Patents

Literature

255 results about "Metal chalcogenides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metal chalcogenide is a compound made from a metallic element and a member of the chalcogenide family, namely the elements under oxygen–sulfur, selenium, and tellurium.

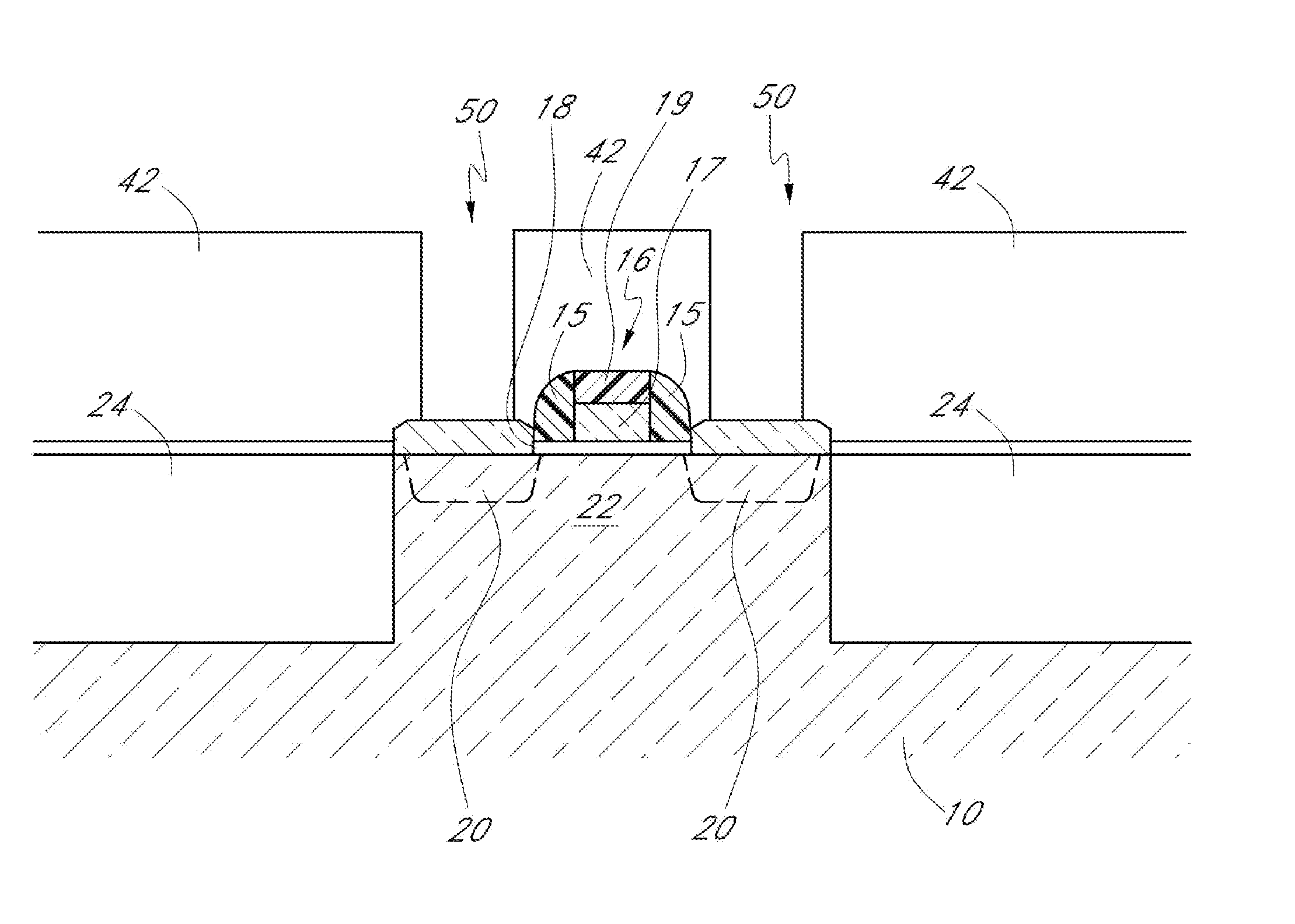

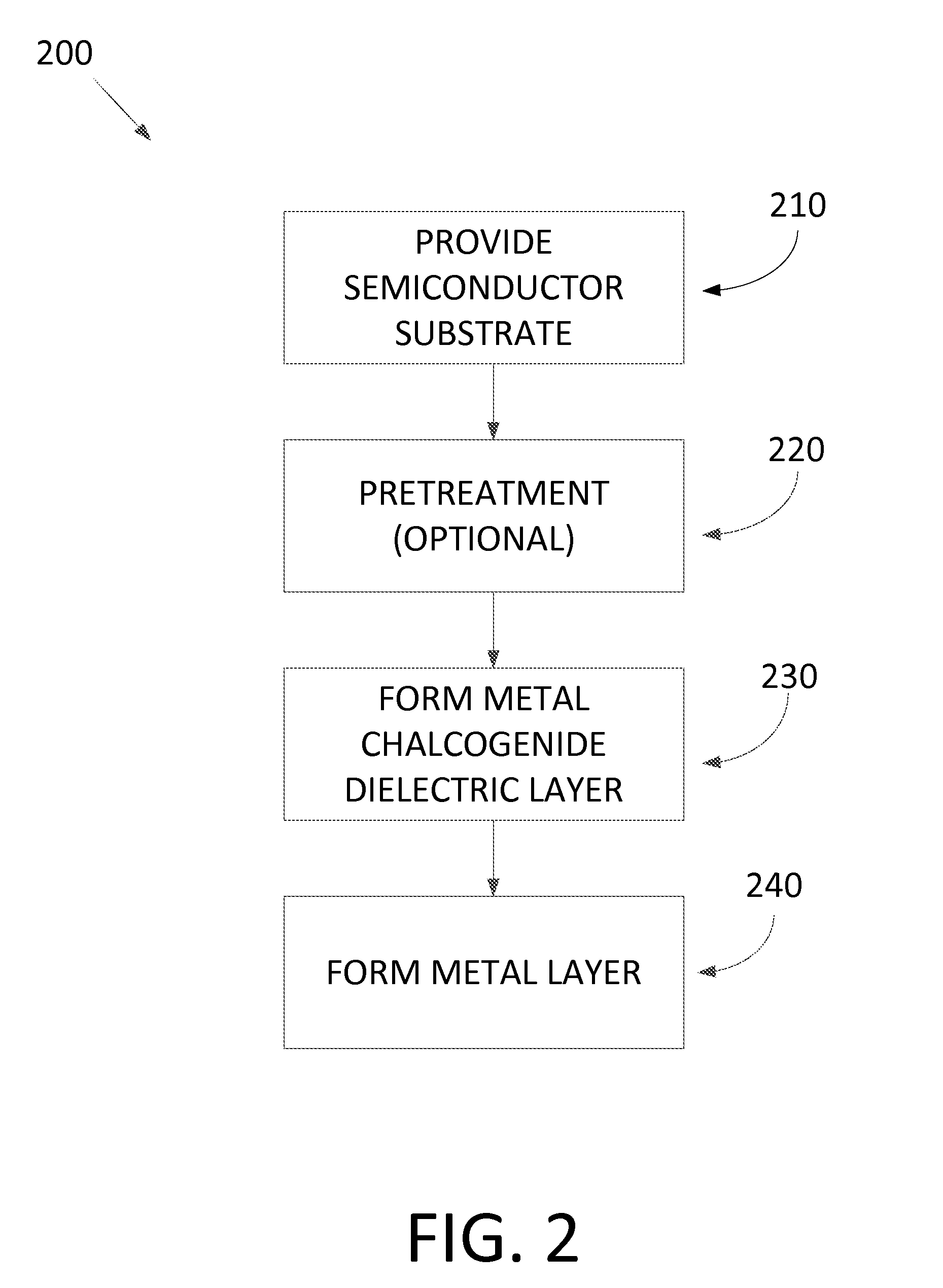

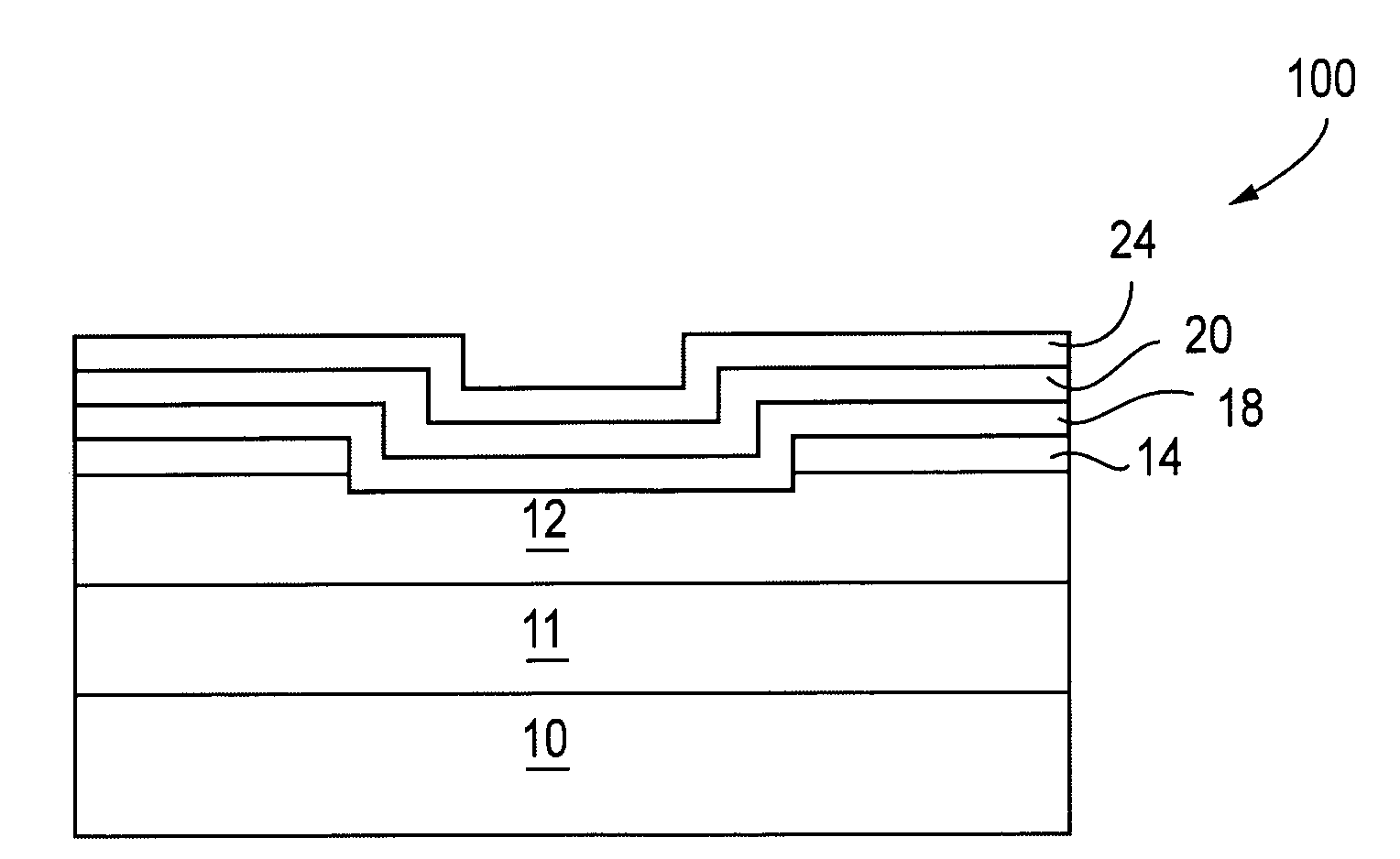

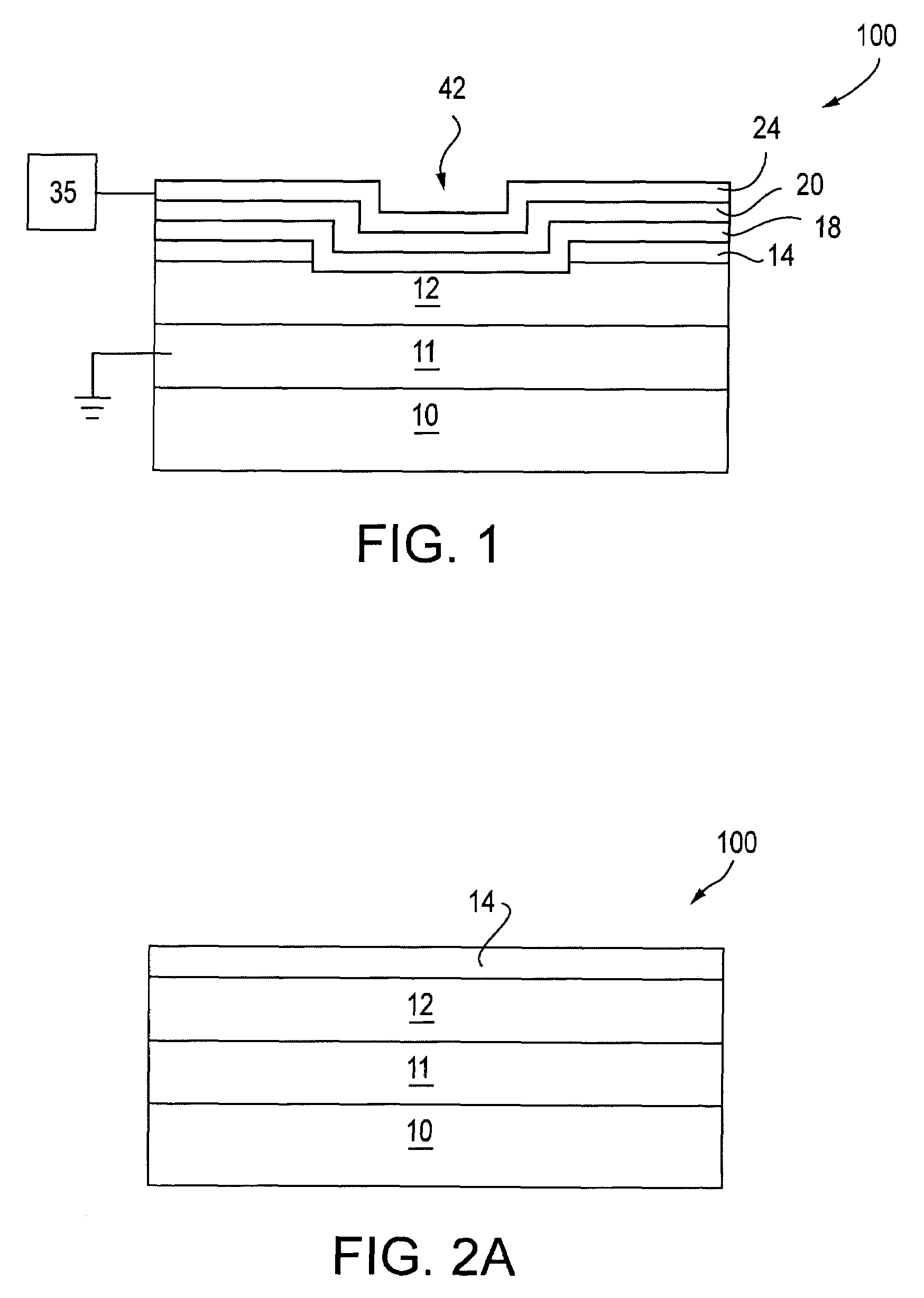

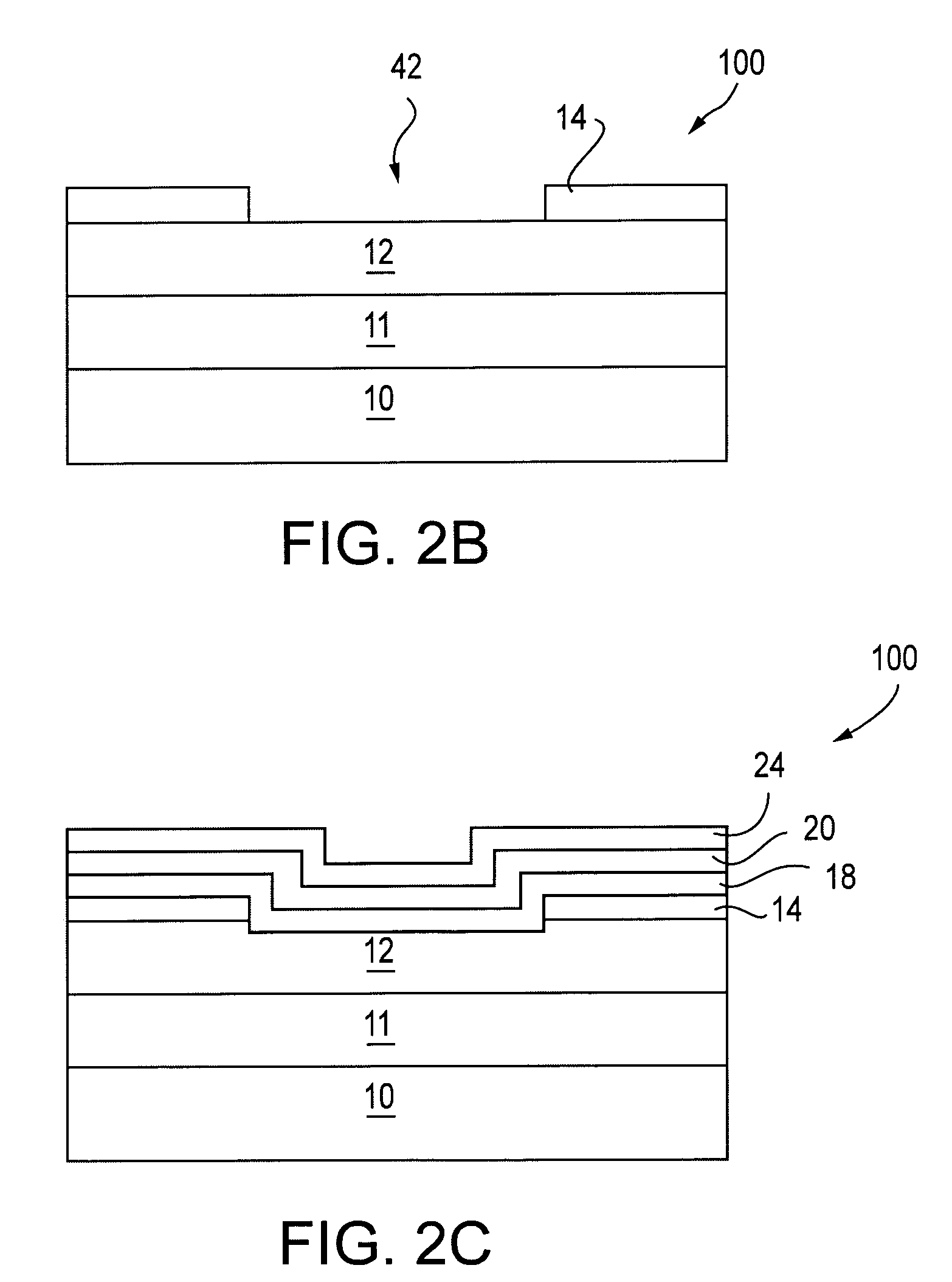

Method for forming metal chalcogenide thin films on a semiconductor device

ActiveUS20160372365A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingGas phaseMetal chalcogenides

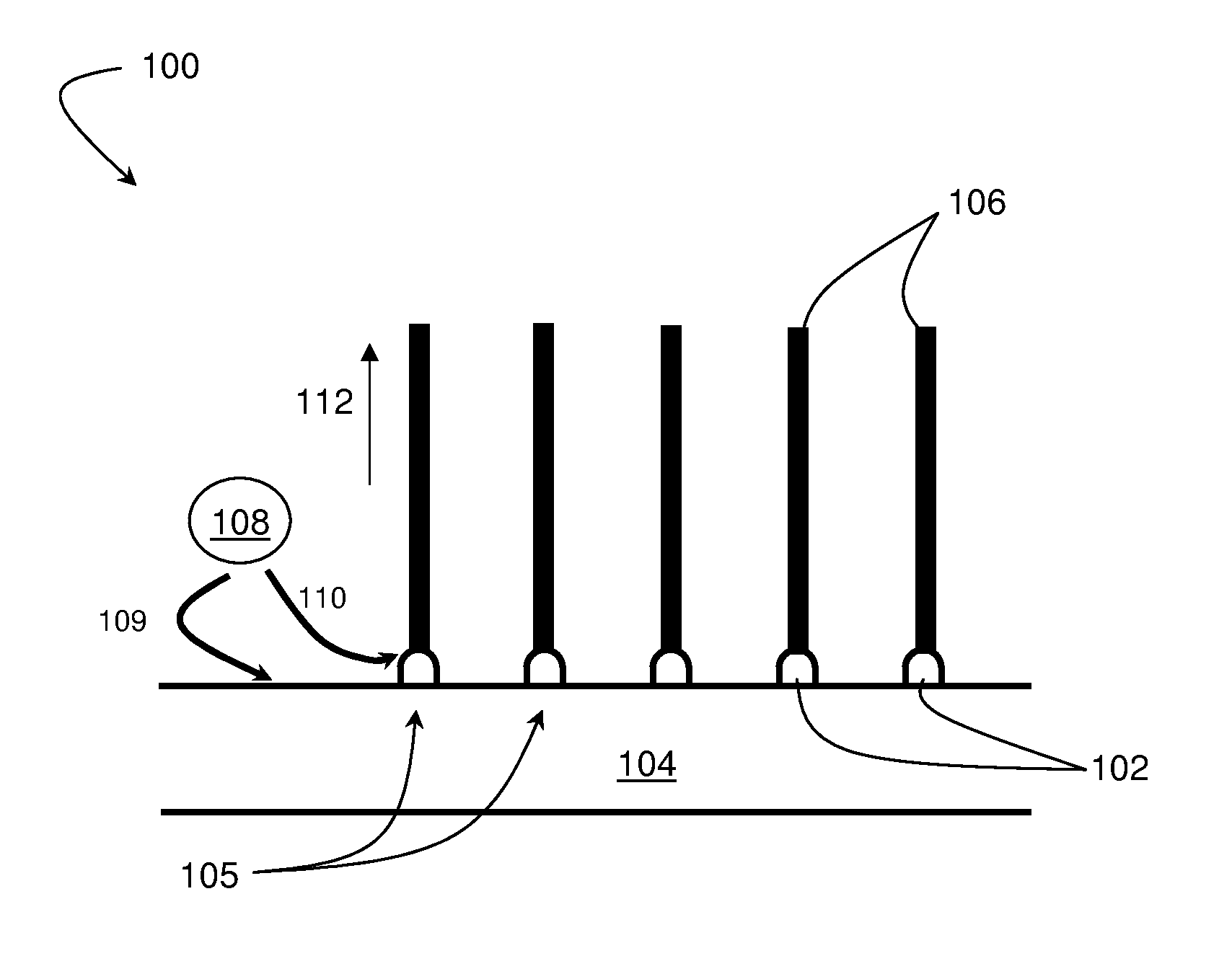

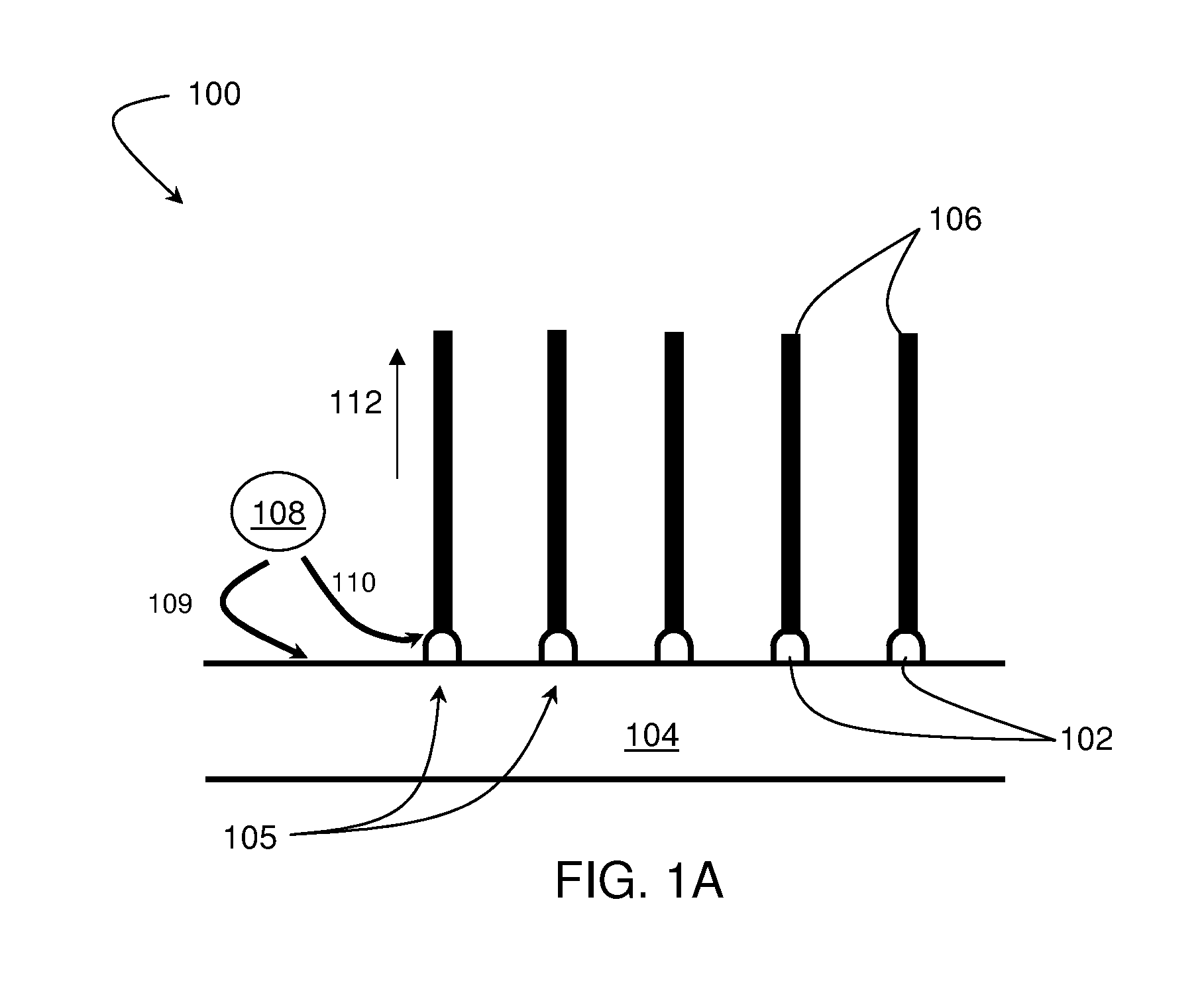

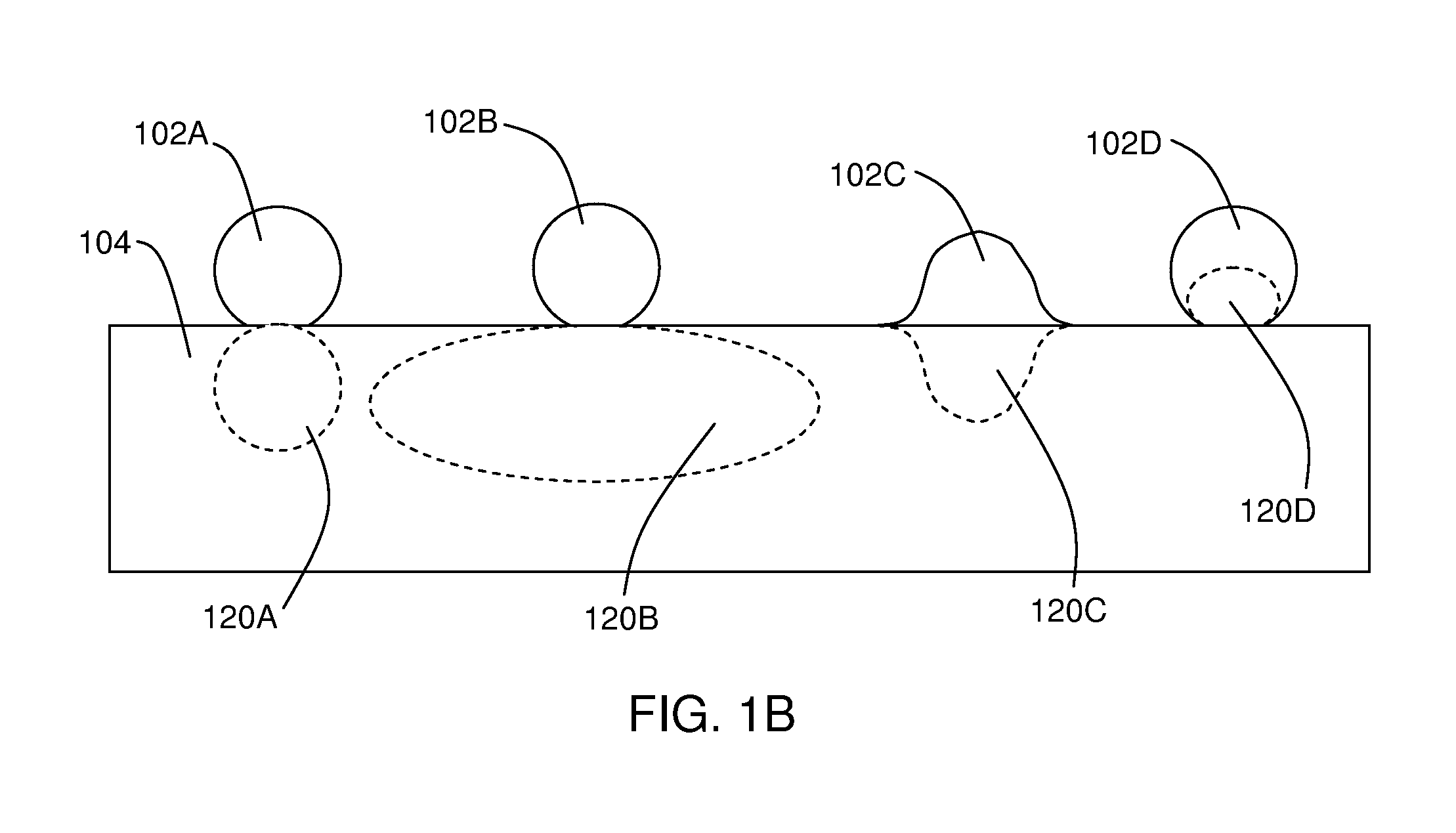

In some aspects, methods of forming a metal chalcogenide thin film are provided. According to some methods, a metal chalcogenide thin film is deposited on a substrate in a reaction space in a cyclical deposition process where at least one cycle includes alternately and sequentially contacting the substrate with a first vapor-phase metal reactant and a second vapor-phase chalcogen reactant. In some aspects, methods of forming three-dimensional structure on a substrate surface are provided. In some embodiments, the method includes forming a metal chalcogenide dielectric layer between a substrate and a conductive layer. In some embodiments the method includes forming an MIS-type contact structure including a metal chalcogenide dielectric layer.

Owner:ASM IP HLDG BV

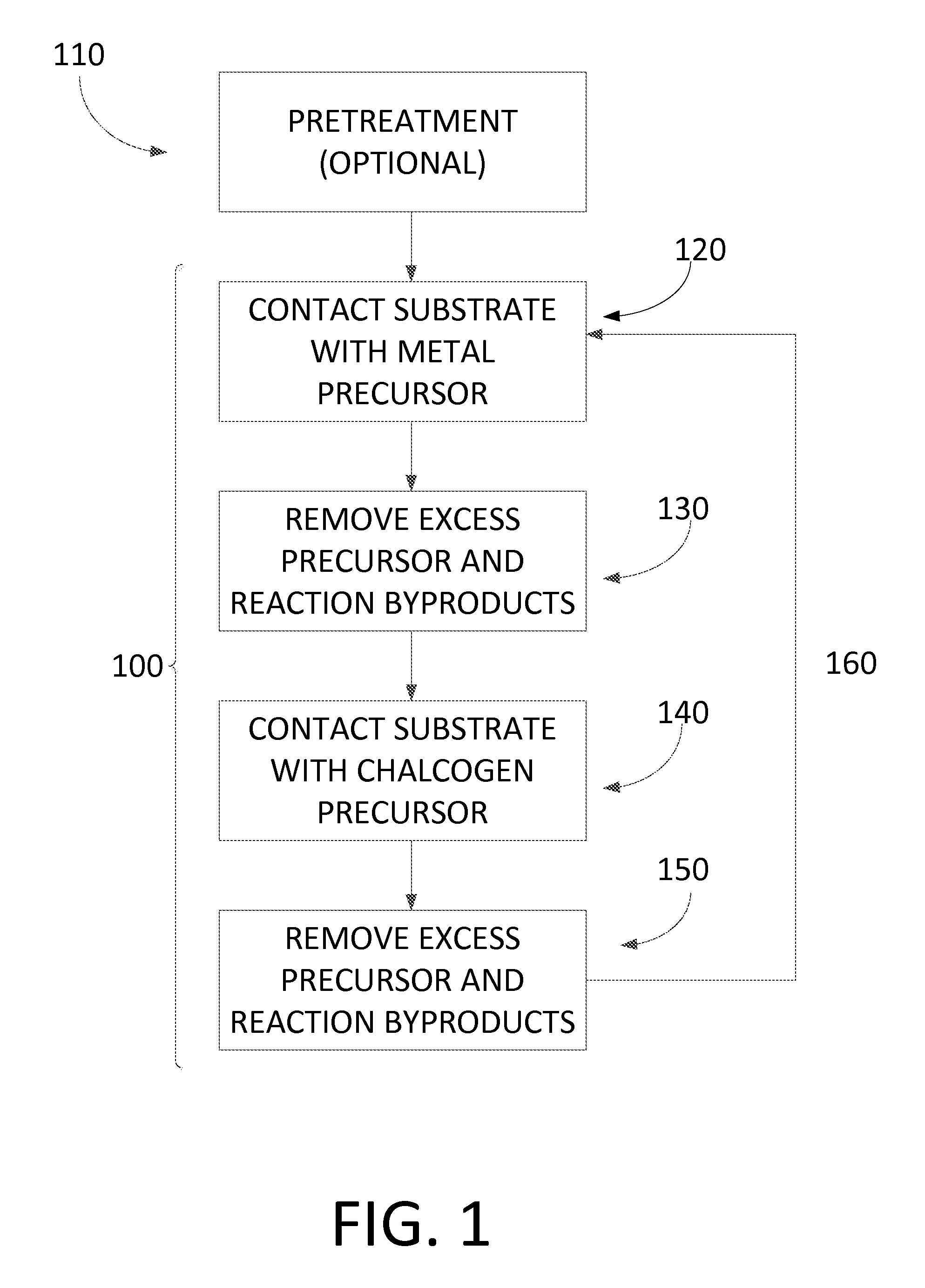

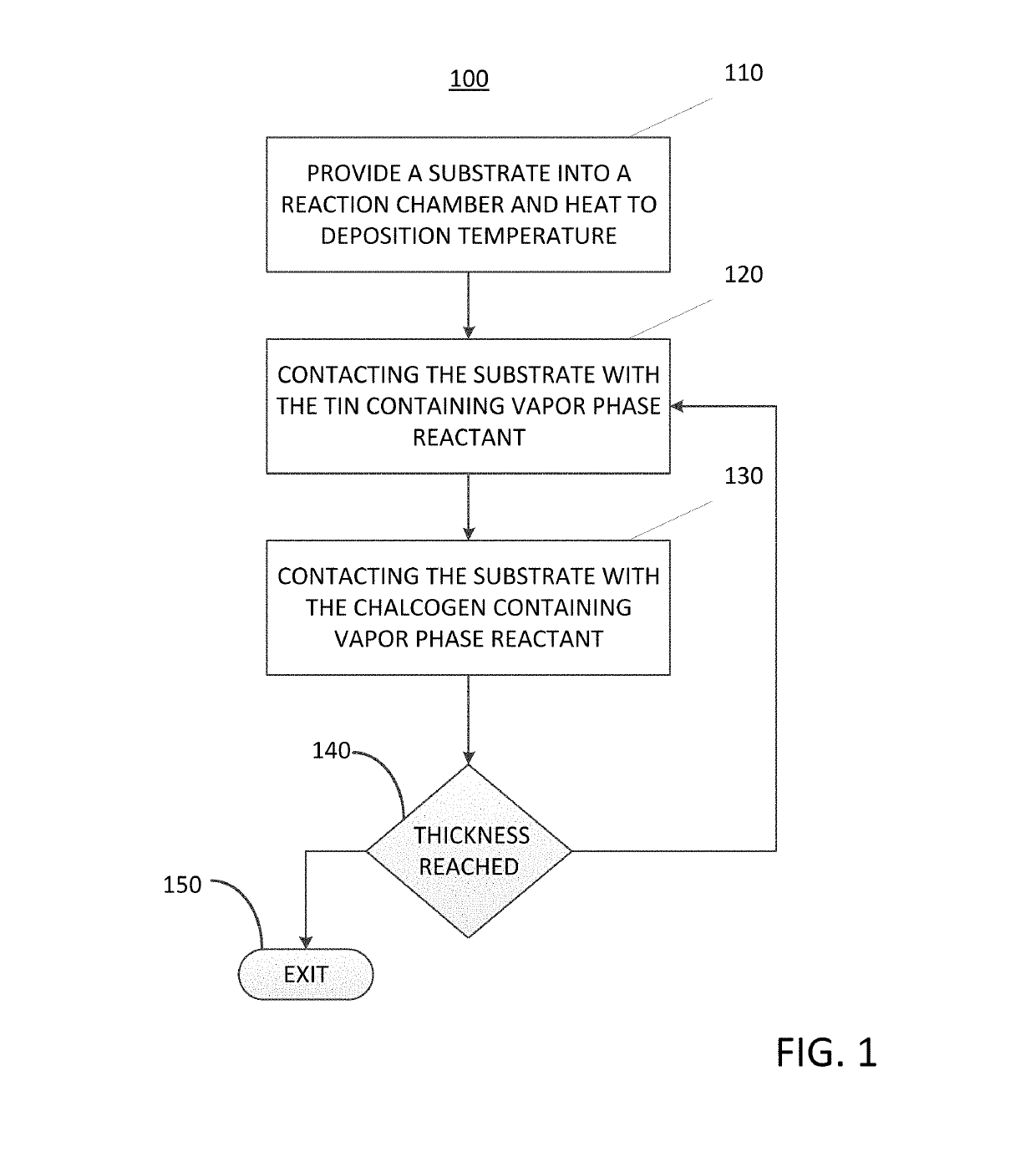

Method for depositing a metal chalcogenide on a substrate by cyclical deposition

ActiveUS10319588B2TransistorSemiconductor/solid-state device manufacturingMetal chalcogenidesChalcogen

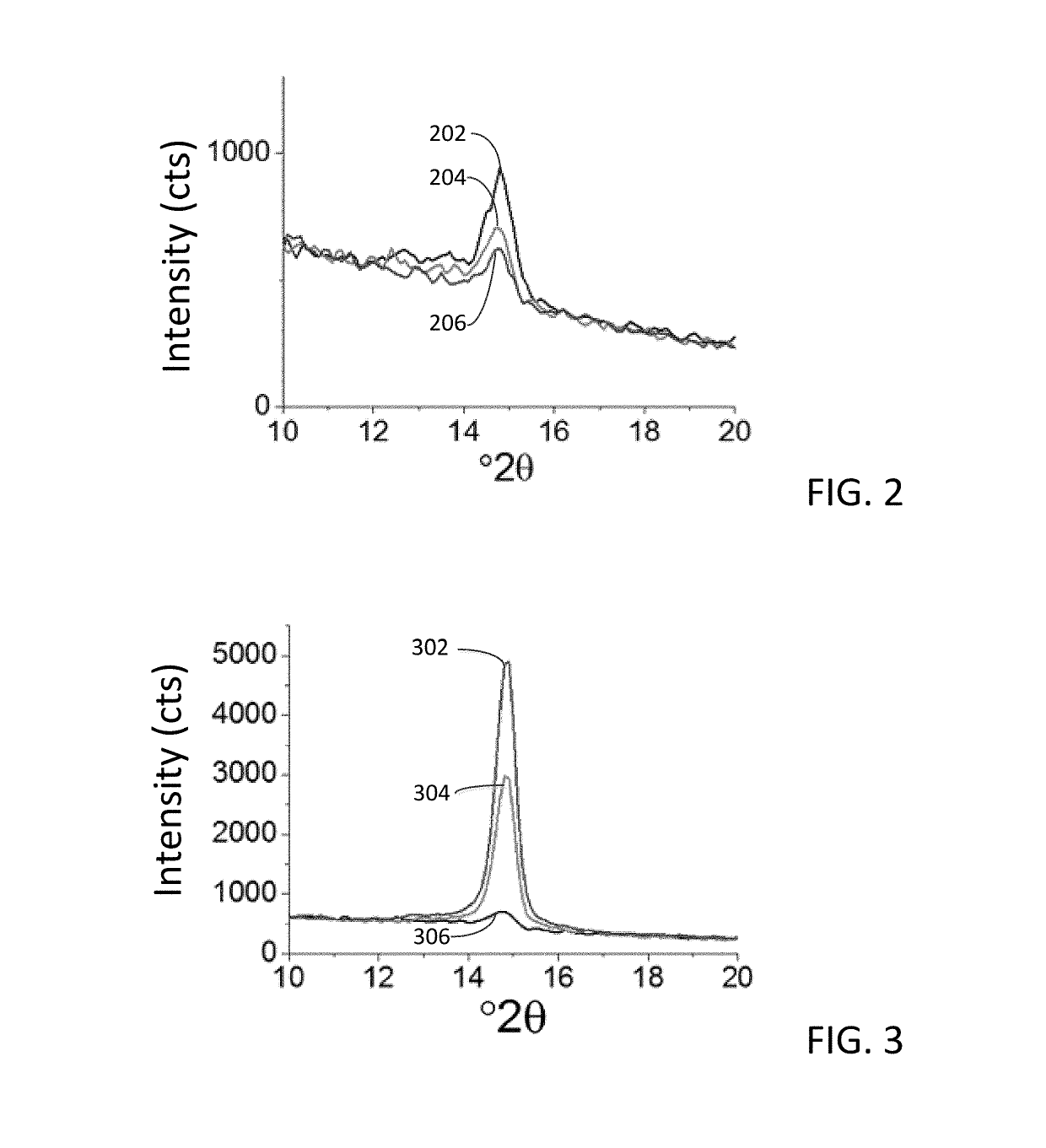

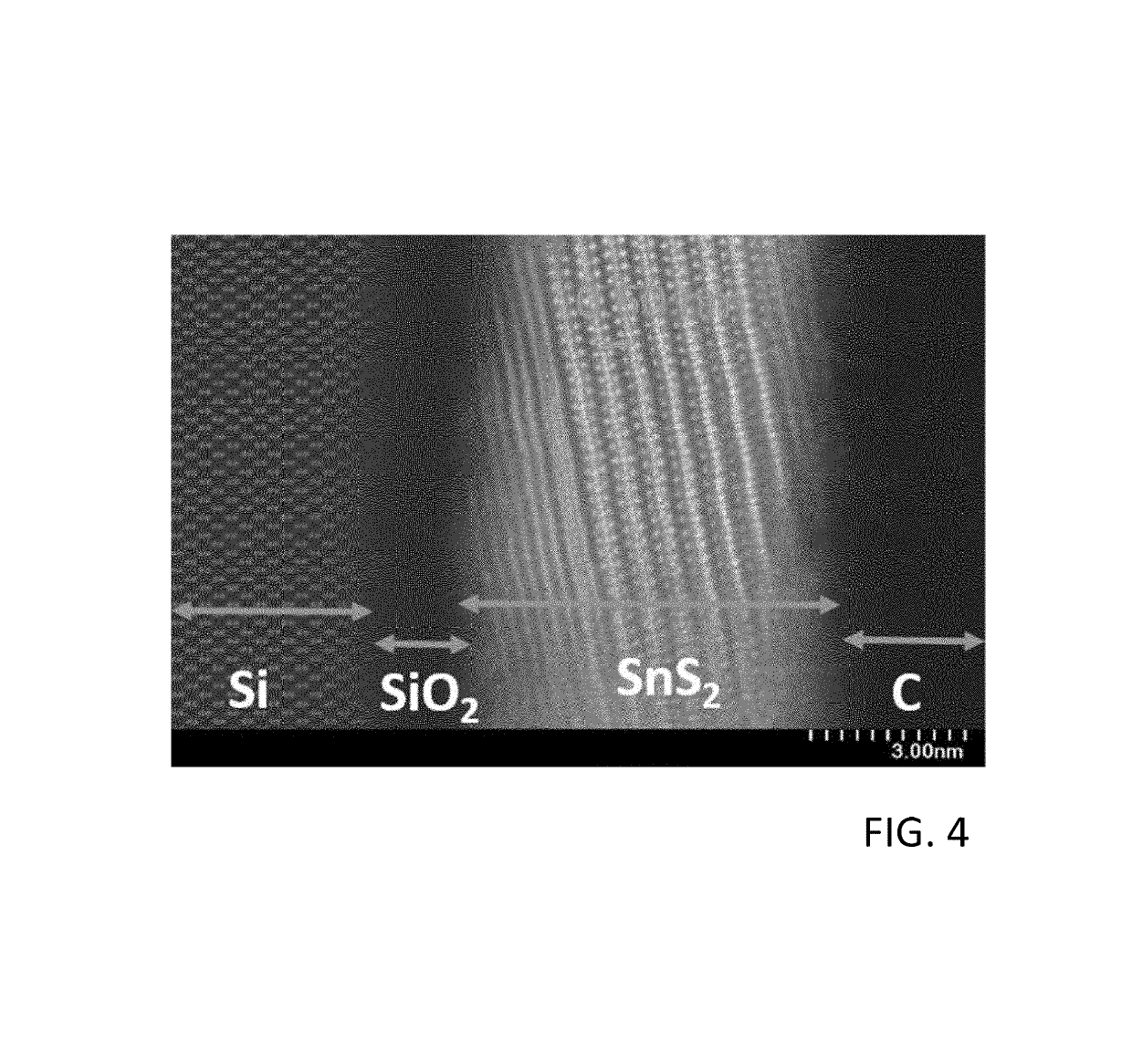

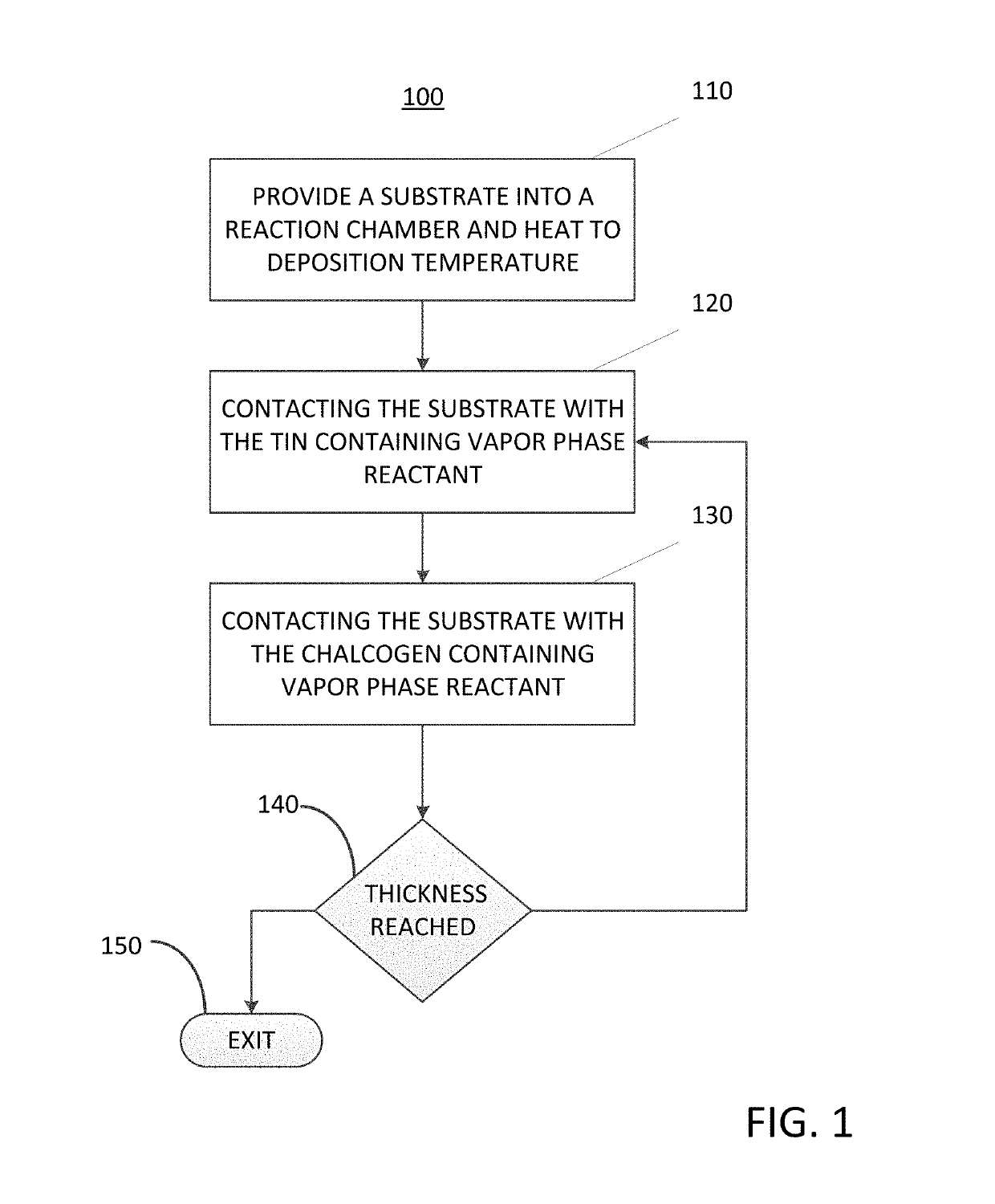

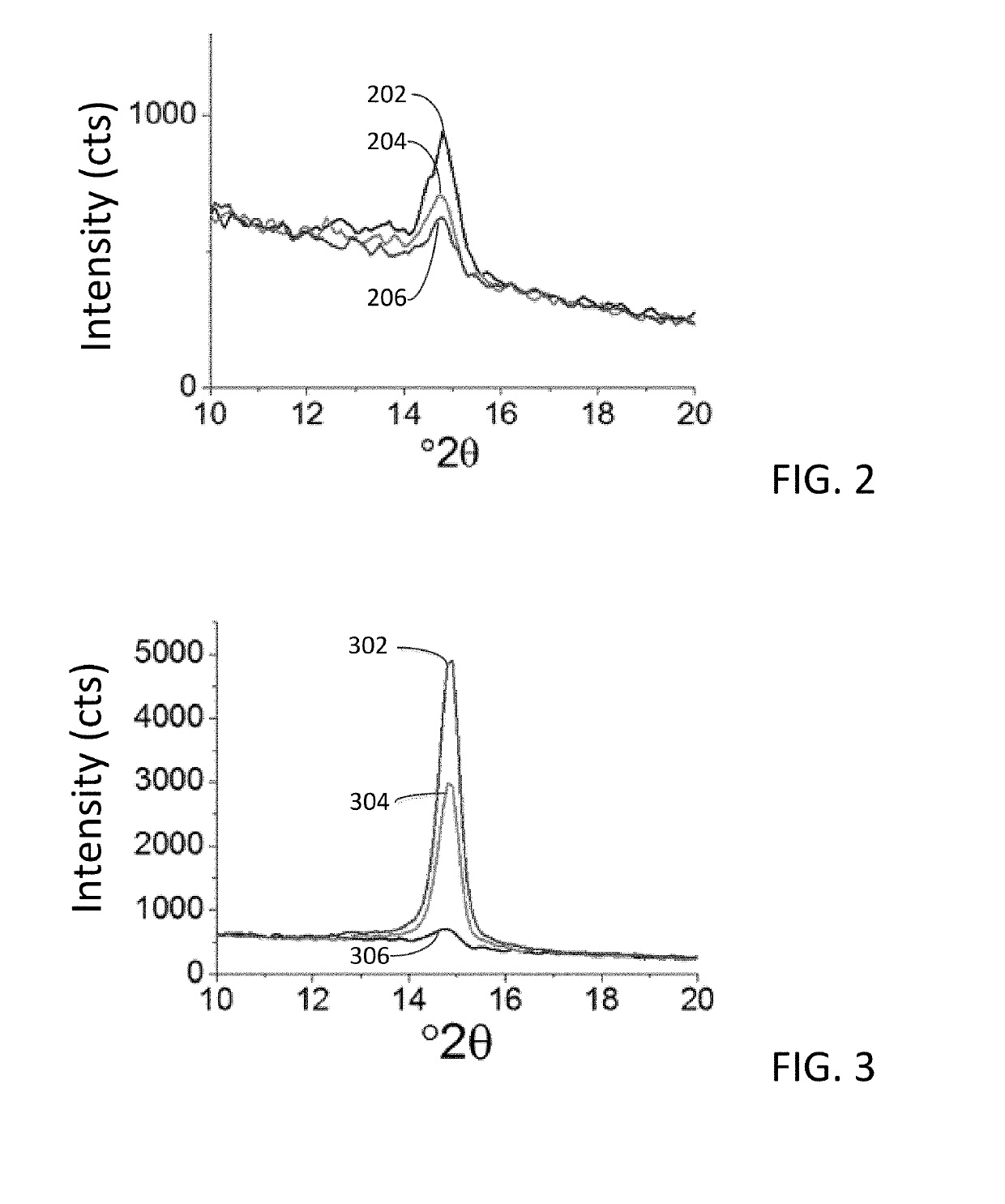

A method for depositing a metal chalcogenide on a substrate by cyclical deposition is disclosed. The method may include, contacting the substrate with at least one metal containing vapor phase reactant and contacting the substrate with at least one chalcogen containing vapor phase reactant. Semiconductor device structures including a metal chalcogenide deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

Method for depositing a metal chalcogenide on a substrate by cyclical deposition

ActiveUS20190109002A1TransistorSemiconductor/solid-state device manufacturingMetal chalcogenidesChalcogen

A method for depositing a metal chalcogenide on a substrate by cyclical deposition is disclosed. The method may include, contacting the substrate with at least one metal containing vapor phase reactant and contacting the substrate with at least one chalcogen containing vapor phase reactant. Semiconductor device structures including a metal chalcogenide deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

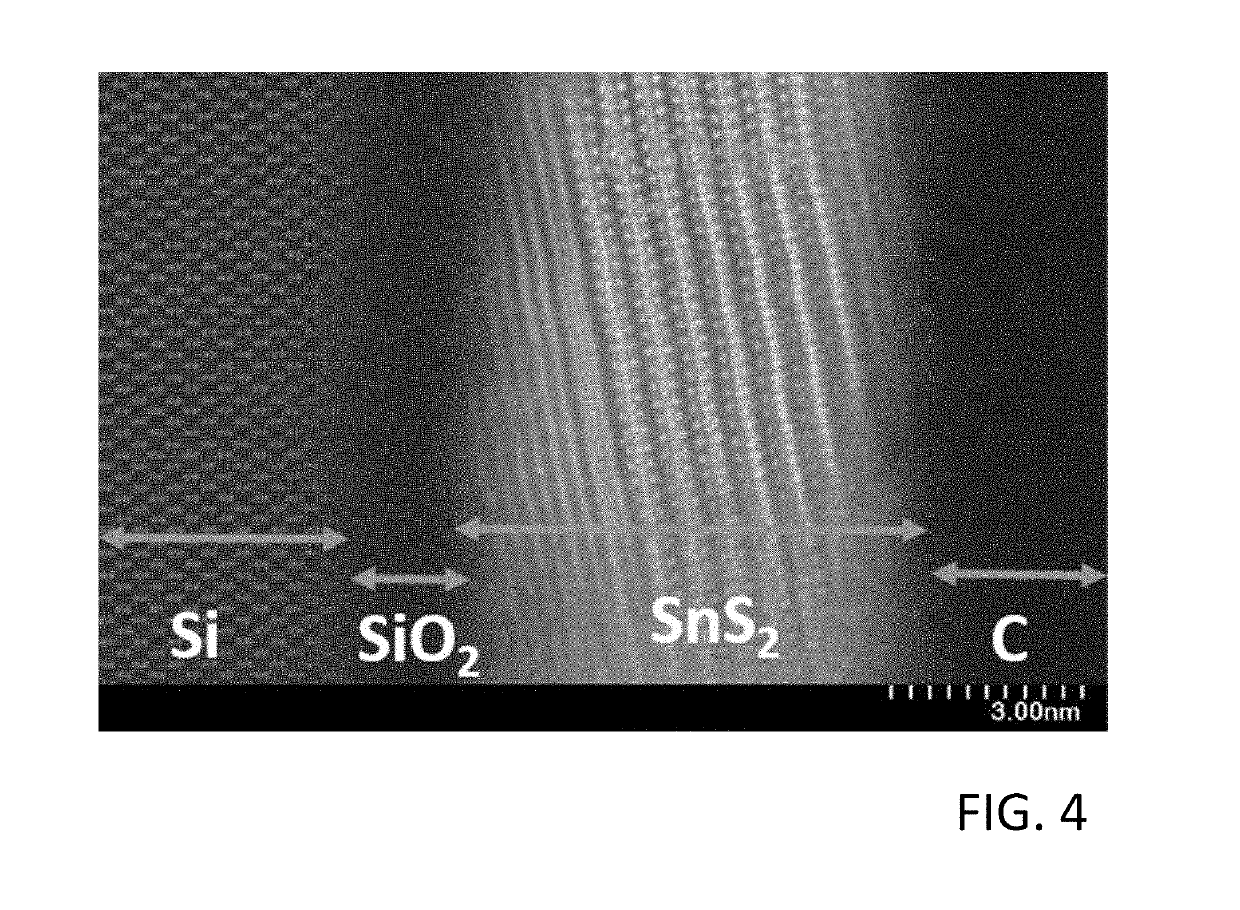

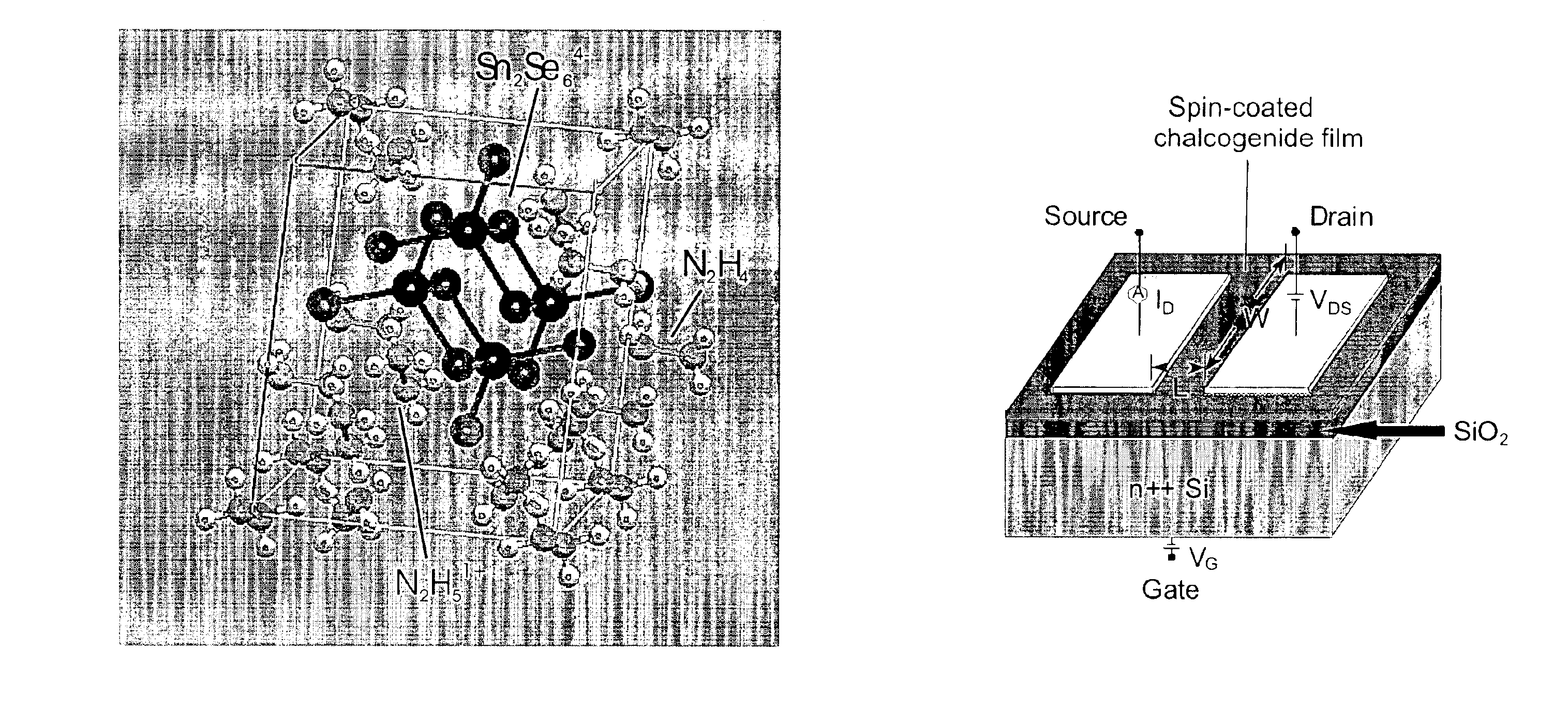

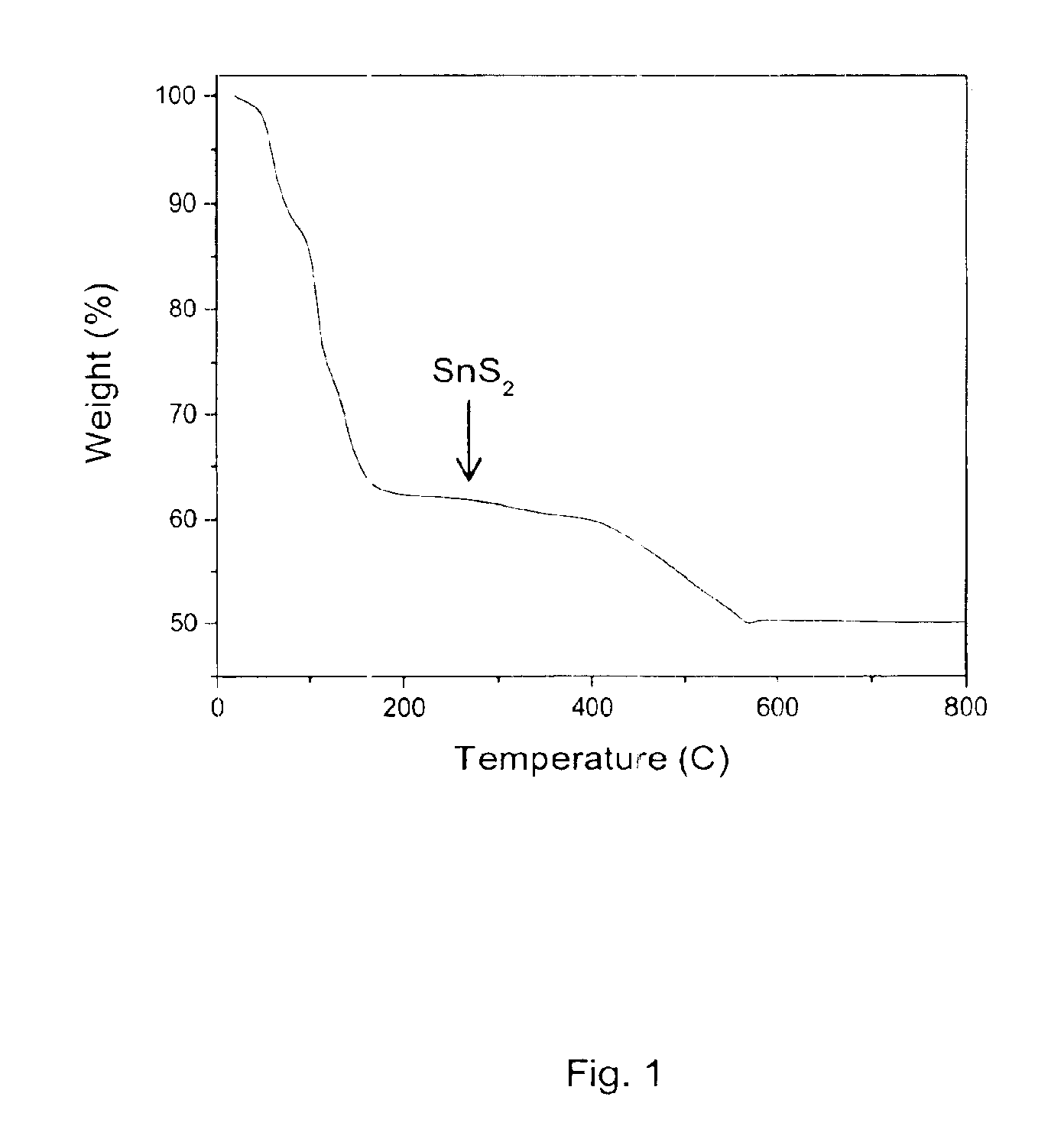

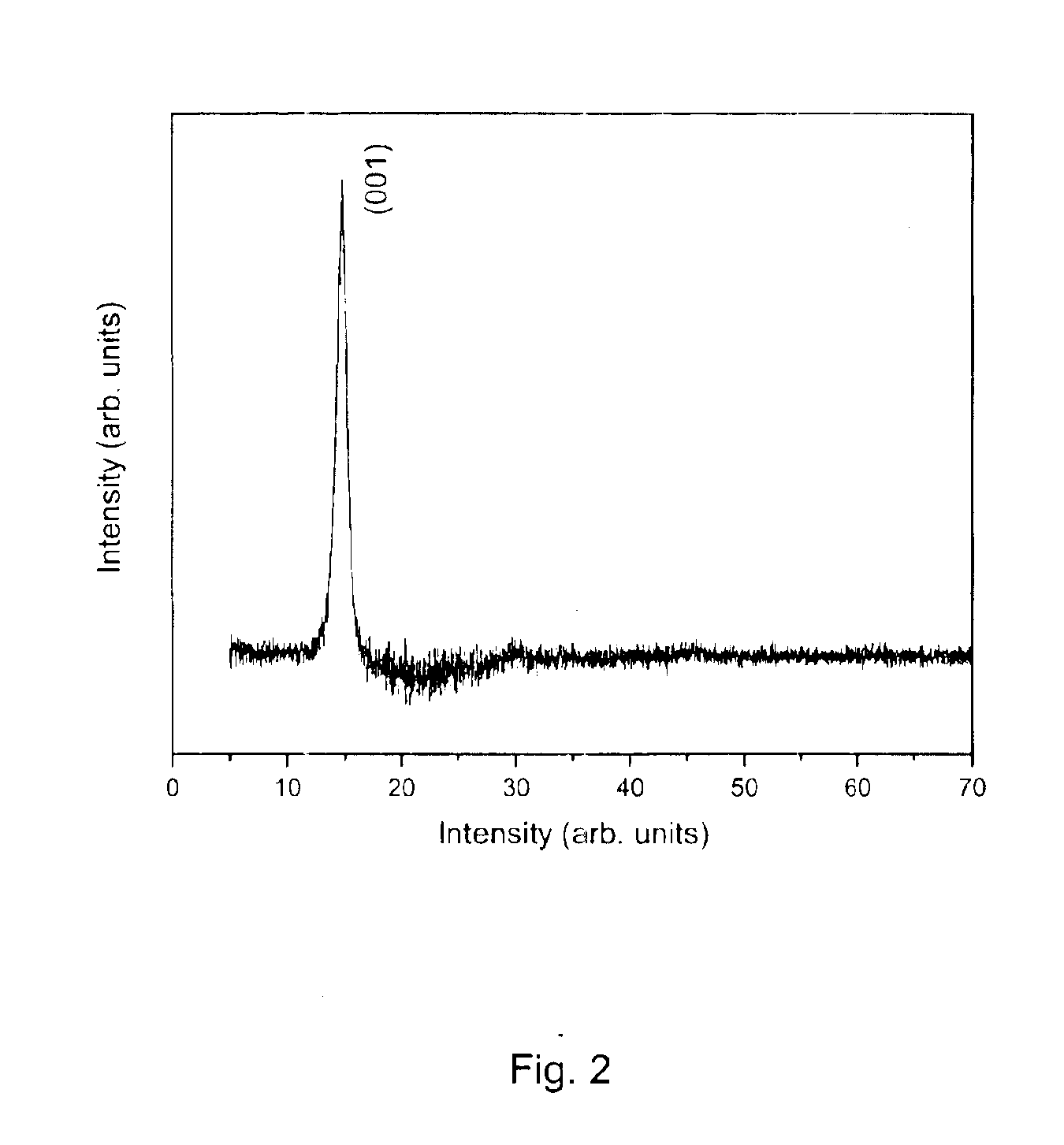

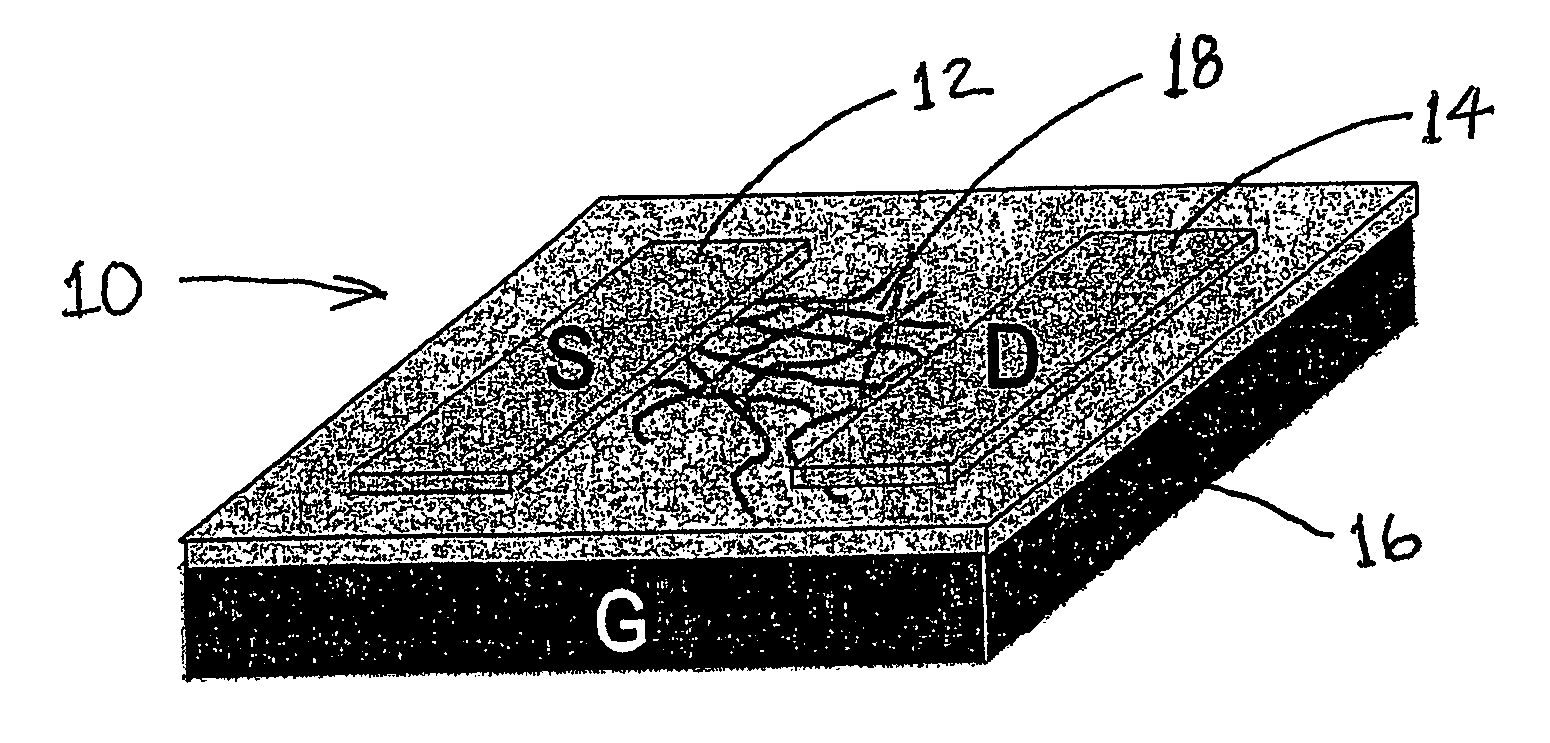

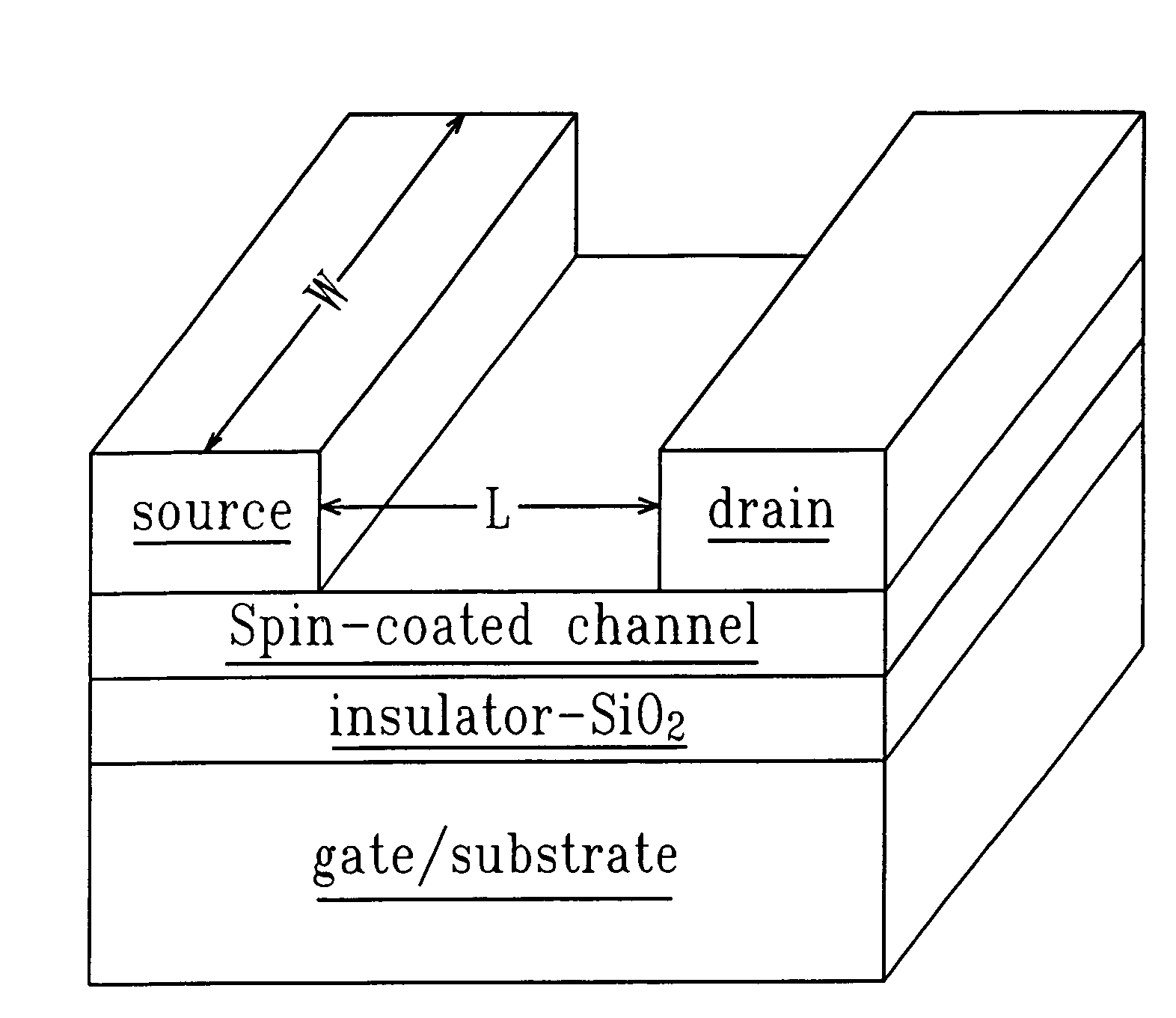

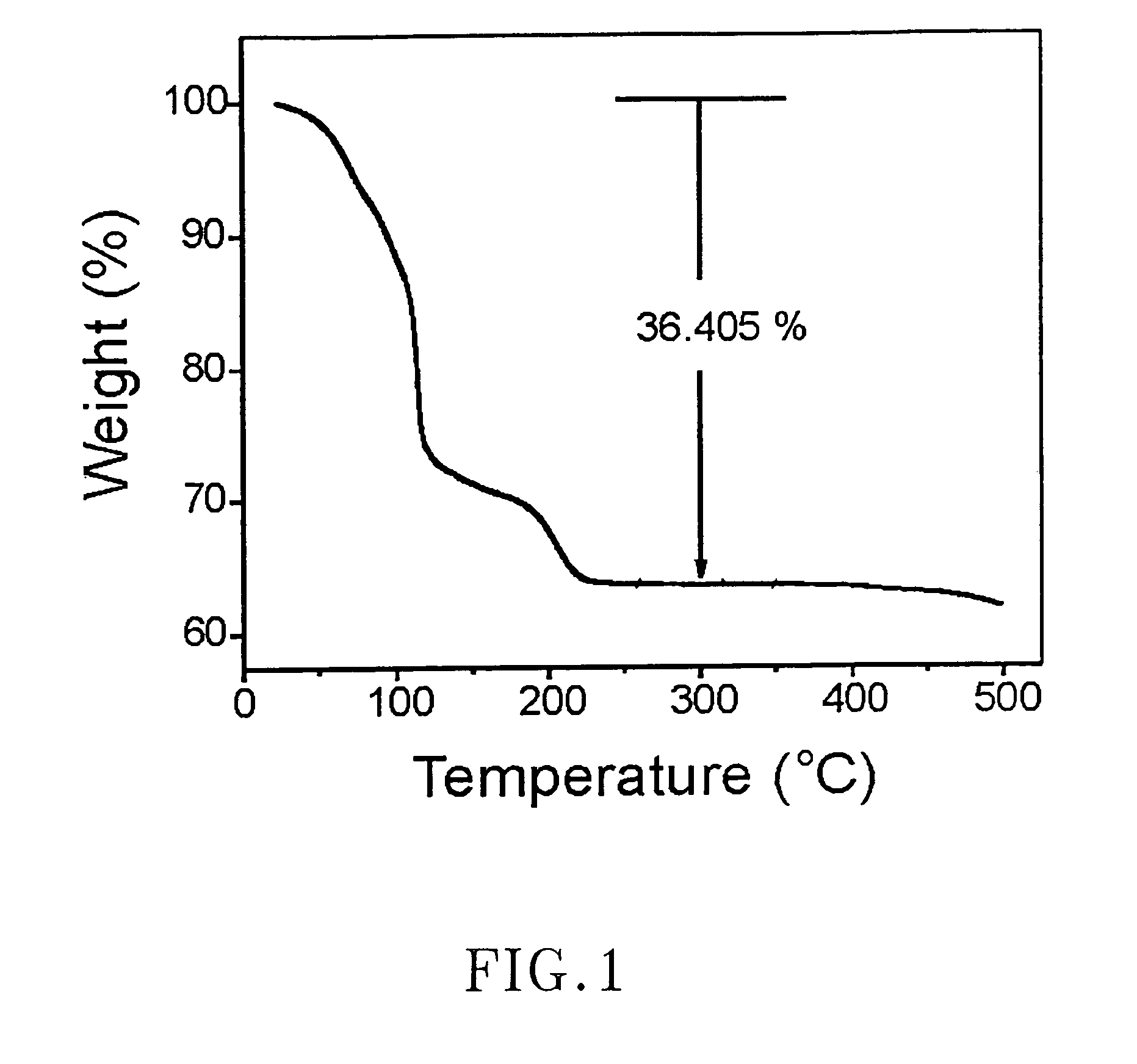

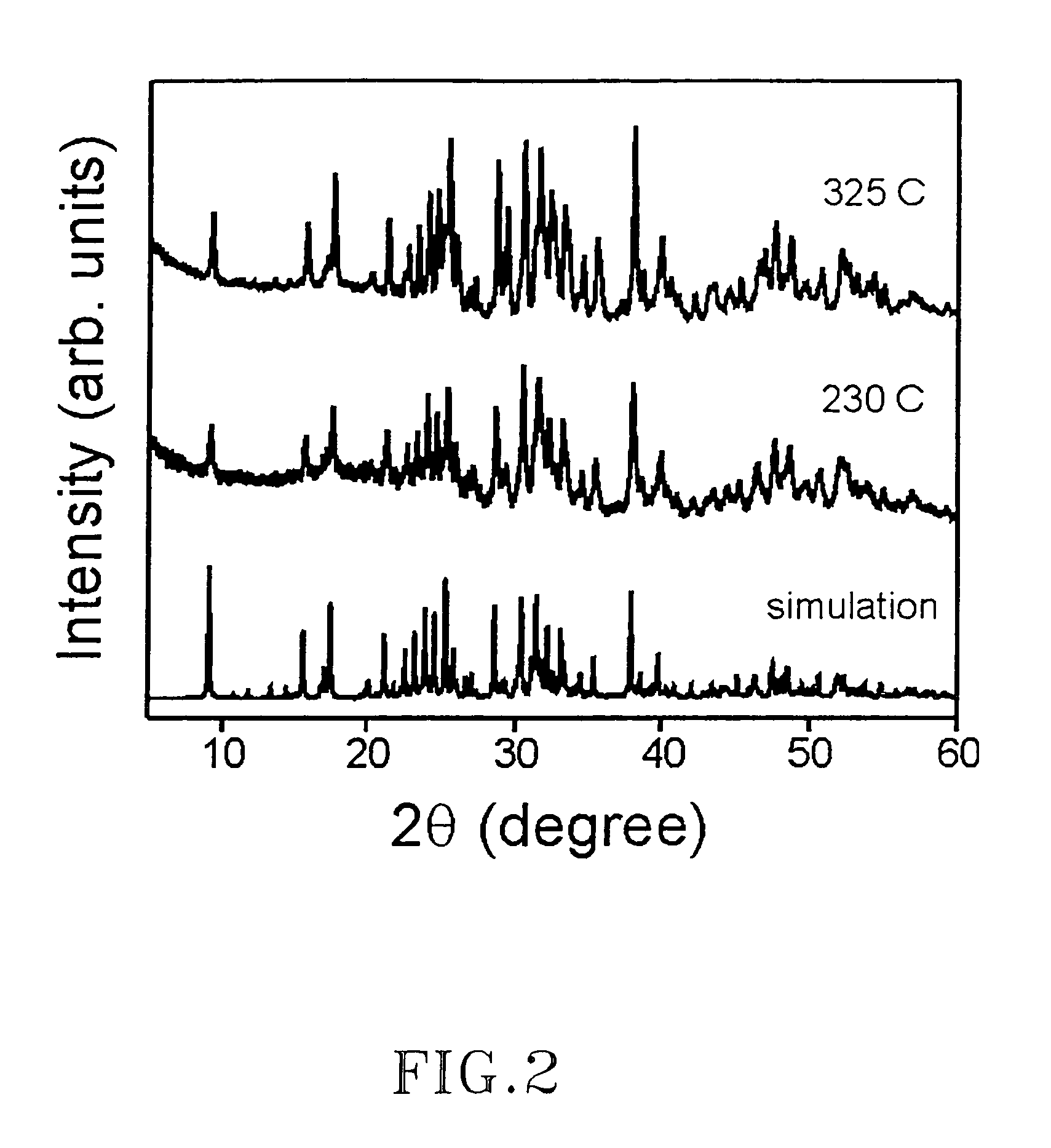

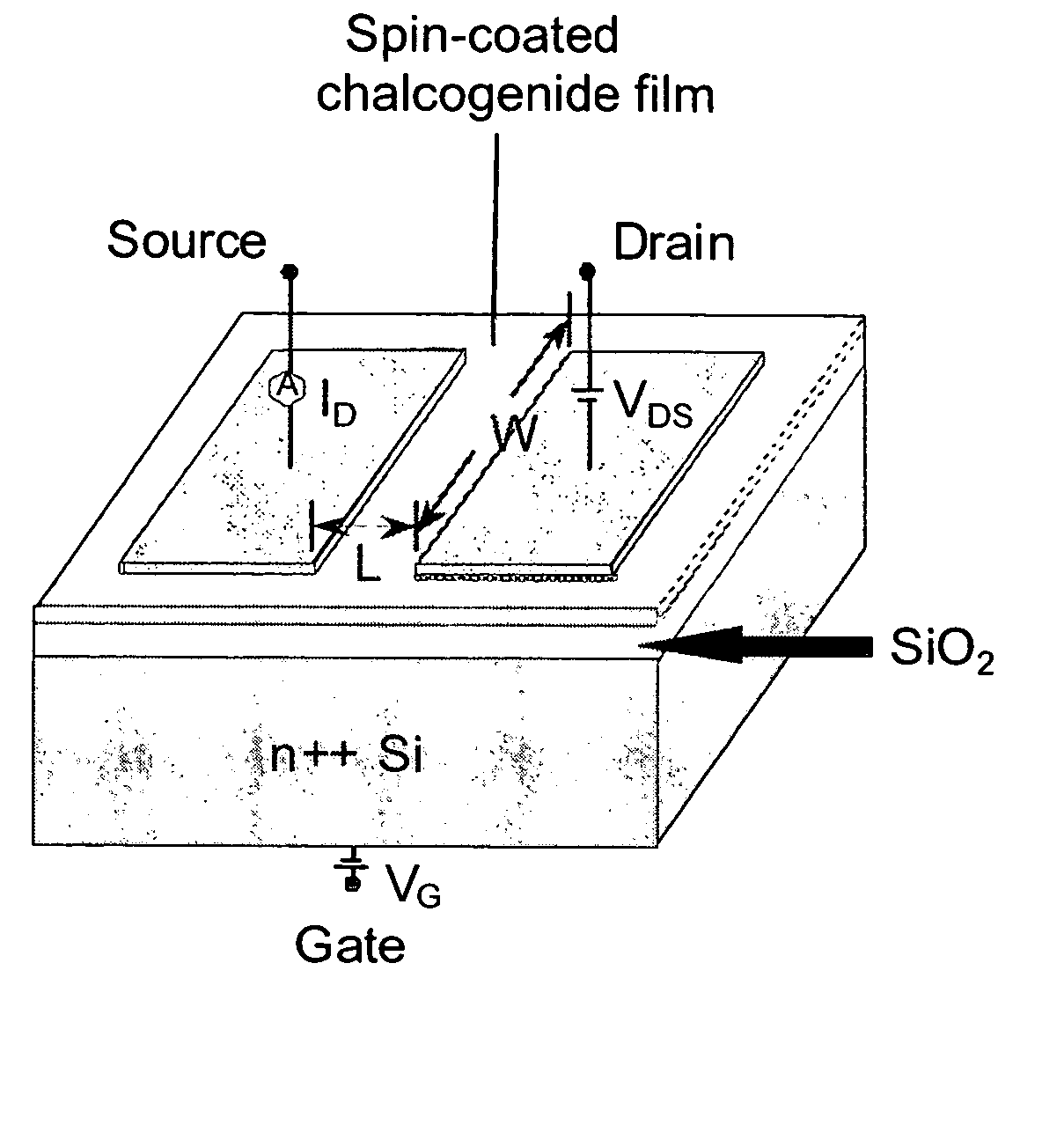

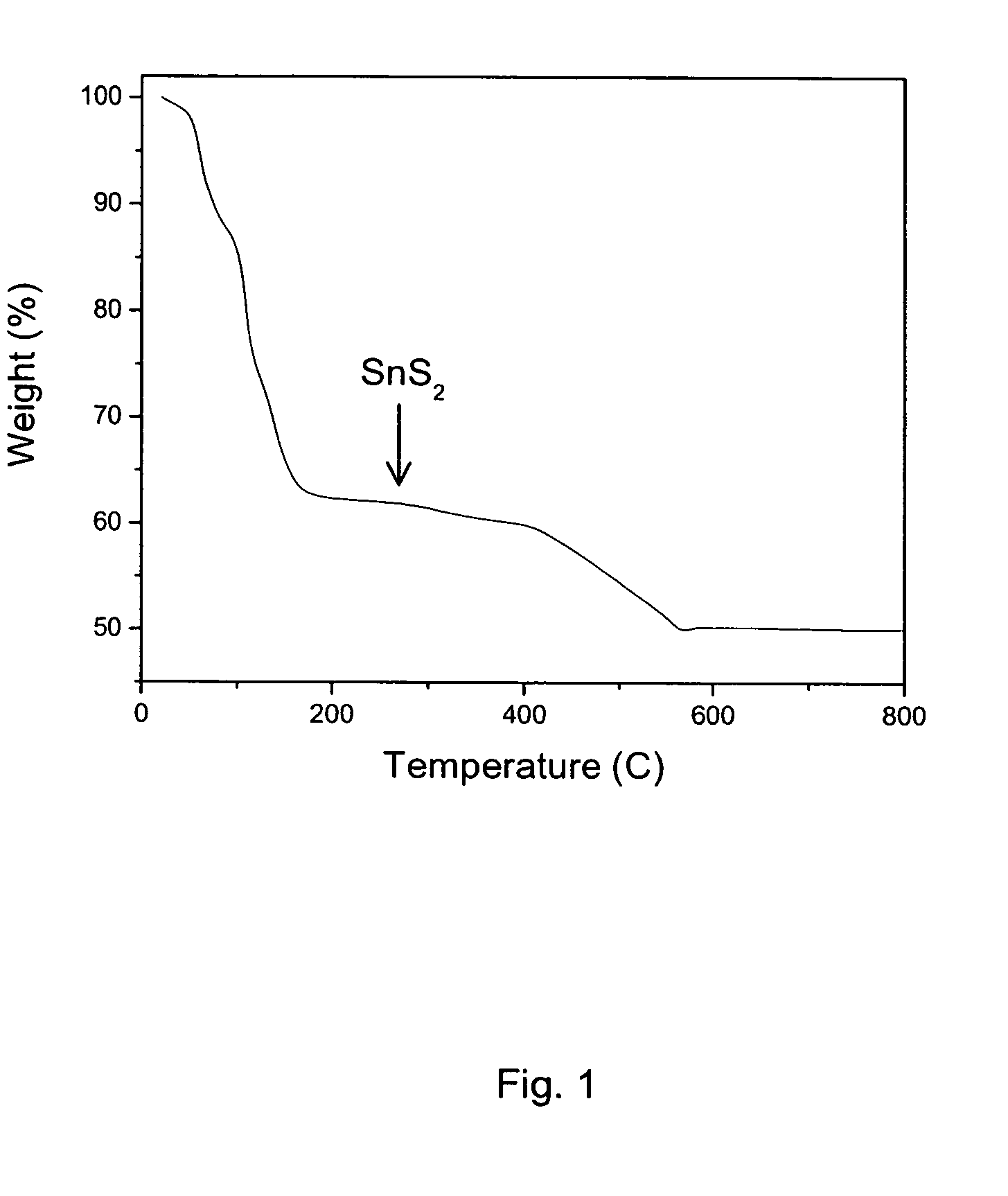

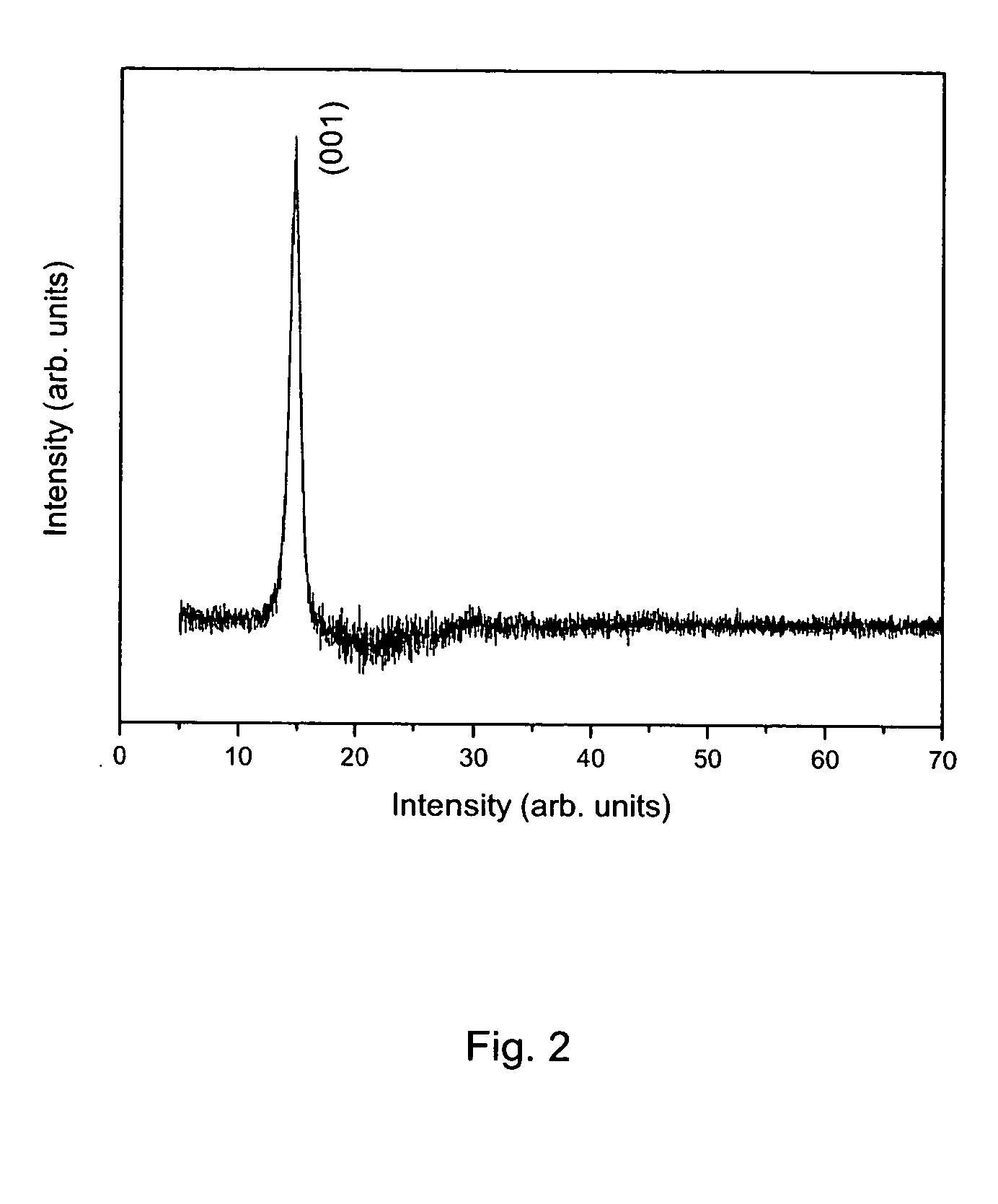

Solution deposition of chalcogenide films

A method of depositing a film of a metal chalcogenide. The first of these methods includes the steps of: contacting at least one metal chalcogenide, a hydrazine compound and optionally, an elemental chalcogen, to produce a solution of a hydrazinium-based precursor of the metal chalcogenide; applying the solution of the hydrazinium-based precursor of the metal chalcogenide onto a substrate to produce a film of the precursor; and thereafter annealing the film of the precursor to remove excess hydrazine and hydrazinium chalcogenide salts to produce a metal chalcogenide film on the substrate. The second of these methods includes the steps of: contacting: at least one metal chalcogenide and a salt of an amine compound to produce an ammonium-based precursor of the metal chalcogenide; contacting the ammonium-based precursor of the metal chalcogenide and a hydrazine compound, and optionally, an elemental chalcogen, to produce a solution of a hydrazinium-based precursor of the metal chalcogenide in the hydrazine compound; applying the solution of the hydrazinium-based precursor onto a substrate to produce a film; and thereafter, annealing to produce a metal chalcogenide film. Also provided is a thin-film field-effect transistor device using the metal chalcogenides as the channel layer.

Owner:GLOBALFOUNDRIES INC

Method for fabricating an inorganic nanocomposite

InactiveUS7517718B2Low costMaterial nanotechnologySemiconductor/solid-state device manufacturingSulfurMetal chalcogenides

An inorganic nanocomposite is prepared by obtaining a solution of a soluble hydrazine-based metal chalcogenide precursor; dispersing a nanoentity in the precursor solution; applying a solution of the precursor containing the nanoentity onto a substrate to produce a film of the precursor containing the nanoentity; and annealing the film of the precursor containing the nanoentity to produce the metal chalcogenide nanocomposite film comprising at least one metal chalcogenide and at least one molecularly-intermixed nanoentity on the substrate. The process can be used to prepare field-effect transistors and photovoltaic devices.

Owner:GLOBALFOUNDRIES INC

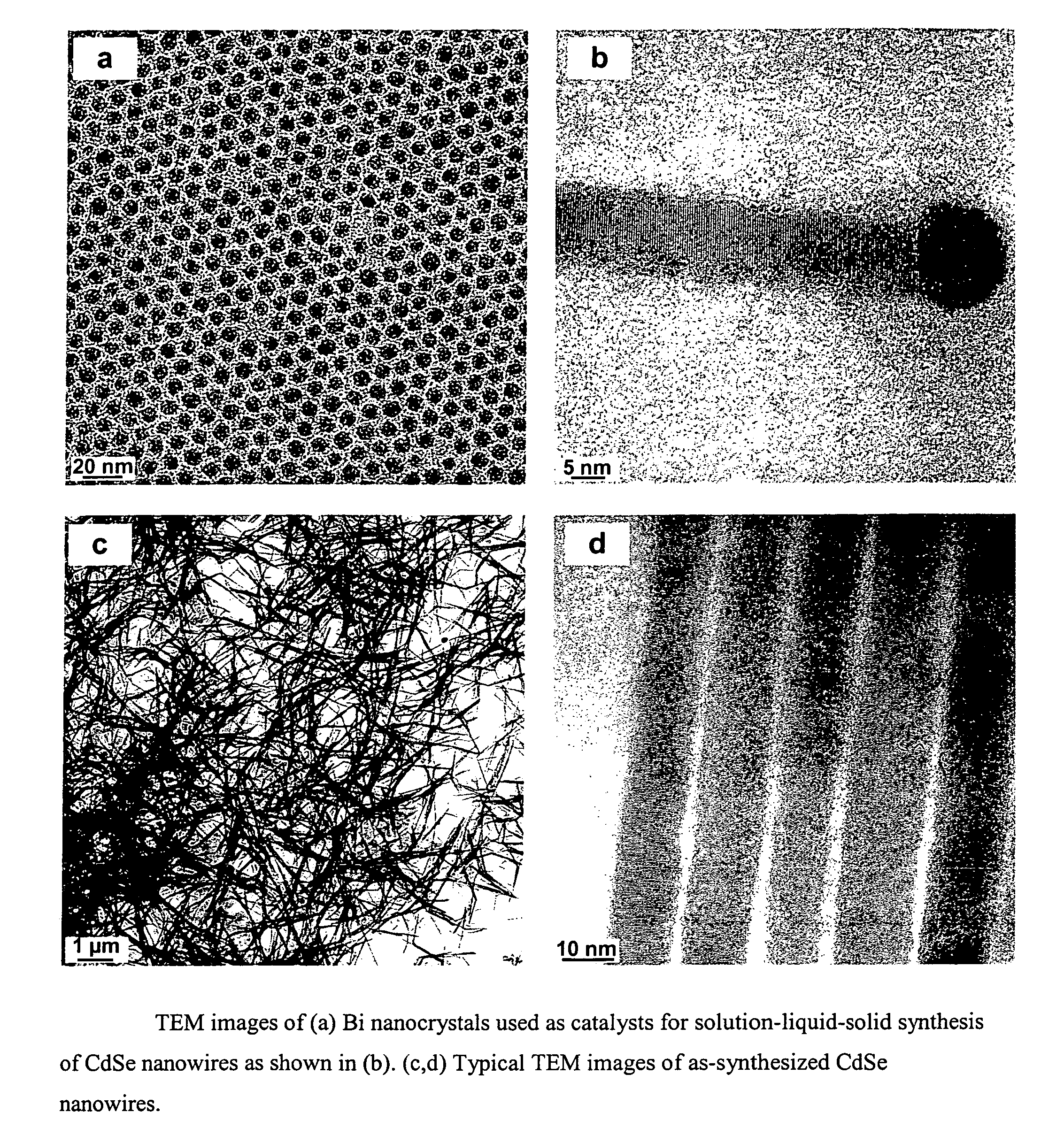

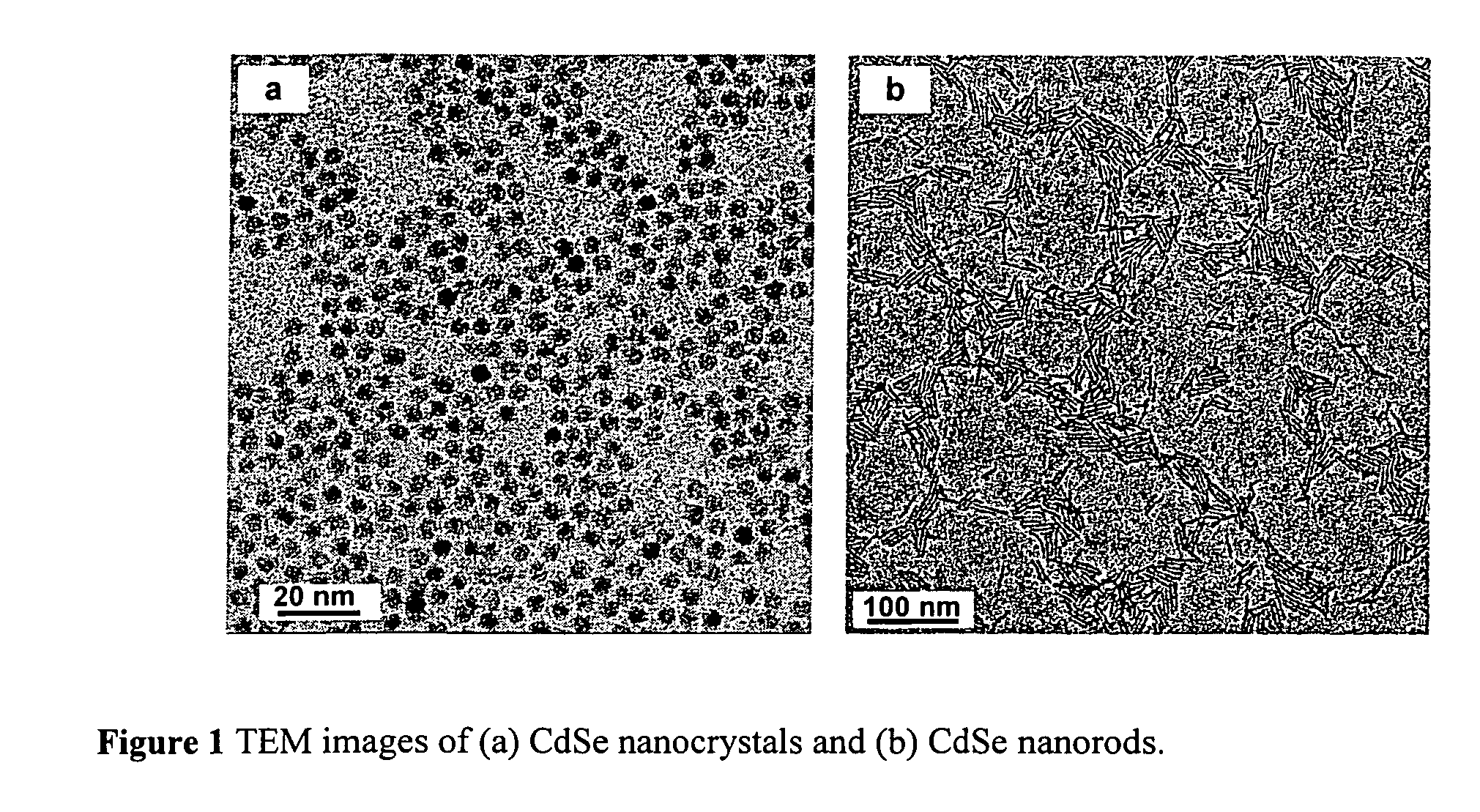

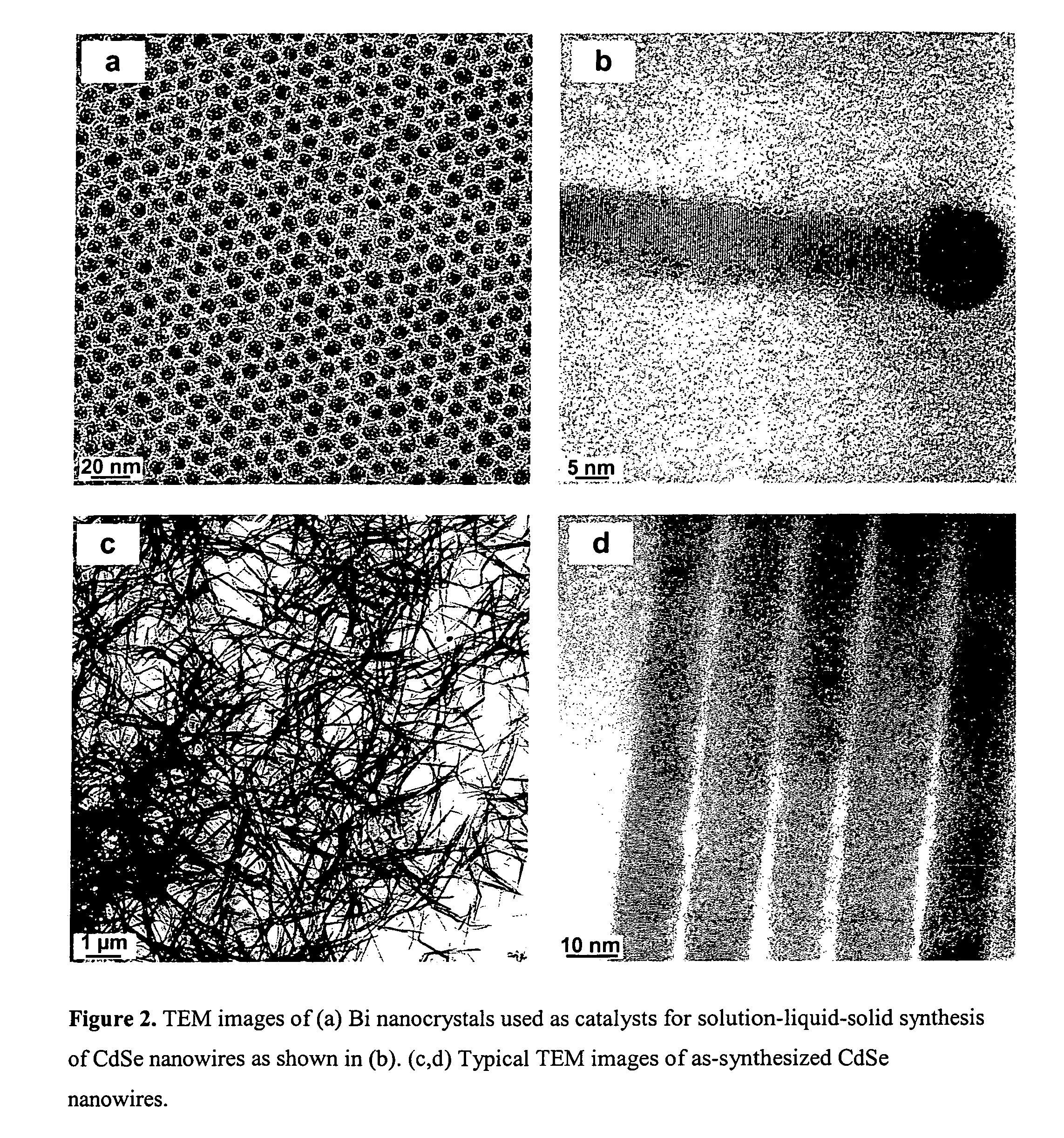

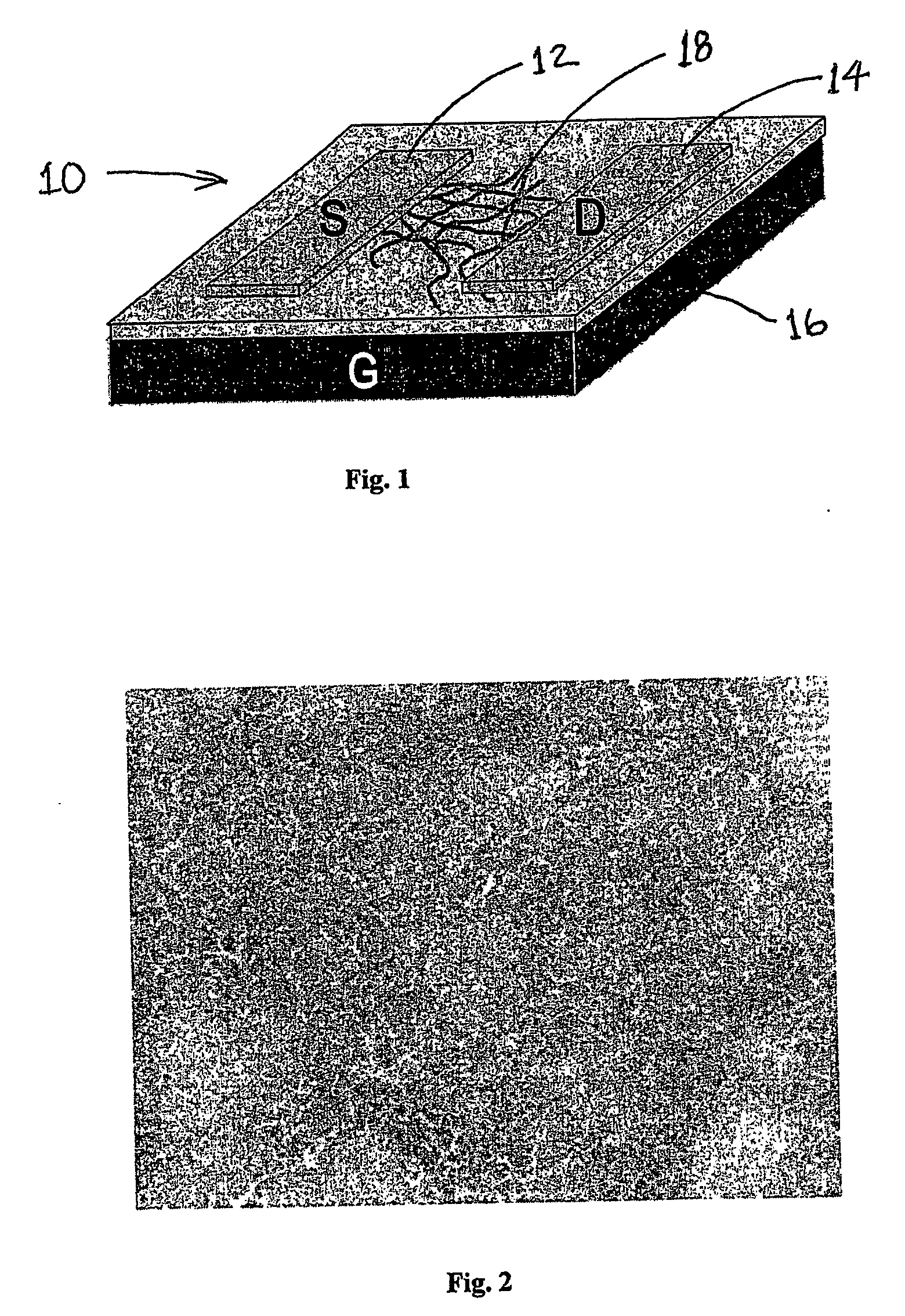

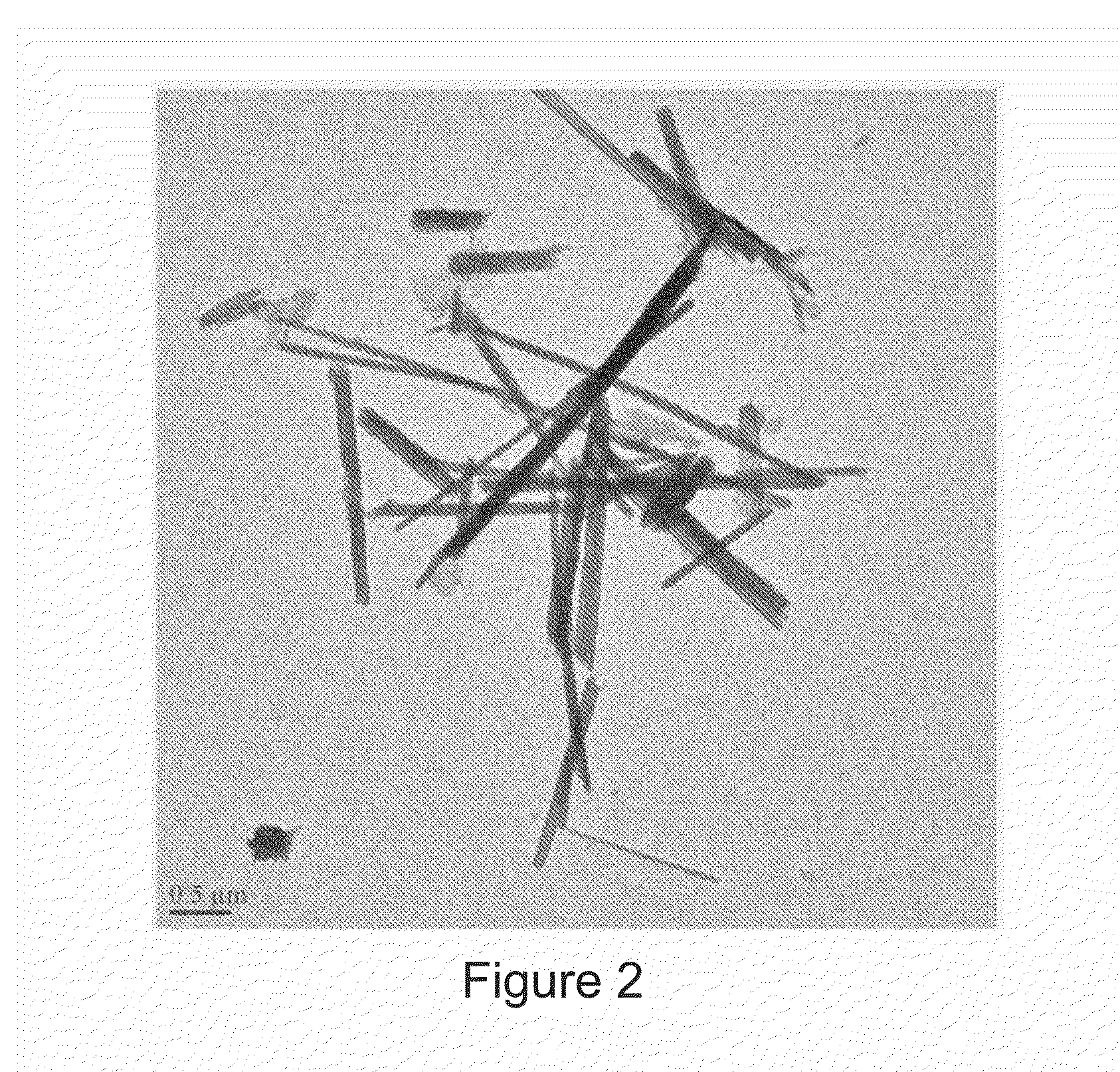

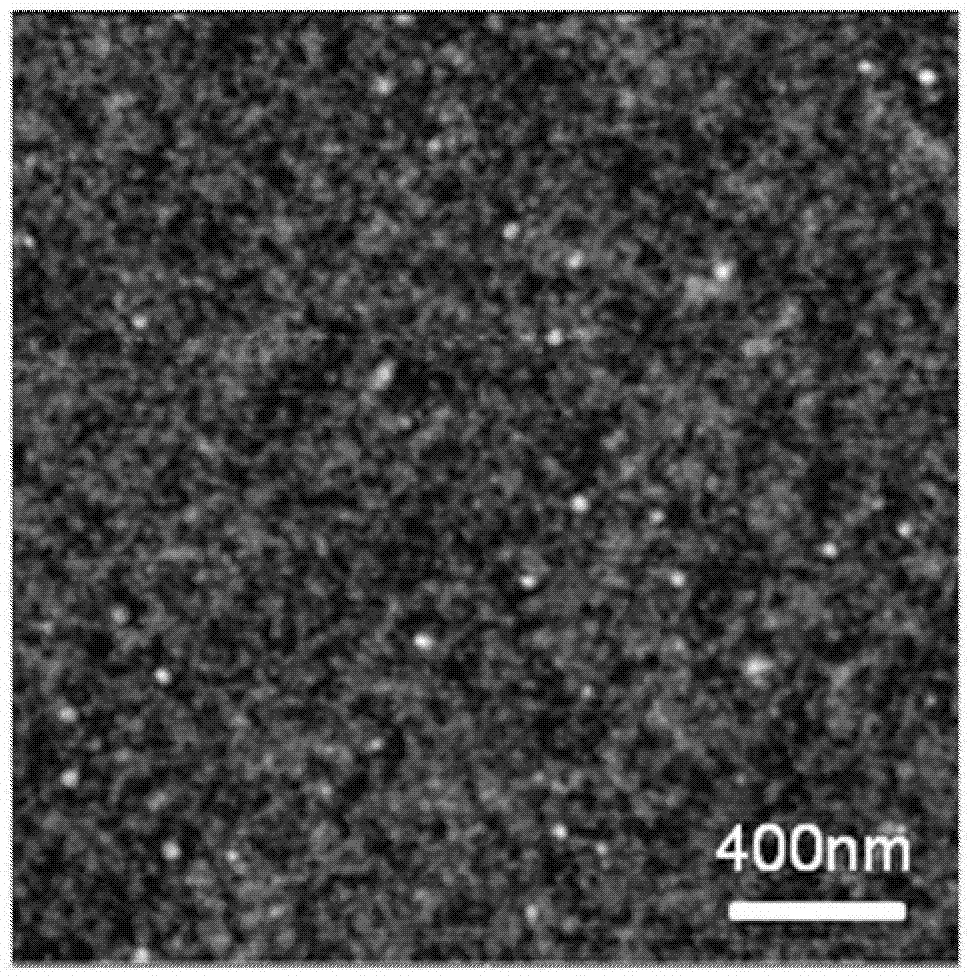

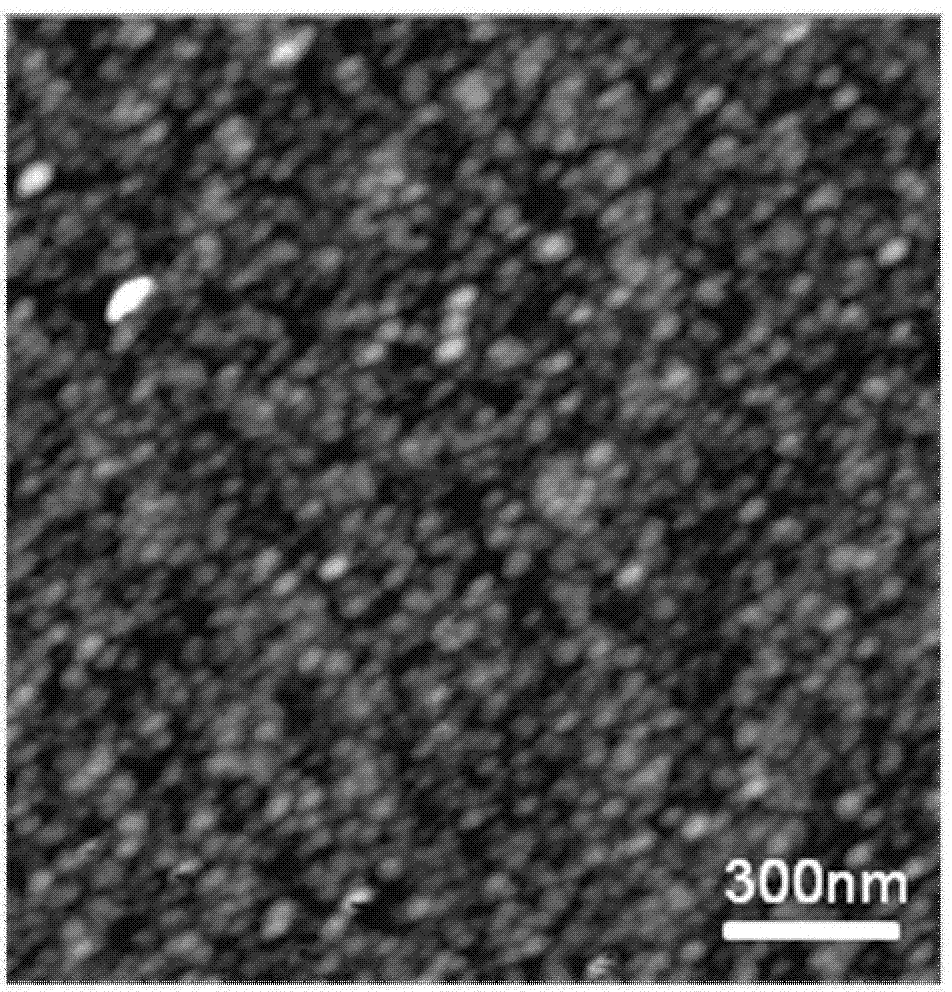

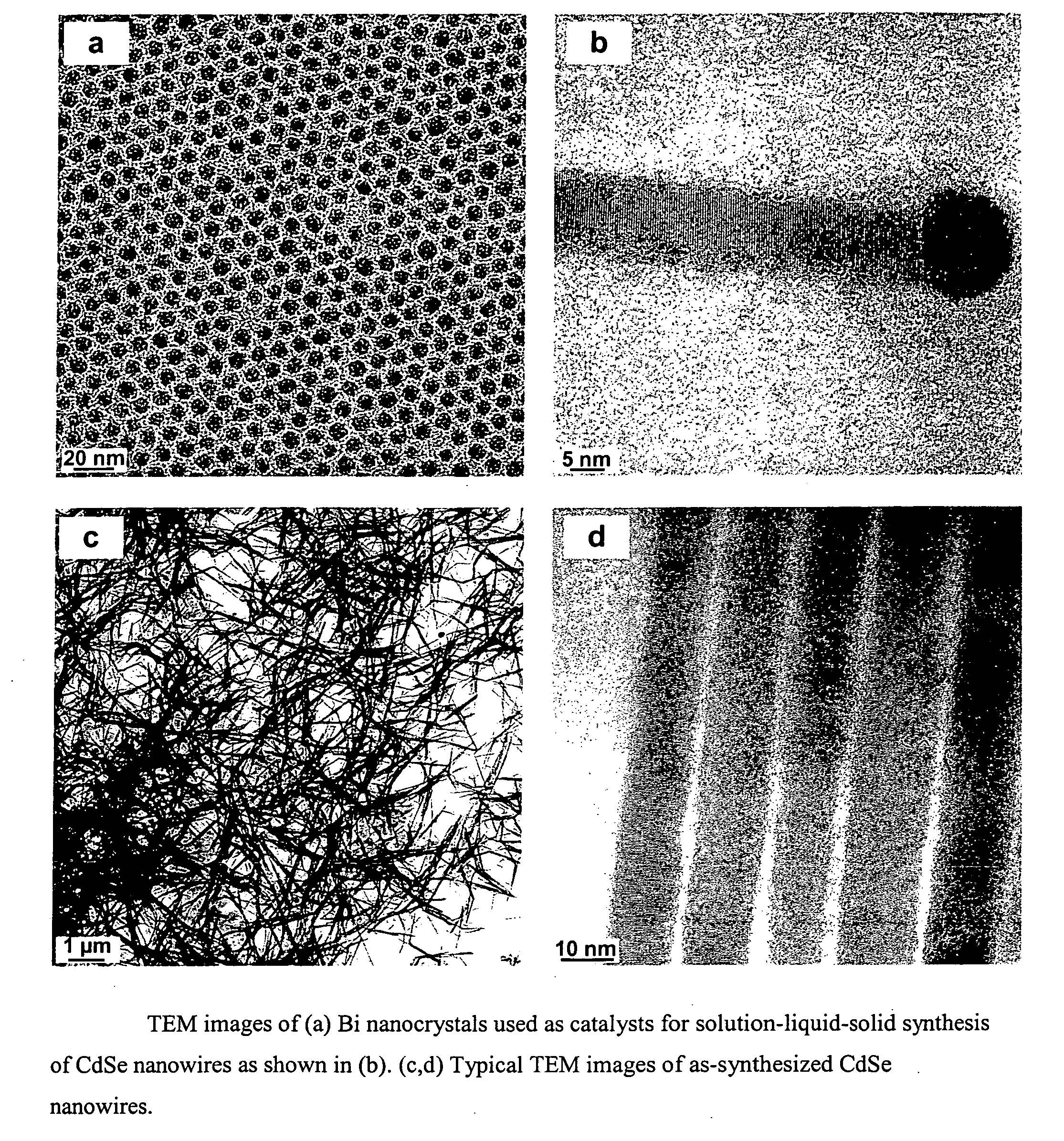

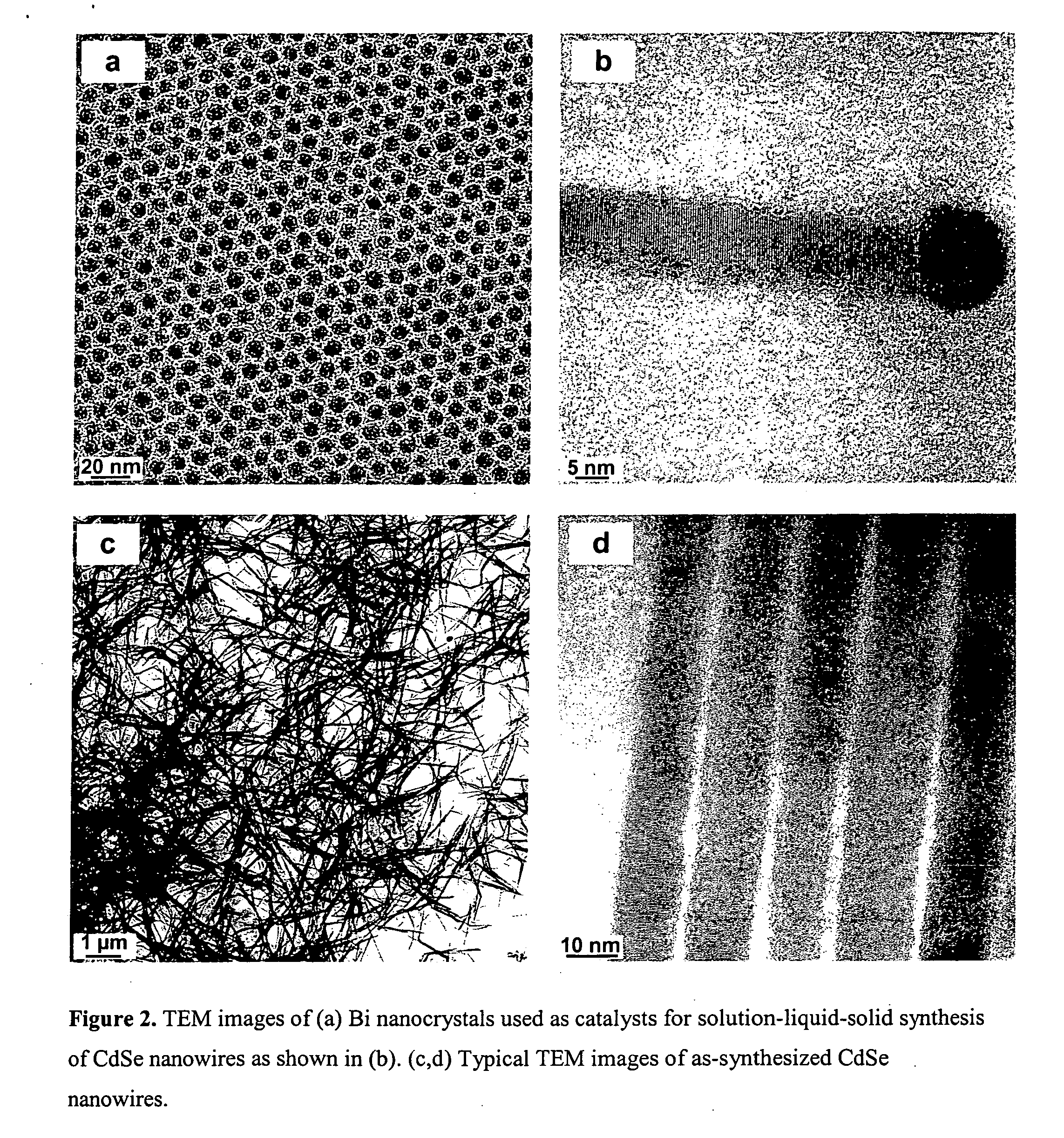

Nanoelectonic devices based on nanowire networks

Semiconductor devices where networks of molecular nanowires (or nanofibers) are used as the semiconductor material. Field effect transistors are disclosed where networks of molecular nanowires are used to provide the electrical connection between the source and drain electrodes. The molecular nanowires have diameters of less than 500 nm and aspect ratios of at least 10. The molecular nanowires that are used to form the networks can be single element nanowires, Group III-V nanowires, Group II-VI nanowires, metal oxide nanowires, metal chalcogenide nanowires, ternary chalcogenide nanowires and conducting polymer nanowires.

Owner:RGT UNIV OF CALIFORNIA

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES U S INC

Hydrazine-free solution deposition of chalcogenide films

InactiveUS20050009225A1Efficient preparationLow costTransistorFrom solid stateHydrazine compoundSulfur

A method of depositing a film of a metal chalcogenide including the steps of: contacting an isolated hydrazinium-based precursor of a metal chalcogenide and a solvent having therein a solubilizing additive to form a solution of a complex thereof; applying the solution of the complex onto a substrate to produce a coating of the solution on the substrate; removing the solvent from the coating to produce a film of the complex on the substrate; and thereafter annealing the film of the complex to produce a metal chalcogenide film on the substrate. Also provided is a process for preparing an isolated hydrazinium-based precursor of a metal chalcogenide as well as a thin-film field-effect transistor device using the metal chalcogenides as the channel layer.

Owner:GLOBALFOUNDRIES US INC

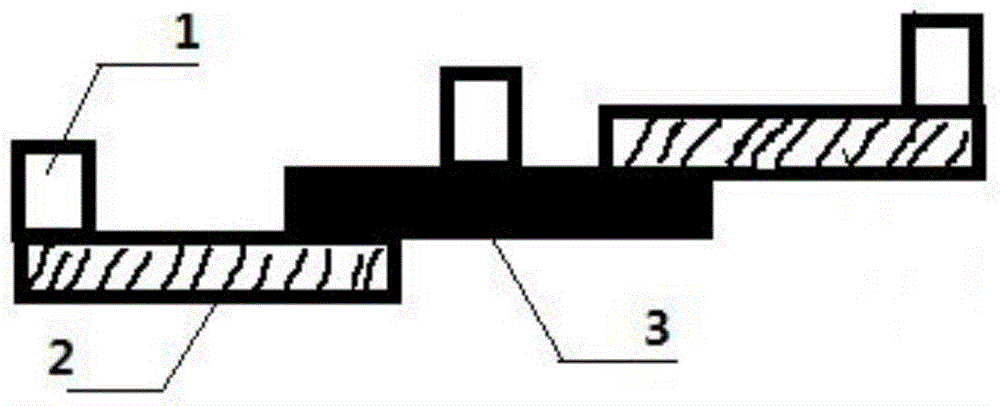

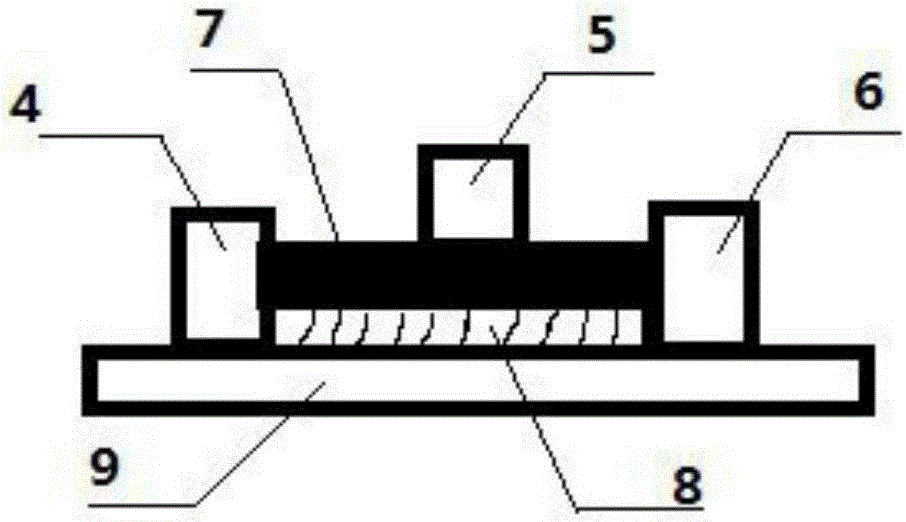

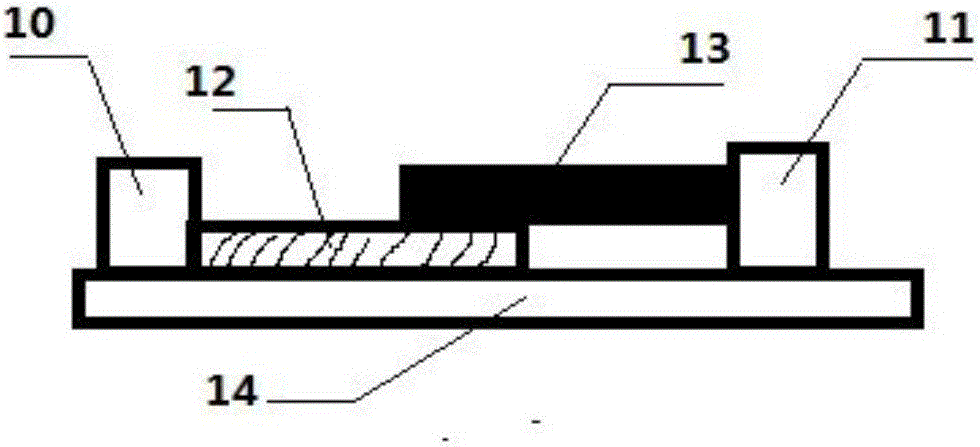

Two-dimensional black phosphorus/transitional metal chalcogenide heterojunction device and preparation method therefor

InactiveCN106024861AHigh carrier mobilityGood electrical propertiesMaterial nanotechnologyFinal product manufactureHeterojunctionPhotovoltaic detectors

The invention discloses a two-dimensional black phosphorus / transitional metal chalcogenide heterojunction based device. The heterojunction adopts a laminated structure of two-dimensional black phosphorus nanometer slices and two-dimensional transitional metal chalcogenide nanometer slices; the number of the two-dimensional black phosphorus layers is 1-50; the two-dimensional transitional metal chalcogenide comprises 1-50 layers in terms of thickness; the two kinds of two-dimensional materials are prepared and synthesized through chemical vapor deposition, mechanical stripping, liquid phase stripping and the like; and the device can be used for preparing a bipolar transistor, a field effect transistor or a photoelectric detector / photoelectric diode. The two-dimensional black phosphorus / transitional metal chalcogenide heterojunction device has the advantages as follows: a combination of the two kinds of two-dimensional materials of black phosphorus and the transitional metal chalcogenide is adopted to form the brand new pn type heterojunction structure; the heterojunction is combined based on natural van der Waals forces among materials; compared with the conventional heterojunction epitaxial growth process, the heterojunction device provided by the invention is easier to prepare; and compared with the existing bulk material, the heterojunction device provided by the invention is smaller in size, thinner, higher in flexibility and higher in the integration degree, so that the two-dimensional black phosphorus / transitional metal chalcogenide heterojunction device has the potential to be applied to the wearable equipment in the future.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for filling holes with metal chalcogenide material

InactiveUS20080124833A1Reduce complexityImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingSulfurMetal chalcogenides

A metal chalcogenide material is deposited into holes within a substrate surface. The method comprises obtaining a hydrophilic substrate surface; obtaining a solution of a hydrazine-based precursor of a metal chalcogenide; applying the solution onto the substrate to fill the holes with said precursor; and thereafter annealing the precursor to convert said precursor to said metal chalcogenide thereby producing holes in the substrate surface filled with a metal chalcogenide material.

Owner:GLOBALFOUNDRIES INC

Coating including inorganic fullerene-like particles and inorganic tubular-like particles

In one embodiment, a coating is provided that includes a deposition surface, and a coating on the deposition surface. The coating may include particles of a metal chalcogenide comprising a fullerene-like geometry, a tubular-like geometry or a combination of fullerene-like geometries and tubular-like geometries. The metal chalcogenide composition has a molecular formula of MX2.

Owner:NANOTECH IND SOLUTIONS

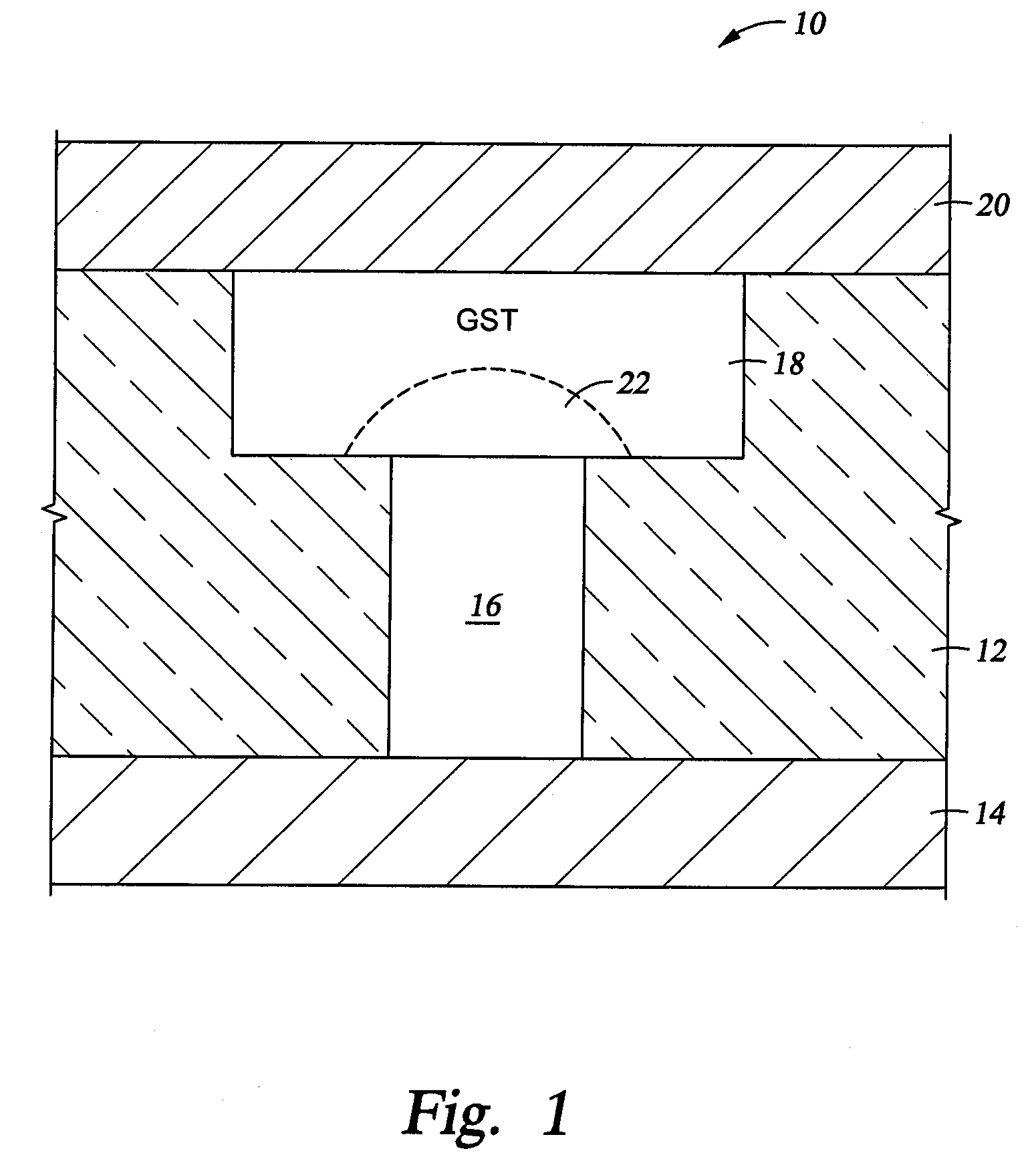

Phase change memory cell and method of formation

ActiveUS7332735B2Reduce power consumptionDigital storageBulk negative resistance effect devicesPhase-change memoryMetal chalcogenides

A phase change memory element and methods for forming the same are provided. The memory element includes a first electrode and a chalcogenide comprising phase change material layer over the first electrode. A metal-chalcogenide layer is over the phase change material layer. The metal chalcogenide layer is tin-telluride. A second electrode is over the metal-chalcogenide layer. The memory element is configured to have reduced current requirements.

Owner:OVONYX MEMORY TECH LLC

Systems and methods related to the formation of carbon-based nanostructures

Systems and methods for the formation of carbon-based nanostructures are generally described. In some embodiments, the nanostructures may be formed on a nanopositor. The nanopositor can comprise, in some embodiments, at least one of metal atoms in a non-zero oxidation state and metalloid atoms in a non-zero oxidation state. For example, the nanopositor may comprise a metal oxide, a metalloid oxide, a metal chalcogenide, a metalloid chalcogenide, and the like. The carbon-based nanostructures may be grown by exposing the nanopositor, in the presence or absence of a growth substrate, to a set of conditions selected to cause formation of carbon-based nanostructures on the nanopositor. In some embodiments, metal or metalloid atoms in a non-zero oxidation state are not reduced to a zero oxidation state during the formation of the carbon-based nanostructures. In some cases, metal or metalloid atoms in a non-zero oxidation state do not form a carbide during the formation of the carbon-based nanostructures.

Owner:MASSACHUSETTS INST OF TECH

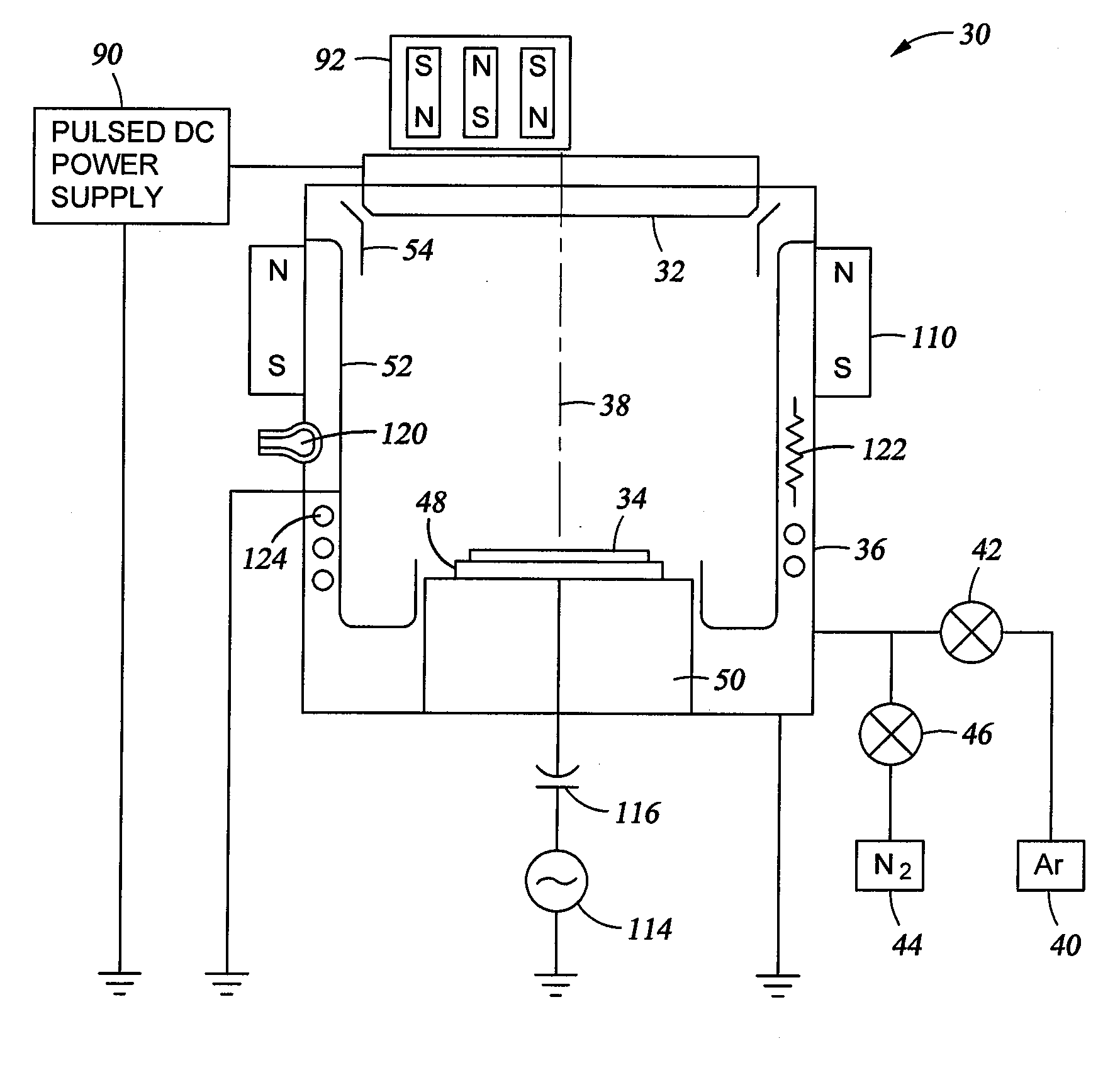

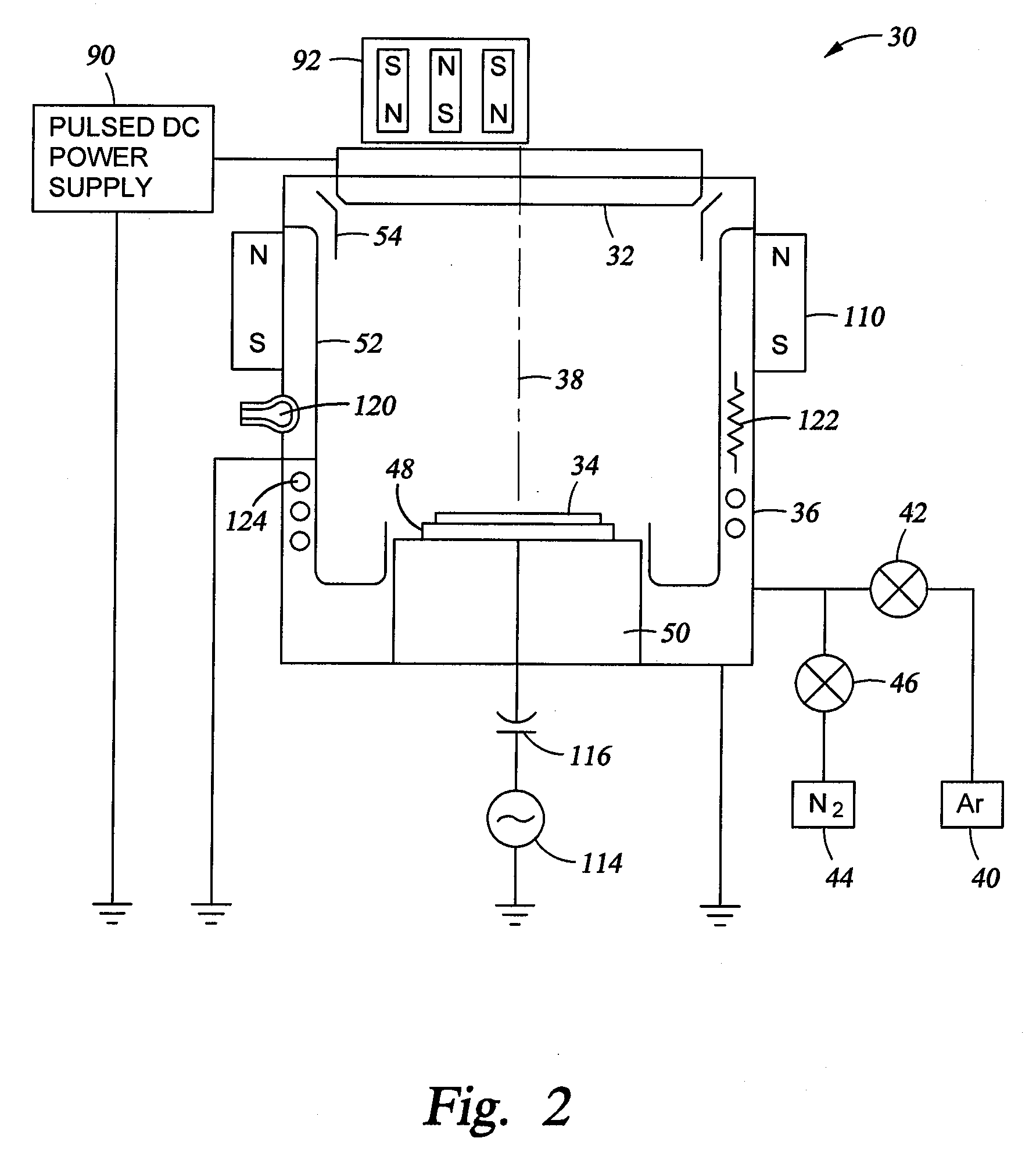

Sputtering of thermally resistive materials including metal chalcogenides

ActiveUS20080099326A1Reduce heat loadLow thermal conductivityVacuum evaporation coatingSputtering coatingPhase-change memoryMetal chalcogenides

A plasma sputtering method for metal chalcogenides, such as germanium antimony telluride (GST), useful in forming phase-change memories. The substrate is held at a selected temperature at which the material deposits in either an amorphous or crystalline form. GST has a low-temperature amorphous range and a high-temperature crystalline range separated by a transition band of 105-120° C. Bipolar pulsed sputtering with less than 50% positive pulses of less than 10:s pulse width cleans the target while maintain the sputtering plasma. The temperature of chamber shields is maintained at a temperature favoring crystalline deposition or they may be coated with arc-spray aluminum or with crystallographically aligned copper or aluminum.

Owner:APPLIED MATERIALS INC

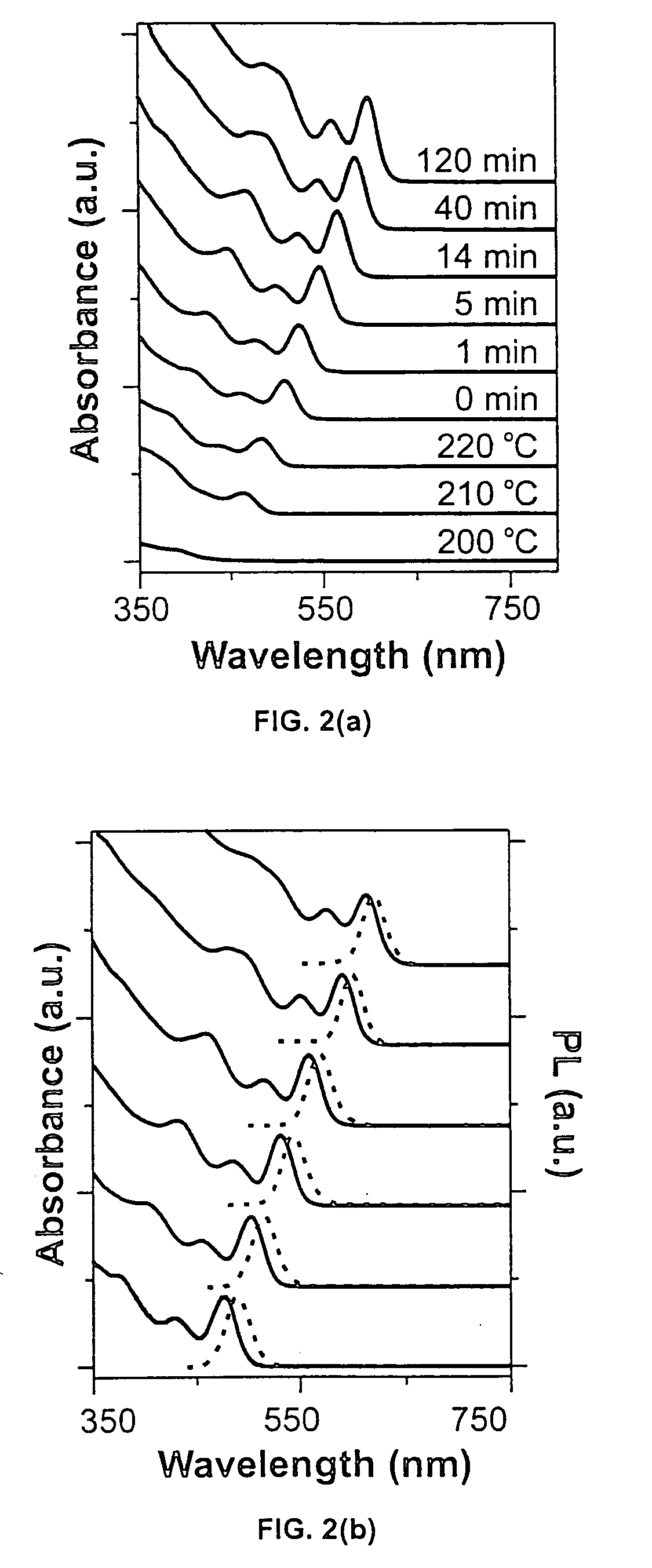

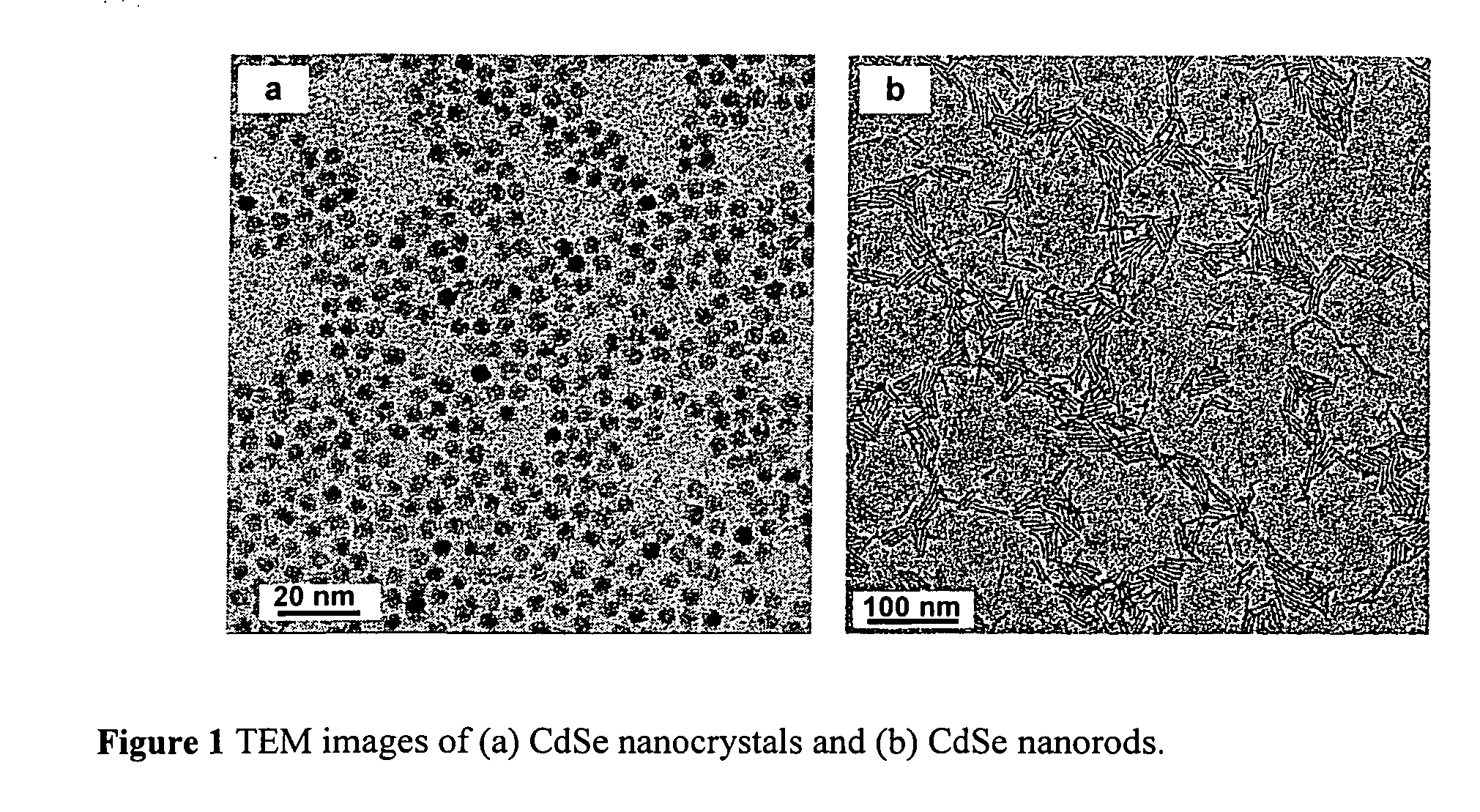

One-pot synthesis of high-quality metal chalcogenide nanocrystals without precursor injection

InactiveUS20060019427A1Material nanotechnologyPolycrystalline material growthSulfurMetal chalcogenides

A method of homogeneously forming metal chalcogenide nanocrystals includes the steps combining a metal source, a chalcogenide source, and at least one solvent at a first temperature to form a liquid comprising assembly, and heating the assembly at a sufficient temperature to initiate nucleation to form a plurality of metal chalcogenide nanocrystals. The plurality of metal chalcogenide nanocrystals are then grown without injection of either the metal source or the chalcogenide source at a temperature at least equal to the sufficient temperature, wherein growth proceeds substantially without nucleation to form a plurality of monodisperse metal chalcogenide nanocrystals. An optional nucleation initiator can help control the final size of the monodisperse crystals. Such synthesis, without the need for precursor injection, is suitable for the industrial preparation of high-quality nanocrystals.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

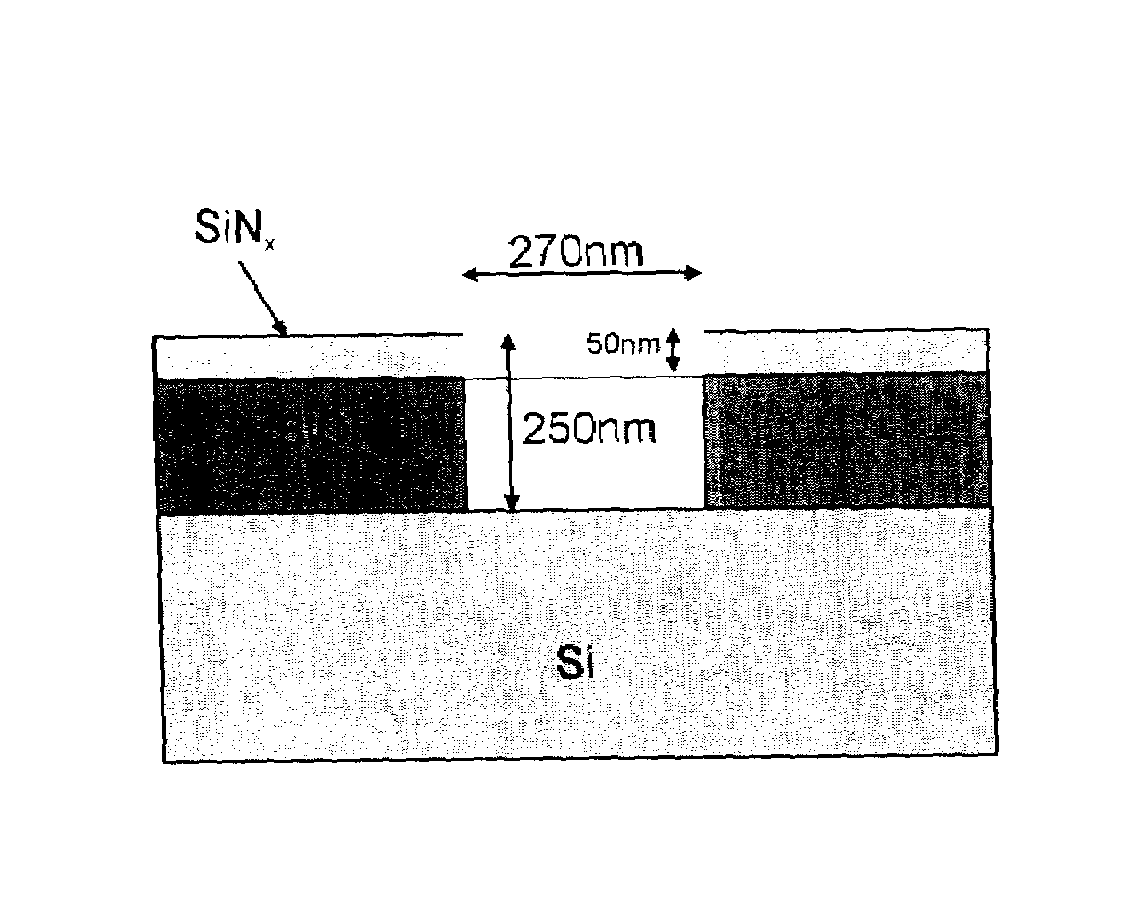

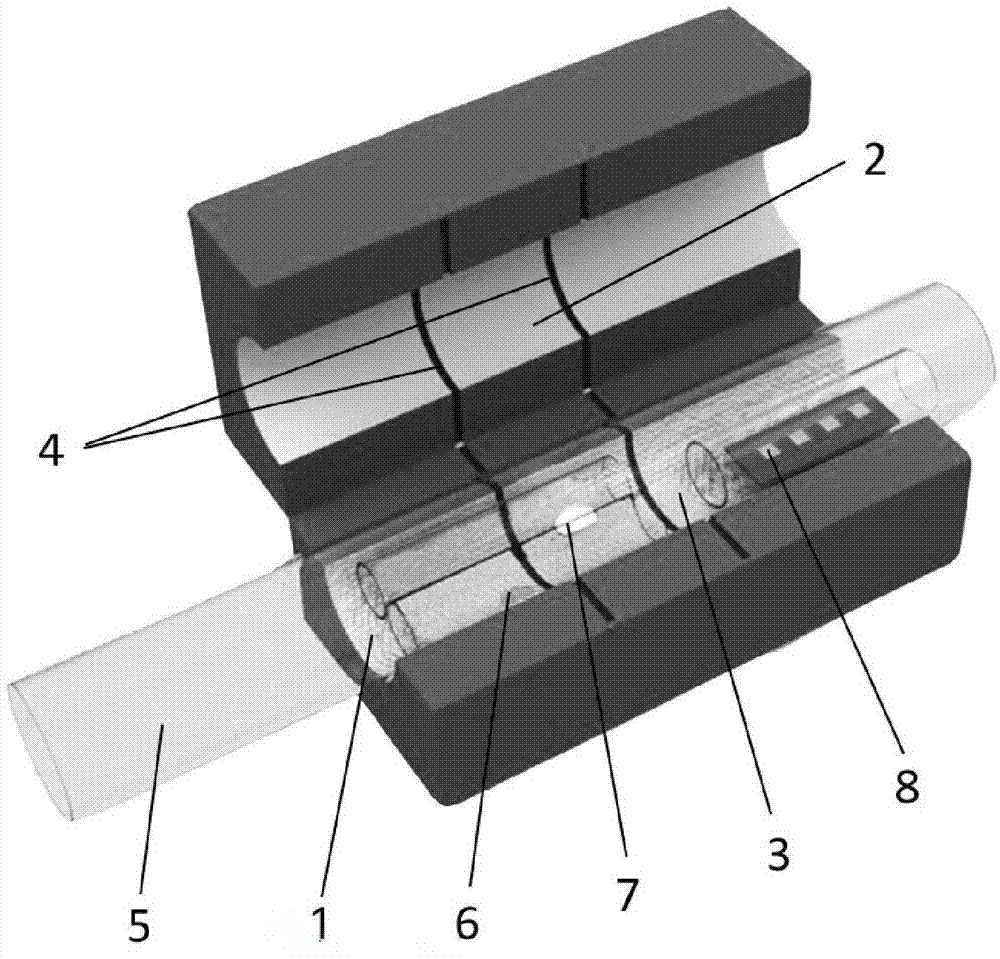

Method for preparing metal chalcogenide film

ActiveCN103194729AControl thicknessSmall sizeChemical vapor deposition coatingDeposition temperatureSulfur

The invention discloses a method for preparing a metal chalcogenide film. The method is used for growing the metal chalcogenide film on a substrate with the vapor deposition process by using a chalcogen source and a metal element source and comprises the following steps of: providing three temperature zones, wherein the temperature of the three temperature zones can be controlled independently, and the chalcogen source, the metal element source and the substrate are put in the three temperature zones respectively; controlling the three temperature zones, evaporating the chalcogen source to generate the chalcogen source steam, evaporating the metal element source to generate the metal element source steam, and heating the substrate to the predetermined deposition temperature; providing a carrier gas, and enabling the carrier gas to flow through the three temperature zones in sequence to deliver the metal element source steam to the substrate to deposit and grow so as to form the metal chalcogenide film. The method disclosed by the invention is simple, dispenses with the original complex step of introducing a nucleation site and effectively ensures the purity and the surface cleanness of a sample. The metal chalcogenide film prepared by adopting the method has high quality.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Metal chalcogenide composite nano-particles and layers therewith

A metal chalcogenide composite nano-particle comprising a metal capable of forming p-type semiconducting chalcogenide nano-particles and a metal capable of forming n-type semiconducting chalcogenide nano-particles, wherein at least one of the metal chalcogenides has a band-gap between 1.0 and 2.9 eV and the concentration of the metal capable of forming p-type semiconducting chalcogenide nano-particles is at least 5 atomic percent of the metal and is less than 50 atomic percent of the metal; a dispersion thereof; a layer comprising the nano-particles; and a photovoltaic device comprising the layer.

Owner:AGFA GEVAERT AG

Method for fabricating an inorganic nanocomposite

InactiveUS20070160747A1Low costMaterial nanotechnologySemiconductor/solid-state device manufacturingMetal chalcogenidesField-effect transistor

An inorganic nanocomposite is prepared by obtaining a solution of a soluble hydrezine-based metal chalcogenide precursor; dispersing a nanoentity in the precursor solution; applying a solution of the precursor containing the nanoentity onto a substrate to produce a film of the precursor containing the nanoentity; and annealing the film of the precursor containing the nanoentity to produce the metal chalcogenide nanocomposite film comprising at least one metal chalcogenide and at least one molecularly-intermixed nanoentity on the substrate. The process can be used to prepare field-effect transistors and photovoltaic devices.

Owner:GLOBALFOUNDRIES INC

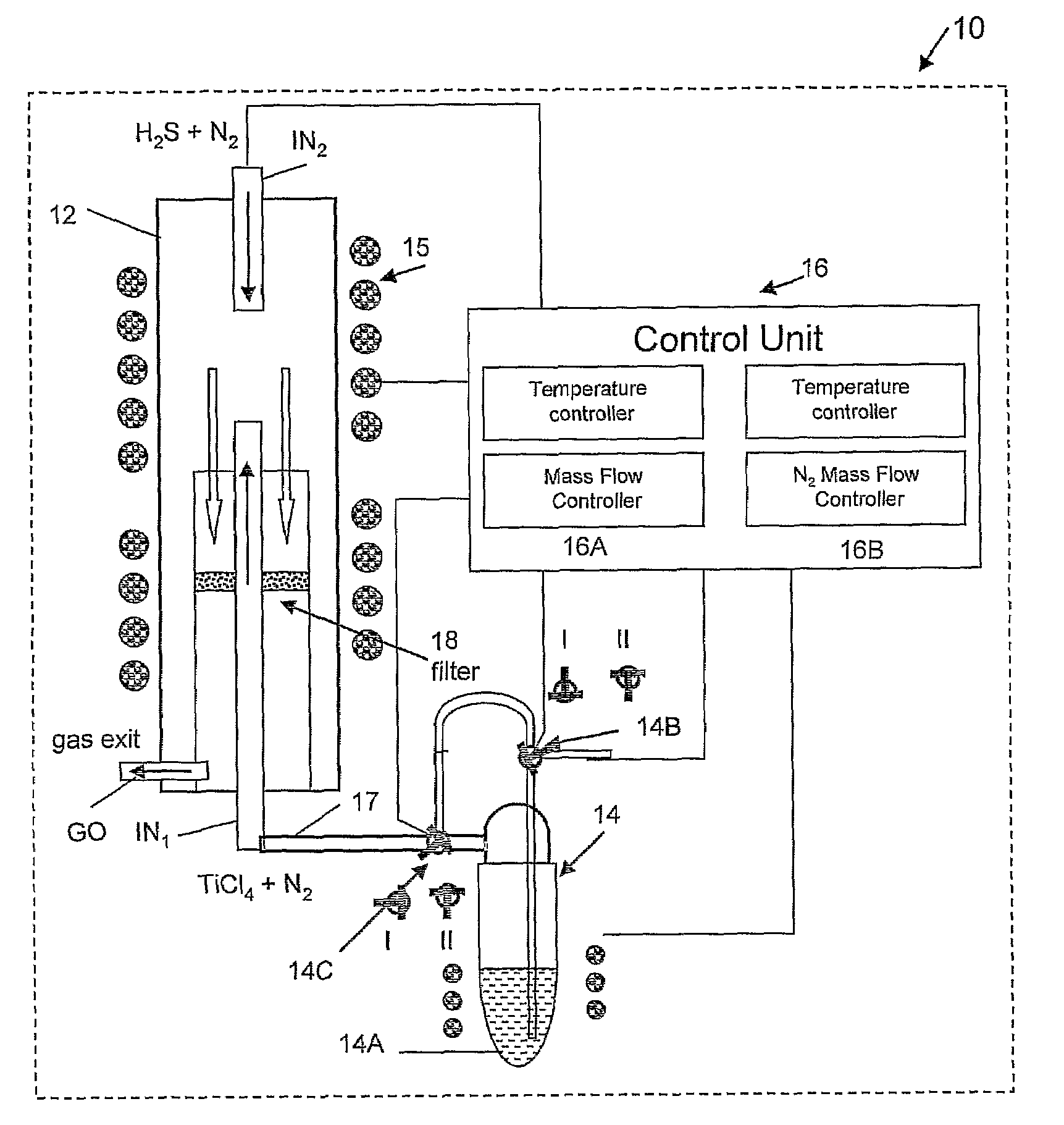

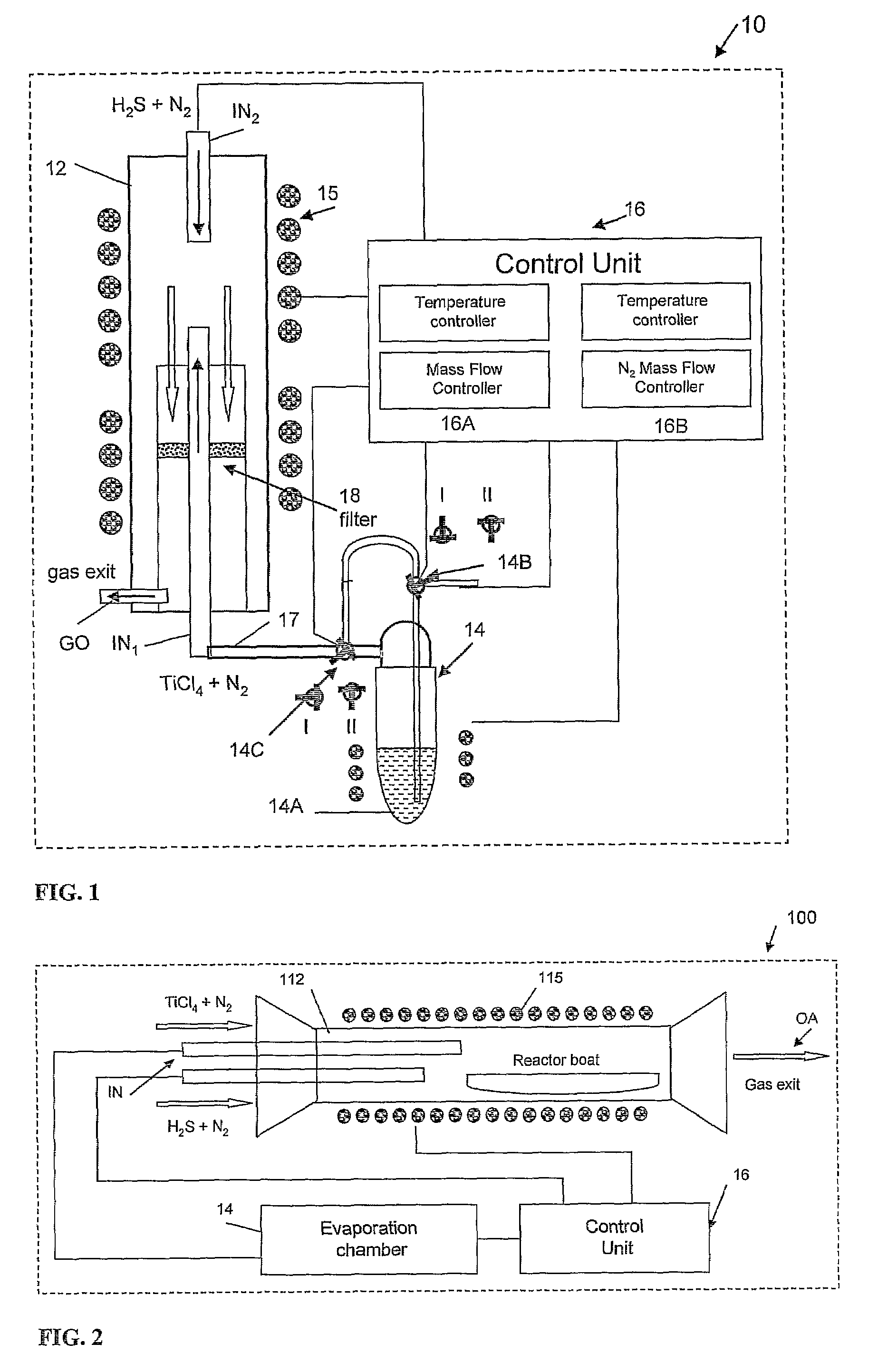

Process and apparatus for producing inorganic fullerene-like nanoparticles

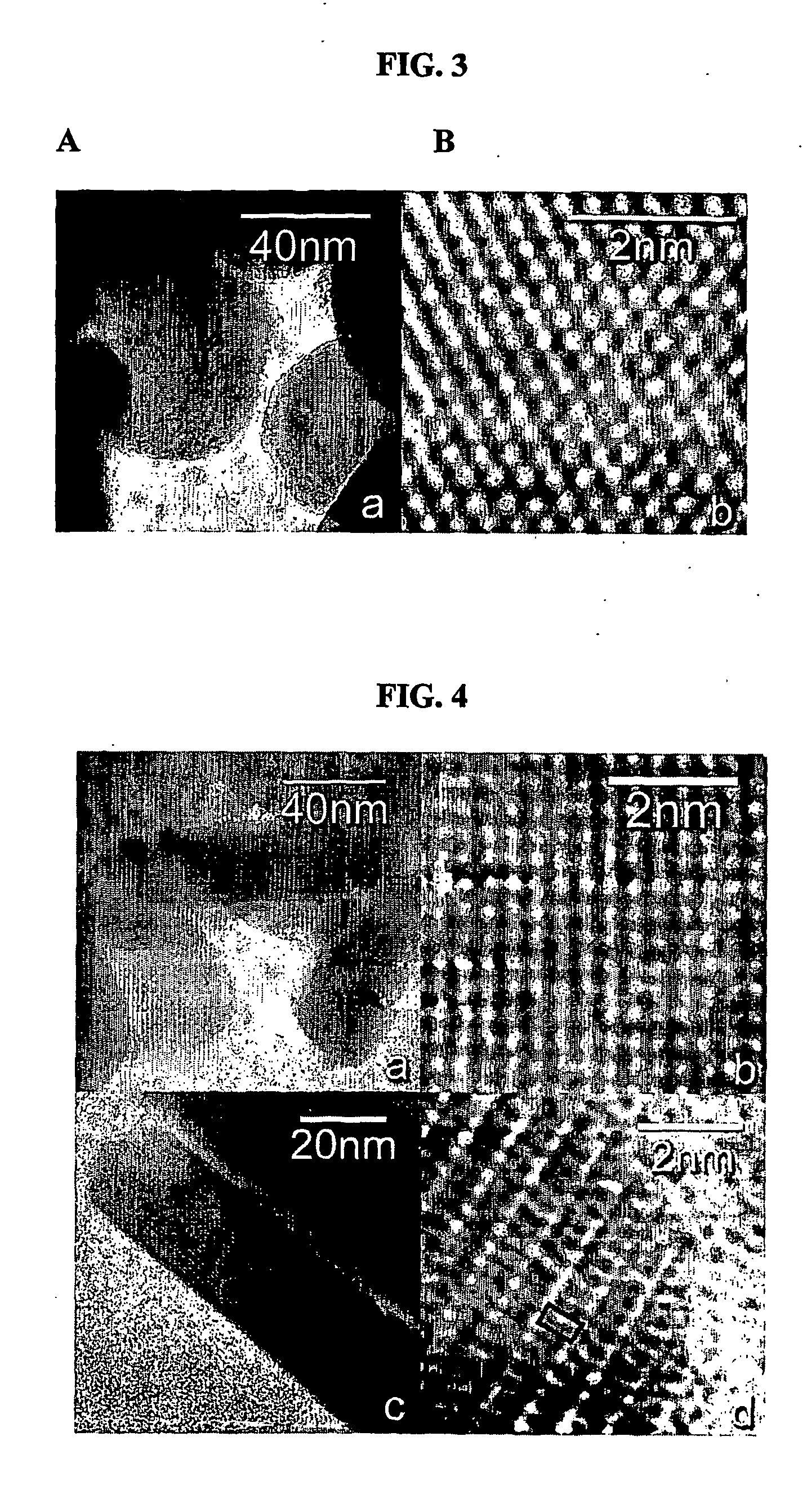

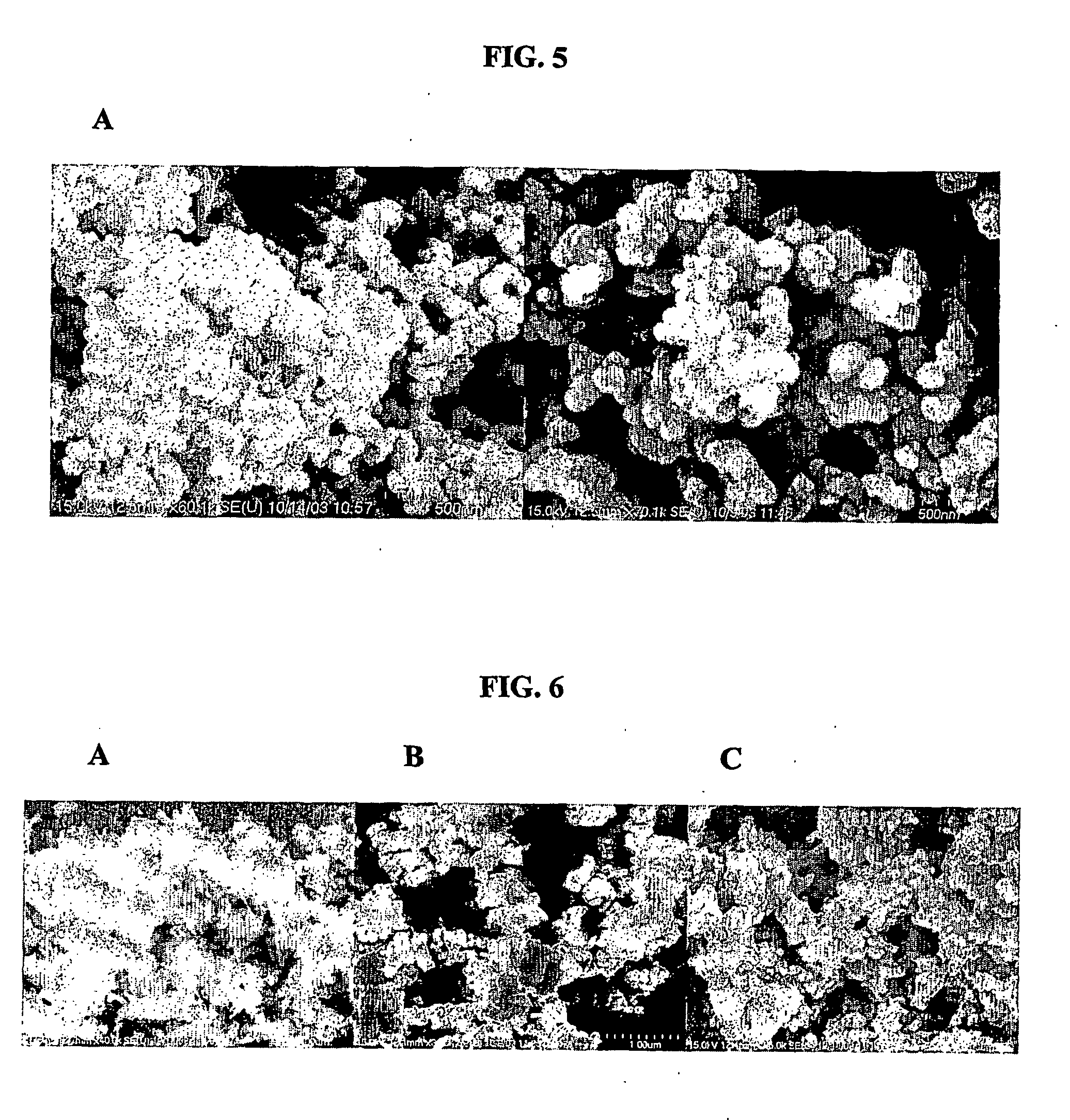

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

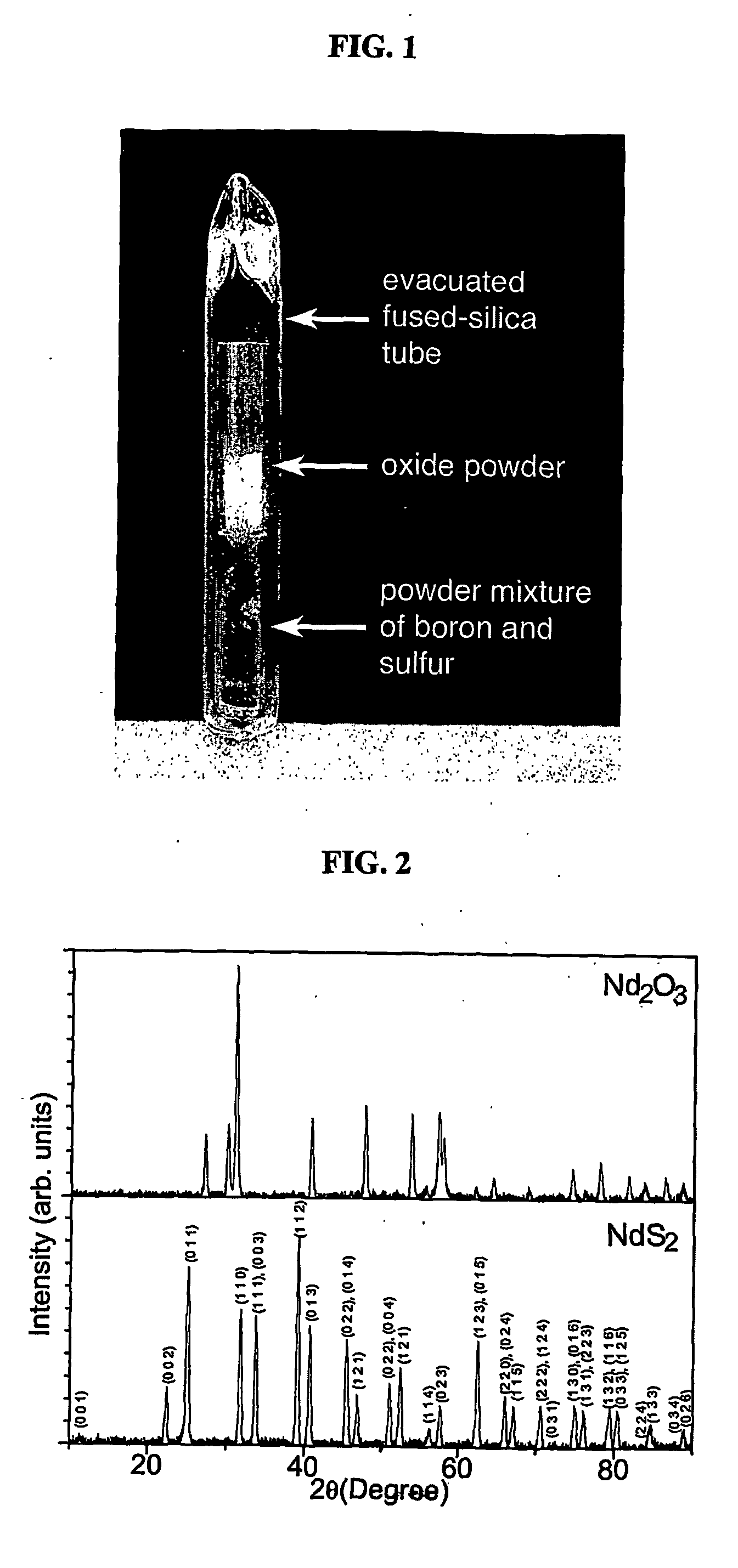

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

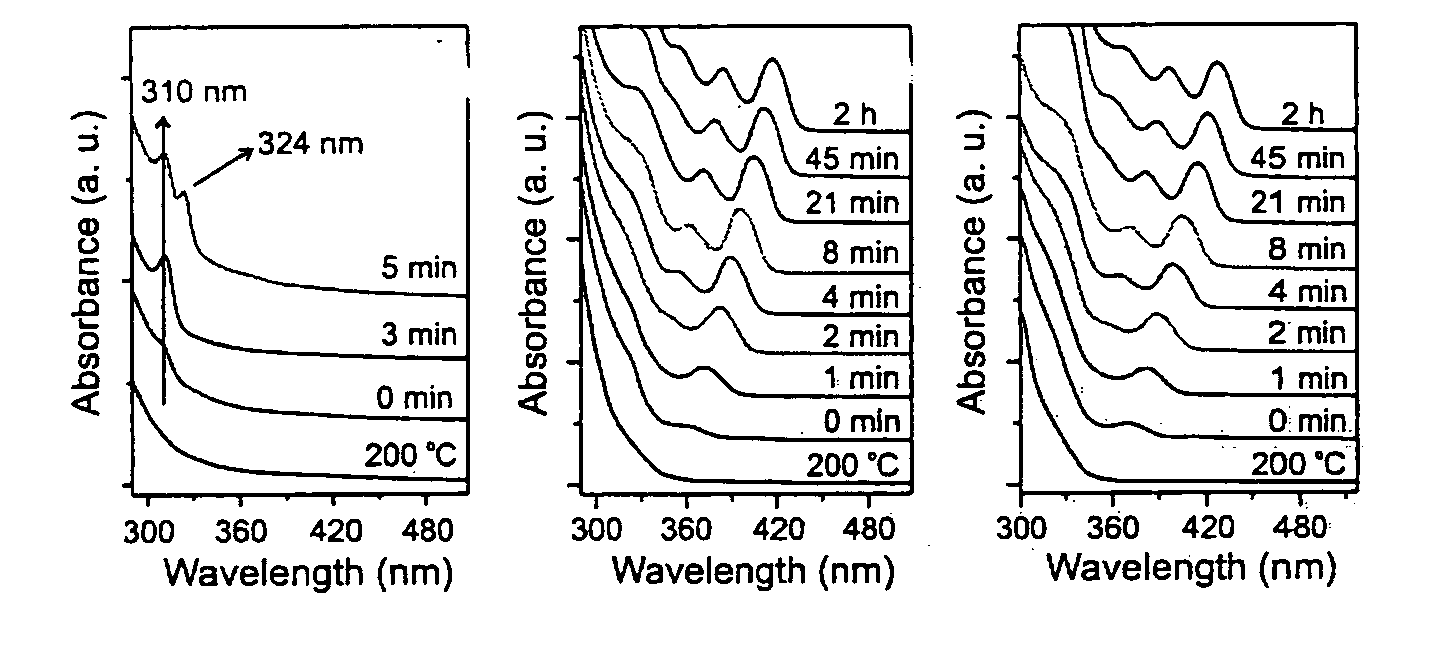

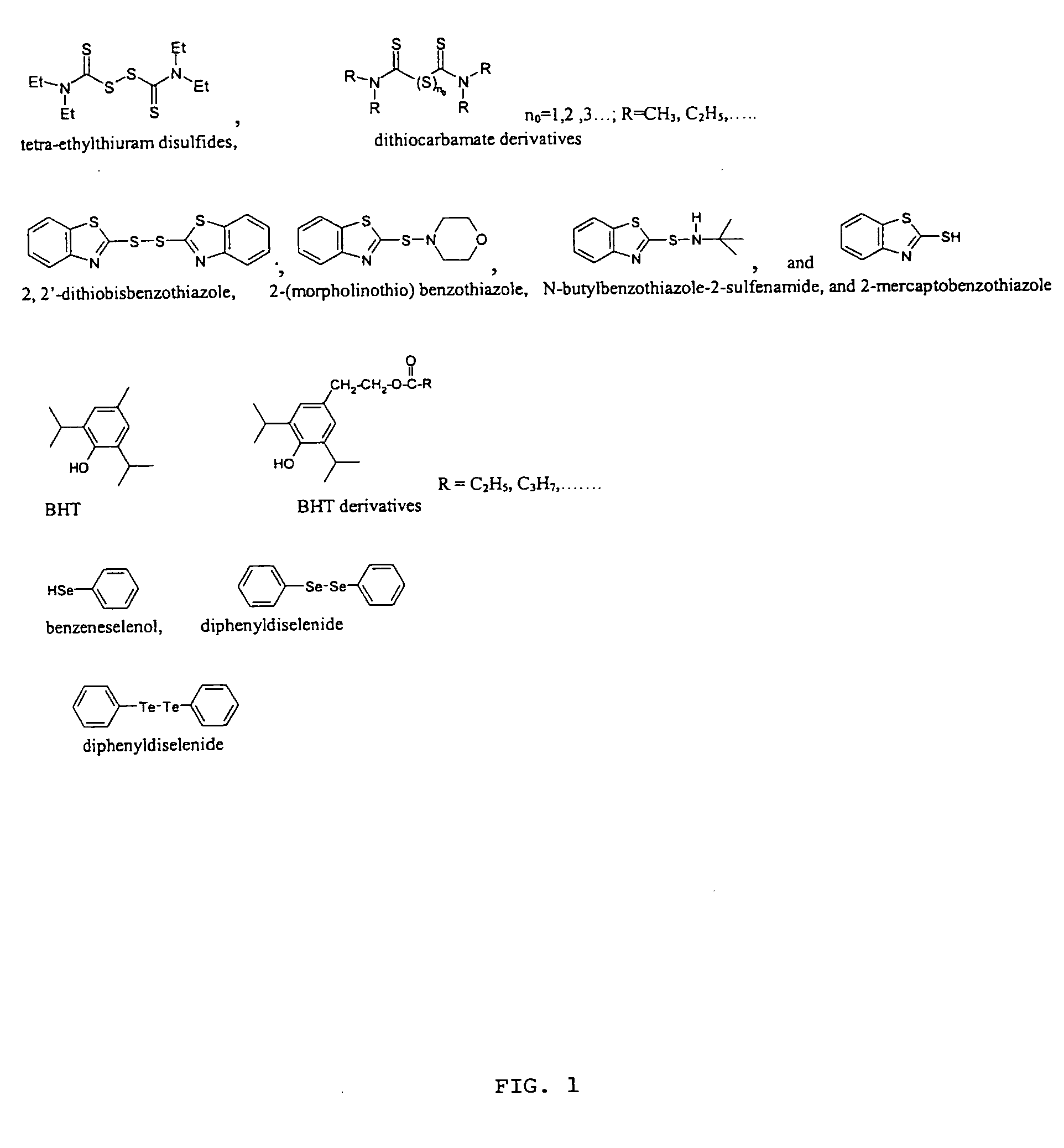

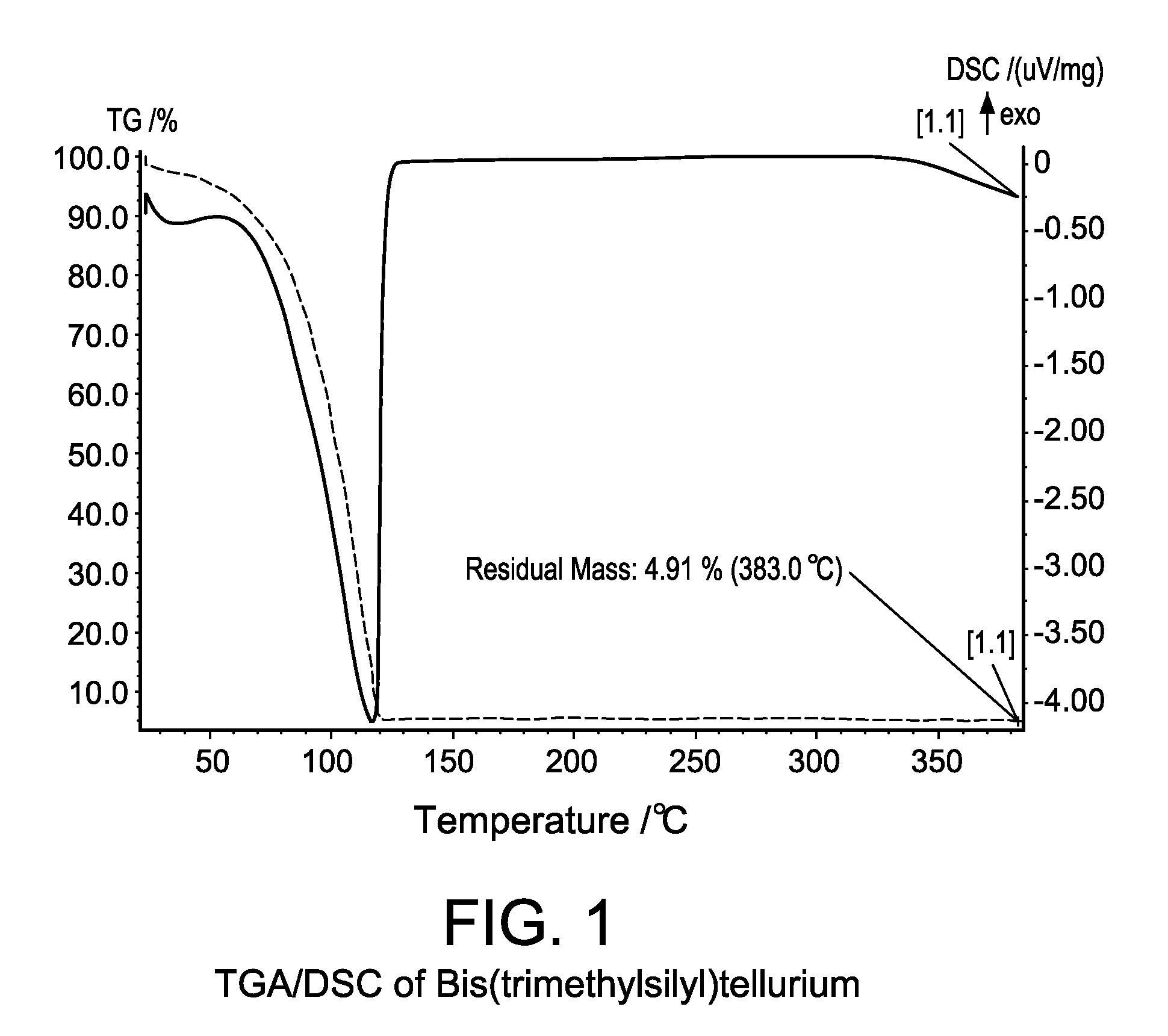

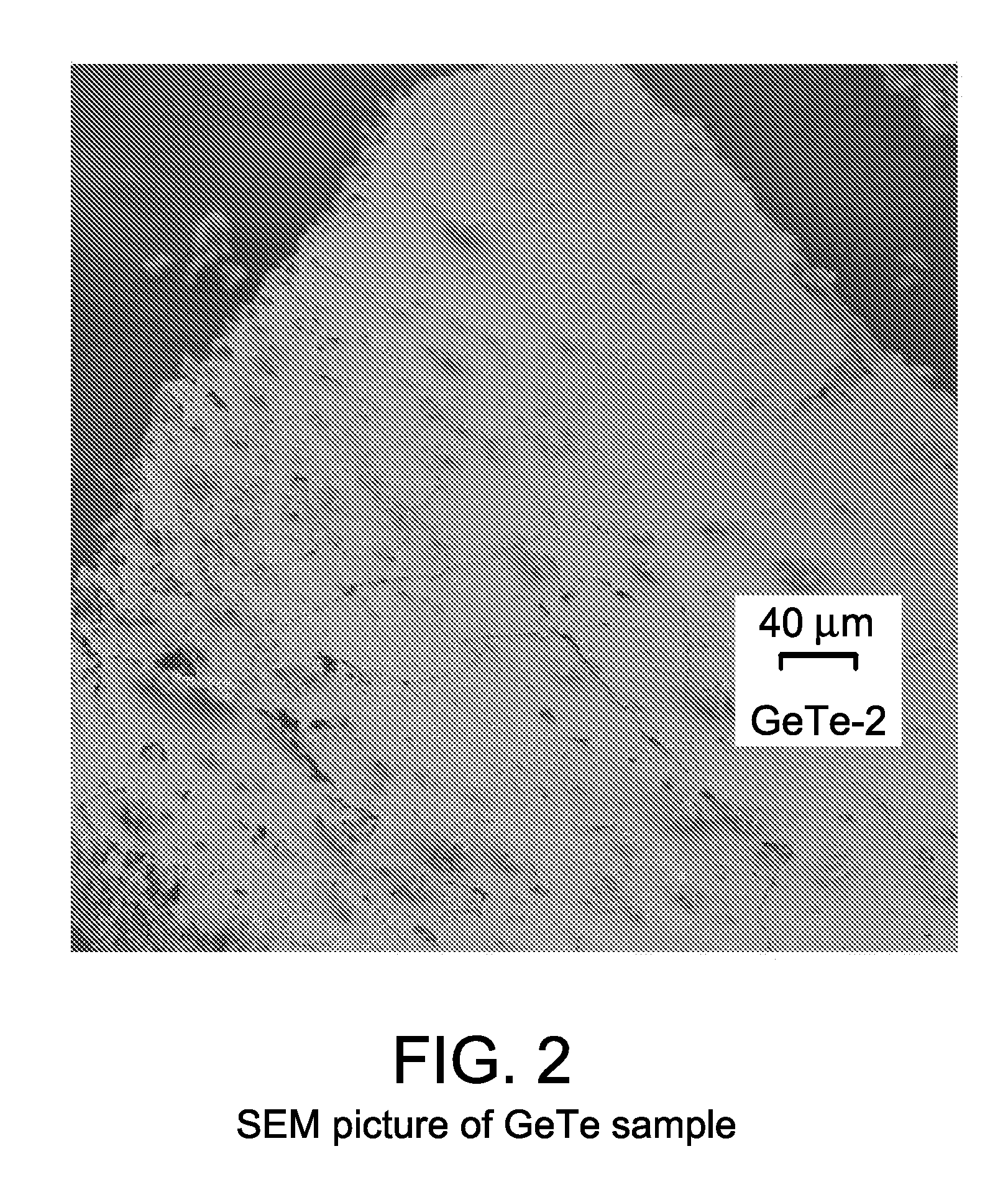

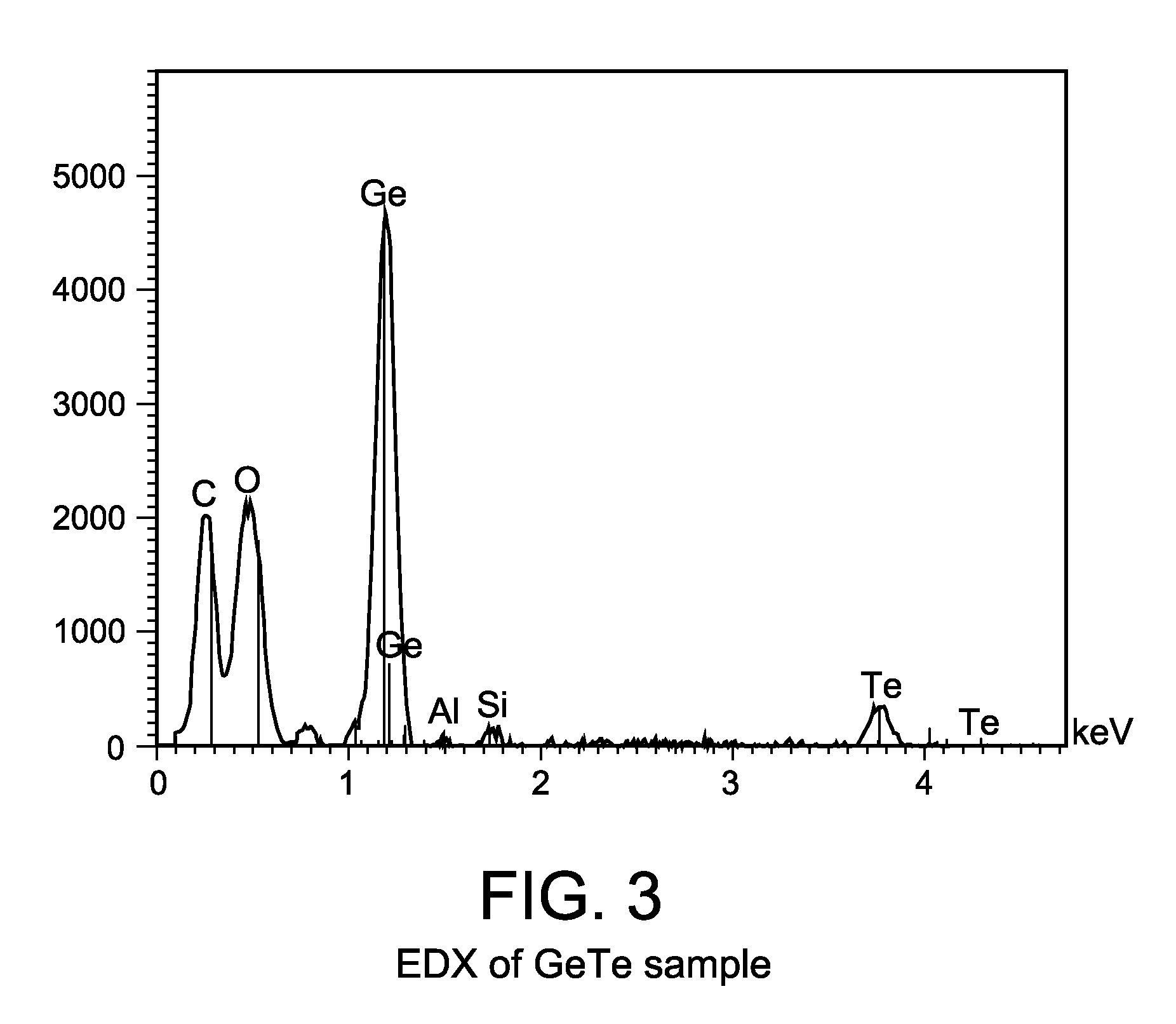

Binary and Ternary Metal Chalcogenide Materials and Method of Making and Using Same

ActiveUS20090280052A1Silicon organic compoundsPhosphorus sulfur/selenium/tellurium compoundsPhase-change memoryMetal chalcogenides

This invention discloses the synthesis of metal chalcogenides using chemical vapor deposition (CVD) process, atomic layer deposition (ALD) process, or wet solution process. Ligand exchange reactions of organosilyltellurium or organosilylselenium with a series of metal compounds having neucleophilic substituents generate metal chalcogenides. This chemistry is used to deposit germanium-antimony-tellurium (GeSbTe) and germanium-antimony-selenium (GeSbSe) films or other tellurium and selenium based metal compounds for phase change memory and photovoltaic devices.

Owner:VERSUM MATERIALS US LLC

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

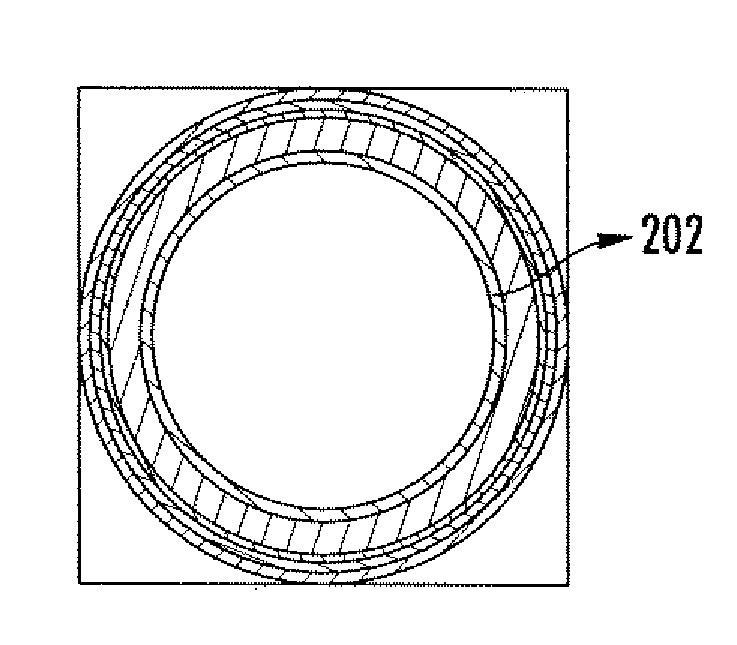

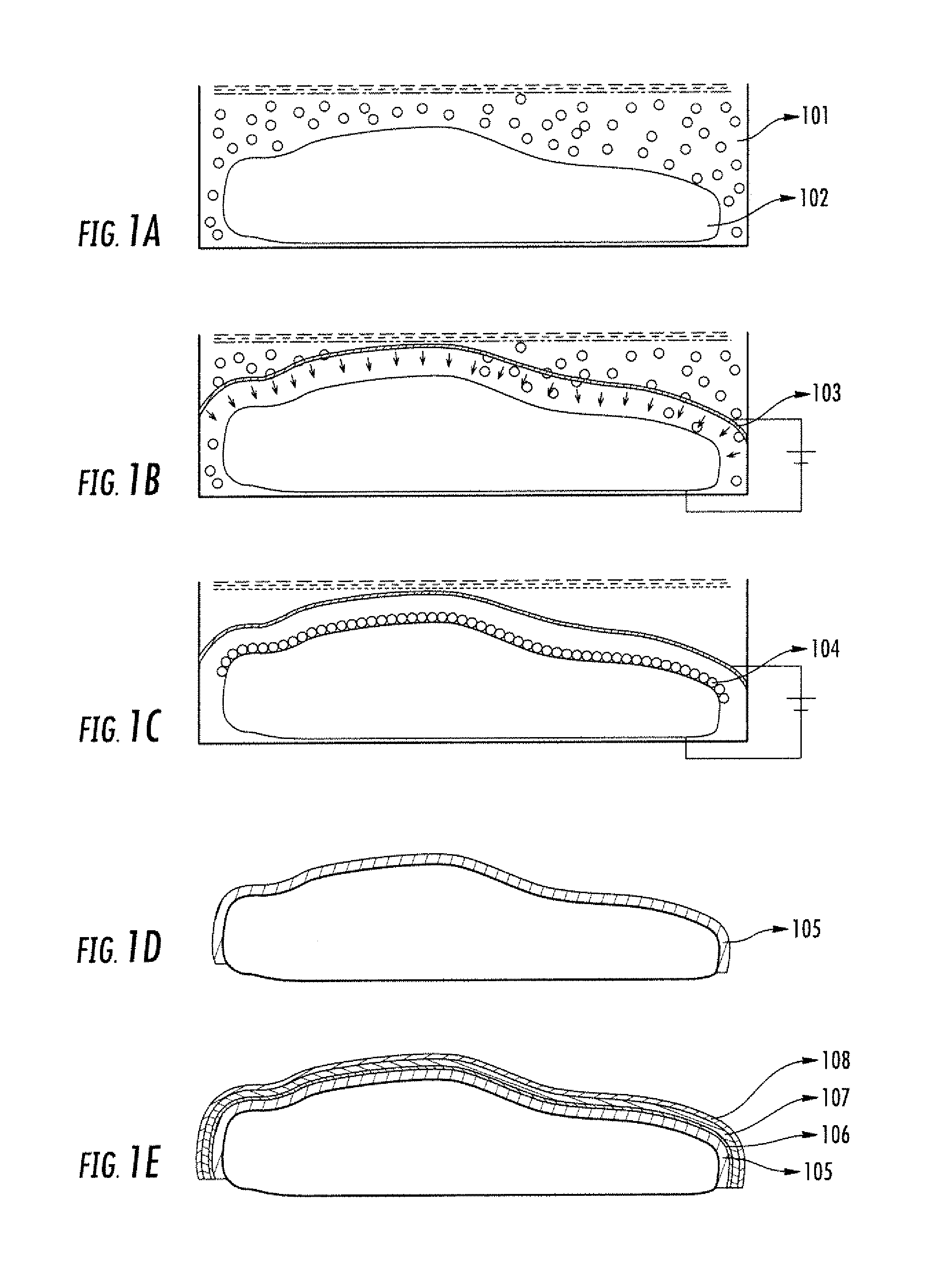

Method for preparation of metal chalcogenide solar cells on complexly shaped surfaces

InactiveUS20120100660A1Electrolytic coatingsSemiconductor/solid-state device manufacturingIndiumMetal chalcogenides

Methods for fabricating a photovoltaic device on complexly shaped fabricated objects, such as car bodies are disclosed. Preferably the photovoltaic device includes absorber layers comprising Copper, Indium, Gallium, Selenide (CIGS) or Copper, Zinc, Tin, Sulfide (CZTS). The method includes the following steps: a colloidal suspension of metal surface-charged nanoparticles is formed; electrophoretic deposition is used to deposit the nanopartieles in a metal thin film onto a complexly shaped surface of the substrate; the metal thin film is heated in the presence of a chalcogen source to convert the metal thin film into a metal chalcogenide thin film layer; a buffer layer is formed on the metal chalcogenide thin film layer using a chemical bath deposition; an intrinsic zinc oxide insulating layer is formed adjacent to a side of the buffer layer, opposite the metal chalcogenide thin film layer, by chemical vapor deposition; and finally, a transparent conducting oxide is formed adjacent to a side of the intrinsic zinc oxide, opposite the buffer layer, by chemical vapor deposition.

Owner:IMRA AMERICA

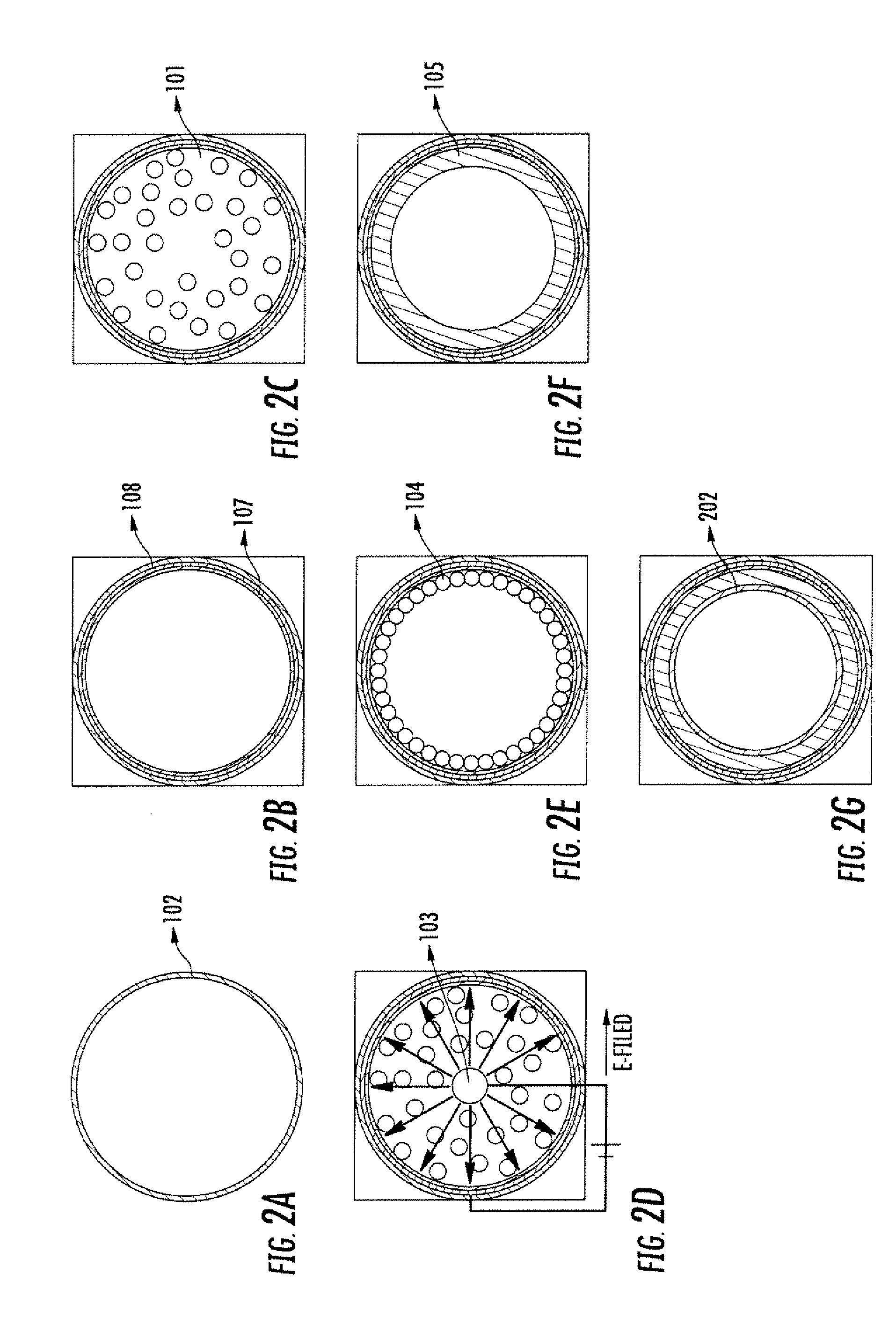

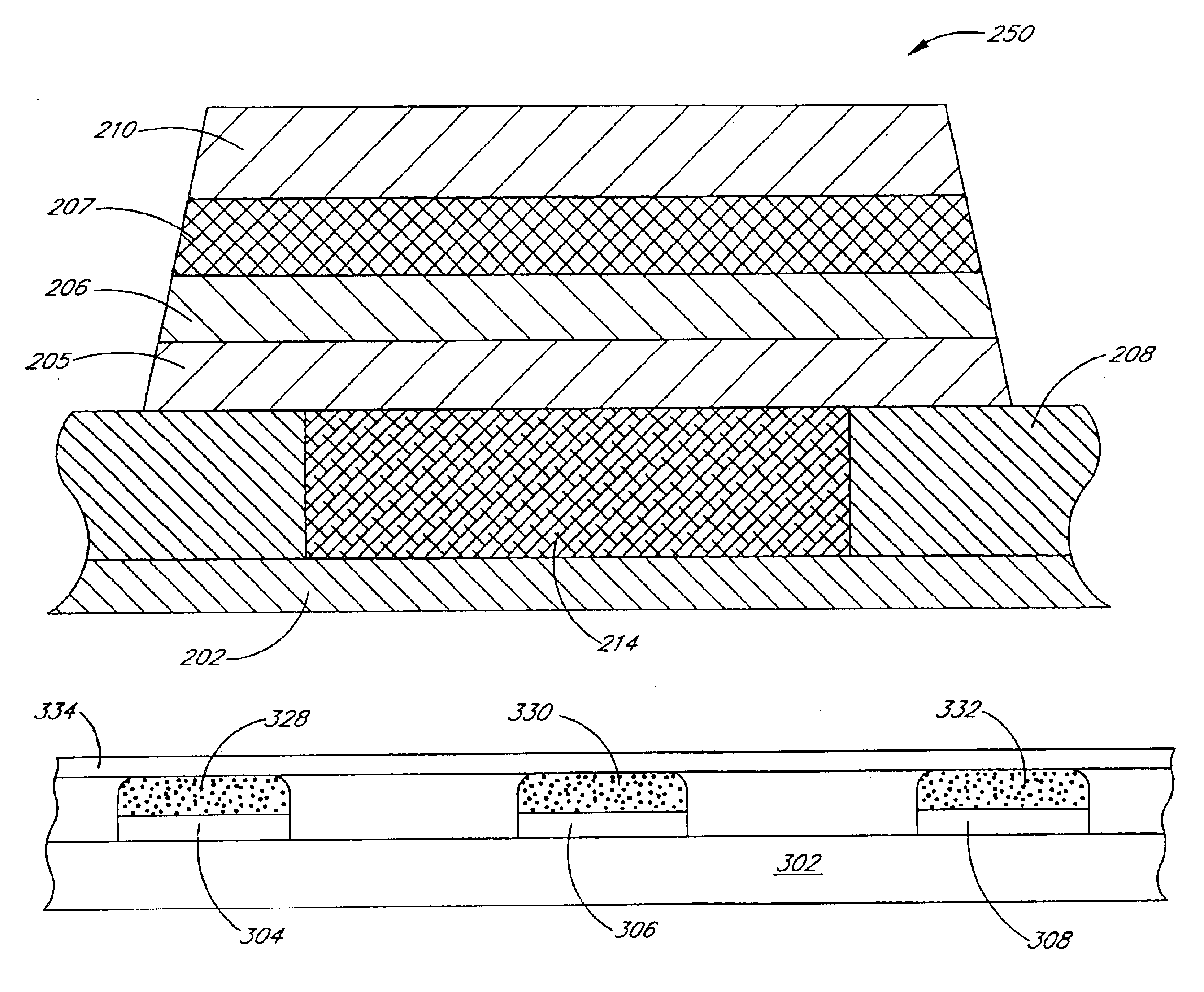

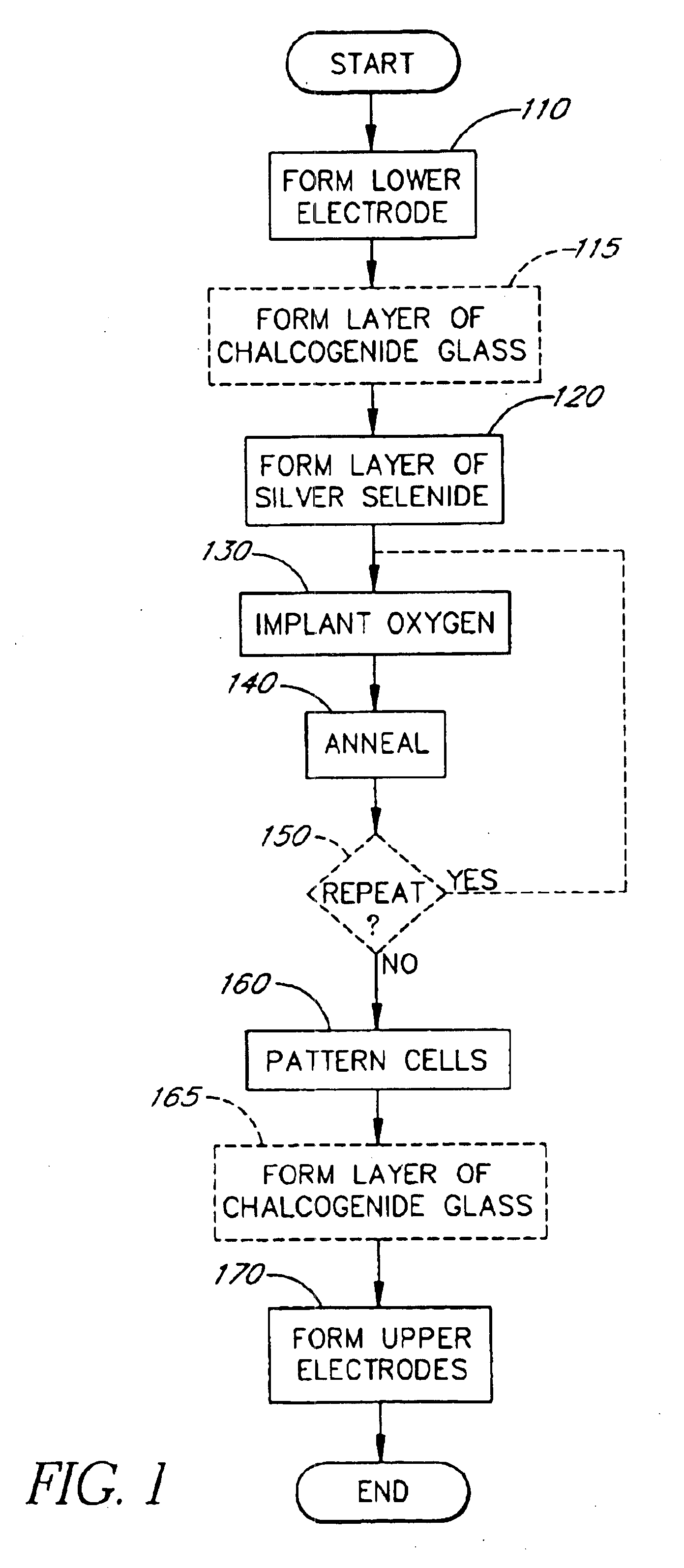

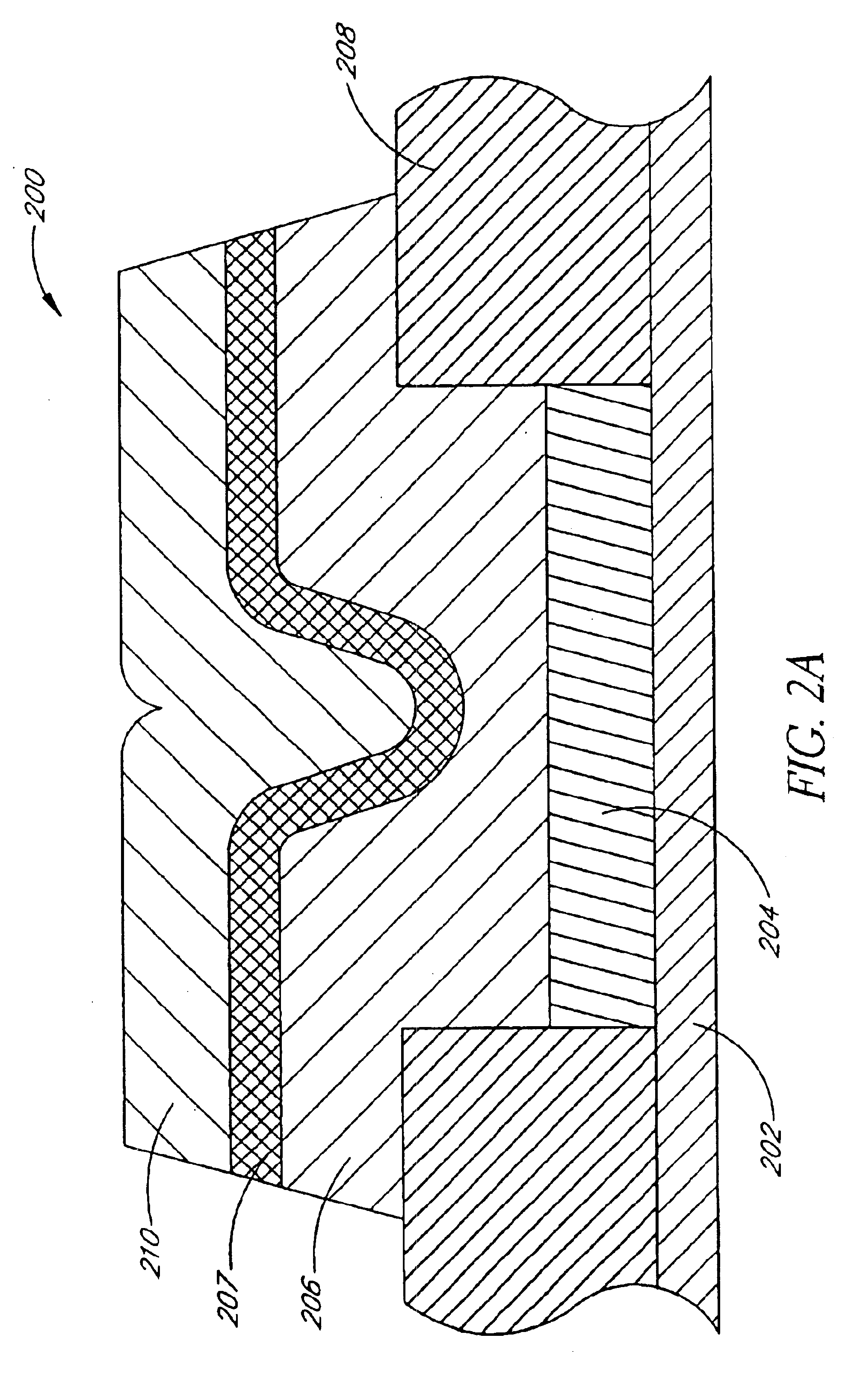

Methods to form a memory cell with metal-rich metal chalcogenide

InactiveUS6867114B2Improve uniformityEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingSulfurMetal chalcogenides

The invention relates to the fabrication of a resistance variable material cell or programmable metallization cell. The processes described herein can form a metal-rich metal chalcogenide, such as, for example, silver-rich silver selenide. Advantageously, the processes can form the metal-rich metal chalcogenide without the use of photodoping techniques and without direct deposition of the metal. For example, the process can remove selenium from silver selenide. One embodiment of the process implants oxygen to silver selenide to form selenium oxide. The selenium oxide is then removed by annealing, which results in silver-rich silver selenide. Advantageously, the processes can dope silver into a variety of materials, including non-transparent materials, with relatively high uniformity and with relatively precise control.

Owner:MICRON TECH INC

Metal chalcogenide aqueous precursors and processes to form metal chalcogenide films

InactiveUS20110206599A1Selenium/tellurium compundsPhosphorus sulfur/selenium/tellurium compoundsSimple Organic CompoundsFormate

Metal chalocogenide precursor solutions are described that comprise an aqueous solvent, dissolved metal formate salts and a chalcogenide source composition. The chalcogenide source compositions can be organic compounds lacking a carbon-carbon bond. The precursors are designed to form a desired metal chalcogenide upon thermal processing into films with very low levels of contamination. Potentially contaminating elements in the precursors form gaseous or vapor by-products that escape from the vicinity of the product metal chalcogenide films.

Owner:INPRIA CORP

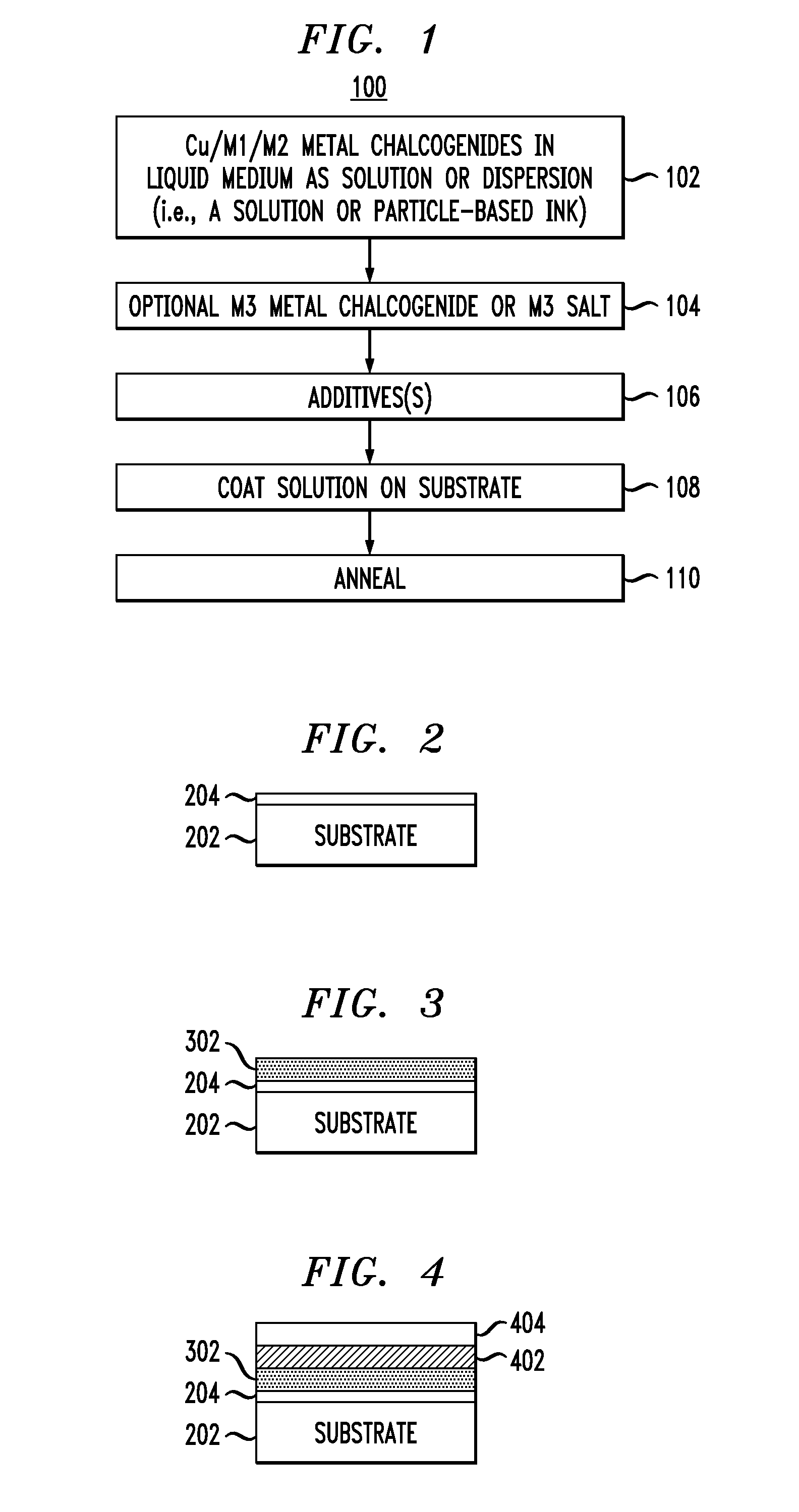

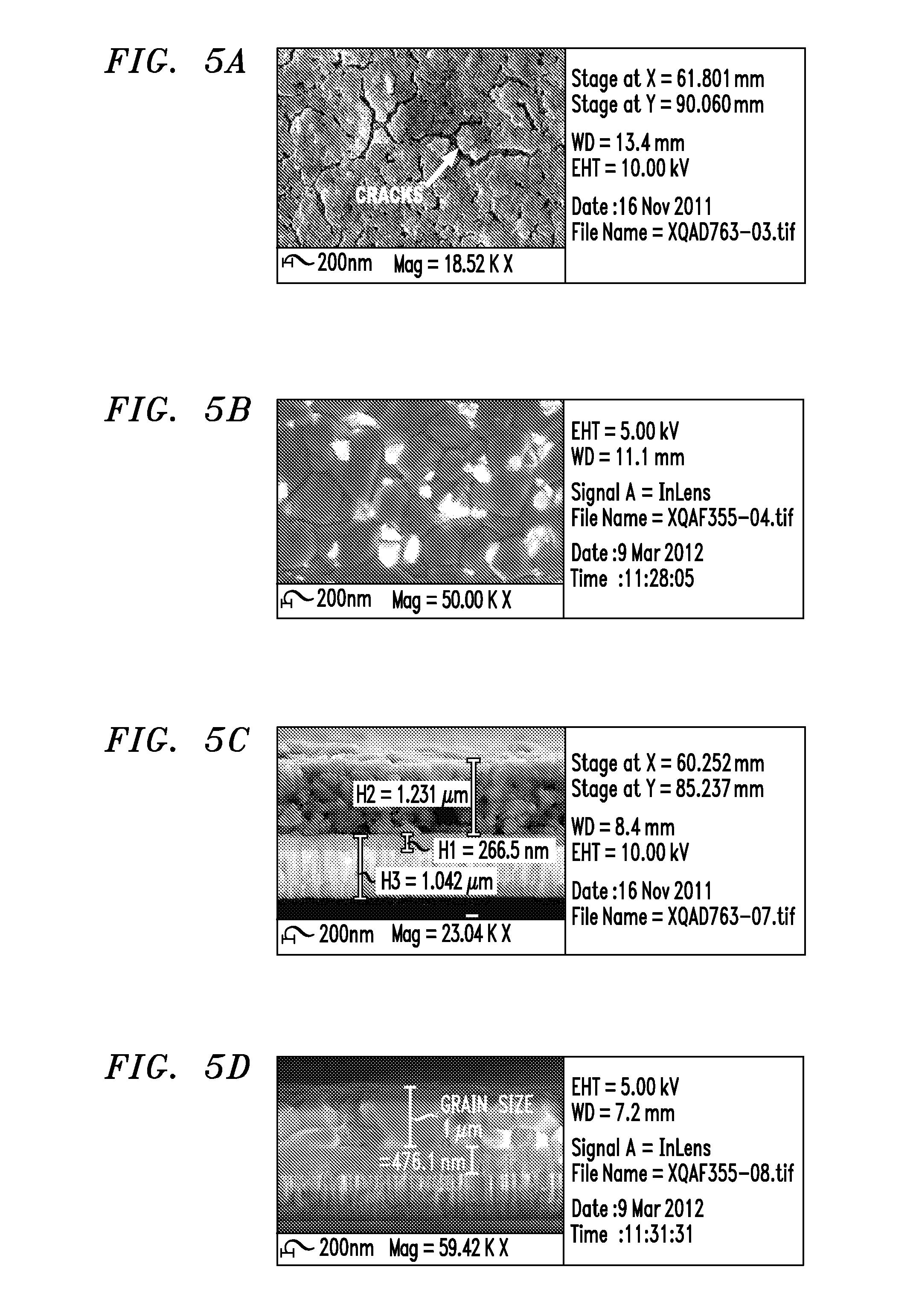

Techniques for Forming a Chalcogenide Thin Film Using Additive to a Liquid-Based Chalcogenide Precursor

InactiveUS20130316519A1Improve energy conversion efficiencyIncrease the granular structureSemiconductor/solid-state device manufacturingSemiconductor devicesLiquid mediumSulfur

Techniques for enhancing energy conversion efficiency in chalcogenide-based photovoltaic devices by improved grain structure and film morphology through addition of urea into a liquid-based precursor are provided. In one aspect, a method of forming a chalcogenide film includes the following steps. Metal chalcogenides are contacted in a liquid medium to form a solution or a dispersion, wherein the metal chalcogenides include a Cu chalcogenide, an M1 and an M2 chalcogenide, and wherein M1 and M2 each include an element selected from the group consisting of: Ag, Mn, Mg, Fe, Co, Cd, Ni, Cr, Zn, Sn, In, Ga, Al, and Ge. At least one organic additive is contacted with the metal chalcogenides in the liquid medium. The solution or the dispersion is deposited onto a substrate to form a layer. The layer is annealed at a temperature, pressure and for a duration sufficient to form the chalcogenide film.

Owner:IBM CORP

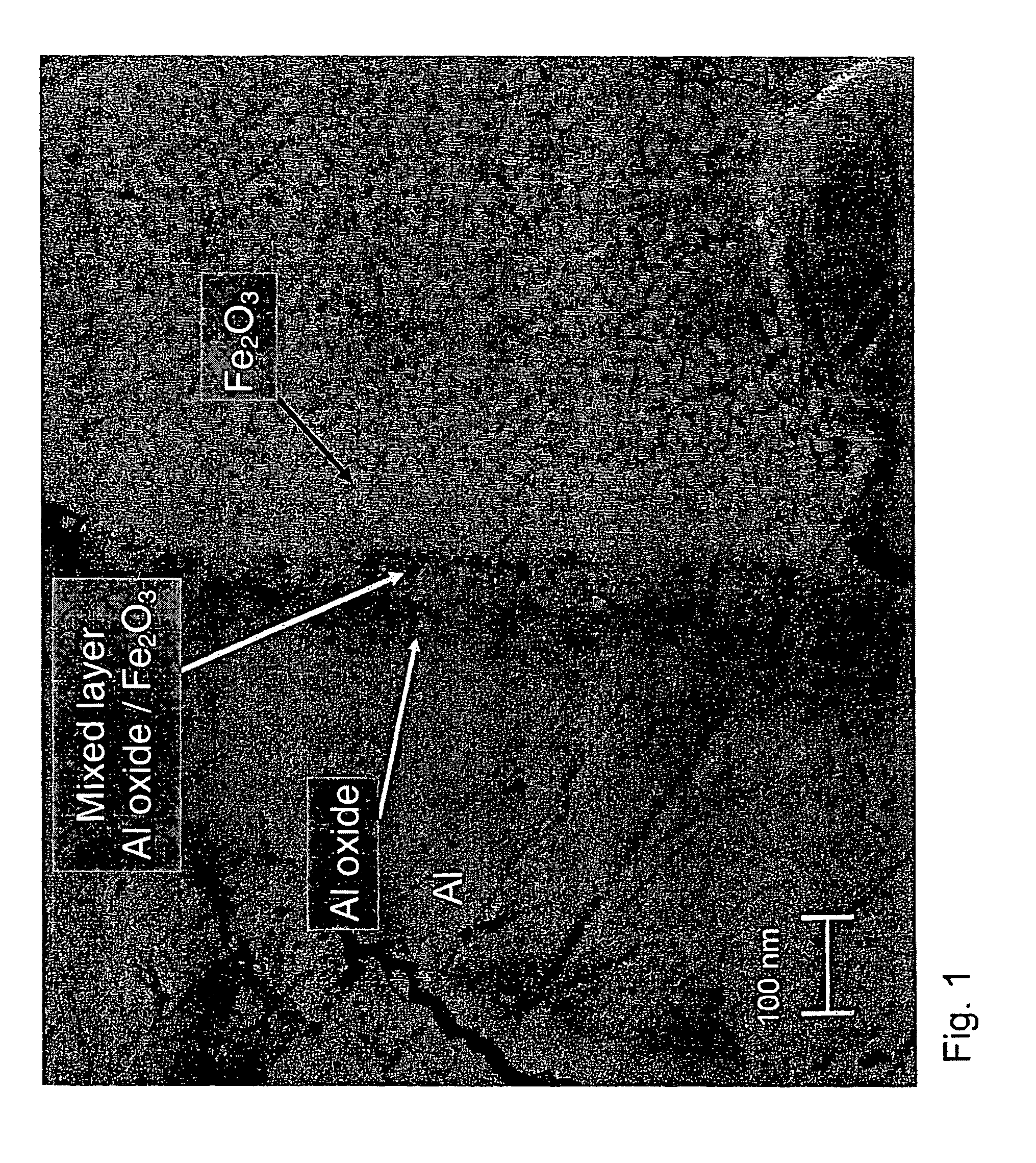

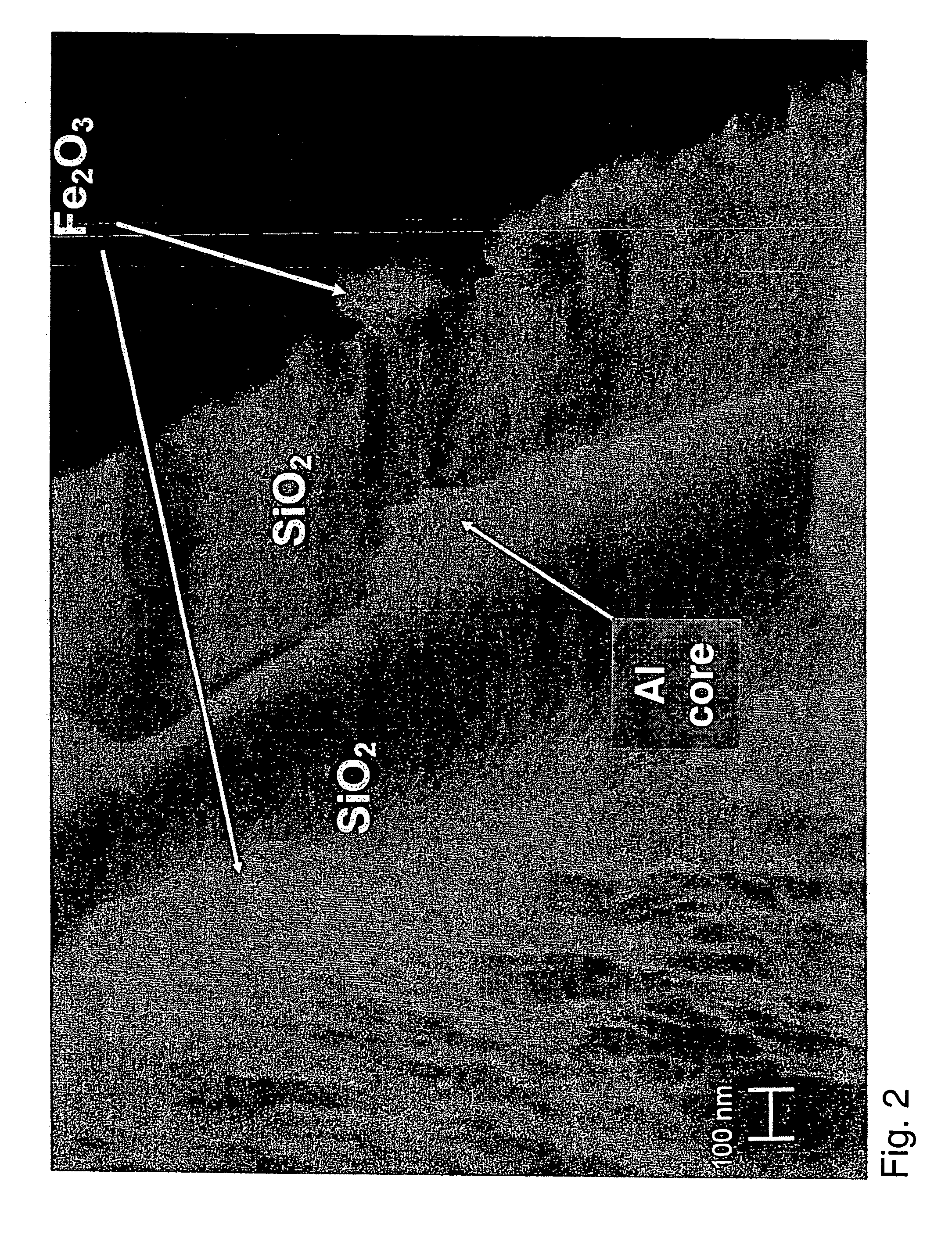

Effect pigments having an aluminum or an aluminum aloy core, process for the production thereof and use thereof

ActiveUS7828890B2Minimal thicknessEasy to useCosmetic preparationsPigmenting treatmentMetallic aluminumRefractive index

The invention relates to effect pigments having an aluminum core or aluminum alloy core and an aluminum oxide-containing or aluminum oxide / hydroxide-containing layer enveloping said aluminum core or aluminum alloy core, obtained by chemical wet-process oxidation of lamellar aluminum pigments or aluminum alloy pigments, the content of metallic aluminum in the aluminum core or aluminum alloy core being not more than 90% by weight, based on the total weight of the pigment, wherein the oxidized aluminum pigments or aluminum alloy pigments exhibit at least one highly refractive metal chalcogenide layer having a refractive index of >1.95, and a mixed layer is formed between the highly refractive metal chalcogenide layer and the enveloping aluminum oxide-containing or aluminum oxide / hydroxide-containing layer. The invention further relates to a process for the production of such effect pigments and to the use thereof.

Owner:ECKART GMBH & CO KG

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES US INC

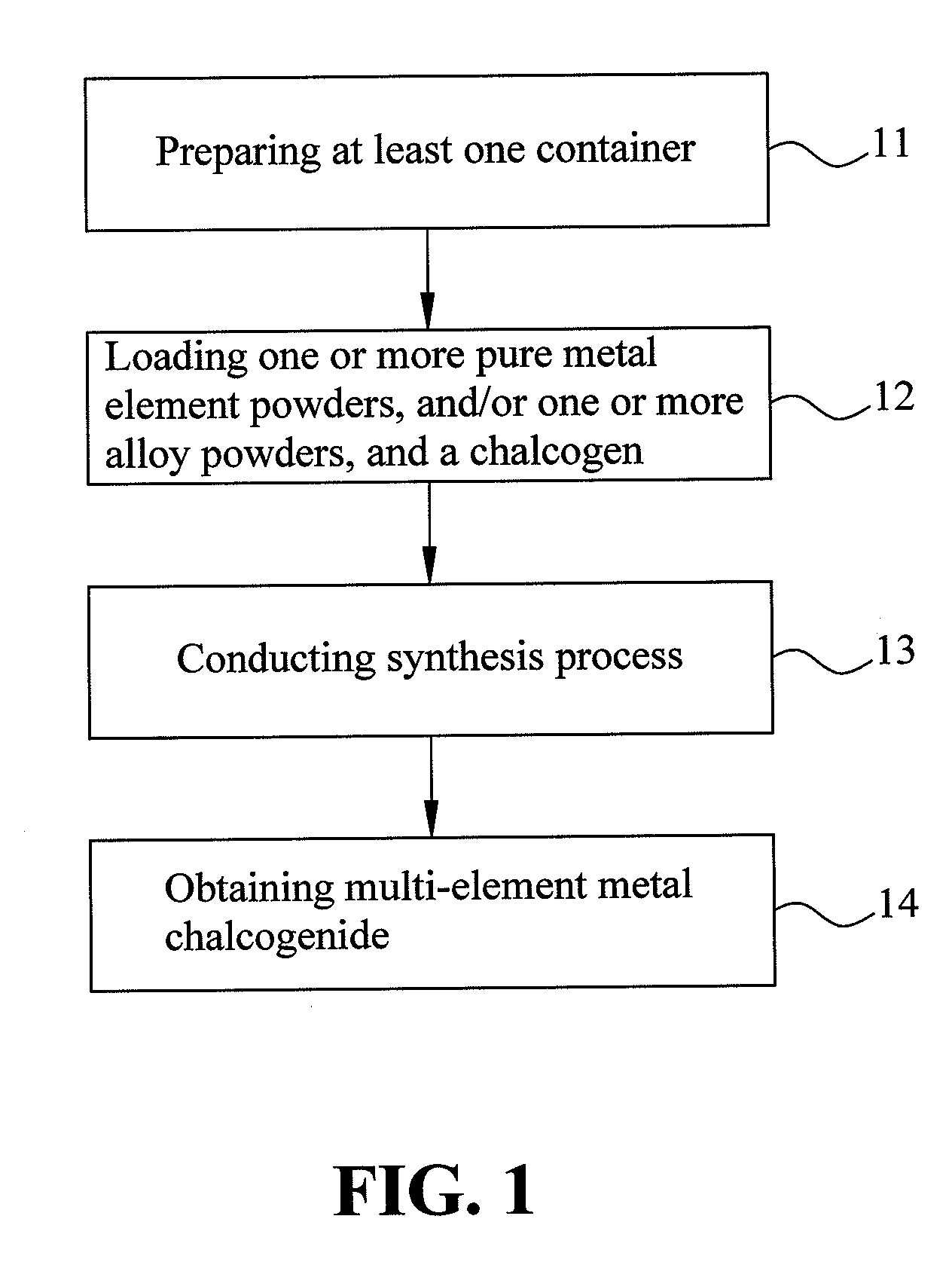

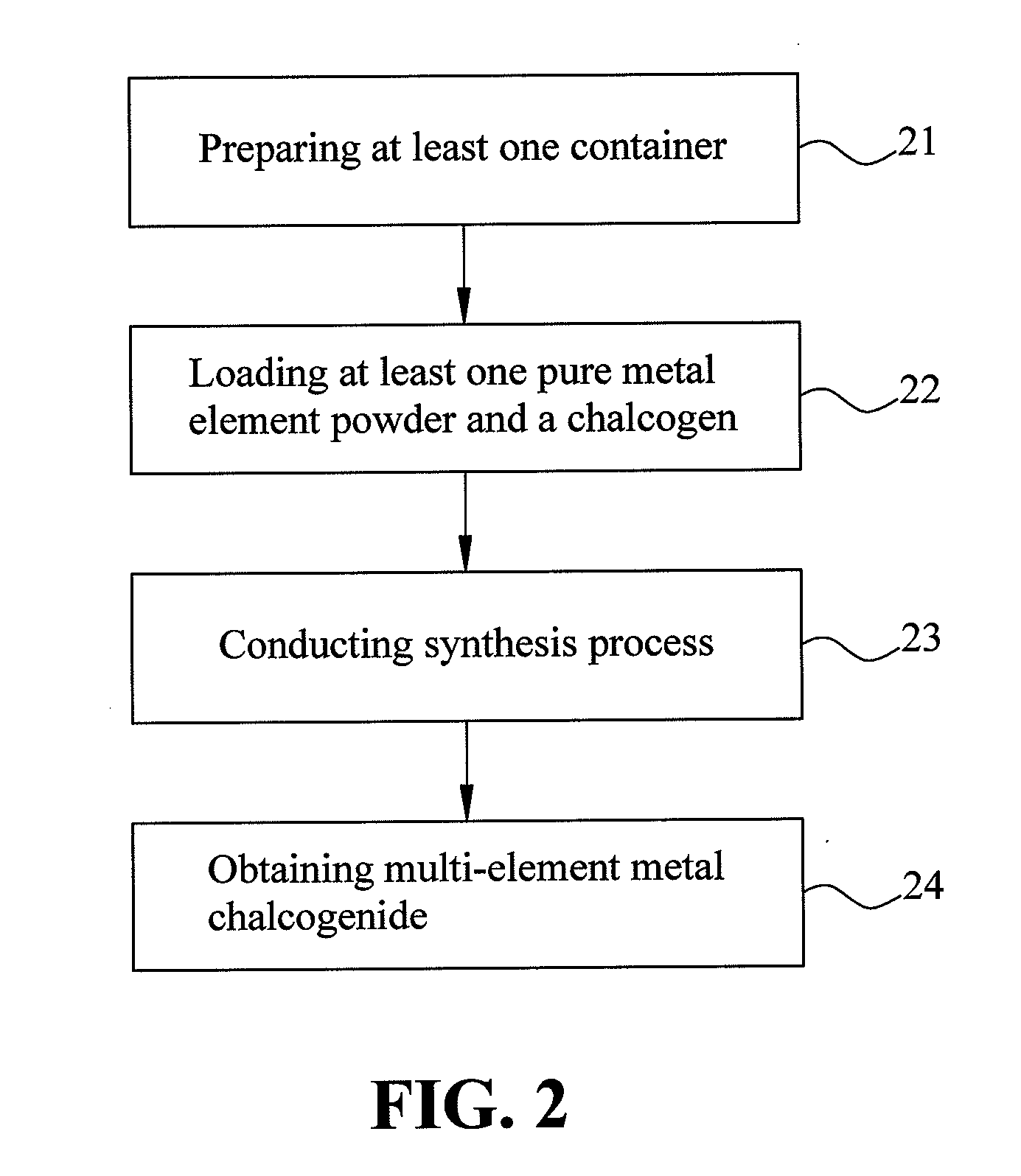

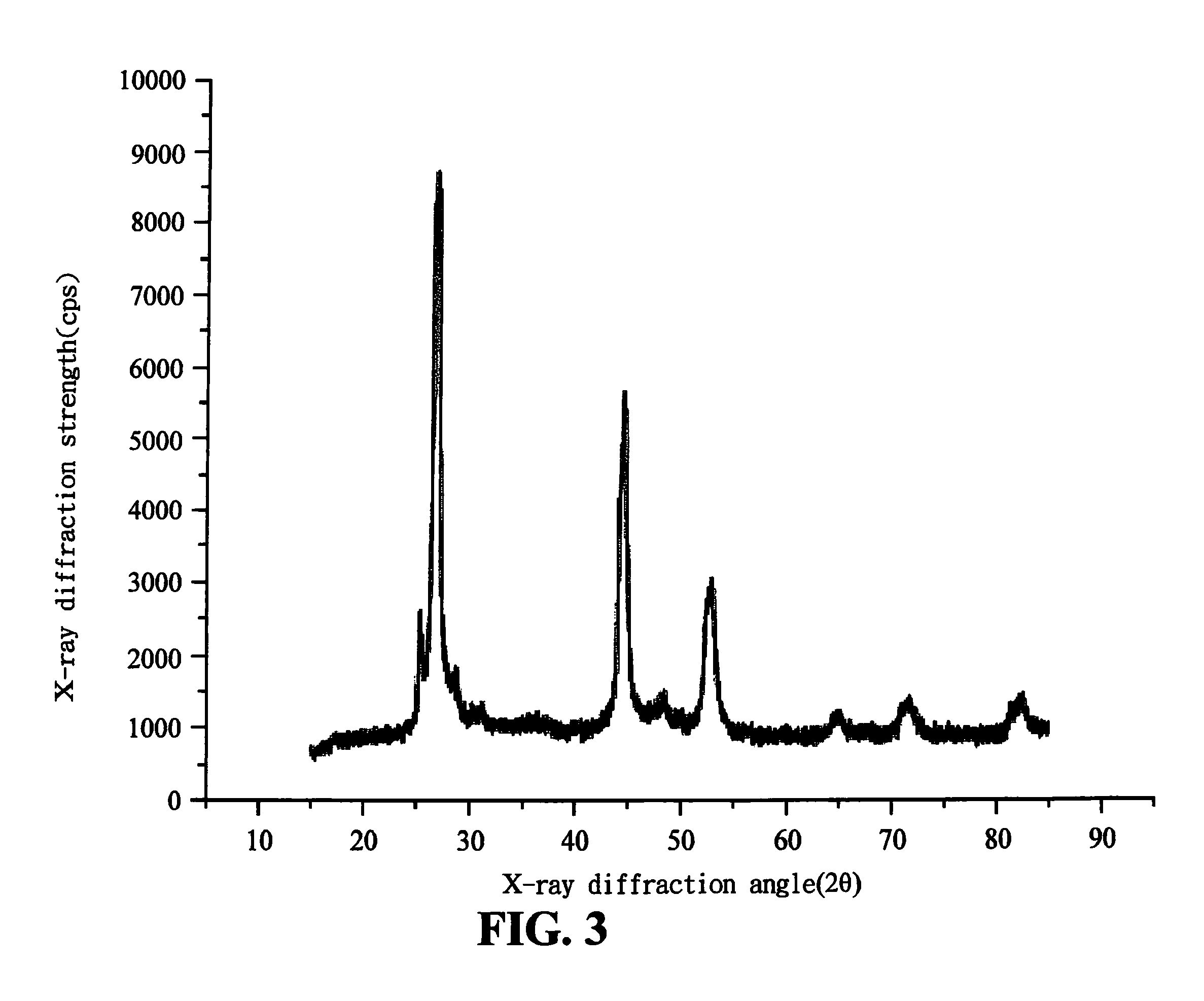

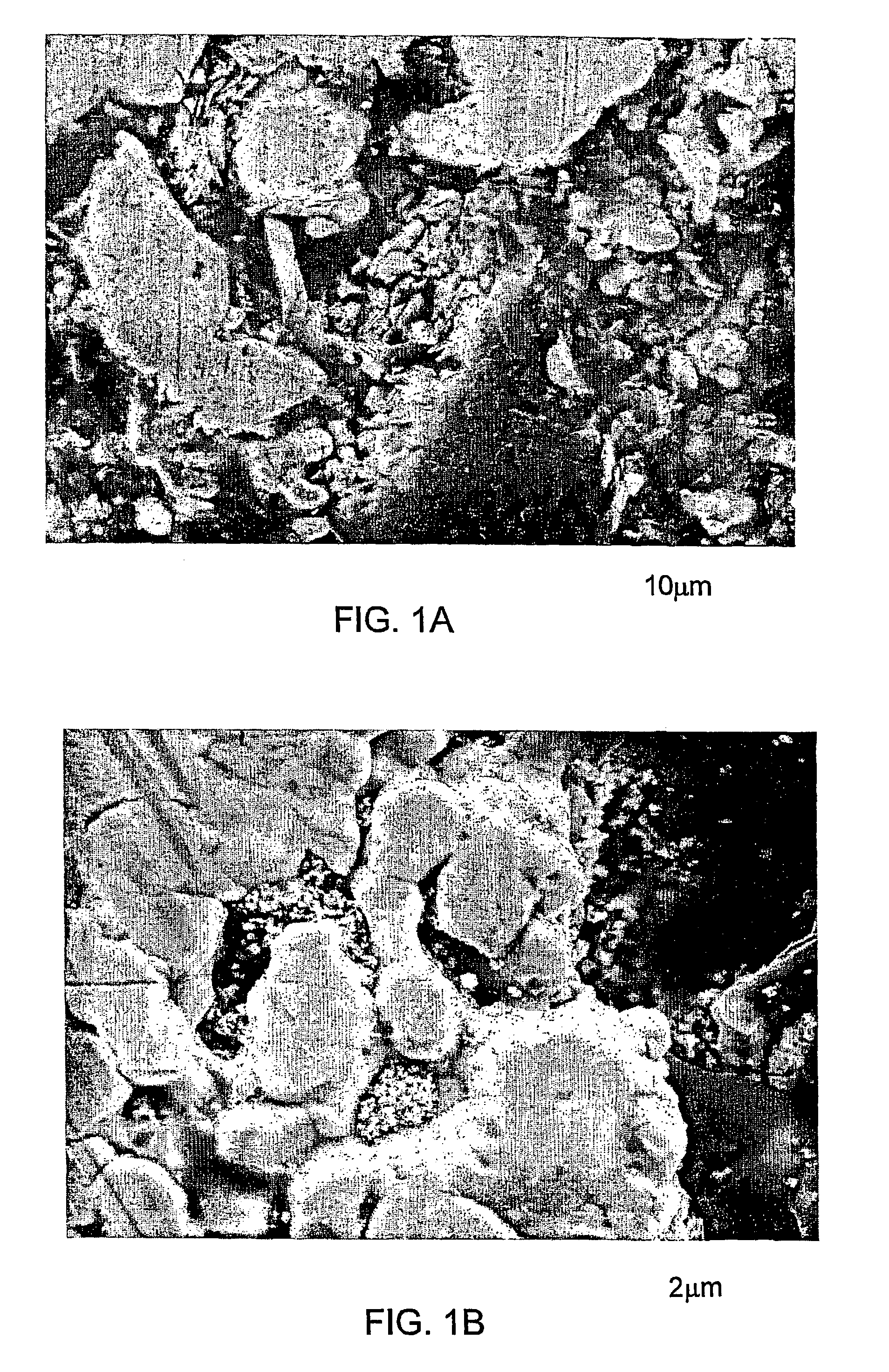

Multi-element metal chalcogenide and method for preparing the same

InactiveUS20100227066A1Simple processLow production costNanotechFinal product manufactureSolution phase synthesisMetal chalcogenides

A multi-element metal chalcogenide and a method for preparing the same are provided. According to the present invention, the multi-element metal chalcogenide includes multiple metal elements. According to the present invention, a multi-element metal chalcogenide powder is prepared, and all of the multiple metal elements of the multi-element metal chalcogenide are derived from simple substance powders of the metal elements, and / or one or more alloy powders mixed in accordance with a mole ratio. Then, a solution phase synthesis of the powder of the multi-element metal chalcogenide is conducted under the normal pressure to prepare the multi-element metal chalcogenide. The multi-element metal chalcogenide can be coated to obtain a film or used to make a target and then bombard the target for sputtering a film. In such a way, a selenization process which is conventional in fabricating the semiconductor solar cell is eliminated, thus improving the production yield and efficiency.

Owner:CHUNG JUN WEN +1

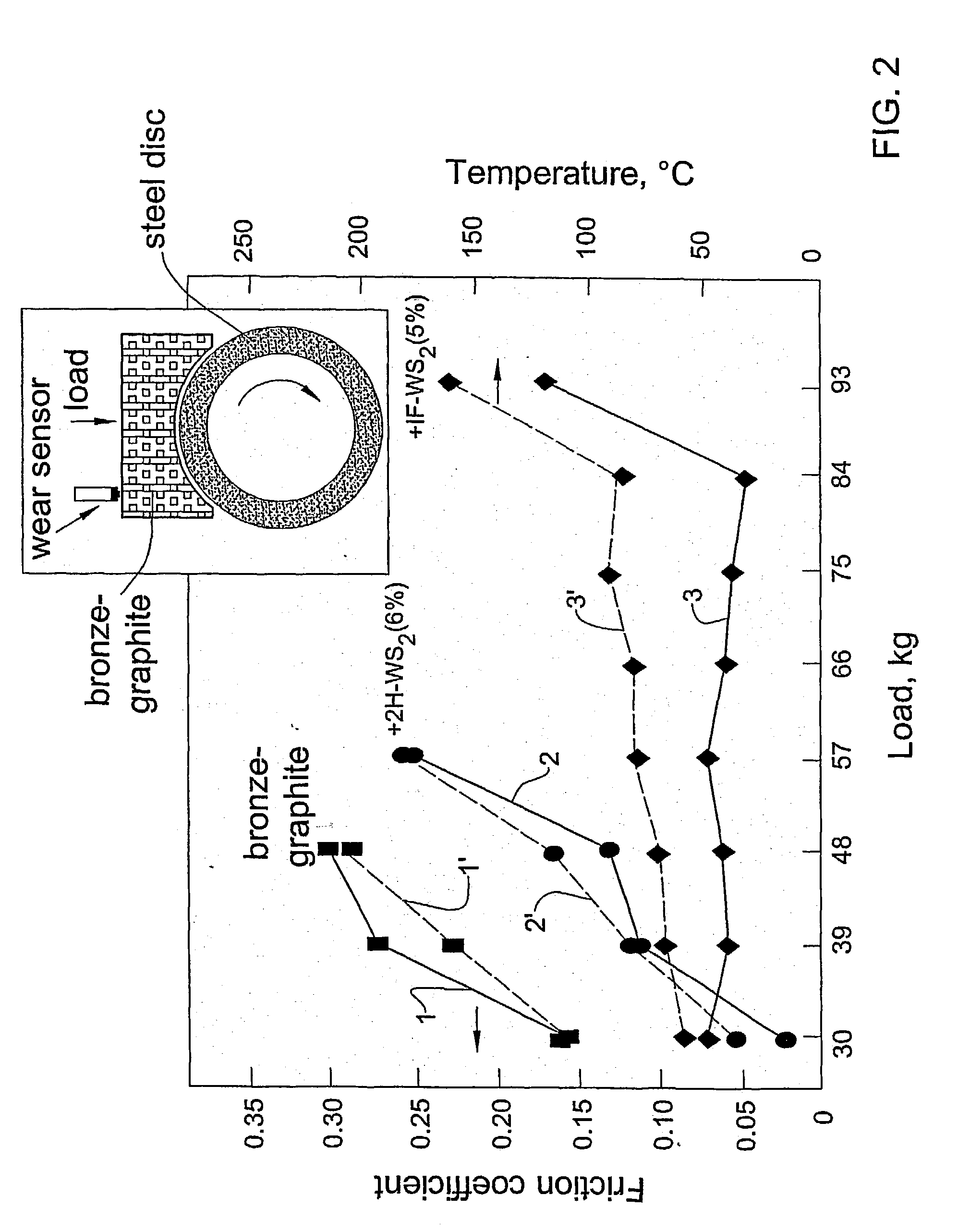

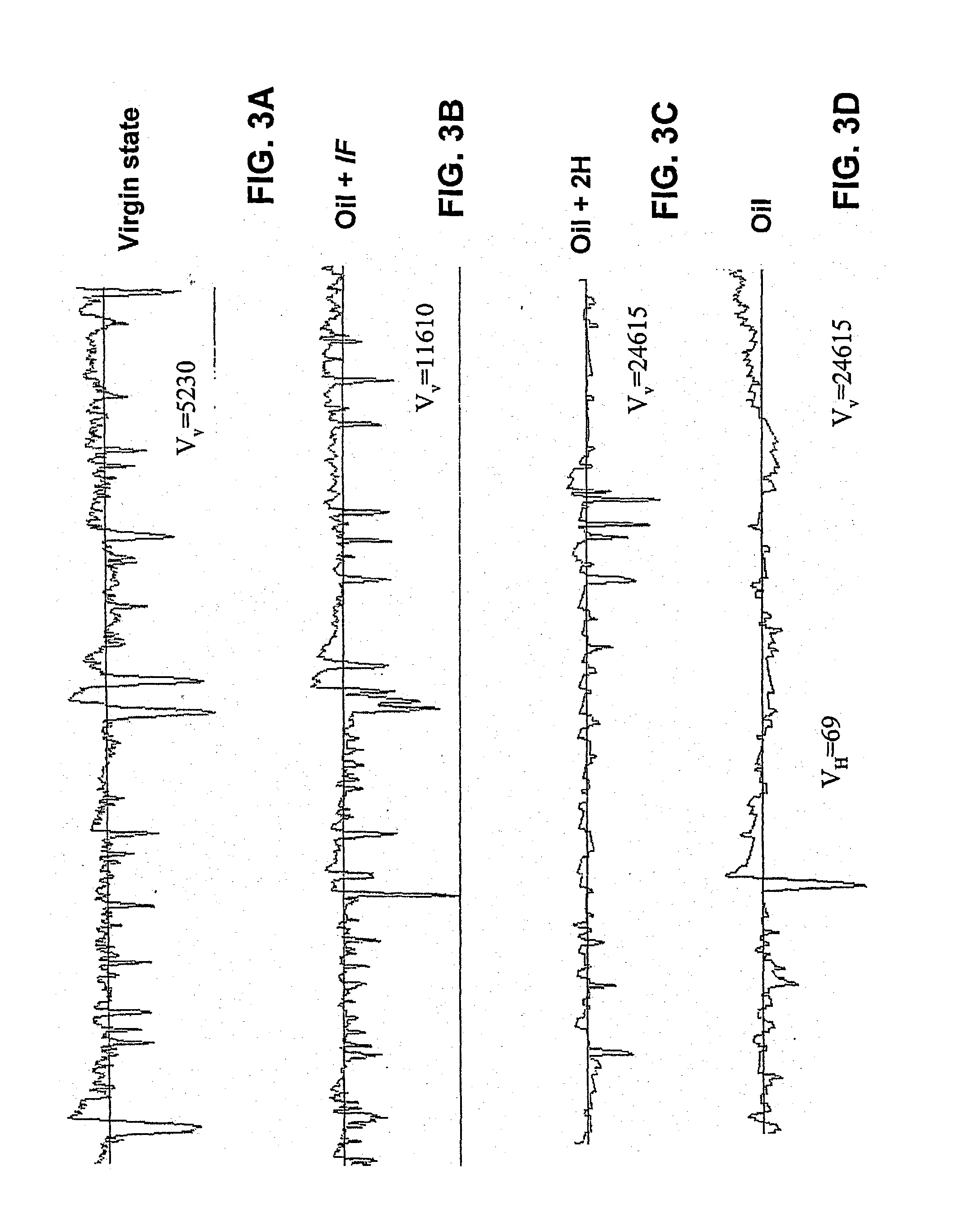

Hollow fullerene-like nanoparticles as solid lubricants in composite metal matrices

InactiveUS20030144155A1Improve carrying capacityReduce wearMaterial nanotechnologyBearing componentsPorositySemiconductor materials

The present invention provides a new composite material comprising a porous matrix made of metal, metal alloy or semiconducting material and hollow fullerene-like nanoparticles of a metal chalcogenide compound or mixture of such compounds. The composite material is characterized by having a porosity between about 10% and about 40%. The amount of the hallow nanoparticles in the composite material is 1-20 wt. %.

Owner:HOLON ACADEMIC INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com