High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

A fluid loss reducing agent and zwitterion technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to meet site needs, limited use range, single product performance, etc., and achieves a simple and feasible preparation method. Easy to operate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The synthesis of embodiment 1PAADS

[0036] Synthesis of PAADS-1

[0037]According to AM: AMPS: DMDAAC: SSS=10: 3.5: 1: 1, the ratio of total monomer concentration is 20% weighs the drug, AMPS and water are dissolved in the three-necked flask according to the feeding ratio, under cooling conditions, use Adjust the pH value to neutral with sodium hydroxide solution, then add AM dissolved in a small amount of water, and raise the temperature to 60°C, add DMDAAC, SSS and stir, pass N 2 After 30 minutes, the initiator ammonium persulfate-sodium bisulfite (0.3%) was added, the reaction was continued for 5 hours, and the reaction was stopped. The viscoelastic copolymer colloid was obtained, which was precipitated with absolute ethanol to obtain a white precipitate. Then it was repeatedly washed with absolute ethanol, and soaked in absolute ethanol for 12 hours to fully remove unreacted monomers. Finally, the precipitate was taken out and placed on a watch glass, dried and ...

Embodiment 2

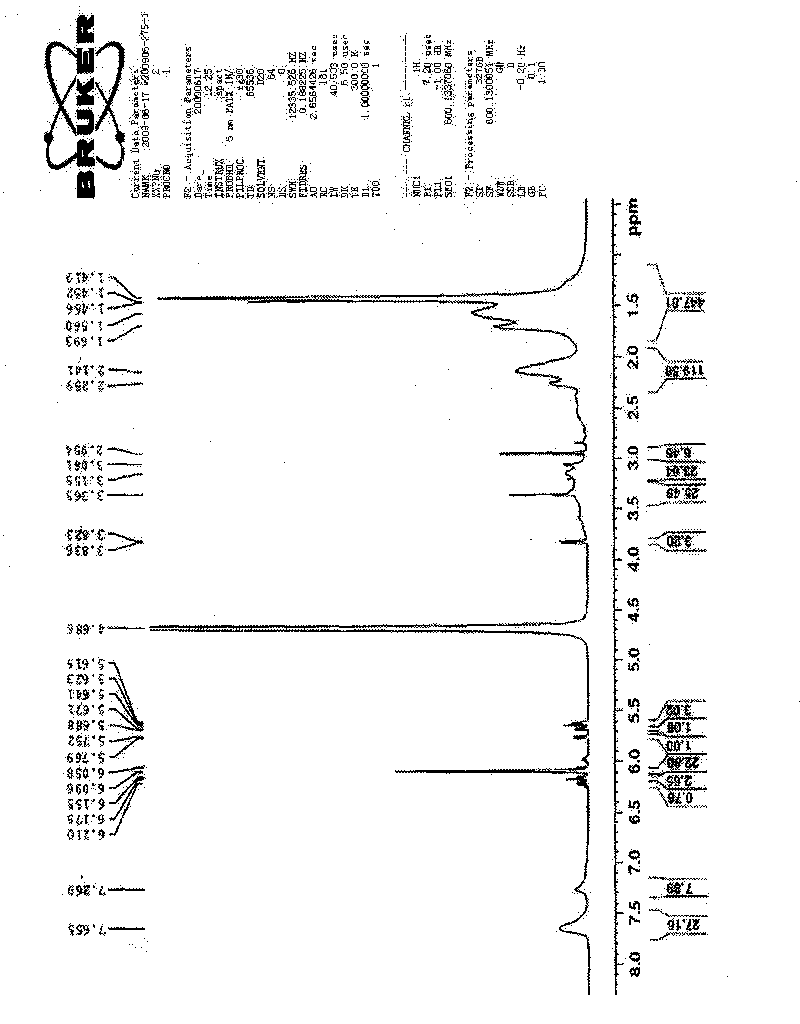

[0040] The structural characterization of embodiment 2PAADS (following PAADS all refers to PAADS-1 product)

[0041] see figure 1 , figure 2 .

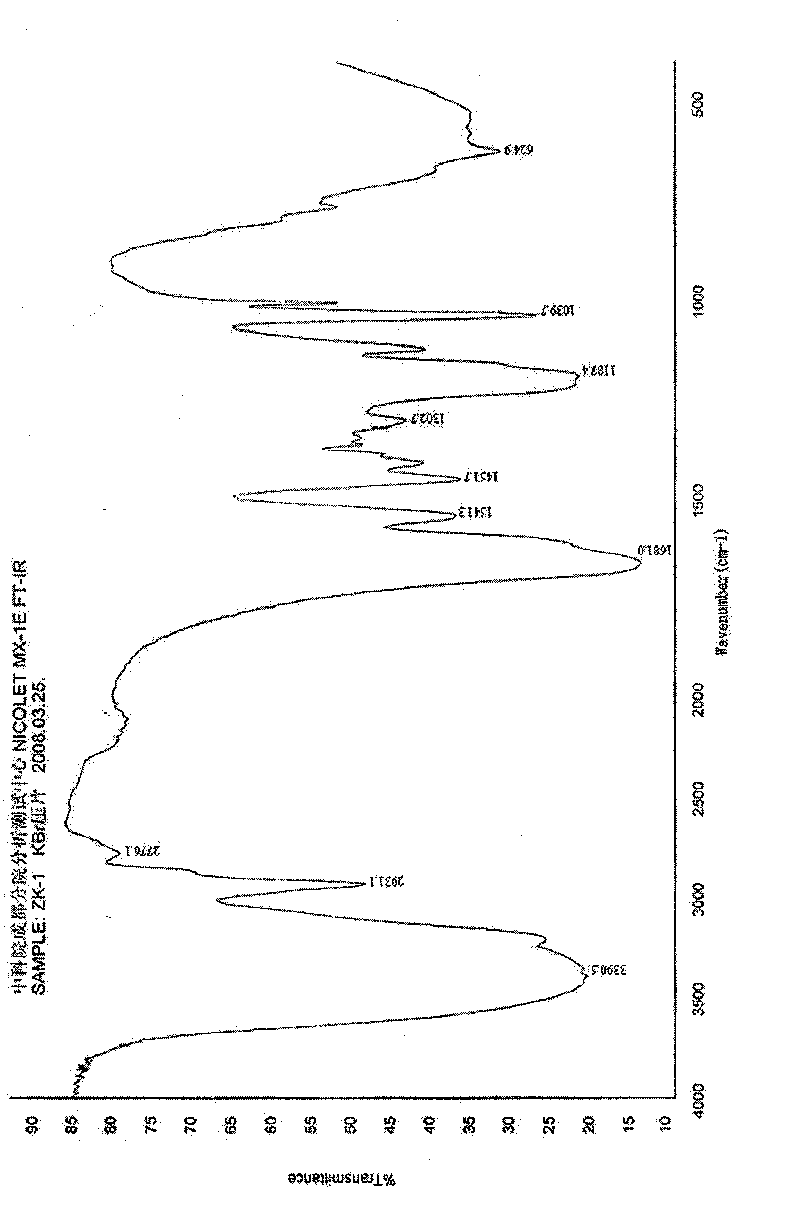

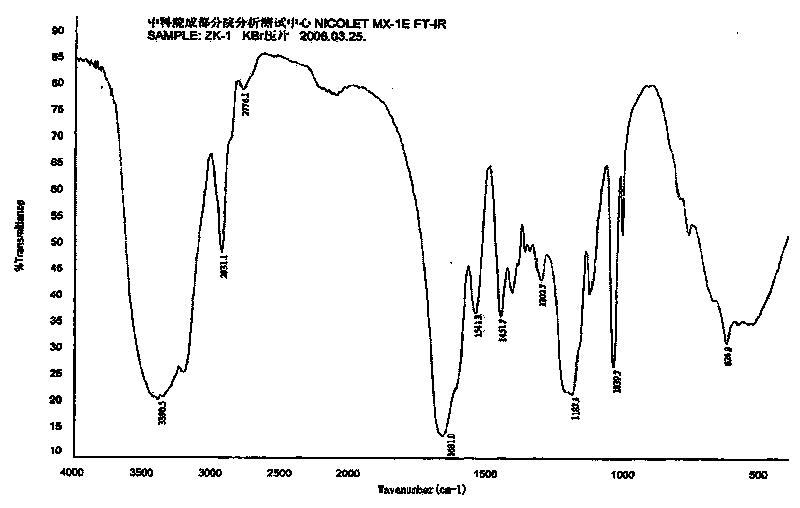

[0042] figure 1 It is the infrared spectrogram of PAADS, and the characteristic absorption peak analysis of the spectrogram is as follows:

[0043] 3390.5cm-1 is the stretching vibration absorption peak of non-associated-NH;

[0044] 2931.1cm-1 for -CH 3 Stretching vibration absorption peak;

[0045] 2776.1cm-1 for -CH 2 Stretching vibration absorption peak;

[0046] 1681.0cm-1 is the stretching vibration absorption peak of -C=O;

[0047] 1541.3cm-1 is the stretching vibration absorption peak of the benzene ring skeleton;

[0048] 1451.7cm-1 is the bending vibration absorption peak of -CH2-;

[0049] 1187.4cm-1, 1039.7cm1302.7cm-1 are the -CN bond stretching vibration absorption peaks of quaternary ammonium salts;

[0050] -1 for -SO 3 - the stretching vibration absorption peak;

[0051] 630.09cm-1 is the vibrational abs...

Embodiment 3

[0061] The performance research of embodiment 3PAADS aqueous solution

[0062] (1) Effect of temperature on apparent viscosity of PAADS aqueous solution

[0063] Prepare the polymer solution with a concentration of 2%, and measure its apparent viscosity after aging for 16 hours at the temperature point in Table 1. The experimental data are shown in Table 4 below:

[0064] The influence of table 4 aging temperature on copolymer PAADS aqueous solution apparent viscosity

[0065] Aging temperature (°C)

[0066] It can be seen from Table 4 that the viscosity of the polymer solution decreased after aging at different temperatures for 16 hours, and the viscosity was still about 12 mPa·s after aging at 180°C, mainly due to the carbon chain structure and molecular chain structure of the polymer. The large side group on the polymer enhances the rigidity of the molecular chain, prevents the breakage of the macromolecular chain, and improves the thermal stability of the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com