Patents

Literature

14352 results about "Air filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

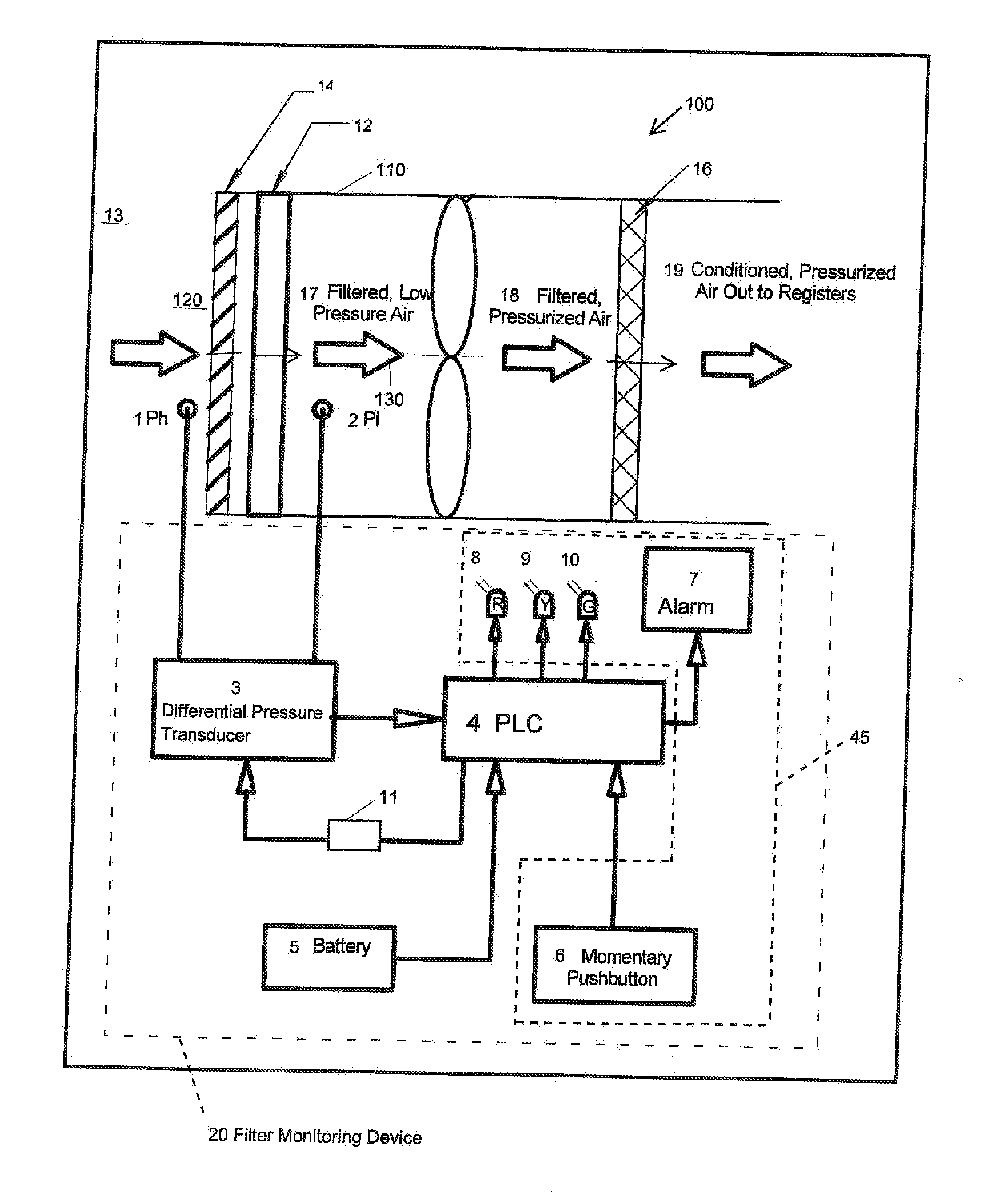

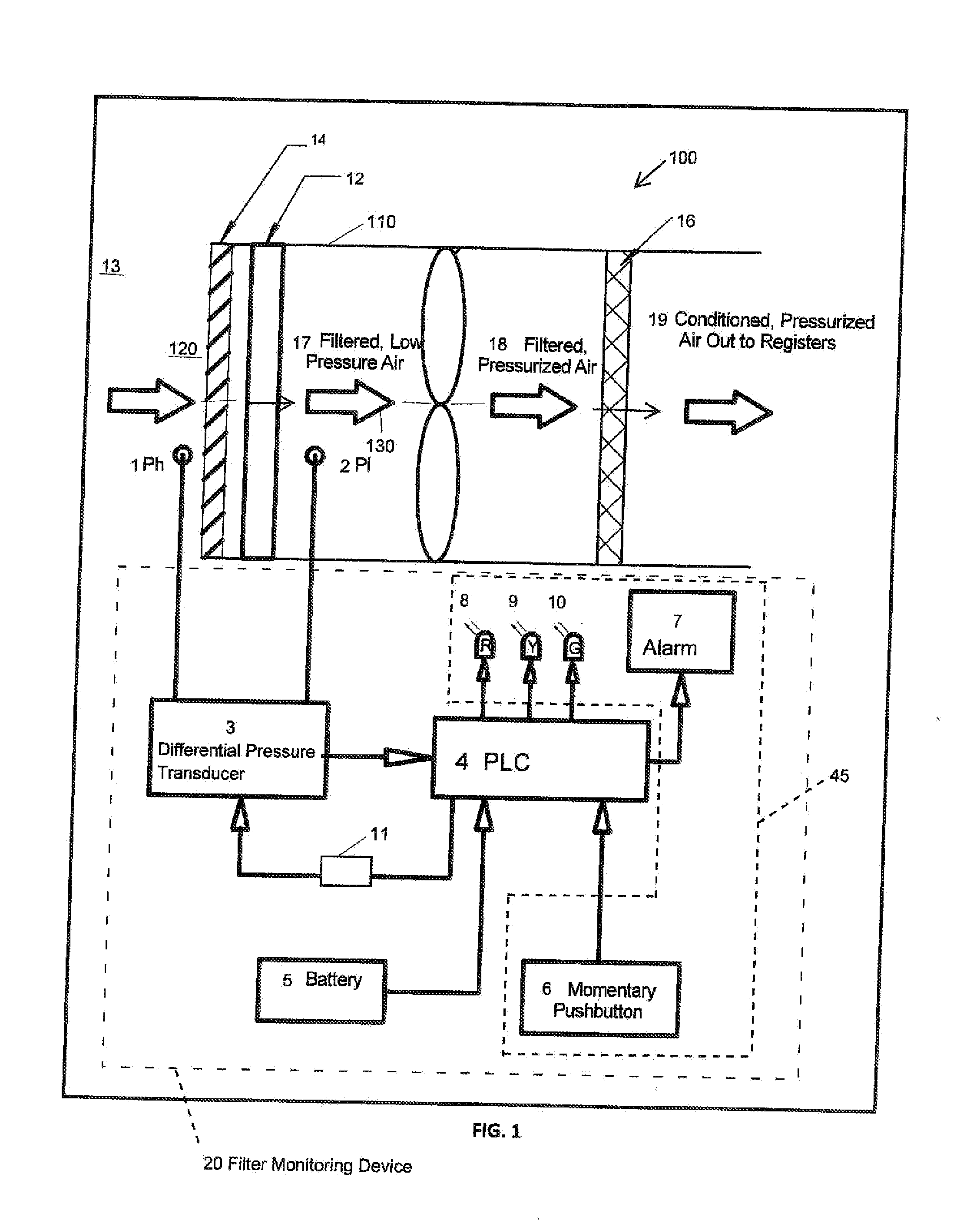

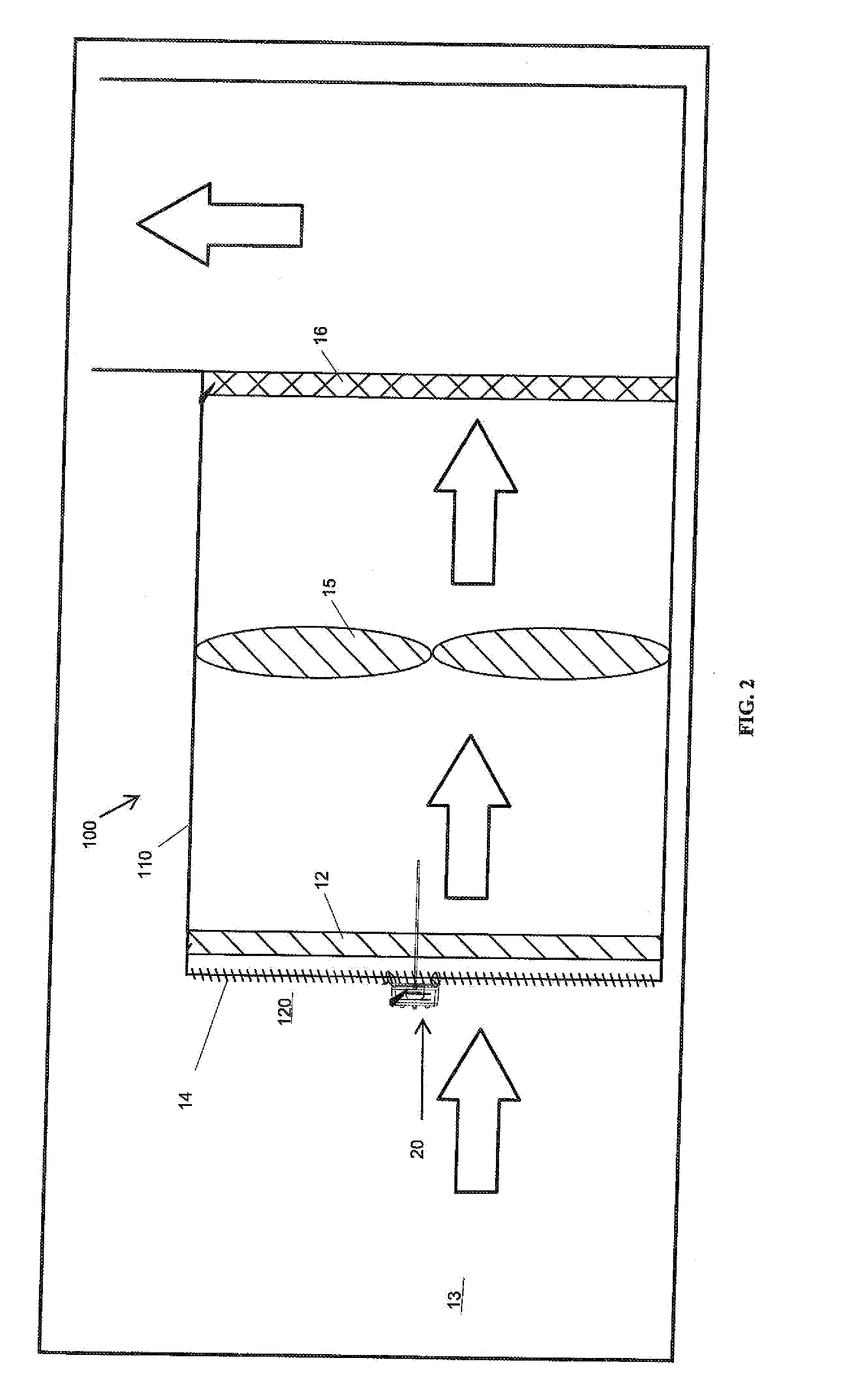

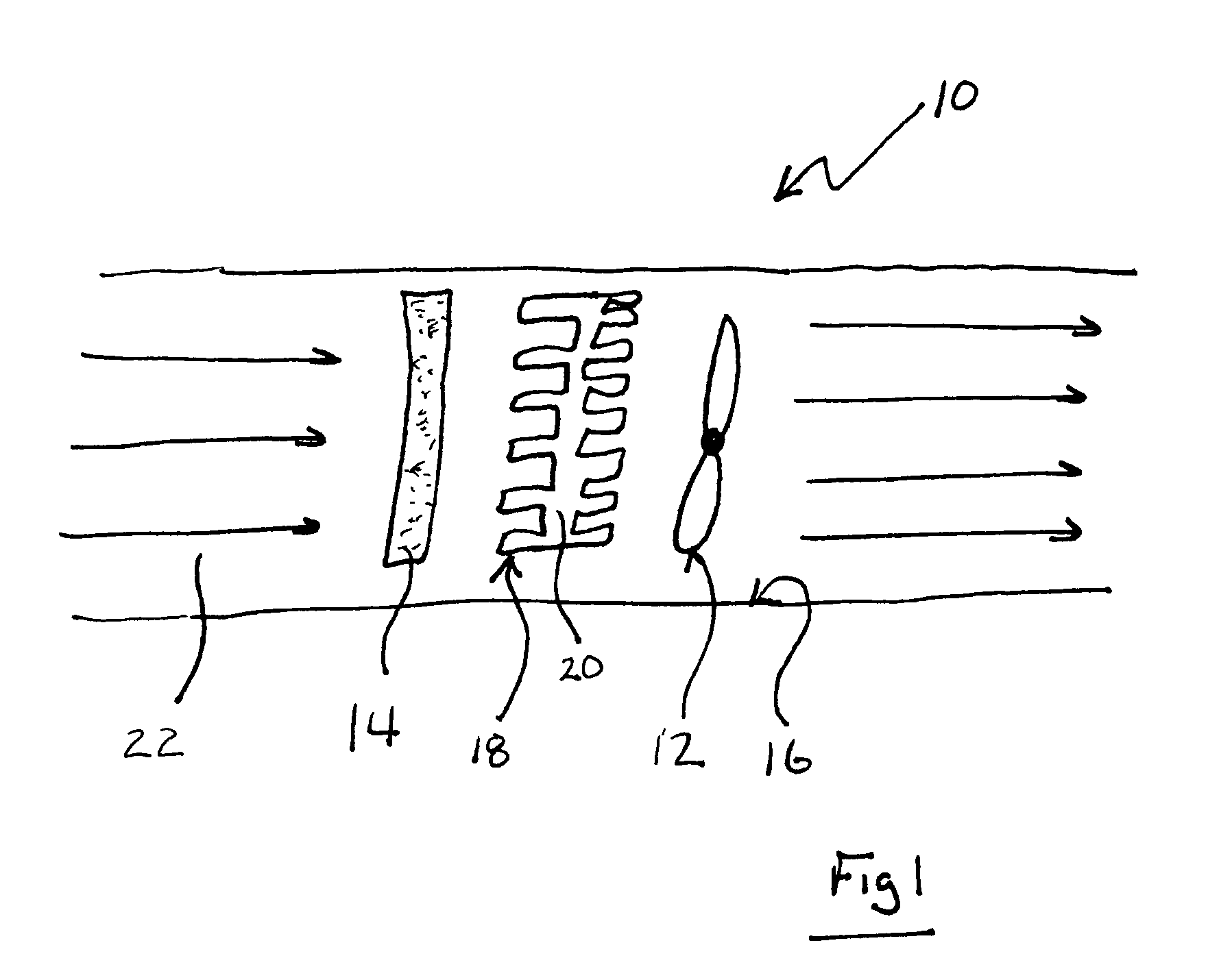

Filter apparatus and method of monitoring filter apparatus

Methods, systems, and products for monitoring an air filter. Methods involve determining a difference between a baseline pressure differential and a current pressure differential, the differential pressure between pressure at an upstream side of the filter and pressure at a downstream side of the filter. The baseline pressure differential may be set automatically or by a user. Reaching or exceeding a predetermined threshold triggers an indication of a clogged condition. The method also includes monitoring the air filter condition intermittently. The filter monitor may operate for extended periods in a sleep state and intermittently power up to a wake state to measure the current pressure differential and compare the current pressure differential with a baseline pressure differential.

Owner:FREEN PAUL

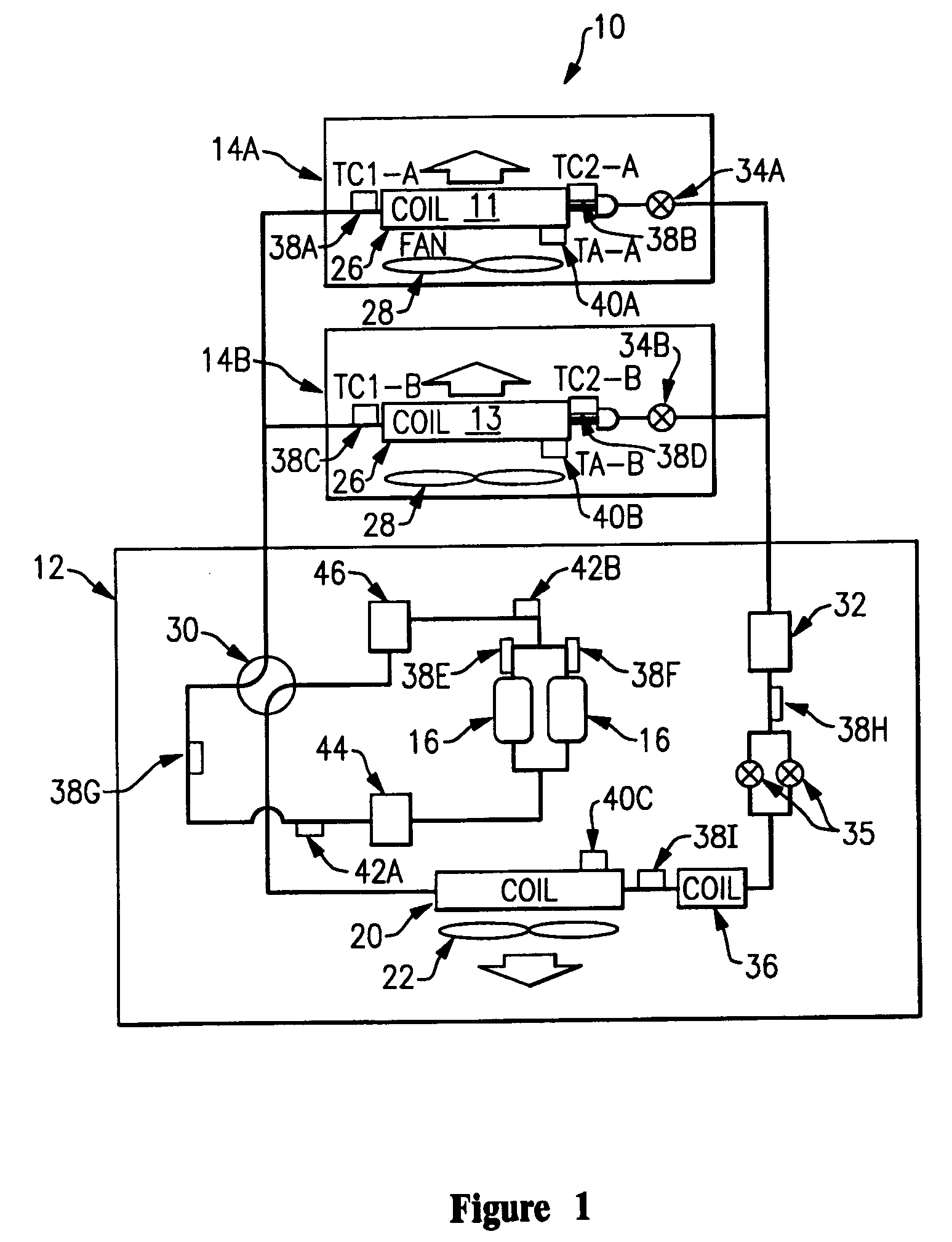

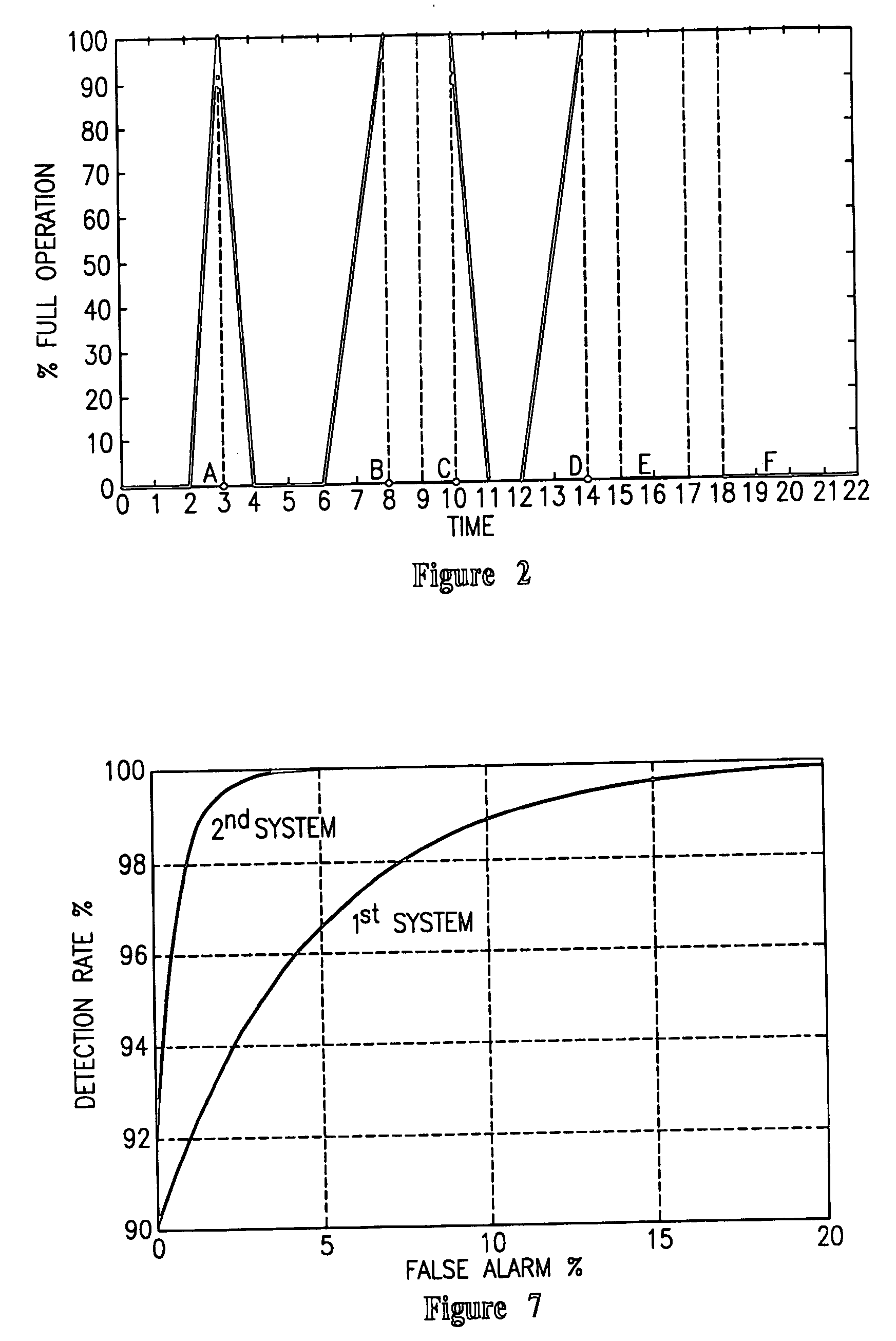

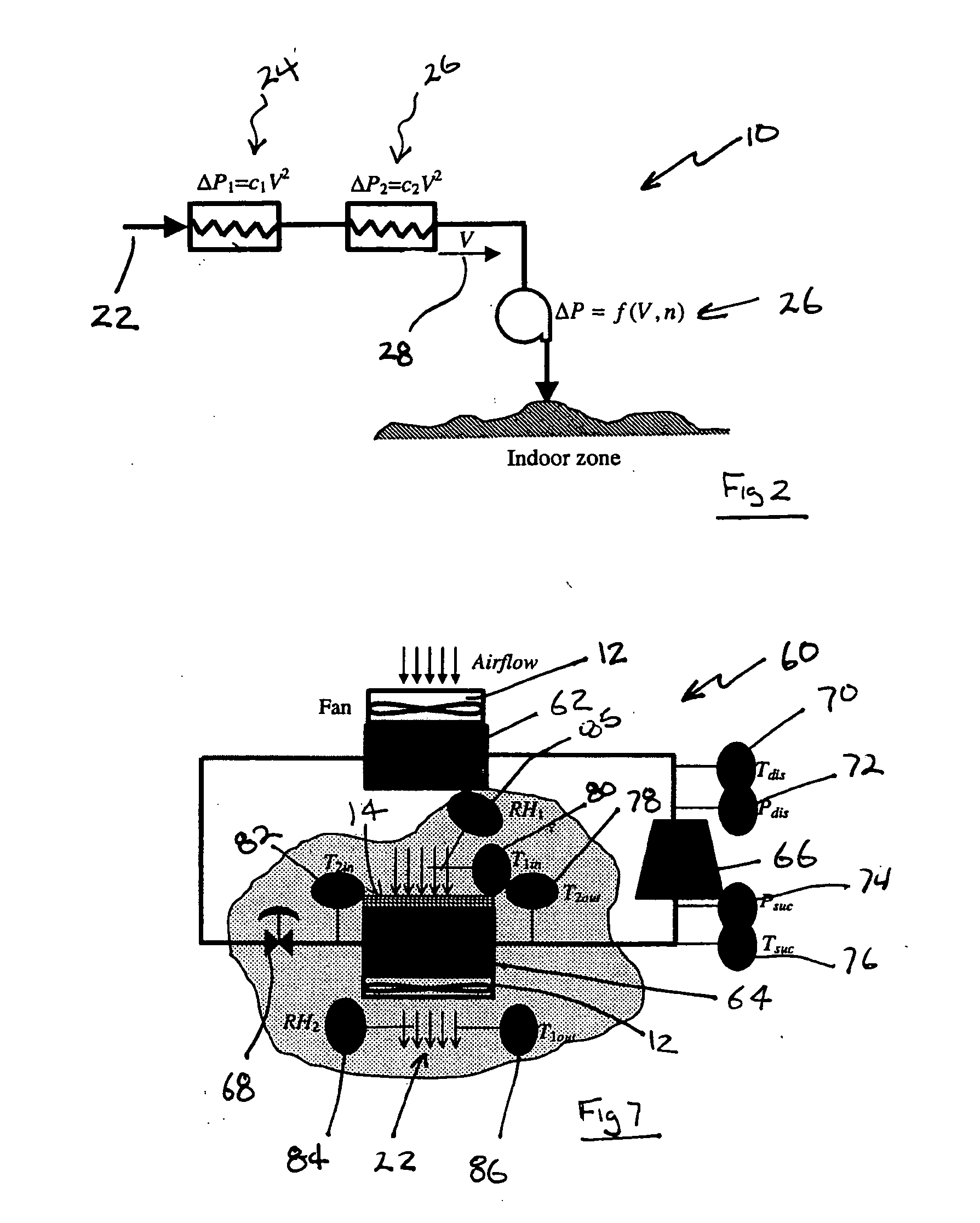

Fault diagnostics and prognostics based on distance fault classifiers

InactiveUS7188482B2Easy to interpret, calibrate and implementMaximize distanceAir-treating devicesSpace heating and ventilationOnline algorithmAir filter

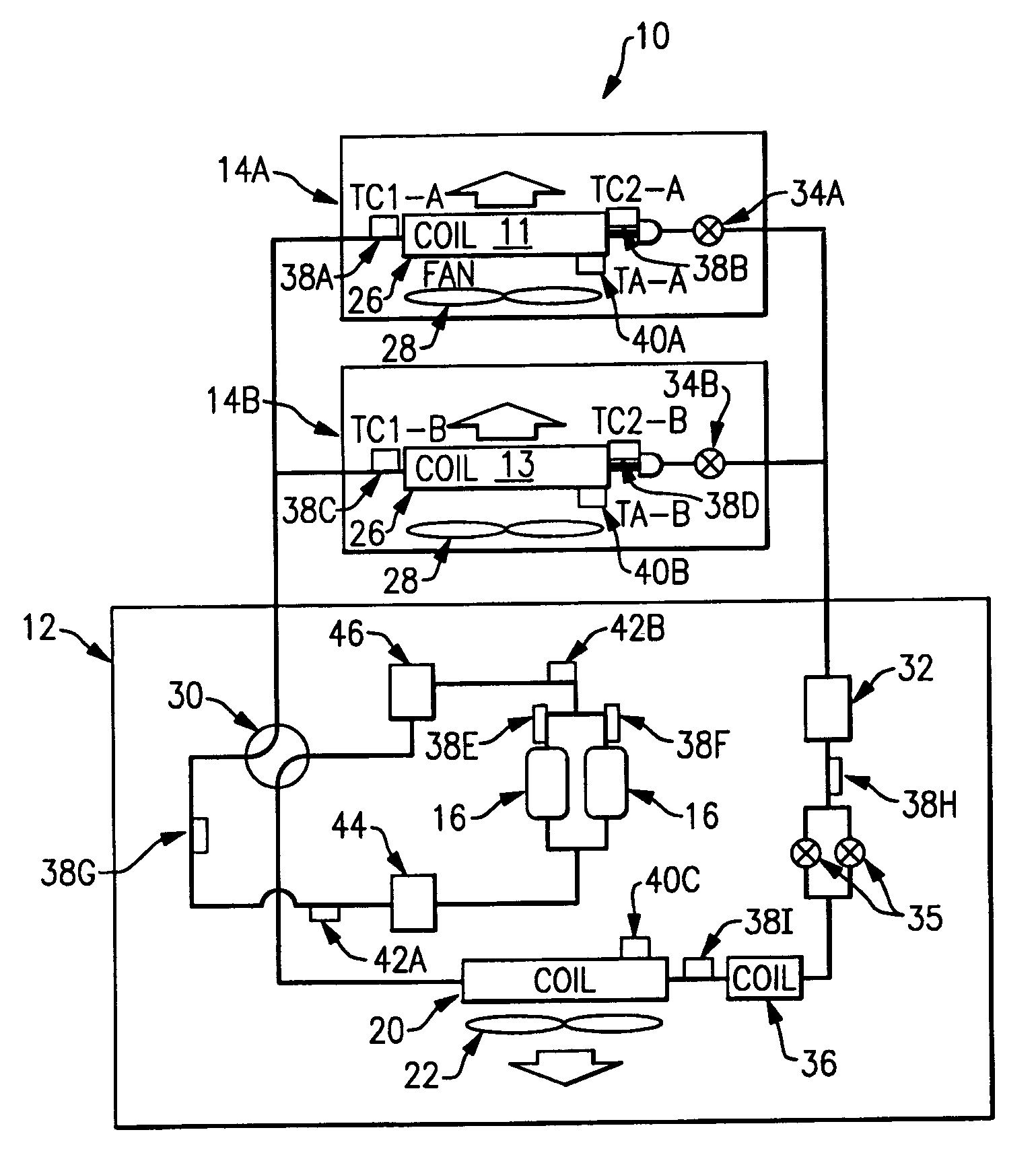

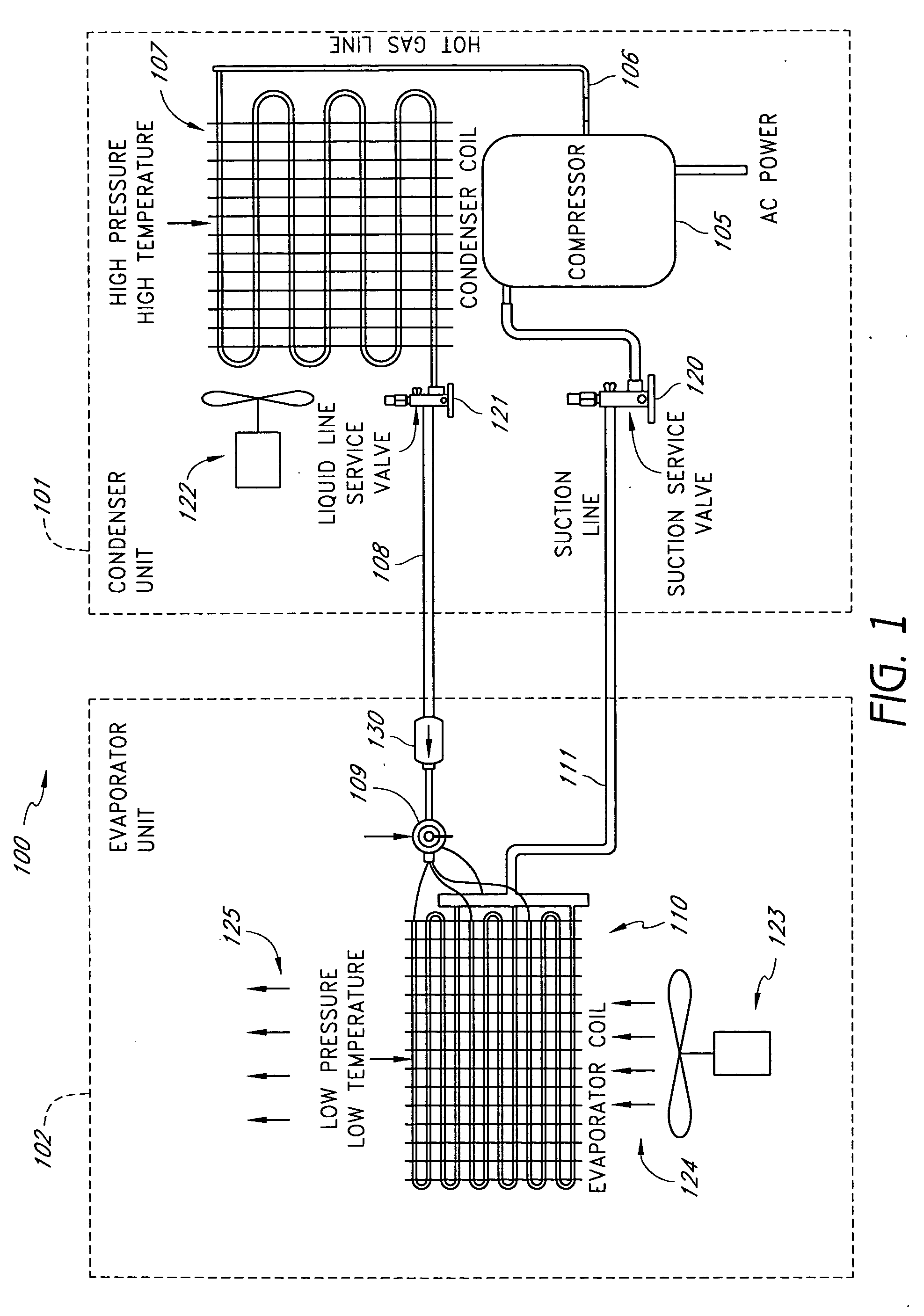

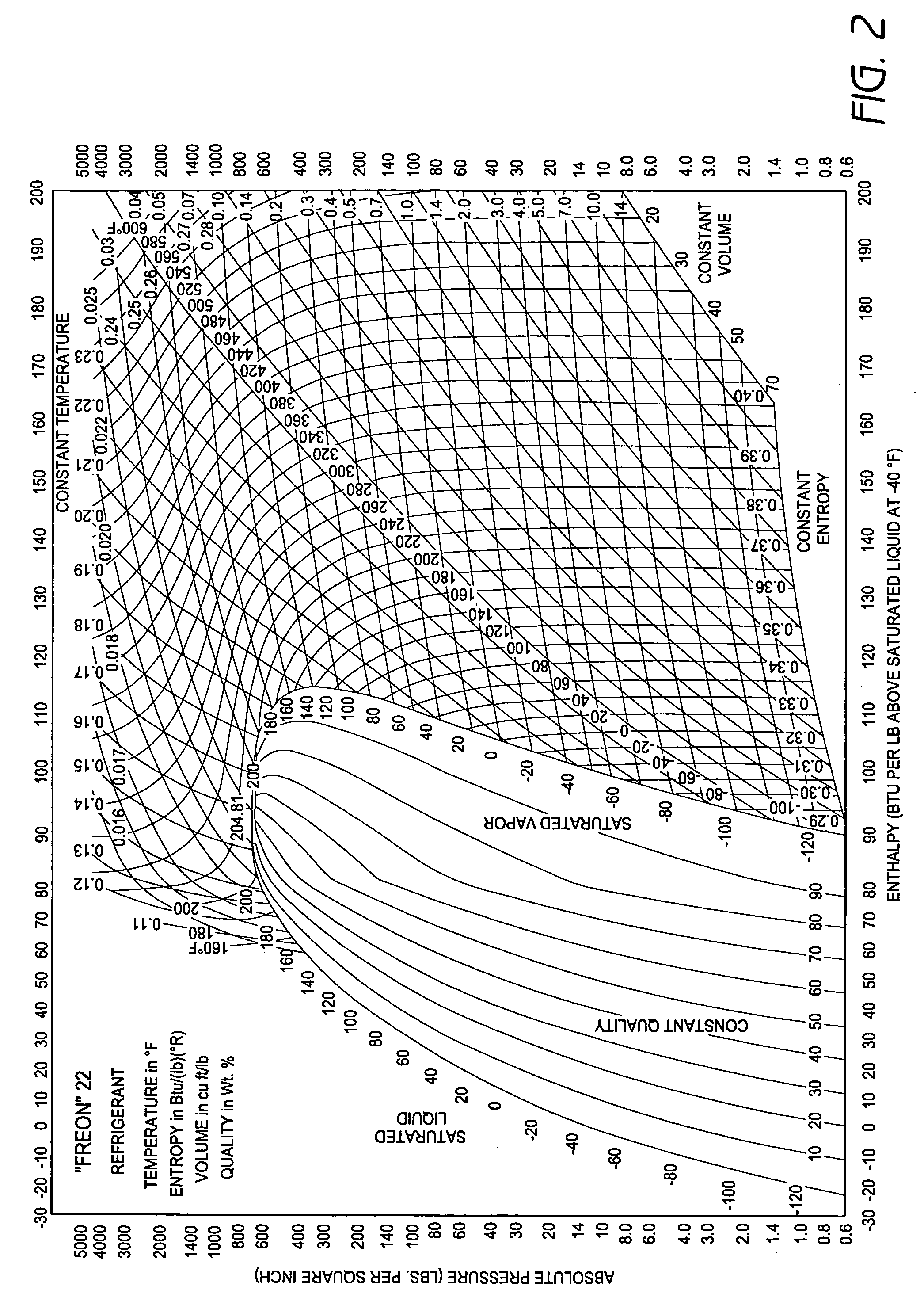

The present invention is directed to a mathematical approach to detect faults by reconciling known data driven techniques with a physical understanding of the HVAC system and providing a direct linkage between model parameters and physical system quantities to arrive at classification rules that are easy to interpret, calibrate and implement. The fault modes of interest are low system refrigerant charge and air filter plugging. System data from standard sensors is analyzed under no-fault and full-fault conditions. The data is screened to uncover patterns though which the faults of interest manifest in sensor data and the patterns are analyzed and combined with available physical system information to develop an underlying principle that links failures to measured sensor responses. These principles are then translated into online algorithms for failure detection.

Owner:CARRIER CORP

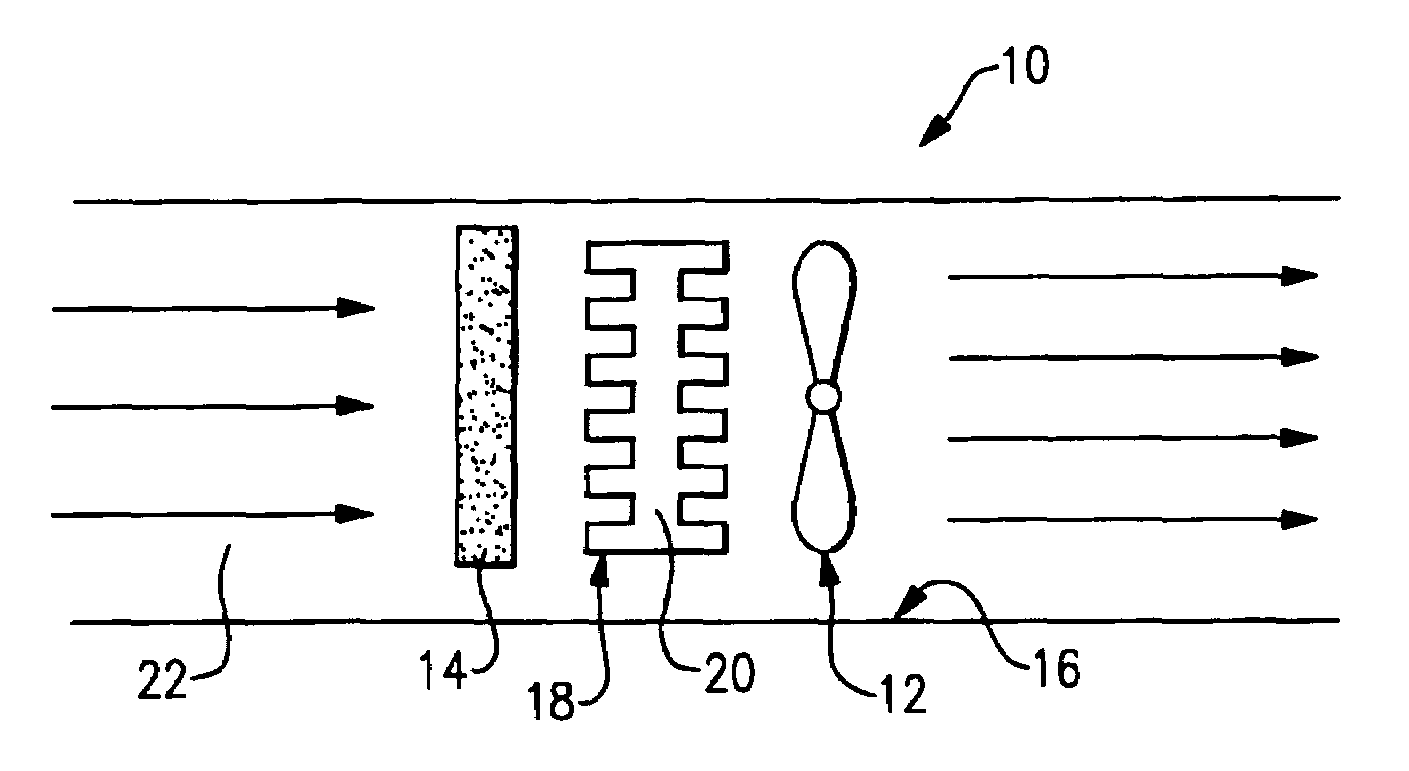

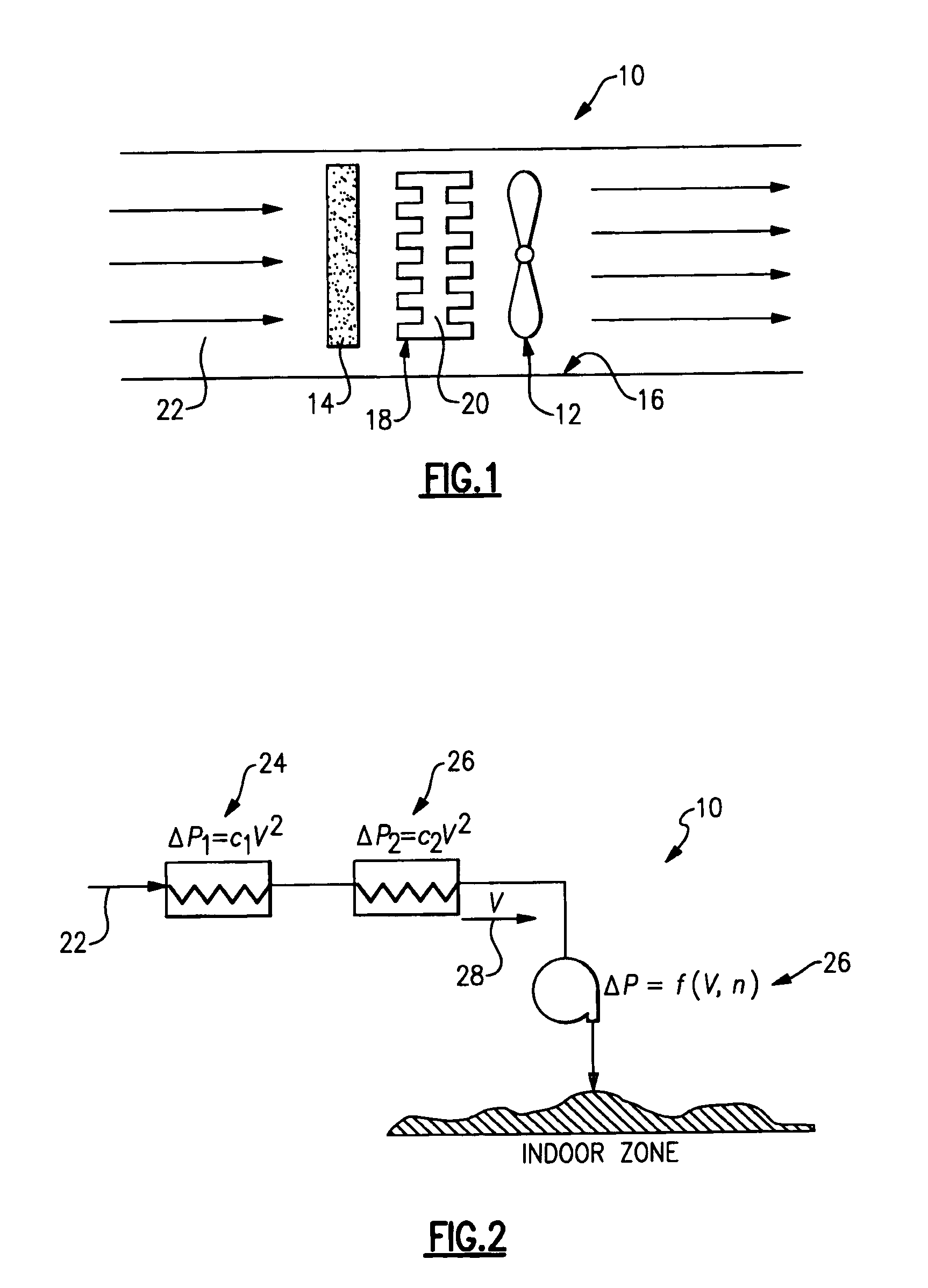

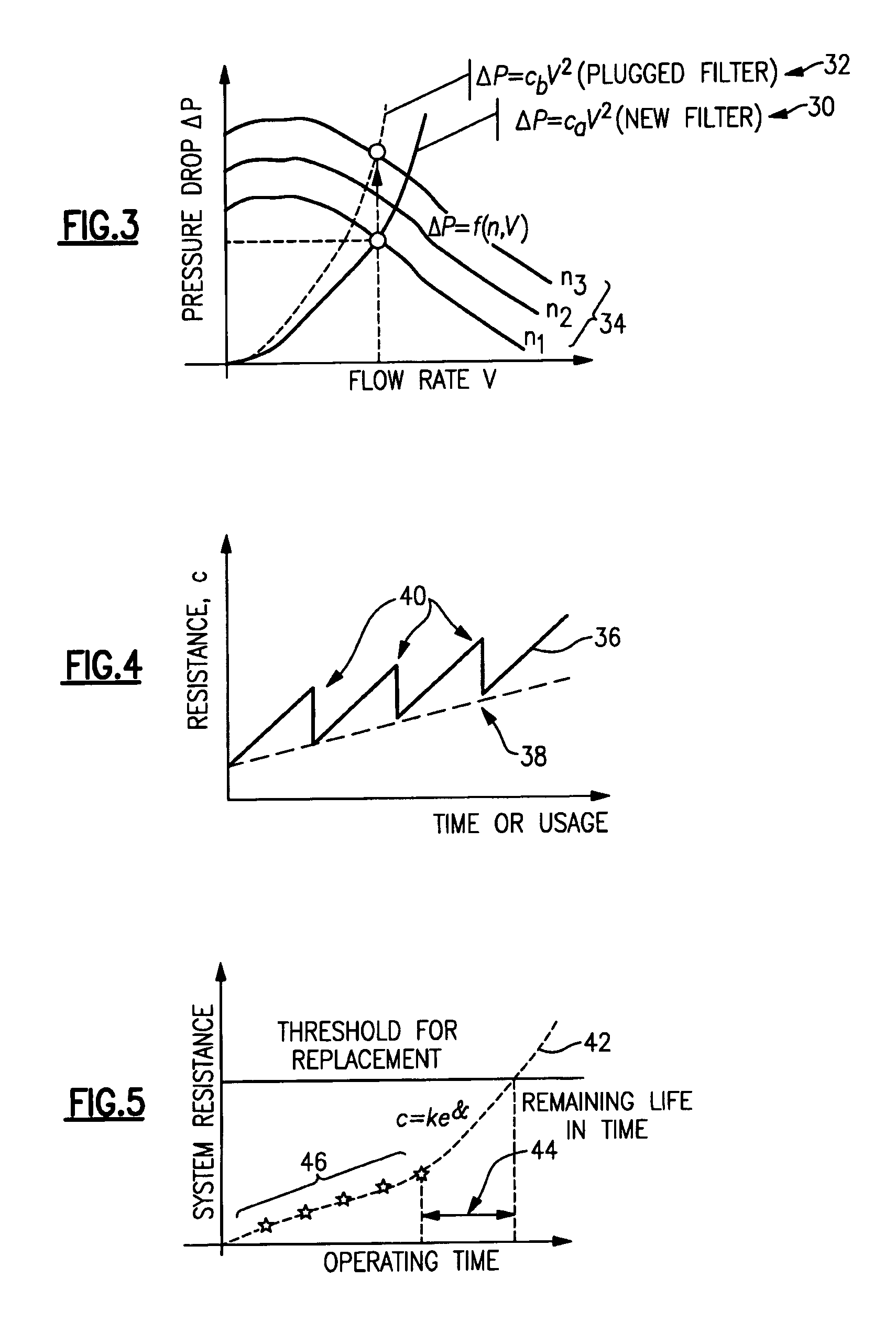

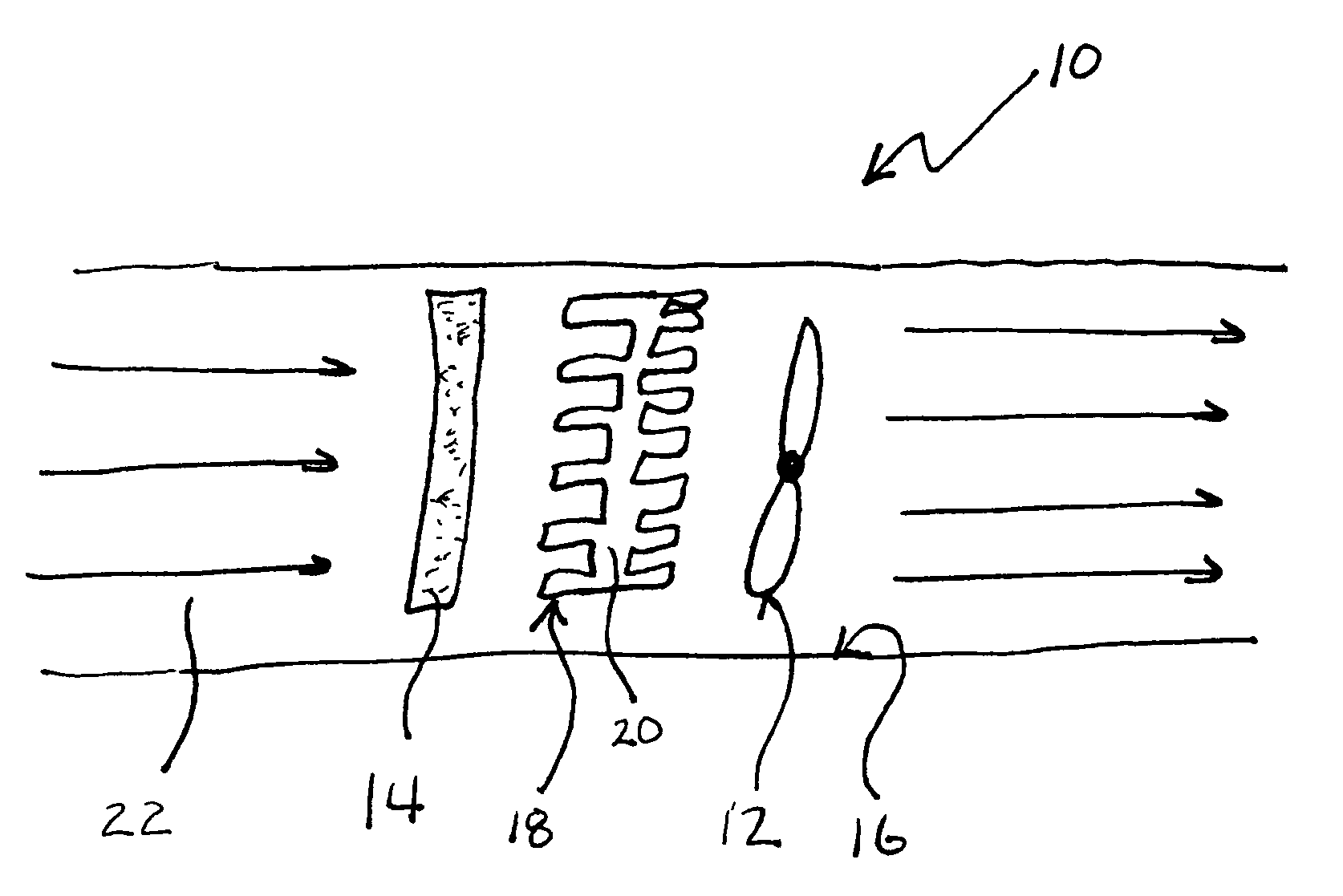

Technique for detecting and predicting air filter condition

InactiveUS7261762B2Combination devicesAuxillary pretreatmentElectrical resistance and conductanceAir filter

Owner:CARRIER CORP

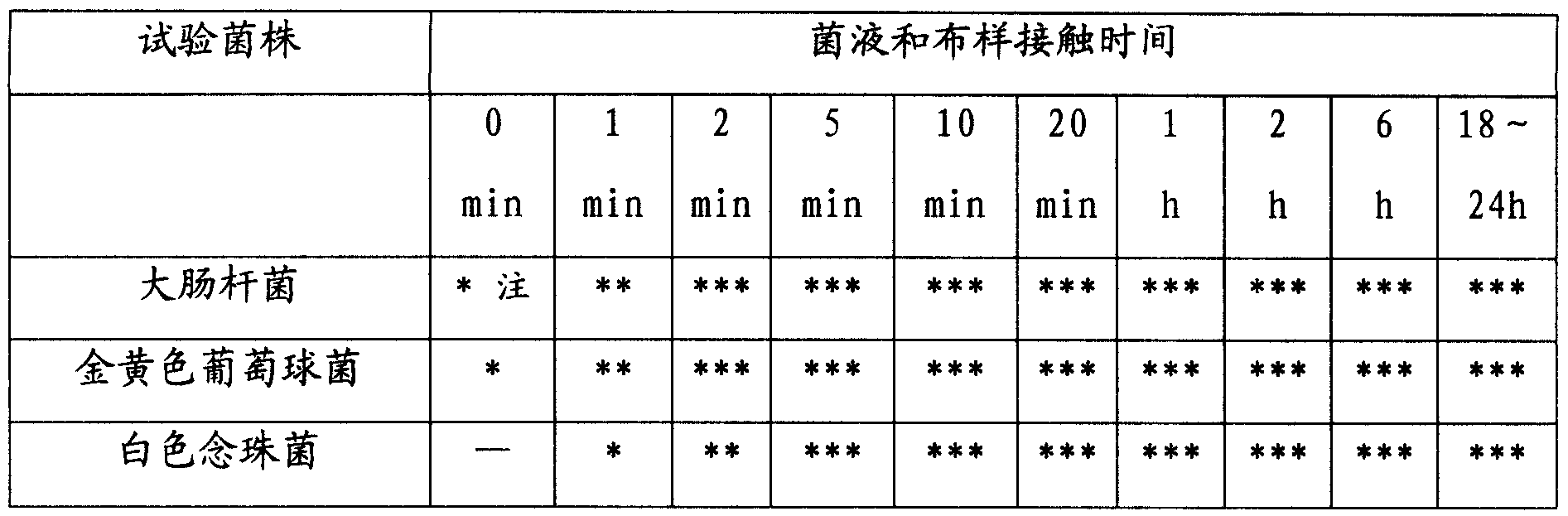

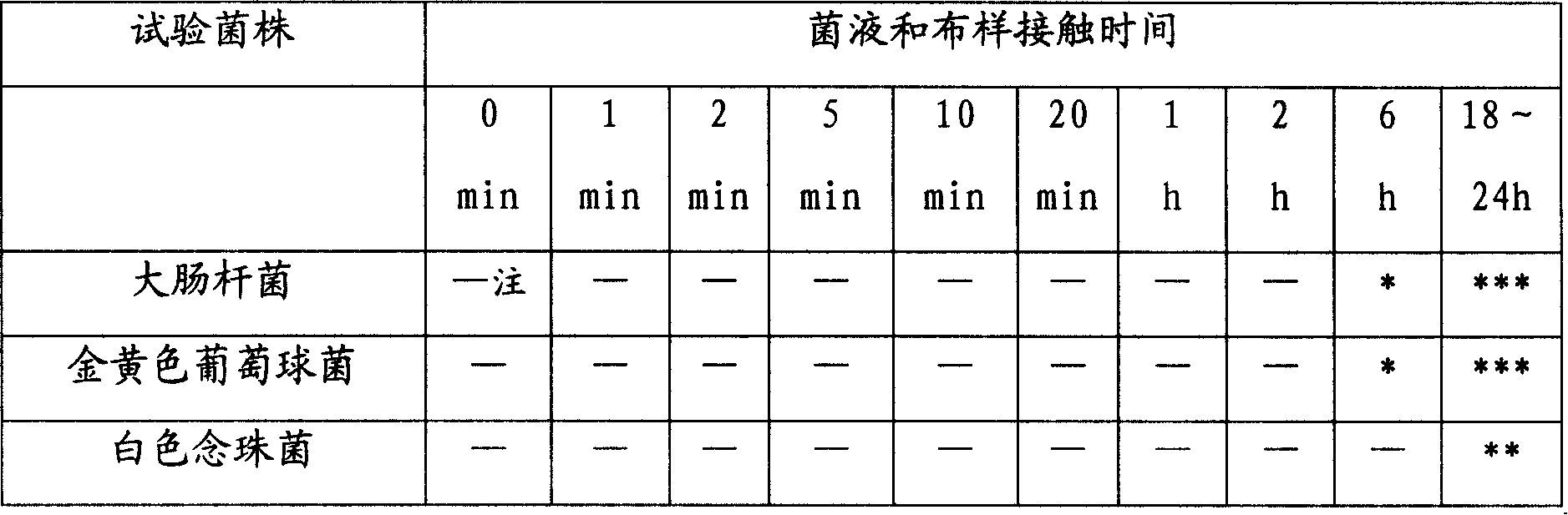

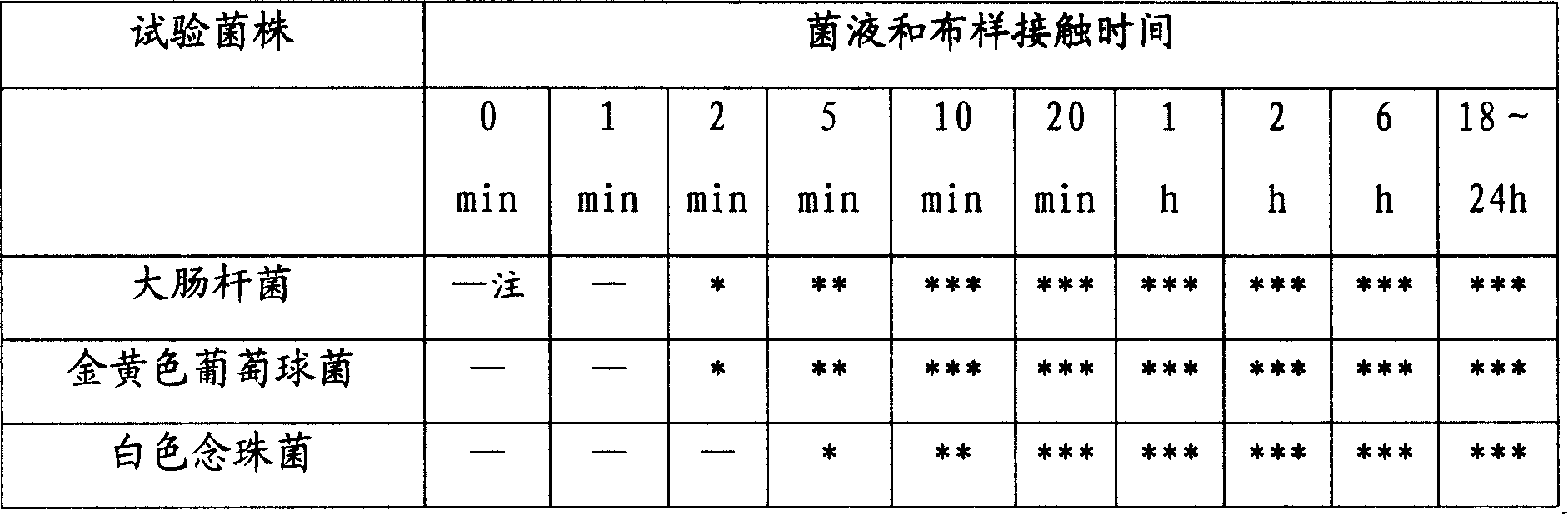

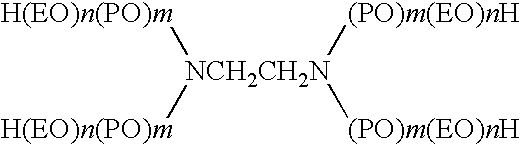

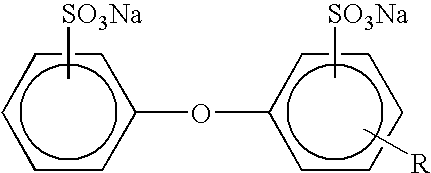

Inorganic/organic nano composite antibacterial agent and its fabric product application

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

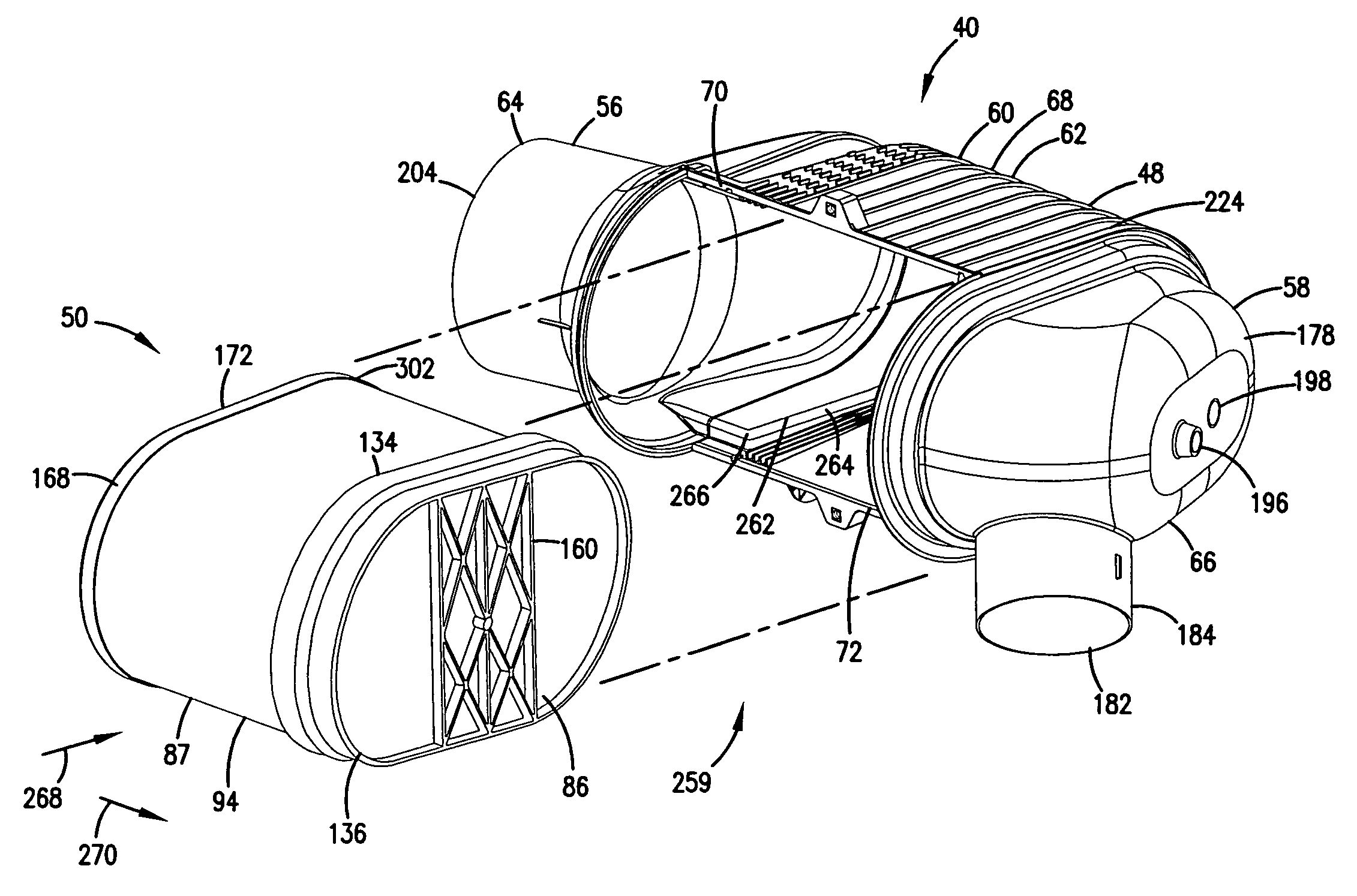

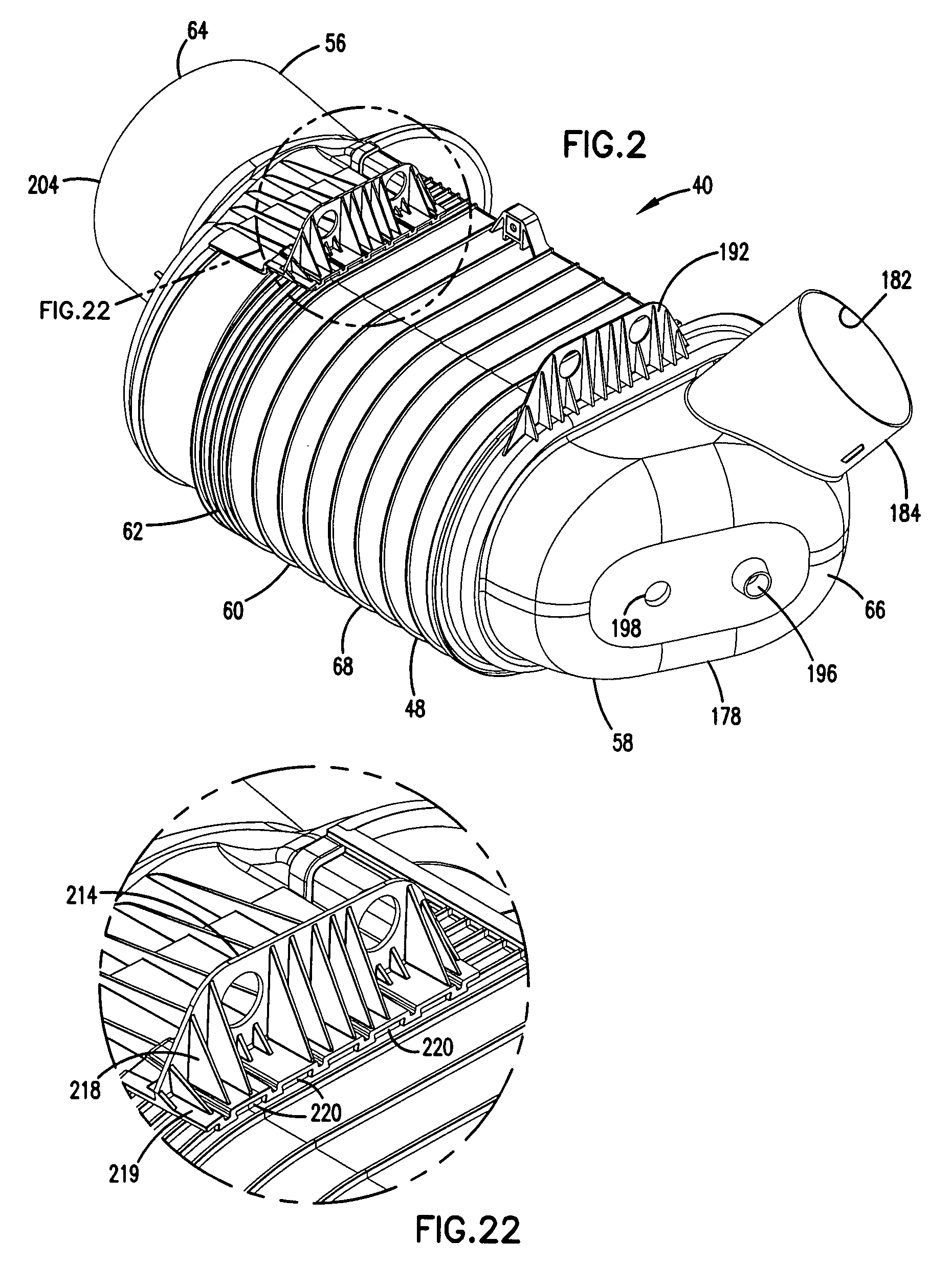

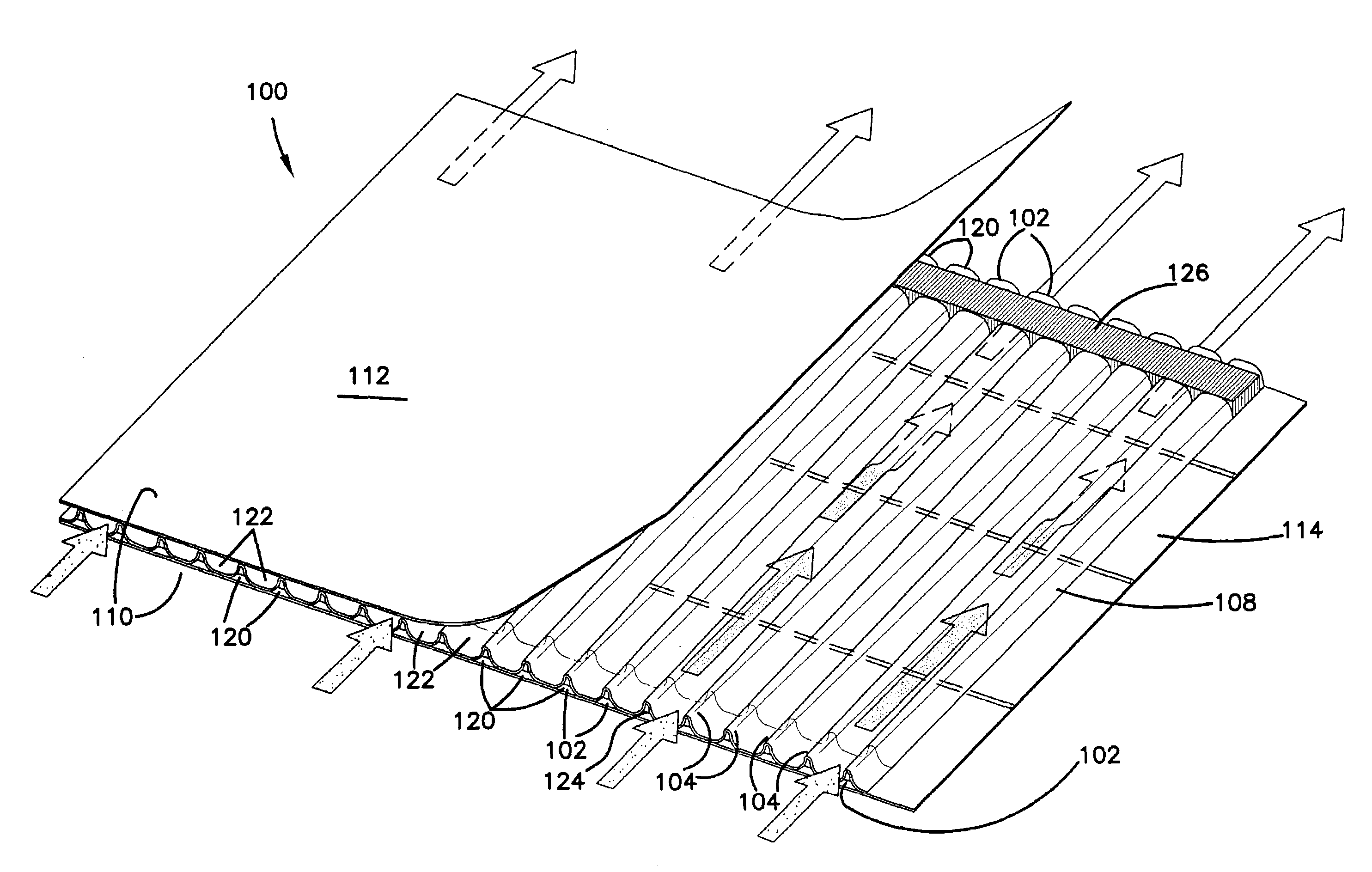

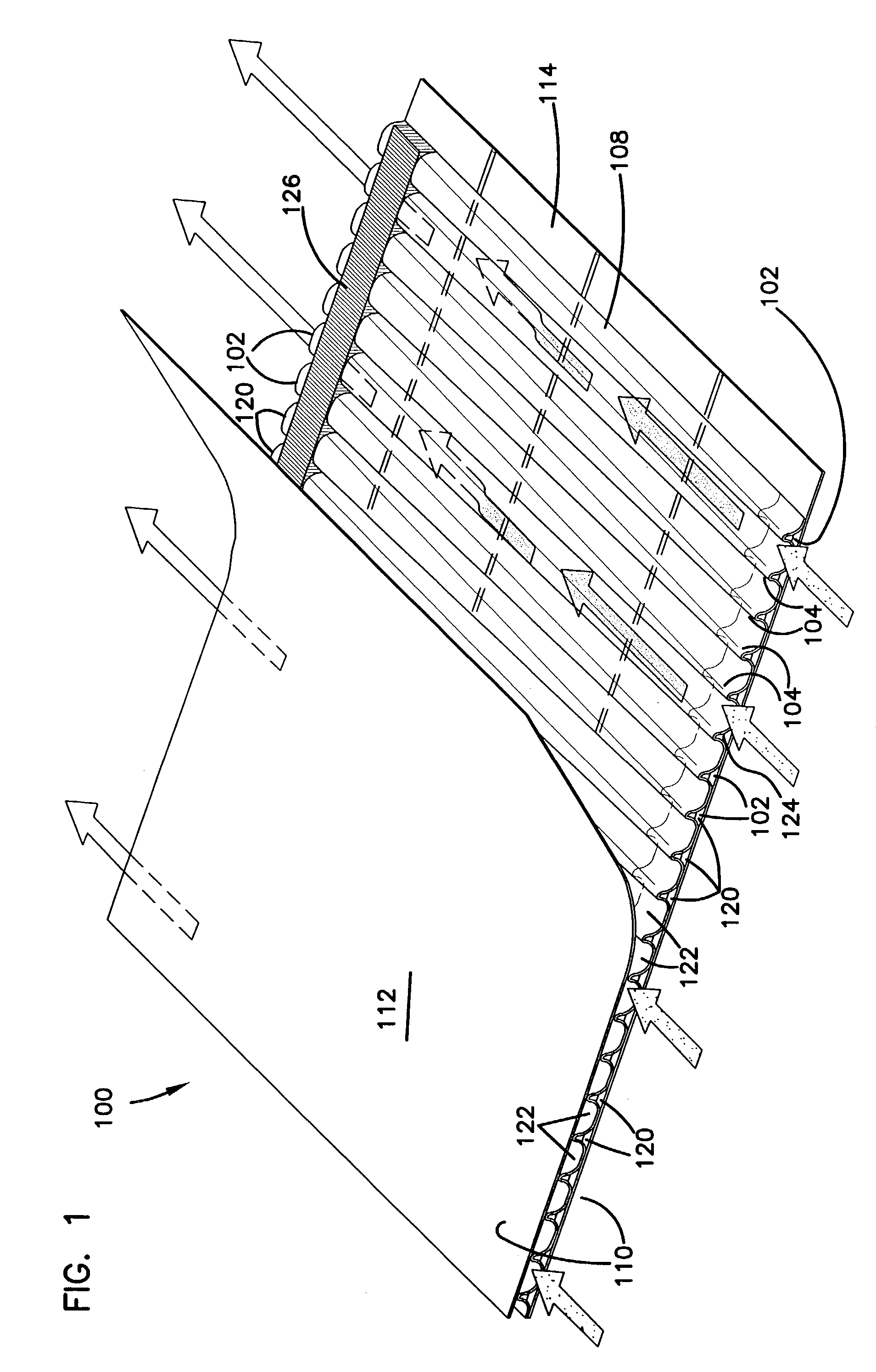

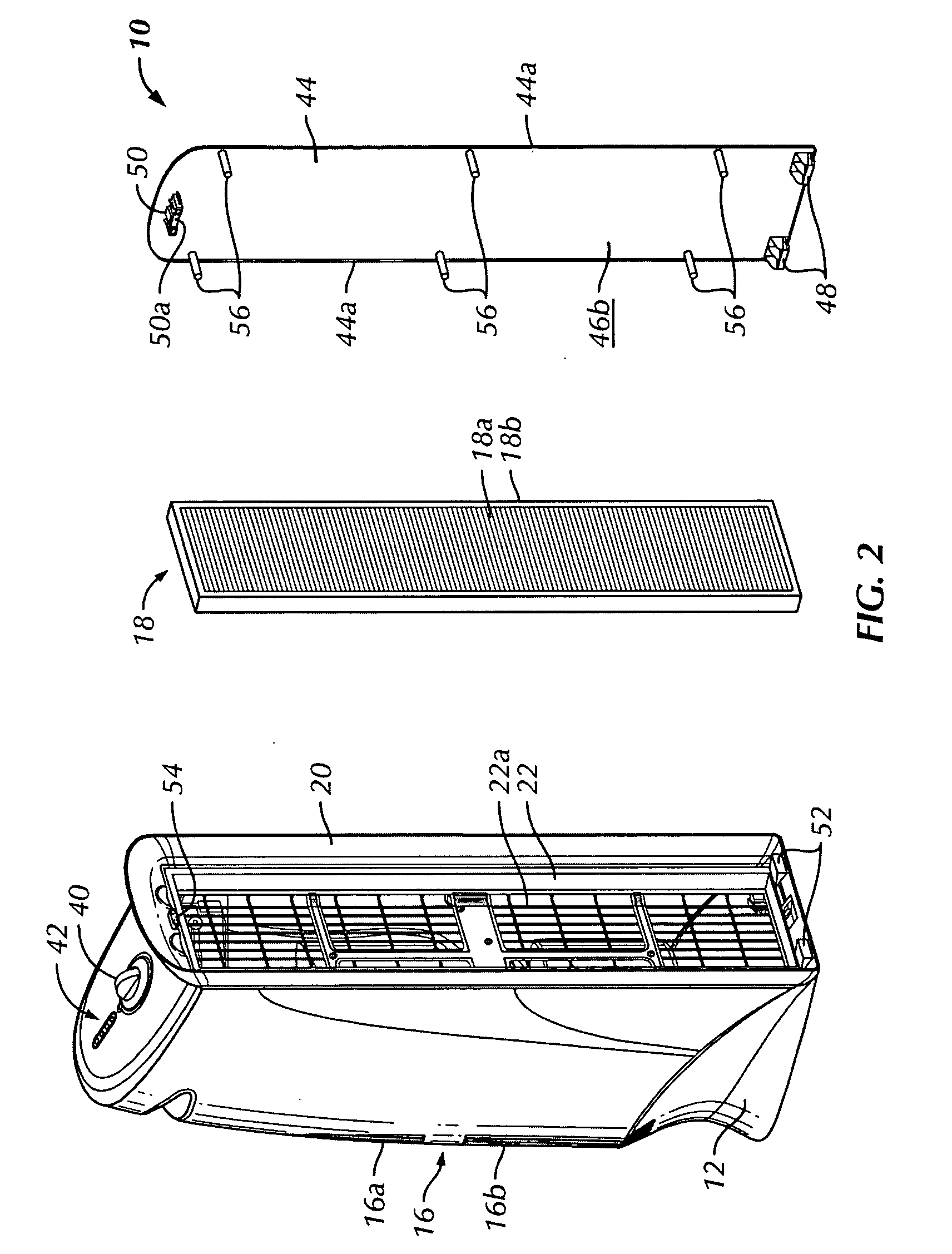

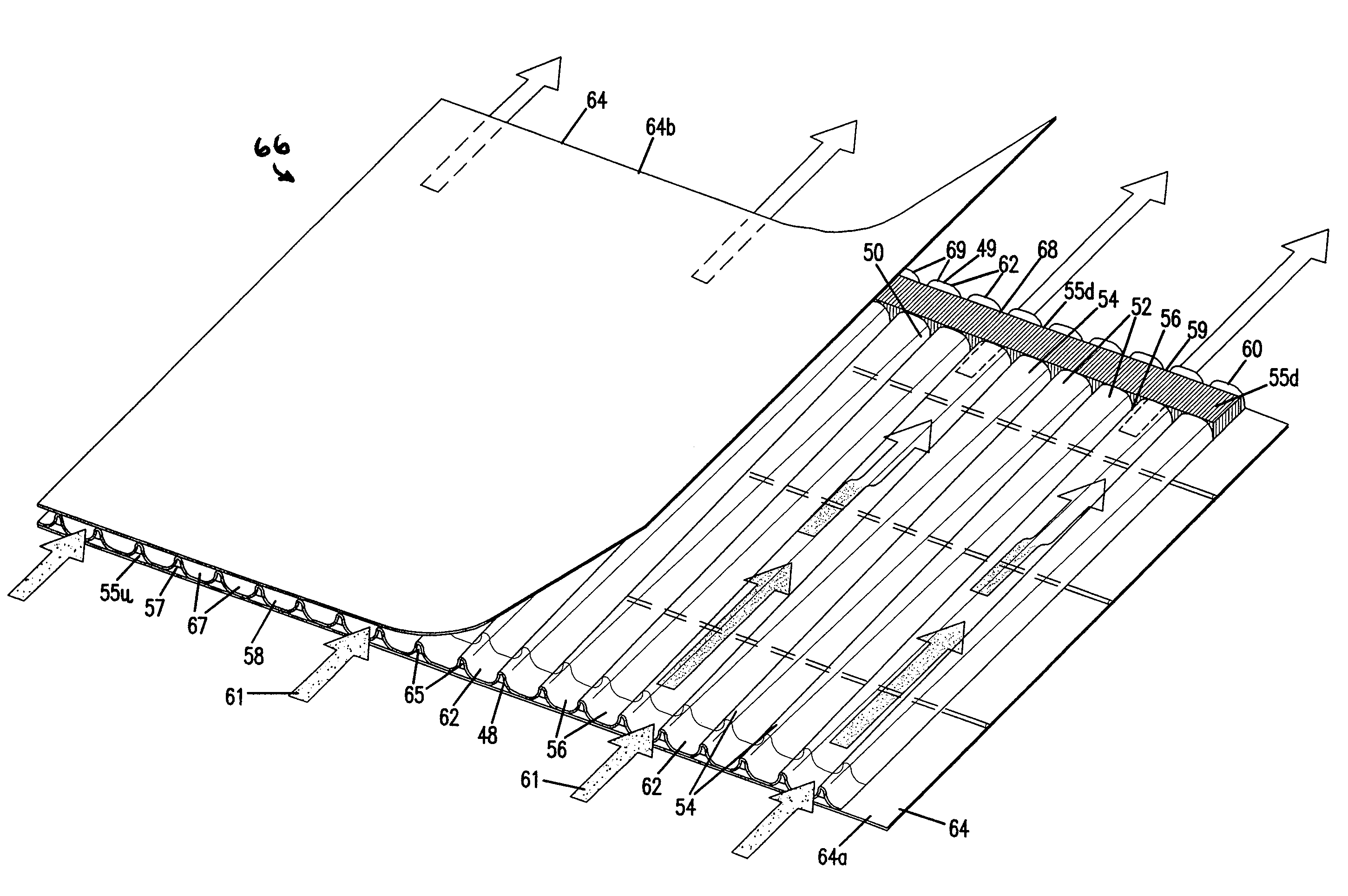

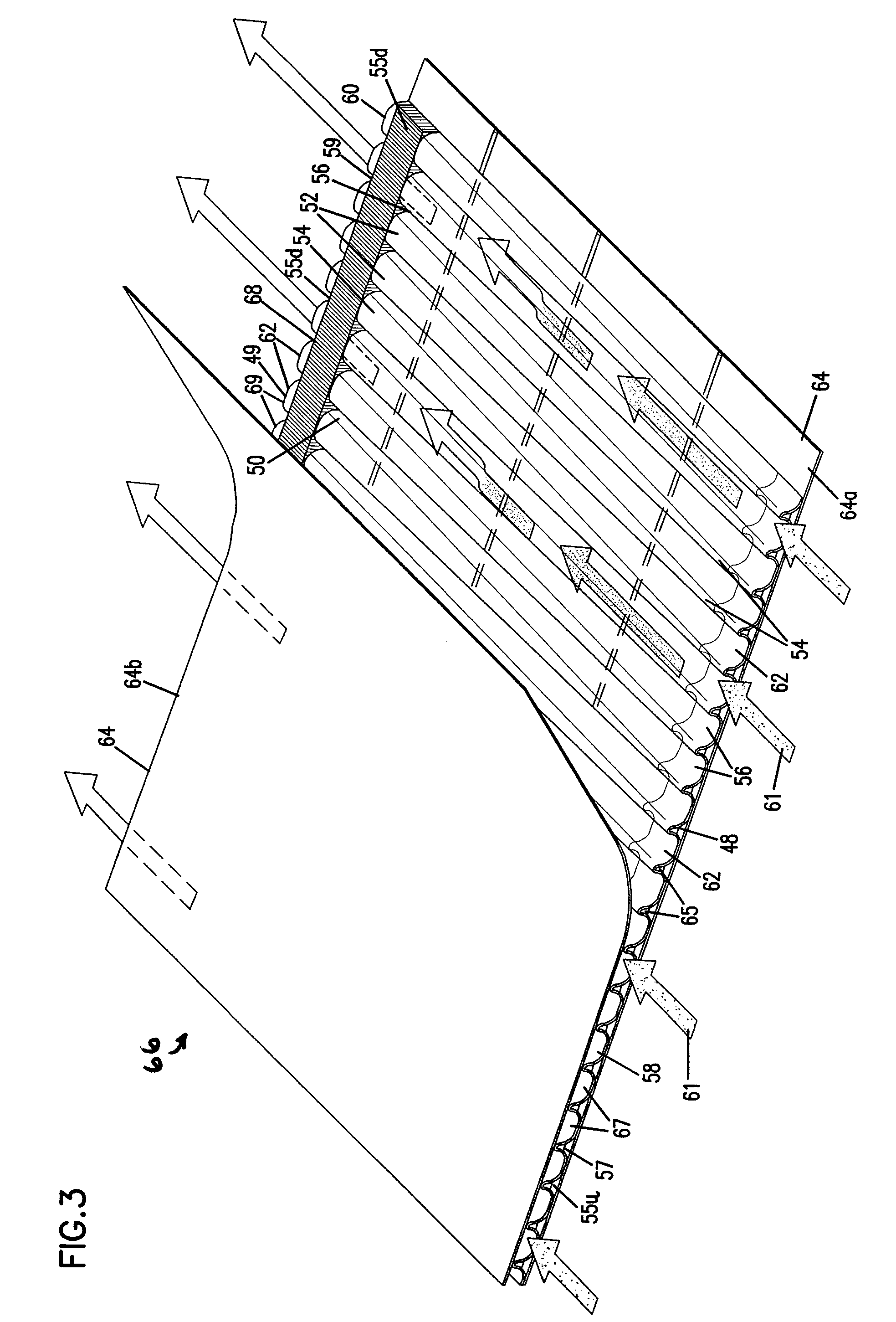

Air filter having fluted filter media

An air cleaner (40) includes a housing (48) and an access cover. The internal volume of the housing (48) can be reached through an opening (70) in a side wall of the housing. A filter element (50) having fluted filter media is removable and replaceable from the air cleaner (40). The housing is constructed and arranged to cam the element (50) into sealing engagement with the housing (48). The access cover includes structure to help support and ensure proper seating of the filter element within the housing. A method of installing the filter element in the air cleaner includes sliding a portion of the filter element against a slide surface in the housing. A method of servicing an air cleaner includes tilting the filter element against a tilt surface in the housing to release a seal between the filter element and the housing. The filter element can have a handle to assist in servicing of the air cleaner. The housing can have a window to allow visual inspection of the internal component of the housing and to determine visually whether a filter element is installed therein.

Owner:DONALDSON CO INC

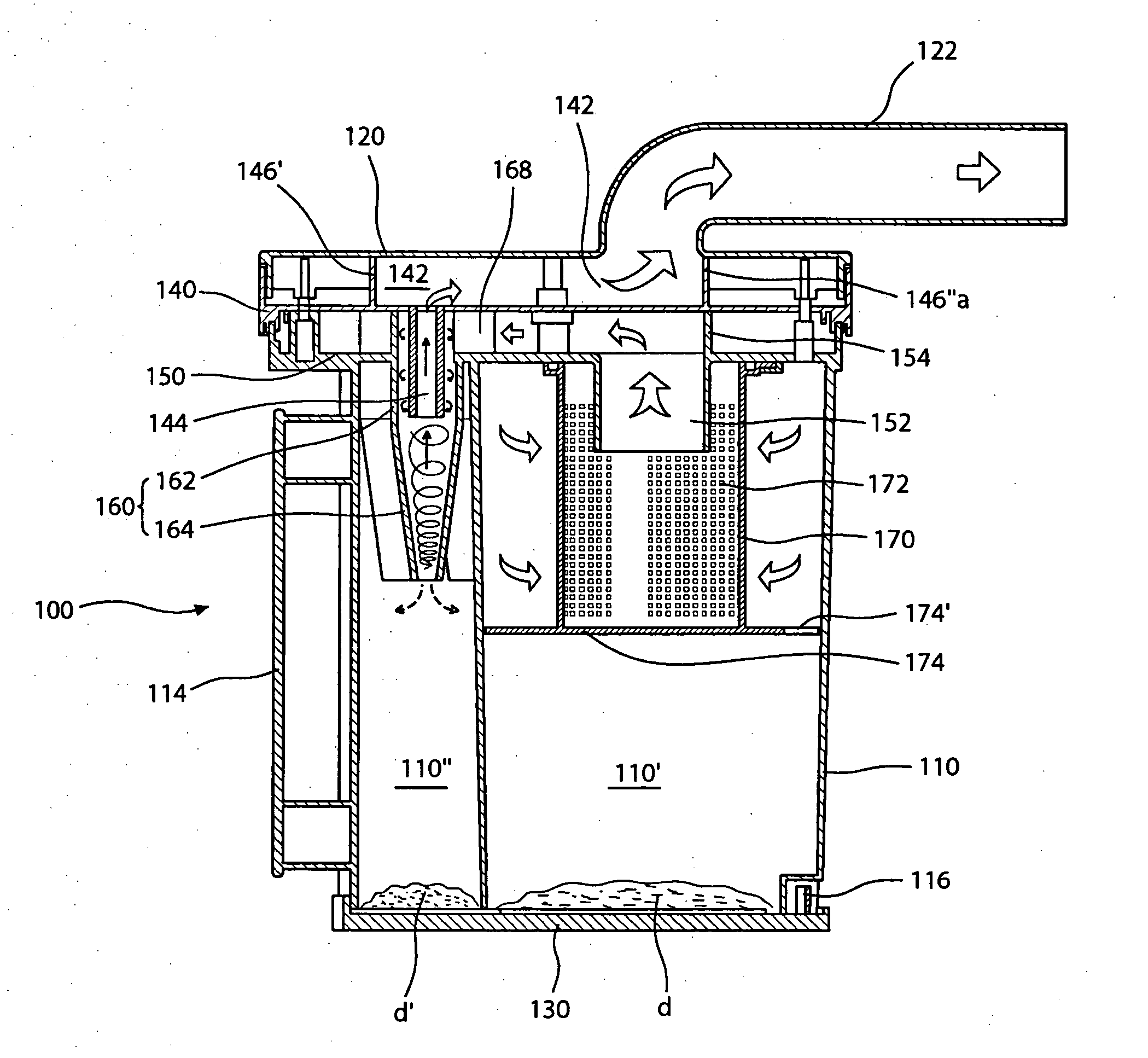

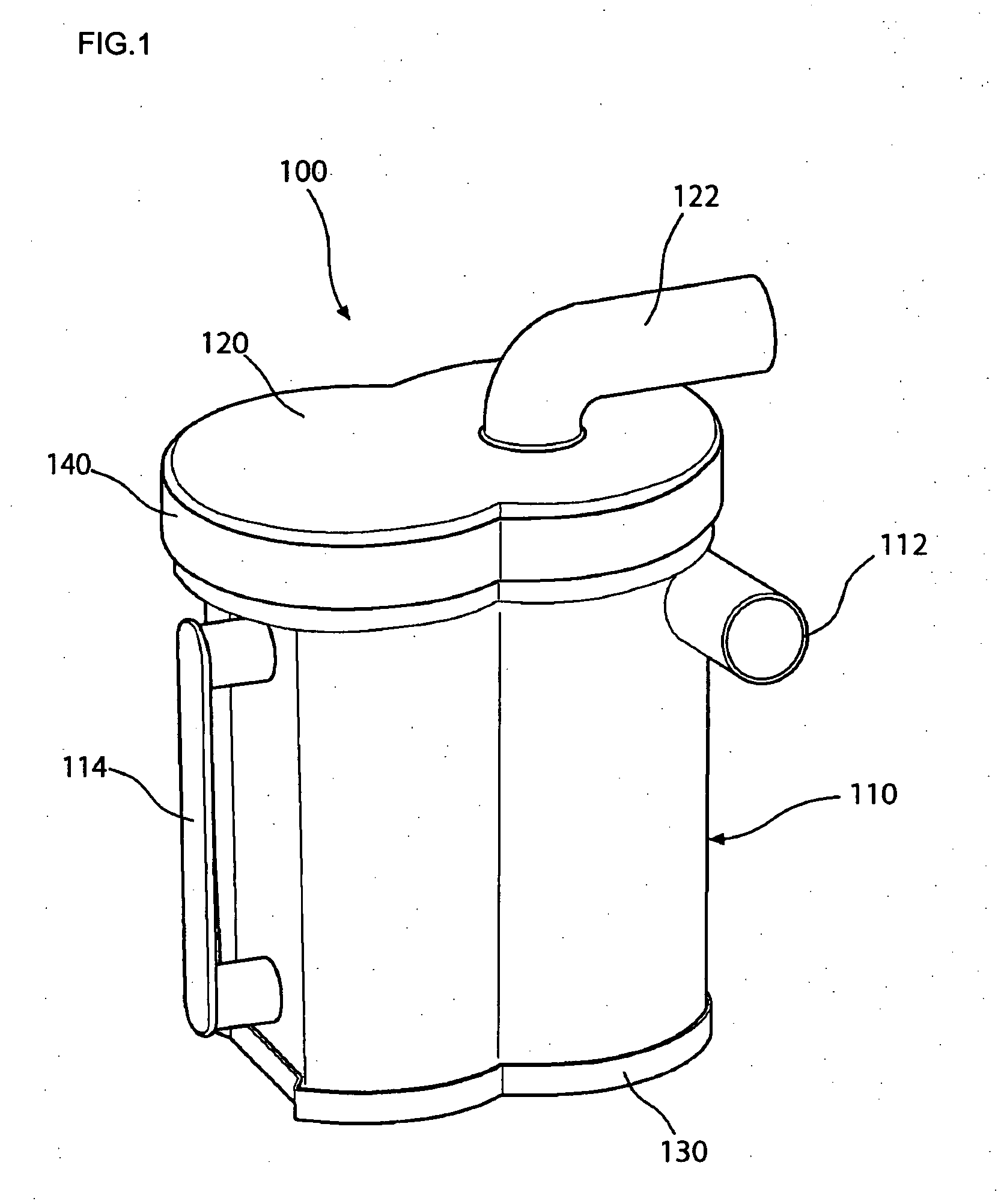

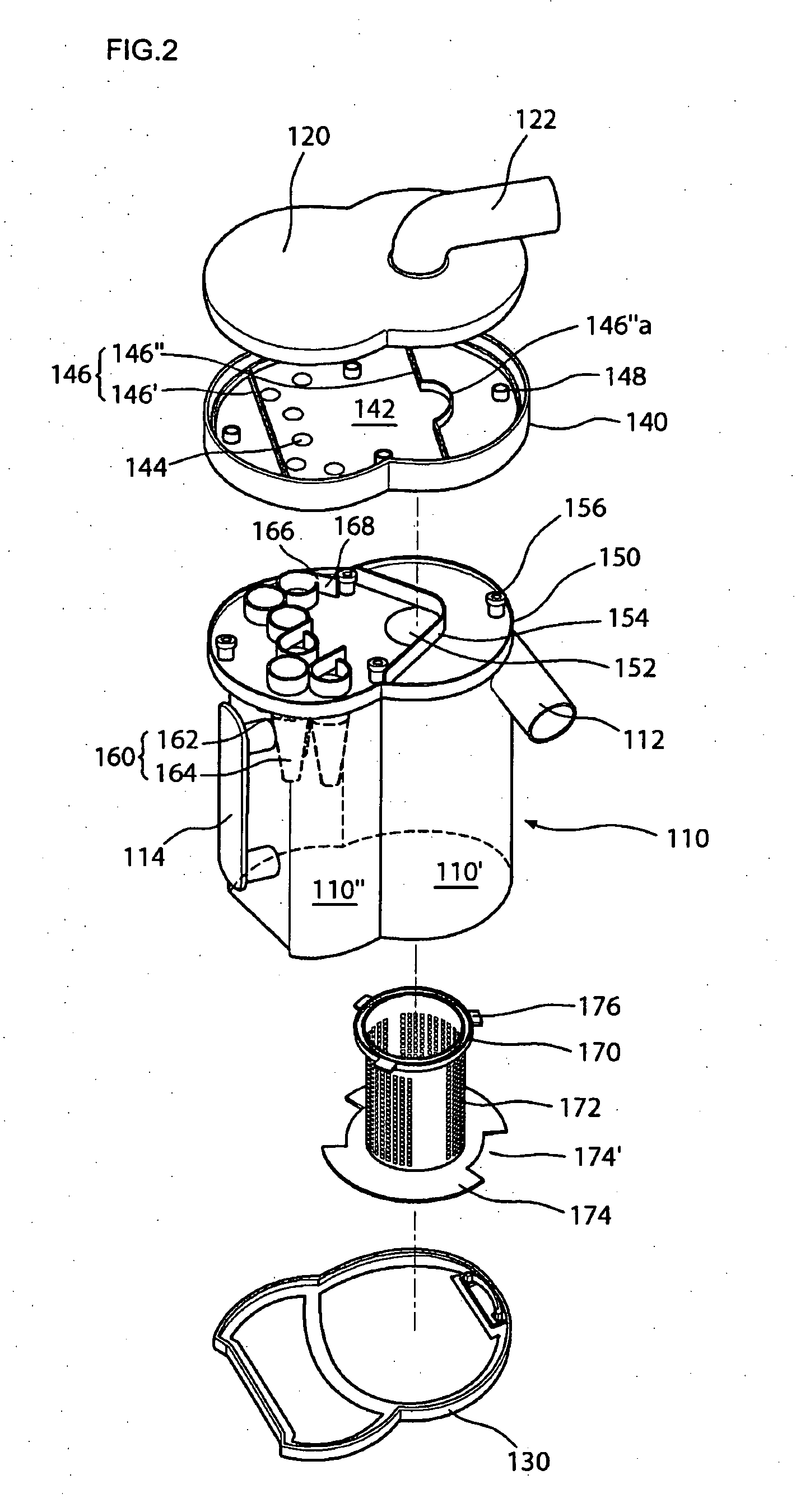

Dust collection assembly of vacuum cleaner

InactiveUS20060137304A1Improve dust removal efficiencyEasy constructionCombination devicesSuction filtersCycloneForeign matter

A dust collection assembly of a vacuum cleaner is provided. The dust collection assembly includes a dust collecting box, a filter, a flow guide unit, an exhaust guider, and an upper cover. The dust collecting box and the flow guide unit are integrally formed in a single body. The dust collecting box includes a first and second dust collecting spaces for collecting foreign objects. The filter is disposed in the inside of the dust collecting space to primarily filter foreign objects during operation of a cyclone. The flow guide unit guides airflow and has small cyclones integrally formed therein, for secondarily filtering the foreign objects in air. The exhaust guider guides airflow and has a plurality of discharge holes through which air filtered by the small cyclone flows. The upper cover is disposed on the upper side of the exhaust guider.

Owner:LG ELECTRONICS INC

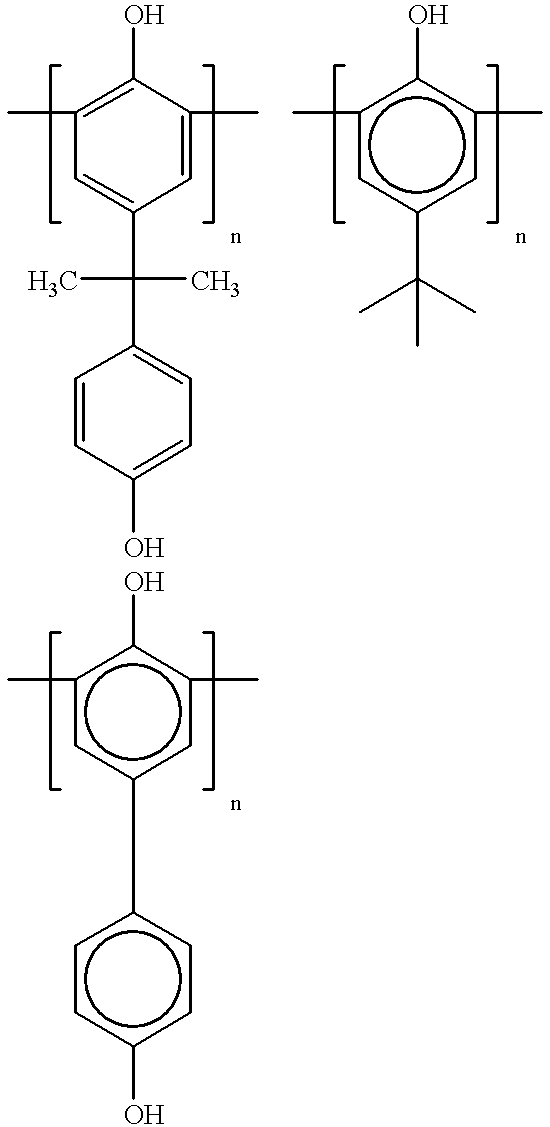

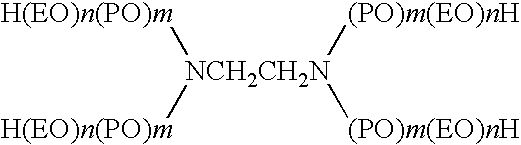

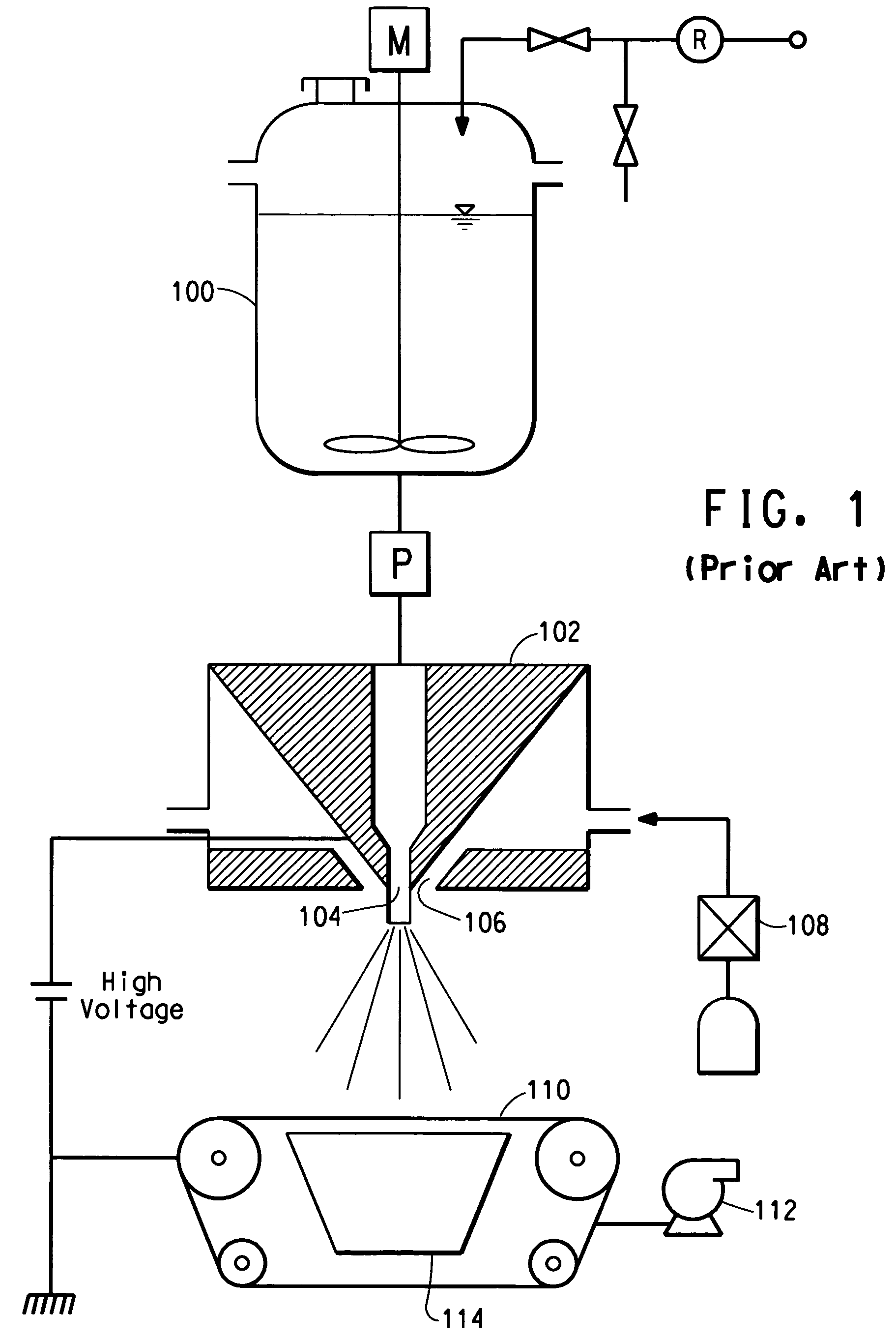

Air filter with fine fiber and spun bonded media

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

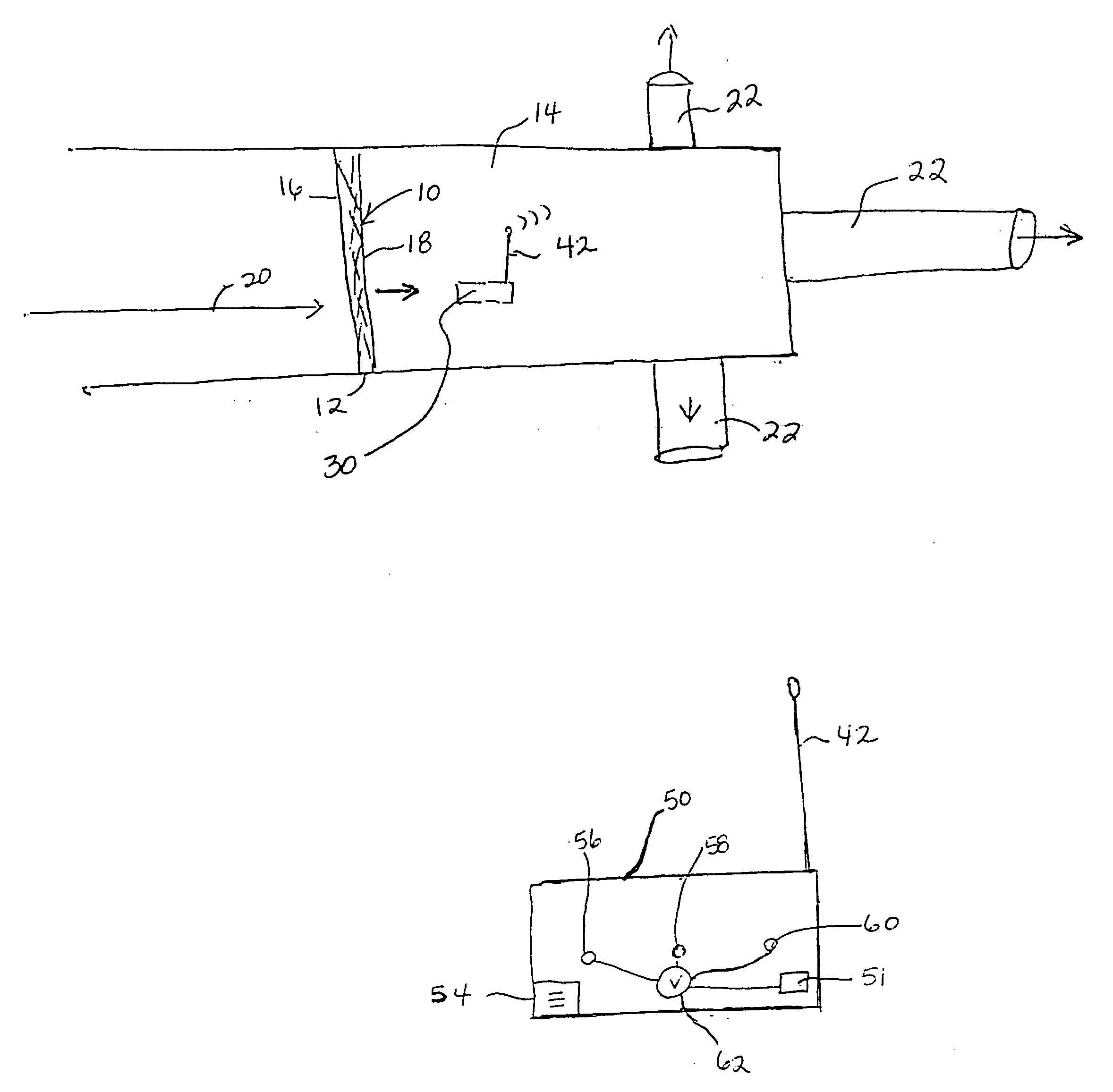

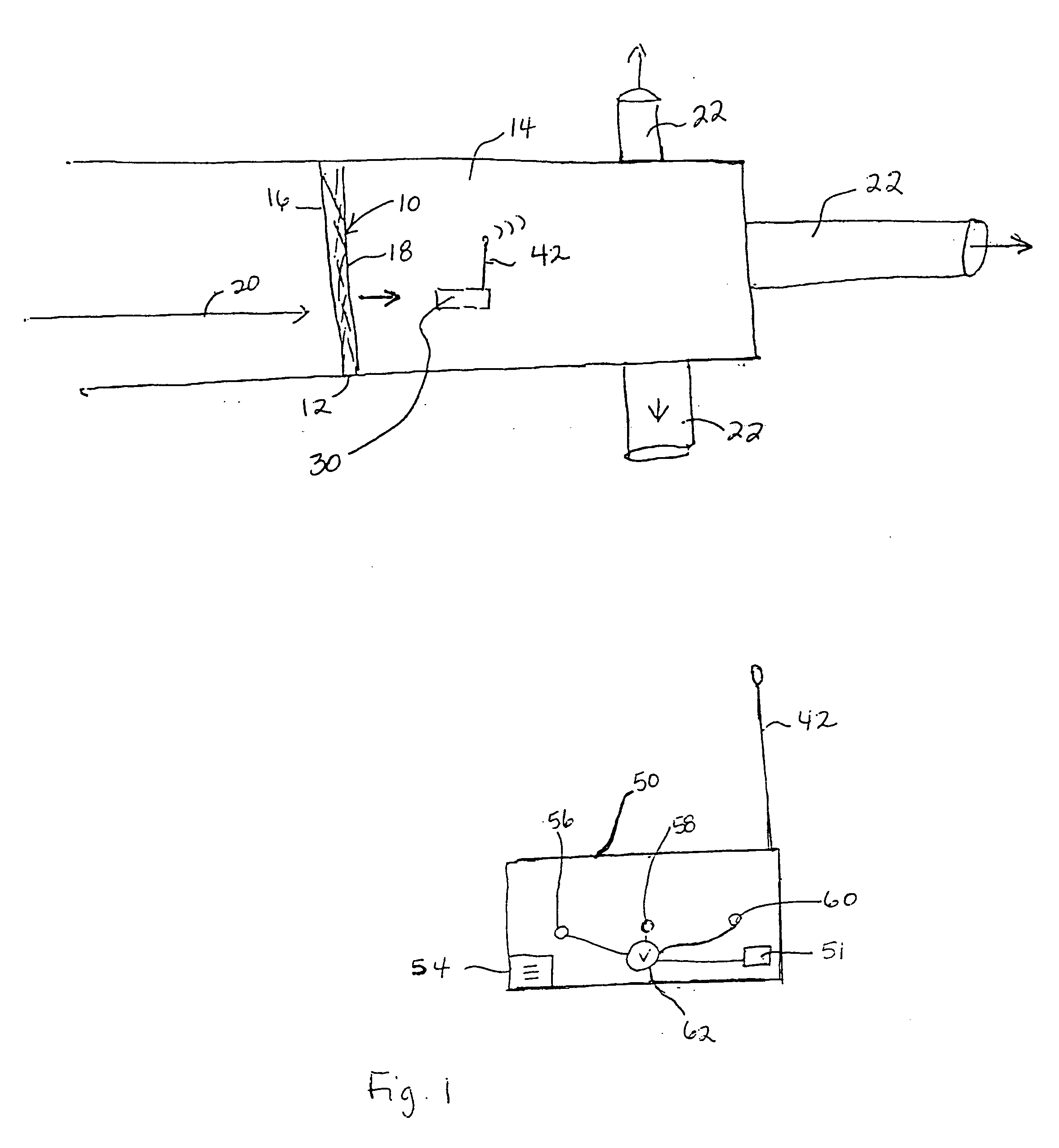

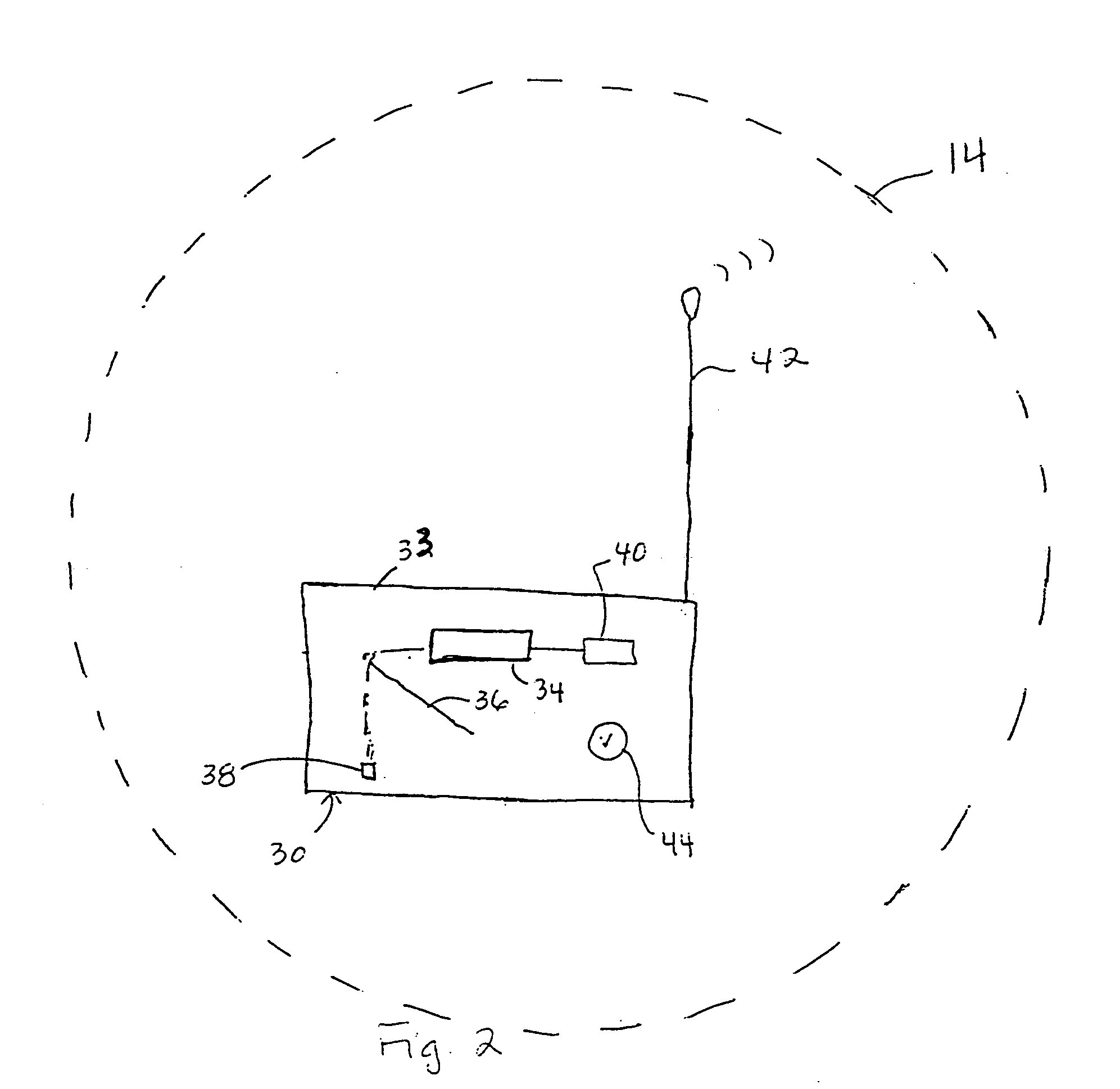

Detection device for air filter

InactiveUS20070013534A1Mechanical apparatusSpace heating and ventilation safety systemsDifferential pressureAir filter

A wireless sensor unit detects an out-of-range condition of an air filter in a HVAC system by sensing the air flow passing across the filter or by pressure differential across the air filter. A The sensor unit sends a signal to a receiver unit that can be positioned a distance from the sensor unit to process the signal sent by the sensor unit and provide audio and / or visual warning of the air filter condition.

Owner:DIMAGGIO EDWARD G

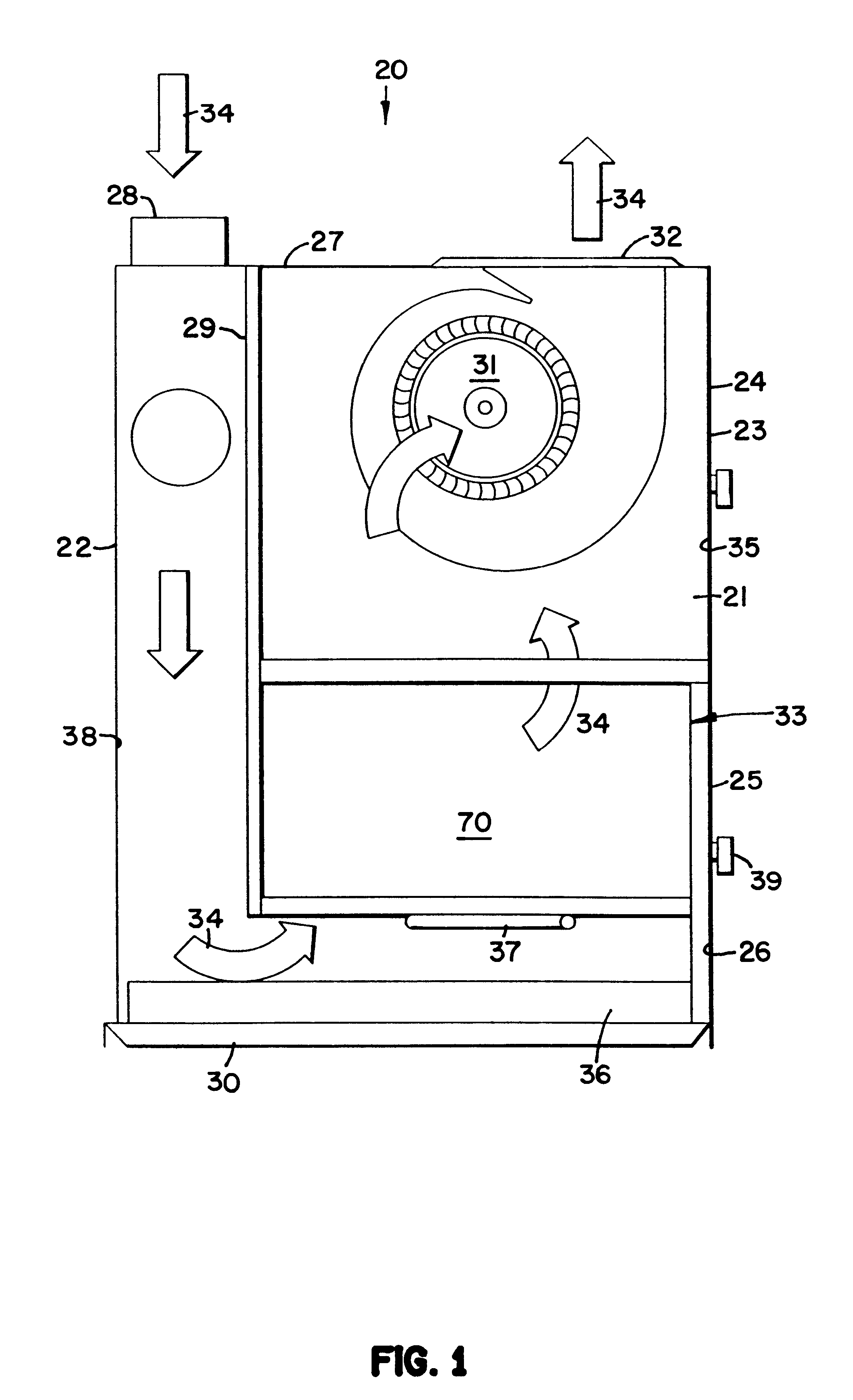

Air filter monitoring system

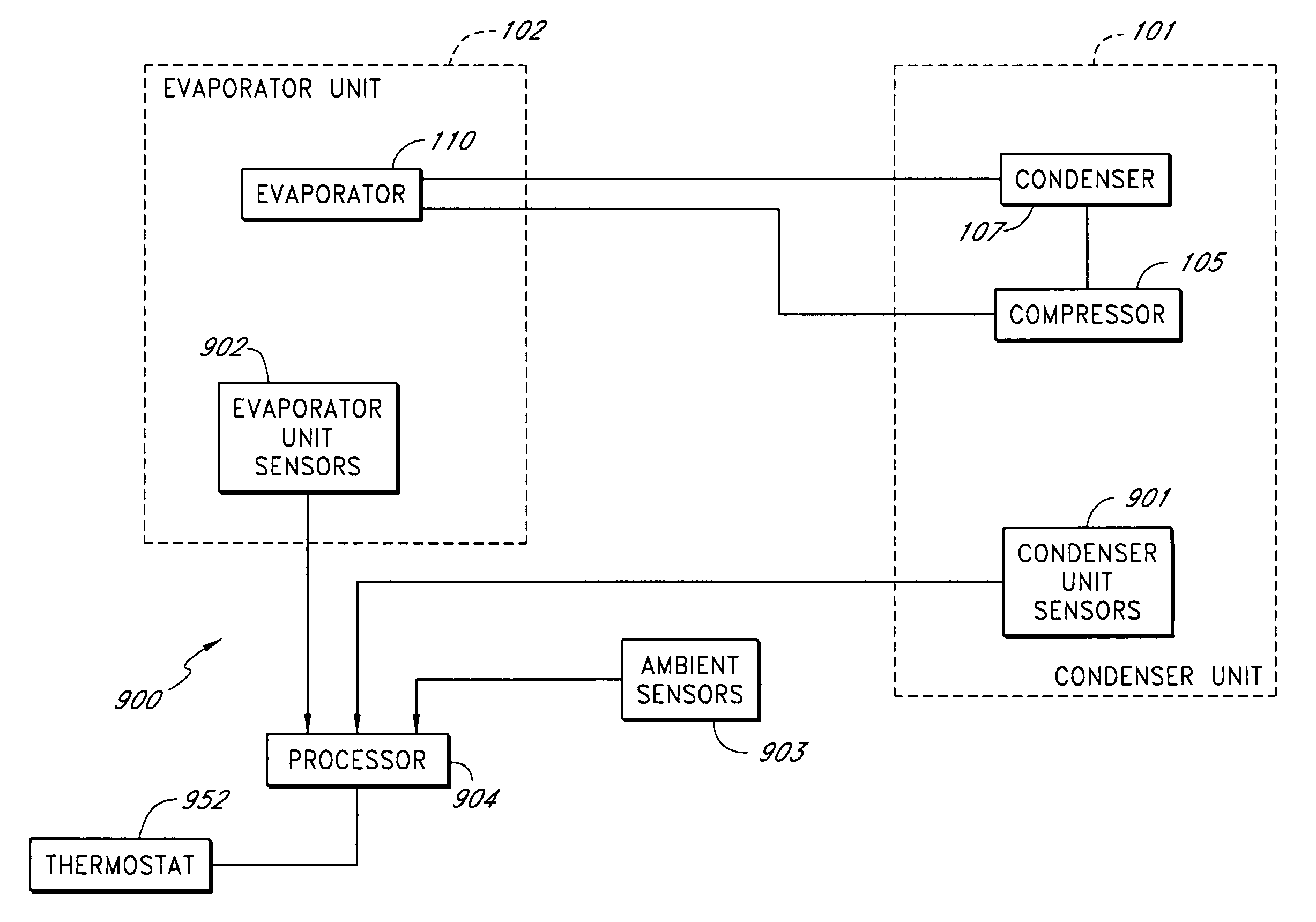

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:EMERSON CLIMATE TECH INC

Technique for detecting and predicting air filter condition

InactiveUS20050247194A1Life predictionCombination devicesAuxillary pretreatmentOperational systemAir filter

Owner:CARRIER CORP

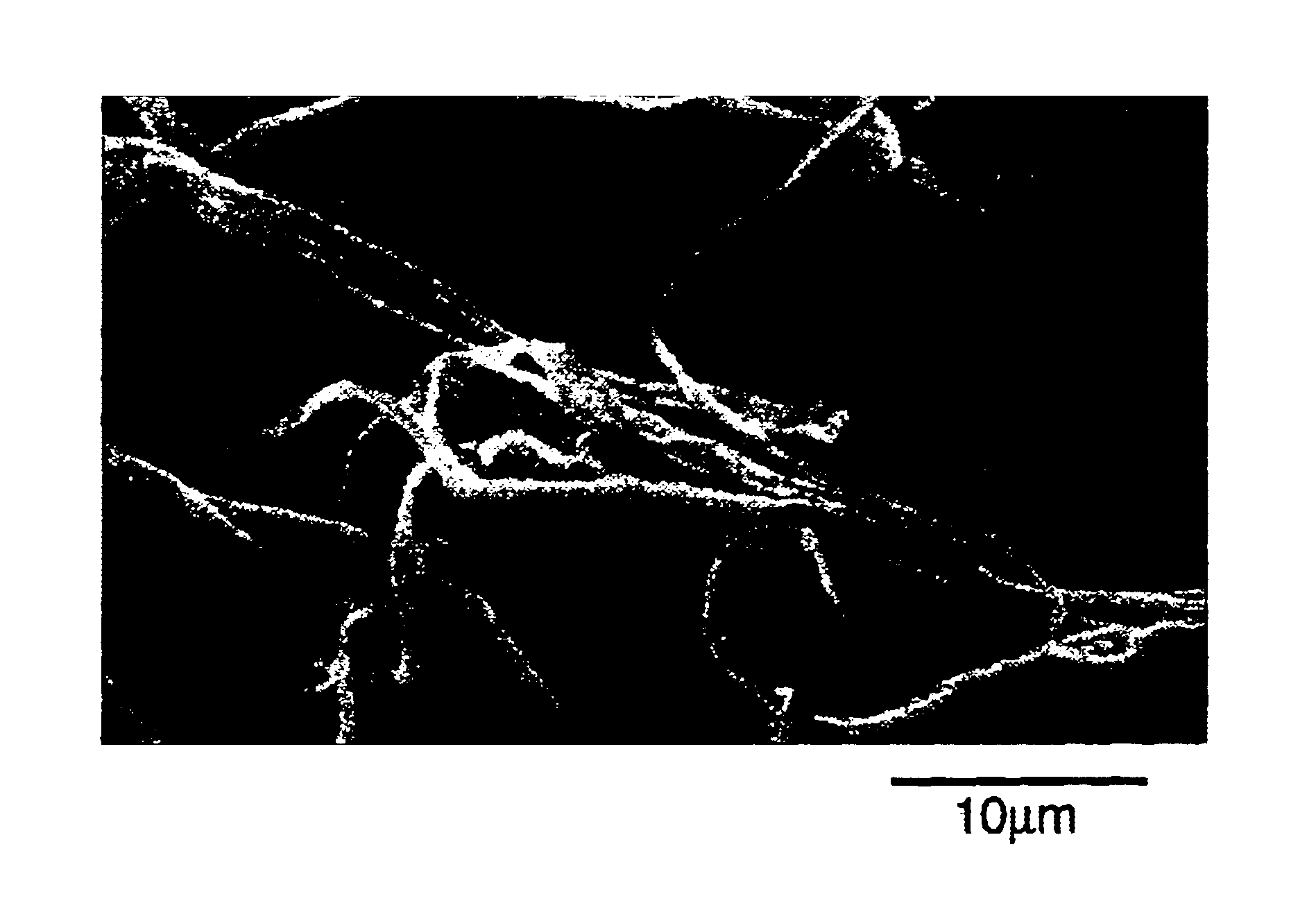

Filtration media for filtering particulate material from gas streams

A filtration medium is disclosed for use in air filters used in heating, ventilating and air conditioning systems. The medium contains at least one nanofiber layer of fibers having diameters less than 1 μm and at least one carrier layer, each nanofiber layer having a basis weight of at least about 2.5 g / m2, and up to about 25 g / m2. The medium has sufficient stiffness to be formed into a pleated configuration.

Owner:EI DU PONT DE NEMOURS & CO

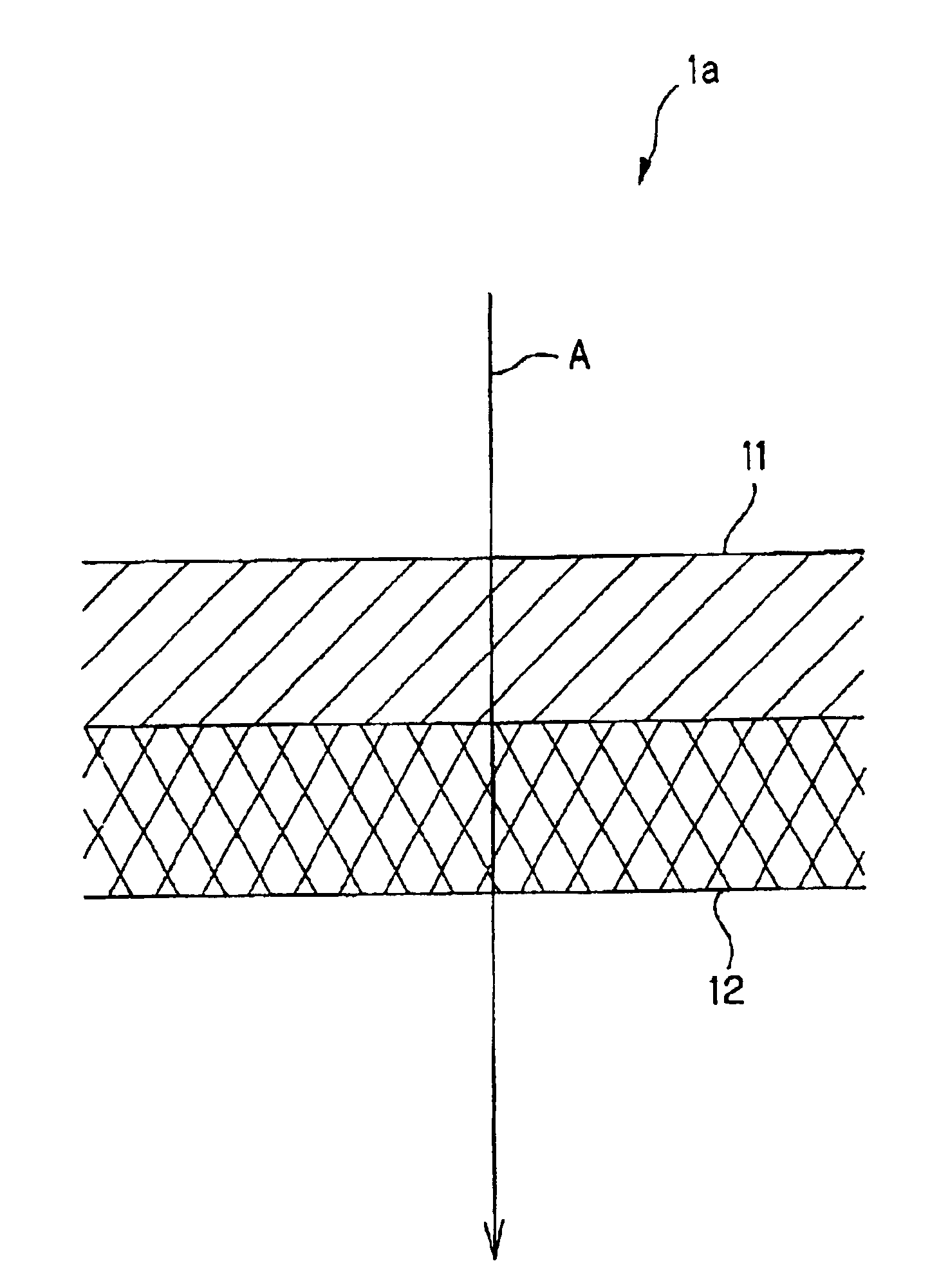

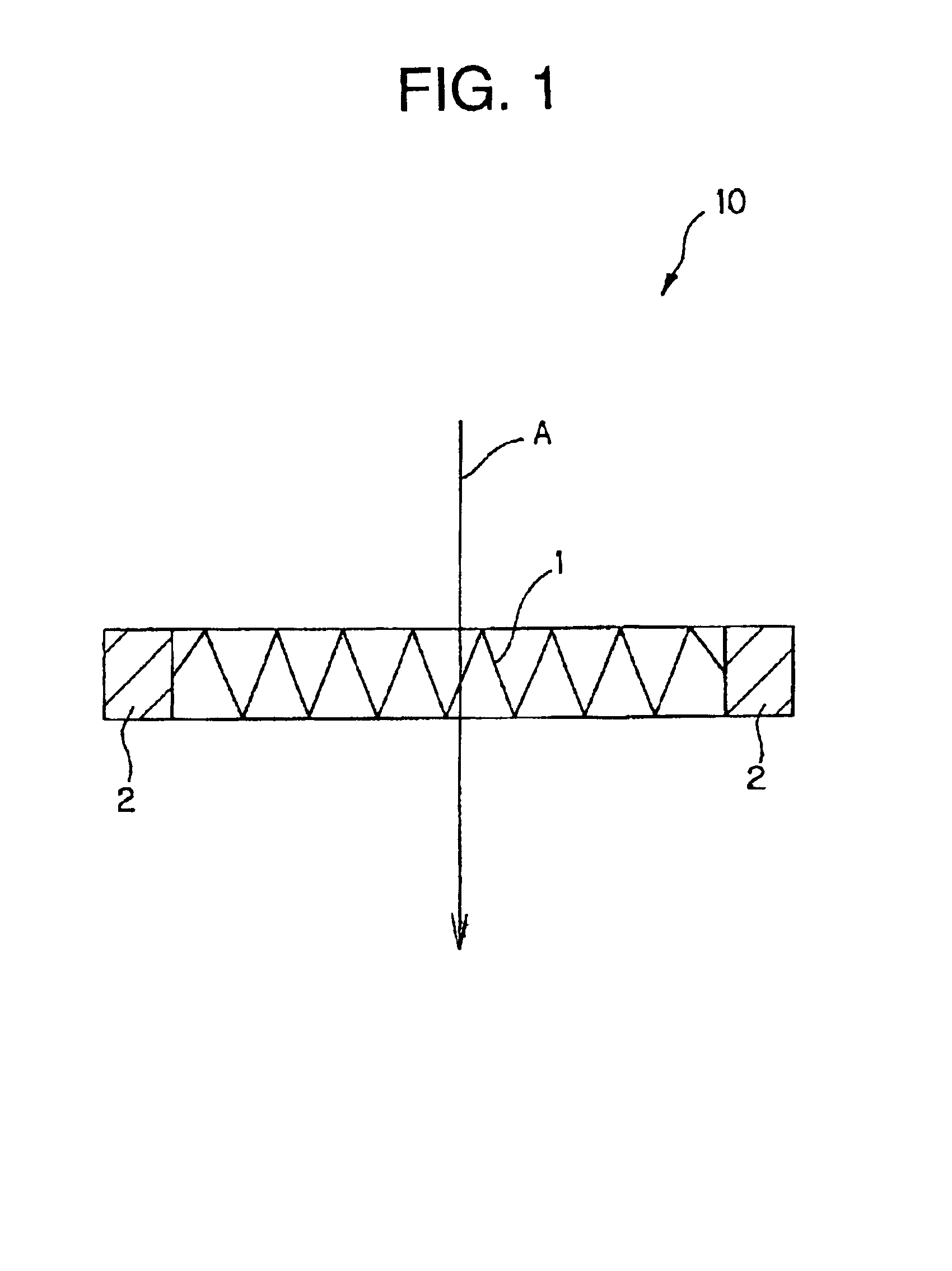

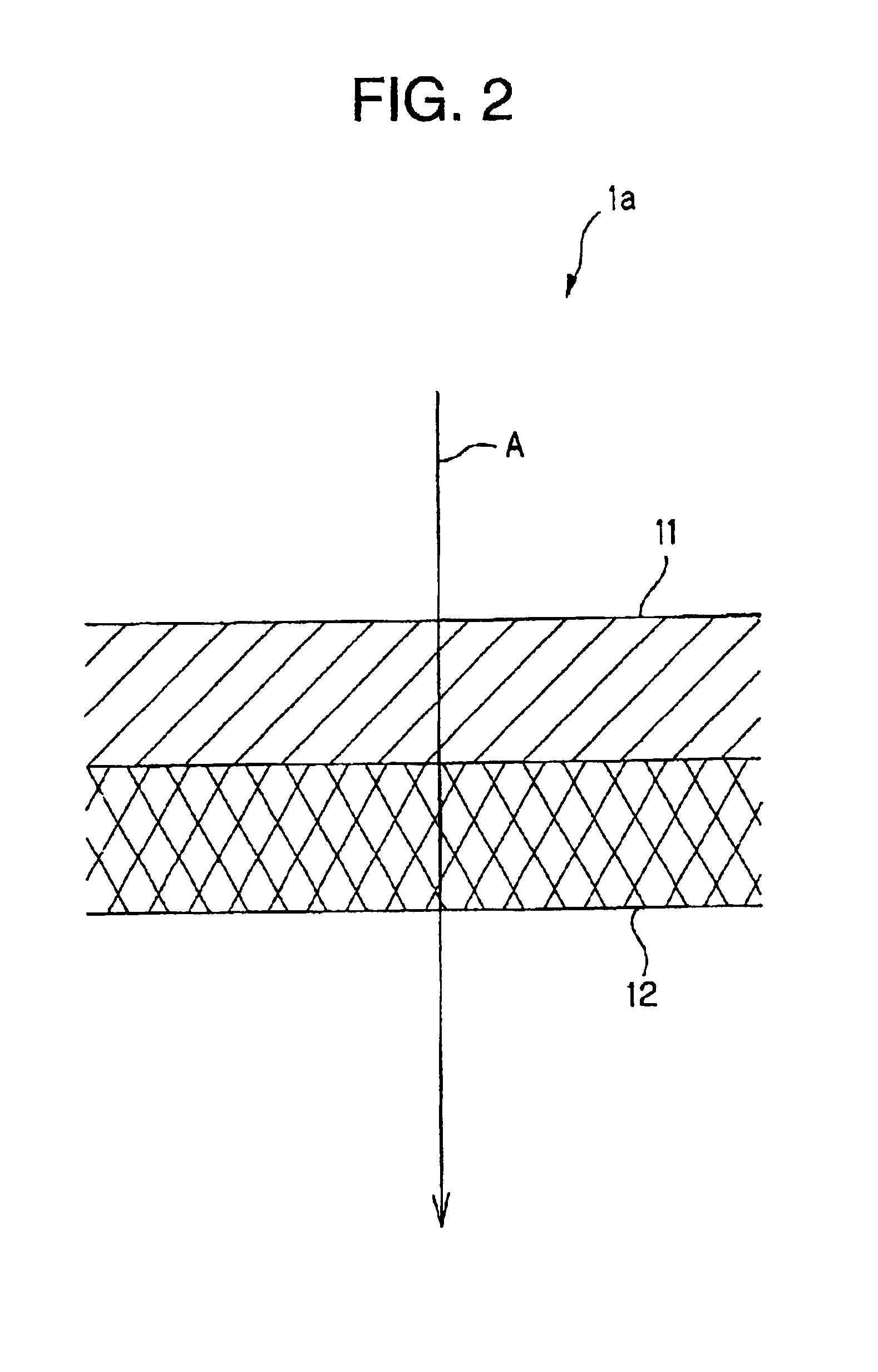

Air filter

InactiveUS6843819B2Low costEfficient captureCombination devicesDispersed particle filtrationHigh densityAir filter

There is provided an air filter, which has a long lifetime and permits to capture effectively carbon particles and reduce costs. The air filter has the first filter layer 11 impregnated with oil and the second filter layer 12, which is provided on the downstream side of the first filter layer 11 and serves as a lipophobic layer having an oil-repellent property. The filter material of the first filter layer 11 has a higher density than the filter material of the second filter material 12.

Owner:TOYO ROKI MFG CO LTD +1

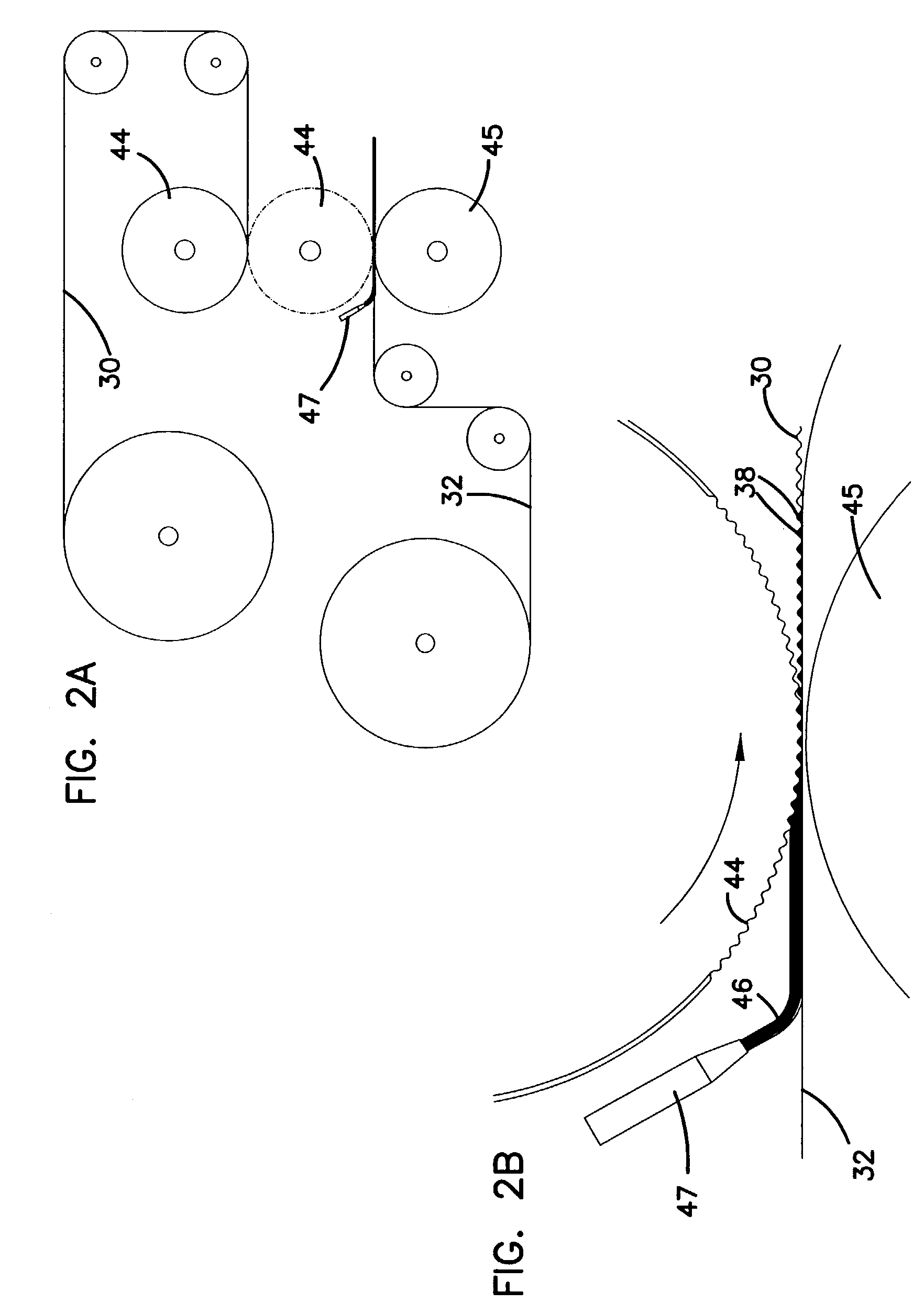

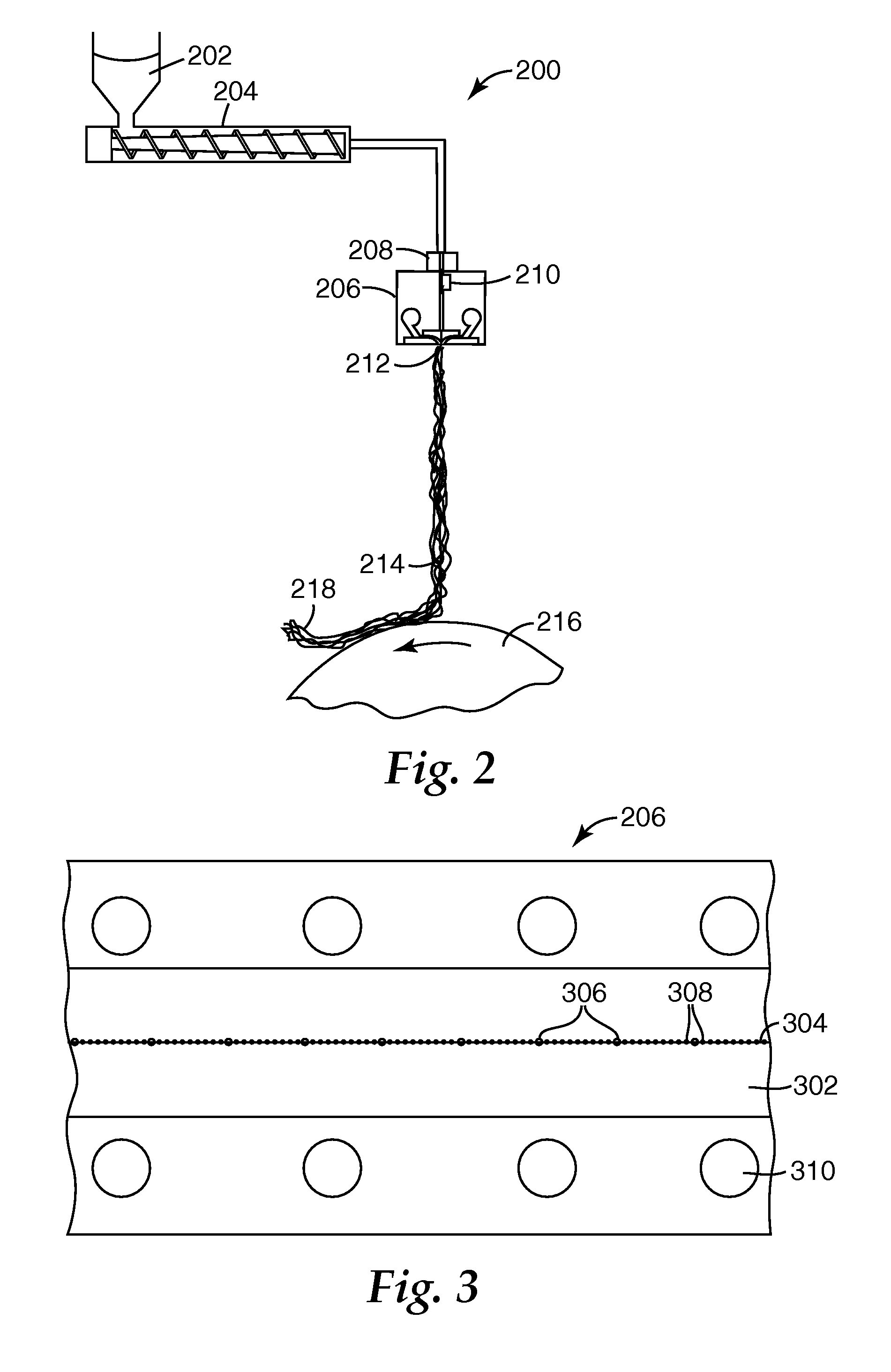

Gathered filter media for an air filter and method of making same

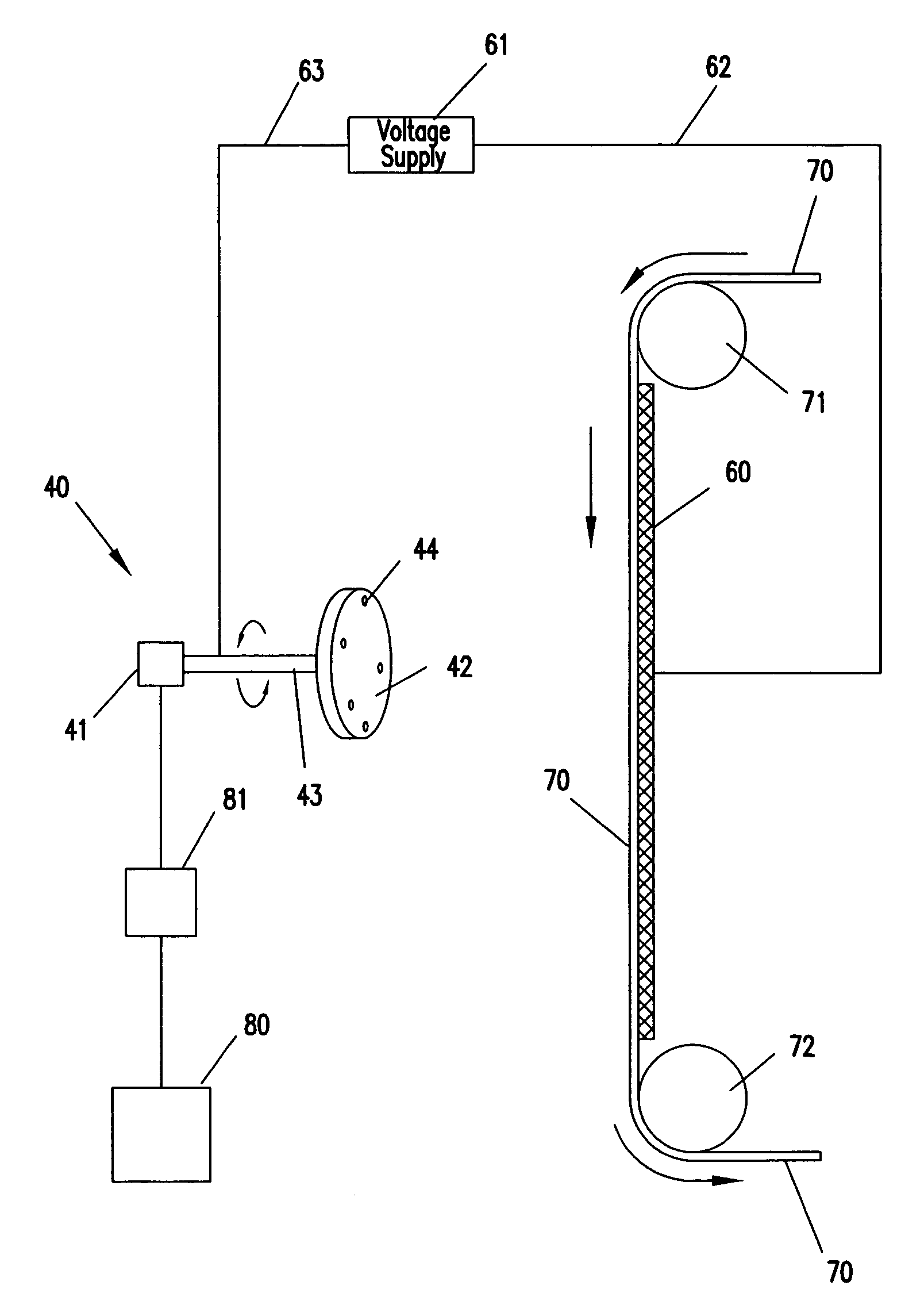

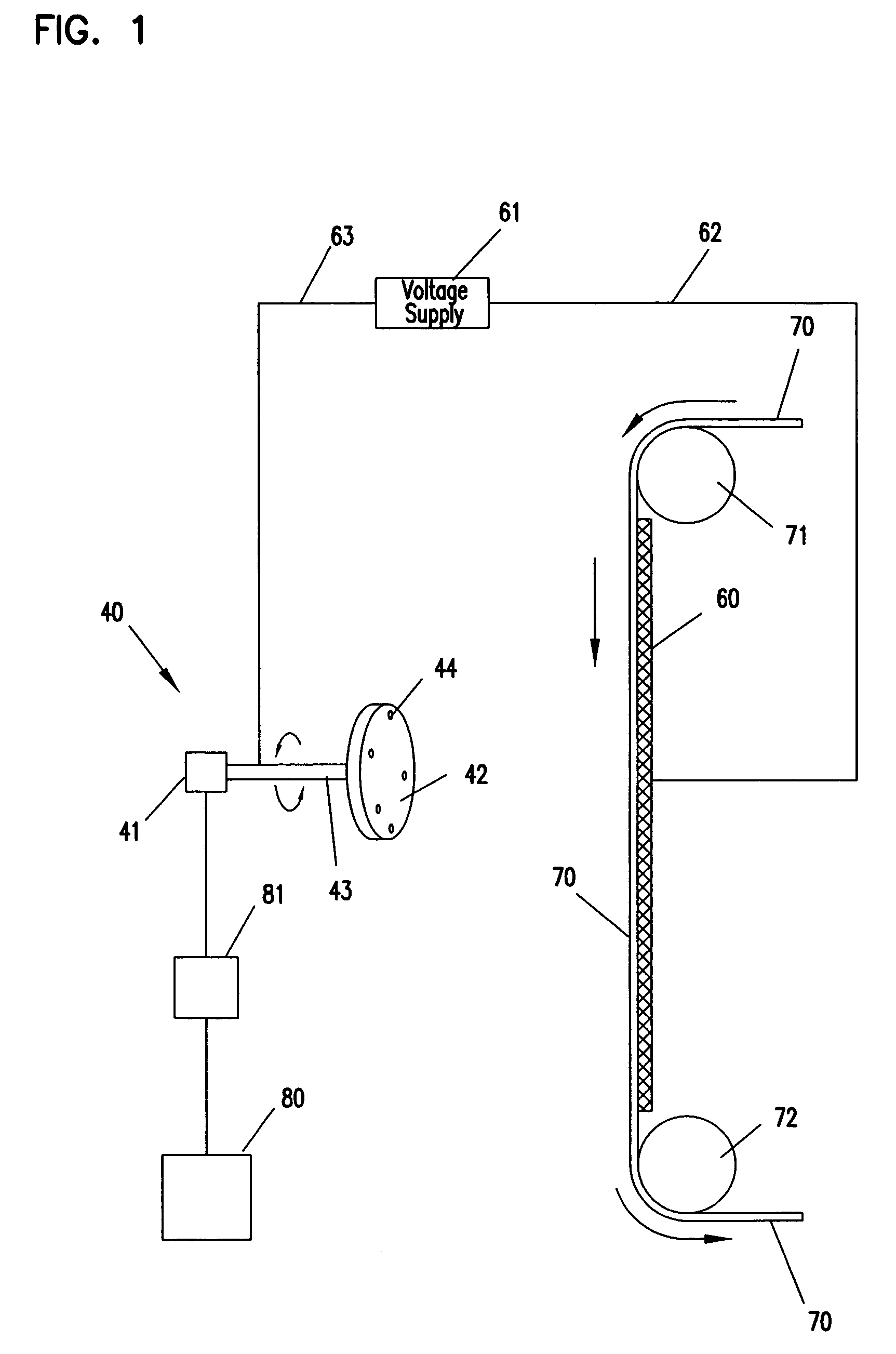

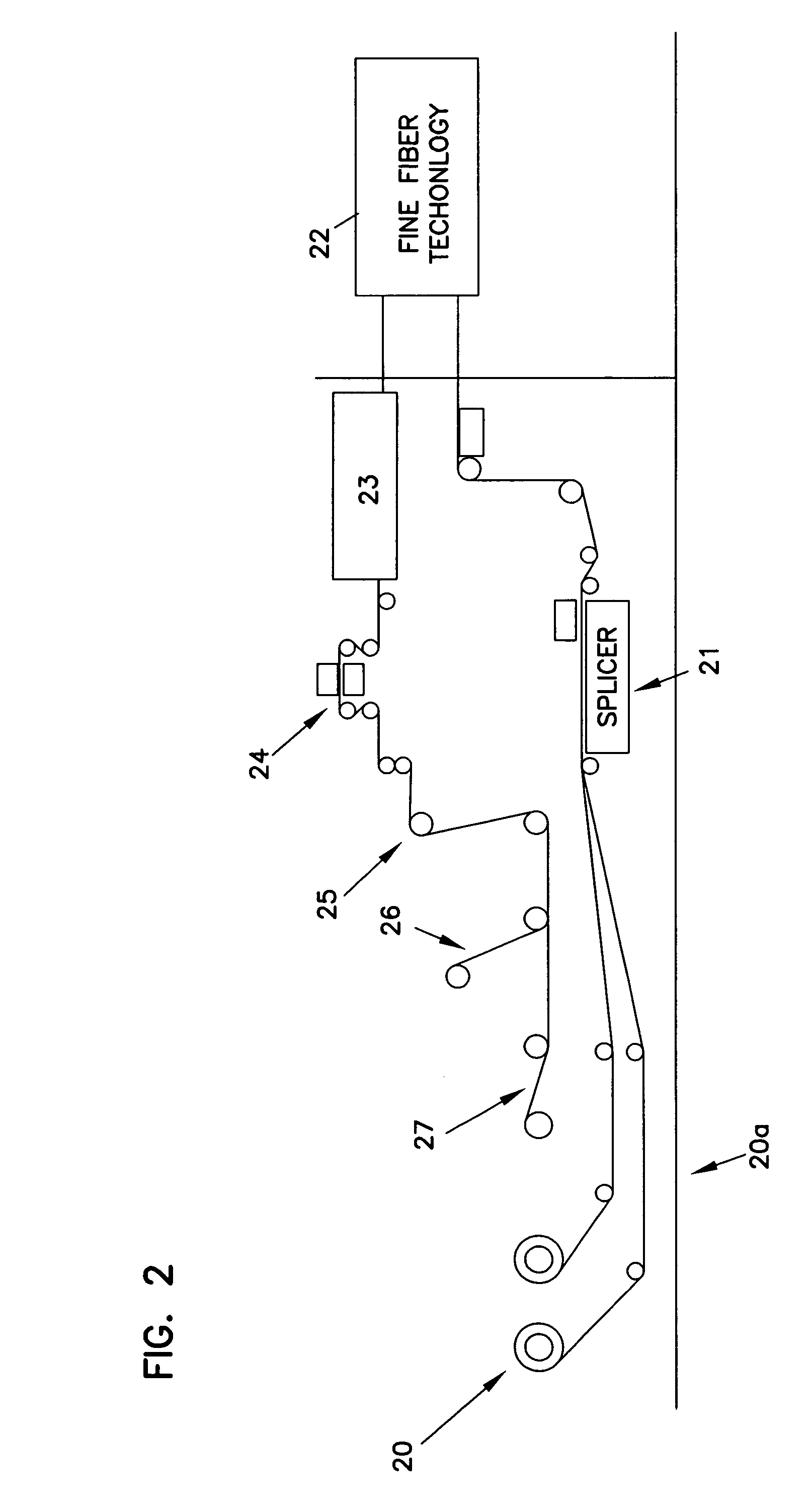

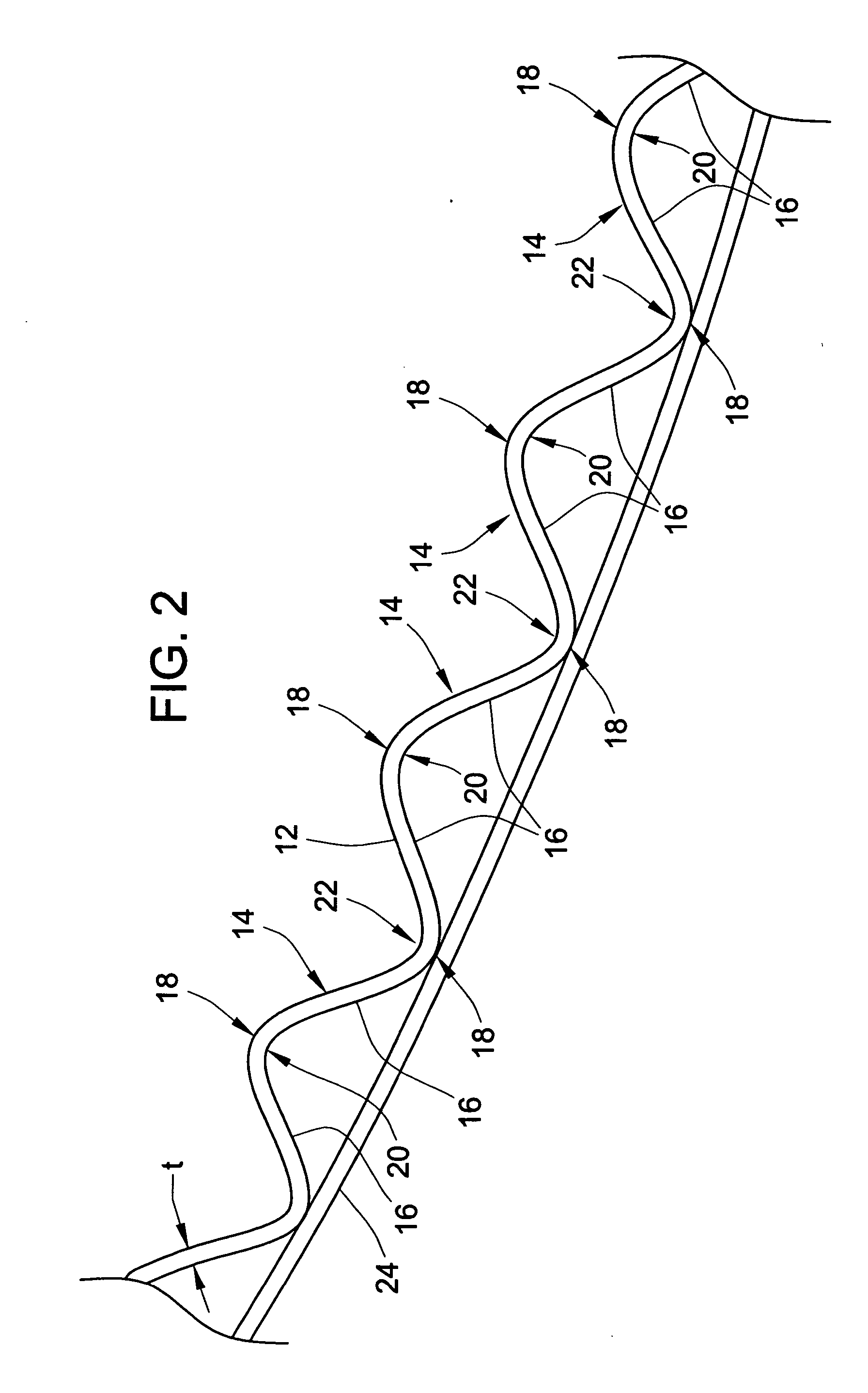

ActiveUS20060091066A1Reduce complexityReduce manufacturing costGas treatmentMechanical working/deformationAir filterFilter media

A filter media including a gathered sheet of porous filter material, is provided, together with an apparatus and method for fabricating such a gathered sheet of porous filter material. An improved filter apparatus incorporating such gathered porous filter material is also provided. By gathering the porous filter material, rather than forming convolutions through corrugating or pleating, as was done in the past, a desirable convoluted shape is achieved with little or no compression of the filter media.

Owner:BALDWIN FILTERS

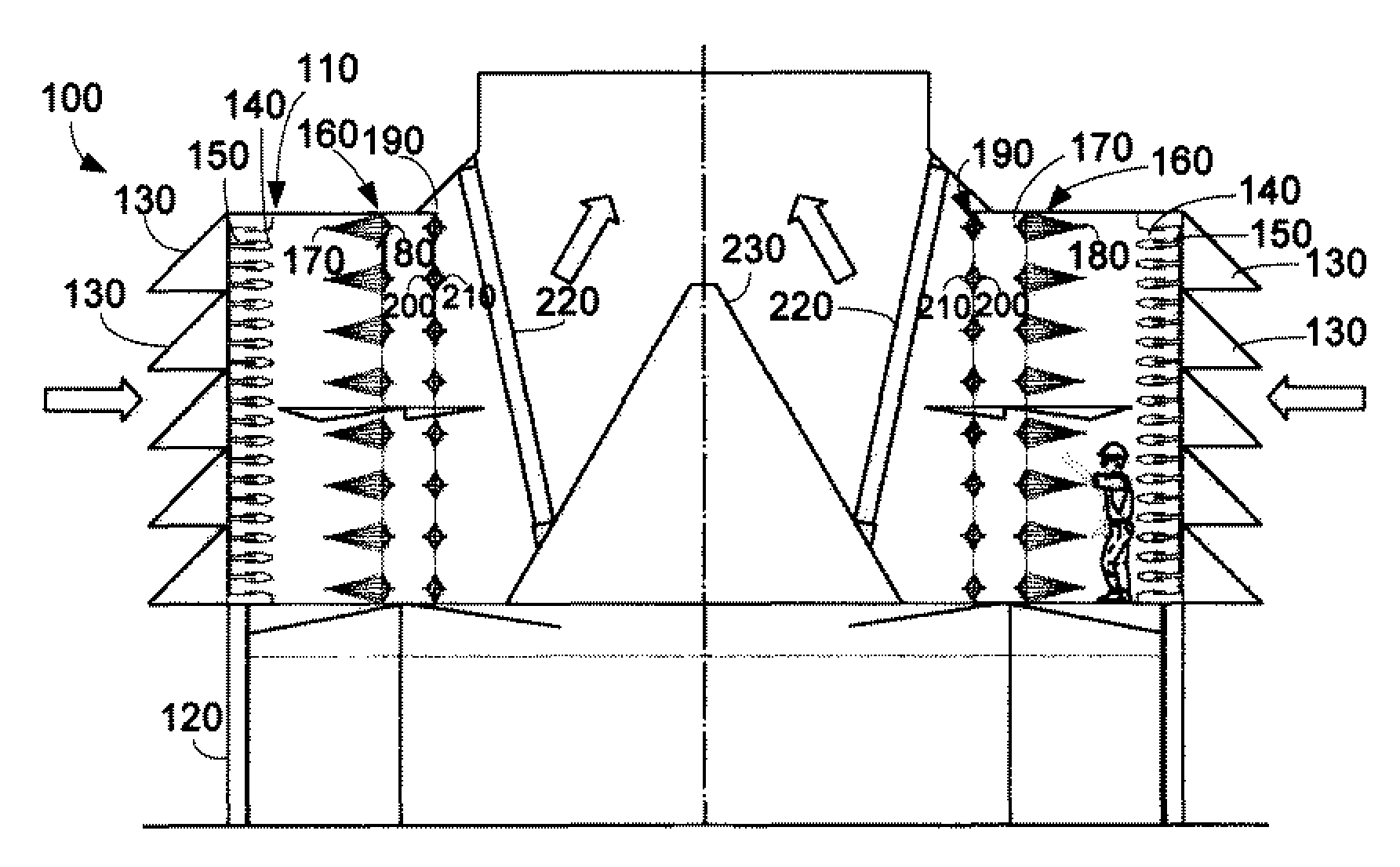

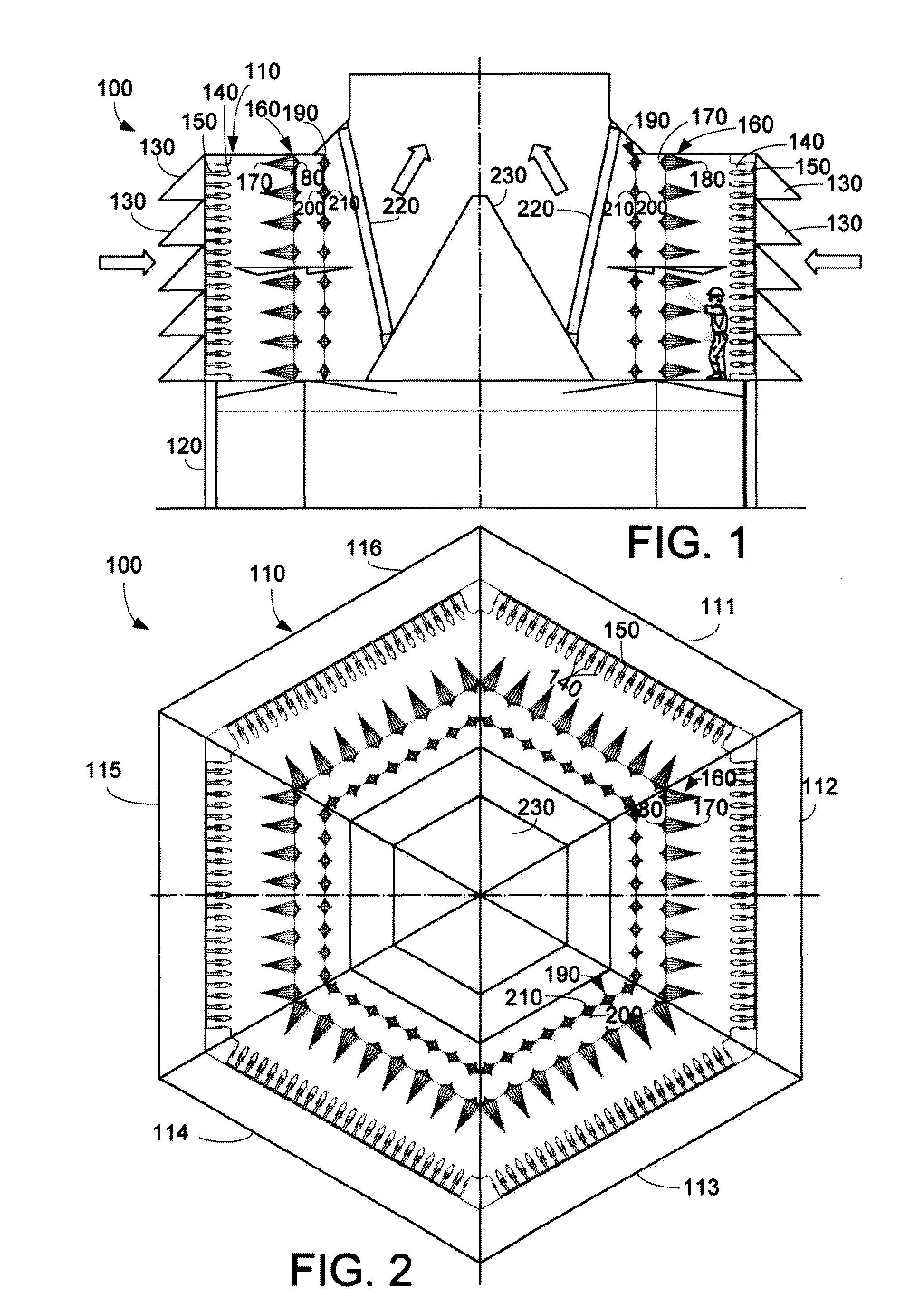

Turbine inlet air treatment apparatus

An inlet air treatment system. The inlet air treatment system includes a housing with more than two symmetric sides. Each of the sides includes a number of air filters and a number of spray arrays. A central air deflector is positioned within the housing.

Owner:GENERAL ELECTRIC CO

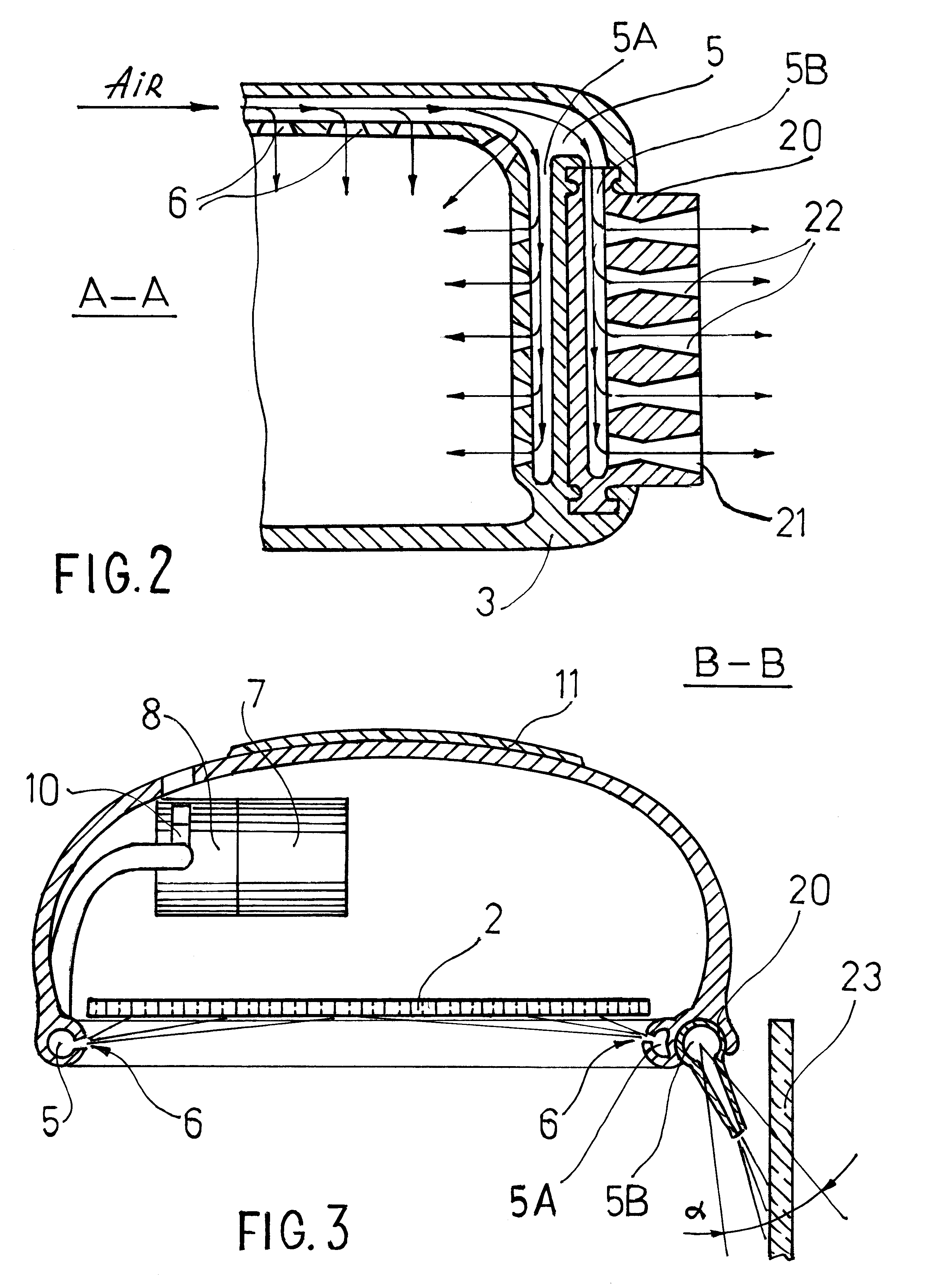

Hydronic rooftop cooling systems

InactiveUS20050056042A1Improve RTU efficiencyEnhanced evaporative cooling effectEnergy recovery in ventilation and heatingHeat recovery systemsAir filterEngineering

A roof top cooling unit has an evaporative cooling section that includes at least one evaporative module that pre-cools ventilation air and water; a condenser; a water reservoir and pump that captures and re-circulates water within the evaporative modules; a fan that exhausts air from the building and the evaporative modules and systems that refill and drain the water reservoir. The cooling unit also has a refrigerant section that includes a compressor, an expansion device, evaporator and condenser heat exchangers, and connecting refrigerant piping. Supply air components include a blower, an air filter, a cooling and / or heating coil to condition air for supply to the building, and optional dampers that, in designs that supply less than 100% outdoor air to the building, control the mixture of return and ventilation air.

Owner:DAVIS ENERGY GROUP

Personal air filtering and isolation device

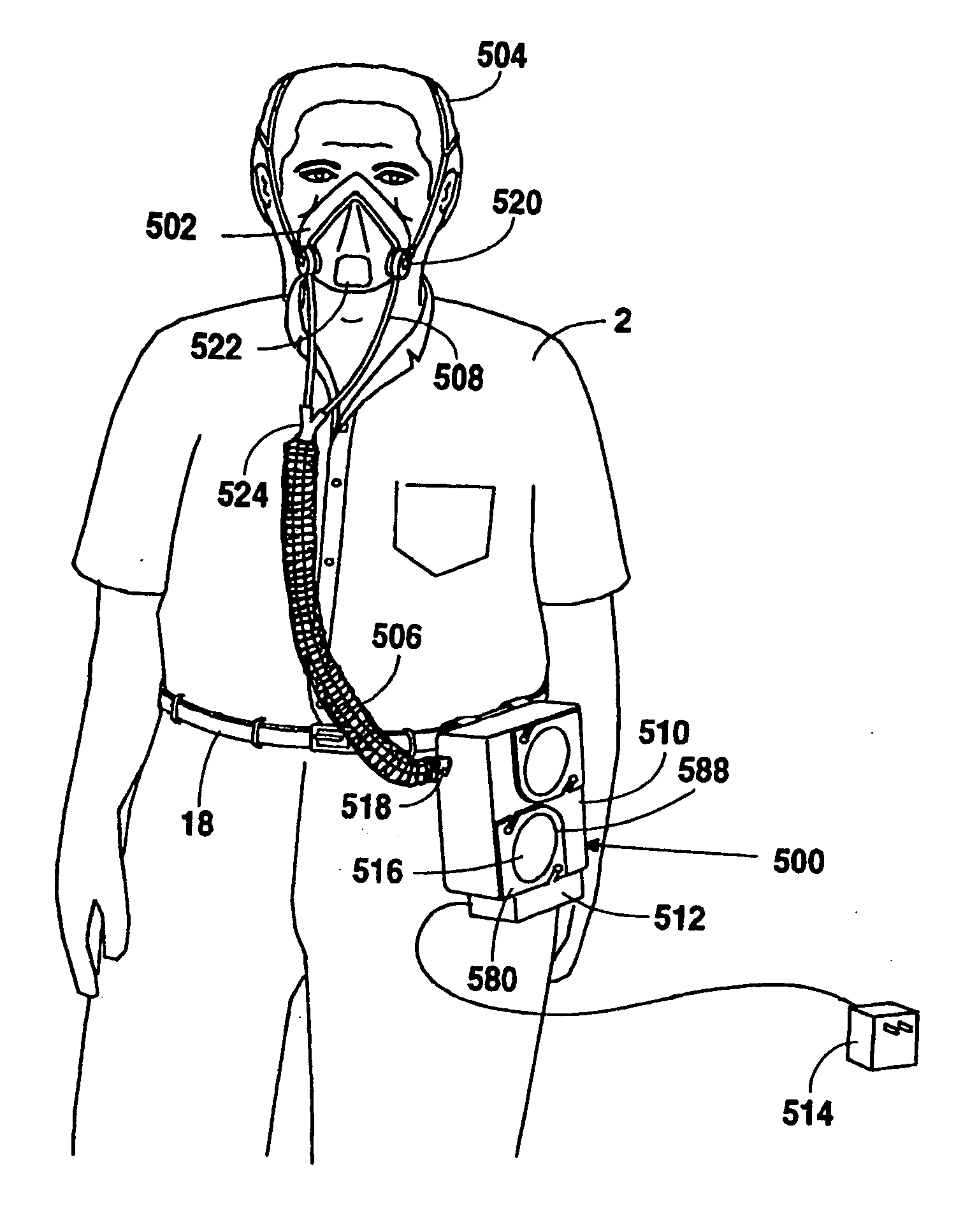

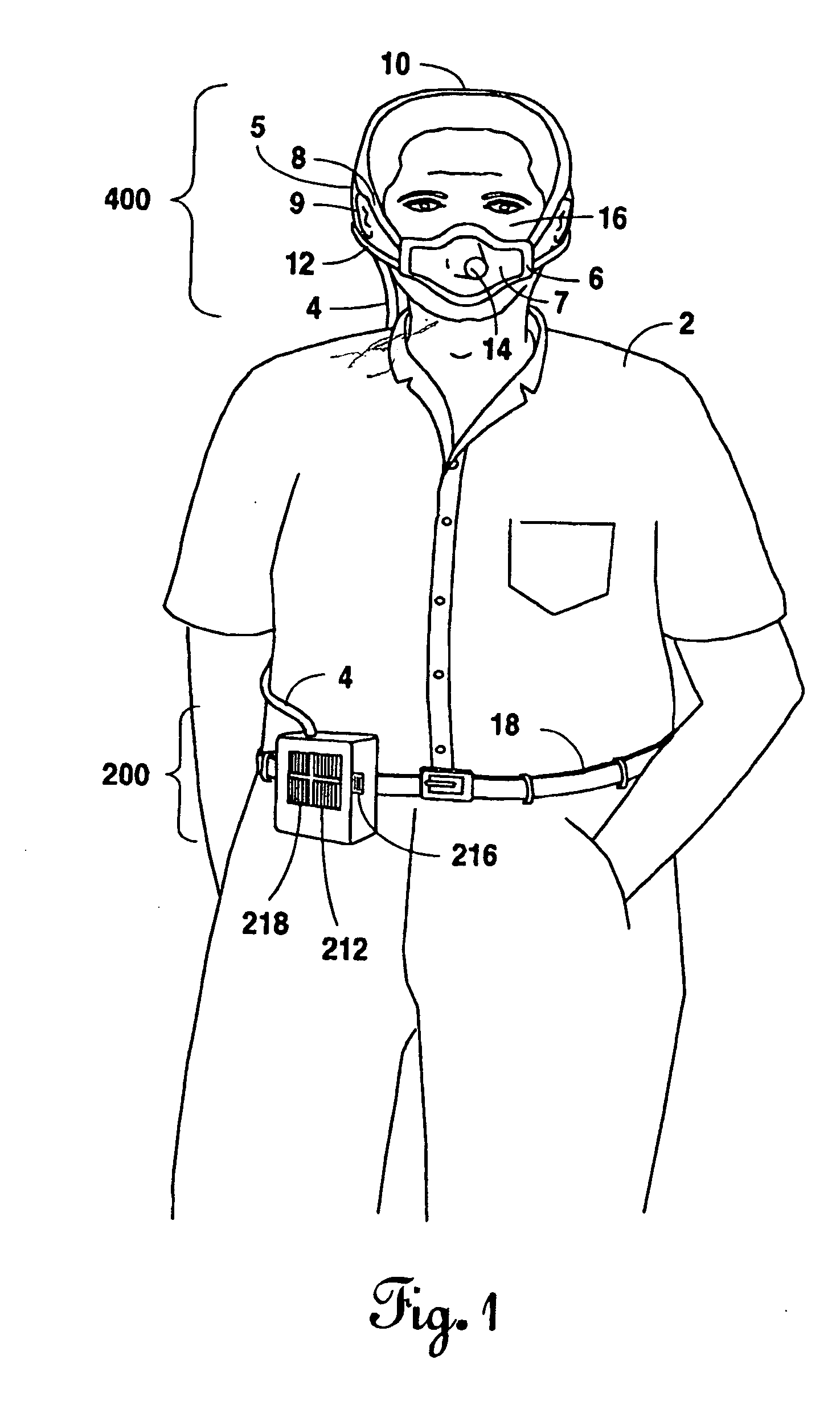

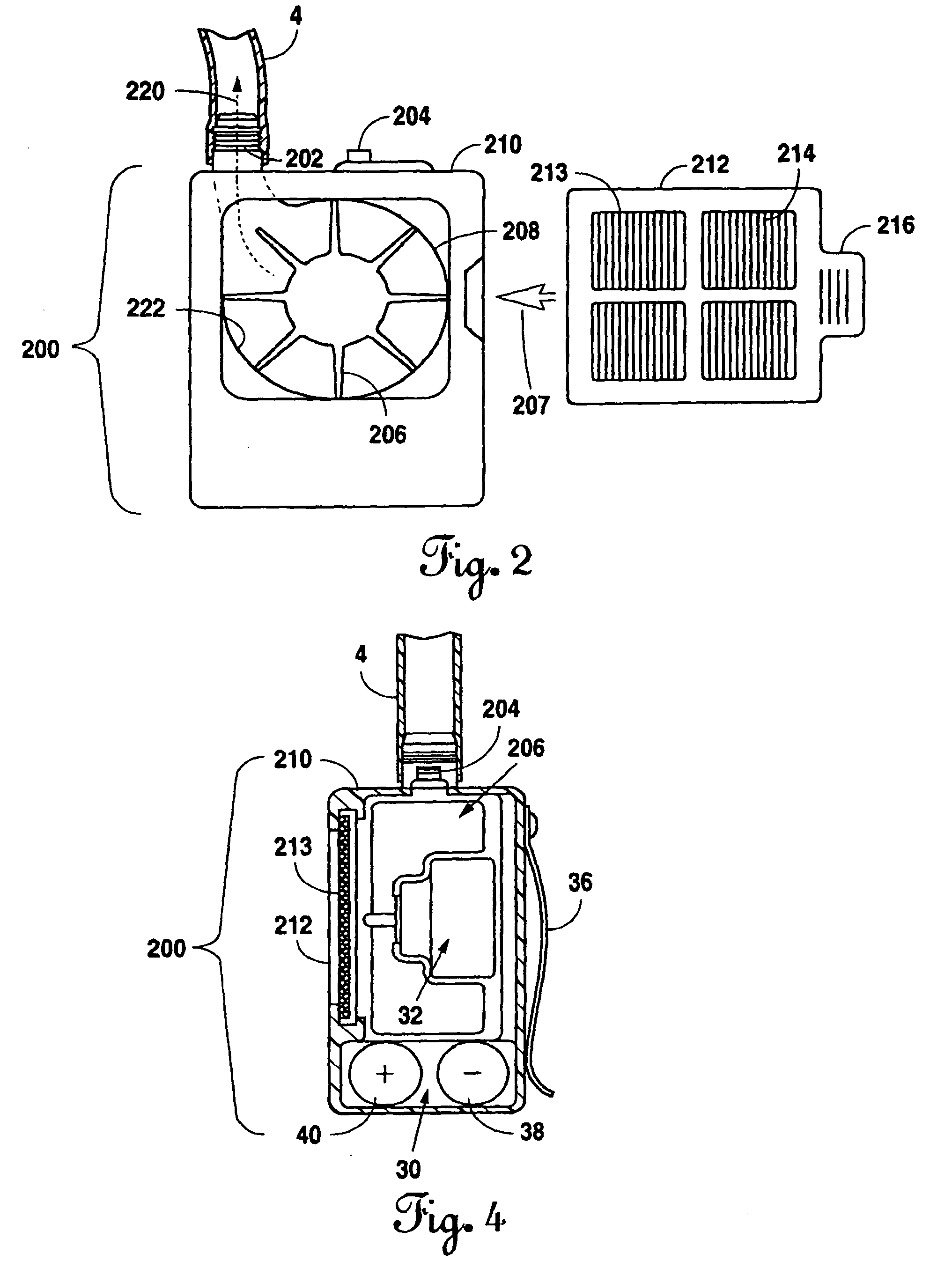

InactiveUS20070240716A1Flow of airBetter fit the user's faceRespiratorsOperating means/releasing devices for valvesParticulatesAir filter

An air filtering device is presented with a face mask of nonporous material, the face mask held onto the user's head by standard elastic straps. The face mask has a flexible gasket about its perimeter to provide an airtight seal between the mask and the user's face. The face mask has an exhaust filter that lets exhaled air out of the mask, but does not let unfiltered air into the mask. A flexible tube enters the face mask at one end and enters an air filtering assembly on the opposite end. The air filtering assembly is enclosed in a housing with the housing having an air intake opening. The air filtering assembly has an air moving device such as a fan or pump, a carbon filter cartridge, a particulate matter filter, a battery power supply, and an on-off switch.

Owner:MARX ALVIN J

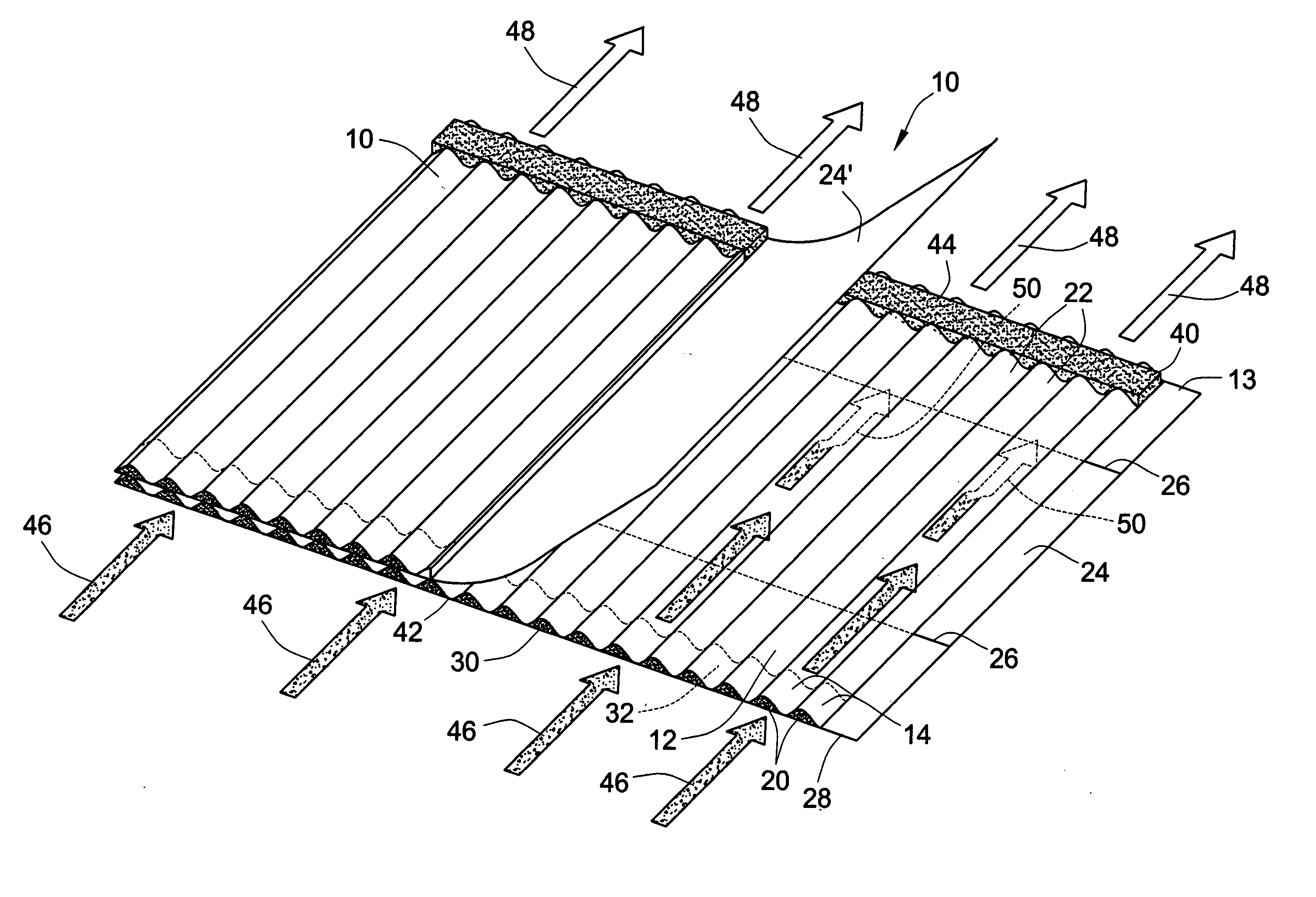

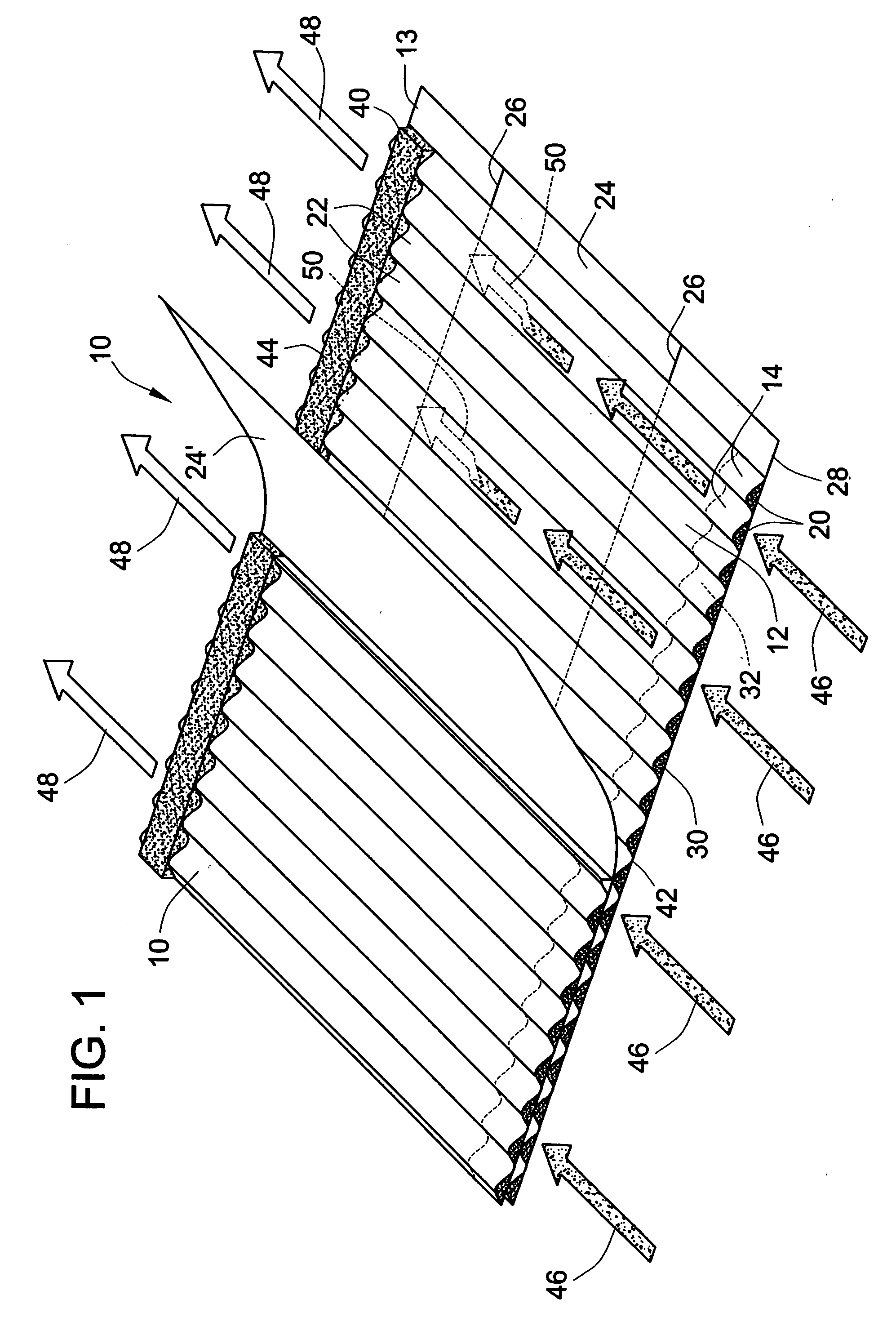

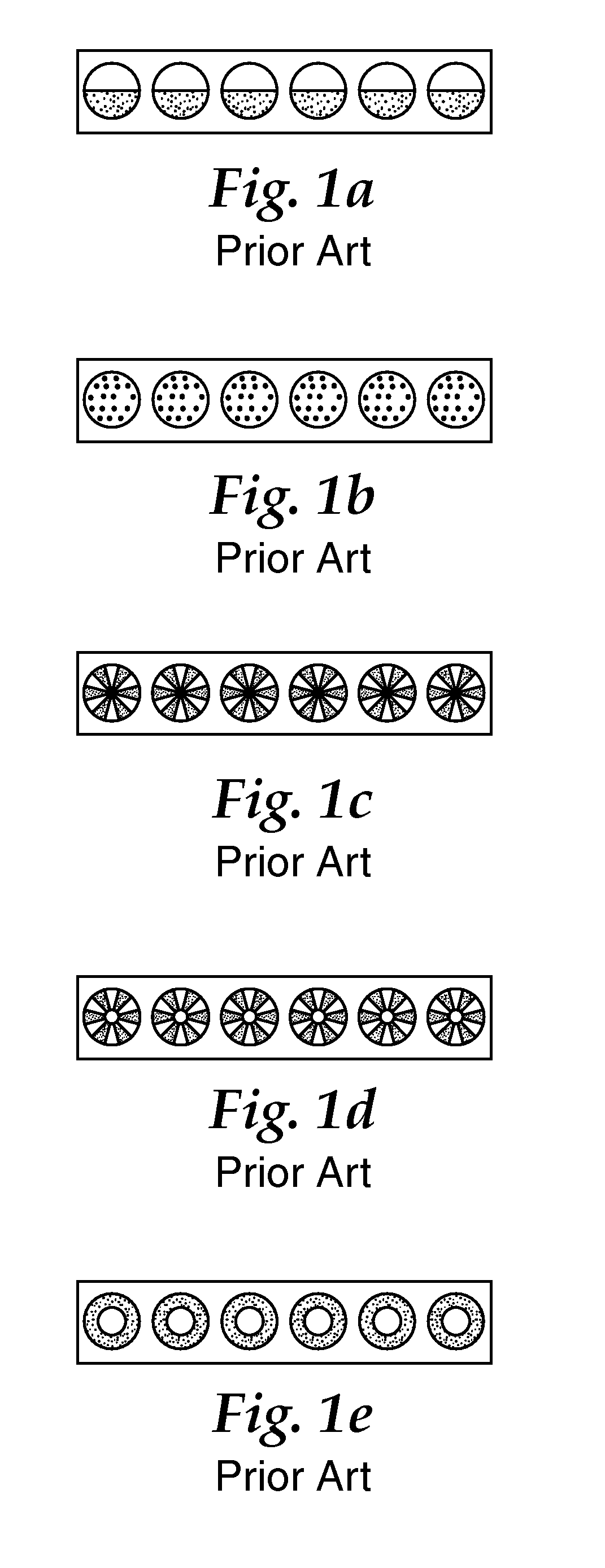

Method of making a fluted filter media for air filter

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

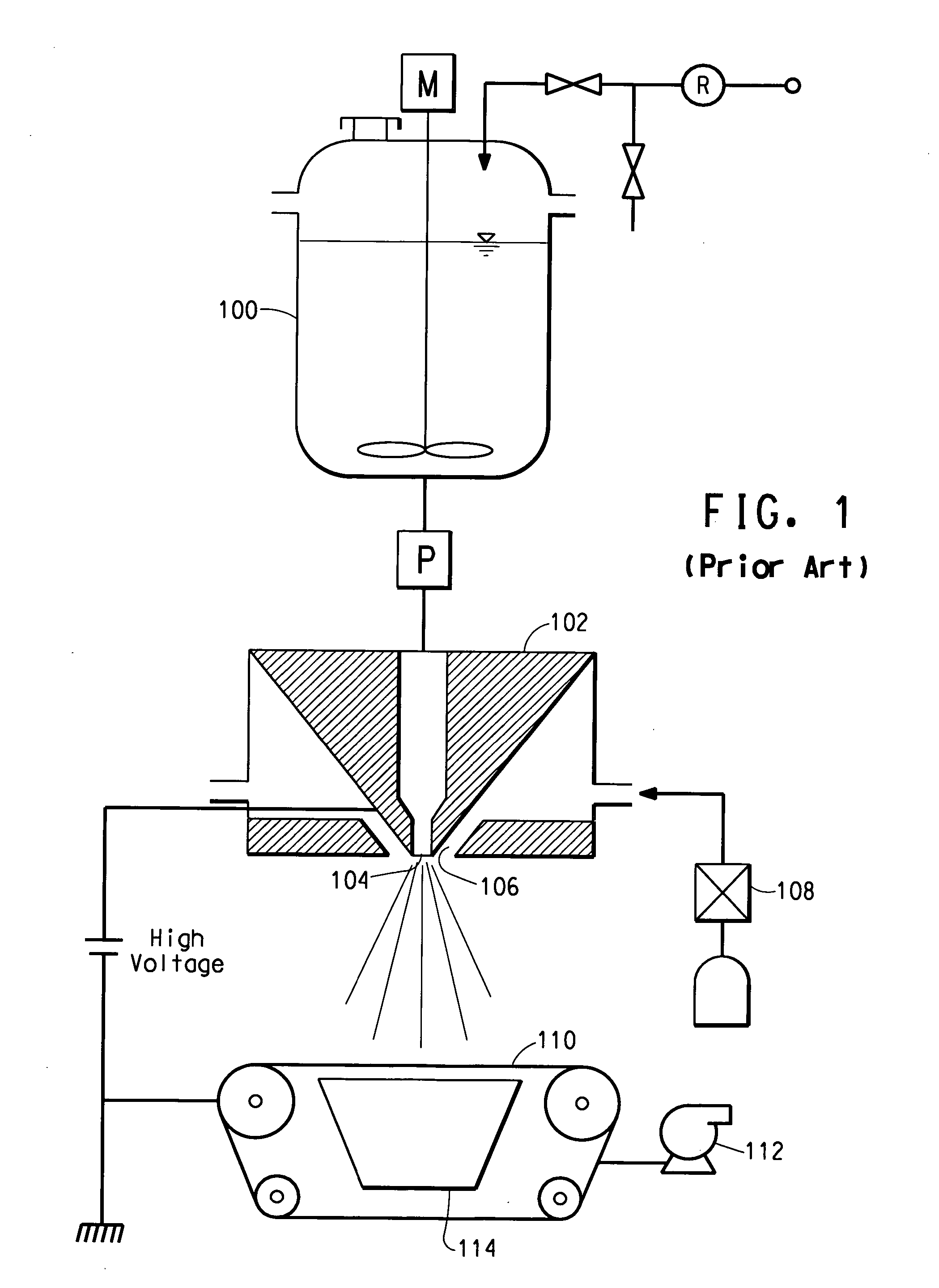

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

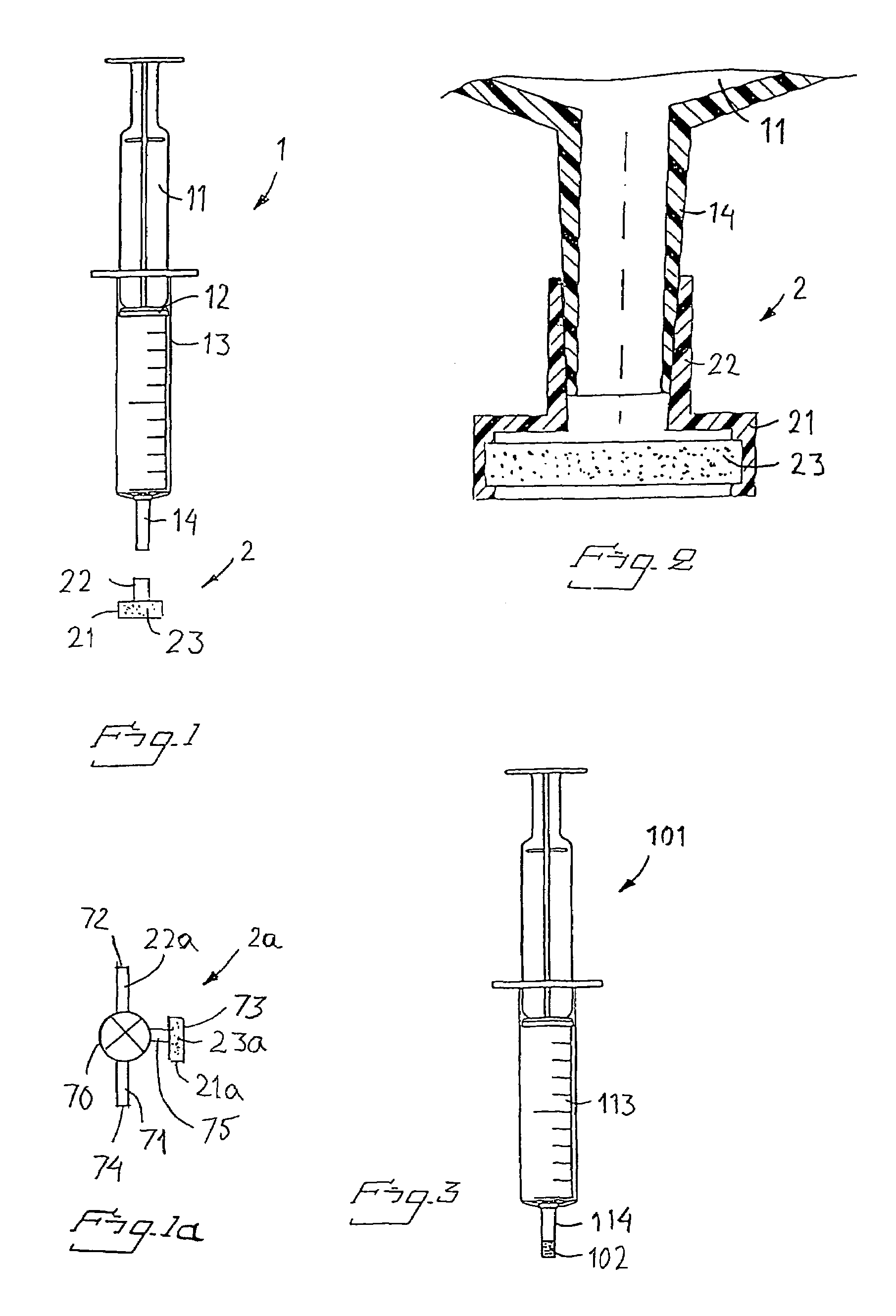

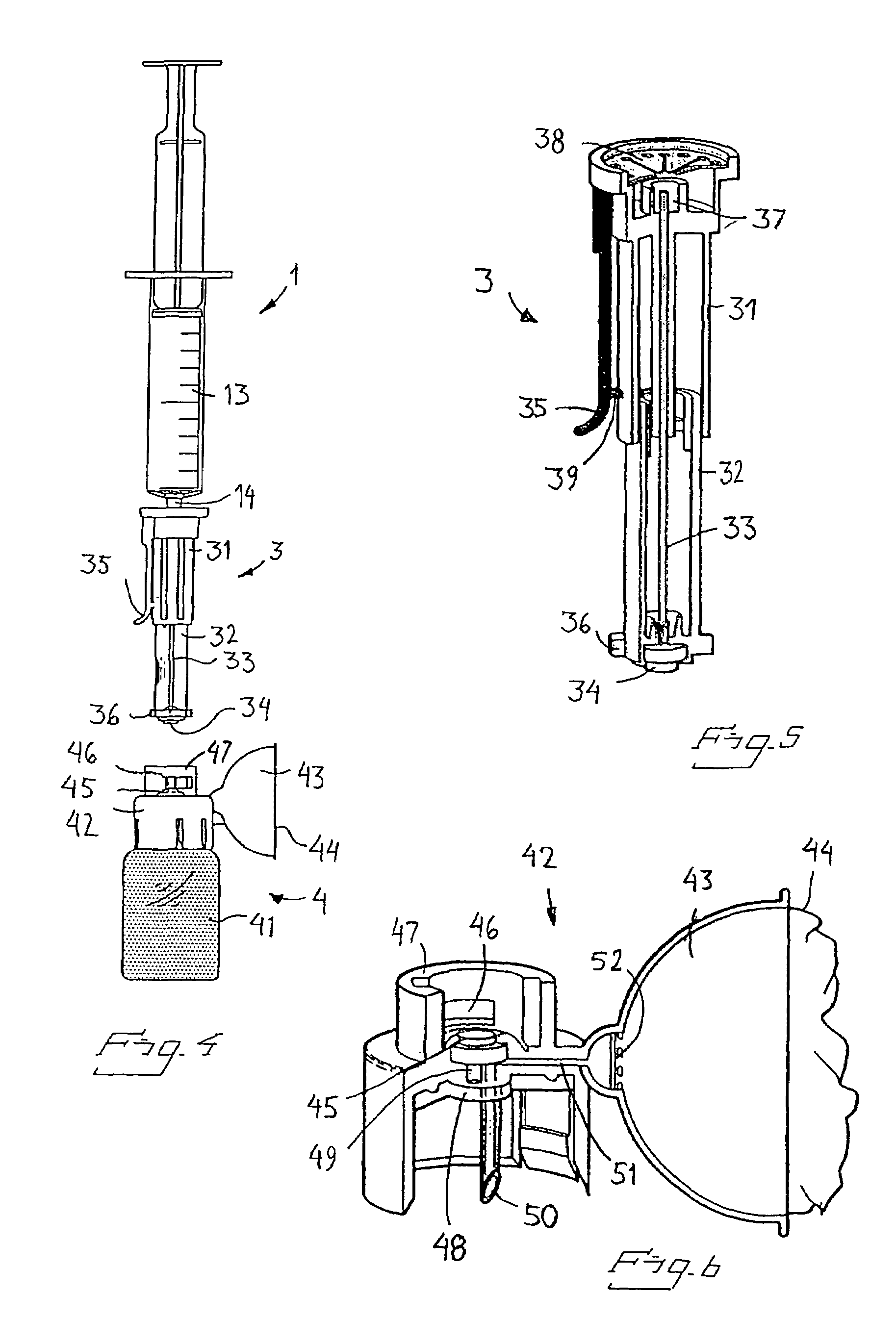

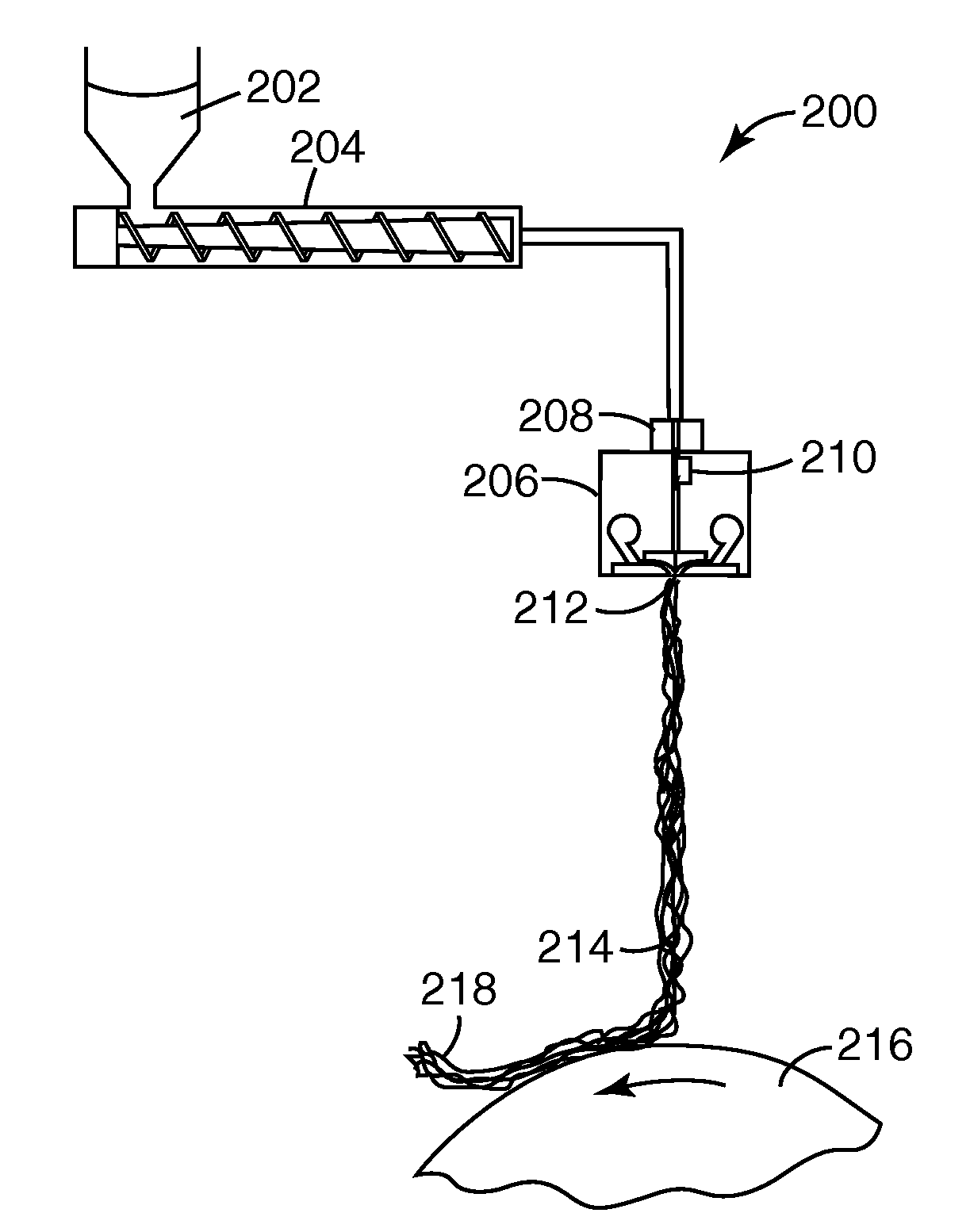

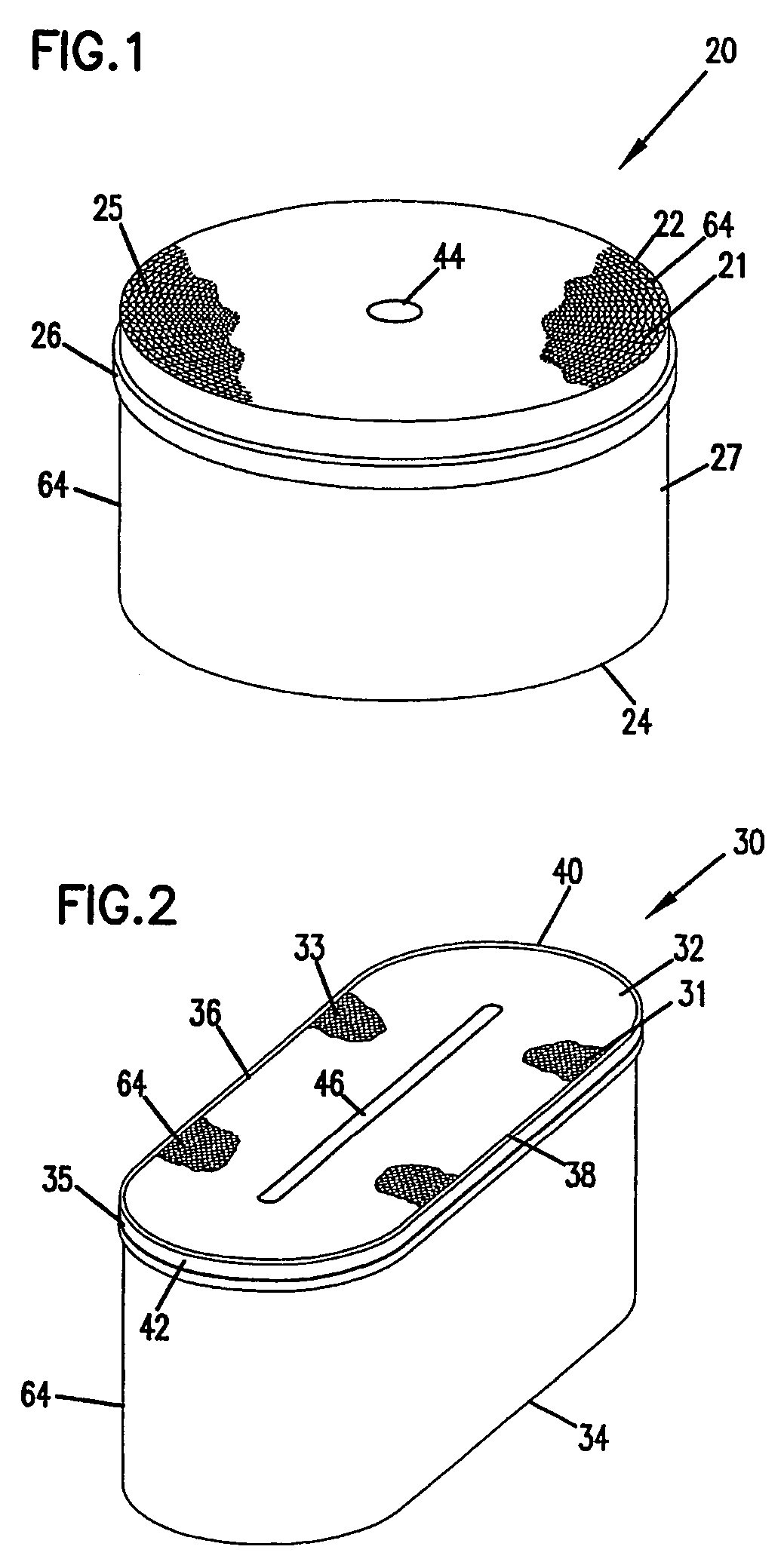

Method and arrangements in aseptic preparation

InactiveUS7306584B2Simple methodLow costInfusion syringesPharmaceutical containersAir filterEngineering

A first aspect of the invention relates to a method for aseptic preparation with an injection syringe. The syringe comprises a container for injection agent and an immovable connection nozzle connected to the container. The method entails charging the container with air. According to the invention air is forced to pass through an air filter arranged on the connection nozzle. This enables the syringe container to be charged with aseptic air in a simple and reliable fashion. Other aspects of the invention relate to devices for performing the method, viz. an injection syringe equipped with an air filter in the connection nozzle, a filter unit (2) connectable to an injection syringe's (1) connection nozzle (13) and a system comprising an injection syringe (1) and a separate filter unit (2). The invention devices convey advantages of the same kind as the invention method.

Owner:CARMEL PHARMA

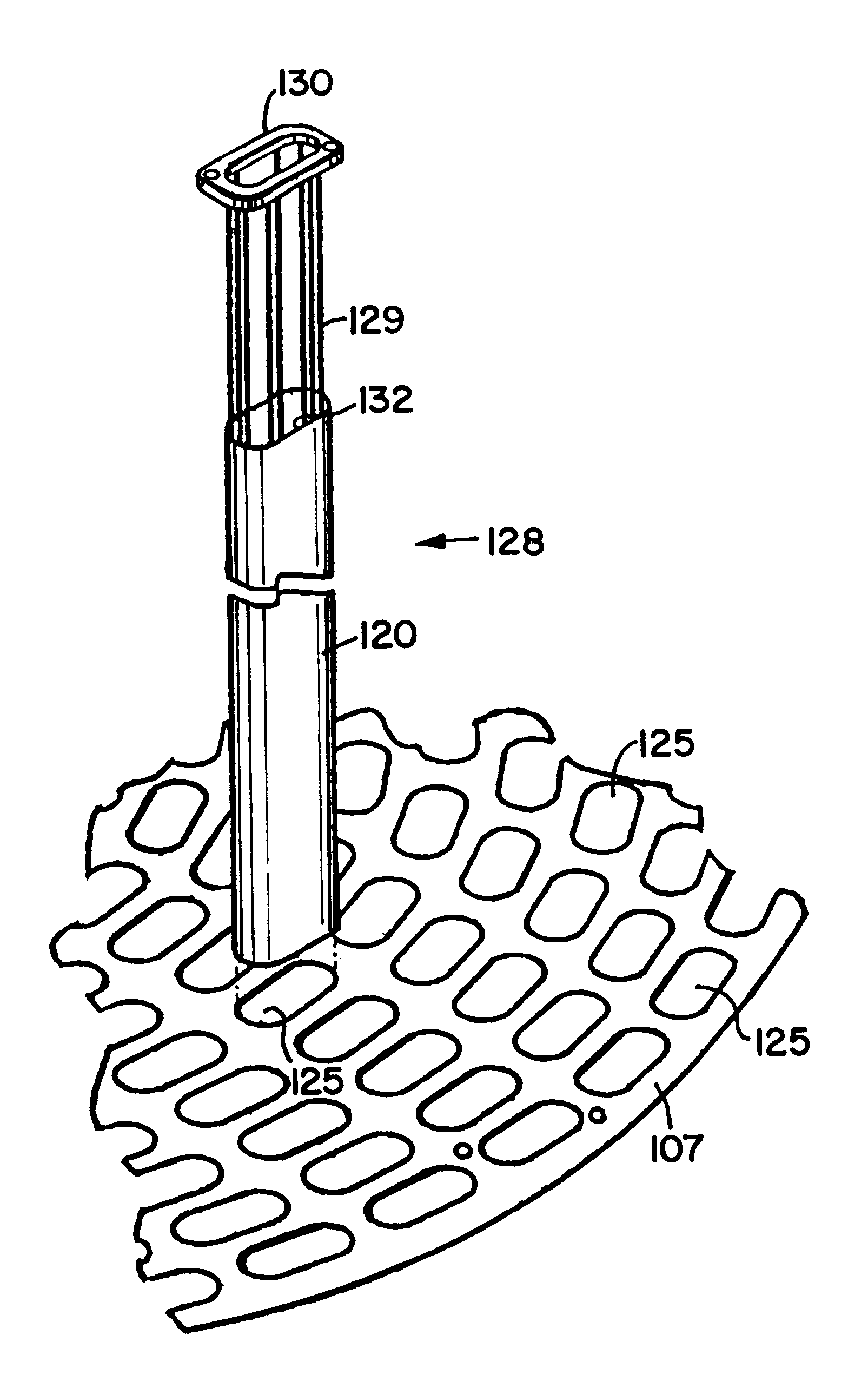

Industrial bag house elements

InactiveUS6740142B2Low efficiencyShort lifeCombination devicesMaterial nanotechnologyAir filterFilter media

The filter structures commonly known as a bag house or a filter bag or an air filter with a bag construction can be made by preparing the bag assembly, either in a tubular or a bi-fold construction by placing a layer of fine fiber on the upstream surface of the filter media structure. The filter assembly includes a filter cabinet with an interior component. The filter component is suspended within the filter cabinet interior. The filter component includes a frame or support for the filter media. The frame or support holds the filter bags such that the filter bags are suspended from the frame in the cabinet interior. The intake air enters the cabinet, passes through the filter assembly and exits the cabinet. The air must pass first into the fine fiber layer, the filter media and then the exterior of the cabinet.

Owner:DONALDSON CO INC

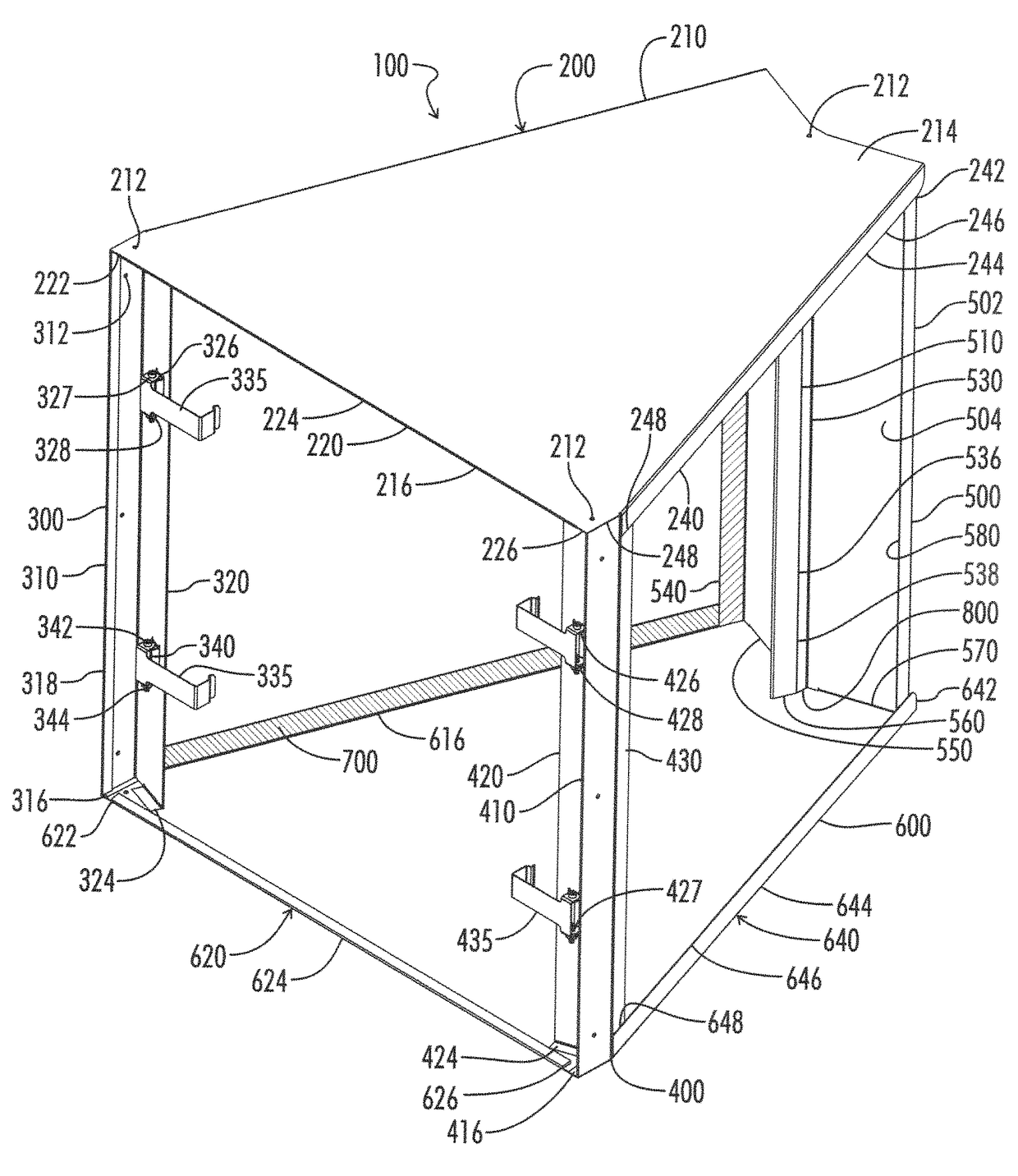

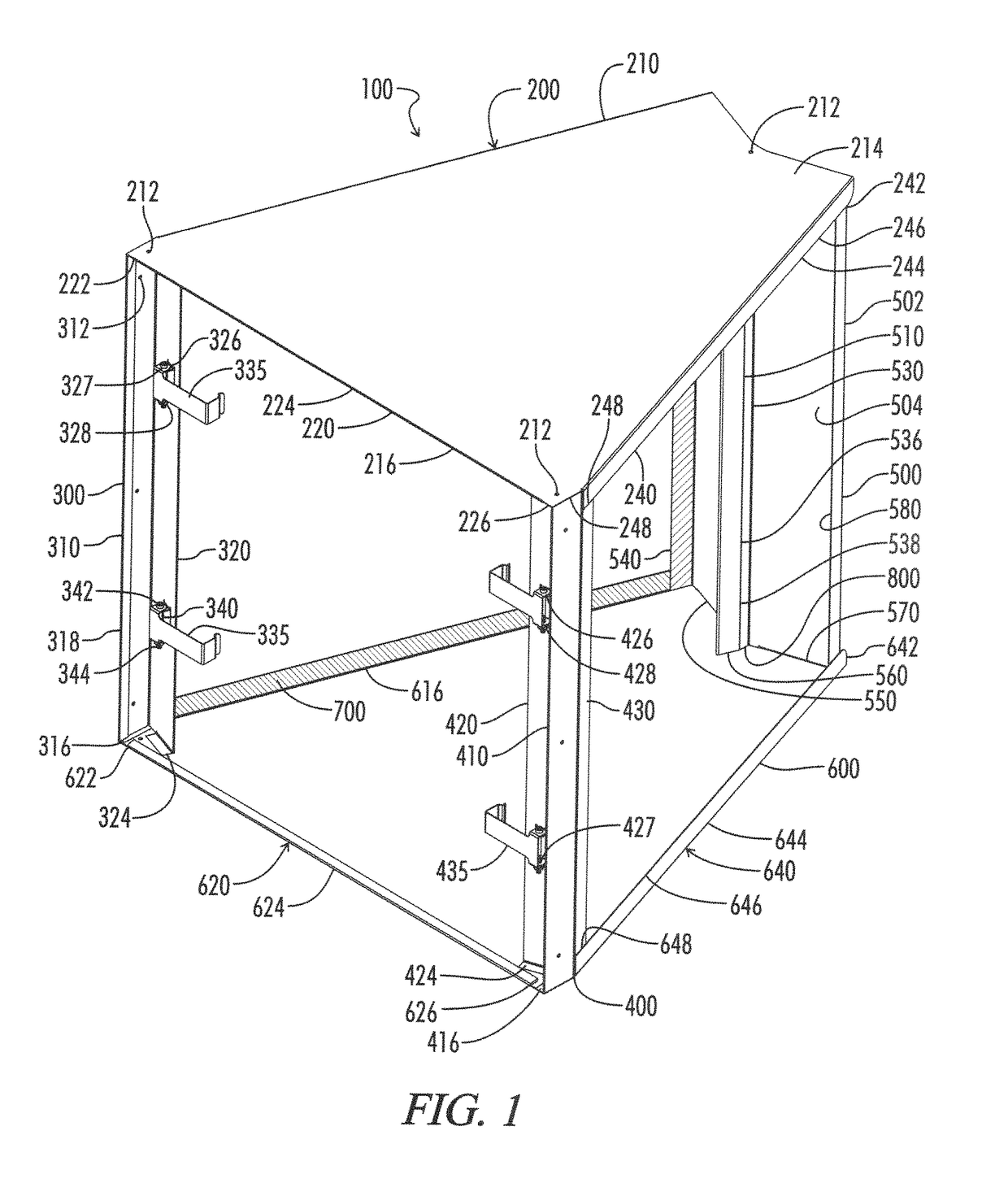

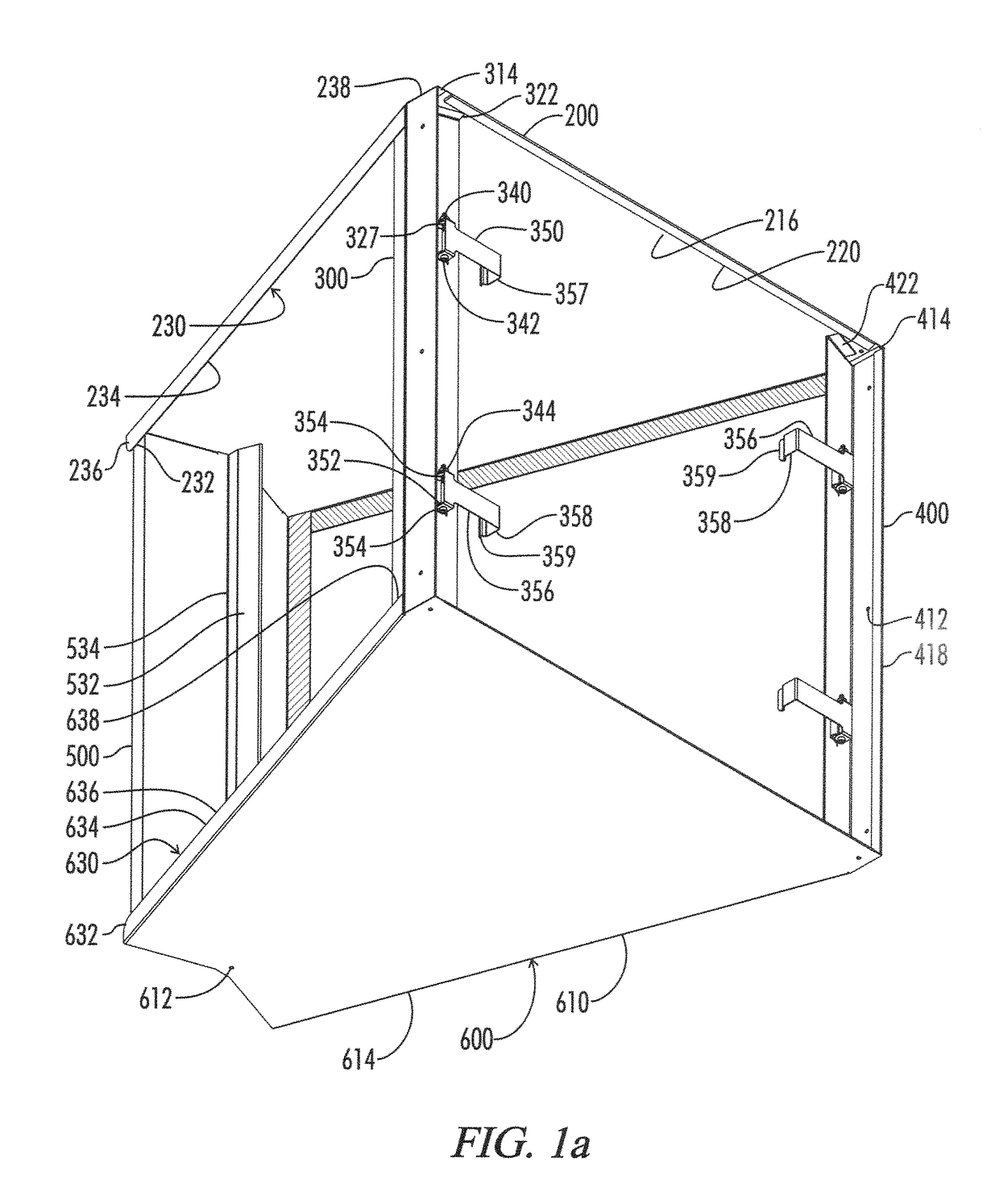

Modular air filter housing

ActiveUS9764266B1Improve sealingImprove efficiencyDispersed particle filtrationTransportation and packagingAir filterMechanical engineering

An air filter module for modularly mounting angled air filters. The module includes a top plate, bottom plate, left and right front corners with the corners defining perpendicular side walls, angled filter end retention walls, angled side walls, and a back wall with angled side walls, parallel end retention walls, and a positioning guide. The positioning guide is constructed from clips or a guide face and an inner side positioning wall.

Owner:CARTER SCOTT

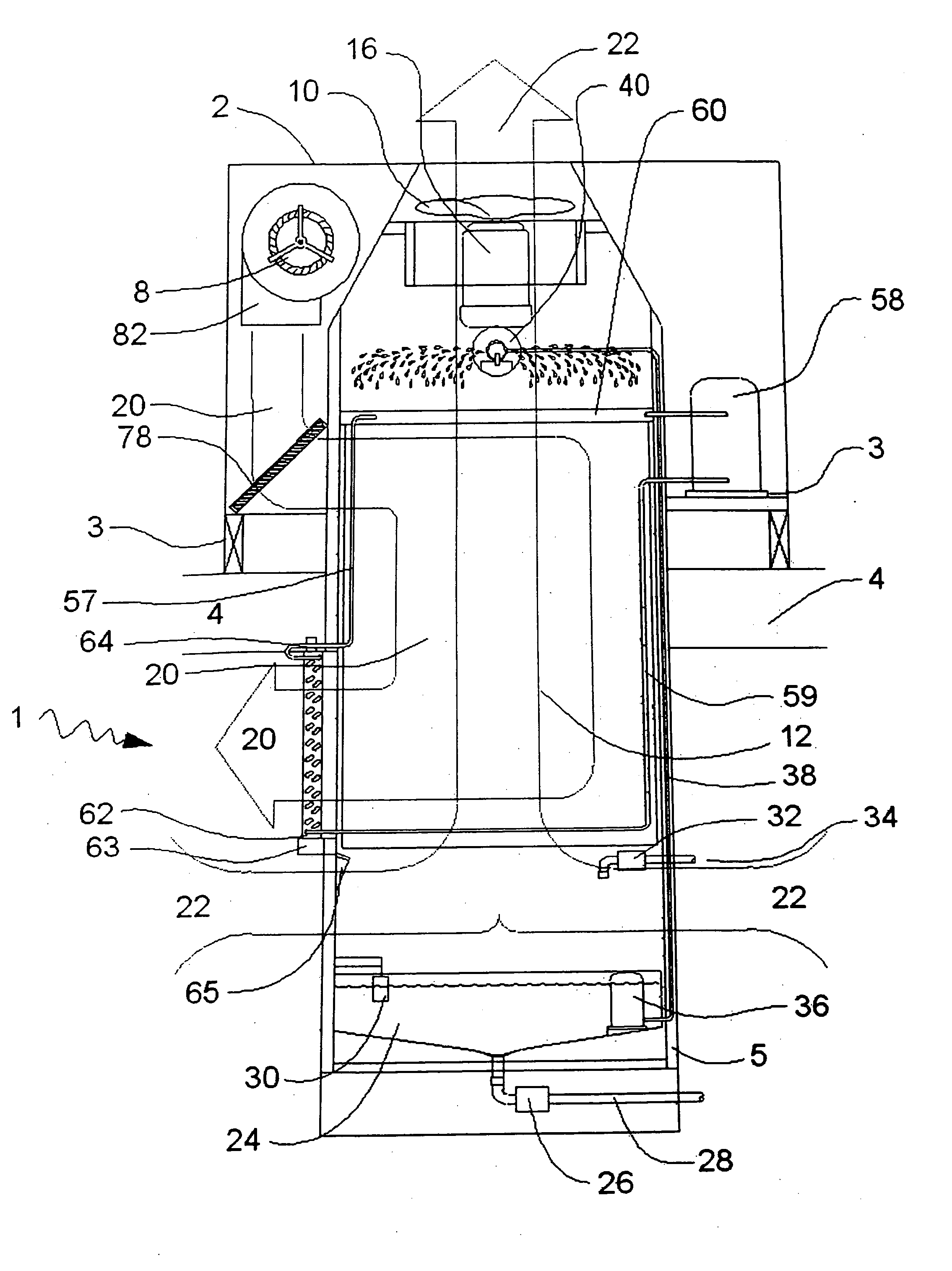

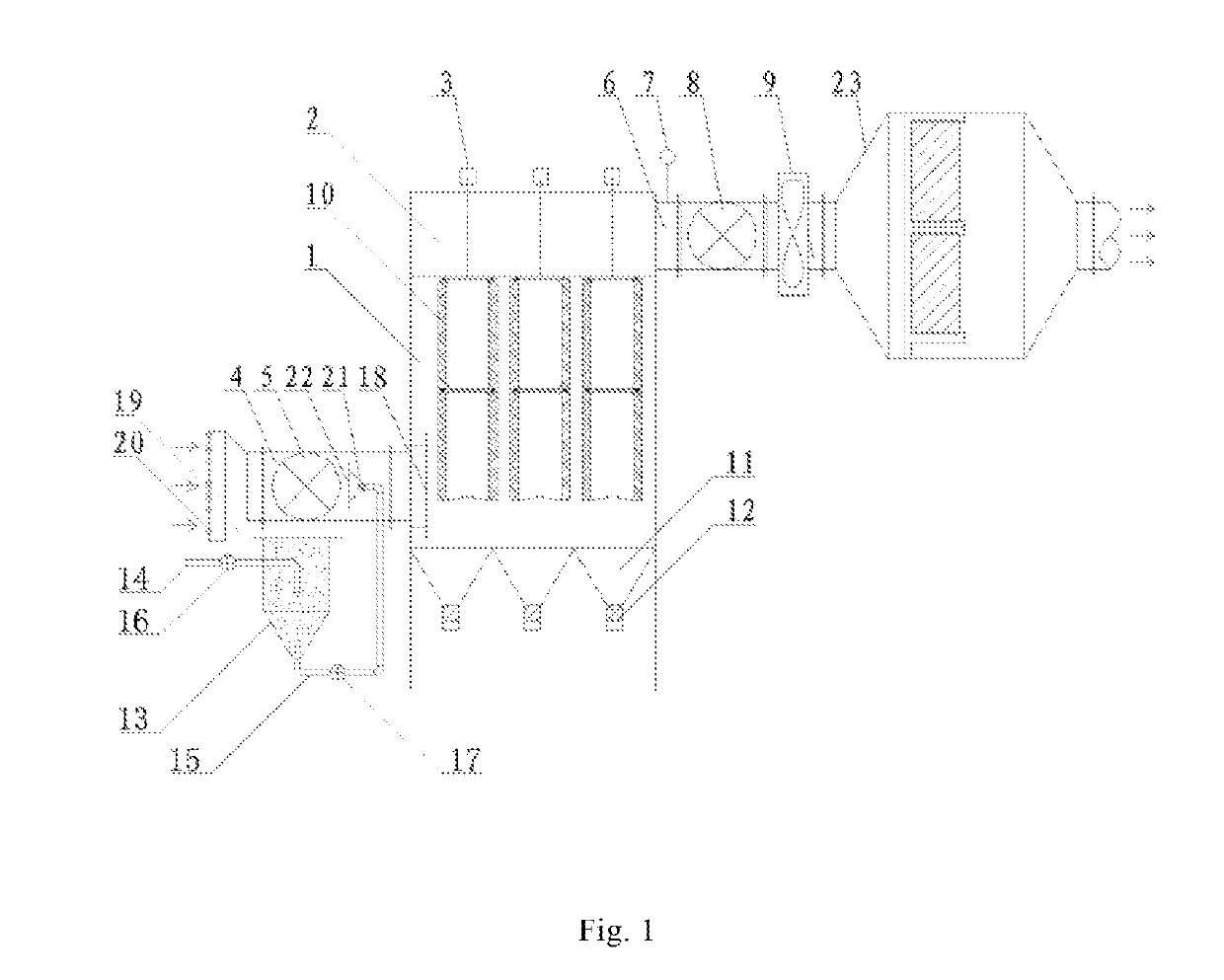

High efficiency air filter device and operating method thereof

PendingUS20190091619A1Improve efficiencyReduce energy consumptionDispersed particle filtrationTransportation and packagingAir filtrationAir filter

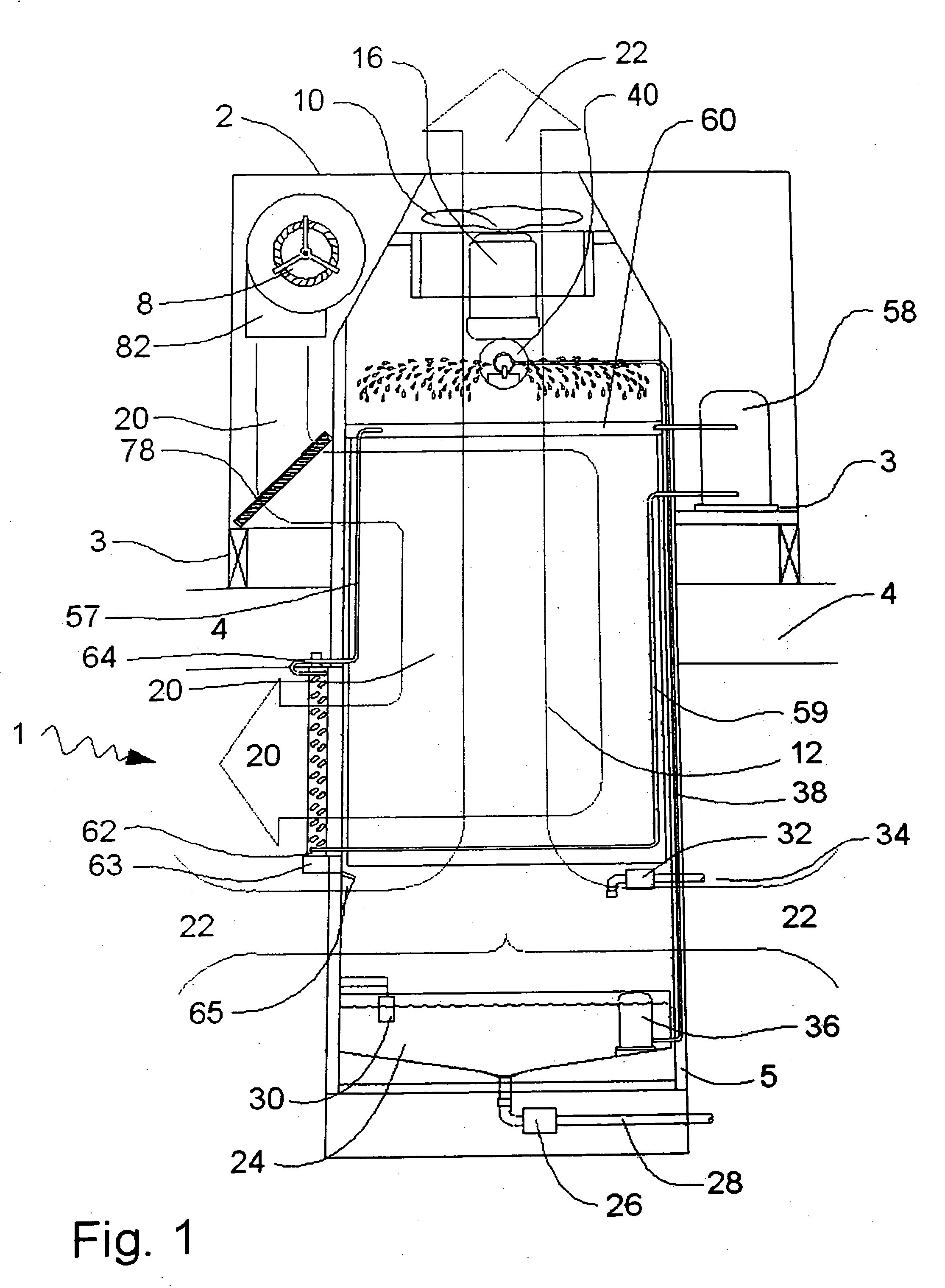

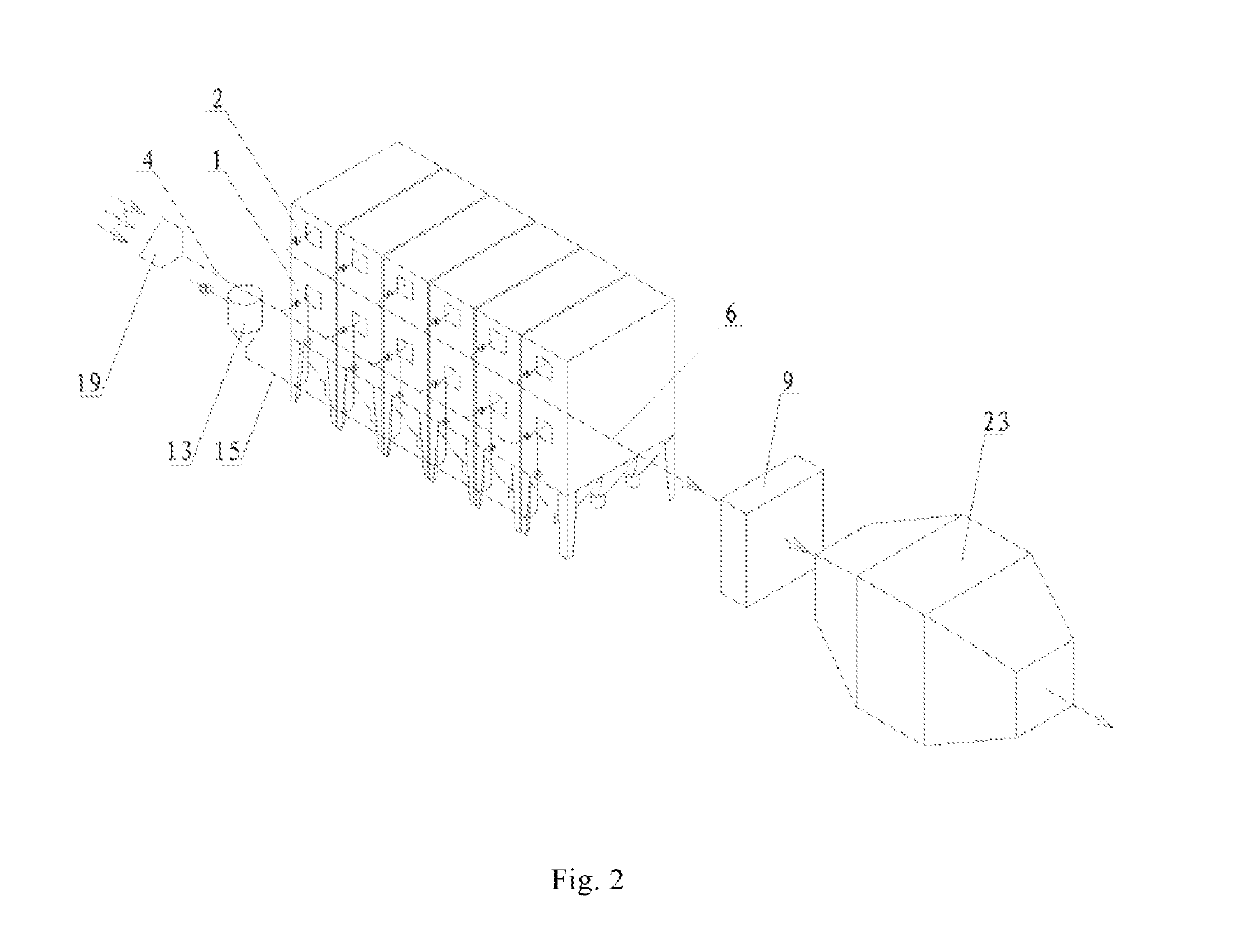

An air filter device and an operating method thereof. The air filter device comprises an air filter system and a powder distribution system. The air filter system comprises an air filter chamber (1), a clean air chamber (2), and a high-pressure jet pulse powder cleaning device (3). An entrance of the air filter chamber (1) is in communication with an air inlet pipe (4); an exit of the clean air chamber (2) is in communication with an air outlet pipe (6), and the air outlet pipe (6) is in communication with an exhaust fan (9). A plurality of bag filters or filter cartridges (10) are disposed in the air filter chamber (1). An opening end of each of the bag filters or filter cartridges (10) is in communication with the clean air chamber (2), and high-pressure jet pulse powder cleaning devices (3) are disposed above the opening end of the corresponding bag filters or filter cartridges (10). The powder distribution system includes a powder storage tank (13), which is in communication, via a powder delivery tube (15), with the air inlet pipe (4) of the air filter chamber (1). The operating method comprises a first powder distribution step and a second powder distribution step, which are respectively performed according to pressure detection status of the air filter chamber (1).

Owner:FOSHAN HUMAN HABITAT ENVIRONMENTAL PROTECTION ENG

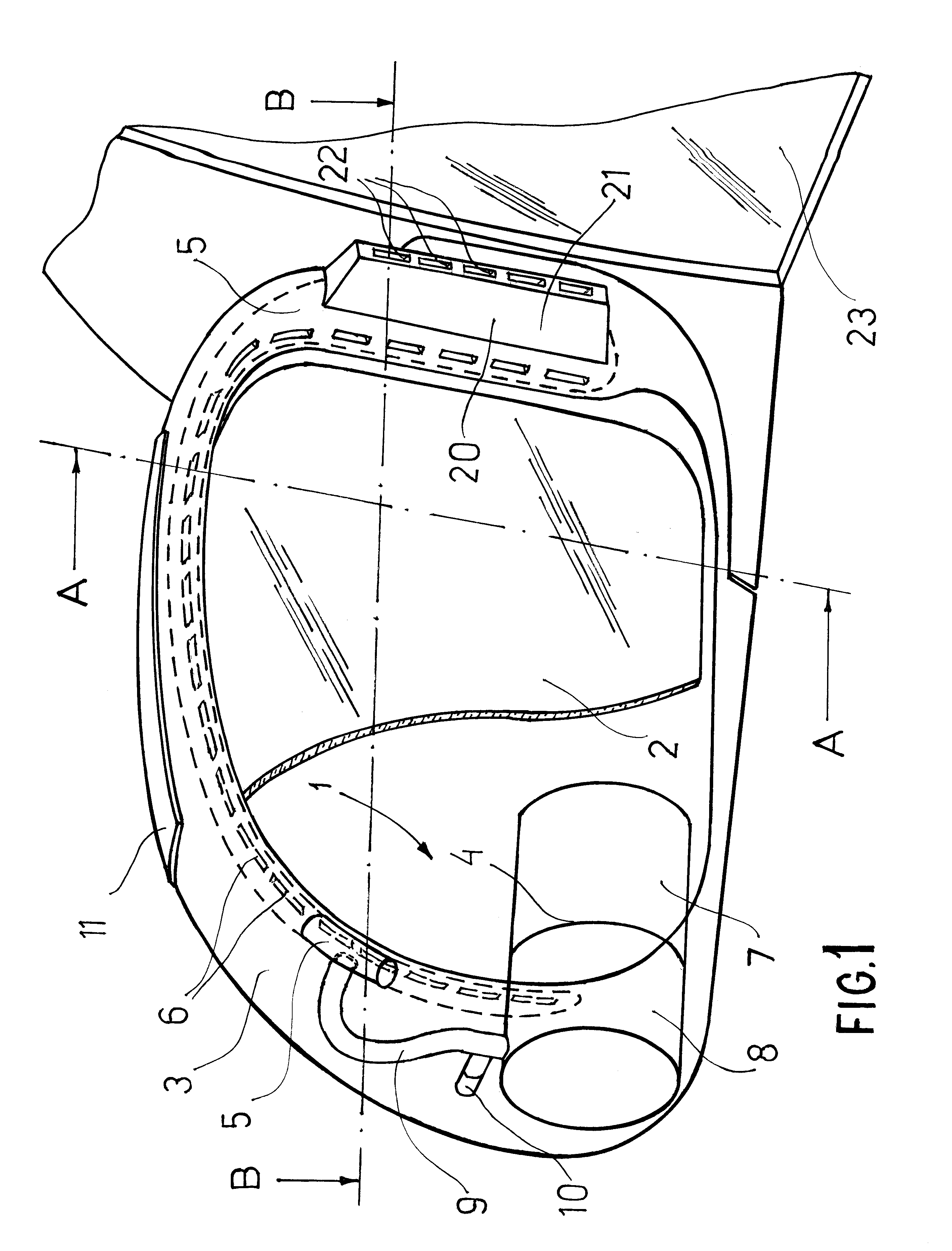

Intake and exhaust system of turbine engine

PendingCN111206994AMeet air intake needsAvoid damageGas turbine plantsTurbine/propulsion air intakesAir filterExhaust fumes

The invention discloses an intake and exhaust system of a turbine engine. The intake and exhaust system of the turbine engine comprises an intake system and an exhaust system, wherein the intake system is connected with an intake port of the turbine engine, the exhaust system is connected with an exhaust port of the turbine engine, the intake system comprises an intake filter and an intake pipeline, the intake filter is connected with the intake pipeline, the intake filter adopts a V-shaped structure, and a rain shielding cap is arranged at the exhaust tail end of the exhaust system. The intake and exhaust system of the turbine engine has the beneficial effects that the air inlet area is large, the air inlet flow speed is lower, the service life of an air filter is long, the rain shieldingcap additionally arranged at the exhaust port avoids the rainwater deposition in an exhaust silencer, the condition that rainwater possibly flows backwards is avoided and damages the turbine engine,and an opening of the rain shielding cap is away from the intake port, so that exhausted waste gas is prevented from being sucked by the intake port, and the quality of inlet air is ensured.

Owner:美国杰瑞国际有限公司

Monocomponent Monolayer Meltblown Web And Meltblowing Apparatus

ActiveUS20080026659A1Good molding effectIncrease fiber surface areaDispersed particle filtrationMagnetic materials for record carriersPolymer scienceRespirator

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

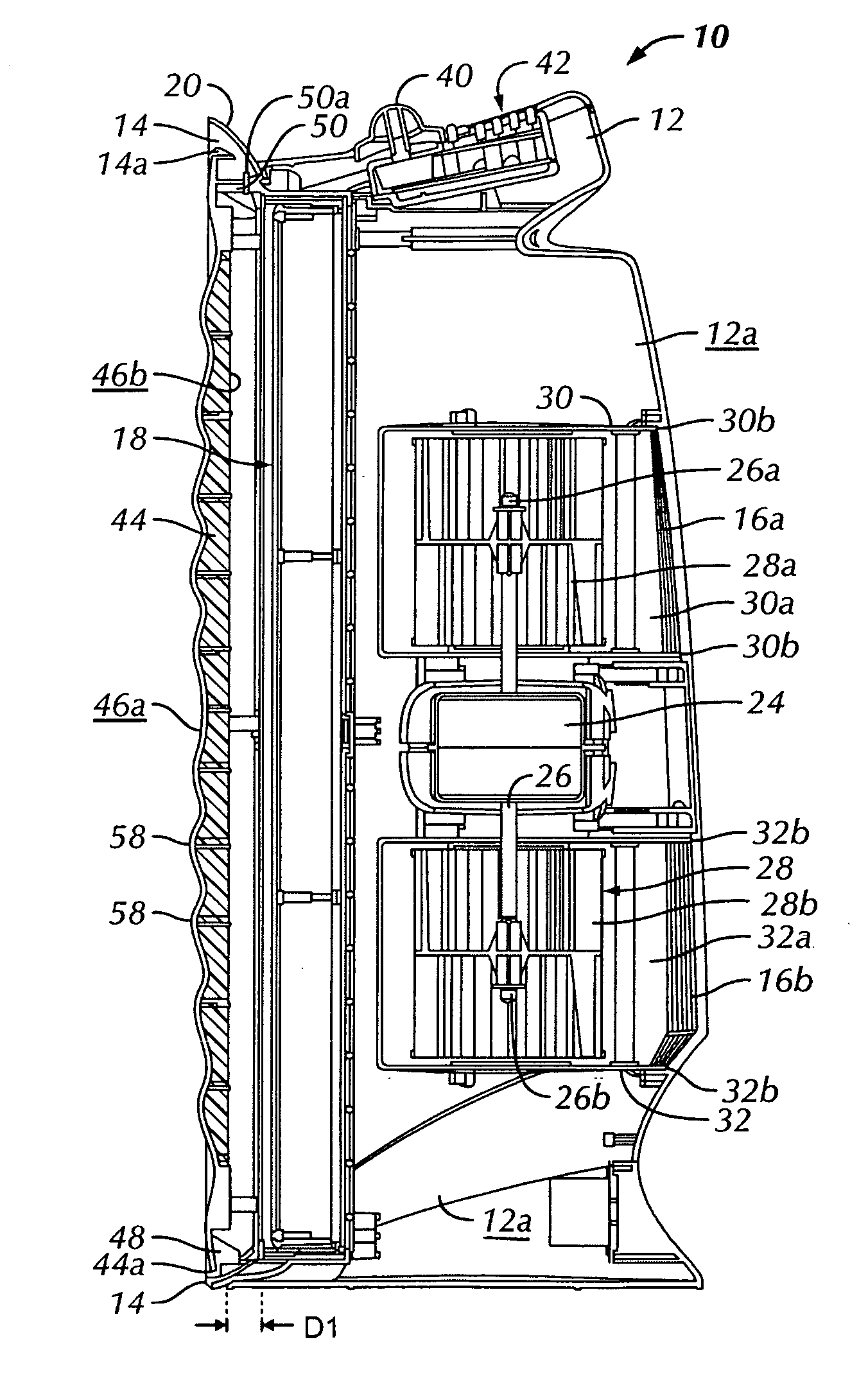

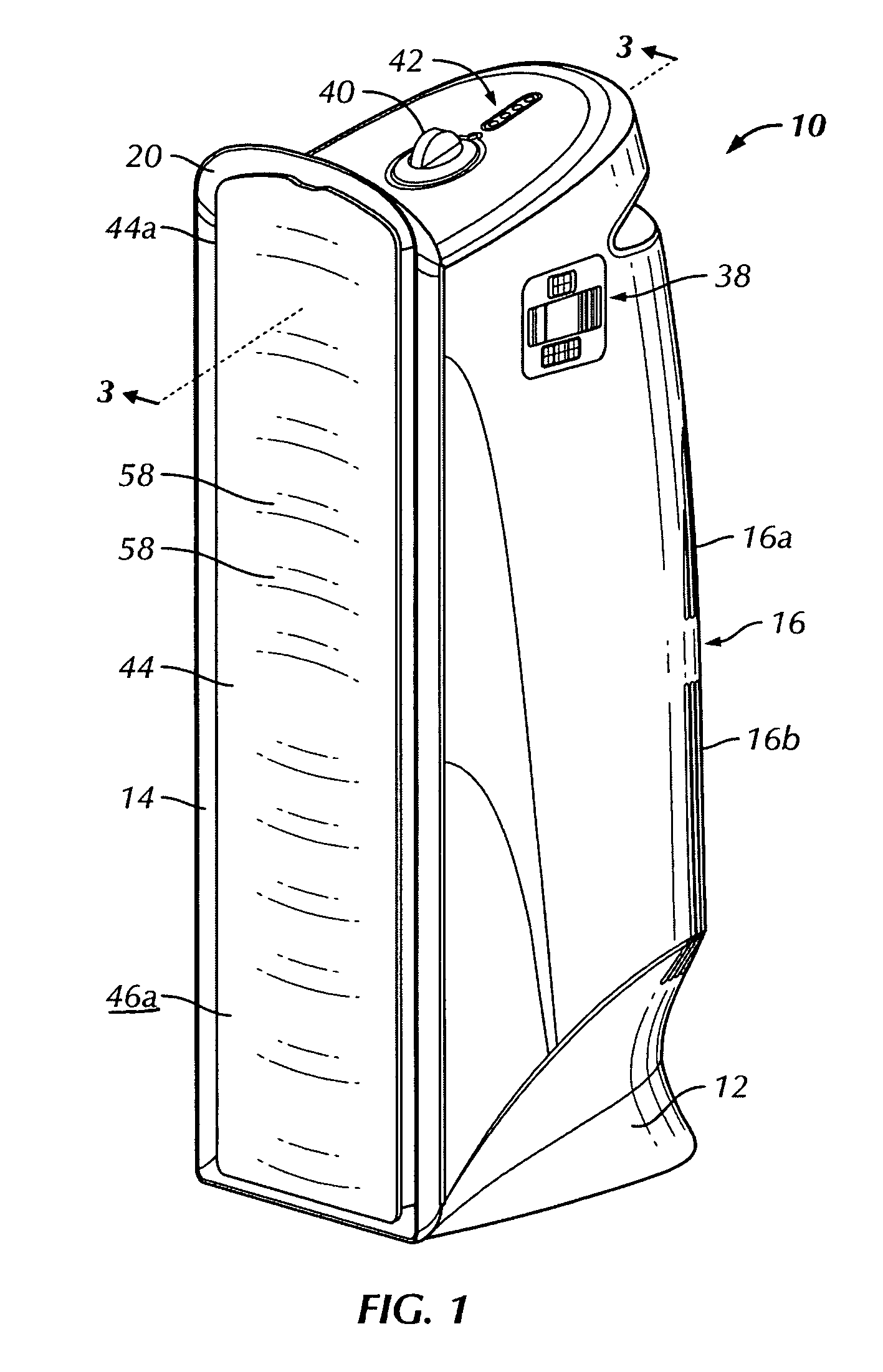

Air purifier

An air purifier for removing particles from air and providing an aesthetically pleasing appearance includes a housing having an air inlet, an air outlet and an airflow path therethrough. An air filter is mounted within the housing in the airflow path and a motor is mounted within the housing. The motor includes a motor shaft and a fan is mounted to the motor shaft for urging air into the air inlet, through the airflow path and out of the air outlet. An air cowl is removably mounted to the housing. The air cowl includes a peripheral edge. The air inlet or the air outlet is defined between the peripheral edge and the housing. A method of operating the air purifier with the inlet or outlet formed between the peripheral edge and the housing is also disclosed.

Owner:HAMILTON BEACH BRANDS

Compositions comprising cyclodextrin derivatives

A stable composition for removing unwanted molecules from a surface comprises low-degree of substitution cyclodextrin derivatives. The compositions are suitable for capturing unwanted molecules from inanimate surfaces, including fabrics, including carpets, and household surfaces such as countertops, dishes, floors, garbage cans, ceilings, walls, carpet padding, air filters, and the like, and from animate surfaces, including skin, hair, and the like. The compositions can further comprise cyclodextrin-compatible and -incompatible materials, and other optional ingredients.

Owner:THE PROCTER & GAMBLE COMPANY

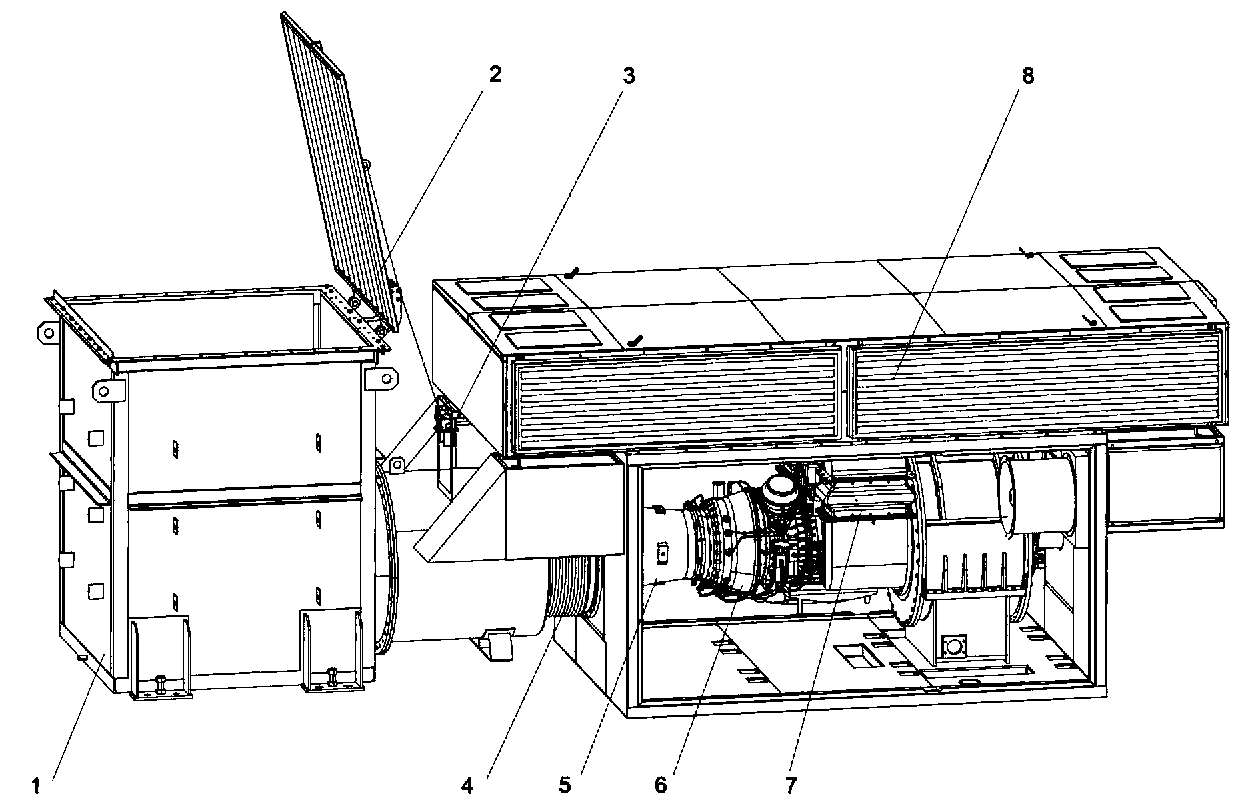

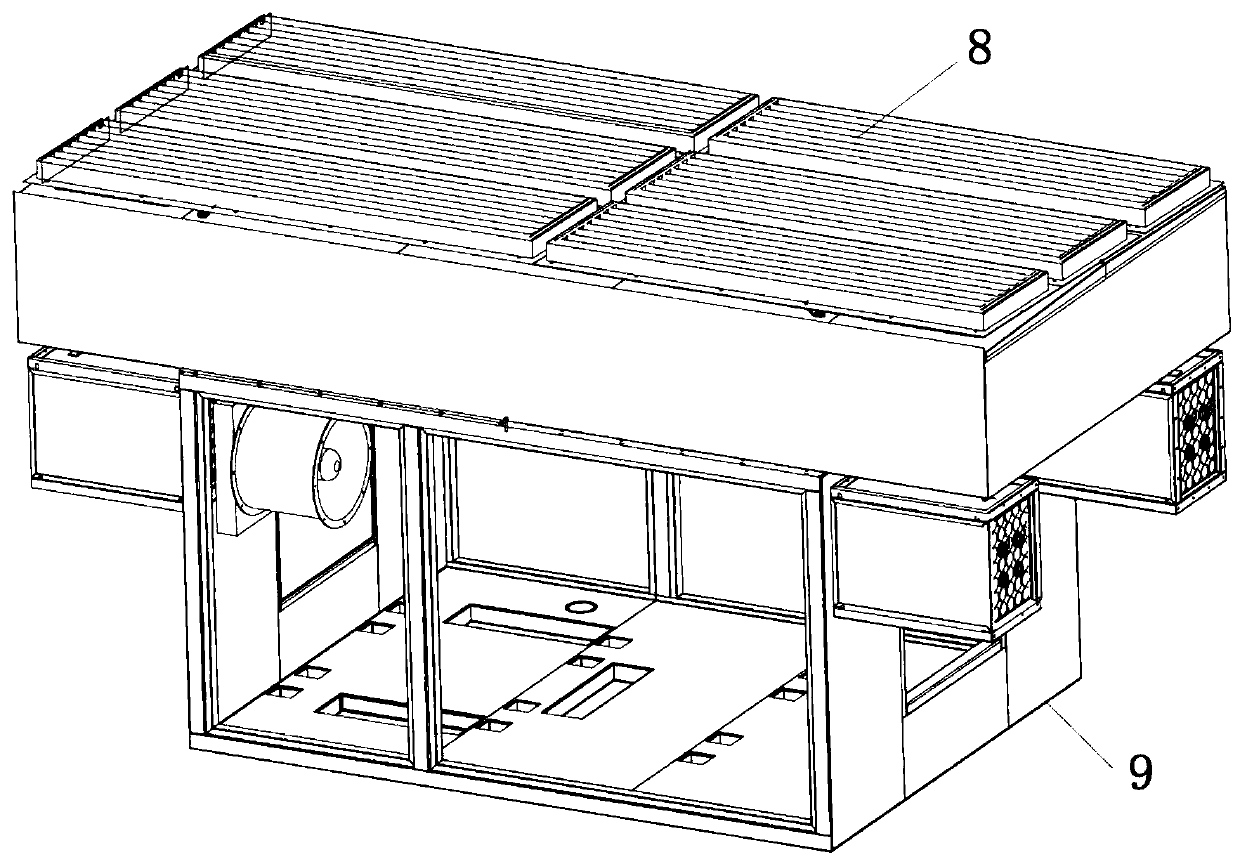

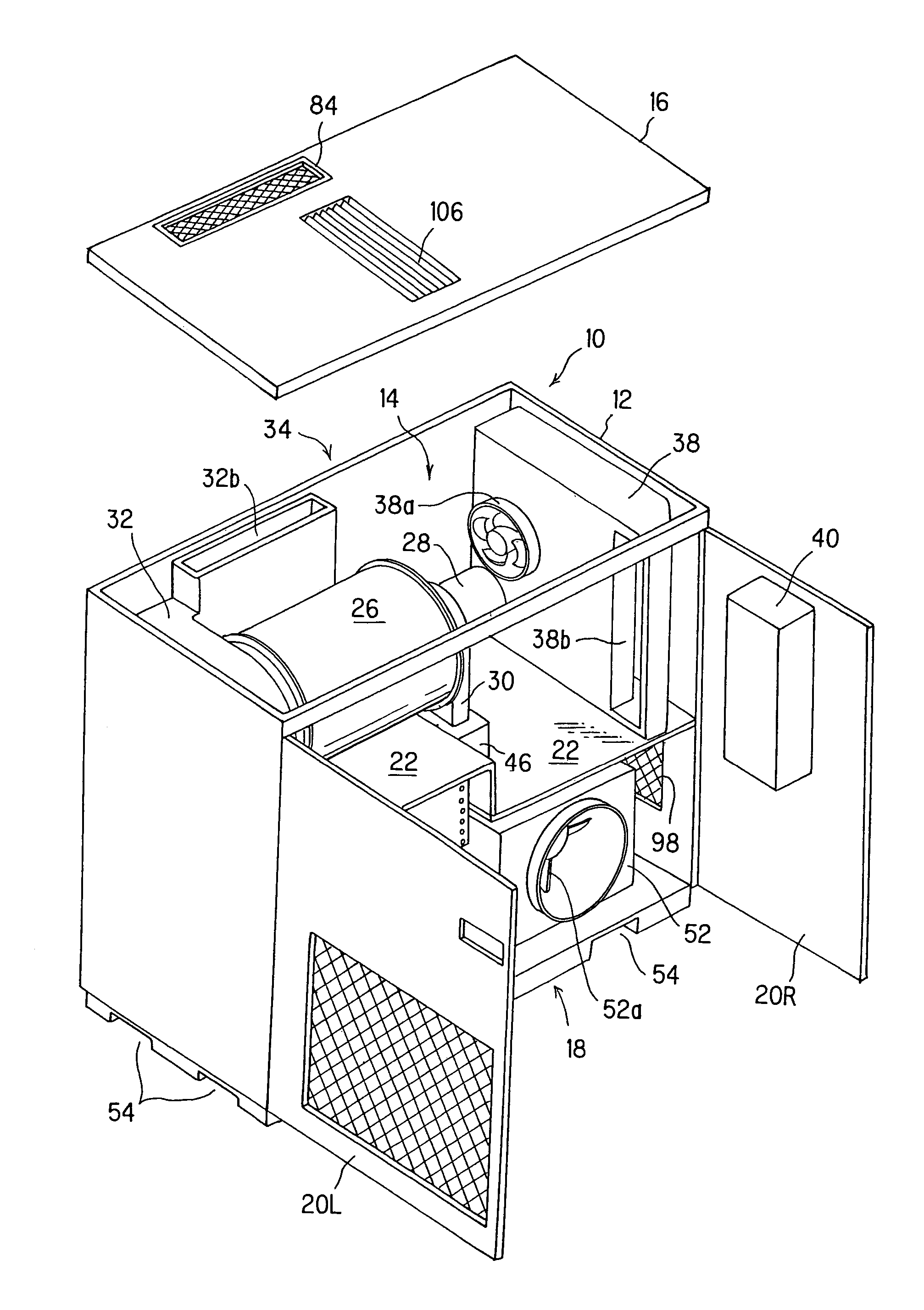

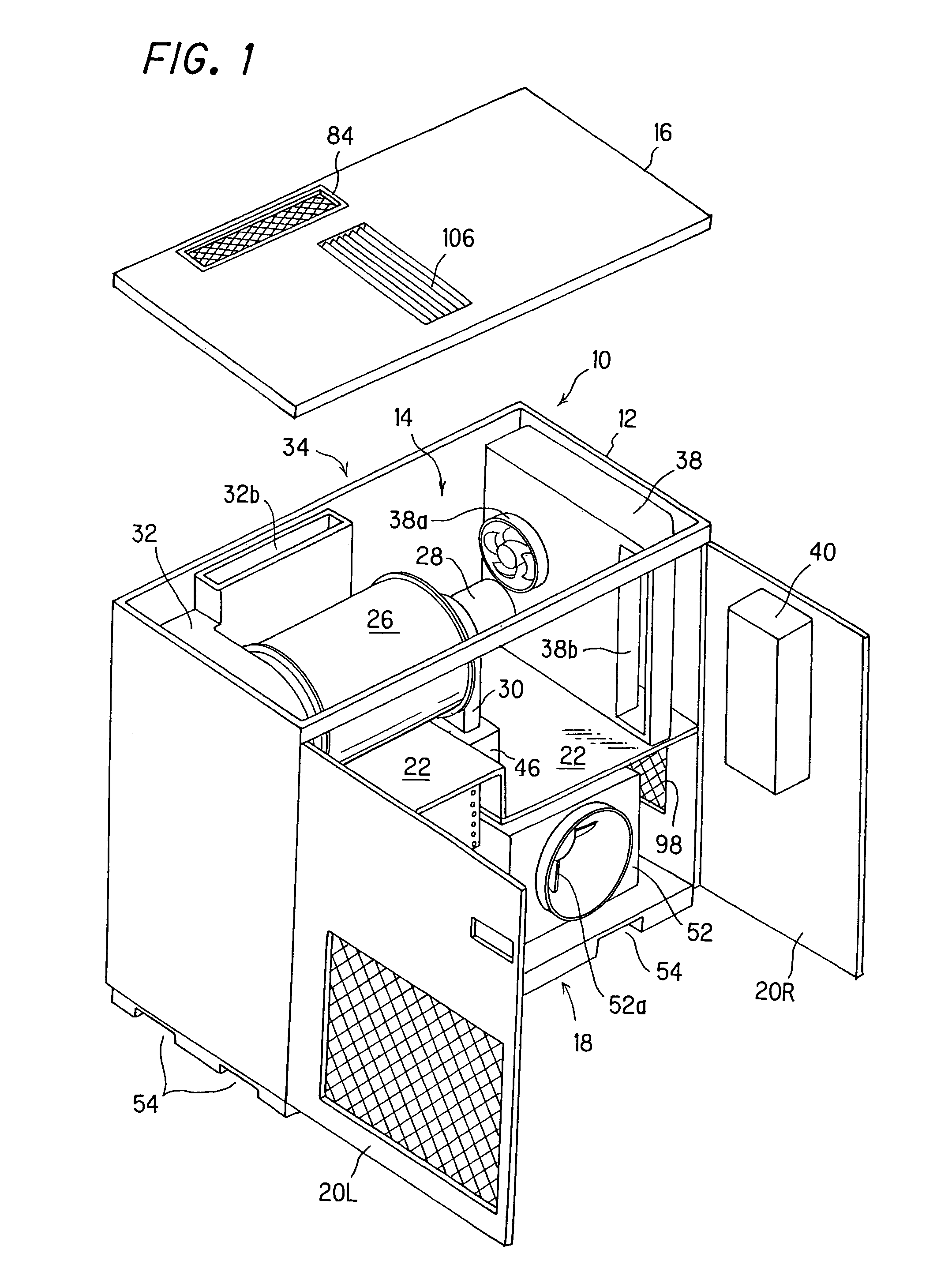

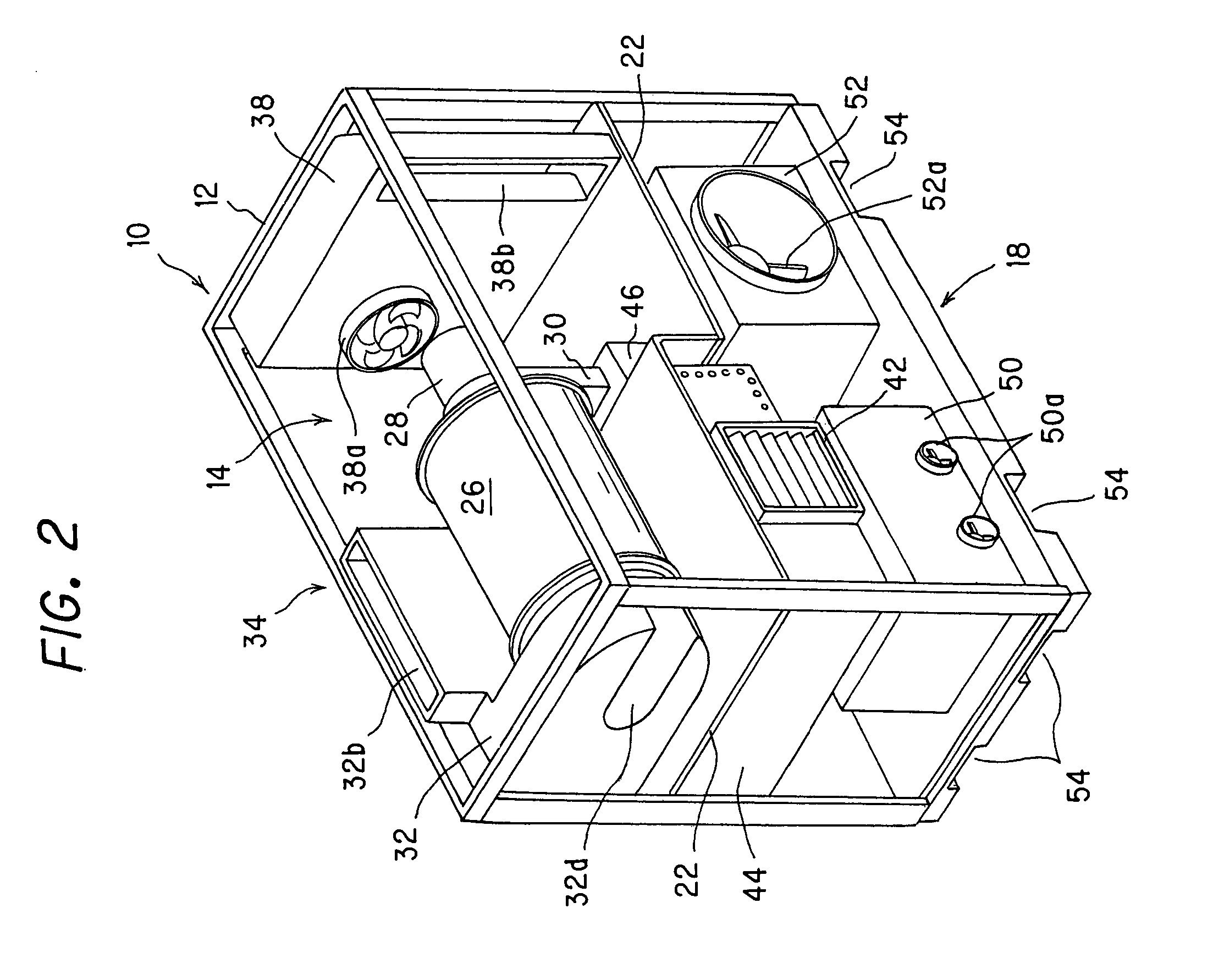

Gas turbine power generation system

InactiveUS6962057B2Reduce dedicated installation spaceFacilitate air filter replacementPortable framesMagnetic circuitInterior spaceAir filter

In a gas turbine power generation system having a gas turbine engine and a generator connected to the engine, maintenance ease is enhanced by forming the housing to have openable maintenance faces at two of its faces. Installation space is reduced and a compact configuration is achieved by providing a partition that divides the interior space of the housing into two regions into an upper bay and a lower bay, mounting the engine in the upper bay and mounting air intake duct in the lower bay at a location directly under the engine. Noise is reduced by using a partition to define two separate spaces (bays) and mounting the engine and the air intake duct in the upper and lower bays. Noise is also reduced by preventing engine rotation noise from escaping to the outside through the air intake duct. Moreover, it achieves a reduction in the amount of dedicated space required by constituting the air intake duct of a duct section having an air inlet at a plane coincident with that of the maintenance opening and a filter-housing section for removably housing an air filter, thereby enabling a common space to be utilized for that required in front of the maintenance opening and the air inlet.

Owner:HONDA MOTOR CO LTD

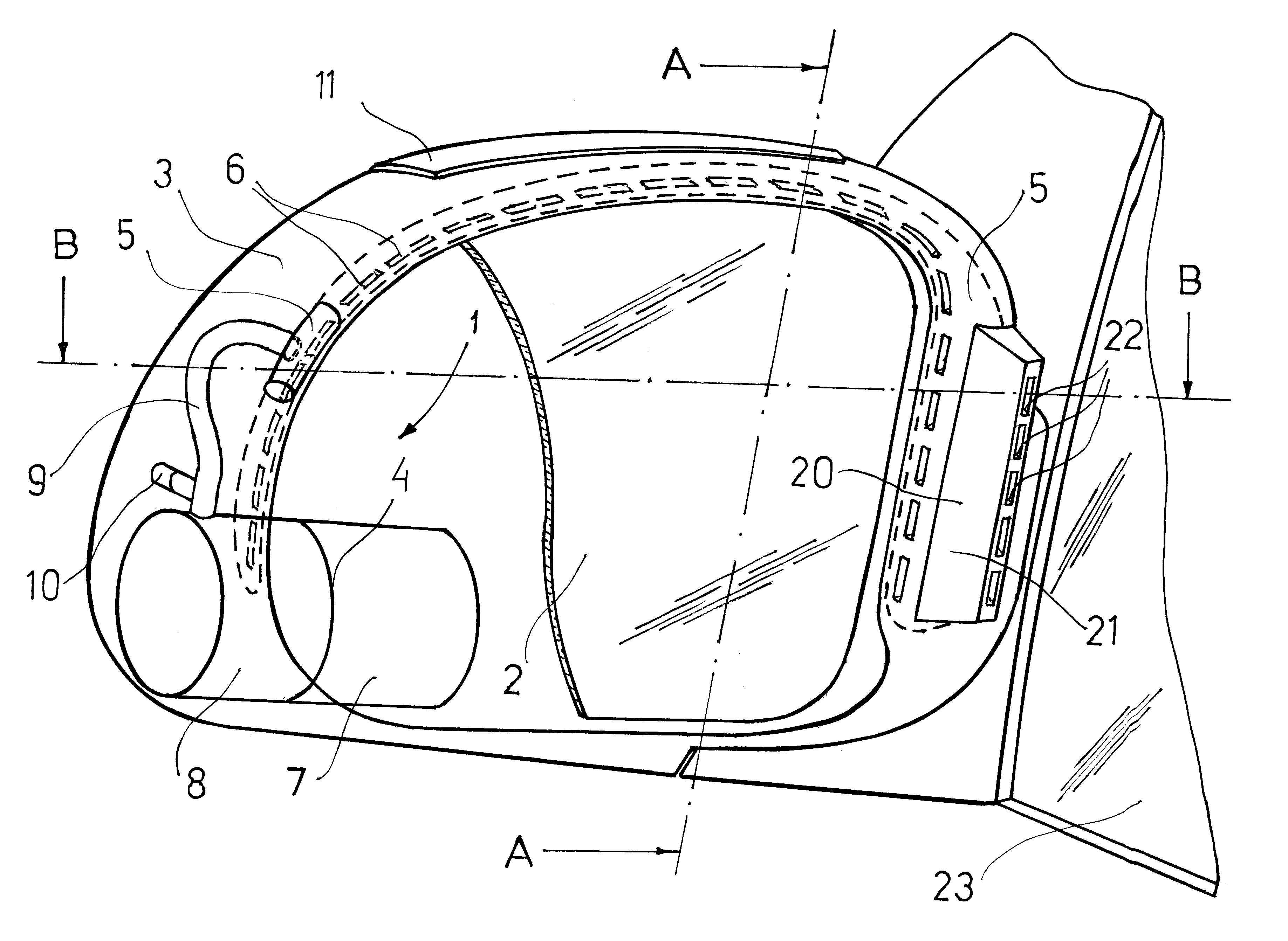

Universal clearing air system for windows and external mirrors of a vehicle

A clearing system for external mirrors and side windows of a vehicle provides a flow of compressed warm air to an air distribution unit equipped with a number of openings to direct the flow of air towards the surface of the mirror or a side window. In one embodiment, the air compressor, the air heater and an optional air filter are located in the housing of the external mirror. In another embodiment, a supplemental air distribution unit is provided to be mounted along the door of the vehicle to increase the coverage area of the side window. In a further embodiment of the invention, the system is made adjustable for allowing the most appropriate angle for the air openings towards the mirror and the side window. Provisions are also made to use the system for newly designed vehicles and incorporate the elements of the system into the design of the vehicle door. Alternately, an add-on elements are described to allow existing vehicles to benefit from the system. Additional supplemental air disbribution units may be attached to the main system to improve visibility throughout the vehicle.

Owner:BERZIN LEONID

Filter element using corrugated media sheet

A corrugated web having tapered flutes is usable in straight-through flow filter elements. The corrugated web can be made by passage between a pair of corrugated rollers having tapered teeth. Methods of making usable corrugated rollers include methods for generating the tapered teeth at the end points and the extension between the end points. Corrugated webs may be made from a variety of media, including certain media that stretches in the machine direction. Methods of forming the corrugated web into filter elements (e.g., air filter elements) includes forming filter media by securing a flat sheet to the corrugated web. The filter media may then be wound into a filter element, including application of sealant during the winding process to close selected flutes.

Owner:DONALDSON CO INC

Filtration media for filtering particulate material from gas streams

Owner:DUPONT SAFETY & CONSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com