Patents

Literature

92 results about "Octyl Stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What it is. Octyl Stearate, also called Ethylhexyl Stearate, is a yellow, oily substance. What it does. Octyl Stearate is an emollient: it gives skin a soft and smooth appearance while preventing water loss. In addition, it is also a thickening agent.

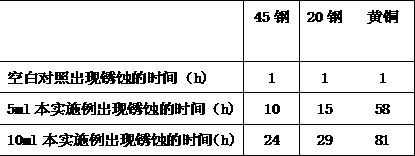

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

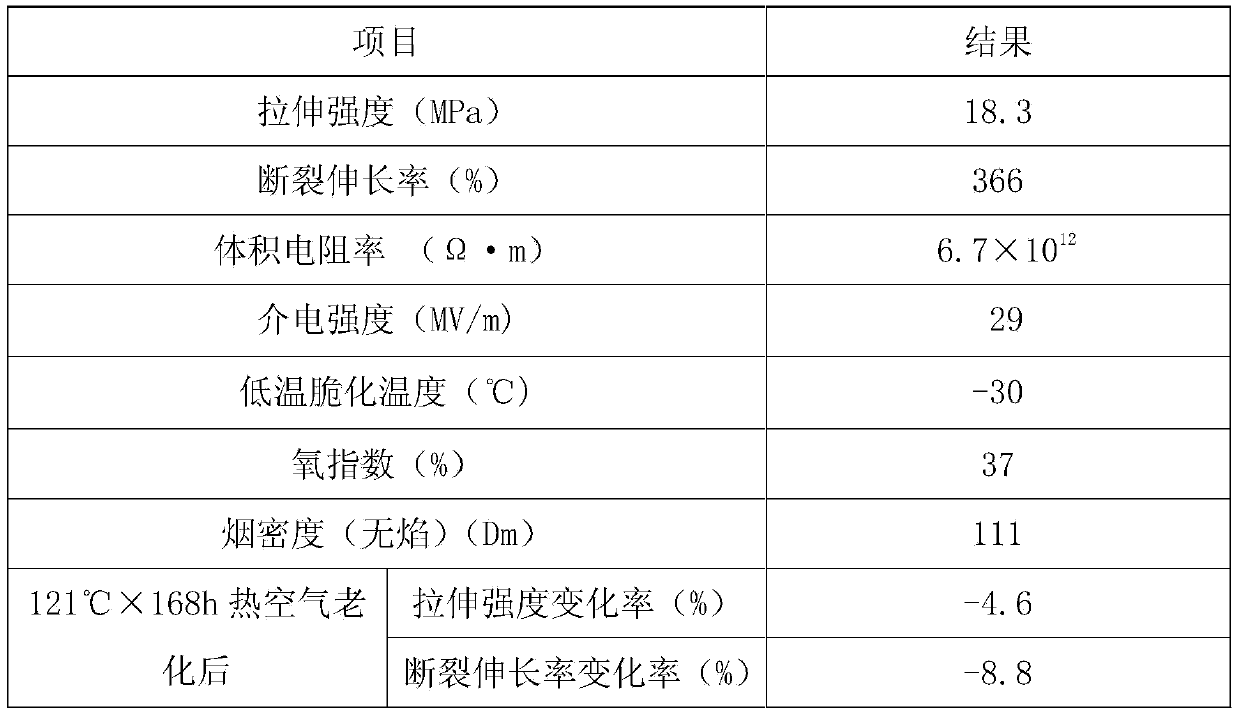

Lead-free termite-proof polyvinyl chloride cable material and preparation method thereof

InactiveCN103467883AExcellent anti-termite performanceAvoid communication failurePlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAluminium hydroxide

The invention discloses a lead-free termite-proof polyvinyl chloride (PVC) cable material and a preparation method thereof. The lead-free termite-proof PVC cable material is prepared from the following raw materials in parts by weight: 80 to 100 parts of SG-4 type PVC resin, 15 to 25 parts of polyvinylidene chloride, 10 to 15 parts of ethylene-propylene-diene monomer rubber, 14 to 18 parts of calcium silicate crystal whisker, 2 to 3 parts of magnesium oxide, 0.5 to 1.5 parts of palm wax, 5 to 10 parts of high impact polystyrene, 15 to 20 parts of fumed silica, 5 to 10 parts of precipitated barium sulphate, 10 to 15 parts of dimethyl fumarate, 1 to 2 parts of calaium strarate, 1 to 2 parts of imarcaptoacetate dioctyltin, 8 to 12 parts of talcum powder, 10 to 15 parts of aluminium hydroxide, 3 to 5 parts of epoxy octyl stearate, 0.5 to 1 part of antioxidant 168, 2 to 3 parts of termite-proof agent S-07 and 8 to 12 parts of composite filler. The cable material provided by the invention has excellent termite-proof performance, can effectively prevent communication faults and economic losses caused by termite corroding and is environment-friendly and lead-free; and the product has reliable physical and mechanical properties, excellent flame-retardant property and excellent low-smoke and low-toxicity characteristics.

Owner:JING FENG GRP

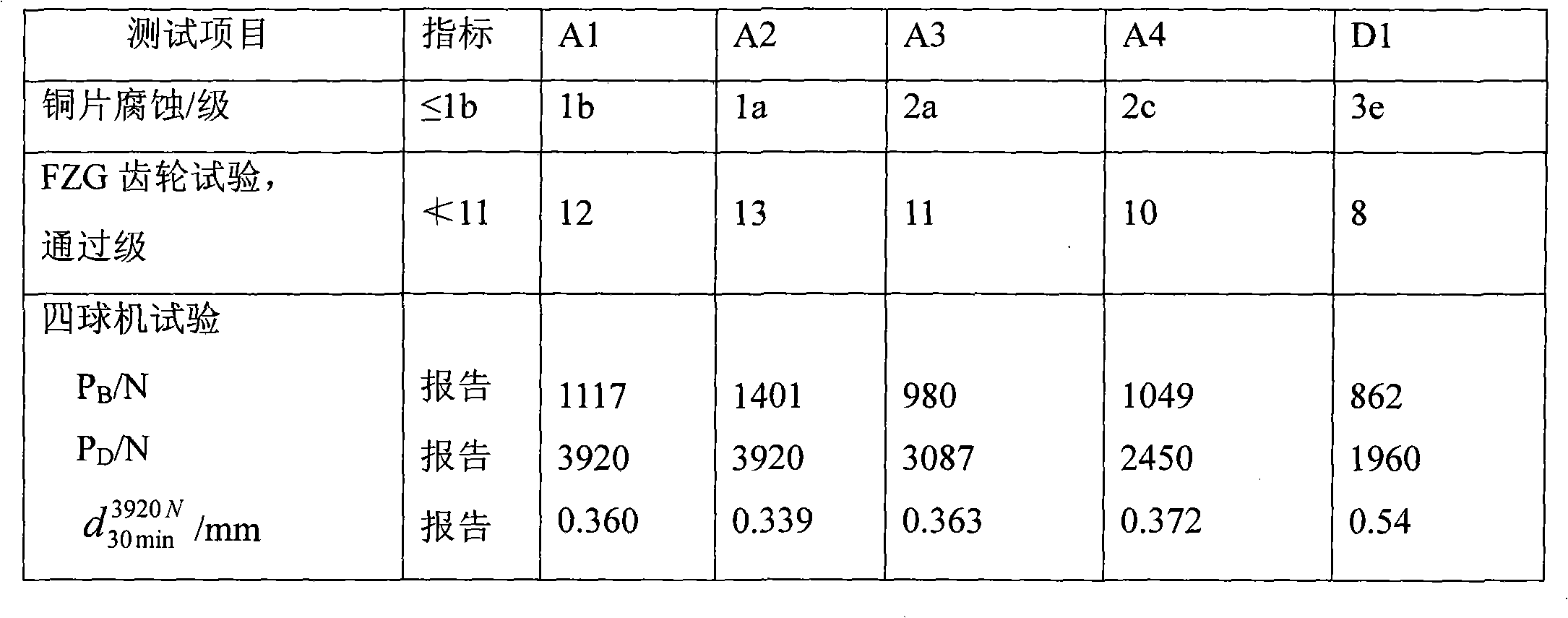

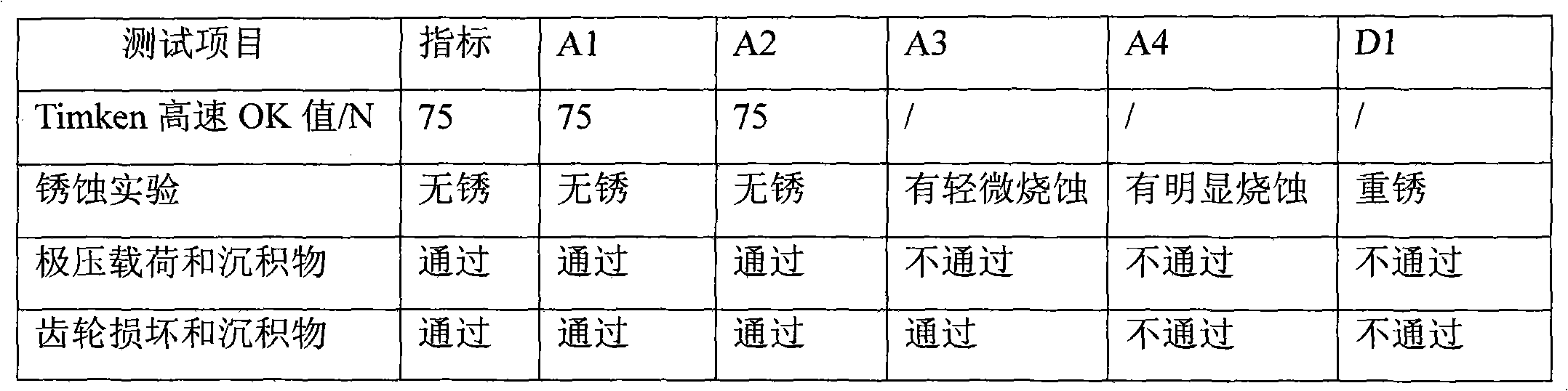

Gear oil composition for automobile

InactiveCN101993763AImprove antioxidant capacityExtend your lifeAdditivesPolymer scienceWear resistant

The invention discloses a gear oil composition for an automobile. The gear oil composition for the automobile comprises viscosity blend base oil, a sulfur-containing extreme pressure additive, a phosphorus-containing wear-resistant additive, an antirust additive, a metal passivator and a synthetic ester oiliness additive, wherein the synthetic ester oiliness additive may be one or more of trimethylolpropane trioleate, octyl stearate, butyl stearate, isooctyl stearate and isooctyl palmitate; and the synthetic ester oiliness additive accounts for 2 to 10 percent of the total weight of the gear oil composition. The gear oil has the advantages of high wear resistance, high maximum non-seizure load, high load-bearing capacity, high viscosity index, high low-temperature flowability, high lubricating property and the like, is suitable for the lubrication of an automobile manual gearbox and a rear drive axle gear and is also suitable for an automobile automatic gearbox.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

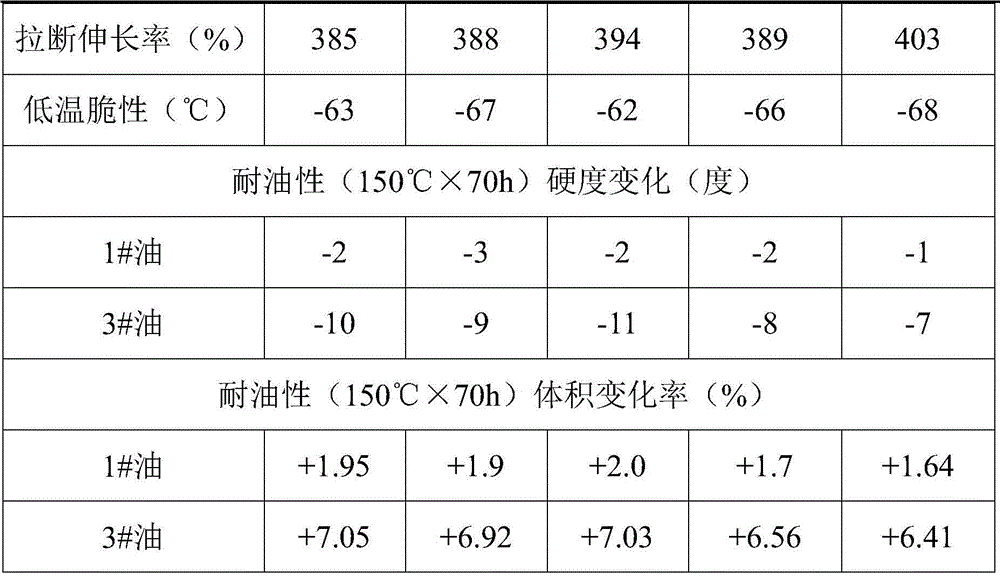

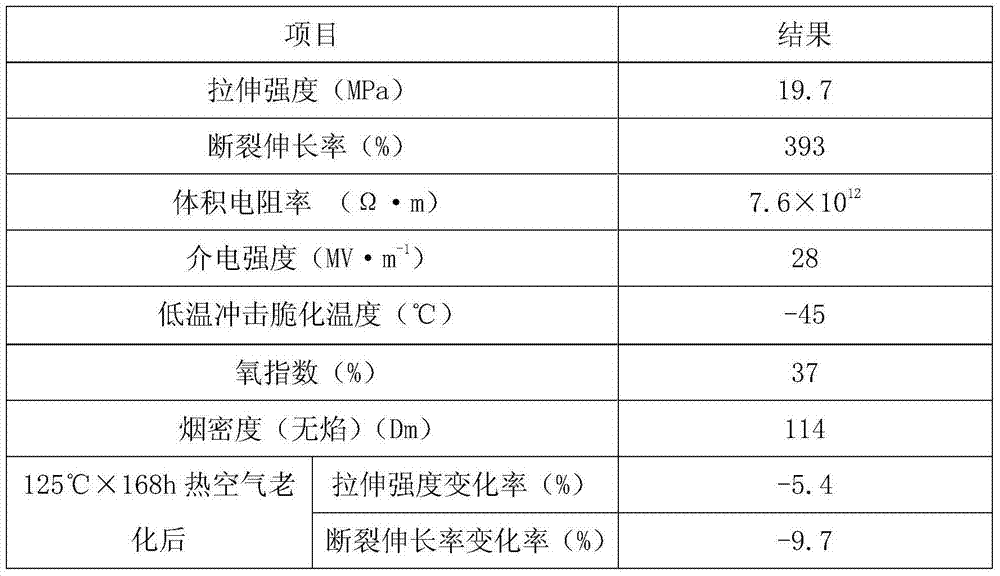

Cold-resisting oil-resisting modified fluorine rubber cable sheath material

The invention discloses a cold-resisting oil-resisting modified fluorine rubber cable sheath material which comprises the following components in parts by weight: 50-70 parts of fluorine rubber, 15-30 parts of silica rubber, 15-20 parts of fluorine silica rubber, 10-25 parts of pre-swelled organic clay, 15-25 parts of white carbon black, 5-13 parts of ternary nylon, 1-2.5 parts of stearic acid, 3-10 parts of active magnesium oxide, 3-9 parts of rare earth complex, 5-12 parts of calcium hydroxide, 0.5-1.8 parts of polyethylene glycol, 1-5 parts of epoxy octyl stearate, 1-2.5 parts of epoxy triglyceride fatty acid, 4-8 parts of a bisphenol vulcanizing agent, 1-3 parts of an accelerant, 0.5-2 parts of an anti-aging agent MB and 0.8-1.5 parts of an anti-aging agent 4010NA. The cold-resisting oil-resisting modified fluorine rubber cable sheath material disclosed by the invention is excellent in cold resistance and oil resistance and is good in comprehensive property and long in service life when used for manufacturing a cable sheath.

Owner:安徽华峰电缆集团有限公司

Capacitor film containing modified bentonite and preparation method thereof

ActiveCN102964666AImprove barrier propertiesImprove air tightnessThin/thick film capacitorFixed capacitor dielectricLow-density polyethylenePolyester

The invention discloses a capacitor film containing modified bentonite and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 50-55 parts of metallocene linear low-density polyethylene resin, 25-30 parts of metallocene polypropylene resin, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyving akohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.7-1.3 parts of poly-4-methy-l-pentene, 8-12 parts of modified bentonite, 0.9-1.1 parts of an antioxidant 1035, 0.6-0.8 part of phthalic acid polyester, 1-2 parts of epoxy octyl stearate, 4-6 parts of calcium stearate and 1.7-2.0 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:BENGBU LIQUN ELECTRONICS

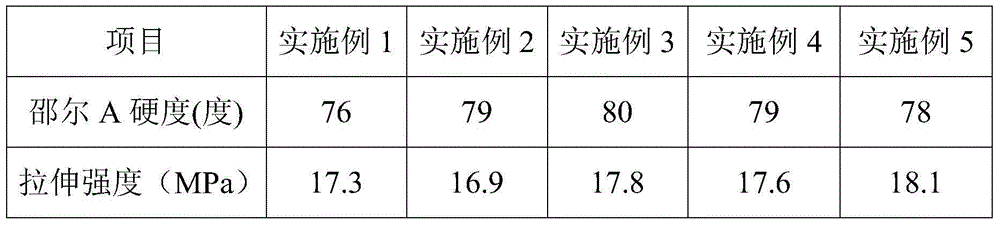

High-abrasion-resistance hydraulic sealing gasket and preparation method thereof

The invention discloses a high-abrasion-resistance hydraulic sealing gasket and a preparation method thereof. The high-abrasion-resistance hydraulic sealing gasket is prepared from nitrile-butadiene rubber, ethylene propylene diene monomer, EVA (ethylene-vinyl acetate) resin, epoxy octyl stearate, terpene resin, diphenyl toluene phosphate, organic montmorillonite, modified nano ceramic, cerium oxide, gadolinium oxide, zinc oxide, barium stearate, calcium stearate, titanium white, nano bauxite and other raw materials. By performing organic composite modification with nano aluminum nitride, nano titanium carbide, nano zirconium boride and many types of nano ceramic powder, the compatibility with rubber can be enhanced; and when being used for filling a modified rubber material to prepare the sealing gasket, the modified nano ceramic powder can obviously enhance the heat resistance, abrasion resistance, mechanical strength and other properties of the sealing gasket. The rare-earth metal oxides (cerium oxide and gadolinium oxide) are added to enhance the aging resistance of the rubber.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

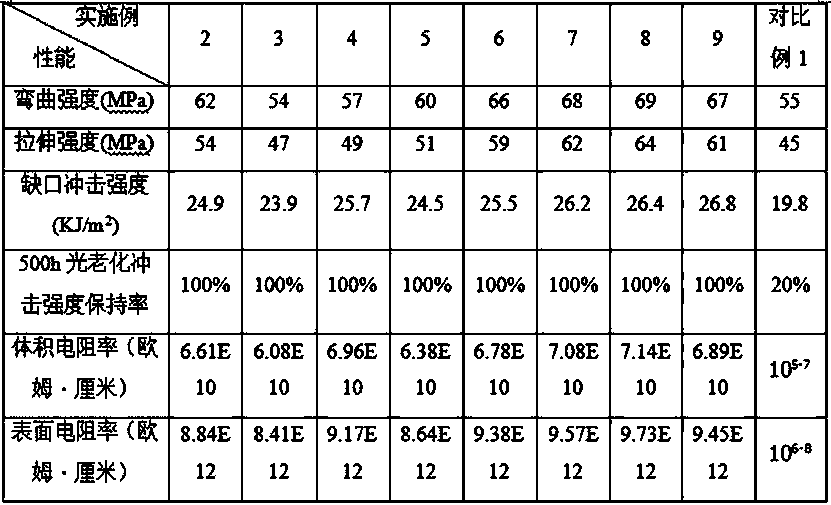

Antistatic anti-aging plastic and preparation method thereof

ActiveCN103396596AImprove notched impact strengthImprove bending strengthPolymer sciencePolyvinyl chloride

The invention discloses an antistatic anti-aging plastic and a preparation method thereof. The antistatic anti-aging plastic is mainly prepared from the following raw materials in parts by weight: 110-130 parts of HDPE (high-density polyethylene), 40-55 parts of PVC (polyvinyl chloride), 30-40 parts of PA6 (polyamide 6), 10-15 parts of coupling agent, 10-12 parts of hydroxymethyl fatty amine, 10-20 parts of shock-resistant modifier, 14-18 parts of polyalcohol, 5-10 parts of antistatic agent, 10-20 parts of carbon black, 5-10 parts of antioxidant, 10-20 parts of DOP (dioctyl phthalate), 10-15 parts of ultraviolet absorbent, 5-10 parts of epoxy octyl stearate and 1-5 parts of barium stearate. The preparation method comprises the following steps: thoroughly mixing the components uniformly, adding the mixture into a double screw extruder, granulating by melting and plastification under certain conditions, and carrying out injection molding on the granules under certain conditions. The method disclosed by the invention is simple in technique, and convenient for large-scale production; and the product has the advantages of high notch impact strength, high bending strength, high hardness, and favorable antistatic and aging resistance.

Owner:ANHUI ANYUAN PLASTIC

Radiation-resisting cable material and preparation method thereof

InactiveCN103613882AGood physical and mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsMicrocrystalline waxPolyetherimide

The invention discloses a radiation-resisting cable material and a preparation method thereof. The radiation-resisting cable is prepared from the following raw materials in parts by weight: 70-80 parts of SG-4 type PVC (Polyvinyl Chloride) resin, 25-35 parts of polyetherimide, 10-15 parts of ABS (Acrylonitrile Butadiene Styrene), 10-15 parts of magnesium hydrate, 5-10 parts of Phenoxycyclotriphosphazene, 8-12 parts of acetyltrioctylcitrate, 3-5 parts of microcrystalline wax, 4-8 parts of coumarone resin, 5-10 parts of calcium phosphate, 3-6 parts of epoxy octyl stearate, 10-15 parts of calcined clay, 4-8 parts of composite filler, 6-12 parts of precipitated barium sulphate, 0.5-1 part of imarcaptoacetate dioctyltin, 1-2 parts of zinc stearate, 3-6 parts of titanium dioxide, 0.3-0.5 part of a light stabilizer 622, 0.2-0.4 part of a light stabilizer 1084 and 0.5-0.8 part of an antioxidant 264. The cable material disclosed by the invention is excellent in physical and mechanical property, flame retardant property, radiation resistance property and electric property, is capable of working in severe environments in nuclear power plants, is long in service life, and can be widely applied to cables in match with wires in the nuclear power plants.

Owner:立宝莱科技股份有限公司

Anti-aging, oil resistant and high strength composite cable material

The invention discloses an anti-aging, oil resistant and high strength composite cable material. The material comprises the following components: nitrile rubber, natural rubber, styrene butadiene rubber, stearate, zinc oxide, sulfur, calcined clay, talcum powder, zinc borate, nanosized aluminium hydroxide, 1,1-di (tert-butylperoxy)cyclohexane, accelerator DM, accelerator TMTD, antioxidant RD, antioxidant, epoxy rice bran oleic acid butyl ester, epoxy octyl stearate, trioctyl phosphate and a silane coupling agent. The anti-aging, oil resistant and high strength composite cable material disclosed by the invention has excellent characteristics of being high in strength, aging resistance and oil resistance; and the cable made from the material can meet demands in various occasions and has wide application prospects.

Owner:繁昌县菲德通讯材料设计有限公司

Topical cosmetic compositions comprising alpha arbutin

InactiveUS20060188559A1Synergistic in skin whitening effectivenessImprove stabilityCosmetic preparationsBiocideALPHA-ARBUTINTyrosinase

This invention is a topical tyrosinase inhibiting combination using alpha arbutin and bearberry extract, in synergism, for the purpose of skin lightening. The active admixture is a dermatological serum comprised of alpha arbutin, octyl stearate and polyolprepolymer-2, introduced onto the human skin in liposome form for ultra-deep penetration.

Owner:E T BROWNE DRUG

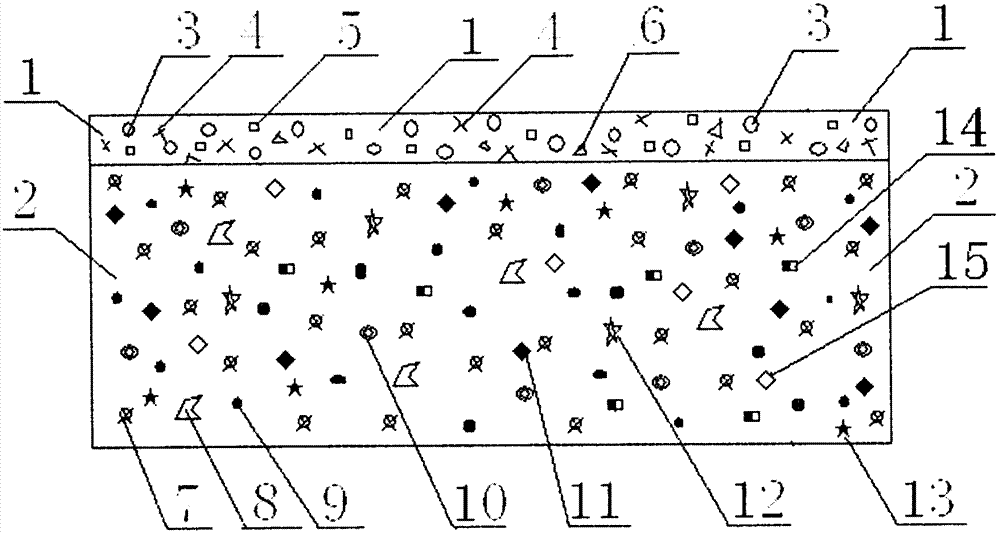

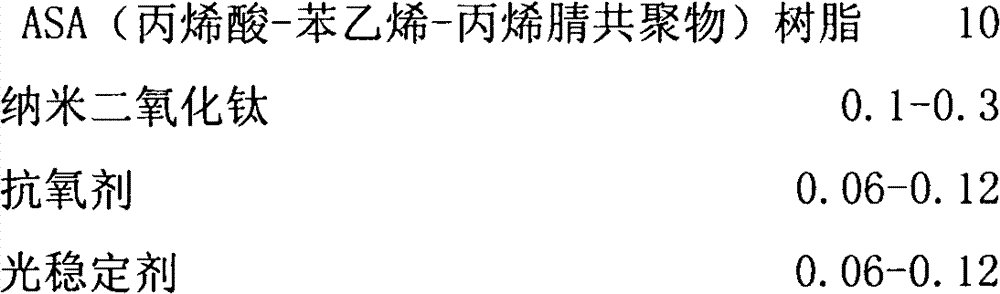

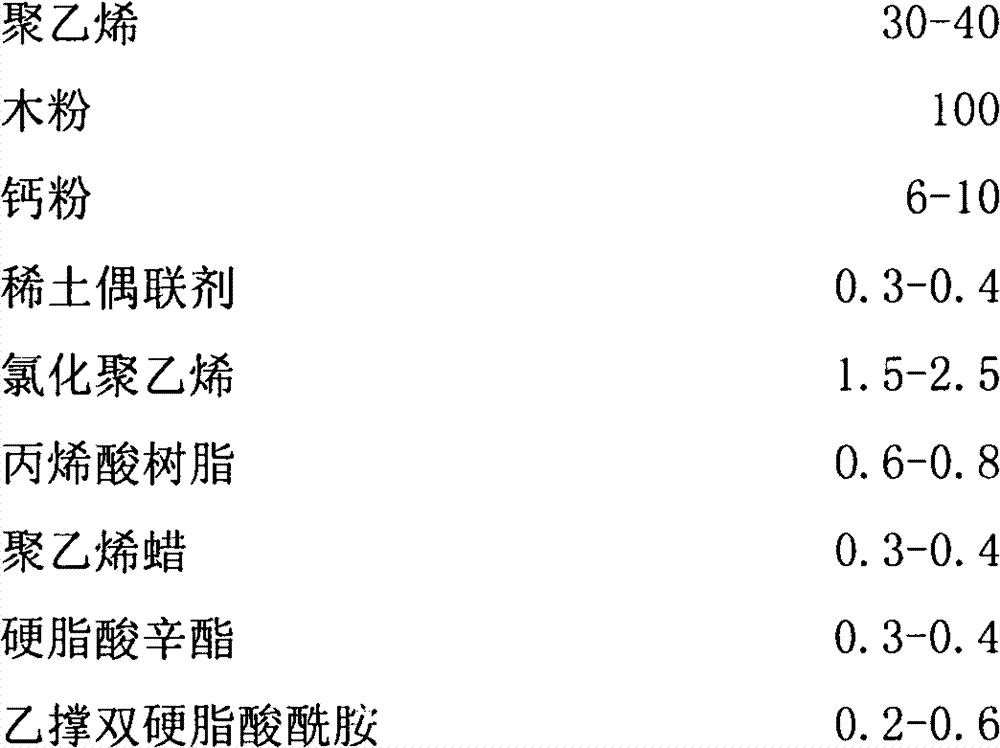

Co-extrusion formed wood-plastic composite plate and preparation method thereof

The invention discloses a co-extrusion formed wood-plastic composite plate and a preparation method thereof, which discloses a composite material, a structural material and the preparation method of the materials. The co-extrusion formed wood-plastic composite plate is composed of an anti-aging resin layer and a wood-plastic structural layer, wherein the anti-aging resin layer is located on the surface of the wood-plastic structural layer. The anti-aging resin layer is formed by melting, blending and extruding an ASA (Acrylonitile-Styrene-Acrylate) resin, titanium dioxide, an antioxidant and a light stabilizer; and the wood-plastic structural layer is formed by extruding polyethylene, wood power, calcium powder, a rare-earth coupling agent, chlorinated polyethylene, acrylic resin, polyethylene wax, octyl stearate and ethylene bis stearamide. Different molten material flows are formed by the anti-aging resin layer and the wood-plastic structural layer, and then the material flows are converged in a compound machine head and co-extruded by a neck mould, so that the co-extrusion formed wood-plastic composite plate is prepared. Besides the characteristics of multiple purposes of common wood-plastic plates, the wood-plastic plate has more excellent anti-aging property and does not age after a long use in the open air. The co-extrusion formed wood-plastic composite plate disclosed by the invention is suitable for preparing indoor and outdoor floors, guardrails, decorative sheets and the like.

Owner:NANJING FORESTRY UNIV

Stainless steel pickling passivator and preparation method thereof

InactiveCN107012472AAvoid harmGood for healthMetallic material coating processesFatty alcoholMaterials science

The invention discloses a stainless steel pickling passivator and a preparation method thereof. The stainless steel pickling passivator comprises citric acid, hydrochloric acid, formic acid, fatty alcohol-polyoxyethylene ether, polyethyleneimine, epoxy octyl stearate, thiosemicarbazide, epoxy chloropropane, hydrogen peroxide, a penetrating agent, a corrosion inhibitor, a thickening agent, an inorganic filler and a viscosity modifier. The preparation method comprises the steps of firstly adding part of raw materials such as the fatty alcohol-polyoxyethylene ether and the like into the hydrochloric acid sequentially, and uniformly stirring the raw materials to obtain a mixed solution I; then sequentially adding part of the raw materials such as the hydrogen peroxide into mixed acid liquor of the citric acid and the formic acid, and uniformly stirring the raw materials to obtain a mixed solution II; then mixing the mixed solution I and the mixed solution II, and adding the inorganic filler into the mixture; and finally adding the penetrating agent, the corrosion inhibitor, the thickening agent and the viscosity modifier sequentially into the mixture, and uniformly mixing the mixture to obtain the finished product. According to the stainless steel pickling passivator and the preparation method thereof, the stainless steel pickling passivator is good in passivation effect, not prone to damage the surface of stainless steel, environment-friendly and simple to prepare and does not cause harm to human bodies and environment.

Owner:合肥协耀玻璃制品有限公司

High-temperature-resistant flame-retardant plastic formula

The invention discloses a high-temperature-resistant flame-retardant plastic formula, and relates to the technical field of chemical engineering. Plastic comprises 12-15 parts of polyvinyl chloride resin, 20-25 parts of polypropylene flame retardant masterbatch, 5-8 parts of polyamide, 7-9 parts of polycarbonate, 6-8 parts of polyether-ether-ketone, 12-15 parts of thermoplastic polyester, 5-10 parts of polyether sulfone, 5-8 parts of modified polyphenylene oxide, 15-20 parts of mercaptan organotin, 25-30 parts of calcium carbonate powder, 6-10 parts of plastic filler masterbatch, 1-4 parts of polypropylene, 7-9 parts of additives, 10-12 parts of 1,3-bis(hydroxymethyl)-5,5-dimethyl hydantoin and 3-6 parts of epoxy octyl stearate. According to the high-temperature-resistant flame-retardant plastic formula, plastic products made of the plastic manufactured by using the formula can keep good mechanical properties at high temperature and are not prone to embrittlement or frangibility when located in a high-temperature environment for a long time, the plastic can be recovered and used, which responds to the requirement for building a resource-saving and environment-friendly society of China, and the plastic formula has wide development prospects.

Owner:丁德凤

High-strength heat-resistant corrosion-resistant polyurethane board and preparation method thereof

The invention discloses a high-strength heat-resistant corrosion-resistant polyurethane board which is prepared from diisocyanate, polycarbonate dibasic alcohol, dioctyl azelate, ethoxylated alkylphenol ammonium sulfate, toluene diisocyanate, heavy calcium carbonate, carbon black, nano attapulgite, nano silicon dioxide, bisphenol a diglycidyl ether, epoxy octyl stearate, a modified filler, methylsilicone oil, sulfur, a phenolic resin, a curing agent, melamine, hypophosphate, a flame-retardant synergistic agent, triallyl isocyanurate, dicumyl peroxide, 3,5-dimethylthiotoluylene diamine and a copper sheet. The invention also discloses a preparation method of the high-strength heat-resistant corrosion-resistant polyurethane board. The polyurethane board has the advantages of high strength, excellent heat resistance and excellent corrosion resistance.

Owner:安徽浩丰特种电子材料有限公司

Plastic blend friction material and preparation method thereof

The invention discloses a plastic blend friction material which is prepared from the following raw materials in parts by weight: 37-40 parts of melamine, 50-60 parts of 37-40% formalin, 4-6 parts of bentonite, 0.7-1 part of copper 8-hydroxyquinoline, 0.1-0.2 part of nonyl phenol, 10-16 parts of liquid ethylene propylene diene monomer rubber, 0.2-0.4 part of sp80, 3-4 parts of epoxy octyl stearate, 140-170 parts of polyvinyl chloride, 6-8 parts of ethyl orthosilicate, 0.2-0.3 part of triethanolamine, 0.3-0.5 part of alkylphenol polyoxyethylene, 2-3 parts of dialkyl pentasulfide RC2540, 1-2 parts of potassium hexatitanate whisker, 0.3-1 part of titanate coupling agent kt105, 0.1-0.2 part of lithium naphthenate, 0.6-1 part of butyl tin mercaptide, 1-2 parts of ammonium polyphosphate, 1-2 parts of citric acid and 0.01-0.02 part of 1,3,5-trimethylbenzene. The plastic blend friction material has the advantages of high temperature friction resistance, favorable comprehensive properties and high stability.

Owner:来安县隆华摩擦材料有限公司

Low temperature-resistant insulated fluororubber cable material

InactiveCN103524805AImprove performanceWith low temperature resistanceInsulated cablesInsulated conductorsTG - TriglyceridePolyamide

The invention relates to a cable material and specifically relates to a low temperature-resistant insulated fluororubber cable material. The cable material comprises the following materials in parts by weight: 20-23 parts of butadiene rubber, 12-15 parts of isoprene rubber, 10-12 parts of nylon PA (Polyamide), 20-24 parts of fluororubber, 20-23 parts of white carbon black, 24-28 parts of N330 carbon black, 15-20 parts of nano argil, 4-7 parts of paraffin oil, 2.2-3 parts of stearic acid, 1-2 parts of sulphur, 1-2 parts of dicumyl peroxide, 3-4 parts of epoxy octyl stearate, 3-4 parts of epoxy triglyceride fatty acid, 8-12 parts of N220 carbon black, 2-3 parts of zinc oxide, 1-2 parts of a silane coupling agent KH550, 1-2 parts of an accelerator M and 4-5 parts of auxiliaries. The cable material disclosed by the invention integrates advantages of butadiene rubber, isoprene rubber, fluororubber as well as nylon and the like, so that performance of the conventional fluororubber cable material is improved; the low temperature-resistant insulated fluororubber cable material disclosed by the invention has the advantages of being low temperature resistant, good in tensile property, good in flexibility, good in insulativity and the like, can satisfy using requirements of a specific occasion, and is harmless to environment and human body, and wide in application prospect.

Owner:安徽文峰电子科技集团有限公司

Antibacterial antiseptic food preservation film

InactiveCN103689750AAntibacterial and antisepticNo damageFood preservationLow-density polyethyleneSide effect

The invention belongs to the technical field of preservation tools, and particularly relates to an antibacterial antiseptic food preservation film which is characterized by being prepared from the following components in parts by weight: 90-100 parts of low-density polyethylene resin, 0.05-0.1 part of ethyl vanillin, 0.05-1 part of potassium sorbate, 5-10 parts of calcium carbonate, 0.5-1 part of antioxidant, 0.5-1 part of sodium alginate, 4-8 parts of epoxy octyl stearate and 4-8 parts of epoxidized soybean oil. By adding the ethyl vanillin and potassium sorbate, the antibacterial antiseptic food preservation film provided by the invention has an antibacterial antiseptic effect, and no toxic and side effect and any harm to a human body.

Owner:栾晓健

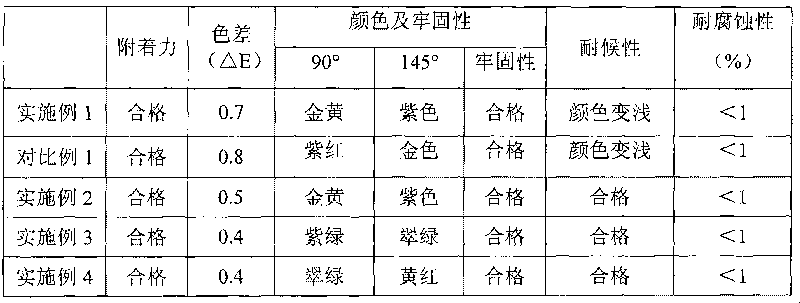

Electroplating solution and method for forming color plating

InactiveCN101724878AGood weather resistanceAccelerated corrosionElectrolytic inorganic material coatingPhosphoric acidMolybdic acid

The invention provides electroplating solution, which is aqueous solution containing molybdic acid and / or molybdate, phosphoric acid, unsaturated sulfonic acid and / or unsaturated sulfonate, octyl stearate, lactic acid and boric acid, and the pH value of the electroplating solution is 5 to 8. The invention also provides a method for forming color plating by using the electroplating solution of the invention. According to the electroplating solution and the method for forming the color plating, a bright nickel layer is not required to electroplate on a base material first, and a color plating which has even and bright color, solid coloring, good weather fastness and corrosion resistance, and high adhesion can be obtained; thus, the method is simple to operate.

Owner:BYD CO LTD

Expanded perlite modified composite sound absorbing material and preparation method thereof

The invention discloses an expanded perlite modified composite sound absorbing material. The material is prepared from the following raw materials in parts by weight: 100-120 parts of barite powder, 50-60 parts of ceramsite, 40-50 parts of expanded perlite, 80-90 parts of acrylic emulsion, 55-65 parts of modified tree ashes, 15-20 parts of talcum powder, 20-30 parts of polyester fibers, 10-20 parts of nanocarbon, 20-30 parts of EVA (ethylene-vinyl acetate copolymer), 15-20 parts of CPE (chlorinated polyethylene), 5-10 parts of polyisobutene, 5-8 parts of epoxy octyl stearate, 4-6 parts of cresyl diphenyl phosphate, 2-3 parts of calcium stearate and 1-2 parts of dibasic lead phthalate. The material has the beneficial effects that the problem of developing and researching the sound absorbing material urgently is solved and the novel sound absorbing material which meets the requirements, can stand the tests of harsh environments and has the advantages of high tensile strength, high elongation, high breaking strength, good sound absorbing effect and the like is prepared.

Owner:芜湖跃飞新型吸音材料股份有限公司

Polyethylene/polybutylece terephthalate (PBT) coated coconut shell powder particle blending foam material and preparation method thereof

InactiveCN103030869AImprove interfacial bond strengthHigh strengthPhosphorous acidLinear low-density polyethylene

The invention discloses a polyethylene / polybutylece terephthalate (PBT) coated coconut shell powder particle blending foam material. The material is prepared from the following materials in part by weight: 60 to 80 parts of LLDPE (Linear low density polyethylene), 20 to 40 parts of HDPE (high-density polyethylene), 30 to 40 parts of PBT, 10 to 15 parts of tourmaline, 15 to 20 parts of water glass, 5 to 10 parts of coconut shell powder, 1 to 2 parts of anilino-methyl-triethoxysilane, 5 to 8 parts of decabromodiphenyl oxide, 4 to 6 parts of di-butyl nylonic acid ester, 5 to 8 parts of epoxy octyl stearate, 3 to 5 parts of foaming agent, 1 to 2 parts of diperoxycarbamate, 1 to 2 parts of zinc oxide, 1 to 2 parts of calcium stearate, 0.5 to 1 part of dibasic lead phosphite, 2 to 3 parts of glycol tristearate, 3 to 5 parts of modified tree ash, and 1 to 2 parts of antioxidant 2461. The polyethylene / PBT coated coconut shell powder particle blending foam material is light in weight, flexible, high in strength, good in resilience, ideal in foaming effect, uniform in cell, compact, high in flame resistance, ageing resistant and durable.

Owner:滁州凯凯建筑节能有限公司

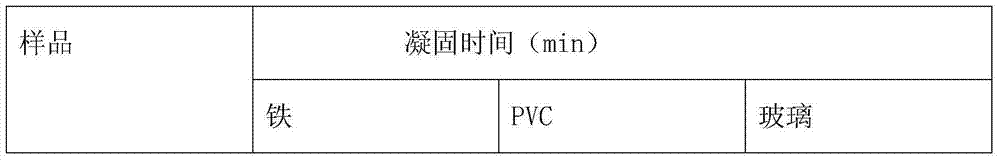

Packaging adhesive containing modified sepiolite powder

ActiveCN103788910AImprove dispersion uniformityImprove heat resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesDibutyltin dilaurateEther

The invention discloses a packaging adhesive containing modified sepiolite powder. The packaging adhesive is prepared from the following raw materials in parts by weight: 50-100 parts of phenol propane epoxy resin, 50-80 parts of polystyrene, 10-15 parts of epoxy octyl stearate, 3-5 parts of polytetrahydrofuran ether glycol, 5-8 parts of cellulose ether, 5-10 parts of butadiene-acrylonitrile rubber, 8-10 parts of lignin, 1-3 parts of boron powder, 10-15 parts of modified sepiolite powder, 2-4 parts of nano titanium dioxide, 5-10 parts of high abrasion furnace black, 1-3 parts of ferrocene, 0.5-0.8 part of dibutyltin dilaurate, 0.3-0.5 part of phosphoric acid, 2-4 parts of mica iron oxide, 2-4 parts of sodium silicate, 2-4 parts of an anti-aging agent MB, 2-4 parts of an accelerant BZ, 1-3 parts of a coupling agent and 10-15 parts of modified fly ash. The packaging adhesive disclosed by the invention, through the modified sepiolite powder and the modified fly ash as well as regulating proportions, is excellent in binding power, chemical corrosion resistance, heat resistance and acid-base resistance, rapid in curing speed and long in service life.

Owner:广西汇智生产力促进中心有限公司

Topical cosmetic compositions containing alpha arbutin

This invention is a topical tyrosinase inhibiting combination using alpha arbutin and bearberry extract, in synergism, for the purpose of skin lightening. The active admixture is a dermatological serum comprised of alpha arbutin, octyl stearate and polyolprepolymer-2, introduced onto the human skin in liposome form for ultra-deep penetration.

Owner:E T BROWNE DRUG

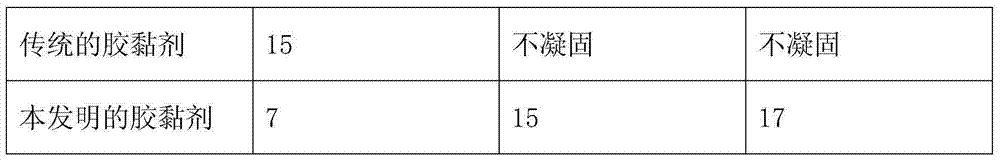

Viscosity breaker and production technique thereof

The invention relates to a viscosity breaker and a production technique thereof, belonging to the technical field of oil production assistants. The viscosity breaker comprises meerschaum, epoxy octyl stearate, sodium polyacrylate, sodium hydroxide, a surface modifier, propanol and water. The meerschaum, epoxy octyl stearate, sodium polyacrylate, sodium hydroxide, surface modifier, propanol and water are proportionally mixed to obtain the viscosity breaker, so that the visbreaking rate of the thick oil can reach 99.9%. Besides, after the viscosity breaker is put in a 400-DEG C high-temperature closed vessel and aged for 36 hours, the visbreaking rate of the viscosity breaker can still reach 99.3% above.

Owner:巩龙海

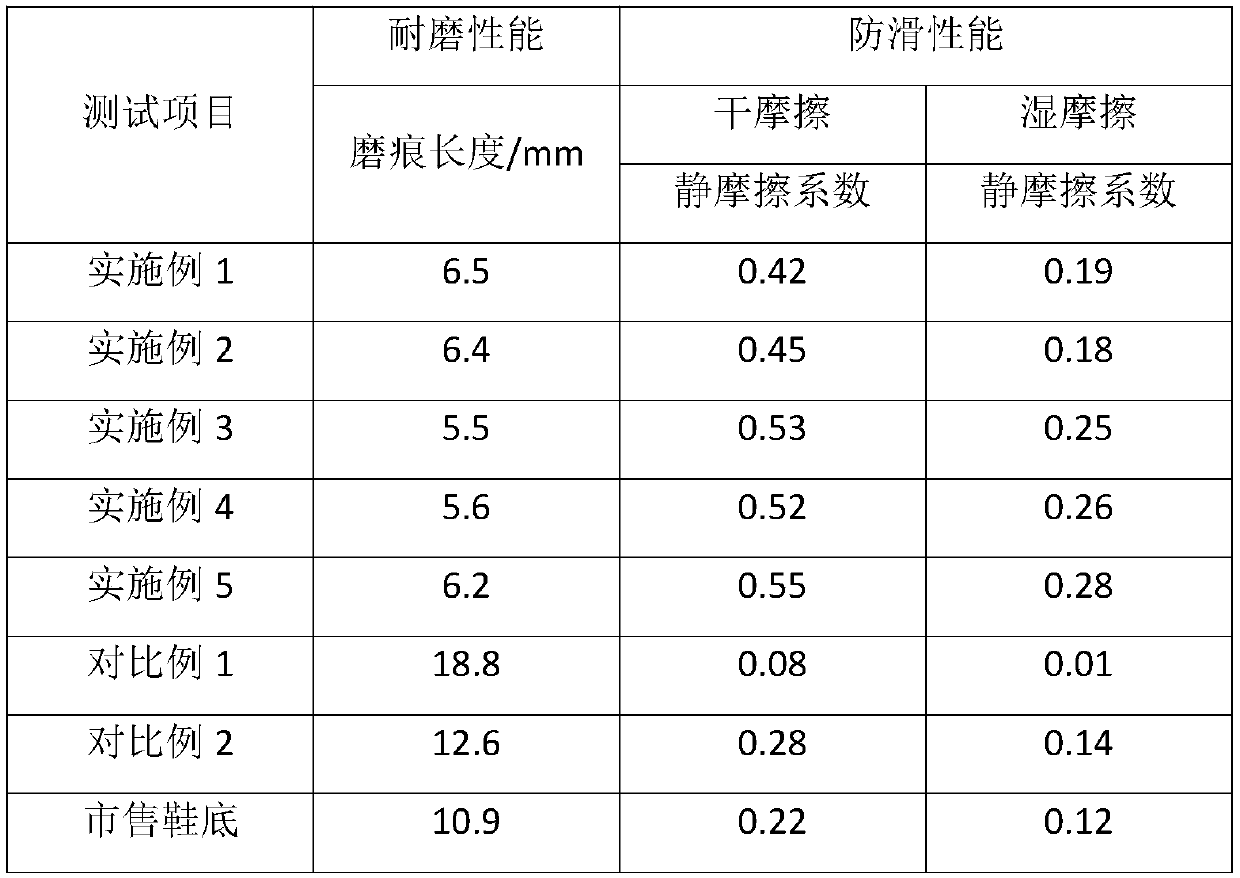

Preparation process of wear-resistant antiskid sole

The invention discloses a preparation process of a wear-resistant antiskid sole, and relates to the technical field of shoe processing. The preparation process comprises the following steps: 1) weighing components in a certain proportion; 2) mixing rubber and polyurethane, heating, adding half of polydimethylsiloxane, and keeping the temperature to obtain a mixture A; 3) mixing an ethylene-vinyl acetate copolymer, a Phylon material and a TPR material, adding residual polydimethylsiloxane, heating, mixing, adding modified nano silicon dioxide, and carrying out heat preservation and vacuum stirring to obtain a mixture B; 4) dispersing a modifying additive and carboxymethyl cellulose into water, performing ultrasonic dispersion, and removing water to obtain a mixture C; 5) adding the mixtureA and the mixture B into a mixing mill, adding octyl epoxy stearate, mixing, adding the mixture C, mixing, adding bamboo charcoal fibers and bamboo pulp fibers, and mixing to obtain a product, 6) foaming, and 7) cutting and polishing to obtain the sole. The sole has a good wear resistant performance and antiskid performance.

Owner:江西正博实业有限公司

Flame-retardant plastic packing and preparation method thereof

The invention discloses a flame-retardant plastic packing, which is prepared from the following raw materials in parts by weight: 3-5 parts of superfine porous silicon dioxide, 2-3 parts of nanoscale antimony trioxide, 1-2 parts of epoxy octyl stearate, 0.4-0.6 part of ethylene glycol monostearate, 0.2-0.3 part of avocado oil, 0.3-0.4 part of tragacanth gum, 2-3 parts of nano-iron slag, 200-220 parts of lightweight calcium carbonate, 5-9 parts of auxiliaries and 20-30 parts of water. Nanoscale antimony trioxide is added in the filler, so that the flame-retardant property of plastics can be improved; calcium carbonate is modified by using epoxy ethylhexyl stearate, ethylene glycol monostearate, avocado oil and tragacanth gum, so that the lipophilicity of calcium carbonate can be improved, and the reinforcement effect is good; through the auxiliaries, the dispersity and self-lubrication property of the packing can be improved.

Owner:青阳县吉祥塑胶有限公司

Anti-aging flame-retardant plastic and preparation method thereof

InactiveCN103396595ANotched impact strengthImprove notched impact strengthPolymer scienceStearic acid

The invention discloses an anti-aging flame-retardant plastic and a preparation method thereof. The anti-aging flame-retardant plastic is prepared from the following raw materials in parts by weight: 110-130 parts of HDPE (high-density polyethylene), 40-55 parts of PA66, 30-40 parts of ABS (acrylonitrile-butadiene-styrene), 10-15 parts of coupling agent, 5-8 parts of disulfiram, 10-15 parts of toughener, 5-10 parts of antioxidant, 10-20 parts of stabilizer, 10-20 parts of nano antimony trioxide, 10-15 parts of ultraviolet absorbent, 10-15 parts of auxiliary antioxidant, 5-10 parts of epoxy octyl stearate and 1-5 parts of zinc borate. The preparation method comprises the following steps: uniformly mixing the components, adding the mixture into a double screw extruder, and granulating by melting and plastifying, and carrying out injection molding on the granules. The plastic disclosed by the invention has the characteristics of high notch impact strength, high bending strength, high hardness, favorable flame retardancy, favorable aging resistance and the like; and the method disclosed by the invention is simple in technique and convenient for large-scale production.

Owner:ANHUI ANYUAN PLASTIC

Sun-proof cable sheath material

ActiveCN103333380AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesDispersityKetone

The invention discloses a sun-proof cable sheath material which is prepared from the following raw materials in parts by weight: 93-103 parts of neoprene SN23, 10-13 parts of polyethylene 6084A, 10-16 parts of celestite powder, 8-10 parts of fly ash, 2-4 parts of glass powder, 2-3 parts of magnesium hydroxide, 12-20 parts of modified filler, 4-6 parts of epoxy octyl stearate, 4-5 parts of polyamide wax micropowder, 1-2 parts of ammonium molybdate, 1-2 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 1-2 parts of anti-aging agent MB, 1-2 parts of diethanolamine, 0.8-1 part of vulcanizing agent DCBP and 0.6-1 part of 2-hydroxy-4-p-octyloxydiphenyl ketone. The cable sheath material disclosed by the invention has the advantages of excellent physical properties, stable dimension, low shrinkage, high tensile strength, high tearing strength, high resilience, favorable oil resistance, favorable heat resistance, favorable flame retardancy, favorable sunlight resistance, favorable ozone resistance, favorable acid / alkali resistance and favorable chemical reagent resistance; and the modified filler has favorable dispersity and low surface tension, further enhances the tensile strength and stress at definite elongation of the cable material, and lowers the generation of heat and compression permanent set, thereby reducing the aging rate of the cable material, resisting the acid / alkali corrosion and lowering the production cost.

Owner:临沂高新区金蓝领劳务有限公司

Preparation method for lightweight high-resilience SEBS foamed shoe sole

The invention discloses a formula for a lightweight high-resilience SEBS foamed shoe sole. The lightweight high-resilience SEBS foamed shoe sole is composed of the following raw materials in parts bymass: 60-85 parts of polystyrene-ethylene-butadiene-styrene (SEBS), 10-20 parts of isoprene rubber (IR), 5-15 parts of an ethylene-vinyl acetate copolymer (EVA), 3-10 parts of talcum powder, 0.3-1 part of octyl stearate (ZnST), 0.3-1 part of stearic acid (STE), 0.5-2 parts of zinc oxide (ZnO), 0.1-0.5 part of a cross-linking agent, namely bis(tert-butylperoxyisopropyl)benzene (BIPB) and 2-4 partsof a foaming agent, namely azodicarbonamide (AC). The lightweight high-resilience shoe sole provided by the invention has the advantages of good aging resistance, light weight, high resilience, high comfort and the like, can be used as an outsole, an insole or an integral sole of slippers, sandals, casual shoes, tourist shoes, sneakers and the like, and can be extensively popularized.

Owner:QUANZHOU NORMAL UNIV

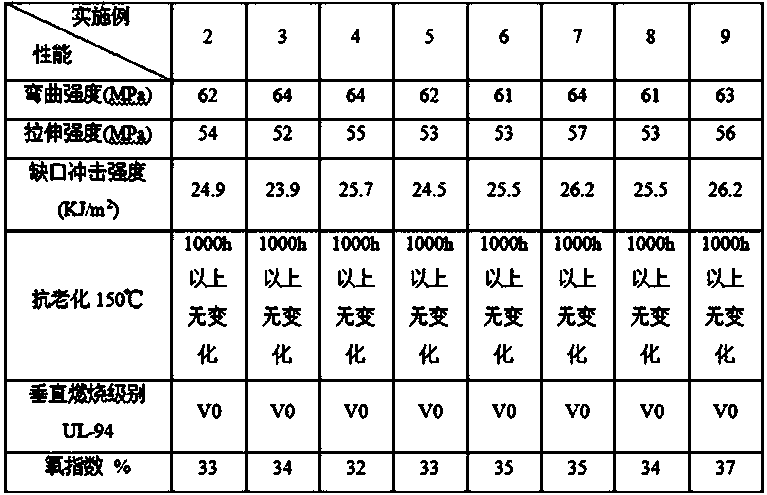

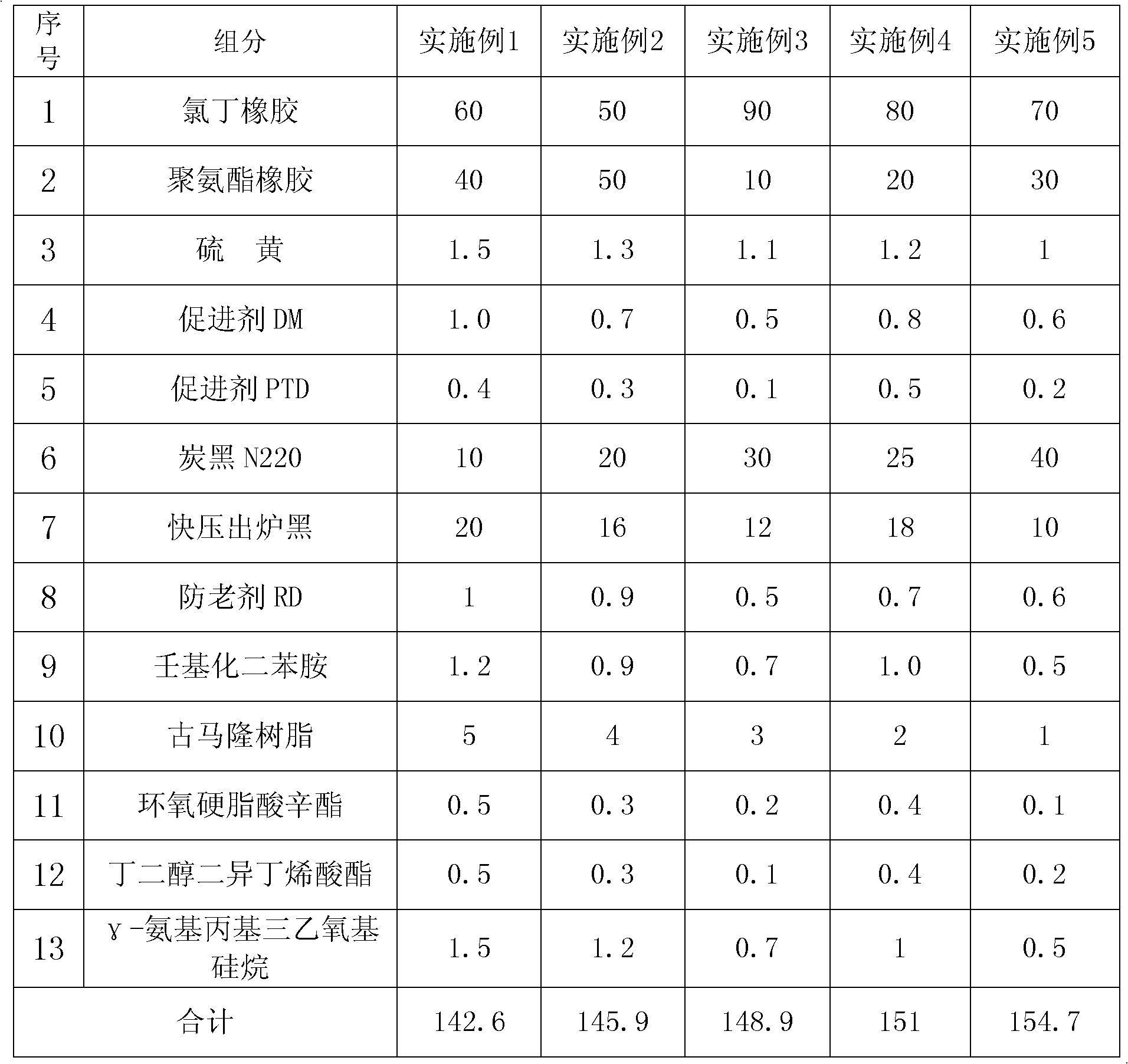

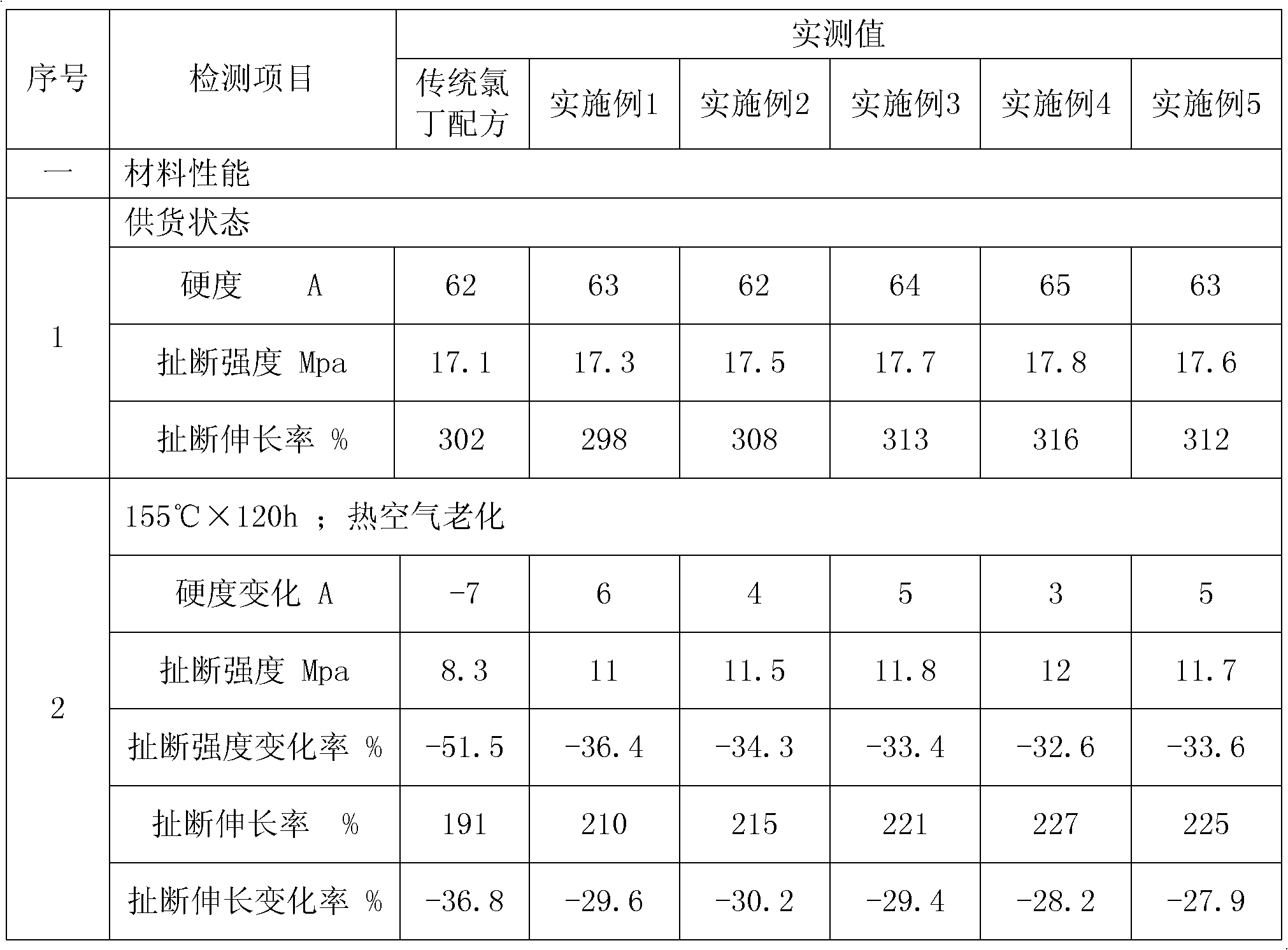

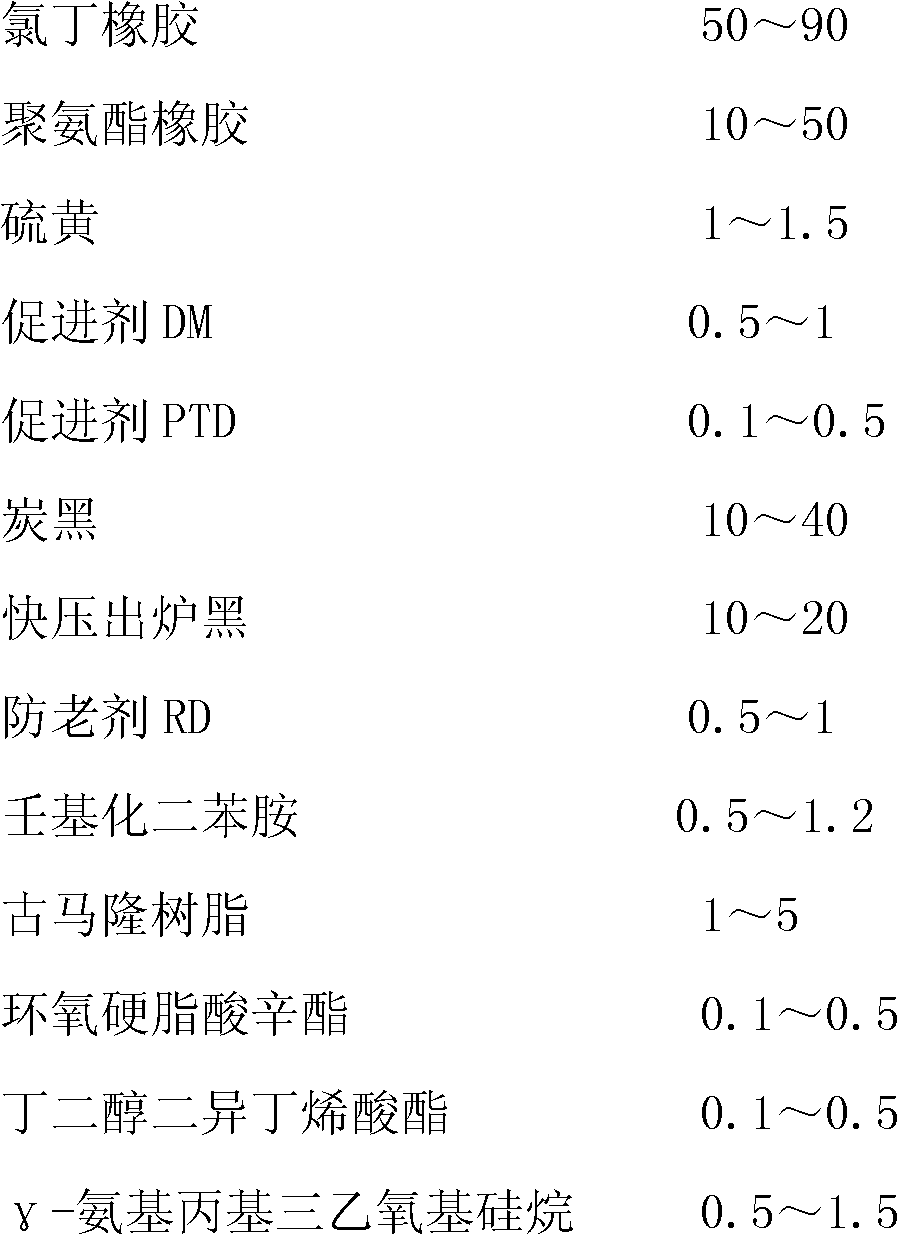

A kind of heat-resistant neoprene composition

InactiveCN102276886AImprove heat resistanceOther properties have not changed significantlyChemical industryPolymer science

The invention relates to a heat-resistant chloroprene rubber composition; the composition is chloroprene rubber, polyurethane rubber, sulfur, accelerator DM, accelerator PTD, carbon black, rapid press furnace black, anti-aging agent RD, nonylated di Aniline, coumarone resin, epoxy octyl stearate, butanediol dimethacrylate and γ-aminopropyl triethoxysilane; wherein: the sum of the parts of neoprene rubber and polyurethane rubber is 100 parts. By adding polyurethane rubber to chloroprene rubber and under the joint action of various additives, the heat resistance of chloroprene rubber has been further improved. The heat resistance temperature has reached 155°C, and the short-term heat resistance can last for 120 hours. And other properties of the rubber have not changed significantly, and the heat resistance effect is good. The improvement of the heat resistance of neoprene rubber also improves the use value of rubber. Neoprene materials and their products can play a better role in the automotive field, petrochemical and other fields, and improve the safety and service life of the products.

Owner:TIANJIN PENGYI GRP CO LTD

Anti-abrasion composite cable material with enhanced tensile strength and preparing method thereof

InactiveCN105778228AReduce injectionReduce aggregationPlastic/resin/waxes insulatorsElastomerDecabromodiphenyl ether

The invention discloses an anti-abrasion composite cable material with enhanced tensile strength. The anti-abrasion composite cable material is prepared from, by weight, 89-91 parts of high-density polyethylene, 15-17 parts of decabromodiphenyl ether, 7-9 parts of antimonous oxide, 2-3 parts of metallocene polyethylene, 2-3 parts of nano magnesium hydrate, 4-5 parts of cyclohexane, 0.2-0.3 part of gamma-aminopropyl triethoxy silane, 5-7 parts of mica powder, 10-12 parts of POE elastomer, 3-4 parts of white wax, 2-3 parts of epoxy octyl stearate, 2-3 parts of glass beads, 7-9 parts of calcium sulfate whiskers, 1-1.2 parts of a titanate coupling agent TMC-TTS, 1.2-1.4 parts of a silane coupling agent kh450 and an appropriate amount of water. The glass beads and the calcium sulfate whiskers are mixed and distributed uniformly, strength, rigidity and abrasion resistance of the composite cable material can be improved, and corrosion resistance is good; the POE elastomer is added, by means of column crosslinking, heat resistance of the composite cable material is improved to some extent, and the tensile strength is enhanced further.

Owner:ANHUI AICS SCI & TECH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com