Patents

Literature

11460results about "Drinking water installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for autonomously controlling the inflow of production fluids from a subterranean well

InactiveUS20080283238A1Reduce trafficReduce the cross-sectional areaFluid removalWell/borehole valve arrangementsEngineeringActuator

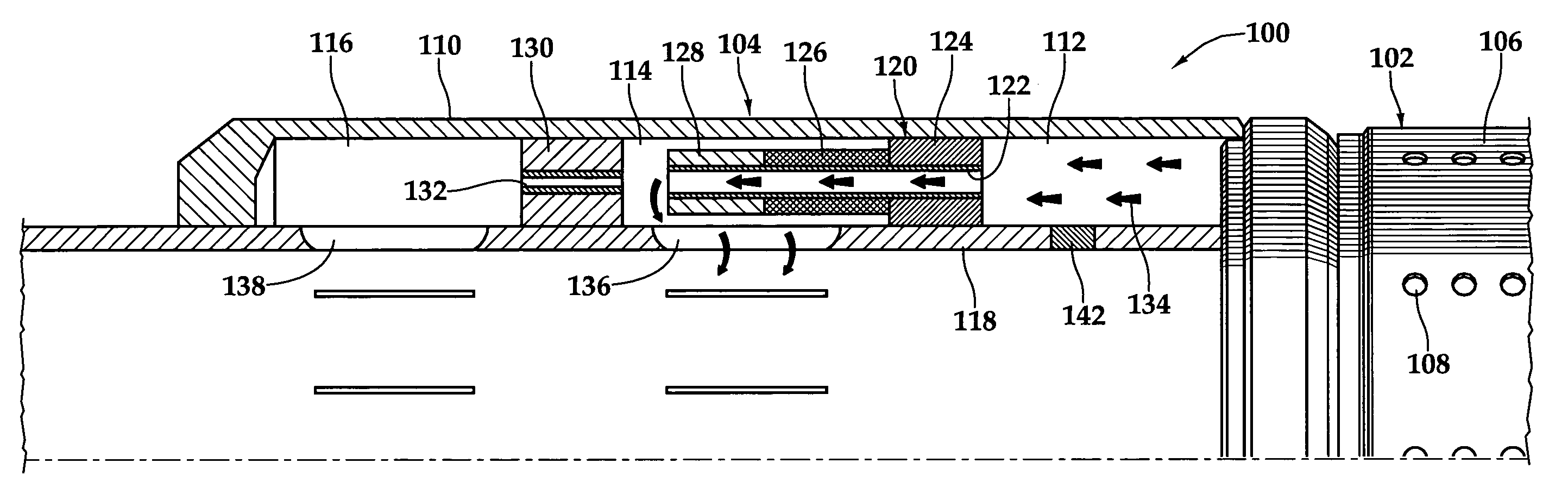

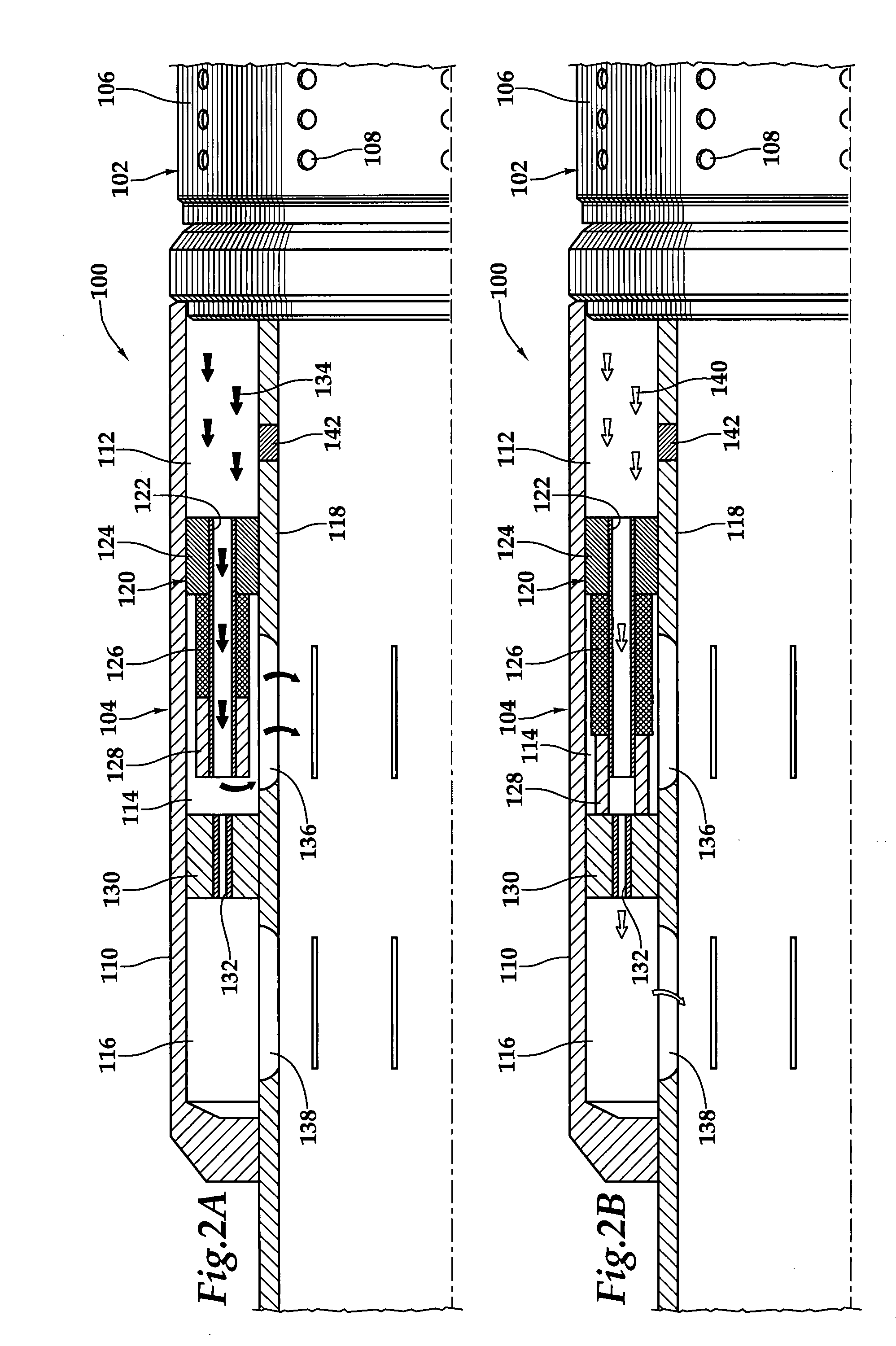

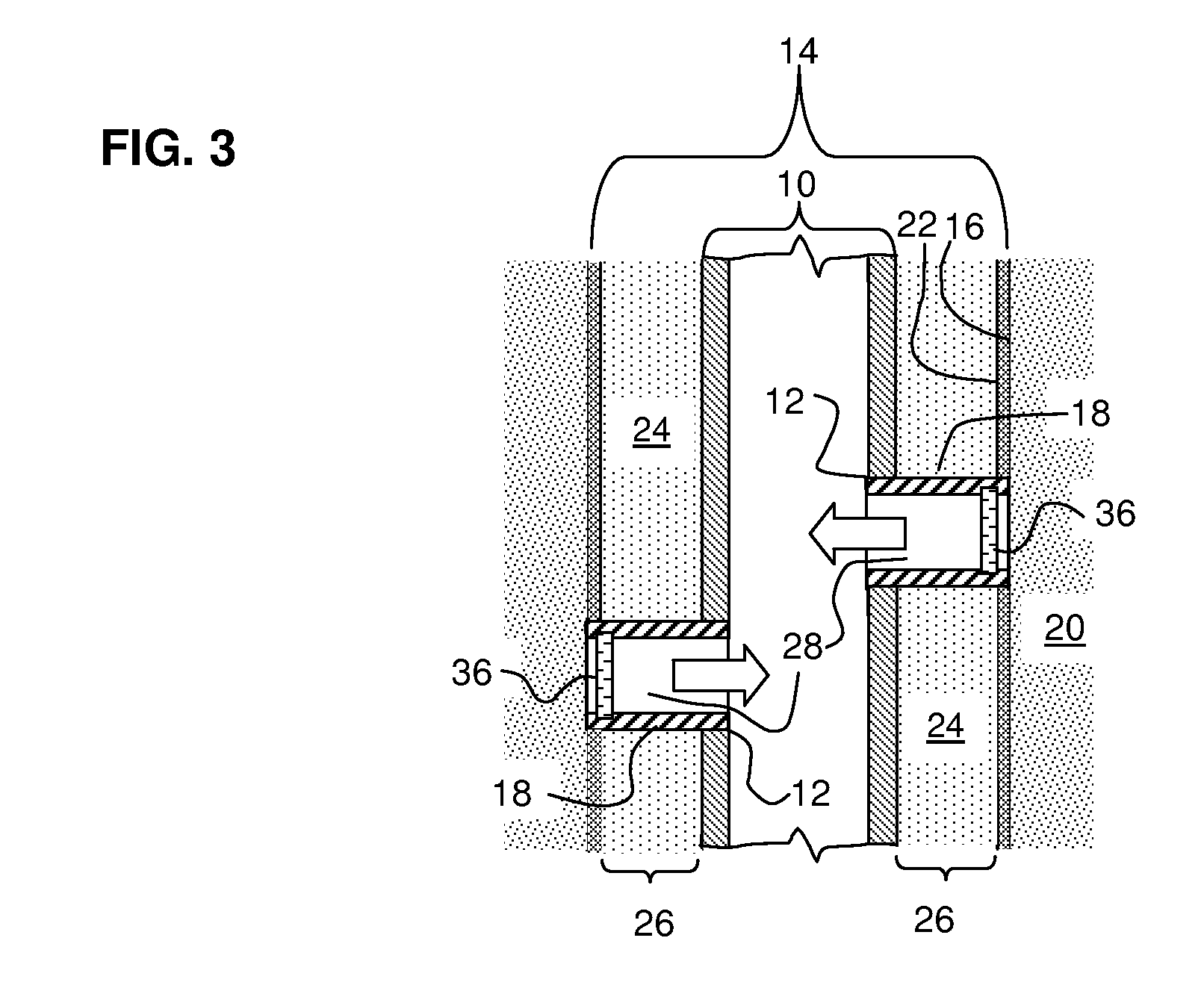

A flow control apparatus (100) for controlling the inflow of production fluids (134, 140) from a subterranean well includes a tubular member (118) having at least one opening (138) that allows fluid flow between an exterior of the tubular member (118) and an interior flow path of the tubular member (118) and a flow restricting device (120) operably positioned in a fluid flow path between a fluid source and the at least one opening (138). The flow restricting device (120) includes a valve (128, 130) and an actuator (126). The actuator (126) includes a material that swells in response to contact with an undesired fluid (140), such as water or gas. The flow restricting device (120) is operable to autonomously reduce the fluid flow through the flow control apparatus (100) in response to contact between the material and the undesired fluid (140).

Owner:HALLIBURTON ENERGY SERVICES INC

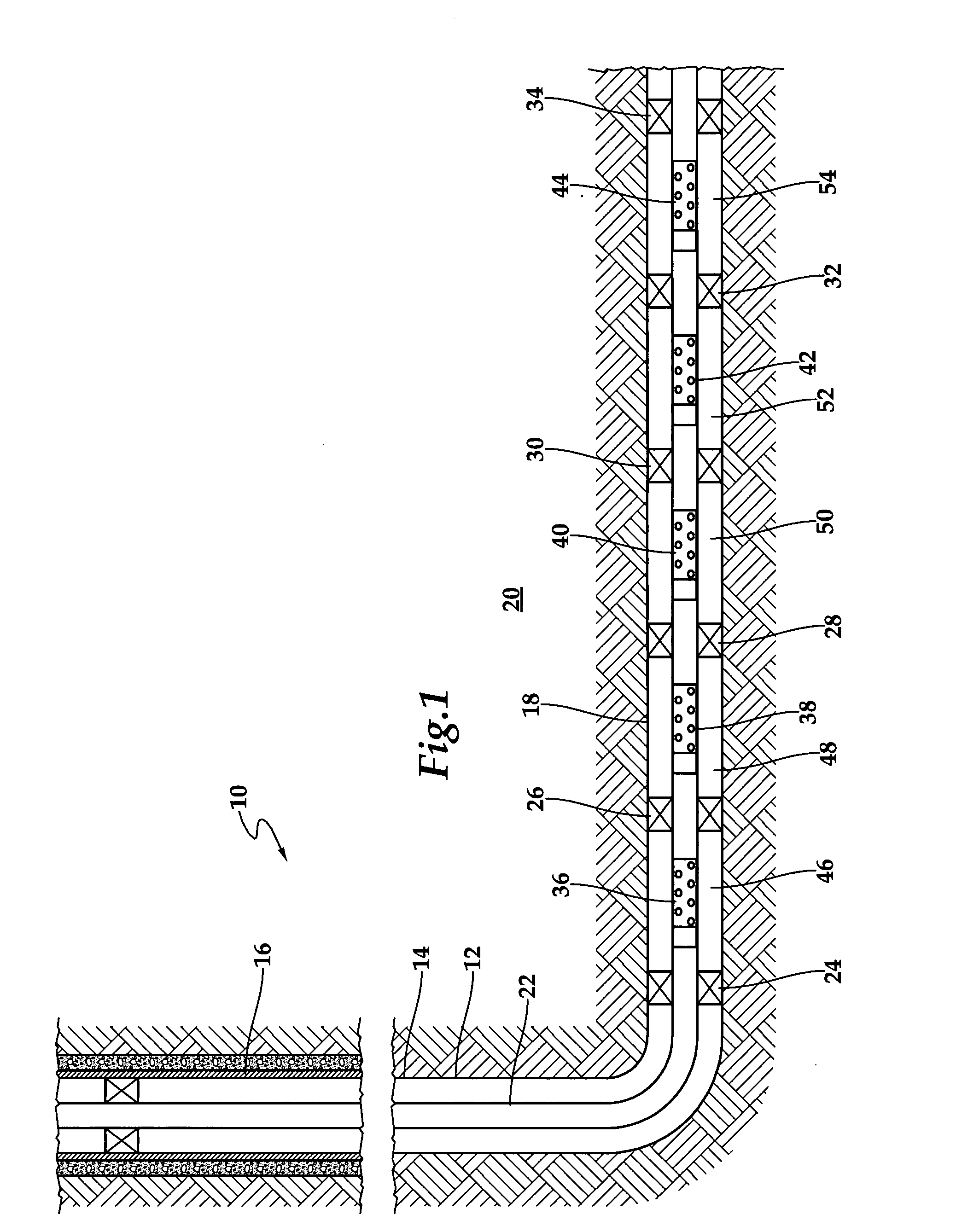

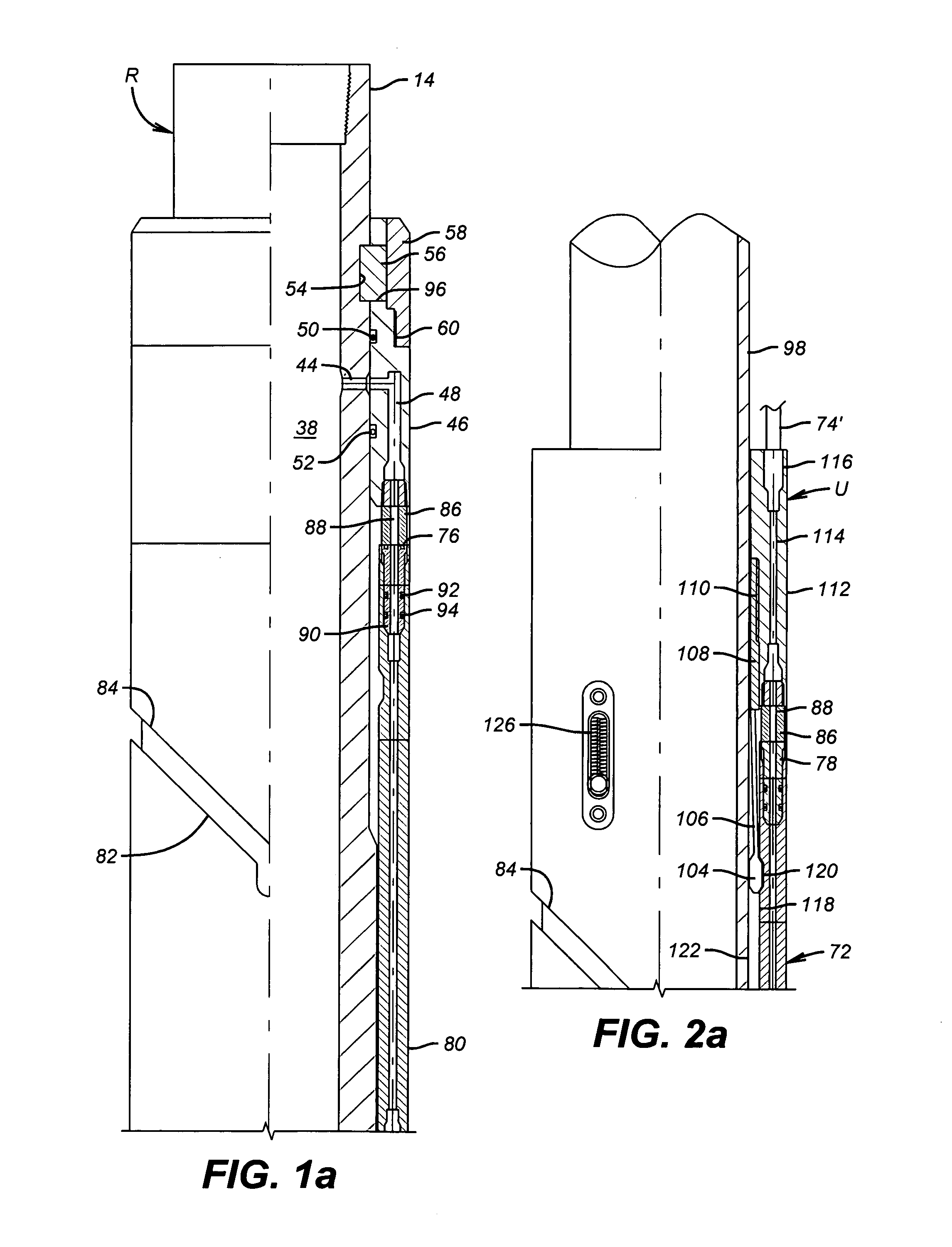

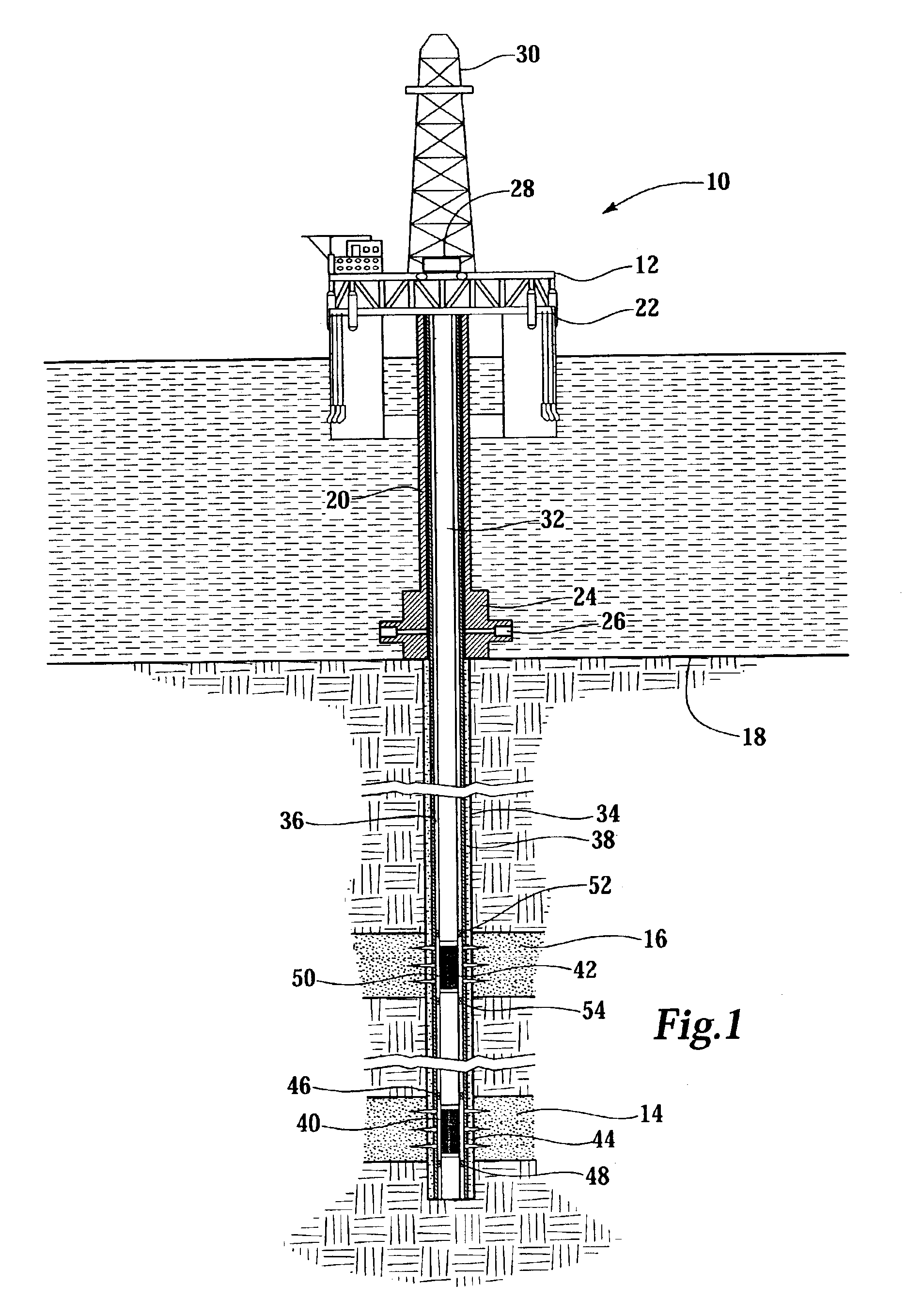

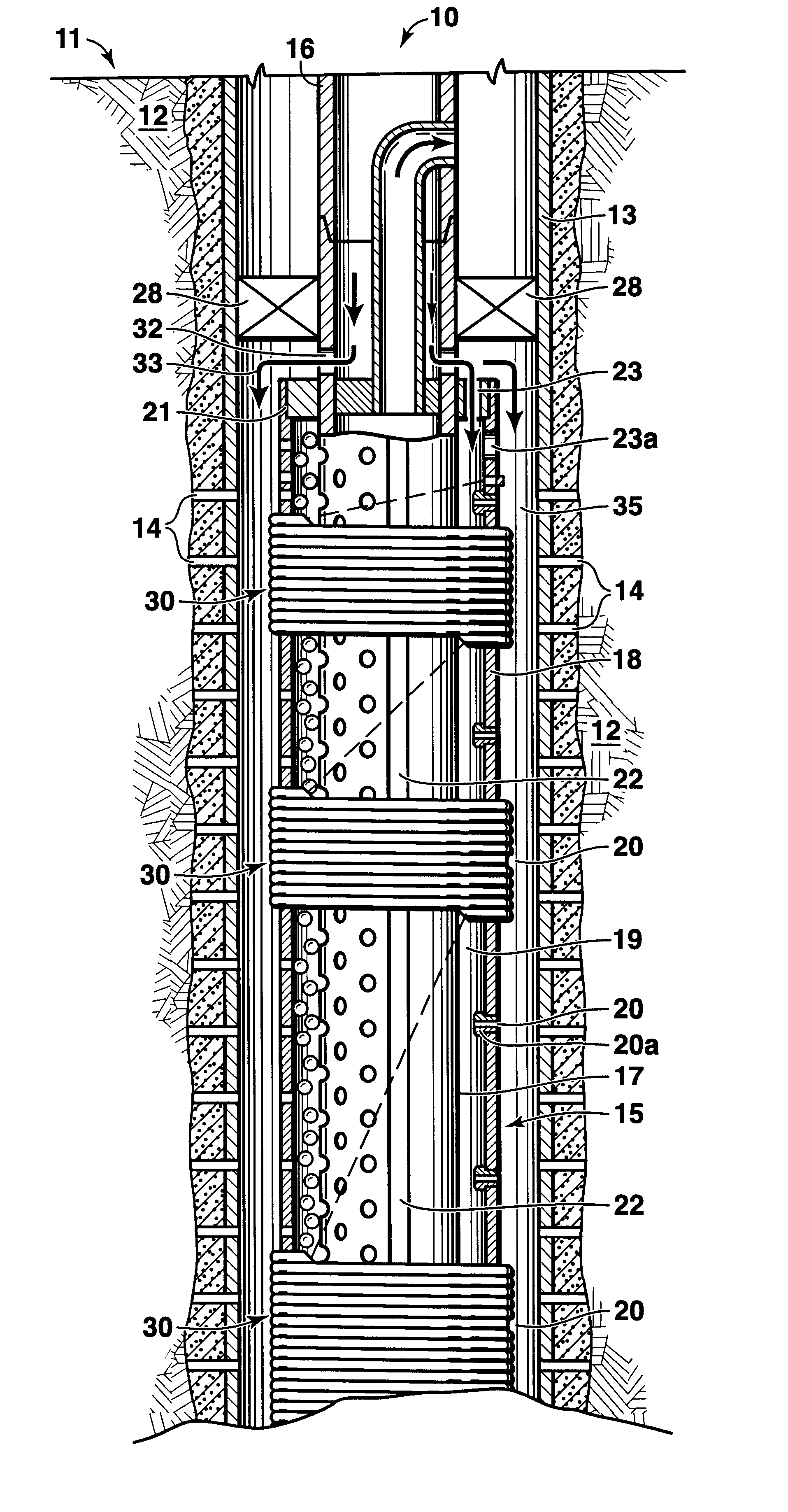

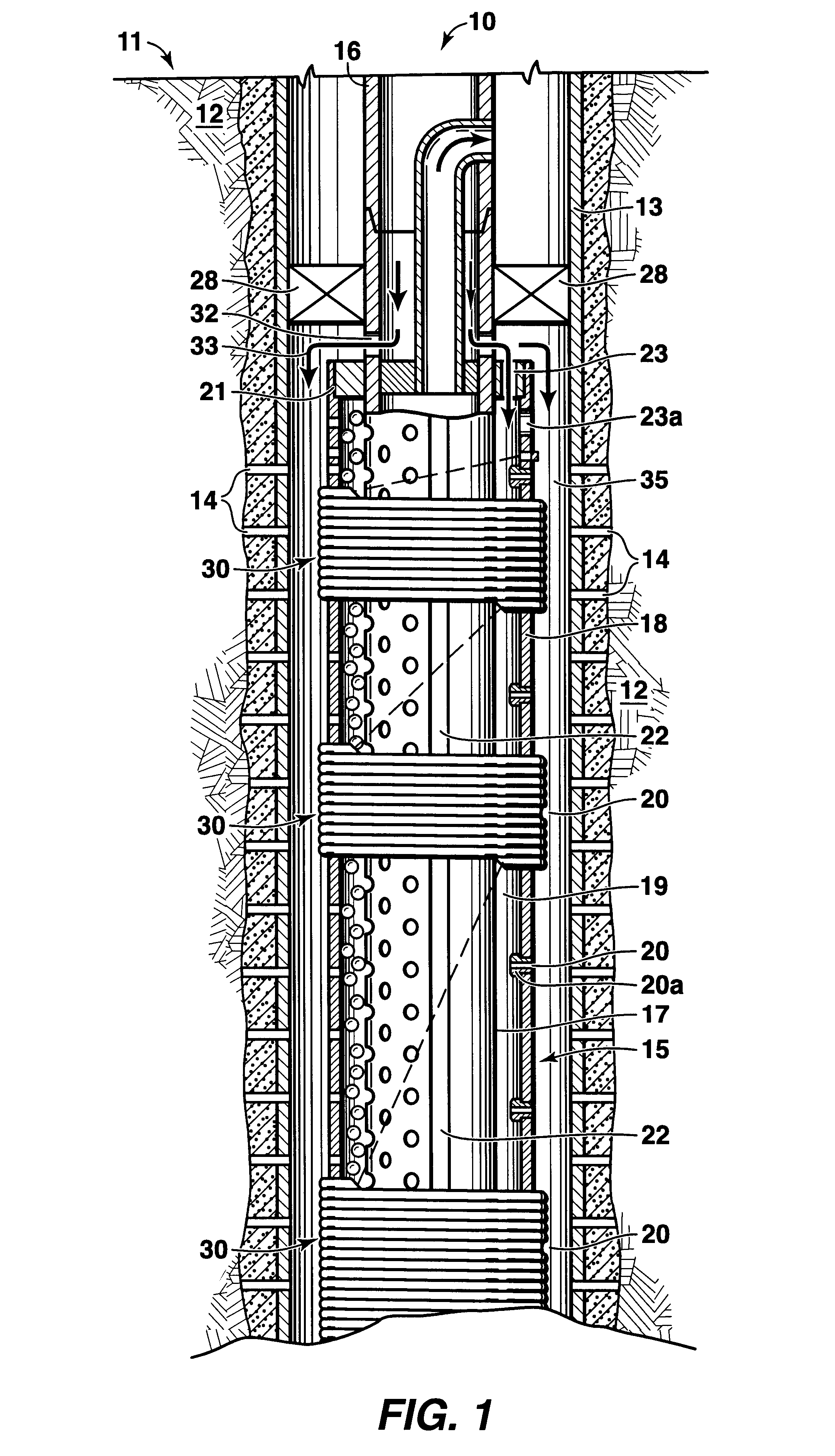

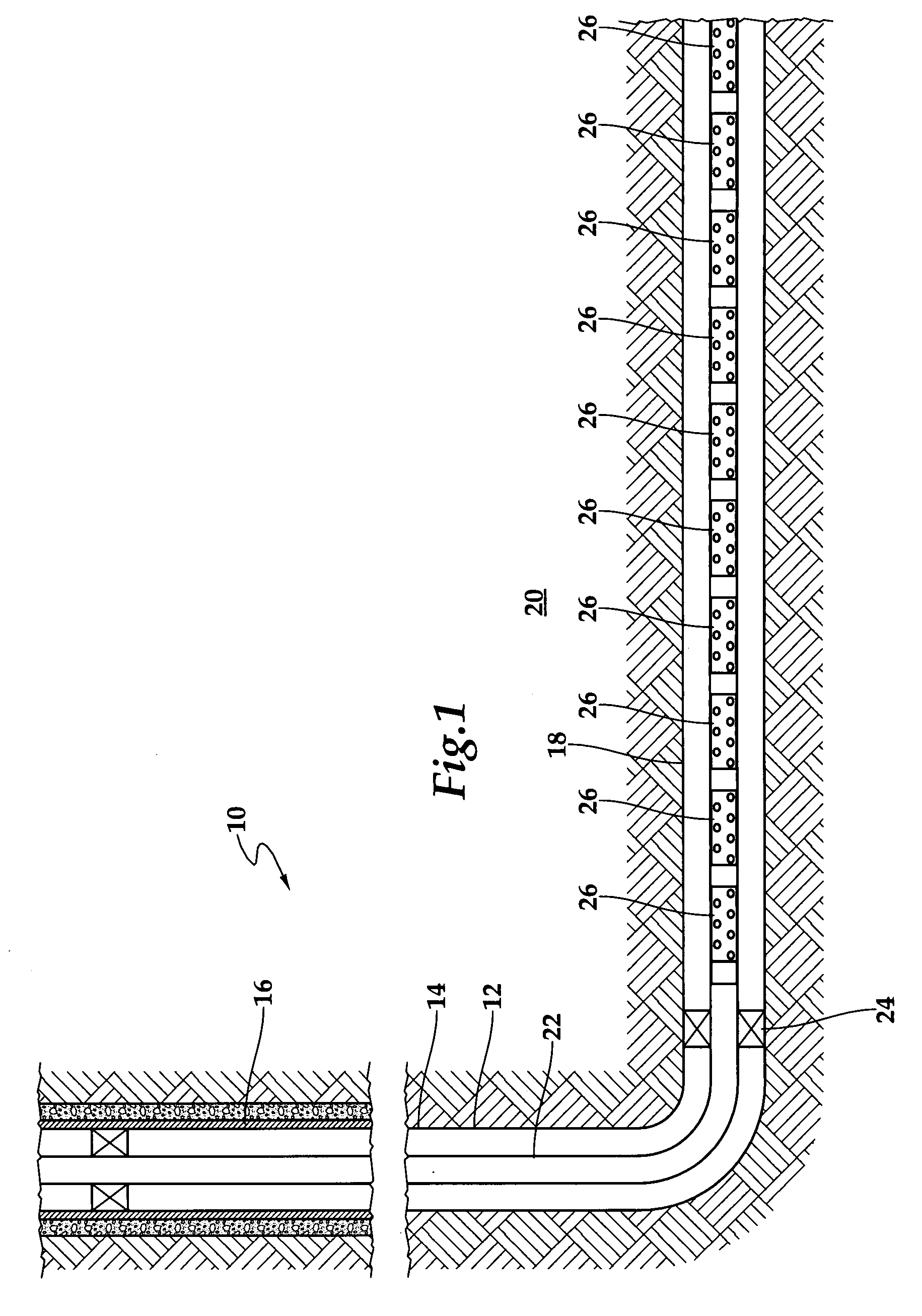

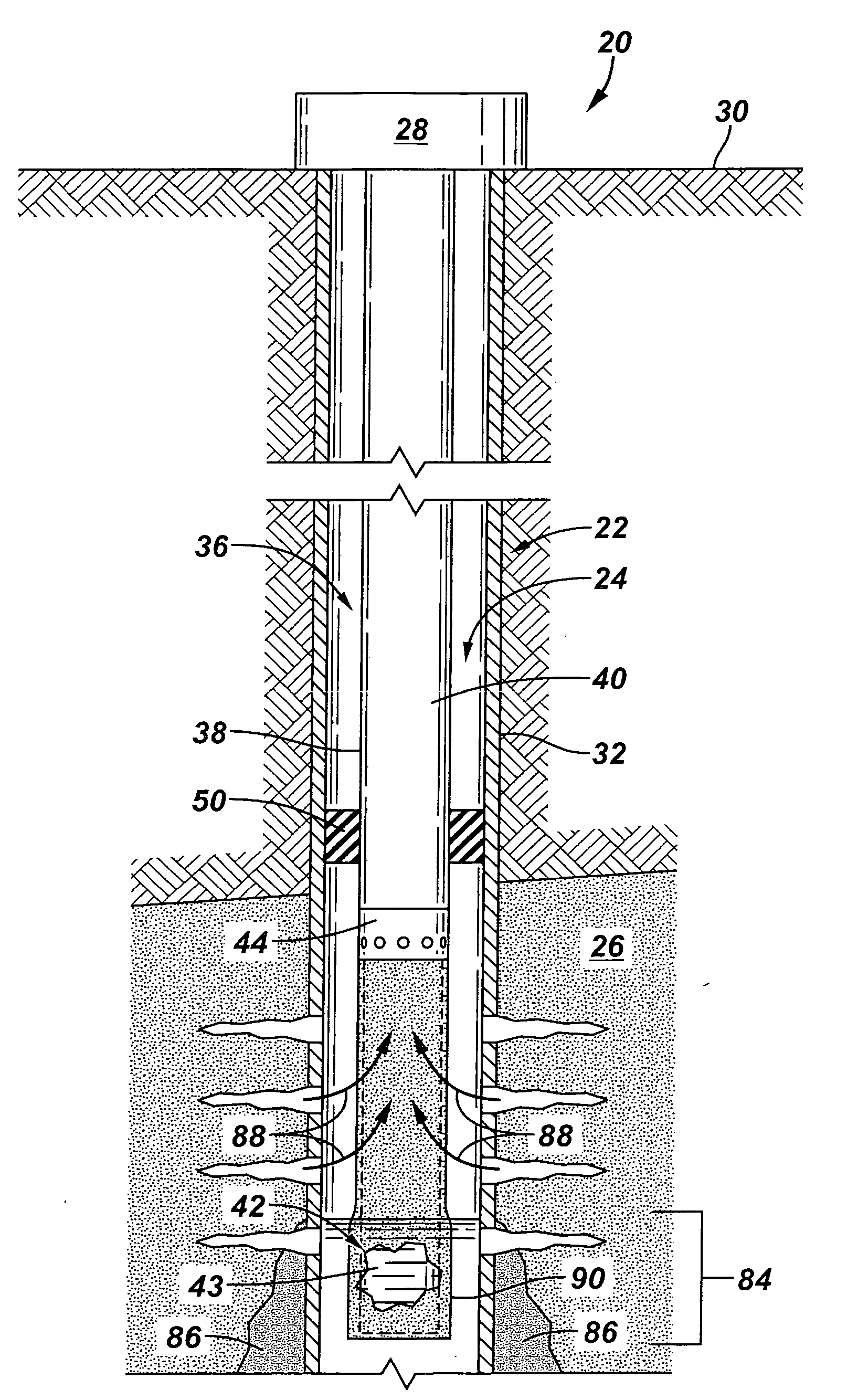

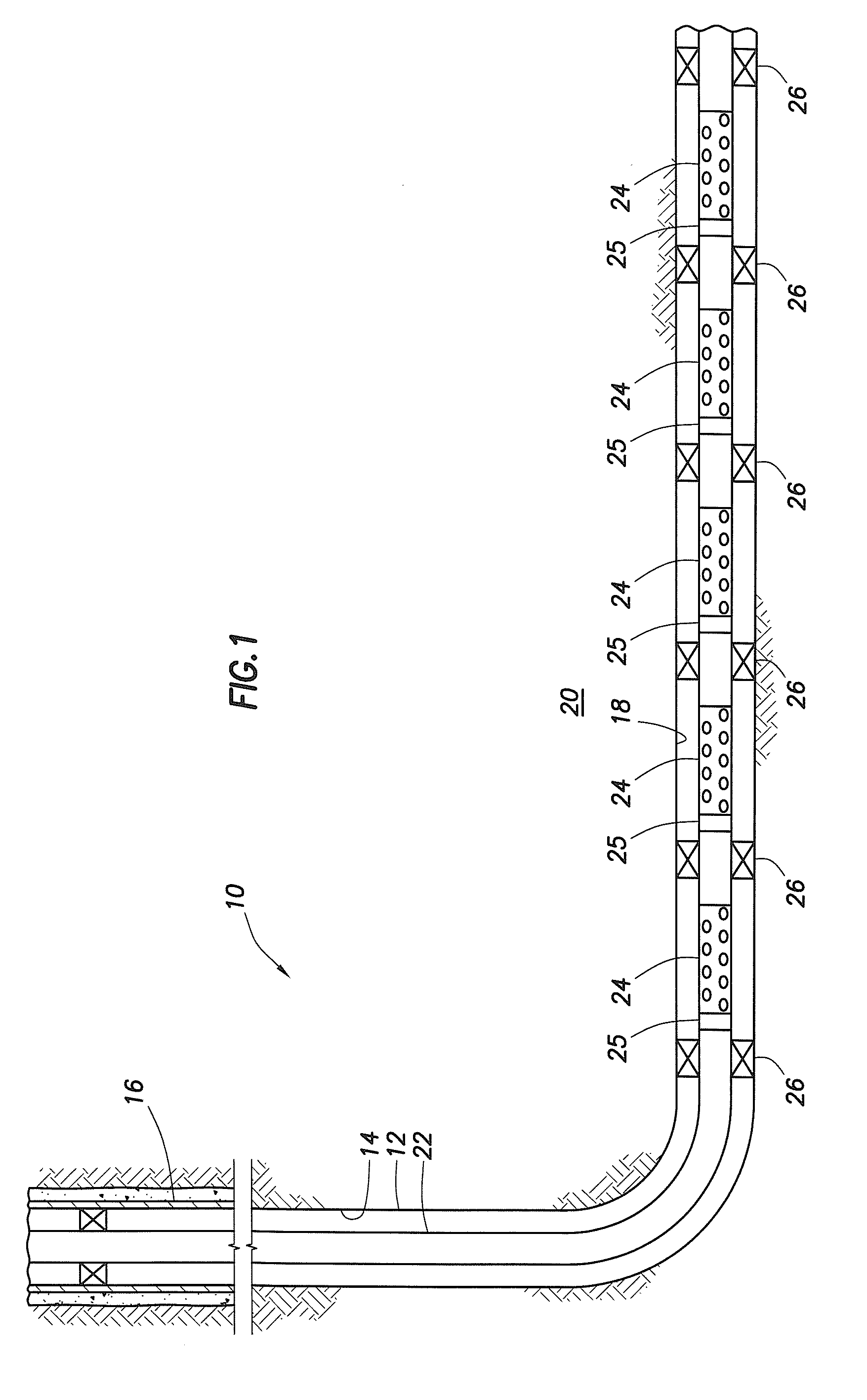

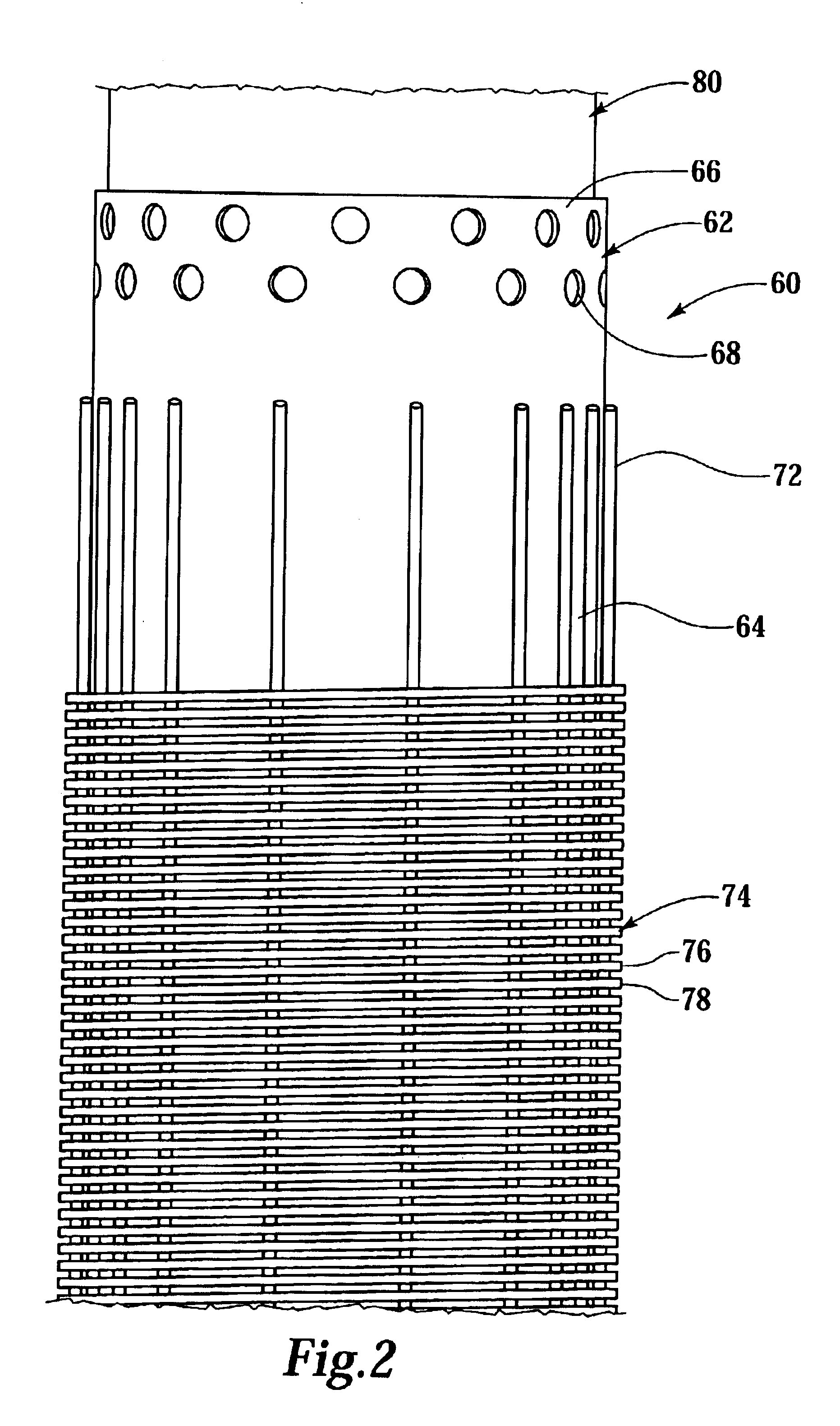

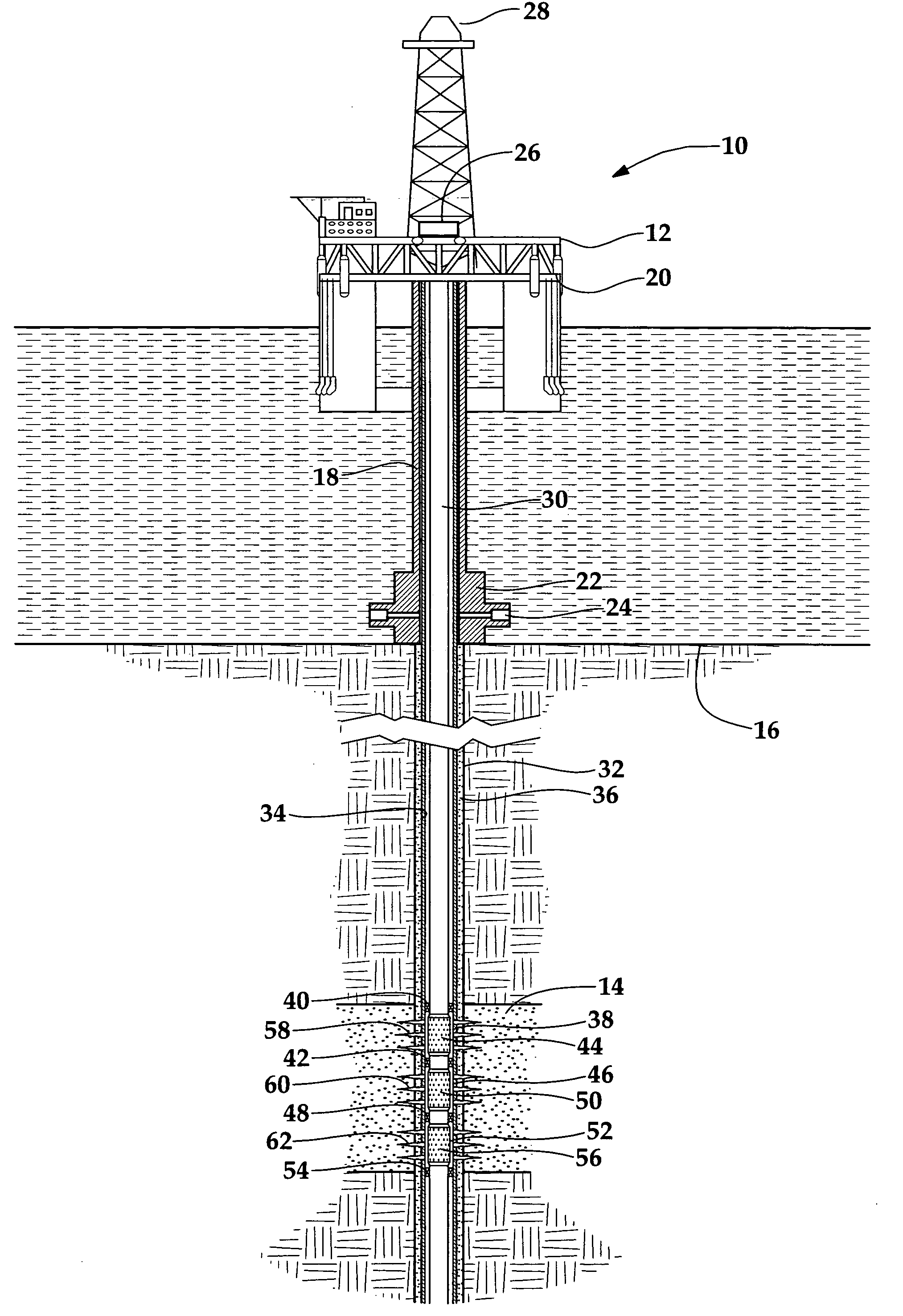

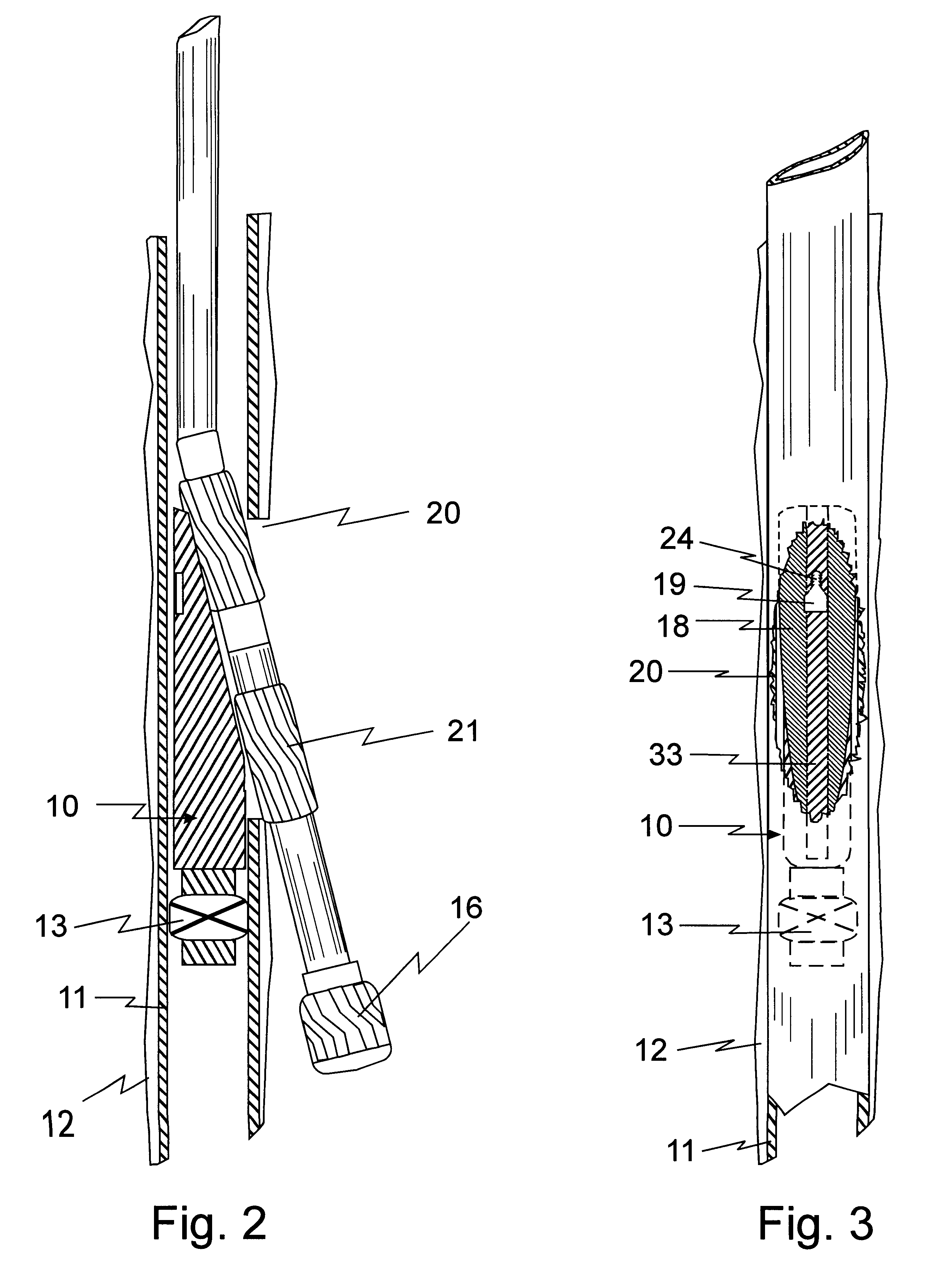

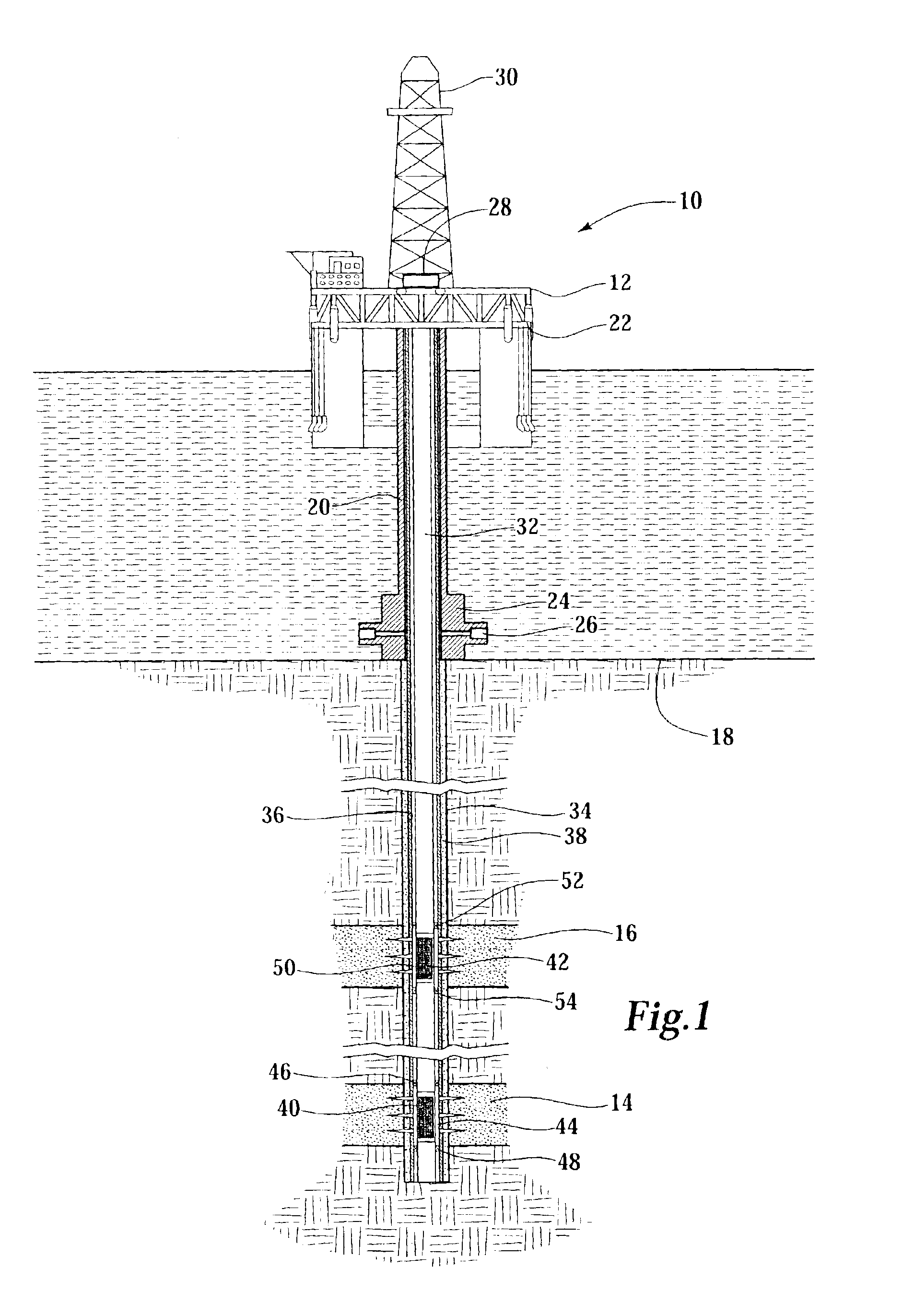

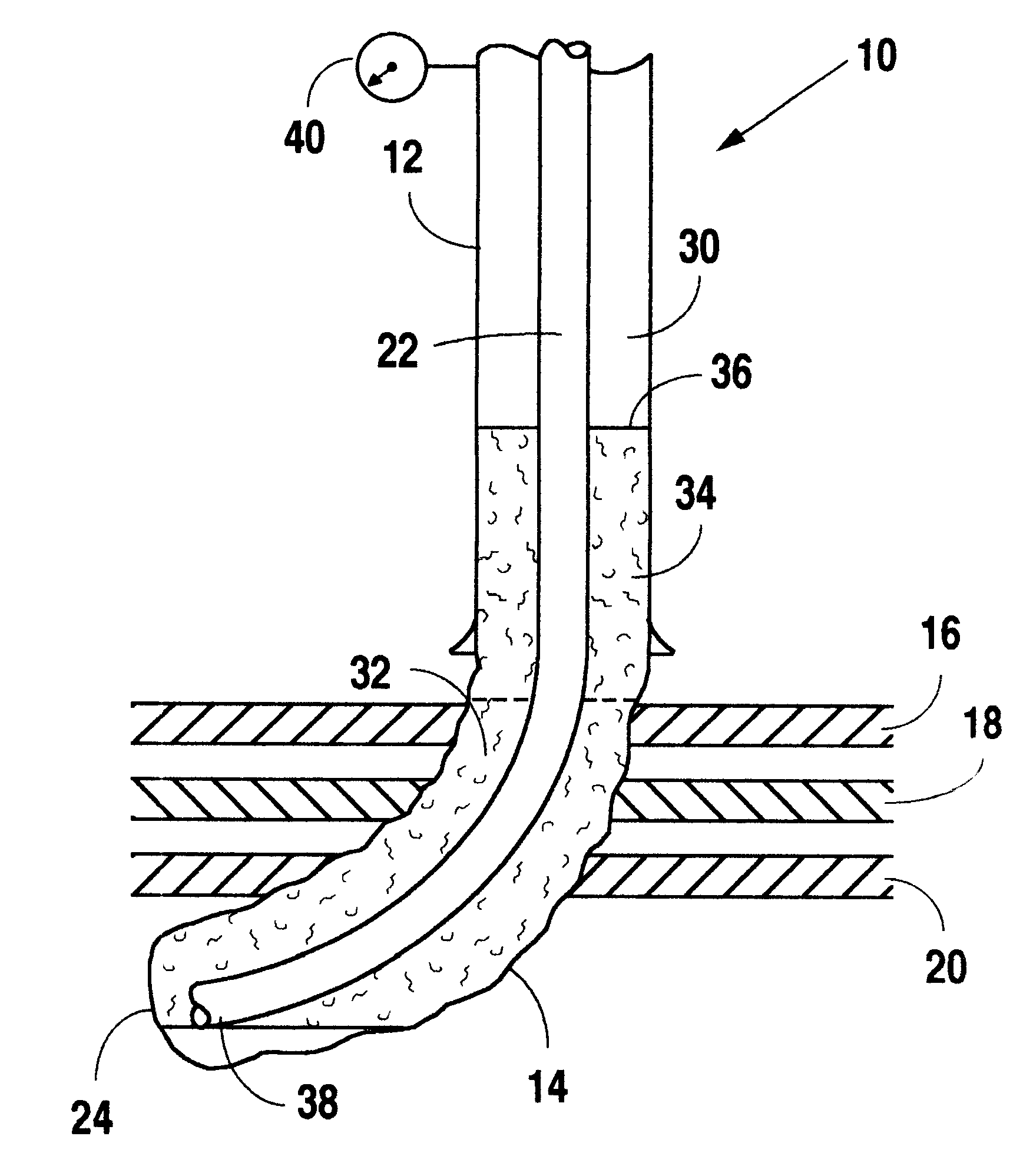

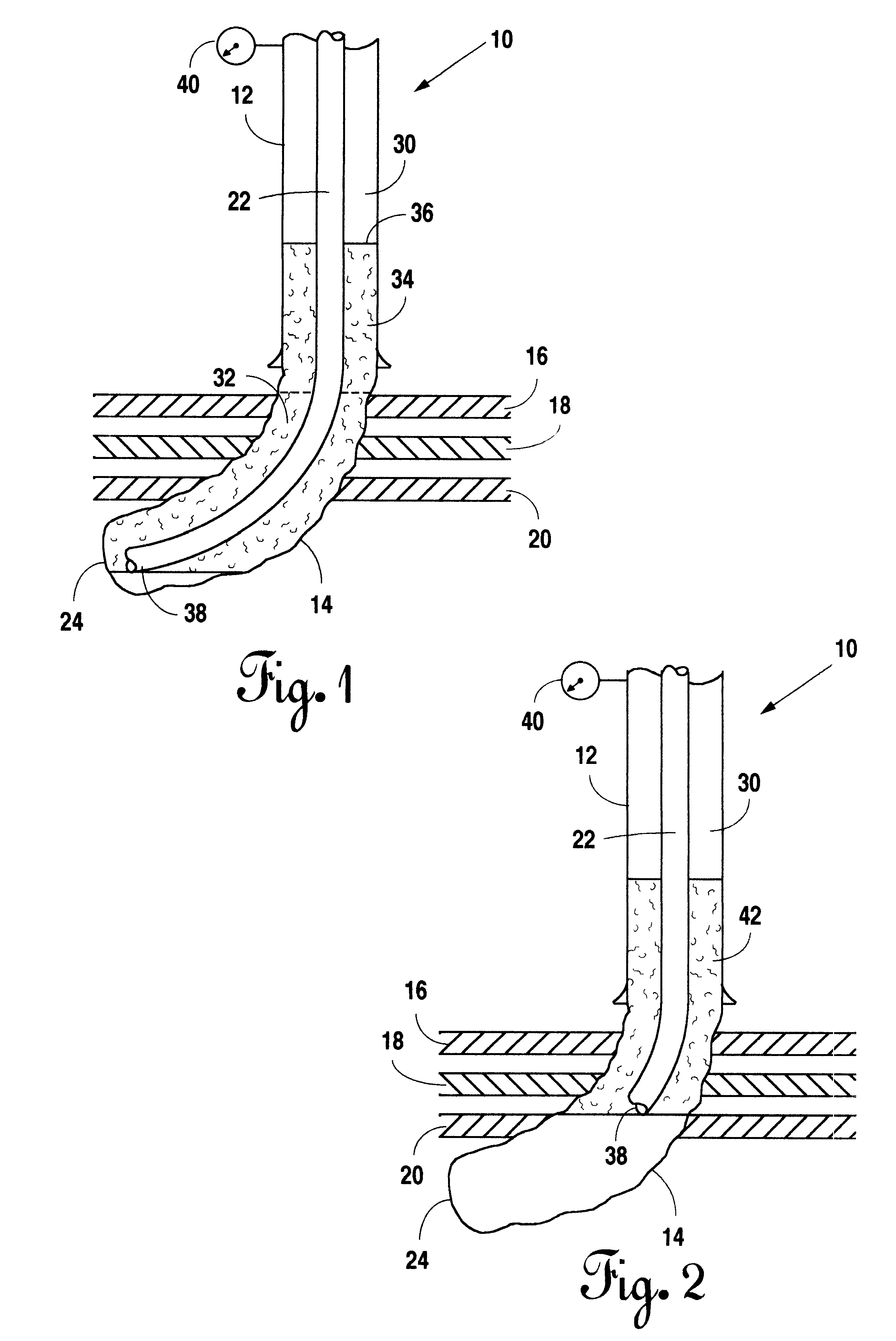

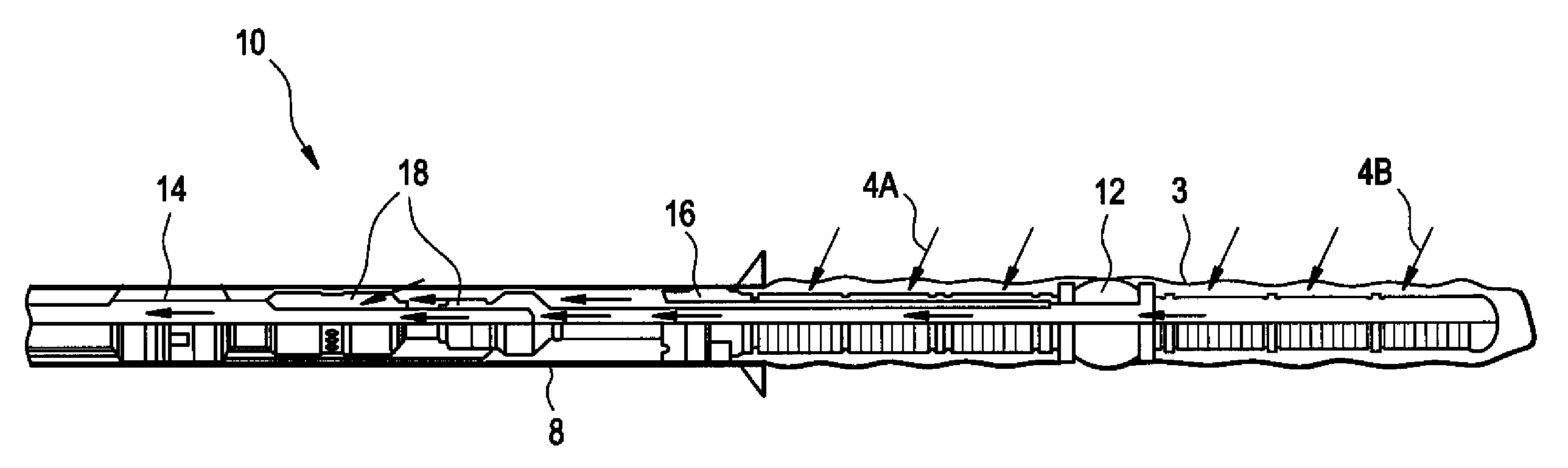

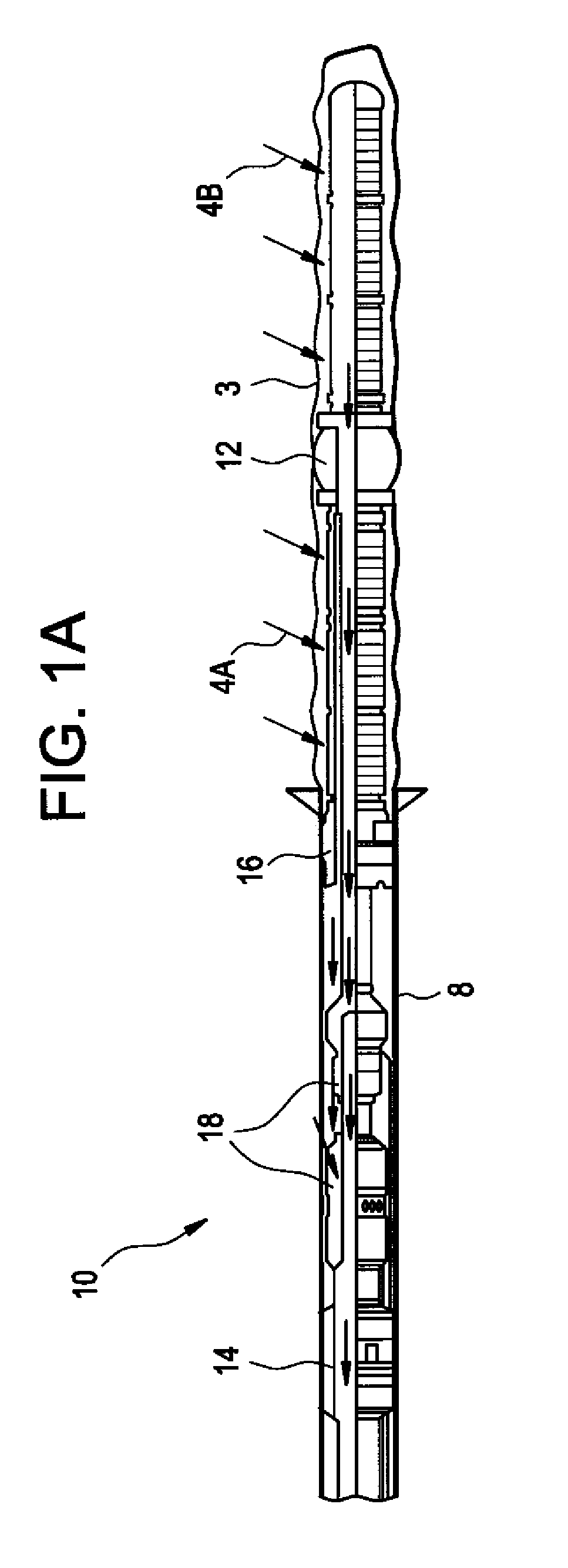

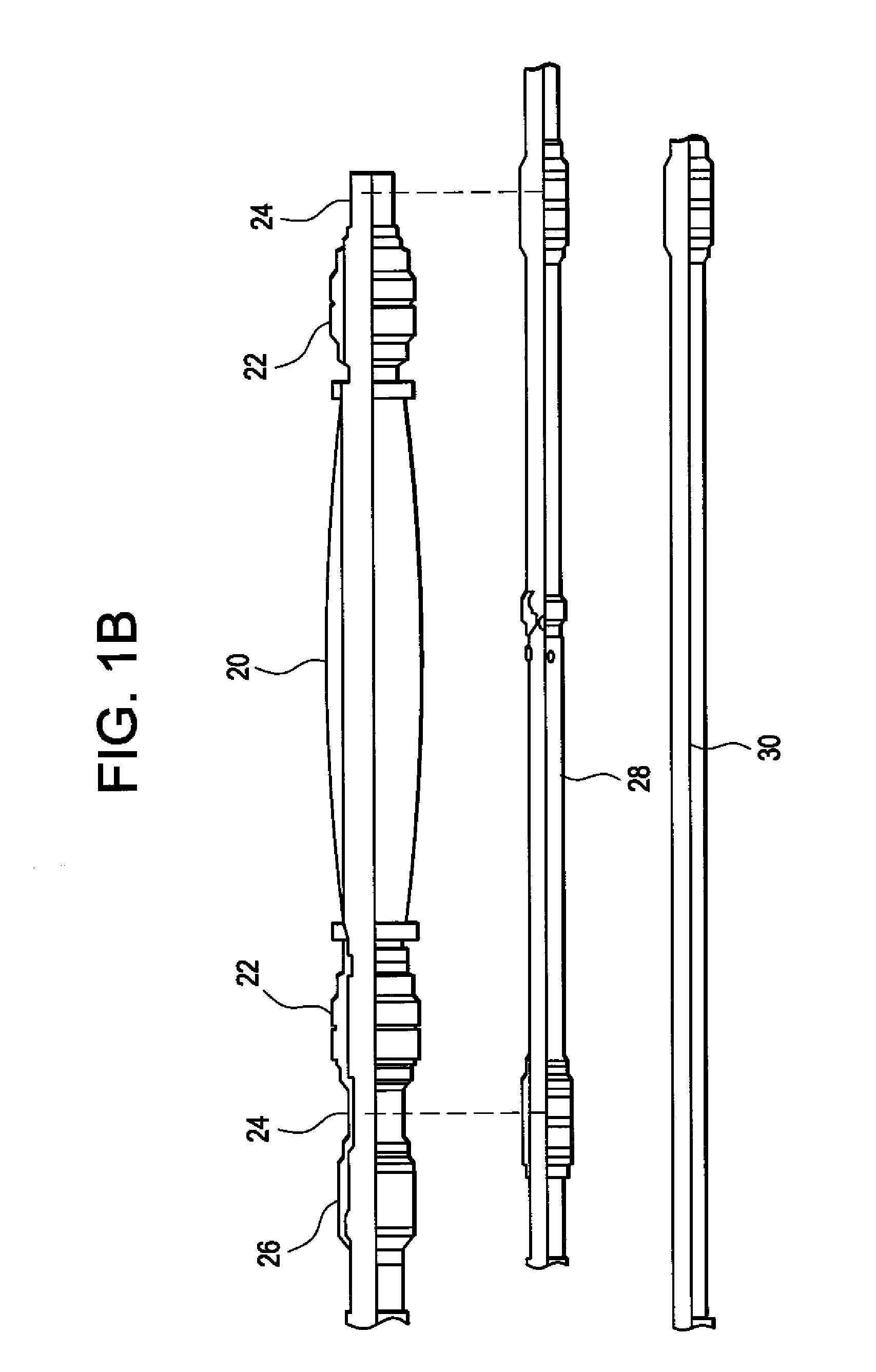

Method of providing hydraulic/fiber conduits adjacent bottom hole assemblies for multi-step completions

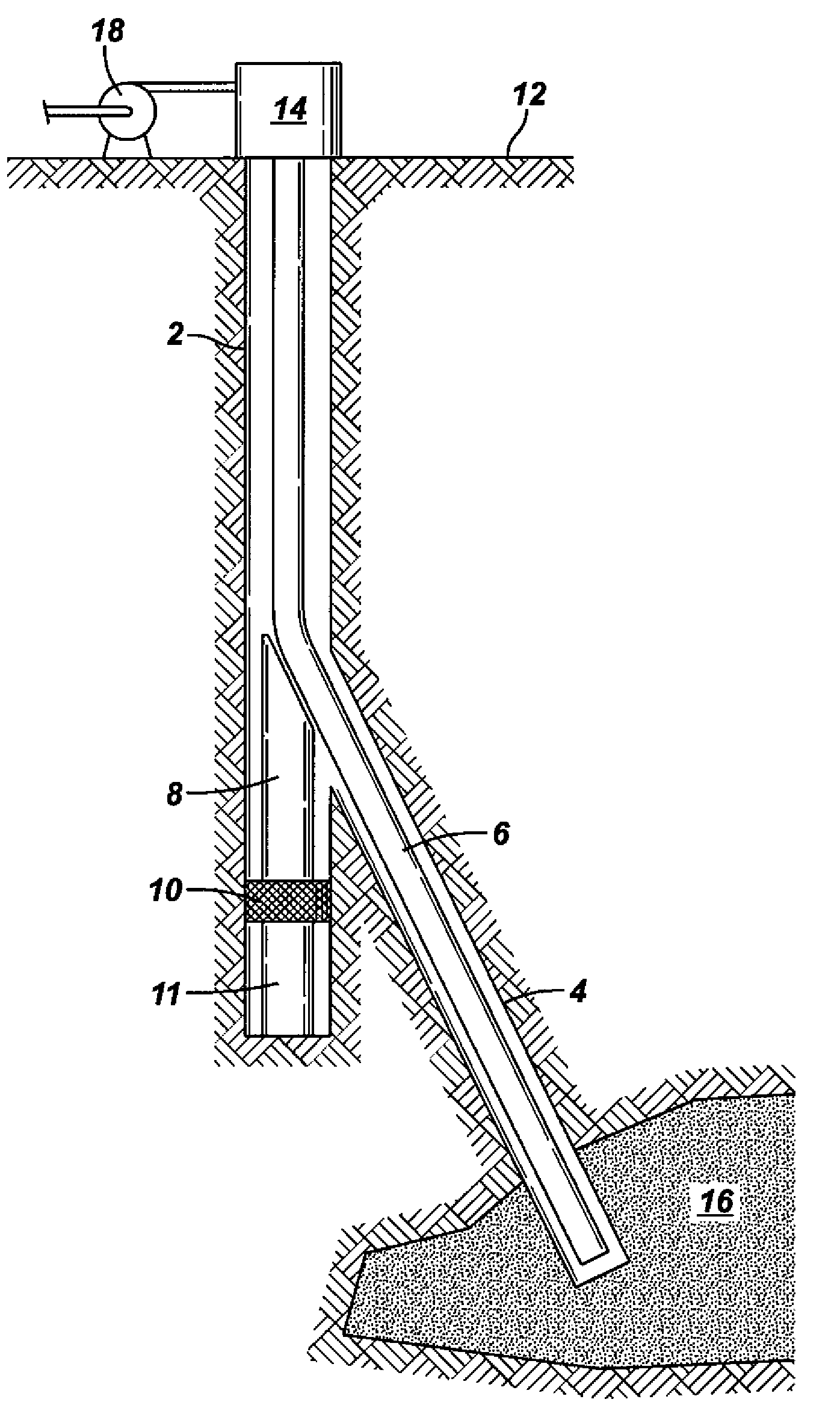

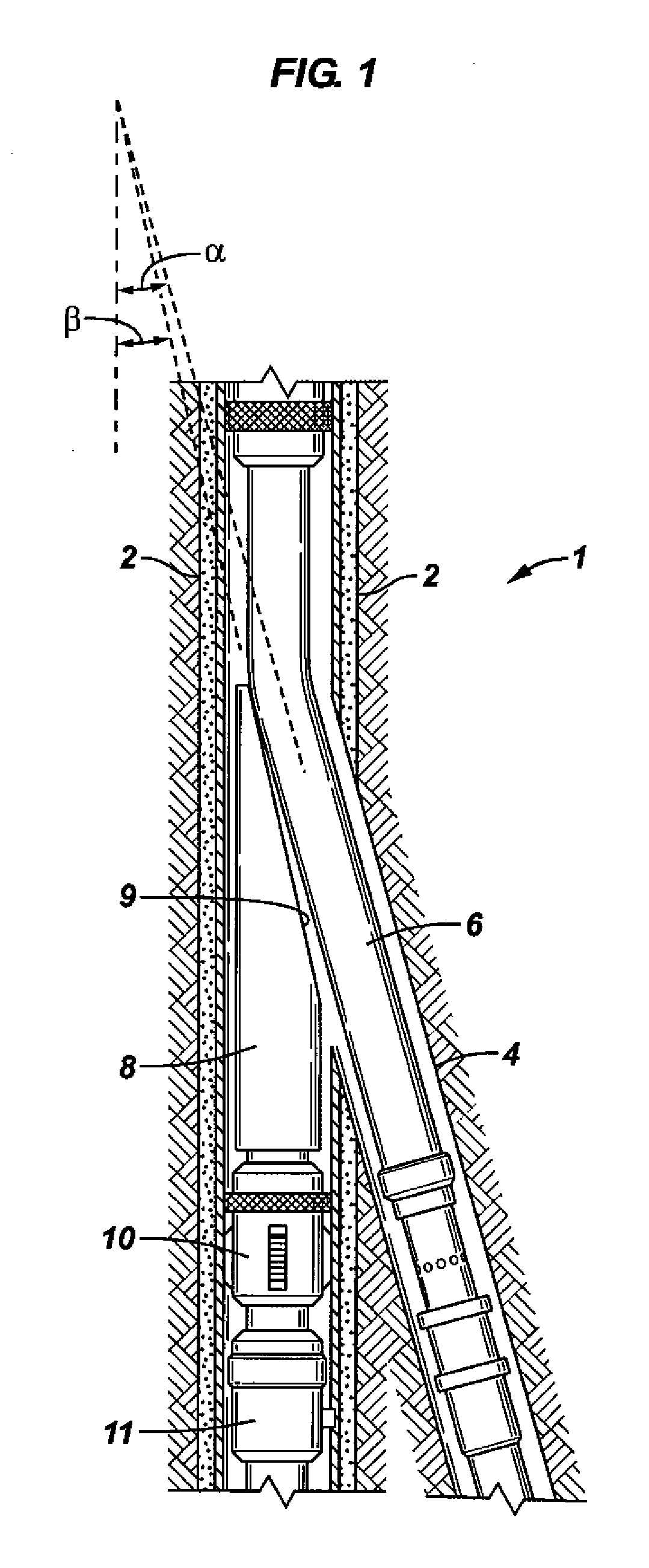

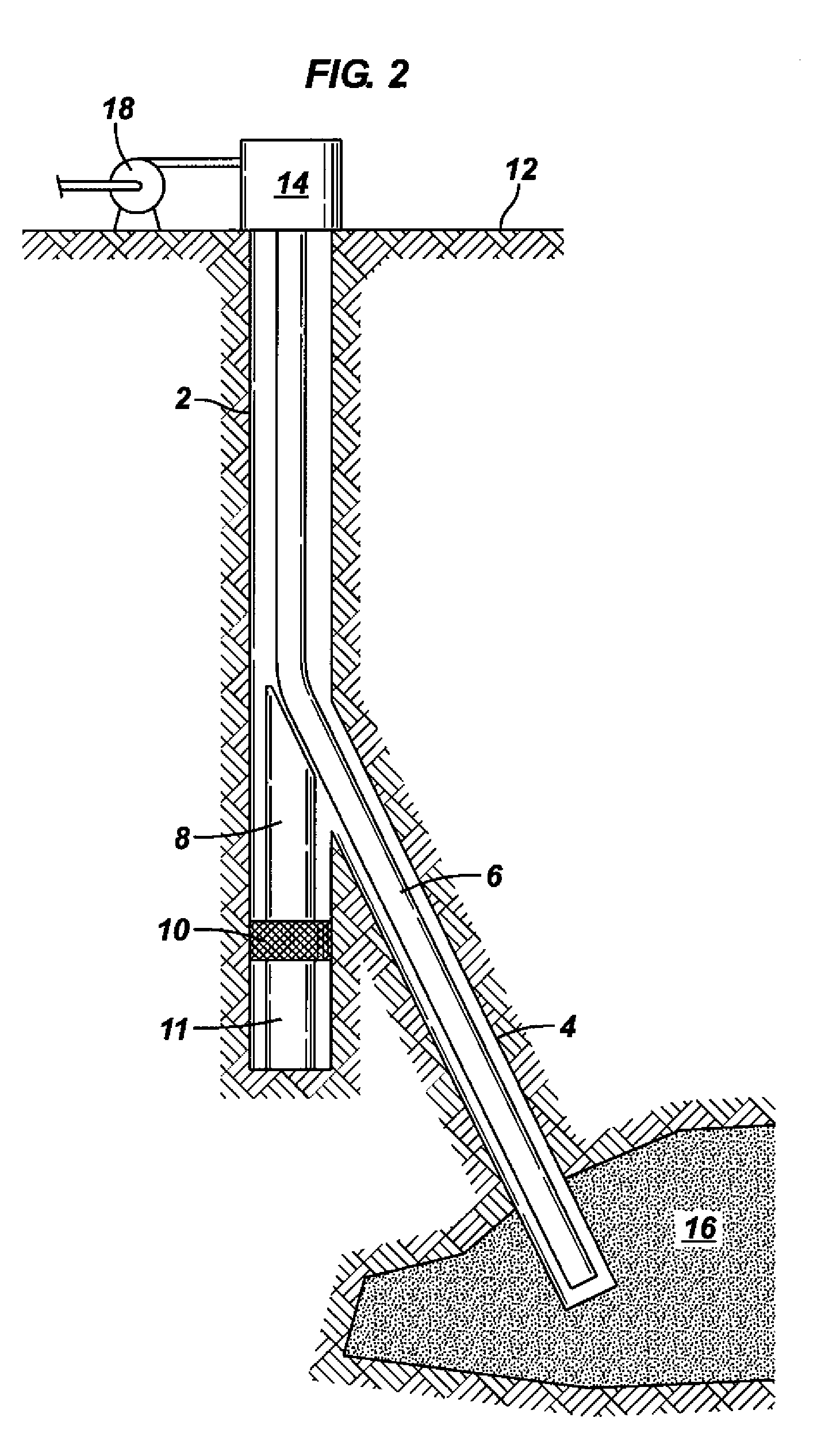

A technique for providing auxiliary conduits in multi-trip completions is disclosed. The technique has particular applicability to liner mounted screens which are to be gravel packed. In the preferred embodiment, a protective shroud is run with the gravel pack screens with the auxiliary conduits disposed in between. The auxiliary conduits terminate in a quick connection at a liner top packer. The gravel packing equipment can optionally be secured in a flow relationship to the auxiliary conduits so as to control the gravel packing operation. Subsequent to the removal of the specialized equipment, the production tubing can be run with an auxiliary conduit or conduits for connection down hole to the auxiliary conduits coming from the liner top packer for a sealing connection. Thereafter, during production various data on the well can be obtained in real time despite the multiple trips necessary to accomplish completion. The various completion and / or production activities can also be accomplished using the auxiliary conduits such as actuation of down hole flow control devices, chemical injection, pressure measurement, distributed temperature sensing through fiber optics, as well as other down hole parameters.

Owner:BAKER HUGHES INC

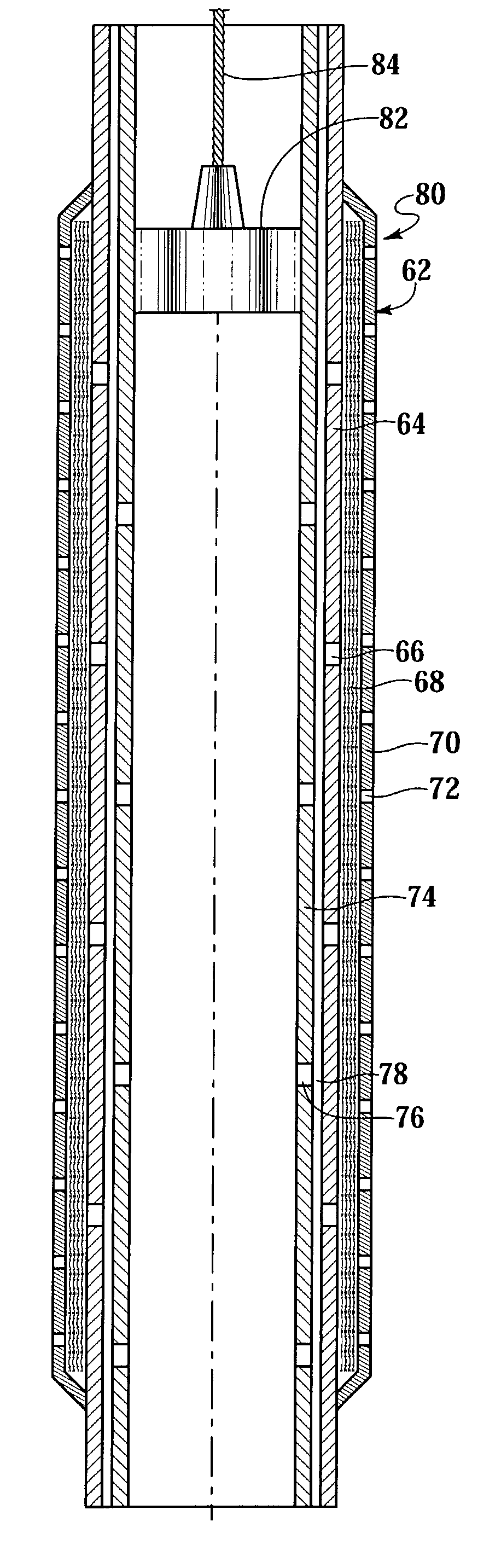

Fluid flow control device and method for use of same

InactiveUS7055598B2Not difficult and expensive to manufactureIncrease pressureSurveyFluid removalStream flowEngineering

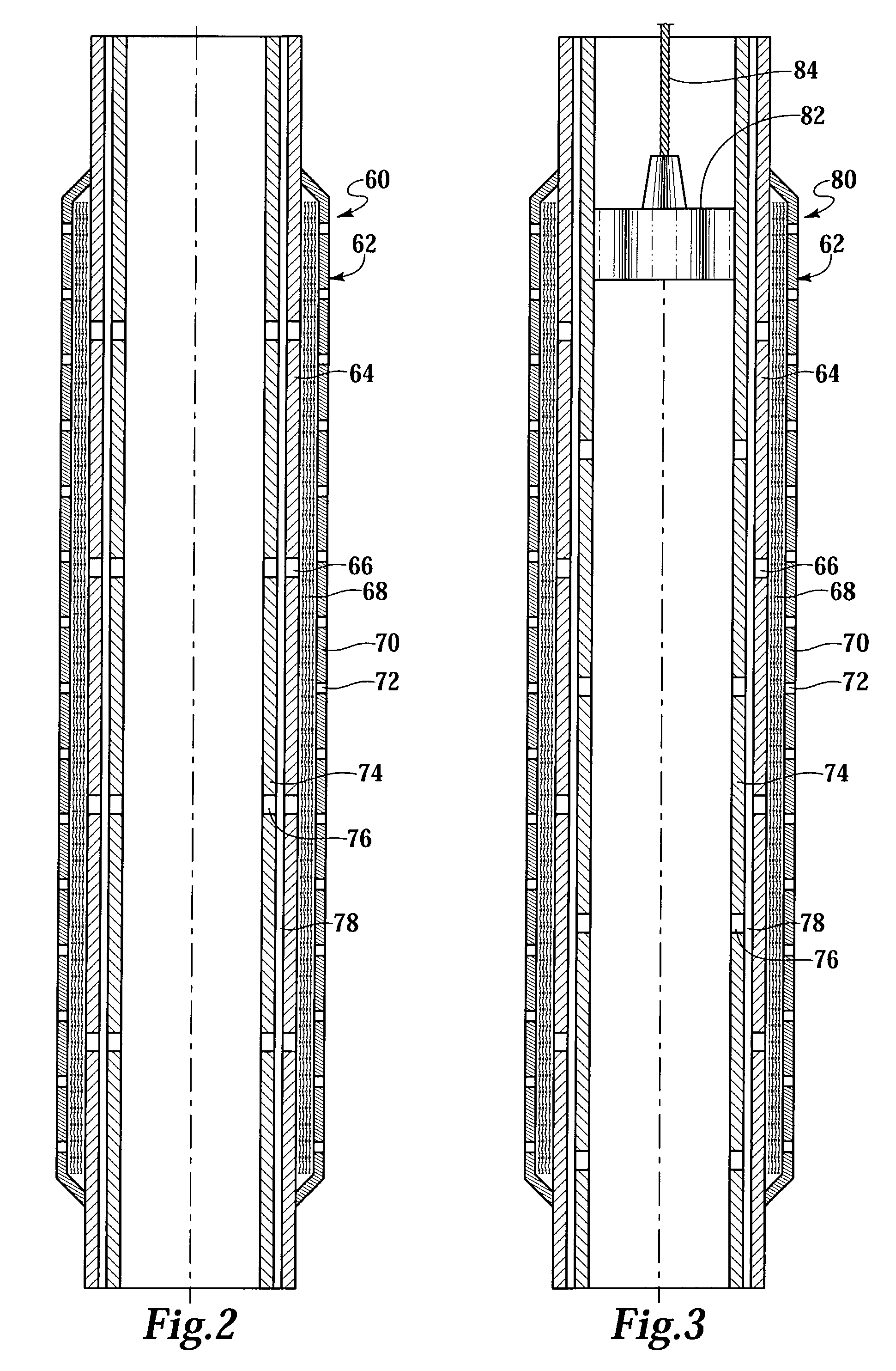

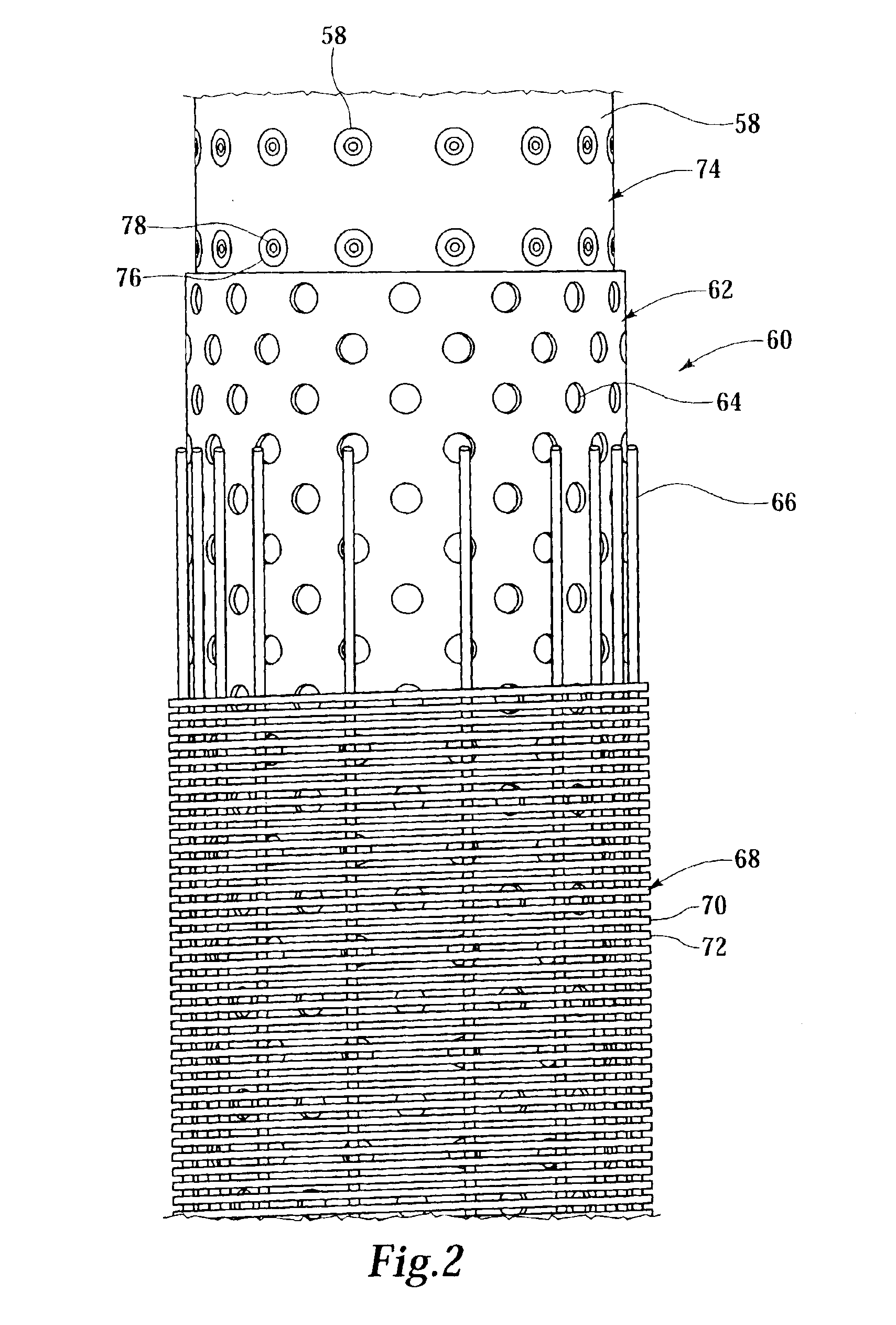

A fluid flow control device (60) for use in a wellbore to control the inflow of production fluids comprises a sand control screen (62) having a base pipe (64) with a first set of openings (66) that allows the production fluids to flow therethrough and a sleeve (74) coaxially disposed adjacent to the base pipe (64). The sleeve (74) has a second set of openings (76) that allows the production fluids to flow therethrough. The sleeve (74) is selectively positionable relative to the base pipe (64) such that a pressure drop in the production fluids is selectively controllable by adjusting an alignment of the first set of openings (66) relative to the second set of openings (76).

Owner:HALLIBURTON ENERGY SERVICES INC

Degradable whipstock apparatus and method of use

InactiveUS20080105438A1Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. In one embodiment the degradable composition consists essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

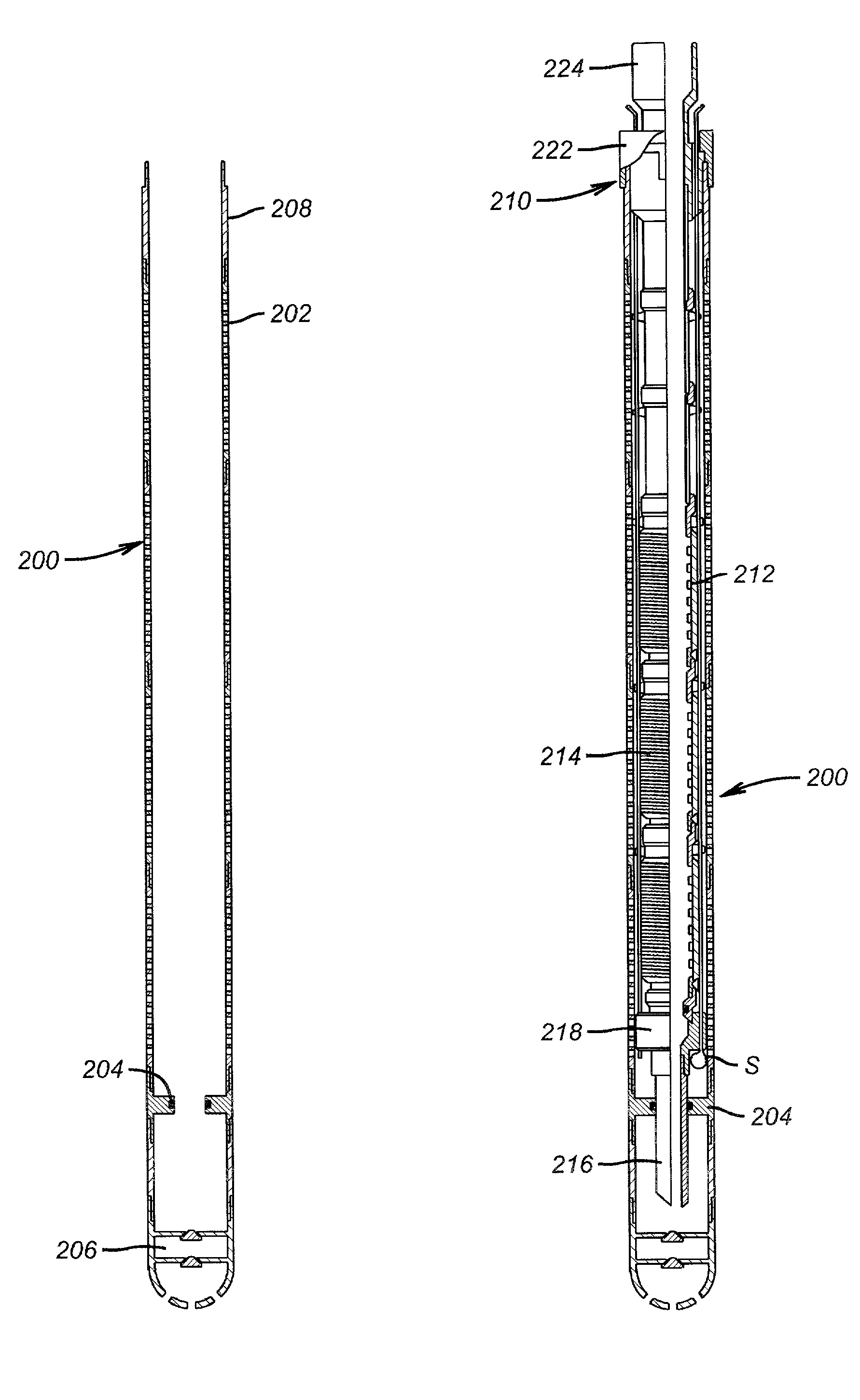

Sand control screen assembly and treatment method using the same

A sand control screen assembly (200) positionable within a production interval of a wellbore that traverses a subterranean hydrocarbon bearing formation comprises a base pipe (202) having openings (204) in a sidewall section thereof that allow fluid flow therethrough. A filter medium (210) is positioned about the exterior of at least a portion of the base pipe (202). The filter medium (210) selectively allows fluid flow therethrough but prevents the flow of particulate of a predetermined size therethrough. A seal member (218, 220, 222) is operably associated with the base pipe (202). The seal member (218, 220, 222) has a one-way valve configuration and a valve open configuration such that the seal member (218, 220, 222) controls fluid flow through the openings (204) of the base pipe (202).

Owner:HALLIBURTON ENERGY SERVICES INC

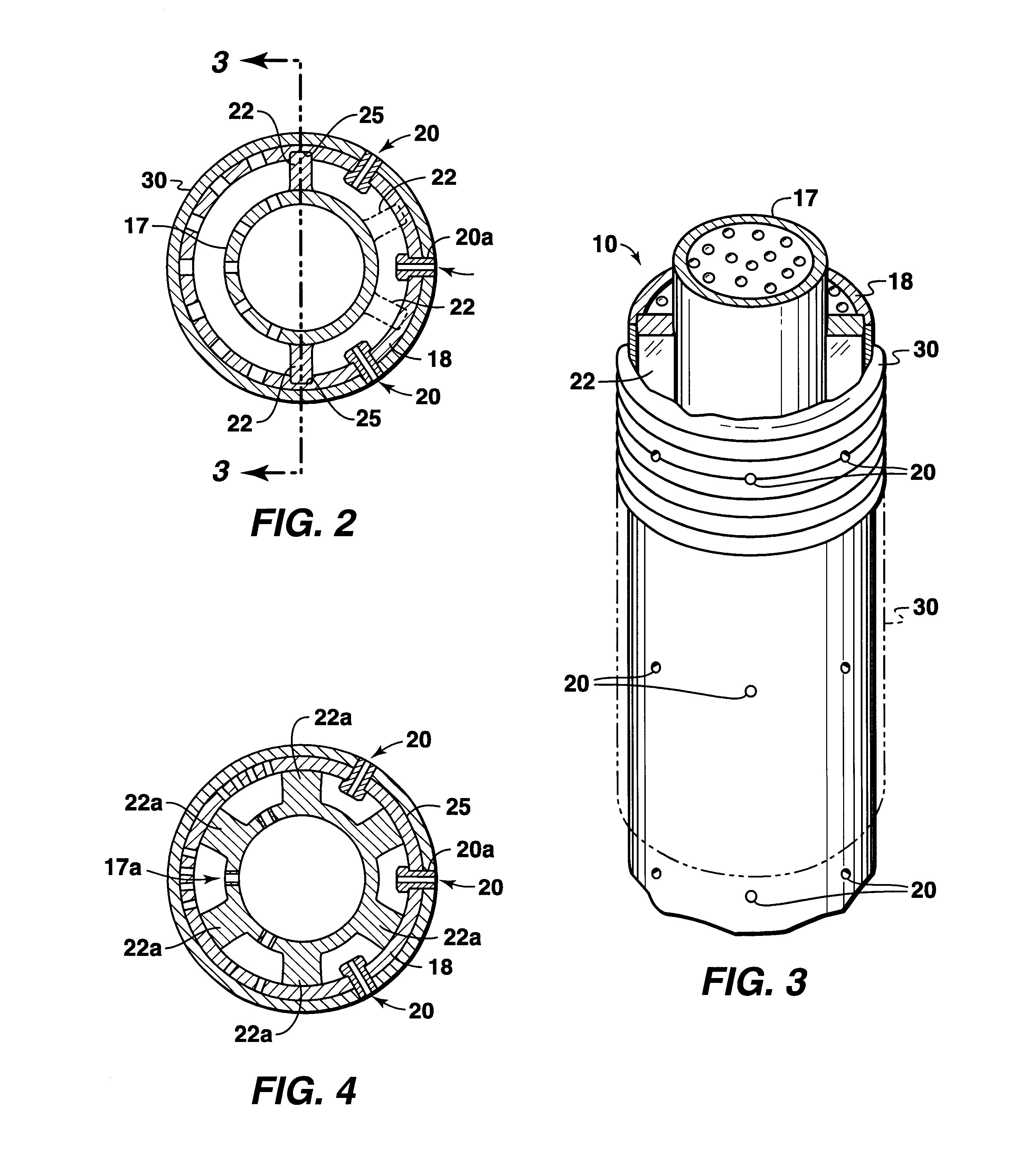

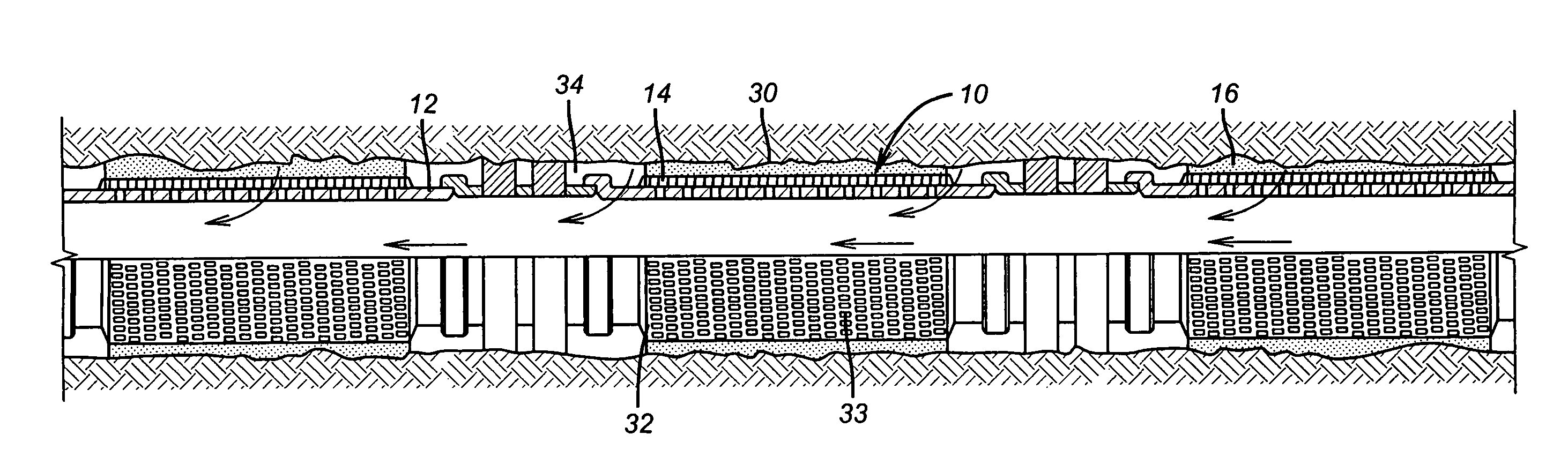

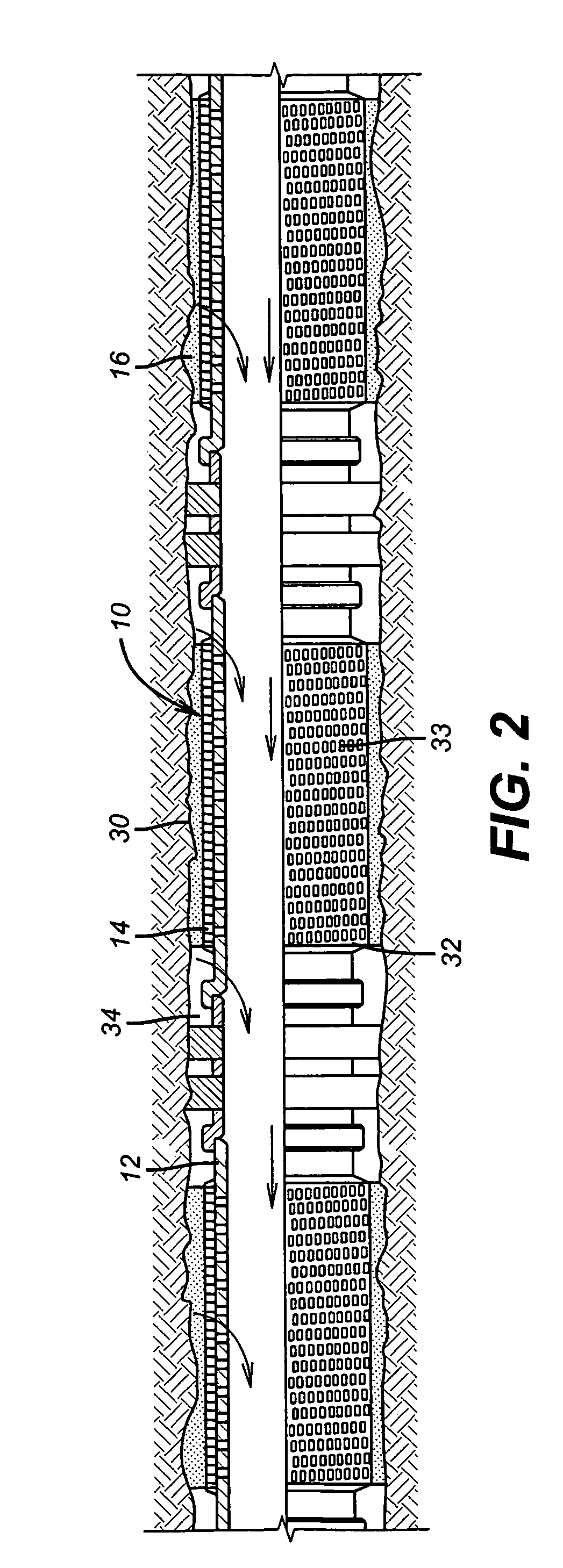

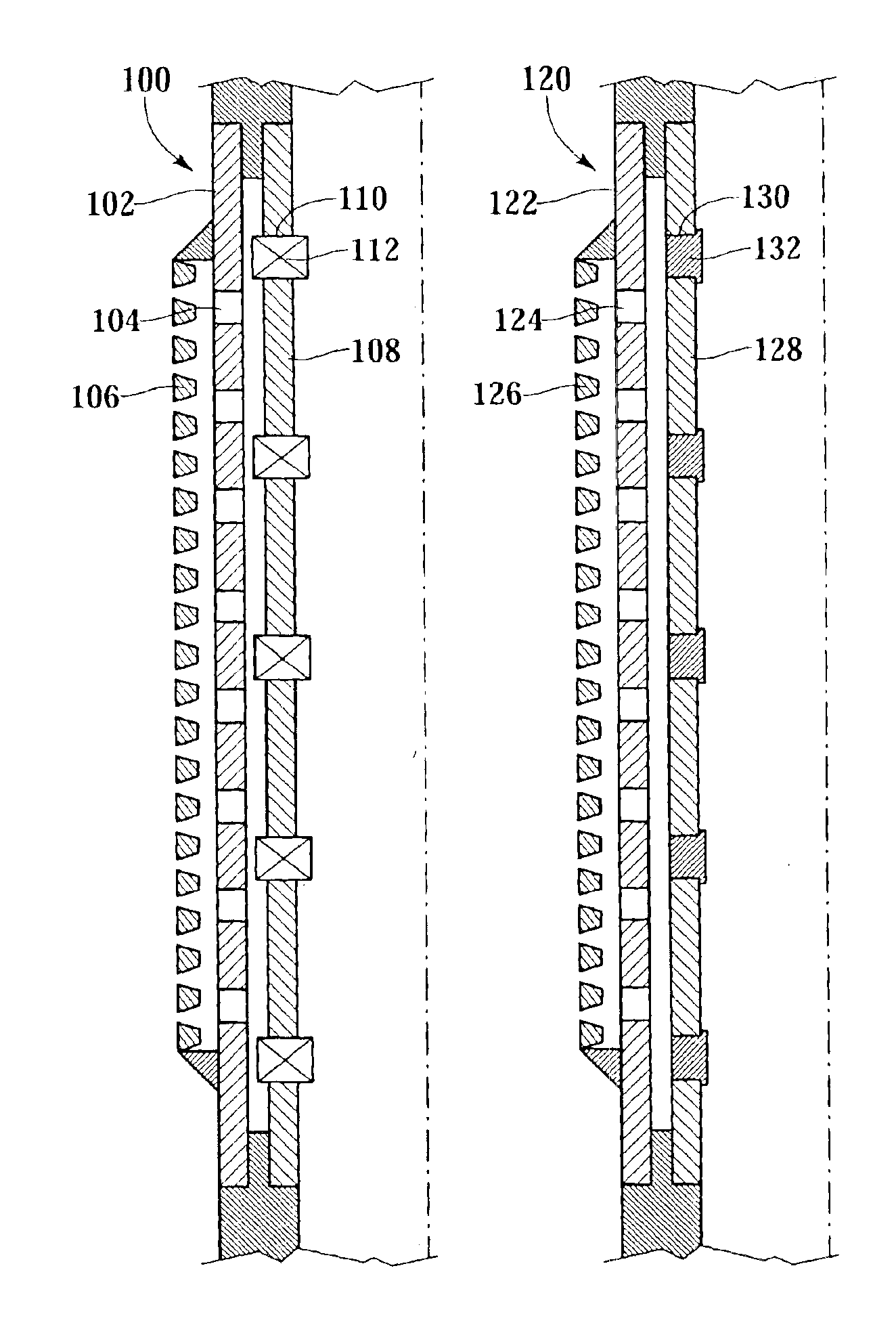

Well screen having an internal alternate flowpath

A well screen having an internal alternate flowpath for delivering gravel slurry to different levels within a well annulus and a method for assembling same. The screen is comprised of an outer pipe which is concentrically positioned over a base pipe so that an annulus is formed therebetween. Both pipes are perforated along their respective lengths but only part way around their respective circumferences. The respective perforated sections radially align with each other when the pipes are assembled. A plurality of longitudinal ribs isolate the annulus adjacent the perforated sections (i.e. production side of screen) from the annulus adjacent the non-perforated sections (i.e. alternate flowpath side of screen). At least one outlet is provided through the non-perforated section of the outer pipe to provide an outlet from the internal alternate flowpath.

Owner:MOBIL OIL CORP

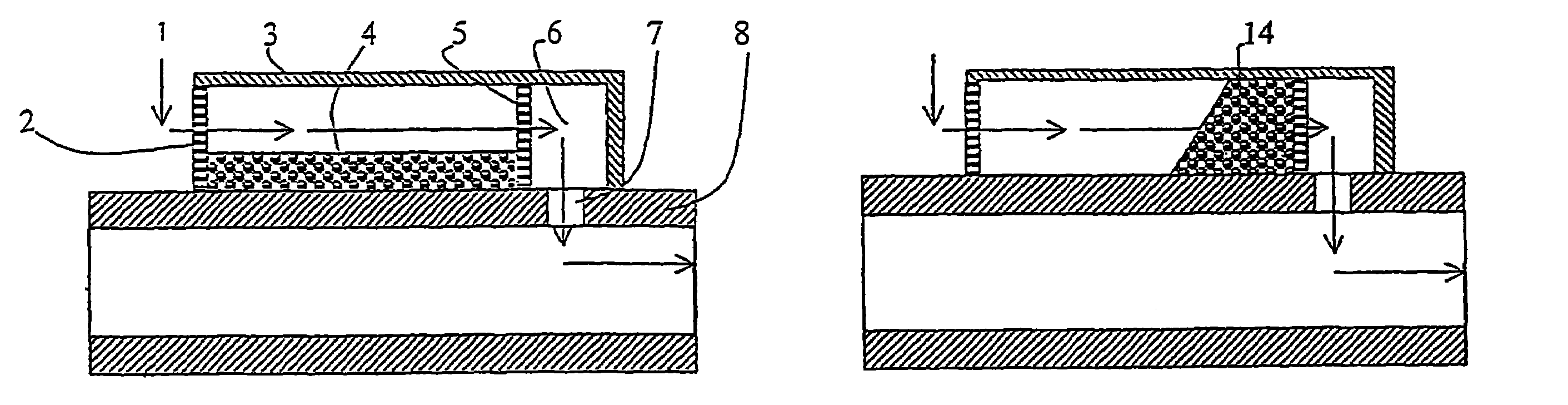

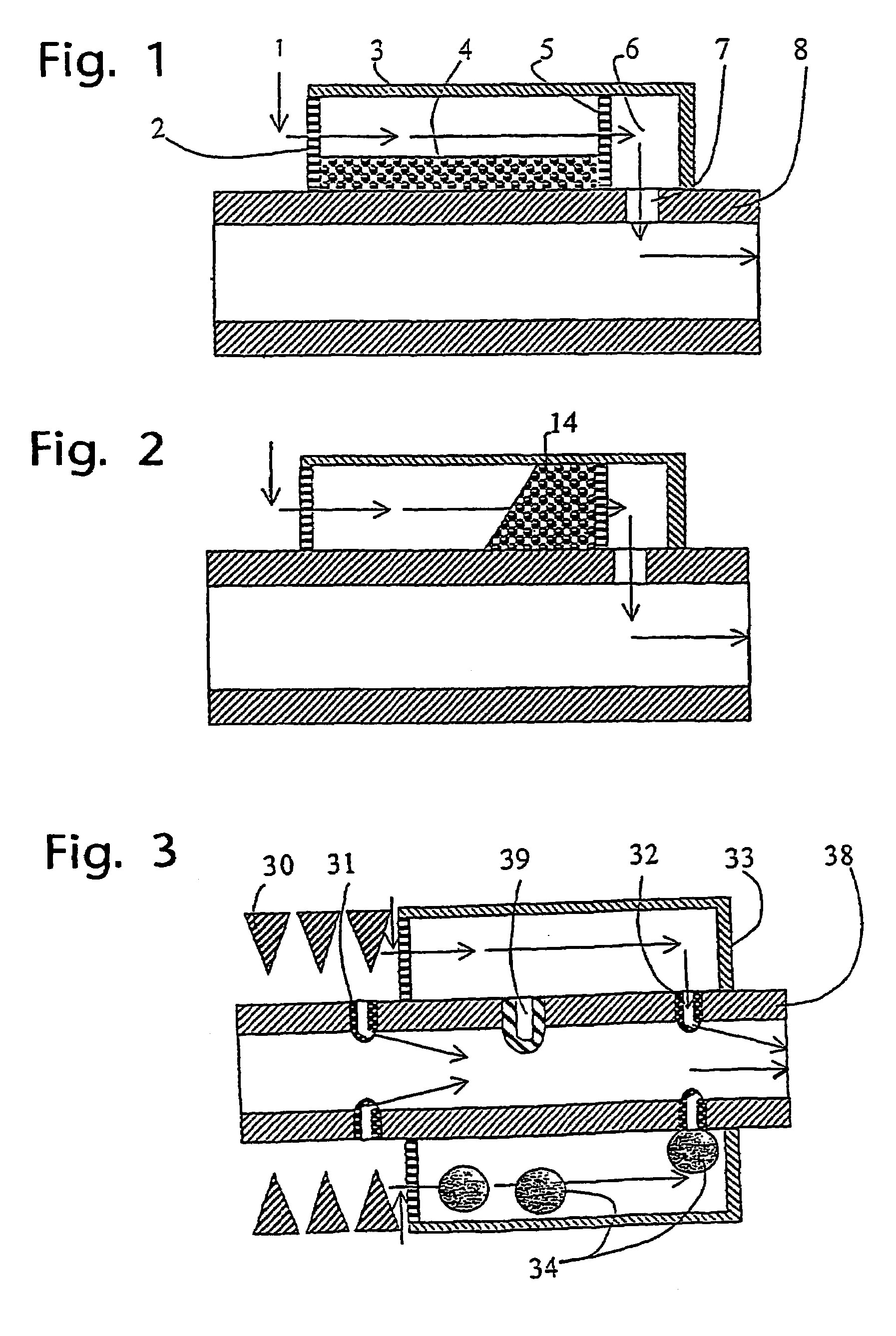

Arrangement for and method of restricting the inflow of formation water to a well

InactiveUS7185706B2Low mobilityNeutral buoyancyDrilling rodsFluid removalWater flowVolumetric Mass Density

An arrangement for restricting the inflow of formation water from an underground formation to a hydrocarbon producing well, where, between the underground formation and a production tubing (38) located in the well, there is disposed at least one flow chamber (3, 33) connected to the production tubing (38), the flow chamber (3, 33), preferably via a filter (2) in one portion, being open to inflow of formation fluid and in communication with the production tubing (38) via at least one opening (7, 32), and where the flow chamber (3, 33) is provided with at least one free-floating body (4, 34) with approximately the same density as the formation water, the at least one body (4, 34) being designed by means of the closing of at least one opening (32) or choking, to reduce the inflow of formation water to the production tubing (38).

Owner:HALLIBURTON ENERGY SERVICES INC

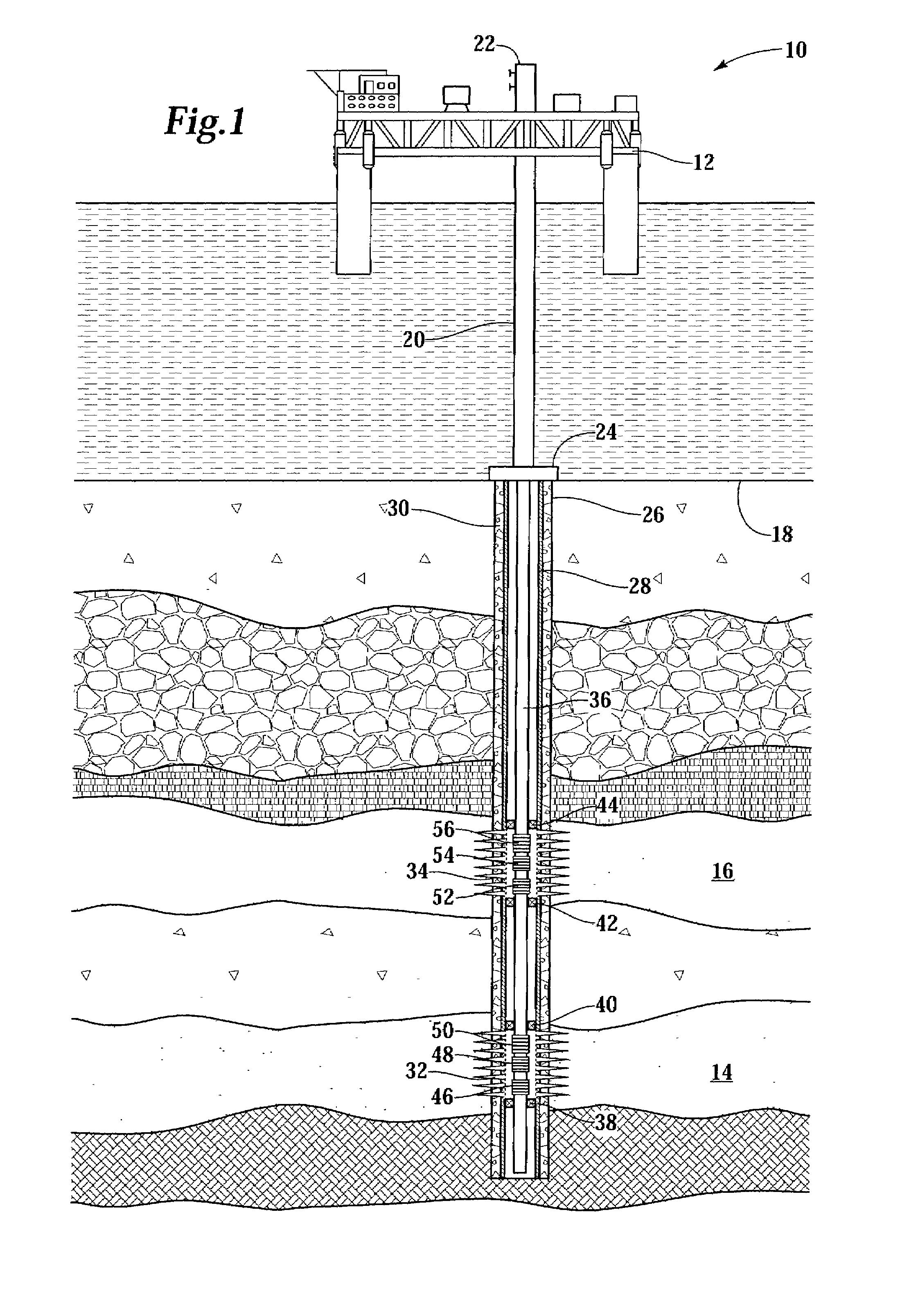

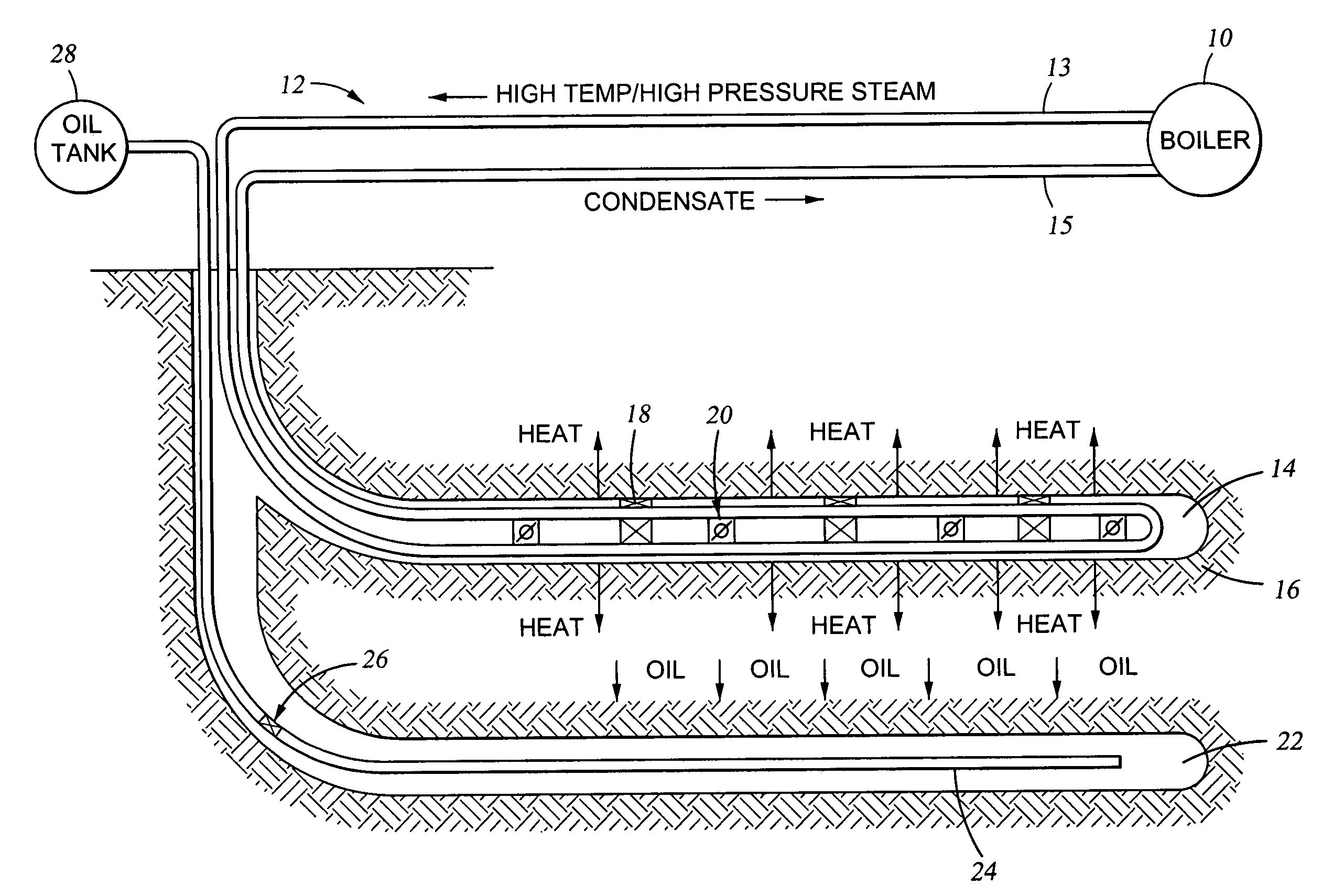

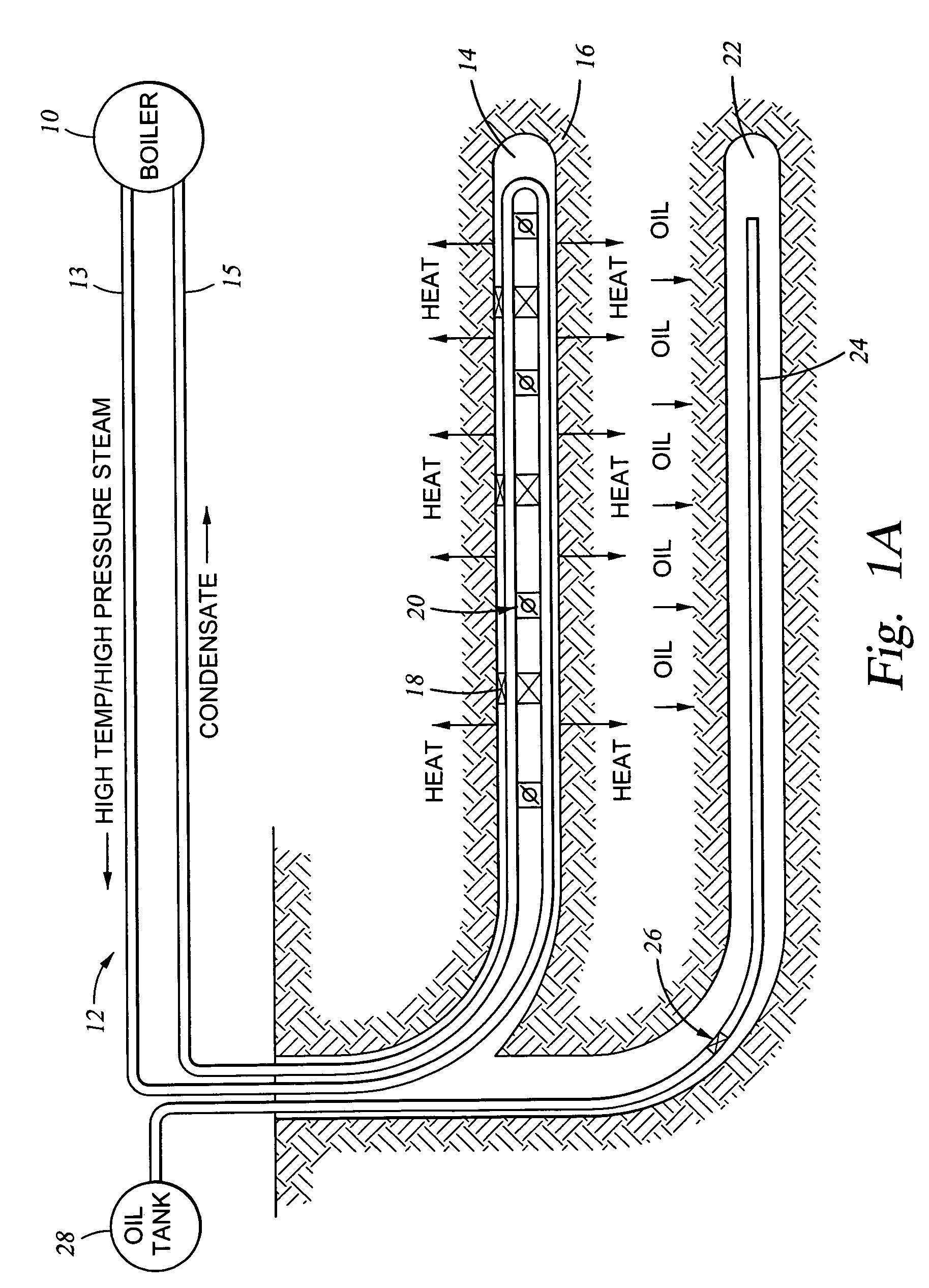

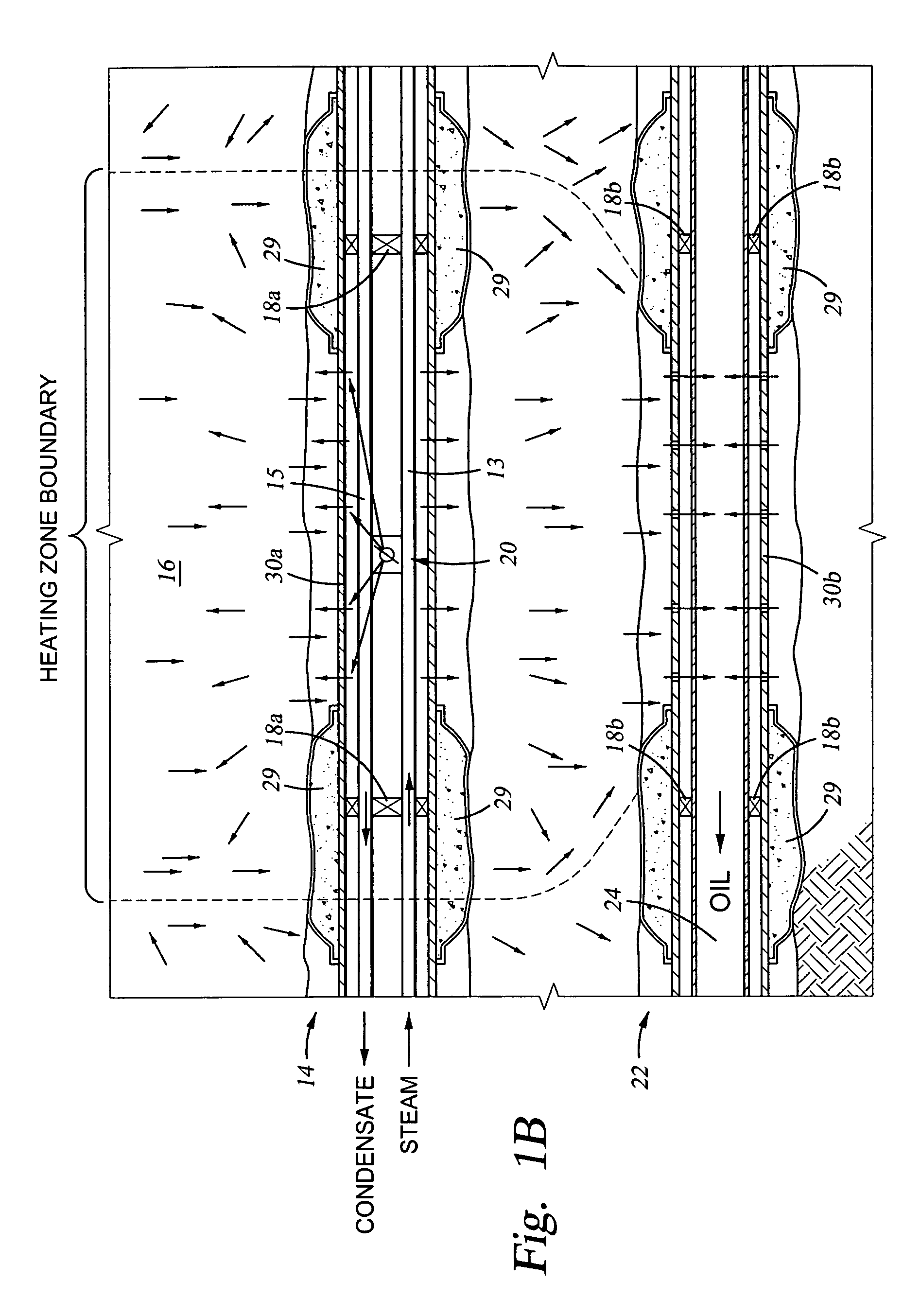

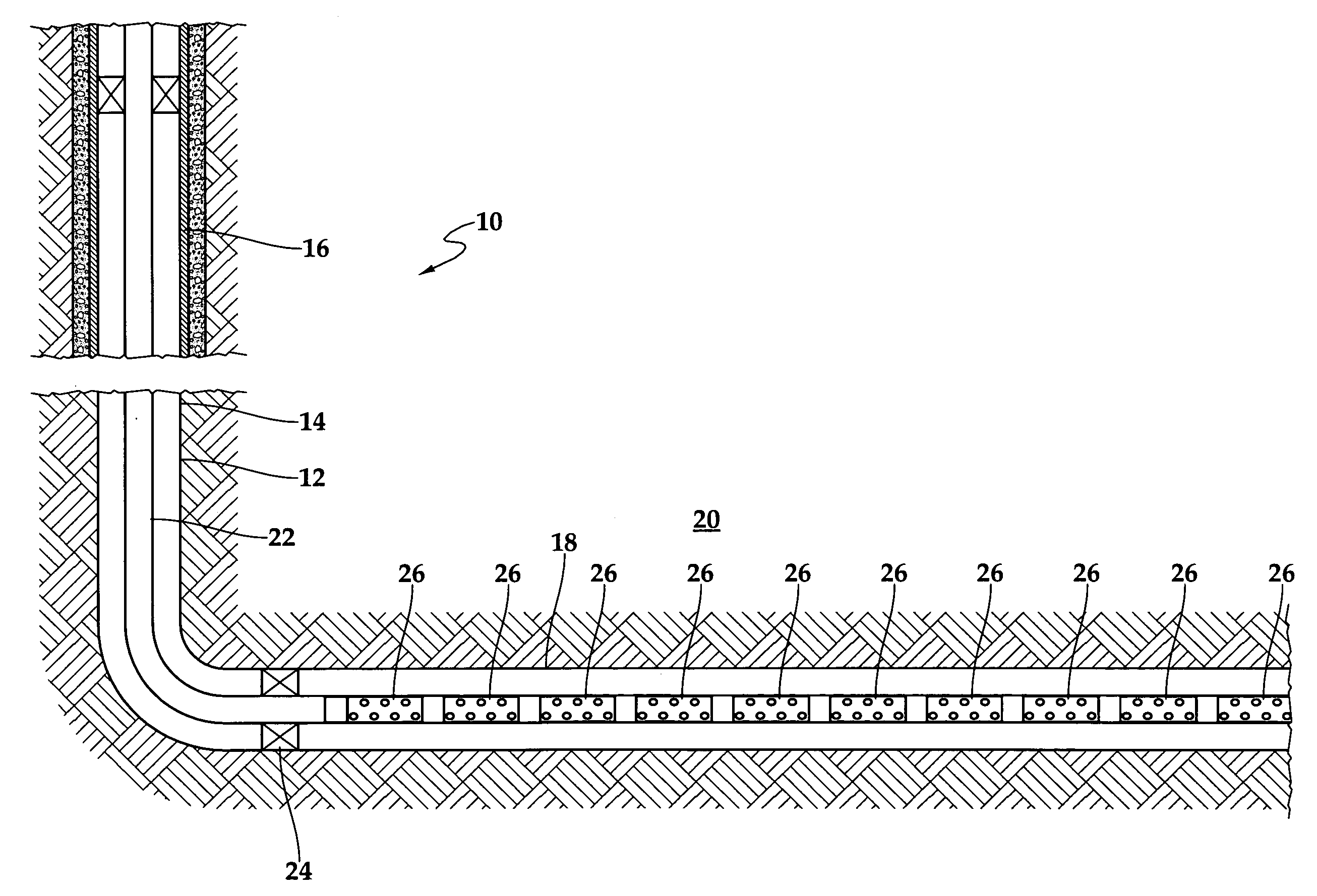

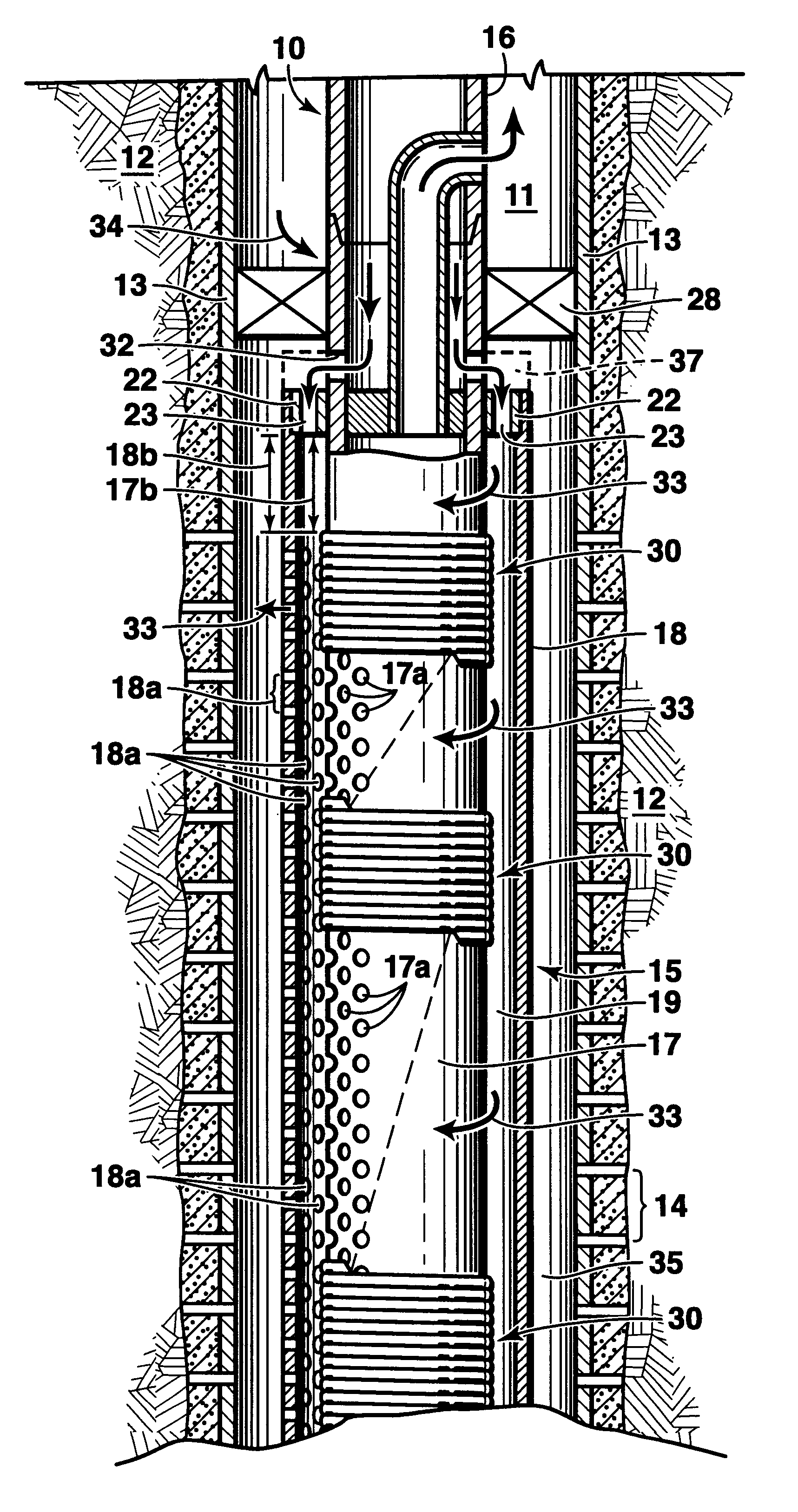

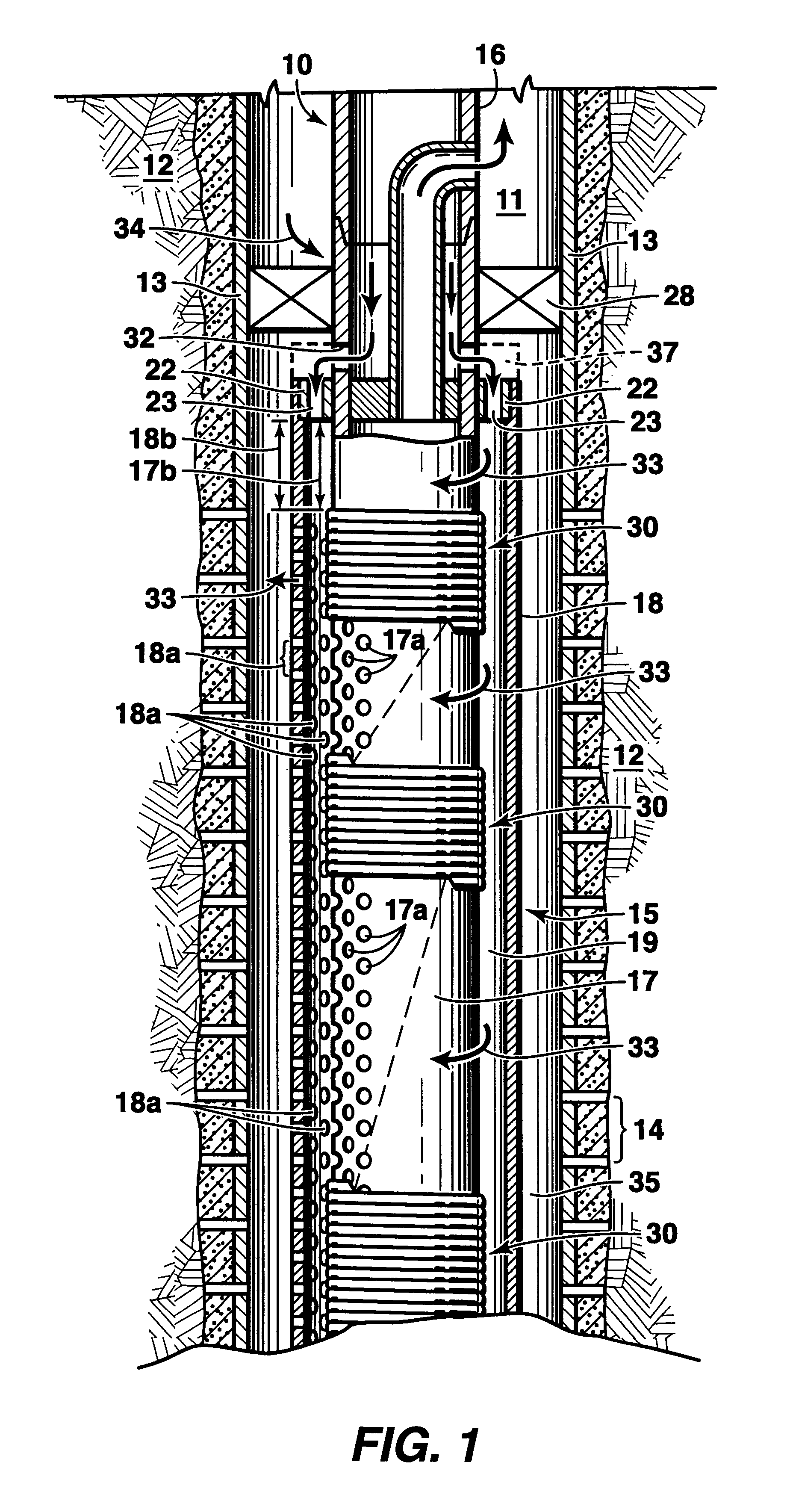

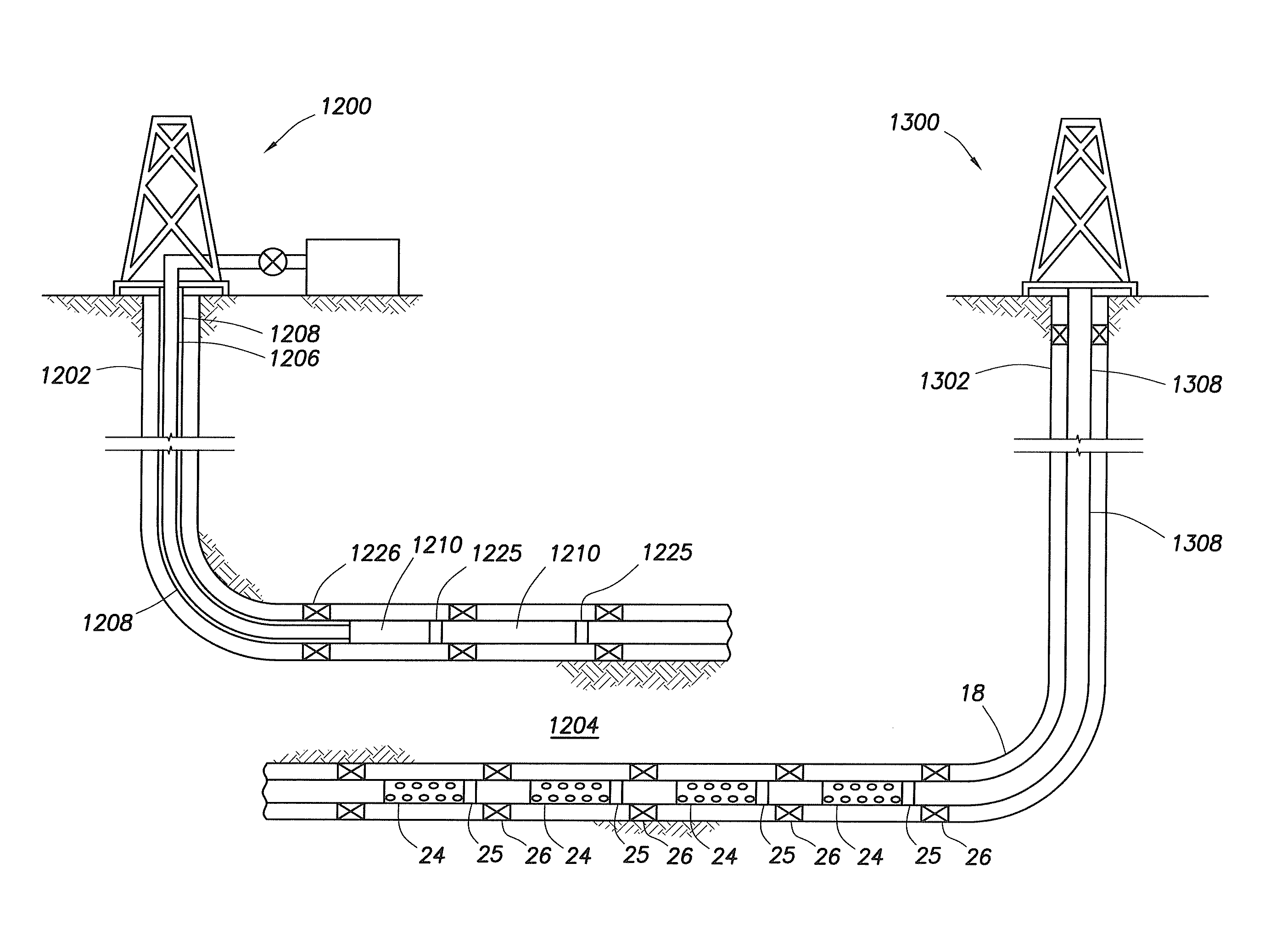

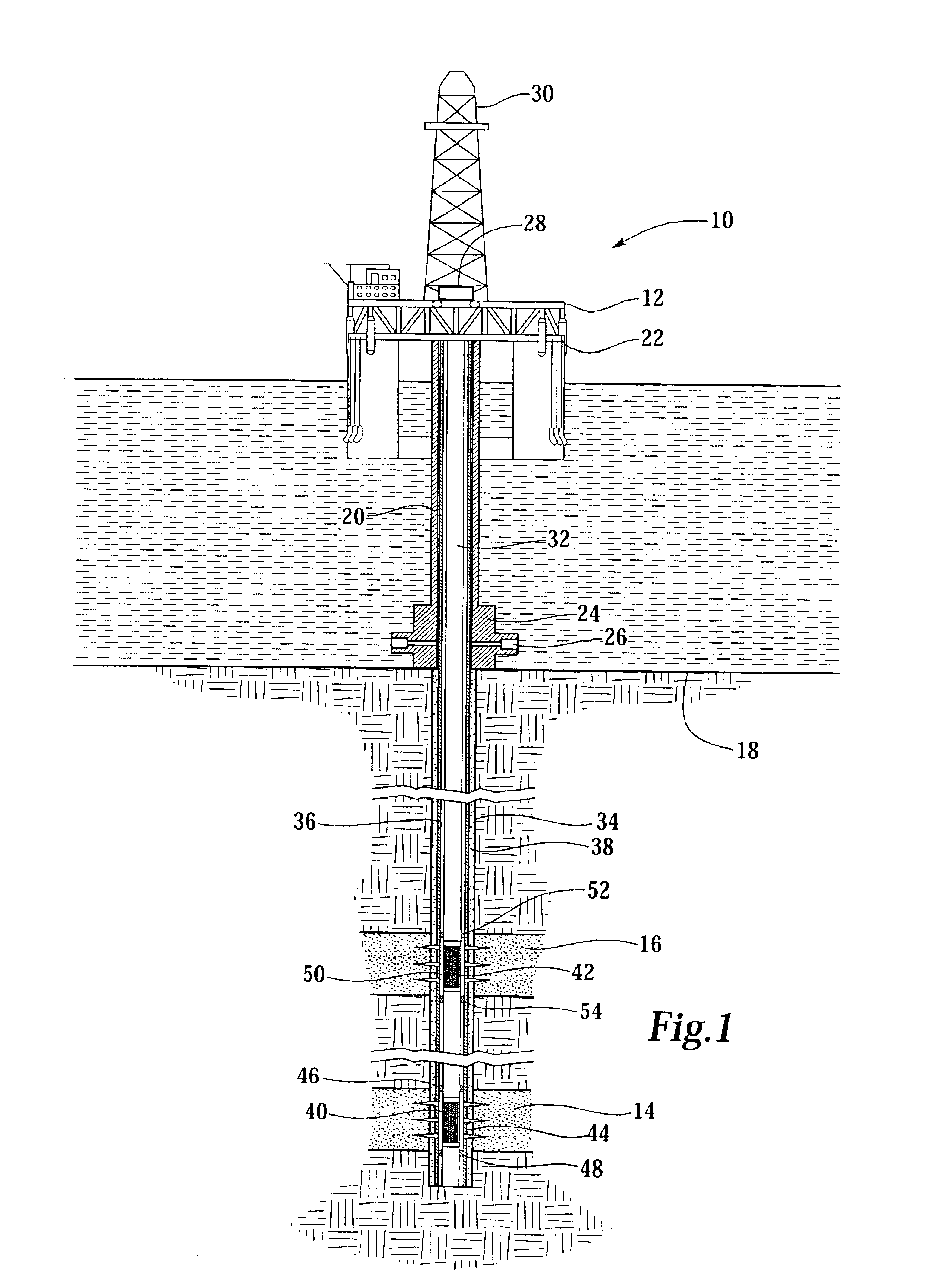

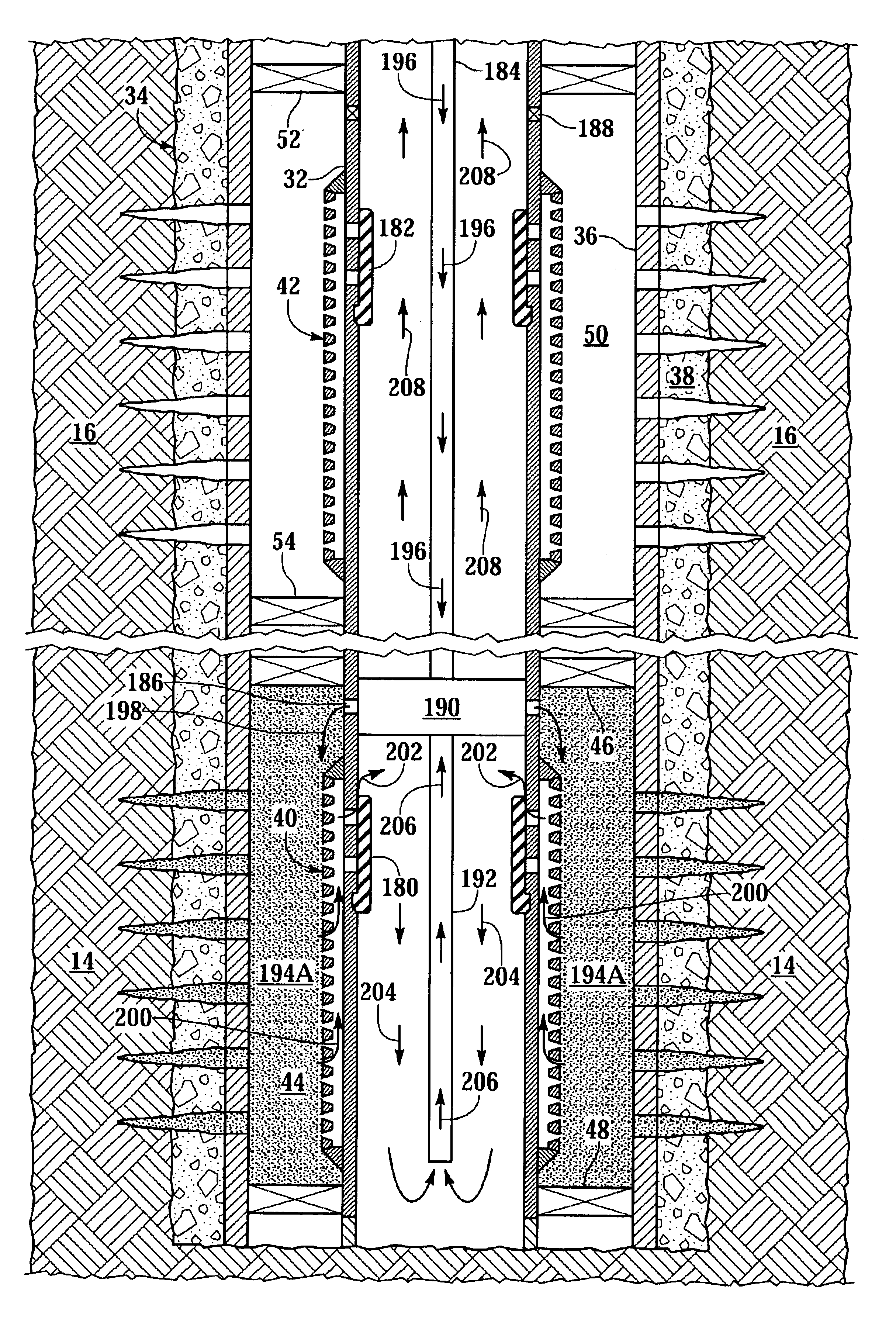

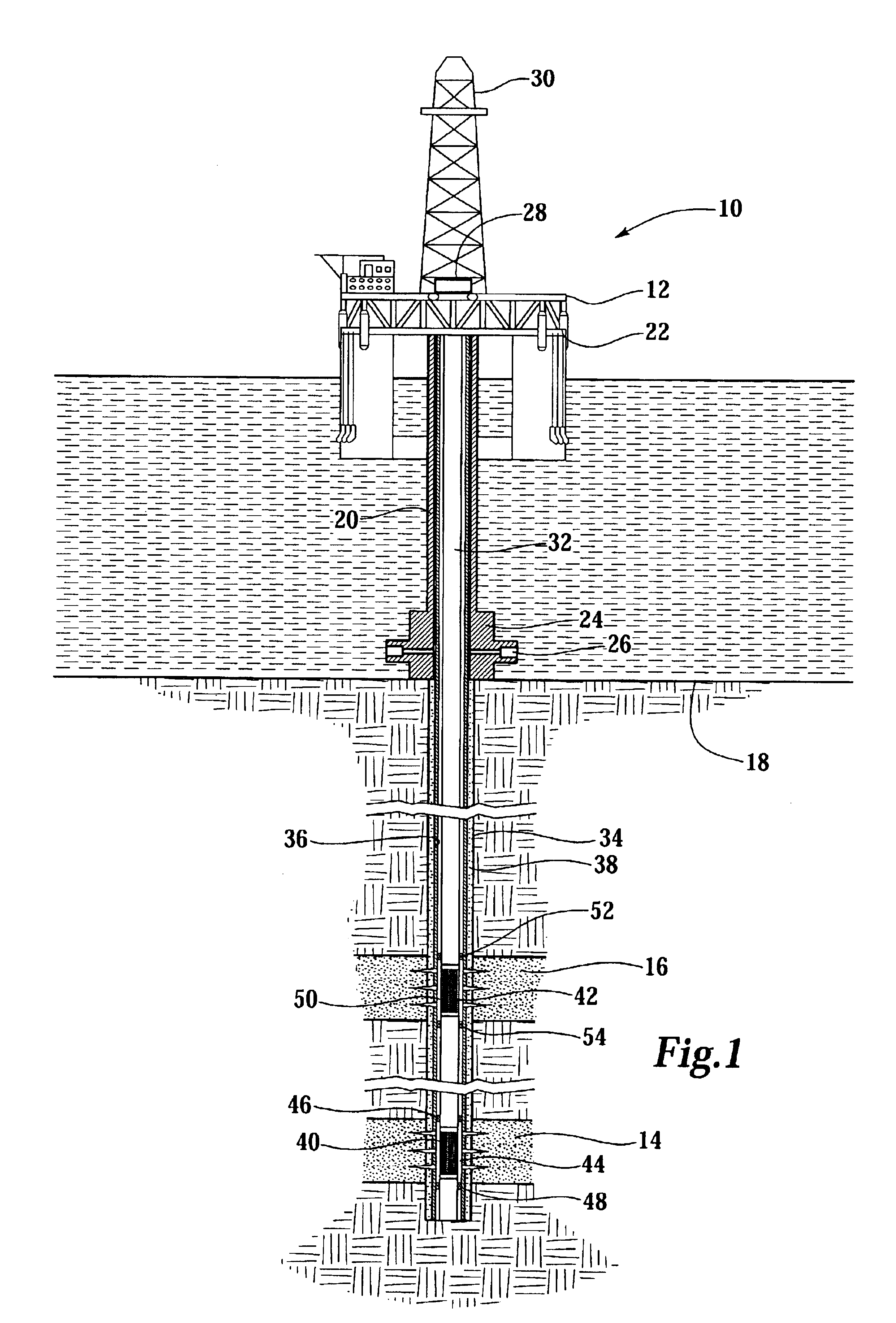

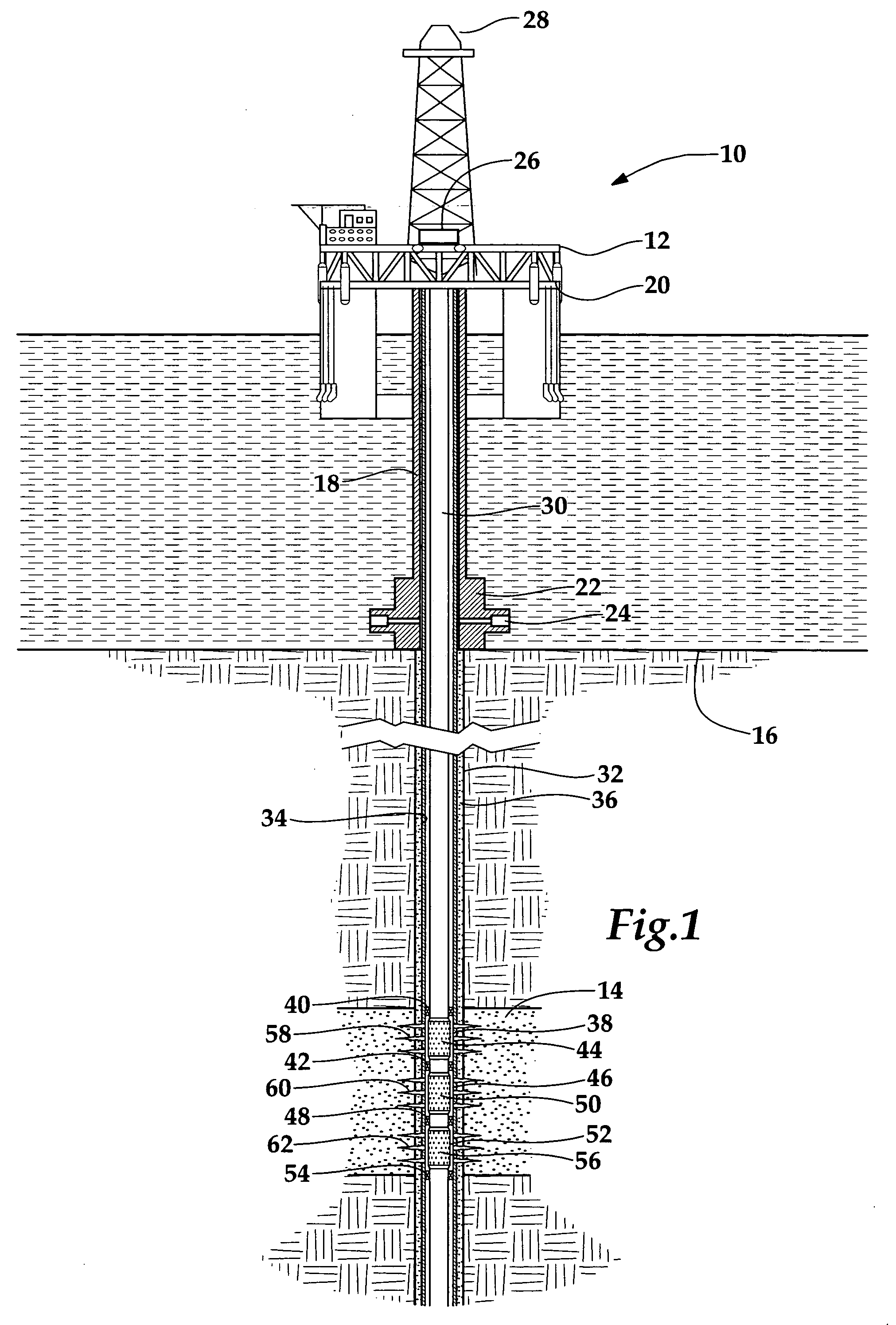

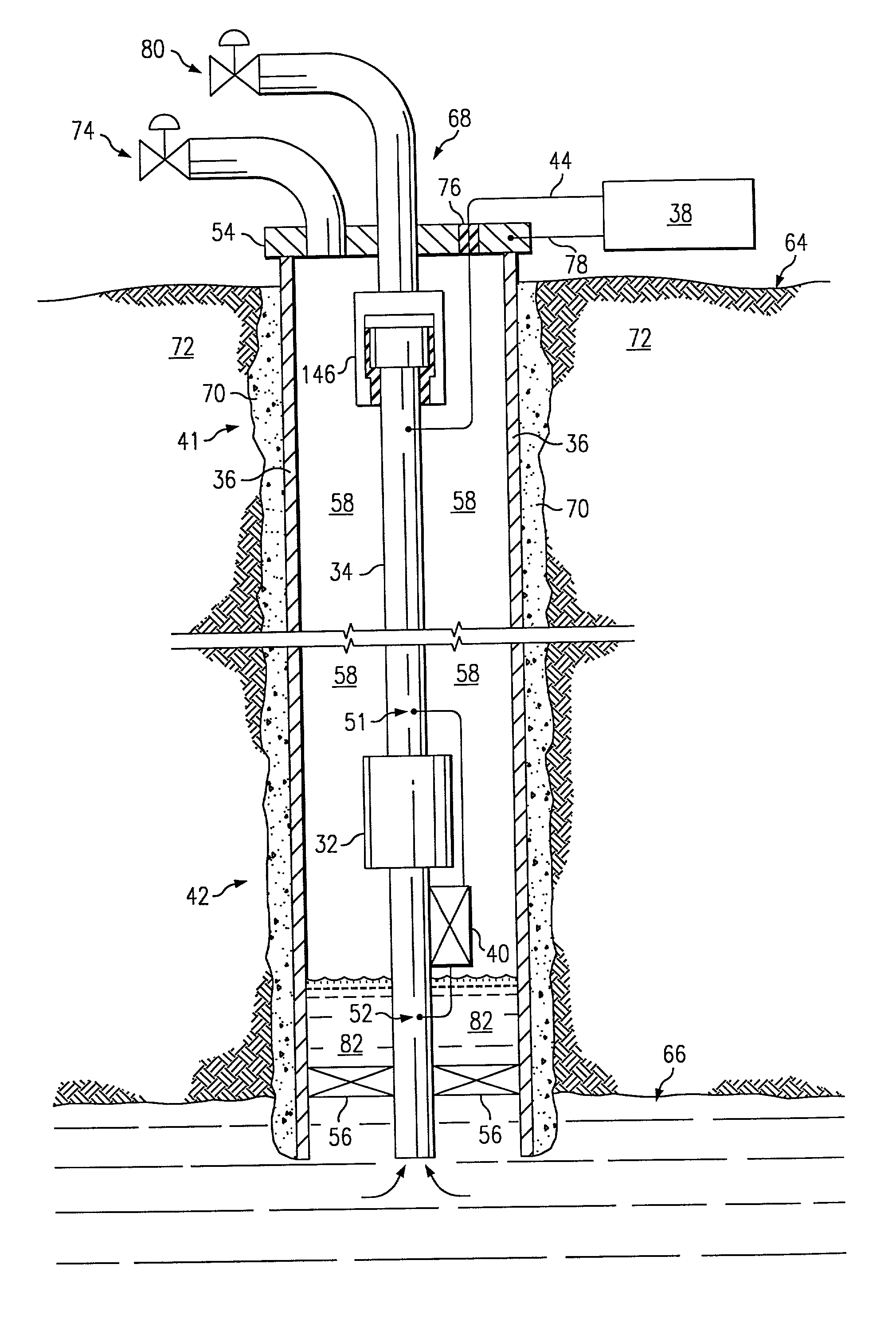

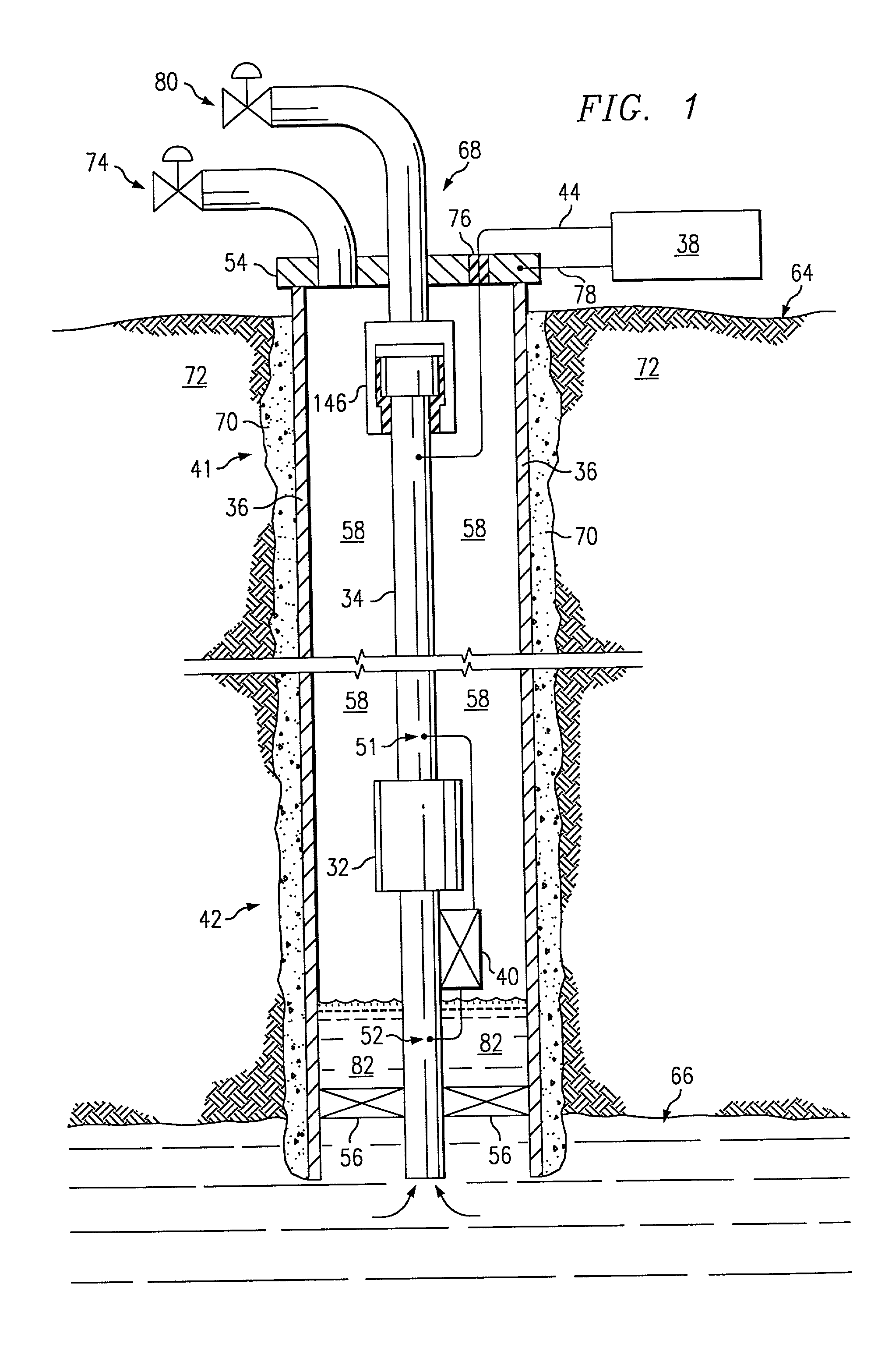

Loop systems and methods of using the same for conveying and distributing thermal energy into a wellbore

Systems and methods are provided for treating a wellbore using a loop system to heat oil in a subterranean formation contacted by the wellbore. The loop system comprises a loop that conveys a fluid (e.g., steam) down the wellbore via a injection conduit and returns fluid (e.g., condensate) from the wellbore via a return conduit. A portion of the fluid in the loop system may be injected into the subterranean formation using one or more valves disposed in the loop system. Alternatively, only heat and not fluid may be transferred from the loop system into the subterranean formation. The fluid returned from the wellbore may be re-heated and re-conveyed by the loop system into the wellbore. Heating the oil residing in the subterranean formation reduces the viscosity of the oil so that it may be recovered more easily.

Owner:HALLIBURTON ENERGY SERVICES INC

Apparatus for adjustably controlling the inflow of production fluids from a subterranean well

InactiveUS20090084556A1Fluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Owner:HALLIBURTON ENERGY SERVICES INC

Well screen having an internal alternate flowpath

InactiveUS6220345B1High viscosityIncrease flow rateFluid removalDrinking water installationFracturing fluidEngineering

A well screen having an internal, blank alternate flowpath for delivering fracturing fluid / gravel slurry to different levels within a well annulus. The well screen includes an outer pipe which is positioned over a base pipe thereby forming an annulus therebetween. The circumference of each pipe has a perforated sector and a blank sector, both of which extend along their respective lengths. When assembled, the respective perforated sectors are aligned to form a perforated, production sector and the respective blank sectors are aligned to form the blank, alternate flowpath. The base pipe is wrapped with wire to prevent solids from flowing through the openings therein. Slurry is pumped into the annulus where it flows circumferently from the blank, alternate flowpath to exit into the well annulus through the openings in the perforated sector of the annulus.

Owner:SCHLUMBERGER TECH CORP +1

Water shut off method and apparatus

A technique is provided to control flow in subterranean applications, such as hydrocarbon fluid production applications. The technique utilizes an material formed, at least in part, of material that swell in the presence of a specific substance or substances. The material is deployed as a membrane outside a base pipe to desired subterranean locations. Once located, the material allows the flow of hydrocarbon fluids but swells upon contact with the specific substance or substances to limit inflow of undesirable fluids.

Owner:SCHLUMBERGER TECH CORP

Reconstitution device and method of use

A reconstitution device is disclosed and includes a first container receiver having a first component cannula disposed therein, the first component cannula having a withdrawal port and a first transfer port formed thereon, a second container receiver having a second component cannula disposed thereon, the second component cannula having a vent port and a second transfer port formed thereon, a device body coupling the first container receiver to the second container receiver and having a transfer lumen formed therein, the transfer lumen in fluid communication with the first and second transfer ports, a selectively sealing interface secured to the device body and in fluid communication with the withdrawal port, and a venting member in communication with the vent port through a vent lumen.

Owner:TAKEDA PHARMA CO LTD

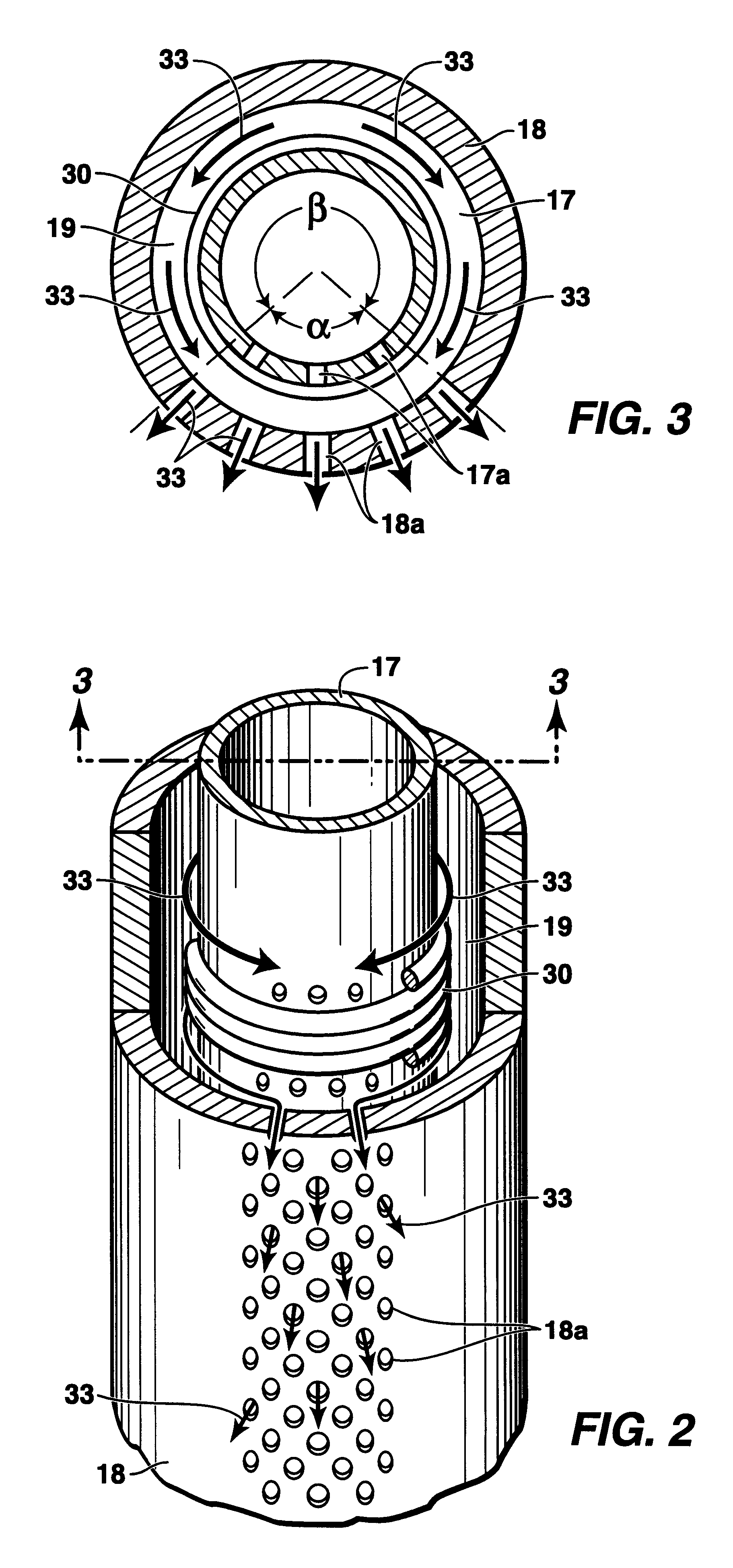

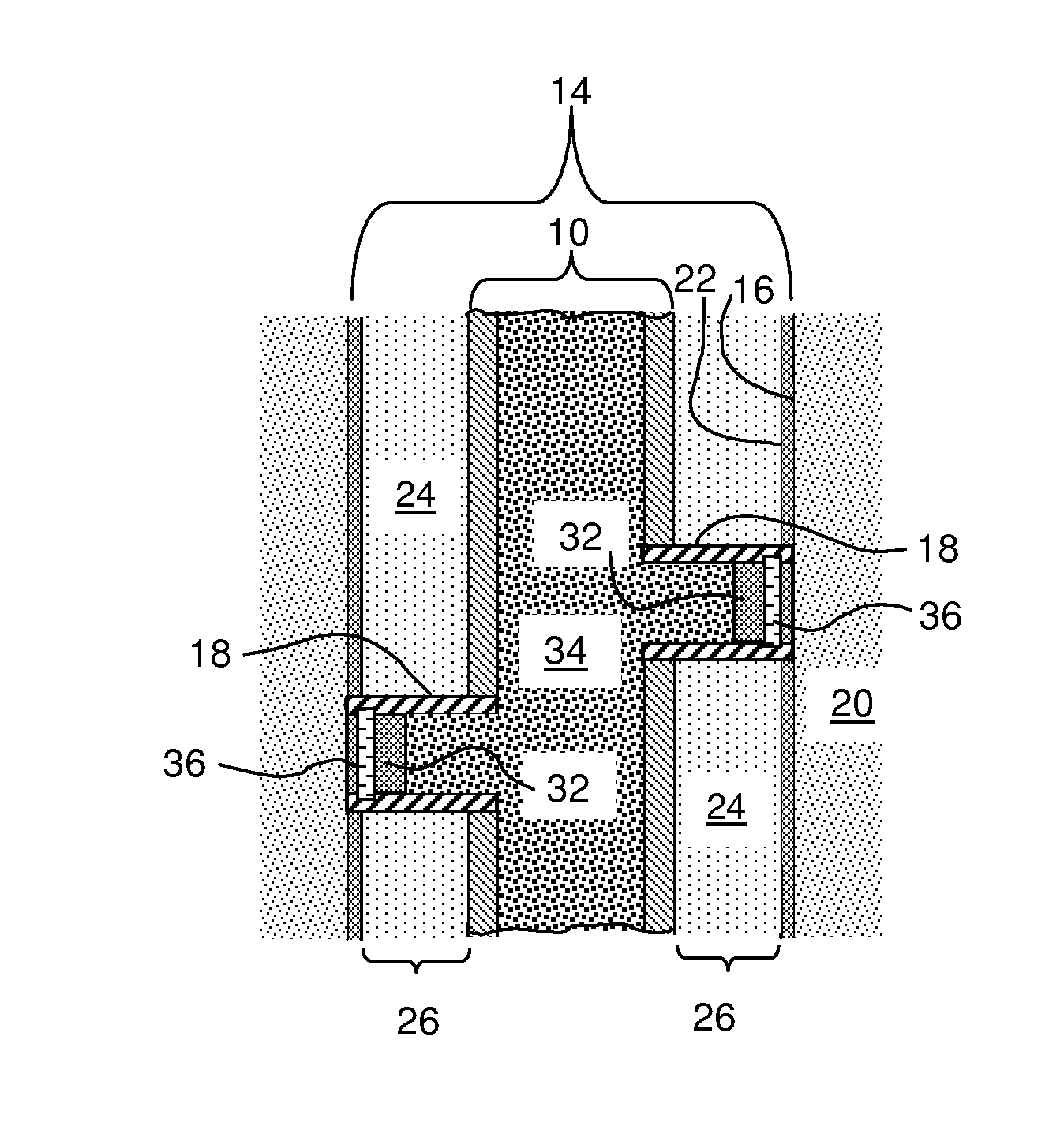

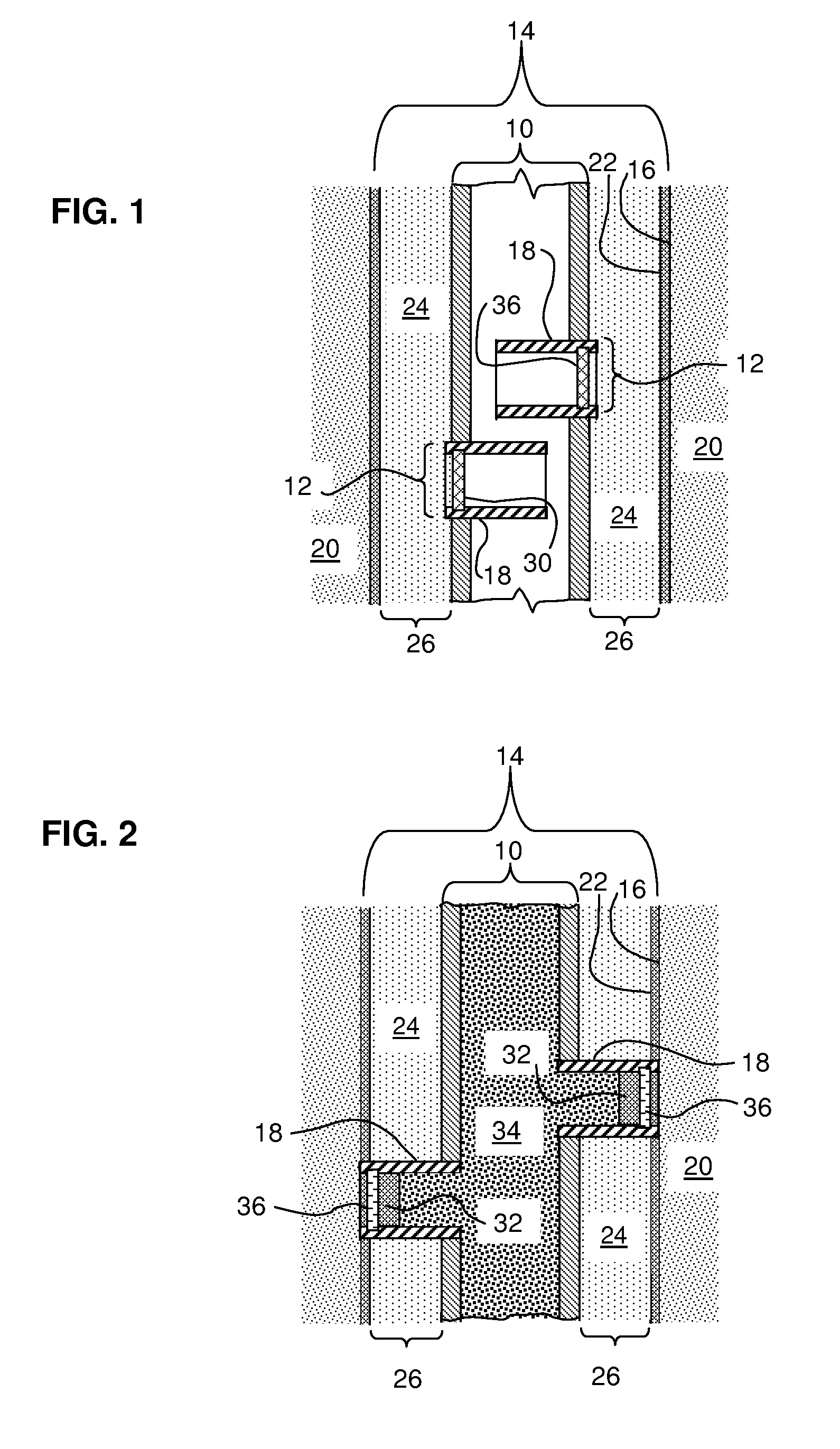

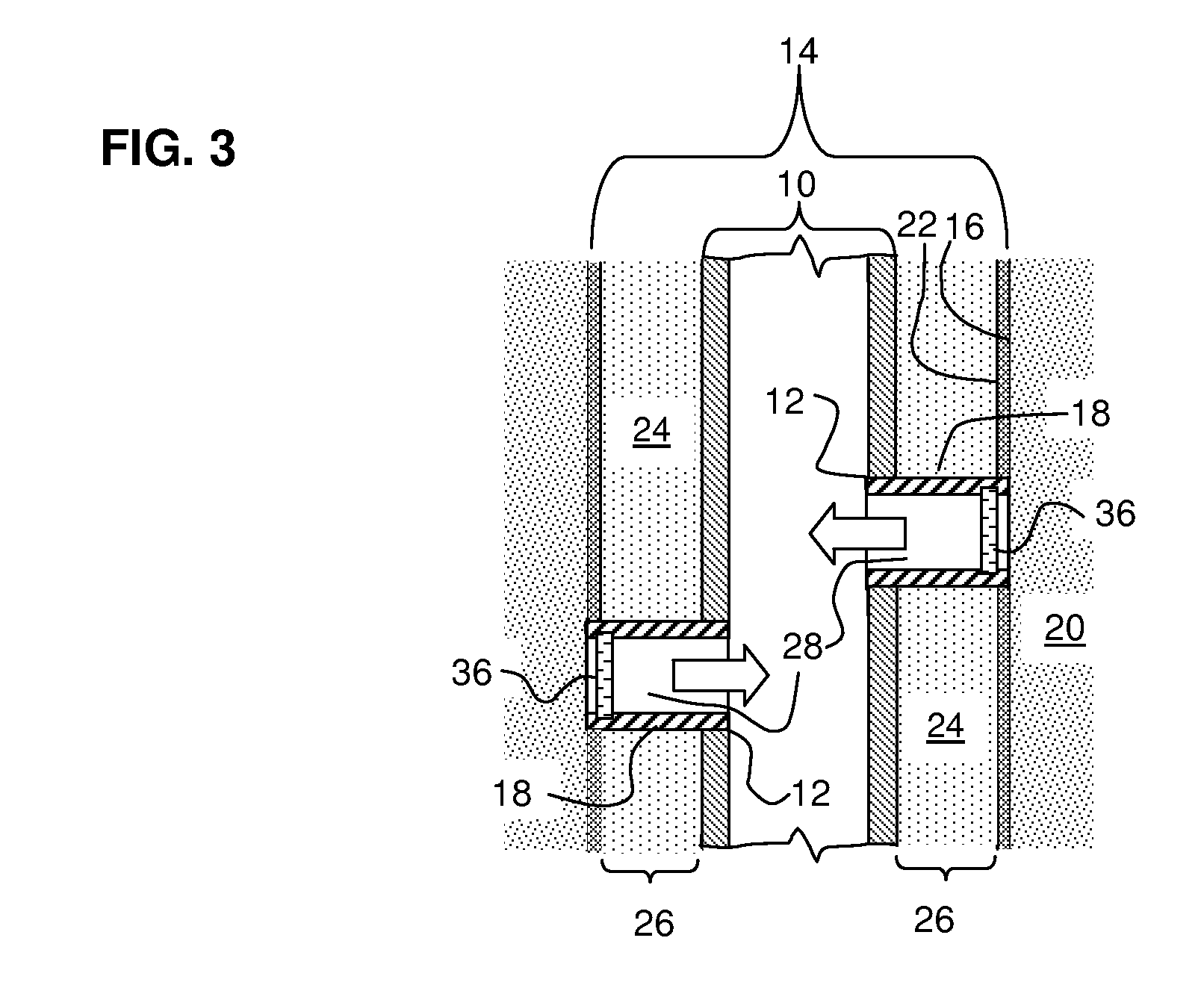

Method and apparatus for autonomous downhole fluid selection with pathway dependent resistance system

An apparatus is described for controlling flow of fluid in a tubular positioned in a wellbore extending through a subterranean formation. A flow control system is placed in fluid communication with a main tubular. The flow control system has a flow ratio control system and a pathway dependent resistance system. The flow ratio control system has a first and second passageway, the production fluid flowing into the passageways with the ratio of fluid flow through the passageways related to the characteristic of the fluid flow. The pathway dependent resistance system includes a vortex chamber with a first and second inlet and an outlet, the first inlet of the pathway dependent resistance system in fluid communication with the first passageway of the fluid ratio control system and the second inlet in fluid communication with the second passageway of the fluid ratio control system. The first inlet is positioned to direct fluid into the vortex chamber such that it flows primarily tangentially into the vortex chamber, and the second inlet is positioned to direct fluid such that it flows primarily radially into the vortex chamber. Undesired fluids, such as natural gas or water, in an oil well, are directed, based on their relative characteristic, into the vortex primarily tangentially, thereby restricting fluid flow when the undesired fluid is present as a component of the production fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

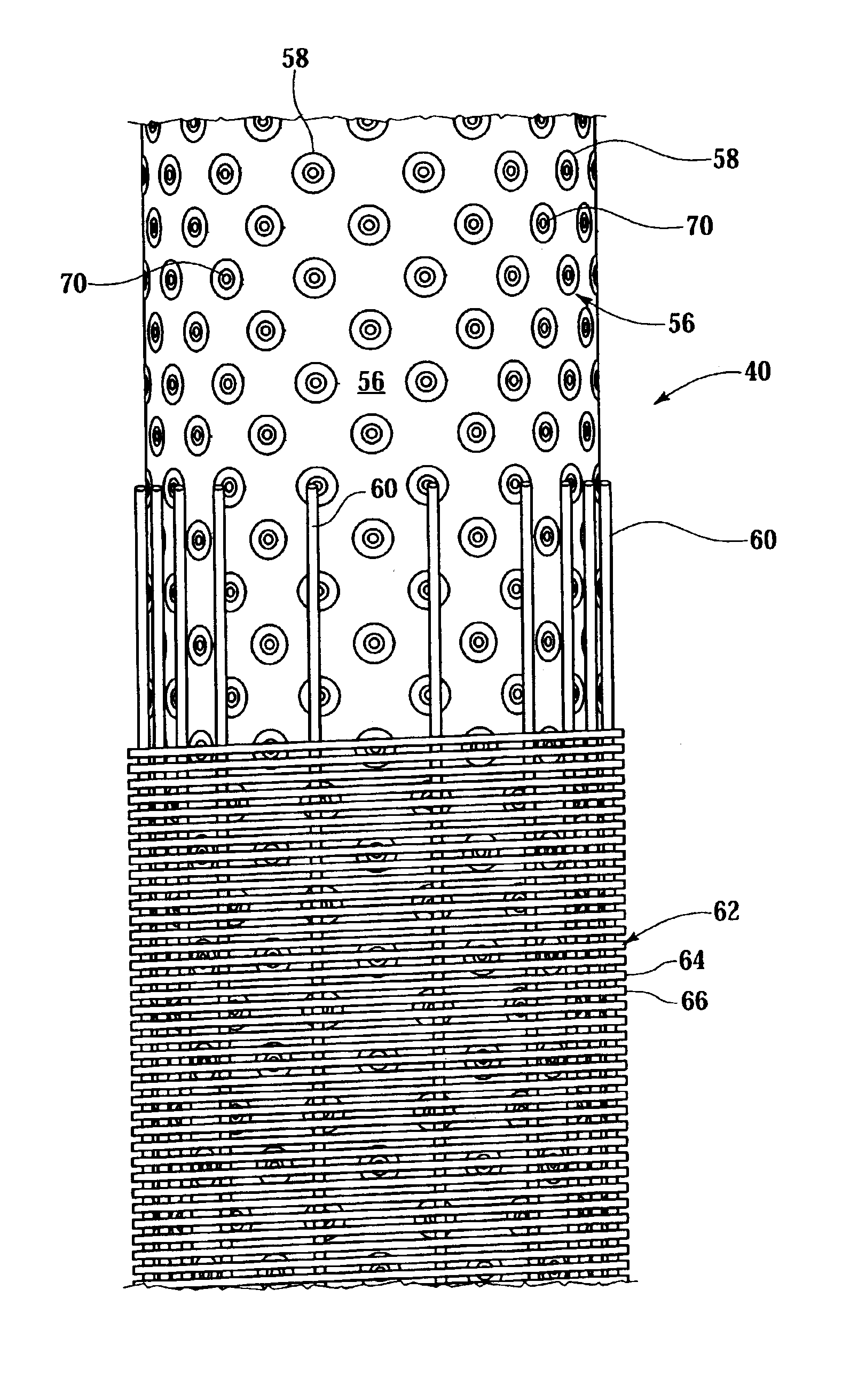

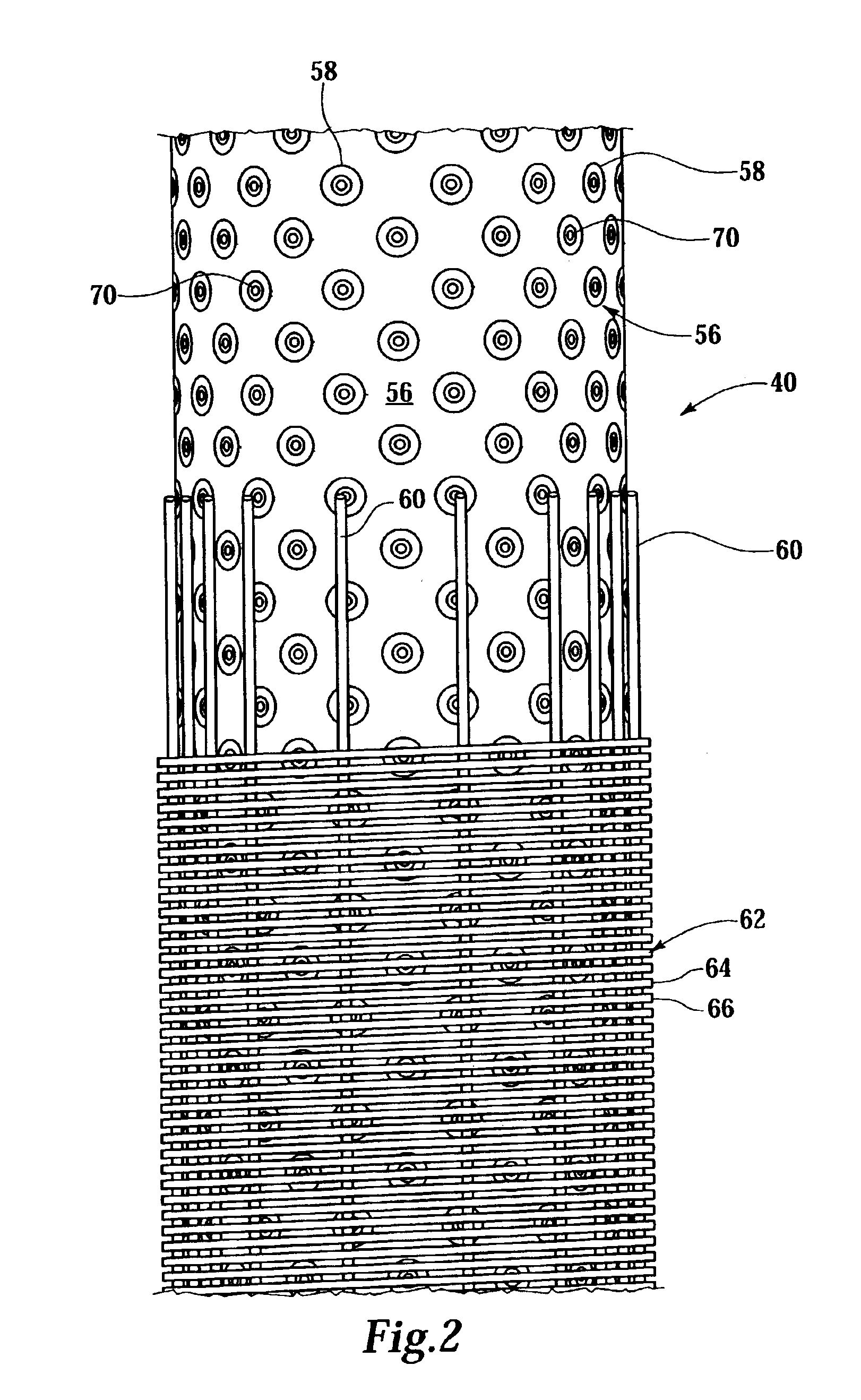

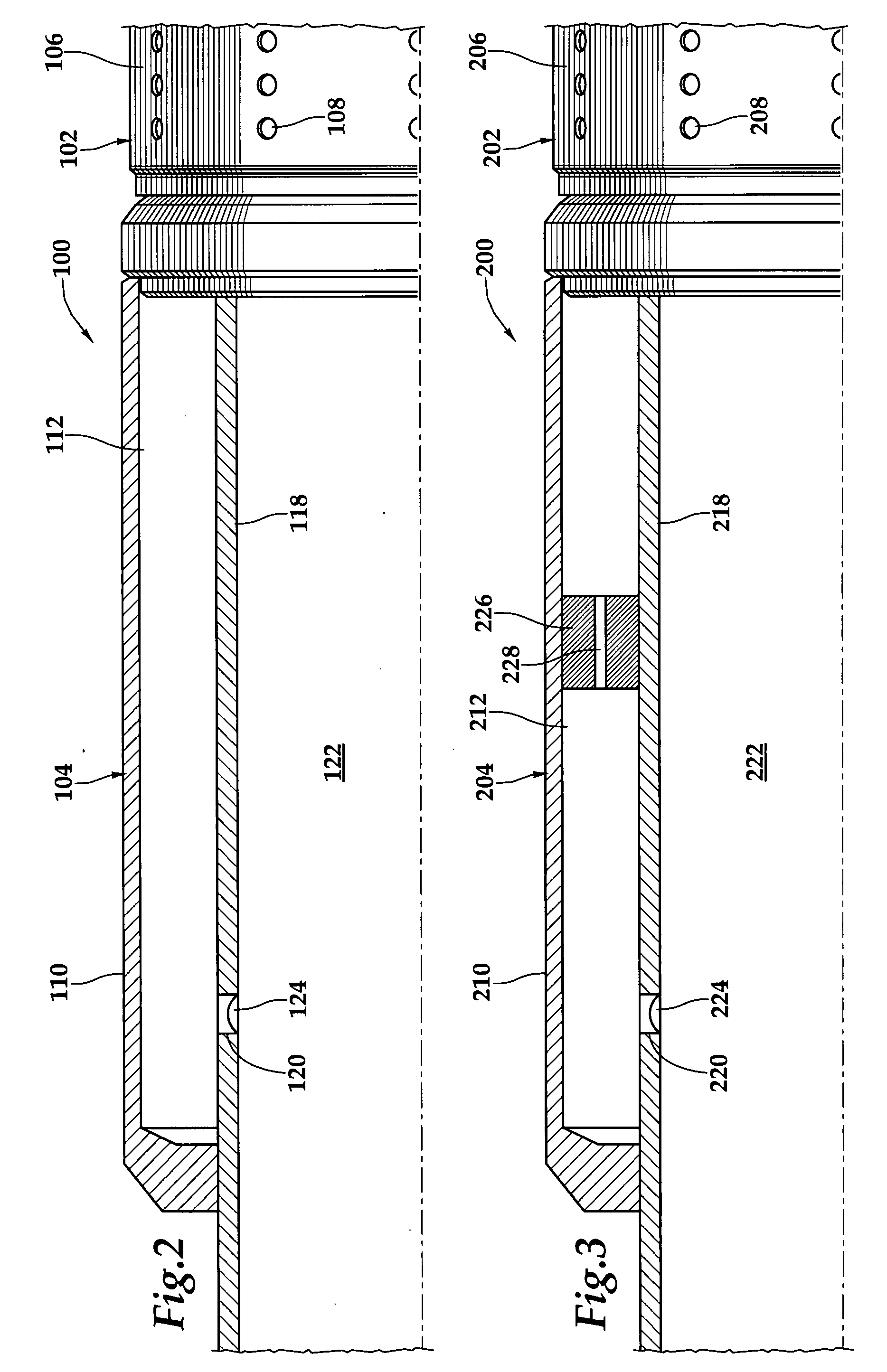

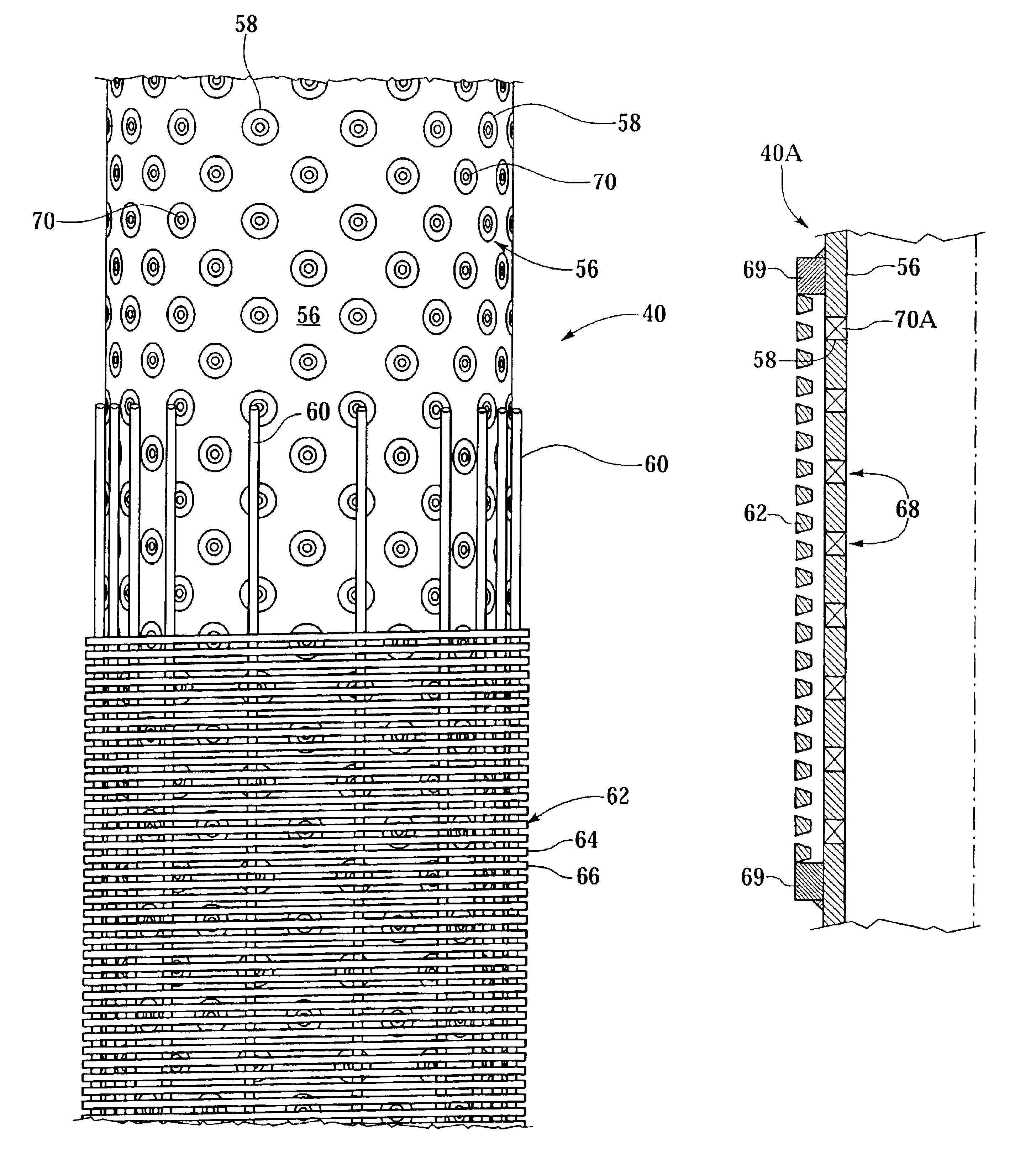

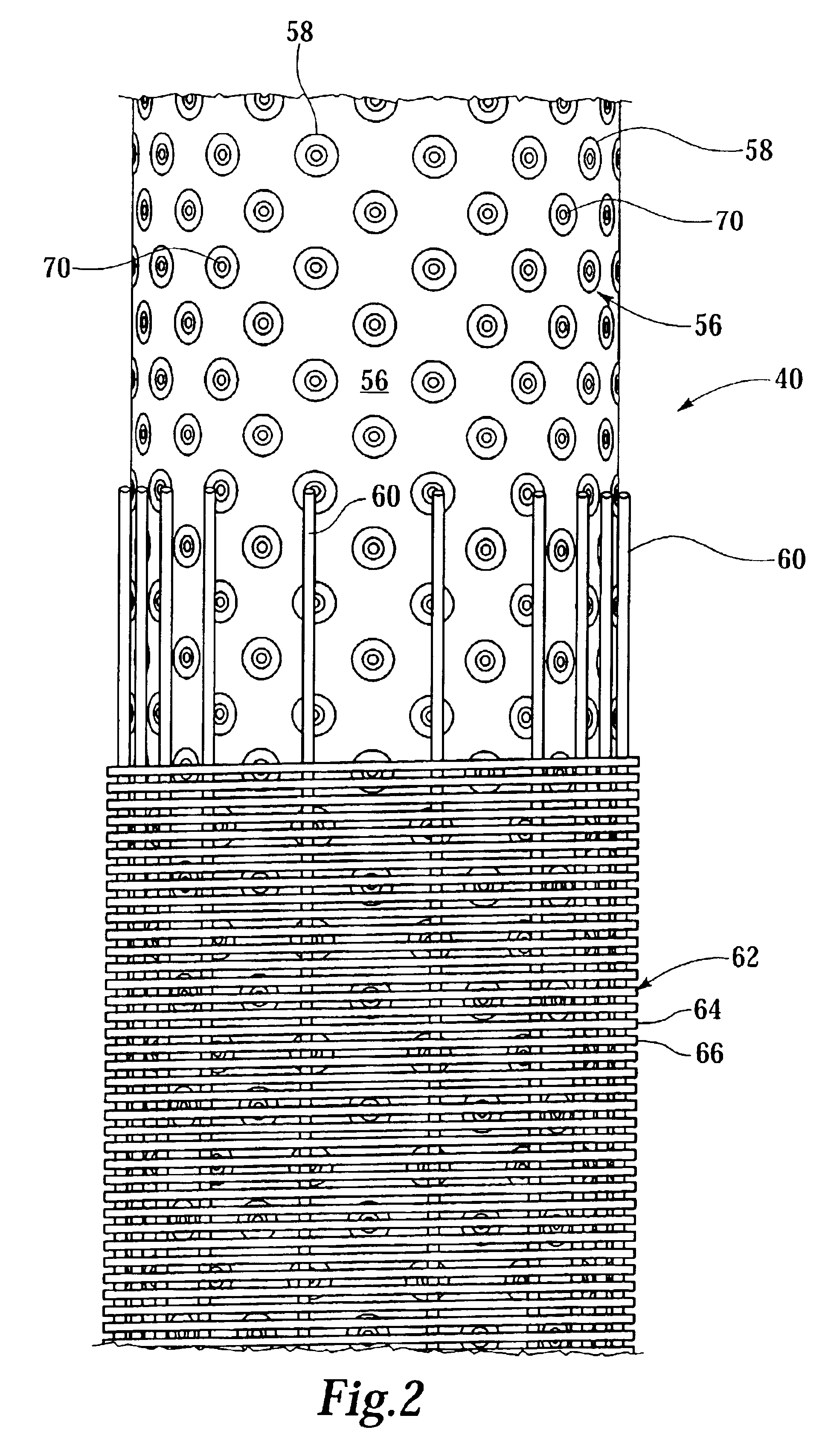

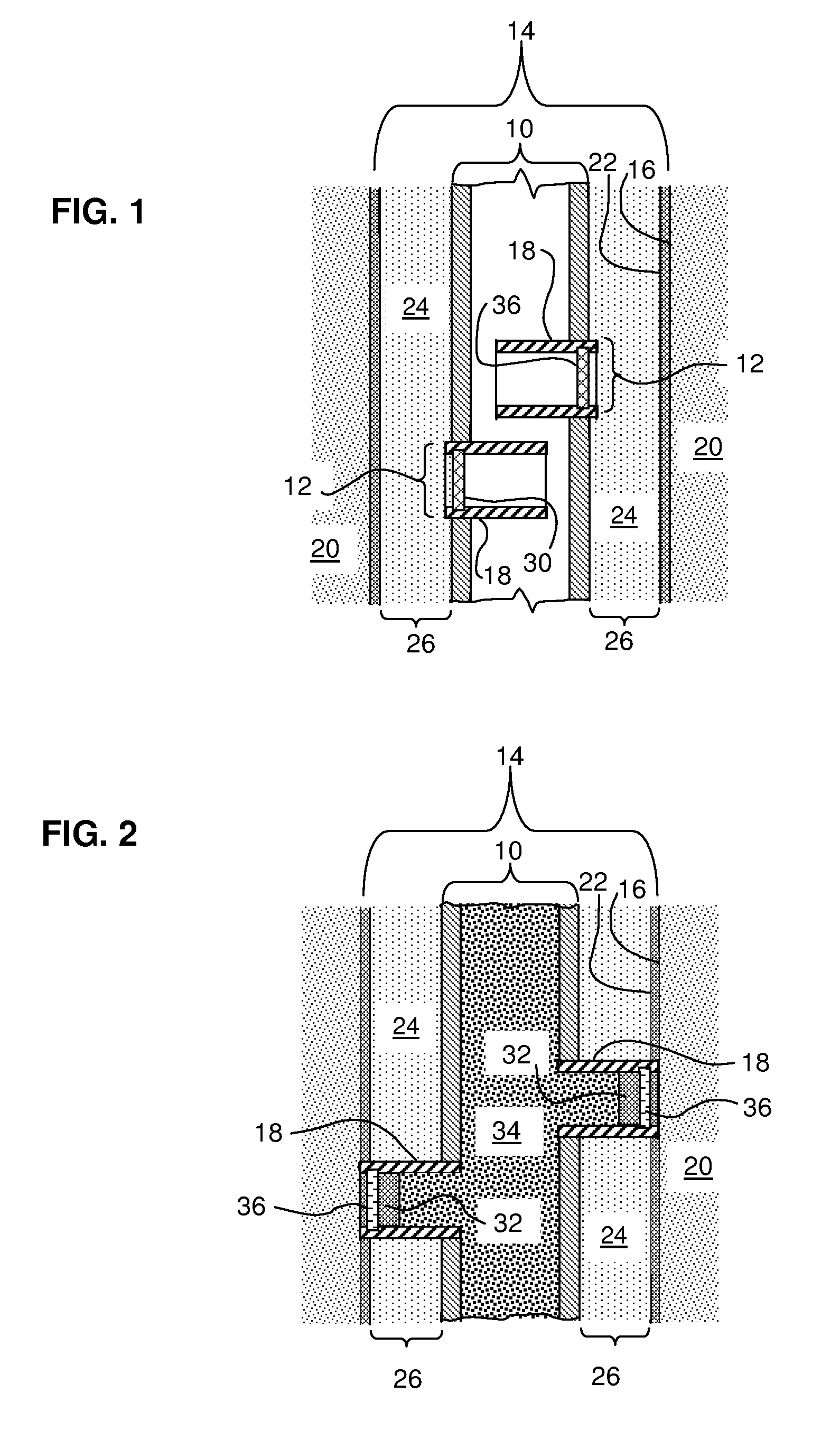

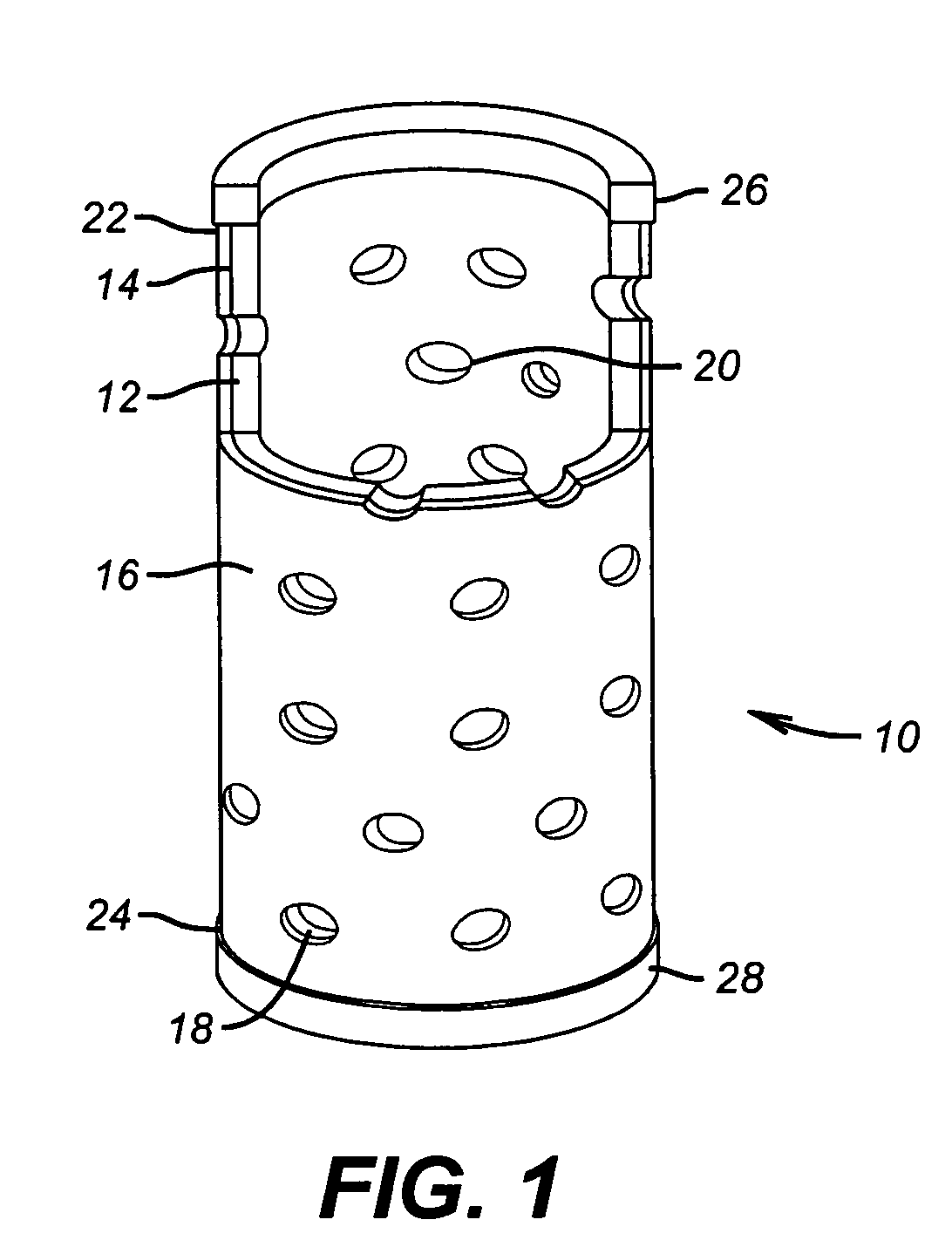

Sand control screen assembly and treatment method using the same

A sand control screen assembly (40) and method for treating formations traversed by a wellbore (34) in a single trip are disclosed. The sand control screen assembly (40) includes a base pipe (56) with a plurality of openings (58) that allow fluid flow therethrough. A filter medium (62) is positioned about the exterior of the base pipe (56) to filter particulate matter out of the production fluids. One-way valves (70) are operably associated within the openings (58) of the base pipe (56) to prevent fluid flow from the interior of the base pipe (56) to the exterior of the base pipe (56) during a treatment process. The one-way valves (70), however, are actuatable to allow fluid flow from the exterior of the base pipe (56) to the interior of the base pipe (56) to allow production of fluids from the formation (14).

Owner:HALLIBURTON ENERGY SERVICES INC

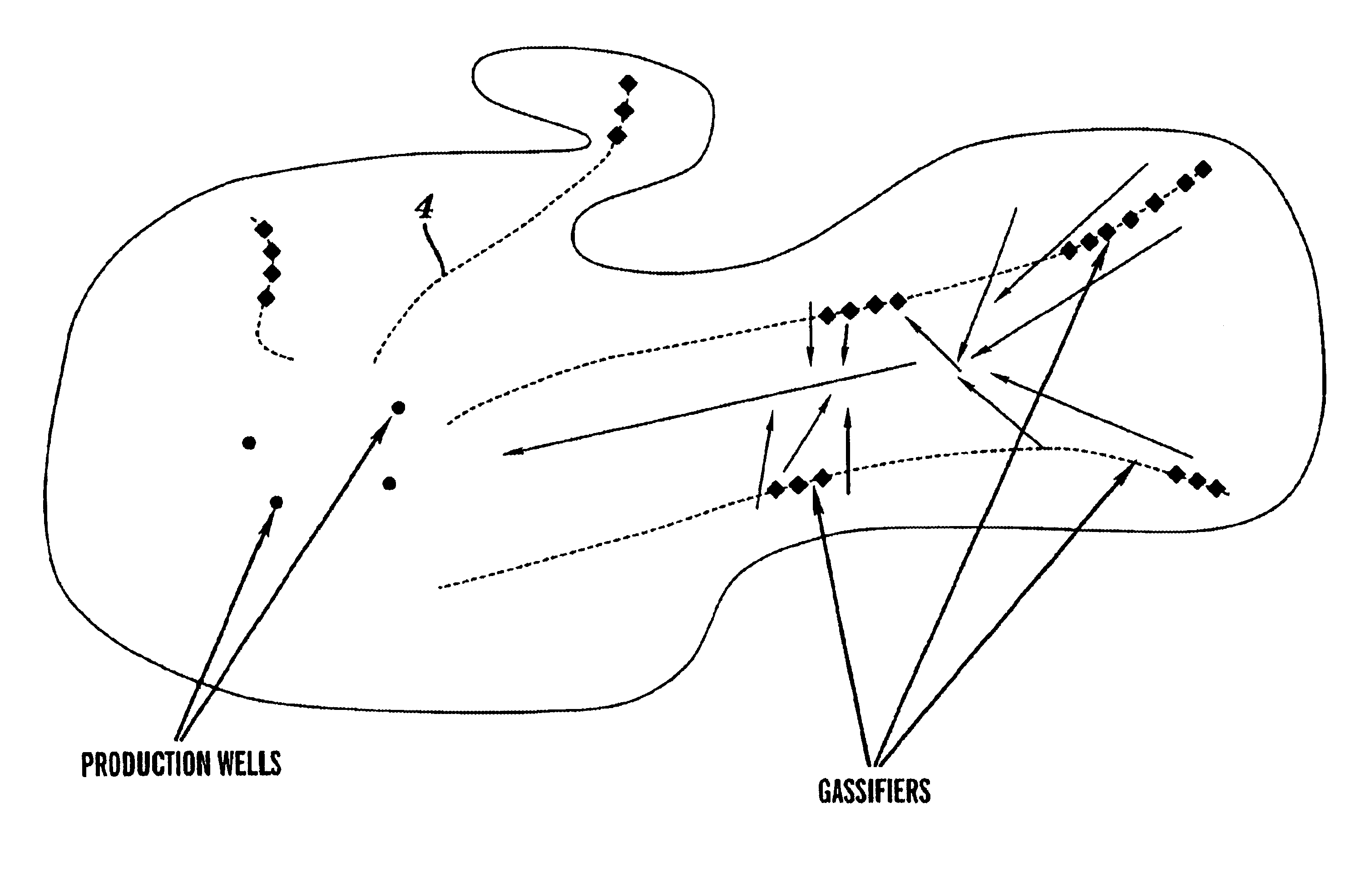

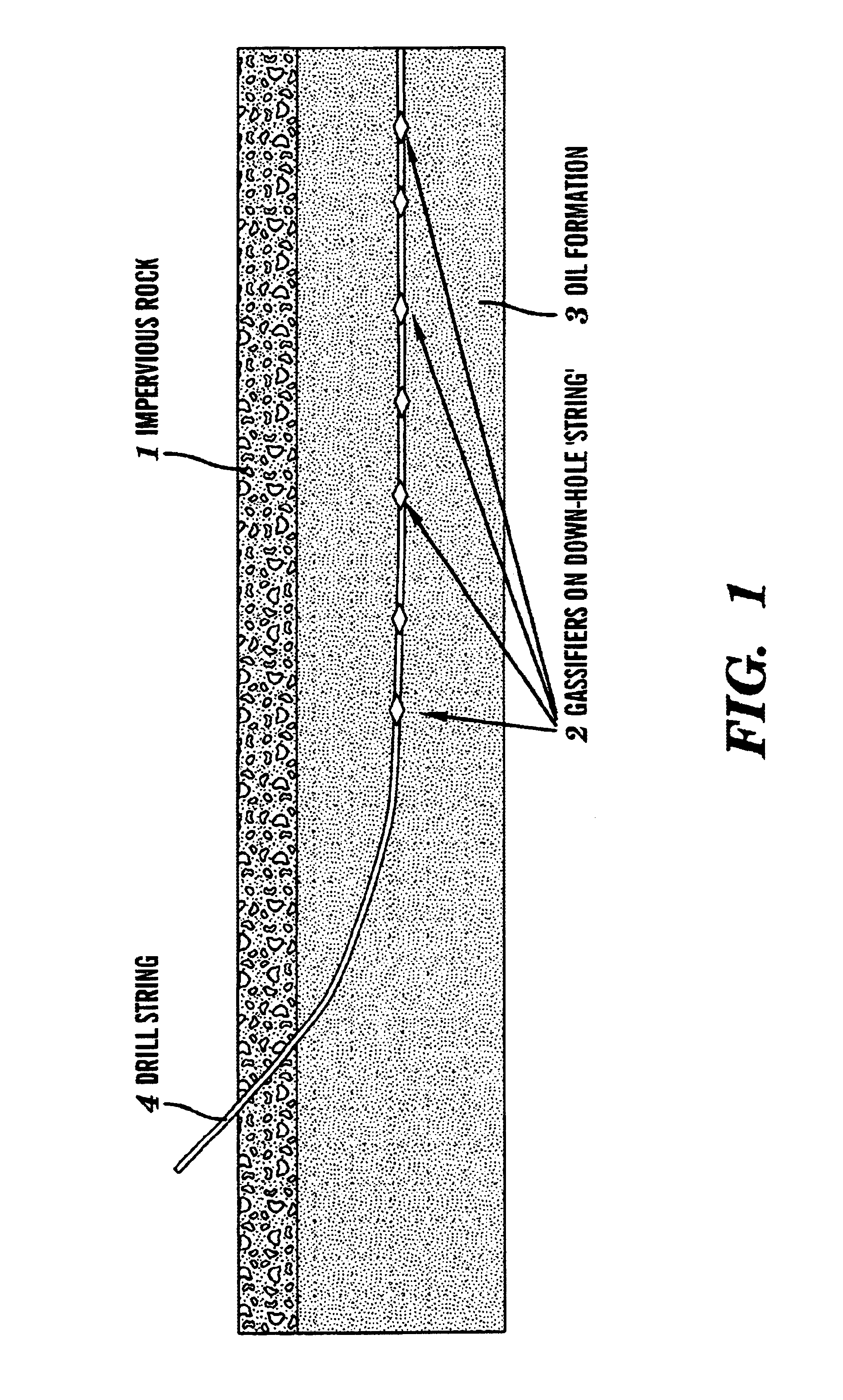

Gas and oil production

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

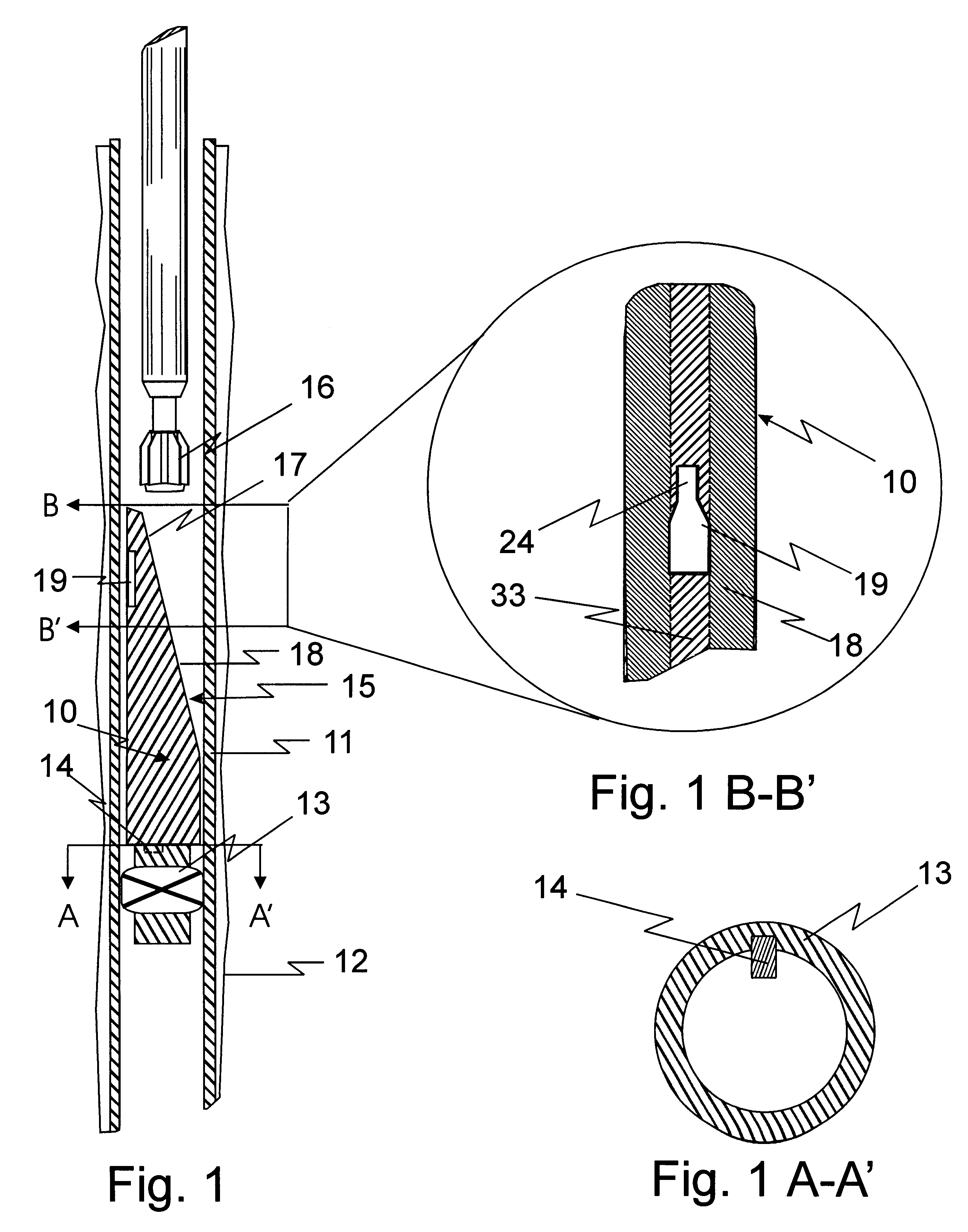

Sand control screen assembly having an internal seal element and treatment method using the same

InactiveUS6857476B2Avoid flowAvoid lostFluid removalDrinking water installationParticulatesFilter media

A sand control screen assembly (90) that is positionable within a wellbore comprises a base pipe (92) having a blank pipe section (94) and a perforated section (96) having at least one opening (98) that allows fluid flow therethrough. A filter medium (100) is positioned about the exterior of the base pipe (92) that selectively allows fluid flow therethrough and prevents particulate of a predetermined size from flowing therethrough. An internal seal element (104) is positioned at least partially within the perforated section (96) of the base pipe (92). The internal seal element (104) controls the flow of fluid through the opening (98) of the base pipe (92) such that fluid flow is prevented from the interior to the exterior of the sand control screen assembly (90) but is allowed from the exterior to the interior of the sand control screen assembly (90).

Owner:HALLIBURTON ENERGY SERVICES INC

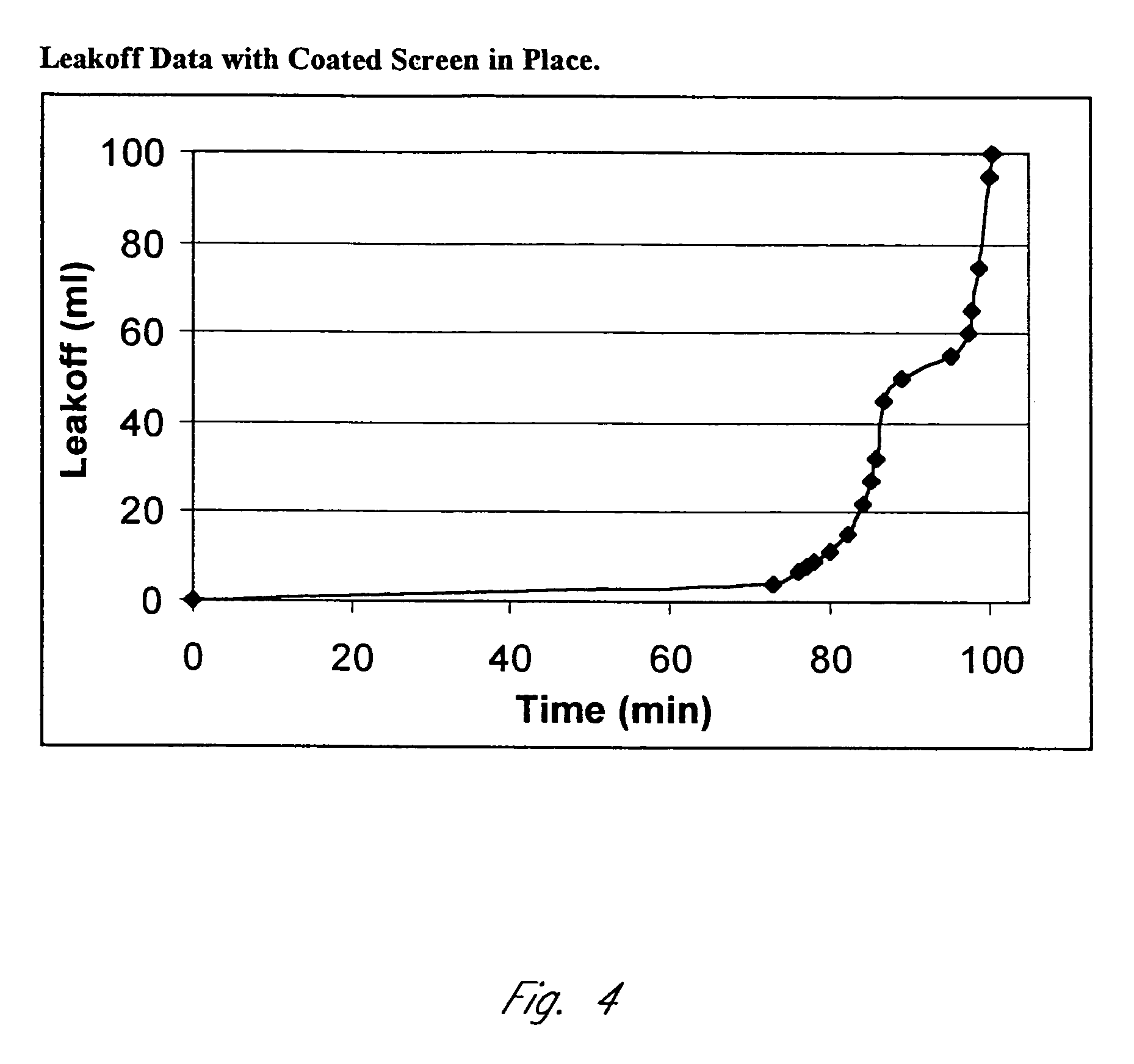

Product for coating wellbore screens

InactiveUS7360593B2Prevent flow capacity damageMinimizes flow capacity damageFluid removalFlushingReactive materialSURFACTANT BLEND

Coatings for well screens that protect the screens from damage as they are inserted into the wellbore and once in the well, release reactive materials to react with and degrade potentially plugging materials such as drill solids, fluid filtercakes, fluid loss additives, and drilling fluids. The coatings can be specifically designed for individual well conditions and are comprised of a binder that either melts or dissolves within the wellbore and one or more reactive materials such as acids, enzymes, surfactants, chelants, oxidizers or free radical generators and the like which are released into the screen and the near wellbore area and which are effective in degrading or dissolving materials which could potentially plug the screen.

Owner:CONSTIEN VERNON GEORGE

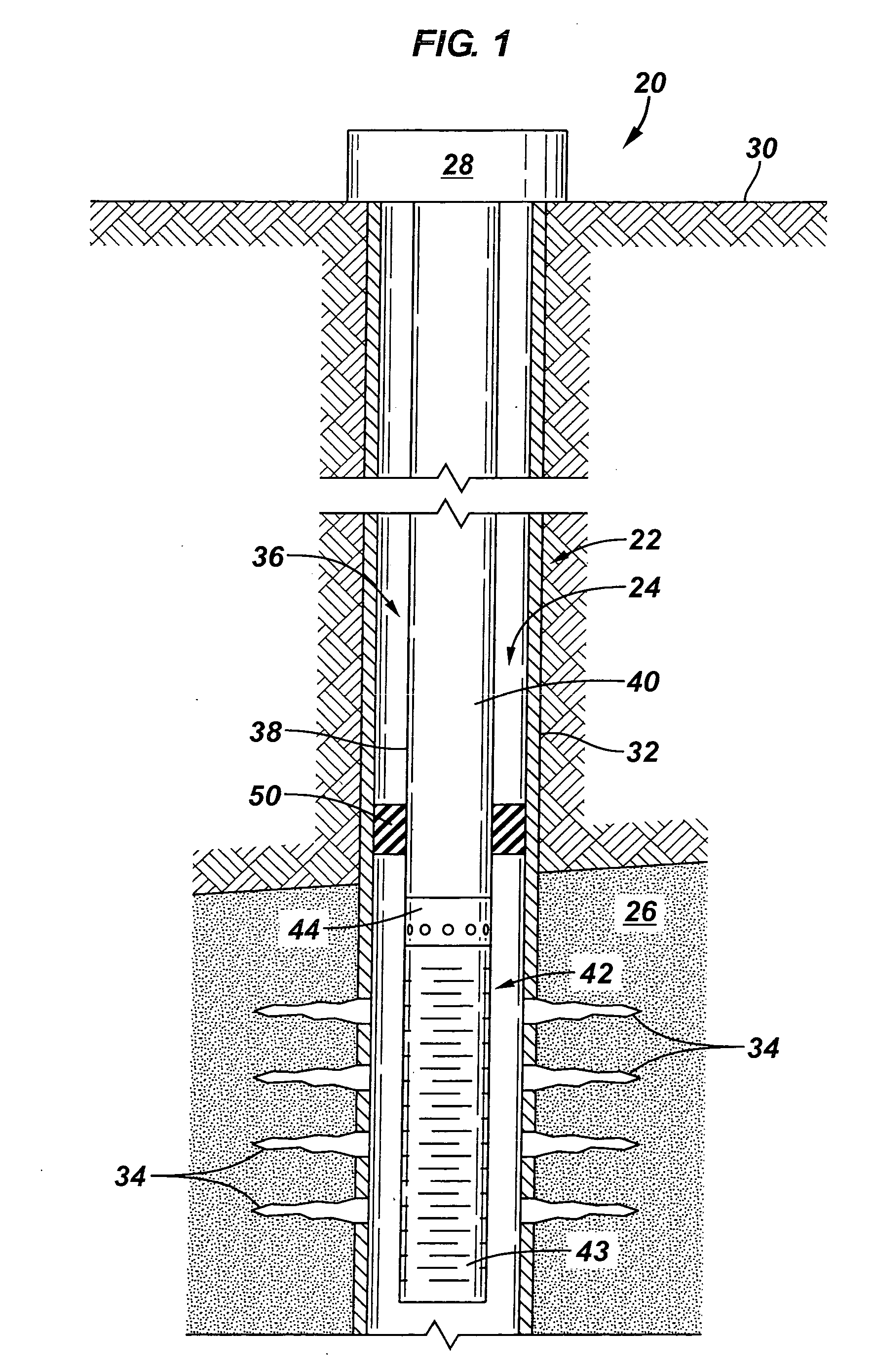

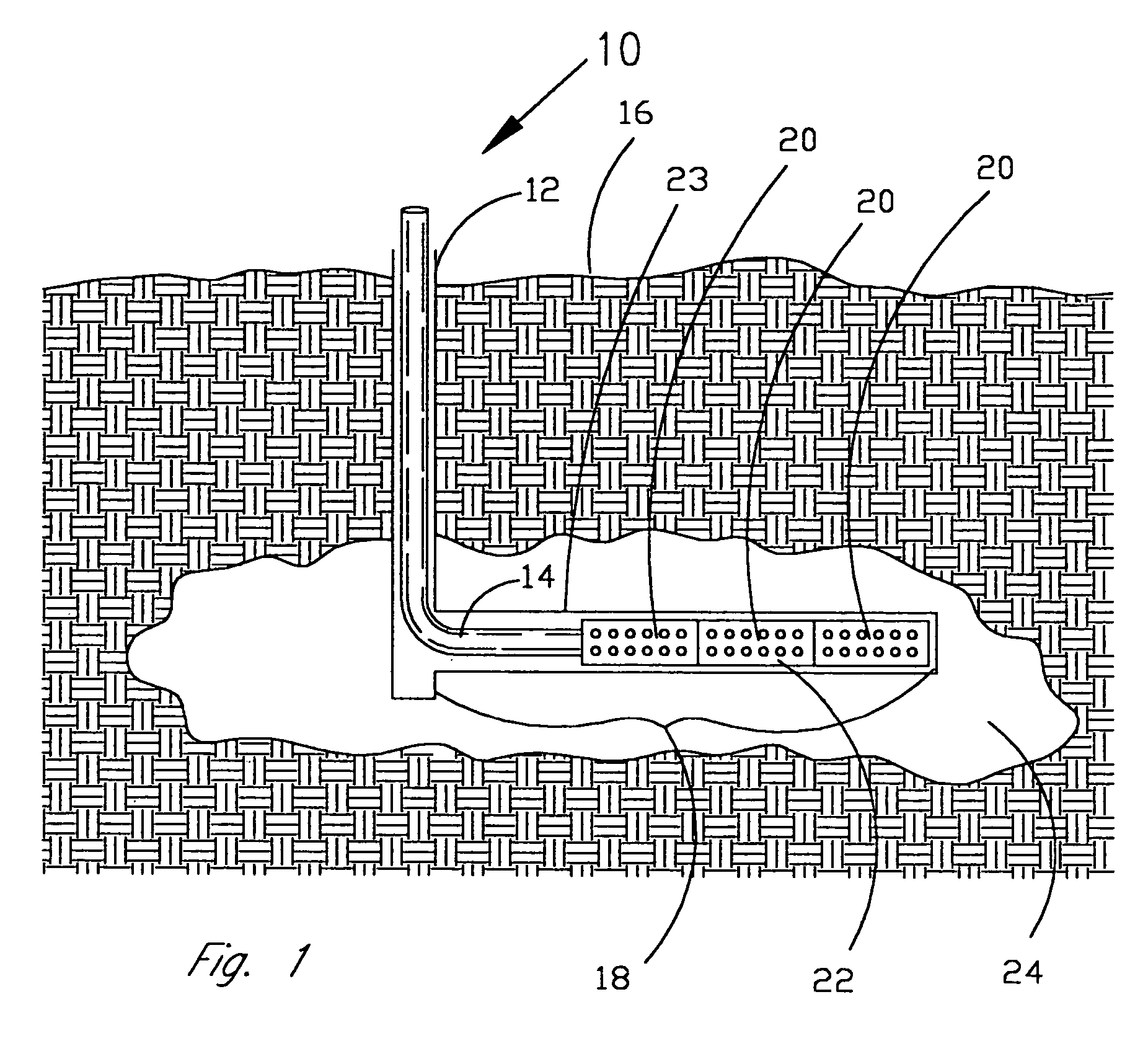

Procedures and Compositions for Reservoir Protection

ActiveUS20080296024A1High viscosityLow viscosityCleaning apparatusFluid removalSolventSURFACTANT BLEND

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

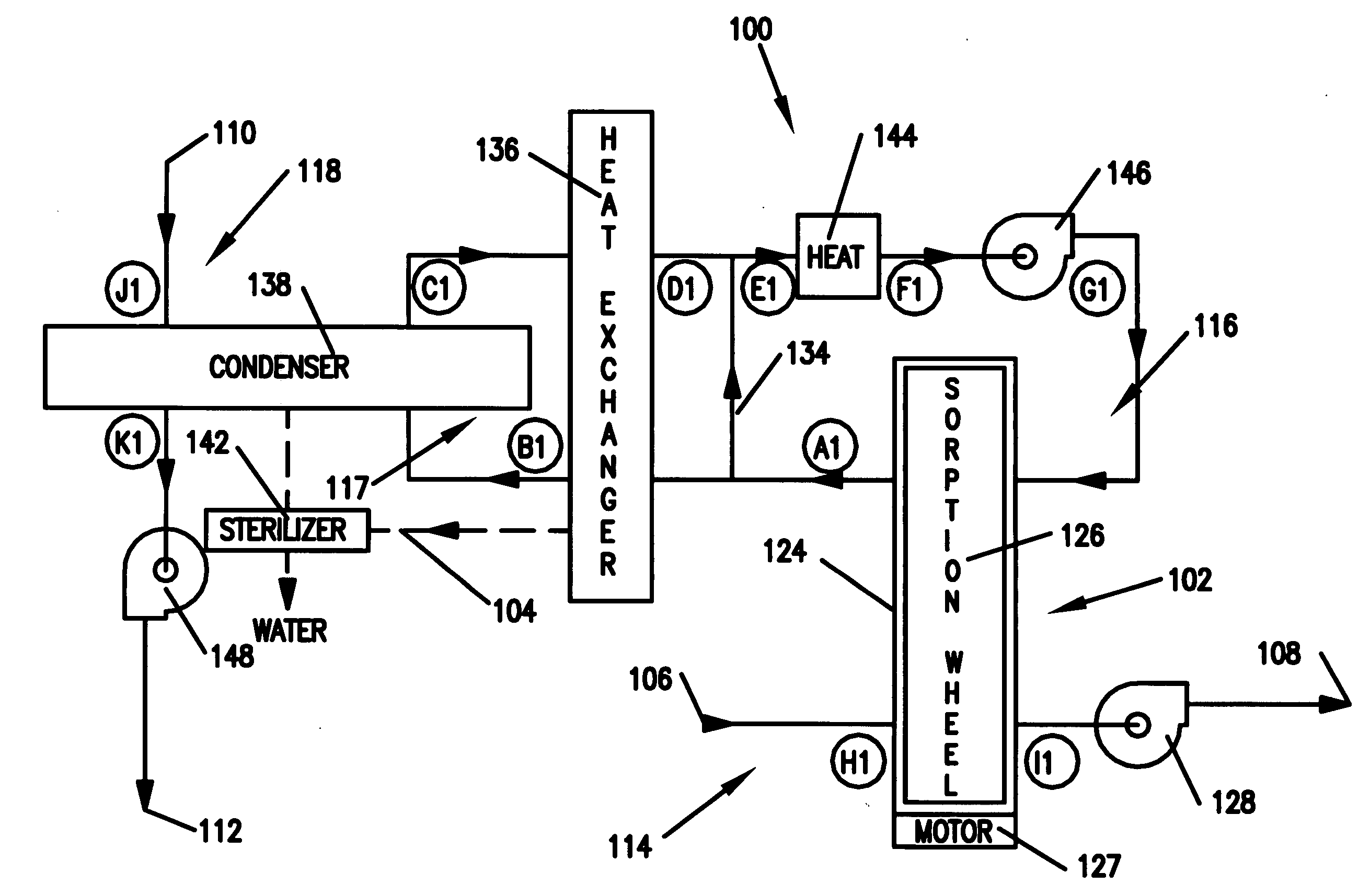

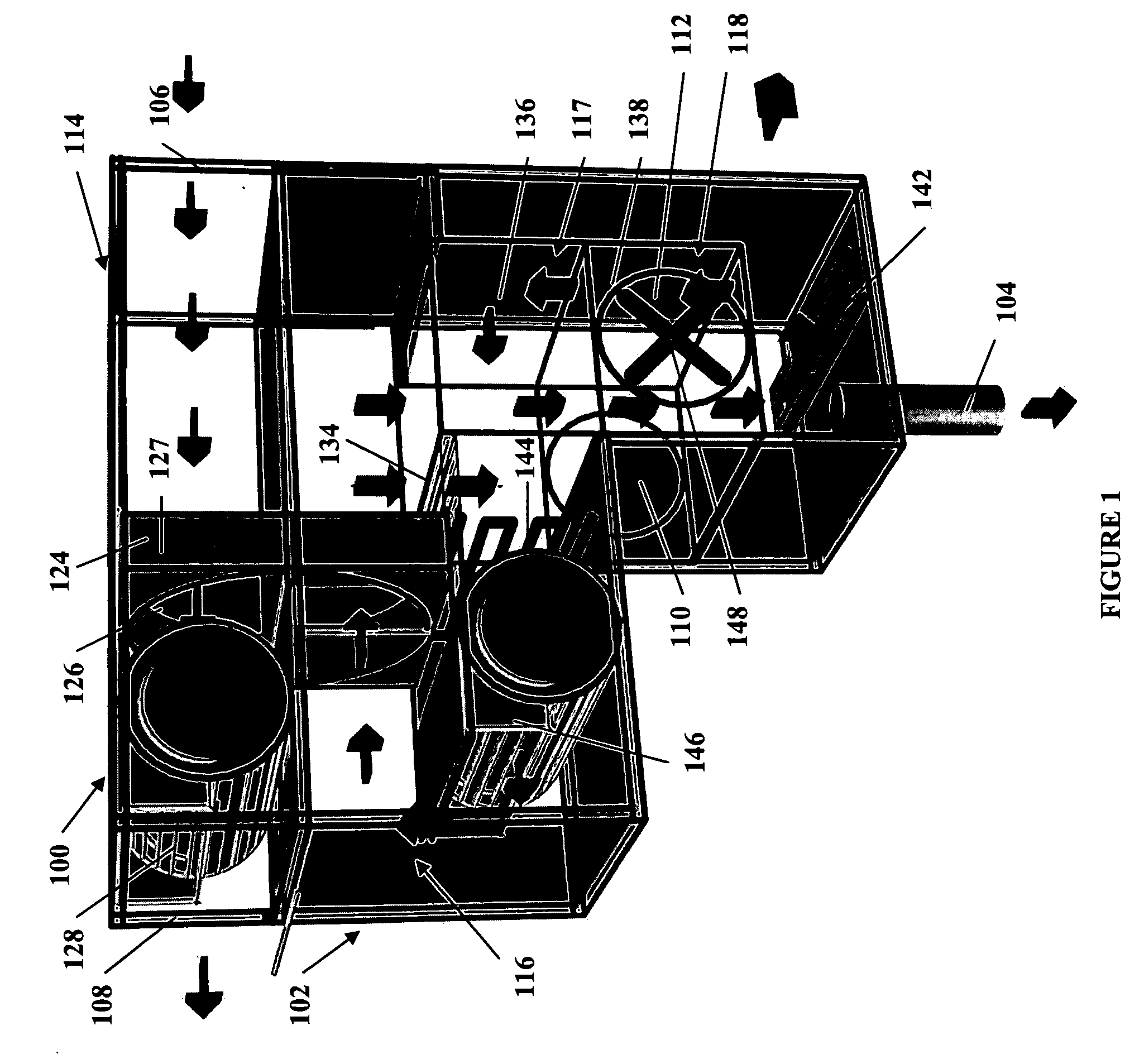

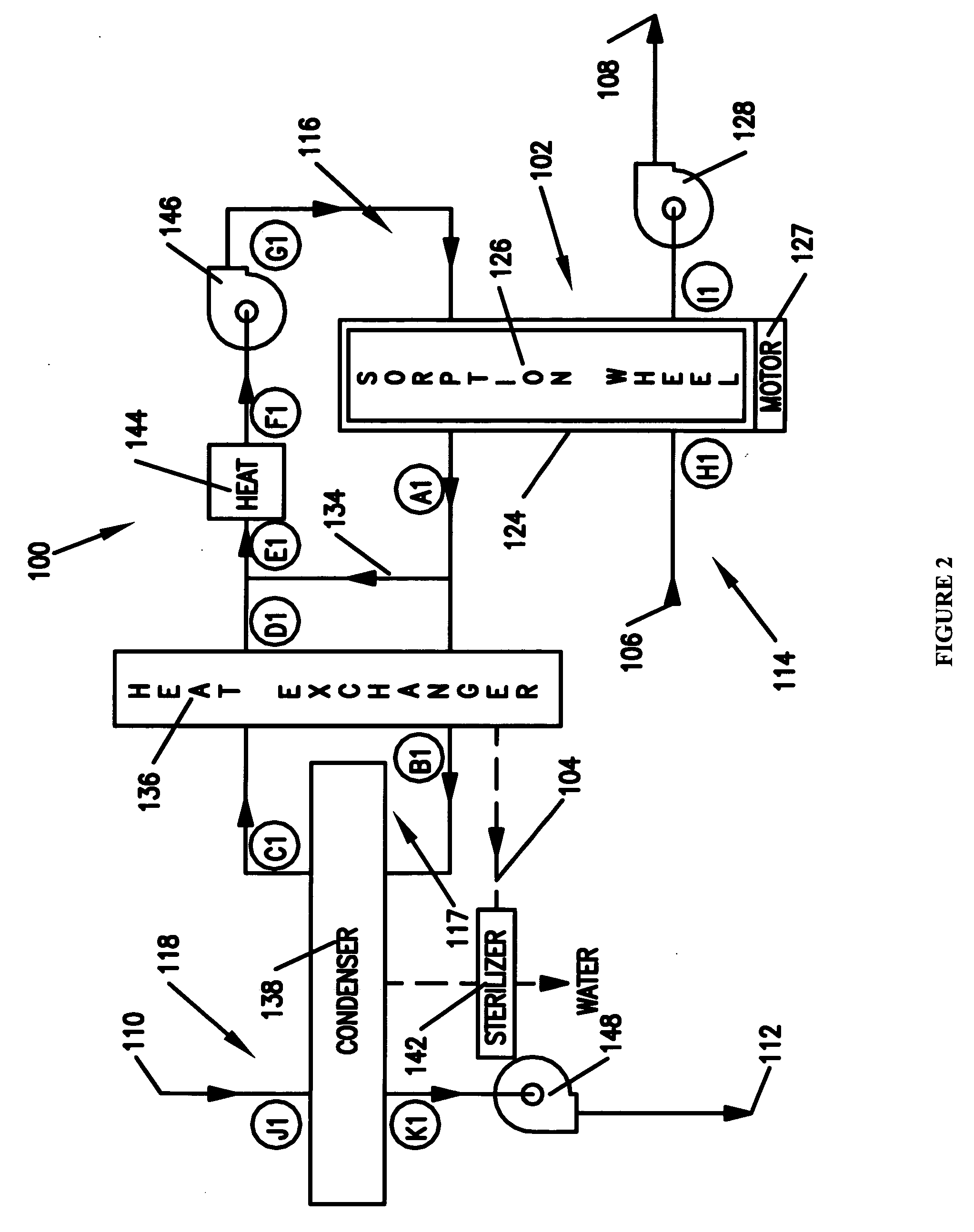

Method and apparatus for producing potable water from air including severely arid and hot climates

Methods and apparatus for extracting liquid water from ambient air, including ambient air in severely arid and hot climates, are described. An example apparatus uses a sorption-desorption-condensation cycle using a sorption wheel to extract moisture from ambient air and concentrate the water vapor driven off from the sorption material in a circulating gas, with condensation of liquid water from the circulating gas.

Owner:EPLEE DUSTIN M +1

Procedures and compositions for reservoir protection

A flow conduit having at least one orifice is placed in the vicinity of a flow source, which in one non-limiting embodiment may be a hydrocarbon reservoir. The flow pathway between the orifice and the source is temporarily blocked with a degradable barrier. Once the flow pathway is physically placed, the degradable barrier is removed under the influence of an acid, a solvent, time and / or temperature. The flow source and the flow pathways are at least partially covered (and flow blocked by) a temporary coating such as a pseudo-filter cake formed by a viscoelastic surfactant-gelled aqueous drill-in fluid, and the flow conduit is extended to the flow source. The pseudo-filter cake is removed when viscosity is reduced by an internal breaker, and flow is then allowed. The method is useful in one context of recovering hydrocarbons where the flow conduit is a telescoping sleeve or tube that contacts the borehole wall.

Owner:BAKER HUGHES INC

Apparatus and method for reducing water production from a hydrocarbon producing well

InactiveUS20070012444A1Reduce water productionReduce penetrationFluid removalSealing/packingHydrophilic monomerWater production

A filtering apparatus for use in a hydrocarbon producing well for reducing water production therein includes a filtering medium treated with a relative permeability modifier such that the relative permeability modifier reduces the permeability of the filtering medium if the relative permeability modifier contacts water production. The relative permeability modifier may be used to treat a metal portion of the filtering medium in the case of a wire wrap screen or a wire mesh screen or may be use treat a metal portion or the prepacked component of a prepacked screen. The relative permeability modifier may be a polymer of at least one hydrophilic monomer and at least one hydrophobically modified hydrophilic monomer, a hydrophobically modified polymer, a hydrophobically modified water-soluble polymer, hydrophobically modified copolymers thereof or the like.

Owner:HALLIBURTON ENERGY SERVICES INC

Down hole assembly and method for forming a down hole window and at least one keyway in communication with the down hole window for use in multilateral wells

Down hole assembly and method for forming a longitudinal window and a key-way in communication with the longitudinal window used in drilling multi-lateral well bores and for entry and reentry thereafter comprising, a first milling drill bit for milling the longitudinal window, a first whip stock having a guide surface, and orientation and positioning members located on the first whip stock for orienting and positioning tools to be used in forming the key-way in communication with the longitudinal window. A guide surface member is provided on the first whip stock member for guiding the first milling drill bit for milling a longitudinal window. A housing member for slidable mating with the first whip stock having a second drill bit member mounted in the housing member is provided for forming a down hole orientation key-way in communication with the longitudinally milled window. A second guide surface member positioned along the center line of the one surface guide member on the first whip stock is provided for guiding the second drill bit to drill a down hole orientation key-way in communication with the longitudinal window. A second whip stock having a forming member for forming an up hole orientation key-way in communication with the longitudinally milled window is provided with at least one guide surface member on the second whip stock member for guiding the forming member for forming the up hole orientation key-way in communication with the longitudinal window.

Owner:WEATHERFORD TECH HLDG LLC

Self-conforming screen

InactiveUS7013979B2Minimizing and eliminating any weldingDrilling rodsFluid removalDrill holeWelding

A screen that conforms to the borehole shape after expansion is disclosed. The screen comprises a compliant outer layer that takes the borehole shape on expansion. The outer layer is formed having holes to permit production flow. The material that is selected preferably swells with prolonged contact to well fluids to further close off annular gaps after expansion. In an alternative embodiment, the screen is not expanded and the swelling of the material alone closes off annular gaps. The outer sleeve is placed over the screen and the screen is placed on a base pipe and initially expanded from within the base pipe to secure the components of the screen assembly for running downhole, while minimizing or eliminating any welding among the layers. A variety of expansion tools can be used to expand the screen or screens downhole.

Owner:BAKER HUGHES HLDG LLC

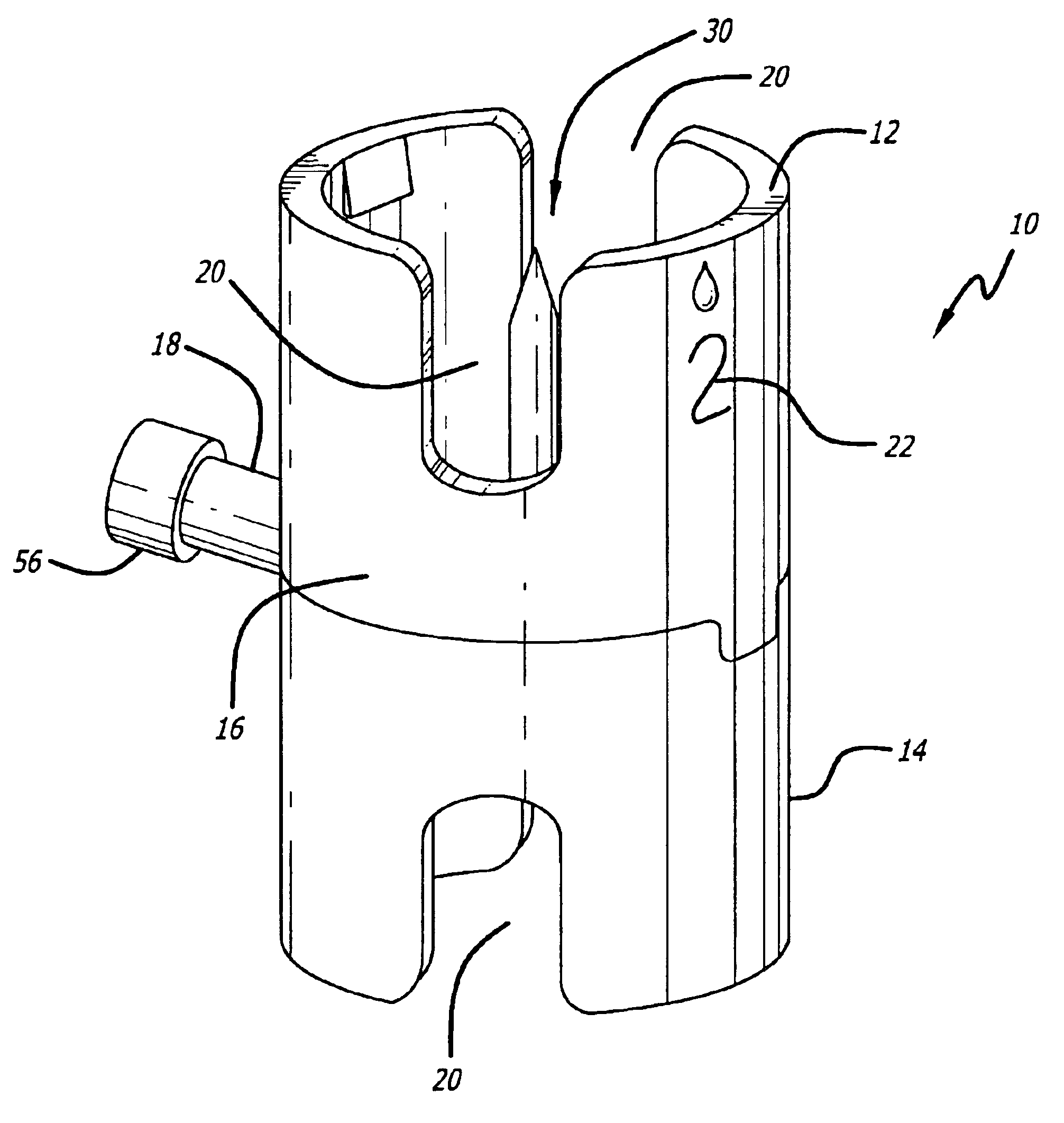

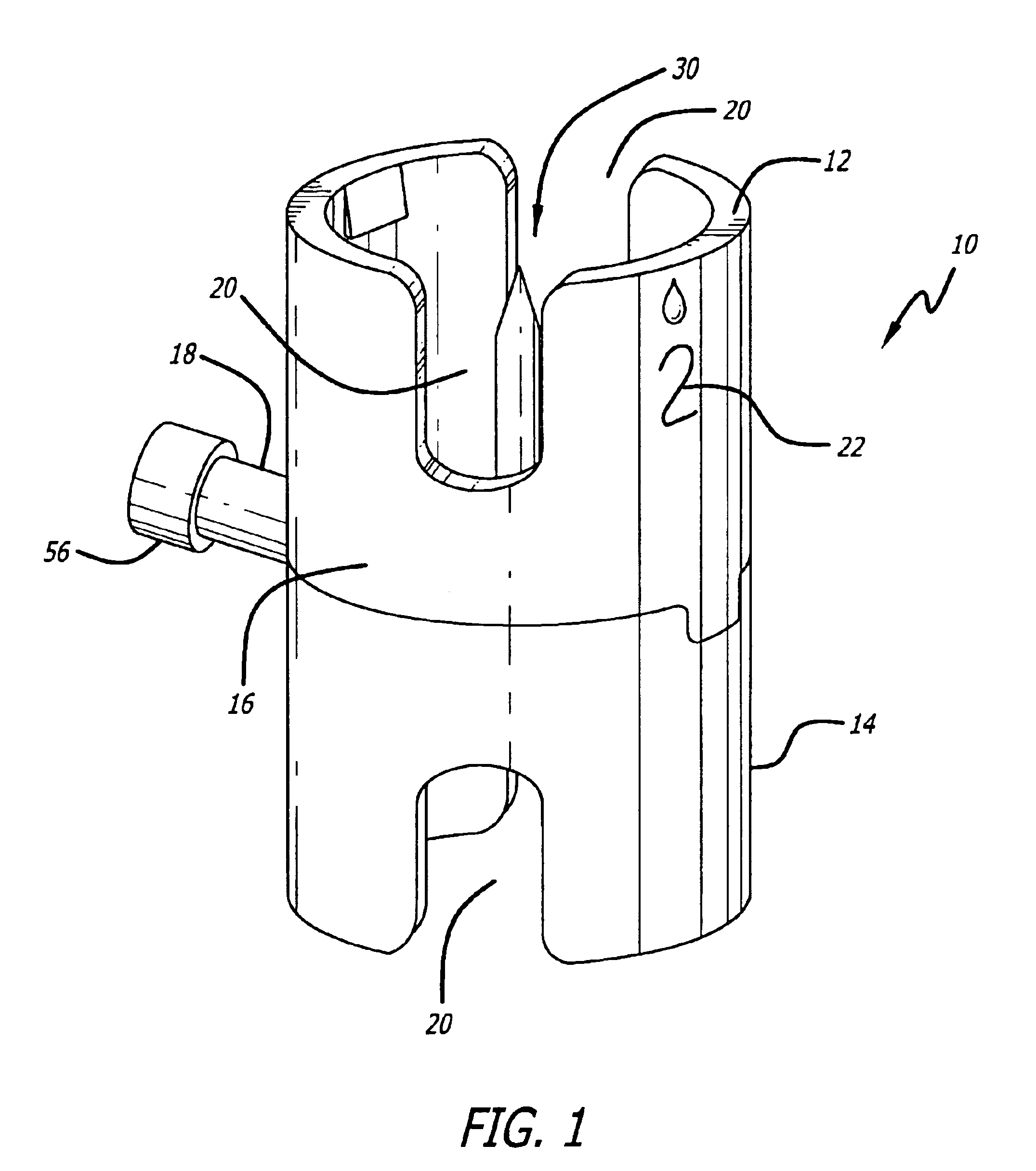

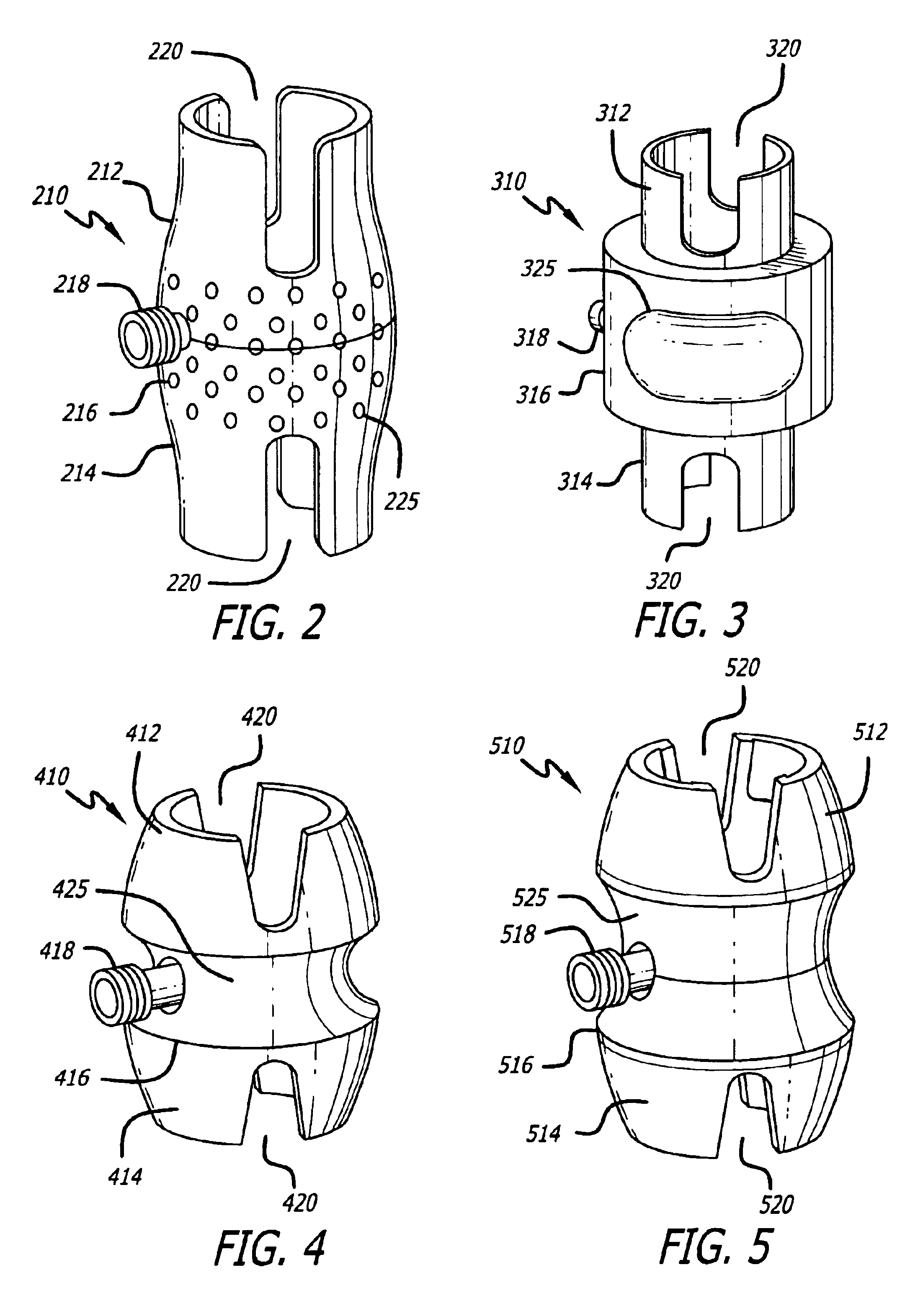

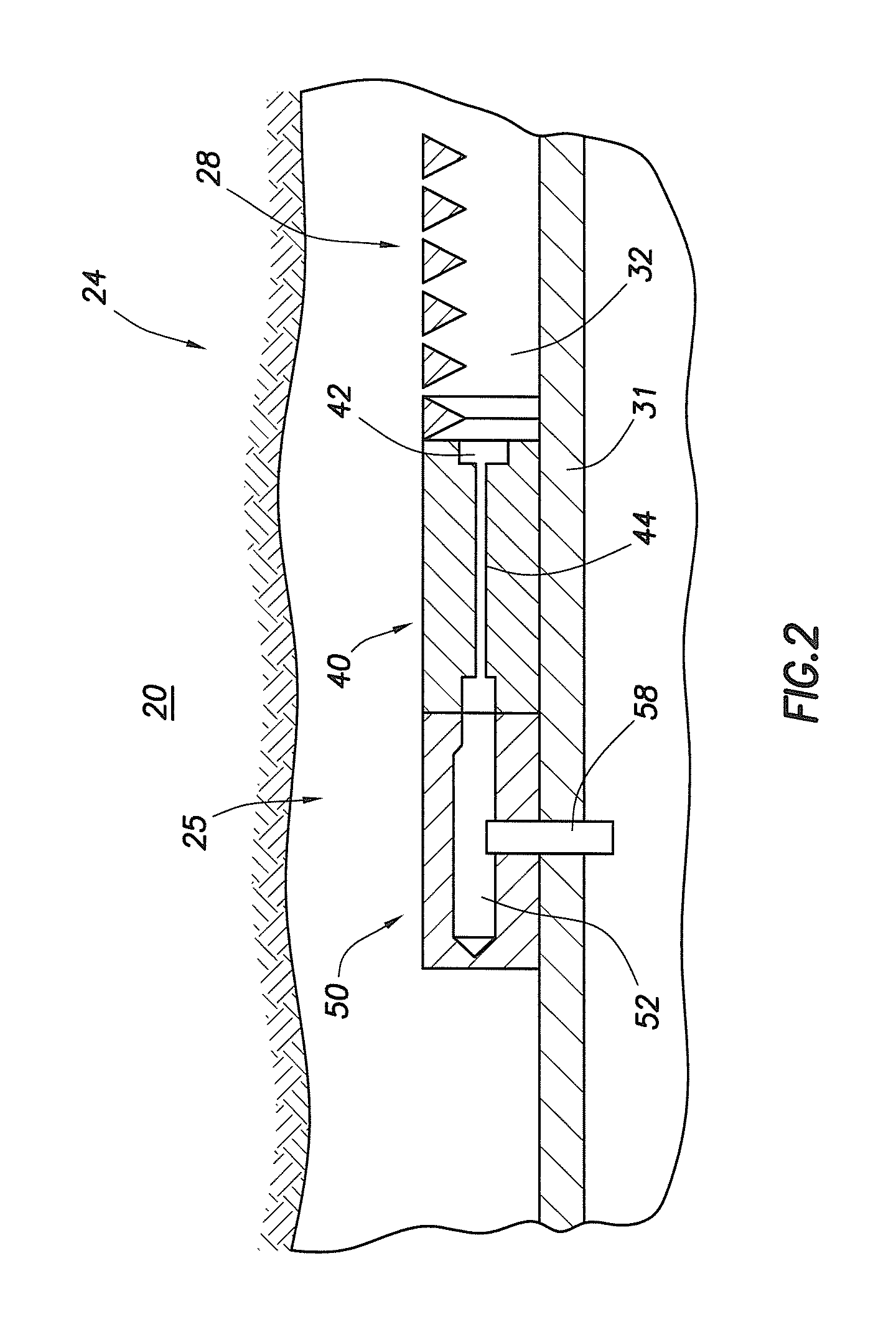

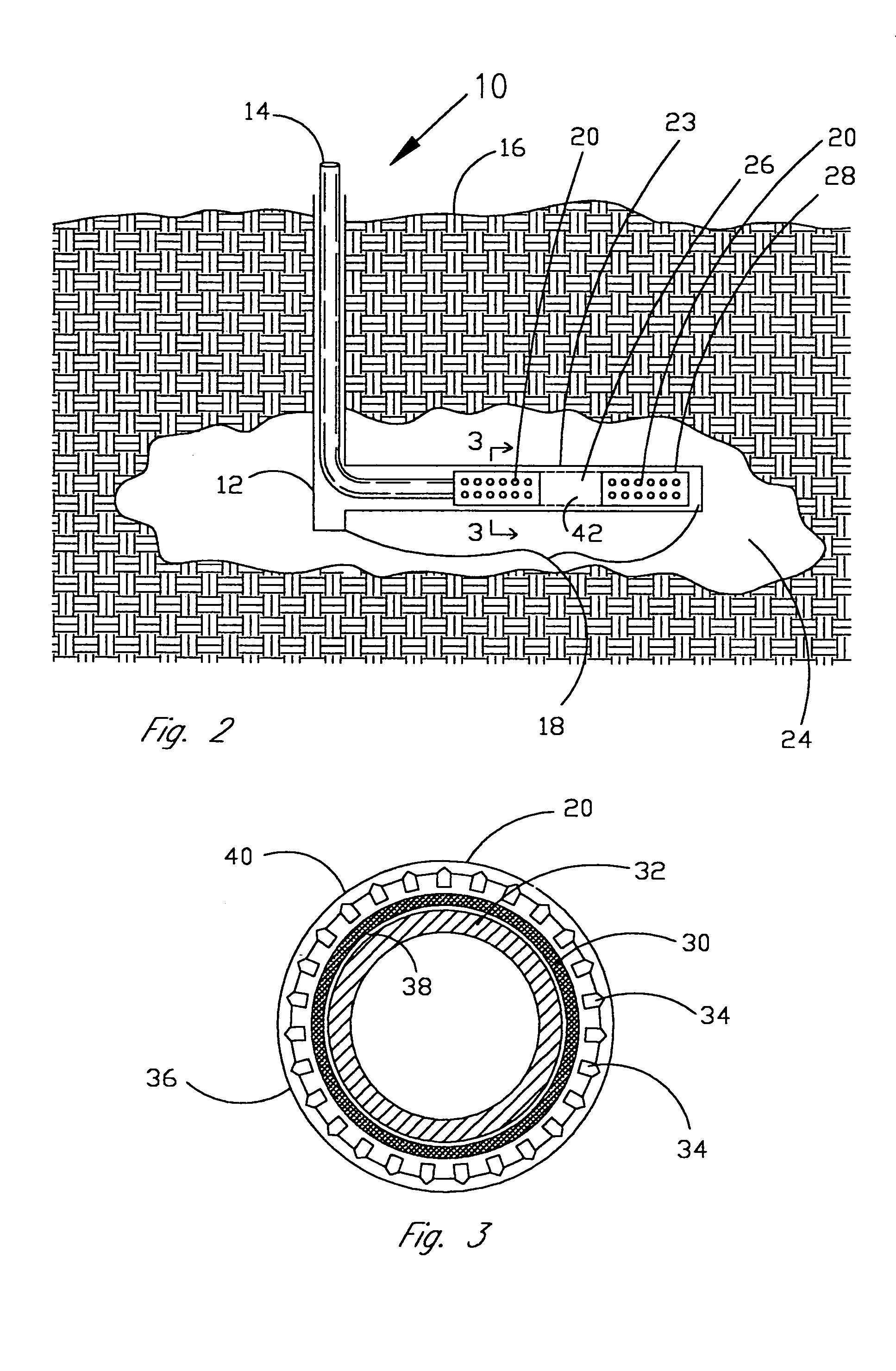

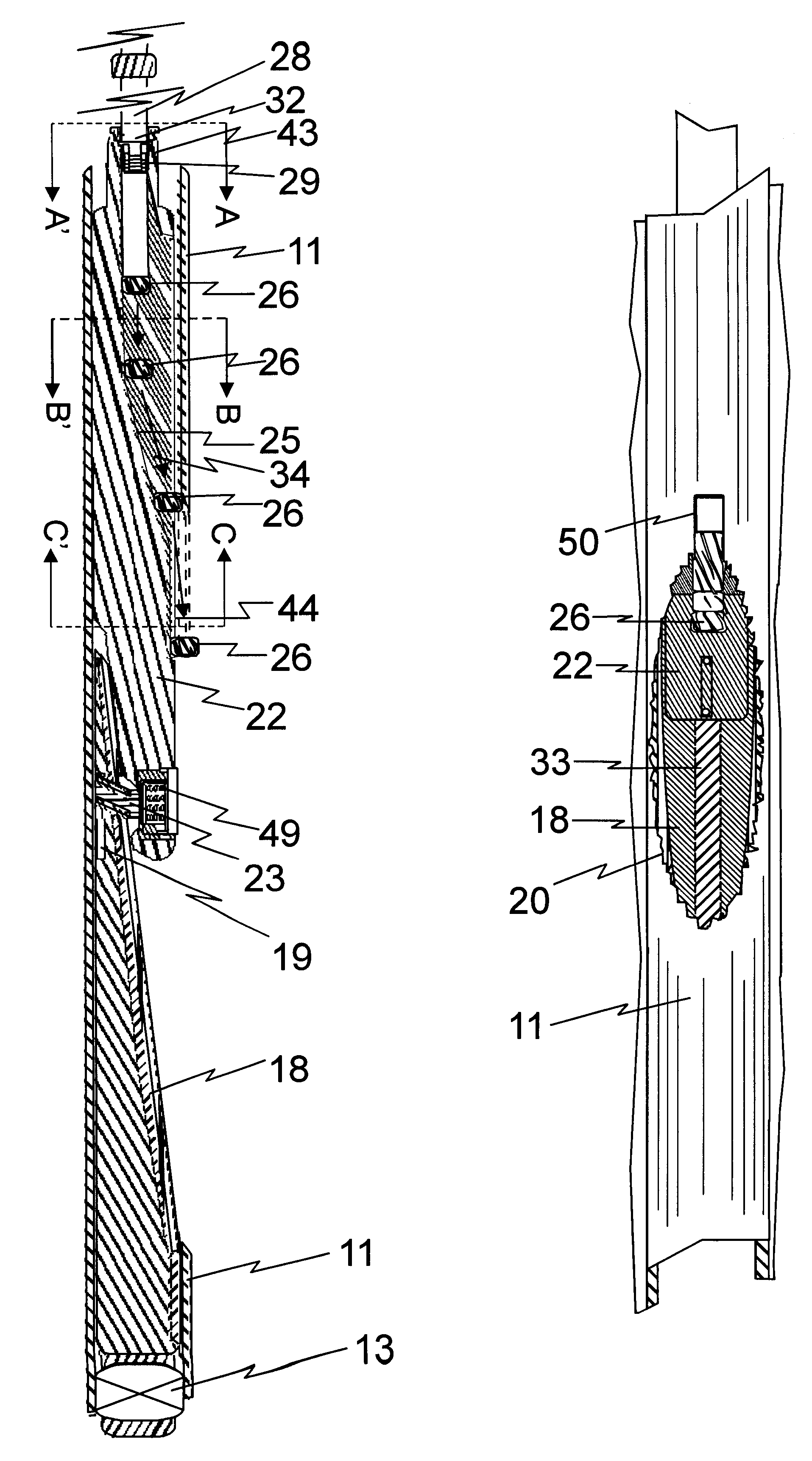

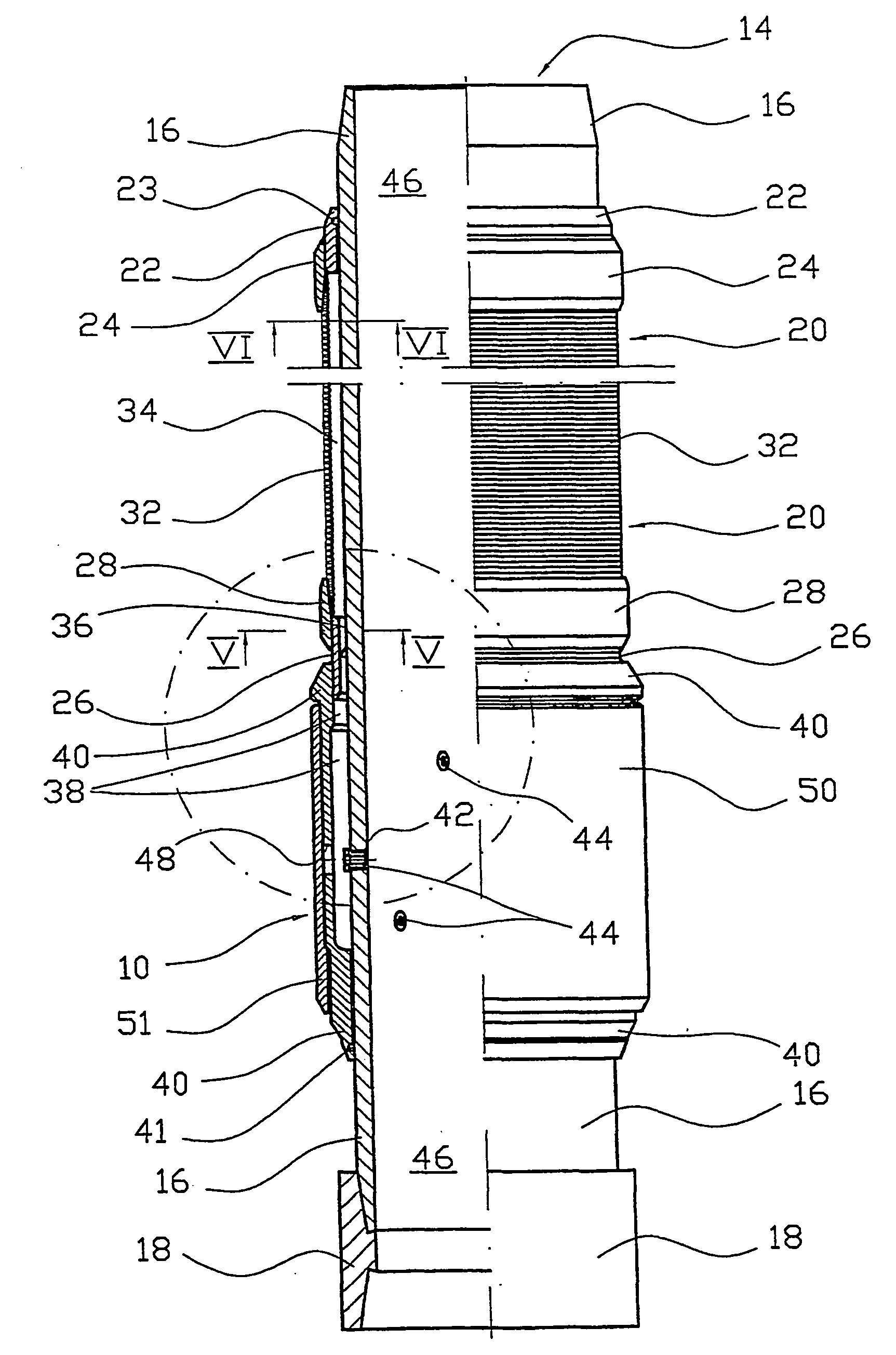

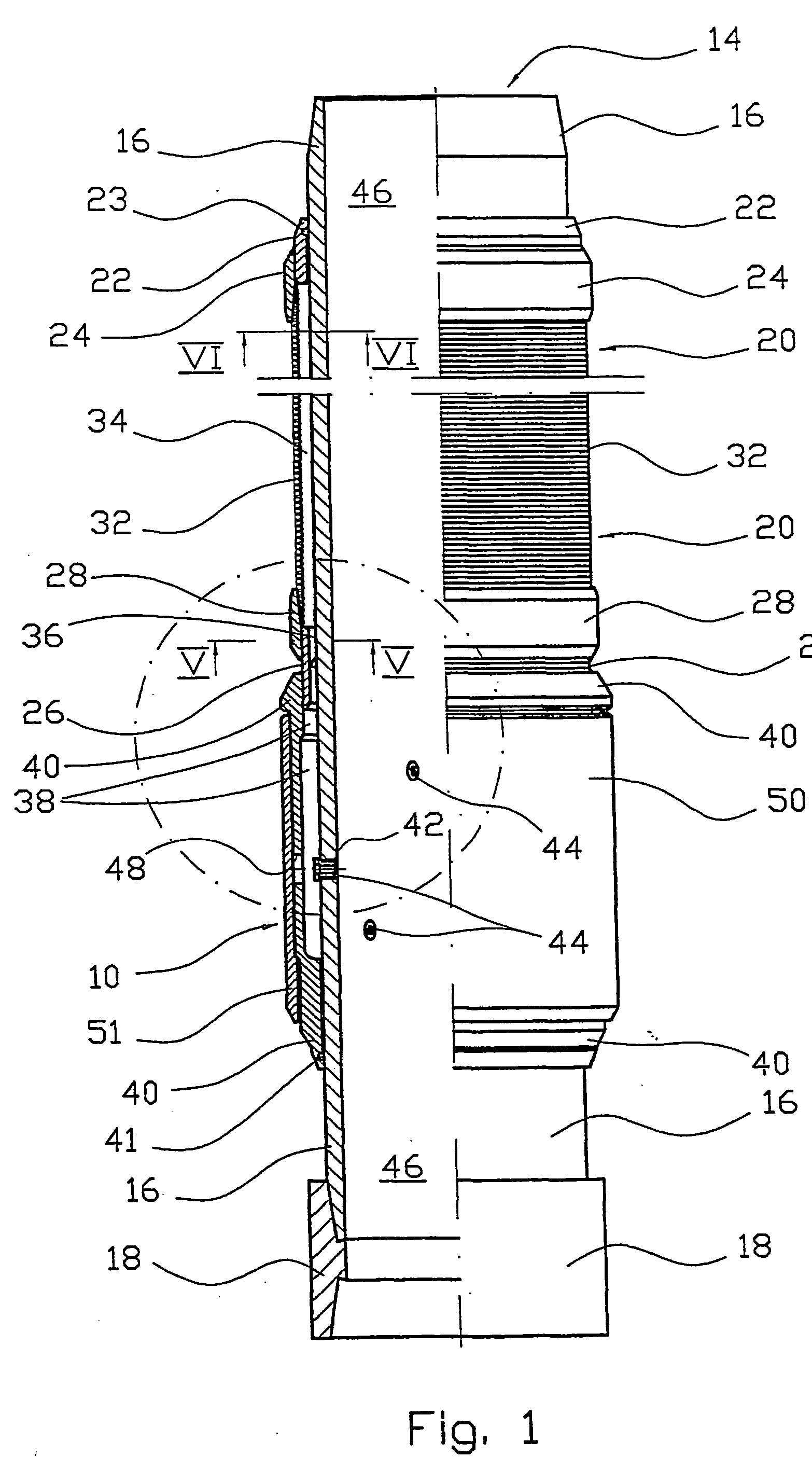

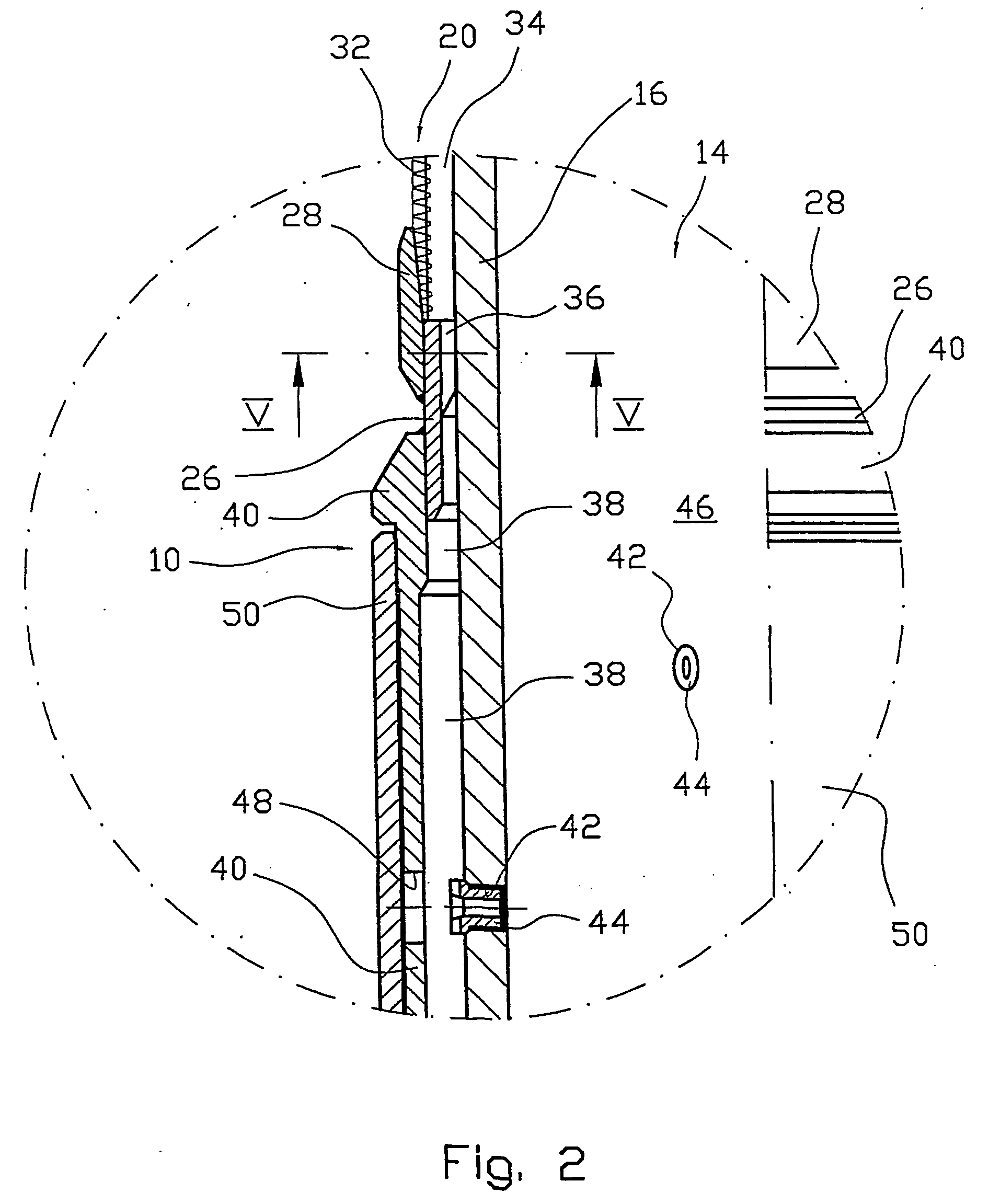

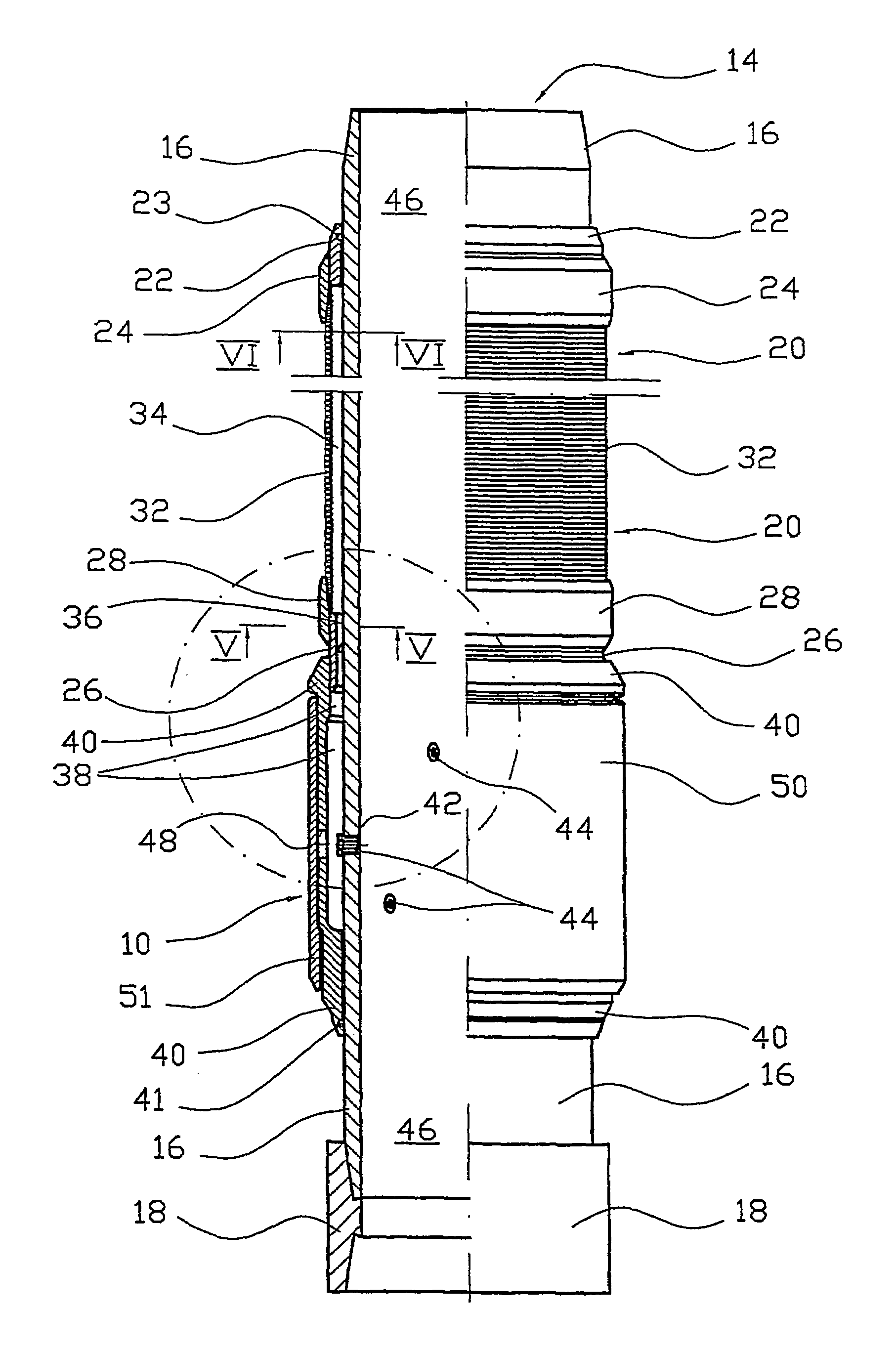

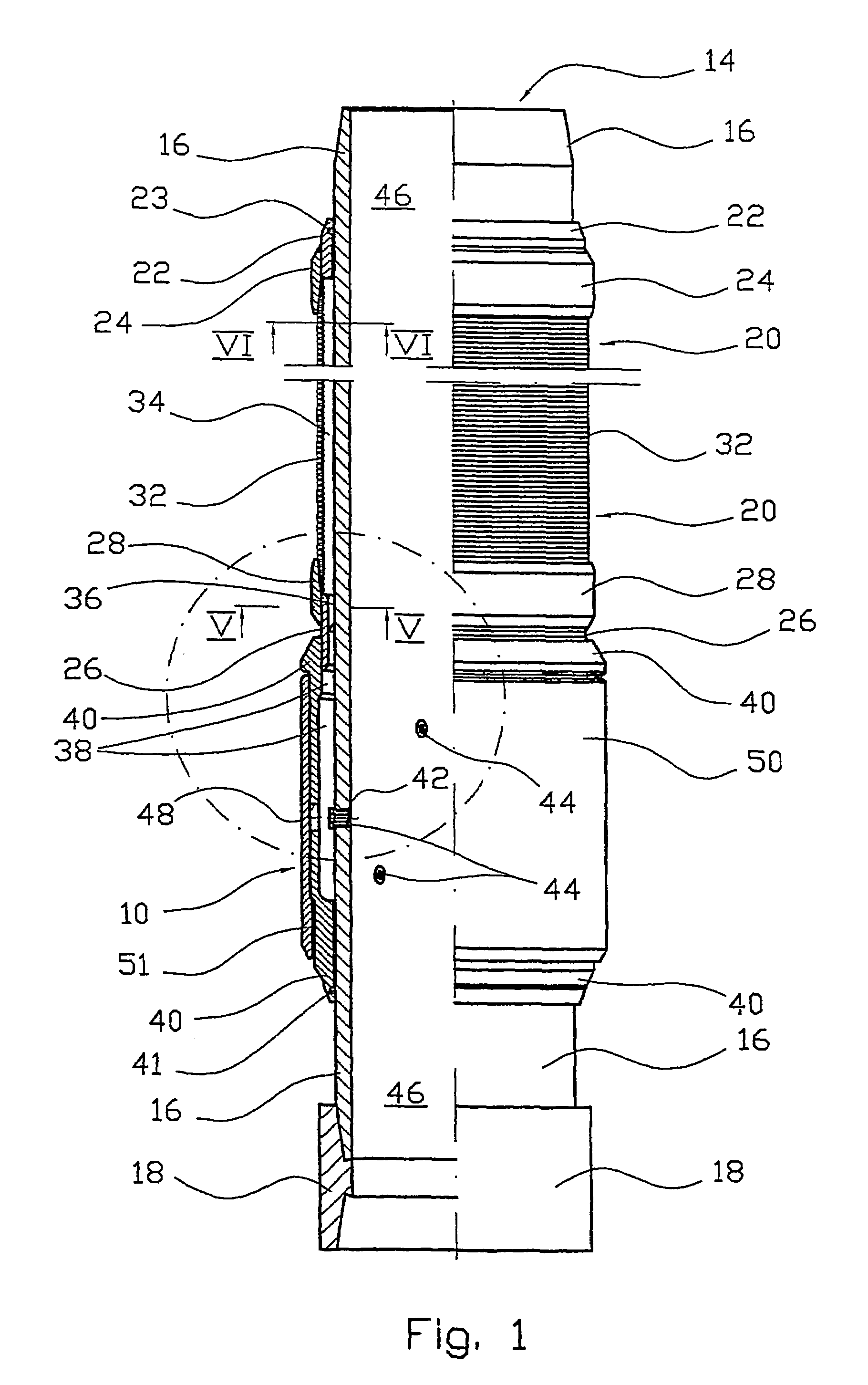

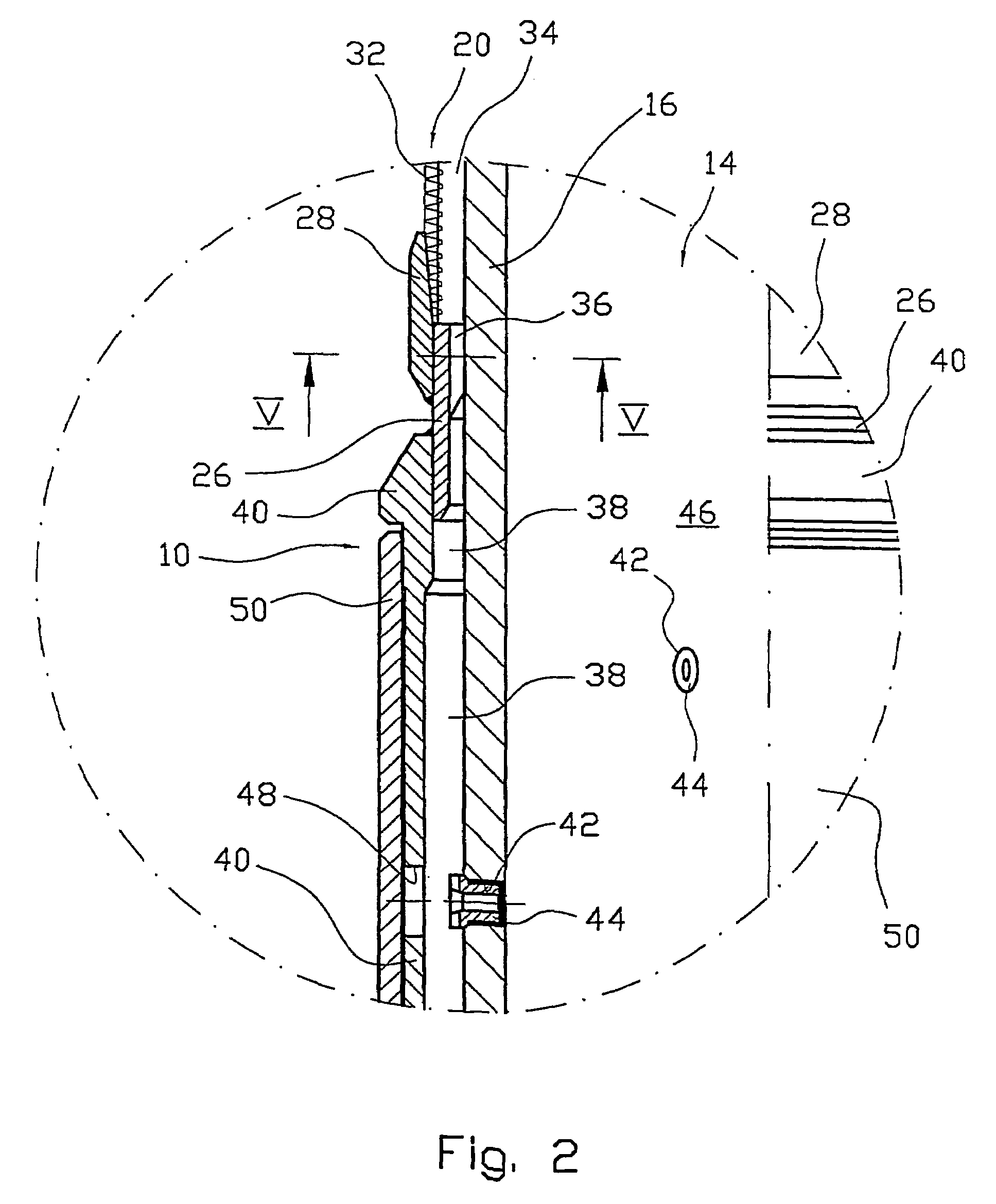

Well device for throttle regulation of inflowing fluids

A flow arrangement (10, 12) for use in a well through one or more underground reservoirs, and where the arrangement (10, 12) is designed to throttle radially inflowing reservoir fluids produced through an inflow portion of the production tubing in the well, the production tubing in and along this inflow portion being provided with one or more arrangements (10, 12). Such an arrangement (10, 12) is designed to effect a relatively stable and predictable fluid pressure drop at any stable fluid flow rate in the course of the production period of the well, and where said fluid pressure drop will exhibit the smallest possible degree of susceptibility to influence by differences in the viscosity and / or any changes in the viscosity of the inflowing reservoir fluids during the production period. Such a fluid pressure drop is obtained by the arrangement (10, 12) comprising among other things one or more short, removable and replaceable flow restrictions such as nozzle inserts (44, 62), and where the individual flow restriction may be given the desired cross section of flow, through which reservoir fluids may flow and be throttled, or the flow restriction may be a sealing plug.

Owner:RESLINK

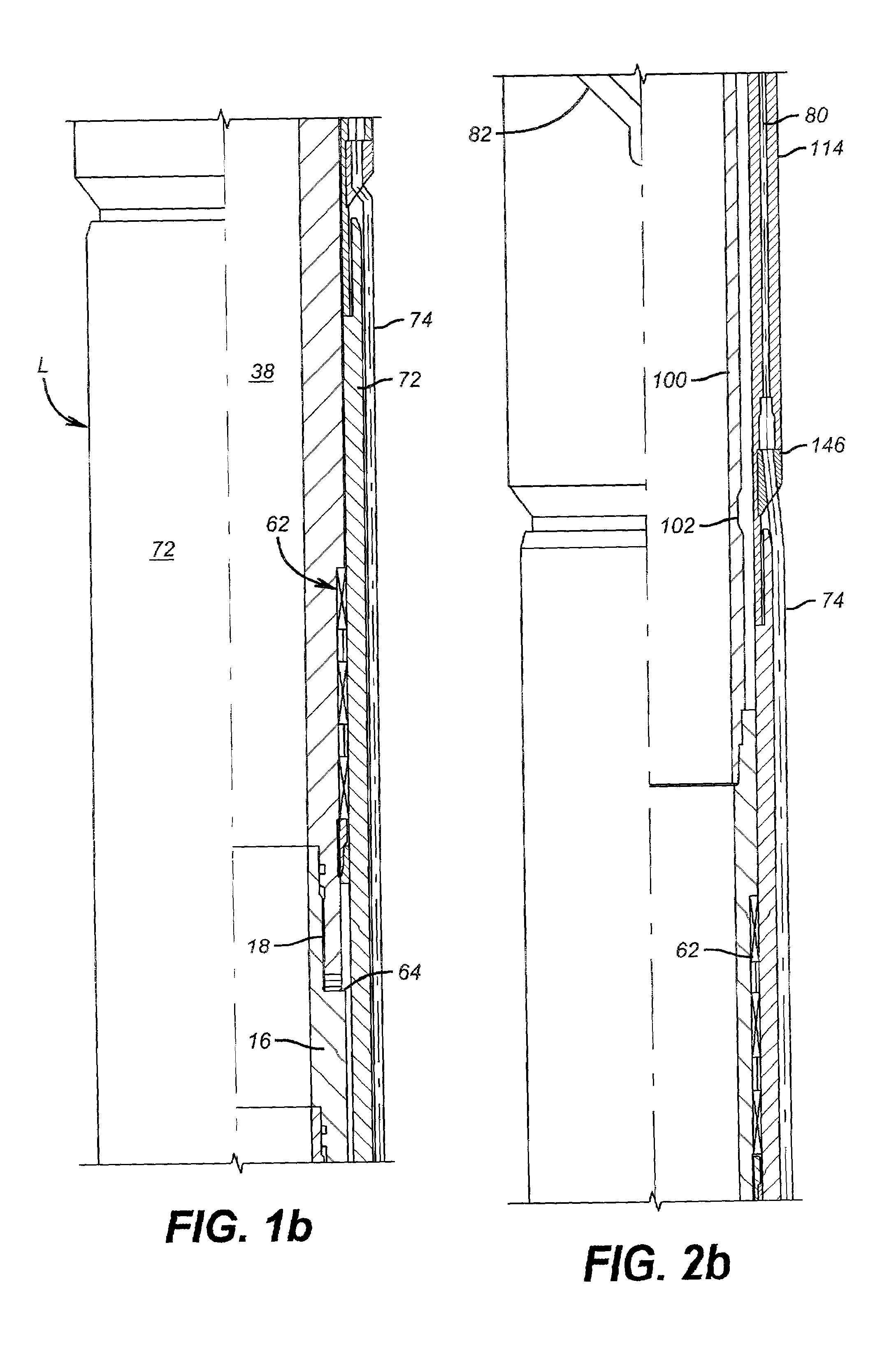

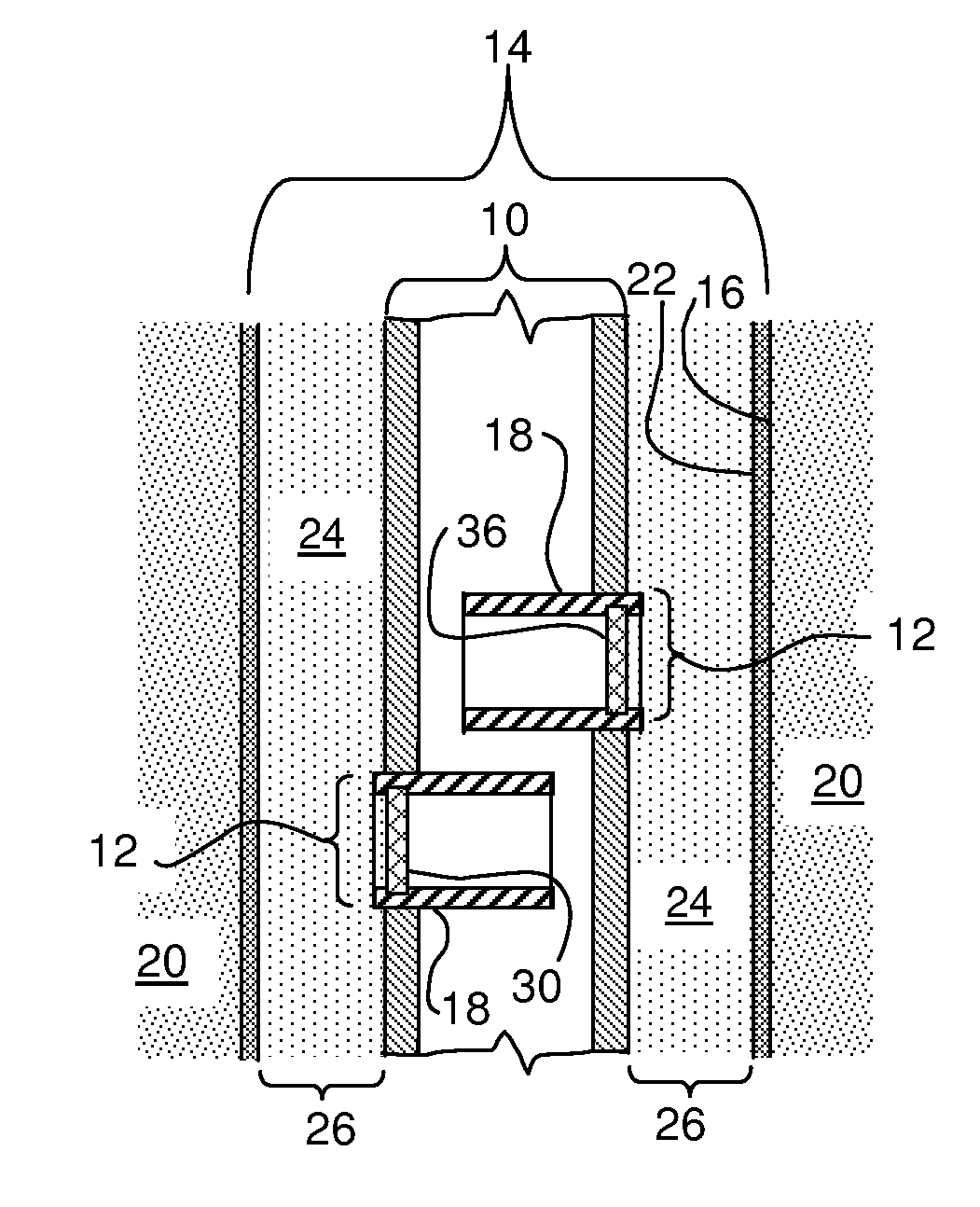

Sand control screen assembly having an internal isolation member and treatment method using the same

InactiveUS6886634B2Avoid flowAvoid lostFluid removalDrinking water installationParticulate flowFilter media

A sand control screen assembly (80) that is positionable within a wellbore comprises a base pipe (82) having at least one opening (84) that allows fluid flow therethrough and a filter medium (86) positioned about the exterior of the base pipe (82) that selectively allows fluid flow therethrough and prevents particulate flow of a predetermined size therethrough. An internal isolation member (88) that has at least one opening (90) is positioned within the base pipe (82). A one-way valve (92) is operably associated with the opening (90) of the internal isolation member (88). The one-way valve (92) controls the flow of fluid through the opening (90) of the internal isolation member (88) such that fluid flow is prevented from the interior to the exterior of the sand control screen assembly (80) but is allowed from the exterior to the interior of the sand control screen assembly (80).

Owner:HALLIBURTON ENERGY SERVICES INC

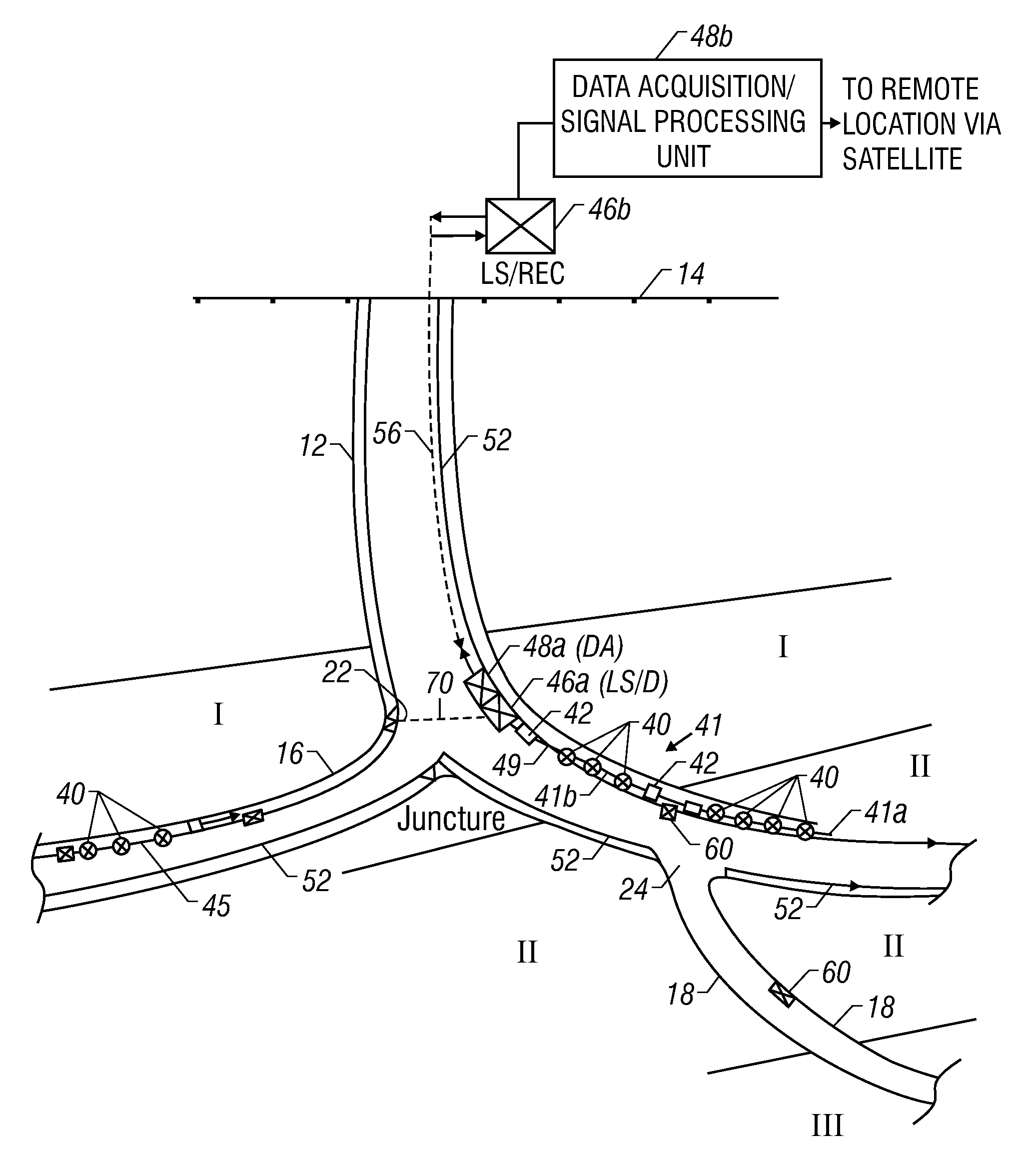

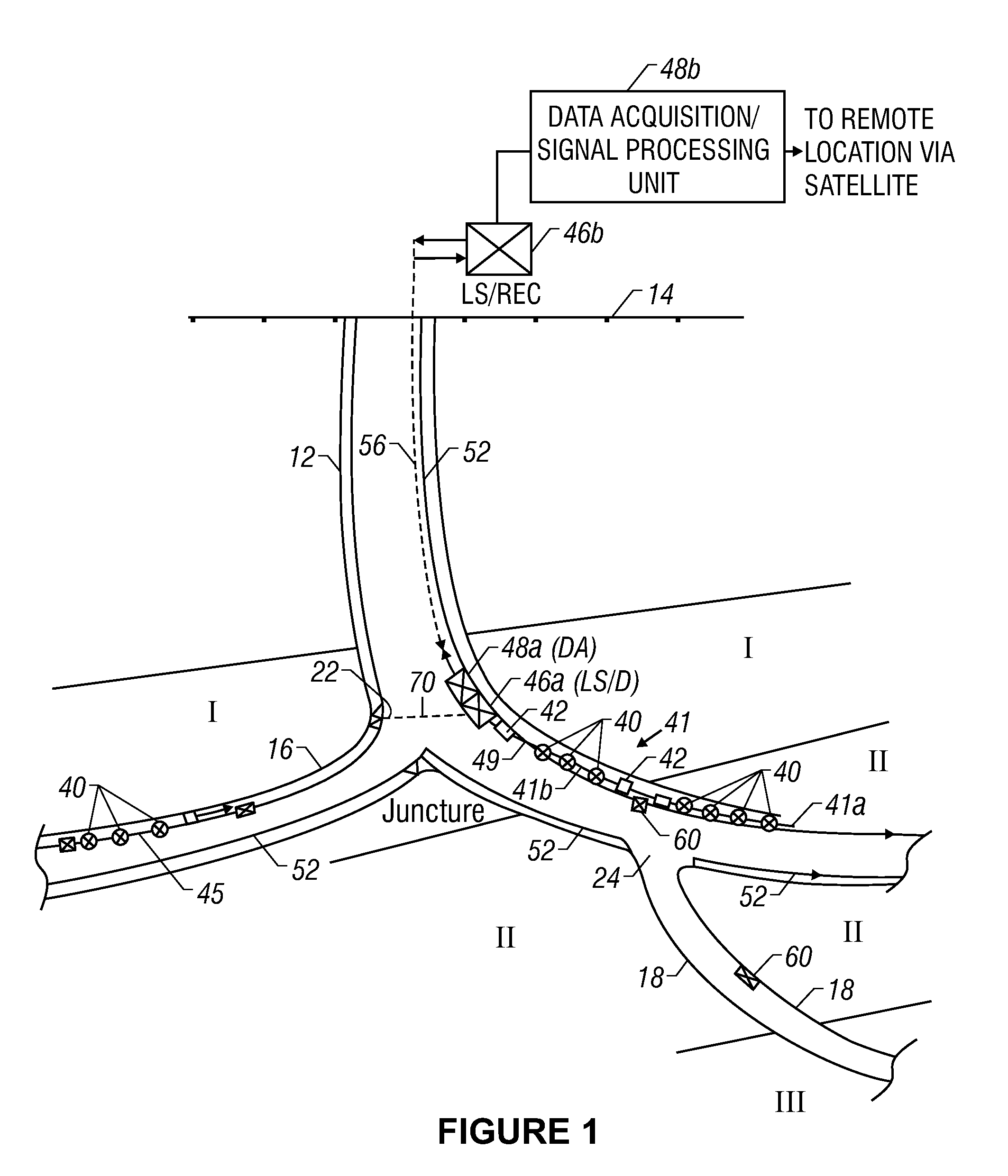

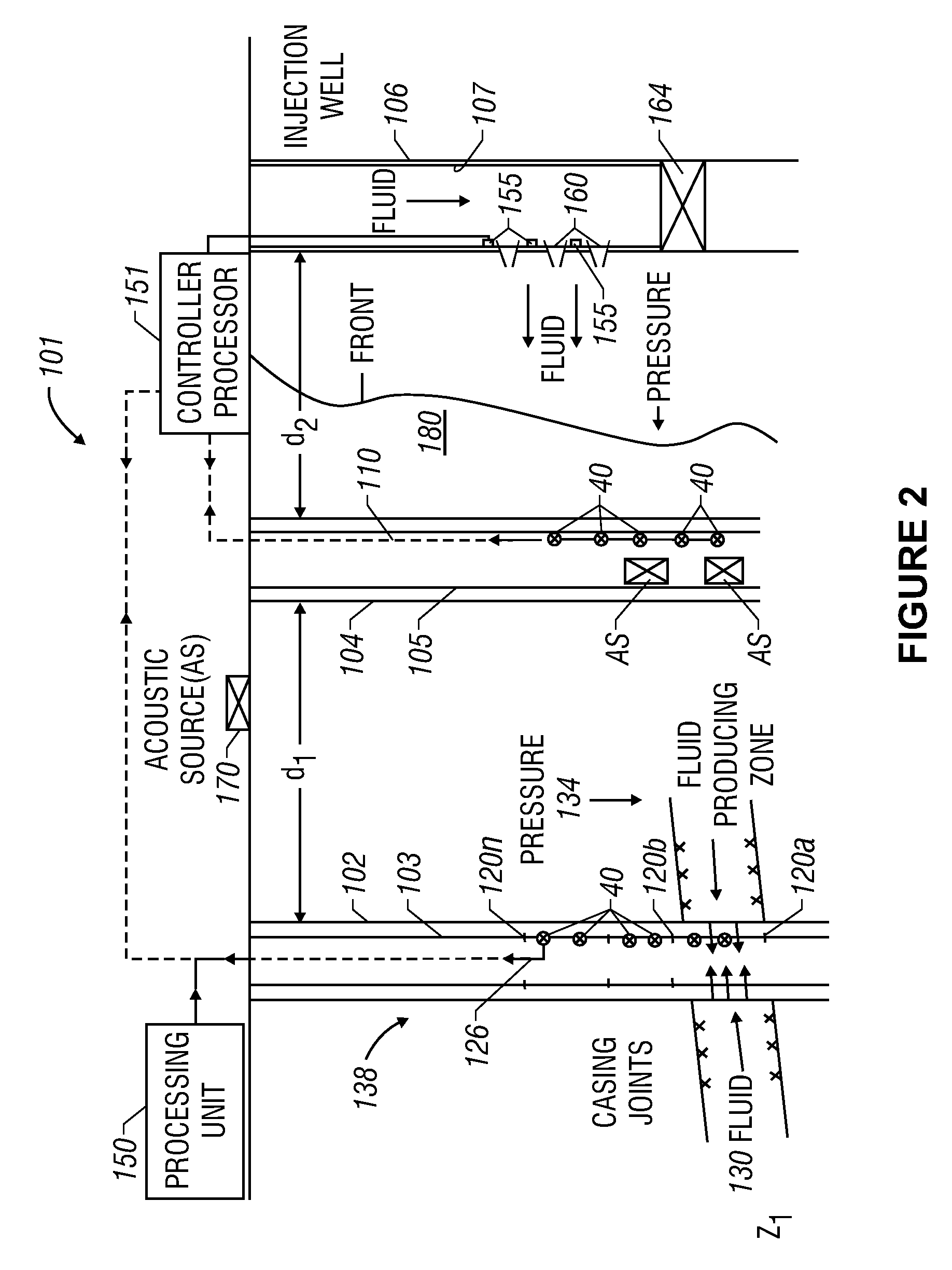

Monitoring of Downhole Parameters and Tools Utilizing Fiber Optics

The present disclosure provides systems utilizing fiber optics for monitoring downhole parameters and the operation and conditions of downhole tools and controlling injection operations based on measurements in an injection well and / or a production well.

Owner:BAKER HUGHES INC

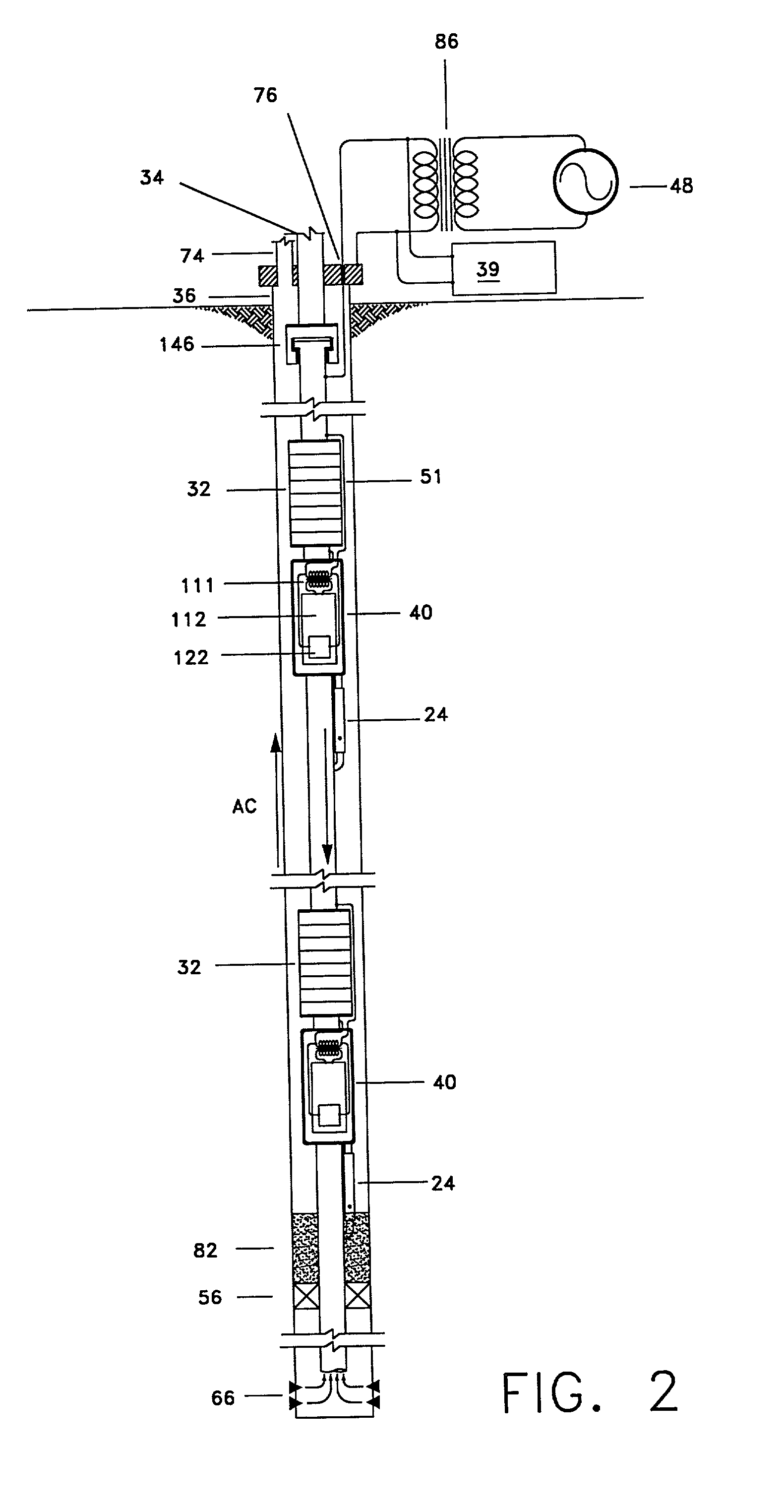

Toroidal choke inductor for wireless communication and control

An induction choke in a petroleum well where a voltage potential is developed across the choke to power and communicate with devices and sensors in the well. Preferably, the induction choke is a ferromagnetic material and acts as an impedance to a time-varying current, e.g. AC. The petroleum well includes a cased wellbore having a tubing string positioned within and longitudinally extending within the casing. A controllable gas lift valve, sensor, or other device is coupled to the tubing. The valve sensor, or other device is powered and controlled from the surface. Communication signals and power are sent from the surface using the tubing, casing, or liner as the conductor with a casing or earth ground. For example, AC current is directed down a casing or tubing or a lateral where the current encounters a choke. The voltage potential developed across the choke is used to power electronic devices and sensors near the choke. Such induction chokes may be used in many other applications having an elongated conductor such as a pipe, where it is desirable to power or communicate with a valve, sensor, or other device without providing a dedicated power or communications cable.

Owner:SHELL OIL CO

Flow control device for choking inflowing fluids in a well

A flow arrangement (10, 12) for use in a well through one or more underground reservoirs, and where the arrangement (10, 12) is designed to throttle radially inflowing reservoir fluids produced through an inflow portion of the production tubing in the well, the production tubing in and along this inflow portion being provided with one or more arrangements (10, 12) Such an arrangement (10, 12) is designed to effect a relatively stable and predictable fluid pressure drop at any stable fluid flow rate in the course of the production period of the well, and where said fluid pressure drop will exhibit the smallest possible degree of susceptibility to influence by differences in the viscosity and / or any changes in the viscosity of the inflowing reservoir fluids during the production period. Such a fluid pressure drop is obtained by the arrangement (10, 12) comprising among other things one or more short, removable and replaceable flow restrictions such as nozzle inserts (44, 62), and where the individual flow restriction may be given the desired cross section of flow, through which reservoir fluids may flow and be throttled, or the flow restriction may be a sealing plug.

Owner:RESLINK

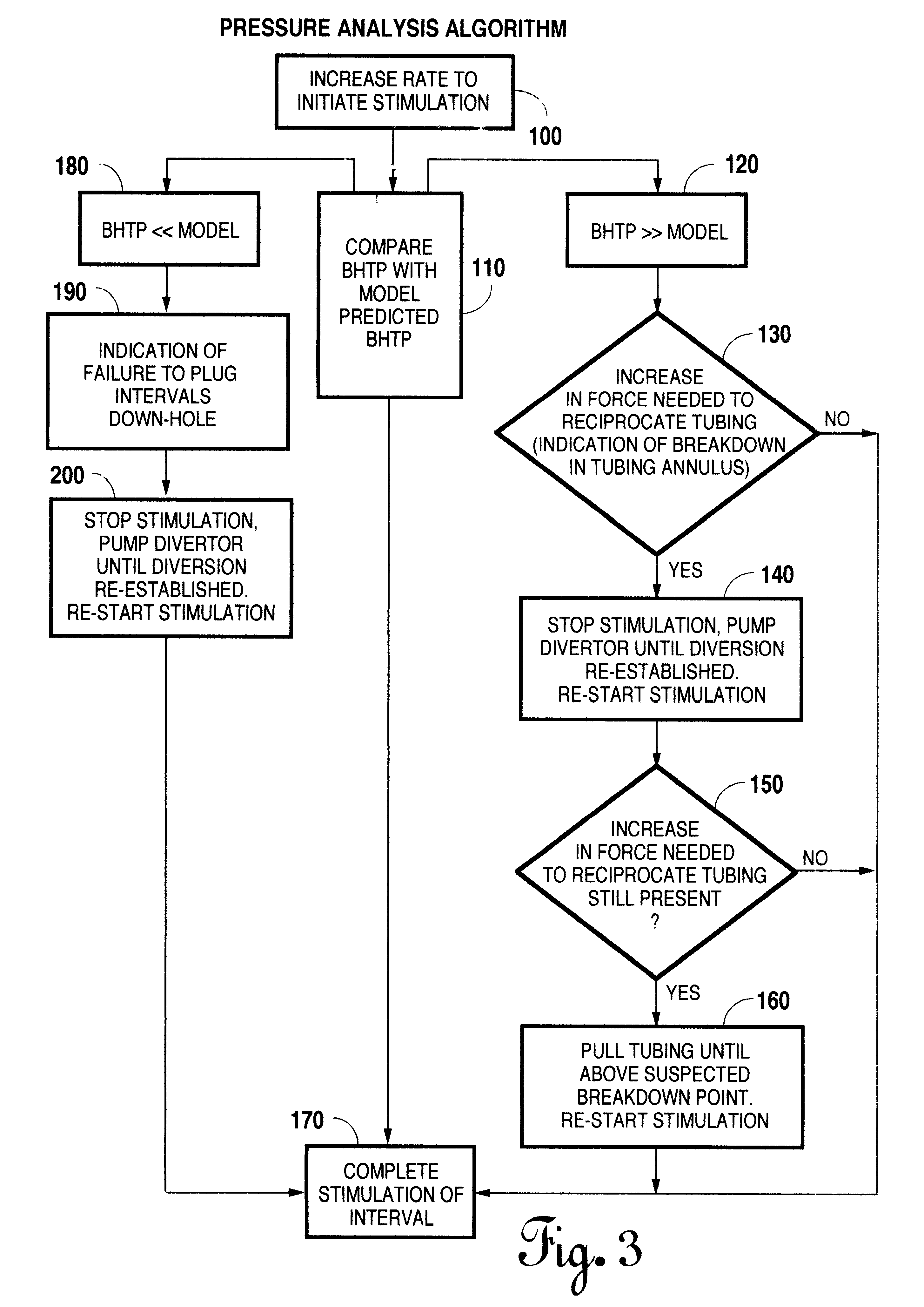

Diversion treatment method

InactiveUS6367548B1For real-time analysisEasy to controlSurveyFluid removalFluid shiftingEnvironmental geology

Owner:OCEAN ENERGY RESOURCES +1

Oilfield Apparatus Comprising Swellable Elastomers Having Nanosensors Therein And Methods Of Using Same In Oilfield Application

Apparatus, oilfield assemblies, and methods of use are described. The apparatus comprises, in one embodiment, a swellable elastomeric composition comprising a swellable elastomer and one or more nanosensors dispersed therein and shaped into an oilfield element. Methods of the invention comprise using an apparatus of the invention in an oilfield operation, thus exposing the oilfield element to an oilfield environment, and sensing one or more reservoir parameters. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com