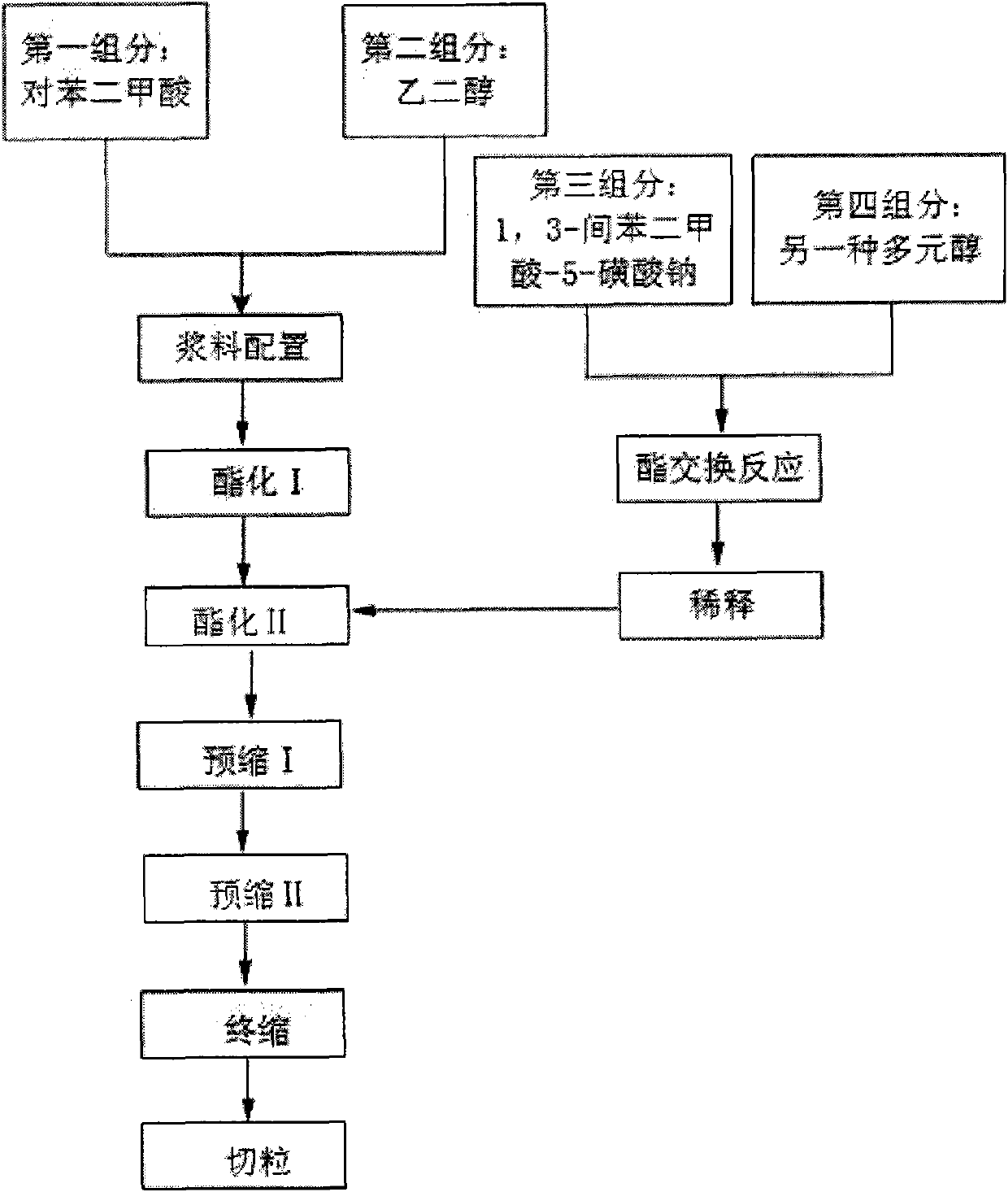

Preparation method of polyol copolyester

InactiveCN102086261AIncrease the chances of participating in a responseAchieve mass ratioDyeing processSlurryPhotochemistry

The invention discloses a preparation method of polyol copolyester. The preparation method comprises the following steps of carrying out slurry preparation, esterifying I, esterifying II, pre-condensing I, pre-condensing II, final condensing and pelletizing on terephthalic acid and glycol. The preparation method also comprises: carrying out ester exchange reaction on 1,3-isophthalic acid-5-sodium sulfonate and another polyol; diluting with the glycol, and then performing the esterifying II. In the preparation method, 1,3-isophthalic acid-5-sodium sulfonate and another polyol react in advance, thereby increasing the reaction probability of another polyol and ensuring that another poyol can reach the required mole ratio in a finished product. The preparation method is mainly applied to production of dye modified polyester by using various dihydric alcohols at normal temperature and normal pressure. The modified polyester is dyed by mainly using anode pigment, the used dye chromatograph is more than that of common polyester, dye-uptake rate can reach above 99%, colour fastness reaches 4-5 grade of European standard, and the color is more flamboyance and beautiful. When filament yarns are subjected to spinning, full-package rate is up to 95%-100%.

Owner:SHANGHAI DEFULUN CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com