Patents

Literature

3330 results about "Liquid water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

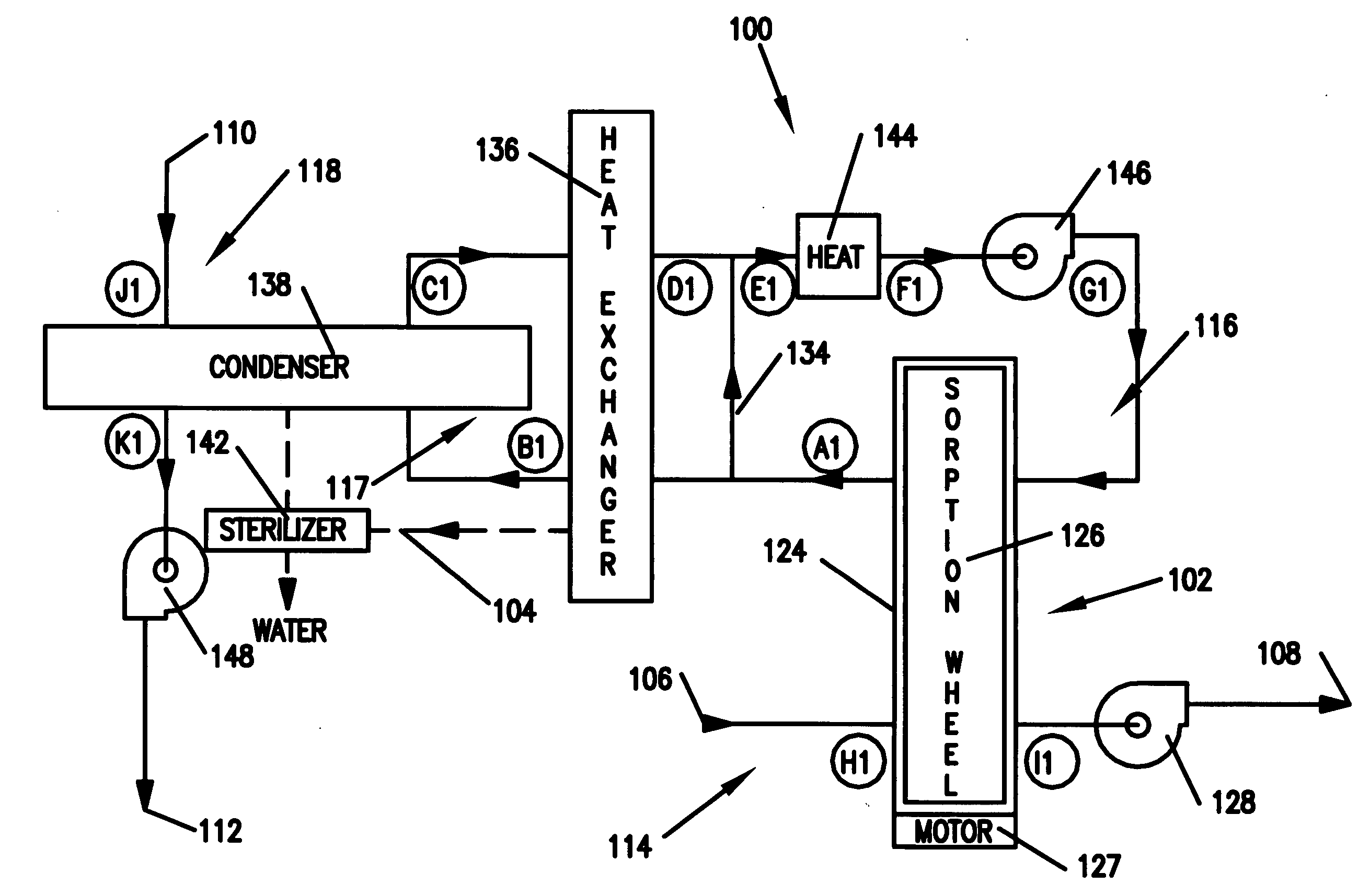

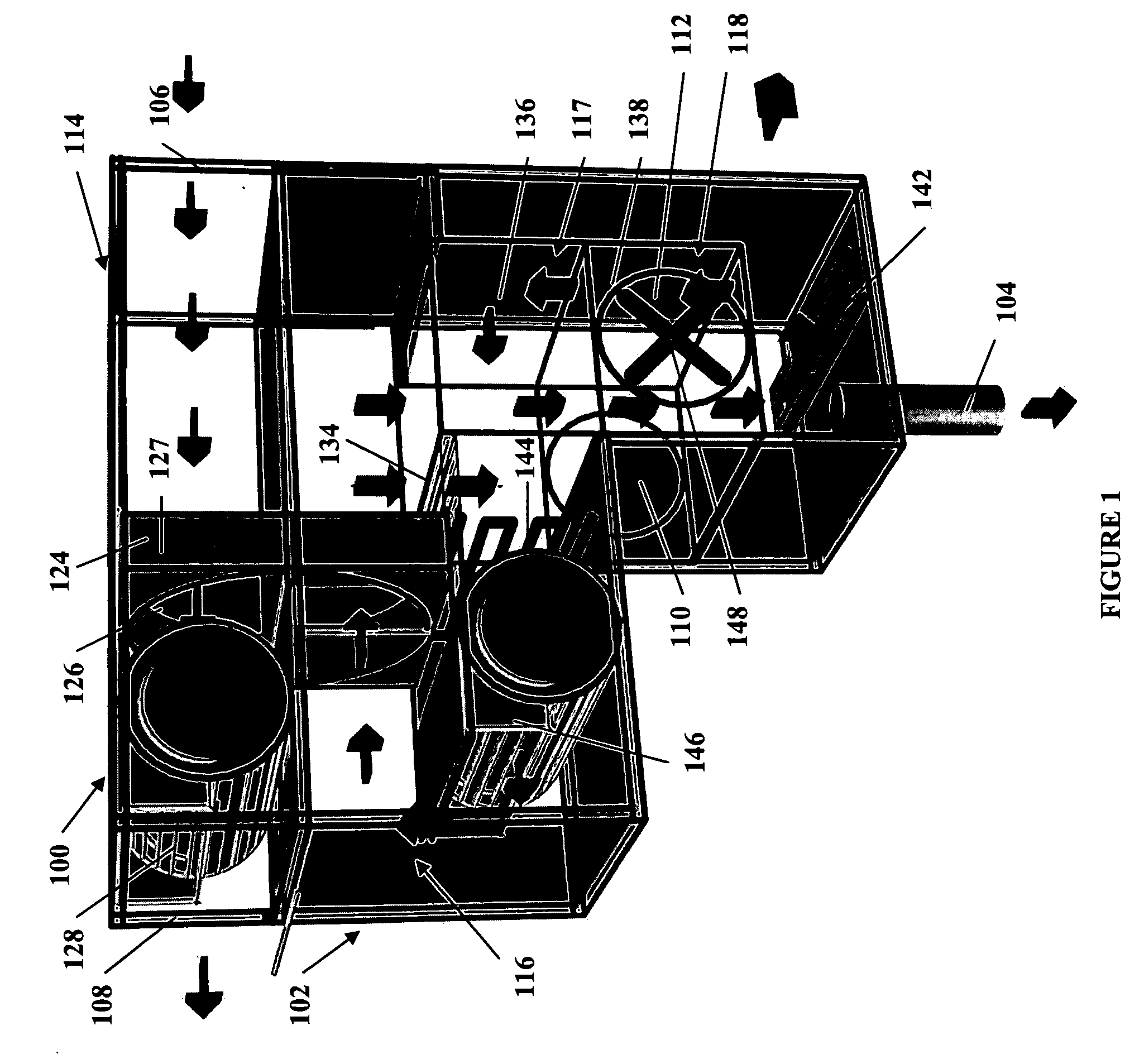

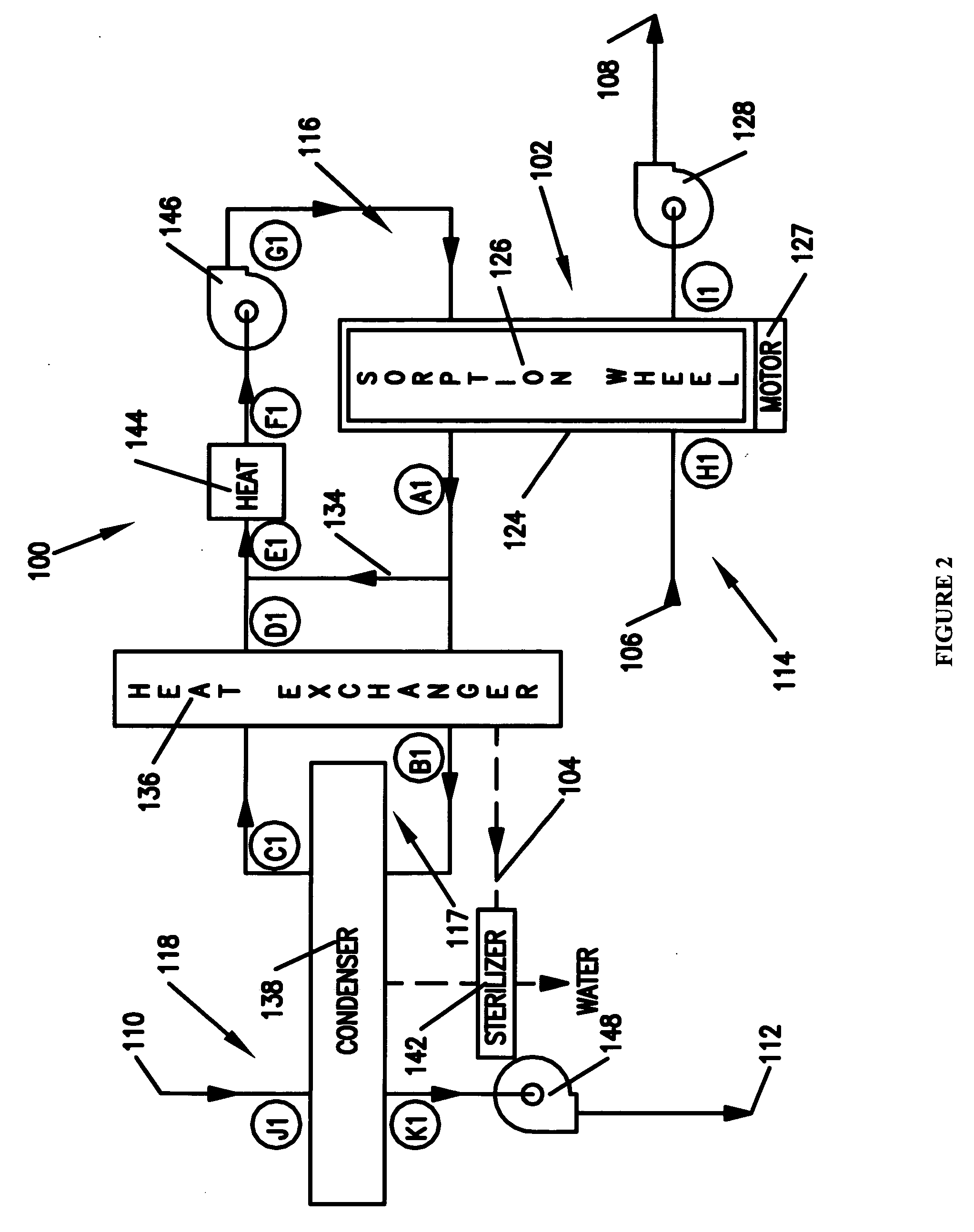

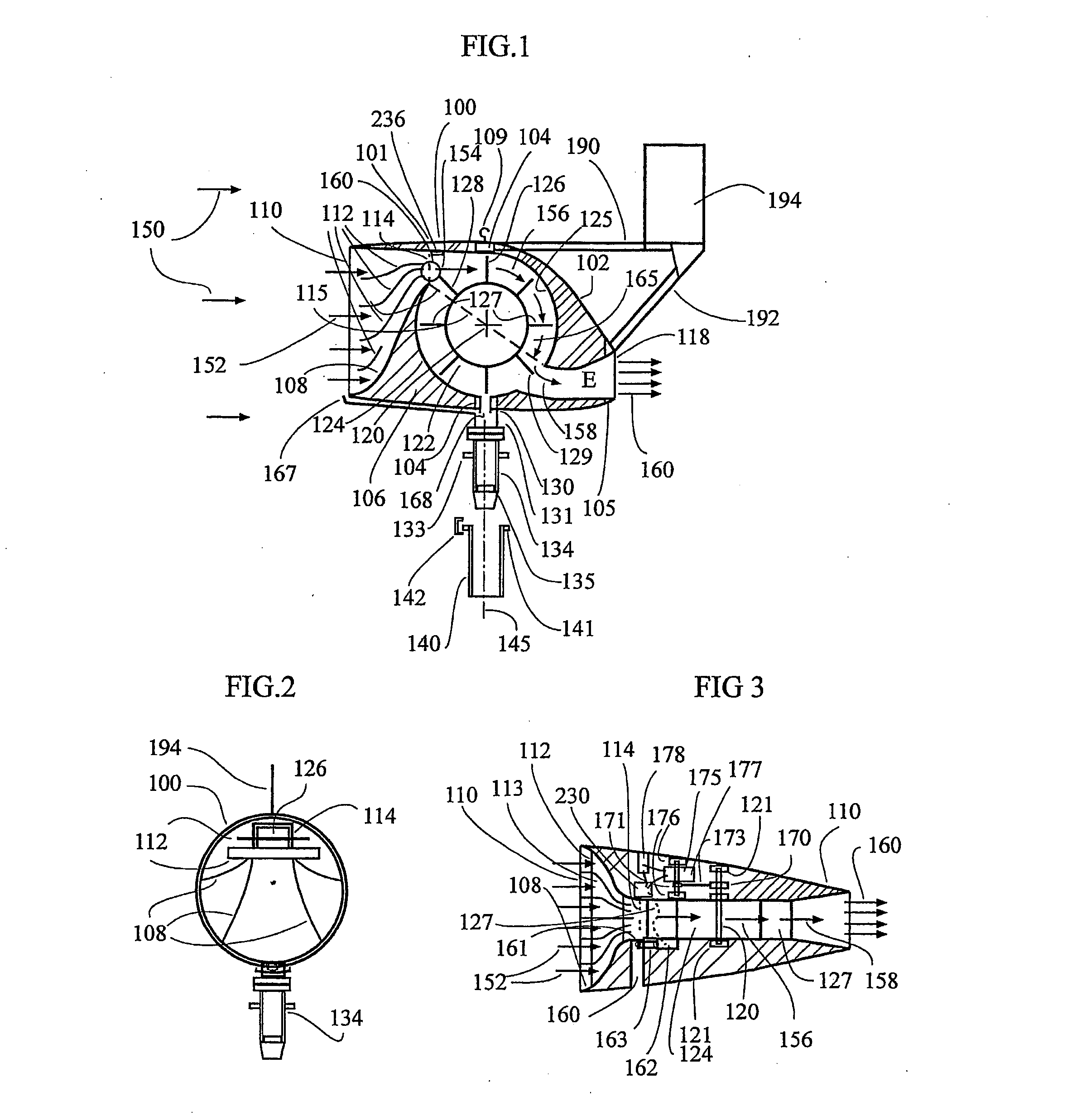

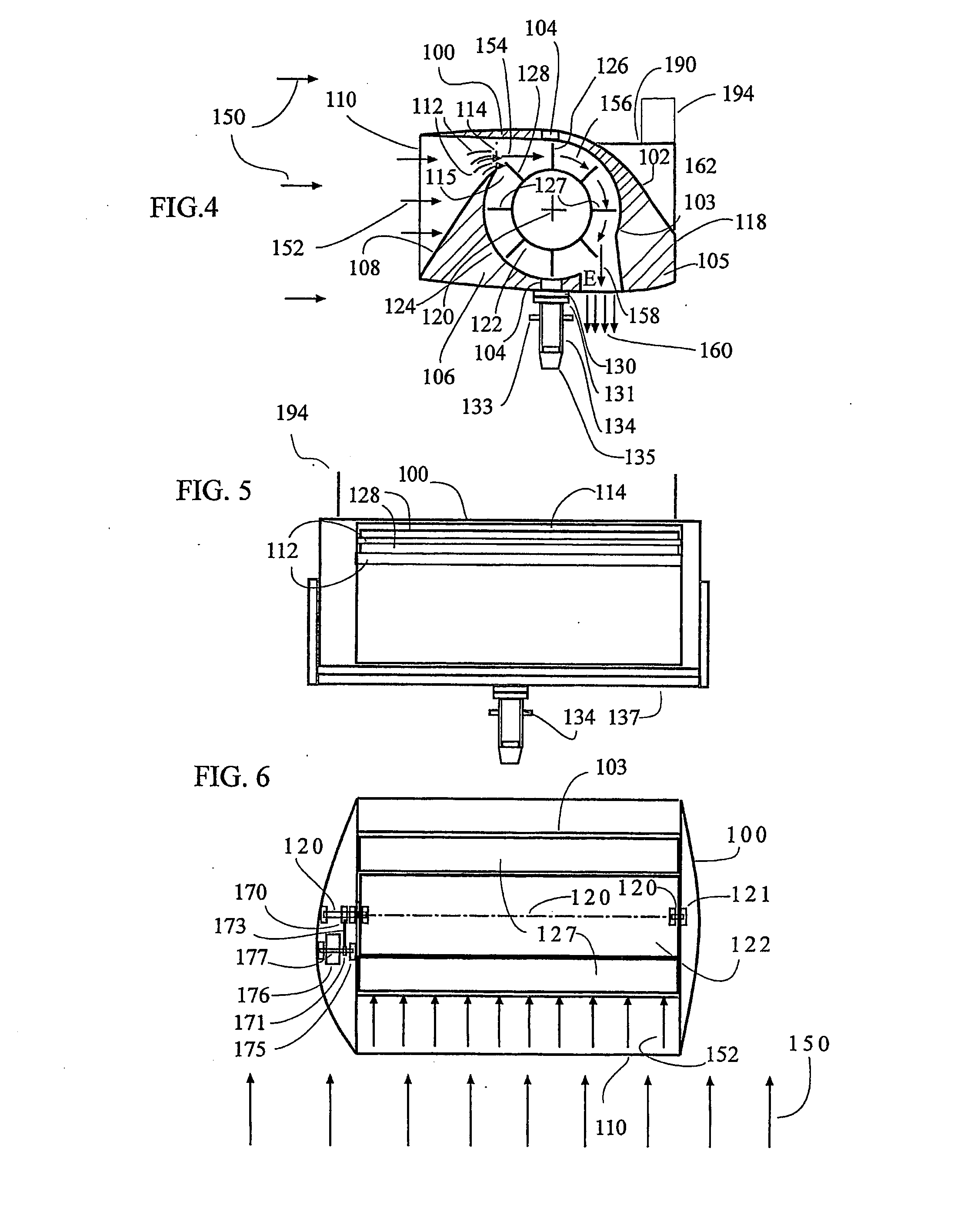

Method and apparatus for producing potable water from air including severely arid and hot climates

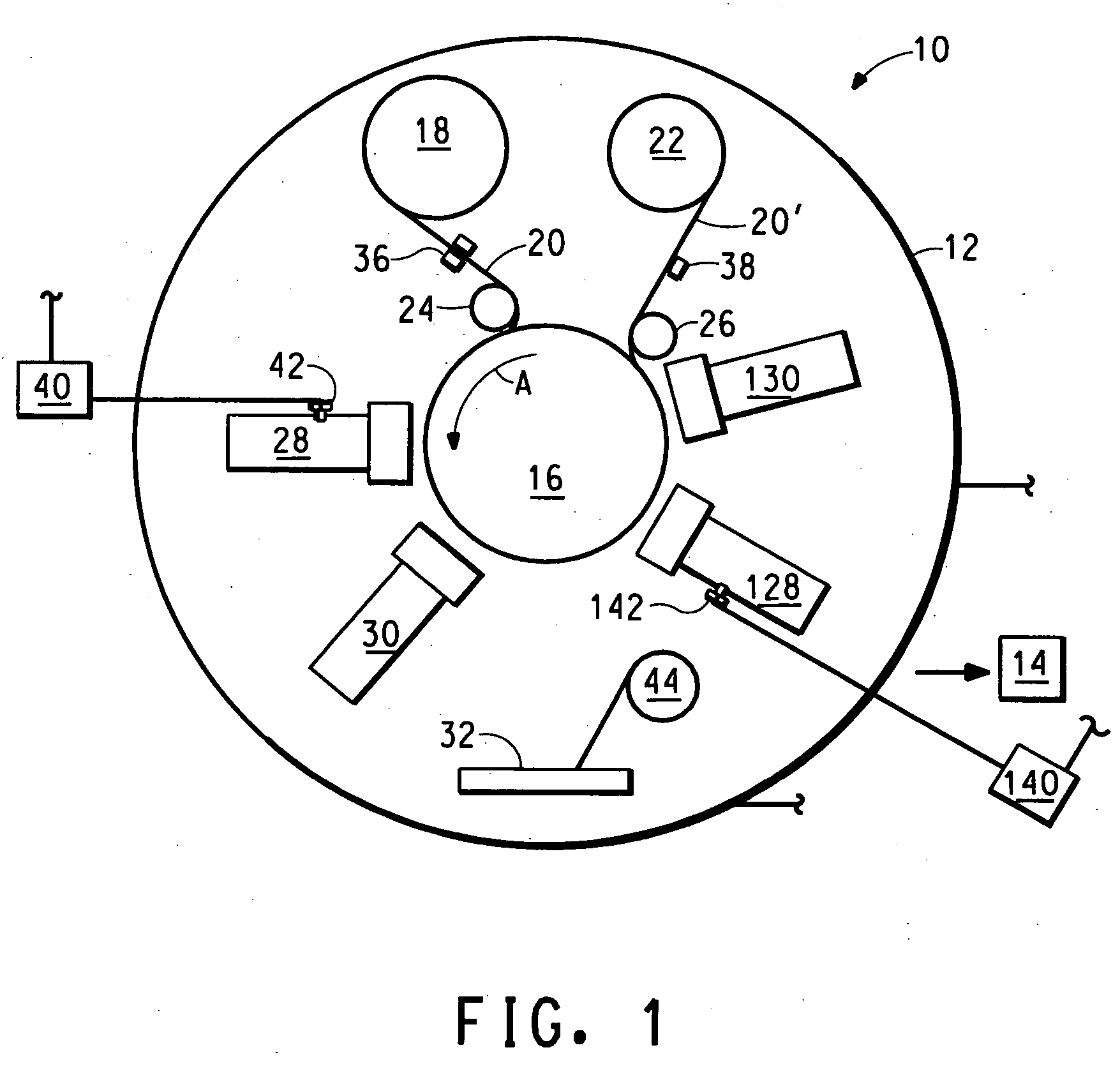

Methods and apparatus for extracting liquid water from ambient air, including ambient air in severely arid and hot climates, are described. An example apparatus uses a sorption-desorption-condensation cycle using a sorption wheel to extract moisture from ambient air and concentrate the water vapor driven off from the sorption material in a circulating gas, with condensation of liquid water from the circulating gas.

Owner:EPLEE DUSTIN M +1

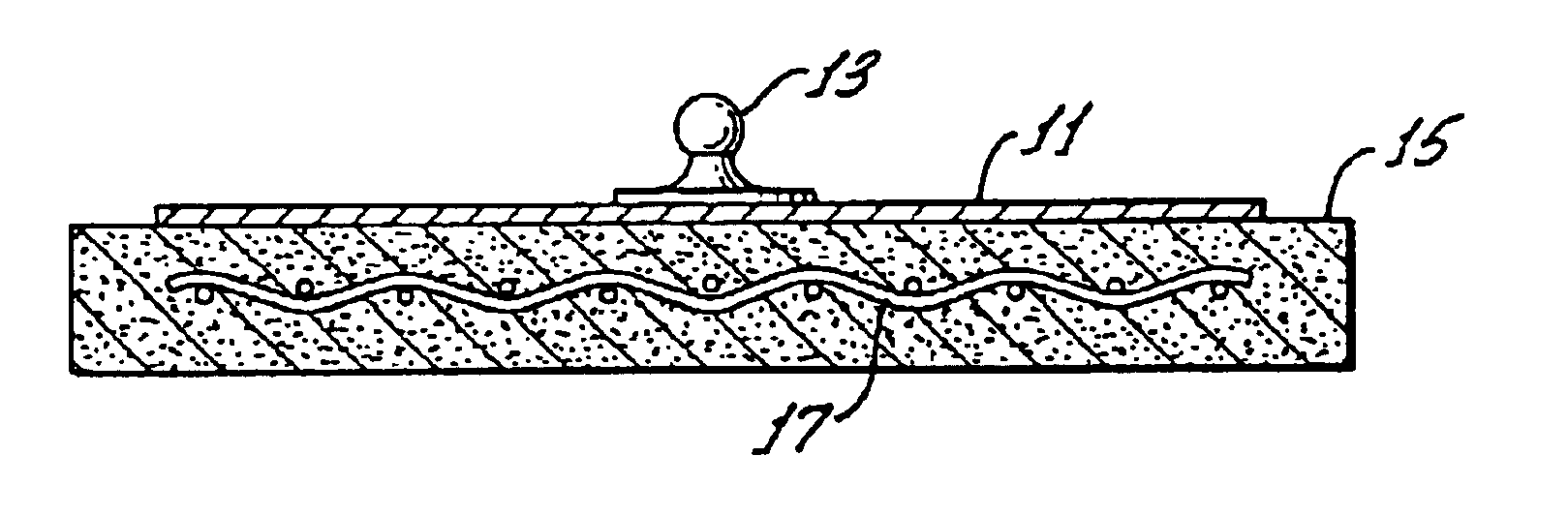

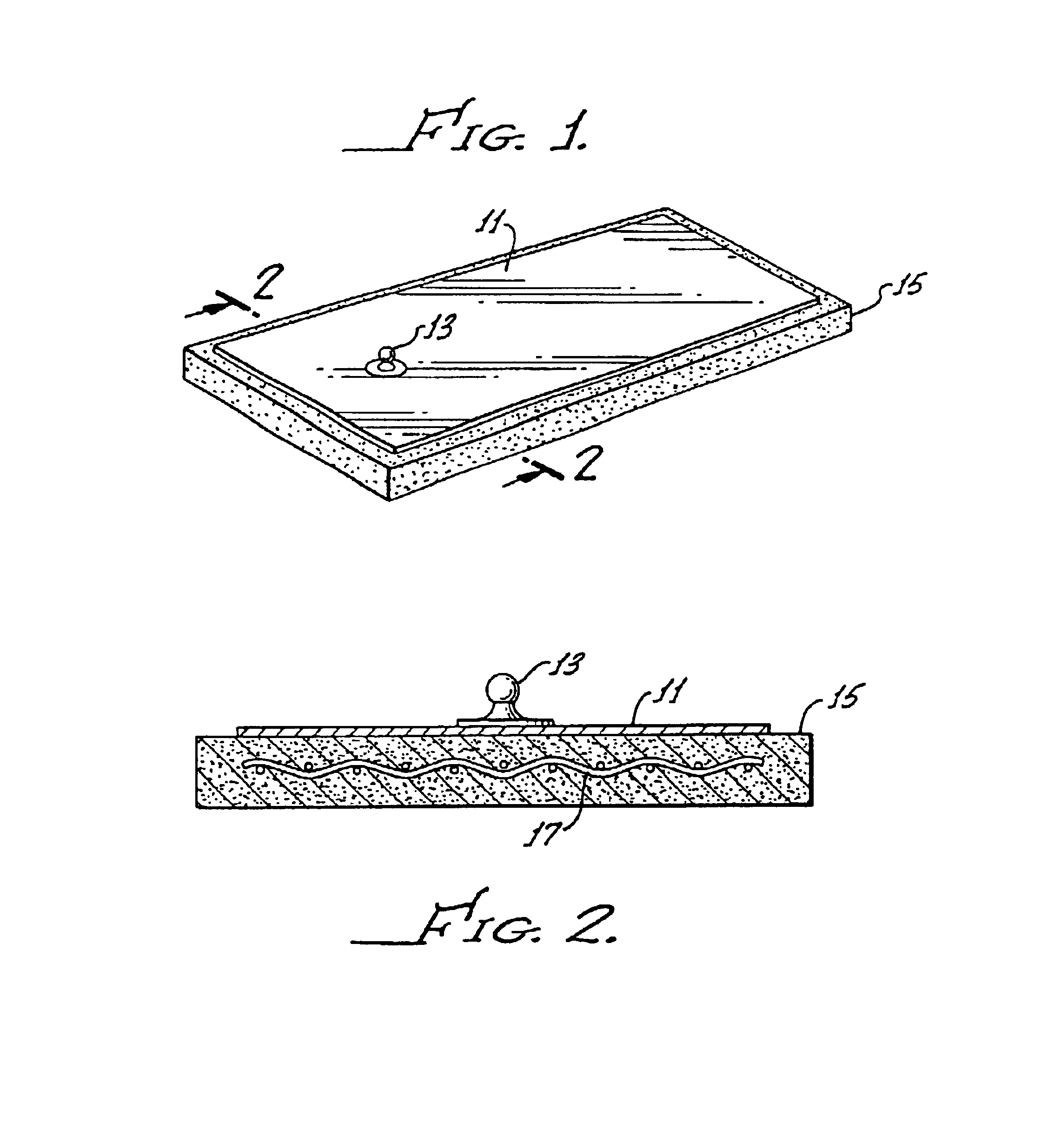

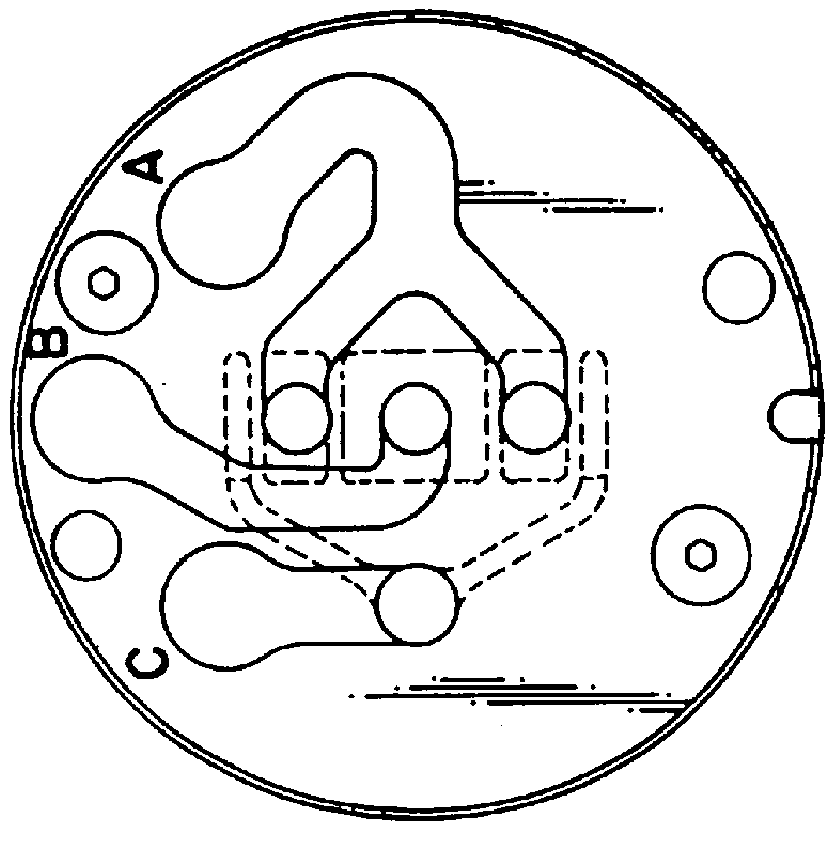

Medical electrode

An electrode providing electrical contact with a patient's skin includes a conductive member adapted for connection to an external electrical apparatus and a non-liquid water containing film for electrically interfacing to said patient's skin, the non-liquid film being electrically and mechanically connected to said conductive member. The non-liquid water containing film includes an electrically conductive organic polymer plasticized with a polyhydric alcohol with said organic polymer being derived from a monomeric mixture comprising from about 2 to 30 pph acrylic acid, 2 to 30 pph of a glycolvinylether and 0.01 to 1.5 pph of a crosslinking agent. Preferably the polyhydric alcohol is glycerol.

Owner:AXELGAARD MANUFACTURING COMPANY INC

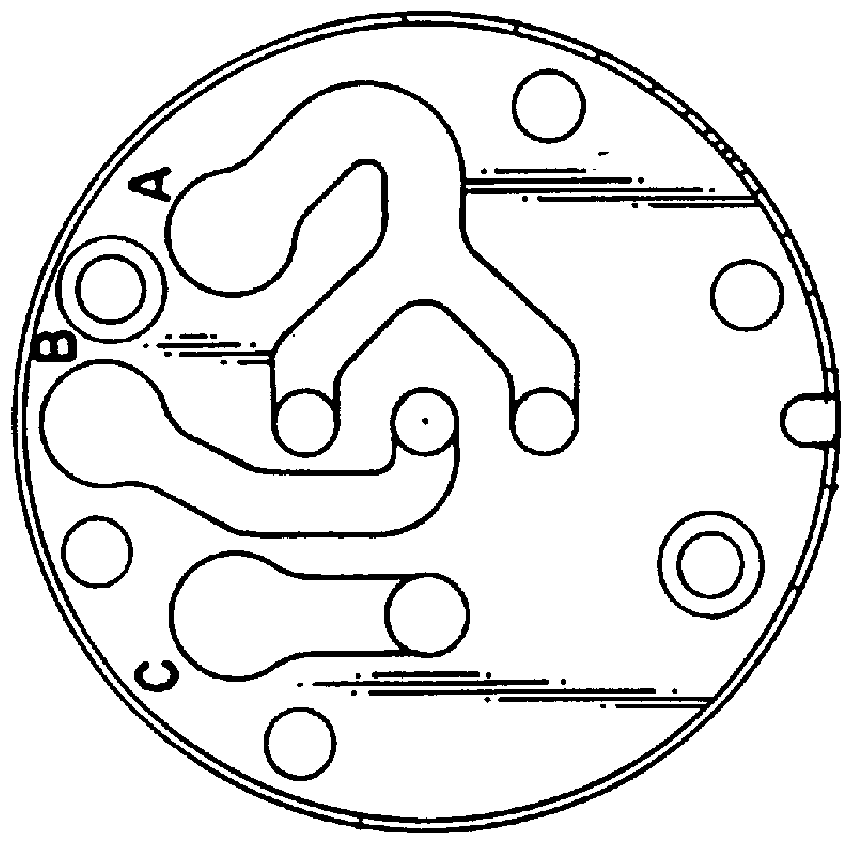

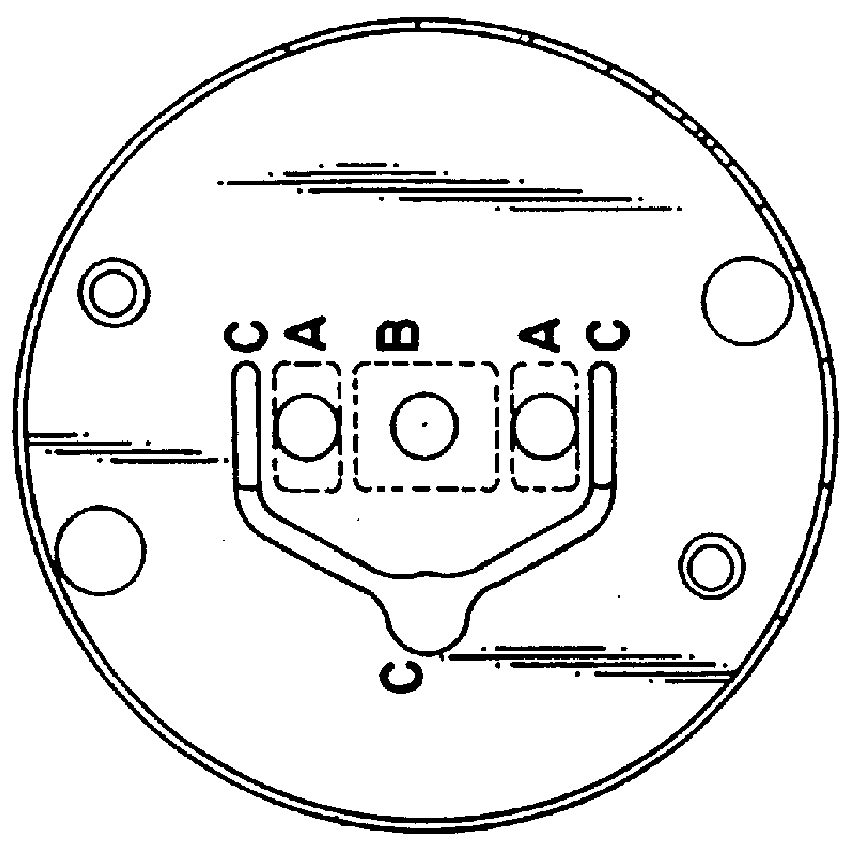

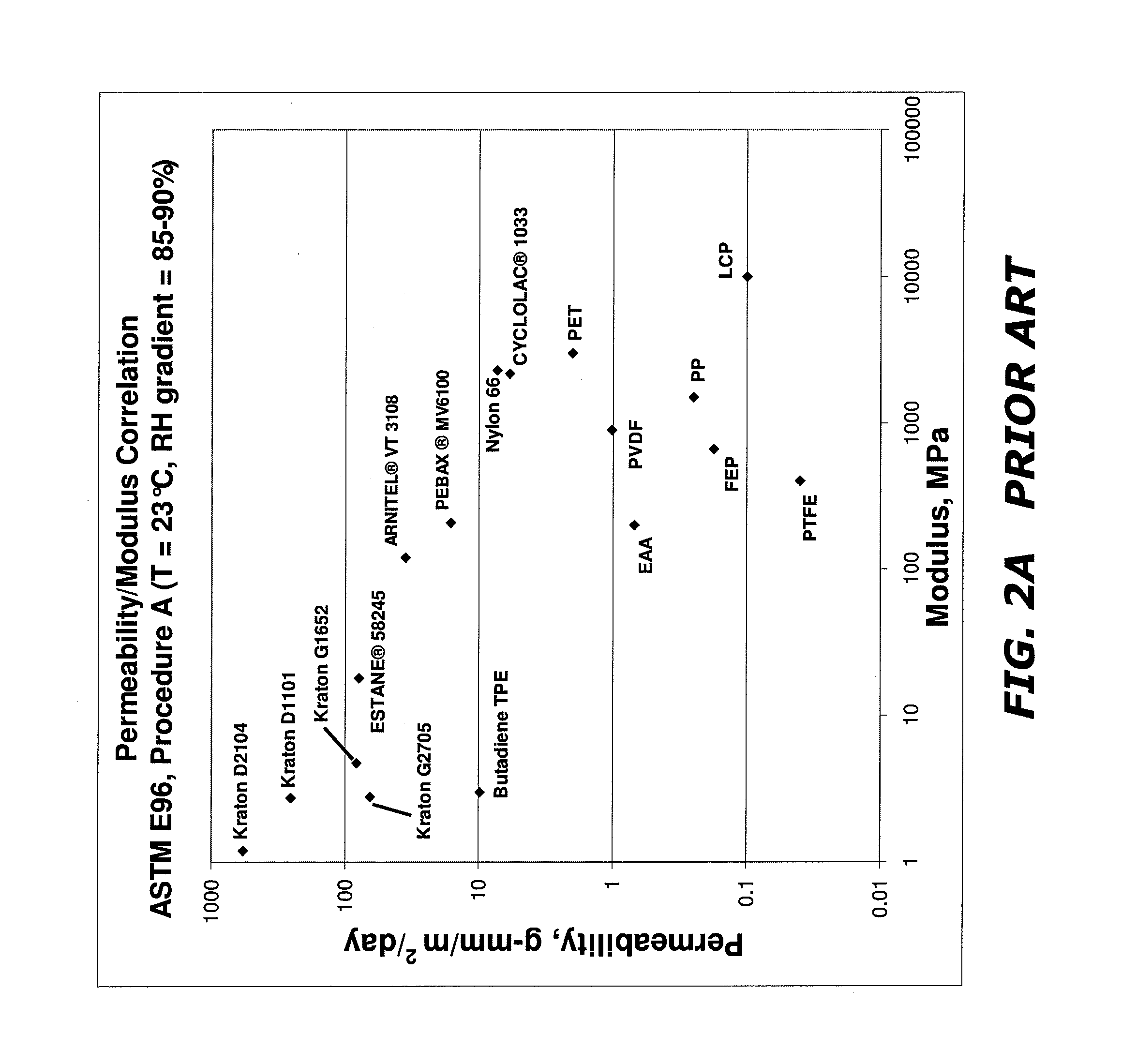

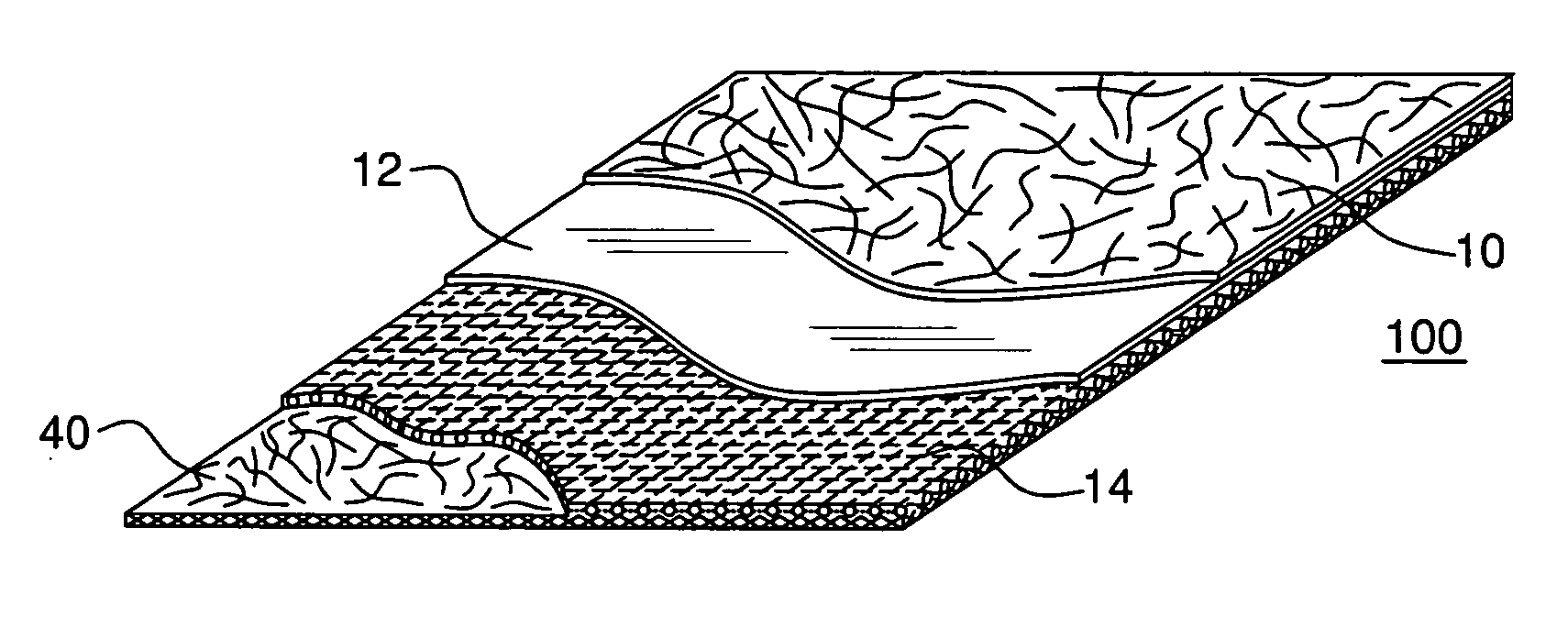

Multilayer breathable film

InactiveUS6114024AGood biological and liquid barrierReduce the amount requiredLamination ancillary operationsSynthetic resin layered productsParticulatesLiquid water

Provided is a method of makinga stretched, multilayer breathable film having the combination of properties of: (i) providing a barrier to microorganisms; and (ii) providing a barrier to blood and bodily fluids; said method comprising the steps of: (a) simultaneously extruding at least a five-layer film from a die, said five-layer film having as a minimum the following structure: C:A:B:A:C; where B comprises a microporous core layer containing at least one thremoplastic polymer and at least one particulate filler; C comprises an outer monolithic layer containing a hydrophilic polymeric resin capable of absorbing and desorbing moisture and providing a barrier to aqueous fluids and microorganisms, said C layer being substantially free of particulate filler; and A comprises a microporous adhesive layer for bonding said C layers to said core layer B, wherein said C layer sustantially prevents the buildup of particulate filler material on said die during said extrusion step; (b) stretching said extruded five-layer film to thereby form micropores in said microporous core layer and said microporous adhesive layer, wherein said stretching step is conducted and said microporous core layer and said microporous adhesive layers have been formulated so as to provide micropores which allow the passage of gaseous water but substantially prevent the passage of liquid water. The invention also relates to a multilayer film.

Owner:KIMBERLY-CLARK WORLDWIDE INC

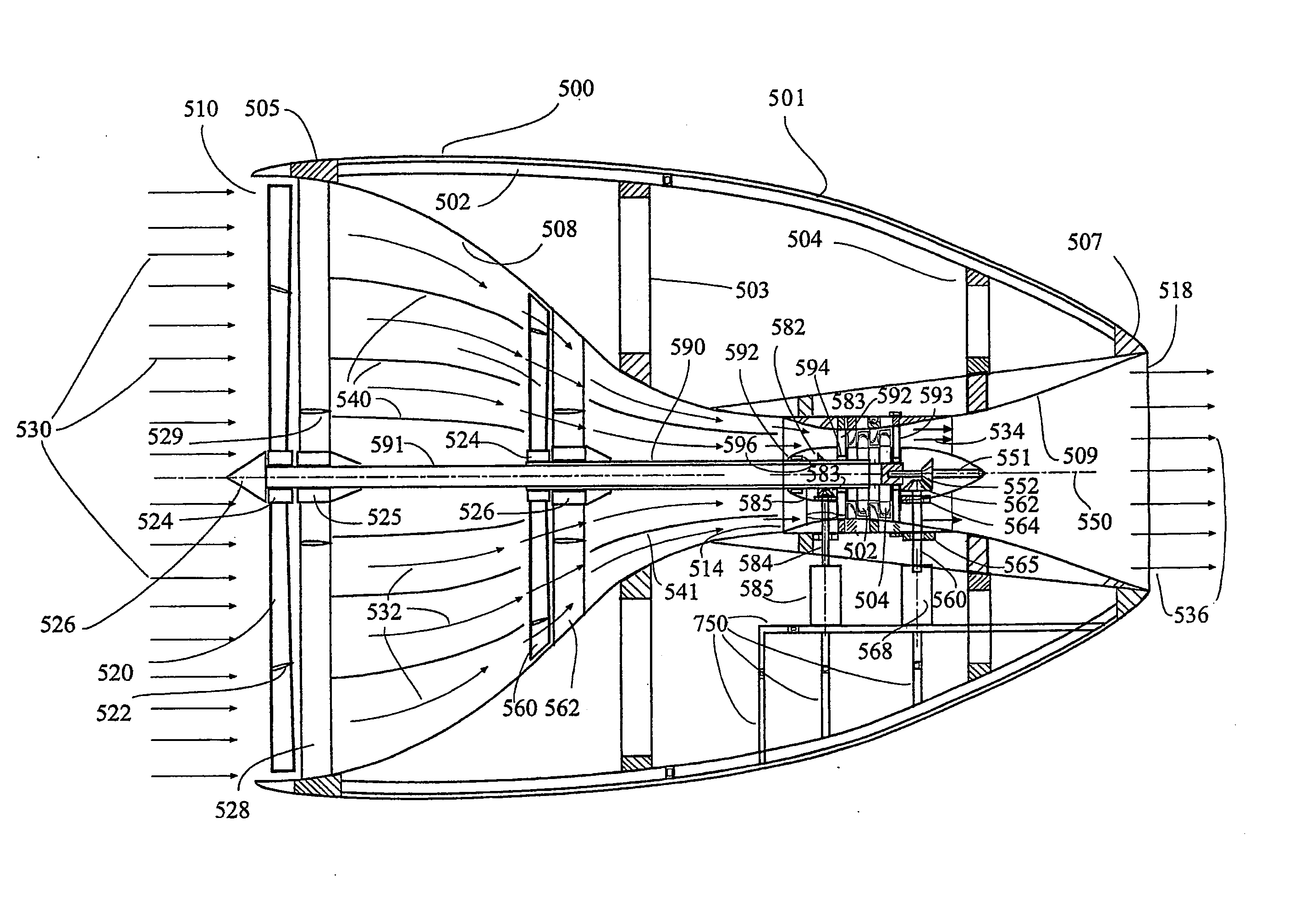

Use of Air Internal Energy and Devices

InactiveUS20080061559A1Increase static pressureAvoid accumulationCosmonautic vehiclesReaction enginesMoisture condensationLiquid water

A method of converting air internal energy into useful kinetic energy is based on air flowing through substantially convergent nozzle, which accelerates the air as the cross section of the nozzle decreases thus increasing the air kinetic energy. The increment of the kinetic energy equals to the decrement of air internal energy, i.e., air temperature. Within said nozzle a turbine is placed to convert airflow kinetic energy into mechanical energy that transformed into electrical energy or transferred into a gearbox to provide driving moment. Devices uses this method could use natural wind as airflow source or artificial airflow means. Devices, which incorporate means to create airflow artificially, can be used as engines for land, sea and flying vehicle. Since air temperature drops within the nozzle, moisture condensation exists and liquid water can be accumulated for further use.

Owner:HIRSHBERG ISRAEL

Metal gas batteries

InactiveUS20030049508A1Reduce passageEffectively block and closeFuel and primary cellsPrimary cell maintainance/servicingLiquid waterWater vapor

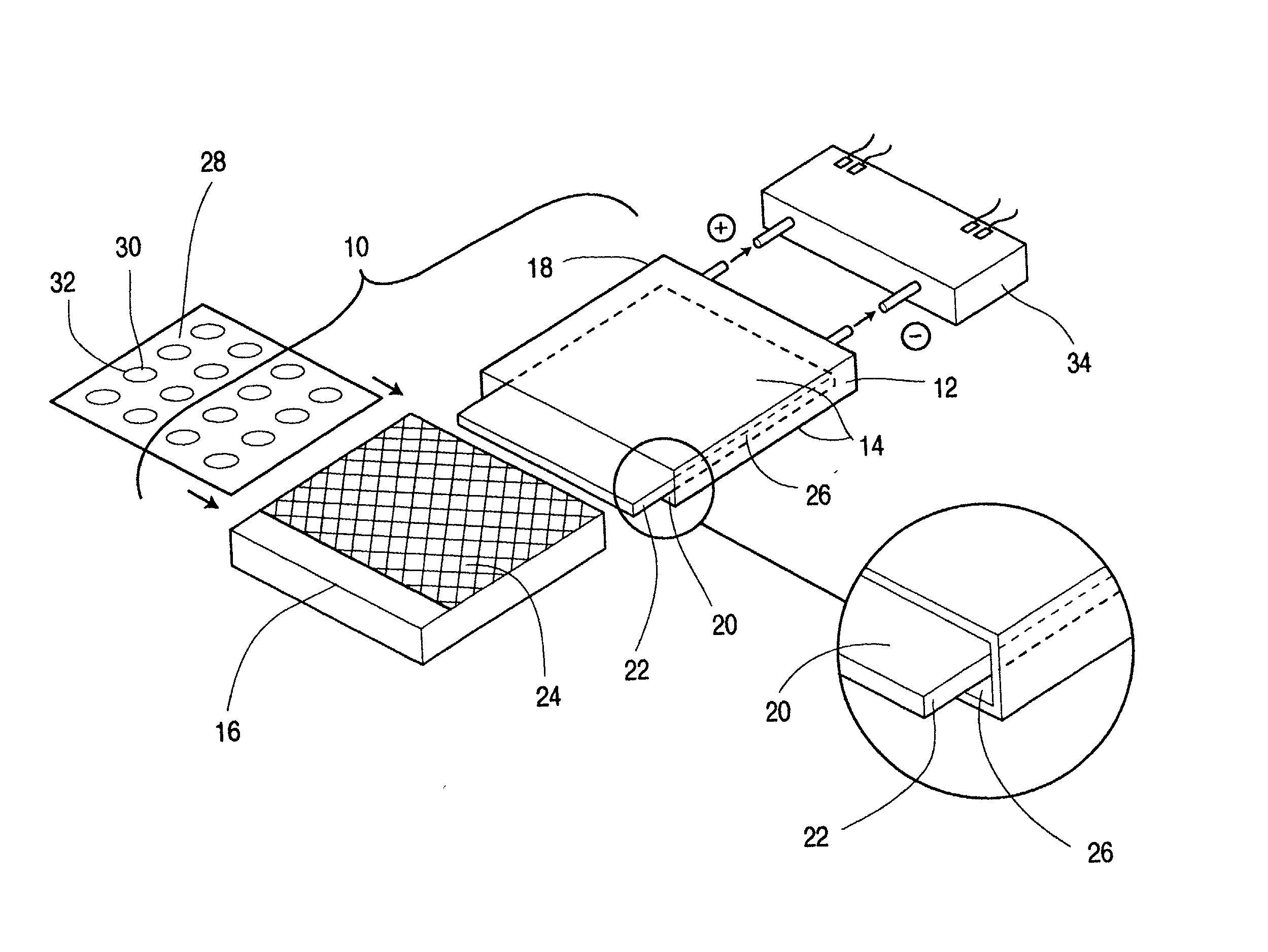

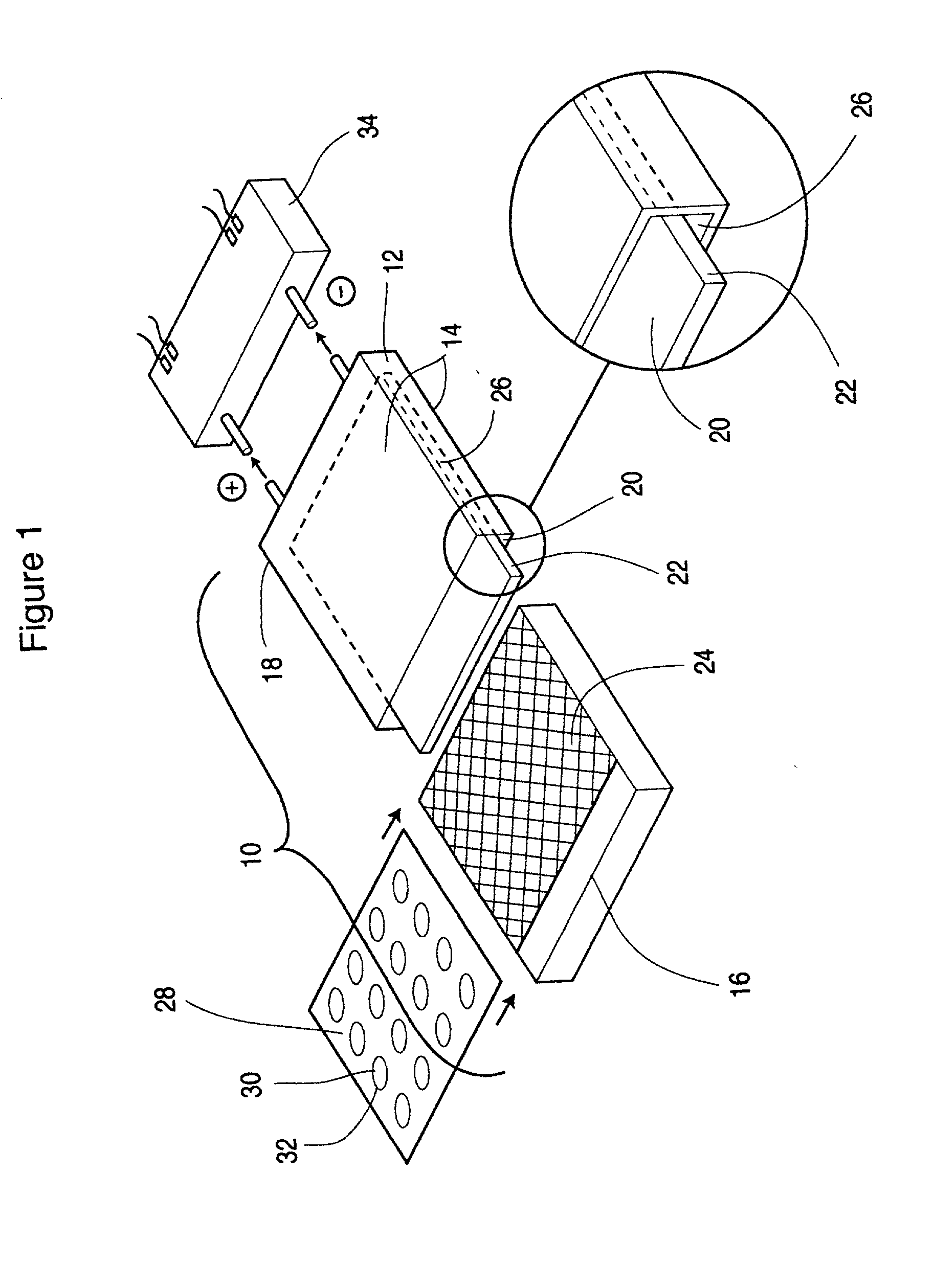

An improved gas-diffusion cathode for use in an electrochemical cell comprising an electrically conductive cathode member having a first side communicable with an aqueous electrolyte and a second side communicable with a gaseous medium; and a water-impermeable membrane adjacent said cathode member second side to reduce passage of liquid water between said cathode member and said gaseous medium and having a membrane first side and a membrane second side wherein said membrane first side faces said cathode member and wherein said water-impermeable membrane comprises one or more portions defining one or more openable and closeable apertures the improvement wherein said apertures are associated with one or more integrally-formed resiliently flexible flaps on said membrane first side to effect said opening and closing. The batteries have reduced unwanted water vapour ingress and egress characteristics in its no-load mode.

Owner:ALUMINUM POWER

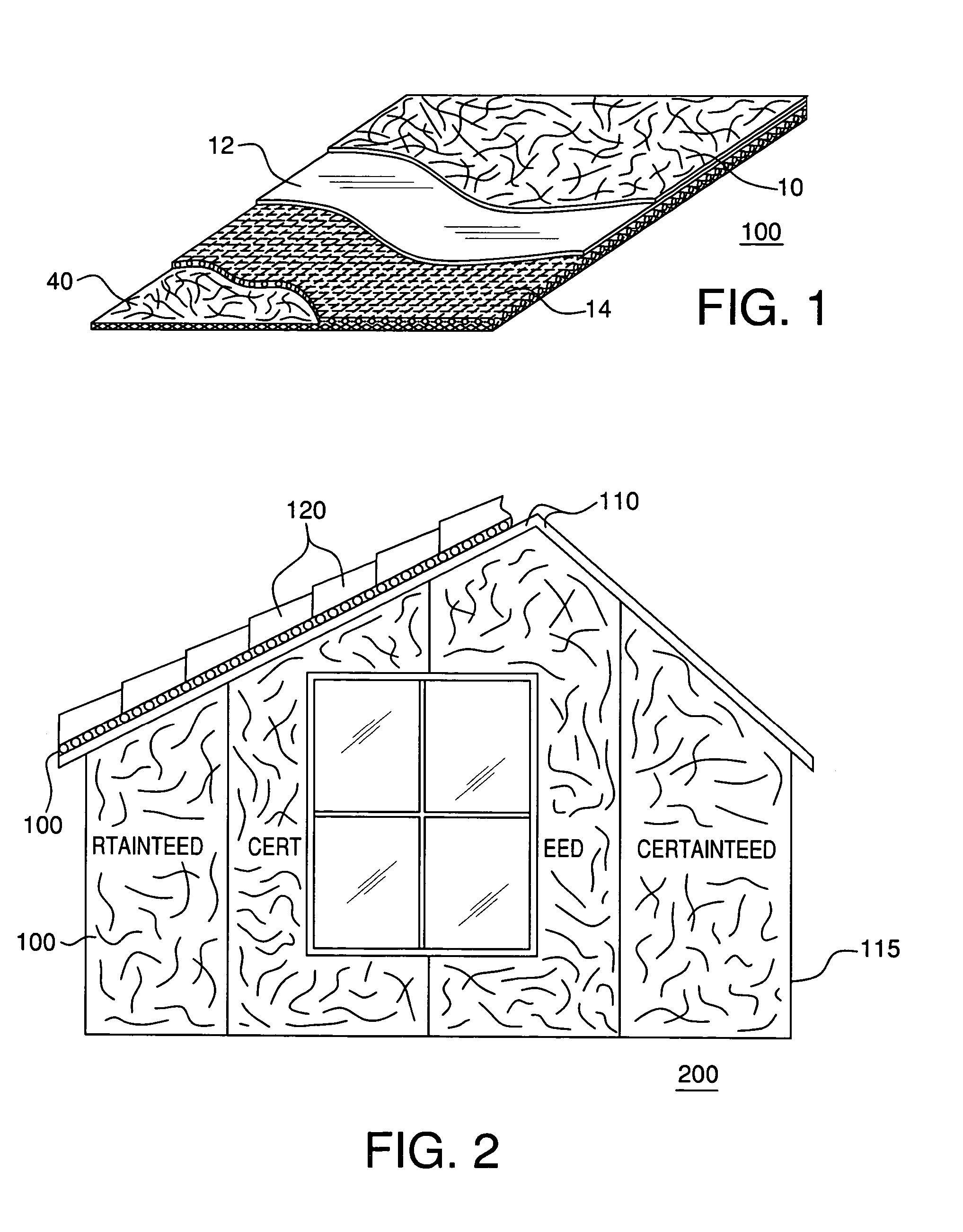

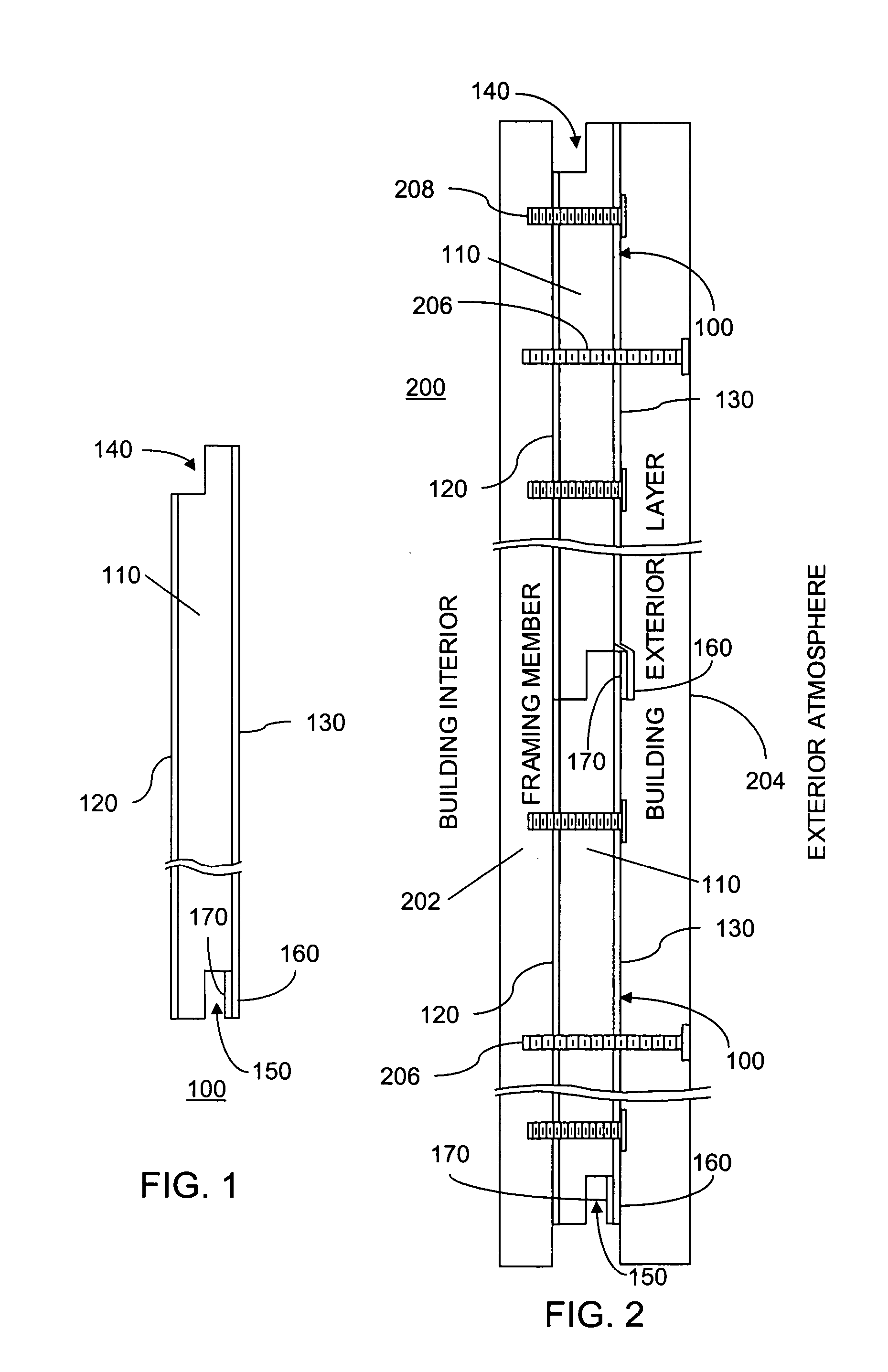

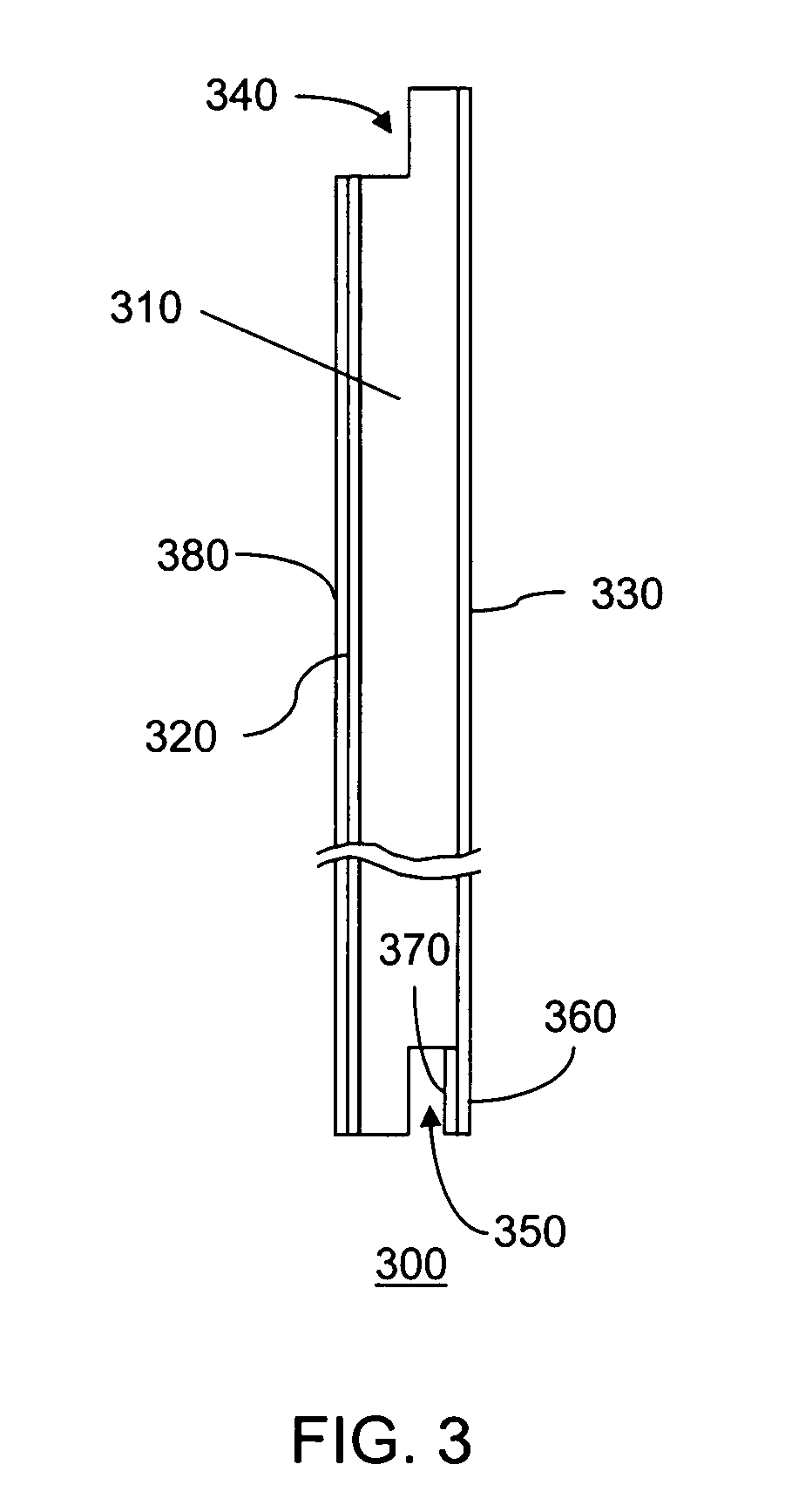

Breathable low-emissivity metalized sheets

A moisture vapor permeable metalized composite sheet is formed by coating a moisture vapor permeable sheet-with at least one metal layer and at least one outer organic coating layer. The moisture vapor permeability of the composite sheet is at least about 80% of the moisture vapor permeability of the starting sheet. The composite sheet provides a barrier to air and liquid water infiltration while having high moisture vapor permeability and good thermal barrier properties. The composite sheet material is suitable for use as a building construction wrap such as roof lining and house wrap.

Owner:EI DU PONT DE NEMOURS & CO

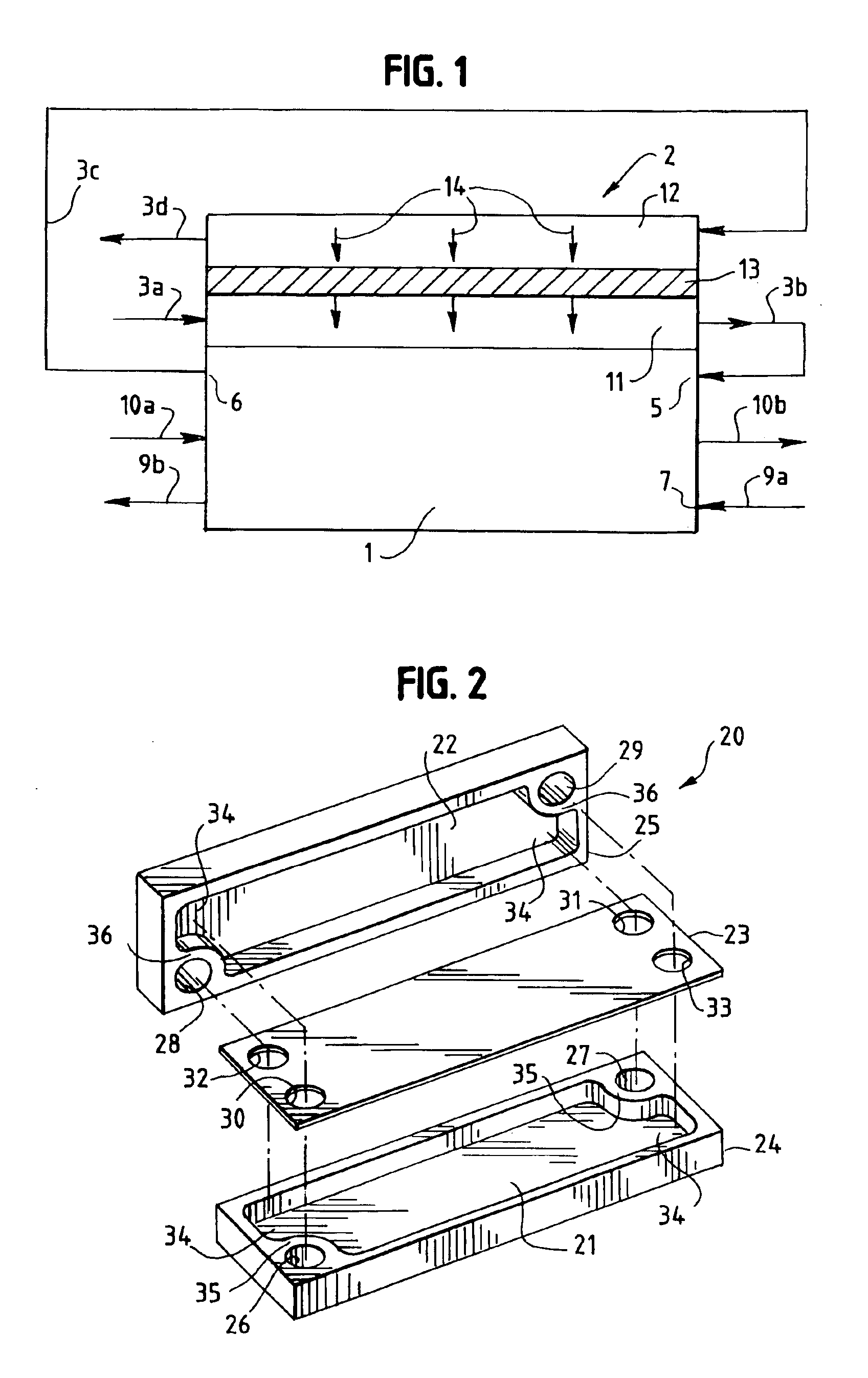

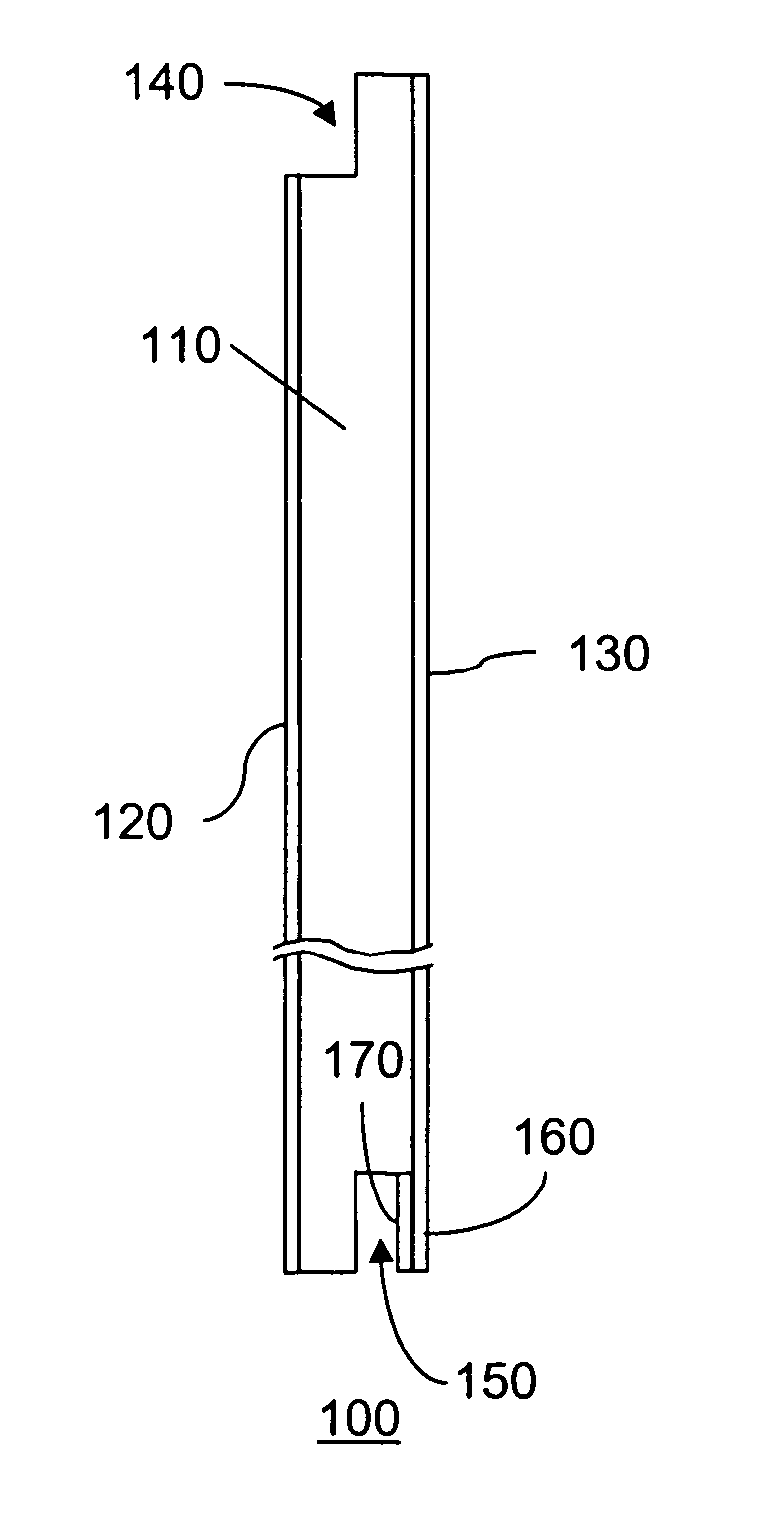

Active device having variable energy/optical properties

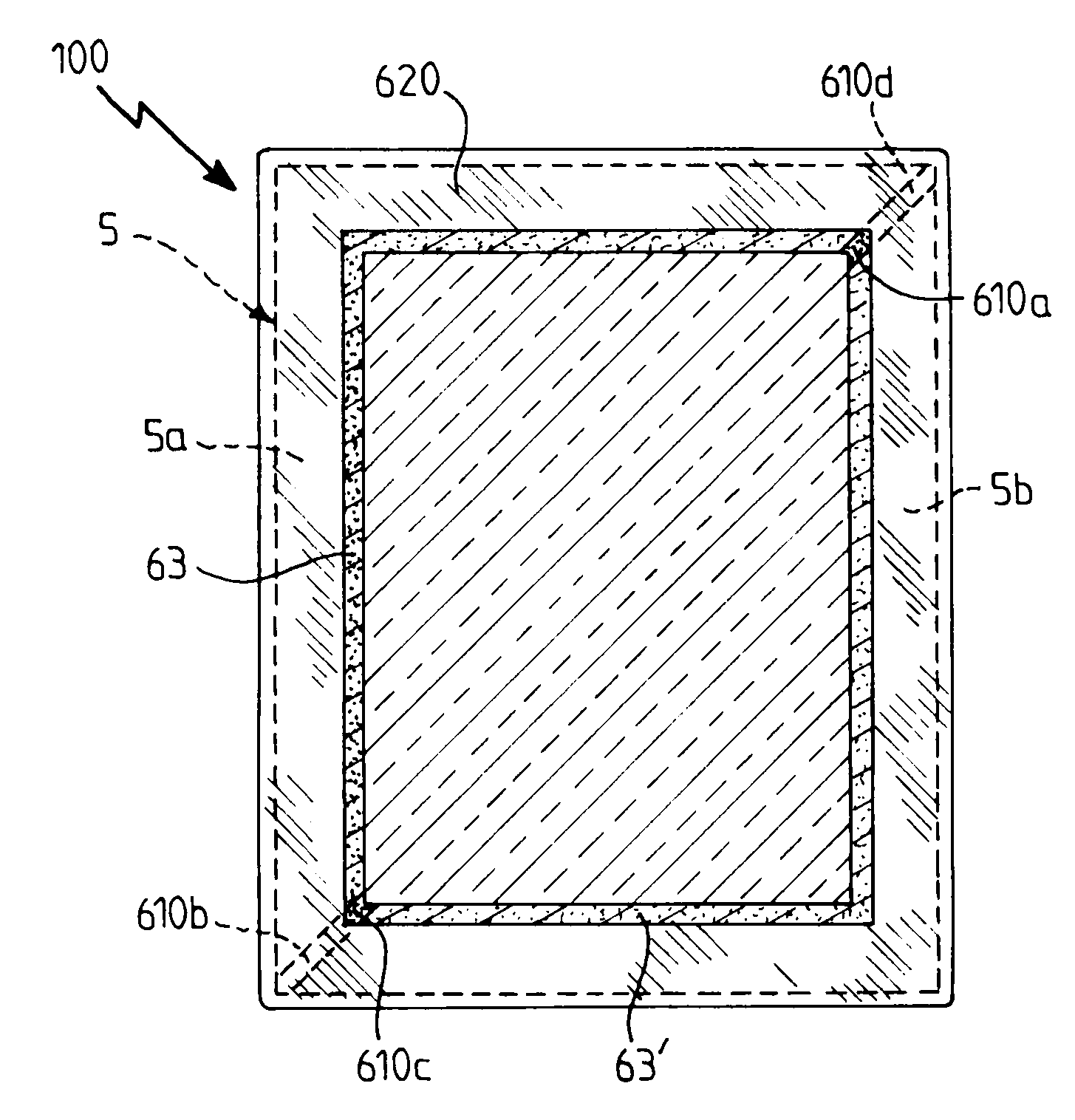

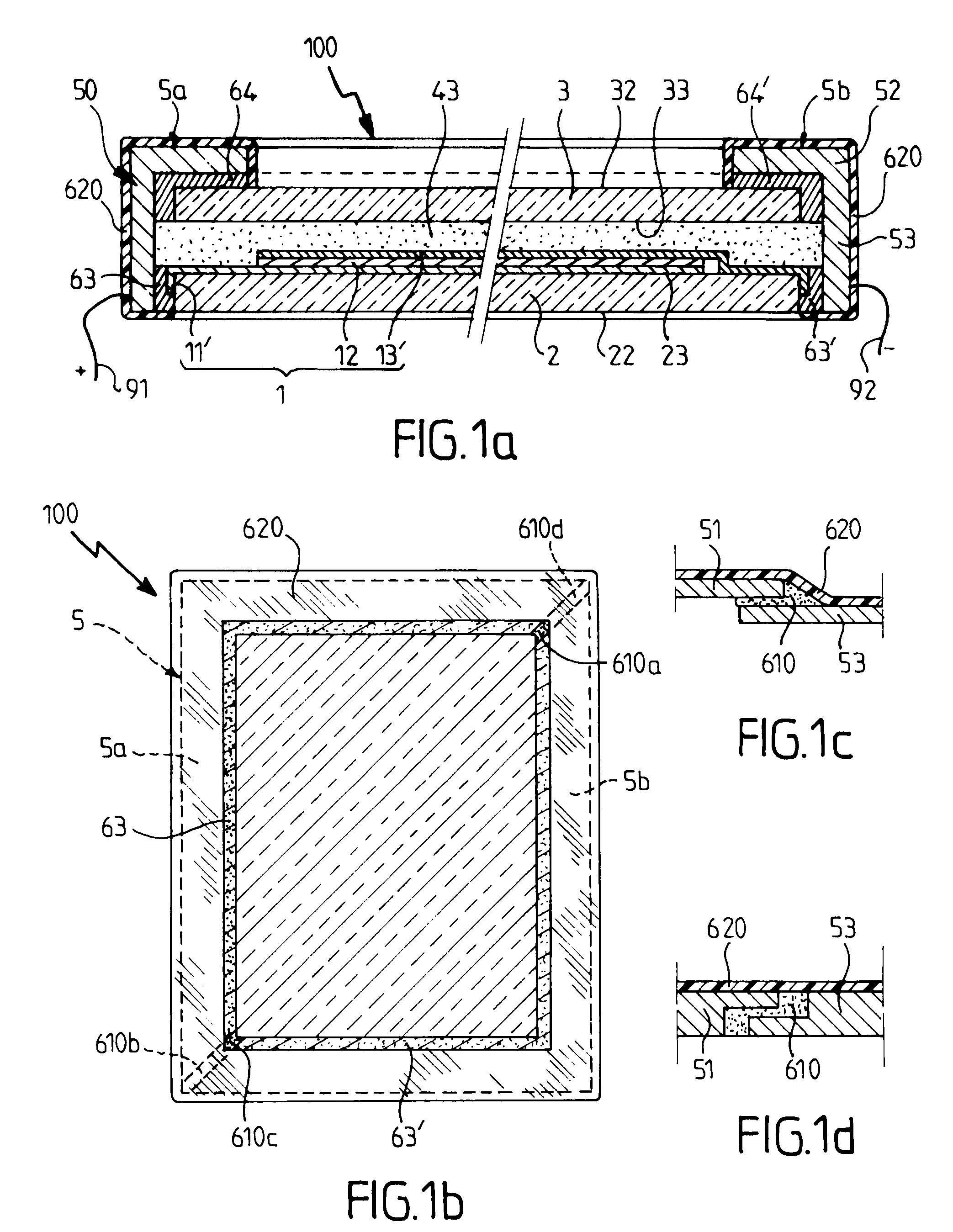

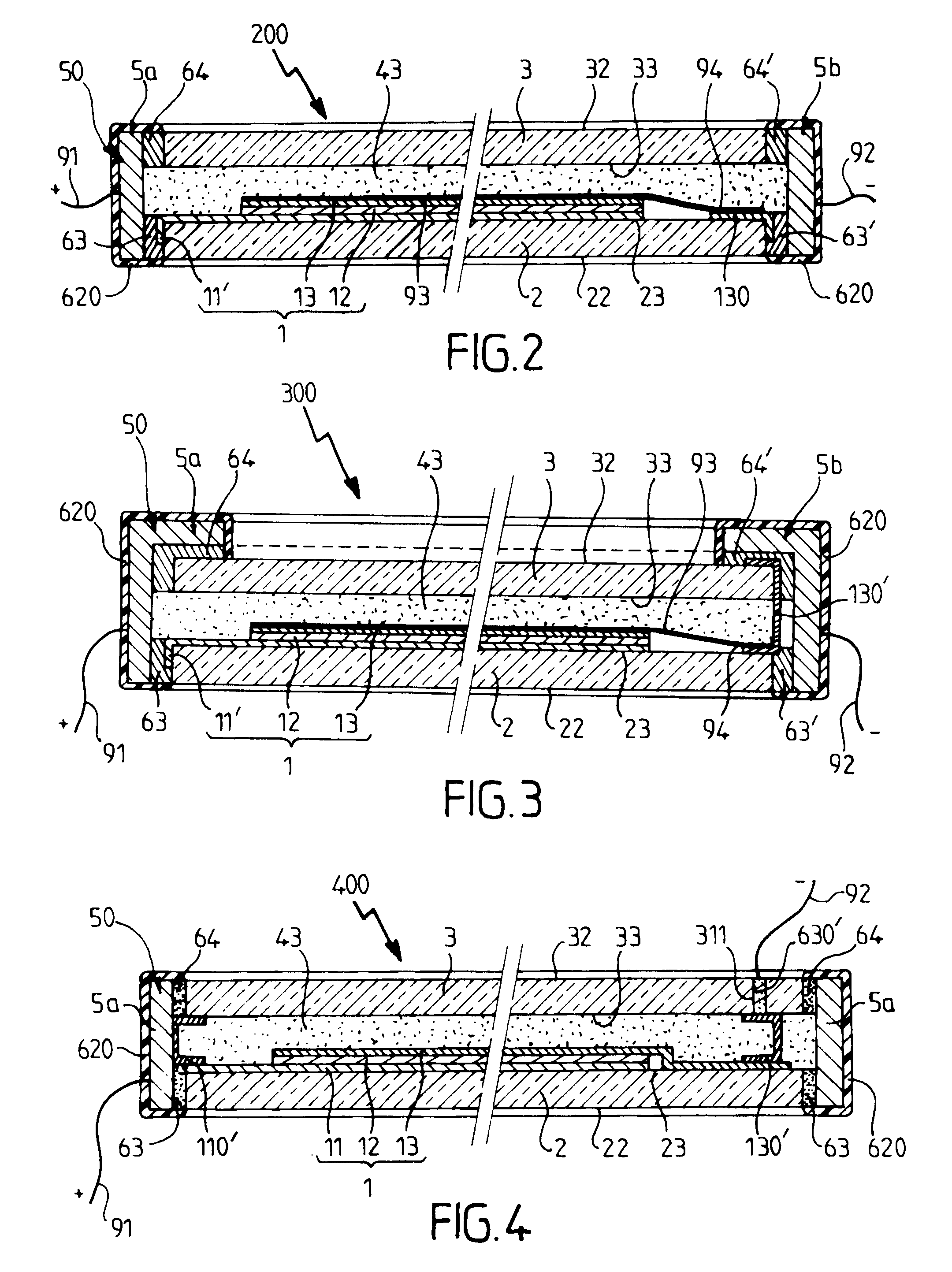

InactiveUS8035882B2Avoid bendingMounting is thereby simplifiedNon-linear opticsWater vaporLiquid water

The invention relates to an active device having variable energy / light transmission properties (100) comprising an active system (1, 12) between a protective substrate (2) and a protective cover (3), selected from an essentially inorganic electrochromic system, a light valve system, a liquid crystal system, a gasochromic system, a thermochromic system, means leakproof to liquid water and / or water vapor, a surround (50) made from at least one metal based part (5a, 5b) on the periphery of the device, the surround being assembled with the cover and with the substrate by assembling means (61′ to 64′) forming at least part of the means leakproof to water vapor.

Owner:SAINT-GOBAIN GLASS FRANCE

Water vapor transport power generator

An improved system for generating electrical power using a fuel cell. More particularly, a system for generating hydrogen gas by reacting water vapor with a substantially non-fluid substance and transporting the generated hydrogen gas to the fuel cell which generates electrical power. Reacting water vapor with the non-fluid hydrogen generating substance rather than liquid water prevents caking of the non-fluid substance and deposition of byproducts onto the non-fluid substance that interfere with continued generation of hydrogen gas.

Owner:HONEYWELL INT INC

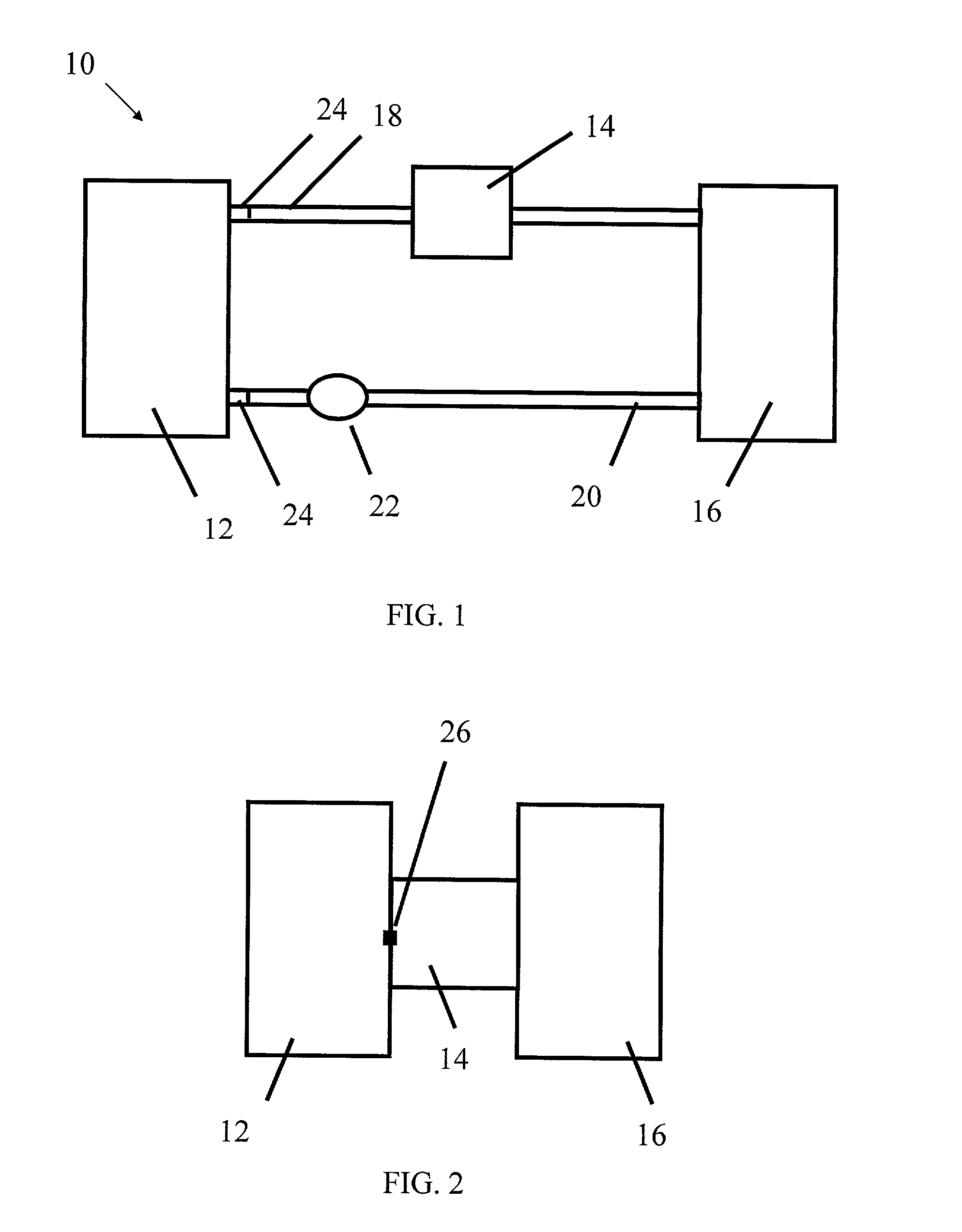

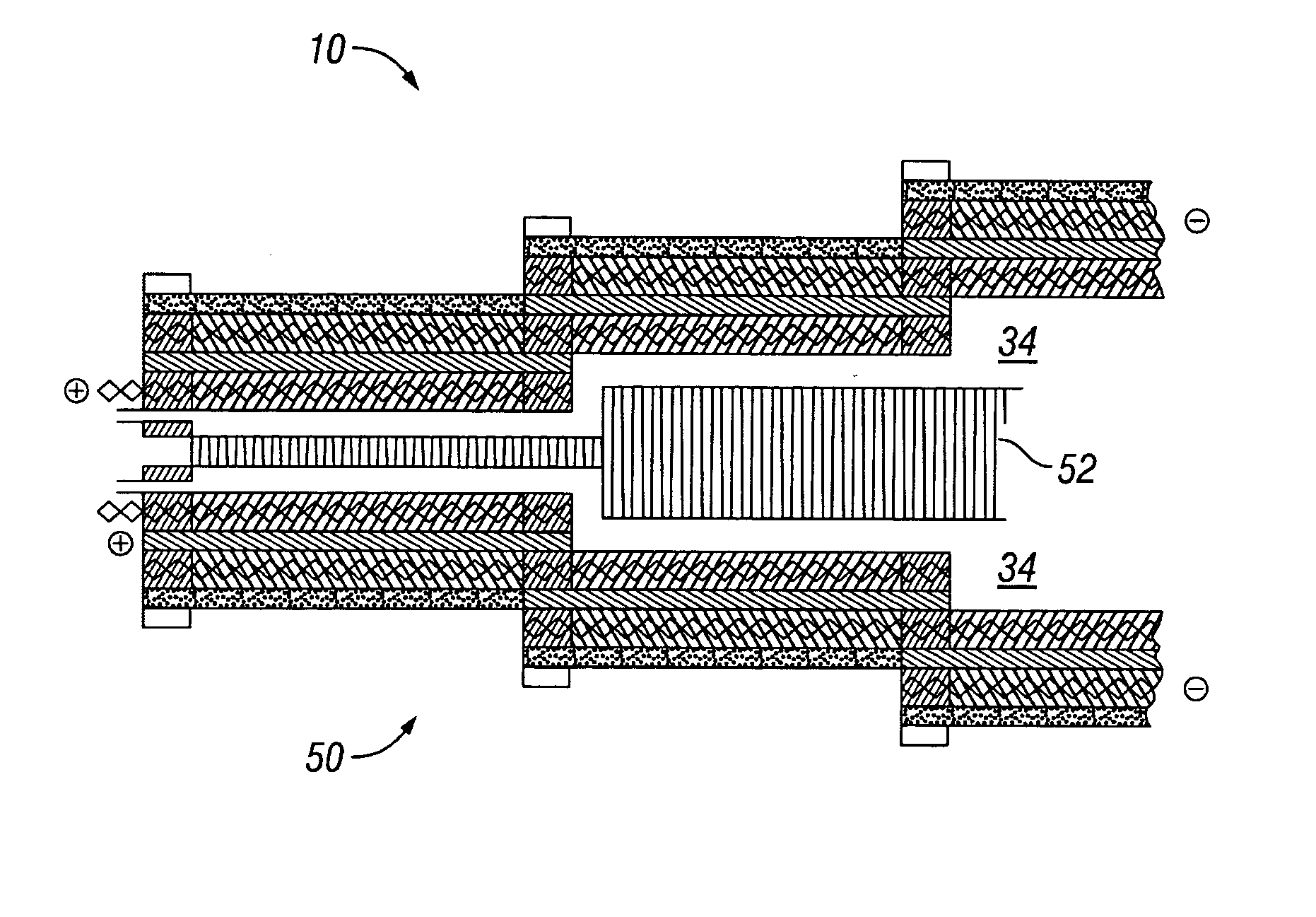

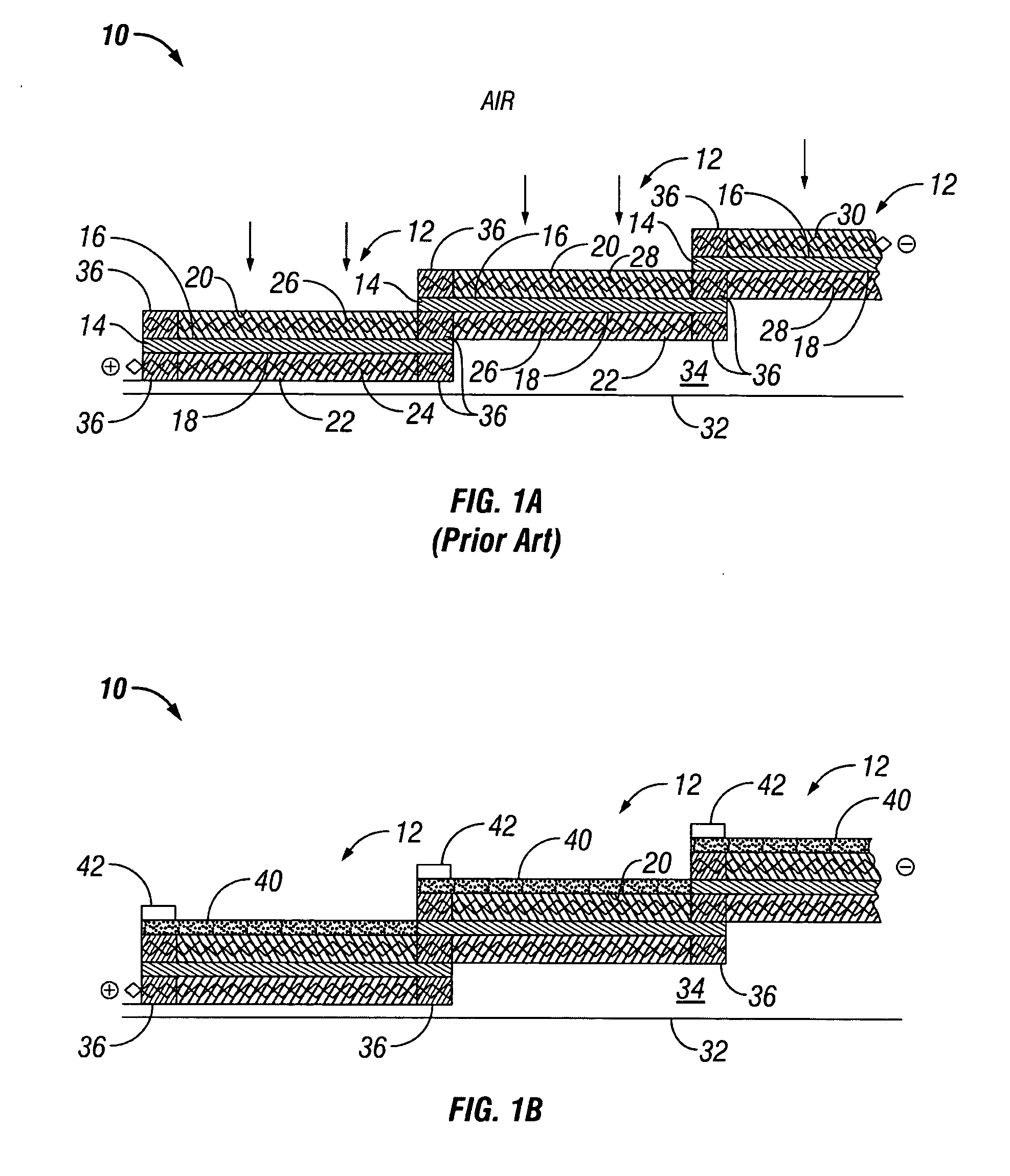

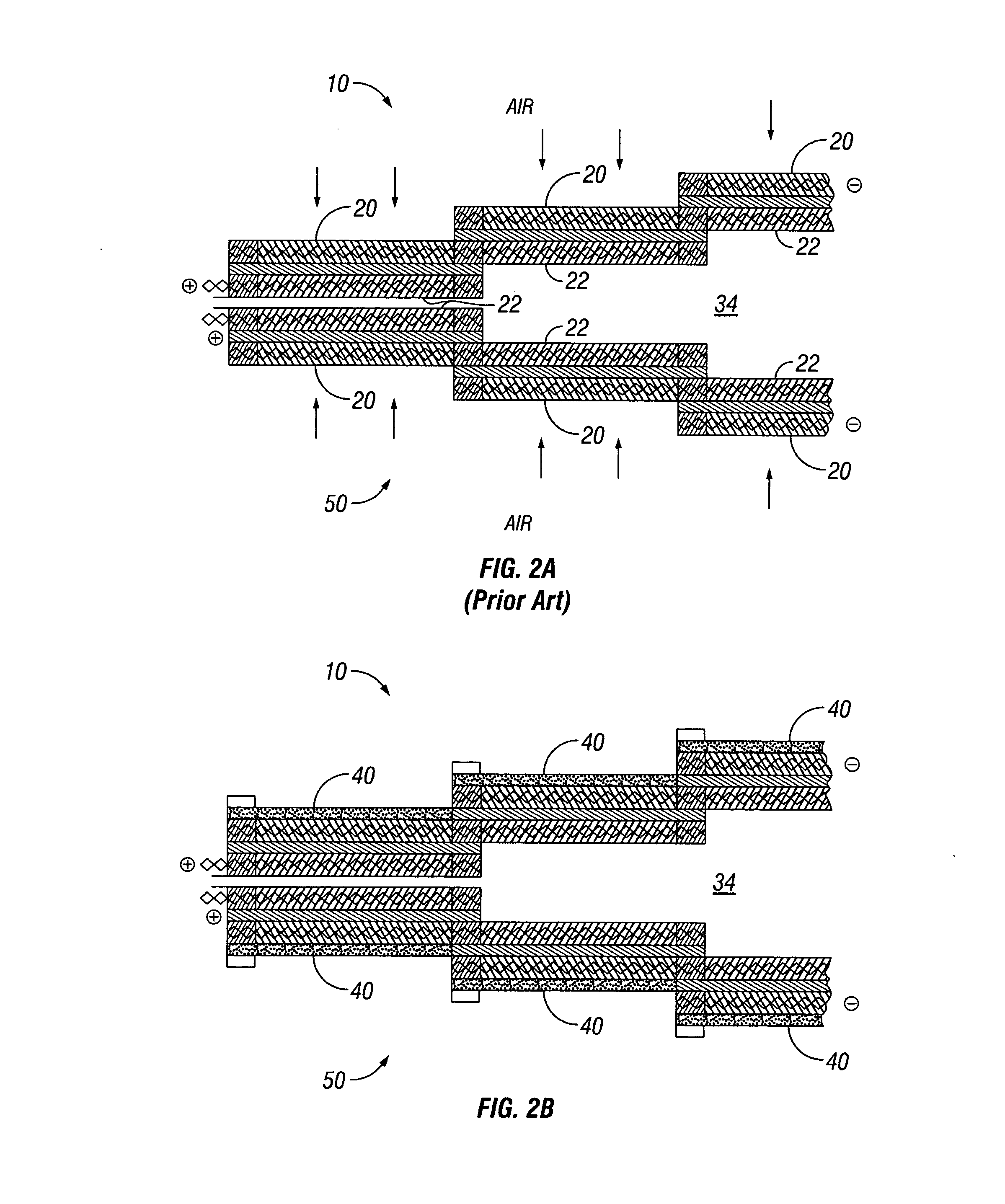

Water management in bipolar electrochemical cell stacks

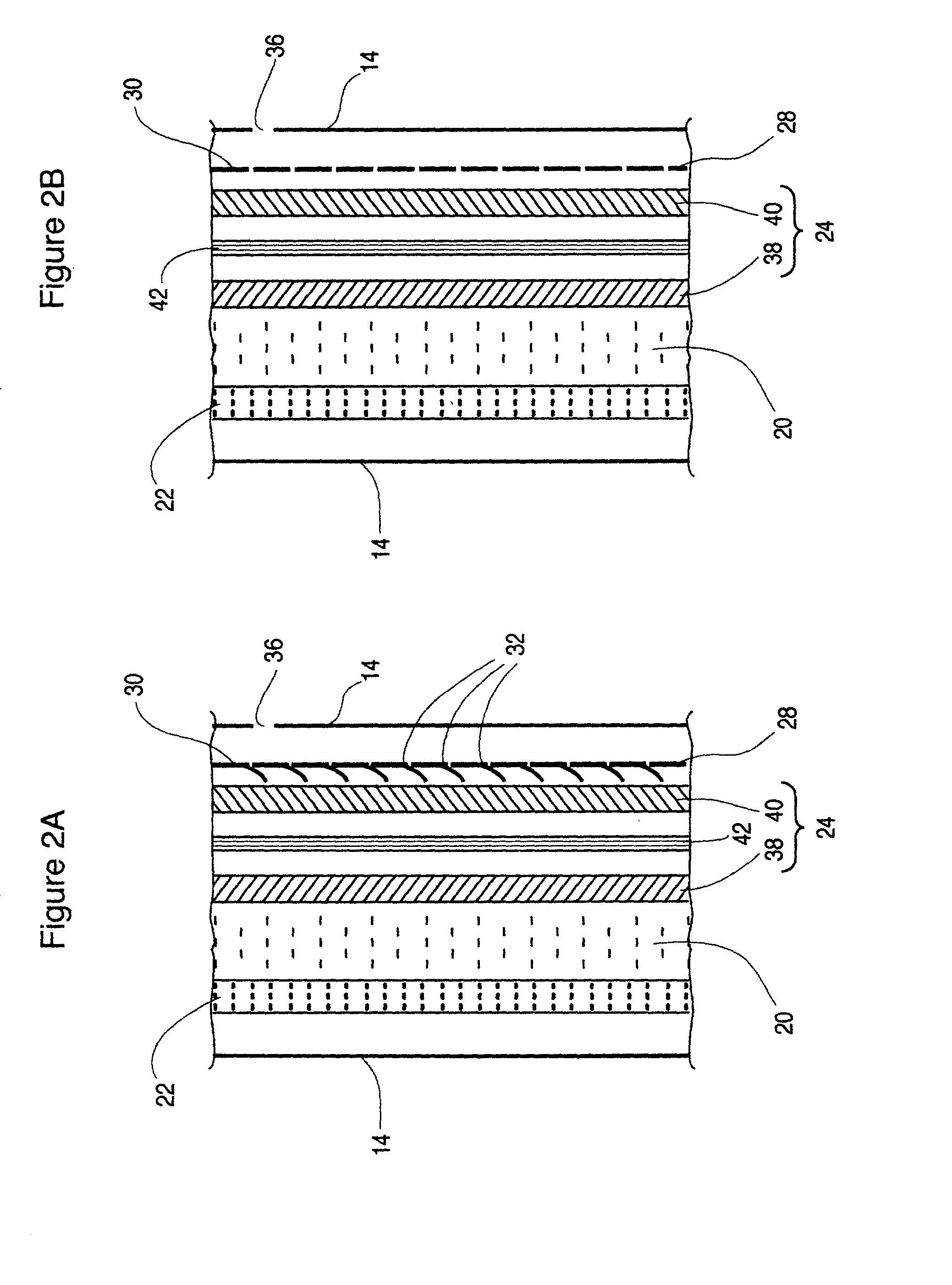

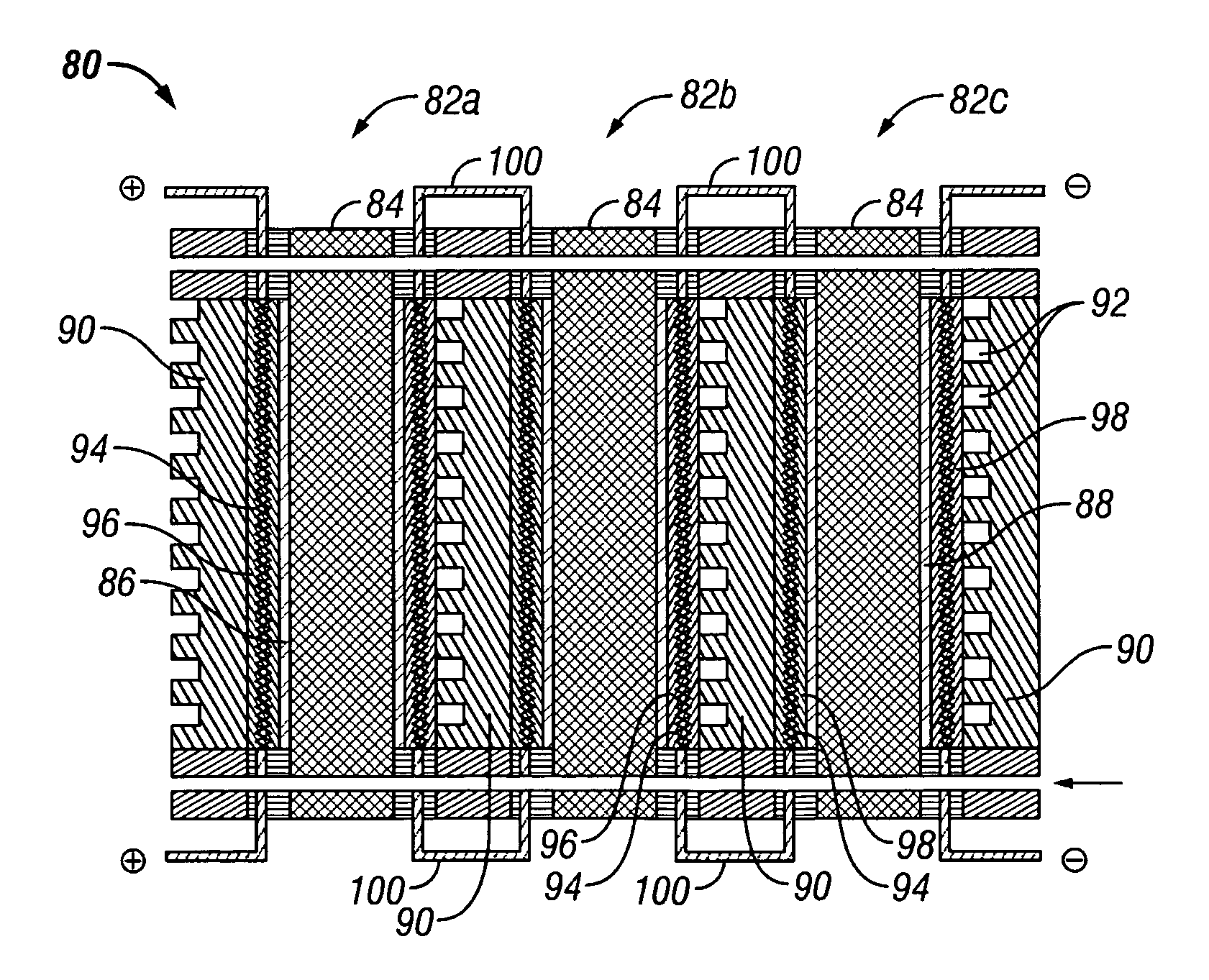

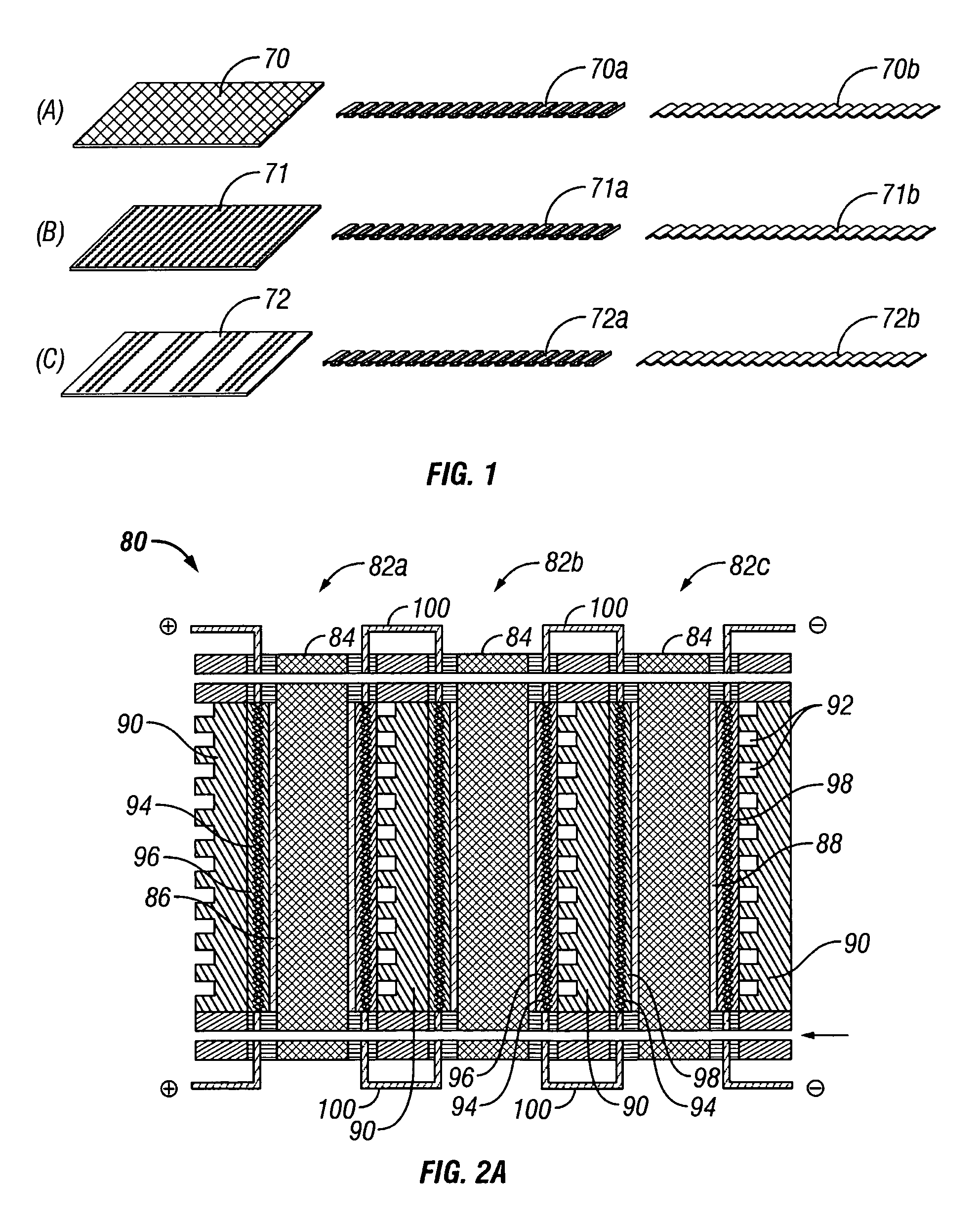

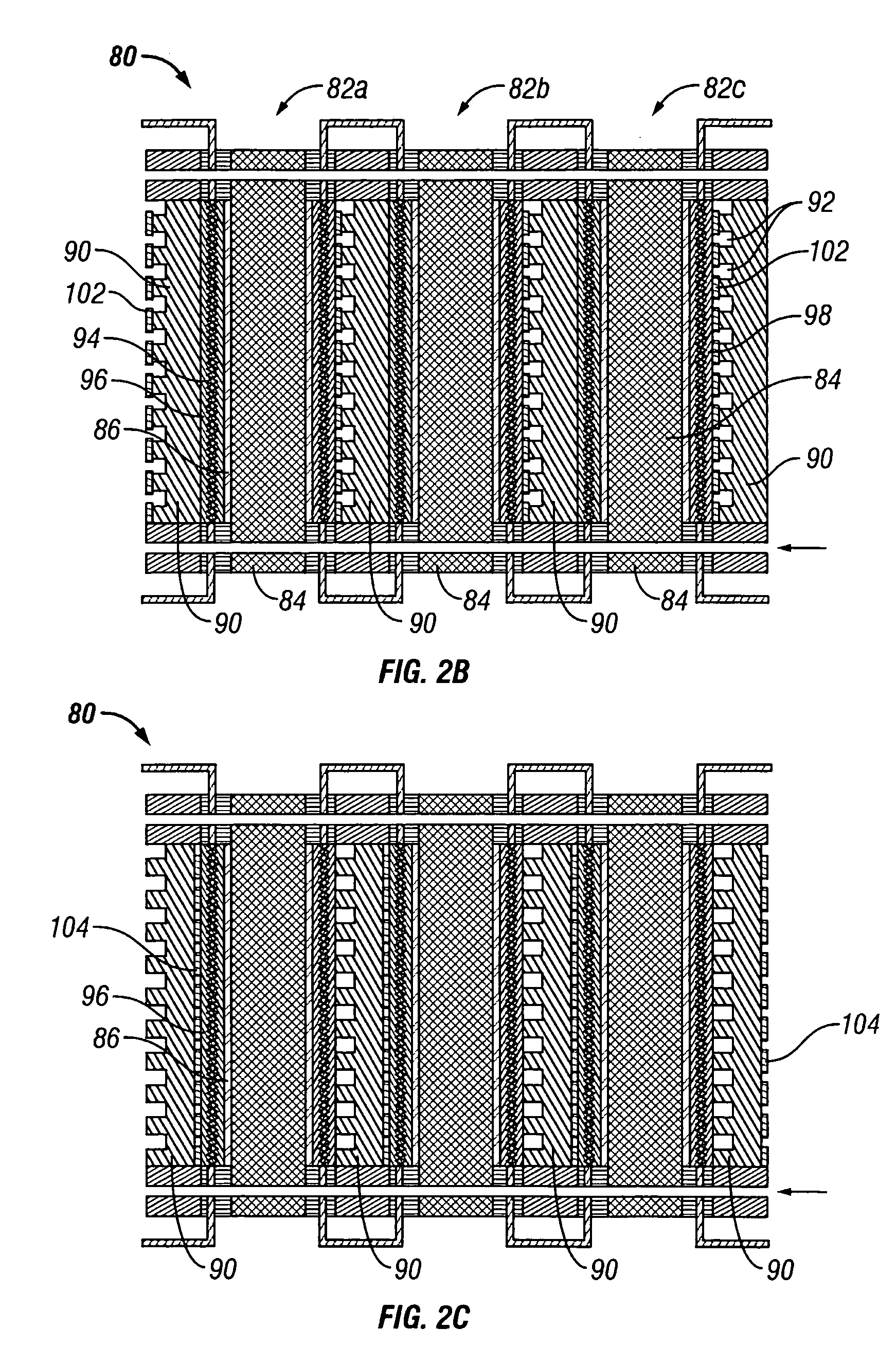

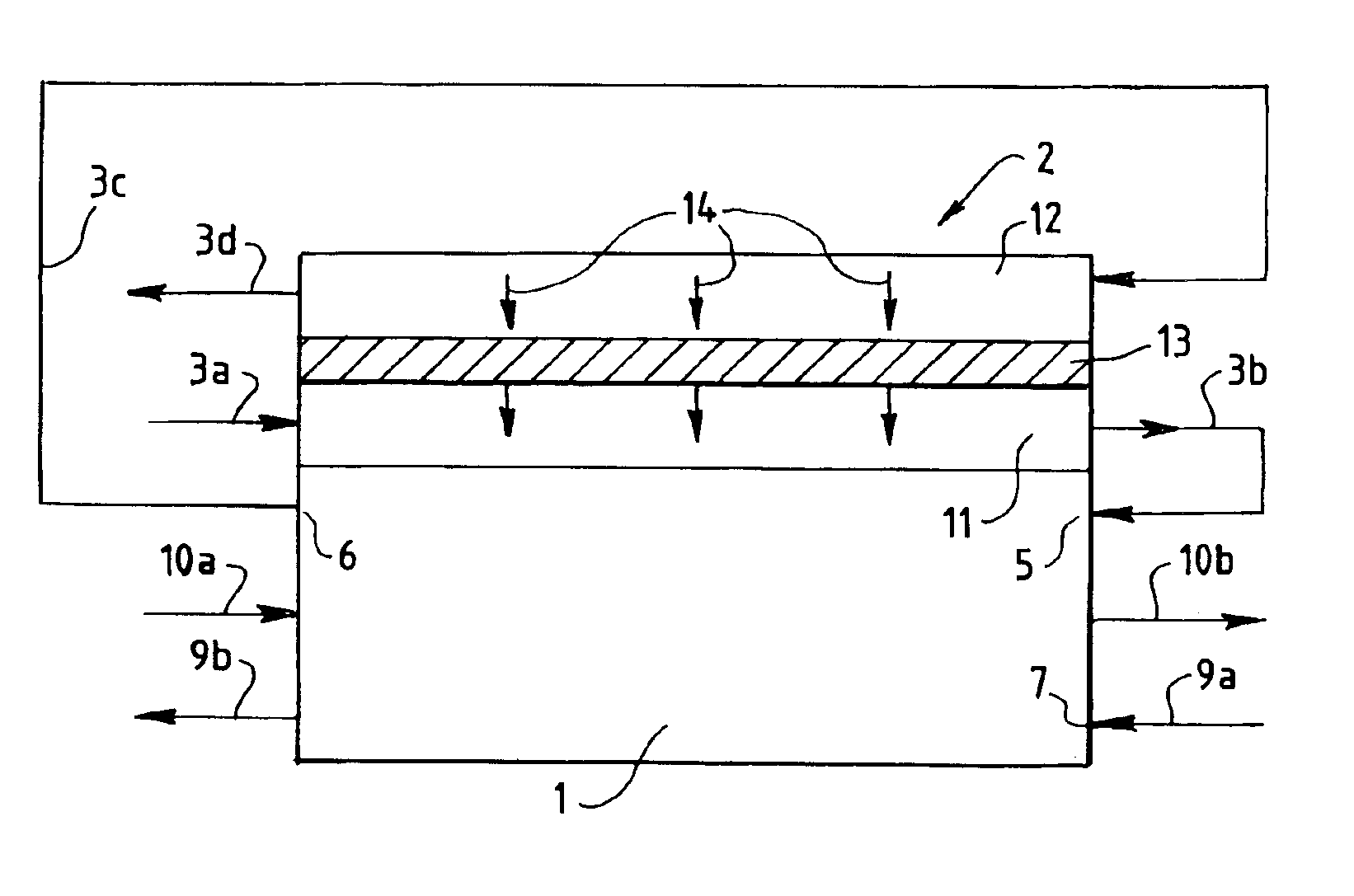

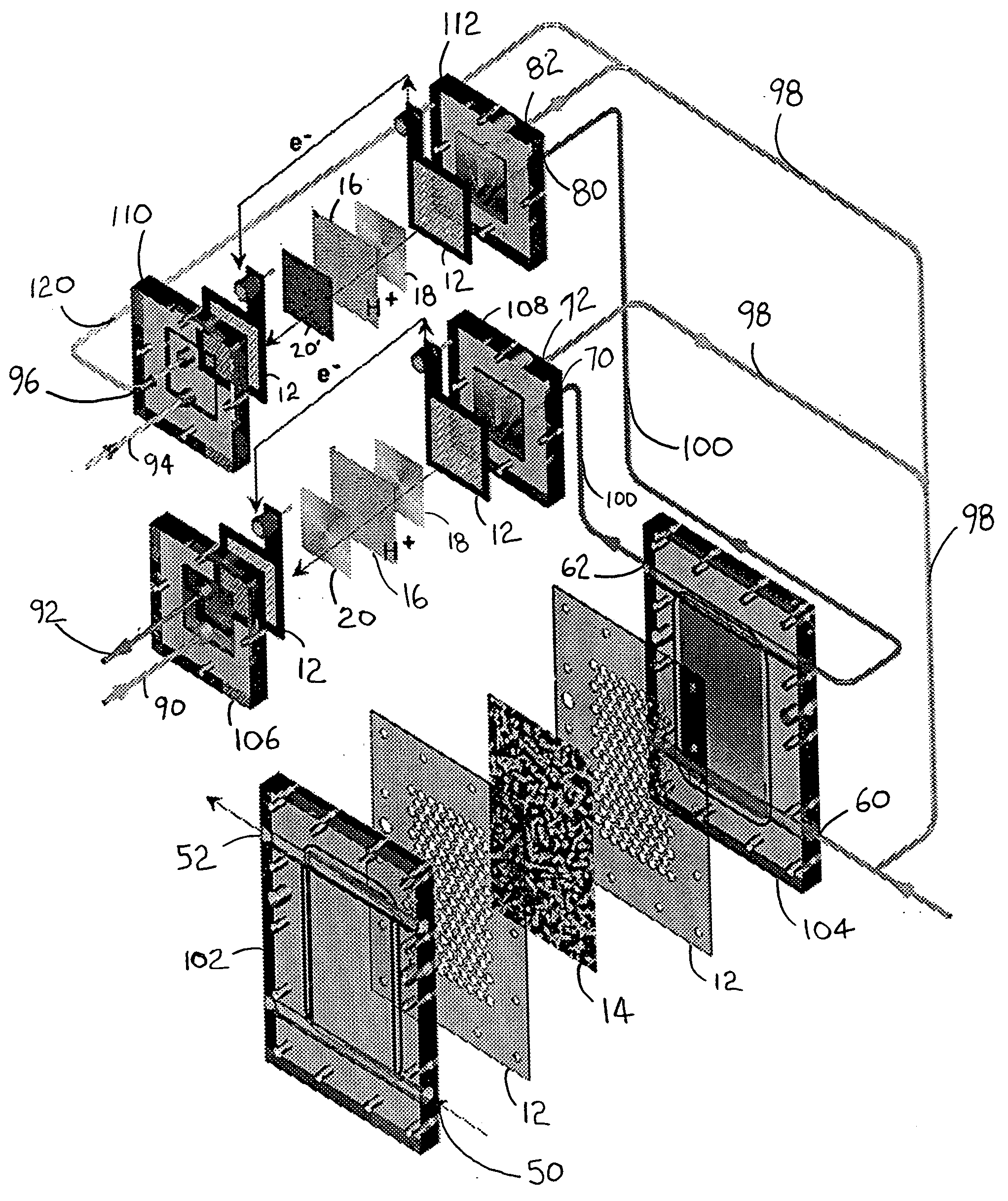

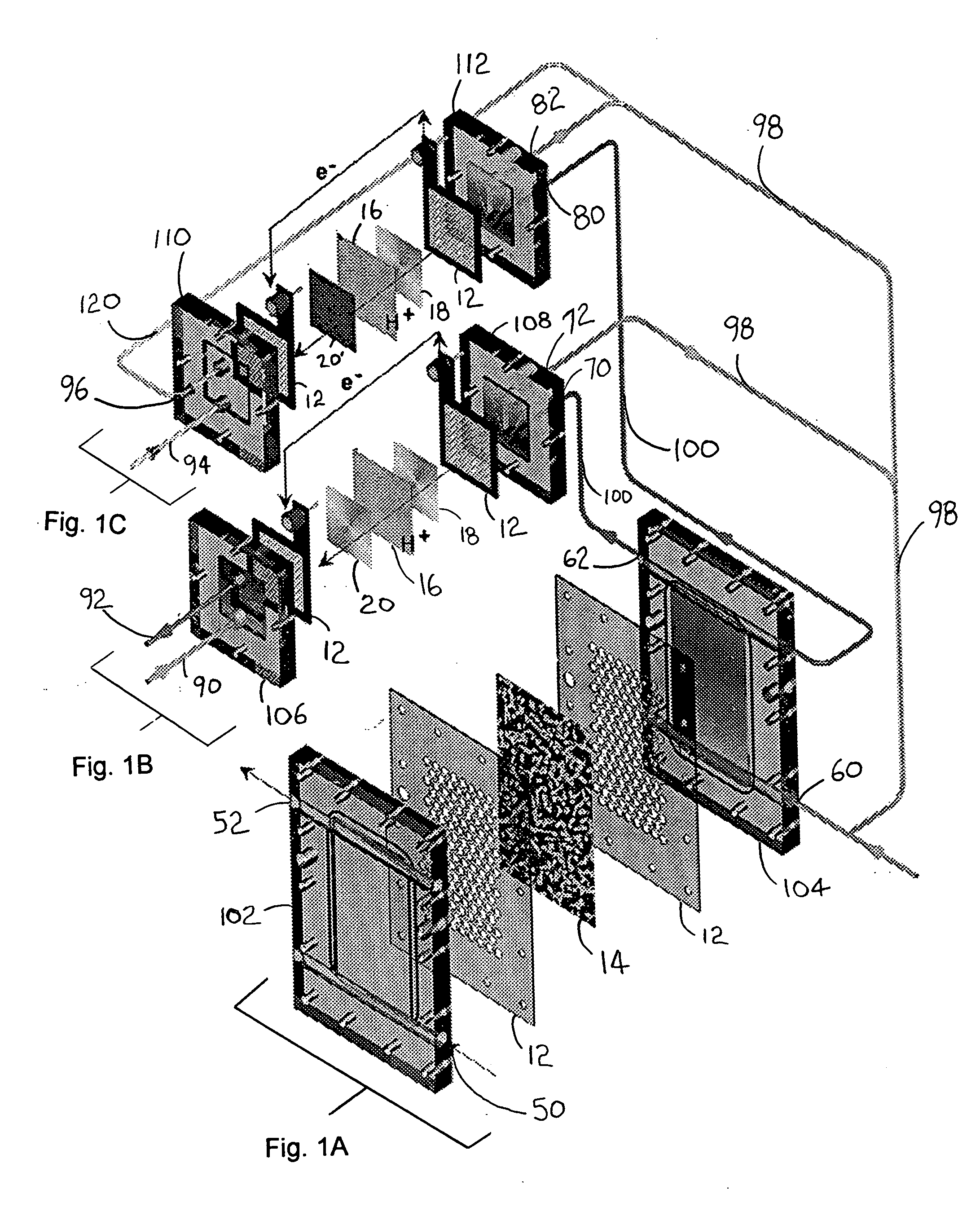

InactiveUS20060199061A1Reduce probabilityPromote loss of waterFuel cells groupingWater management in fuel cellsPolymer electrolytesLiquid water

A bipolar, filter press-like electrochemical cell stack comprising a plurality of electrochemical cells, where each electrochemical cell is supplied with a gaseous anodic reactant and either supplied with a gaseous cathodic reactant or produces a gaseous cathodic product, and where each electrochemical cell avoids drying out the ion exchange membrane polymer electrolyte, avoids flooding at the cathode, facilitates recovery of liquid water at the anode, and reduces water losses from at least one of the electrodes. A water retention barrier is variously positioned, such as between a gas diffusion electrode and a fluid flow field. The barrier may be either: (i) a thin, gas permeable, liquid water impermeable membrane; (ii) a thin, porous sheet of material; or (iii) a thin, substantially solid sheet of material except for a plurality of small through-holes that penetrate from one side of the sheet to an opposing side of the same sheet. The barrier is advantageously used at the cathode and facilitates air cooling of the cell.

Owner:LYNNTECH

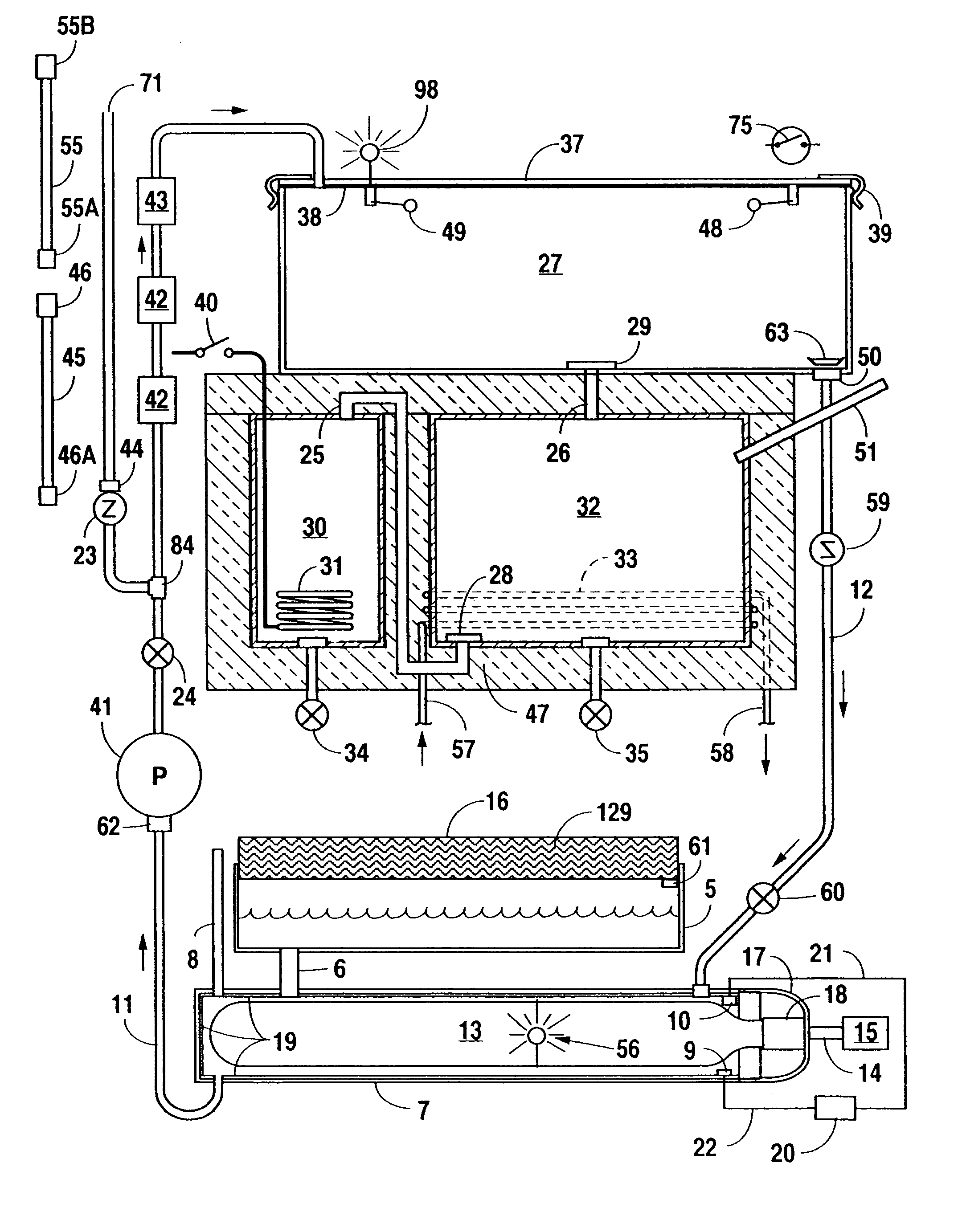

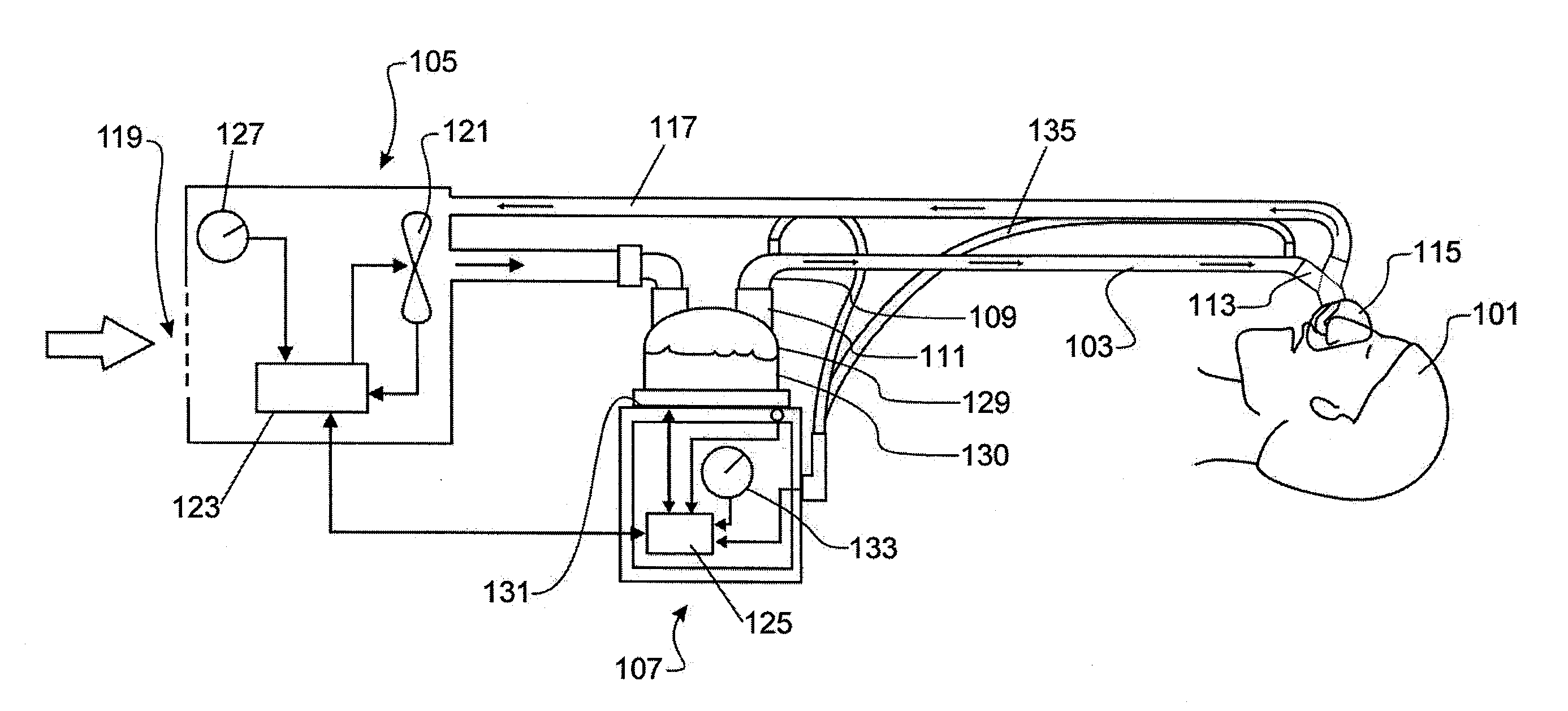

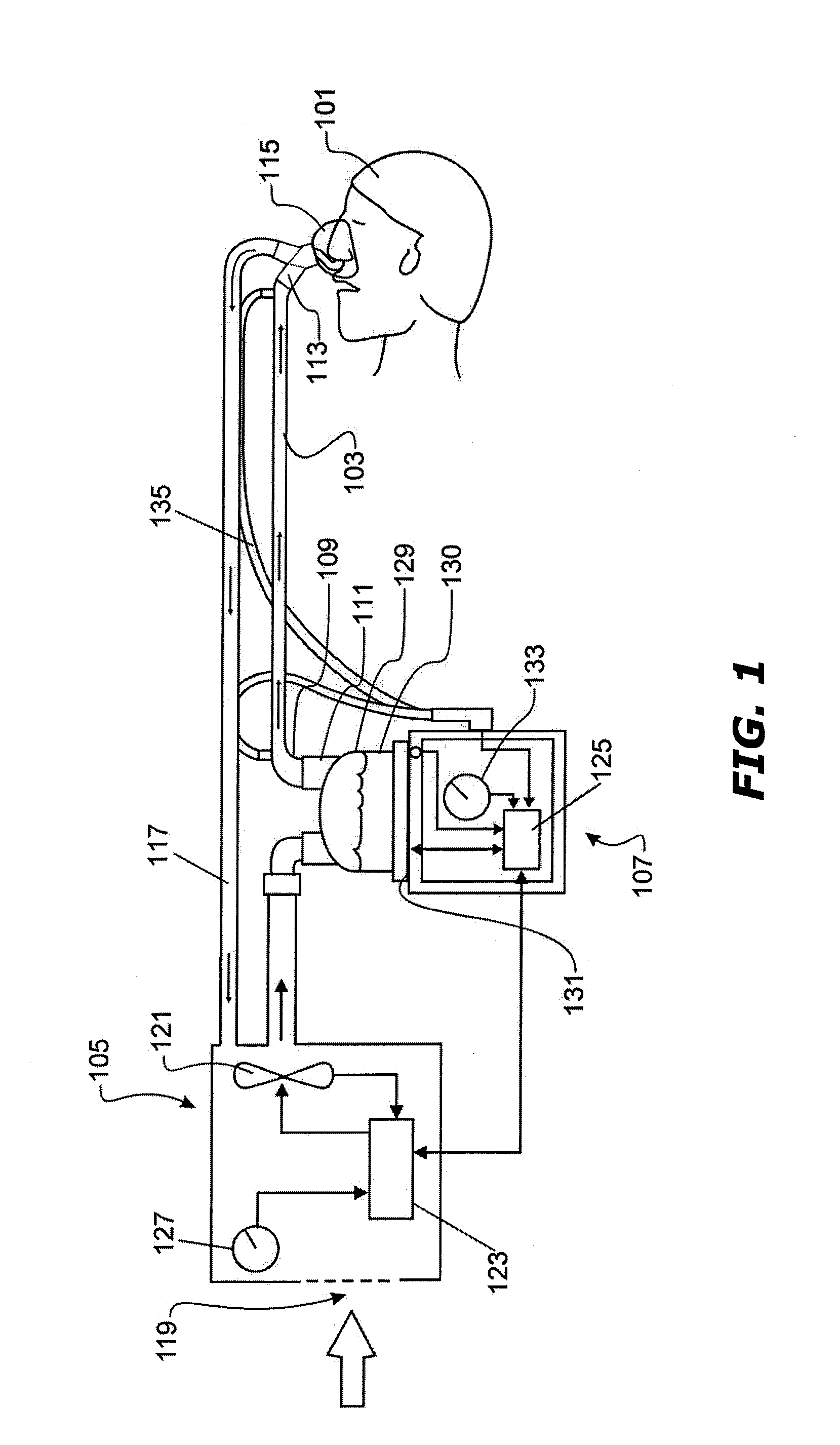

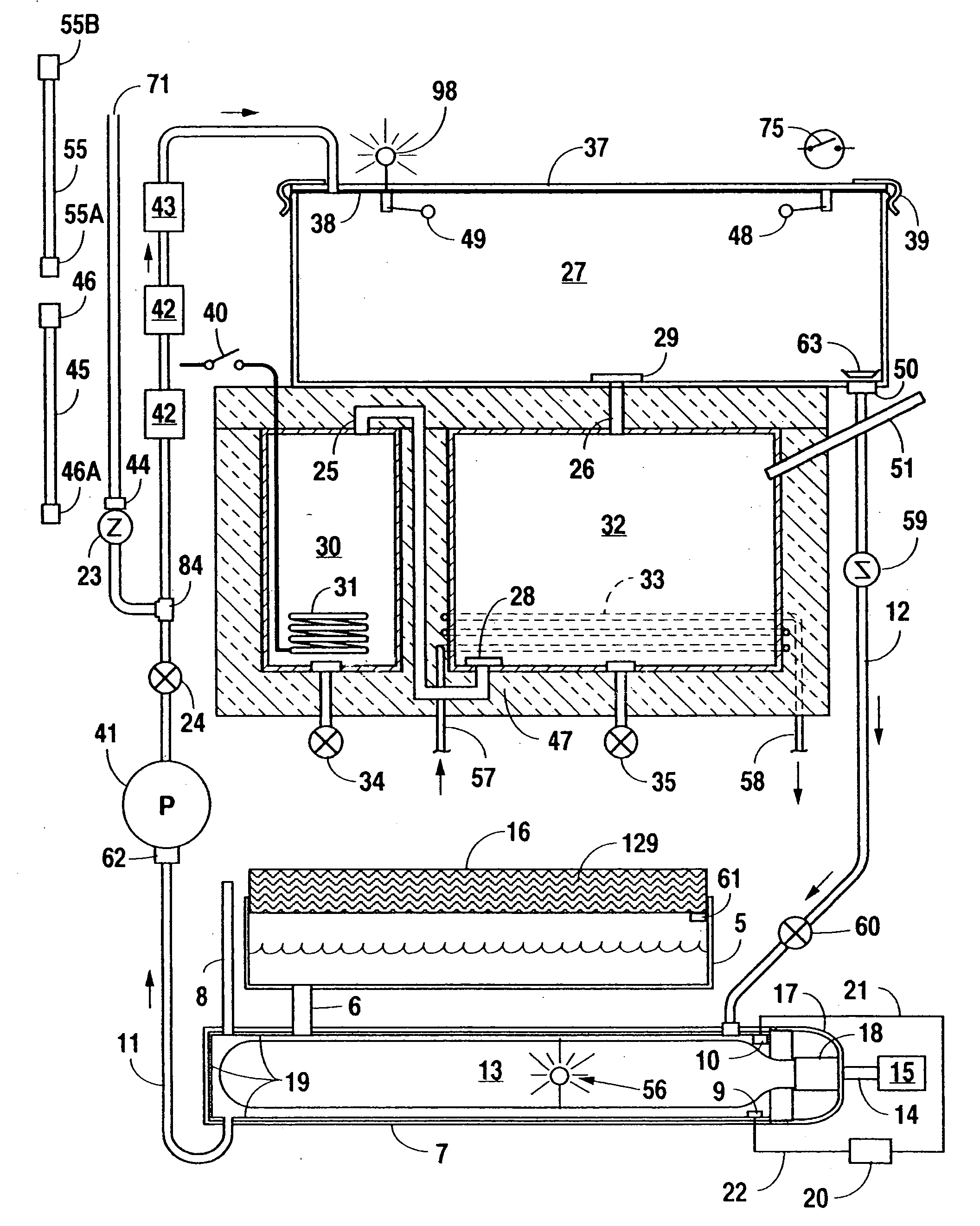

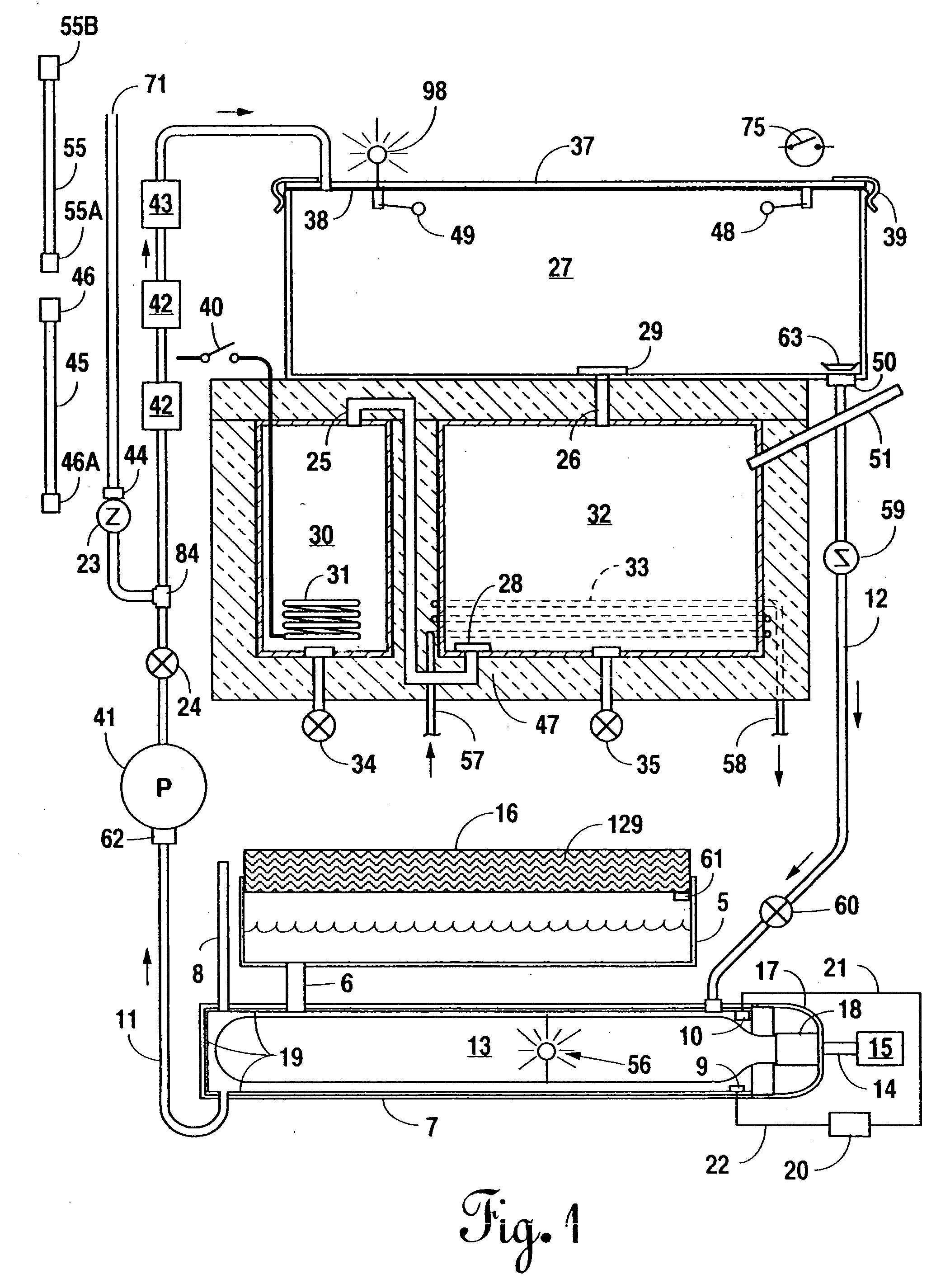

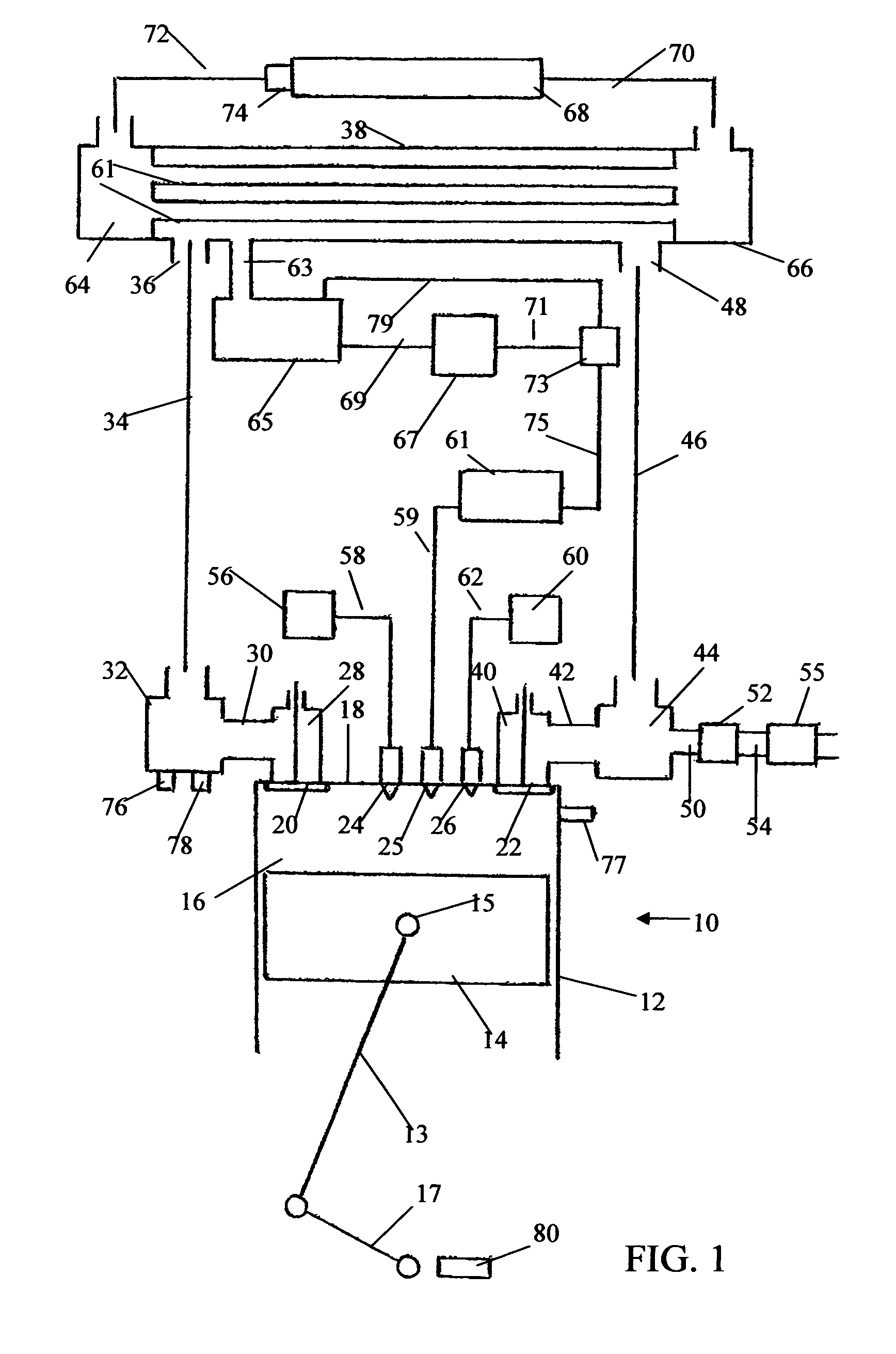

Portable, potable water recovery and dispensing apparatus

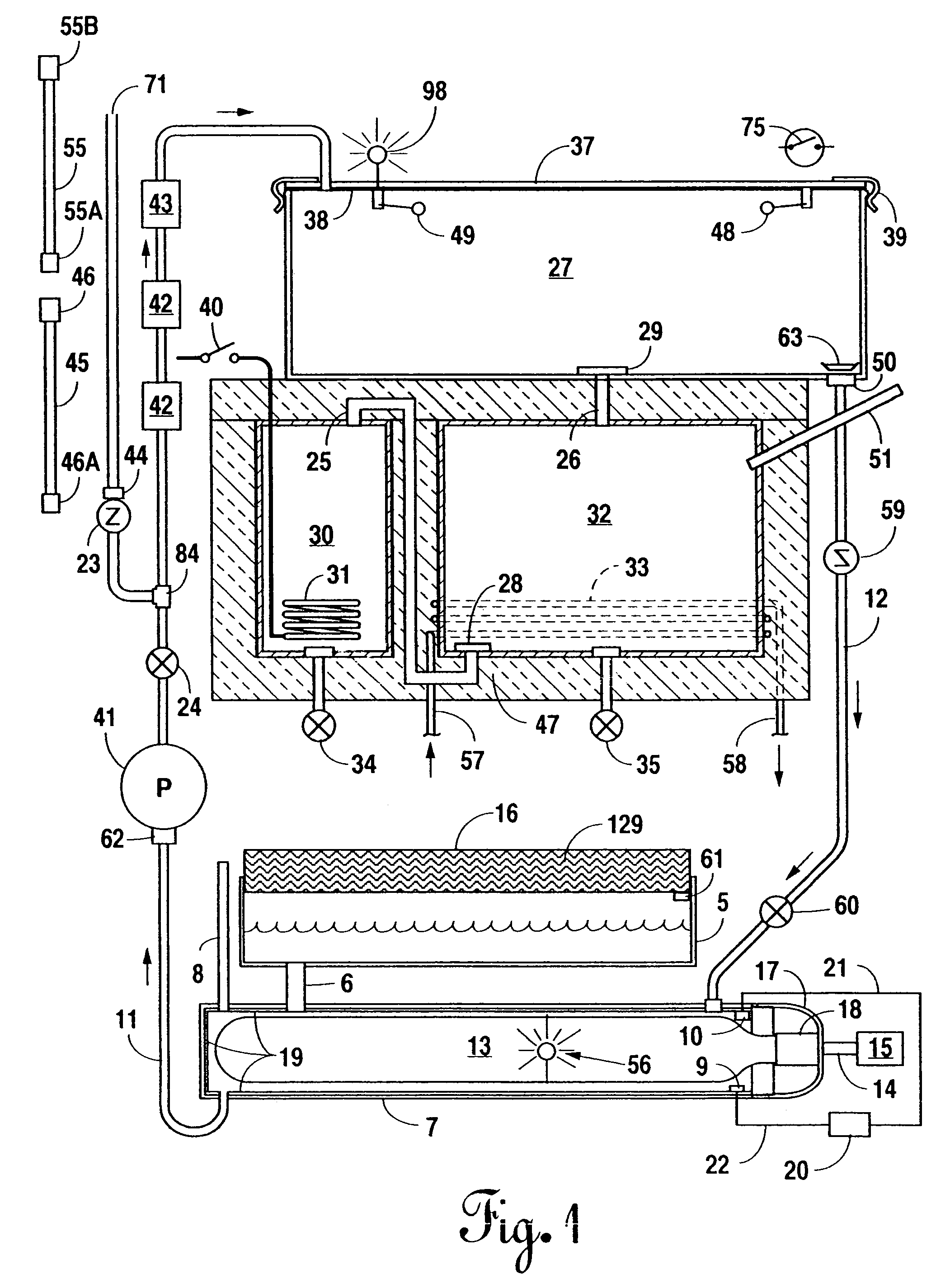

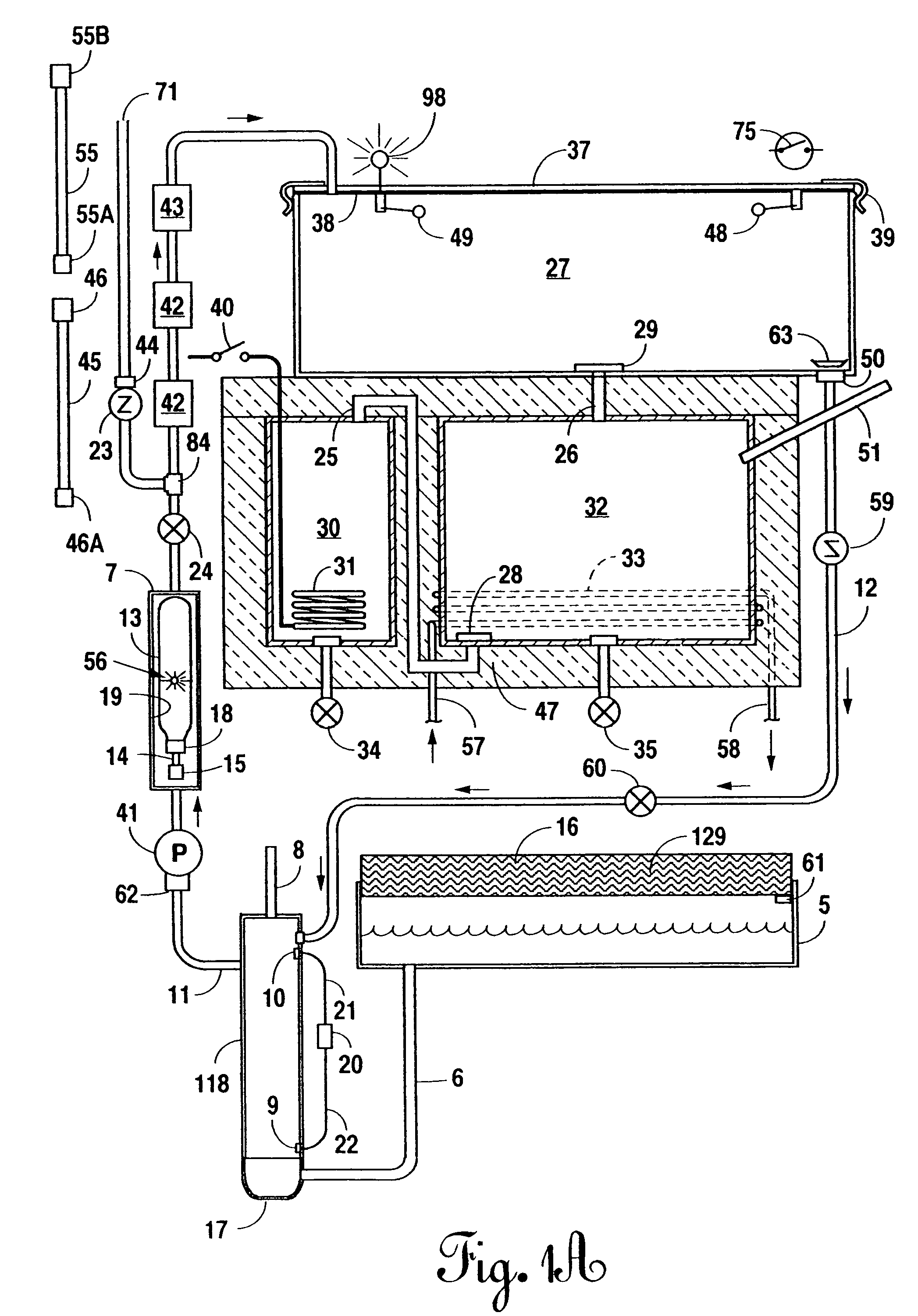

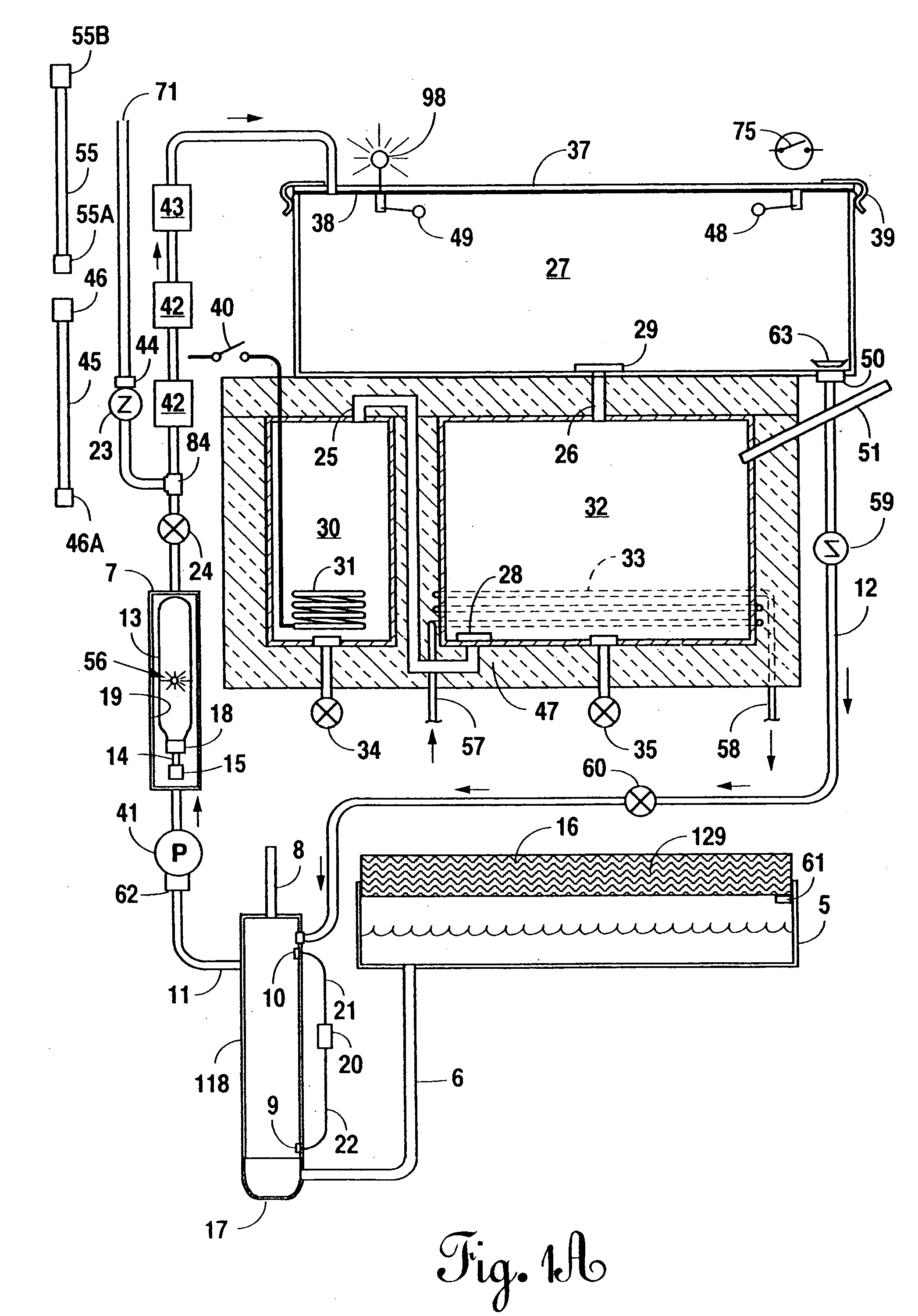

InactiveUS7089763B2Maximum efficiencyMaximum productionLiquefactionSpace heating and ventilationParticulatesBiological body

A portable, potable-water generator for producing high-purity liquid water by condensation of water vapor from ambient air. The generator (125) employs an air filter (119) to remove particulates and aerosols from the incoming air. An enclosed heat absorber cools the filtered air to its dew point and collects droplets of condensate into a condensate collector (5). Before discharge, the collected dew is treated in a bacteriostat loop to destroy adventitious living organisms and to filter out undesirable and dangerous contaminants. A recirculation loop provides the ability to recirculate stored condensate, including during periods of inactivity. Further, quick disconnect fittings (55b) and variable length flexible tubing allows use of the invention to serve remote dispensers and / or appliances and allow use of municipal water treated through the apparatus in low condensate situations.

Owner:WORLDWIDE WATER INC

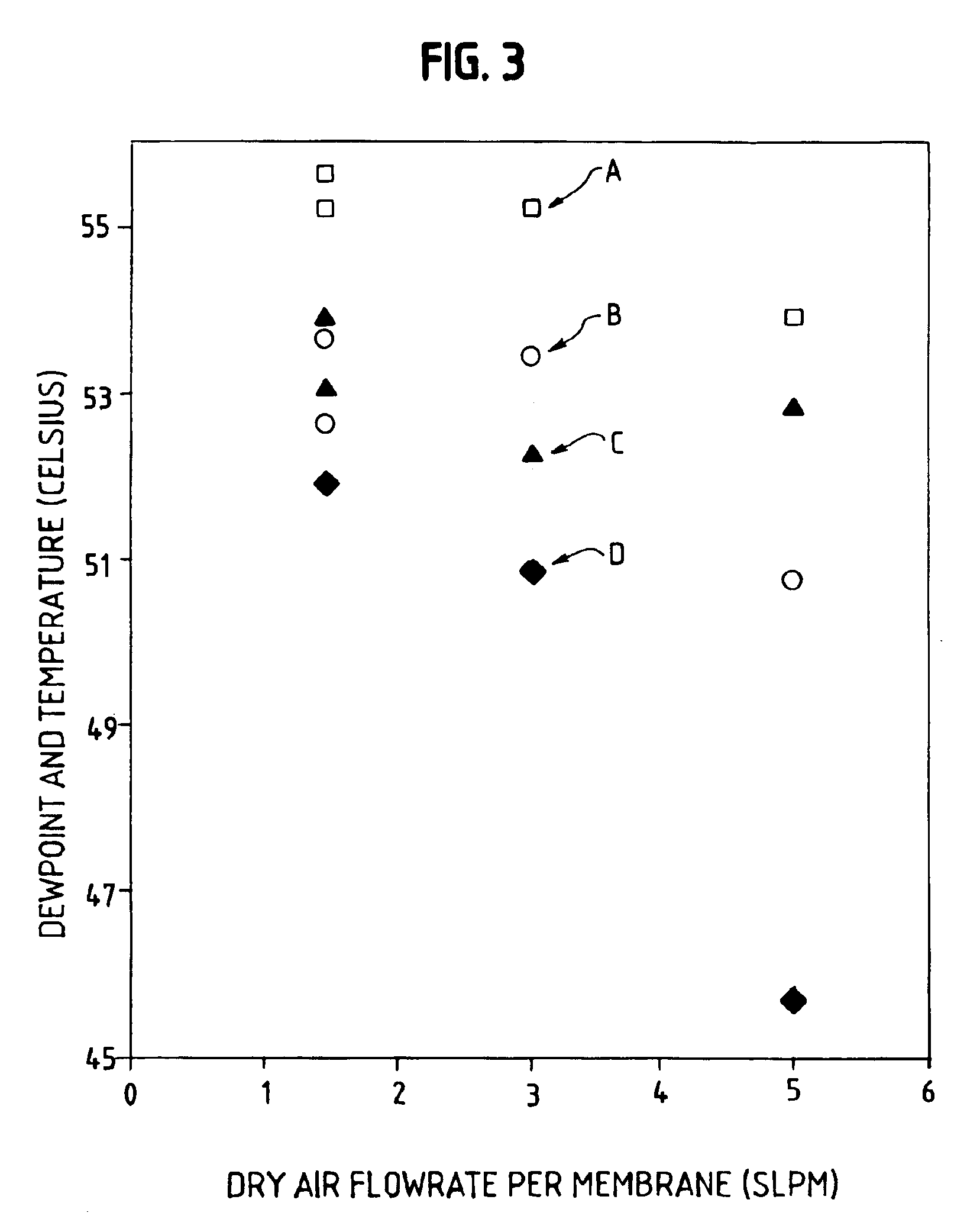

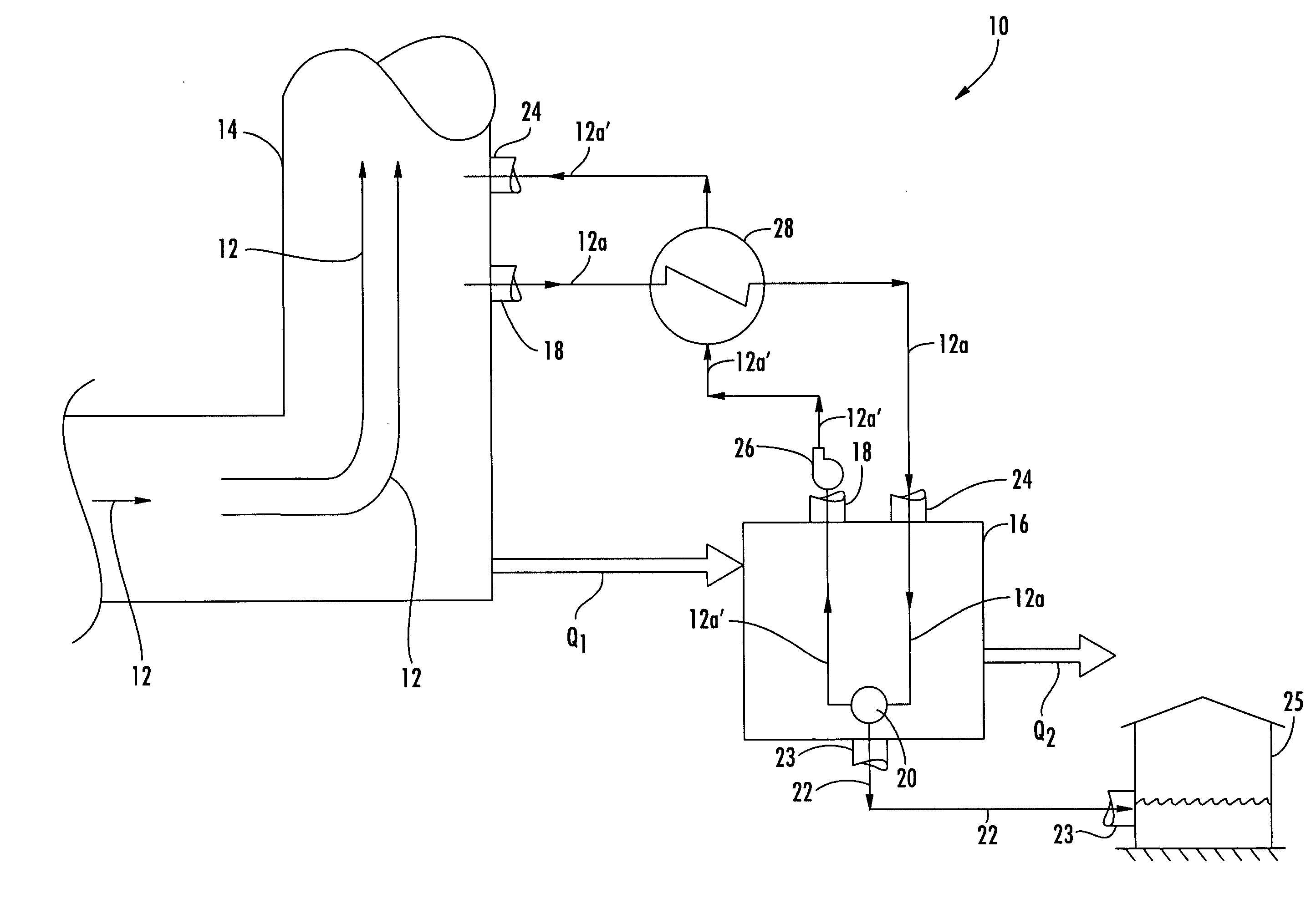

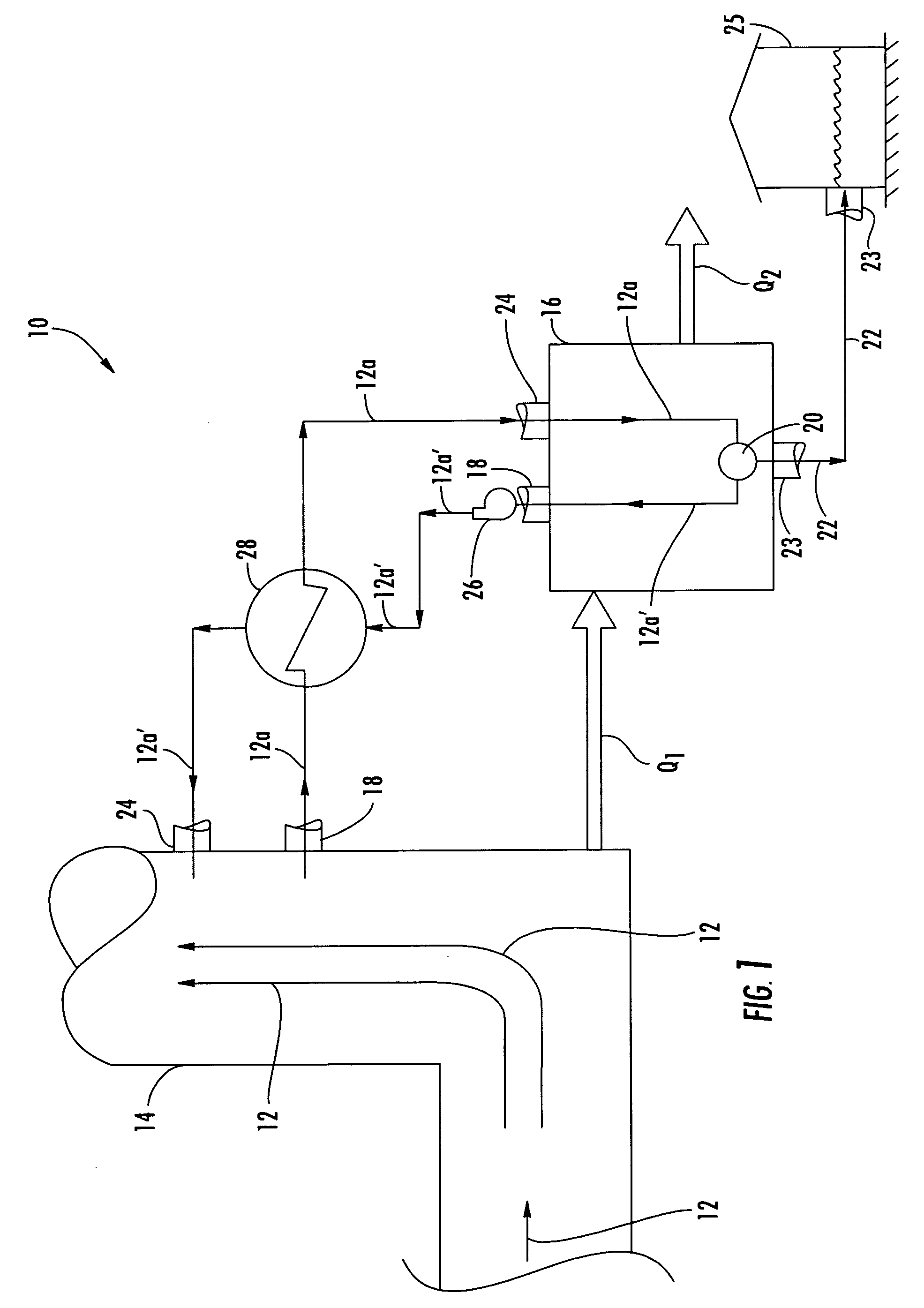

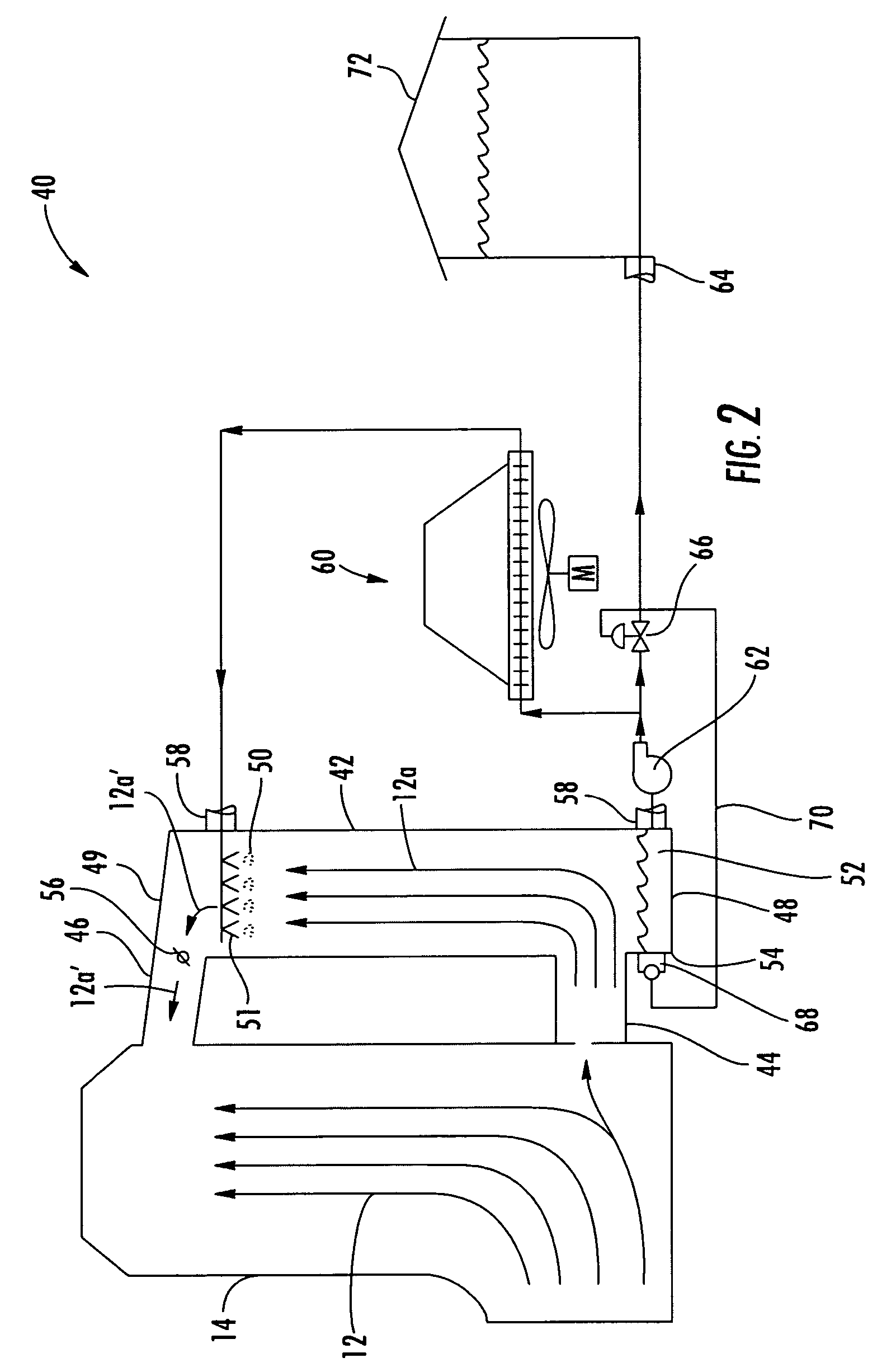

Membrane exchange humidifier for a fuel cell

InactiveUS6864005B2Simpler humidifier constructionFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsLiquid water

Owner:BDF IP HLDG

Turbine exhaust water recovery system

ActiveUS7194869B2Reduce the temperaturePromote sportsUsing liquid separation agentGas turbine plantsWater sourceLiquid water

The exhaust gas of a turbine engine can include water vapor. Aspects of the invention relate to various systems for recovering water from the exhaust gas of a gas turbine engine. In one system, a portion of the exhaust gas can be routed to an absorption chiller. In another system, a portion of the exhaust gas can be routed to a direct contact heat exchanger. In a third system, a portion of the exhaust gas can be routed to a fin-fan cooler. In each of these systems, the portion of gas can be cooled below its dew point temperature to release a portion of its humidity as liquid water. Aspects of the invention can be used with the turbine exhaust of simple and combined cycle power plants. A water recovery system according to aspects of the invention can minimize or eliminate a power plant's dependence on local water sources.

Owner:AMEC FOSTER WHEELER IND POWER CO INC

Components for medical circuits

ActiveUS20130098360A1Avoid spreadingRespiratory masksSynthetic resin layered productsWater vaporLiquid water

Breathable medical circuit components and materials and methods for forming these components are disclosed. These components incorporate breathable foamed materials that are permeable to water vapor and substantially impermeable to liquid water and the bulk flow of gases. The disclosed materials and methods can be incorporated into a variety of components, including tubes, Y-connectors, catheter mounts, and patient interfaces and are suitable for use in a variety of medical circuits, including insufflation, anesthesia, and breathing circuits.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Water vapor breathable, liquid water resistant material

InactiveUS7148160B2Breathability to water retardance ratioMore cost-effectiveSynthetic resin layered productsLaminationLiquid waterHousewrap

The present invention relates to a composite sheet material that is water vapor permeable and substantially liquid water impermeable. The composite sheet material includes an outer layer, a film, and a reinforcing layer and, preferably, has an ASTM D3833 water vapor transmission rate of greater than 250 g / m2 / day, and a tensile strength of at least about 100 N / 5 cm when tested in accordance with ASTM D5035. The sheet material is useful as a membrane for roofing, housewrap, insulation facing and in the fabrication of protective apparel.

Owner:SAINT GOBAIN ADFORS CANADA LTD

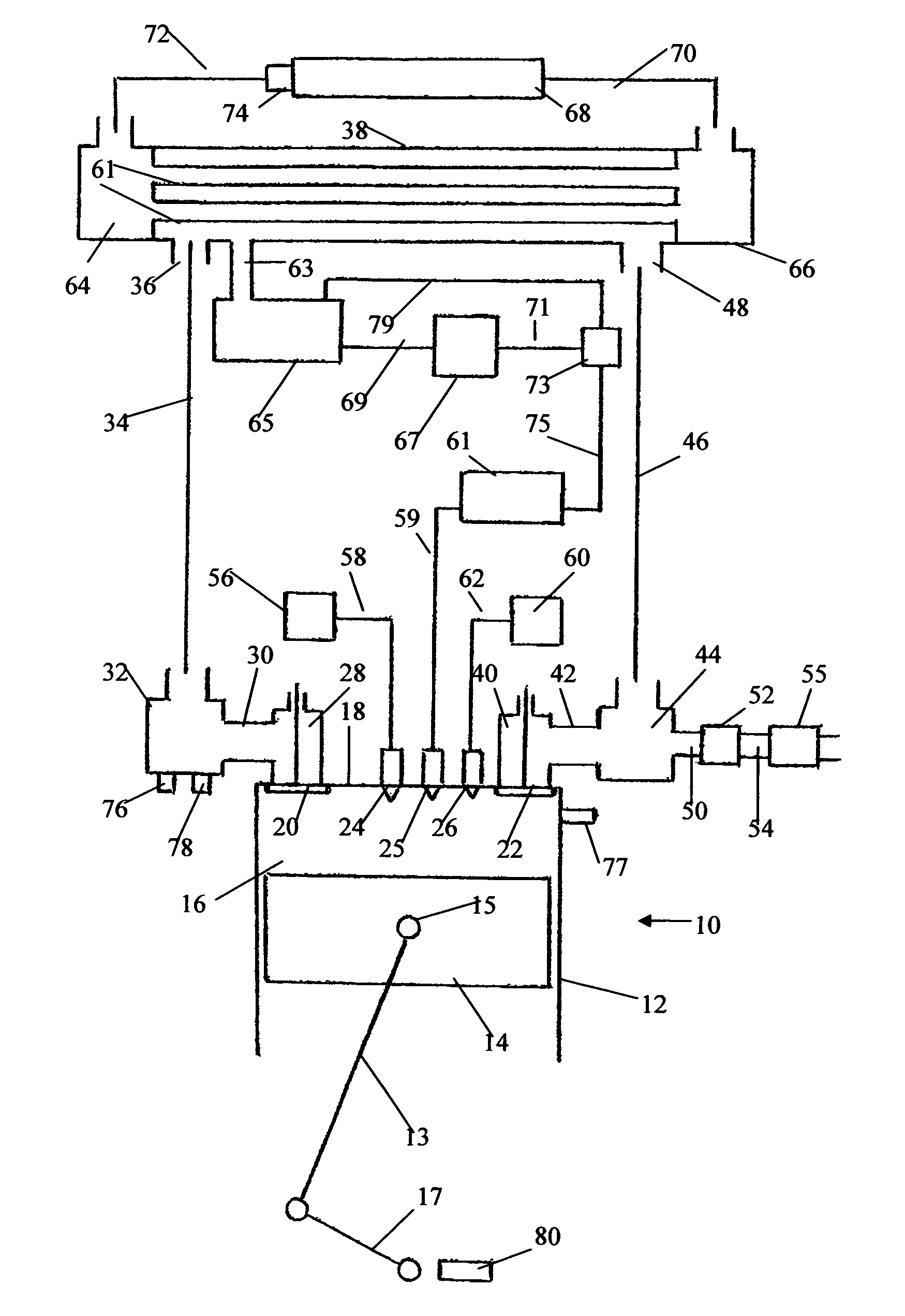

Portable, potable water recovery and dispensing apparatus

InactiveUS20050139552A1Maximum productionMaximum efficiencyLiquefactionSpace heating and ventilationParticulatesBiological body

A portable, potable-water generator for producing high-purity liquid water by condensation of water vapor from ambient air. The generator (125) employs an air filter (119) to remove particulates and aerosols from the incoming air. An enclosed heat absorber cools the filtered air to its dew point and collects droplets of condensate into a condensate collector (5). Before discharge, the collected dew is treated in a bacteriostat loop to destroy adventitious living organisms and to filter out undesirable and dangerous contaminants. A recirculation loop provides the ability to recirculate stored condensate, including during periods of inactivity. Further, quick disconnect fittings (55b) and variable length flexible tubing allows use of the invention to serve remote dispensers and / or appliances and allow use of municipal water treated through the apparatus in low condensate situations.

Owner:WORLDWIDE WATER INC

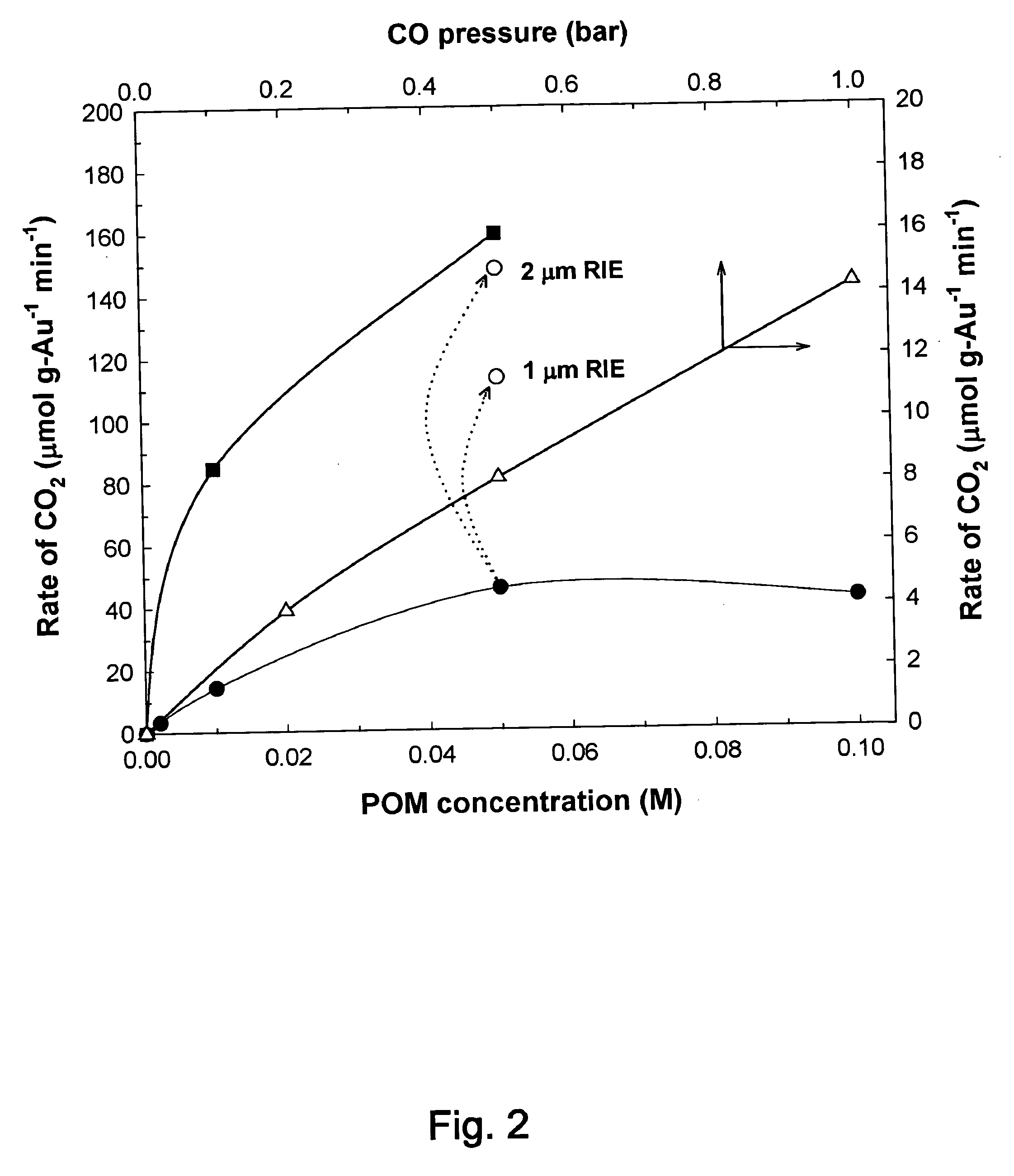

Catalytic method to remove CO and utilize its energy content in CO-containing streams

InactiveUS20060024539A1Low costUse minimizedMaterial nanotechnologyGas treatmentFuel cellsCatalytic method

Disclosed are a reactor and a corresponding method for producing electrical energy using a fuel cell by selectively oxidizing CO at room temperature using polyoxometalate compounds and transition metal compounds over metal-containing catalysts, thereby eliminating the water-gas shift reaction and the need to transport and vaporize liquid water in the production of H2 for fuel cells. The reactor also functions to deplete CO from an incoming gas stream.

Owner:WISCONSIN ALUMNI RES FOUND

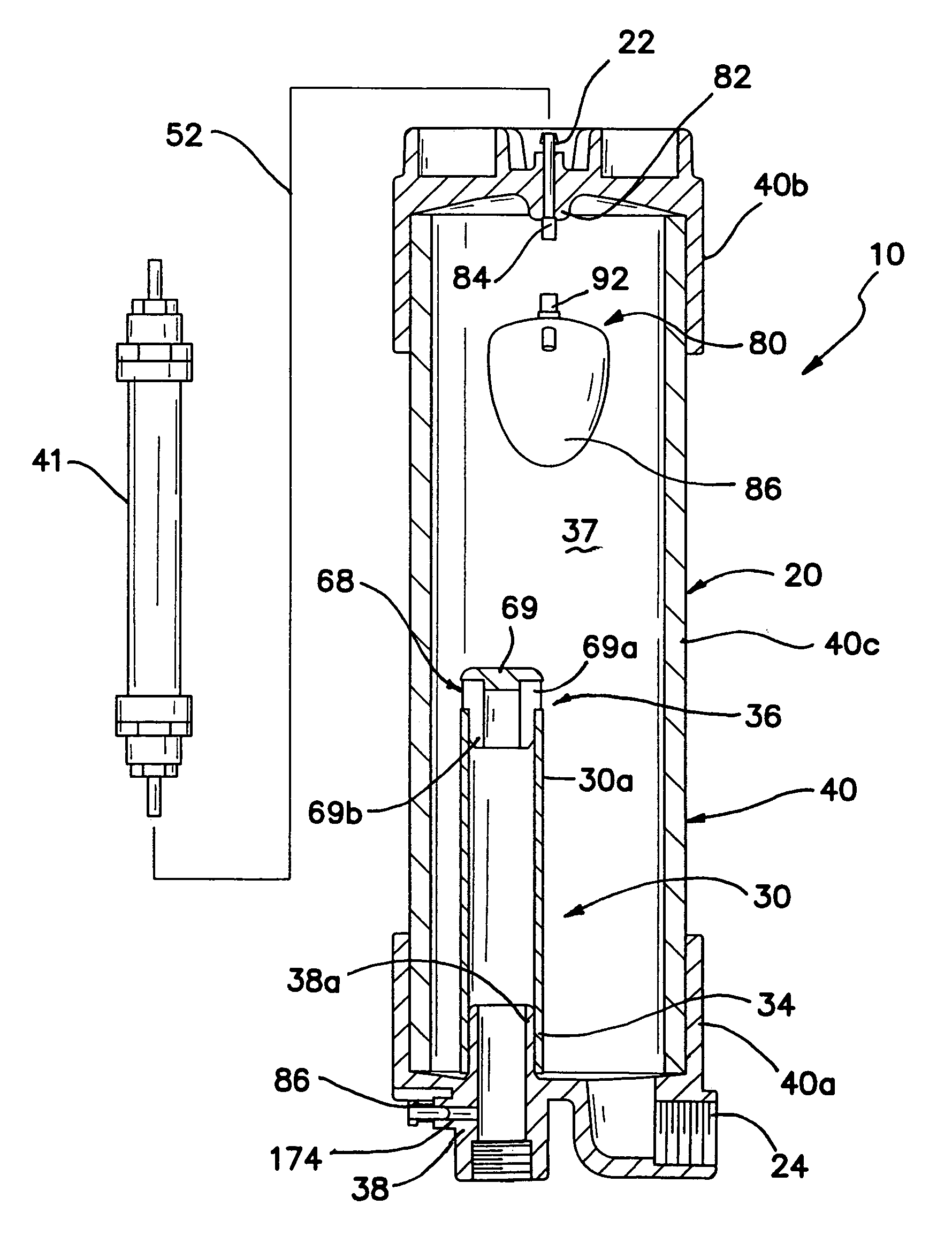

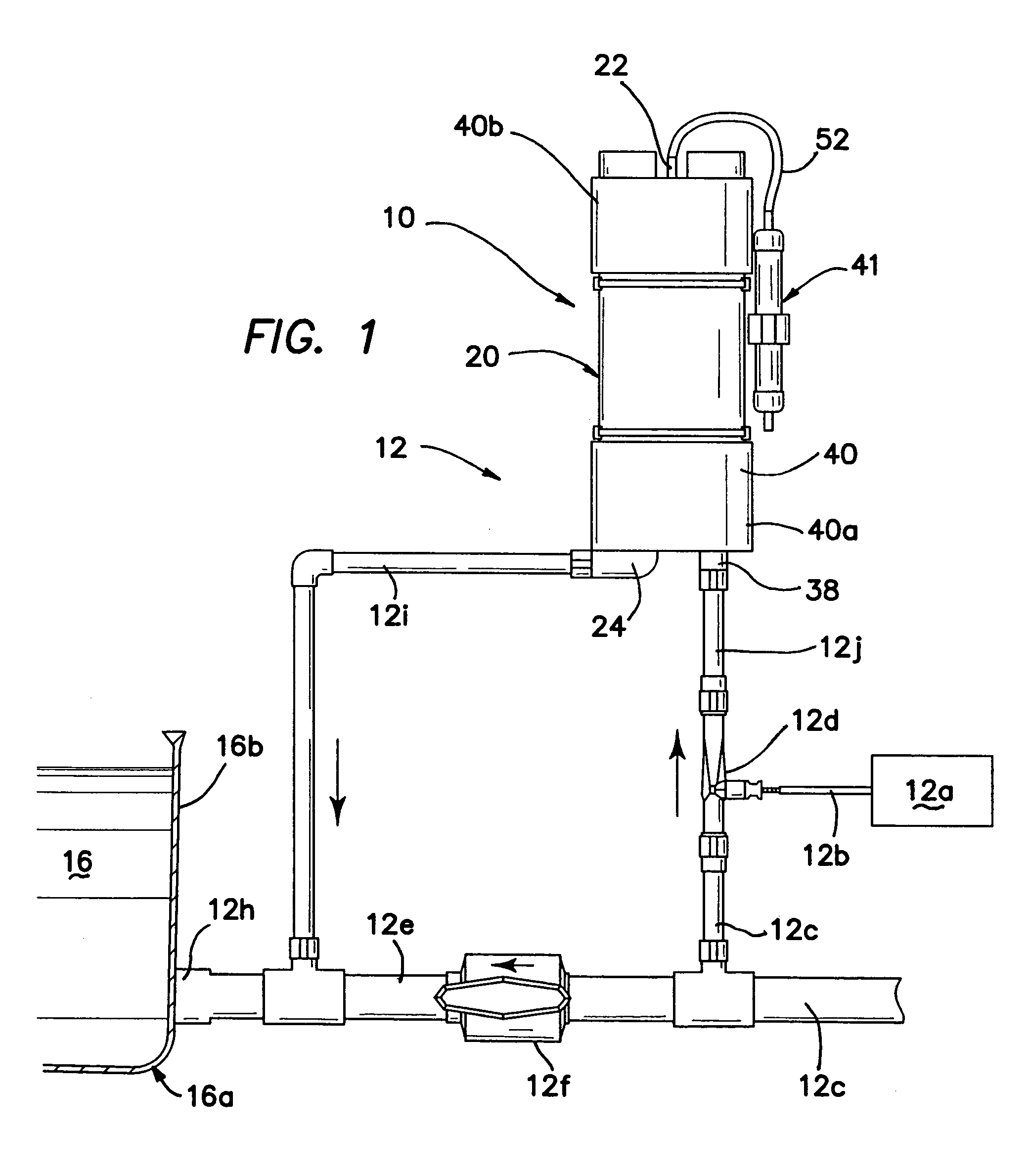

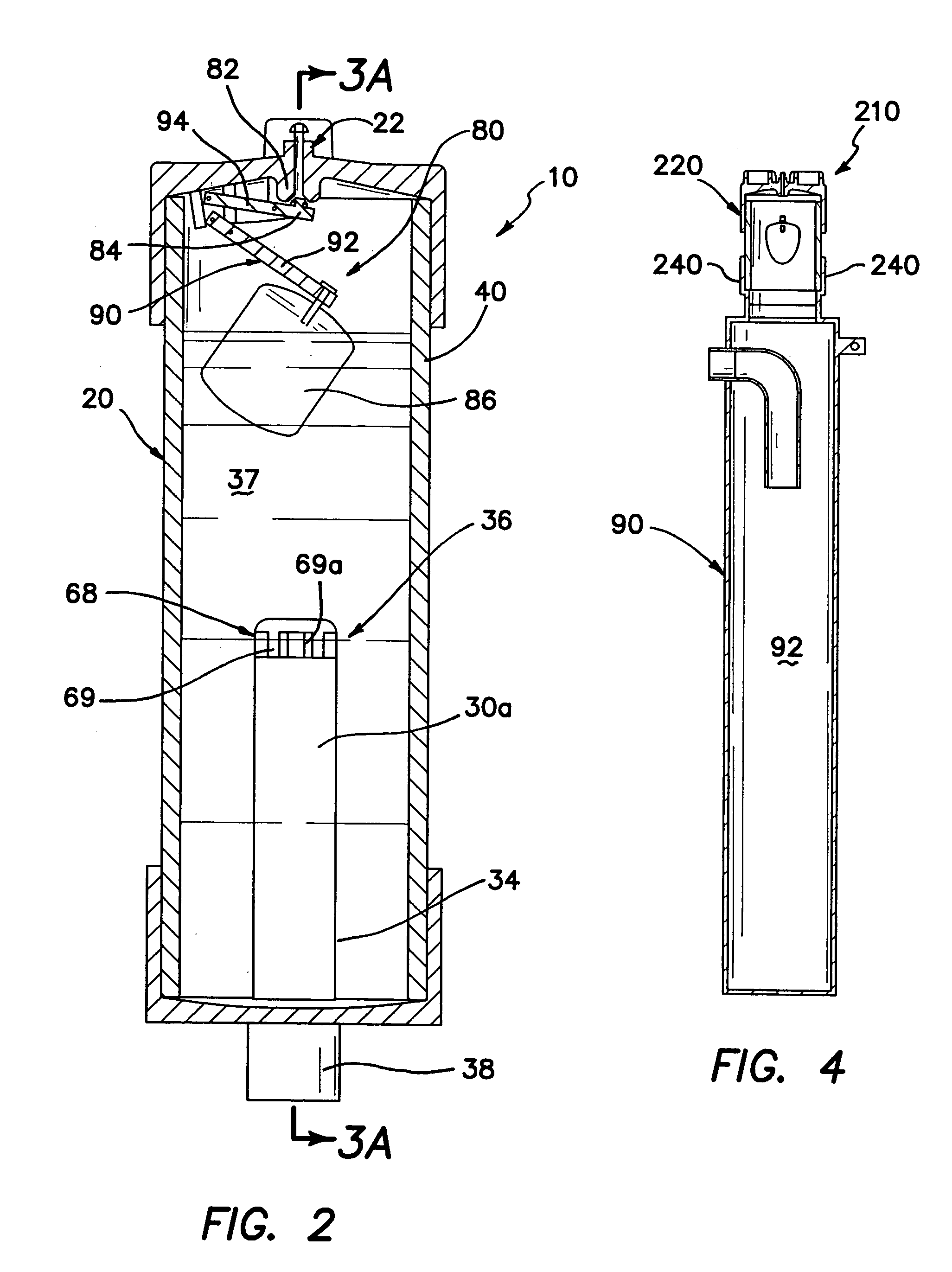

Water ozonation mixing and degassing system

ActiveUS7022225B1Straightforward in constructionEasy to useOther chemical processesDispersed particle separationLiquid waterExhaust fumes

An apparatus and system for mixing and separating ozonated water is provided. The apparatus is especially useful as a component of a system for cycling sanitizing ozonated water to a body of water such as a pool, spa or pond. The apparatus generally includes a separating vessel including a mixing tower, preferably located substantially entirely within the separating vessel and including a diffuser element for enhancing mixing of ozonated water without increasing turbulence in the separating vessel. Preferably, the apparatus includes a seal mechanism that substantially prevents liquid water from escaping the separating vessel with vented off-gas. The invention further provides an ozone destruct assembly including a condensate collection portion, and may also include a return line for passing a treated off-gas into the body of water.

Owner:CUSTOM MOLDED PROD

Massive bodies containing free halogen source for producing highly converted thickened solutions of chlorine dioxide

A massive body, e.g., a tablet, for producing a thickened solution of chlorine dioxide when the massive body is added to liquid water is disclosed. The massive body comprises a metal chlorite, an acid source and a thickener (incorporated directly into the massive body or added as a component separate from the massive body) and optionally a source of free halogen. The concentration of free chlorine in the solution will be: (a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or (b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:BASF AG

Insulation board with air/rain barrier covering and water-repellent covering

A product comprises: a mineral fiber insulation board which is resistant to liquid water-penetration and has first and second major surfaces, a facing material, which is resistant to air infiltration and liquid water-penetration, laminated to the first major surface of the insulation board, the facing material being permeable to water vapor, and an interior facing laminated to the second surface of the insulation board with an adhesive, so that the second major surface with the interior facing and adhesive thereon is resistant to liquid water-penetration, thereby to form a unitary building exterior envelope product.

Owner:CERTAINTEED CORP

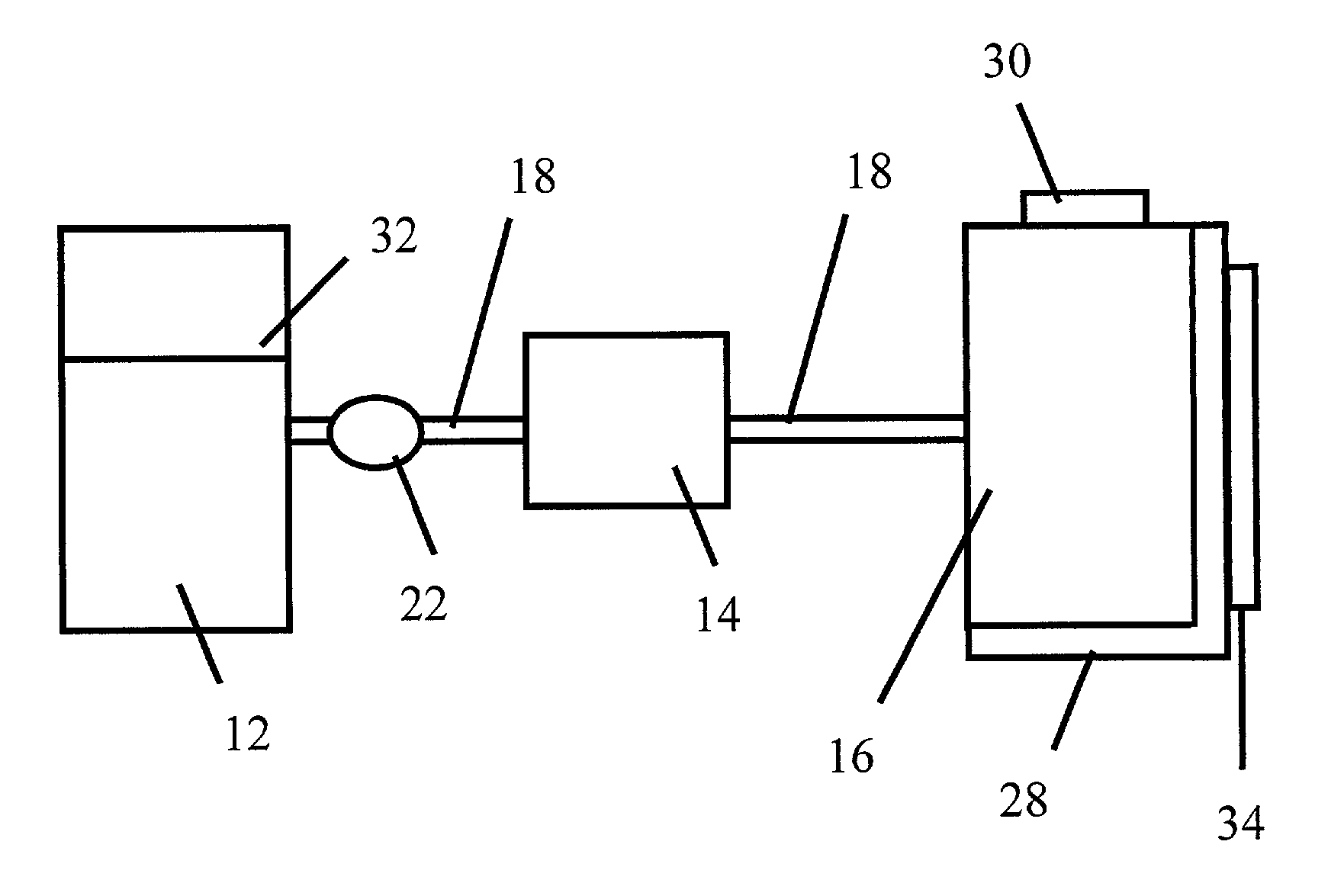

Water management in monopolar fuel cells

A monopolar fuel cell stack comprising proton exchange membrane fuel cells supplied with a gaseous anodic reactant, preferably hydrogen, and a gaseous cathodic reactant, preferably air. The monopolar fuel cell stack, forming at least one substantially planar array, includes a liquid water retention barrier disposed over an electrode to retain liquid water within the fuel cells. The barrier is preferably used over the cathode side of each fuel cell and allows excess air flow to cool the fuel cell stack without drying the membrane in each fuel cell. The liquid water retention barrier may be either: (i) a thin, gas permeable, liquid water impermeable membrane; (ii) a thin, porous sheet of material; or (iii) a thin, substantially solid sheet of material except for a plurality of small through-holes that penetrate from one side of the sheet to an opposing side of the same sheet.

Owner:LYNNTECH

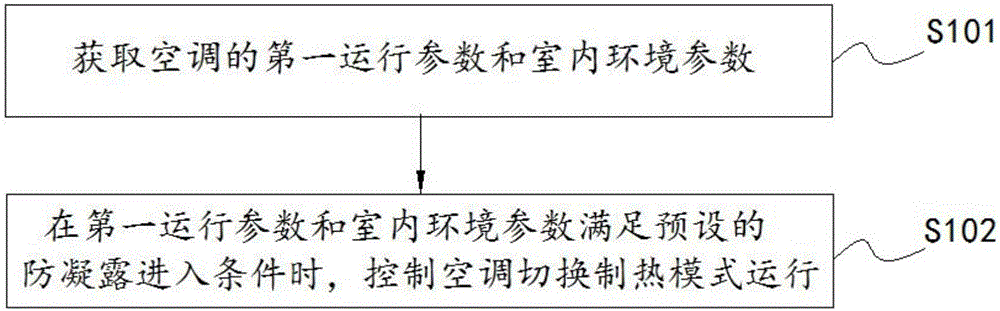

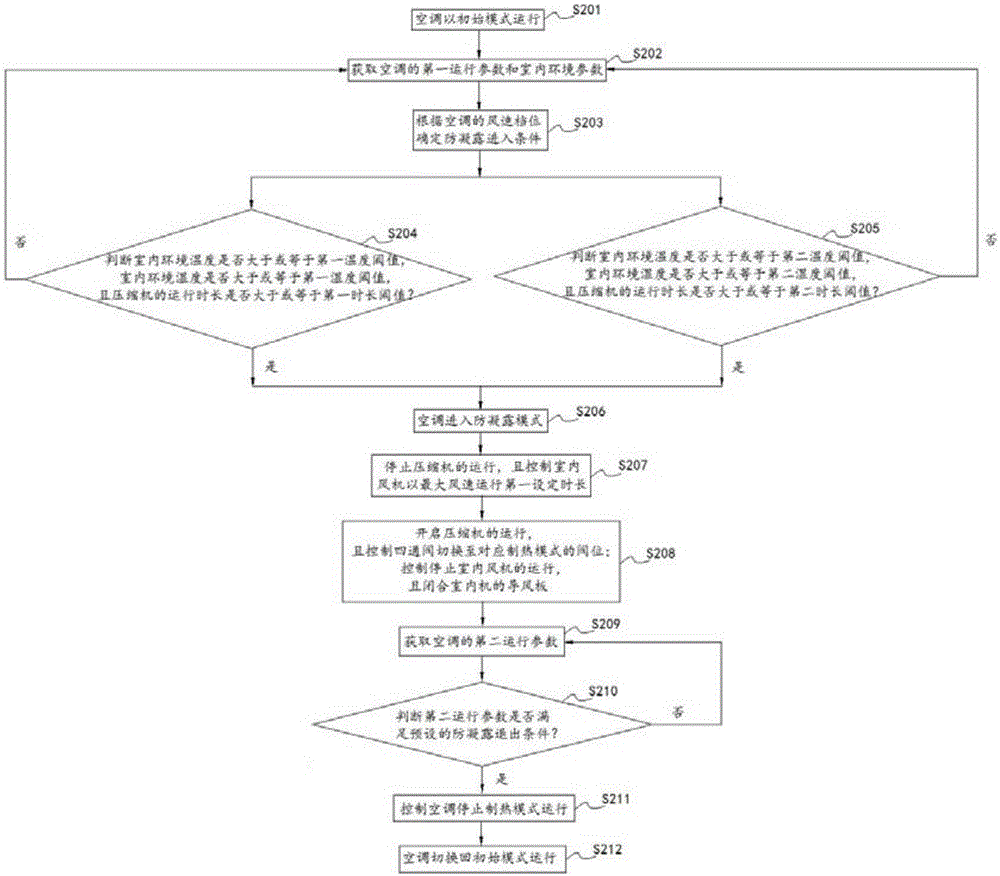

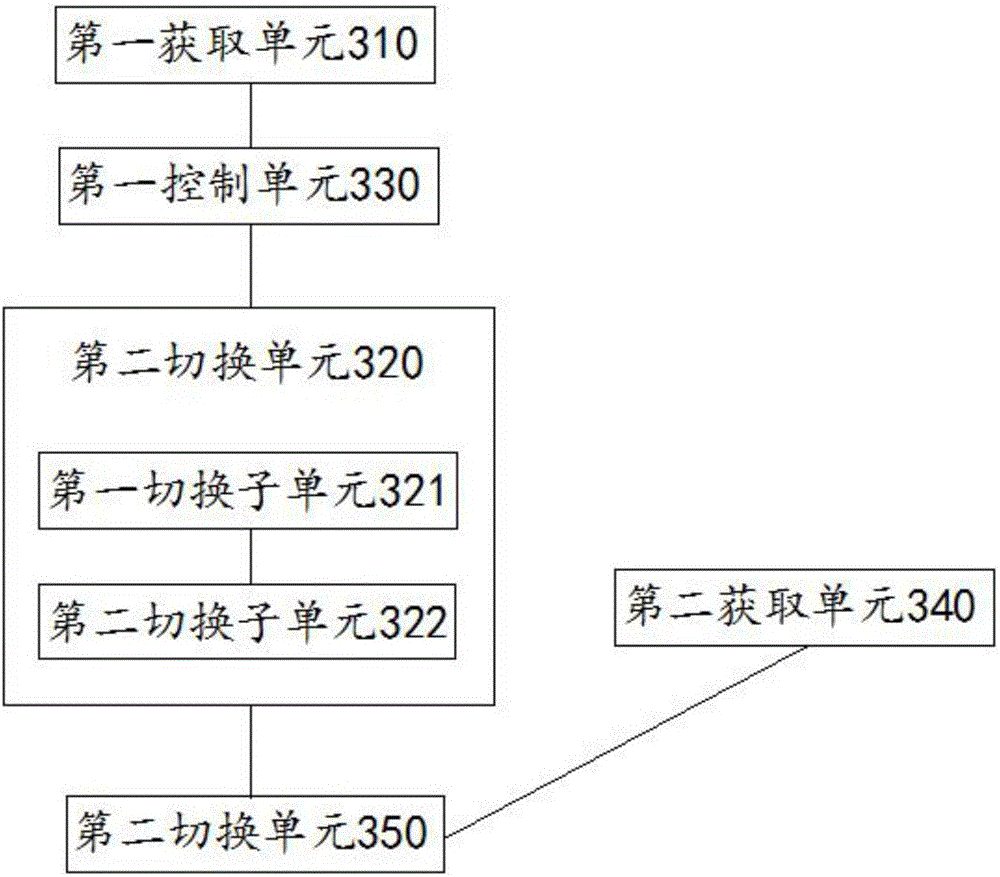

Control method and device for condensation prevention of air conditioner

ActiveCN107525222AAvoid dripping problemsEasy to useCondensate preventionSpace heating and ventilation safety systemsLiquid waterWater vapor

The invention discloses a control method and device for condensation prevention of an air conditioner and belongs to the technical field of condensation prevention of air conditioners. The control method includes the steps of obtaining first operation parameters and indoor environment parameters of the air conditioner, and controlling the air conditioner to be switched to operate in a heating mode when the first operation parameters and the indoor environment parameters meet preset condensation prevention starting conditions. According to the control method for condensation prevention of the air conditioner, the air conditioner can be switched to operate in the heating mode when the condensation prevention starting conditions are met, water drops condensed inside an indoor unit can be evaporated into water vapor through heat of a high-temperature refrigerant conveyed to an indoor heat exchanger, and thus the quantity of liquid water inside the indoor unit is reduced, the problems of condensed water dripping, water blowing during air exhausting and the like of the air conditioner are avoided, and the operational performance and user experience of the air conditioner are improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

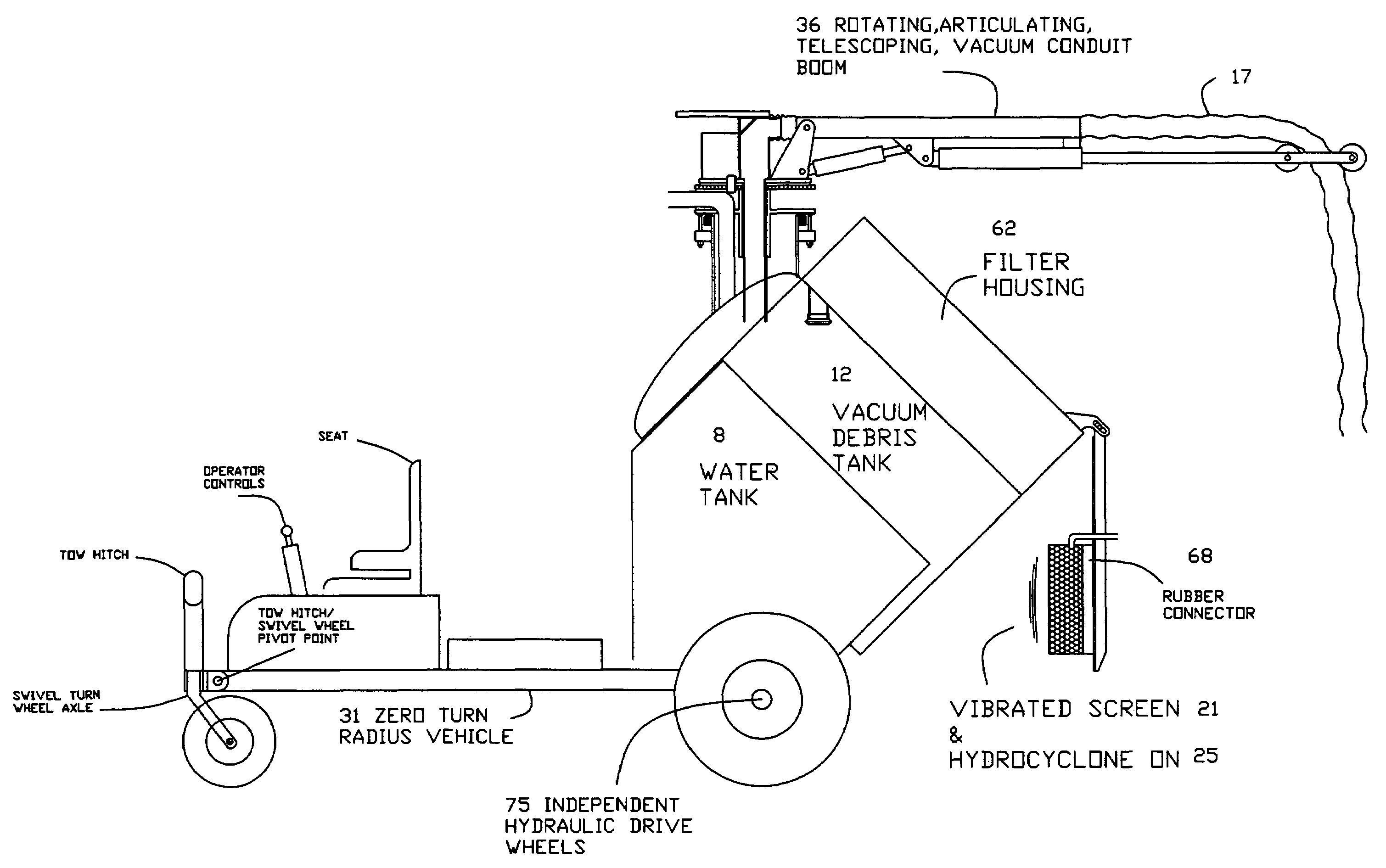

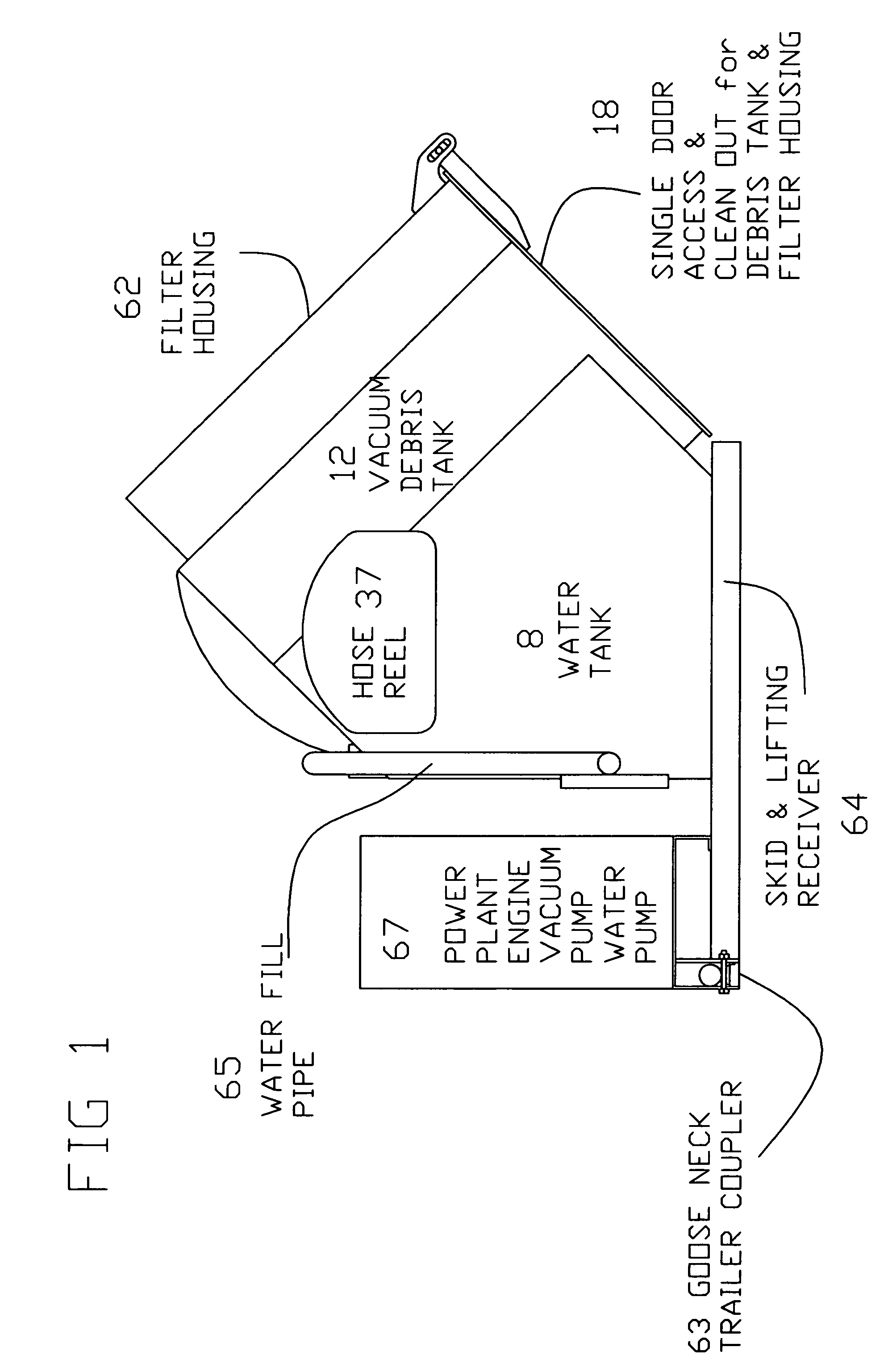

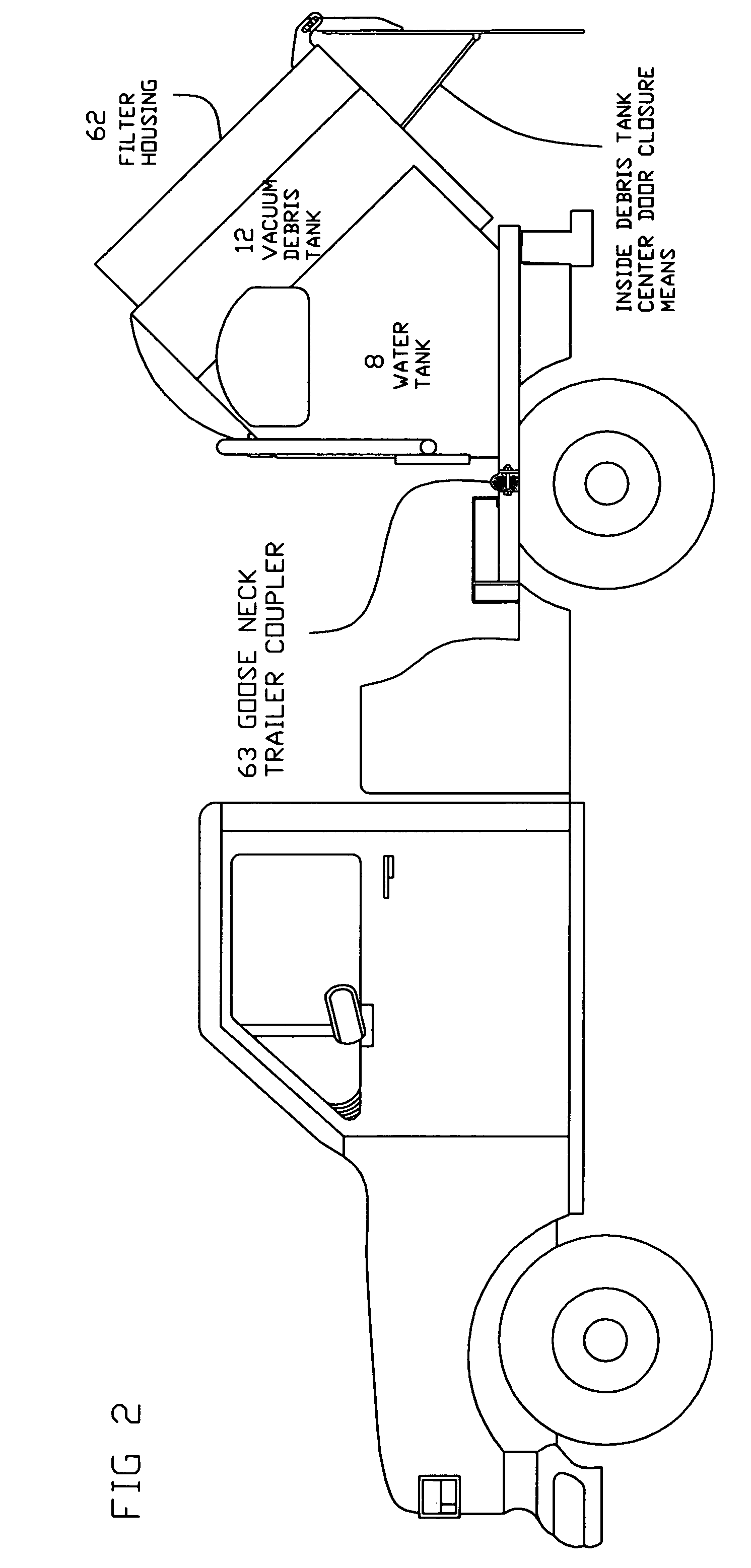

Inclined slope vacuum excavation container

InactiveUS7503134B2Efficient interaction and plumbingConcentrating weightMechanical cleaningPressure cleaningWater storageLiquid water

A vacuum container mounted on an inclined slope and having a liquid water storage container mounted beneath the incline of the vacuum container. The water storage container may support the vacuum container. The slope may be of sufficient angle to allow debris to be emptied from the vacuum container by gravity when the access door is opened. A filter housing may be mounted to and supported by the vacuum container. By flush mounting the clean out end of the filter housing with the clean out end of the vacuum container, a single access clean out door may be used to access both simultaneously.

Owner:BUCKNER LYNN A

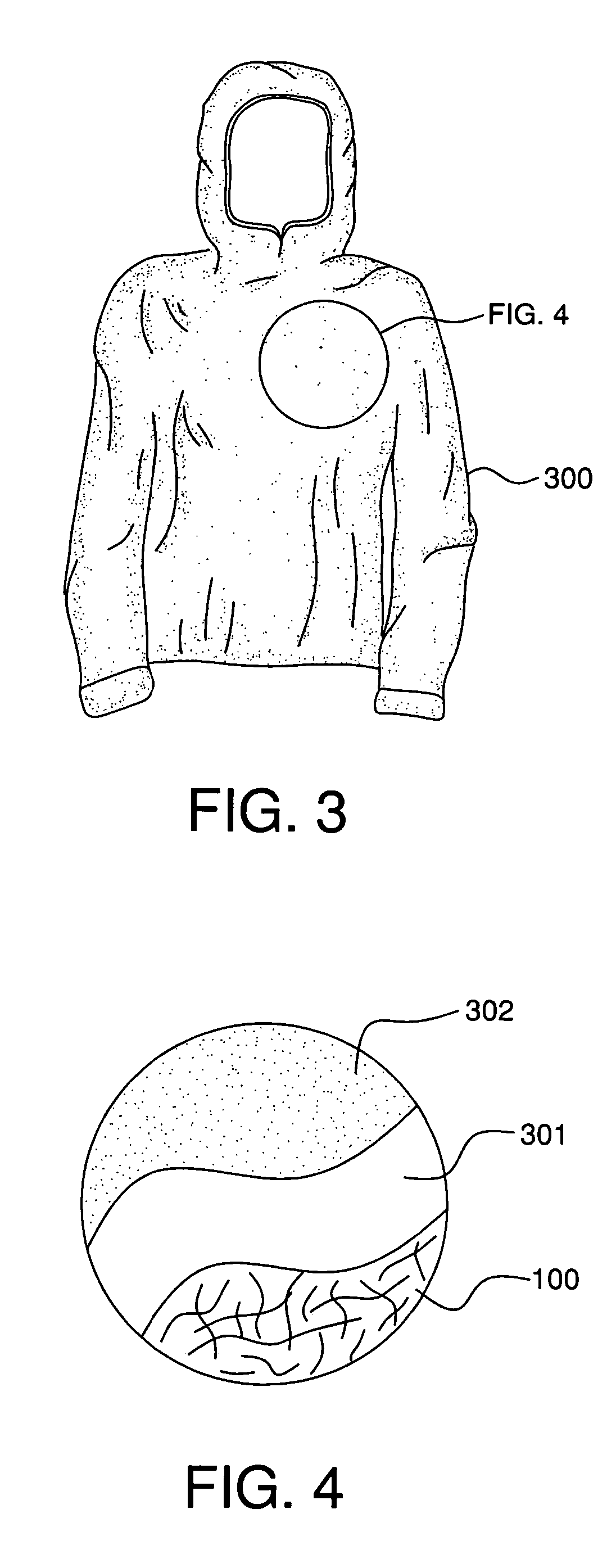

Liquid water resistant and water vapor permeable garments

A water resistant garment is disclosed having regions of high MVTR while maintaining water resistance. The garment has a fabric layer adjacent one major surface of a nanofiber layer. The surface of the nanofibers are coated with a coating containing a fluorocarbon polymeric moiety and a resin binder or extender which is soluble in water and / or other solvents. The coated nanofiber layer has a contact angle of greater than 145°. The garment optionally includes a second fabric layer adjacent the other major surface of the nanofiber layer. The garment has regions having a Frazier air permeability of between about 0.5 m3 / min / m2 and about 8 m3 / min / m2, an MVTR of greater than about 500 g / m2 / day and a hydrostatic head of at least about 50 cmwc.

Owner:EI DU PONT DE NEMOURS & CO

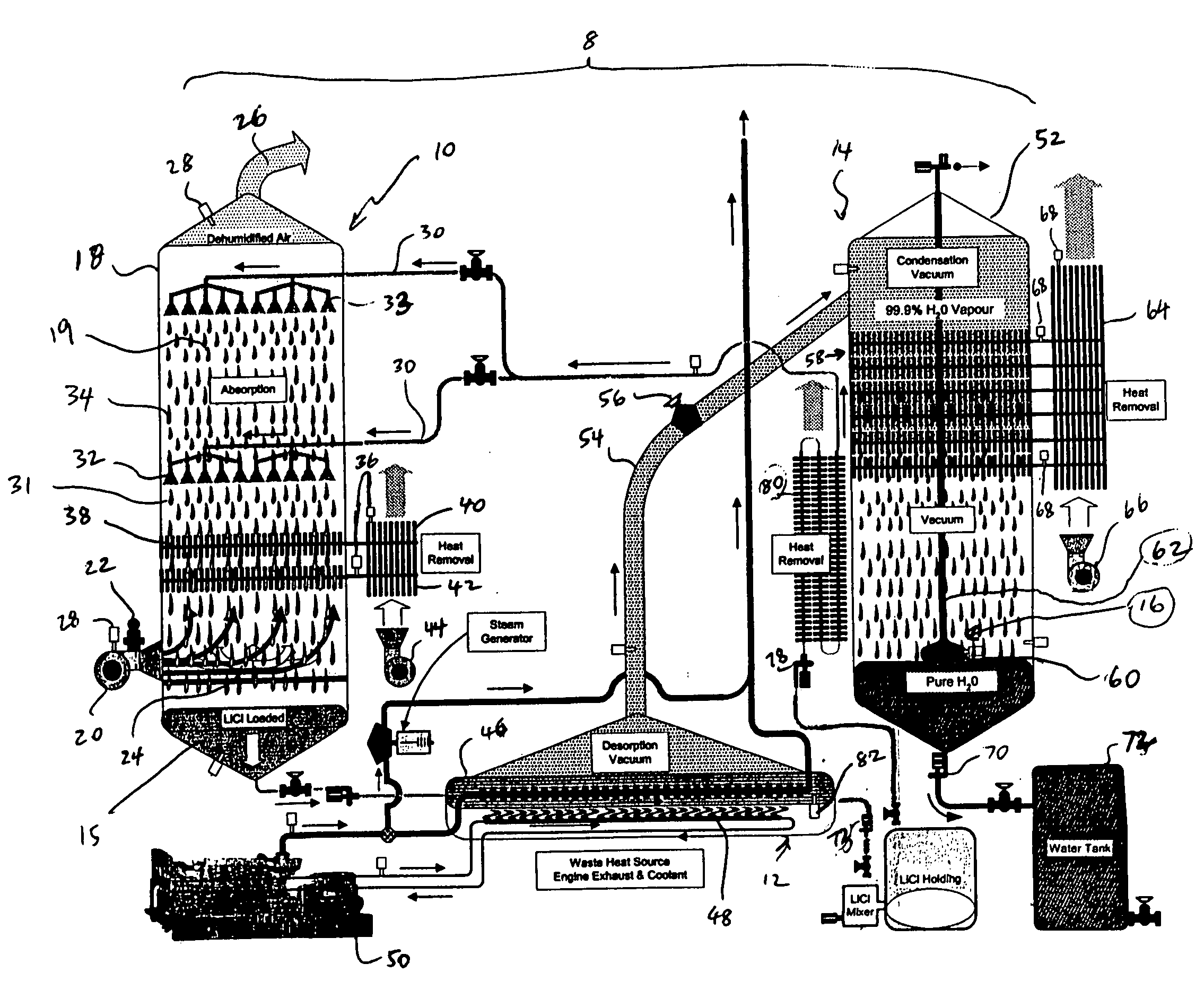

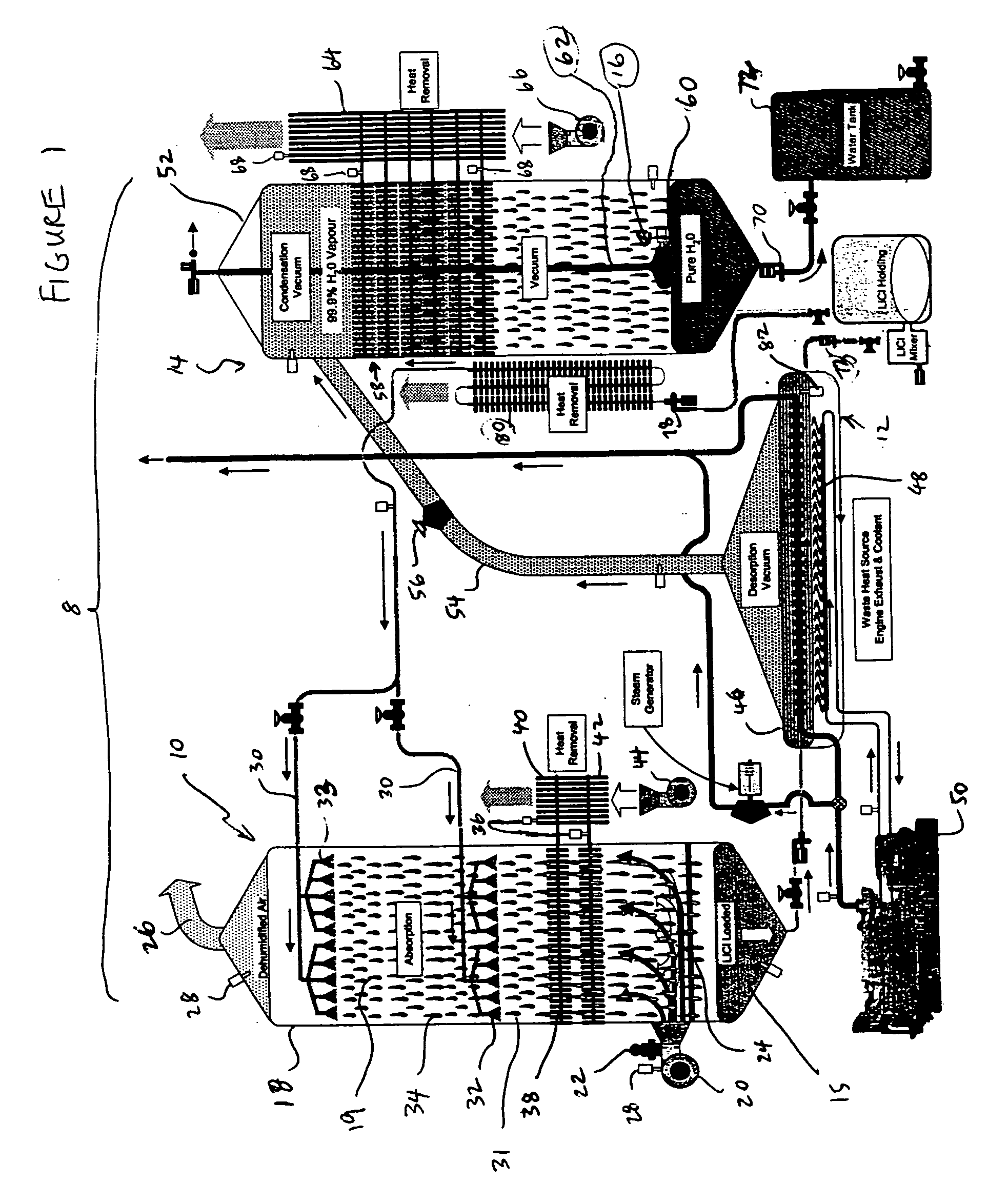

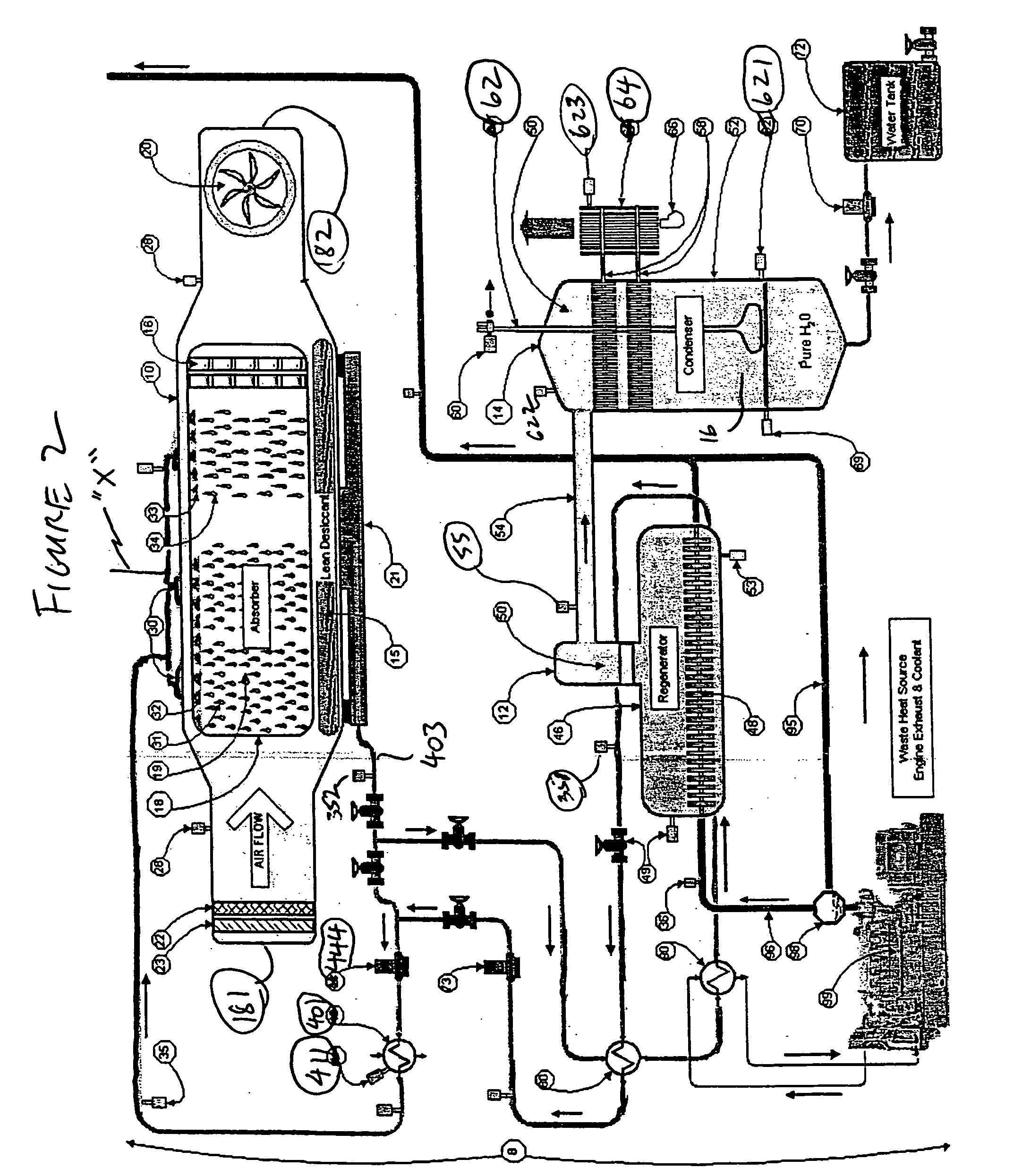

Method and apparatus for recovering water from atmospheric air

A method of separating water from air is provided comprising the steps of (a) contacting air having water vapour with an hygroscopic liquid mixture to produce a water rich hygroscopic liquid mixture, (b) heating at least a portion of the water rich hygroscopic liquid mixture to produce a gaseous mixture including water vapour and at least one other gaseous component, (c) condensing at least a portion of the water vapour in the gaseous mixture to produce liquid water and a depleted gaseous mixture at a first pressure, and (d) removing at least a portion of the at least one other gaseous component to maintain the first pressure below a predetermined pressure, wherein the depleted gaseous mixture is in fluid communication with the water rich hygroscopic liquid mixture. An absorber vessel is also provided for effecting the method of separating water from air.

Owner:KING RONALD +1

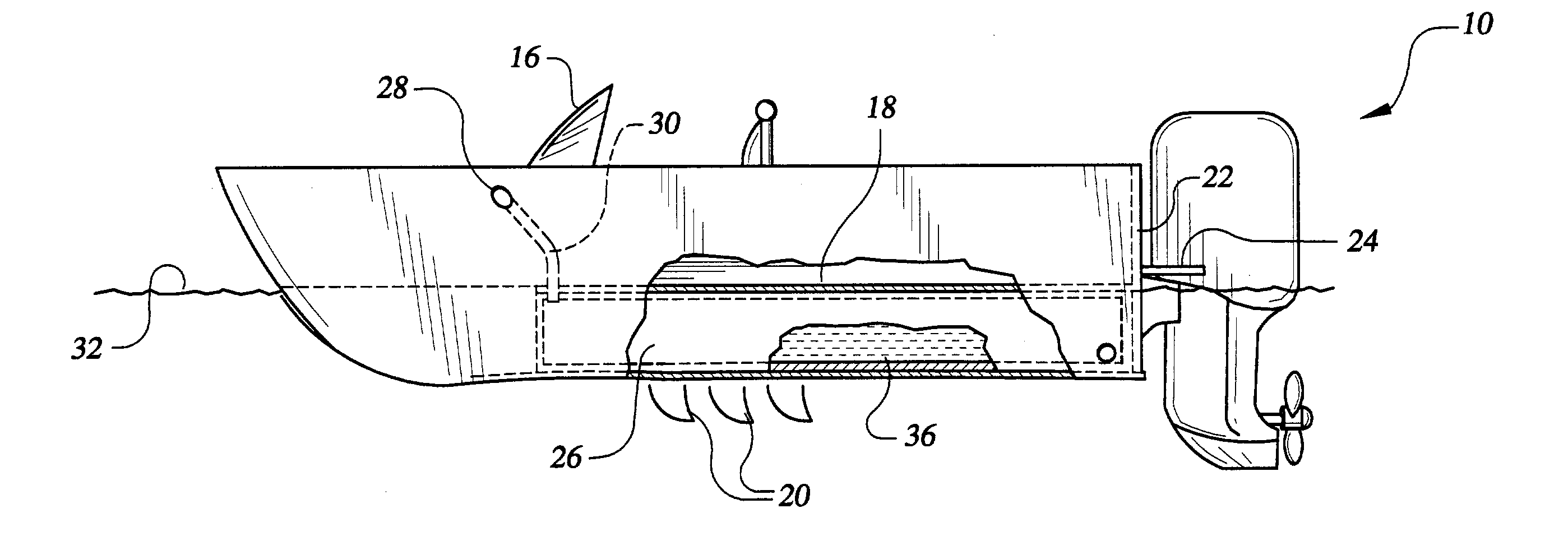

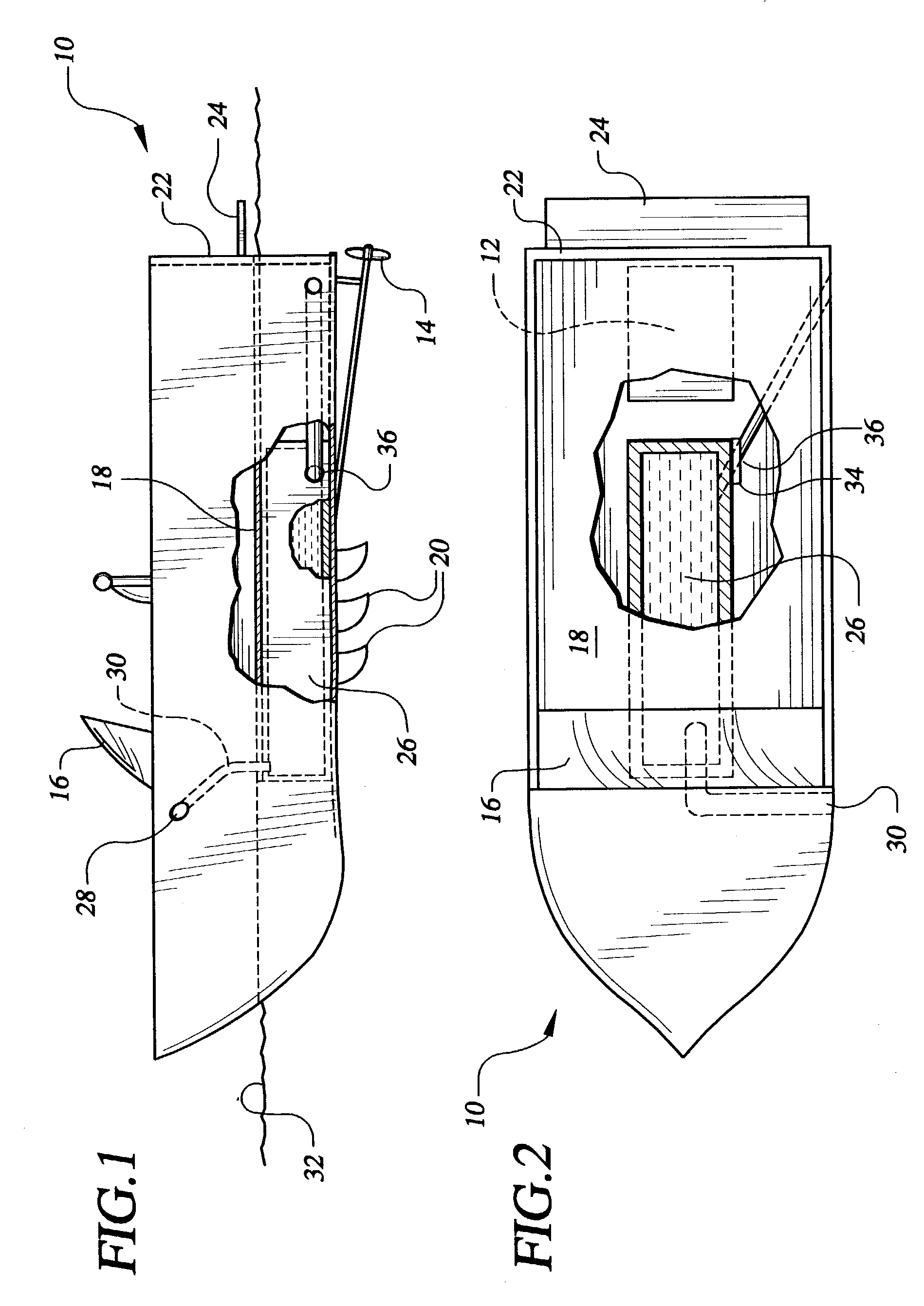

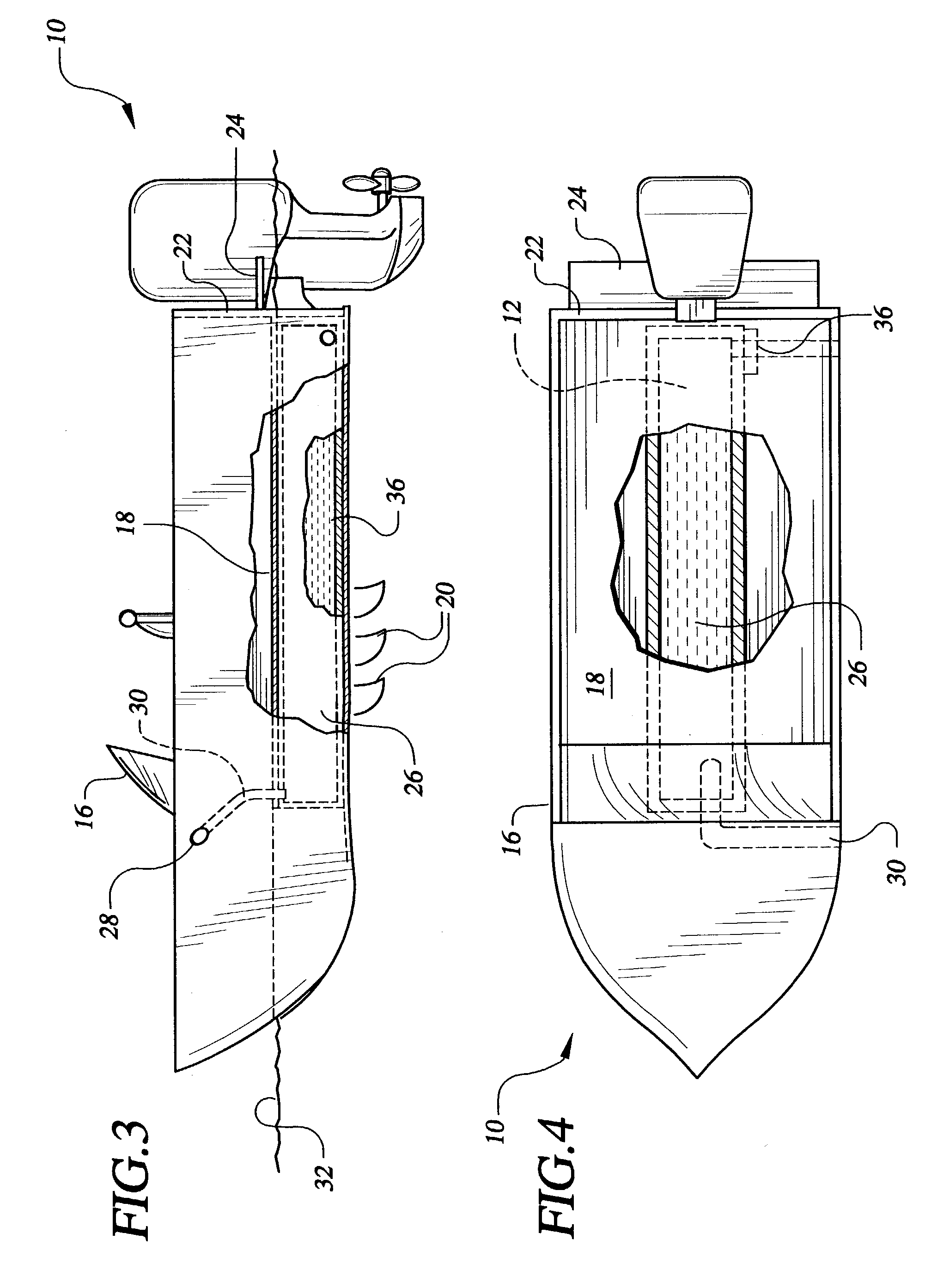

Boat wake system

InactiveUS6953002B2Enhance wake sizeIncrease speedWatercraft hull designVessel partsKeelLiquid water

A water craft having a bow and a stern including an engine of sufficient thrust to create an enlarged wake at the stern of the boat as the boat moves along the surface of a body of water.The water tight compartment is positioned to carry water below the water line and essentially astride the centerline or keel of the boat. The compartment is adapted to contain liquid water in an amount sufficient to enhance or equalize the size of the boat wake.The compartment extends from a point forward of the transom and engine, and extends to a point forward of the midpoint between the bow and the stern, and terminates short of the bow while serving to exert downward force on the bow against the water when the water craft is underway and the compartment carries water.

Owner:MIKE MURPHYS ENTERPRISES

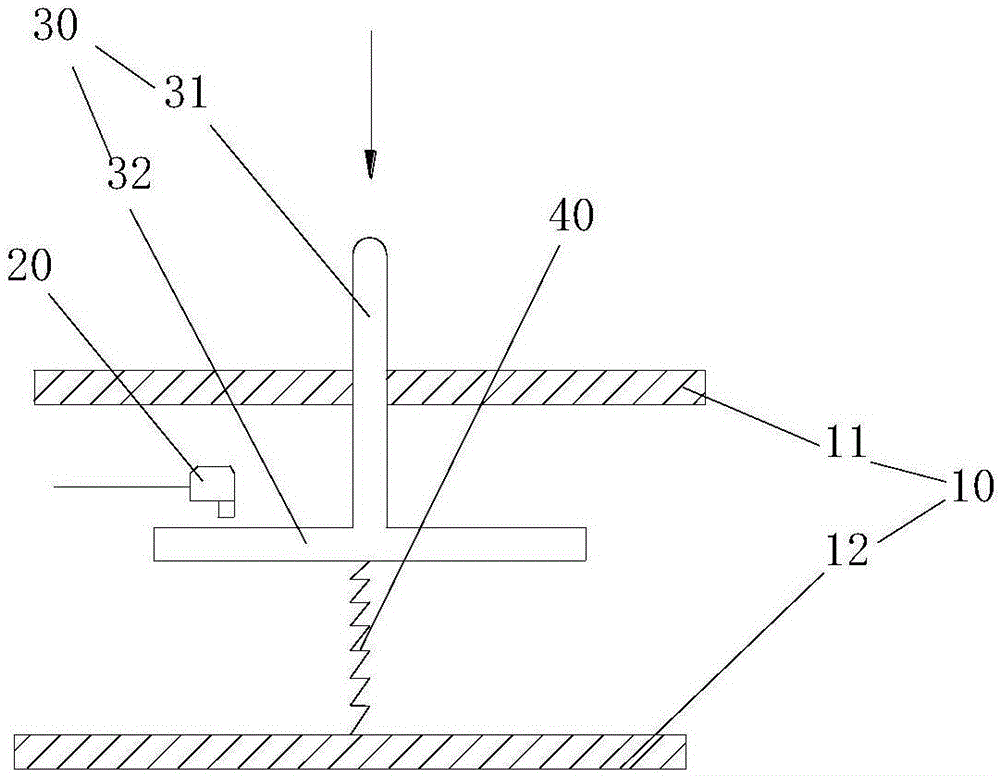

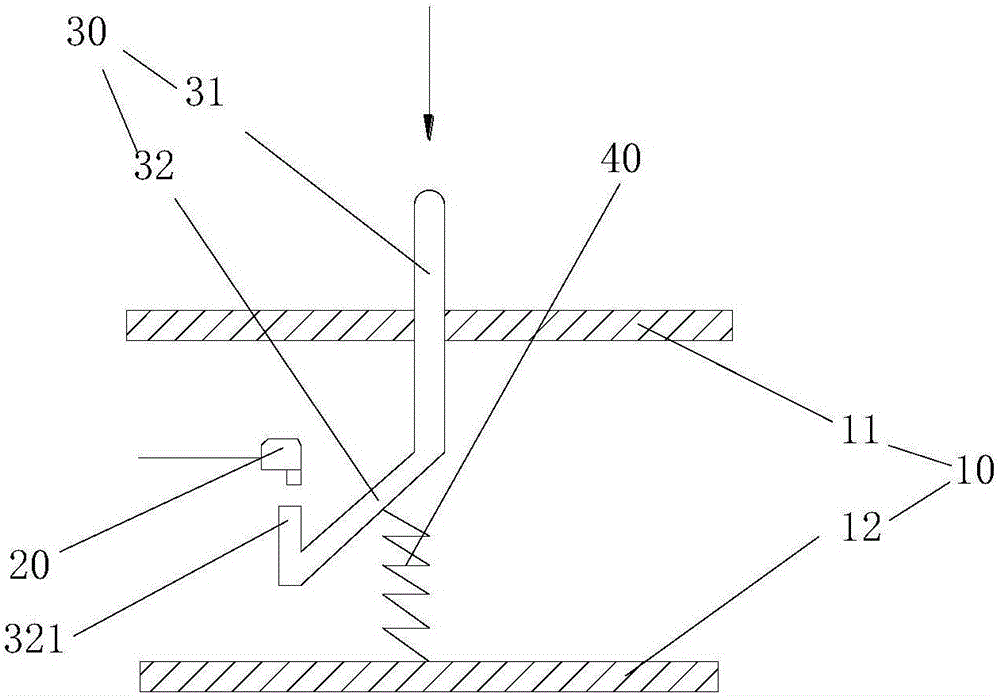

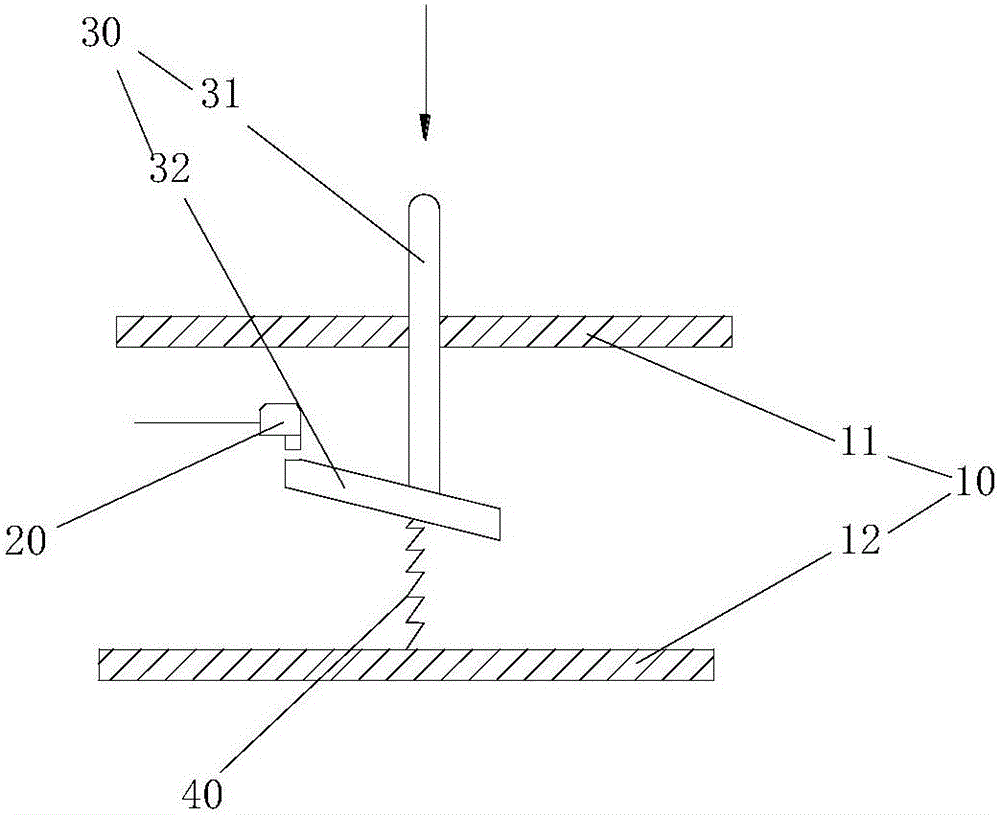

Cover detection devices and electric pressure cookers with the same

ActiveCN106419520AAvoid failureAvoid contactMeasurement devicesPressure-cookersPressure transmissionLiquid water

The invention provides a cover detection device and an electric pressure cooker with the same. The cover detection devices includes a body, an induction device which is arranged on the body, and a pressure transmitting device which is arranged on the body movably. A contact part contacted with the induction device is arranged on the press transmitting device. The pressure transmitting device has a first position contacted with the induction device and a second position separated with the induction device, and the induction device is above the contact part. The induction device of cover detection devices and electric pressure cookers with the same is above the contact part. When the liquid water flows from the pressure transmission device, the liquid water can be effectively prevented from contacting with the induction device, so as to avoid the failure of the induction device.

Owner:GREE ELECTRIC APPLIANCES INC

Airless engine with gas and water recycling

InactiveUS7958872B1Low costEliminate the problemNon-fuel substance addition to fuelInternal combustion piston enginesLiquid waterTurbocharger

An internal-combustion engine receives no air from outside atmosphere. Instead, combustion gas expelled from the engine is cooled and recycled back into the engine. That gas contains no nitrogen and consists mostly of carbon dioxide and water vapor. Oxygen and fuel are added to the recycled gas, and the resulting mixture is used to perform an internal-combustion cycle. Cooling that gas condenses its water vapor, and liquid water is separated from the gas. That water is used for injection into the recycled gas at a later time. A small amount of the expelled combustion gas is discharged into outside environment, and the rest is recycled. Water too is recycled back into the engine, and whatever is lost to outside environment is replaced by reclaiming water produced in combustion. No additional supply of water is needed. Since no nitrogen is present, no nitrogen oxides are produced. The amount of other harmful exhaust emissions is greatly reduced too, since most of them are recycled back into the engine. Water evaporation in the cylinders greatly improves fuel economy. The engine is inherently supercharged with combustion-gas pressure, and no turbocharger is needed. Since the combustion gas is heavier than air, the engine can be substantially smaller than a conventional engine of equal power. A smaller engine has less friction.

Owner:SCHECHTER MICHAEL MOSES

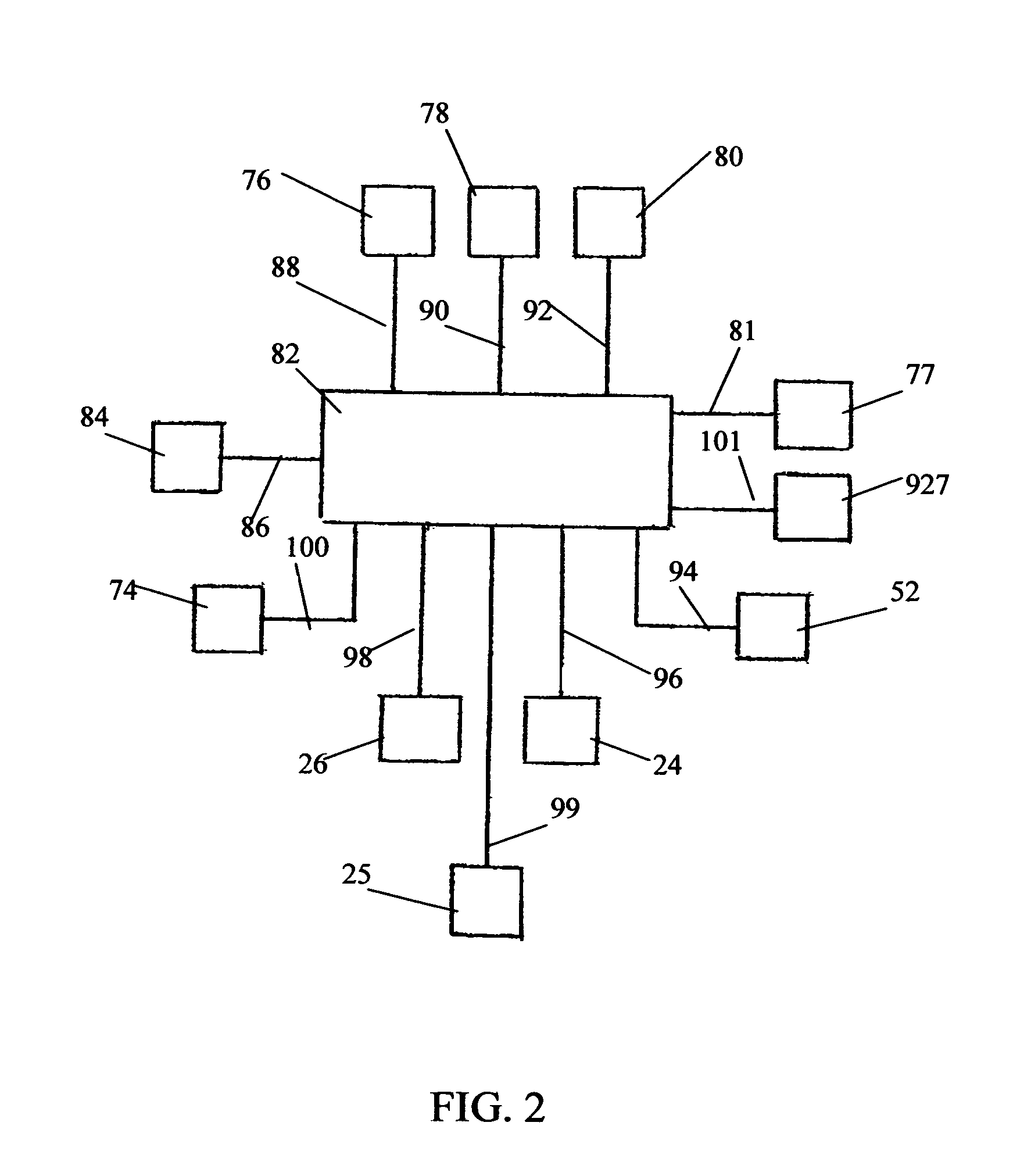

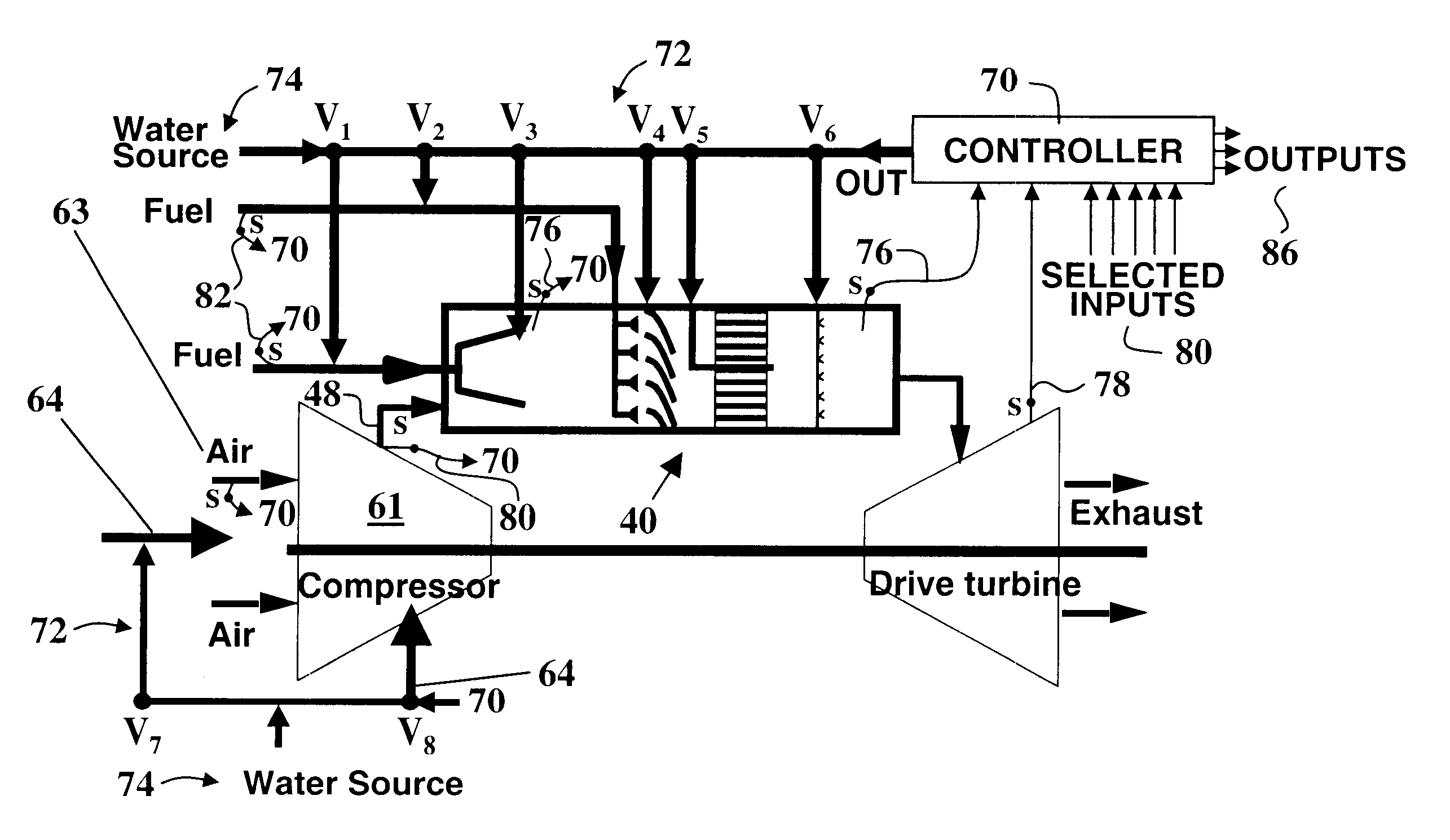

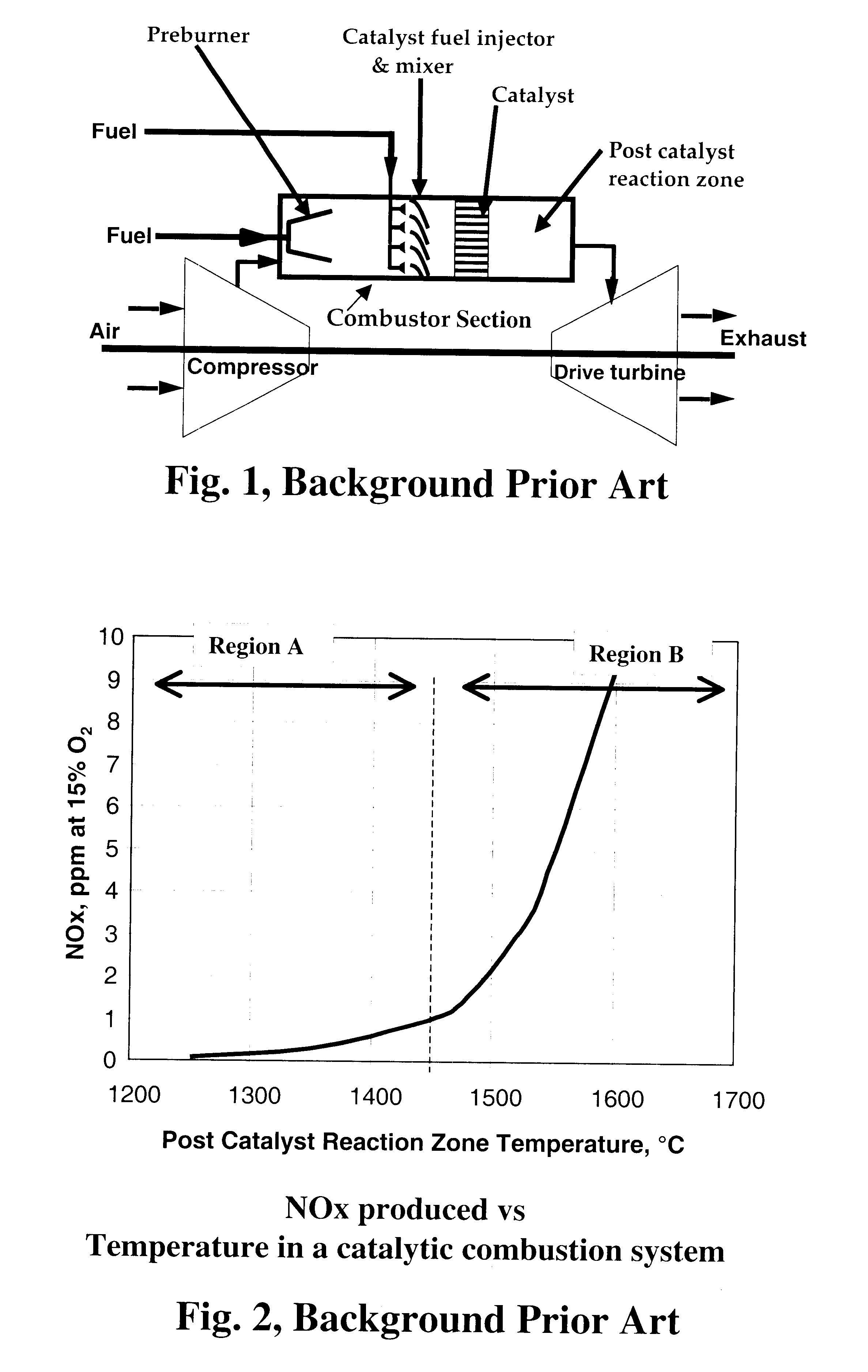

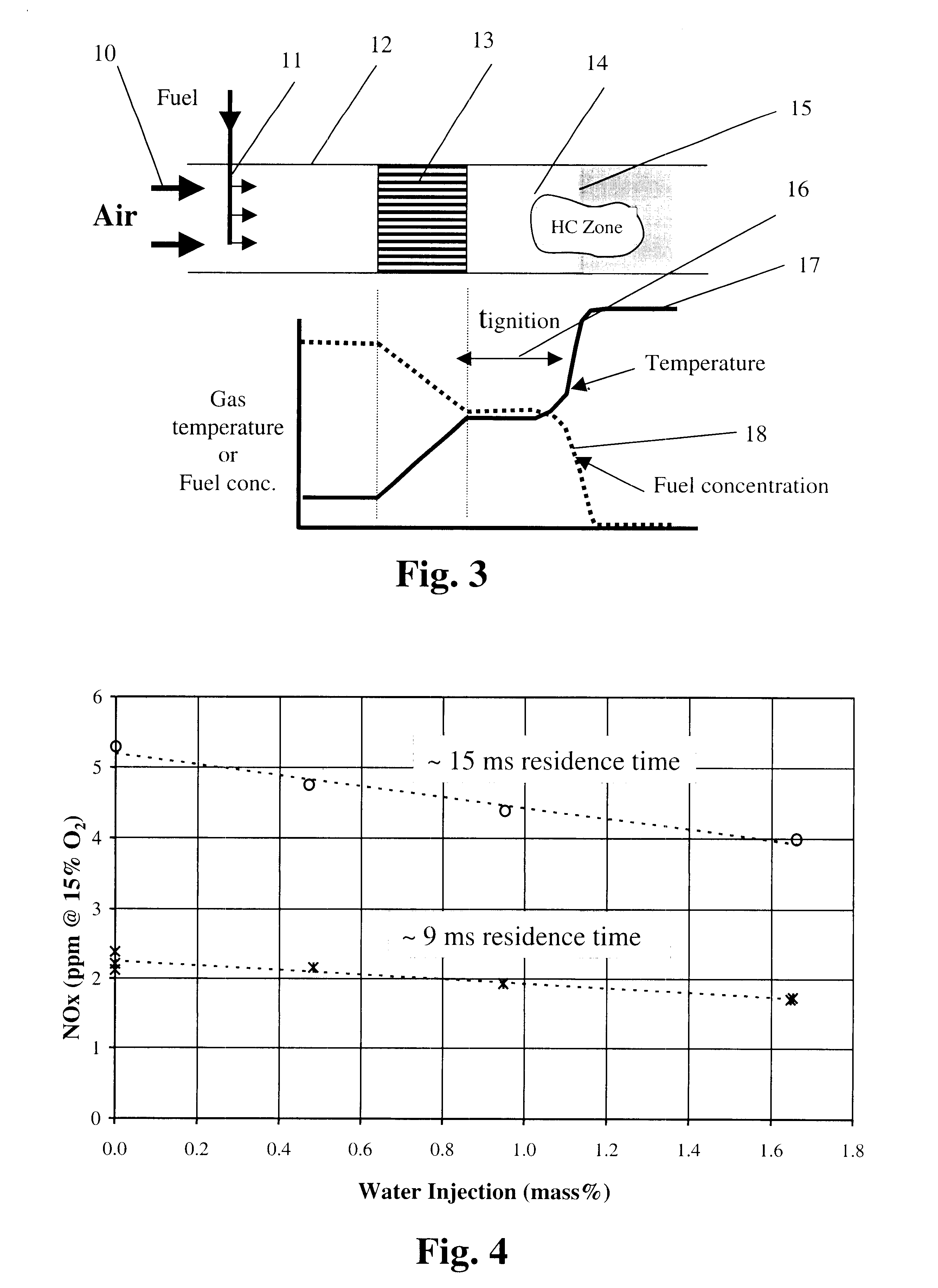

Process and apparatus for control of NOx in catalytic combustion systems

InactiveUS6595003B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemLiquid water

Methods and apparatus for control of NOx in catalytic combustion systems, and more particularly to control of thermal or / and prompt NOx produced during combustion of liquid or gaseous fuels in the combustor sections of catalytic combustor-type gas turbines, by controlled injection of water in liquid or vapor form at selected locations, orientations, amounts, rates, temperatures, phases, forms and manners in the compressor and combustor sections of gas turbines. The ratio of thermal NOx ppm reduction to water addition, in weight %, is on the order of 4-20, with % NOx reduction on the order of up to about 50-80% and NOx of below 2 ppm. Liquid water, steam or superheated steam can be used to reduce NOx in combustion systems operating at reaction zone temperatures above 900° C., preferably 1400° C. to 1700° C. The amount of water added is sufficient to provide a concentration of water in the range of from about 0.1% to about 20% by weight of the total air and fuel mixture flowing into the post catalyst reaction zone. Water is introduced simultaneously or sequentially in a plurality of locations, at selected rates, amounts, temperatures, forms, and purity, preferably in accord with a suitable control algorithm.

Owner:KAWASAKI HEAVY IND LTD

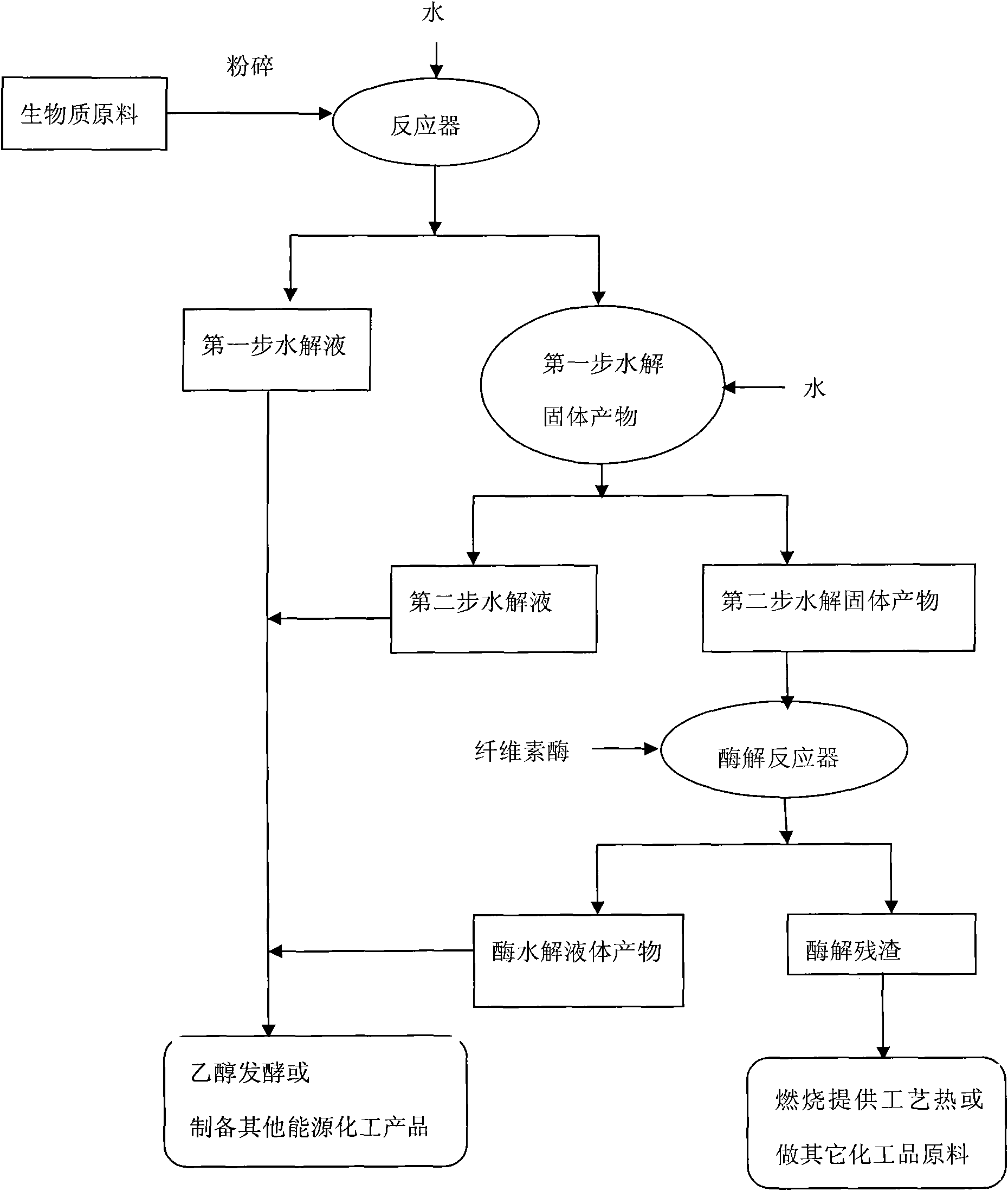

Method of high-efficiency pretreatment on biomass

InactiveCN101586136AReduce degradationHigh recovery rateLignin derivativesOligosaccharidesPretreatment methodLiquid water

The invention discloses a method capable of carrying out green high-efficiency hydrolysis pretreatment on lignocellulose biomass. The method in the invention comprises the steps of hydrolyzing the hemicellulose in the cellulose biomass into saccharide products mainly containing xylose and oligose thereof using a two-step temperature-changing segmentation hydrolysis method so as to accomplish the pretreatment, and adding the pretreated solid raw material mainly containing cellulose and lignin to cellulase so as to accomplish enzymatic hydrolysis and recover the saccharide products to the utmost extent. The invention uses high-temperature liquid water as reaction medium, has the advantages that the method has low cost and is environment-friendly and green. The reaction conditions are moderate, the saccharide products are degraded less, and the recovery rate is high. By adopting the two-step temperature-changing segmentation hydrolysis method, the method not only hydrolyzes the hemicellulose to the utmost extent to obtain the saccharide products, but also further pre-treats the raw material such that the cellulose is made into glucose through enzymatic hydrolysis, reaching the purpose of protecting environment and hydrolyzing the lignocellulose biomass highly effectively. The raw material is capable of realizing waste utilization and promotes the development of green industries.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com