Patents

Literature

623 results about "Metallic alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy Metals is a metallic material, such as steel, brass, or bronze consisting of a mixture two or more metals or of metallic elements with nonmetallic elements that are melted.

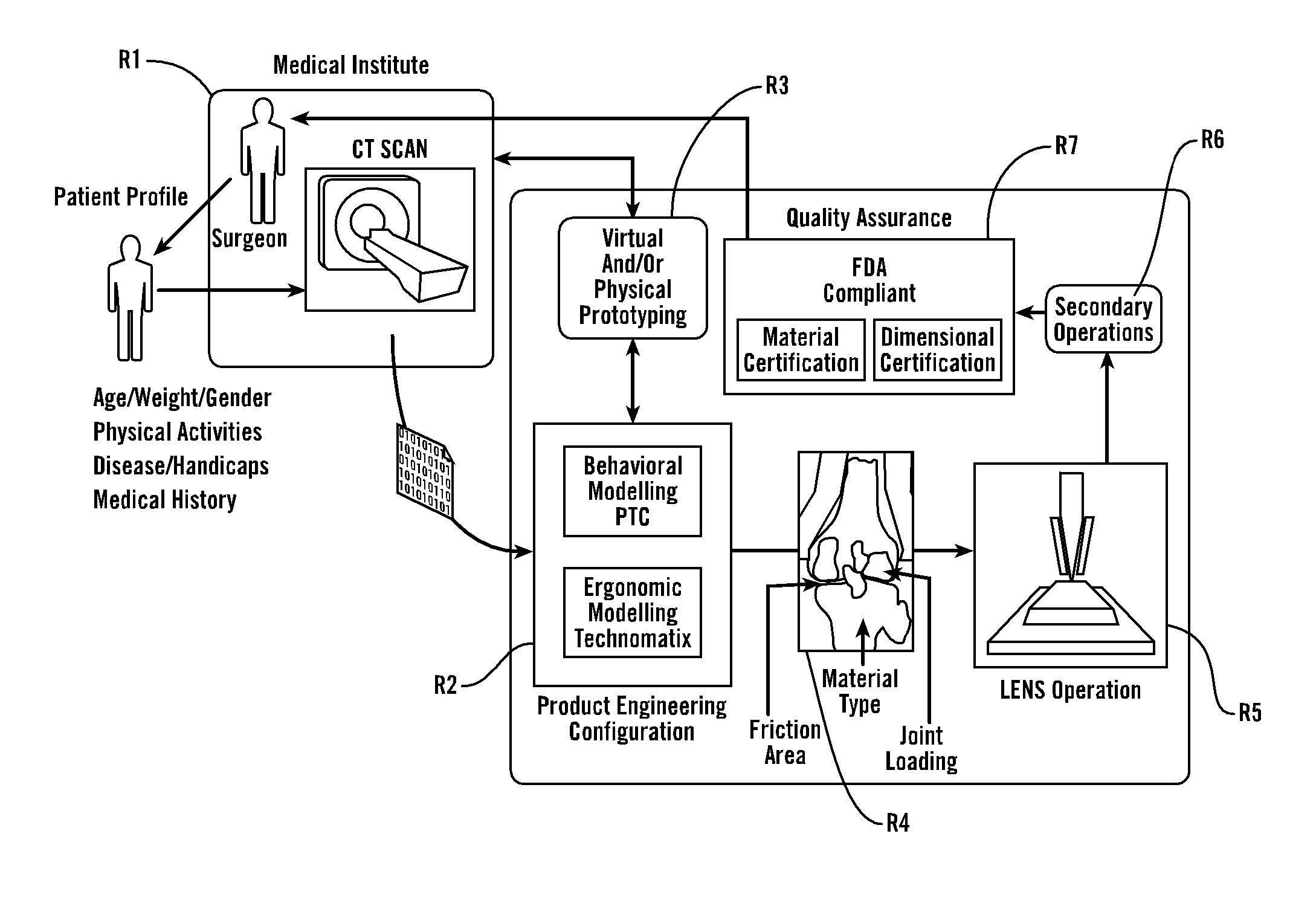

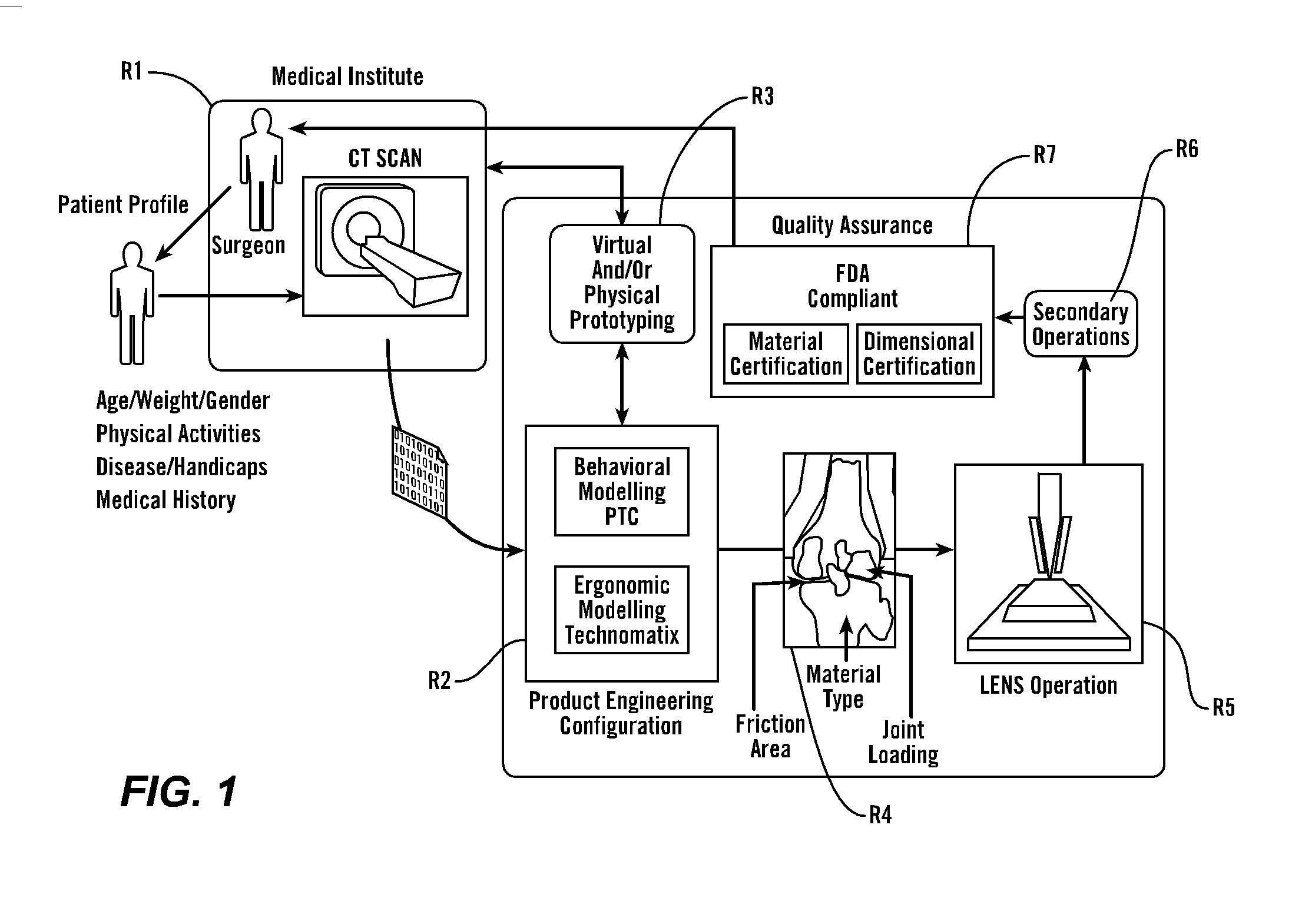

Personal fit medical implants and orthopedic surgical instruments and methods for making

InactiveUS20070118243A1Minimizing Ni toxicityImprove visualizationElectrotherapyMechanical/radiation/invasive therapiesPersonalizationManufacturing technology

The present invention provides methods, techniques, materials and devices and uses thereof for custom-fitting biocompatible implants, prosthetics and interventional tools for use on medical and veterinary applications. The devices produced according to the invention are created using additive manufacturing techniques based on a computer generated model such that every prosthesis or interventional device is personalized for the user having the appropriate metallic alloy composition and virtual validation of functional design for each use.

Owner:VANTUS TECH CORP

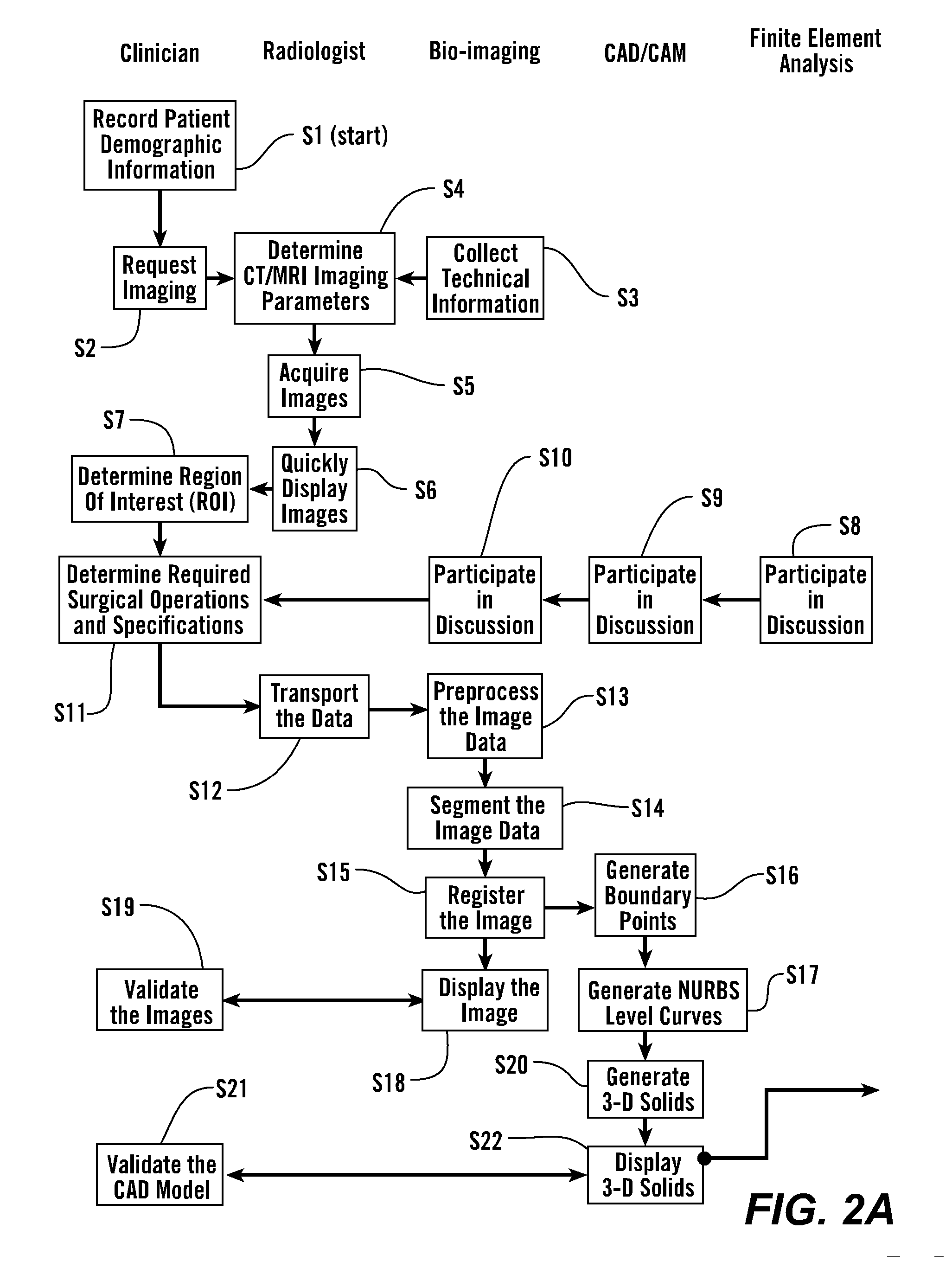

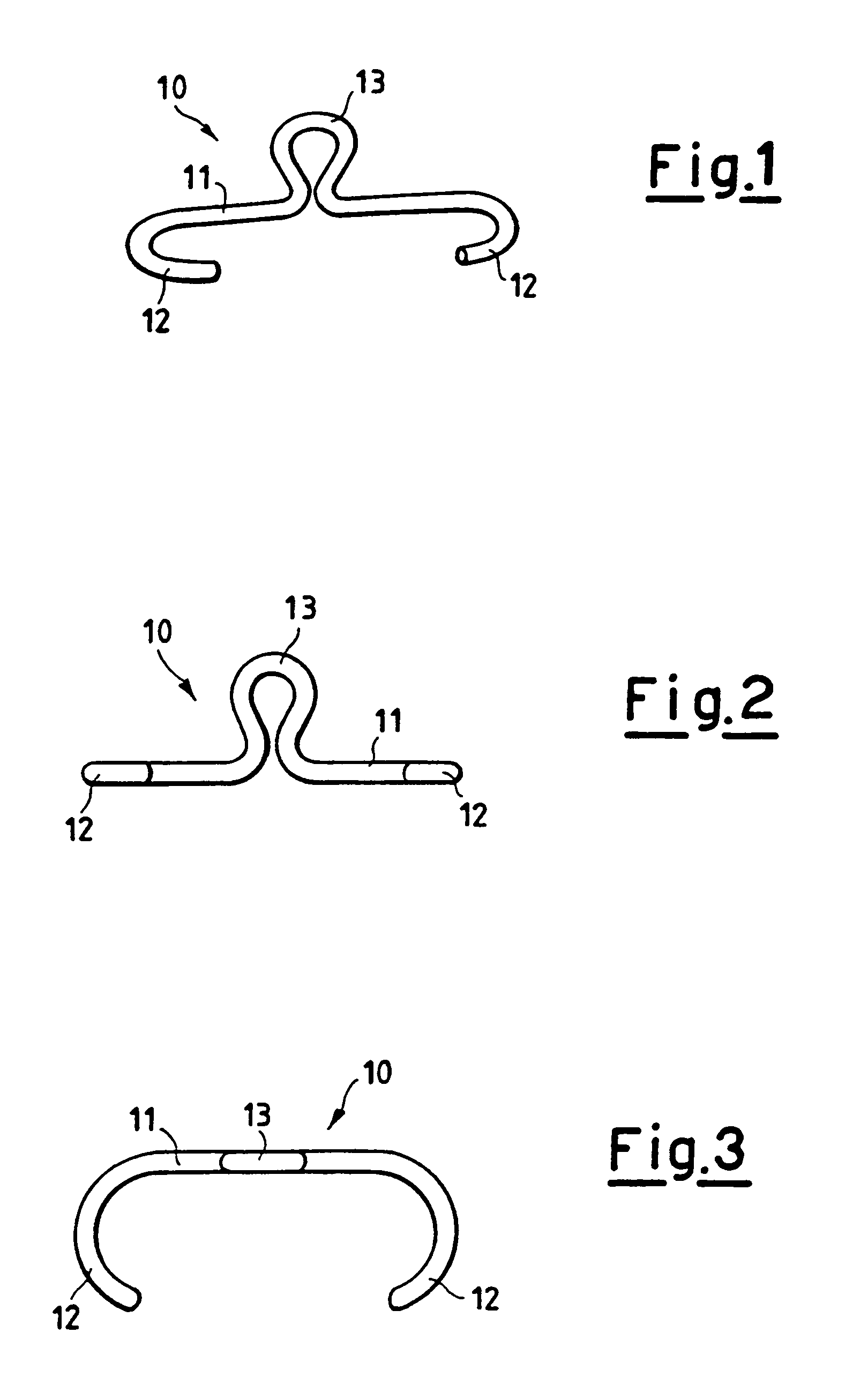

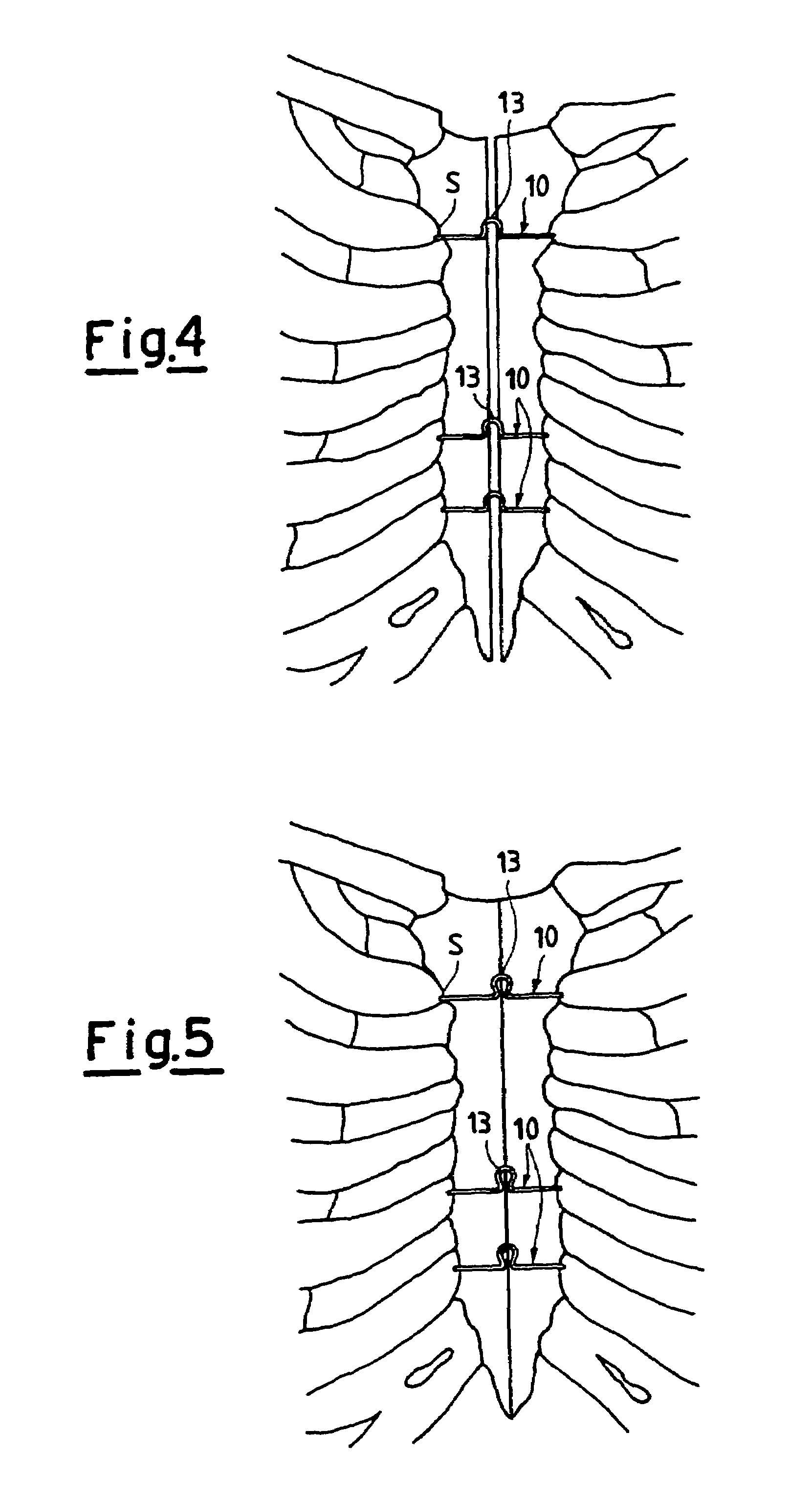

Semi-rigid compressive clamp for use in sternotomy, and forceps for its application

A clamp designed for use in the heart-surgery field for osteosynthesis following on sternotomy has a roughly C-shaped configuration with a core (11) terminating at opposite ends with hooks (12) set opposite to one another. In the centre, the said core (11) extends vertically according to a plane which is substantially perpendicular to the one on which the end hooks (12) lie, with a loop (13) which is elastically compliant. The said clamp is made of a so-called “shape-memory” metallic alloy, i.e., an alloy which is malleable at a low temperature and which re-acquires its original form at body temperature, exerting a semi-rigid compression on the ends or edges of the bones requiring synthesis.

Owner:PRAESIDIA

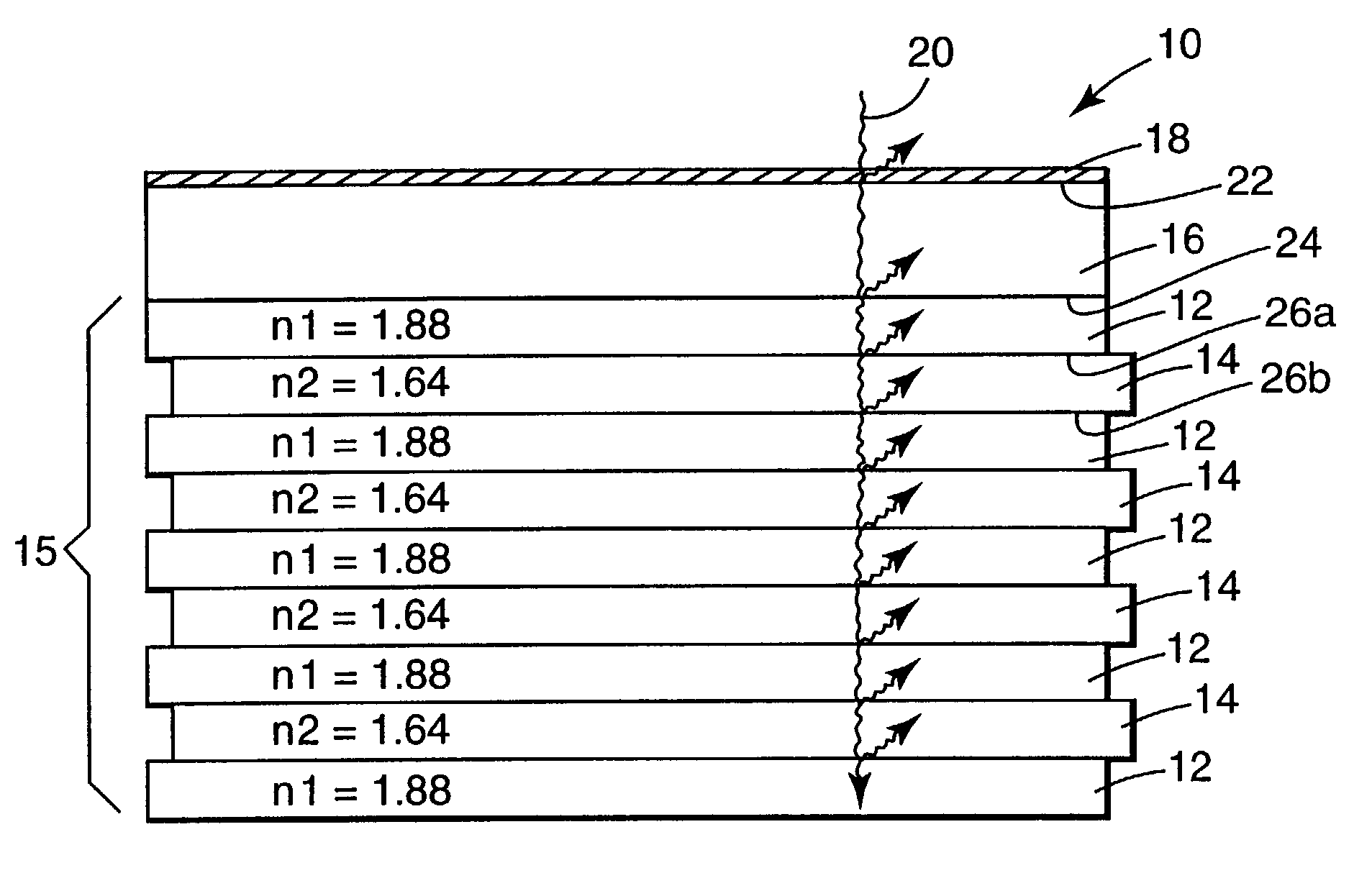

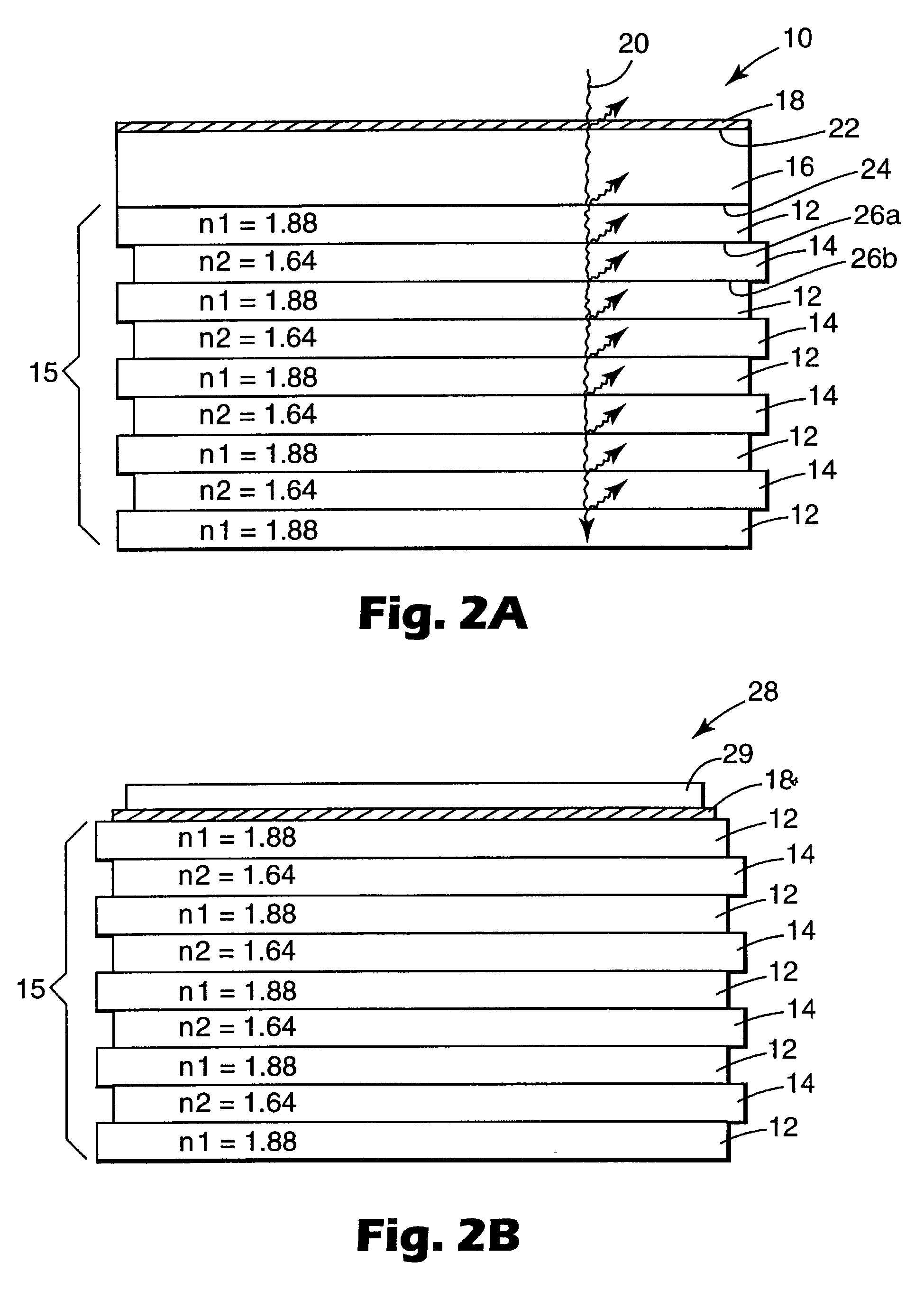

Enhanced heat mirror films

ActiveUS7215473B2Function increaseImprove interlayer adhesionMirrorsSynthetic resin layered productsMetal alloyHot mirror

A heat mirror film containing visible light-transmissive and infrared reflective film comprising a birefringent dielectric multilayer support that reflects at least 50% of light in a band at least 100 nm wide in a wavelength region of interest, a metal or metal alloy layer whose thickness is such that the film is visible light-transmissive and its reflection band is broadened, and a crosslinked polymeric layer has improved infrared reflecting properties. The film can be joined or laminated into glazing (especially non-planar vehicular safety glazing) with reduced likelihood that the metal or metal alloy layer will be damaged or distorted.

Owner:3M INNOVATIVE PROPERTIES CO

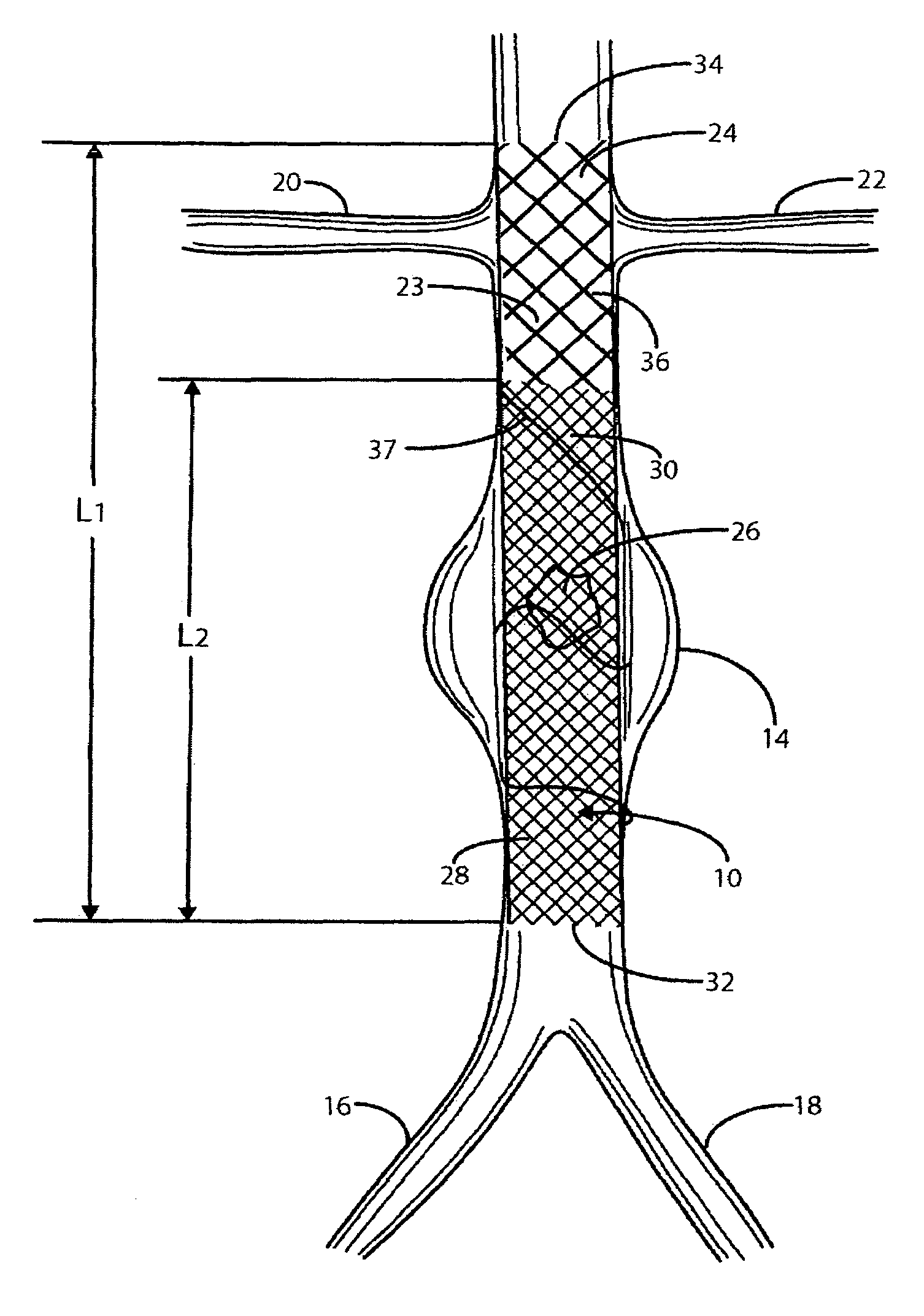

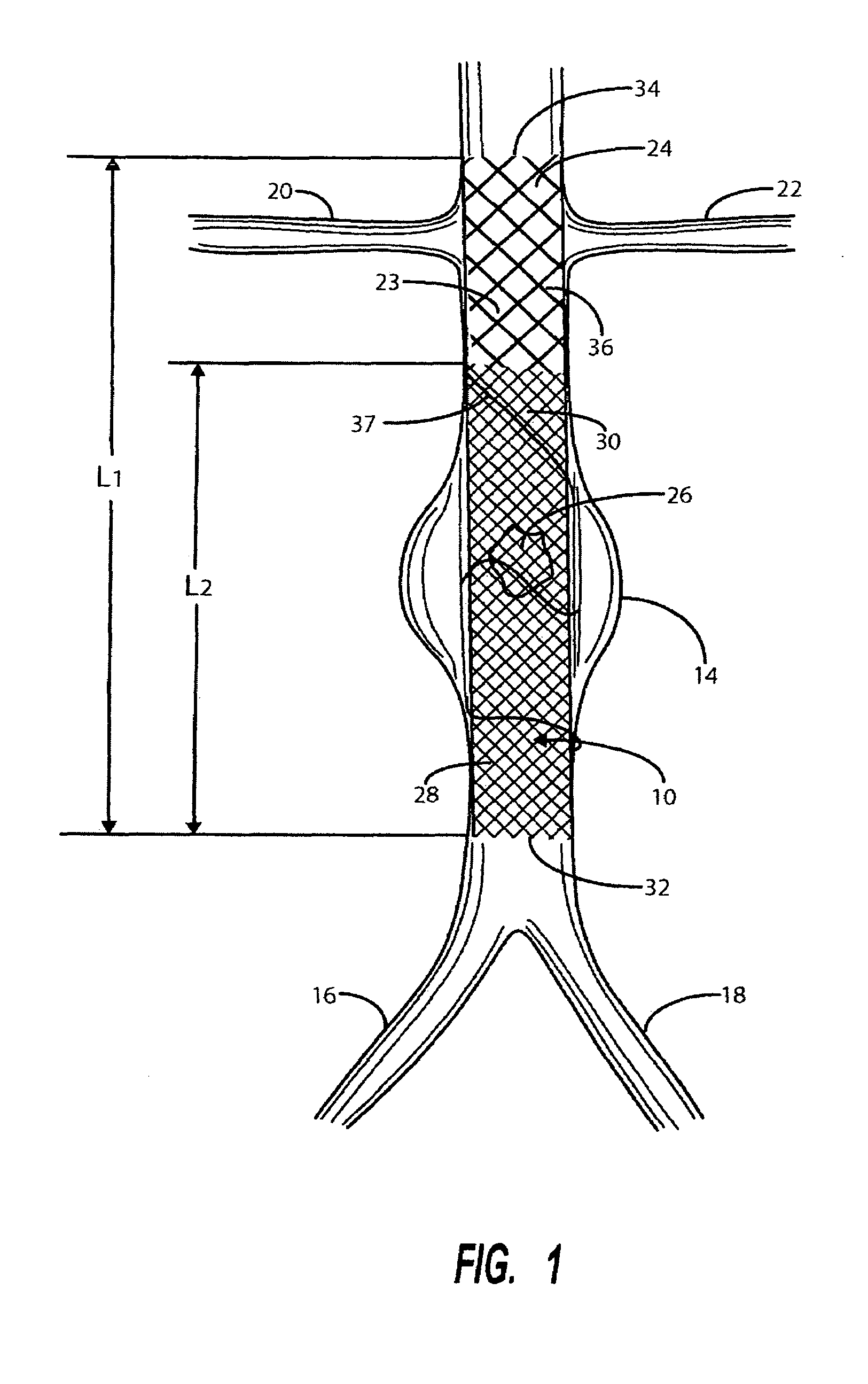

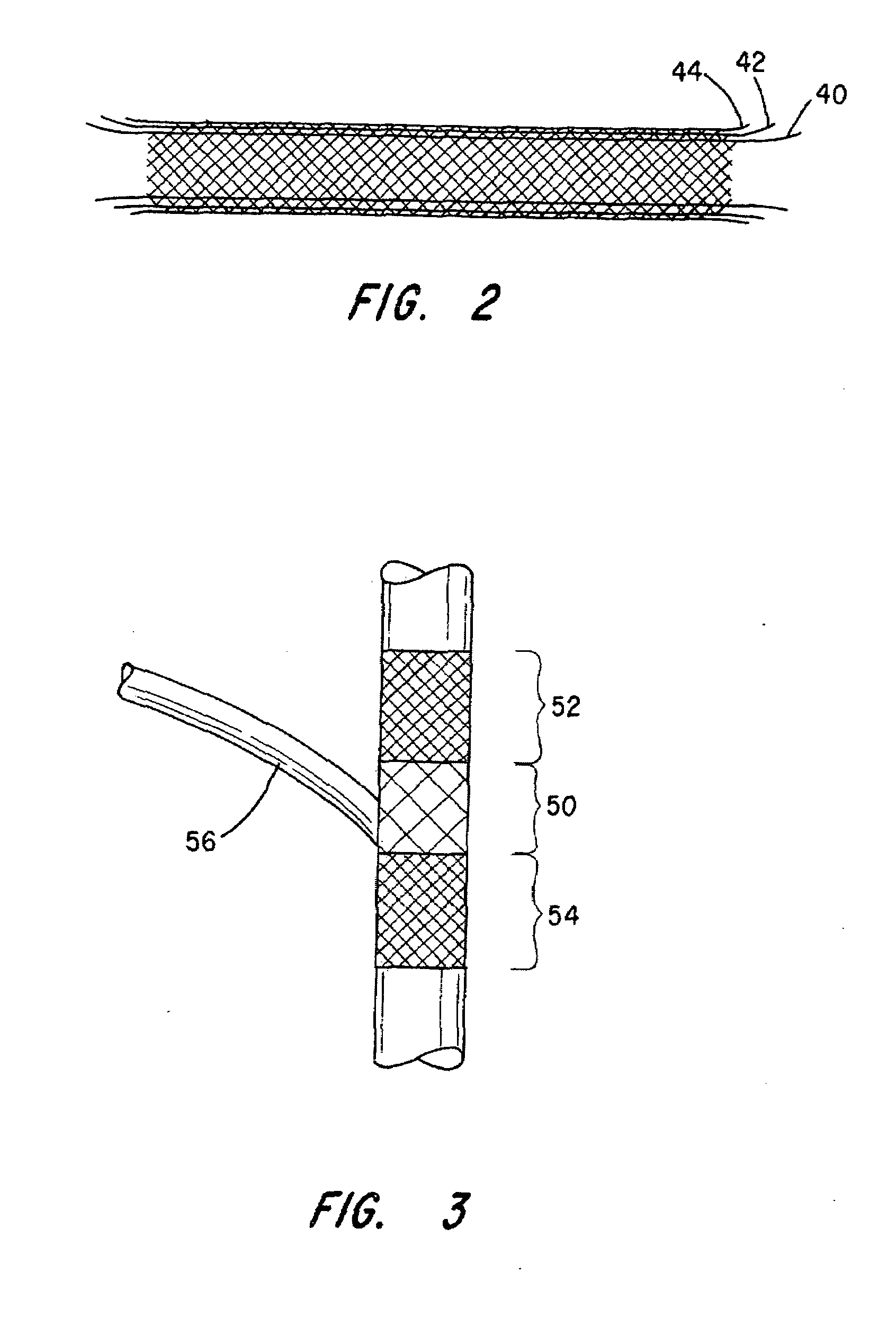

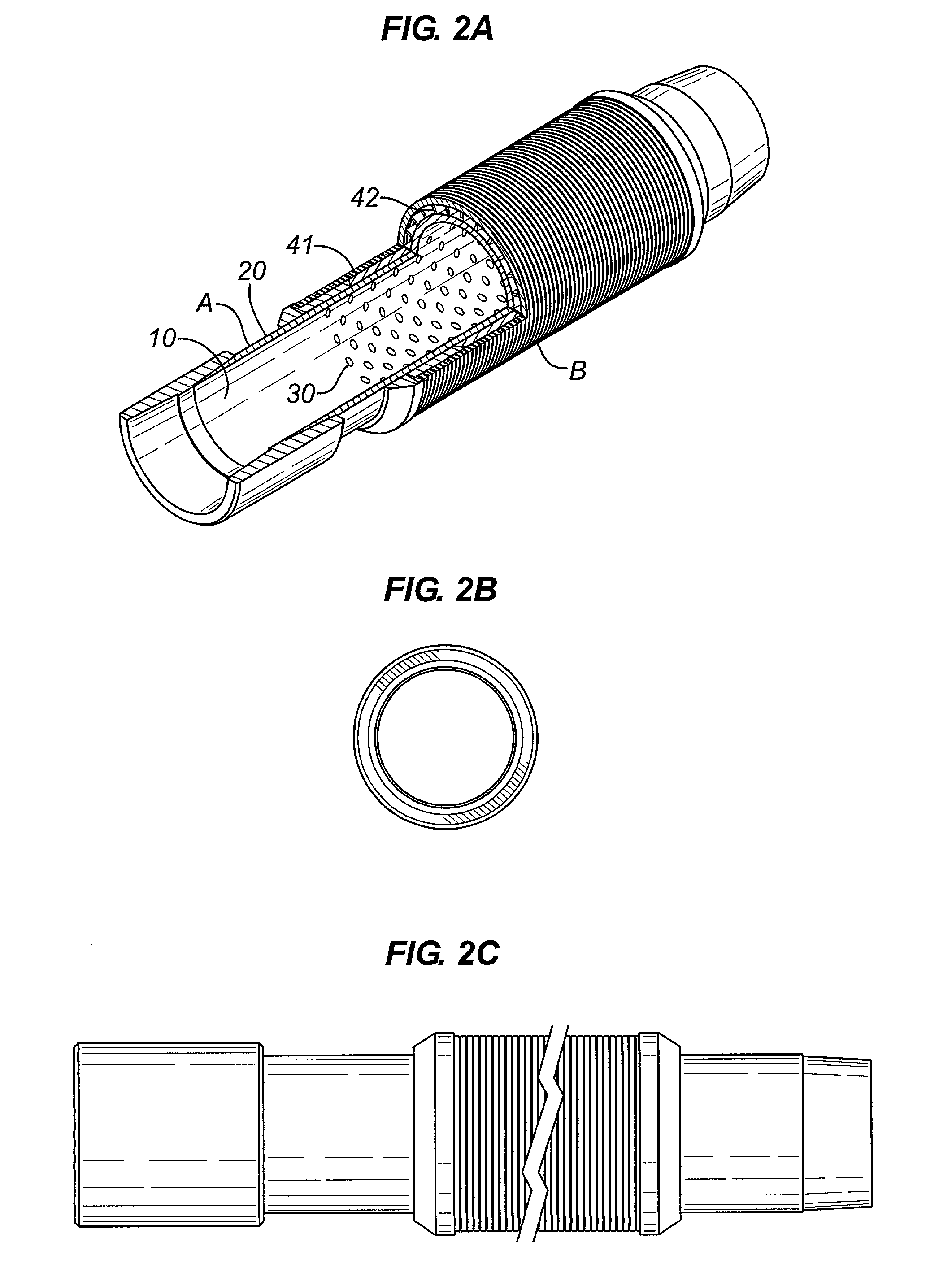

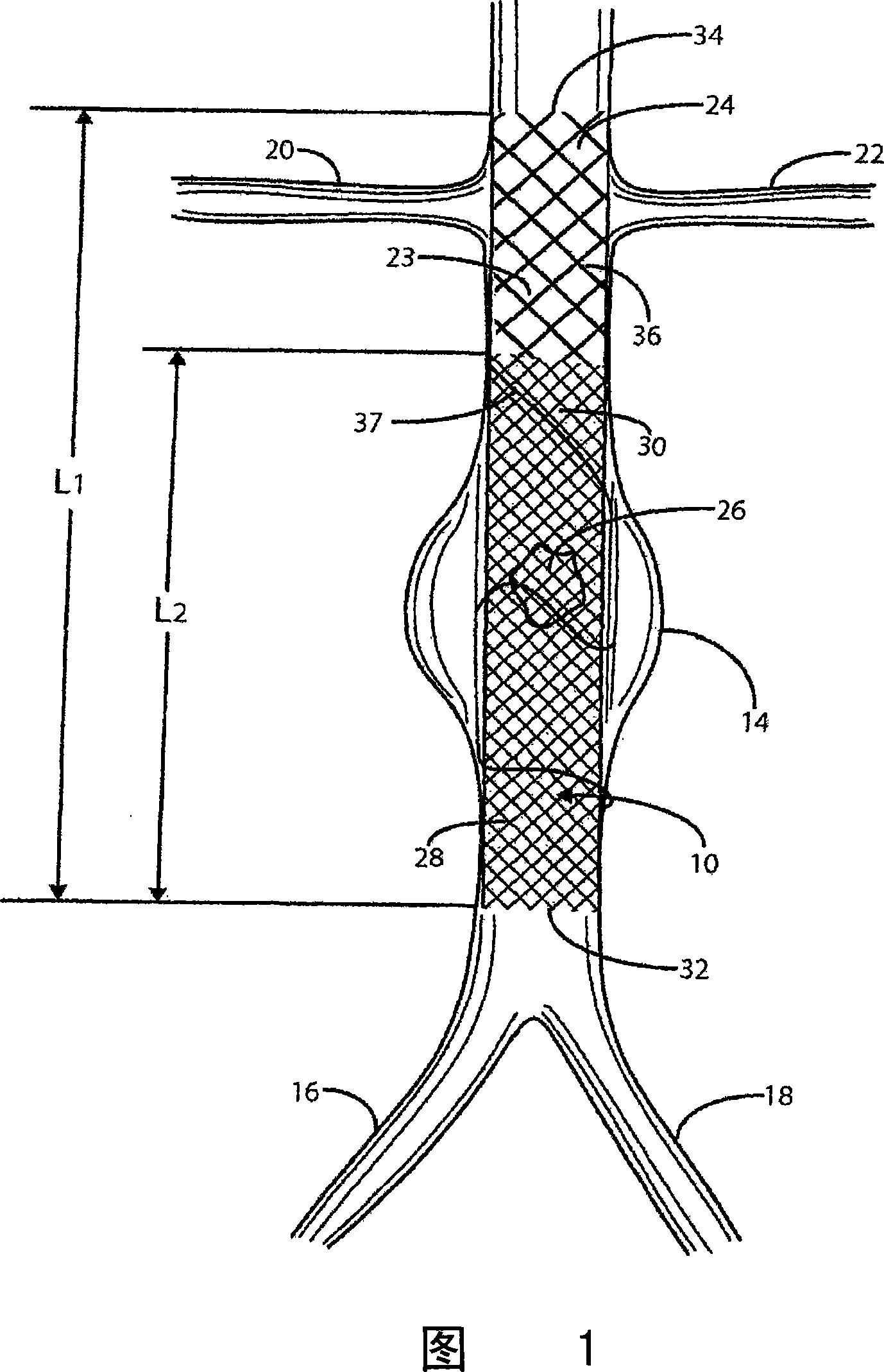

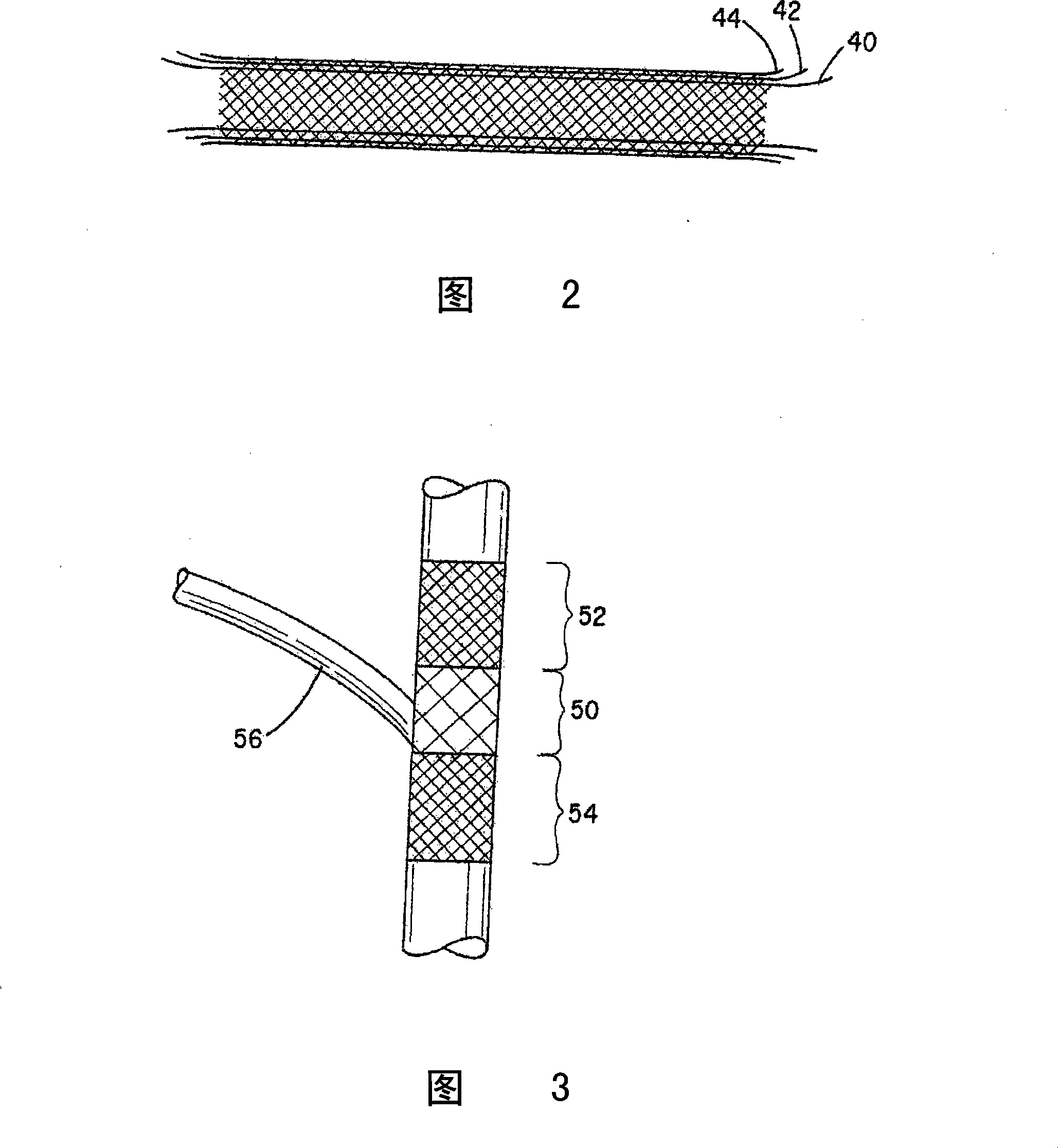

Intravascular deliverable stent for reinforcement of vascular abnormalities

InactiveUS20070168019A1Avoid interactionReduce overall outer diameterStentsCatheterVascular Skin TumorSaphenous veins

A catheter deliverable stent / graft especially designed to be used in a minimally invasive surgical procedure for treating a variety of vascular conditions such as aneurysms, stenotic lesions and saphenous vein grafts, comprises an innermost tubular structure and at least one further tubular member in coaxial arrangement. In one embodiment, the innermost tubular structure is of a length (L1) and is formed by braiding a relatively few strands of highly elastic metallic alloy. The pick and pitch of the braid are such as to provide relative large fenestrations in the tubular wall that permit blood flow through the wall and provide the primary radial support structure. A portion of the innermost tubular structure of a length L1 is surrounded by a further braided tubular structure having relatively many strands that substantially inhibit blood flow through the fenestrations of the innermost tubular structure. The composite structure can be stretched to reduce the outer diameter of the stent / graft, allowing it to be drawn into a lumen of a delivery catheter. The catheter can then be advanced through the vascular system to the site of treatment and then released, allowing it to self-expand against the vessel wall. Various optional embodiments are disclosed that allow one skilled in the art to tailor the design to the specific application.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

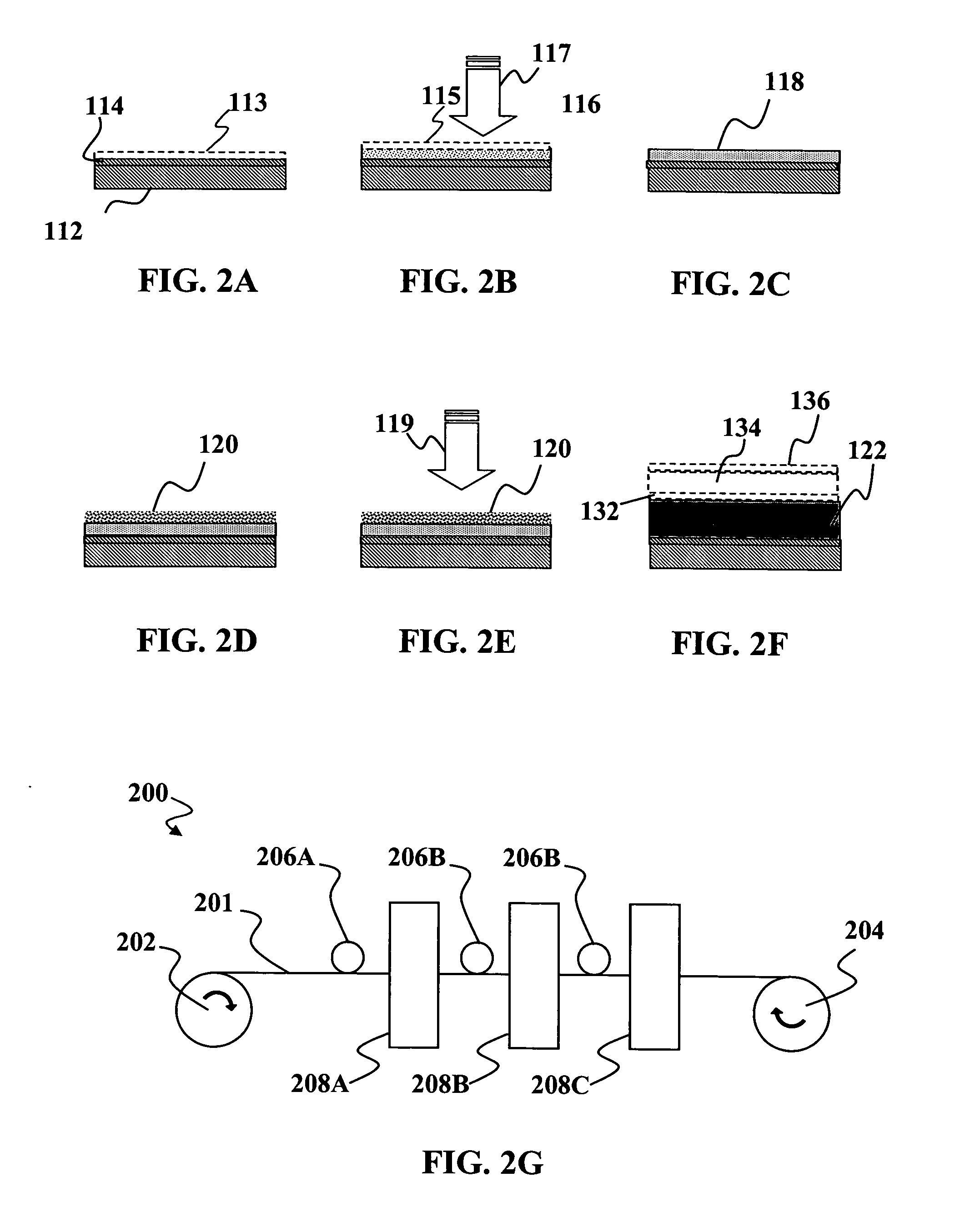

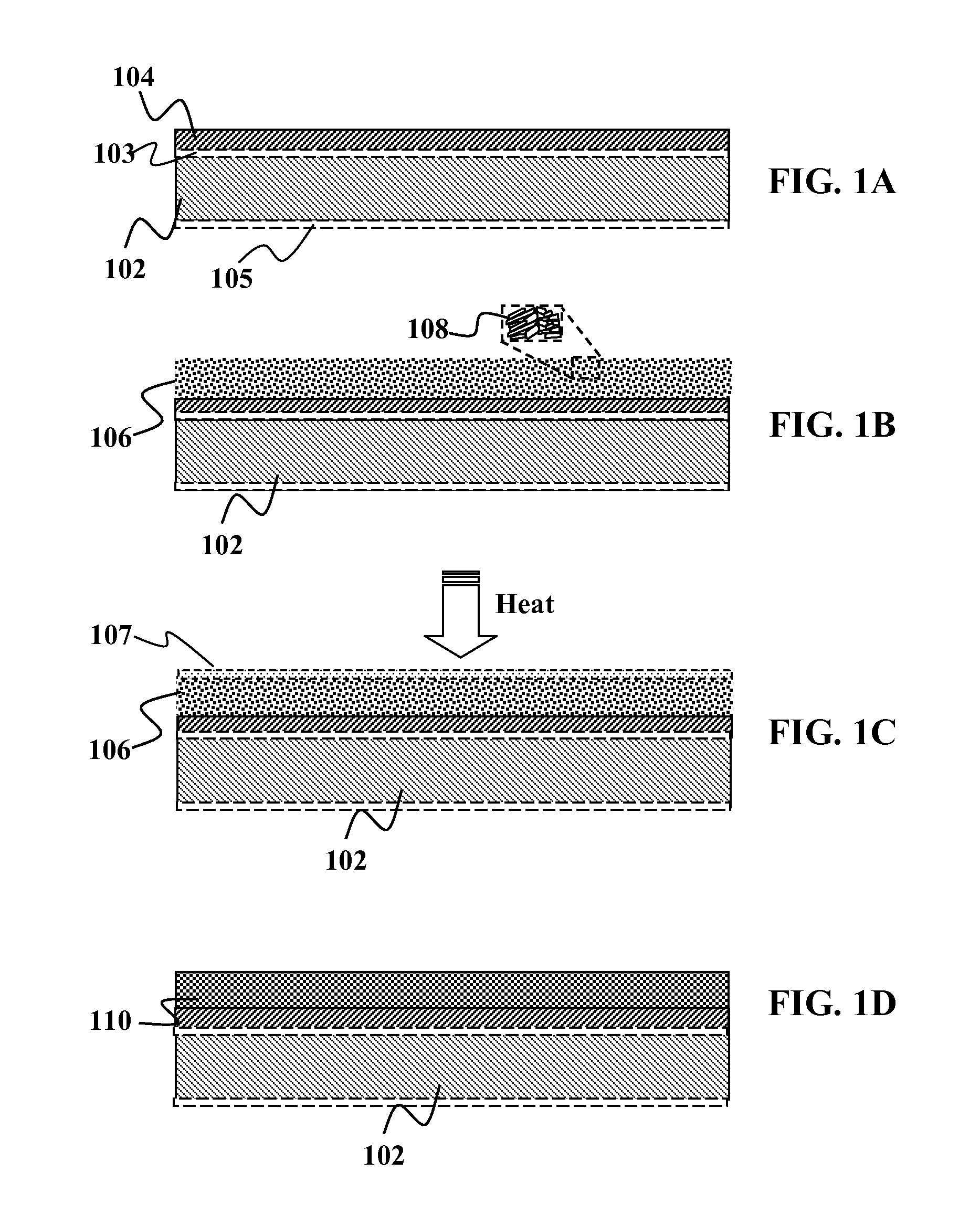

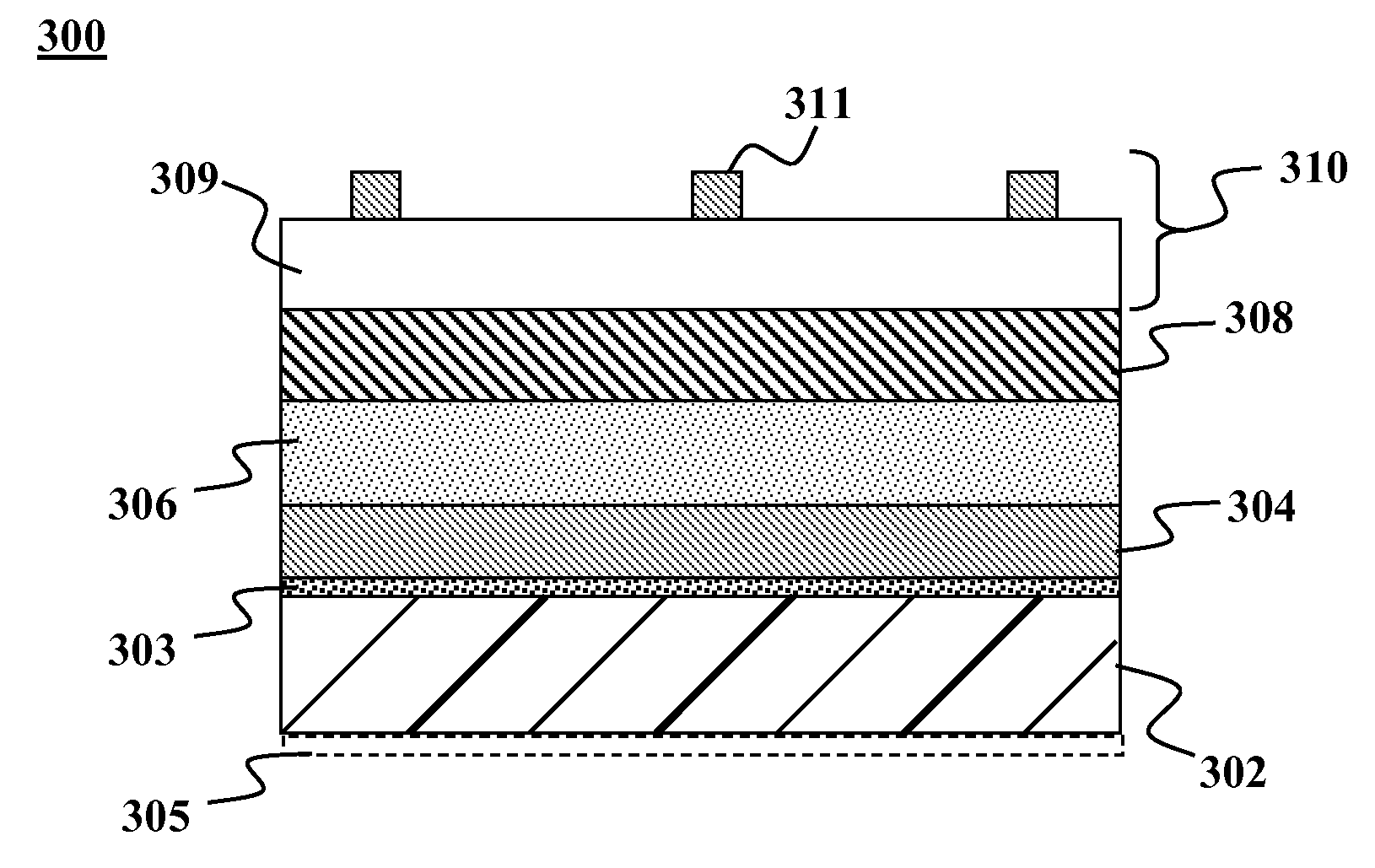

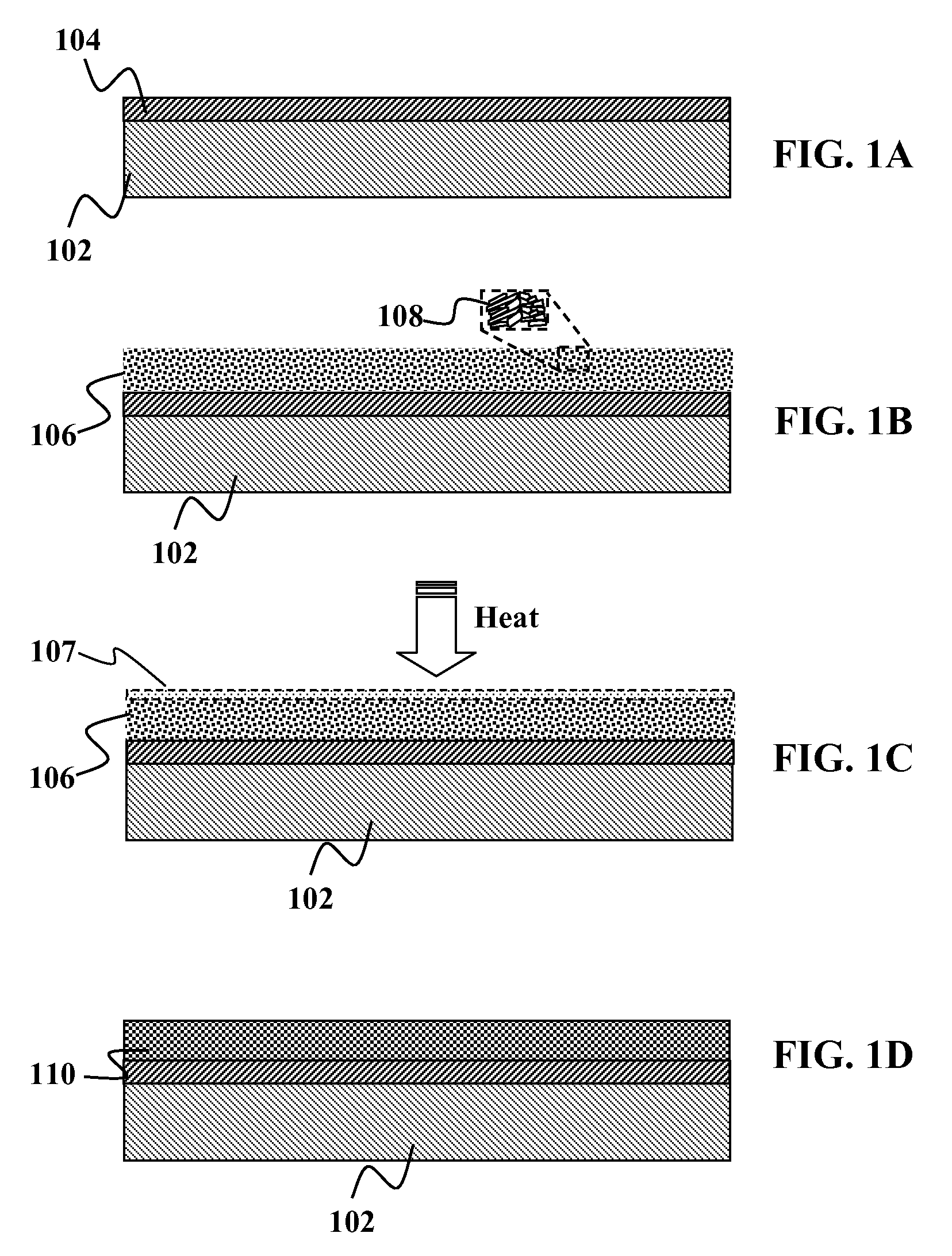

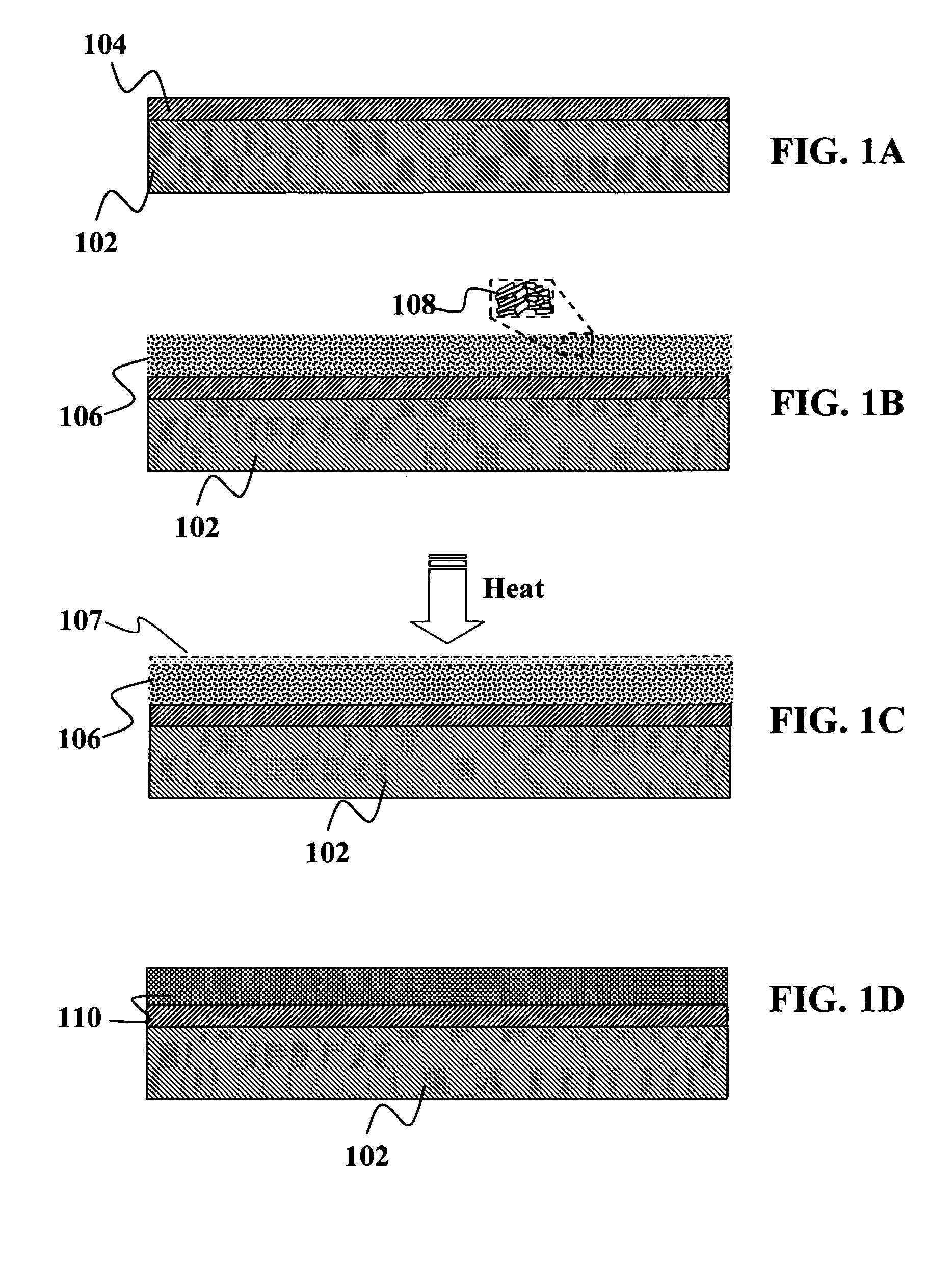

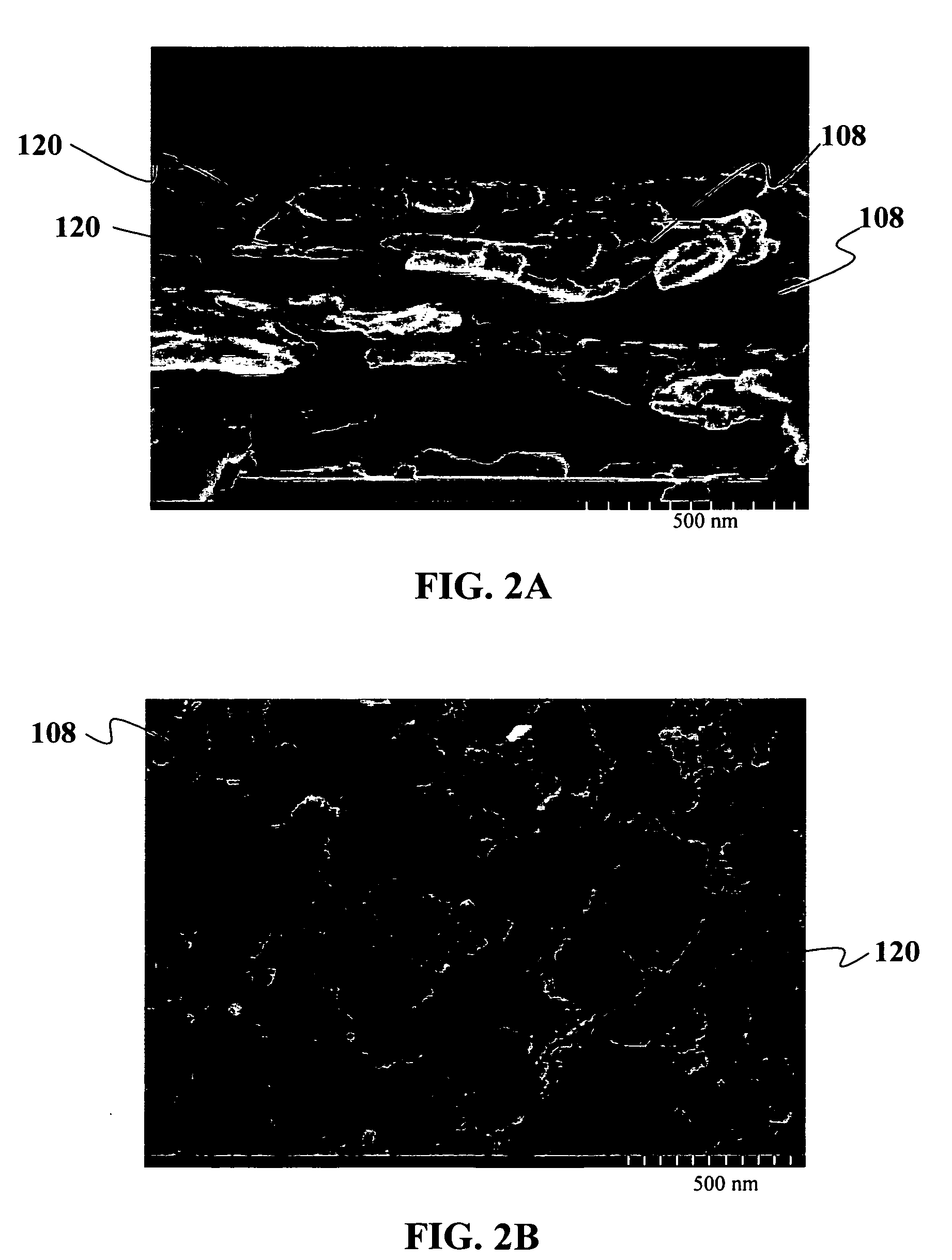

High-throughput printing of chalcogen layer and the use of an inter-metallic material

InactiveUS20070163643A1Reduce the temperaturePretreated surfacesLiquid/solution decomposition chemical coatingNanoparticleSulfur

Methods and devices for high-throughput printing of a precursor material for forming a film of a group IB-IIIA-chalcogenide compound are disclosed. In one embodiment, the method comprises forming a precursor layer on a substrate, wherein the precursor layer comprises one or more discrete layers. The layers may include at least a first layer containing one or more group IB elements and two or more different group IIIA elements and at least a second layer containing elemental chalcogen particles. The precursor layer may be heated to a temperature sufficient to melt the chalcogen particles and to react the chalcogen particles with the one or more group IB elements and group IIIA elements in the precursor layer to form a film of a group IB-IIIA-chalcogenide compound. At least one set of the particles in the precursor layer are inter-metallic particles containing at least one group IB-IIIA inter-metallic alloy phase. The method may also include making a film of group IB-IIIA-chalcogenide compound that includes mixing the nanoparticles and / or nanoglobules and / or nanodroplets to form an ink, depositing the ink on a substrate, heating to melt the extra chalcogen and to react the chalcogen with the group IB and group IIIA elements and / or chalcogenides to form a dense film.

Owner:NANOSOLAR

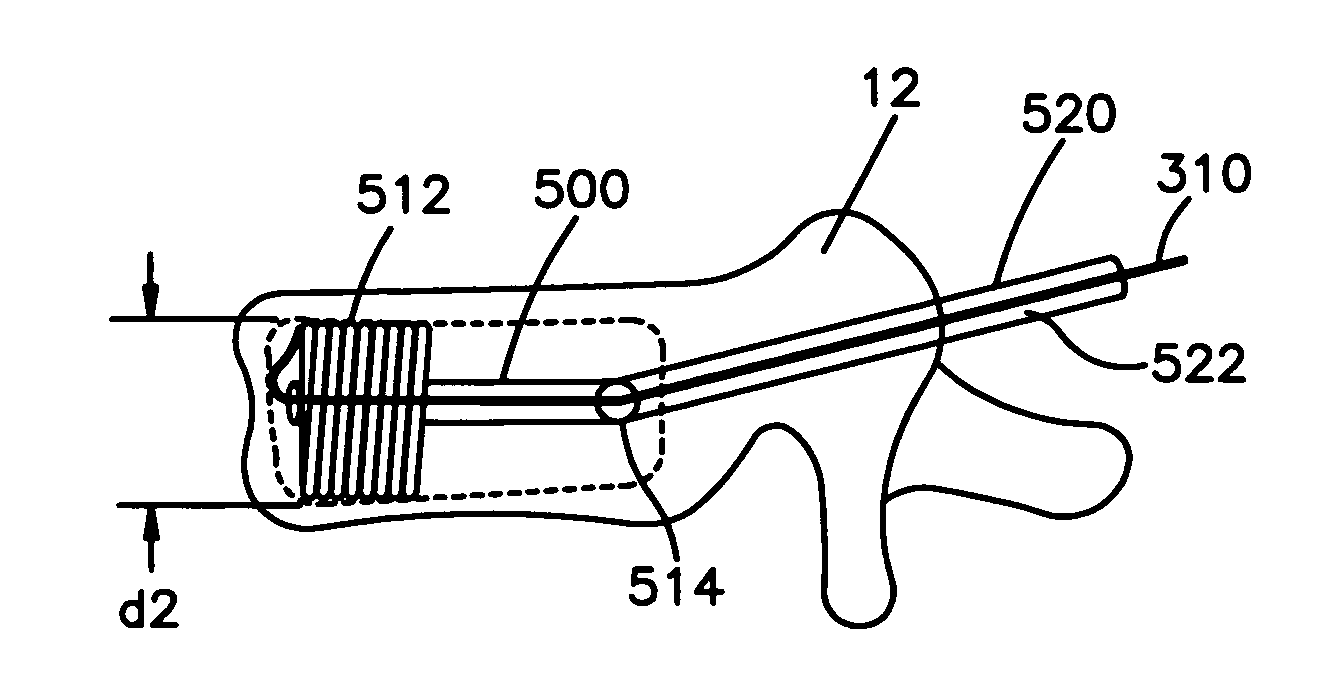

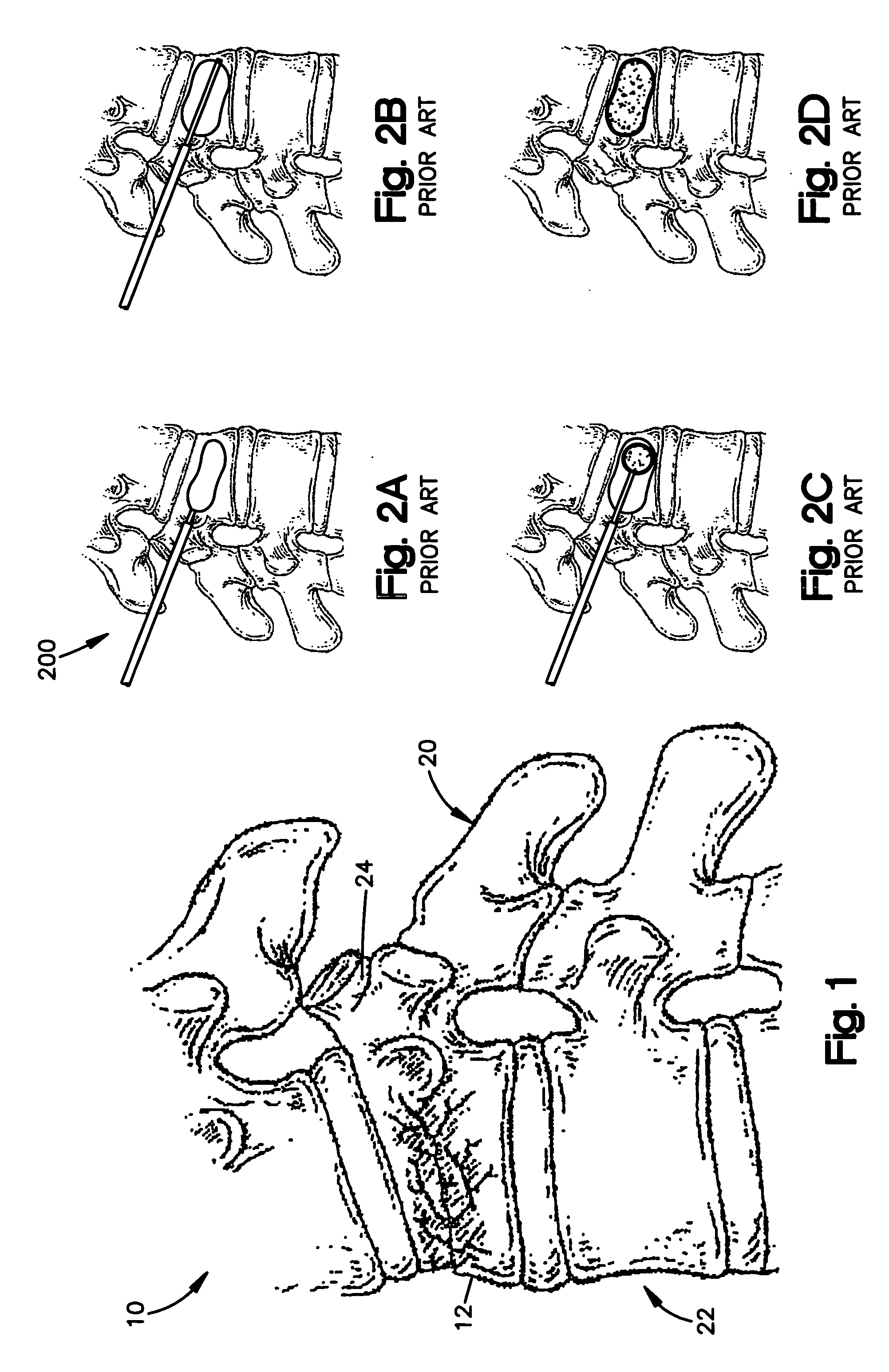

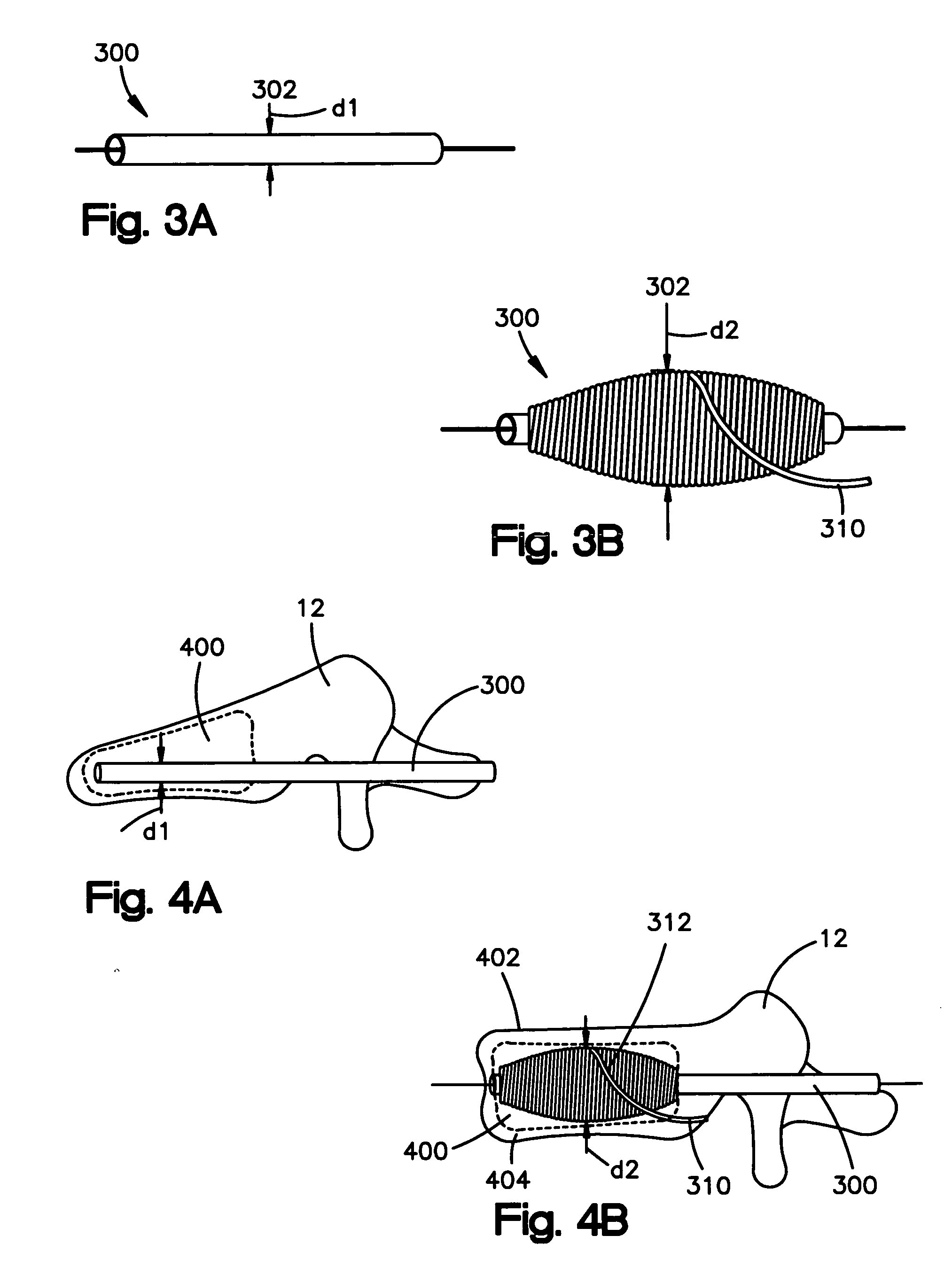

Apparatus and methods for treating bone

ActiveUS20070055274A1Increased radialIncreasing diameter of coilInternal osteosythesisSpinal implantsFiberBobbin

Implants and methods for bone treatment, preferably minimally invasive treatment, including repositioning of vertebrae may comprise insertion of a bobbin having a wire, string, thread or band, coiled around the bobbin. During coiling, the diameter of the bobbing / band complex may increase. Such increase in diameter can push against the inner side of the endplates of the vertebral body, and augment the vertebral body to its original height. The implant may also take the form of a coiled sleeve which when inserted into the vertebral body is uncoiled. The force of the uncoiling sleeve pushes against the inner side o the endplates of the vertebral body, restoring the vertebral body to its original height. The implant may also take the form of fibrous masses comprised of a thread or other relatively thin structure, for example a fiber or strand, of any biocompatible material having desired characteristics, for example a shape memory alloy, titanium, stainless steel, another metal or metal alloy, a ceramic, a composite or any combination thereof. The, strand, thread or other fiber may be coiled, woven, matted, tangled or otherwise formed into a wool-like mass or body having a desired configuration. Expansion of the expandable member within the vertebral body or other bone may reposition the fractured bone to a desired height and augment the bone to maintain the desired height. A bone cement or other filler can be added to further treat and stabilize the vertebral body or other bone.

Owner:SYNTHES USA

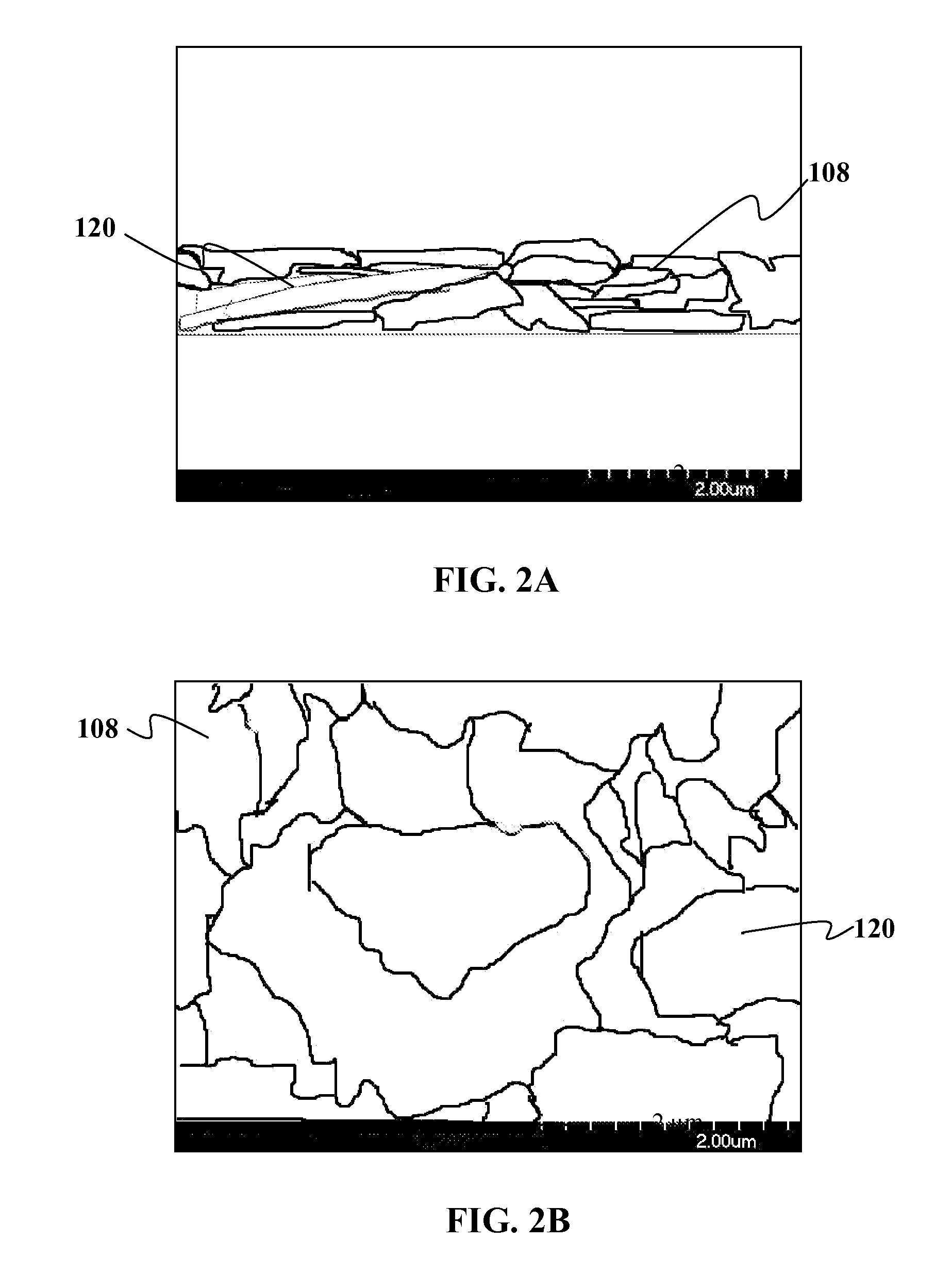

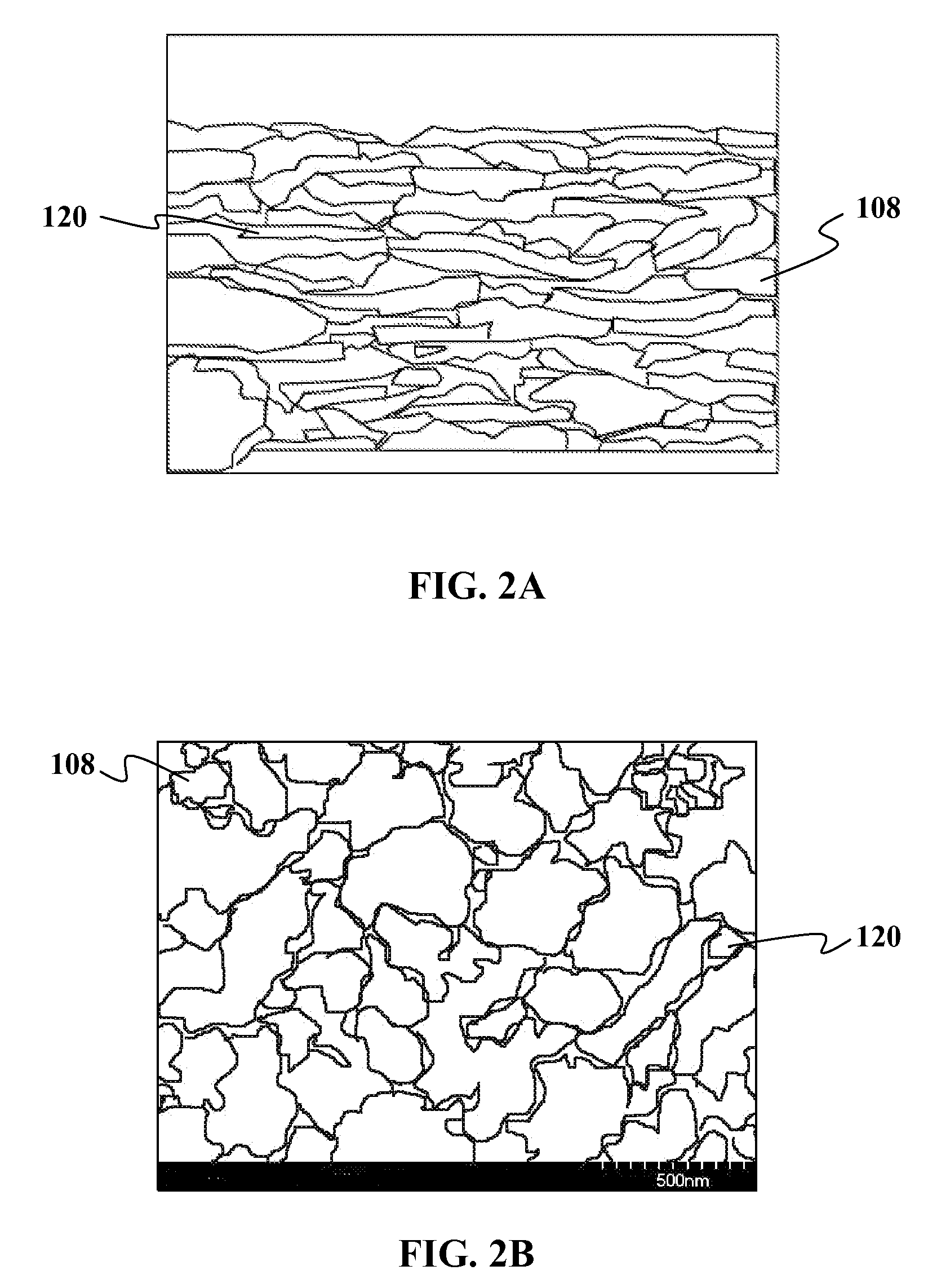

High-throughput printing of semiconductor precursor layer from chalcogenide microflake particles

InactiveUS20080121277A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes is particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

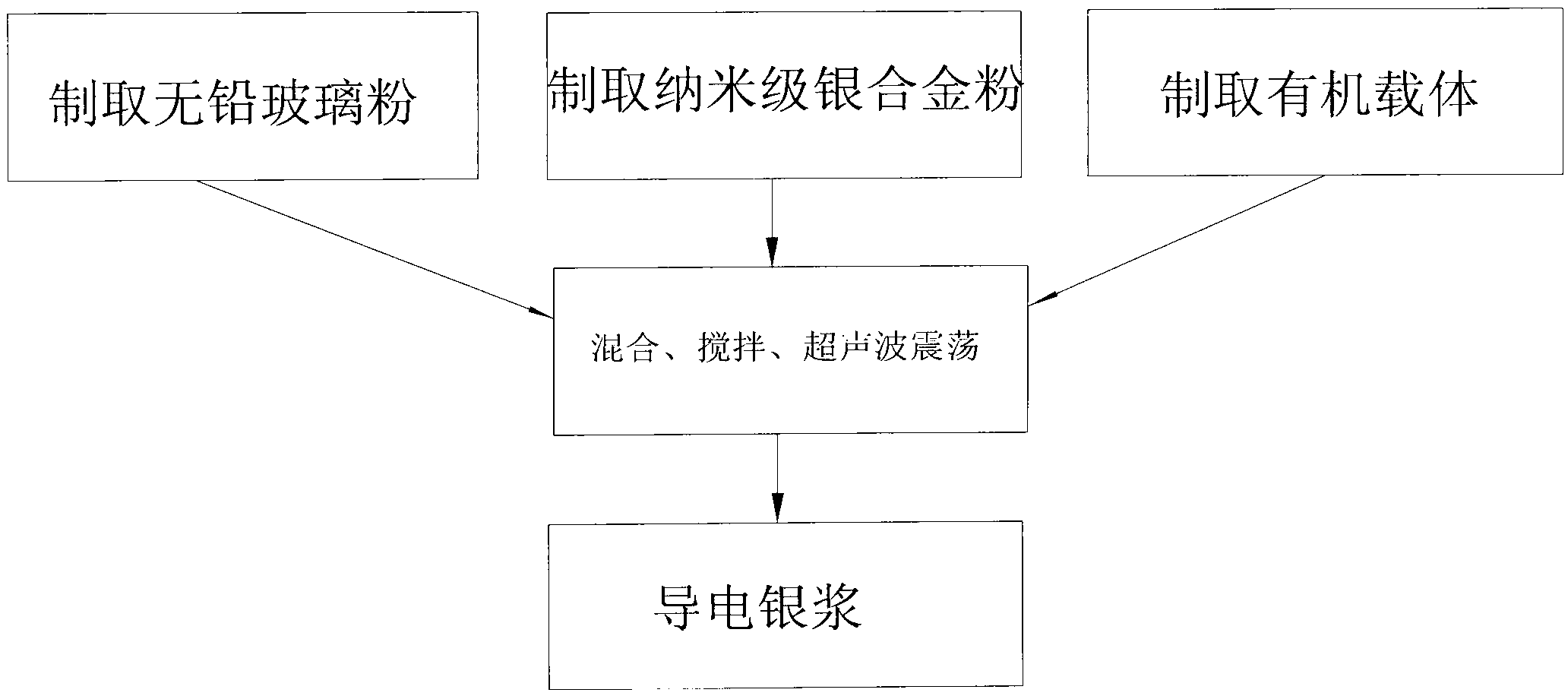

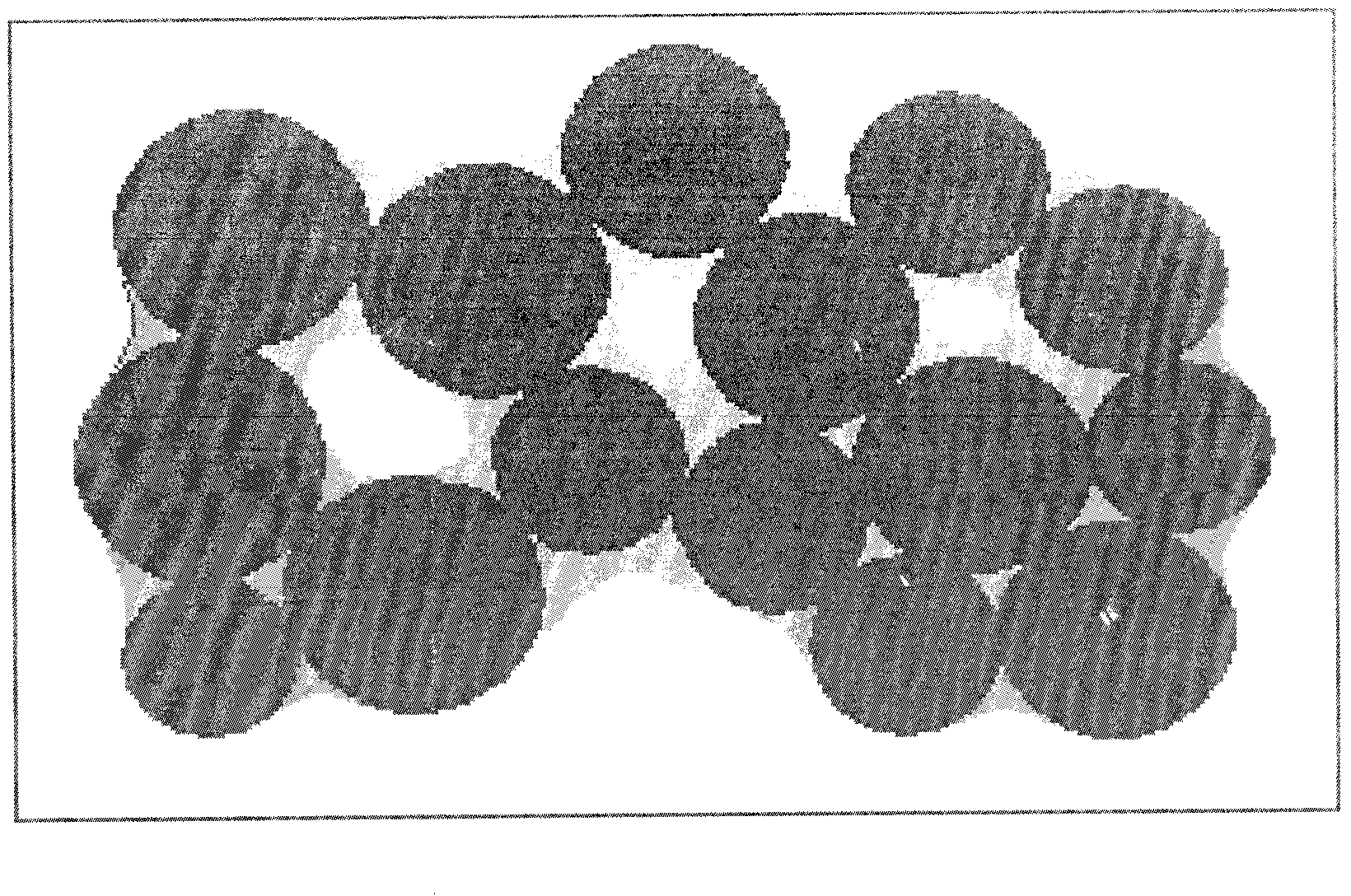

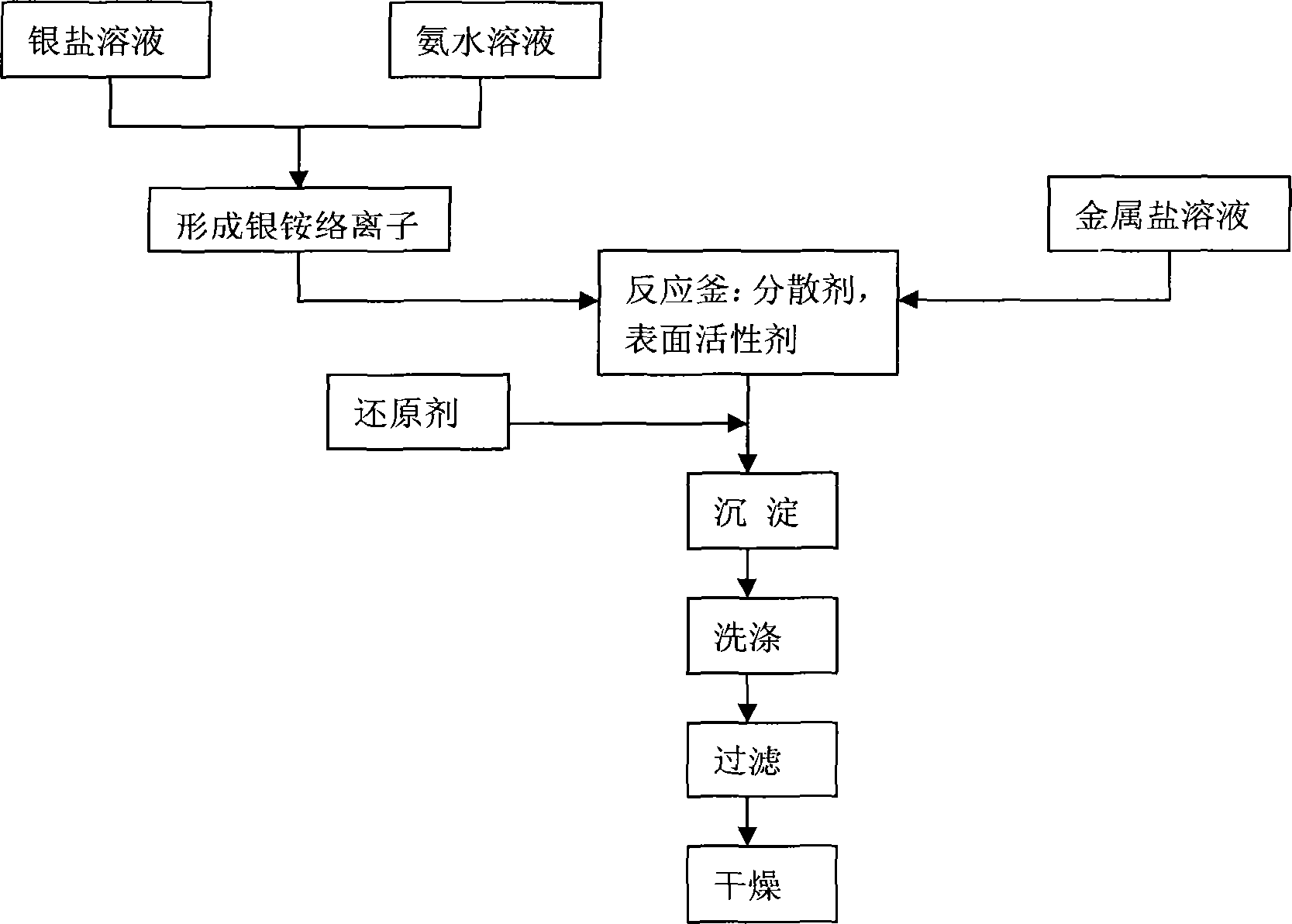

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

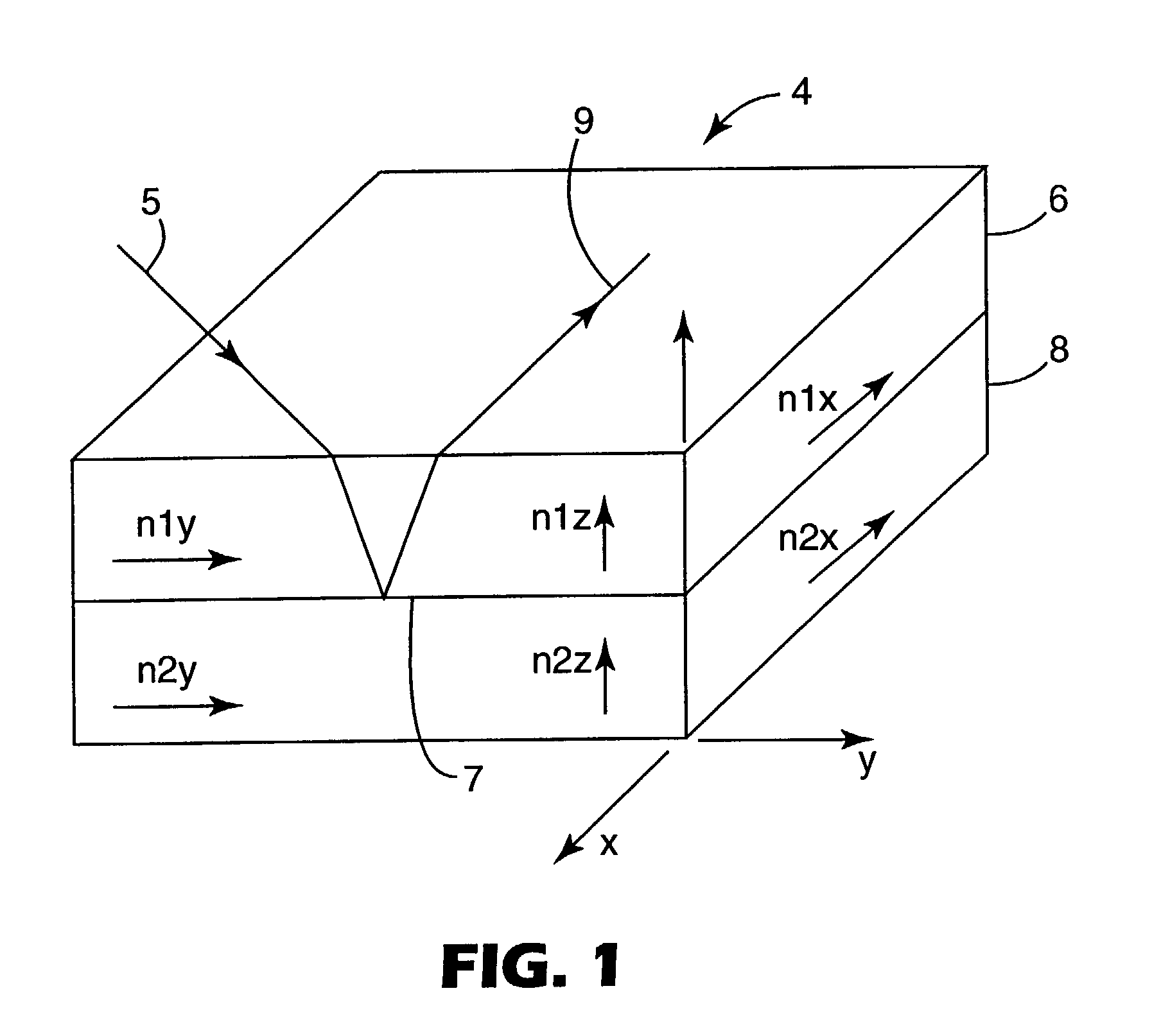

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS20020034603A1Improve reflectivitySimilar sputtering characteristicMagnetic materials for record carriersVacuum evaporation coatingManganeseHigh reflectivity

A silver-based alloy thin film is provided for the highly reflective or semi-reflective coating layer of optical discs. Alloy additions to silver include zinc, aluminum, zinc plus aluminum, manganese, germanium, and copper plus manganese. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

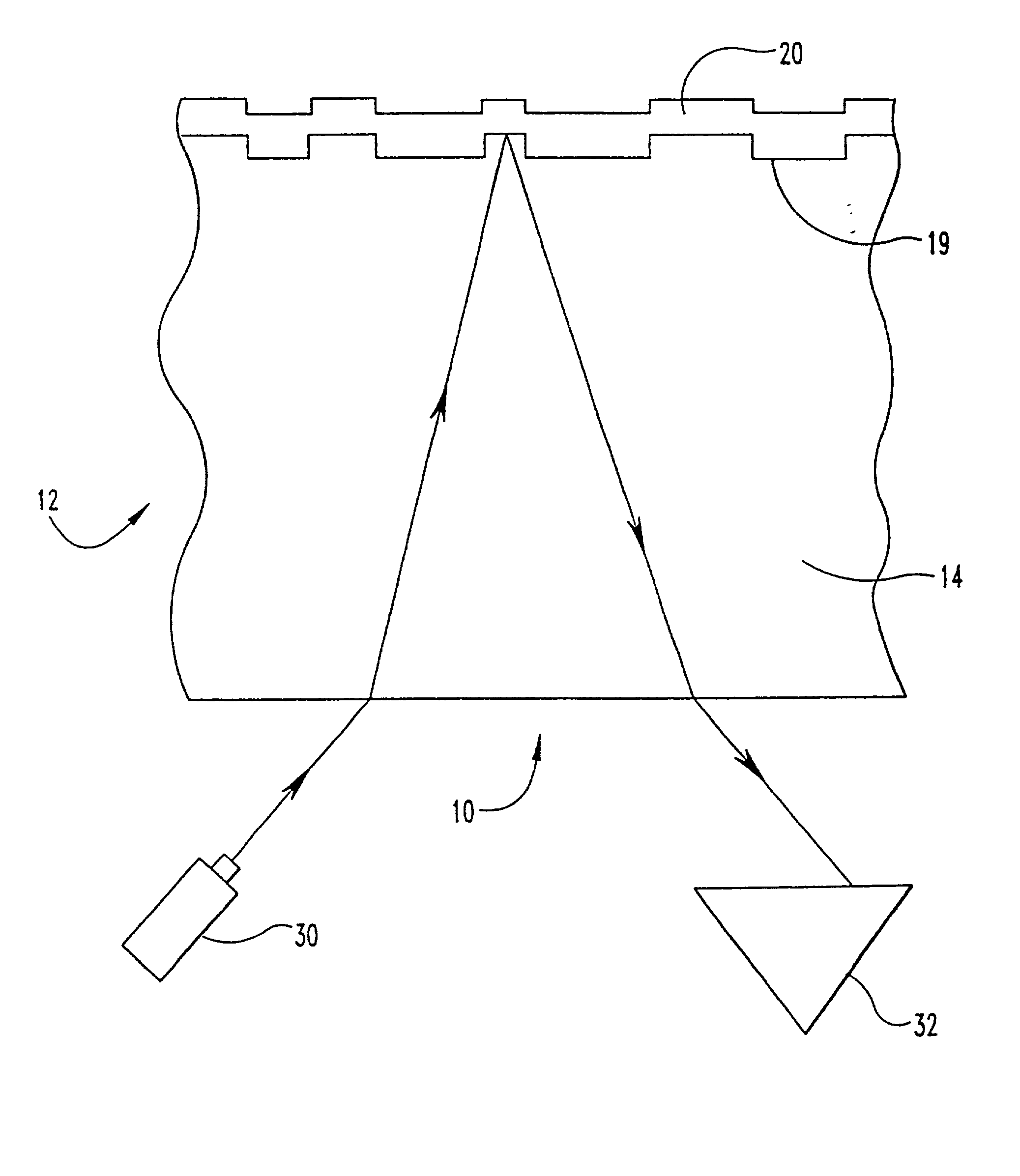

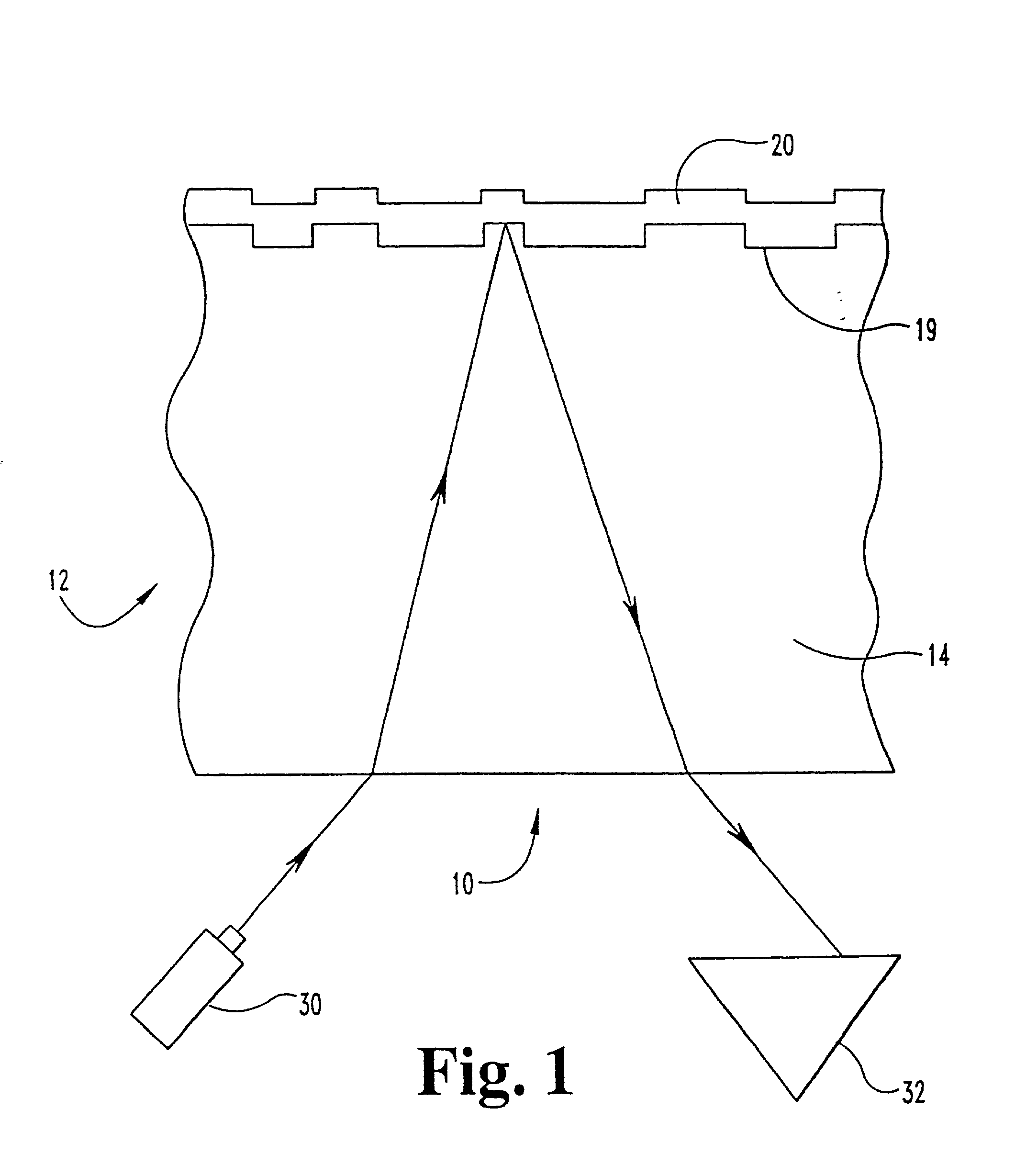

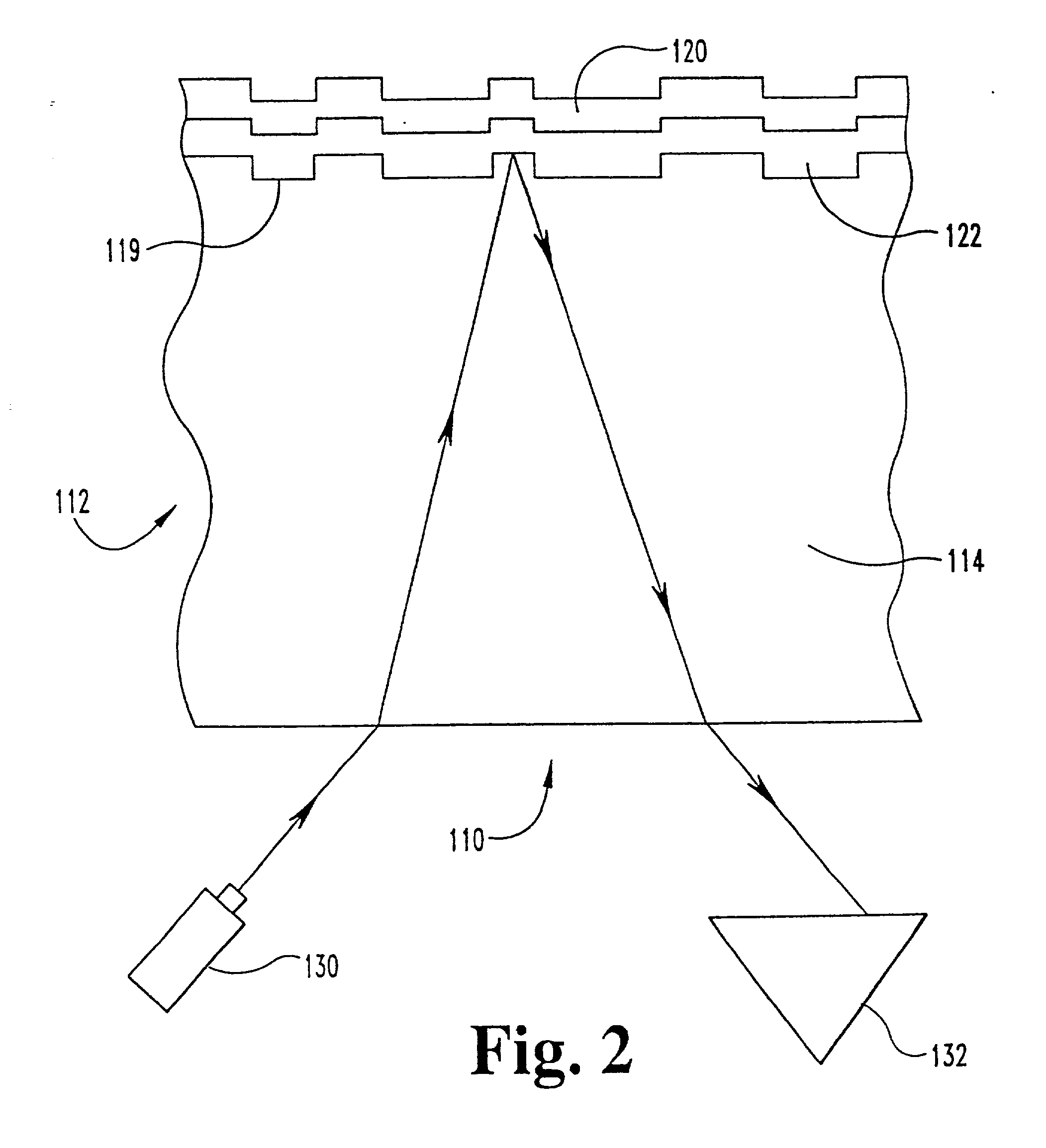

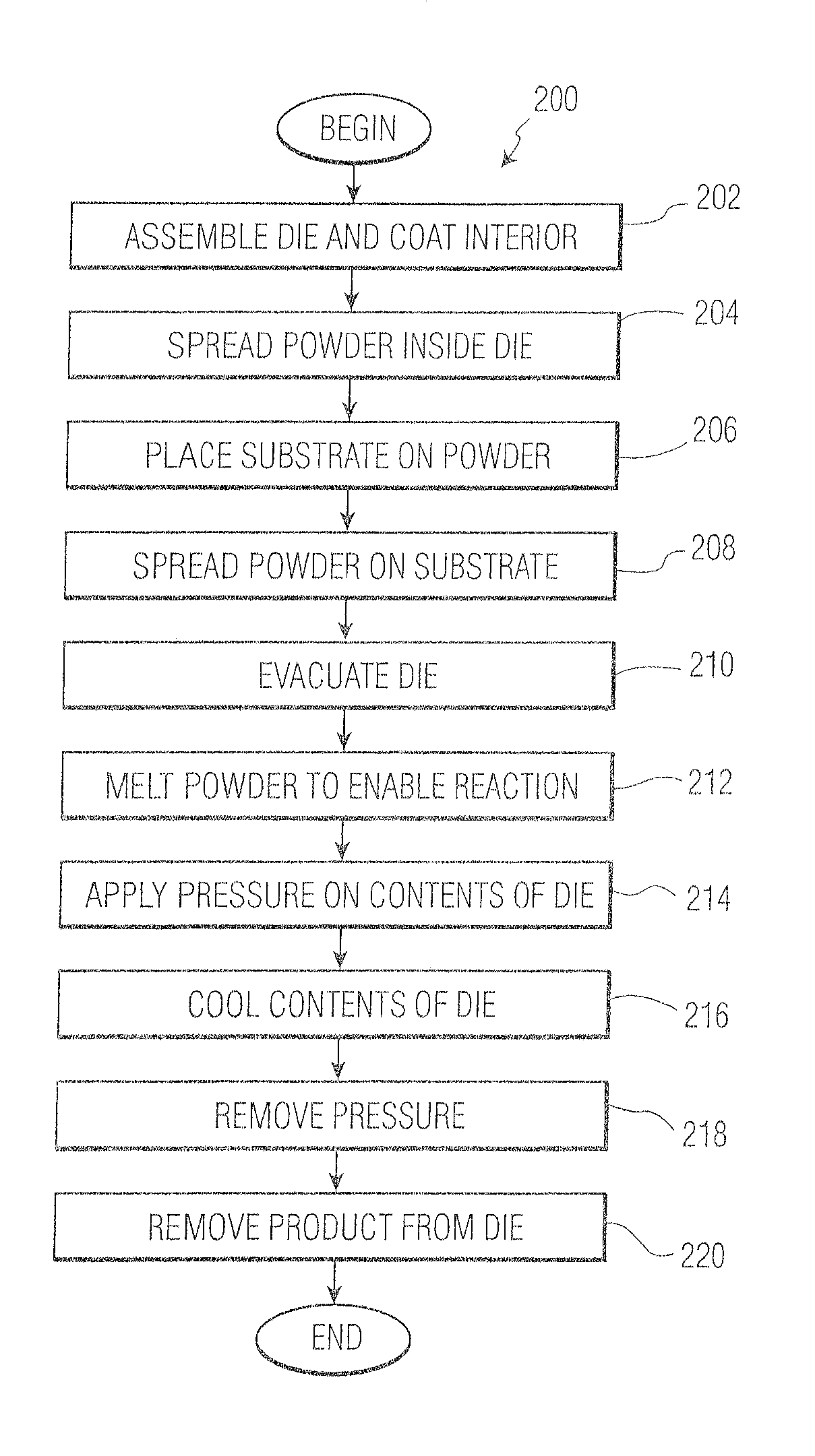

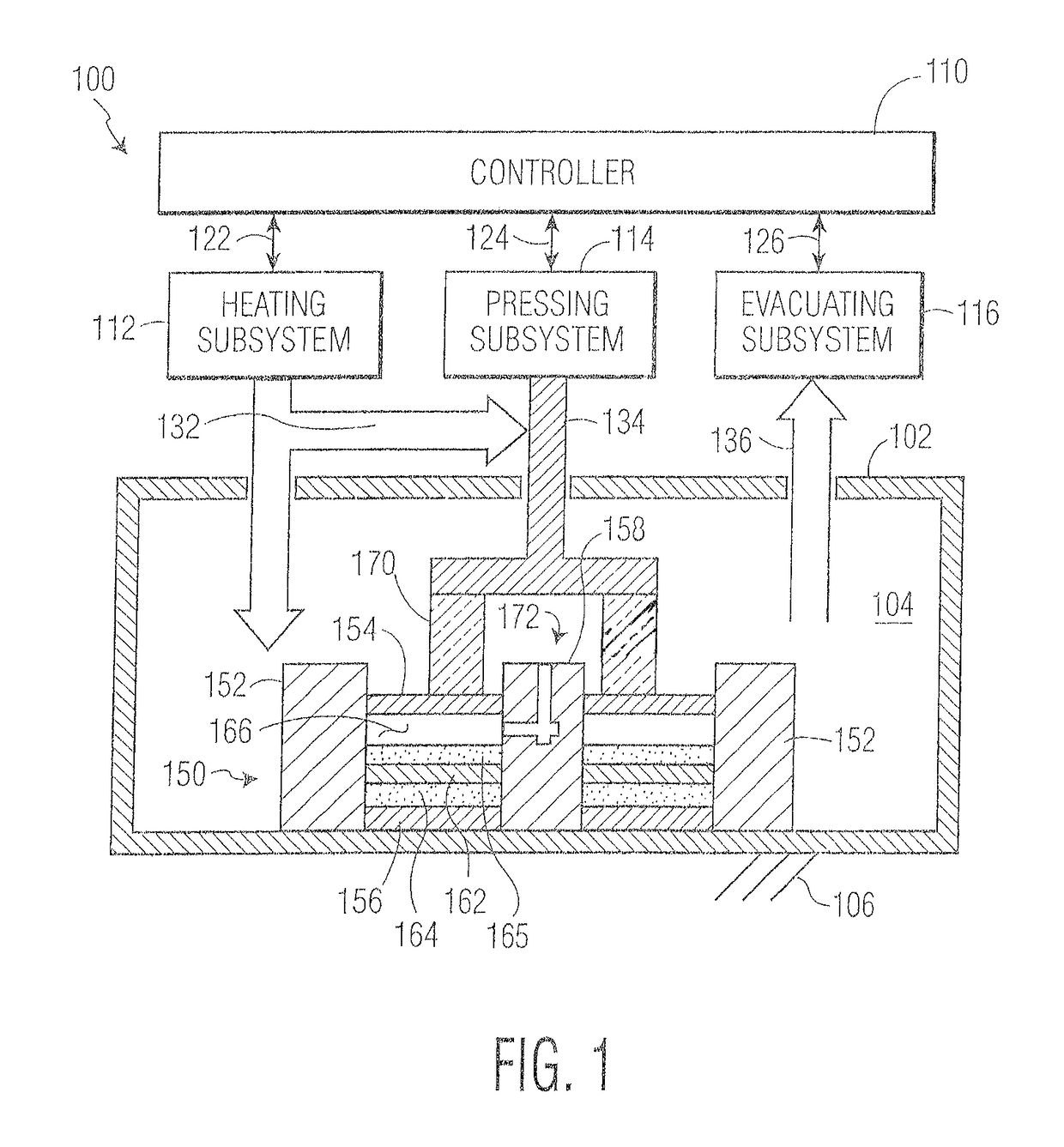

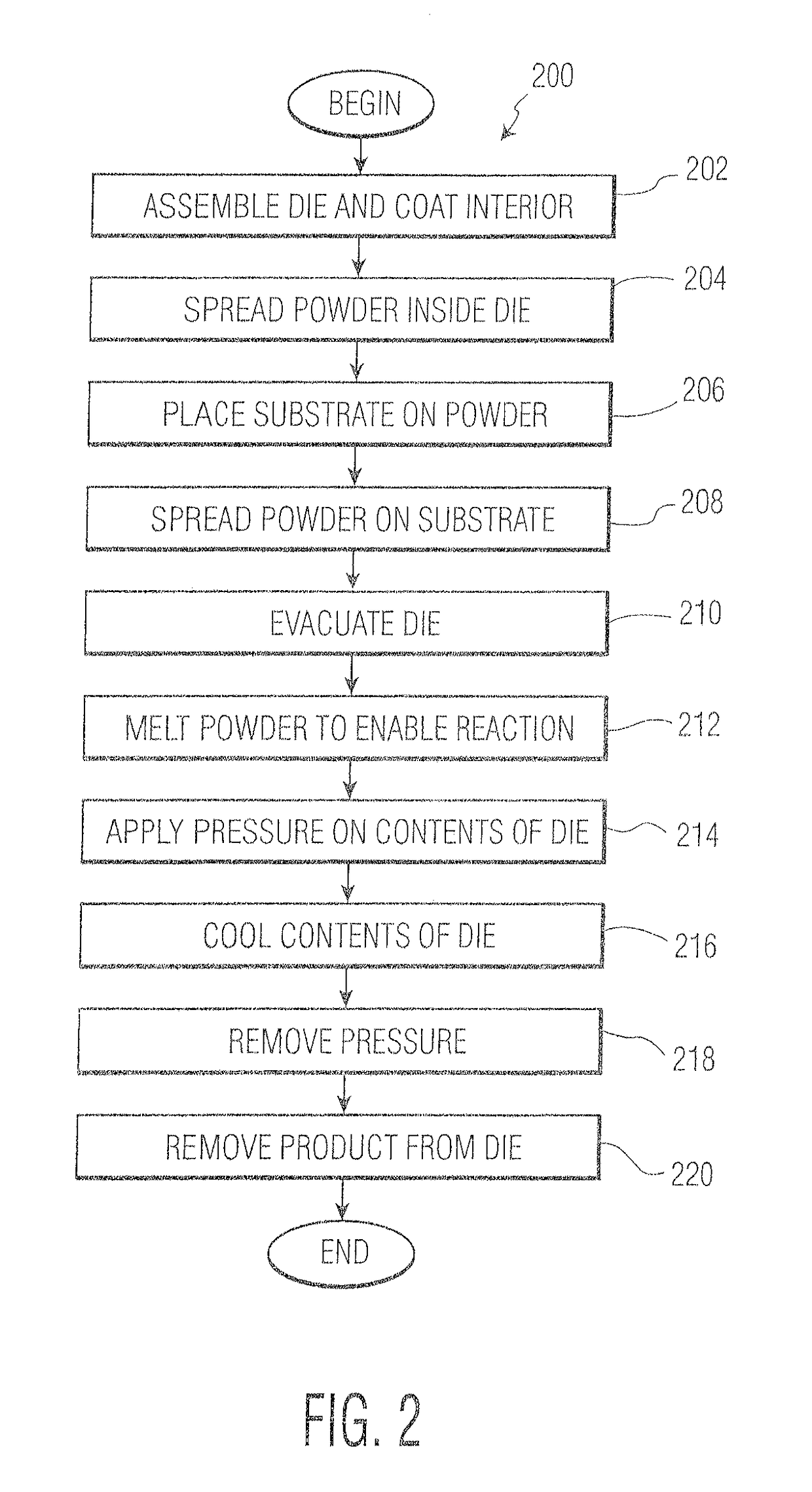

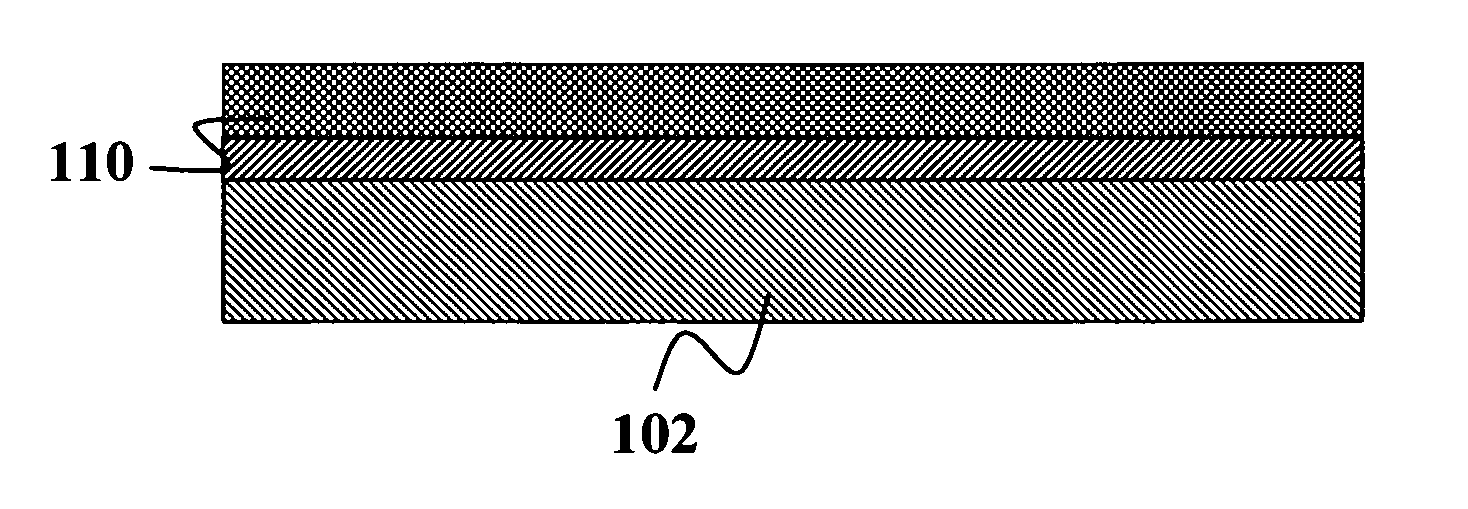

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

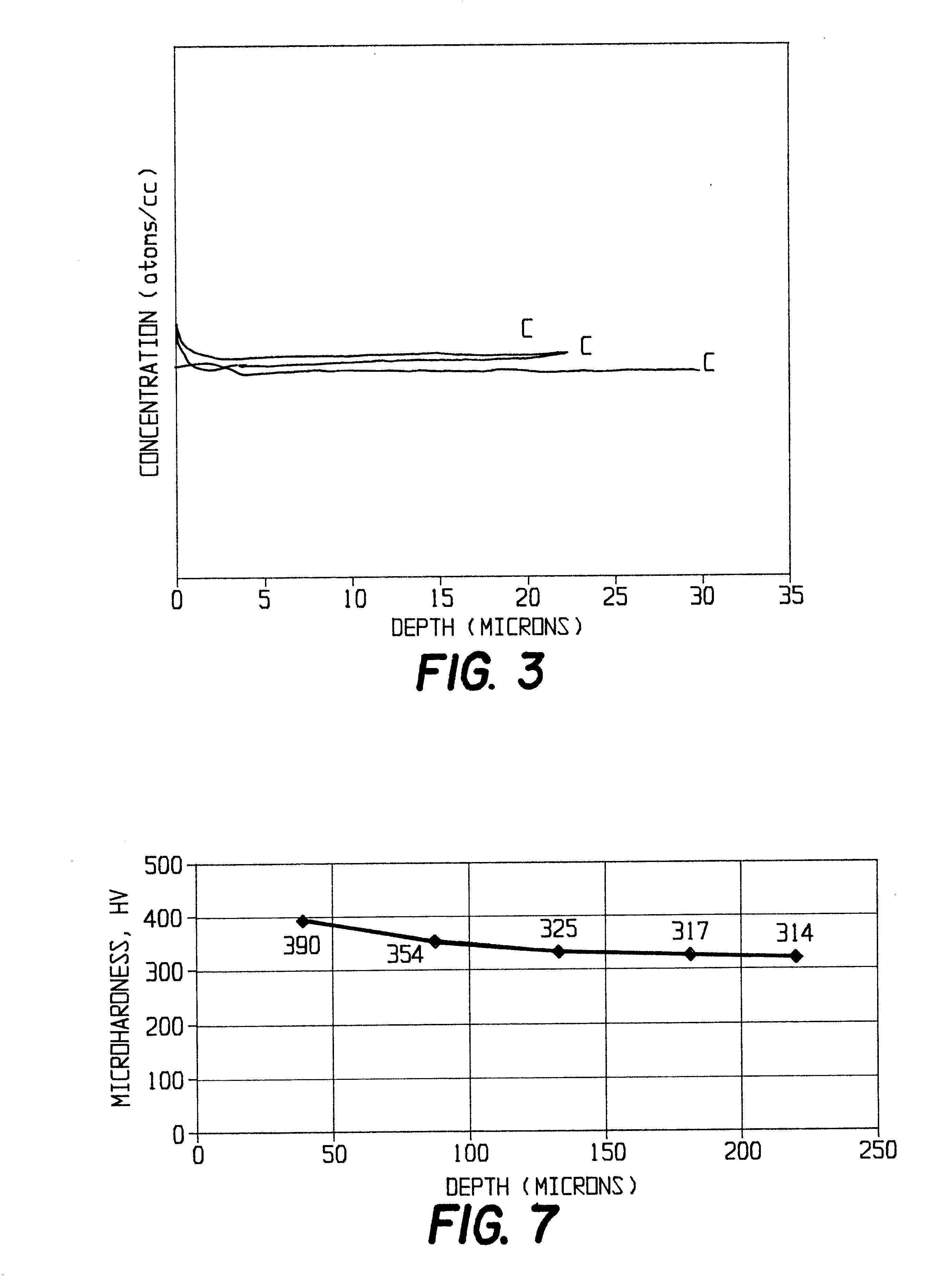

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

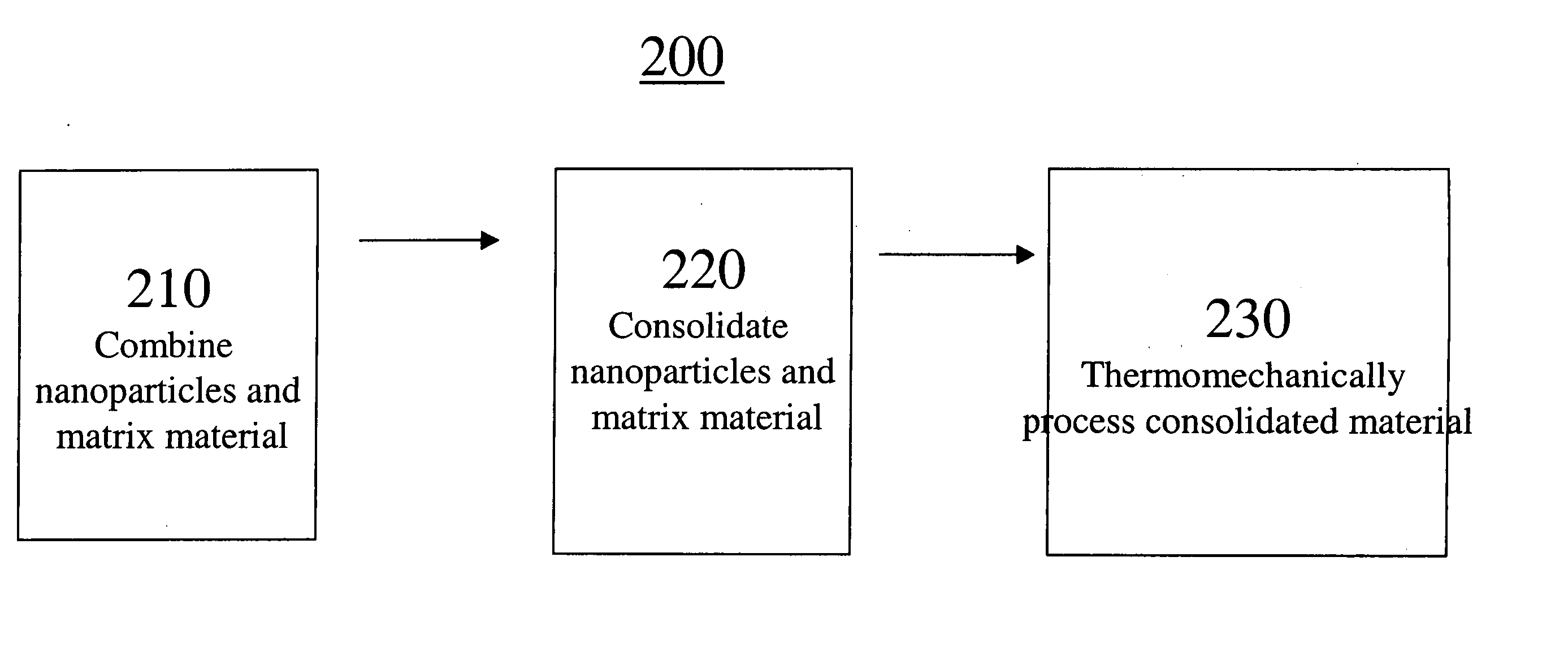

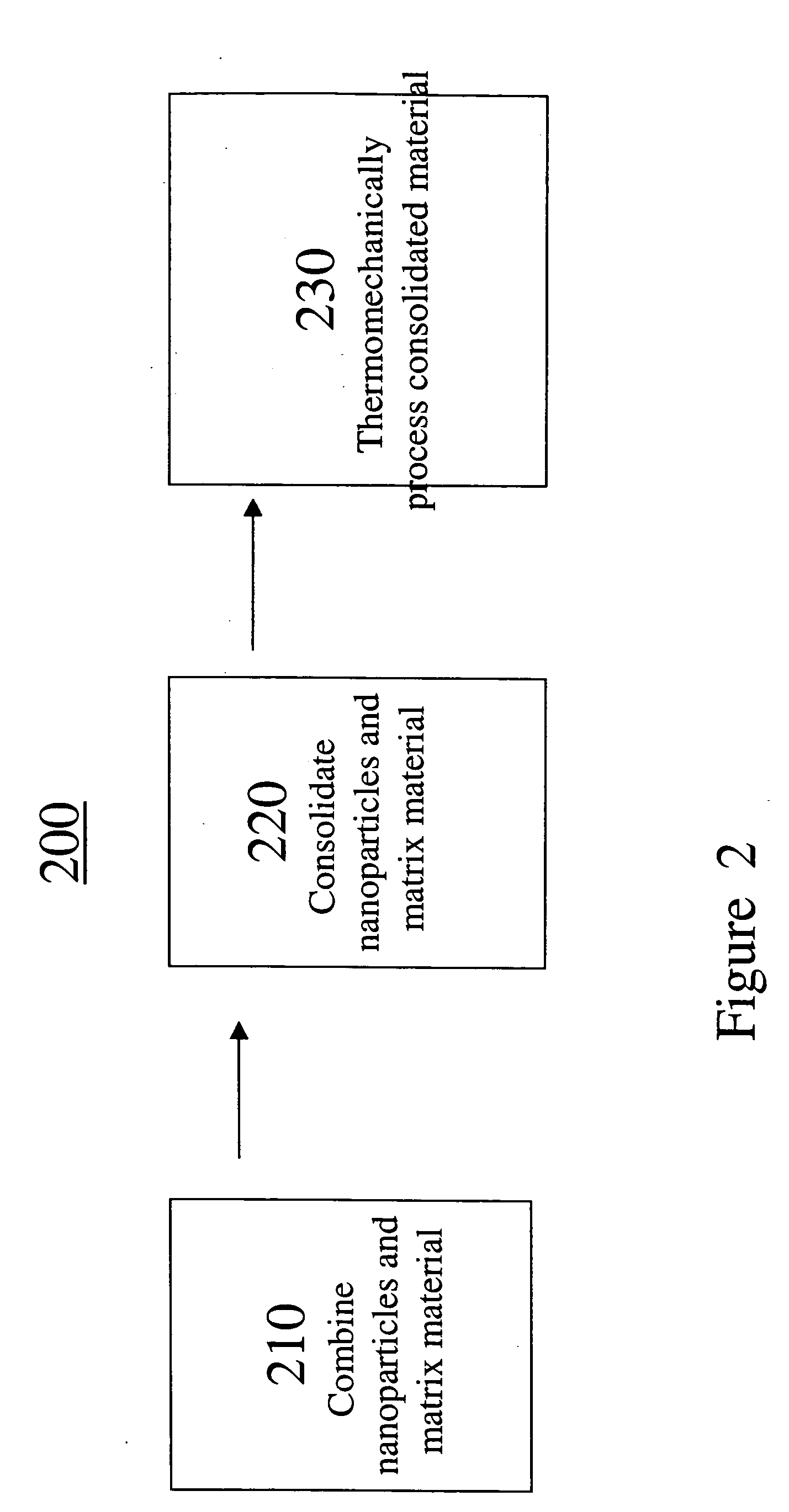

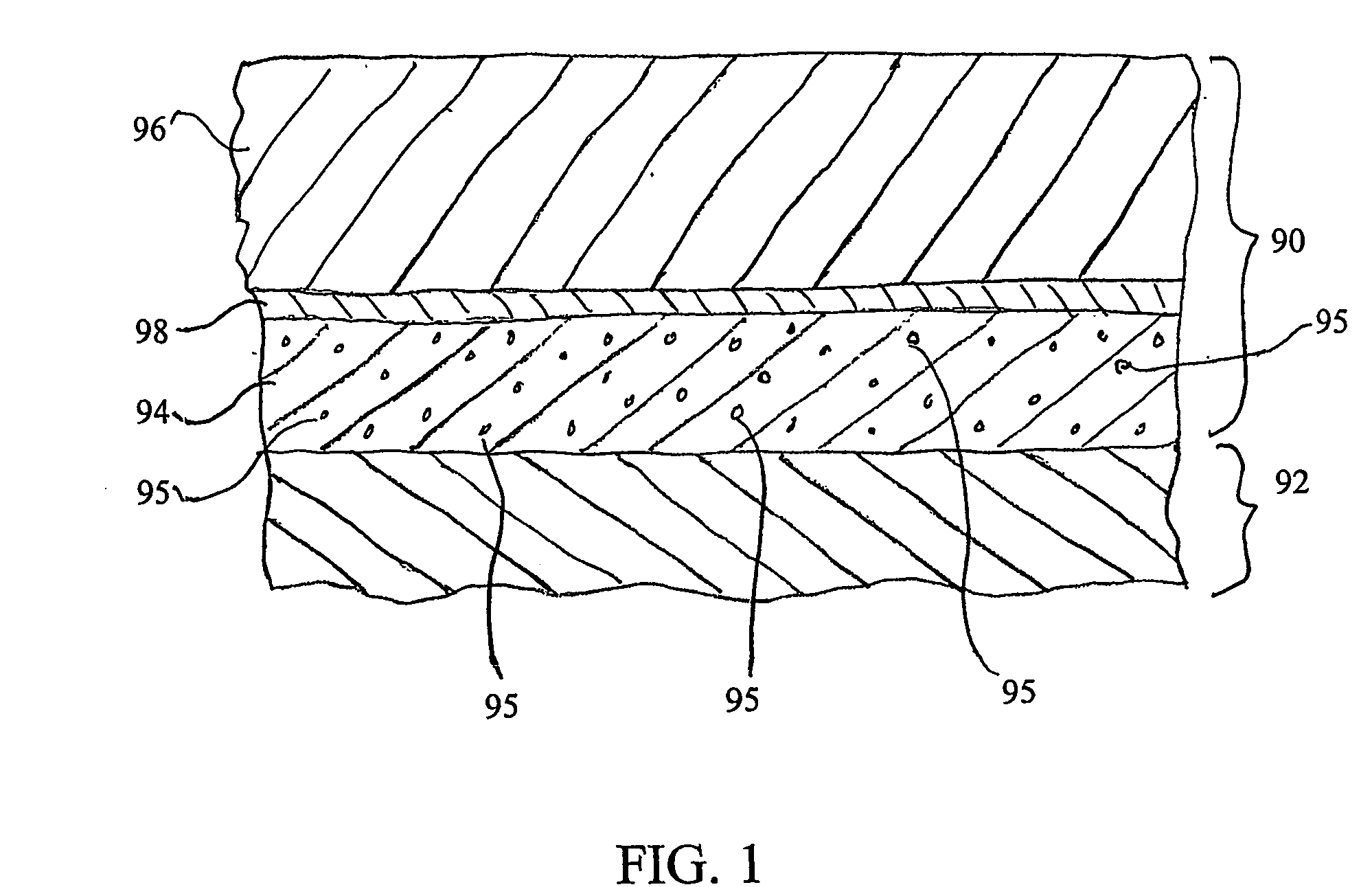

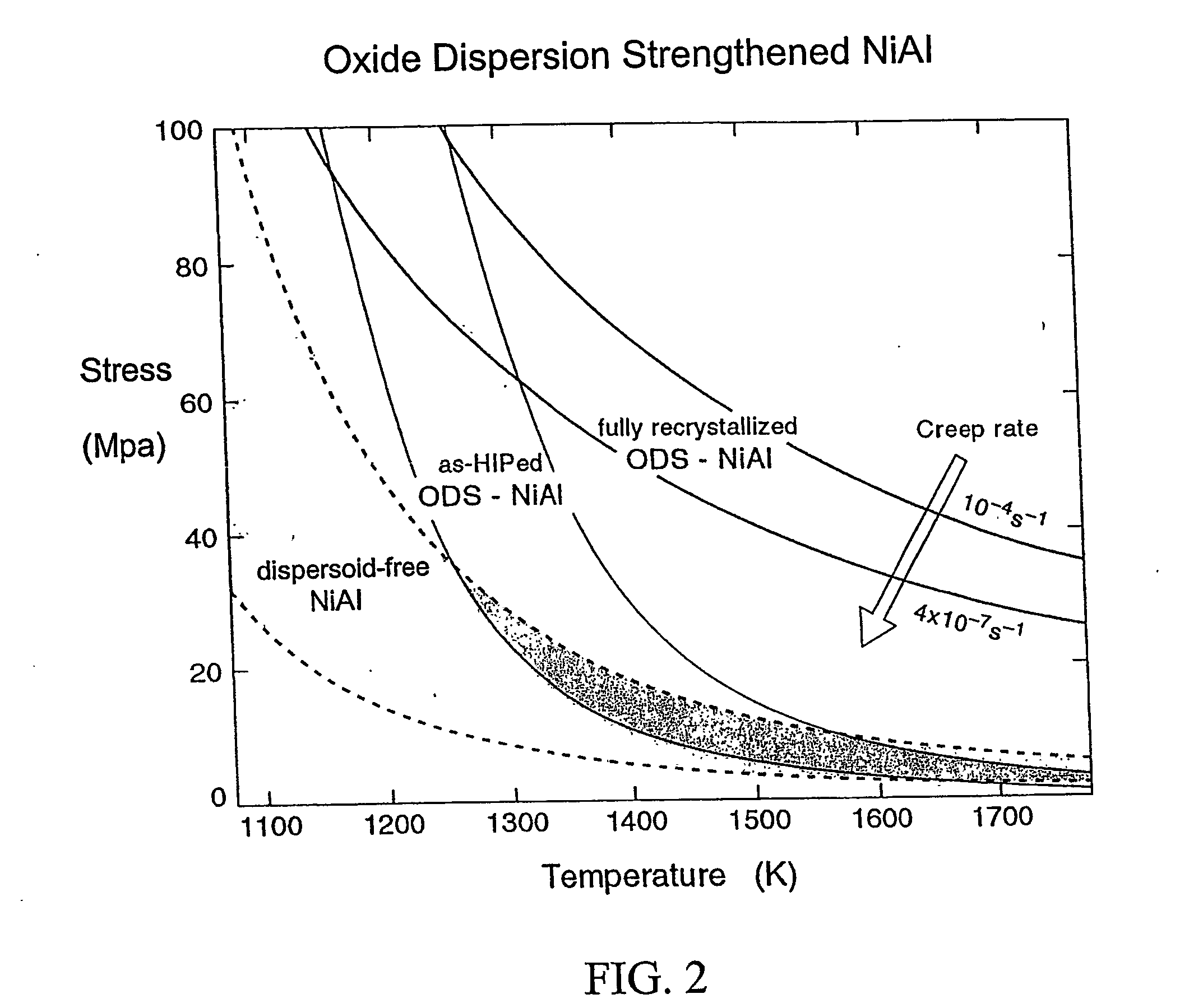

Metallic alloy nanocomposite for high-temperature structural components and methods of making

InactiveUS20050133121A1Increase volume fractionTransportation and packagingMetal-working apparatusNanocompositeAirplane

A nanocomposite comprising a plurality of nanoparticles dispersed in a metallic alloy matrix, and a structural component formed from such a nanocomposite. The metallic matrix comprises at least one of a nickel-based alloy and an iron-based alloy. The nanocomposite contains a higher volume fraction of nanoparticle dispersoids than those presently available. The structural component include those used in hot gas path assemblies, such as steam turbines, gas turbines, and aircraft turbine. A method of making such nanocomposites is also disclosed.

Owner:GENERAL ELECTRIC CO

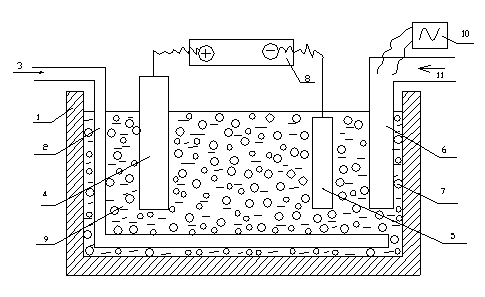

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

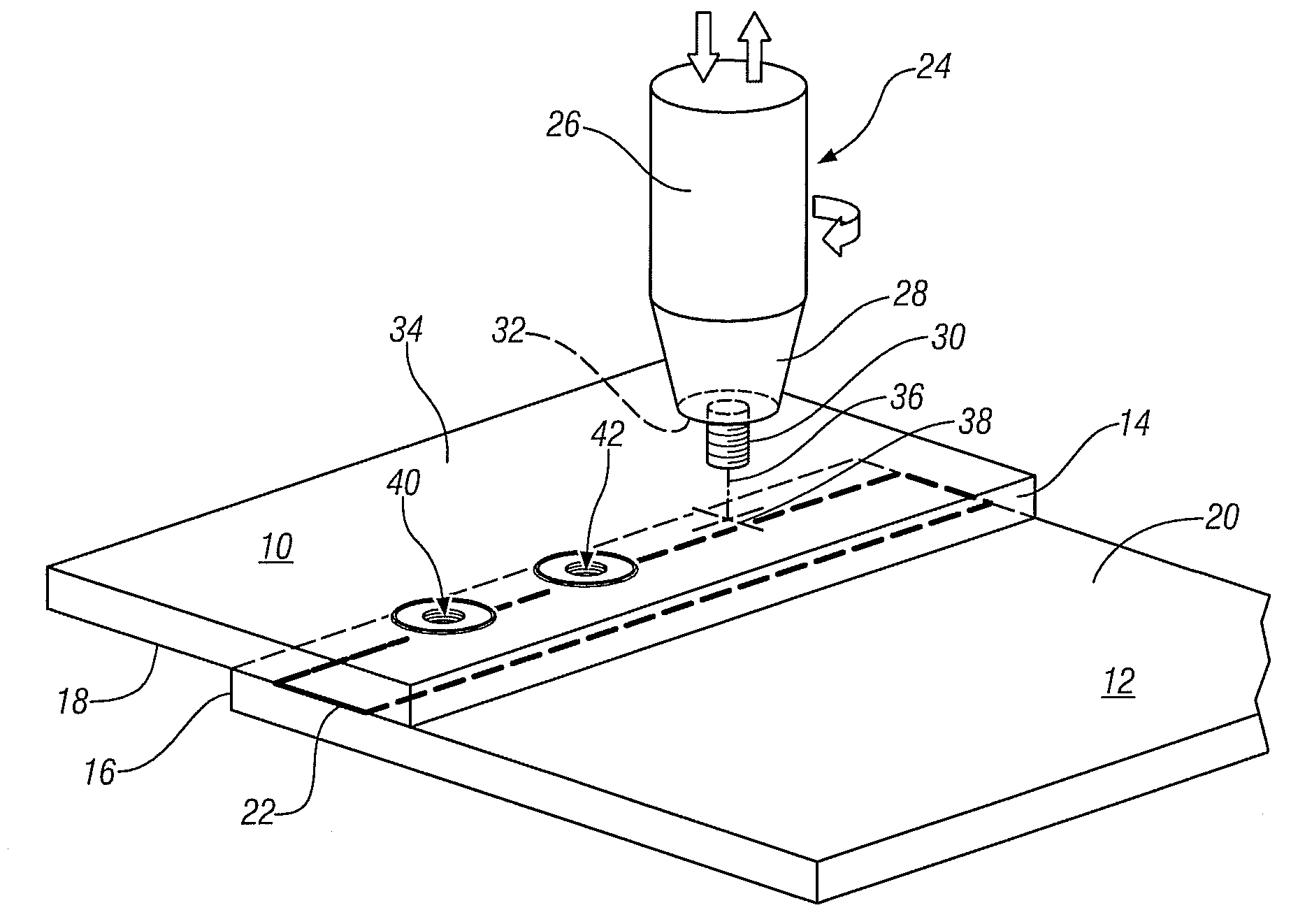

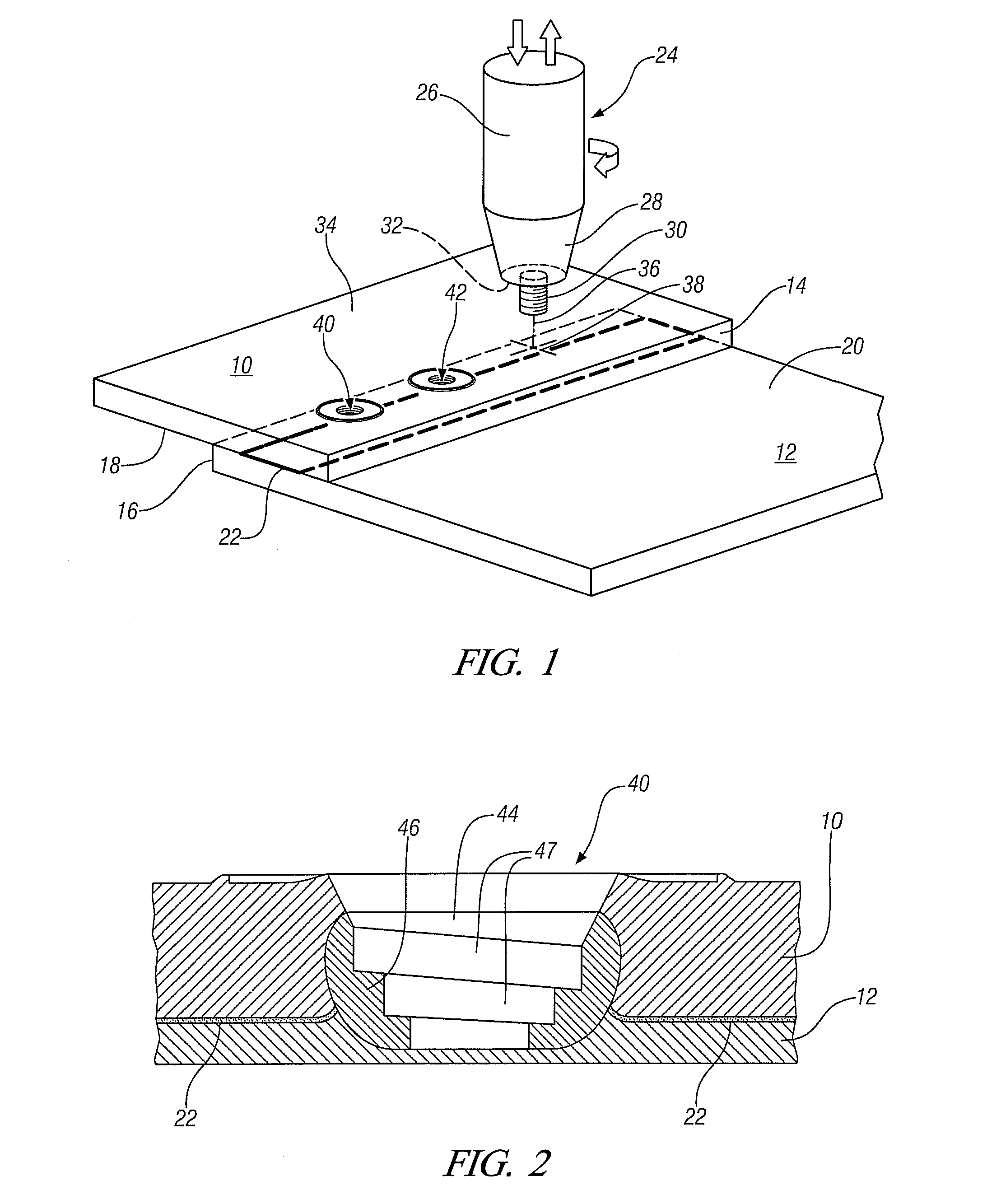

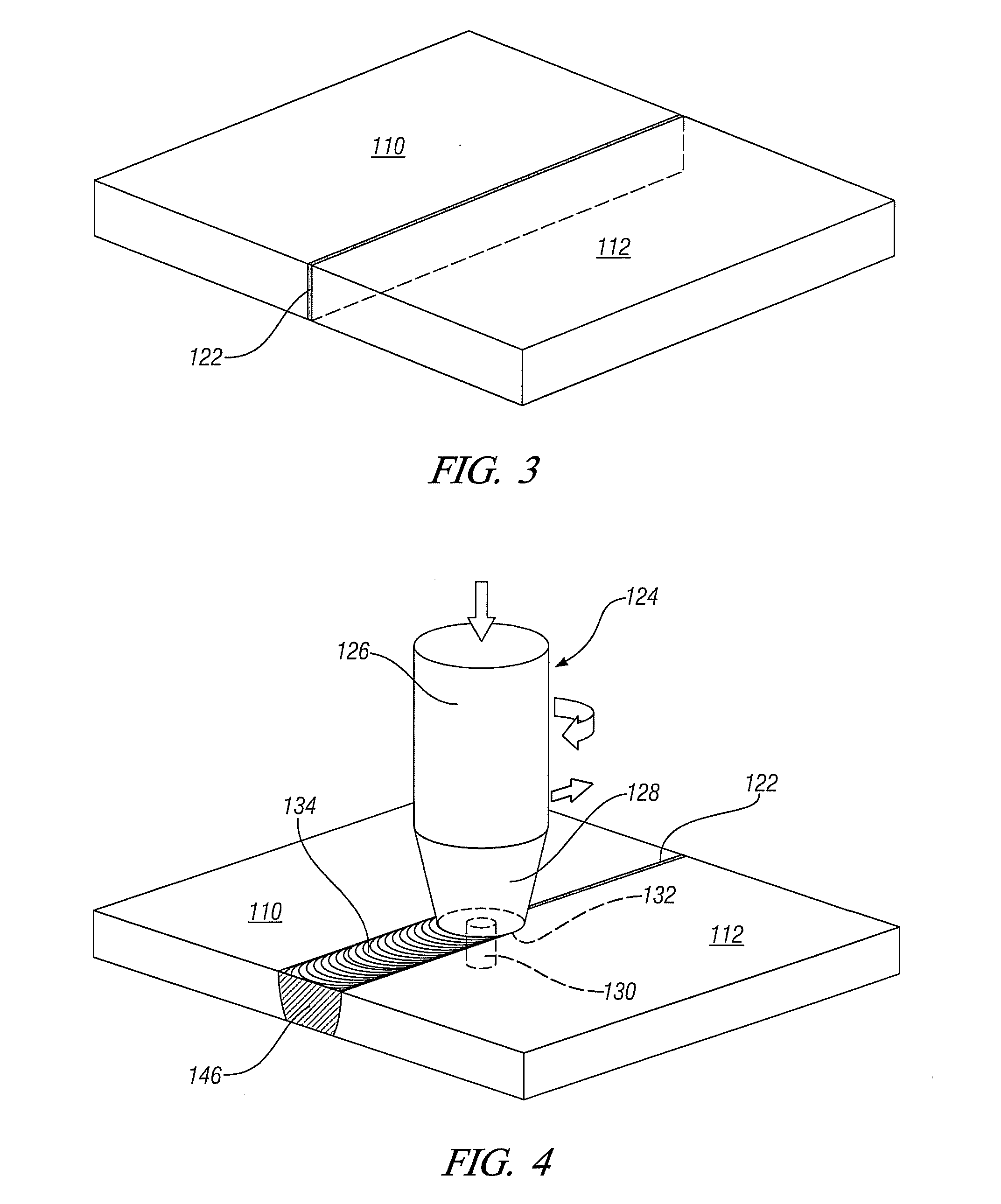

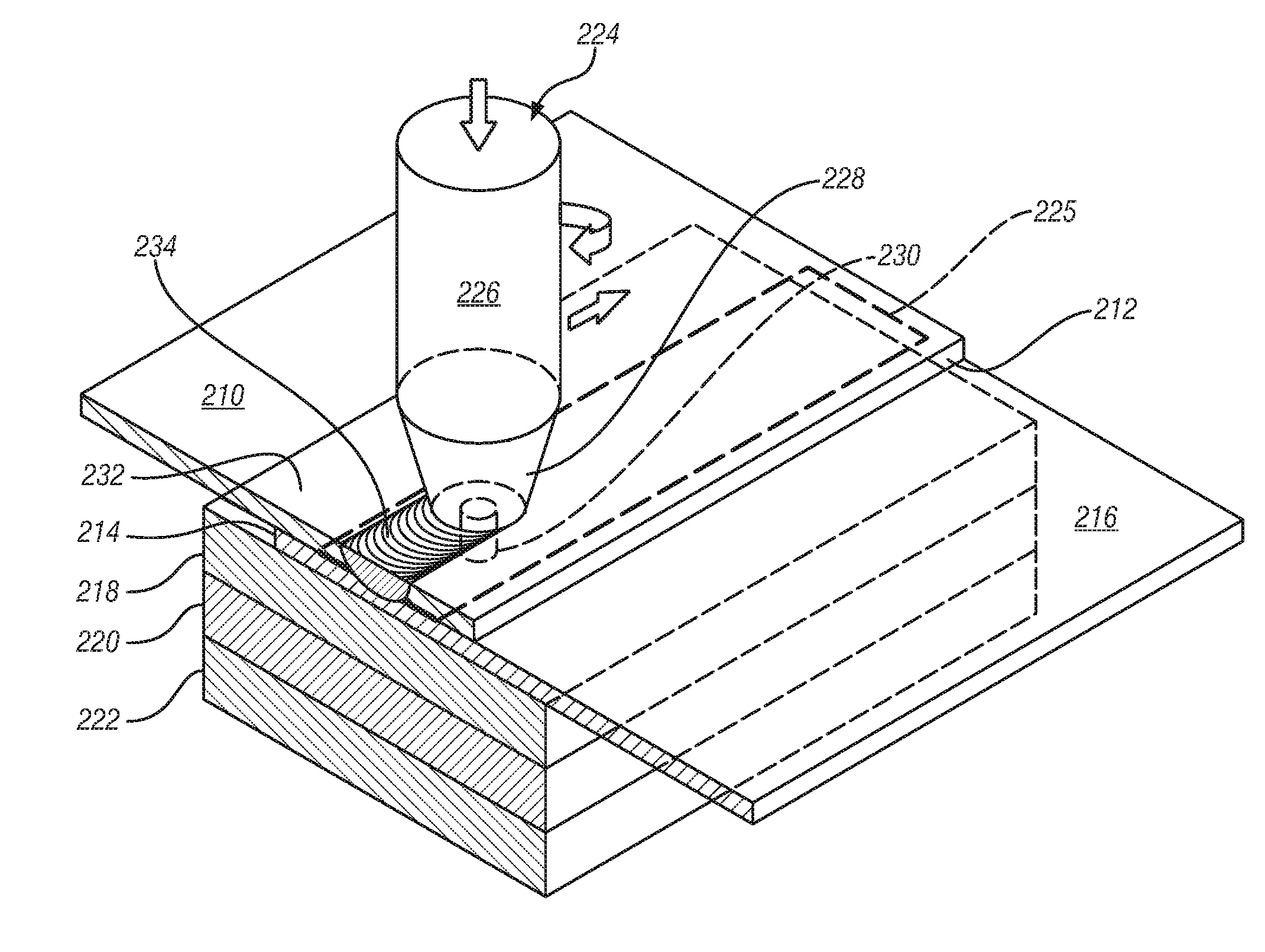

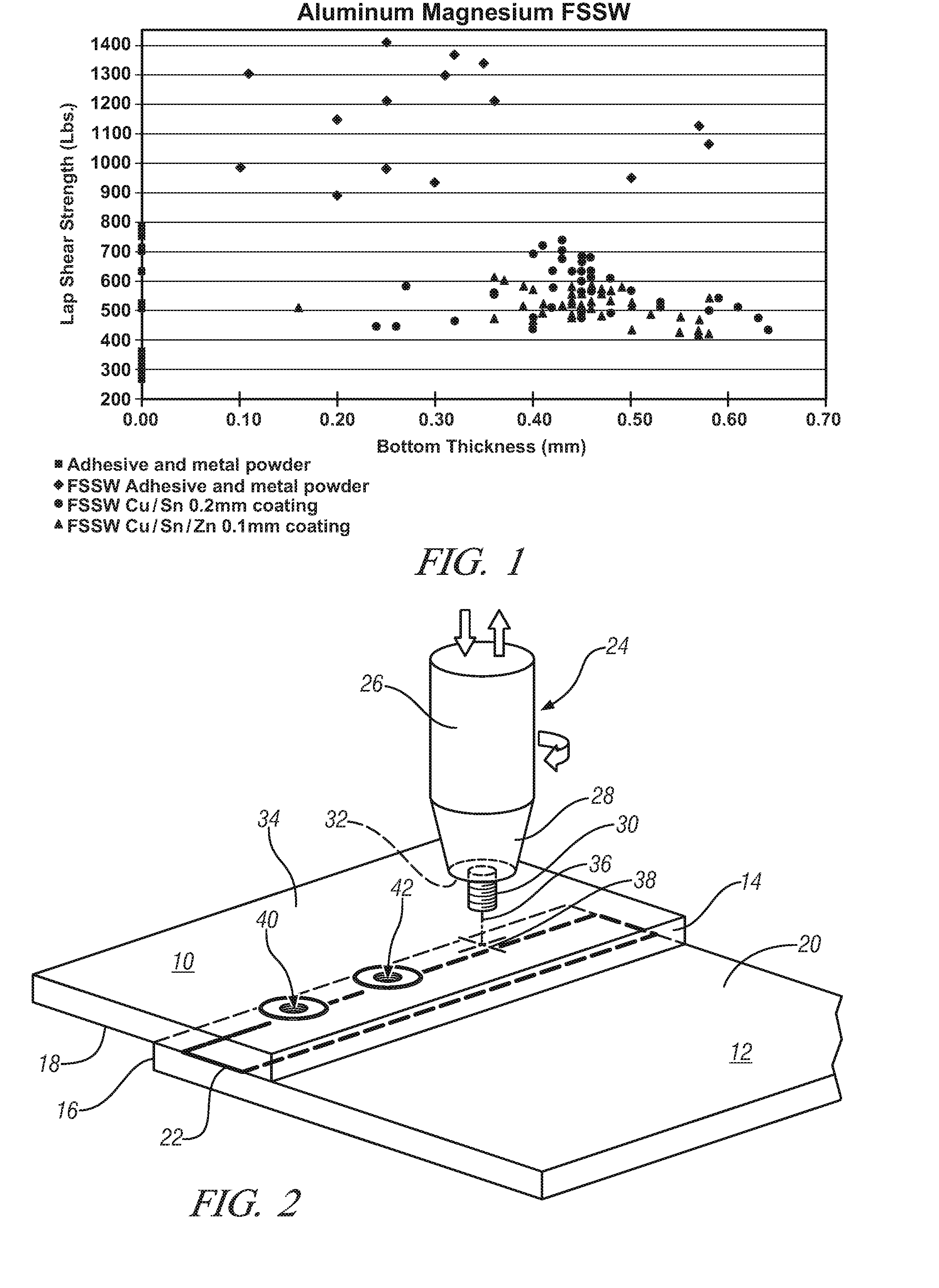

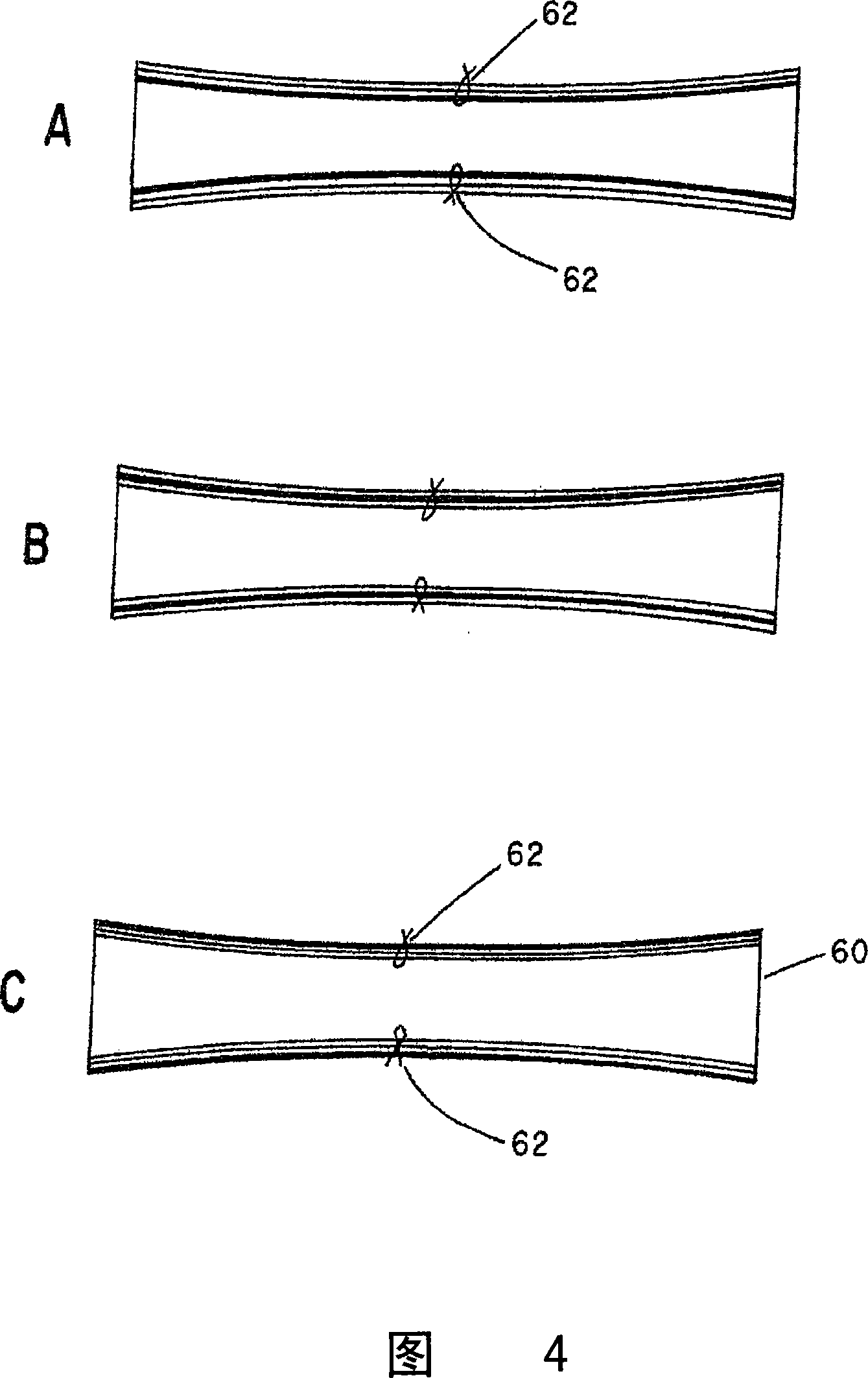

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

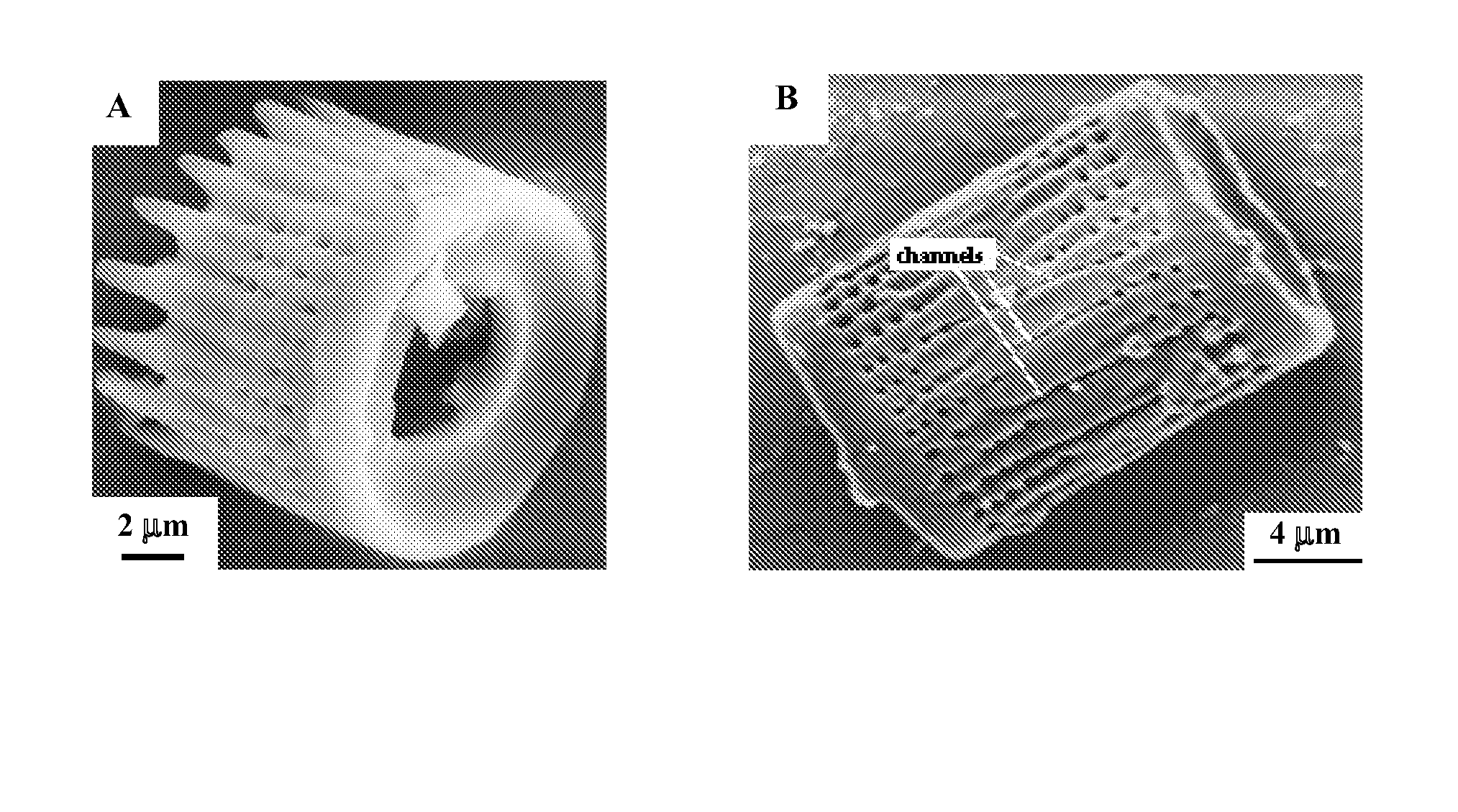

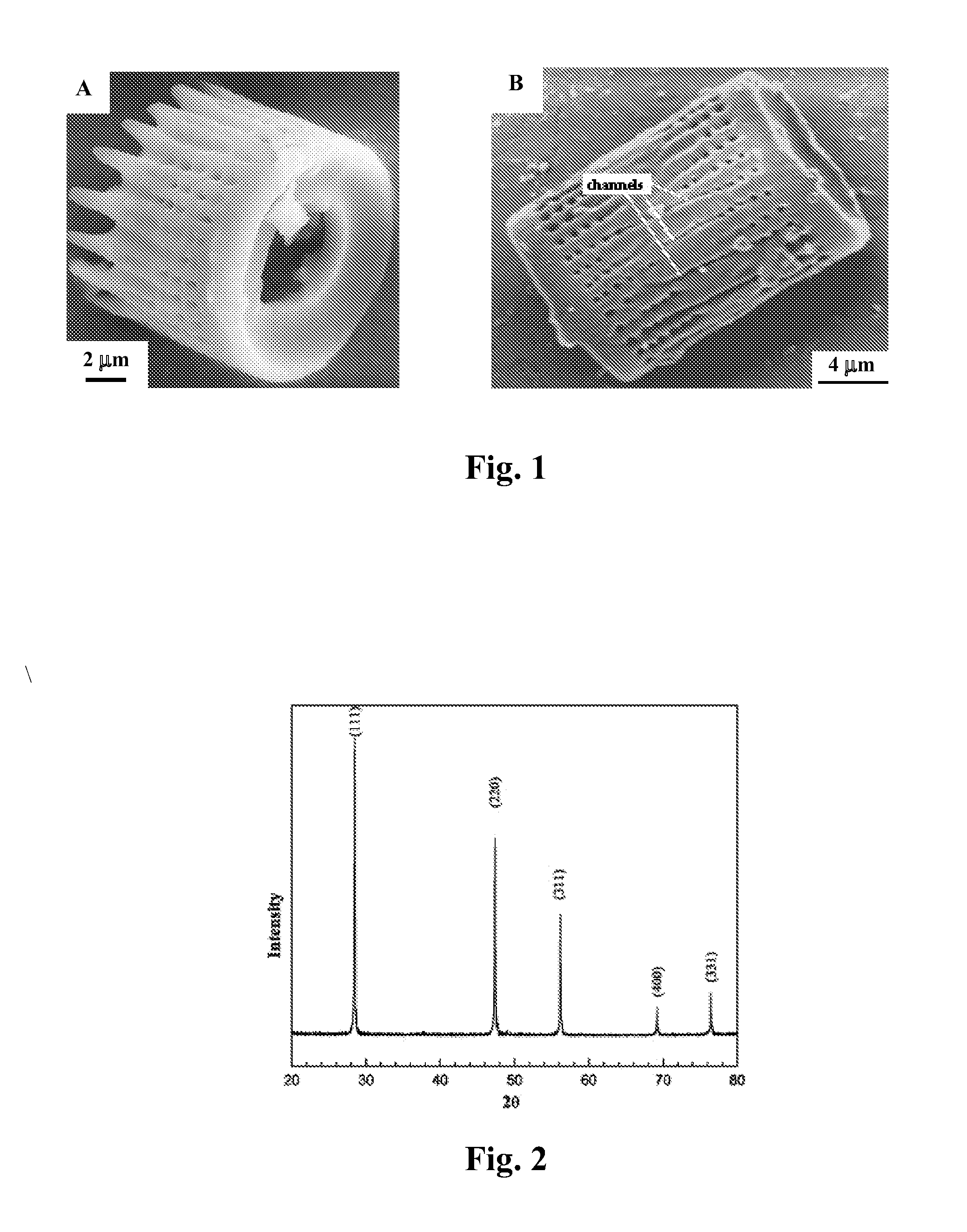

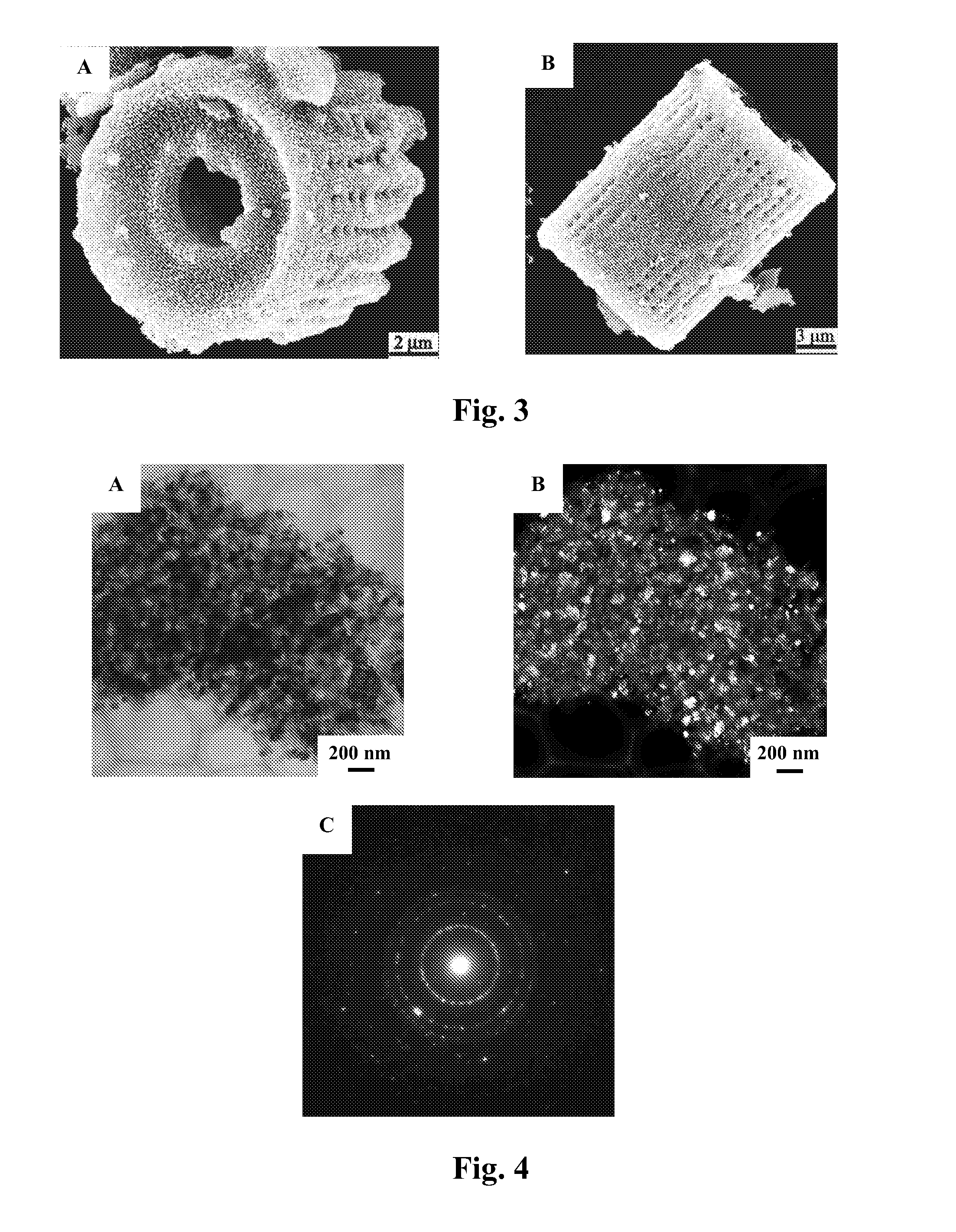

Methods of fabricating nanoscale-to-microscale structures

InactiveUS20080038170A1Attractive and optical propertyAttractive mechanical propertySilicaMixing methodsChemical compositionChemical reaction

Methods for the production of shaped nanoscale-to-microscale structures, wherein a nanoscale-to-microscale template is provided having an original chemical composition and an original shape, and the nanoscale-to-microscale template subjected to a chemical reaction, so as to partially or completely convert the nanoscale-to-microscale template into the shaped nanoscale-to-microscale structure having a chemical composition different than the original chemical composition and having substantially the same shape as the original shape, being a scaled version of the original shape. The shaped nanoscale-to-microscale structure formed comprises an element (such as silicon), a metallic alloy (such as a silicon alloy), or a non-oxide compound (such as silicon carbide or silicon nitride).

Owner:GEORGIA TECH RES CORP

High-throughput printing of semiconductor precursor layer from chalcogenide nanoflake particles

InactiveUS20090107550A1Efficient and simplified creationGood dispersionPigmenting treatmentTransportation and packagingNanoparticleParticle method

Methods and devices are provided for transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after selective forces settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be nanoflakes that have a high aspect ratio. The resulting dense films formed from nanoflakes are particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

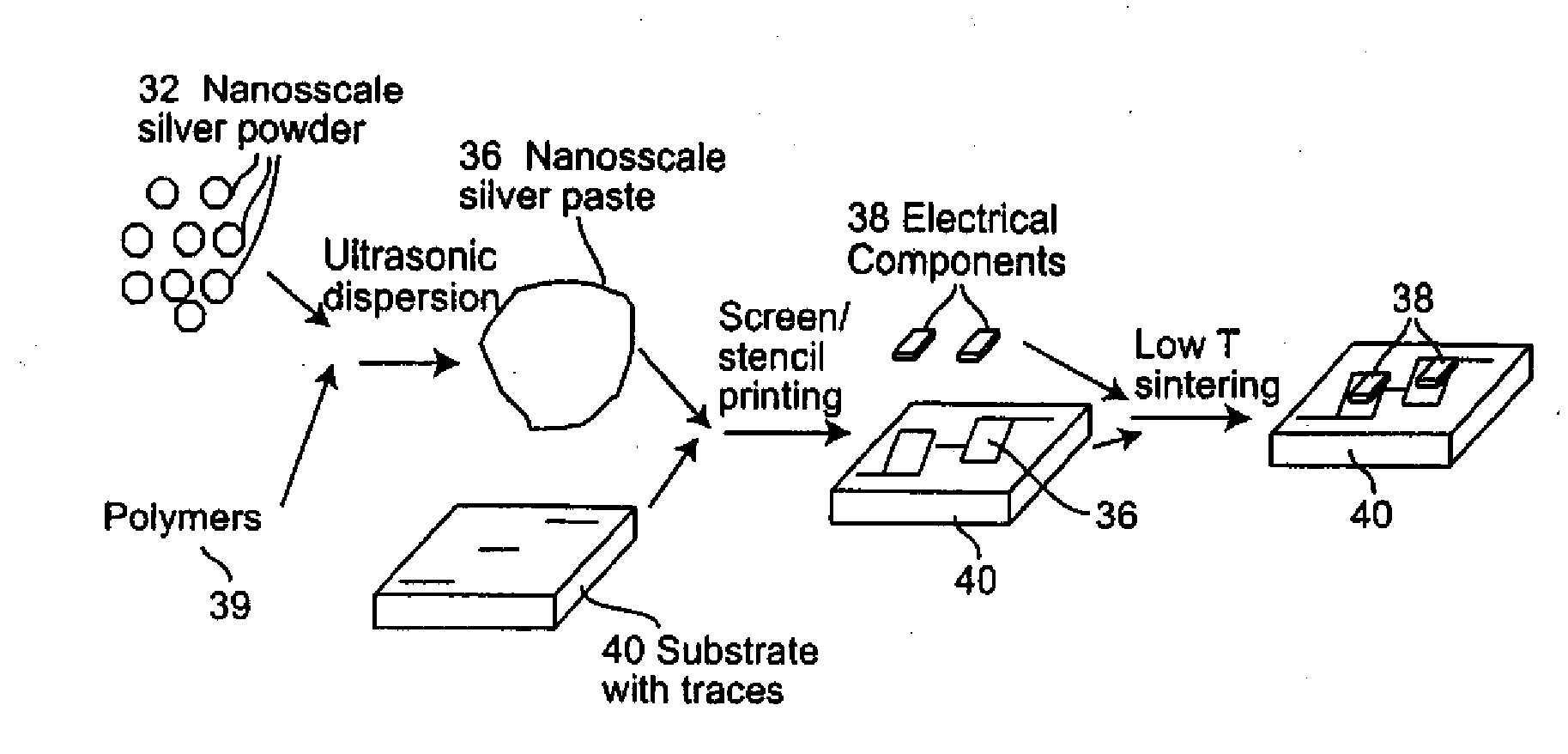

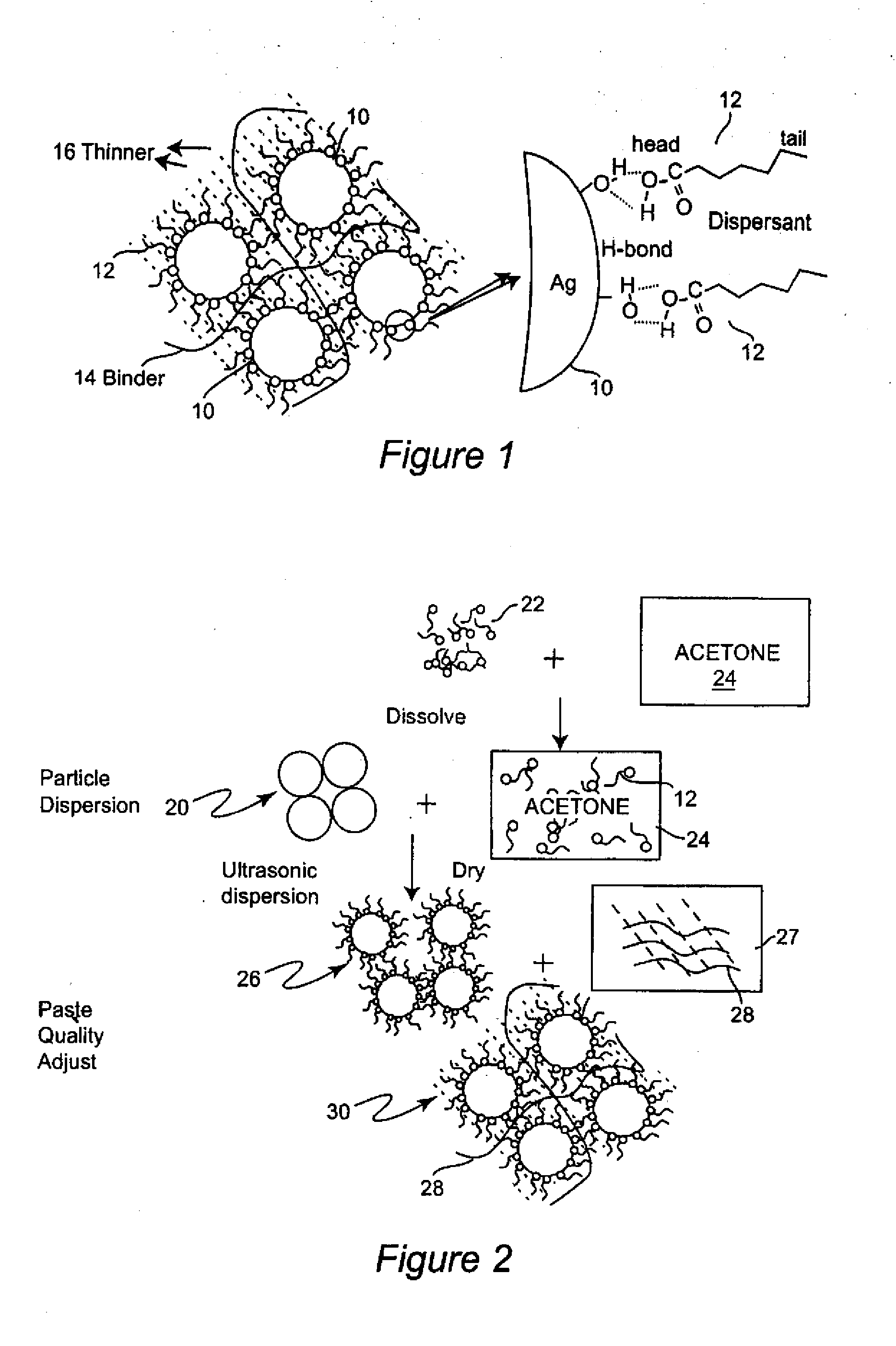

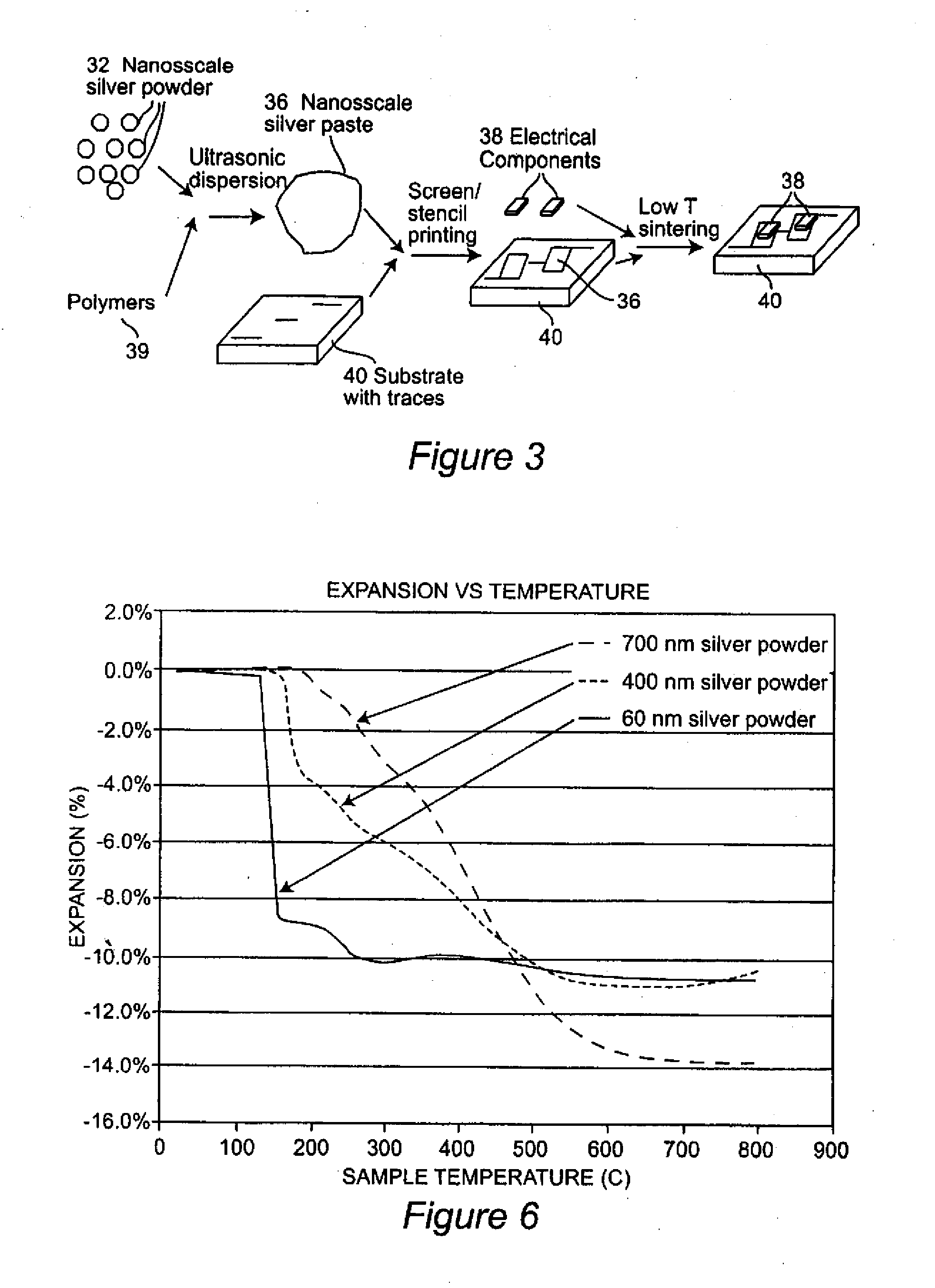

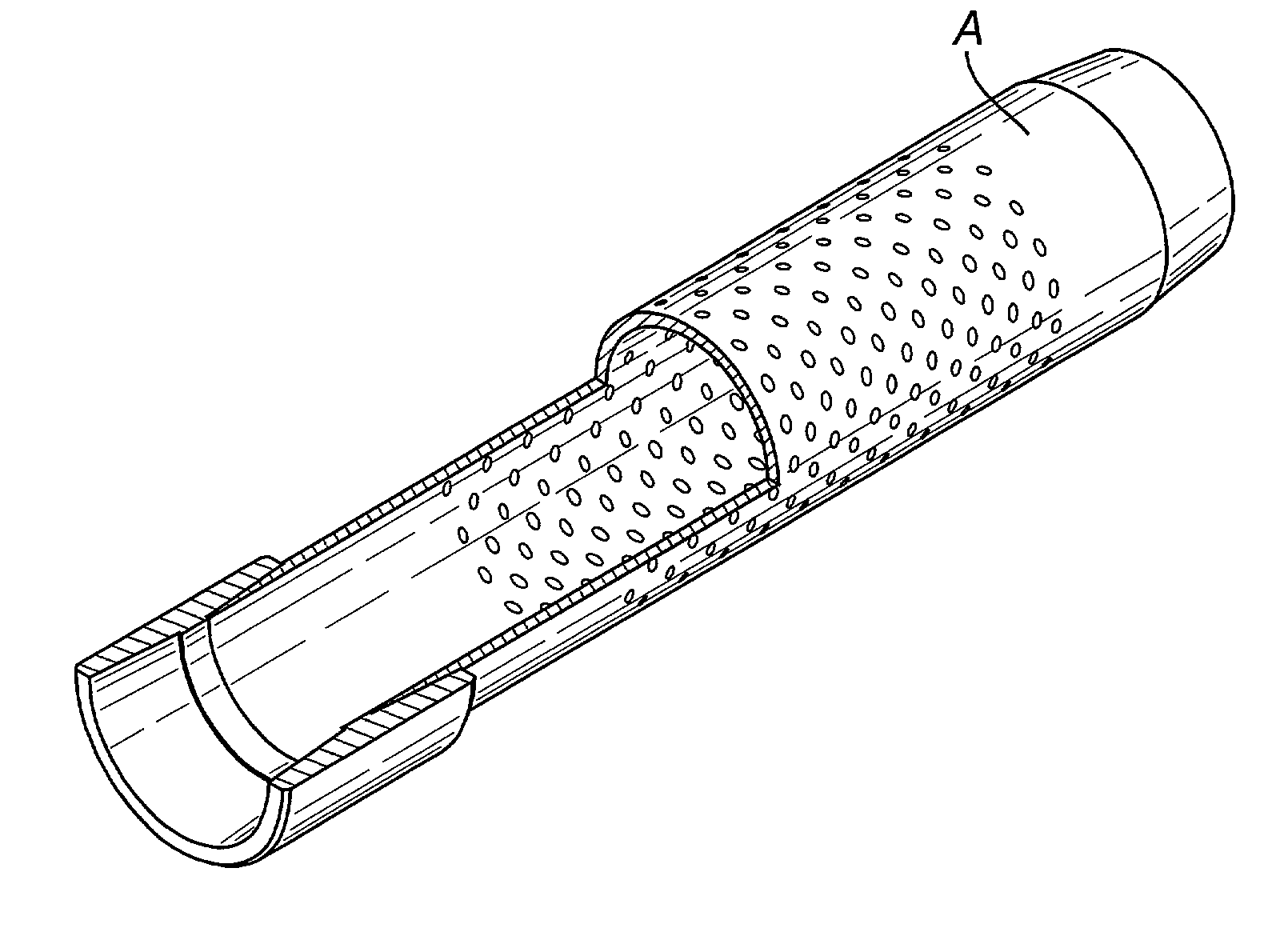

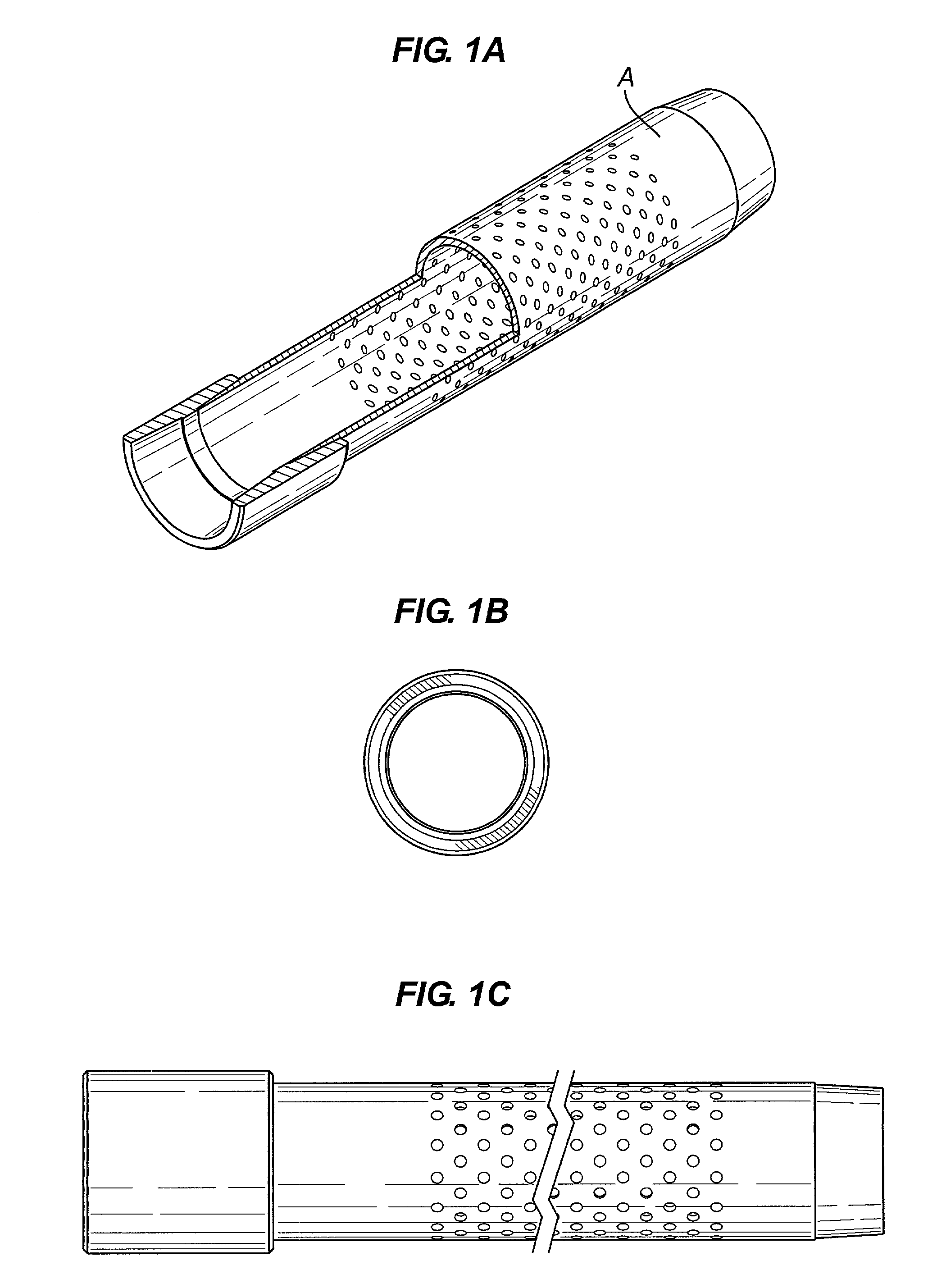

Nanoscale metal paste for interconnect and method of use

ActiveUS20090162557A1Broaden applicationEasy to handleTransportation and packagingPrinted circuit aspectsMicrometerMetal particle

A paste including metal or metal alloy particles (which are preferably silver or silver alloy), a dispersant material, and a binder is used to form an electrical, mechanical or thermal interconnect between a device and a substrate. By using nanoscale particles (i.e., those which are less than 500 nm in size and most preferably less than 100 nm in size), the metal or metal alloy particles can be sintered at a low temperature to form a metal or metal alloy layer which is desired to allow good electrical, thermal and mechanical bonding, yet the metal or metal alloy layer can enable usage at a high temperature such as would be desired for SiC, GaN, or diamond (e.g., wide bandgap devices). Furthermore, significant application of pressure to form the densified layers is not required, as would be the case with micrometer sized particles. In addition, the binder can be varied so as to insulate the metal particles until a desired sintering temperature is reached; thereby permitting fast and complete sintering to be achieved.

Owner:VIRGINIA TECH INTPROP INC

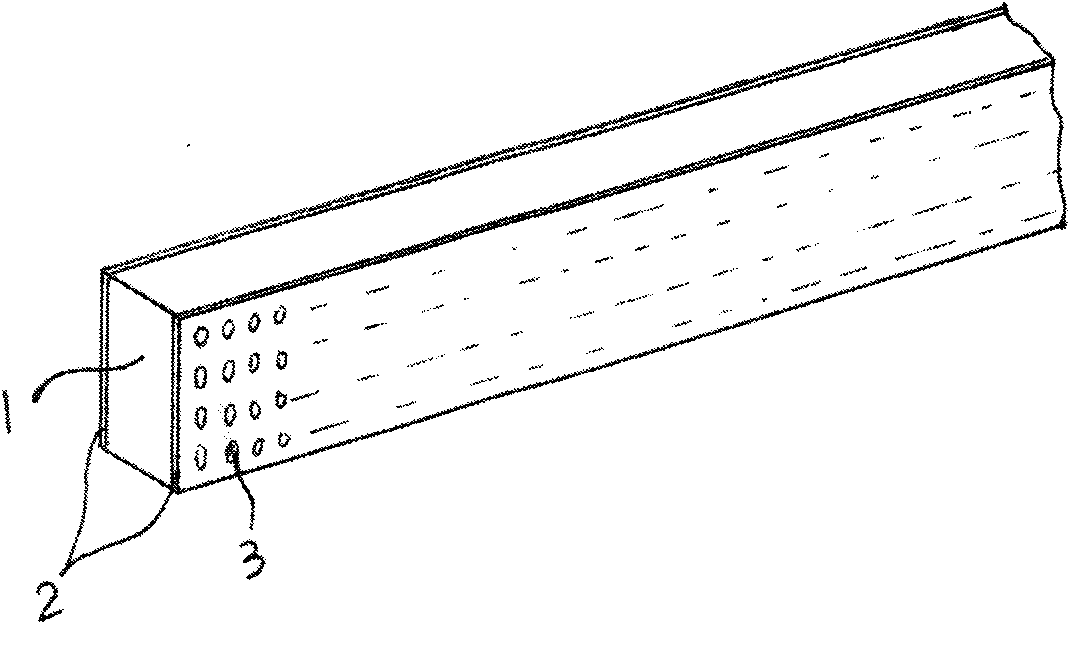

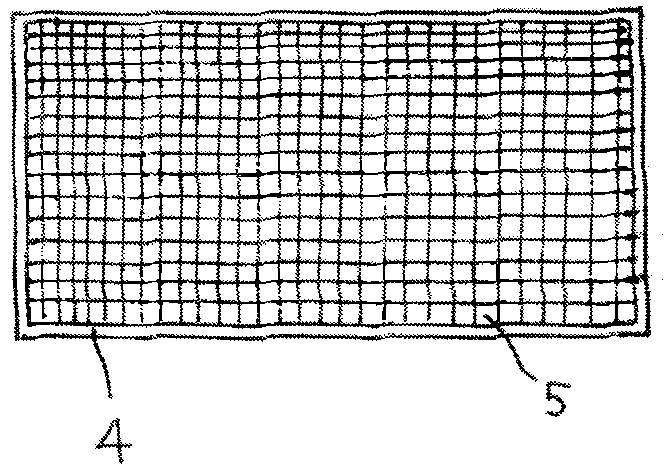

Knitted wire fines discriminator

InactiveUS20030173075A1Reduce riskReduce erosion damageFluid removalDrinking water installationDiscriminatorTerrain

Particularly, the knitted wire fluid / gas energy absorber and fines discriminator is designed to provide significantly, enhanced erosion resistance and durability through absorbing energy from fluid moving at elevated and erosive velocities through an energy absorbing and flexible structure, providing also a tortuous path for the fluid / gas, thereby, reducing the risk of sand production and sub terrain erosion damage to tubulars. The wire used for the knitted wire fluid / gas energy absorber and fines discriminator may be made from a range of different materials which possess the desired combination of properties required for this process, and lend themselves to knitting, may be compressed, exhibit desired mechanical strength and flex. Such materials may be: Stainless steel of various grades, metallic alloys of various kinds, (zinc, copper etc), wire made of various fibers such as Kevlar, Aramid and a range of other suitable materials.

Owner:MORVANT DAVE +1

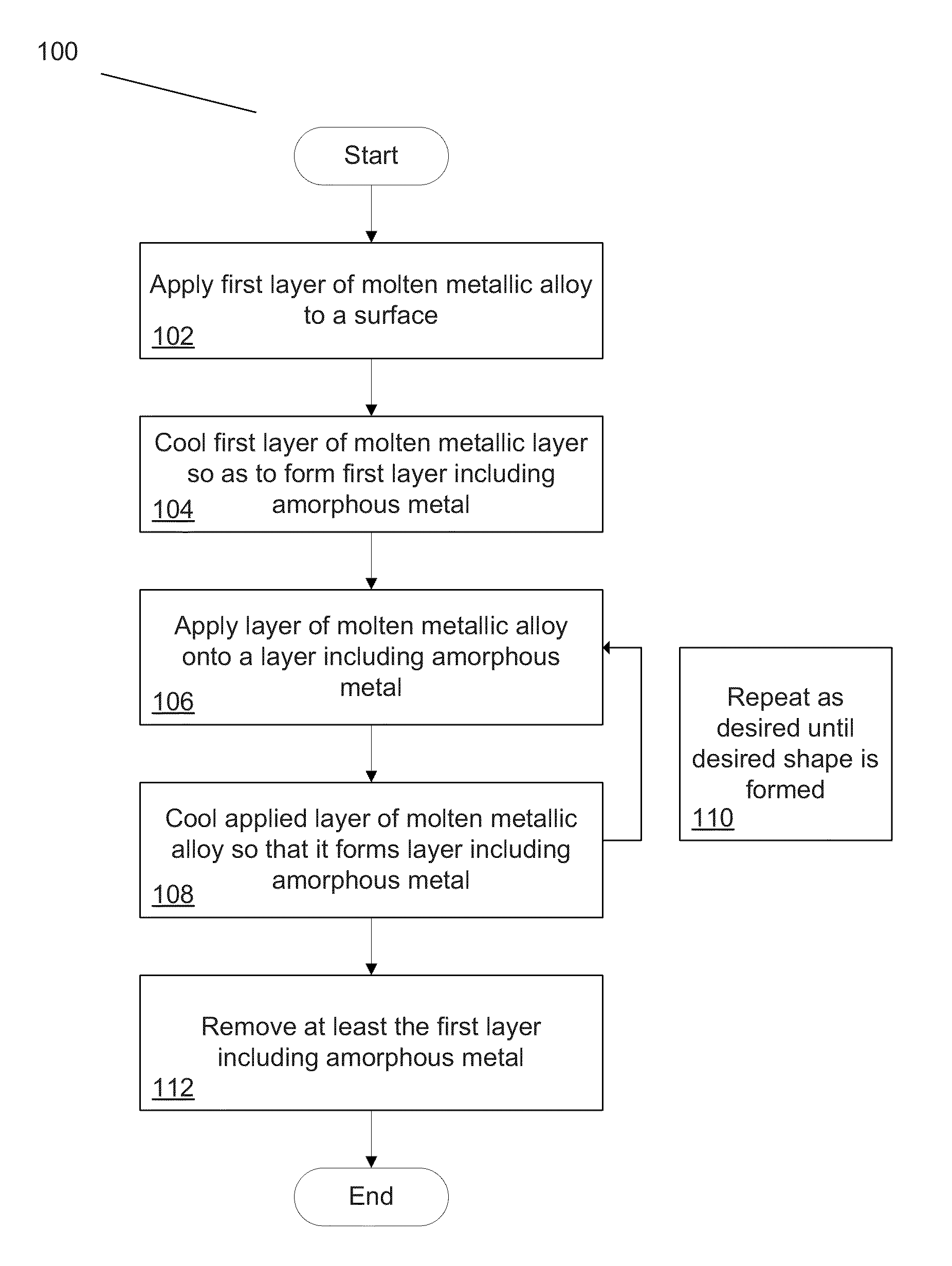

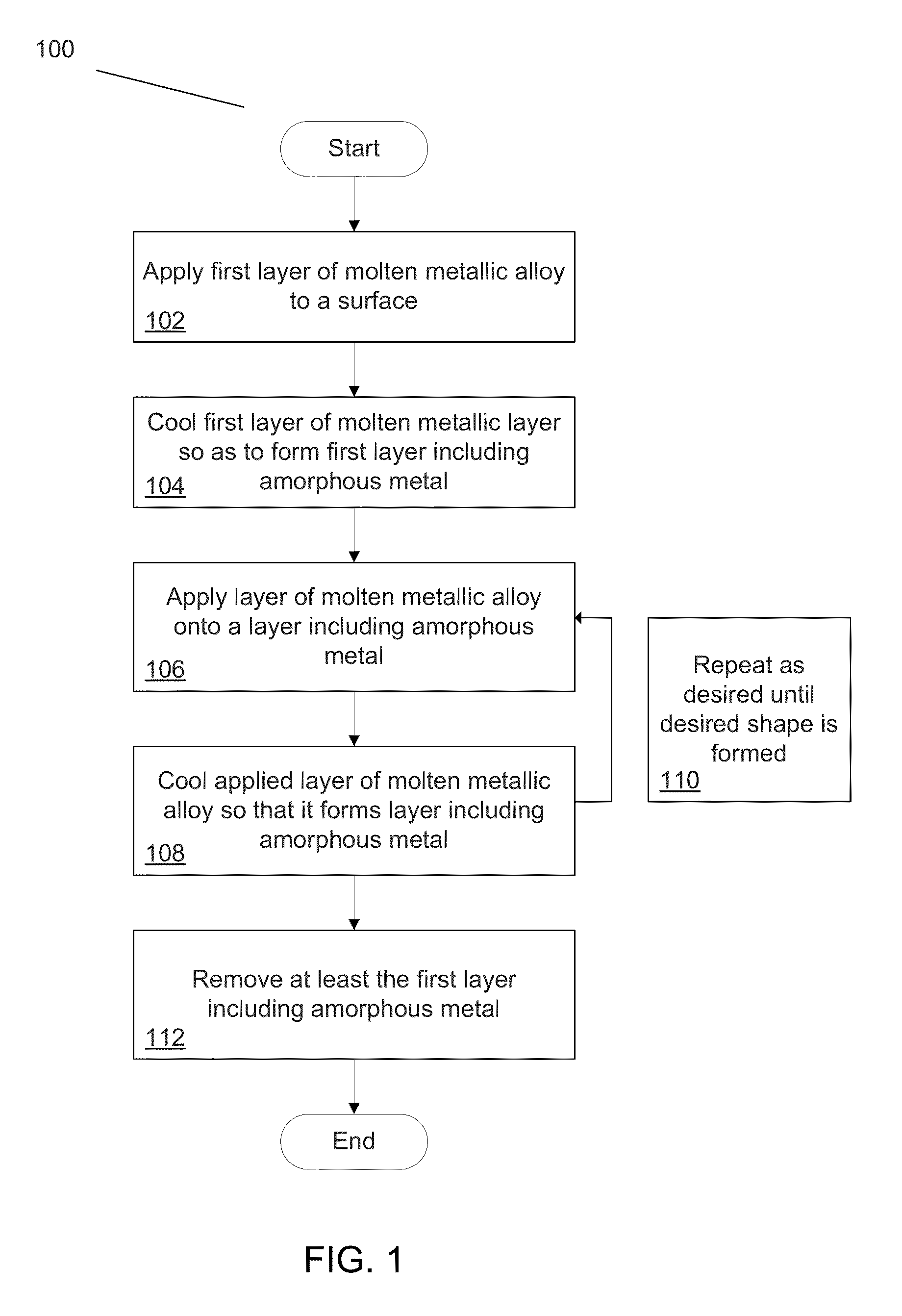

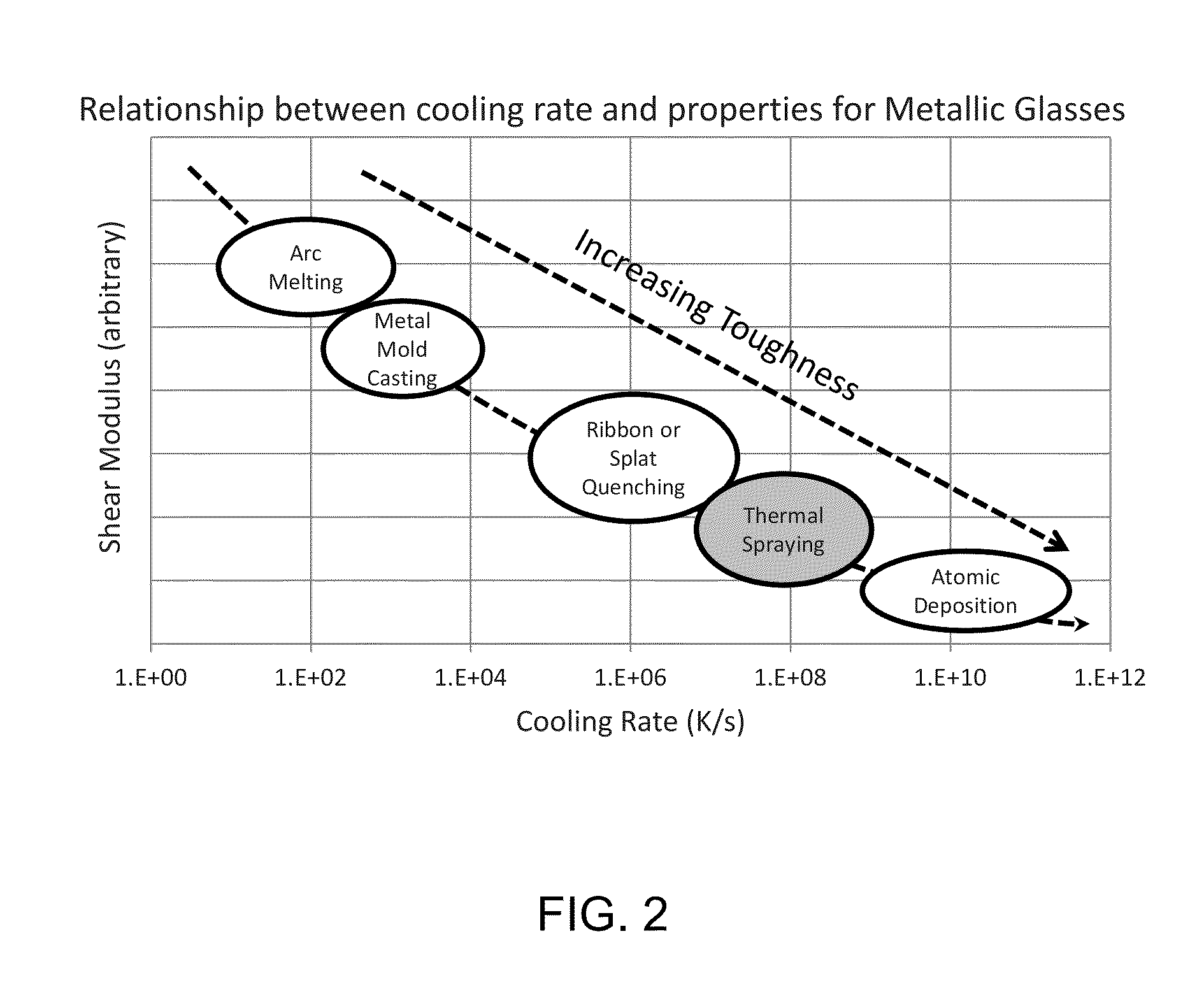

Systems and methods for fabricating objects including amorphous metal using techniques akin to additive manufacturing

ActiveUS20140202595A1Additive manufacturing apparatusMolten spray coatingLaser additive manufacturingAmorphous metal

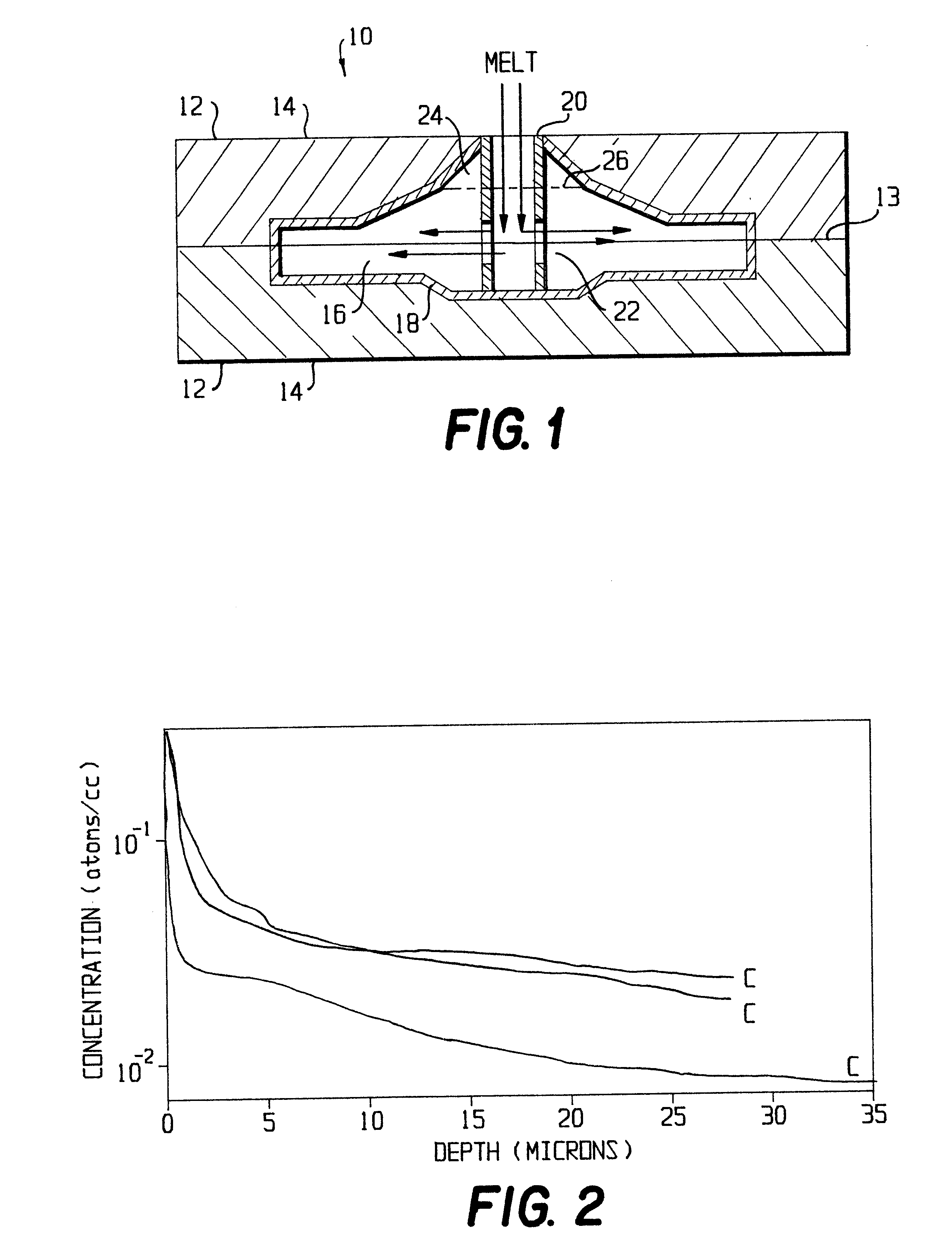

Systems and methods in accordance with embodiments of the invention fabricate objects including amorphous metals using techniques akin to additive manufacturing. In one embodiment, a method of fabricating an object that includes an amorphous metal includes: applying a first layer of molten metallic alloy to a surface; cooling the first layer of molten metallic alloy such that it solidifies and thereby forms a first layer including amorphous metal; subsequently applying at least one layer of molten metallic alloy onto a layer including amorphous metal; cooling each subsequently applied layer of molten metallic alloy such that it solidifies and thereby forms a layer including amorphous metal prior to the application of any adjacent layer of molten metallic alloy; where the aggregate of the solidified layers including amorphous metal forms a desired shape in the object to be fabricated; and removing at least the first layer including amorphous metal from the surface.

Owner:CALIFORNIA INST OF TECH

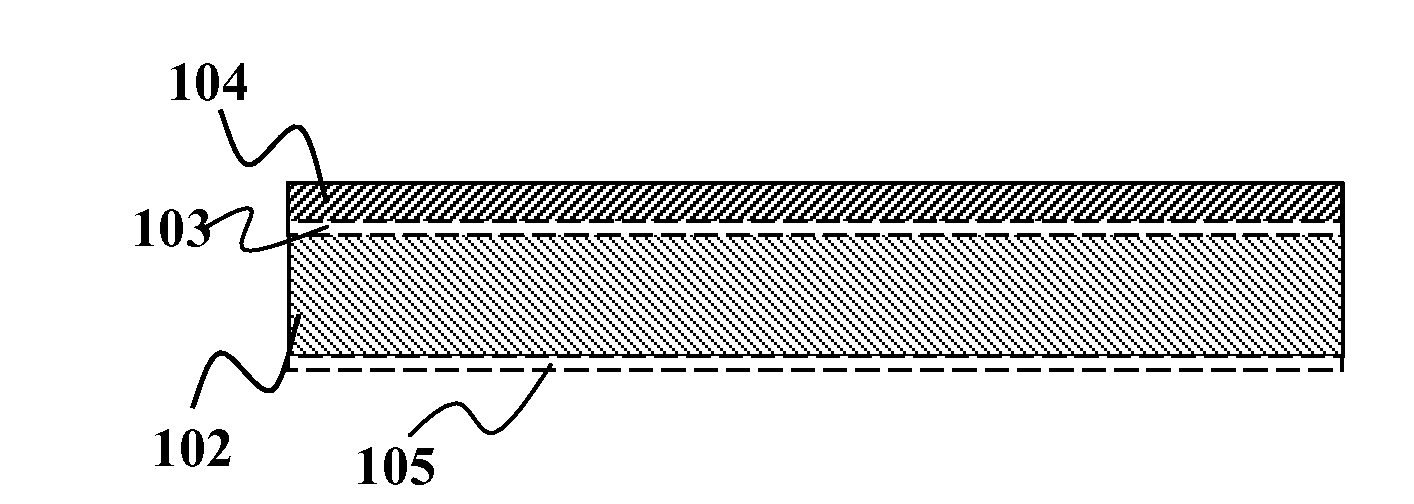

High-throughput printing of semiconductor precursor layer from inter-metallic nanoflake particles

InactiveUS20070163641A1Increase contactReduce the temperatureLiquid/solution decomposition chemical coatingPhotovoltaic energy generationNanoparticleParticle method

Methods and devices are provided for transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after selective forces settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be nanoflakes that have a high aspect ratio. The resulting dense films formed from nanoflakes are particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

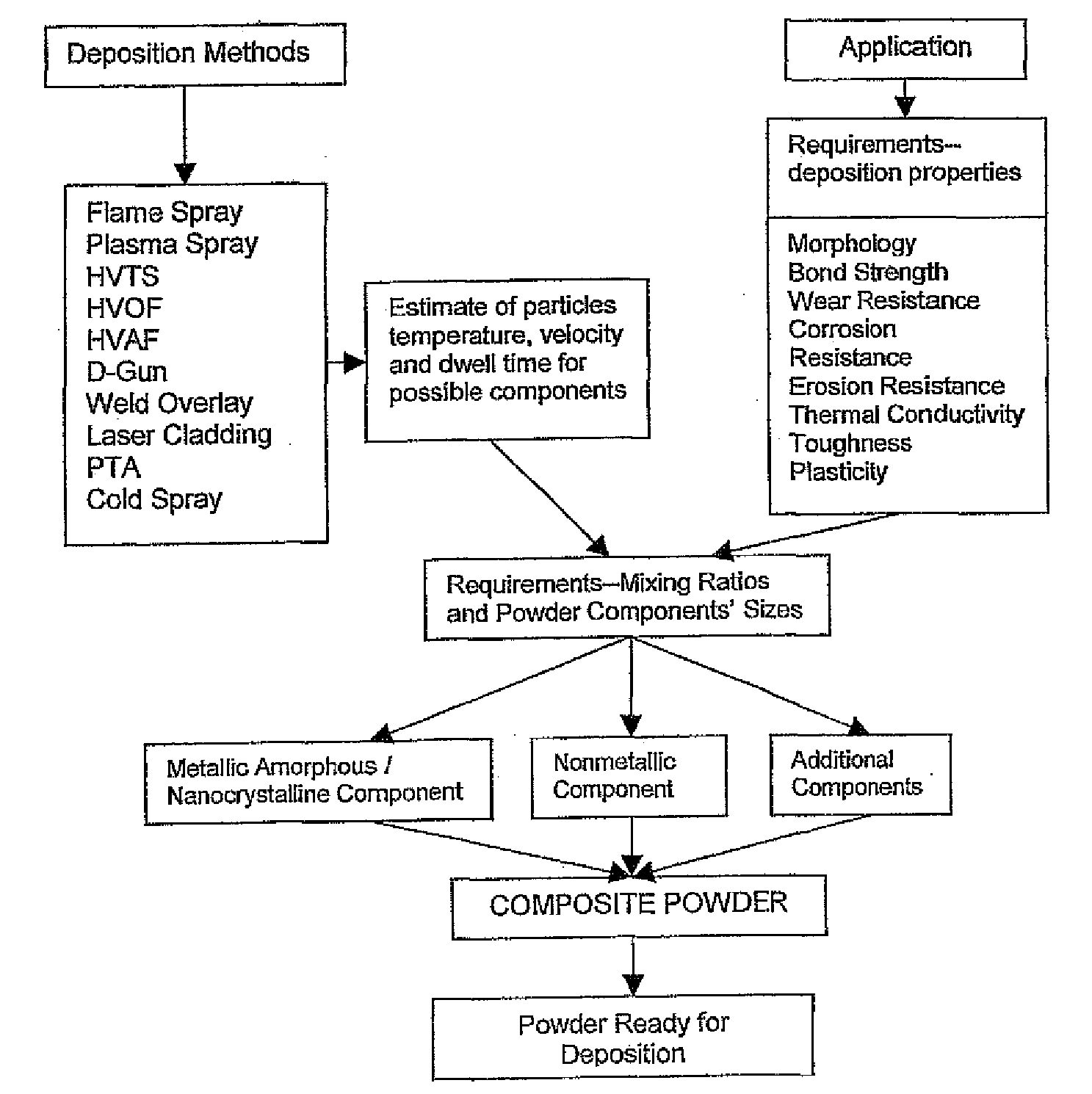

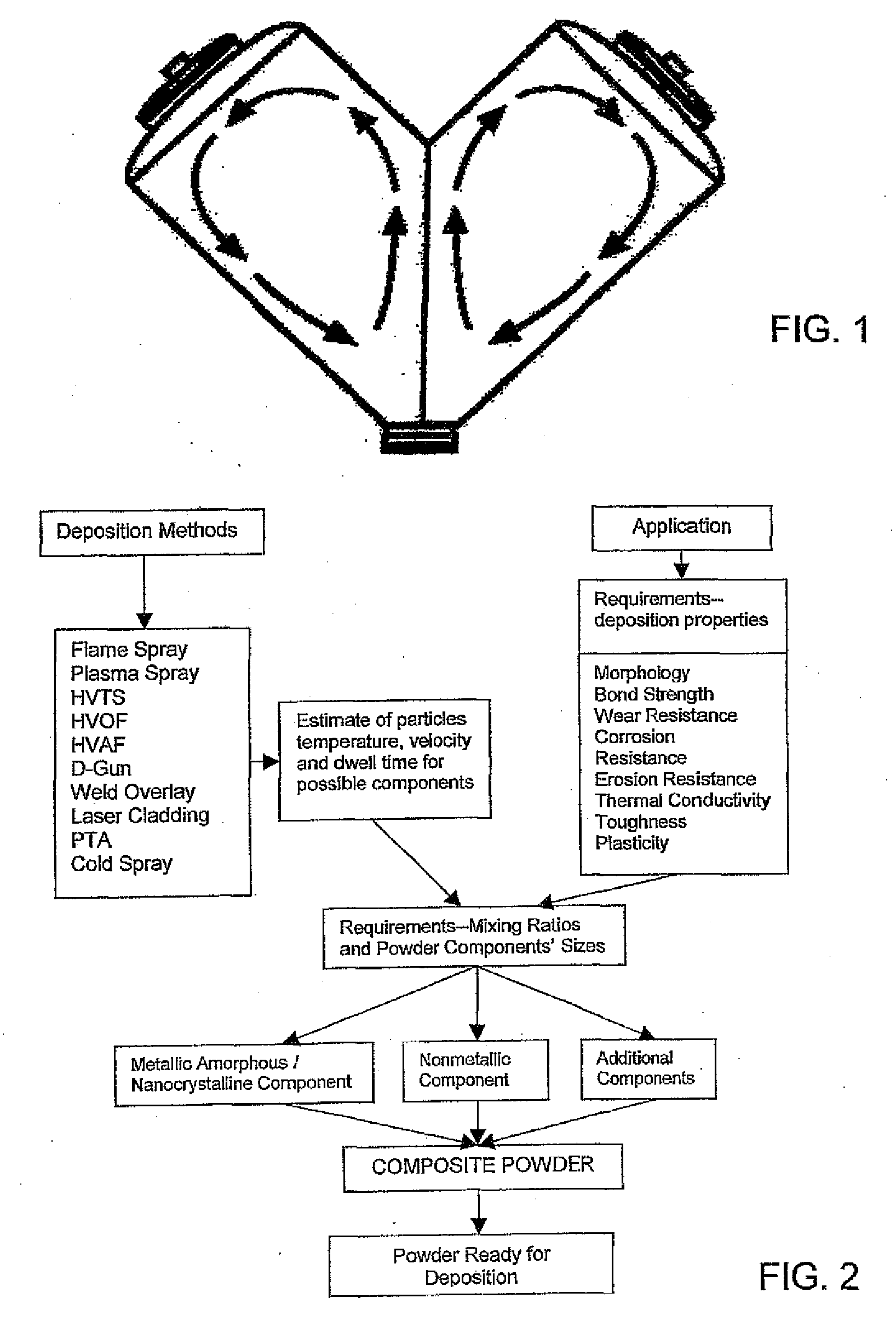

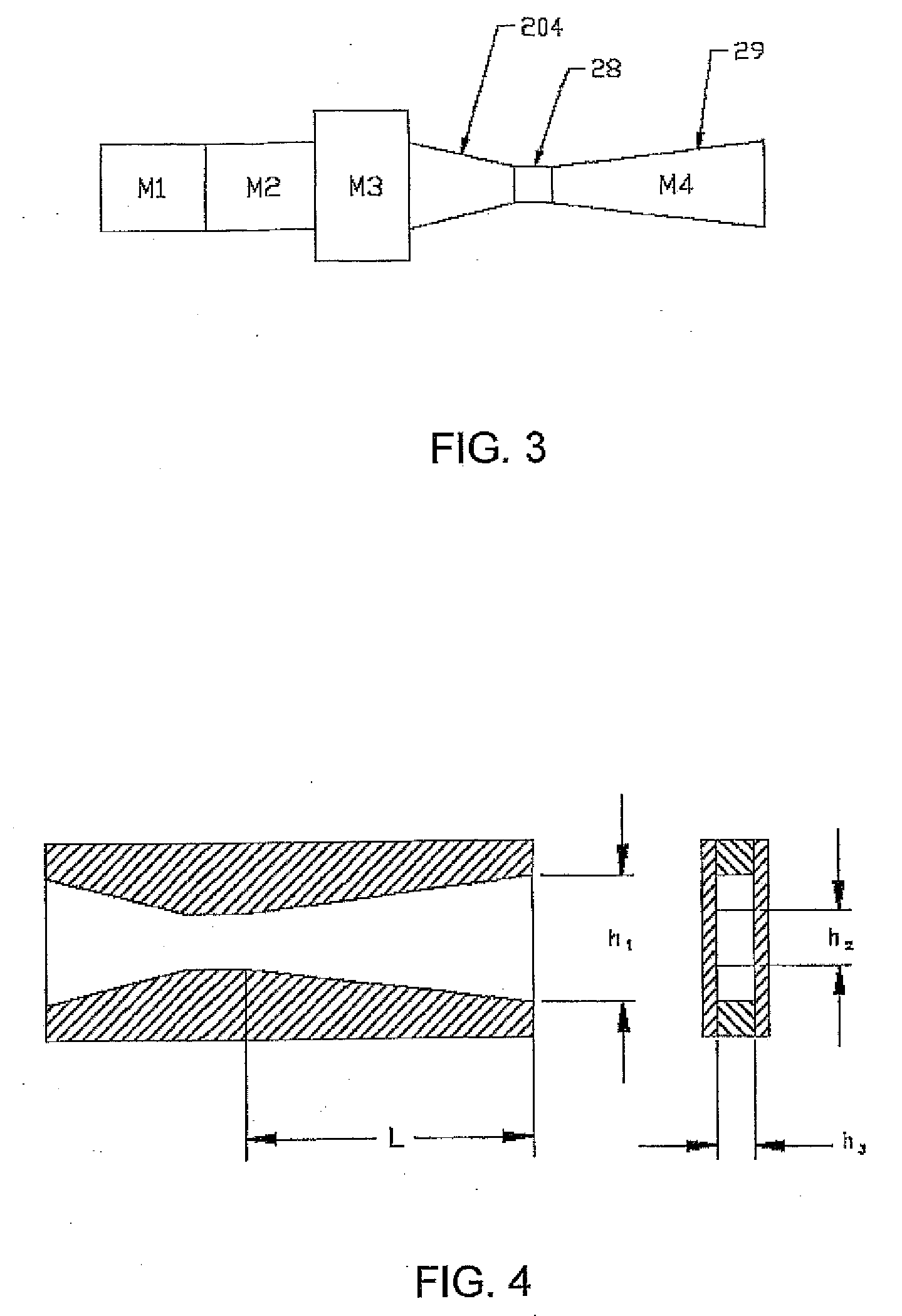

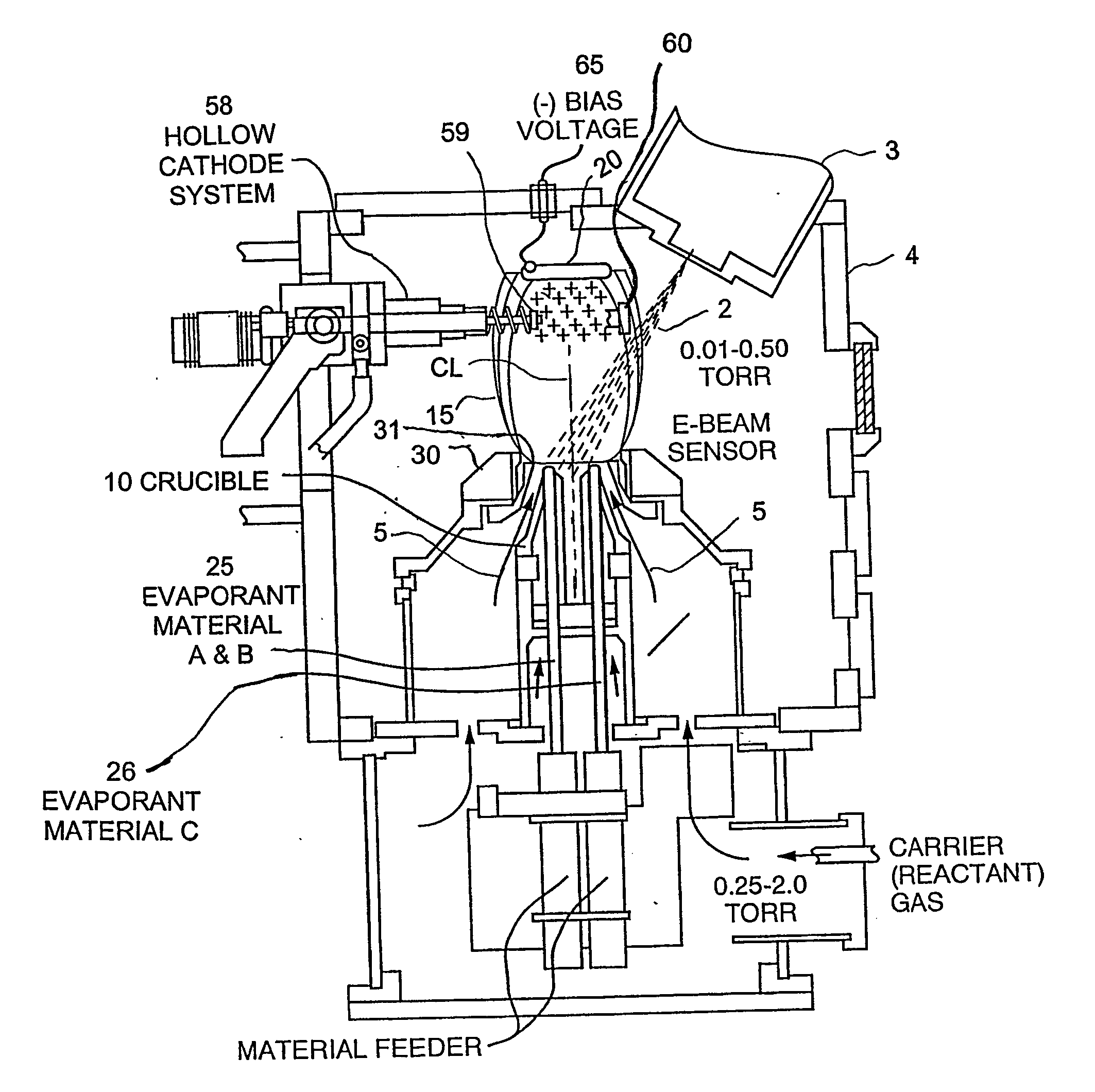

Deposition System, Method And Materials For Composite Coatings

InactiveUS20070243335A1Improve corrosion resistanceImprove structural performanceMolten spray coatingMetal-working apparatusHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

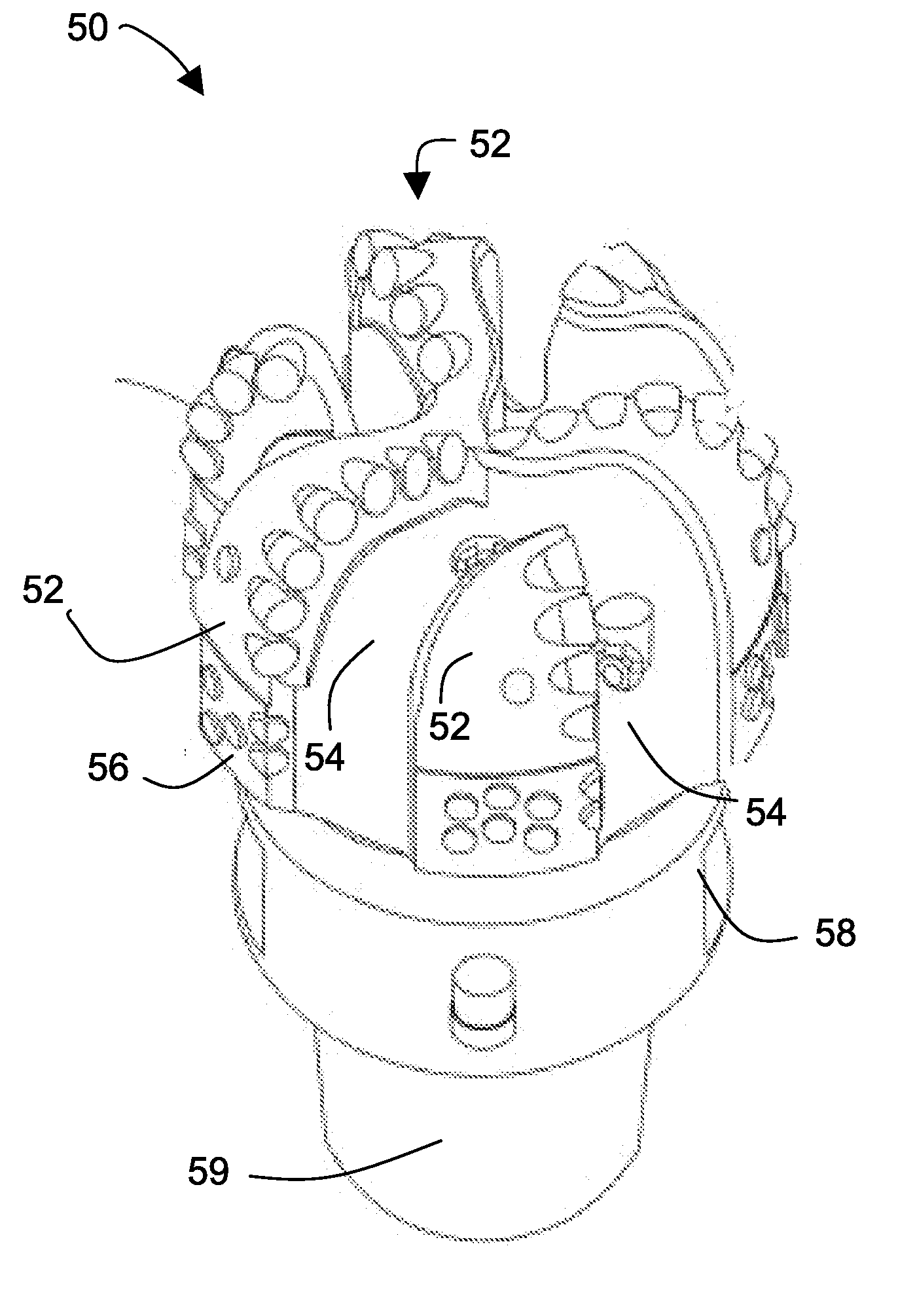

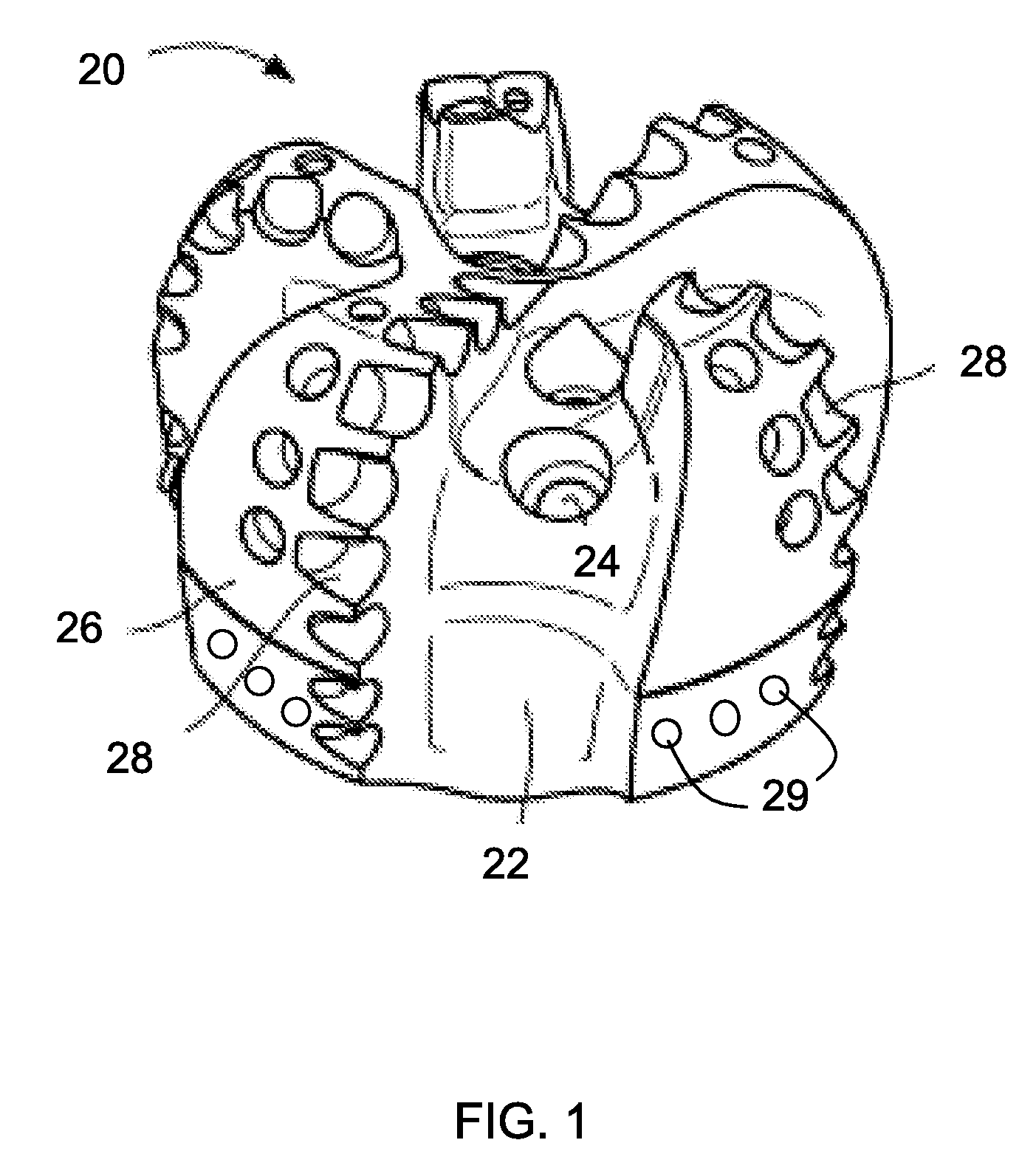

Earth-boring bits and other parts including cemented carbide

An article of manufacture includes a cemented carbide piece, and a joining phase that binds the cemented carbide piece into the article. The joining phase includes inorganic particles and a matrix material. The matrix material is a metal and a metallic alloy. The melting temperature of the inorganic particles is higher than the melting temperature of the matrix material. A method includes infiltrating the space between the inorganic particles and the cemented carbide piece with a molten metal or metal alloy followed by solidification of the metal or metal alloy to form an article of manufacture.

Owner:KENNAMETAL INC

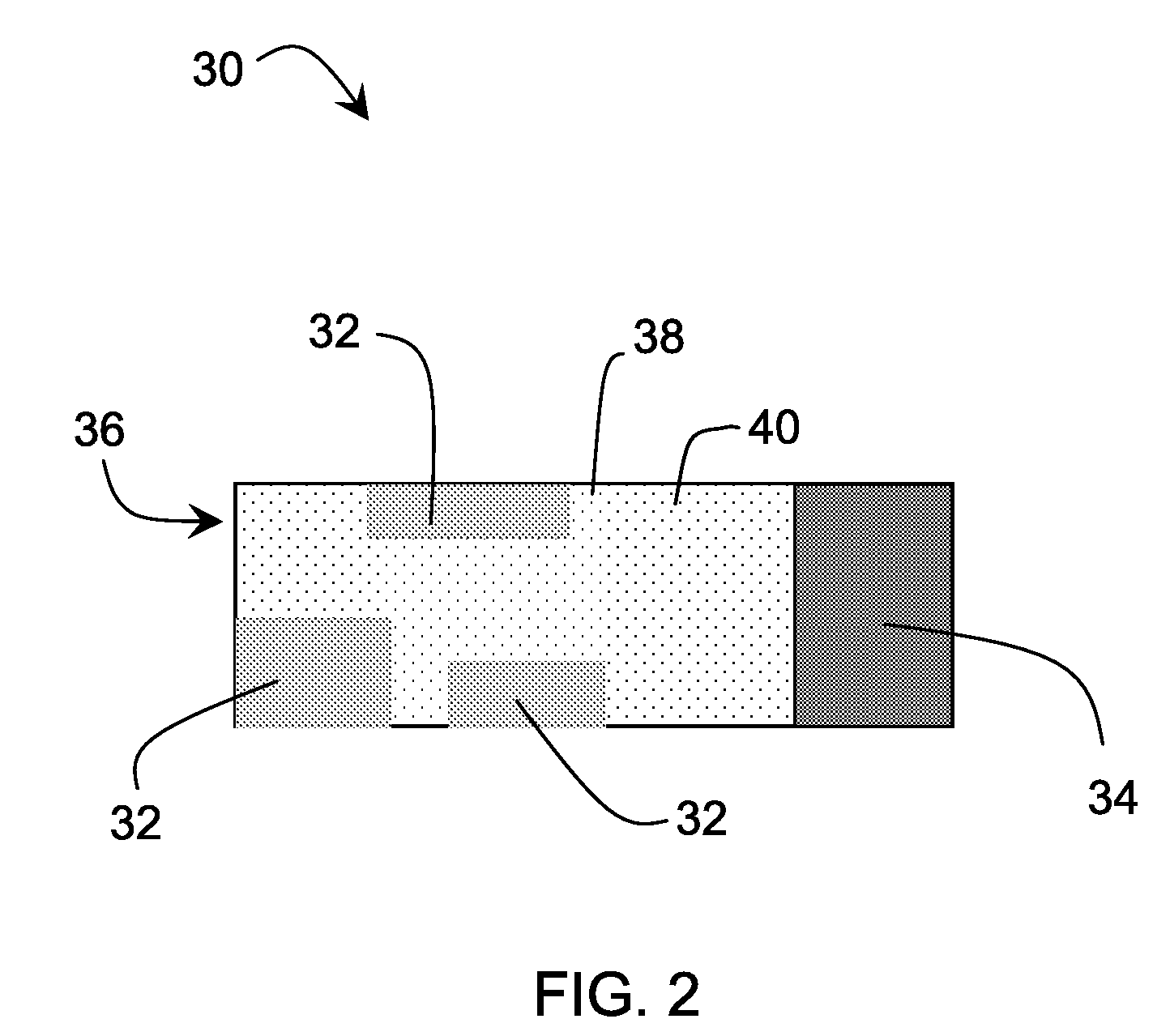

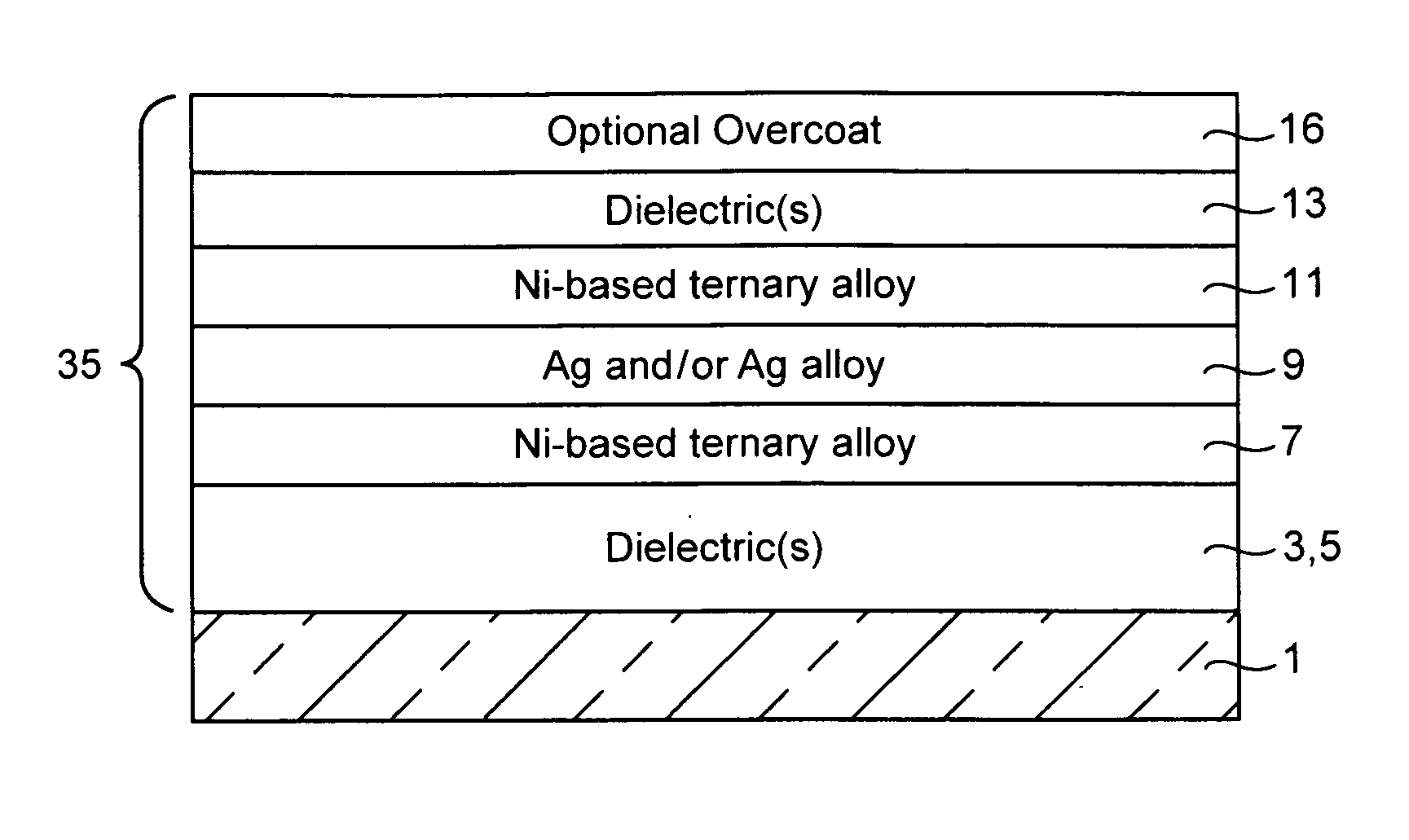

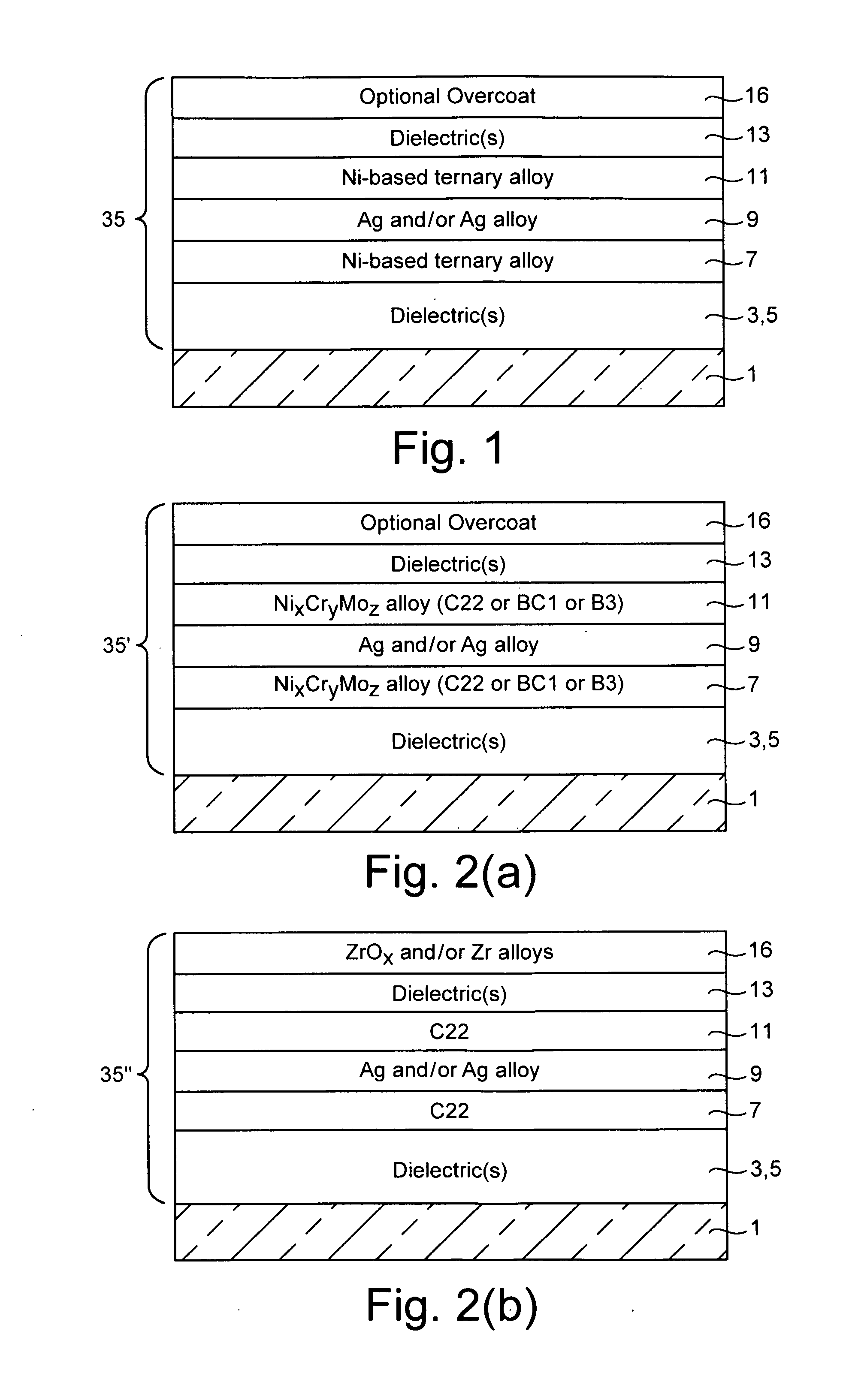

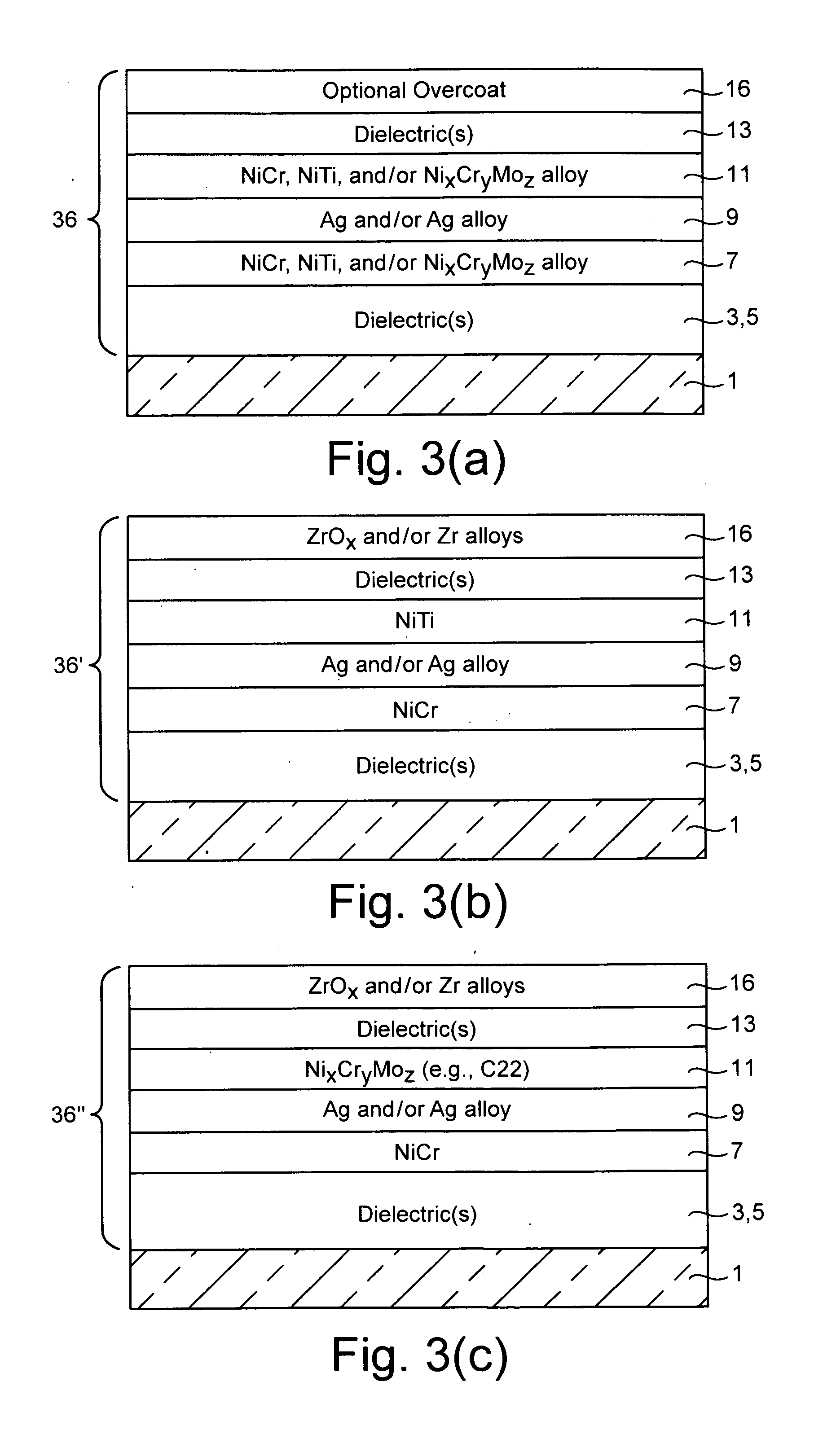

Barrier layers comprising NI-inclusive alloys and/or other metallic alloys, double barrier layers, coated articles including double barrier layers, and methods of making the same

InactiveUS20120225304A1Reduce sheet resistanceImprove transmittanceLight protection screensGlass/slag layered productsDouble barrierMetallic Nickel

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

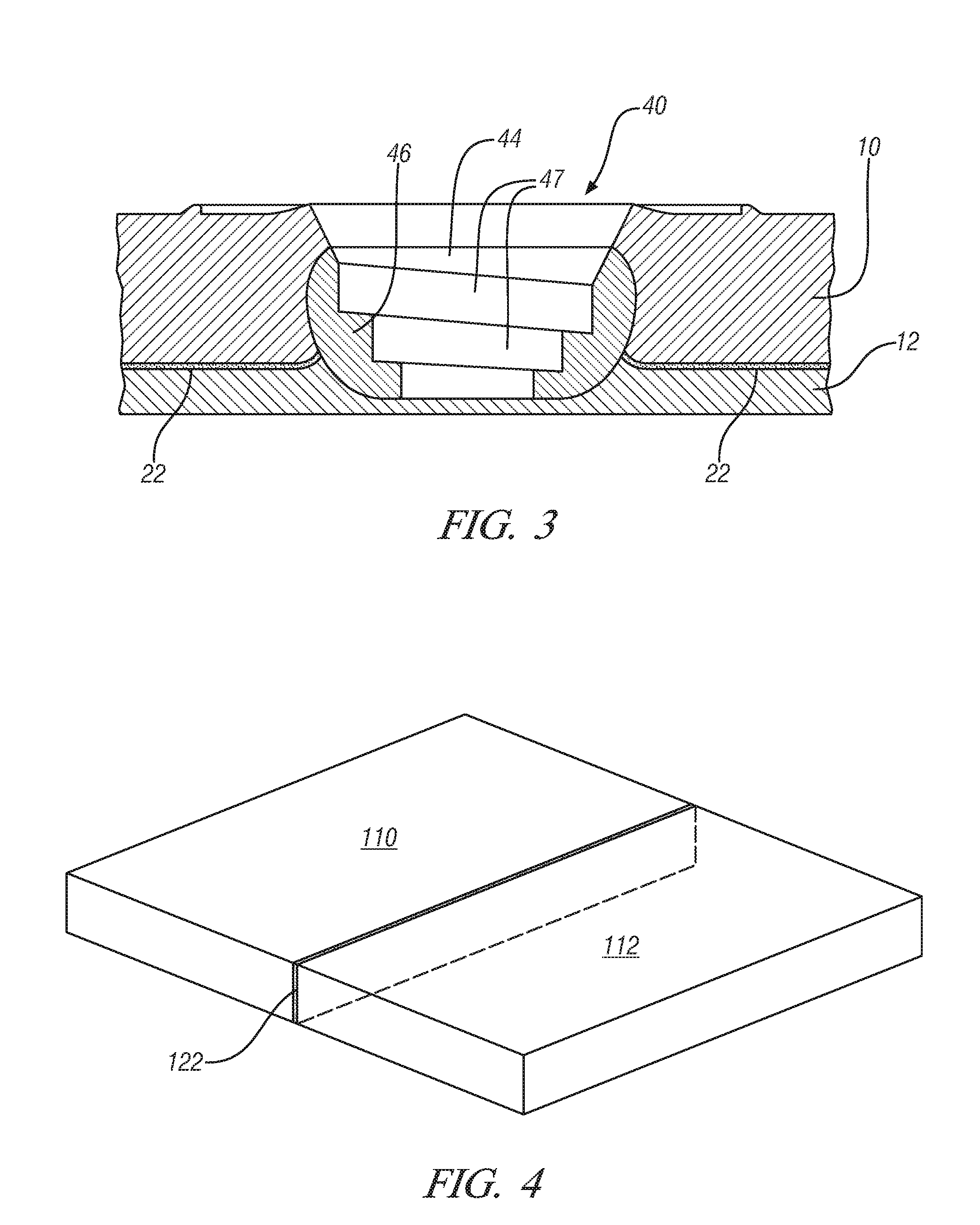

Friction stir welding of dissimilar metals

InactiveUS20100089976A1Improve adhesionImprove joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveMaterials science

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions including an adhesive placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of an adhesive with copper, tin, zinc, and / or other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

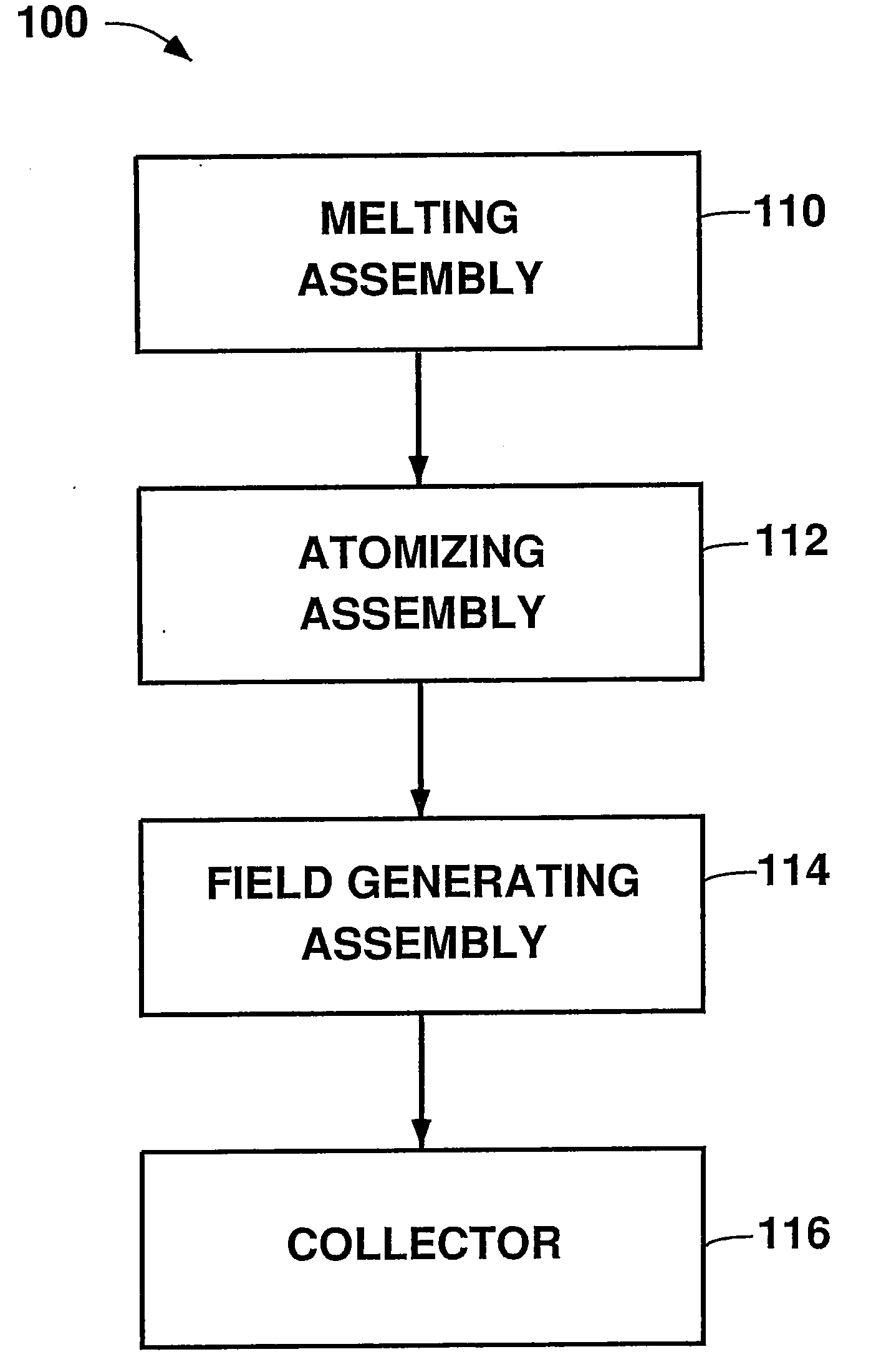

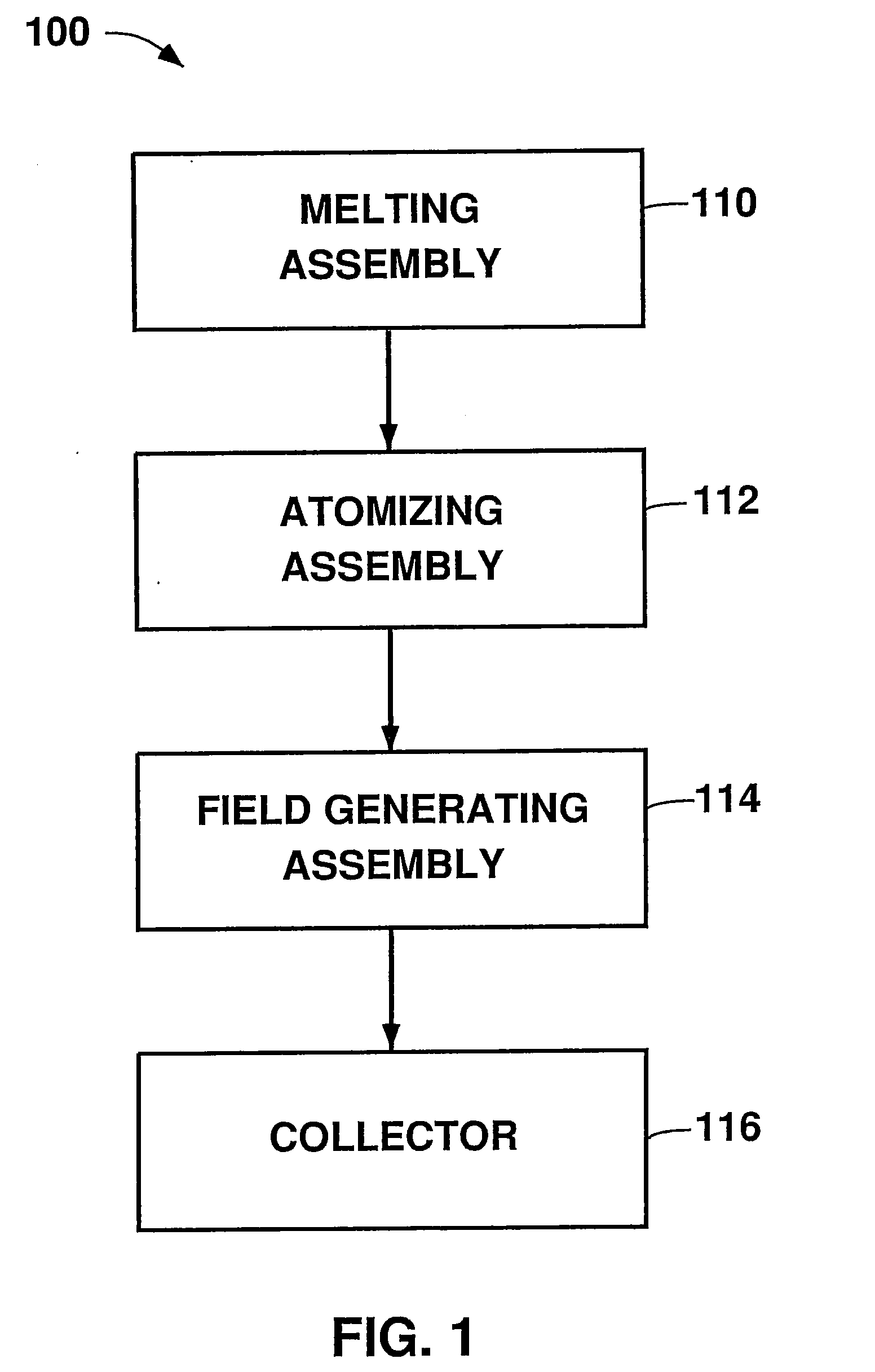

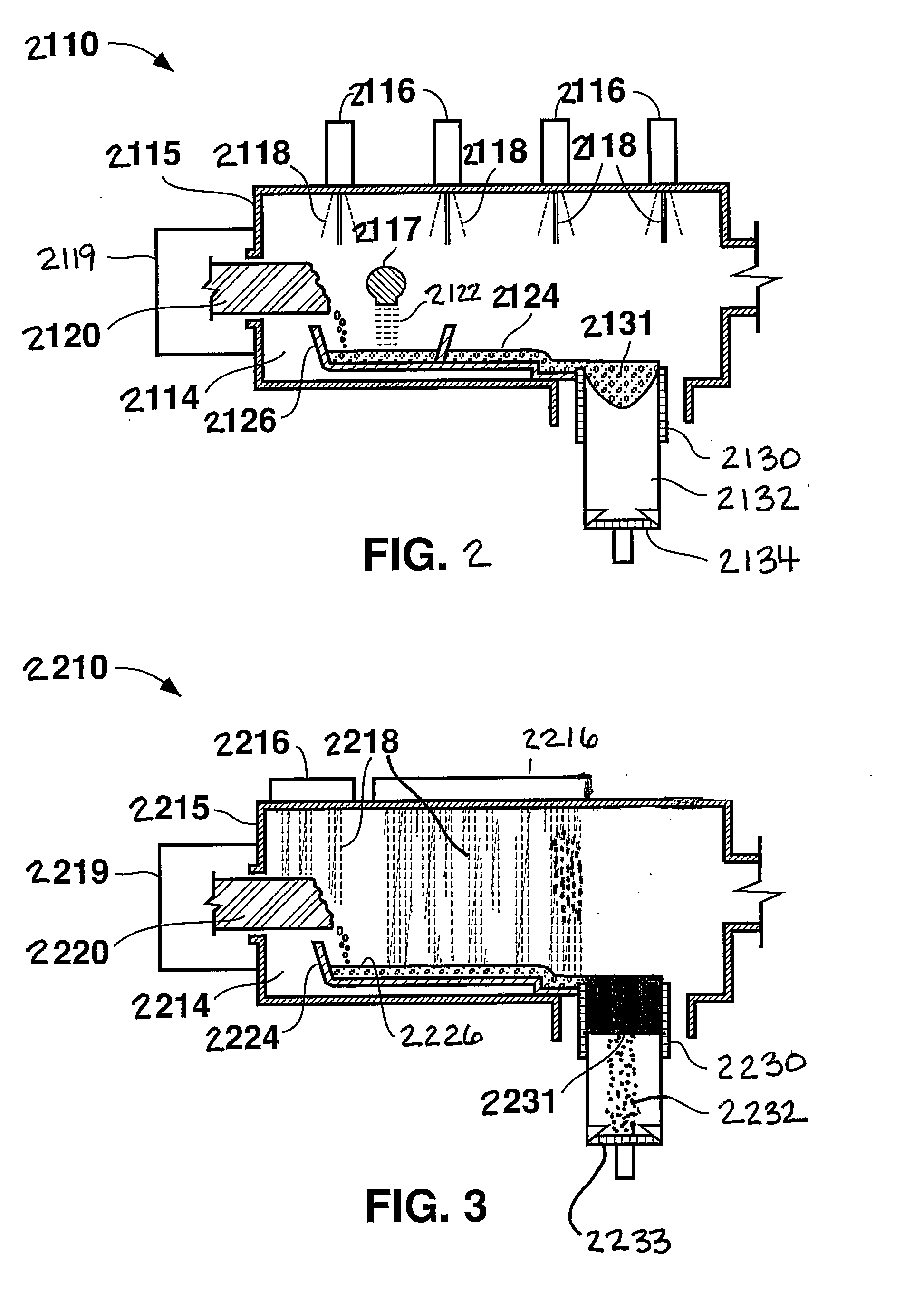

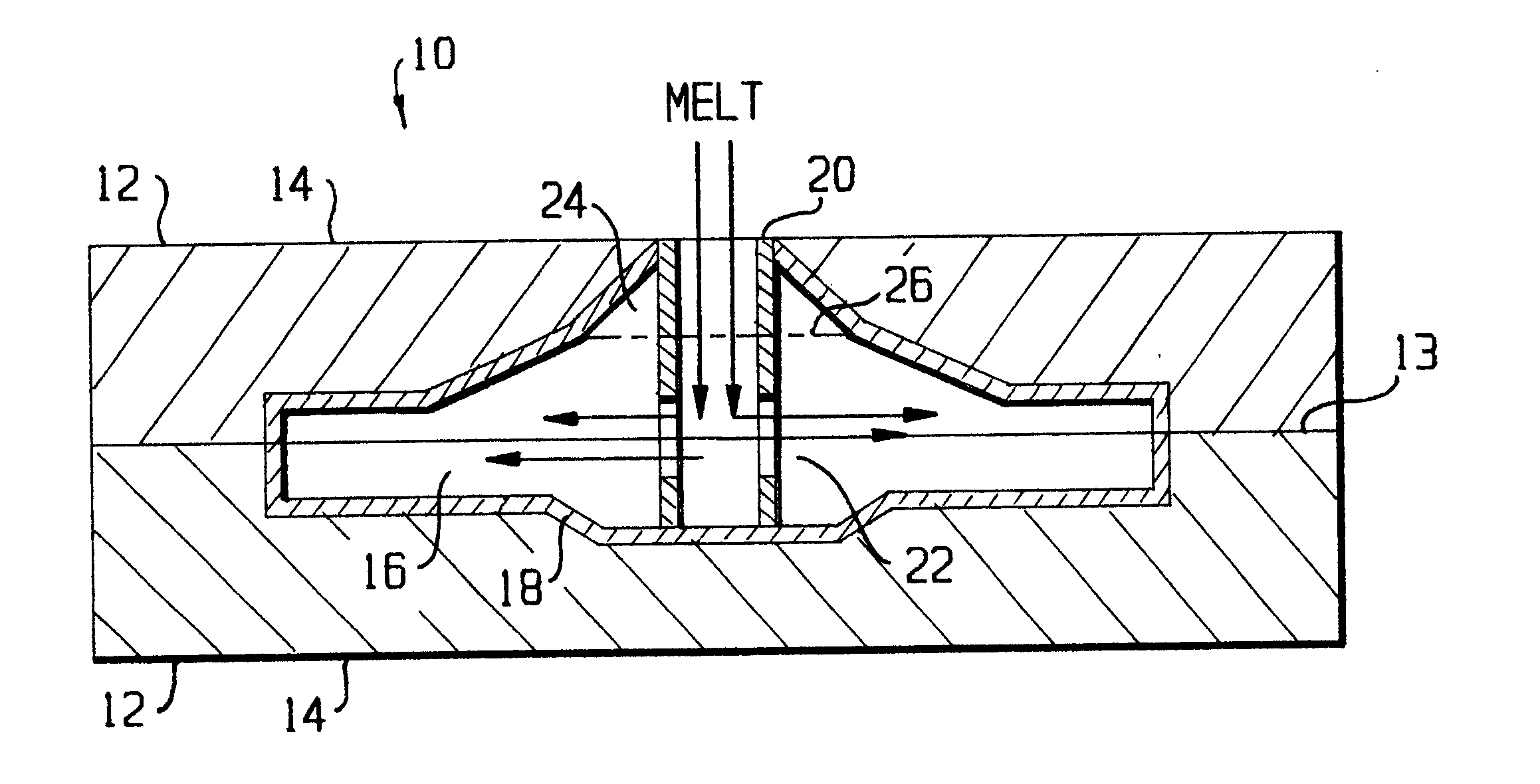

Method and apparatus for producing large diameter superalloy ingots

Methods and apparatus for producing large diameter superalloy ingots are disclosed. A material comprising at least one of a metal and a metallic alloy is introduced into a pressure-regulated chamber in a melting assembly. The material is subjected to a wide-area electron field within the pressure-regulated chamber to heat the material to a temperature above the melting temperature of the material to form a molten alloy. At least one stream of molten alloy from the pressure-regulated chamber is provided from the melting assembly and is fed into an atomizing assembly, where particles of the molten alloy are generated by impinging electrons on the molten alloy to atomize the molten alloy. At least one of an electrostatic field and an electromagnetic field are produced to influence the particles of the molten alloy. The particles of the molten alloy are deposited onto a collector in a spray forming operation to form an alloy ingot.

Owner:ATI PROPERTIES

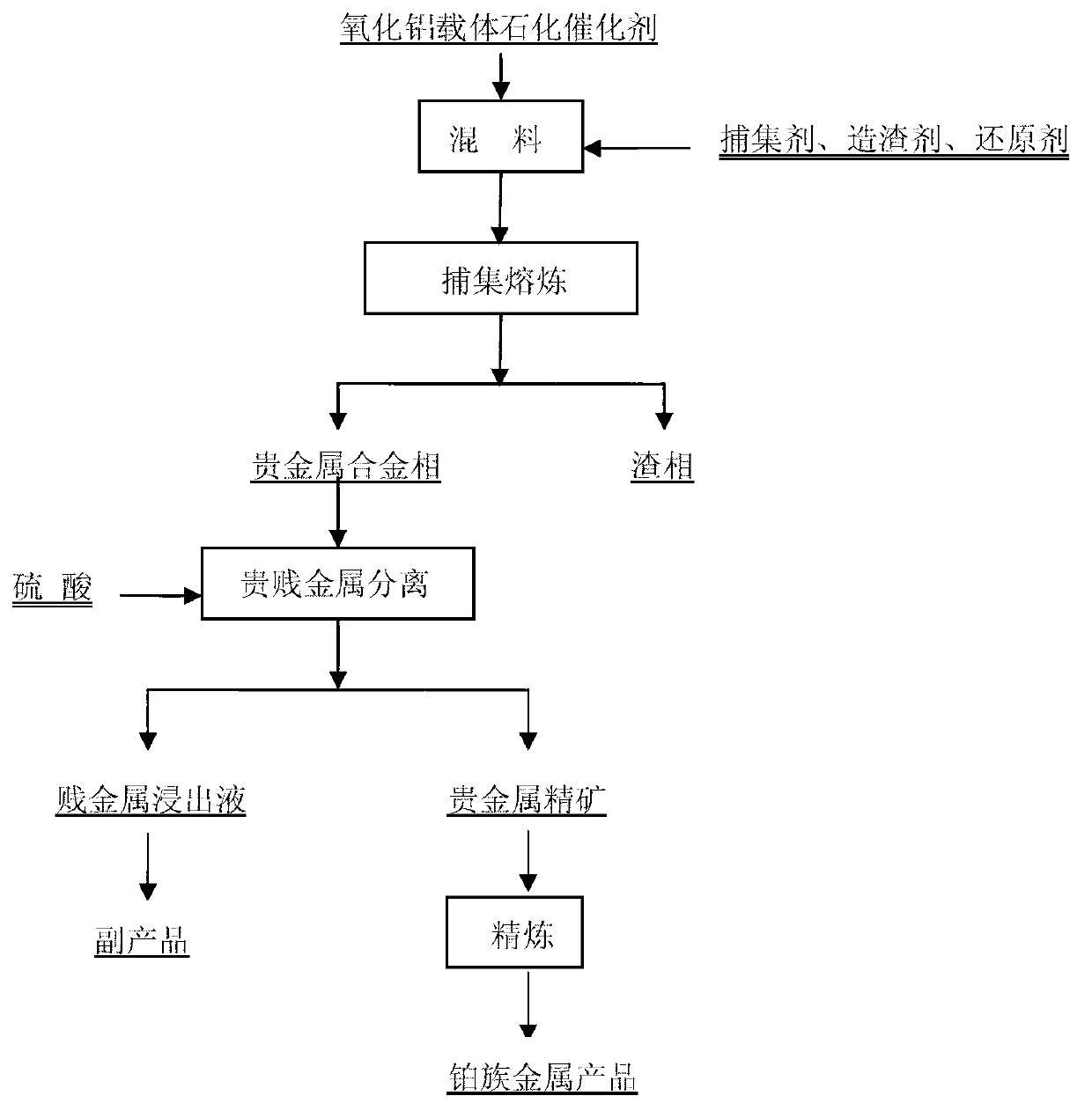

Method for smelting and extracting platinum metal from alumina-supported petrochemical catalyst

The invention discloses a method for smelting and extracting platinum metal from an alumina-supported petrochemical catalyst, and the method comprises the following steps: mixing the alumina-supported petrochemical catalyst with a trapping agent, a reductant and a slag forming agent and then smelting to trap the platinum metal from the alumina-supported petrochemical catalyst to obtain subsidiary product and alloy containing the platinum metal; using a sulfuric acid solution to dissolve the alloy containing the platinum metal to separate noble metal and base metal so as to obtain noble metal ore; and refining the noble metal ore to obtain the platinum metal product. The method disclosed by the invention has the characteristics that the process design does not produce wastewater, the wastewater treatment and filtration difficulty in a wet treatment process of the alumina-supported petrochemical catalyst are avoided, the recycling rate is higher than 98%, and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

Intravascular deliverable stent for reinforcement of vascular abnormalities

A catheter deliverable stent / graft especially designed to be used in a minimally invasive surgical procedure for treating a variety of vascular conditions such as aneurysms, stenotic lesions and saphenous vein grafts, comprises an innermost tubular structure and at least one further tubular member in coaxial arrangement. In one embodiment, the innermost tubular structure is of a length (L 1 ) and is formed by braiding a relatively few strands of highly elastic metallic alloy. The pick and pitch of the braid are such as to provide relative large fenestrations in the tubular wall that permit blood flow through the wall and provide the primary radial support structure. A portion of the innermost tubular structure of a length (L 1 ) is surrounded by a further braided tubular structure having relatively many strands that substantially inhibit blood flow through the fenestrations of the innermost tubular structure.

Owner:AGA MEDICAL CORP MS US

Diffuse reflection type tin-coated welding strip and method for producing same

ActiveCN101789452AIncrease power consumptionLower the immersion temperatureFinal product manufacturePhotovoltaic energy generationDiffuse reflectionAir blower

The invention discloses a diffuse reflection type tin-coated welding strip and a method for producing the same. The diffuse reflection type tin-coated welding strip comprises a copper strip and a tin coating on the copper strip, wherein the surface of the tin coating is provided with distributed pit-shaped bodies. The production method comprises the following steps of: raising the temperature in a tin furnace to between 230 and 250 DEG C, and putting the copper strip in metallic alloy coating solution in the tin furnace for immersion tin-coating, wherein the speed of the immersion tin-coating is controlled to be 1 to 2m / min; and taking the tin-coated welding strip subjected to the immersion coating out, and cooling the tin coating on the surface of the copper strip by an air blower and a screen arranged on the air blower to obtain the distributed pit-shaped bodies. Because the surface of the tin coating is provided with the distributed pit-shaped bodies, the physical indexes of the diffuse reflection type tin-coated welding strip are stable, and the diffuse reflection type tin-coated welding strip can diffuse sunlight, so that more sunlight can be reflected to a battery plate, and the received solar energy is increased.

Owner:QINHUANGDAO DONGWU ELECTRONICS

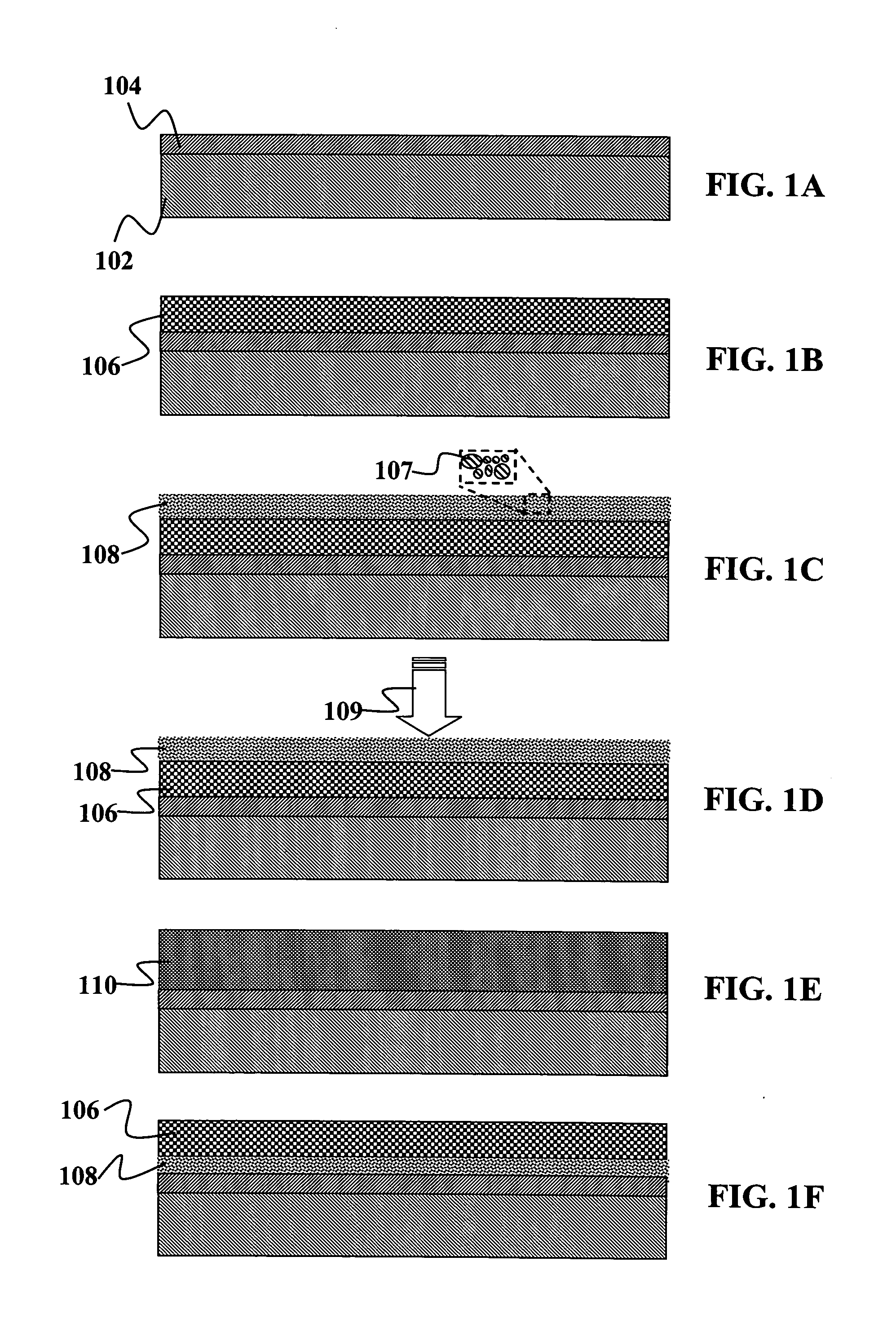

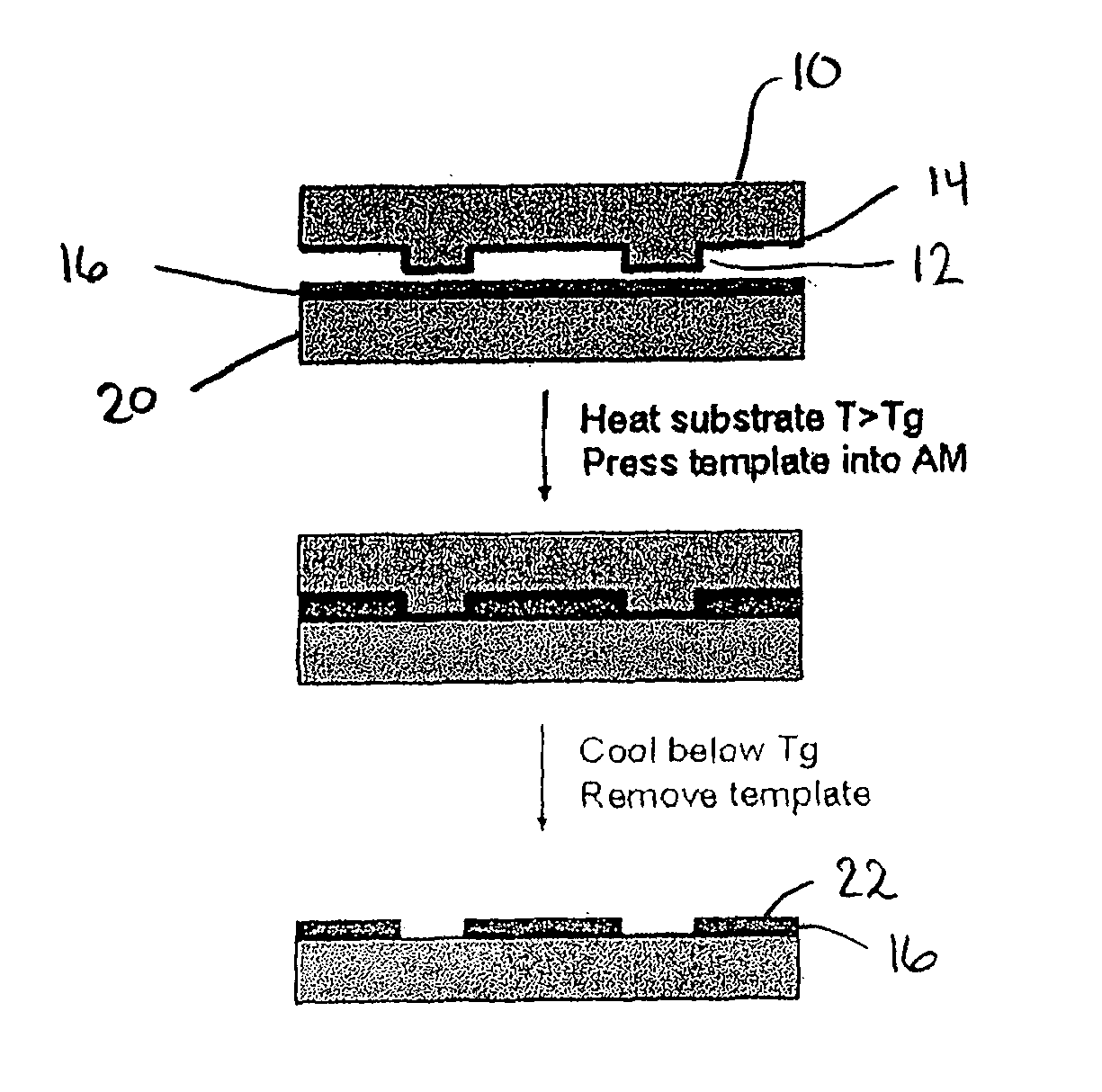

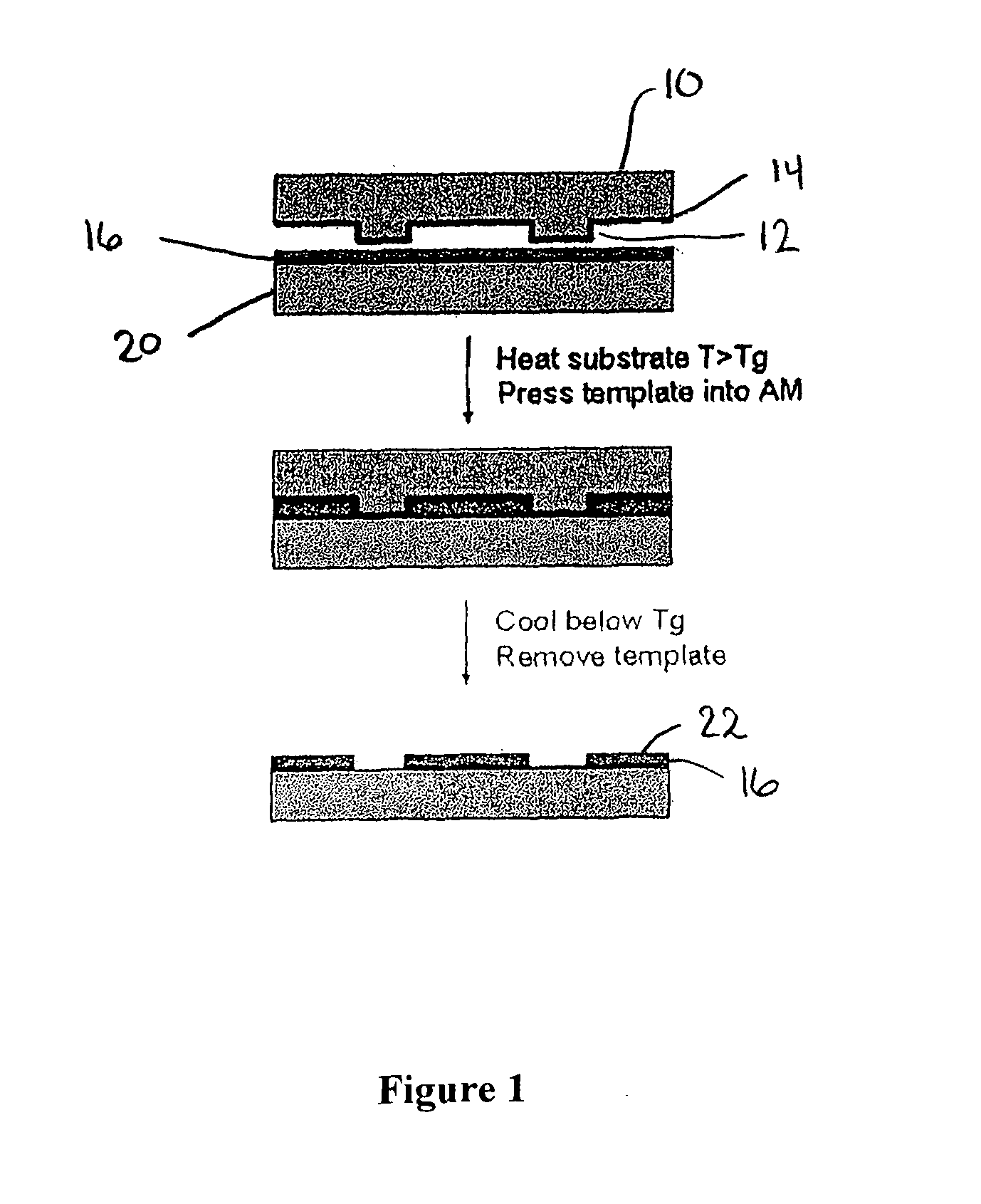

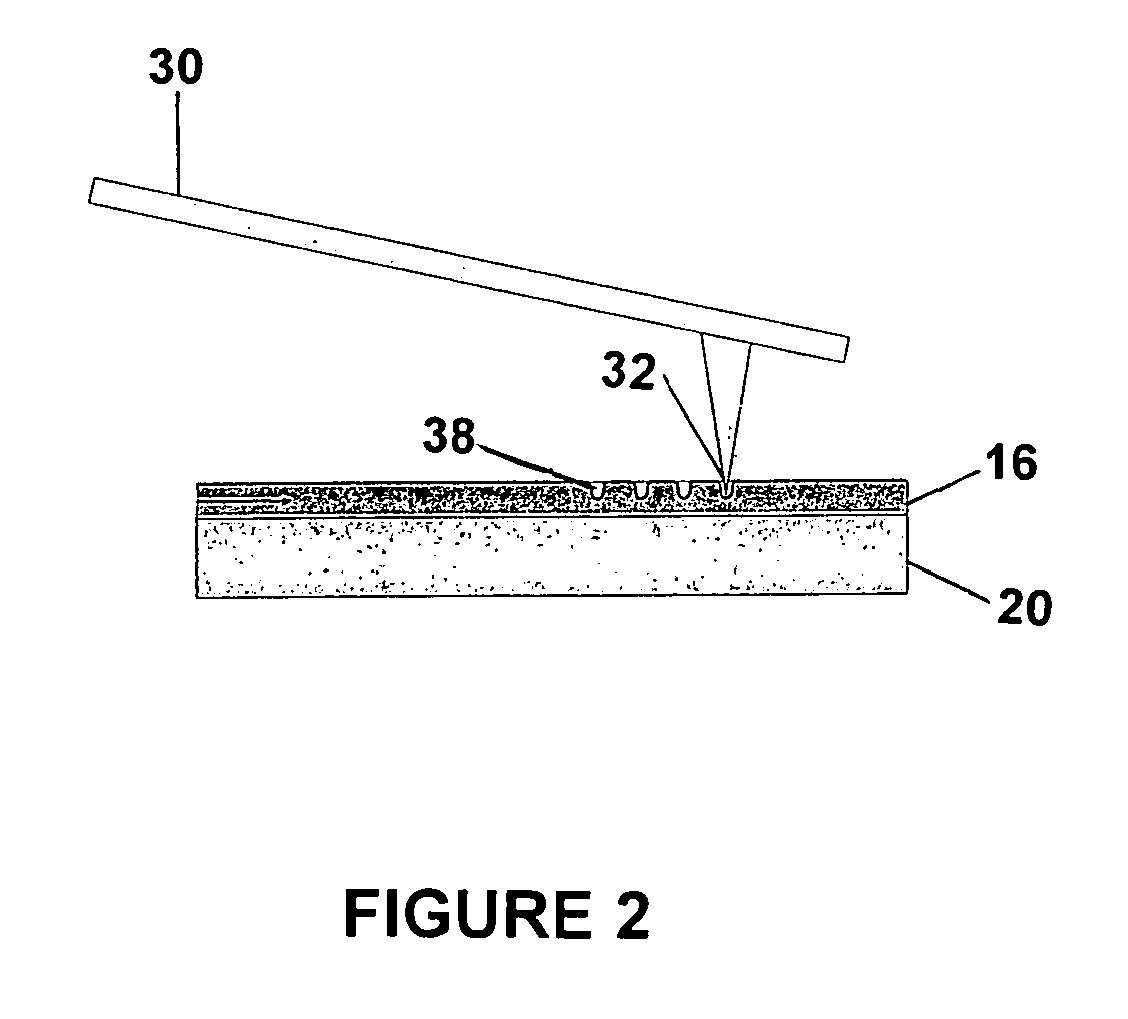

Method for Imprinting and Erasing Amorphous Metal Alloys

ActiveUS20100098967A1Surface roughnessLayered productsMechanical recordingMicron scaleNano manufacturing

The present invention relates to materials, methods and apparatuses for performing imprint lithography using amorphous metallic materials. The amorphous metallic materials can be employed as imprint media and thermoplastic forming processes are applied during the pattern transfer procedure to produce micron scale and nanoscale patterns in the amorphous metallic layer. The pattern transfer is in the form of direct mask embossing or through a serial nano-indentation process. A rewriting process is also disclosed, which involves an erasing mechanism that is accomplished by means of a second thermoplastic forming process. The amorphous metallic materials may also be used directly as an embossing mold in imprint lithography to allow high volume imprint nano-manufacturing. This invention also comprises of a method of smoothening surfaces under the action of the surface tension alone.

Owner:YALE UNIV

Method and apparatus for dispersion strengthened bond coats for thermal barrier coatings

InactiveUS20050287296A1Effective applicationIncrease chanceEngine manufactureElectric discharge tubesBorideGas phase

A directed vapor deposition (DVD) method and system for applying at least one bond coating on at least one substrate for thermal barrier coating systems. The method and system provides for alloy strengthening in high temperature metallic alloys that can be melt or solid state processed to materials that one applies by vapor deposition. The creep strengthened coating contains nanoscopic particles of oxides, nitrides, borides, carbides, and other materials which are formed by reactive codeposition. An approach for reactive codeposition is plasma assisted directed vapor deposition. Accordingly, the resultant structure may be utilized for, but not limited thereto, high temperature coatings, e.g. for protecting rocket or power turbines, or diesel engine components. The resultant structure is has a greatly extended lifetime attributed in part to the elimination of coating spallation by the “rumpling” mechanism.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Castings of metallic alloys with improved surface quality, structural integrity and mechanical properties fabricated in anisotropic pyrolytic graphite molds under vacuum

Molds are fabricated having a substrate of high density, high strength ultrafine grained isotropic graphite, and having a mold cavity coated with pyrolytic graphite. The molds may be made by making the substrate (main body) of high density, high strength ultrafine grained isotropic graphite, by, for example, isostatic or vibrational molding, machining the substrate to form the mold cavity, and coating the mold cavity with pyrolytic graphite via a chemical deposition process. The molds may be used to make various metallic alloys such as nickel, cobalt and iron based superalloys, stainless steel alloys, titanium alloys and titanium aluminide alloys into engineering components by melting the alloys in a vacuum or under a low partial pressure of inert gas and subsequently casting the melt in the graphite molds under vacuum or low partial pressure of inert gas.

Owner:SANTOKU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com