Patents

Literature

1315 results about "Naphthenic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

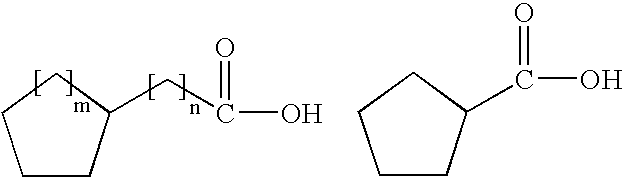

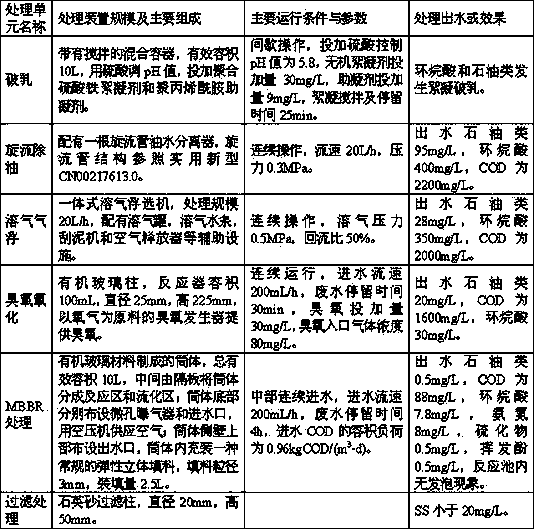

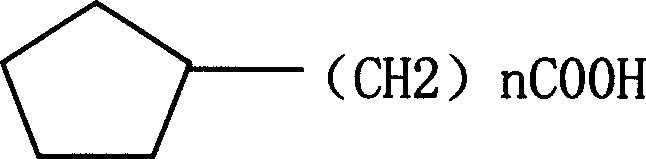

Naphthenic acids (NAs) are a mixture of several cyclopentyl and cyclohexyl carboxylic acids with molecular weight of 120 to well over 700 atomic mass units. The main fraction are carboxylic acids with a carbon backbone of 9 to 20 carbons. McKee et al. claim that "naphthenic acids (NAs) are primarily cycloaliphatic carboxylic acids with 10 to 16 carbons", although acids containing up to 50 carbons have been identified in heavy petroleum. The term naphthenic acid has roots in the somewhat archaic term "naphthene" (cycloaliphatic but non-aromatic) used to classify hydrocarbons. It was originally used to describe the complex mixture of petroleum-based acids when the analytical methods available in the early 1900s could identify only a few naphthene-type components with accuracy. Today "naphthenic" acid is used in a more generic sense to refer to all of the carboxylic acids present in petroleum, whether cyclic, acyclic, or aromatic compounds, and carboxylic acids containing heteroatoms such as N and S. Although commercial naphthenic acids often contain a majority of cycloaliphatic acids, multiple studies have shown they also contain straight chain and branched aliphatic acids and aromatic acids; some naphthenic acids contain >50% combined aliphatic and aromatic acids.

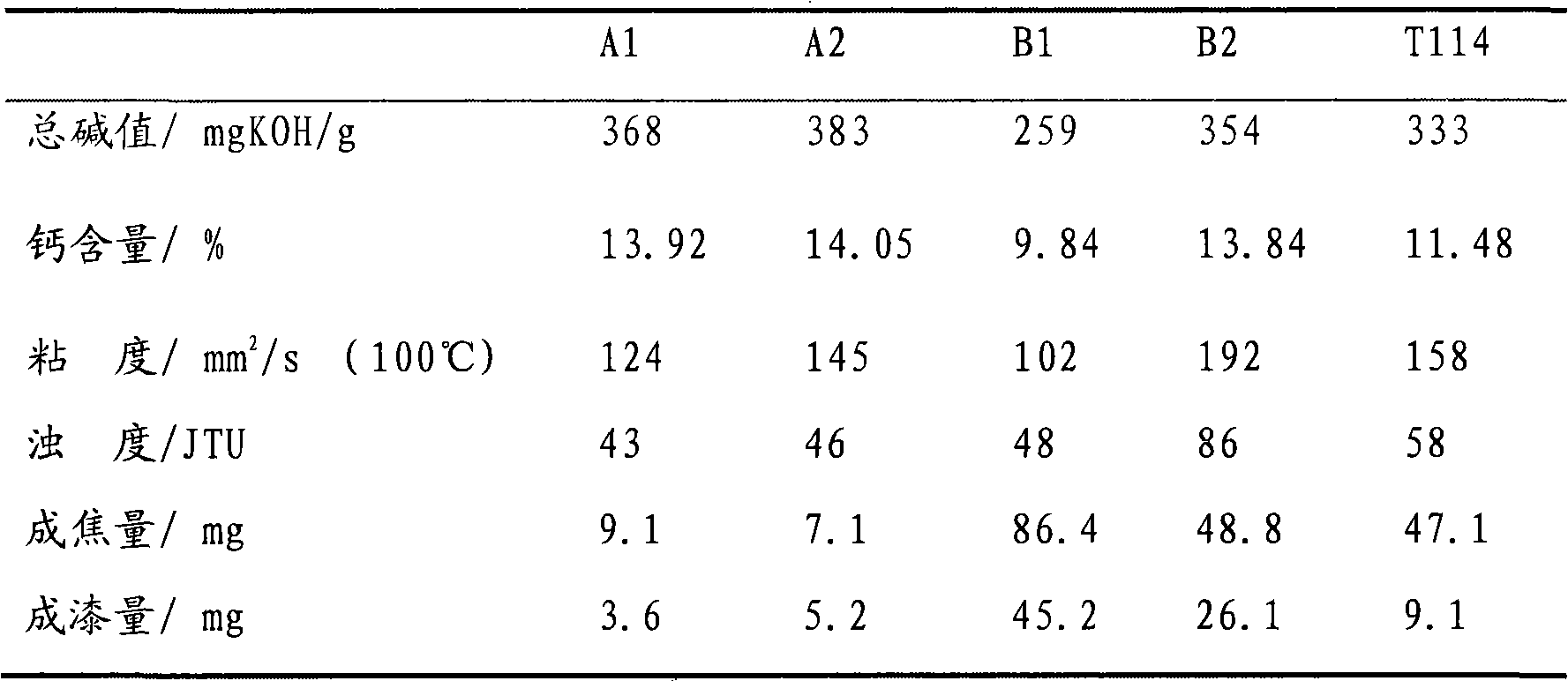

Preparation method for high-alkaline calcium naphthenate

ActiveCN101885677AAvoid aggregation and sedimentationHelps neutralize the reactionAdditivesCarboxylic acid salt preparationCalcium hydroxideAlkaline water

The invention relates to a preparation method for high-alkaline calcium naphthenate. In the method, calcium hydroxide and calcium oxide are taken as calcifying agents, pure water is replaced by alkaline aqueous solution, and a mode of multiple addition is adopted to prepare a calcium naphthenate product with the base number of more than or equal to 350 mgKOH / g. The product has the advantages of low viscosity and turbidity and better high temperature cleanliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

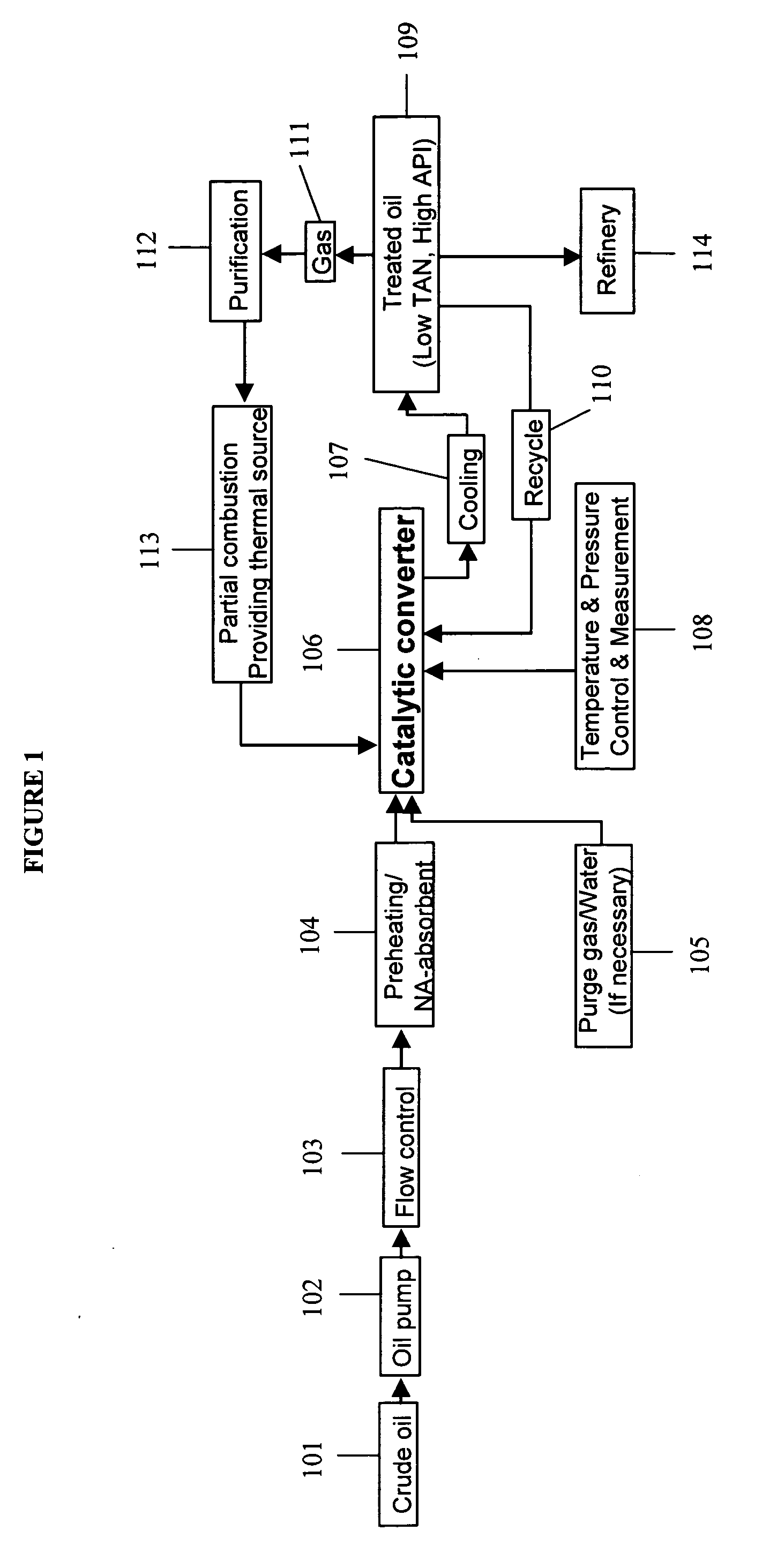

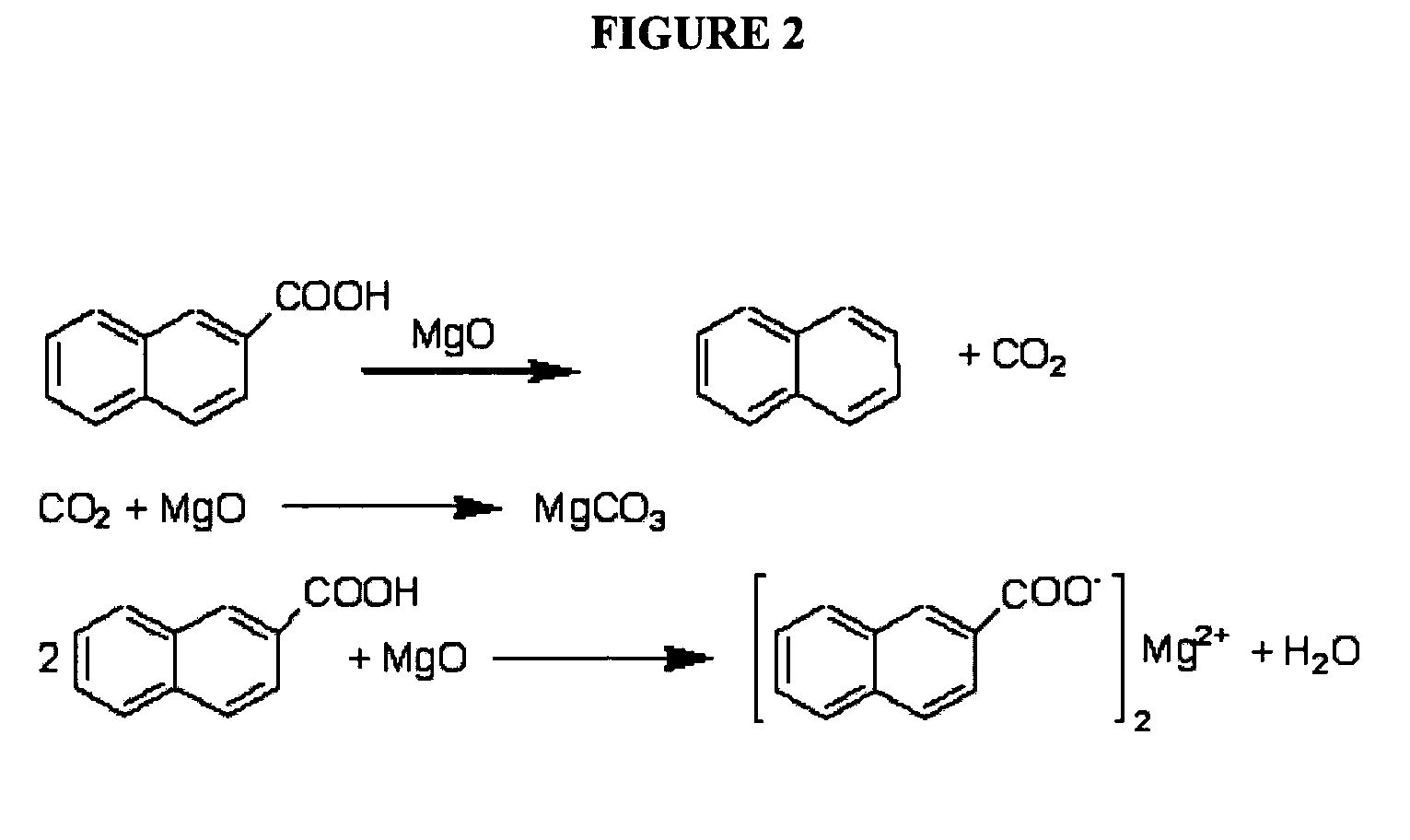

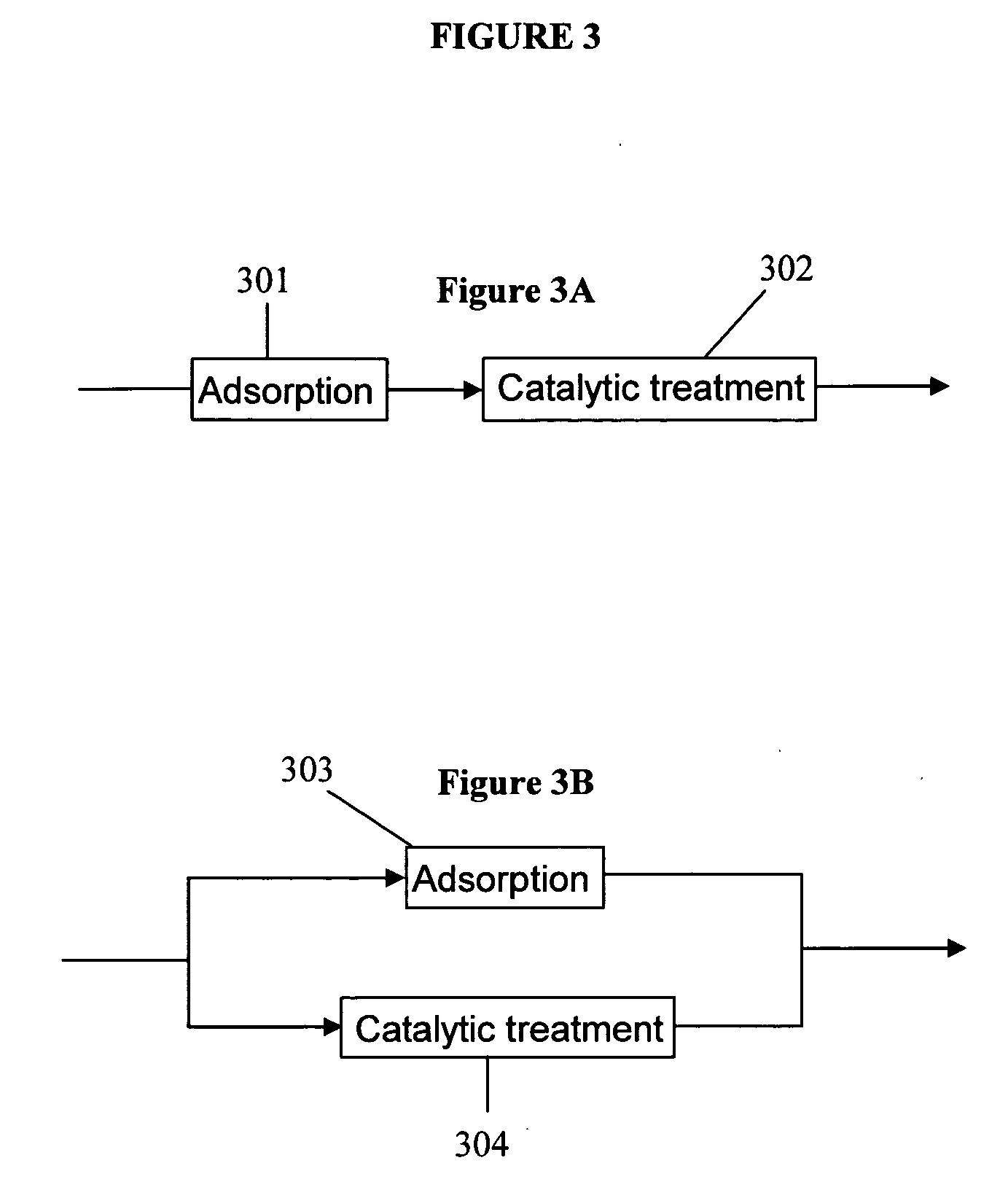

Process to upgrade oil using metal oxides

InactiveUS20060016723A1Reduce acidityReduce the numberRefining with metalsLiquid organic insulatorsHydrocotyle bowlesioidesCarboxylic acid

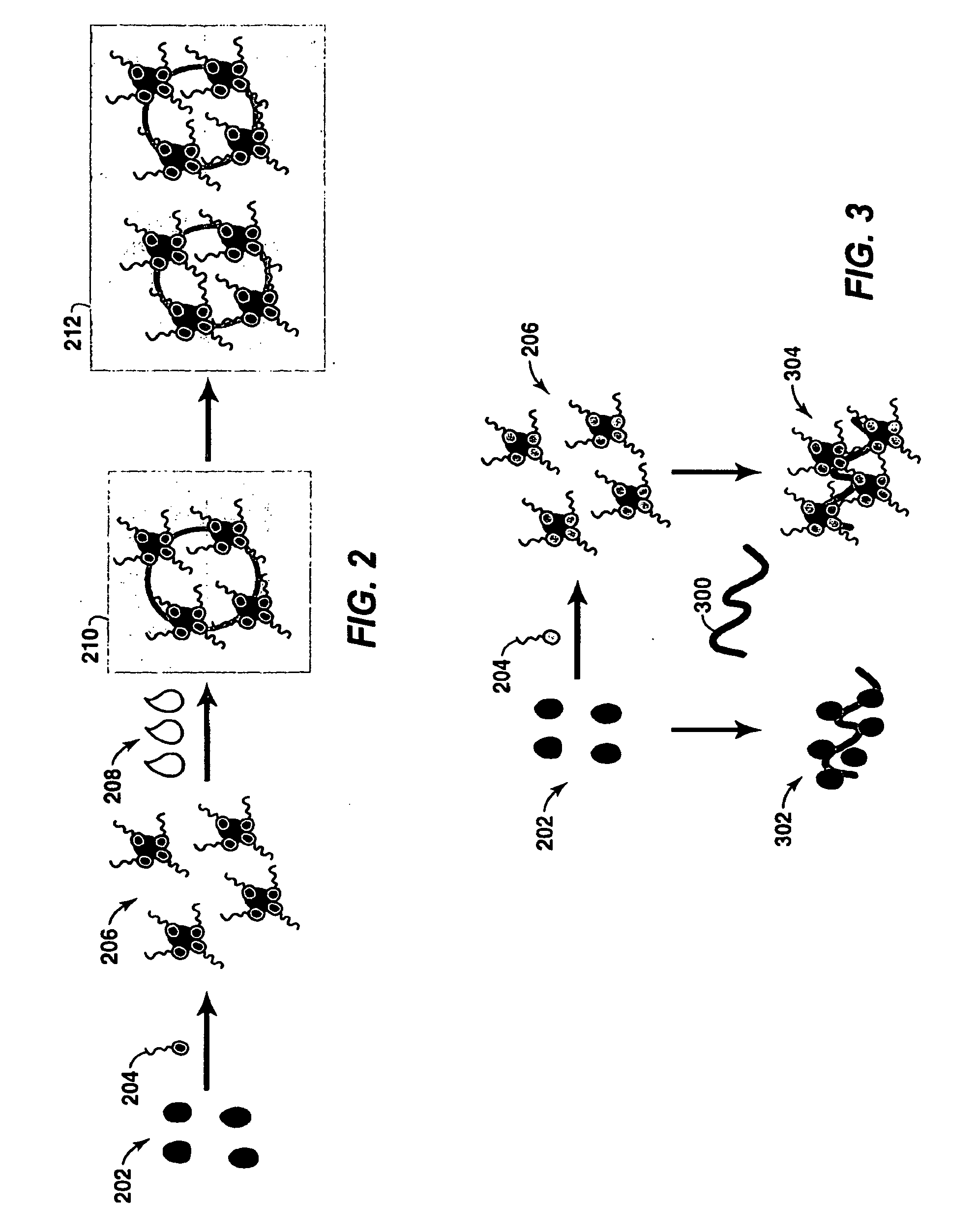

Described herein are compositions and methods for using metal oxides to upgrade oil. Metal oxides may be used as catalysts to reduce the TAN of the oil by converting carboxylic acids such as naphthenic acids into non-corrosive products. In some cases, the conversion occurs by a decarboxylation of the carboxylic acid to produce CO2. A second process promoted by metal oxides is hydrocarbon cracking. Cracking decreases the viscosity and increases the API, and produces lower molecular-weight hydrocarbons that are useful for many fuels and lubricants. Reductions in TAN and the increases in API improve the quality of increase the value of oil.

Owner:CALIFORNIA INST OF TECH

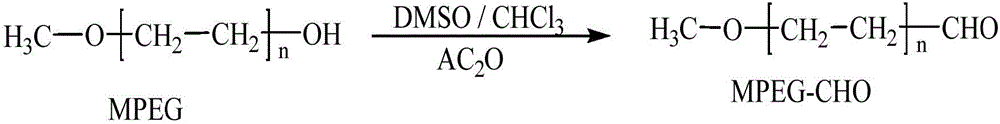

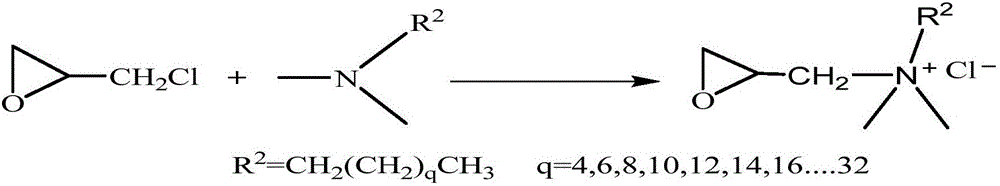

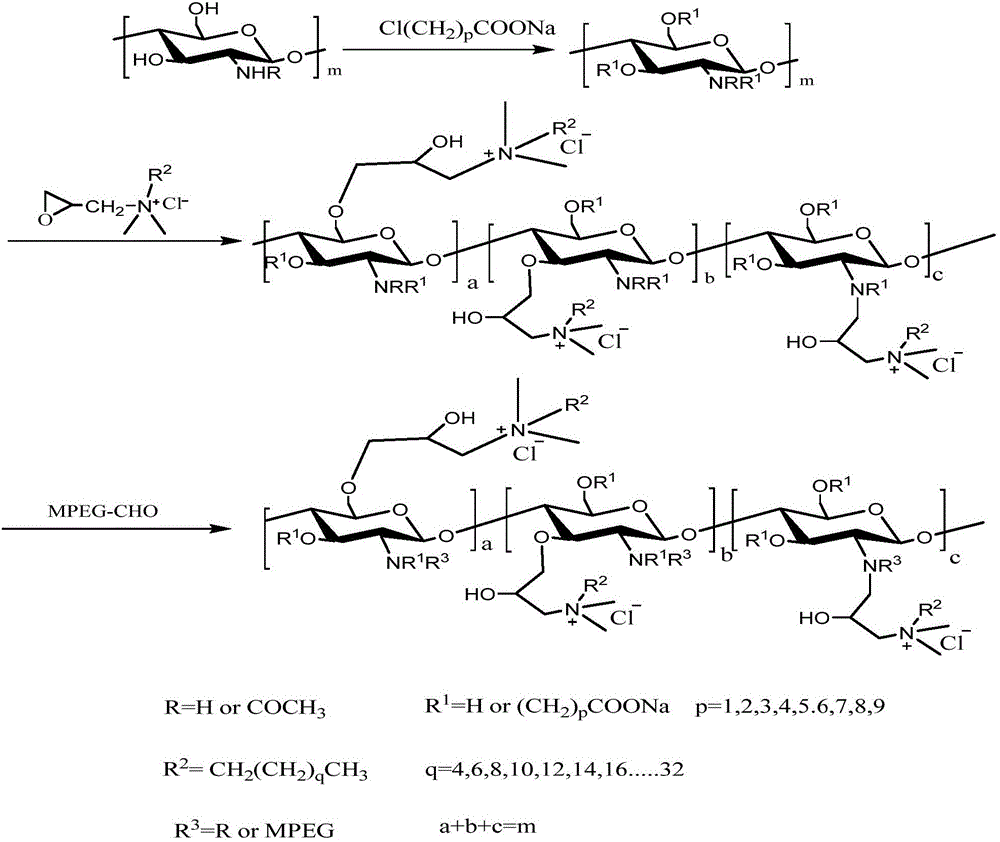

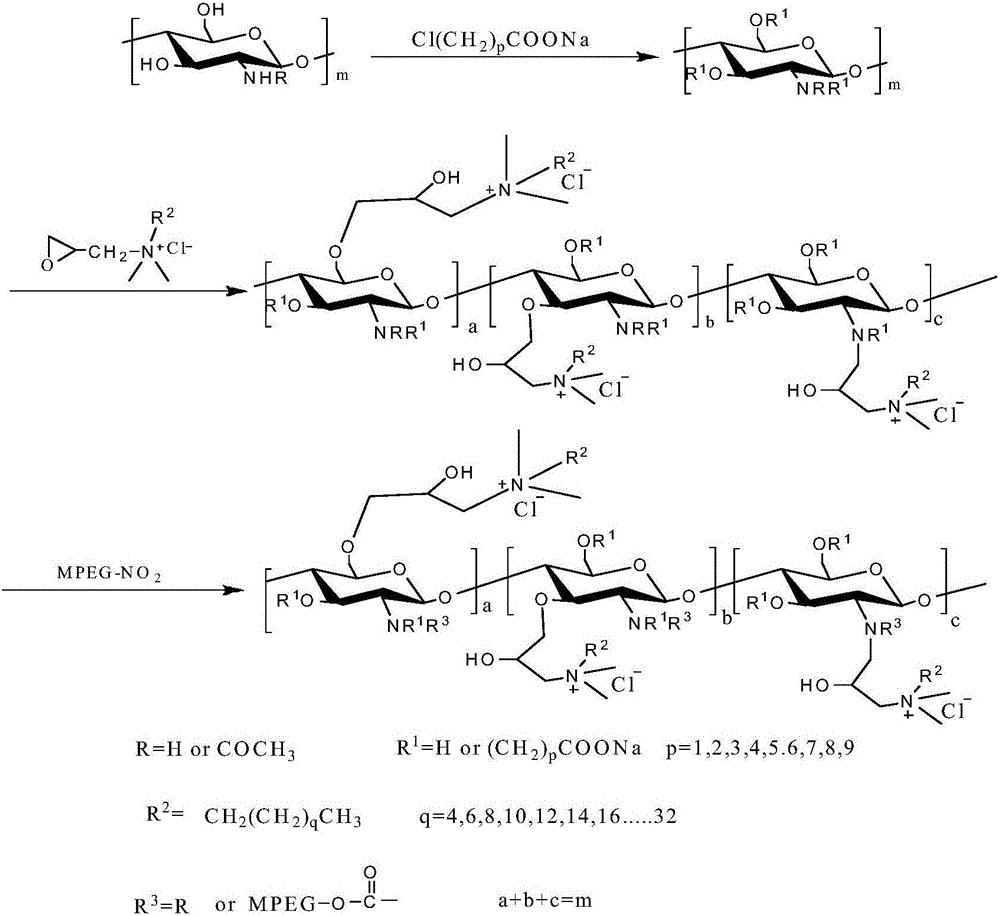

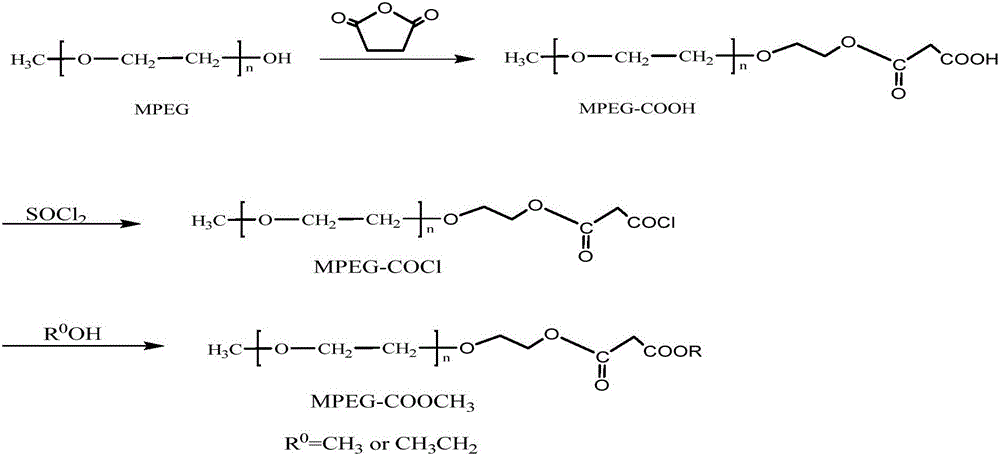

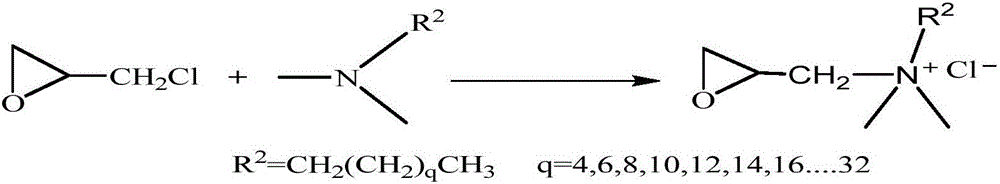

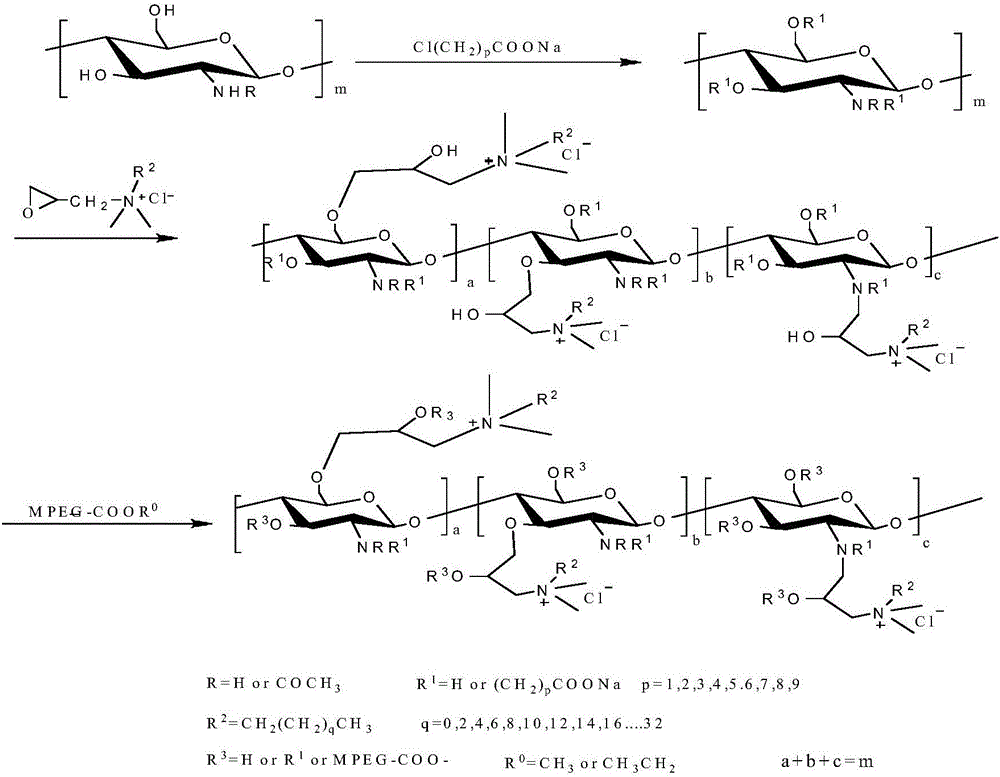

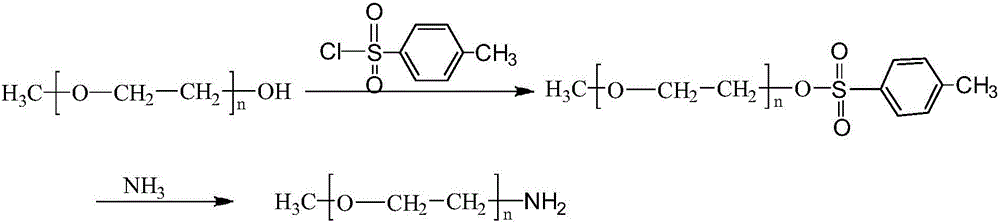

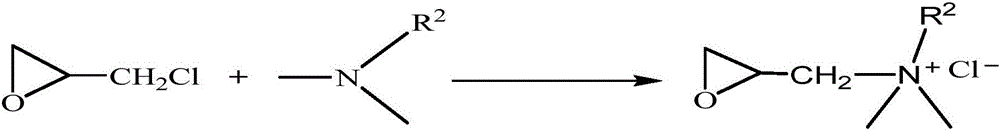

Preparation method of polyether-grafted chitosan derivative crude oil desalting demulsifier

ActiveCN106279706AWide variety of sourcesDegradableDewatering/demulsification with chemical meansQuaternary ammonium cationPolyethylene glycol

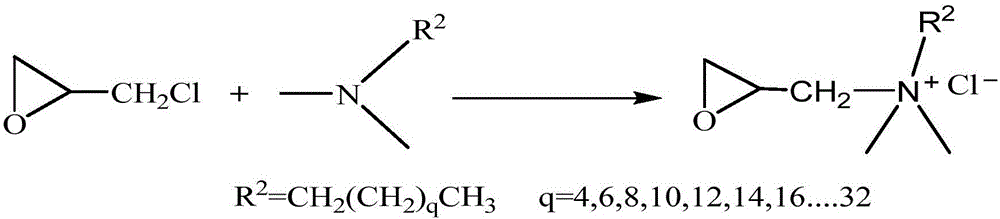

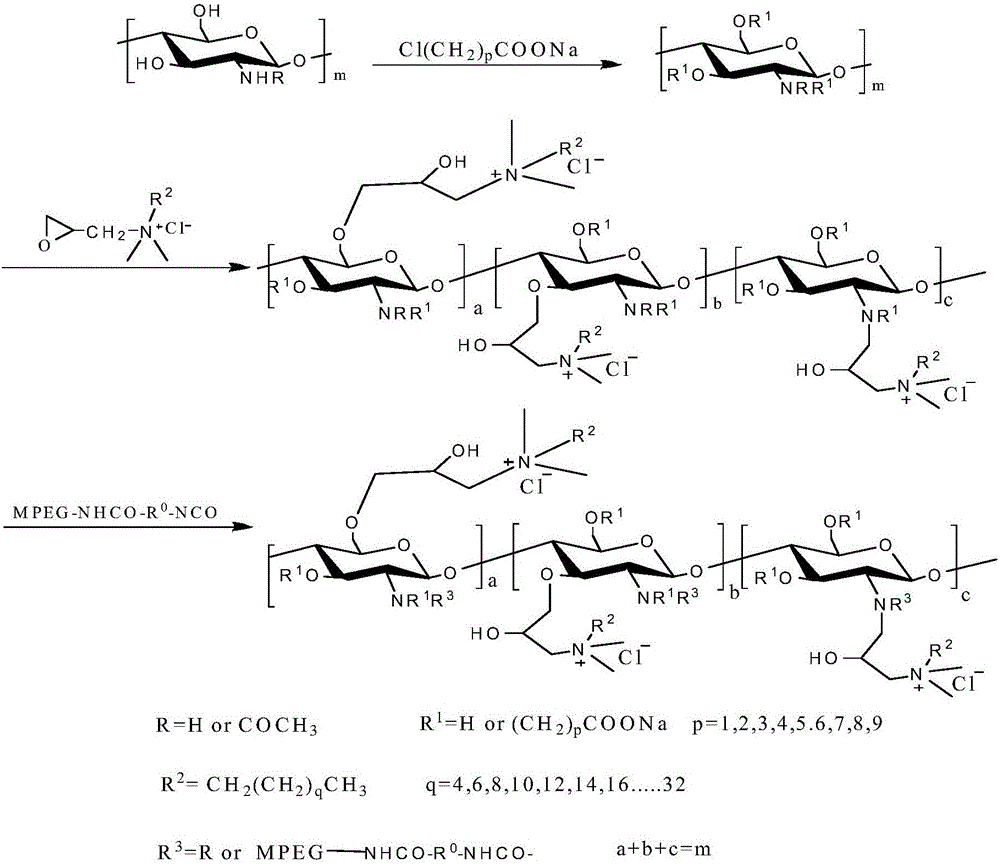

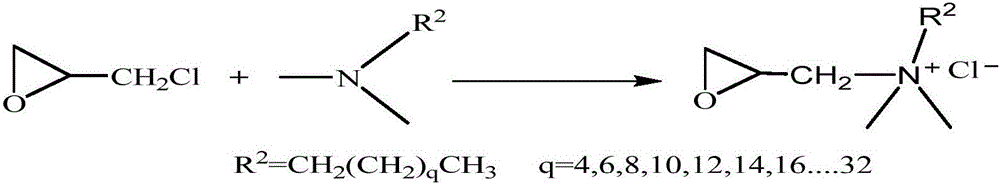

The invention relates to a preparation method of a polyether-grafted chitosan derivative crude oil desalting demulsifier. The preparation method comprises the following specific steps: firstly, performing formylation modification on polyethylene glycol monoethylether; secondly, preparing glycidyl dimethyl alkyl ammonium chloride; thirdly, preparing quaternarization carboxyalkyl chitosan; fourthly, enabling formylation modified polyethylene glycol monoethylether to react with carboxy alkyl chitosan to obtain the polyether-grafted chitosan derivative crude oil desalting demulsifier. The polyether-grafted chitosan derivative crude oil desalting demulsifier disclosed by the invention is prepared by taking chitosannatural polymeric compounds as raw materials, and has the advantages of wide sources, naturalness, no toxicity, sustainability, good biocompatibility of a product, degradability and the like. The prepared demulsifier is good in demulsifying and dehydrating effect; meanwhile, a demulsifying molecule contains a large amount of carboxyalkyl groups and quaternary ammonium salt groups which have strong combining capacity to metal cation, ions with negative electricity such as naphthenic acid radicals as well as particles of which the surfaces are electronegative, so the polyether-grafted chitosan derivative crude oil desalting demulsifier has capacity of removing oil-soluble salts while demulsifying.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

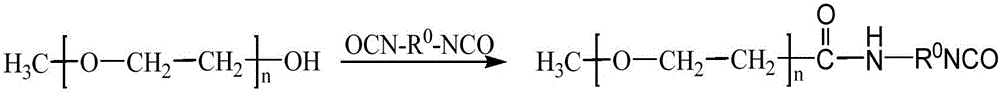

Preparation method of efficient crude oil desalting demulsifier

ActiveCN106221729ALimited demulsibilityIntensify the degree of emulsificationDewatering/demulsification with chemical meansHydrocarbon oils refiningQuaternary ammonium cationBiocompatibility Testing

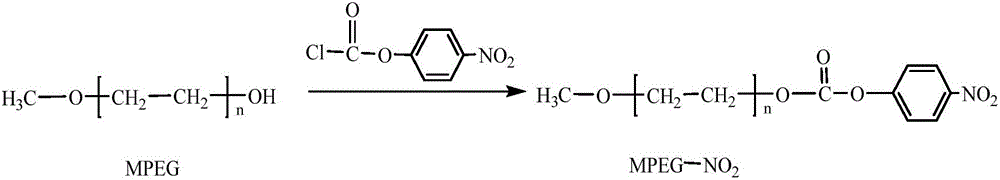

The invention relates to a preparation method of an efficient crude oil desalting demulsifier. The preparation method comprises the following specific steps: (1) performing isocyanic acid esterification modification on methoxy polyethylene glycol; (2) preparing glycidyl dimethyl alkylammonium chloride; (3) preparing quaternized carboxyalkyl chitosan; (4) modifying the methoxy polyethylene glycol and the quaternized carboxyalkyl chitosan for reaction to obtain a target product, namely, methoxy polyethylene glycol-grafted quaternized carboxyalkyl chitosan. By taking chitosan type natural macromolecular compounds as raw materials, the efficient crude oil desalting demulsifier has many advantages of wide availability, nature, nontoxicity, sustainability, high biocompatibility, degradability and the like. The prepared demulsifier is good in demulsifying and dehydration effect; meanwhile, molecules of the demulsifier contain a large quantity of carboxy alkyl groups and quaternary ammonium salt groups, so that the demulsifier is extremely high in combination capacity for negatively charged ions such as metal cations and naphthenic acid radicals, and particles with electronegativity on the surfaces, and can remove oil-soluble salt during dehumidification.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Synthesis method of crude oil desalting demulsifying agent

ActiveCN106279707ALimited demulsibilityIntensify the degree of emulsificationDewatering/demulsification with chemical meansHydrocarbon oils treatmentQuaternary ammonium cationSynthesis methods

The invention relates to a synthesis method of a crude oil desalting demulsifying agent. The method specifically includes the steps of firstly, conducting p-nitrophenyl ester modification on methoxypolyethylene glycol; secondly, preparing glycidyl dimethyl alkyl ammonium chloride; thirdly, preparing quaternized carboxy alkyl chitosan; fourthly, making the modified methoxypolyethylene glycol react with quaternized carboxy alkyl chitosan to obtain a product, namely polyethylene glycol questin grafted quaternized carboxy alkyl chitosan. A chitosan type natural high-molecular compound serves as the raw material and has the advantages of being wide in resource, natural, free of toxin, sustainable, good in product biocompatibility, degradable and the like; The prepared demulsifying agent is good in demulsifying dewatering effect; meanwhile, due to the fact that lots of carboxy alkyl groups and quaternary ammonium salt groups are contained in demulsifying agent molecules and have strong binding capacity with metal cations, naphthenic acid radicals and other ions with negative charges and particles with surface electronegativity, the oil-soluble salt removing capacity is achieved during demulsifying.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of double-ion type crude oil desalting demulsifier

ActiveCN106220857AWide variety of sourcesSustainableDewatering/demulsification with chemical meansStrong bindingCarboxymethyl-chitosan

The invention relates to a preparation method of a double-ion type crude oil desalting demulsifier. The preparation method specifically comprises the following steps: (1) carrying out esterification modification on polyethylene glycol monomethyl ether; (2) preparing glycidyl dimethyl alkyl ammonium chloride; (3) preparing quaternary ammonium carboxymethyl chitosan; (4) making the modified polyethylene glycol monomethyl ether react with the quaternary ammonium carboxymethyl chitosan to obtain a polyethylene glycol monomethyl ether grafted quaternary ammonium carboxymethyl chitosan. The double-ion type crude oil desalting demulsifier takes natural macromolecular compounds of chitosan as raw materials, thereby having many advantages of wide sources, naturalness, no toxicity, sustainability, good product bio-compatibility and degradation and the like. The prepared demulsifier is good in demulsification and dehydration effects, furthermore, demulsifier molecules contain a large number of carboxyl alkyl groups and quaternary ammonium salt groups, so that the demulsifier has a very strong binding capacity for negatively charged ions such as metal cations, naphthenic acid radicals and particles of which the surfaces are electronegative, thereby further having the removal ability for oil soluble salts while performing demulsification.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of polyelectrolyte-type crude oil-desalting demulsifier

ActiveCN106221728AWide variety of sourcesSustainableDewatering/demulsification with chemical meansHydrocarbon oils refiningQuaternary ammonium cationNon toxicity

The invention relates to a preparation method of a polyelectrolyte-type crude oil-desalting demulsifier. The preparation method comprises the following specific steps: (1) performing amination modification on methoxypolyethylene glycol; (2) preparing glycidyl dimethyl alkyl ammonium chloride; (3) preparing quaternized carboxyalkyl chitosan; (4) carrying out a reaction between the modified methoxypolyethylene glycol and the quaternized carboxyalkyl chitosan to obtain a target product methoxypolyethylene glycol-grafted quaternized carboxyalkyl chitosan. The polyelectrolyte-type crude oil-desalting demulsifier takes a natural macromolecule chitosan compound as a raw material, and has the advantages of wide sources, naturalness, non-toxicity, sustainability, good product biocompatibility, biodegradability and the like. The prepared demulsifier has good demulsifying and dehydrating effects; a demulsifier molecule contains a large number of carboxyalkyl groups and quaternary ammonium groups, which have very strong capacity of bonding metal cations, negatively-charged ions such as naphthenic acid radicals, and particles with negative charges on the surfaces, so that besides the demulsifying capability, the demulsifier also has the capability of removing oil-soluble salts.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

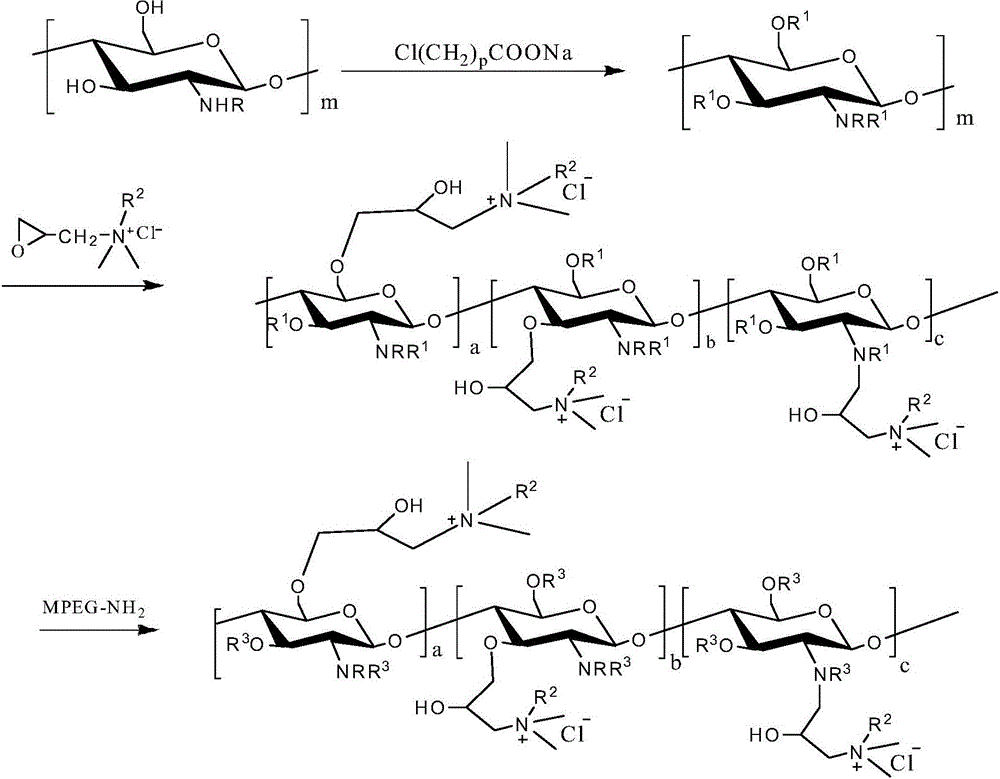

Method for extracting iron titanium vanadium from high-titanium iron concentrate

InactiveCN101113495AHigh yieldFew kindsBlast furnace detailsManufacturing convertersSteelmakingCarbonization

The invention discloses an iron-titanium-vanadium extracting method from high-titanium ferrovanadium concentrate ore. By adopting the method to make steel, fine TiCI4 and V2O5 have the advantages that: technological processes are simple and reasonable; energy consumption is low; yield rate of iron-titanium-vanadium is high and three wastes (waste gas, waste water and waste slag) are fewer. The method comprises the steps: iron smelting: a high furnace or an electric furnace is adopted to smelt iron to make melten iron containing vanadium and chromium and make titanium-enriched slag as byproduct and the rate of vanadium reduced and added into iron is 60-78 percent; single-slag steel-making: melten iron containing vanadium and chromium is put into a converter furnace directly to make steel by the function of oxygen blowing, and steel slag containing vanadium and chromium is obtained as byproduct; carbonized titanium-vanadium-chromium slag with 80-95 percent of carbonization rate is made by smelting reduction carbonization by the electric furnace smelting selection; TiCl4 containing vanadium is made by selective chlorination of carbonized titanium-vanadium-chromium slag in a fluidized bed at low temperature, and residual slag of chlorination containing CrCl3 is byproduct; vanadium titanium separation: VOCI3 is directly reduced by cycloolefine or naphthenic acid to make VOCl2 which can not dissolve in TiCI4, while the VOCI3 can be dissolved in TiCI4. Then the fine TiCI4 is made and the slurry TiCI4 containing rich vanadium is also made as byproduct; V2O5 is extracted from the rich vanadium containing slurry TiCI4.

Owner:张荣禄

Method for removing aluminum from rare-earth feed liquid

ActiveCN101979680AGood aluminum removal effectLow cost of aluminum removalProcess efficiency improvementRare-earth elementKerosene

The invention discloses a method for removing aluminum from rare-earth feed liquid, belongs to rare-earth feed liquid treatment technology and aims to provide the method for removing the aluminum from the rare-earth feed liquid, of which the aluminum-removing effect is good, the aluminum-removing cost is low, the rare-earth recovery rate is high, the operation and control are convenient, the process is simple and the investment in equipment is small. The key point of the technical scheme mainly comprises the following steps of: (1) preparing an organic phase from 15 to 25 volume percent of naphthenic acid and 15 to 25 volume percent of alcohol-kerosene; (2) adding the prepared organic phase and the rare-earth feed liquid into a stirring tank in a volume ratio of 2-5:1, starting the tank, stirring and uniformly mixing; (3) adding alkaline solution into the mixed liquid obtained in the step (2) with stirring, wherein the total number of moles of the added alkali is 50 to 100 percent of that of rare-earth elements in the rare-earth feed liquid; and (4) after adding the alkaline solution, continuously stirring for a certain time, stopping stirring and standing for a certain time, wherein the solution is separated into an aqueous phase and an organic phase and the aqueous phase is the rare-earth feed liquid from which the aluminum is removed. The method is applied to aluminum removal for the rare-earth feed liquid.

Owner:广东省富远稀土有限公司 +1

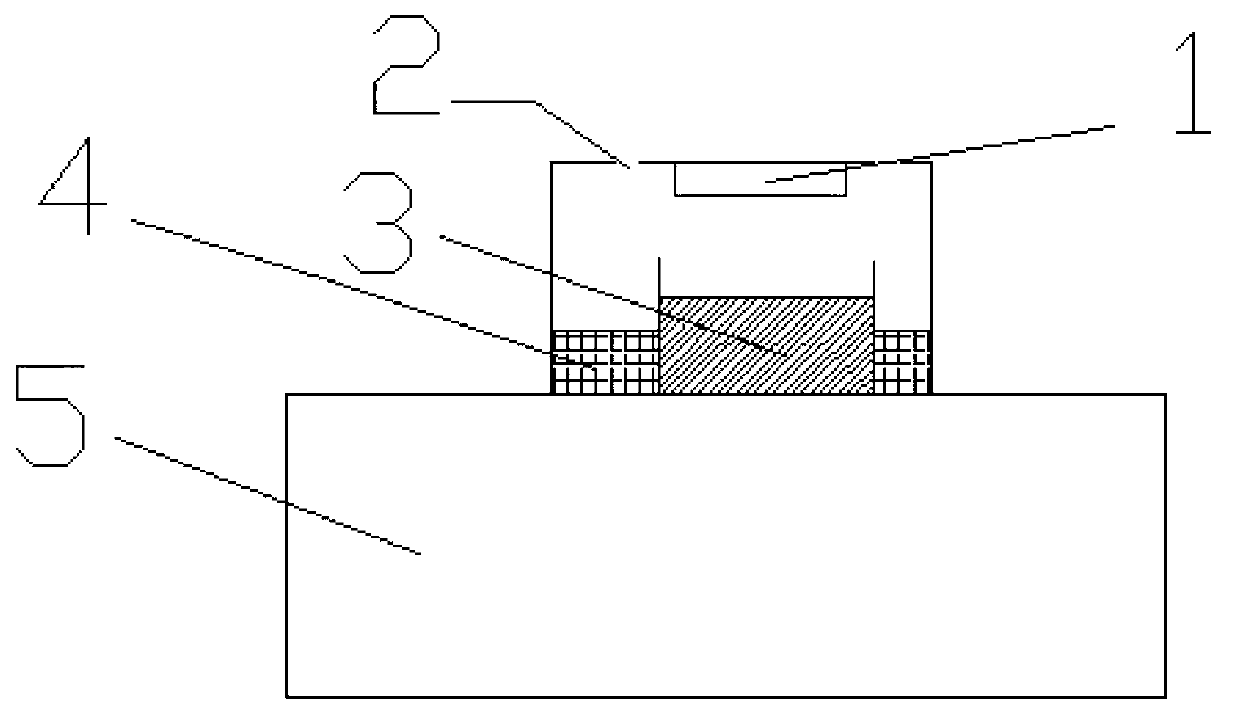

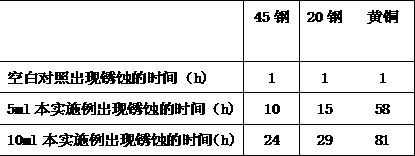

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

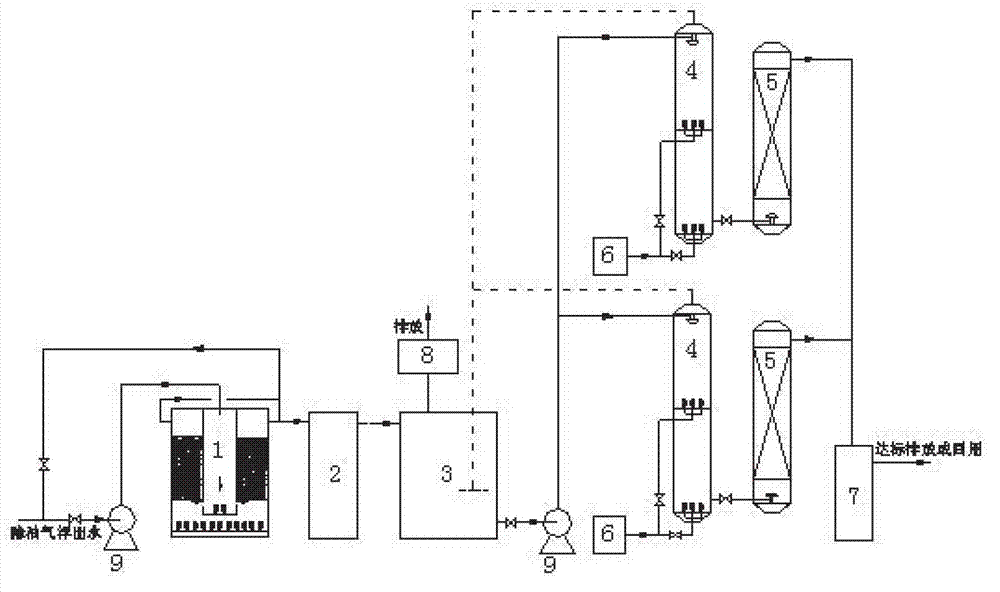

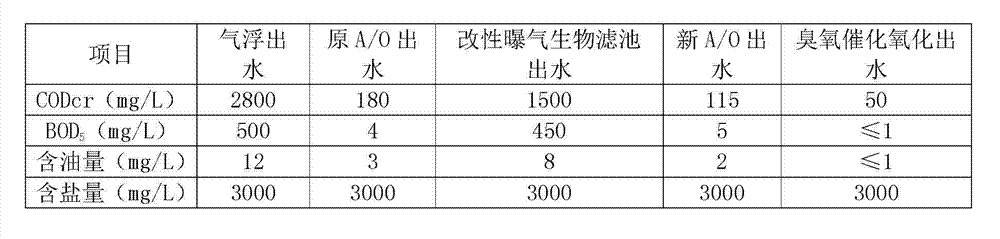

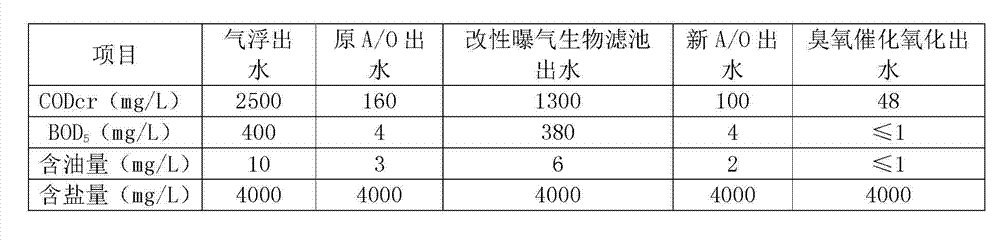

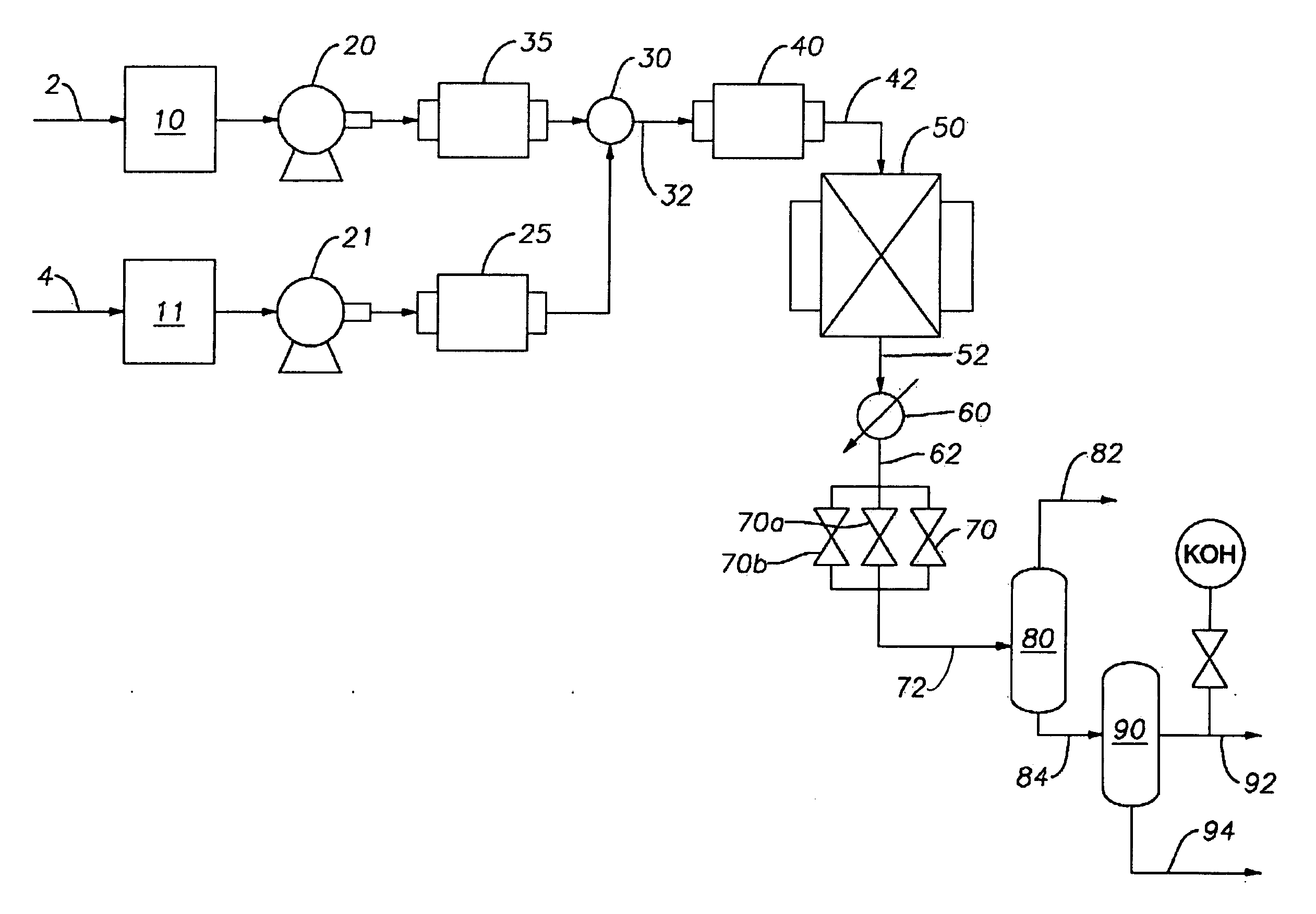

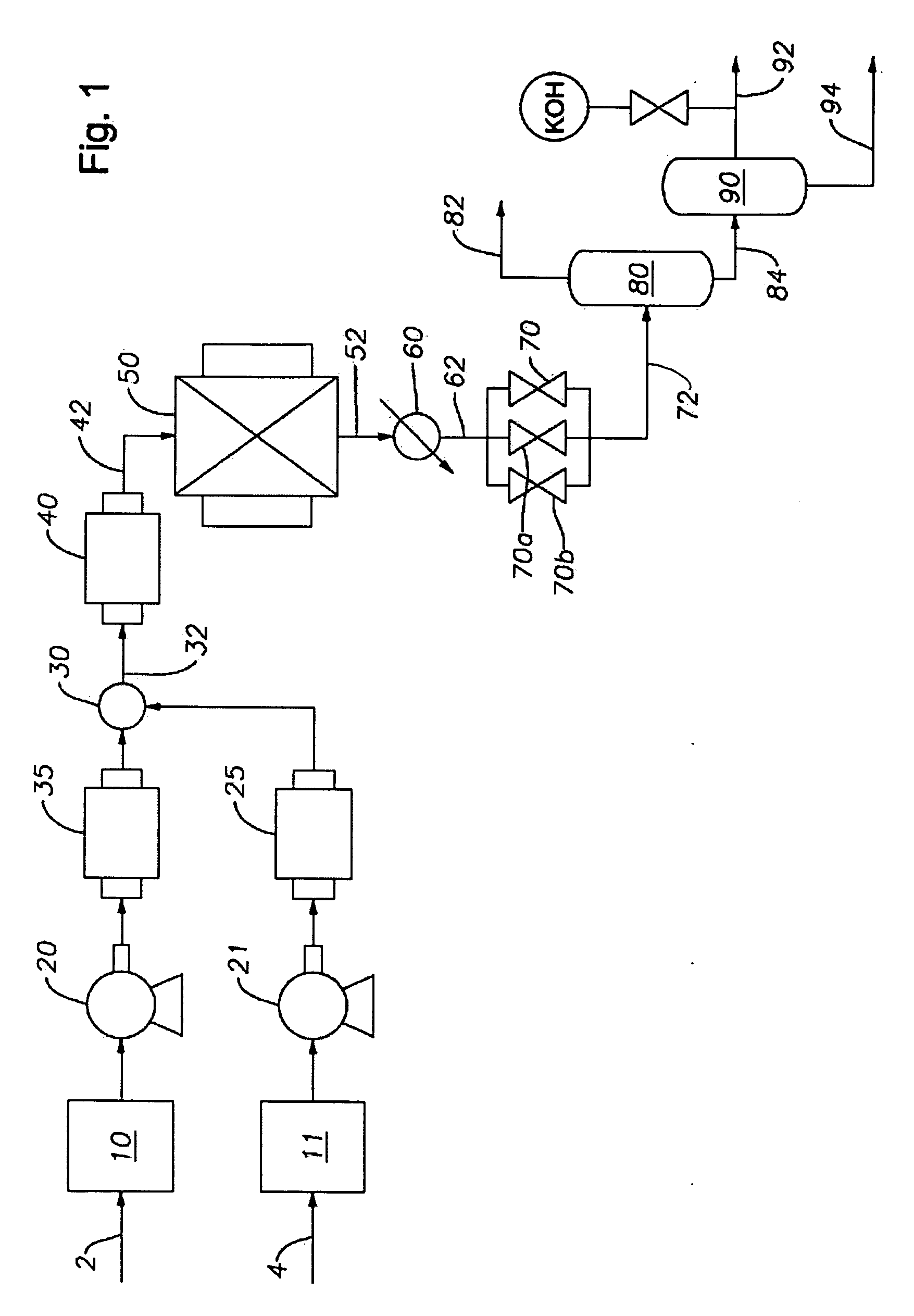

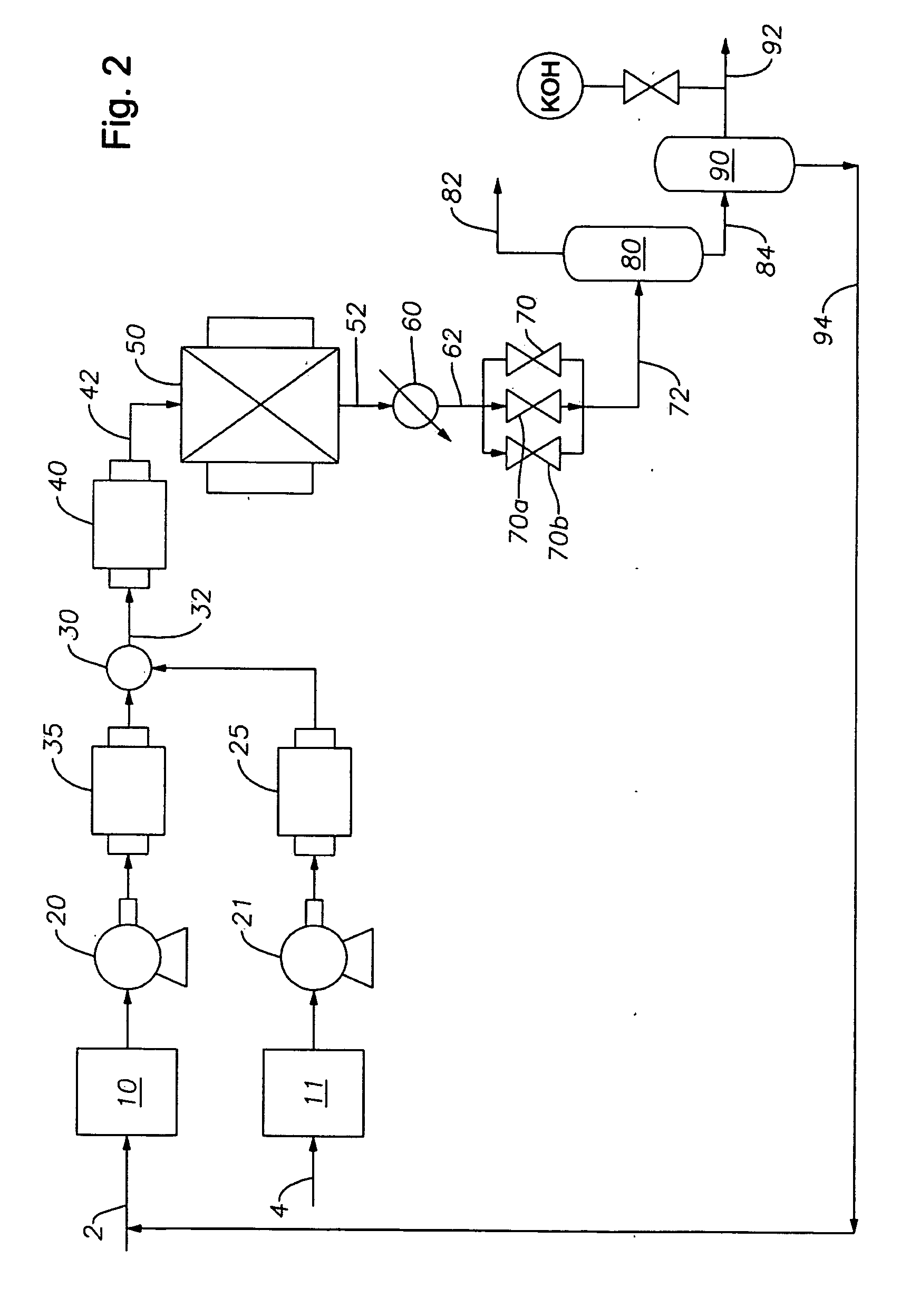

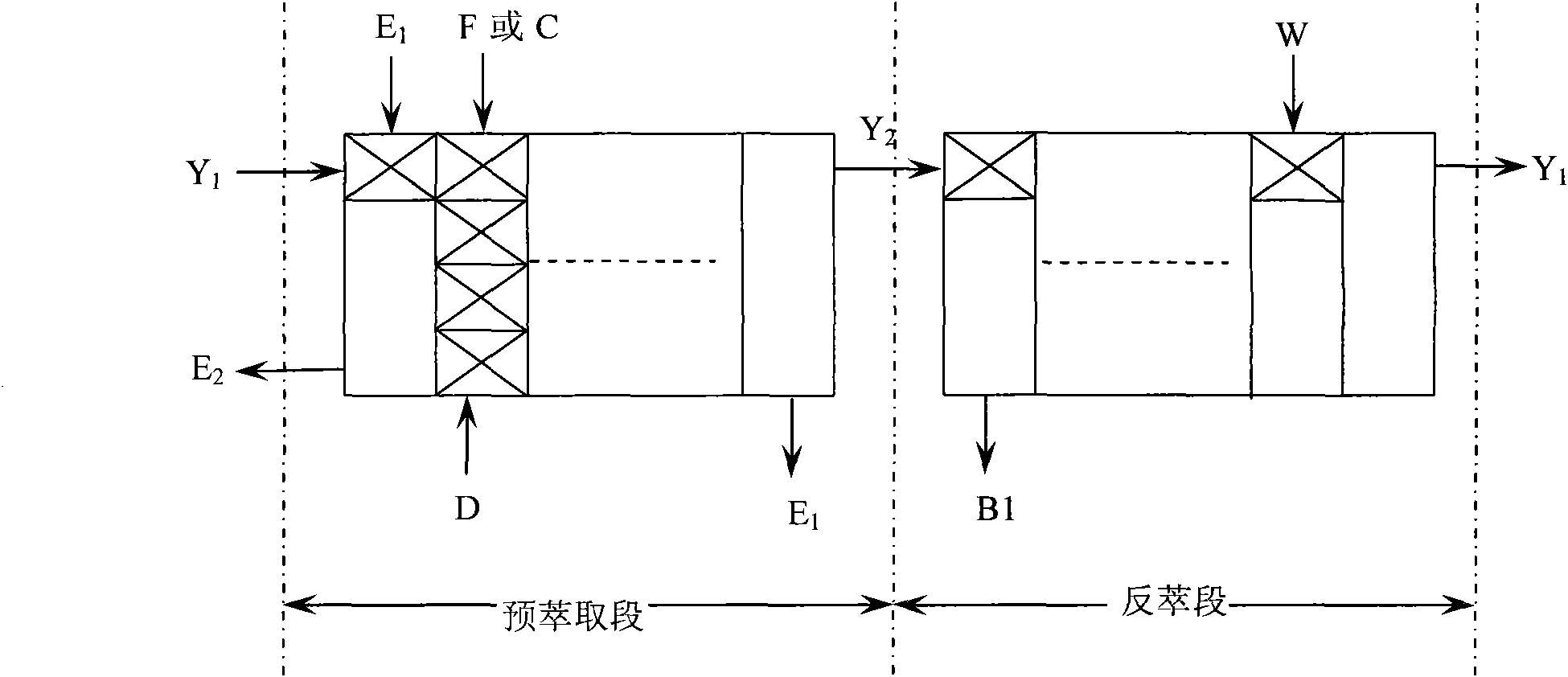

Combined treatment method of oil-refining wastewater containing naphthenic acid

ActiveCN102923913AImprove ozone utilizationEnhance the role of adsorption and enrichment of organic matterWater contaminantsMultistage water/sewage treatmentChemical oxygen demandCatalytic oxidation

The invention relates to a combined treatment method of oil-refining wastewater containing naphthenic acid. The combined treatment method of the oil-refining wastewater containing naphthenic acid is characterized in that a pre-treatment technology is added at the front end of an 'anoxic / oxic' ('A / O') step of an oil removing + A / O process, and an advanced treatment process is added at the back end of the 'A / O' step. Air-floatation oil removing effluent enters a modified biological aerated filter to be pre-treated, a filler is subjected to modification treatment, and the combined treatment method adopts upstream continuous operation. Hydraulic loading is controlled in a range of 1.0-3.0 m<3> / m<2>-h, the temperature is controlled in a range of 25-35 DEG C, the reflux ratio is controlled to be 100-150%, the gas-water ratio is controlled to be 3:1-5:1, and an automatic back washing period is controlled to be 48-72 hours. The effluent of the modified biological aerated filter is subjected to treatment of an 'A / O' biochemical system, enters an intermediate reaction tank and then enters a pre-mixing tower in parallel. The effluent of the pre-mixing tower enters a catalytic oxidation tower to quickly oxidize difficultly-biodegradable organic matter in sewage and reduce chemical oxygen demand (COD) of the sewage, and finally treated effluent enters a clean water pond.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Process to reduce acidity of crude oil

ActiveUS20090159504A1Reduce corrosionSimple methodThermal non-catalytic crackingRefining with metalsOrganic acidNaphthenic acid

Owner:SAUDI ARABIAN OIL CO

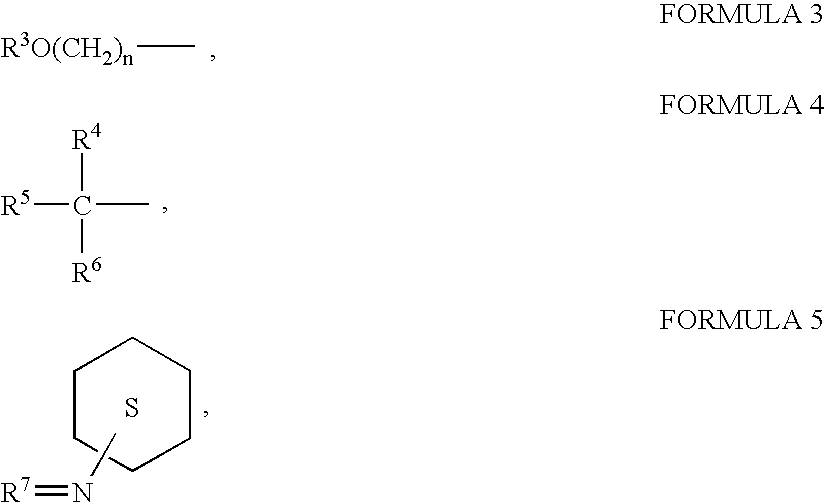

Fuel oil additive and fuel oil products containing the fuel oil additive

InactiveUS20040065002A1Improve performanceBoost octaneLiquid carbonaceous fuelsFuel additivesAlkaline earth metalKerosene

The present invention provides a fuel oil additive capable of effectively improving the quality of fuel oils, which comprises an oil-soluble metal salt of organic acid having the general formula MR, where R is an organic acid radical and the corresponding organic acid is a C1-C40 saturated or unsaturated fatty acid, naphthenic acid, aromatic acid or alkylphenol, M is a metal cation and the corresponding metal is an alkali metal, alkali-earth metal, rare-earth metal, transition metal, or the like. The present invention also provides fuel oil products added to the fuel oil additive, including gasoline, diesel oil, kerosene, heavy oil, resid, or the like. The present invention especially provides a gasoline antiknock agent and a gasoline having excellent antiknock property, and this kind of gasoline antiknock agent is characteristic of effectiveness, economy, safety, no environmental pollution, no toxicity to human body, no adverse effect on parts of automobile engine, use convenience, and the like.

Owner:HU SHIBIN

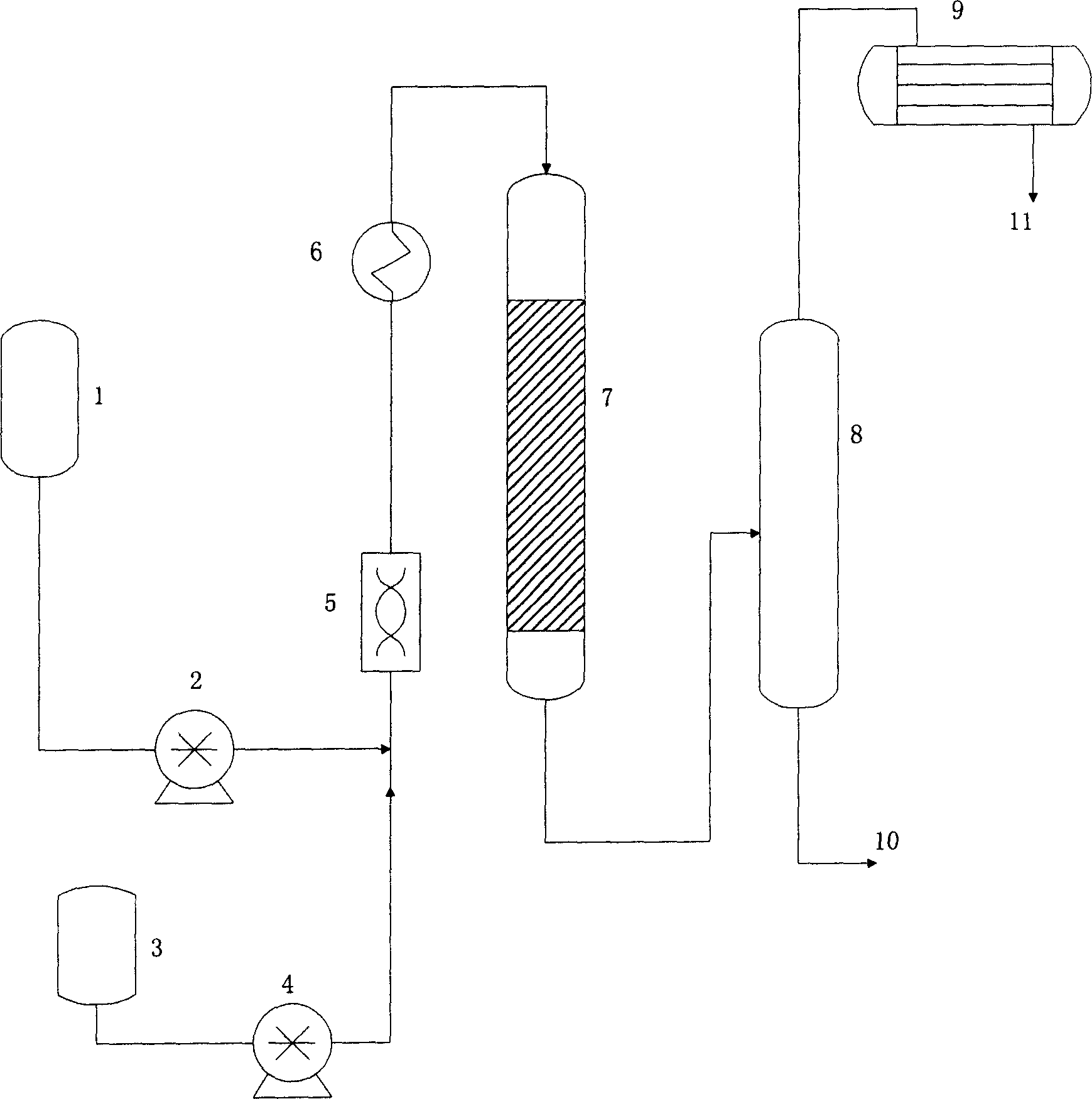

Catalyst for esterification deacidification of crude oil and distillate oil and process thereof

The invention discloses a process for lowering acid value of crude oil and distillate oil, which comprises proceeding esterification reaction by menthol with crude oil or naphthenic acid in distillate oil, producing naphthenic acid ester in fixed bed reactor equipped with catalyst, then recovering the non-reacted methanol through distillation. The catalyst comprises carrying agent, which includes aluminium oxide, silica gel, molecular sieve, diatomite and carclazyte, amounting to 20-98 wt% of the catalyst, and active component including Sn or Zn, amounting to 2-40 wt% of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

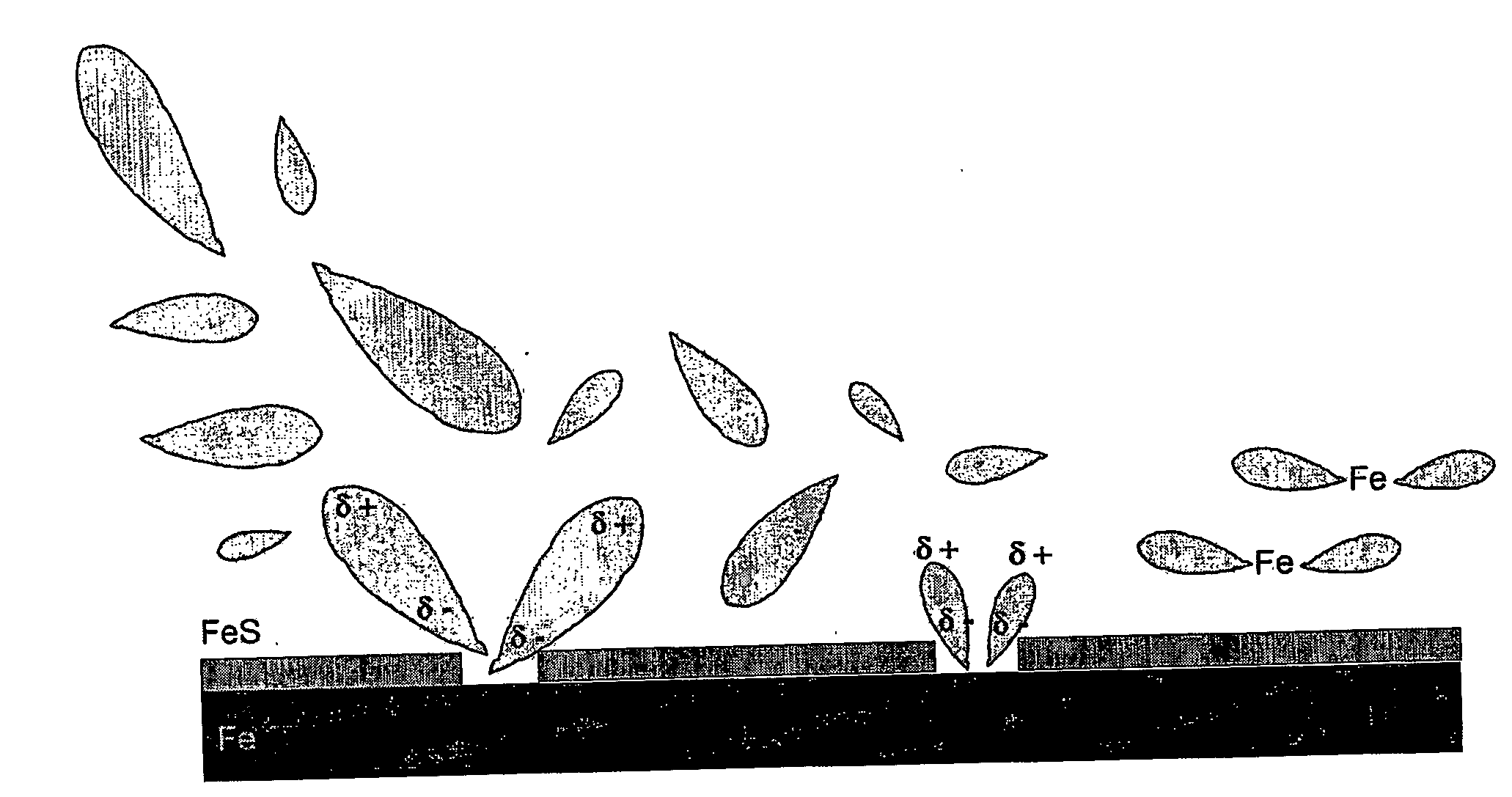

Corrosion inhibitor

InactiveUS20070119747A1Avoid corrosionInhibiting naphthenic acid corrosionDistillation corrosion inhibitionOther chemical processesSulfur hydrideCorrosion inhibitor

A composition and method of inhibiting corrosion caused by naphthenic acid in fluids includes using a combination of a thiophosphorus compound and a hydrogen sulfide scavenging compound. The hydrogen sulfide scavenging compound significantly enhances the performance of the thiophosphorus compound and may be included at relatively low levels in the composition. The treatment may be applied to fluids including crude oils and lighter fractions thereof.

Owner:BAKER HUGHES INC

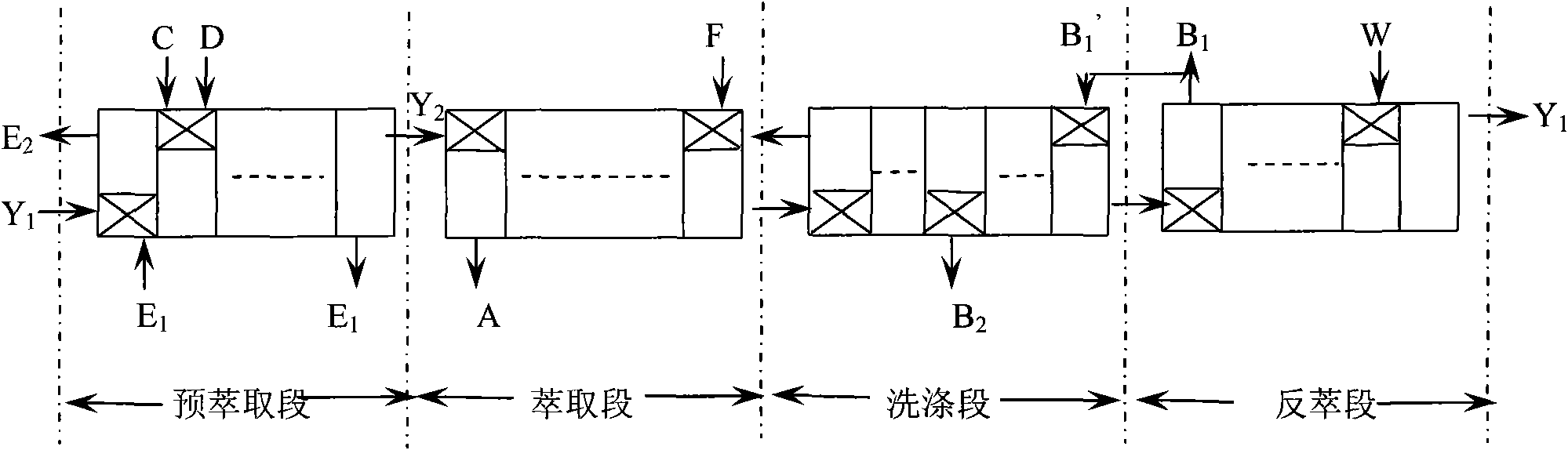

Process for separating rare-earth element by extraction

InactiveCN101781706ALow impurity contentEliminate pollutionProcess efficiency improvementRare-earth elementCalcium bicarbonate

The invention mixes and pre-extracts the mixed solution of acidic organic extractants such as P507, P204, C272, and naphthenic acid with magnesium bicarbonate and / or calcium bicarbonate solution and rare-earth solution. The rare-earth ions are extracted into the organic phase, then the loaded organic phase containing rare-earth ions are obtained through clarification, and can be used for the extract separation of the mixed rare-earth feed liquid. After a plurality of different levels of extraction, washing, stripping, single rare-earth compounds or rare-earth elements-containing enrichments can be obtained. The magnesium bicarbonate and / or calcium bicarbonate solution are prepared by roasting, digesting, carbonizing magnesite, limestone, calcite, dolomite and similar minerals, so that the content of impurities, such as silicon, iron, aluminum is lower. Ternary phase sediment is not produced in the pre-extraction and extraction separation process, so that the purity of the rare-earth products are not affected. The organic phase does not need ammonia saponification and does not produce ammonia-nitrogen wastewater. By adopting the invention, the production cost of rare-earth products is greatly lowered and the cost for three waste disposal is also greatly saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

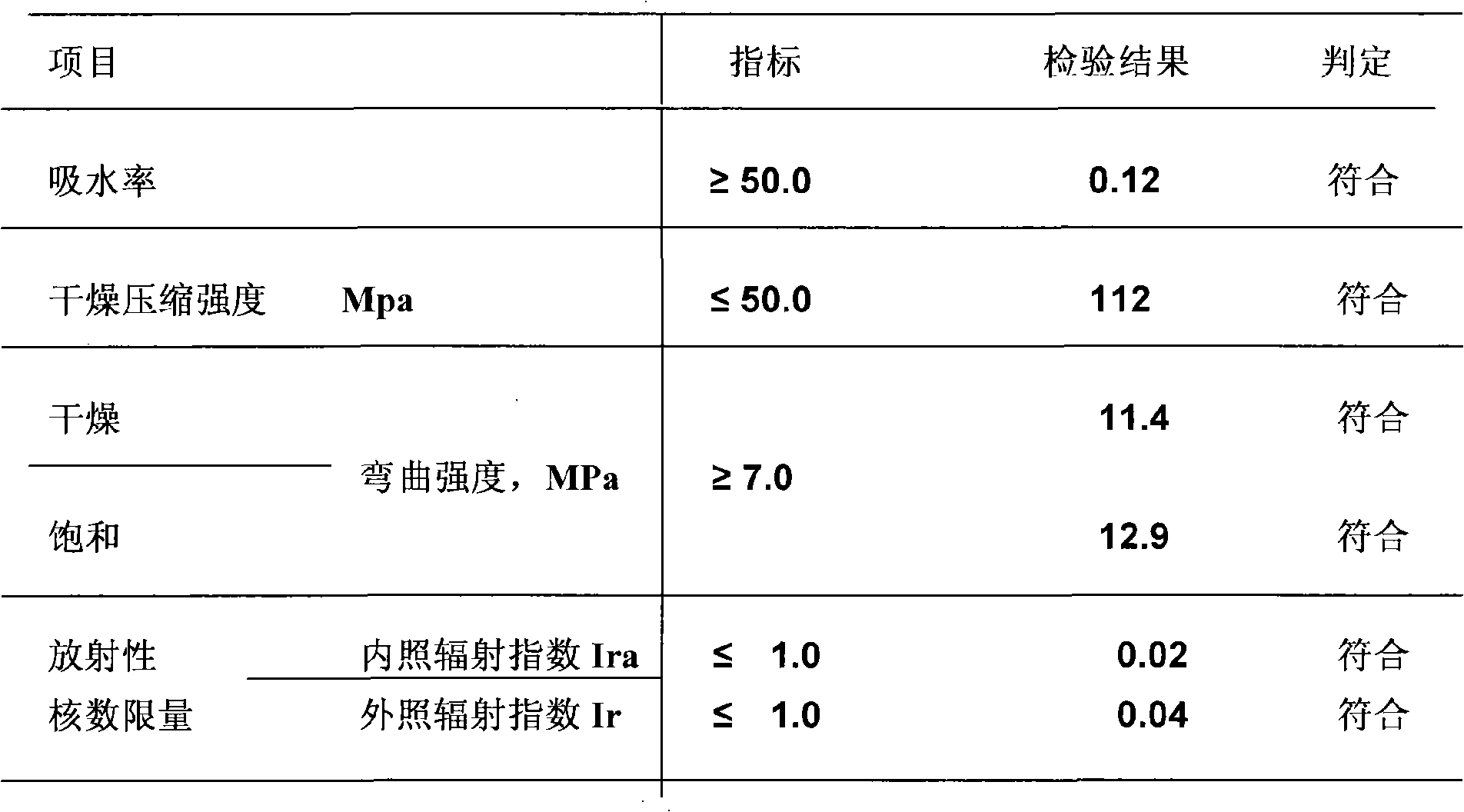

Artificial stone panel and manufacturing method thereof

InactiveCN101328039AGood wear resistanceNoble and elegant decorative effectCalcium carbonateArtificial stone

The invention discloses a artificial stone plate prepared by adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin. The preparation method includes the following steps: firstly modifying the aluminium hydroxide and / or calcium carbonate to get surface modified aluminium hydroxide and / or calcium carbonate or pure aluminium hydroxide powder, then adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin, uniformly mixing and stirring the mixture in a high speed stirring reactor, adding surface modified aluminium hydroxide and / or calcium carbonate powder or pure aluminium hydroxide powder, stirring and casting the mixture into a mould after vacuum defoamtion, heating up to 60-80 DEG C and curing to get the artificial stone and marble panel.

Owner:覃庆峰

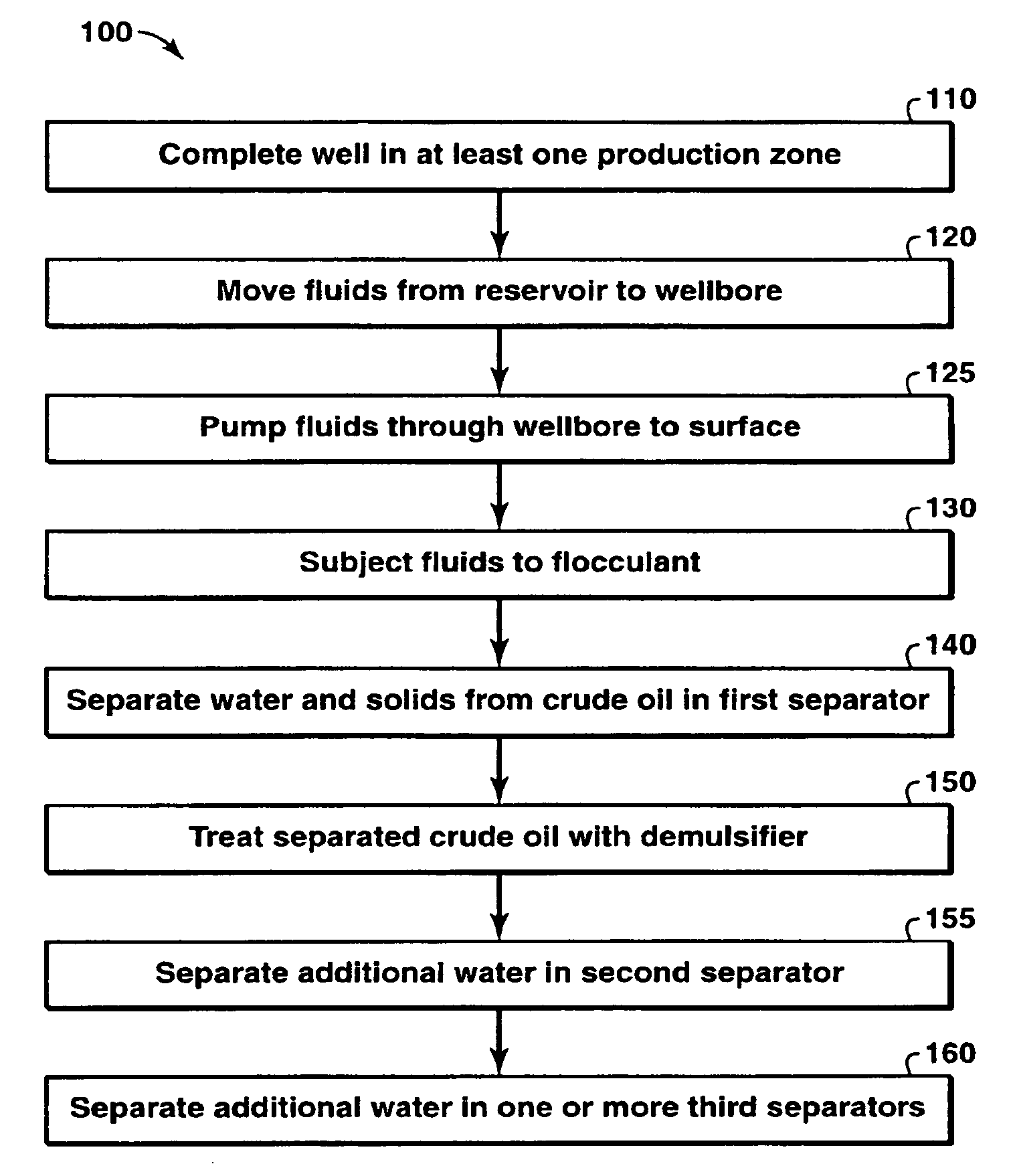

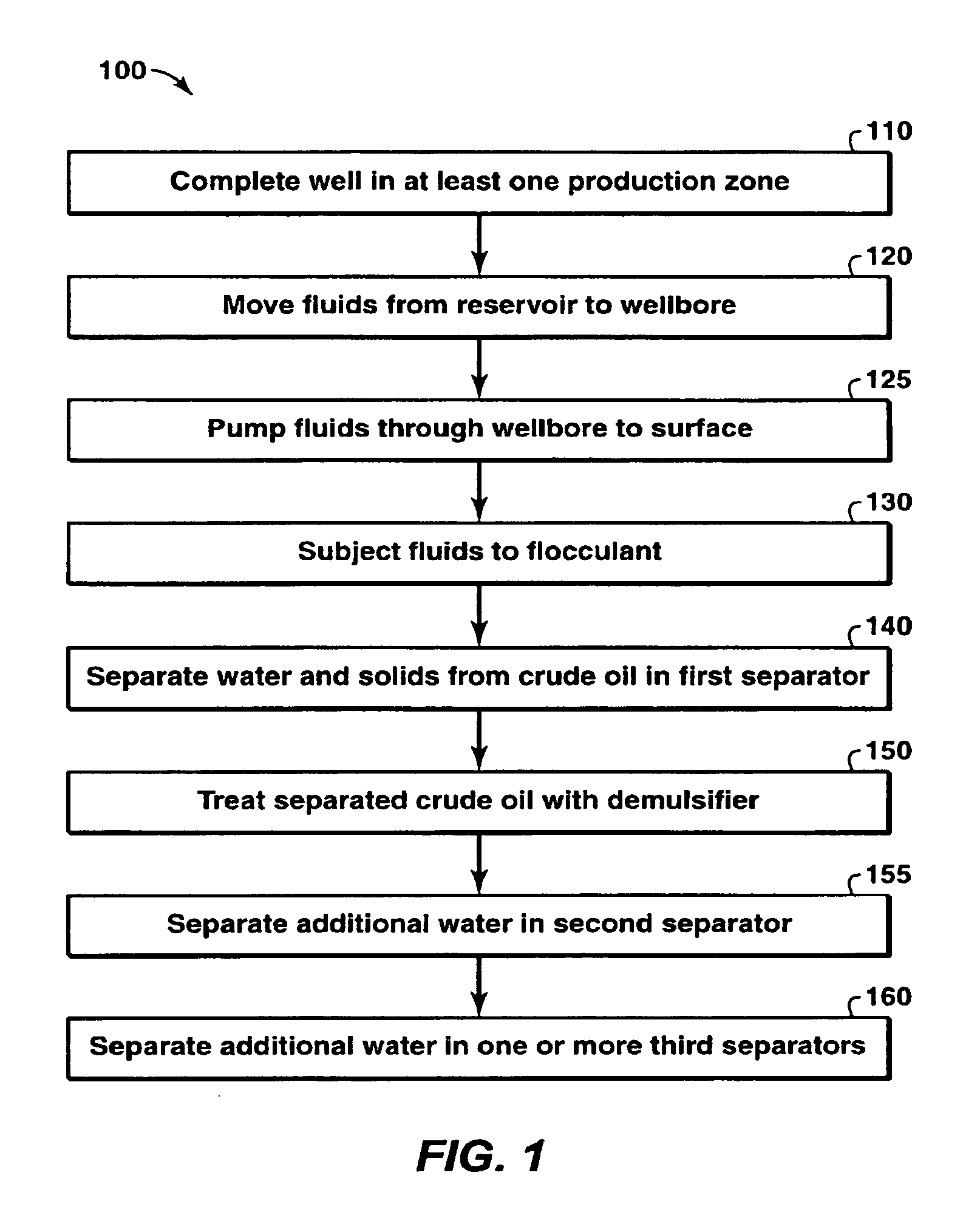

Oil/Water Separation of Full Well Stream By Flocculation-Demulsification Process

ActiveUS20090200213A1Speed up the processDewatering/demulsification with chemical meansSedimentation separationDemulsifierFlocculation

A process for the separation of production fluids is provided. The production fluids comprise an oil / water emulsion stabilized with fine solids. The emulsion may further comprise asphaltenes and naphthenic acids and resins. The process includes subjecting the emulsion to a flocculating agent to flocculate solids within the emulsion, and separating water and solids from crude oil in a first separator. The process further includes subjecting the separated crude oil to a demulsifier after subjecting the emulsion to a flocculating agent, and further separating water from the crude oil in a second separator. A process for producing fluids from a hydrocarbon-bearing reservoir is also provided, using the separation processes herein.

Owner:EXXONMOBIL UPSTREAM RES CO

Steam cracking of high tan crudes

ActiveUS20070066860A1Prevent steppingThermal non-catalytic crackingHydrocarbonsButyric acidChemistry

The invention is directed to a process comprising feeding high TAN feedstreams to a steam cracker, whereby naphthenic acids in the feedstreams are substantially converted to CO, CO2, and low amounts of smaller acids (e.g., formic, acetic, propionic, and butyric acids). The feedstream is preferably a high TAN feedstream comprising crude or high TAN feedstream which has previously been subjected to a refinery process to remove resid.

Owner:EXXONMOBIL CHEM PAT INC

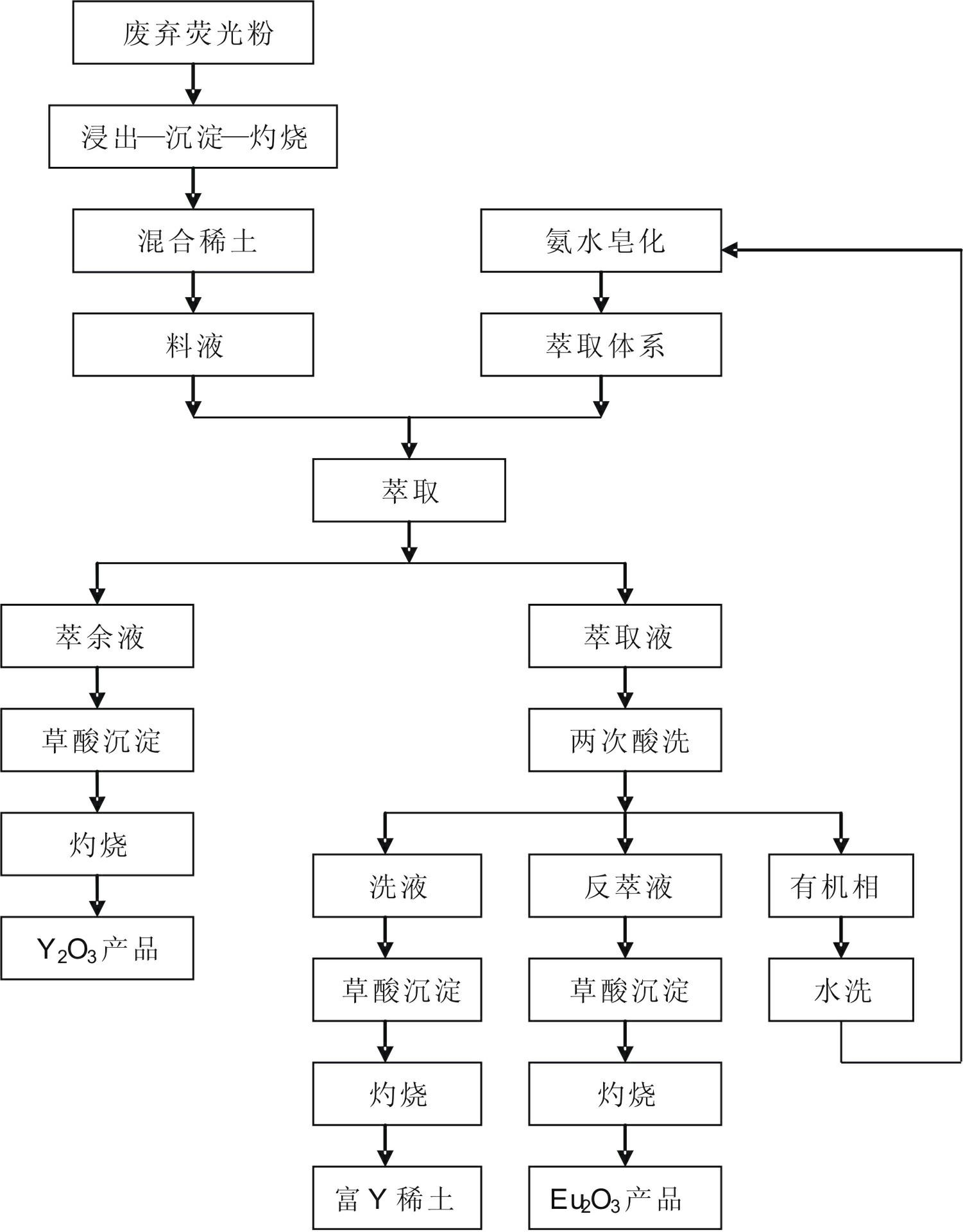

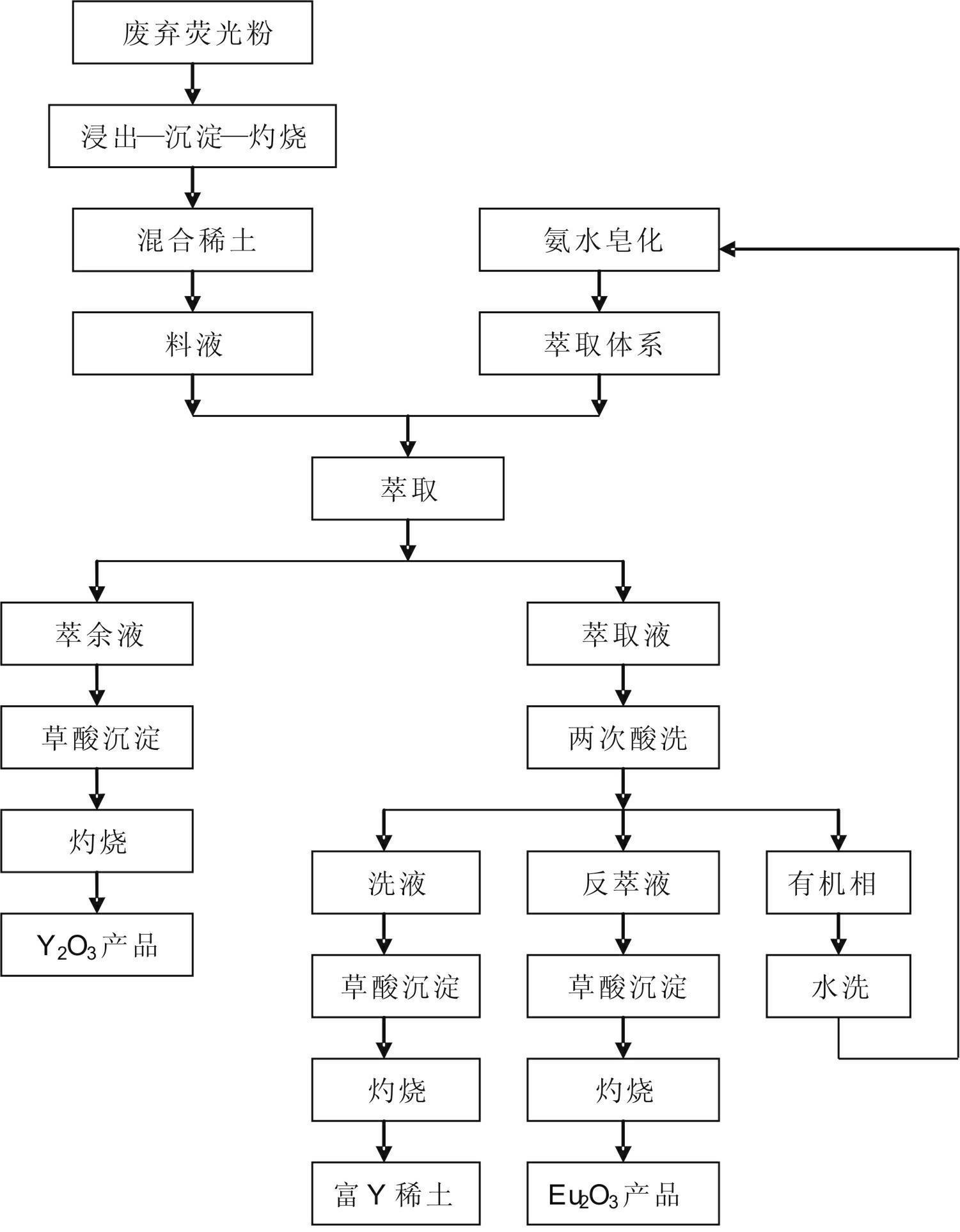

Method for separation and purification of fluorescent grade yttrium oxide and europium oxide from waste phosphor powder

InactiveCN102312098AWide variety of sourcesLow priceProcess efficiency improvementFiltrationRare earth

The invention relates to a method for separation and purification of fluorescent grade yttrium oxide and europium oxide from waste phosphor powder, comprising the steps of: first conducting impurity removal so as to obtain mischmetal containing Y2O3 and Eu2O3, then dissolving the mischmetal with an acid solution for preparing a rare earth feed liquid, and carrying out extraction with an extraction system after alkaline solvent saponification, thus obtaining the raffinate, washing liquid and strip liquor; adding an oxalic acid solution and conducting filtration, then subjecting the obtained filter residue to calcination, thus obtaining the fluorescent grade yttrium oxide, and yttrium-rich rare earth and europium oxide. The invention has the advantages that, reagents are of wide source, lowprice and easy availability, and the simple process of the method can greatly shorten the extraction process of naphthenic acid. In the invention, three deposition impurity-removal treatments before extraction can remove most impurities and leave only a small amount of aluminium and silicon, so that an emulsification phenomenon in the naphthenic acid extraction system cannot be caused, thus providing a good solution to the problem that naphthenic acid extraction is susceptible to high valent metal ions and results in emulsification.

Owner:WUHAN UNIV OF TECH

Method of flotation desulfur desilicon in bauxite

ActiveCN1868599AAdvanced technologyIncrease production capacityAluminates/aluminium-oxide/aluminium-hydroxide purificationFlotationResource utilizationFatty acid

A floatation process for bauxite to remove S and Si includes such steps as grinding the crude bauxite, adding the yellow catching agent B, reverse floatation for removing S, grinding, adding the match of saponified fatty acid and naphthenic acid, and forward floatation. The resultant bauxite concentrate can be used to prepare aluminum oxide by Bayer method.

Owner:中铝郑州有色金属研究院有限公司

Complex lithium grease and preparation method thereof

The invention provides complex lithium grease and a preparation method thereof. The complex lithium grease comprises grease base oil, complex lithium thickening agents and surfactants with mass part ratio of (290-1450):(50.4-251.3):(2-10), wherein the grease base oil is at least one of vacuum second line base oil, vacuum third line base oil and vacuum fourth line base oil; the complex lithium thickening agents are formed by C12-C24 fatty acid lithium and auxiliary acid lithium with mass part ratio of (34-70):(16.4-81.3); and the auxiliary acid lithium is any two of C1-C22 fatty acid lithium, lithium borate, lithium phosphate, aromatic acid lithium, lithium naphthenate, dicarboxylic acid lithium and polybasic acid lithium. The invention also provides the preparation method of the complex lithium grease. The surfactants are added to the complex lithium grease to have synergistic effect with soap molecules of the complex lithium grease and further improve the arrangement of the soap molecules and the capability of curing the base oil, thus increasing the dropping point of the grease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

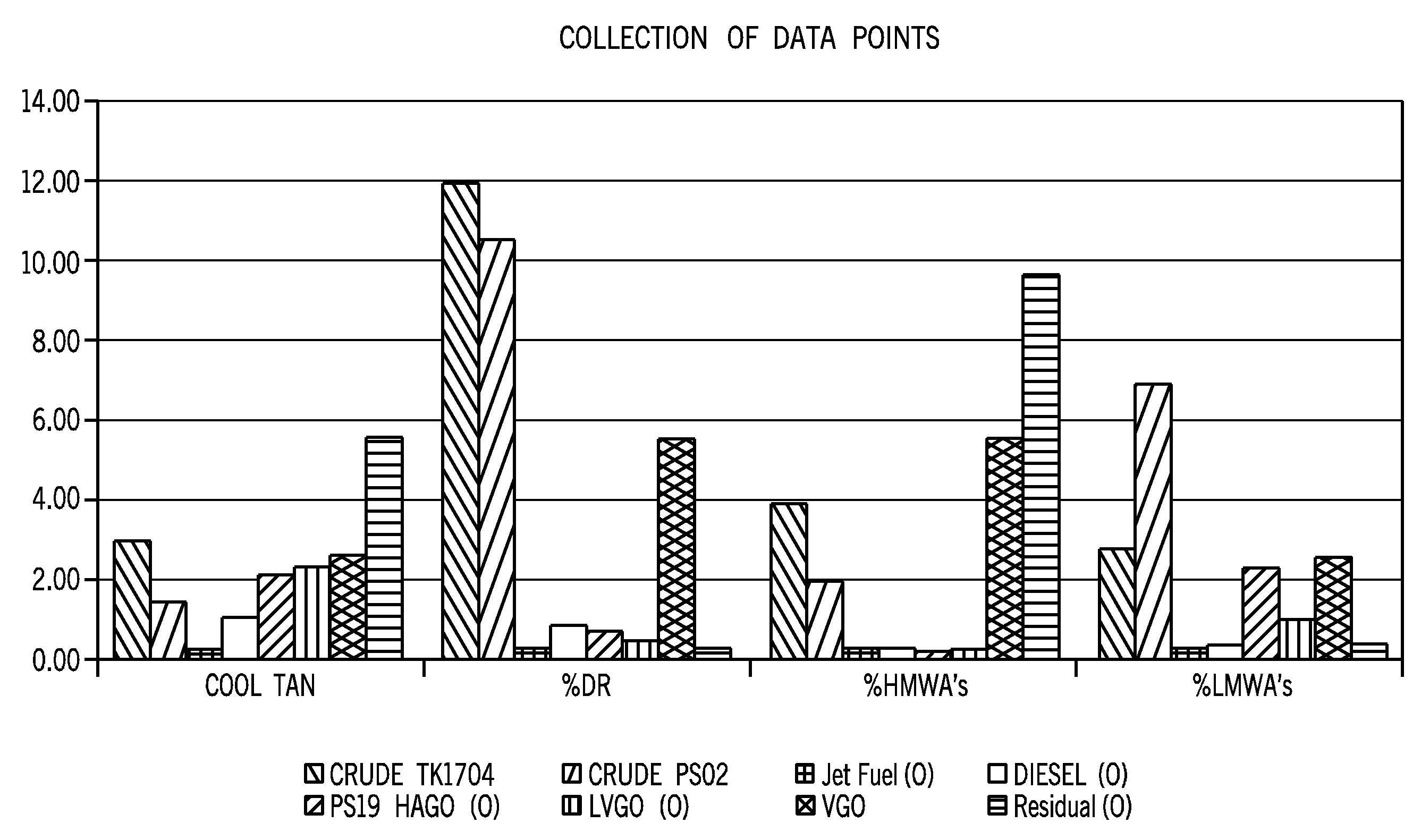

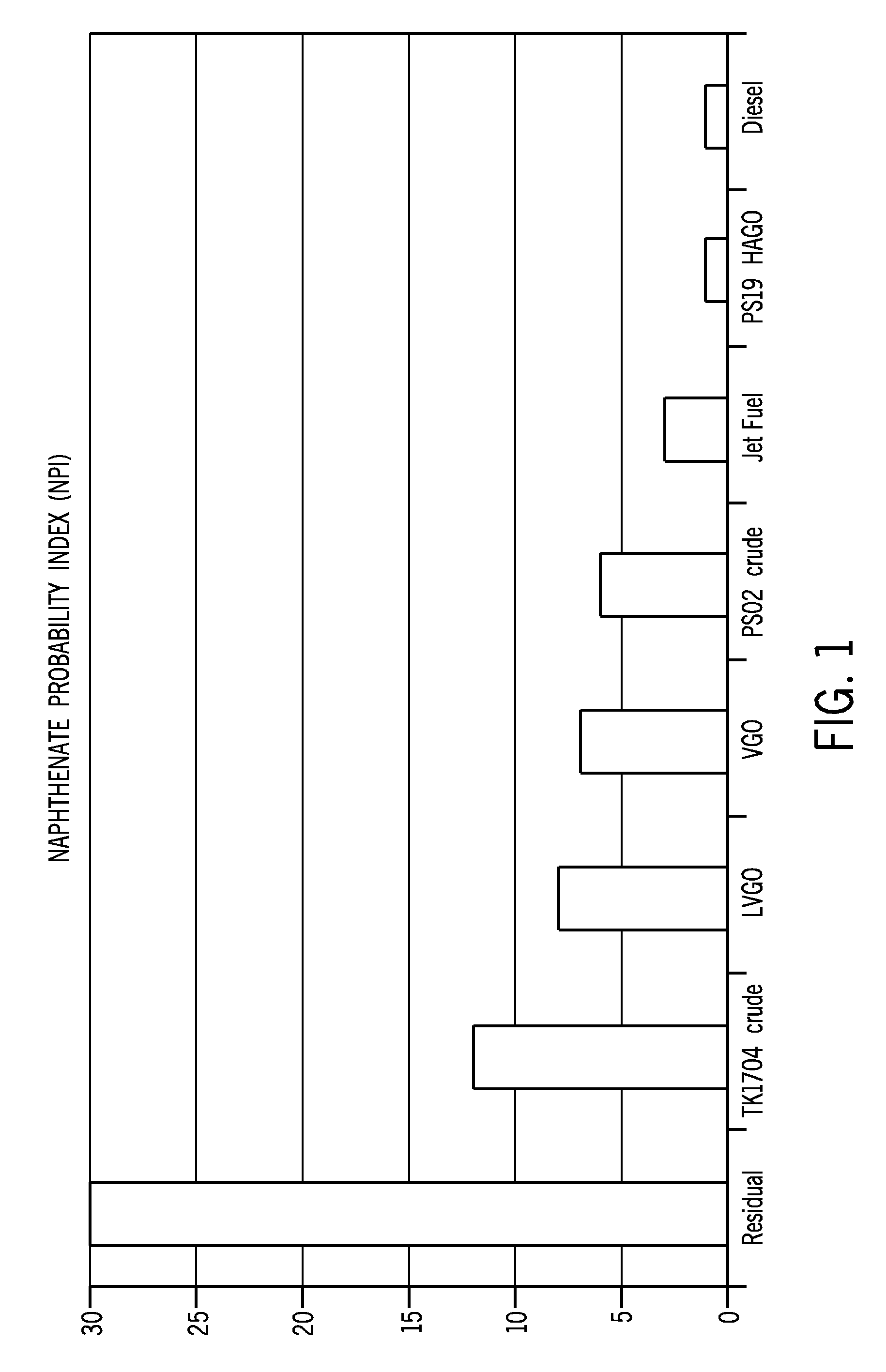

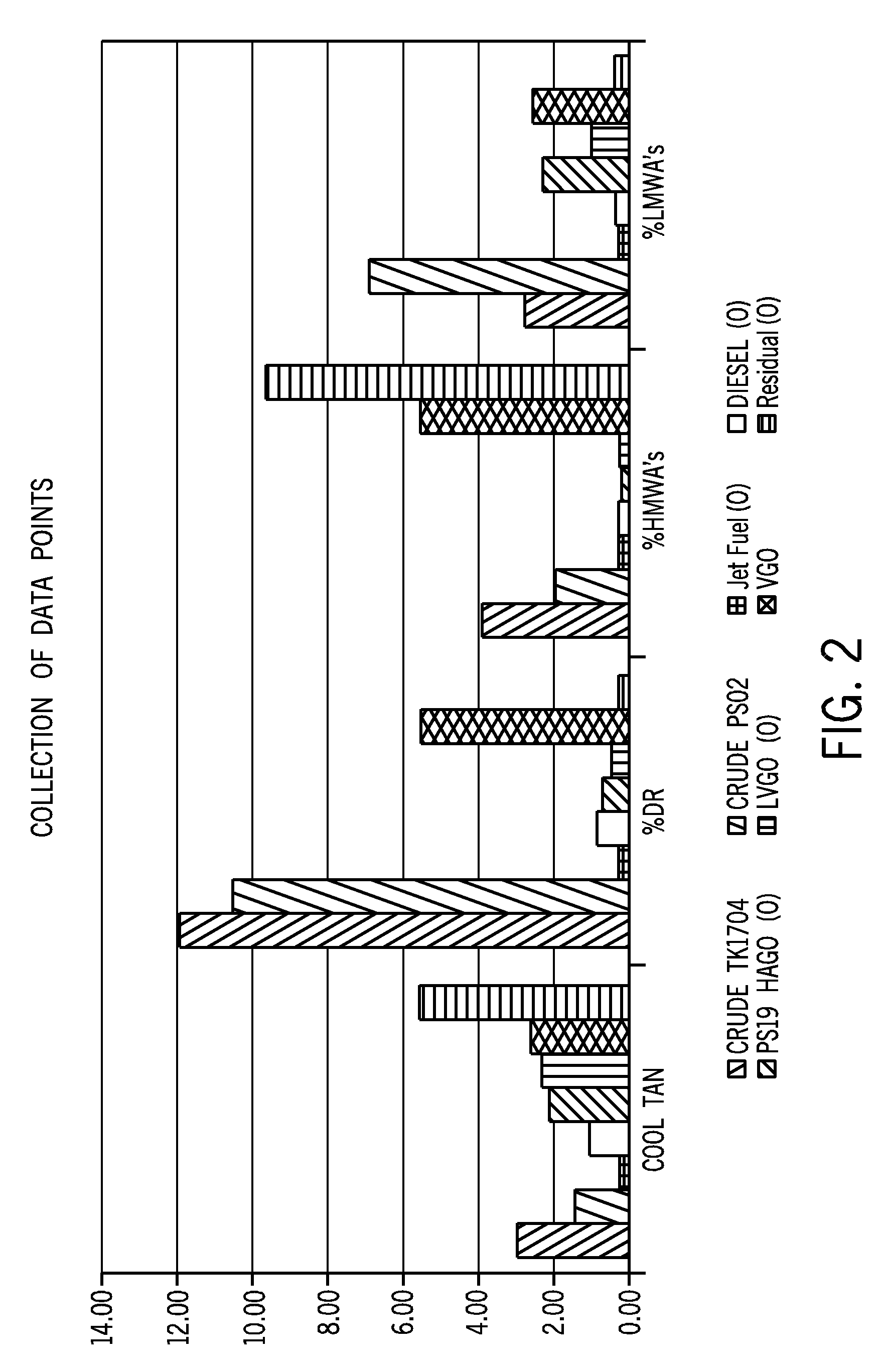

Method of Screening Crude Oil for Low Molecular Weight Naphthenic Acids

InactiveUS20070298505A1Simple to learnSimple to runComponent separationSolid sorbent liquid separationPhysical chemistryIon exchange

A method for the quantitation of the naphthenic acid content of molecular weight less than 600 Daltons in a hydrocarbon composition, in which naphthenic acids are separated from the hydrocarbon composition and applied to a macroreticular ion-exchange resin. The resin is washed and the naphthenic acid-metal ion complexes are eluted from the resin. The number of naphthenic acid-metal ion complexes present in the eluate from the resin are then quantitated.

Owner:OIL PLUS

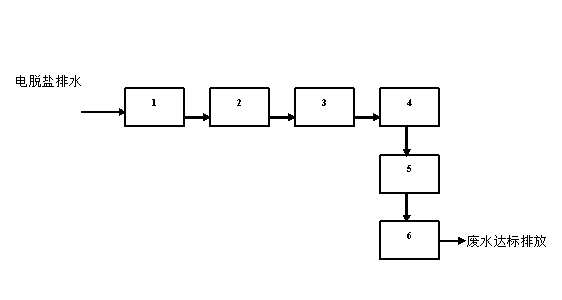

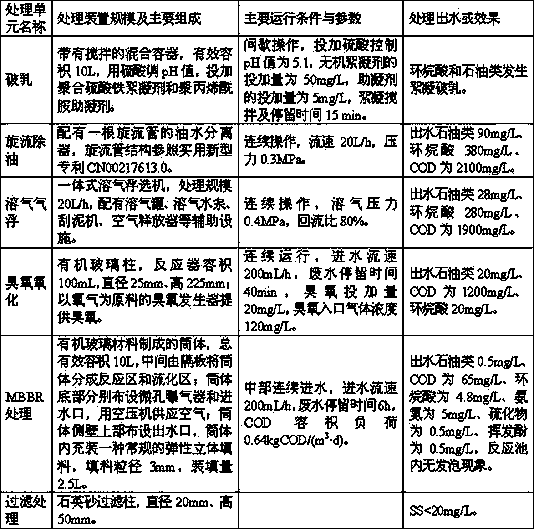

Treatment method for waste water from processing acid-containing crude oil

ActiveCN103771652ASolve the failure to meet the standardSolve processingMultistage water/sewage treatmentAfter treatmentOil separation

The invention relates to a treatment method for waste water from processing acid-containing crude oil, and the method is used in the treatment of waste water containing naphthenic acid from the refining process of acid-containing crude oil. The method adopts a combined process including demulsification, cyclone oil removal, dissolved air flotation, ozone oxidation, MBBR and filtering to treat the wastewater containing naphthenic acid discharged from an electric desalting device in the crude oil refining process, and the outlet water after treatment reaches discharge standards. The method can prevent the treatment process of other waste water, such as oil-containing sewage and salt-containing waste water from the influence from naphthenic acid, and benefit the stable operation of oil separation, flotation, biochemical treatment and depth treatment units in final sewage works, so as to solve the problems of unqualified waste water from processing acid-containing crude oil and foaming of biochemical treatment, and provide a good basis for waste water reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of removal of calcium from hydrocarbon feedstock

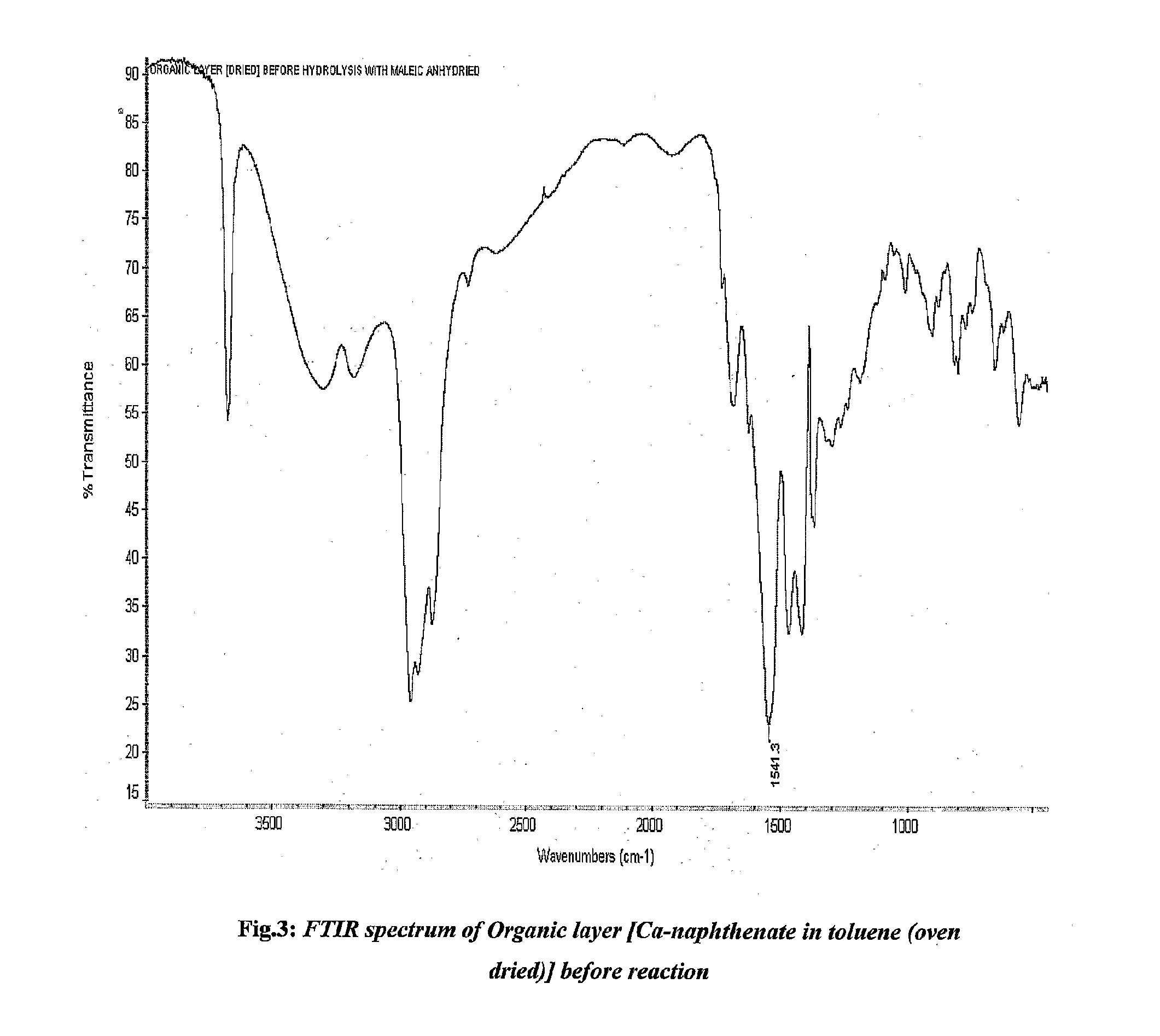

InactiveUS20100163457A1Treatment with plural serial refining stagesRefining with acid-containing liquidsFumaropimaric acidDesalter

The invention relates to field of processing hydrocarbon feedstock including crude oil, wherein metals such as calcium are removed. In the face of the rising prices of crude oil, refiners are forced to process opportunity crudes such as DOBA, which pose many problems including fouling of equipment due to certain metallic salts, such as calcium napthenate. Calcium, which cannot be removed from crude oil during normal desalting process, poses very serious problems. The invention provides method for removal of calcium, wherein crude oil is mixed, with effective metal removing amount of aqueous extraction solution of an additive comprising a chemical compound selected from a group consisting of metallic acid, maleic anhydride or fumaric acid or salts or derivatives thereof, enabling separation of hydrocarboneous phase and aqueous phase containing metal ions, in crude desalter. Only hydrocarboneous phase devoid of calcium is processed further, thereby preventing fouling of equipment.

Owner:DORF KETAL CHEM (I) PTE LTD

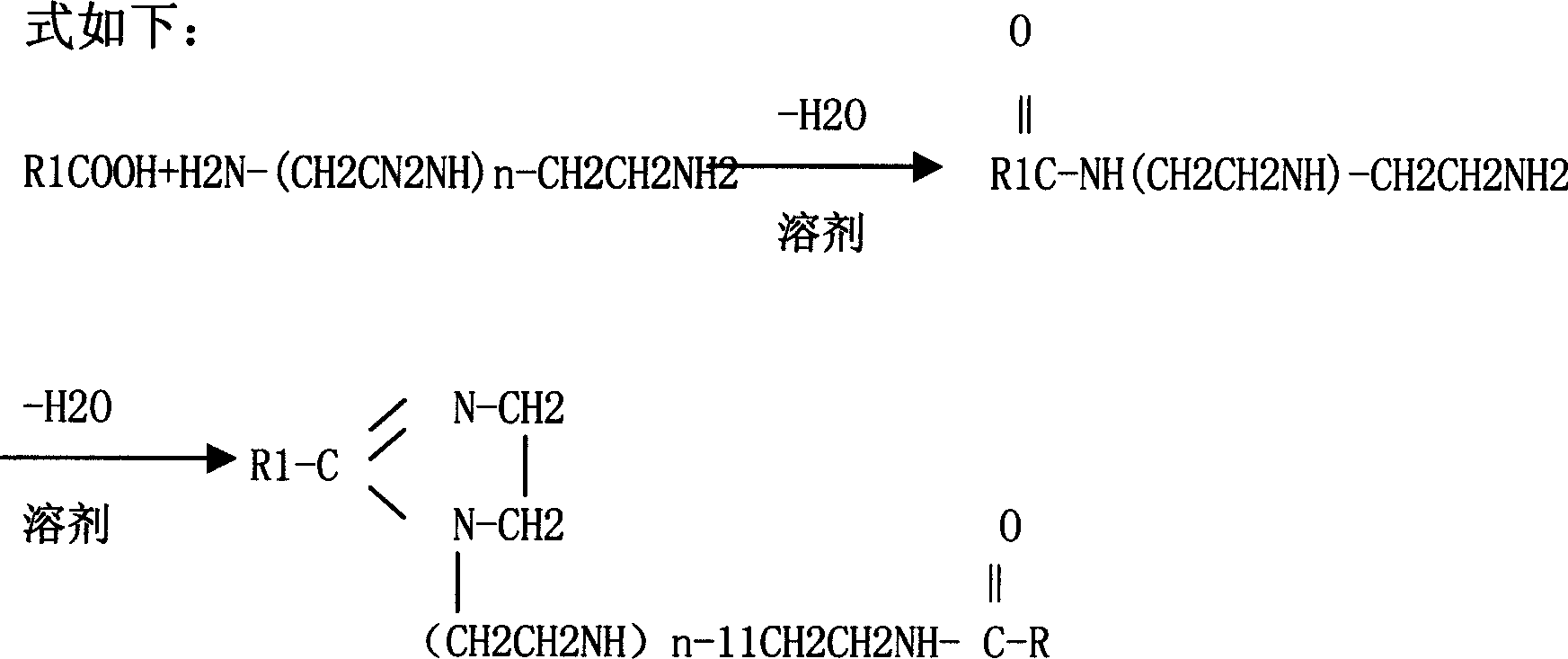

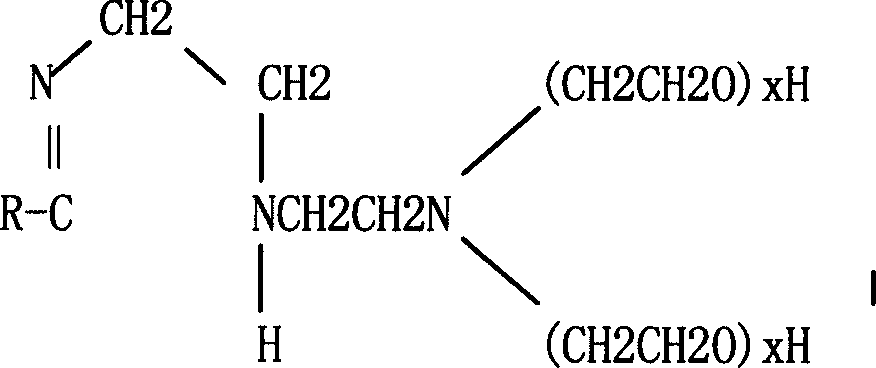

Water-soluble corrosion-retarding neutralizer and its preparation process

The invention relates to a water-soluble neutralizing agent mainly for oil-extraction plant low-temperature light oil position metallic conservation, which is prepared form naphthenic acid, polyenamine and organic acid anhydrides or ethylene oxide as raw material through mixing with neutralization agent and dissolvent.

Owner:PETROCHINA CO LTD

Super-high extreme pressure type micro-emulsification cutting fluid and preparation method thereof

ActiveCN102766510AHigh extreme pressureExcellent anti-rustLubricant compositionPhenyl EthersChlorinated paraffins

The invention relates to a metal processing cutting fluid and specifically relates to a super-high extreme pressure type micro-emulsification cutting fluid and a preparation method thereof. According to the super-high extreme pressure type micro-emulsification cutting fluid, 5# white oil is used as basic oil and is easy to emulsify; emulsification lubricating agents comprise tall oil, oleic diethanolamide, polyoxyethylene(10)nonyl phenyl ether, isononanoicacid, synthetic petroleum sodium sulfonate and zinc naphthenate, and the emulsifying capacity is stronger when the emulsification lubricating agents are matched for using; and more chlorine containing extreme-pressure agent chlorinated paraffin S52 and sulfur containing extreme-pressure agents TPS32 can be emulsified into the basic oil to obtain the super-high extreme pressure type micro-emulsification cutting fluid. According to the super-high extreme pressure type micro-emulsification cutting fluid, emulsification particles are small, and the cutting fluid is stable; simultaneously, a synthetic ester of a fatty acid methyl ester which serves as a lubrication reinforcing agent is added, extreme pressure lubrication requirements of medium-high temperature processing are met, and the super-high extreme pressure type micro-emulsification cutting fluid is suitable for mechanical processing with wider ranges of processing temperatures; and triazine amino-acid esters are used for reinforcing rust protection so that the rust-protecting effects can reach to the best.

Owner:温州宝罗润滑材料有限公司

Collector for bauxite flotation

The present invention relates to one kind of collecting agent for floating and desilicating bauxite, and the collecting agent consists of industrial chemicals fatty acid, naphthenic acids and hydroximic acid in the weight ratio of 25-98 to 0-75 to 0-25. The re-compounded collecting agent features the mutual solubilization and homogenization of its components and no negative effect of emulsifier. The naphthenic acids have cyclopentyl formic acid with smelting point of -7 deg.c as the main component, and are suitable for low temperature use. The collecting agent is suitable for for floating and desilicating bauxite of different types, especially low grade bauxite, and has high collecting performance, low consumption and good low temperature use effect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Compositions, Configurations, and Methods of Reducing Naphtenic Acid Corrosivity

InactiveUS20080164137A1Reduce naphthenic acid corrosivityReduce naphthenic acid corrosionDistillation corrosion inhibitionDistillation regulation/controlChemical compositionPhotochemistry

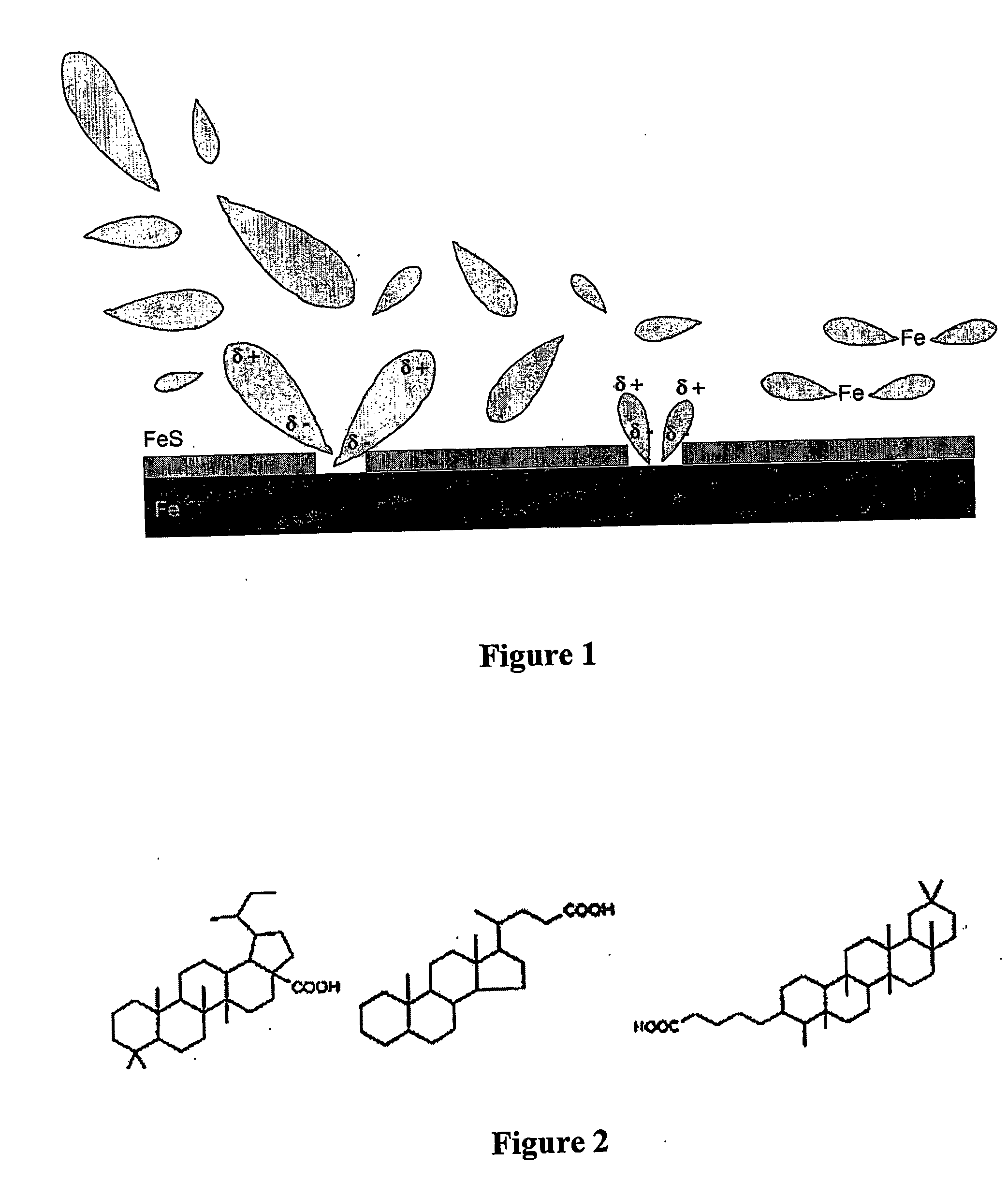

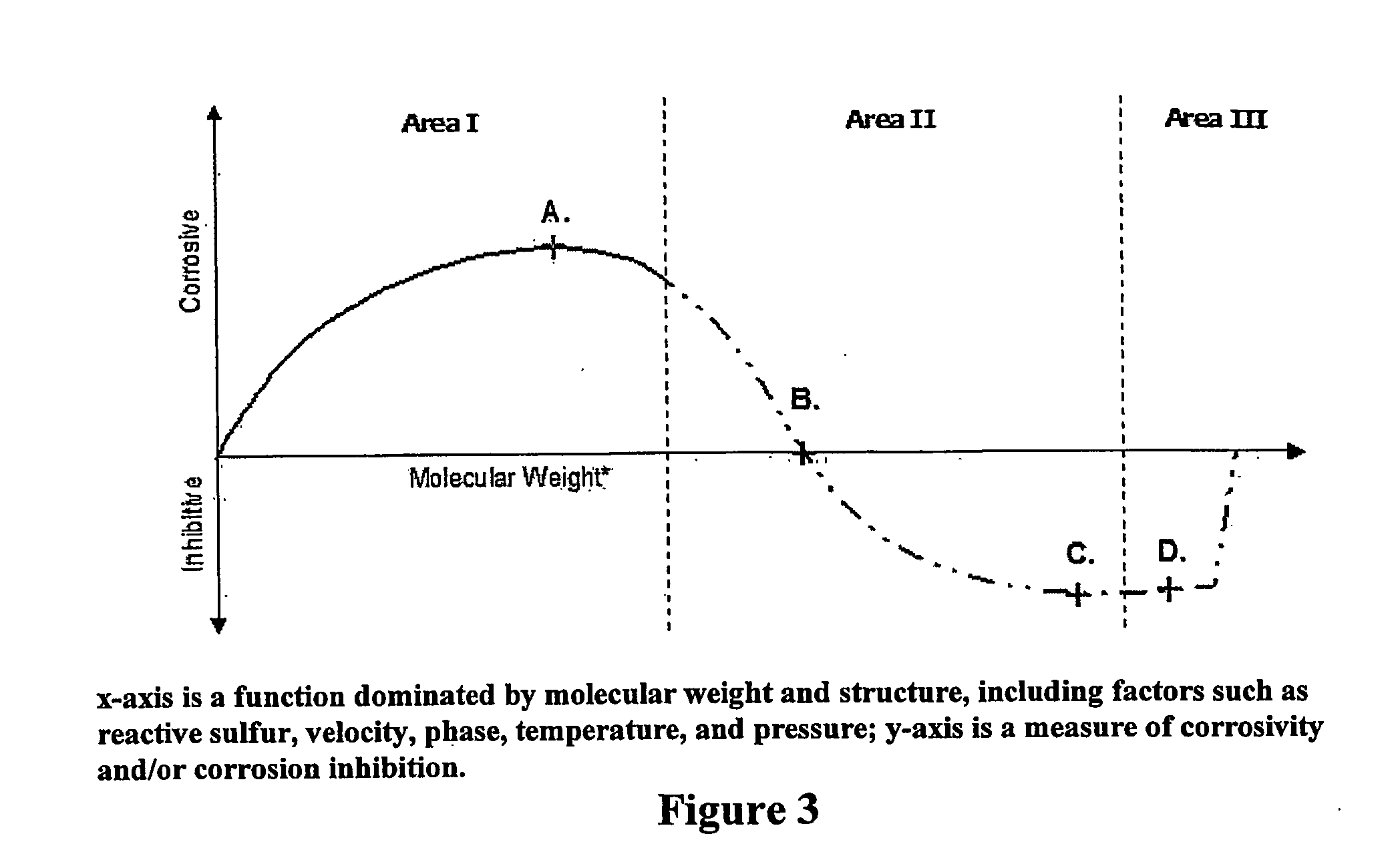

Naphthenic acid corrosivity of hydrocarbon feedstocks is correlated with the chemical composition of naphthenic acids, and especially with a ratio between an alpha fraction and a beta fraction of naphthenic acids. Contemplated plants, configurations, and methods are directed to reducing naphthenic acid corrosivity of hydrocarbon feedstocks by increasing the beta fraction over the alpha fraction.

Owner:FLUOR TECH CORP

Biodiesel based fuel oil and preparation thereof

The invention provides biodiesel based fuel oil which comprises the following components by weight: 50-80 percent of crude biodiesel, 4-35 percent of compound emulsifying agent, and one or two mixture of water and methanol, wherein the compound emulsifying agent is the mixture of the two types of materials, the first-type material is one or the mixture of a plurality of oleic acid, palmitoleic acid, naphthenic acid, aliphatic amine polyethenoxy ether with C atomicity being 40-100, dehydration sorbitan fatty acid ester with C atomicity being 40-100, polyoxyethylenec dehydration sorbitan fatty acid ester with C atomicity being 40-100; the second-type material is one or the mixture of a plurality of monoethanol amine, diethanolameine, trolamine, diglycol amine, 1-octanol and tertiary butyl alcohol. The preparation method is as follows: the mixtures are mixed according to the percent by weight and are mixed uniformly so as to obtain transparent solution. The fuel oil has good stability, non layering for a long time, no discolor and no turbidity, and is directly prepared by adopting the crude biodiesel. Methanol or water or the mixture of the water and the methanol is added, thus the consumption of the biodiesel is saved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com