Method for preparing metal chalcogenide film

A metal chalcogenide and thin film technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem that the thickness of molybdenum disulfide thin film is difficult to control accurately, randomness limits large-scale integrated production, size , position and thickness are uncontrollable, etc., to achieve the effect of simple method, good crystal quality and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

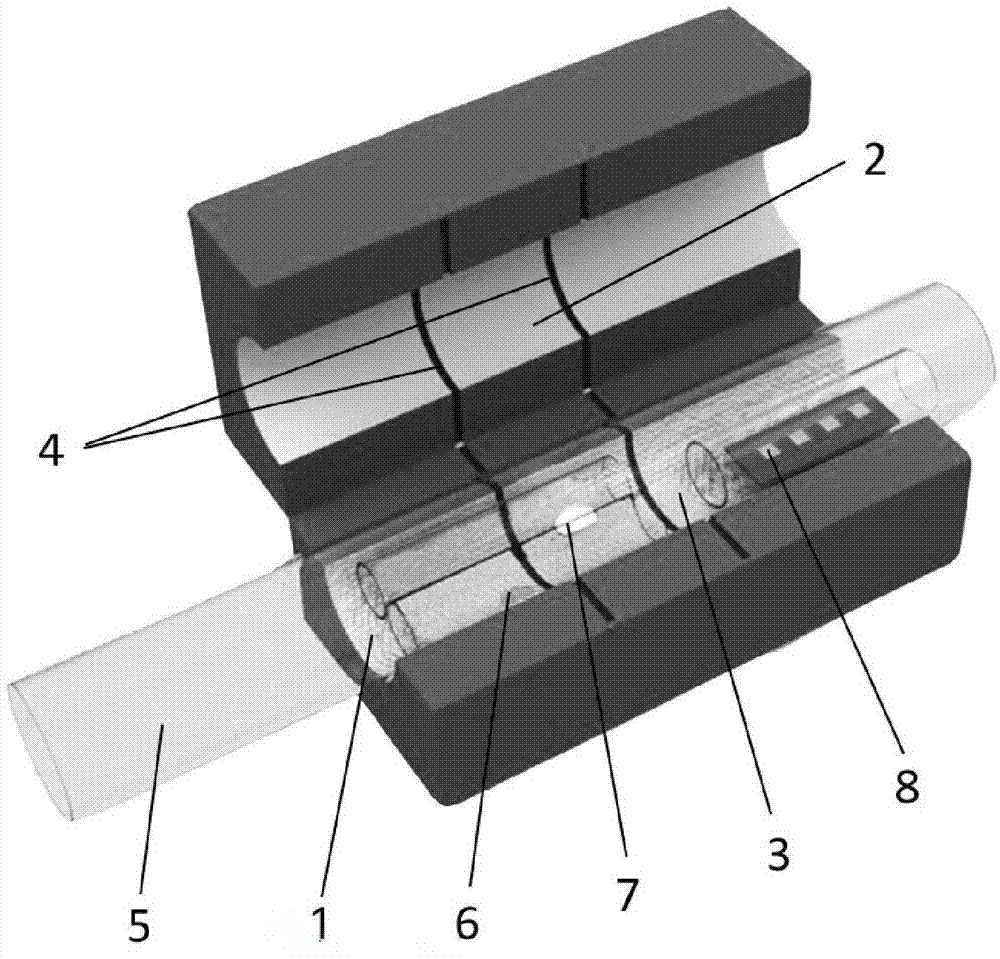

Method used

Image

Examples

Embodiment 1

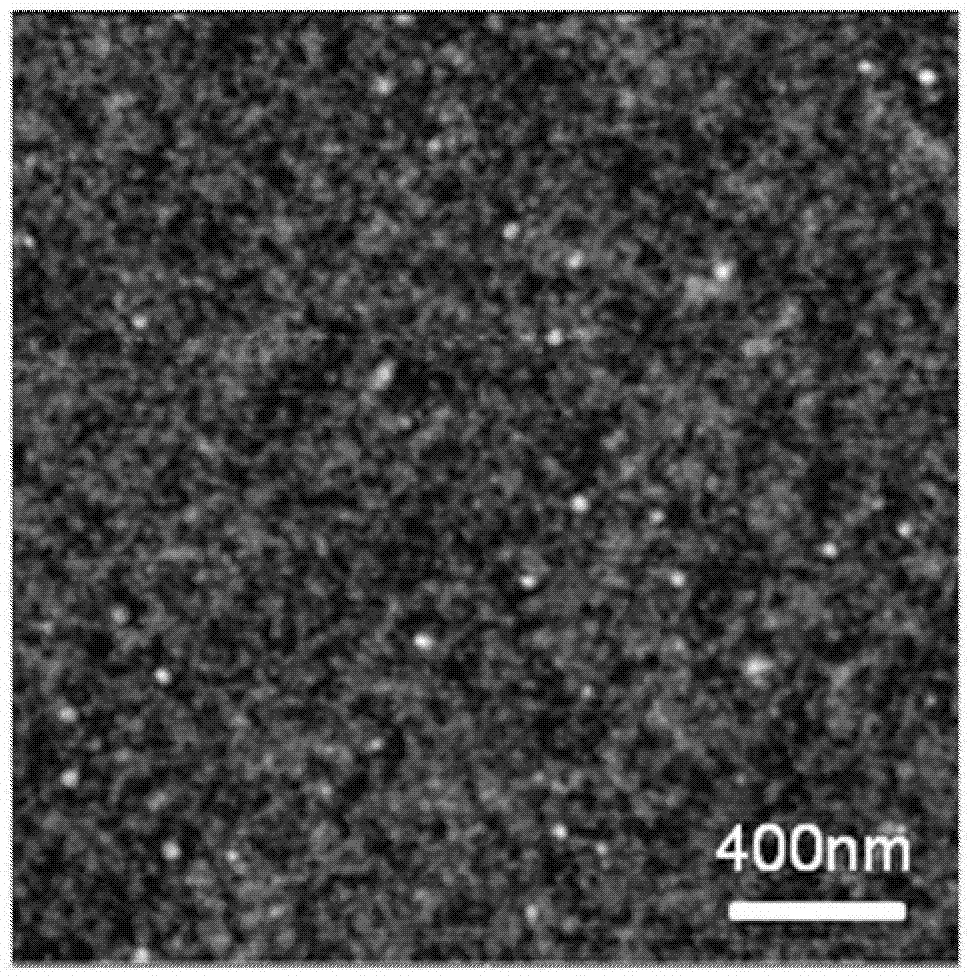

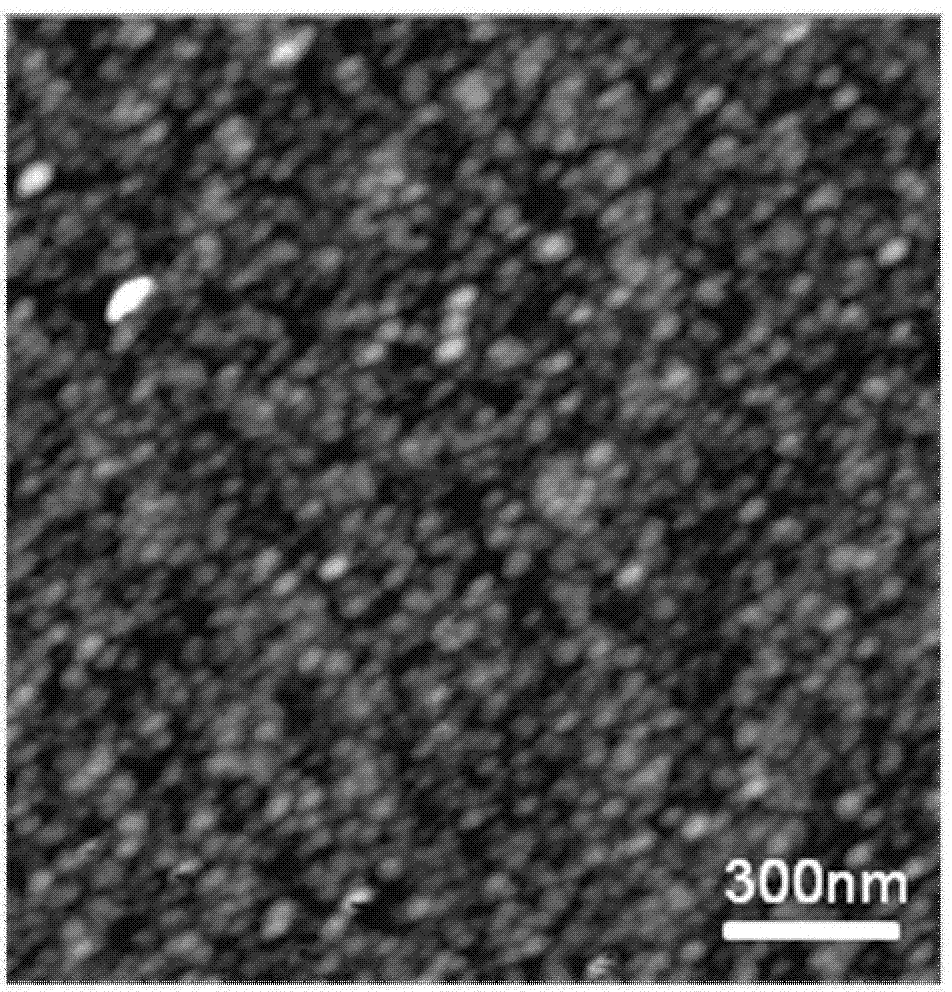

[0058] The sulfur powder and molybdenum trioxide are 30mg and 0.3g respectively, the evaporation temperature is 120°C and 500°C respectively, the deposition temperature of silicon dioxide is 750°C, the air pressure is 1.39torr, and the growth time is 15min.

Embodiment 2

[0060] The sulfur powder and molybdenum trioxide are 50mg and 0.3g respectively, the evaporation temperature is 120°C and 530°C respectively, the deposition temperature of silicon dioxide is 750°C, the air pressure is 1.39torr, and the growth time is 20min.

Embodiment 3

[0062] The sulfur powder and molybdenum trioxide are 50mg and 0.4g respectively, the evaporation temperature is 120°C and 530°C respectively, the deposition temperature of silicon dioxide is 750°C, the air pressure is 1.39torr, and the growth time is 40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com