Patents

Literature

12582results about How to "Guaranteed cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

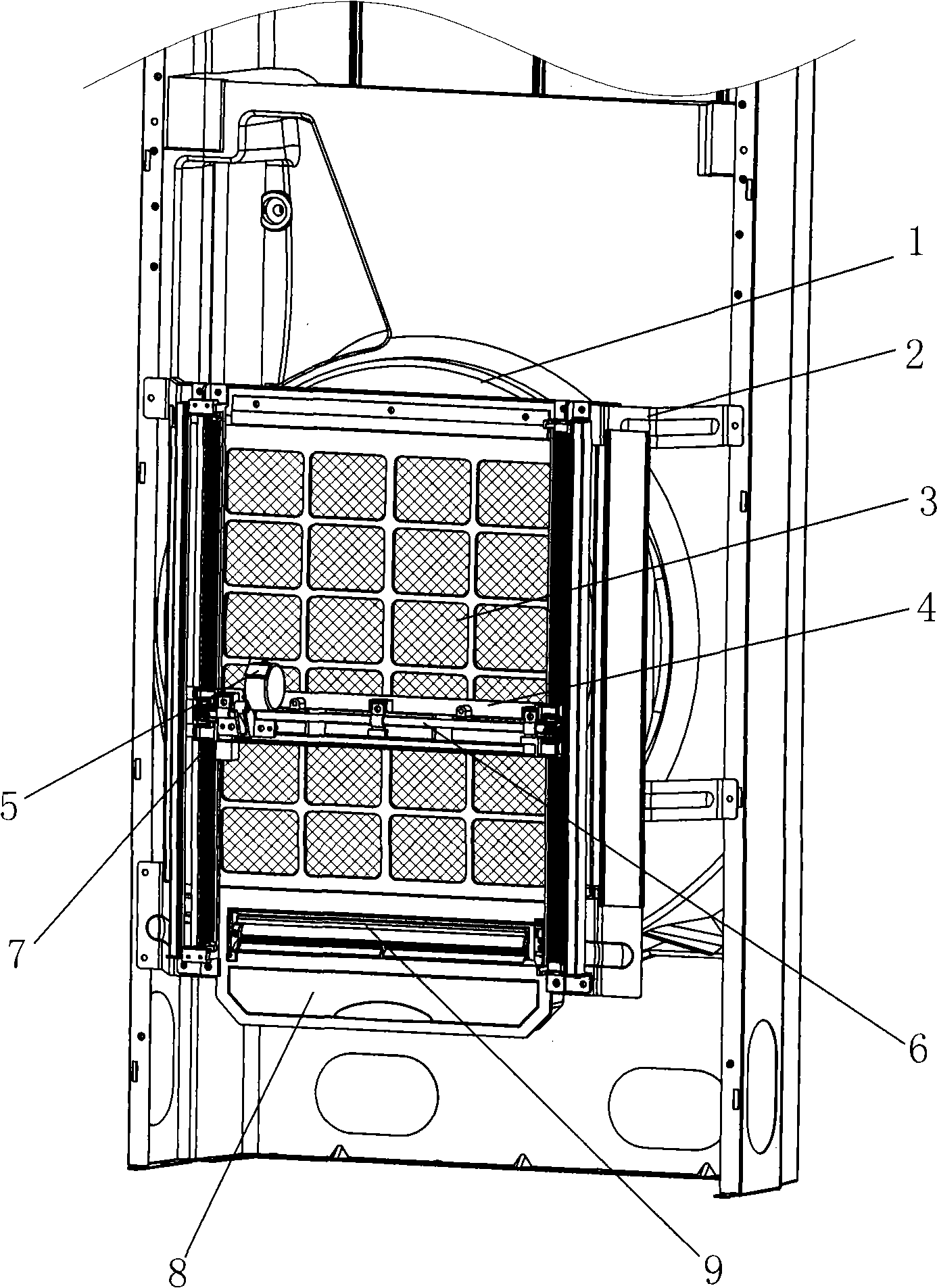

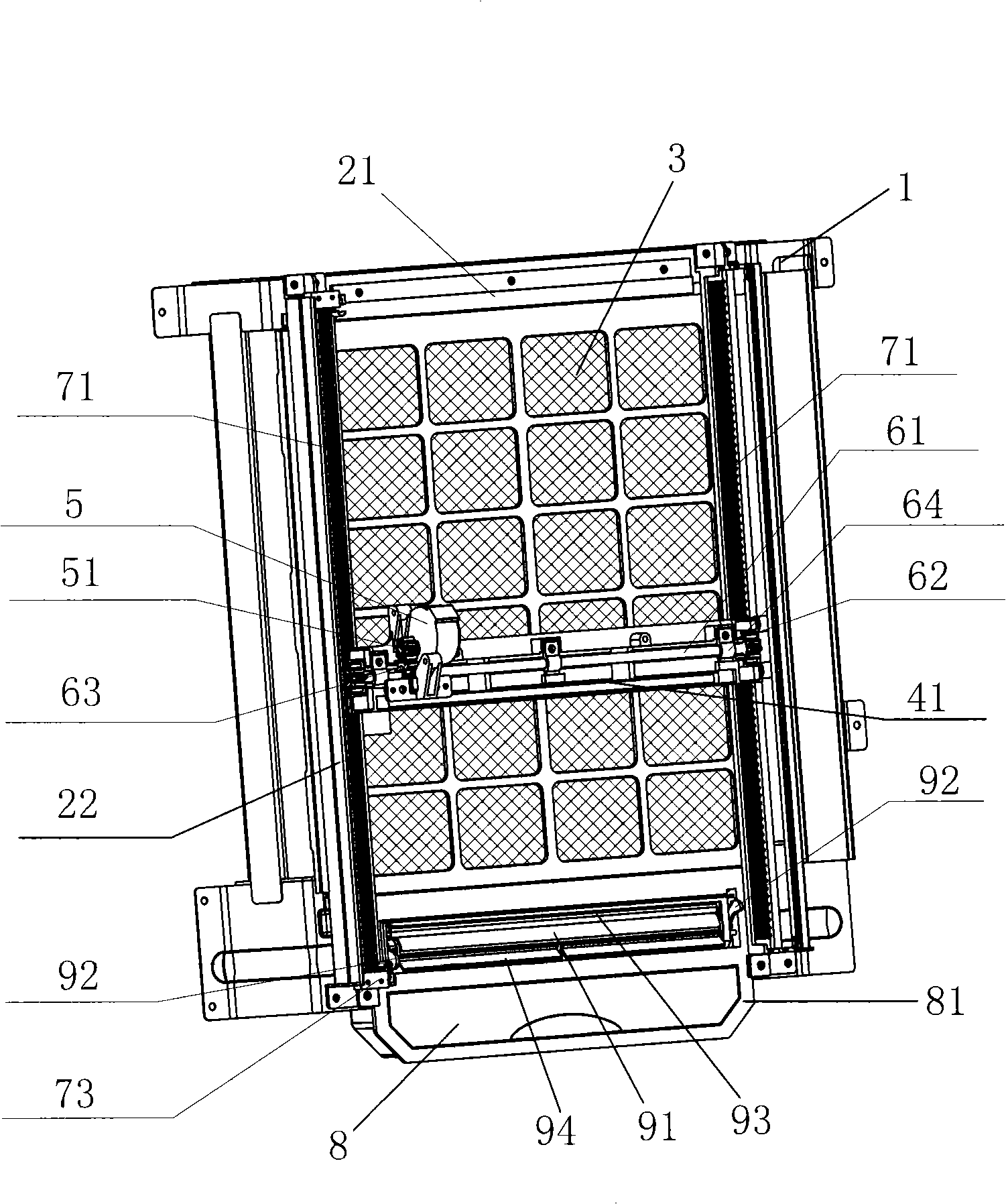

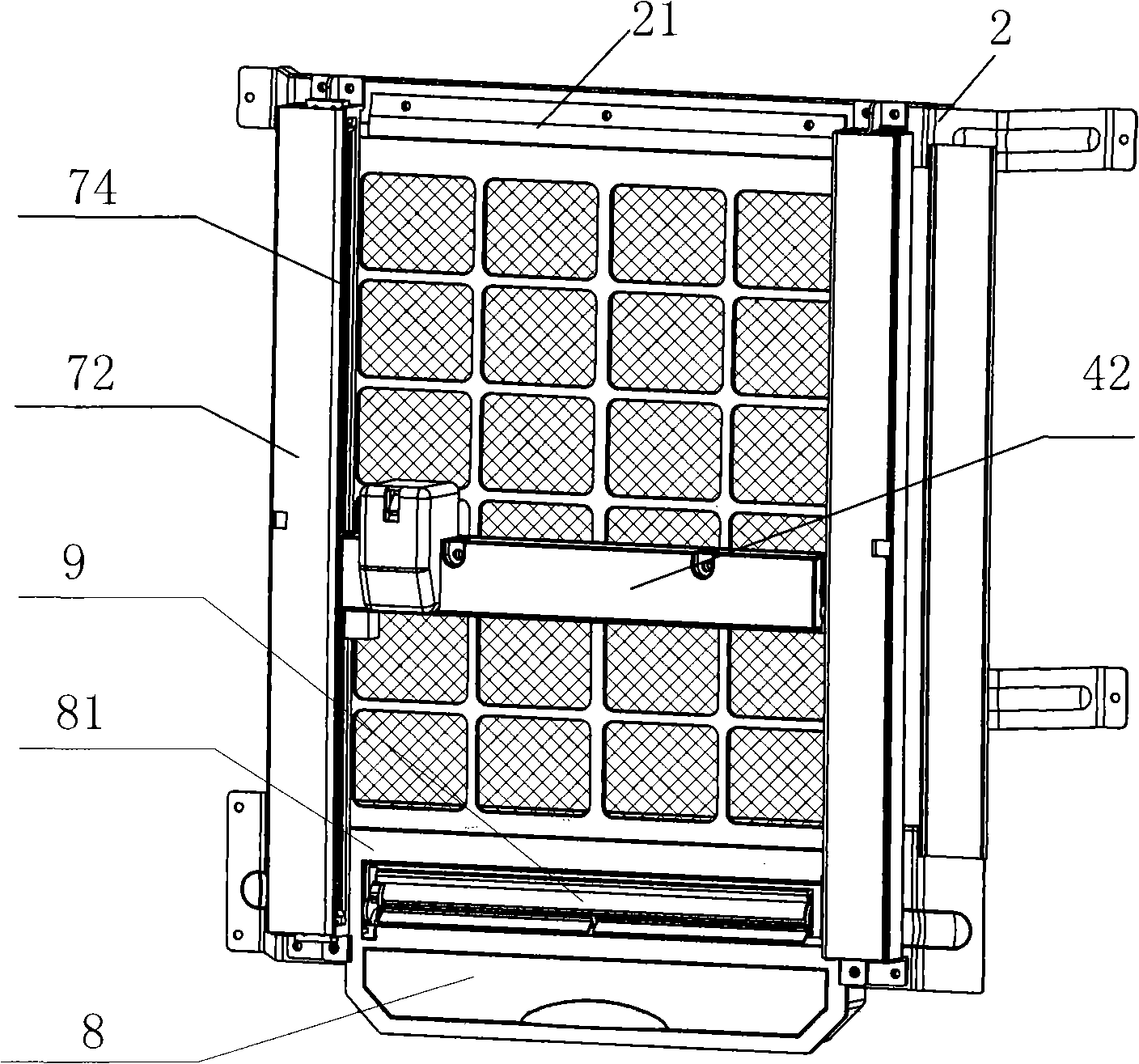

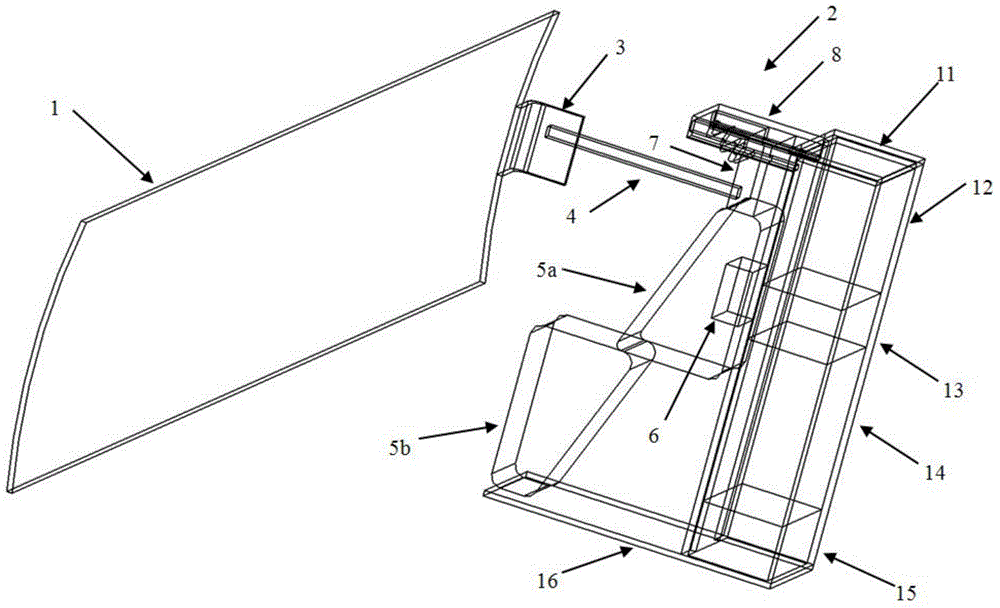

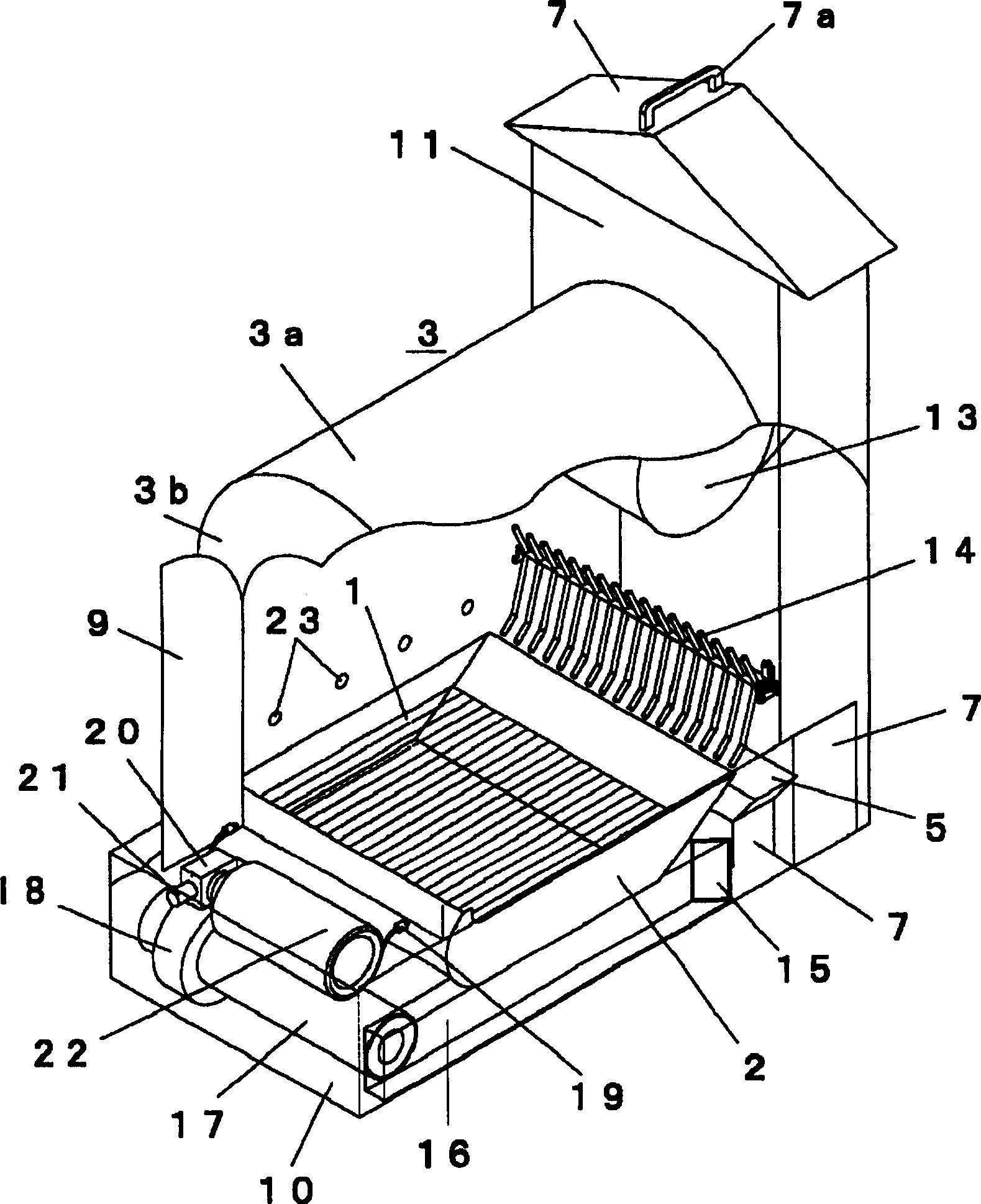

Air conditioner filter screen self-cleaning device

ActiveCN101290151AGuaranteed cleanlinessGuarantee the quality of workMechanical apparatusDispersed particle filtrationDrive motorSelf cleaning

The invention discloses a self-cleaning device for an air conditioner filter screen, which is arranged on filter screen brackets at an air passage spiral casing air inlet of a cabinet air conditioner and is arranged outside the filter screen, an upper bracket and a lower bracket are provided with filter screen guide rails with slots, the filter screen is fixed on the filter screen brackets through the slots of the guide rails, a filter screen cleaning device comprises a cleaning component with a brush, a drive motor fixed on the cleaning component, a driving mechanism connected with the drive motor, a rack set arranged at the left side part and the right side part of the filter screen and a dust box arranged under the filter screen and used for collecting dust; a dust exchange device is arranged between the dust box and the filter screen; the drive motor connected with the driving mechanism drives the cleaning component to slide up and down along the rack set adhering to the filter screen in order to enable the brush to clean dust down; the cleaning component slides down to pass through the dust exchange device and cleans the dust down in the dust exchange device, and then the dust exchange device pours the dust to the dust box. The self-cleaning device for air conditioner filter screen saves time and labor and can be cleaned at any time without disassembling.

Owner:HAIER GRP CORP +1

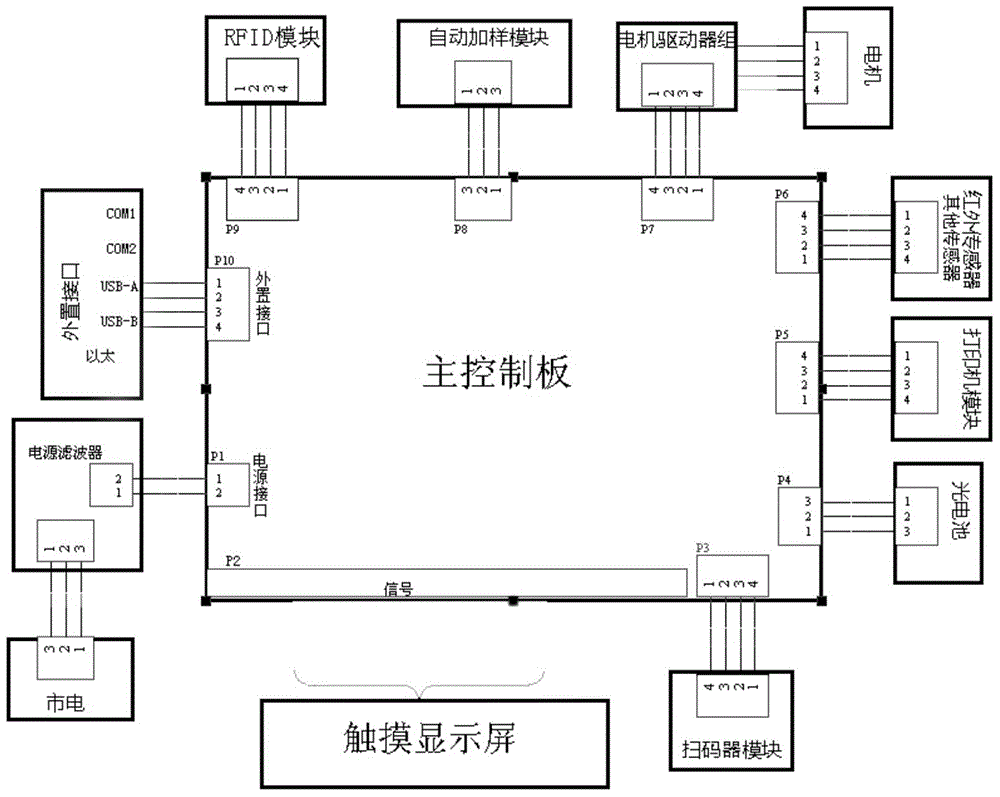

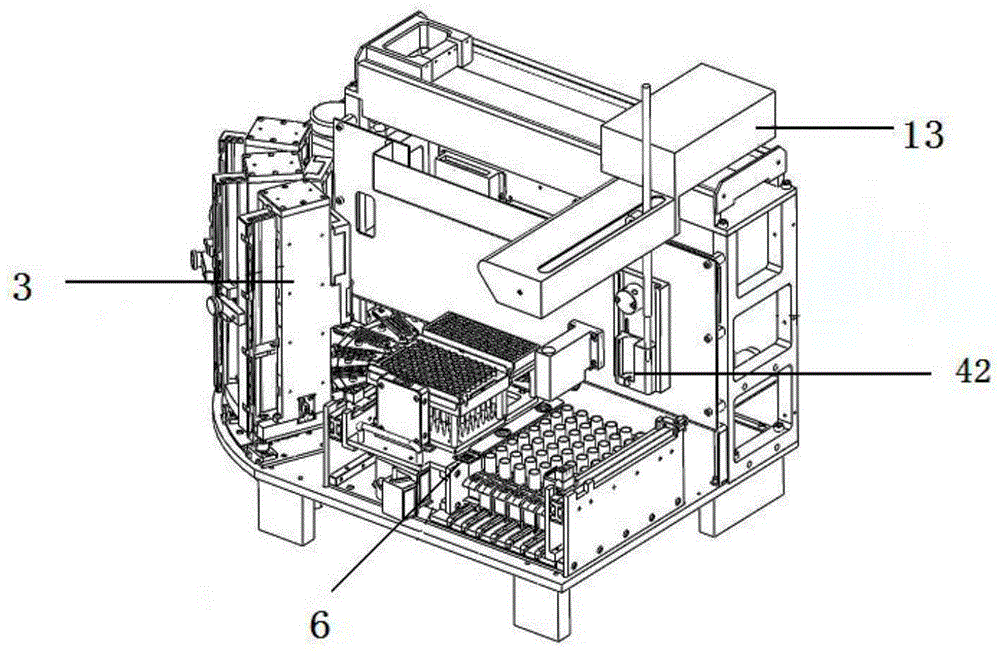

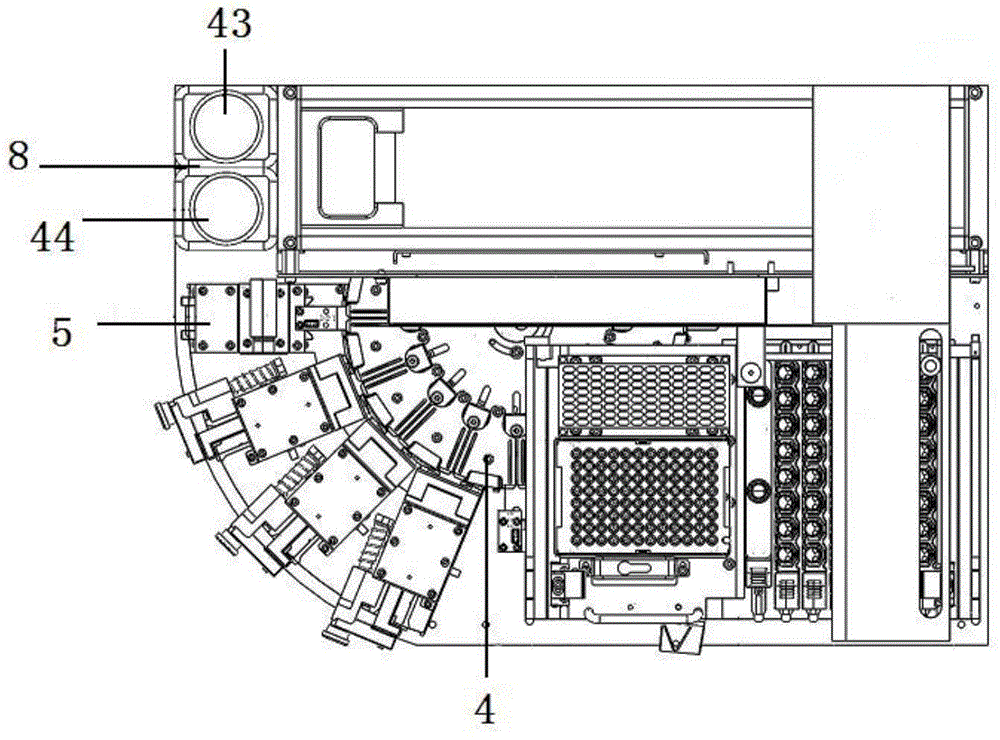

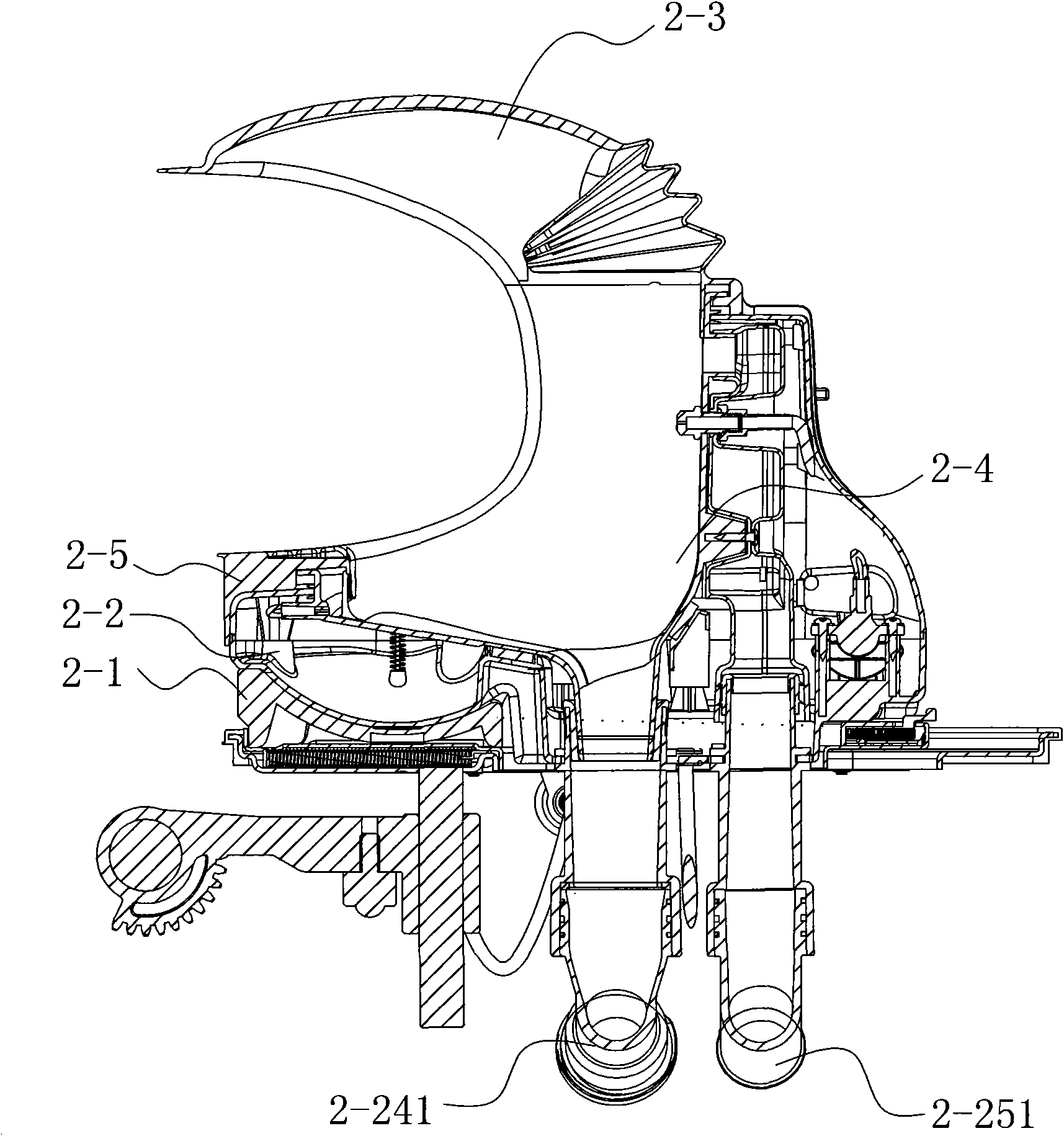

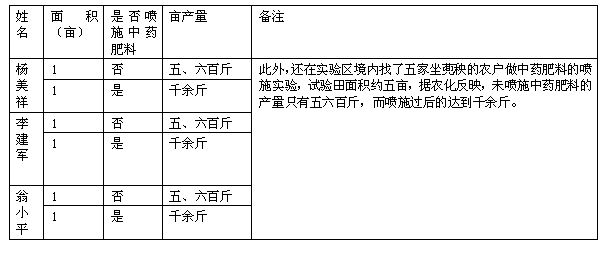

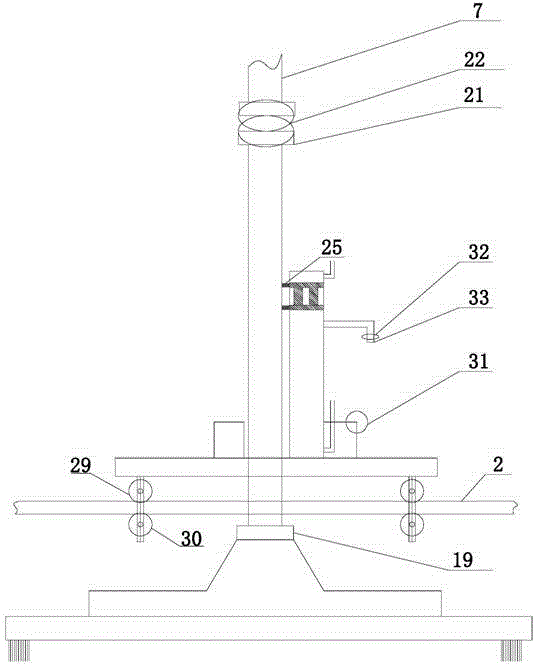

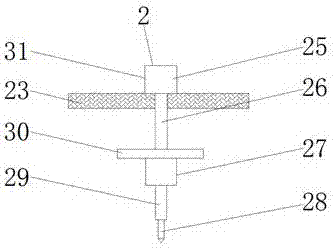

Full-automatic immuno-fluorescence quantitative analysis device and implementation method

ActiveCN104535782ASolving hard-to-automate challengesImprove repeatability and test accuracyMaterial analysisReagent stripControl system

The invention discloses a full-automatic immuno-fluorescence quantitative analysis device and an implementation method, belonging to the field of quantitative immuno-fluorescence analysis and detection. The full-automatic immuno-fluorescence quantitative analysis device comprises a supporting bottom plate, a reagentstrip storage and automatic loading module, a reactiondisc module, a detection module, a sample module, a sample adding module, a washing module and a control system, wherein the reagentstrip storage and automatic loading module, the reactiondisc module, the detection module, the sample module, the sample adding module and the washing module are arranged on the supporting bottom plate in sequence; the reagentstrip storage and automatic loading module provides a reagent strip for the reactiondisc module; the sample adding module is used for adding samples in the sample module into the reactiondisc module to carry out reaction, and after reaction is finished, the samples enter the detection module to be detected. The full-automatic immuno-fluorescence quantitative analysis device and the implementation method disclosed by the invention have the advantages that the difficulty that automation is hard to implement for an in-vitro diagnosis product is solved, the artificial error is reduced, the testing accuracy is improved and the detection efficiency is improved.

Owner:GETEIN BIOTECH

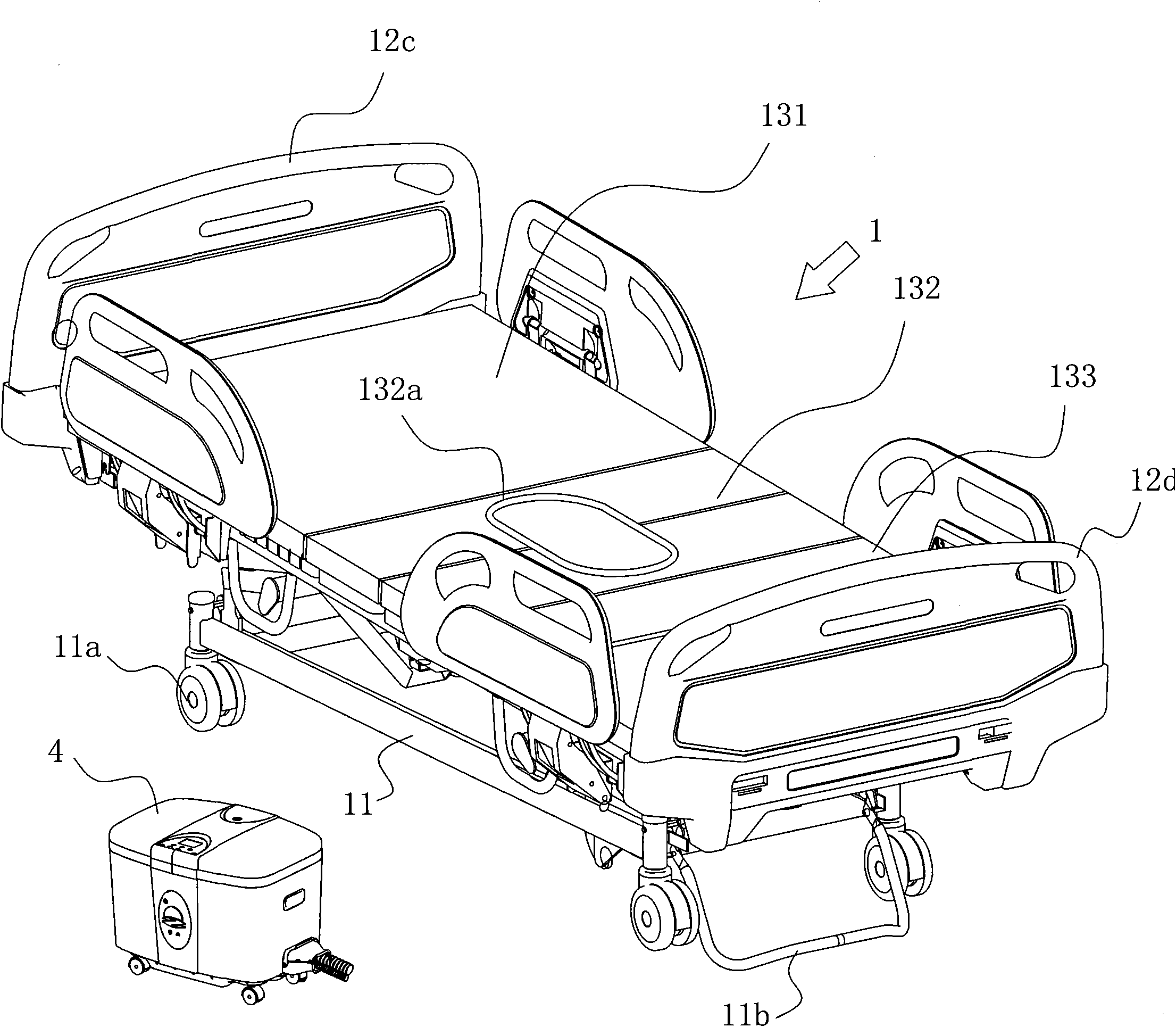

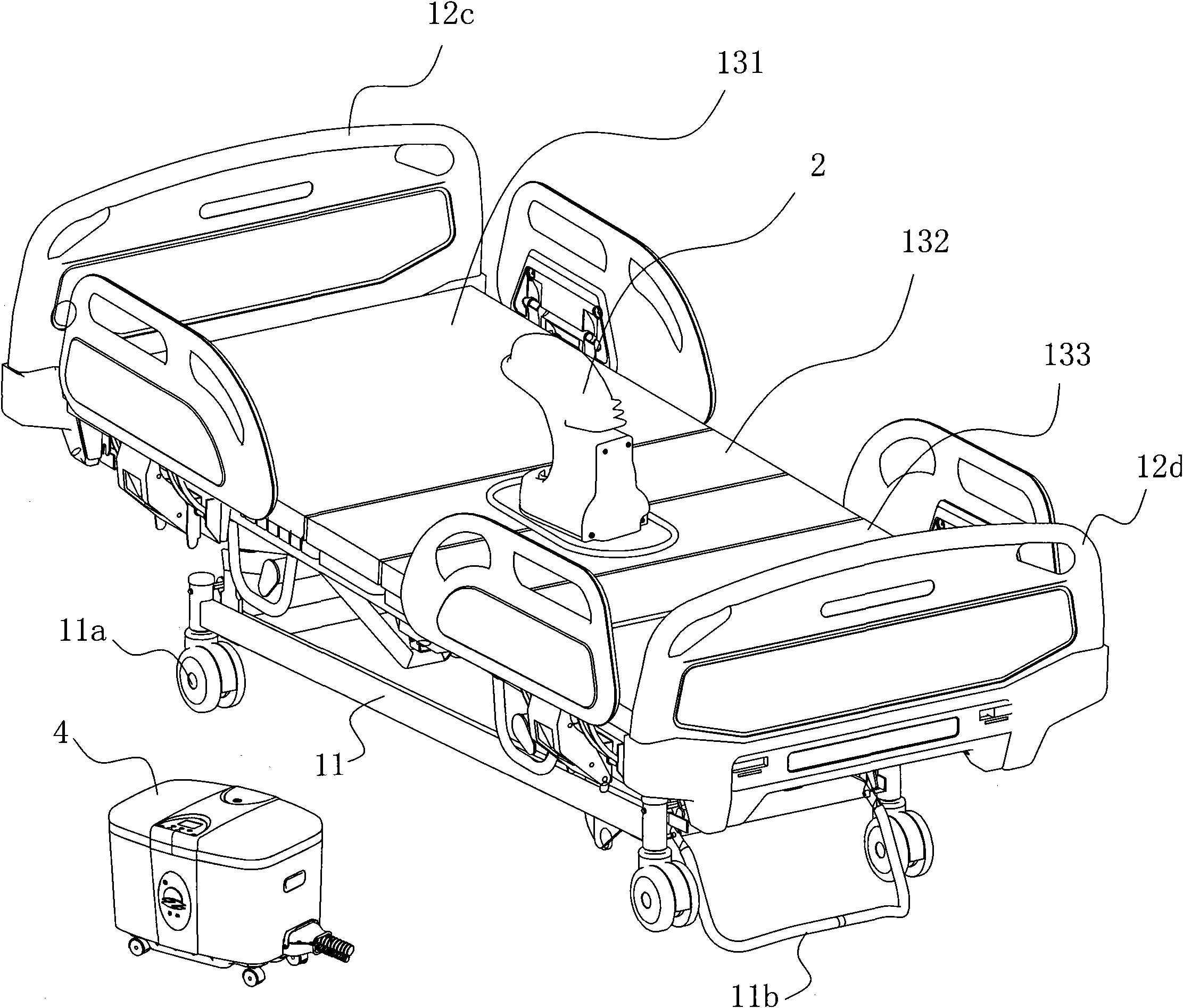

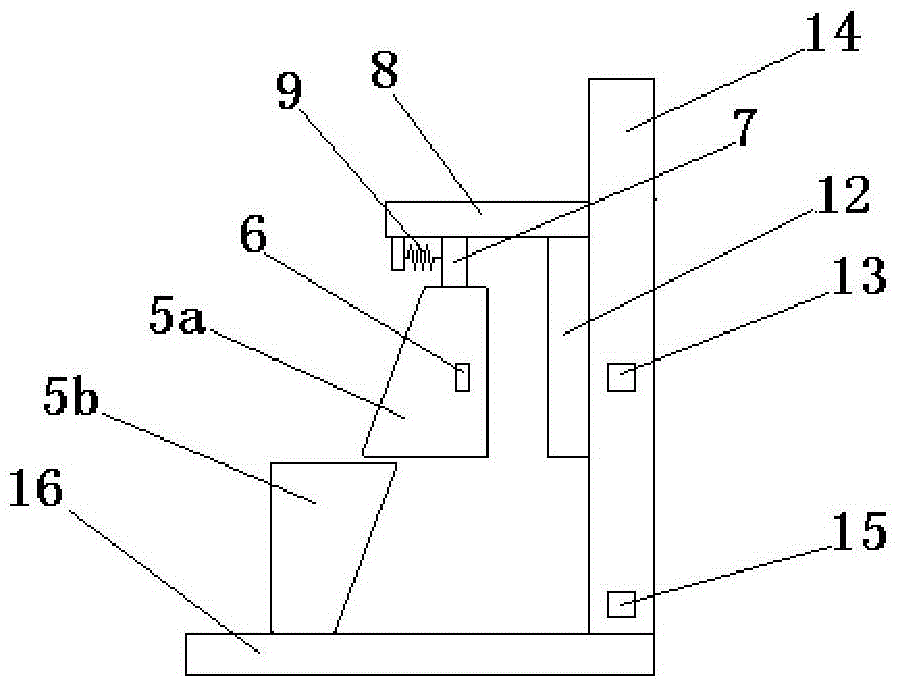

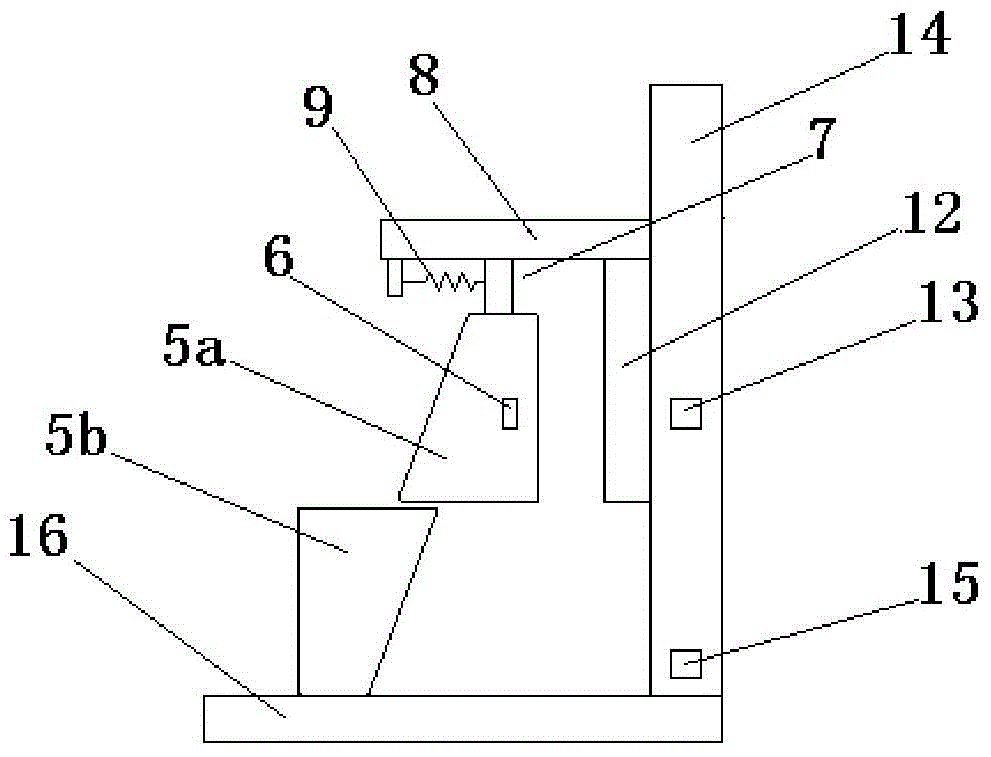

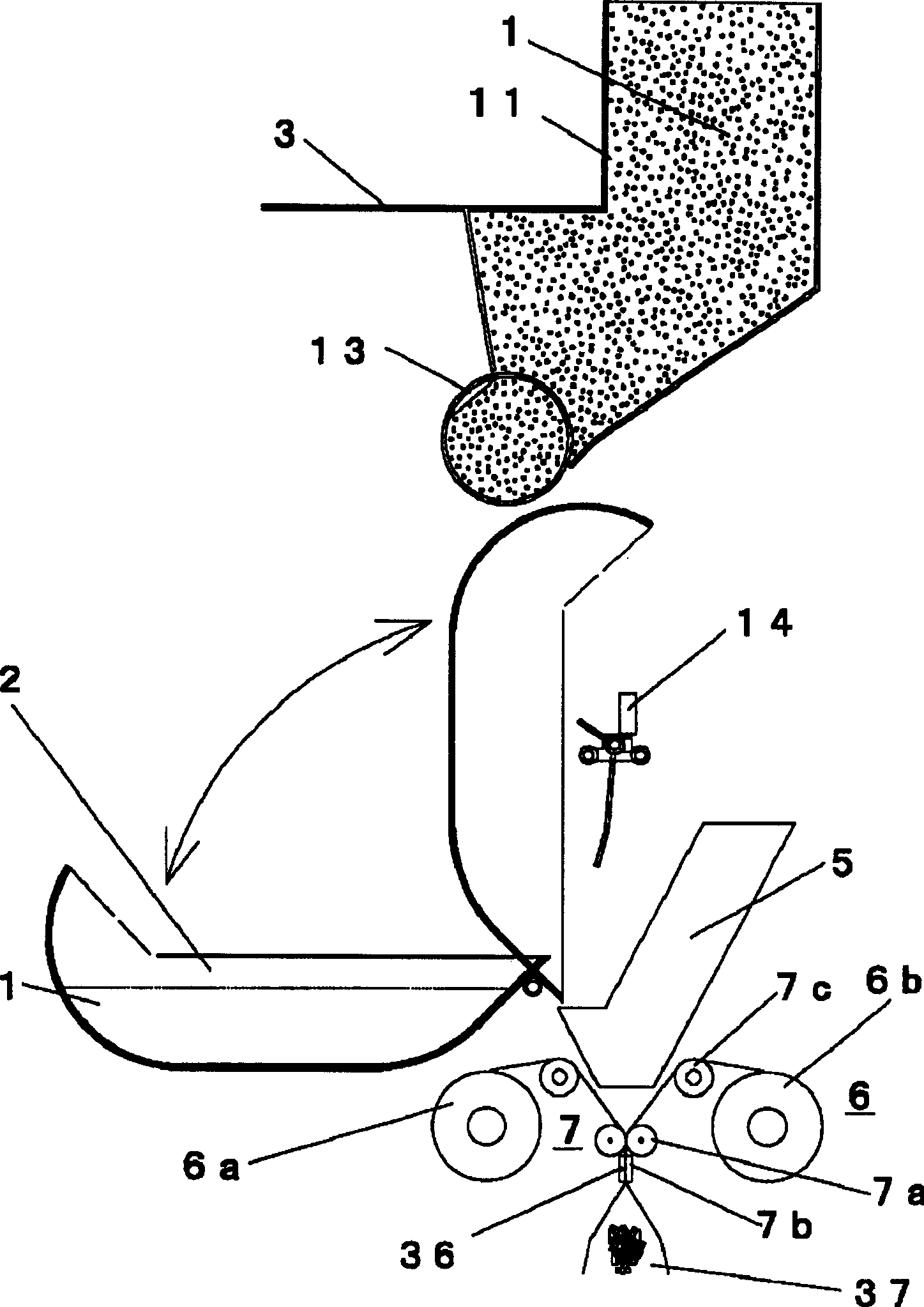

Automatic nursing bed

The invention discloses an automatic nursing bed, which comprises a bed body, a nursing bed mattress, a defecation absorption seat, an automatic defecation absorption seat turnover assembly and a defecation collection treatment assembly. The automatic defecation absorption seat turnover assembly comprises a cross beam fixedly arranged on a nursing bed frame, a pull rod bracket is fixedly arranged on the cross beam, a pull rod capable of moving along the axis is arranged in the pull rod bracket, and an absorption seat turnover sleeve and a plugging plate turnover sleeve capable of rotating along the pull rod respectively are sleeved on the pull rod; a defecation absorption seat mounting stand is arranged on the absorption seat turnover sleeve, and a nursing hole plugging plate is arranged on the plugging plate turnover sleeve; the end of the pull rod is provided with a pull rod length adjusting device which is connected with a pull rod pushing device for driving the defecation absorption seat mounting stand or the nursing hole plugging plate to move to the lower part of a nursing hole; and the bed frame is also provided with a turnover driving device in power connection with the absorption seat turnover sleeve or the plugging plate turnover sleeve. The automatic nursing bed well combines defecation and nursing together, has reliable operation and comfortable use, realizes humanized nursing service, and saves time and labor.

Owner:山东旭日鑫医疗器械有限责任公司

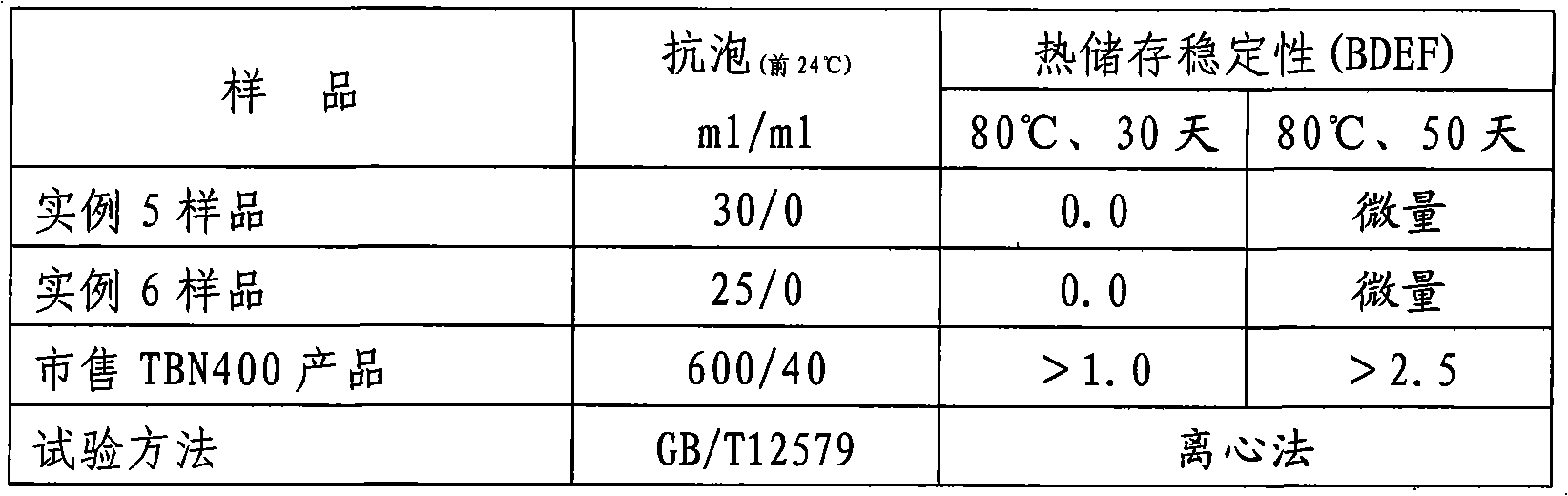

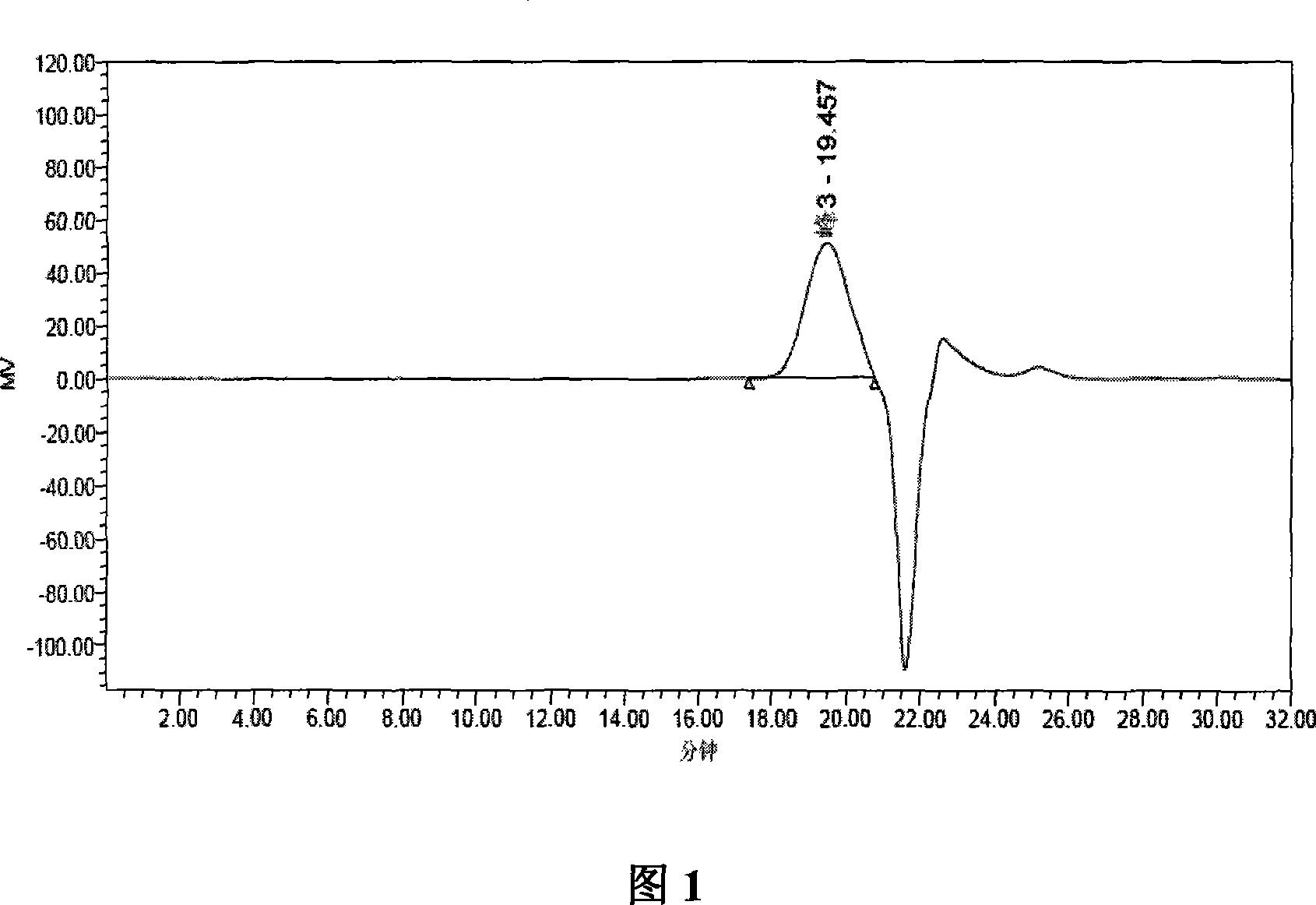

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

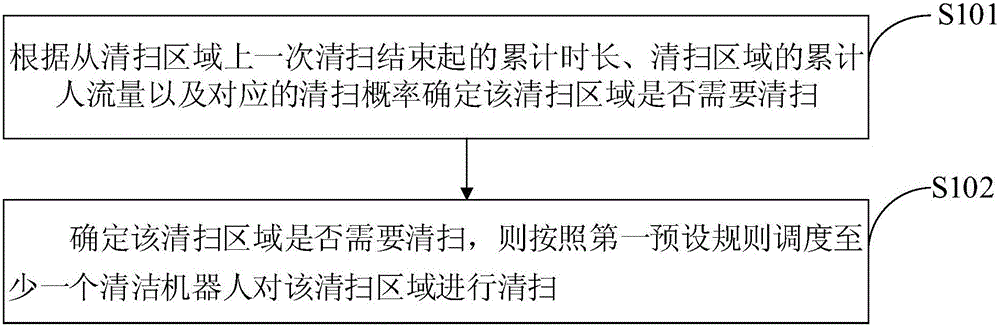

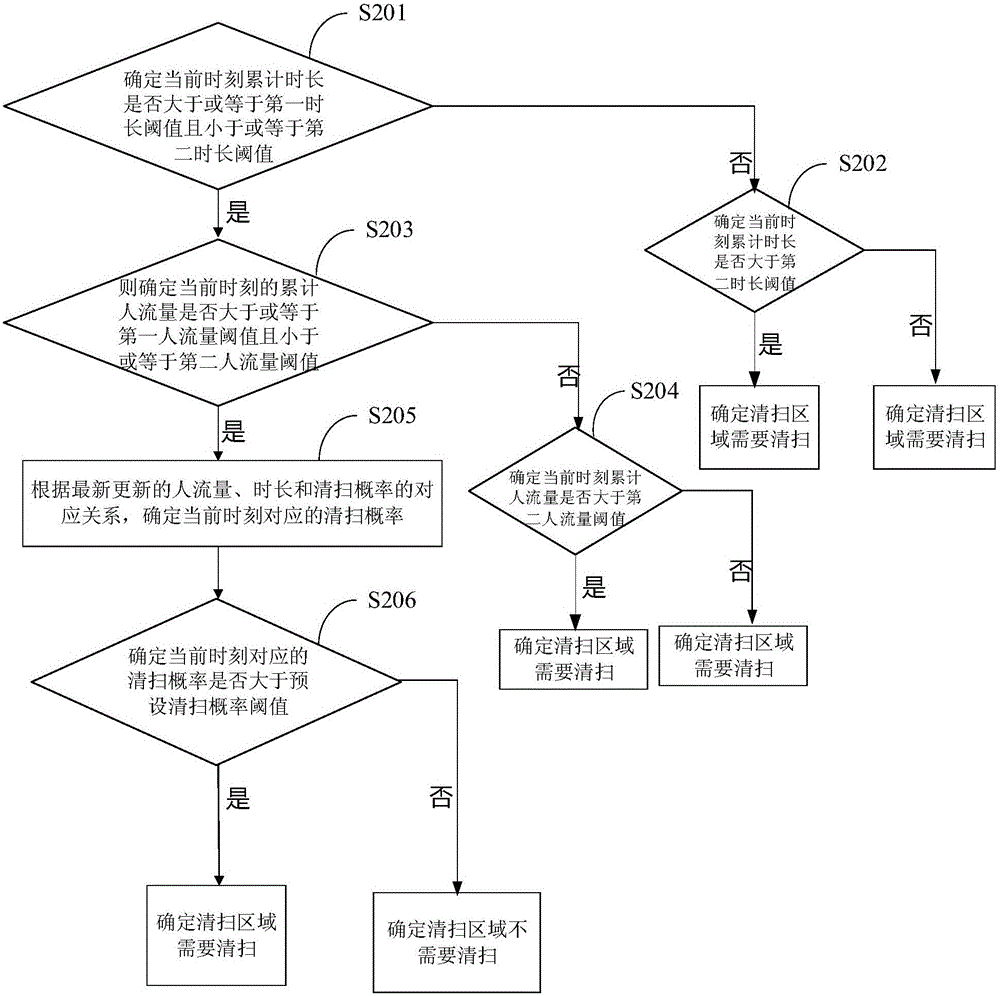

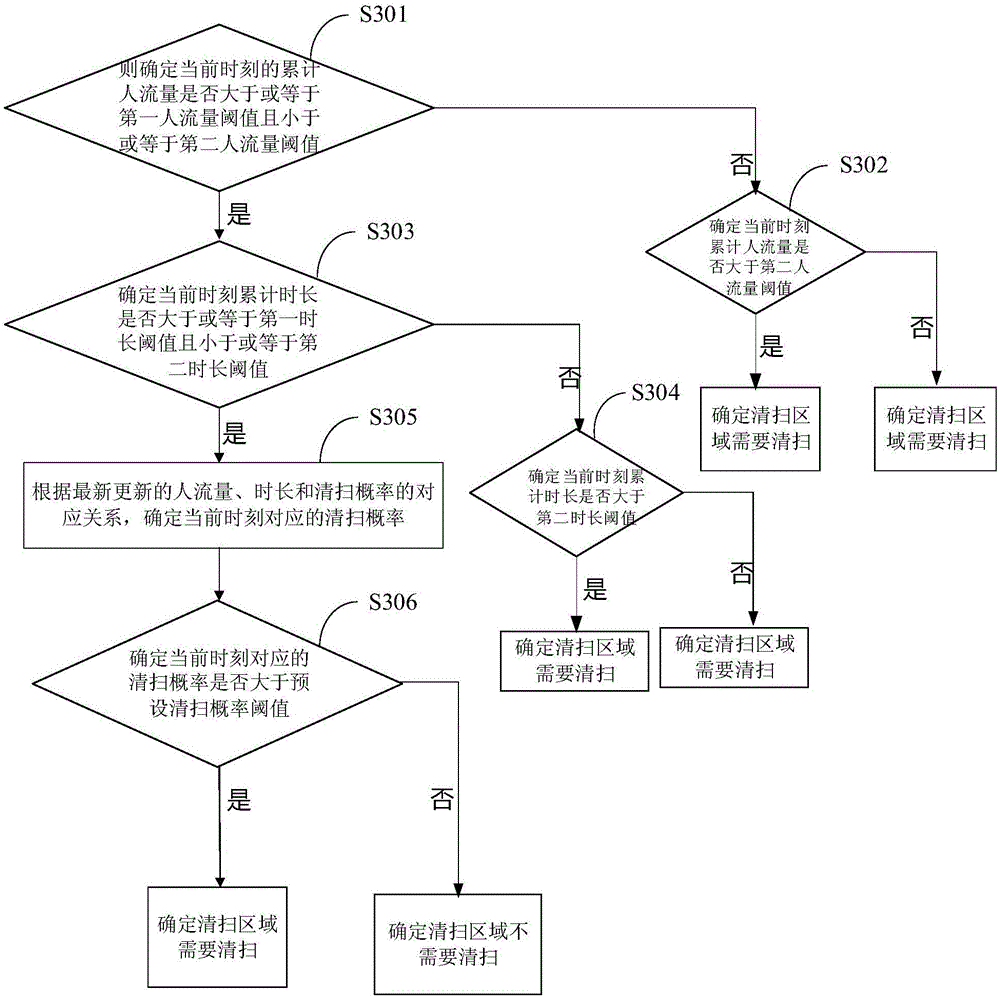

Dispatching method and device for cleaning robot

ActiveCN105892321AGuaranteed cleanlinessSave human resourcesProgramme-controlled manipulatorComputer controlEngineeringTraffic volume

The invention discloses a dispatching method and device for a cleaning robot. The method determines whether a cleaned region needs to be cleaned or not according to the accumulated time of one-time cleaning of the cleaned region, the accumulated human traffic rate of the cleaned region and the corresponding cleaning probability, thereby replacing a subjective judgment process of a person in the prior art, and saving human resources on the basis of guaranteeing the cleaning degree of the cleaned region.

Owner:BOE TECH GRP CO LTD

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

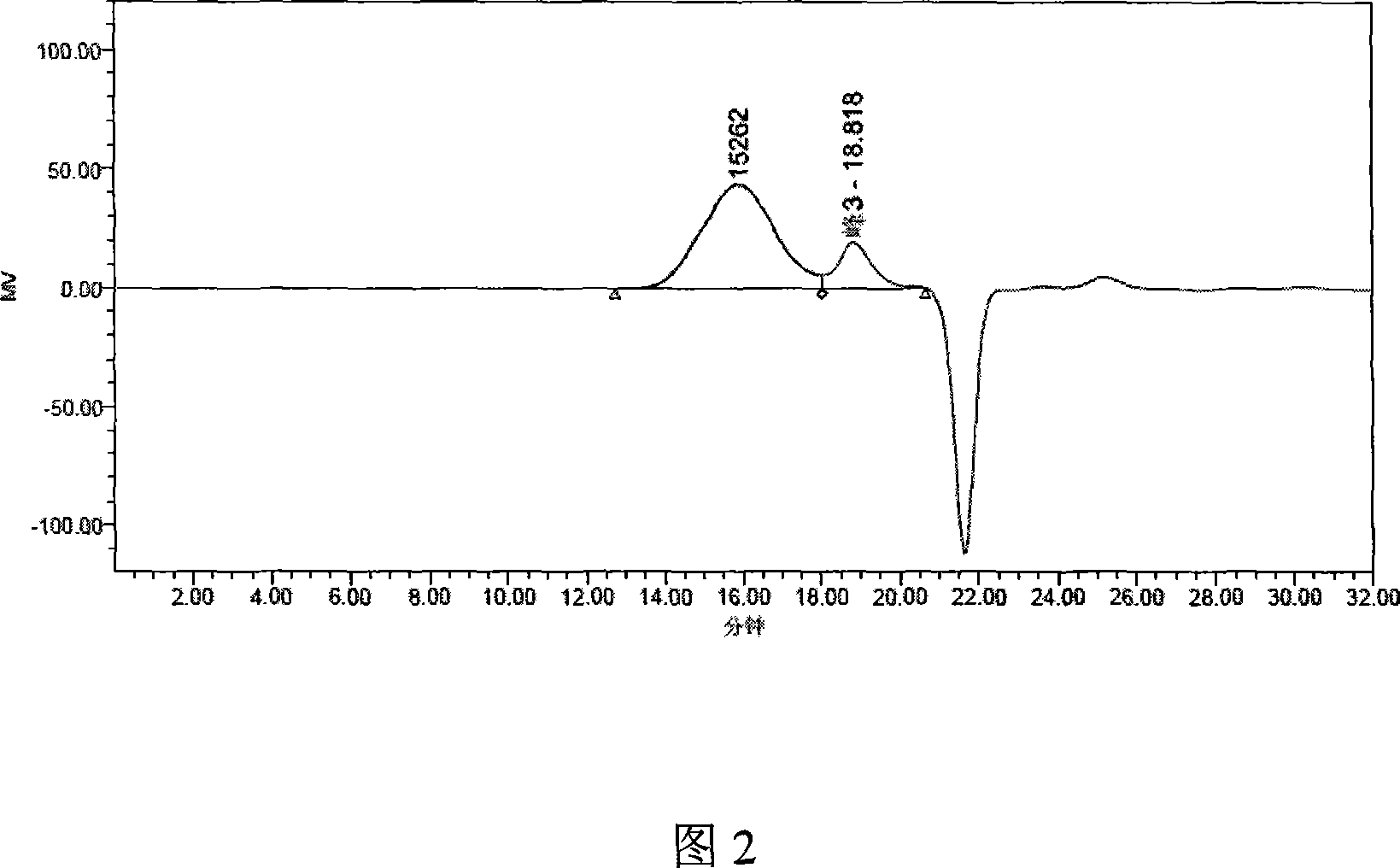

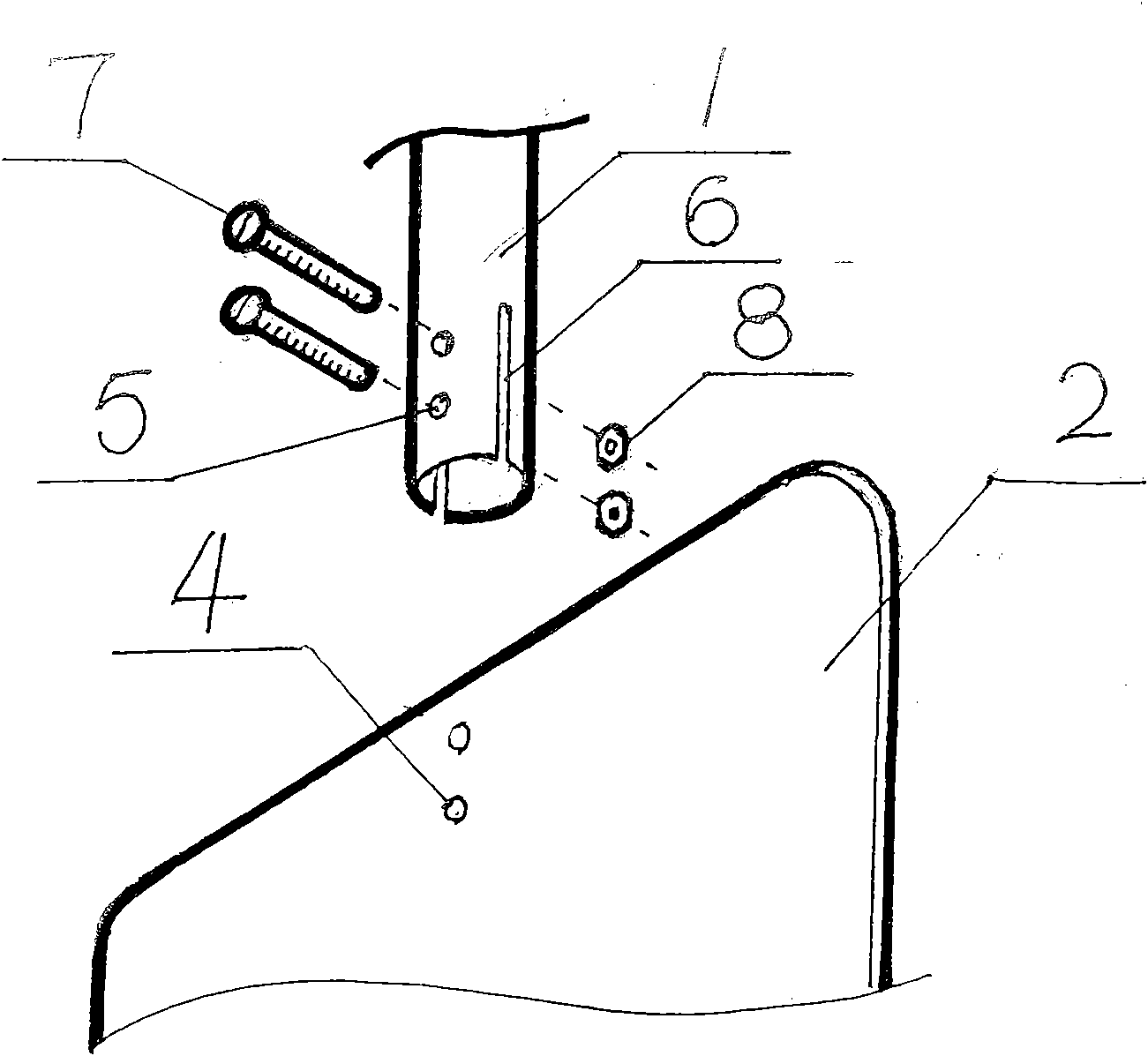

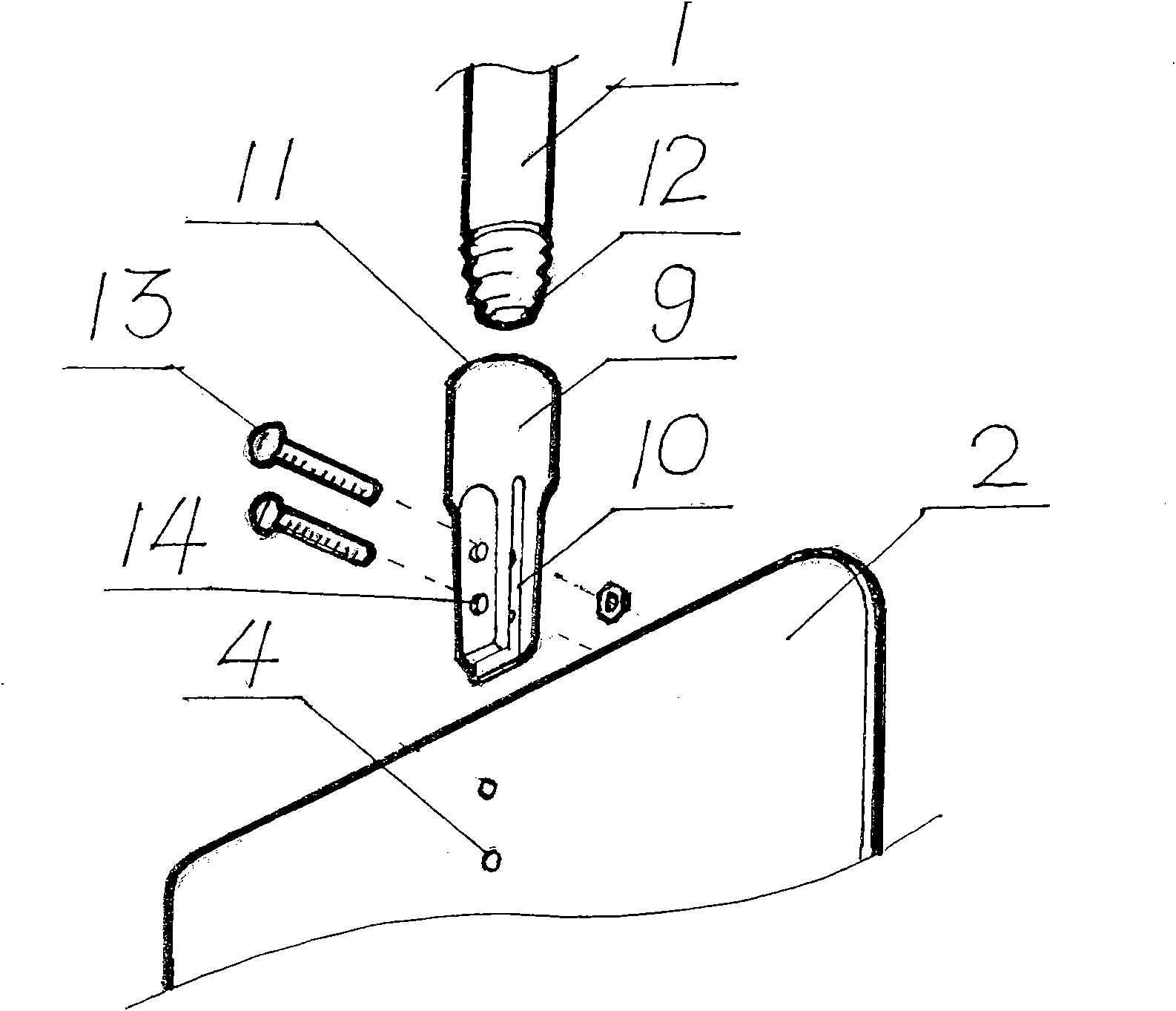

Portable mop and assorted mop barrel

The invention discloses a portable mop with simple structure, comprising a mop rod and a mop panel; the mop panel is a polygonal panel made of elastic material; an insertion connecting mechanism and a limiting device for rotating the mop panel forwardly and backwardly corresponding to the mop rod in a limiting angle are installed between the upper end of the mop panel and the lower end of the mop rod; the mop panel has straight and bent positions; in standby state, the central axis of the mop rod and the midline of the vertical section of the mop panel are located on the same straight line; in work state, the mop panel is deformed by means of external force; the upper end of the mop panel is parallel to a working surface; and the upper end of the mop panel has a crown face and can be formed into an angle with the mop rod. Meanwhile, the invention further discloses a mop barrel assorted to the portable mop. The mop barrel can remove the dirt on the mop and dehydrate the mop by means of upward and downward or forward and backward movements of the mop.

Owner:李军

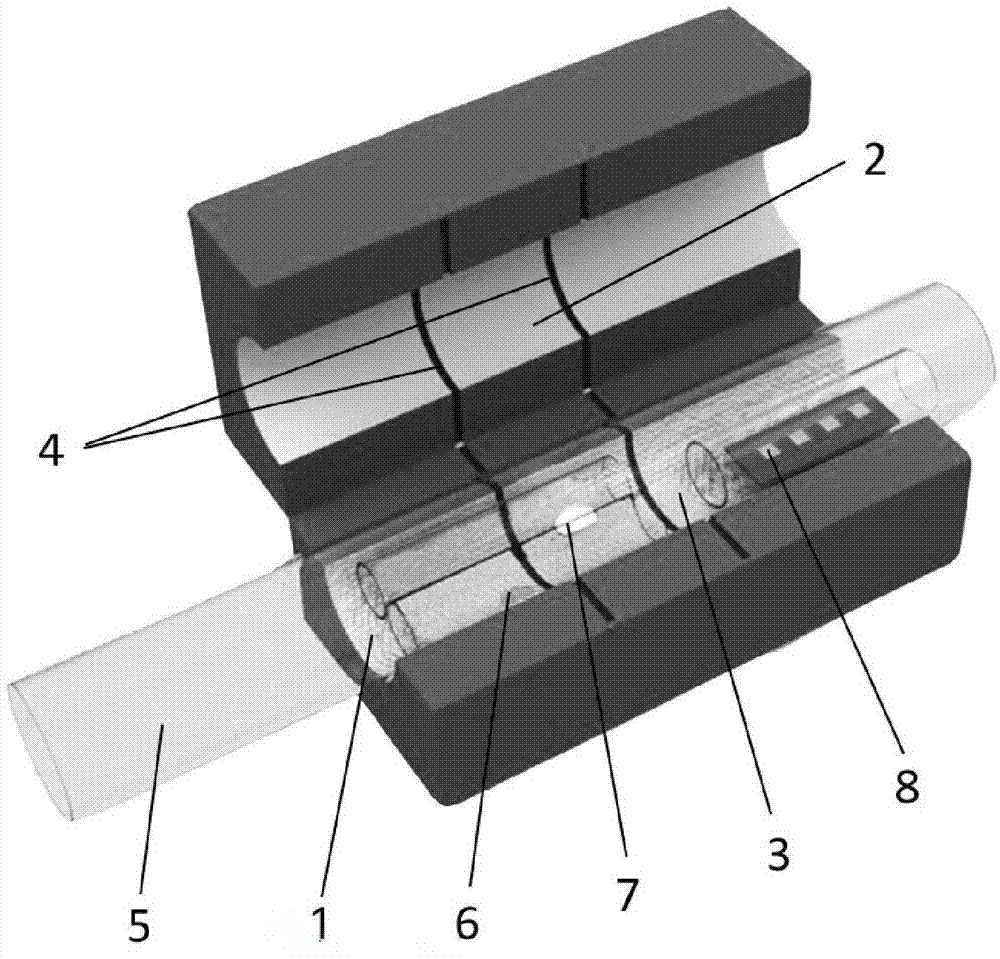

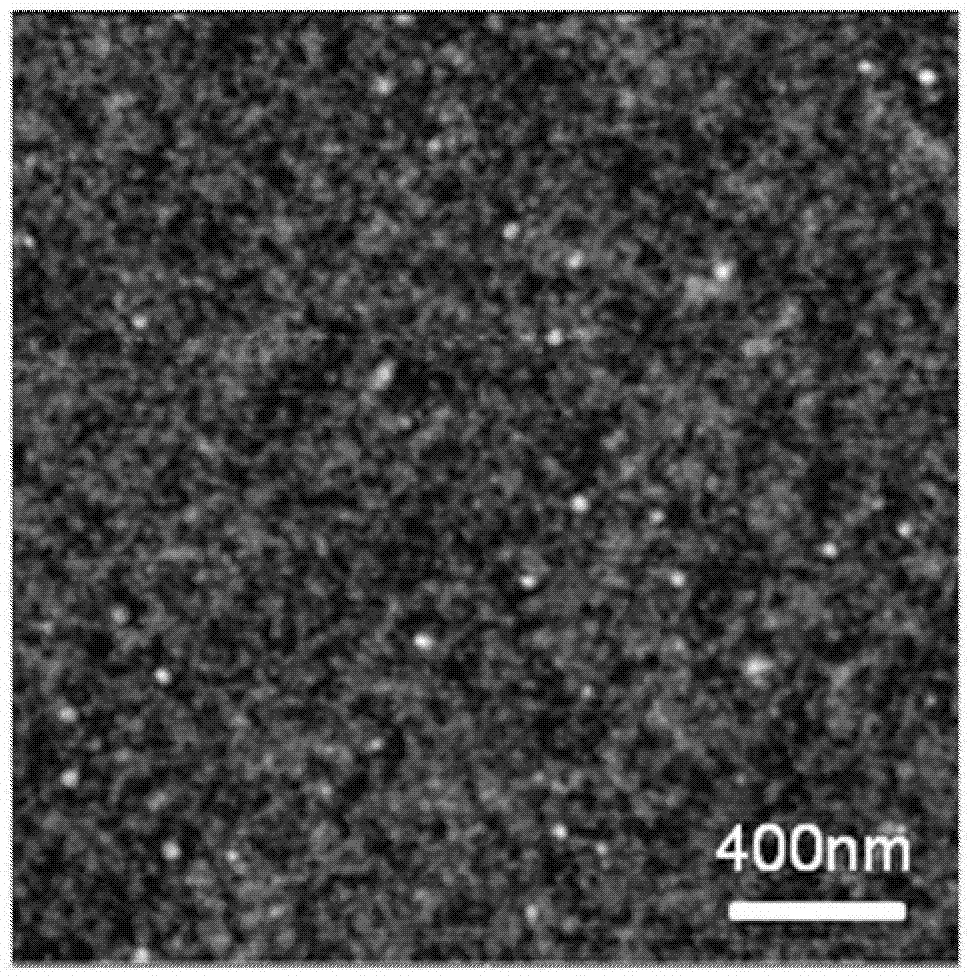

Method for preparing metal chalcogenide film

ActiveCN103194729AControl thicknessSmall sizeChemical vapor deposition coatingDeposition temperatureSulfur

The invention discloses a method for preparing a metal chalcogenide film. The method is used for growing the metal chalcogenide film on a substrate with the vapor deposition process by using a chalcogen source and a metal element source and comprises the following steps of: providing three temperature zones, wherein the temperature of the three temperature zones can be controlled independently, and the chalcogen source, the metal element source and the substrate are put in the three temperature zones respectively; controlling the three temperature zones, evaporating the chalcogen source to generate the chalcogen source steam, evaporating the metal element source to generate the metal element source steam, and heating the substrate to the predetermined deposition temperature; providing a carrier gas, and enabling the carrier gas to flow through the three temperature zones in sequence to deliver the metal element source steam to the substrate to deposit and grow so as to form the metal chalcogenide film. The method disclosed by the invention is simple, dispenses with the original complex step of introducing a nucleation site and effectively ensures the purity and the surface cleanness of a sample. The metal chalcogenide film prepared by adopting the method has high quality.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

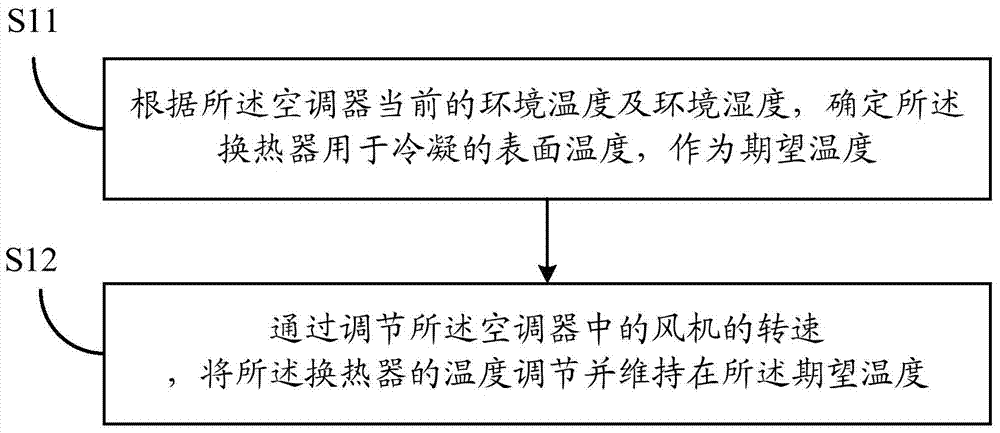

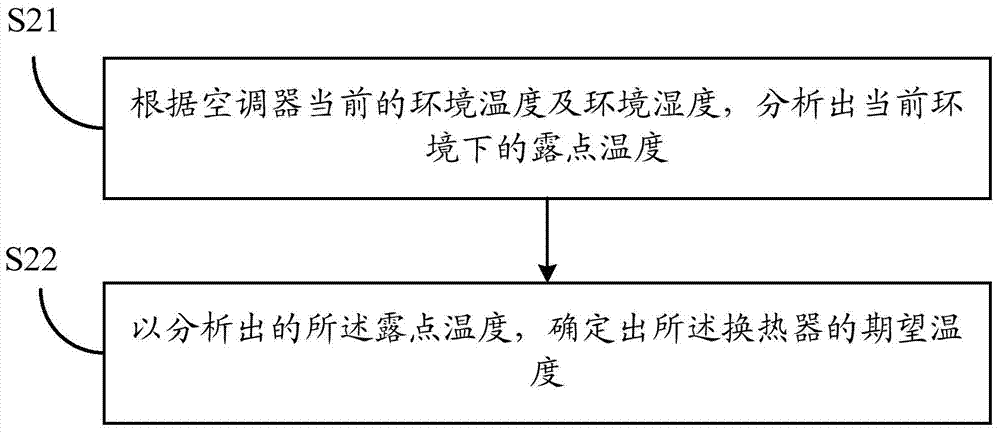

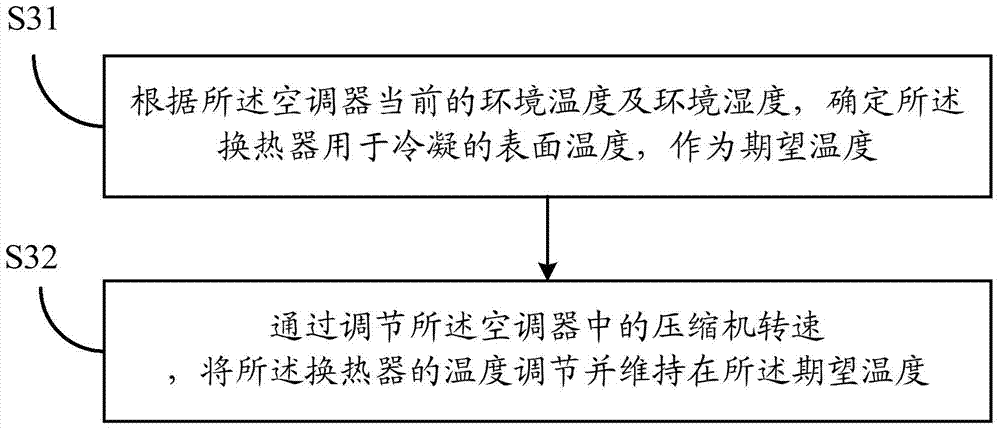

Cleaning method and cleaning device of air conditioner

ActiveCN104848507AGuaranteed cleanlinessSatisfy the cleaning effectMechanical apparatusCondensate preventionLiquid waterCleaning methods

The invention provides a cleaning method and cleaning device of an air conditioner. The cleaning method comprises the steps of utilizing a heat exchanger in the air conditioner to condense water vapor in the air conditioner into liquid water, removing dirt adhered to the surface of the heat exchanger, judging whether the air conditioner meets the trigger condition of cleaning procedure execution or not before the cleaning procedure execution, and if the air conditioner meets the trigger condition of cleaning procedure execution, executing the cleaning procedure by adopting processing strategies corresponding to the operation working conditions according to the current operation working conditions. The current operation working conditions of the air conditioner are monitored, corresponding cleaning strategies are respectively taken according to different operation working conditions, and accordingly the cleaning effects of the different operation working conditions are met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

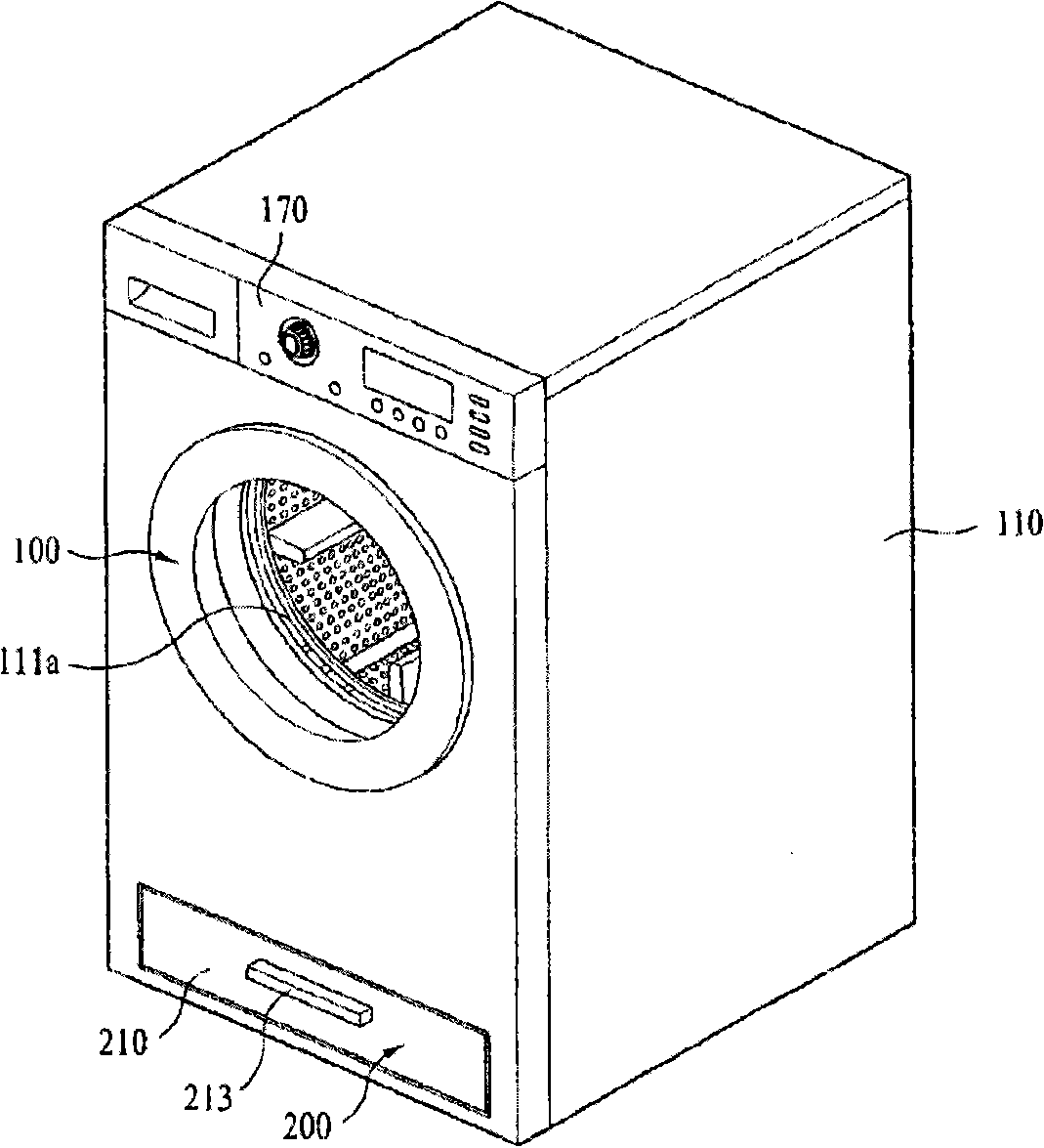

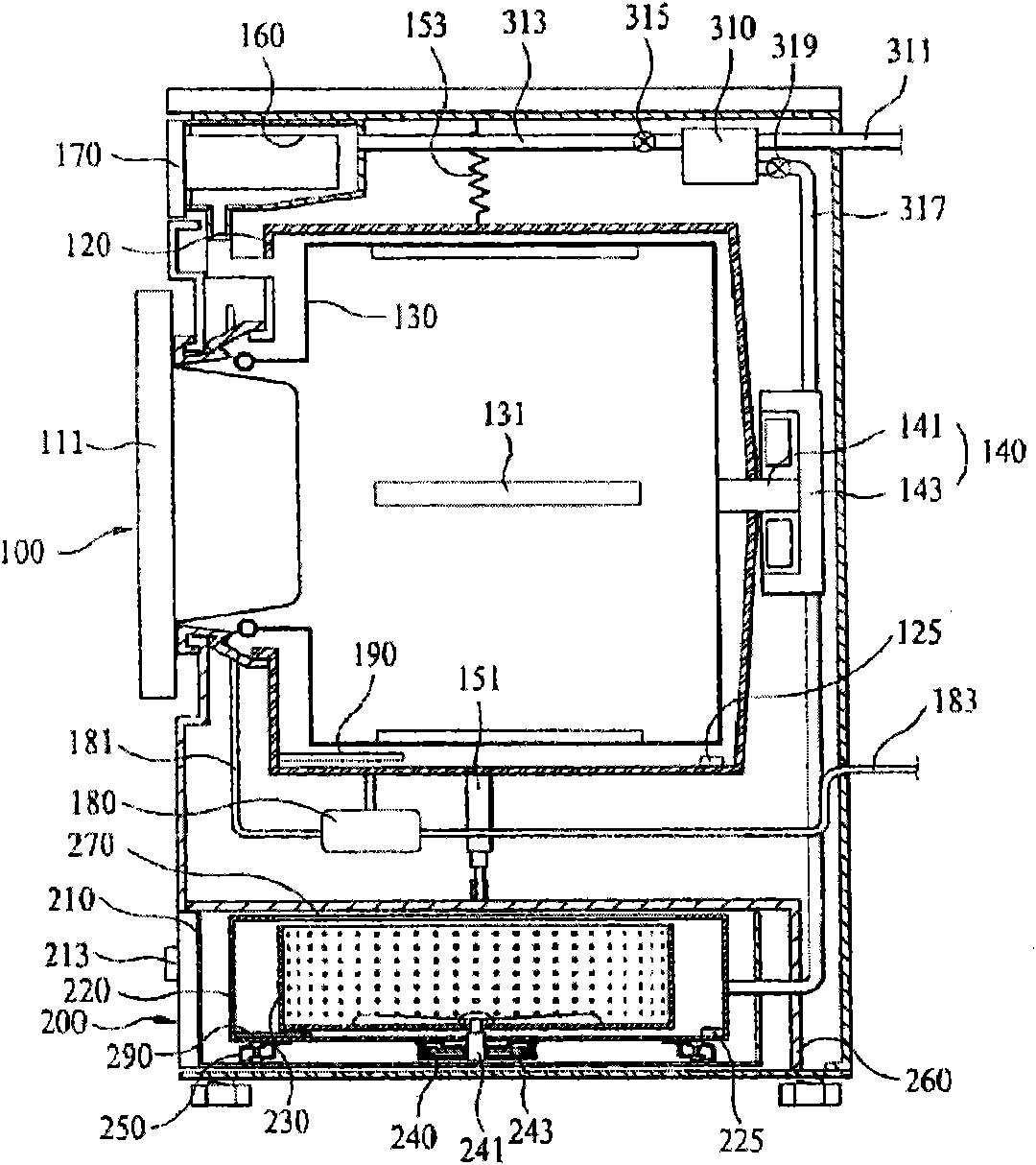

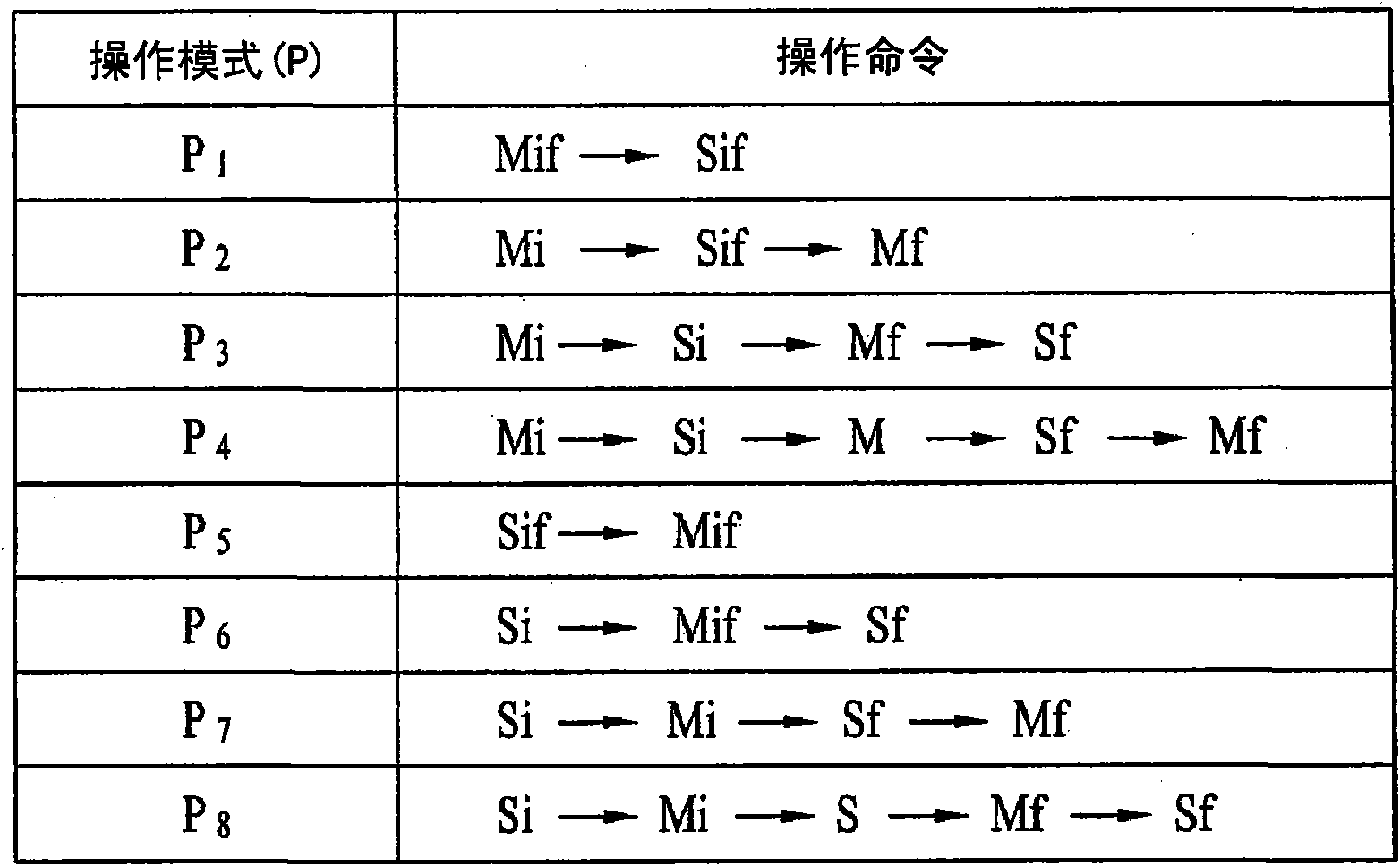

Laundry treating device and method of controlling the same

ActiveCN102203337AGuaranteed cleanlinessReduce power consumptionOther washing machinesControl devices for washing apparatusBiomedical engineering

A laundry treating device includes a first laundry treating device and a second laundry treating device adjacent to the first laundry treating device. A first heater provided in the first laundry treating device and a second heater provided in the second laundry treating device can be selectively and alternatively operated to heat washing water.

Owner:LG ELECTRONICS INC

Vehicle door handle covering device and vehicle comprising same

ActiveCN104863438AReduce wind noiseShorten the durationElectrical locking actuatorsCar doorEngineering

The invention discloses a vehicle door handle covering device and a vehicle comprising the same. The vehicle door handle covering device comprises a handle cover plate and a driving device, wherein the driving device is in transmission connection with the handle cover plate and used for driving the handle cover plate to move between a covering position and an uncovering position, and the handle cover plate covers the a vehicle door handle in the covering position and uncovers the vehicle door handle in the uncovering position. According to the vehicle door handle covering device, the handle cover plate can cover the handle and can be driven between the covering position and the uncovering position, so that the vehicle door handle can be covered as required, wind noise during high-speed running of the vehicle is reduced, the exposure time of the vehicle door handle is shortened, and the vehicle door handle is kept clean.

Owner:BEIQI FOTON MOTOR CO LTD

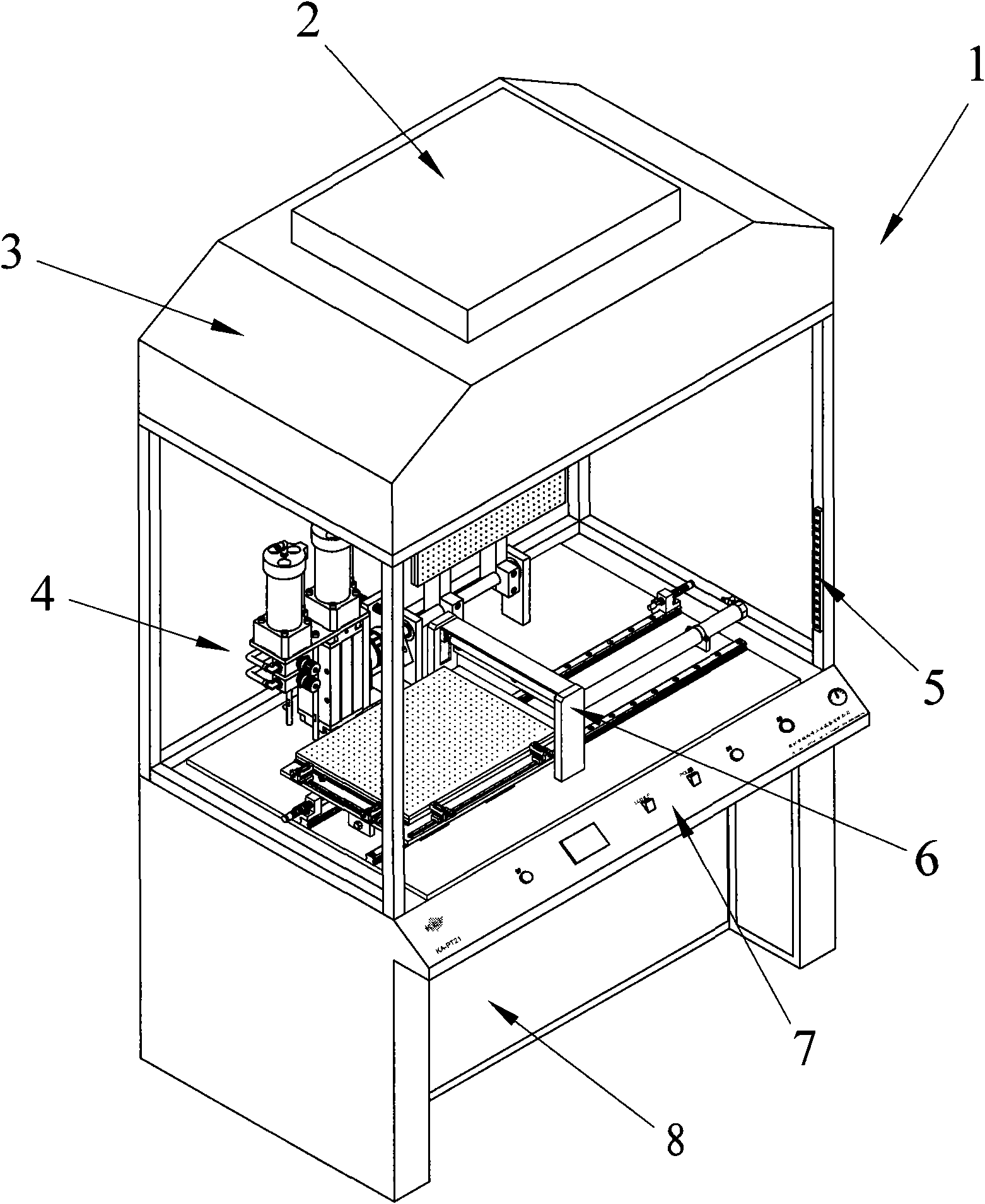

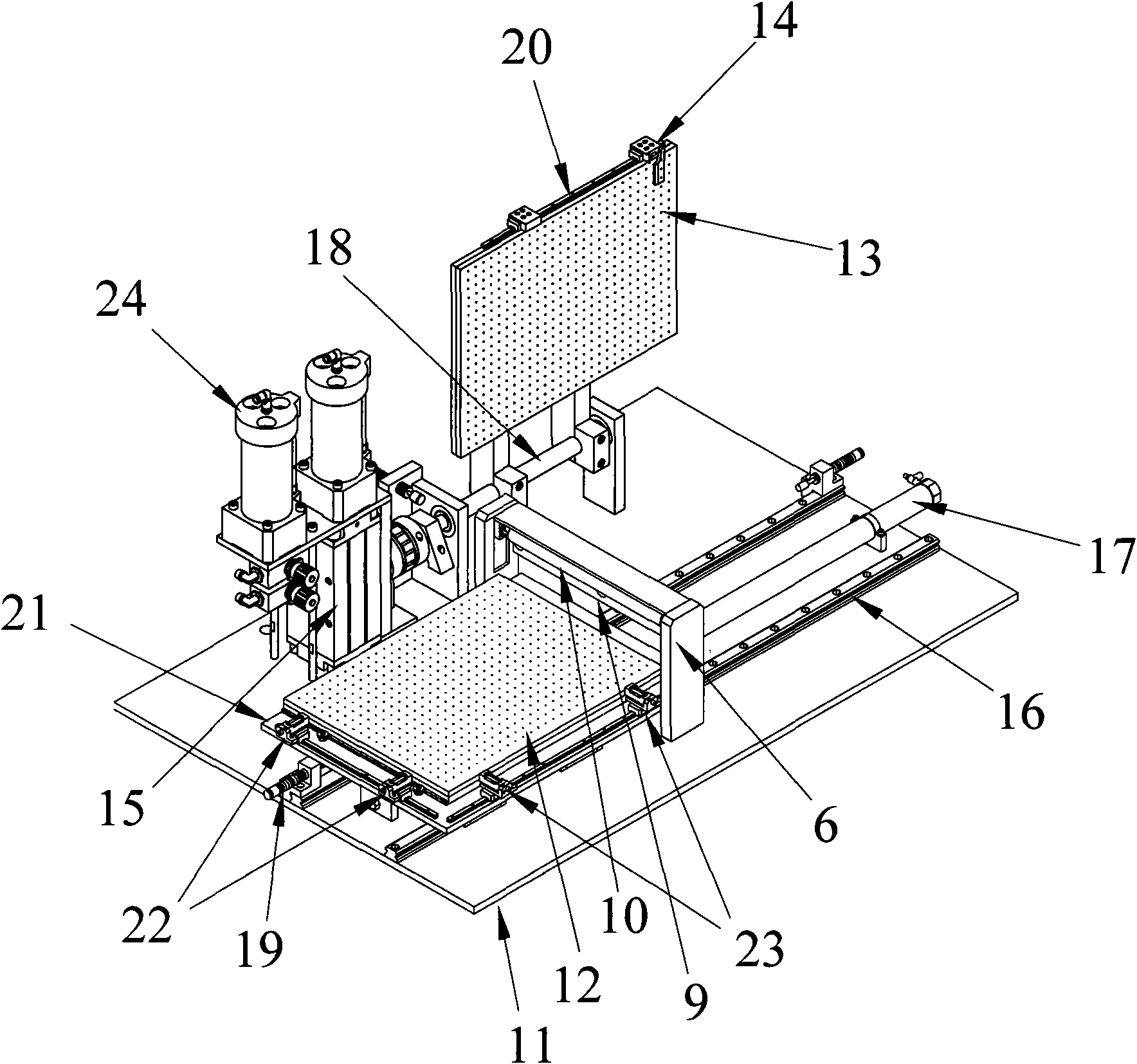

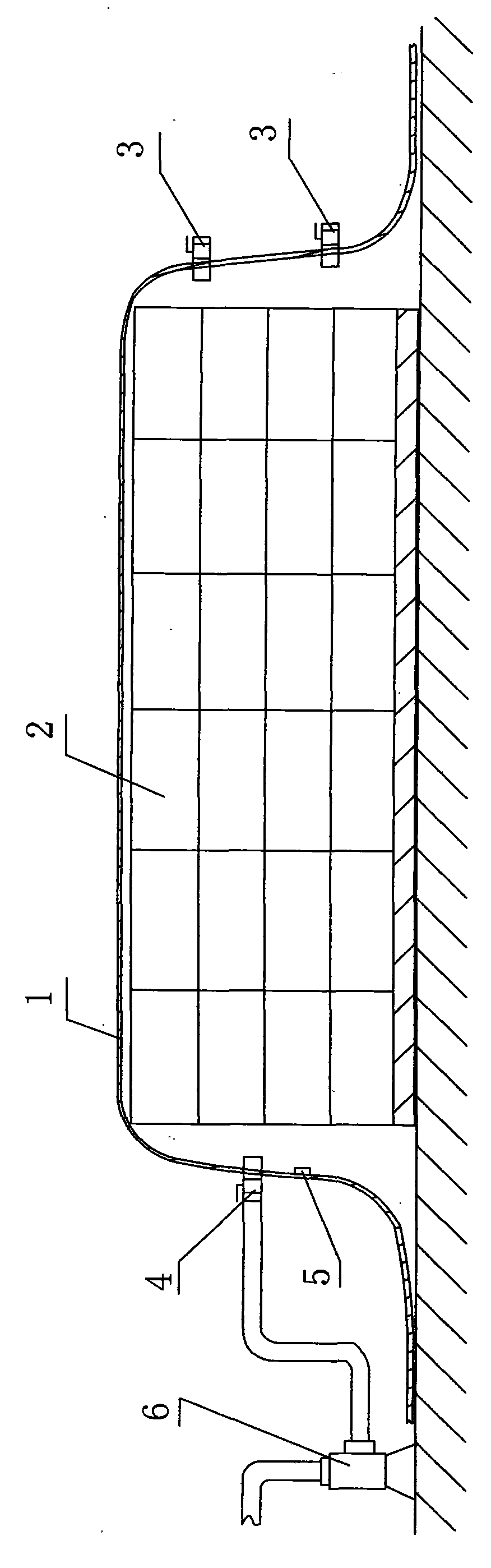

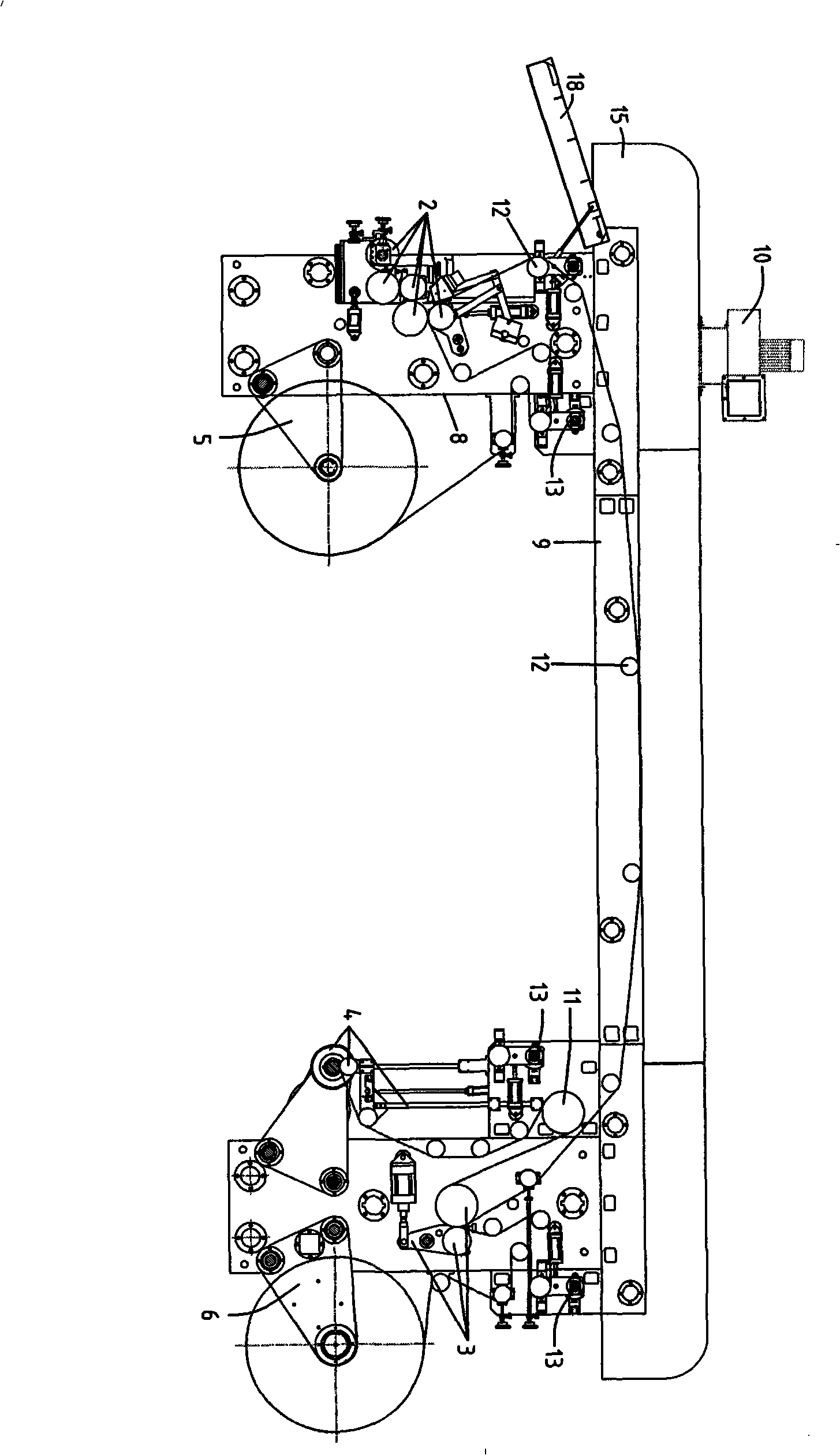

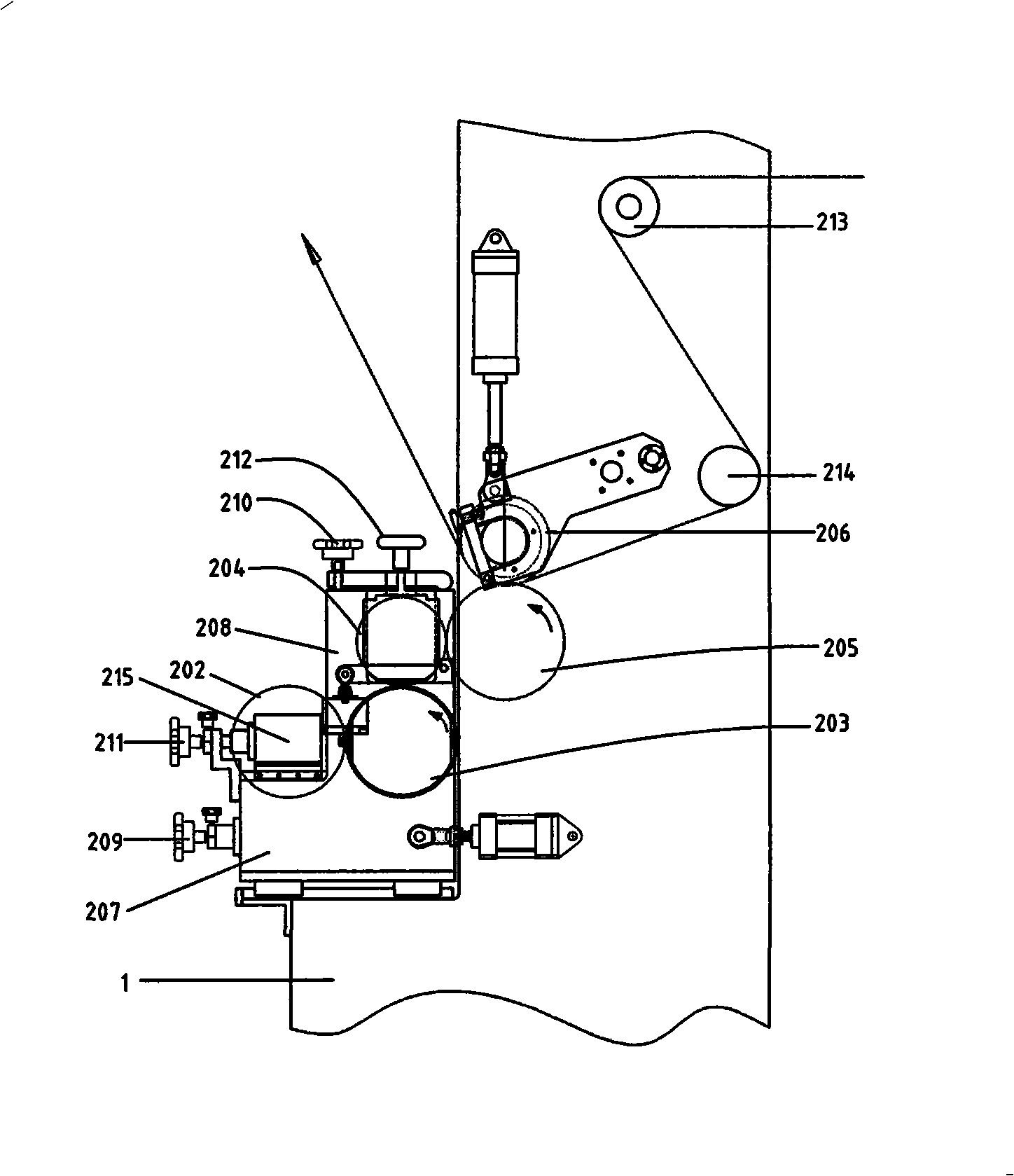

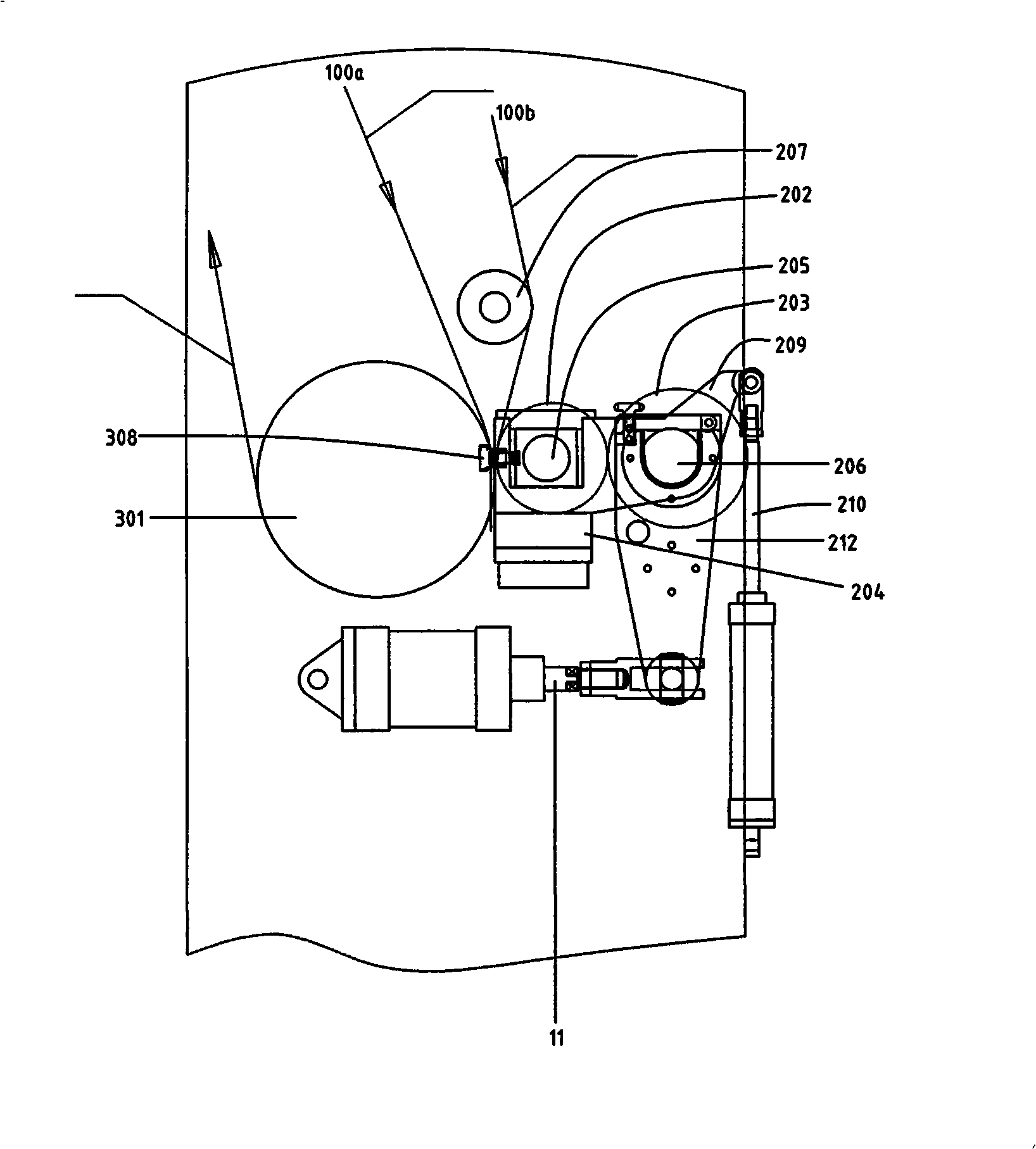

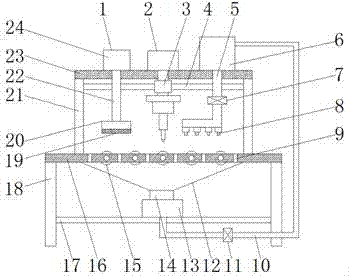

Semi-automatic laminating machine and laminating method thereof

InactiveCN101581850AGuaranteed cleanlinessEasy to operateLaminationLamination apparatusSemi automaticAtmospheric pressure

The invention discloses a semi-automatic laminating machine and a laminating method thereof. The semi-automatic laminating machine is provided with a stand, wherein an operating space for accommodating a laminating device is arranged in the middle part of the stand, an electric component box is placed in the stand and positioned below the laminating device, an air inlet opening is arranged at the top of the stand, an air purifier is placed at the top of the stand and an operating panel is installed on the stand and used for controlling the laminating machine. The material laminating is carried out by material placing, aligning, laminating by pressure roller, laminating completion and returning for standby. The semi-automatic laminating machine adopts various ways of vacuum adsorption, mechanical positioning and pneumatic motion to be provided with a precision fine adjustment device, a limitator, an oil-gas convertor, a linear slide rail and other precision components, thereby ensuring the laminating accuracy, reducing the dependence on the operators, overcoming the phenomenon of inaccurate positioning, low yield, air bubble, gauffer and defects existing in the laminating process of the diaphragm and the base material, reducing the running time due to the overlapped type motion and improving the production efficiency.

Owner:郑春晓

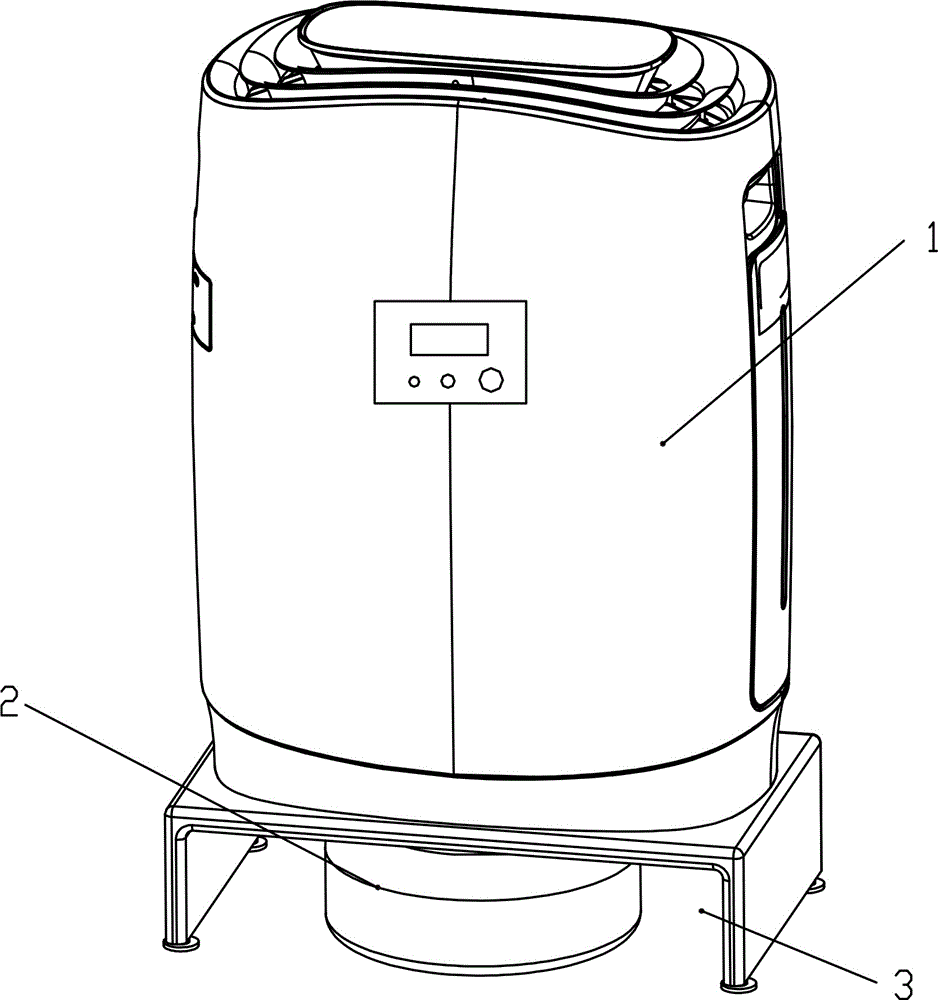

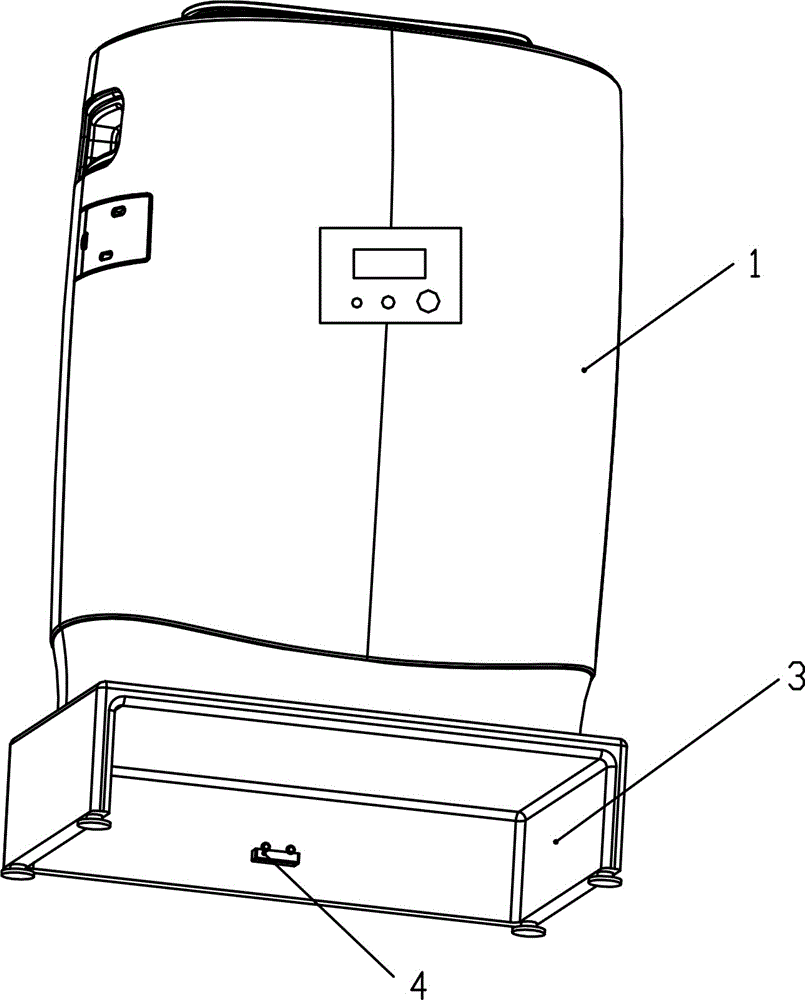

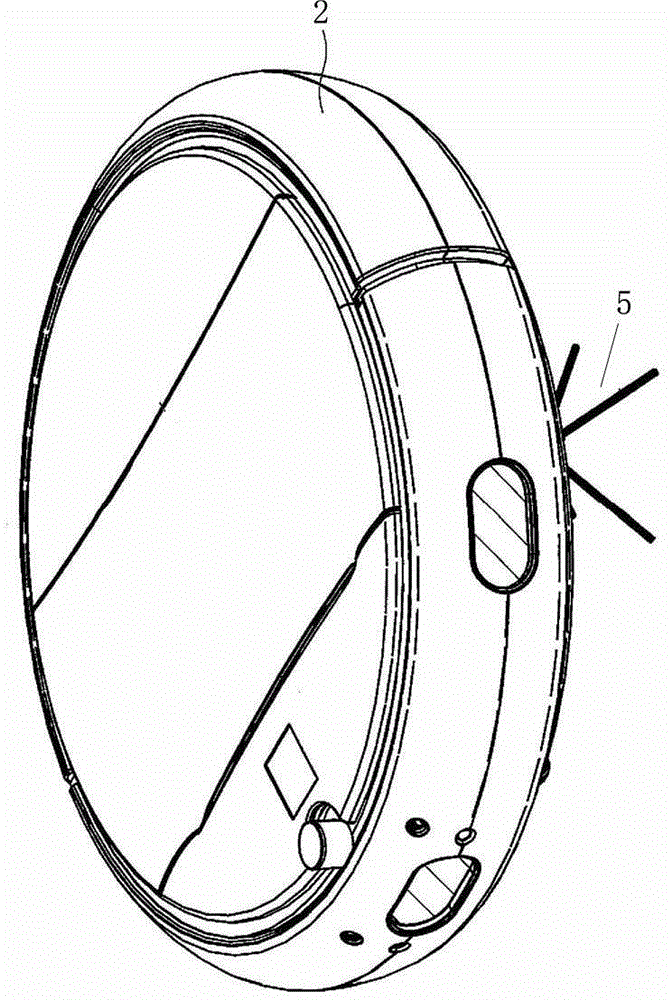

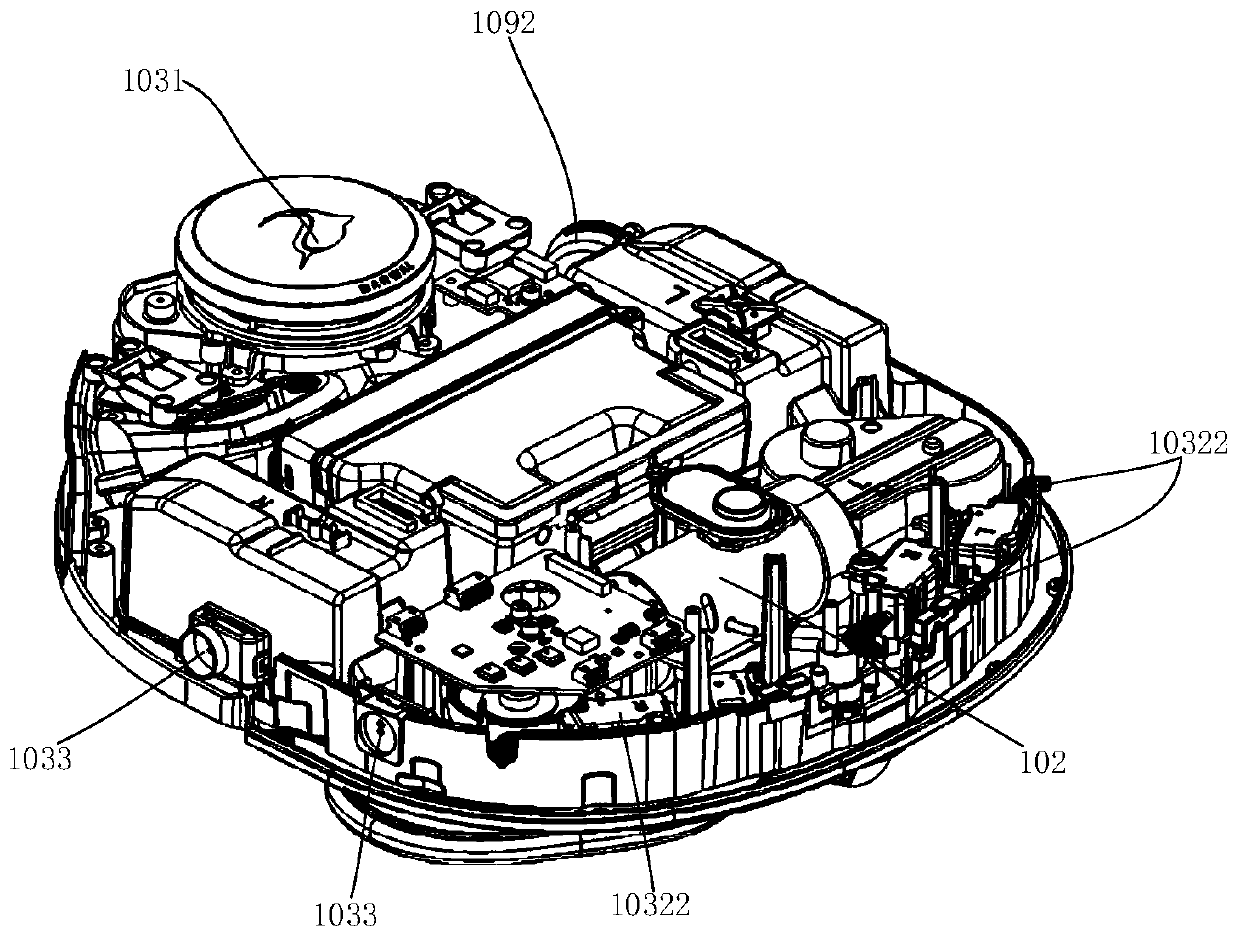

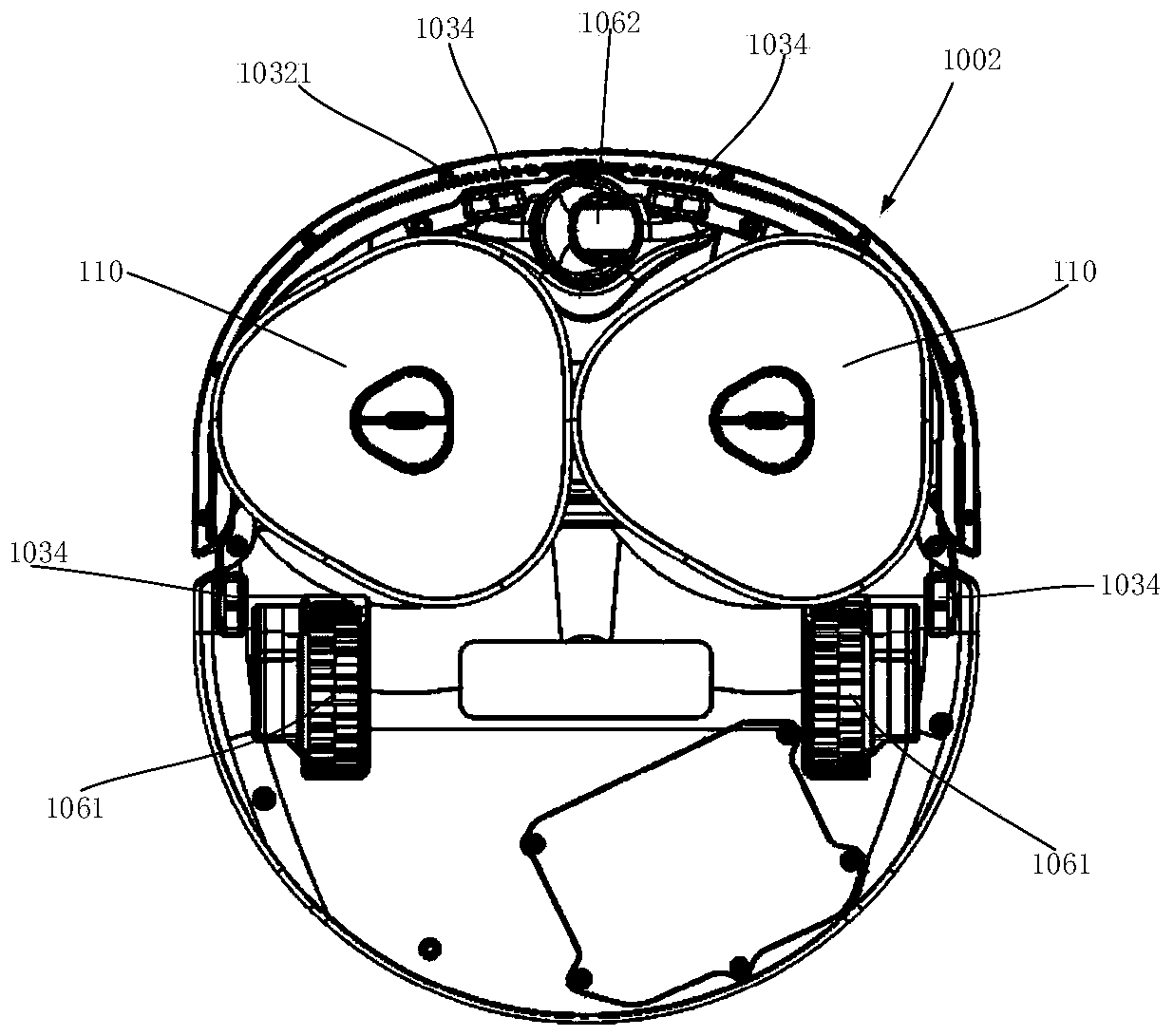

Novel air purification and automatic sweeping integrated machine

ActiveCN104132412ASo neatSave interior spaceCarpet cleanersLighting and heating apparatusEmbedded systemElectricity

The invention relates to a novel air purification and automatic sweeping integrated machine. The integrated machine comprises an air purifier. The air purifier comprises a shell and an electric control device. The integrated machine further comprises an automatic walking sweeping robot used in combination with the air purifier. A containing chamber for containing the automatic walking sweeping robot is formed in the bottom of the shell. A storage battery is arranged on the sweeping robot. A charging socket allowing the sweeping robot to be charged is arranged on the shell. The sweeping robot and the charging socket are connected through a separable electric connector. The electric control device comprises a controlled module arranged on the sweeping robot and a master control module arranged on the air purifier. The master control module and the controlled module are in wireless communication. The novel air purification and automatic sweeping integrated machine has the advantages of being convenient to use and capable of saving energy.

Owner:XIAMEN BRI ENVIRONMENTAL IND CO LTD

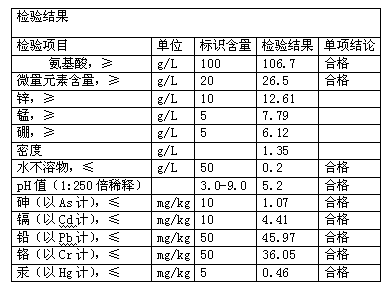

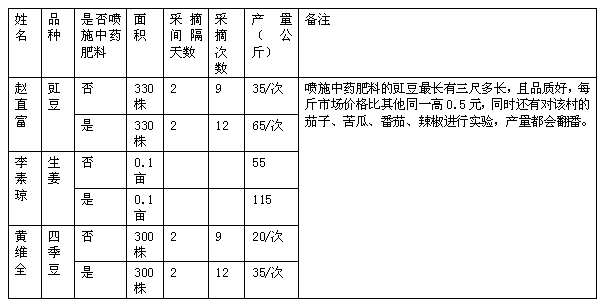

Disease and insect resistant fertilizer produced by traditional Chinese medicines and preparation technology thereof

ActiveCN103319282AAntibacterial and anti-pest functionsRich in nutrientsFertilizer mixturesOysterRhizome

The invention relates to a?fertilizer,?in particular to a?fertilizer produced by the adoption of traditional Chinese medicines and a production method?thereof. The fertilizer comprises the following raw materials: artemisia capillaris, Tripterygium wilfordii,?radix stemonae,?Scutellaria,?coptis,?Phellodendron amurense,?Chinese rhubarb 1, honeysuckle,?Salvia miltiorrhiza,?safflower,?astragalus membranaceus,?bighead atractylodes rhizome, Paris polyphylla,?Poria cocos, Polygonum bistorta L.,?kelp, Chinese angelica, Polygonum multiflorum, root of chinese barberry, radix polygonati officinalis, Manis pentadactyla, gypsum, keel, oysters, limonite, cuttlebone and silkworm excrement. The fertilizer is extracted from pure organic raw materials, causes no pollution to the environment, has no residue, and is safe and environmentally friendly. Nutritive elements such as amino acid, synthetase, polysaccharide and the like contained in the fertilizer can be rapidly absorbed and utilized by plants, not stimulating or damaging plants. Due to diversity of the raw materials, nutrient composition of the fertilizer is more comprehensive, thus meeting the nutritive element diversity requirement of crops. Alkaline substances and other active substances in the traditional Chinese medicines can destroycell membrane so as to inhibit germs well. Meanwhile, the fertilizer has effects of repelling insects and inhibiting breeding of insects.

Owner:韦文礼

Automatic opening and closing type large-trumpet trash bin

InactiveCN103723403AReduce laborGuaranteed cleanlinessRefuse receptaclesRoad cleaningEngineeringMechanical engineering

An automatic opening and closing type large-trumpet trash bin comprises a trash bin body, a cover and wheels. The cover is arranged on the trash bin body. The wheels are arranged below the trash bin body. A left mechanical hand and a left cover opening probe are arranged on the left side of the trash bin body. A right mechanical hand and a right cover opening probe are arranged on the right side of the trash bin body. A battery is arranged in a bottom layer of the trash bin body. A left trash probe, a right trash probe and a front trash probe are respectively arranged on the two sides and the front of the bottom layer of the trash bin body. A front cover opening probe is arranged on the front trash probe. A trash can is arranged in the trash bin body. A trumpet mouth is arranged at the top of the trash can. The trash can is connected with the bottom of the trash bin body. A trash bag is arranged in the trash can. The automatic opening and closing type large-trumpet trash bin enables cleaning workers not to pick up trash around the trash bin laboriously and repeatedly. By the adoption of the automatic opening and closing type large-trumpet trash bin, trash around the trash bin can be automatically picked back to the trash bin body through the mechanical hands. The automatic opening and closing type large-trumpet trash bin reduces labor amount of cleaning workers and maintains environments clean and sanitary.

Owner:何韩梅

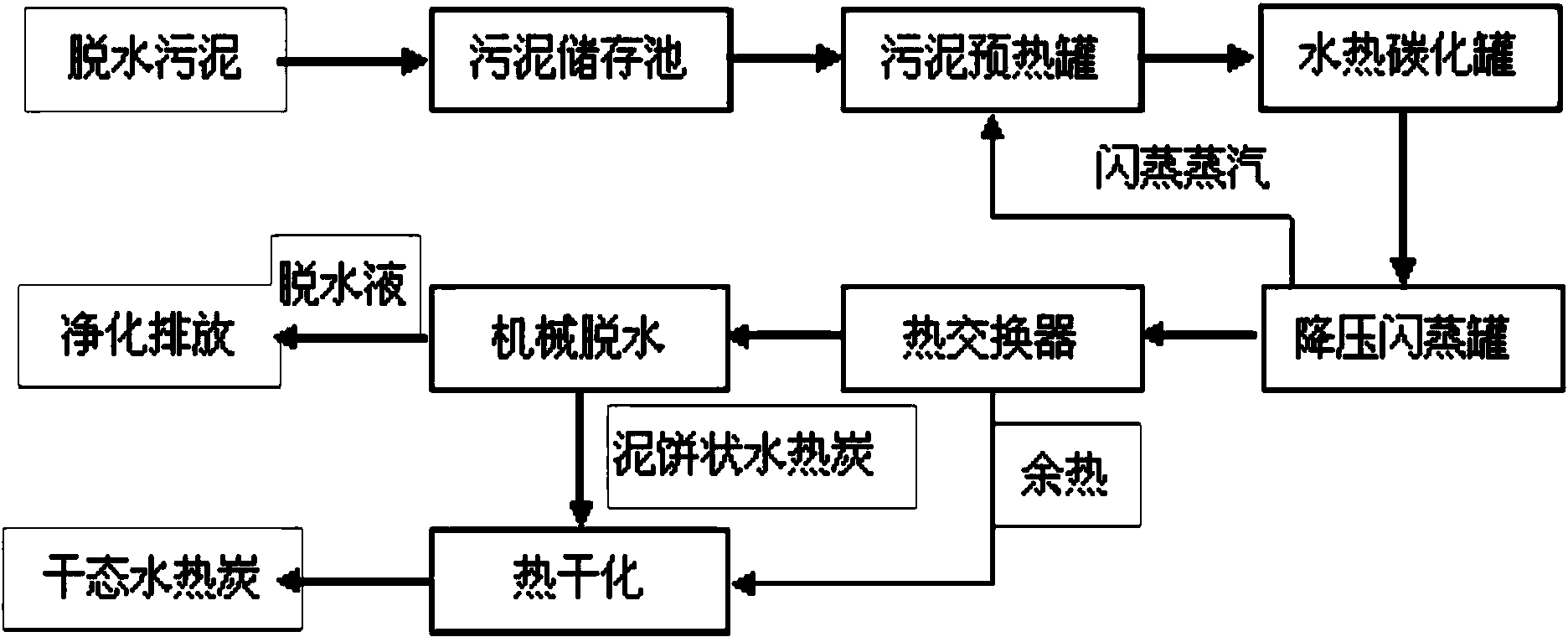

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

Multifunctional tobacco leaf stack sealing storage method capable of adjusting storage environment

ActiveCN101584280AImprove air tightnessImprove moisture resistanceAgriculture tools and machinesTobacco treatmentNatural ventilationInput control

The invention relates to a tobacco leaf stack sealing storage method capable of adjusting storage environment, comprising the following steps: 1) building a tobacco leaf stack sealing space capable of adjusting storage environment: covering the warehoused tobacco leaf stack using a plastic seal tent and enclosing the tobacco leaf stack in the sealed space; the sealed space enclosed by the plastic seal tent is perform air flow commutation with the outside when an air input control joint and an air output control joint are turned on and the sealed space enclosed by the plastic seal tent is at full sealed state when the air input control joint and the air output control joint are turned off; 2) gassing to disinfect; 3) filtering and purifying the steamed and disinfected noxious gas; 4) performing the daily tobacco-leaf mould proof conservation; 5) in winter, starting the plastic seal tent to perform the winder general investigation and natural ventilation and conservation of the tobacco leaf and restoring the plastic seal tent until the next early spring. The sealing storage method has low cost and environmental protection.

Owner:WUHAN DONGCHANG STORAGE TECH

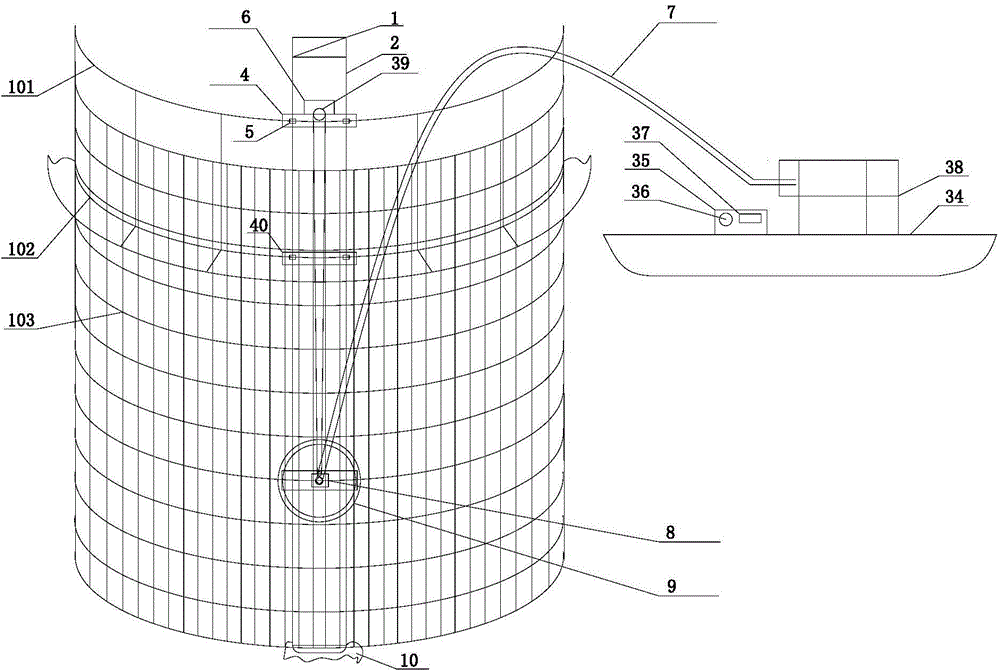

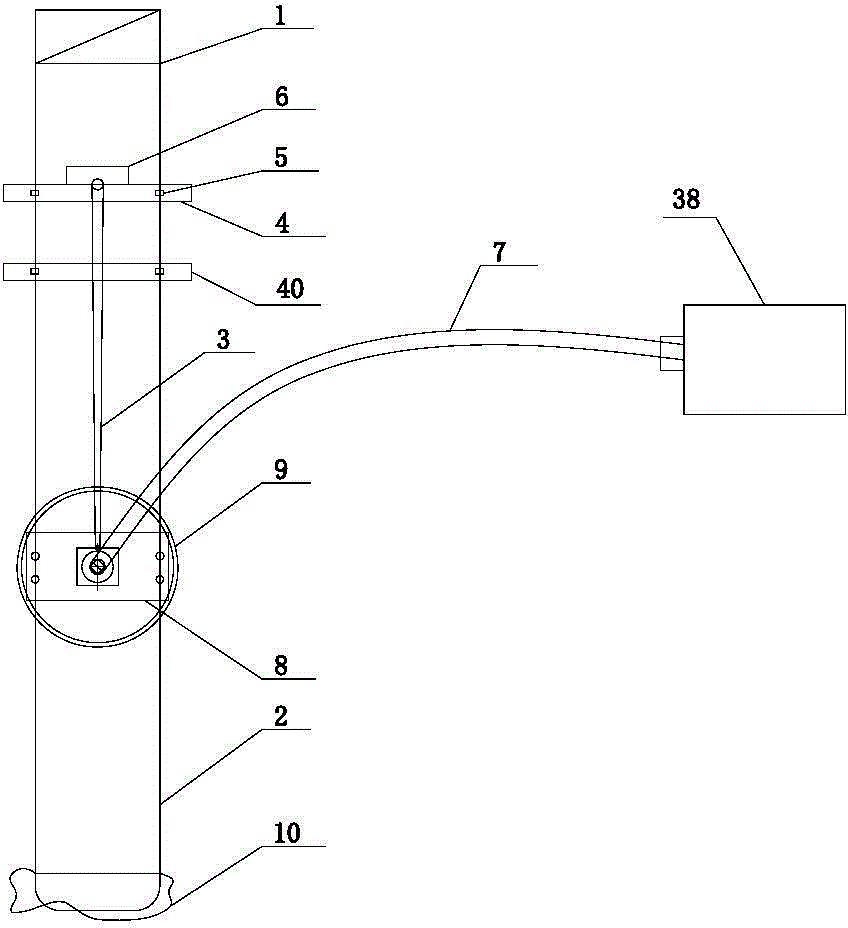

Equipment and method for cleaning current-resistance submerged cage netting

InactiveCN104798703AGuaranteed cleanlinessImprove efficiencyClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

The invention discloses equipment for cleaning a current-resistance submerged cage netting and a method for cleaning the current-resistance submerged cage netting. The cleaning equipment is characterized in that a current-resistance submerged cage comprises a circular cage floating collar and a netting installed on the cage floating collar; a guardrail tube is installed at the top of the cage floating collar, a floating collar track is installed on the cage floating collar through a first movable fixing support platform, a cleaning trolley with a cleaning shower is installed on the floating collar track, and the cleaning shower is connected with a movable host platform which can provide high-pressure water, electric energy and high pressure gas. According to the cleaning equipment, when the netting is cleaned, each position of the netting can realize the cleaning effect of 'cleaning with a hairbrush-flushing with high pressure water-cleaning with the hairbrush', the cleaned netting can be effectively ensured in cleanliness, meanwhile the cleaning effect can be achieved when relevant cleaning equipment is in a progressive process, and thus the cleaning equipment and the cleaning method are relatively high in efficiency.

Owner:JIANGSU UNIV OF SCI & TECH

Solvent-free composite machine

ActiveCN101259772AGuaranteed cleanlinessEnsure safetyLamination ancillary operationsControlling laminationSolvent freeEngineering

The invention aims to provide a novel high-safety and high-production-efficiency solvent-free compound machine with good finished product quality, which comprises a frame, a coating mechanism, a recombination mechanism, a winding mechanism, a first unwinding mechanism, a second unwinding mechanism, a power mechanism, a wallboard, a machine head, a waste gas recycling part, a cooling steel sword, a transition steel sword group, a swing tension steel sword group and a control box; the clearance and pressure between various steel swords of the coating mechanism can be independently adjusted and a novel structure in which centers of separate steel swords are in the same horizontal line is applied to the compound mechanism; in the winding mechanism, the winding pressure is kept constant during the winding in any diameter and a novel mechanism which pneumatically controls an observation window is applied to the observation window; a novel humanized control panel mechanism with reasonable operation panel structure which can adjust the lighting direction is applied to the control box, thus ensuring the efficiency, quality and safety of the production. Furthermore, the compound machine can be more conveniently operated, has more reasonable structure and more pleasant shape compared with the original equipment.

Owner:SINOMECH CORP

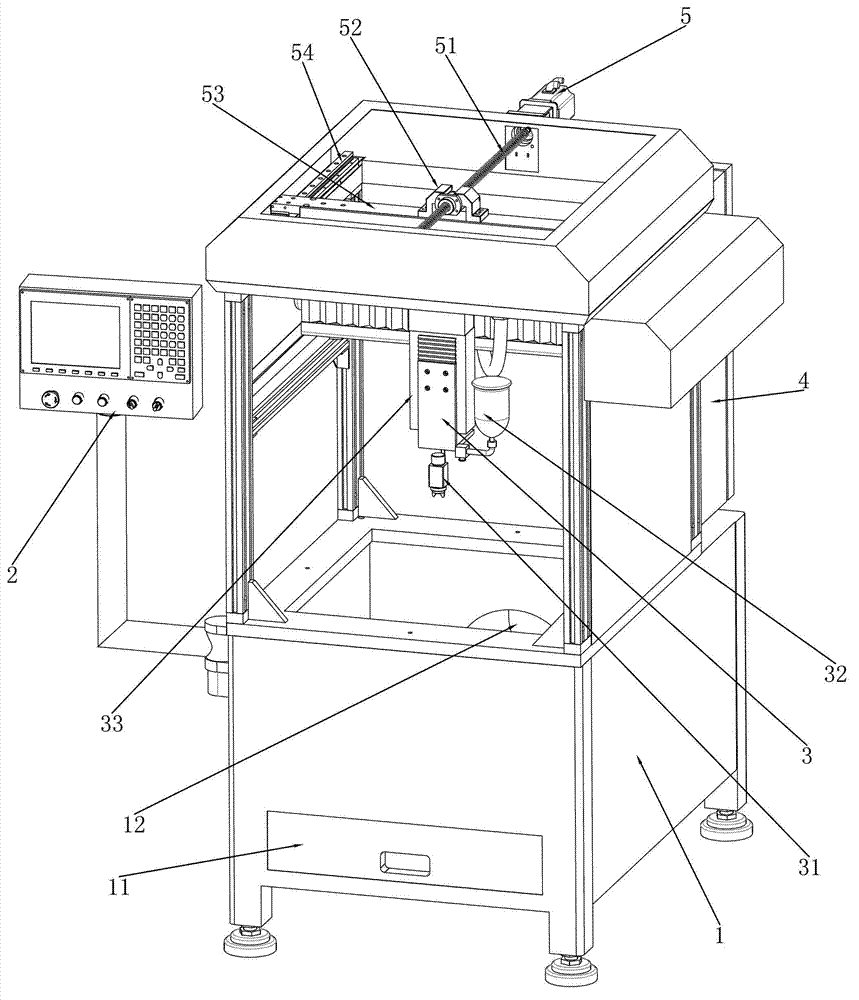

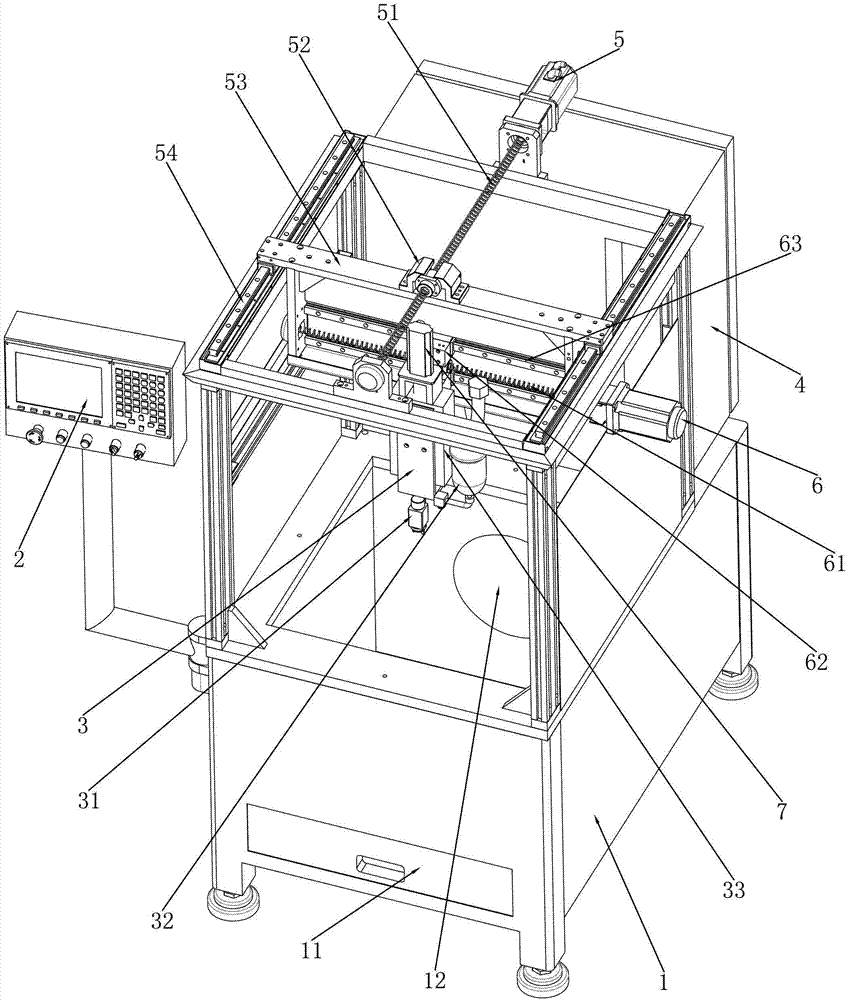

Automatic spraying machine

InactiveCN102872999ASimple structureImprove work efficiencyLiquid surface applicatorsSpraying apparatusEngineeringCoating

The invention discloses an automatic spraying machine which comprises a machine frame, an operation panel used for inputting and displaying work signals, and a control cabinet, wherein a Y-axis guide rail is arranged on the machine frame; a Y-axis guide frame capable of sliding on the Y-axis guide rail forwards and backwards is arranged on the Y-axis guide rail; an X-axis guide rail is arranged on the Y-axis guide frame; an X-axis guide frame capable of moving on the X-axis guide rail horizontally is arranged on the X-axis guide rail; a Z-axis guide rail is arranged on the X-axis guide frame; a Z-axis guide frame capable of moving on the Z-axis guide rail up and down is arranged on the Z-axis guide rail; an oil can for containing a coating material is arranged on one side of the Z-axis guide frame; a nozzle for spraying is also arranged below the Z-axis guide frame and is communicated with the oil can; an air pipe used for spraying the coating material is also connected with the nozzle; a Y-axis driving device capable of driving the Y-axis guide frame to move forwards and backwards is also arranged on the machine frame; an X-axis driving device capable of driving the X-axis guide frame to move horizontally is also arranged on the Y-axis guide frame; and a Z-axis driving device capable of driving the Z-axis guide frame to move up and down is arranged on the Z-axis guide rail.

Owner:JINHUI ZHONGSHAN METAL MFG

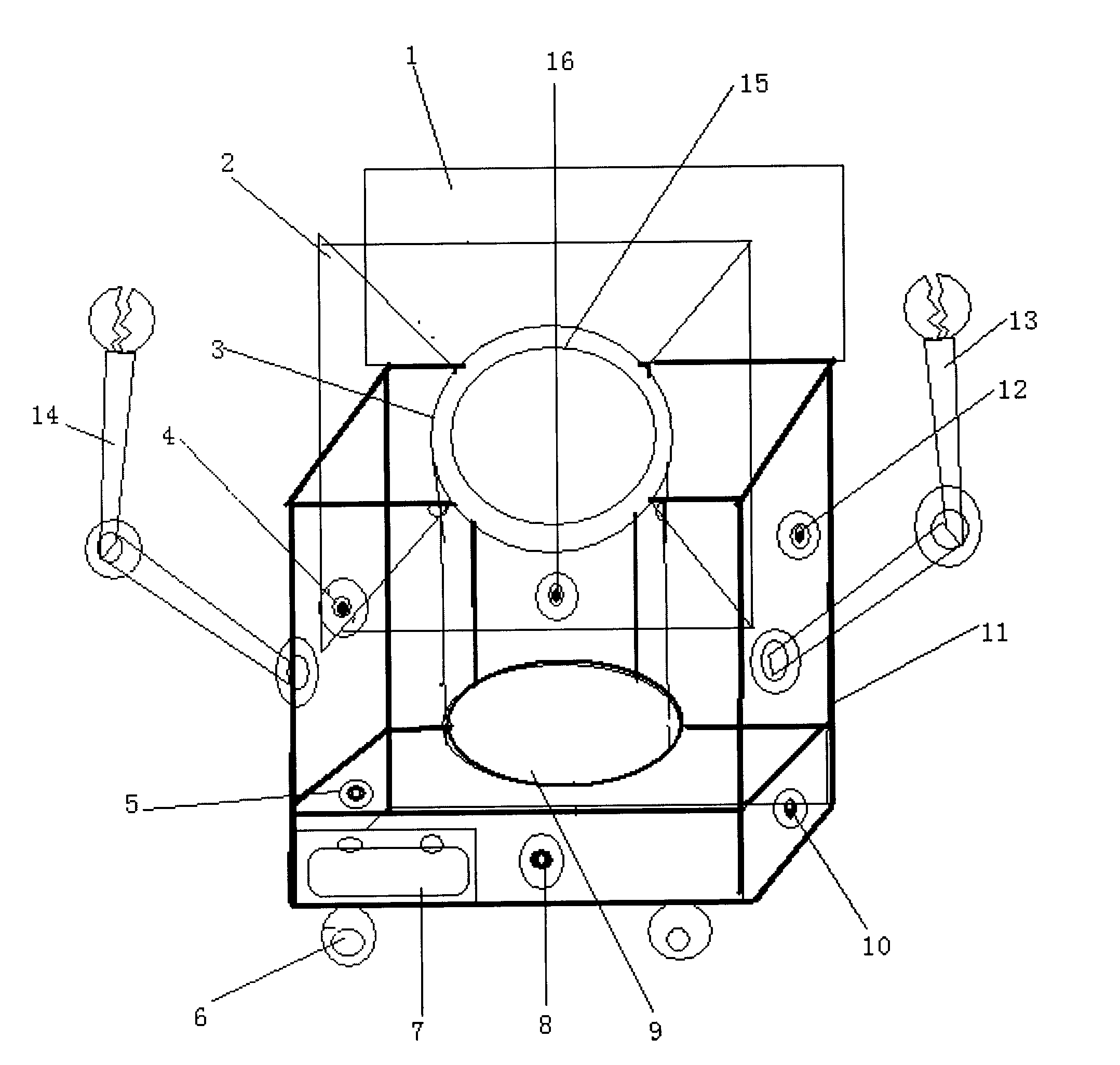

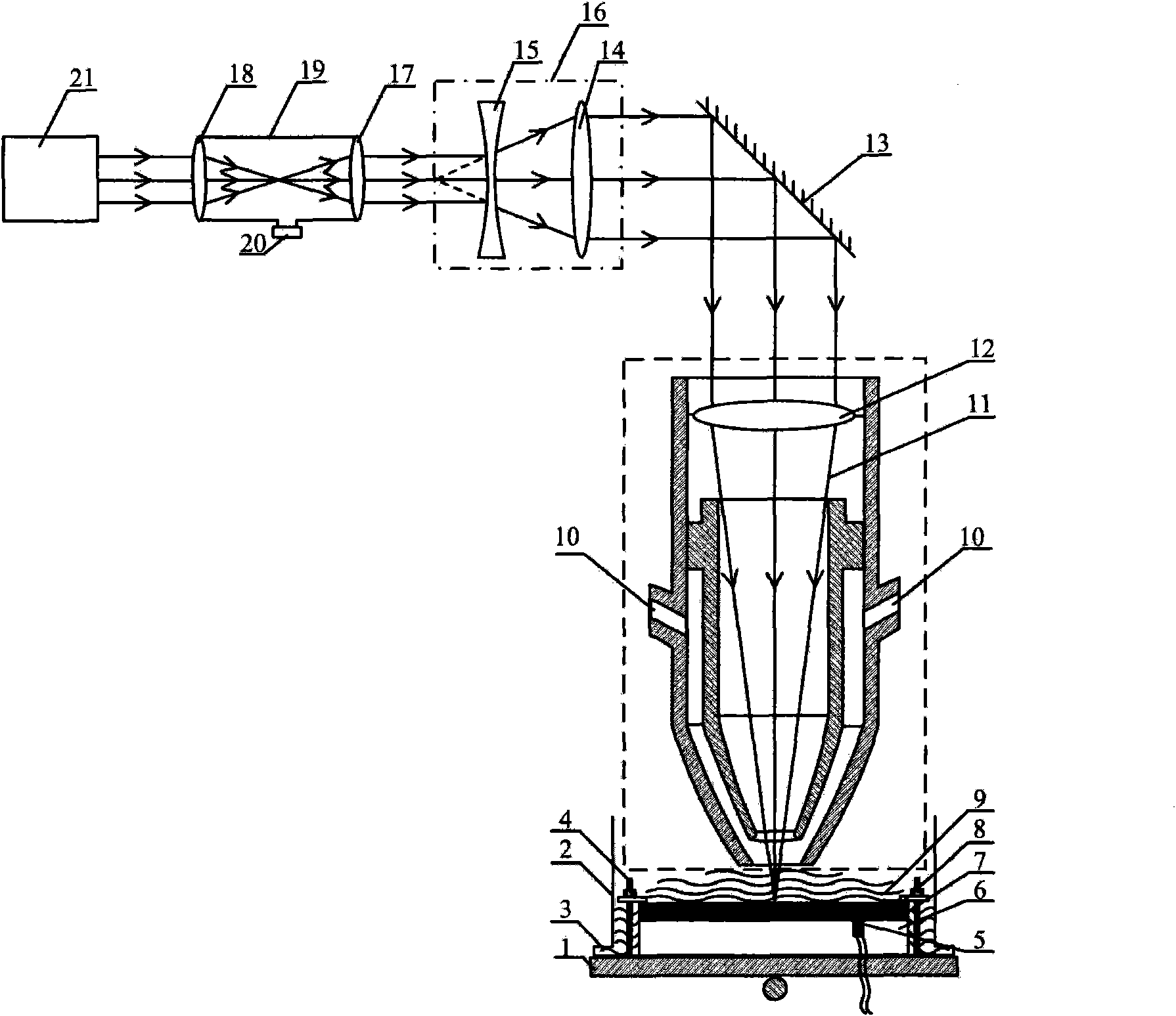

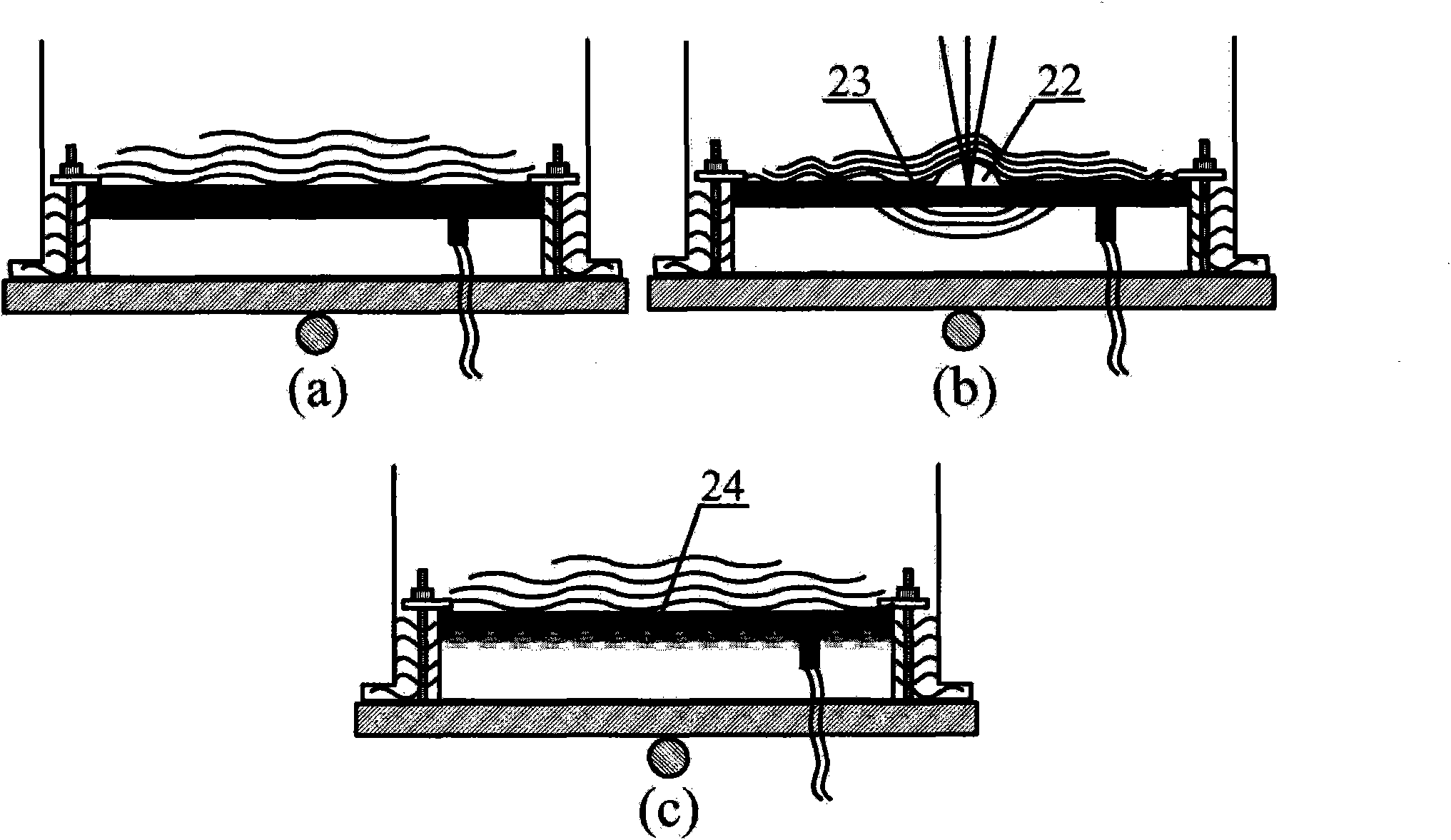

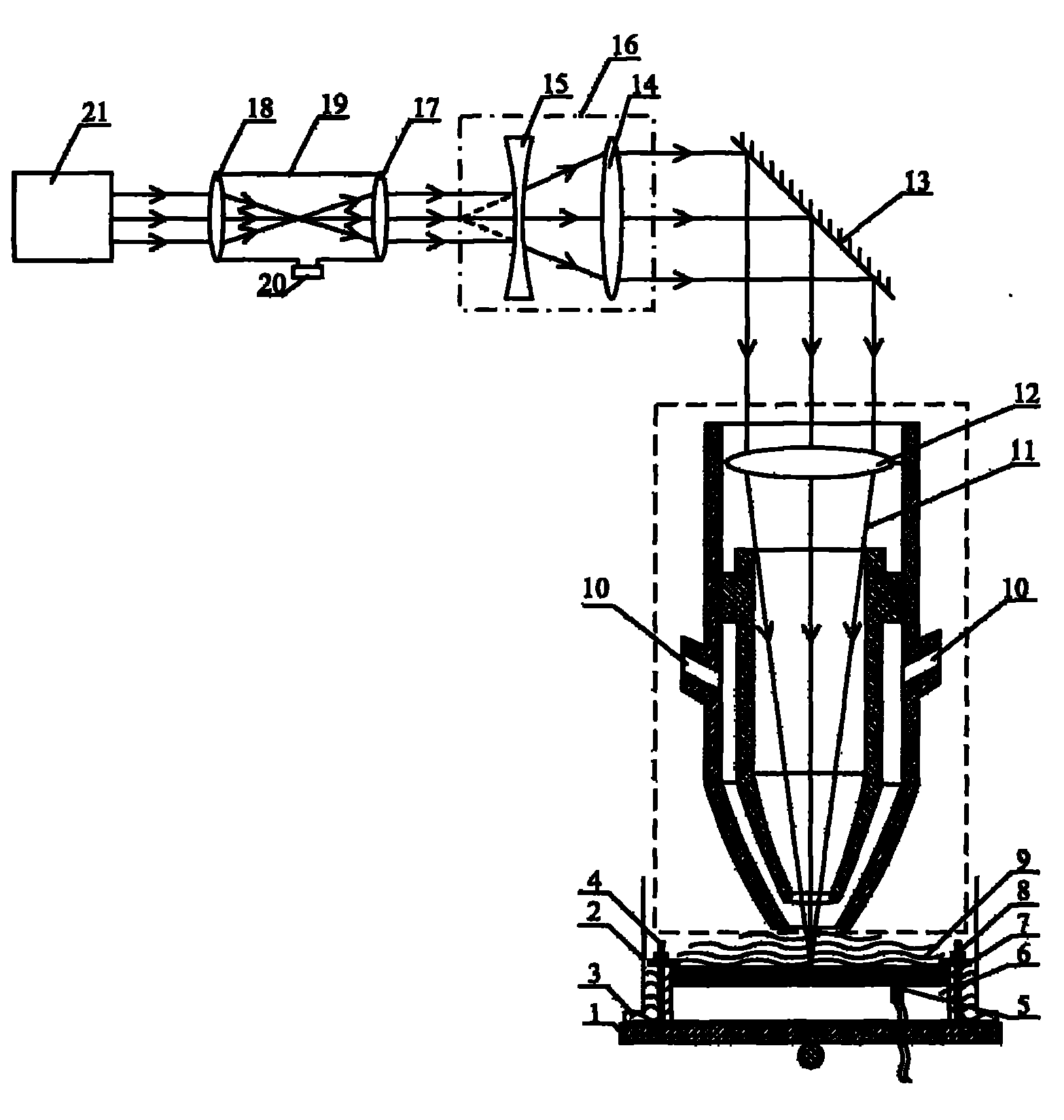

Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

InactiveCN101787528AChange compositionChange organizationMetallic material coating processesLaser beamsMechanical property

The invention discloses nano coating method and device based on ultrafast ultrahigh pressure photodynamics effect, belonging to the technical field of material surface. The invention is characterized by embedding or cold welding nanometer metal powder, nanometer nonmetal powder or compound nanometer powder which are precoated on the surface of a metal matrix in the surface layer of the metal matrix by means of laser induction mechanics effect, forming a thick nanometer particle strengthening layer or a coating layer which is called as a nano coating on the surface of the metal matrix, wherein the metal matrix is impacted and strengthened by laser. The device comprises a three-dimensional hexad working platform, a water tank, a clamp, a thermocouple, a coaxial synchronous water sender, a laser beam focusing system, a 45-degree fully-reflecting mirror, a laser beam optimizing system and a nanosecond laser. By the invention, the obtained surface nano coating has firm interface joint with the matrix and the mechanical property on the surface of the metal matrix is remarkably improved. The invention has simple technical process and lower cost, and is easy to realize automation and suitable for large-scale batch production.

Owner:JIANGSU UNIV

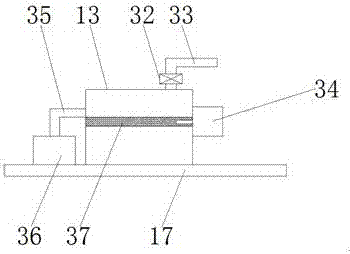

Steel plate drilling machine with scrap recycling and fixing functions

PendingCN107378024ARealize the purpose of drilling in different positionsImprove stabilityMaintainance and safety accessoriesBoring/drilling machinesFixed-functionHydraulic cylinder

The invention discloses a steel plate drilling machine with scrap recycling and fixing functions. According to the steel plate drilling machine, a first hydraulic cylinder drives a first hydraulic rod to drive a pressure plate to move downwards, so that a steel plate is extruded and fixed, the influence of movement of the steel plate in drilling on drilling effects and drilling accuracy is avoided, stability of a second hydraulic rod in the downward movement process is improved by the aid of a sliding sleeve, so that the drilling accuracy is further improved, water in a water storage tank enters a water outlet pipe by the aid of a first booster pump and is sprayed from a flushing sprayer, so that scraps generated by drilling the steel plate are flushed, cleanness of the surface of the steel plate is ensured, waste water generated by flushing the scraps falls into a water receiving funnel through a through hole, the waste water is collected by the water receiving funnel, environmental pollution caused by the waste water is avoided, the waste water entering a scrap recycling and drying box is filtered by the aid of a screen plate, the scraps are recycled, resources are saved, and practicability of the steel plate drilling machine is improved.

Owner:湖州南浔永方机械有限公司

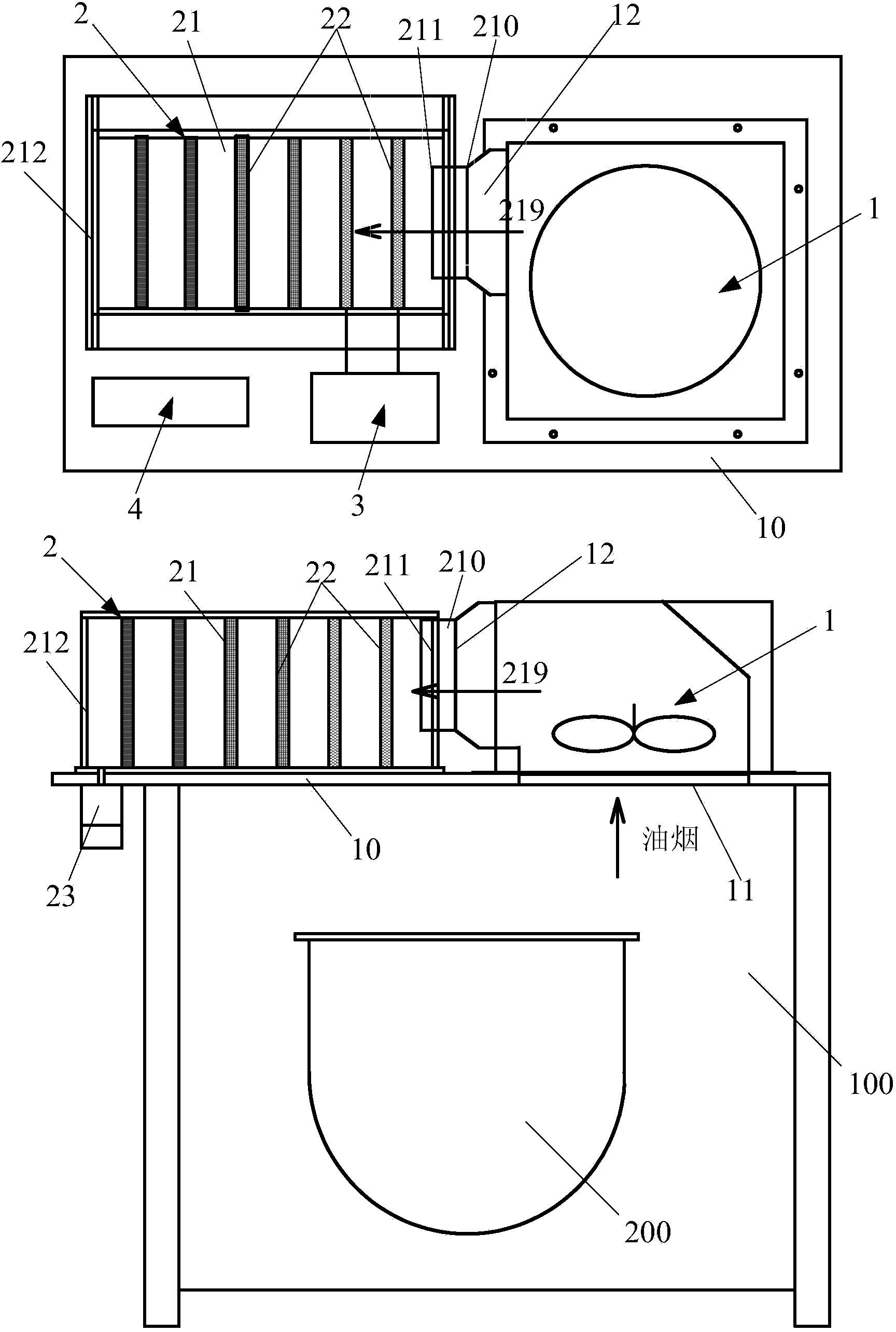

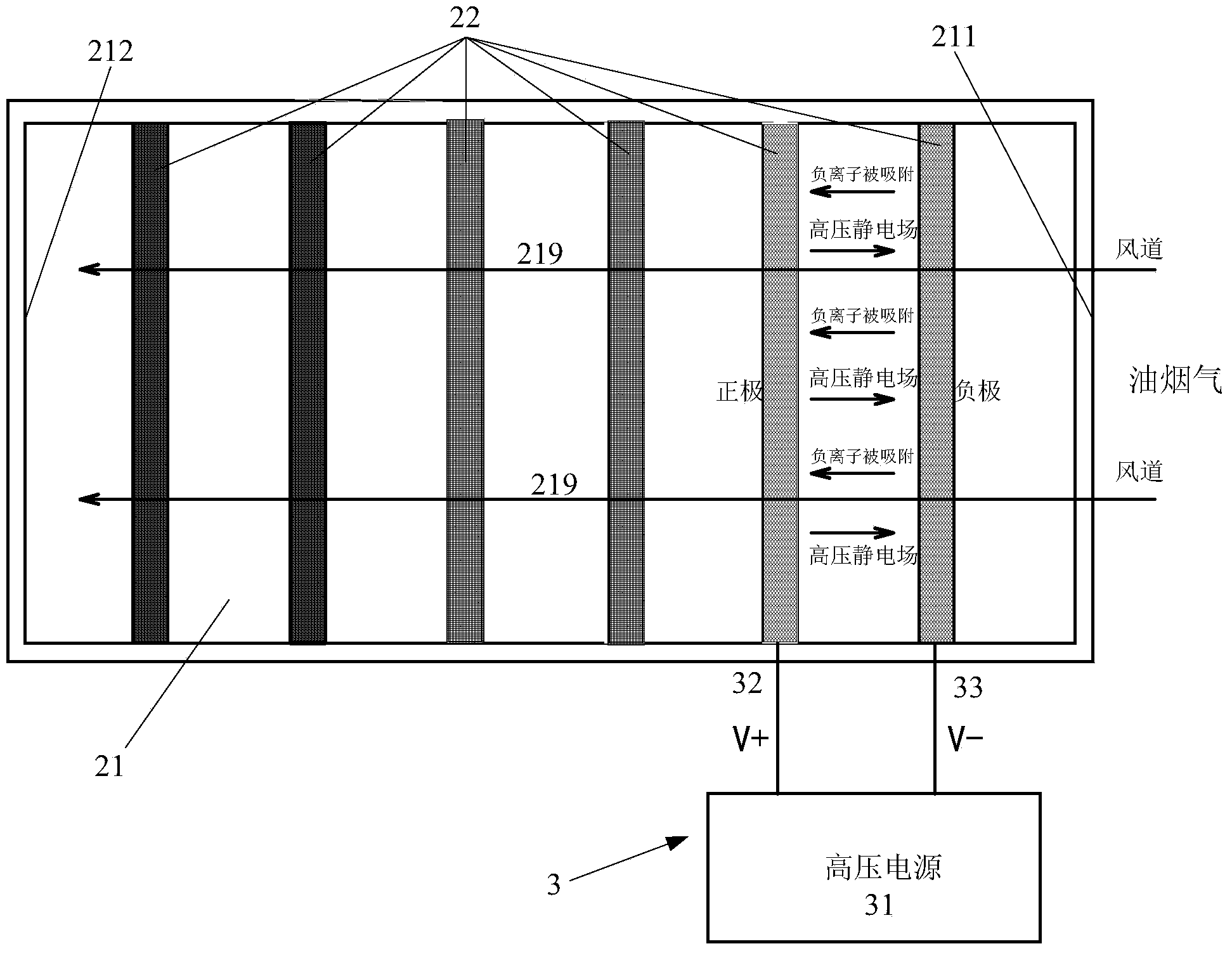

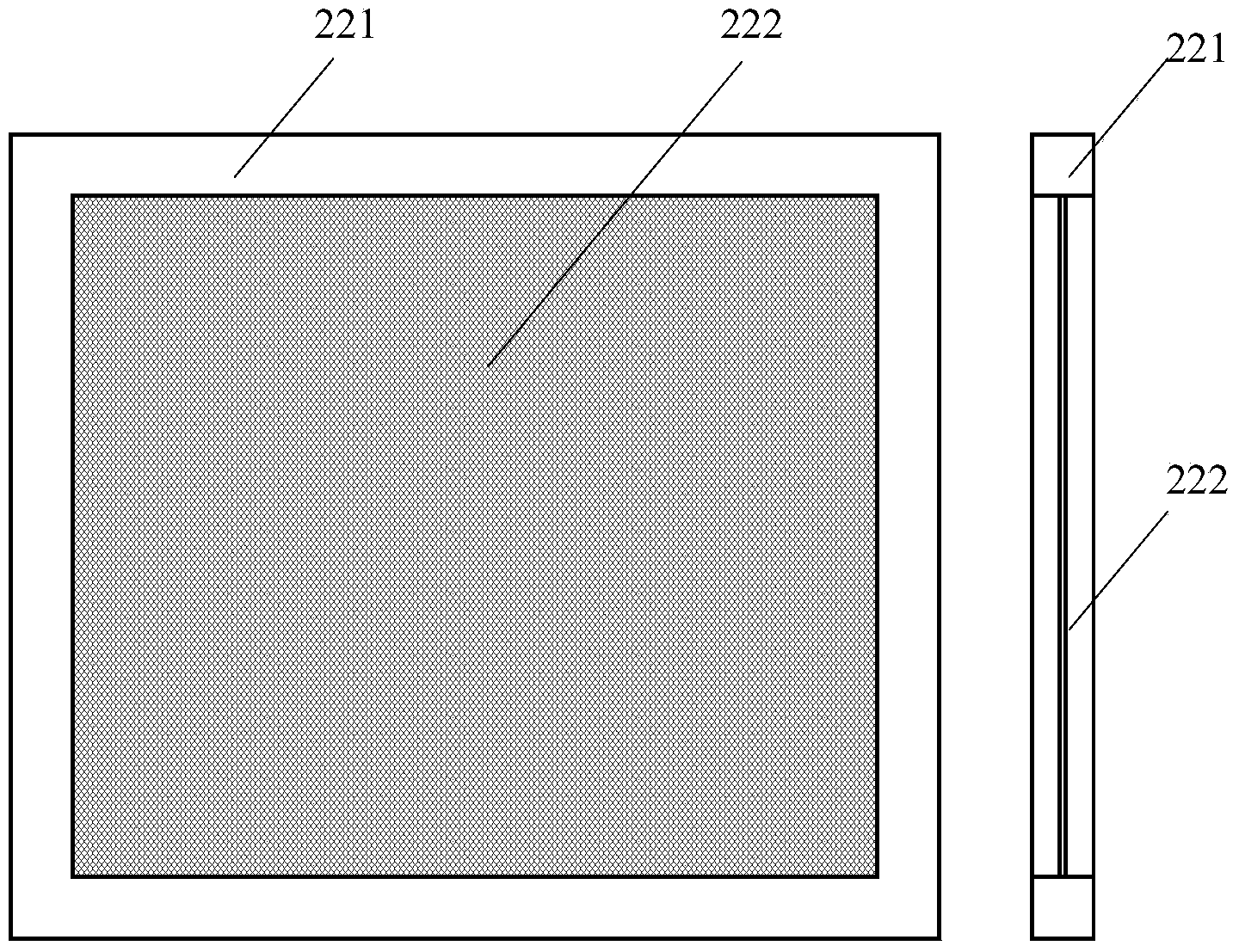

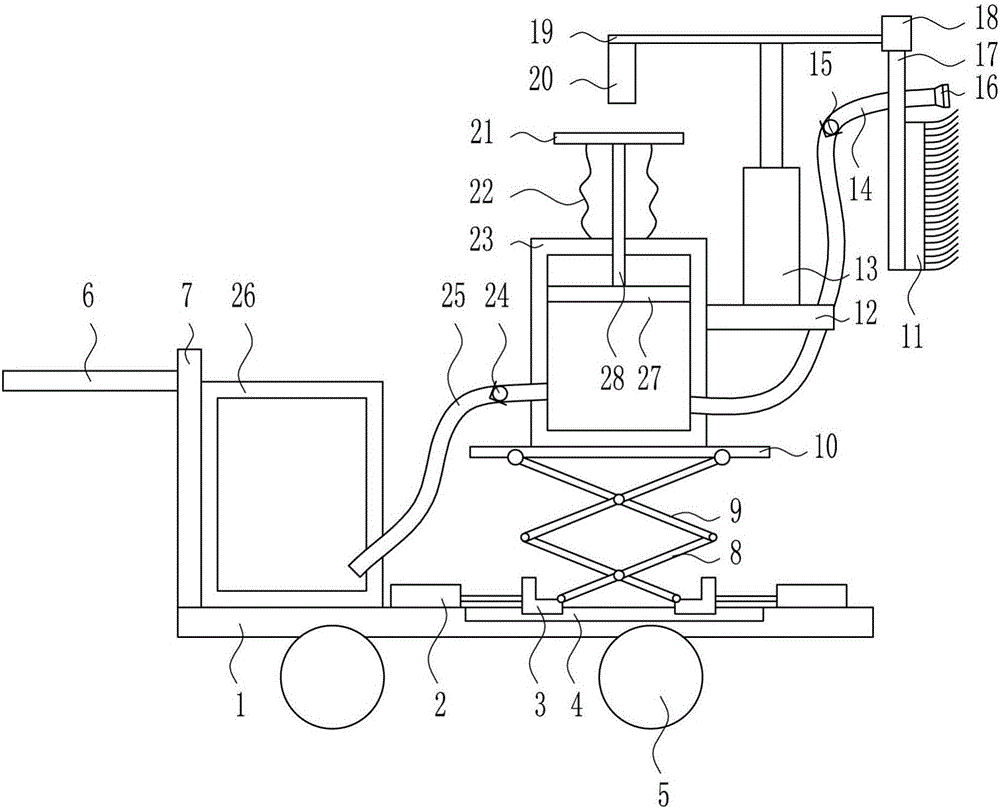

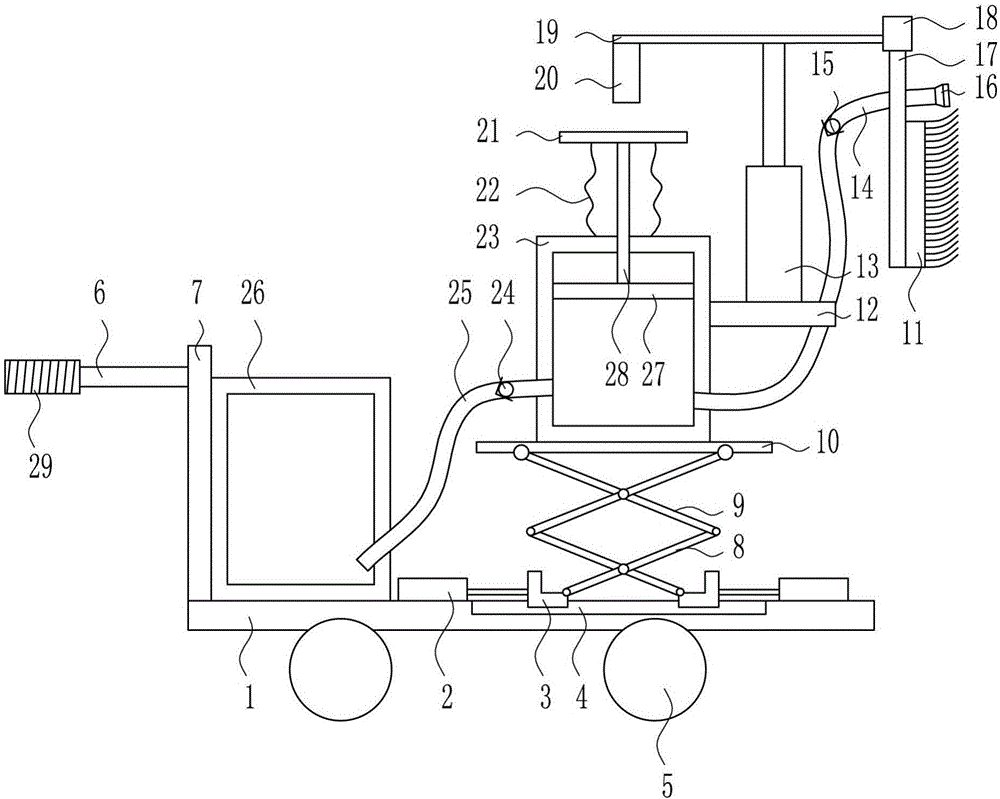

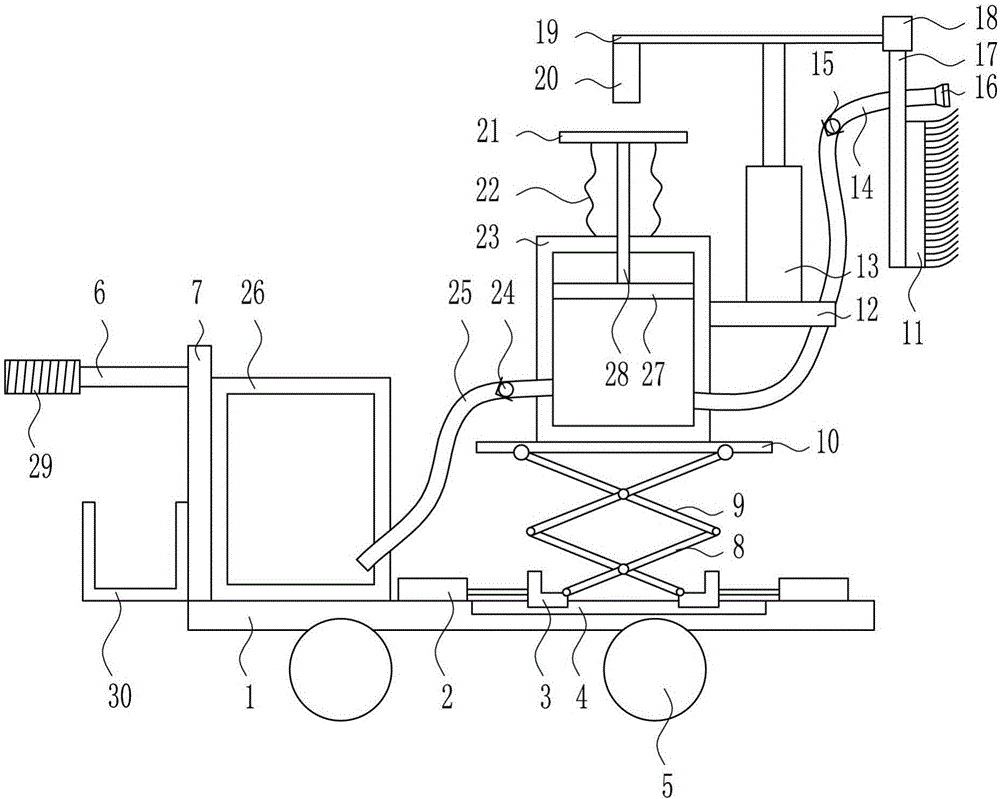

Cooking fume processing device applicable to full-automatic cooker

InactiveCN104019480ARealize conversion recovery functionGuaranteed cleanlinessCombination devicesDomestic stoves or rangesElectricityHigh pressure

The invention discloses a cooking fume processing device applicable to a full-automatic cooker. The cooking fume processing device comprises an exhaust fan, a gas-liquid conversion recycling and filtering device and an electrostatic processing device, wherein an air inlet of the exhaust fan is communicated with a sealed inner cavity of the full-automatic cooker and close to a pot body, and an air outlet of the exhaust fan is communicated with the gas-liquid conversion recycling and filtering device; the gas-liquid conversion recycling and filtering device comprises a recycling and filtering box body, a plurality of conductive recycling filter screens arranged inside the recycling and filtering box body and a detachable oil collecting container communicated with the bottom of the recycling and filtering box body, wherein the air inlet of the recycling and filtering box body is connected with the air outlet of the draught fan, and the air outlet of the recycling and filtering box body is connected with the outside atmosphere; the plurality of conductive recycling filter screens are arranged in sequence between the air inlet and the air outlet; the electrostatic processing device comprises a high-voltage power supply, as well as a high-voltage positive electrode and a high-voltage negative electrode connected with the high-voltage power supply, wherein the high-voltage positive electrode and the high-voltage negative electrode are respectively connected oto any two conductive recycling filter screens, so as to form an electrostatic field between the two conductive recycling filter screens.

Owner:许锦标 +1

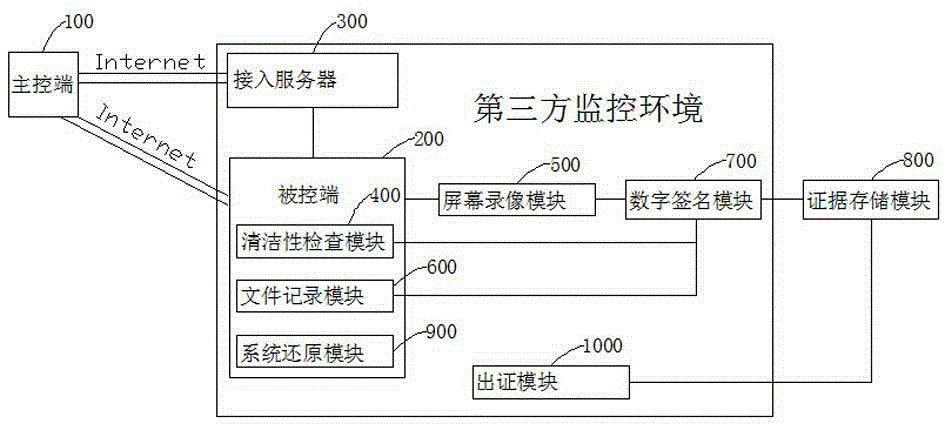

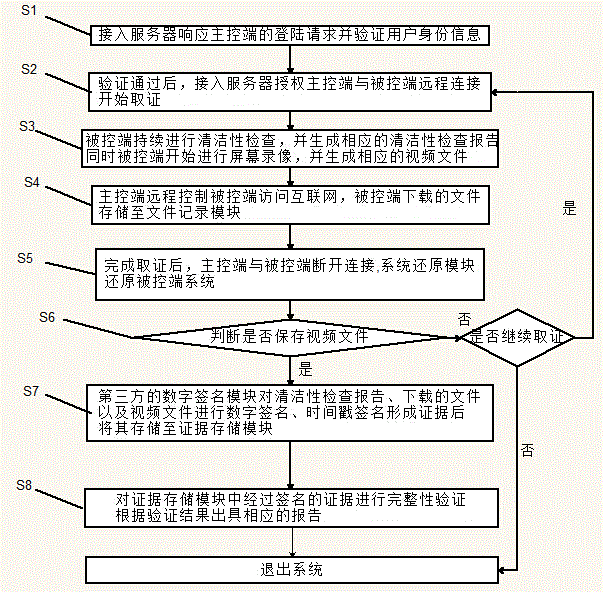

Network electron evidence processing system and processing method

InactiveCN105046168ASolve untrustworthyGuaranteed cleanlinessUser identity/authority verificationDigital data protectionThird partyEngineering

The invention discloses a network electron evidence processing system and a processing method; the processing system comprises a main control end, an access server, a controlled end remotely connected with the main control end, a cleanness check module, a screen recording module, a file recording module, a digital signature module, an evidence storage module, a system reduction module, and a testify module; the access server, the controlled end, the cleanness check module, the screen recording module, the file recording module, the digital signature module, the system reduction module and the testify module are respectively under a third party monitoring environment. The processing method comprises the following steps: a user uses the main control end to remotely control the controlled end to visit the internet; simultaneously the screen recording module carries out screen recording; the third party uses the digital signature module to do digital signature on evidence obtaining files, and stores the files; when needing testify, the testify module can do integrity verification for the evidence with digital signature, and provides a corresponding report. The evidence obtaining, evidence storage and a testifying process are witnessed by the third party, so a user networking real process can be restored.

Owner:上海人科数据科技有限公司

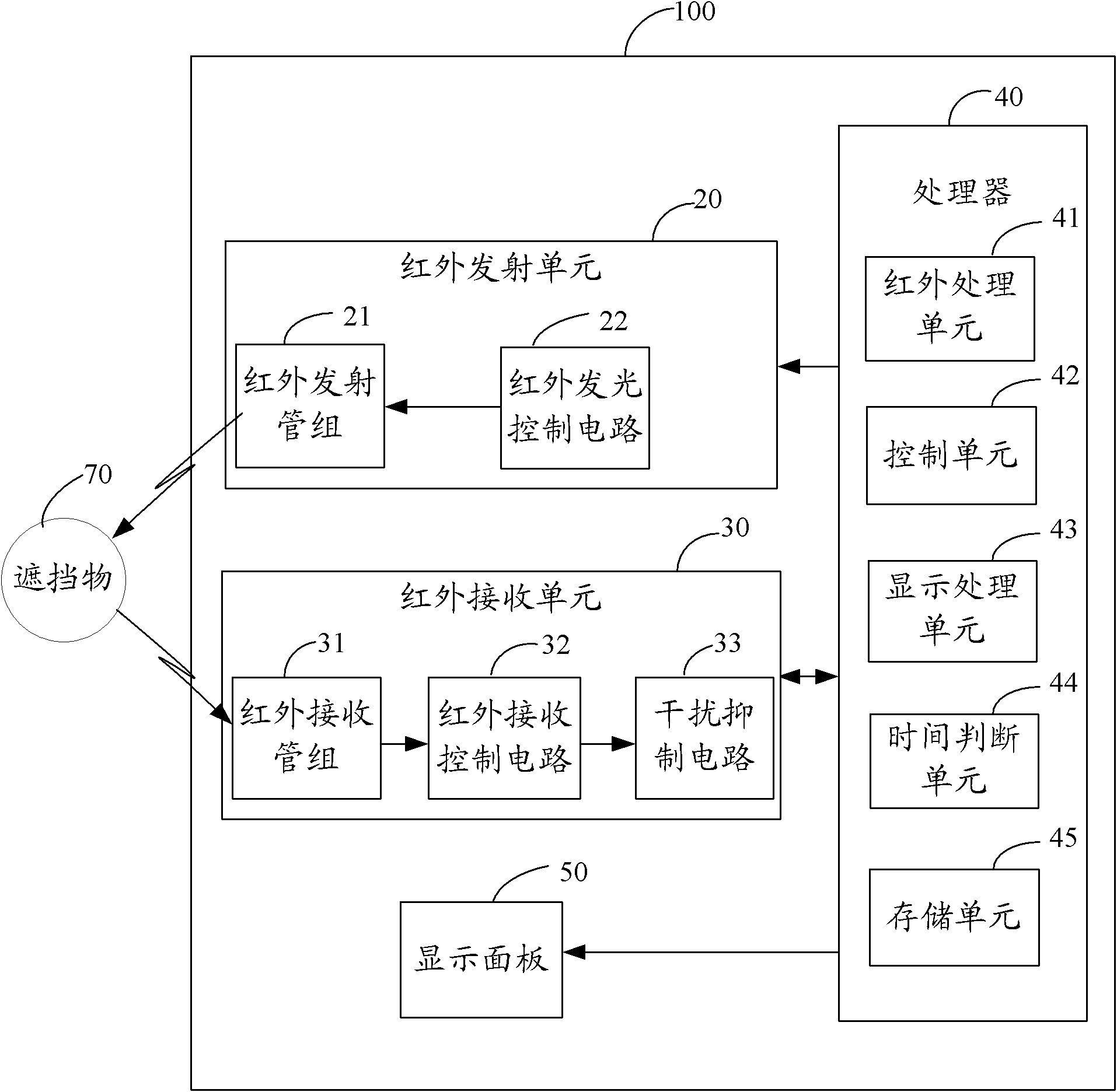

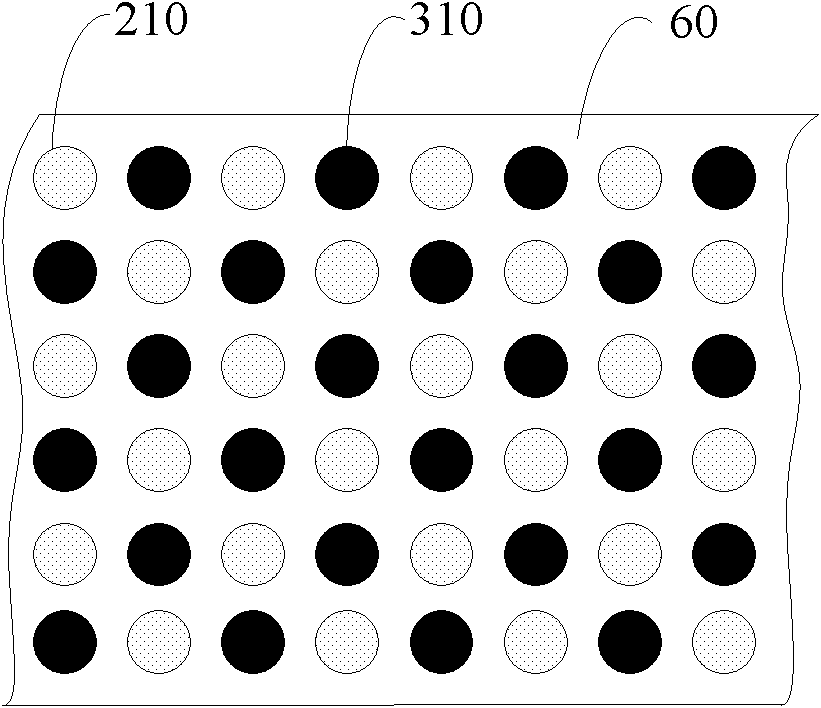

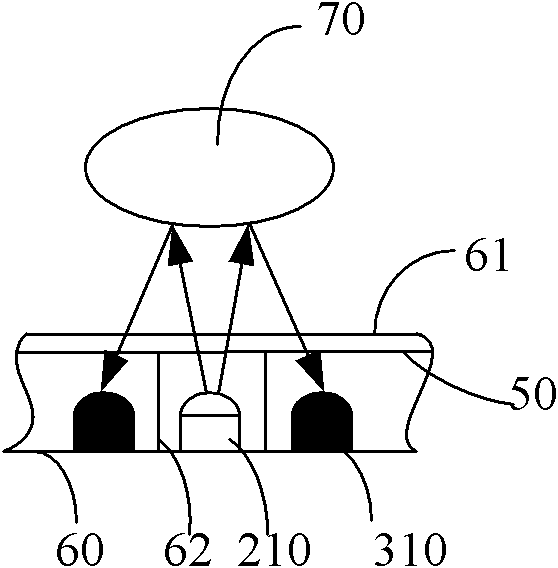

Infrared control device

InactiveCN101901088AReduce thicknessGuaranteed cleanlinessInput/output processes for data processingInfraredControl signal

The invention relates to an infrared control device which comprises a plurality of infrared transmitting tubes, a plurality of infrared receiving tubes, an infrared luminescence control circuit, an infrared receiving control circuit, a processor and a display panel, wherein the infrared transmitting tubes and the infrared receiving tubes are arranged in a staggered mode below the display panel and towards the same direction, the infrared transmitting tubes are controlled by the processor through the infrared luminescence control circuit to transmit infrared signals, the infrared receiving tubes are controlled by the infrared receiving control circuit to receive the reflected infrared signals transmitted by the infrared transmitting tubes, and state sampling signals are transmitted into the processor after the states of the infrared receiving tubes are sampled. The processor comprises an infrared processing unit, a control unit and a display processing unit, wherein the position of a control point is determined by the infrared processing unit according to the state sampling signals of the infrared receiving tubes, a corresponding control signal is output by the control unit according to the position of the control point, a corresponding function is started, and the display panel is controlled by the display processing unit to display a corresponding interface.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

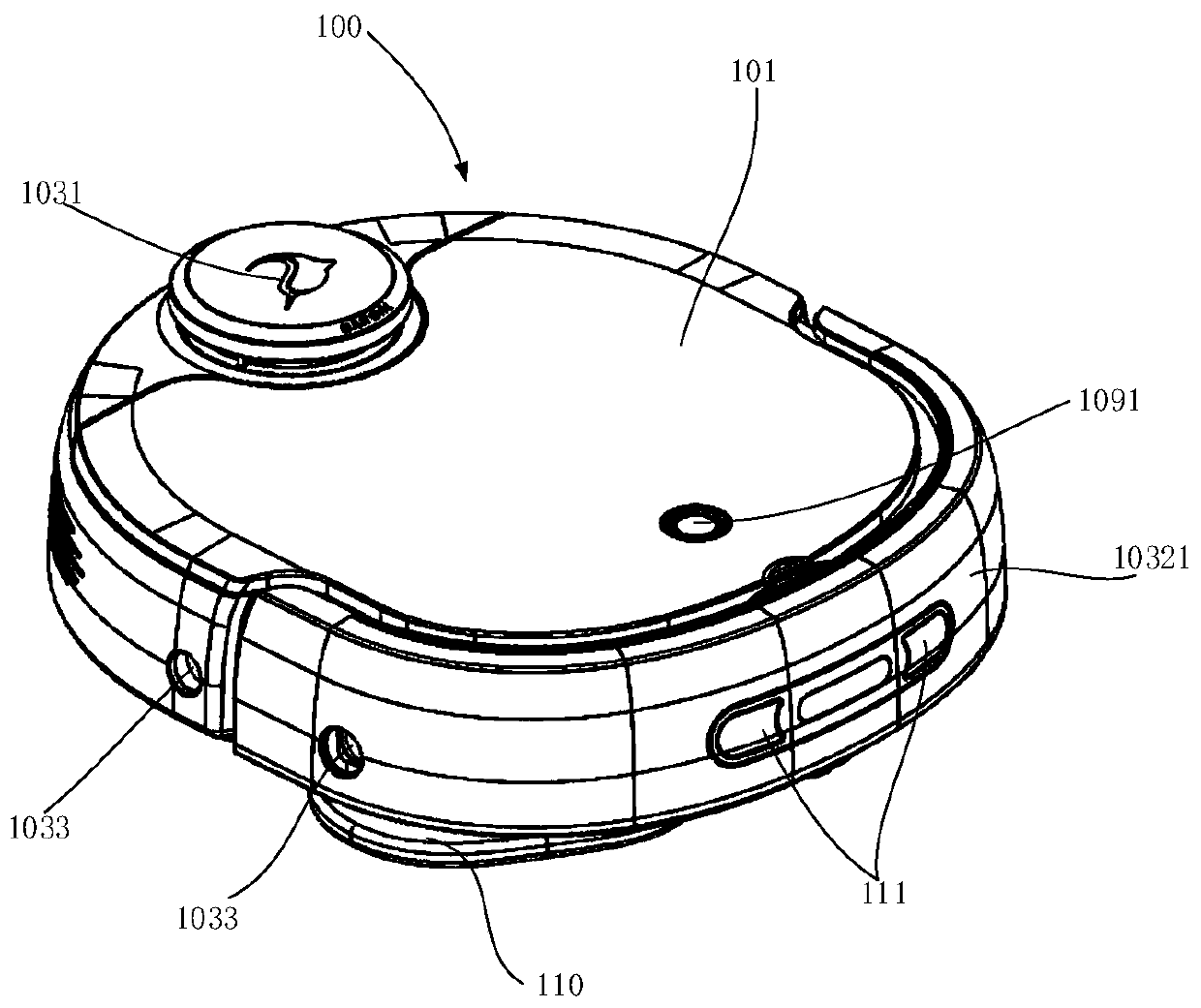

Control method, control device and control equipment of mopping robot and storage medium

ActiveCN110236455AClean in timeGuaranteed cleanlinessAutomatic obstacle detectionTravelling automatic controlControl mannerEngineering

The invention discloses a control method, a control device and control equipment of a mopping robot and a storage medium, and belongs to the technical field of smart home. The method is applied to the floor mopping robot. The floor mopping robot is provided with a mopping and wiping part. The mopping and wiping part is used for mopping and cleaning the floor. The method comprises the steps that if the floor mopping robot wipes the floor through the mopping and wiping part, the mopping and wiping numerical value of the mopping and wiping part is adjusted, and the mopping and wiping numerical value is used for representing the dirt degree of the mopping and wiping part; if the mopping and wiping numerical value meets the cleaning condition, the mopping and wiping part cleaning operation related to the cleaning of the mopping and wiping part is executed. According to the invention, the mopping numerical value of the mopping and wiping part is adjusted, wherein the mopping numerical value represents the dirt degree of the mopping and wiping part. The mopping robot is controlled to execute the cleaning operation of the mopping and wiping part under the condition that the mopping numerical value meets the cleaning condition. The cleaning of the mopping and wiping part is controlled based on the dirt degree of the mopping and wiping part. Therefore, the control mode is more intelligent and flexible. The mopping and wiping part can be cleaned in time, and the cleaning effect of the floor is guaranteed.

Owner:云鲸智能创新(深圳)有限公司

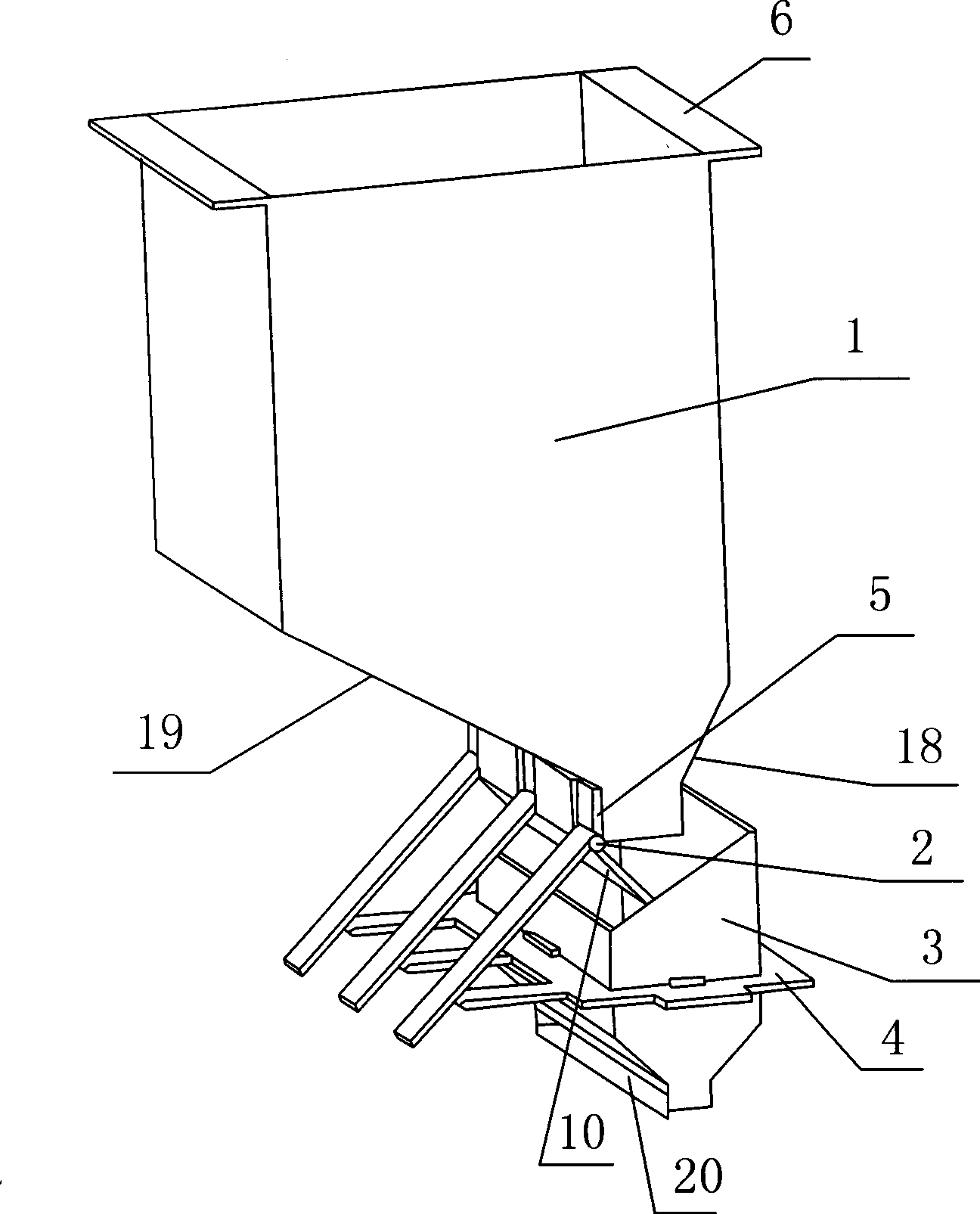

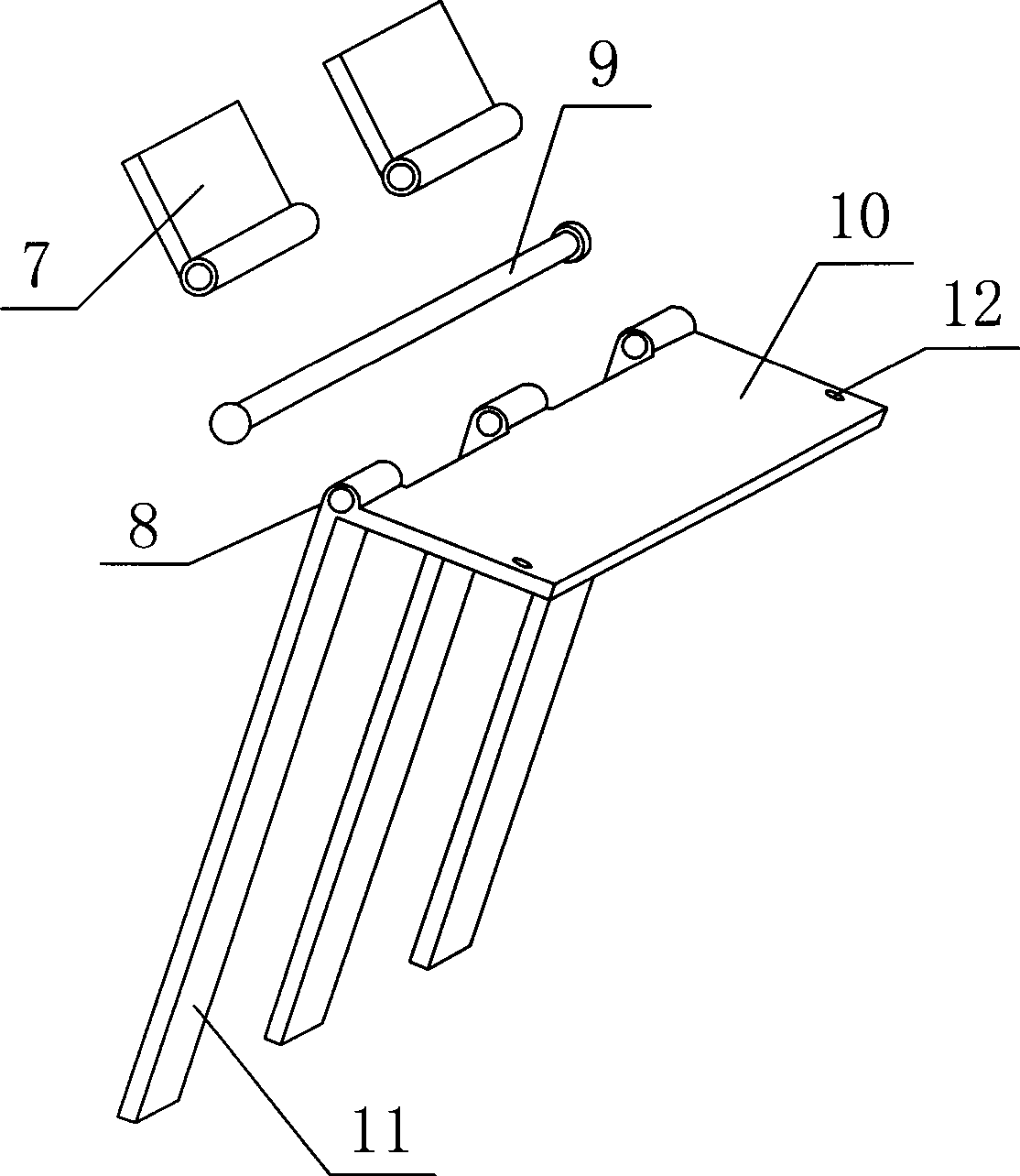

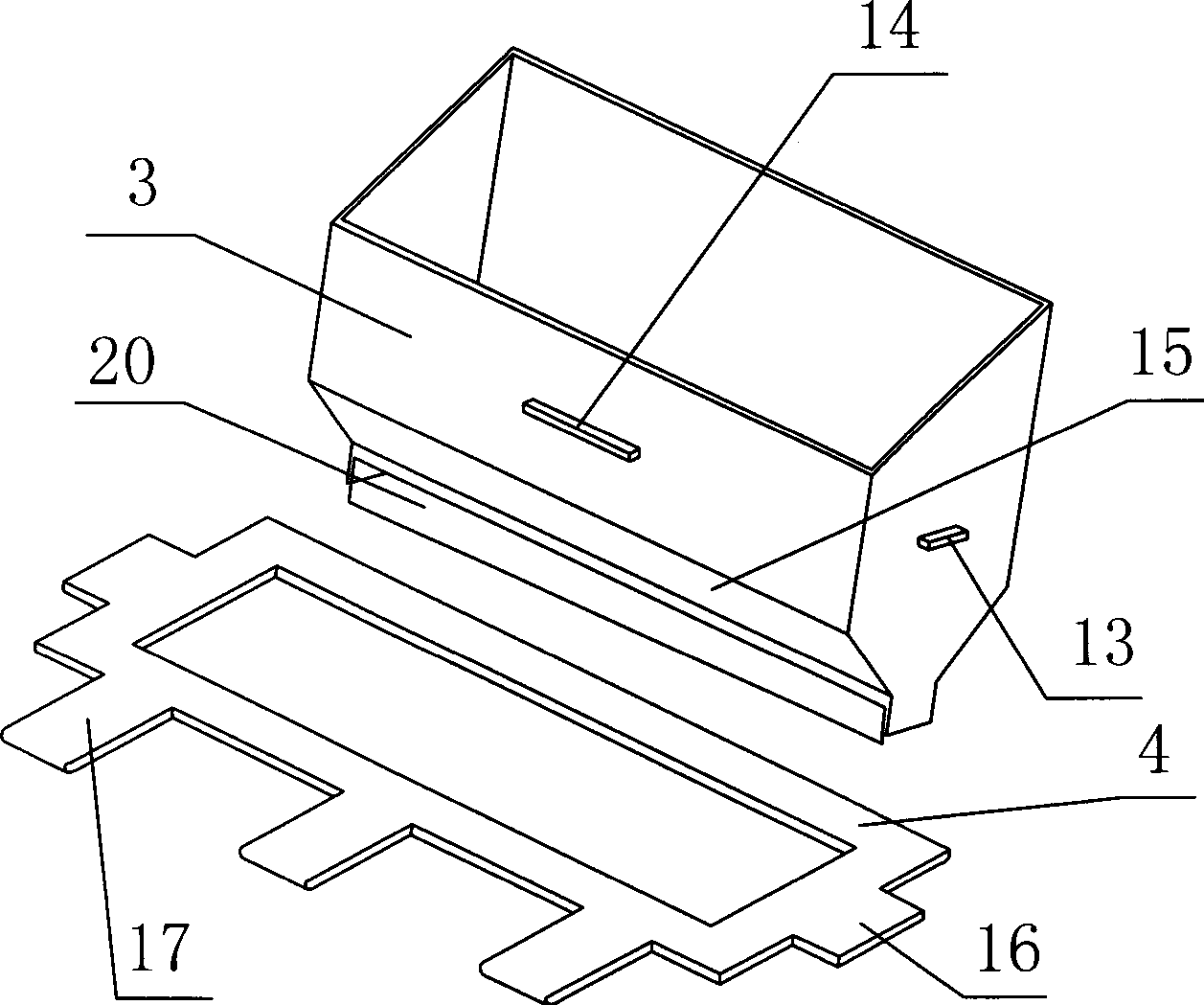

Powder sending and laying device for quickly shaping device

ActiveCN101362202APrevent dispersalAvoid wandering situationsAdditive manufacturing apparatusLoading/unloadingHigh rateReciprocating motion

The invention discloses a powder feeding and laying device applied to a high rate former, which consists of a powder storing case and a movable hopper, wherein, the powder storing case is an upper powder storing case positioned above the movable hopper and provided with a power outlet at the bottom; the powder storing case is fixed and stable; a movable baffle capable of automatically opening and closing the powder outlet is arranged at the bottom of the powder outlet; a movable bracket is fixed outside the movable hopper which moves to and fro from left to right along a horizontal line on a forming working platform of a high rate former by a driving mechanism; an unlocking component which is matched to be used with the movable bracket is arranged on the movable baffle; a receiving port at the upper part of the movable hopper corresponds to the powder outlet; a powder laying port is arranged at the bottom of the movable hopper, which is a rectangular port enclosed by two lateral baffles in the front and the back and two flexible doctor blades on the left and the right. The powder feeding and laying device applied to a high rate former has simple structure, handy assembly and deinstallation of all parts and easy regulation and control, the capability of modular working independently, rapid powder laying, and high reliability.

Owner:西安赛隆增材技术股份有限公司

High-efficiency cleaning device for livestock shed for livestock farming

InactiveCN106180018AImprove corrosion resistanceStrong acid resistanceCleaning using toolsCleaning using liquidsSprayerEngineering

The invention relates to a cleaning device for a livestock shed for livestock farming, in particular to a high-efficiency cleaning device for the livestock shed for livestock farming. In order to achieve the technical purposes of thorough cleaning, high cleaning efficiency and convenient operation, the high-efficiency cleaning device for the livestock shed for livestock farming comprises a bottom board, a first electric push rod, an L-shaped sliding block, a sliding rail, wheels, a push handle, a left frame, a first connection rod, a second connection rod, a fixing board, a brush, a supporting board, a second electric push rod, a second hose, a second one-way valve, a sprayer, a fixing rod and the like, wherein the left frame and a water tank are arranged on the left side of the top of the bottom board; and the left frame is located on the left of the water tank. The high-efficiency cleaning device for the livestock shed for livestock farming achieves the effects of thorough cleaning, high cleaning efficiency and convenient operation. A livestock shed is closely linked with living of livestock, frequent cleaning of the livestock shed is beneficial for keeping the livestock shed clean, and the situation that the livestock get sick due to breeding of bacteria is avoided.

Owner:邵鹏程

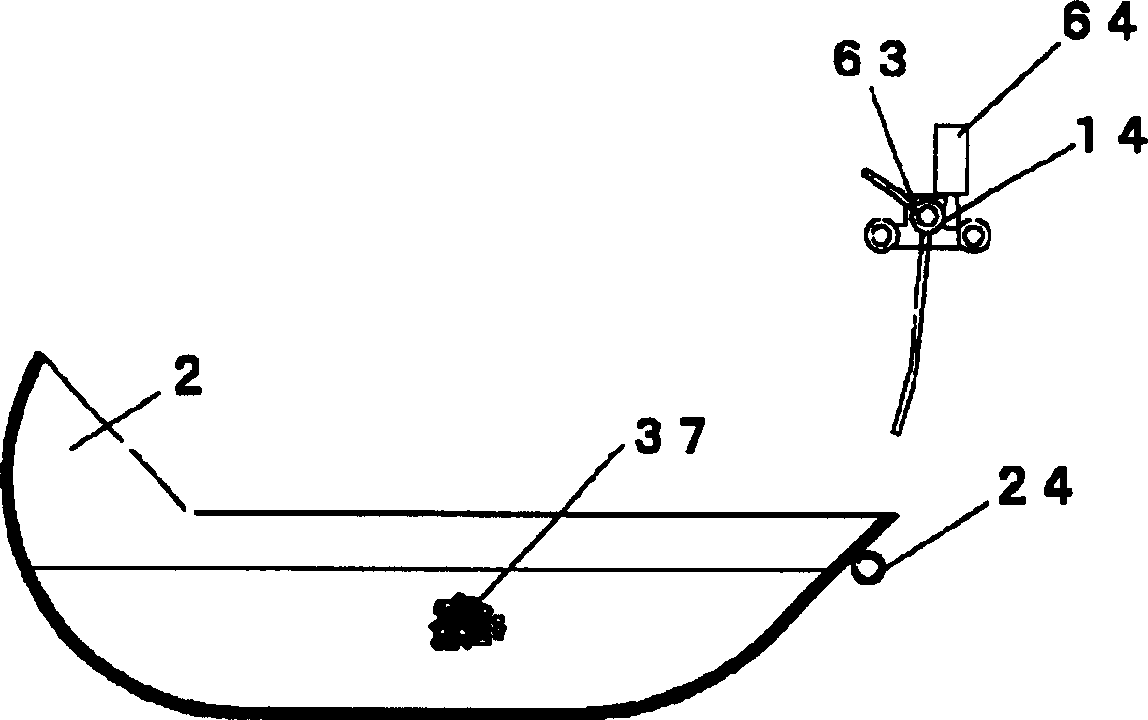

Automatic cleaning and packaging device for pet excrement and collecting material for pet excrement

By moving the feces or urine excreted into the pet toilet to the packing device, the source of the bad smell is sealed by the packing device, and the pet toilet is always kept clean, preventing the bad smell from spreading into the house, and eliminating the troubles of the breeder. Equipped with: a collection material for collecting excrement, a storage container for placing the collection material, a mechanism for moving the collection material collected together with the excrement from the container to the packaging part, and a mechanism for moving the excrement moved together with the moving mechanism The packaging mechanism that packs the collected materials with sheet materials can reduce the care of excrement when raising pets by packaging the excrement, and the bad smell can be completely eliminated through the packaging, and the toilet for pets can always be kept clean.

Owner:赵龙植

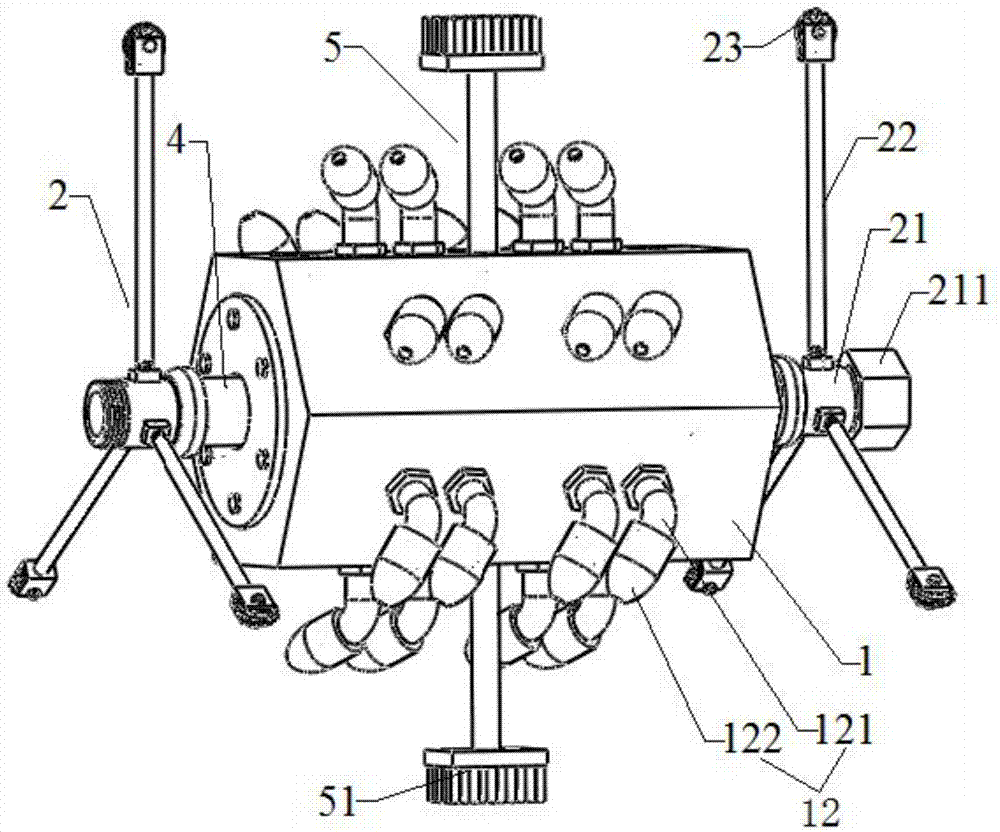

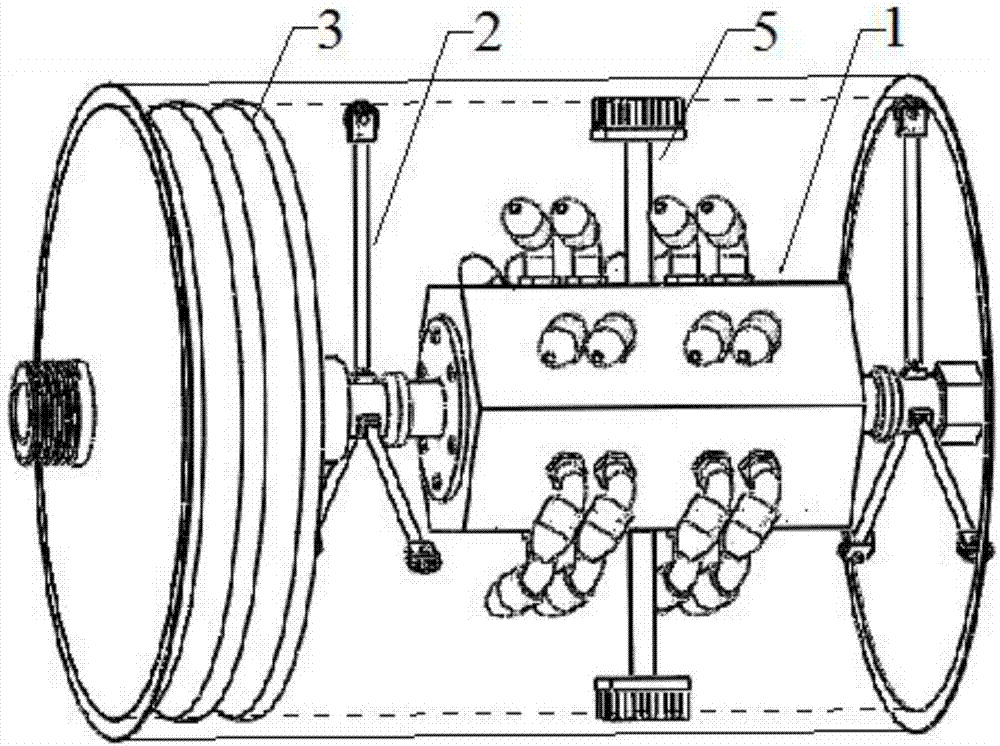

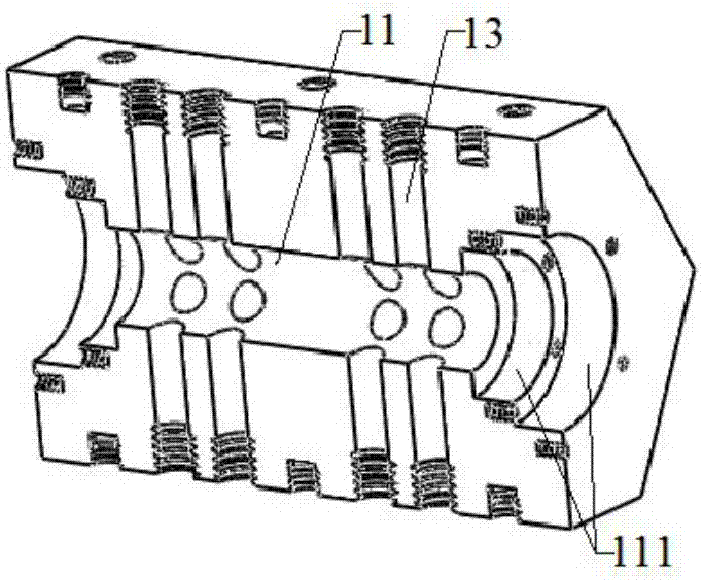

Multifunctional pipe tool inner wall cleaning device and cleaning method thereof

ActiveCN106890828ASimple structureEasy to useHollow article cleaningCleaning methodsMechanical engineering

The invention relates to a multifunctional pipe tool inner wall cleaning device and a cleaning method of the multifunctional pipe tool inner wall cleaning device. The device comprises a spray cylinder, a pipe cleaning device, walking mechanisms and a center shaft which are coaxially arranged. A cavity is formed in the spray cylinder. The center shaft penetrates the cavity and communicates with the cavity. Multiple spray head assemblies are mounted on the periphery of the spray cylinder and communicate with the cavity. Steel brush assemblies are arranged on the periphery of the spray cylinder. Walking joints communicating with the center shaft are mounted at the two ends of the center shaft. The end, close to the spray cylinder, of the pipe cleaning device is a liquid outlet end, one end of the center shaft is connected with and communicates with the liquid outlet end through the corresponding walking joint, and the walking joint corresponding to the other end of the center shaft is provided with a sealing plug; the walking mechanisms are mounted on the walking joints in a one-to-one manner; and the spray directions of the spray head assembles are consistent in the radial direction, and the spray head assemblies are obliquely arranged towards the inner wall of a pipe tool to be cleaned and the pipe cleaning device. The multifunctional pipe tool inner wall cleaning device and the cleaning method have the beneficial effects that the inner wall of the pipe tool is cleaned in an omnibearing manner through the cleaning manner of combining the high-pressure spray cleaning and boosting, scraping of the steel brush assemblies and scraping of the pipe cleaning device, and the cleaning device is environmentally-friendly, efficient, capable of saving energy and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com