Process to upgrade oil using metal oxides

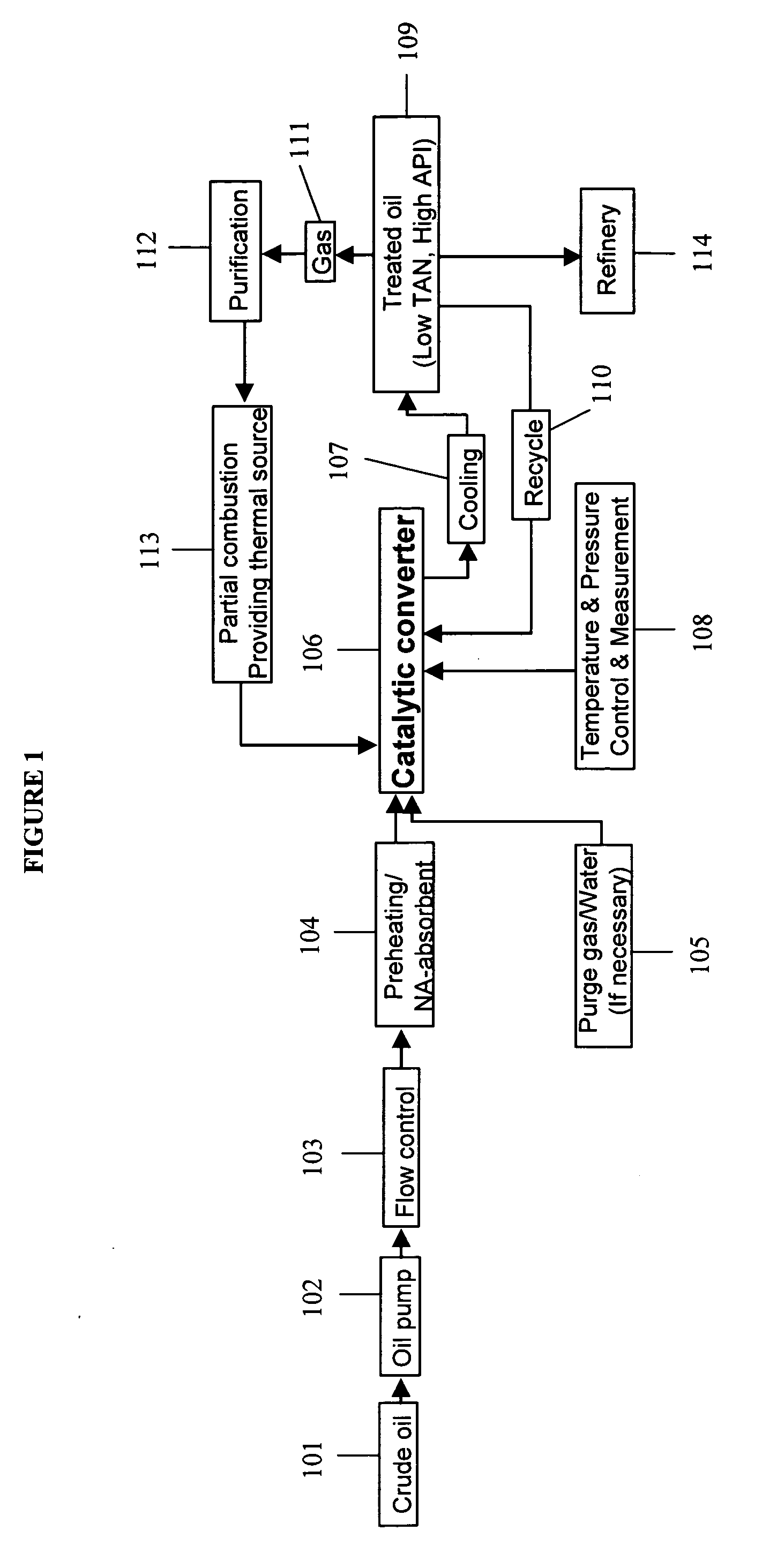

a technology of metal oxides and oil, applied in the direction of metal/metal-oxide/metal-hydroxide catalysts, hydrocarbon oil treatment products, physical/chemical process catalysts, etc., can solve the problems of reducing the acidity of the total quantity, reducing the quality of oil, and presently difficult to predict the severity of the corrosion of an individual or a small group of na compounds by any analytic measurement. , to achieve the effect of reducing the total acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

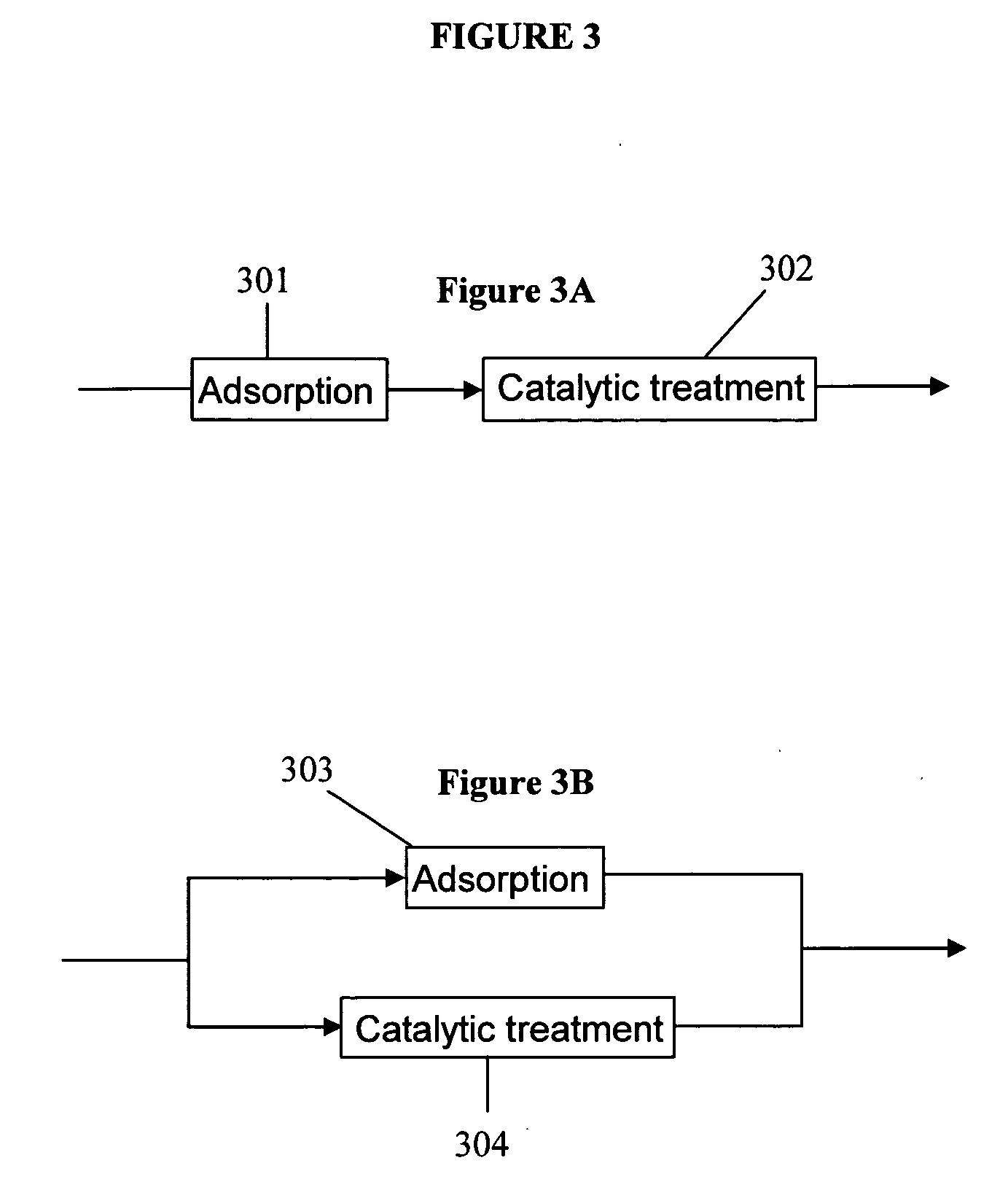

Method used

Image

Examples

example 1

Total Acid Number Measurement

[0078] An in-house Total Acid Number (TAN) measurement method was developed following the procedure of ASTM standard method D664. The principle of this measurement is based on non-aqueous acid base potentiometric titration determined by a PH / mv meter (Oakton PH510 Series).

Procedures

Preparation of Alcoholic Potassium Hydroxide Solution

[0079] 6 g of KOH were added to approximately 1 L of anhydrous isopropanol. The solution was then gently boiled for 30 min to increase the solubility of KOH in the solution. The solution was stored overnight and then standardized with potassium acid phthalate (KHC8H4O4 or KHP).

Standardization of Alcoholic KOH Solution

[0080] The solution was standardized with potentiometric titration of weighed quantities of KHP dissolved in CO2-free water.

Preparation of Oil Sample

[0081] One 5 g oil sample was dissolved in 125 mL titration solvent (500 mL toluene / 495 mL anhydrous isopropanol / 5 mL water). The resulting solution was...

example 2

Catalytic Decarboxylation for Naphthenic Acid Removal from Crude Oils

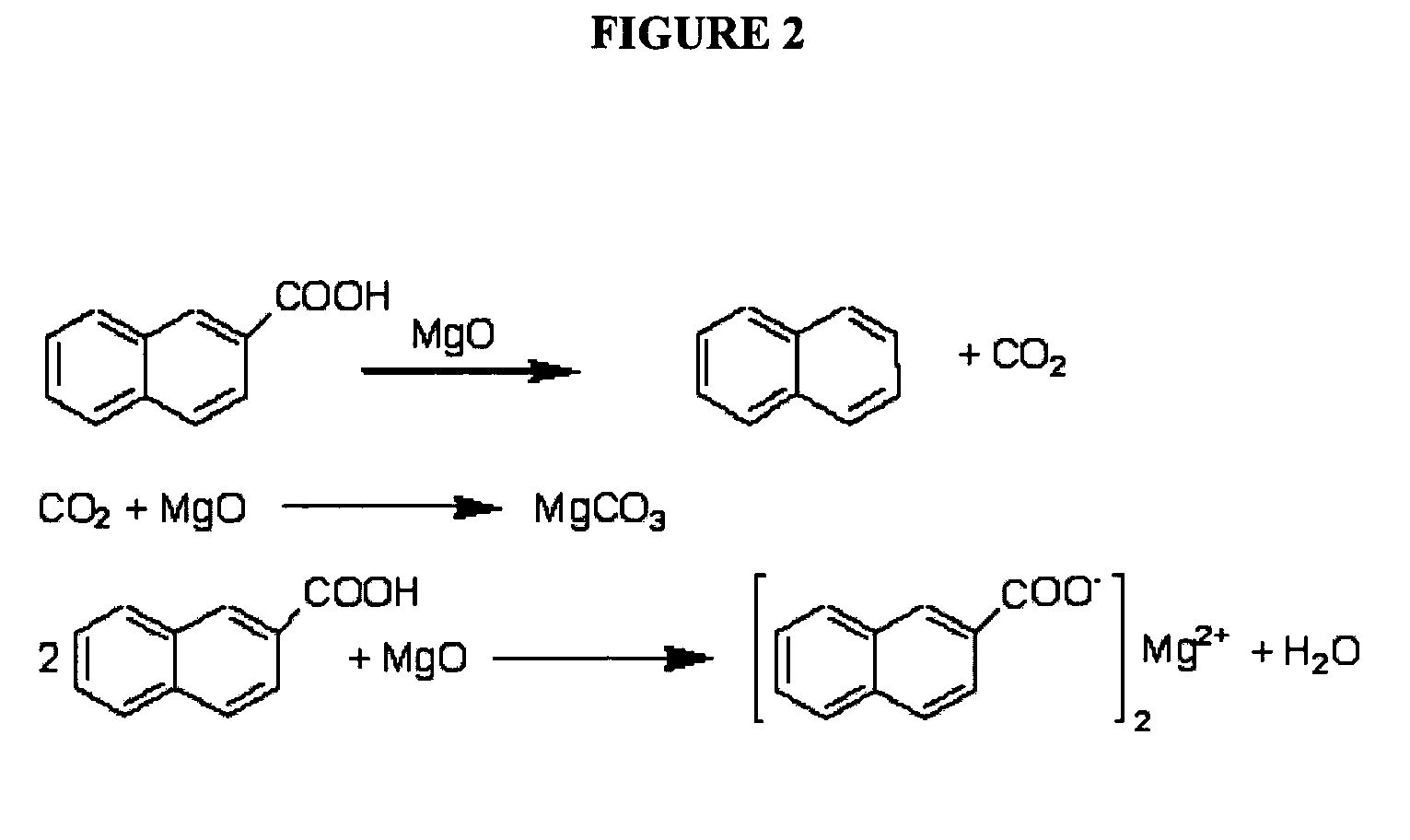

[0085] This Example outlines a process useful for the catalytic decarboxylation of naphthenic acids in crude oil. MgO was shown to have decarboxylation activity with both saturated and aromatic model naphthenic acid compounds in a 4 hour reaction carried out at a temperature range of 150° C. to 250° C. In the presence of Ag2O, the amount of CO2 produced matched the amount of the other decarboxylation product, naphthalene, resulting in a “direct” catalytic decarboxylation. These findings provide a low-temperature, cost-effective catalytic decarboxylation process to remove naphthenic acids from oil. Furthermore, this Example demonstrates that catalytic decarboxylation reactions of naphthenic acids in the presence of various solid catalysts have been investigated. Among catalysts tested, MgO exhibits the high reactivity toward the decarboxylation of model saturated and aromatic naphthenic acid compounds. Ag2O not onl...

example 3

Catalytic Decarboxylation of Naphthoic Acid Using Rare Earth Metal Oxides

[0105] Several rare earth metal oxides, including CeO2, La2O3, Y2O3 and ZrO2 were tested with model acid, naphthoic acid (C10H7COOH) and the result was shown in Table 2. The low CO2 yields, defined as the carbon conversion to CO2 as shown in Table 5, suggest that they were inactive towards catalytic decarboxylation. The metal oxide ZrO2 exhibited acid-base dual functionalities.

TABLE 5Catalytic Decarboxylation of Naphthoic Acid in the Presence of RareEarth Metal OxidesTempRun #Acid (mg)Catalyst (mg)(° C.)RT (hr)CO2 yield (%)151NA51.6152NA47.7CeO210.625040.16152NA49.7La2O310.425040.01154NA50.6Y2O310.525040.00155NA51.2ZrO211.125040.00177NA51.6ZrO213.330040.94

NA, C10H7COOH, 2-naphthoic acid

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com