Patents

Literature

3108 results about "Hydrocotyle bowlesioides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

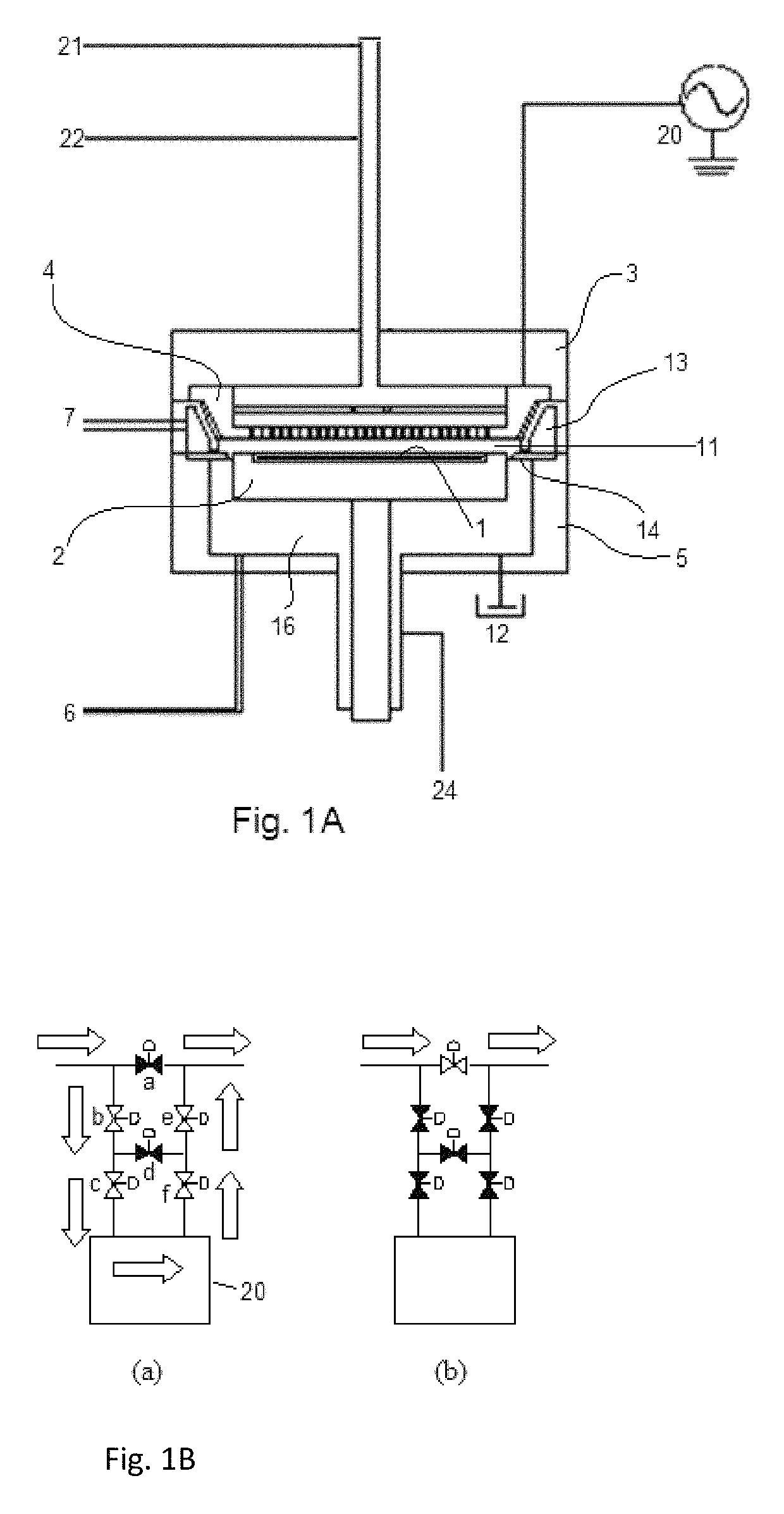

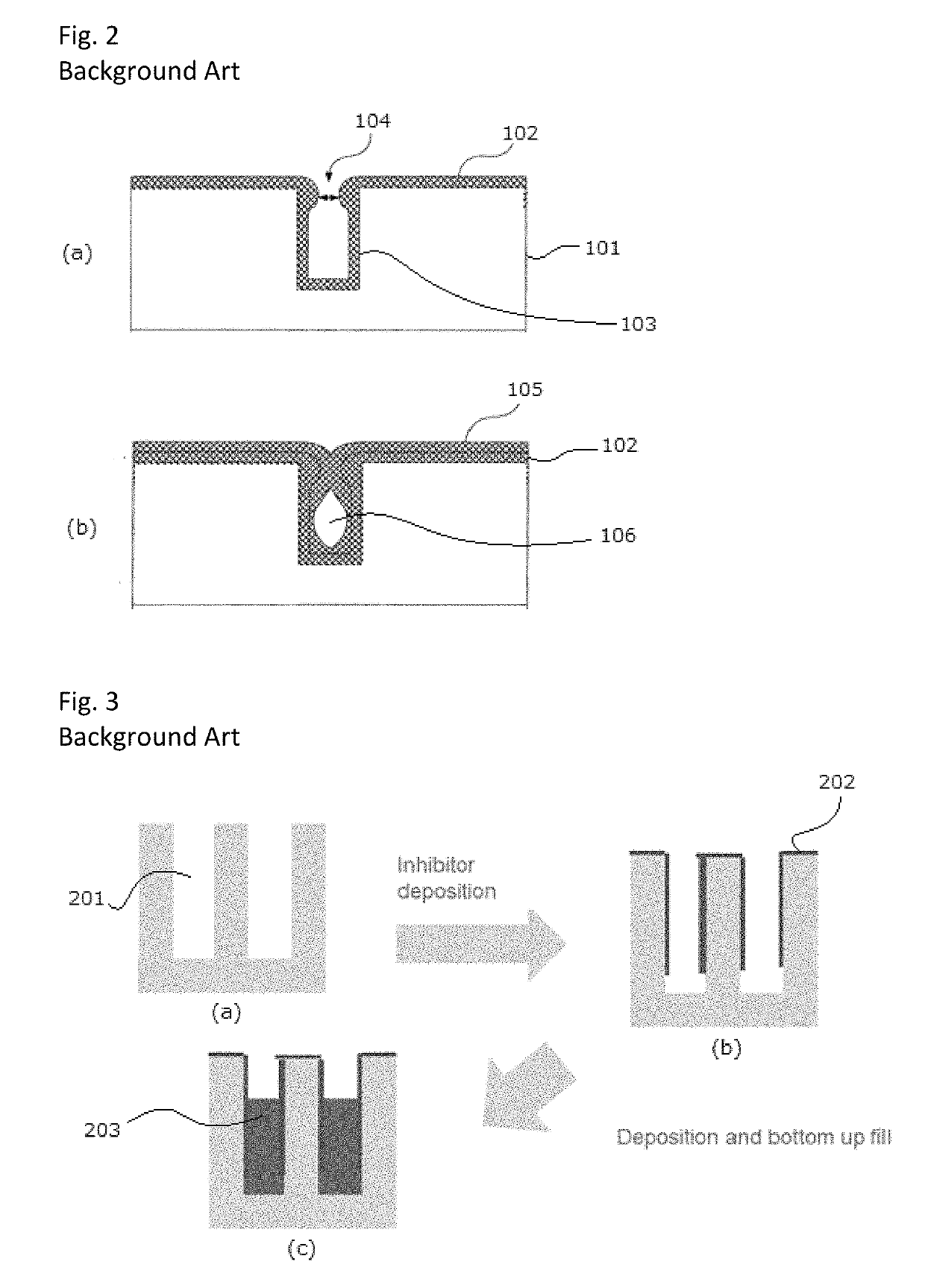

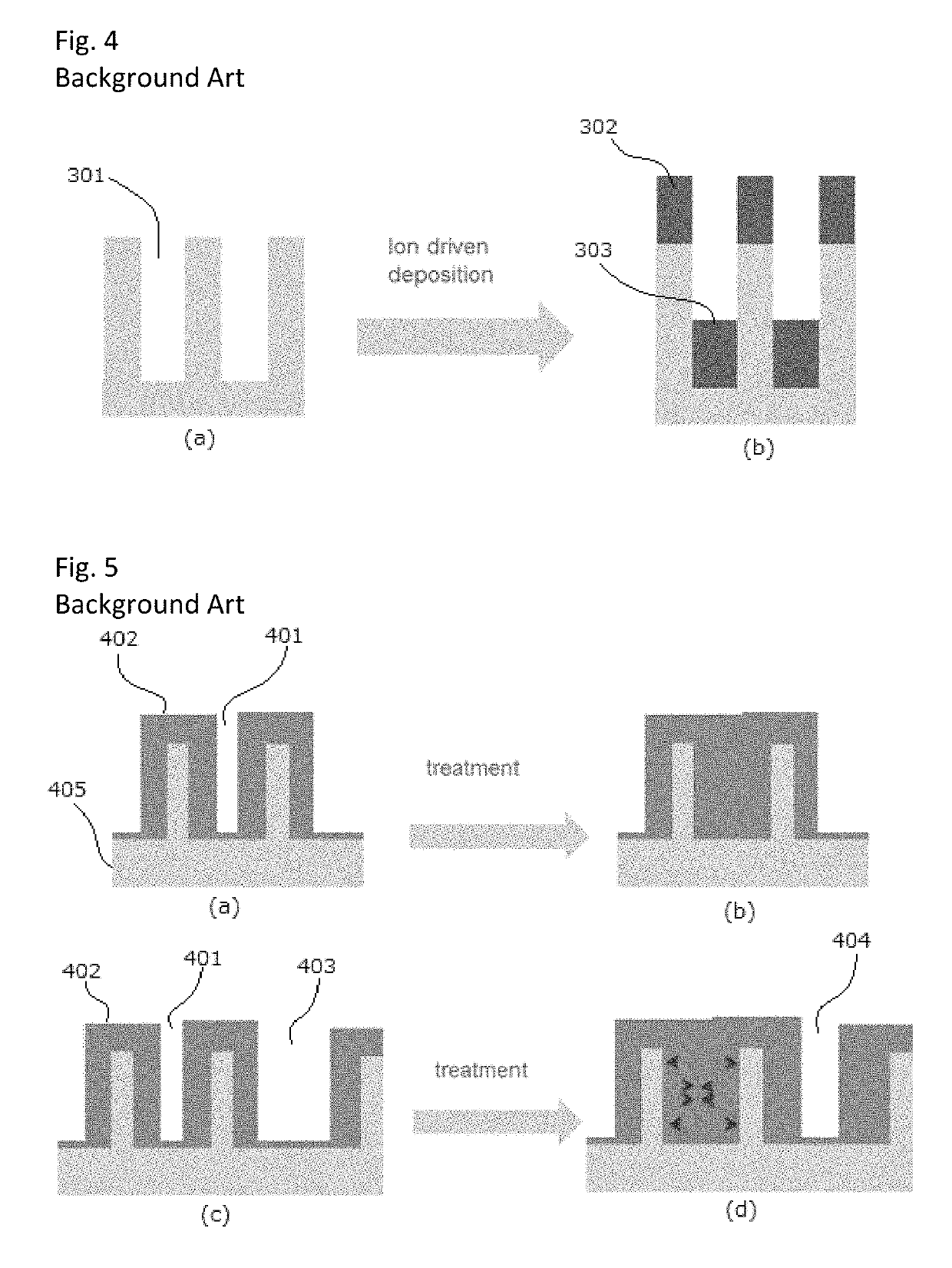

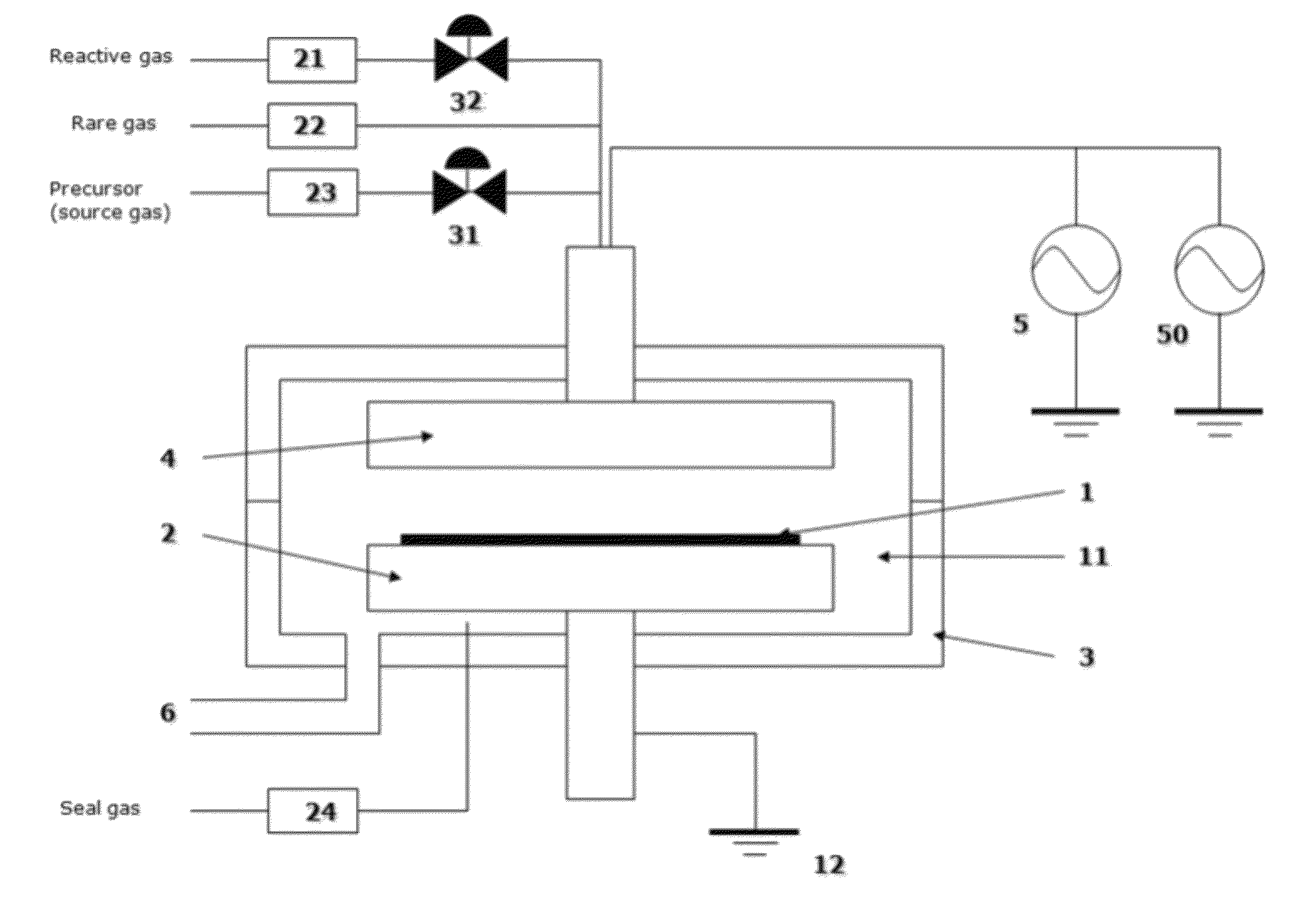

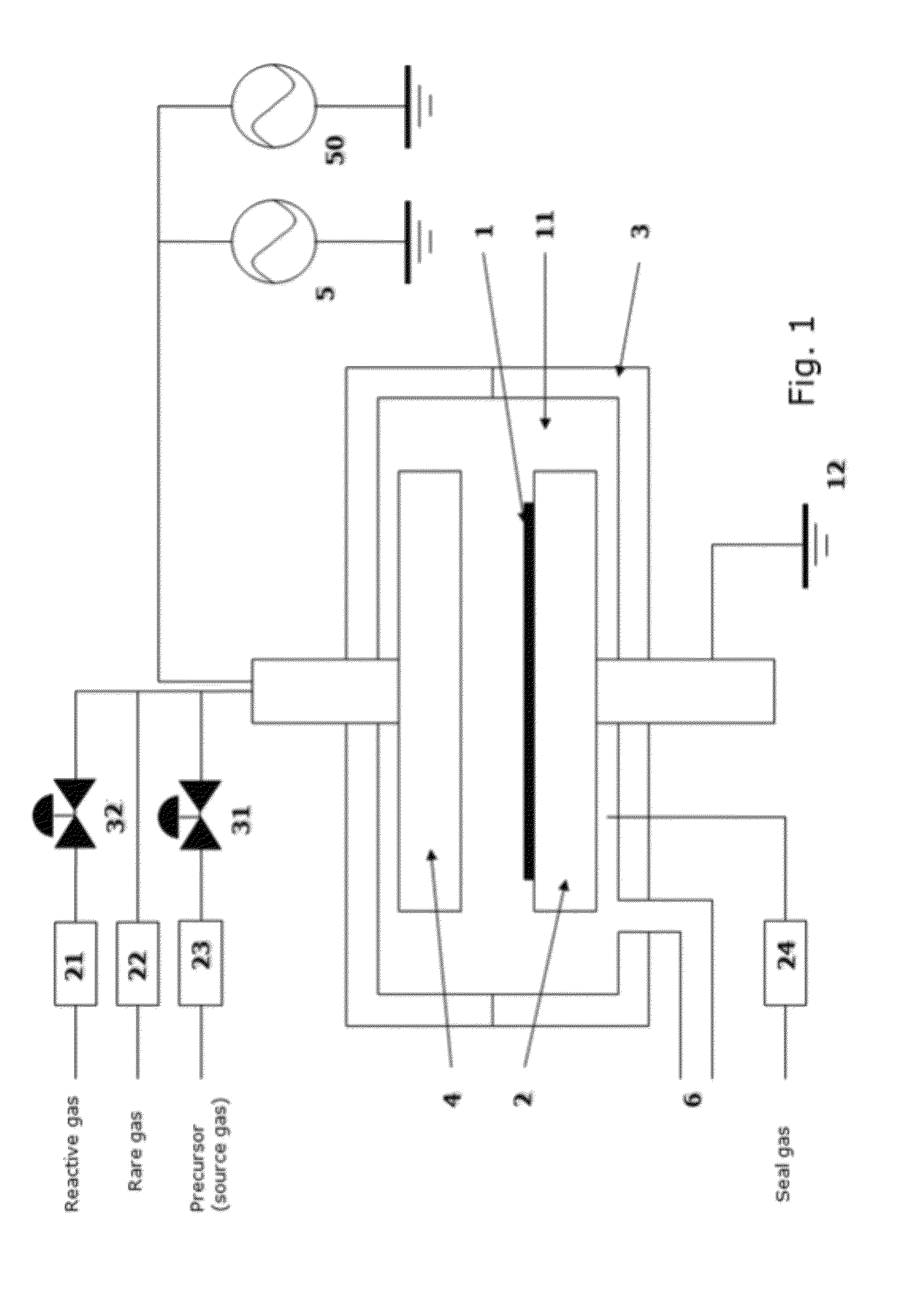

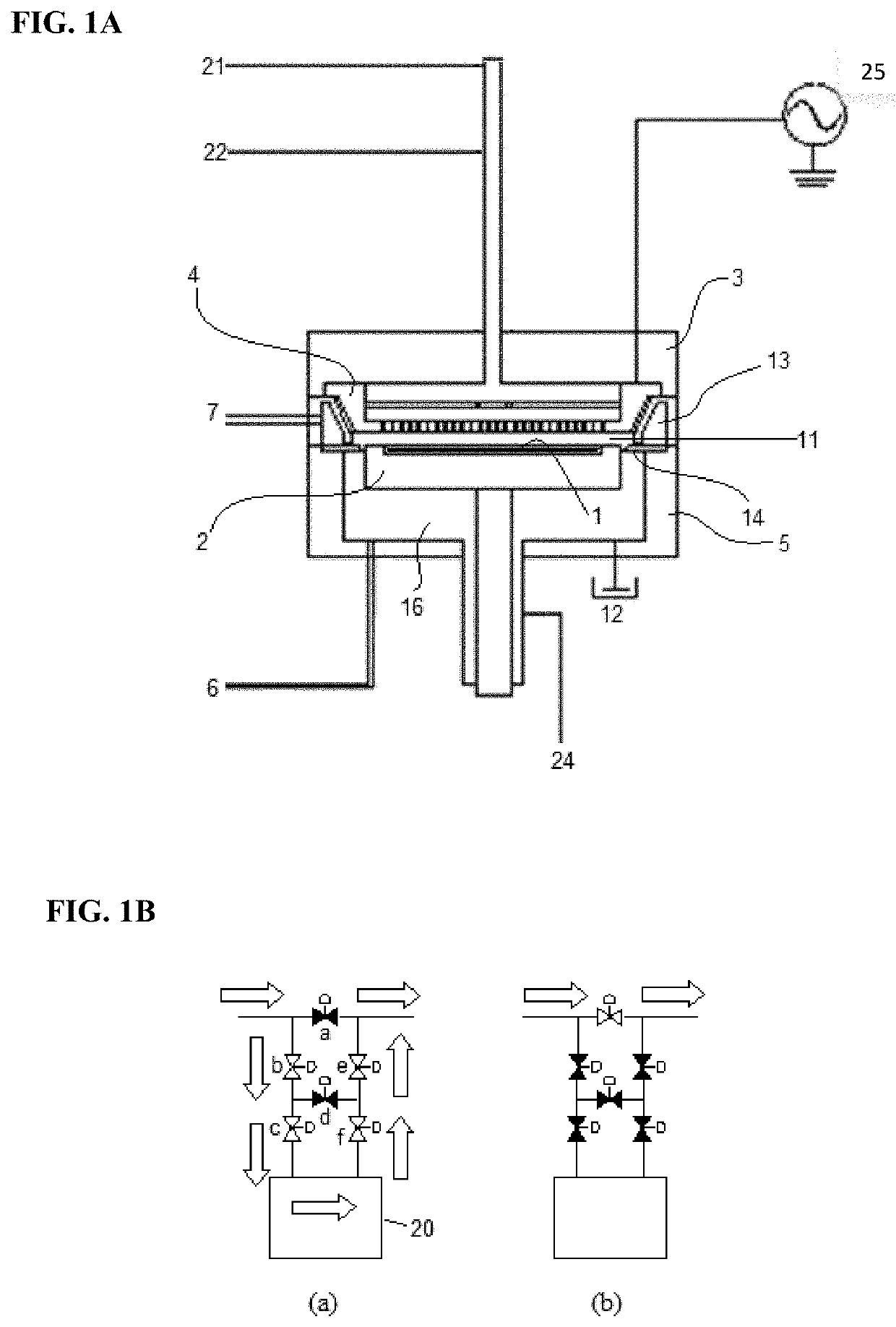

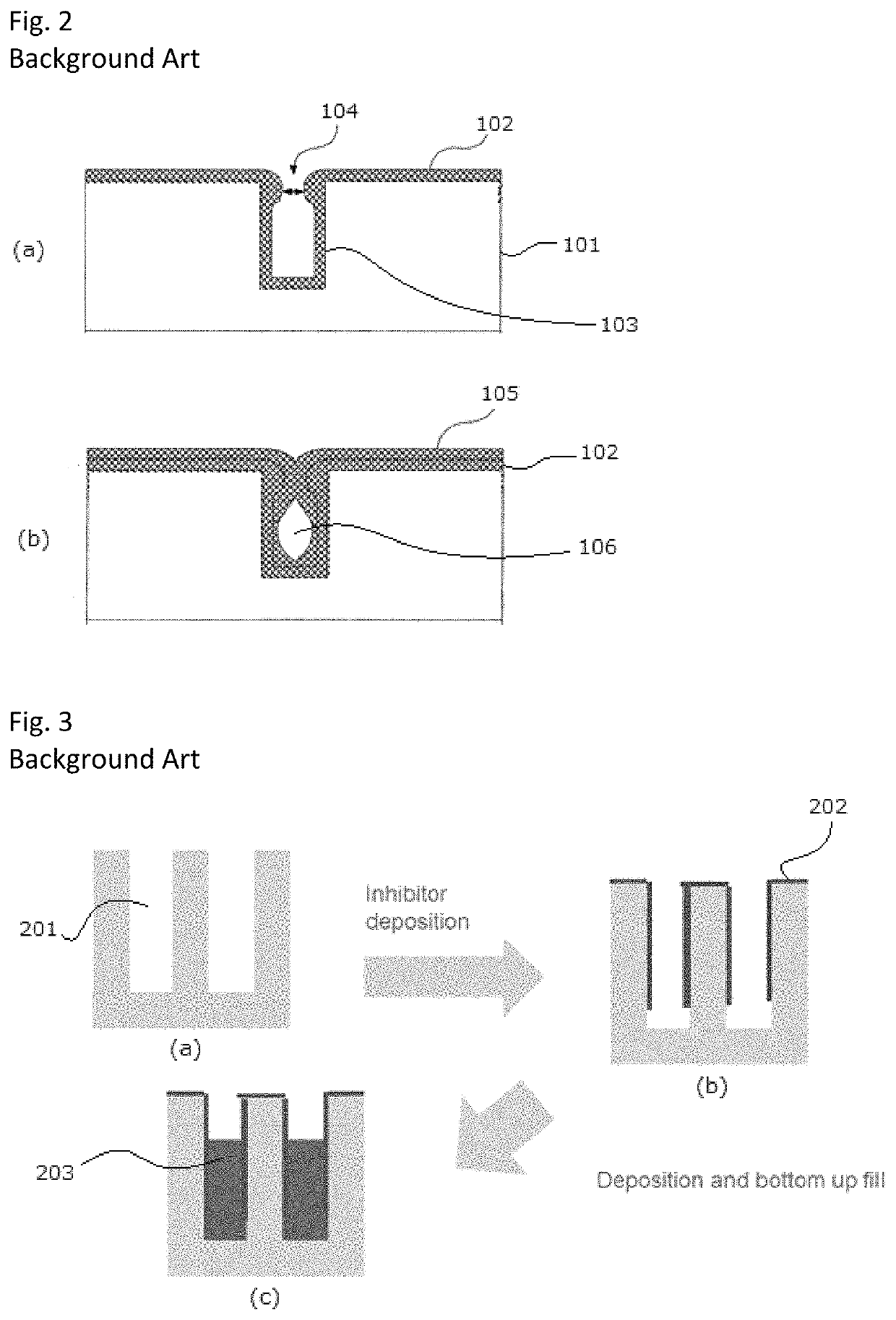

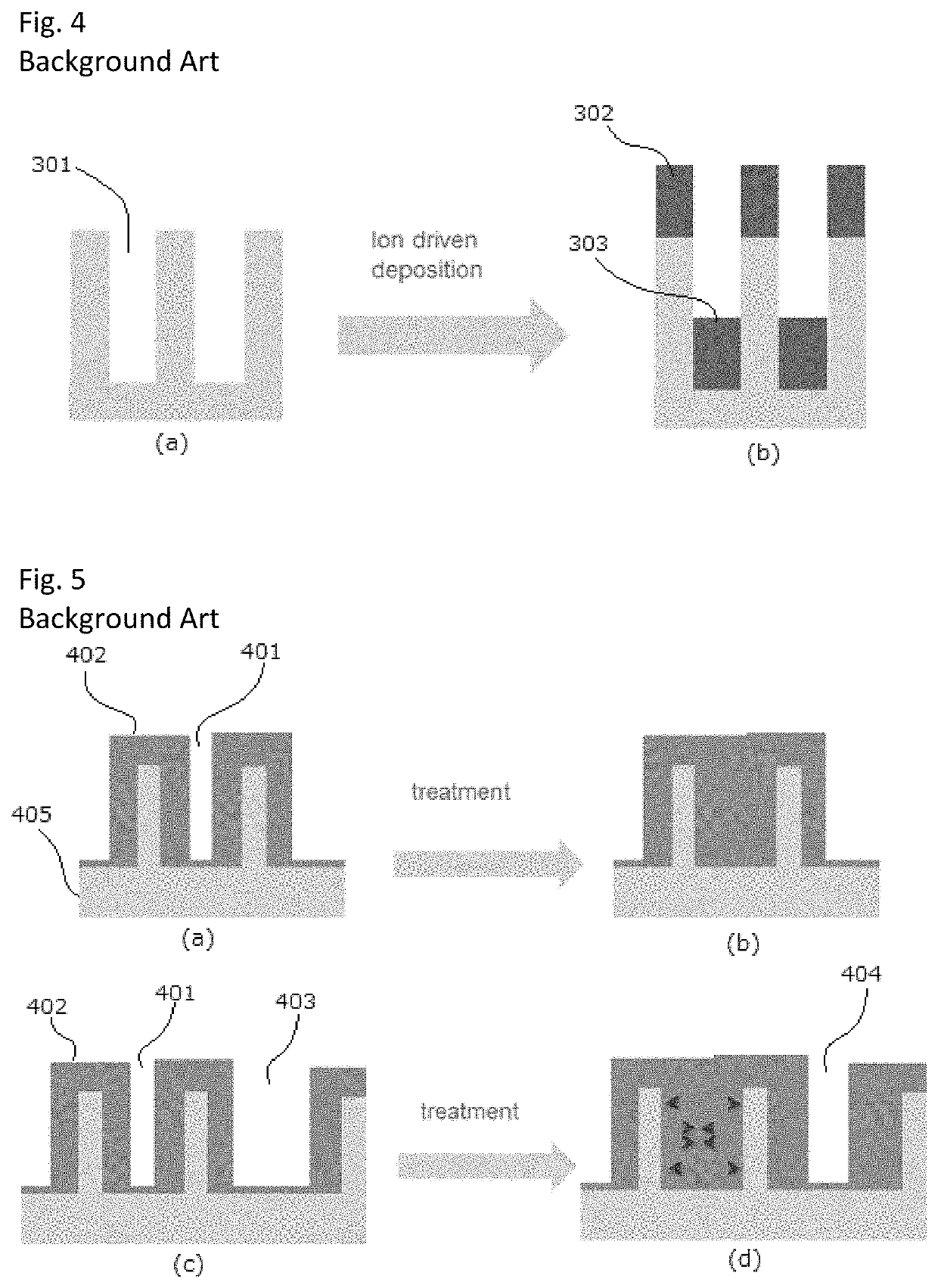

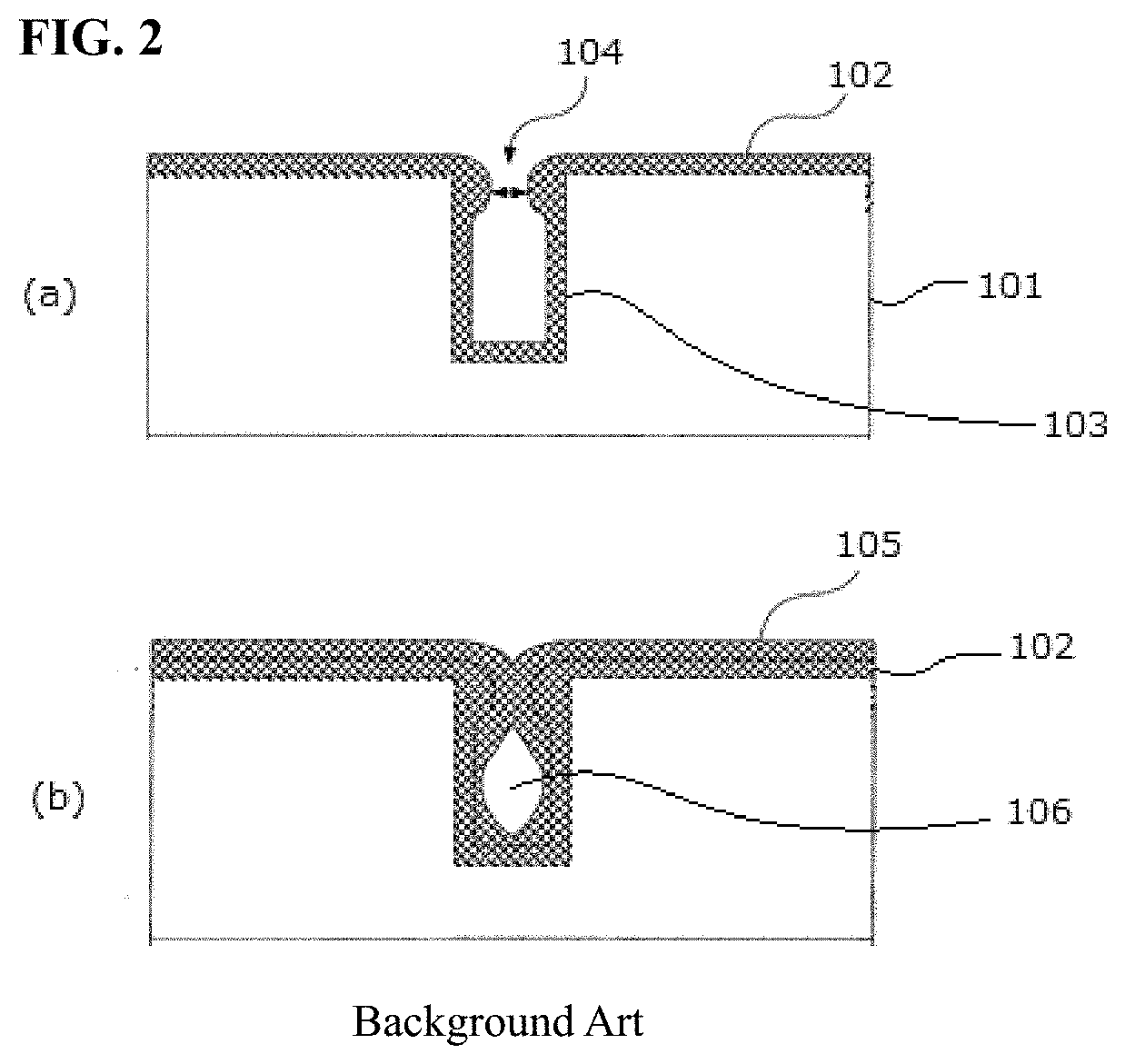

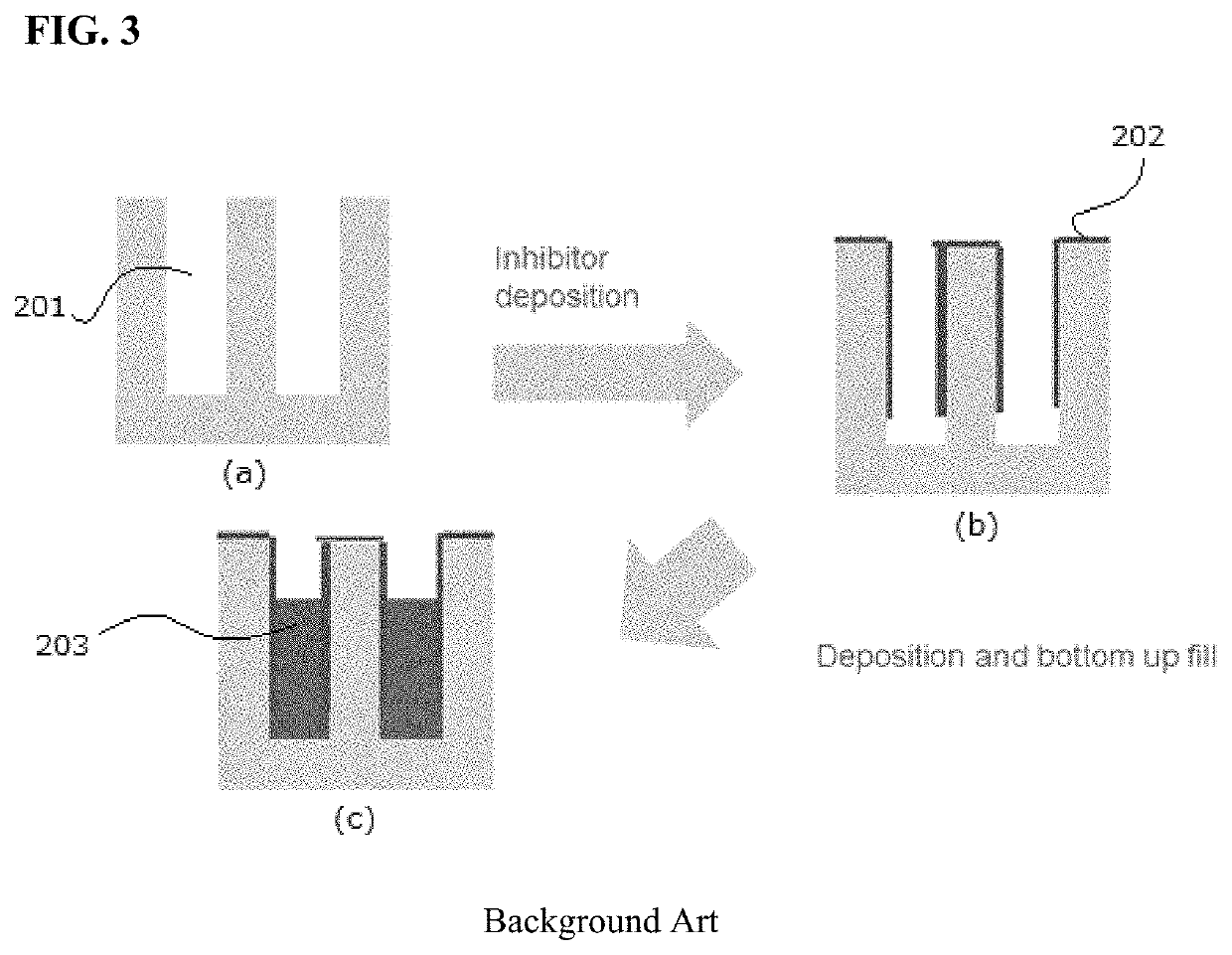

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS10388513B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon

A Si-free C-containing film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

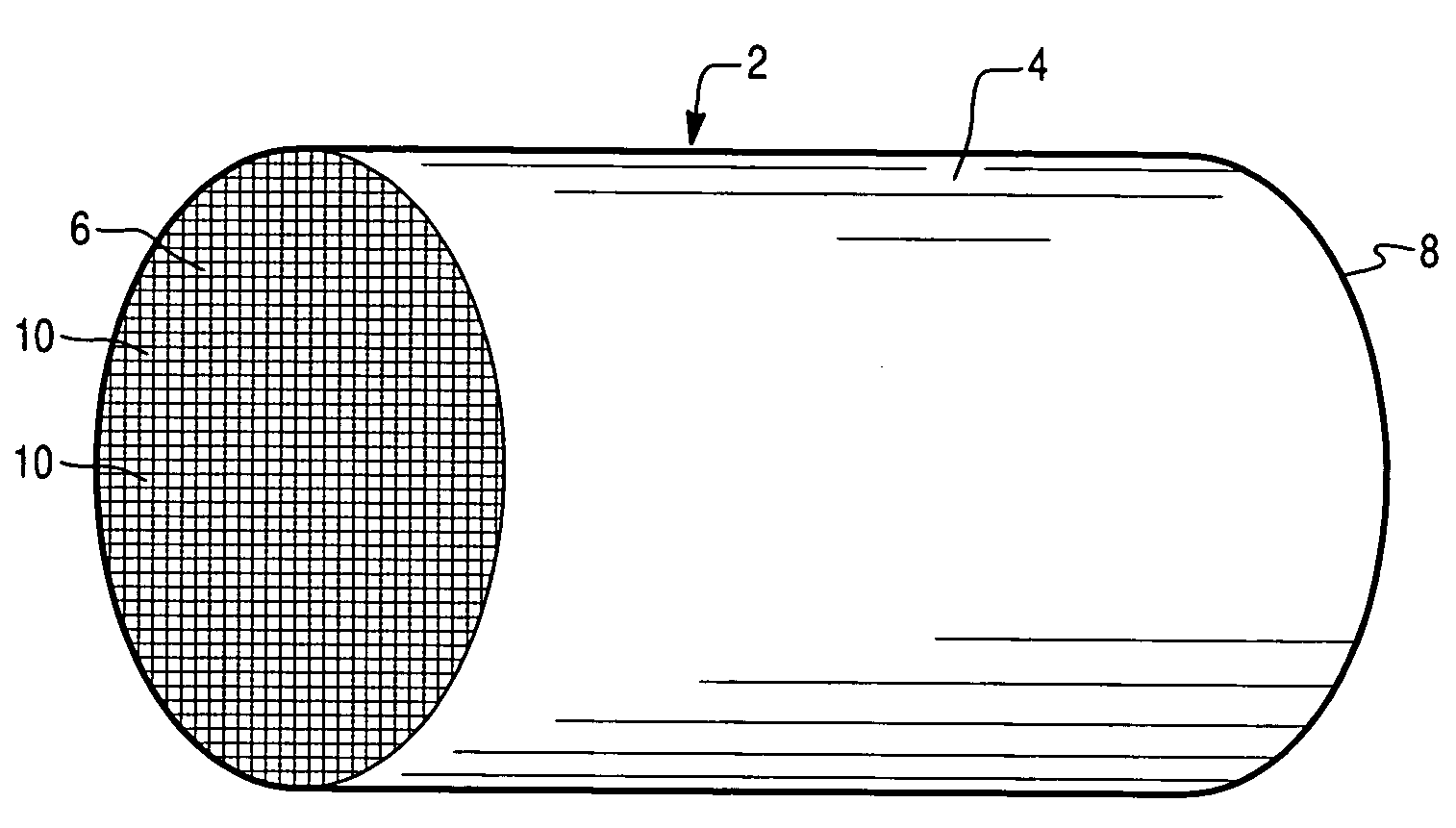

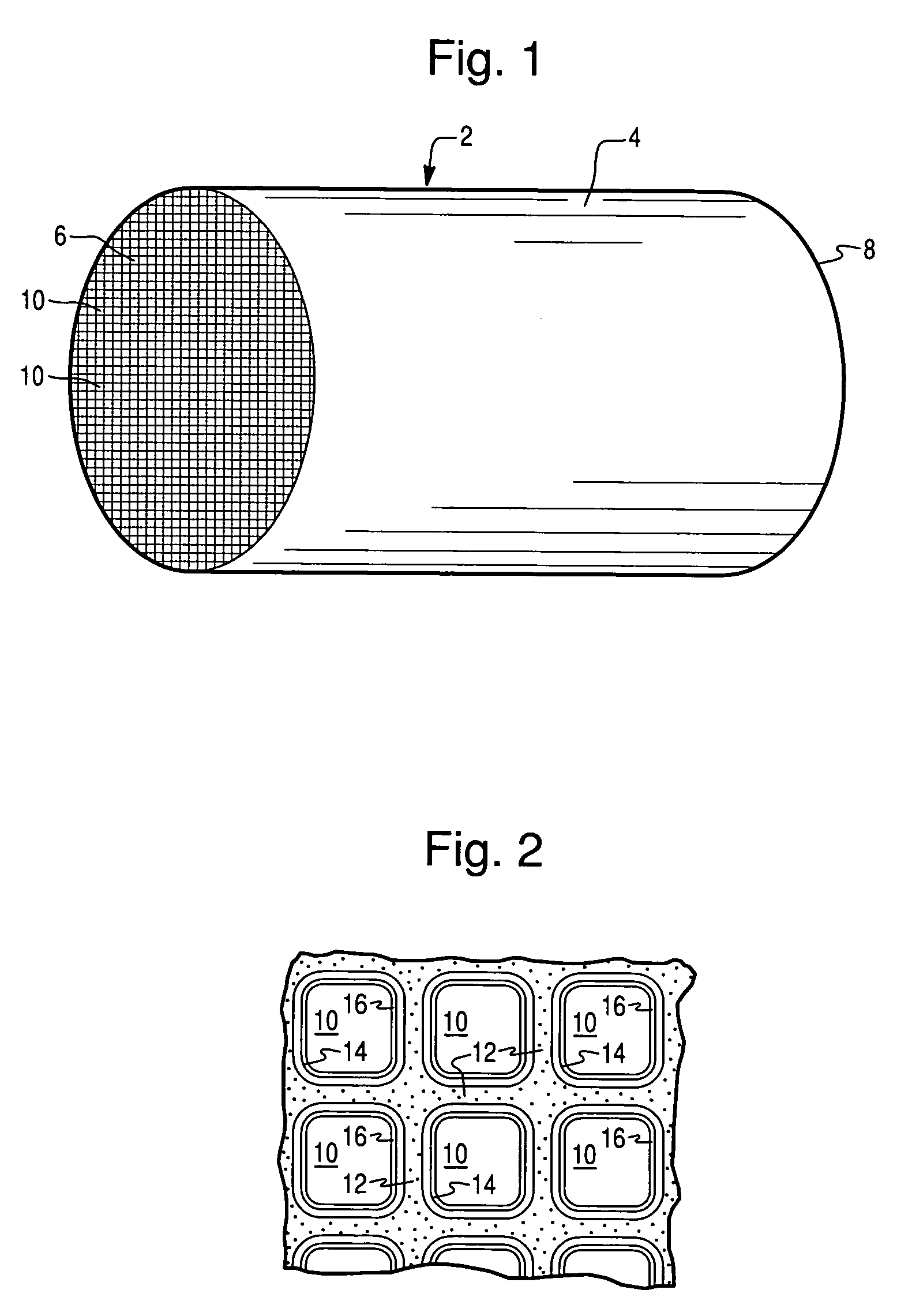

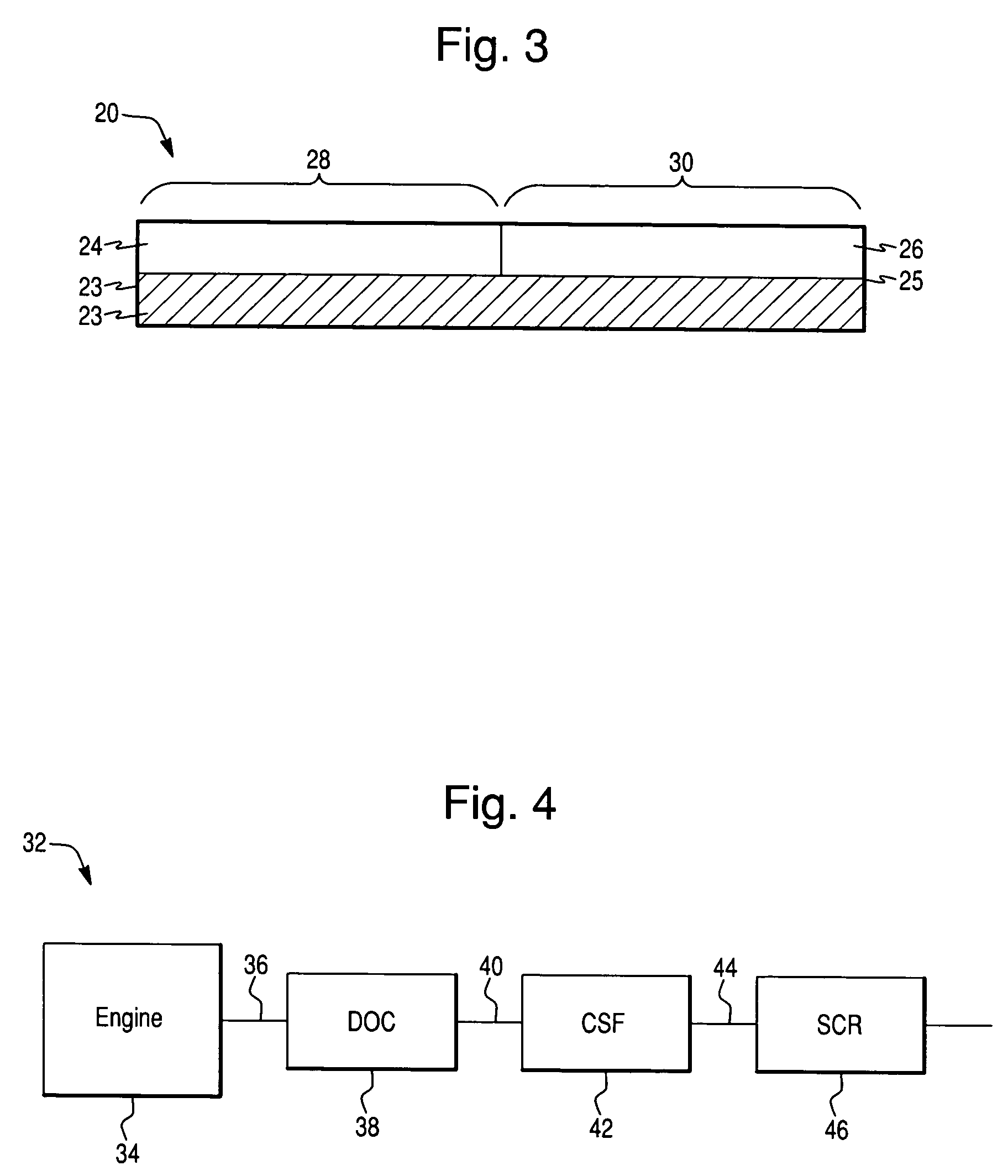

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

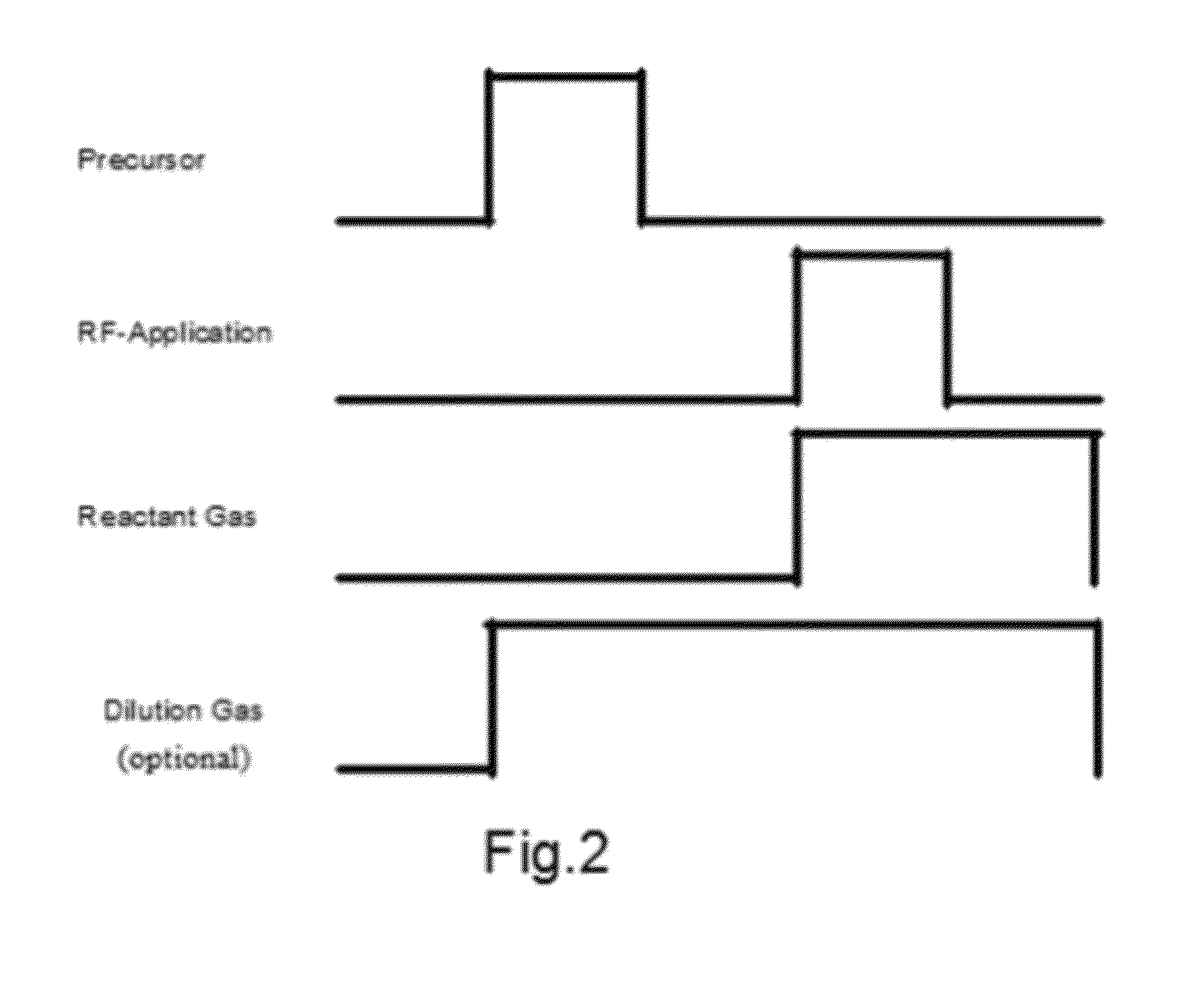

Method of Depositing Dielectric Film by ALD Using Precursor Containing Silicon, Hydrocarbon, and Halogen

ActiveUS20120295449A1Accelerates the carbonization processHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHalogen

A method of forming a dielectric film having at least Si—N, Si—C, or Si—B bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: supplying a precursor in a pulse to adsorb the precursor on a surface of a substrate; supplying a reactant gas in a pulse over the surface without overlapping the supply of the precursor; reacting the precursor and the reactant gas on the surface; and repeating the above steps to form a dielectric film having at least Si—N, Si—C, or Si—B bonds on the substrate. The precursor has at least one Si—C or Si—N bond, at least one hydrocarbon, and at least two halogens attached to silicon in its molecule.

Owner:ASM JAPAN

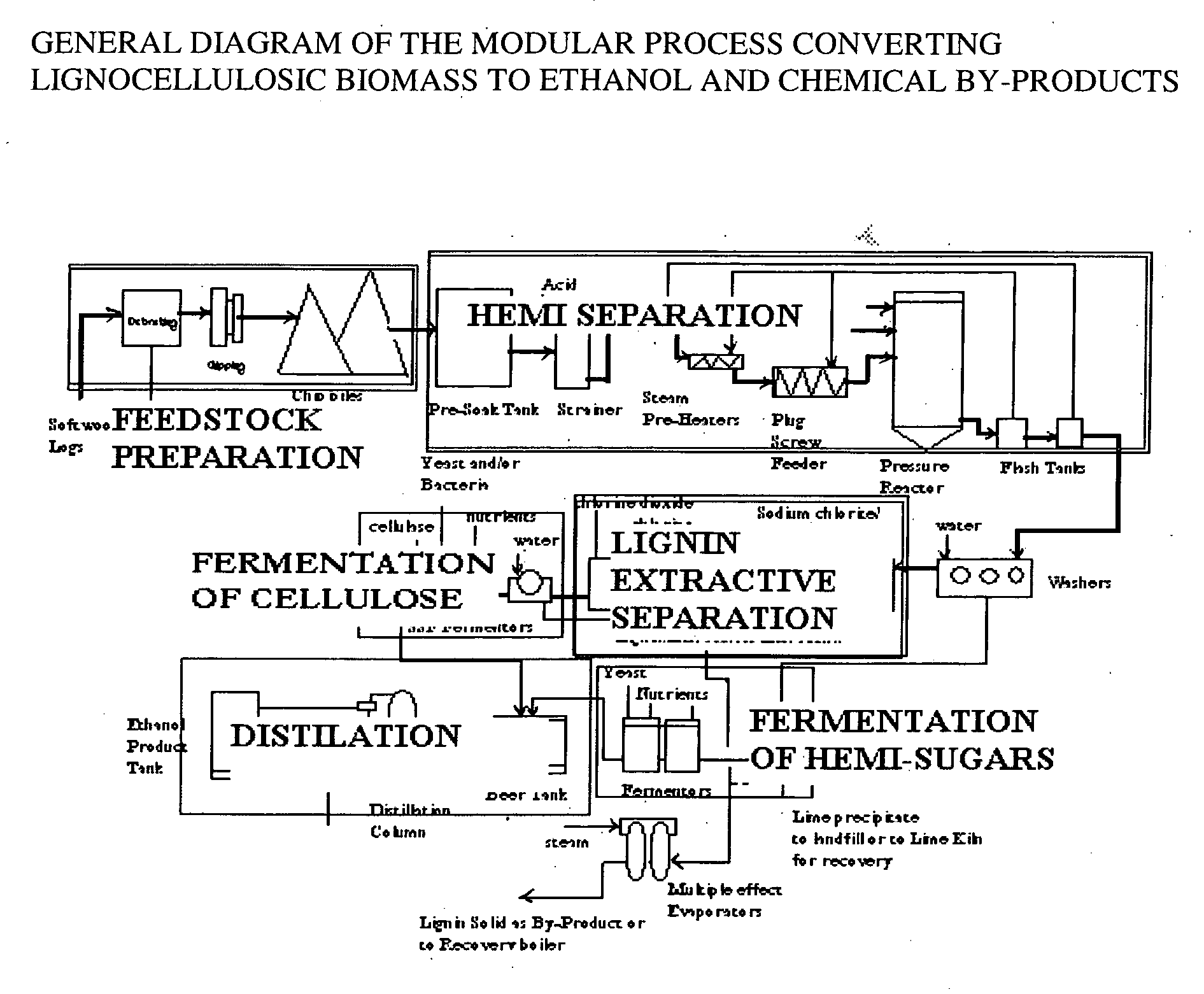

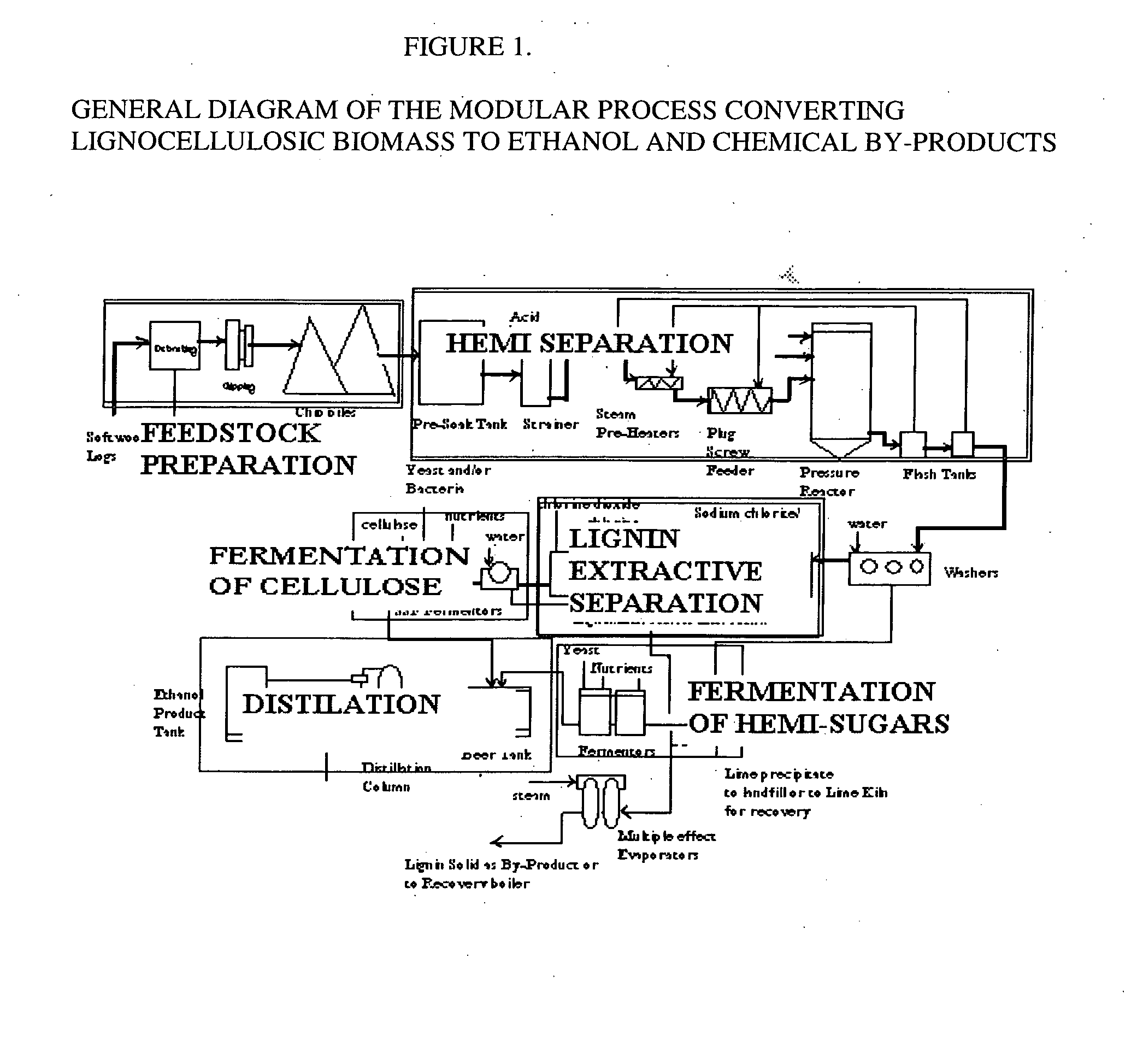

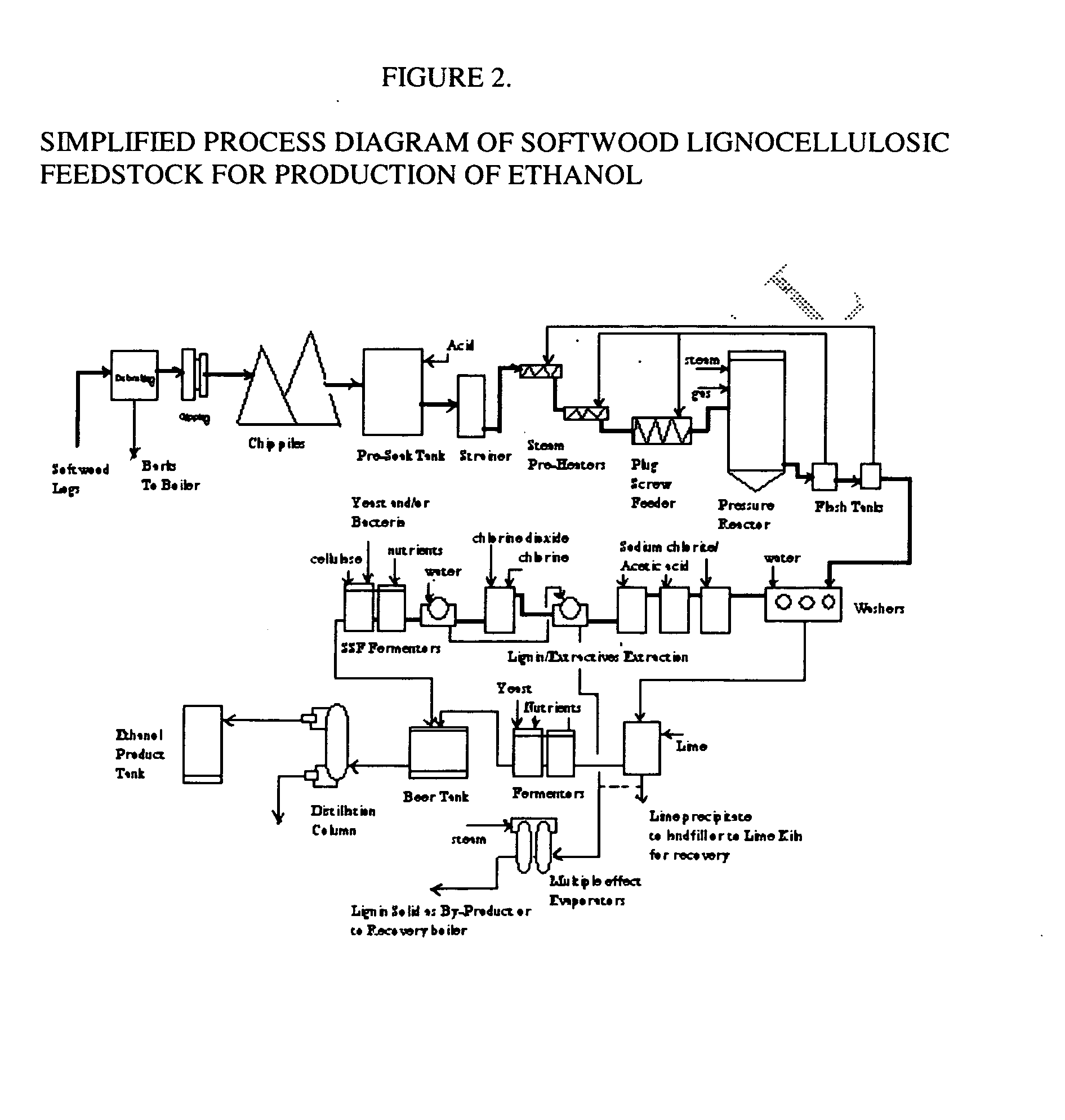

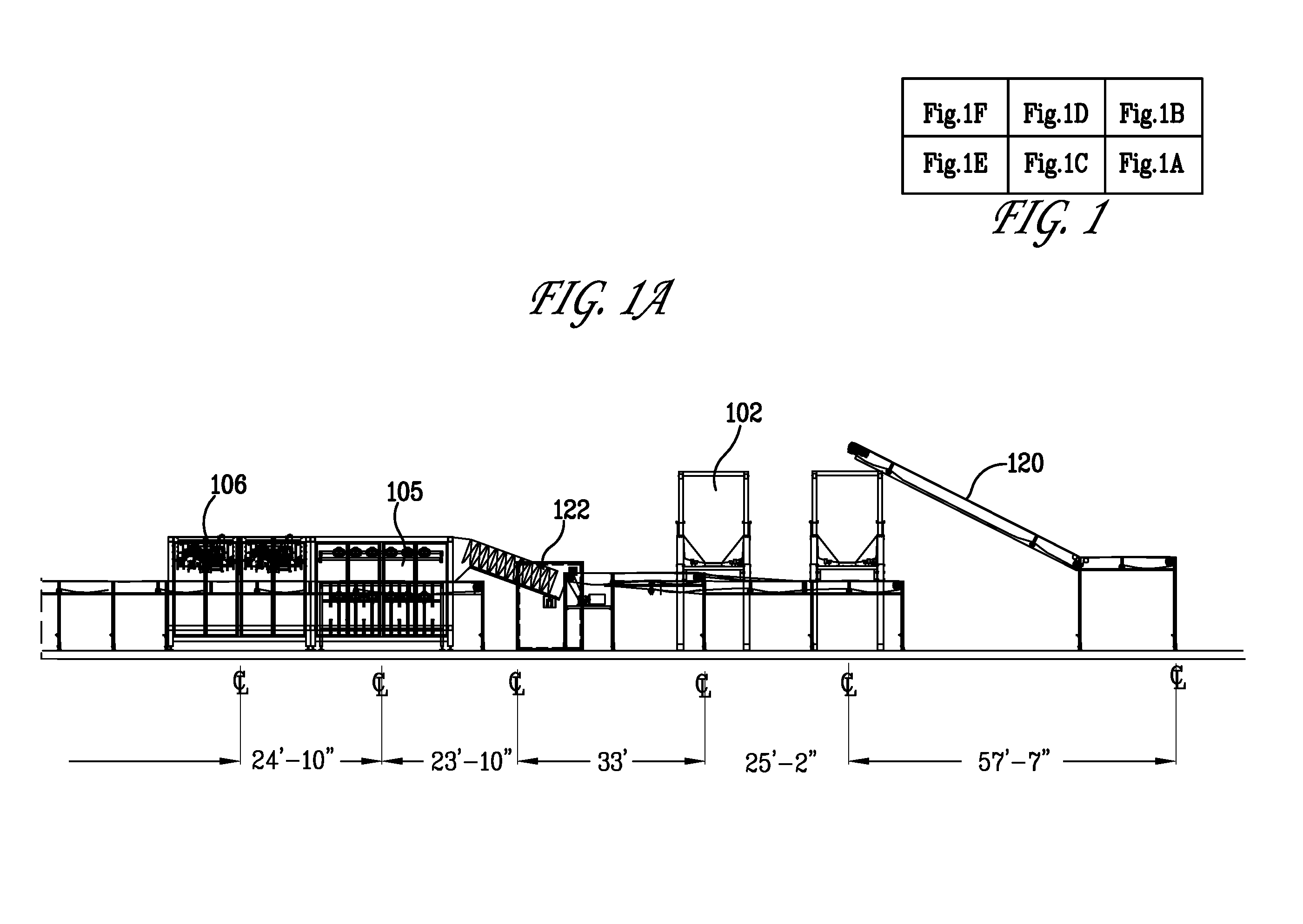

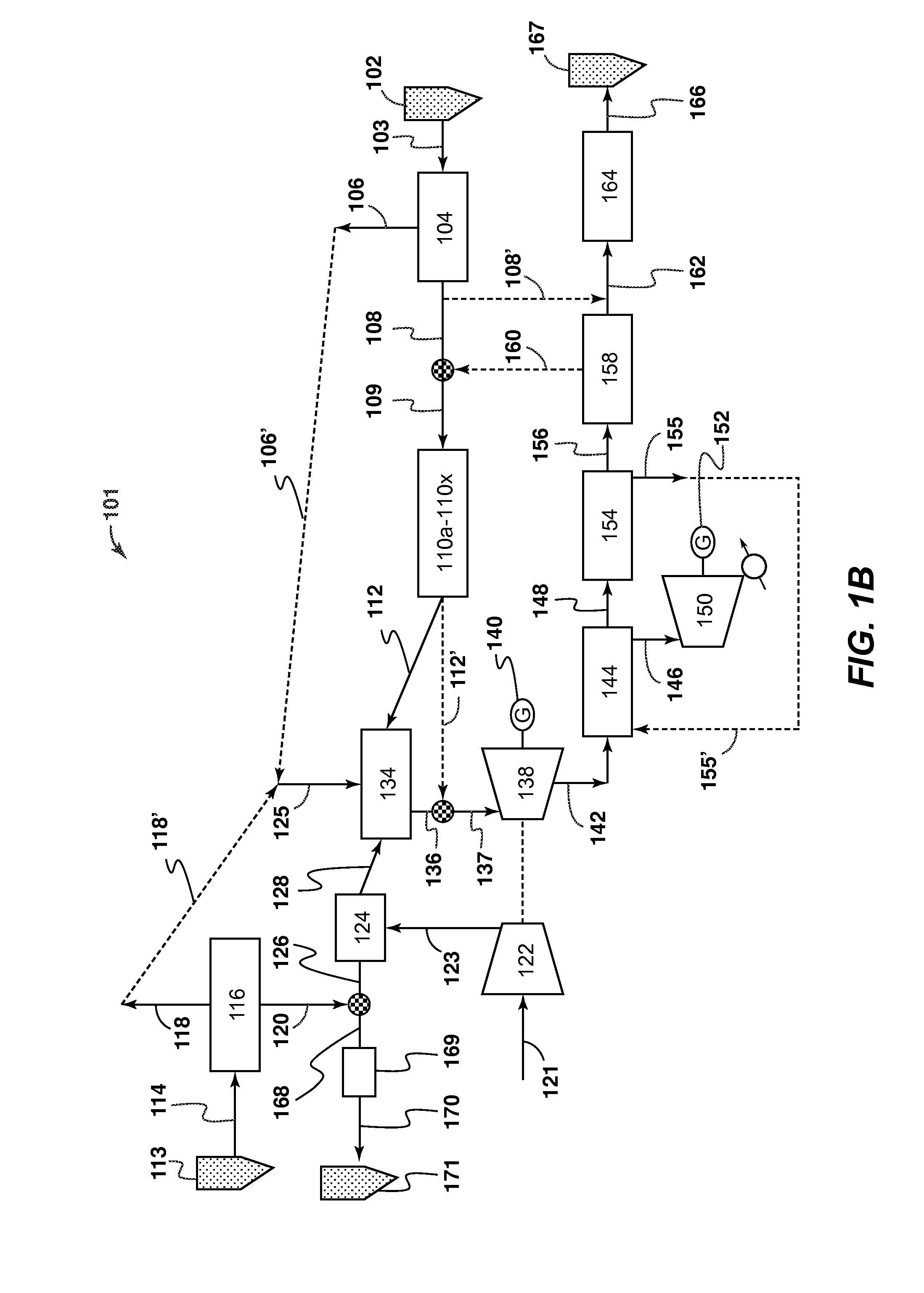

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013613A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A Si-free C-containing film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

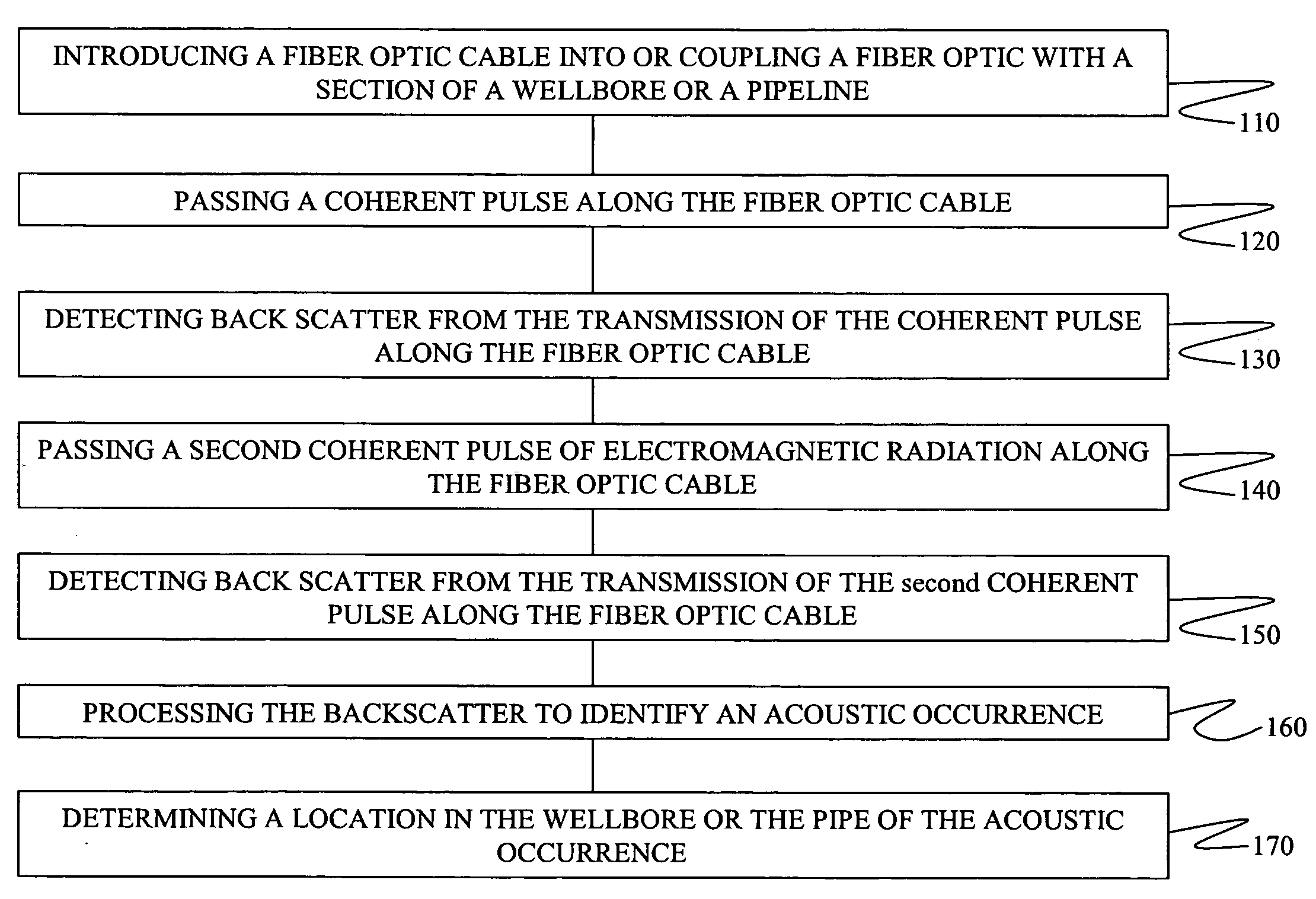

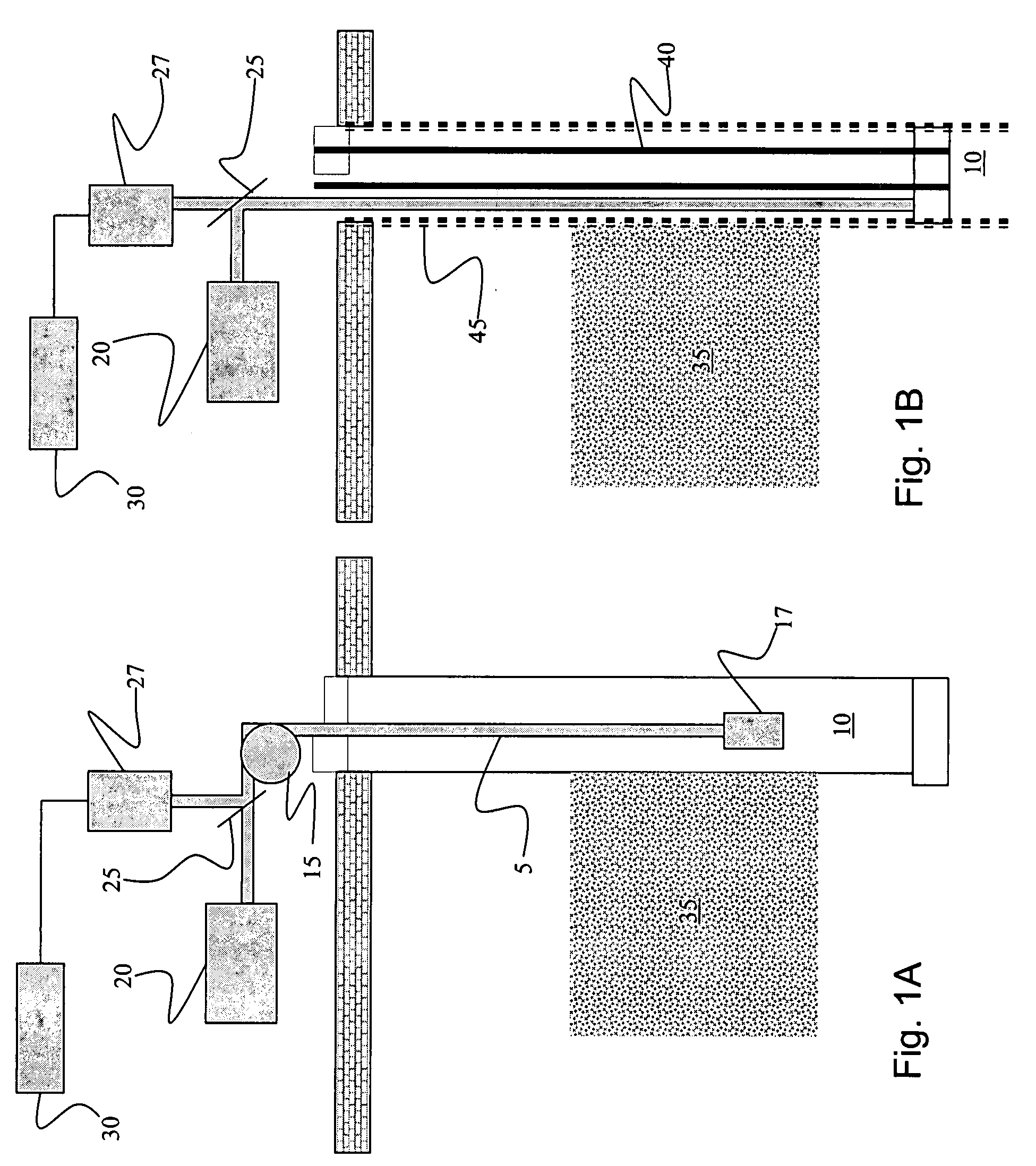

Systems and methods for distributed interferometric acoustic monitoring

This disclosure relates in general to a method and system for monitoring a conduit, a wellbore or a reservoir associated with hydrocarbon production or transportation and / or carbon dioxide sequestration. More specifically, but not by way of limitation, embodiments of the present invention provide for using an optical fiber as a distributed interferometer that may be used to monitor the conduit, wellbore or reservoir. In certain aspects, the distributed interferometric monitoring provides

Owner:SCHLUMBERGER TECH CORP

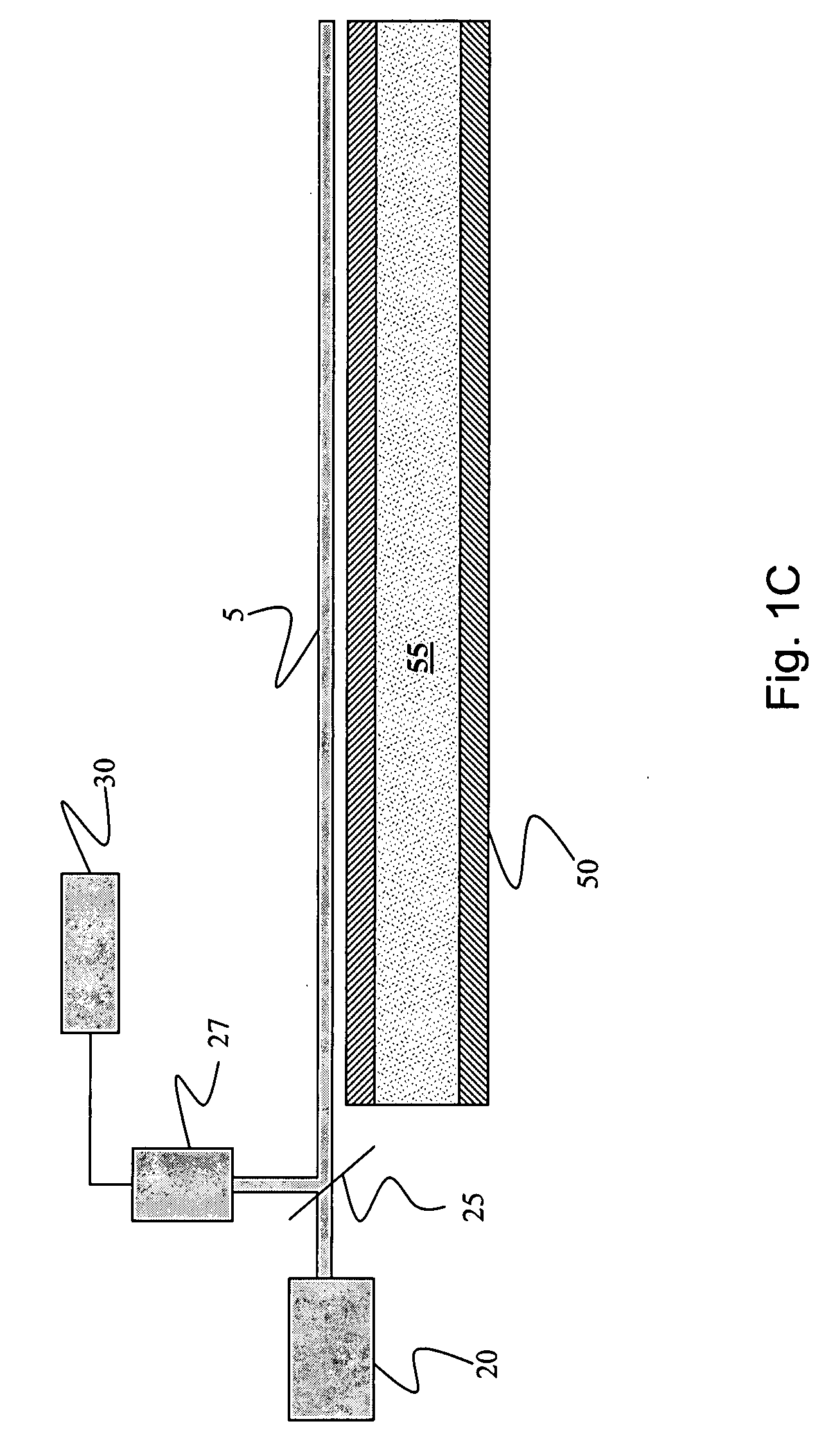

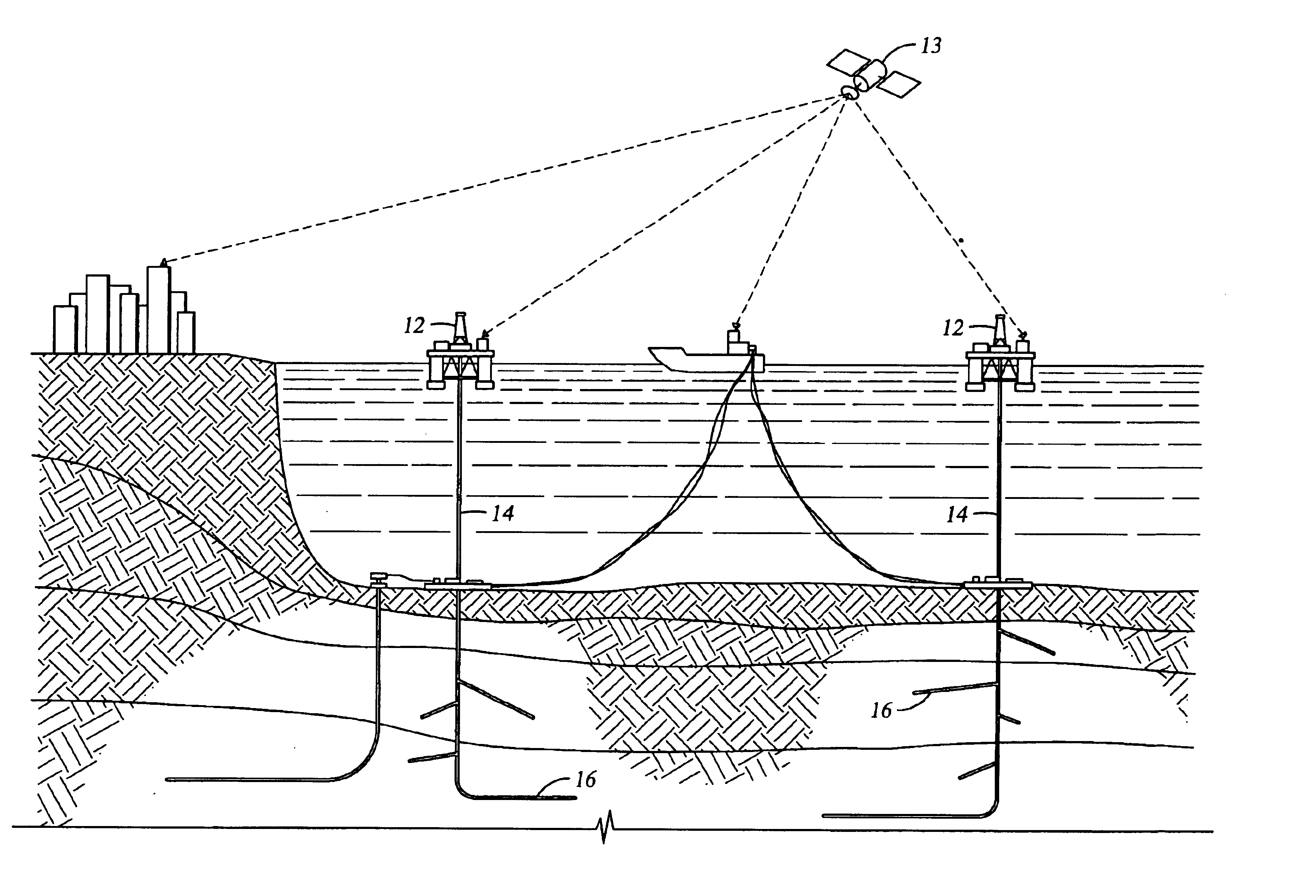

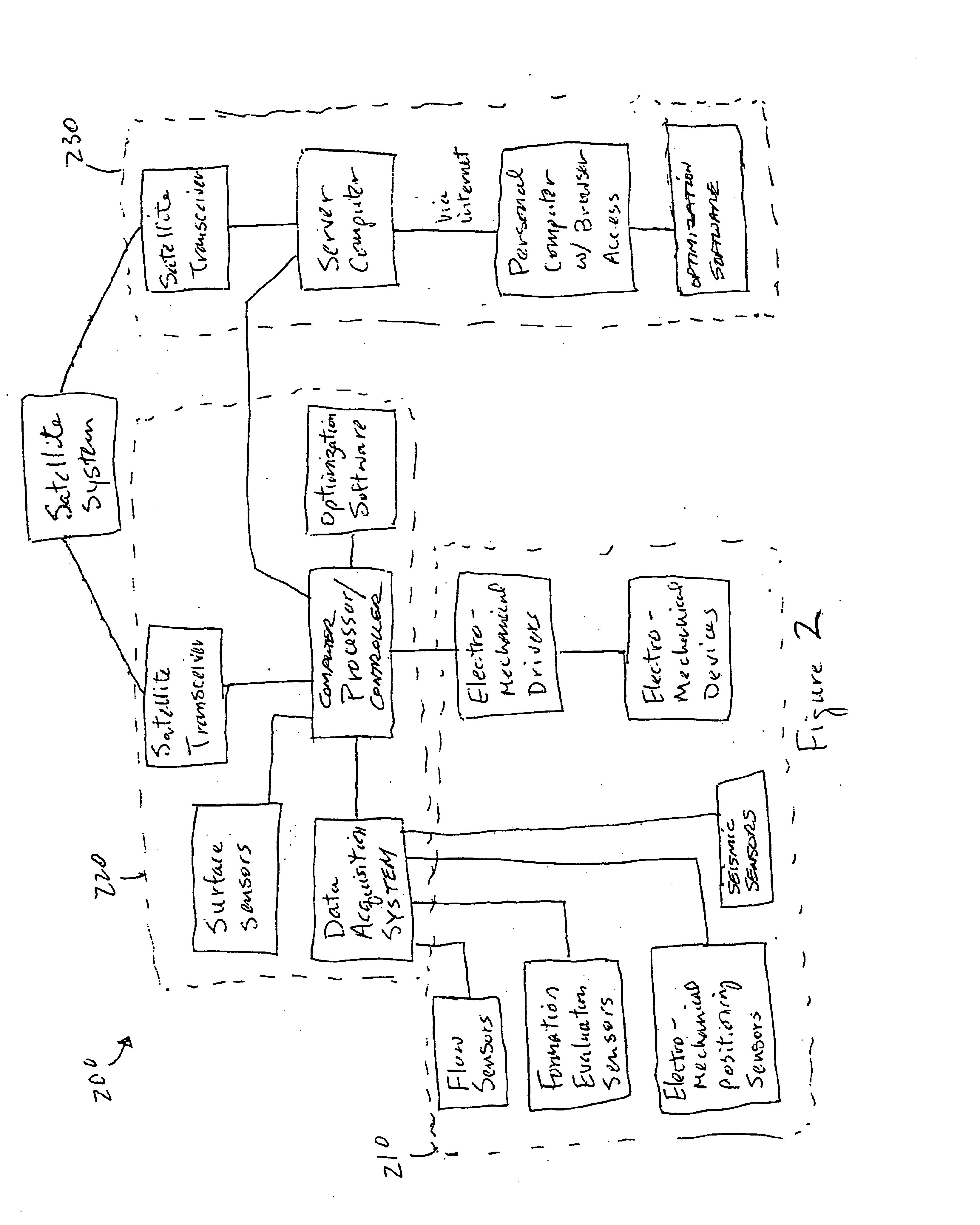

Methods and apparatus for monitoring and controlling oil and gas production wells from a remote location

The invention provides apparatus and methods for monitoring and controlling hydrocarbon production wells and / or injection wells from a remote location. The apparatus for monitoring and controlling one or more hydrocarbon production wells or injection wells from a remote location comprises one or more surface control and data acquisition systems; one or more sensors disposed in communication with the one or more control and data acquisition systems; one or more downhole flow control devices disposed in communication with the one or more control and data acquisition systems; and one or more remote controllers disposed in communication with the one or more control and data acquisition systems. Preferably, the remote controller comprises a computer having an internet access disposed in communication with the one or more control and data acquisition systems through a communication device comprising an internet web site server. The method for monitoring and controlling a downhole hydrocarbon production well or an injection well comprises: transmitting data collected by a downhole sensor module to a control and data acquisition system; evaluating downhole operating conditions and optimizing downhole operating parameters utilizing an optimization software program disposed in communication with the control and data acquisition system; and transmitting signals between the control and data acquisition system system and a remote controller utilizing a satellite communication system, the remote controller comprising a computer and an internet browser control access adapted to display operating conditions and parameters and to accept instructions to change operating parameters.

Owner:WEATHERFORD TECH HLDG LLC

Methods and fluid compositions designed to cause tip screenouts

InactiveUS6837309B2Increase probabilityTreatment is limitedFluid removalDrilling compositionHigh concentrationFiber

In stimulation treatments to increase the production of hydrocarbons from subterranean formations, especially in treatments including hydraulic fracturing followed by gravel packing, desirable short wide fractures are created and filled with proppant by deliberately including in the first fluid / proppant slurry pumped a sufficiently high concentration of a bridging-promoting material, such as fibers, that reduces the mobility of the slurry when it dewaters so that screenout at or near the tip occurs.

Owner:SCHLUMBERGER TECH CORP

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200365391A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

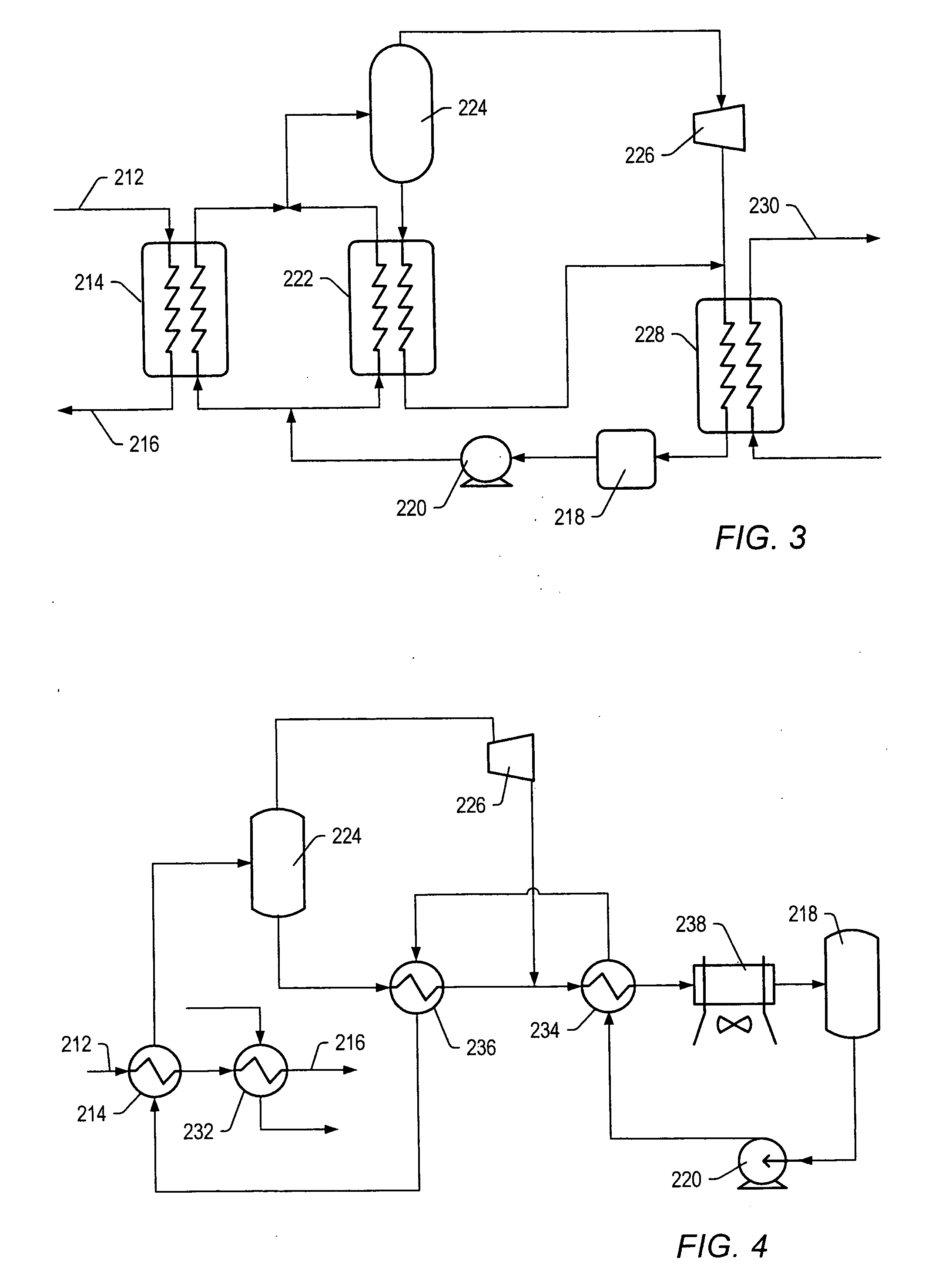

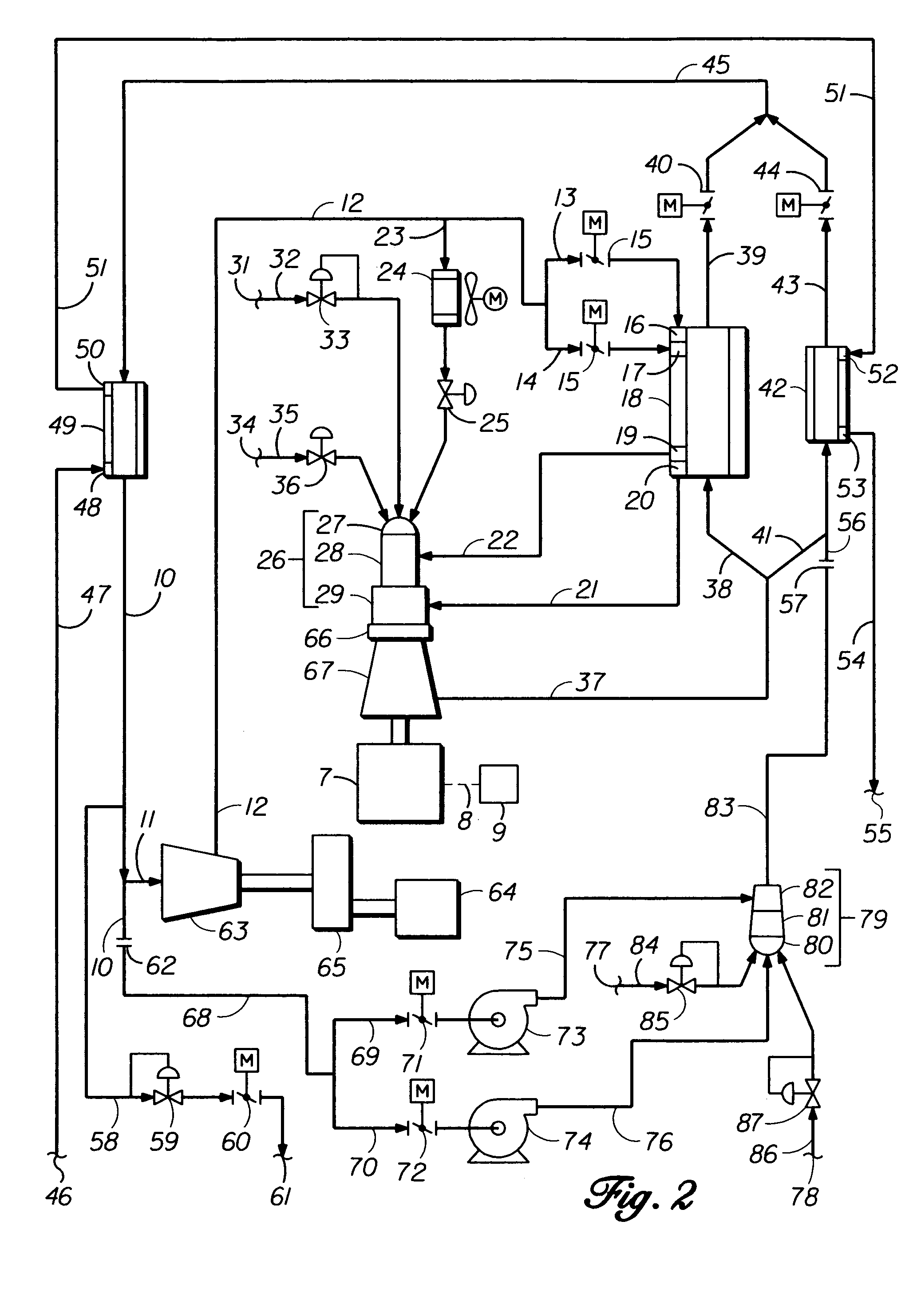

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

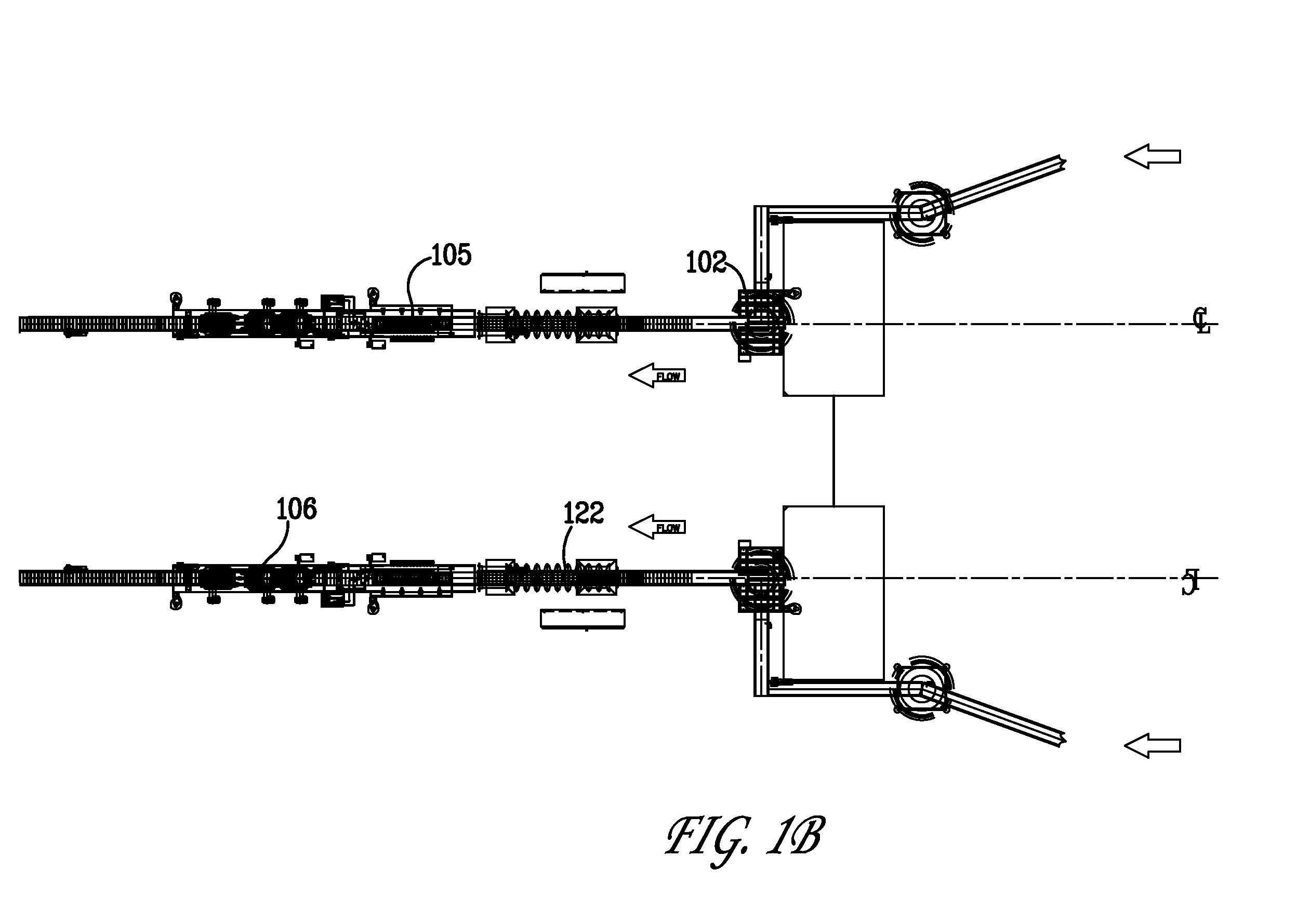

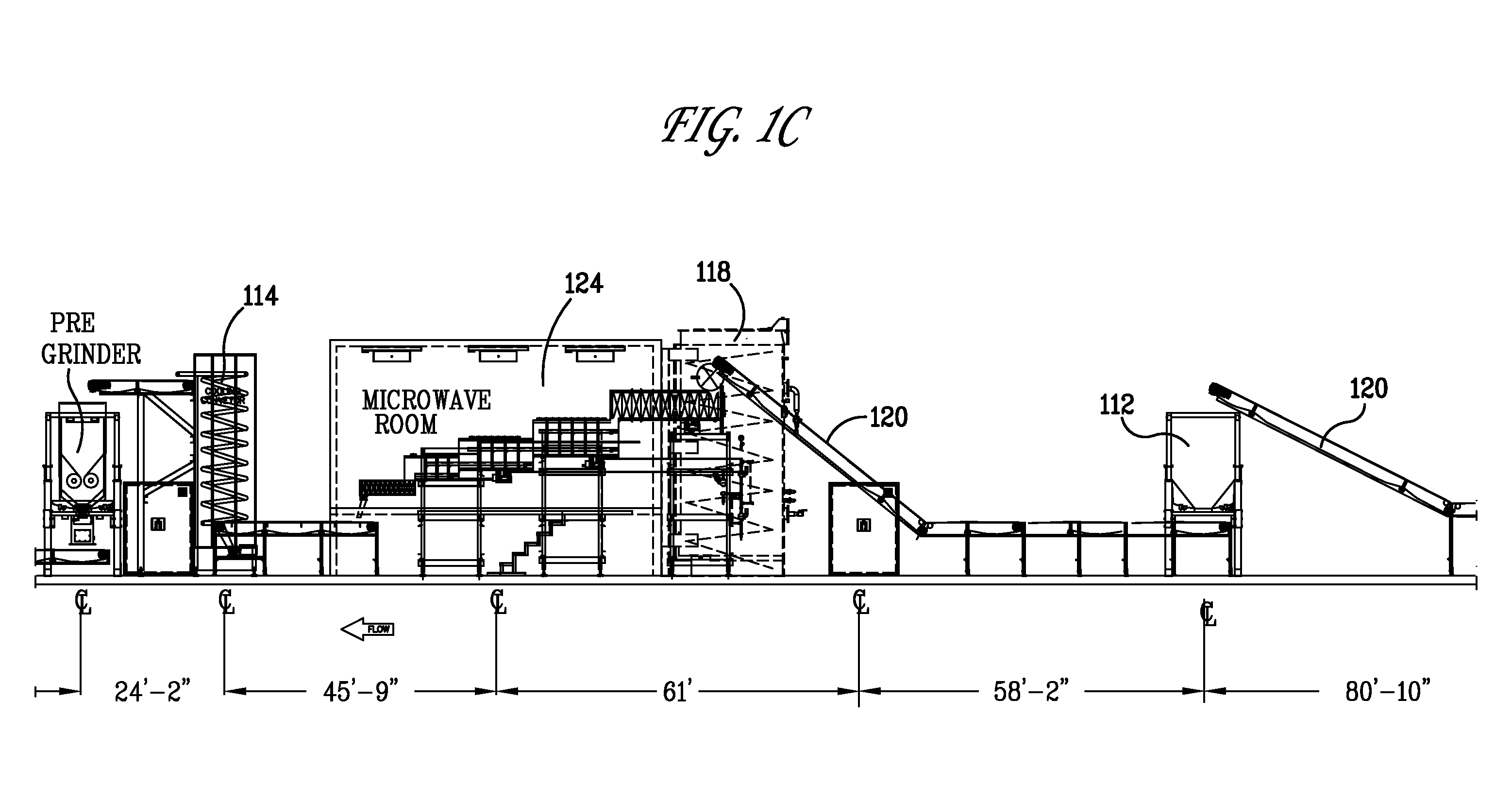

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS20070131591A1Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processHydrocotyle bowlesioidesPetroleum

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

Petroleum Coke Compositions for Catalytic Gasification

InactiveUS20090166588A1Improve efficiencyReduce moisture contentOther chemical processesMixing methodsPtru catalystThermodynamics

Particulate compositions are described comprising an intimate mixture of a petroleum coke, coal and a gasification catalyst, where the gasification catalyst is loaded onto at least the coal for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

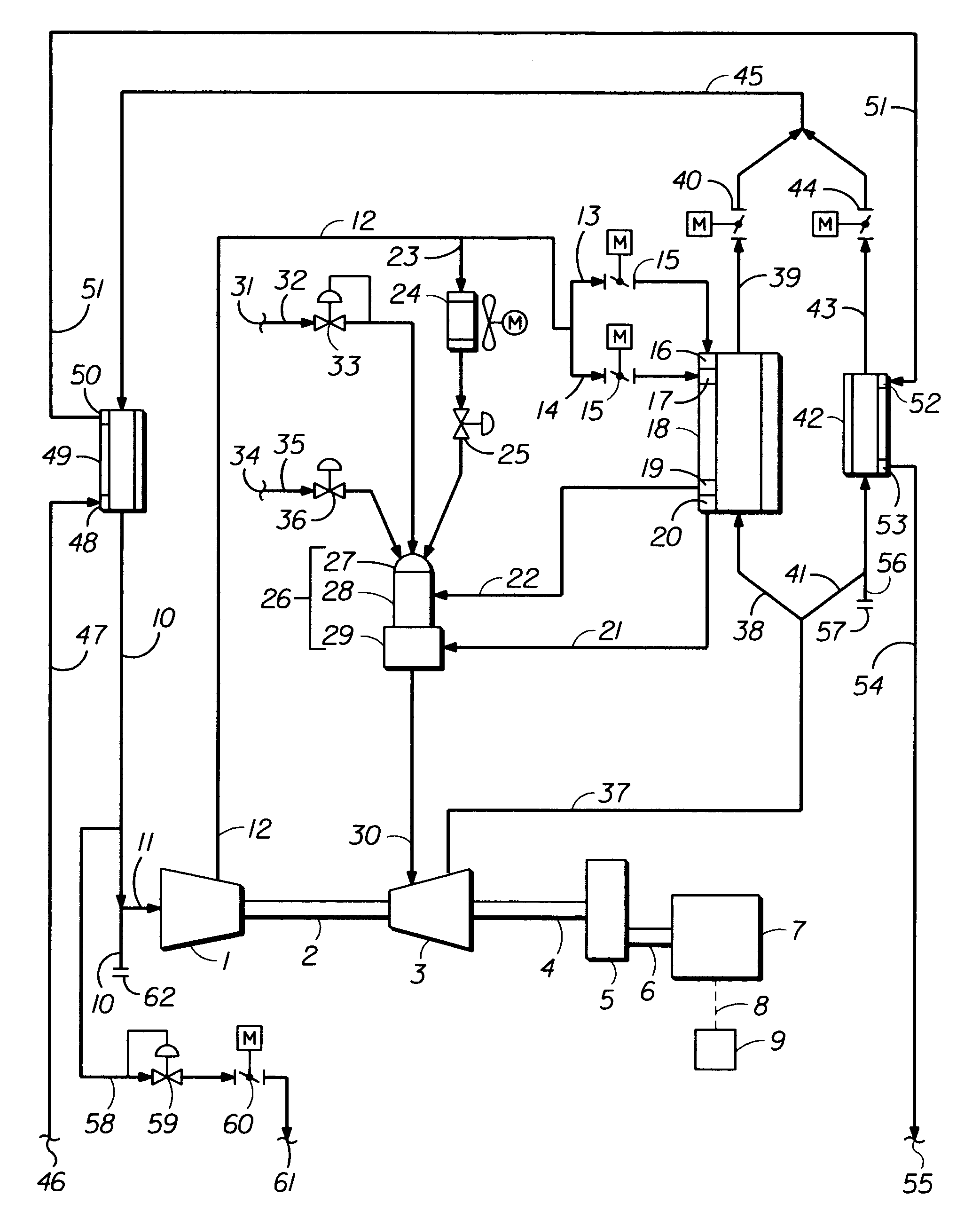

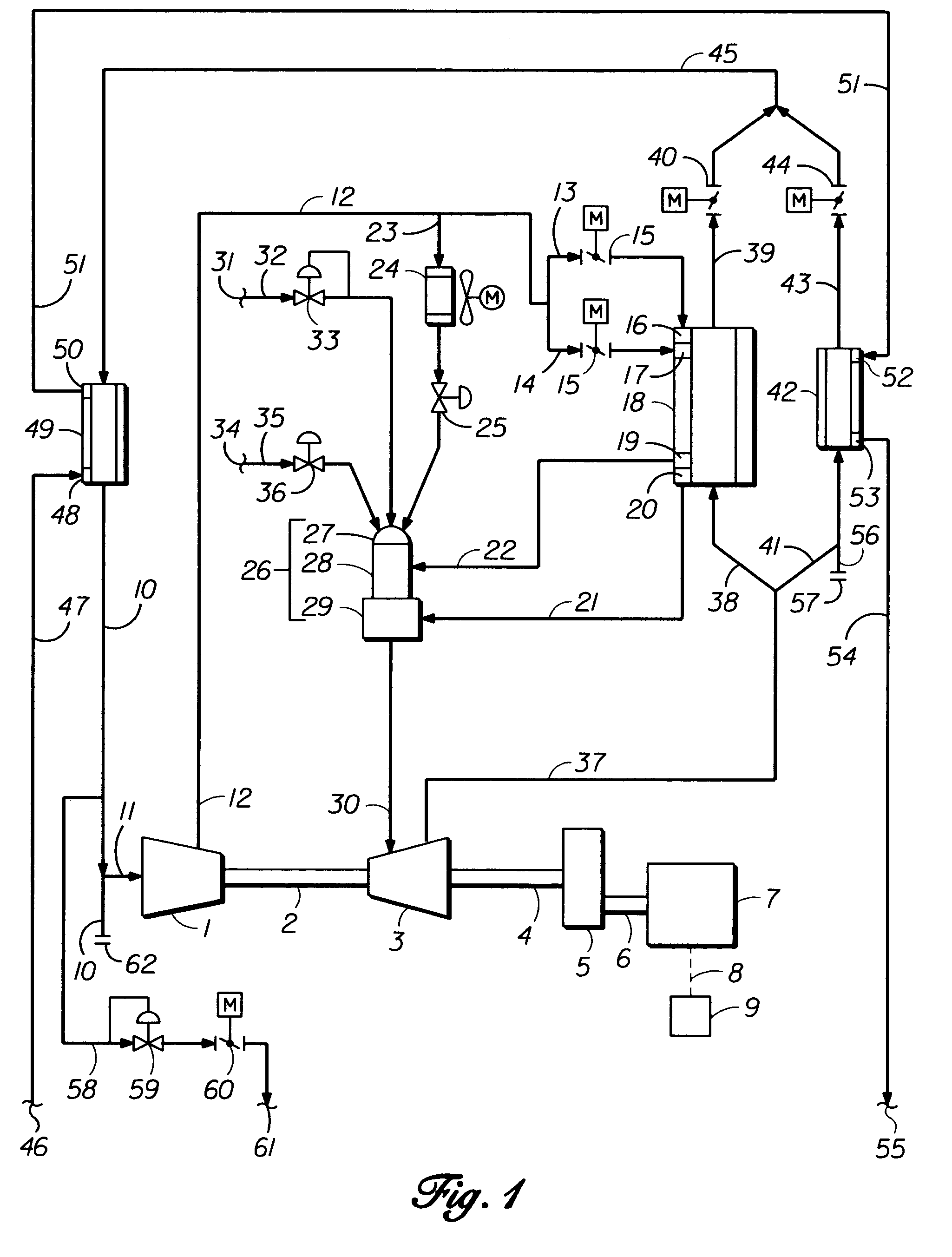

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS7124589B2Improve thermal efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

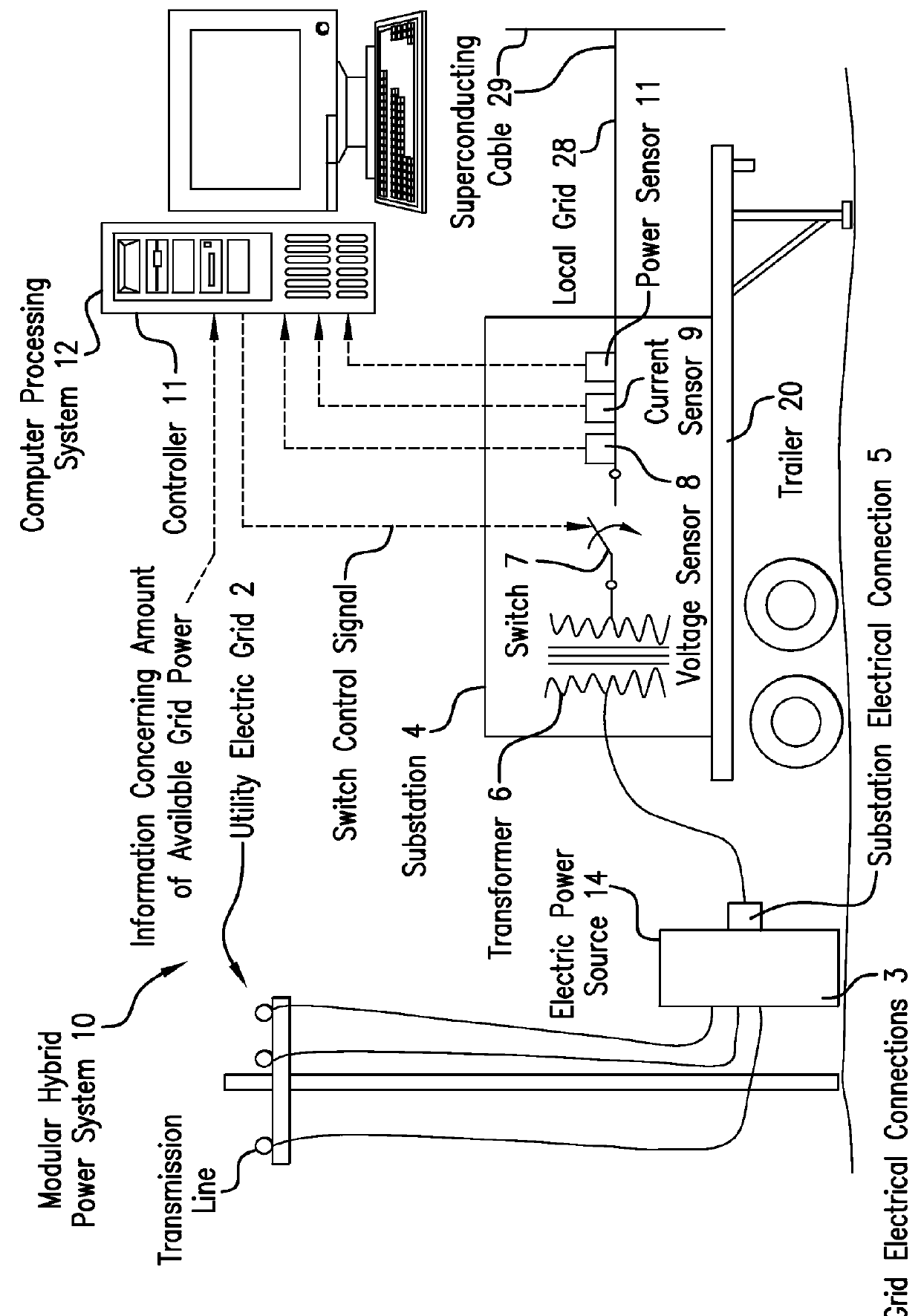

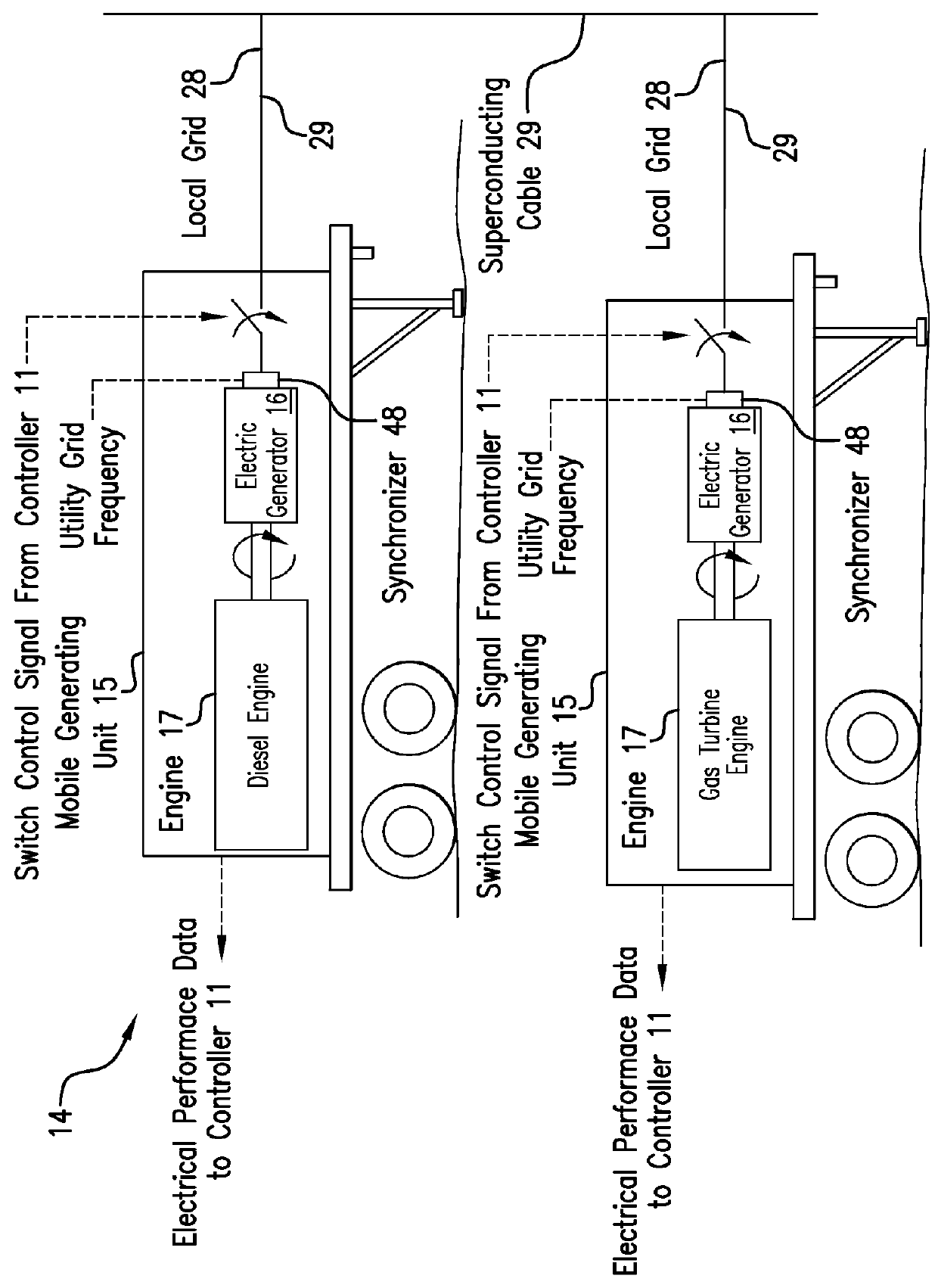

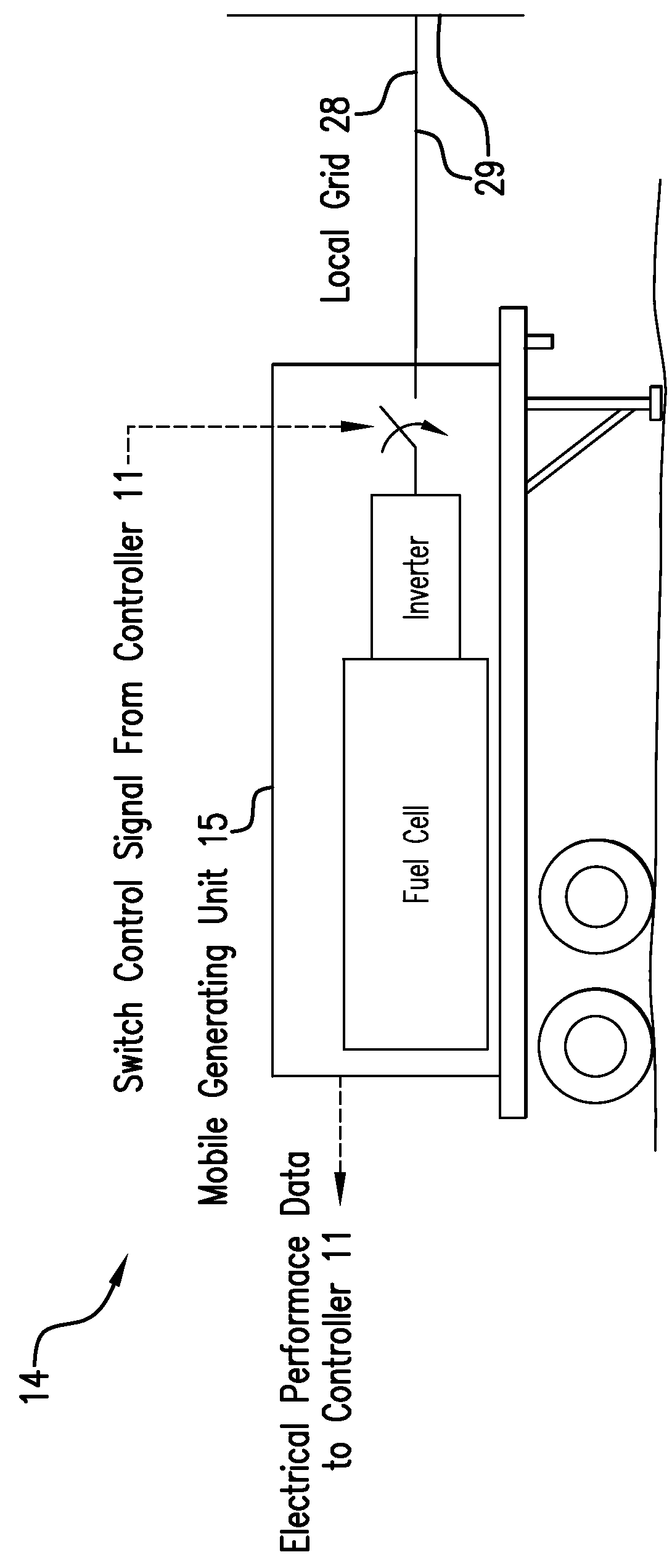

Modular hybrid low emissions power for hydrocarbon extraction

ActiveUS10008880B2Dc network circuit arrangementsElectricity cogenerationElectric power systemModularity

A system for supplying electric power includes: a plurality of electric motors coupled to well treatment pumps; a mobile substation that receives power from a utility electric grid; a plurality of mobile electric power generating units; a controller configured to (i) receive a total required flow rate of the liquid; (ii) calculate a total amount of electric power required to achieve the required total flow rate; (iii) receive an amount of power available from the utility electric grid; (iv) direct the substation to provide electric power to the plurality of electric motors; and (v), direct one or more electric power generating units in the plurality of electric power generating units to provide electric power to the plurality of electric motors according to a priority order to meet the total amount of electric power, if the required amount of electric power exceeds the amount of power available from the utility grid.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

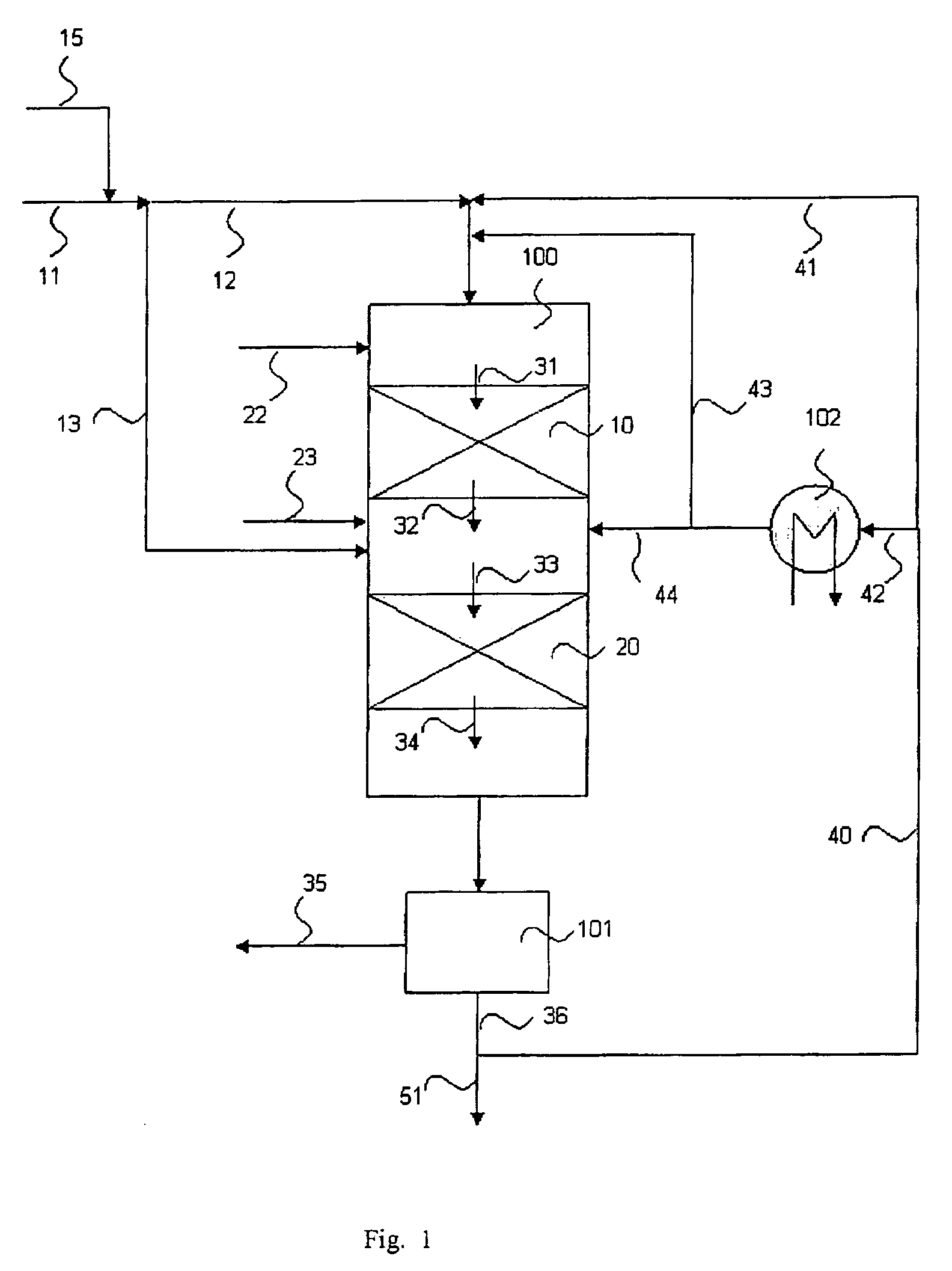

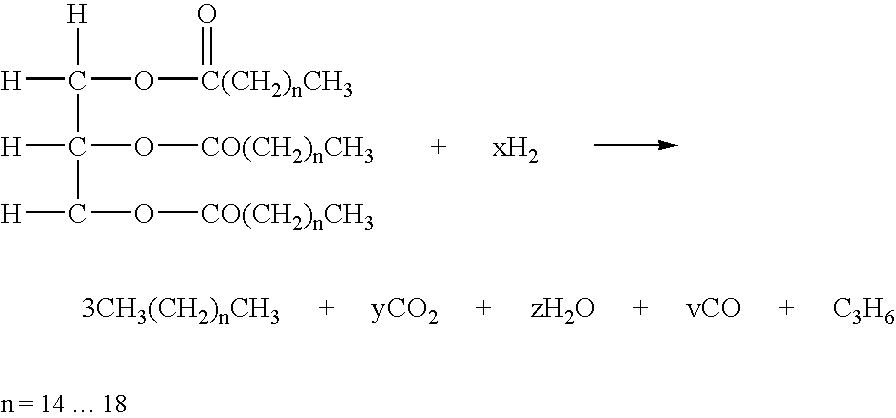

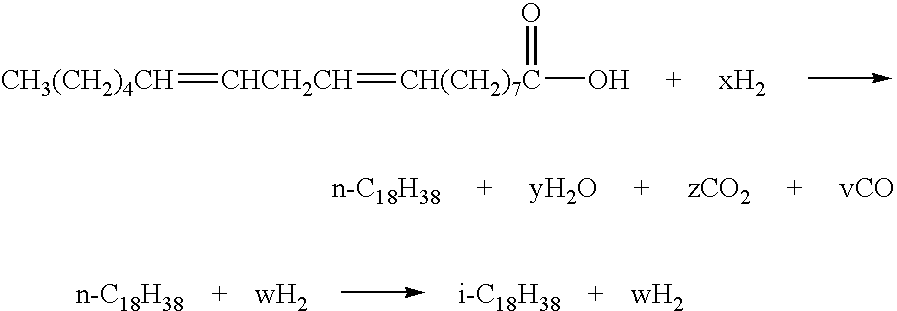

Process for the manufacture of diesel range hydro-carbons

ActiveUS20070006523A1Improve low temperature performanceBig ratioBiofuelsLiquid carbonaceous fuelsChemical industryAlkane

The invention relates to chemical industry and is directed to the production of middle distillate from vegetable oils. In the first step of the production method, the fatty acids or triglycerides of said vegetable oils are hydrogenated to give n-paraffins, and in the second step, the n-paraffins are catalytically converted to paraffins with branched chains. Using this process having two steps, a high-quality middle distillate useful as a component of diesel fuels without any particular specifications may be produced.

Owner:NESTE OIL OY

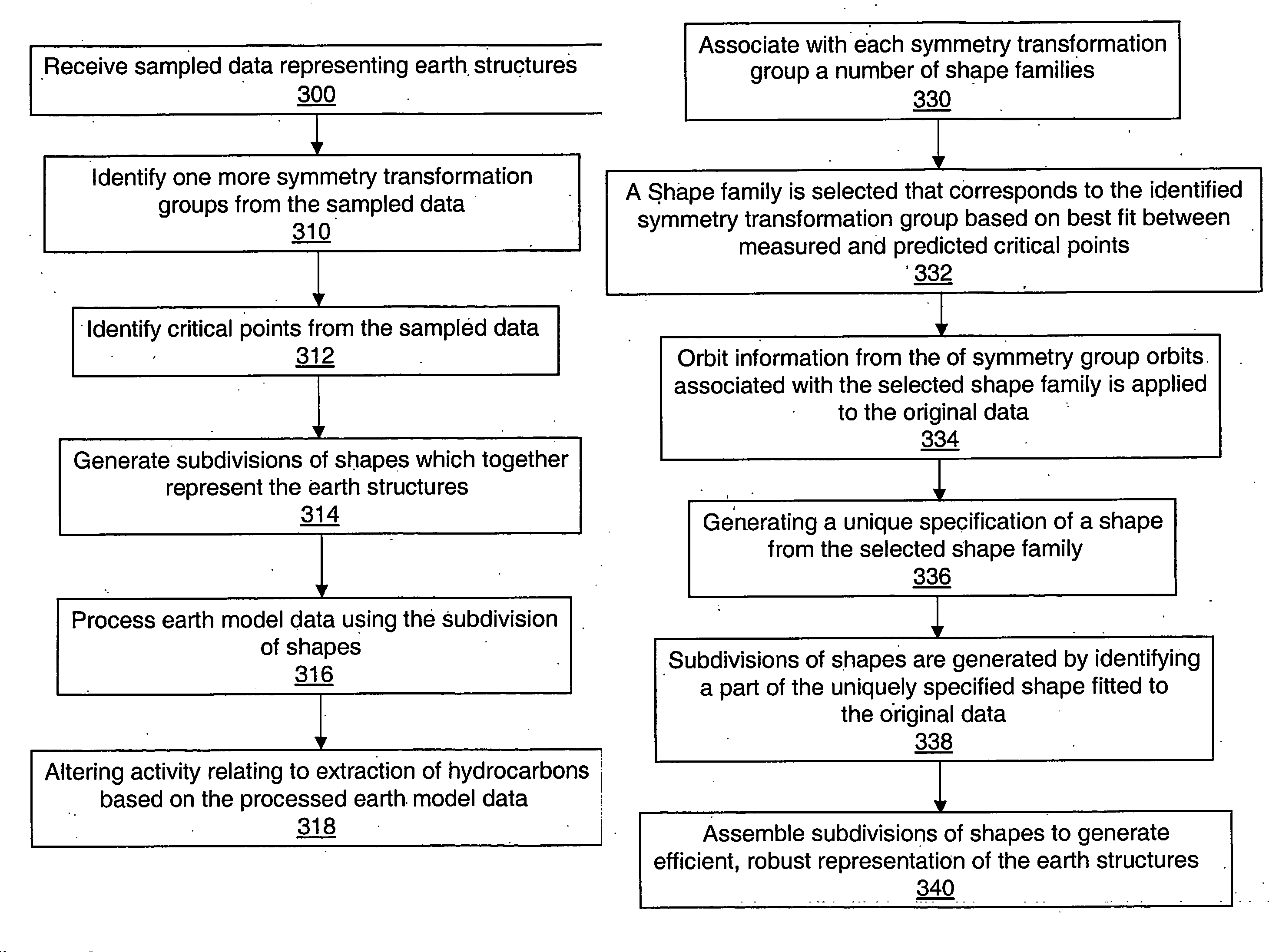

System and method for representing and processing and modeling subterranean surfaces

InactiveUS20060235666A1Enhance memoryImprove efficiencyGeological measurementsAnalogue processes for specific applicationsCrucial pointHydrocotyle bowlesioides

Methods and systems are disclosed for processing data used for hydrocarbon extraction from the earth. Symmetry transformation groups are identified from sampled earth structure data. A set of critical points is identified from the sampled data. Using the symmetry groups and the critical points, a plurality of subdivisions of shapes is generated, which together represent the original earth structures. The symmetry groups correspond to a plurality of shape families, each of which includes a set of predicted critical points. The subdivisions are preferably generated such that a shape family is selected according to a best fit between the critical points from the sampled data and the predicted critical points of the selected shape family.

Owner:SCHLUMBERGER TECH CORP

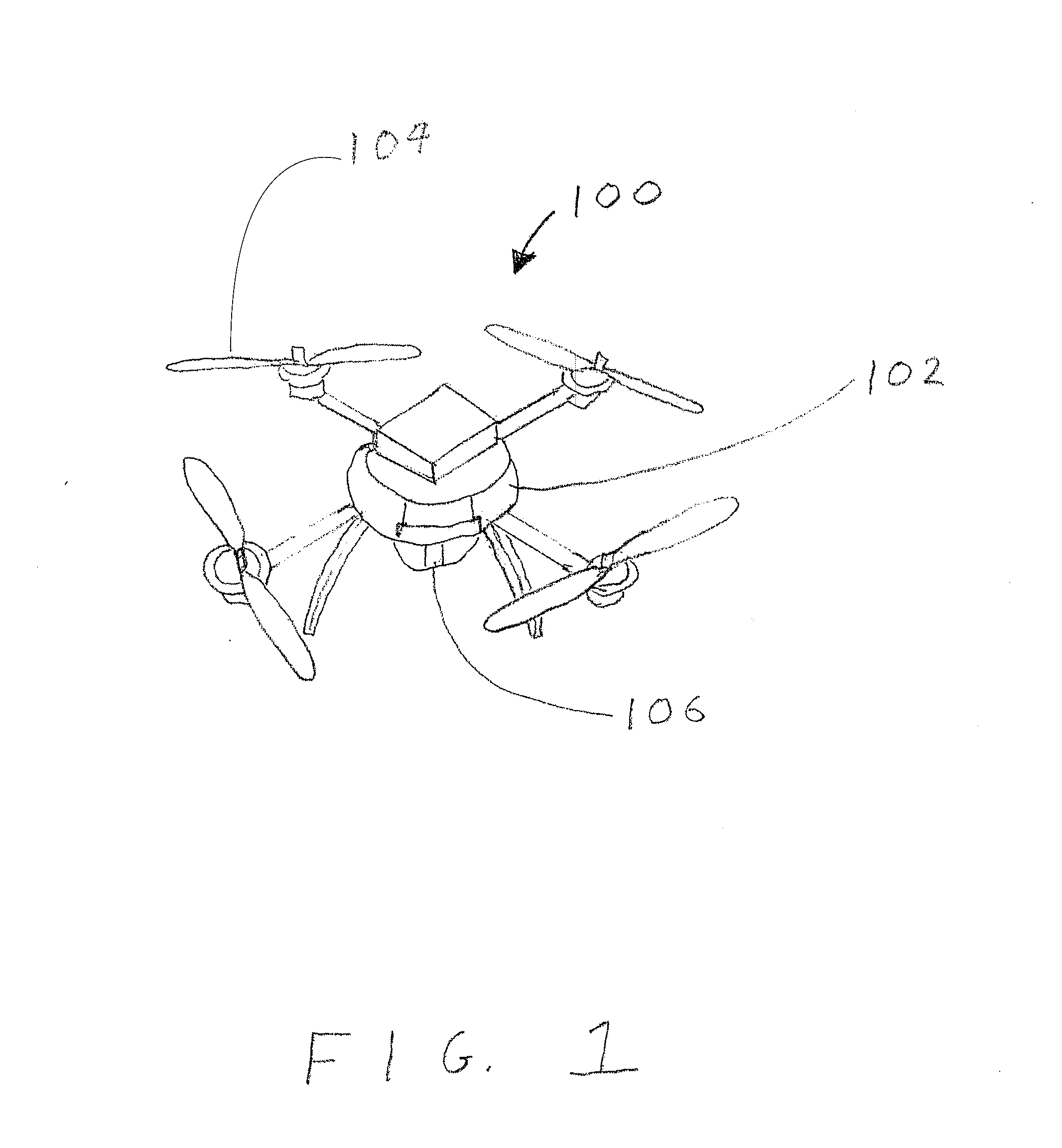

Systems, Methods and Devices for Collecting Data at Remote Oil and Natural Gas Sites

InactiveUS20160214715A1Avoid flyingAccurately determinedAircraft componentsUnmanned aerial vehiclesParticulatesHydrocotyle bowlesioides

Systems, methods and devices are provided for detecting airborne particulates and / or gases at remote oil and natural gas sites, such as wells, and / or processing and refinery plants. One such system comprises an unmanned aerial vehicle (UAV), such as a drone aircraft, configured for aerial dispatch to the remote site and wireless connection to an external processor, cloud apparatus or the like. The UAV includes one or more on-board sensors configured to detect airborne particulates or gases, such as methane gas, hydrogen sulfide, hydrocarbons, weather conditions, ground-based elements or compounds or the like. The on-board sensors may comprise light transmitters, such as lasers, configured for transmitting light or laser pulses into the ambient environment around the remote site and detecting backscatter to detect the concentration and / or velocity vector(s) of the airborne particulates or gases. The UAV is further configured to wirelessly transmit data associated with the airborne particulates or gases to the external processor or cloud apparatus in real-time.

Owner:OIL & GAS IT LLC

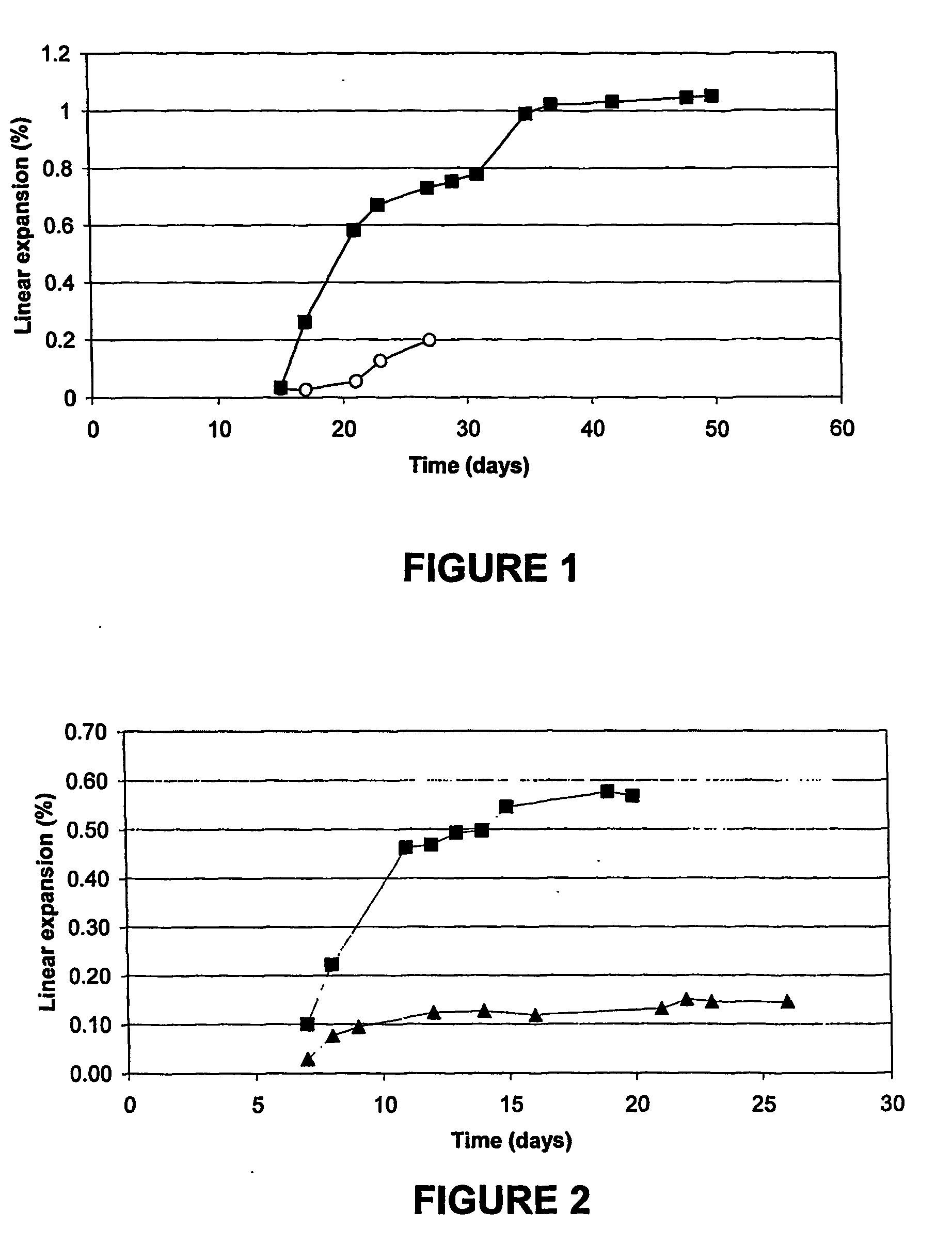

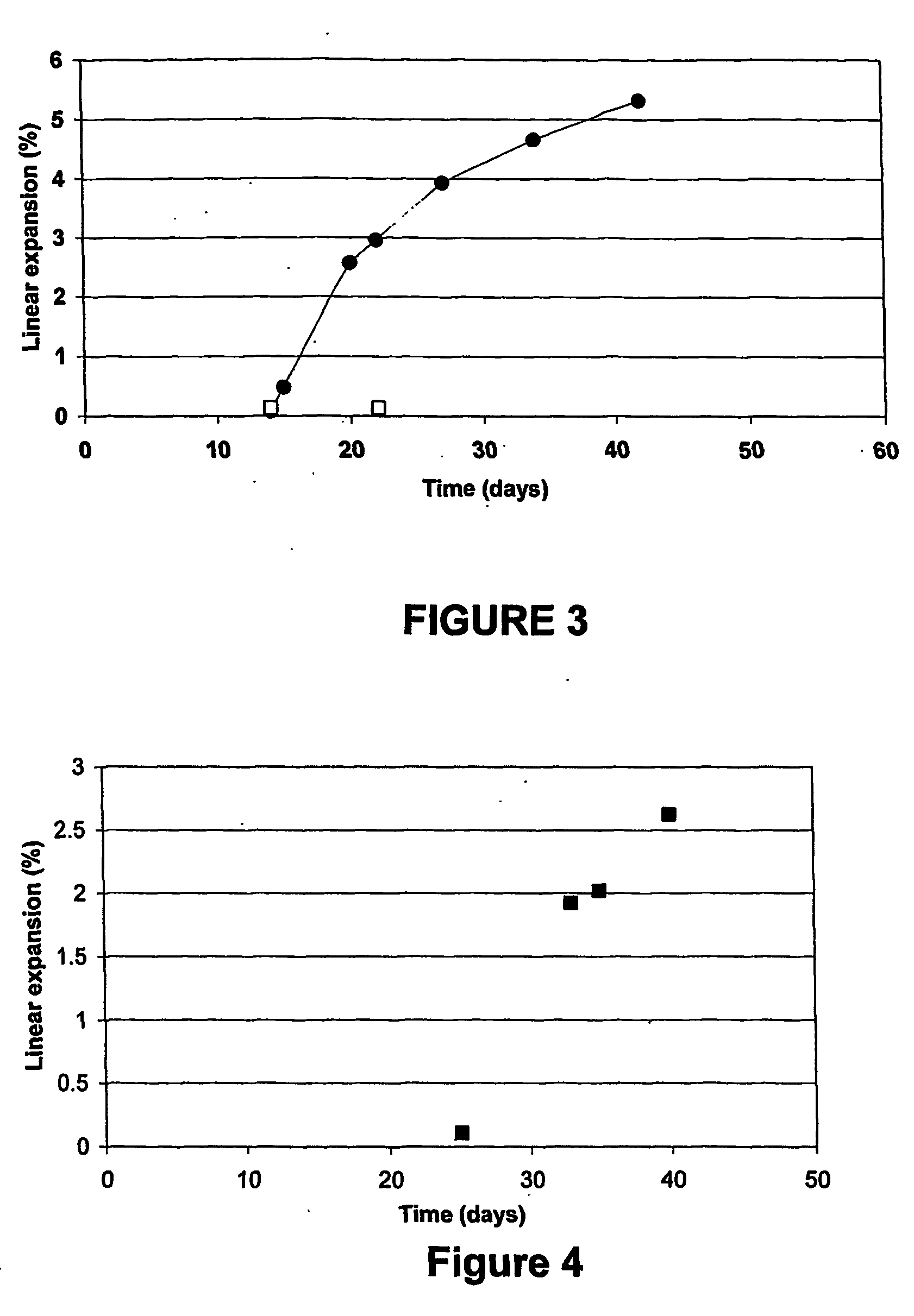

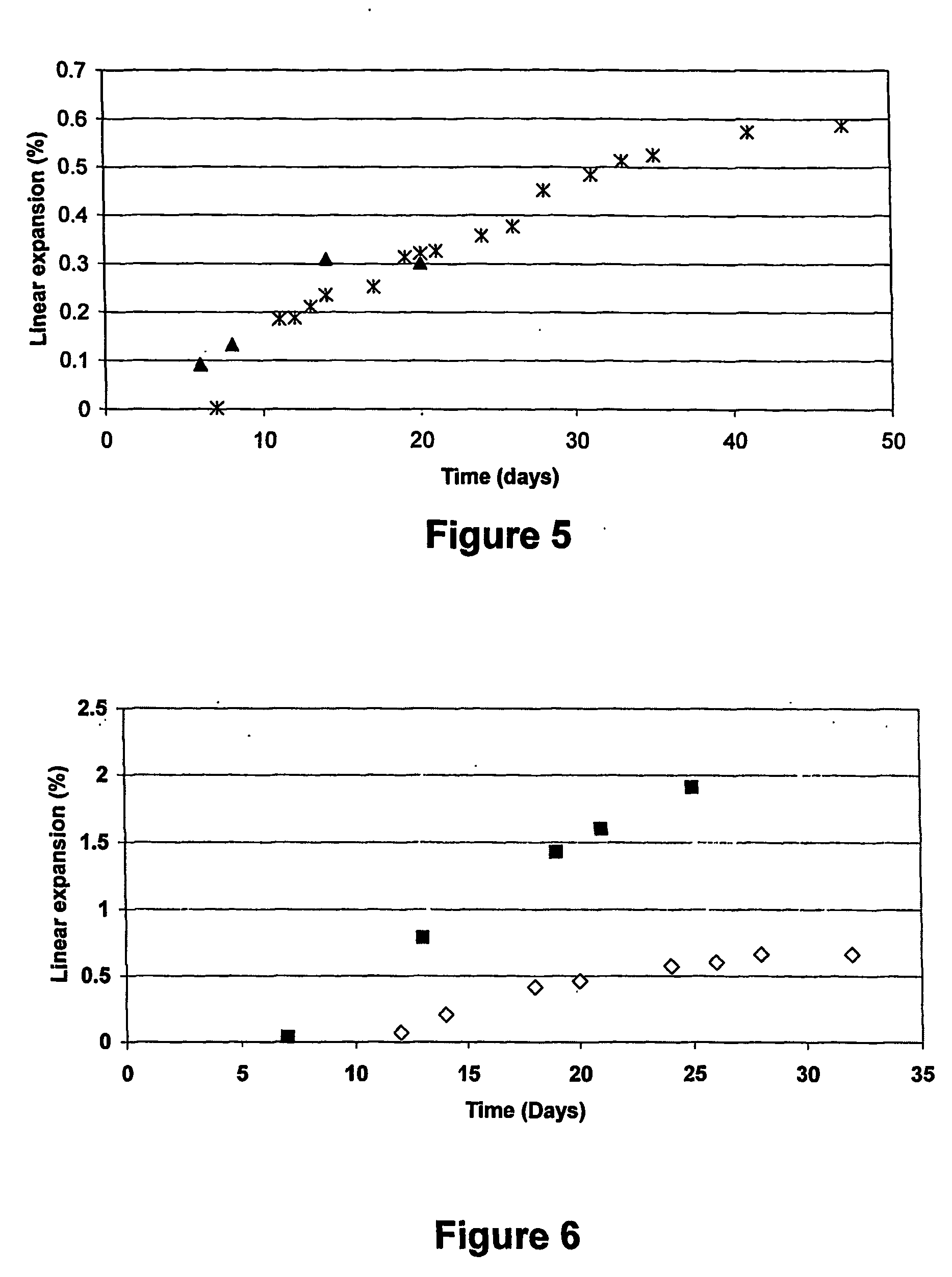

Self adaptive cement systems

InactiveUS20070137528A1Avoid seizuresInhibit migrationSolid waste managementDrilling compositionSelf-healingChemical products

A self-adaptive cement system includes cement, water and at least one additive that reacts or and expands in contact with oil and gas. Several chemical products have been identified including rubber alkylstyrene, polynorbornene, resins such precrosslinked substituted vinyl acrylate copolymers and diatomaceous earth. These additives have the effect of making the cement self-healing in the event of physical failure or damage such as micro-annuli. The self healing property is produced by the contact with subterranean hydrocarbon fluids, the potential repair mechanism is thus activated if and when needed in case of start of loss of zonal isolation. In another embodiment, the expansion is deliberately induced by pumping a hydrocarbon fluid in the vicinity of the set cement.

Owner:SCHLUMBERGER TECH CORP

Process for converting triglycerides to hydrocarbons

ActiveUS20070175795A1High reaction yieldIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBoiling pointHydrocotyle bowlesioides

Processes for the conversion of hydrocarbons boiling in the temperature range of from about 80° F. to about 1000° F. to diesel boiling range hydrocarbons, and processes for increasing the cetane number and amount of n-C17 hydrocarbon products in such processes. Diesel boiling range hydrocarbons may be produced by contacting a hydrocarbon boiling in the above-mentioned boiling range with a triglyceride-containing compound to form a mixture, and then contacting the mixture with a hydrotreating catalyst under suitable reaction conditions.

Owner:PHILLIPS 66 CO

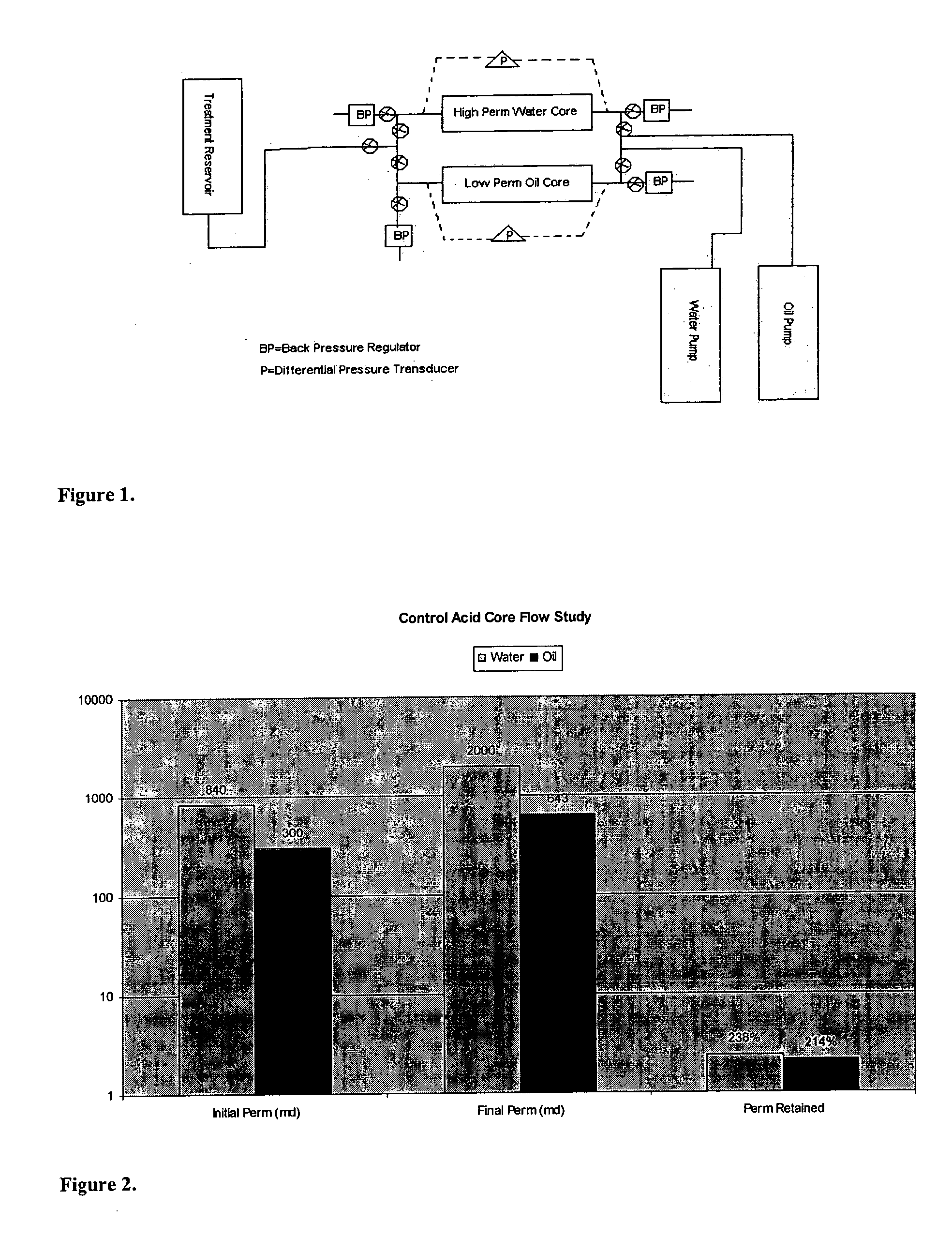

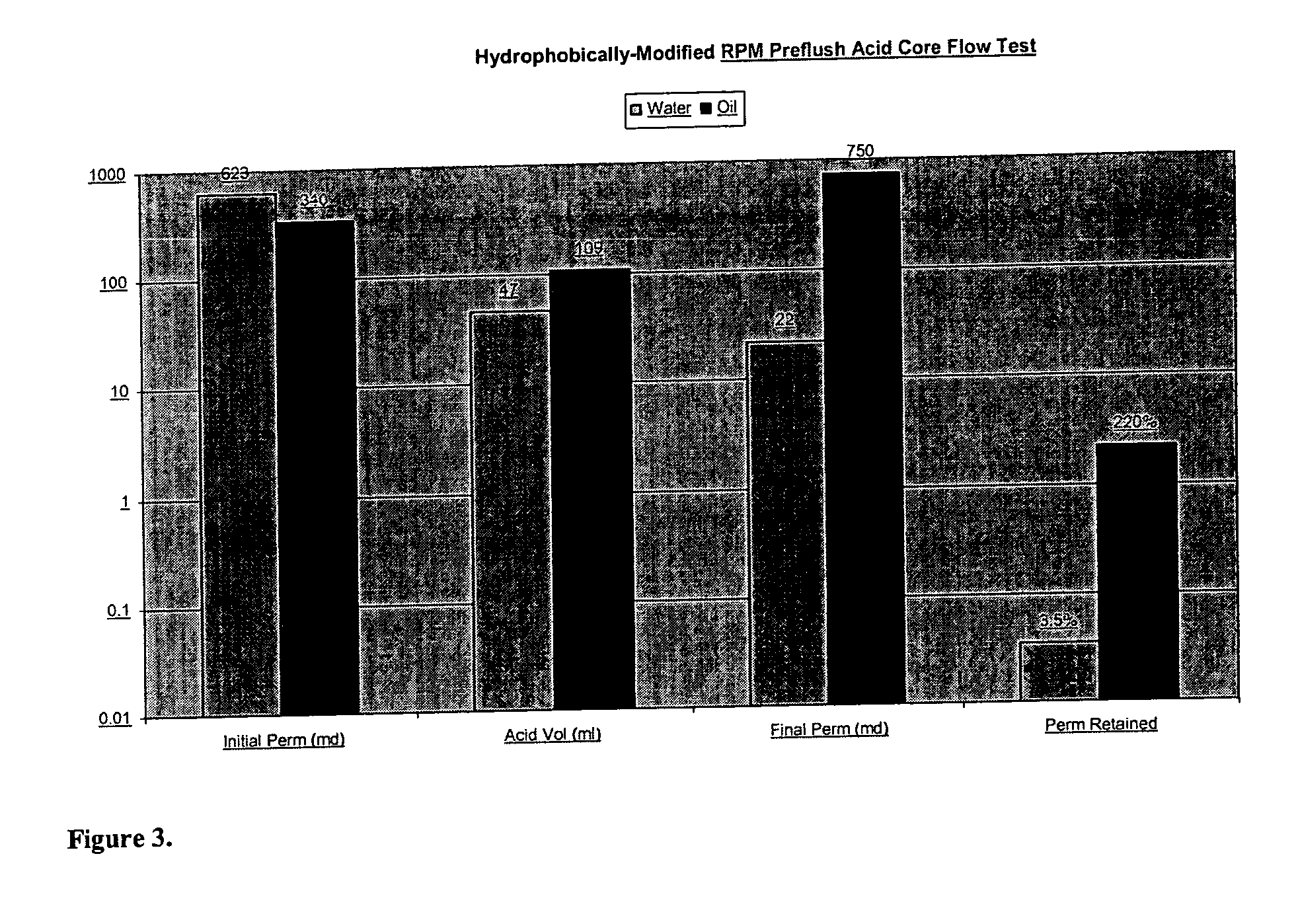

Methods of reducing water permeability for acidizing a subterranean formation

InactiveUS20050000694A1Reducing and precluding production of waterEliminate needFluid removalFlushingHydrophilic polymersHydrocotyle bowlesioides

The present invention provides a method of stimulating a subterranean formation penetrated by a well. The formation has a water-bearing section and a hydrocarbon-bearing section. The method includes the steps of: (a) introducing into the formation an aqueous treatment fluid containing a hydrophobically-modified relative permeability modifier, and (b) introducing an acidizing treatment fluid into the formation. The hydrophobically-modified RPM can be formed and introduced into the formation in several ways. For example, the hydrophobically-modified RPM can be the reaction product of a hydrophilic polymer and a hydrophobic compound that are capable of reacting with each other. The hydrophilic polymer is a polymer containing reactive amino groups in the polymer backbone or as pendant groups, which are capable of reacting with a hydrophobic alkyl halide compound. The hydrophobically-modified RPM can include, for example, a polymer of DMAEMA quaternized with an alkyl halide, wherein the alkyl halide has an alkyl chain length of 6 to 22 carbons.

Owner:HALLIBURTON ENERGY SERVICES INC

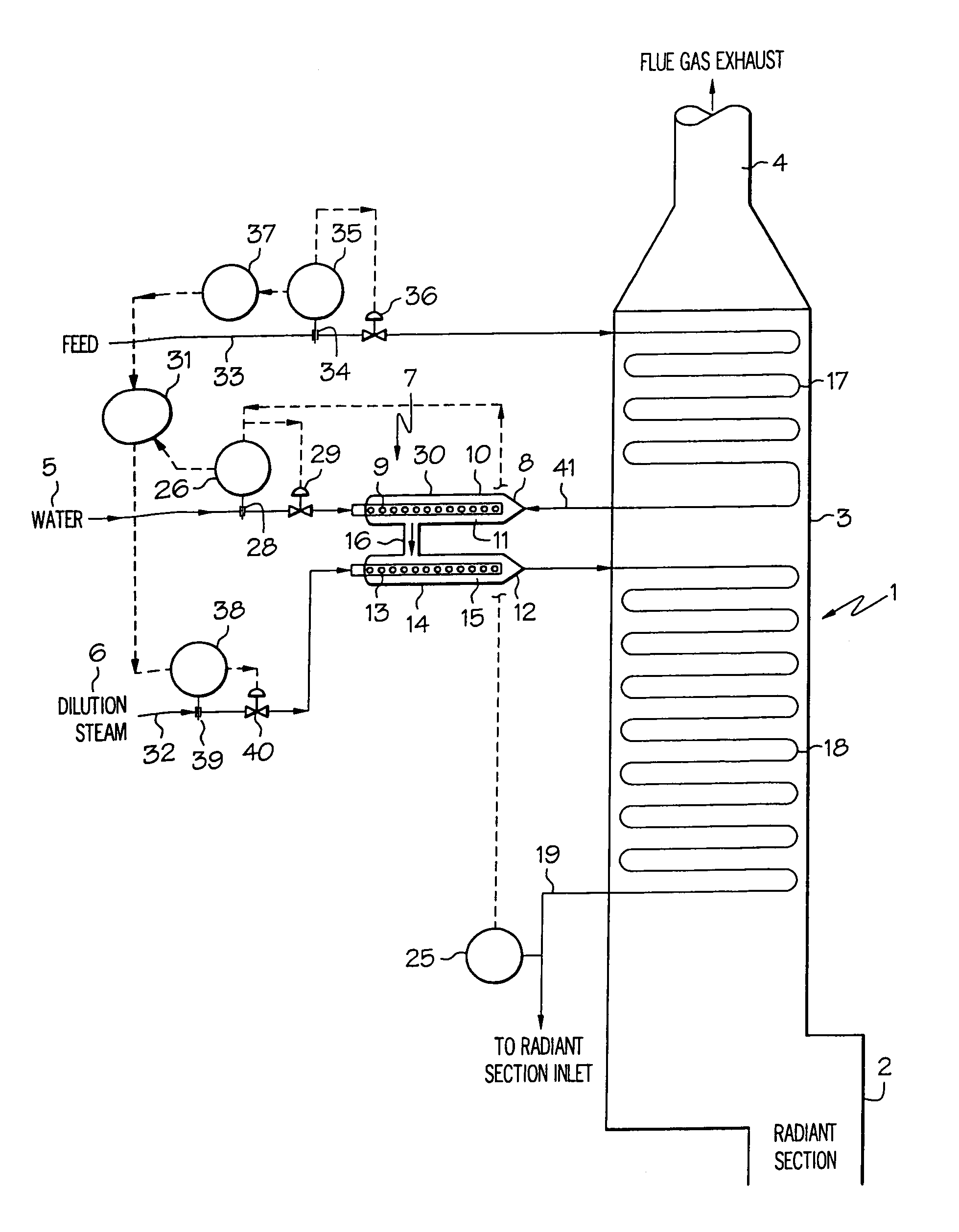

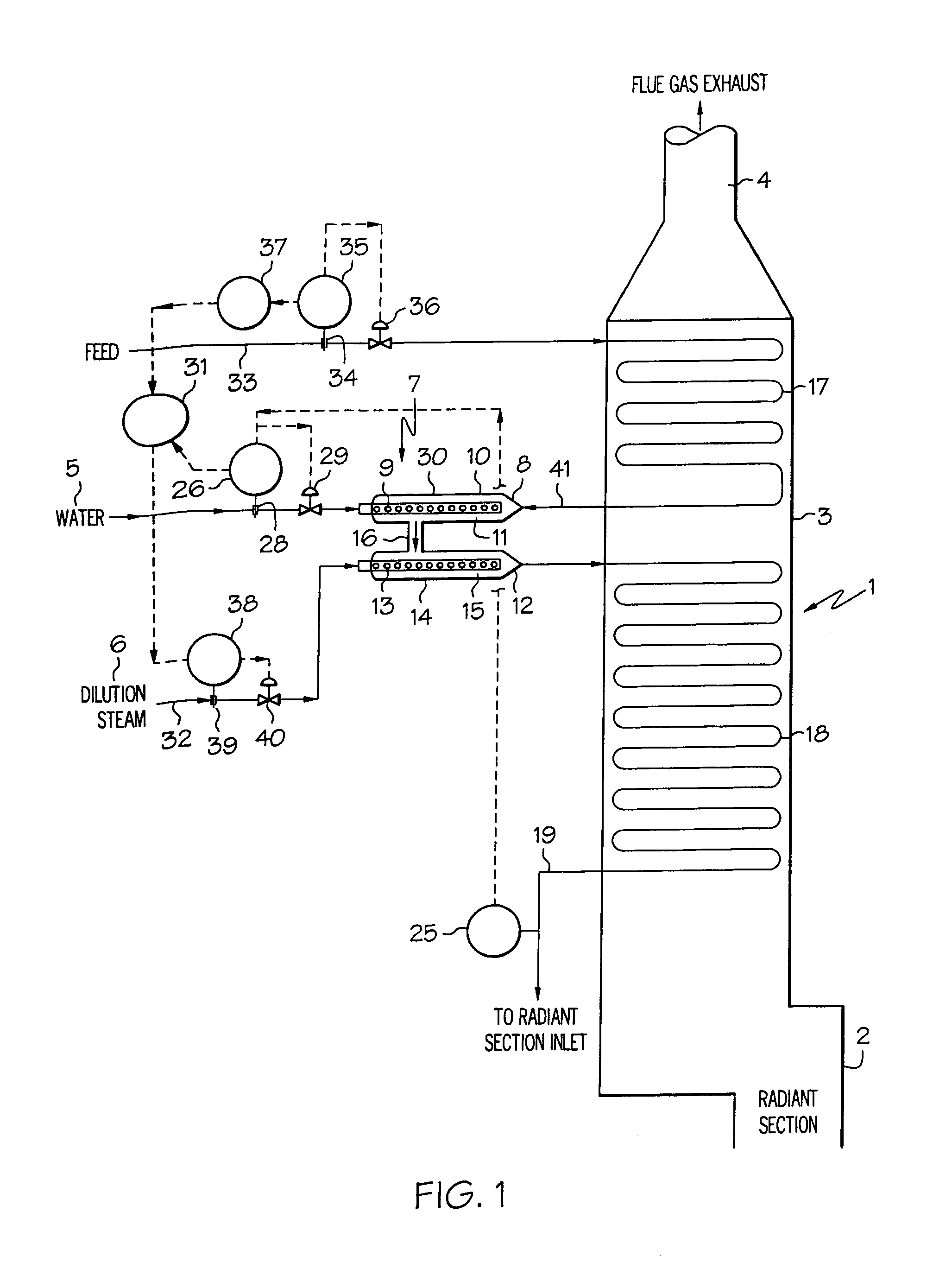

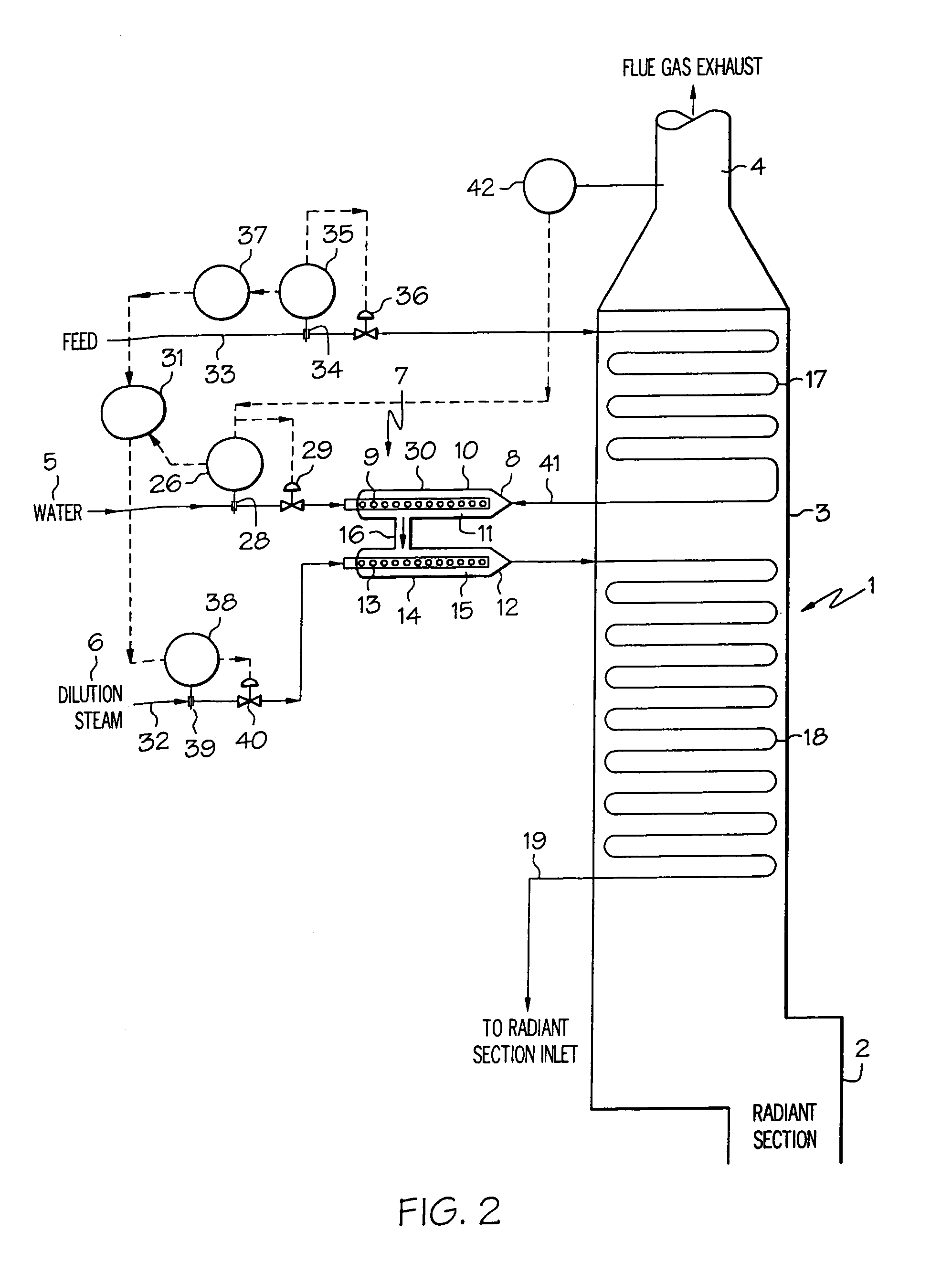

Process for cracking hydrocarbon feed with water substitution

InactiveUS7090765B2Thermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonHydrocotyle bowlesioides

A process for treating hydrocarbon feed in a furnace, the process comprising: (a) heating hydrocarbon feed, (b) adding water to the heated feed, (c) adding dilution steam to the heated feed to form a mixture, (d) heating the resulting mixture and feeding the resulting heated mixture to the furnace, wherein the water in (b) is added in an amount of from at least about 1% to 100% based on water and dilution steam by weight.

Owner:EXXONMOBIL CHEM PAT INC

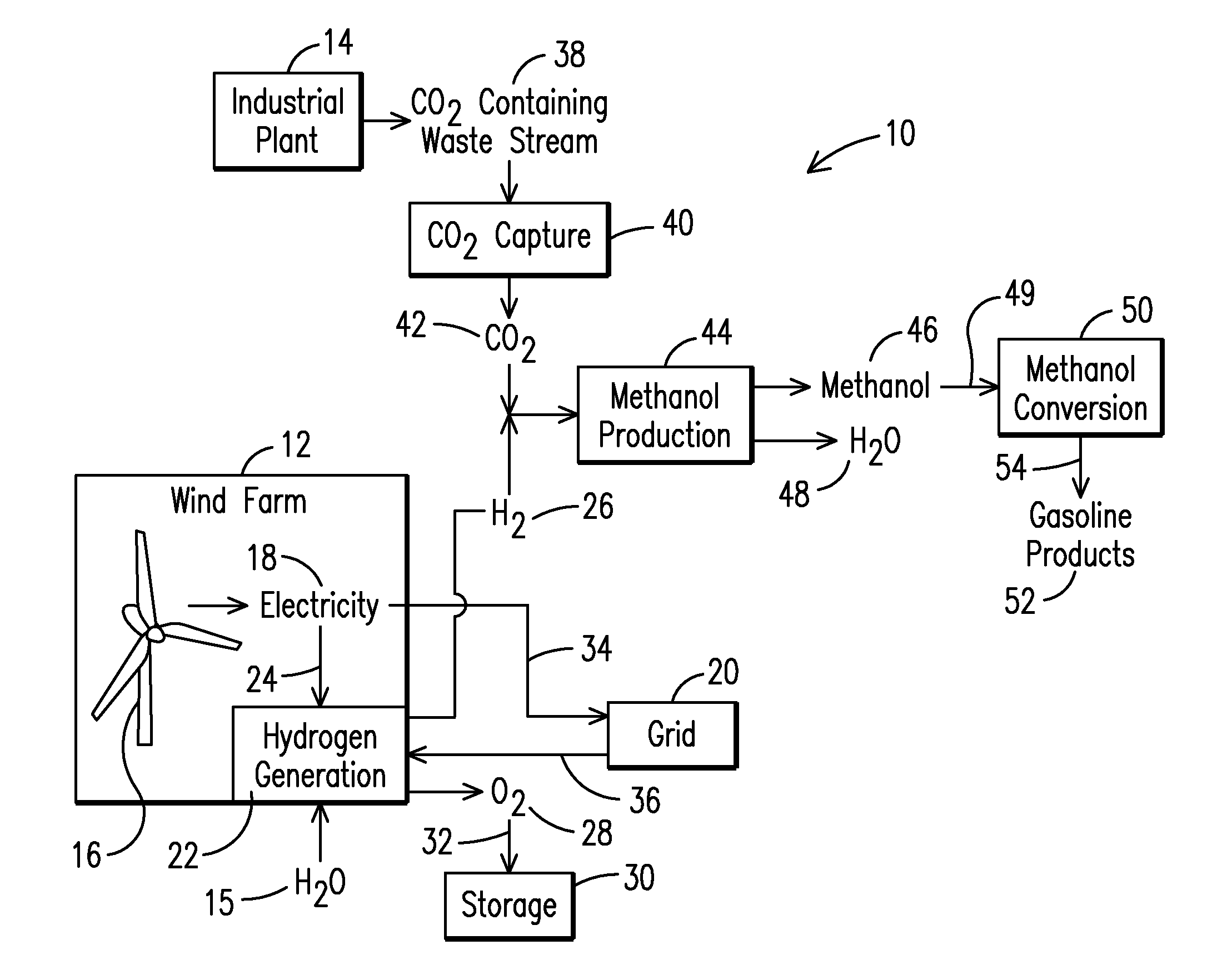

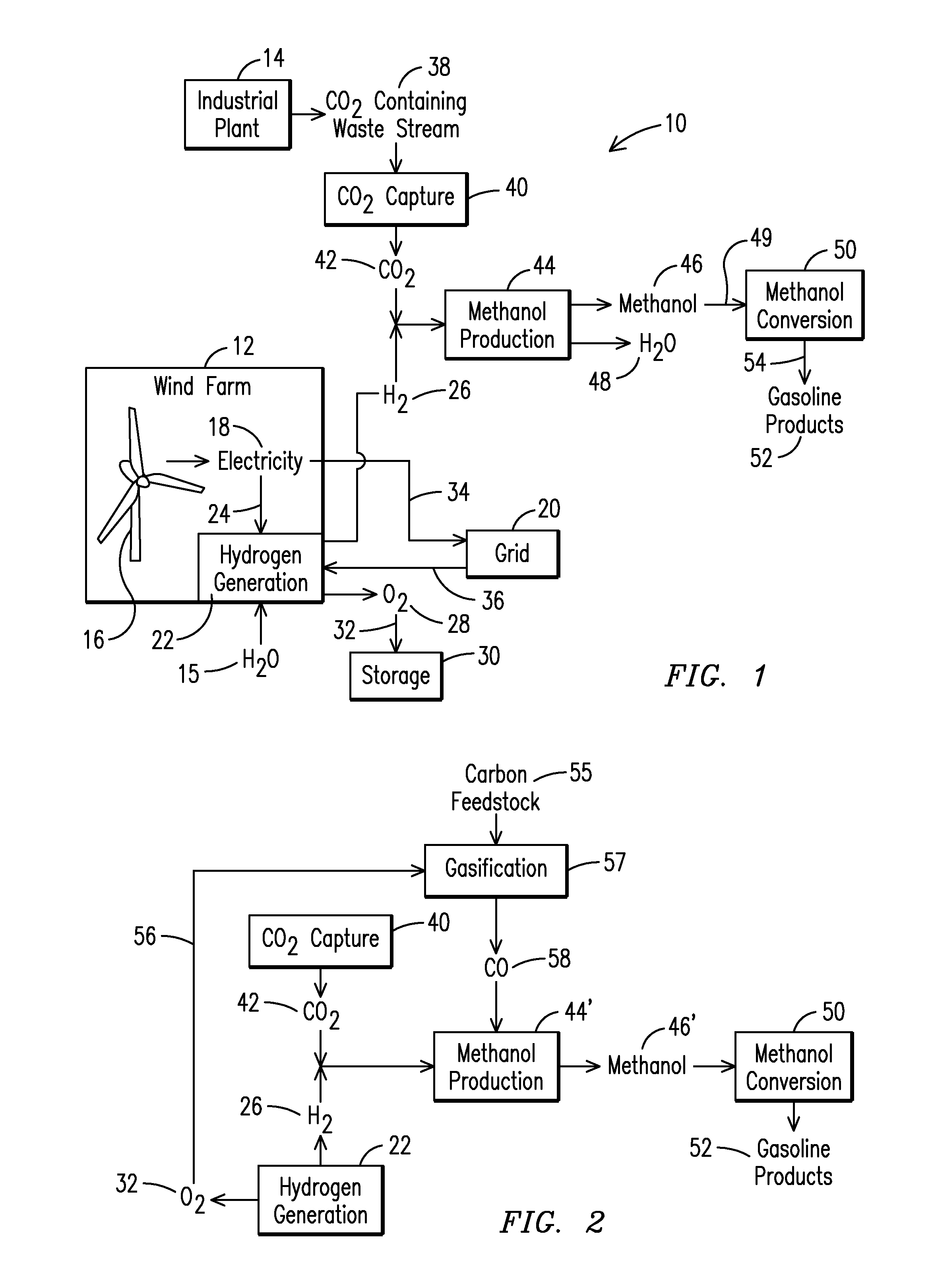

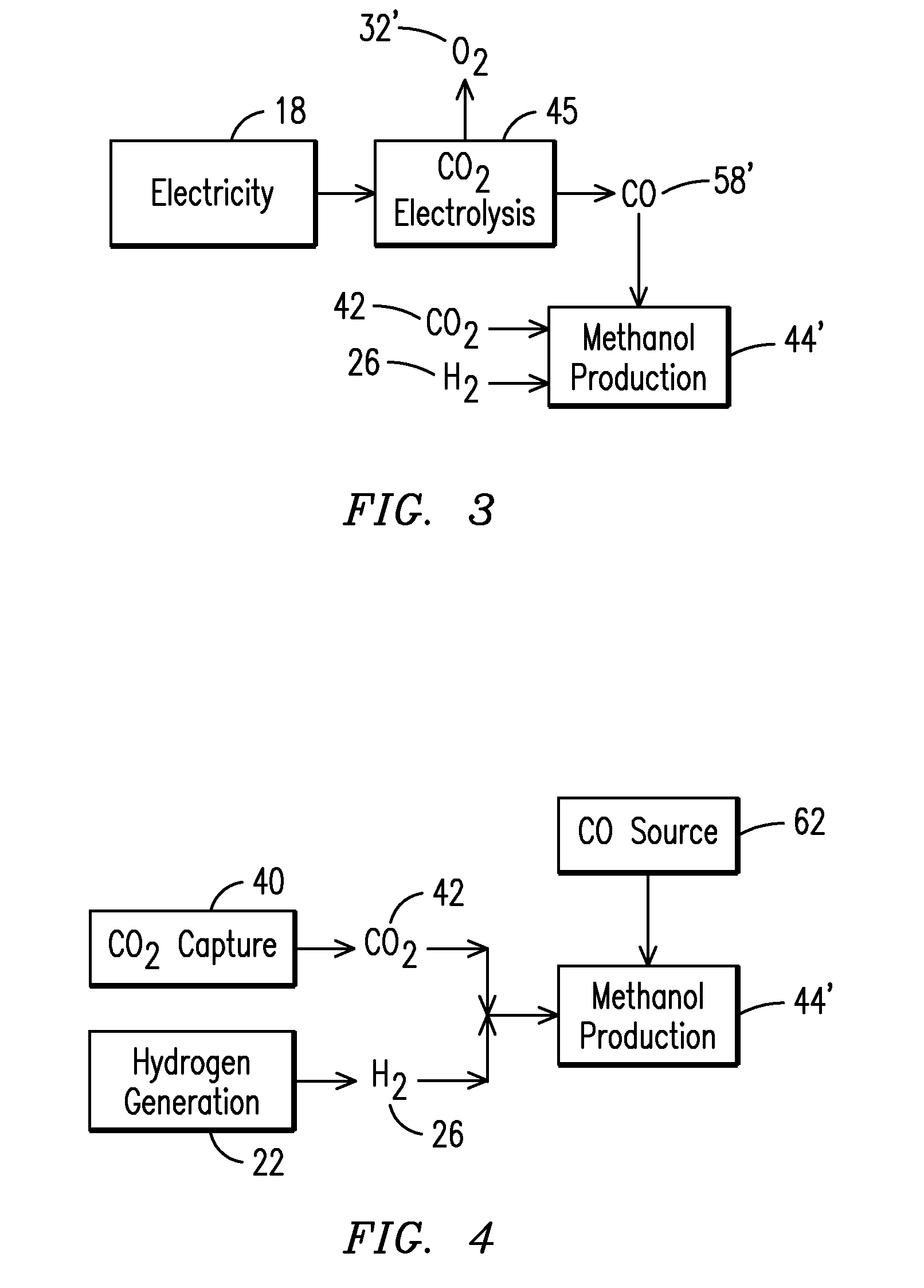

Production of Fuel Materials Utilizing Waste Carbon Dioxide and Hydrogen from Renewable Resources

ActiveUS20090289227A1Emission reduction for energy storageHydrogen/synthetic gas productionChemistryRenewable resource

The present invention is directed to a method for utilizing CO2 waste comprising recovering carbon dioxide from an industrial process that produces a waste stream comprising carbon dioxide in an amount greater than an amount of carbon dioxide present in starting materials for the industrial process. The method further includes producing hydrogen using a renewable energy resource and producing a hydrocarbon material utilizing the produced hydrogen and the recovered carbon dioxide.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

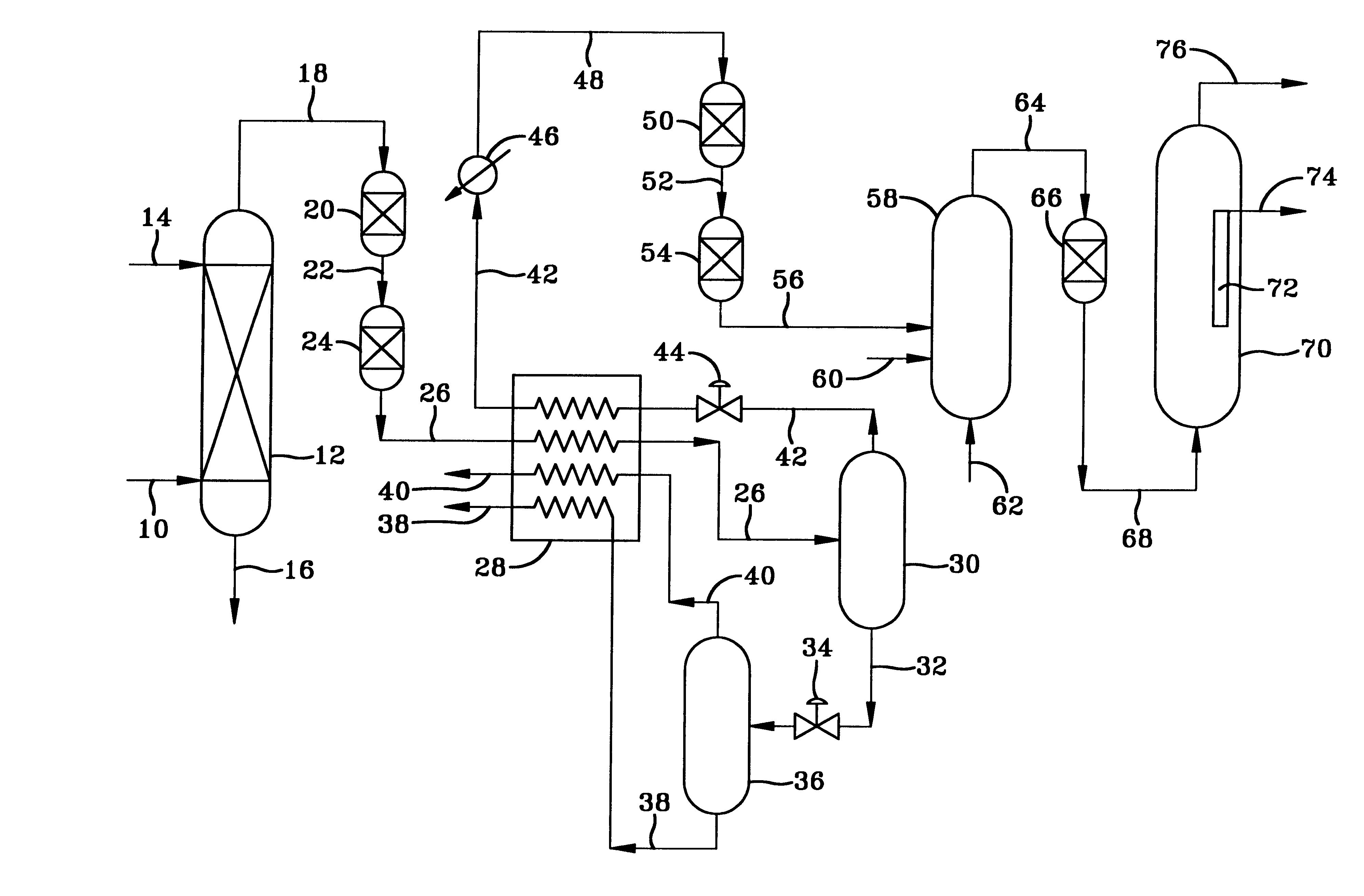

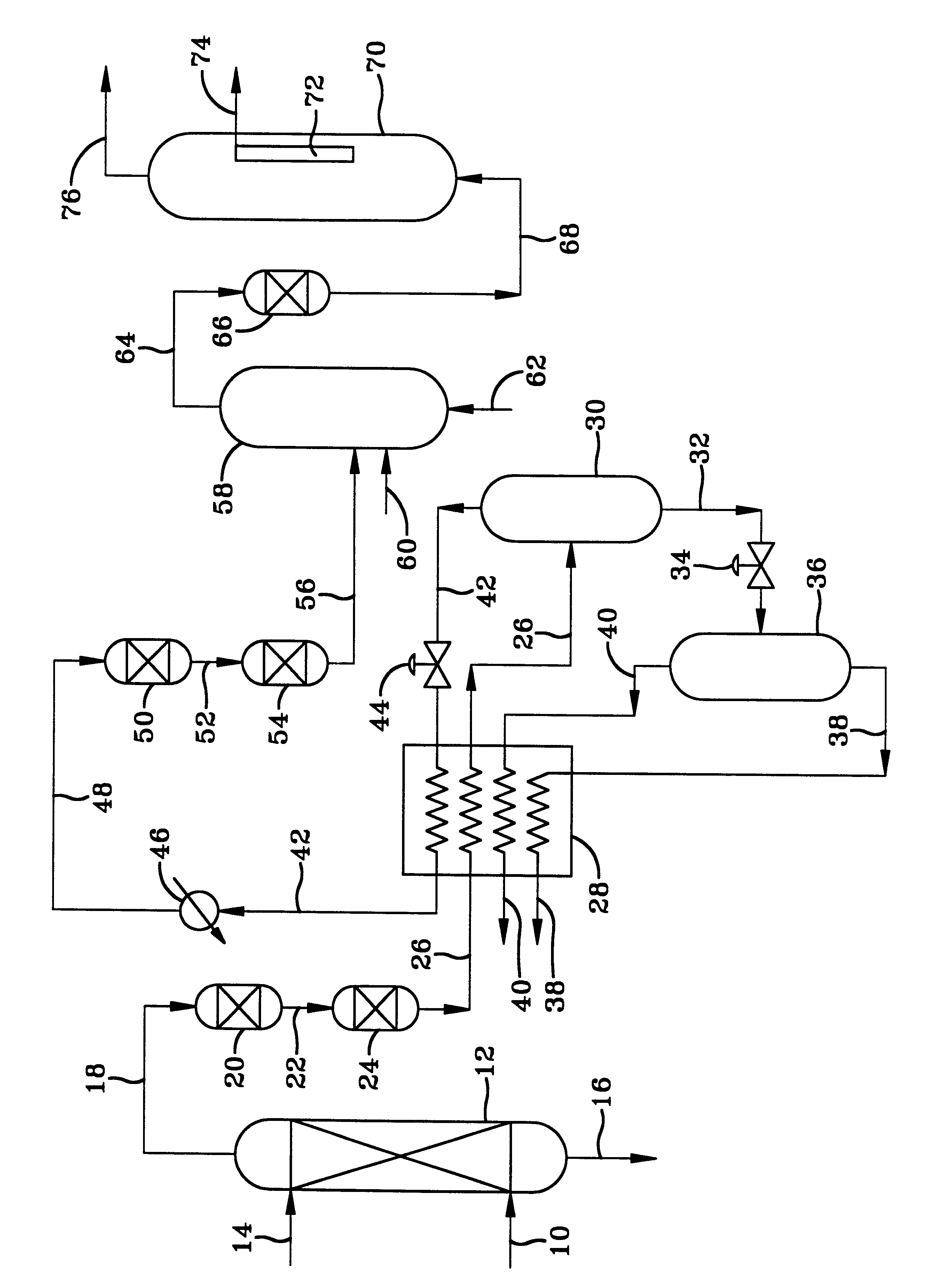

Production of low sulfur syngas from natural gas with C4+/C5+ hydrocarbon recovery

Sour natural gas is processed to remove the sulfur compounds and recover C4+ / C5+ hydrocarbons by scrubbing the gas with an amine solution to remove most of the sulfur, followed cooling the gas to remove C4+ / C5+ hydrocarbons and more sulfur compounds as liquid condensate to produce a gas having less than 20 vppm of total sulfur. The condensate is sent to a fractionator to recover the C4+ / C5+ hydrocarbons. The sulfur and hydrocarbon reduced gas is contacted first with zinc oxide and then nickel, to produce a gas having less than 10 vppb of total sulfur which is passed into a synthesis gas generating unit to form a very low sulfur synthesis gas comprising a mixture of H2 and CO. This synthesis gas is useful for hydrocarbon synthesis with increased life of the hydrocarbon synthesis catalyst and greater hydrocarbon production from the hydrocarbon synthesis reactor. Contacting the synthesis gas with zinc oxide further reduces the sulfur content to below 3 vppb.

Owner:EXXON RES & ENG CO

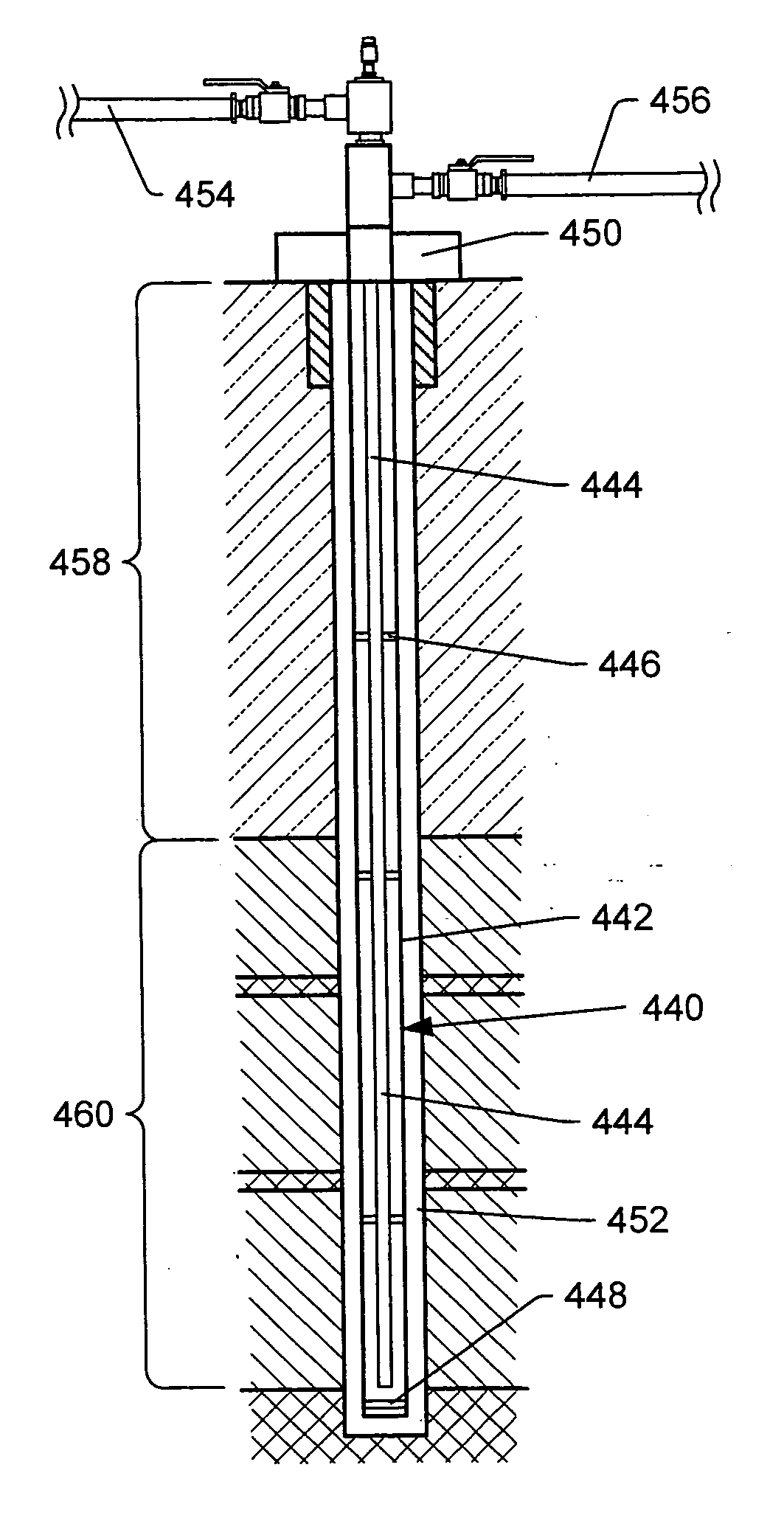

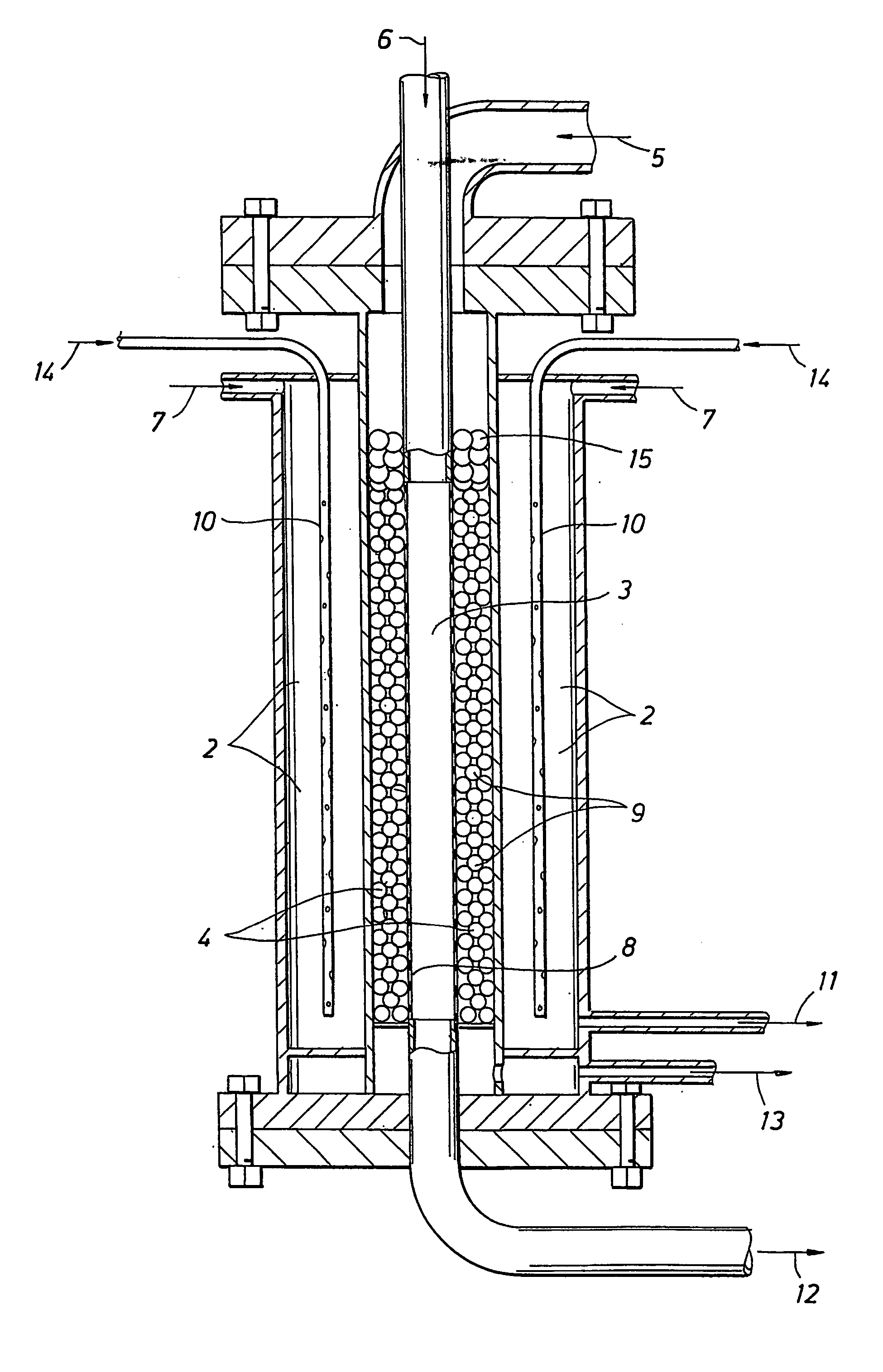

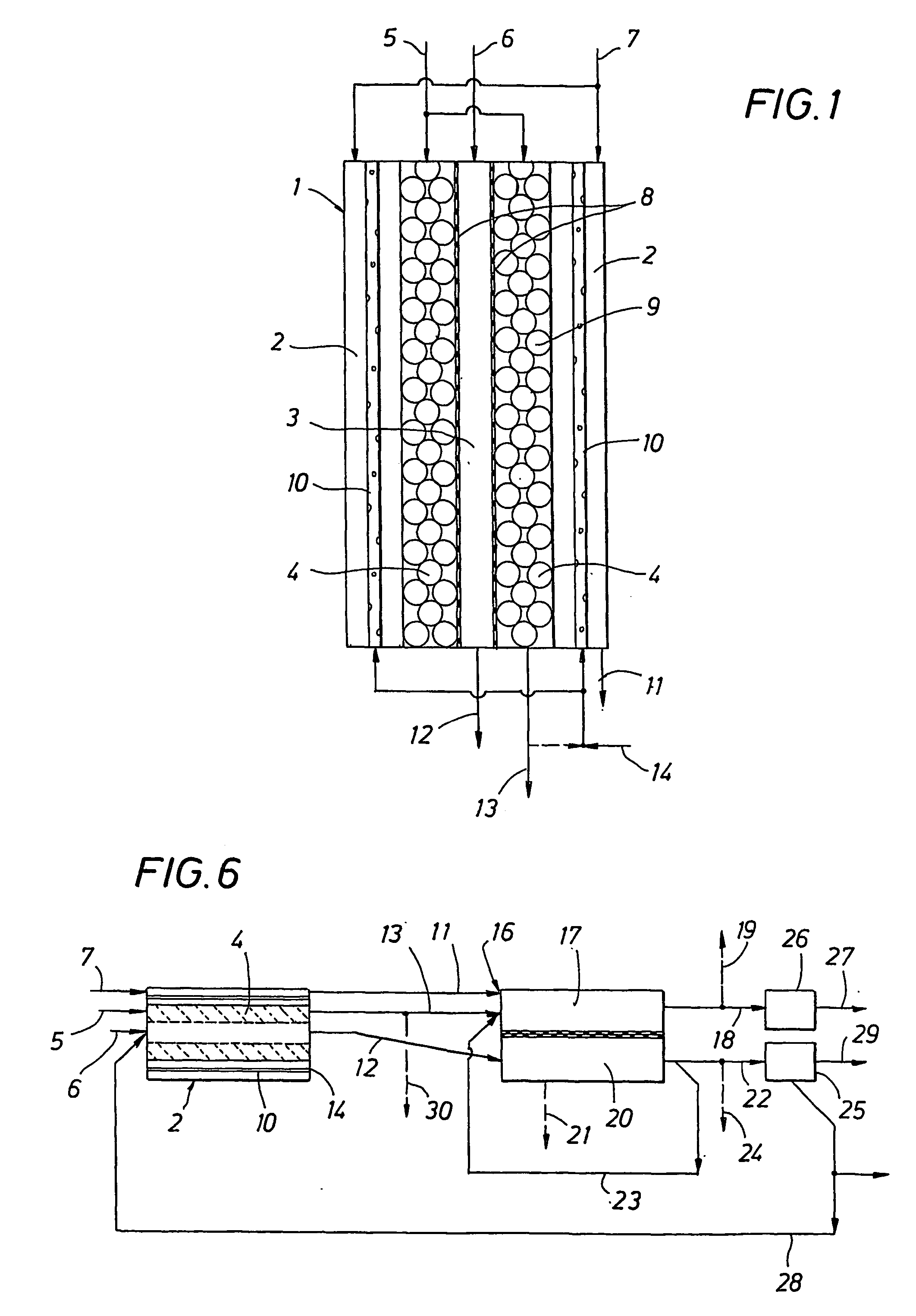

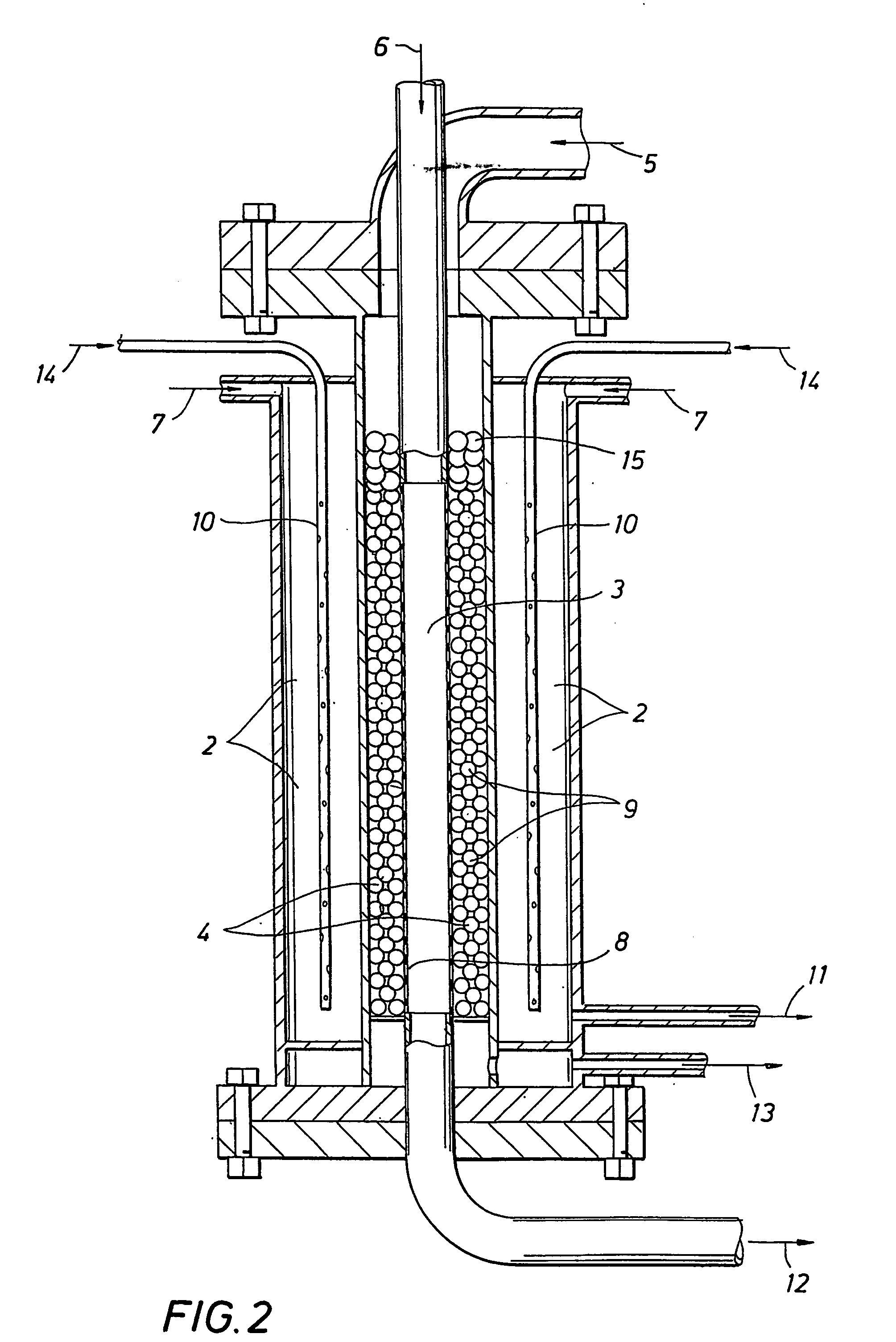

Apparatus and process for production of high purity hydrogen

InactiveUS20060248800A1High purityEnhanced overall recoveryCarbon compoundsIndirect carbon-dioxide mitigationSteam reformingCombustion chamber

The invention relates to a new and improved process and apparatus for the production of high purity hydrogen by steam reforming. The apparatus is an integrated flameless distributed combustion-membrane steam reforming (FDC-MSR) or reactor for steam reforming of a vaporizable hydrocarbon to produce H2 and CO2, with minimal CO, and minimal CO in the H2 stream. The flameless distributed combustion drives the steam reforming reaction which pro-vides great improvements in heat exchange efficiency and load following capabilities. The reactor may contain multiple flameless distributed combustion chambers and multiple hydrogen-selective, hydrogen-permeable, membrane tubes. The feed and reaction gases may flow through the reactor either radially or axially. A further embodiment of the invention involves producing high purity hydrogen by dehydrogenation using an integrated FDC-membrane de-hydrogenation reactor. A still further embodiment of the invention involves a zero emission hybrid power system wherein the produced hydrogen is used to power a high-pressure internally manifolded molten carbonate fuel cell. In addition, the design of the FDC-SMR powered fuel cell makes it possible to capture good concentrations of CO2 for sequestration or use in other processes.

Owner:SHELL OIL CO

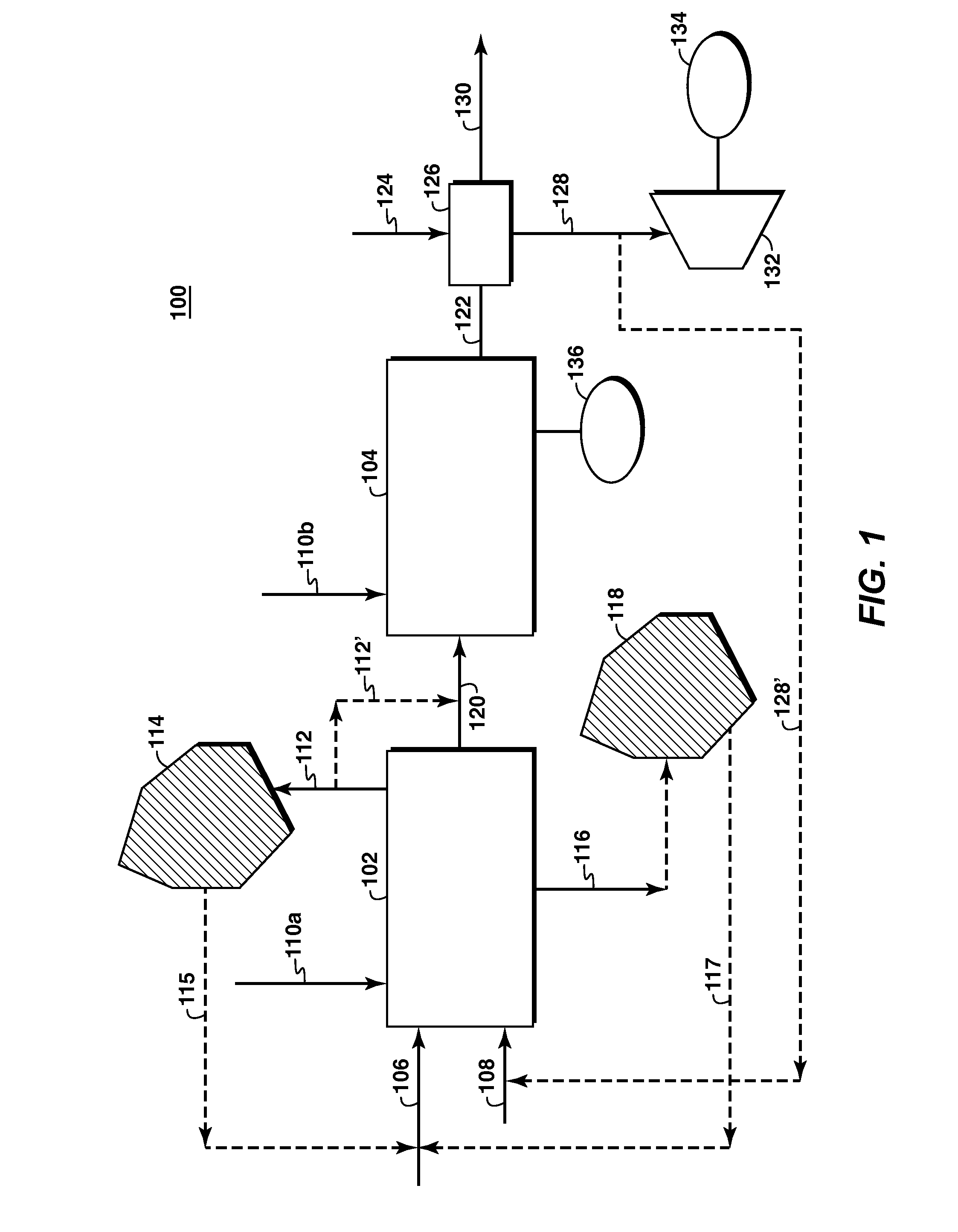

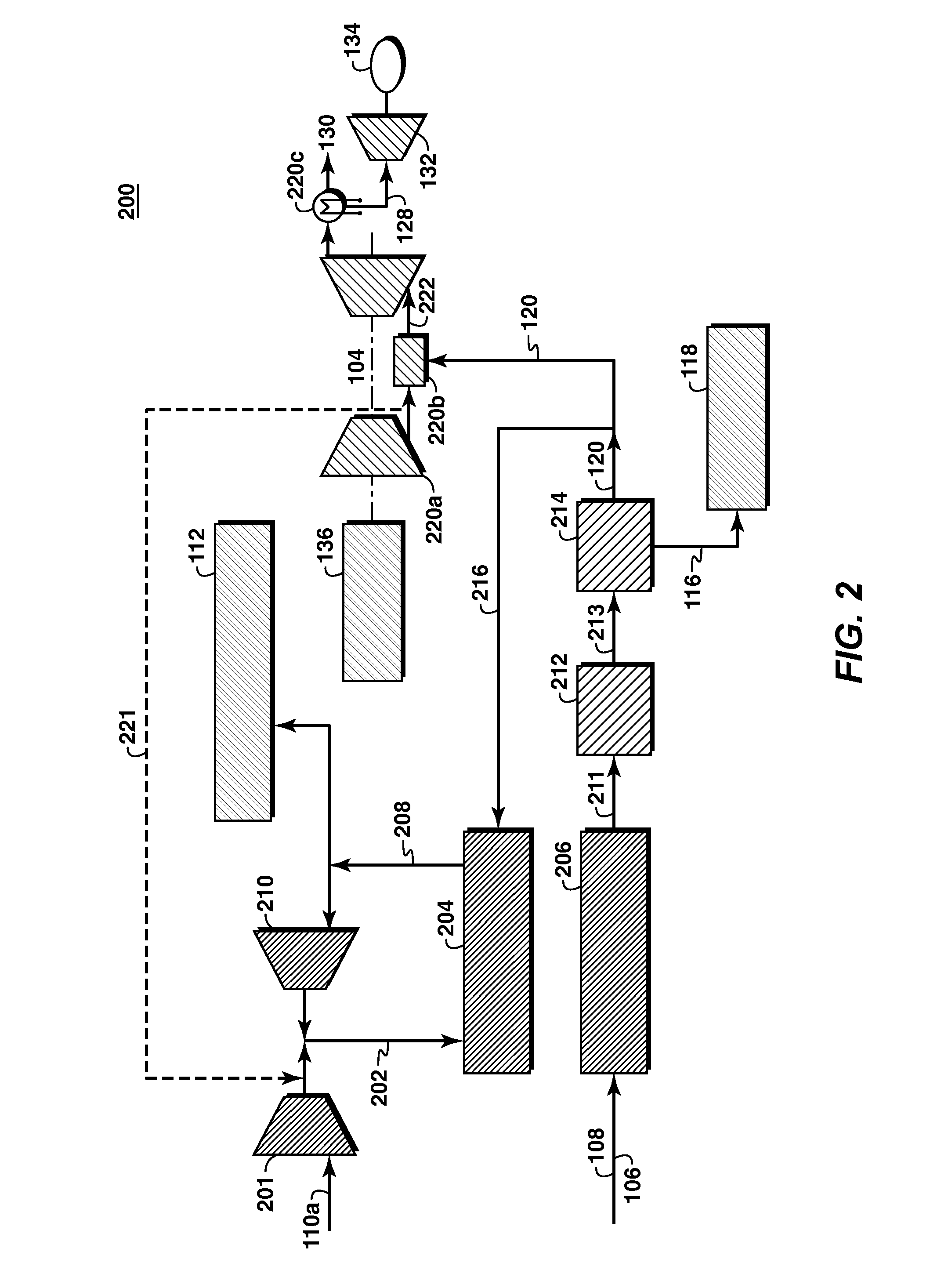

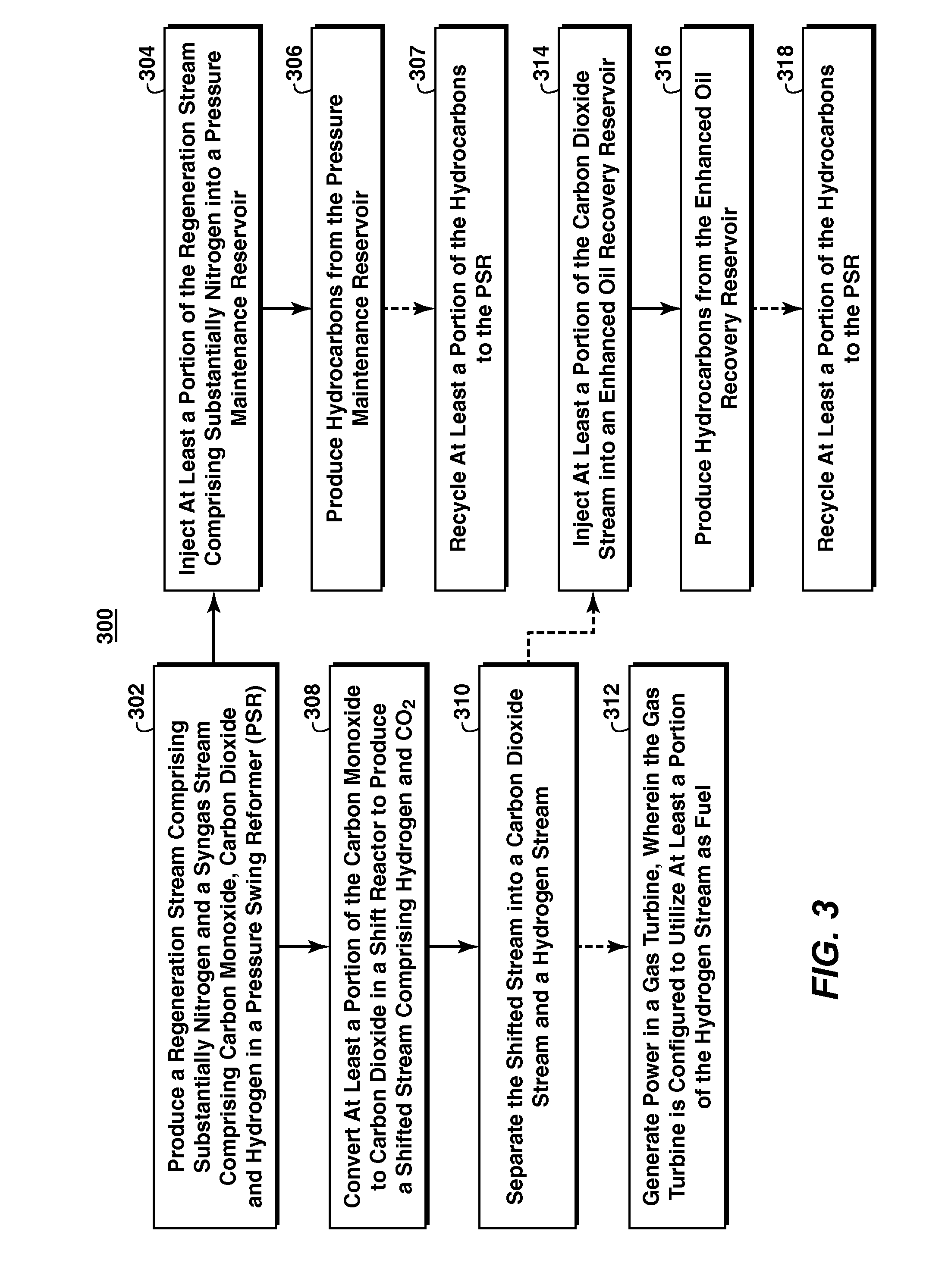

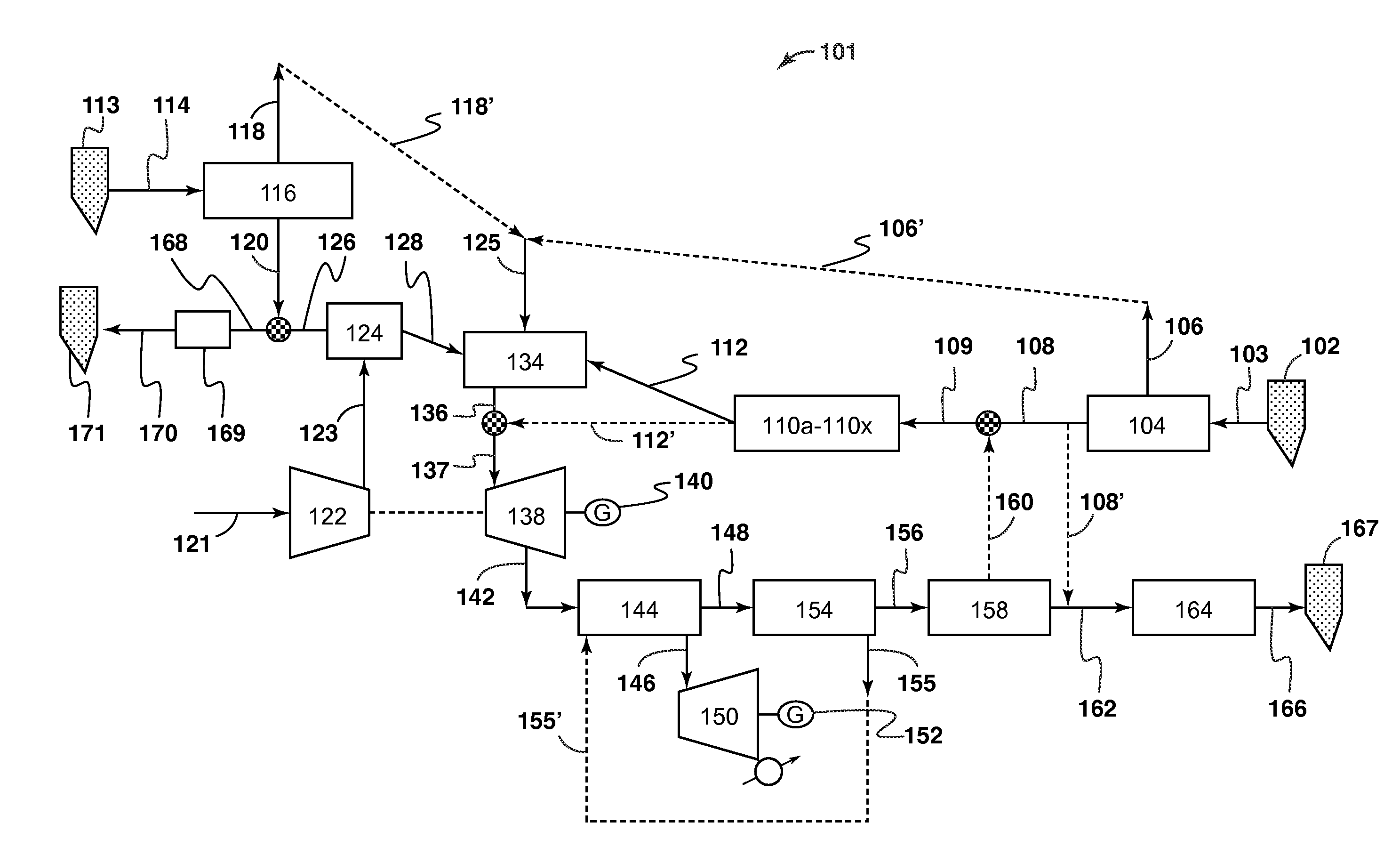

Low Emission Power Generation and Hydrocarbon Recovery Systems and Methods

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes integrated pressure maintenance and miscible flood systems with low emission power generation. The system may also include integration of a pressure swing reformer (PSR), air-blown auto-thermal reformer (ATR), or oxygen-blown ATR with a gas power turbine system, preferably a combined cycle gas power turbine system. Such systems may be employed to capture and utilize greenhouse gases (GHG) and generate power for use in hydrocarbon recovery operations.

Owner:EXXONMOBIL UPSTREAM RES CO

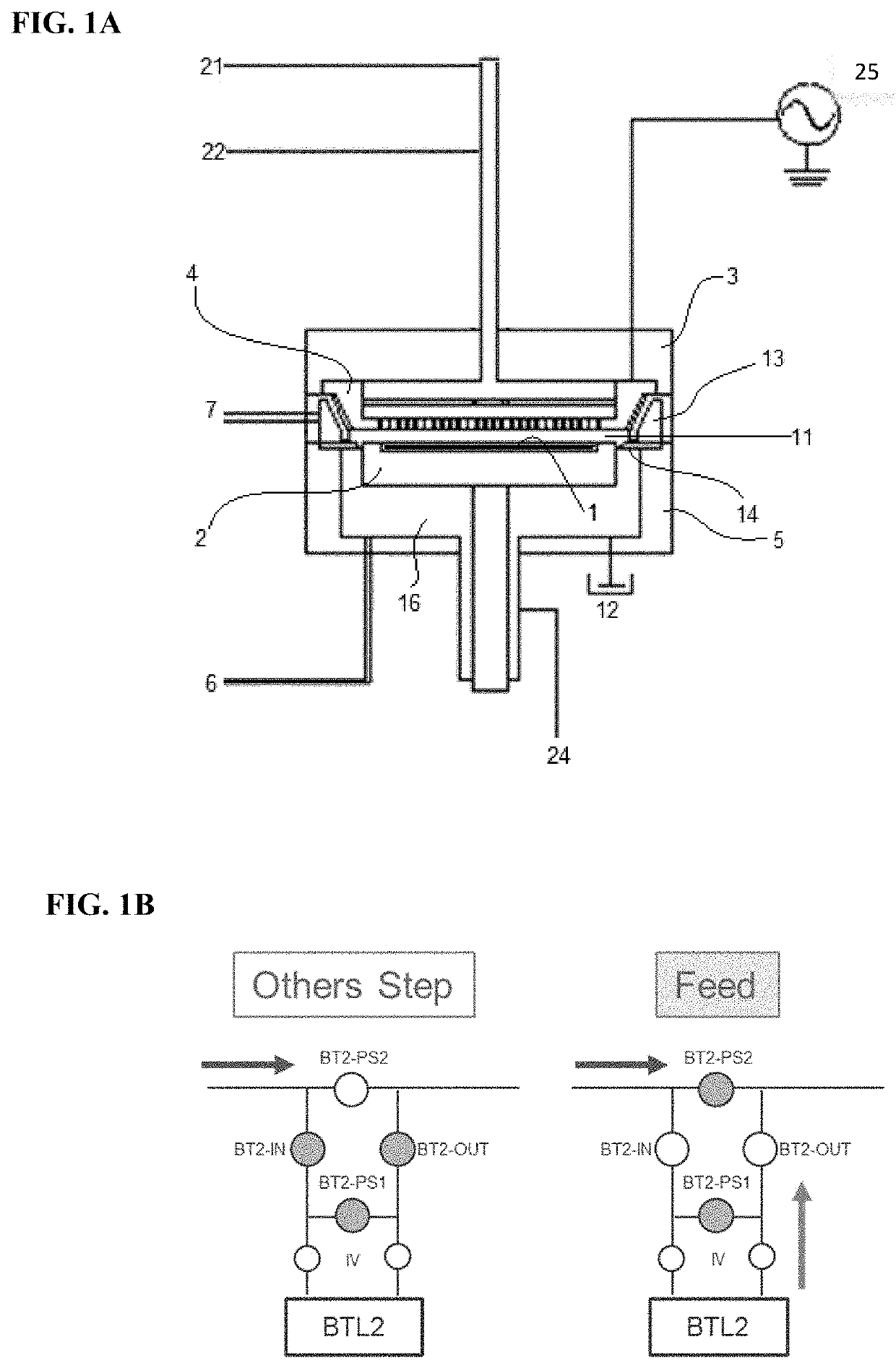

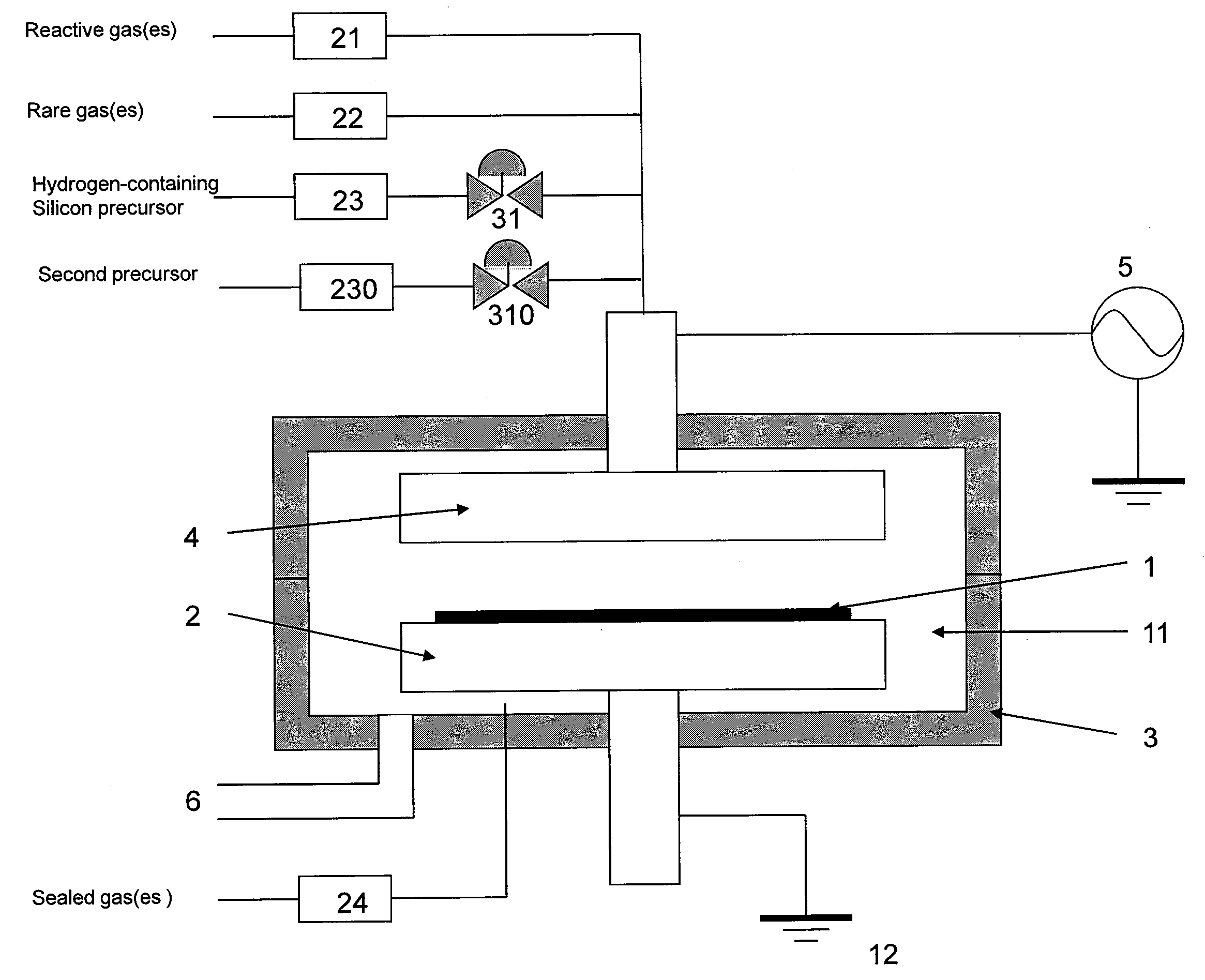

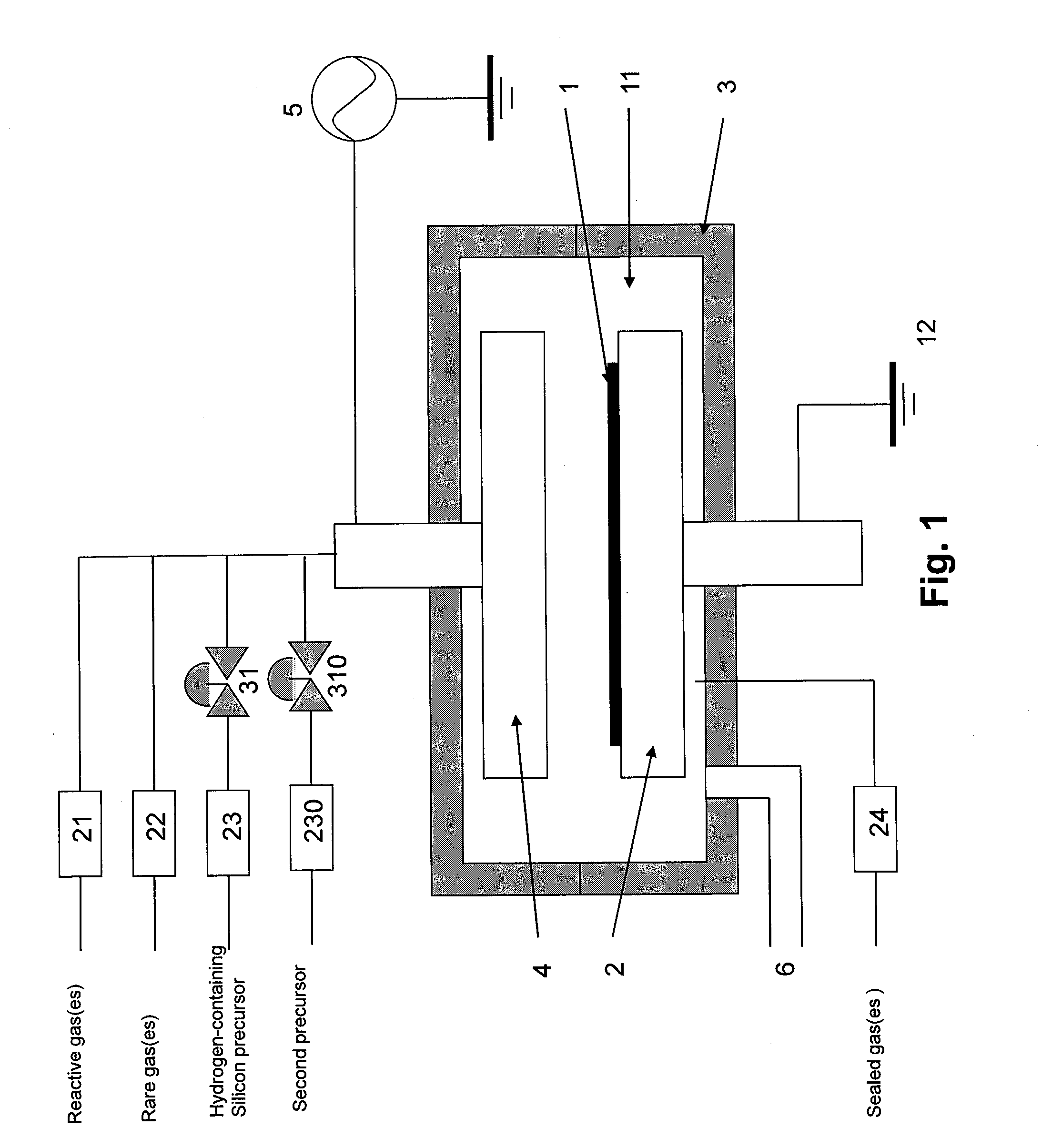

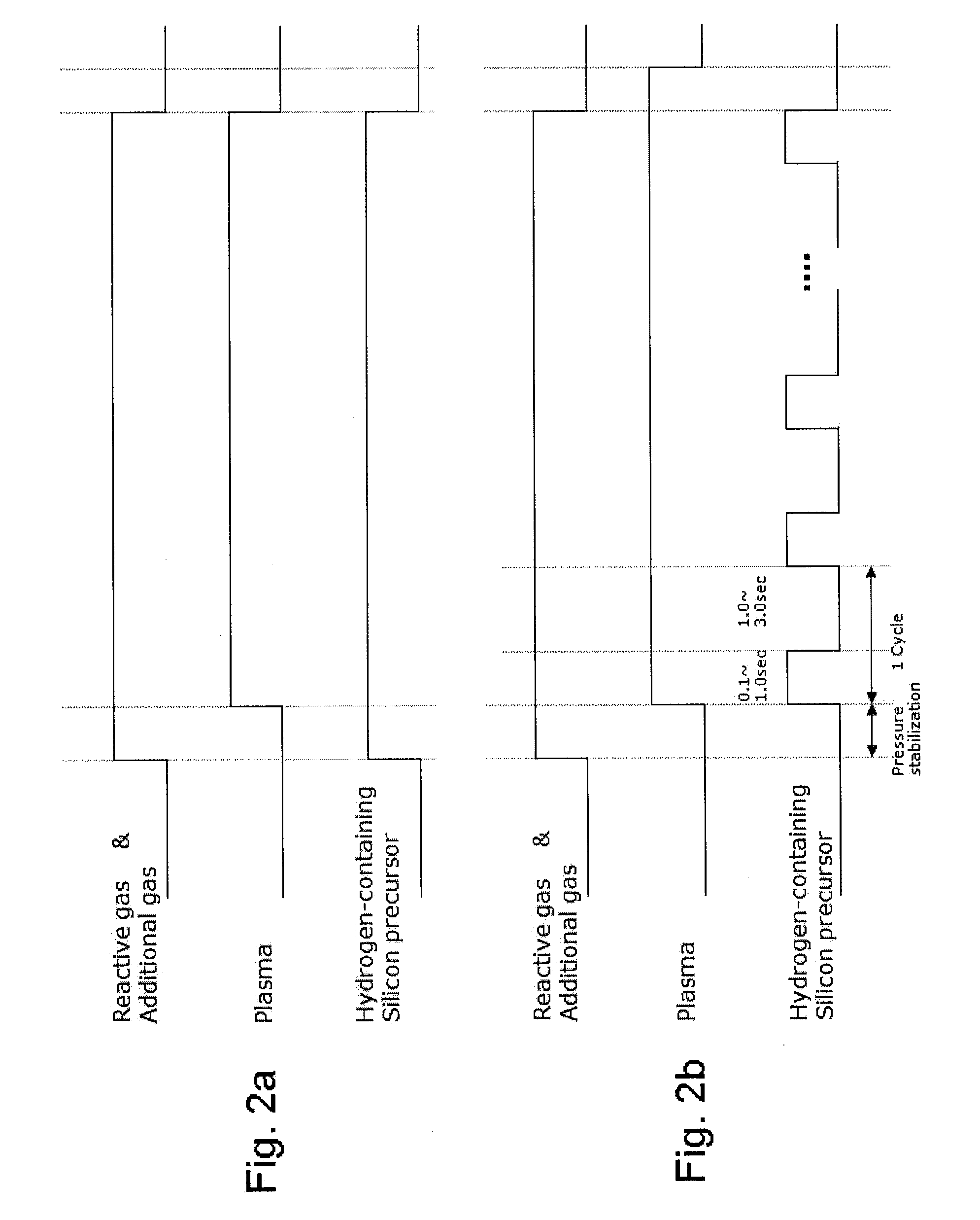

METHOD OF FORMING CONFORMAL DIELECTRIC FILM HAVING Si-N BONDS BY PECVD

ActiveUS20100221925A1Reduce the temperatureIncrease deposition rateSemiconductor/solid-state device detailsSolid-state devicesDielectricHydrocotyle bowlesioides

A method of forming a conformal dielectric film having Si—N bonds on a semiconductor substrate by plasma enhanced chemical vapor deposition (PECVD) includes: introducing a nitrogen- and hydrogen-containing reactive gas and a rare gas into a reaction space inside which a semiconductor substrate is placed; applying RF power to the reaction space; and introducing a hydrogen-containing silicon precursor as a first precursor and a hydrocarbon gas as a second precursor in pulses into the reaction space wherein a plasma is excited, thereby forming a conformal dielectric film doped with carbon and having Si—N bonds on the substrate.

Owner:ASM JAPAN

Low Emission Power Generation and Hydrocarbon Recovery Systems and Methods

ActiveUS20110000221A1Enhanced recovery of hydrocarbonEnhanced overall recoveryTurbine/propulsion fuel supply systemsOther gas emission reduction technologiesCogenerationDrug Substitution

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes integrated pressure maintenance and miscible flood systems with low emission power generation. An alternative system provides for low emission power generation, carbon sequestration, enhanced oil recovery (EOR), or carbon dioxide sales using a hot gas expander and external combustor. Another alternative system provides for low emission power generation using a gas power turbine to compress air in the inlet compressor and generate power using hot carbon dioxide laden gas in the expander. Other efficiencies may be gained by incorporating heat cross-exchange, a desalination plant, co-generation, and other features.

Owner:EXXONMOBIL UPSTREAM RES CO

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com