Patents

Literature

1293 results about "Oil drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

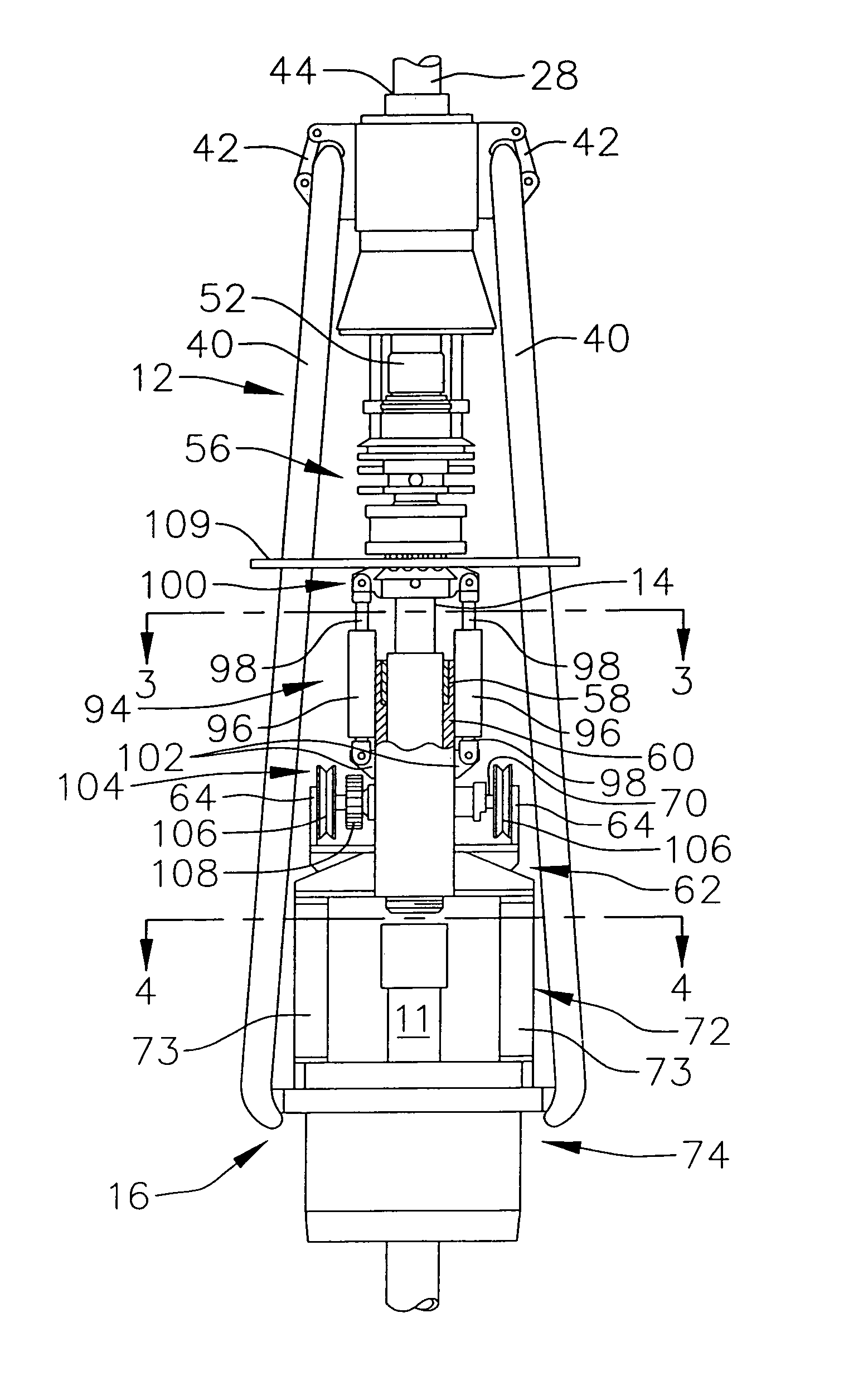

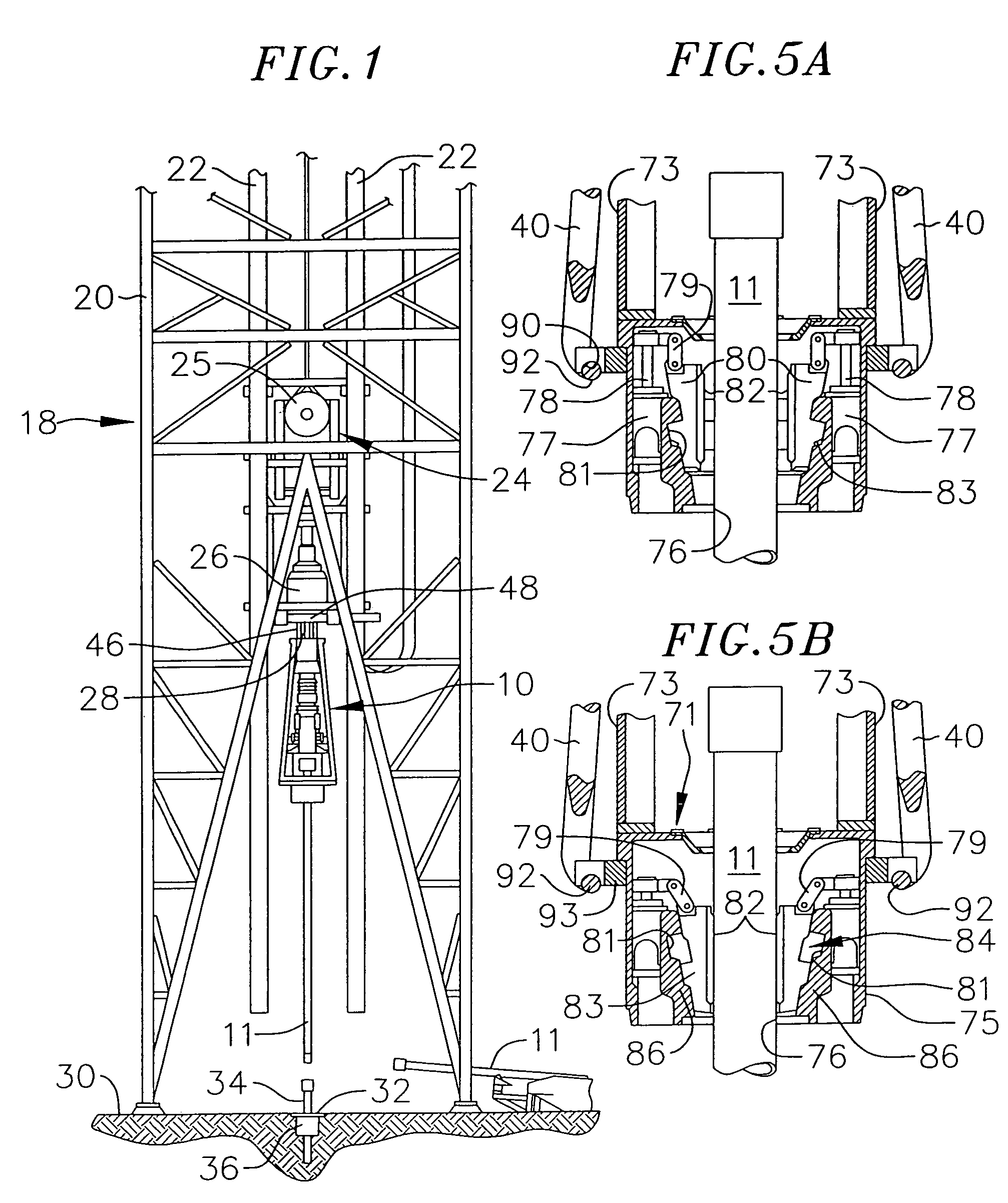

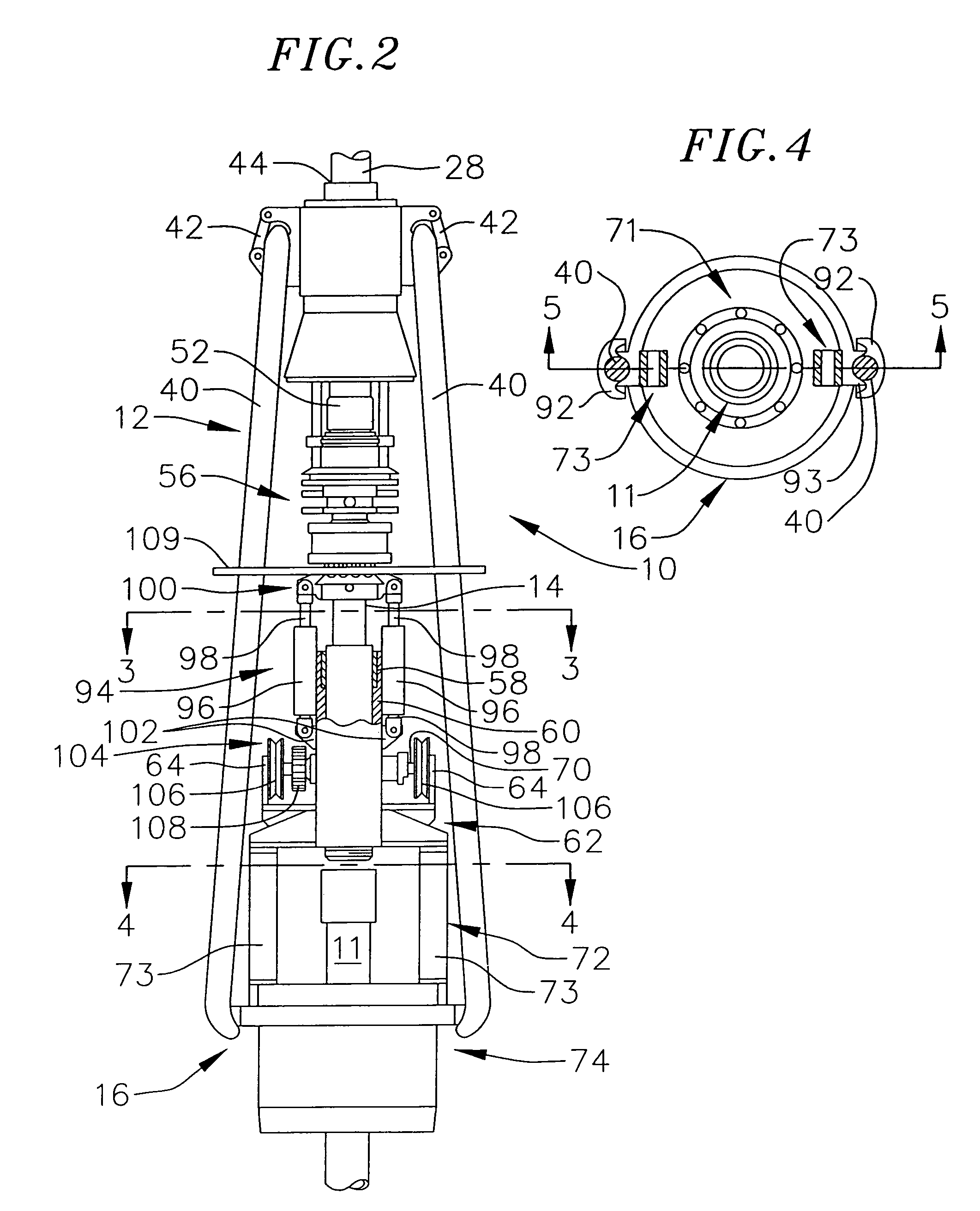

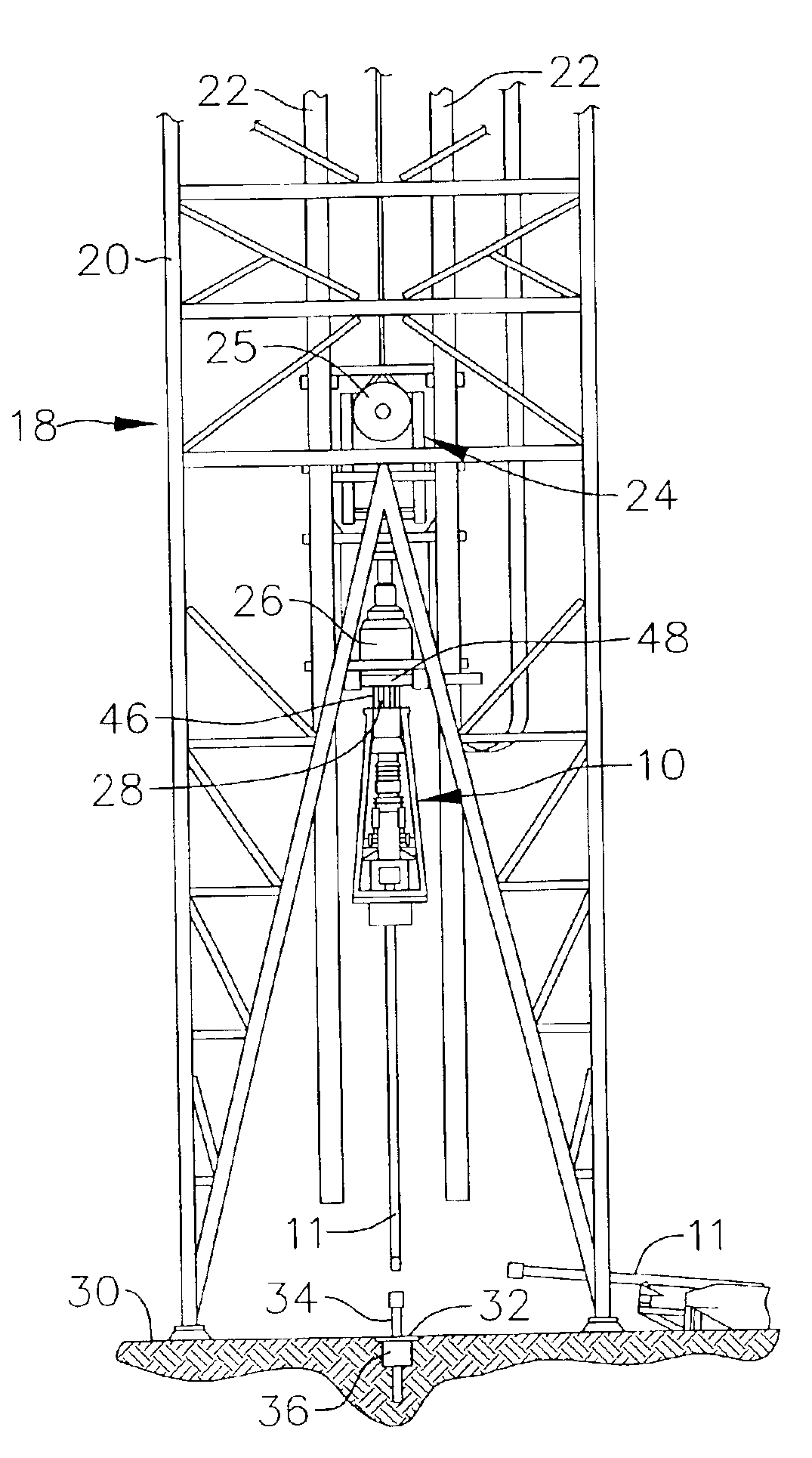

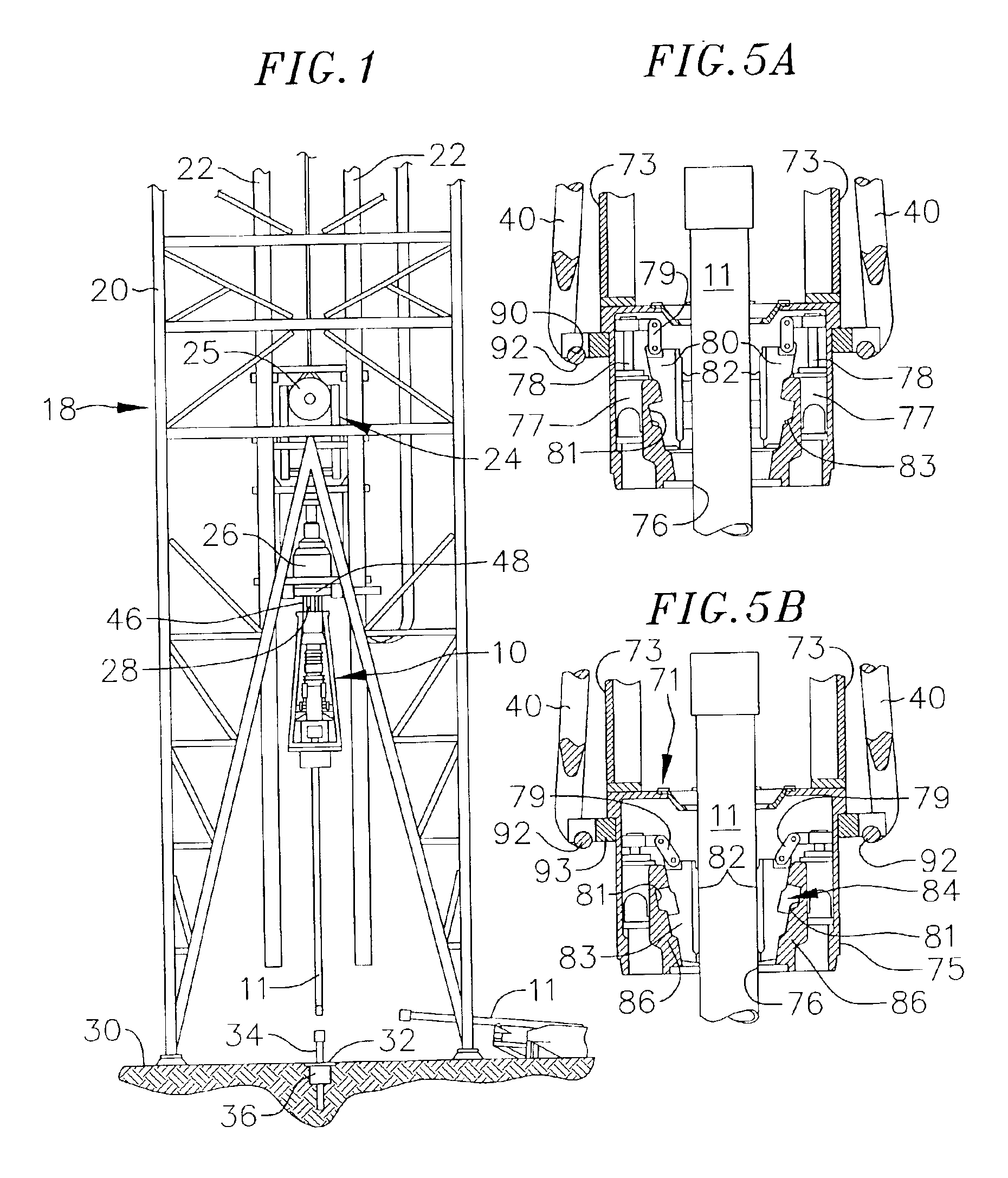

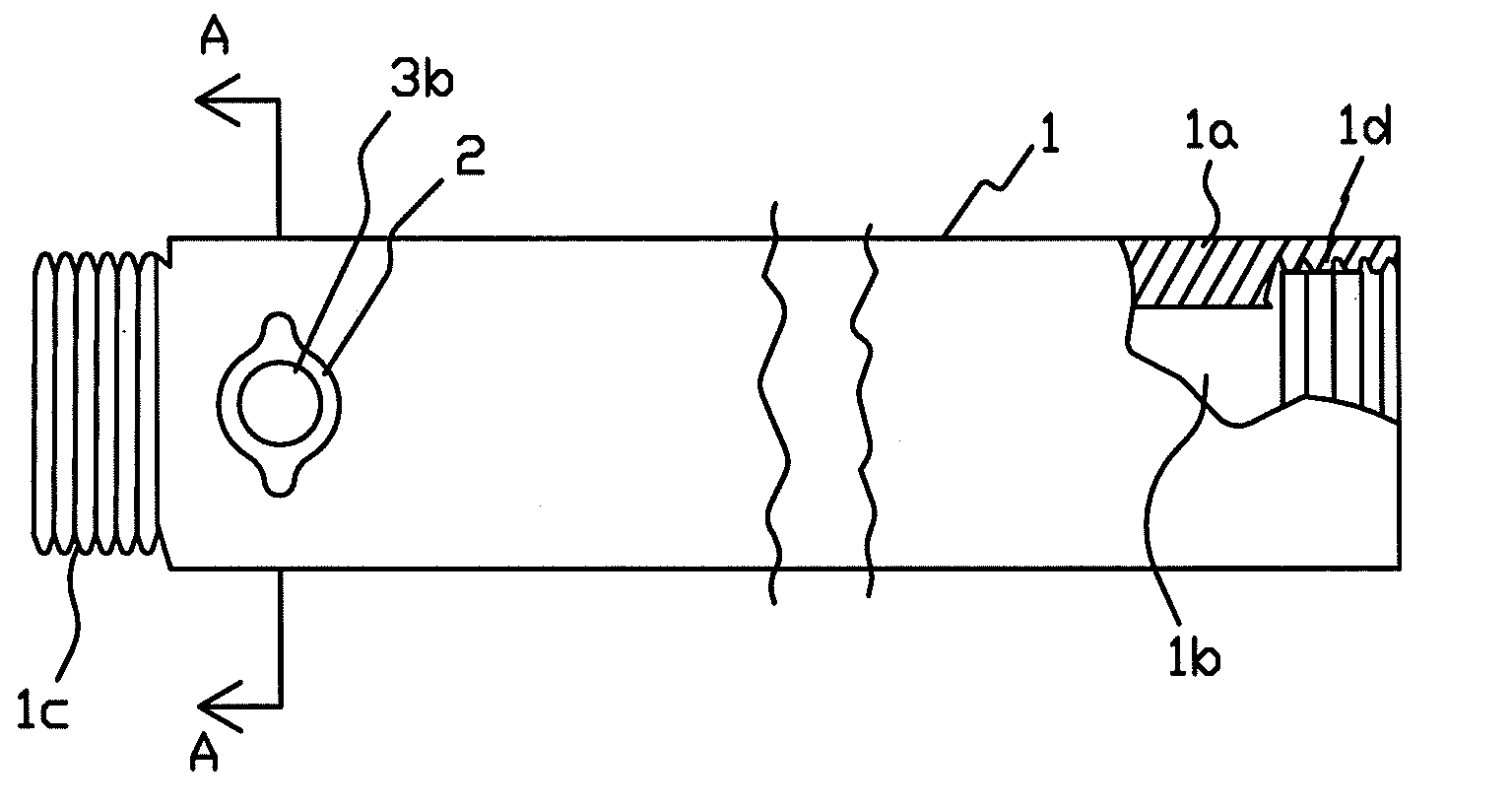

Pipe running tool

A pipe running tool for use in an oil drilling system and the like comprises a lower drive shaft adapted to engage a drive shaft of a top drive assembly for rotation therewith. The pipe running tool further includes a lower pipe engagement assembly which is driven to rotate by the lower drive shaft, and is designed to releasably engage a pipe segment in such a manner to substantially prevent relative rotation between the two. Thus, when the lower pipe engagement assembly is actuated to securely hold a pipe segment, the top drive assembly may be actuated to rotate the top drive output shaft, which causes the lower drive shaft and lower pipe engagement assembly to rotate, which in turn rotates the pipe segment.

Owner:NAT OILWELL VARCO LP

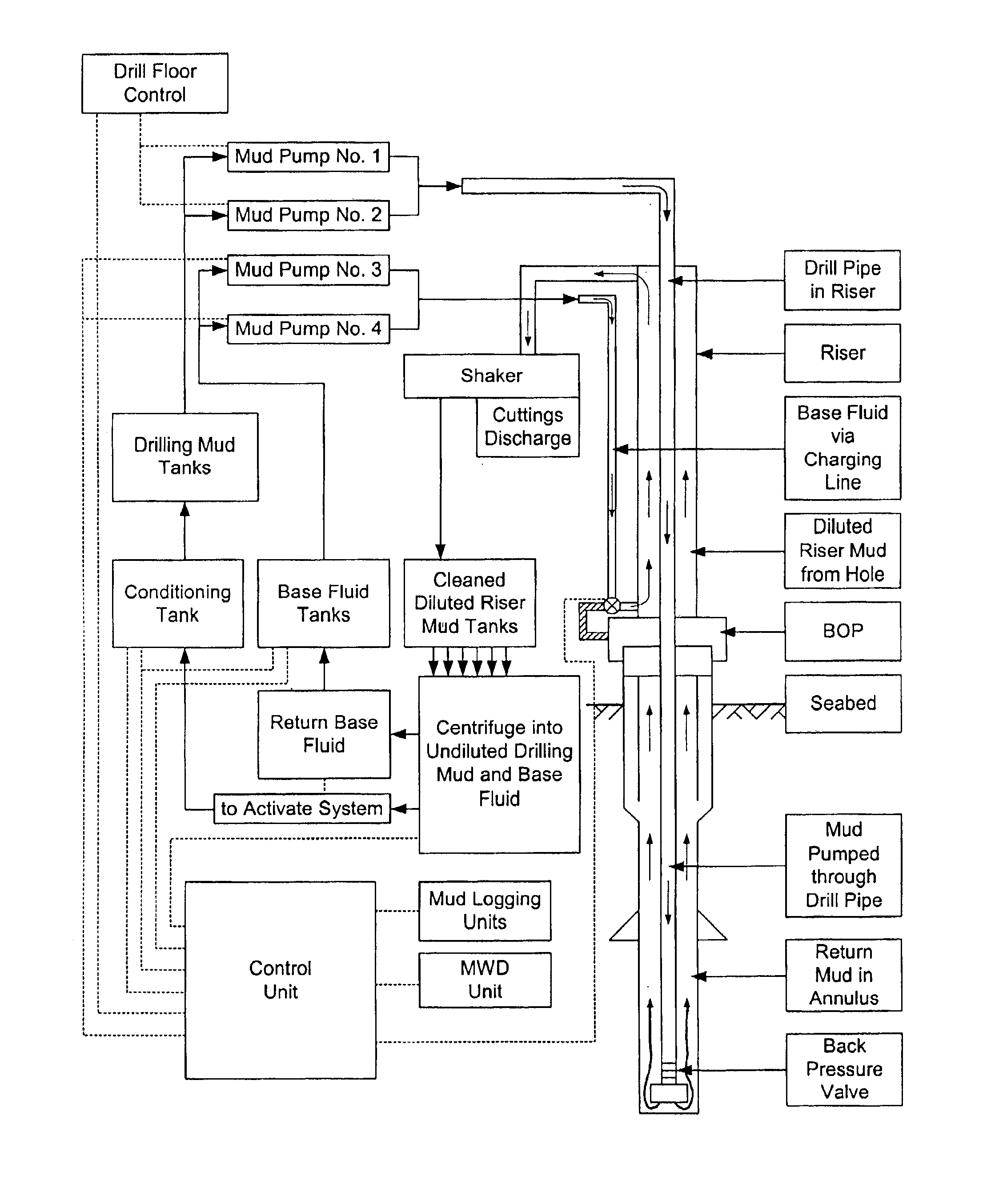

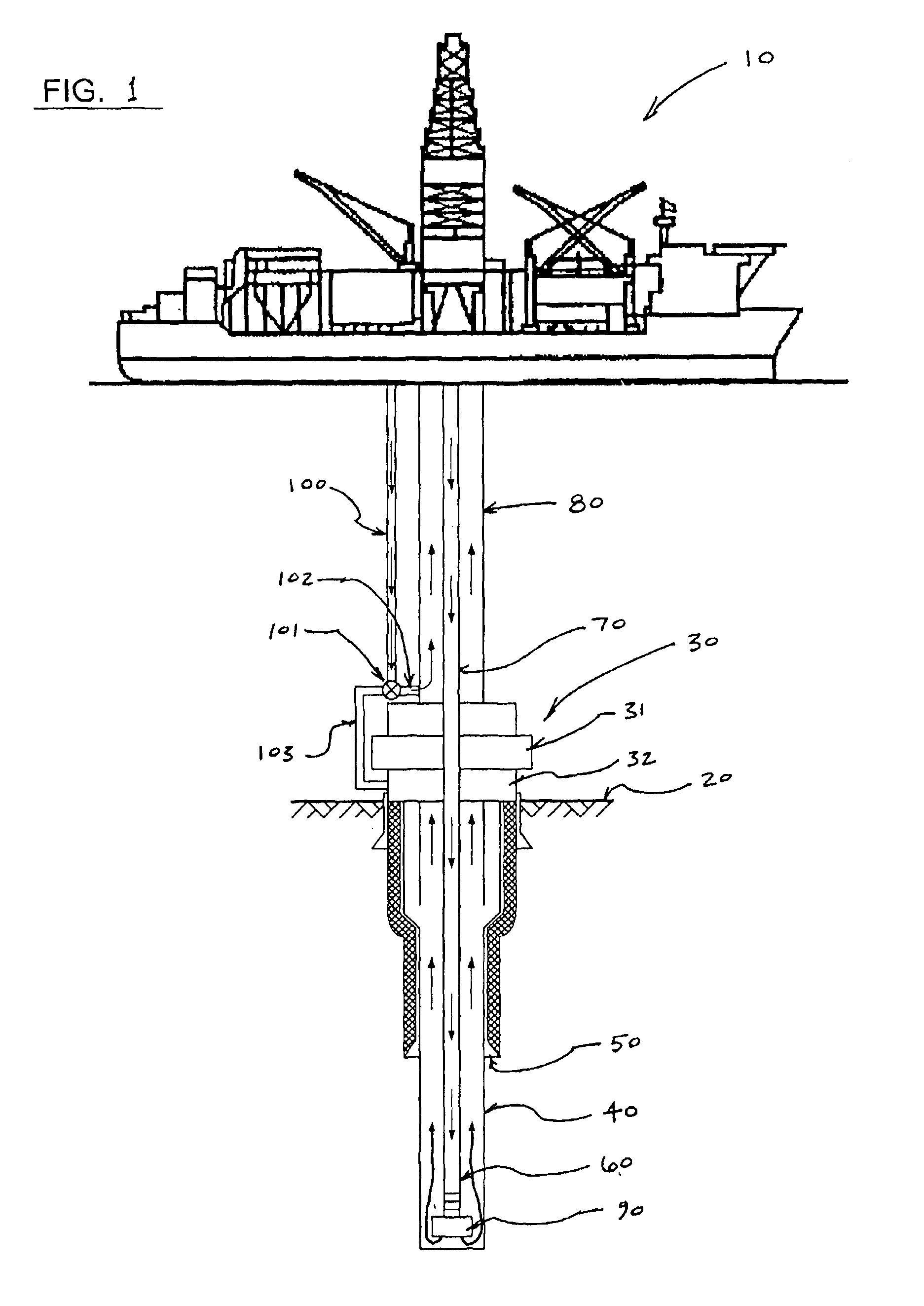

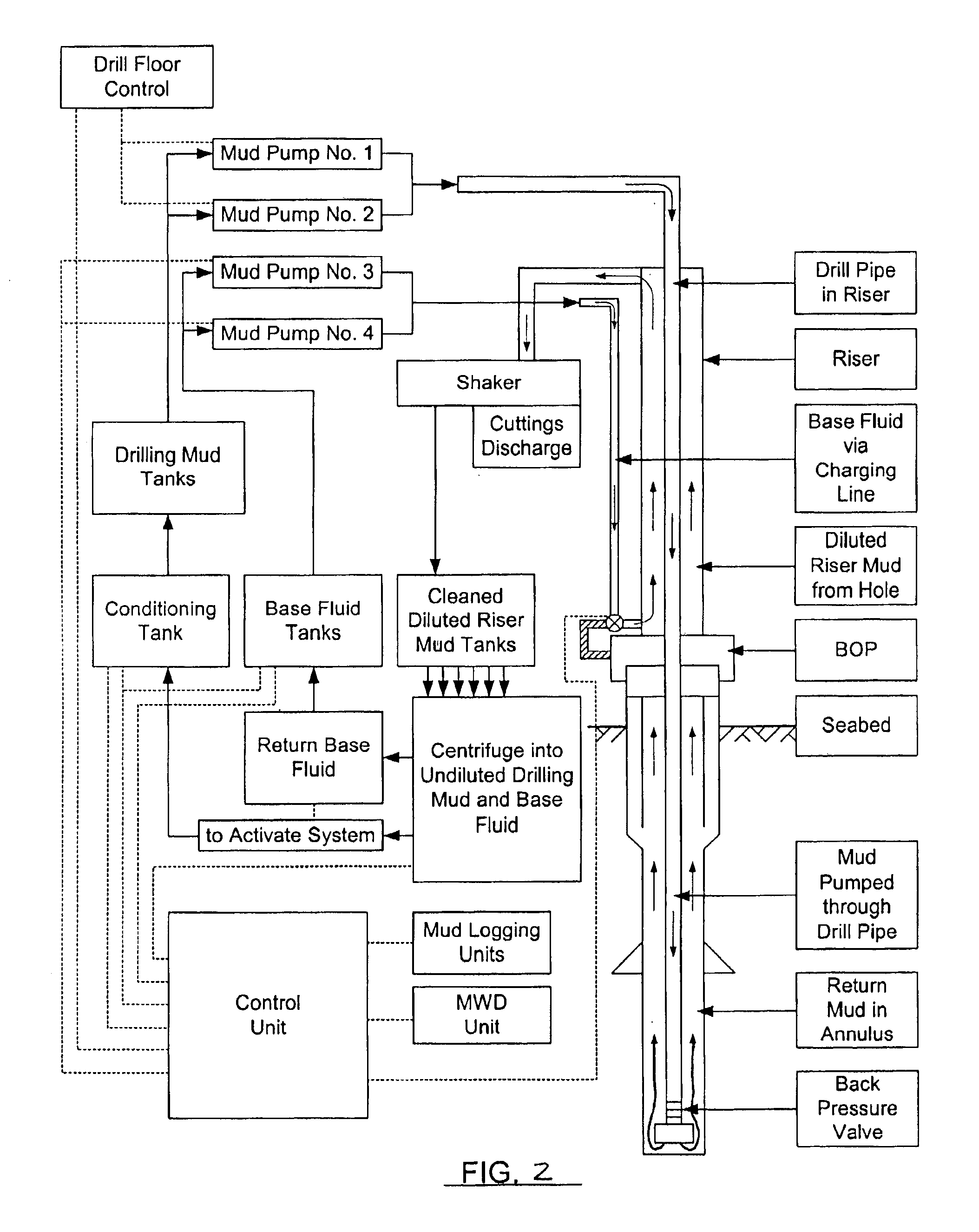

Method and apparatus for varying the density of drilling fluids in deep water oil drilling applications

Owner:DUAL GRADIENT SYST

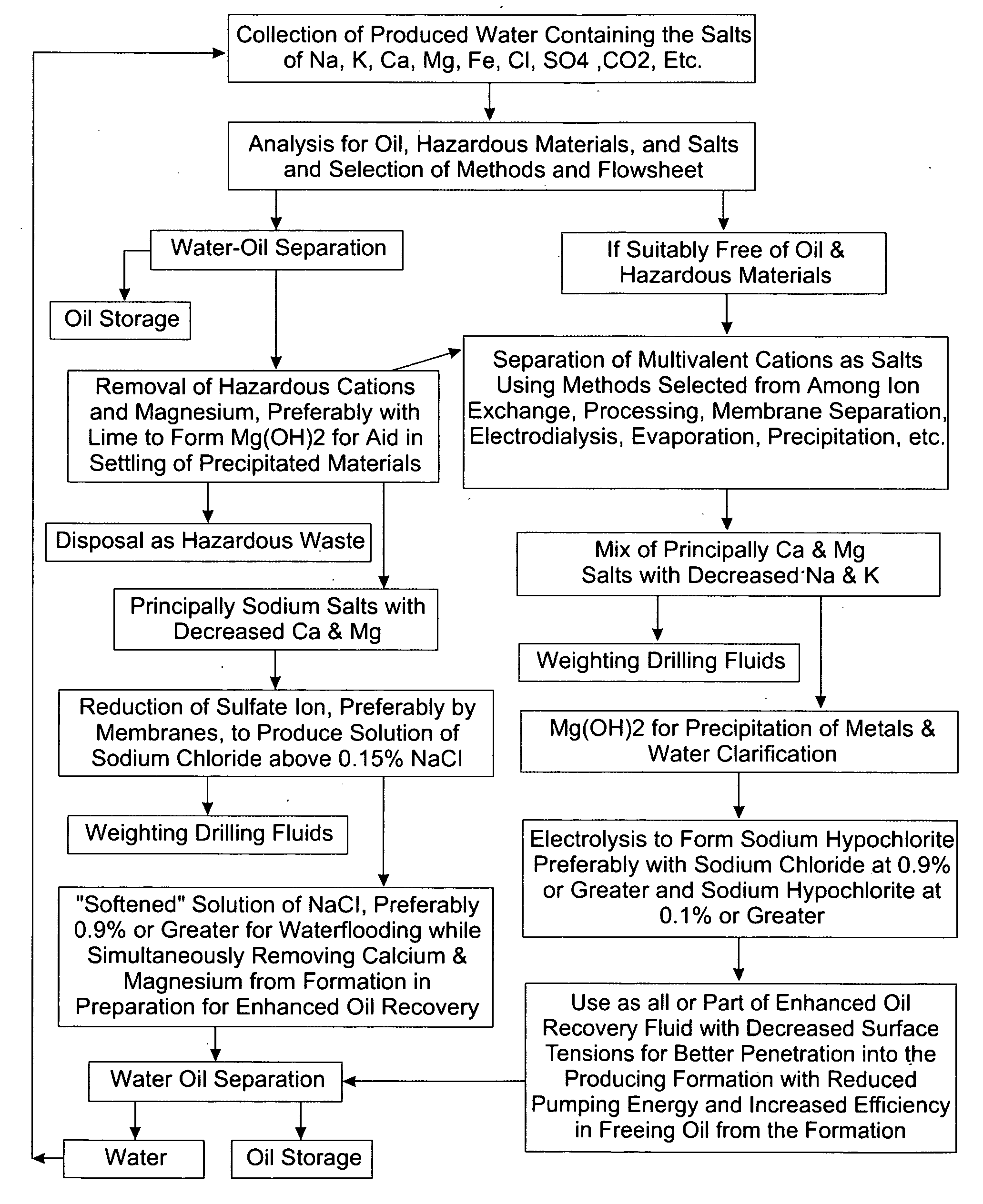

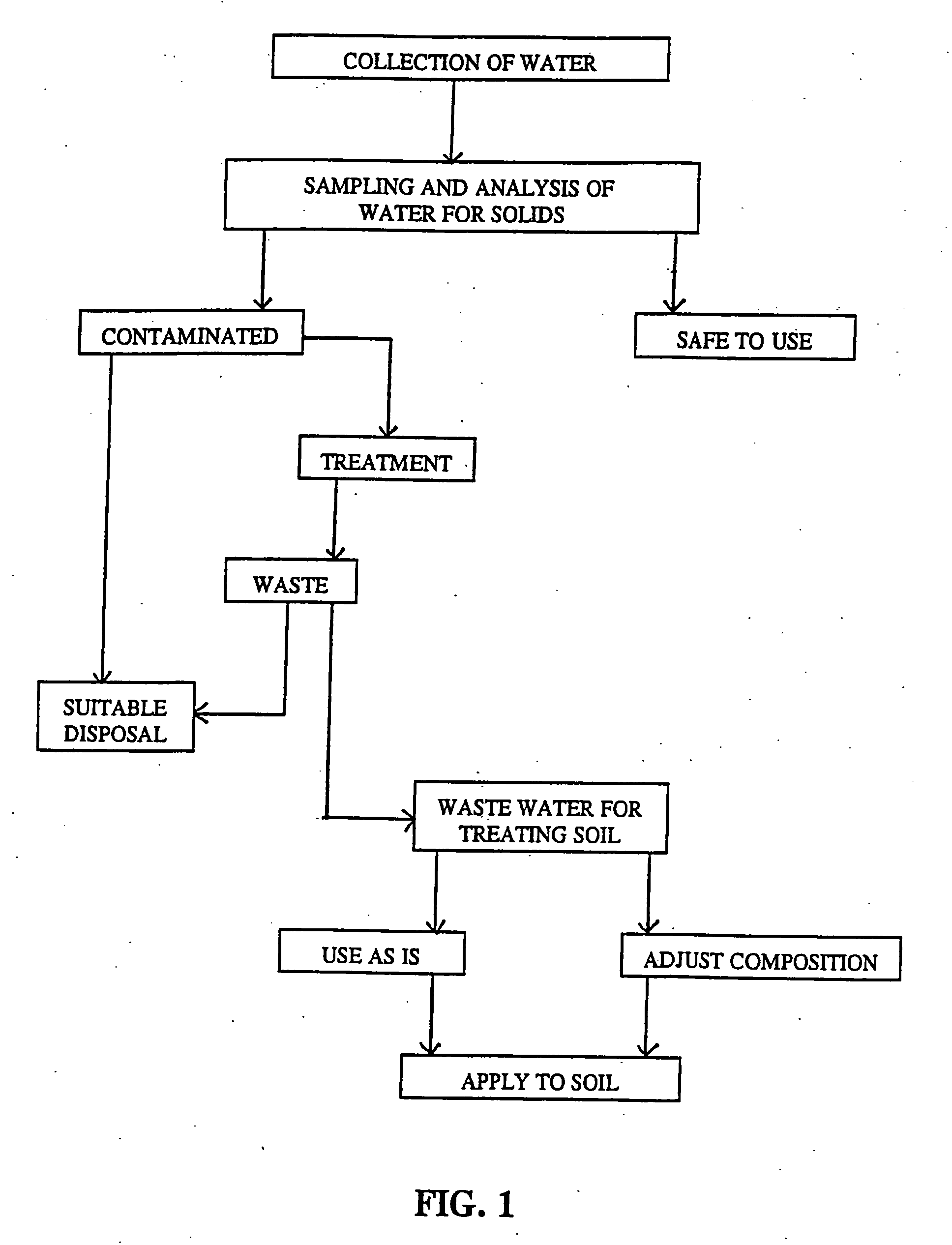

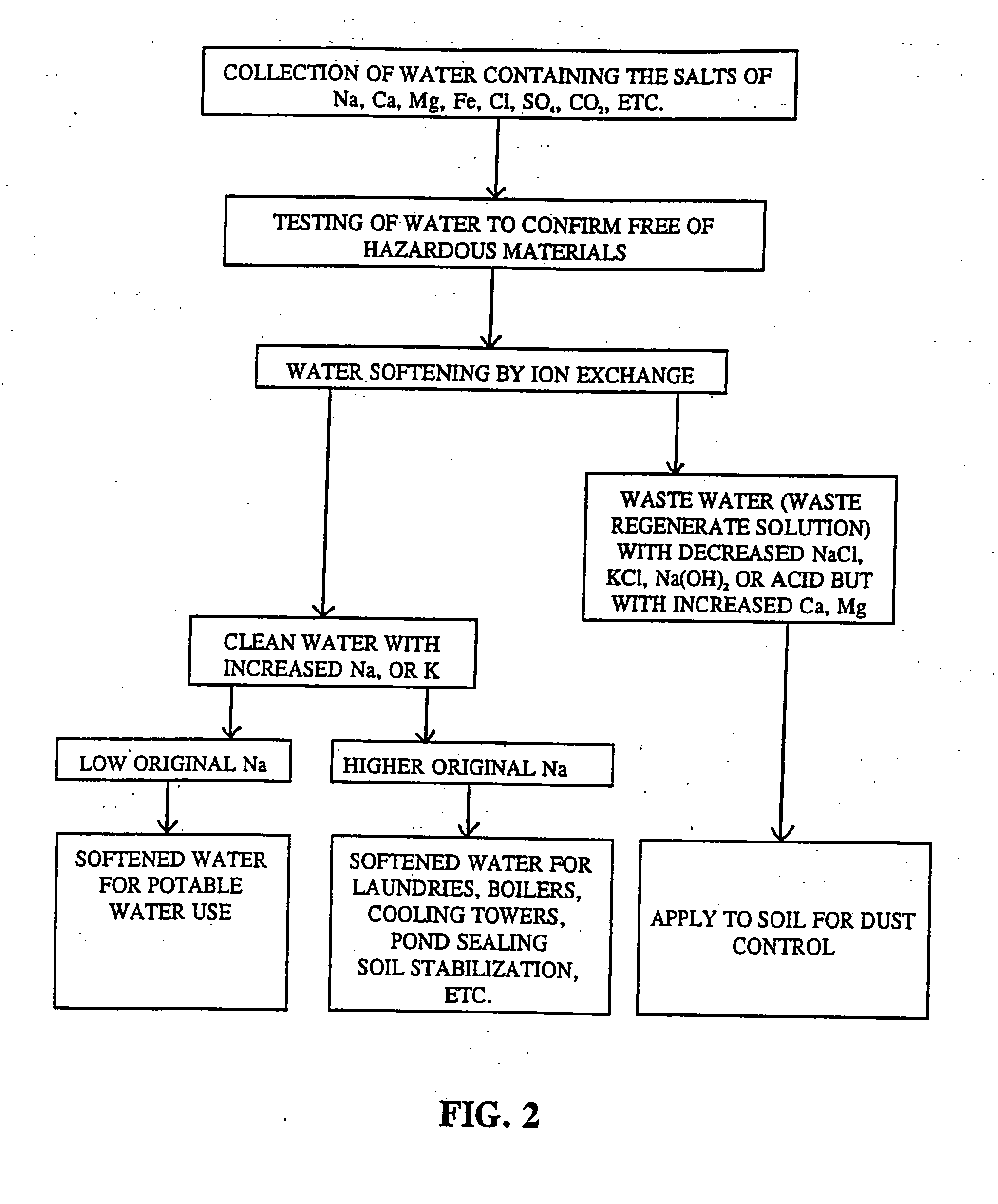

Mothods of utilizing waste wasters produced by water purification processing

InactiveUS20070102154A1Reduce root rotEconomically and efficiently utilizingSpecific water treatment objectivesScale removal and water softeningPetroleumOil drilling

The methods of the present invention include processing waste water containing 0.15% by weight of the salts of Na, K, Ca, Mg, Fe, Cl, SO4, and CO3 and mixtures thereof to produce products useful for enhancing oil or gas well production, and particularly for oil drilling applications including as additives for drilling muds and cement well casings, as well as for injection into an oil well oil or gas well formation.

Owner:ECYCLING

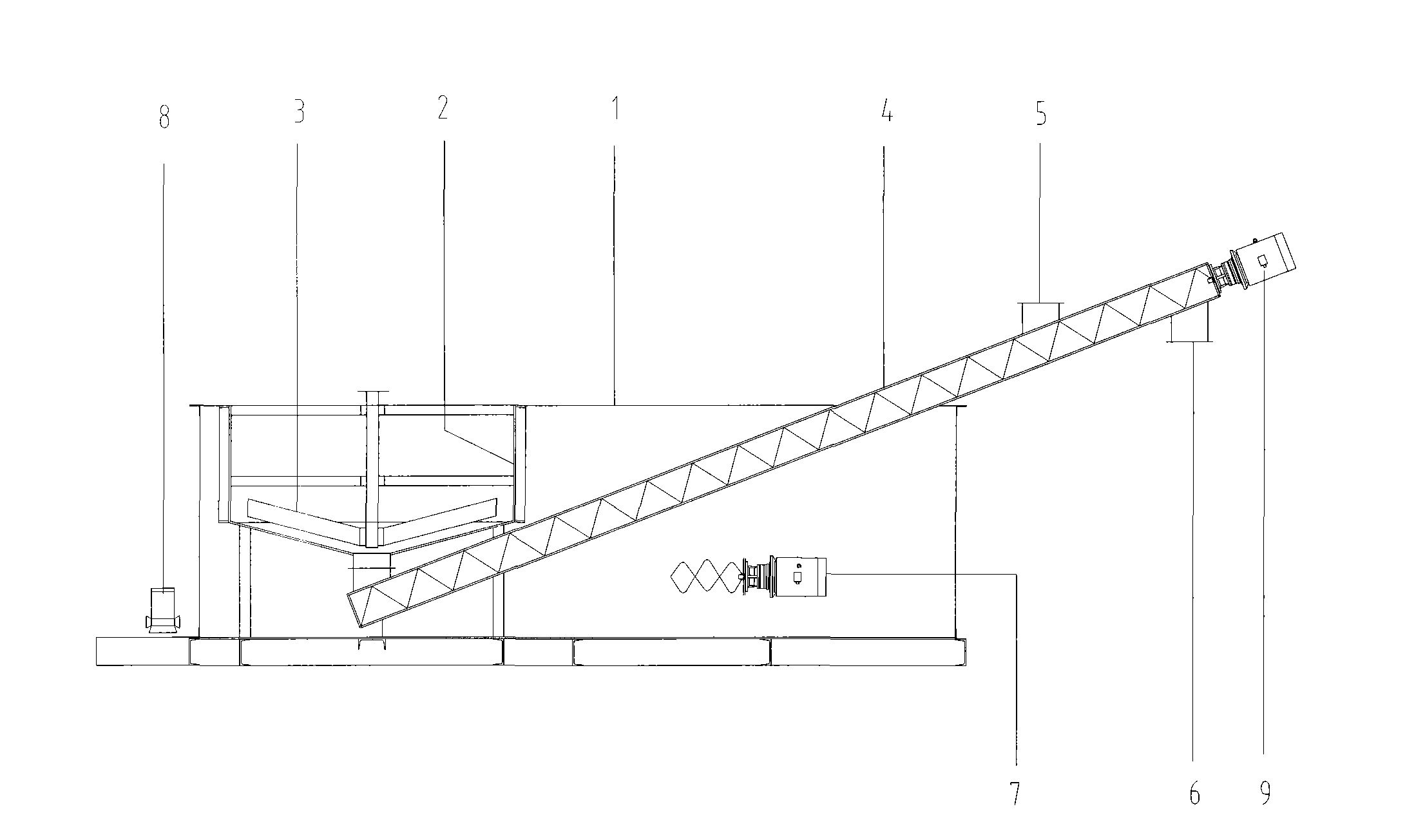

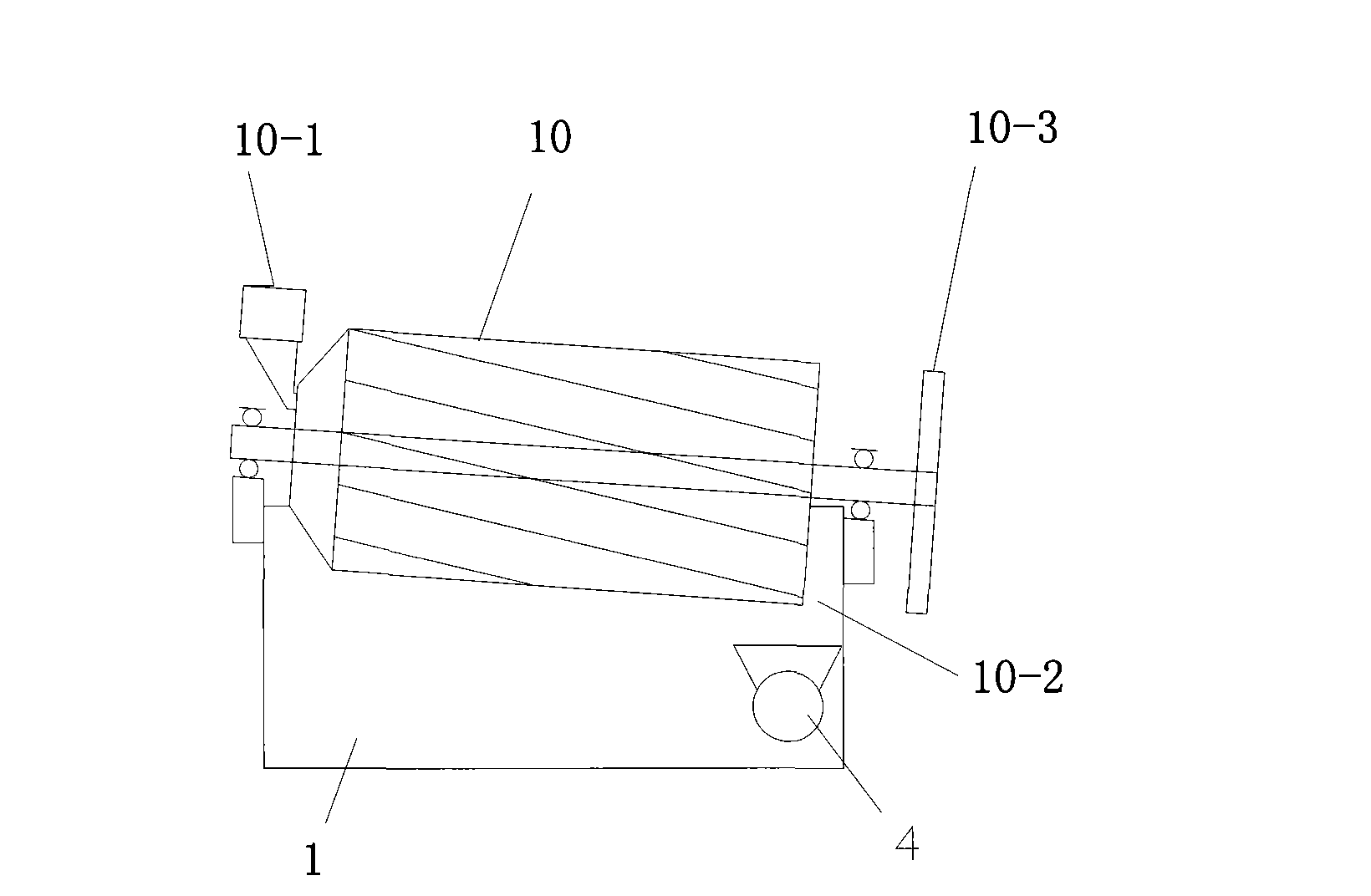

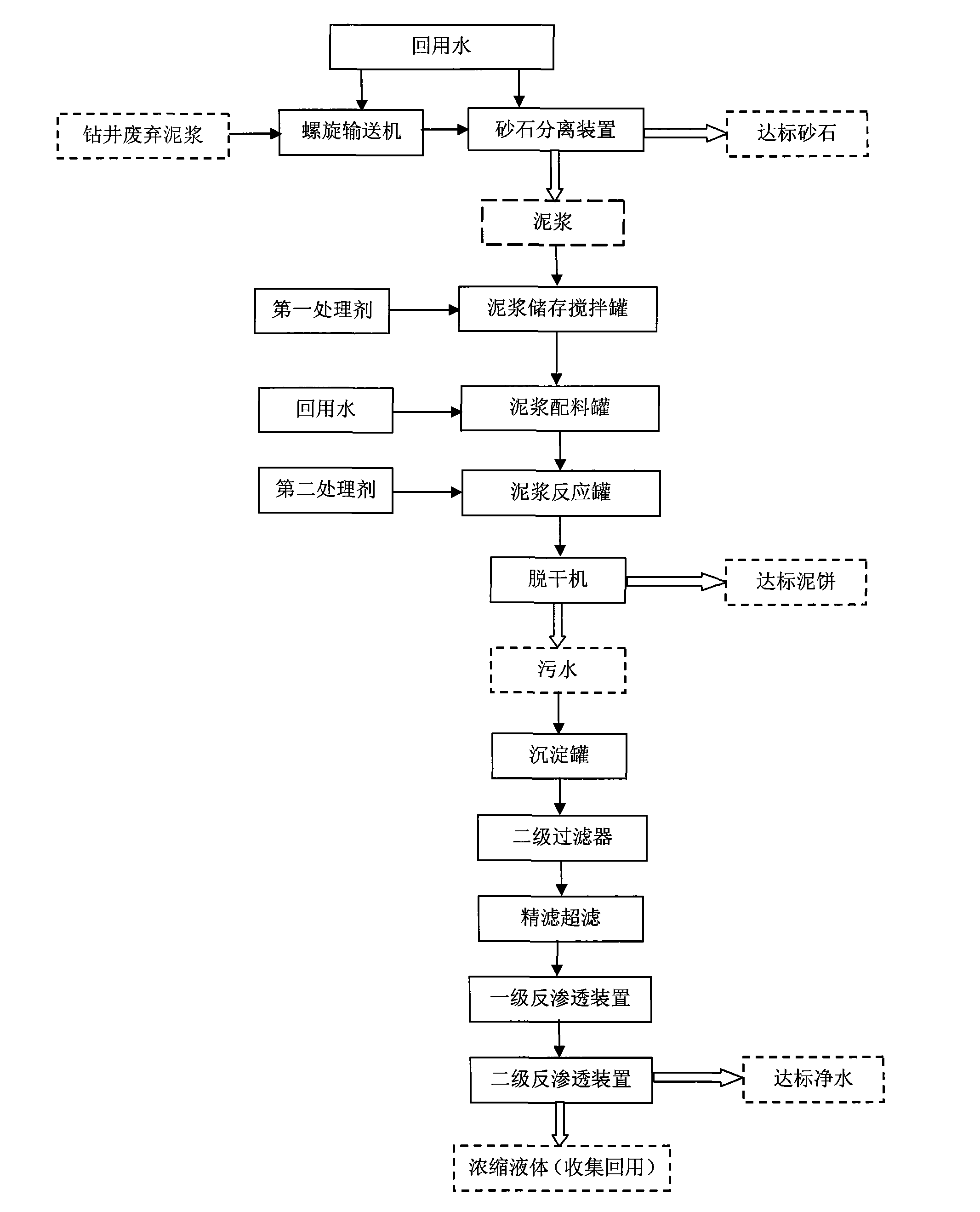

Method for processing waste slurry

ActiveCN101538096ASave land resourcesObvious technical advantagesWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningFiltrationWell drilling

The invention discloses a method for processing waste slurry, comprising the following steps: firstly, a sand-stone segregation apparatus separates, washes and discharges the drill cuttings sand and stone in the slurry; the pH value of the remaining slurry is adjusted and the COD value thereof is reduced; the solid and the liquid are separated from each other in a way of composite flocculating; water solution is separated out from the solid in a way of mechanical drying; the dried solid isolate meets the relative standard so as to be processed in a way of stacking or land filling; finally the separated water solution is processed in a way of filtration and reverse osmosis so as to obtain fresh water which is recycled or discharged on the spot. The method can be carried out by matching with an unit device and make continuously impending treatment of the well drilling waste slurry during drilling synchronously with normal well drilling production so as to continuously process the efflux hazardous waste to meet the discharge standard with out loading in the well drilling of oil-gas field, change the prior traditional whole efflux curingprocess mode, and fills the gap of an environmentally friendly governing field of oil drilling in the domestic.

Owner:北京华盛坤泰环境科技股份有限公司

Pipe running tool

A pipe running tool for use in an oil drilling system and the like comprises a lower drive shaft adapted to engage a drive shaft of a top drive assembly for rotation therewith. The pipe running tool further includes a lower pipe engagement assembly which is driven to rotate by the lower drive shaft, and is designed to releasably engage a pipe segment in such a manner to substantially prevent relative rotation between the two. Thus, when the lower pipe engagement assembly is actuated to securely hold a pipe segment, the top drive assembly may be actuated to rotate the top drive output shaft, which causes the lower drive shaft and lower pipe engagement assembly to rotate, which in turn rotates the pipe segment.

Owner:VARCO INT INC

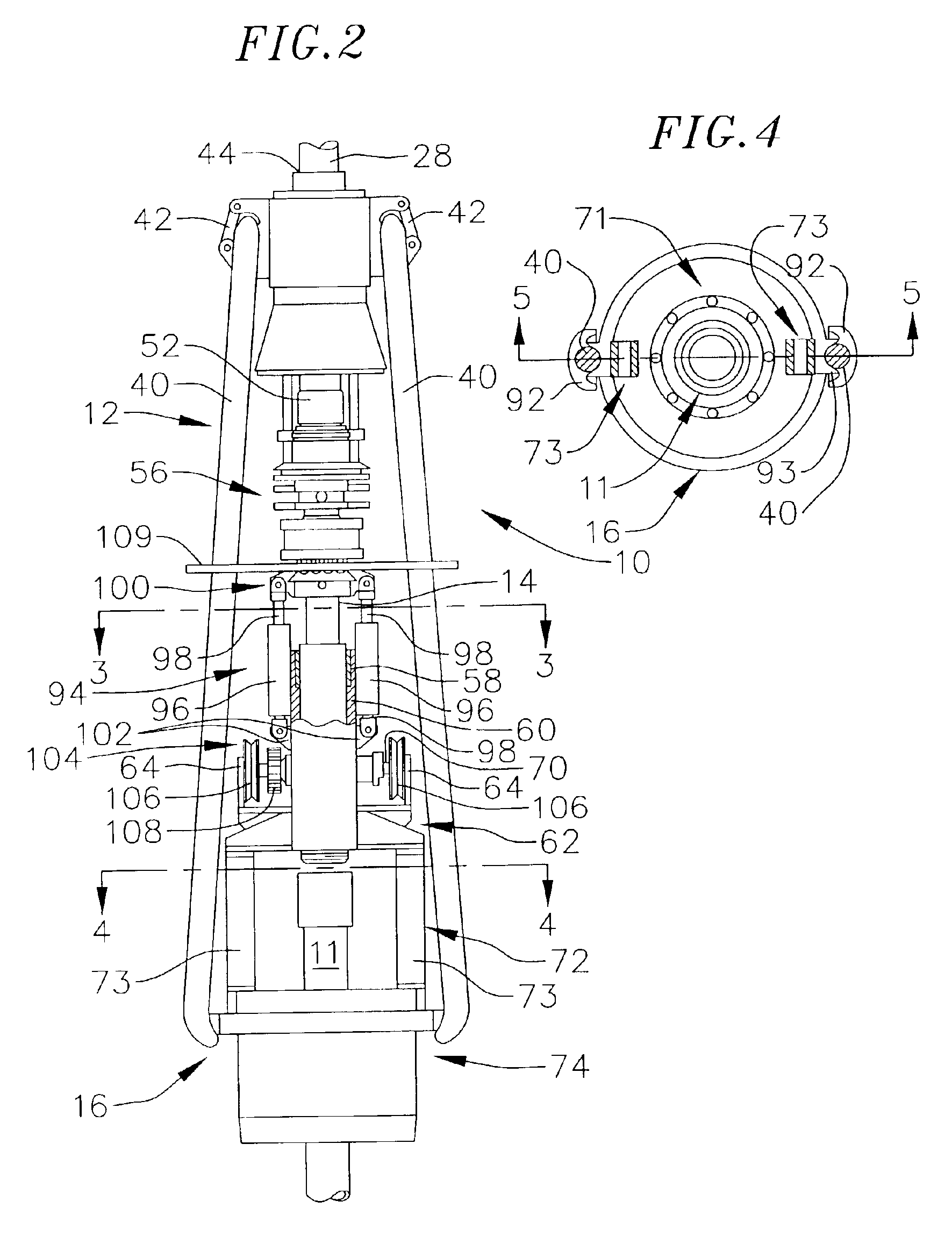

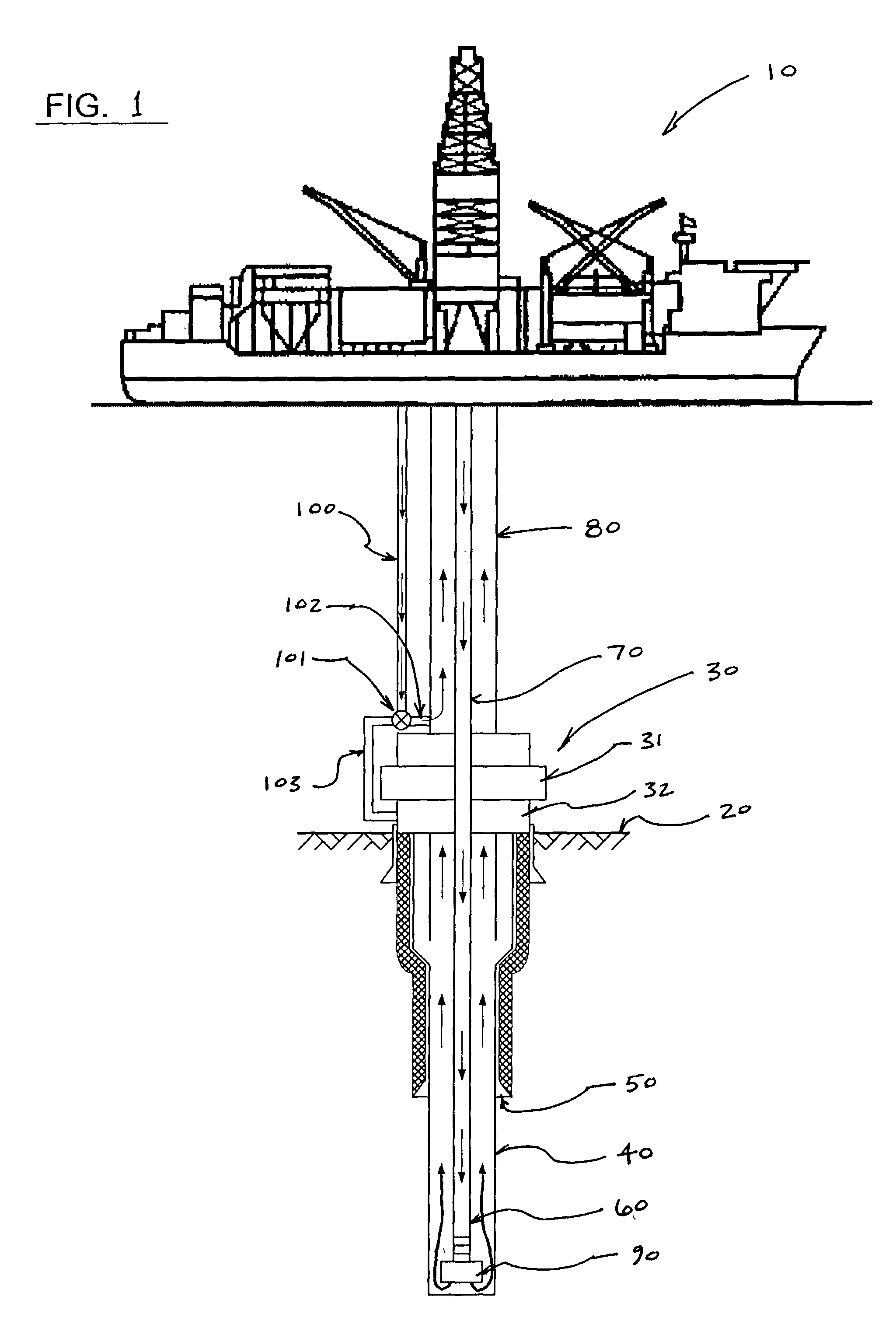

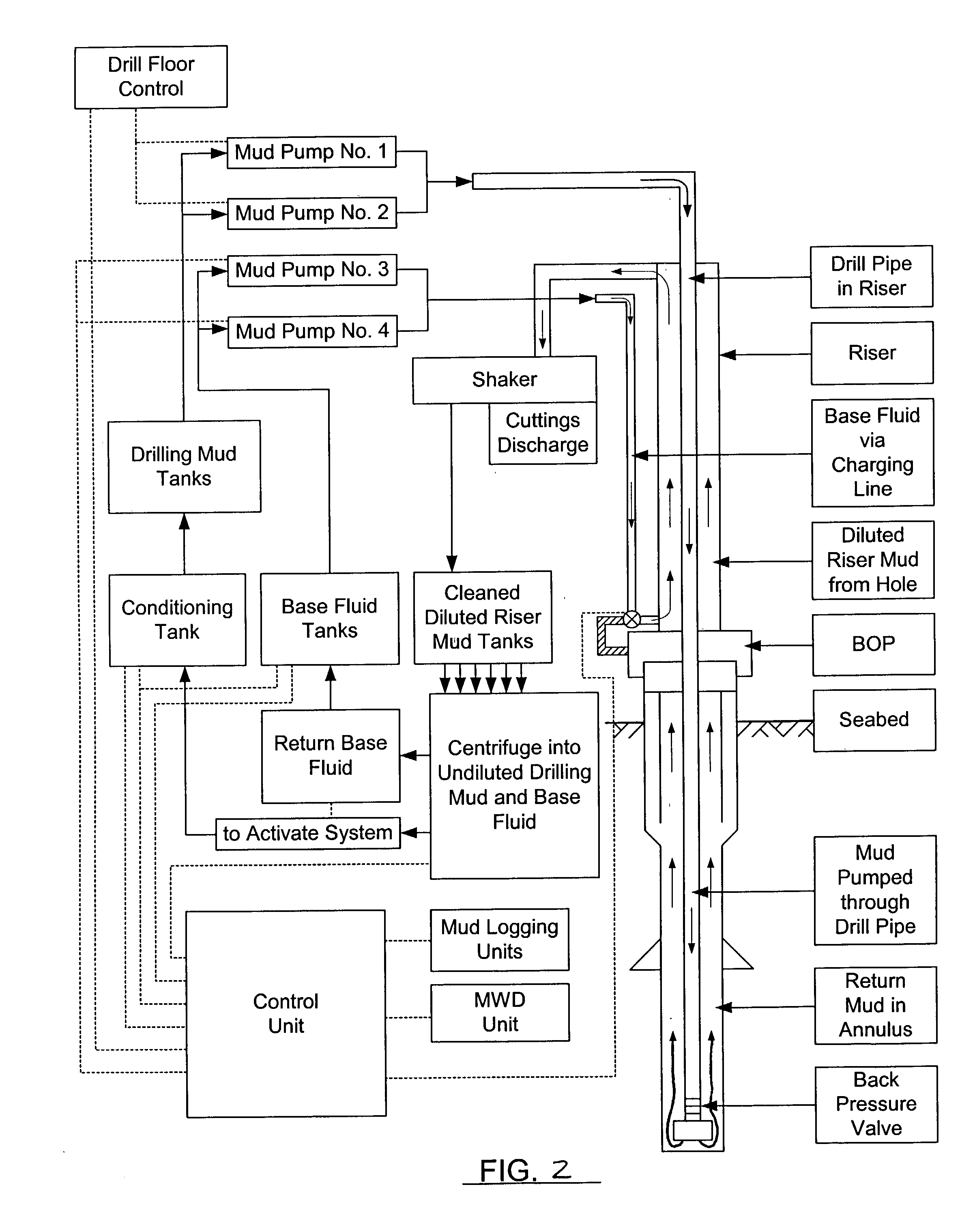

Method and apparatus for varying the density of drilling fluids in deep water oil drilling applications

A method and apparatus for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in deep water and ultra deep water applications are disclosed. The present invention combines a base fluid of lesser density than the mud required at the wellhead to produce a diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, a riser mud density at or near the density of seawater may be achieved. The present invention also includes a wellhead injection device for attachment to the wellhead and for injecting the base fluid into the rising drilling mud at a location below the seabed. The riser charging lines are used to carry the low density base fluid to the injection device for injection into the drilling mud below the seabed. The cuttings are brought to the surface with the diluted mud and separated in the usual manner. The diluted mud is then passed through a centrifuge system to separate the heavier drilling mud from the lighter base fluid.

Owner:DUAL GRADIENT SYST

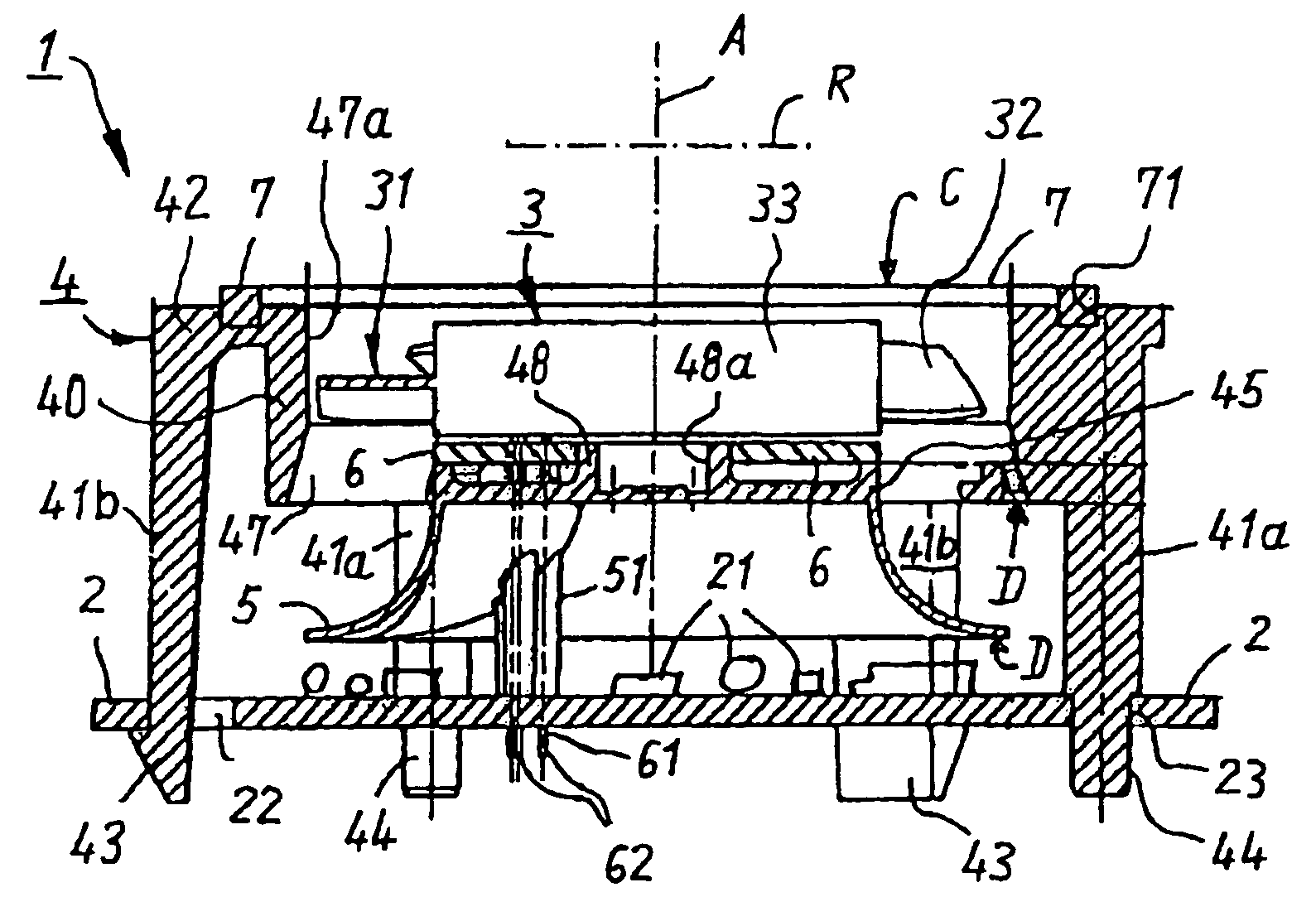

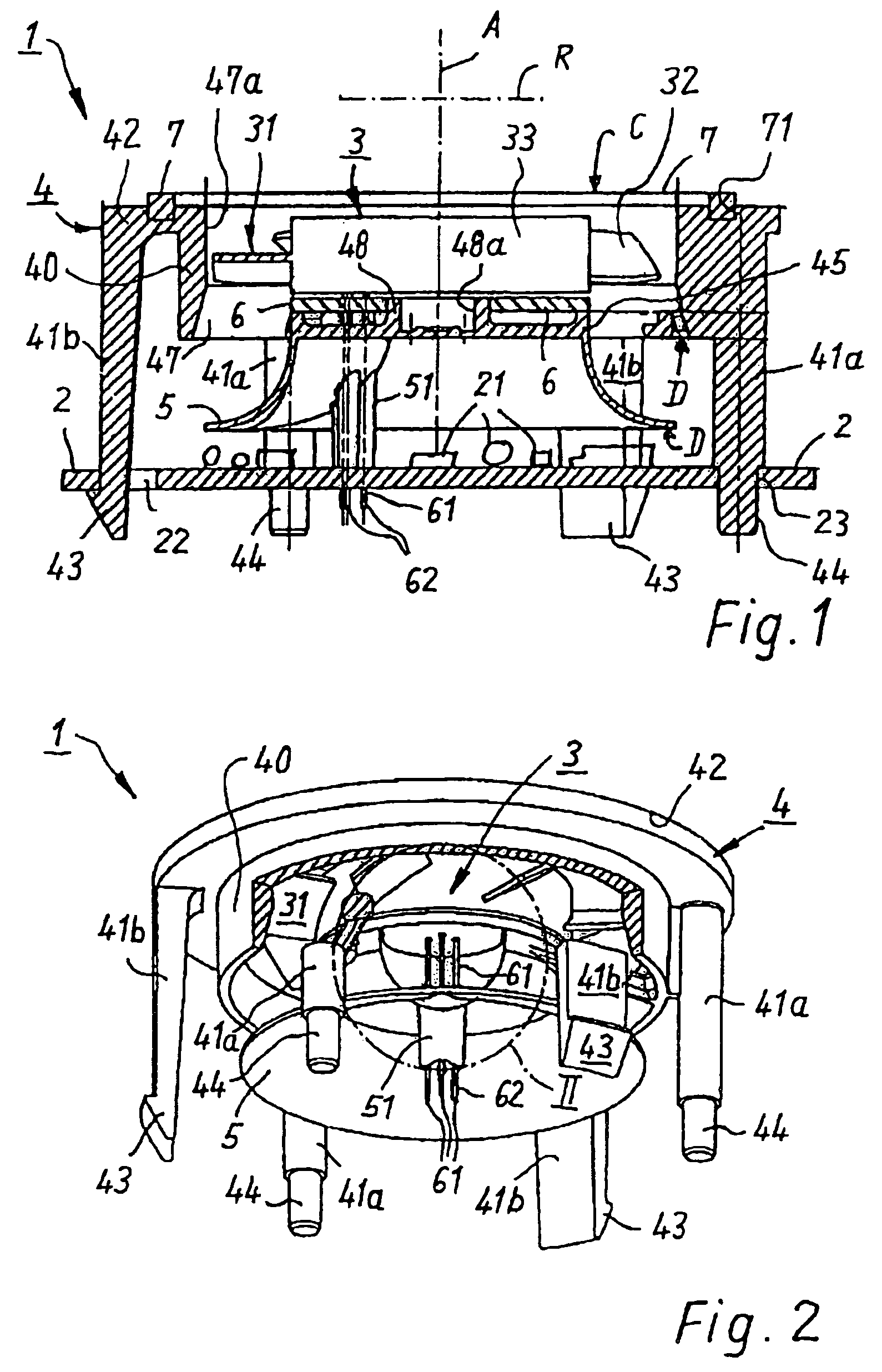

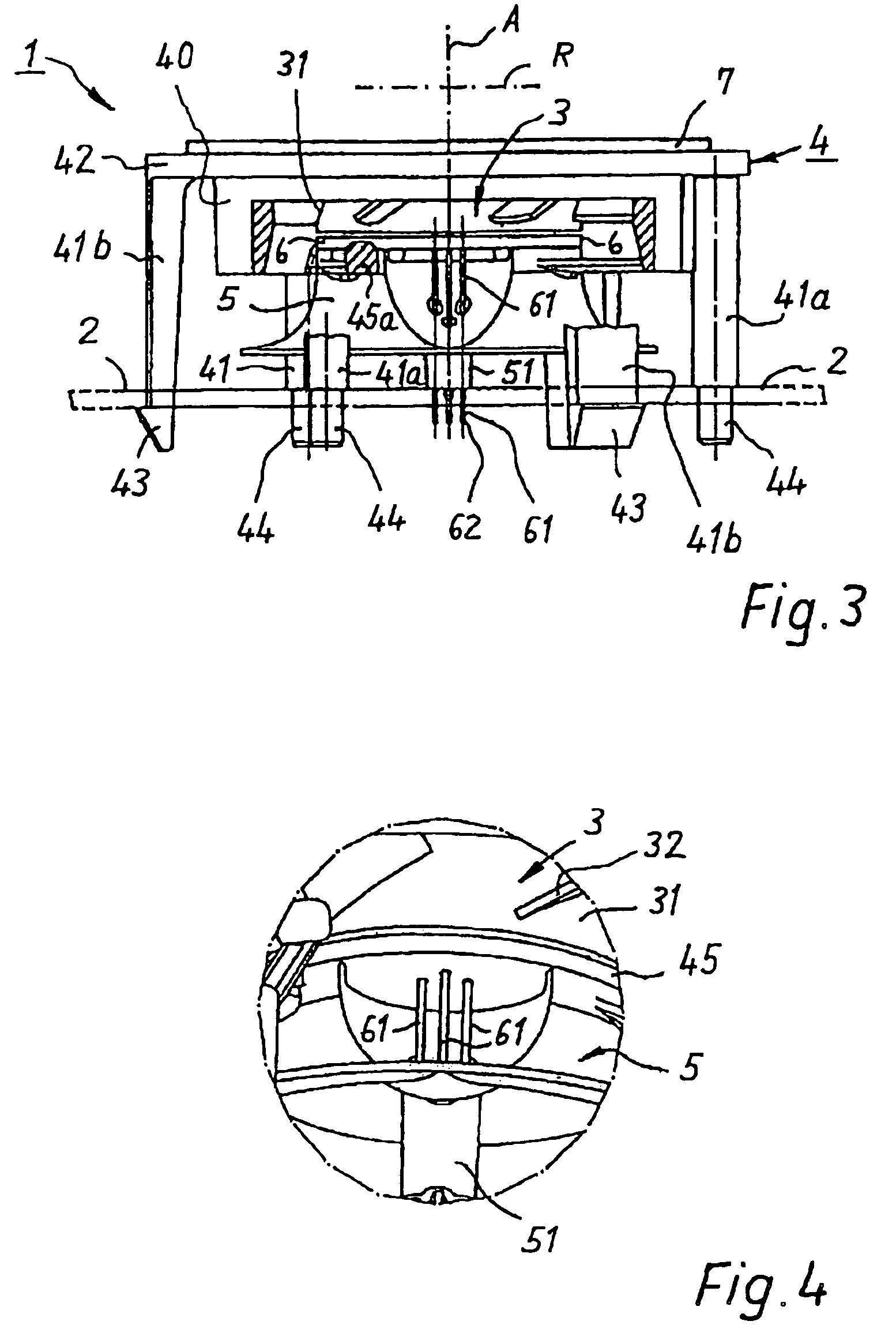

Assembly used for cooling a circuit board or similar

Owner:EBM PAPST ST GEORGEN & -

High-temperature water-in-oil drilling fluid

InactiveCN102031095AOvercoming the problem of insufficient temperature resistanceMeet the requirements of temperature resistanceDrilling compositionMineral oilSODIUM DODECYL BENZENE SULFONATE

The invention relates to a high-temperature water-in-oil drilling fluid which is composed of the following components in parts by weight: 70-90 parts of base oil, 3-7 parts of organic bentonite, 2-5 parts of oxidized asphalt, 2-5 parts of sulfonated gilsonite, 20-60 parts of CaCl2 aqueous solution of which the mass concentration is 20%, 6-10 parts of calcium oxide, 1.5-5.5 parts of UZEMUL-S, 2-5 parts of ABS (acrylonitrile butadiene styrene) and barite, wherein the base oil is non-blooming mineral oil with low aromatic hydrocarbon; the UZEMUL-S is a main emulsifier, the HLB (hydrophile-lipophile balance) value is 2.5, and the UZEMUL-S is formed by synthetizing an organic acid and an organic acid amide; and the ABS auxiliary emulsifier is sodium dodecyl benzene sulfonate, and the HLB value is 10. The invention resists temperature of 240 DEG C, can overcome the difficulty of insufficient heat-resistant capability of the existing drilling fluid and is favourable for satisfying the requirement of drilling fluid heat-resistant capability for deep wells and ultra deep wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

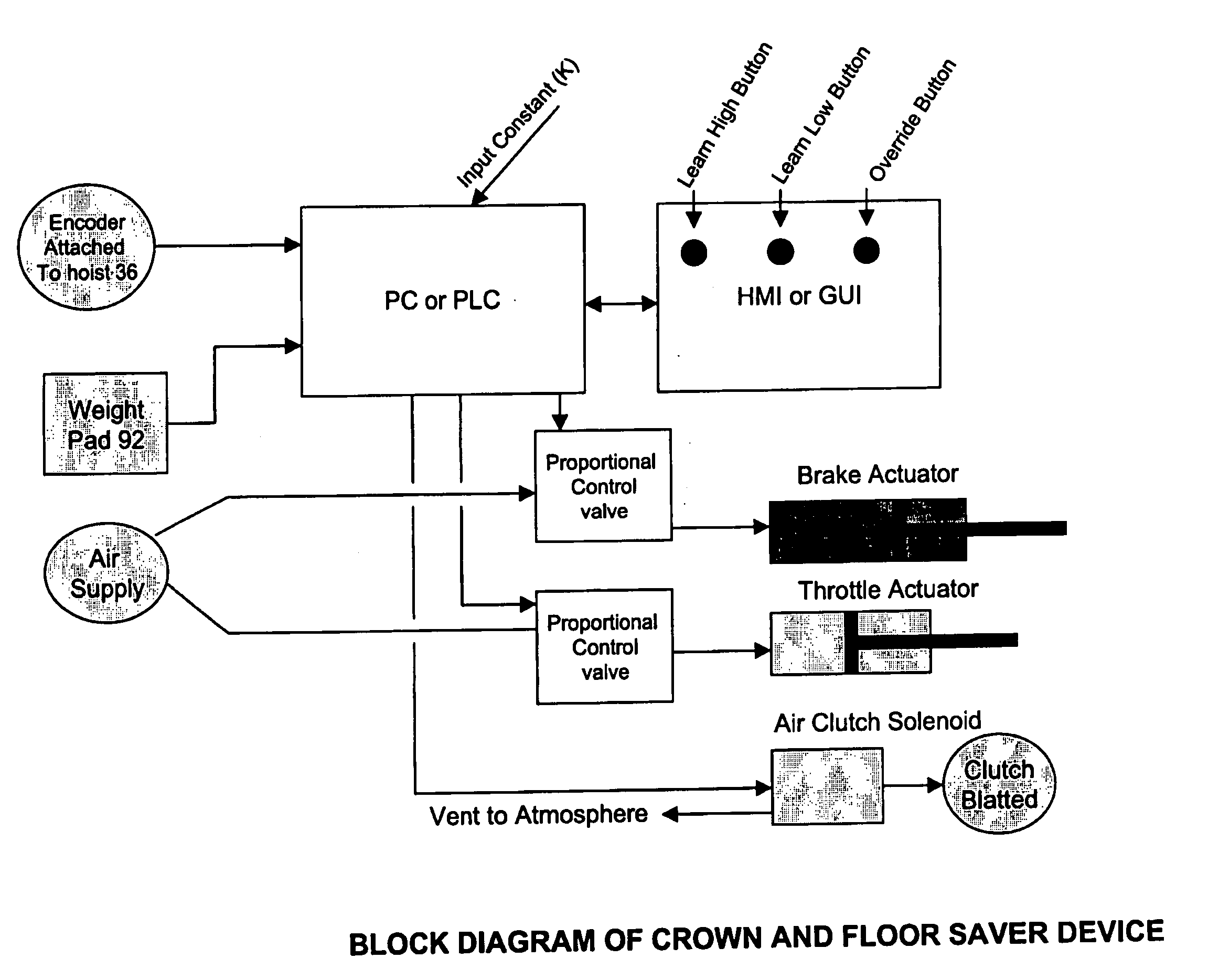

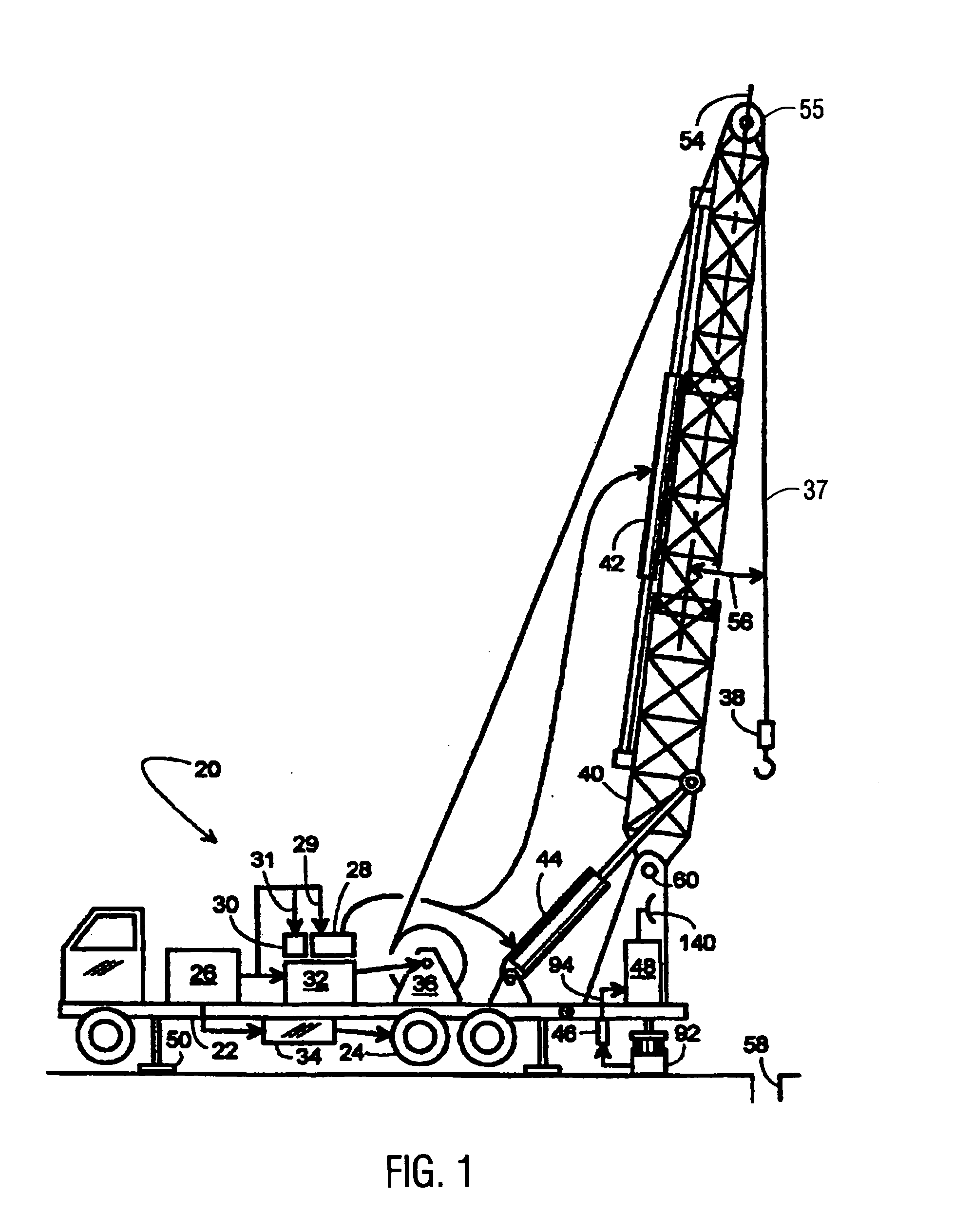

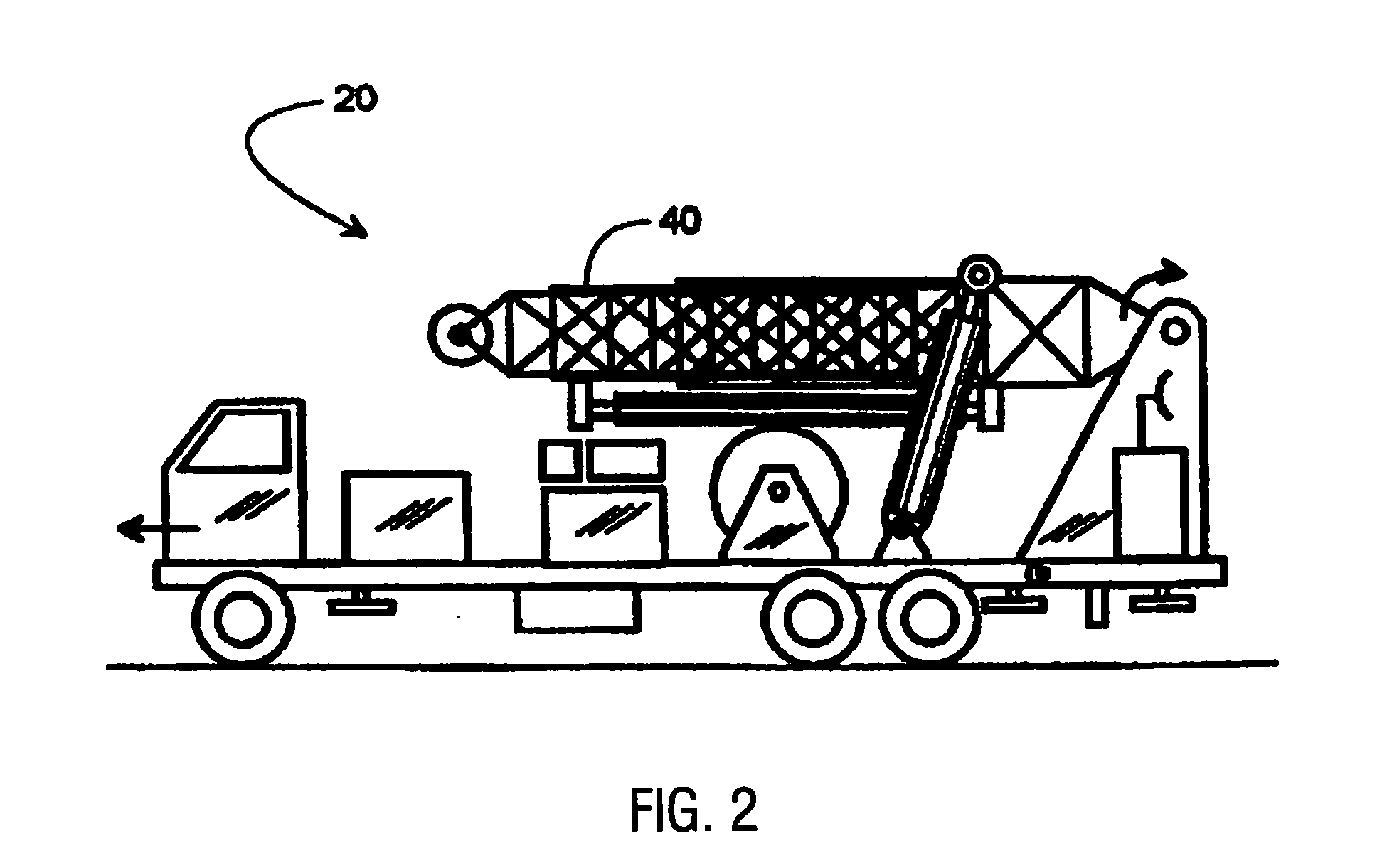

Multiple sensor for preventing a crown-block incursion on an oil well rig

ActiveUS20050114001A1Easy to useOperational securityDrilling rodsAnalogue computers for trafficMultiple sensorOil drilling

The technology disclosed herein provides a multiple sensor system that prevents crown incursion by a traveling block in an oil rig. This system calculates traveling block position, traveling block velocity and weight supported by the traveling block, and uses this information to calculate emergency stopping positions to prevent crown out by the traveling block. The system takes all these parameters into consideration when slowing and / or stopping the traveling block when it reaches a crown out position. The result is much safer operation of the traveling block on a workover rig, as well as on an oil drilling rig.

Owner:KEY ENERGY SERVICES

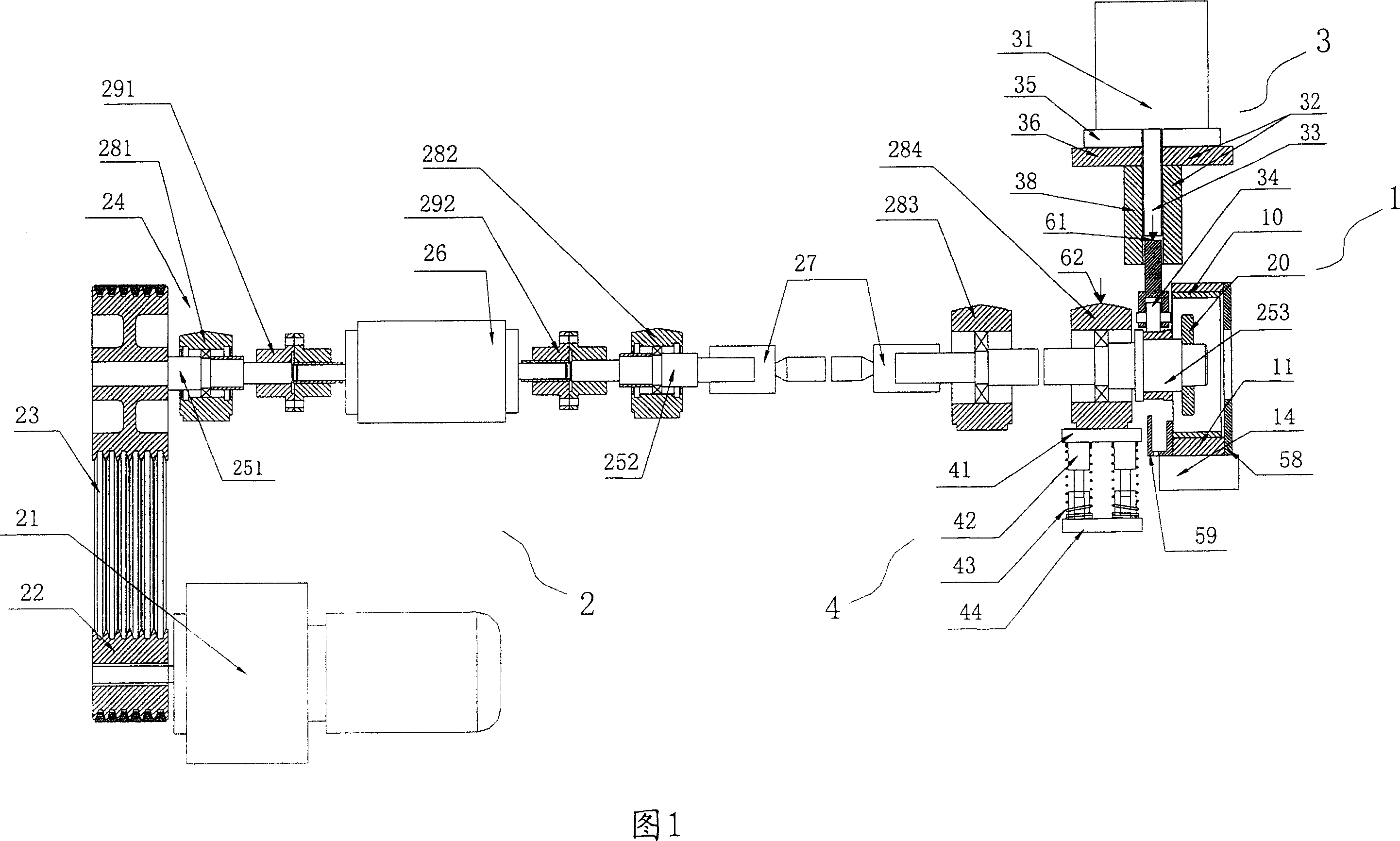

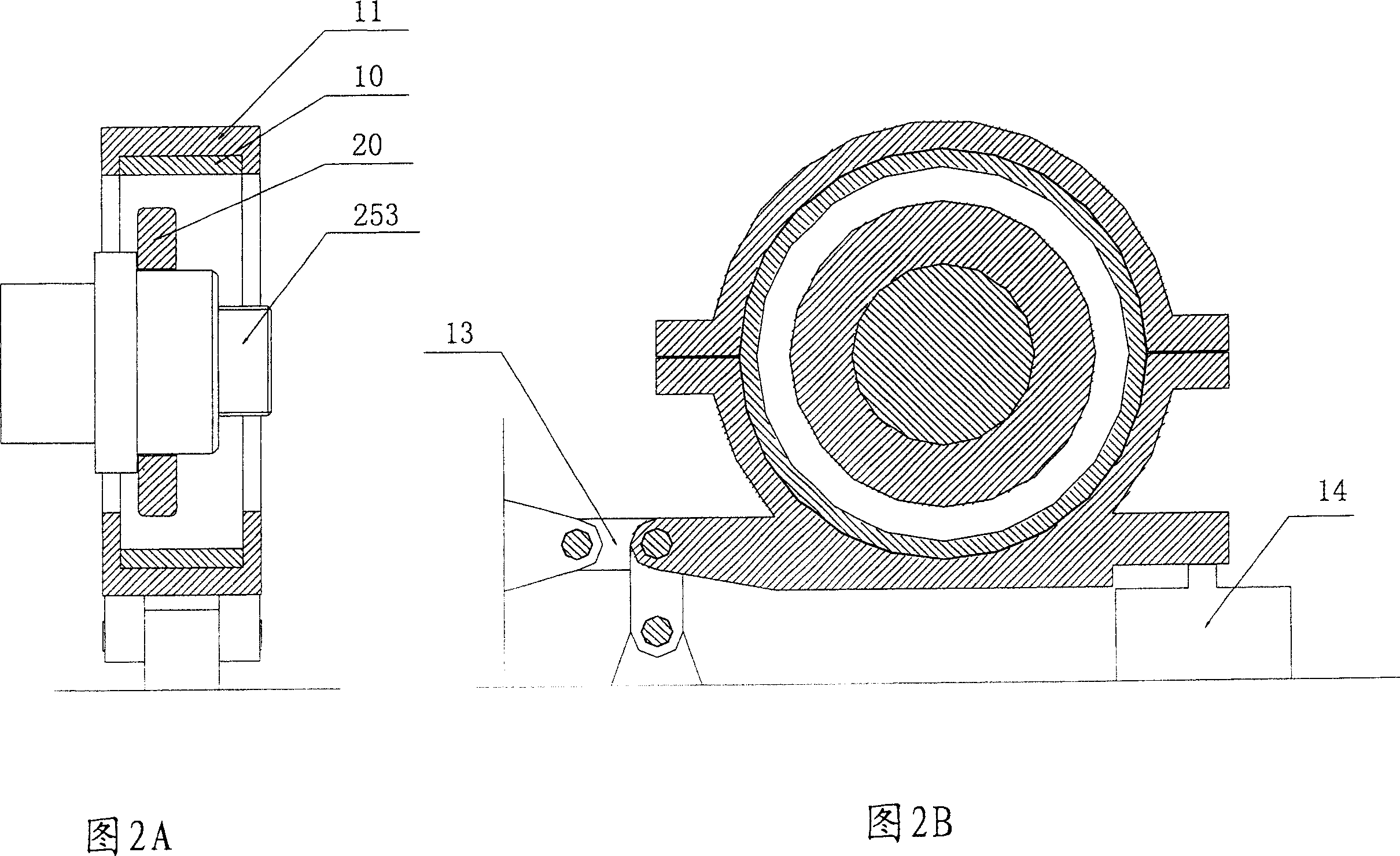

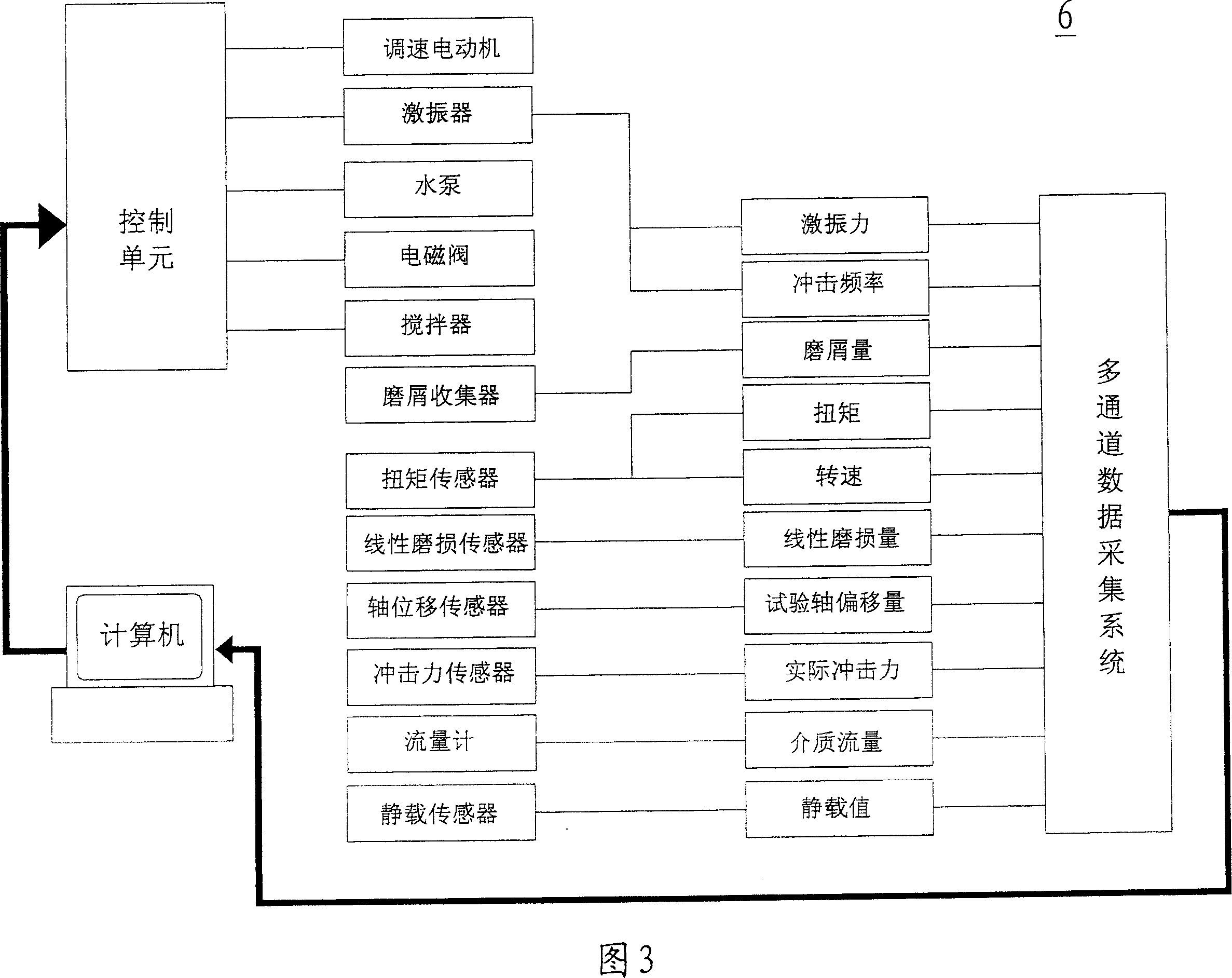

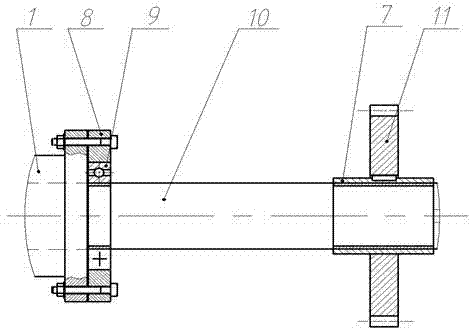

Petroleum drilling pipe shocking and sliding wear tester

InactiveCN1967202ARealize multi-phase circulationFlow adjustableStructural/machines measurementUsing mechanical meansOil drillingPetroleum

The invention discloses an oil drilling rod shock slide abrasion tester, including the fixture system, the transmission system and the excitation system, in which the said fixture system clamping fixes the tubular specimen, and the one end of the said transmission system equips the rod specimen corresponding to the tubular specimen, and the said transmission system drives the rod specimen rotating with the axis, and the said excitation system provides radial shock to the said rod specimen, to drive the rod specimen shocks the tubular specimen fixed in the fixture system at the same time of rotating, to realize the composite shock slide friction, and through the friction, transmit the torque to the rod specimen. The invention overcomes the limitation of the existing abrasion testers, and it can realize rod friction and abrasion study of shock slide composite working conditions of controlled shock load type under the condition of multiphase cycle lubricating medium, and it can not only realize multiphase media cycle of adjustable flow and variable components, but also realize the complex impact of adjustable shock size, controllable wave-type.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High-strength drilling rod for petroleum and method for making same

ActiveCN1690241AImprove hardenabilityFully hardenedDrilling rodsDrilling casingsHigh intensityOil drilling

A high strength oil drilling rod, the constituent is (mass ratio): C 0.20 to 0.30 percent, Si 0.1 to 0.5 percent, Mn 0.7 to 1.5 percent, Cr 0.7 to 1.5 percent, Mo 0.1 to 0.4 percent, and the rest being Fe and inescapable impurity. The method for preparation includes: thickening the end of the related steel pipe to prepare the body-pipe of upset drilling rod; heating the whole steel pipe and cooling, lying on a rotating quenching stand, spraying water by axial-flow inside surface and spraying water by laminar flow outside surface when the steel pipe is rotating; by controlling the various amount of outer water delivered to the thickening end of the steel pipe and the body-pipe, or by decreasing the amount of outer water delivered to the body-pipe, or increasing the amount of outer water delivered to the thickening end of the steel pipe, makes the thickness-different pipe and the thickening end have the same cooling rate and the same quenching structure, and also have the same dynamic behavior after quenching.

Owner:BAOSHAN IRON & STEEL CO LTD

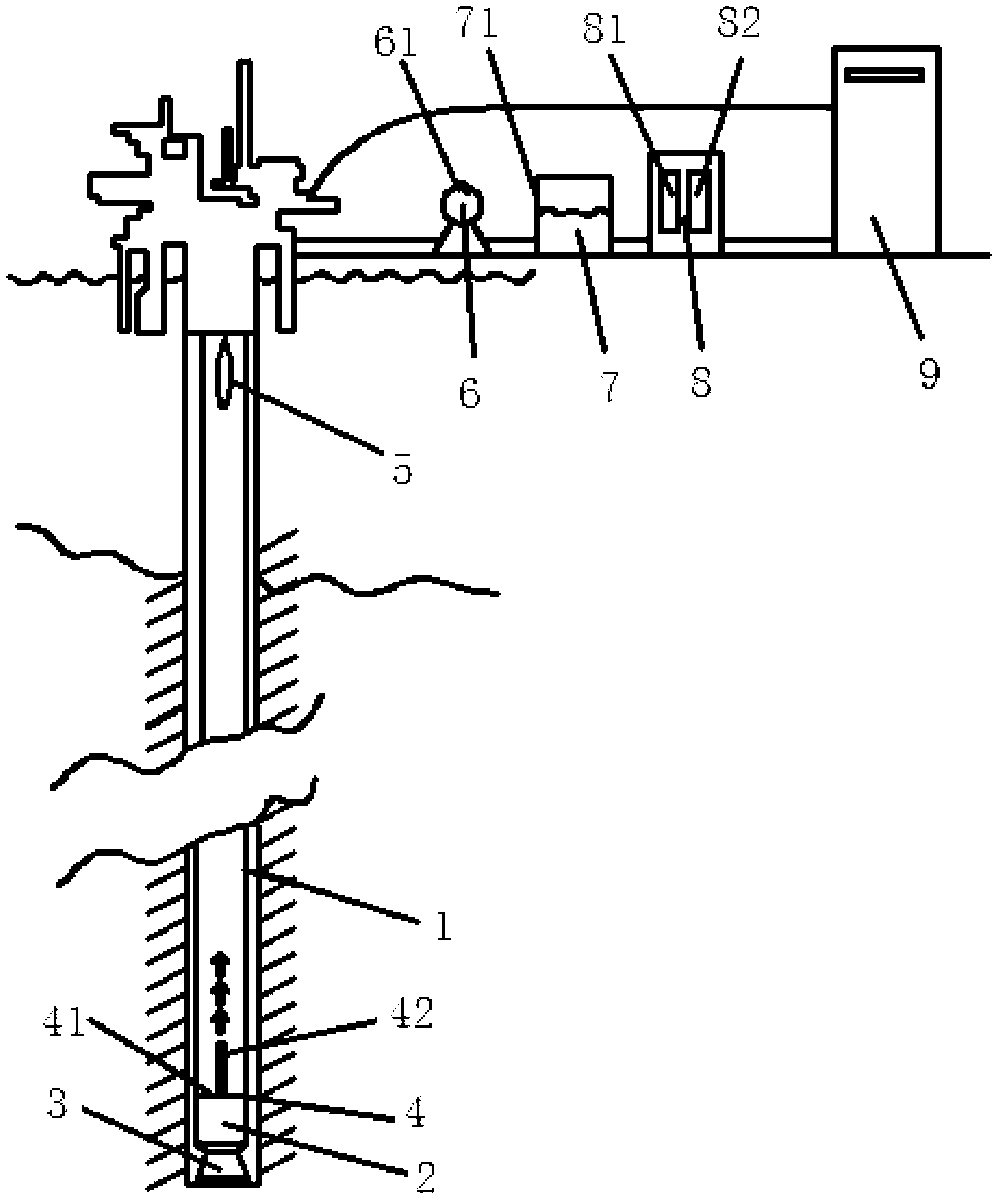

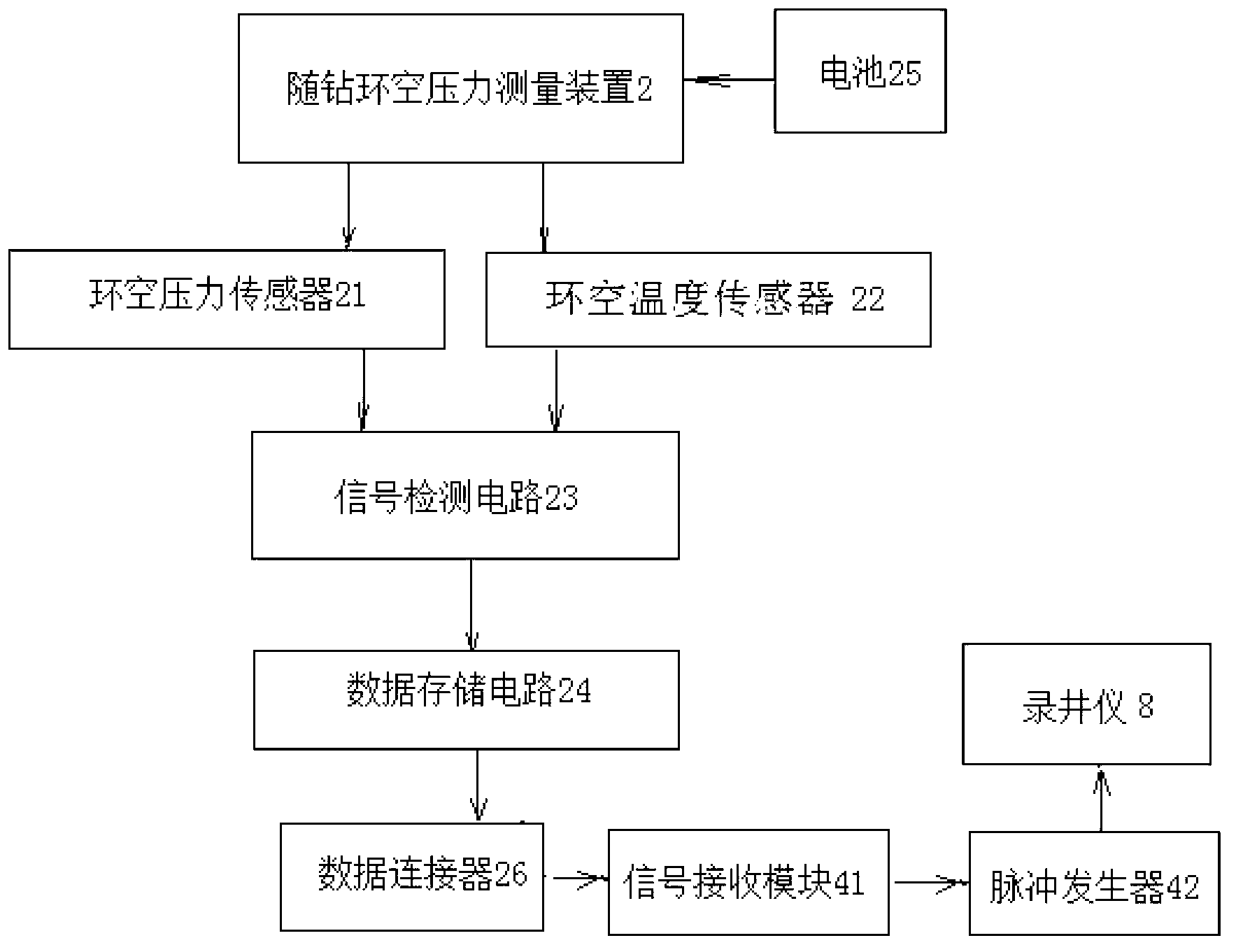

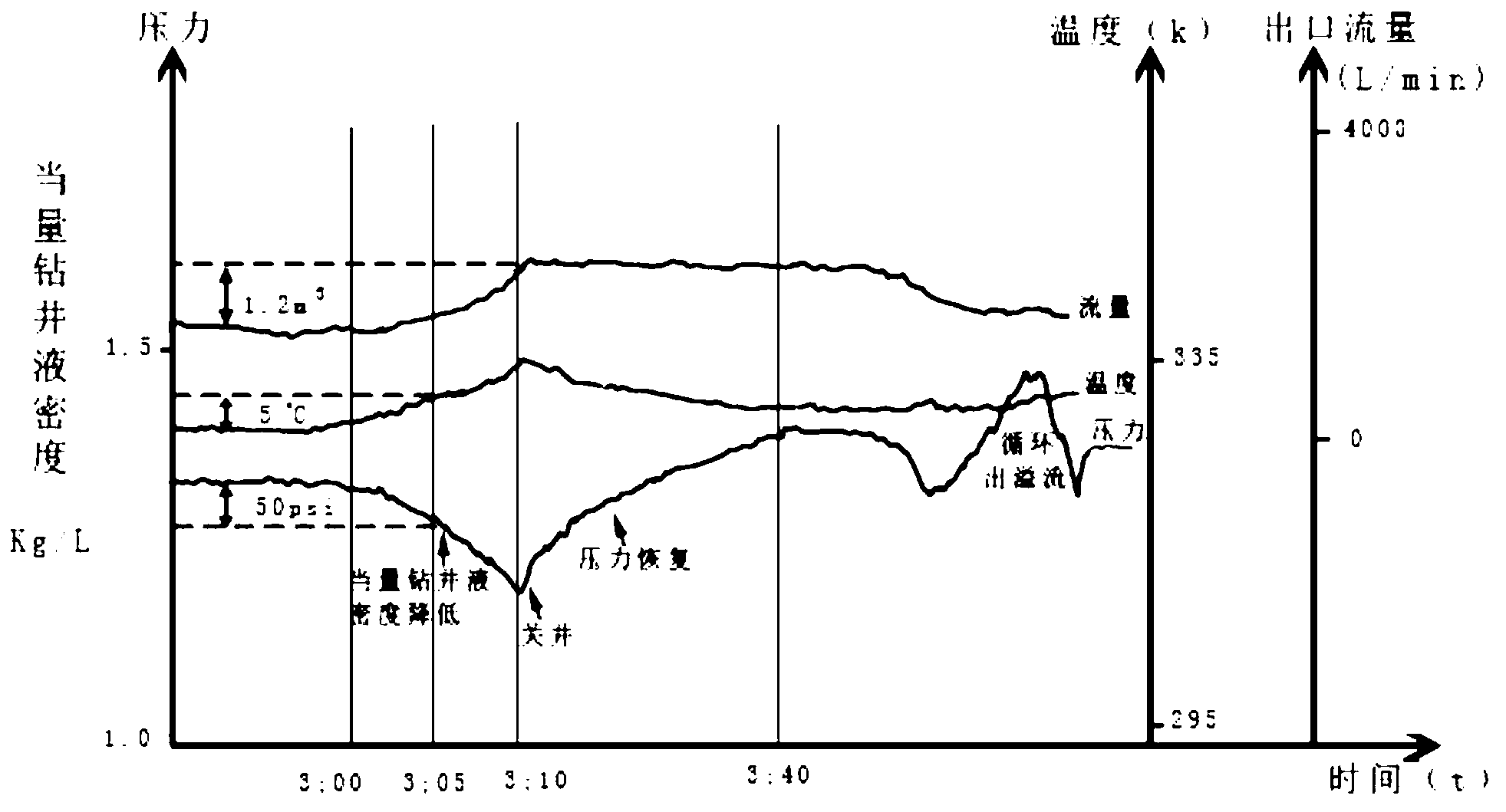

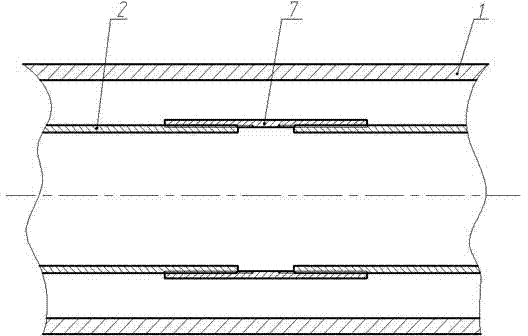

Method and device both based on annulus pressure measuring while drilling and for early monitoring gas invasion of wellhole

The invention relates to a method and a device both based on annulus pressure measuring while drilling and for early monitoring gas invasion of a wellhole. The device is characterized in that the device comprises a drilling column arranged in the wellhole, the bottom of the drilling column is connected with an annulus pressure measuring while drilling device and a drilling bit, the annulus pressure measuring while drilling device comprises an annulus pressure sensor, an annulus temperature sensor, a signal monitoring circuit, a data storage circuit, a battery and a data connector, the top of the annulus pressure measuring while drilling device is connected with a measuring while drilling device which comprises a signal receiving module and a pulse generator, a drilling fluid returning flowmeter is arranged on the upper portion of the drilling column, one side of a wellhead is connected with a mud pump and a mud circulating pool through a pipeline, a mud pressure sensor is mounted on the mud pump, a mud level meter is arranged in the mud circulating pool, the drilling fluid returning flowmeter, the mud pressure sensor and the mud level meter are in wire connection with a well logging instrument respectively, a filter module and a signal measuring module are arranged in the well logging instrument, and the well logging instrument is connected with a data analyzing and alarming module through a wire. The method and the device can be applied to deepwater oil drilling operations.

Owner:CHINA NAT OFFSHORE OIL CORP +2

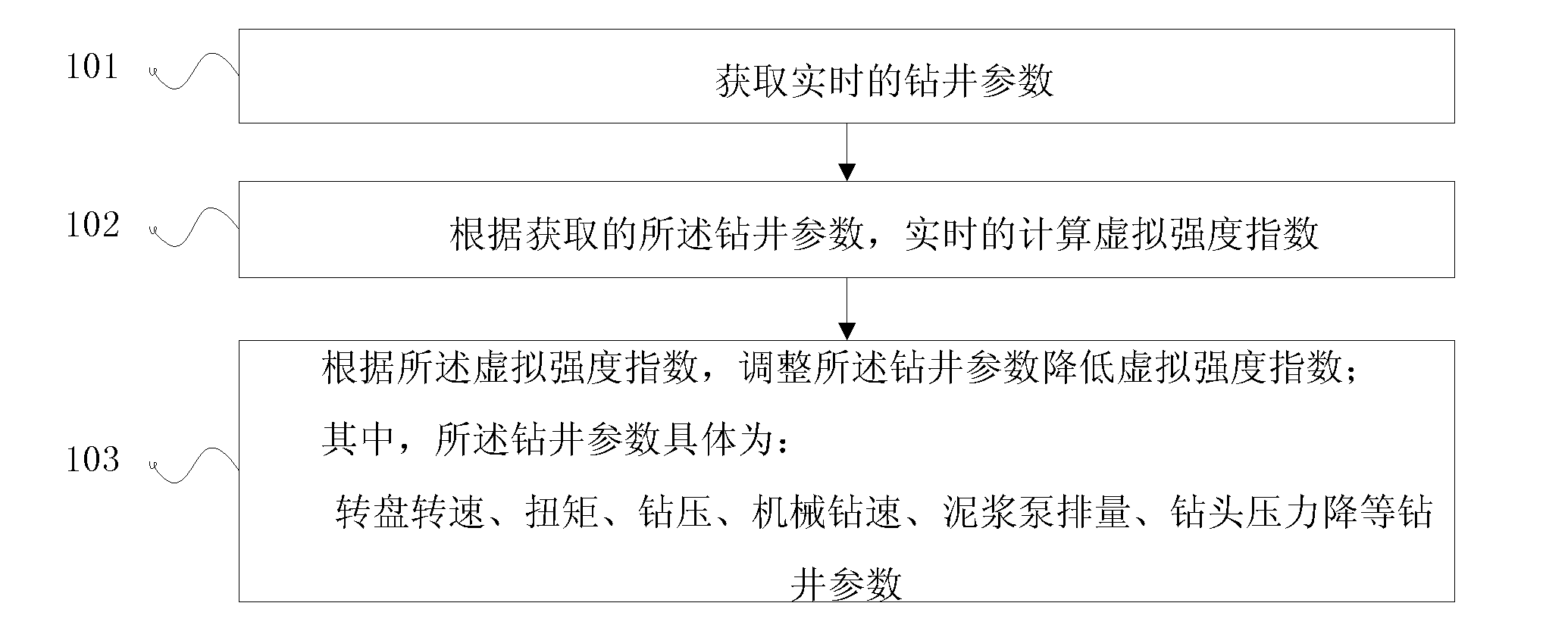

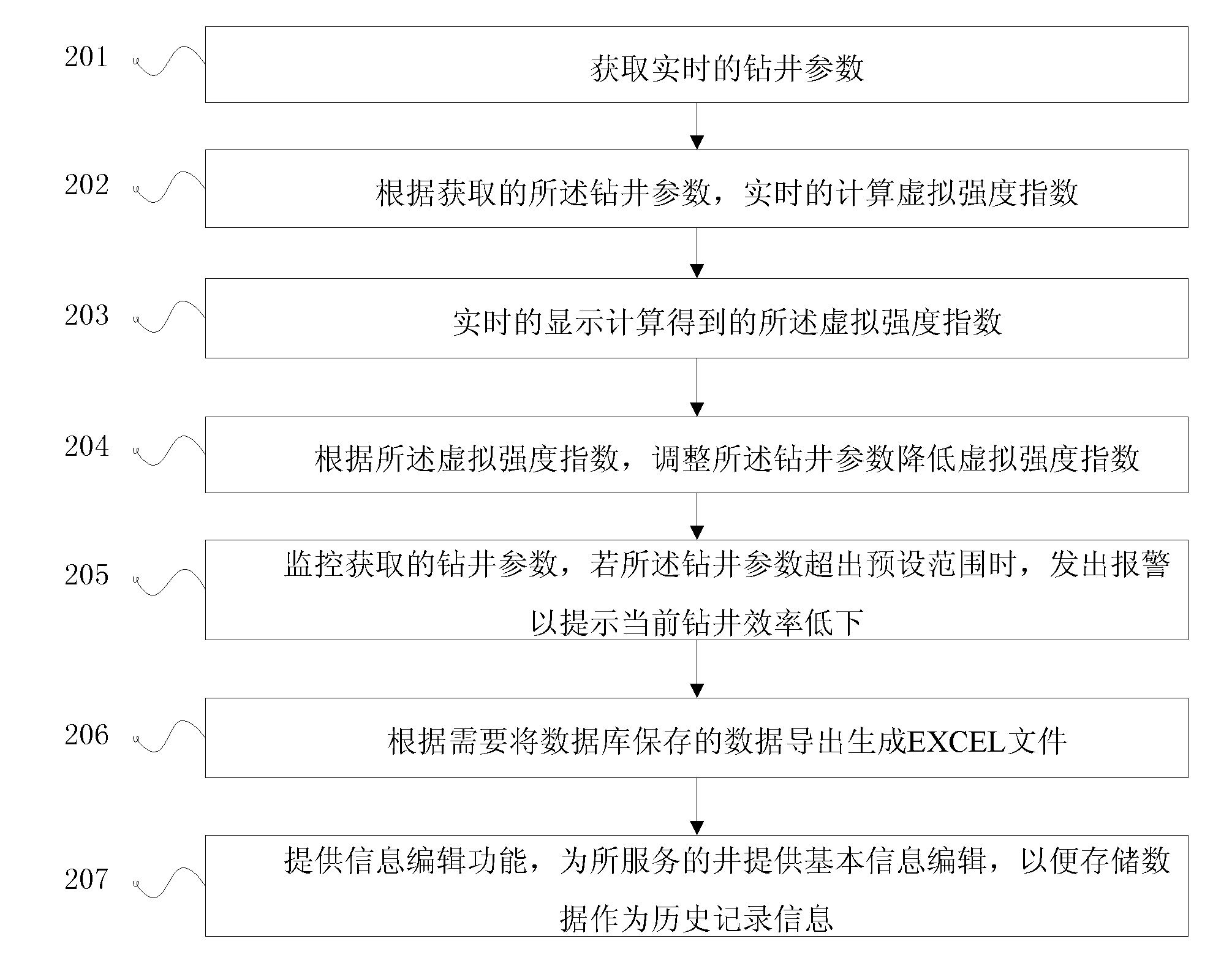

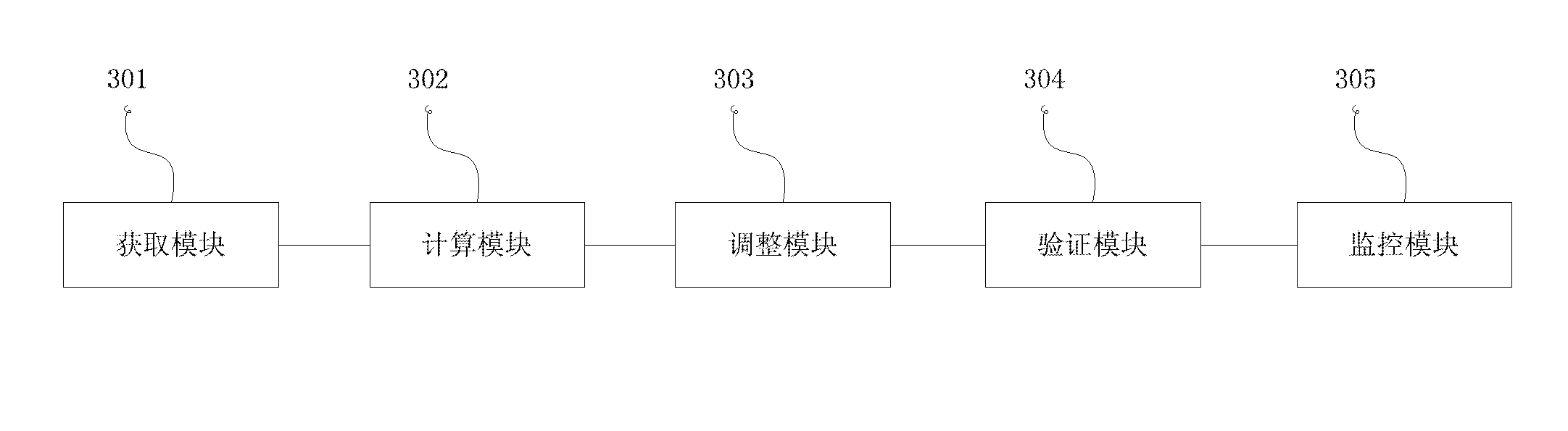

Method and system for optimizing drilling parameters

ActiveCN103046918AImprove cutting efficiencySurveyAutomatic control for drillingWell drillingOil drilling

The invention discloses a method and a device for optimizing drilling parameters, and belongs to the oil drilling field. The method comprises obtaining drilling parameters obtained in real time; calculating a virtual strength index (VSI) in real time according to the obtained drilling parameters which comprise rotary disc rotation speed, torque, drilling pressure, mechanical drilling speed, slush pump displacement, bit pressure drops and the like; and adjusting the drilling parameters to reduce the VSI according to the virtual strength index. According to the method and the device for optimizing drilling parameters, the VSI is calculated in real time through the drilling parameters fed back through real-time geological environment changes, and the drilling parameters are adjusted in real time according to the VSI relevant to an actual strength index, so that the bit cutting efficiency is in a possible optimal state, and the drilling efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High strength aluminosilicate hollow glass microsphere and preparation method thereof

The invention discloses a high strength aluminosilicate hollow glass microsphere and a preparation method thereof. The hollow glass microsphere is characterized by comprising the following chemical components by mass percent: 60-75% of SiO2, 10-15% of Al2O3, 10-15% of Na2O, 1-3% of CaO, 0-1% of MgO, 0.02-0.5% of S, 0-3% of R2O and 0-3% of Fe2O3, wherein R in R2O is an alkali metal except Na. The density of the hollow glass microsphere is 0.2-0.6g / cm<3>, the compressive strength is 3-130MPa, the grain size is not greater than 80mu m, the floating rate is not less than 95%, and the softening temperature is not less than 750 DEG C. The hollow glass microsphere disclosed by the invention not only can be used in the fields in which common hollow glass microspheres are applied, but also is suitable for the high temperature and high pressure fields having special requirements in which the common hollow glass microspheres can not be applied. The hollow glass microsphere can be the hollow glass microsphere solid buoyancy material used 1000m, 2000m, 4500m and below under water, the hollow glass microsphere used for cementing wells with depth beyond 6000m during oil drilling and the hollow glass microsphere used for plastic hot extrusion molding.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

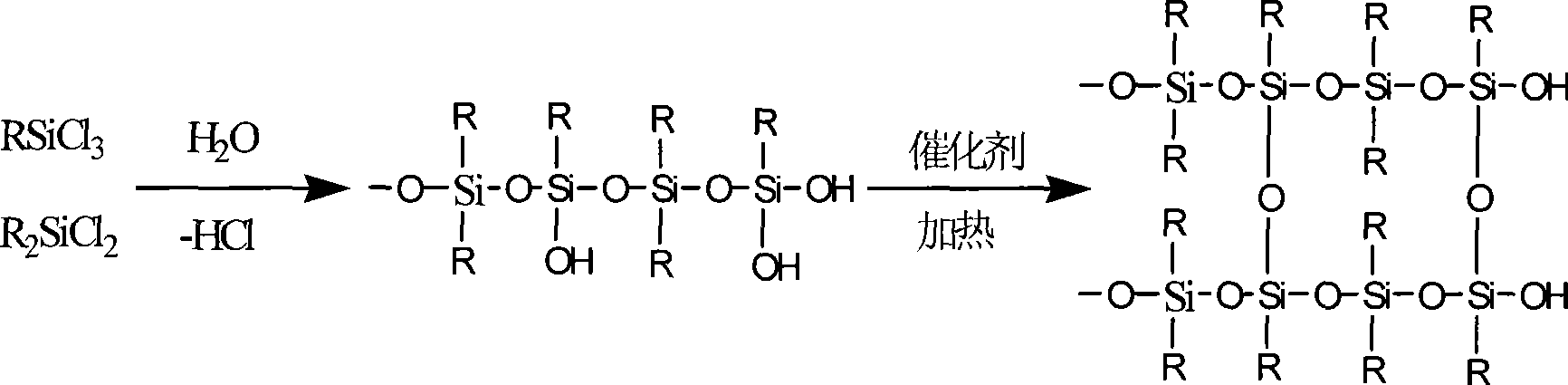

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

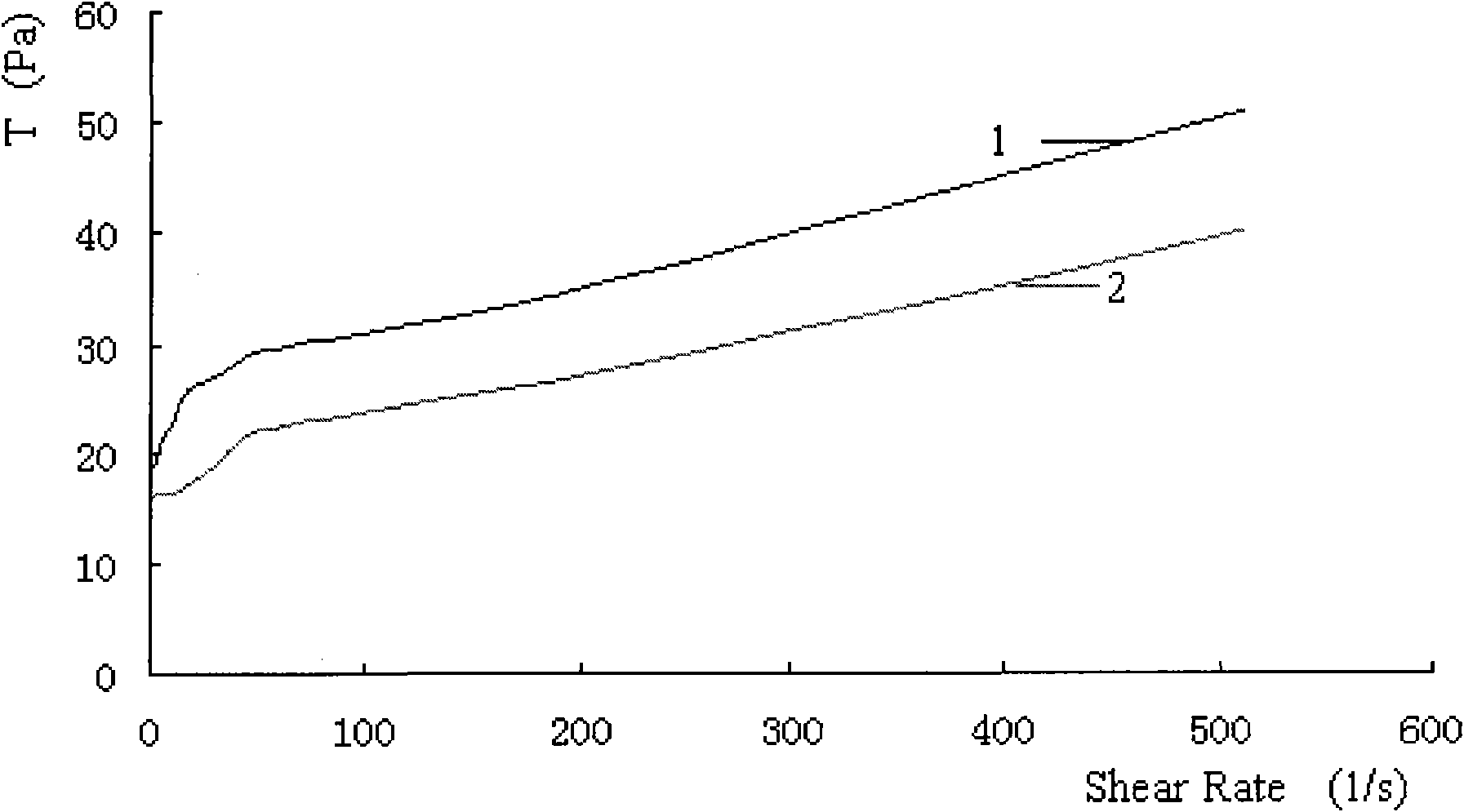

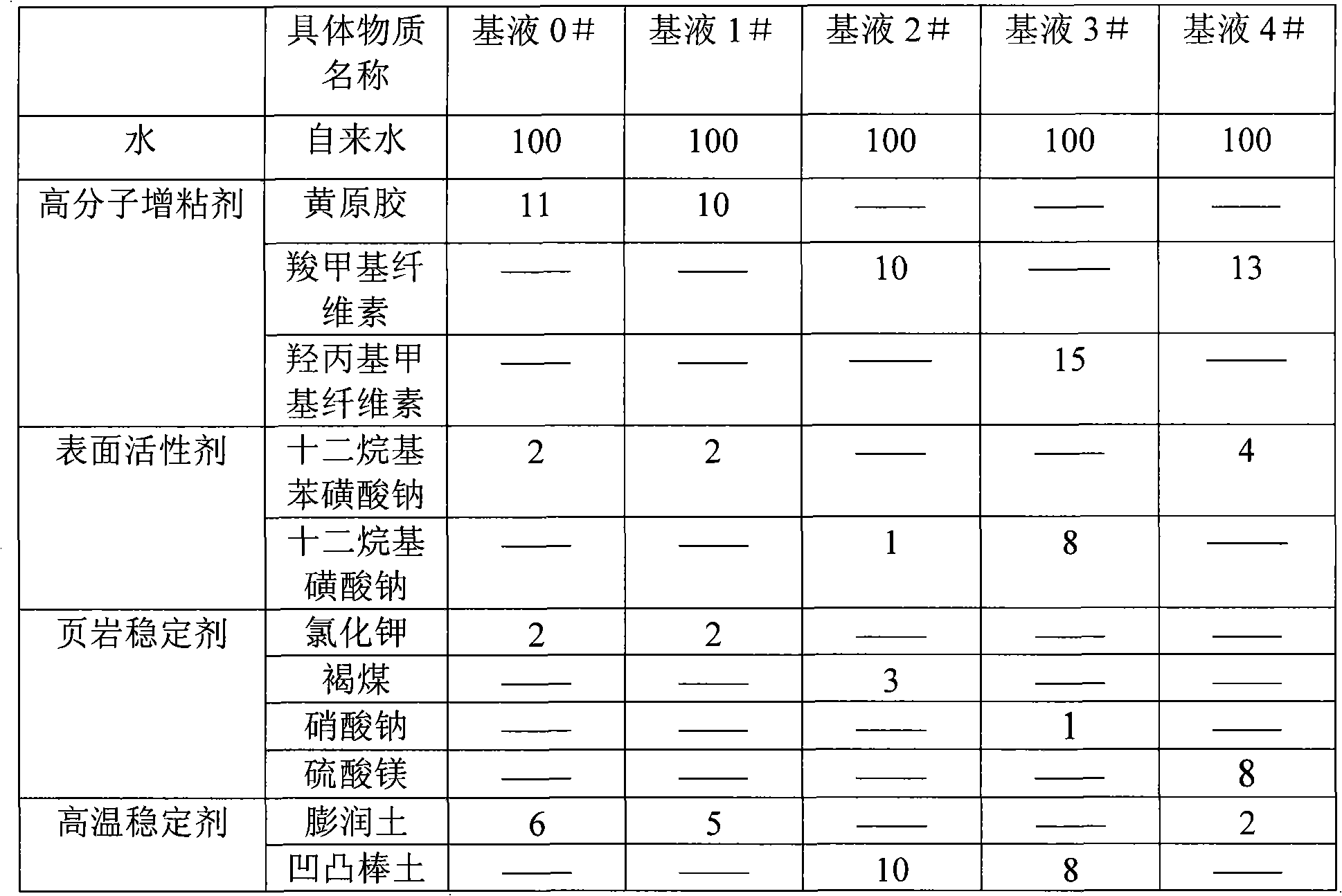

High-temperature resistance base fluid for well cementing of oil gas well, preparation method and application thereof

ActiveCN101775273AImproved rheological propertiesAddition to spacer fluid rheology has little effect on rheologyDrilling compositionFiberAlkaline earth metal

Owner:CHINA PETROLEUM & CHEM CORP +1

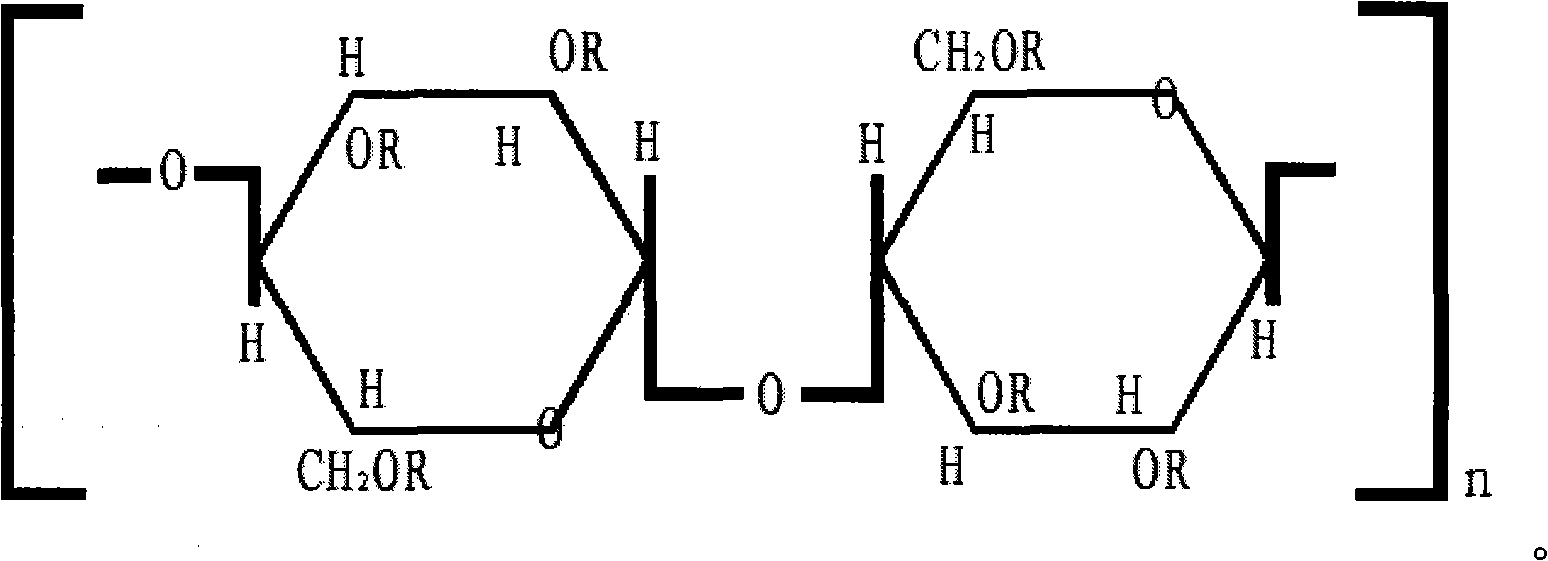

Method of preparing high viscosity carboxymethyl cellulose by slurry method

This invention relates to a preparation method of carboxymethyl cellulose with special high viscosity, in particular belonging to polymer chemistry technology, which technical program includes four steps namely cellulose activating reaction, etherification, neutralization reaction and cleaning. The key points of this invention are that slurry method can prepare the carboxymethyl cellulose with high degree of substitution and high viscosity, without the addition of cross-linker or hydrophobic reagent. The practical significance of this invention is that it can improve product performance, namely viscosity and substitution, so that it can be better used in oil drilling, textile, sewage treatment, food processing and other fields.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

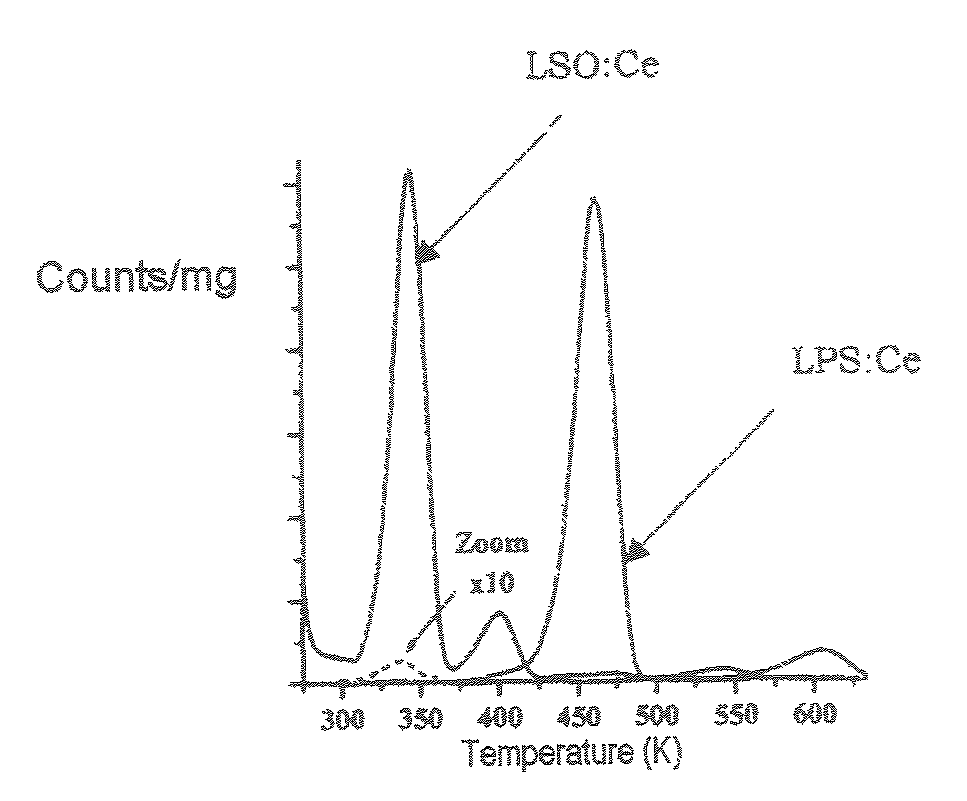

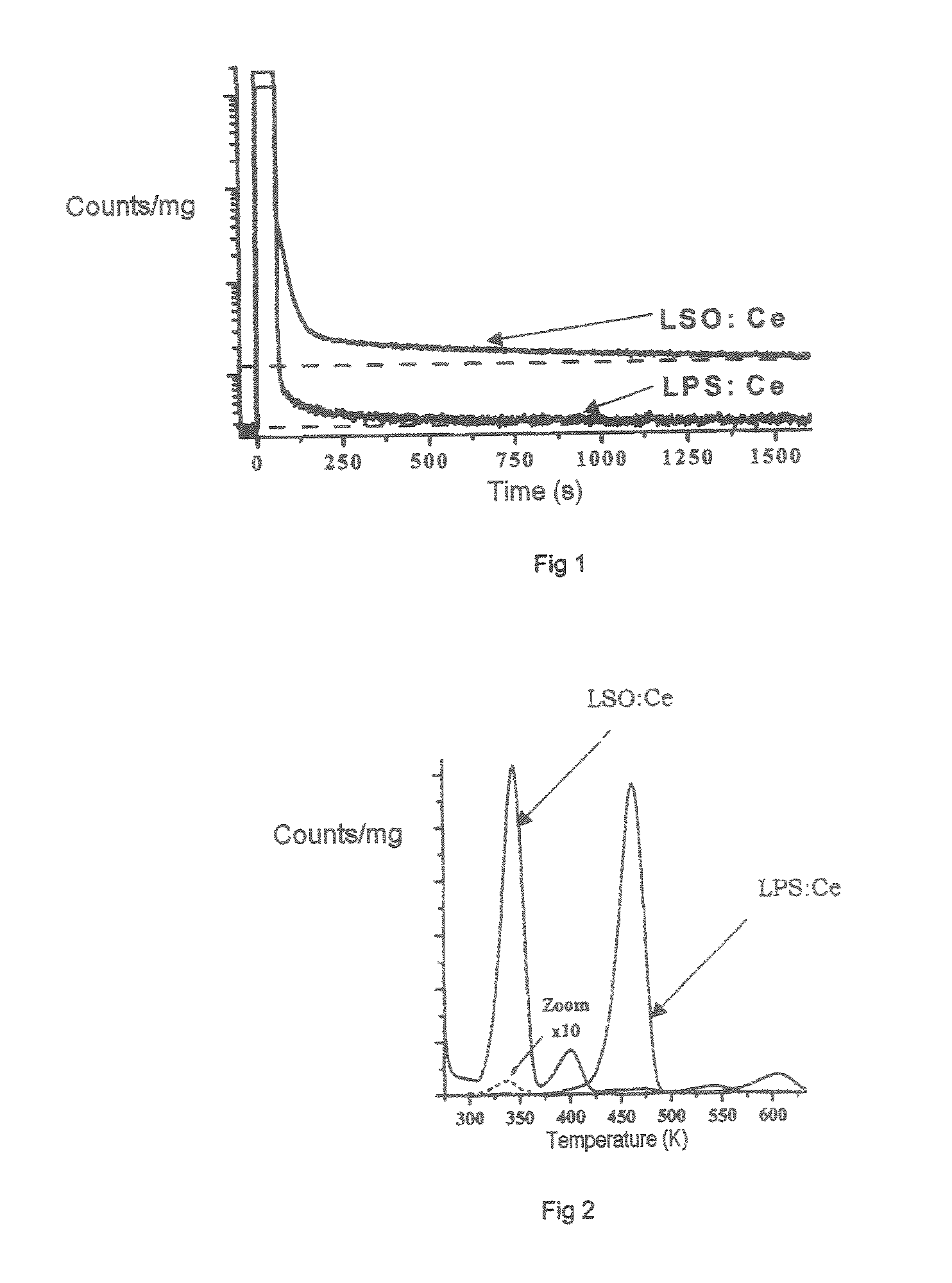

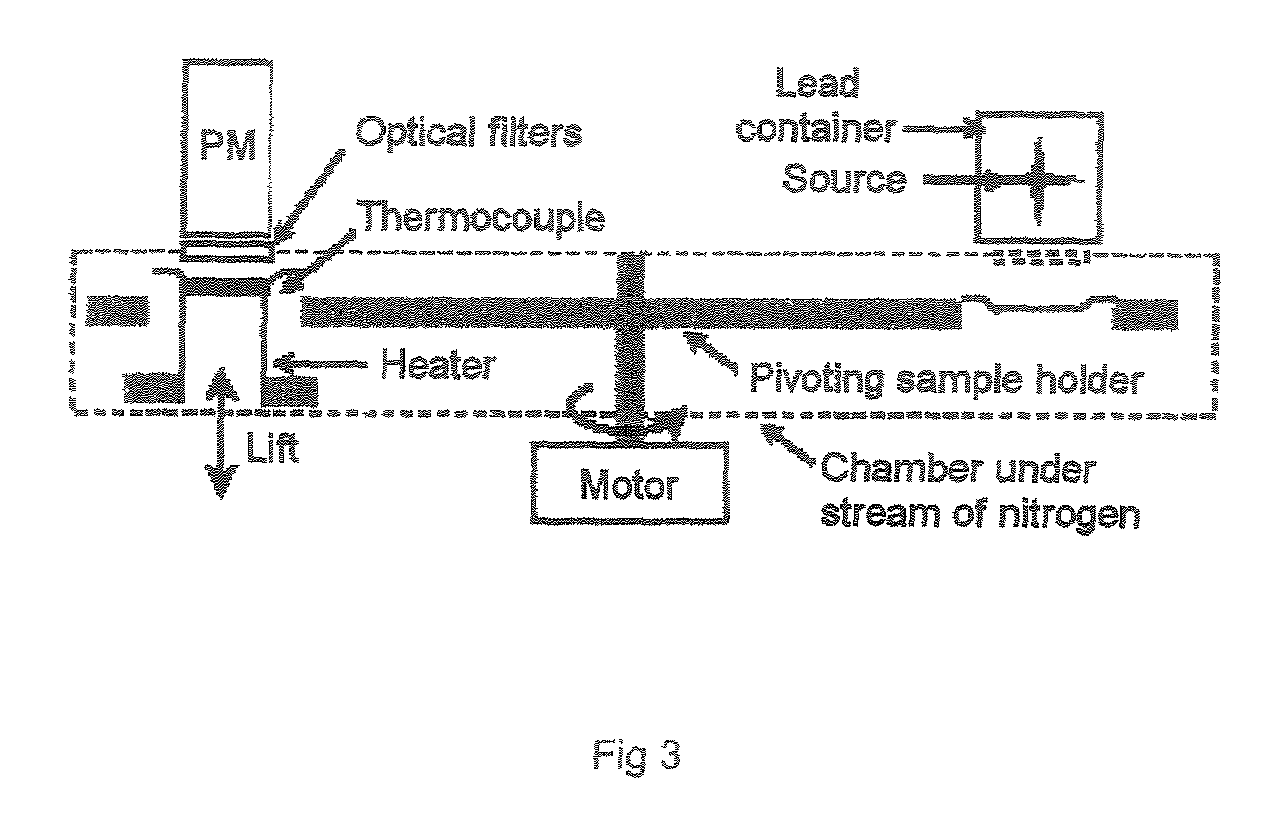

Low-delayed luminescence dense and rapid scintillator material

ActiveUS7651632B2Material analysis by optical meansLuminescent compositionsAlkaline earth metalMetallurgy

The invention relates to an inorganic scintillator material of formula Lu(2−y)Y(y−z−x)CexMzSi(1−v)M′vO5, in which:M represents a divalent alkaline earth metal and M′ represents a trivalent metal, (z+v) being greater than or equal to 0.0001 and less than or equal to 0.2,z being greater than or equal to 0 and less than or equal to 0.2;v being greater than or equal to 0 and less than or equal to 0.2,x being greater than or equal to 0.0001 and less than 0.1; andy ranging from (x+z) to 1.In particular, this material may equip scintillation detectors for applications in industry, for the medical field (scanners) and / or for detection in oil drilling, The presence of Ca in the crystal reduces the afterglow, while stopping power for high-energy radiation remains high.

Owner:LUXIUM SOLUTIONS LLC

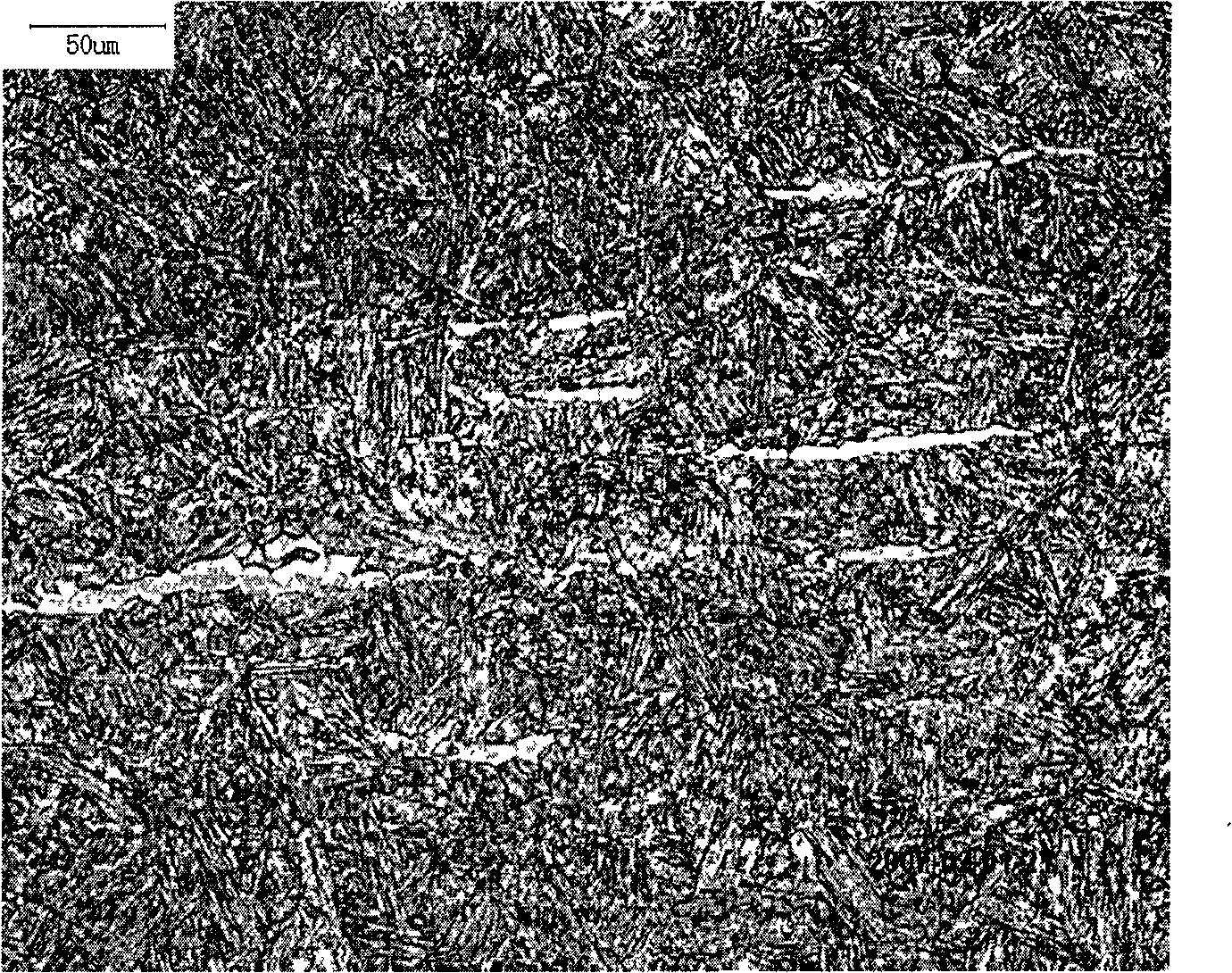

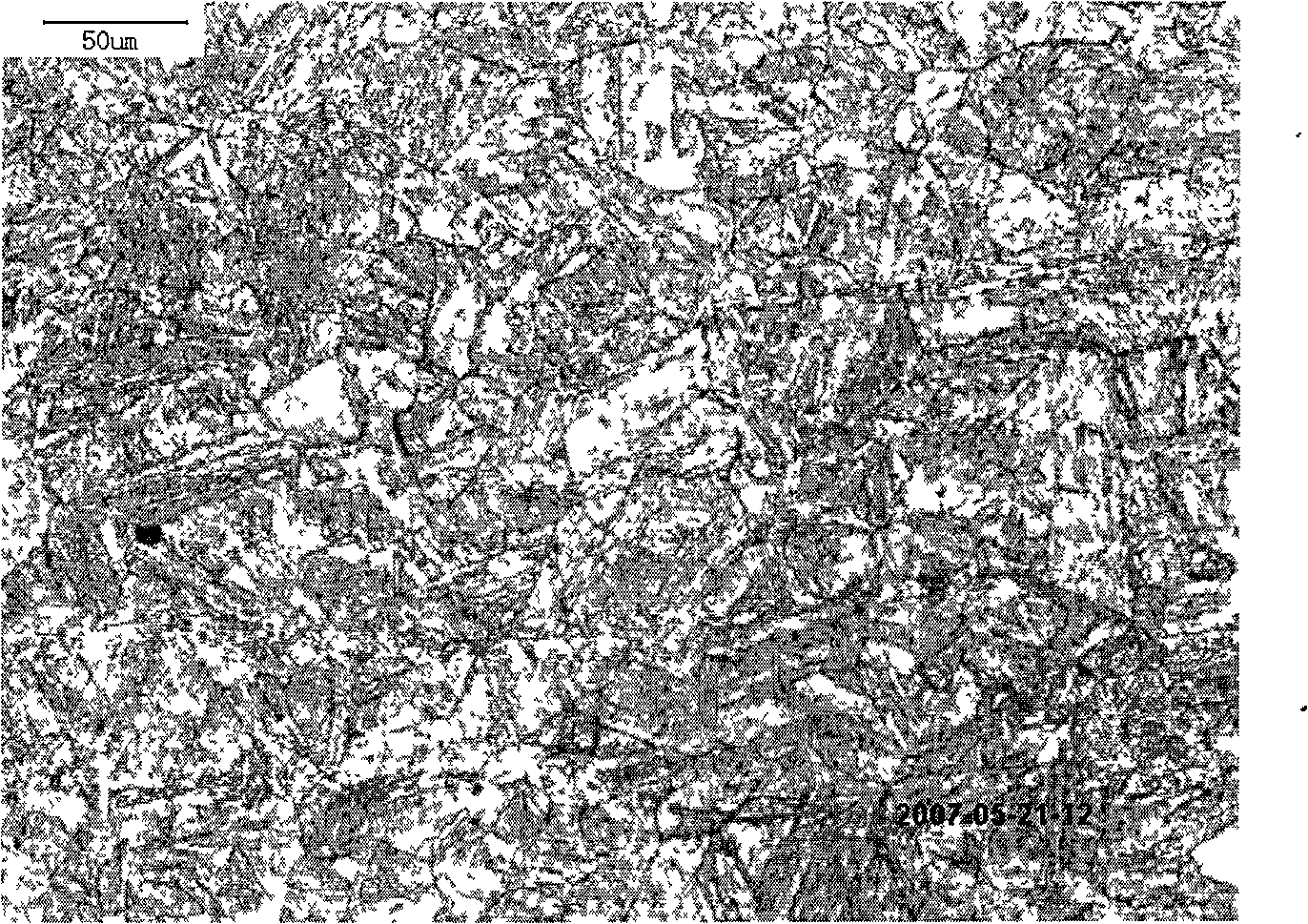

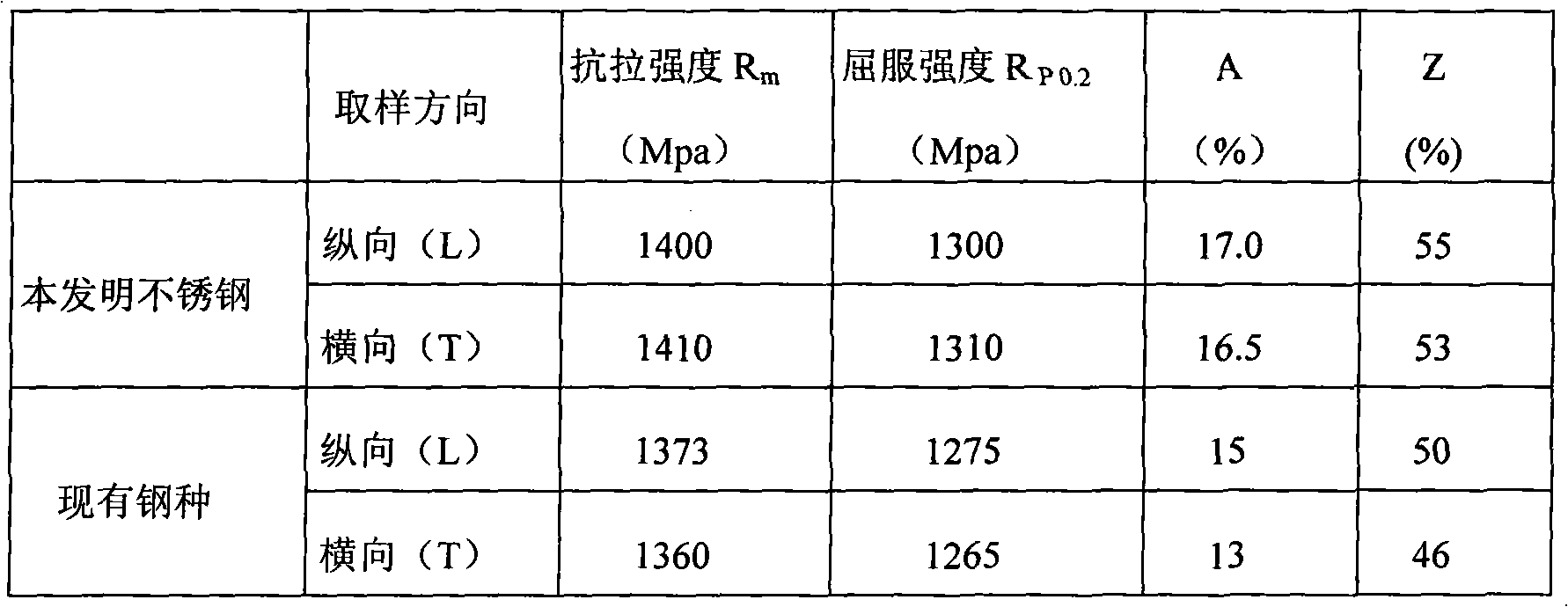

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

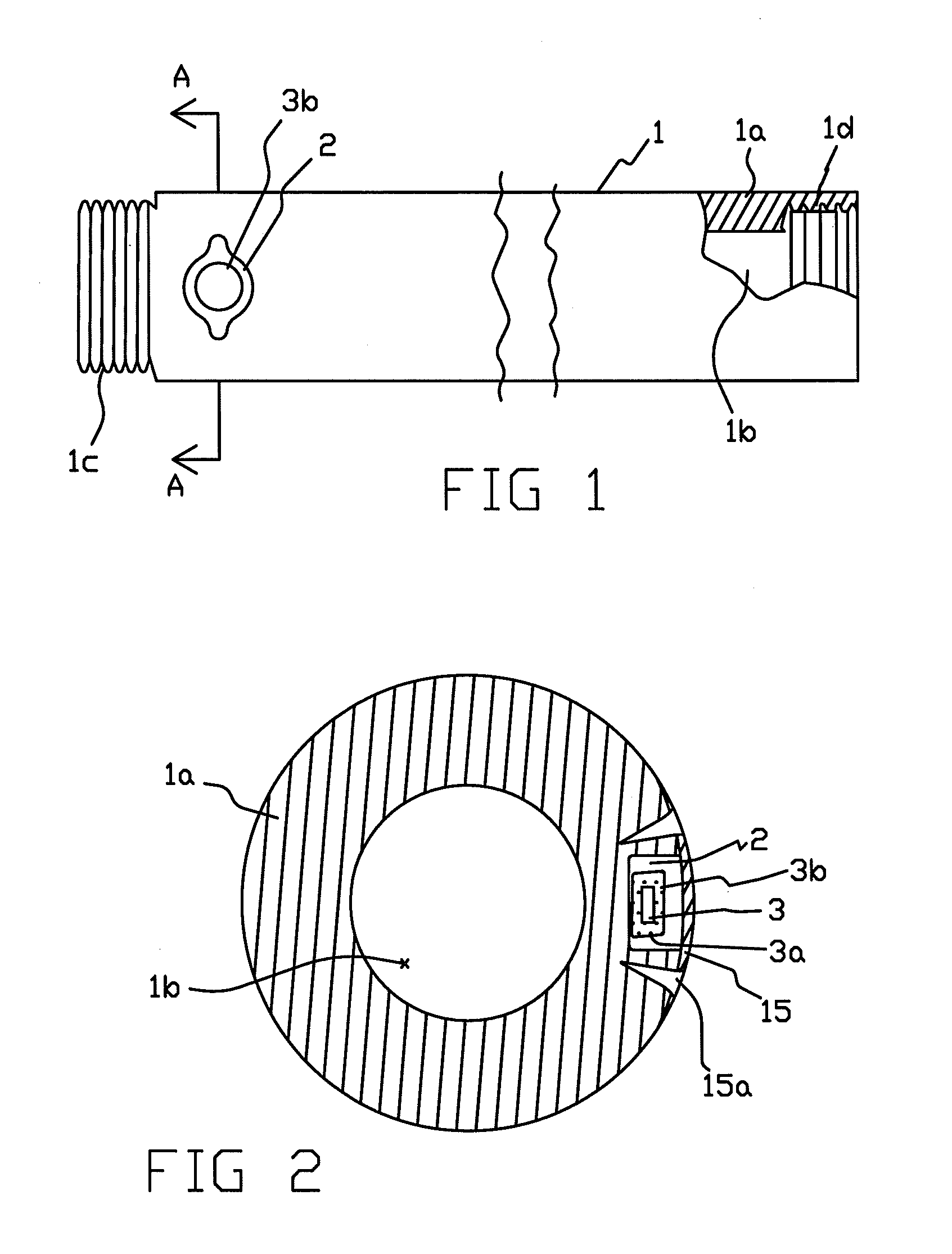

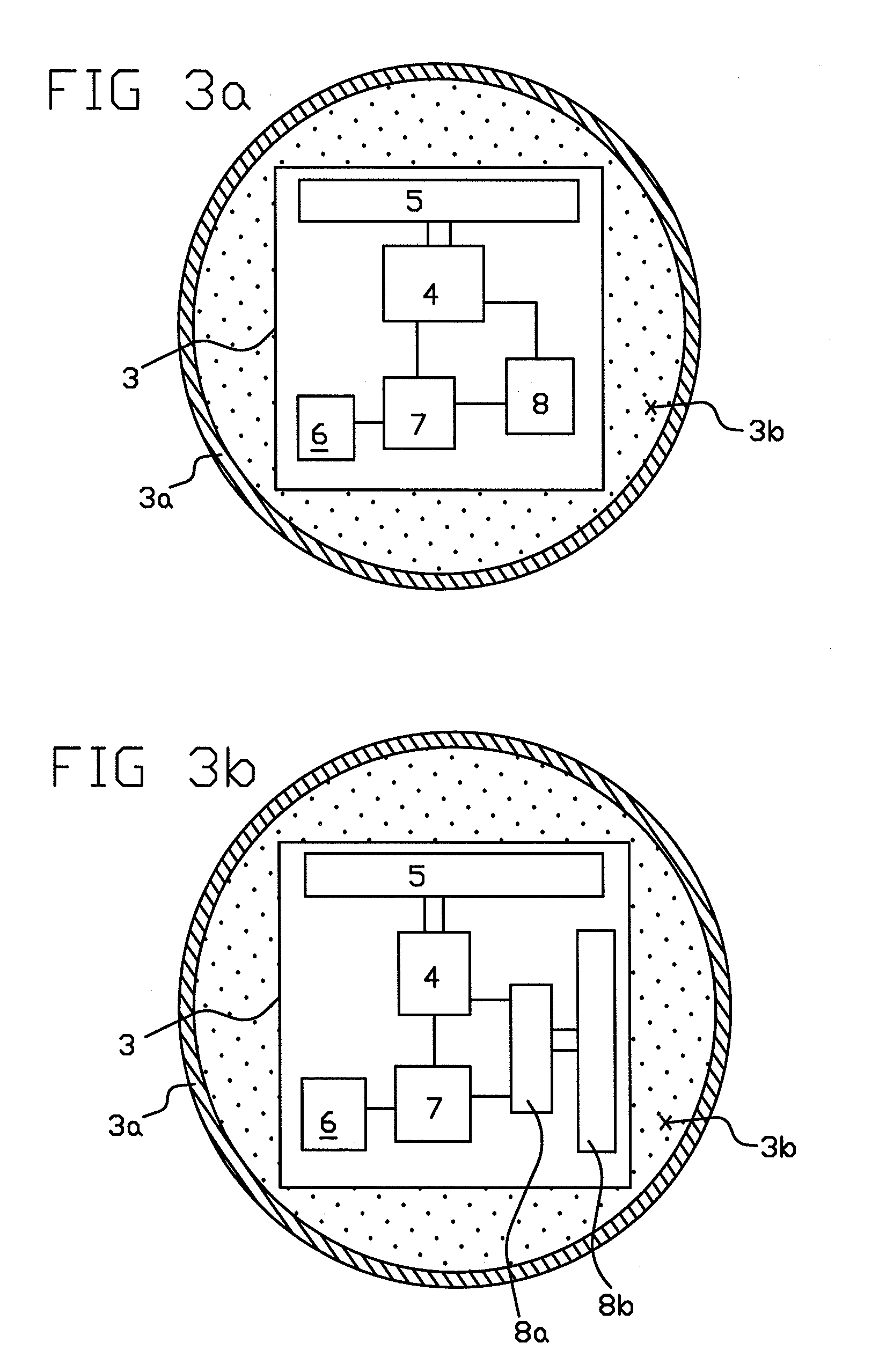

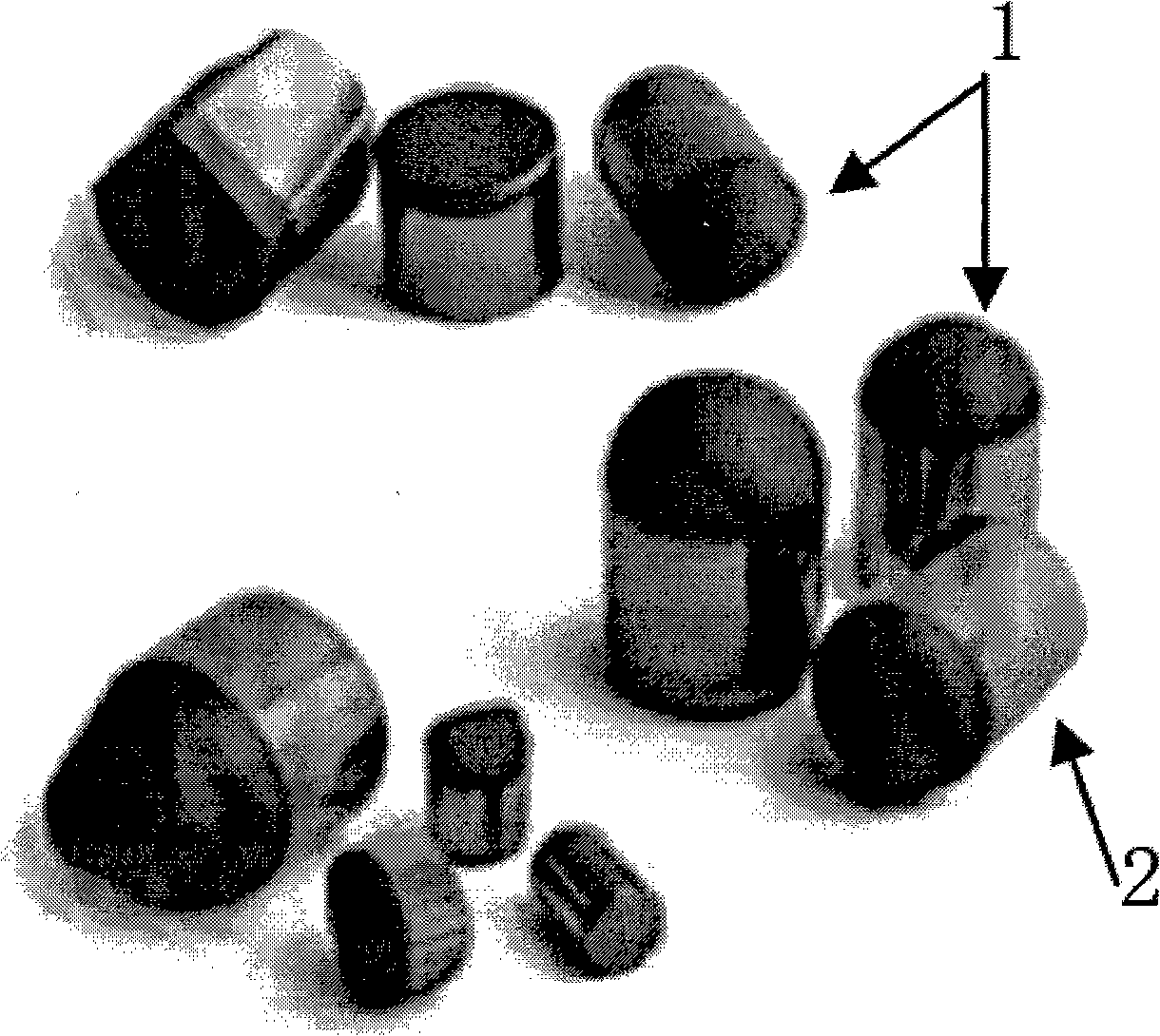

Tracking of Oil Drilling Pipes and Other Objects

ActiveUS20100245075A1Facilitate data communicationMaximize signal strengthSurveyIndividual entry/exit registersWell drillingEngineering

Identification and tracking of hollow pipes at a site where the hollow pipes are to be stored or interconnected, such as an oil drilling site where the aforesaid hollow pipes are to be connected and the drillstring of pipes is to be inserted into a drilled hole on solid ground or under a deepsea drilling platform is achieved. Each hollow pipe is provided with a low frequency radio frequency identification (RFID) tag attached to the pipe's outer surface. The RFID tag is operable at a low radio frequency not exceeding 1.0 megahertz and may be disposed within a recess in the pipe's outer surface. A tracking system provides communication be the tags and a reader.

Owner:VISIBLE ASSET INC

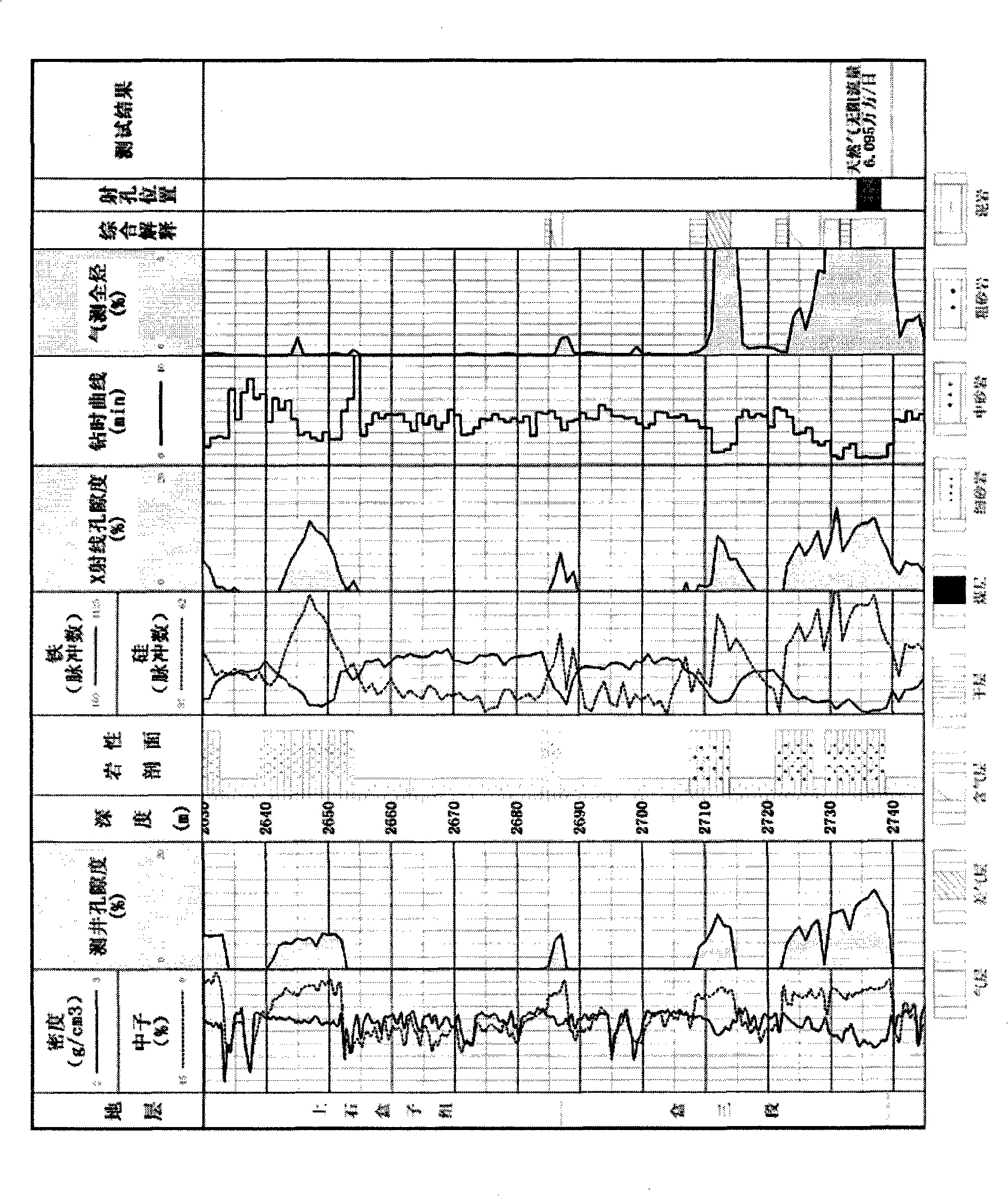

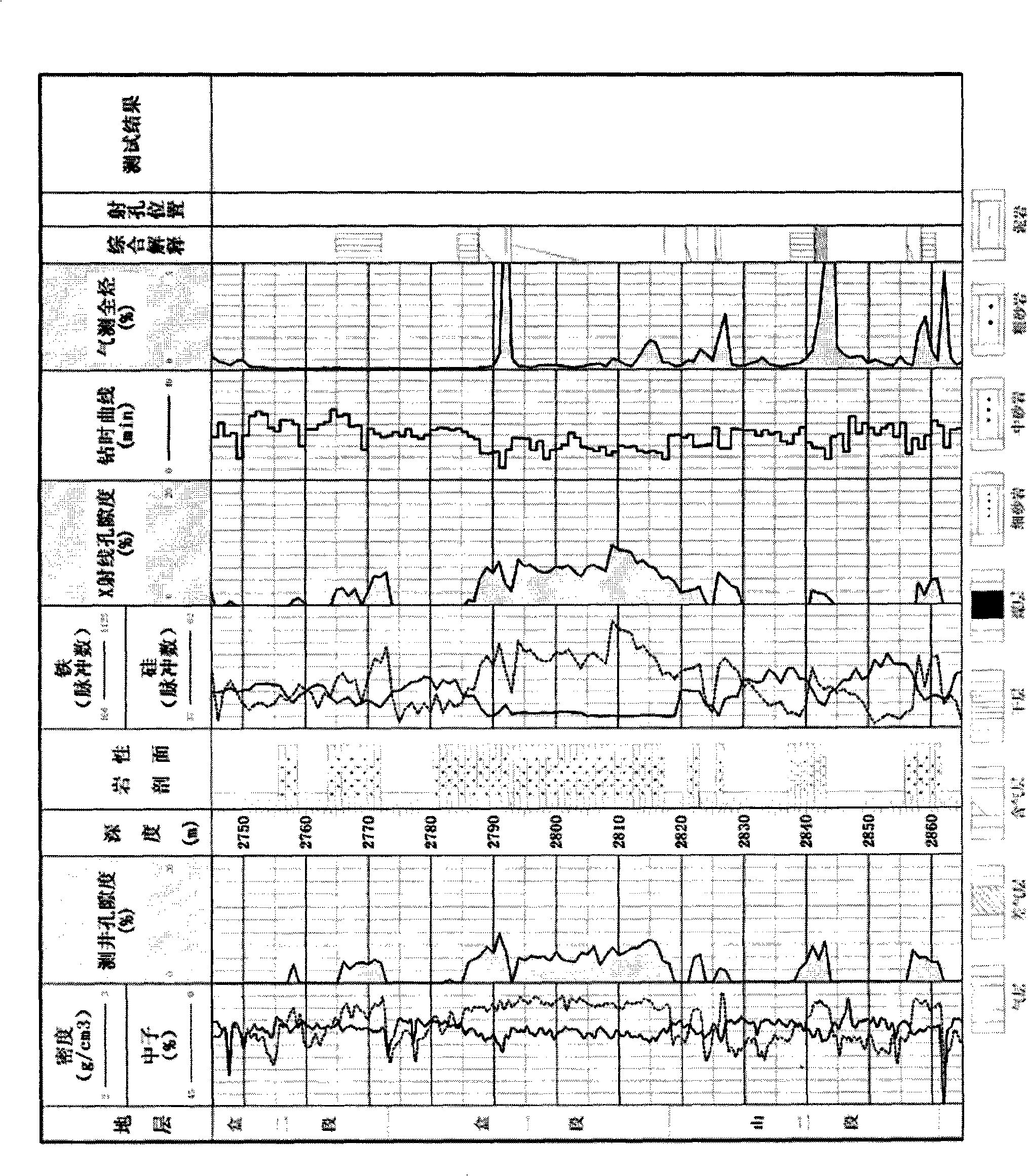

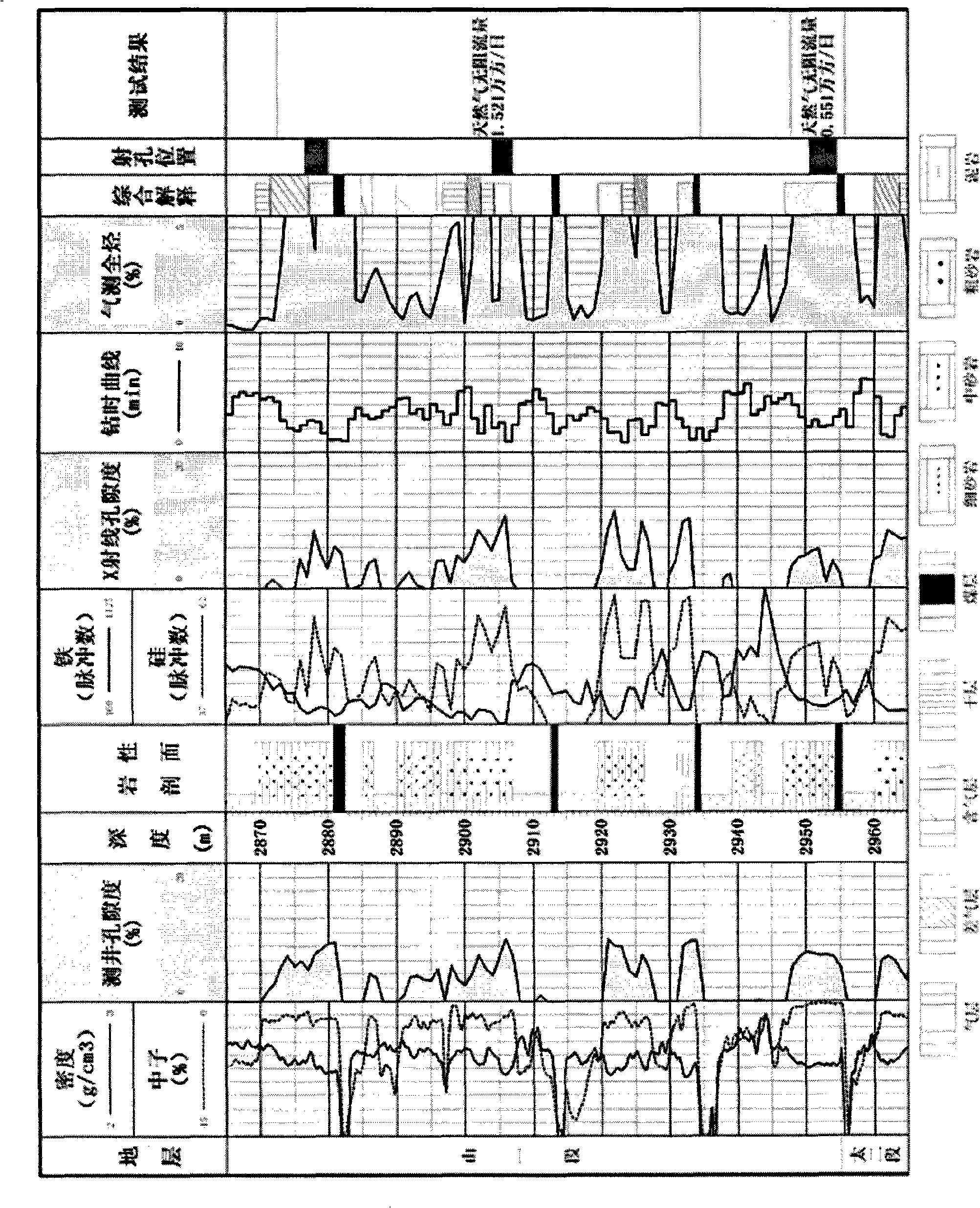

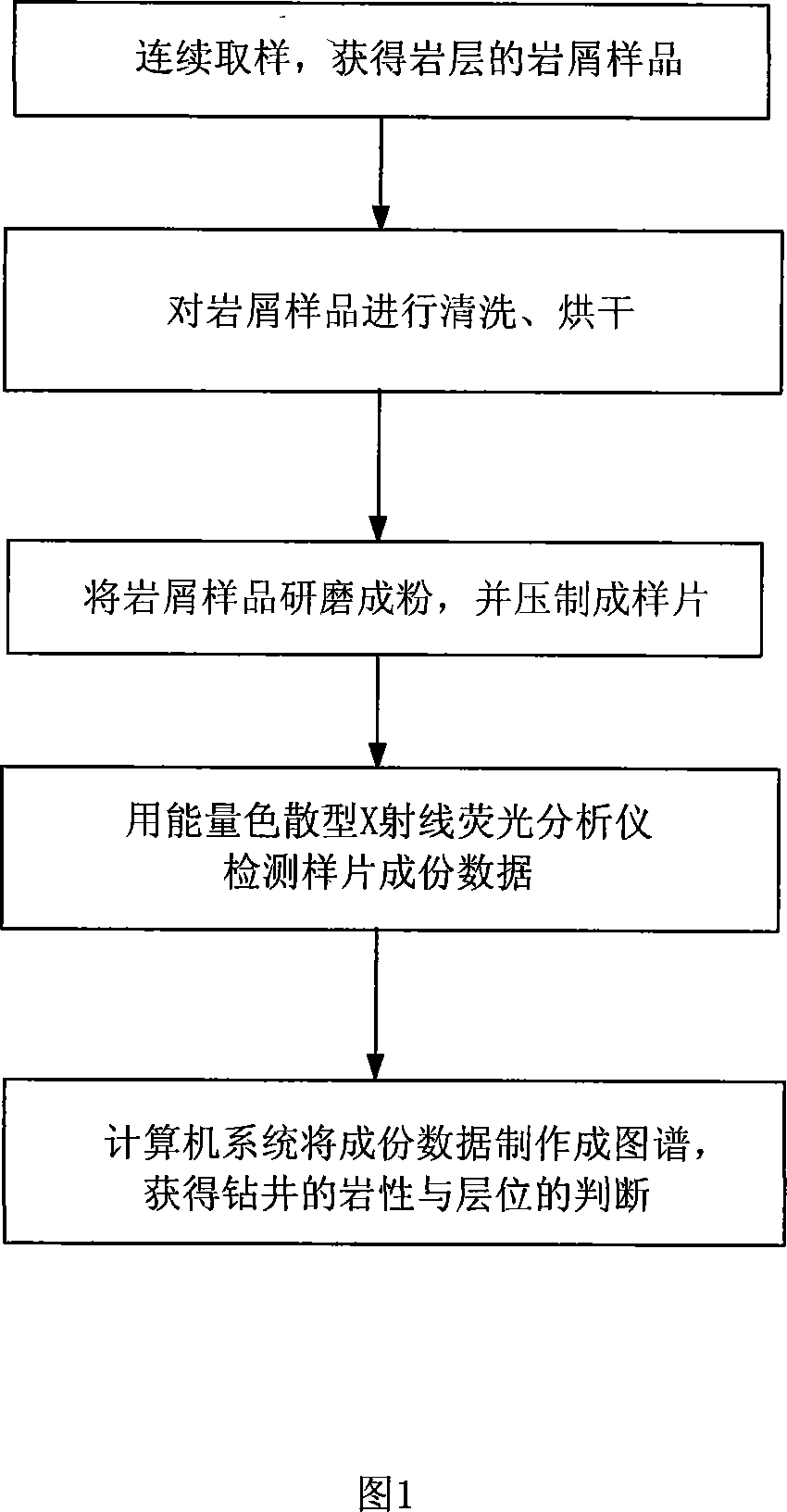

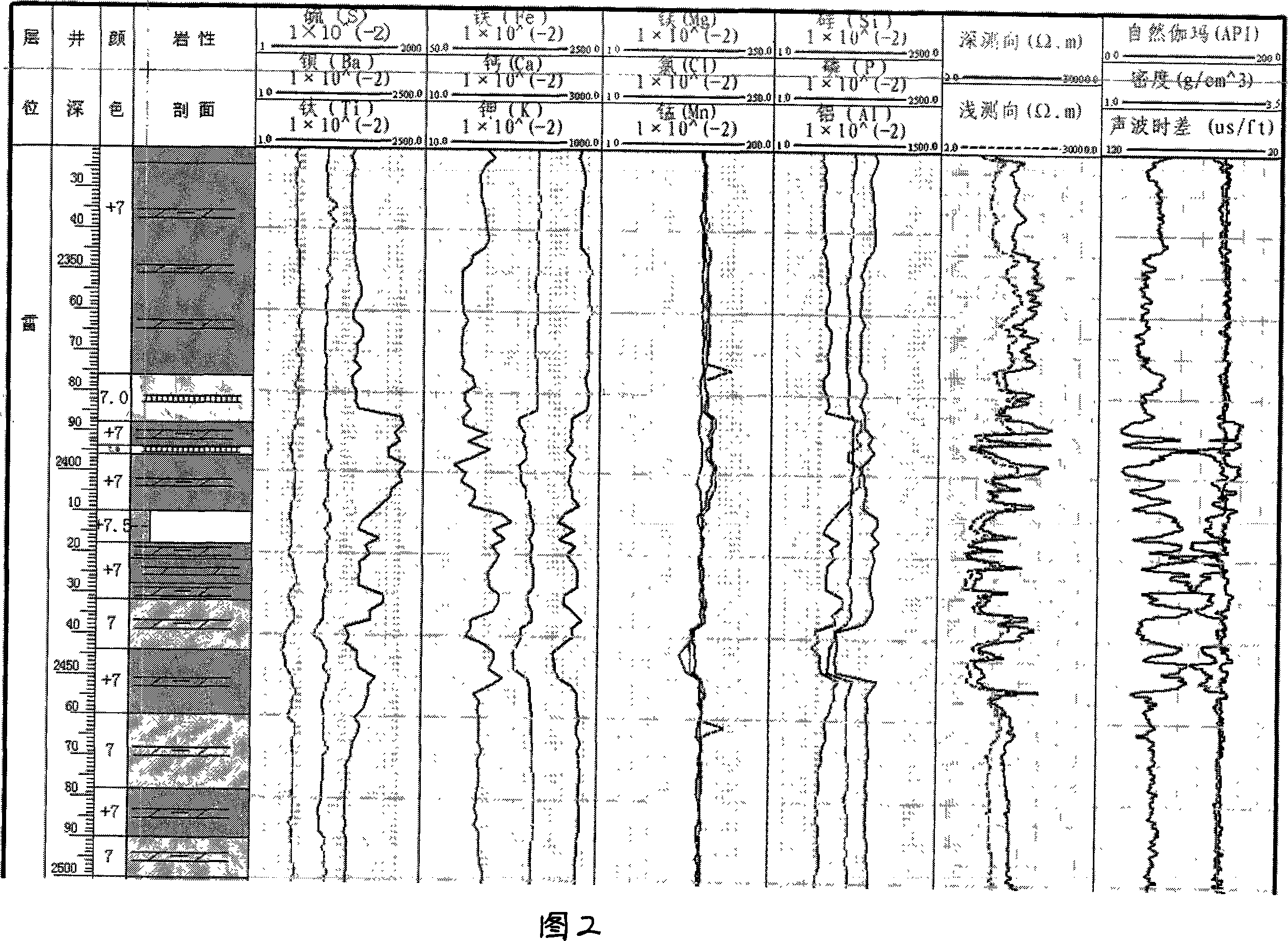

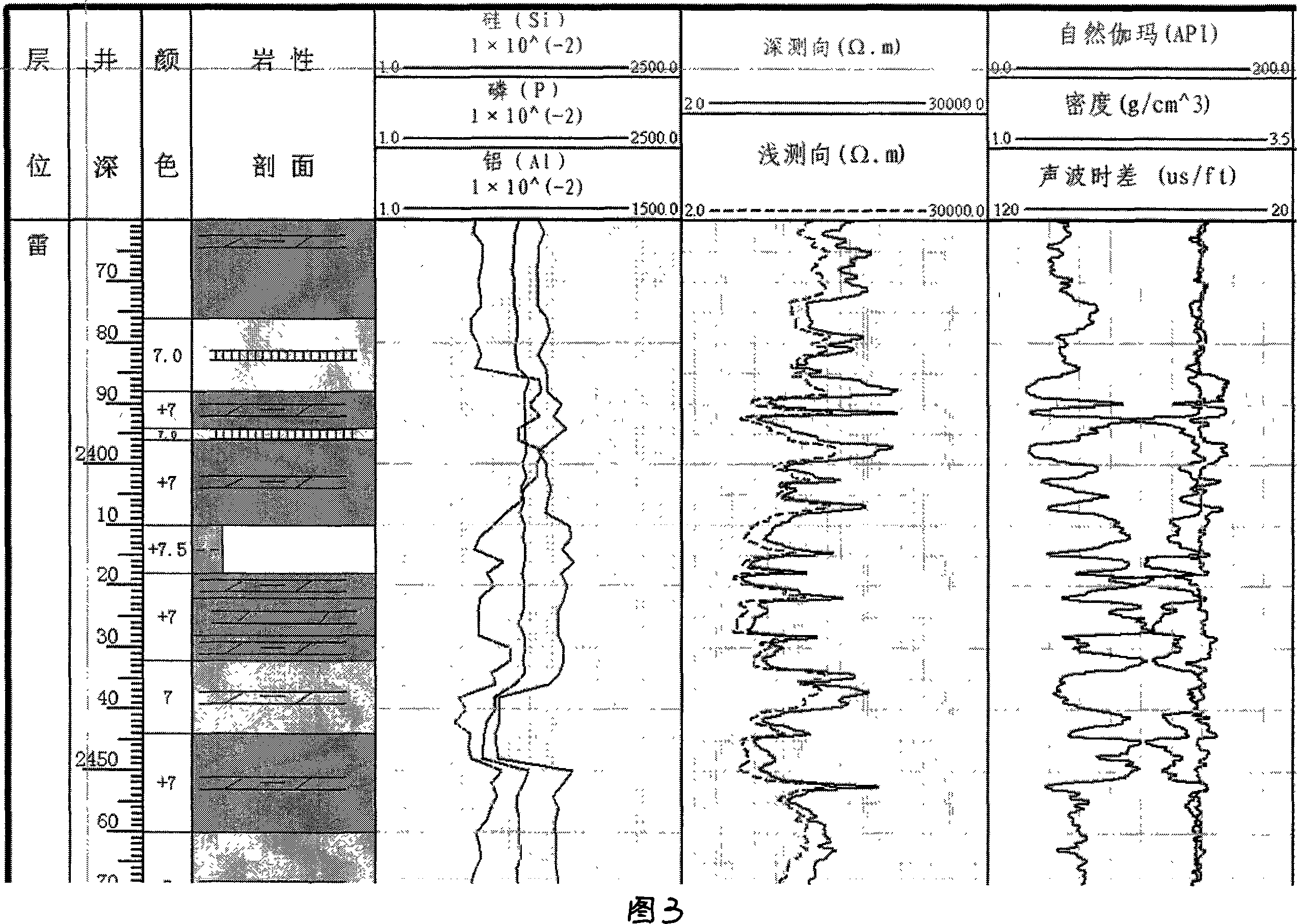

Analytical method of X-ray fluorescence terrigenous clastic rock porosity in petroleum well drilling

ActiveCN101344001ACorrect and effective guidanceCorrect and Effective Exploration and Development PracticeBorehole/well accessoriesPorosityAnalysis data

The invention relates to a method for using X-ray fluorescence to analyze the extent of porosity of terrigenous clasolite in oil drilling; the method comprises the following steps of: adopting an energy dispersion-typed X-ray fluorescence analyzer to carry out continuous analysis to the chemical elements in the rock core and rock debris in the oil drilling field with the drilling depth; obtaining the analysis data of the X-ray fluorescence changing with the depth; selecting silicon and ferrum elements which have obvious positive and negative relationship with the reservoir property of the rock; using the data of the silicon and ferrum elements to carry out 0-1 normalization data calculation; then calculating the extent of porosity; finally mapping the curve of the extent of porosity; and evaluating the reservoir property according to the curve of the extent of porosity and the value of the extent of porosity. The method of the invention can carry out X-ray fluorescence analysis and the analysis of the extent of porosity of the terrigenous clasolite in real time, use the data of the extent of porosity in real time to carry out quantitative evaluation to the reservoir property of the rock, form a geology explanation and evaluation method with the drilling based on the analysis of the X-ray fluorescence and guide exploration and development practice of oil and natural gas accurately and effectively.

Owner:中石化石油工程技术服务有限公司 +3

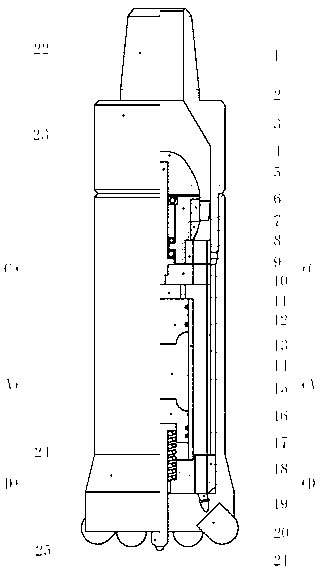

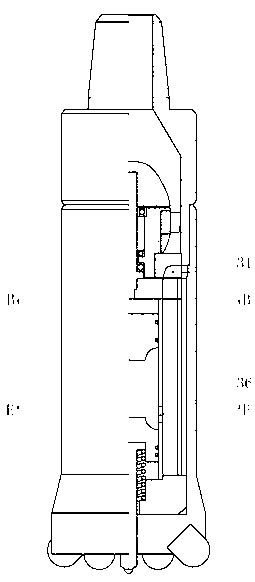

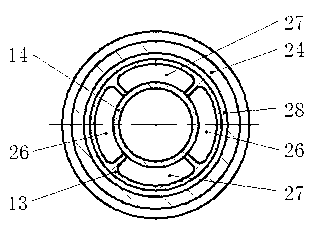

Hydraulic hammer rod type impact drilling tool

ActiveCN103244052AIncrease ROPTo achieve the requirements of different impact frequenciesBorehole drivesBall bearingThrust bearing

The invention provides a hydraulic hammer rod type impact drilling tool and belongs to the field of geological exploration engineering and oil drilling. The technical scheme of the hydraulic hammer rod type impact drilling tool includes that the hydraulic hammer rod type impact drilling tool is composed of a turbine driving device, a rotary valve flow distribution mechanism, a impact device, an end cap, a punch hammer, an outer cylinder, an inner cylinder, sealing rings, a flow diversion disk, a casing and drill bit. The turbine driving device comprises a fixed shaft, an upper deep groove ball bearing, a turbine disk, turbine blades, a pressing disk, a lower deep groove ball bearing and a thrust bearing, the rotary valve flow distribution mechanism comprises an upper valve plate and a lower valve plate, and the impact device comprises an impact base, a spring and a hammer rod. When the hydraulic hammer rod type impact drilling tool is operated, the turbine driving device drives the upper valve plate to rotate, an input hole is communicated with a first overflowing hole and a second overflowing hole of the lower valve plate alternately so as to enable the punch hammer to reciprocate in the inner cylinder to achieve circulation impact on an impact base, and impact energy is transmitted to the hammer rod for rock breaking. The hydraulic hammer rod type impact drilling tool can form high frequency axial impact force for assisting rock breaking, facilitates prolonging of service life of the drill bit, improves mechanical drilling speed, and is particularly suitable for hard formation drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Oil well drilling geological X-ray fluorescent debris logging method

InactiveCN101082277AReduce testing costsGuaranteed accuracyBorehole/well accessoriesLithologyHorizon

An X-ray fluorescence debris recording method of oil drilling geology is characterized in that: it contains the following steps: 1. sample from shallow to deep continuously on the drilling depth to get the debris samples of each drilling depth rock formation. 2. Clear the debris samples of each drilling depth rock formation on the drilling depth and dry these debris samples. 3. Grind the debris samples to powder and put them into the pressing die. Press the powder to print by using the tablemachine under the vacuum. 4. Test the component data of the print sequentially by using the energy dispersing-type X-ray fluorescence analyzer on the drilling depth. 5. The computer system makes the rock component data to the atlas on the drilling depth. Based on the analysis of the data and the atlas, the decision of the drilling lithologic characters and horizon is achieved. The distinct effects of this invention are: the cheap price, the low testing cost, the shorter analysis cyclic, the rock structure can be achieved simultaneously as the drilling speed.

Owner:重庆奥能瑞科石油技术有限责任公司

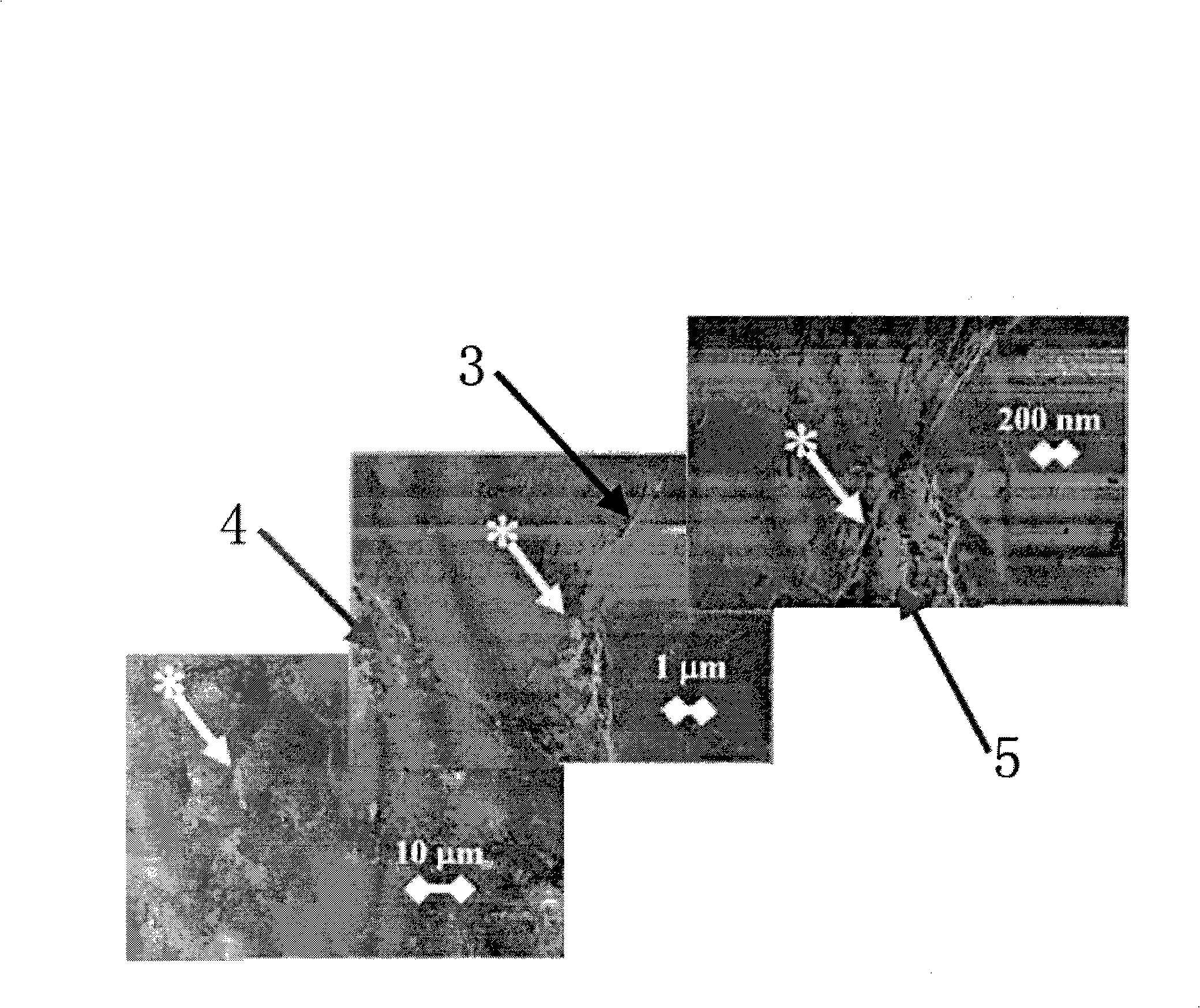

Diamond-silicon carbide combination drill teeth for petroleum probe boring and manufacture method thereof

The invention relates to a diamond-silicon carbide composite drilling tooth used for oil drilling, the material of a substrate is hard alloy, and the material of a tooth crown is a diamond-silicon carbide compound in nano-structure. The microstructure of the diamond-silicon carbide compound in the nano-structure is formed by the direct combination of micron-sized diamond grains, and nano-silicon carbide binder and nano-diamond grains are filled in the slits of the micron-sized diamond grains. The preparation method of the composite drilling tooth comprises the steps that: diamond powder and silica powder are ground by a ball grinder after being mixed, then ground mixed powder material is mixed with carbon nanotube fiber to form diamond-amorphous silicon-carbon nanotube fiber mixed powder material which is put into a die, and the substrate is covered and treated with pressure forming to form a blank; high pressure sintering is carried out to the blank. The product greatly improves the fracture toughness and the anti-impact strength of the material on the premise of keeping the high hardness, high wearing resistance and high heat stability of the diamond-silicon carbide composite.

Owner:贺端威 +1

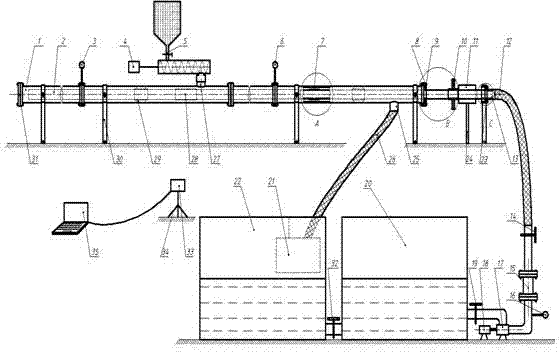

Horizontal well rock debris transportation simulation experiment set and experiment method

The invention relates to a horizontal well rock debris transportation simulation experiment set and experiment method which are used for simulating oil drilling and coal bed gas drilling. The horizontal well rock debris transportation simulation experiment set comprises a drill fluid system, a rock debris transportation system, a rock debris supply system, a power system, a data processing system and a rock debris recovering system. The drilling liquid system is composed of a liquid storage tank, a motor, a centrifugal pump, a flowmeter and a butterfly valve which are connected. The rock debris transportation system is composed of a converting connector, a glass tube, a PVC tube, a rock carrying tool, an eccentric triangular plate and the like. The rock debris supply system is composed of a spiral feeder and a rock debris filling device. The power system is composed of a speed regulating motor and a speed changing gear. The rock debris recovering system is composed of a recovering tube, a filter and a rock debris recovering pool. The horizontal well rock debris transportation simulation experiment set and the experiment method can be used for visually observing the transportation condition of horizontal well rock debris, and the influence of different discharge capacities, drill stem rotating speeds, the eccentricity between a drill stem and a borehole, rock debris amounts and rock debris grain sizes on a horizontal well rock debris transportation rule can be simulated. The horizontal well rock debris transportation simulation experiment set is simple and practical, and low in construction cost.

Owner:SOUTHWEST PETROLEUM UNIV

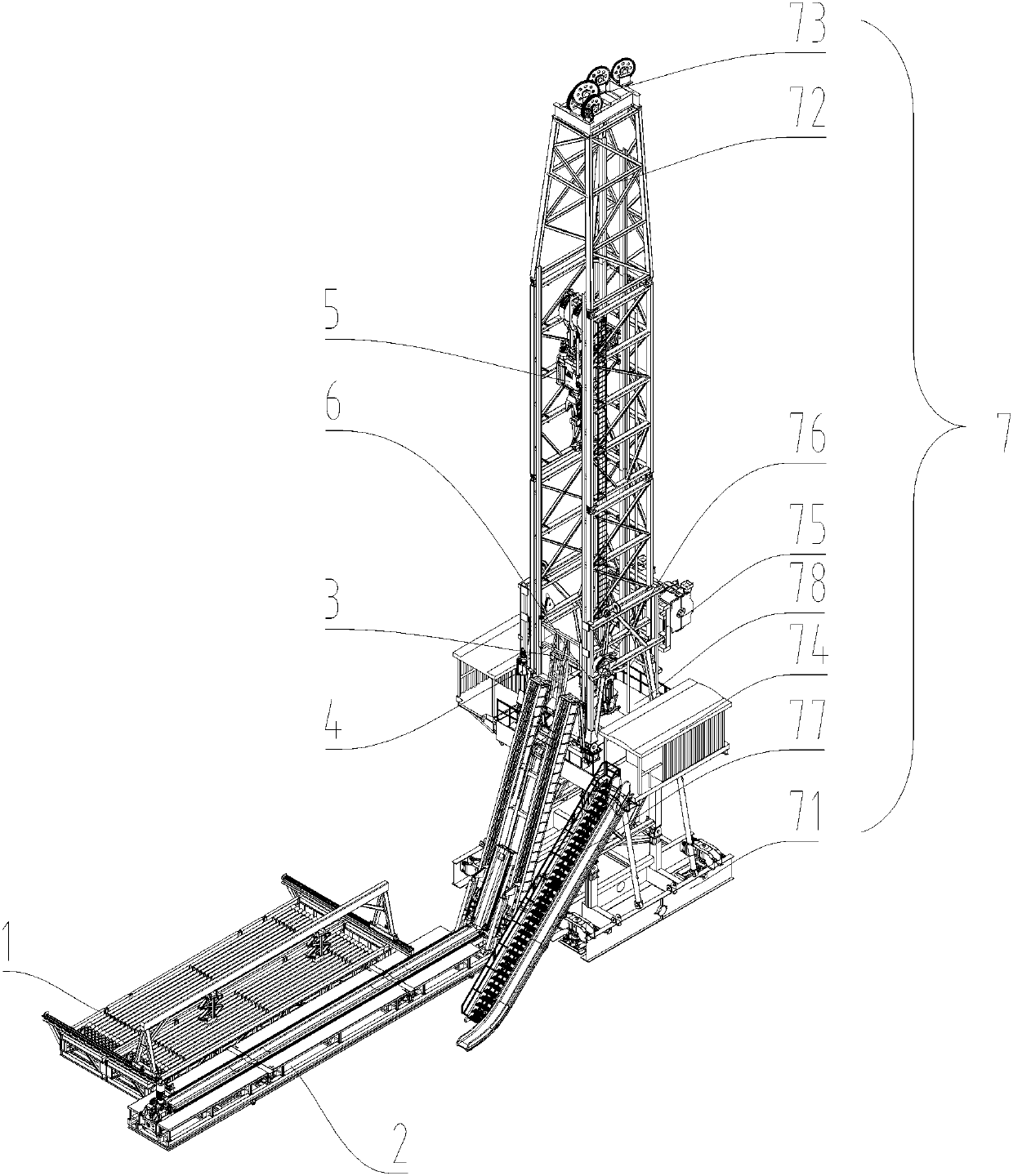

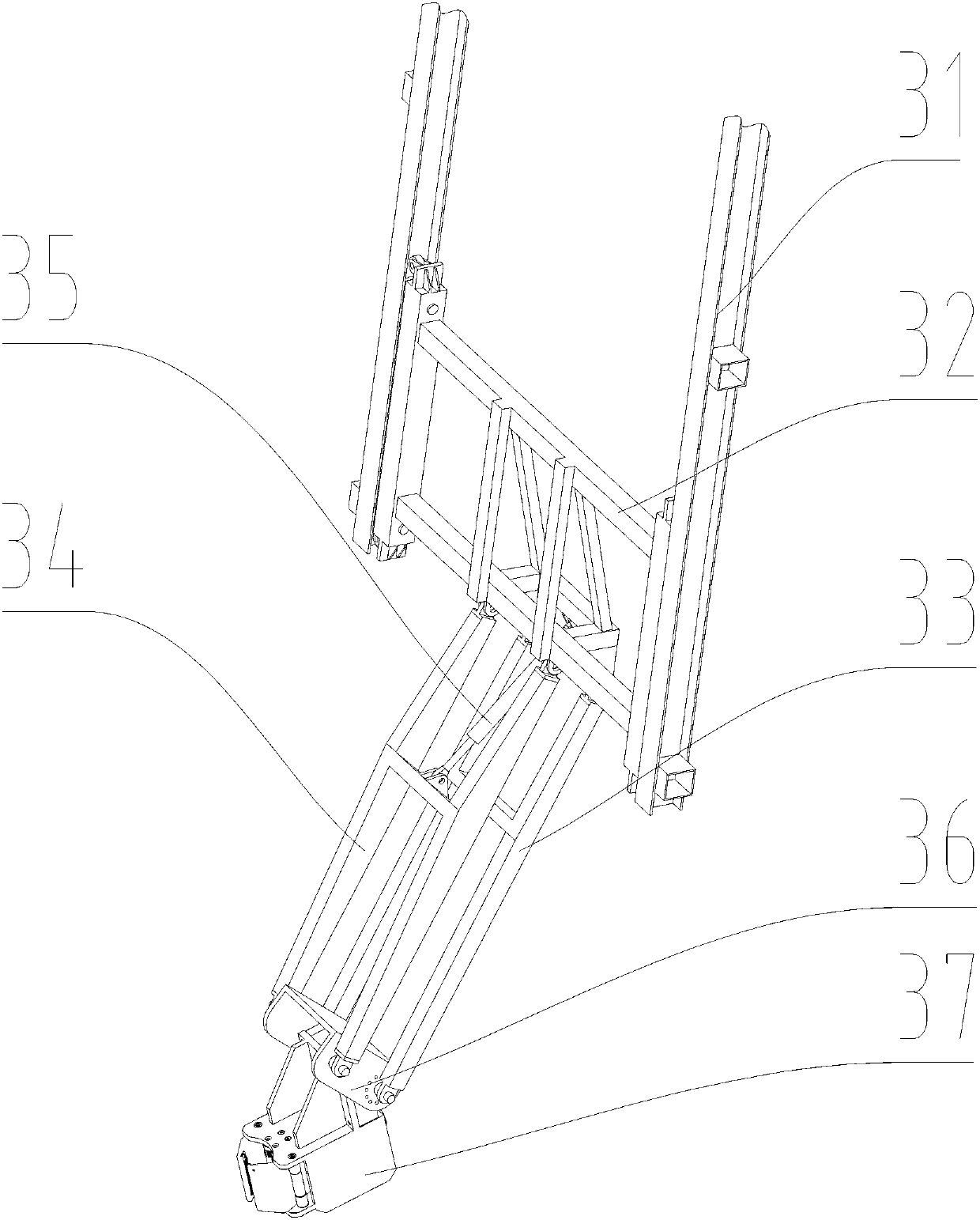

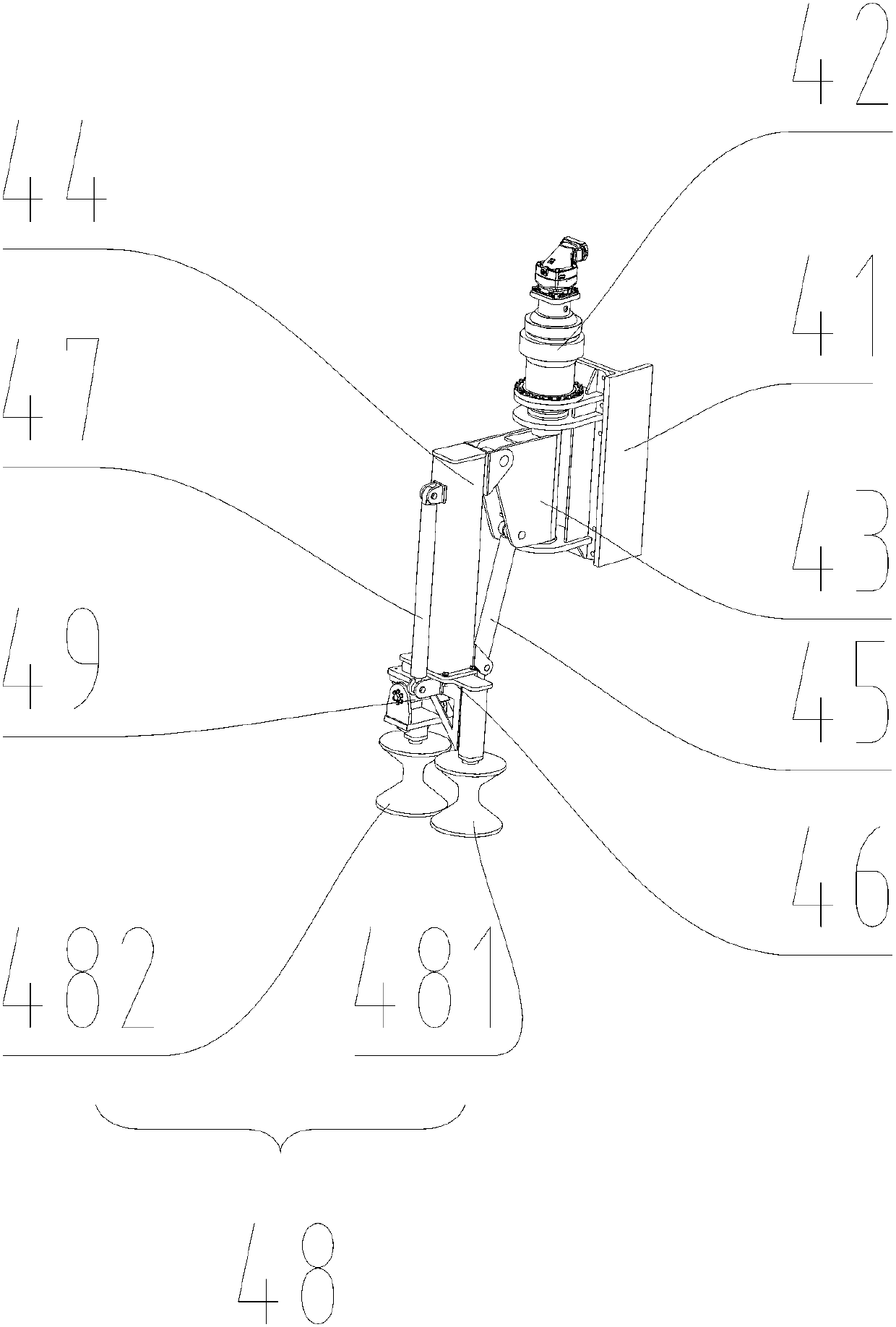

Automated drilling rig and method for moving and transporting pipe columns through automated drilling rig

PendingCN110043203AImprove work efficiencyLow running costDrilling rodsDrilling casingsRoughneckOil drilling

The invention relates to the field of oil drilling equipment, in particular to an automated drilling rig. The automated drilling rig comprises a derrick assembly fixedly connected with a foundation, atop driving assembly movably connected with the derrick assembly, and an iron roughneck fixedly connected with the derrick assembly; and the automated drilling rig further comprises a power pipe-arranging box fixedly connected with the foundation, a power catwalk fixedly connected with the foundation and the derrick assembly, a double-joint grabbing manipulator and a supporting manipulator, wherein the double-joint grabbing manipulator and the supporting manipulator are fixedly connected with the derrick assembly. The invention further discloses a pipe column moving and transporting method. The automated drilling rig occupies the small space and is simple in structure, the process is concise and easy to realize, the operation cost of the whole drilling rig is lowered, the working efficiency is improved, and the risk of safety incidents is lowered.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Anti-ice paint and preparation method thereof

The invention discloses an anti-ice paint and a preparation method thereof. The paint comprises a polyacrylate graft PDMS (Poly Dimethyl Siloxane) copolymer containing POSS (Polyhedral Oligomeric SilSesquioxane), a curing agent and a diluent. A coating prepared by utilizing the paint and adopting a paint coating process has the advantages of anti-ice ability, good mechanical property, good compatibility with other materials, good adhesive force and difficulty in dropping. According to the anti-ice paint and the preparation method disclosed by the invention, the preparation process of the paint is simple, and coating of the paint does not need special construction conditions and can be used by matching with a universal acrylics priming paint, so that the using range of the traditional organosilicone anti-ice paint is expanded, and the anti-ice paint can be widely used for the surfaces of outdoor facilities of traffic transportation, oil drilling platforms, electricity systems, communication systems and the like with the anti-ice needs and has an application value.

Owner:TIANJIN UNIV

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN1804016AAvoid underperformanceStable structureDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Ultra-high-pressure steel wire winding composite hose

ActiveCN104100783AImprove stress resistanceImprove pulse lifeFlexible pipesPolymer scienceMicrocrystalline wax

The invention discloses an ultra-high-pressure steel wire winding composite hose, which comprises an inner rubber pipe, a framework layer, a middle rubber layer and an outer rubber layer, wherein the framework layer is arranged outside the inner rubber pipe, the middle rubber layer and the framework layer are made into a whole, the outer rubber layer is arranged outside the middle rubber layer, inner rubber of the inner rubber pipe is prepared from the following ingredients including nitrile rubber, high styrene rubber, solution polymerized styrene-butadiene rubber, sulphur S, vulcanizing agents DTDM, vulcanization accelerators CZ, accelerators D, nanometer zinc oxides, stearic acid, scorch retarders CTP, flowing exhaust agents SC617, integral anti-aging agents 4020, anti-aging agents BLE, microcrystalline wax, carbon black, nanometer silicon dioxide, bonding agents RC, bonding agents RC-23, tackifying resin SP1068, dioctyl sebacate and polyolefin, and the middle rubber layer and the outer rubber layer are respectively made of different materials. The rubber pipe belongs to the ultra-high-pressure steel wire winding composite hose capable of bearing the pressure as high as 50 to 300 Mpa, and belongs to an ultra-high-pressure hydraulic rubber pipe meeting the requirements of engineering machinery and oil drilling.

Owner:河南亿博科技股份有限公司

Copper-nickel-tin alloy bar and manufacturing method thereof

The invention discloses a copper-nickel-tin alloy bar. The copper-nickel-tin alloy bar comprises, by mass, 14%-16% of nickel, 7%-9% of tin, 0.05%-0.3% of yttrium, 0.8%-1.0% of aluminum, 0.2%-1.0% of niobium, and the balance copper and other impurities. The invention further discloses a manufacturing method of the copper-nickel-tin alloy bar. The method comprises the steps that alloy powder is prepared according to the ingredients and the mass percentages through a gas atomization method, then an alloy ingot blank is prepared through the methods of cold isostatic pressing molding, vacuum sintering and ingot blank covering, and finally the high-quality copper-nickel-tin alloy bar is obtained through the processes of water-sealing hot extrusion, cold rotary swaging, aging treatment and the like. By means of the method, the problems of composition segregation and the like generated in the casting process of a copper-nickel-tin alloy can be avoided, and the yield is high; the copper-nickel-tin alloy bar can have high strength, high toughness and excellent abrasion and corrosion resistance at the same time, and the overall performance is higher than that of beryllium bronze. The copper-nickel-tin alloy bar can be widely applied to manufacturing of bearings, shaft sleeves, bearing bushes and other wear-resisting components which are used in high-load, high-speed and high-corrosion environments like space flight and aviation and oil drilling platforms.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com