Patents

Literature

3140results about How to "Avoid flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

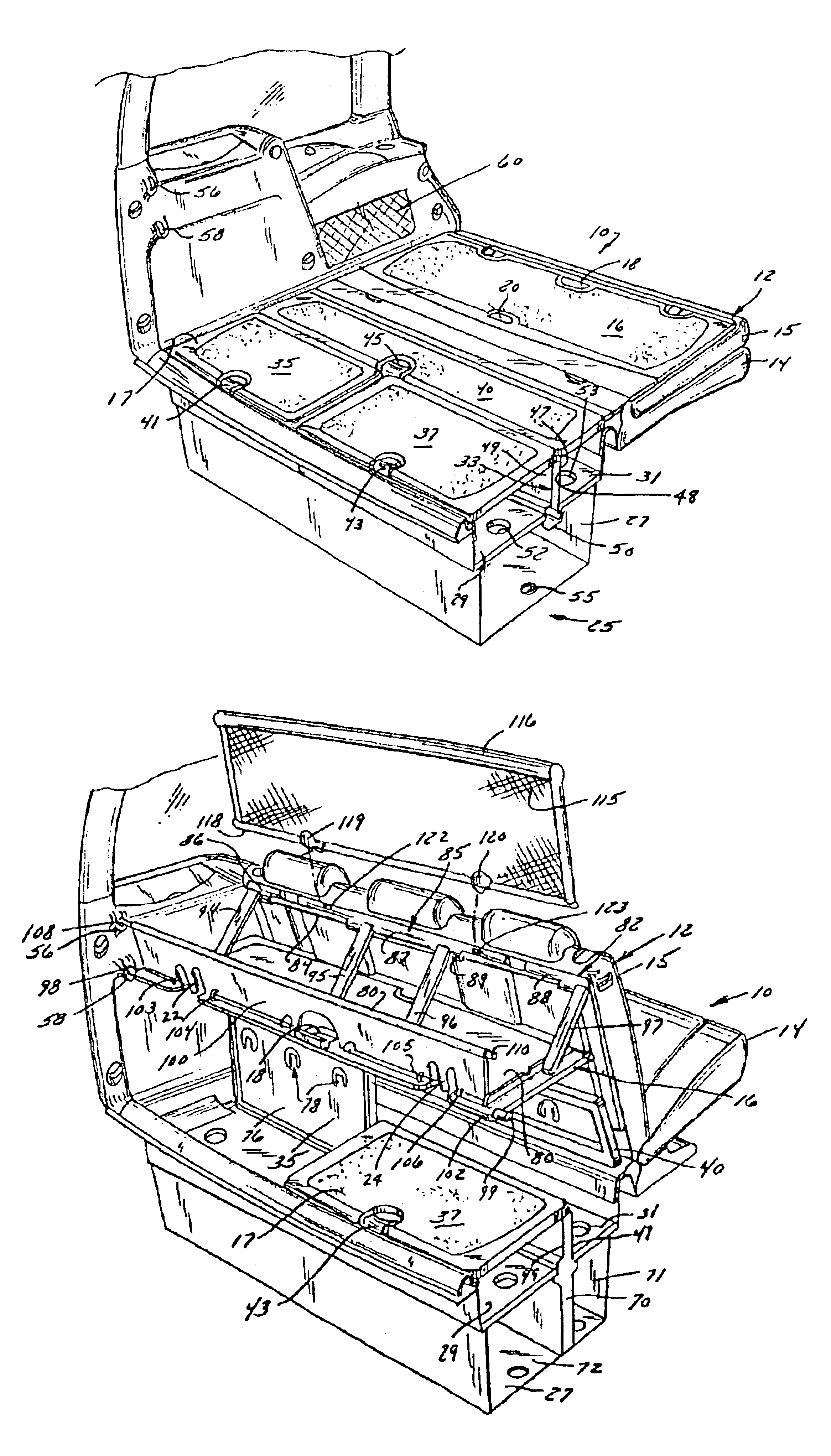

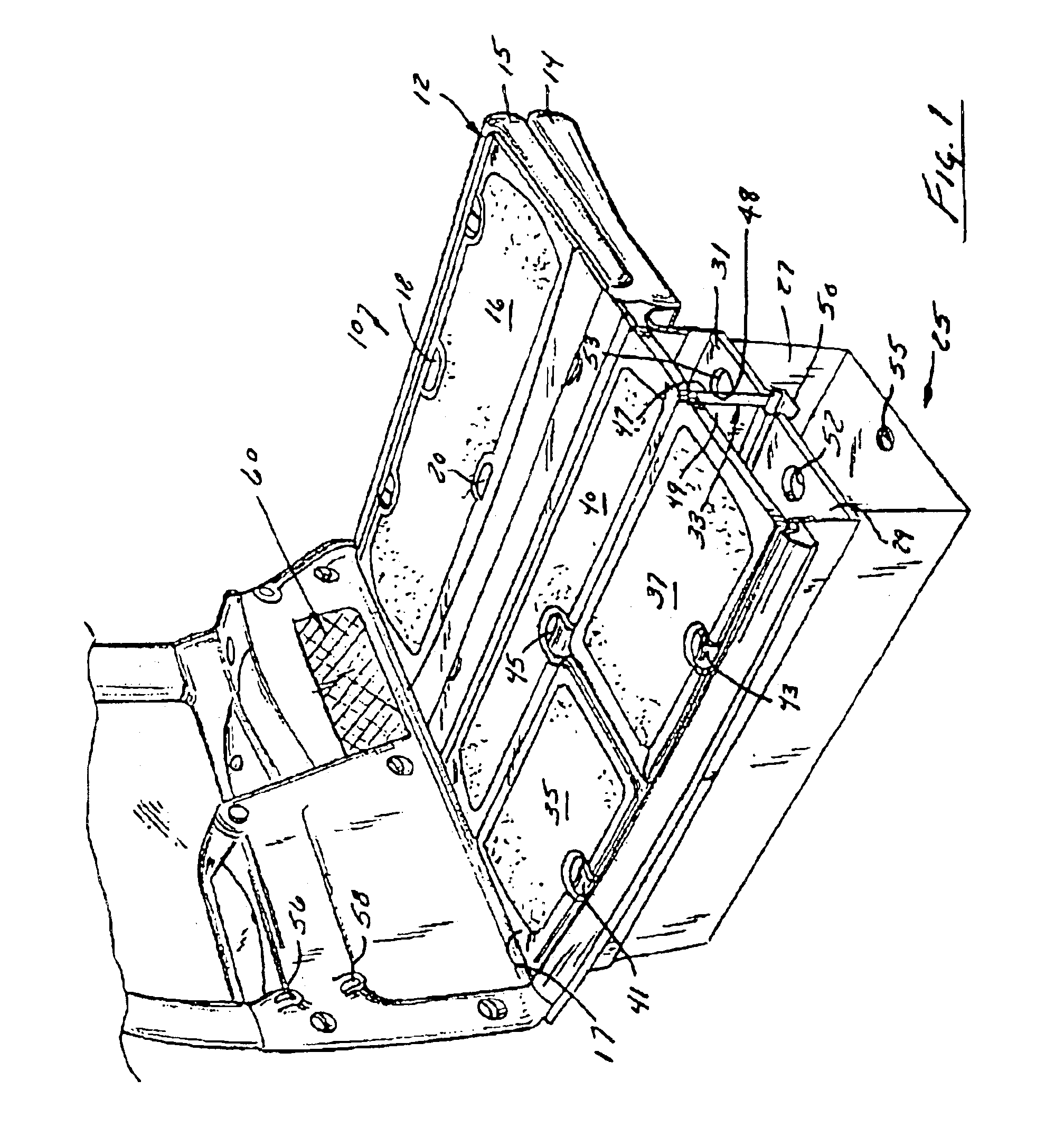

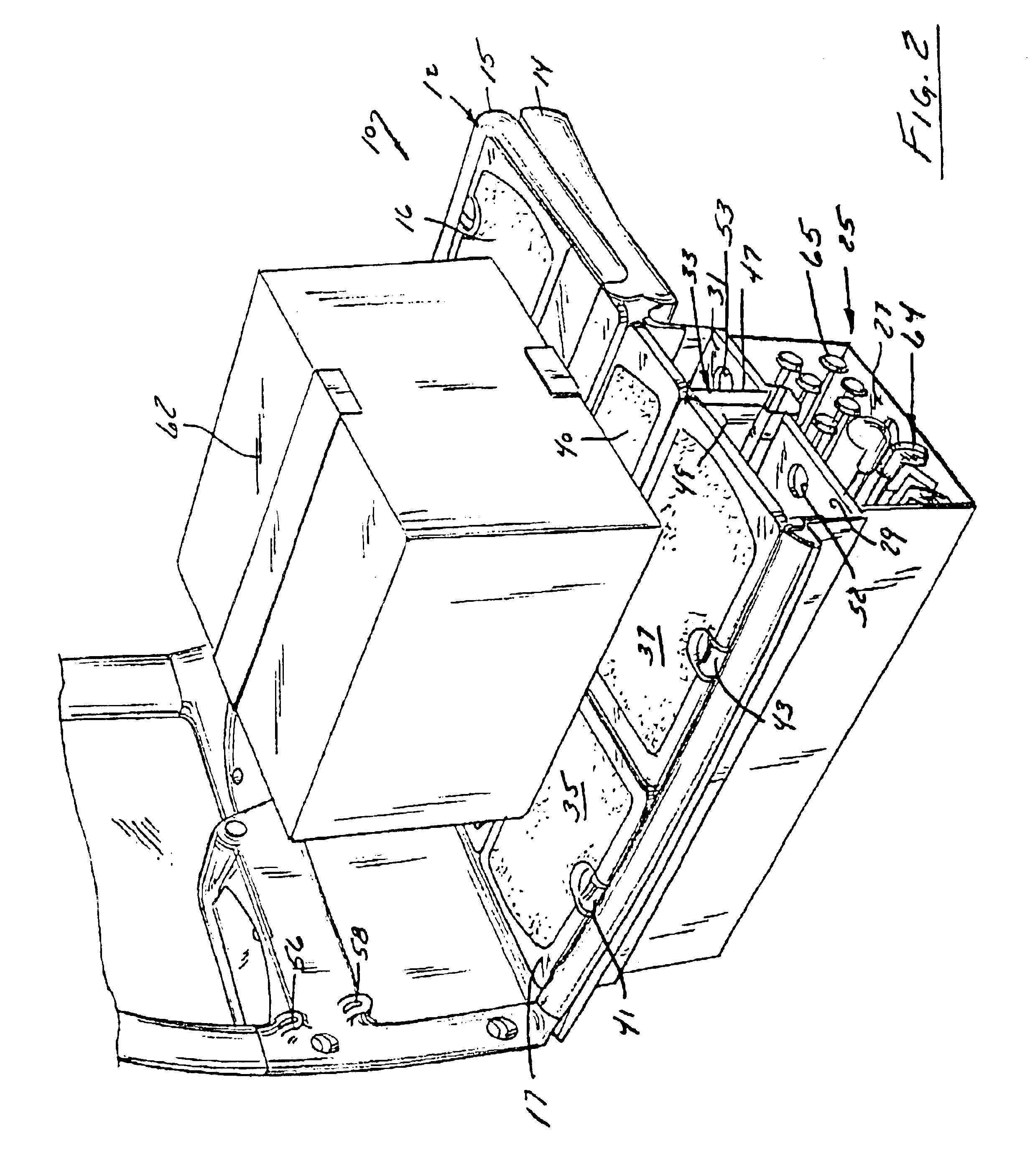

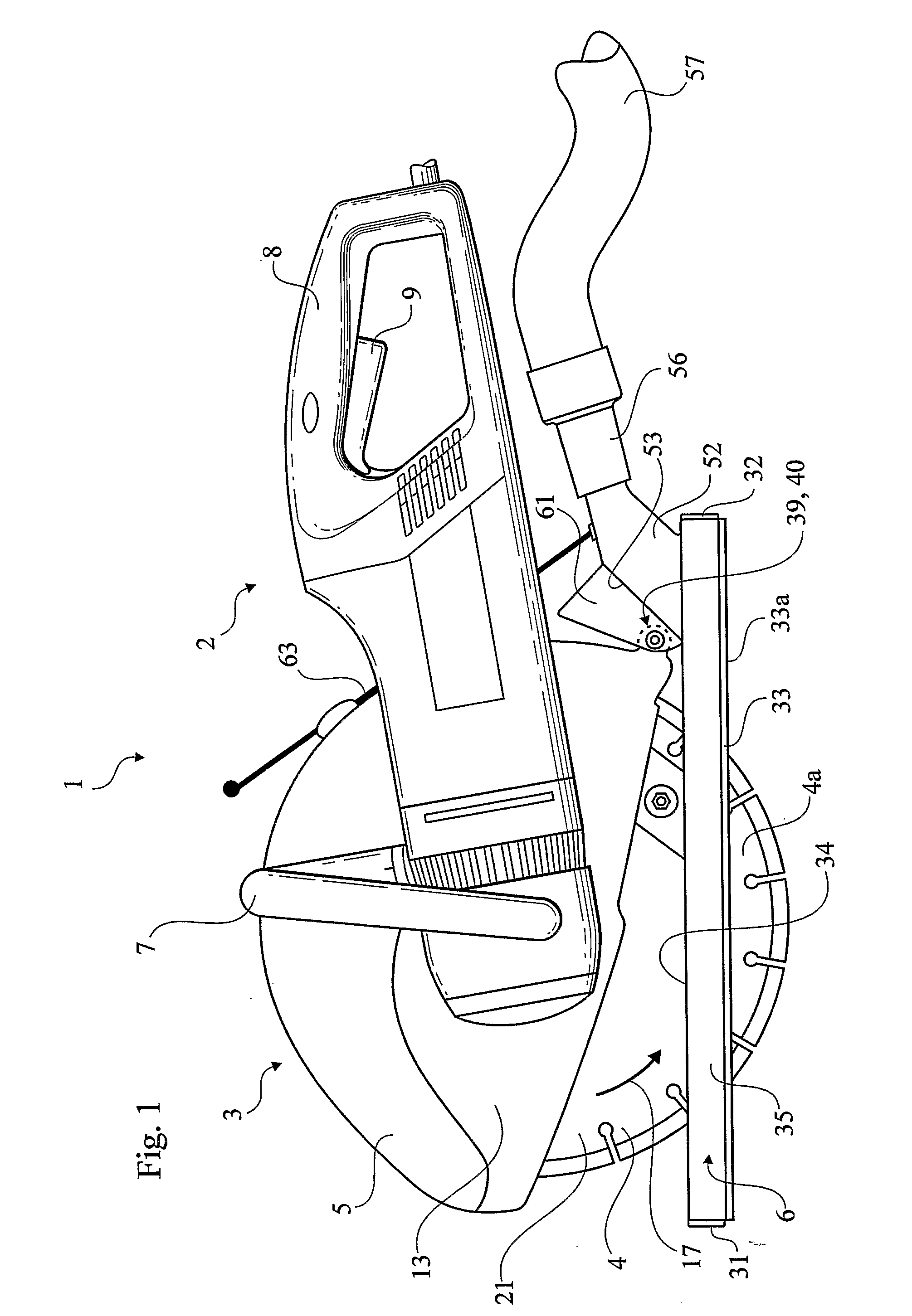

Vehicle cargo management system

InactiveUS6874667B2Avoid flyingPrevent fallingLuggage compartmentTravelling carriersManagement systemSurface plate

A cargo management system of this invention includes a deep well storage area beneath a cargo floor, which well may be horizontally and / or vertically divided and which preferably includes a plurality of doors to access the well. In the illustrated embodiment, the management system also includes a panel which may be placed into three positions: a first storage position in which the panel is flush against the back of the rear seat; a second shelf position in which the panel is horizontal and spaced from the cargo floor by a first distance; and a third privacy shield position in which the panel is also horizontal but is spaced from the cargo floor a second distance, the second distance exceeding the first distance.

Owner:JOHNSON CONTROLS TECH CO

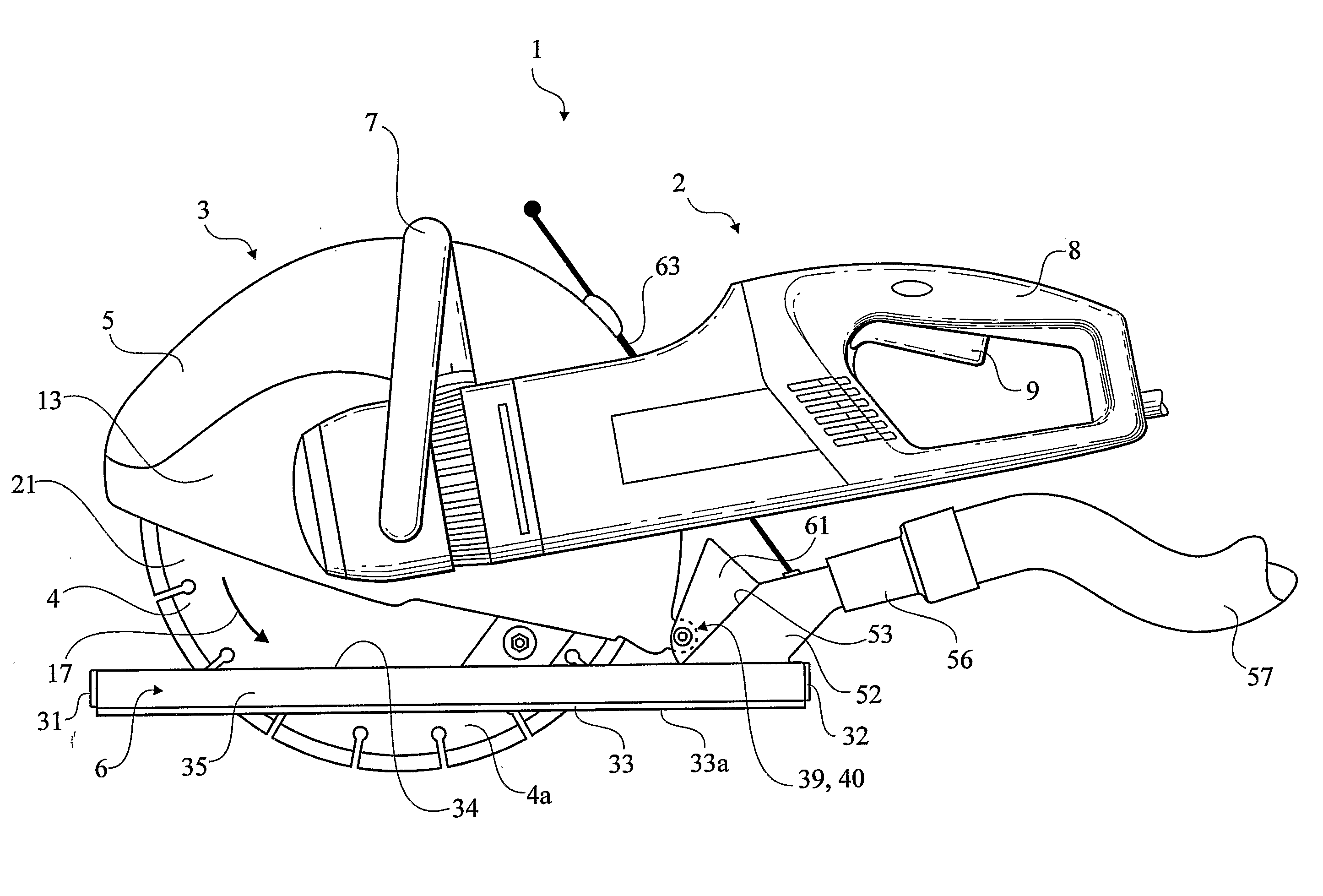

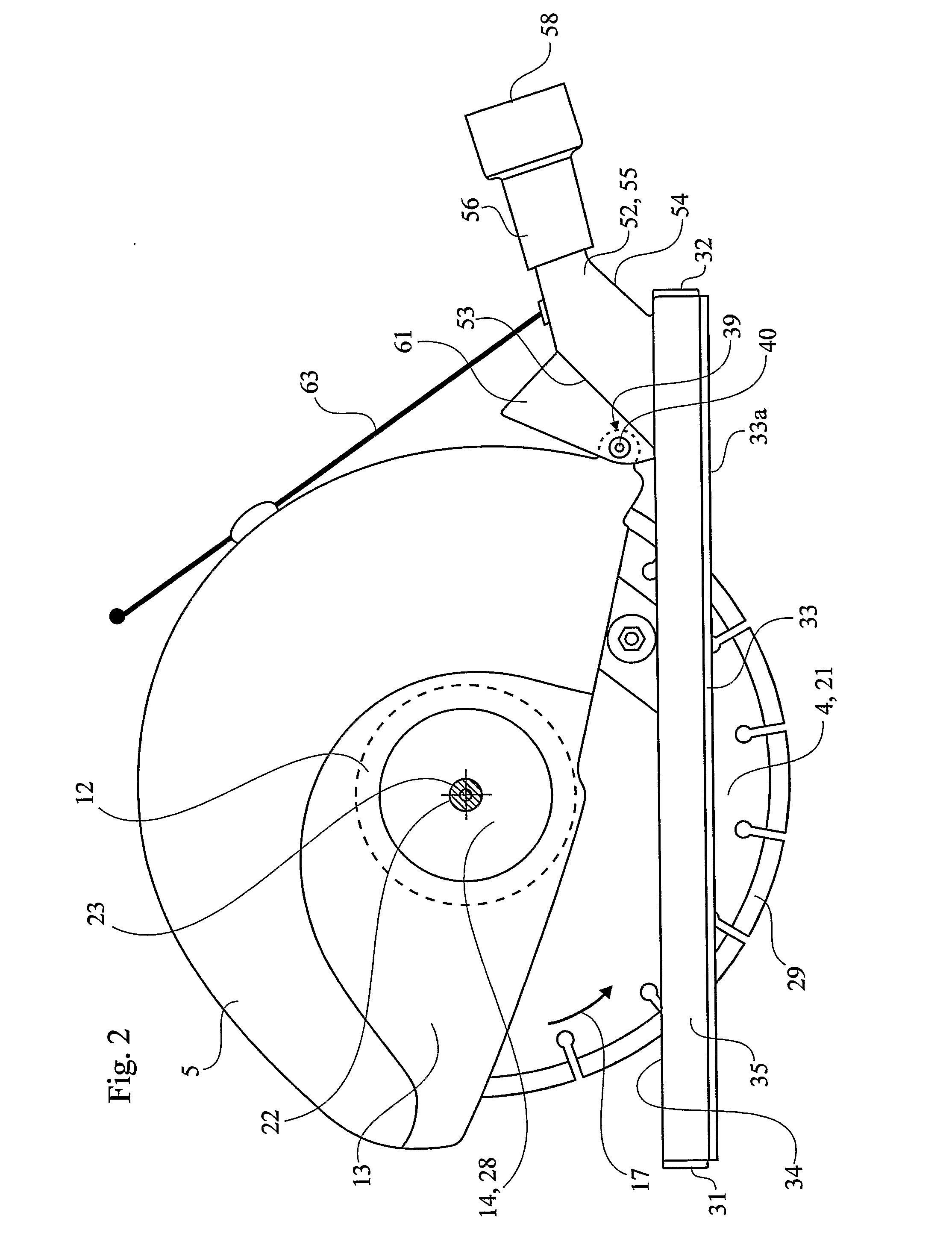

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

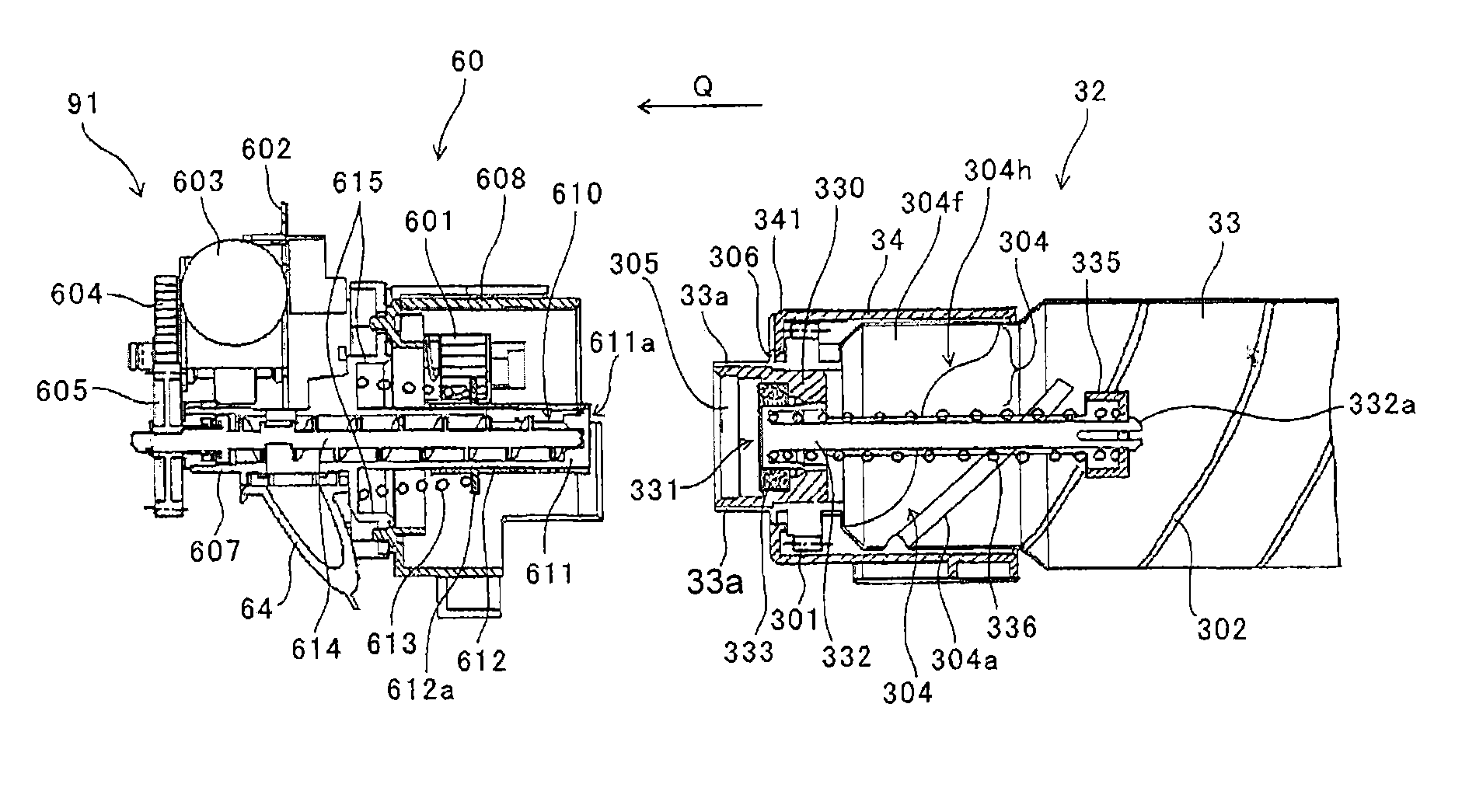

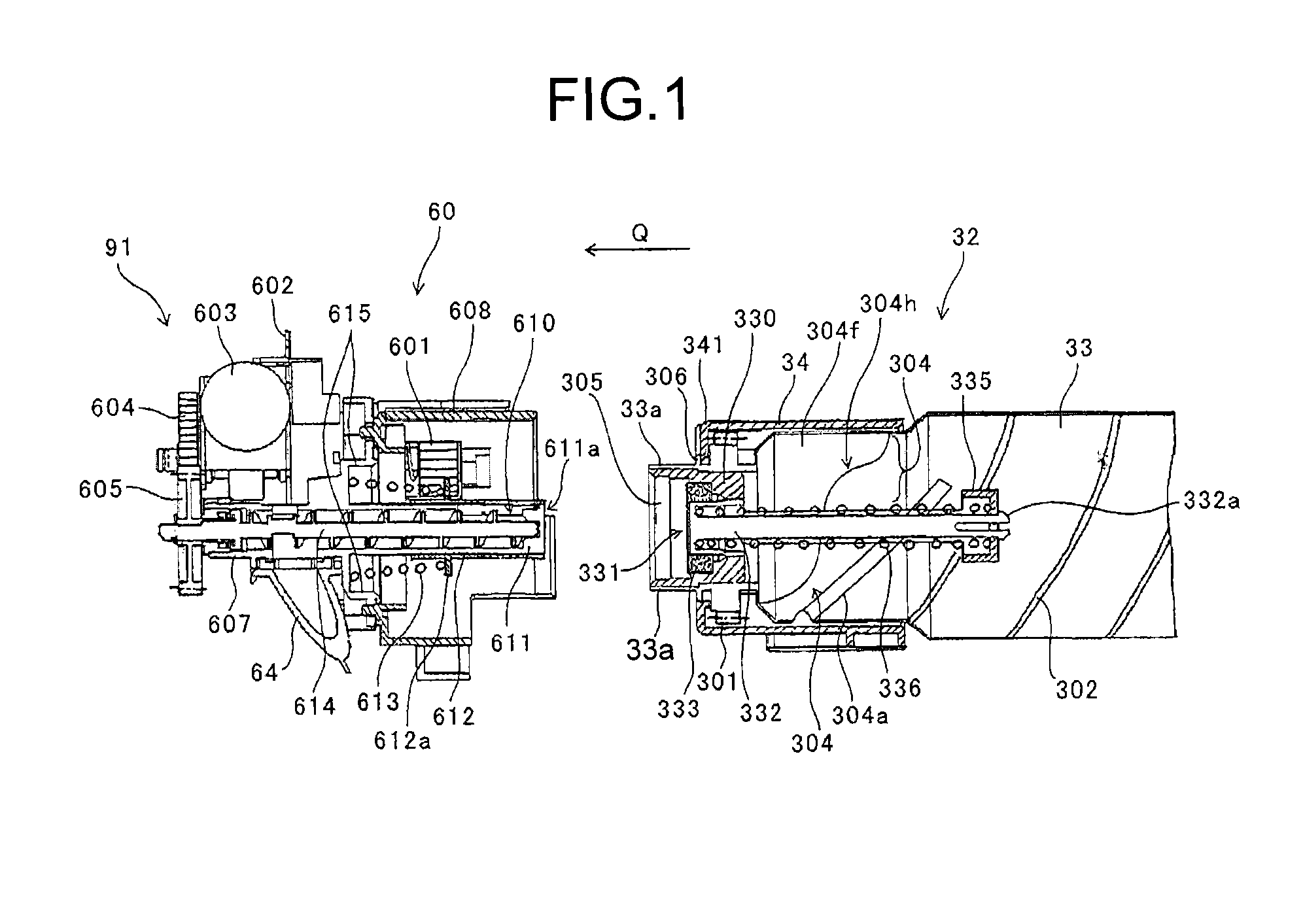

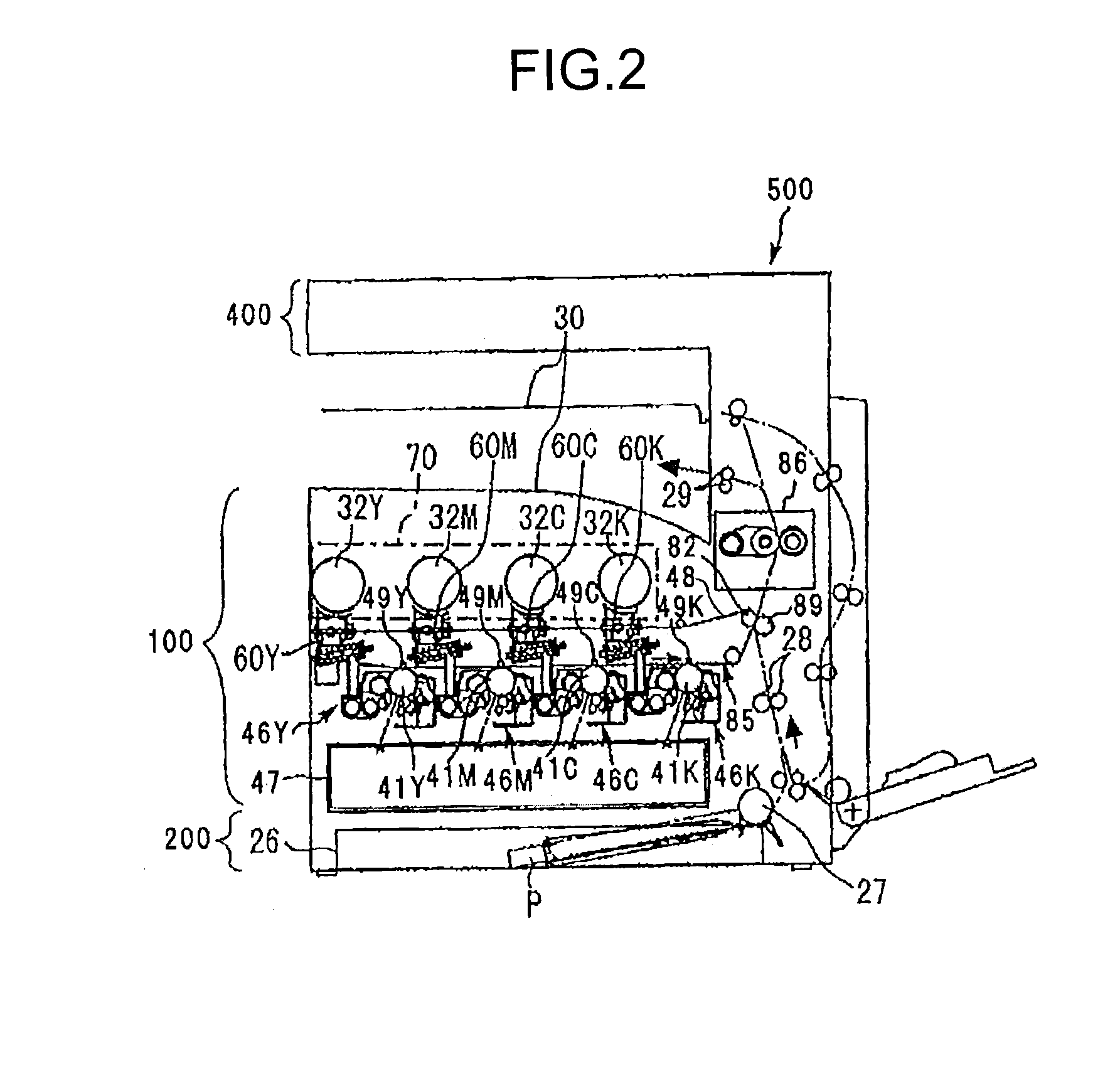

Powder container and image forming apparatus

A powder conveying device includes: a conveying nozzle, provided with a powder receiving opening; an open / close member to open / close the powder receiving opening; a flange provided to the open / close member; a biasing member to bias the open / close member; and a container setting section to which a part of a powder container is to be fit. The powder container includes: a conveyor to convey the powder from a second end of the powder container to a first end; a container opening protruding from the first end; a nozzle receiving opening into which the conveying nozzle is to be inserted; and a butting portion provided in the container opening, to butt against the flange. When the powder container is attached to the powder conveying device, the container opening is fitted to the container setting section, and the flange and the biasing member are housed in an inner space of the container opening.

Owner:RICOH KK

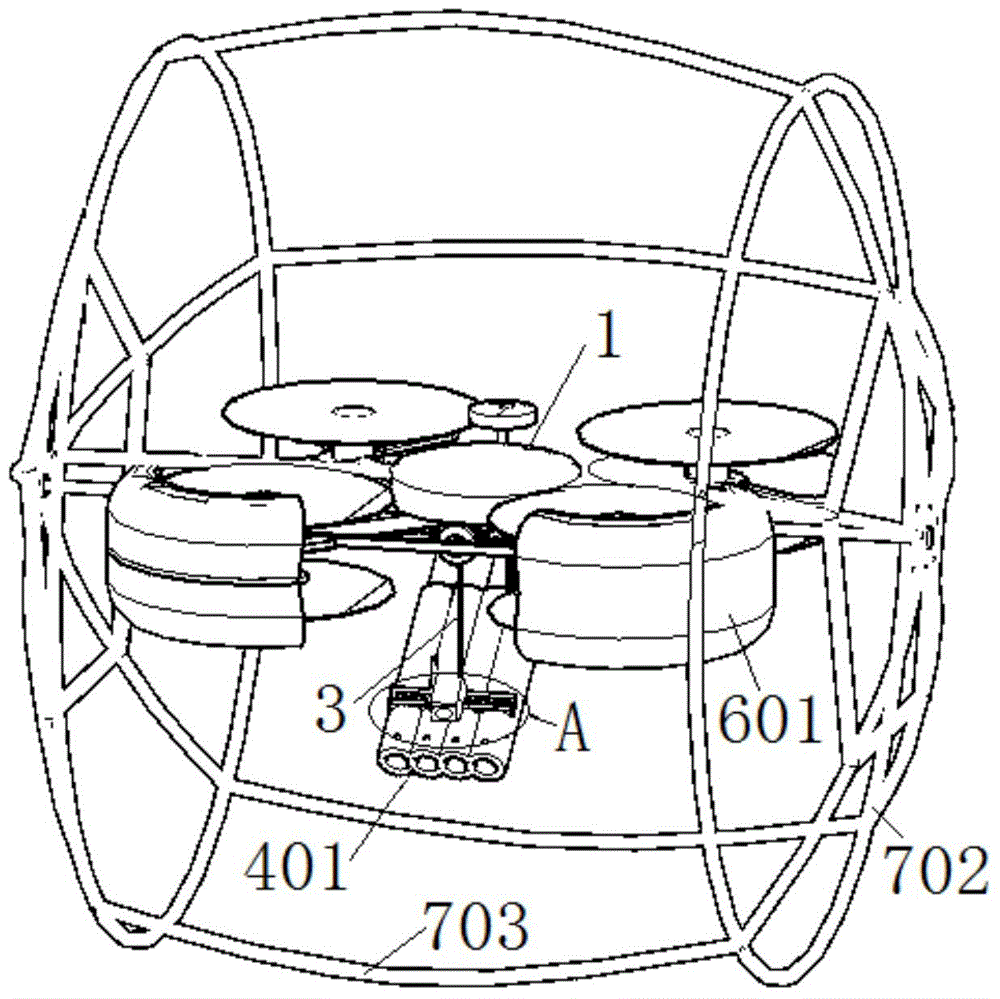

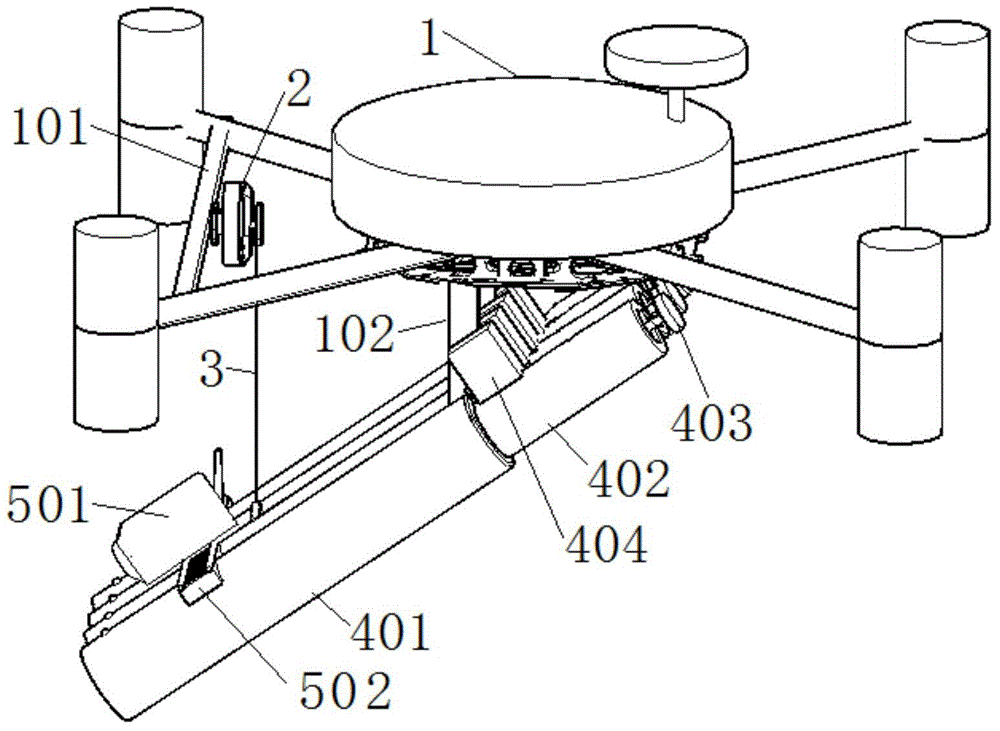

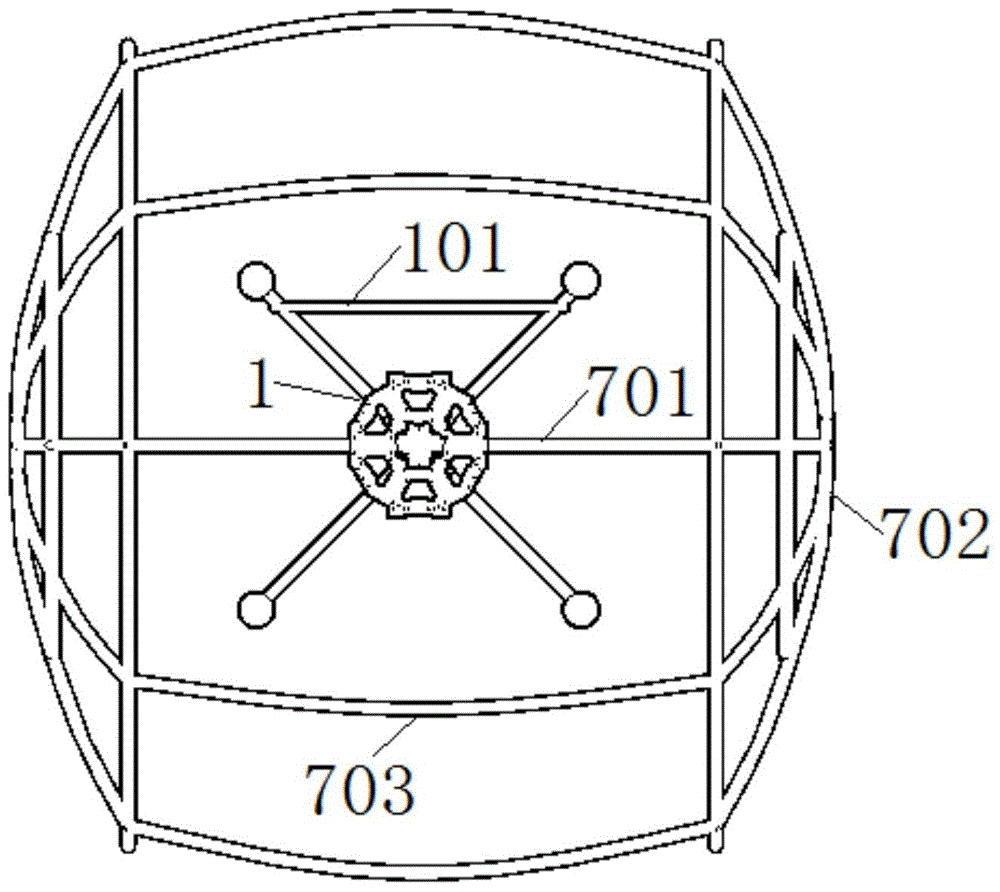

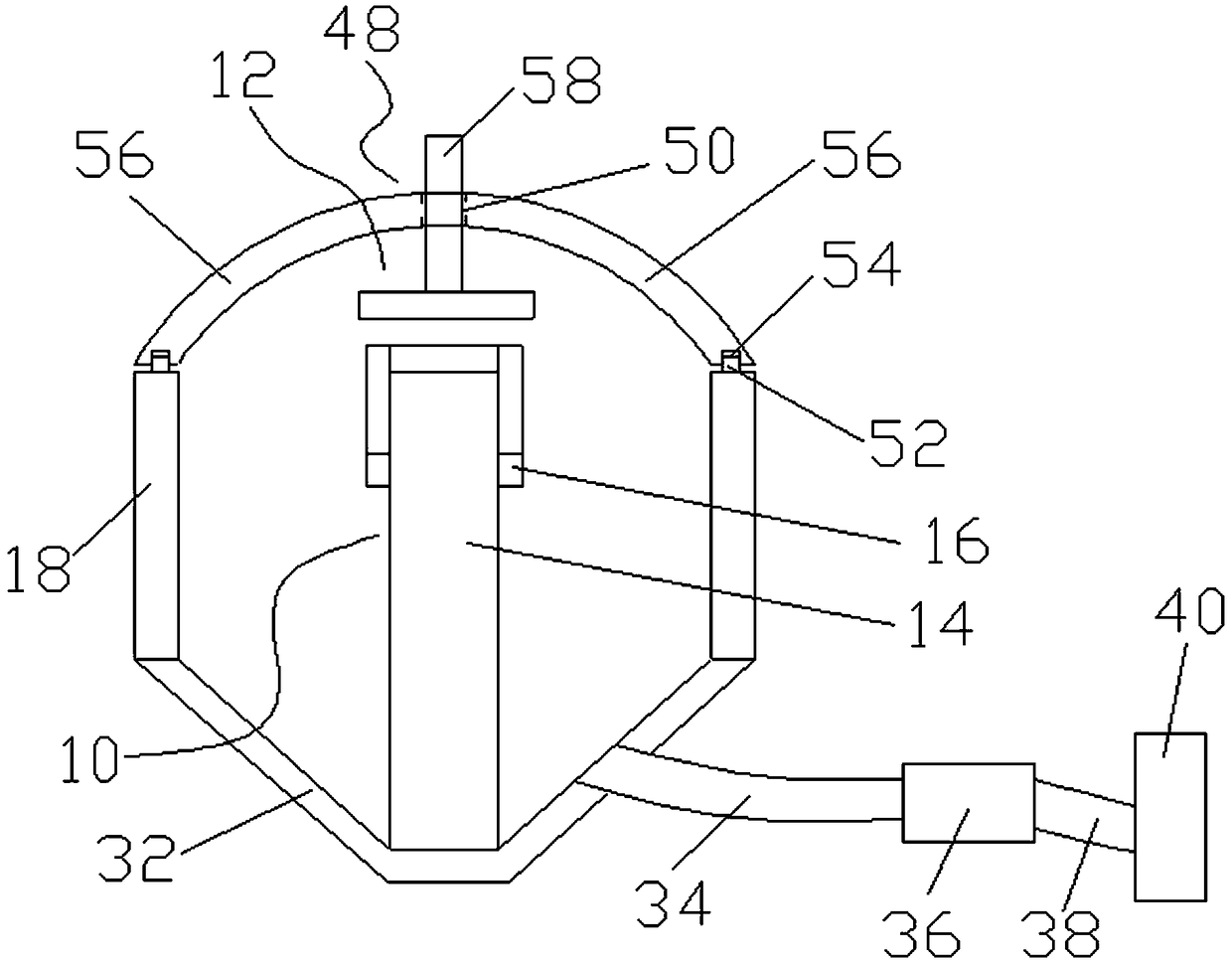

Anti-collision fixed-point unmanned aerial vehicle for fire control

The invention discloses an anti-collision fixed-point unmanned aerial vehicle for fire control, and belongs to the field of unmanned aerial vehicles. The anti-collision fixed-point unmanned aerial vehicle for fire control comprises an unmanned aerial vehicle body, a bomb-dropping gun and an anti-collision cover, wherein the bomb-dropping gun is arranged below the unmanned aerial vehicle body; a steering engine is mounted on the bomb-dropping gun and is used for controlling the bomb-dropping gun to launch a fire extinguishing bomb; a collimation mechanism is mounted on the parallelly arranged bomb-dropping gun, so that the bomb-dropping accuracy is improved; the anti-collision cover adopts a cage-shaped structure; the cage-shaped structure encircles the periphery of the unmanned aerial vehicle body to protect the unmanned aerial vehicle body from being collided; a waterproof cover is also arranged on a spiral paddle support to prevent the spraying of flames. According to the anti-collision fixed-point unmanned aerial vehicle, fixed-point fire extinguishment on high-rise buildings and narrow channels is carried out without geographical environment limitation, and the unmanned aerial vehicle is unlikely to collide and damage, high in flying speed, sensitive in actions and wide in application range.

Owner:如东道博智能设备有限公司

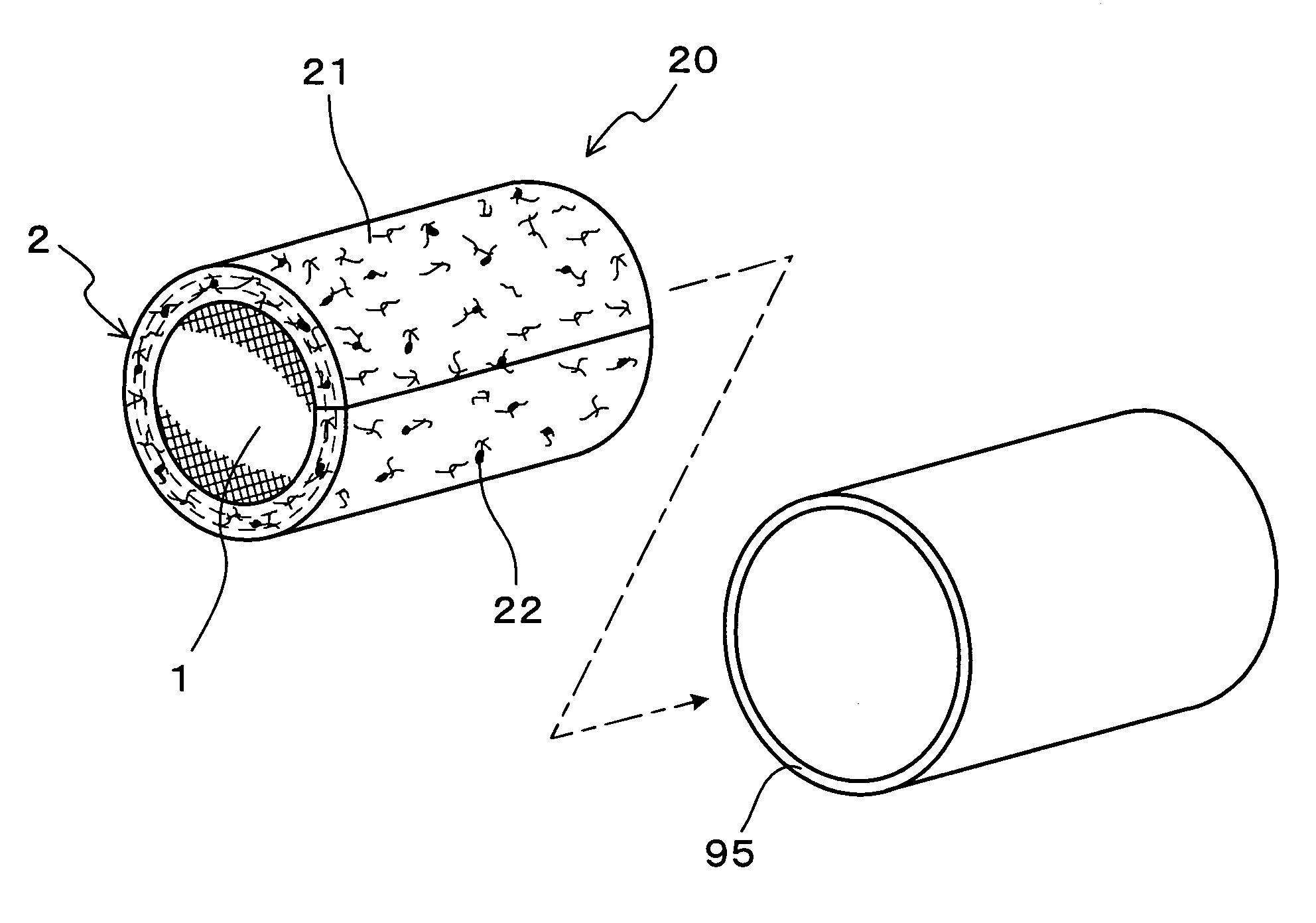

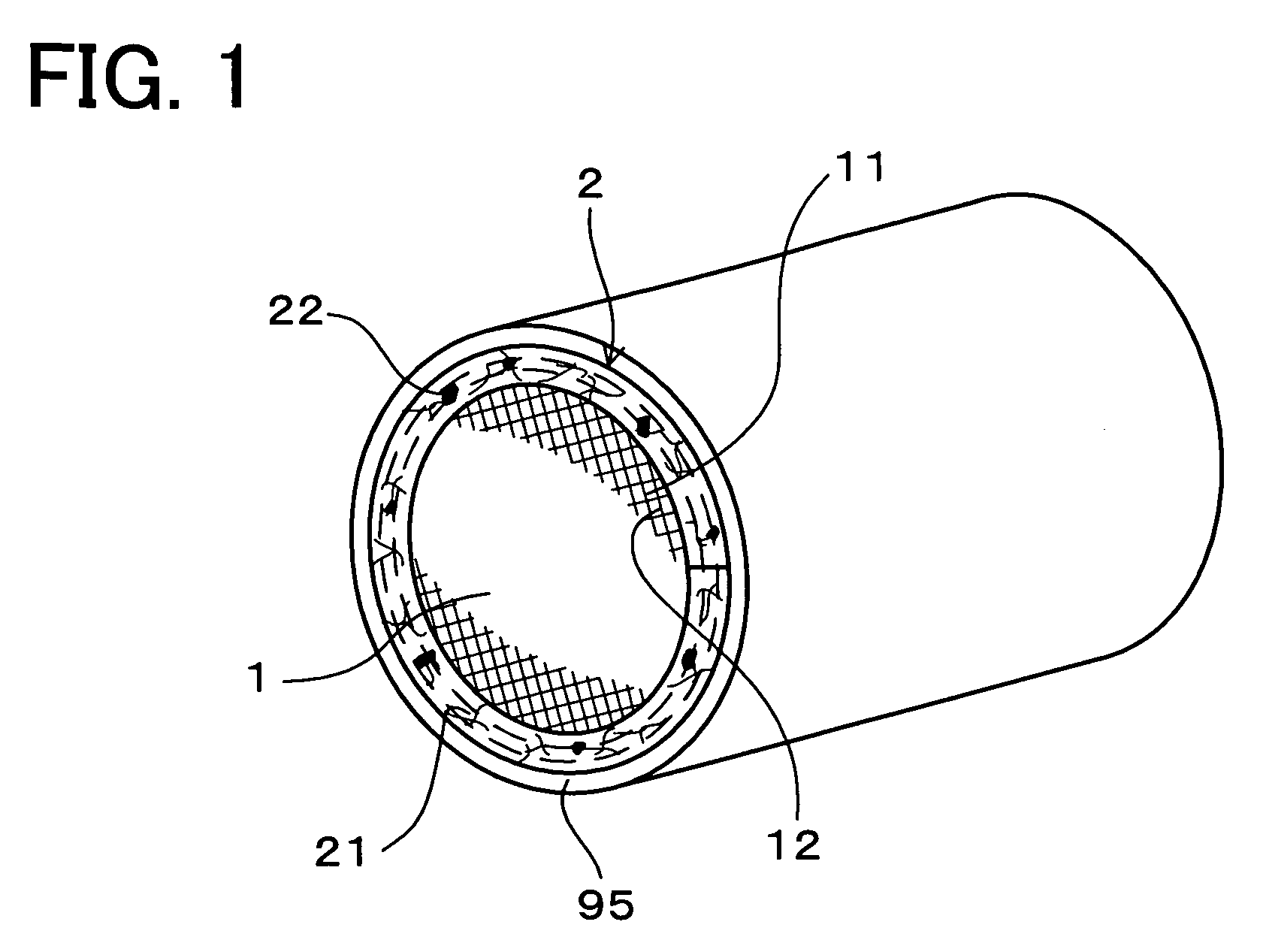

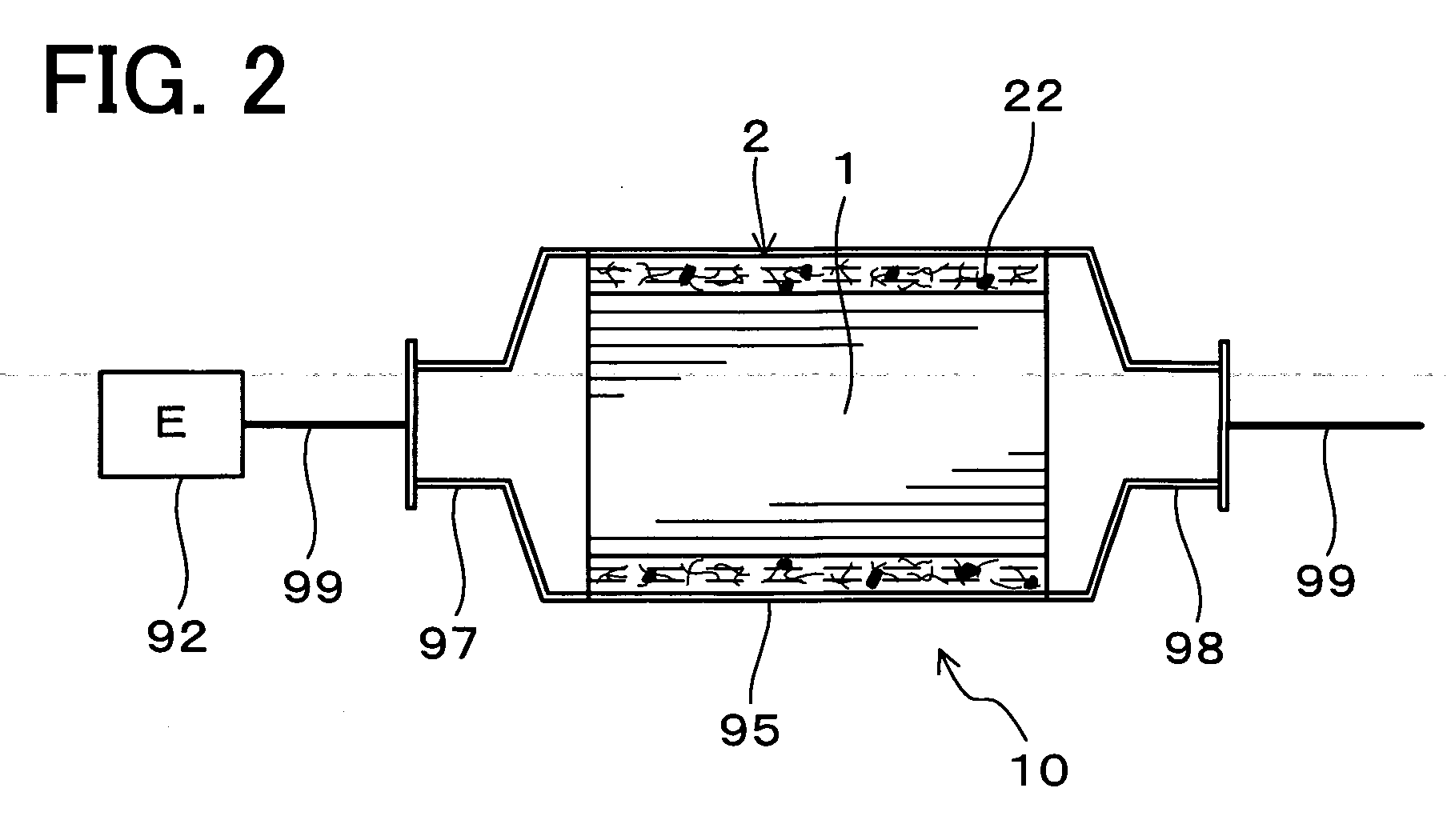

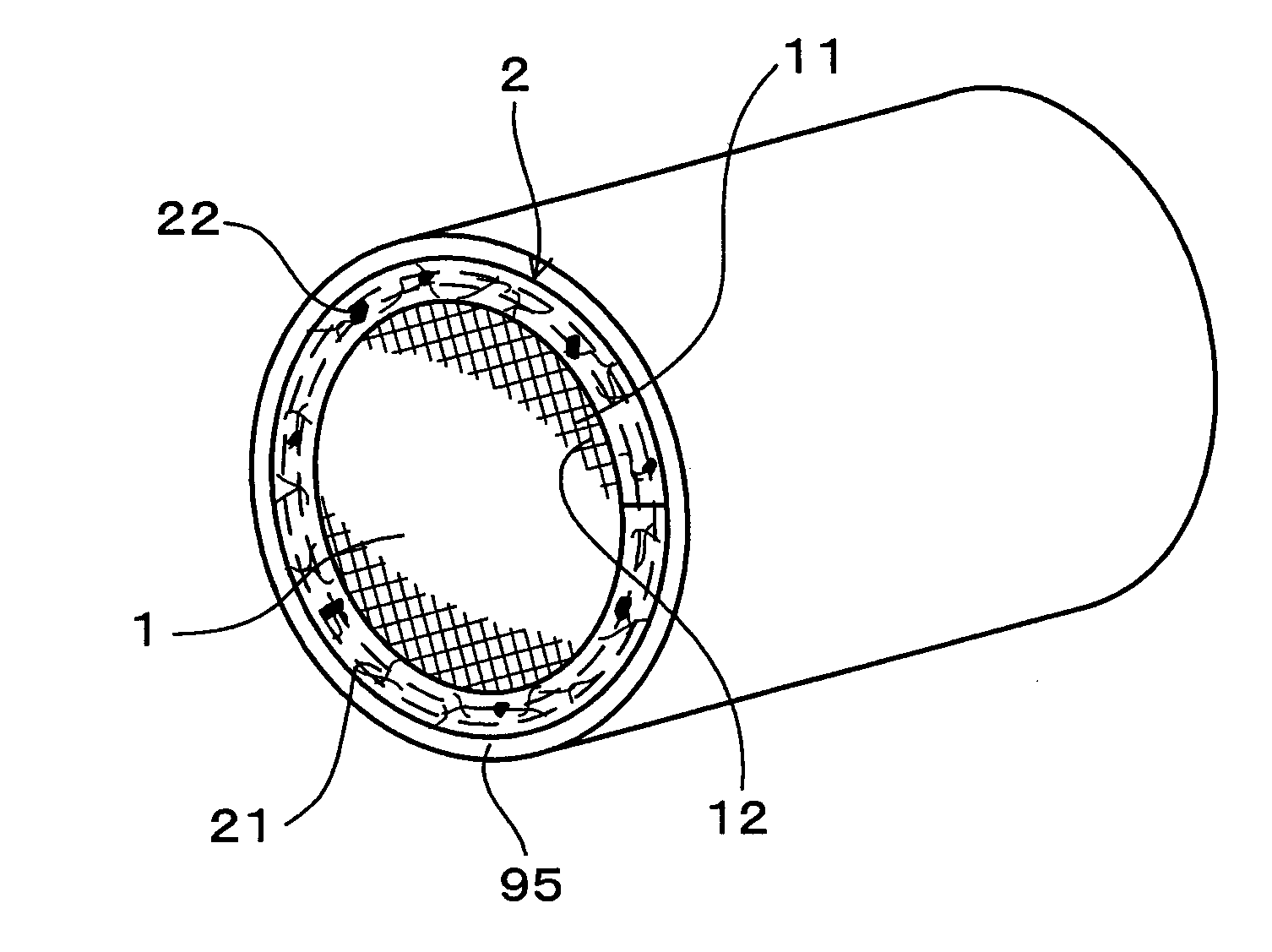

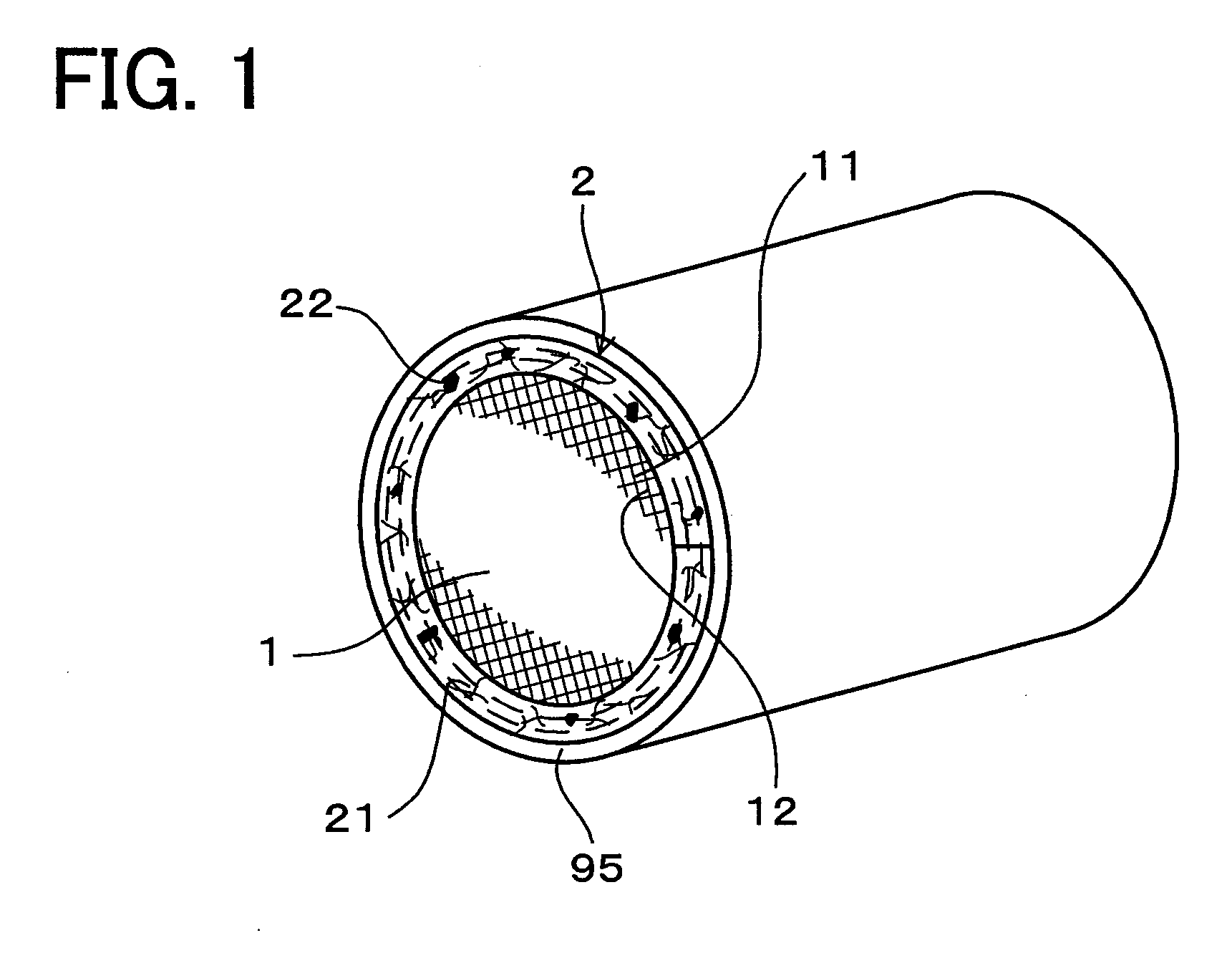

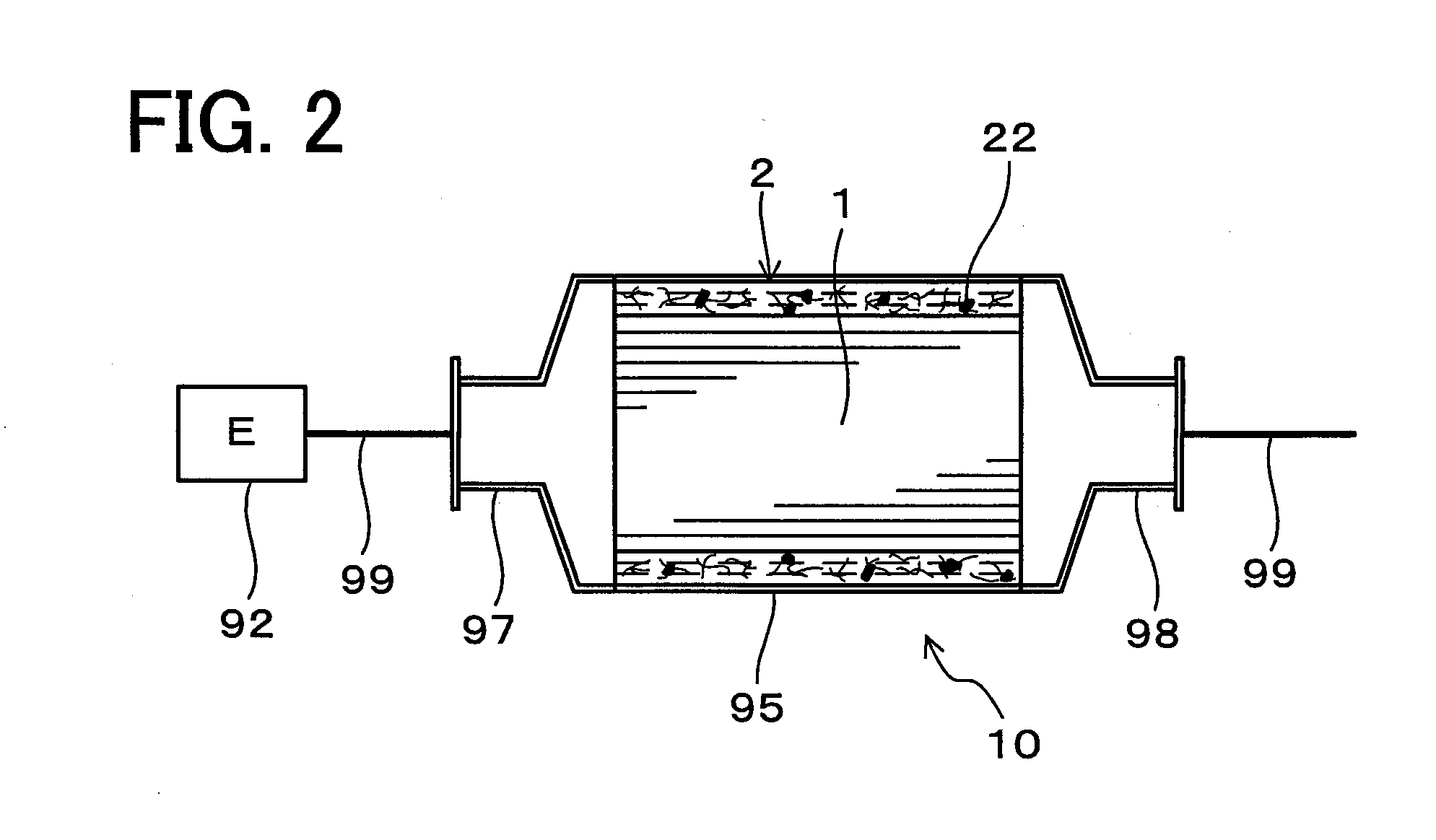

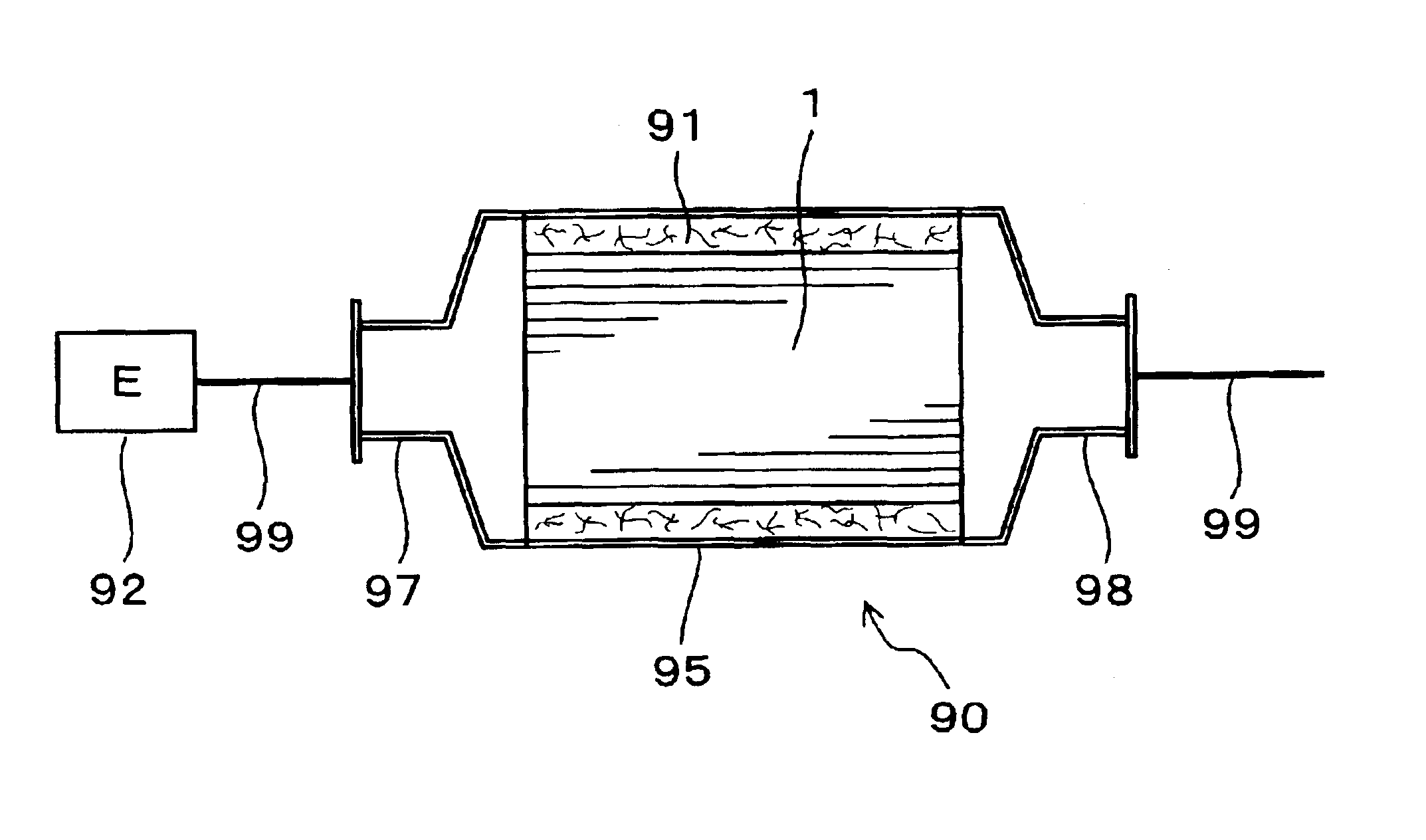

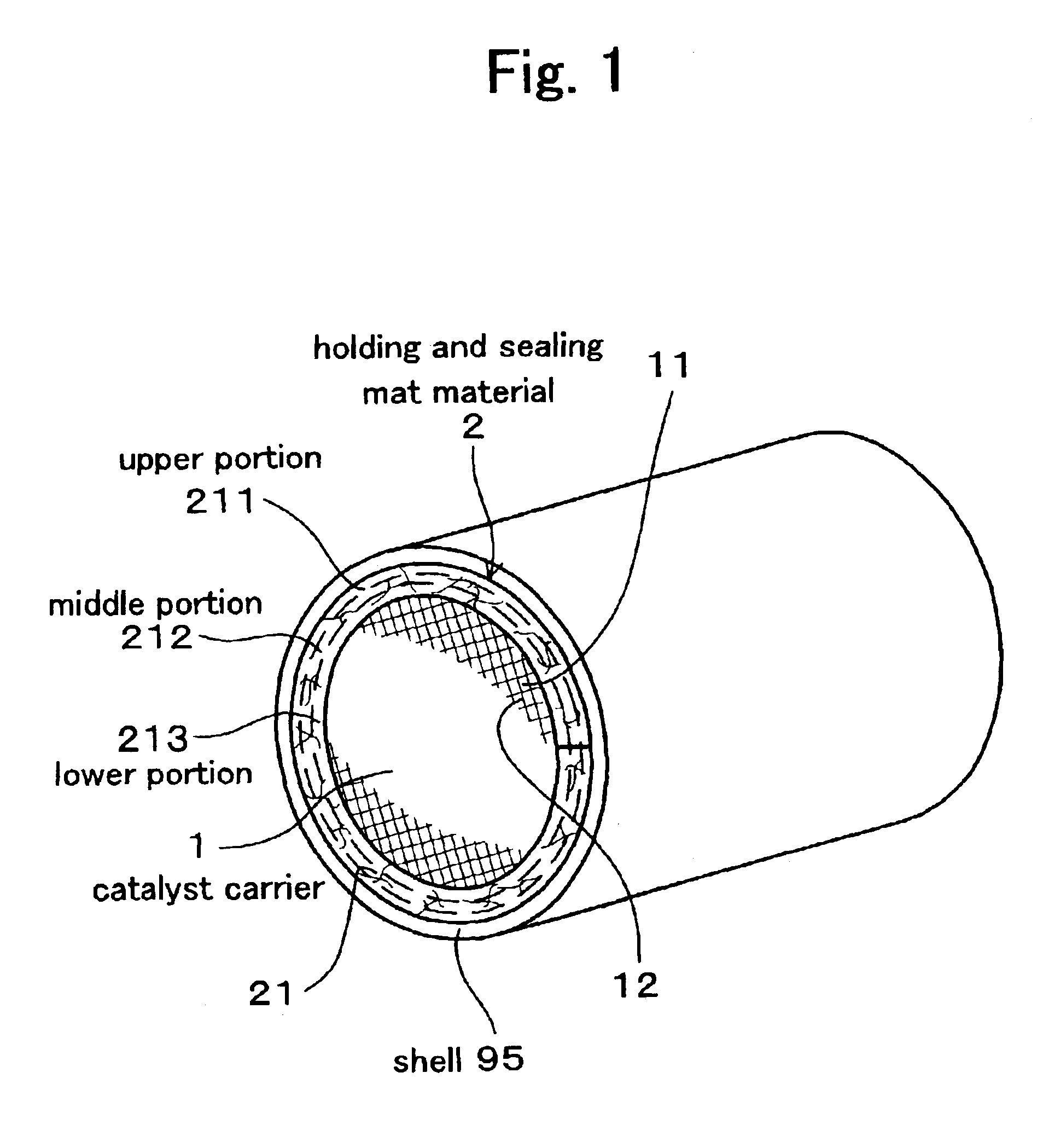

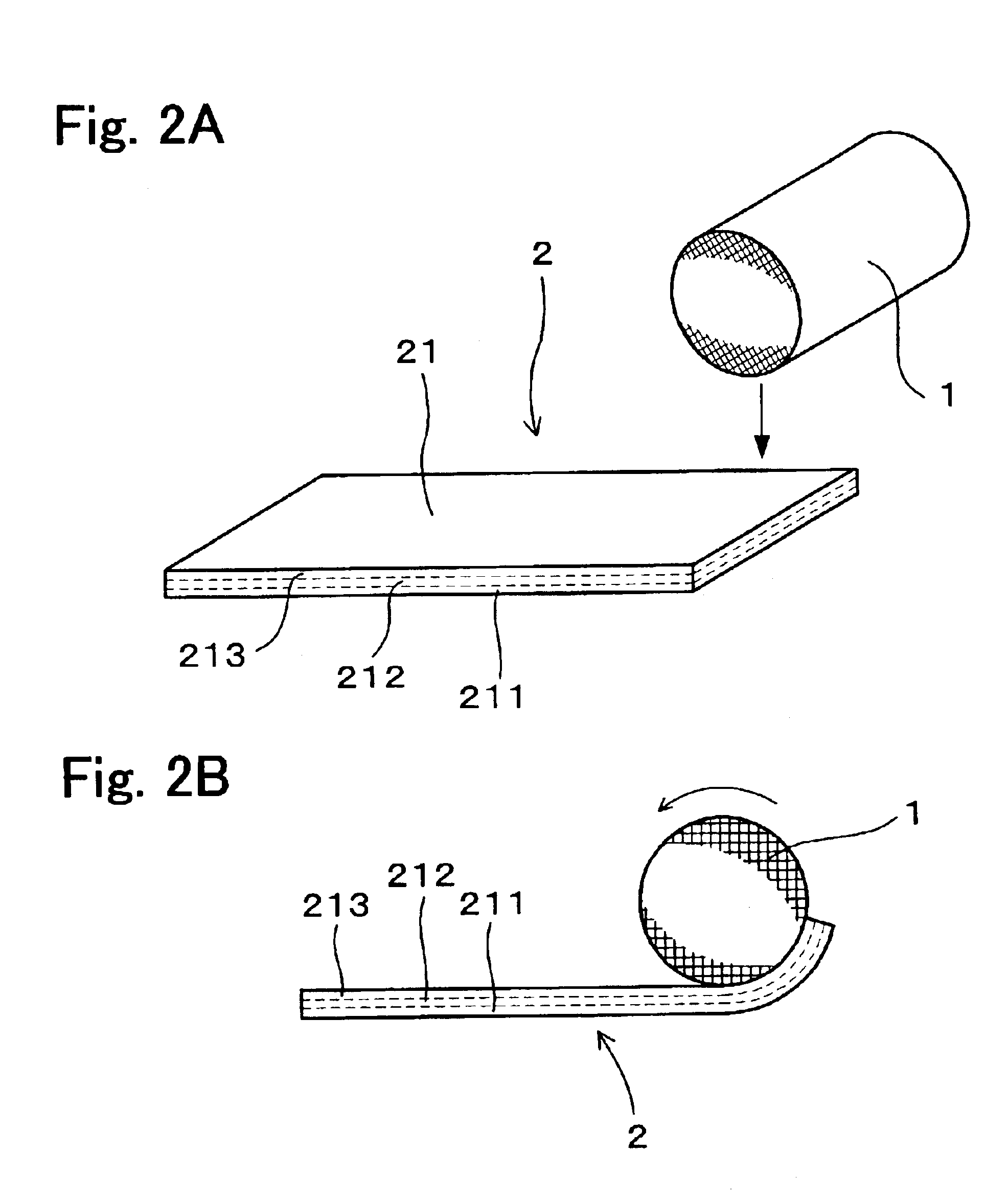

Holding and sealing material and manufacturing method thereof

InactiveUS20060278323A1Improve athletic abilityImprove good performanceInternal combustion piston enginesExhaust apparatusEmulsionEngineering

The present invention relates to a holding and sealing material 2 set between a catalyst carrier 1 and a shell 95 which covering the outside of the catalyst carrier 1 in a catalytic converter for purifying an exhaust gas and manufacturing method thereof. An organic binder 22 on the holding and sealing material 2 has the glass transition point Tg (° C.) of less than or equal to approximately 5° C. In addition, an infiltrating step and a drying step are conducted during the manufacturing. In the infiltrating step, the mat-like material is infiltrated with emulsion containing the organic binder. In the drying step, the mat-like material containing the emulsion is dried.

Owner:IBIDEN CO LTD

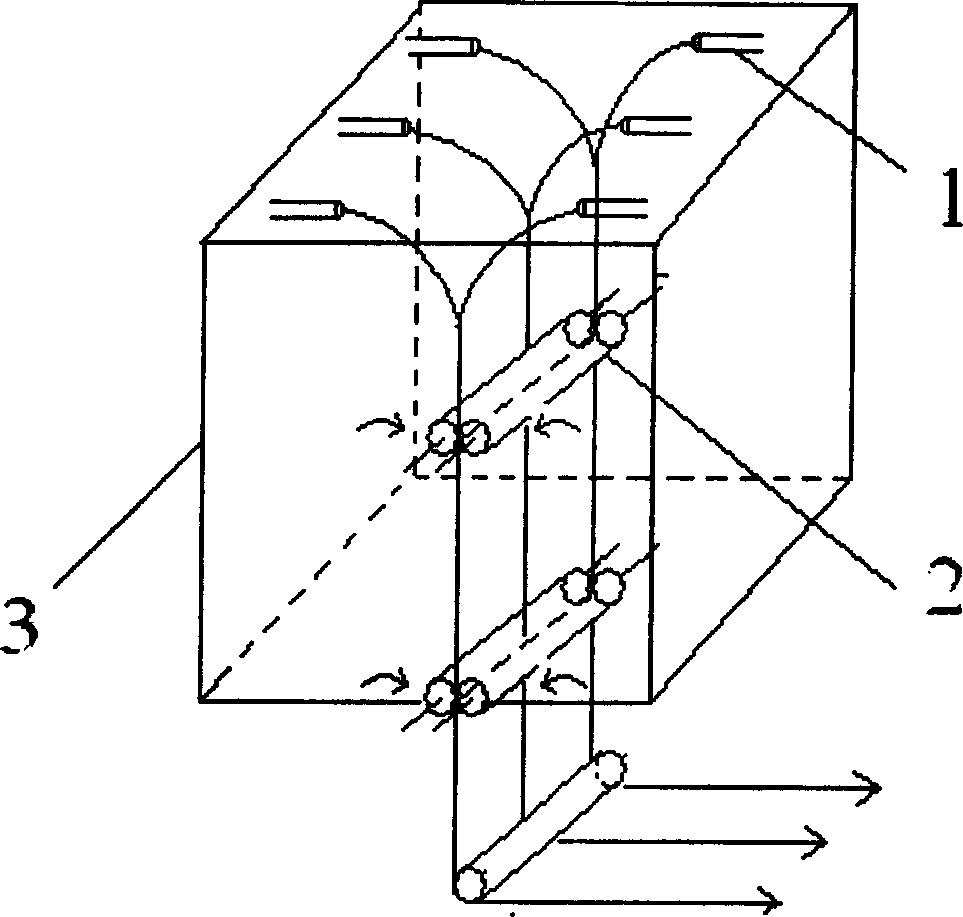

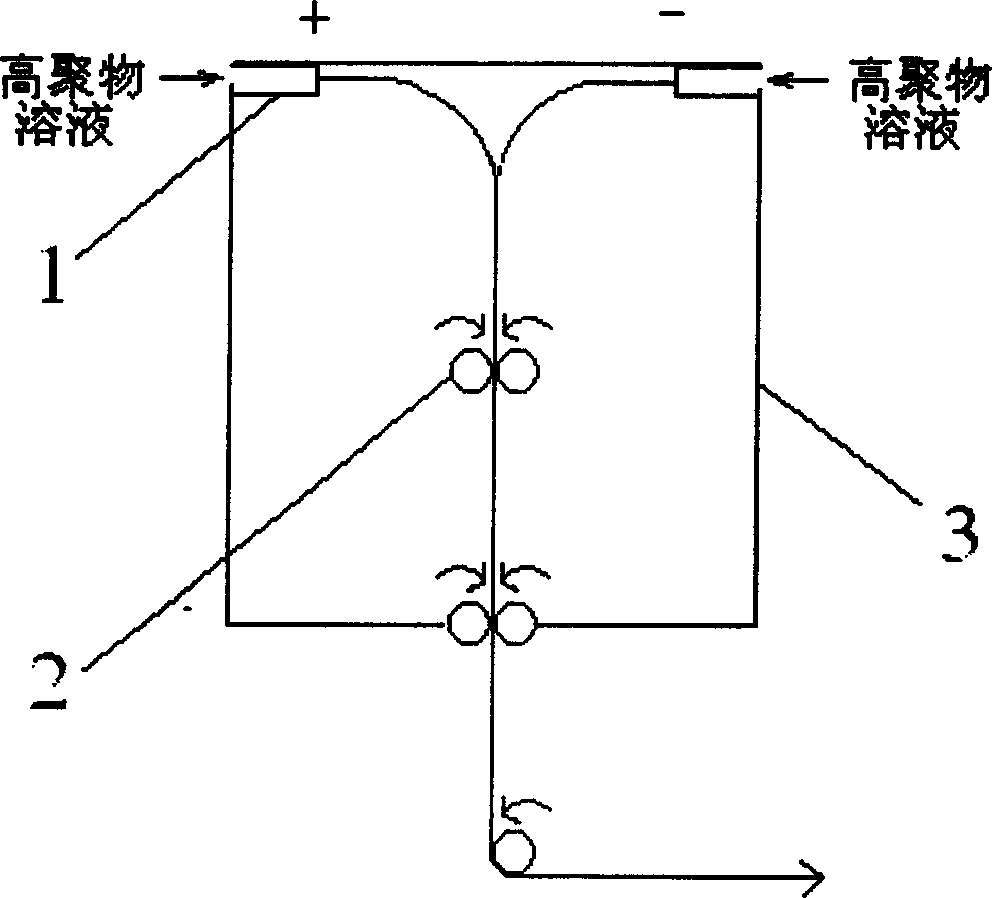

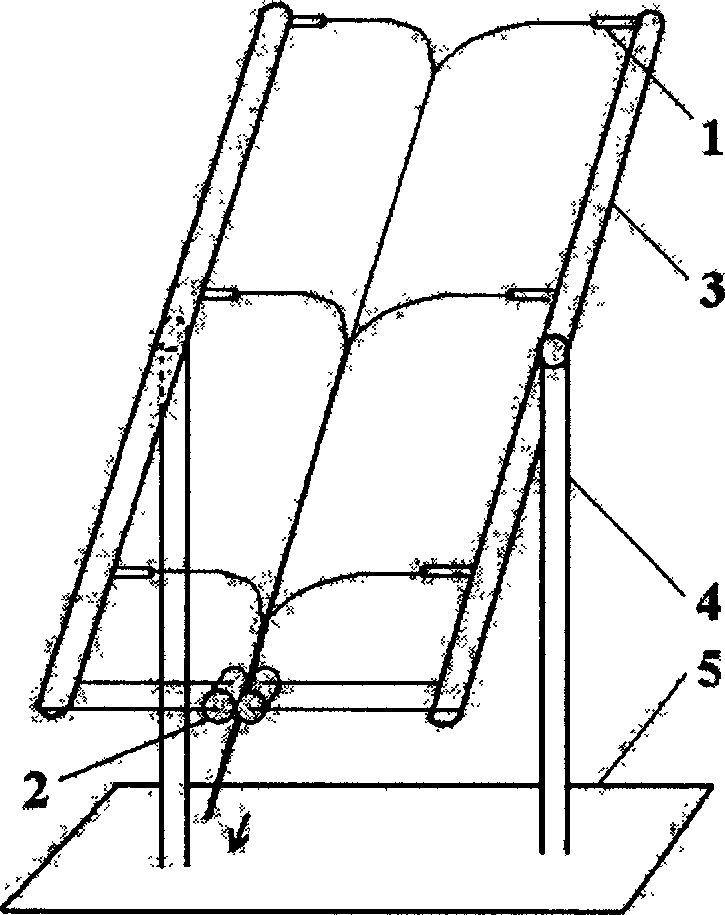

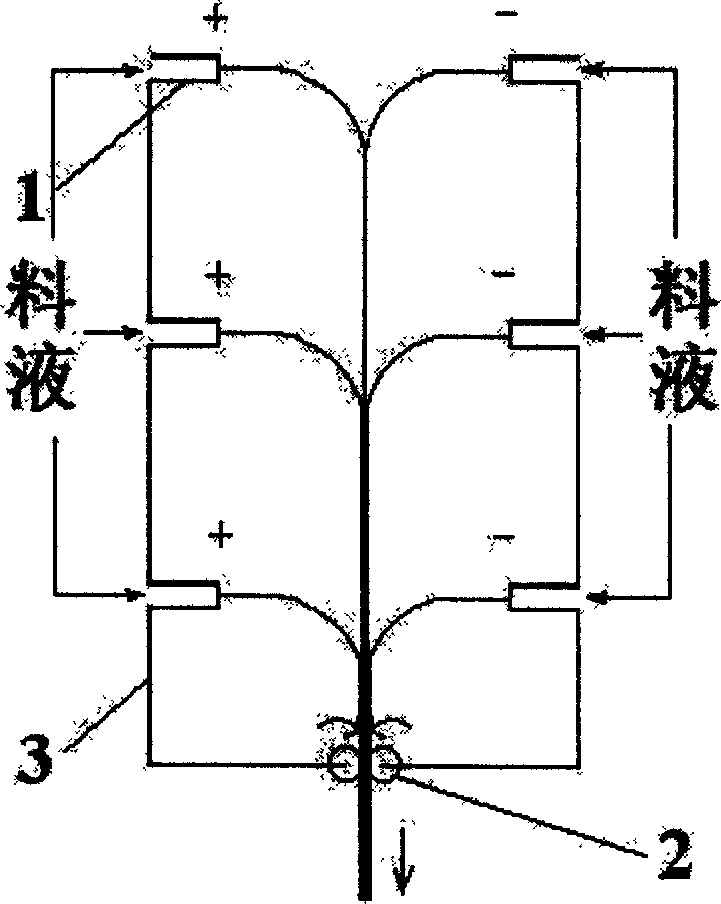

Method for preparing nano fiber endless tow

The production method of filament of nanofibers is a simply and high efficiency way. It adopts spinning trunk (3). There are two lines of nozzles (1) whose spout are opposite at the height of the top of the trunk. There are several group of pare of thread guide roller (2) in the trunk.. The distance between thread guide roller and nozzles are equal. The material process is: 1) Transport high polymer solution to nozzles in the trunk of filament of nanofibers; 2) Bring high-voltage DC of opposite polarity to bear to the nozzles. 3) High polymer solution at the top of the nozzles is stretched and whipping responded to form nanofibers which contain electric charge. The opposite nozzle spray nanofibers contains contrary electric charge. They are allure and collide in the air and form nanofibers. The nanofibers are stretched and towed by nozzle and filament of nanofibers comes into being. The operation is simple, highly effective and has no losing of nanofibers.

Owner:SOUTHEAST UNIV

Holding and sealing material and manufacturing method thereof

ActiveUS20090049690A1Improve athletic abilitySuppress interruptCombination devicesInternal combustion piston enginesEmulsionGlass transition point

The present invention relates to a holding and sealing material 2 set between a catalyst carrier 1 and a shell 95 which covering the outside of the catalyst carrier 1 in a catalytic converter for purifying an exhaust gas and manufacturing method thereof. An organic binder 22 on the holding and sealing material 2 has the glass transition point Tg (° c) of less than or equal to approximately 5° C. In addition, an infiltrating step and a drying step are conducted during the manufacturing. In the infiltrating step, the mat-like material is infiltrated with emulsion containing the organic binder. In the drying step, the mat-like material containing the emulsion is dried.

Owner:IBIDEN CO LTD

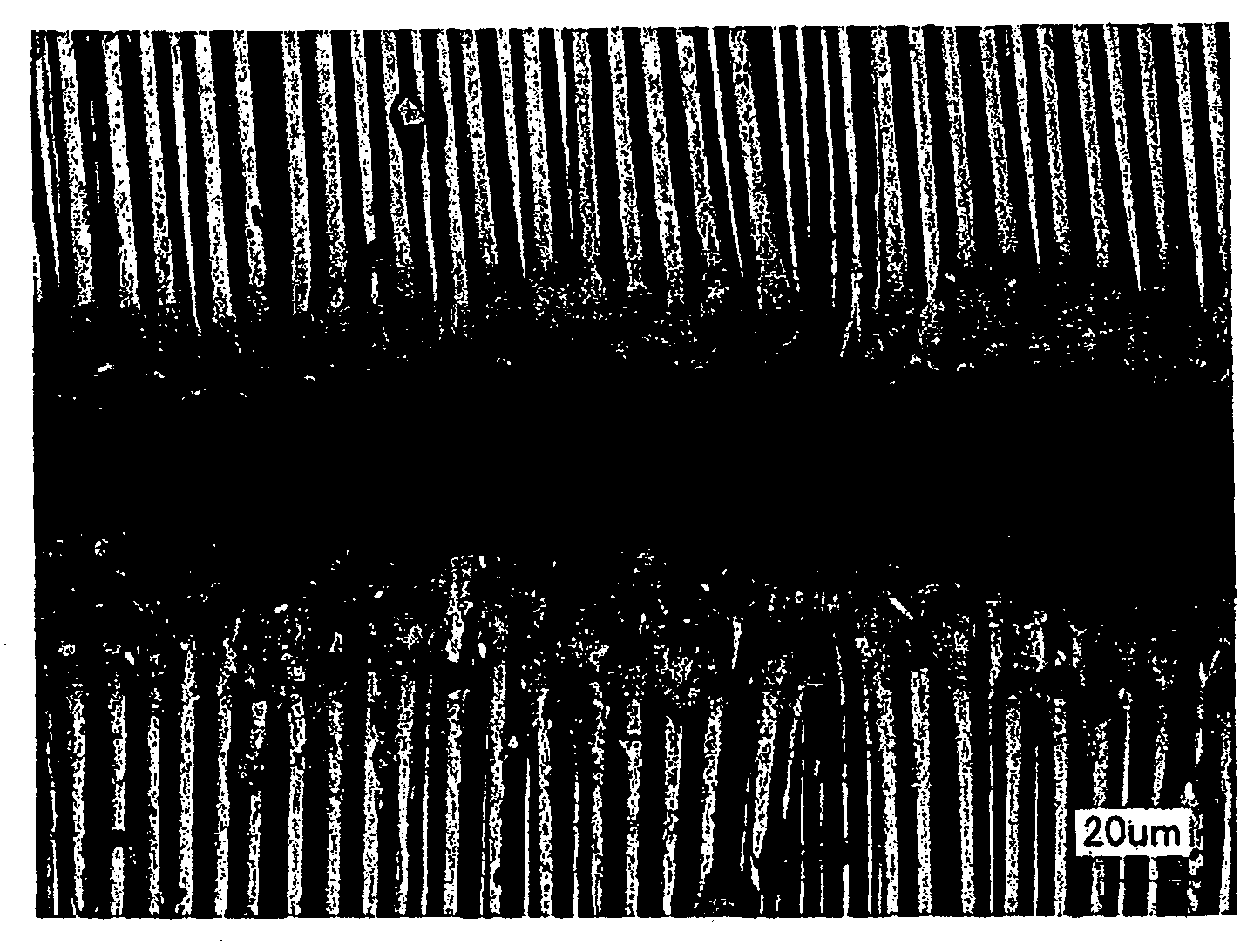

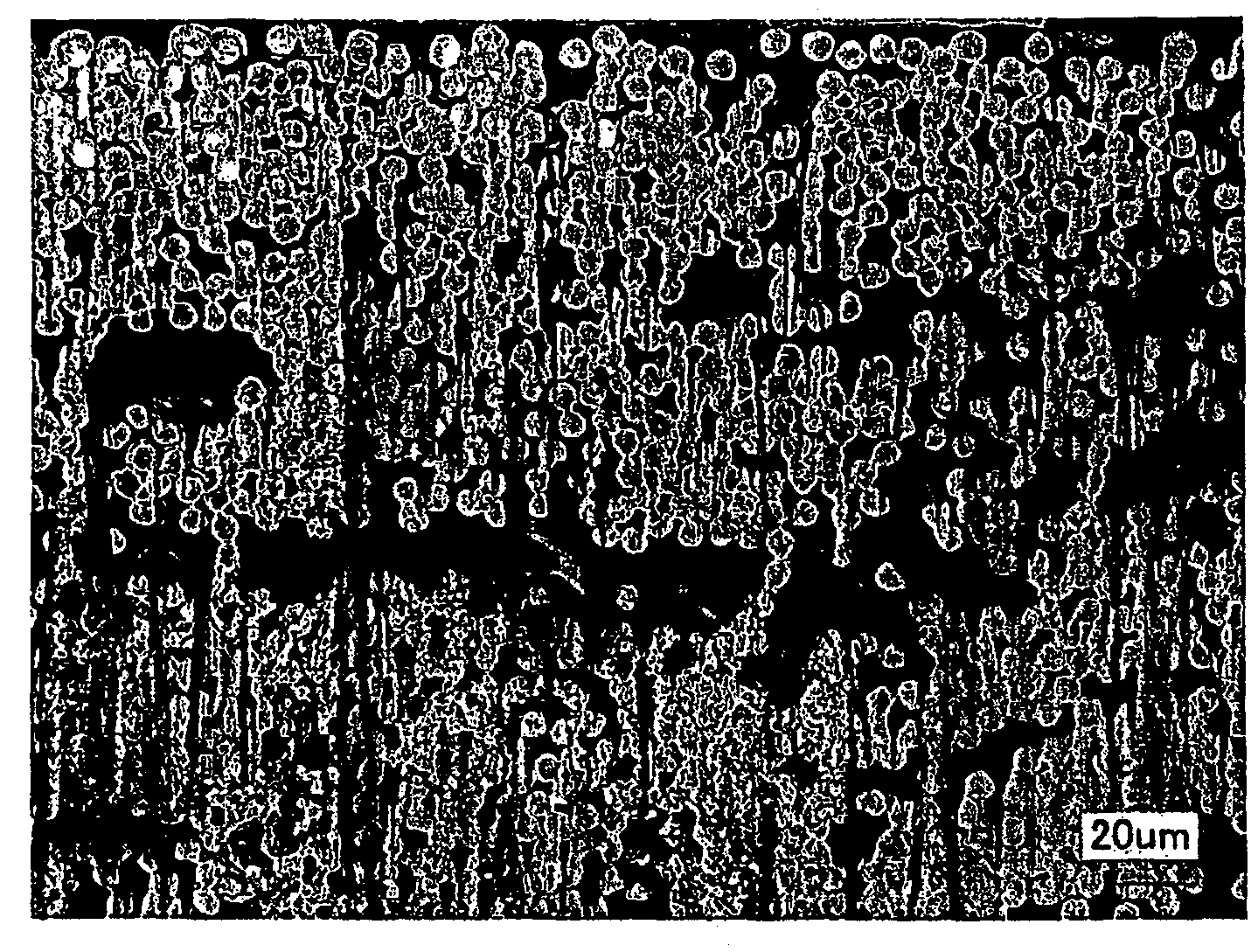

Sputtering target producing few particles, backing plate or sputtering apparatus and sputtering method producing few particles

InactiveUS6858116B2Avoid separationAvoid flyingCellsLiquid surface applicatorsOptoelectronicsPlasma sprayed

A sputtering target producing few particles, a backing plate or a sputtering apparatus, and a sputtering method producing few particles. An arc-spraying coating film and a plasma-spraying coating film over the former are formed on the sputtering target, a backing plate, or another surface in the sputtering apparatus, where an unwanted film might be formed. Thus a deposit is prevent from separating / flying from the target, backing plate, or another surface where an unwanted film might be formed in the sputtering apparatus.

Owner:JX NIPPON MINING& METALS CORP

Method of laser machining of fiber-reinforced composite material and product made by the method

InactiveCN102438787AAvoid flyingWelding/soldering/cutting articlesLaser beam welding apparatusButt weldingLaser processing

A method of laser machining of a fiber-reinforced composite material of the present invention is characterized in that the fiber-reinforced composite material or composite ply material (ply material consisting of plates of metal or inorganic material and fiber-reinforced material) is cut using an ultra short pulse solid-state laser having a pulse-width ranging from 10 pico to 100 nano second and a pulse energy of 1mJ-500J, repeatedly irradiated to the material with the number of frequency ranging from 10Hz to 100kHz. According to the present invention, it is possible to work, e.g., cut, pierce, groove, or carve a fiber-reinforced composite material including CFRP, by removing materials by means of a laser with a high precision and good quality. It is also possible to form a fitting joint of proper shape so that a male-female joint may be available in a butt welding that has been hardly feasible. It is further possible to produce structural members such as a light weight panel or an H-column because the male-female joint can be used for a plate of any desired dimension (width, length and thickness).

Owner:沓名宗春

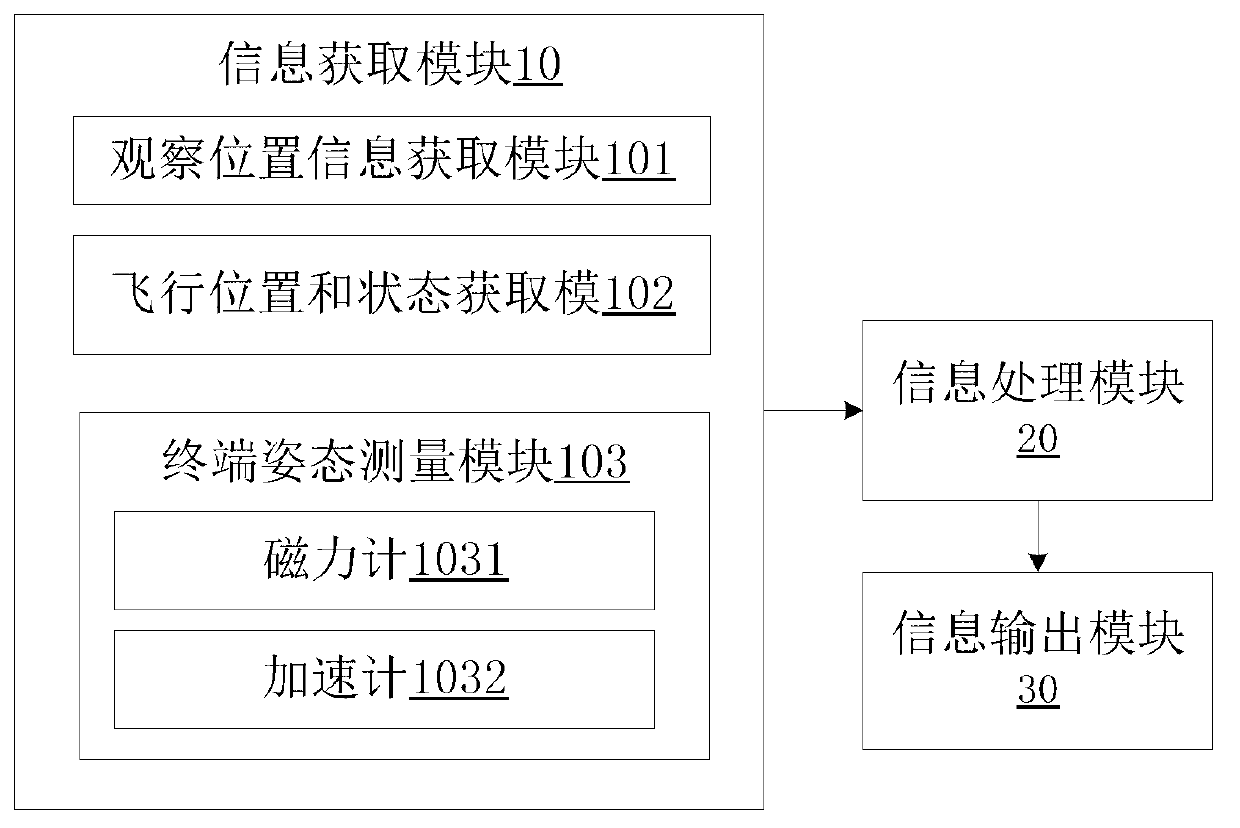

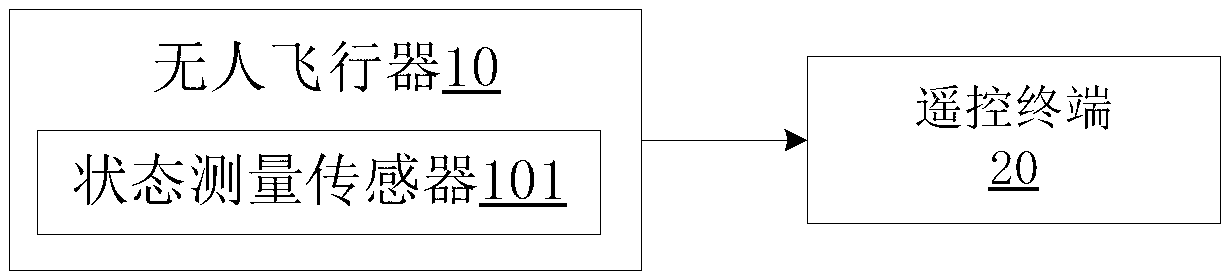

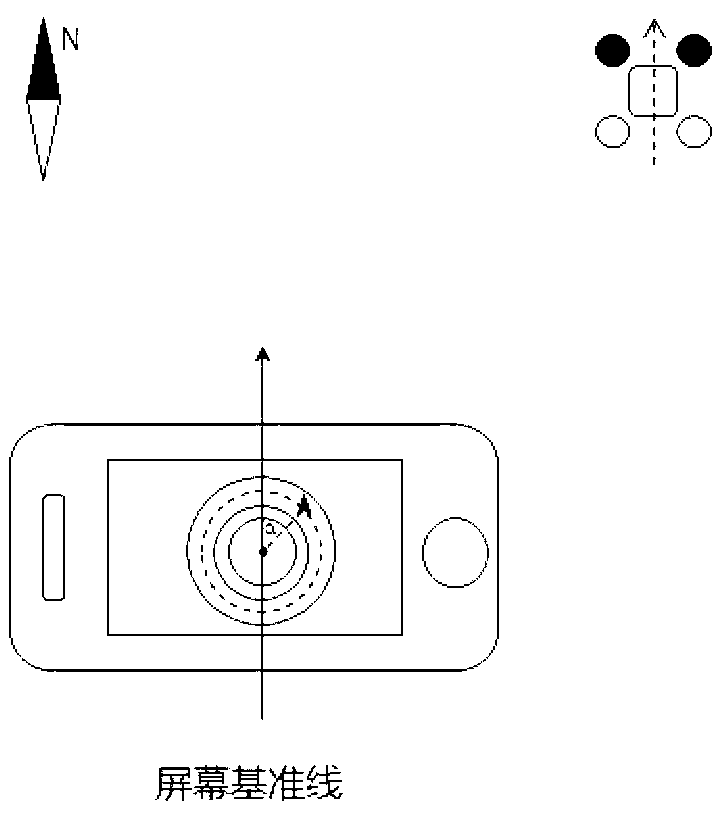

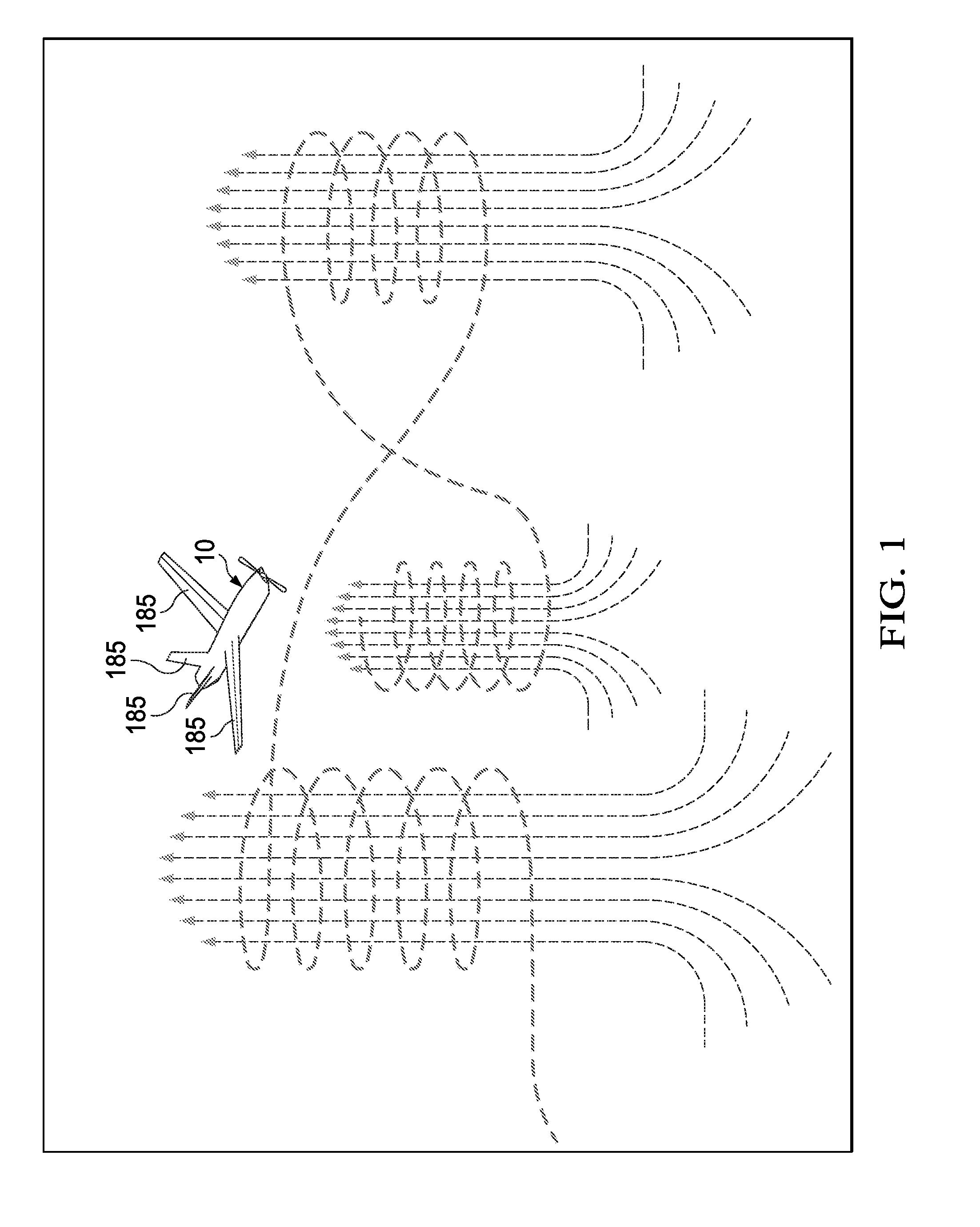

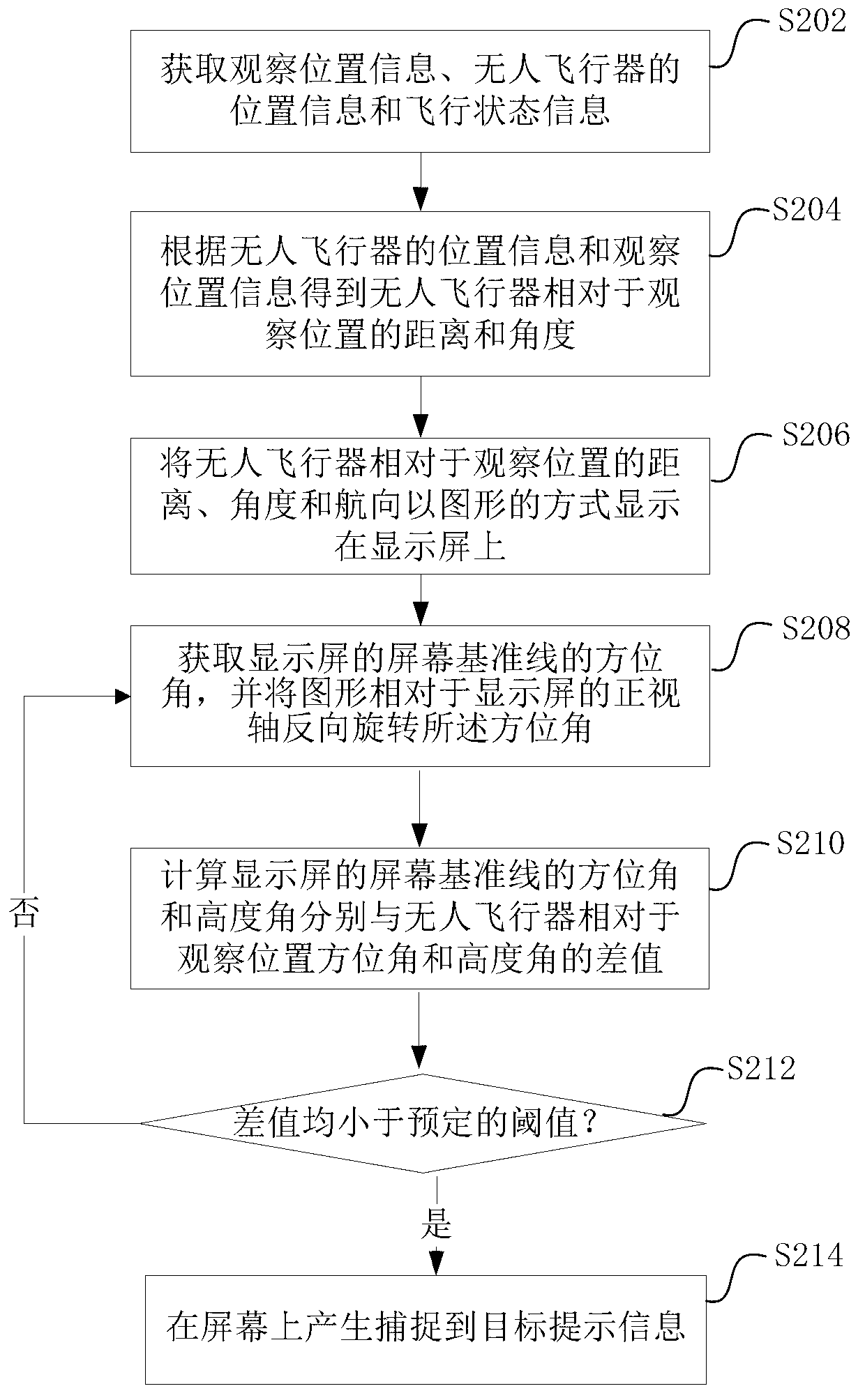

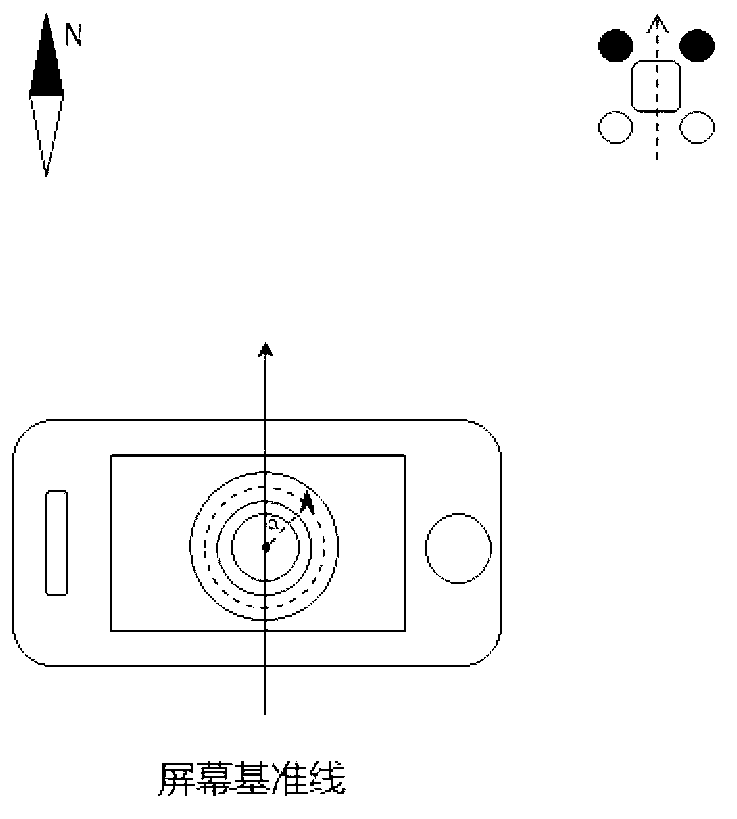

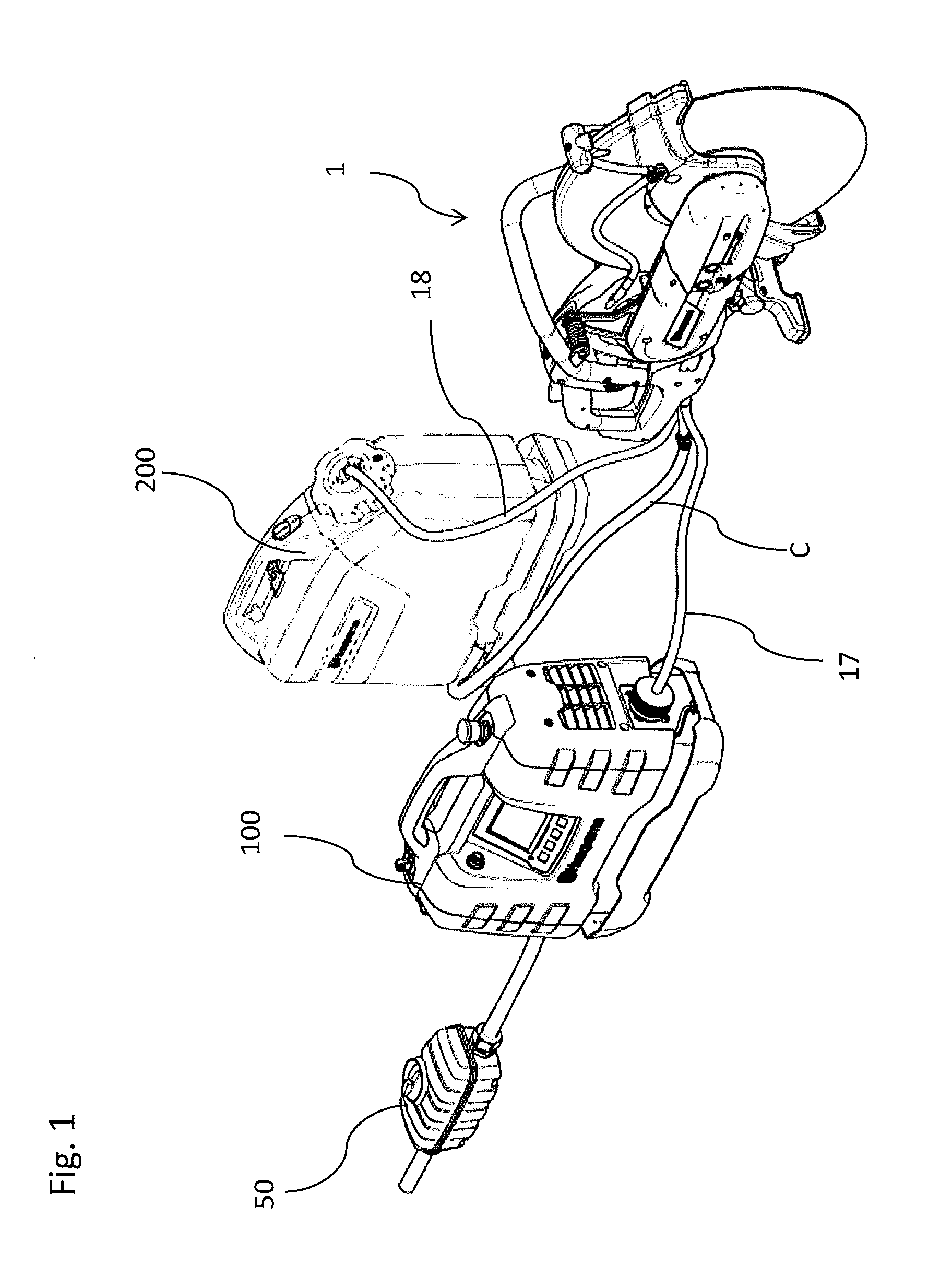

Remote control terminal of unmanned flight vehicle, as well as flight auxiliary system and method of unmanned flight vehicle

ActiveCN103345826AImprove flight experienceAvoid flying blindTransmission systemsVehicle position/course/altitude controlInformation processingFlight vehicle

The invention discloses a remote control terminal of an unmanned flight vehicle, as well as a flight auxiliary system and method of the unmanned flight vehicle, and belongs to the field of unmanned flight vehicles. The remote control terminal comprises an information acquisition module, an information processing module and an information output module; the information acquisition module is used for acquiring position information of an observation position, and acquiring position information and flight state information of the unmanned flight vehicle through a wireless network; the information processing module is used for acquiring the position information, relatively to the observation position, of the unmanned flight vehicle, according to the position information of the unmanned flight vehicle and the position information of the observation position; the information output module is used for outputting the flight state information of the unmanned flight vehicle and the position information of the unmanned flight vehicle relativley to the observation information. According to the remote control terminal of the unmanned flight vehicle, as well as the flight auxiliary system and method of the unmanned flight vehicle, a manipulator controls a flight path of the unmanned flight vehicle in an assisting manner through mastering the current flight position and the flight state of the unmanned flight vehicle; the blind flight and thw lost flight are prevented; meanwhile, the flight experience of the manipulators is improved.

Owner:SZ DJI TECH CO LTD

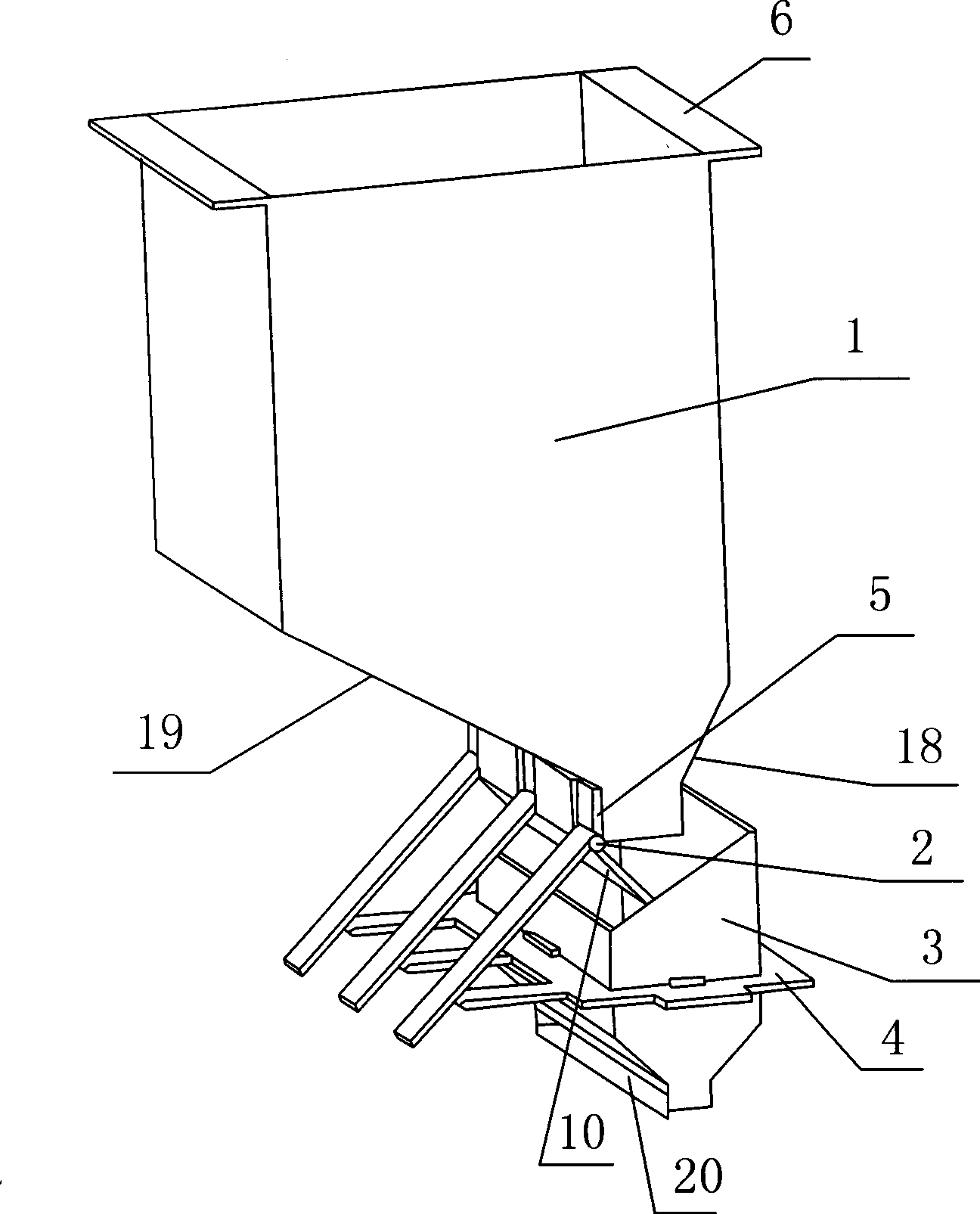

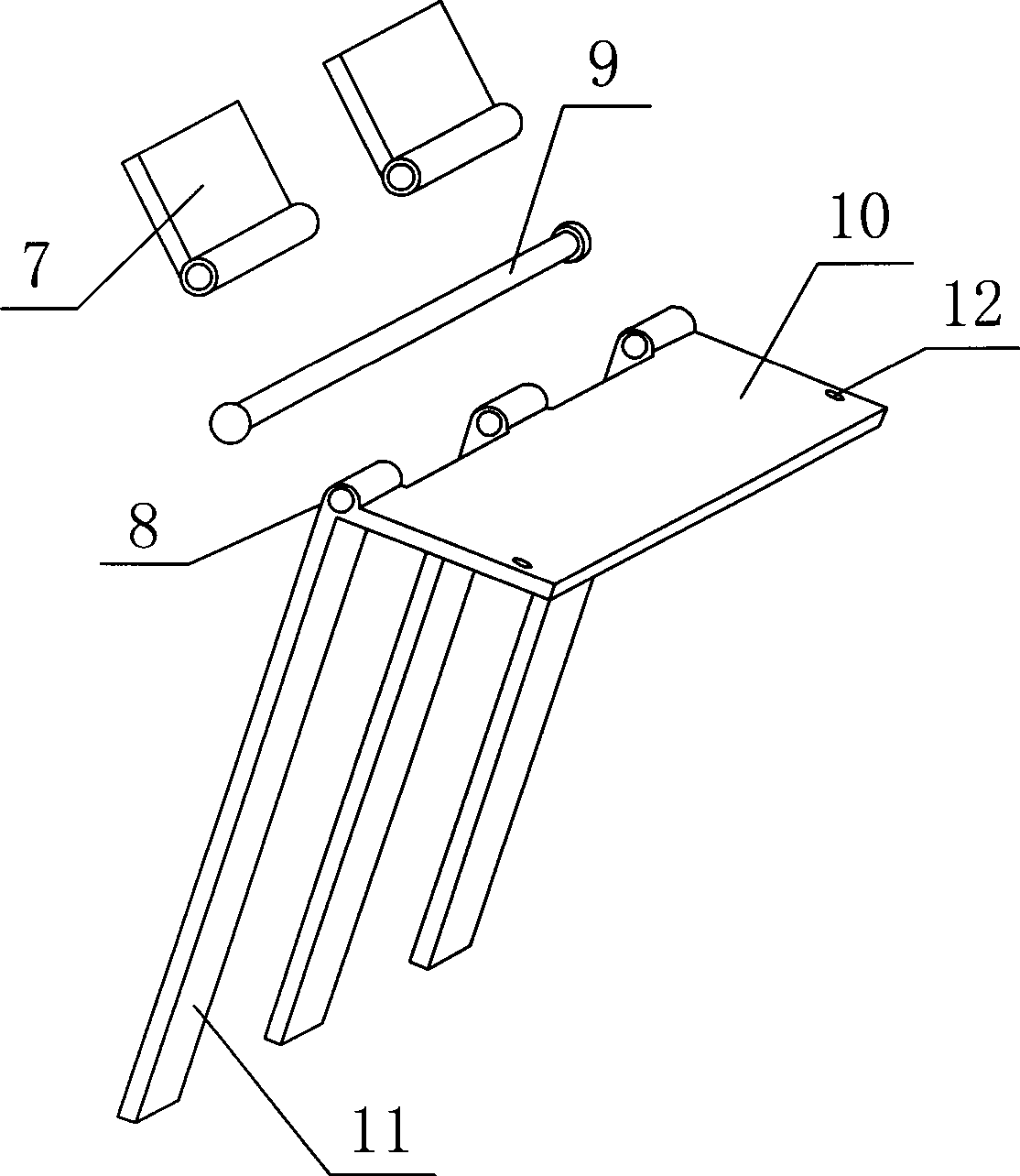

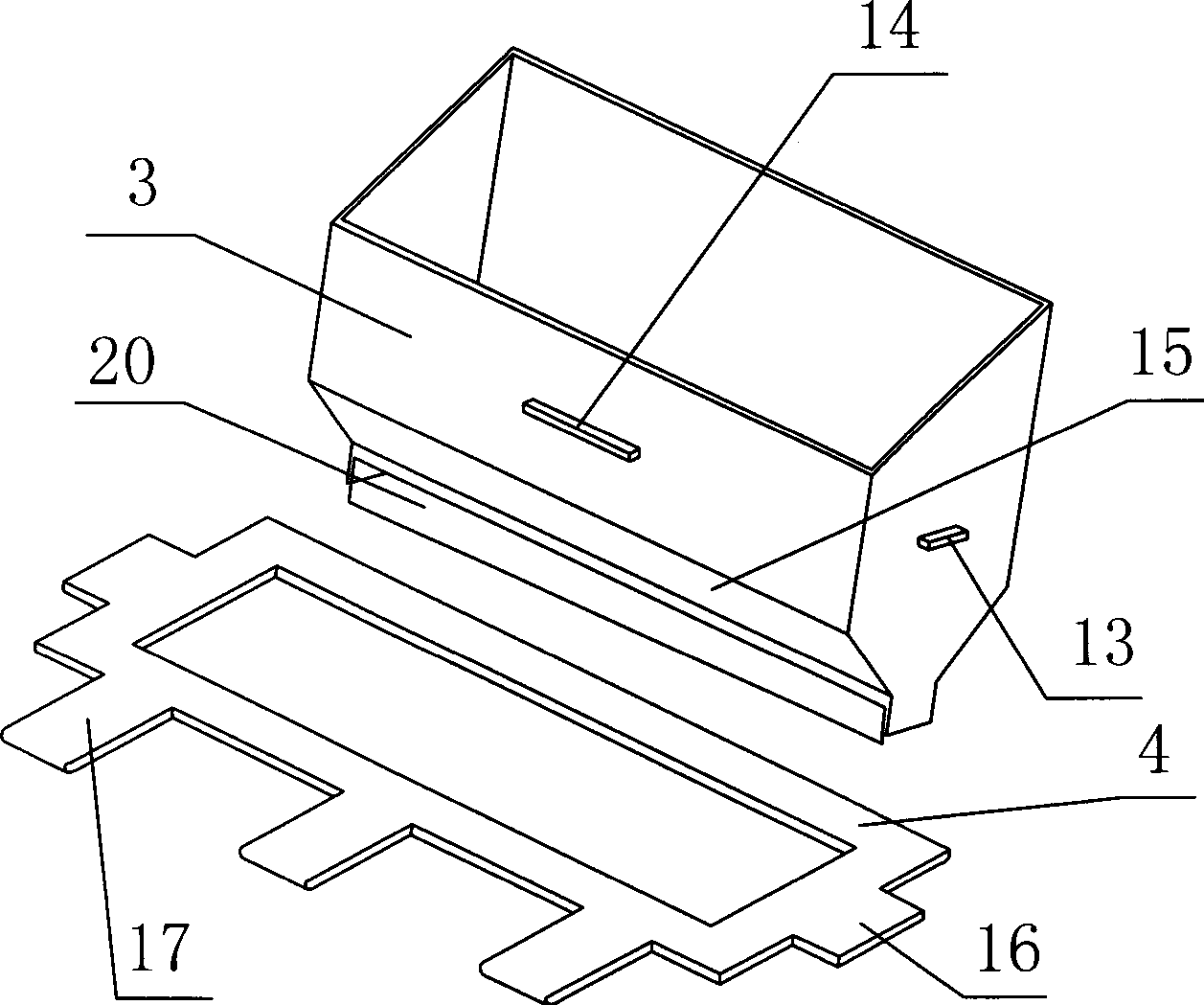

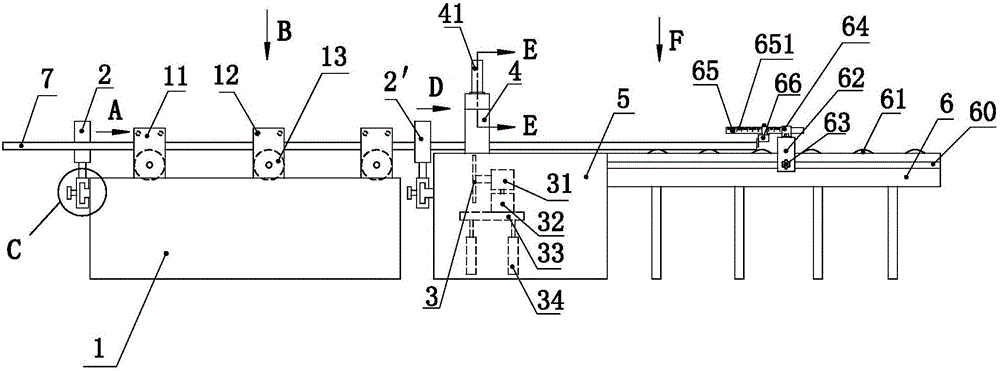

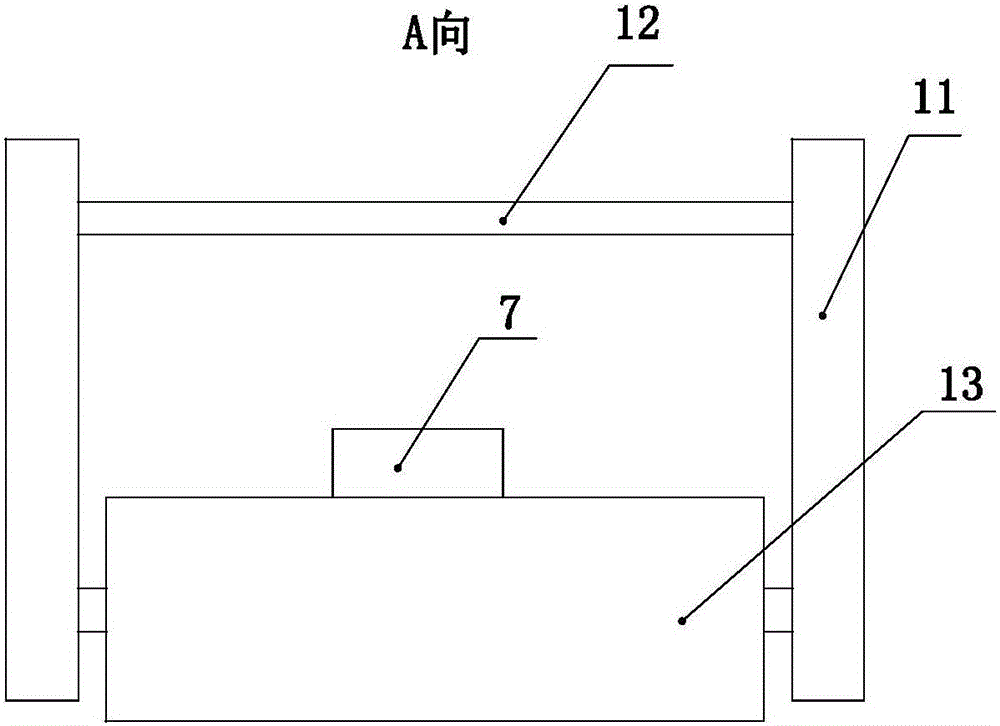

Powder sending and laying device for quickly shaping device

ActiveCN101362202APrevent dispersalAvoid wandering situationsAdditive manufacturing apparatusLoading/unloadingHigh rateReciprocating motion

The invention discloses a powder feeding and laying device applied to a high rate former, which consists of a powder storing case and a movable hopper, wherein, the powder storing case is an upper powder storing case positioned above the movable hopper and provided with a power outlet at the bottom; the powder storing case is fixed and stable; a movable baffle capable of automatically opening and closing the powder outlet is arranged at the bottom of the powder outlet; a movable bracket is fixed outside the movable hopper which moves to and fro from left to right along a horizontal line on a forming working platform of a high rate former by a driving mechanism; an unlocking component which is matched to be used with the movable bracket is arranged on the movable baffle; a receiving port at the upper part of the movable hopper corresponds to the powder outlet; a powder laying port is arranged at the bottom of the movable hopper, which is a rectangular port enclosed by two lateral baffles in the front and the back and two flexible doctor blades on the left and the right. The powder feeding and laying device applied to a high rate former has simple structure, handy assembly and deinstallation of all parts and easy regulation and control, the capability of modular working independently, rapid powder laying, and high reliability.

Owner:西安赛隆增材技术股份有限公司

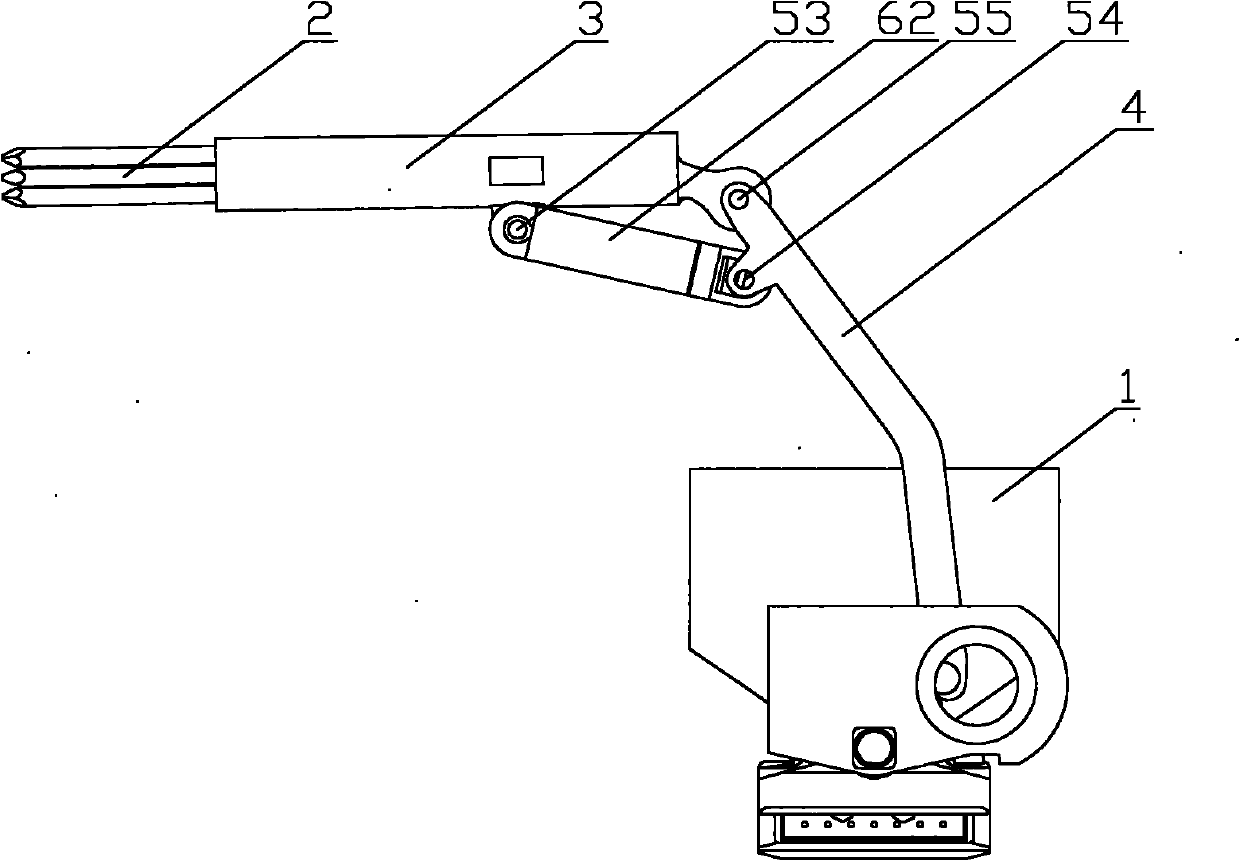

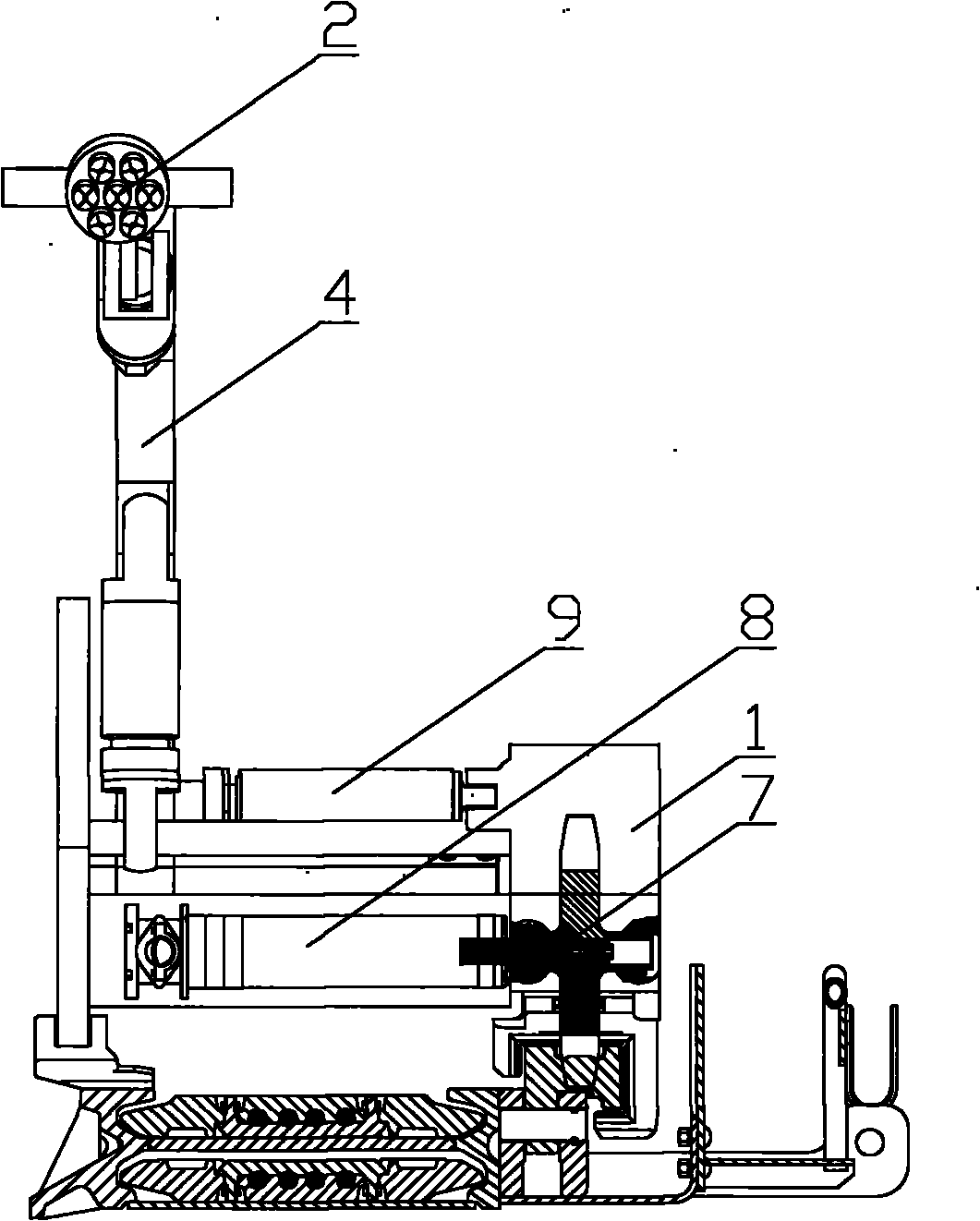

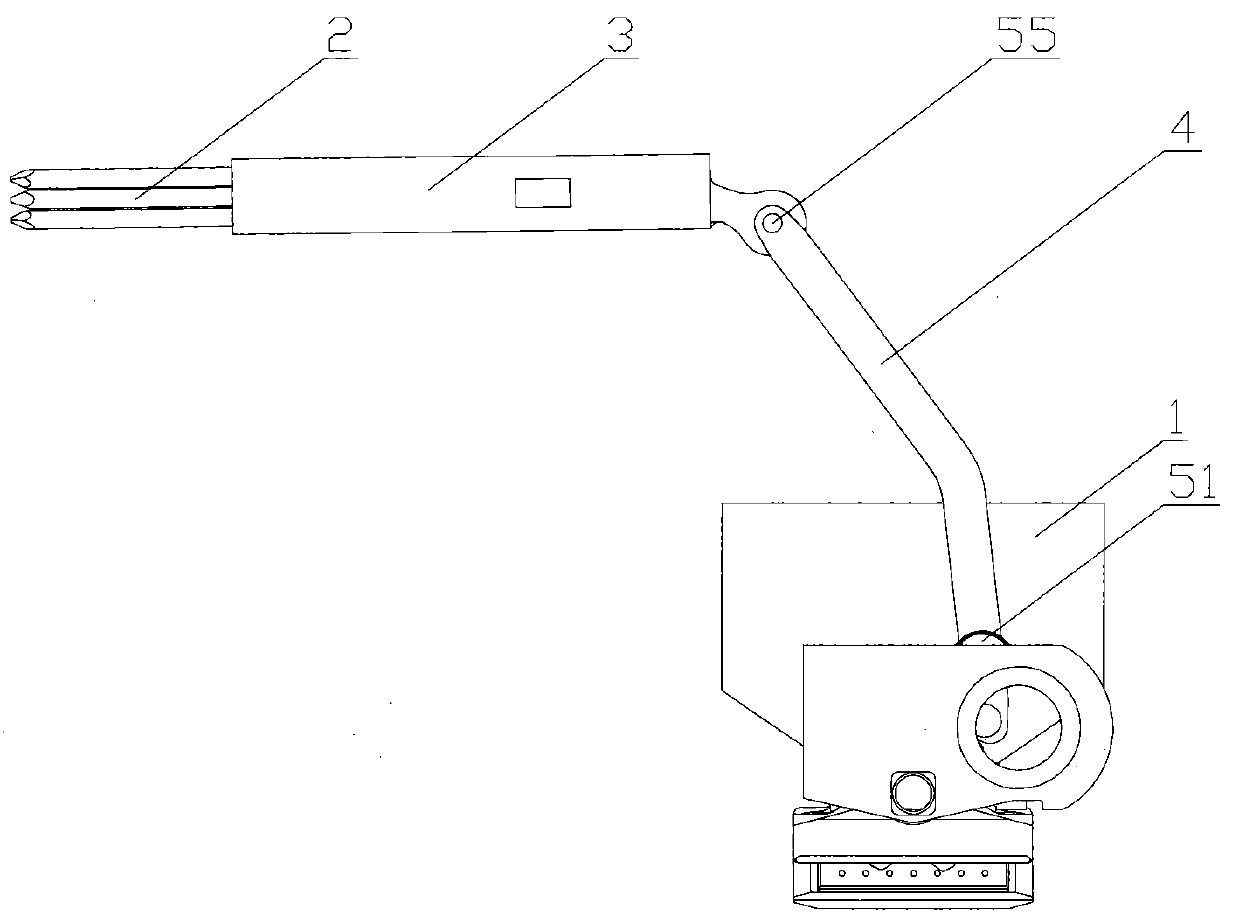

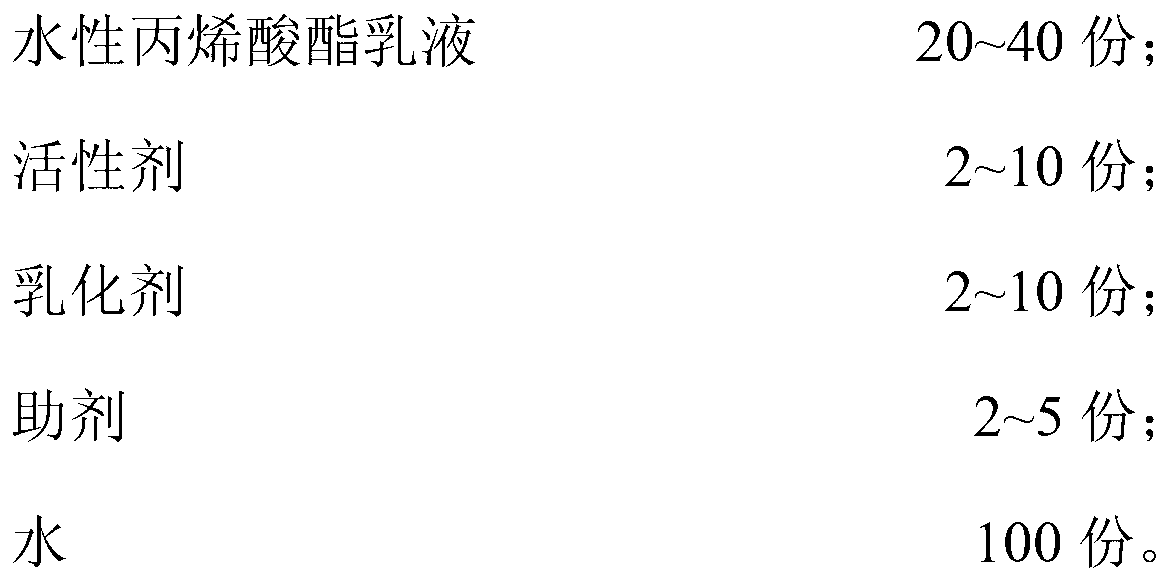

Coal mining device and crushing mechanism thereof

InactiveCN101906969AImprove crushing efficiencyPrevent flying outDriving meansEngineeringCentrifugal force

The invention discloses a crushing mechanism for a coal mining device, comprising a main body part (1), a power component installed on the main body part (1) and a work component (2) driven by the power component, wherein the power component is used for driving the work component (2) to do the reciprocating straight line motion. In the work process of the crushing mechanism, the straight line motion does not generate a centrifugal force, thereby preventing the crushed coals from flying out in crushing process and guaranteeing the personal safety of the staffs in the tunnel; meanwhile, the coal crushed by the straight line motion is not cut into powders so as to prevent coal dusts from flying in the tunnel and to improve the air quality in the tunnel; in addition, the single motion stroke of the straight line motion is large so as to improve the crushing efficiency of the crushing mechanism. The invention further discloses a coal mining device including the crushing mechanism.

Owner:SANY HEAVY EQUIP

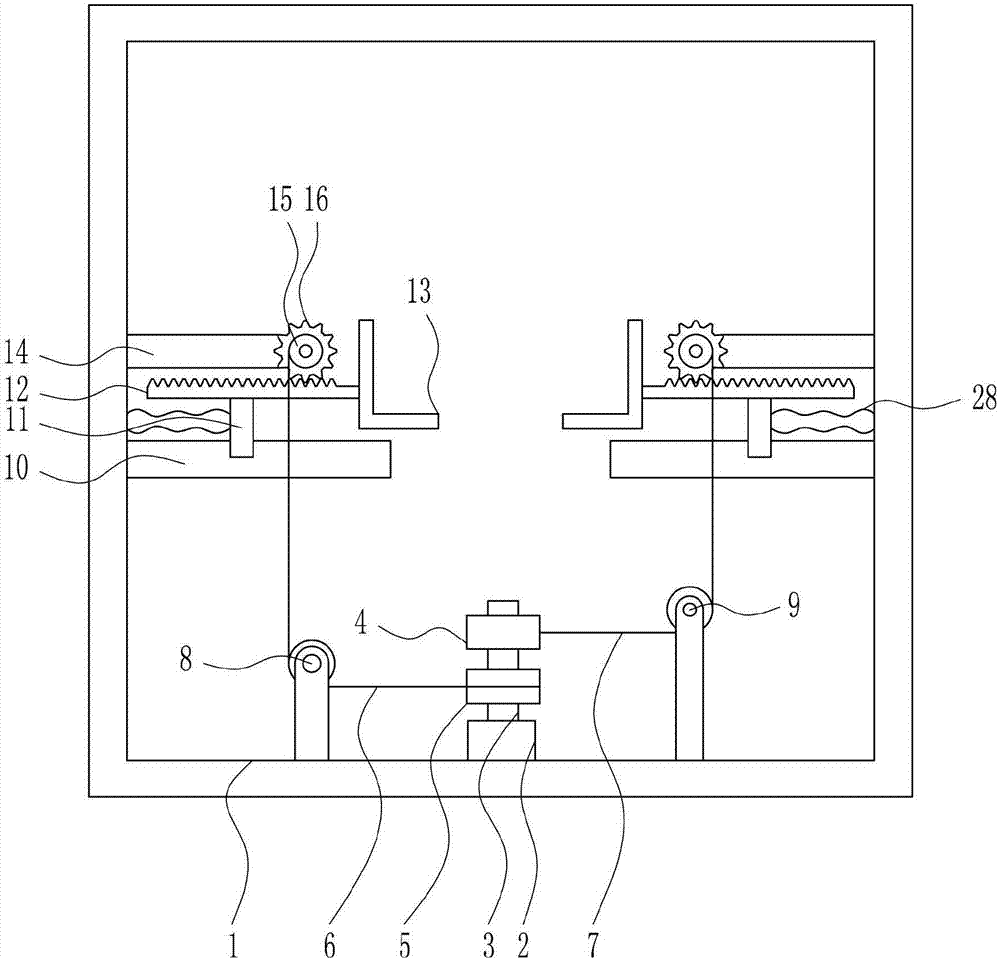

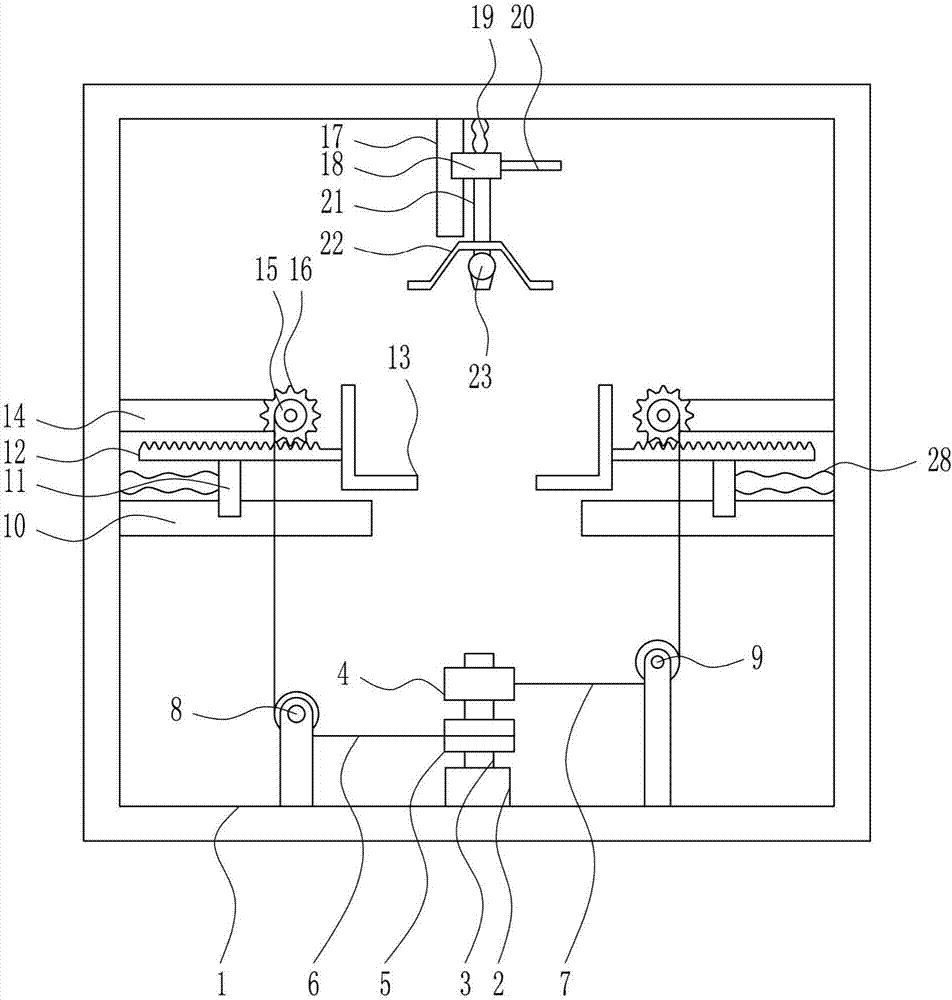

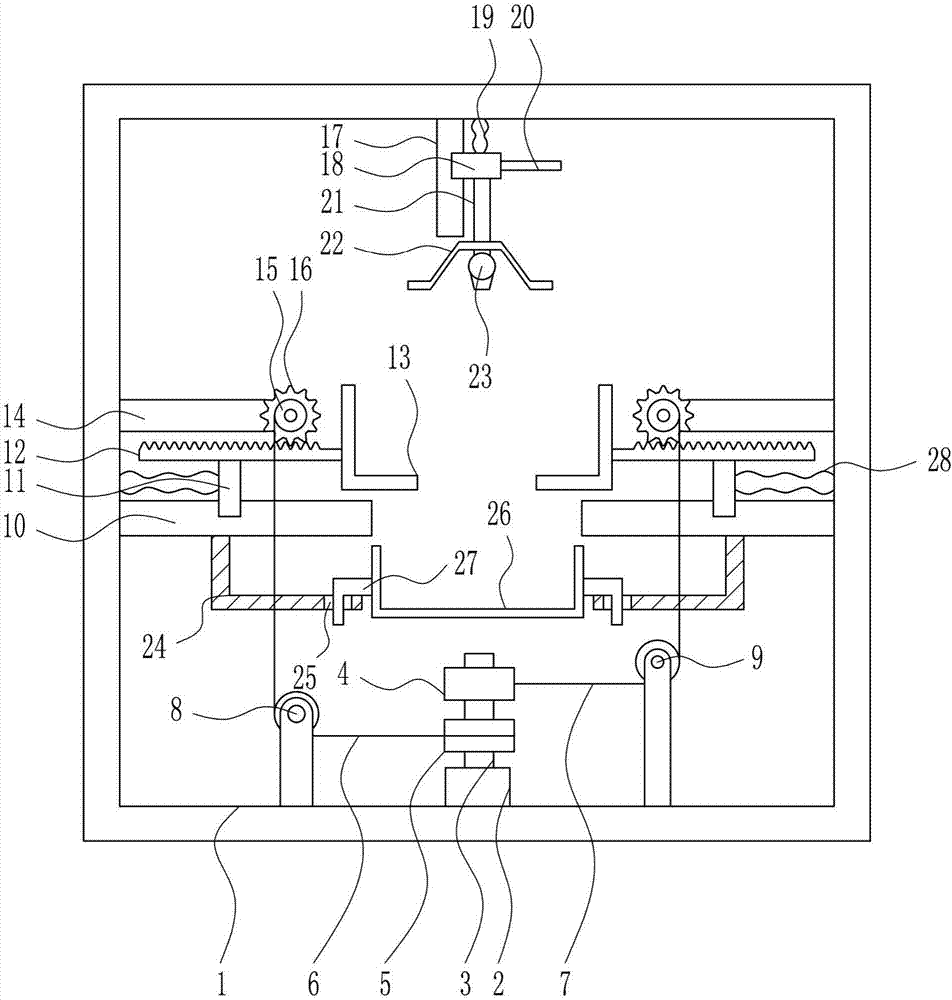

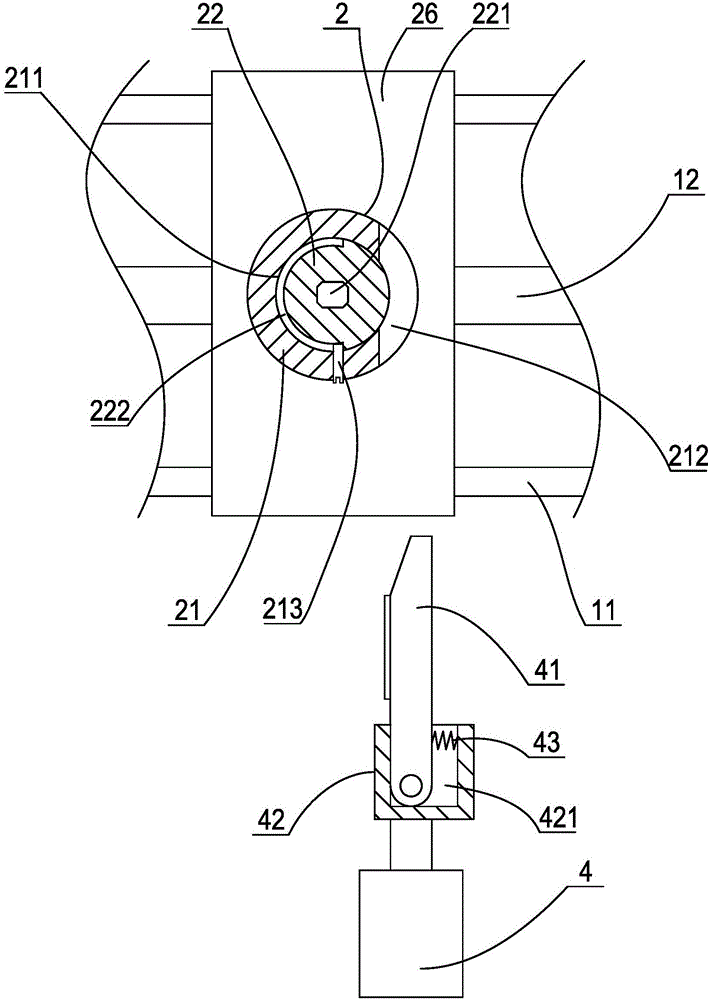

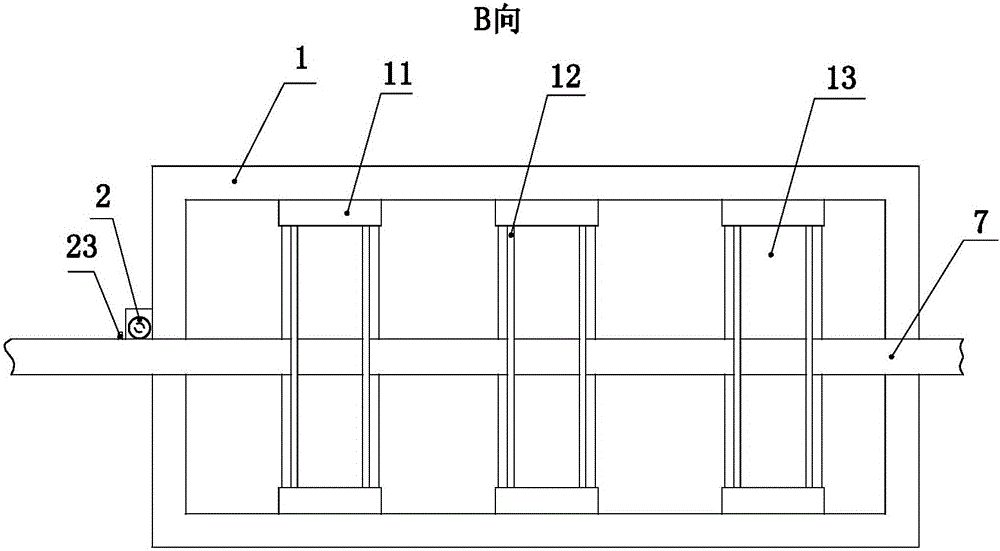

Tool fixture for cylindrical workpiece punching

ActiveCN106903521AExtended service lifeAvoid flying debrisPositioning apparatusMaintainance and safety accessoriesEngineeringPulley

The invention relates to a tool fixture, in particular to a tool fixture for cylindrical workpiece punching. In order to solve the technical problems, the invention provides the tool fixture for cylindrical workpiece punching, and the tool fixture is convenient to operate and is convenient in collecting waste chippings. The tool fixture for cylindrical workpiece punching comprises a mounting frame, a motor, a rotary shaft, a first wire winding wheel, a second wire winding wheel, a second stay wire, a first stay wire, a left fixed pulley, a right fixed pulley, a first slide rail and the like, wherein the left fixed pulley, the motor and the right fixed pulley are sequentially arranged on the bottom inside the mounting frame from left to right; the rotary shaft is arranged on the top of the motor; the first wire winding wheel and the second wire winding wheel are arranged on the rotary shaft; and the second wire winding wheel is arranged below the first wire winding wheel. According to the tool fixture, the motor drives an L-shaped clamping plate to get close to the middle for clamping the workpieces; and moreover, a collecting frame for collecting waste chippings and a fan for blowing away the waste chippings are arranged.

Owner:杭州萧山鹏达汽车部件制造有限公司

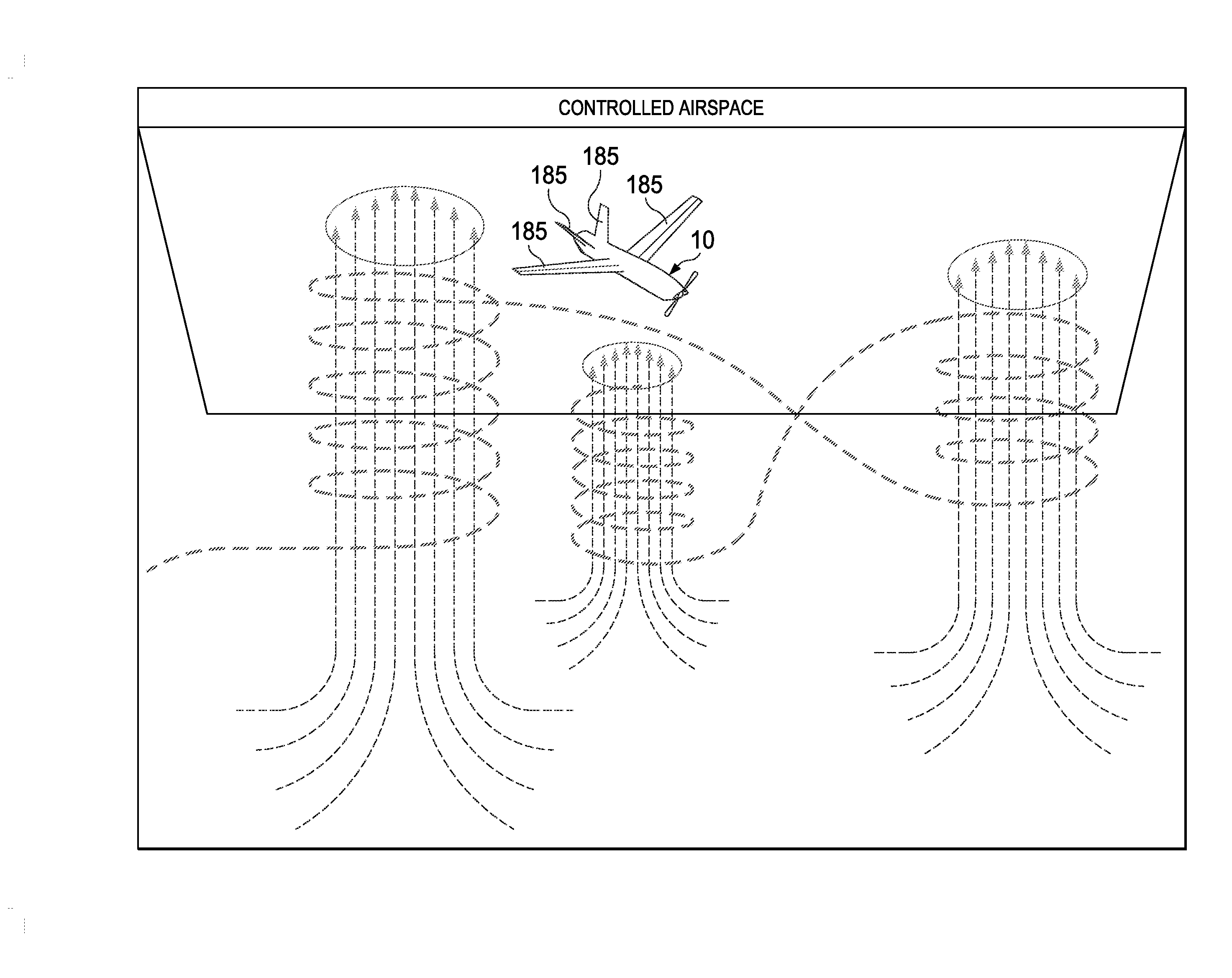

Unmanned aerial vehicle

InactiveUS20140129056A1Slow downAvoid flyingPower installationsEnergy saving arrangementsElectricityForward speed

The present disclosure relates to an unmanned aerial vehicle (UAV) able to harvest energy from updrafts and a method of enhancing operation of an unmanned aerial vehicle. The unmanned aerial vehicle with a gliding capability comprises a generator arranged to be driven by a rotor, and a battery, wherein the unmanned aerial vehicle can operate in an energy harvesting mode in which the motion of the unmanned aerial vehicle drives the rotor to rotate, the rotor drives the generator, and the generator charges the battery. In the energy harvesting mode regenerative braking of the generator reduces the forward speed of the unmanned aerial vehicle to generate electricity and prevent the unmanned aerial vehicle from flying above a predetermined altitude.

Owner:THE BOEING CO

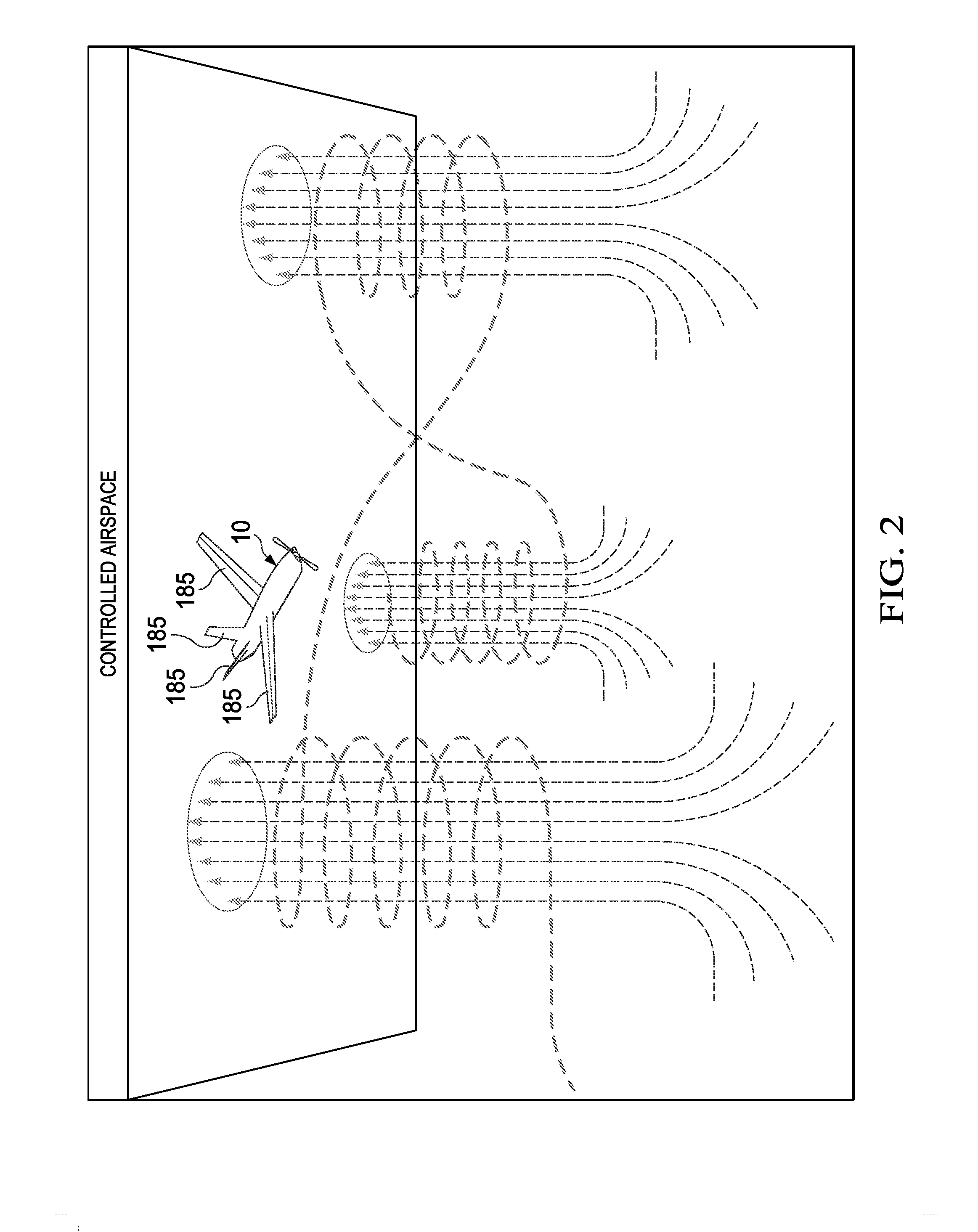

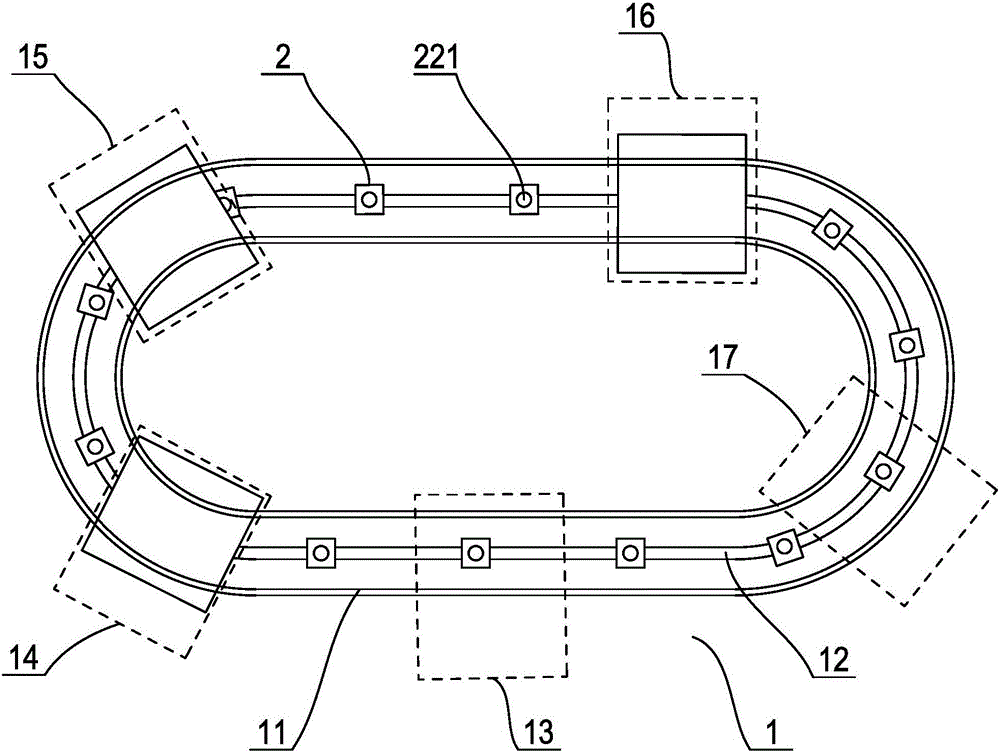

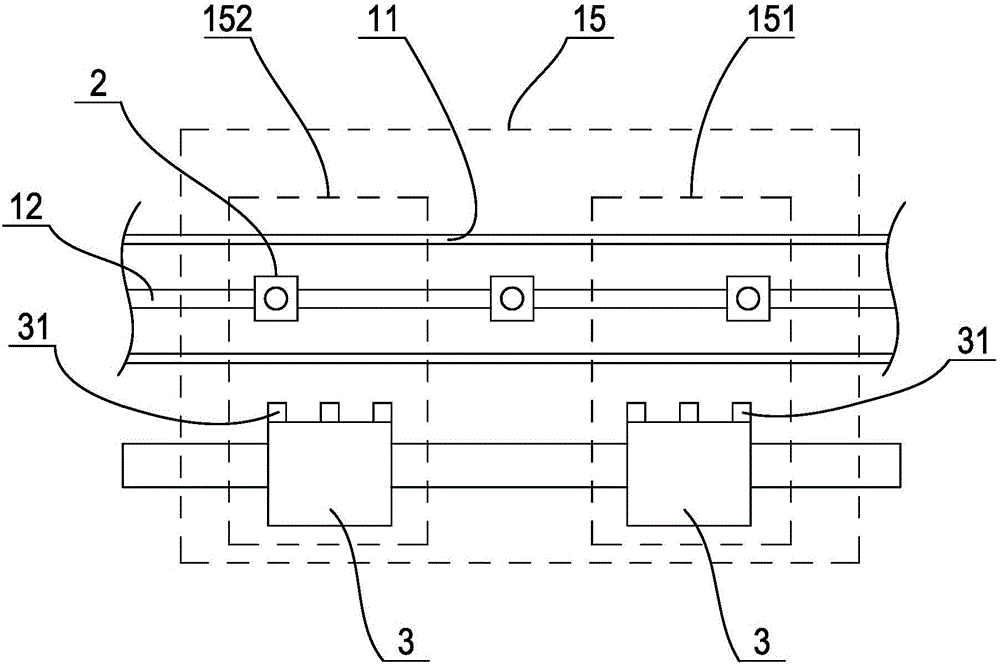

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

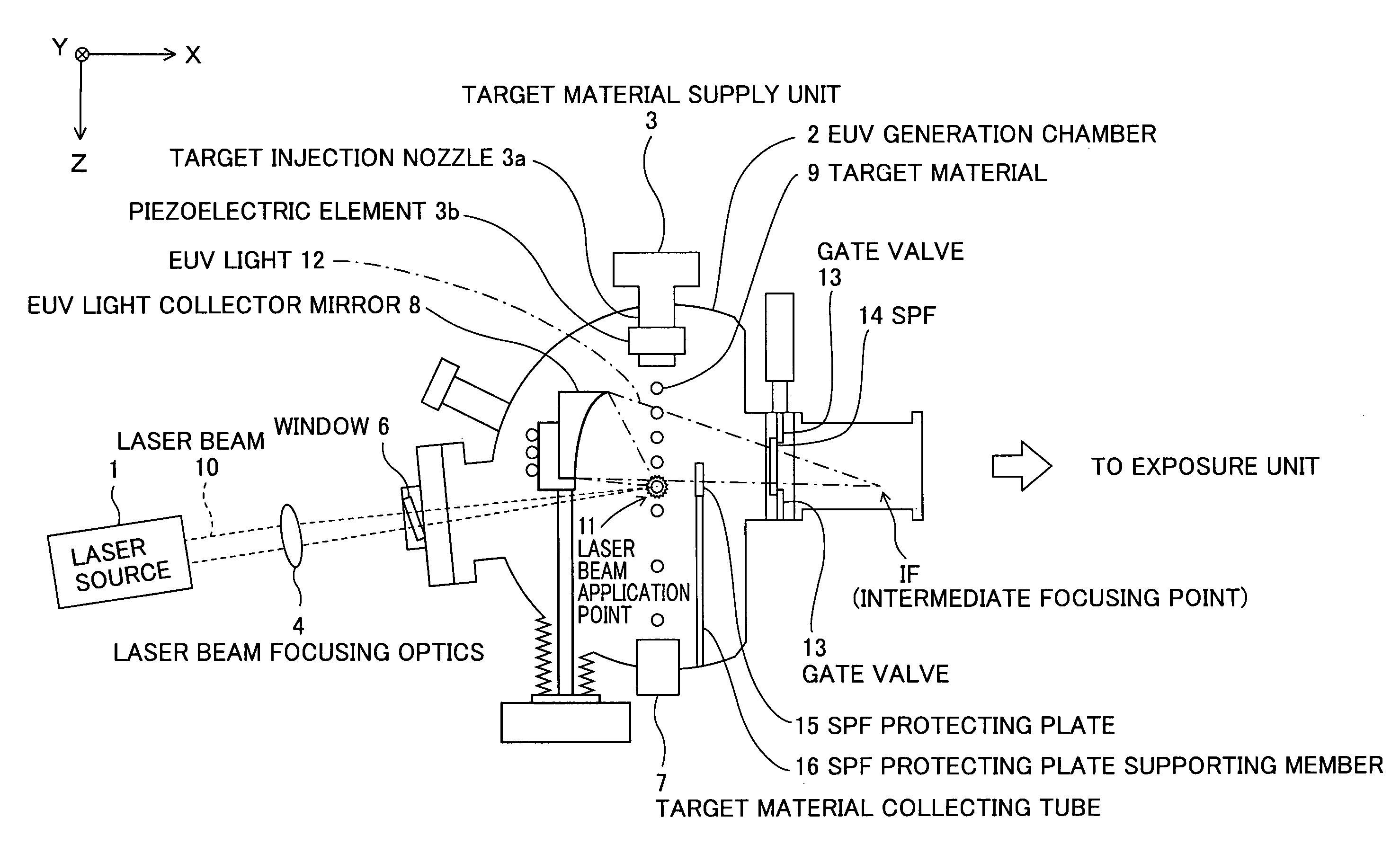

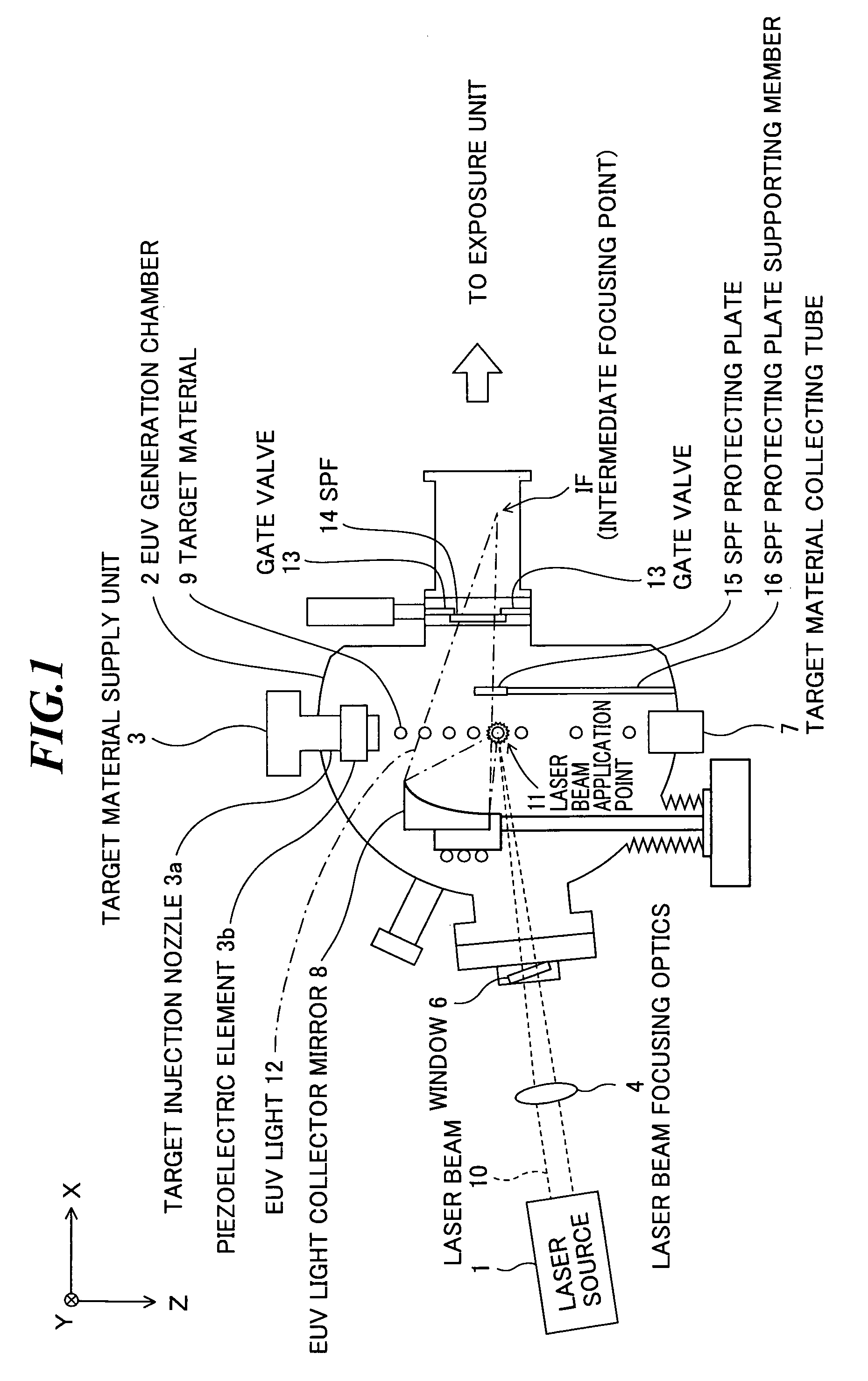

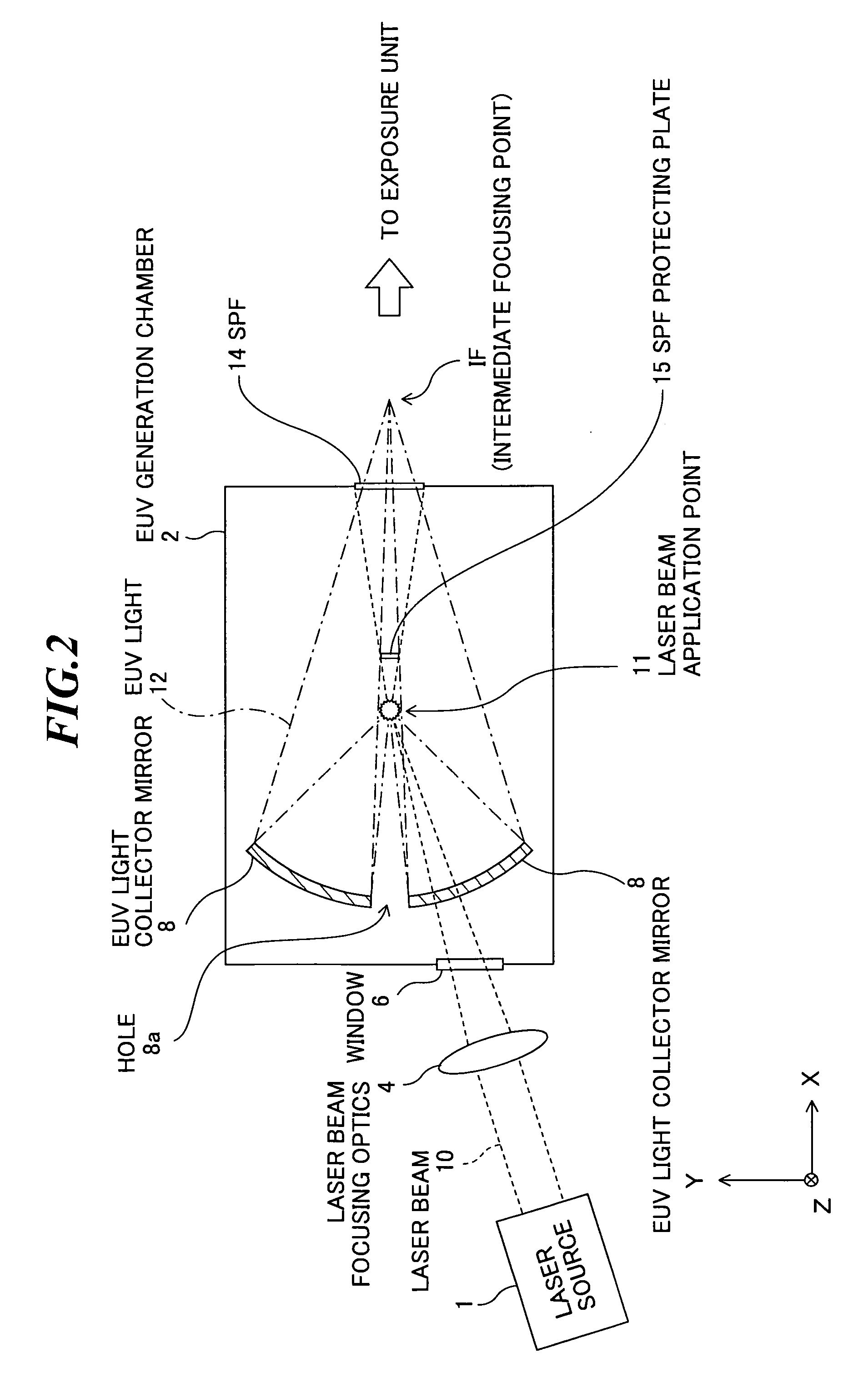

Extreme ultra violet light source apparatus

ActiveUS20080210889A1Inhibit deteriorationAvoid breakingRadiation pyrometryPhotomechanical apparatusMaterial supplyLaser source

An EUV light source apparatus capable of preventing deterioration and / or breakage of a filter for filtering EUV light. The EUV light source apparatus includes an EUV generation chamber in which EUV light is generated; a target material supply unit for supplying a target material into the EUV light generation chamber; a laser source for applying a laser beam to the target material supplied into the EUV light generation chamber to generate plasma; collection optics for collecting EUV light radiated from the plasma; a filter for filtering the EUV light collected by the collection optics; and a filter protecting member provided between the plasma and the filter, for protecting the filter by blocking flying matter flying from the plasma toward the filter.

Owner:GIGAPHOTON

Holding/sealing material for use in catalytic converter for clarifying gaseous emission

InactiveUS6960386B2Small specific gravityAvoid flyingInternal combustion piston enginesExhaust apparatusFiberWorking environment

An object of the invention is to provide a holding and sealing mat material of a catalytic converter for purifying an exhaust gas which can prevent inorganic fibers from flying in all directions from a surface of the holding and sealing mat material, and can keep a working environment at a time of assembling good. In the holding and sealing mat material of a catalytic converter for purifying an exhaust gas, which is arranged between a catalyst carrier and a shell covering the catalyst carrier from the outside thereof, the holding and sealing mat material includes a mat-like material consisting of inorganic fibers and being formed in a mat shape and a binder of 0.5 to 20 weight % of an organic binder or an inorganic binder, which is attached to the mat-like material, wherein a filling bulk density of the holding and sealing mat material after being assembled is within a range between 0.1 and 0.6 g / cm3, and wherein in the case of estimating distribution rates of solids constituents in the binder attached to the mat-like material by dividing the mat-like material into three equal parts of an upper portion, a middle portion and a lower portion in a thickness direction, the distribution rates of the upper portion and the lower portion are higher than that of the middle portion.

Owner:IBIDEN CO LTD

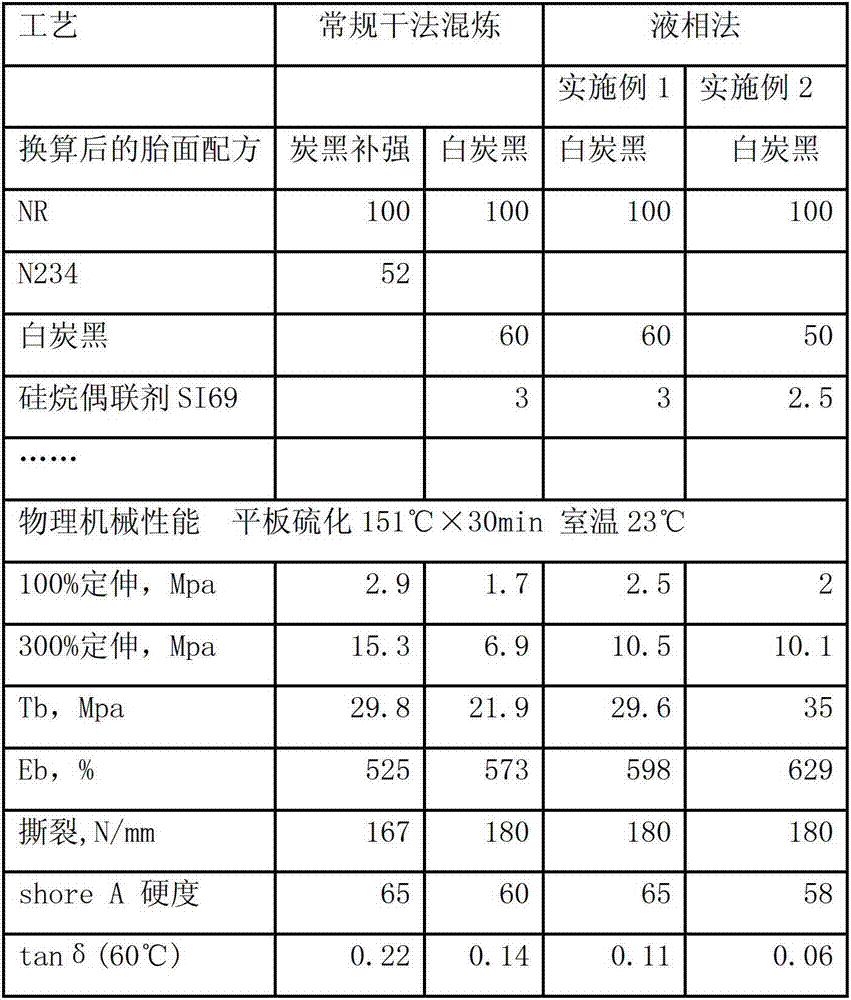

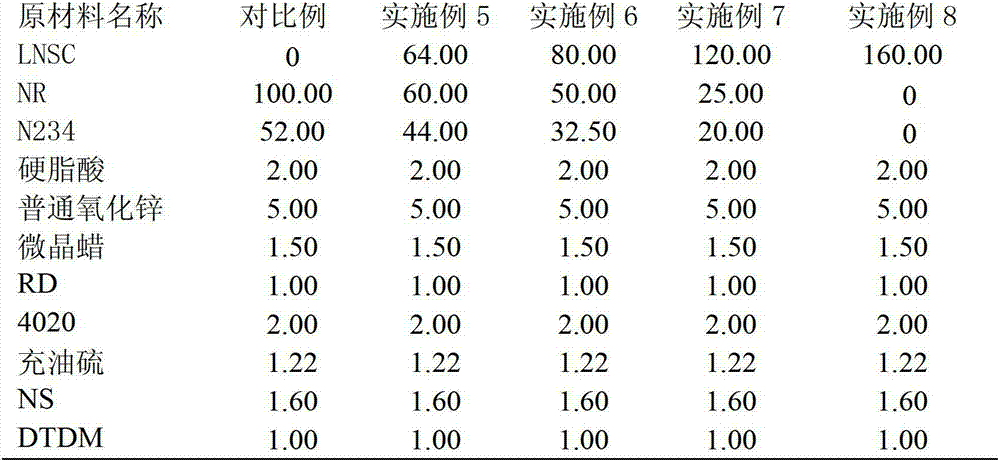

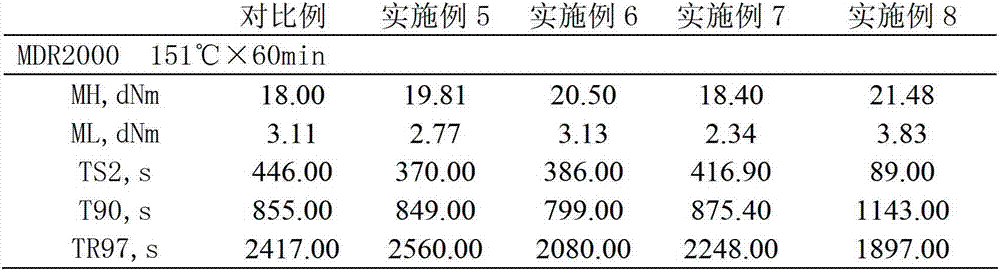

Preparation method for liquid phase stirring and mixing of white carbon black and natural rubber

ActiveCN102775654APreserve the status quoKeep strongSpecial tyresRolling resistance optimizationHysteresisBrute force

The invention relates to the production field of tire rubber sizing materials, in particular to a method for mixing liquid state white carbon black and liquid state natural rubber in a liquid phase. The preparation method for liquid phase stirring and mixing of the white carbon black and the natural rubber comprises the steps of (1) preparing slurry; (2) mixing; (3) solidifying, dehydrating, washing and stoving. The method adopts liquid-liquid high speed stirring and mixing to effectively preserve original states of natural rubber macromoleculars, effectively preserves brute force of the natural rubber and substantially promotes brute force and abrasive resistance of mixed glue. Brute force of sizing materials mixed by using the method is substantially promoted, and themogenesis and hysteresis loss are obviously reduced. The mixed glue produced by the method can be singly used and can also be blended with the natural rubber, rubber polymer, natural rubber carbon black rubber master batch and rubber polymer carbon black rubber master batch according to certain proportion. According to the method, the liquid state white carbon black and the liquid state natural rubber are mixed directly, the process is simple, the land occupation is small, the equipment investment is low, and dust pollution does not exist in a production process.

Owner:ZHONGCE RUBBER GRP CO LTD

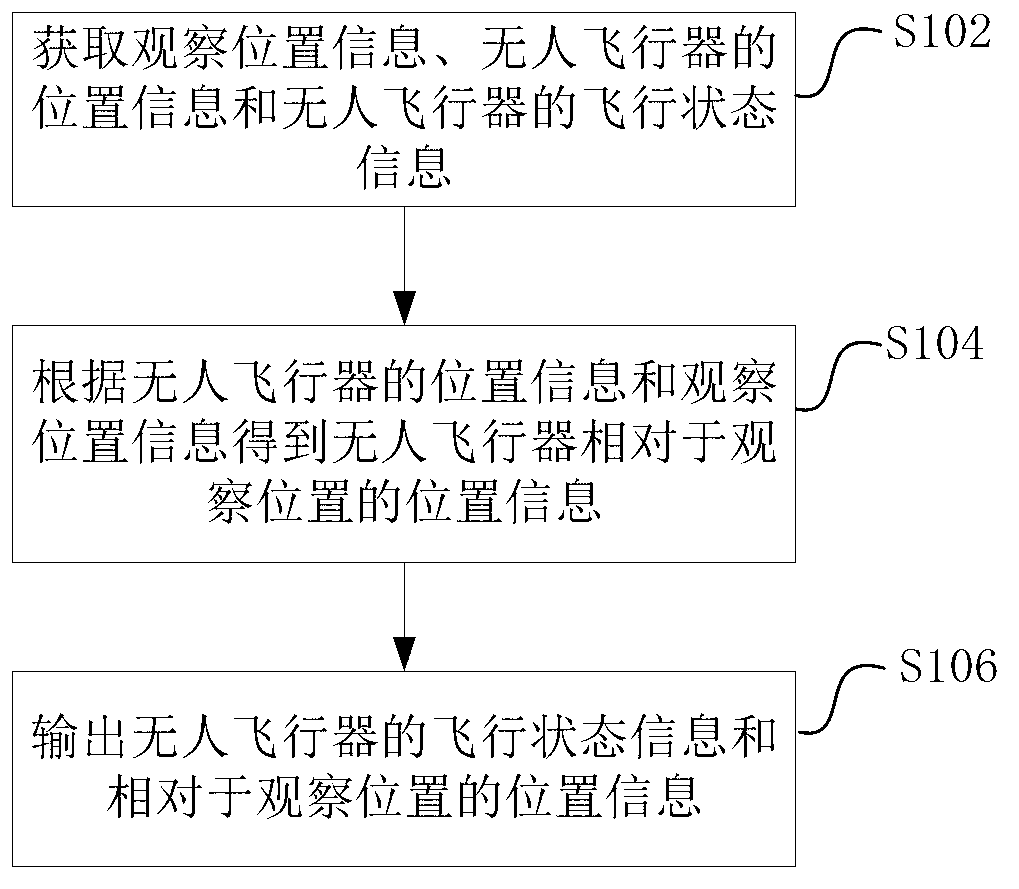

Flight assisting method and device of unmanned aerial vehicle

ActiveCN103344250AImprove flight experienceAvoid flying blindTransmission systemsNavigation instrumentsManipulatorFlight experience

The invention discloses a flight assisting method and device of an unmanned aerial vehicle, belonging to the field of unmanned aerial vehicles. The flight assisting method comprises the steps of: acquiring observation position information, and position information and flight status information of the unmanned aerial vehicle; acquiring position information of the unmanned aerial vehicle relative to an observation position according to the position information of the unmanned aerial vehicle and the observation position information; and outputting the flight status information and the position information relative to the observation position of the unmanned aerial vehicle. The method and the device provided by the invention can be used for helping a manipulator to control the flight path of the unmanned aerial vehicle through holding a current flight position and status of the unmanned aerial vehicle, so that blind flight and loss are avoided, and the flight experience of the manipulator is improved.

Owner:SZ DJI TECH CO LTD

Plastic fiber cultivating soil and preparation method thereof

ActiveCN105367216AReduce weightGood construction curingOrganic fertilisersFertilizer mixturesPlastic fiberPlant soil

Plastic fiber cultivating soil is prepared from 15-35% of foundation soil, 5-35% of plant fiber powder, 10-50% of perlite, 5-15% of peat soil and 5-15% of dual-component hot-melt adhesion composite fibers. The composite fibers are formed by compositing two thermoplastic polymers through composite spinning according to a sheath-core type structural mode. The difference of melting points of the adopted two thermoplastic polymers is not lower than 30 DEG C. The composite fibers are composed of dual-component hot-melt adhesion composite fibers A with the particle size being 15-25 mm and dual-component hot-melt adhesion composite fibers B with the particle size being 3-8 mm. The composite fibers A and the composite fibers B can be made of same materials or different materials. The particle size of the plant fiber powder is 0.2-0.9 mm. The plastic fiber cultivating soil has the advantages that the cultivating soil can be cured and formed and is long in service life, not prone to weathering, low in weight, high in moisture-preserving performance and breathability, capable of being recycled after being discarded and the like. The plastic fiber cultivating soil has the main effects that the problems that in the vertical greening construction process, plants cannot be easily attached to walls, planting soil is large in gravity, and the soil is not easily shaped and is prone to dispersion are solved, and the problem that large-scale mechanical seedling inserting is difficult in upland soil planting. Due to the fact that most raw materials come from agricultural and forestry waste, a contribution can be made to agriculture and environmental protection, and the fiber soil can be recycled or directly used as combustion improver after being used.

Owner:湖南尚佳绿色环境有限公司

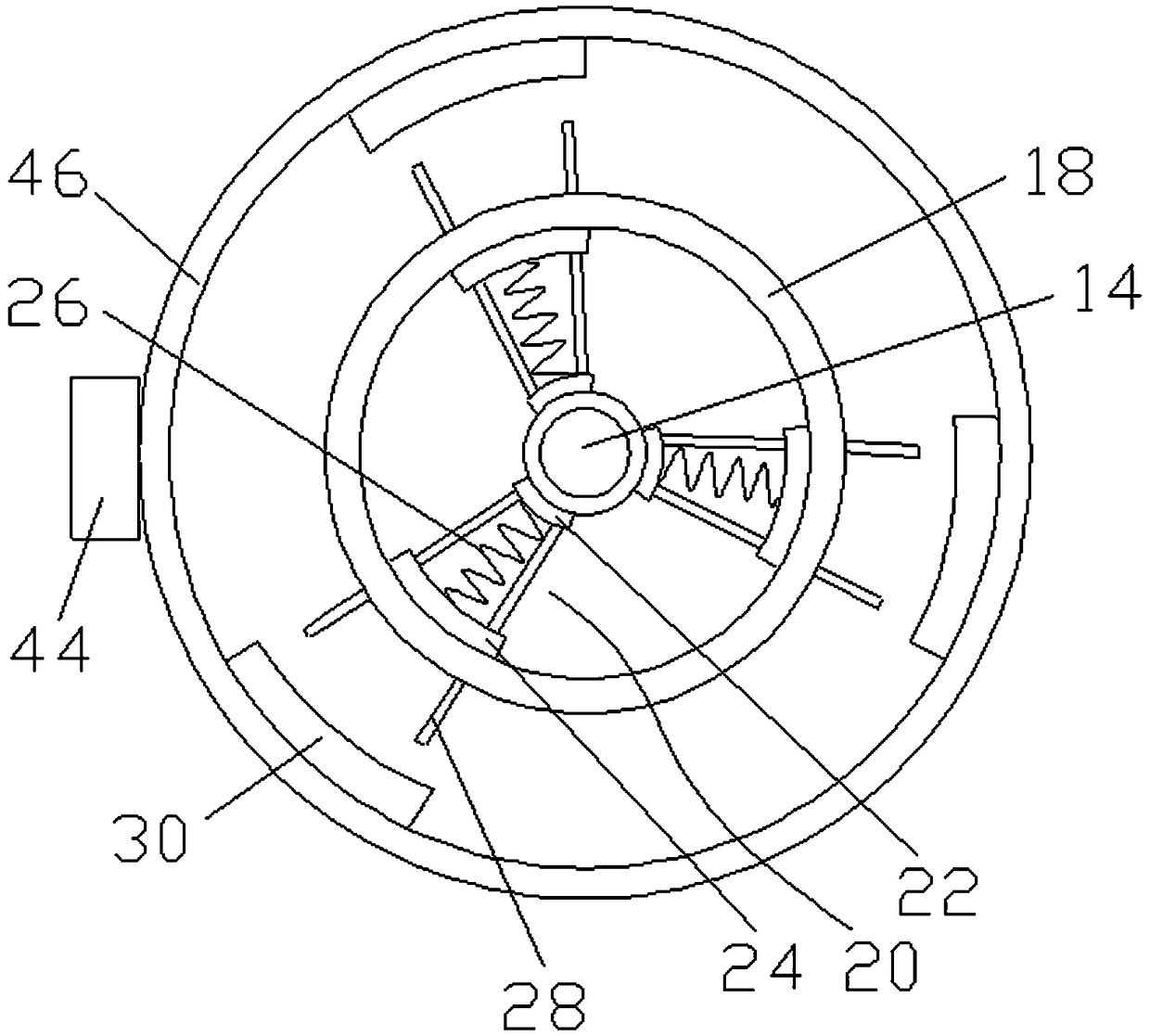

Grinding device for ring-shaped workpieces

ActiveCN109015138AAvoid flyingKeep healthyRevolution surface grinding machinesGrinding work supportsEngineeringElectromagnet

The invention relates to a grinding device for ring-shaped workpieces. The grinding device for the ring-shaped workpieces comprises a vertical frame, a clamping assembly and a grinding mechanism, wherein the vertical frame comprises a stand column and at least one stop block fixed to the stand column; a cylinder is arranged outside the stand column; the clamping assembly comprises three clamping parts arranged in the circumferential direction at equal intervals; each clamping part comprises a first circular arc plate, a second circular arc plate, a spring connected with the first circular arcplate and the second circular arc plate, and two iron rods connected with the first circular arc plate; each iron rod extends out of the cylinder; three electromagnets are arranged outside the cylinder, and each electromagnet corresponds to the two iron rods of the corresponding clamping part; the grinding mechanism is located above the stand column; a dust collection trough is fixed below the stand column and connected with a fan through a first air duct; and the fan is connected with a dust storage barrel through a second air duct. By means of the grinding device for the ring-shaped workpieces, the to-be-ground ring-shaped workpieces are tightly positioned, the grinding quality is good, and due to dual matching of the dust collection trough and a dust hood, dust flying is avoided.

Owner:SUZHOU SUTENG ELECTRONICS TECH

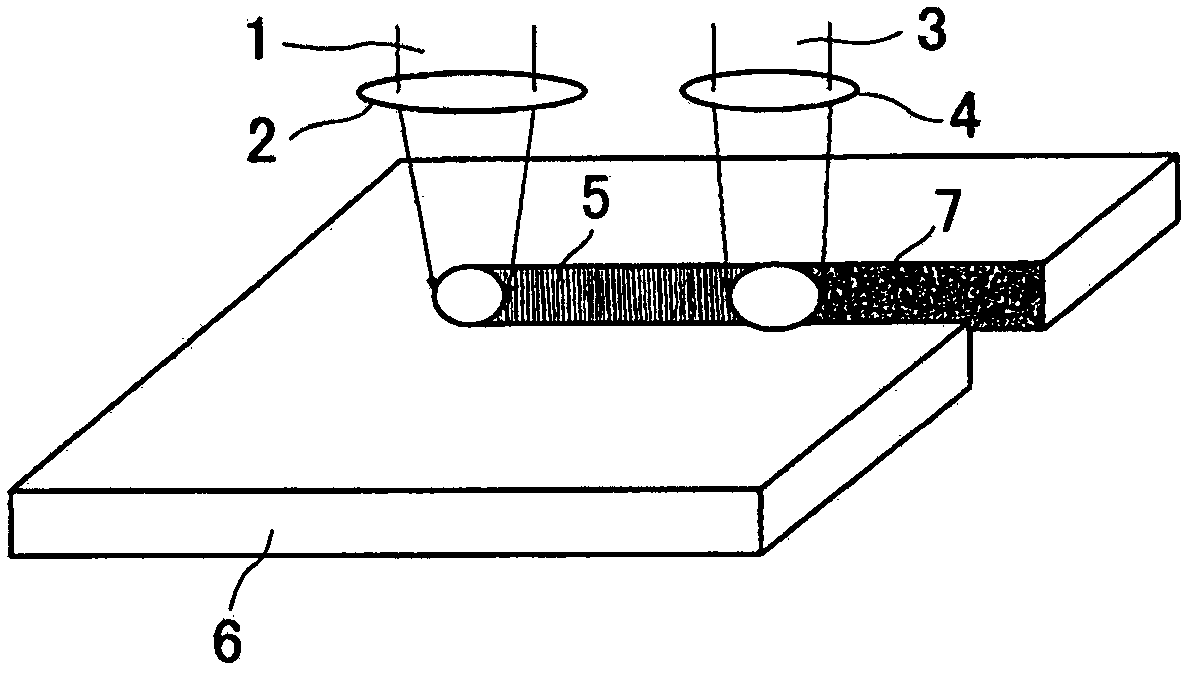

Composite nano fiber endless tow preparing apparatus and its preparing method

InactiveCN1776033AAvoid flyingAvoid lostConjugated artificial filamentsArtifical filament manufactureFiberComposite nanofibers

A device and method for preparing compound nano fiber endless tow, which contains feeding material liquid to pair of electric spinning nozzle on frame, each nozzle respectively applied with high dc voltage with opposite polarity, each pair of nozzle jetting out nano fiber with opposite electric charge, said nano fiber attracting and colliding each other to form compound nano fiber, then forming nano fiber endless tow after drawing and stretching, the first opposite set pair of electric spinning nozzle jetted compound nano fiber endless tow is stretched down and used as acceptor which covered by the nano fiber jetted by second pair of nozzle an d forming two layers of compound nano fiber endless tow after drawing and stretching, in turn to get multilayer compound nano fiber endless tow after drawing and stretching by godet roller.

Owner:SOUTHEAST UNIV

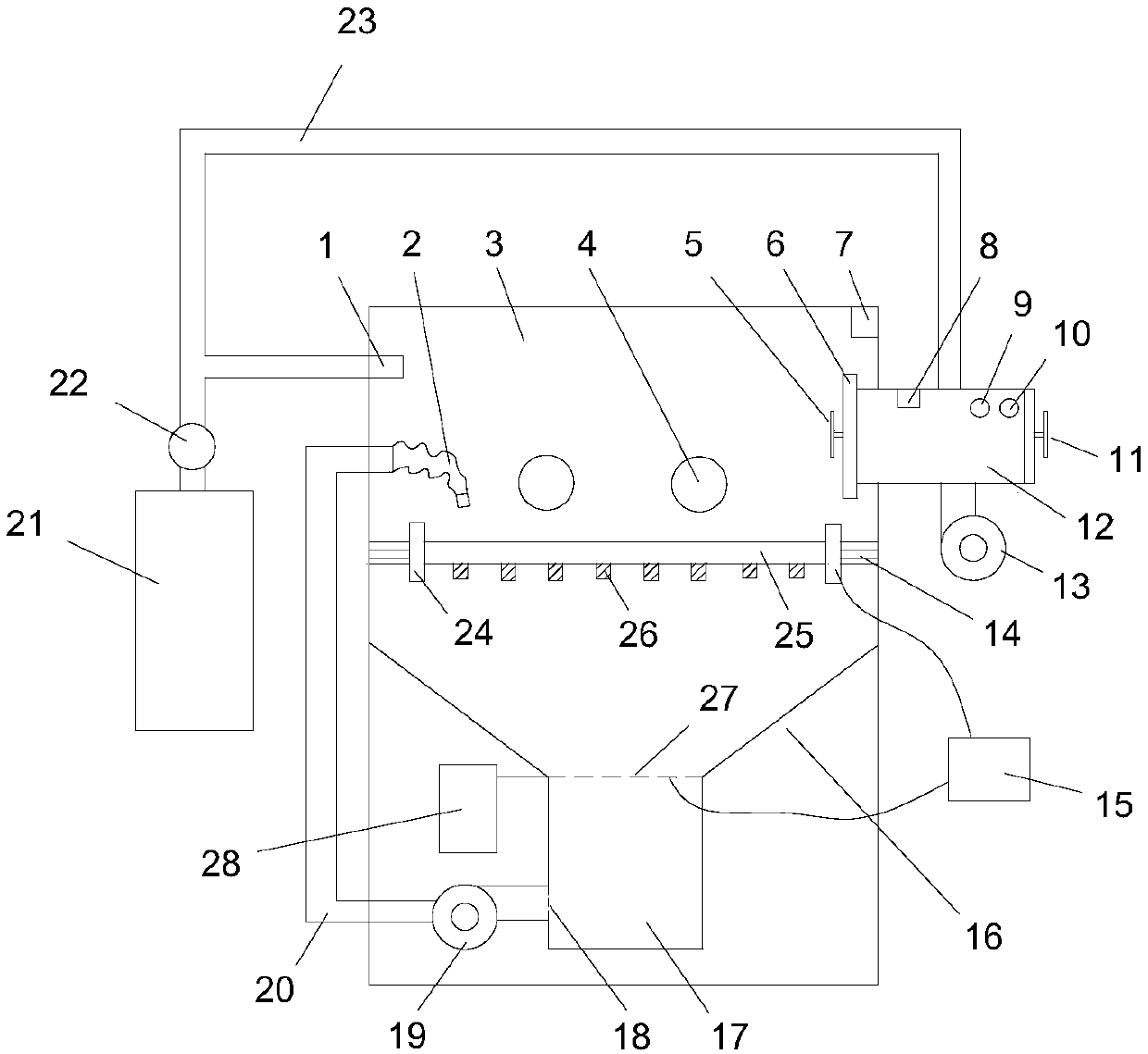

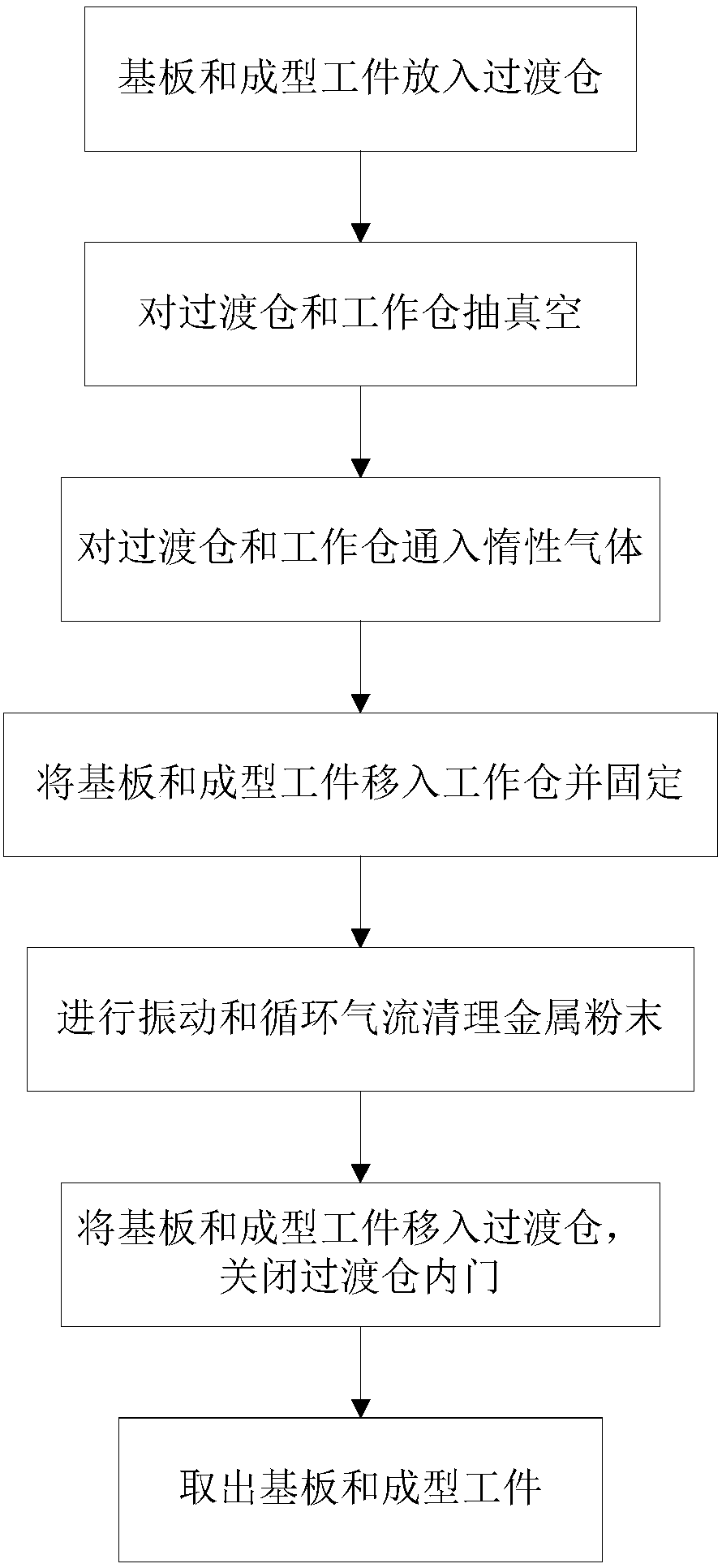

Device and method for recovering residual powder on SLM molding substrates

ActiveCN107671292AAvoid flyingGuaranteed cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAir blower

The invention relates to a device and a method for recovering residual powder on SLM molding substrates. The device comprises a working bin provided with a glove box inlet; the working bin communicates with a gas storage tank through an inert gas pipe; a rotating shaft with a fixture is arranged in the working bin; a powder guide surface inwards, downwards and aslant extending from the inner sidesurface of the working bin is arranged below the rotating shaft; a filter screen connected with an impurity collecting barrel is arranged in the lowest place of the powder guide surface; a powder collecting barrel is connected below the filter screen; the filter screen and the fixture are connected with a vibrator arranged outside the working bin; the side wall or the bottom surface of the powdercollecting barrel is connected with an intake port of an air blower through a gas circulating screen; and an exhaust port of the air blower communicates with the internal of the working bin above therotating shaft through a gas circulating pipe. The device can effectively recover the residual powder on substrates and parts, effectively maintains cleanness in the working bin, can prevent more lossof inert gas when the substrates and the parts are put in or taken out by multiple times, and effectively saves the production cost.

Owner:OPTIMAL MATERIAL TECH CO LTD

Earth cementation agent in use for roadway construction

InactiveCN1562851AImprove responseGood water hardnessSolid waste managementOrganic fertilisersPower stationRoad surface

In the invention, two kinds of waste material dry dust discharging coal ash and desulfurize gyp produced by power plant burning sub-bituminous coal or lignitous coal are used as main composition, shell and or cement, calcined gypsum and aluminum sulfate or alunite are used as secondary composition, they are prepared to dry powder soil curing agent by weighing, matching, forced stirring and mixing. The soil can be concreted by mixing a proper quantity of curing agent into the soil and processes of stirring, compacting, soaking and maintaining.

Owner:徐尔昌

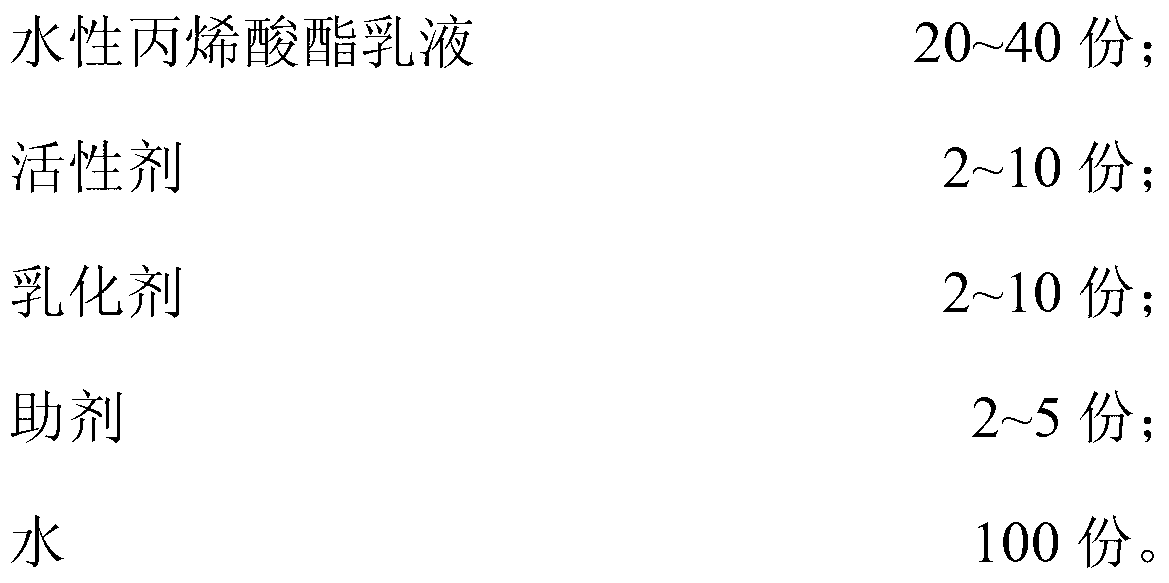

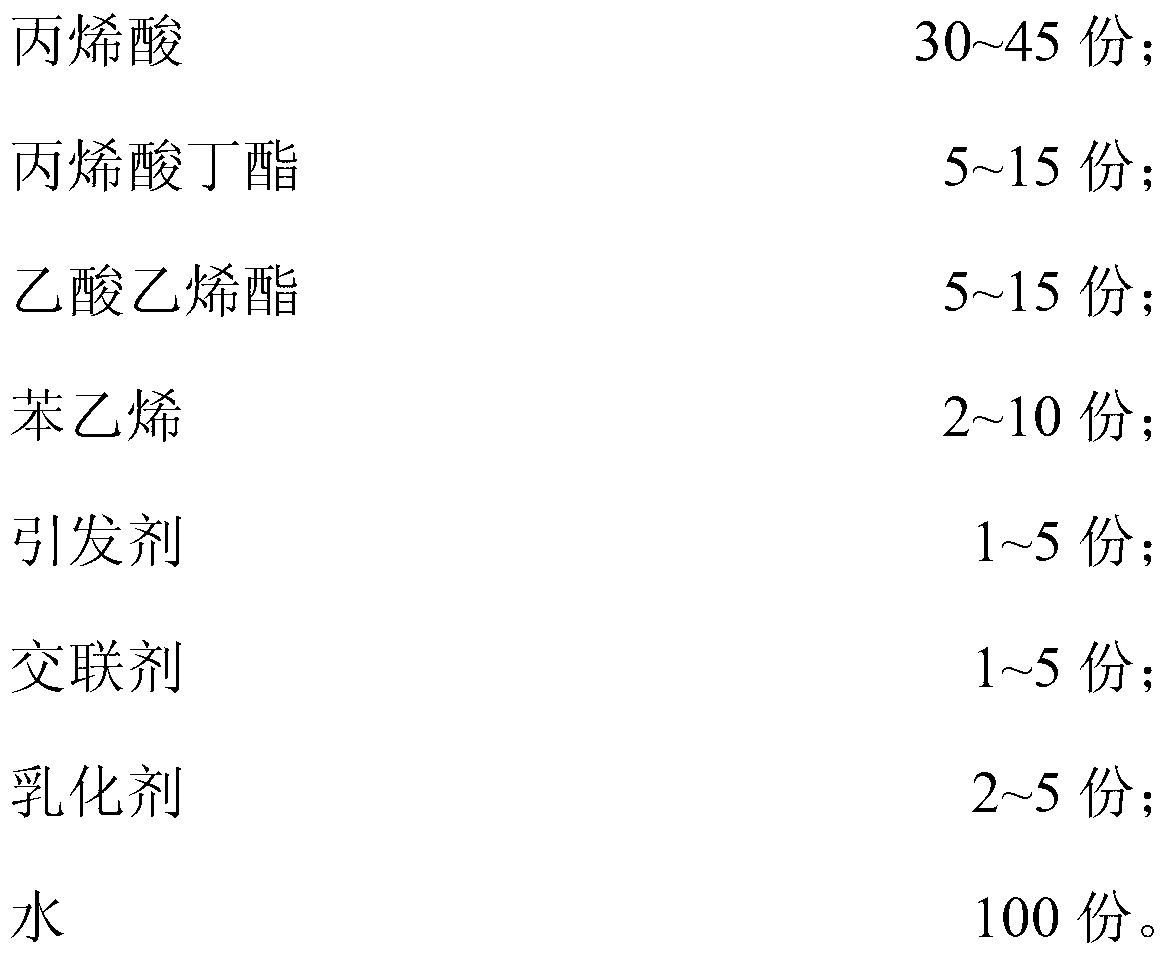

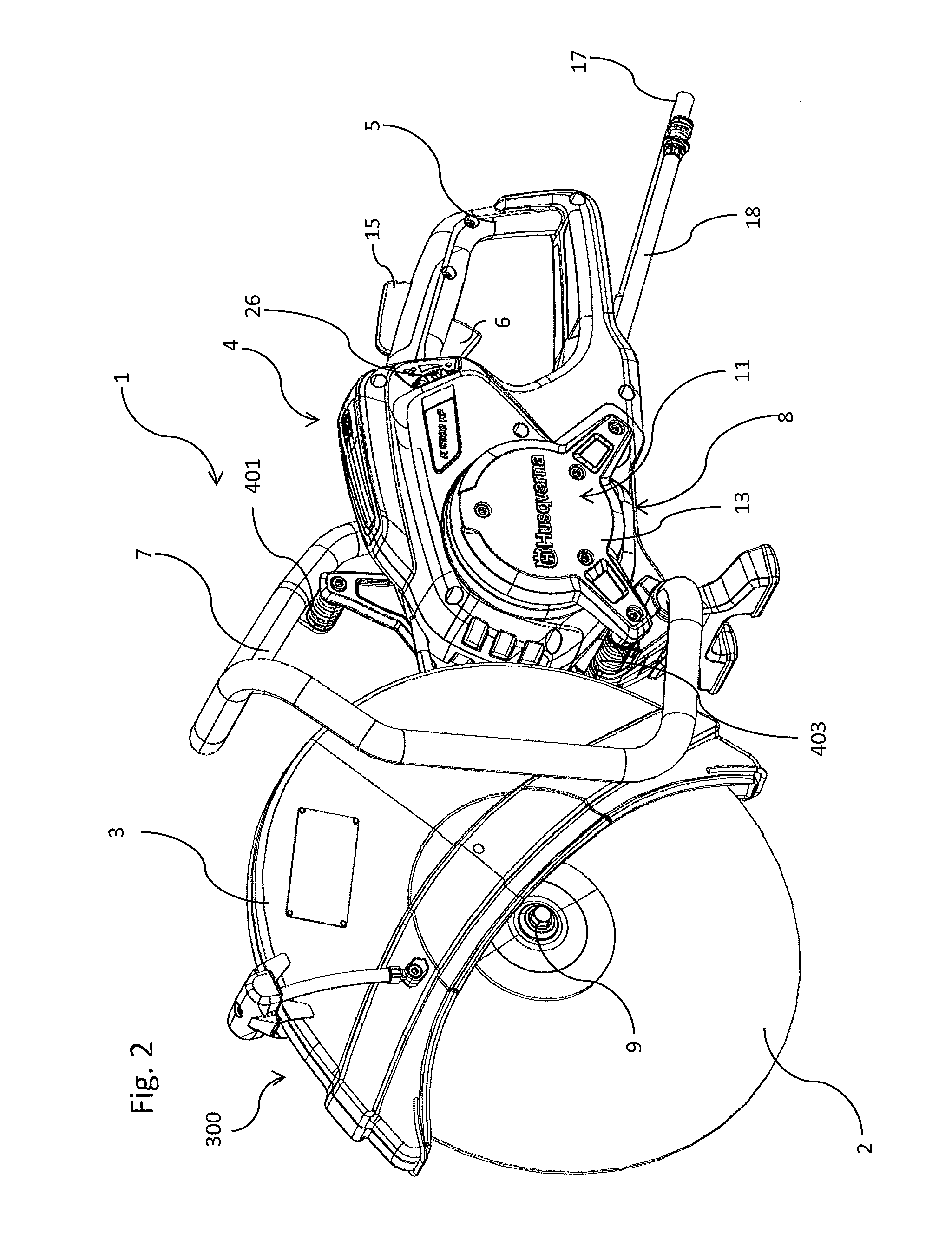

Compound chemical coal dust suppressant and preparation method thereof

ActiveCN103305187AFly effectivelyEffectively suppress flyingOther chemical processesWater basedEmulsion

The invention discloses a compound chemical coal dust suppressant and a preparation method thereof. The preparation method comprises the steps of uniformly stirring 20-40 parts of water-based acrylate emulsion, 2-10 parts of activating agents, 2-10 parts of emulsifying agents, 2-5 parts of aids and 100 parts of water uniformly for 0.5 hour at 40-60 DEG C and then cooling the mixture to the room temperature. The compound chemical coal dust suppressant has the functions of wetting, bonding and coagulating. When used, the dust suppressant is diluted with water according to a ratio of 1:(10-1000), then the dust suppressant water solution is injected into a sprayer, and coal pile dust flying can be effectively suppressed for a long time by uniformly spraying the dust suppressant water solution onto the coal pile surface according to the amount of 1.0-2L / m<2>.

Owner:SHAANXI COAL & CHEM TECH INST

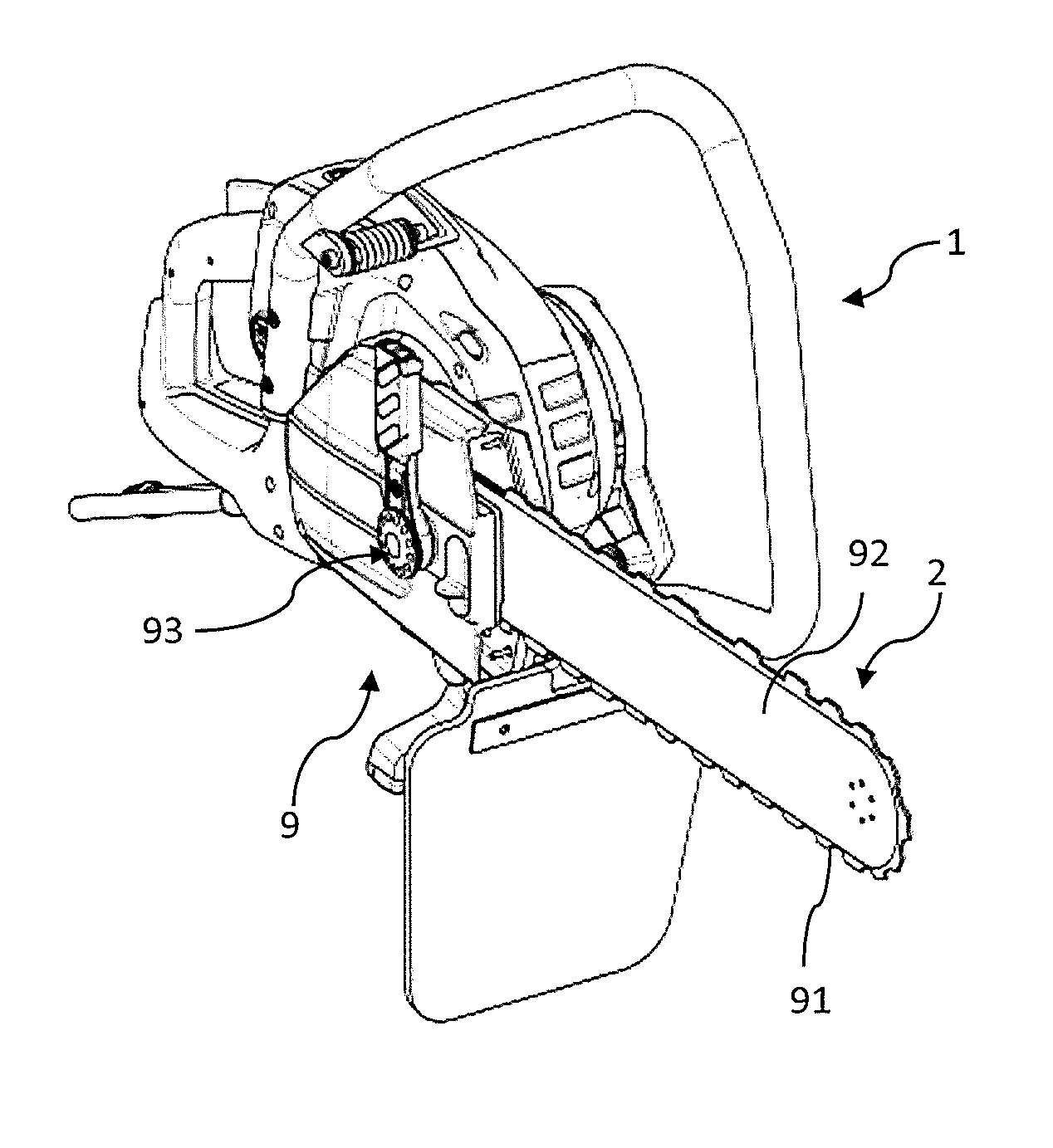

Electric cutting system

ActiveUS20150151447A1Avoid insufficient output powerSmall and less-expensiveAC motor controlSynchronous motors startersElectric power systemEngineering

An electric power saw / cutter (1) comprising: a. a rotatable saw structure (2) b. a rear handle (5) with a switch / speed control (6) c. a front handle (7) d. a drive unit (8) for rotating the saw structure (2), the drive unit (8) itself comprising: e. a saw structure drive arrangement (9) to which the saw structure is attachable f. a transmission (10) for driving the saw drive arrangement (9) g. an electric motor (11) for driving an input shaft (12) of the transmission h. a support structure (13) for holding / carrying the saw structure drive arrangement (9), the transmission (10) and the electric motor (11), characterised in, that the front handle (7) and the rear handle (5) are directly connected to each other to form a handle unit (4), which unit is resiliently connected to the drive unit (8), so that vibrations from the saw blade (2) and drive unit (8) will be reduced in the handle unit (4).

Owner:HUSQVARNA AB

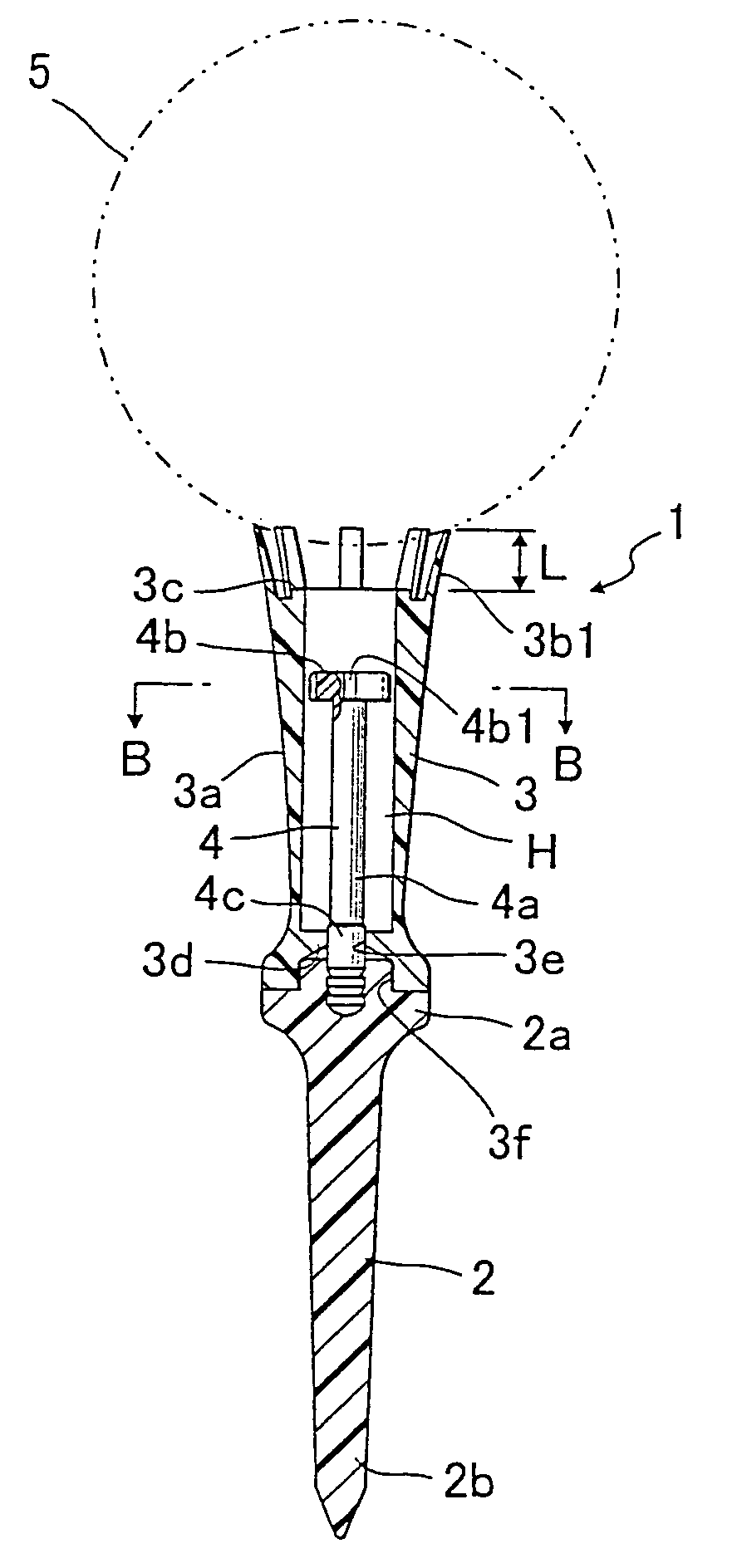

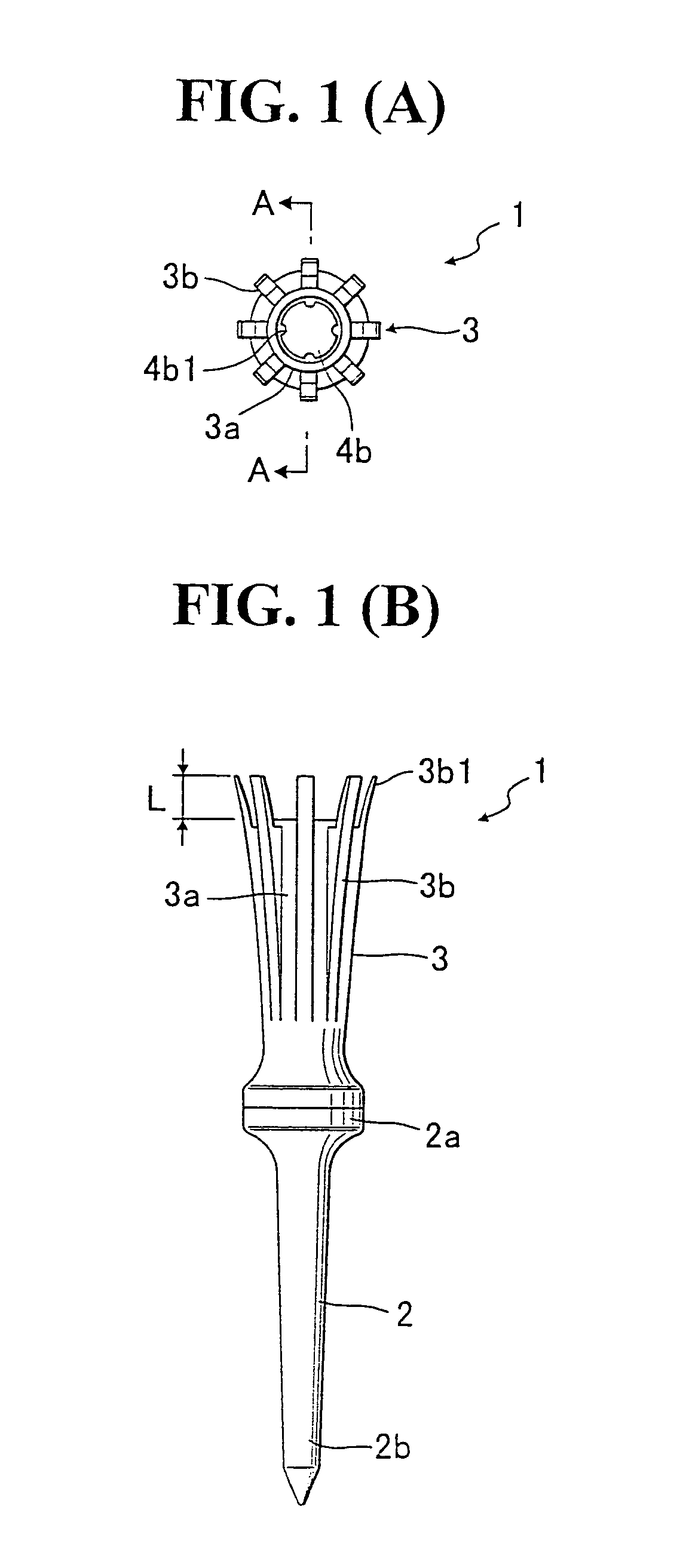

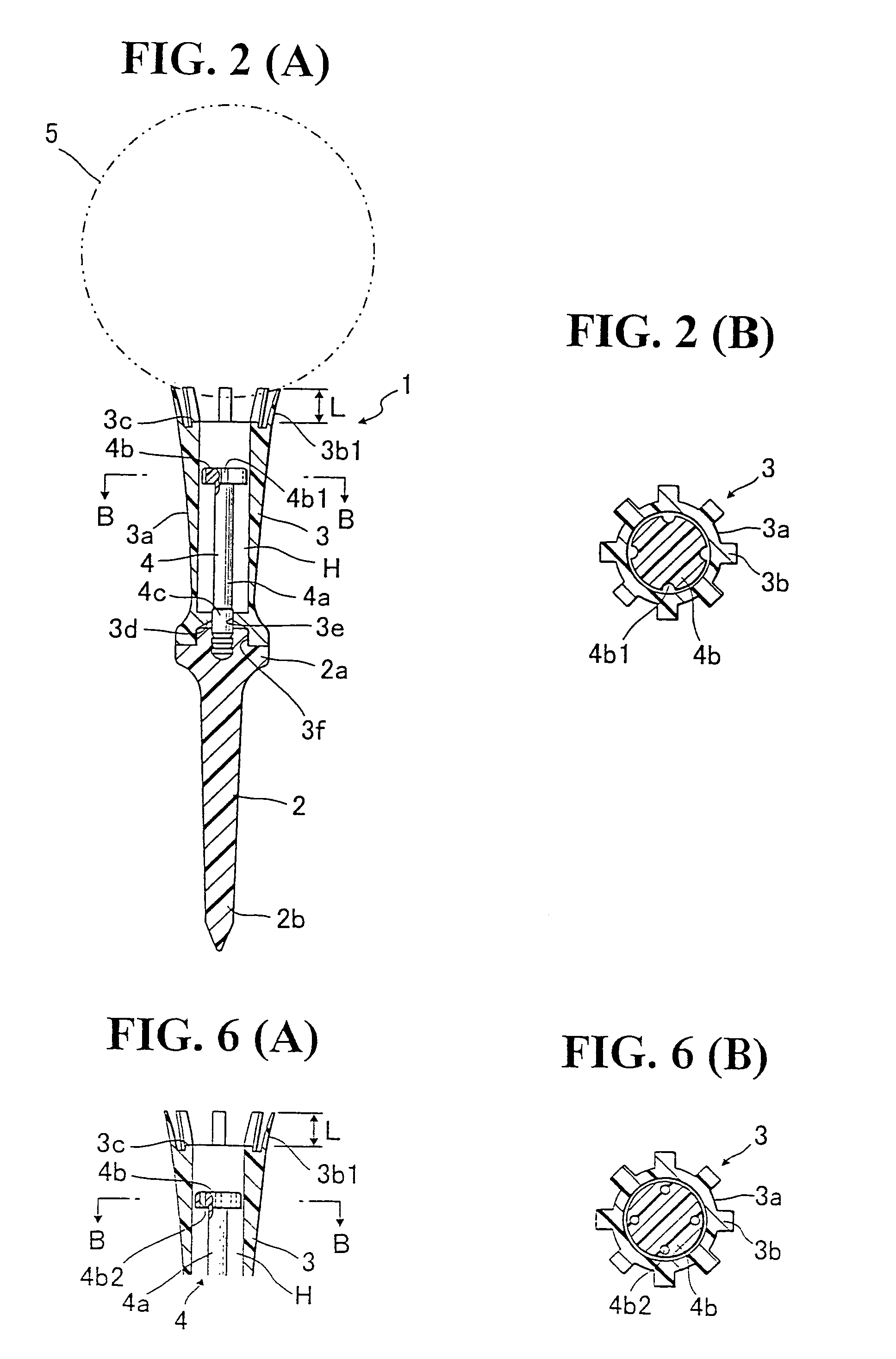

Golf tee

The present invention provides a durable golf tee capable of conserving as much as possible the impact energy transmitted to the golf tee and preventing possible flight thereof from the ground. The golf tee comprises a stick pin, the lower end of which is formed in a tapered shape, to stick into the ground, a ball-holding member placed on the top of the stick pin and provided with a small hole at the bottom of a hollow part, and a flexible connecting member, the lower end of which is fixed on the stick pin. The connecting member is provided with a flange on the upper end for binding slidably the ball-holding member to the stick pin and inserted into a hollow part H through a small hole perforated at the bottom of the ball-holding member. Notches 4b1 are formed between the flange of the connecting member and the ball-holding member to let air escape upward.

Owner:DIA SRL

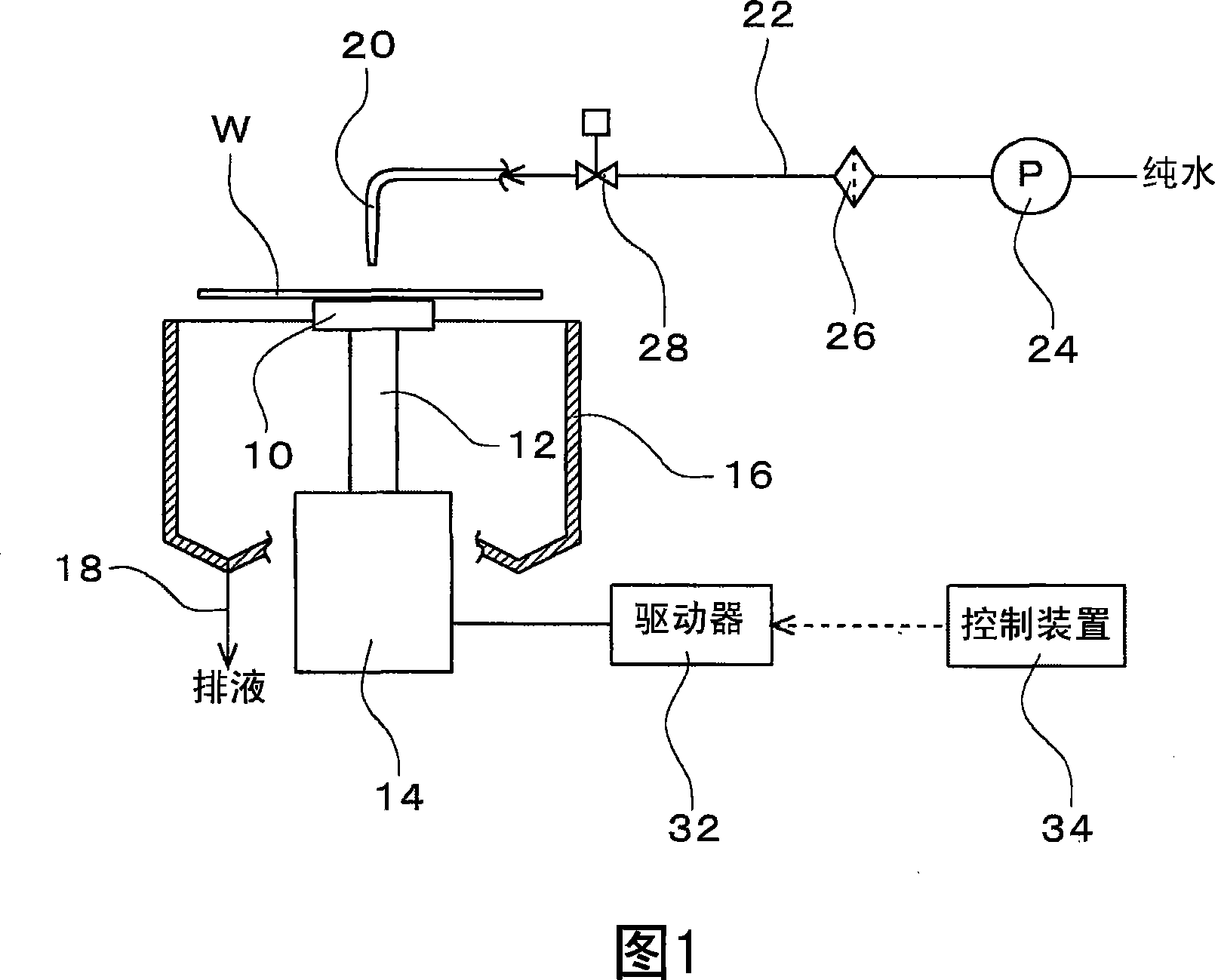

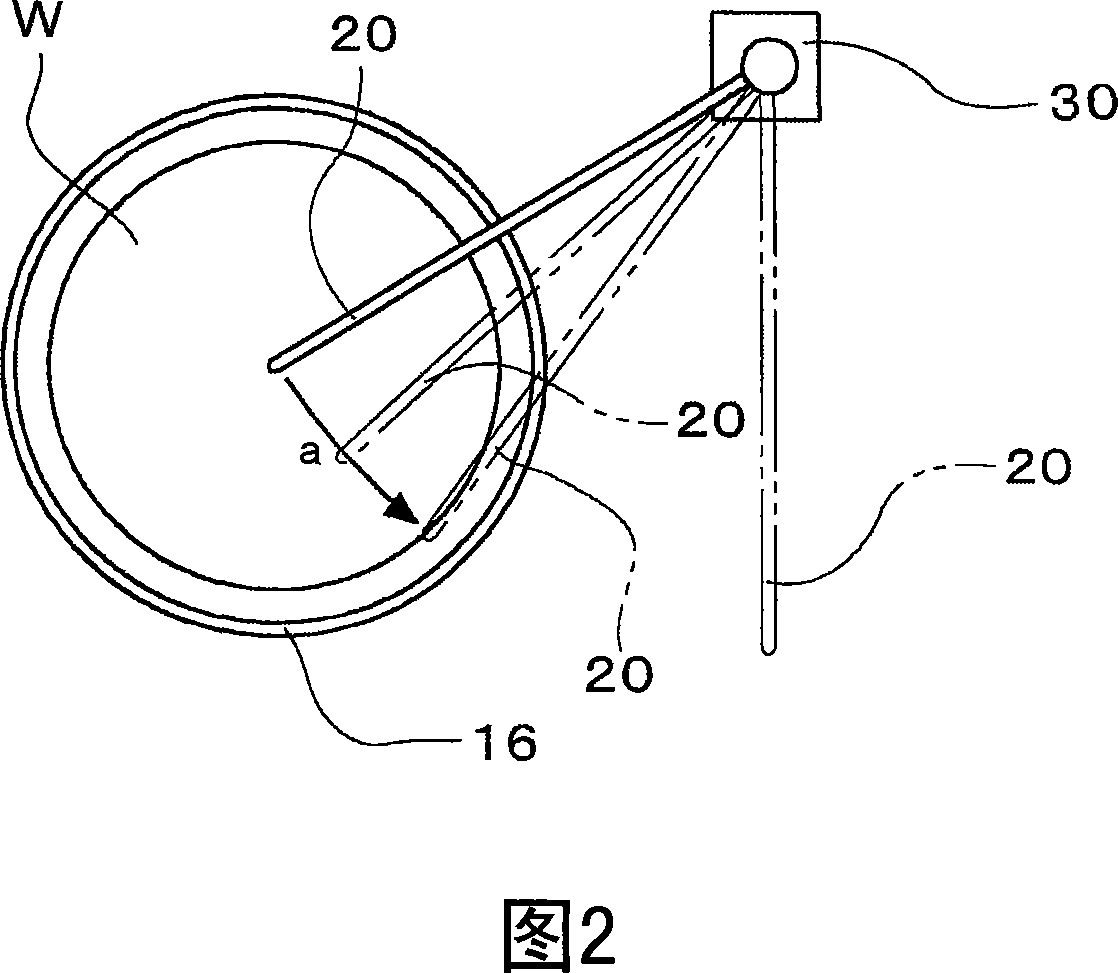

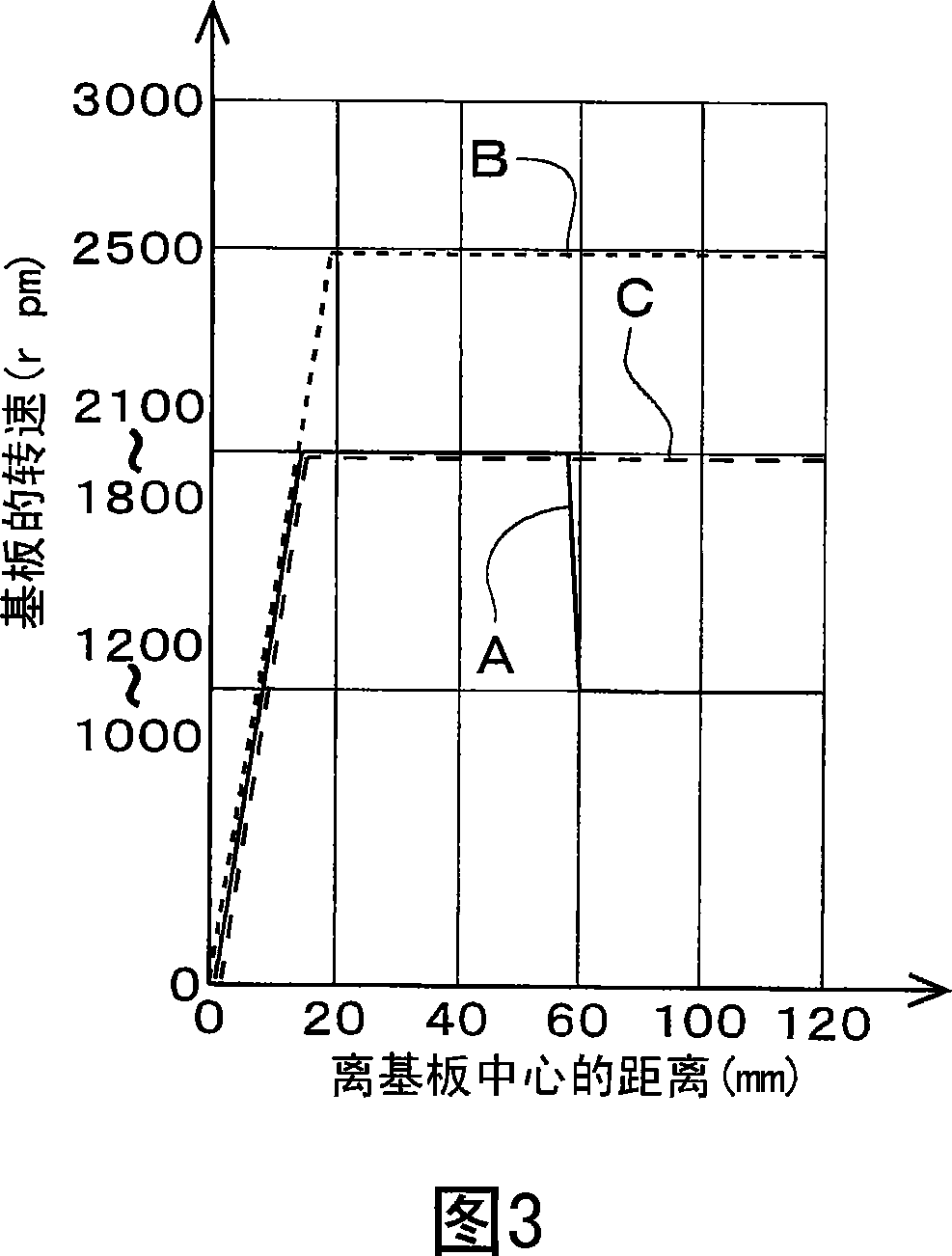

Substrate processing method and substrate processing apparatus

ActiveCN101075553ASuppress splashReduce speedSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringVertical axis

The invention provides a method capable of suppressing liquid splash at the circumferential edge of a substrate, and preventing liquid droplets due to liquid splash from adhering to the substrate again when moving a discharge nozzle for scanning while discharging a cleaning solution from the discharge nozzle to the surface of the substrate to make spin drying of the substrate. When a substrate W is held in a horizontal posture by a spin chuck 10 and rotated about a vertical axis with a rotation motor 14, while discharging the cleaning solution onto the surface of the substrate from an outlet of a de-ionized water discharge nozzle 20, the rotation speed of the substrate is decreased in a process that the outlet of the discharge nozzle is traveled from a position opposed to a center of the substrate to a position opposed to the circumferential edge of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

Automatic steel bar cutting device

The invention relates to the technical field of steel bar cutting, in particular to an automatic steel bar cutting device used for reducing the error generated during steel bar cutting. The automatic steel bar cutting device comprises a conveying assembly, a clamping assembly, a guiding assembly, a cutting assembly and a measuring assembly. The conveying assembly mainly comprises a first support and conveying rollers, and the multiple conveying rollers are connected with a stepping motor through a transmission mechanism, wherein the stepping motor is arranged on the first support. A second support is arranged on one side of the first support, two vertical first air cylinders are fixedly installed at the bottom of the second support, and a tray is fixedly installed at the free ends of piston rods of the two first air cylinders. A motor is fixedly installed on the tray, and the output end of the motor is connected with a cutting saw through a speed reducer. A fixing frame of a gantry structure is arranged over the cutting saw, and blocking curtains are fixedly arranged at the two ends of the fixing frame respectively. A third support is arranged on one side of the second support, and the measuring assembly is arranged on the third support. The automatic steel bar cutting device is easy to operate, accurate in positioning and high in saw cutting efficiency, and the work efficiency can be greatly improved.

Owner:STATE GRID SHANDONG SHANGHE POWER SUPPLY +1

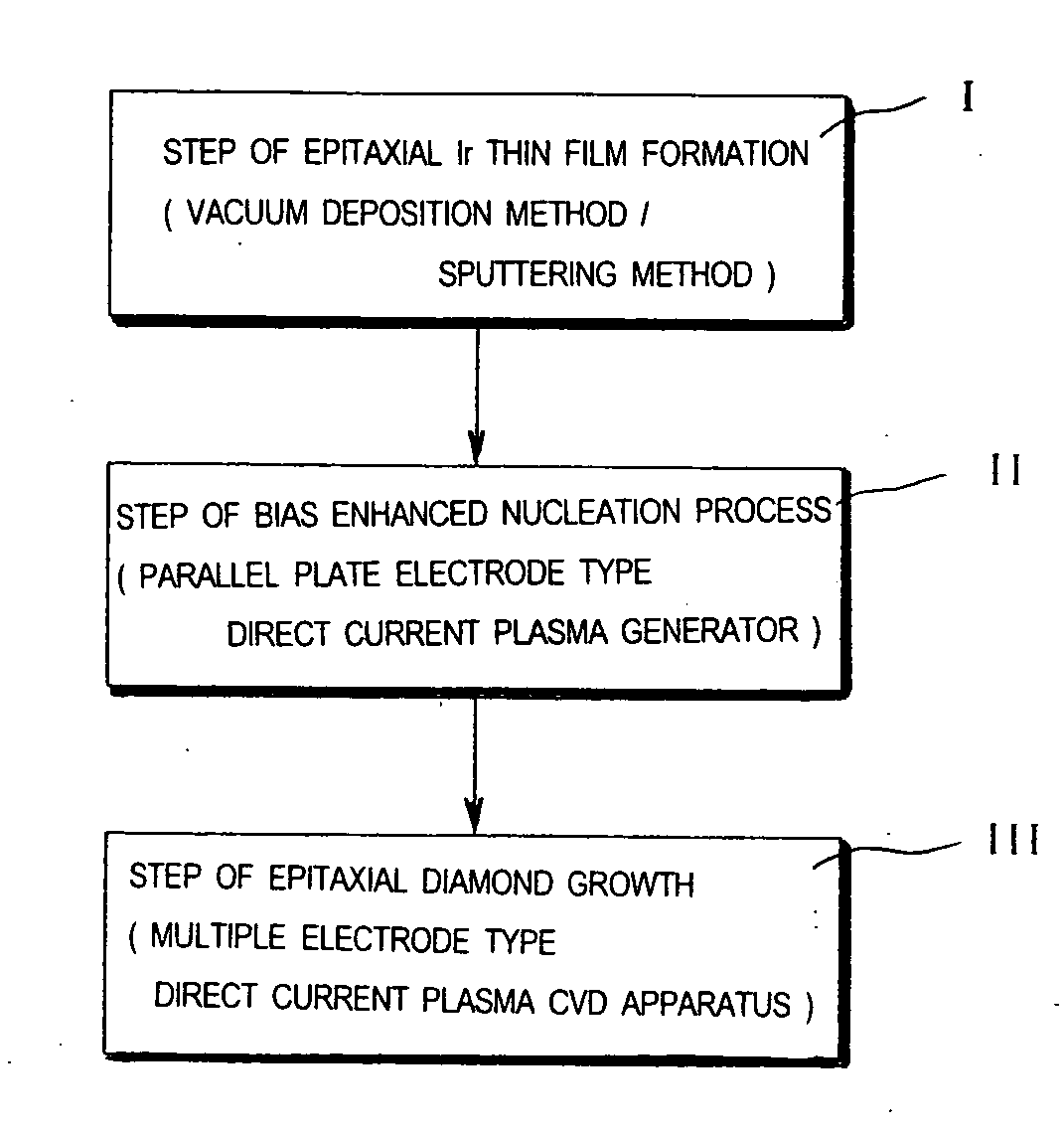

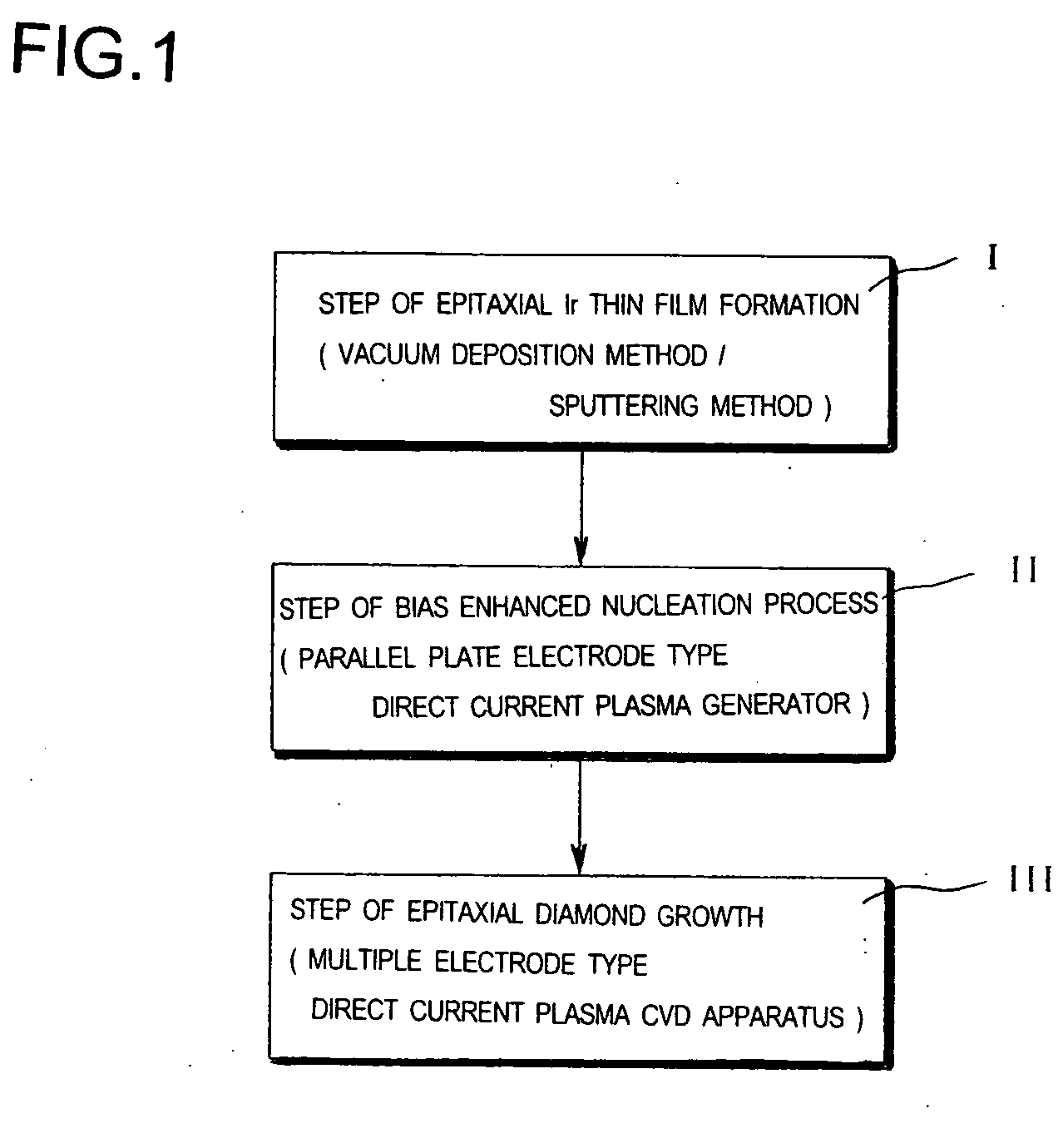

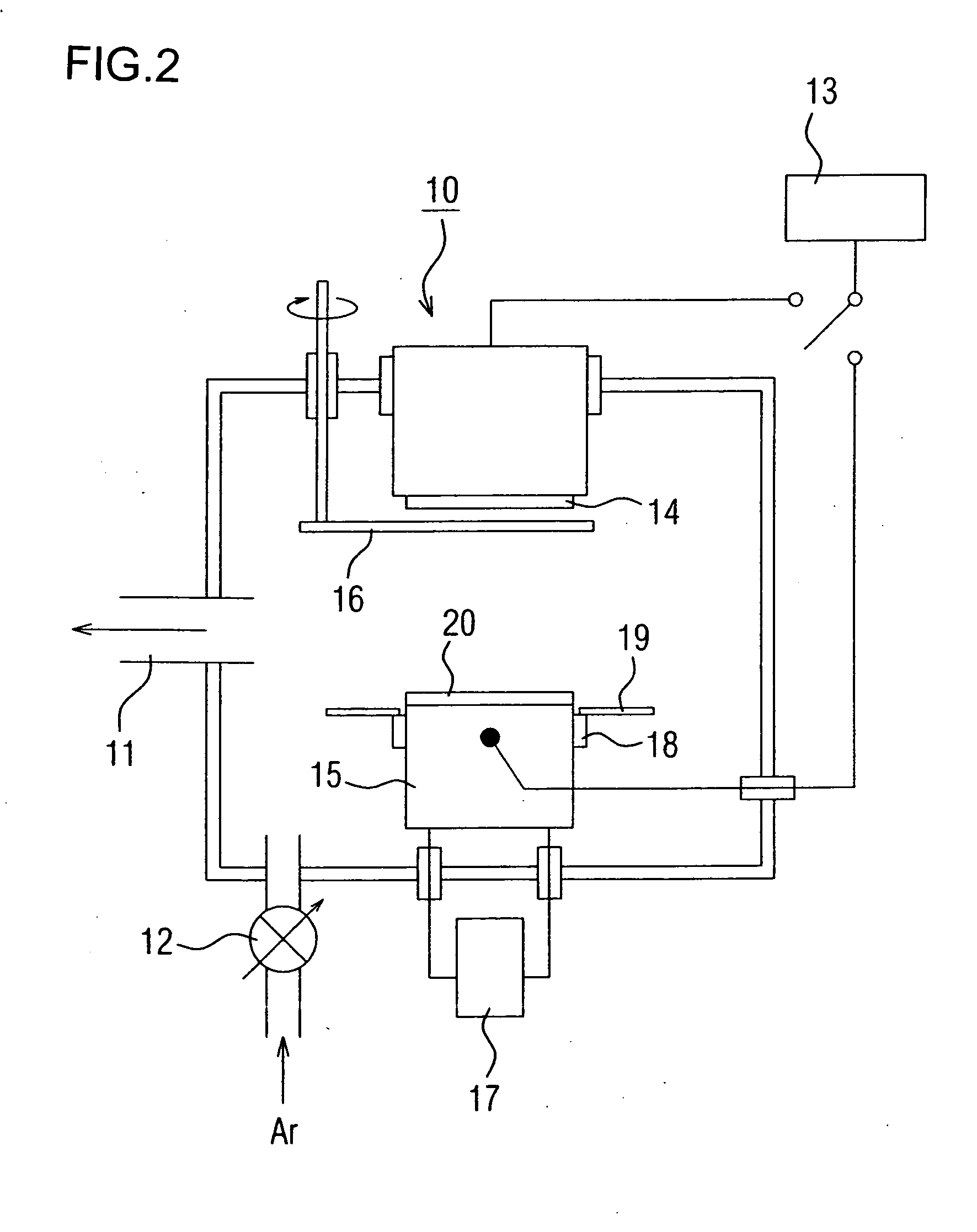

Base Substrate for Epitaxial Diamond Film, Method for Producing the Base Substrate for Epitaxial Diamond Film, Epitaxial Diamond Film produced With the Base Substrate for Epitaxial Diamond Film, and Method for Producing the Epitaxial Diamond Film

ActiveUS20090176114A1Easy to produceUniformly and highly densely generatingFrom gel stateFrom solid stateIridiumGeneration process

The present invention provides a base substrate for epitaxial diamond film capable of epitaxially growing a large area of high quality diamond, having a diameter of 1 inch (2.5 cm) or more, on an iridium base by using the CVD method, a method for producing the base substrate for epitaxial diamond film, an epitaxial diamond film produced with the base substrate for epitaxial diamond film and a method for producing the epitaxial diamond film. An iridium (Ir) film is formed by epitaxial growth on a single crystal magnesium oxide (MgO) substrate or a single crystal sapphire (α-Al2O3) substrate by means of a vacuum deposition method or a sputtering method, and a bias nucleus generation process of forming epitaxial diamond nuclei is applied to the surface of the iridium (Ir) base formed as a film by exposing an ion-containing direct current plasma to the surface of the iridium (Ir) base formed as a film.

Owner:SAWABE ATSUHITO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com