Patents

Literature

937 results about "Ambient humidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ambient humidity is what’s happening outside your container of cannabis. It could be your bedroom, the trunk of your car, or the outdoors. In air conditioned homes, the humidity is usually 20-30% because the AC scrubs moisture out of the air. In a heated home, the humidity will often be even lower as the furnace scrubs much of the ambient humidity.

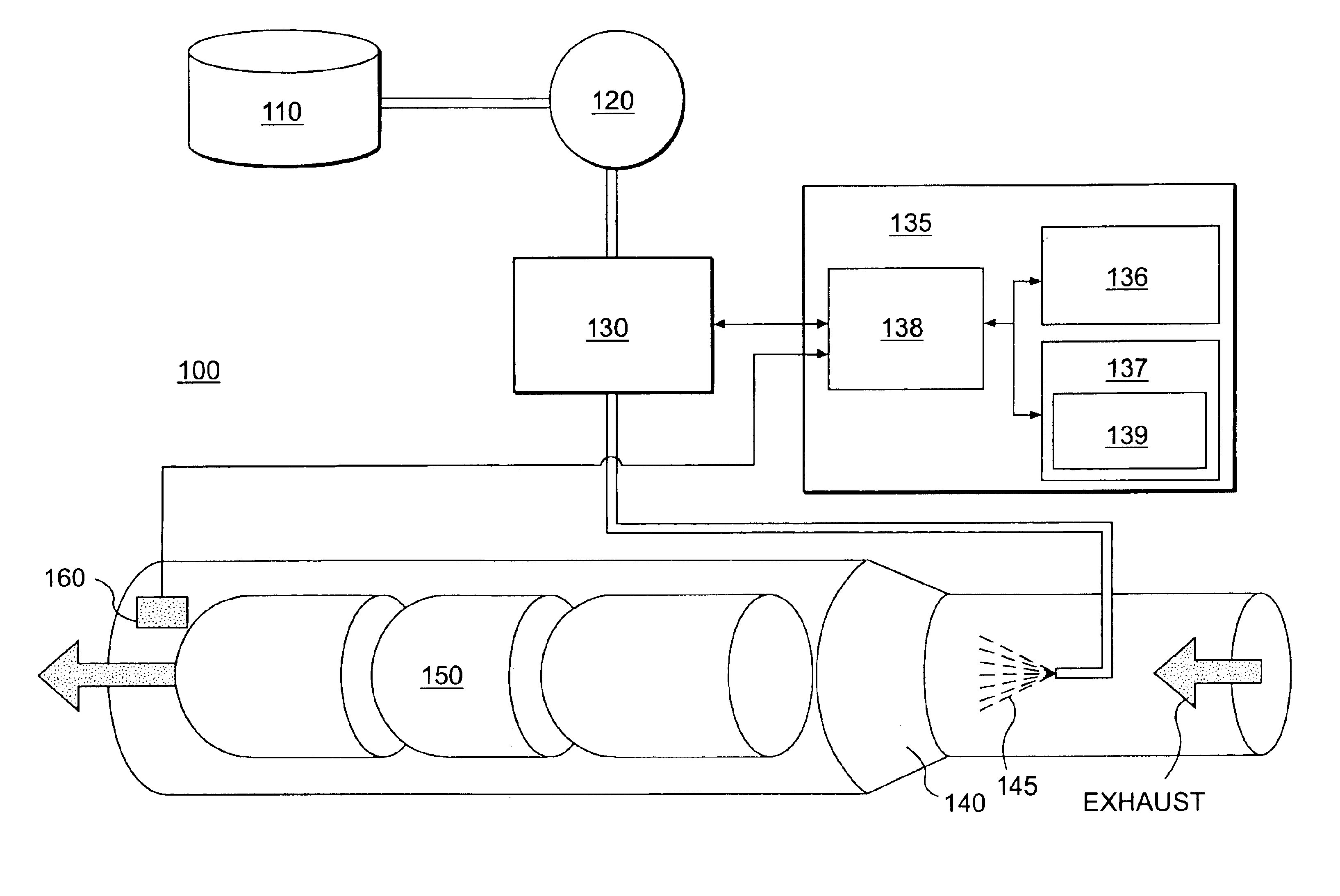

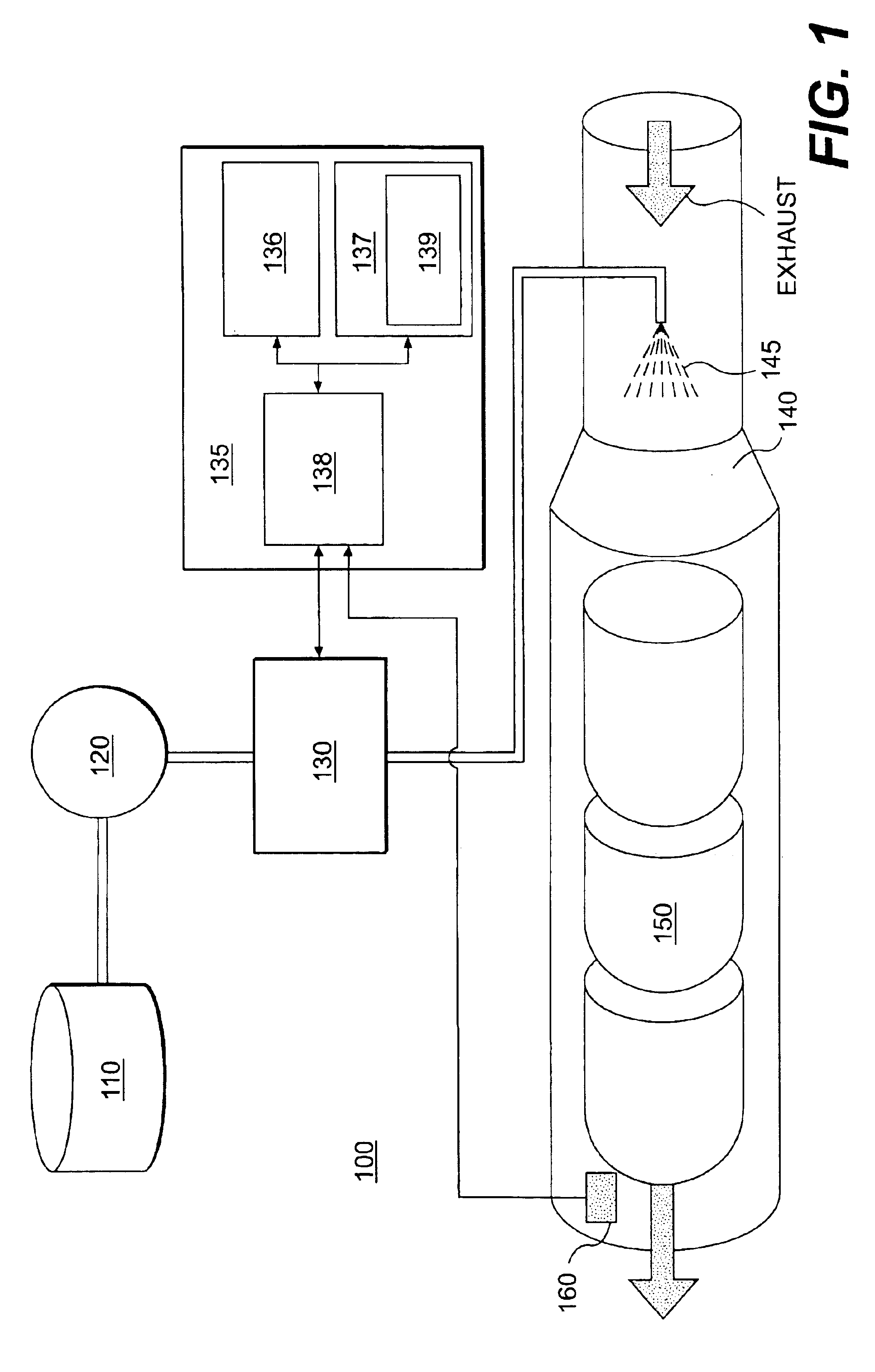

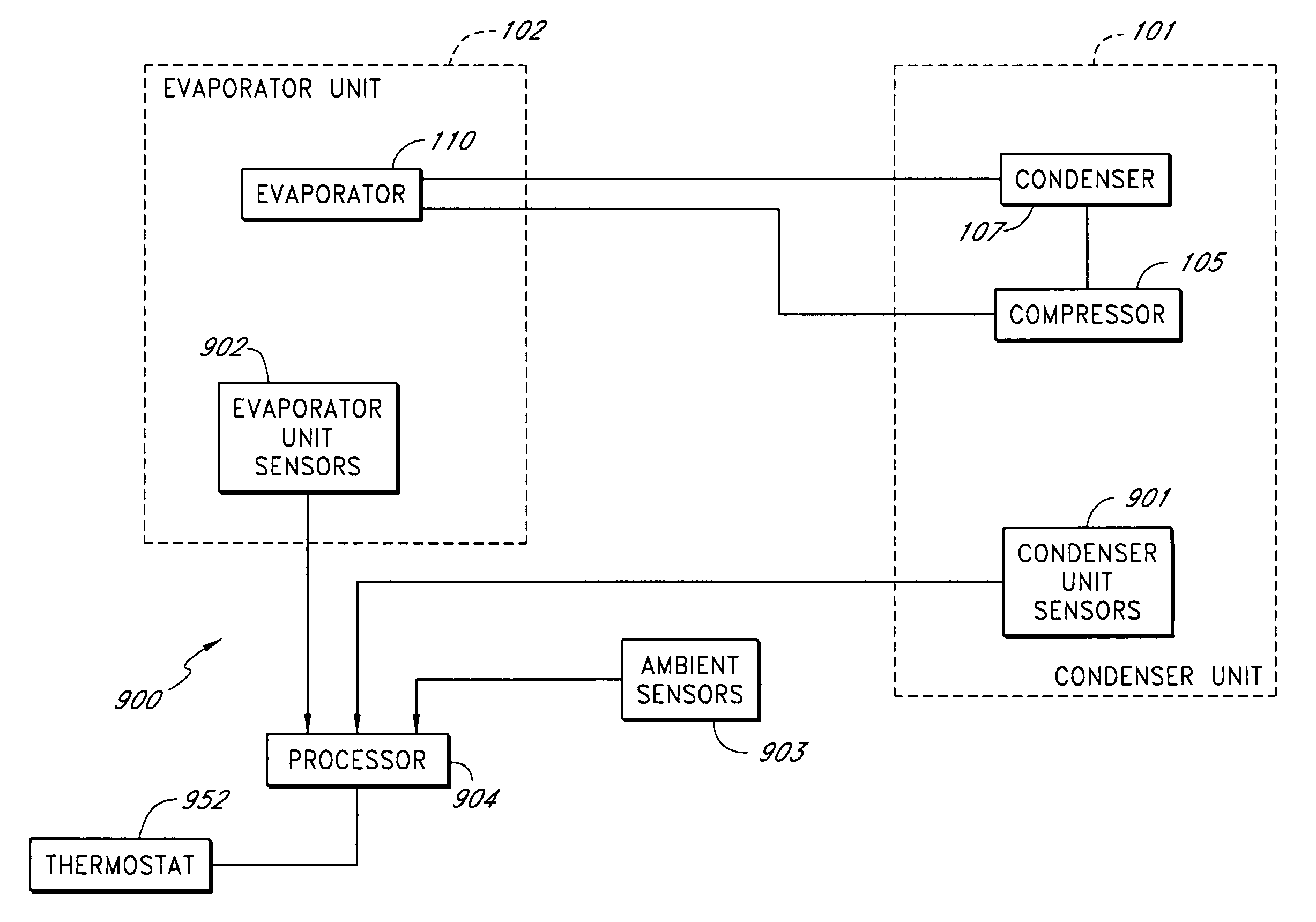

NOx emission-control system using a virtual sensor

InactiveUS6882929B2Reduce nitrogen oxide emissionsInternal combustion piston enginesDigital data processing detailsAmbient humidityControl system

A method and system may be provided to perform a process for controlling NOx emissions of an target engine. In one embodiment of the invention, the process may include determining predicted NOx values based on a model reflecting a predetermined relationship between control parameters and NOx emissions, wherein the control parameters include ambient humidity, manifold pressure, manifold temperature, fuel rate, and engine speed associated with the engine. Further, the process may include adjusting the model based on a determination of whether the predicted NOx values meet a predetermined criteria associated with actual NOx values. The adjusted model may be stored in a memory associated with the engine whereby NOx emissions exhausted from the engine may be reduced based on virtual NOx emission values determined from the adjusted model.

Owner:CATERPILLAR INC

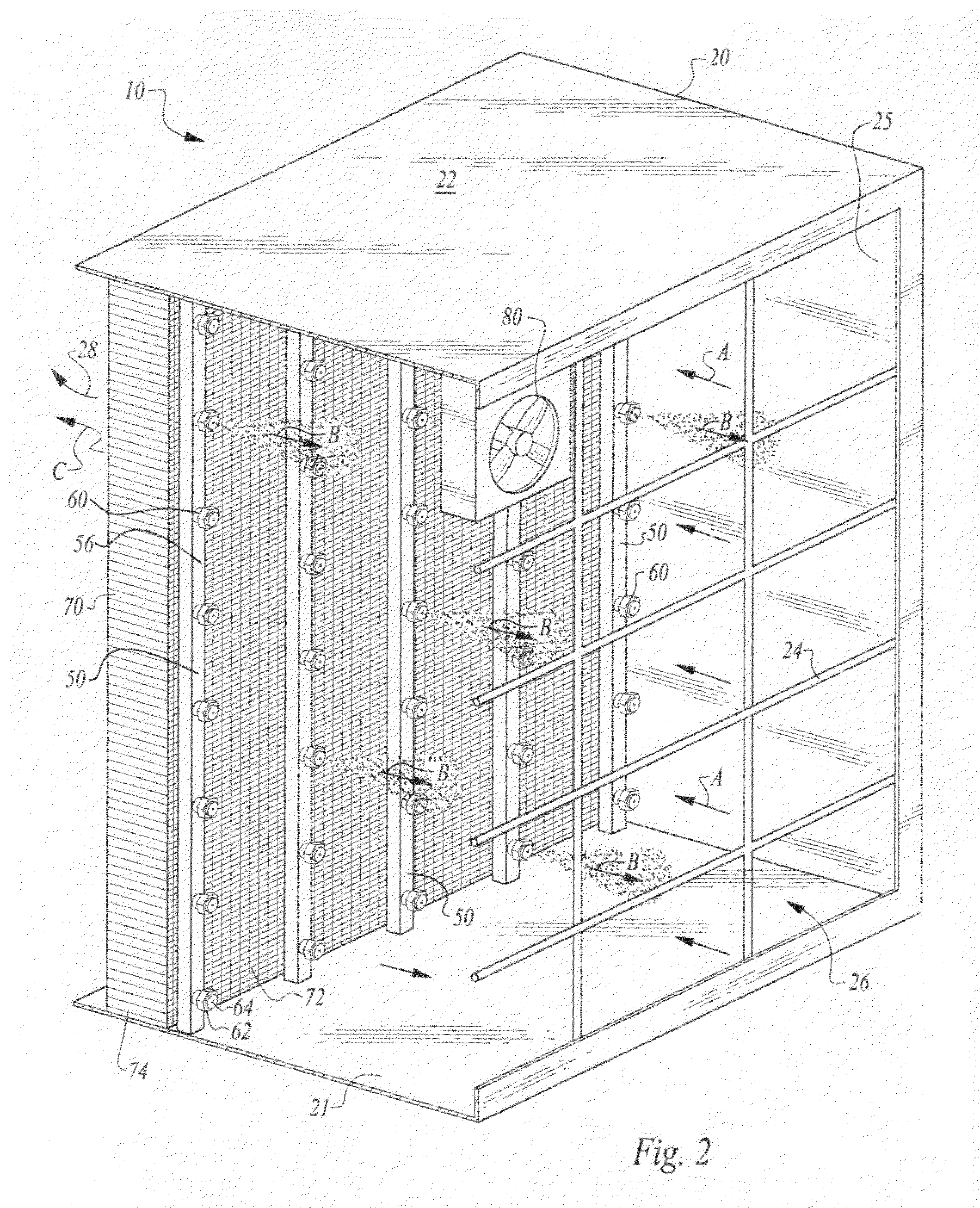

Air filter monitoring system

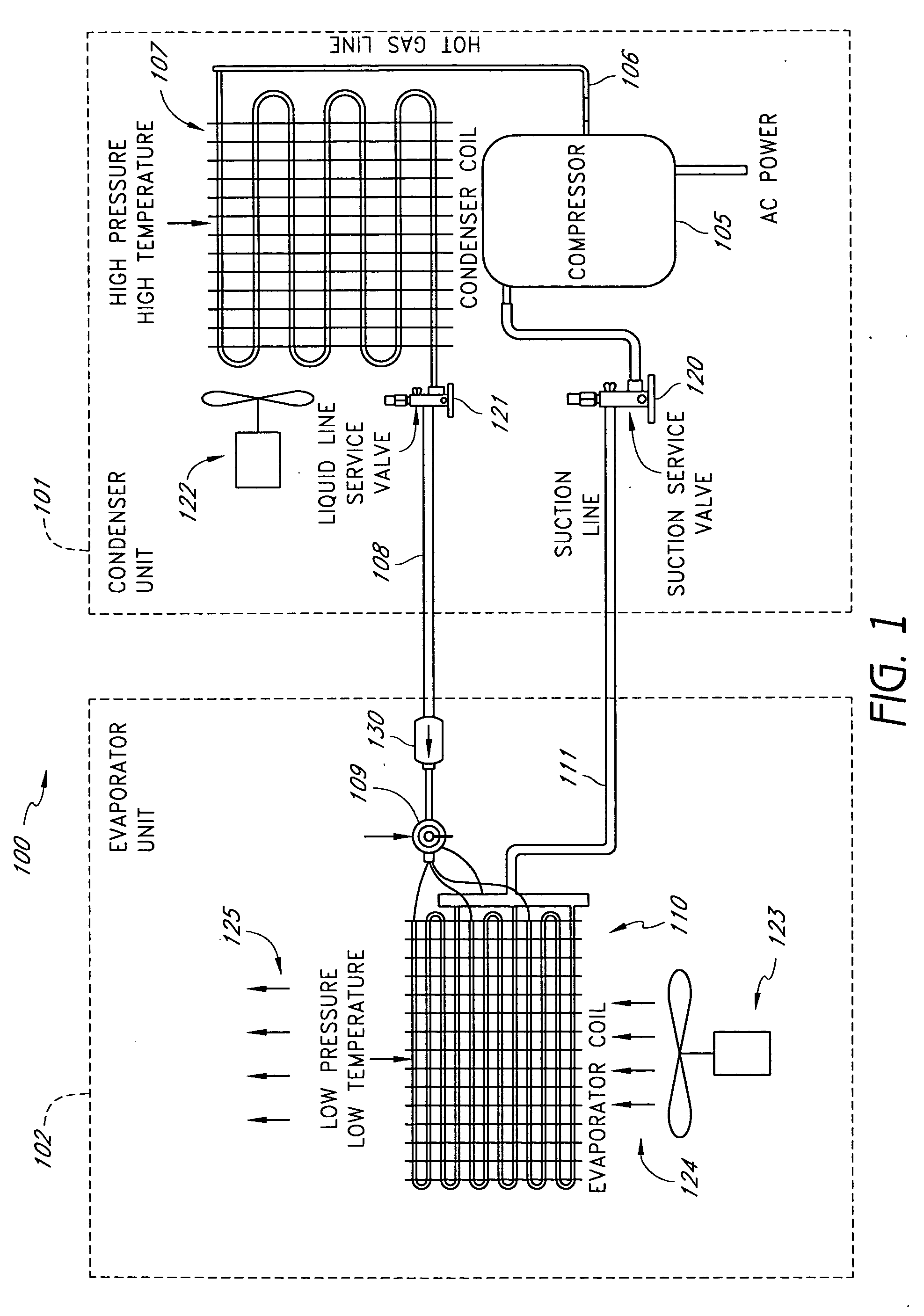

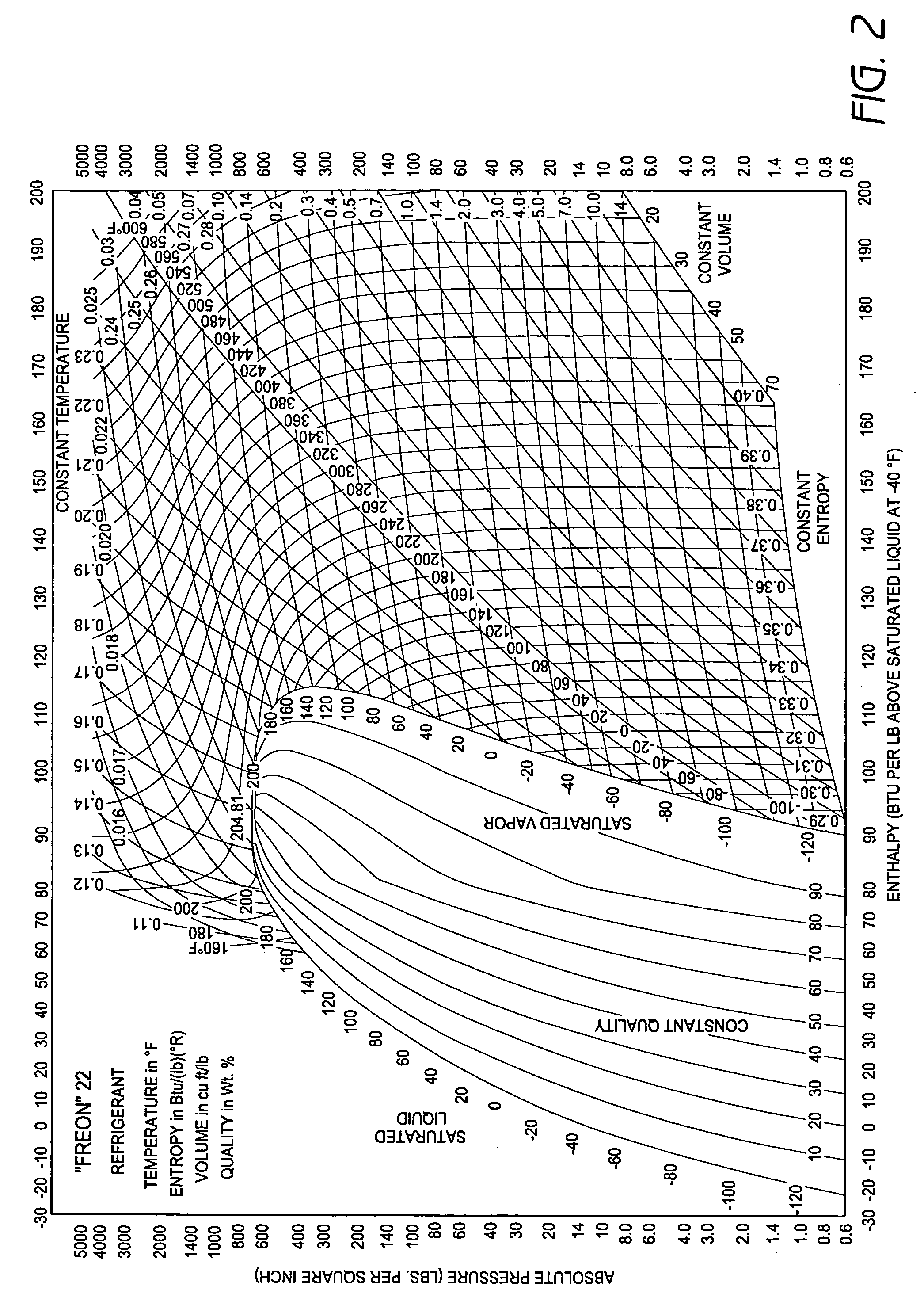

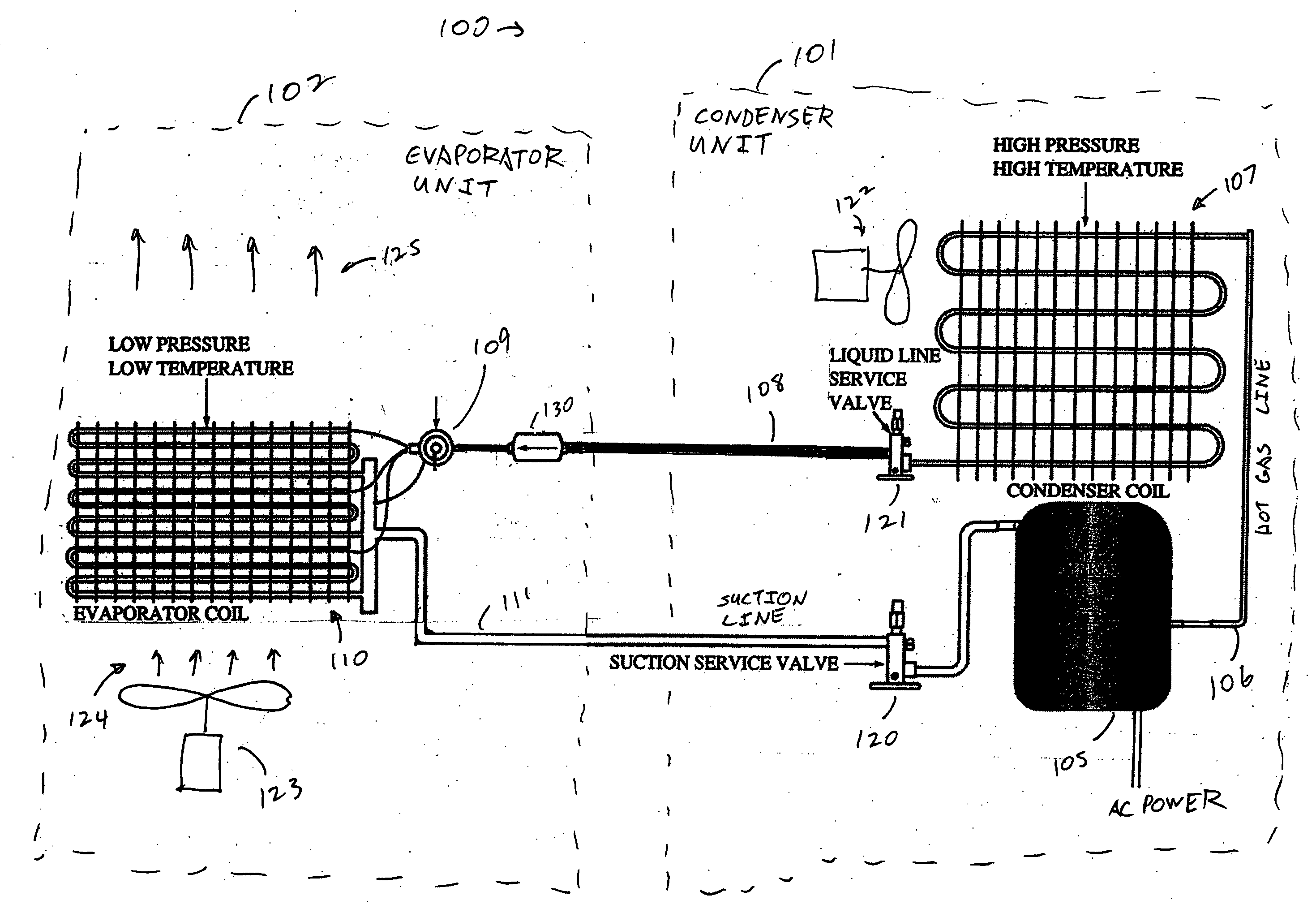

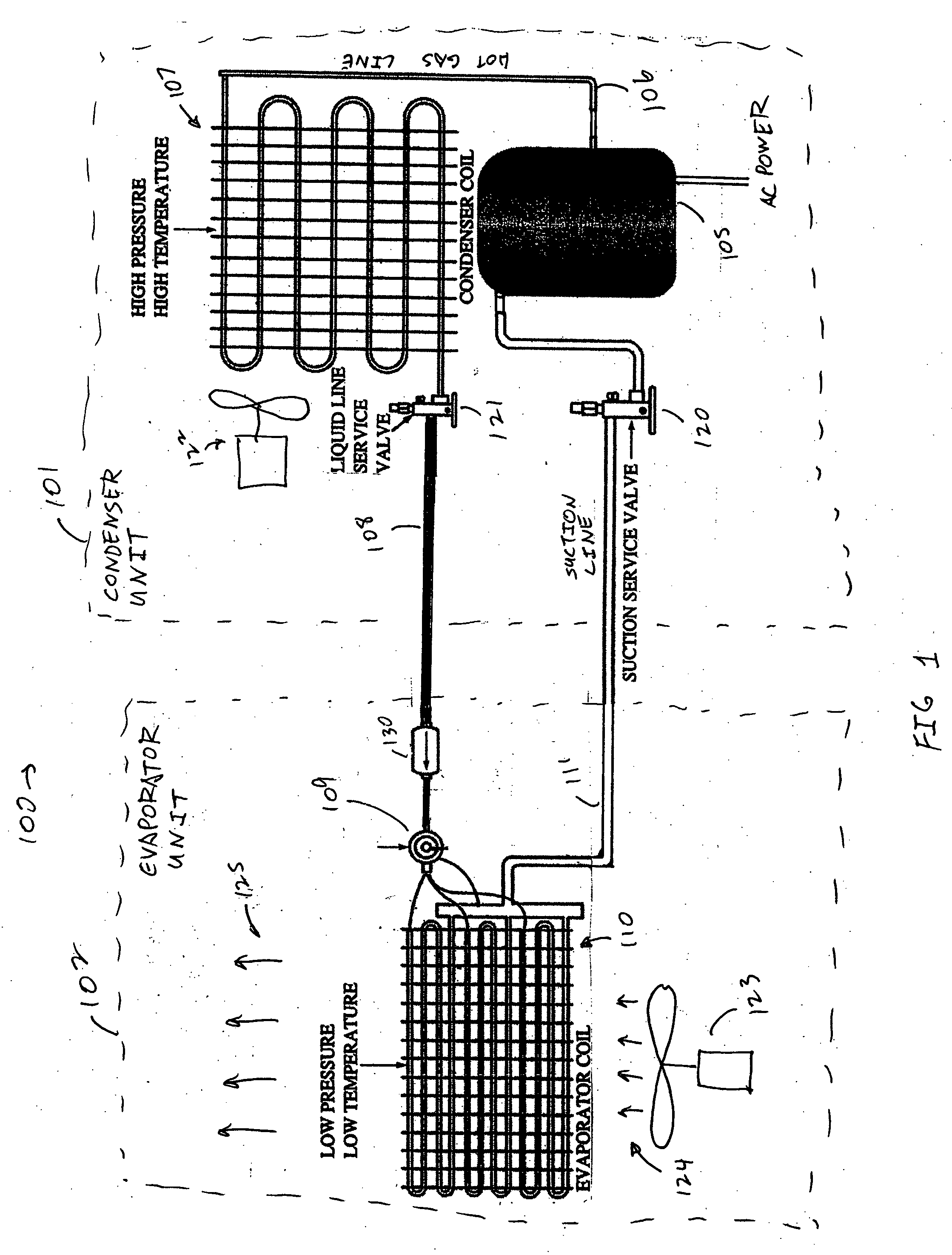

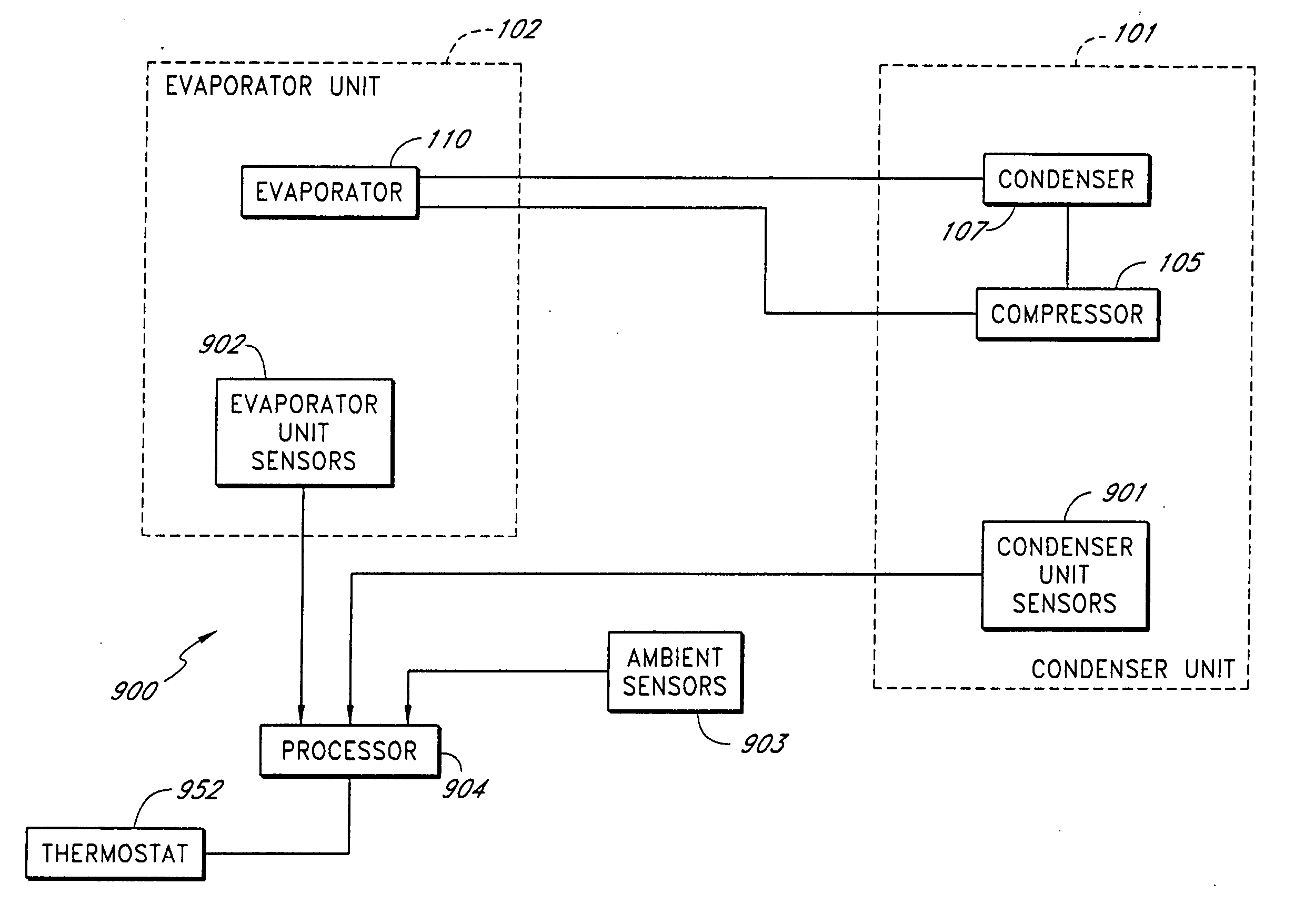

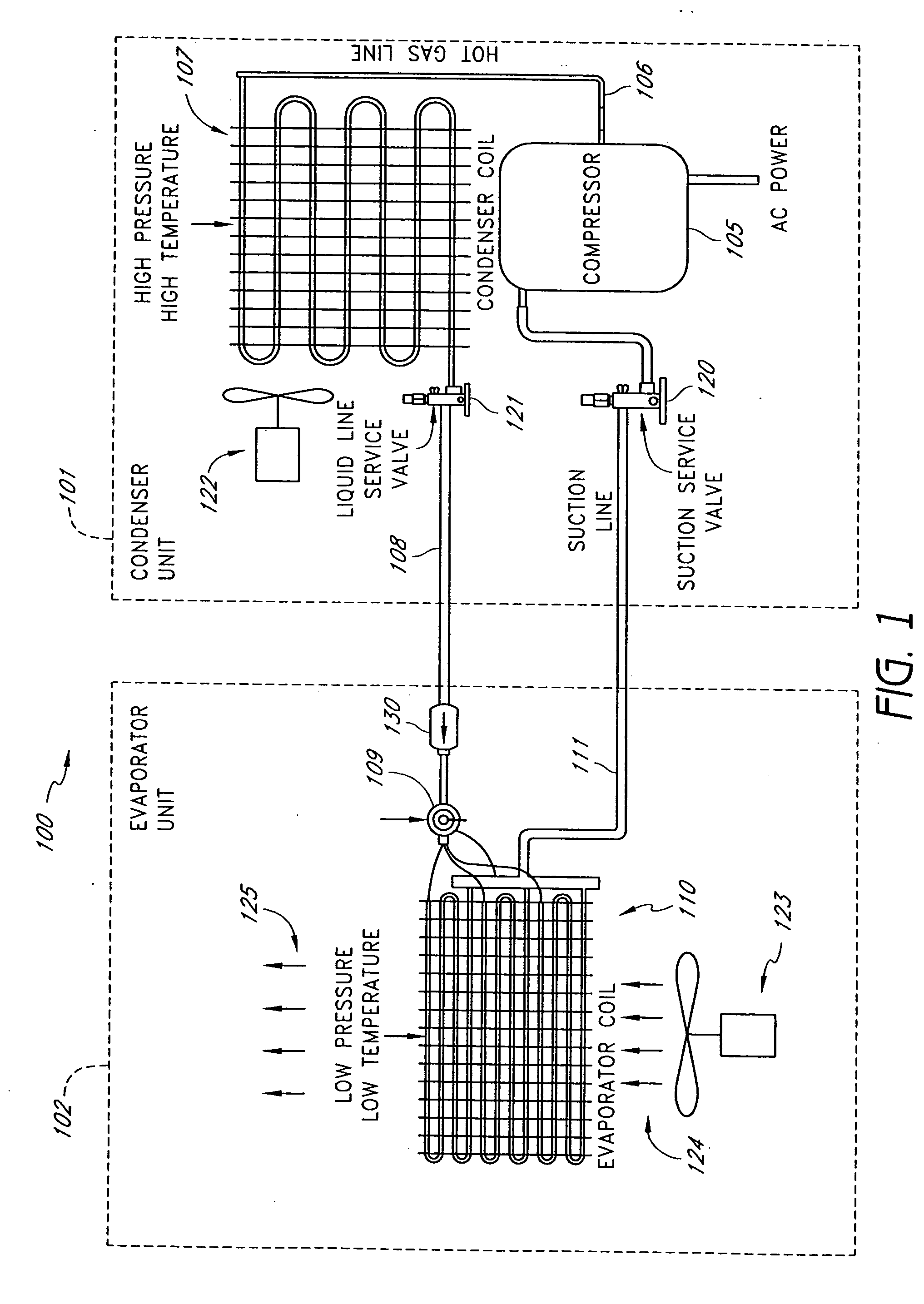

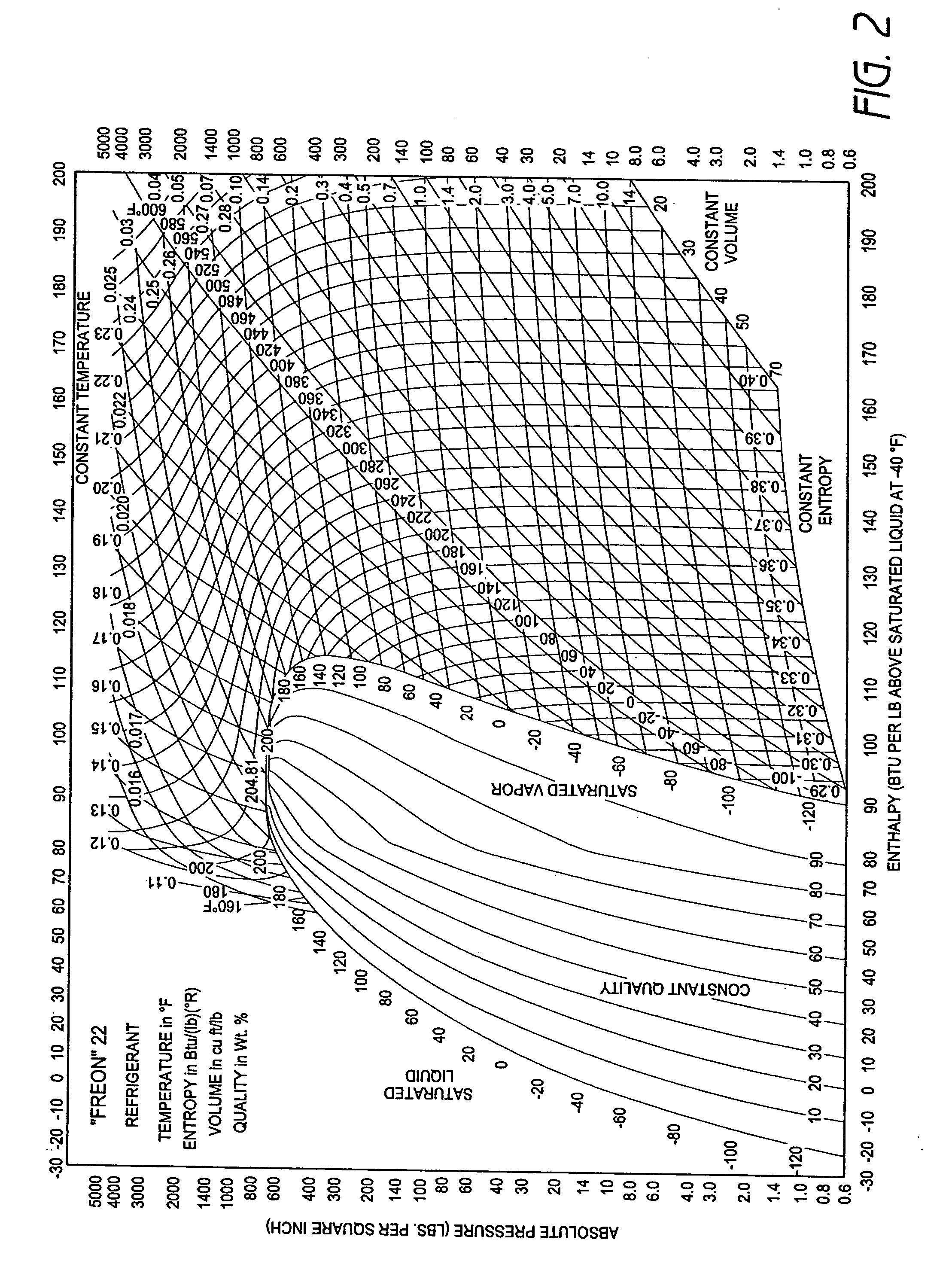

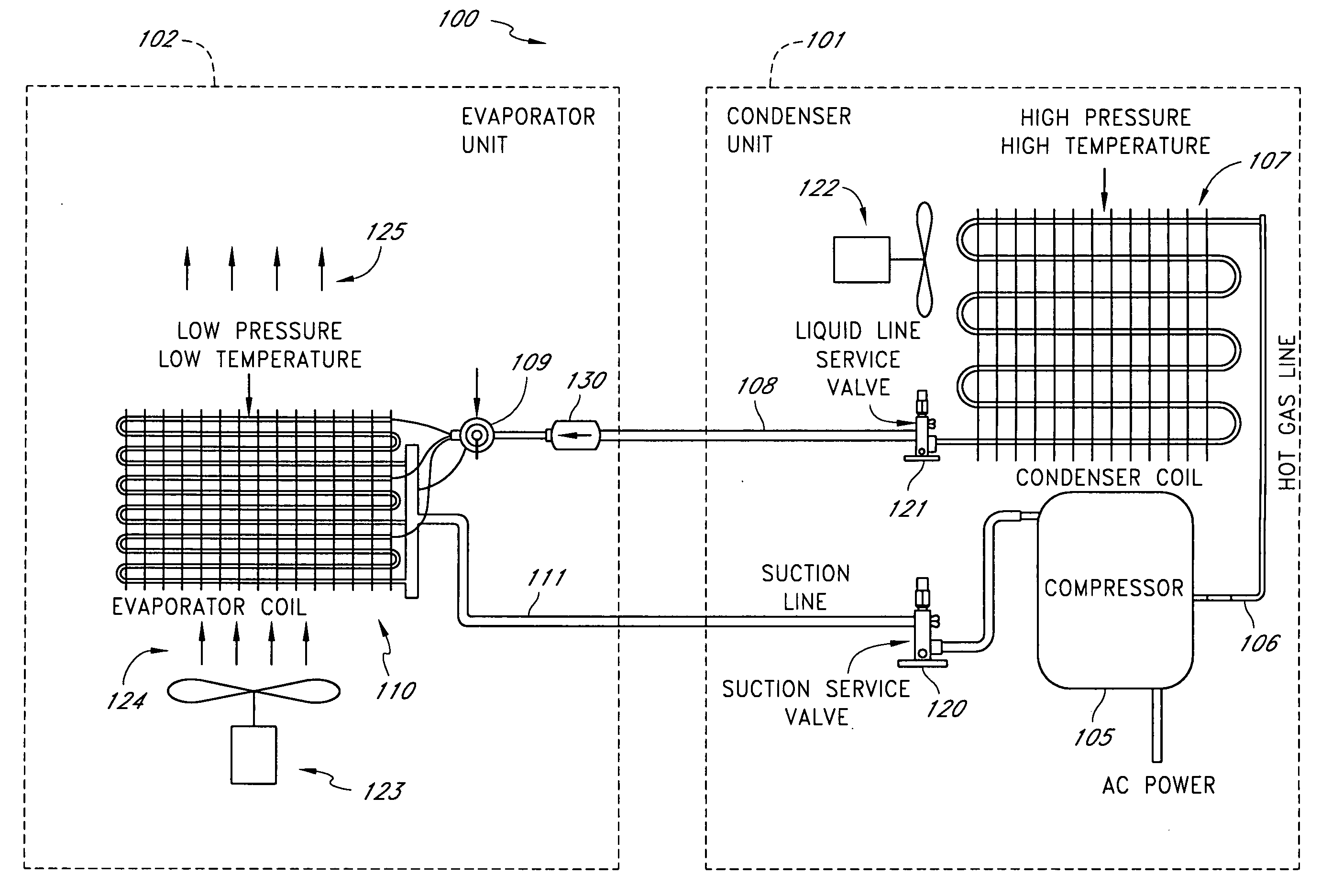

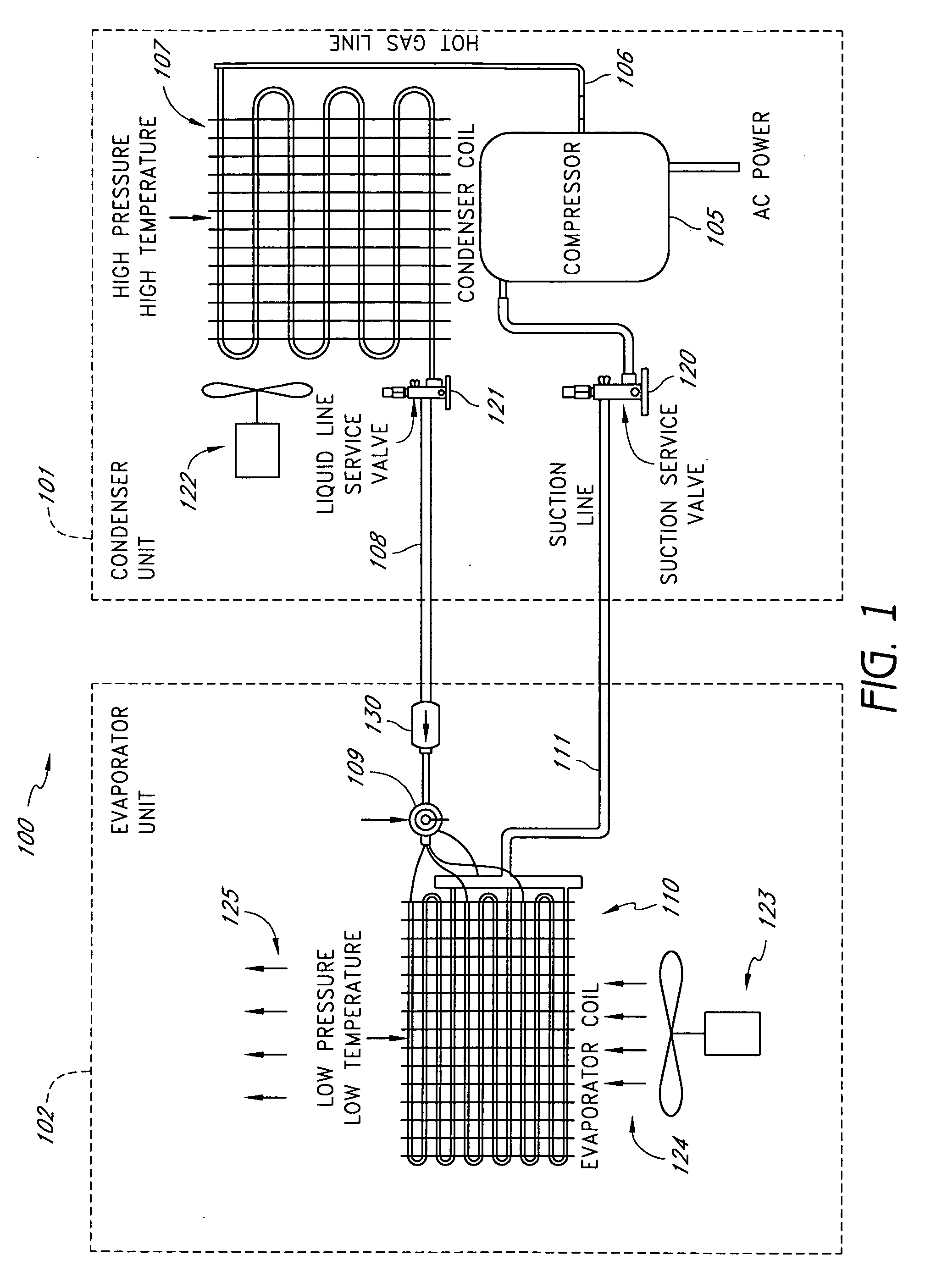

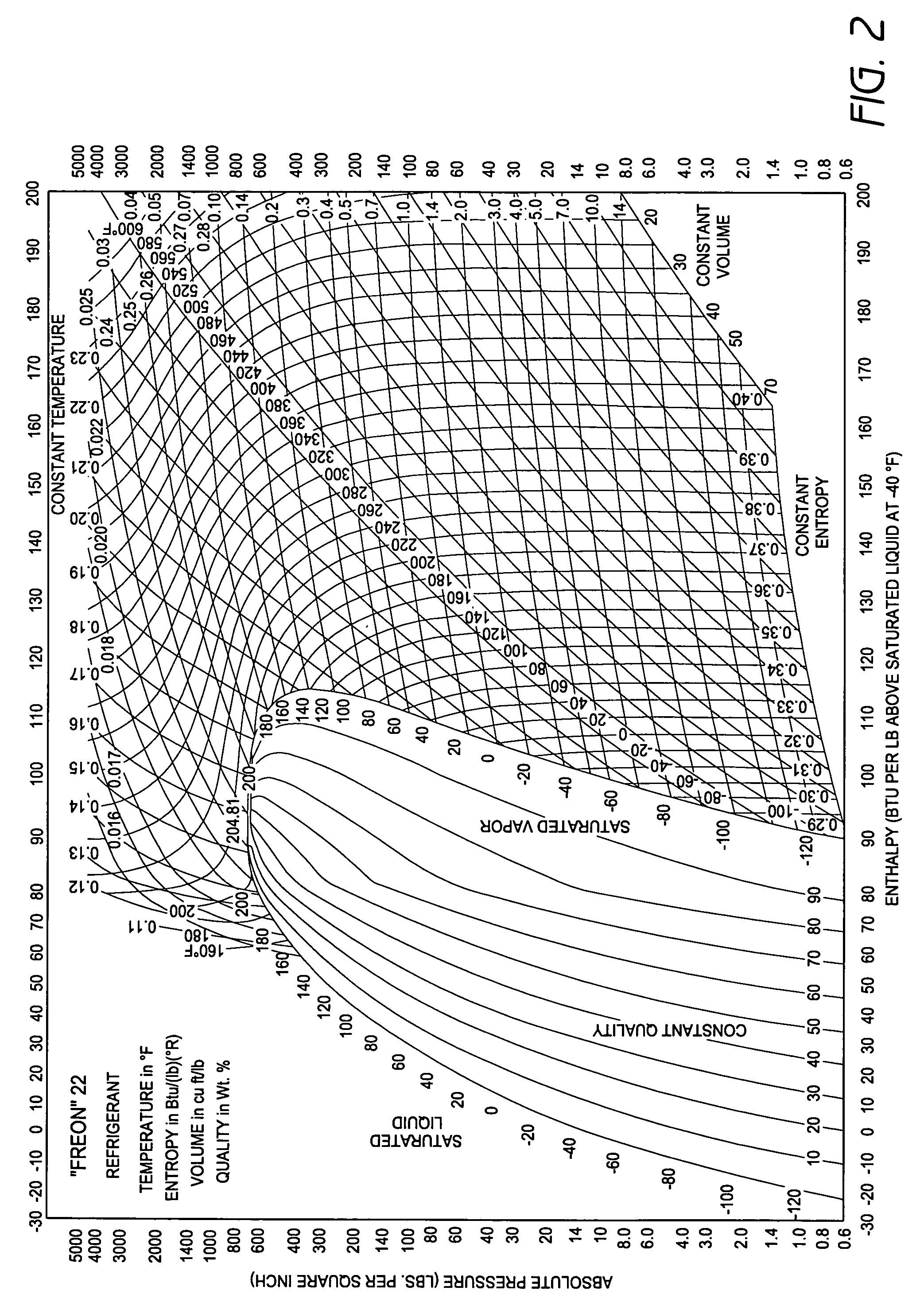

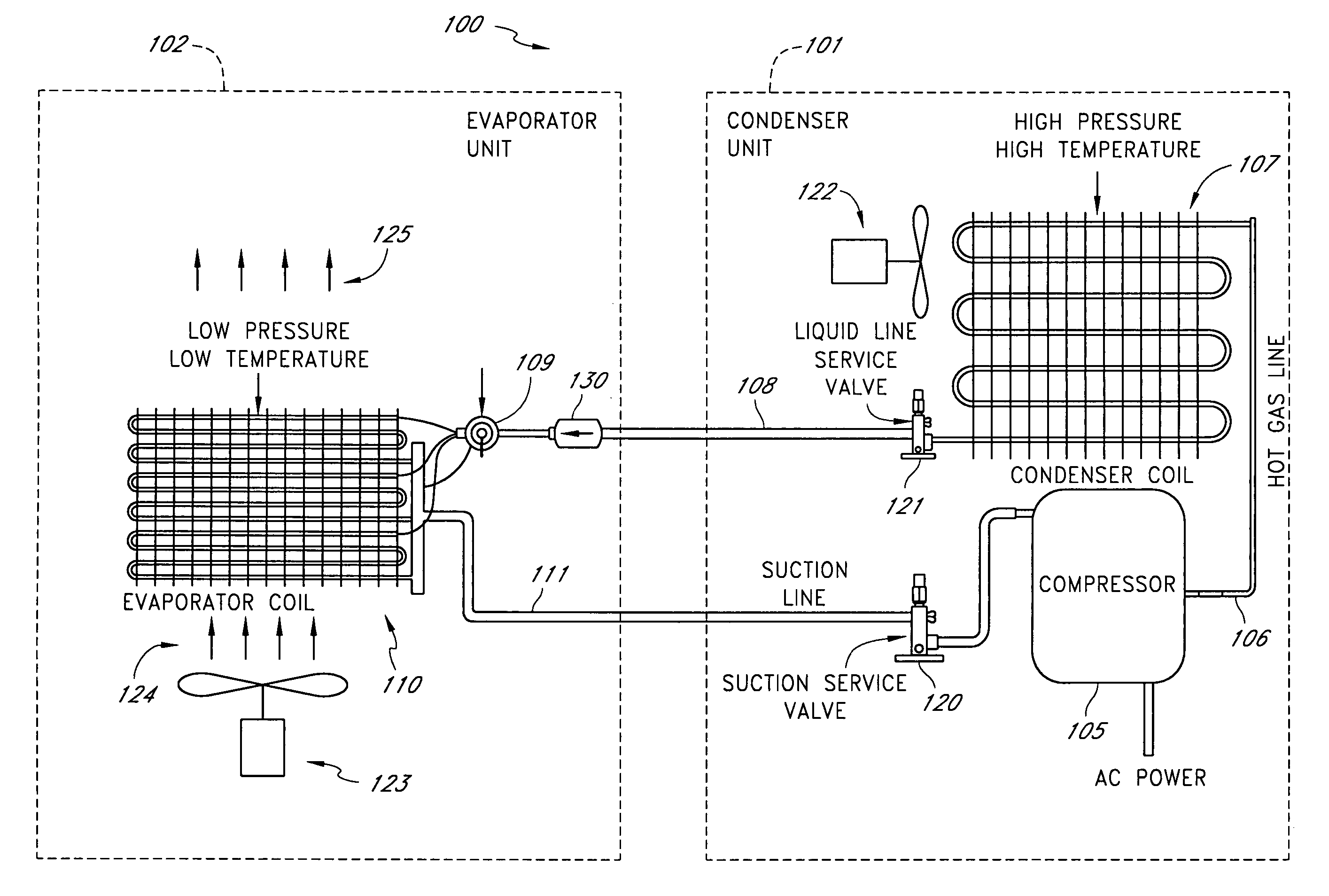

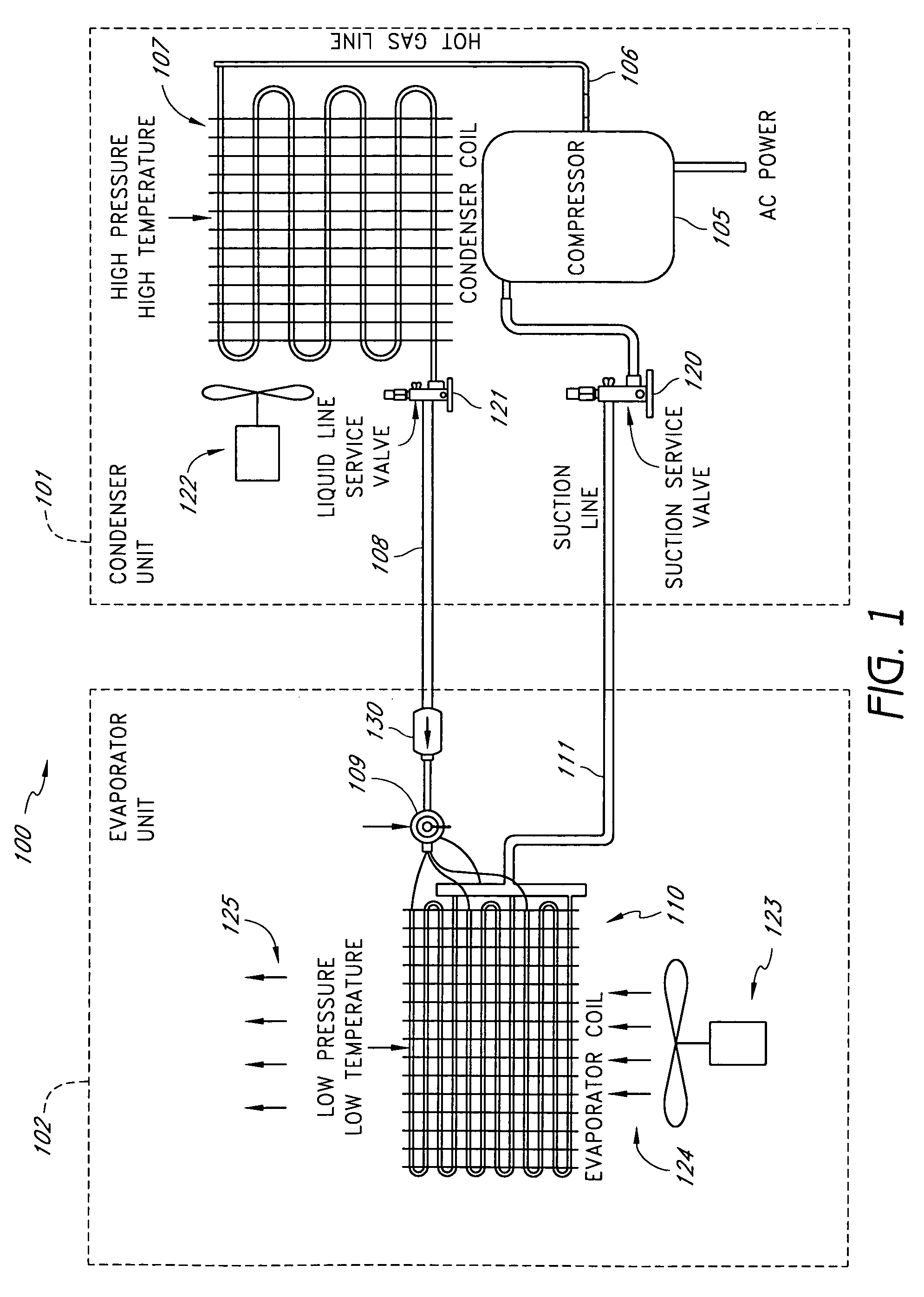

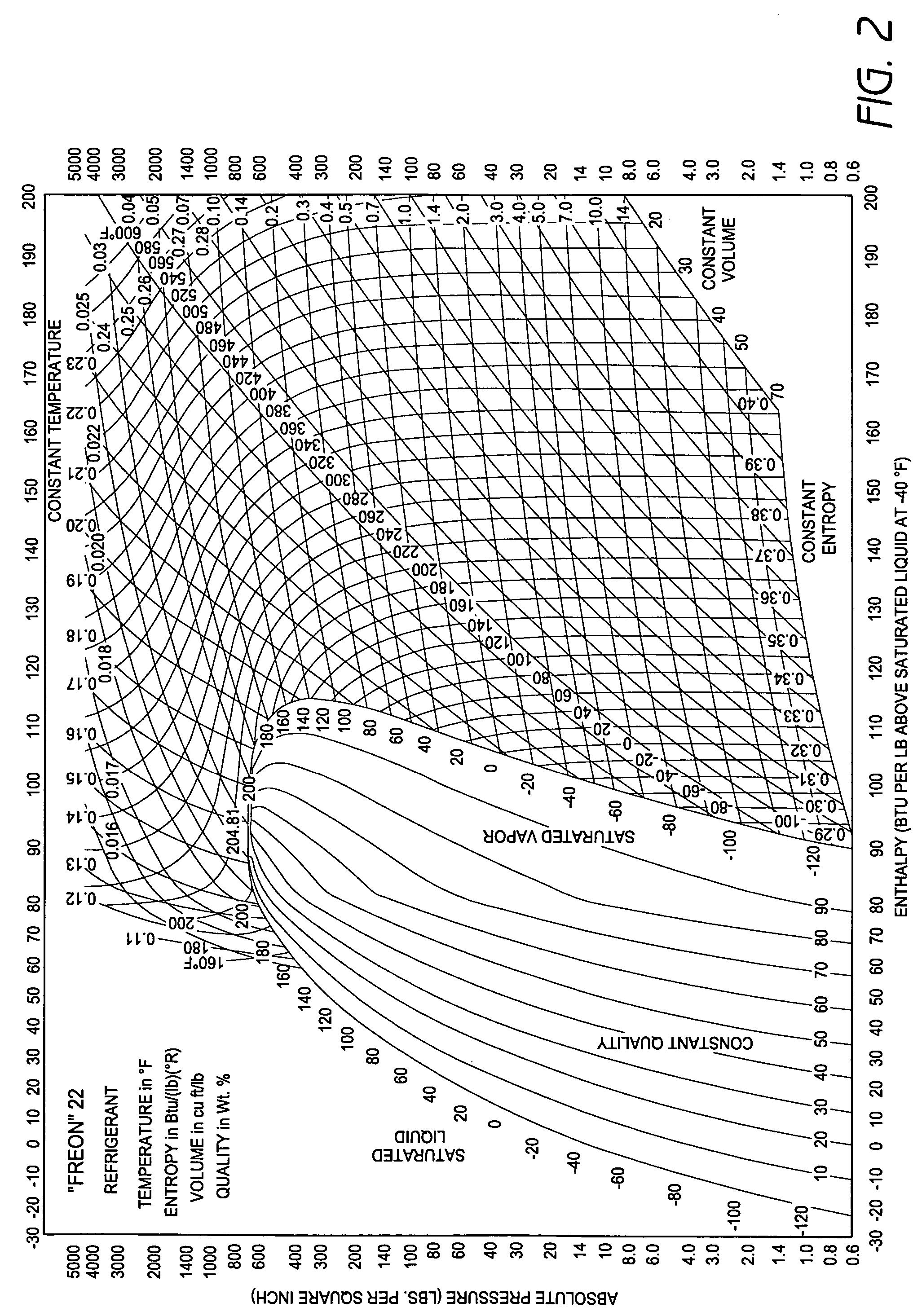

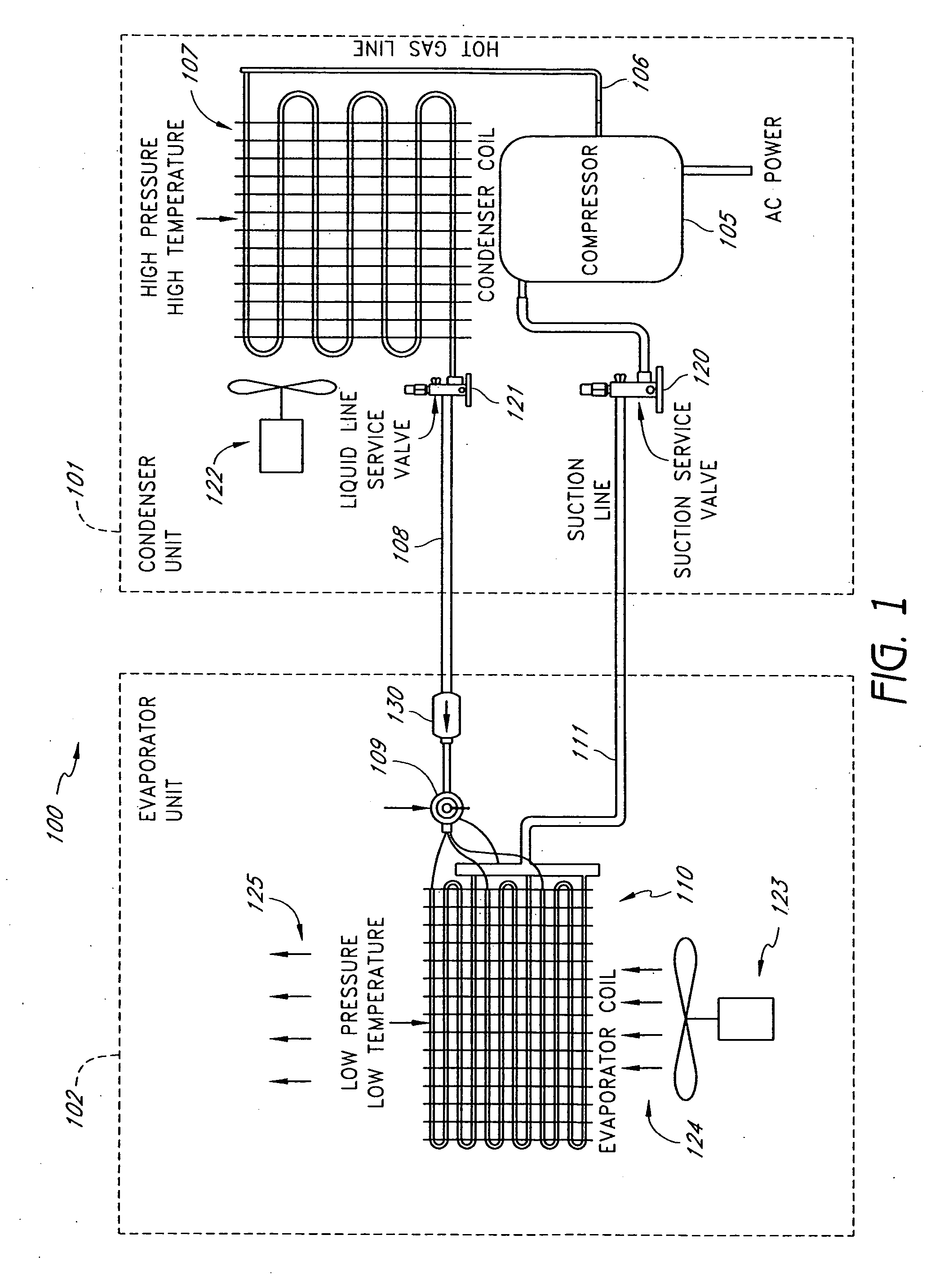

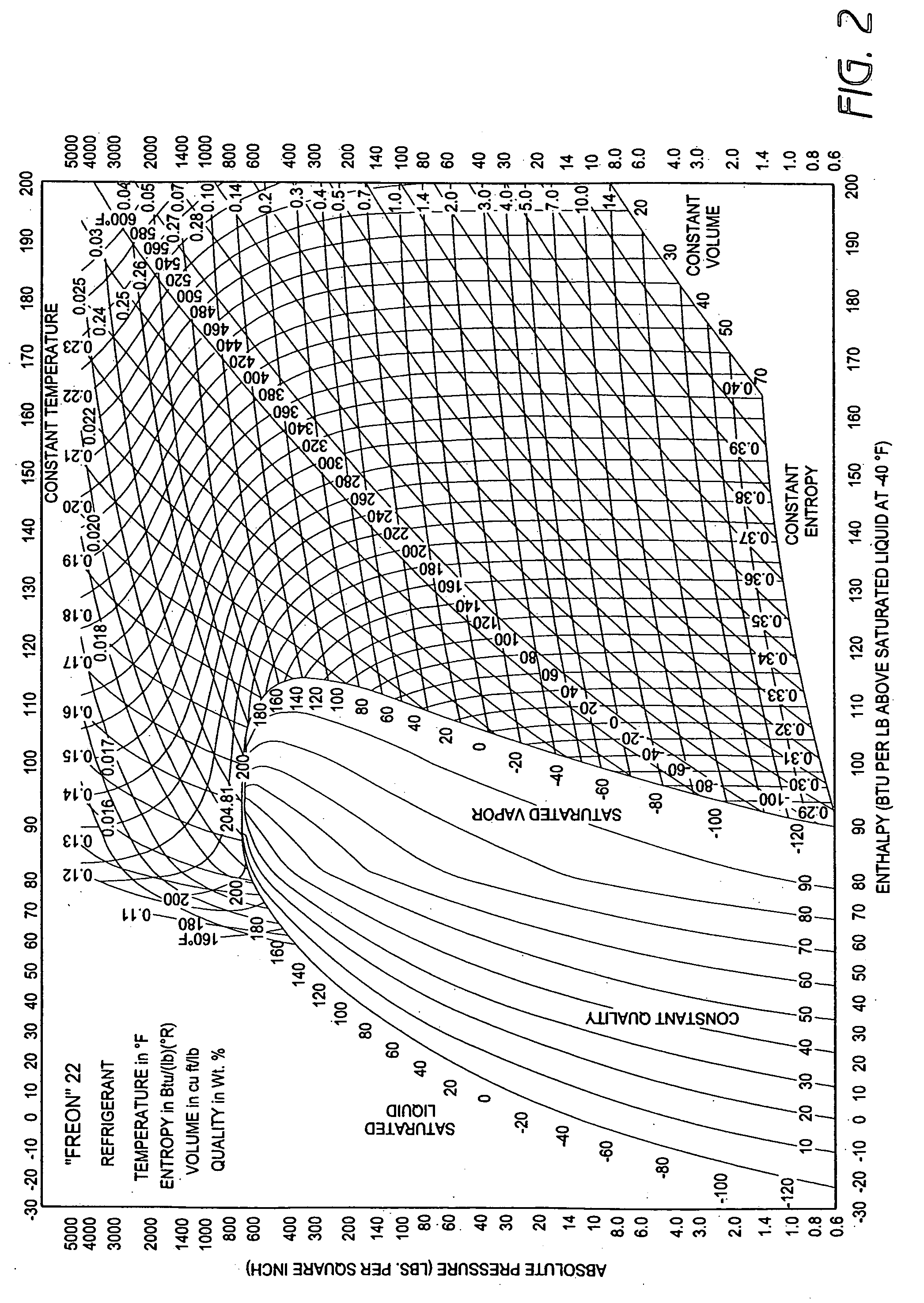

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:EMERSON CLIMATE TECH INC

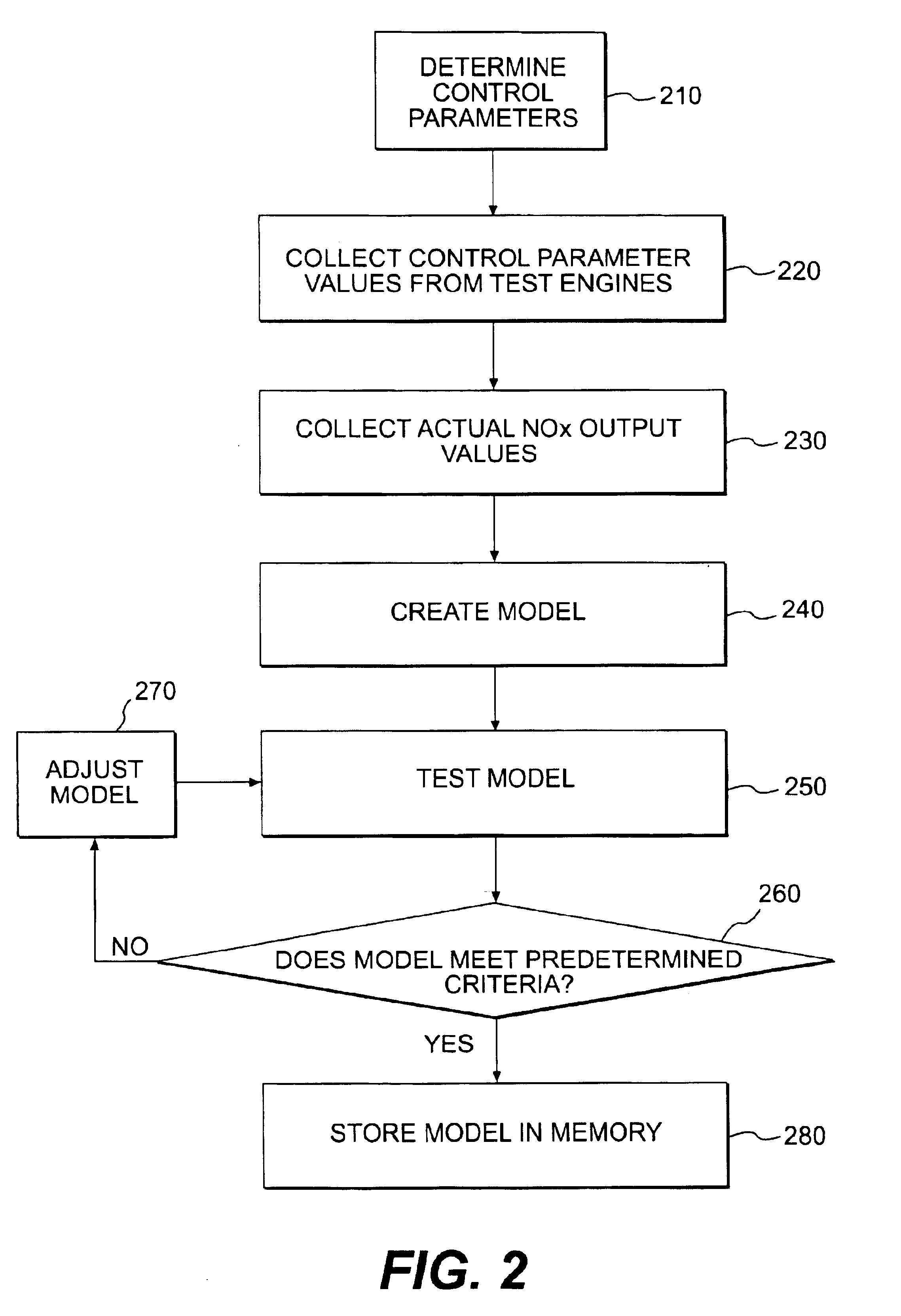

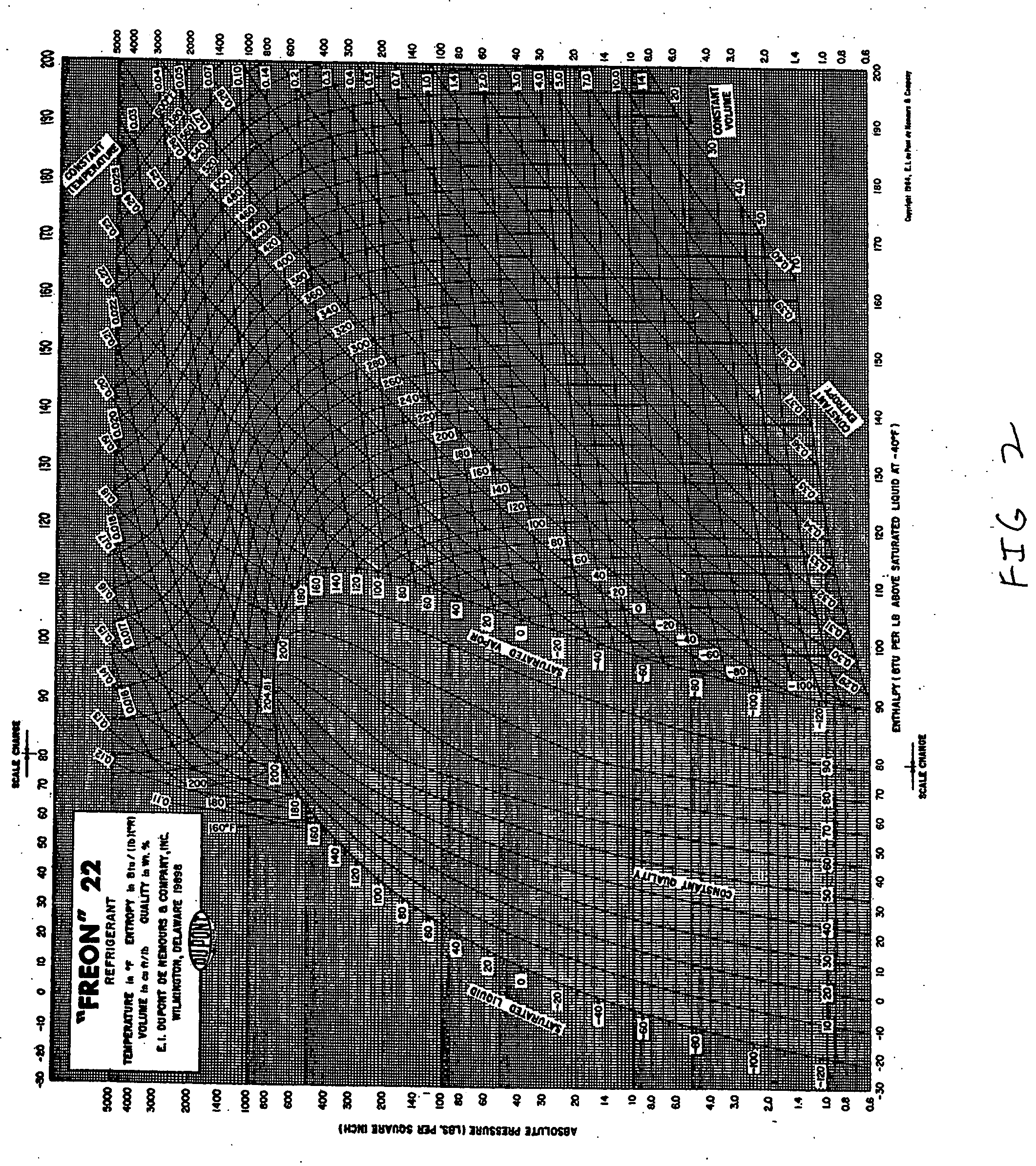

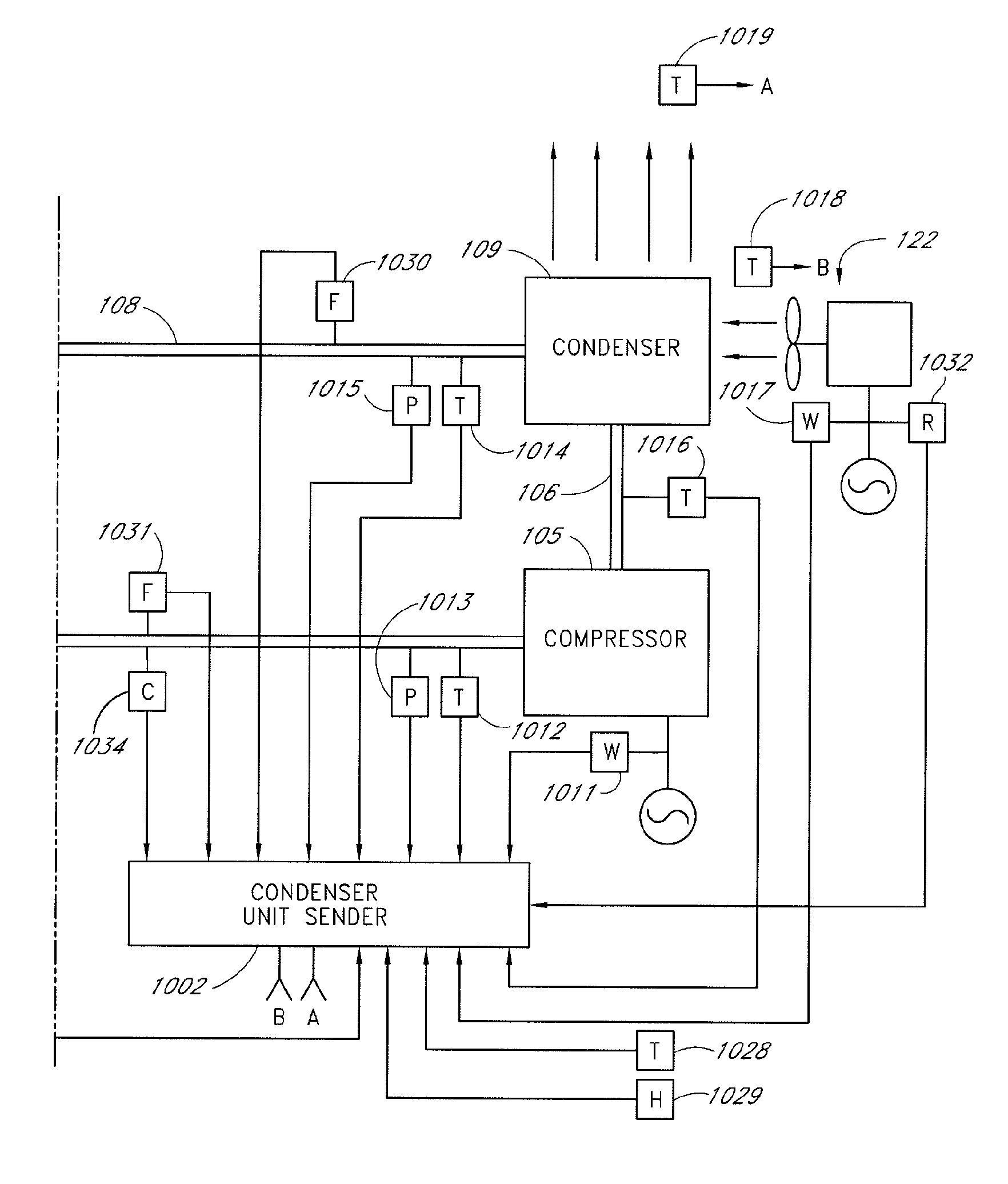

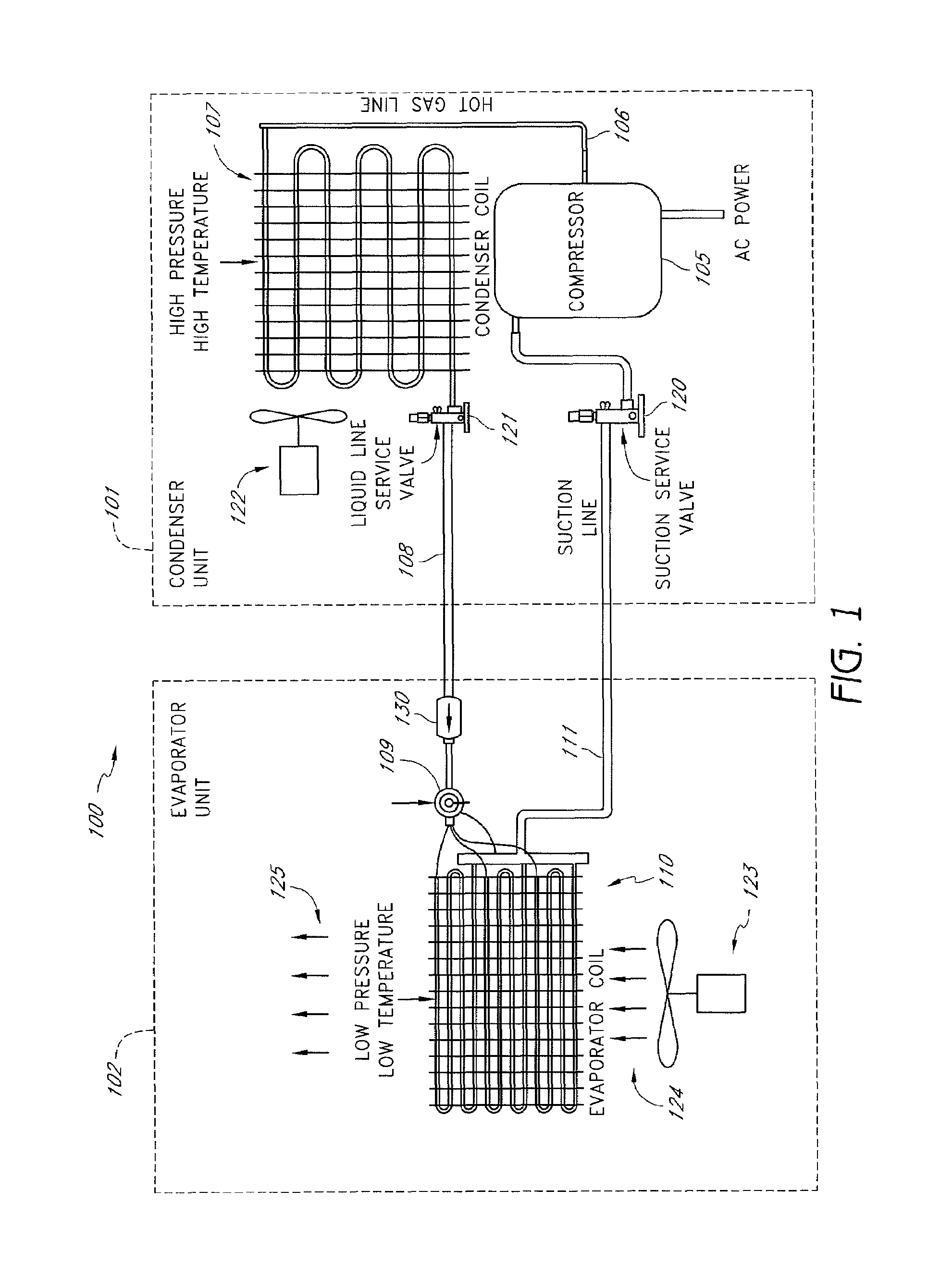

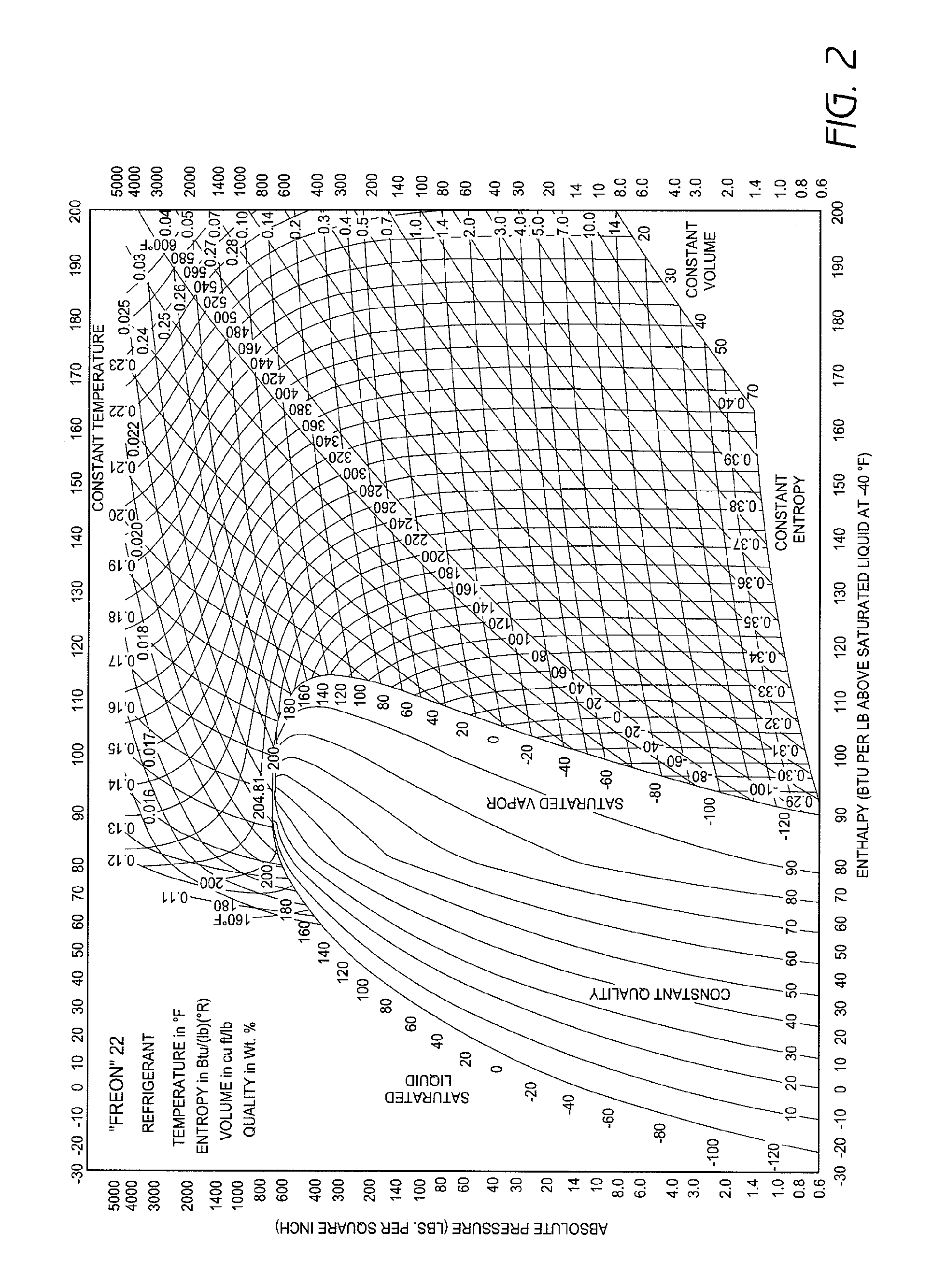

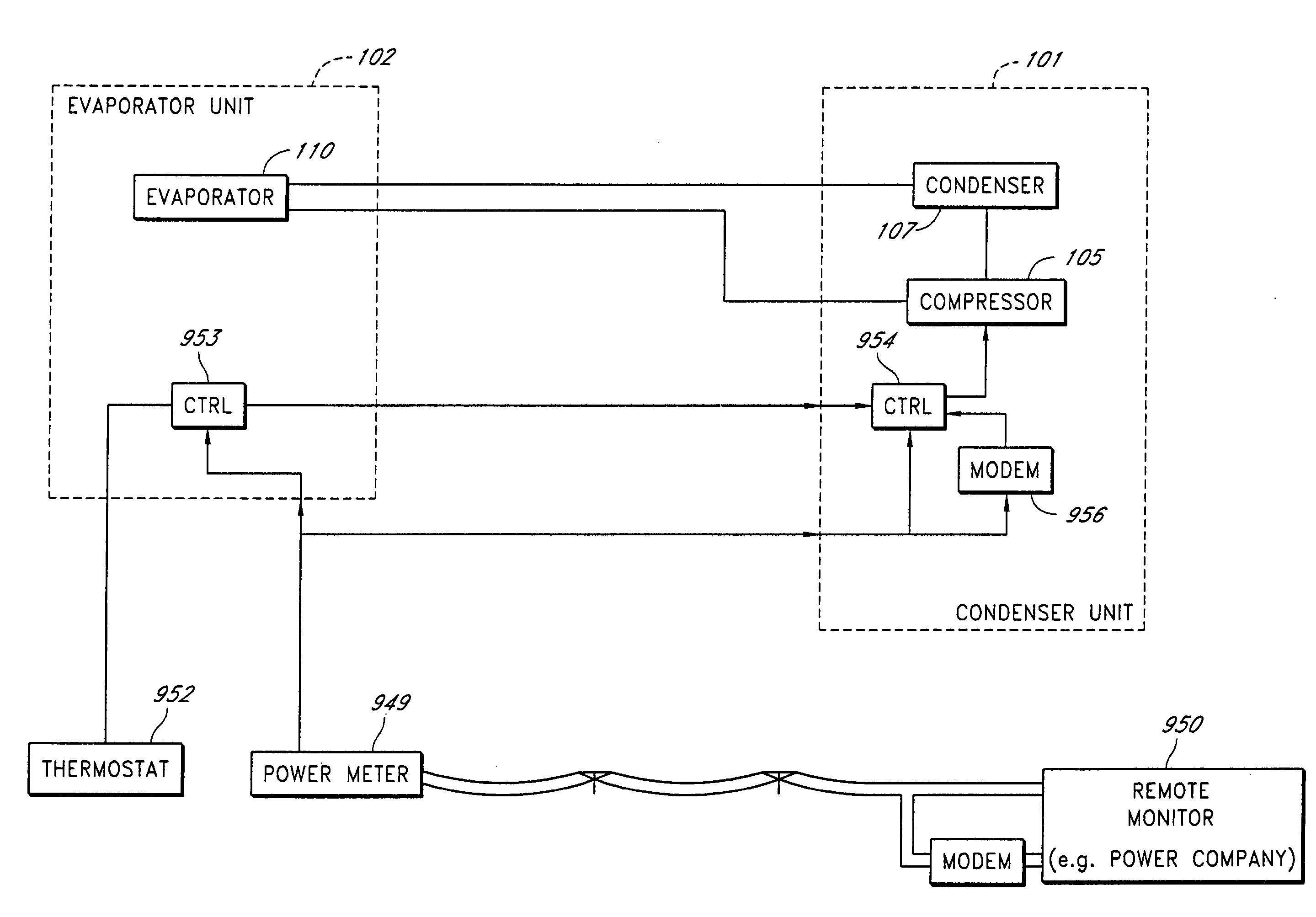

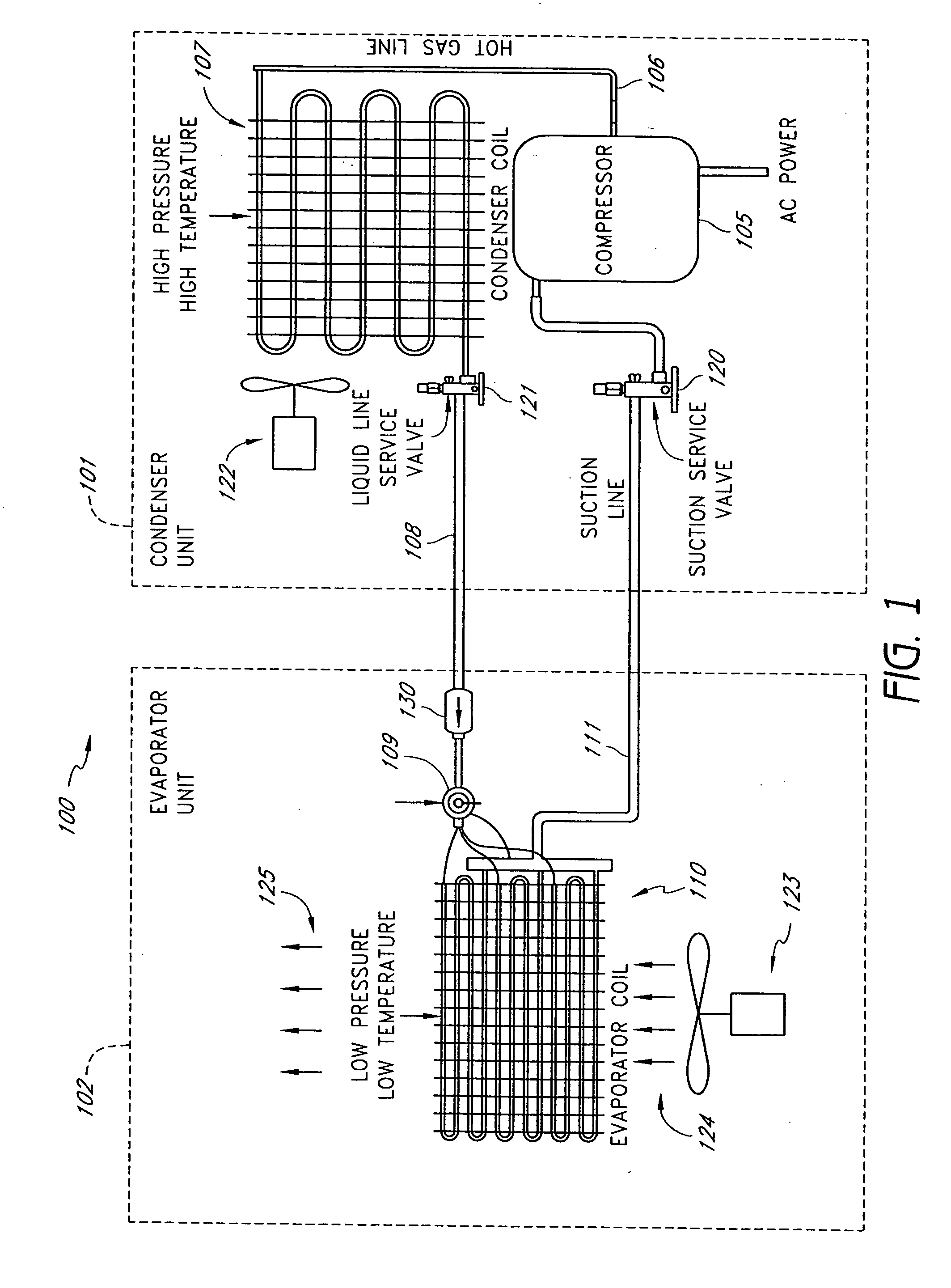

Method and apparatus for monitoring refrigerant-cycle systems

ActiveUS20060032245A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

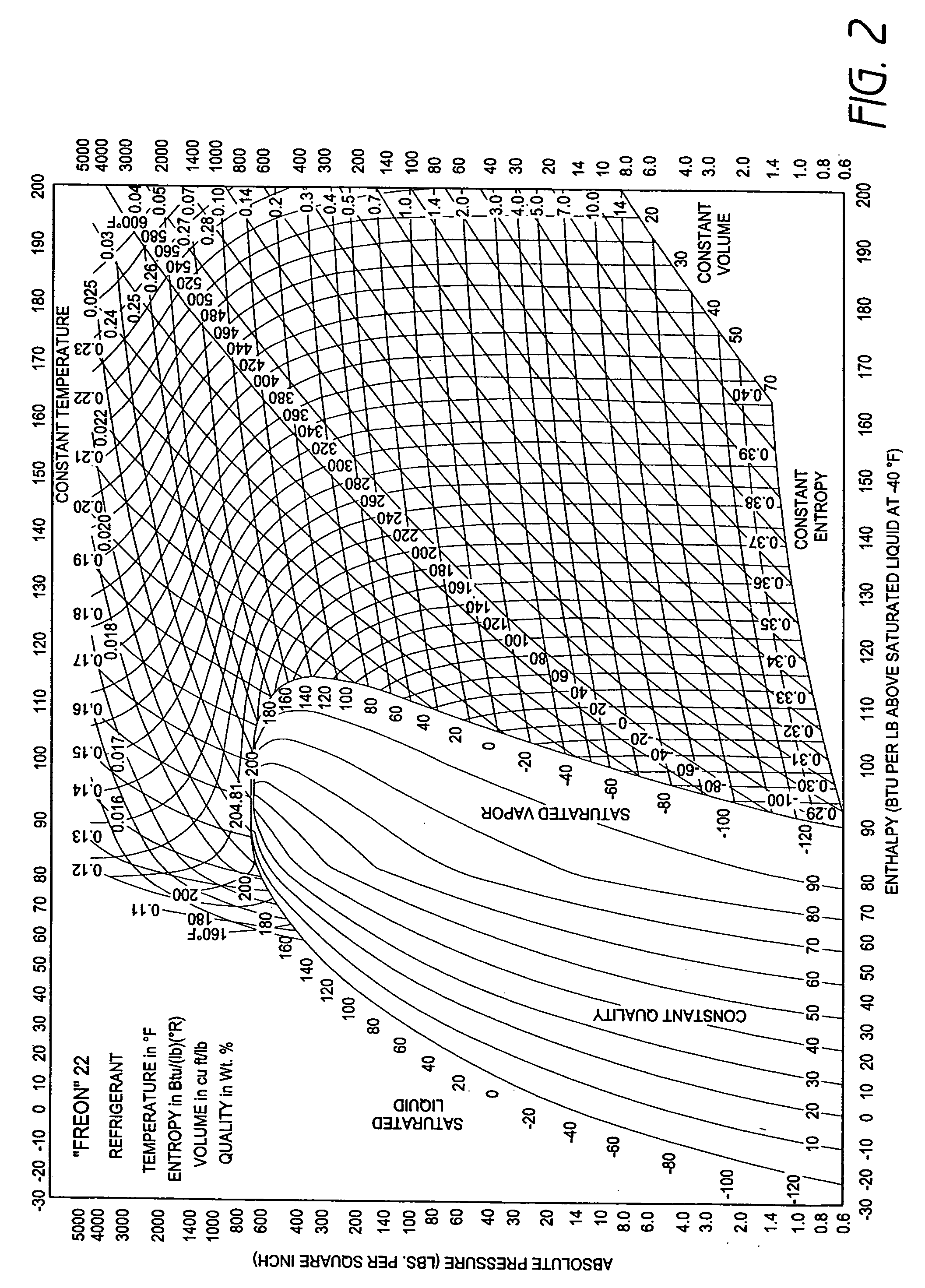

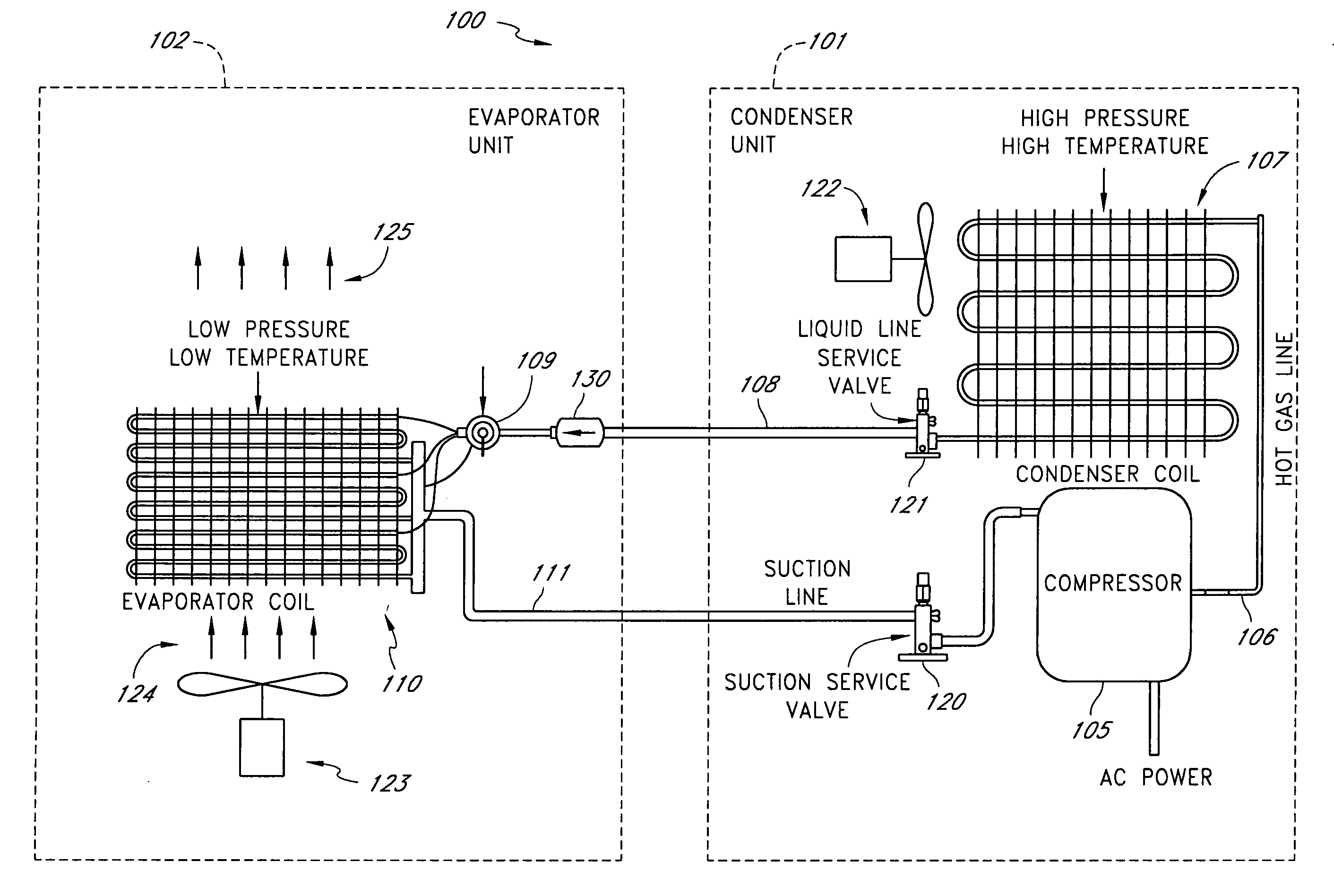

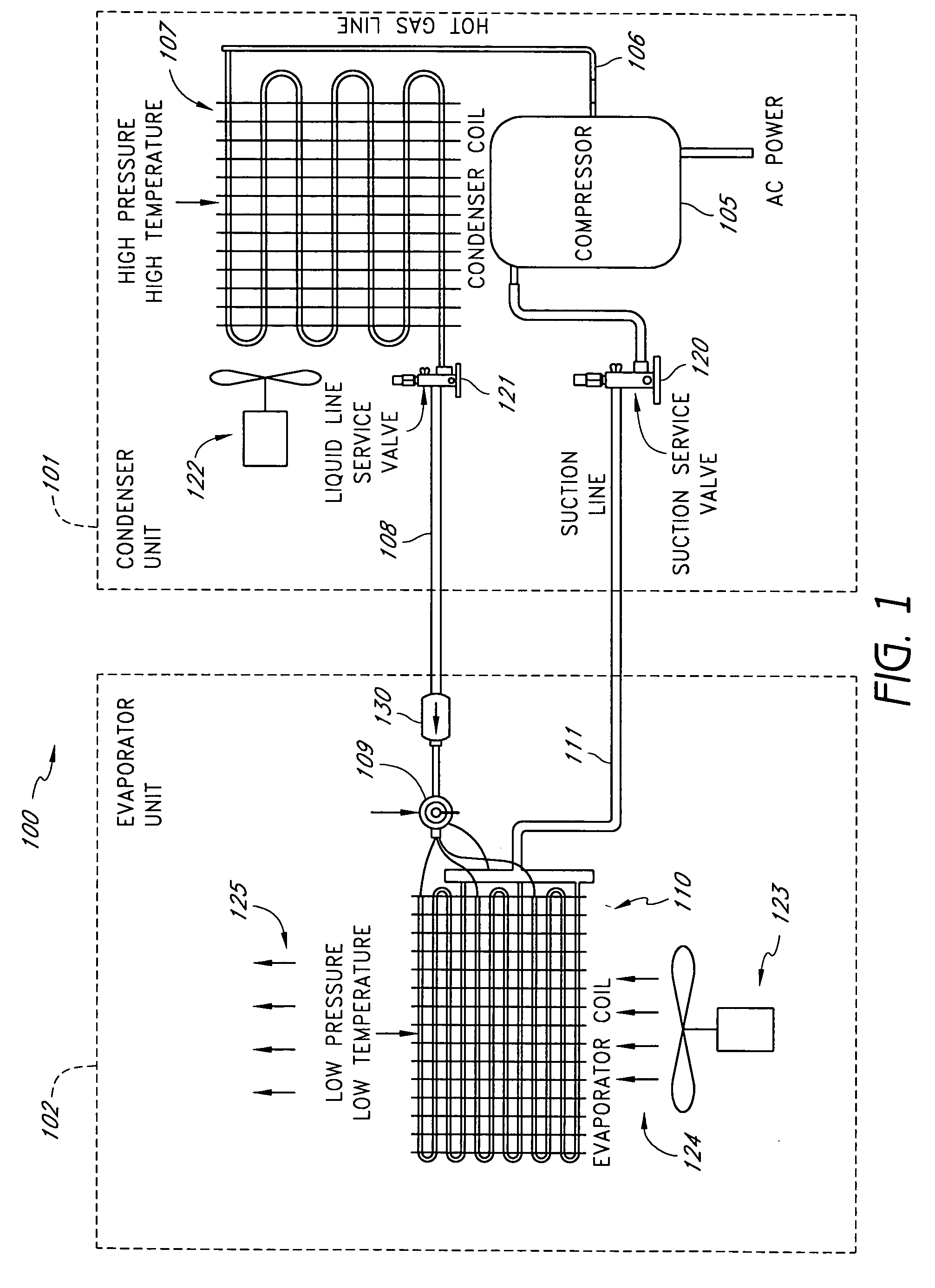

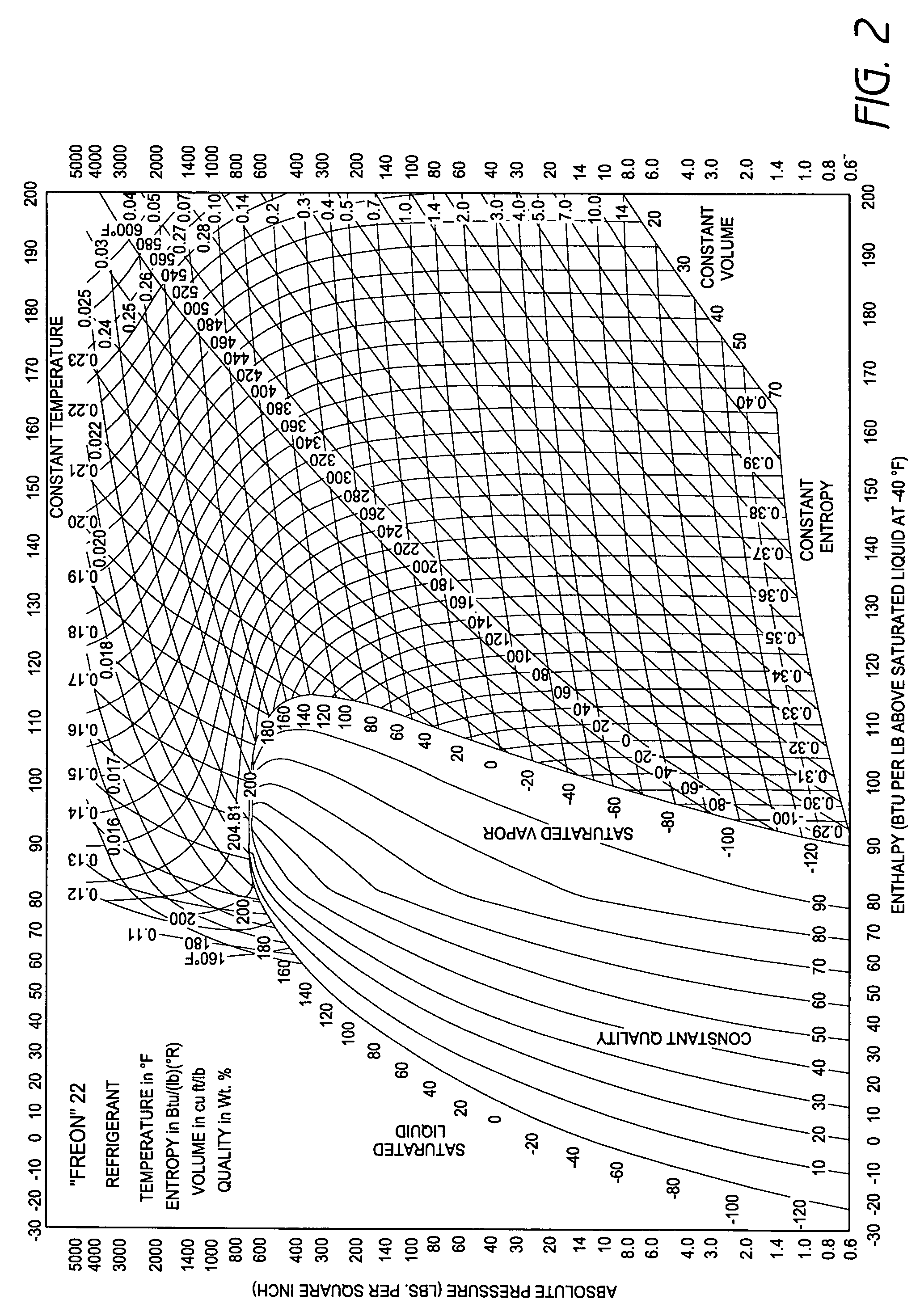

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a calibrated condenser unit in a refrigerant-cycle system

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a calibrated condenser unit in a refrigerant-cycle system

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

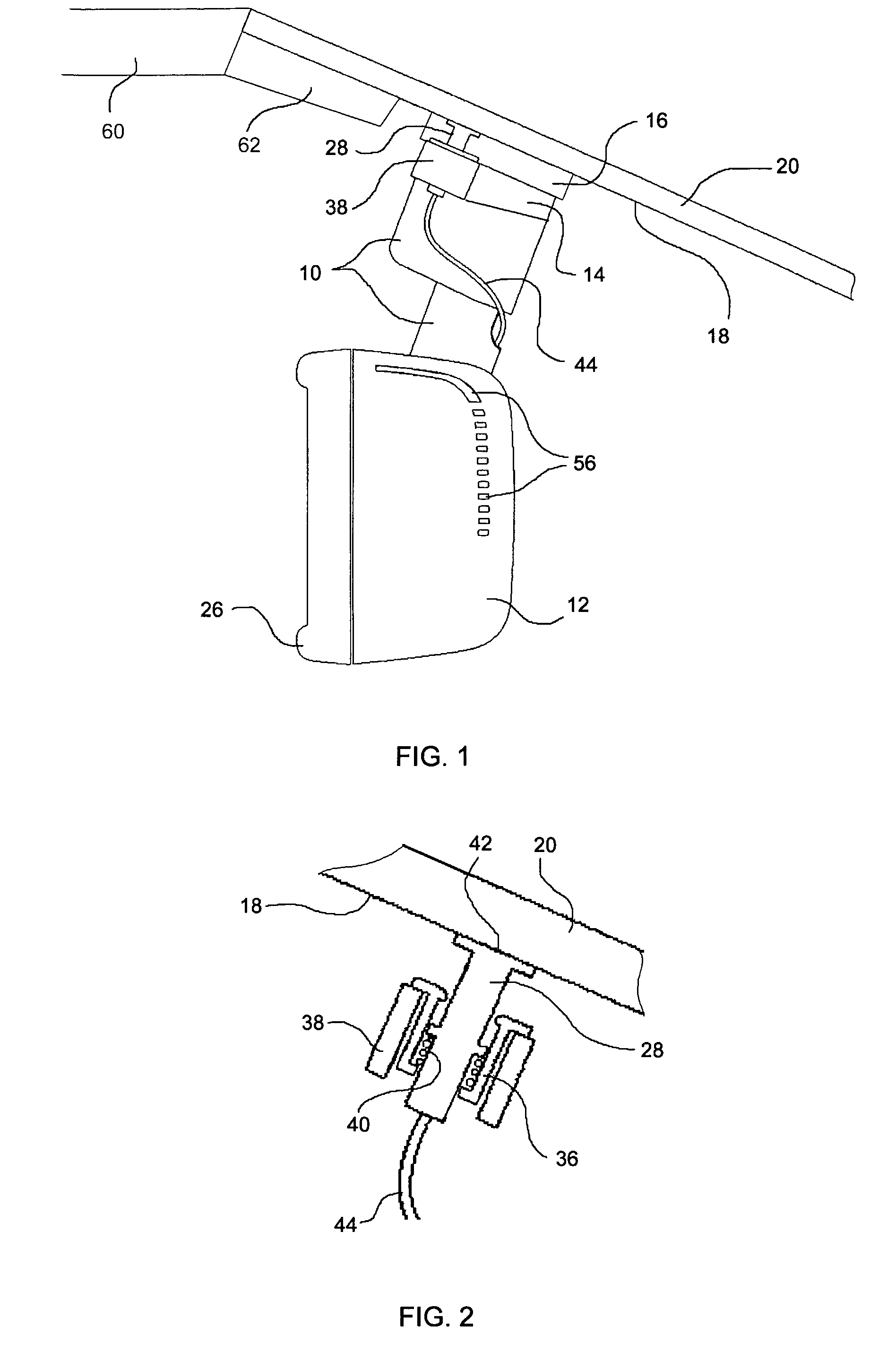

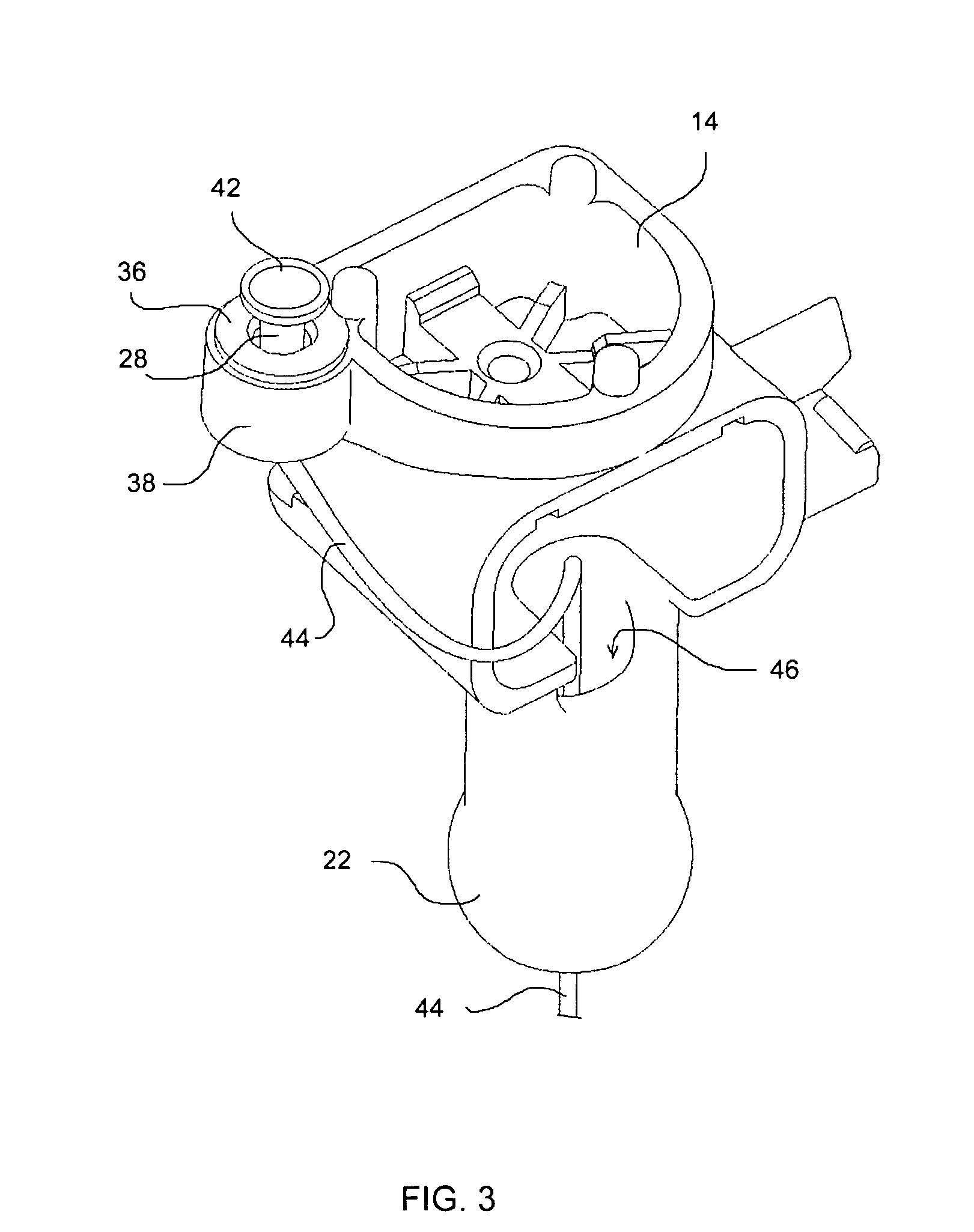

Environmental control system for a vehicle

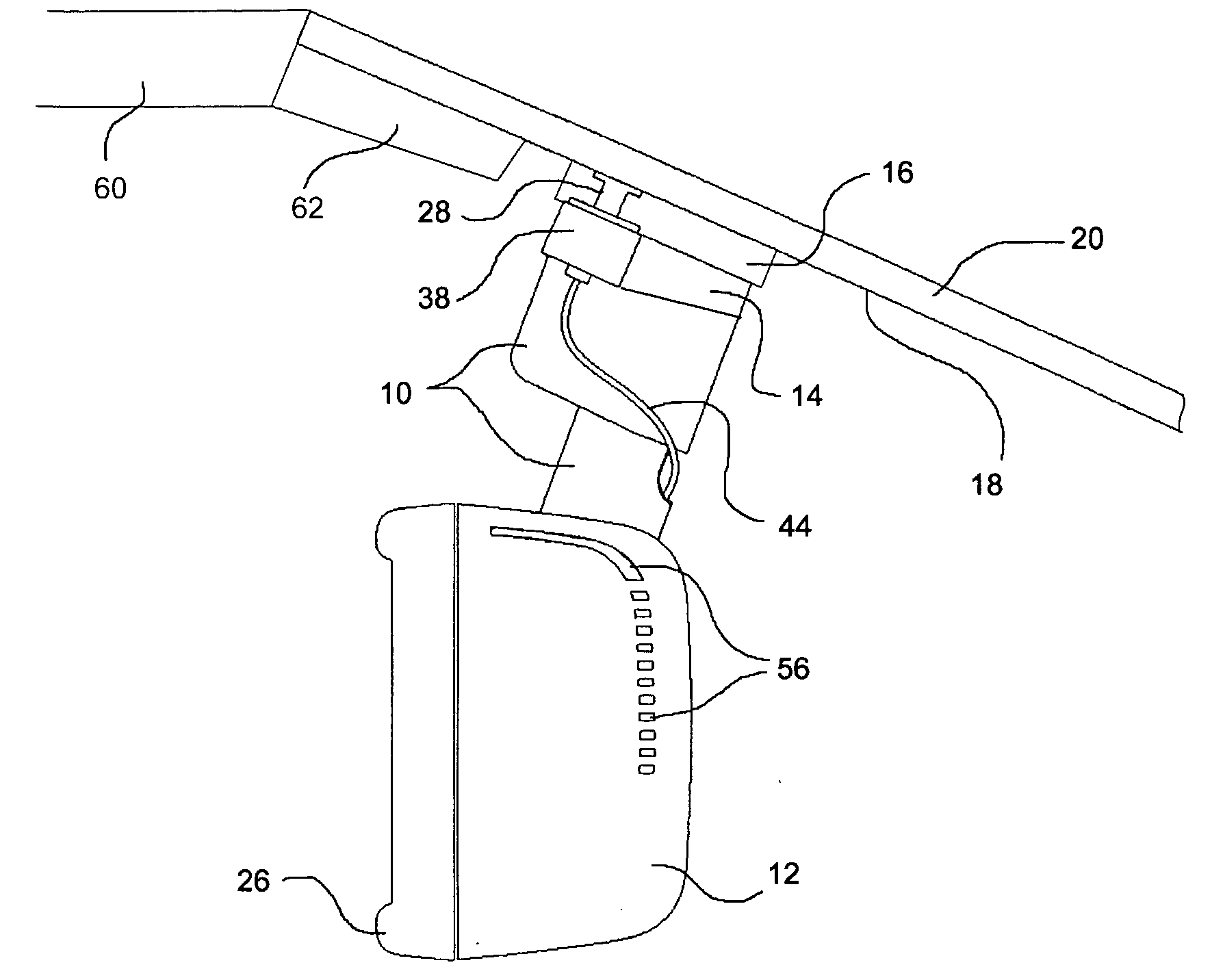

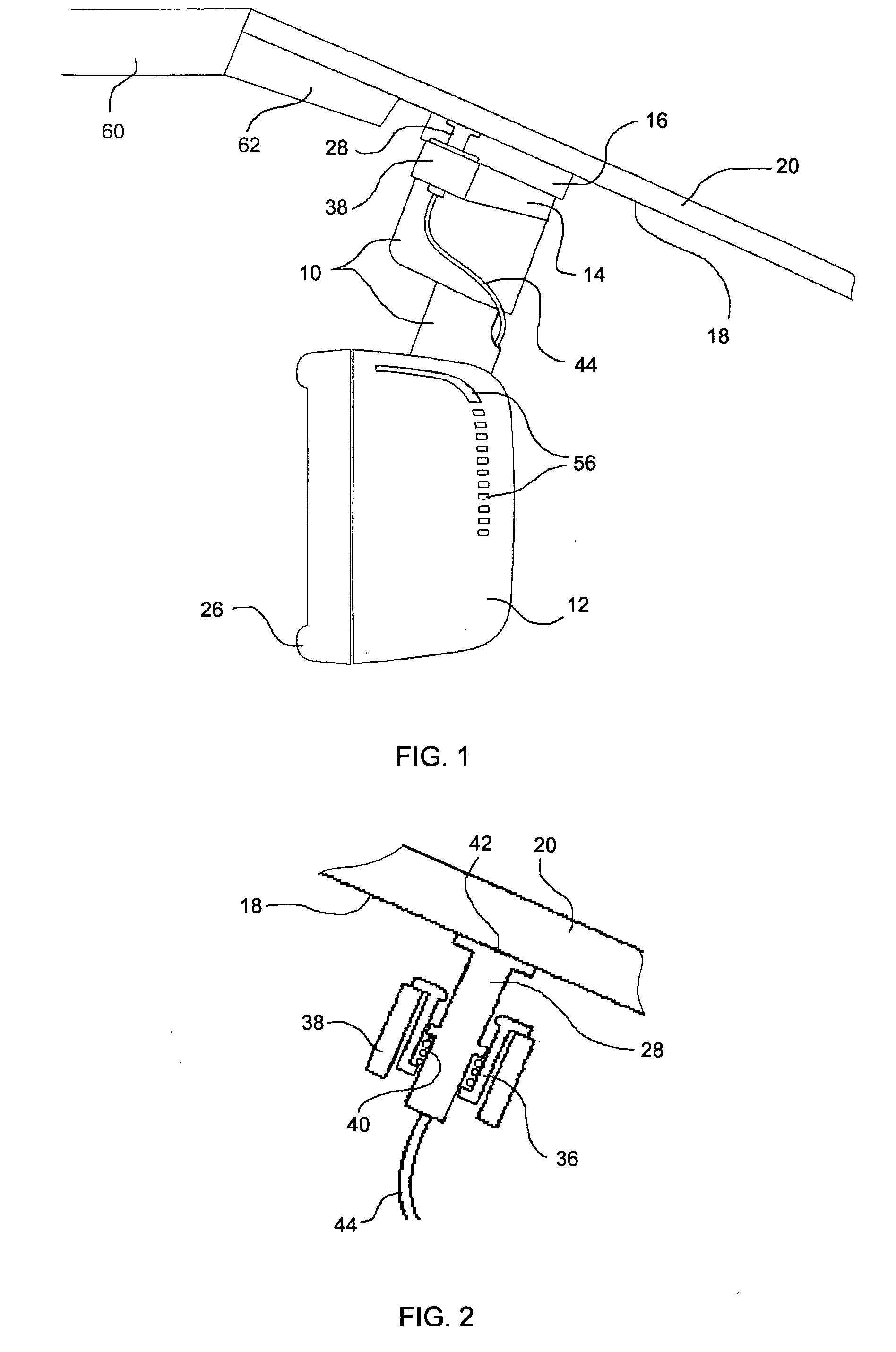

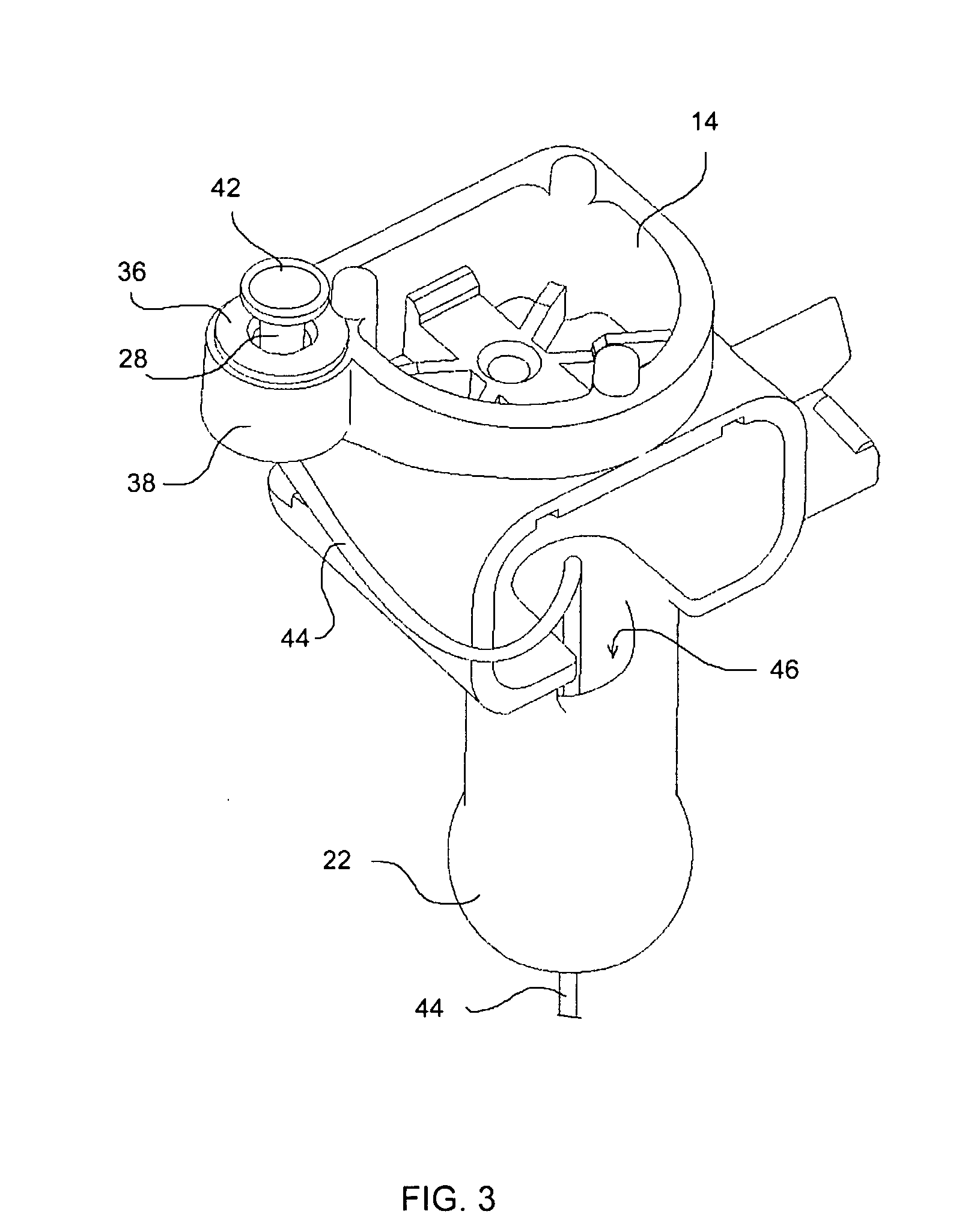

ActiveUS7946505B2Obscure his visionThermometer detailsThermometers using electric/magnetic elementsAmbient humidityControl system

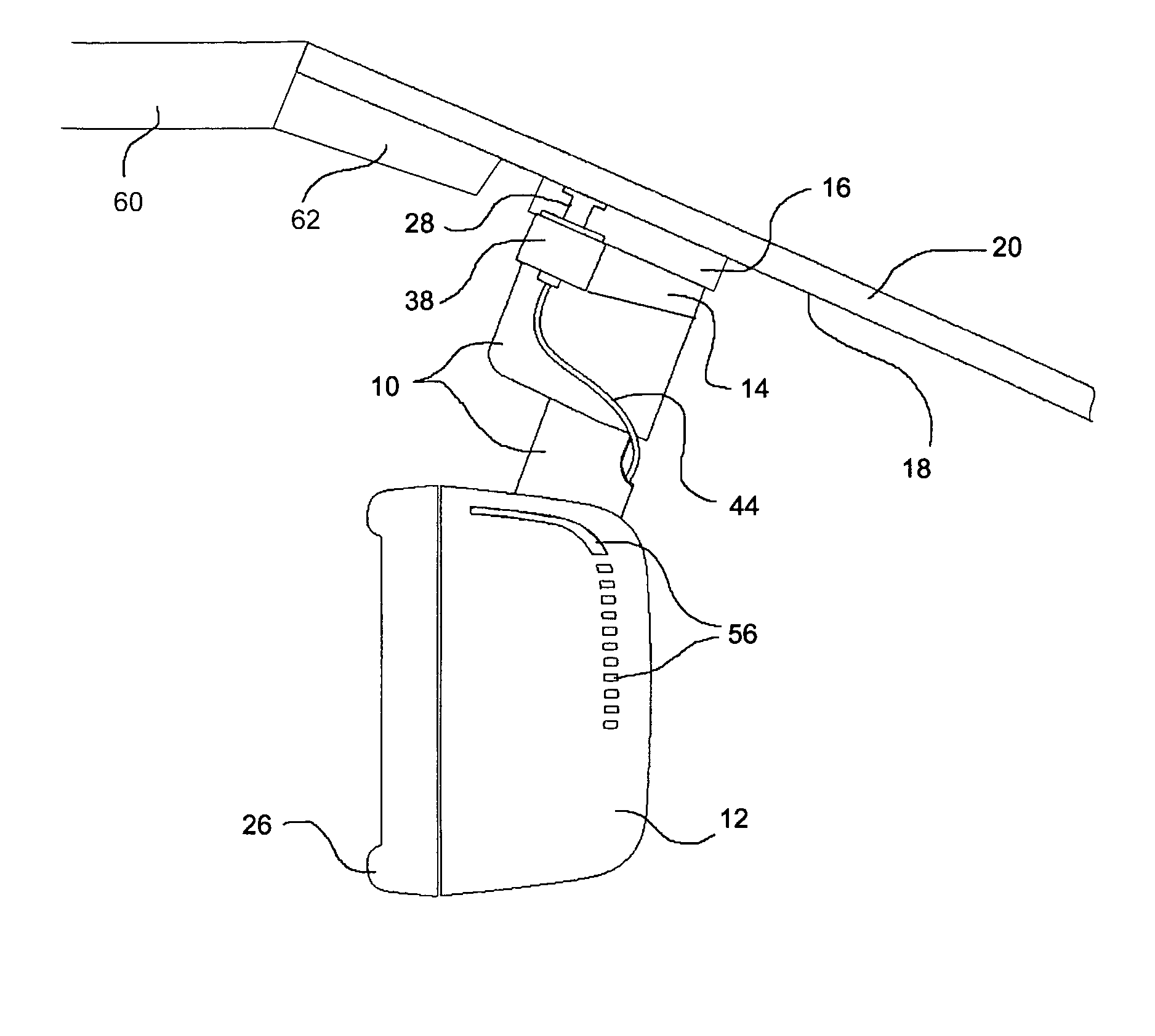

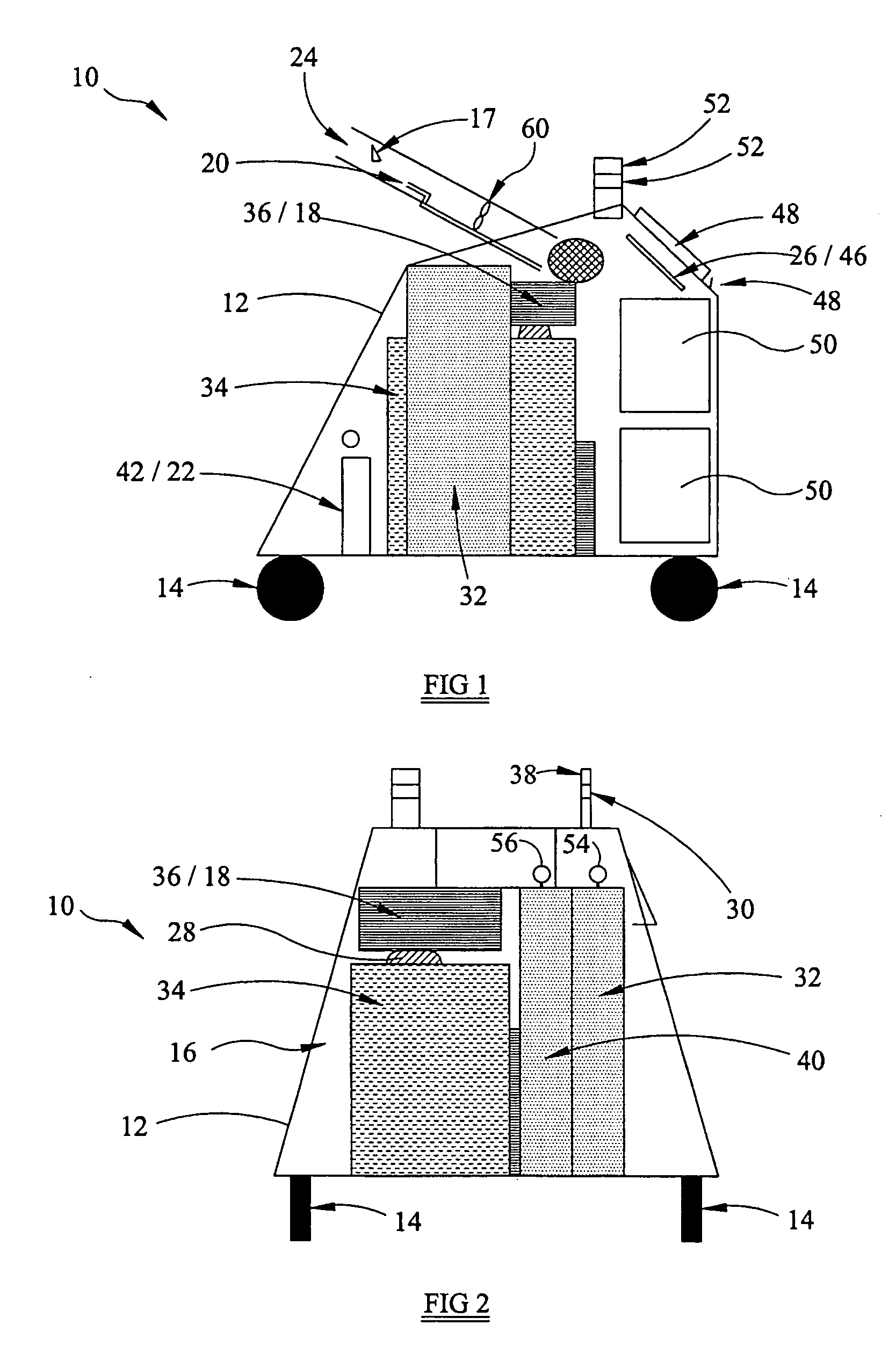

An environmental control system for a vehicle, in particular for predicting internal misting of a vehicle windscreen, the system comprising a windscreen temperature sensor assembly 28, an ambient humidity sensor assembly 32 and a second temperature sensor assembly 30 for sensing the temperature of the humidity sensor assembly 32. The windscreen temperature sensor assembly 28 is mounted on an interior rearview mirror support bracket 10 for engagement with the interior surface 18 of the windscreen, and the second temperature and humidity sensor assemblies are mounted within a rearview mirror housing 12 mounted to the mirror support bracket 10.

Owner:MAGNA MIRRORS HLDG

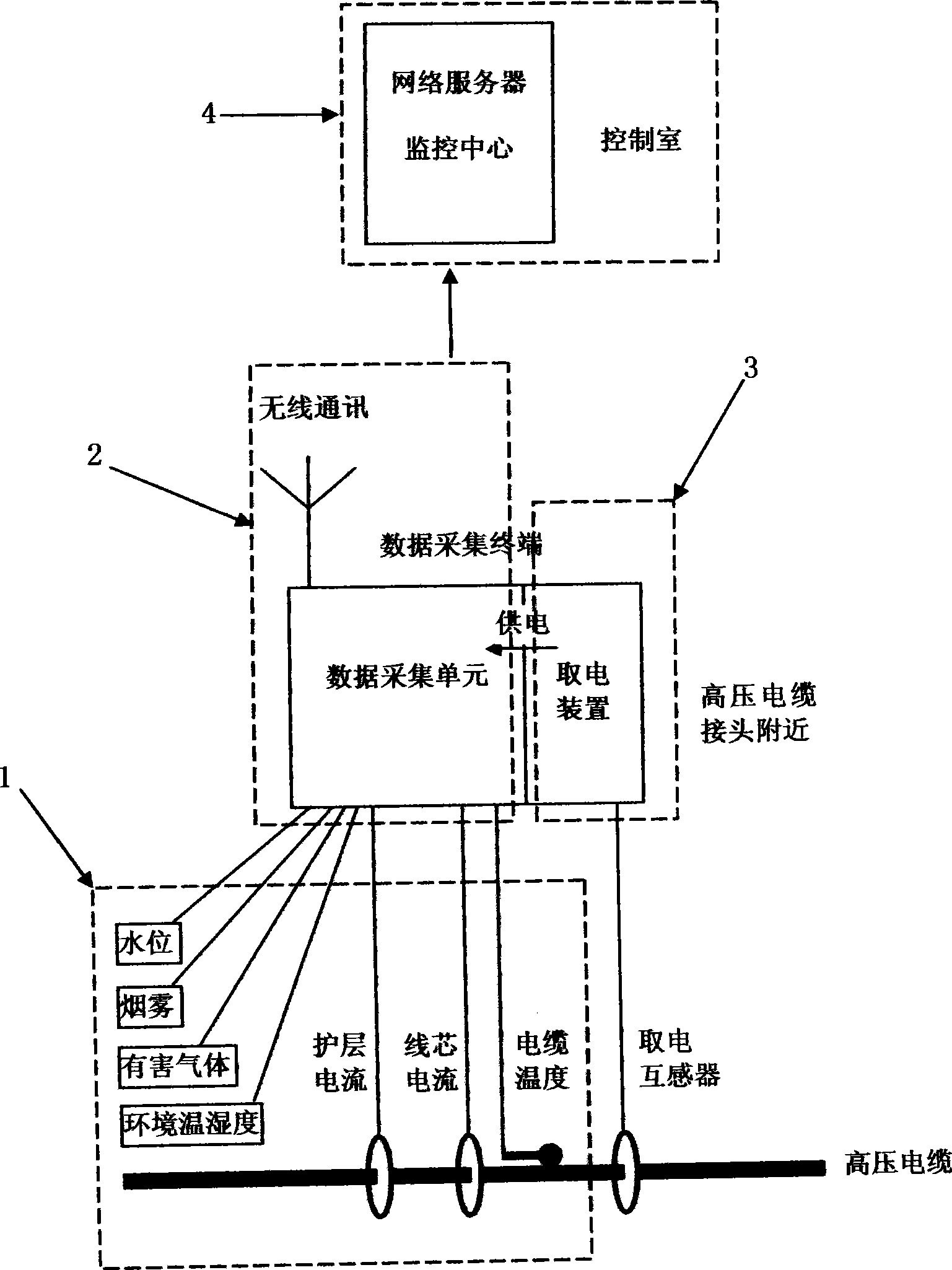

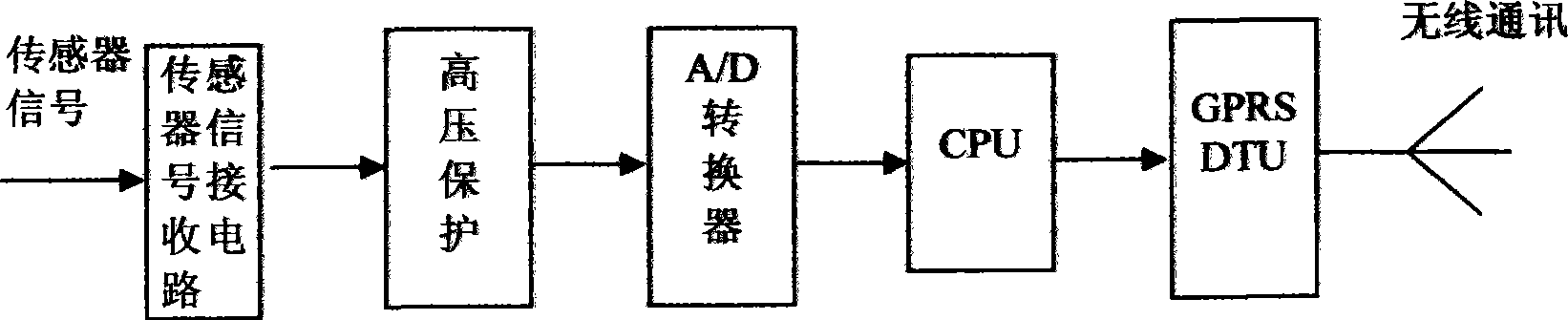

On-line monitoring system for high voltage cable

ActiveCN101464488AAvoid electrical accidentsTransmission systemsFault locationCirculating currentEngineering

The invention relates to an online monitoring system for high-voltage cables, which comprises a sensor, a data collection unit, a power supply device, and a network server. The sensor is arranged at the joint of a high-voltage cable and is used for collecting data such as the shield circulating current of the high-voltage cable joint, the core current, the surface temperature of the cable, and the ambient humidity and temperature and transmitting the data to the data collection unit. The data collection unit is arranged nearby the high-voltage cable joint and is used for collecting the data transmitted from the sensor and transmitting the date to the network server via a wireless network. The power supply device acquires power from the high-voltage cable and provides power to the data collection unit. The network server is installed in a control room and is used for receiving the data transmitted from the data collection unit in order to determine whether the power cable is in safe operation condition via special data analysis, thereby serving the purpose of helping maintenance personnel monitor the operation condition of the power cable at any time, and preventing the electrical faults from happening. In case that faults occur with the cable, the online monitoring system can send alarms promptly and locate fault points, thereby providing assistance for cable repair.

Owner:上海慧东电气设备有限公司 +3

Method and apparatus for monitoring air-exchange evaporation in a refrigerant-cycle system

ActiveUS20060032248A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEvaporation

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

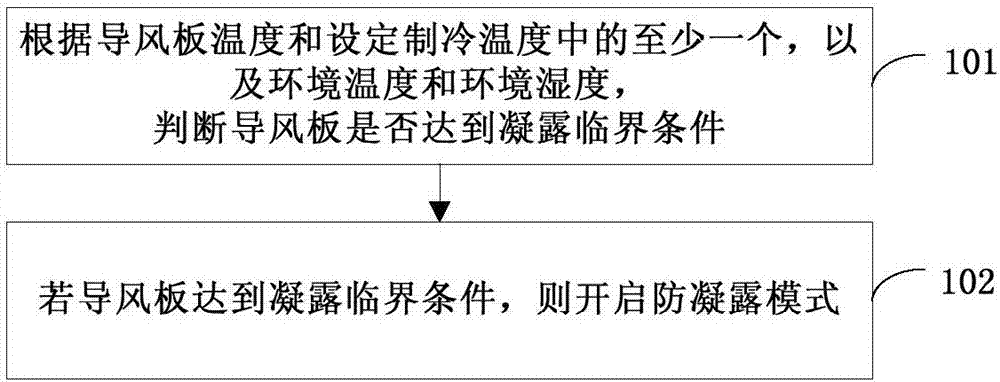

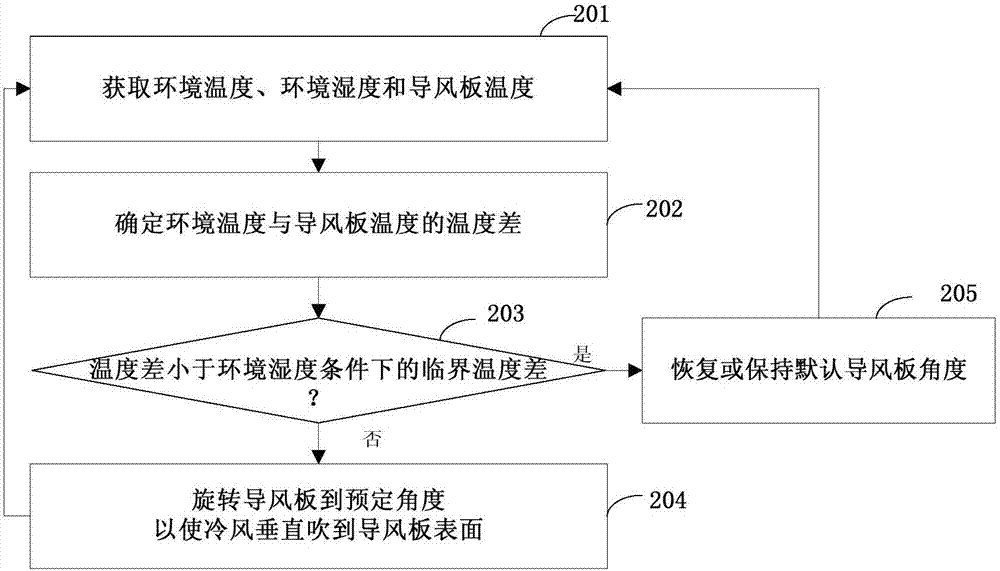

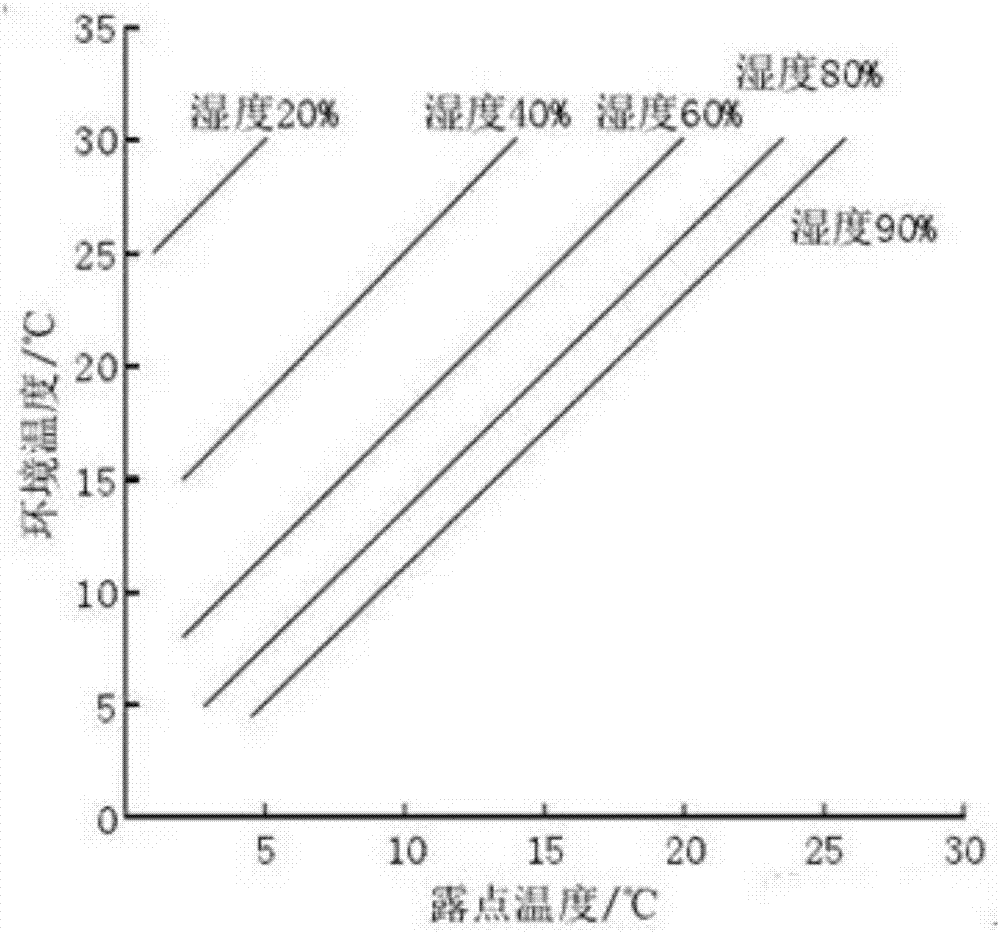

Condensation prevention method for air conditioner, controller, system and air conditioner

ActiveCN107166661AReduce condensationSpace heating and ventilation safety systemsCondensate preventionAmbient humidityCritical condition

The invention provides a condensation prevention method for an air conditioner, a controller, a system and the air conditioner, and relates to the technical field of air conditioners. The condensation prevention method for the air conditioner comprises the steps that whether an air deflector reaches the condensation critical condition or not is judged according to at least one of the temperature of the air deflector and the set refrigeration temperature, the environment temperature and the ambient humidity, wherein the condensation critical condition comprises the critical temperature difference when condensation occurs under each humidity condition; and if the air deflector reaches the condensation critical condition, the condensation prevention mode is started. According to the method, whether the condition for generating condensation is reached or not can be judged according to the ambient humidity, the temperature, the temperature of the air deflector and the set refrigeration temperature, generation of the condensation can be determined in time, the air conditioner is adjusted to enter the condensation prevention mode under the condition that the condensation is determined to be generated, and therefore the generation of the condensation on the air deflector of an indoor unit can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

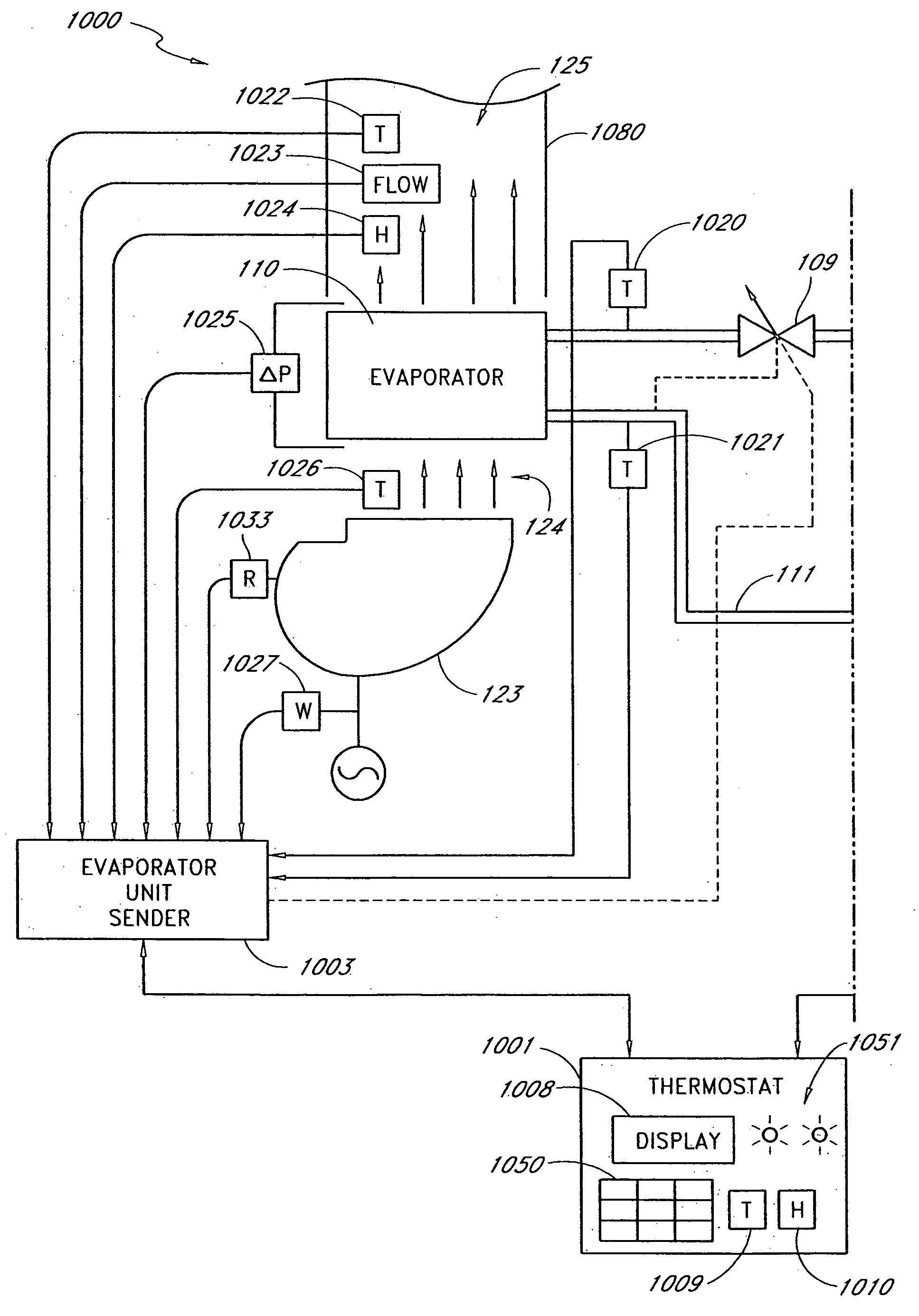

Intelligent thermostat system for load monitoring a refrigerant-cycle apparatus

ActiveUS20060196197A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Intelligent thermostat system for monitoring a refrigerant-cycle apparatus

ActiveUS20060032246A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureThermostat

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a condenser unit in a refrigerant-cycle system

ActiveUS20060032247A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for airflow monitoring refrigerant-cycle systems

InactiveUS20060196196A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:KATES LAWRENCE

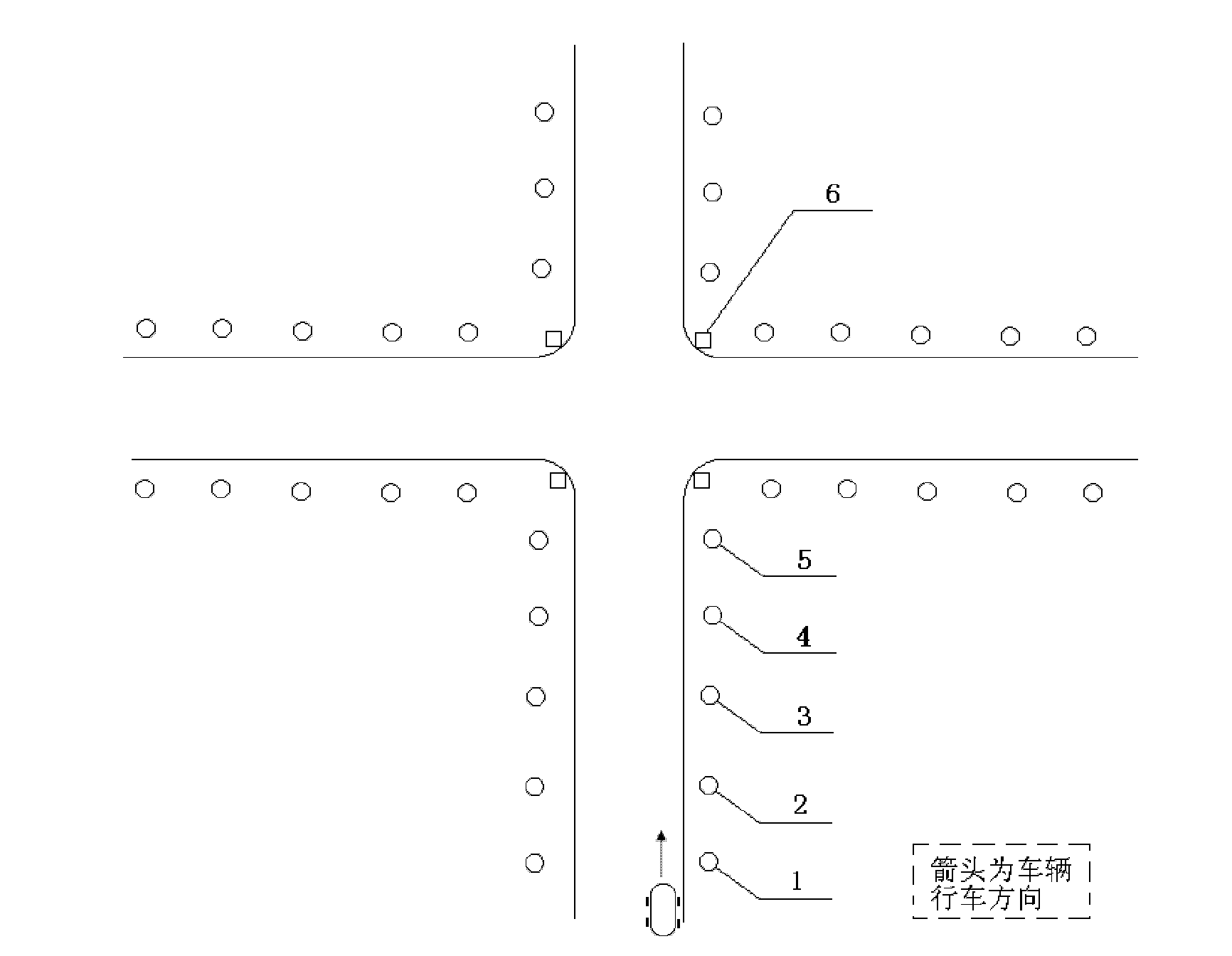

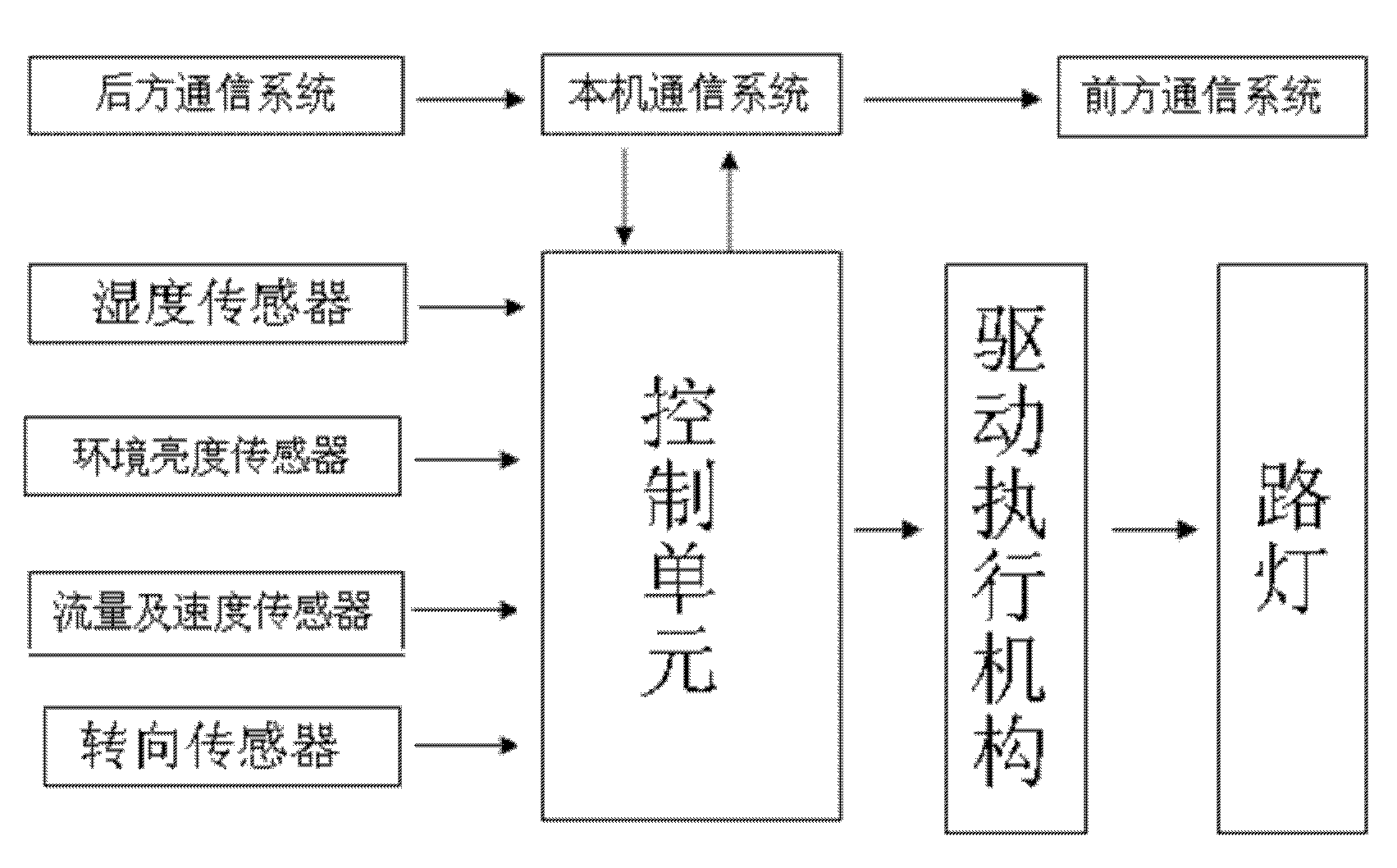

Streetlight network control method and network structure thereof

ActiveCN102421219AProper lighting intensityImprove life expectancyElectric light circuit arrangementEnergy saving control techniquesEngineeringTraffic flow

The invention discloses a streetlight network control method, comprising the steps of: immediately turning on a streetlight when the streetlight acquires a vehicle passing condition and measures a measured vehicle speed signal through a signal acquisition unit; meanwhile, commanding a plurality of streetlights ahead to be turned on for several seconds according to a preset corresponding value between the vehicle speed and the number of the turned-on streetlights ahead as well as a preset corresponding value between the vehicle speed and the light-on time; and turning off the streetlight after the vehicle runs through the streetlight. Meanwhile, by monitoring ambient brightness, vehicle traffic flow and ambient humidity and regulating the illumination brightness of the streetlight, invalid illumination is avoided. The control method disclosed by the invention has the advantages that the proper illumination brightness can be provided by the streetlights according to specific environments in bustling downtown areas and solitude road sections, and the electricity can be saved by 30%; and the method is completely adopted in the solitude road sections, the electricity can be saved by 70% in average and 90% at most. If an LED light source is adopted, the service life of the streetlight can be prolonged by 5 times.

Owner:WUHU LANJIANG LIGHTING

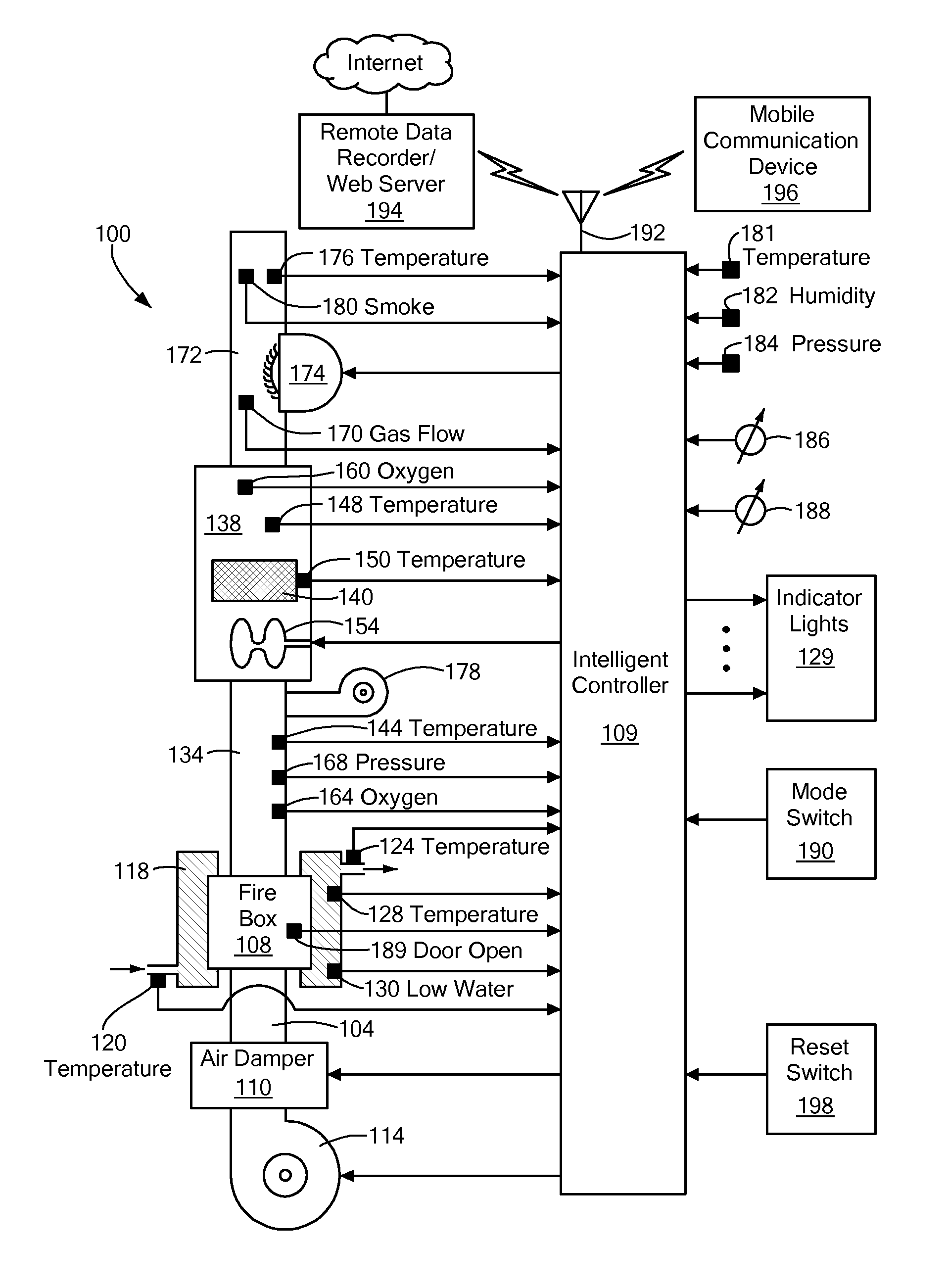

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

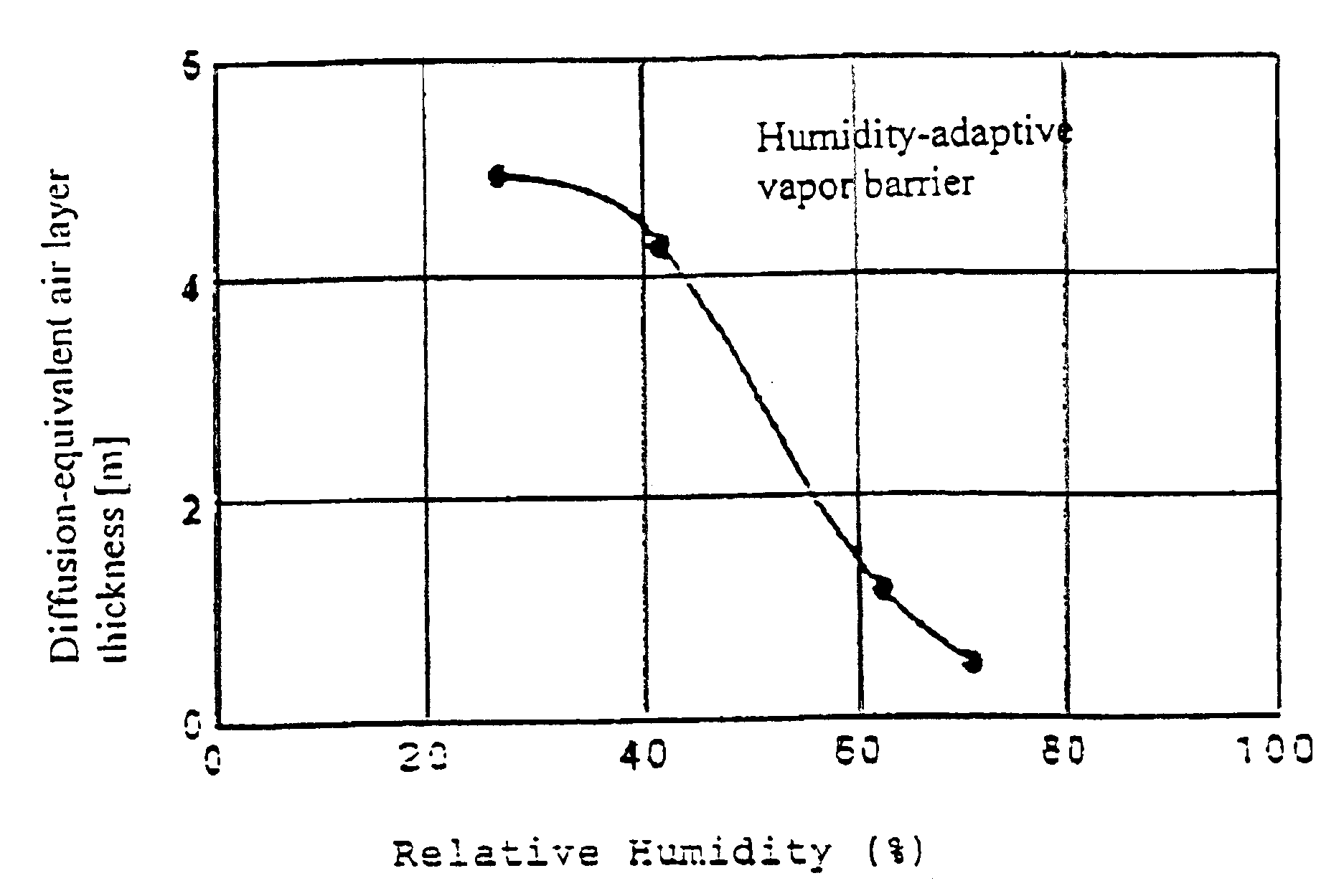

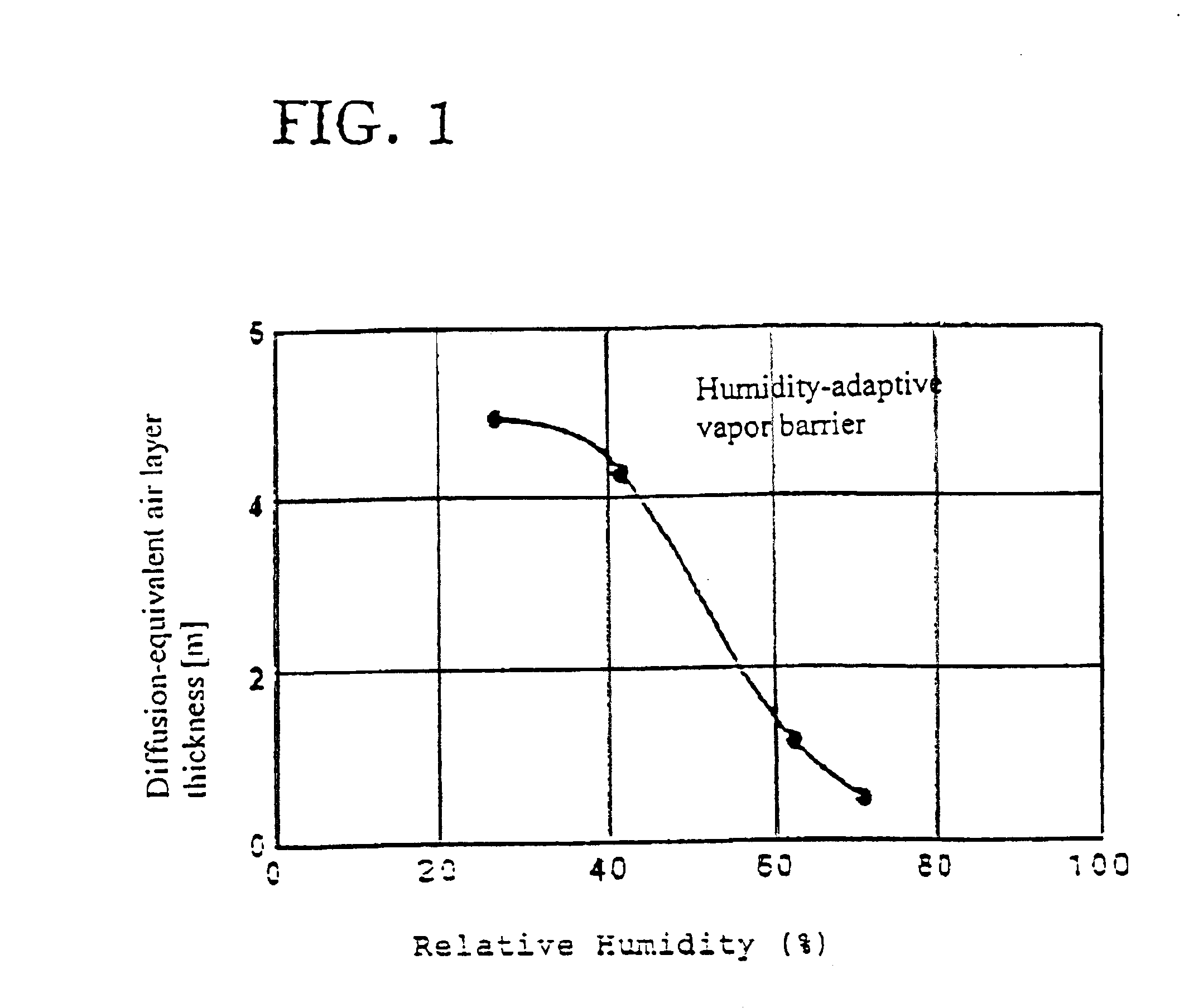

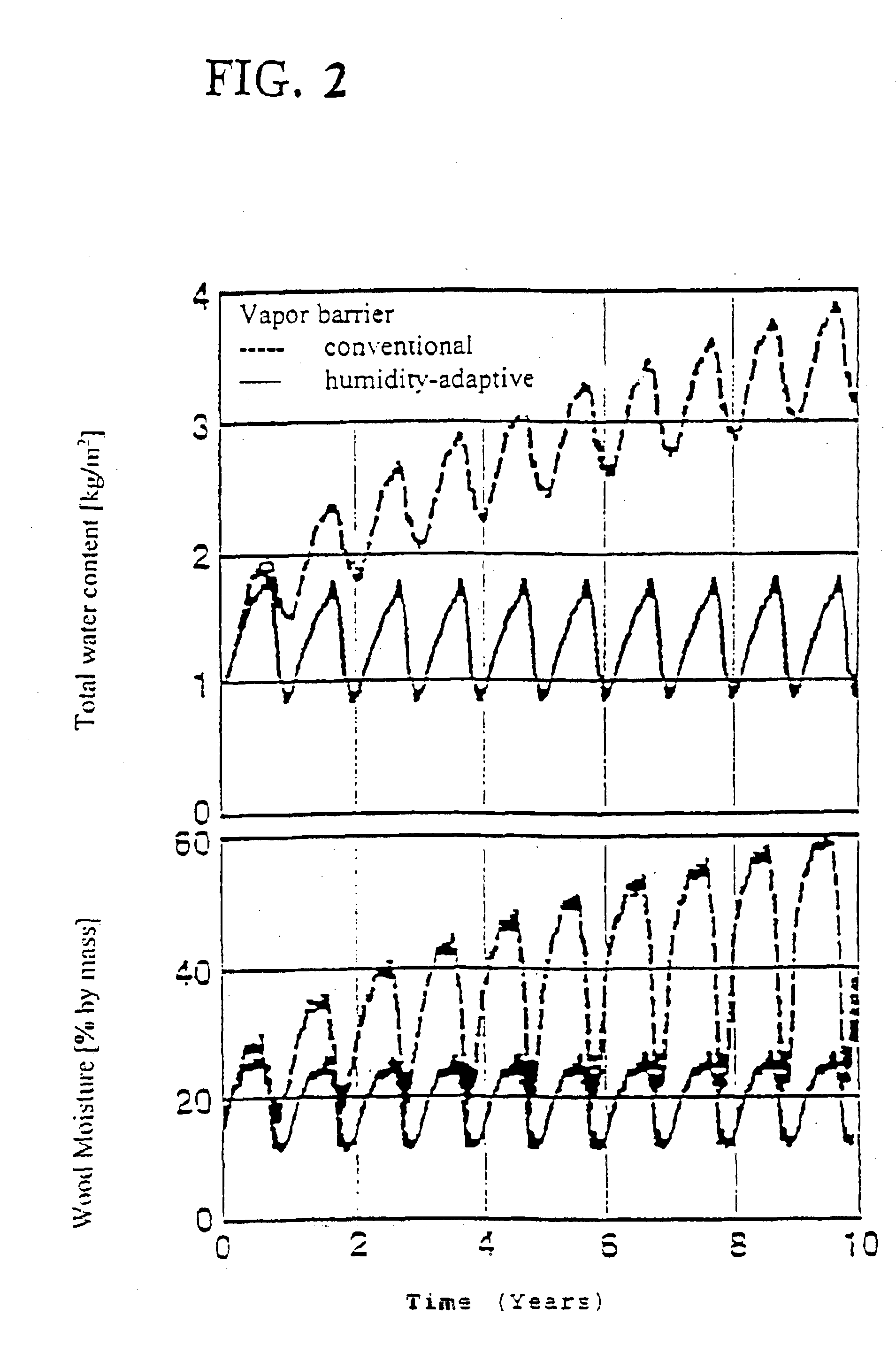

Vapor barrier for use in the heat insulation of buildings

InactiveUS6890666B2Synthetic resin layered productsCellulosic plastic layered productsVapor barrierAmbient humidity

The invention relates to a vapor barrier for use in cthe thermal insulation of buildings which can be used, in particular, for thermal insulation procedures in new buildings or in the renovation of old buildings. The vapor barrier in accordance with the invention is thereby capable of achieving water vapor exchange under different ambient conditions. This is achieved by using a material which has a water vapor diffusion resistance which is dependent on the ambient humidity and which also has adequate tensile strength and tear resistance.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Sterilisation and decontamination

InactiveUS20050031486A1Mechanical apparatusLighting and heating apparatusAmbient humidityAromatic hydrocarbon

A method of sterilisation and decontamination comprises the steps of producing a humidified environment having a relative humidity which is higher than ambient humidity; discharging ozone into the humidified environment; and then introducing an aromatic hydrocarbon into the humidified environment to preferentially react with the discharged ozone to form hydroxyl radicals. Apparatus is also provided for use with the method.

Owner:DOW GLOBAL TECH LLC

Air conditioner and method thereof

InactiveCN101294733AReduces problems with phase changesReduce or even avoid phase change problemsSpace heating and ventilation safety systemsLighting and heating apparatusAmbient humidityEvaporation

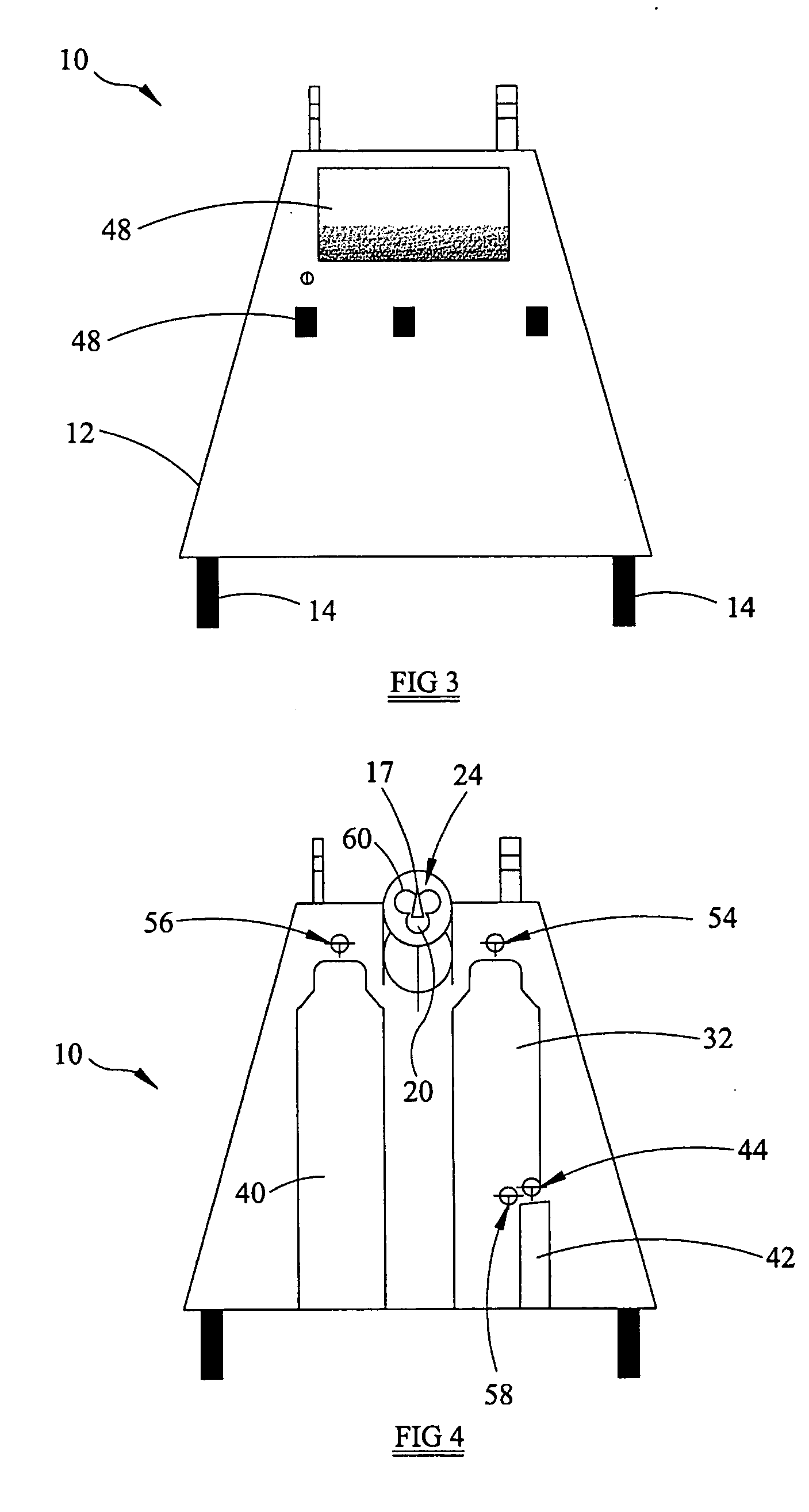

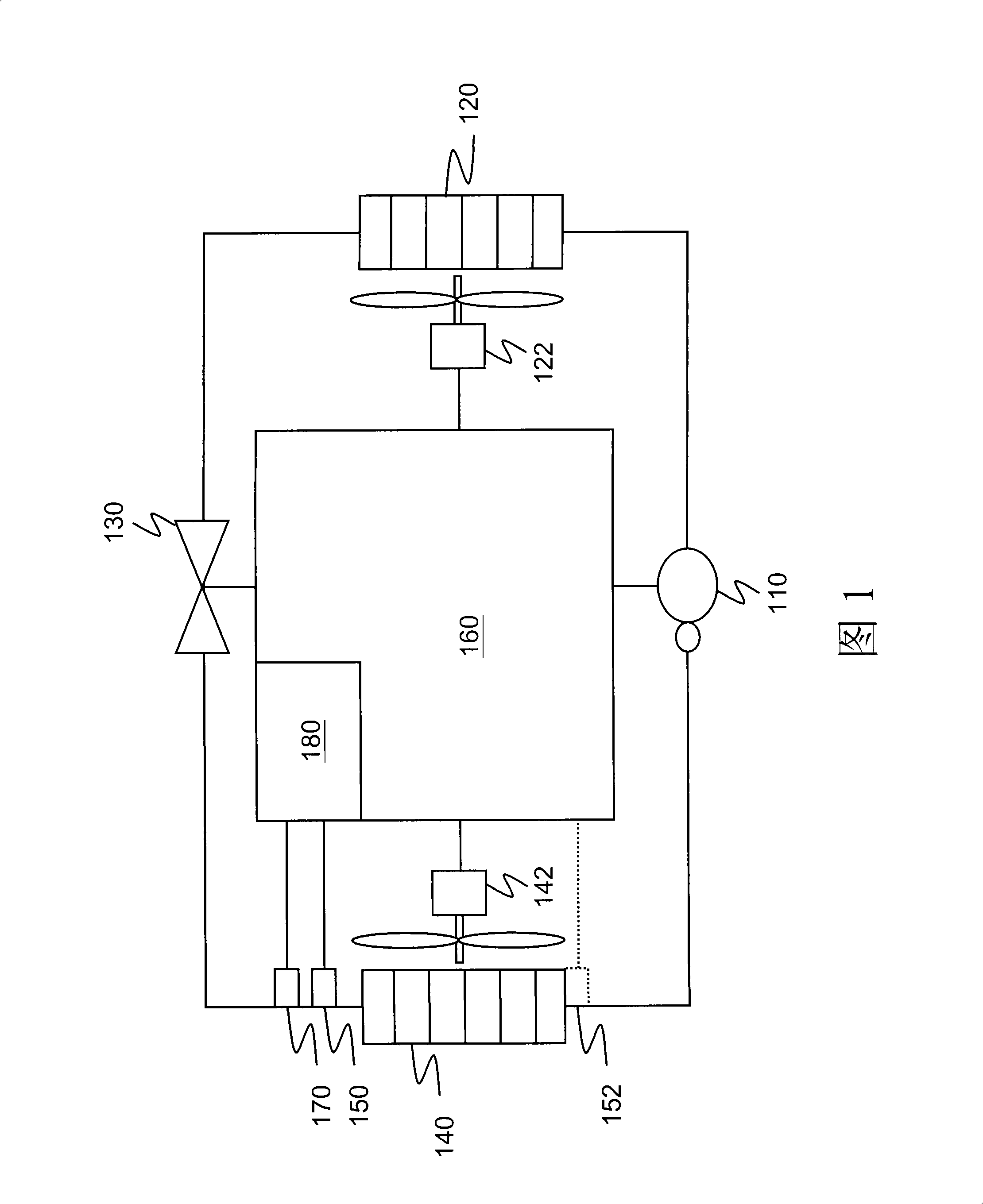

An air conditioner and the method thereof are provided. The air conditioner includes a compressor, a condenser, a condensation fan, an expansion valve, an evaporator, an evaporation fan, an ambient temperature sensor, an ambient humidity sensor and a controller. The controller can obtain a target temperature according to the ambient temperature measured by the ambient temperature sensor and the relative humidity measured by the ambient humidity sensor, thereby adjusting the temperature of the secondary refrigerant in the evaporator according to the target temperature, and further reducing the phase change of water molecules in air.

Owner:TECO ELECTRIC AND MACHINERY

Metal injection molding product and carbon control method thereof in manufacturing process

The invention relates to a metal injection molding product which contains material ingredients and a molding agent ingredient, wherein the material ingredients comprise 90-95 percent of iron powder, 2-5 percent of nickel powder and 0.5-1 percent of molybdenum powder; the molding agent ingredient contains paraffin wax, low density polyethylene, polypropylene, carnauba wax and stearic acid; and theadjustment range of the molding agent content is 6.0 percent to 8.0 percent. The carbon content range of a finally-sintered product can be effectively controlled by adopting the percentages and the contents of the materials, and therefore, the carbon content is controlled easily and accurately. In addition, the molding agent has the advantages of easy removal, environment protection, good fluidityand shaping effect, and the like, therefore, the quenched product has even and uniform internal and external hardness, and the processed product is ensured not to deform easily; and due to appropriate temperature, push speed and gas flow adopted on a thermal adsorption process as well as skilled drive to the ambient humidity, the stability of the process sand and the carbon content can be ensured, and the product with optimal performance is prepared.

Owner:深圳市注成科技股份有限公司

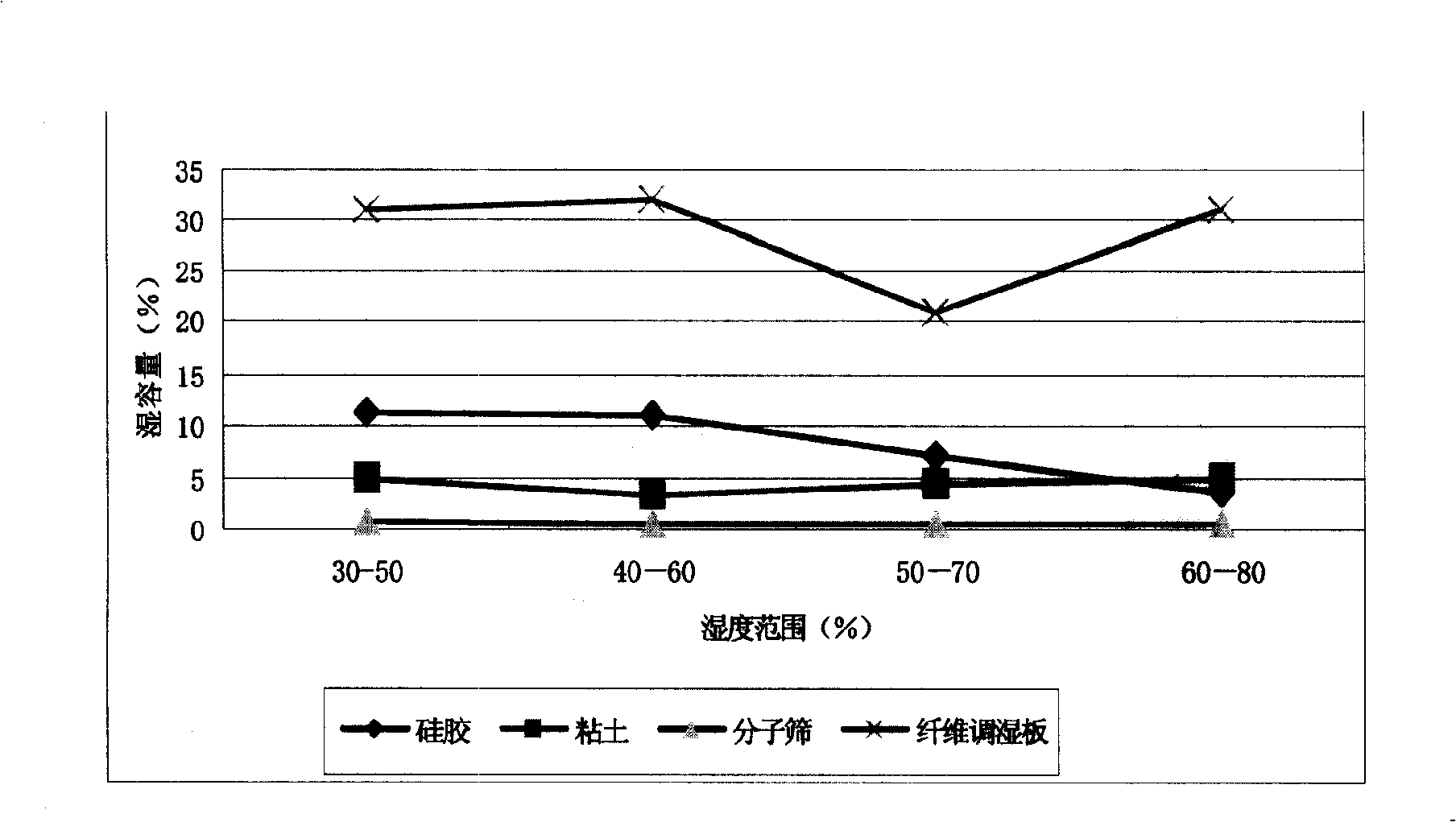

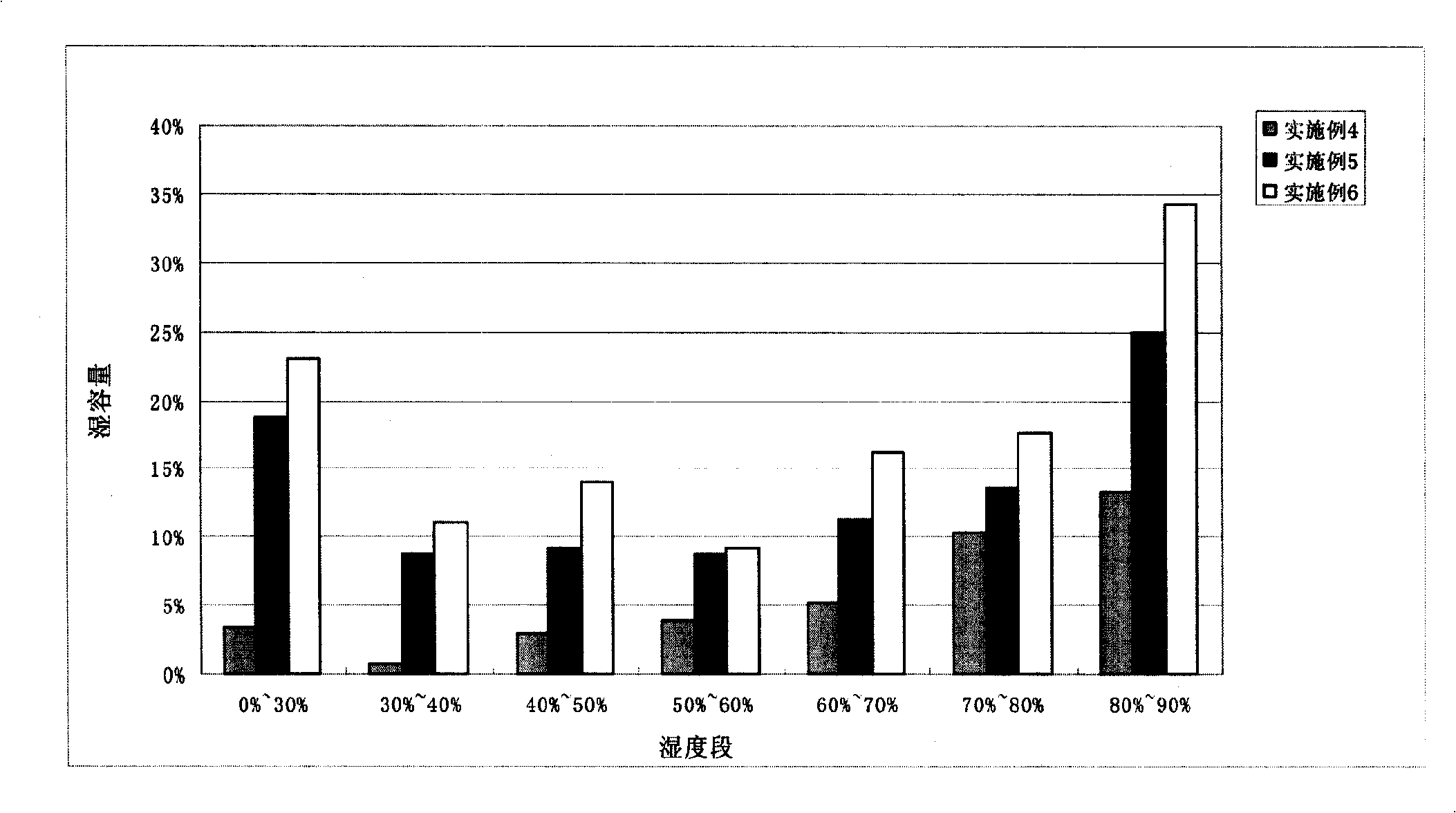

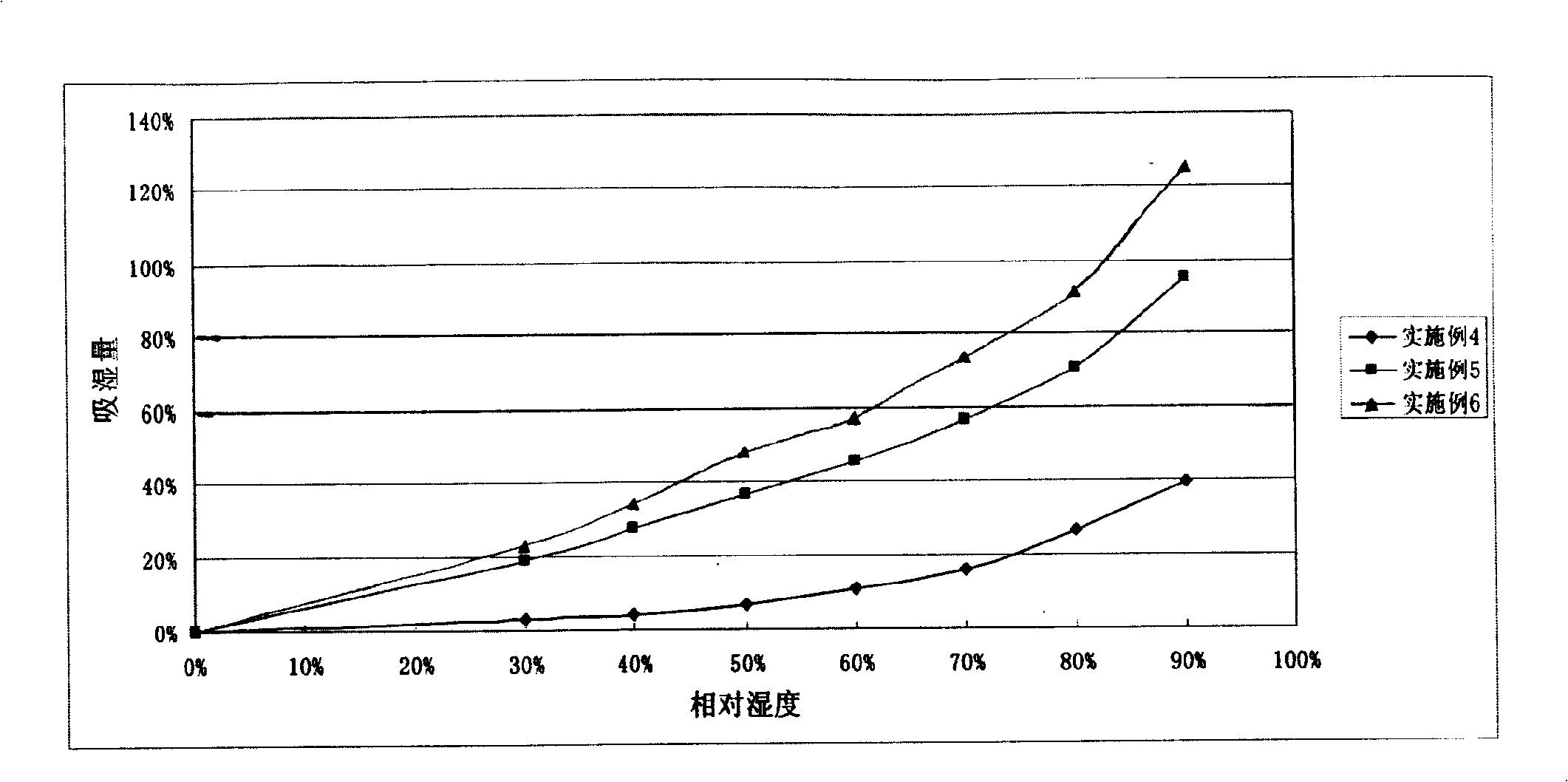

Fibre conditioning plate

InactiveCN101343850AFully adsorbedConstant humidityFibreboardInorganic fibres/flakesSilica gelMoisture

The invention provides a fiber humidity adjusting board. The fiber humidity adjusting board is obtained by soaking a composite board in a humidity adjusting liquid, and the composite board is composed of a fiber material treated by carboxylation and porous inorganic particles dispersed in the fiber material, wherein the mass of the inorganic particles accounts for 5 to 30 percent of the solid content of the fiber, and the inorganic particles adopt one or the combination of silica gel, clay, concavo-convex rods, diatomaceous earth, activated carbon, wood charcoal and bamboo charcoal. The invention has the advantages that the fiber humidity adjusting board is a precise humidity adjusting product, when the ambient humidity changes, response can be rapidly made, and through moisture absorbing and releasing, the ambient humidity can be balanced, so as to maintain the humidity in the environment to be constant and ensure that the phenomena of wetting, mould damage or drying and cracking of the stored articles can not occur within the adjusting environment. A strap-shaped fiber humidity adjusting board is adopted, which can be cut arbitrarily; the humidity adjustment can be performed in function, and the moisture holding amount can reach and surpass the equivalent international humidity adjusting products. The fiber humidity adjusting board adopts non-toxic, harmless and recoverable raw material, and the fiber humidity adjusting board is a new-generation green and environment-friendly product.

Owner:SHANGHAI HENGYUAN MACROMOLECULAR MATERIALS CO LTD +1

Environmental Control System for a Vehicle

ActiveUS20080121034A1Obscure visionThermometer detailsAir-treating devicesAmbient humidityControl system

Owner:MAGNA MIRRORS HLDG

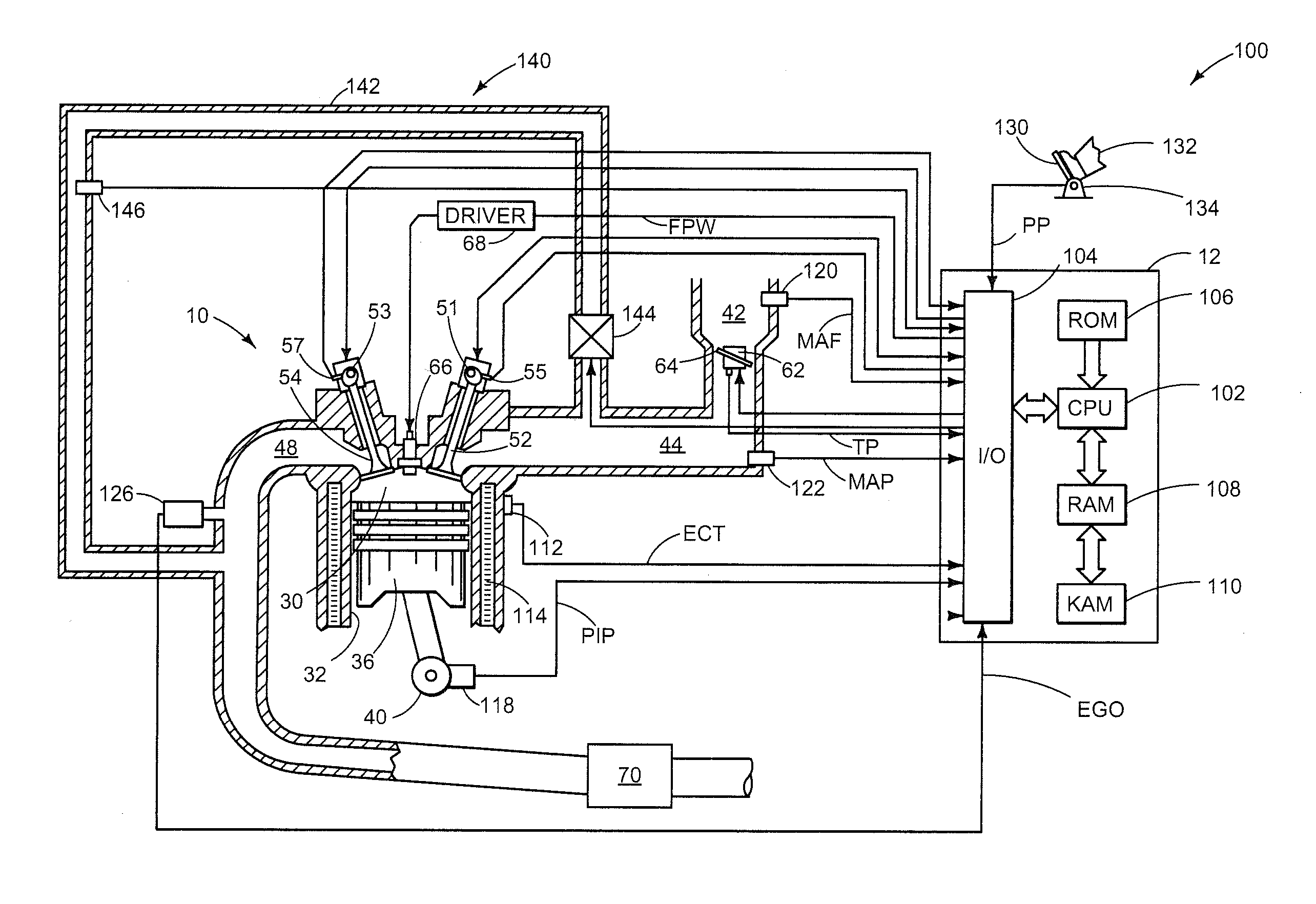

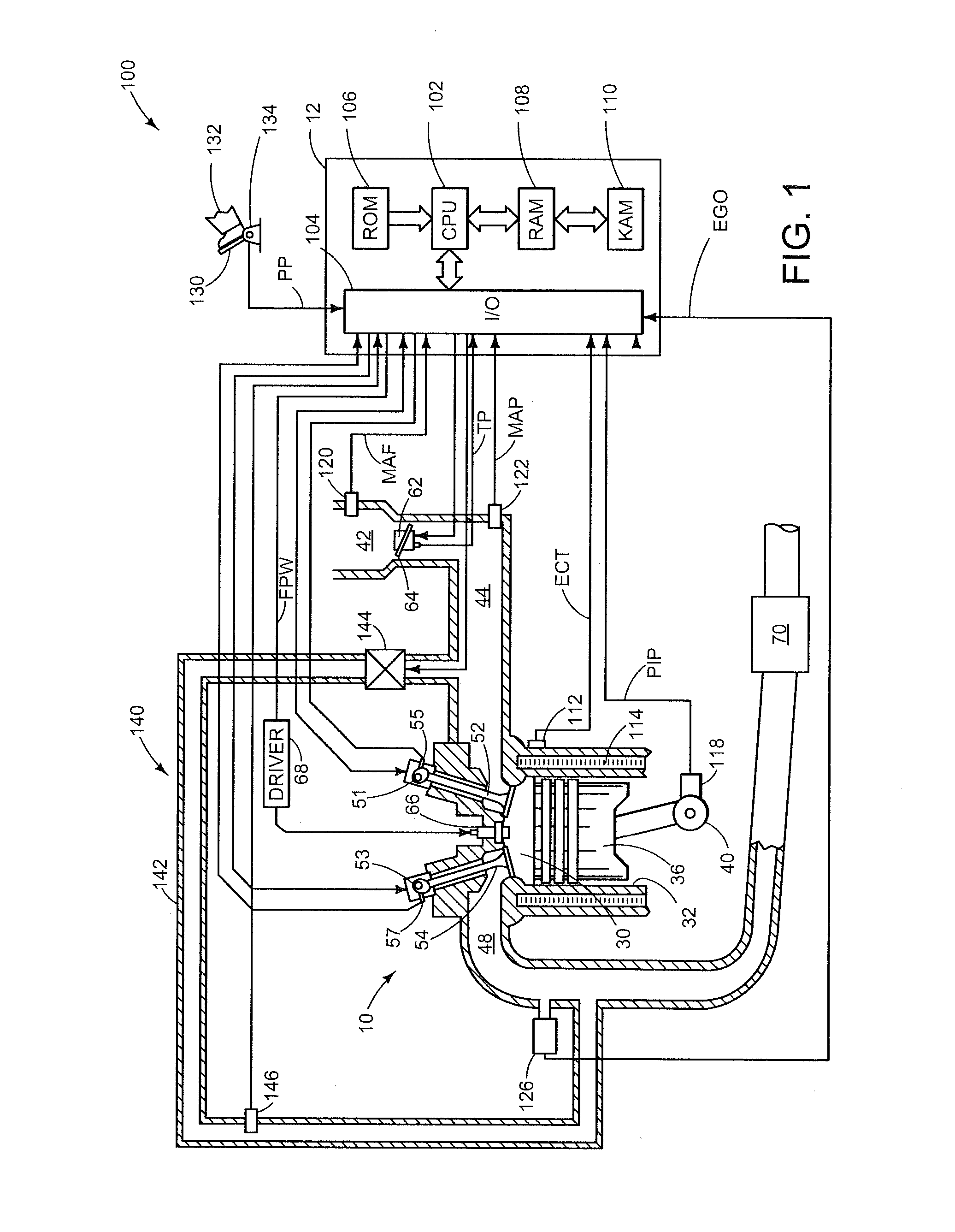

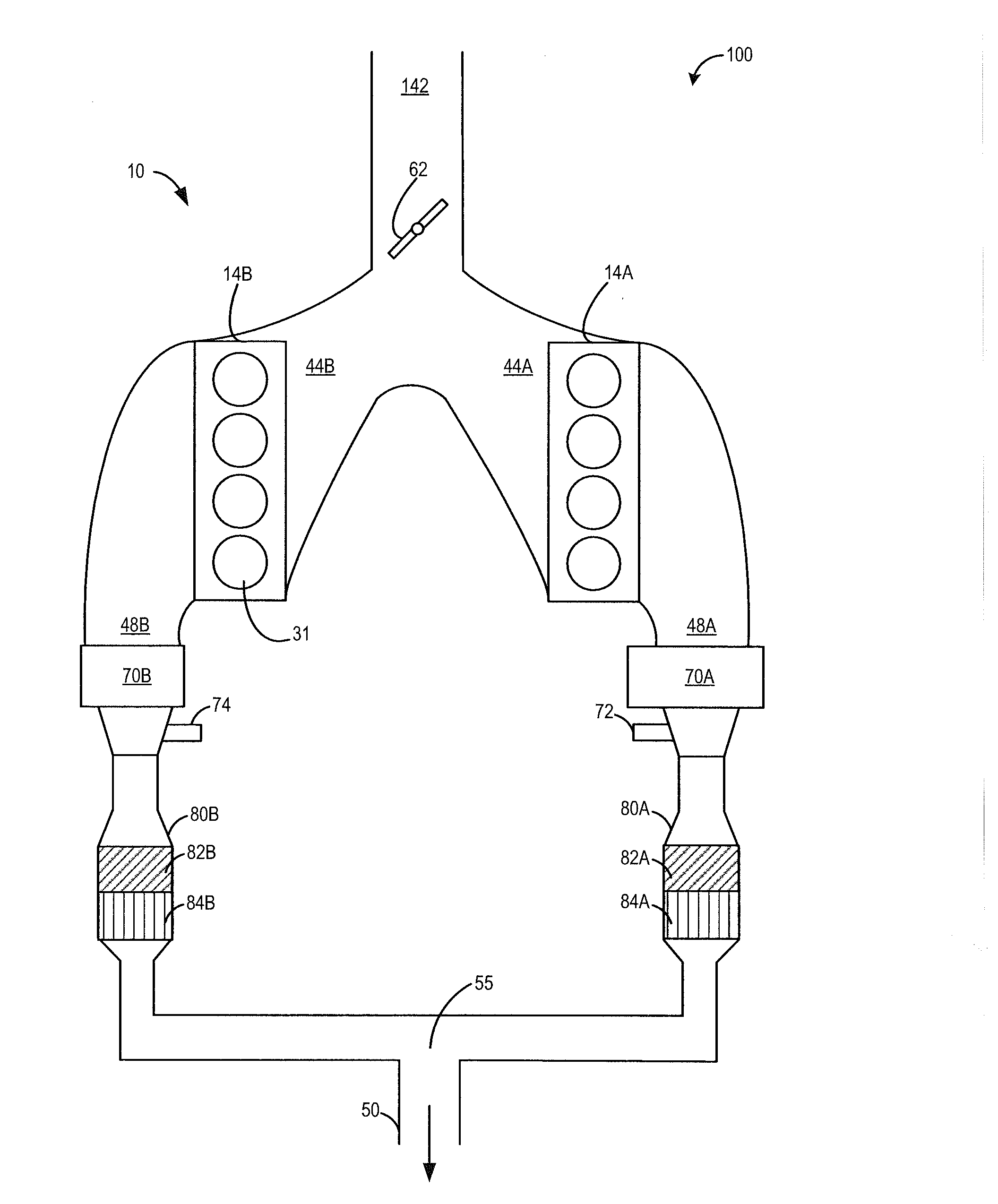

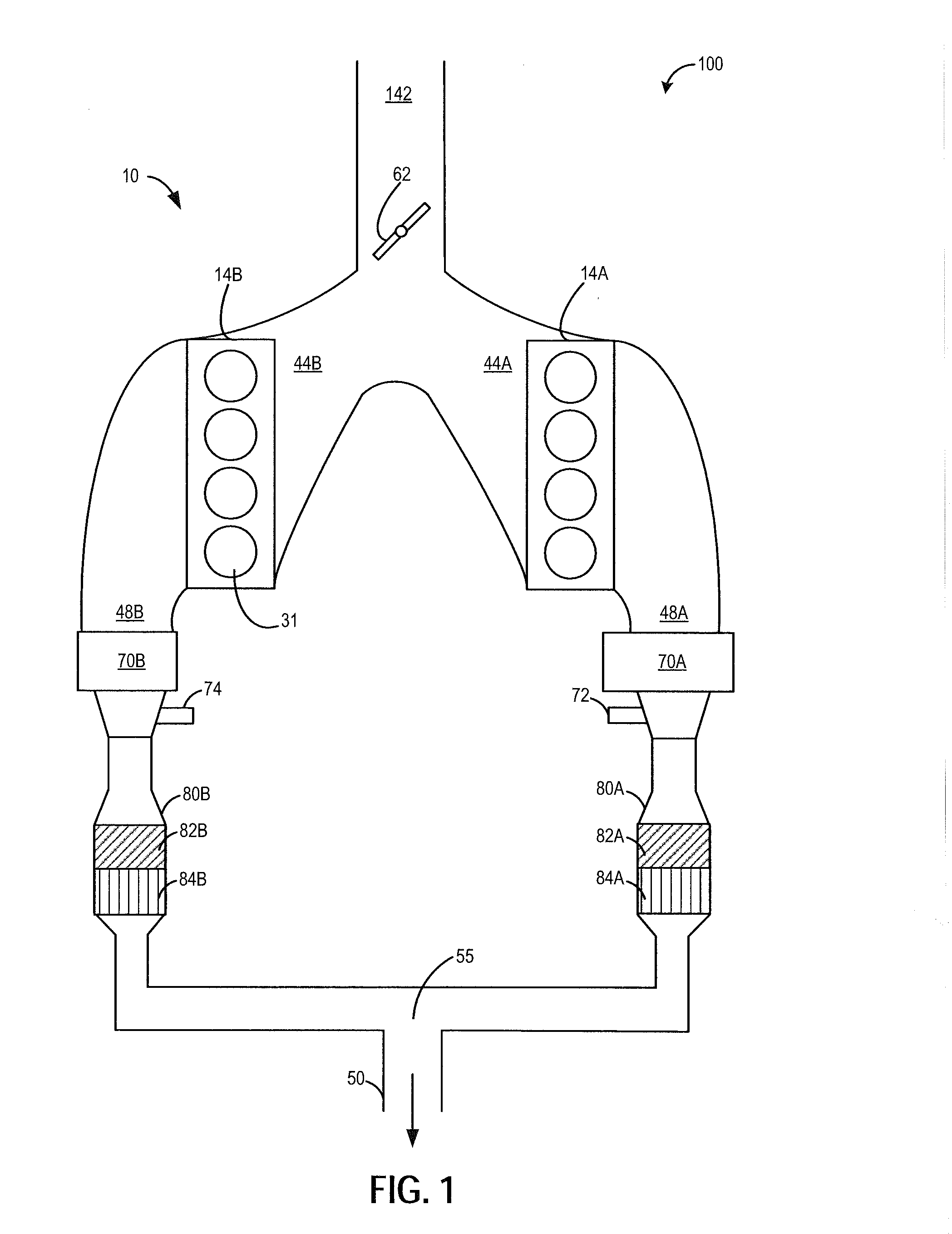

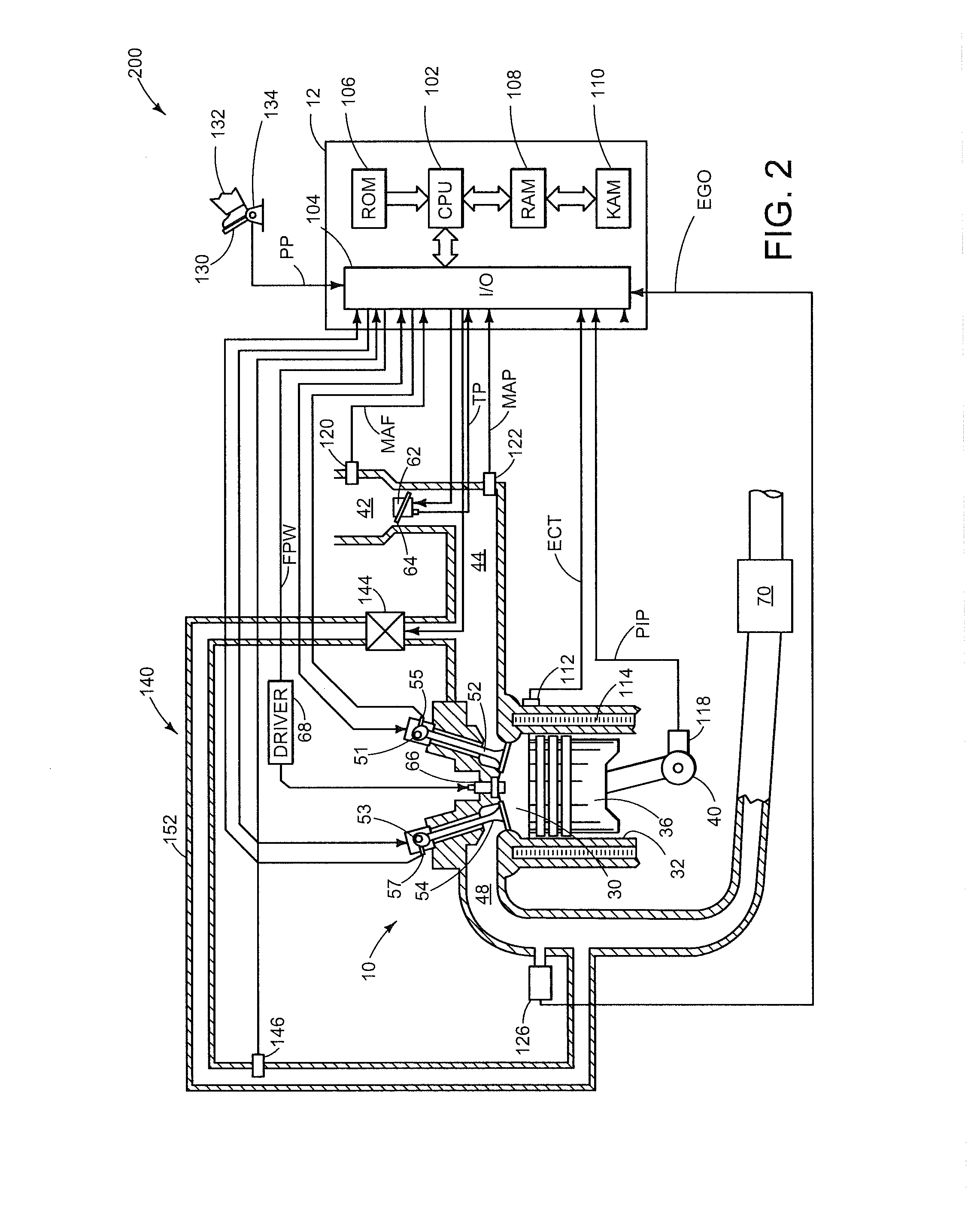

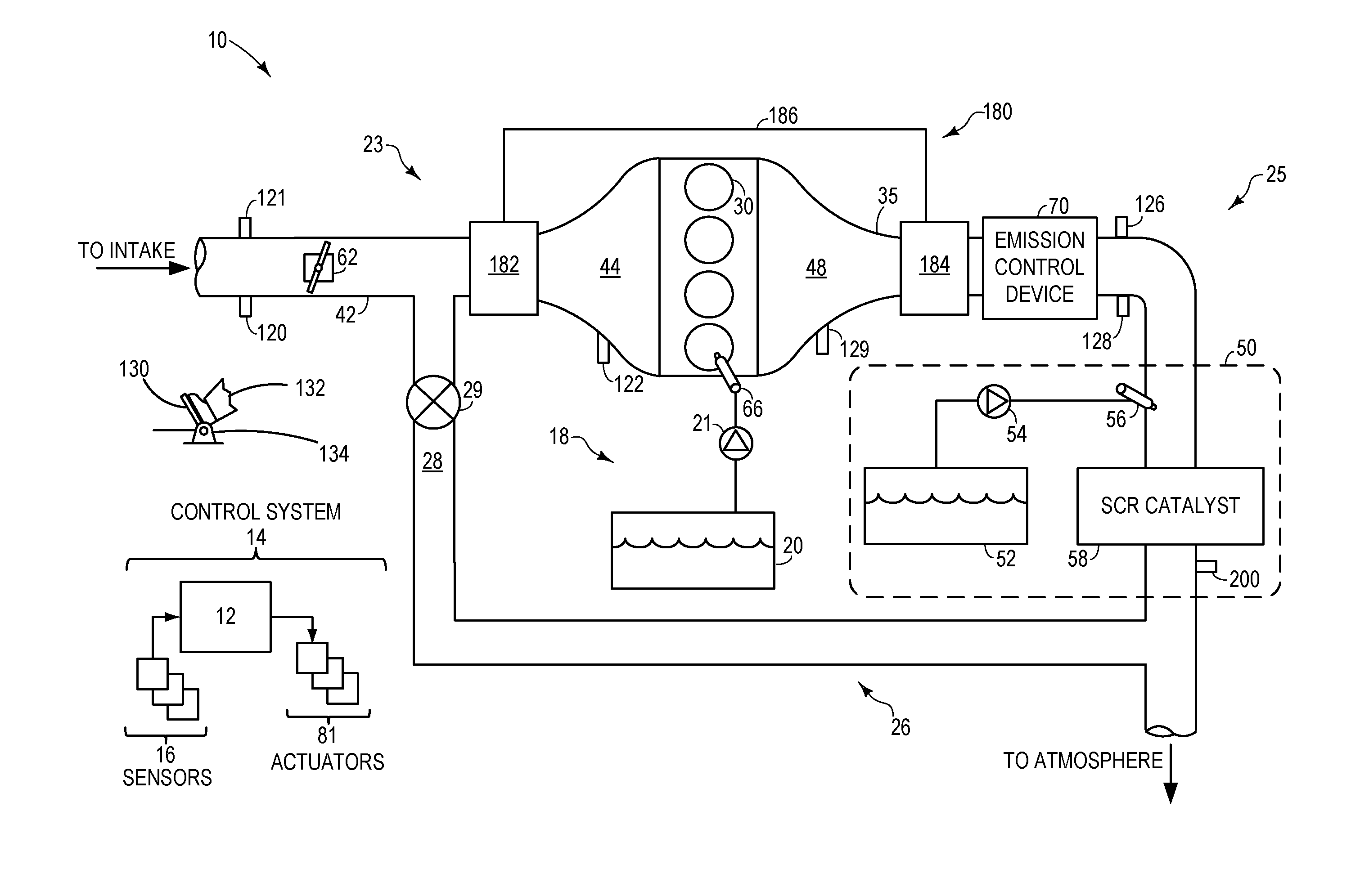

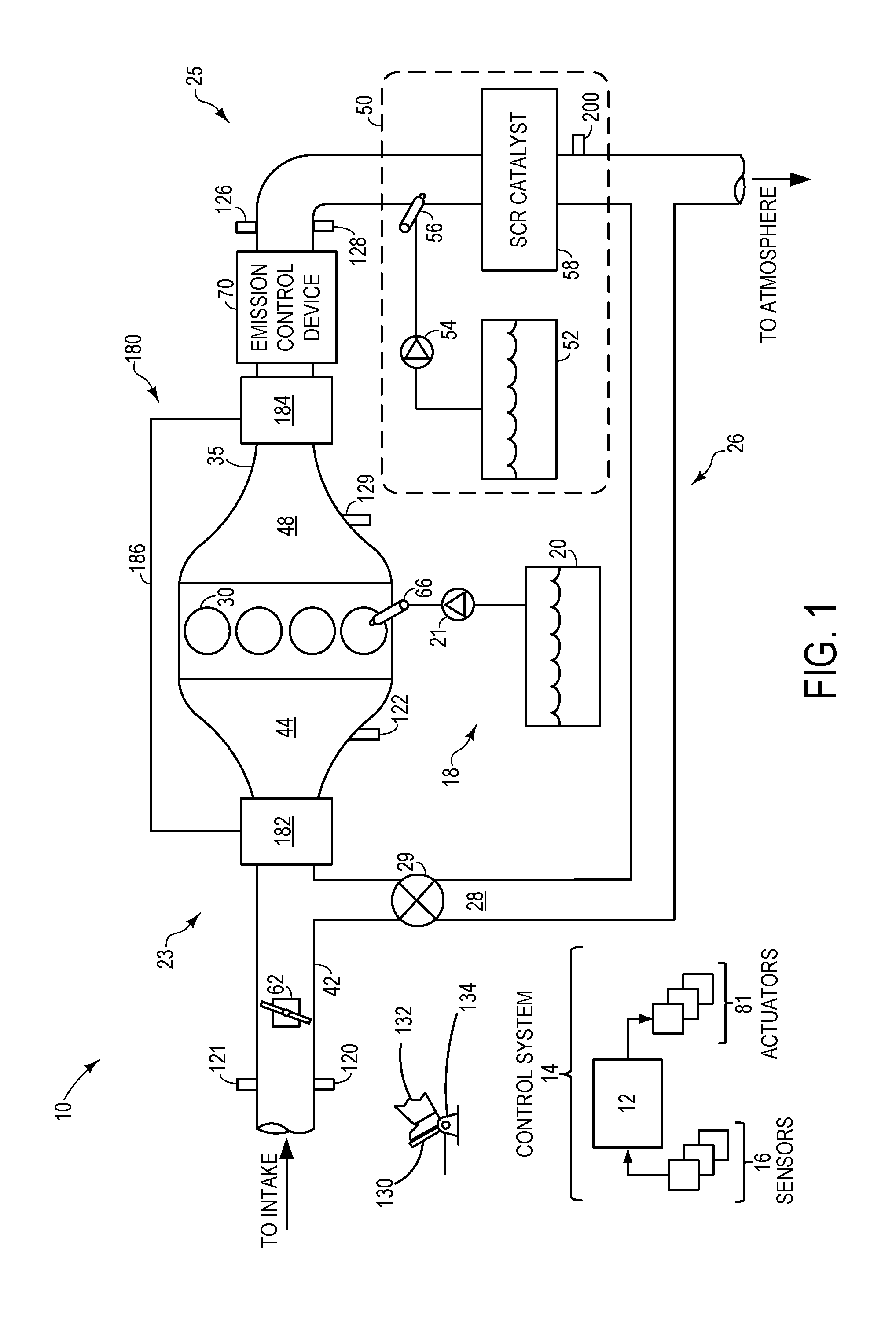

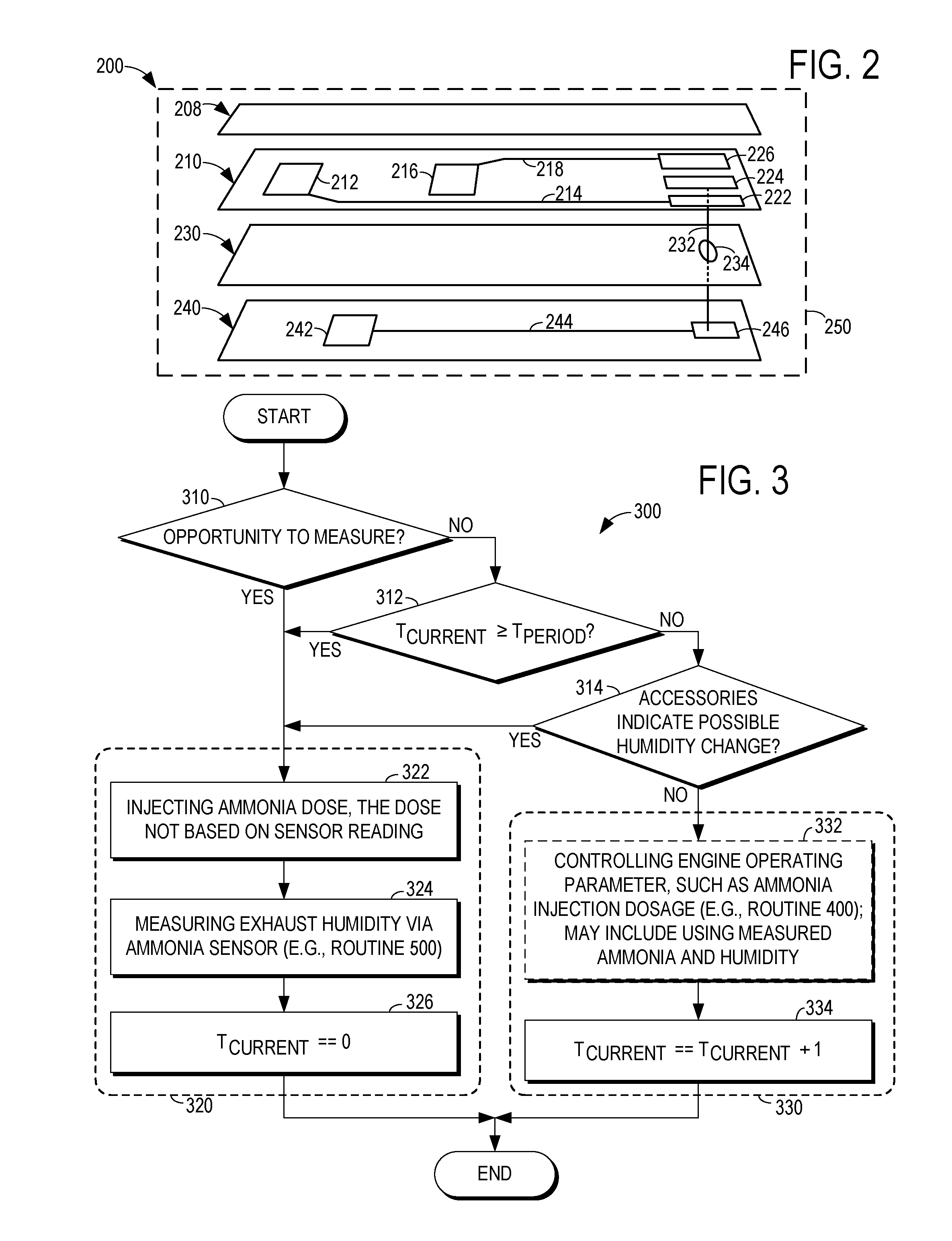

Methods and systems for humidity and pcv flow detection via an exhaust gas sensor

ActiveUS20140202437A1Accurate humidityIncrease pressureInternal-combustion engine testingElectrical controlAmbient humidityOxygen sensor

Methods and systems are provided for estimating a PCV flow to an engine based on the output of an exhaust gas oxygen sensor. During DFSO conditions, a reference voltage of the sensor is modulated initially with an intake throttle open and then with the intake throttle closed. PCV flow leaking past the piston valves in an aging engine, as well as an ambient humidity estimate, are inferred based on the outputs of the sensor during the modulating with the intake throttle open and closed.

Owner:FORD GLOBAL TECH LLC

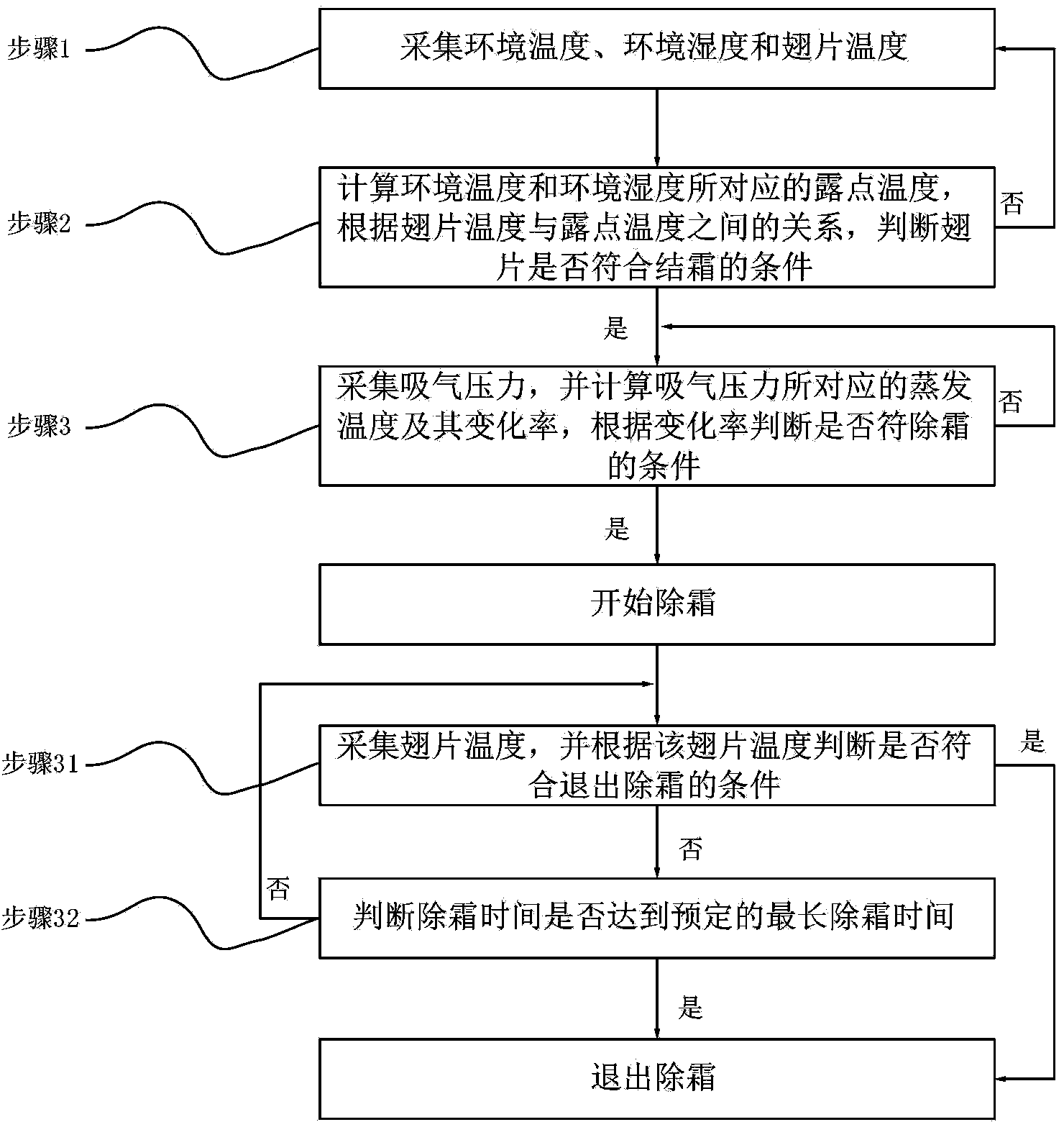

Defrosting method of air conditioner

ActiveCN103836857AAvoid False Defrost PhenomenaExert heating capacitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsAmbient humidityEngineering

The invention relates to a defrosting method of an air conditioner. The defrosting method includes the following steps that firstly, environment temperature, environment humidity and fin temperature are acquired; secondly, dew-point temperature corresponding to the environment temperature and the environment humidity is calculated, and whether fins meet the defrosting condition or not is judged according to the relation between the fin temperature and the dew-point temperature, if yes, the third step is executed, if not, the first step is executed again; thirdly, suction pressure is acquired, evaporation temperature corresponding to the suction pressure and the change rate of the evaporation temperature are calculated, if the change rate is larger than a preset change rate, defrosting is started, and if the change rate is not larger than the preset change rate, the third step continues to be executed. The defrosting method has the advantages that the change rate of the evaporation temperature of a heat exchanger on the air side in the heating process is used as the condition for judging whether defrosting is conducted or not, false defrosting of a unit is avoided, defrosting efficiency is improved, and heating capacity of the air cooling heat pump unit is exerted.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

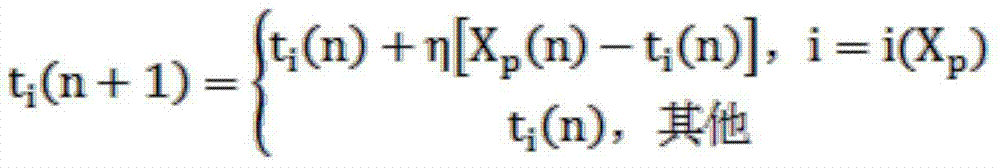

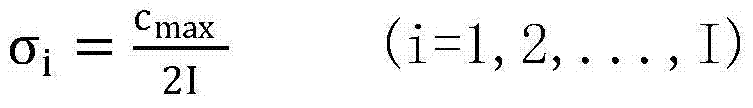

Cable joint wire temperature prediction method based on RBF neural network

ActiveCN103886374AAvoid errorsImprove forecast accuracyNeural learning methodsFault analysisEngineering

The invention relates to a cable joint wire temperature prediction method based on an RBF neural network. The cable joint wire temperature prediction method based on the RBF neural network mainly includes the first step of collection of sample data, wherein factors such as environment humidity, environment temperature, sheath temperature, joint insulation temperature, contact temperature and various surface temperatures which are related with the cable joint wire temperature are measured in real time; the second step of network training, wherein the collected data in the step (1) are preprocessed, training data and prediction data are divided, various parameters are set, a network is built, and the data are predicted finally. As the neural network technology is applied to predication of the cable joint wire temperature, the cable joint wire temperature can be well monitored in a real-time and on-line mode, and faults can be well analyzed.

Owner:合肥珞珈创新研究院有限公司

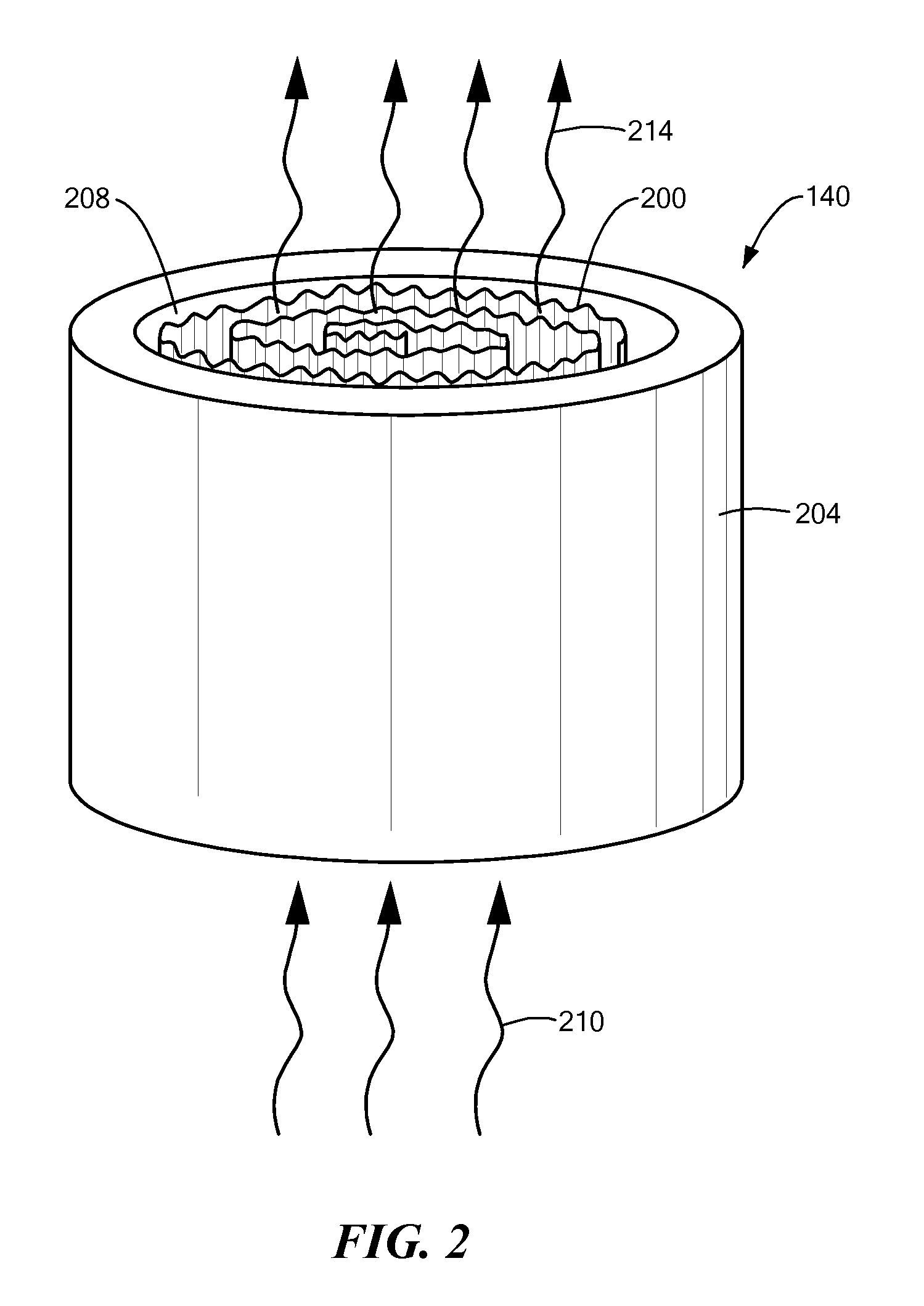

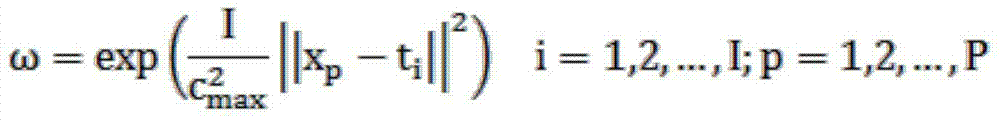

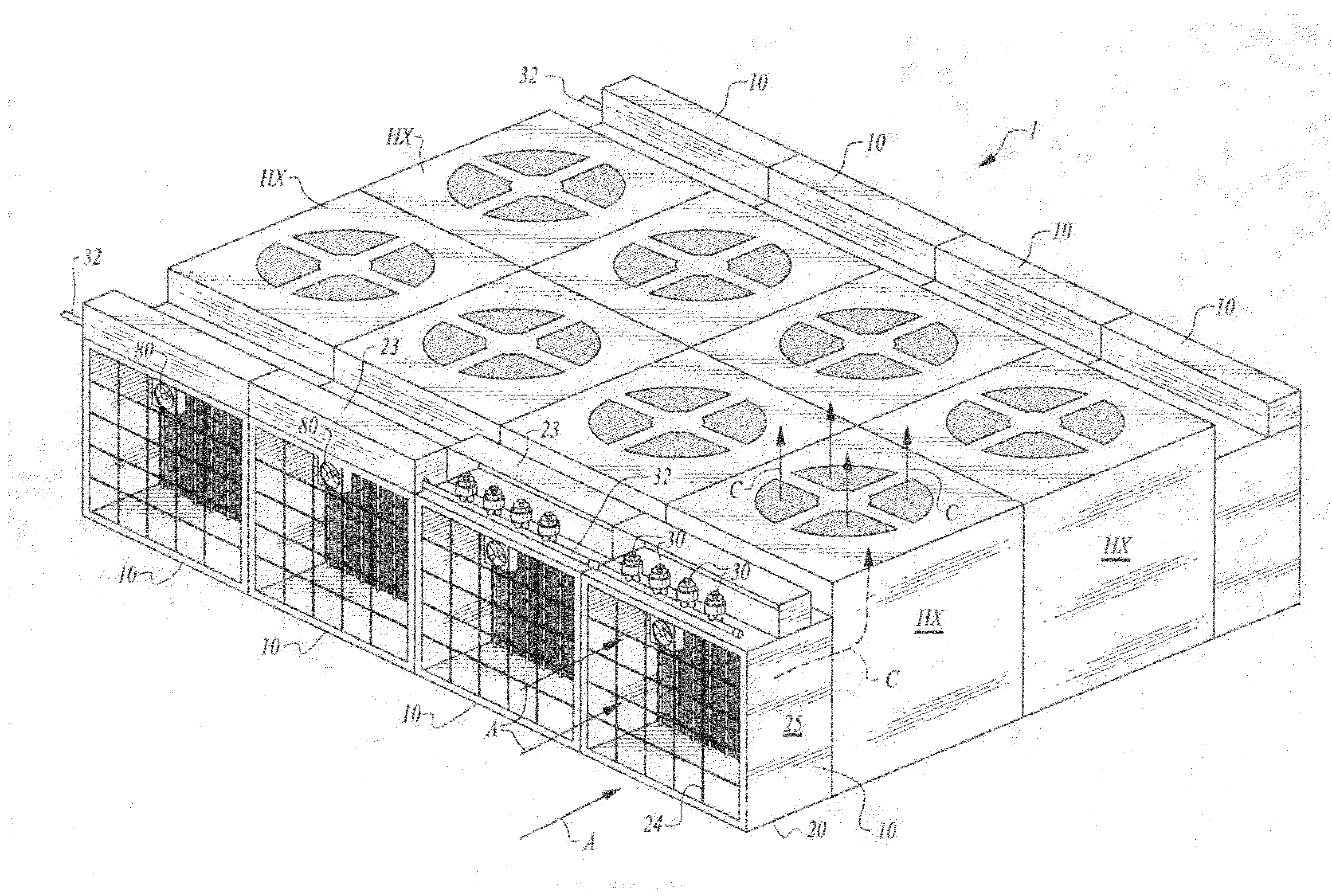

Evaporative pre-cooler for air cooled heat exchangers

InactiveUS20110023506A1Improve power efficiencyCombustion temperature can be reducedSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAmbient humidityStreamflow

The pre-cooler includes one or more cells which are oriented about an air stream to be cooled. A housing defines a perimeter of the cell with an inlet and outlet for air passing therethrough. Water outlet nozzles within the housing are preferably supported upon bars which orient the nozzles facing in a direction counter to flow of air through the housing. Each nozzle is coupled to a separate stage with multiple stages of nozzles coupled to separate valves. A controller opens or closes different valves. The controller measures ambient humidity and temperature conditions as well as air flow rates to calculate the amount of water to be added to the air and then opens appropriate numbers of stages of valves so that an appropriate number of nozzles spray water into the air to saturate the air. Flow rate control is thus provided without pressure variations, for optimal nozzle performance.

Owner:DAY MICHAEL S +3

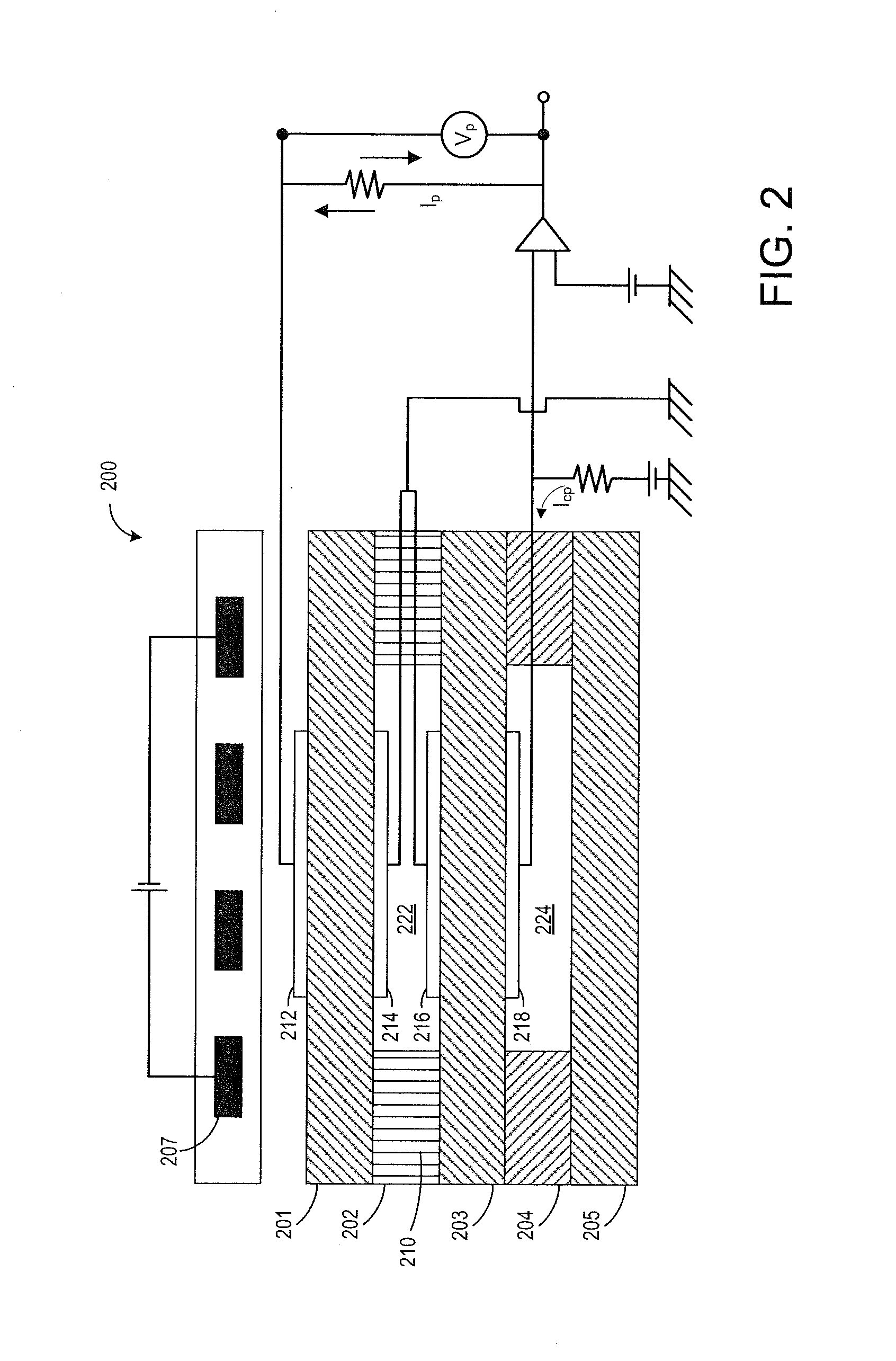

Methods and systems for humidity detection via an exhaust gas sensor

ActiveUS20140202426A1Less waitingReduces pumping lossElectrical controlInternal combustion piston enginesAlcohol contentAmbient humidity

Various methods and system are described for determining ambient humidity via an exhaust gas sensor disposed in an exhaust system of a variable displacement engine. A reference voltage of a sensor coupled to an inactive engine bank is modulated between a first and second voltage to estimate ambient humidity. Concurrently, a reference voltage of a sensor coupled to an active engine bank is modulated between the first and second voltage, or at the first voltage, to estimate fuel alcohol content, or exhaust air-fuel ratio, respectively.

Owner:FORD GLOBAL TECH LLC

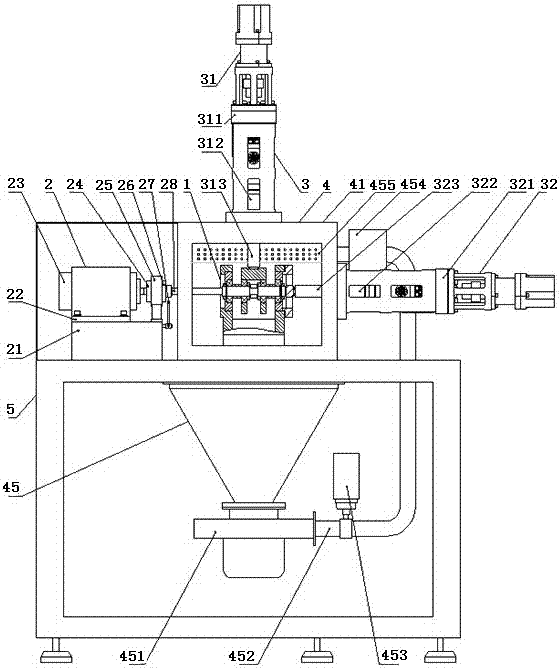

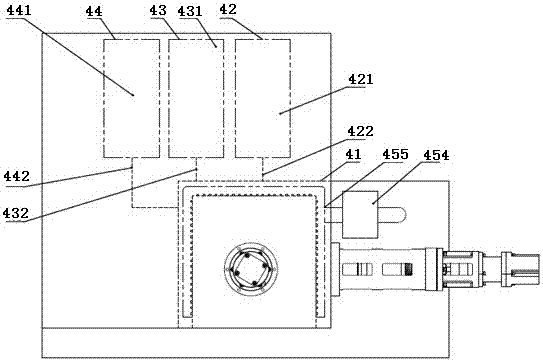

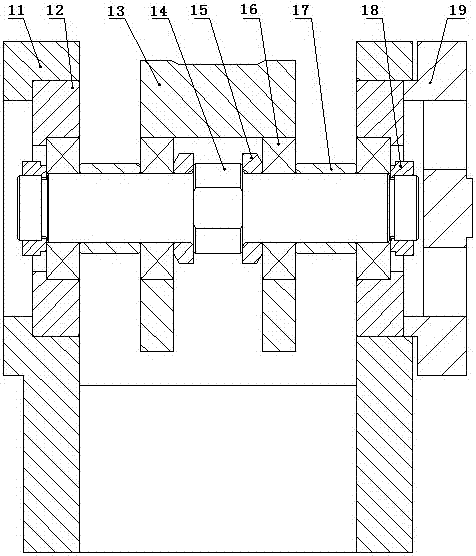

Sealed bearing comprehensive performance simulation testing machine

PendingCN107024353AReal performanceAuthenticityMachine bearings testingAmbient humidityControl system

The invention relates to a sealed bearing comprehensive performance simulation testing machine and belongs to the field of bearing performance testing. The sealed bearing comprehensive performance simulation testing machine comprises a bearing test unit, a driving unit, a loading unit, an environment simulation system and a control system. The bearing test unit is arranged in the environment box of the environment simulation system, is arranged on the same plate with the driving unit, and is connected with the loading unit. The driving unit is arranged on the left side of the environment box. The loading unit comprises a radial loading mechanism and an axial loading mechanism. The environment simulation system comprises the environment box, a high-temperature simulation unit, a low-temperature simulation unit, a humidity simulation unit and a dust simulation unit. The control system is connected with the driving unit, the loading unit, and the environment simulation system, and controls test rotating speed, test load, test ambient temperature, and test ambient humidity, and test environment dust concentration. The sealed bearing comprehensive performance simulation testing machine is reasonable in structure, complete in simulated working conditions, good in test results, and easy to operate, and satisfies the evaluation demands of sealed bearing comprehensive performance.

Owner:浙江省机电产品质量检测所有限公司

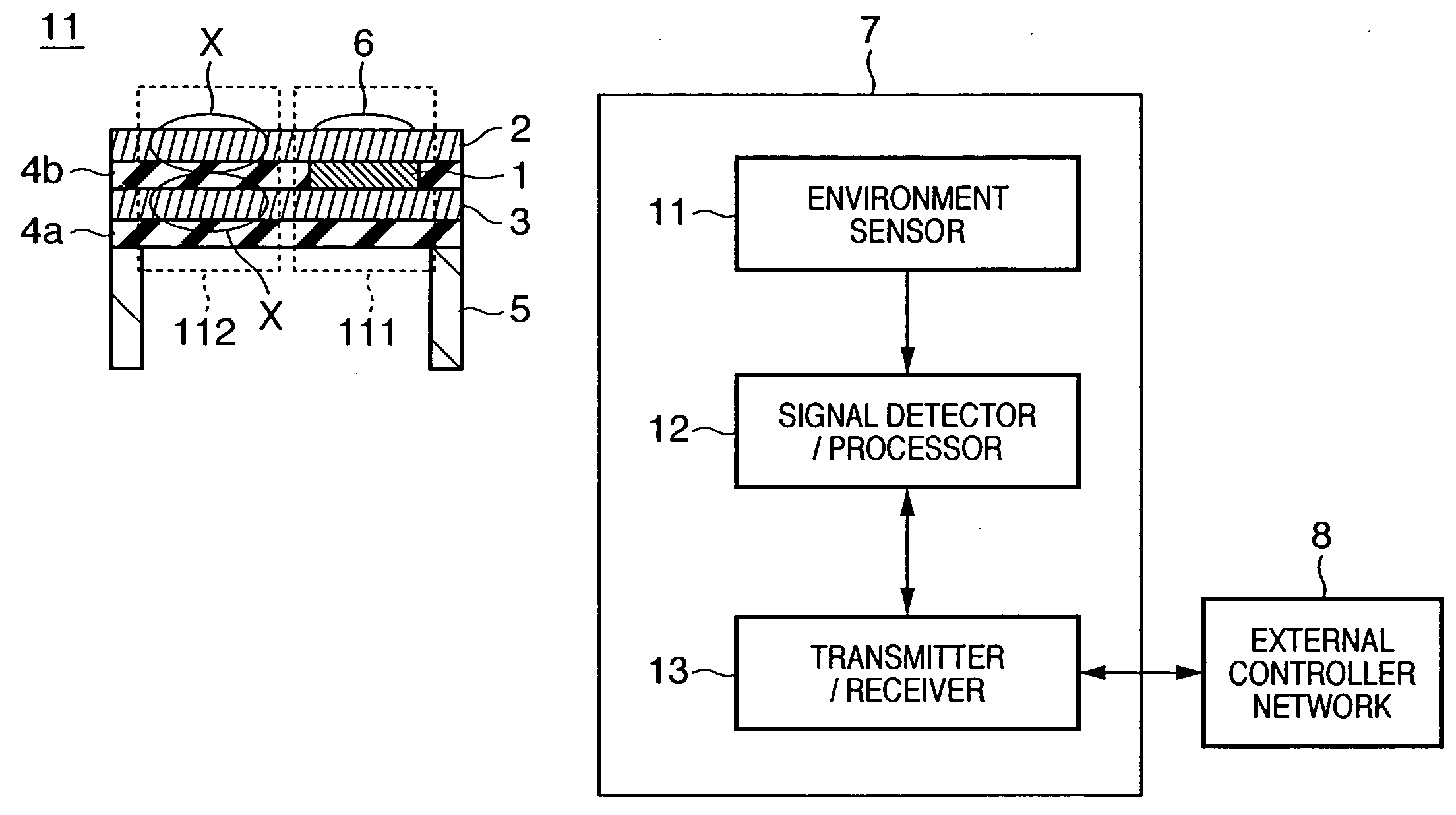

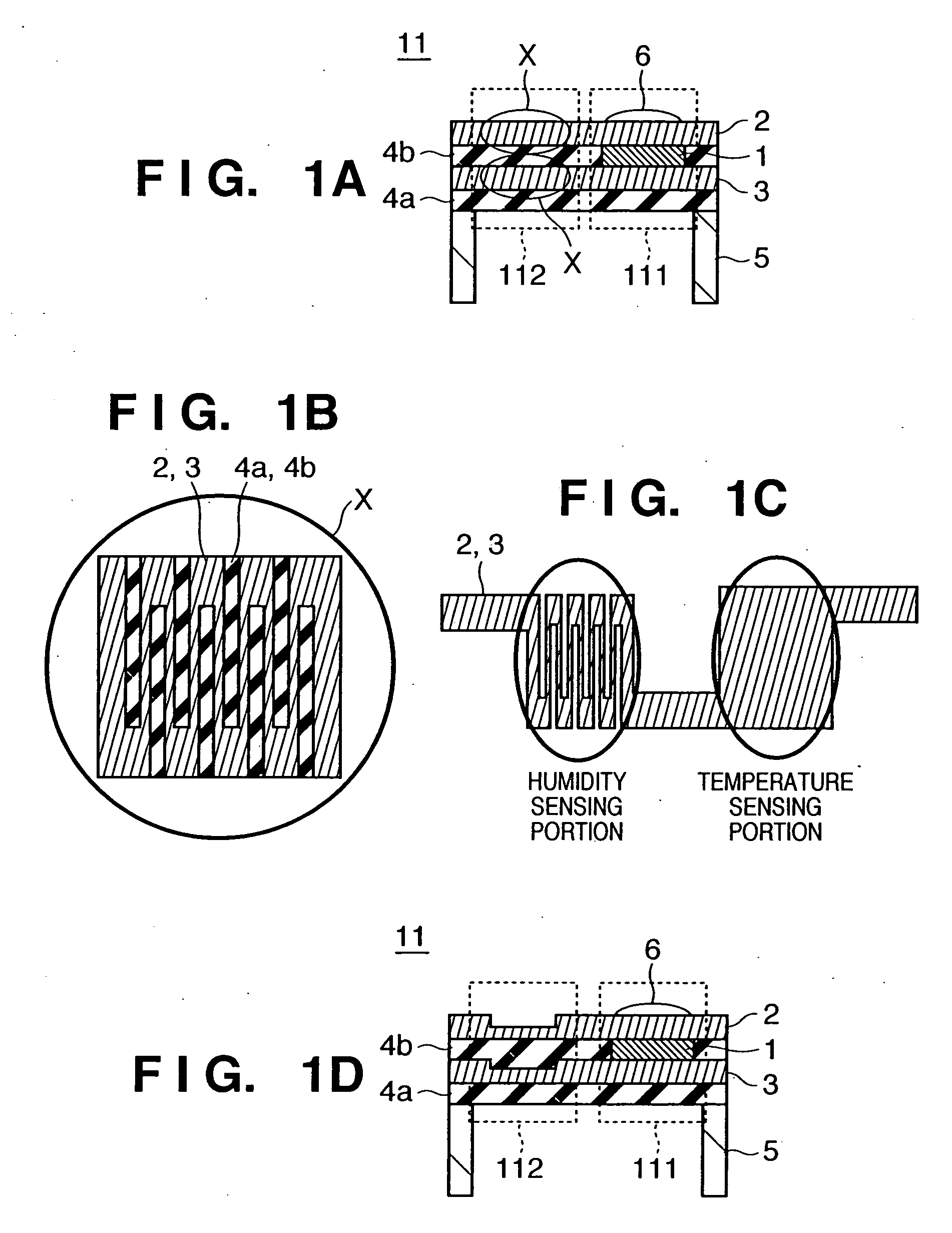

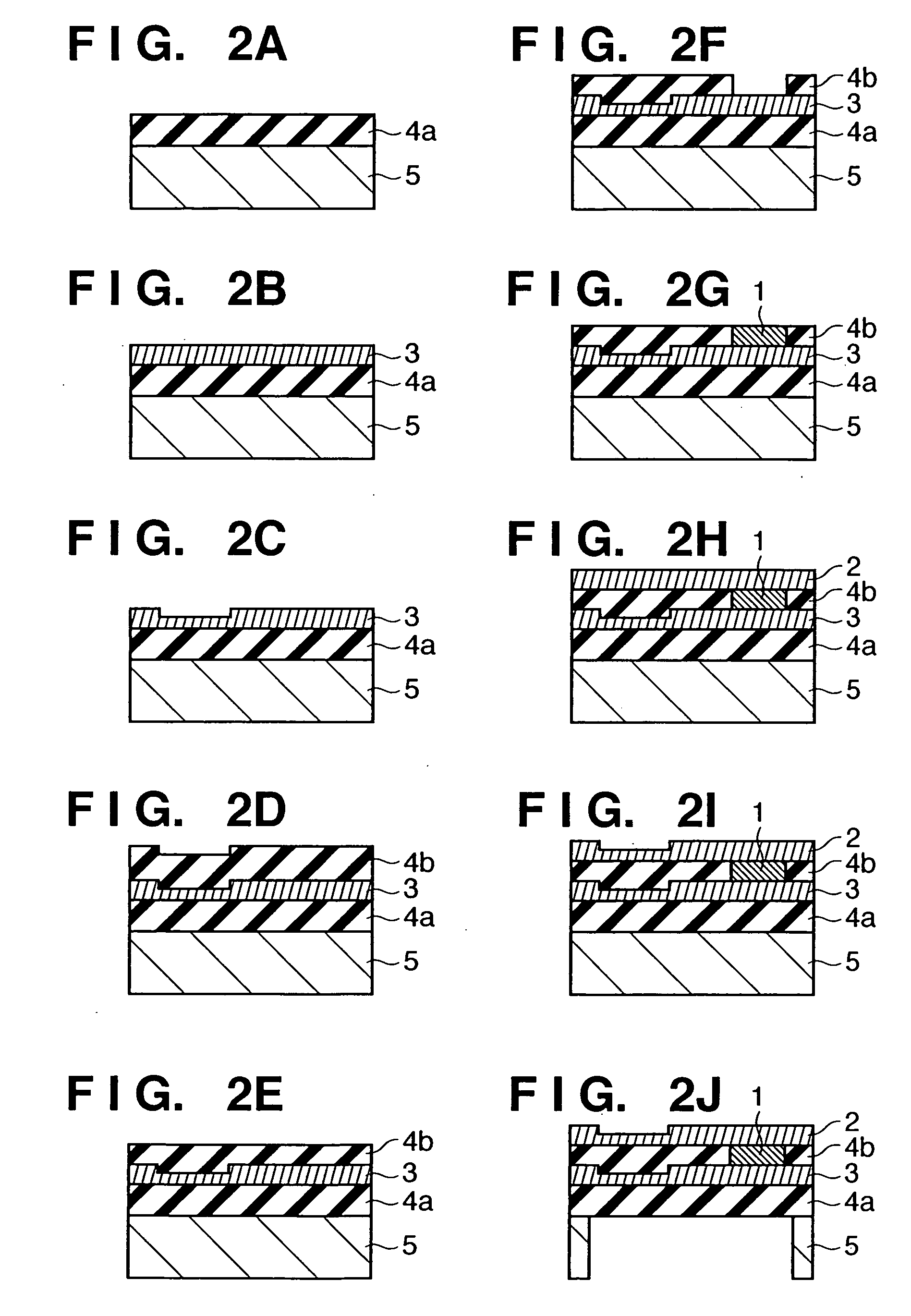

Environment sensor

InactiveUS20050008061A1Increase speedThermometer detailsHumidity indicationAmbient humidityEngineering

An environment sensor (11) for measuring the temperature and humidity can be miniaturized and can respond at high speed. The environment sensor (11) includes a temperature sensing portion (111) having a temperature-sensitive material (1) made of a metal oxide, and a humidity-sensing portion (112) which is formed on the same substrate as the temperature sensing portion (111) and measures the ambient humidity by using a change in electrical characteristics. At least one of a pair of electrodes (2, 3) of the temperature sensor (111) is integrated with an electrode of the humidity-sensing portion (112).

Owner:CANON KK

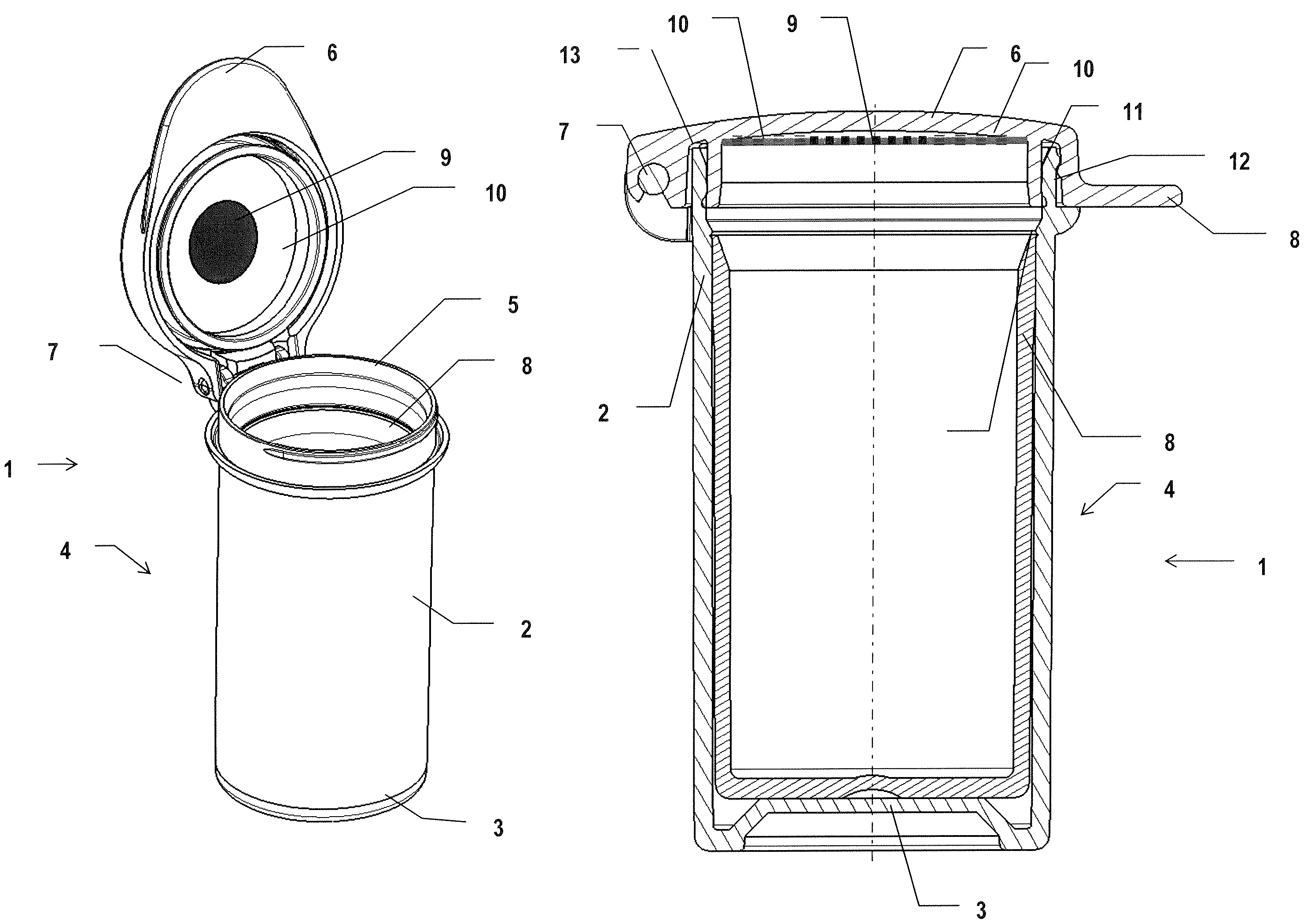

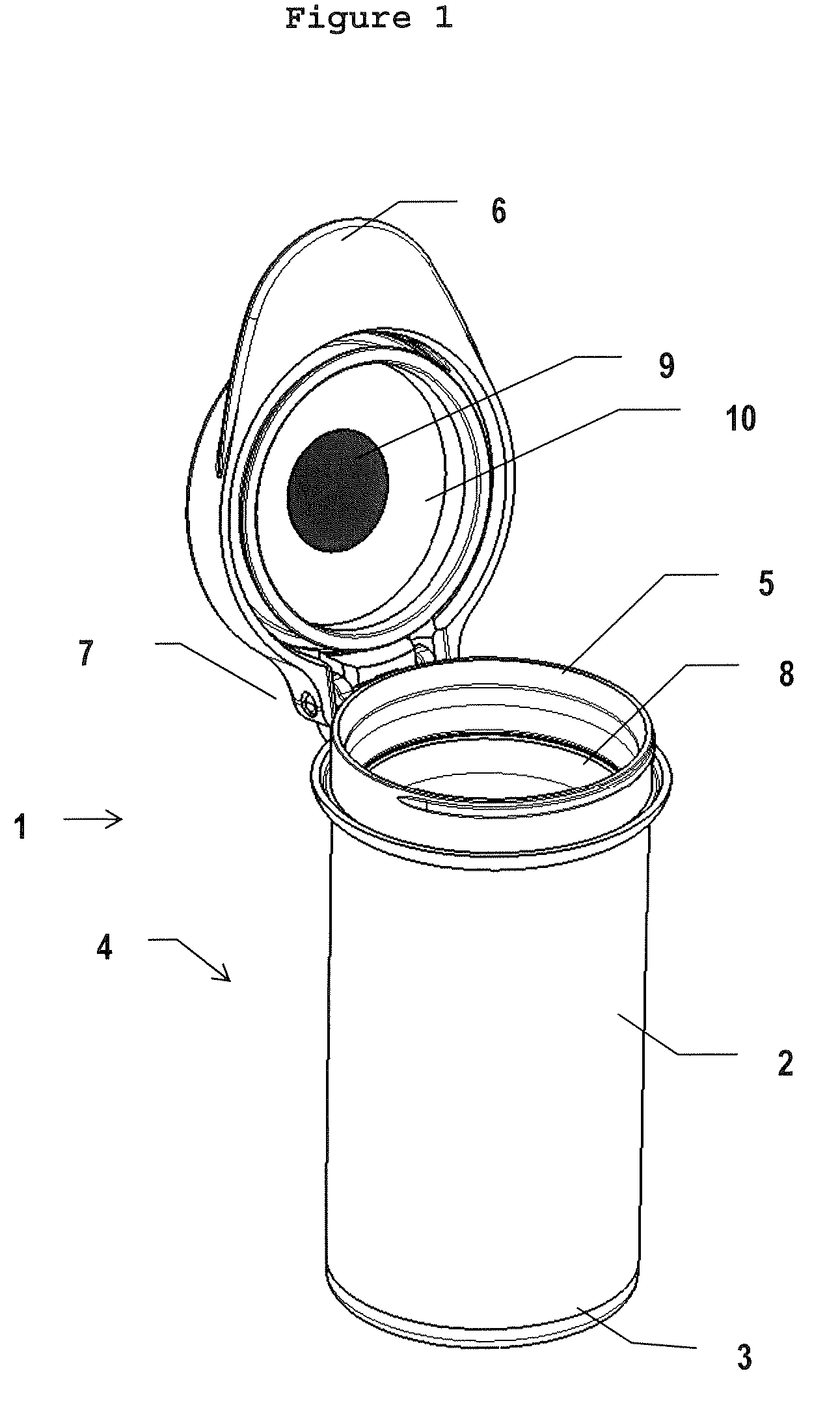

Dehydrating container comprising a humidity state indicator

InactiveUS7665601B2Easy to mass produceEliminate disadvantagesOther accessoriesContainer/bottle contructionAmbient humidityChange color

A dehydrating container made of a thermoplastic polymer suitable for packaging products sensitive to ambient humidity, said containing comprising: a visual humidity state indicator, a container body forming a casing, closed at one of its ends by a base and open at another end thereof, a reclosable closure capable of cooperatively fitting on the open end of said casing, optionally, a connector placed between the closure and the casing, and a humidity absorber inside the containing for absorbing humidity from the atmosphere inside the container. The absorber comprises a dehydrating agent and the reclosable closure comprises a visual humidity state indicator that changes color according to the existing humidity level and / or to a maximum humidity level. The visual indicator is advantageously located on an internal surface of the closure.

Owner:CLARIANT PROD (FRANCE) SAS

Method, systems and sensor for detecting humidity

InactiveUS20110023855A1Analogue computers for vehiclesElectrical controlAmbient humidityDiesel engine

Methods systems and device for detecting humidity in air through use of an ammonia sensor included in the exhaust of an engine, such as a diesel engine are provided. In one example, a method for an engine having an exhaust with an ammonia sensor includes adjusting an operating parameter in response to ambient humidity, the ambient humidity based on a first ammonia sensor reading at a first exhaust air-fuel-ratio and a second ammonia sensor reading at a second exhaust air-fuel-ratio.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com