Patents

Literature

398 results about "Chalcogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chalcogens (/ˈkælkədʒɪnz/) are the chemical elements in group 16 of the periodic table. This group is also known as the oxygen family. It consists of the elements oxygen (O), sulfur (S), selenium (Se), tellurium (Te), and the radioactive element polonium (Po). The chemically uncharacterized synthetic element livermorium (Lv) is predicted to be a chalcogen as well. Often, oxygen is treated separately from the other chalcogens, sometimes even excluded from the scope of the term "chalcogen" altogether, due to its very different chemical behavior from sulfur, selenium, tellurium, and polonium. The word "chalcogen" is derived from a combination of the Greek word khalkόs (χαλκός) principally meaning copper (the term was also used for bronze/brass, any metal in the poetic sense, ore or coin), and the Latinised Greek word genēs, meaning born or produced.

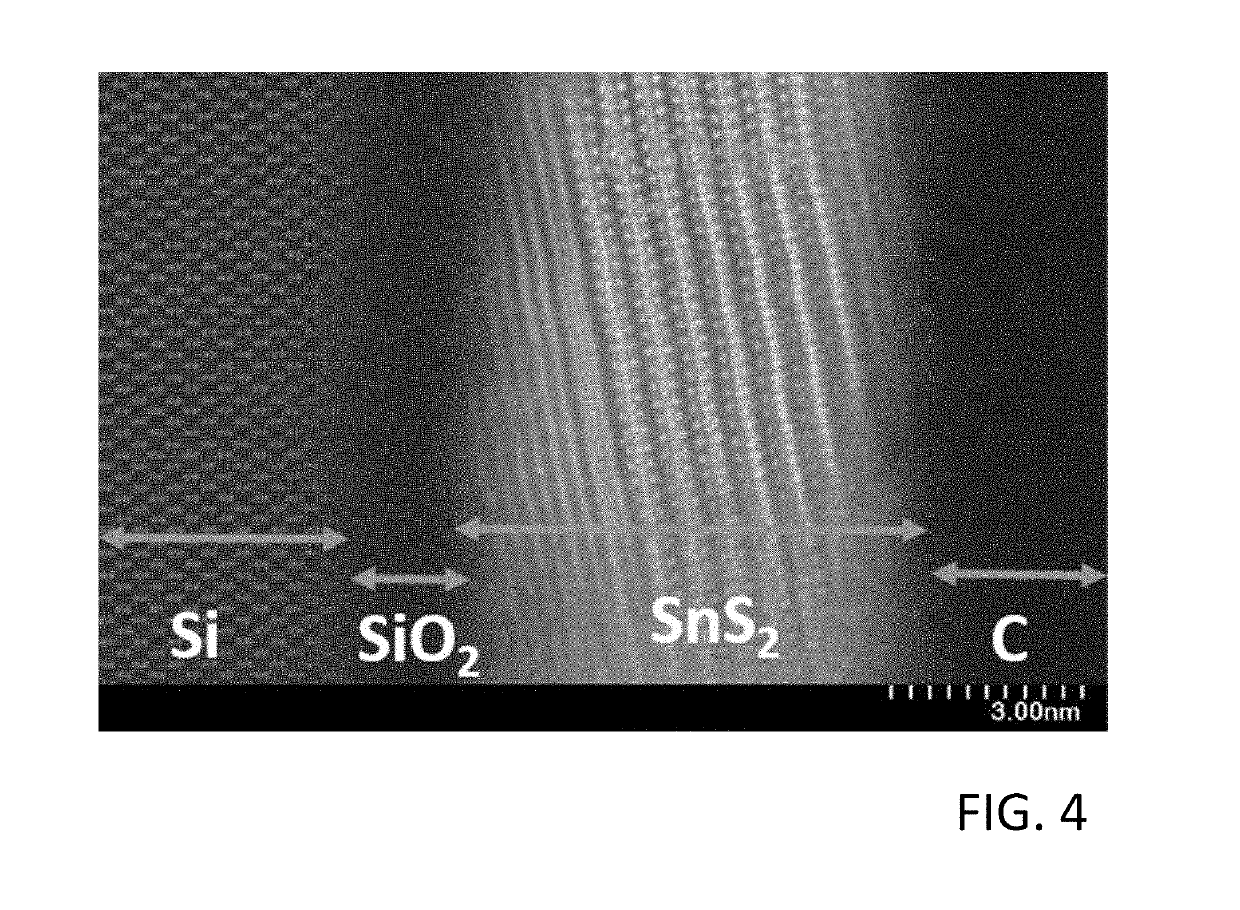

Method of Producing Transition Metal Dichalcogenide Layer

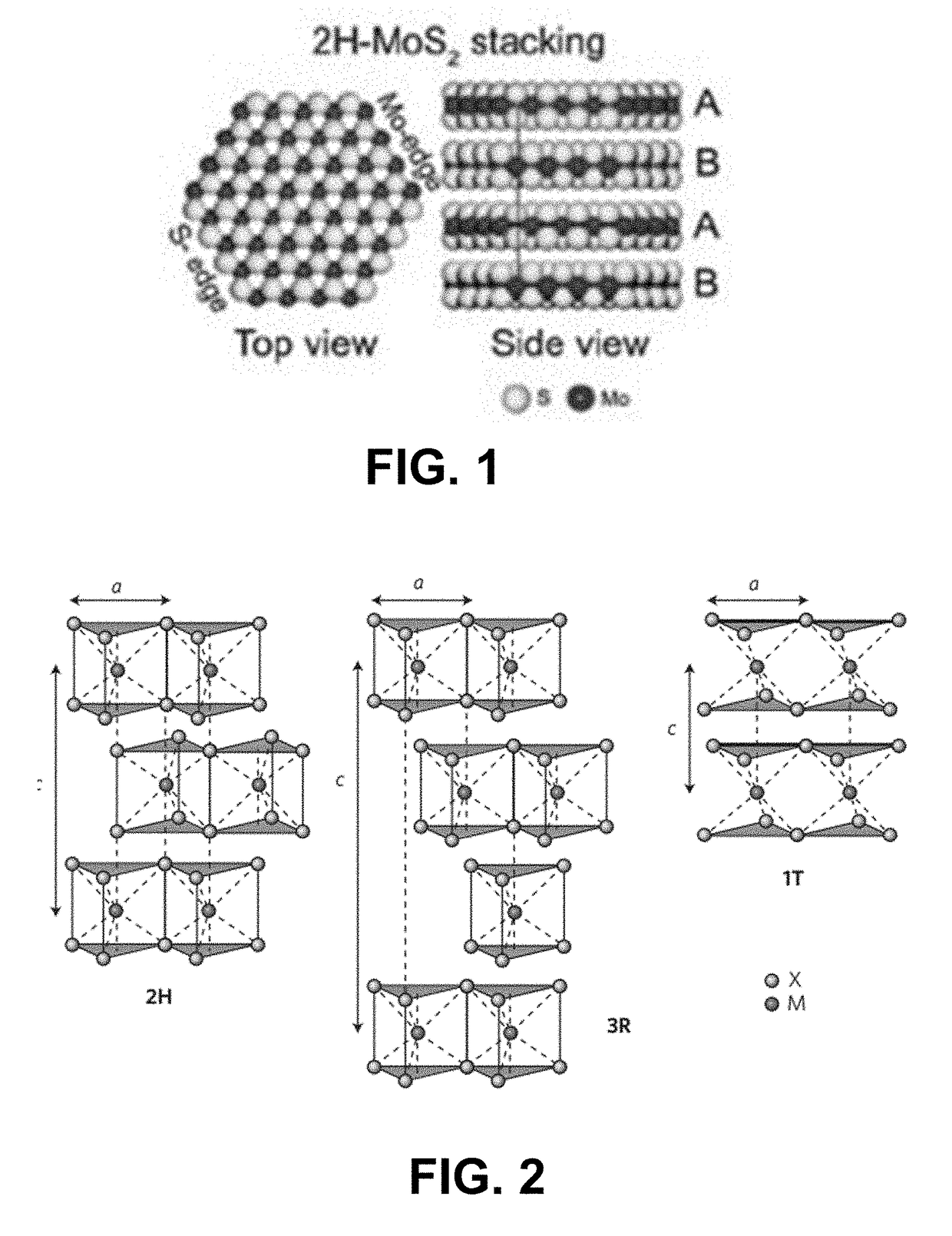

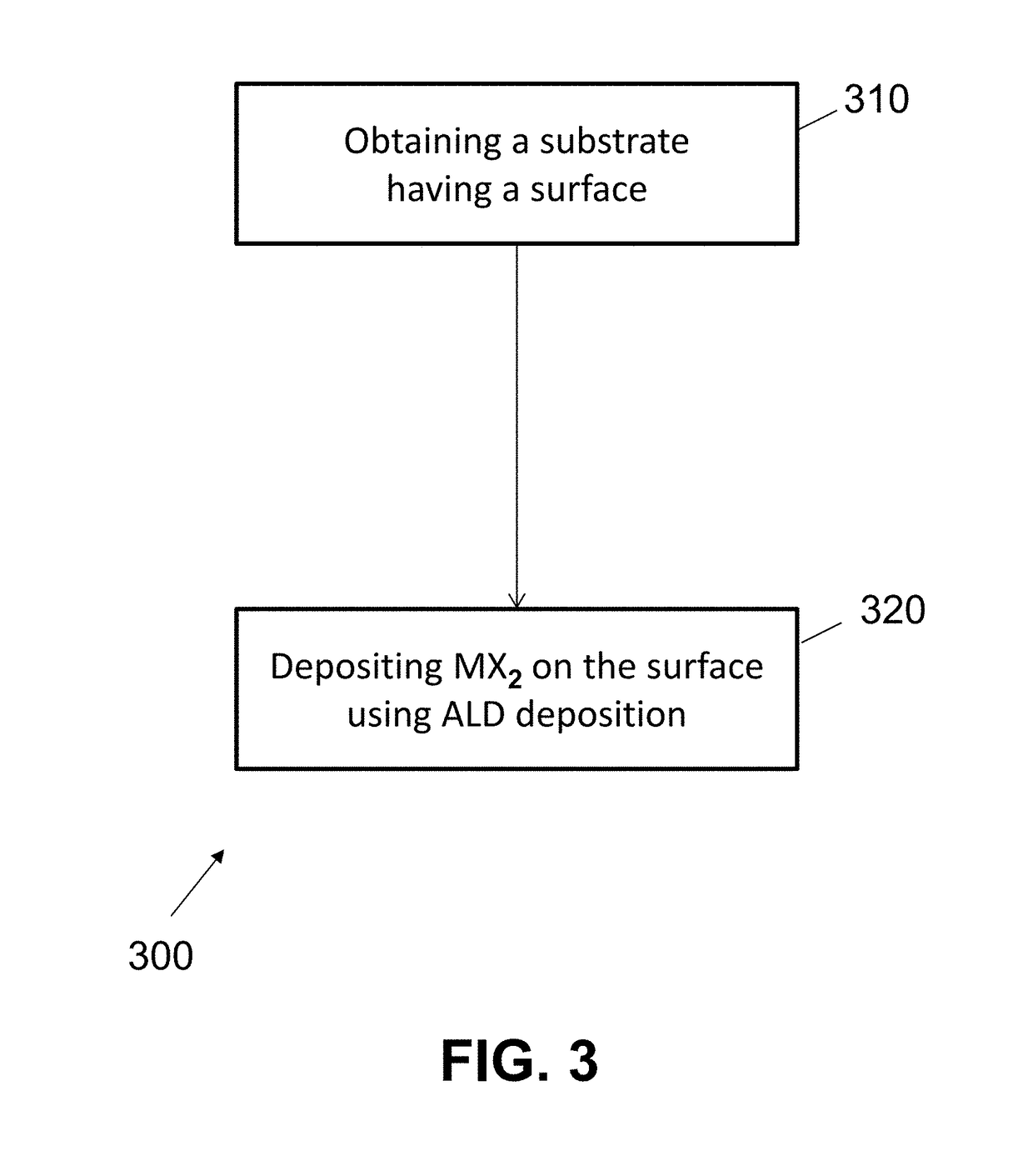

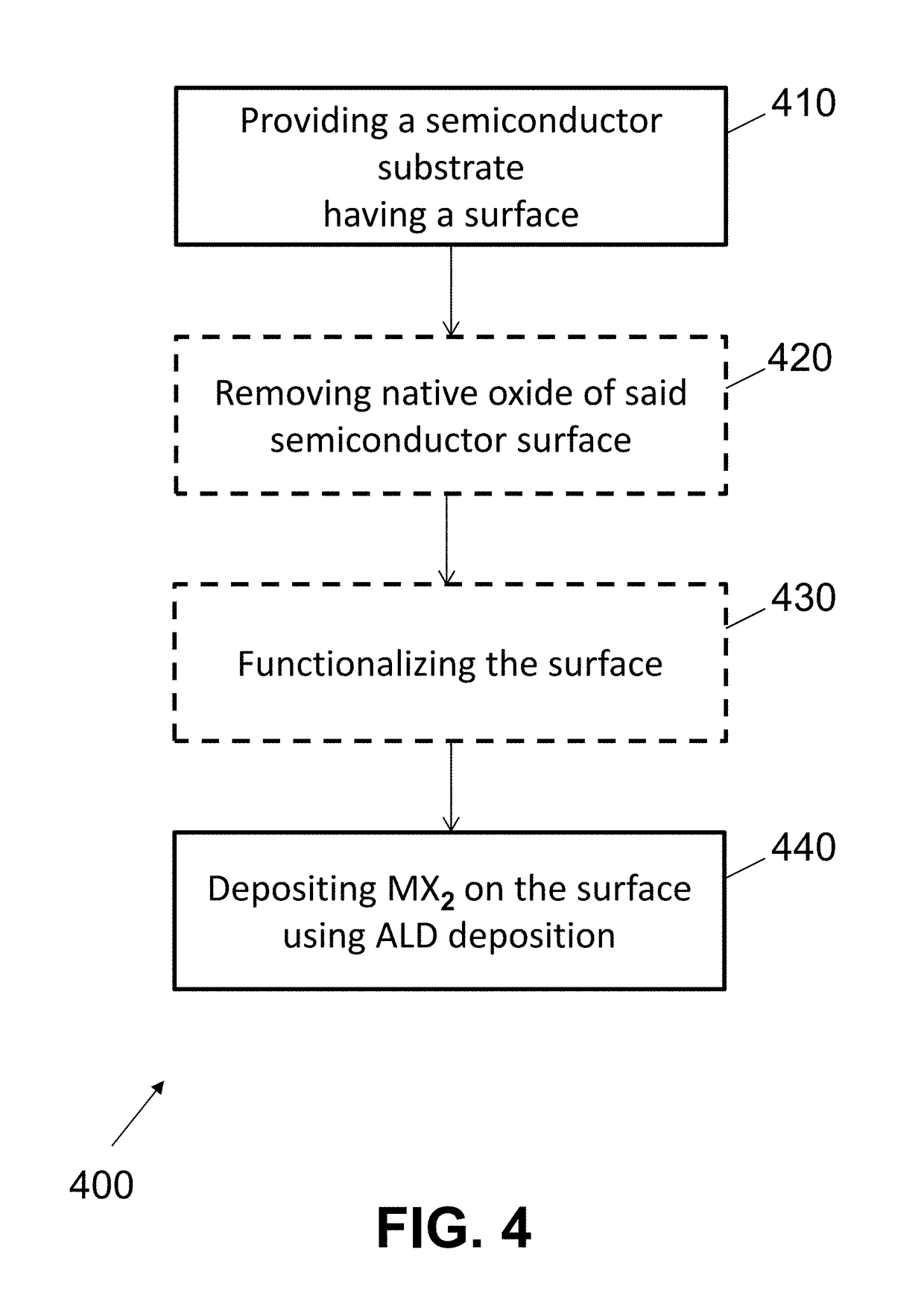

ActiveUS20170250075A1Advantageously producedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDeposition temperatureChalcogen

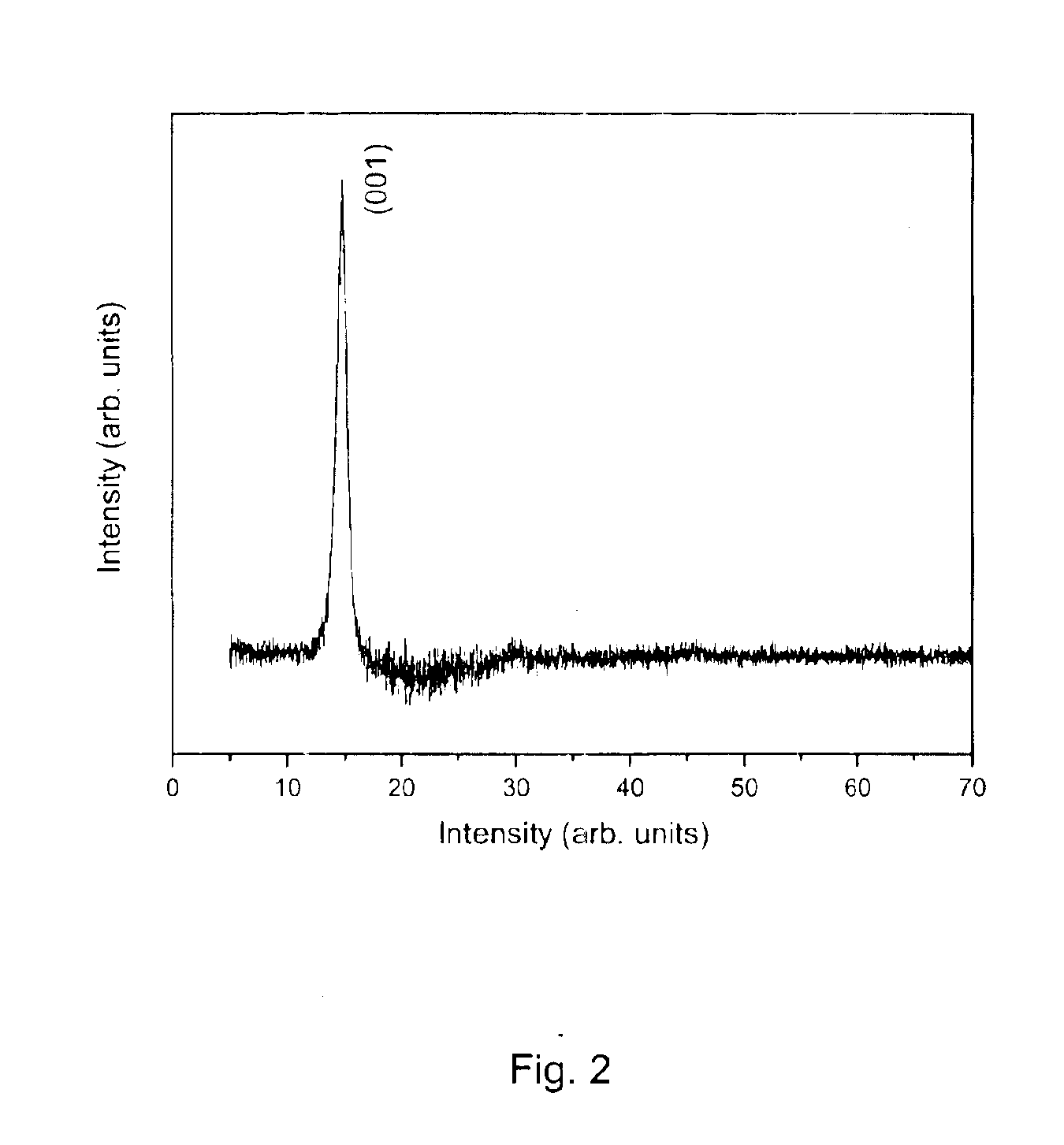

Method of producing one or more transition metal dichalcogenide (MX2) layers on a substrate, comprising the steps of: obtaining a substrate having a surface and depositing MX2 on the surface using ALD deposition, starting from a metal halide precursor and a chalcogen source (H2X), at a deposition temperature of about 300° C. Suitable metals are Mo and W, suitable chalcogenides are S, Se and Te. The substrate may be (111) oriented. Also mixtures of two or more MX2 layers of different compositions can be deposited on the substrate, by repeating at least some of the steps of the method.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

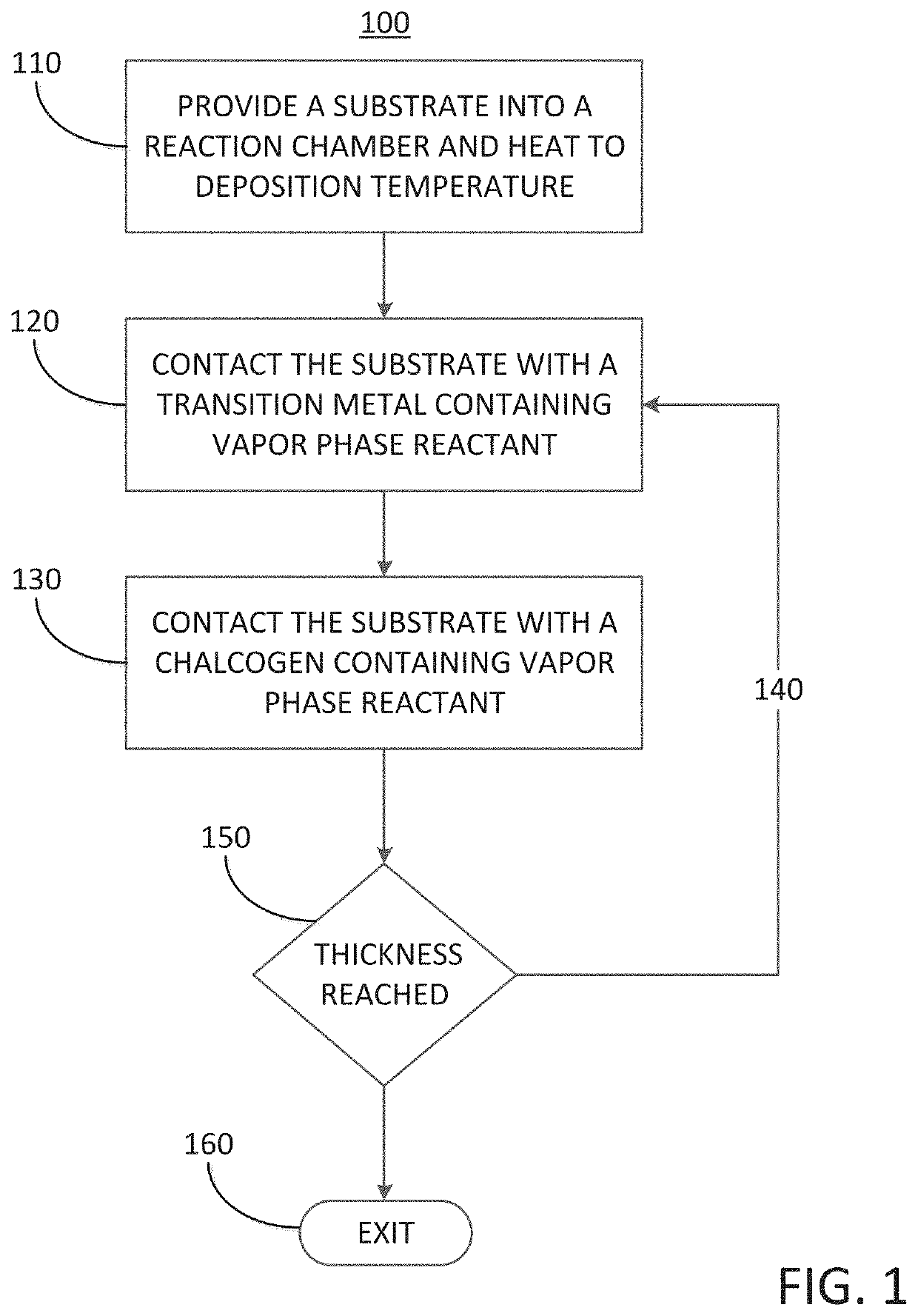

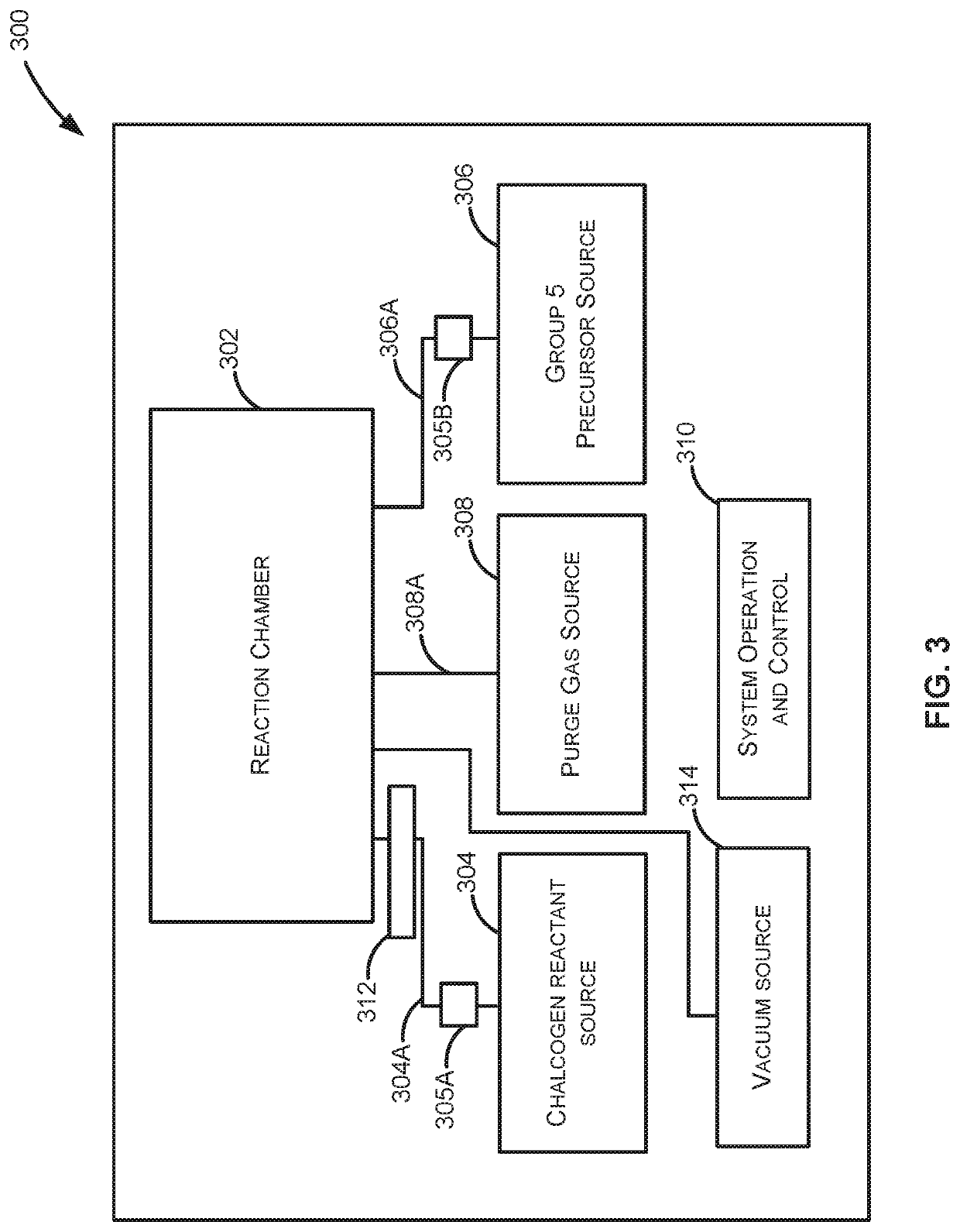

Method for depositing a metal chalcogenide on a substrate by cyclical deposition

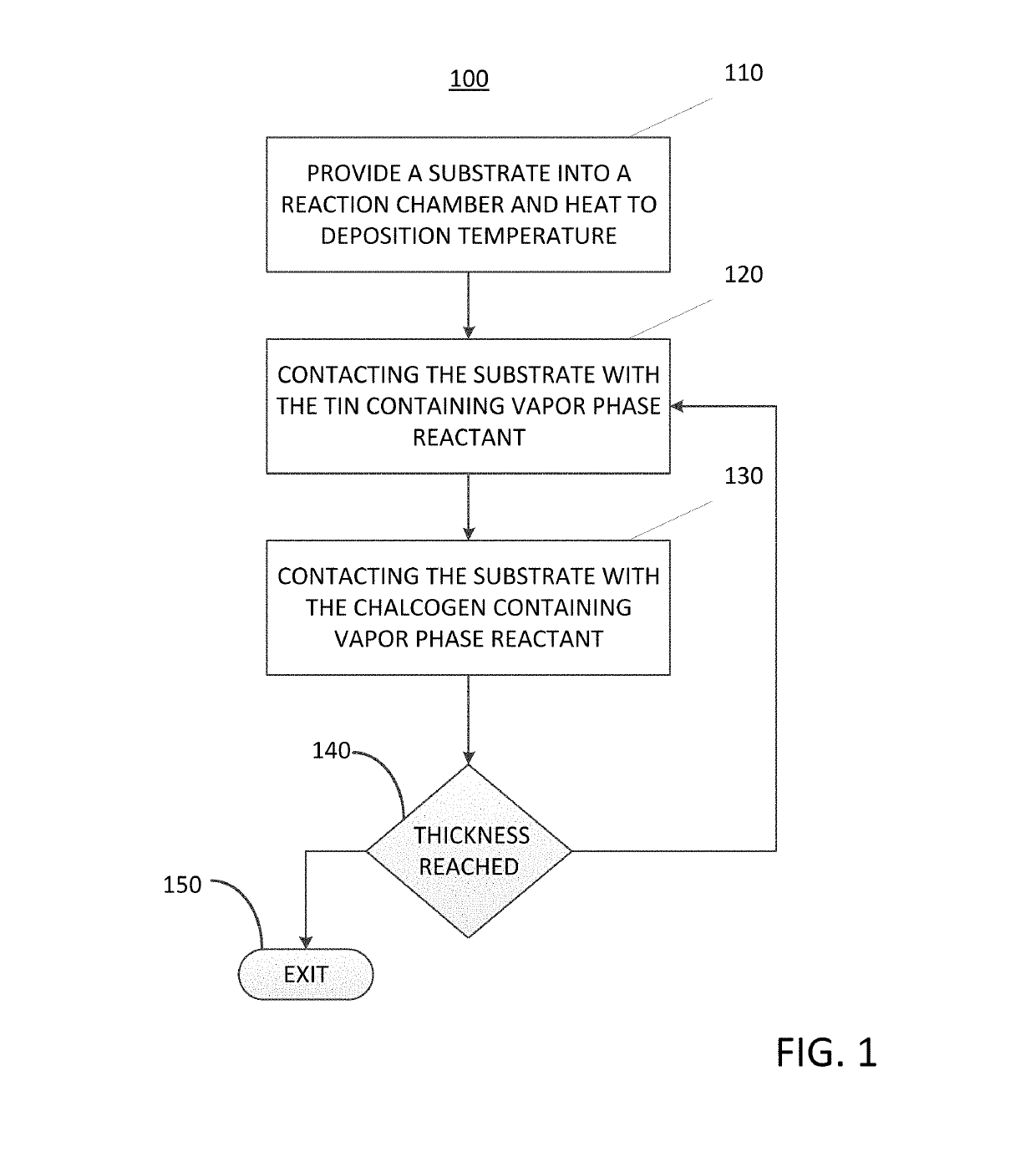

ActiveUS10319588B2TransistorSemiconductor/solid-state device manufacturingMetal chalcogenidesChalcogen

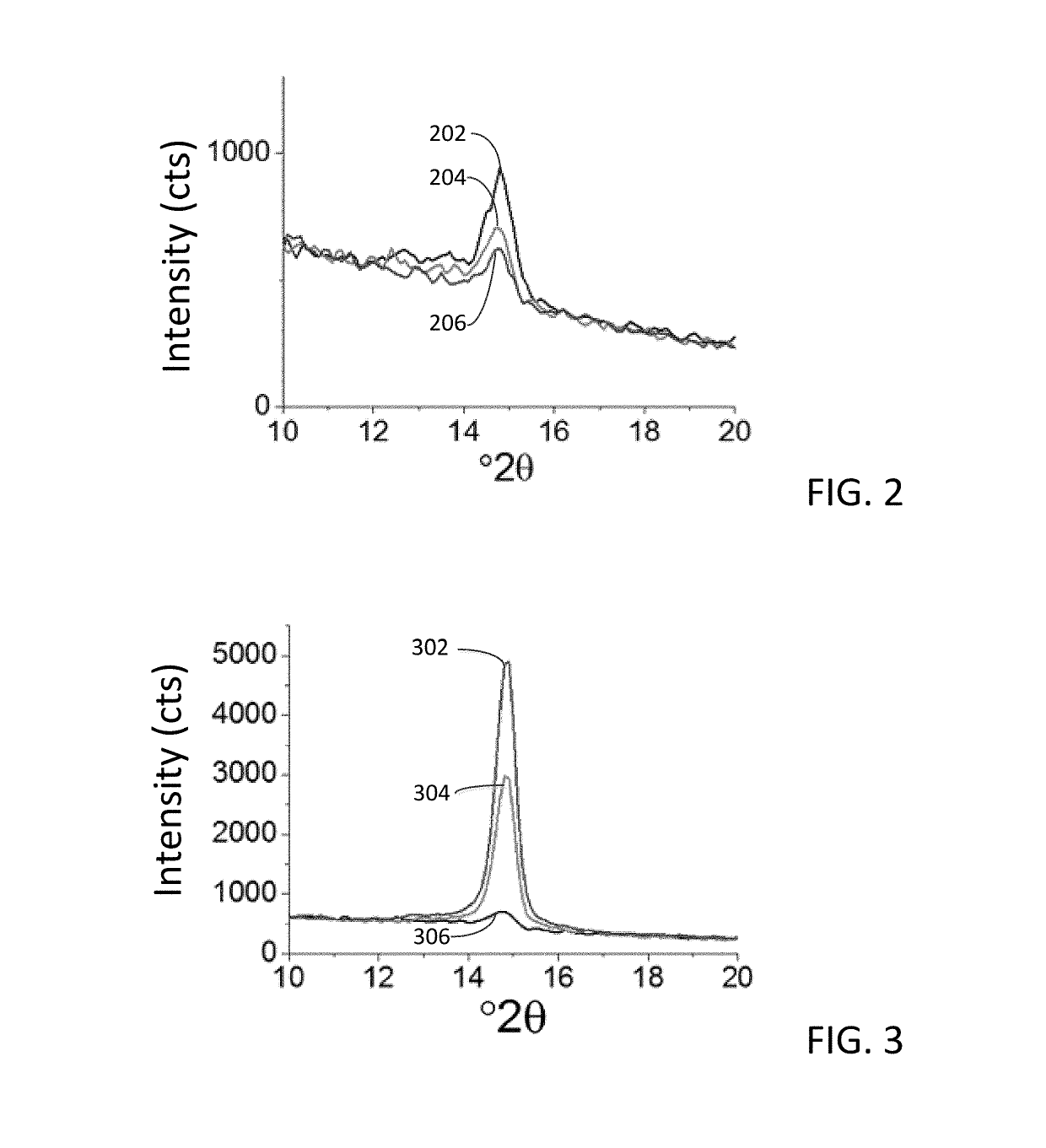

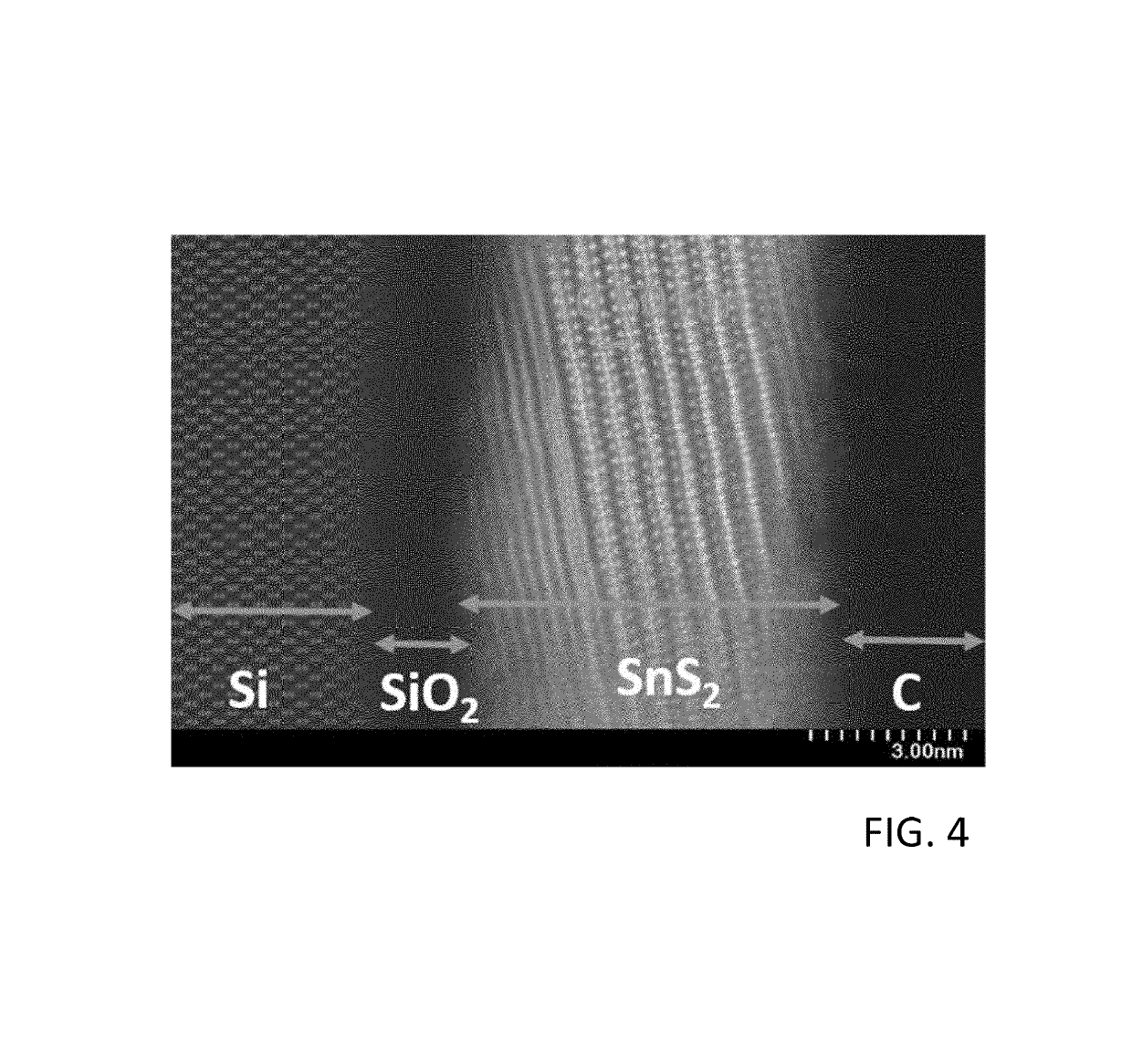

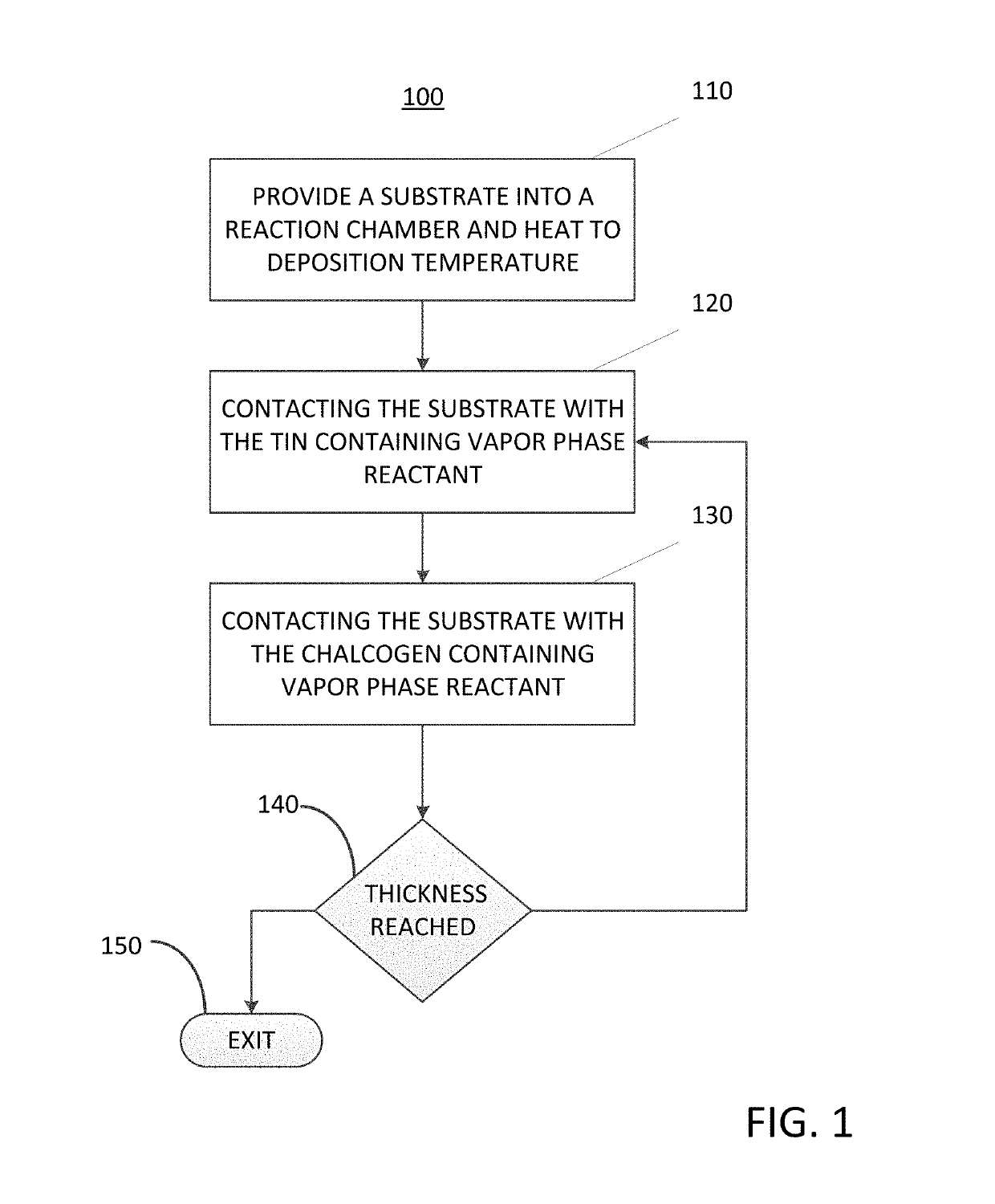

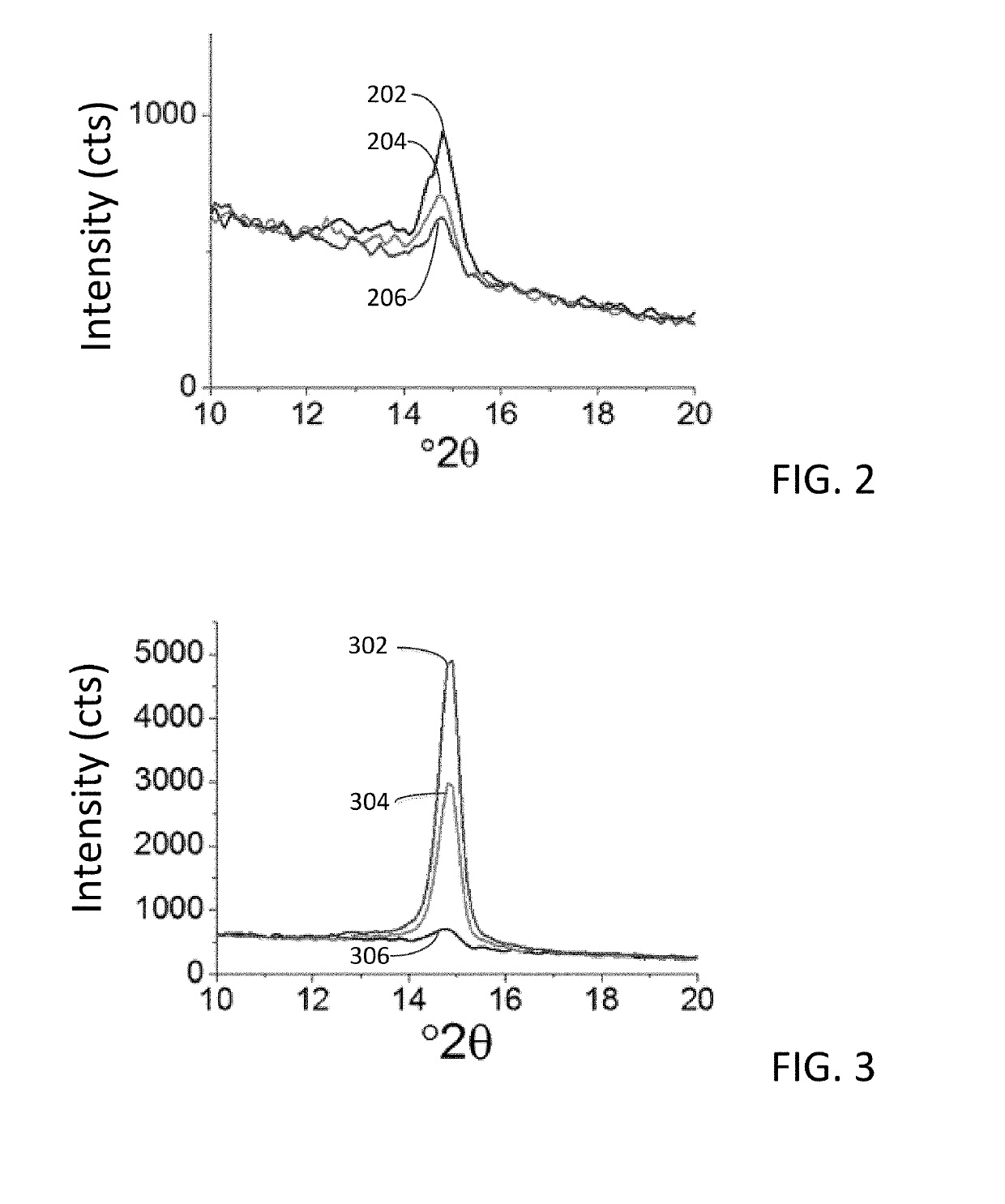

A method for depositing a metal chalcogenide on a substrate by cyclical deposition is disclosed. The method may include, contacting the substrate with at least one metal containing vapor phase reactant and contacting the substrate with at least one chalcogen containing vapor phase reactant. Semiconductor device structures including a metal chalcogenide deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

Method for depositing a metal chalcogenide on a substrate by cyclical deposition

ActiveUS20190109002A1TransistorSemiconductor/solid-state device manufacturingMetal chalcogenidesChalcogen

A method for depositing a metal chalcogenide on a substrate by cyclical deposition is disclosed. The method may include, contacting the substrate with at least one metal containing vapor phase reactant and contacting the substrate with at least one chalcogen containing vapor phase reactant. Semiconductor device structures including a metal chalcogenide deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

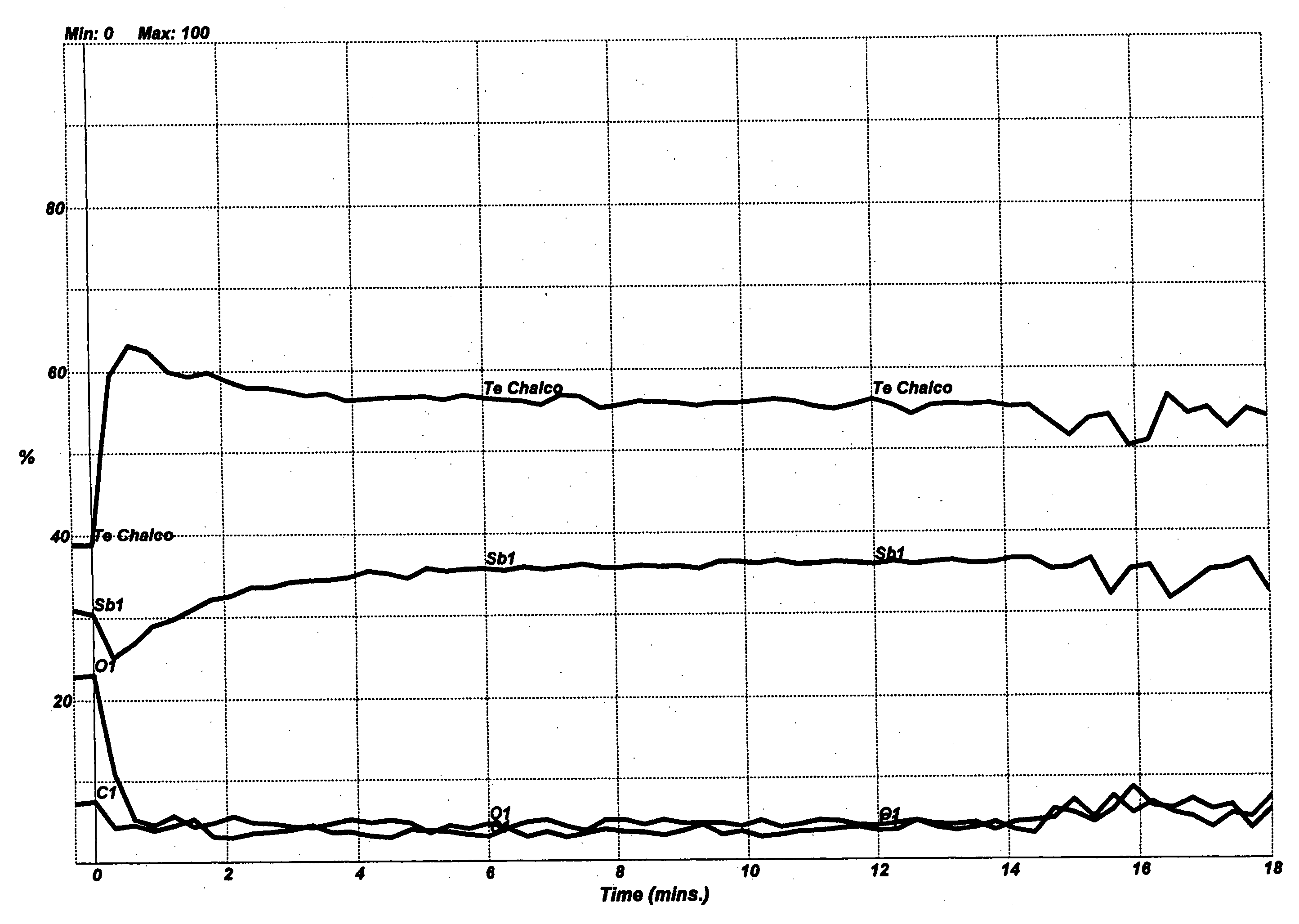

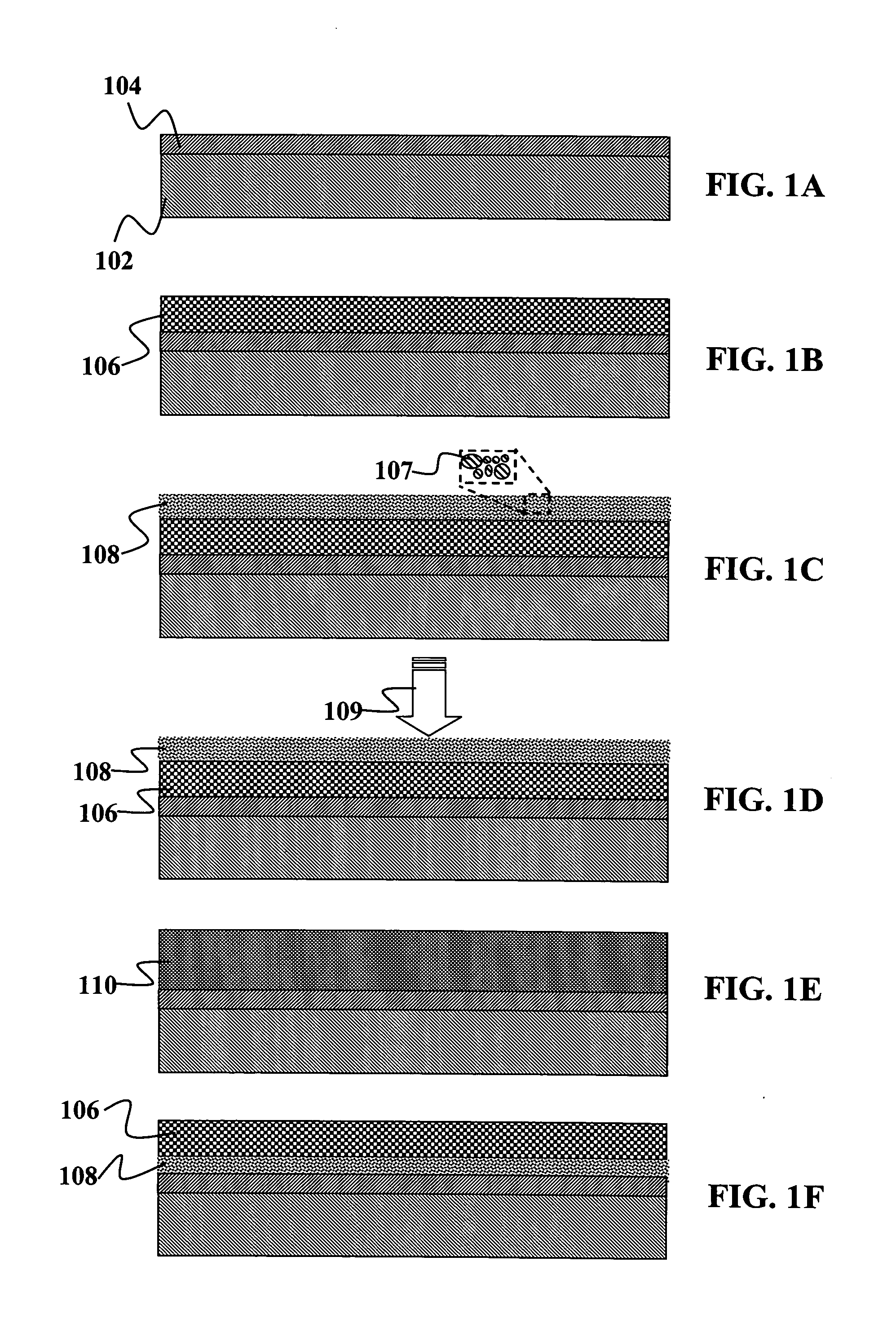

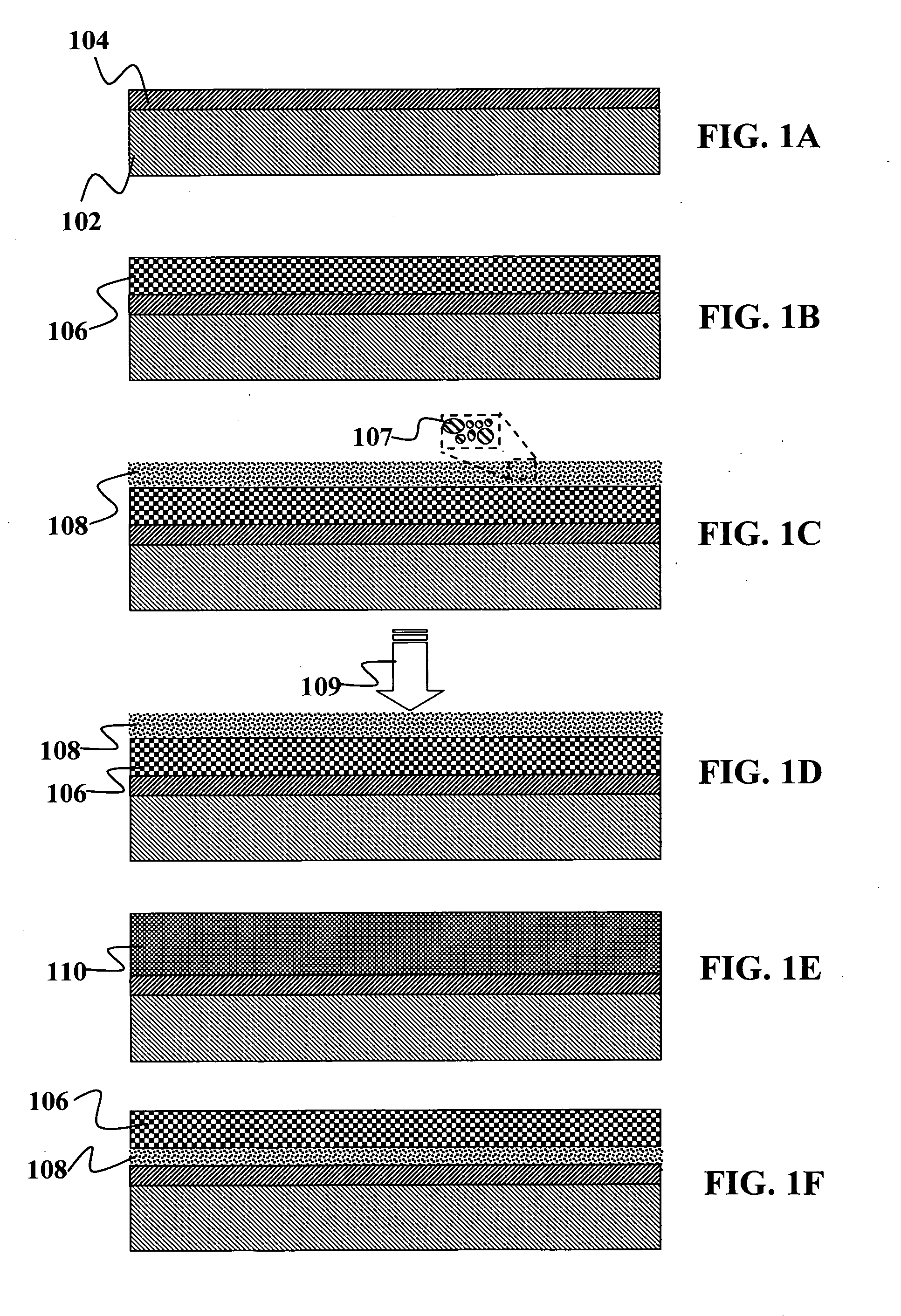

Chemical vapor deposition of chalcogenide materials

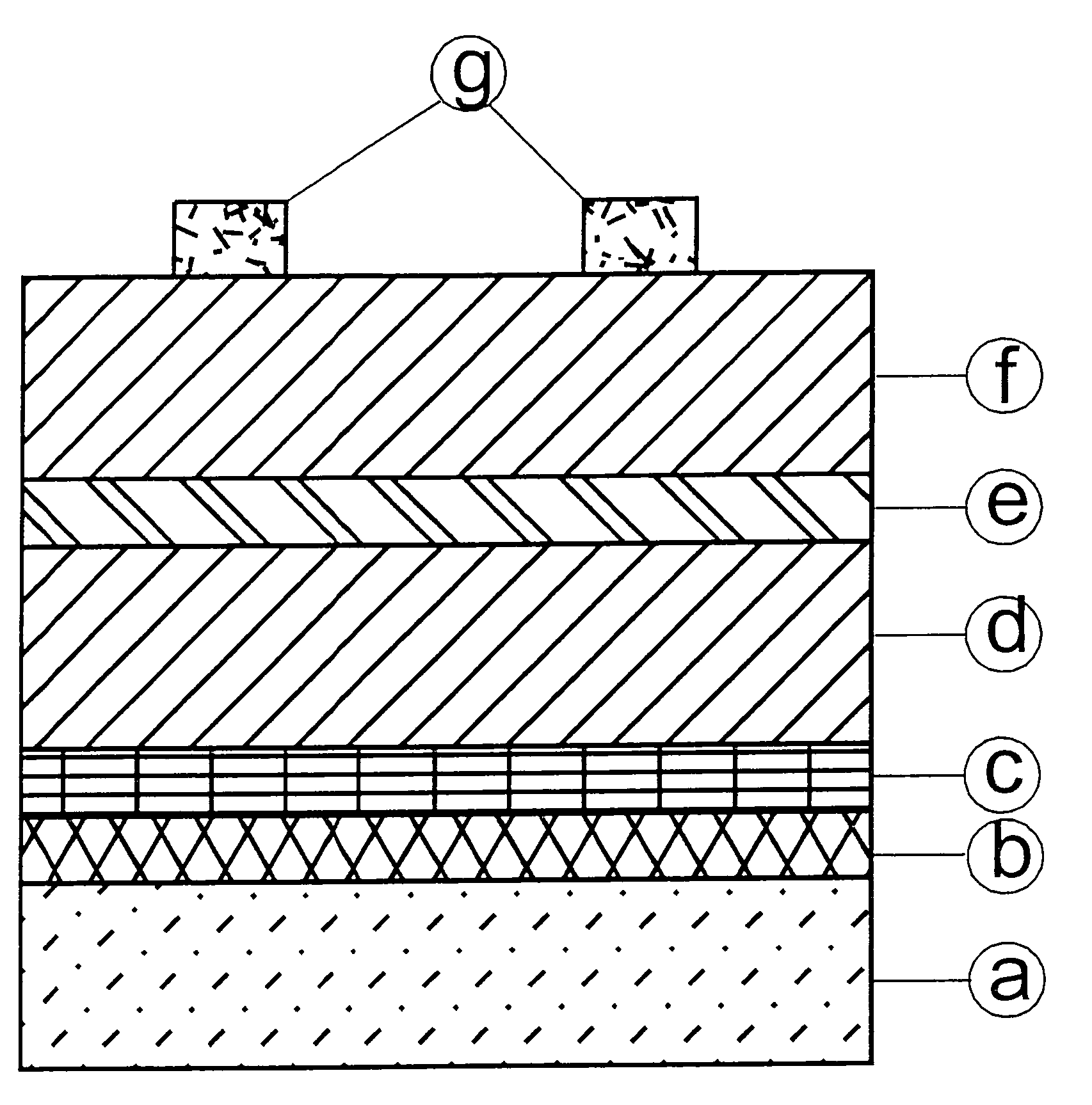

A chemical vapor deposition (CVD) process for preparing electrical and optical chalcogenide materials. In a preferred embodiment, the instant CVD-deposited materials exhibit one or more of the following properties: electrical switching, accumulation, setting, reversible multistate behavior, resetting, cognitive functionality, and reversible amorphous-crystalline transformations. In one embodiment, a multilayer structure, including at least one layer containing a chalcogen element, is deposited by CVD and subjected to post-deposition application of energy to produce a chalcogenide material having properties in accordance with the instant invention. In another embodiment, a single layer chalcogenide material having properties in accordance with the instant invention is formed from a CVD deposition process including three or more deposition precursors, at least one of which is a chalcogen element precursor. Preferred materials are those that include the chalcogen Te along with Ge and / or Sb.

Owner:OVONYX

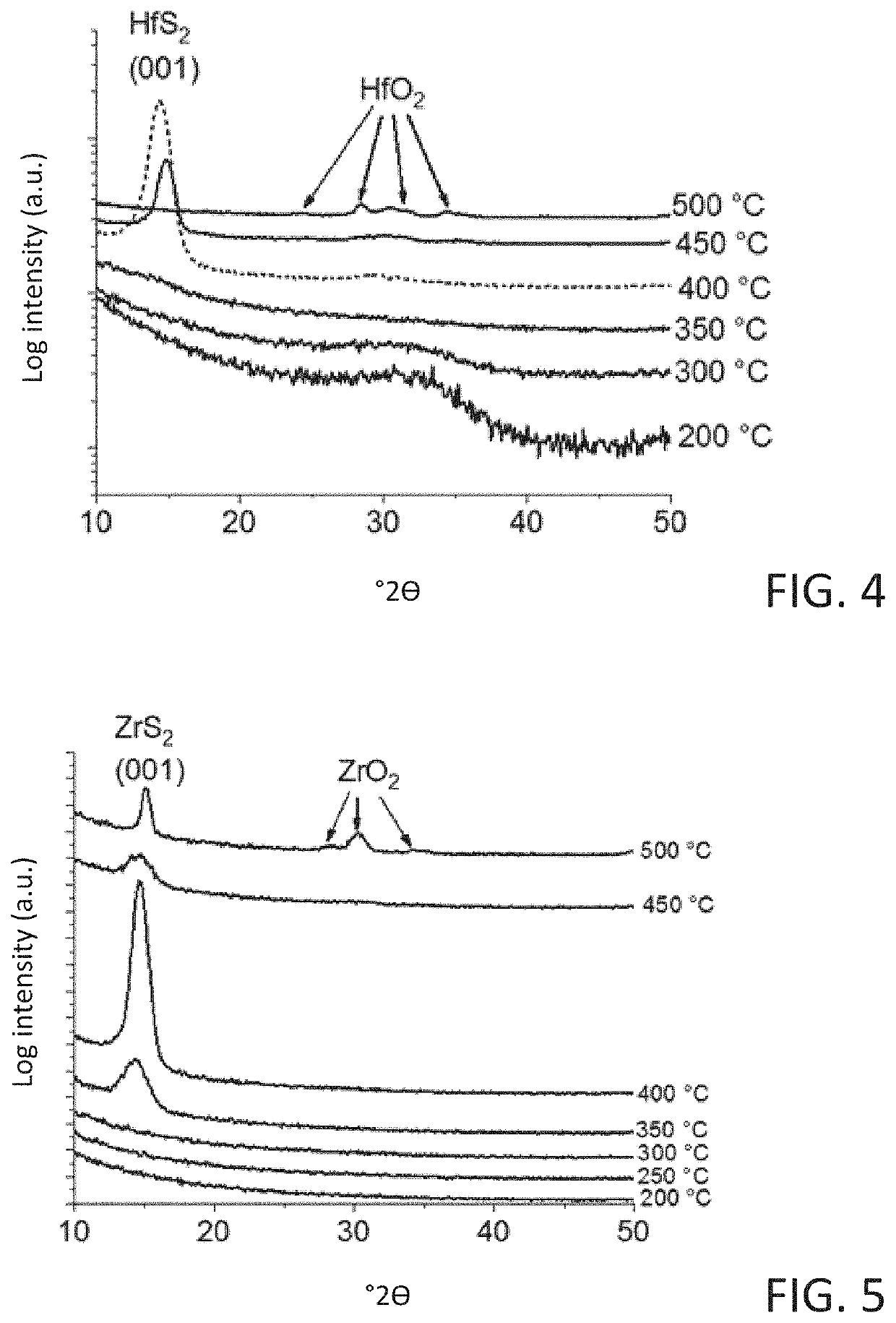

Methods for depositing a transition metal chalcogenide film on a substrate by a cyclical deposition process

ActiveUS20200161129A1TransistorSemiconductor/solid-state device manufacturingDevice materialPhysical chemistry

Methods for depositing a transition metal chalcogenide film on a substrate by cyclical deposition process are disclosed. The methods may include, contacting the substrate with at least one transition metal containing vapor phase reactant comprising at least one of a hafnium precursor, or a zirconium precursor, and contacting the substrate with at least one chalcogen containing vapor phase reactant. Semiconductor device structures including a transition metal chalcogenide film deposited by the methods of the disclosure are also provided.

Owner:ASM IP HLDG BV

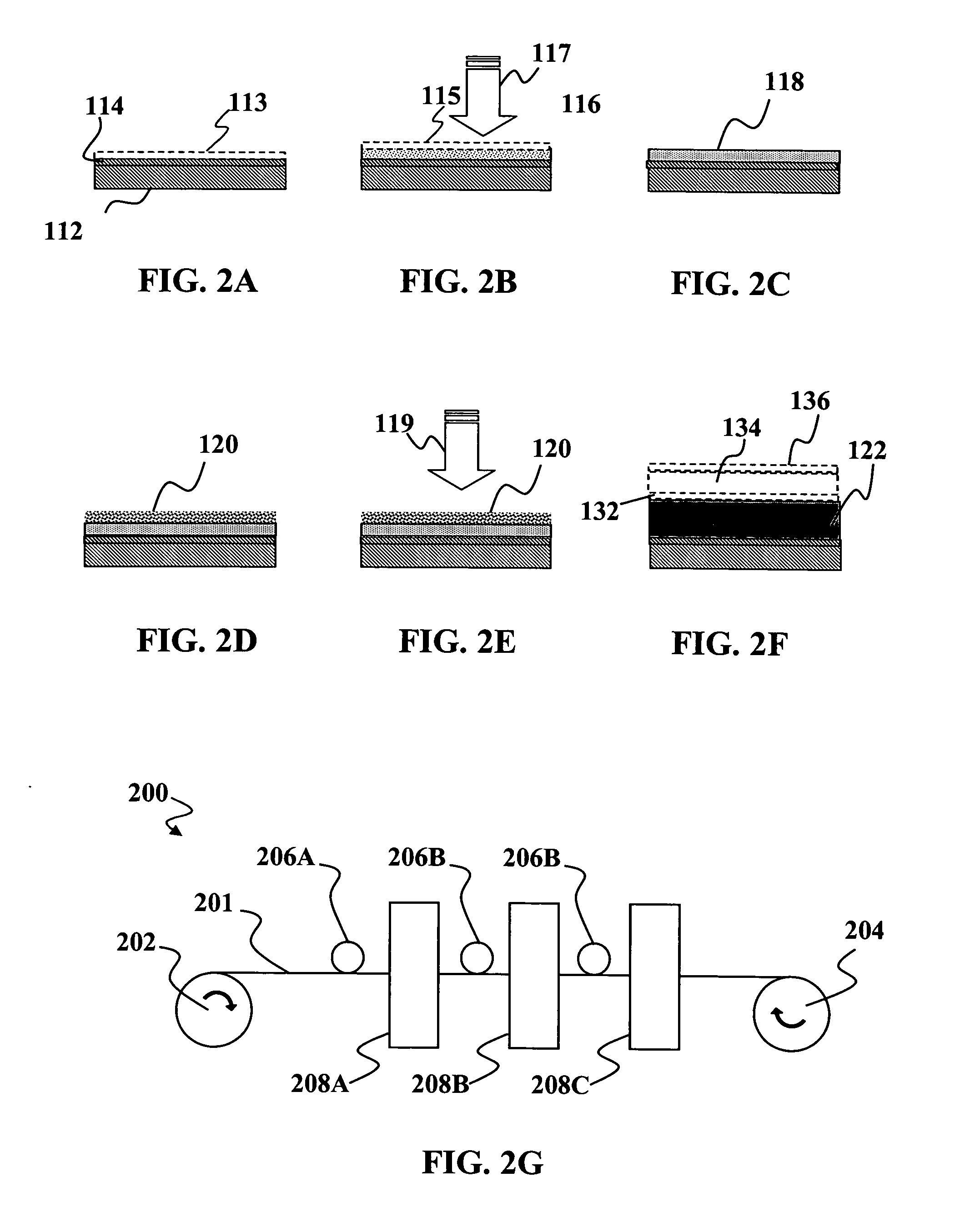

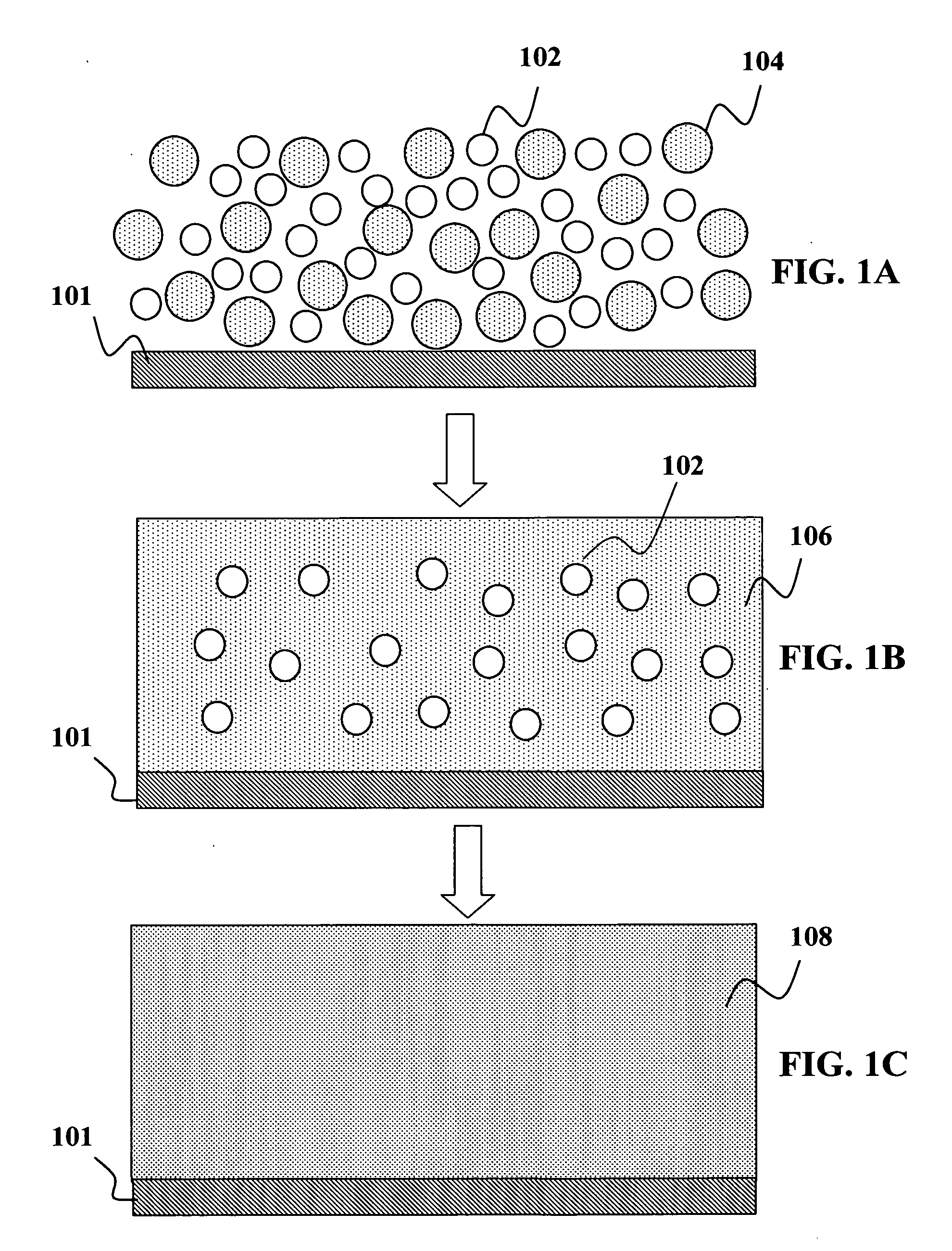

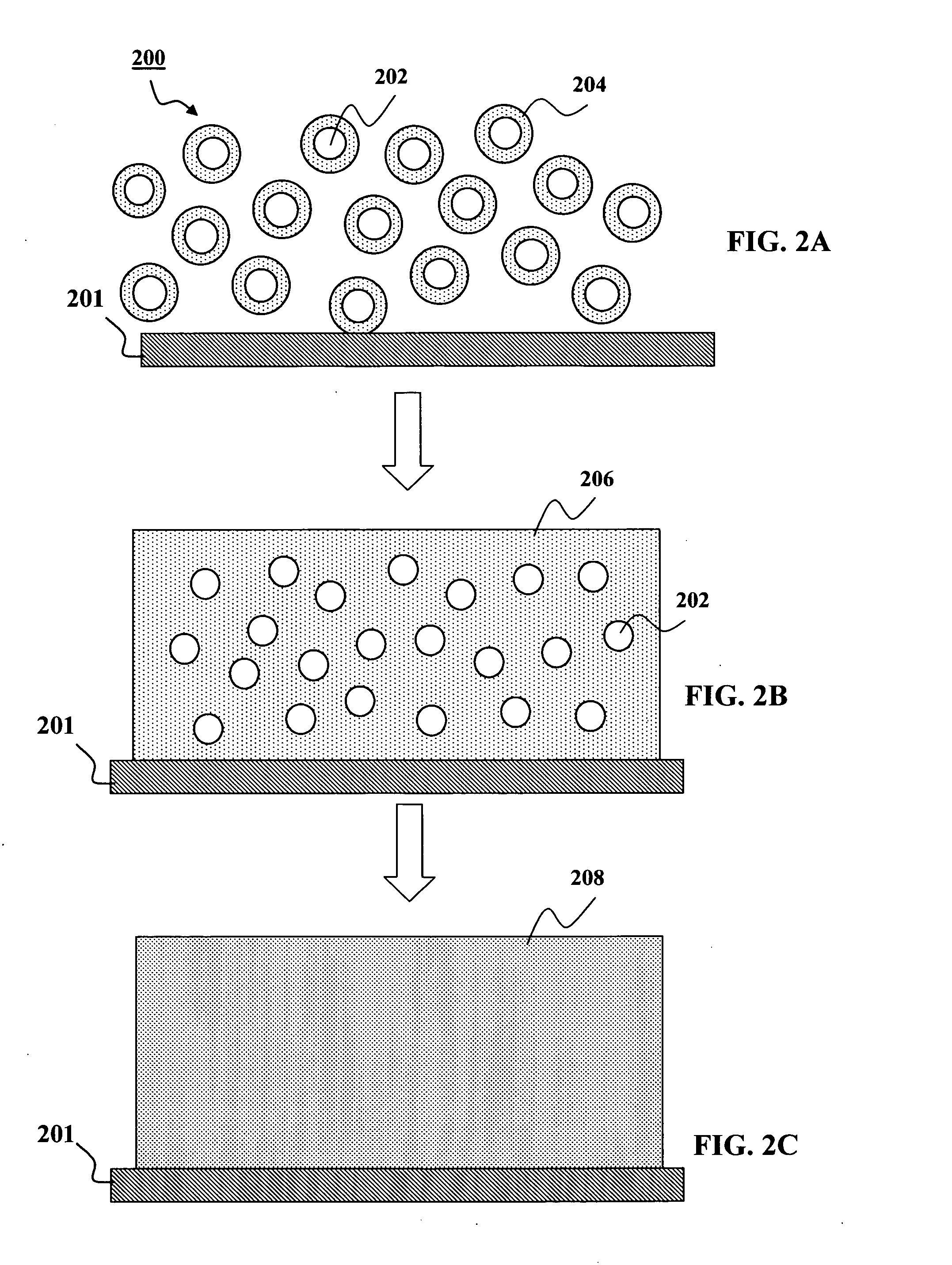

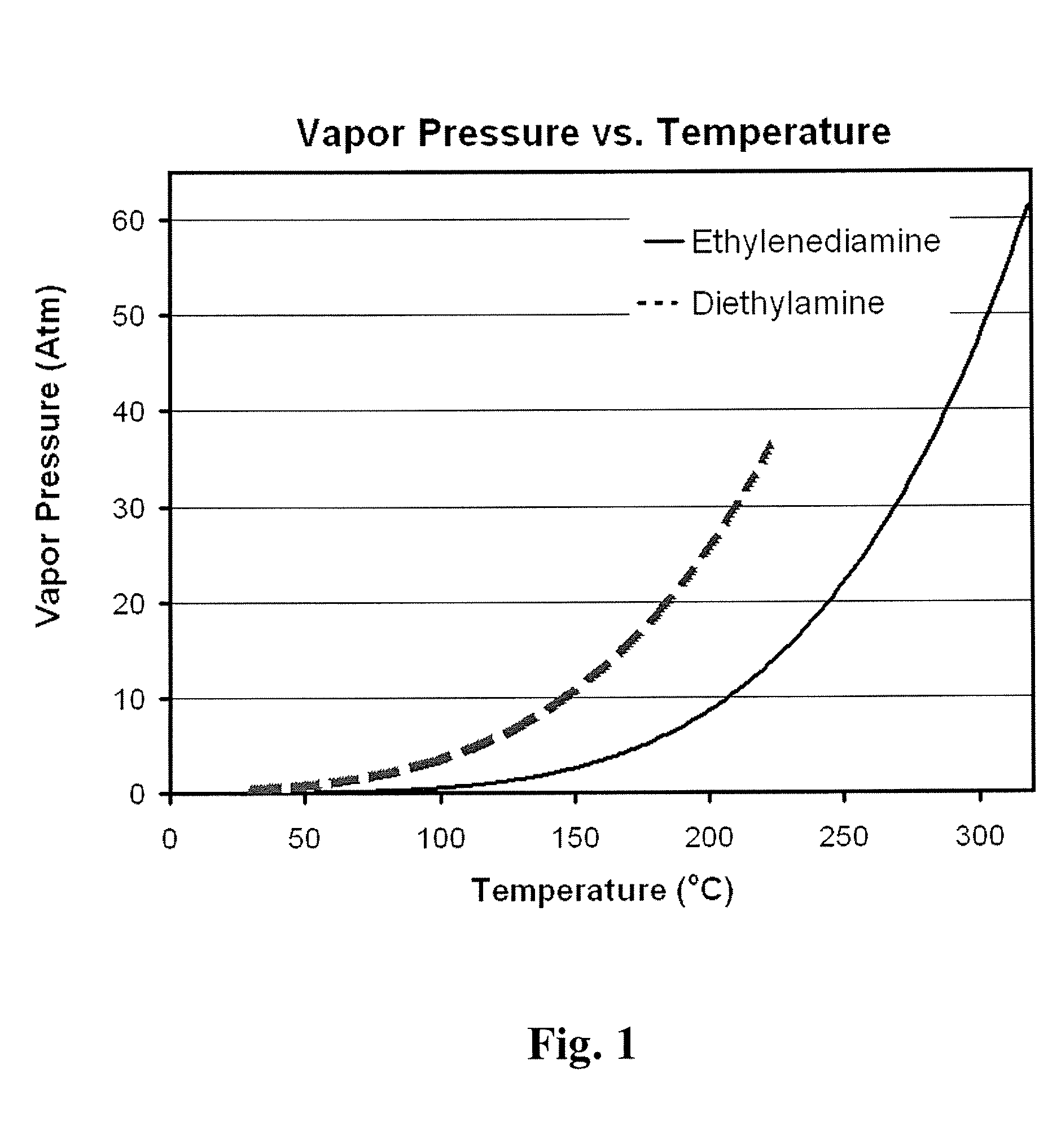

High-throughput printing of semiconductor precursor layer by use of chalcogen-containing vapor

InactiveUS20070169810A1Well mixedReduce lossesLiquid/solution decomposition chemical coatingPhotovoltaic energy generationSulfurChalcogen

A high-throughput method of forming a semiconductor precursor layer by use of a chalcogen-containing vapor is disclosed. In one embodiment, the method comprises forming a precursor material comprising group IB and / or group IIIA particles of any shape. The method may include forming a precursor layer of the precursor material over a surface of a substrate. The method may further include heating the particle precursor material in a substantially oxygen-free chalcogen atmosphere to a processing temperature sufficient to react the particles and to release chalcogen from the chalcogenide particles, wherein the chalcogen assumes a liquid form and acts as a flux to improve intermixing of elements to form a group IB-IIIA-chalcogenide film at a desired stoichiometric ratio. The chalcogen atmosphere may provide a partial pressure greater than or equal to the vapor pressure of liquid chalcogen in the precursor layer at the processing temperature.

Owner:NANOSOLAR

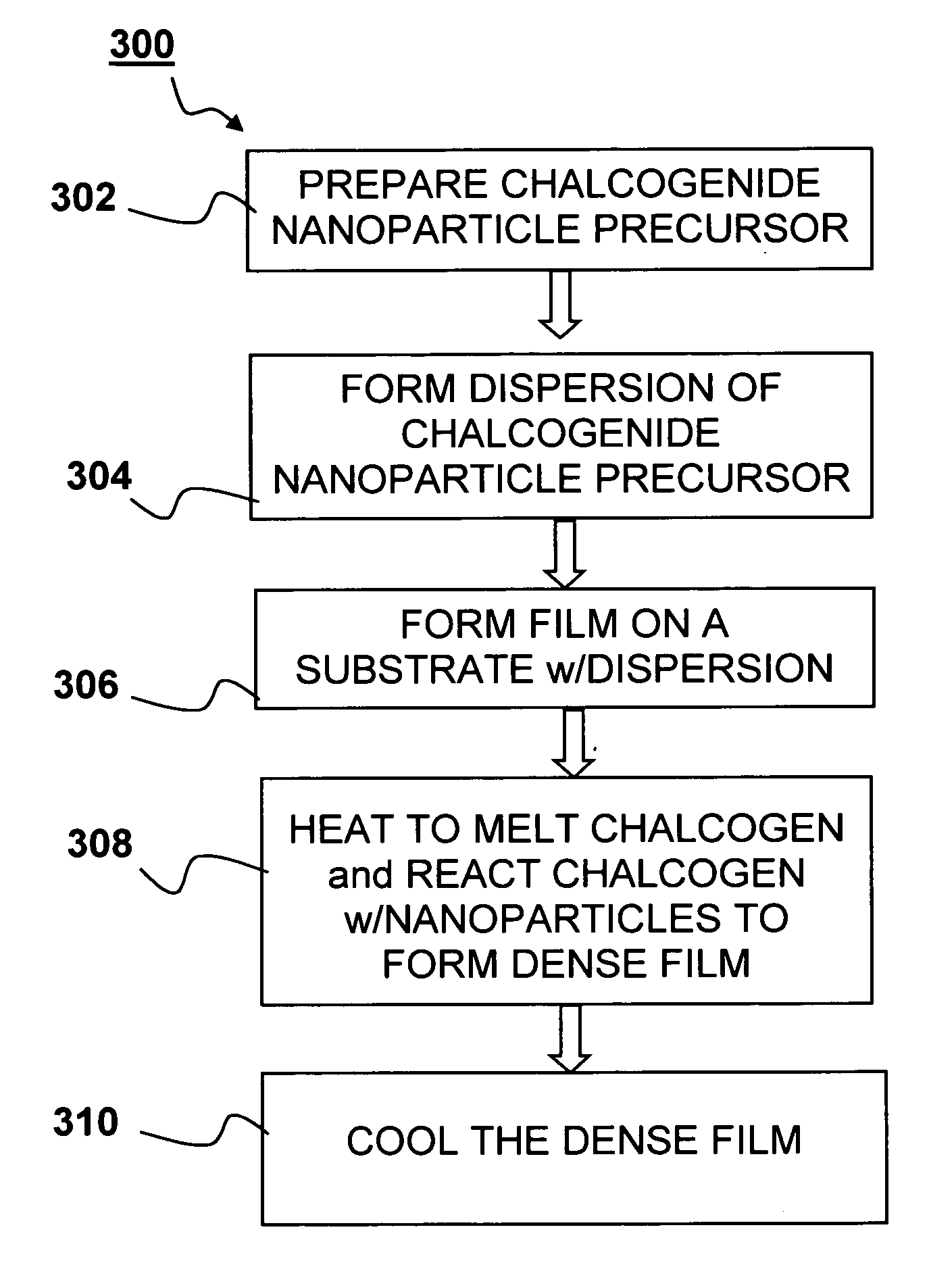

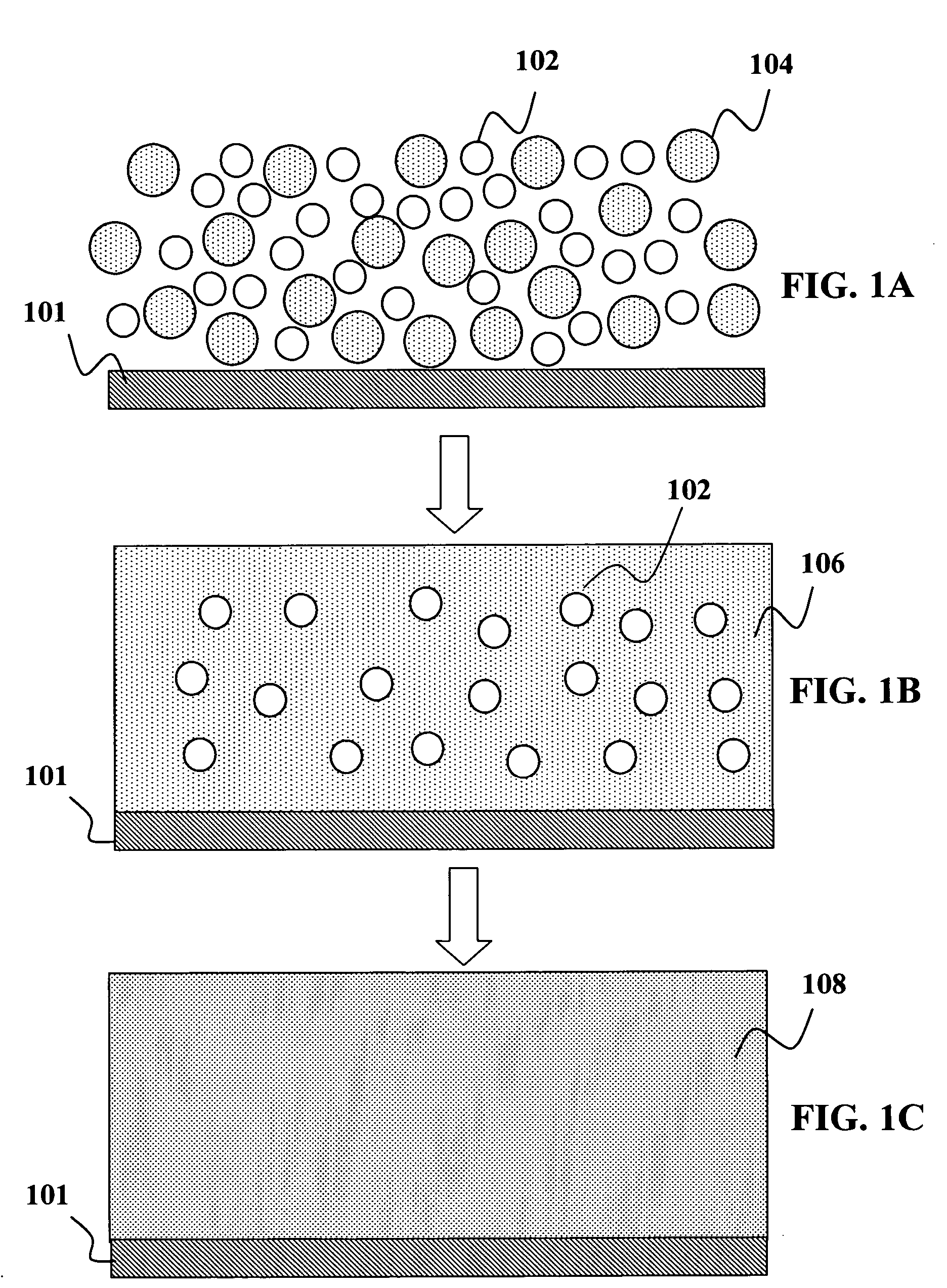

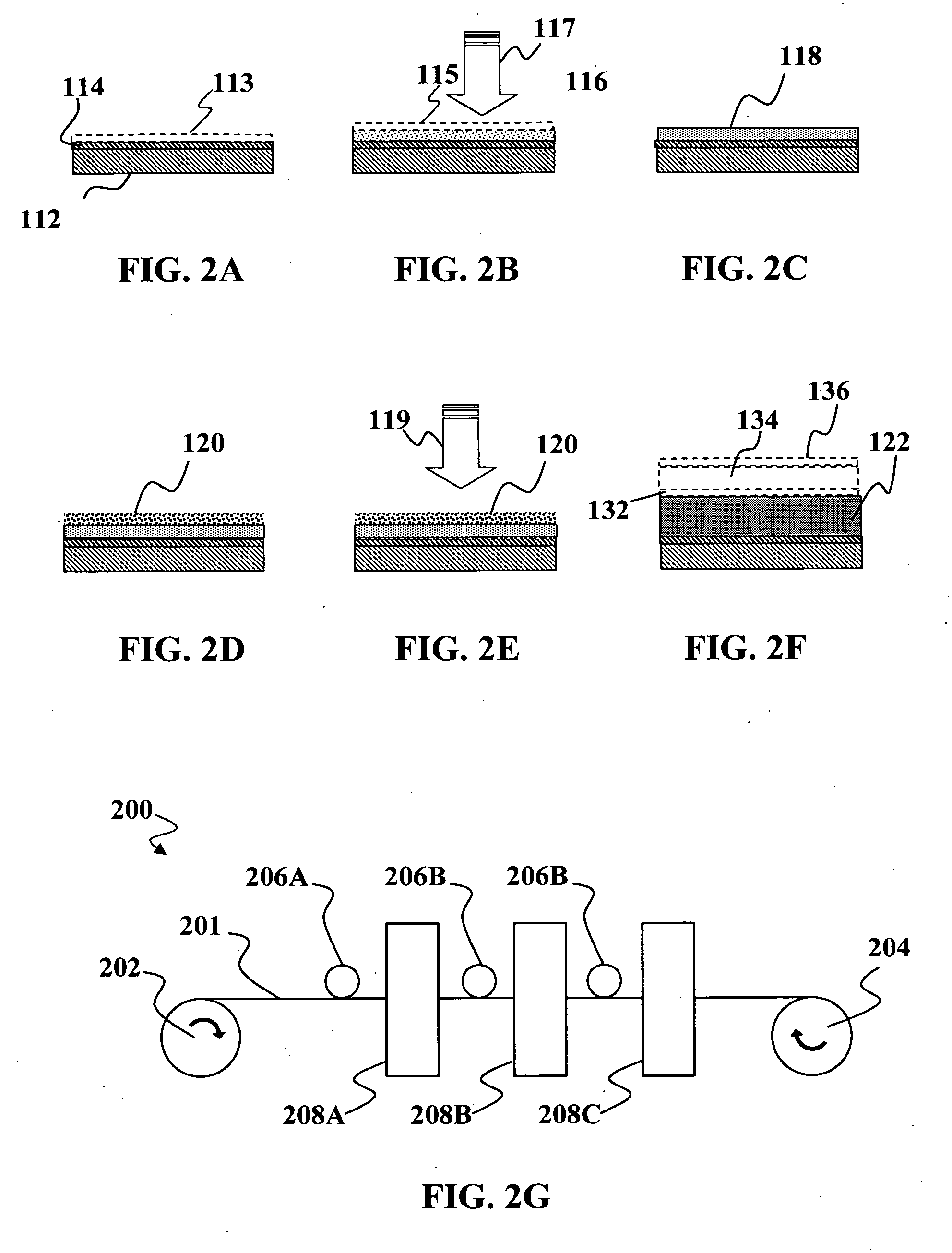

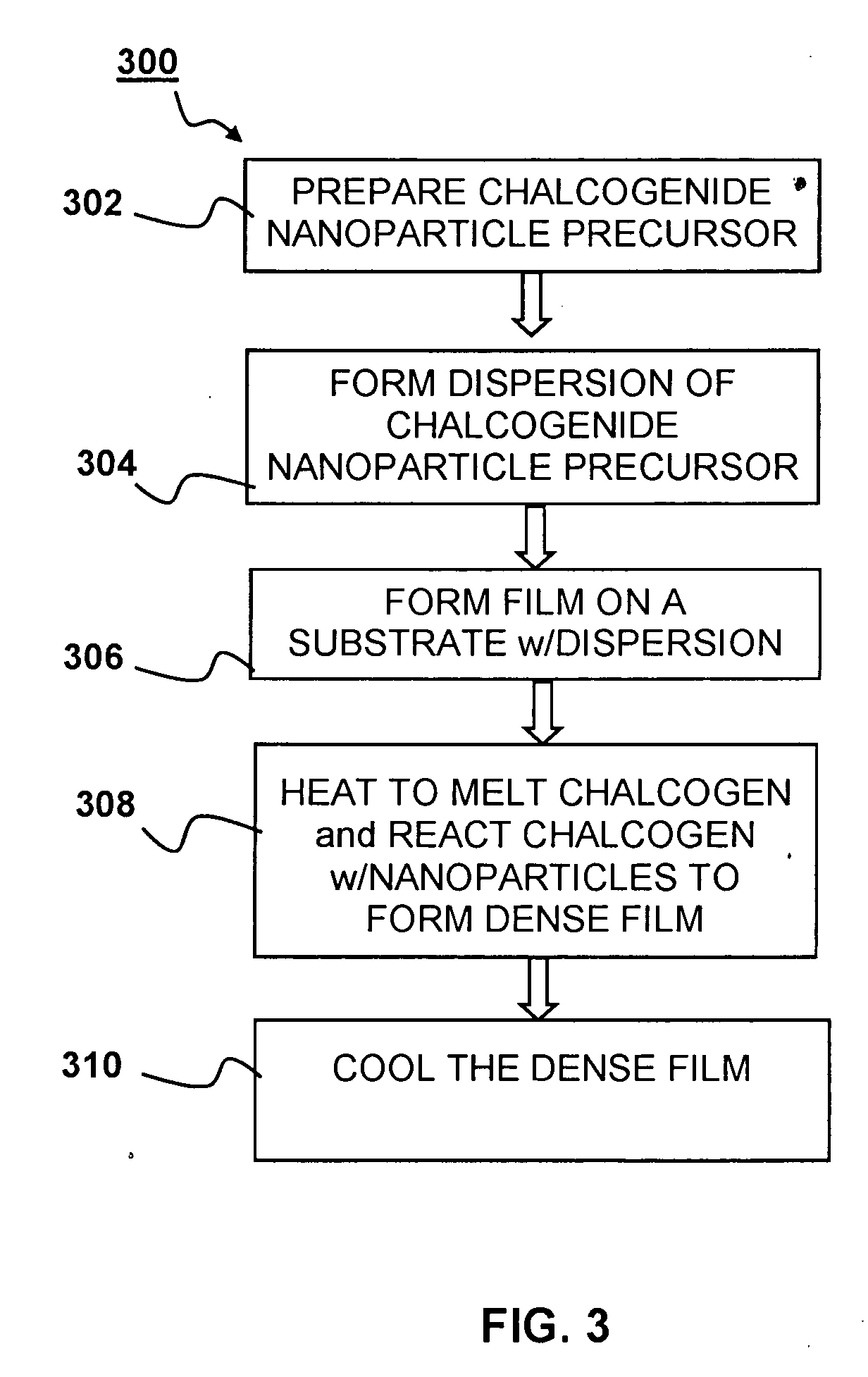

High-throughput printing of chalcogen layer and the use of an inter-metallic material

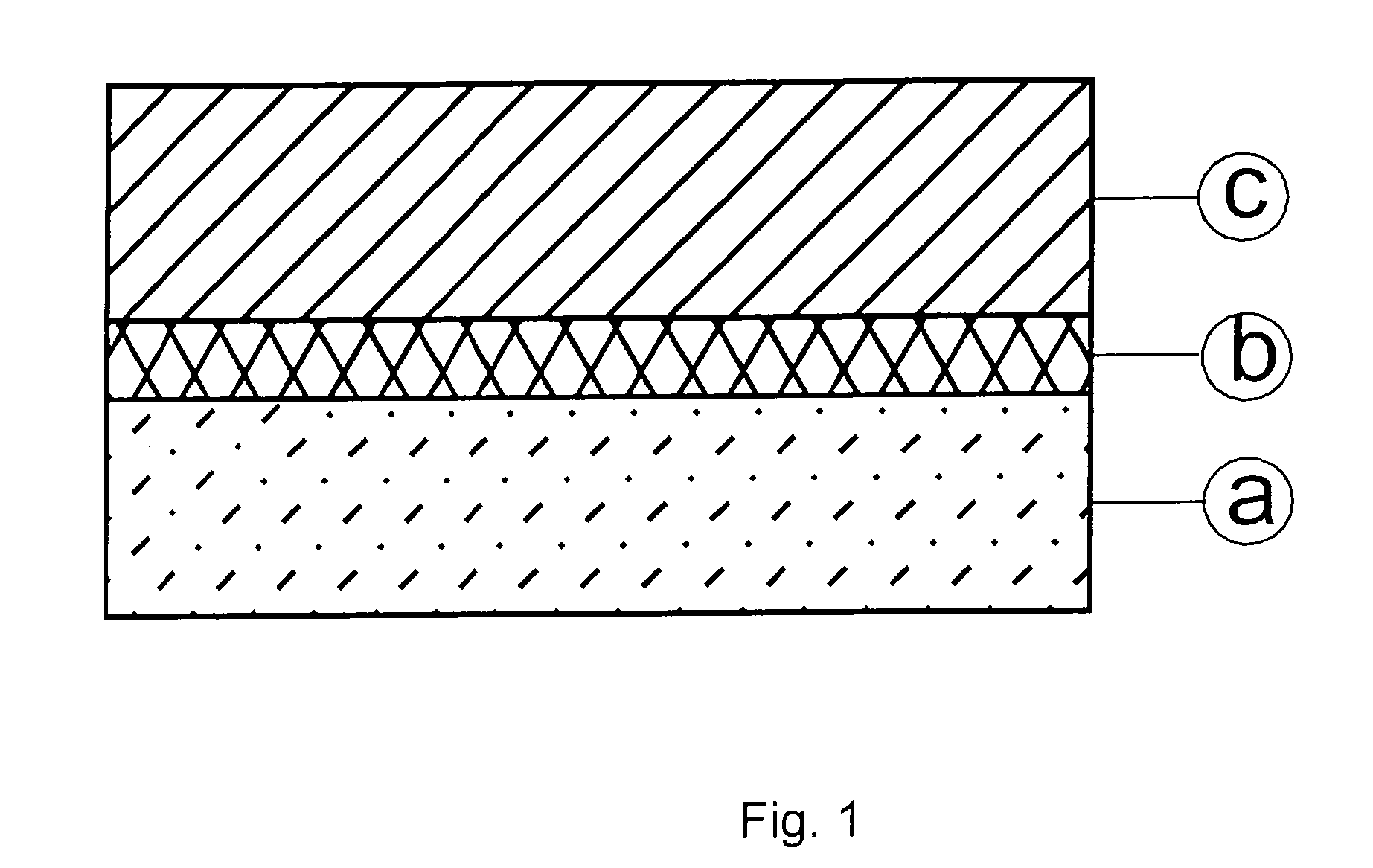

InactiveUS20070163643A1Reduce the temperaturePretreated surfacesLiquid/solution decomposition chemical coatingNanoparticleSulfur

Methods and devices for high-throughput printing of a precursor material for forming a film of a group IB-IIIA-chalcogenide compound are disclosed. In one embodiment, the method comprises forming a precursor layer on a substrate, wherein the precursor layer comprises one or more discrete layers. The layers may include at least a first layer containing one or more group IB elements and two or more different group IIIA elements and at least a second layer containing elemental chalcogen particles. The precursor layer may be heated to a temperature sufficient to melt the chalcogen particles and to react the chalcogen particles with the one or more group IB elements and group IIIA elements in the precursor layer to form a film of a group IB-IIIA-chalcogenide compound. At least one set of the particles in the precursor layer are inter-metallic particles containing at least one group IB-IIIA inter-metallic alloy phase. The method may also include making a film of group IB-IIIA-chalcogenide compound that includes mixing the nanoparticles and / or nanoglobules and / or nanodroplets to form an ink, depositing the ink on a substrate, heating to melt the extra chalcogen and to react the chalcogen with the group IB and group IIIA elements and / or chalcogenides to form a dense film.

Owner:NANOSOLAR

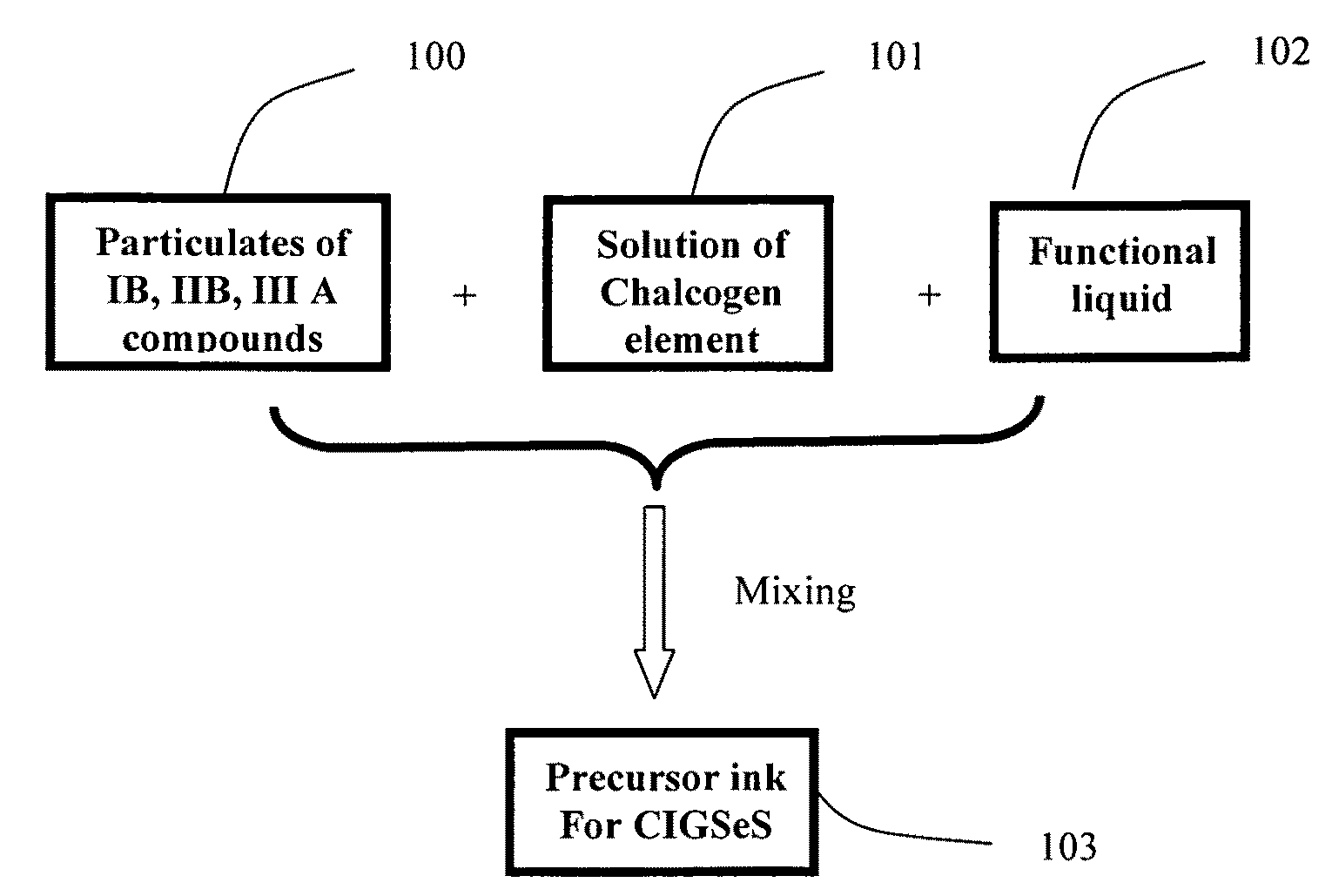

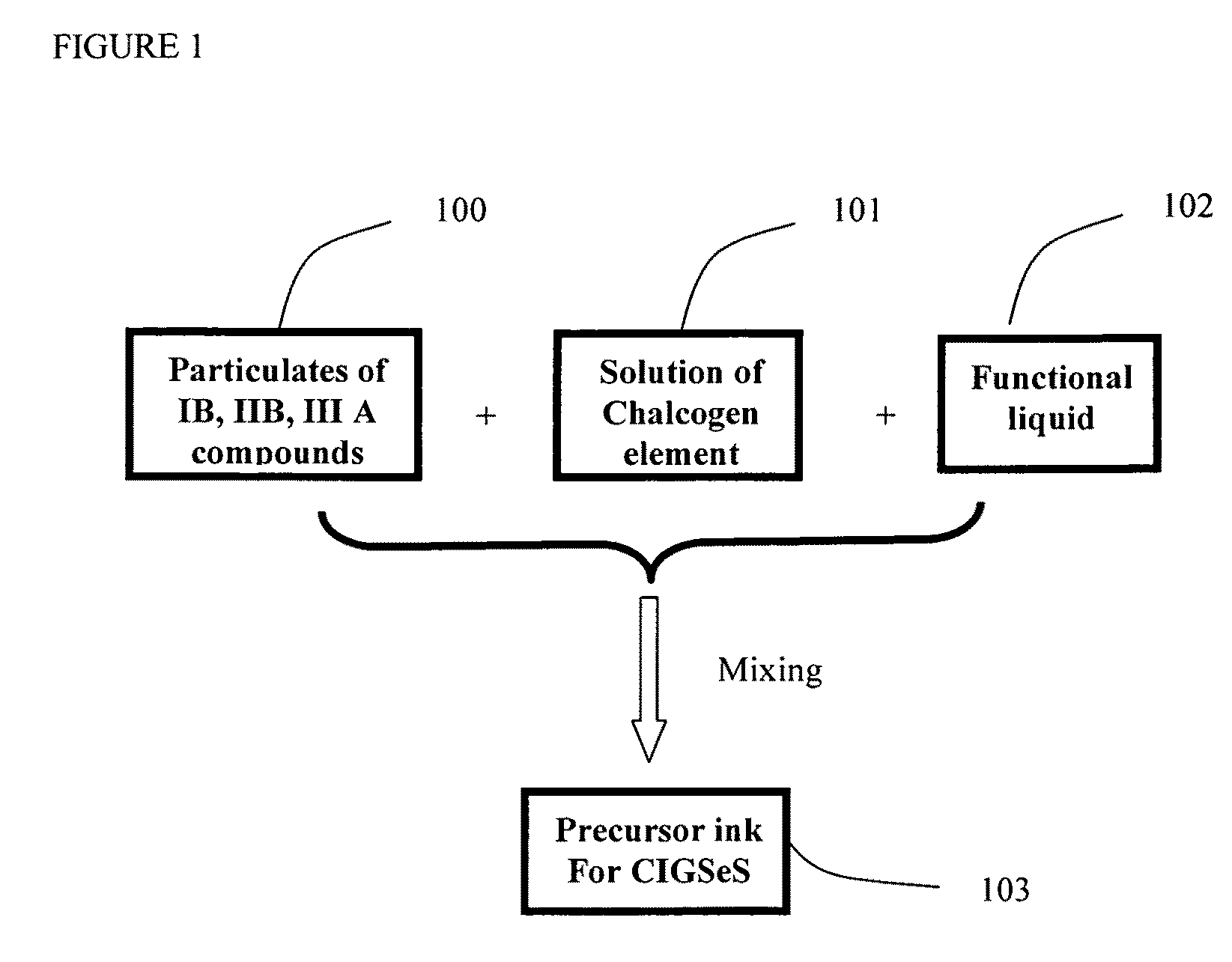

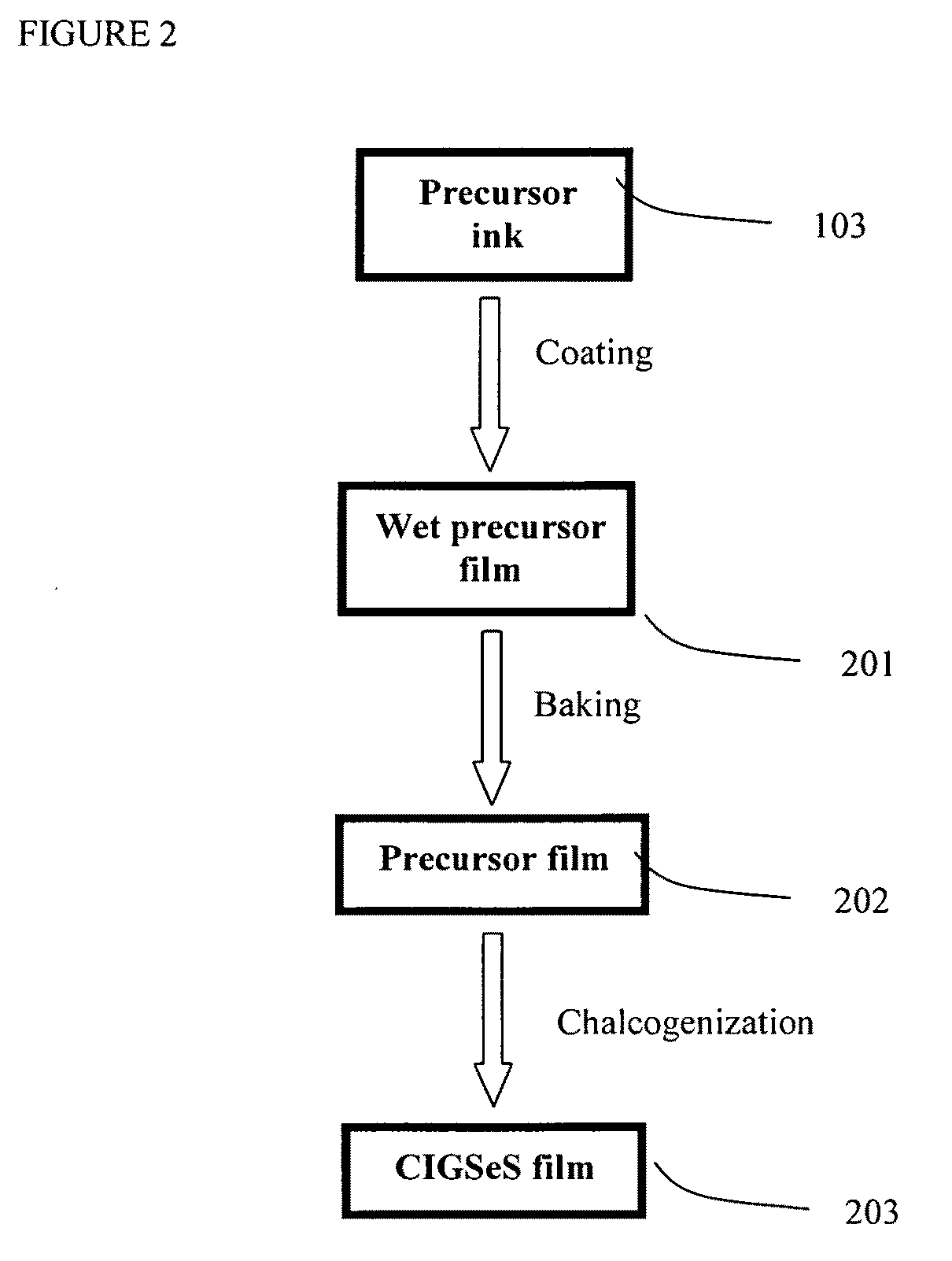

Precursor ink for producing IB-IIIA-VIA semiconductors

InactiveUS20090260670A1Overcome disadvantagesFinal product manufacturePV power plantsIndiumSemiconductor thin films

Copper indium diselenide, copper indium gallium diselenide, and other IB-IIIA-VIA compounds are produced by the liquid deposition on a substrate of a precursor-containing ink, followed by heating to produce the desired material. The precursor containing ink is a mixture of three parts. The first part is plurality of particulates of metal compounds of IB, IIIA. The second part is chalcogen source of selenium, sulfur, or organic chalcogen compounds dissolved in a liquid organic solvent. The third part solution function as viscosity adjustment, as introduction of dopant of sodium ion and / or as ink stabilizer. The precursor ink can be coated on substrate at room temperature and it can be transferred into copper indium (gallium) chalcogenide semiconductor thin film upon baking and a chalcogenization process. The resulting thin film semiconducting material can be incorporated into photovoltaic and other electronic devices.

Owner:LI XIAO CHANG CHARLES

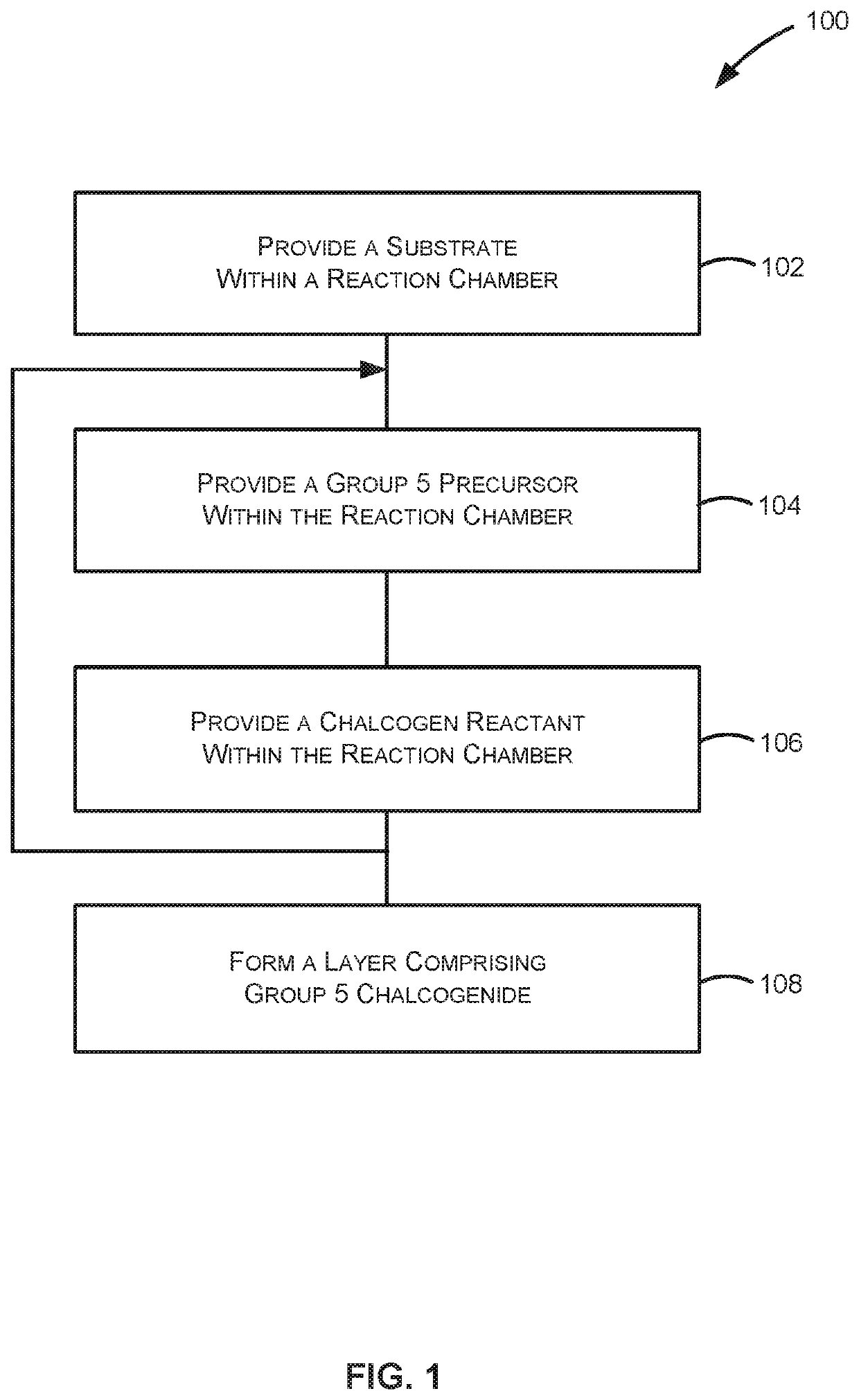

Methods and apparatus for depositing a chalcogenide film and structures including the film

PendingUS20210066080A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChalcogenChalcoides

Methods for depositing group 5 chalcogenides on a substrate are disclosed. The methods include cyclical deposition techniques, such as atomic layer deposition. The group 5 chalcogenides can be two-dimensional films having desirable electrical properties.

Owner:ASM IP HLDG BV

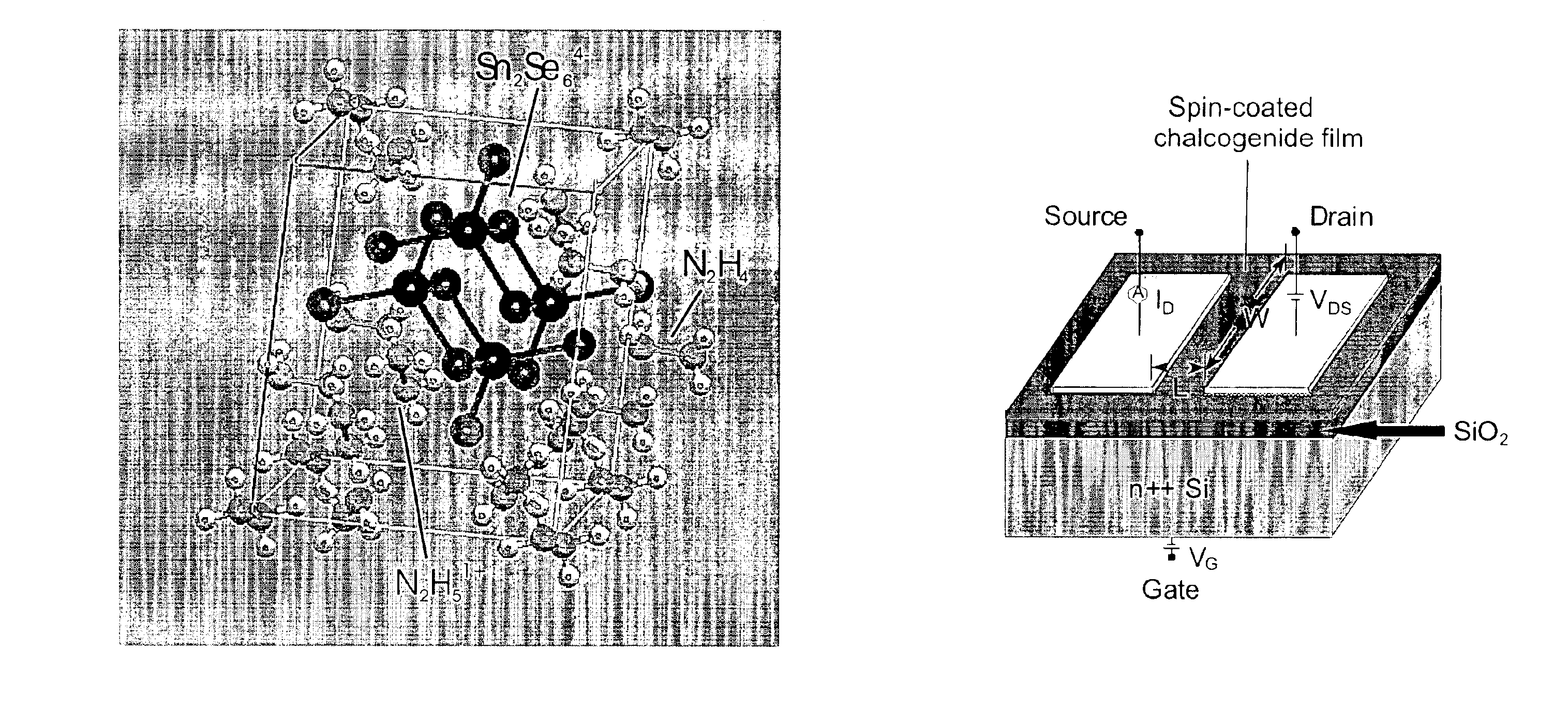

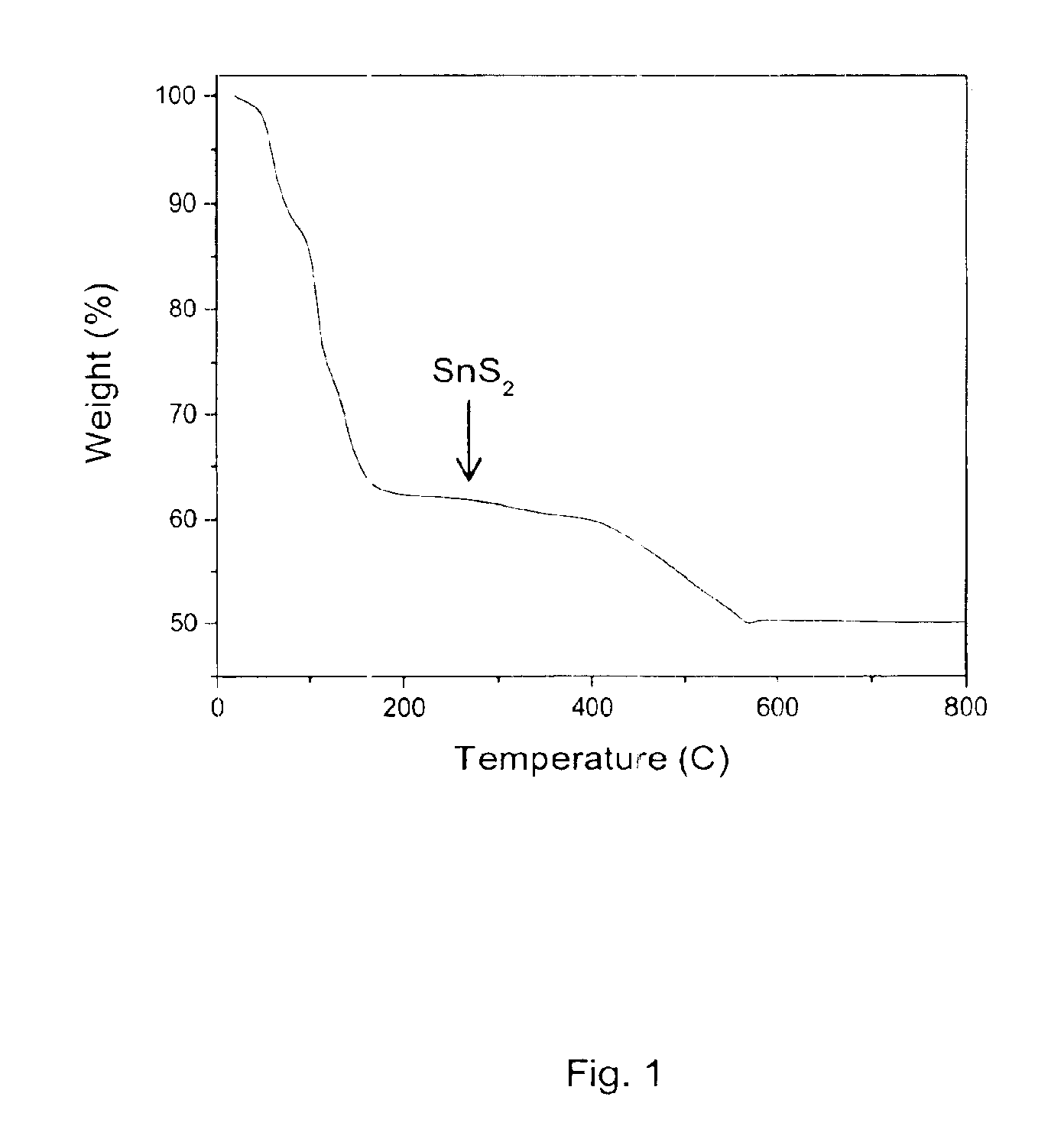

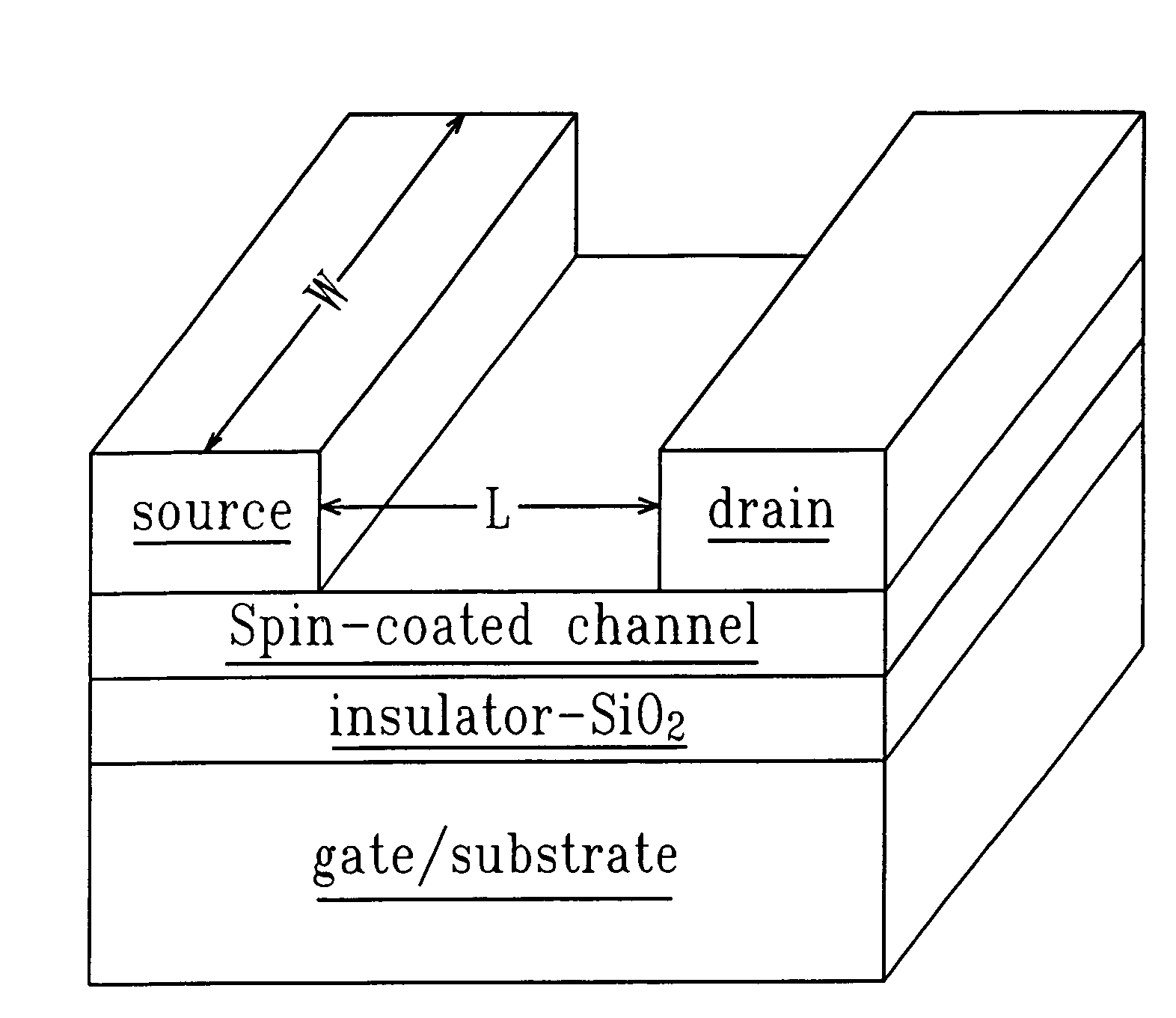

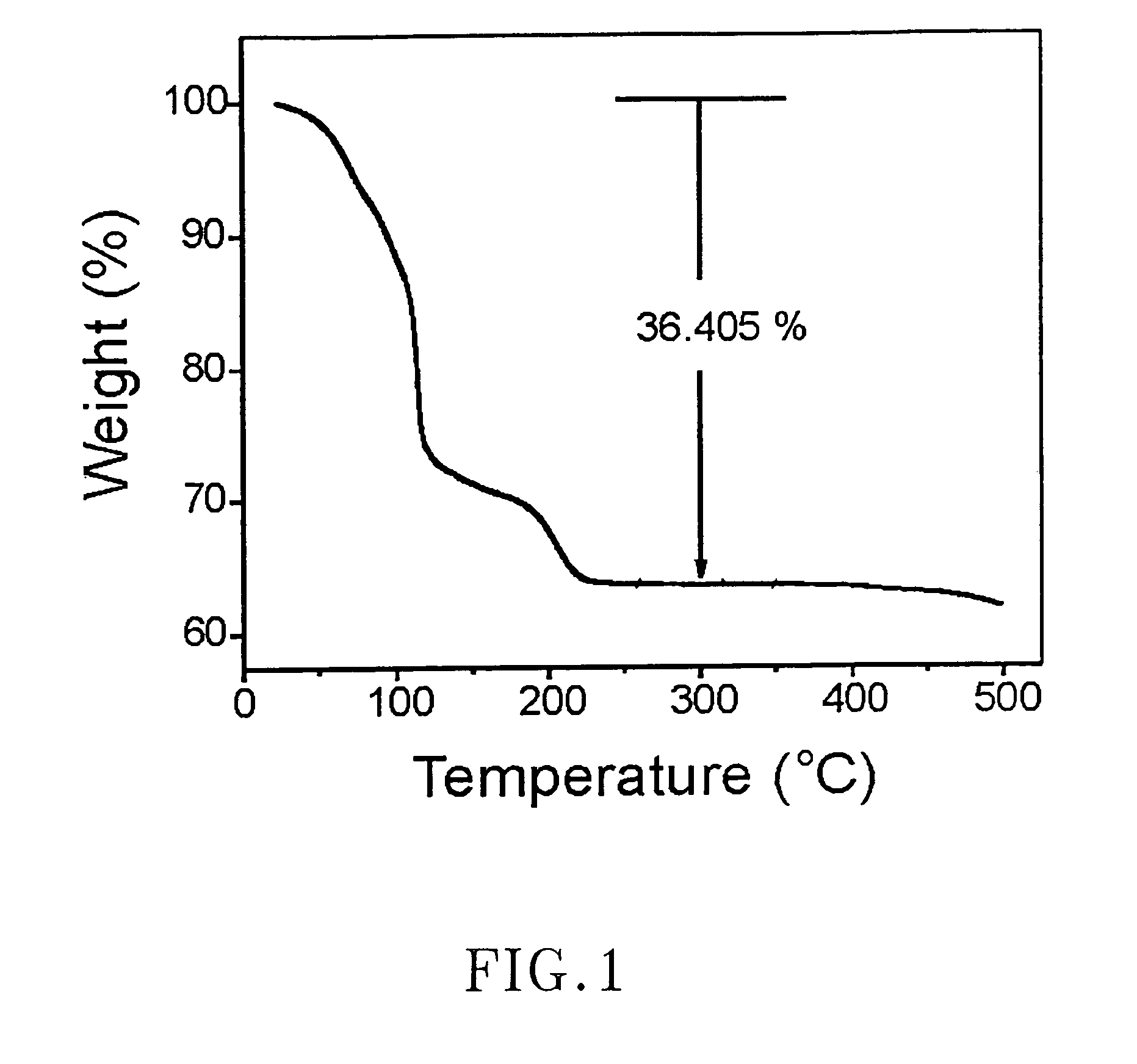

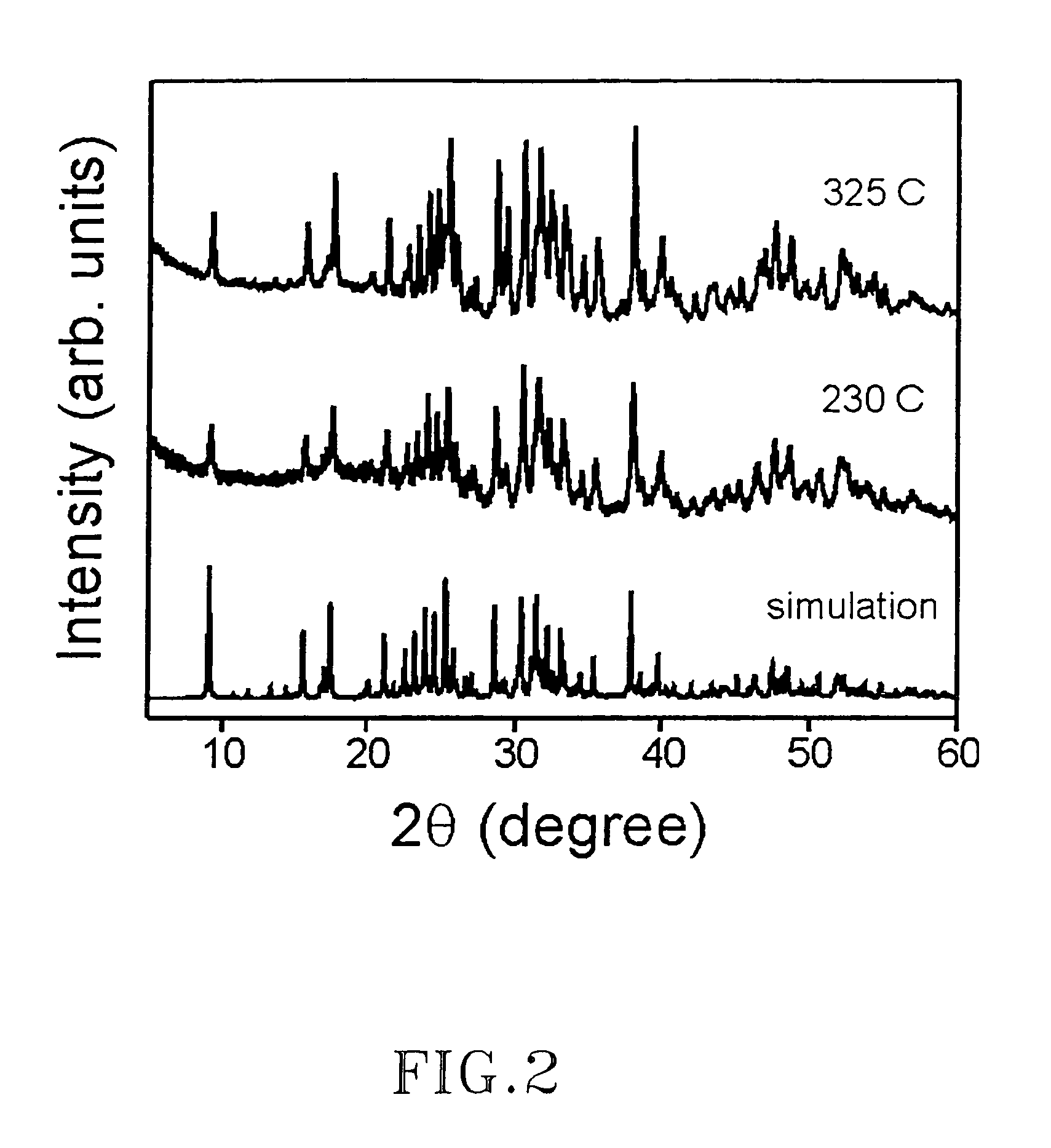

Solution deposition of chalcogenide films

A method of depositing a film of a metal chalcogenide. The first of these methods includes the steps of: contacting at least one metal chalcogenide, a hydrazine compound and optionally, an elemental chalcogen, to produce a solution of a hydrazinium-based precursor of the metal chalcogenide; applying the solution of the hydrazinium-based precursor of the metal chalcogenide onto a substrate to produce a film of the precursor; and thereafter annealing the film of the precursor to remove excess hydrazine and hydrazinium chalcogenide salts to produce a metal chalcogenide film on the substrate. The second of these methods includes the steps of: contacting: at least one metal chalcogenide and a salt of an amine compound to produce an ammonium-based precursor of the metal chalcogenide; contacting the ammonium-based precursor of the metal chalcogenide and a hydrazine compound, and optionally, an elemental chalcogen, to produce a solution of a hydrazinium-based precursor of the metal chalcogenide in the hydrazine compound; applying the solution of the hydrazinium-based precursor onto a substrate to produce a film; and thereafter, annealing to produce a metal chalcogenide film. Also provided is a thin-film field-effect transistor device using the metal chalcogenides as the channel layer.

Owner:GLOBALFOUNDRIES INC

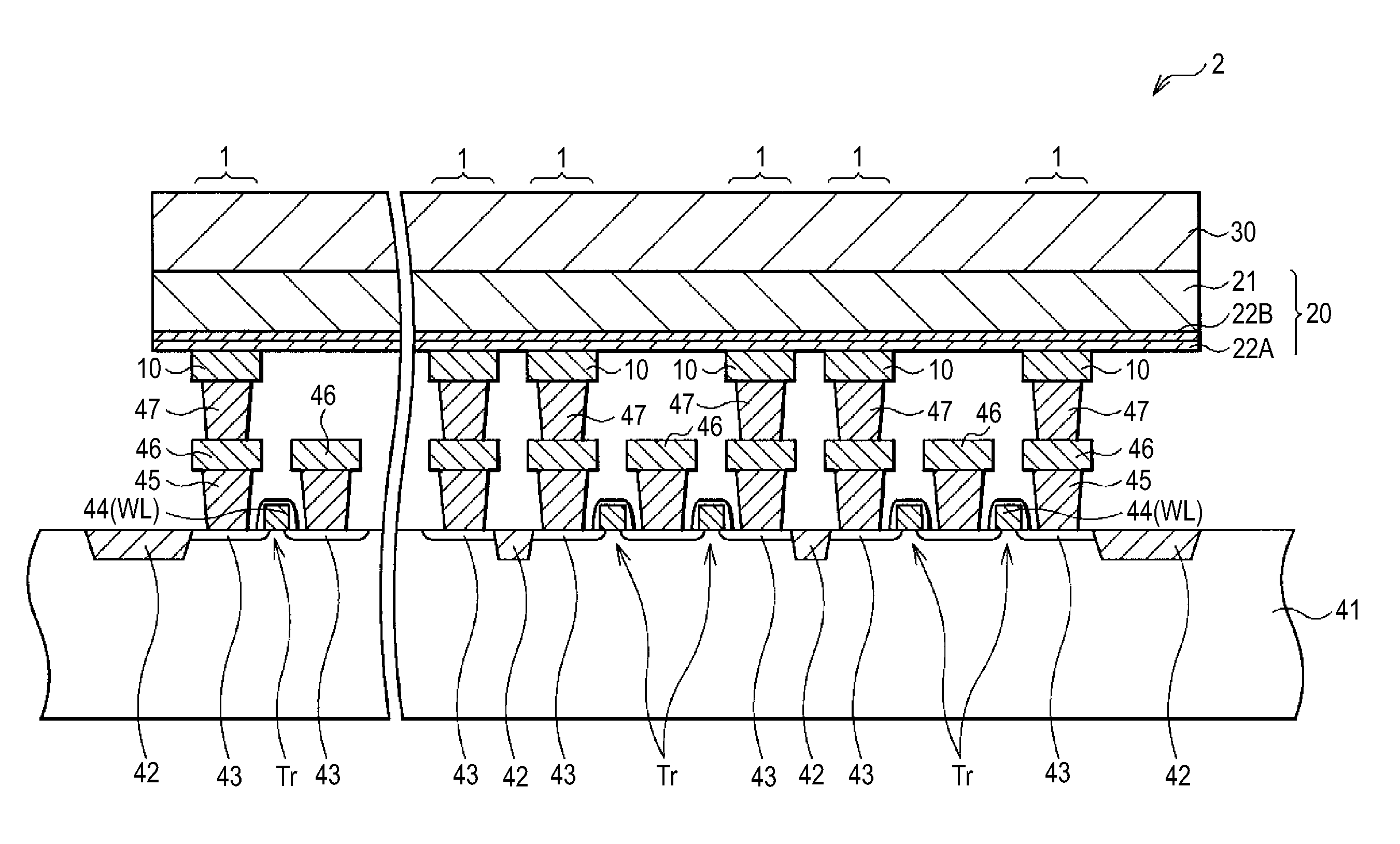

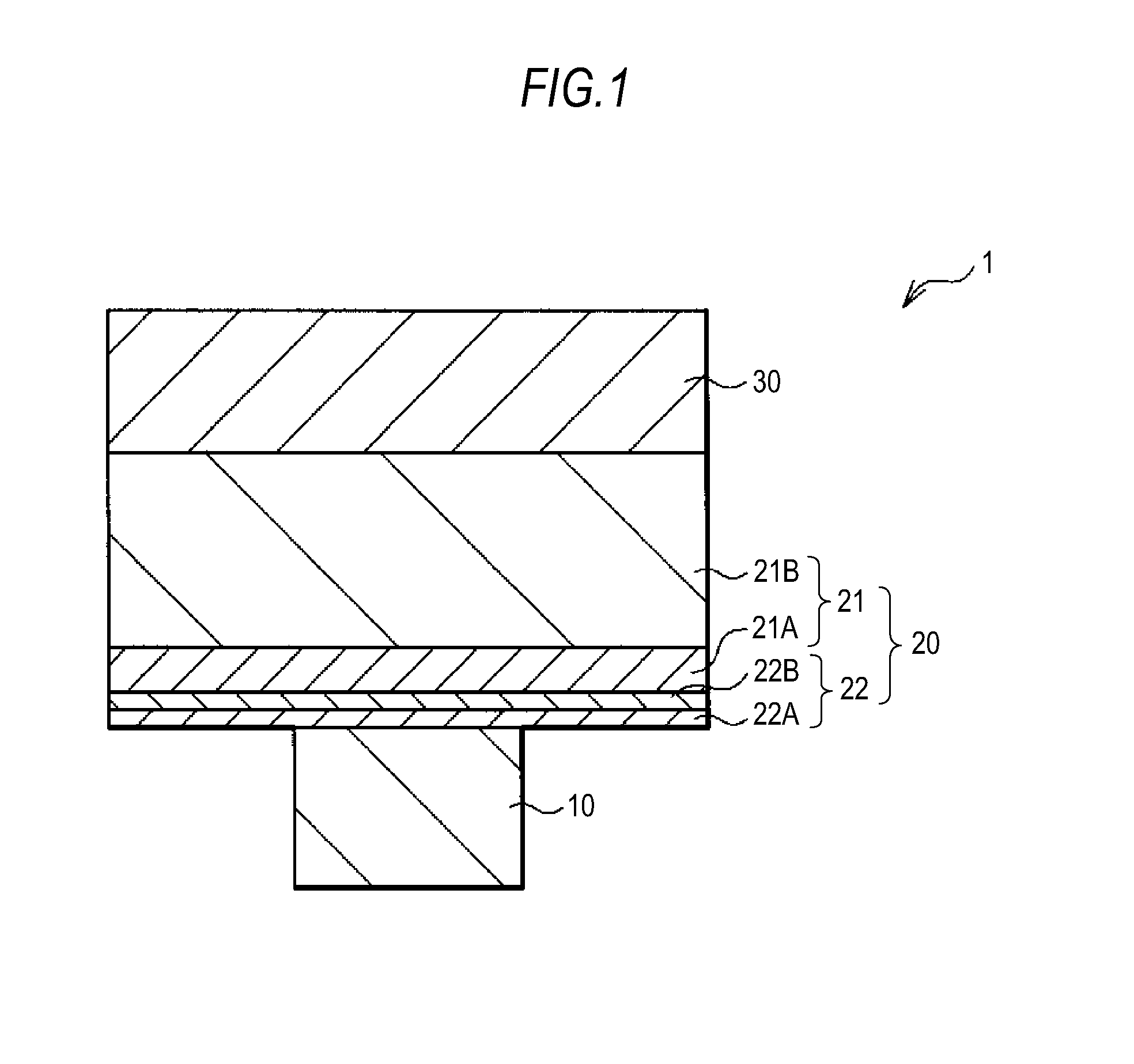

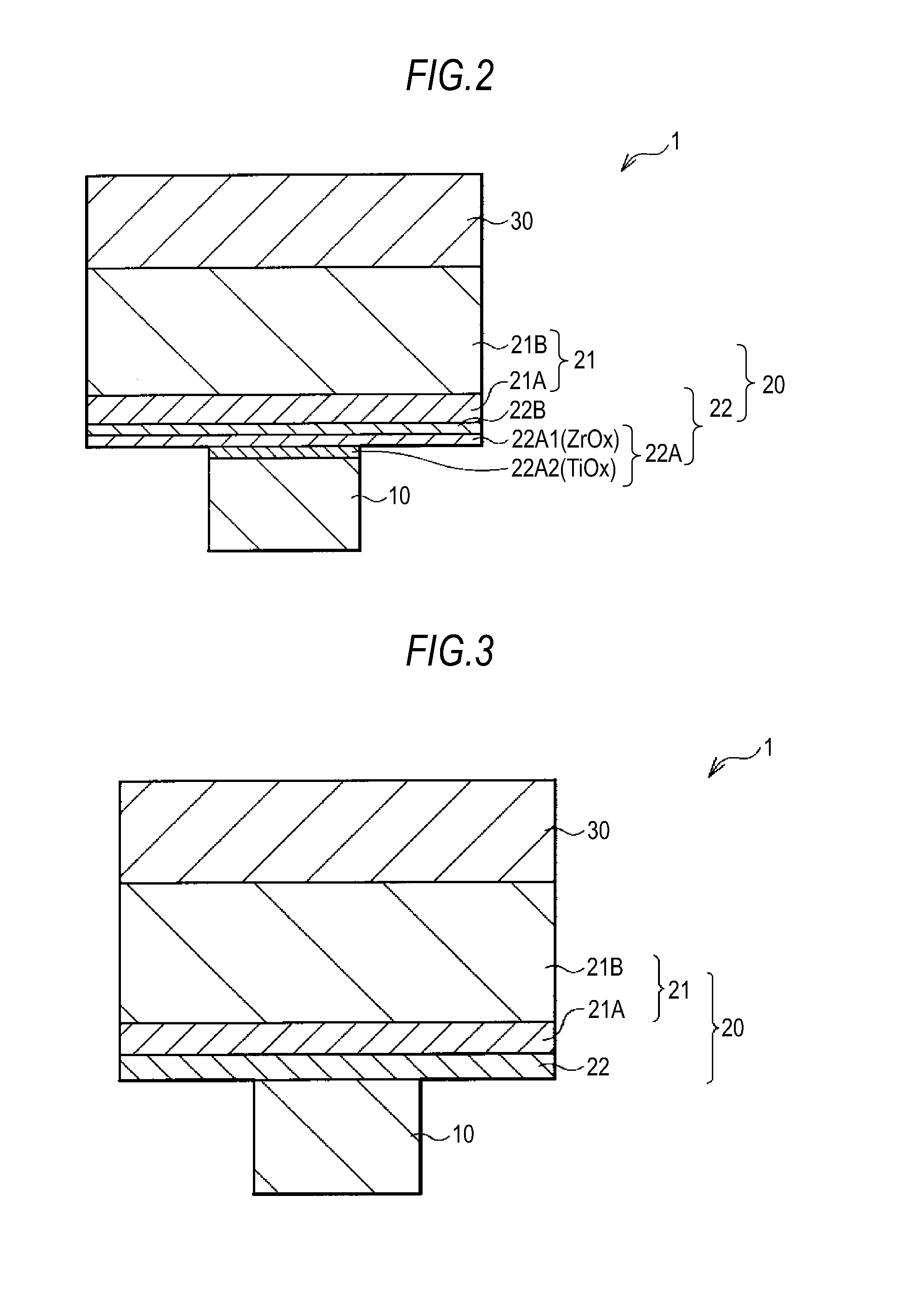

Memory component, memory device, and method of operating memory device

InactiveUS20110194329A1Avoid reactionImprove repetition durabilitySolid-state devicesDigital storageLow resistanceTellurium

A memory component includes: a first electrode; a memory layer; and a second electrode which are provided in that order, wherein the memory layer includes an ion source layer containing aluminum (Al) together with at least one chalcogen element selected from the group consisting of tellurium (Te), sulfur (S), and selenium (Se), and a resistance variable layer provided between the ion source layer and the first electrode and containing an aluminum oxide and at least one of a transition metal oxide and a transition metal oxynitride having a lower resistance than the aluminum oxide.

Owner:SONY SEMICON SOLUTIONS CORP

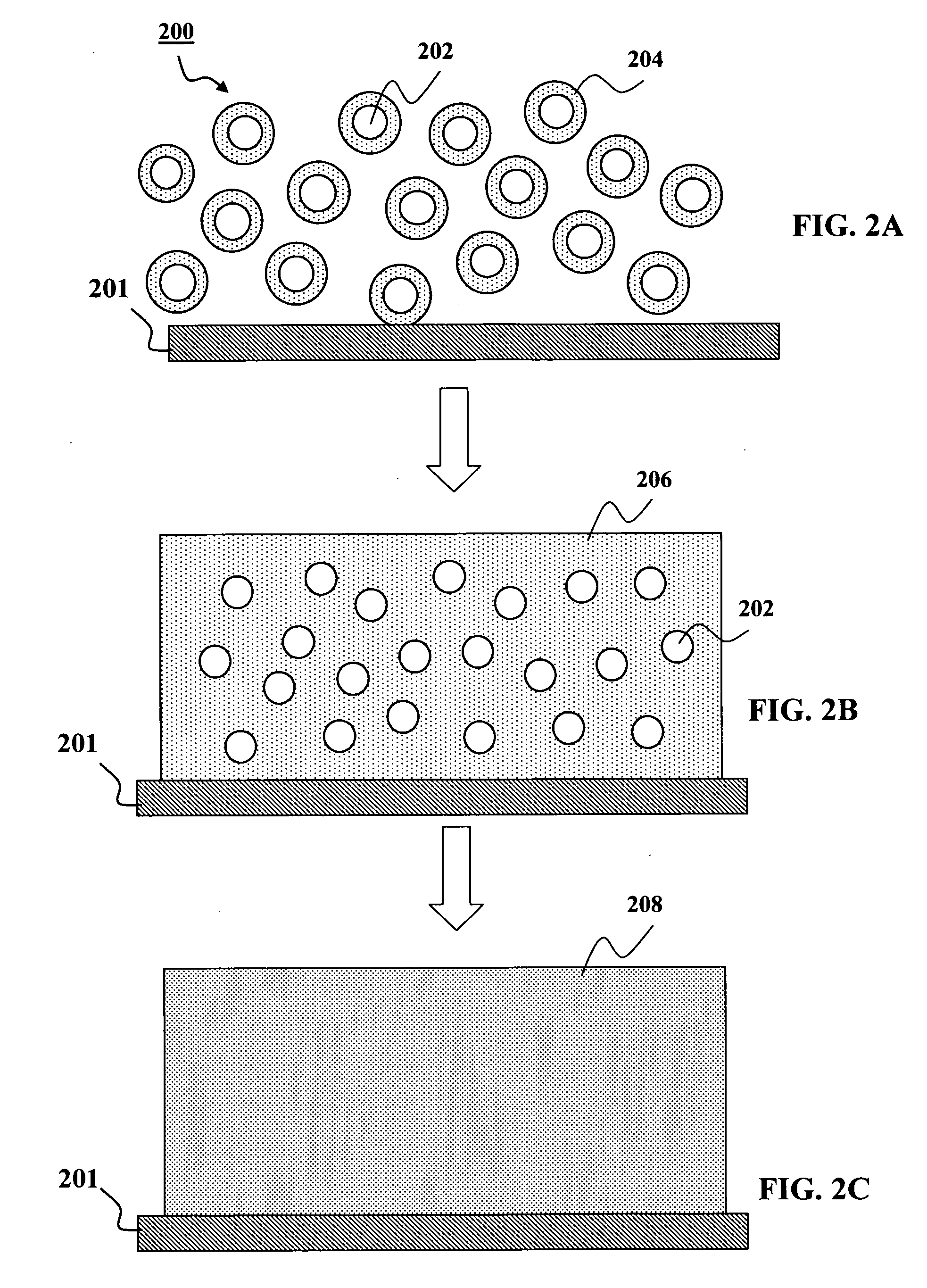

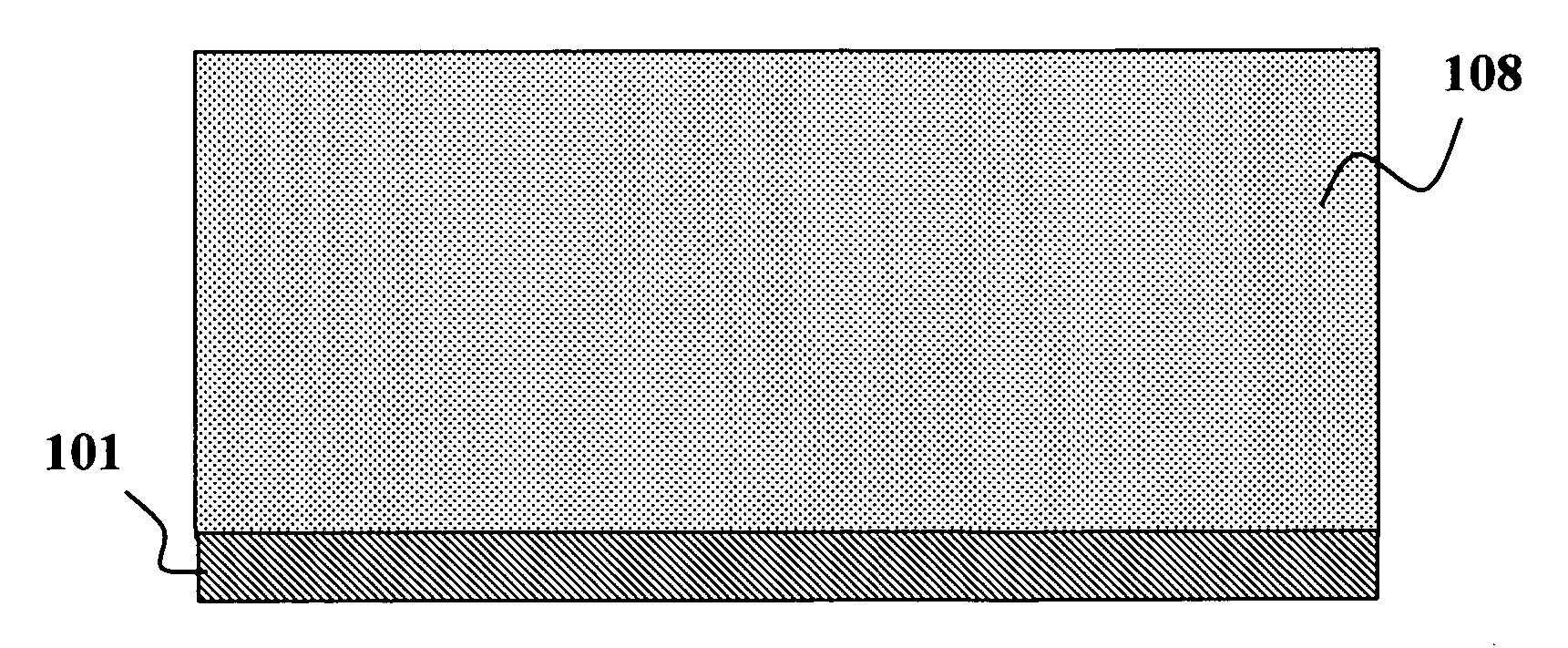

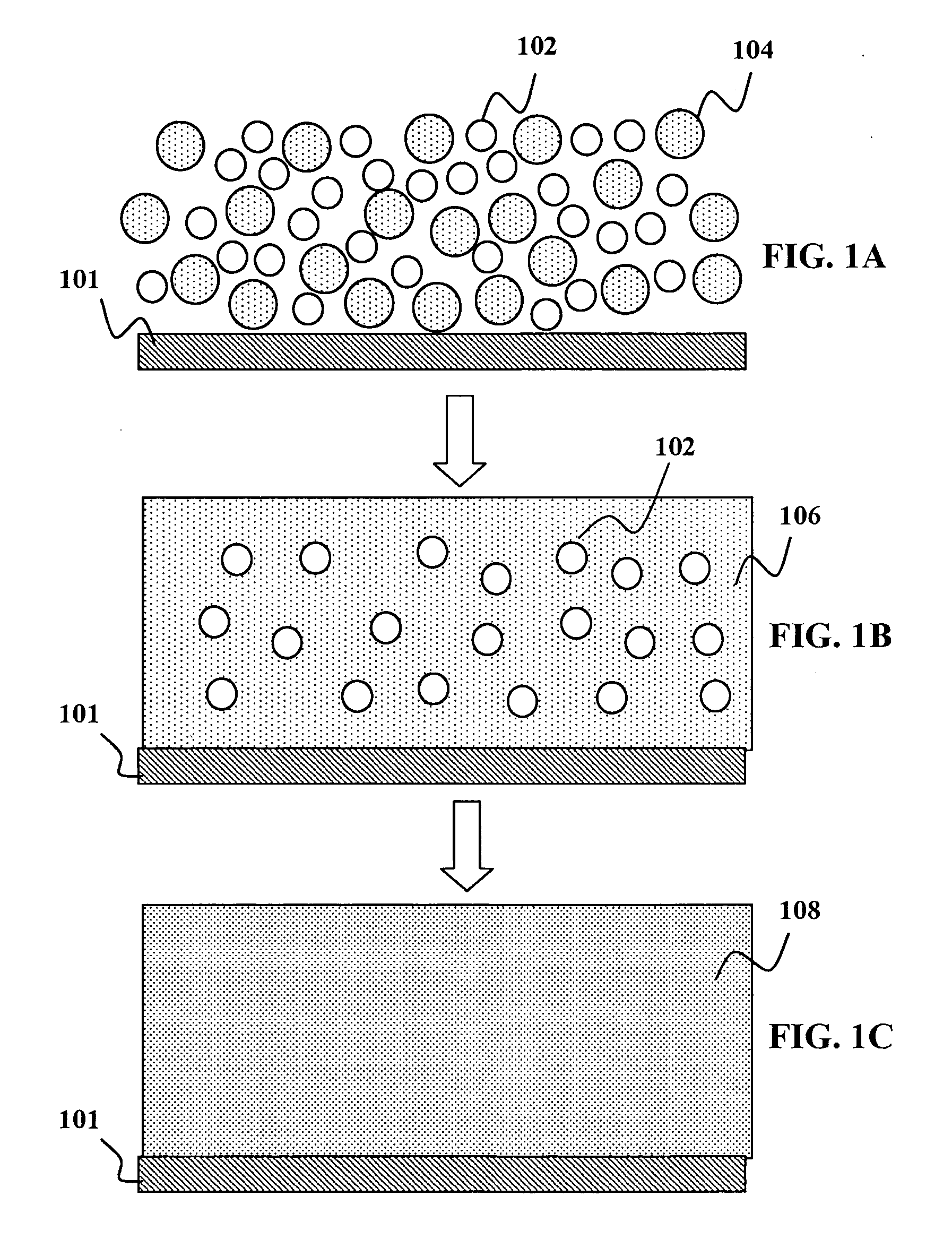

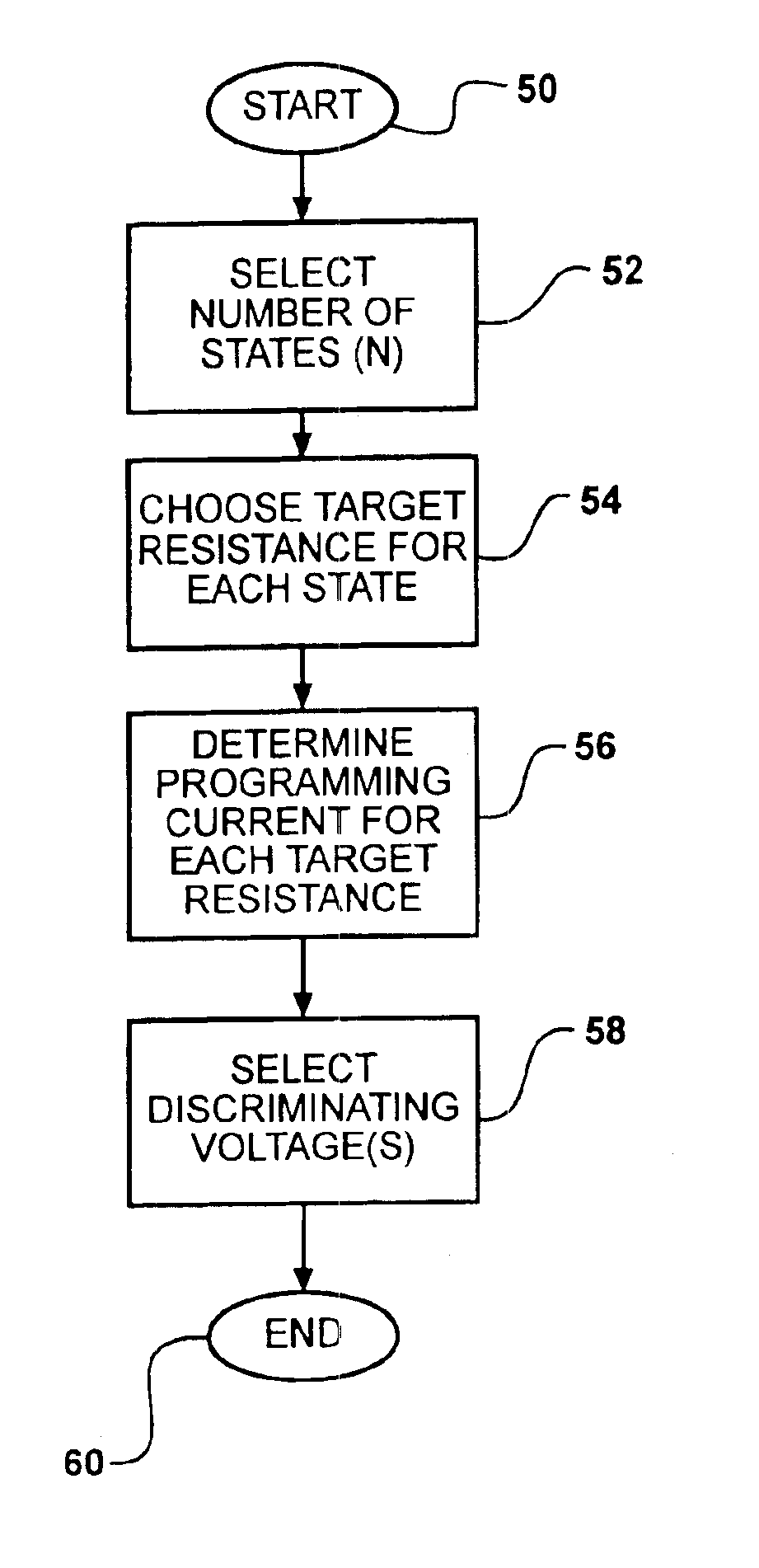

High-throughput printing of semiconductor precursor layer by use of chalcogen-rich chalcogenides

A high-throughput method of forming a semiconductor precursor layer by use of a chalcogen-rich chalcogenides is disclosed. The method comprises forming a precursor material comprising group IB-chalcogenide and / or group IIIA-chalcogenide particles, wherein an overall amount of chalcogen in the particles relative to an overall amount of chalcogen in a group IB-IIIA-chalcogenide film created from the precursor material, is at a ratio that provides an excess amount of chalcogen in the precursor material. The excess amount of chalcogen assumes a liquid form and acts as a flux to improve intermixing of elements to form the group IB-IIIA-chalcogenide film at a desired stoichiometric ratio, wherein the excess amount of chalcogen in the precursor material is an amount greater than or equal to a stoichiometric amount found in the IB-IIIA-chalcogenide film.

Owner:NANOSOLAR

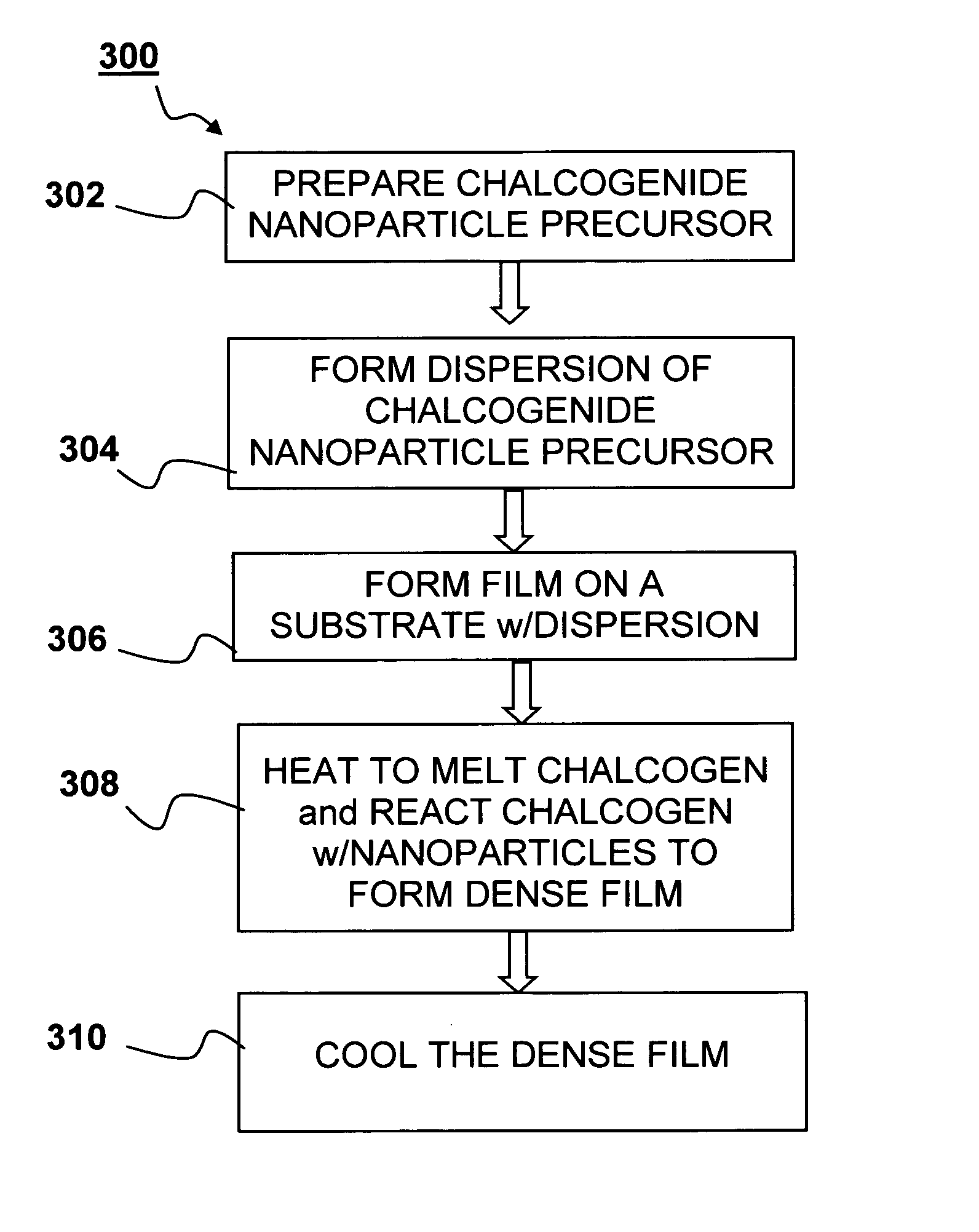

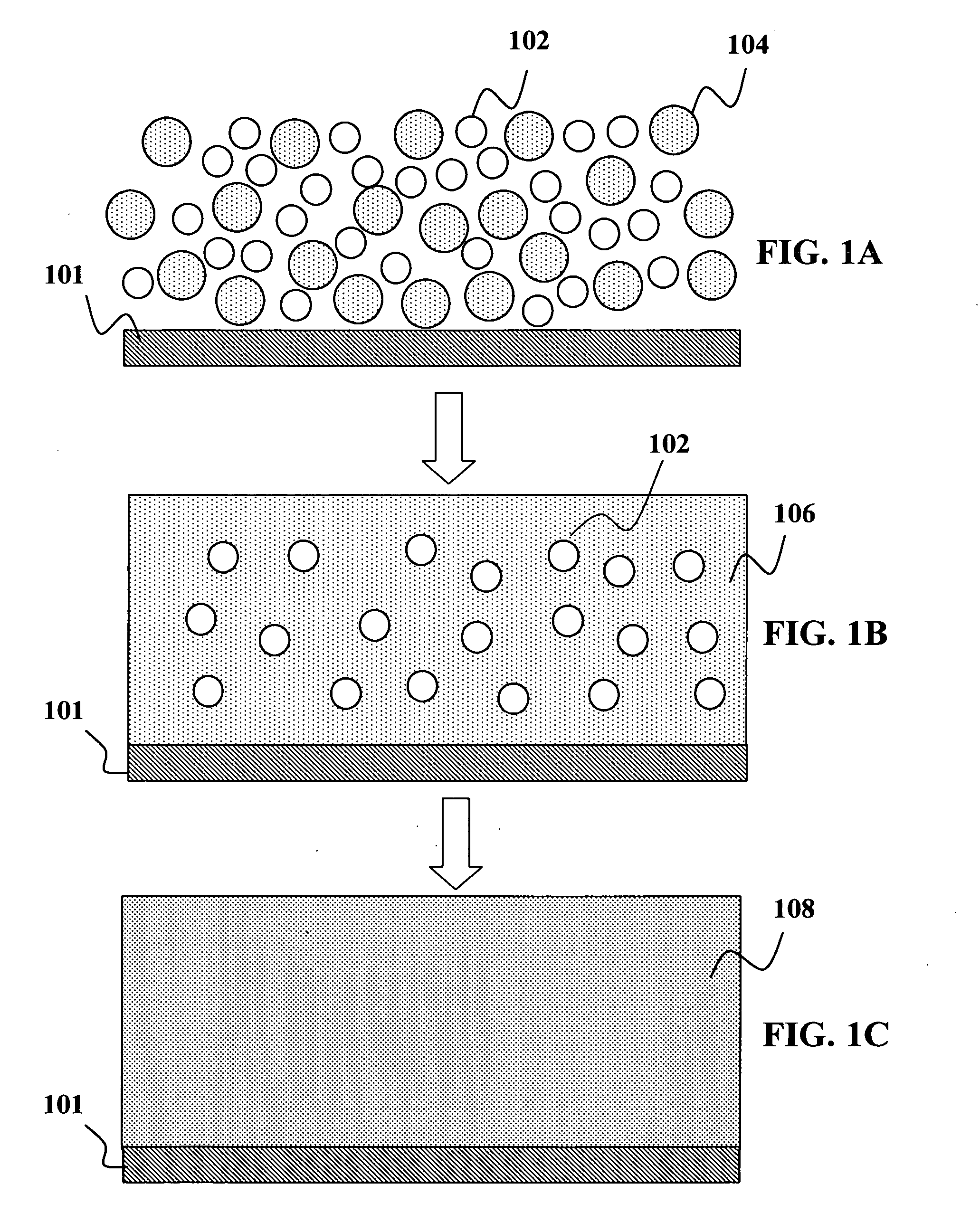

High-throughput printing of chalcogen layer

InactiveUS20070166453A1Reduce the temperatureFinal product manufacturePretreated surfacesNanoparticleSulfur

Methods and devices for high-throughput printing of a precursor material for forming a film of a group IB-IIIA-chalcogenide compound are disclosed. In one embodiment, the method comprises forming a precursor layer on a substrate, wherein the precursor layer comprises one or more discrete layers. The layers may include at least a first layer containing one or more group IB elements and two or more different group IIIA elements and at least a second layer containing elemental chalcogen particles. The precursor layer may be heated to a temperature sufficient to melt the chalcogen particles and to react the chalcogen particles with the one or more group IB elements and group IIIA elements in the precursor layer to form a film of a group IB-IIIA-chalcogenide compound. The method may also include making a film of group IB-IIIA-chalcogenide compound that includes mixing the nanoparticles and / or nanoglobules and / or nanodroplets to form an ink, depositing the ink on a substrate, heating to melt the extra chalcogen and to react the chalcogen with the group IB and group IIIA elements and / or chalcogenides to form a dense film.

Owner:NANOSOLAR

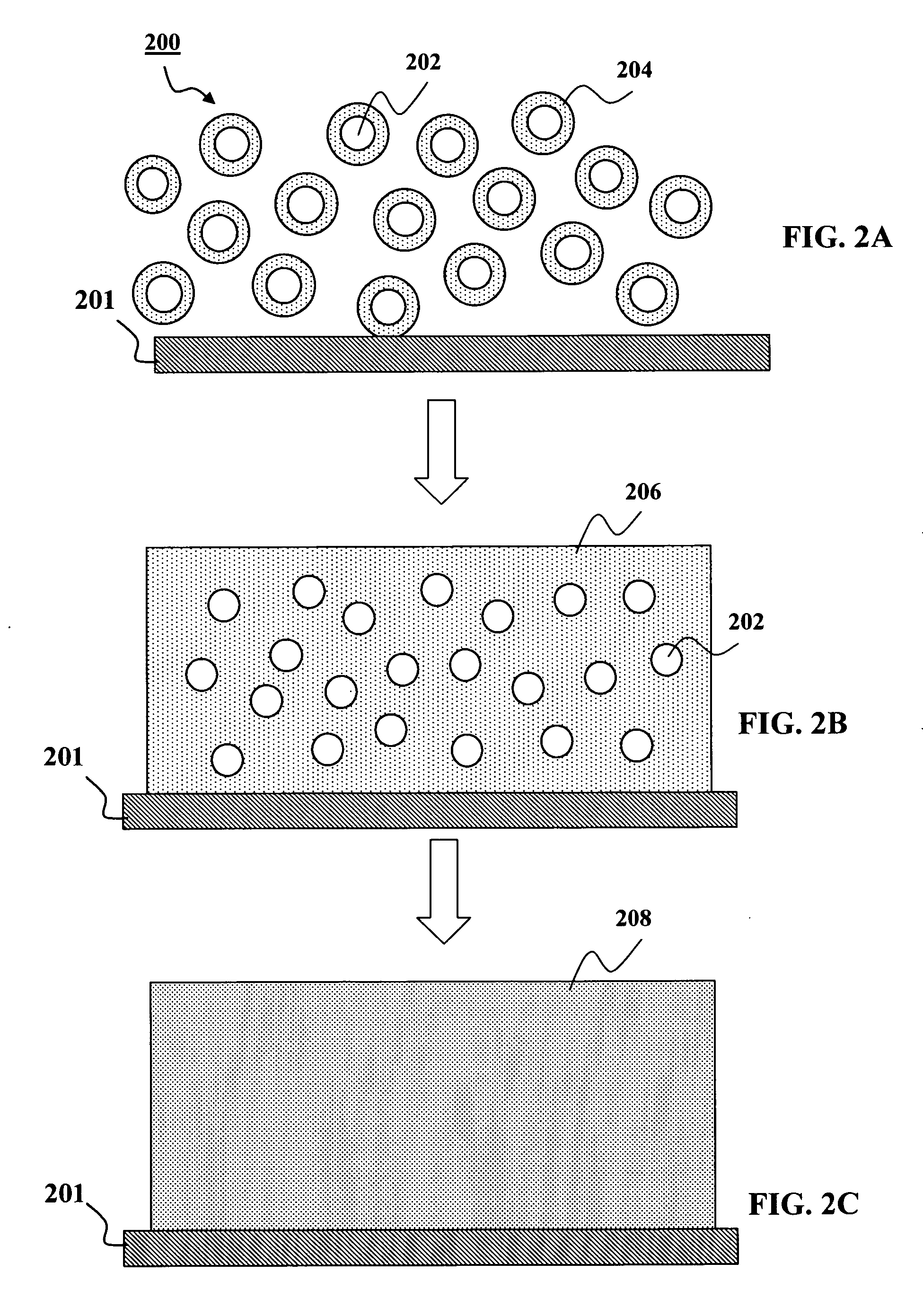

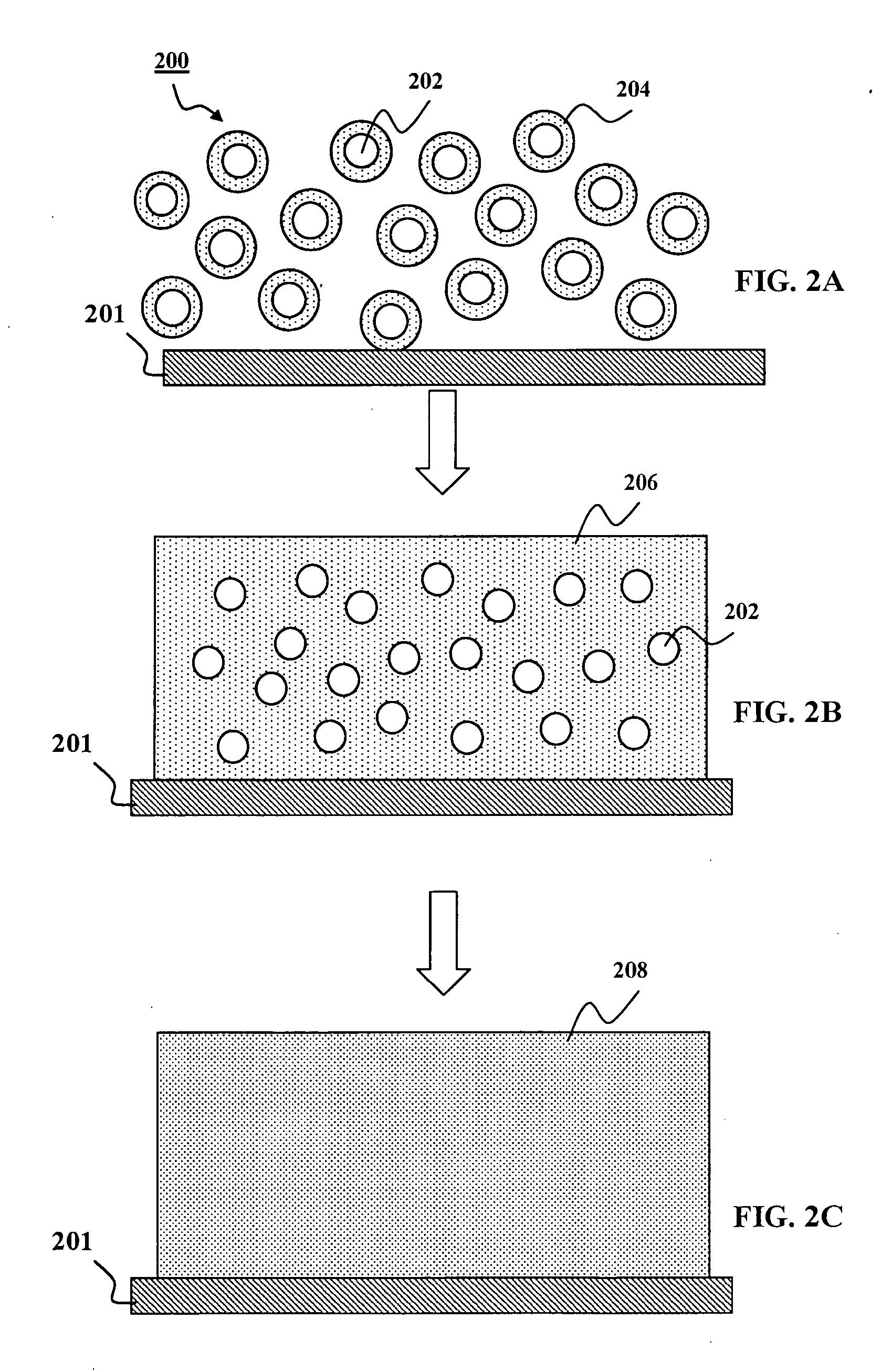

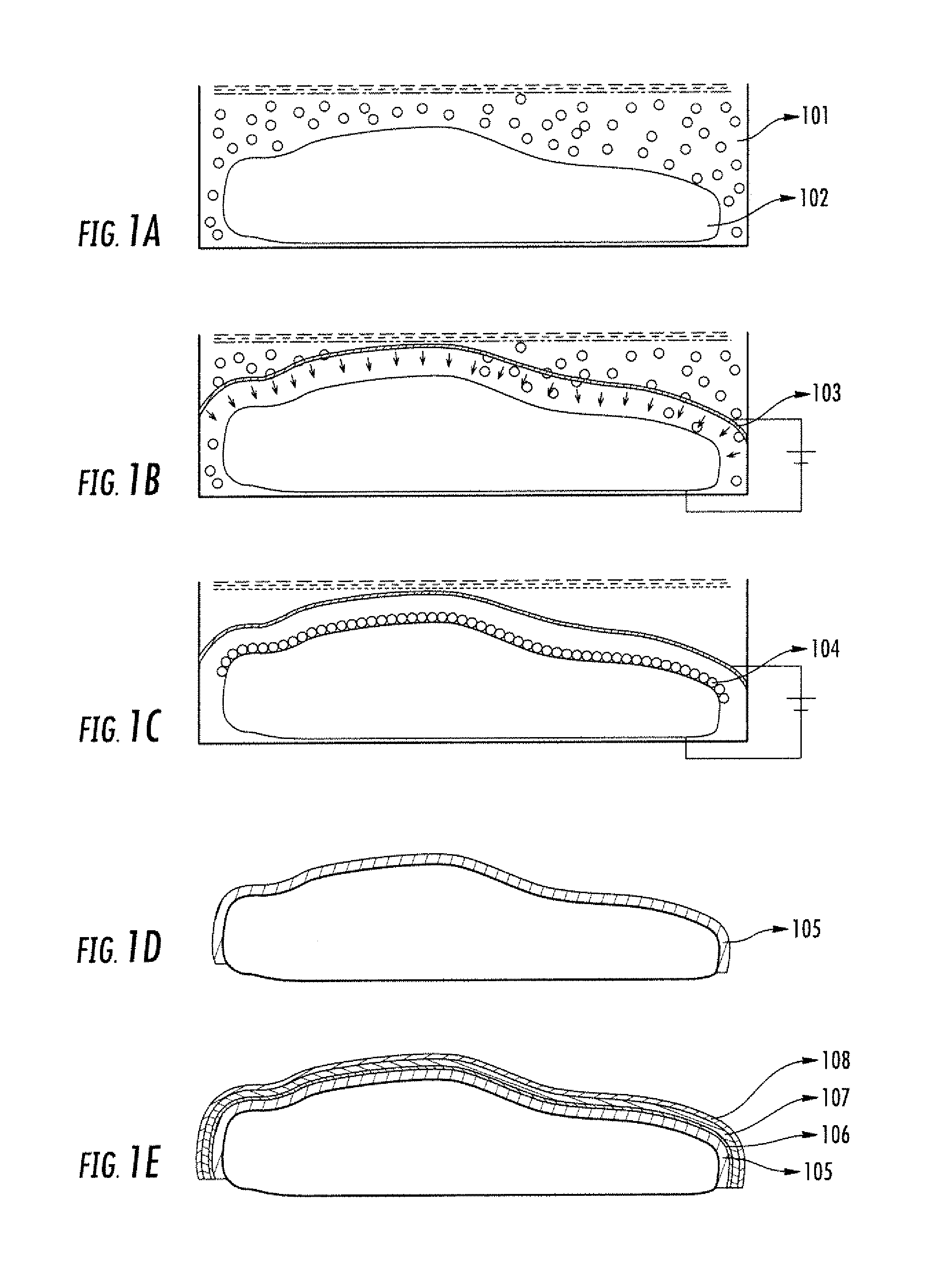

Chalcogenide solar cells

InactiveUS20070092648A1Overcome disadvantagesMolten spray coatingSolid-state devicesCore shell nanoparticlesSulfur

A precursor material for forming a film of a group IB-IIIA-chalcogenide compound and a method of making this film are disclosed. The film contains group IB-chalcogenide nanoparticles and / or group IIIA-chalcogenide nanoparticles and / or nanoglobules and / or nanodroplets and a source of extra chalcogen. Alternatively, the film may contain core-shell nanoparticles having core nanoparticles include group IB and / or IIIA elements, which are coated with a shell of elemental chalcogen material. The method of making a film of group IB-IIIA-chalcogenide compound includes mixing the nanoparticles and / or nanoglobules and / or nanodroplets to form an ink, depositing the ink on a substrate, heating to melt the extra chalcogen and to react the chalcogen with the group IB and group IIIA elements and / or chalcogenides to form a dense film.

Owner:AERIS CAPITAL SUSTAINABLE IP

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES U S INC

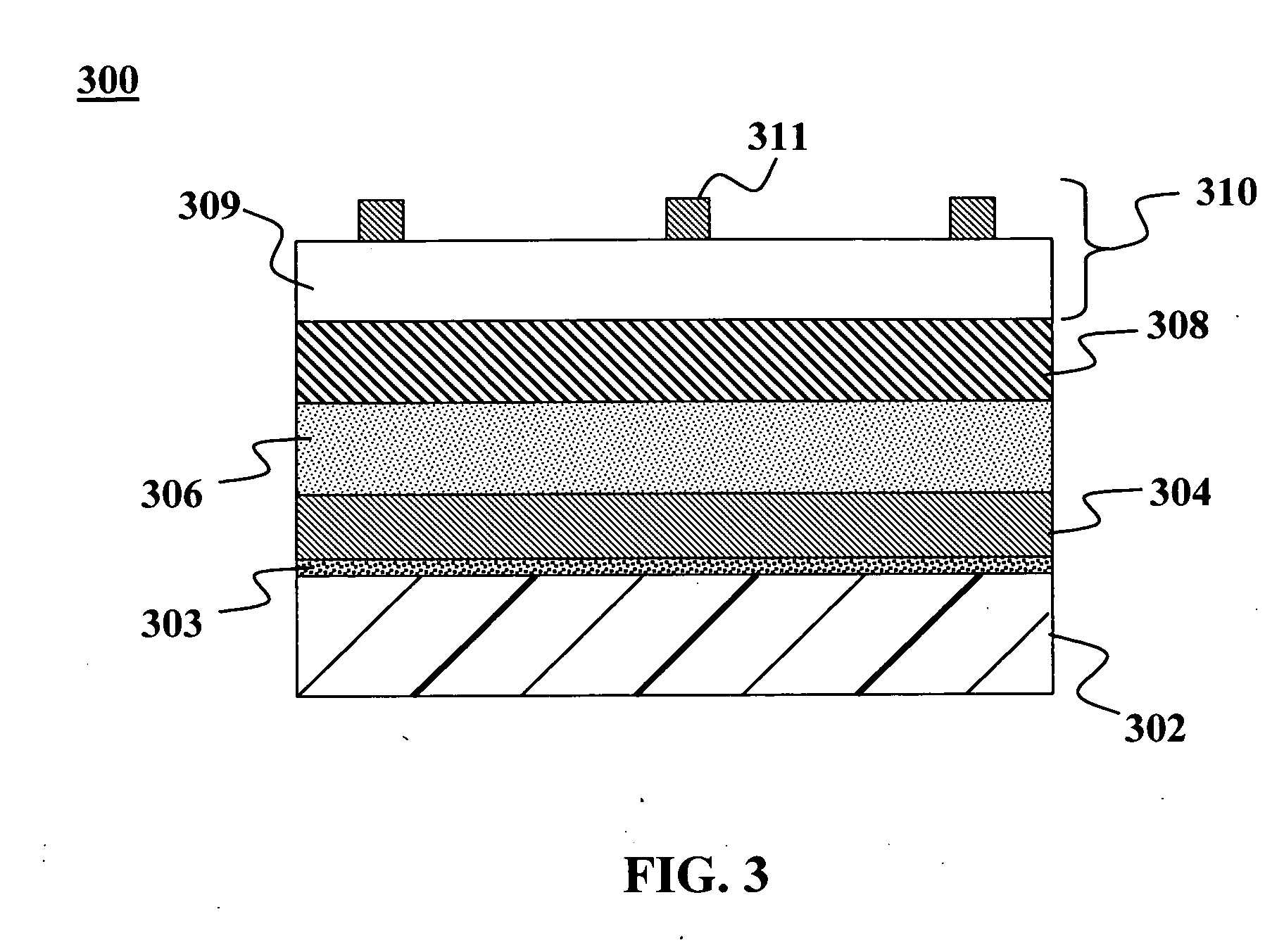

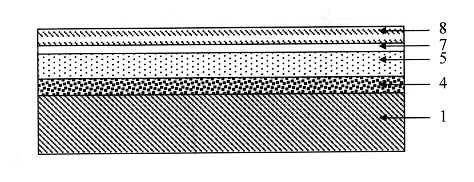

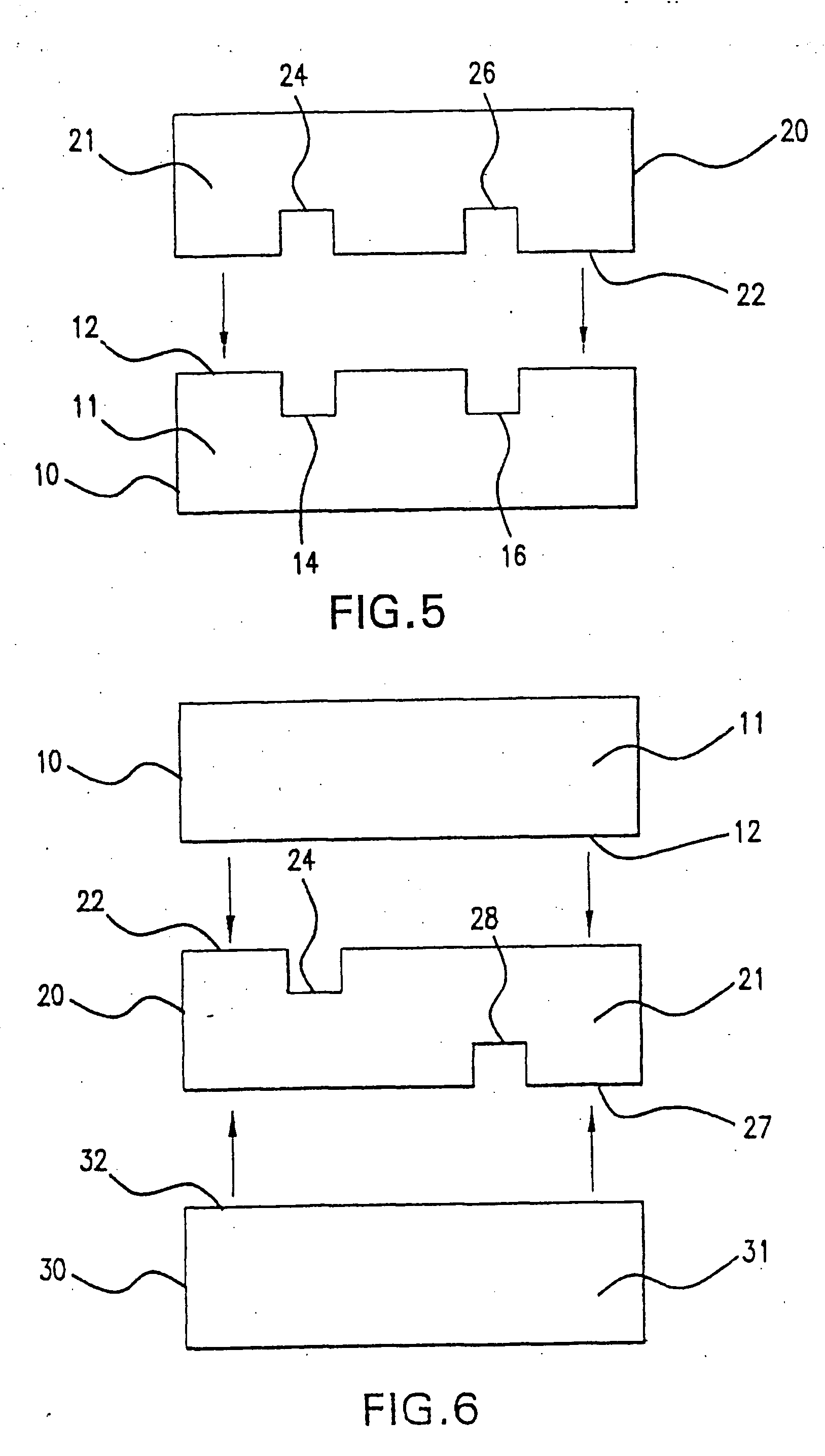

Thin-film solar cells on the basis of IB-IIIA-VIA compound semiconductors and method for manufacturing same

InactiveUS6429369B1Improve adhesionReduce capacityFinal product manufactureSolid-state devicesSulfurEngineering

The invention relates to a thin-film solar cell on the basis of IB-IIIA-VIA compound semiconductors and a method for producing such a solar cell. Between the polycrystalline IB-IIIA-VIA absorber layer of the p-type conductivity and the carrier film serving as a substrate, a back electrode of intermetallic phases of the same IB- and IIIA-metals are located which are deposited for the generation of the absorber layer. The absorber layer and the back electrode are produced in such a way that the precursor consisting of IB-IIIA-metals is vertically only incompletely converted into the photovoltaicly active absorber material from the side opposite to the carrier film by reaction with chalcogen such that intermetallic phases of the IB- and IIIA-metals are directly located on the carrier film, which metals serve as back electrode of the solar cell structure.

Owner:ODERSUN

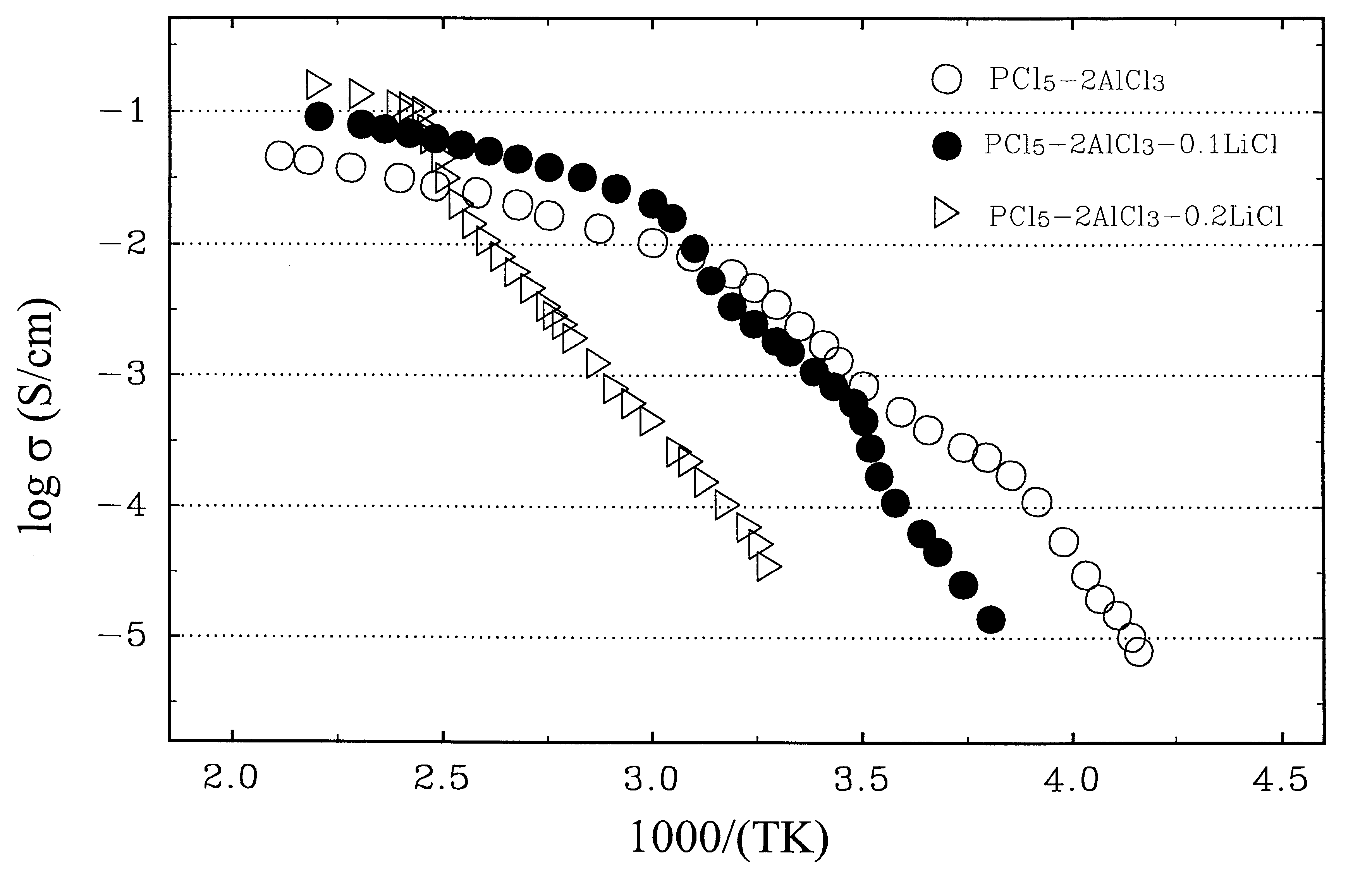

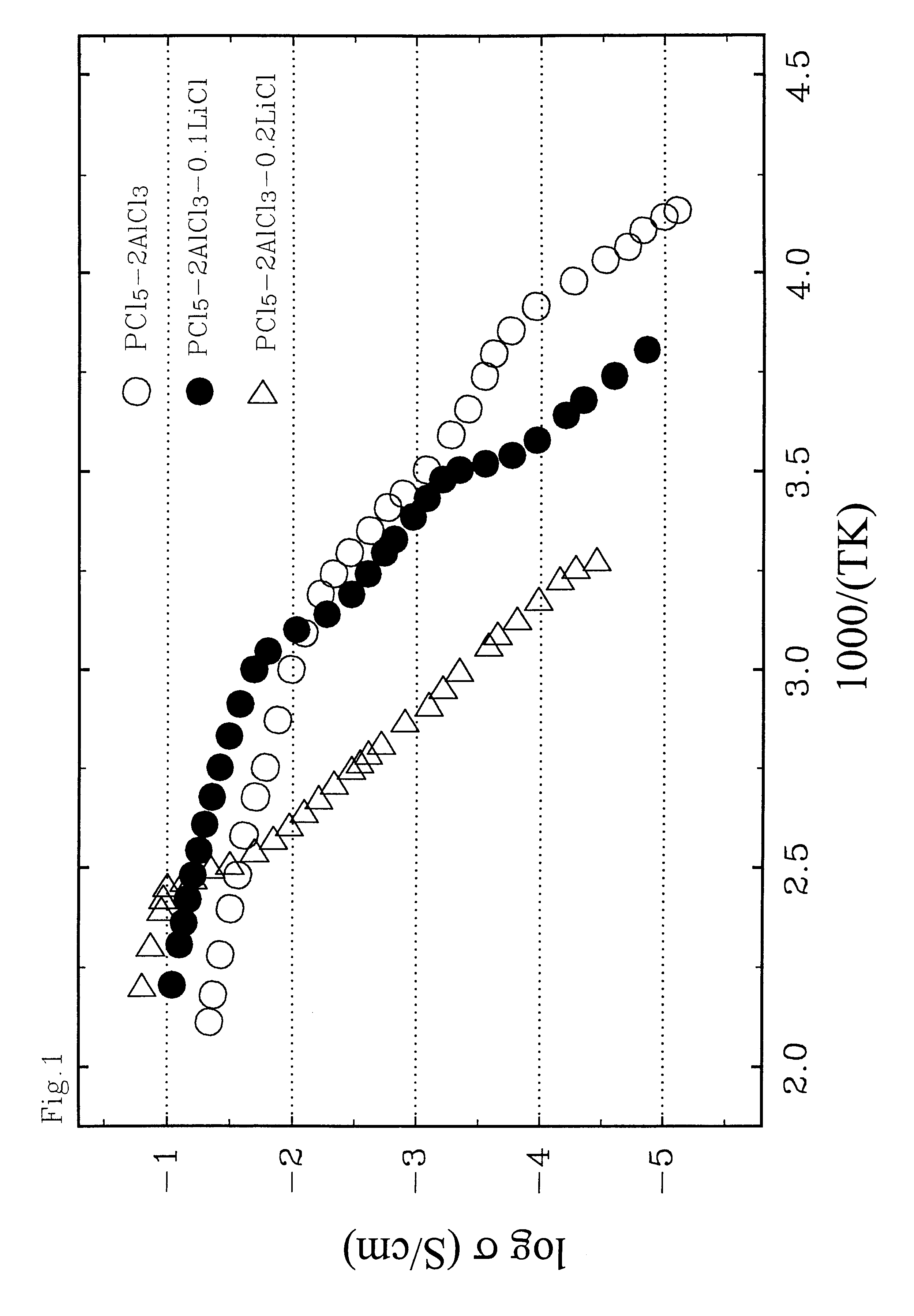

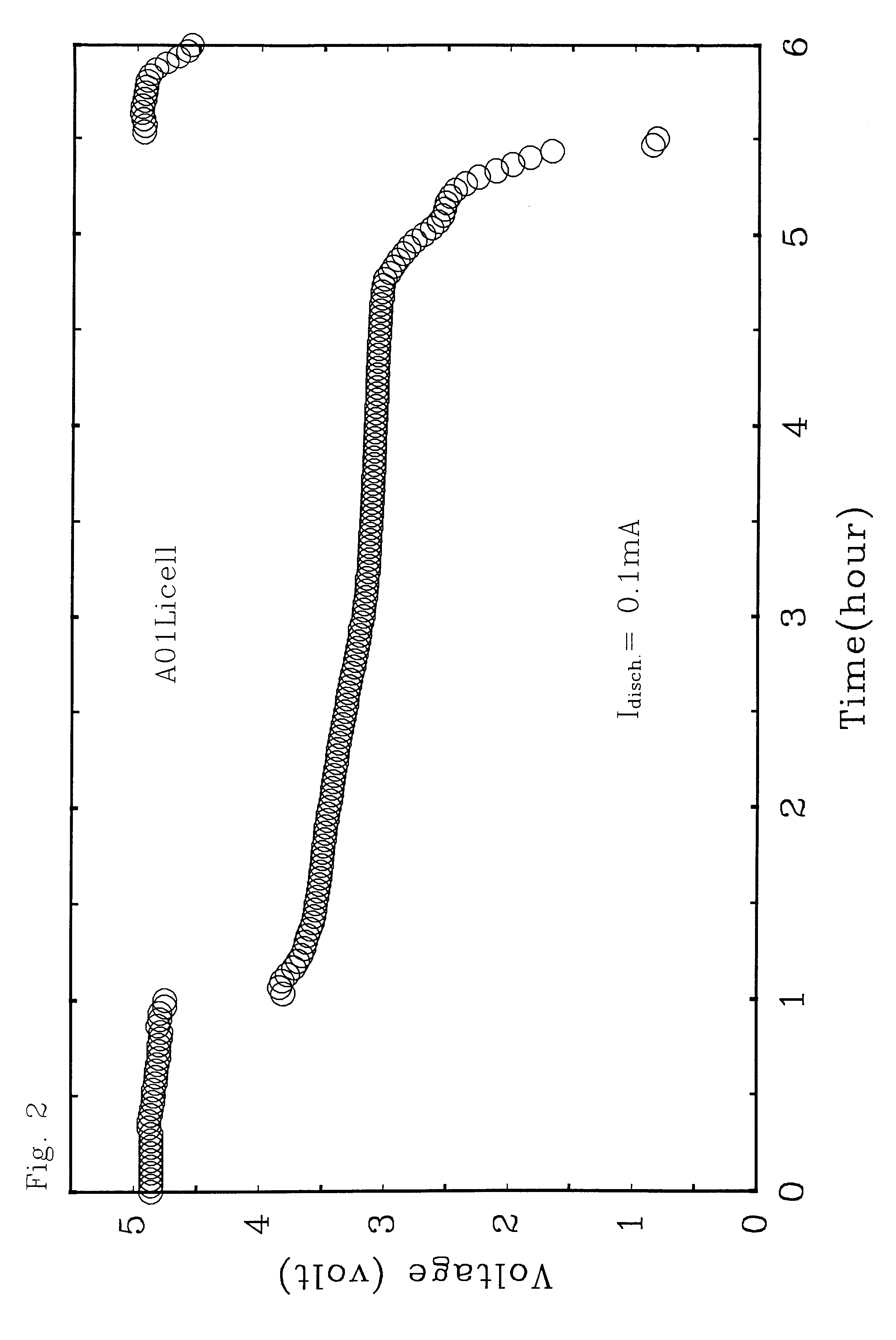

Ambient temperature, rechargeable cells with metal salt-based electrodes and a system of cell component materials for use therein

InactiveUS6187479B1Improve battery performanceImprove performanceLead-acid accumulatorsNon-aqueous electrolyte cellsHalogenRechargeable cell

A rechargeable battery or cell is disclosed in which the electrode active material consists of at least one nonmetallic compound or salt of the electropositive species on which the cell is based, and the electrolyte or electrolyte solvent consists predominantly of a halogen-bearing or chalcogen-bearing covalent compound such as SOCl2 or SO2Cl2. Also disclosed are cell component materials which include electrodes that consist primarily of salts of the cell electropositive species and chemically compatible electrolytes. These latter electrolytes include several newly discovered ambient temperature molten salt systems based on the AlCl3-PCl5 binary and the AlCl3-PCl5-PCl3 ternaries.

Owner:LIU CHANGLE

Metal Plating Composition and Method for the Deposition of Copper-Zinc-Tin Suitable for Manufacturing Thin Film Solar Cell

InactiveUS20090205714A1Easy to manufactureClear processSemiconductor/solid-state device manufacturingOrganic dyesCopper platingTin plating

To be able to form a copper-zinc-tin alloy which optionally comprises at least one chalcogenide and thus forms a semiconductor without the use of toxic substances a metal plating composition for the deposition of a copper-zinc-tin alloy is disclosed, wherein said metal plating composition comprises at least one copper plating species, at lease one zinc plating species, at least one tin plating species and at least one complexing agent and further, if the alloy contains at least one chalcogen, at least one chalcogen plating species.

Owner:ATOTECH DEUT GMBH

Method for preparing metal chalcogenide film

ActiveCN103194729AControl thicknessSmall sizeChemical vapor deposition coatingDeposition temperatureSulfur

The invention discloses a method for preparing a metal chalcogenide film. The method is used for growing the metal chalcogenide film on a substrate with the vapor deposition process by using a chalcogen source and a metal element source and comprises the following steps of: providing three temperature zones, wherein the temperature of the three temperature zones can be controlled independently, and the chalcogen source, the metal element source and the substrate are put in the three temperature zones respectively; controlling the three temperature zones, evaporating the chalcogen source to generate the chalcogen source steam, evaporating the metal element source to generate the metal element source steam, and heating the substrate to the predetermined deposition temperature; providing a carrier gas, and enabling the carrier gas to flow through the three temperature zones in sequence to deliver the metal element source steam to the substrate to deposit and grow so as to form the metal chalcogenide film. The method disclosed by the invention is simple, dispenses with the original complex step of introducing a nucleation site and effectively ensures the purity and the surface cleanness of a sample. The metal chalcogenide film prepared by adopting the method has high quality.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

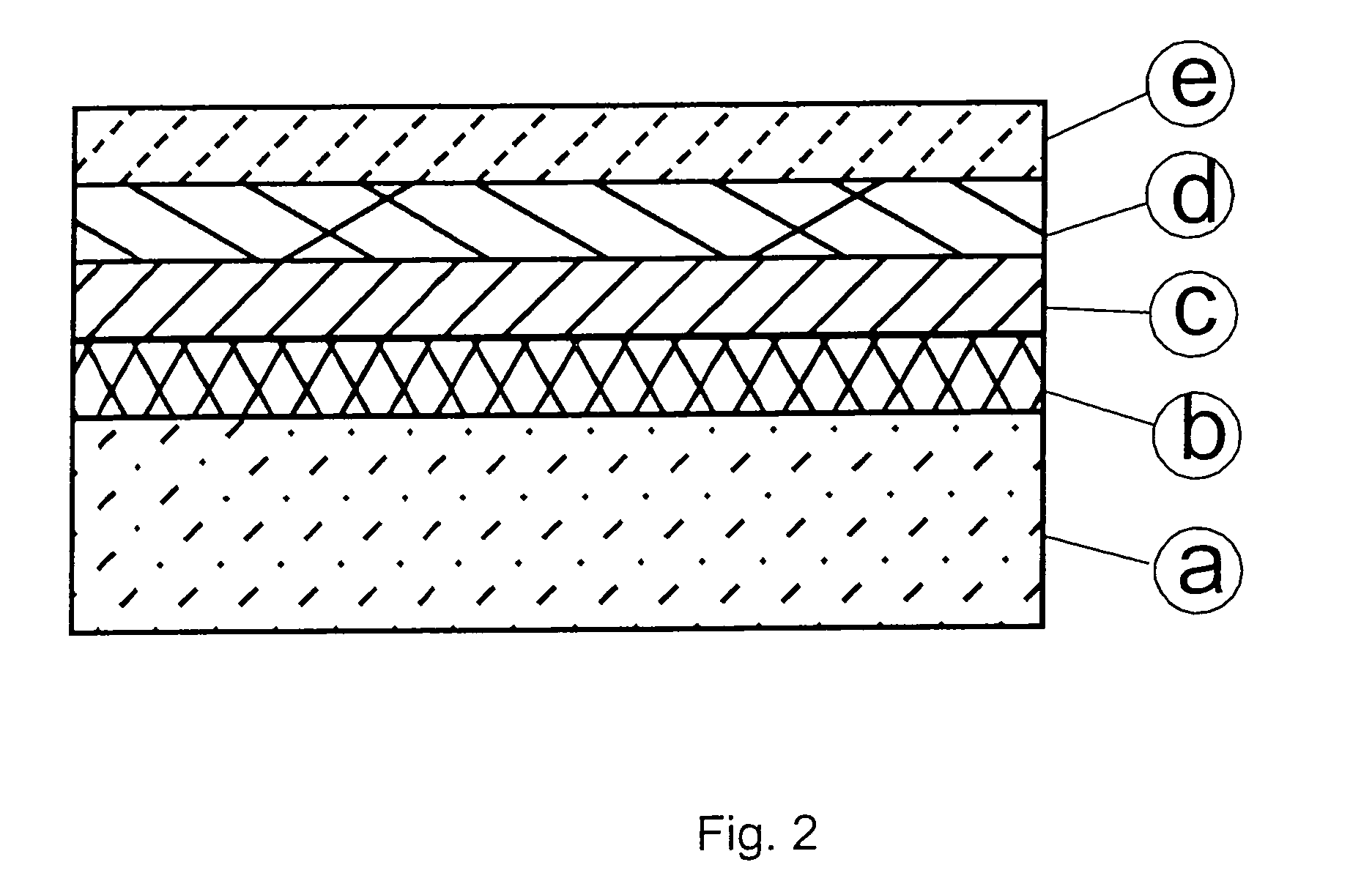

High-throughput printing of semiconductor precursor layer by use of thermal and chemical gradients

InactiveUS20070169811A1Well mixedReduce lossesMolten spray coatingTransportation and packagingSulfurChalcogen

A high-throughput method of forming a semiconductor precursor layer by use of a chalcogen-containing vapor is disclosed. In one embodiment, the method includes forming a first layer of a first precursor material over a surface of a substrate, wherein the precursor material comprises group IB-chalcogenide and / or group IIIA-chalcogenide particles. The method may include forming at least a second layer of a second precursor material over the first layer, wherein the second precursor material comprises group IB-chalcogenide and / or group IIIA-chalcogenide particles and wherein the second precursor material has a chalcogen content greater than that of the first material. The method may also include heating the first layer and the second layer in a suitable atmosphere to a temperature sufficient to react the particles and to release at least the surplus amount of chalcogen from the chalcogenide particles, wherein the surplus amount of chalcogen assumes a liquid form and acts as a flux to improve intermixing of elements to form the group IB-IIIA-chalcogenide film at a desired stoichiometric ratio

Owner:NANOSOLAR

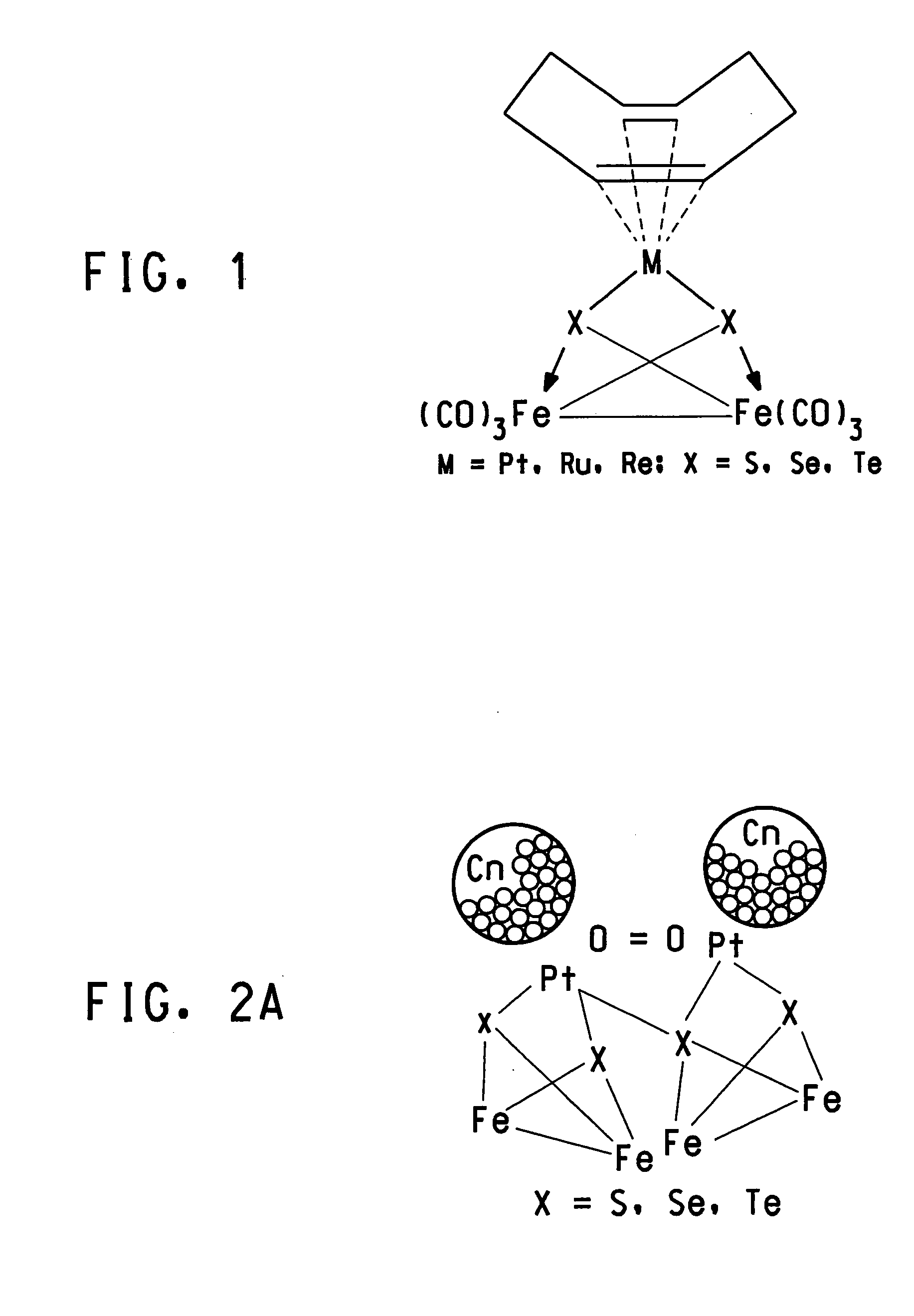

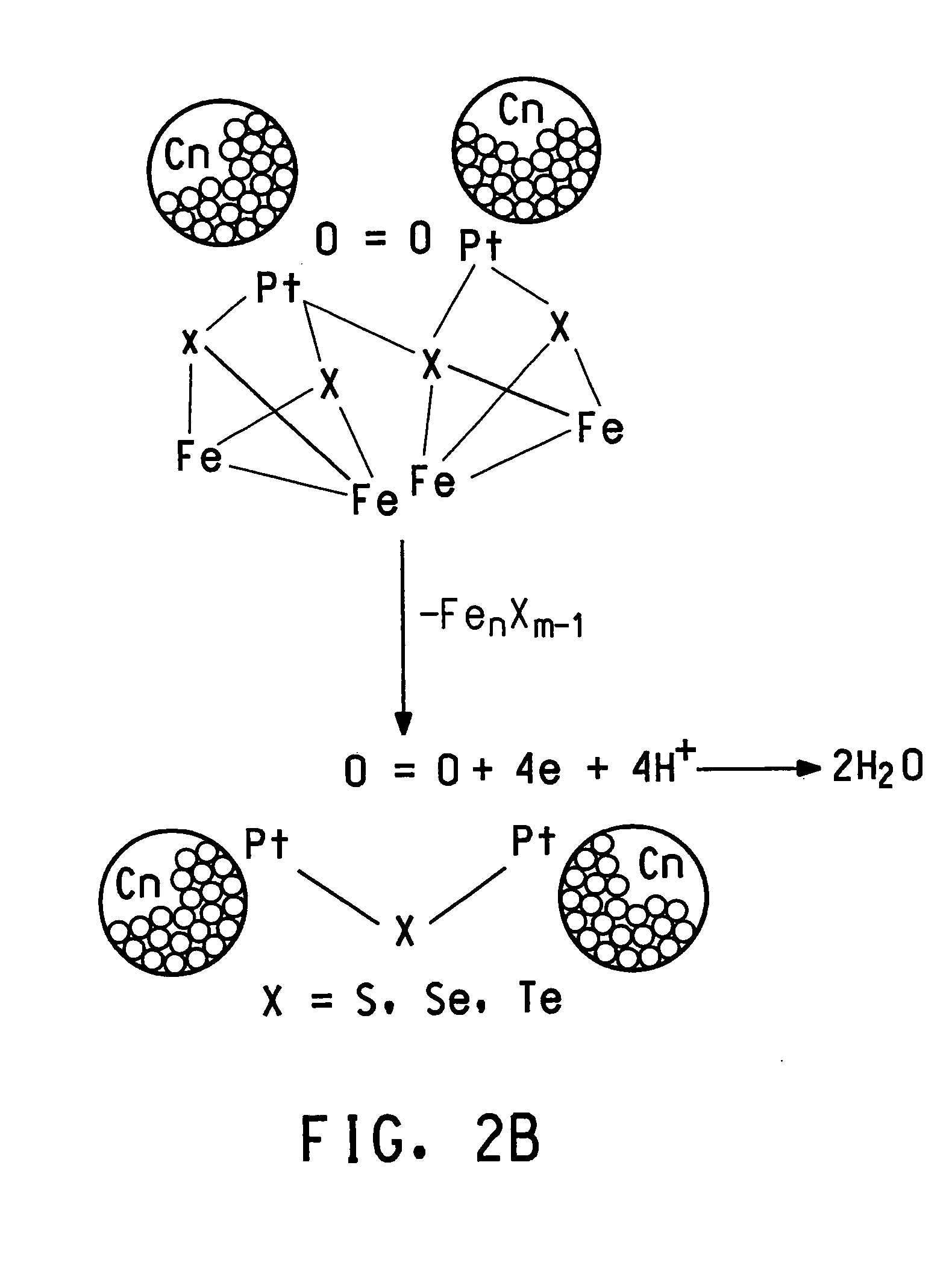

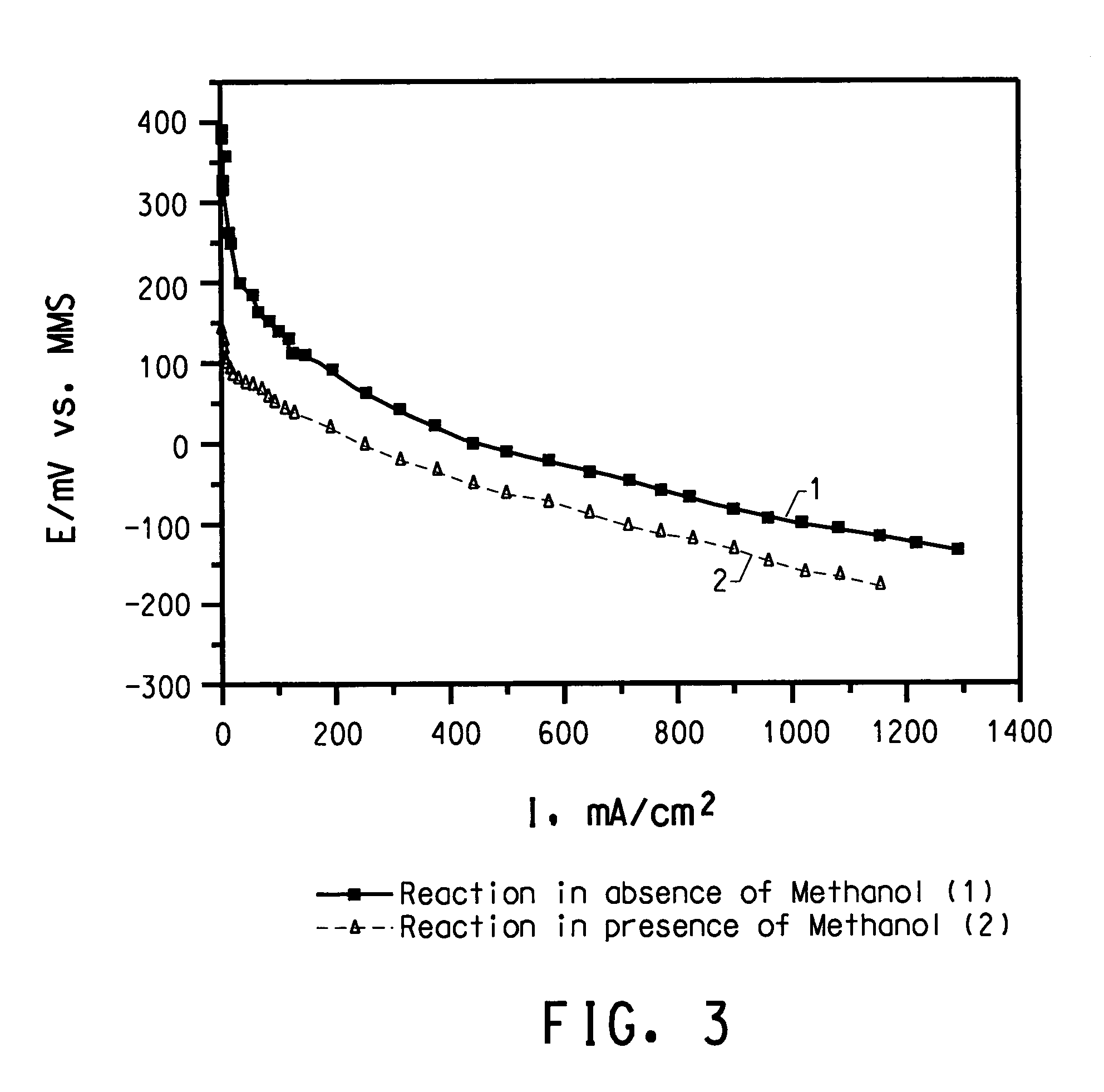

Methanol tolerant catalyst material

InactiveUS20070078052A1Definite compositionLong-term stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesOrganic solventUnsaturated hydrocarbon

Methanol tolerant catalyst material and method of its preparation are provided. These novel catalyst materials are based on organometallic clusters containing (i) a carbonyl group or a cyclic unsaturated hydrocarbon ligand group, and (ii) a chalcogen containing group selected from MnFepXm, MnXm, MnClpXm, or mixtures thereof wherein M=Pt, Ru or Re, X=S, Se or Te, and m, n and p=1 or 2. The catalyst materials are obtained by mixing together organometallic clusters of definite composition with an electrically conductive component in an organic solvent, subsequent removing of the solvent, and in a non-oxidizing environment, heat-treating the clusters adsorbed on the electrically conductive component at the temperature of at least 175° C.

Owner:EI DU PONT DE NEMOURS & CO

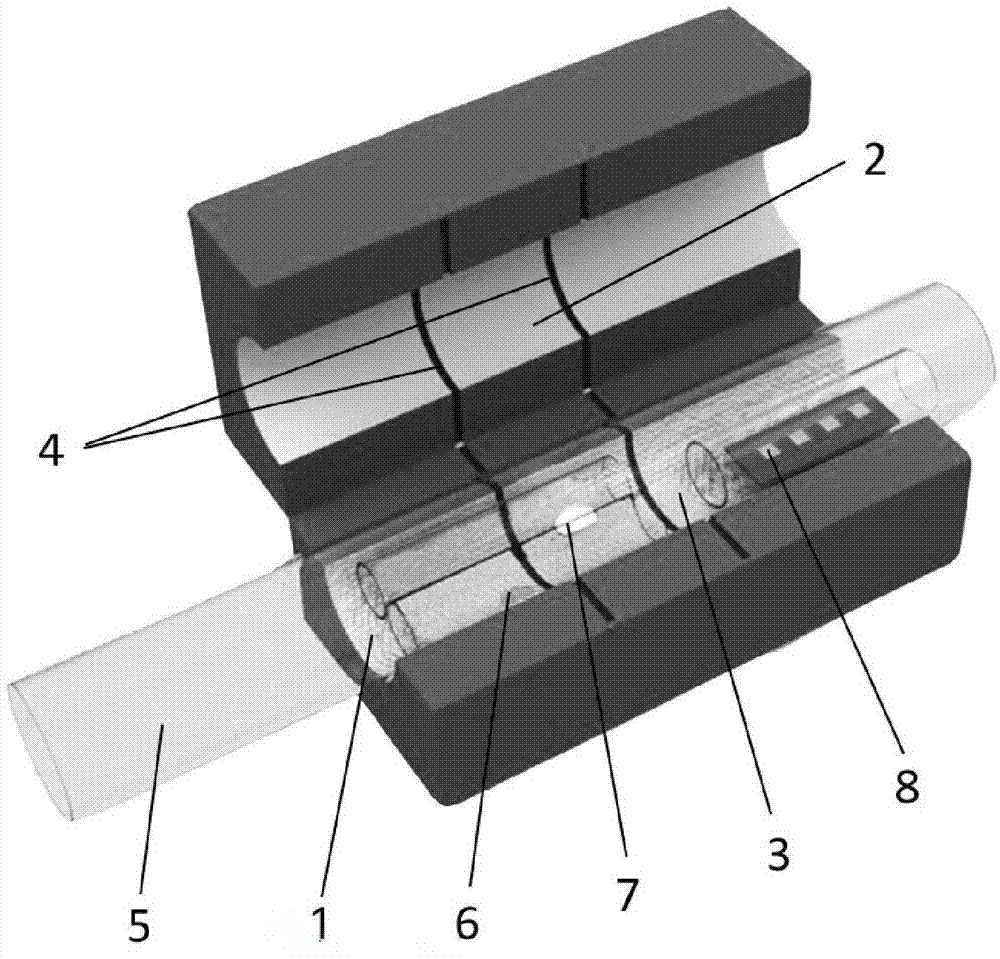

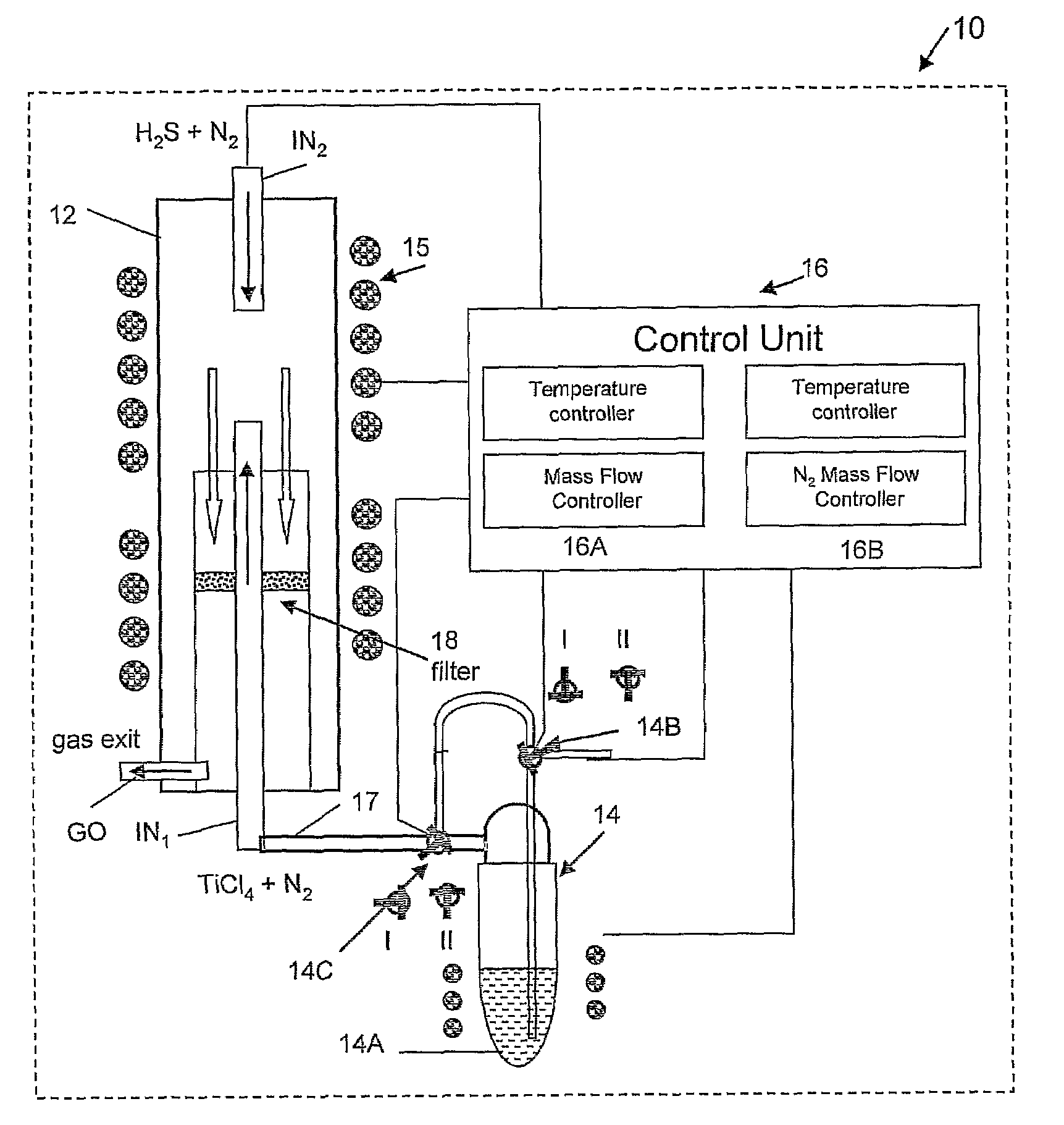

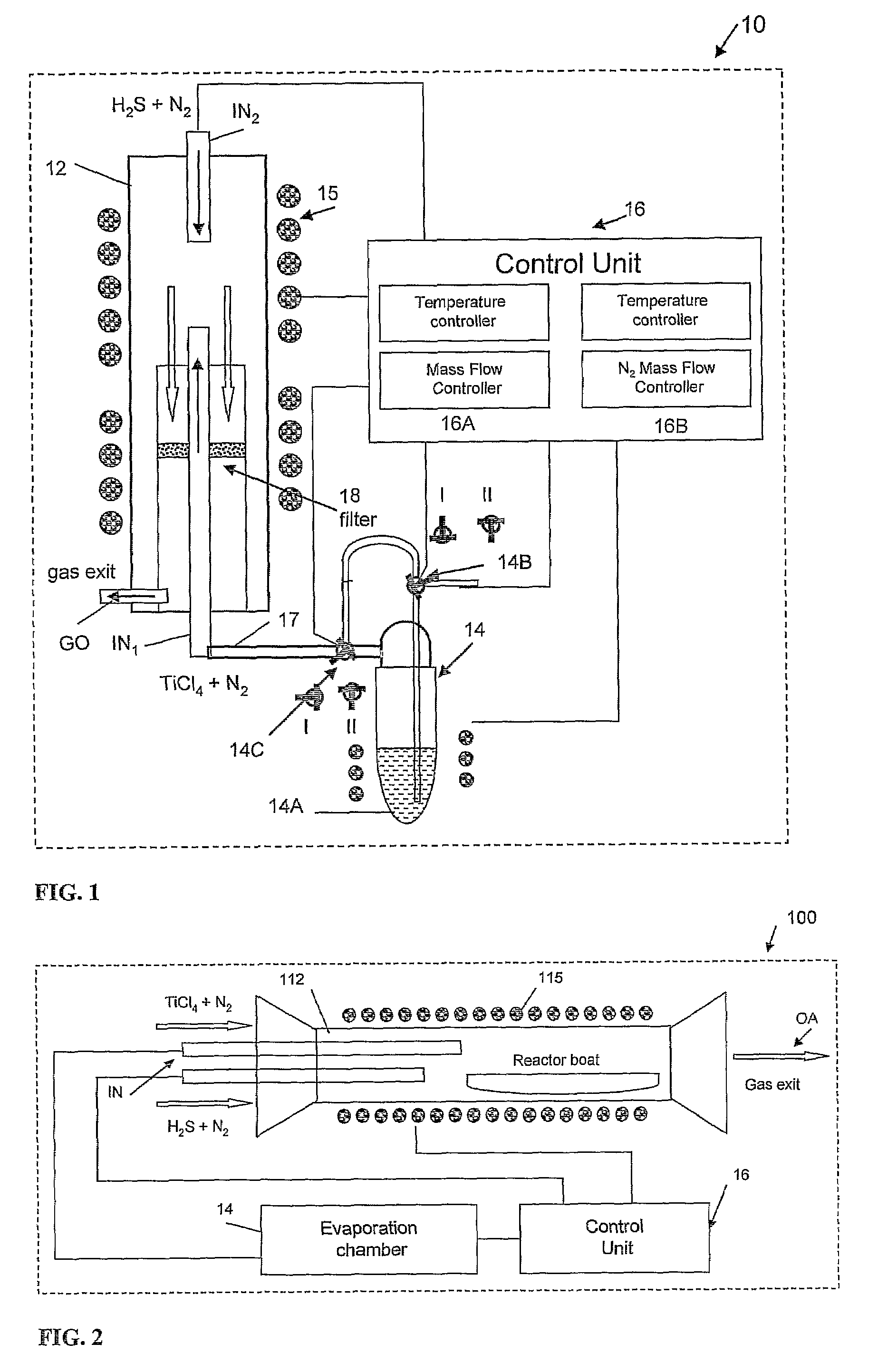

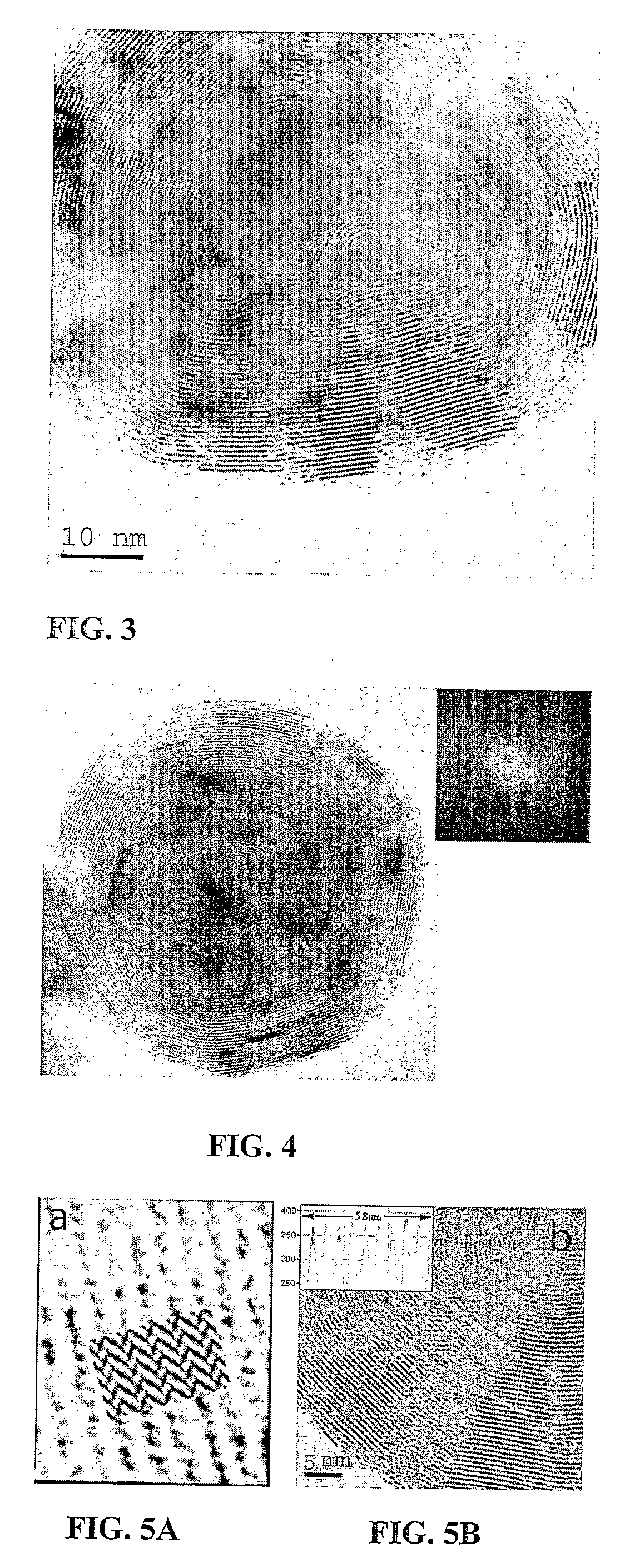

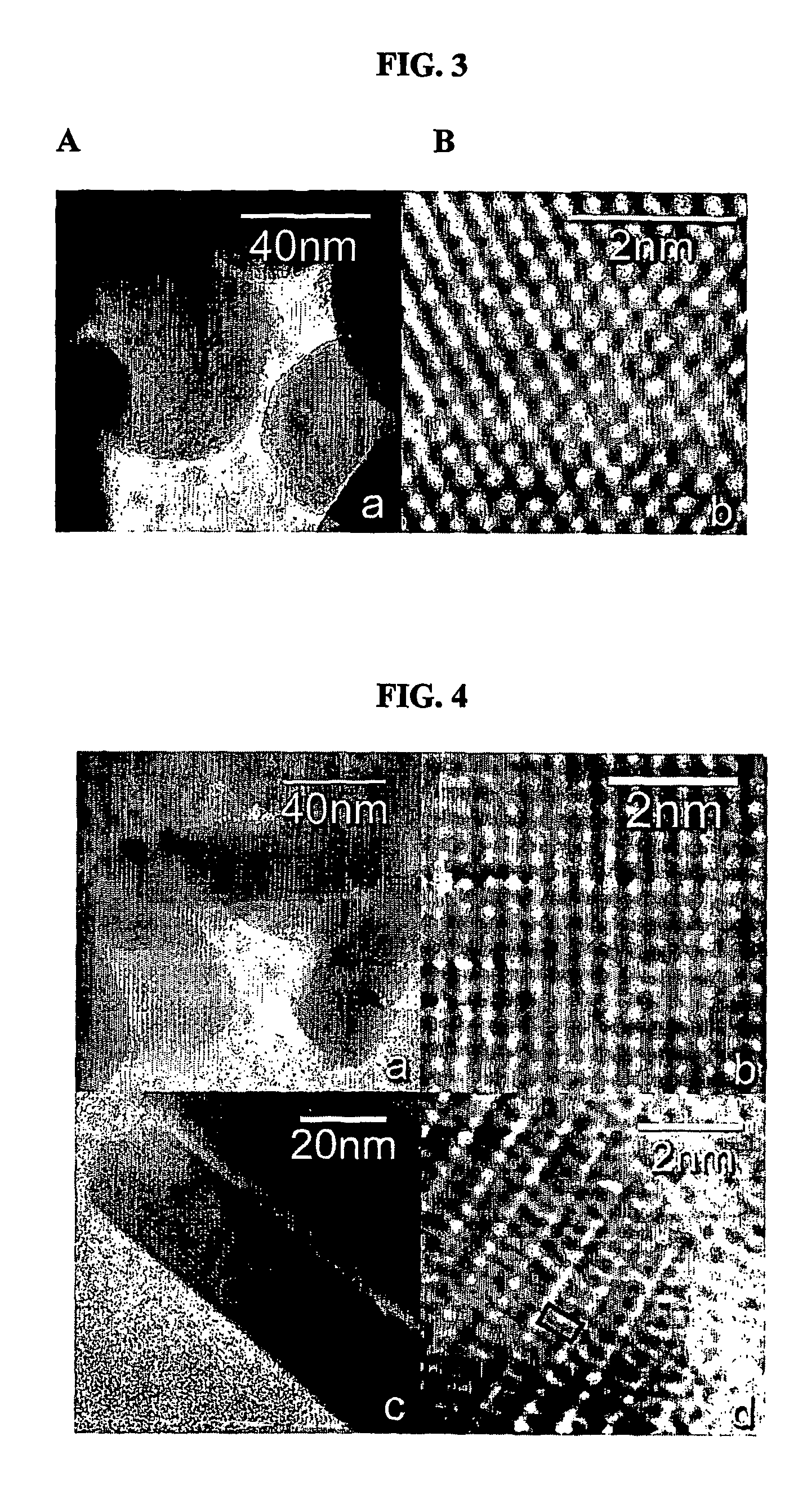

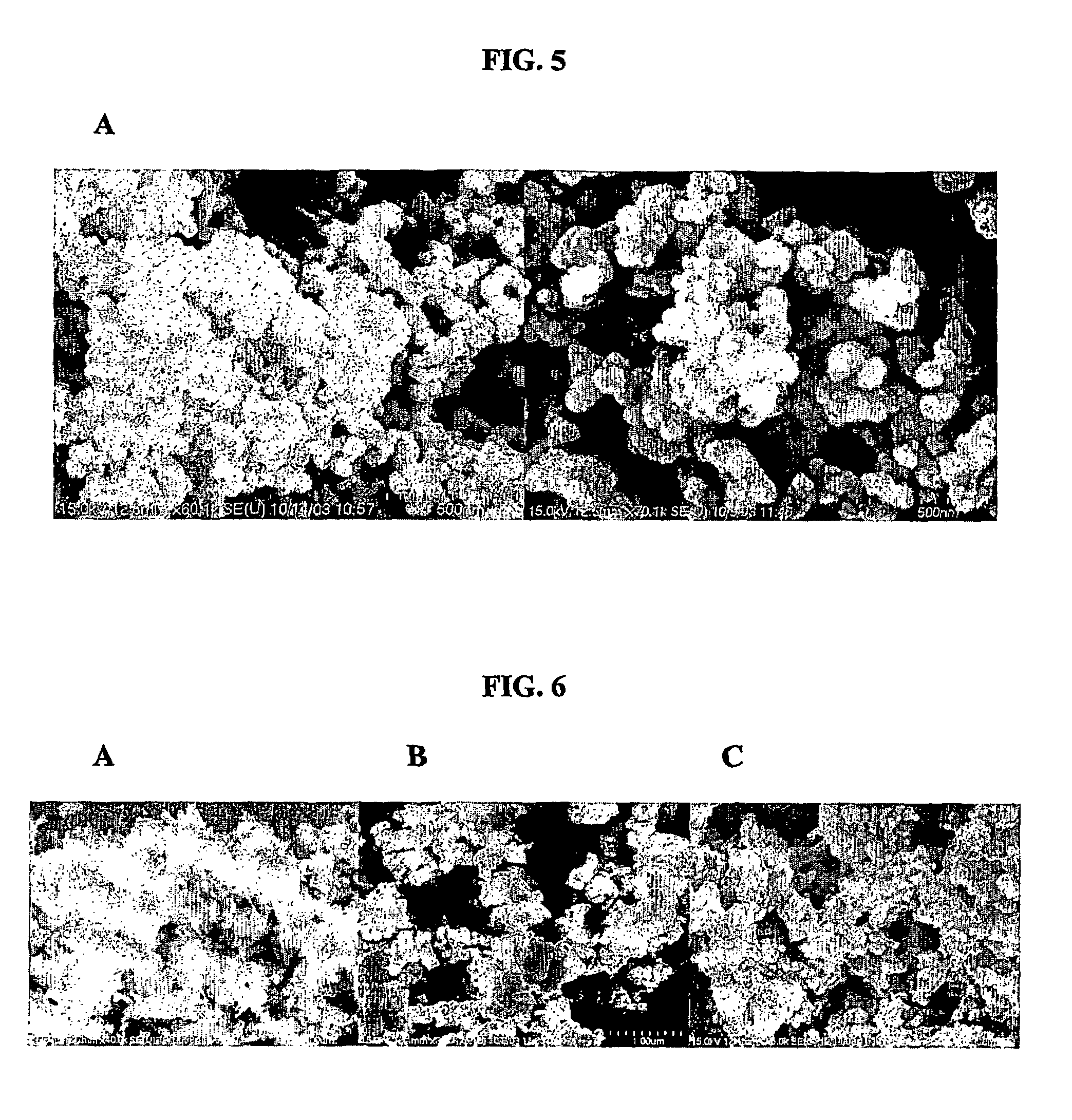

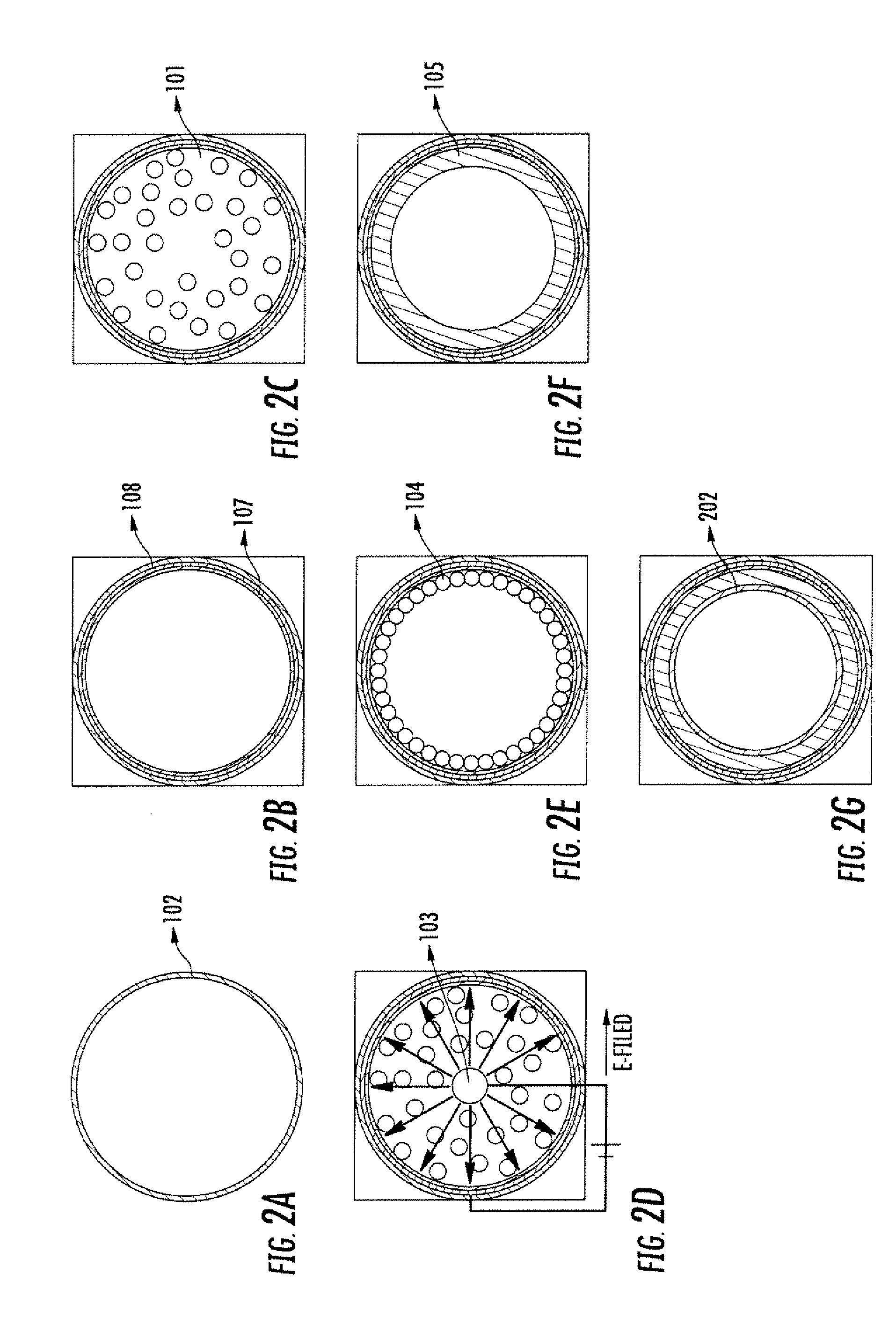

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

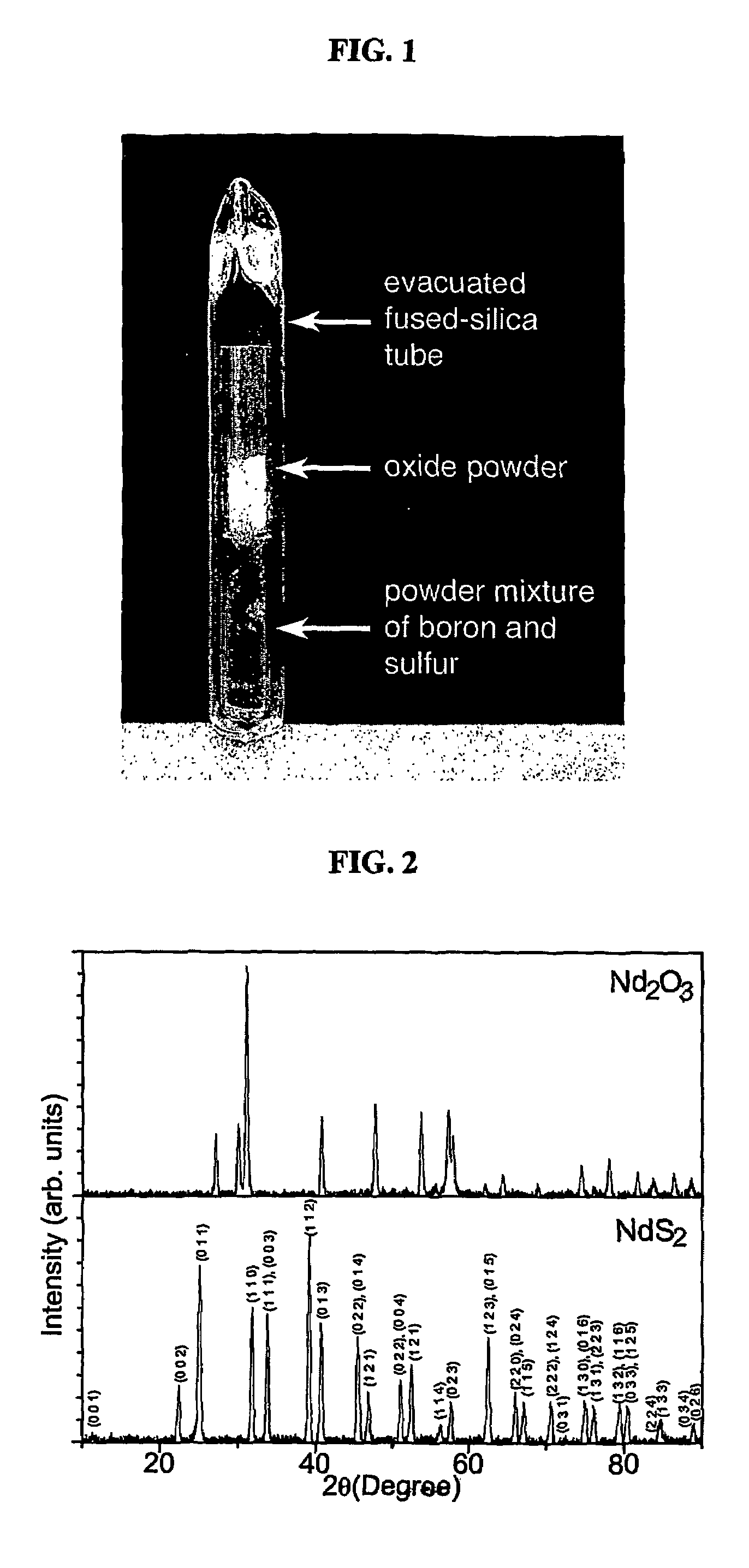

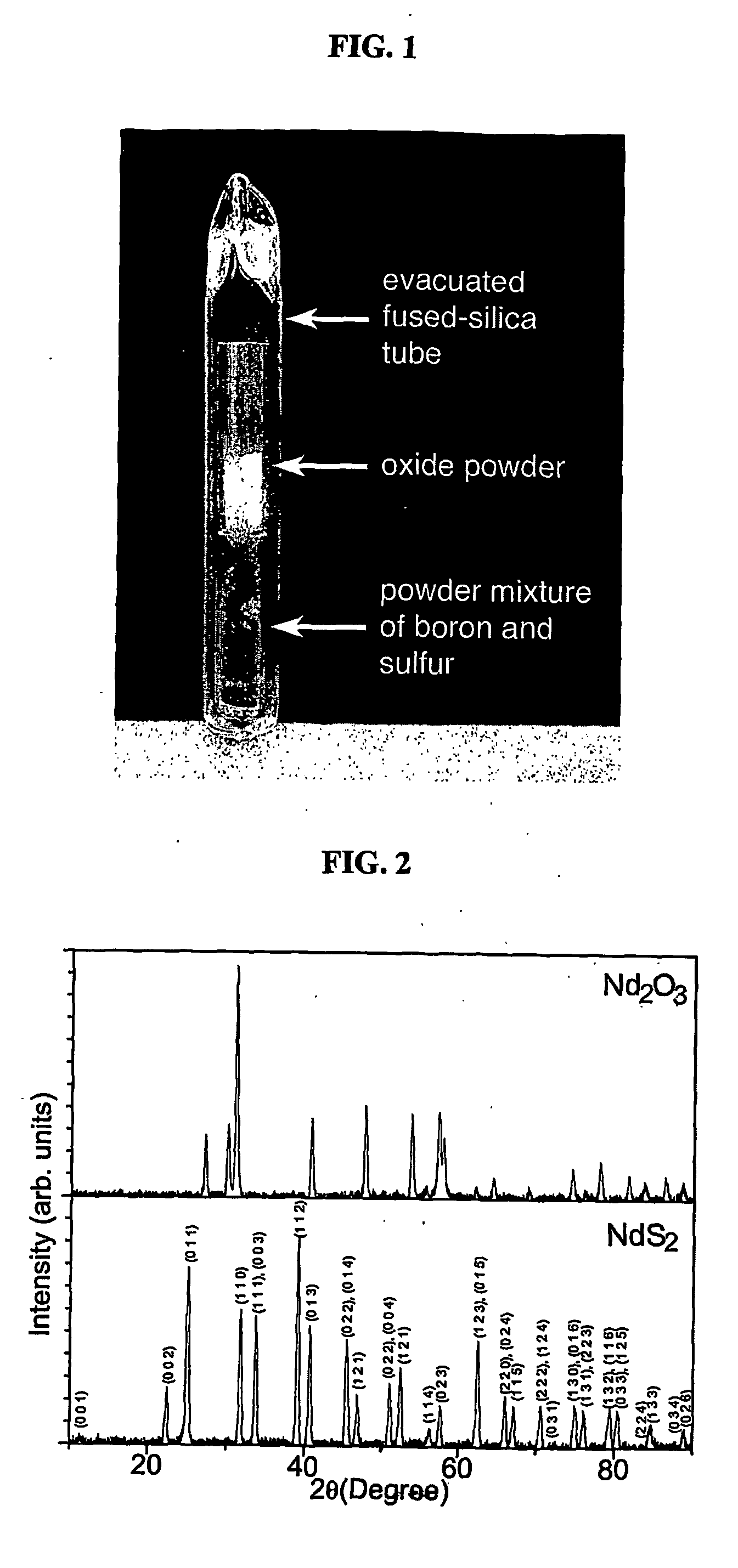

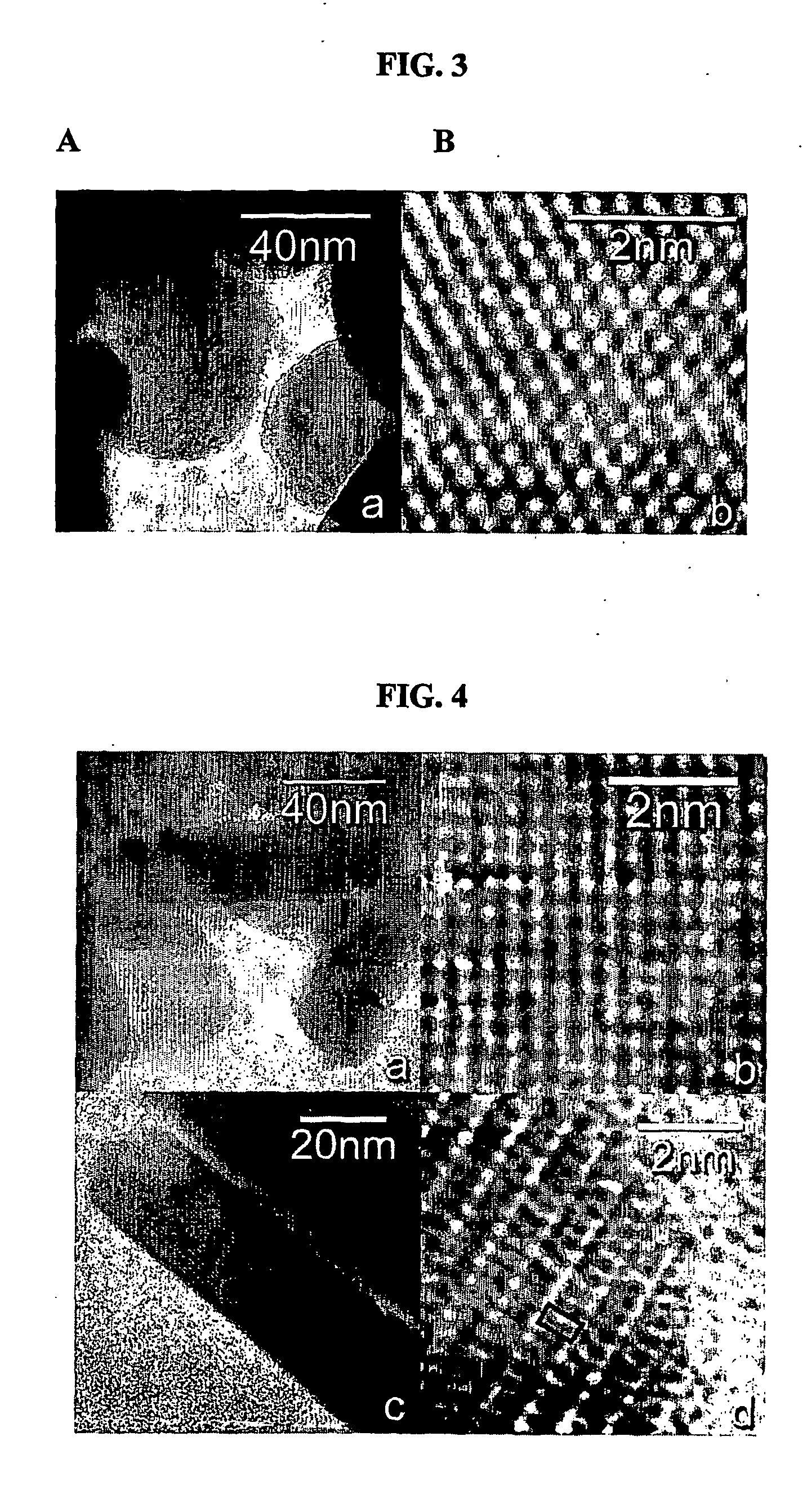

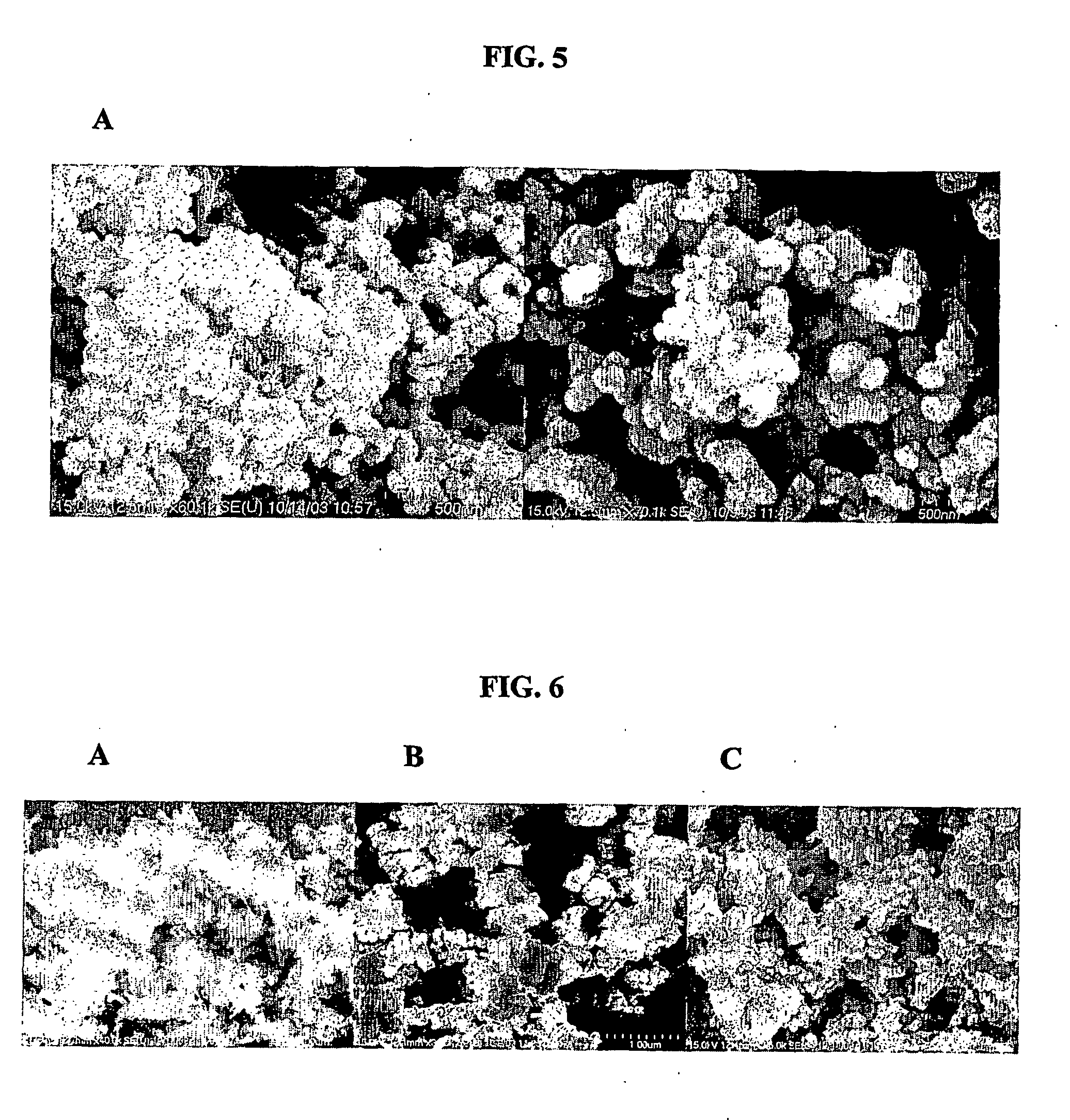

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

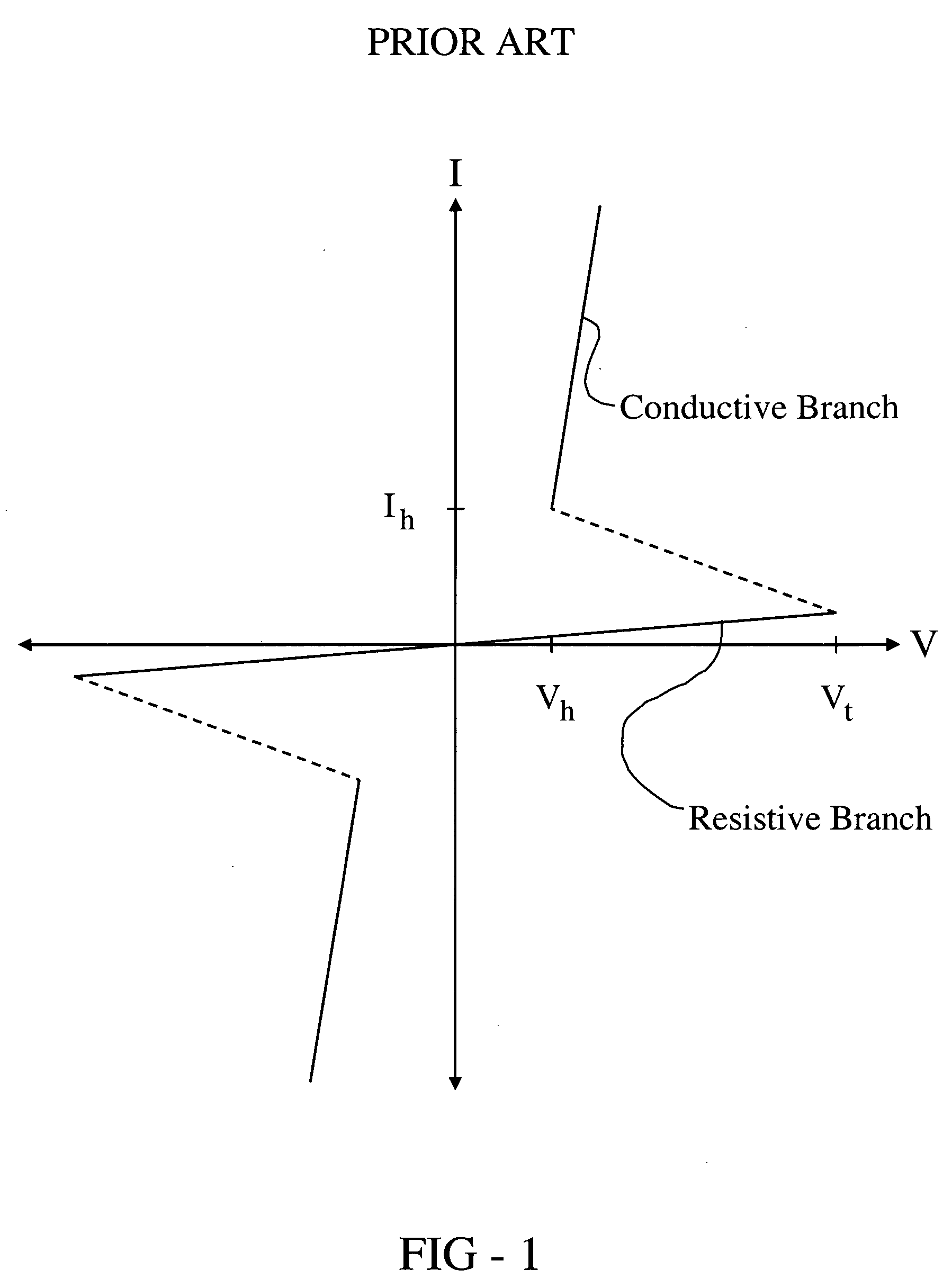

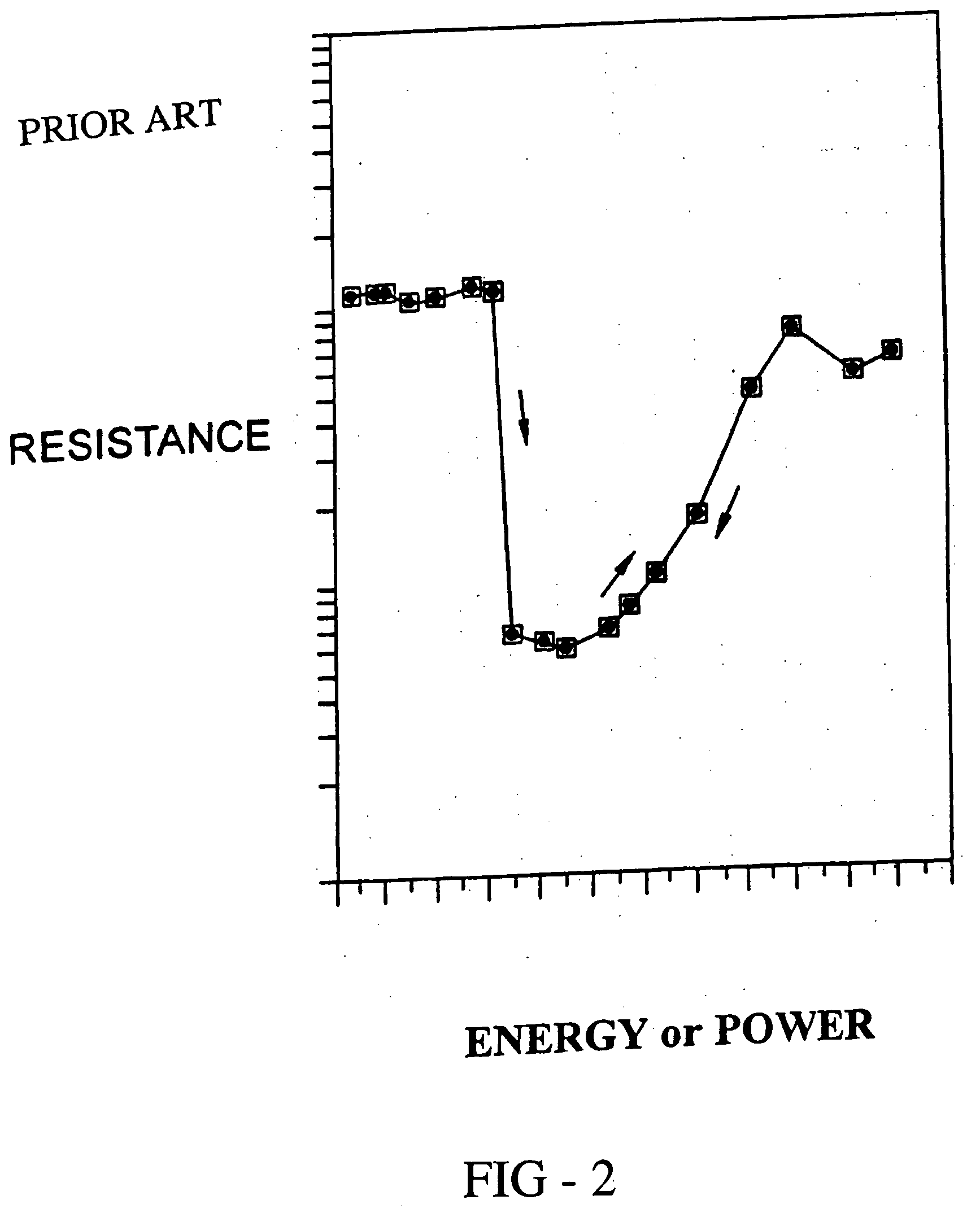

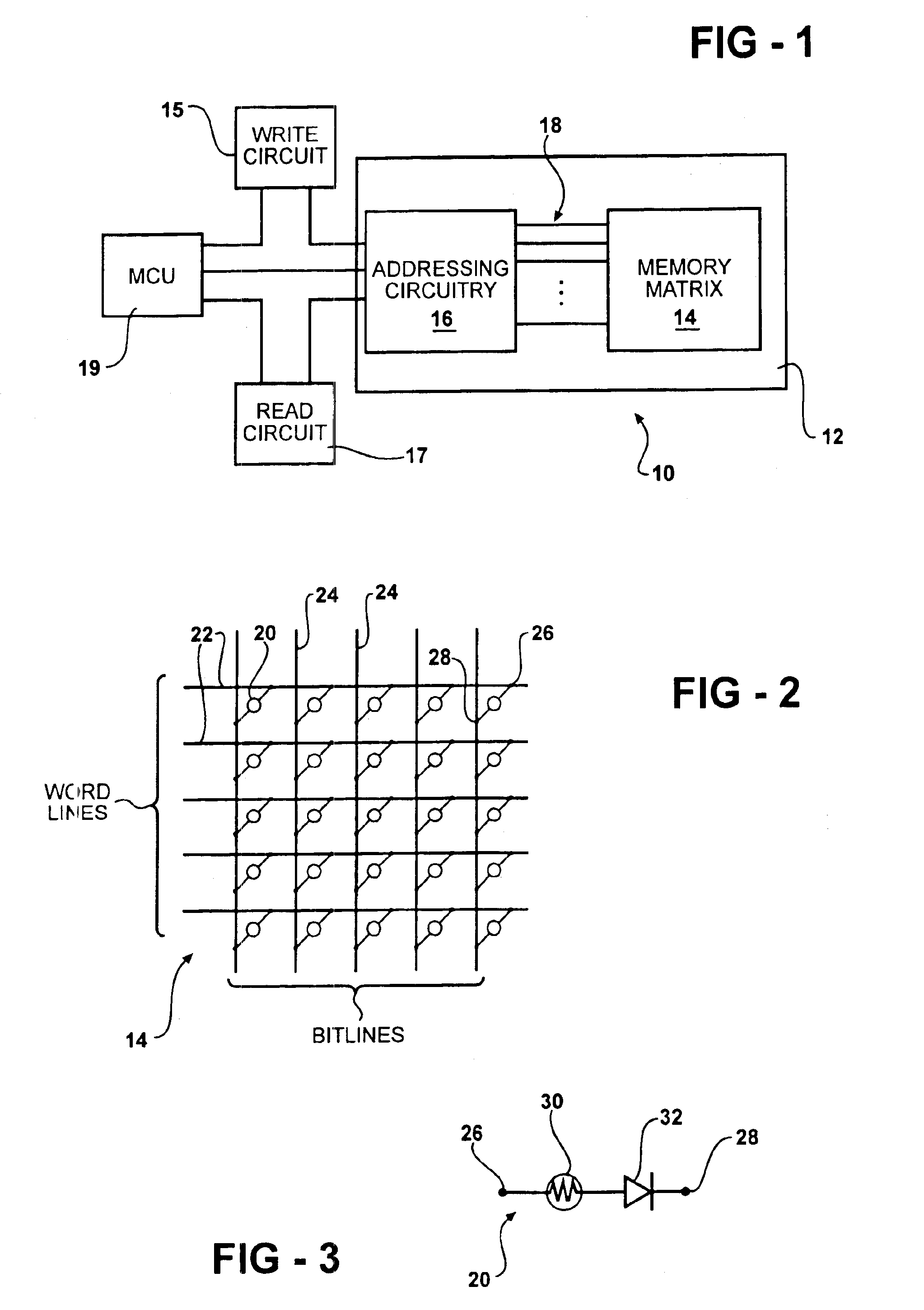

Phase-change memory element and method of storing data therein

InactiveUS6859390B2Lower average energyStructural failureRead-only memoriesDigital storagePhase-change memoryEngineering

A phase-change memory element including a phase-change material. The phase-change memory element has a plurality of memory state wherein each of the memory states has a corresponding threshold voltage. The threshold voltages may be used to determine the current memory state of the memory element. The phase-change material may include a chalcogen element.

Owner:OVONYX MEMORY TECH LLC

Functionalization of carbon for embedding in chalcogen particles to enhance electronic conductivity

A particle having a core of elemental chalcogen elements, such as sulfur, selenium and tellurium, and a coating of at least one polymeric layer on the core. A functionalized conductive carbon material is dispersed in the core. A cathode containing the particles and a battery constructed with the cathode are also provided.

Owner:TOYOTA JIDOSHA KK

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

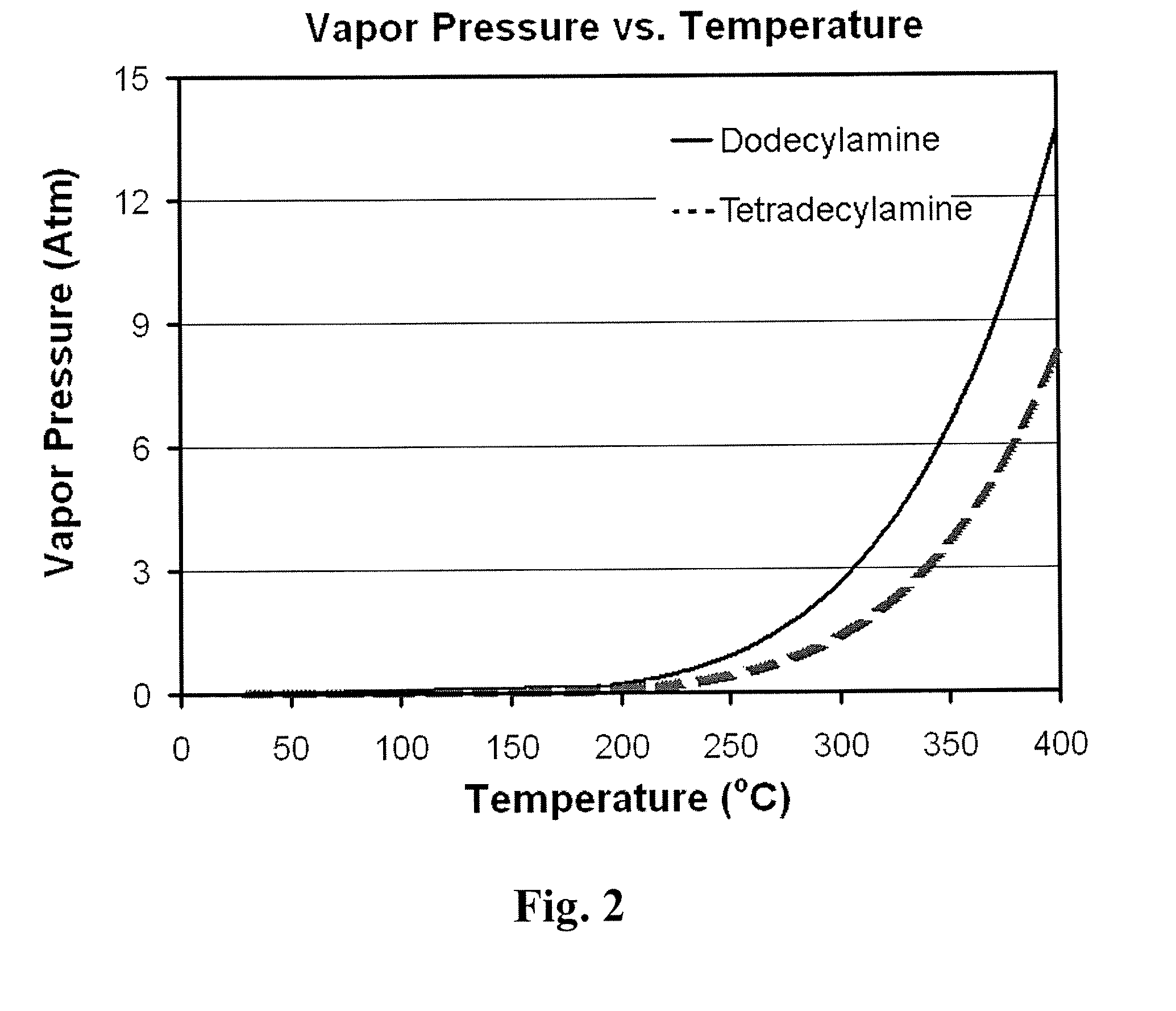

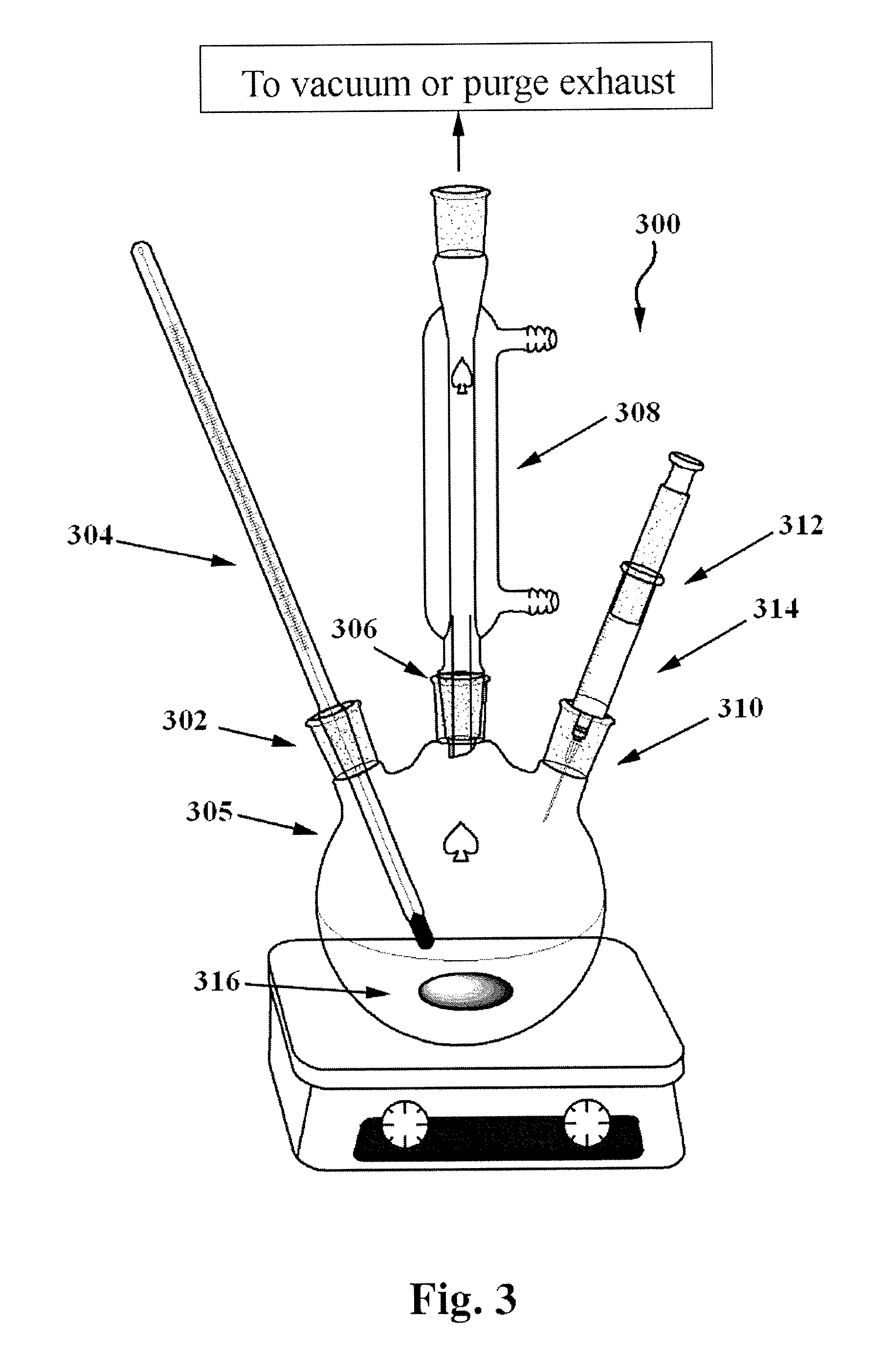

Rapid synthesis of ternary, binary and multinary chalcogenide nanoparticles

InactiveUS20100003187A1Rapid responseEasy to handleMaterial nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsOrganic solventSulfur

A method for synthesizing a chalcogenide nanoparticle is provided. The method comprises reacting a metal component with an elemental chalcogen precursor in the presence of an organic solvent. The chalcogenide nanoparticles include ternary, binary and / or multinary chalcogenide nanoparticles and the metal component comprises metal halides or elemental metal precursors. The alkylamine solvent has a normal boiling temperature of above about 220° C. and an average particle size of from about 5 nm to about 1000 nm.

Owner:PURDUE RES FOUND INC

Method for preparation of metal chalcogenide solar cells on complexly shaped surfaces

InactiveUS20120100660A1Electrolytic coatingsSemiconductor/solid-state device manufacturingIndiumMetal chalcogenides

Methods for fabricating a photovoltaic device on complexly shaped fabricated objects, such as car bodies are disclosed. Preferably the photovoltaic device includes absorber layers comprising Copper, Indium, Gallium, Selenide (CIGS) or Copper, Zinc, Tin, Sulfide (CZTS). The method includes the following steps: a colloidal suspension of metal surface-charged nanoparticles is formed; electrophoretic deposition is used to deposit the nanopartieles in a metal thin film onto a complexly shaped surface of the substrate; the metal thin film is heated in the presence of a chalcogen source to convert the metal thin film into a metal chalcogenide thin film layer; a buffer layer is formed on the metal chalcogenide thin film layer using a chemical bath deposition; an intrinsic zinc oxide insulating layer is formed adjacent to a side of the buffer layer, opposite the metal chalcogenide thin film layer, by chemical vapor deposition; and finally, a transparent conducting oxide is formed adjacent to a side of the intrinsic zinc oxide, opposite the buffer layer, by chemical vapor deposition.

Owner:IMRA AMERICA

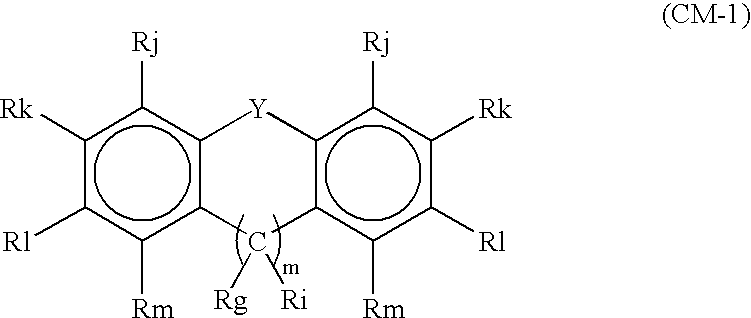

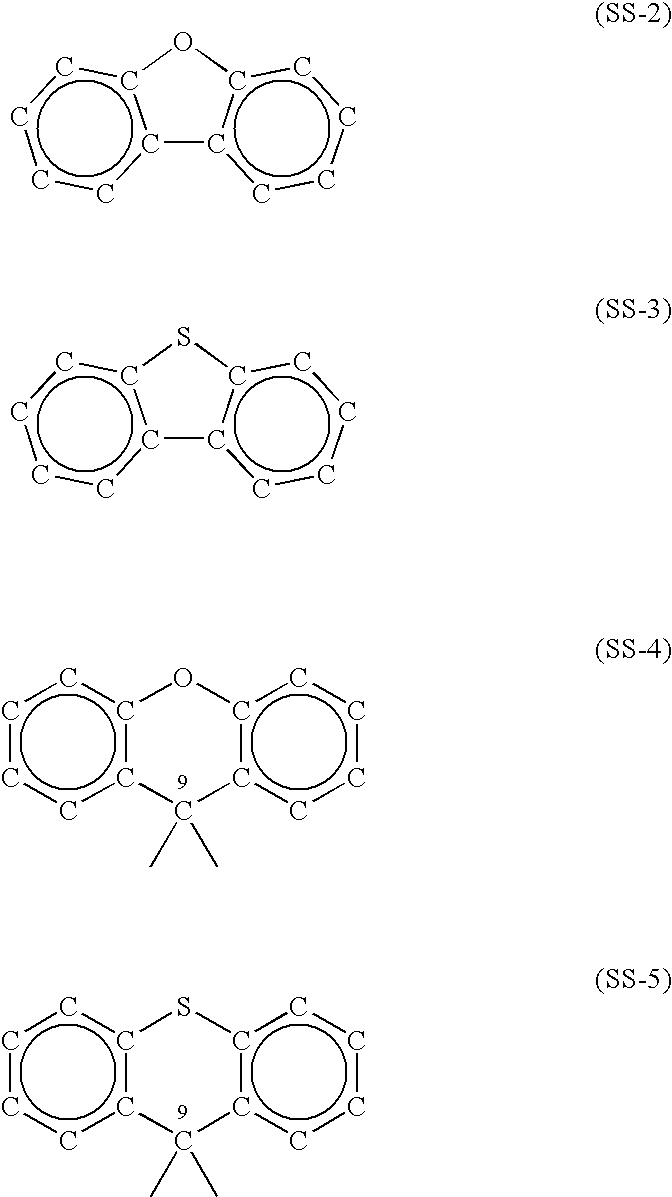

Aromatic chalcogen compounds and their use

This invention relates to dibenzothiophene, dibenzofuran, dibenzopyran, and dibenzothiapyran compounds. This invention also relates to layers and devices including at least one of the above compounds.

Owner:EI DU PONT DE NEMOURS & CO

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com