Patents

Literature

474 results about "Extreme pressure additive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extreme pressure additives, or EP additives, are additives for lubricants with a role to decrease wear of the parts of the gears exposed to very high pressures. They are also added to cutting fluids for machining of metals.

Composition and process for lubricated plastic working of metals

InactiveUS6455476B1Work treatment devicesMetallic material coating processesInorganic saltsPhosphate

A lubricant composition for the plastic working of metals that does not require a phosphate undercoating, is waterborne, requires only a simple application process of immersion or spraying followed by drying, and provides an excellent lubricating performance comprises synthetic resin, water-soluble inorganic salt, and water. The weight ratio of the content of salt to that of synthetic resin is from 0.25:1 to 9: 1. This composition can also contain liquid and / or solid lubricating agent(s) and an extreme pressure additive.

Owner:HENKEL KGAA

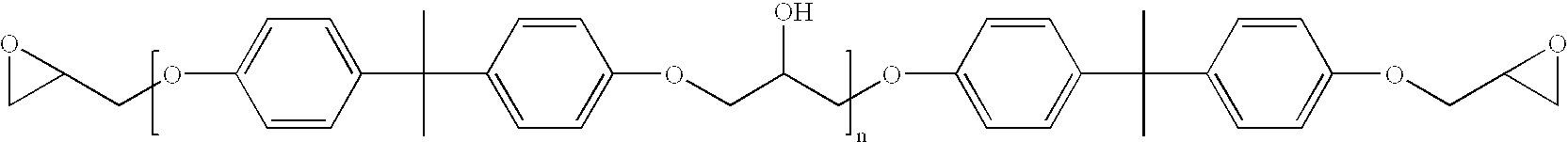

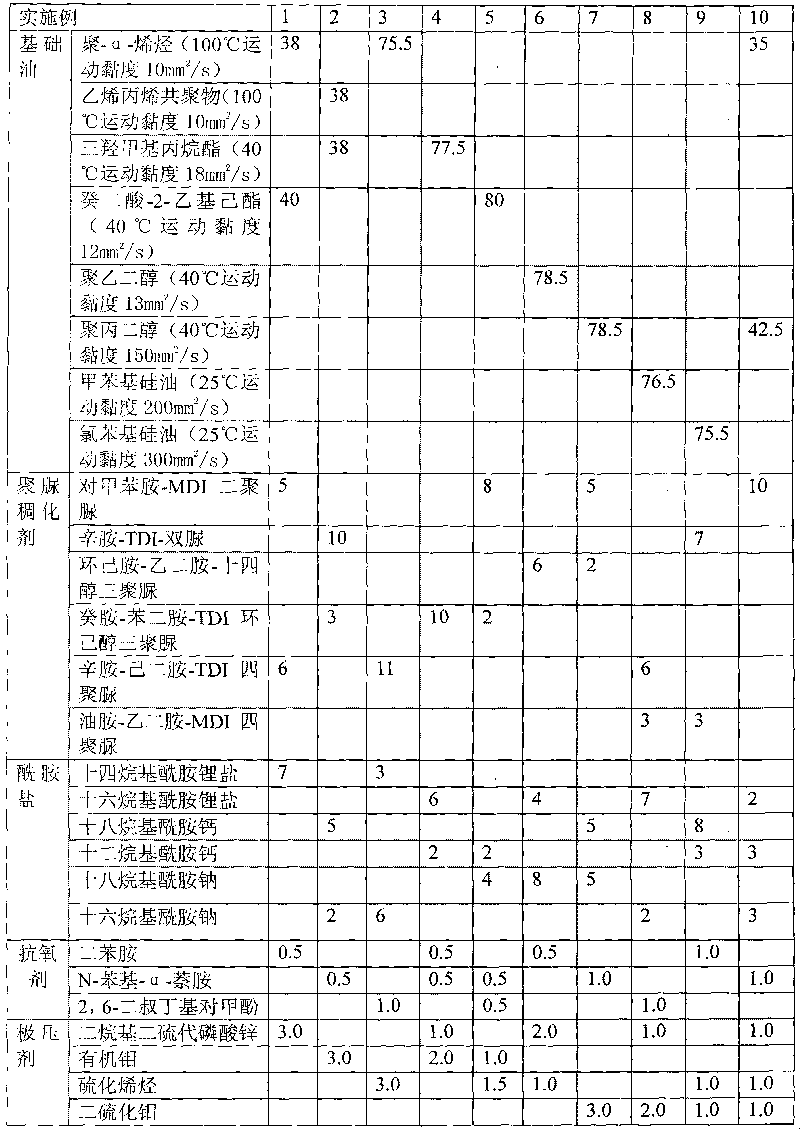

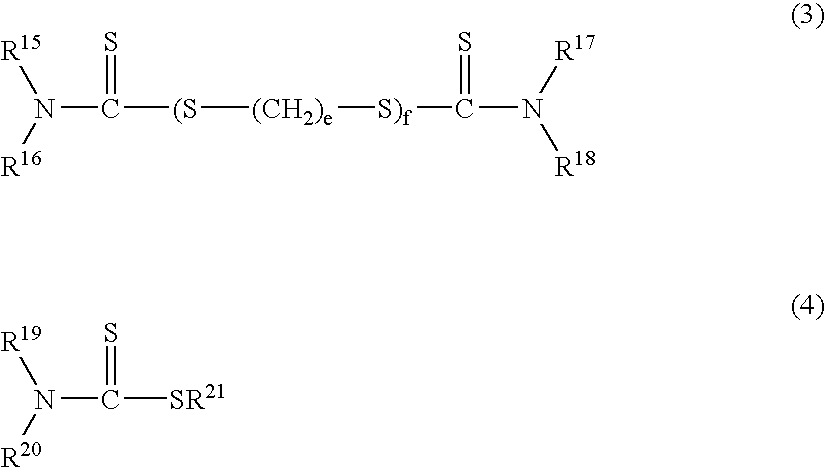

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

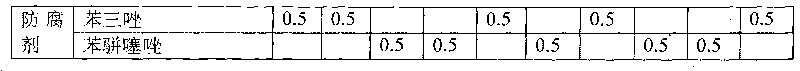

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Open-type gear grease composition

The invention provides an open gear grease composition, which comprises the following components and the weight percentage contents are that gelatinizer 2-6%, mineral oil 20-60%, synthetic oil 20-60%, antioxidant 0.3-1%, oil solubility anti-wear extreme pressure additive 1-15%, solid additive 3-20% and rust inhibitor 1-3%. The open gear grease composition of the invention does not contain dissolvent and bitumen, which has no harmless to environment, and solves the problems that bitumen-type open gear oil has bad pollution and low-temperature performance, and the flowability of open gear grease is bad. The open gear grease composition has outstanding water resistance, adhesiveness and antiwear and extreme pressure property.

Owner:益田润石(北京)化工有限公司

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

Lubricating oil composition for transmissions

InactiveUS20060135378A1Low viscosityImprove fatigue lifeAdditivesBase-materialsHydrogenOxidation stability

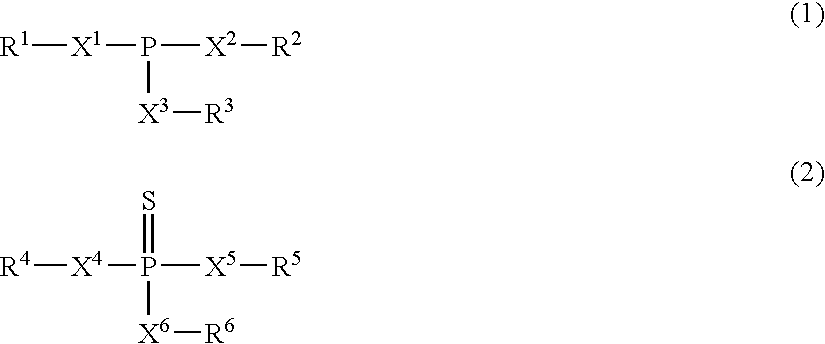

A lubricating oil composition for transmissions comprises a lubricating base oil comprising (A) a lubricating base oil so adjusted to have a kinematic viscosity at 100° C. of from 1.5 to 5 mm2 / s and a % CN of from 10 to 60 (B) a mineral lubricating base oil having a kinematic viscosity at 100° C. of from 10 to 50 mm2 / s and a sulfur content of from 0.3 to 1 percent by mass and (C) a synthetic oil composed of carbon and hydrogen and having a number average molecular weight of from 2,000 to 20,000, in respective specific amounts and (D) an extreme pressure additive of from 0.05 to 2 percent by mass, based on the total amount of the composition, of comprising a phosphorus-based extreme pressure additive, a sulfur-based extreme pressure additive and / or a phosphorus-sulfur-based extreme pressure additive, wherein in the composition, the phosphorus content (P) is from 0.01 to 0.05 percent by mass, the total sulfur content (S) is from 0.05 to 0.3 percent by mass, and the P / S ratio is from 0.10 to 0.40. The lubricating oil composition has both excellent fuel economy performance and satisfactory durability for gears and bearings and furthermore excellent low temperature viscosity and oxidation stability.

Owner:NIPPON OIL CORP

Water-based cutting fluid for vermicular cast iron processing, and dilution solution thereof

ActiveCN104877749AImprove the lubrication effectImprove cooling effectLubricant compositionWater basedNitro compound

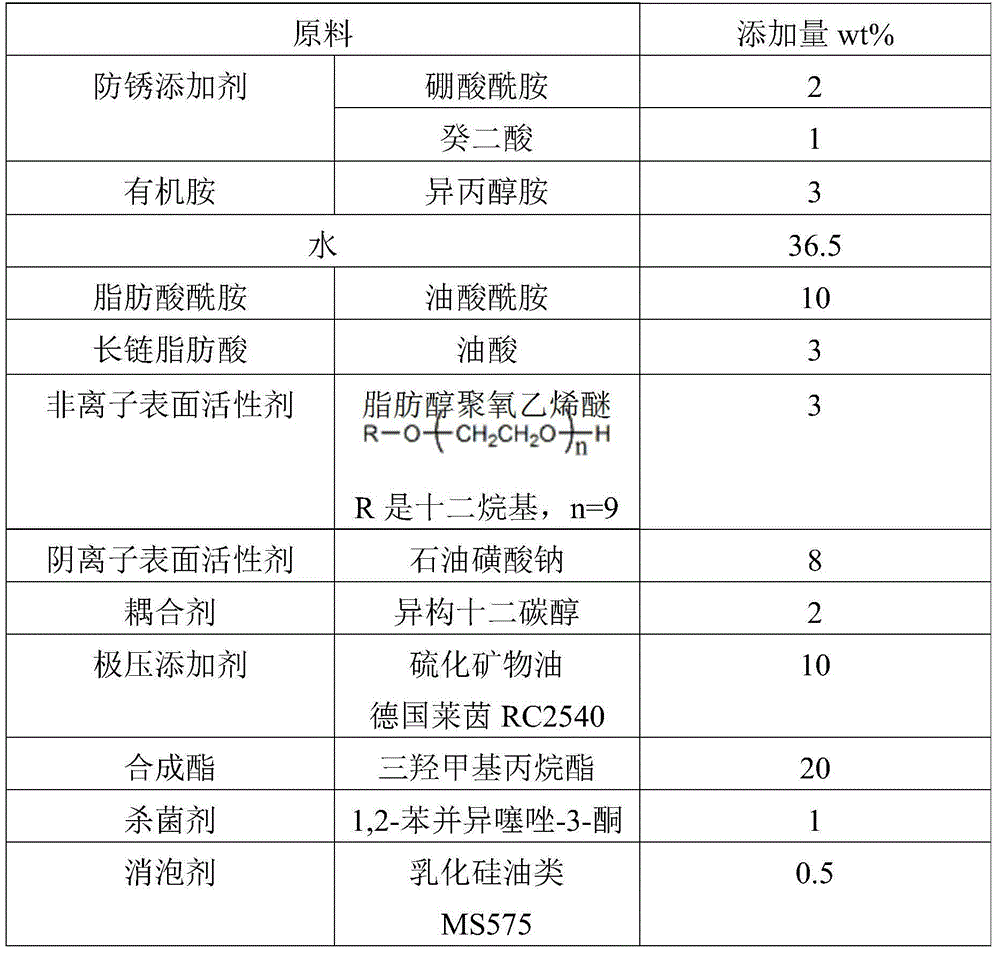

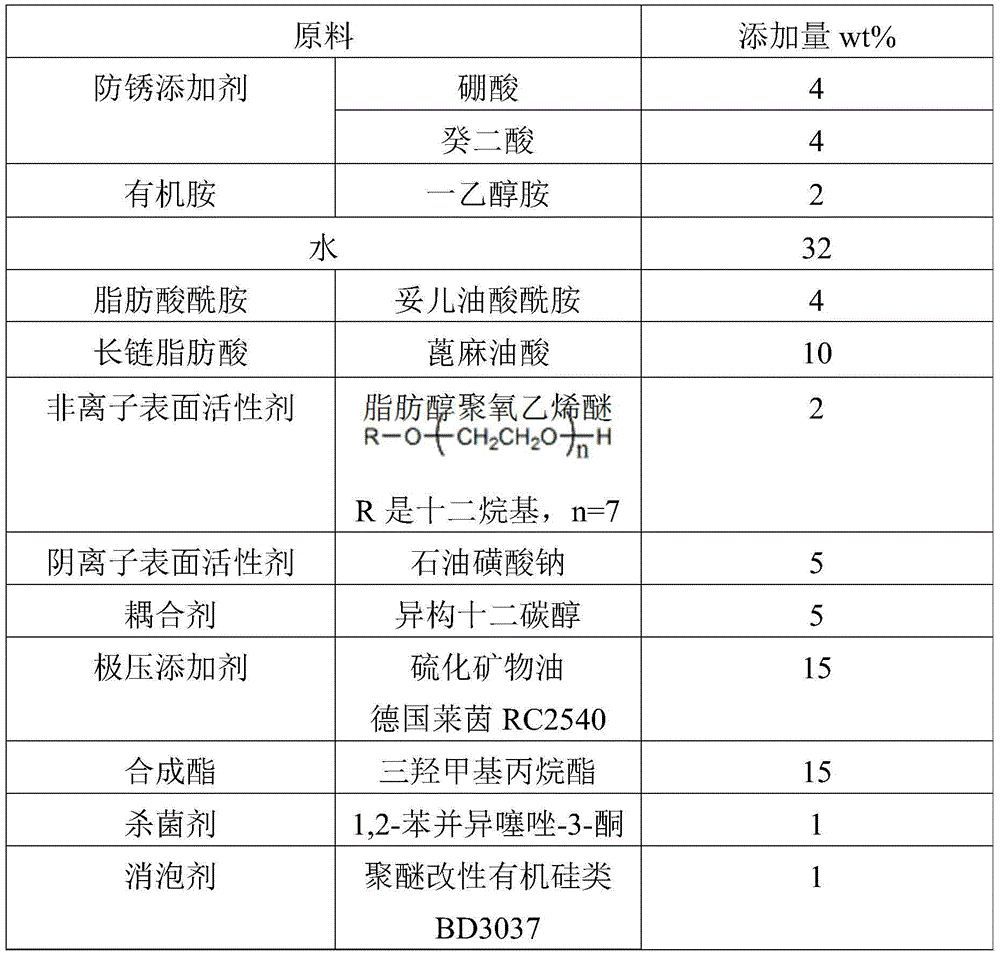

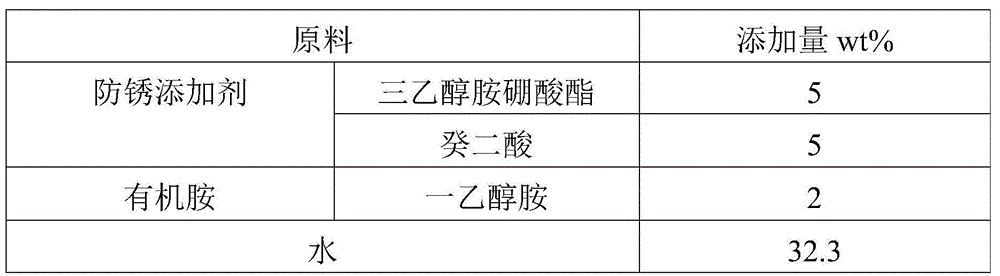

The present invention discloses a water-based cutting fluid for vermicular cast iron processing, and a dilution solution thereof. The water based cutting fluid comprises 3-10% of an anti-rust additive, 4-10% of fatty acid amide, 2-3% of organic amine, 3-10% of long-chain fatty acid, 2-5% of fatty alcohol polyoxyethylene ether, 5-8% of petroleum sodium sulfonate, 1-5% of a coupling agent, 10-15% of an extreme pressure additive, 15-20% of a synthetic ester, 1-2% of a sterilization agent, 0.5-1.0% of an anti-forming agent, and 32-45% of water, wherein the anti-rust additive is a boric acid anti-rust additive and dicarboxylic acid, and the coupling agent is a fatty alcohol and / or aliphatic ether. The water-based cutting fluid of the present invention has characteristics of good lubrication performance, good cooling performance, good anti-rust property, no chlorine, diamine, nitrite and other nitro compounds, no environmental pollution, no irritating odor, easy cutting, easy powder settlement, and effective cutter service life prolonging.

Owner:上海德润宝特种润滑剂有限公司

Highly-efficient lubricant for drilling fluid

InactiveCN101735778AImprove the lubrication effectIncrease the extreme pressure valueDrilling compositionPolyesterPhosphate

The invention discloses a highly-efficient lubricant for a drilling fluid. The highly-efficient lubricant comprises the following components in percentage by weight: 10 to 40 percent of white oil, 30 to 70 percent of fatty acid methyl ester or methyl oleate, 5 to 20 percent of polyester, 2 to 8 percent of organic phosphate, 1 to 6 percent of oilness extreme-pressure additive, 0.5 to 2 percent of emulsifier OP-10 and 0.5 to 2 percent of span-80. The invention also discloses a method and steps for preparing the highly-efficient lubricant for the drilling fluid. The highly-efficient lubricant can enhance the lubricating property of the drilling fluid and increase an extreme pressure value of the drilling fluid, and is suitable for the demand of ordinary drilling and use in a high-difficulty highly deviated directional well and a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

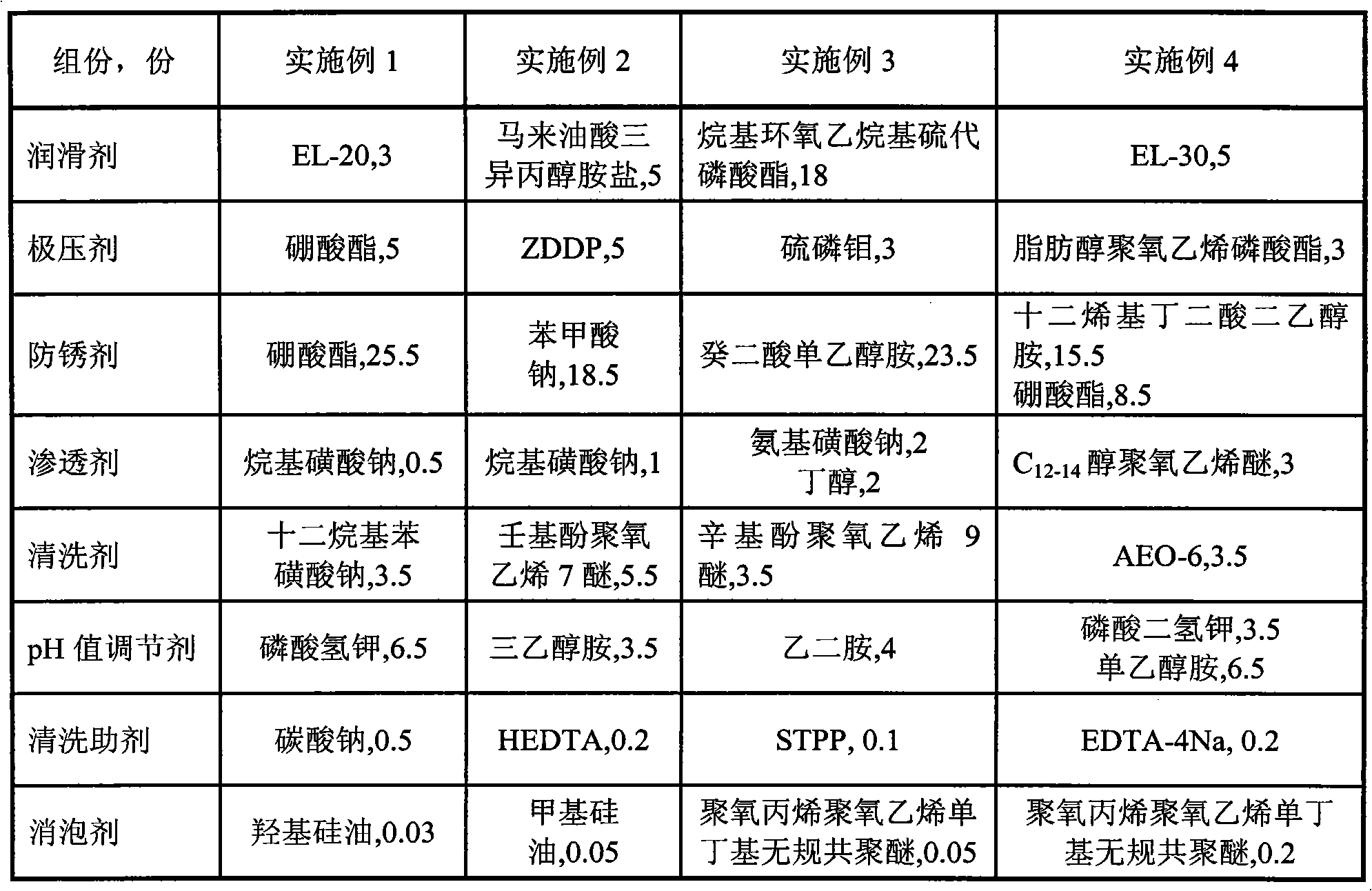

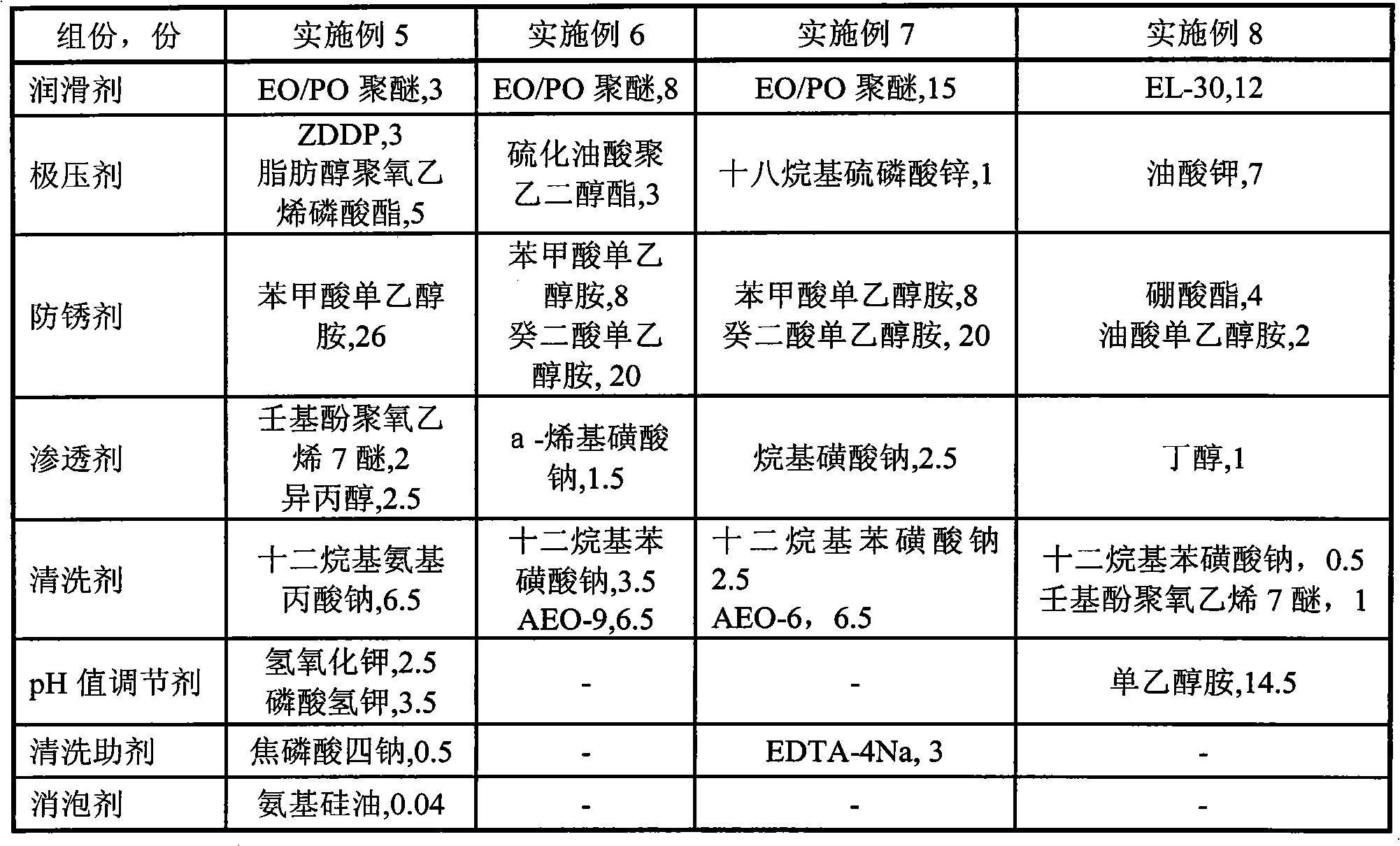

Water-soluble rolling liquid composition and application thereof

ActiveCN102757848AImprove the lubrication effectImprove rust resistanceLubricant compositionEmulsionMetallurgy

The invention relates to a water-soluble rolling liquid composition and application thereof. The water-soluble rolling liquid composition mainly solves the problems of low cooling performance of pure oil type rolling liquid and low emulsion stability and low detergency of emulsion type rolling liquid in the prior art. The water-soluble rolling liquid composition comprises the following components by weight: a) 3 to 30 parts of lubricating agent; b) 0.5 to 10 parts of extreme pressure additive; c) 5 to 30 parts of antirusting agent; d) 0.1 to 5 parts of penetrating agent; e) 0.1 to 10 parts of cleaning agent; and f) 15 to 92.3 parts of water. Through the adoption of the technical scheme, the problem is solved well and the water-soluble rolling liquid composition can be applied to the rolling and lubricating procedure of a cold-rolled steel plate.

Owner:CHINA PETROLEUM & CHEM CORP

Silane additives for lubricants and fuels

InactiveUS6887835B1Improve functional propertiesSilicon organic compoundsLiquid carbonaceous fuelsSilanesZinc

Lubricants, especially lubricating oils, and fuels, especially hydrocarbon fuels, contain a class of anti-wear, anti-fatigue, and extreme pressure additives that are derived from silanes. The additives can be used as either partial or complete replacements for zinc dialkyldithiophosphates currently used in lubricants and fuels.

Owner:CHEMTURA CORP

Transmission fluid compositions for automobiles

A transmission fluid composition for automobiles comprises a lubricating base oil, (A) an oil-soluble metal salt overbased with a specific alkaline earth metal borate, and (B) a sulfur-containing extreme pressure additive. The transmission fluid can enhance a metallic friction coefficient, leading to the achievement of improved transmission torque.

Owner:NIPPON OIL CORP

Micro emulsion cutting fluid composition and preparation method thereof

InactiveCN102002424AGood rust protectionImprove the lubrication effectLubricant compositionEmulsionOil additive

The invention relates to a micro emulsion cutting fluid composition and a preparation method thereof. The composition comprises the following raw materials in percentage by weight: 22-32 mineral oil, 2-10 anionic surfactant, 1-5 nonionic surfactant, 1-3 emulsion stabilizer, 5-10 oiliness additive, 5-10 extreme pressure additive, 5-15 rust-inhibiting additive, 0.5-3 anticorrosion fungicide, 0.1-0.3 antifoam additive and the balance of water. The preparation method of the micro emulsion cutting fluid composition is simple and convenient, the provided cutting fluid S50 composition is an ecological stable product and has good lubricity and cooling performance, and the machining accuracy of workpieces can be improved. The cutting fluid S50 composition has strong antimicrobial capability, long service life and good PH value stability and provides good rust-inhibiting performance for the workpieces.

Owner:上海德润宝特种润滑剂有限公司

Gear lubricating oil additive composition

The invention provides an additive composite for gear lubricating oil, comprising (A) a certain amount of mineral oil, (B) at least one type of extreme pressure additive with sulfurs, (C) at least one type of anti-wear additive with phosphors, (D) at least one type of anti-rusting additive, (E) at least one type of friction improver, and (F) at least one type of metal passivator. By adding the additive composite into base oil or into a mixture of the base oil according to weight percentage between 3.8 and 4.5, vehicle gear oil up to the indexes of GB13895-92(APIGL-5) standards is prepared. By adding the additive composite into the base oil according to the weight percentage between 0.6 and 1.2, industrial gear oil up to the indexes of GB5903-95 standards is prepared.

Owner:PETROCHINA CO LTD

Steel cord drawing lubricant and preparation method thereof

InactiveCN102010779ADrawing die consumption is lowImprove adhesionLubricant compositionFood additiveOil additive

The invention discloses a steel cord drawing lubricant and a preparation method thereof, belonging to the filed of lubricants for metals. The lubricant is prepared from the following components by weight percent: 7-15% of oil additives, 8-10% of surface active agent, 7-10% of extreme pressure additives, 3-6% of solid additives, and the balance water and one or more of antirust additive, preservative, antifoaming agent or bactericide. The preparation method comprises the following steps: 1) weighting the oil additives, the surface active agent, the extreme pressure additives and the solid additive according to the weight proportion, mixing, heating to 140-150 DEG C, and mixing fully; 2) adding water (water percent), mixing, heating to 80-90 DEG C and mixing fully; and 3) mixing and dissolving the obtained mixture, and emulsifying fully, thus obtaining a homogeneous liquid, namely the end product. The lubricant has the characteristics of good lubricating effect, low consumption, high drawing speed, smooth steel tube surface, good quality, no corrosion and damage to pipelines and devices and quite low cost, and can ensure that the steel cord coating is undamaged, and the adhesive force between the steel cord and the rubber is enhanced.

Owner:NANJING INST OF TECH

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN1804016AAvoid underperformanceStable structureDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

High-extreme pressure water-resistant antirust lubricating grease and preparation method thereof

ActiveCN101705143AImprove water stabilityAntioxidantLubricant compositionLithium hydroxideAntioxidant

The invention relates to high-extreme pressure water-resistant antirust lubricating grease and a preparation method thereof. The high-extreme pressure water-resistant antirust lubricating grease is prepared by the reaction of various substances by weight parts as follows: 43.5-77.5 parts of high-viscosity mineral oil, 7-10 parts of fatty acid, 0.7-1.0 part of lithium hydroxide, 0.3-0.5 part of calcium hydroxide, 10-30 parts of high base number calcium petroleum sulfonate, 1-3 parts of transforming agent, 1-3 parts of antirust agent, 1-3 parts of extreme-pressure additive, 0.5-1.0 part of antioxidant, and 1-5 parts of thickening agent. In the invention, the water comprehensive stability and water antirust performance of the lubricating grease are improved, and the water stability of the thickening agent and the extreme-pressure additive is improved.

Owner:辽宁海华科技股份有限公司

Spray supply mode cutting oil for metal material cutting processing

ActiveCN101717684AEasy to useImprove extreme pressure lubrication performanceAdditivesPhosphoric Acid EstersVegetable oil

The invention relates to spray supply mode cutting oil for metal material cutting processing, which is prepared from the following raw materials in parts by weight: 40-60 parts of base oil, 30-40 parts of vulcanized fat and 10-20 parts of phosphoric acid ester, wherein the base oil is vegetable oil or synthetic ester or a mixture of the vegetable oil and the synthetic ester; since the consumptionof the vulcanized fat and the phosphoric acid ester used as extreme pressure additives of the cutting oil is large, the cutting oil has good extreme pressure lubricating performance, thereby ensuringthat process requirements are satisfied by consuming a minute quantity of cutting oil when the cutting oil is used for the cutting processing and spray oil supply of difficultly processed materials; and the adopted raw materials are biodegradable and have no toxicity to human bodies, small damage to ecological environment and low pollution.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

Urea grease composition and preparation method thereof

ActiveCN101368129AImprove water resistanceImprove performanceThickenersAdditivesSulfurExtreme pressure additive

The invention relates to a urea grease composition and a preparation method thereof; the urea grease composition consists of base oil, thickener and additive; wherein, the base oil is various mineral base oil, synthetic oil or the mixture of the mineral base oil and the synthetic oil, and the base oil accounts for 85 percent to 95 percent of the total amount of the grease; the thickener is composed of diurea compound and the amount of the thickener accounts for 4 percent to 15 percent of the total amount of the grease; the additive consists of T361A borate extreme pressure and antiwear additive, anti-oxidant and anti-corrosion additive and anti-oxidant; wherein, the addition amount of the borate extreme pressure and antiwear additive accounts for 1 percent to 3 percent of the total amount of the grease, the addition amount of the anti-oxidant and anti-corrosion additive accounts for 0.5 percent to 2 percent of the total amount of the grease and the addition amount of the anti-oxidant accounts for 0.3 percent to 1 percent of the total amount of the grease; the invention combines the advantages of the borate and the traditional sulfur-phosphorous additive and the urea grease added with the borate extreme pressure and antiwear additive still has excellent water resistance, thus improving the comprehensive performance of the product and reducing the cost.

Owner:杭州得润宝油脂股份有限公司

Multi-station cold heading oil and preparation method thereof

InactiveCN104403738AExtended service lifeGood extreme pressure and anti-wear propertiesLubricant compositionVegetable oilFoaming agent

The invention relates to an oil product of a petroleum chemical product, and especially relates to multi-station cold heading oil and a preparation method thereof. According to the method, a deep refining mineral oil is taken as a base oil, an extreme pressure additive, an anti-rust agent, an oiliness additive, an anti-foaming agent, and animal and vegetable oil are added by blending, the cold heading oil comprises the following components by weight: 75% of base oil, 6% of extreme pressure additive, 3.7% of anti-rust agent, 8% of oiliness additive, 2.3% of anti-foaming agent and 5% of animal and vegetable oil. The cold heading oil is suitable for a cold heading machine, and has the advantages of good extreme pressure abrasion resistance, good antirust performance and anti-foaming performance, so that the usage life of the cold heading machine can be increased.

Owner:NINGBO BAORUN PETROCHEM

Process for metalworking fluid from heavy alkylate

InactiveUS20050215440A1Component is toxicHigh specific and latent heatWork treatment devicesLiquid carbonaceous fuelsMetalworking fluidVegetable oil

The process relates to composition of metalworking fluid and for its preparation based on heavy alkyl benzenes having 22 to 26 carbon atoms to replace mineral oil and process for the same. A process for heavy alkylate based less toxic metalworking fluid composition comprising of heavy alkyl benzene, one emulsifier which is a sodium oleate, sulfonate or mixtures thereof, a vegetable oil as lubricity booster, an antioxidant, a fungicide, an extreme pressure additive, an antirust, a co-surfactant, a coupling agent and alkali component. The process comprising of removing of insoluble matter from the heavy alkylate, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture at 20-120° C., followed by conditioning of the metal working fluid concentrate which can be used as emulsion in water.

Owner:COUNCIL OF SCI & IND RES

Lube base oil and lubricating oil composition

InactiveUS20060166844A1Reduction of evaporation lossLow viscosityLiquid carbonaceous fuelsBase-materialsAniline pointAntioxidant

The invention provides a lube base oil other than silicone oil having a kinematic viscosity of 12 mm2 / s or below at 40° C., exhibiting, in Noack test (250° C., 1 hr), an evaporation loss of 30 mass % or below and / or a flash point of 200° C. or higher, and exhibiting an aniline point of 60° C. or higher. There is also provides a lubricating oil composition comprising the lube base oil mixed with at least one additive selected from the group consisting of an antioxidant, a viscosity index improver, a detergent dispersant, a friction reducing agent, a metal inactivator, a pour point depressant, an abrasion resisting agent, a defoamer, and an extreme-pressure additive. The lube base oil and the lubricating oil composition realize reduction of evaporation loss despite being of low viscosity and excellent compatibility with organic materials.

Owner:IDEMITSU KOSAN CO LTD

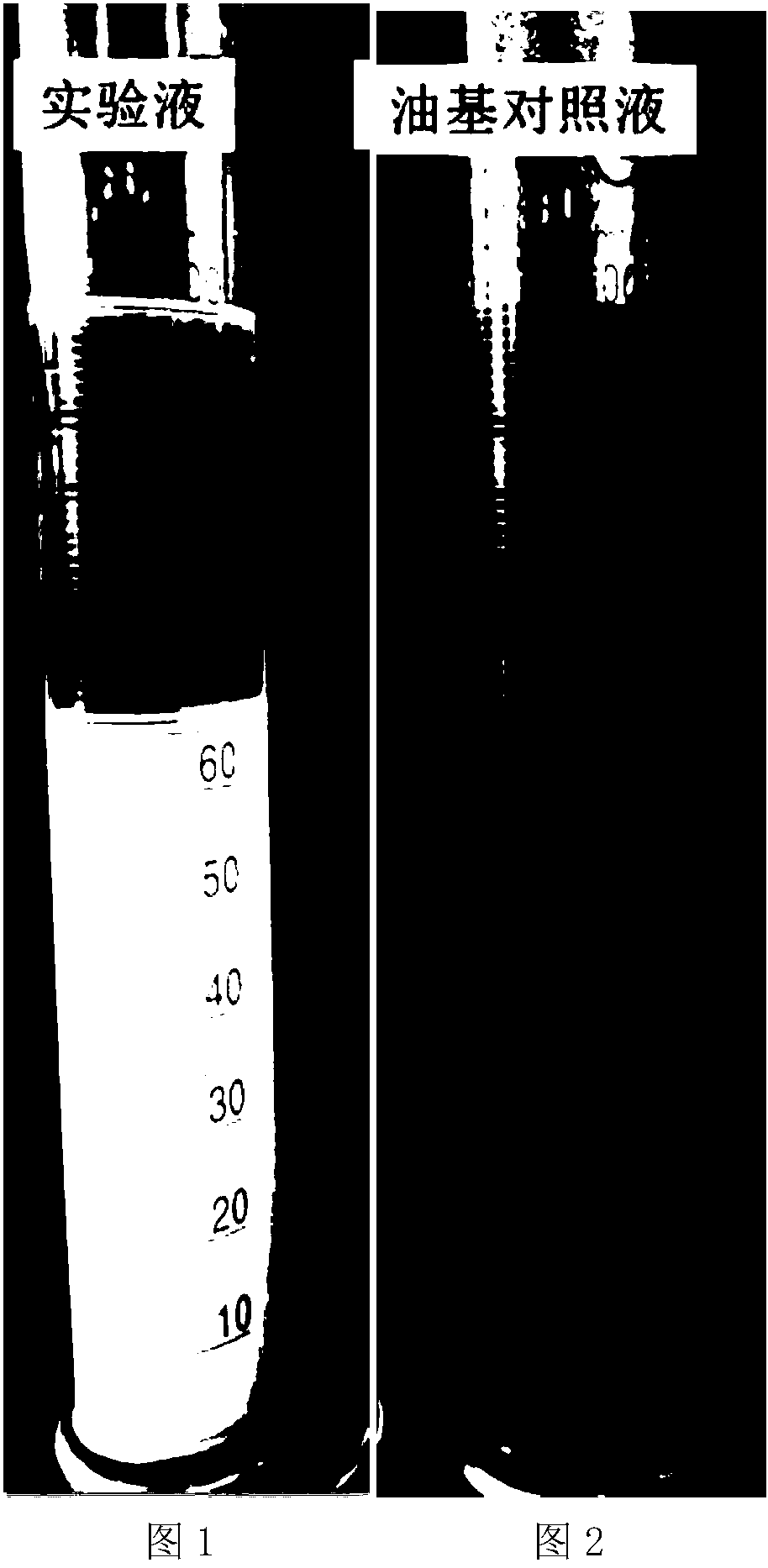

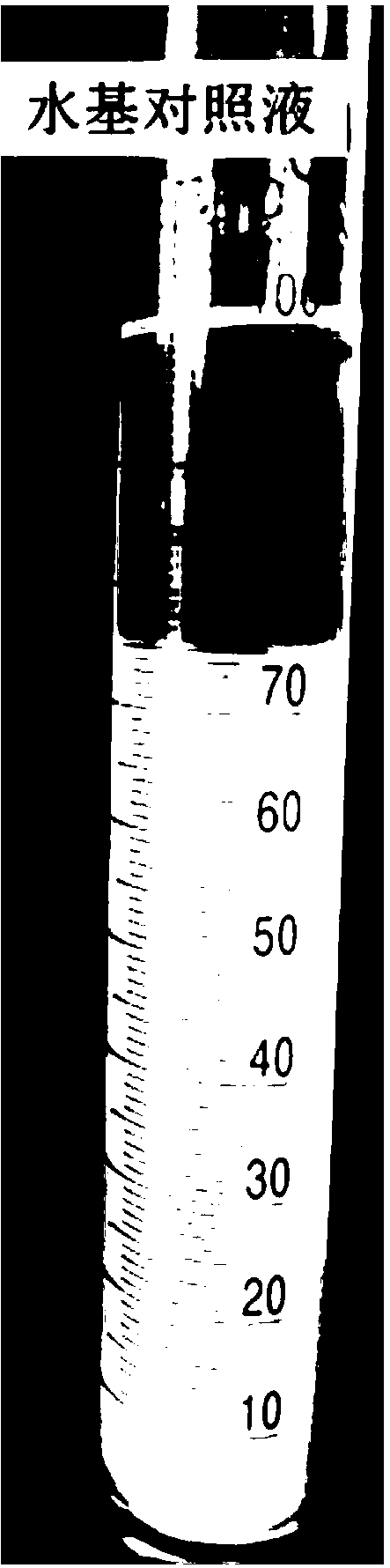

Total-synthesis water-based cutting fluid for sapphire and preparation method of cutting fluid

ActiveCN108165362AEnhanced extreme pressure lubricationImprove wettability and permeabilityLubricant compositionWater basedEngineering

The invention provides total-synthesis water-based cutting fluid for sapphire and a preparation method of the cutting fluid. The cutting fluid for the sapphire comprises the following components of: in percent by weight, 8-25% of lubricant, 2-10% of rust inhibitor, 2-7% of an extreme-pressure additive, 0.25-2% of a settling agent, 0.5-3% of fungicide, 0.2-0.8% of a wetting agent, 3-5% of a cosolvent, 4-15% of pH stabilizer, 0.2-0.8% of defoamer and the balance water. According to the total-synthesis water-based cutting fluid for the sapphire, the reasonable additives are adopted for compounding, lubricating and wetting permeation performance of the cutting fluid are better than common water-based cutting fluid for sapphire, the total-synthesis water-based cutting fluid for the sapphire canreach the level of oil-based cutting fluid for the sapphire, and meanwhile the defects of poor powder sedimentation, large oil mist, potential risks for open flames, difficult post-processing and thelike of the oil-based product are avoided.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

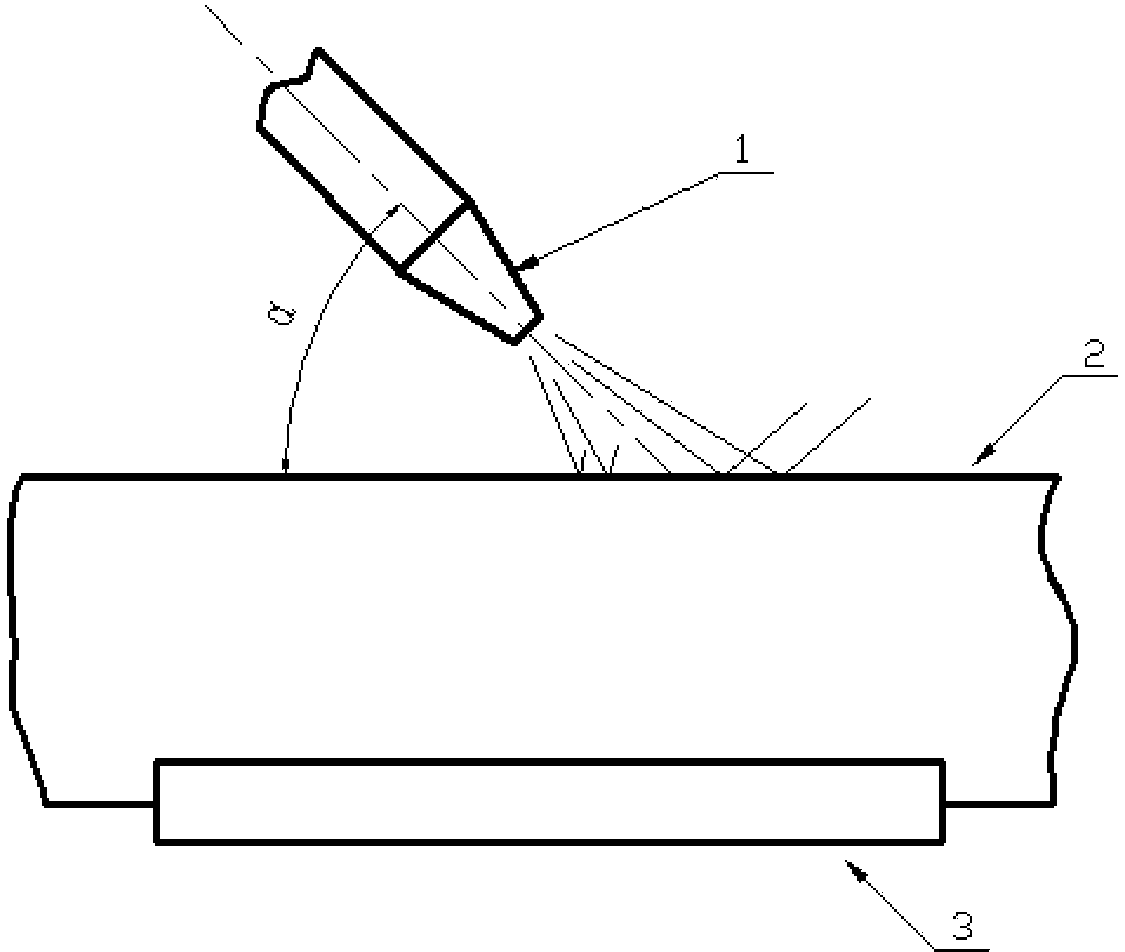

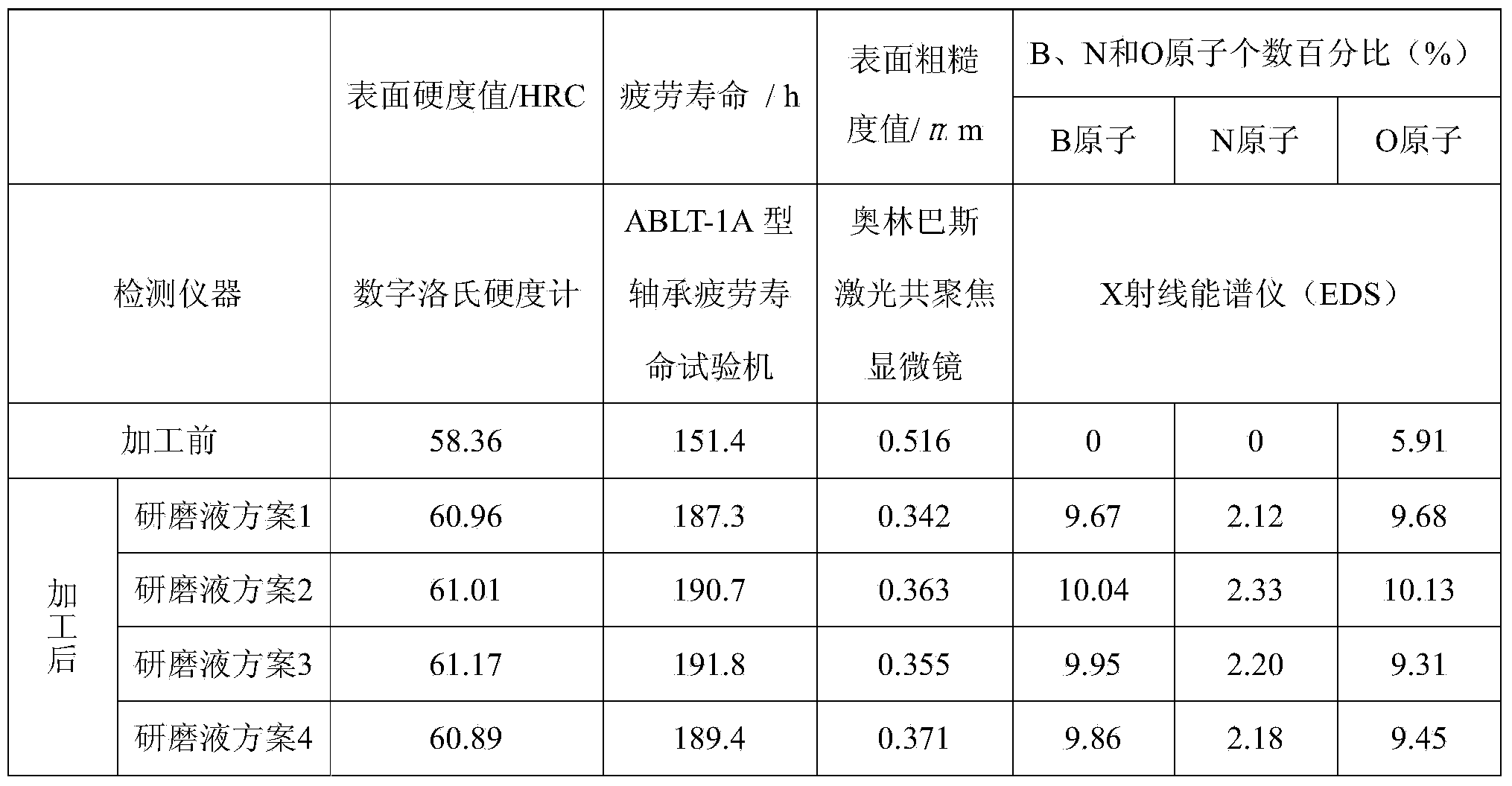

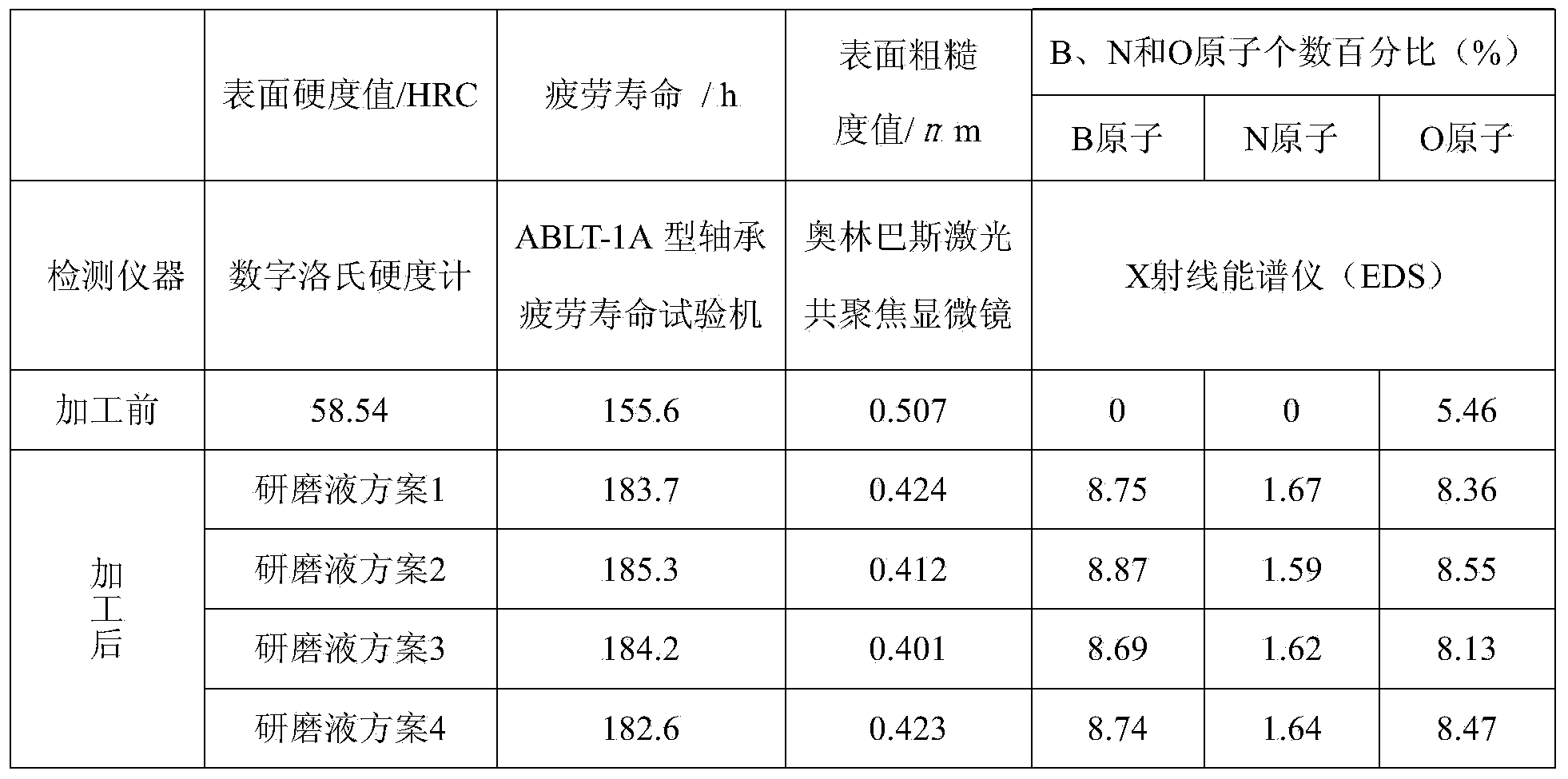

Strengthened grinding method for wear-resisting alloy steel workpiece surface

InactiveCN103878703AImprove fatigue lifeNo thermal deformationAbrasion apparatusPh bufferingSteel ball

The invention relates to a strengthened grinding method for wear-resisting alloy steel workpiece surface. The method comprises the steps of ejecting a mixture to the surface of a wear-resisting alloy steel workpiece with speed of 100-300 m / s and an ejecting angle of 15-75 degrees, and completely covering the surface of the wear-resisting alloy steel workpiece by ejecting points, wherein the mixture is composed of steel balls, grinding powder and strengthened grinding modified liquid with the mass ratio of the steel balls to the grinding powder to the strengthened grinding modified liquid of (1:1:1) to (5:1:3); the steel balls are cast steel balls or bearing steel balls with the hardness greater than 62 HRC (rockwell hardness) and the diameter of phi1-phi8; the strengthened grinding modified liquid is composed of the following raw materials by weight percentage: 15%-25% of extreme pressure additive, 2-3% of corrosion remover, 10-15% of penetrant, 4-6% of pH conditioning agent, 2-8% of non-ionic surface active agent, 2-5% of pH buffering agent, 0.3-0.8% of softener, 1% of alkali, 0.1-0.2% of defoamer, 0.2-0.5% of antirust agent and the balance of water. By utilizing the strengthened grinding method, strengthened treatment can be carried out on the wear-resisting alloy steel workpiece surface in the grinding process of ejecting a grinding material so as to prolong the fatigue life and improve the surface hardness of a workpiece.

Owner:GUANGZHOU UNIVERSITY

High-performance environment-friendly water-soluble punching oil

ActiveCN103525529AExtended service lifeImprove the lubrication effectLubricant compositionVegetable oilCarboxylic acid

The invention discloses a high-performance environment-friendly water-soluble punching oil which is composed of high-polymer carboxylic acid, organic amine, higher alcohols, a surfactant, vegetable oil or synthetic lubricant, a vulcanizing extreme pressure additive, a chlorination extreme pressure additive, pure water, a defoaming agent and a preservative. The punching oil has superhigh lubricating property; after the product is diluted by 30 times, the tapping torque is less than or equal to 3000 N.cm, the cutter life is long, and the single batch cutter part processing quantity is greater than or equal to 300000. When adopting design formula of excellent-biodegradability vegetable oil (or synthetic fat) and other assistants, after the product is diluted by 30 times, the BOD / COD (biochemical oxygen demand / chemical oxygen demand) is greater than or equal to 0.6.

Owner:SHANGHAI YUSHIRO CHEM IND +1

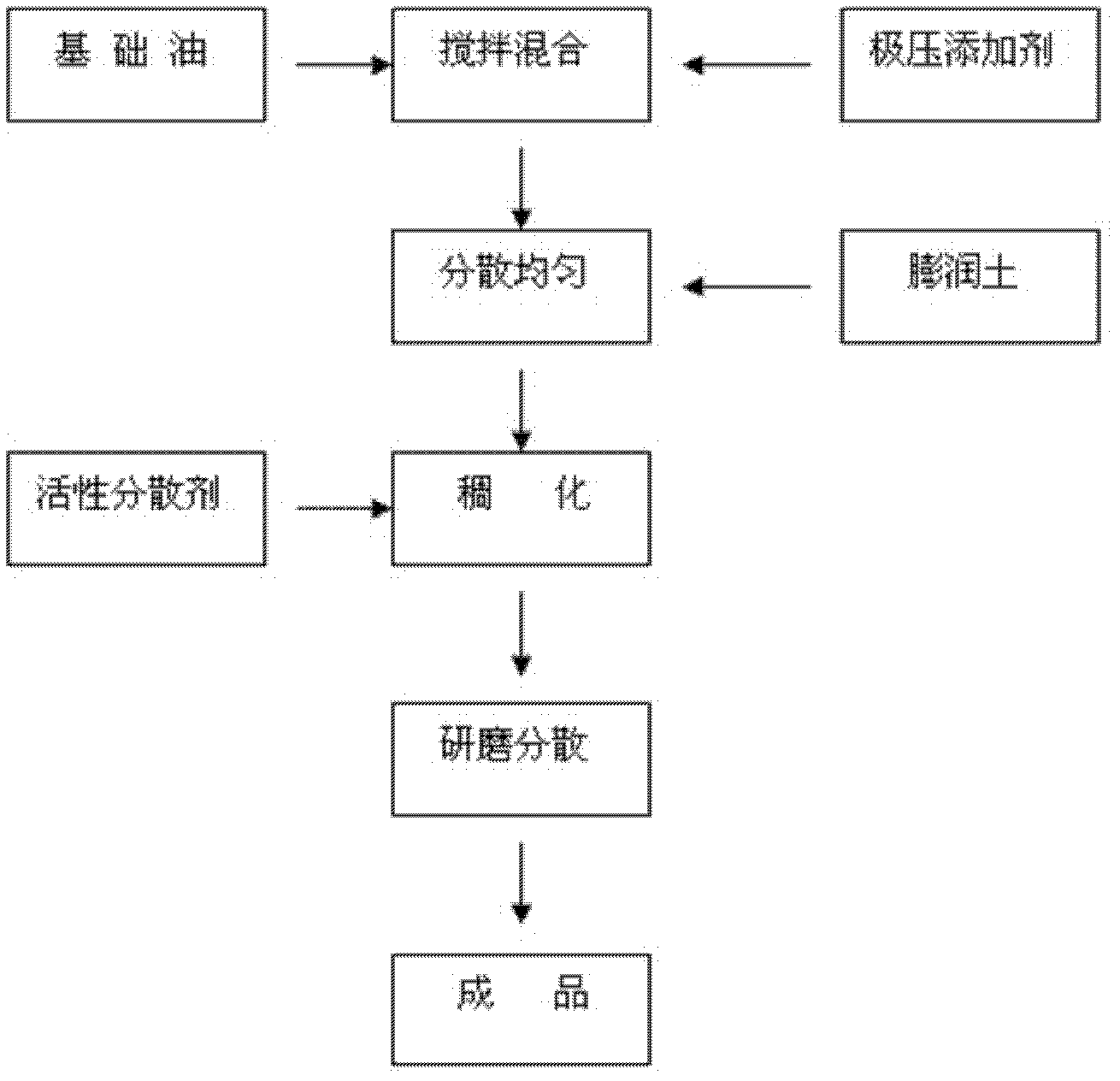

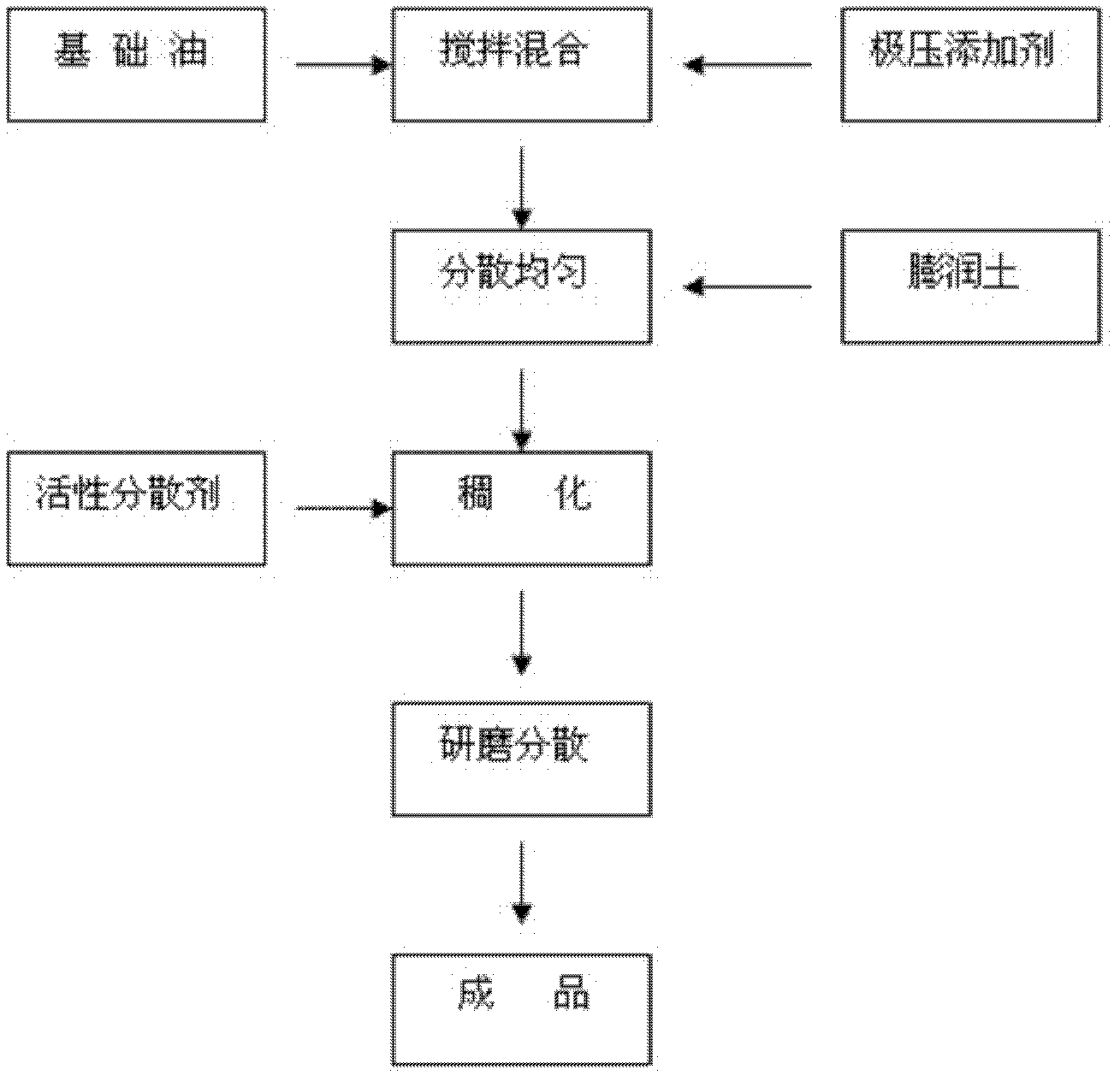

High-temperature extreme-pressure bentonite grease lubricant

InactiveCN102627997AGood high temperature performanceGood mechanical stabilityLubricant compositionMechanical stabilityColloid

The invention relates to a high-temperature extreme-pressure bentonite grease lubricant. The grease lubricant comprises the following components, by weight 80-95% of base oil, 5-15% of a thickener, 5-20% of an extreme pressure additive and 10-30% of an active dispersant, wherein the base oil is one of a mineral oil and a synthetic oil or a mixture of the two oils, and the extreme pressure additive is a solid lubricant. A preparation method of the grease lubricant comprises the following steps: fully stirring the base oil and the extreme pressure additive to uniformly mix them, adding the thickener, continuously fully stirring to uniformly mix, adding the active dispersant, stir-mixing for a certain amount of time, and grinding to uniformly disperse to obtain the grease lubricant. The grease lubricant of the invention has good high temperature performances, a good colloid stability, and a good mechanical stability, and is especially suitable for mechanical lubrication parts working under high-temperature heavy-load high-pollution conditions.

Owner:SUZHOU HUIFENG LUBRICANT

Lubricant for drawing spring steel wire

ActiveCN103897787AConsistent colorSignificant change in softening pointLubricant compositionSide effectBorax

The invention provides a lubricant for drawing a spring steel wire. The lubricant for drawing the spring steel wire comprises the following components in percentage by weight: 40-60% of calcium stearate, 35-55% of softening point regulator and 5%-8% of extreme pressure additive, wherein the softening point regulator is one or more selected from calcium hydroxide, titanium dioxide, zinc oxide, sodium carbonate, sodium silicate, borax and paraffin. The lubricant is characterized in that the softening point of the lubricant changes obviously in a drawing process, and in the viscosity-temperature change of the lubricant, the lubricant is brought into a mold during drawing, and therefore, the requirements of the drawing process can be met. The lubricant has the advantages that the protection capacity of the lubricant on the surface of the steel wire is further improved, the subsequent heat treatment is not affected after drawing, no toxic or side effects are produced, a stable lubricating film can be formed on the surface of the steel wire under severe wire drawing conditions, and the wire drawing process is stabilized and the surface of the steel wire is protected against scratch.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

High-temperature grease and preparation method thereof

The invention relates to a high-temperature grease and a preparation method thereof, which are widely applied to equipment bearings of production lines in steel mills and steel works. The high-temperature grease contains the following components in weight parts: 45 to 81.5 parts of high-viscosity mineral oil, 4 to 10 parts of polyurea, 10 to 30 parts of high-base number calcium petrolem sulfonate, 1 to 3 parts of transforming agent, 1 to 3 parts of anti-rust agent, 1 to 3 parts of extreme-pressure additive, 0.5 to 1 part of antioxidant, and 1 to 5 parts of thickening agent. The high-viscosity mineral oil is 150BS. The high-temperature grease has higher dropping point, does not turn thin or has lower thinning degree after meeting water; the antirust performance is as good as the new grease after meeting water; and the extreme-pressure performance thereof is reduced by a lower degree or does not reduce after meeting water.

Owner:辽宁海华科技股份有限公司

Water insoluble cutting oil

InactiveCN1548507AExtended service lifeExcellent extreme pressure lubricityAdditivesLow speedWater insoluble

The water insoluble cutting oil consists of base oil, grease, sulfide extreme pressure additive, lubricant agent, antioxidant and mist inhibitor mixed together. The product of the present invention excellent extreme pressure lubricating performance, and is suitable for low speed high load cutting to raise service life of cutting tool and ensure excellent machining surface. It is used as common cutting oil for broaching and forming gear, has excellent use effect, no uncomfortable smell and no harmful matter, and is good for environment protection.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD

Multipurpose carbon-deposition-free environmental-friendly water soluble drawing lubricant

InactiveCN104928000AImprove the lubrication effectStrong anti-wear and extreme pressure performanceLubricant compositionWater solubleRust converter

The invention discloses a multipurpose carbon-deposition-free environmental-friendly water soluble drawing lubricant which consists of base oil, a synthetic ester compound, an antirust agent, an ashless anti-wear extreme pressure additive, a metal corrosion inhibitor, a surfactant, a co-emulsifier, a bactericide, a defoamer and water. The multipurpose carbon-deposition-free environmental-friendly water soluble drawing lubricant disclosed by the invention is excellent in performance and convenient to prepare.

Owner:SHANGHAI YUSHIRO CHEM IND

Gear oil composition for automobile

InactiveCN101993763AImprove antioxidant capacityExtend your lifeAdditivesPolymer scienceWear resistant

The invention discloses a gear oil composition for an automobile. The gear oil composition for the automobile comprises viscosity blend base oil, a sulfur-containing extreme pressure additive, a phosphorus-containing wear-resistant additive, an antirust additive, a metal passivator and a synthetic ester oiliness additive, wherein the synthetic ester oiliness additive may be one or more of trimethylolpropane trioleate, octyl stearate, butyl stearate, isooctyl stearate and isooctyl palmitate; and the synthetic ester oiliness additive accounts for 2 to 10 percent of the total weight of the gear oil composition. The gear oil has the advantages of high wear resistance, high maximum non-seizure load, high load-bearing capacity, high viscosity index, high low-temperature flowability, high lubricating property and the like, is suitable for the lubrication of an automobile manual gearbox and a rear drive axle gear and is also suitable for an automobile automatic gearbox.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com