Patents

Literature

748 results about "Contact temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

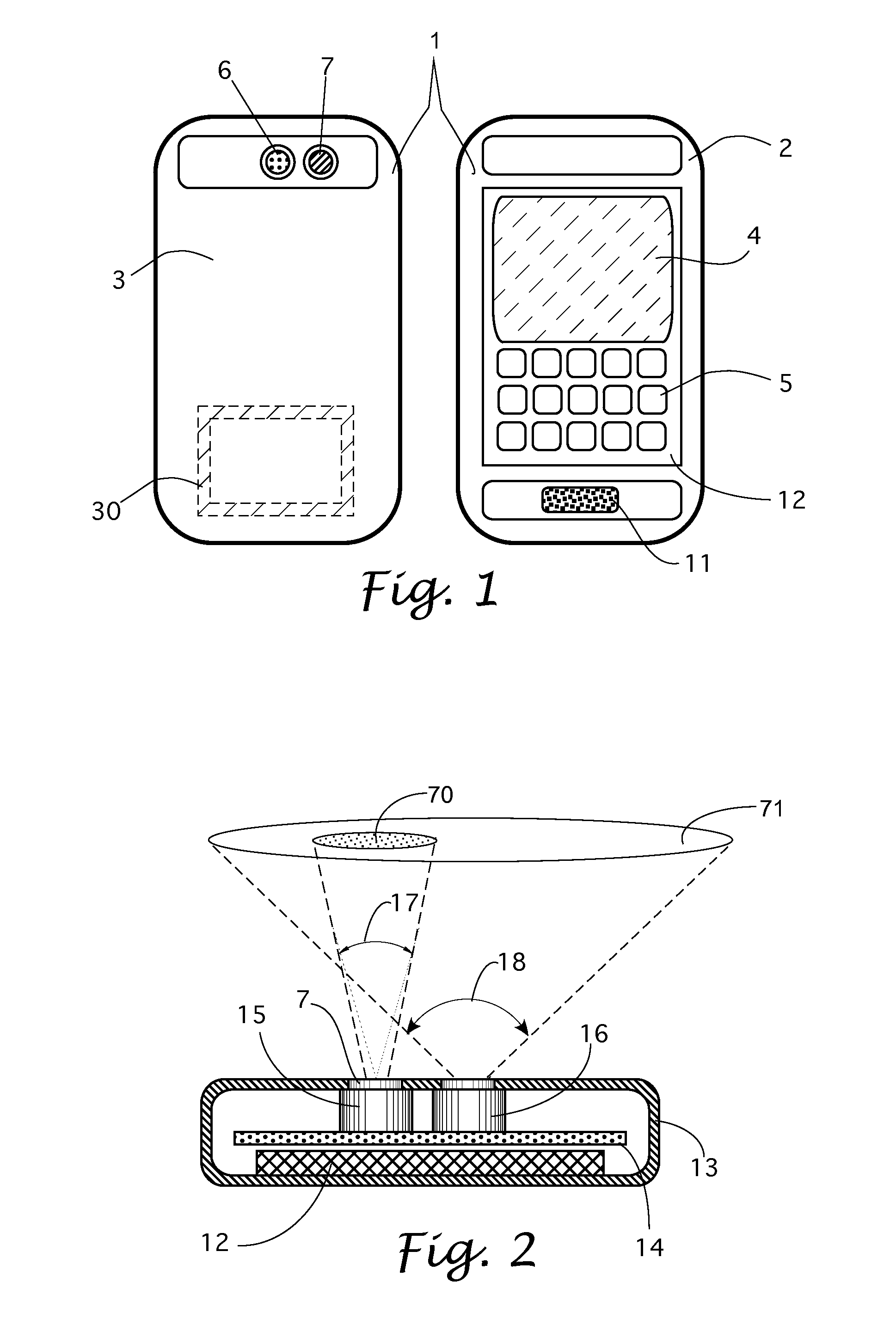

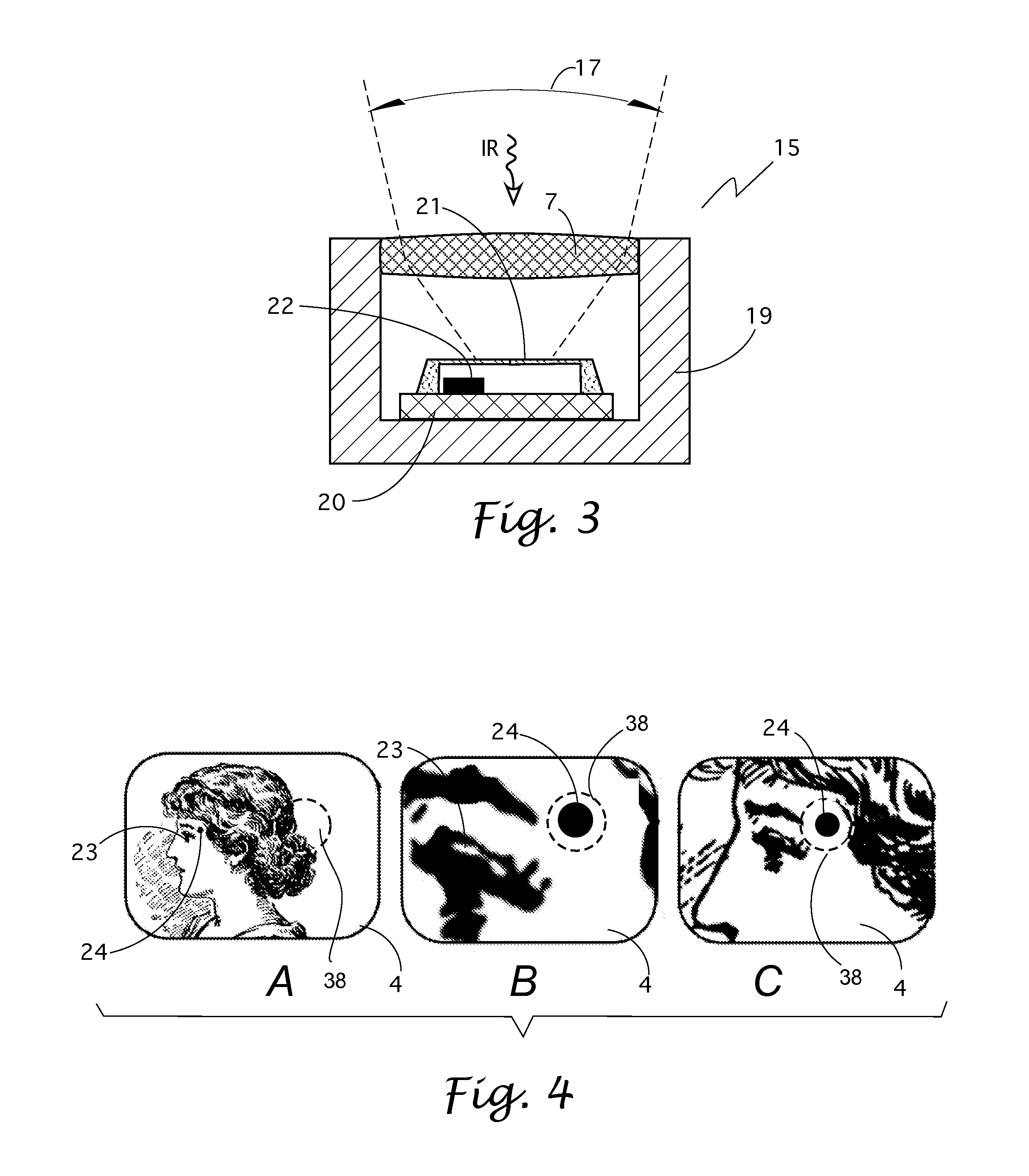

Wireless communication device with integrated electromagnetic radiation sensors

ActiveUS8275413B1Easy to aimDevices with sensorSensing radiation from moving bodiesThermopileHand held

A hand-held mobile communication device, such as smart telephone, incorporating sensors and signal conditioning modules for measuring signals from external sources of electromagnetic radiation (EMR) in the low, radio, ultraviolet, and infrared spectral ranges. These include the detector for receiving and monitoring electromagnetic fields originating from various external sources of radiation that pose potential health hazards or may interfere with various electronic devices. The mobile phone equipped with such sensors could alternate between communication and monitoring functions. Other integrated EMR sensors are a photodiode for the ultraviolet detection to monitor the user's sun exposure and a thermopile for non-contact measurement of temperature of humans or inanimate objects. This infrared sensor in combination with a photographic digital camera and a pattern recognition signal processing allows measuring temperatures at specific locations and from optimal distances to the surface of the object to enhance accuracy of non-contact temperature measurements.

Owner:PATENT ARMORY INC

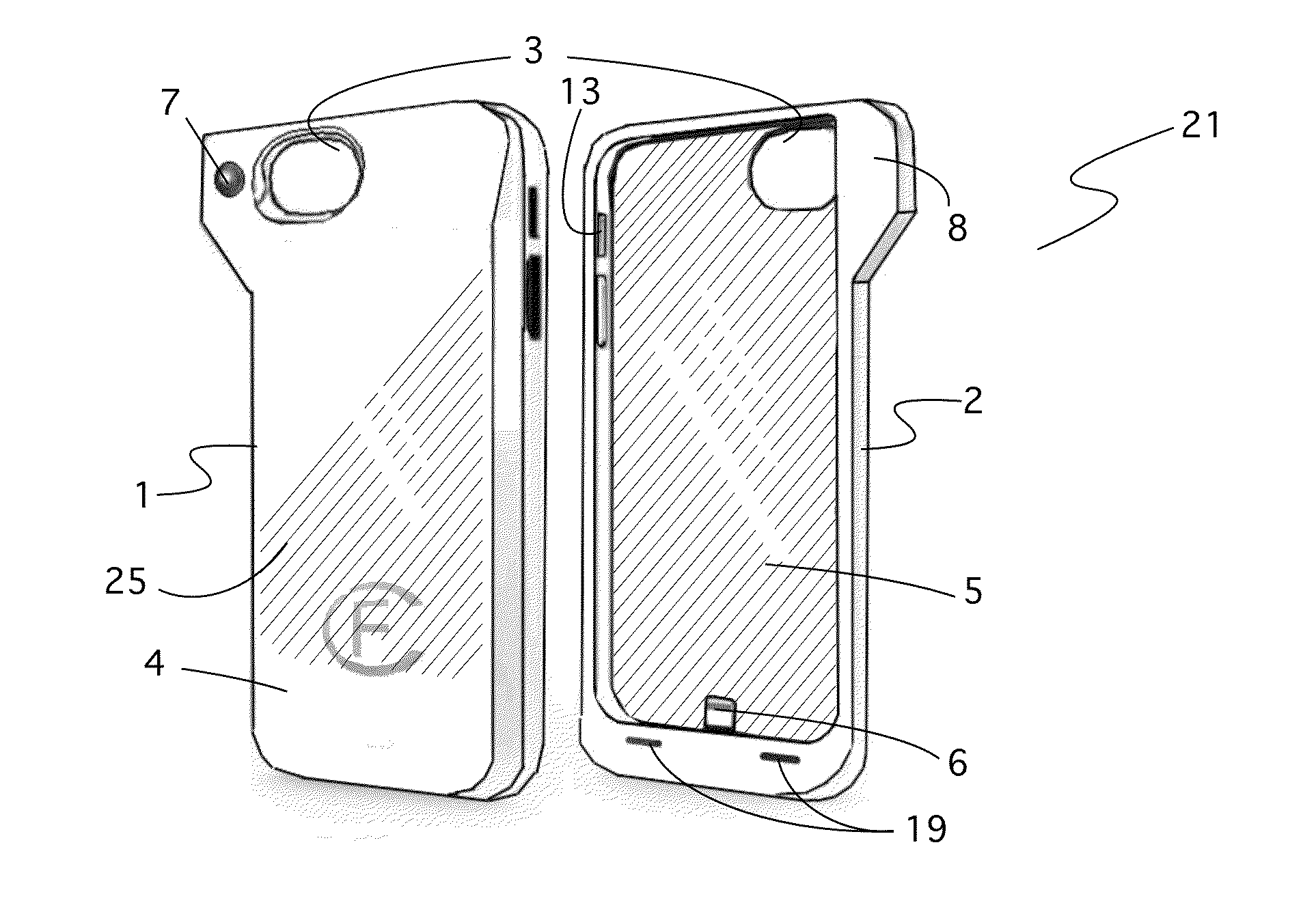

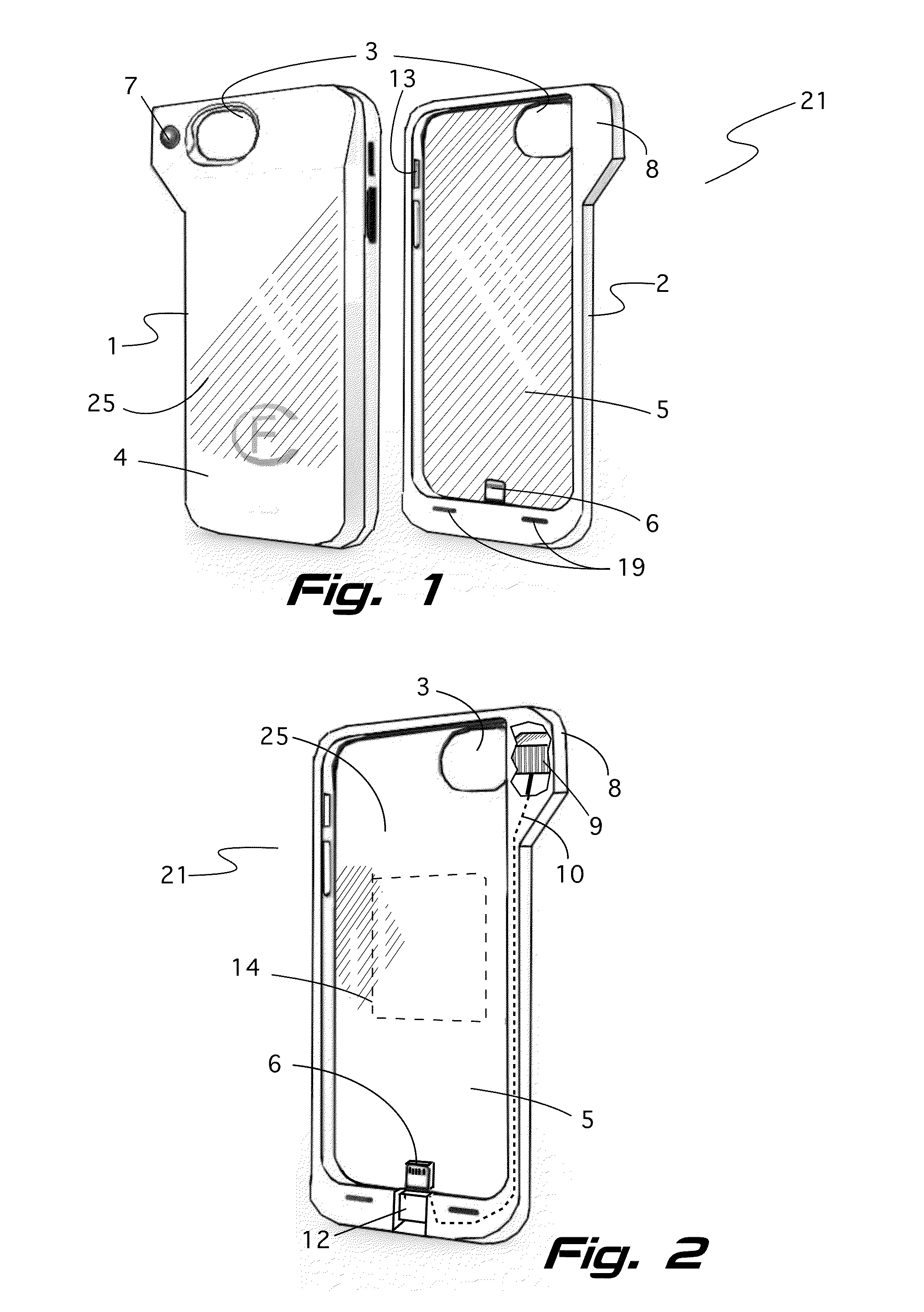

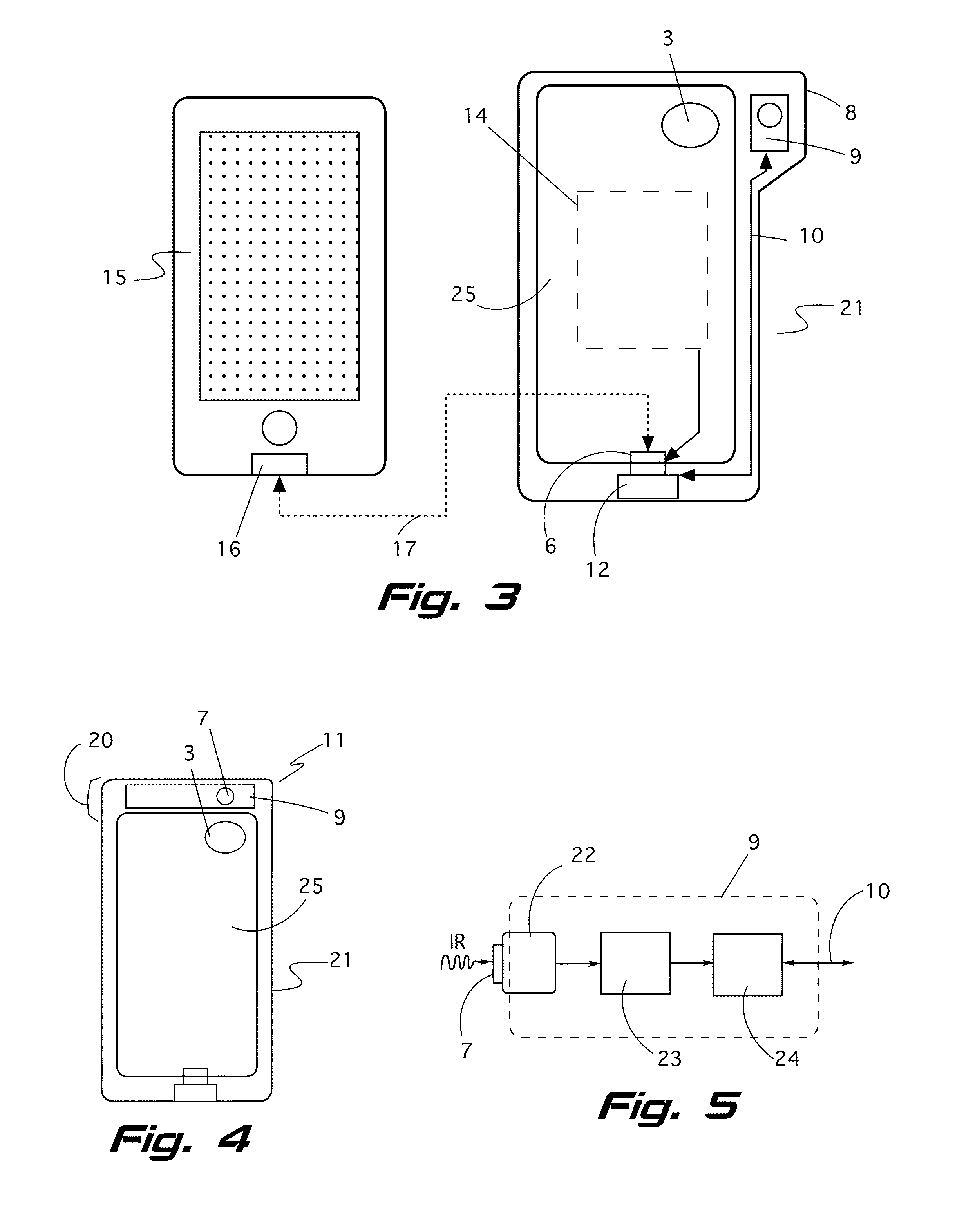

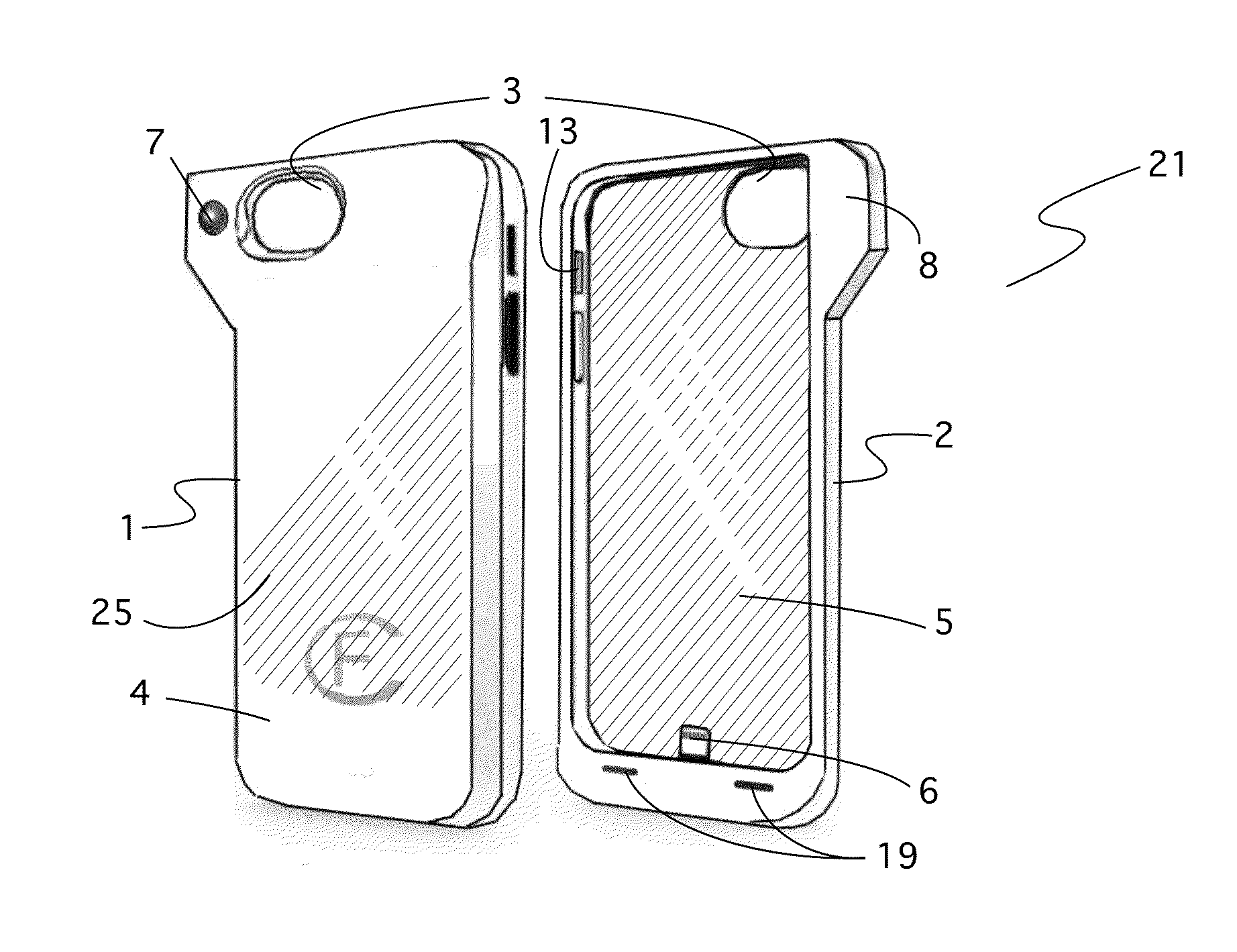

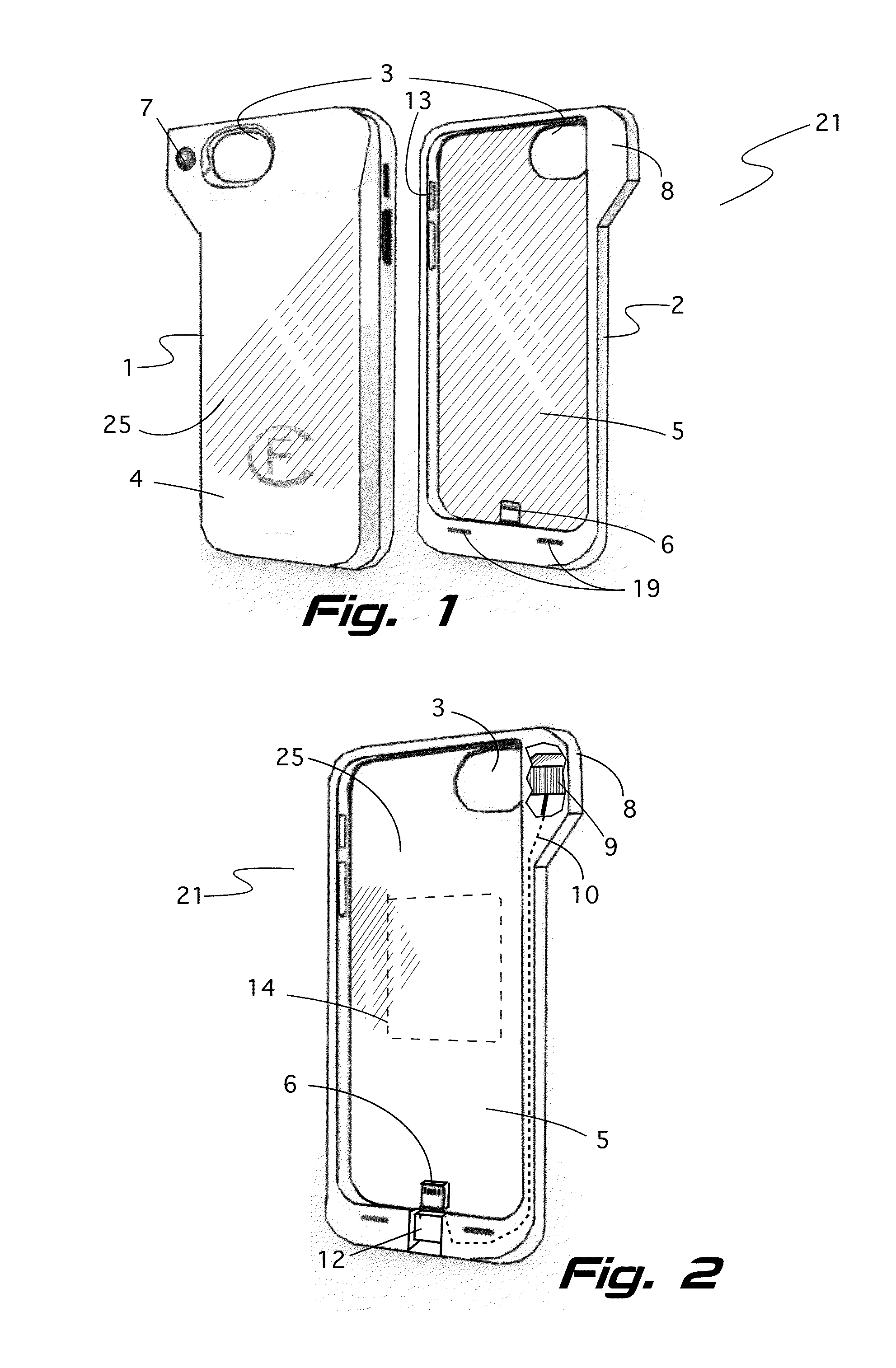

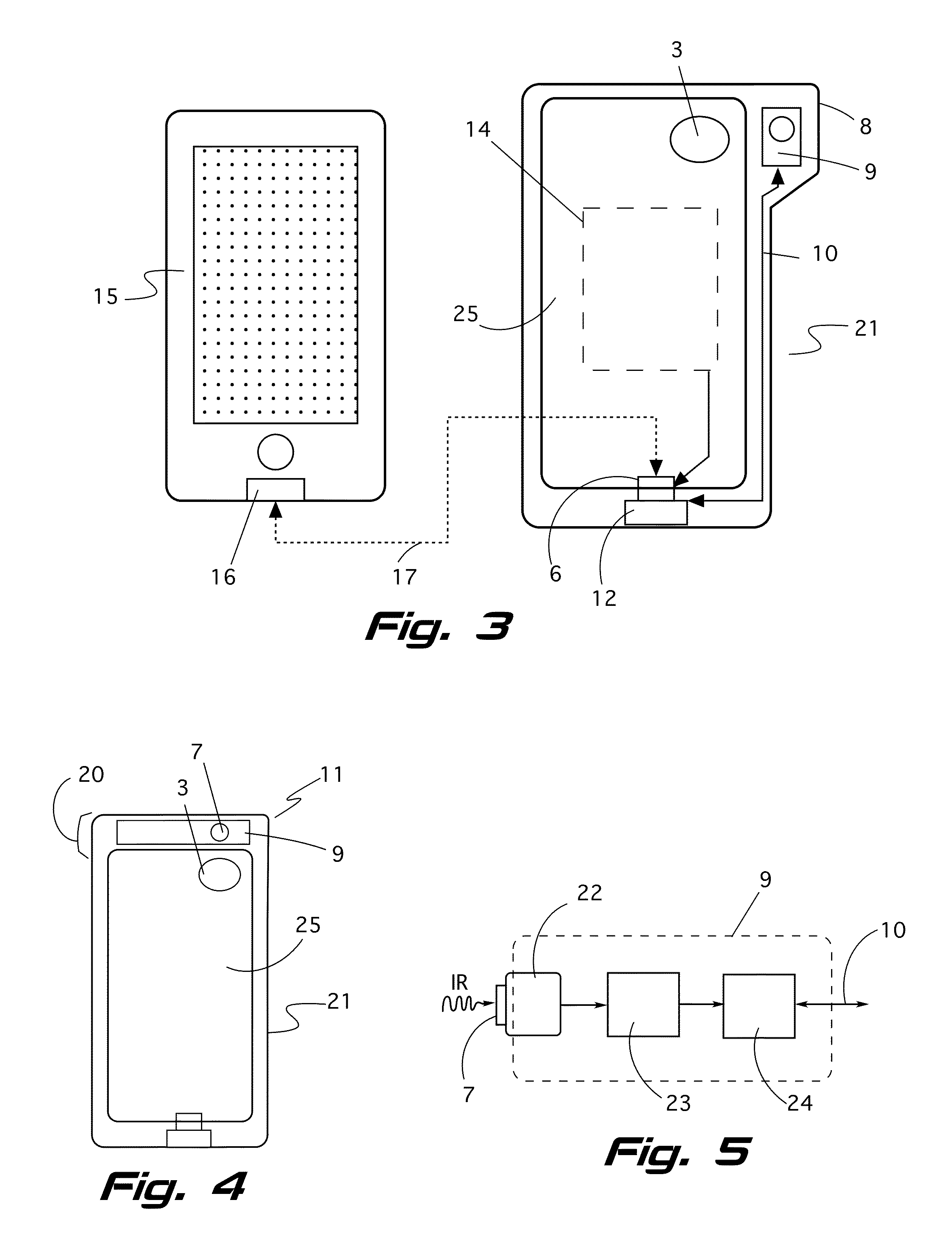

Sensing case for a mobile communication device

A protective case for enveloping a smartphone incorporates at least one sensor for detecting stimuli arriving from outside of the smartphone. The case and the phone form an integral unit that possess extra features than the phone alone wouldn't have. The sensor is supplemented by a signal conditioning and interface electronic circuit for communicating the sensed information to the smartphone inner processor. The communication is via a wired connection to the smartphone's connector or wireless via a radio waves or optical link. For expanding versatility of the smartphone, the sensors may be adapted for detecting non-contact temperature, light, ultrasonic, smell, material composition, human vital signs, and other signals.

Owner:SENSORJACKET

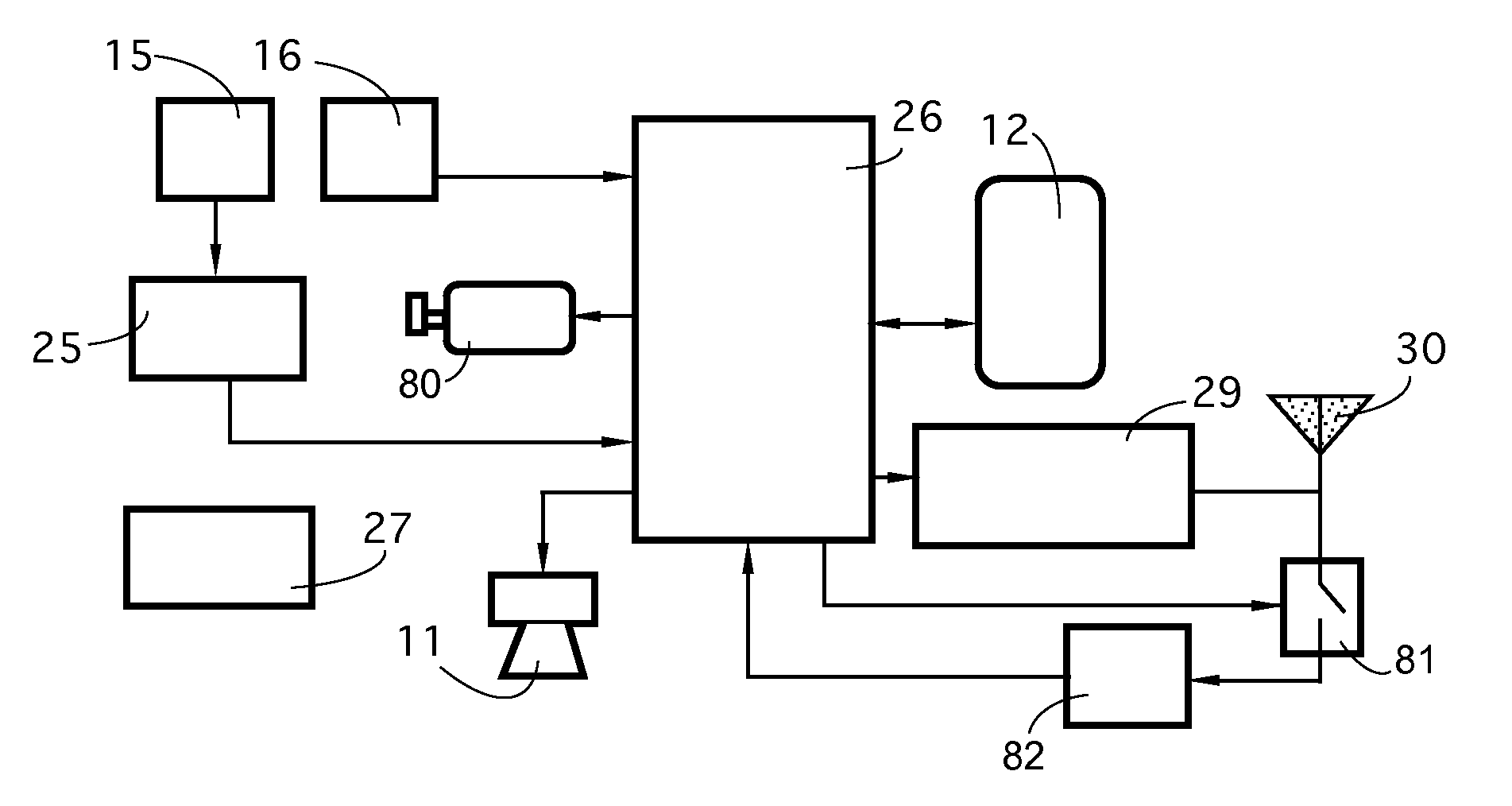

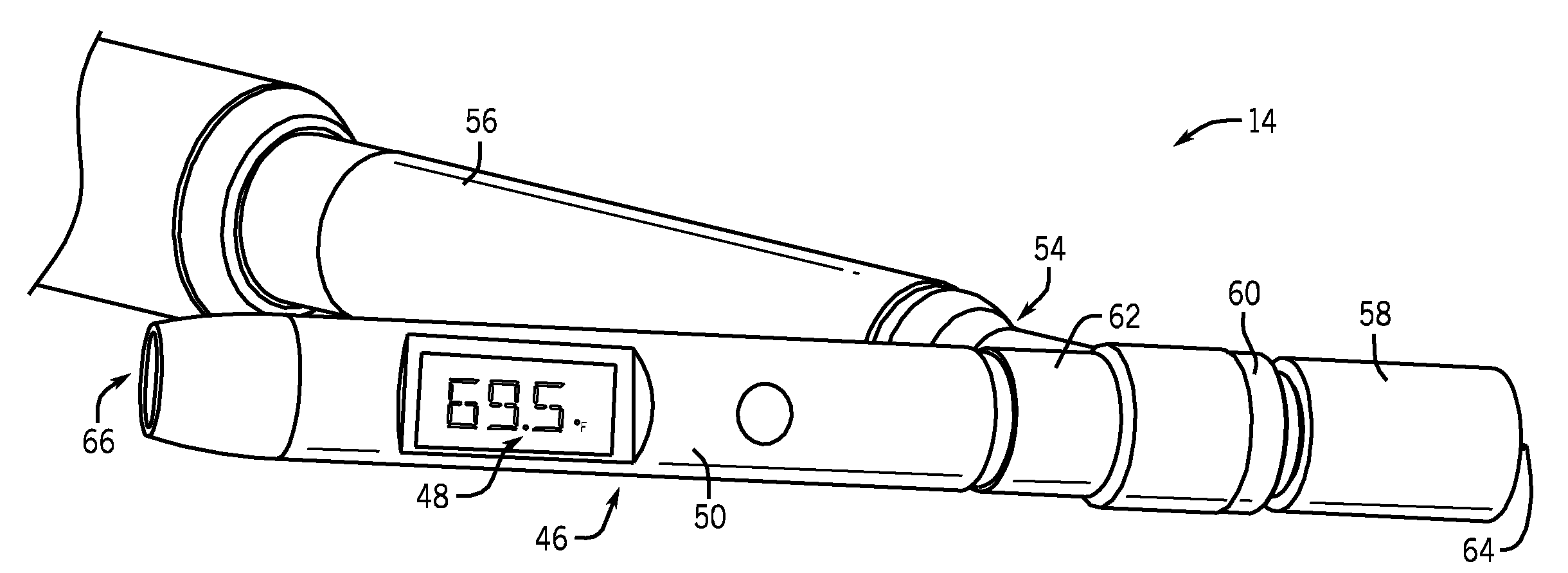

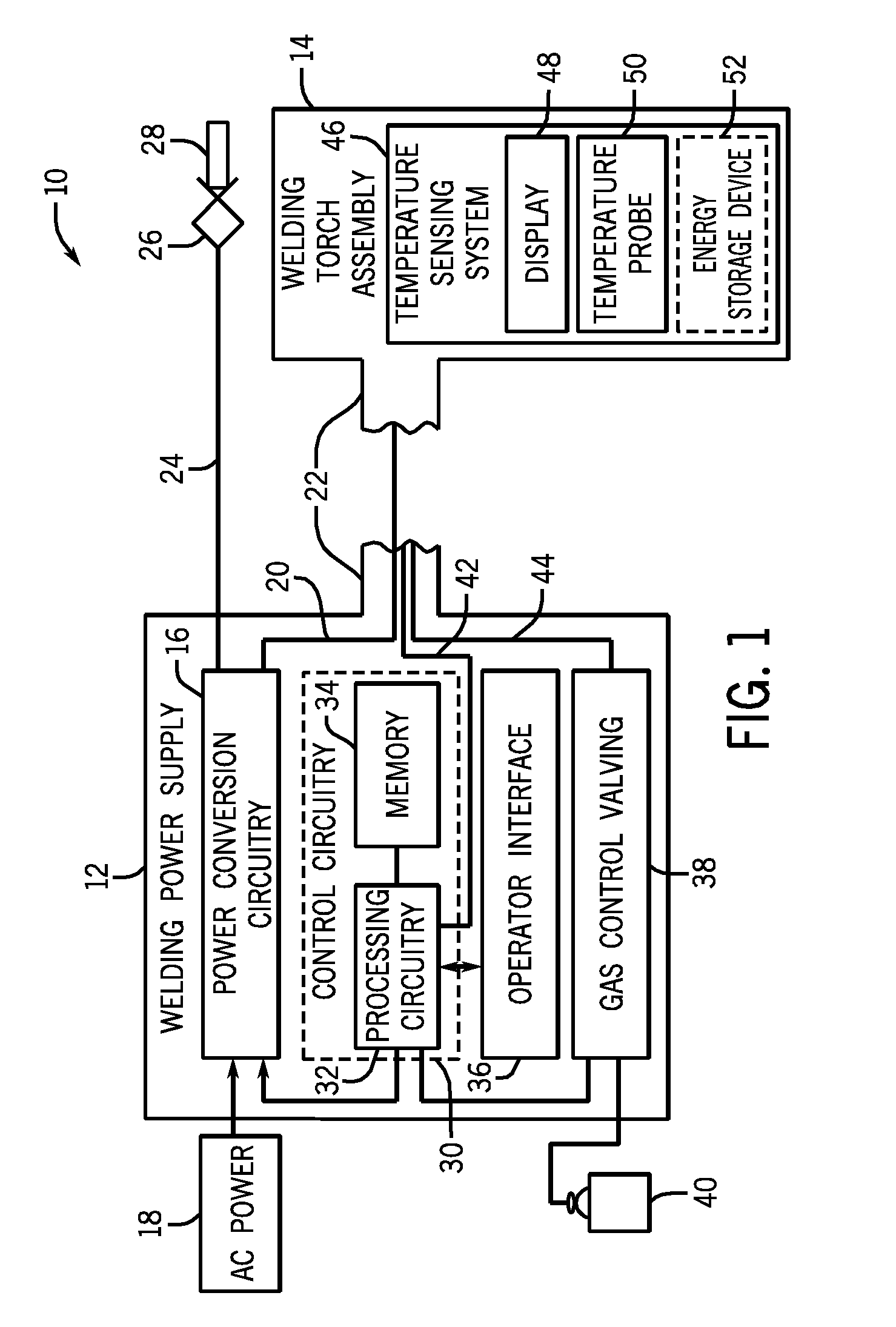

Welding systems having non-contact temperature measurement systems

ActiveUS20130264322A1Pyrometry using electric radation detectorsWelding accessoriesShielding gasCarbon Dioxide / Helium

Welding systems including welding torch assemblies are provided. The welding torch assembly may include a welding torch adapted to be utilized in a welding operation to establish a welding arc between the welding torch and a workpiece. Shielding gas may be supplied to the welding torch for establishment of a gas shielding area around a weld pool. The welding torch assembly may also include a temperature sensing system having a non-contact temperature sensor coupled to the welding torch and adapted to sense a temperature of the workpiece at a location outside of the molten weld pool.

Owner:ILLINOIS TOOL WORKS INC

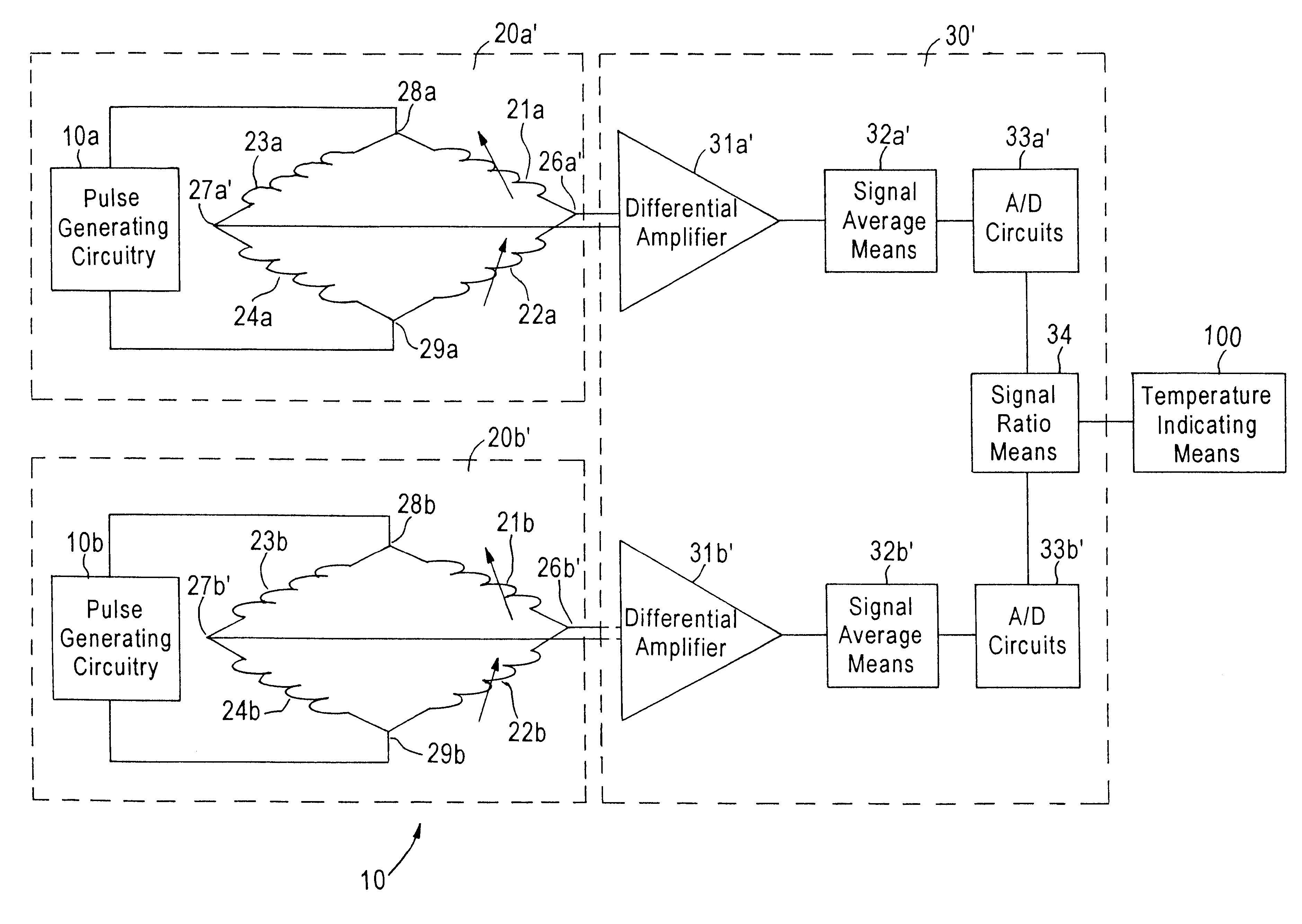

Non-contacting temperature sensing device

InactiveUS6222454B1Material analysis by optical meansSensing radiation from moving bodiesSpectral bandsDifferential amplifier

The device according to the invention provides a non-contacting temperature sensing device incorporating micro-bolometric detectors as the suitable infrared sensors for automotive applications. A first and second infrared sensors each include an active infrared sensing element and a temperature drift compensating element. A current bias is applied to the active infrared sensing element as well as to the temperature drift compensating element, which is identical in structure with the active infrared sensing element, and the voltage outputs of these two elements pass through a differential amplifier. The fluctuation in the substrate temperature or the ambient temperature affects the active sensing element and the compensating element in the same way, thus it is cancelled out. Instead of using one spectral band of the infrared radiation, as in the prior art, two spectral bands are used resulting in a first and second signal generated by the first and second infrared sensors. A ratio of the first and second signals is obtained. The ratio of the signals is emissivity independent, so that the device of the present invention provides a more accurate measurement of temperature. The need to compensate for window contamination is also eliminated by this two band approach. The filtering elements for the two bands can be multi-layer thin film filters either coated on flat windows or on diffractive micro-lenses. The use of diffractive micro-lenses further reduces the size of the device, and eliminates the need for a separate optical lens.

Owner:MONTEREY RES LLC +1

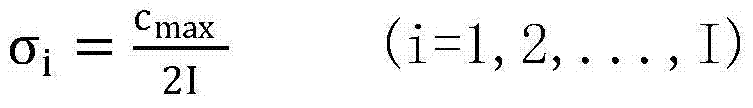

Power equipment current-carrying fault trend prediction method based on least squares support vector machine

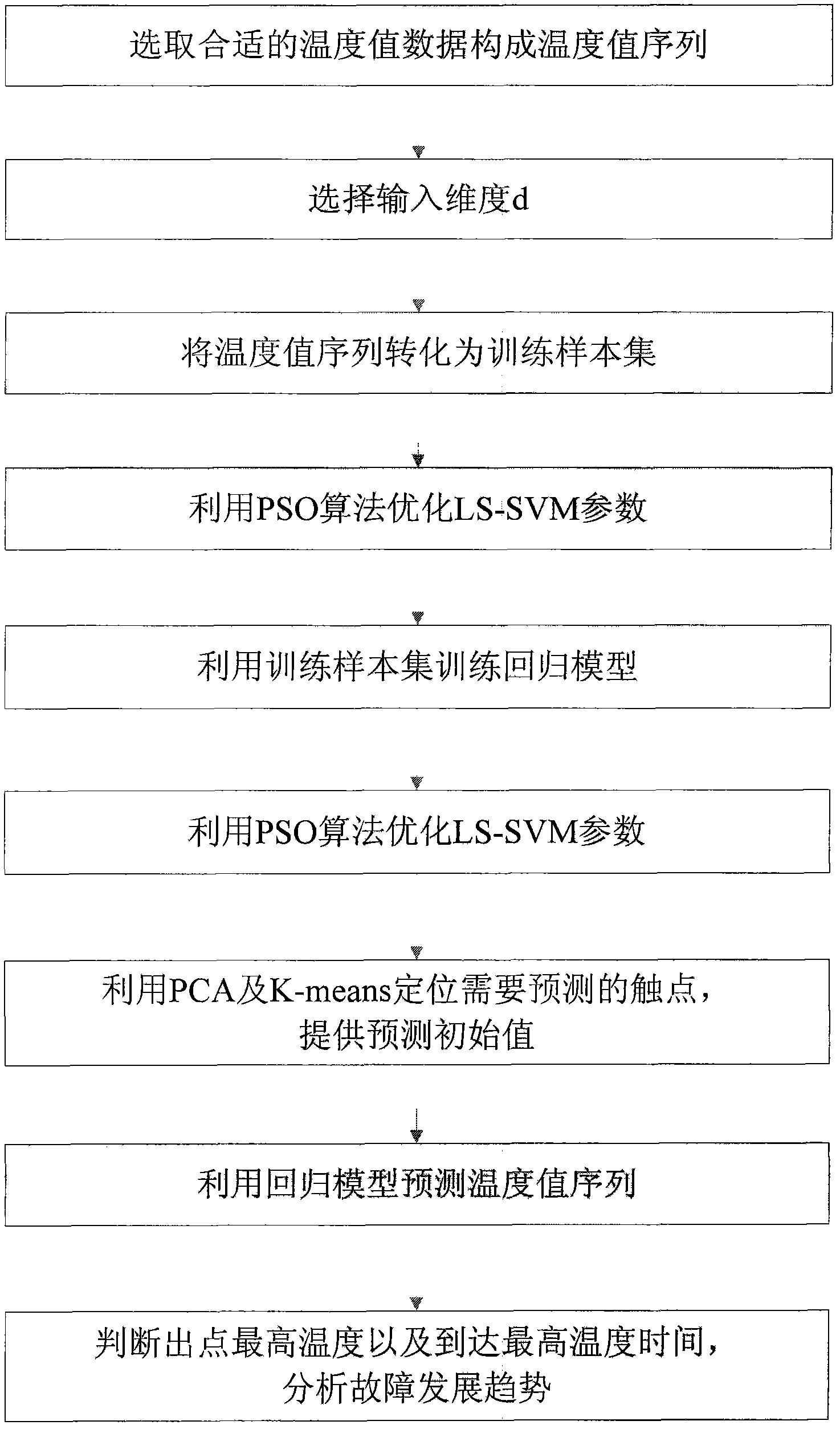

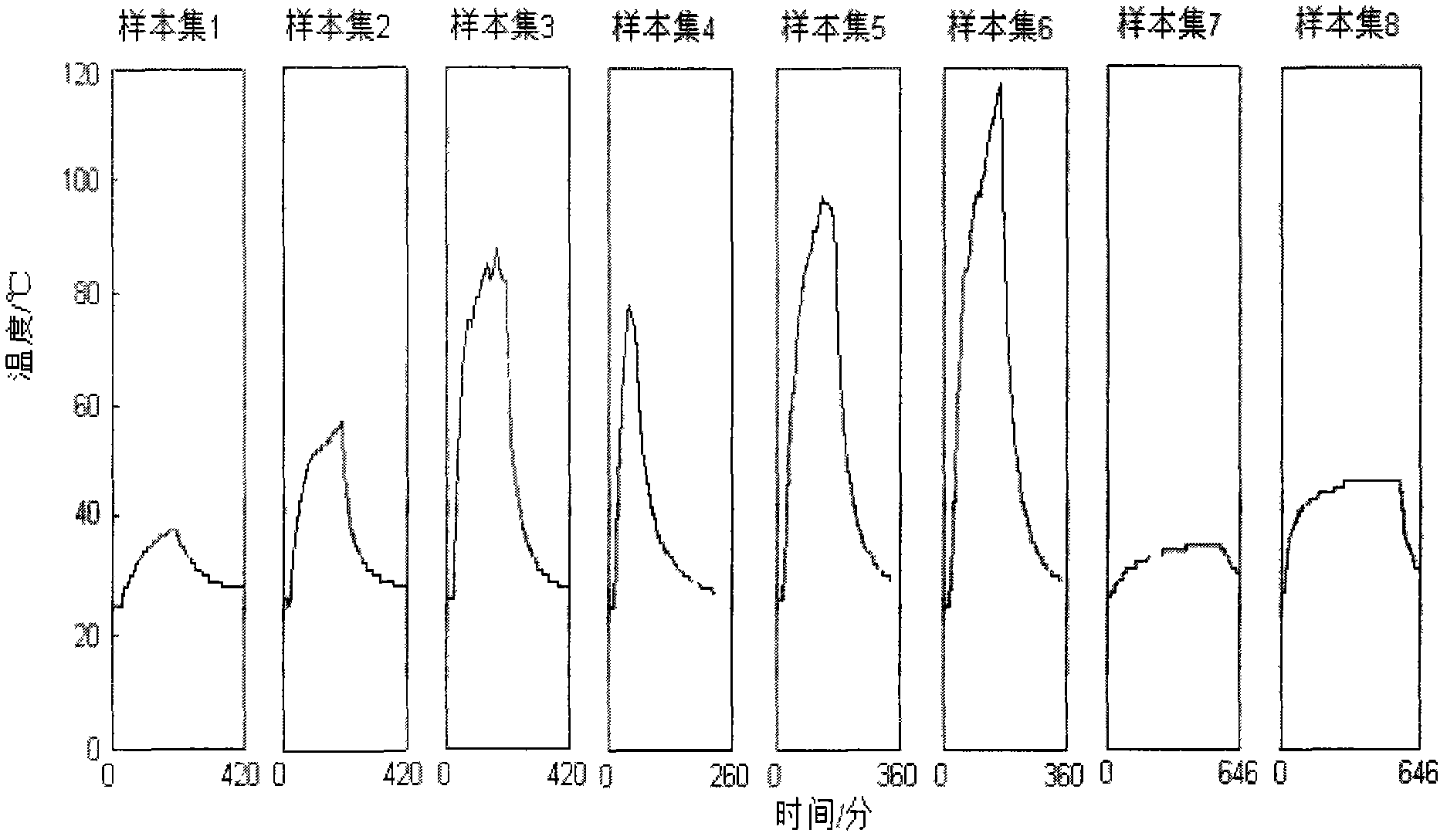

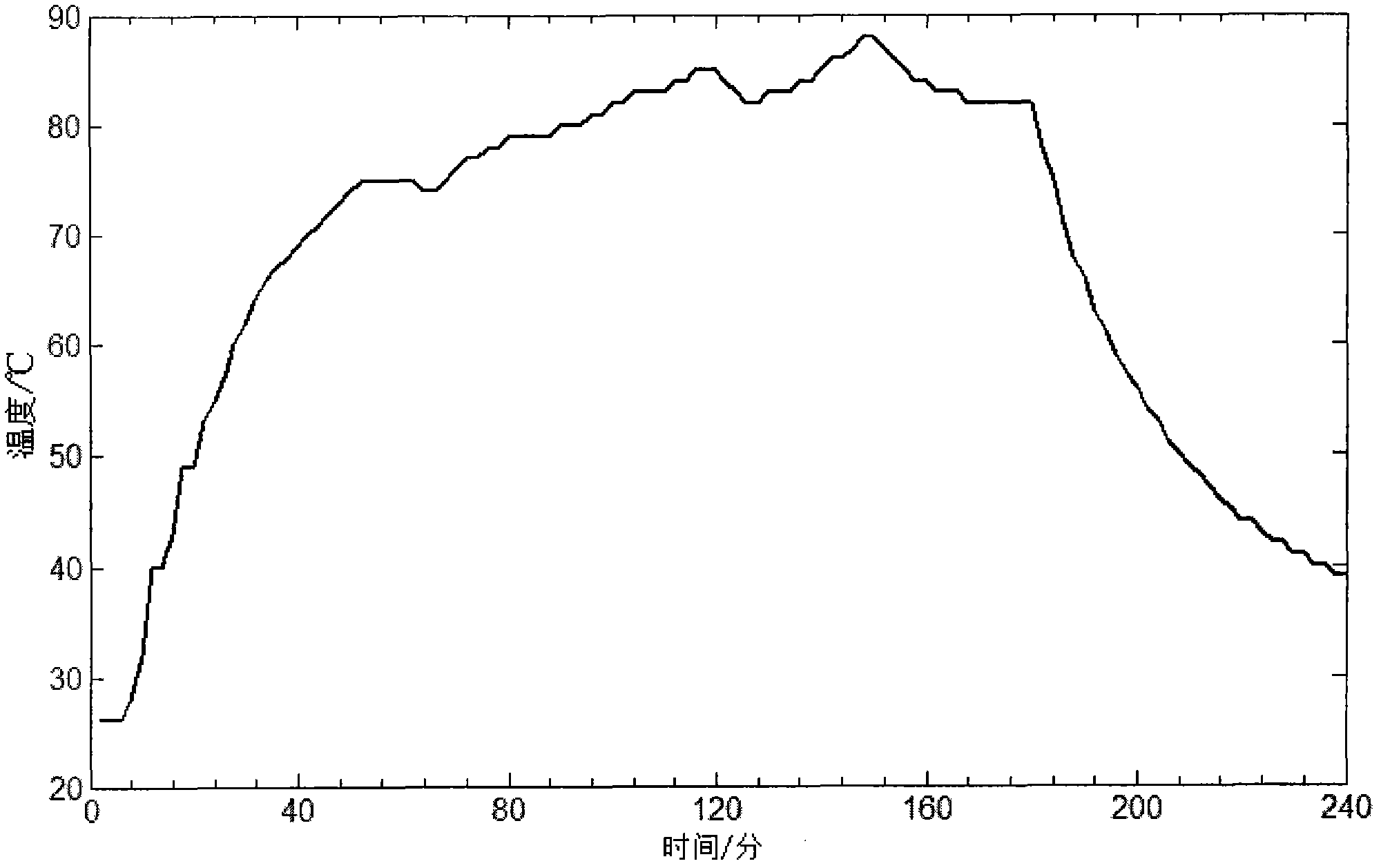

InactiveCN102663412AHigh precisionImprove reliabilityCharacter and pattern recognitionLeast squares support vector machinePower equipment

The invention discloses a power equipment current-carrying fault trend prediction method based ona least squares support vector machine. The method provided by the invention comprises the steps of employing historical temperature data to train an LS-SVM regression model, and employing a PSO optimization algorithm to adjust two parameters of the model, namely nucleus width sigma and punishment parameter gamma; employing a PCA algorithm and a K-means clustering algorithm to real-time analyze the temperature of equipment contacts to find contacts with abnormal temperature rising, and using the temperature value asan initial value sequence of prediction;and finally employing the regression model obtained by training to predict the temperature value of the initial value for a long term and for a short term, and analyzing the highest point the contact temperature may reach and the time when the contact temperature reaches the highest point. Through predictive analysis based on PSO-LSSVM, fault development trend of equipment contacts is actively controlled, so the time for timely measures and ensuring the safe operation of power grid is bought. The method provided by the invention can be widely used in the field of power equipment forecast alarm protection.

Owner:ZHEJIANG UNIV +1

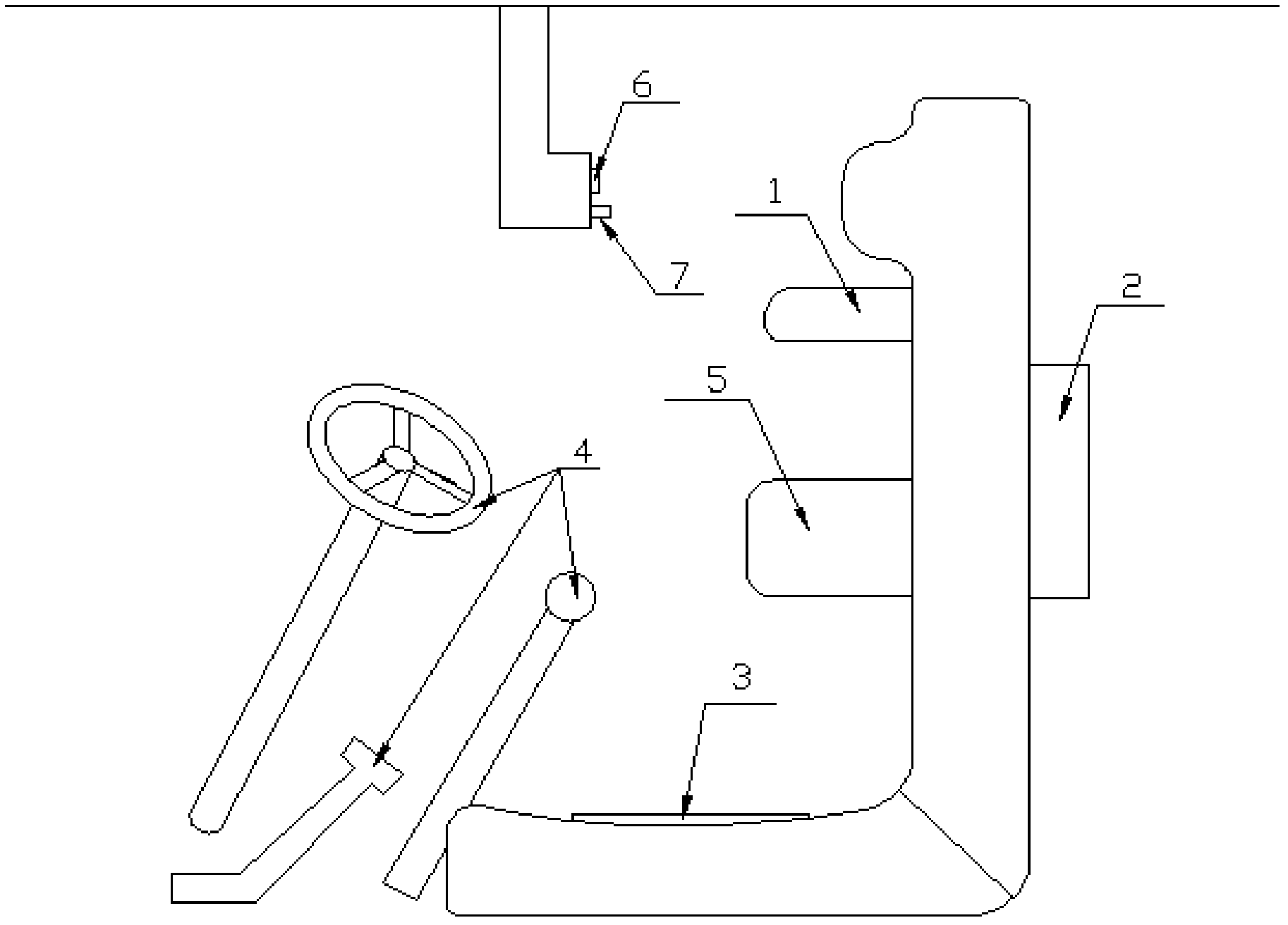

Safe driving monitoring device capable of monitoring physical and psychological states of driver

InactiveCN102490701AReduce intensityReduce riskAcoustic signal devicesAutomatic initiationsDriver/operatorEngineering

A safe driving monitoring device capable of monitoring physical and psychological states of a driver belongs to the field of safe driving of automobiles and solves the problem that an existing safe driving device only detects some single index, does not consider changes of the physical and psychological states of the driver and cannot carry out corresponding reaction movements when the states of the driver change. A neck pulse sensor detects pulse signals, a pressure sensor detects signals indicating whether the driver sits in an automobile, an air bag pressure sensor detects hand gripping signals or foot power signals of the driver, a breathing signal detection circuit detects breathing signals of the driver, a non-contact temperature measuring sensor detects body-temperature signals, an alcohol concentration measuring sensor detects alcohol concentration signals, an ear type sphygmomanometer detects blood pressure signals, and a distance measuring sensor detects relative distance signals. All the signals are analyzed by a control and analysis processor, and the control and analysis processor outputs analysis results to an alarming module so as to give an alarm.

Owner:HARBIN INST OF TECH

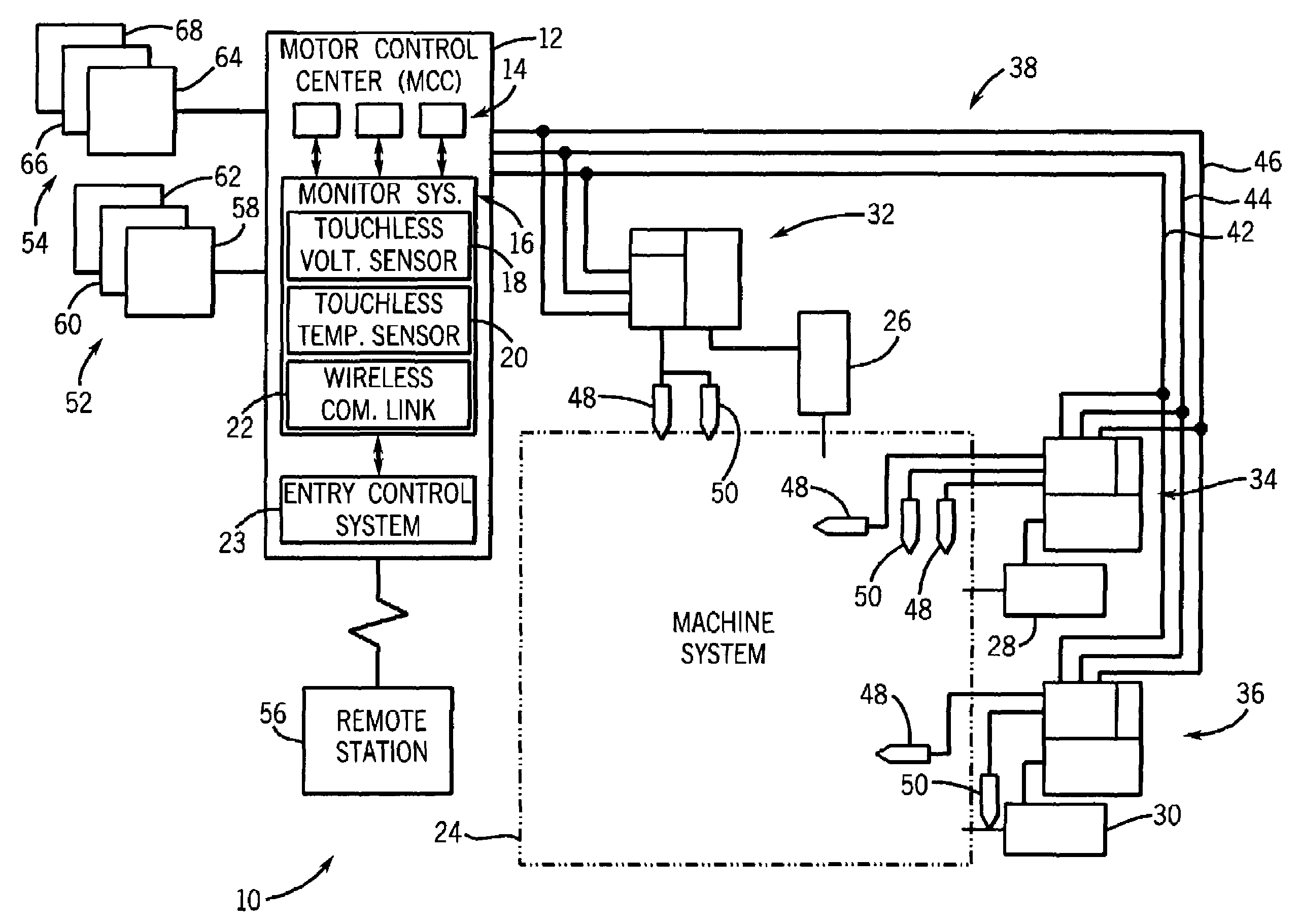

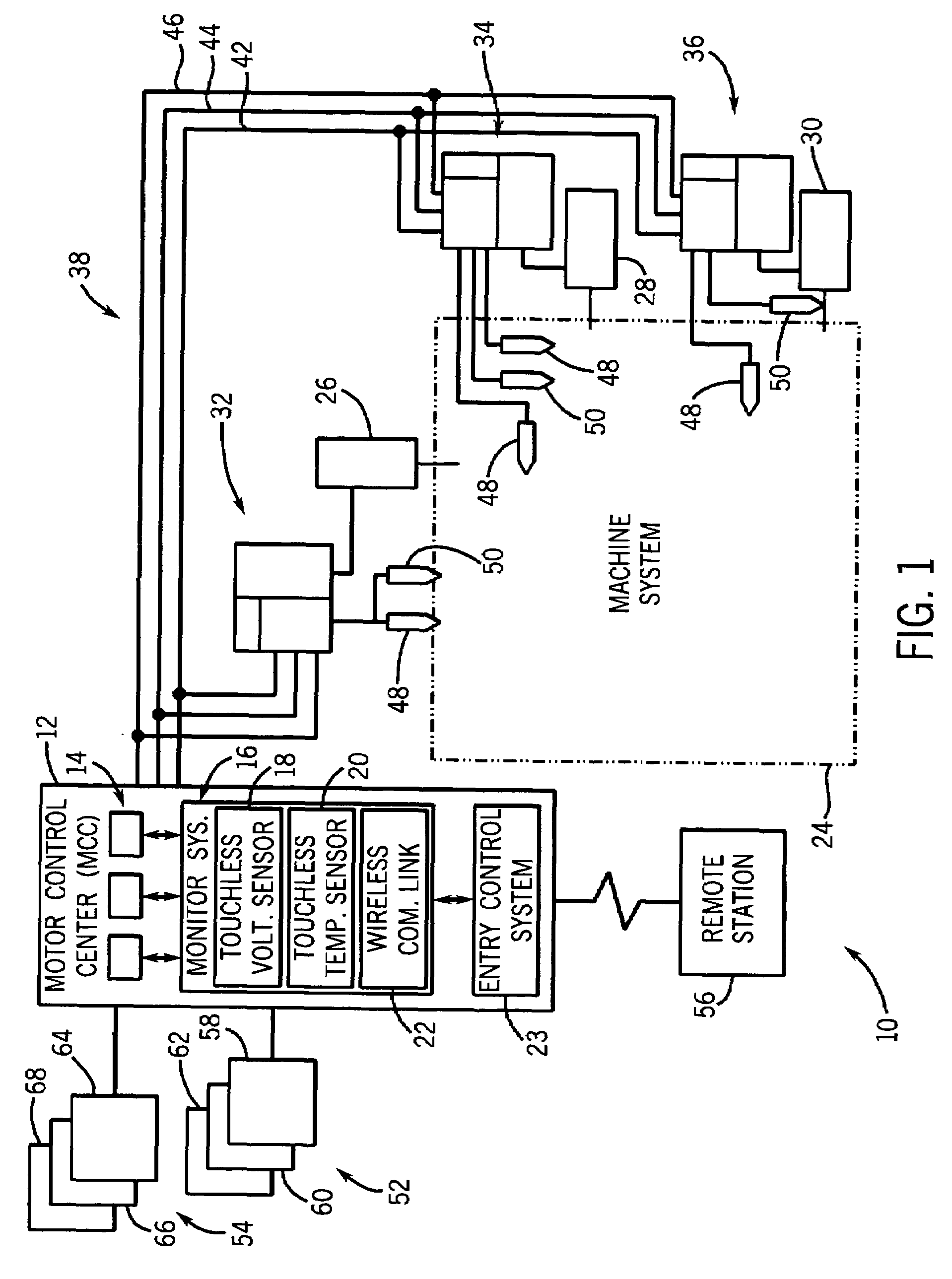

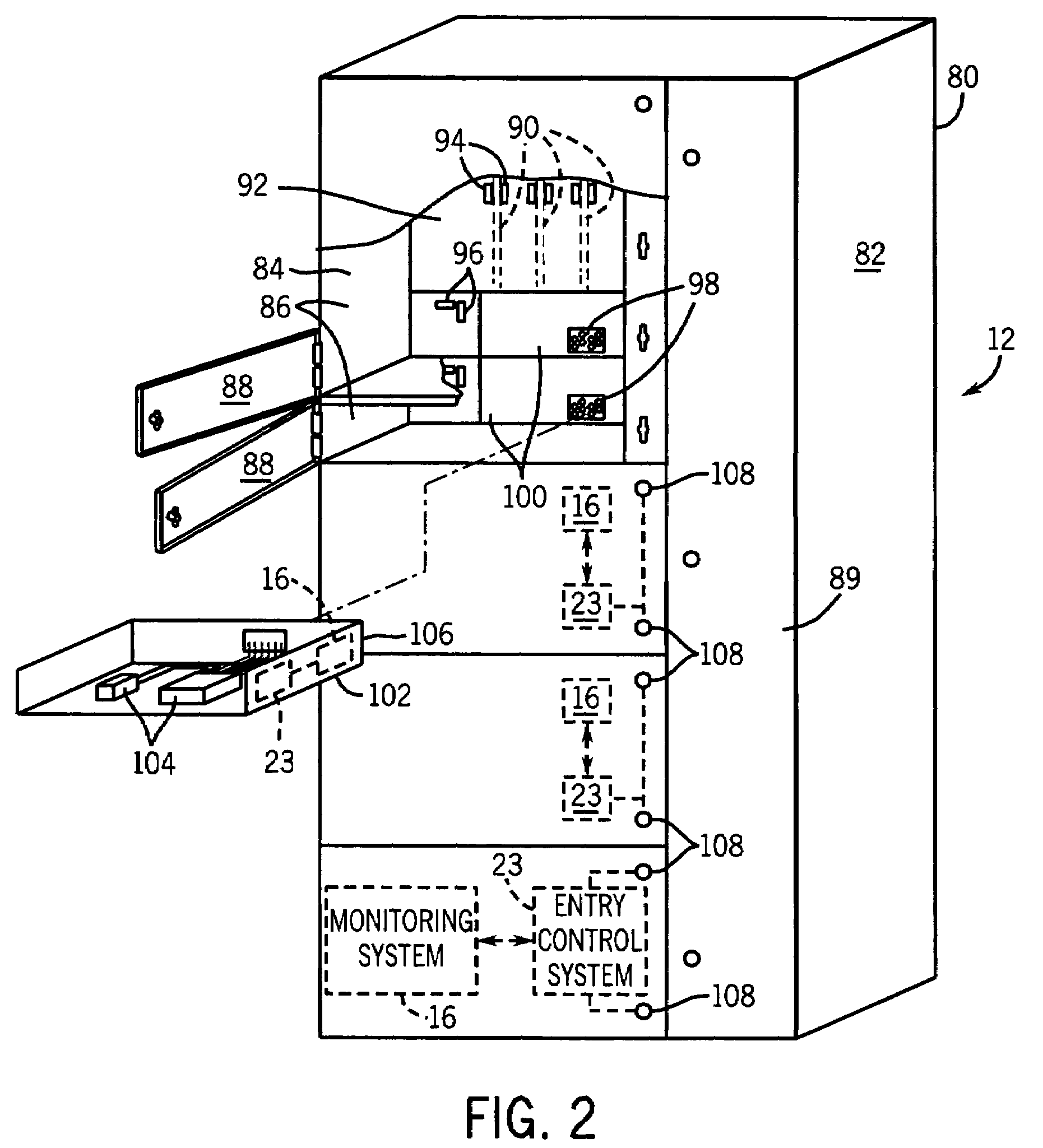

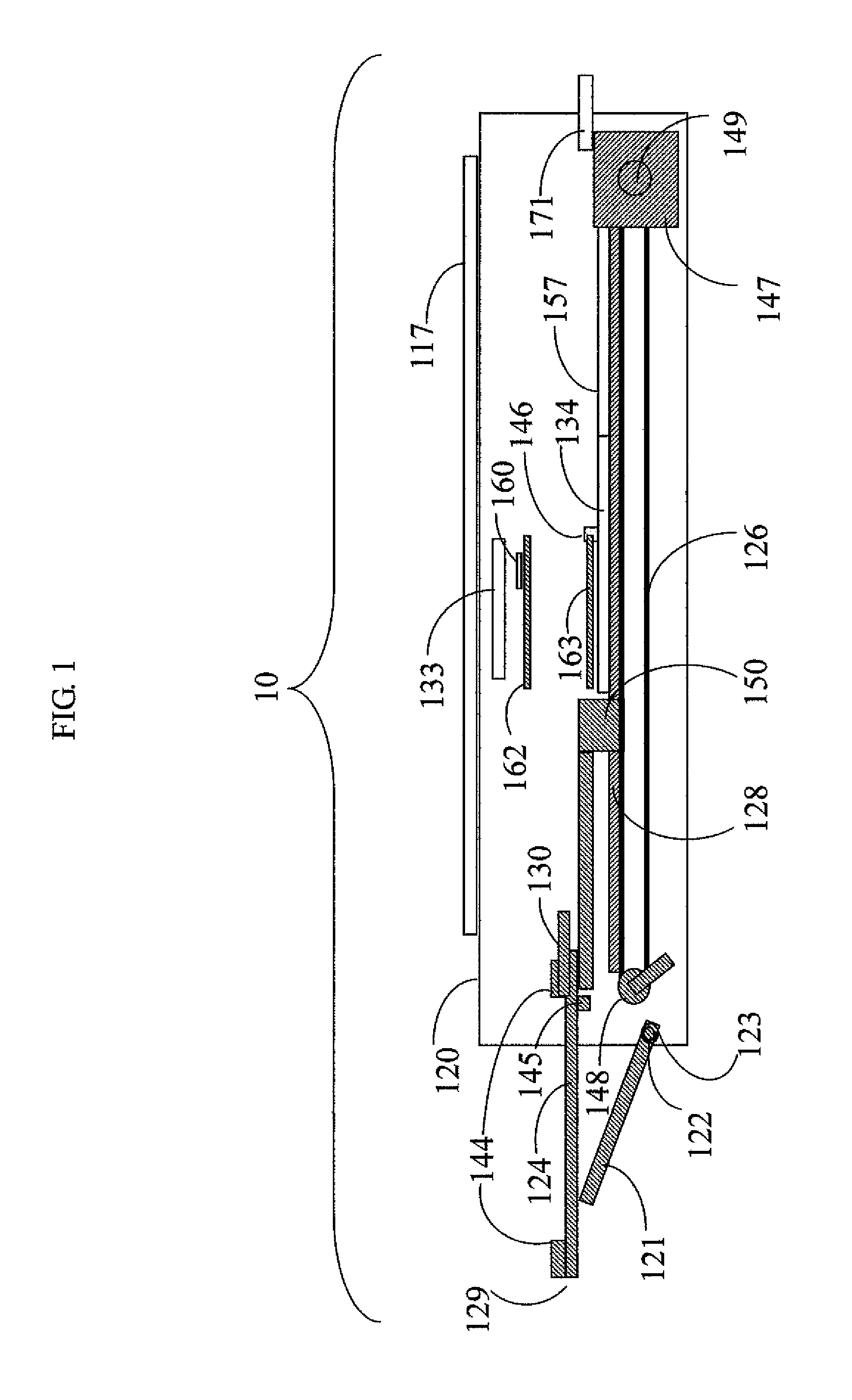

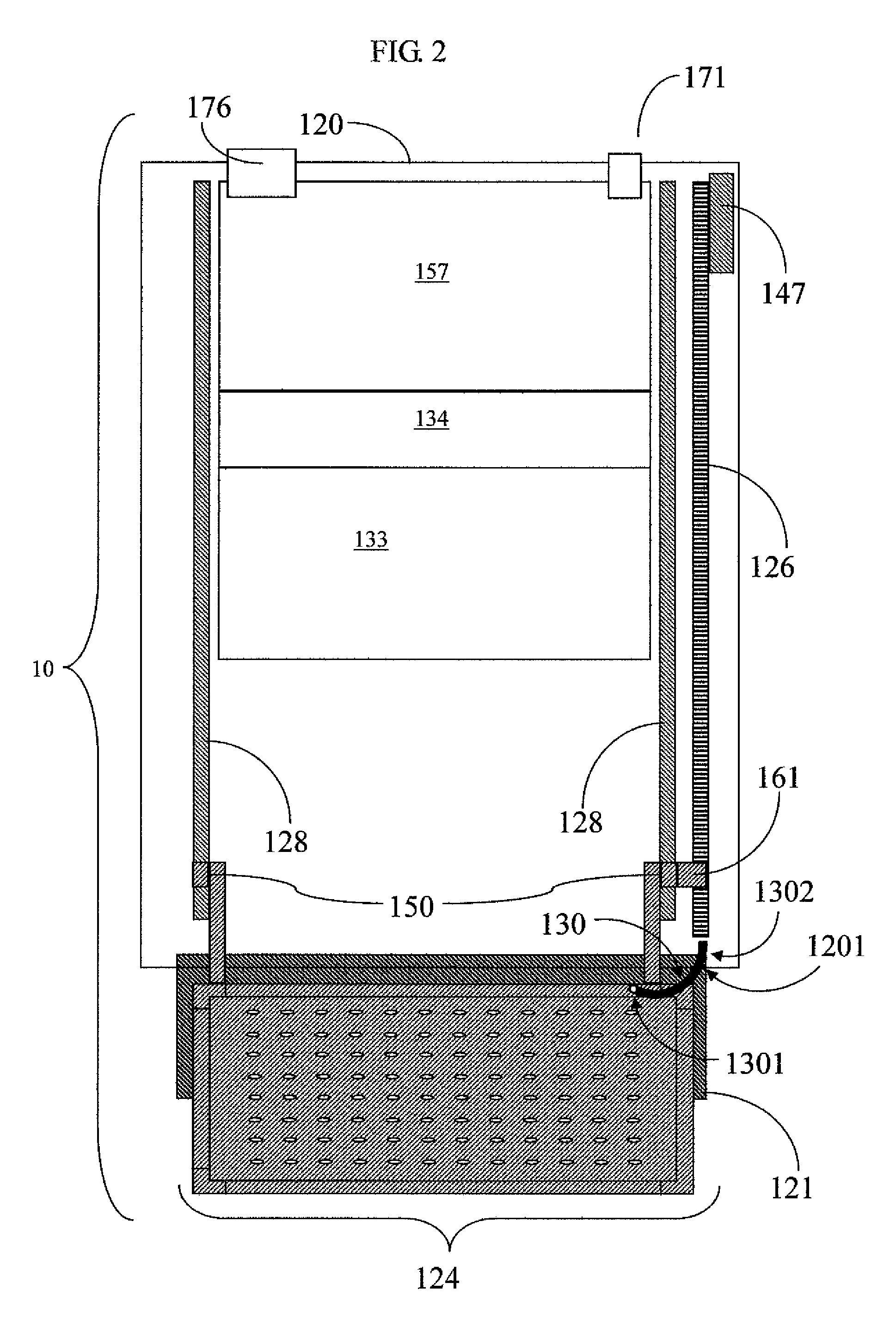

System and method for monitoring a motor control center

ActiveUS20080079436A1Coupling device connectionsSwitchgear arrangementsPower distribution centerMotor control

A system, in one embodiment, includes a power distribution center having an enclosure with an access door configured to move between a closed position and an open position. The power distribution center includes a non-contact sensor disposed inside the enclosure, wherein the non-contact sensor comprises a non-contact voltage sensor, or a non-contact temperature sensor, or a combination thereof. The power distribution center also includes an indicator viewable outside of the enclosure while the door is in the closed position, wherein the indicator is coupled to the non-contact sensor.

Owner:ROCKWELL AUTOMATION TECH

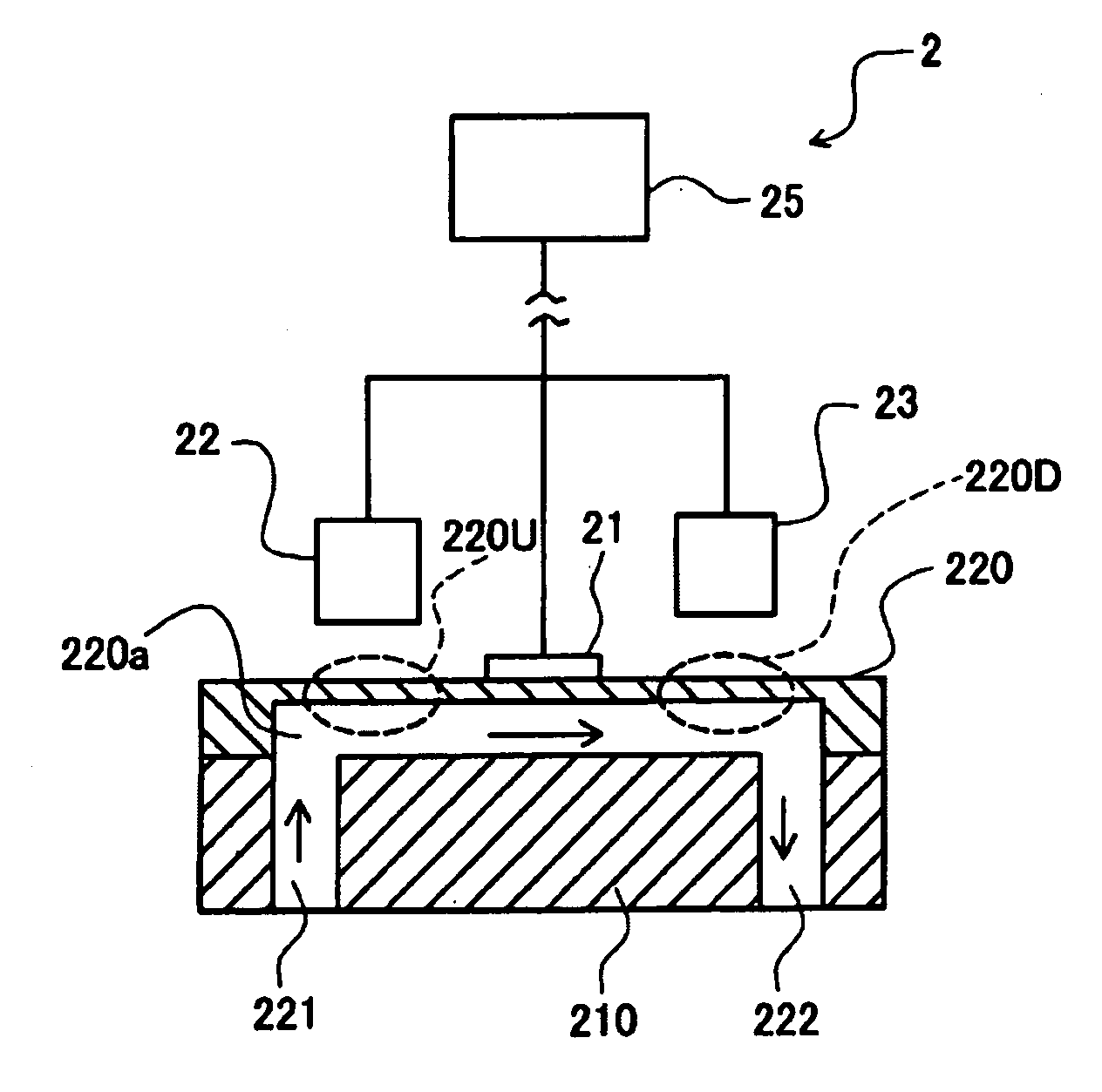

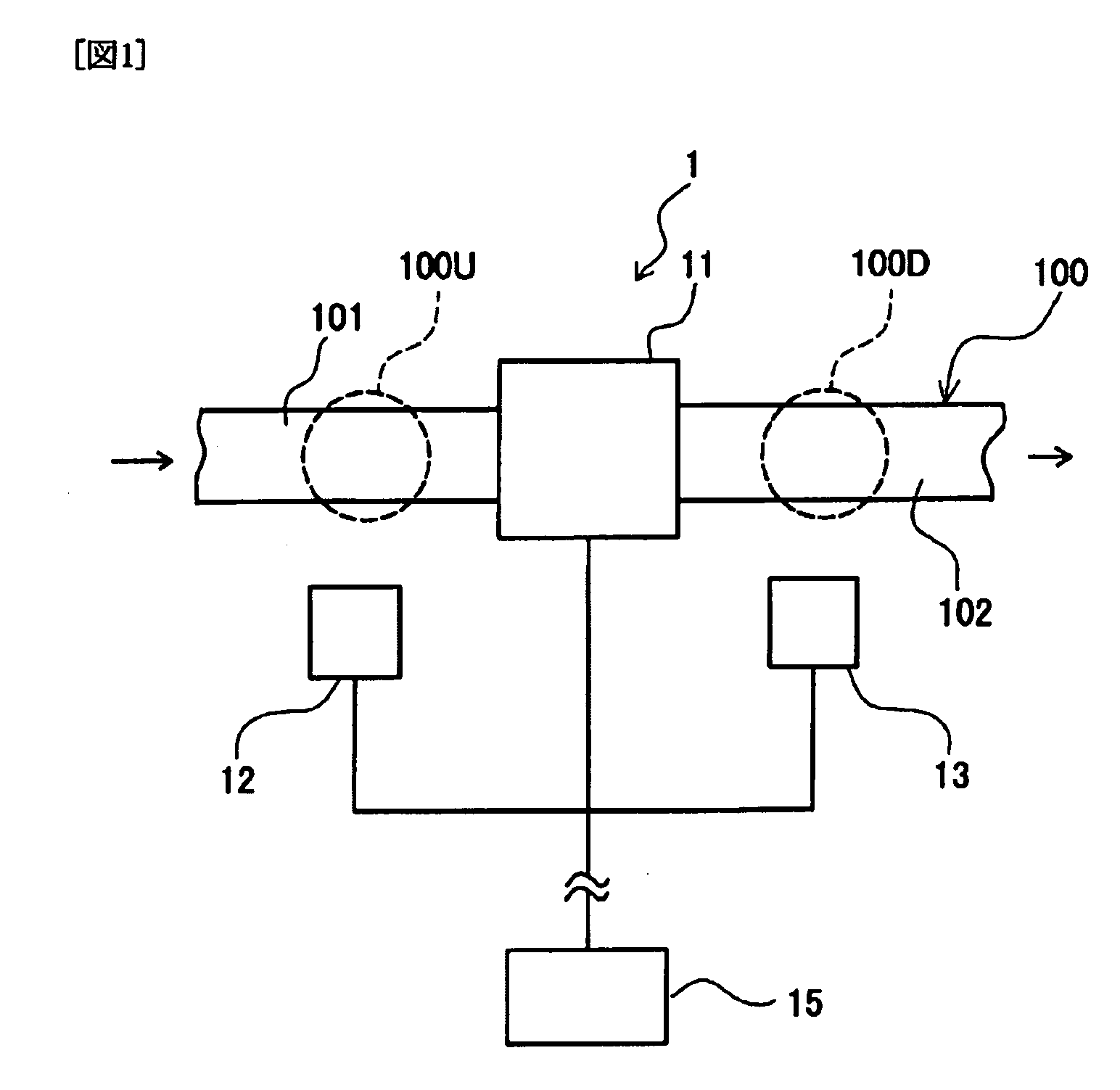

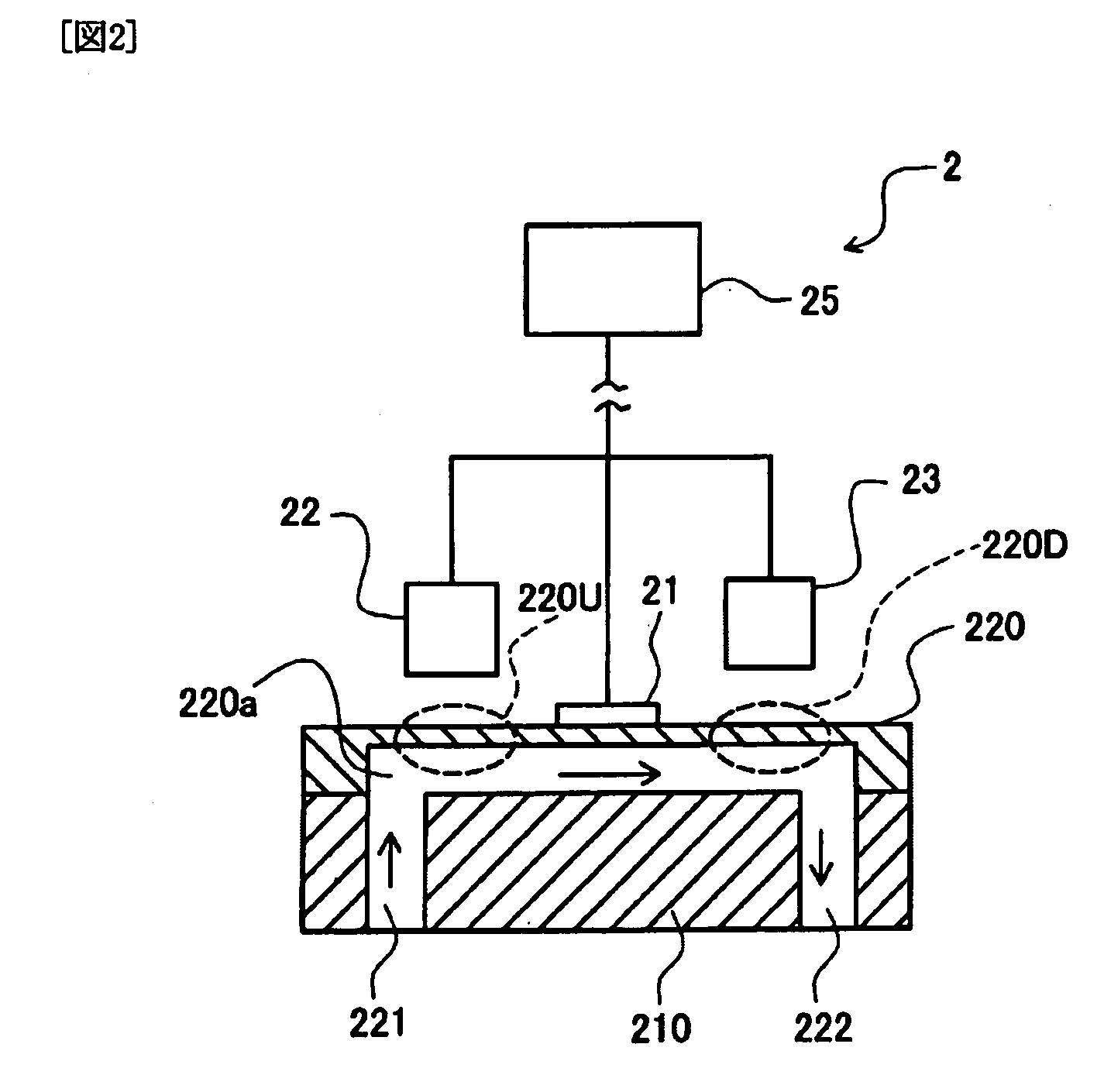

Flow Sensor

InactiveUS20080210002A1Detection can be maintainedMaintain detection accuracyVolume/mass flow by thermal effectsInfraredTemperature difference

A flow meter includes a heating means (11) for heating a partial region of the outer wall surface of a pipe forming a flow path or for heating a particular region in the pipe; and temperature detecting means for measuring the temperatures of regions for radiating the temperature influence from the heated region to the outside as heat energy (infrared rays), the regions being on the upstream side and the downstream side of the pipe with respect to the heated region. The temperature detecting means consist of an upstream-side non-contact temperature detecting means (12) and a downstream-side non-contact temperature detecting means (13) arranged near the outer wall surface of the pipe in a state of being not in contact with the outer wall surface, and the non-contact temperature detecting means can measure the temperatures of the upstream-side heat energy radiating region and downstream-side heat energy radiating region in a state of being not in contact with the outer wall surface of the pipe. The flow rate of a fluid to be measured flowing in the flow path is measured from the temperature difference between the temperatures of the upstream-side heat energy radiating region and downstream-side heat energy radiating region measured by the non-contact temperature detecting means or from the output caused by the temperature difference.

Owner:YAMATAKE HONEYWELL CO LTD

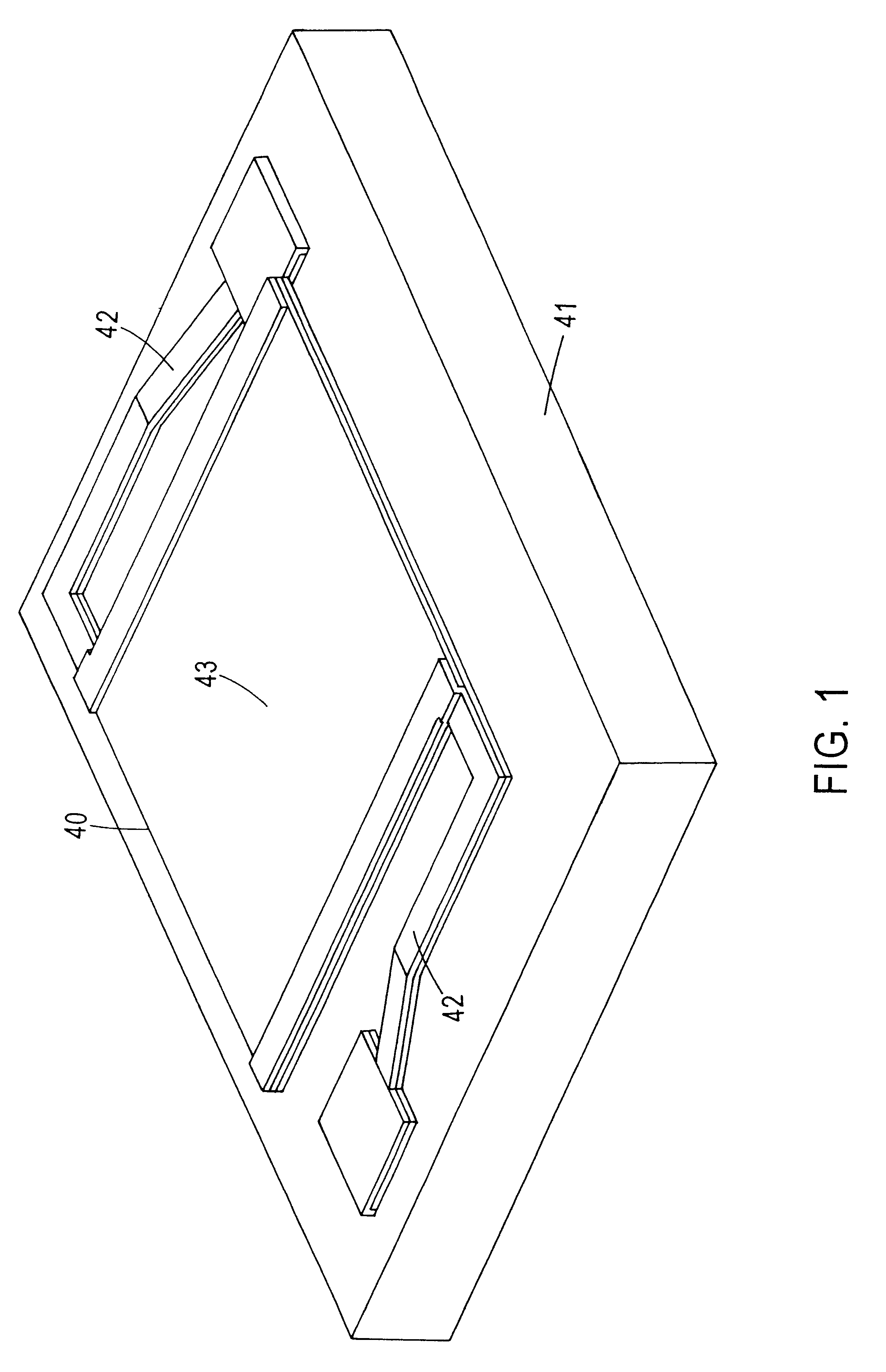

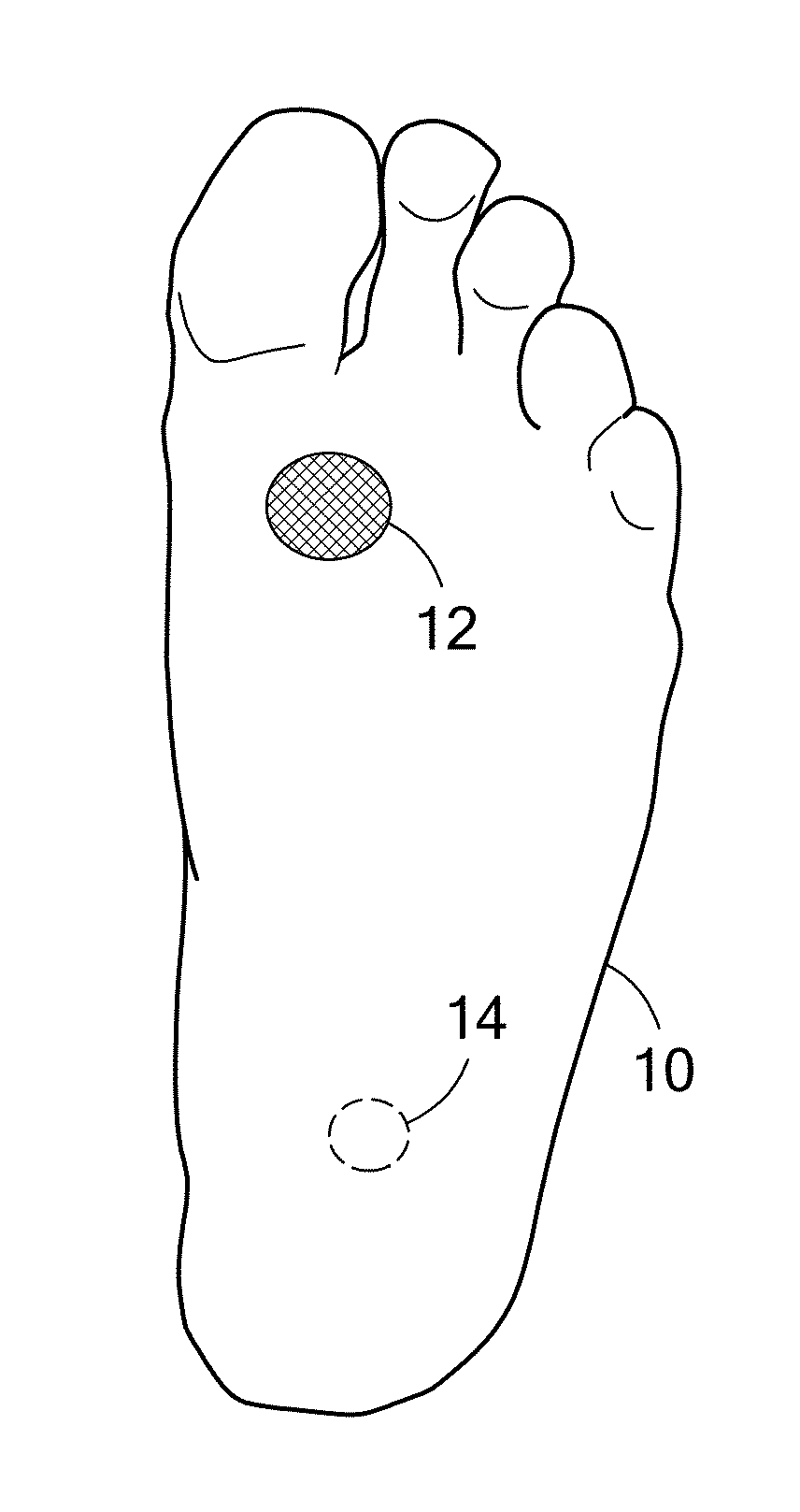

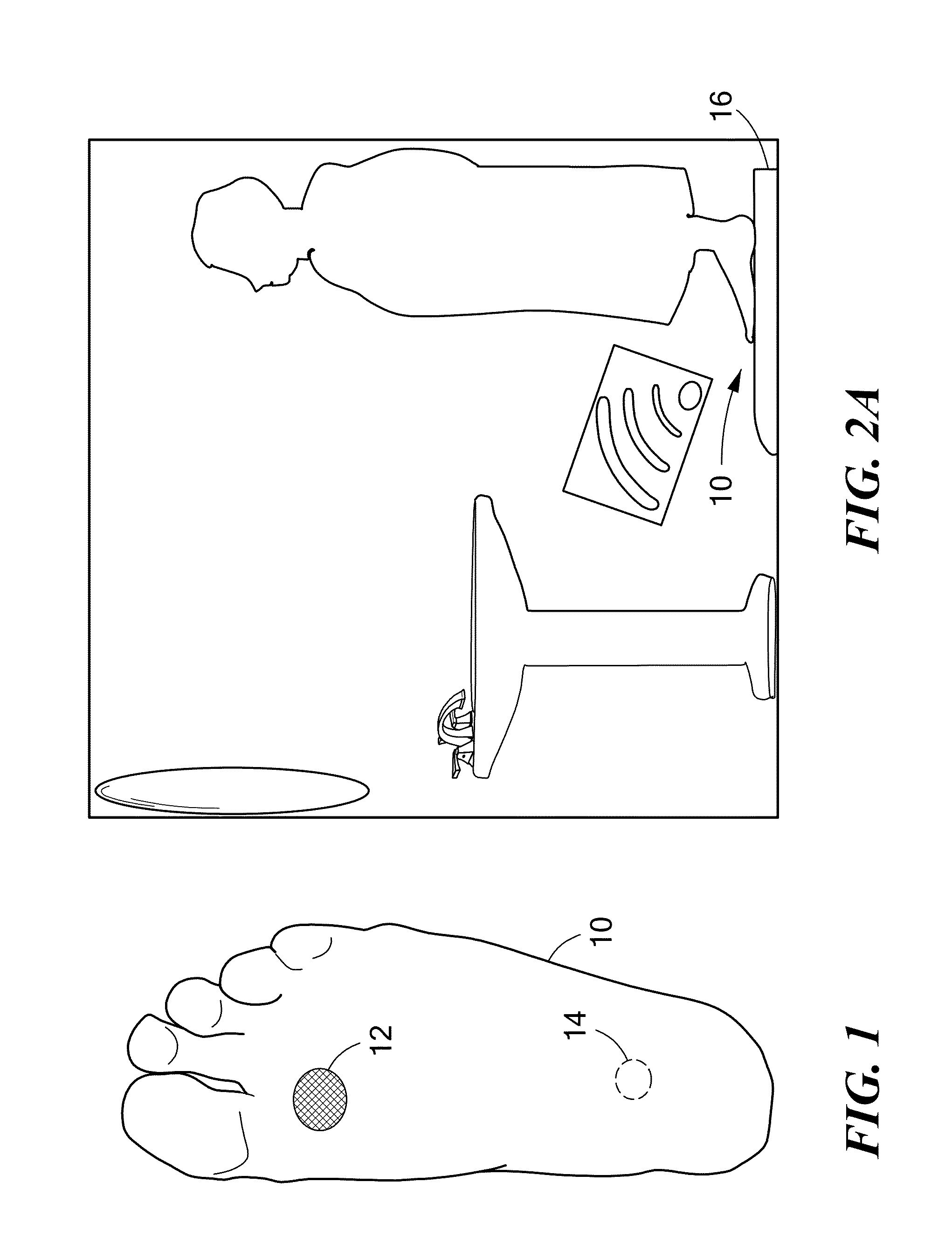

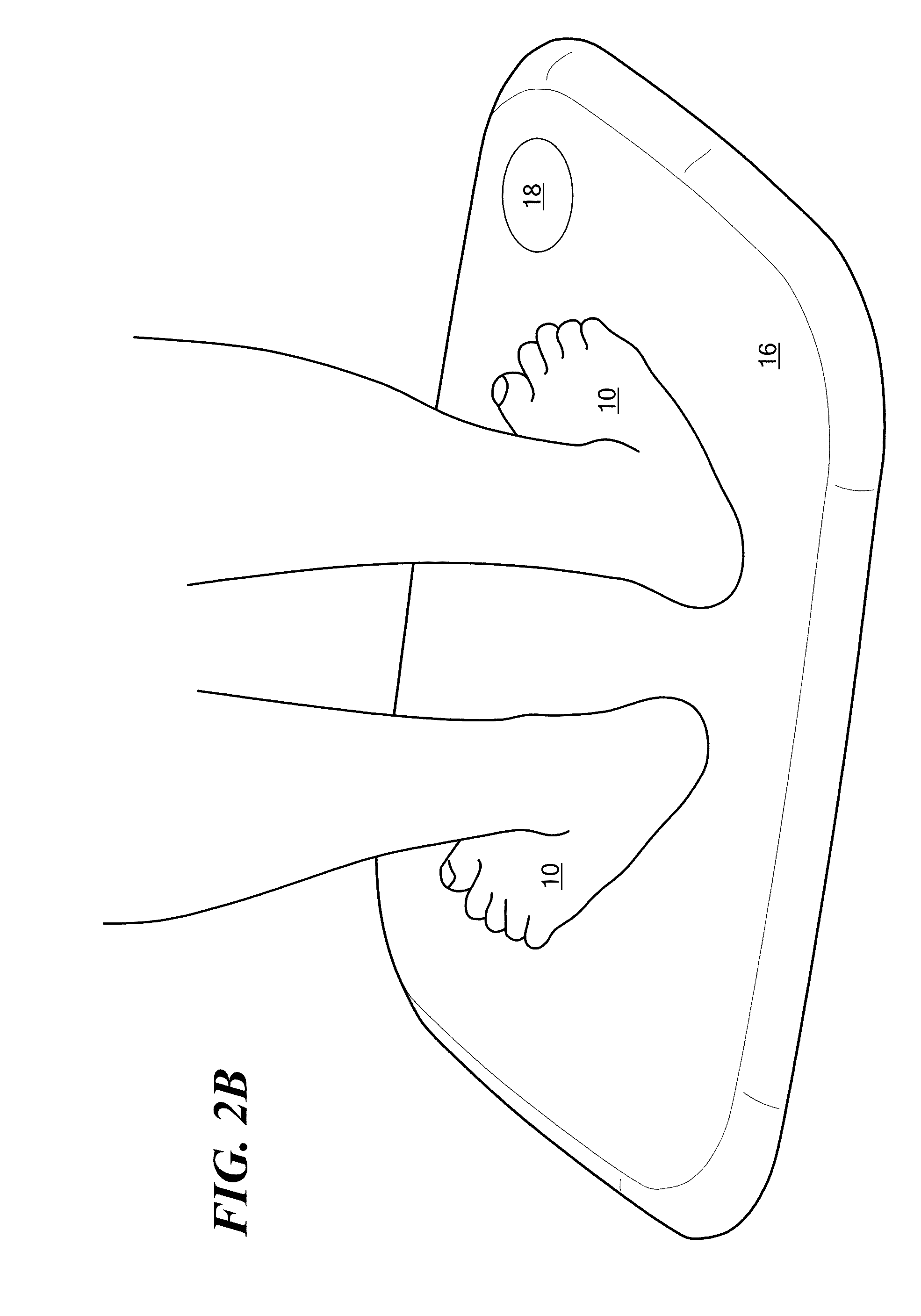

Apparatus for measuring temperature distribution across the sole of the foot

InactiveUS20150057562A1Certain performanceThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceElectrical and Electronics engineering

An apparatus for measuring the temperature distribution over the sole of the foot has a flexible substrate. The substrate defines a plurality of discontinuities forming a plurality of substrate segments. Each substrate segment has a sensor region with a surface for coupling a sensor, and at least one connector to connect to at least one sensor region of an adjacent substrate segment. Each of a plurality of the sensor regions is configured to be movable relative to other sensor regions. The discontinuities cause the flexible substrate to exhibit elastic properties in the aggregate. The apparatus also has a plurality of resistive contact temperature sensors coupled with the flexible substrate.

Owner:PODIMETRICS

Sensing case for a mobile communication device

InactiveUS20150263777A1Diagnostic recording/measuringSubstation equipmentSignal conditioningEngineering

A protective case for enveloping a smartphone incorporates at least one sensor for detecting stimuli arriving from outside of the smartphone. The case and the phone form an integral unit that possess extra features than the phone alone wouldn't have. The sensor is supplemented by a signal conditioning and interface electronic circuit for communicating the sensed information to the smartphone inner processor. The communication is via a wired connection to the smartphone's connector or wireless via a radio waves or optical link. For expanding versatility of the smartphone, the sensors may be adapted for detecting non-contact temperature, light, ultrasonic, smell, material composition, human vital signs, and other signals.

Owner:FRADEN JACOB

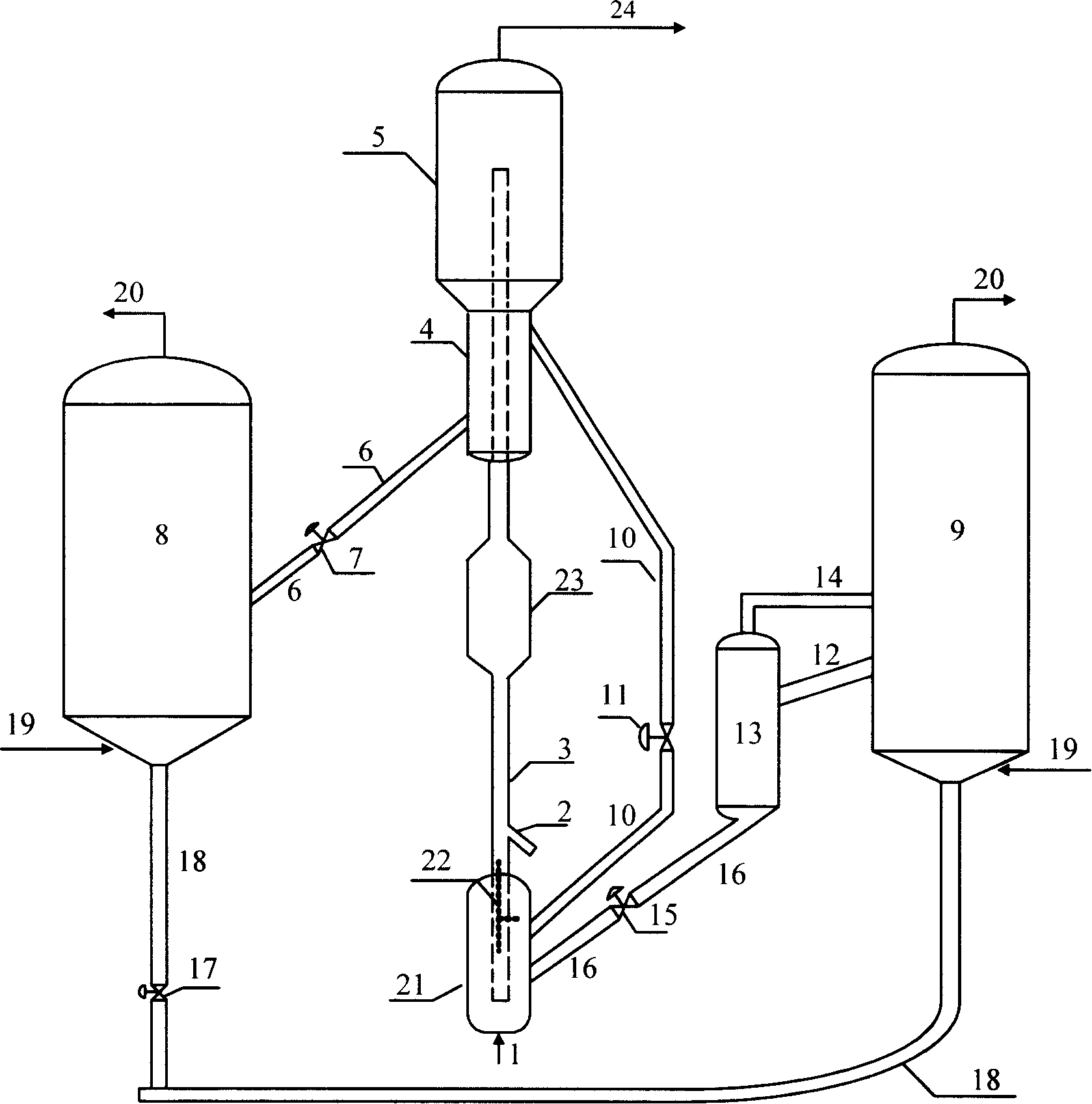

Conversion method for petroleum hydrocarbons

A transformation method for petroleum hydrocarbons includes the following steps: hot regenerated catalyst is returned to the bottom of a reactor after cooling down and is conveyed to the bottom of the first reaction zone of the reactor by pre-lifting gas so as to contact preheated base oil for cracking reaction; the mixture of reaction products, water vapor and catalyst enters into a diameter-expanded second reaction zone for further hydrocarbon transformation reaction with the reaction products, water vapor and spent catalyst undergoing gal-solid separation; gas phase products are separated to obtain various products; in addition, the spent catalyst is conveyed to a regenerator after steam stripping for recycling use after singeing regeneration or part of the spent catalyst directly enters into the mixer arranged at the bottom of the reactor. The method which adopts a reactor riser with two reaction zones improves the contact state of base oil and catalyst through lowering oil contact temperature so as to increase the yield and the selectivity of object reactant and to improve the properties of object product.

Owner:CHINA PETROLEUM & CHEM CORP +1

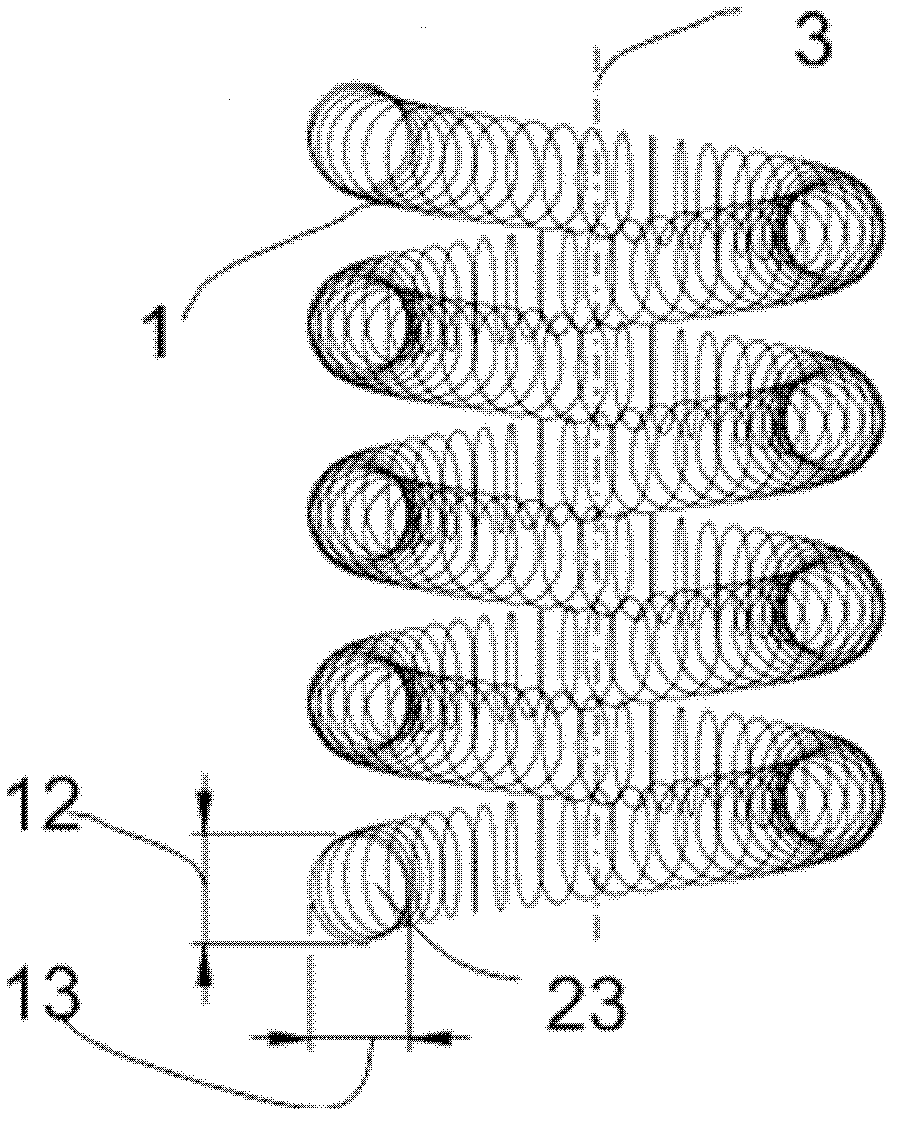

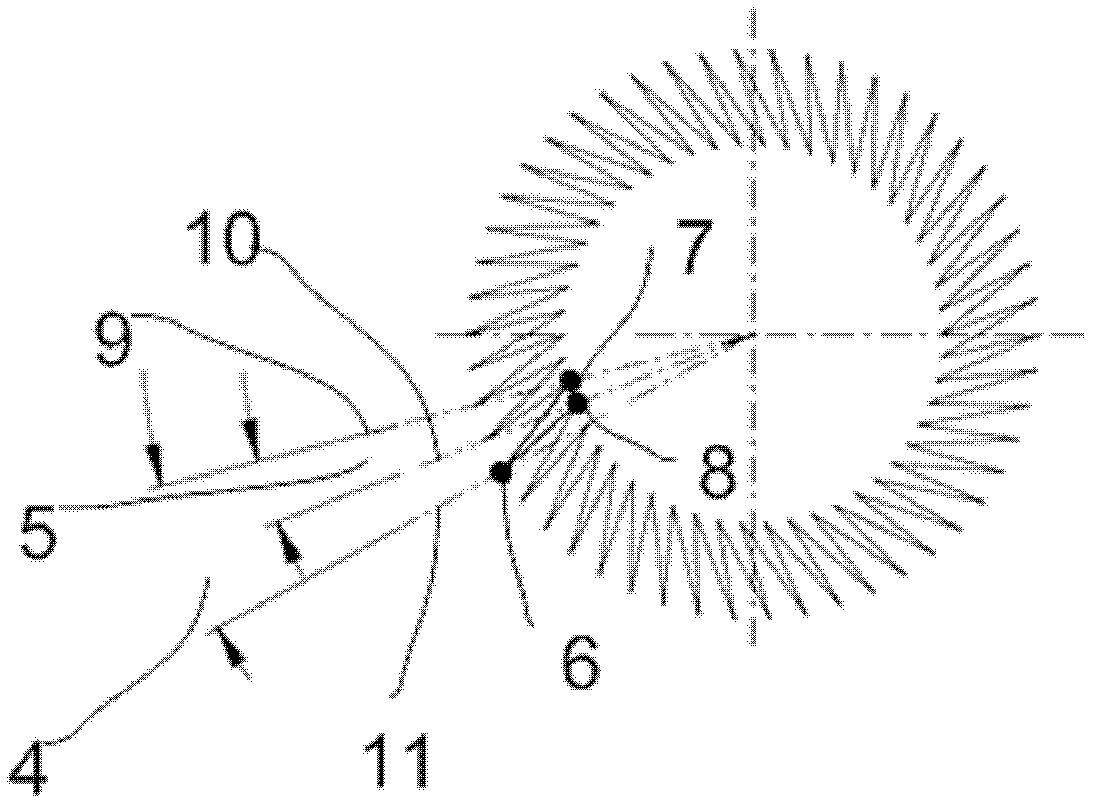

Spring contact finger, socket and socket system

InactiveCN102427180AIncrease the number of touchpointsExtended service lifeCoupling contact membersContact pressureEllipse

The embodiment of the invention discloses a spring contact finger, a socket and a socket system, wherein the spring contact finger comprises a spring wire; the spring wire is spirally coiled along an oblique elliptical track to form a unit ring; and multiple unit rings are bi-directionally spirally coiled along the axial line to form an oblique ellipse spring contact finger. The spring contact finger follows two spiral tracks, the unit ring of the spring contact finger is formed by coiling along the oblique elliptical track, and multiple unit rings are bi-directionally spirally coiled along the axial line track again to form an oblique ellipse bi-directional spring contact finger. When the contact finger receives contact pressure to generate stress and deformation, on the basis of guaranteeing reliable contact and slow stress, because the oblique ellipse bi-directional spring contact finger can provide multiple row-type contact points to combine with the contact points on the oblique ellipse of the unit ring, the number of the contact points between the socket and the spring contact finger are greatly increased, contact temperature rise is effectively reduced, the service life of the spring contact finger and the socket is prolonged, and accident probability is reduced.

Owner:深圳市簧中簧电子有限公司

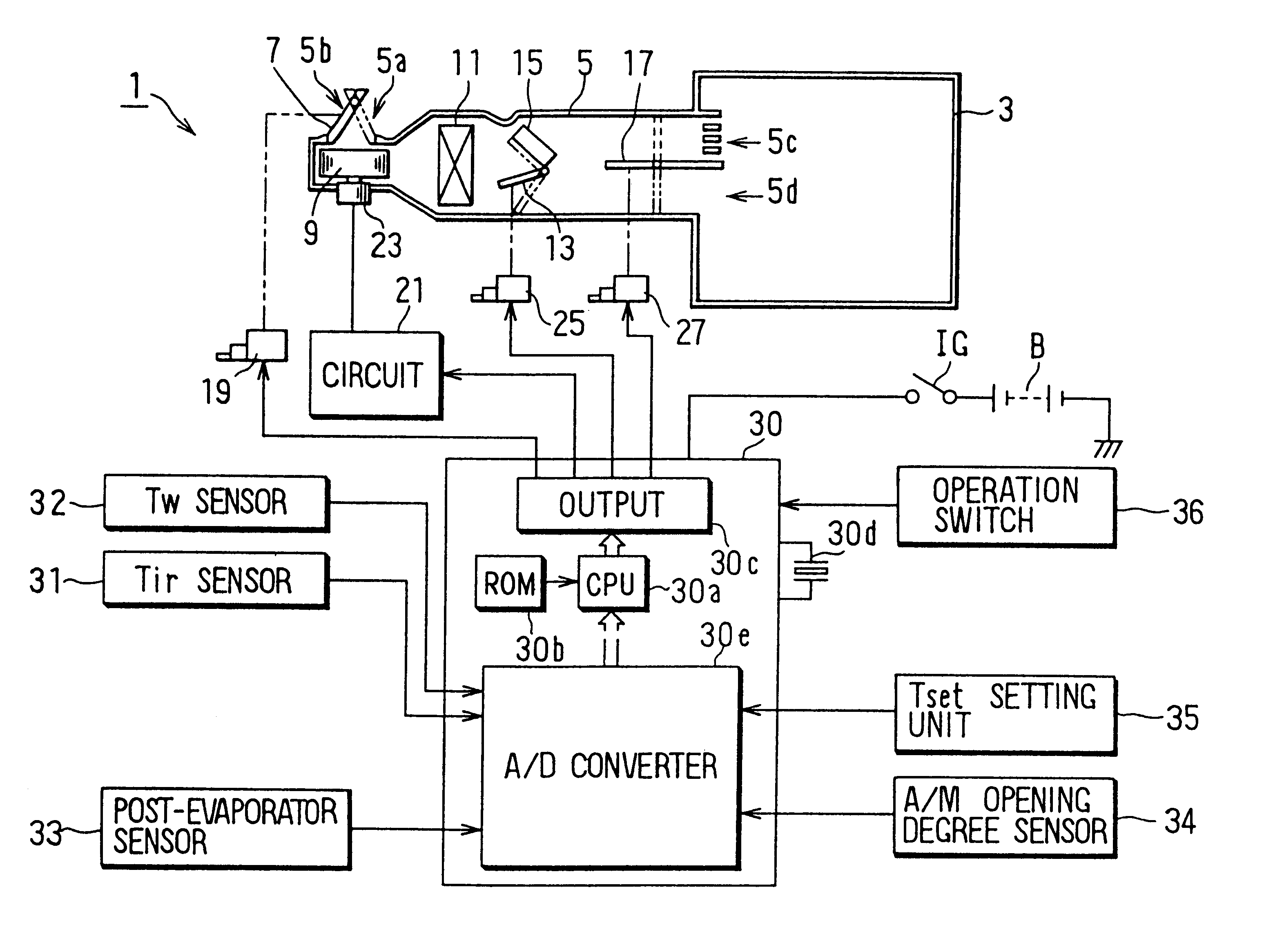

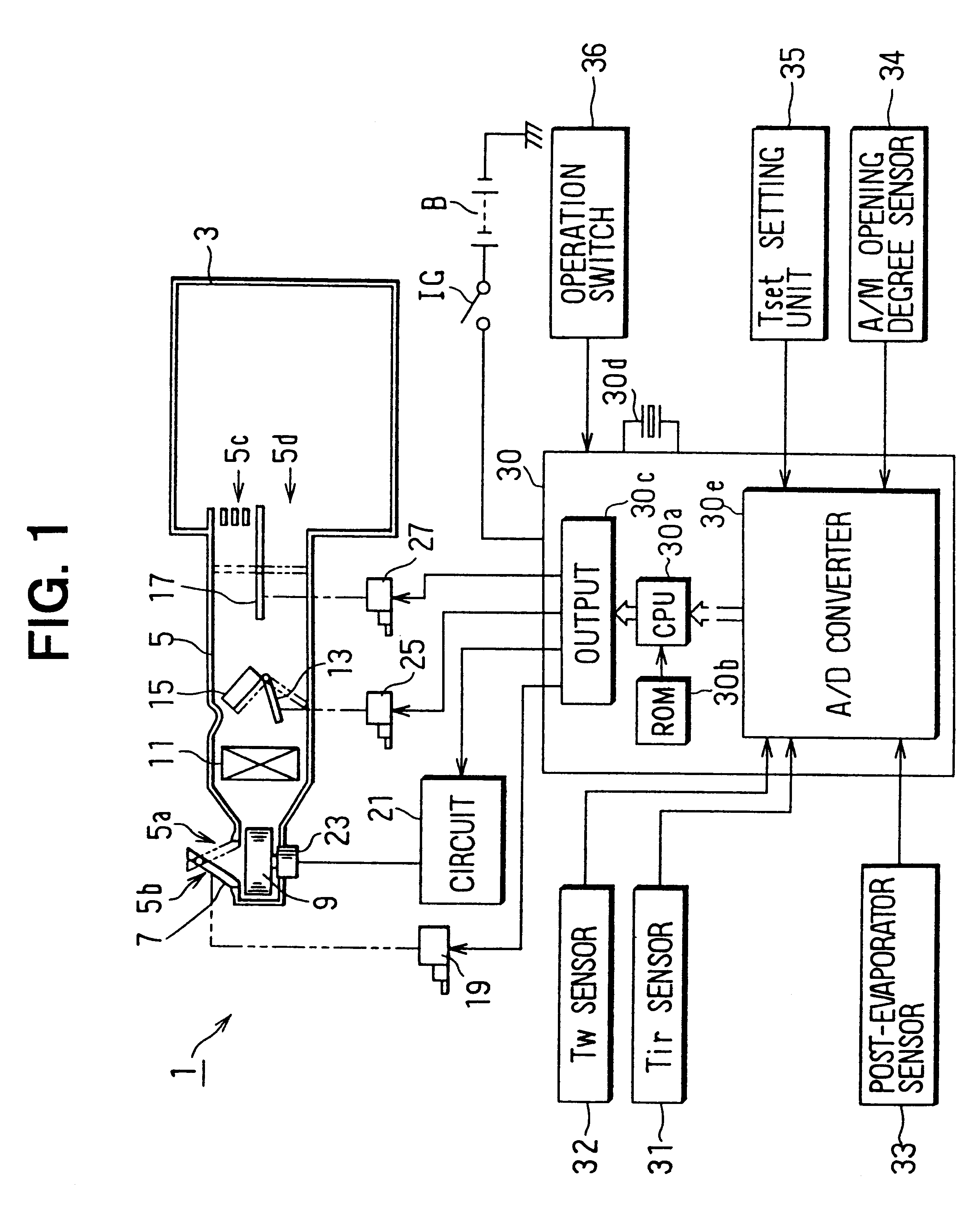

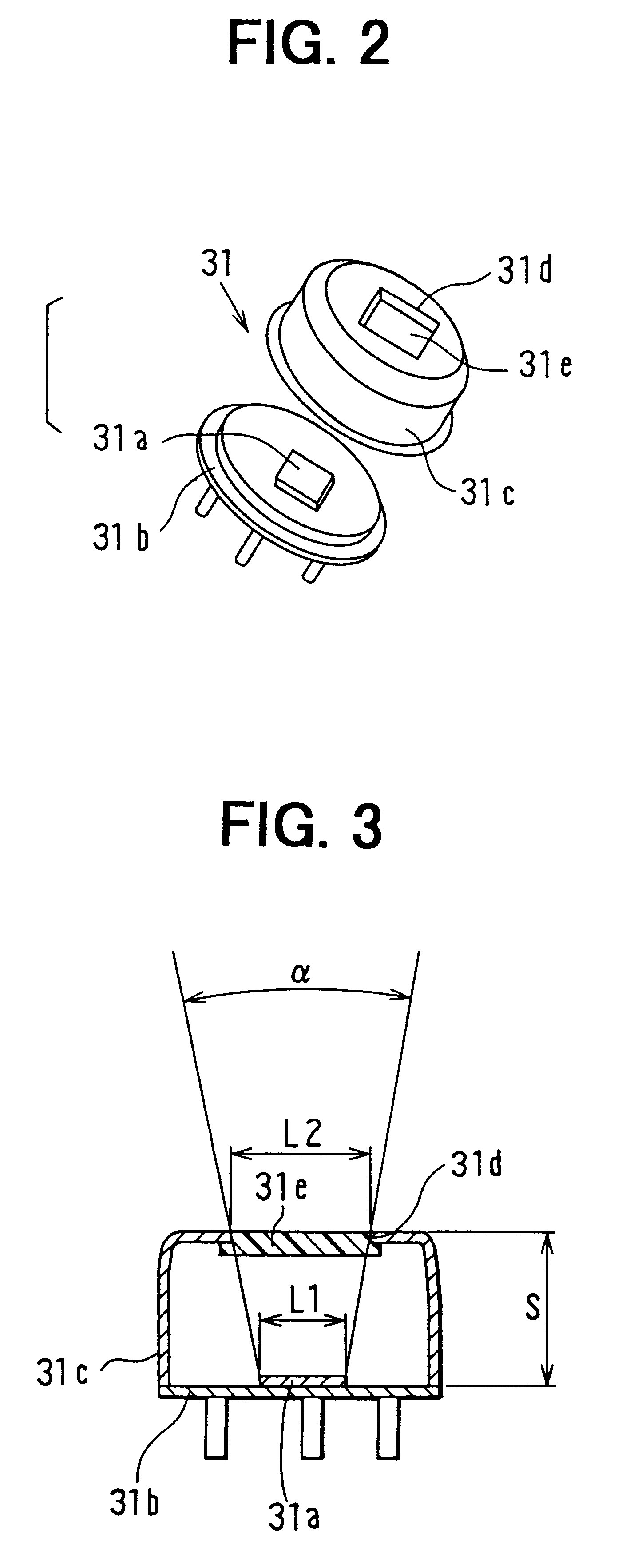

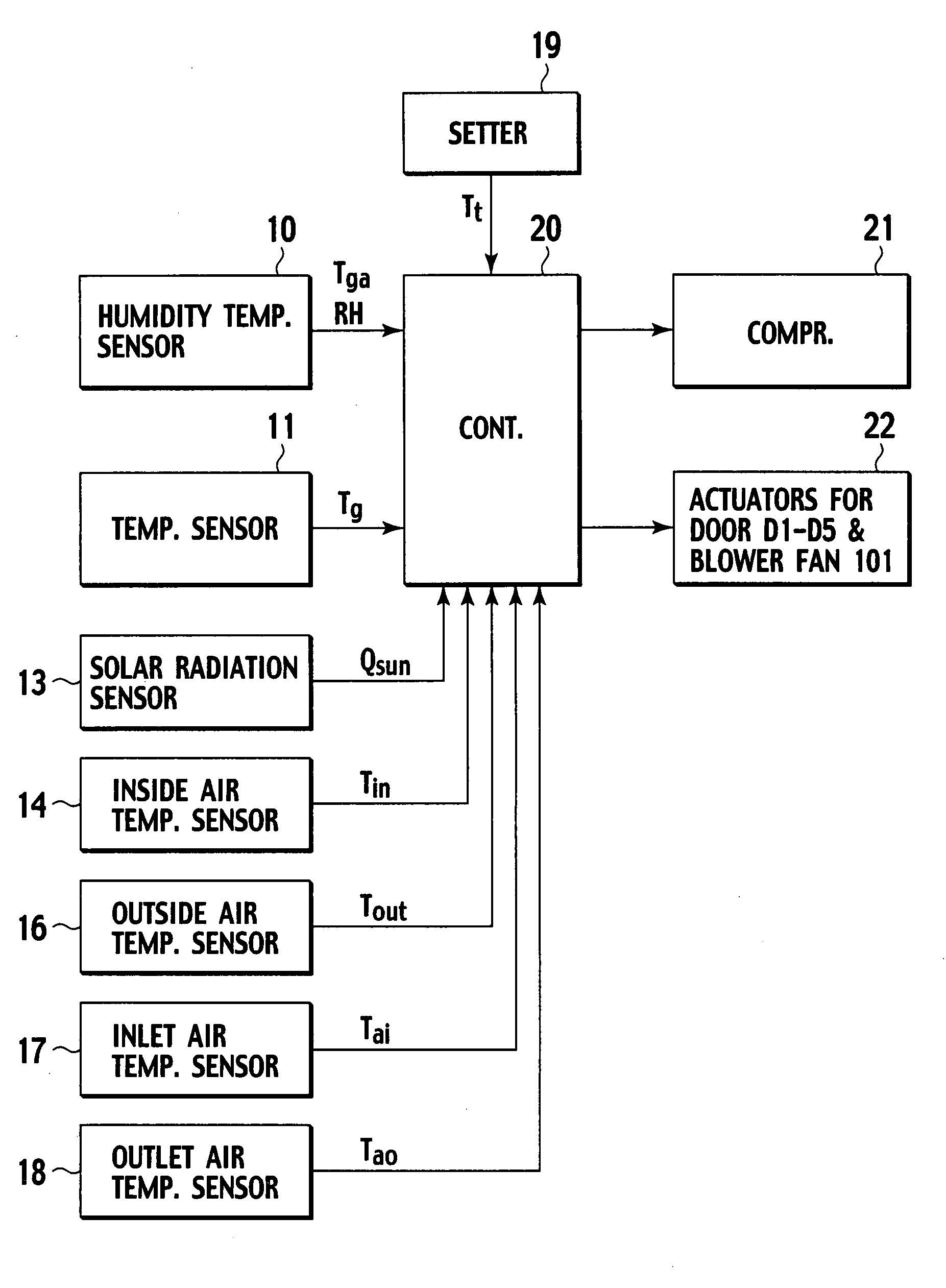

Vehicle air conditioner with non-contact temperature sensor

InactiveUS6397615B1Effectively using non-contact temperature sensorRadiation pyrometryAir-treating devicesEngineeringAir temperature

A vehicle air conditioner has a non-contact temperature sensor for detecting a surface temperature of a detection range of a passenger compartment. The detection range includes a first detection portion in which a surface temperature is changed to approximately correspond to an inside air temperature, a second detection portion in which a surface temperature is changed in accordance with an outside air temperature, and a third detection portion in which a surface temperature is changed in accordance with a sunlight amount entering the passenger compartment. In the vehicle air conditioner, a target temperature of air blown into the passenger compartment is calculated based on a set temperature and a surface temperature from the non-contact temperature sensor, while air-conditioning performance is improved.

Owner:DENSO CORP

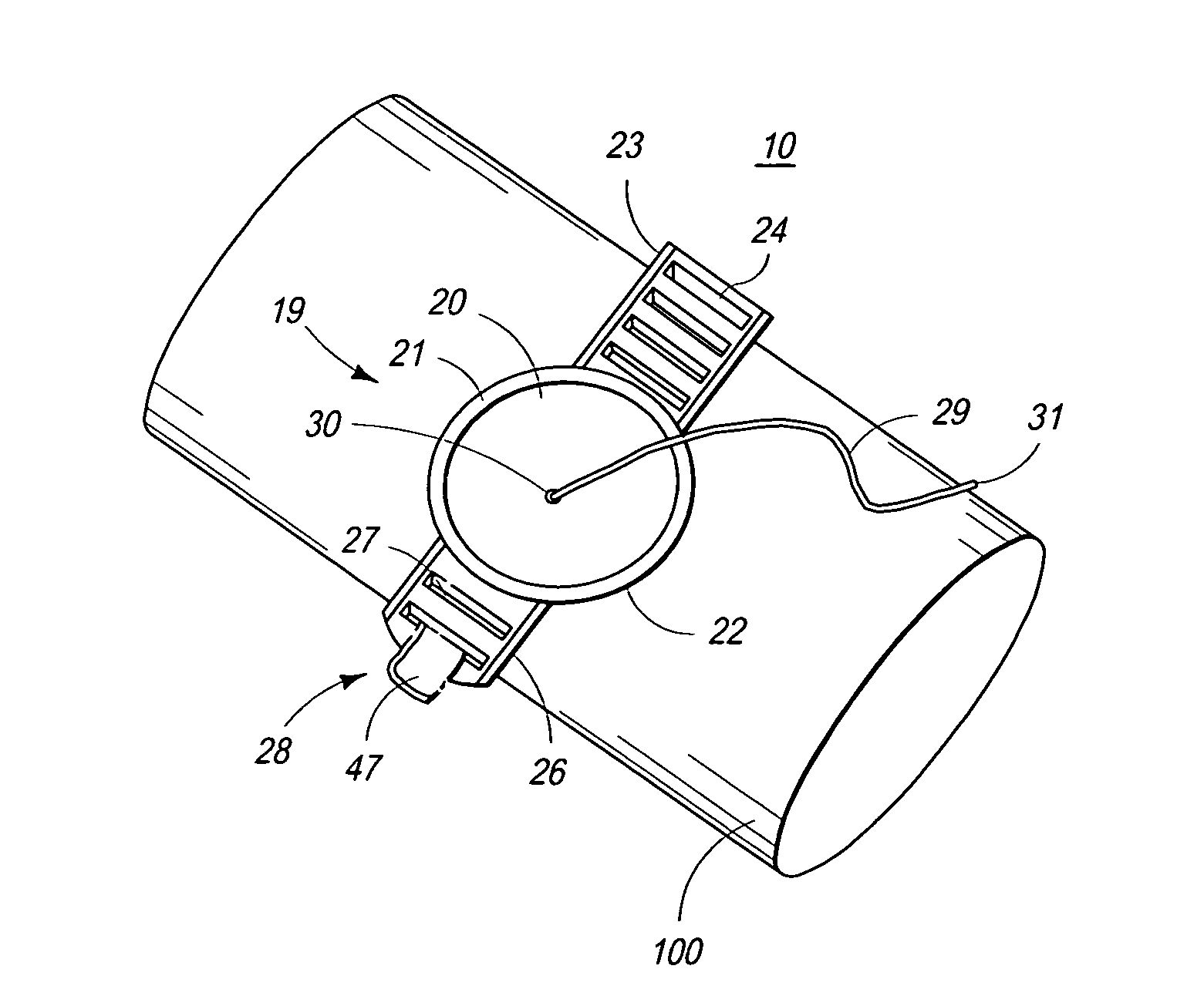

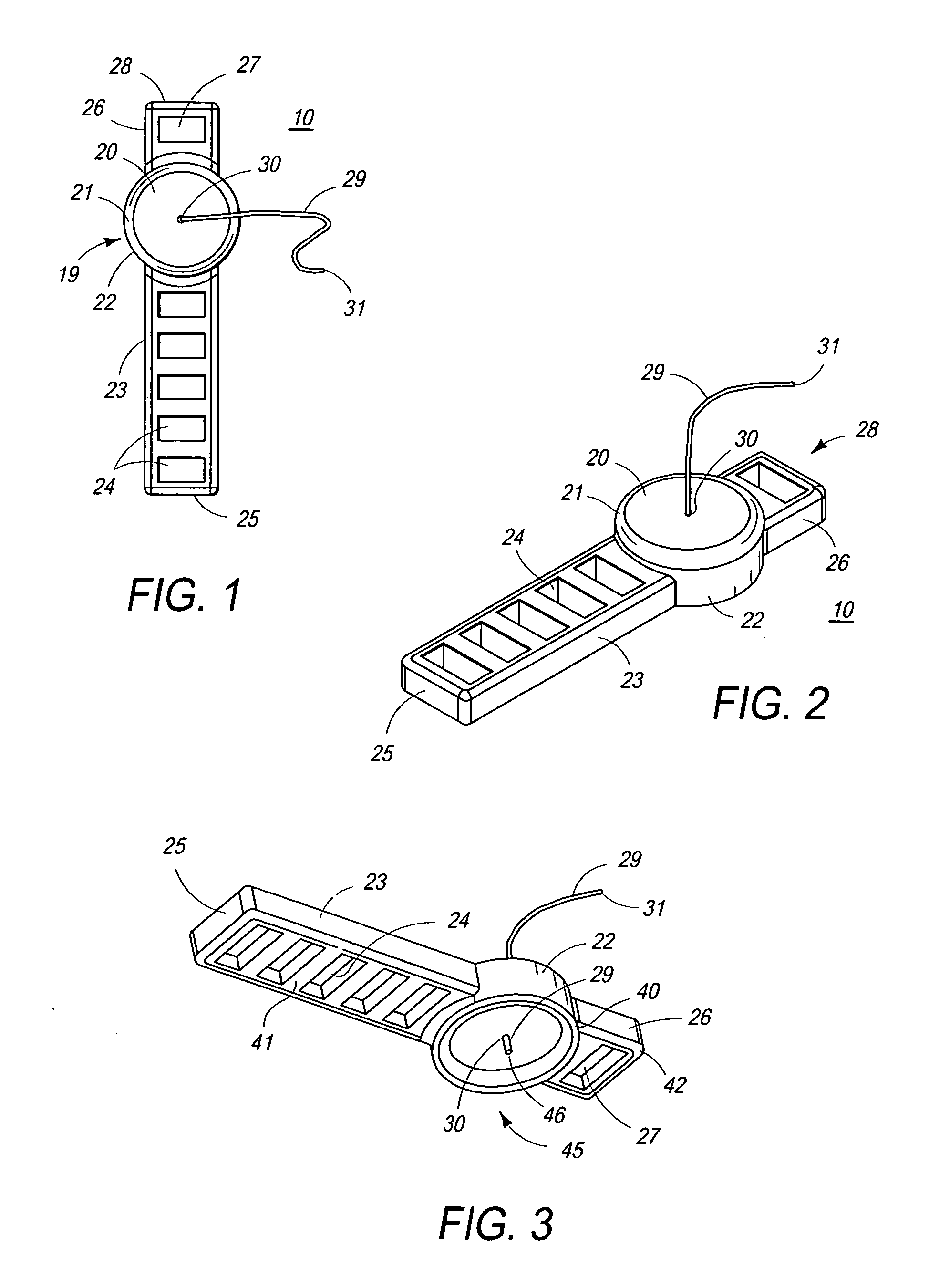

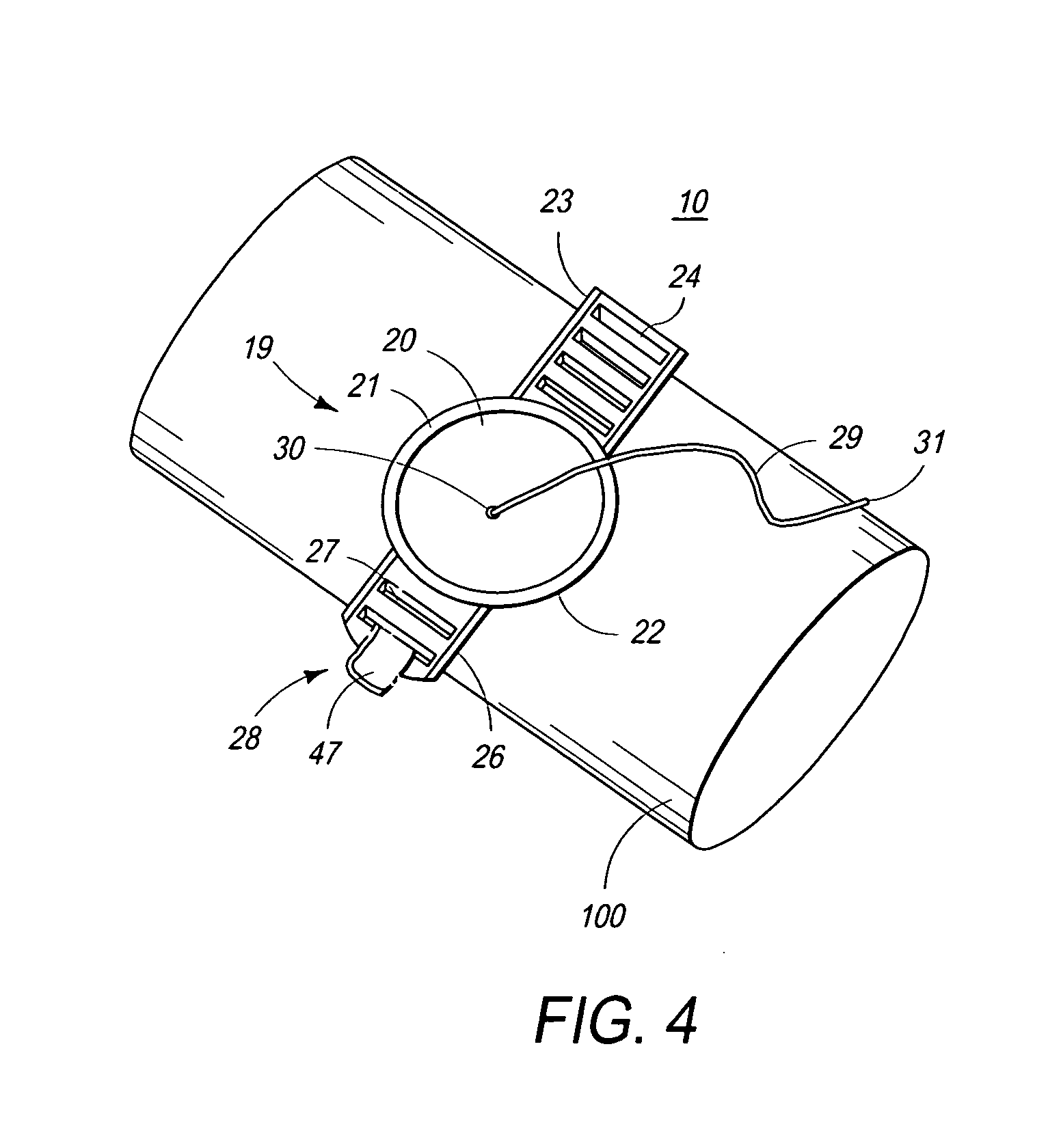

Line & pipe flexible temperature sensor assembly

InactiveUS20140161151A1Low profileAvoid flowThermometer detailsTemperature measurement of flowing materialsLine tubingBiomedical engineering

A temperature sensor assembly is disclosed, formed of flexible, resilient, and insulative material, so that a contact temperature sensor, situated in a housing and connected to an electrical meter, may be affixed temporarily or permanently to a (generally) cylindrical tube, pipe, or other “line,” the distal ends of the housing straps stretched and tensioned to press the housing and contact temperature sensor on to the exterior of such fluid line to keep the housing in the correct position on the fluid line, and the distal ends of the straps joined to secure the assembly to the fluid line, so that the temperature on the exterior of the fluid line, and the temperature of the fluid therewithin, may thereby be measured.

Owner:PROCTOR ENG GRP

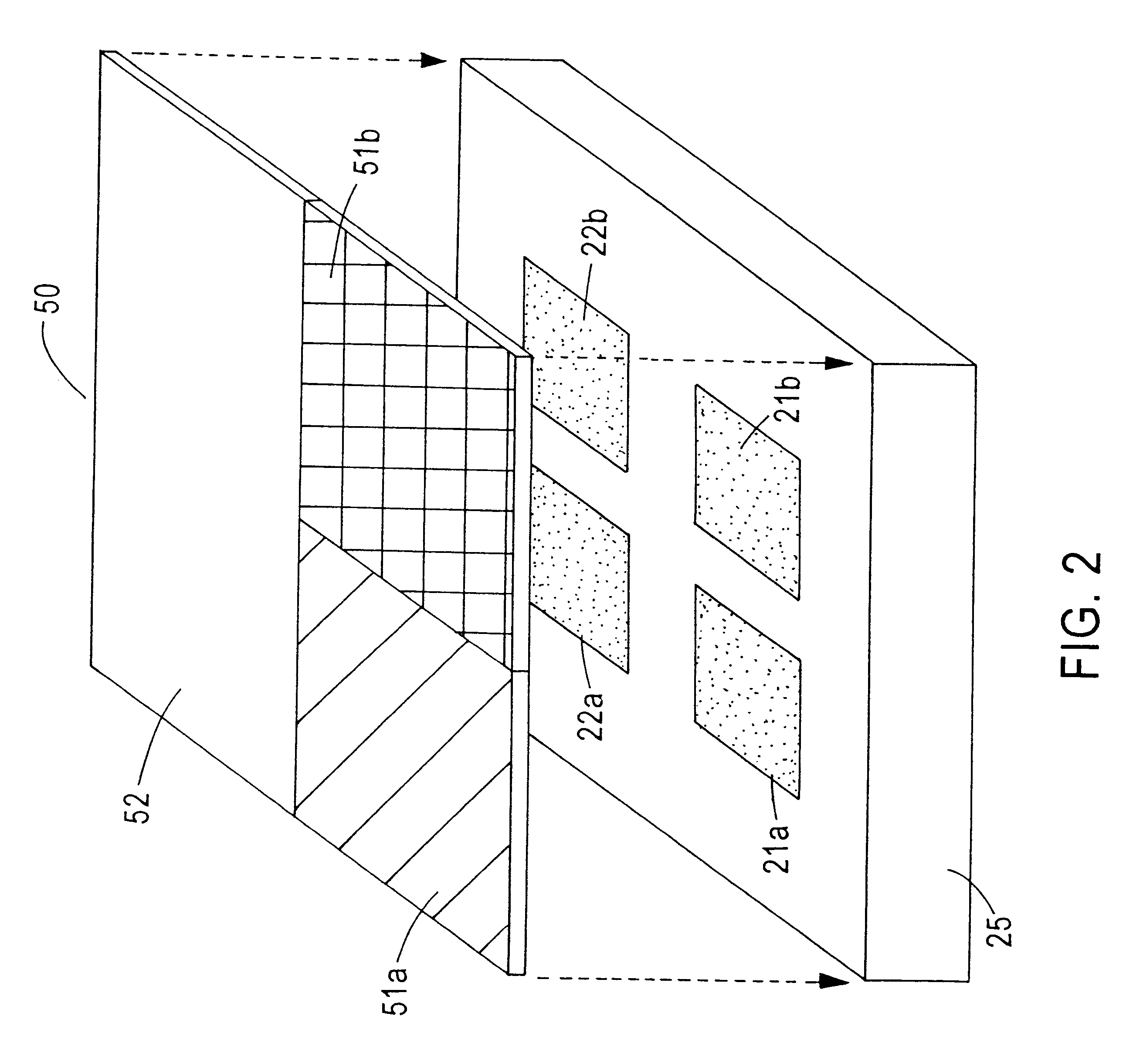

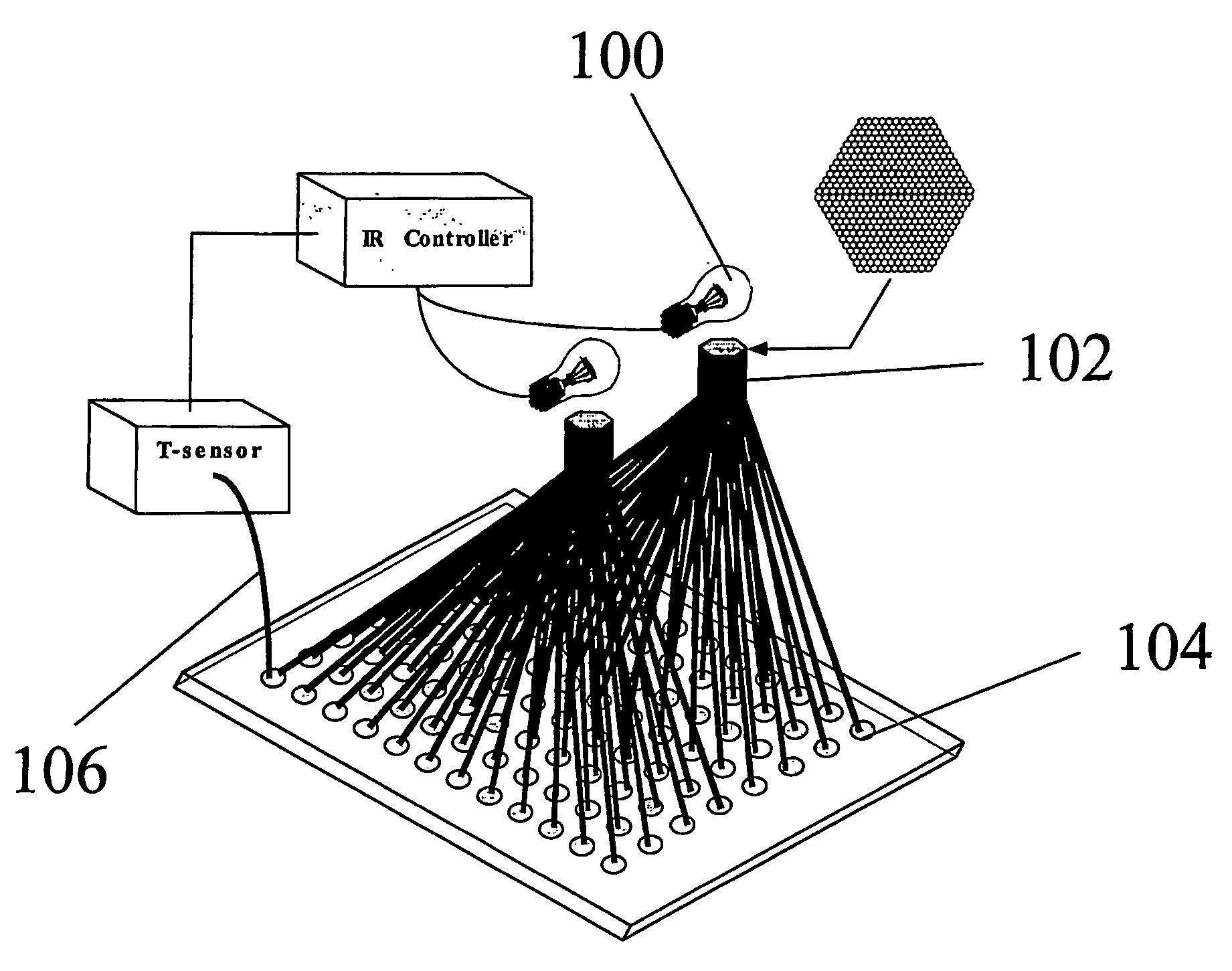

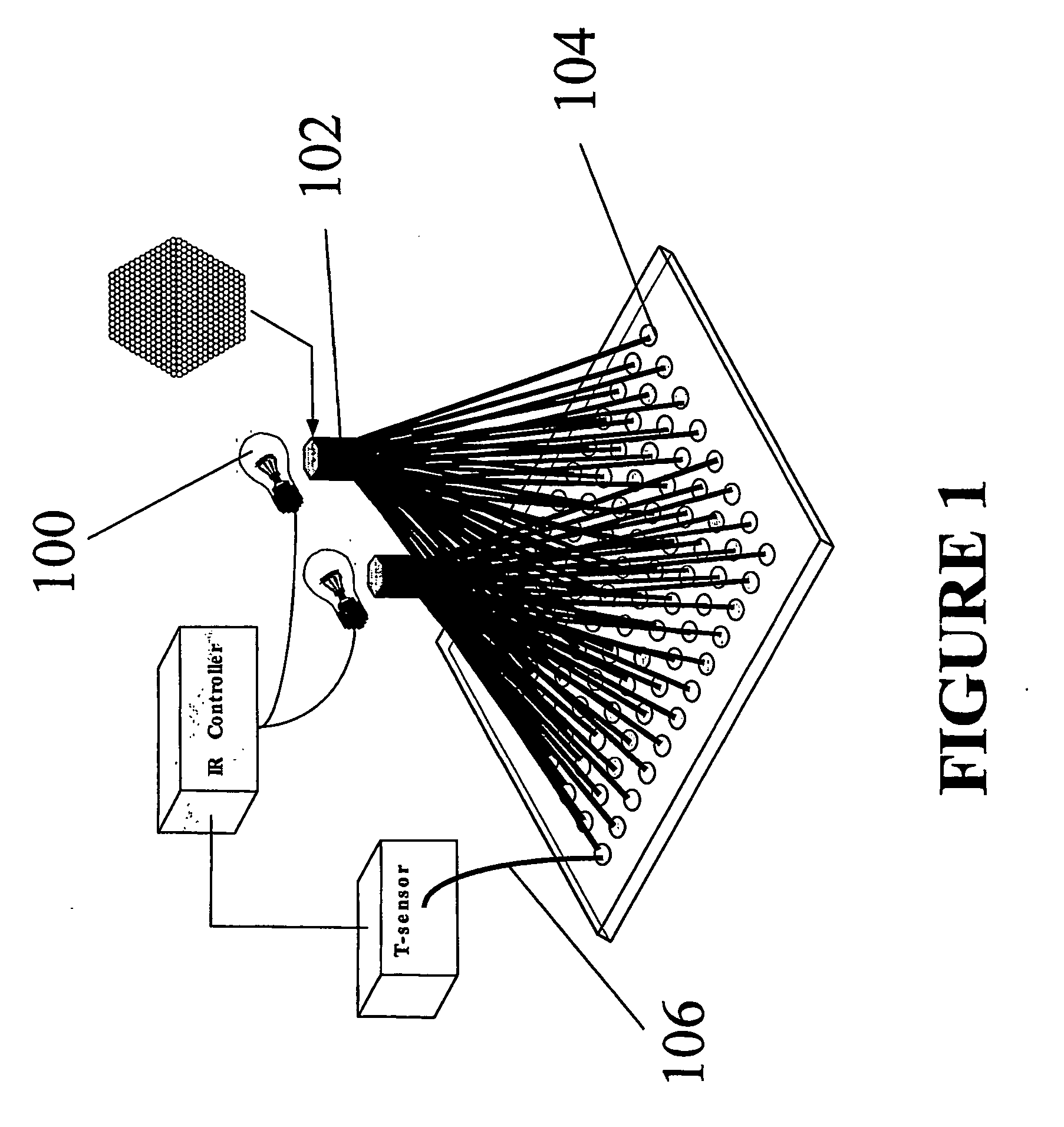

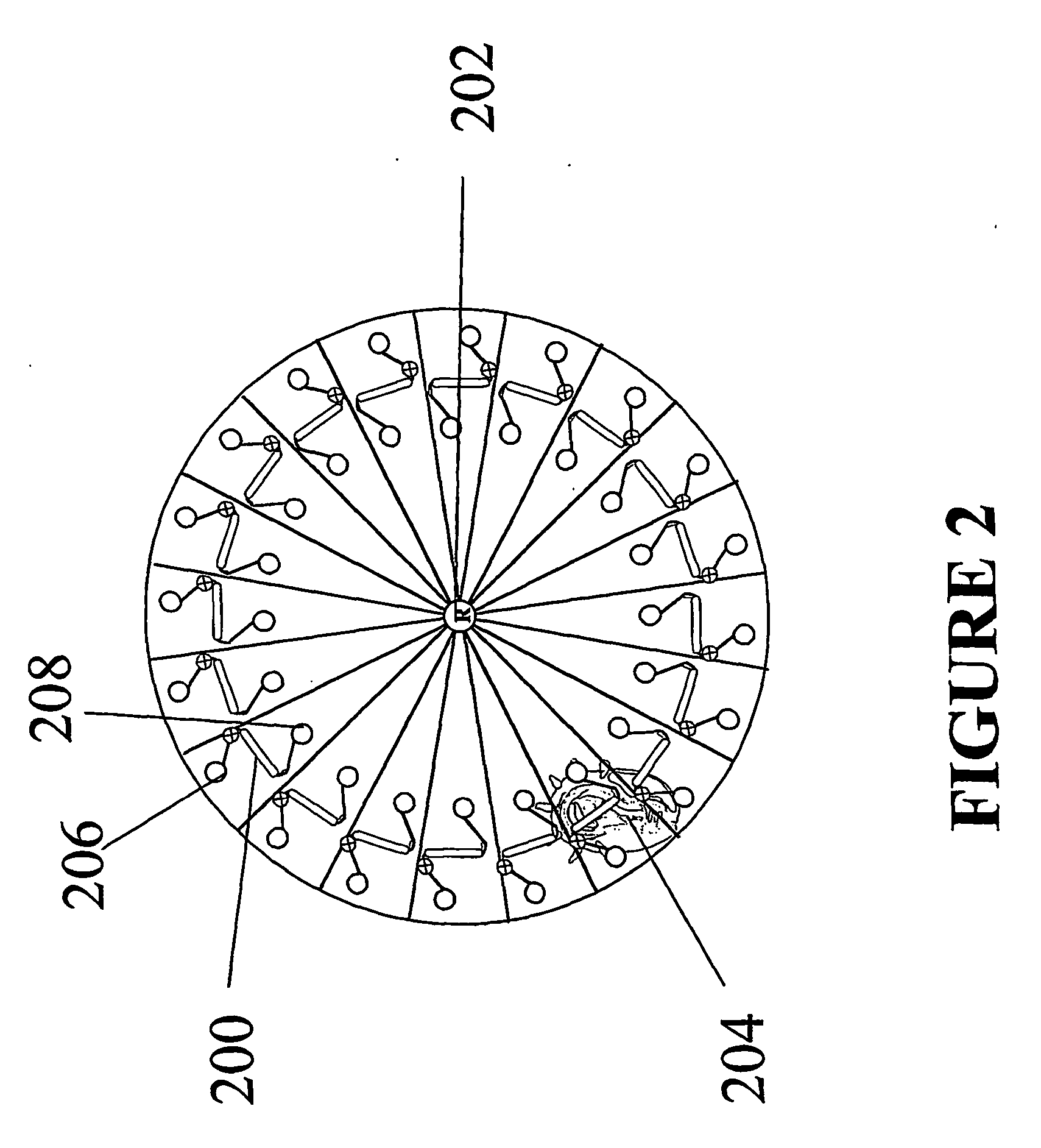

Methods and systems for multiplexing ir-mediated heating on a microchip

InactiveUS20050287661A1Increase speedAvoid heatBioreactor/fermenter combinationsBiological substance pretreatmentsFiberMultiplexing

The present invention relates to methods and systems for rapid multiplexed heating of a plurality of small volume samples on a microchip. More specifically, the present invention relates to methods and systems for non-contact temperature cycling of the samples using infrared (IR)-mediated heating of small, micro to nanoliter, volume samples, wherein each cycle can be completed in as little as a few seconds. Depending on the system used, the present invention involves a spinning microchip or an immobile microchip having a plurality of micro-heating areas thereon. In the case of the spinning chip, the micro-heating areas are located in a circular configuration on the chip, so the micro-heating areas can be accessed by static heating source(s) by spinning the microchip. In case of the immobile microchip, fiber optics are used to direct radiation from a heating source or multiple heating sources directly to the micro-heating areas on a microchip.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

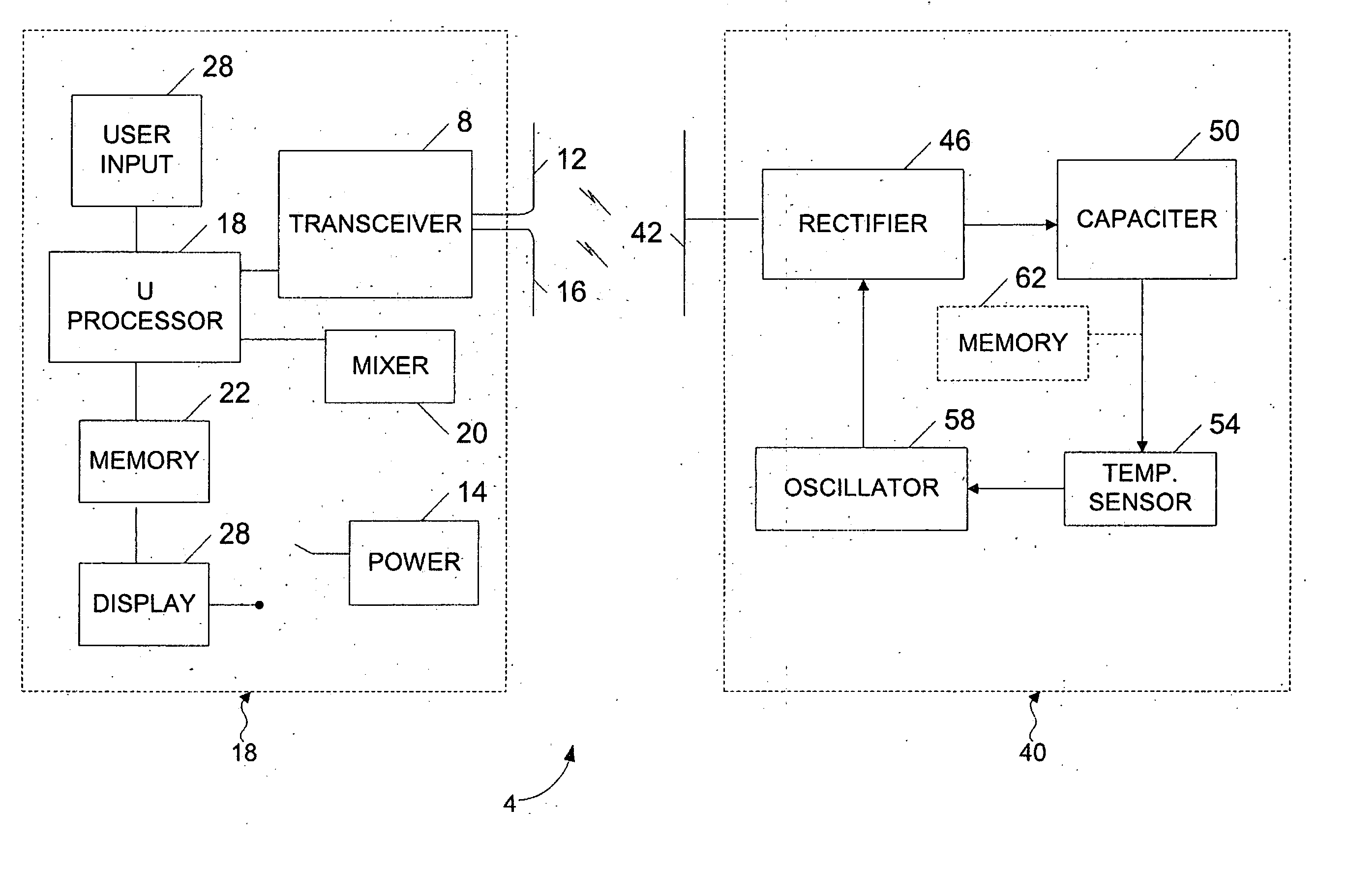

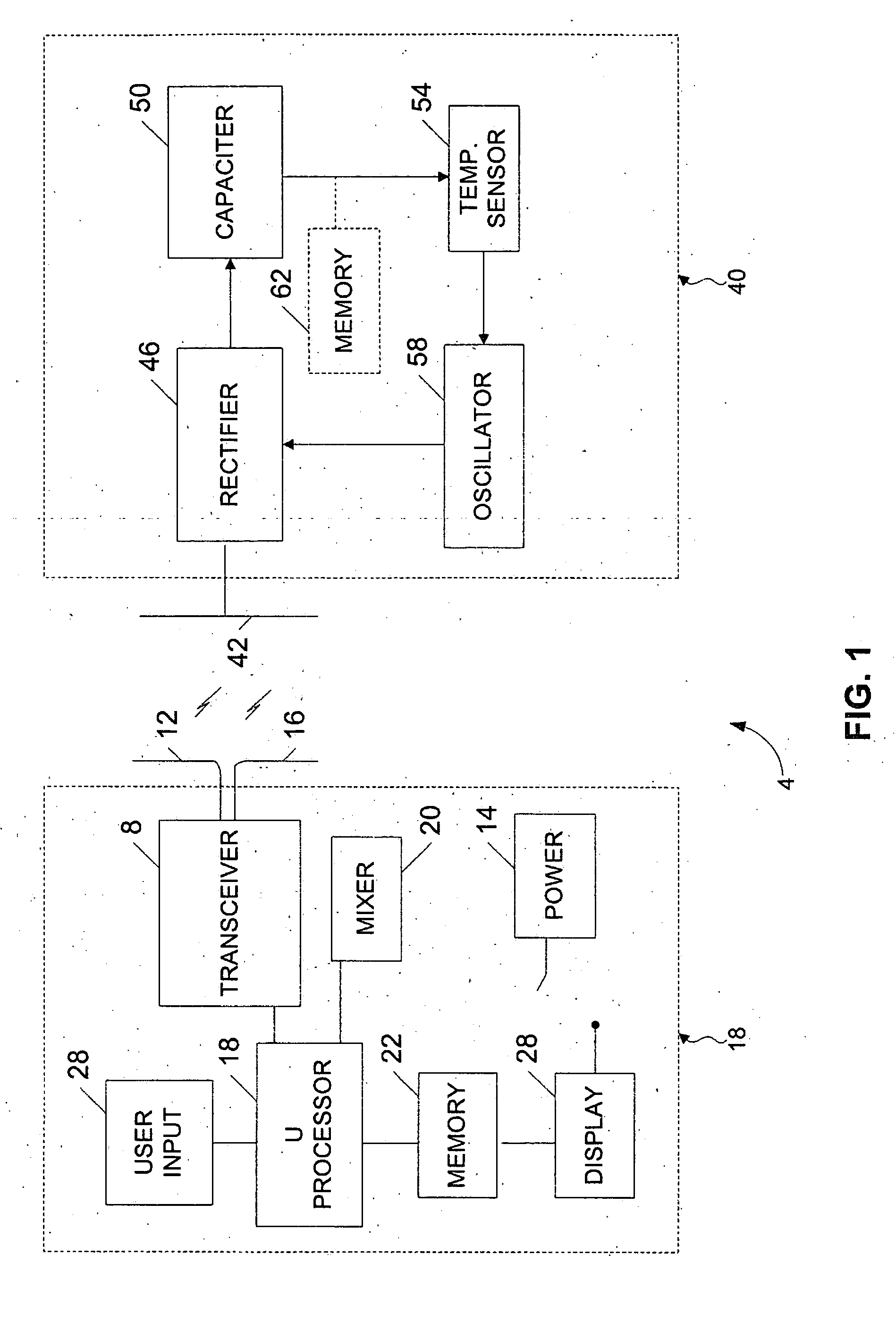

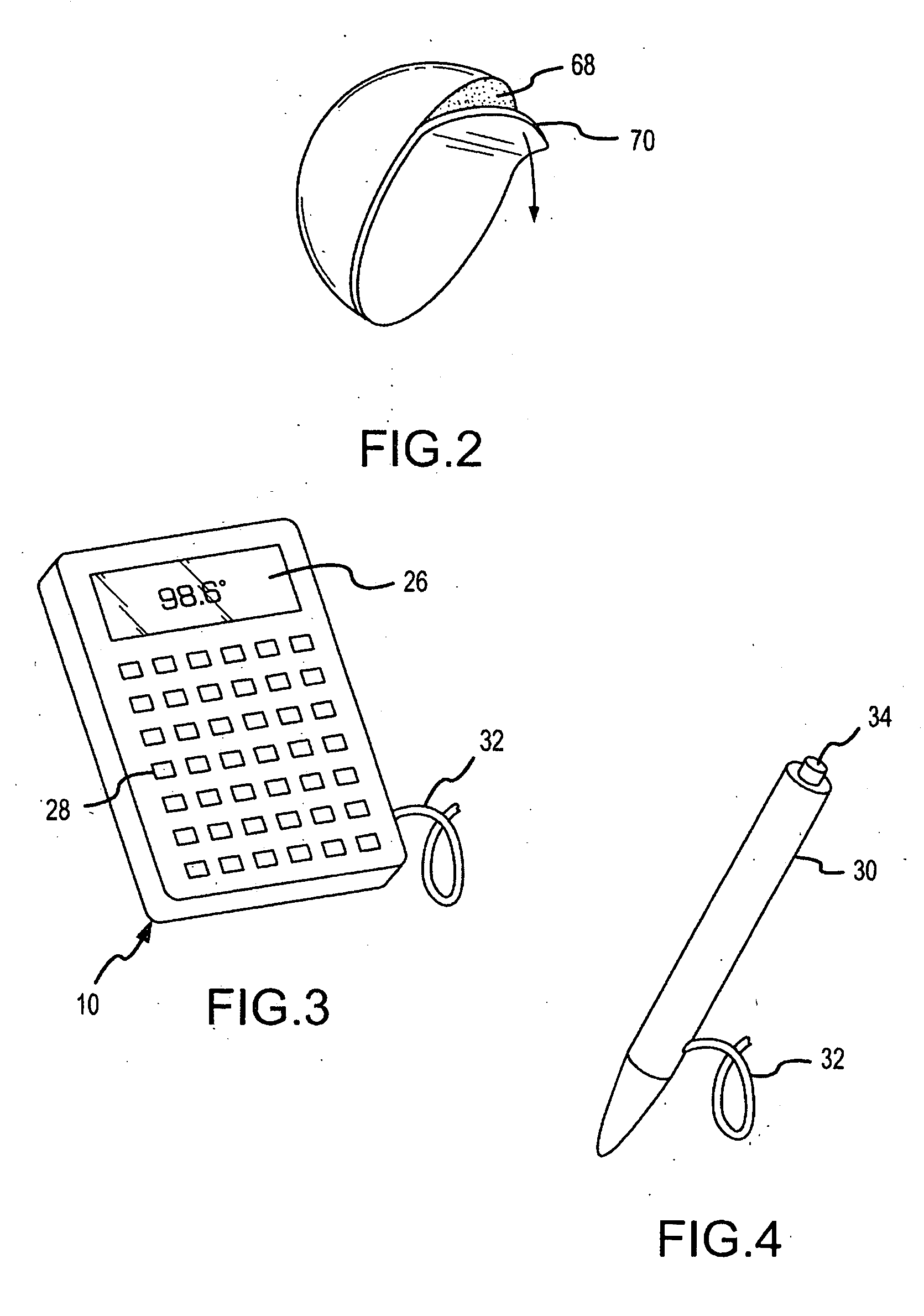

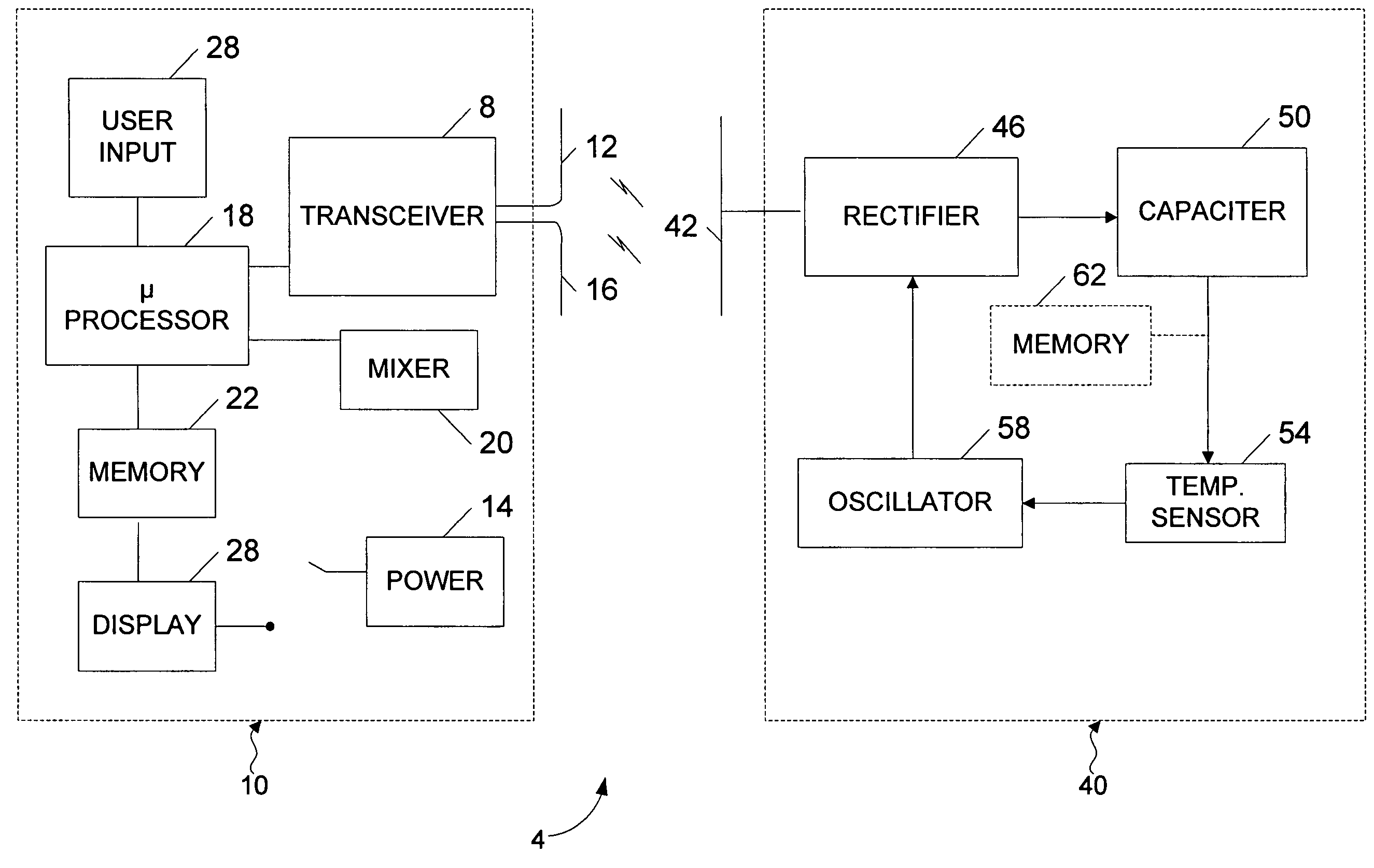

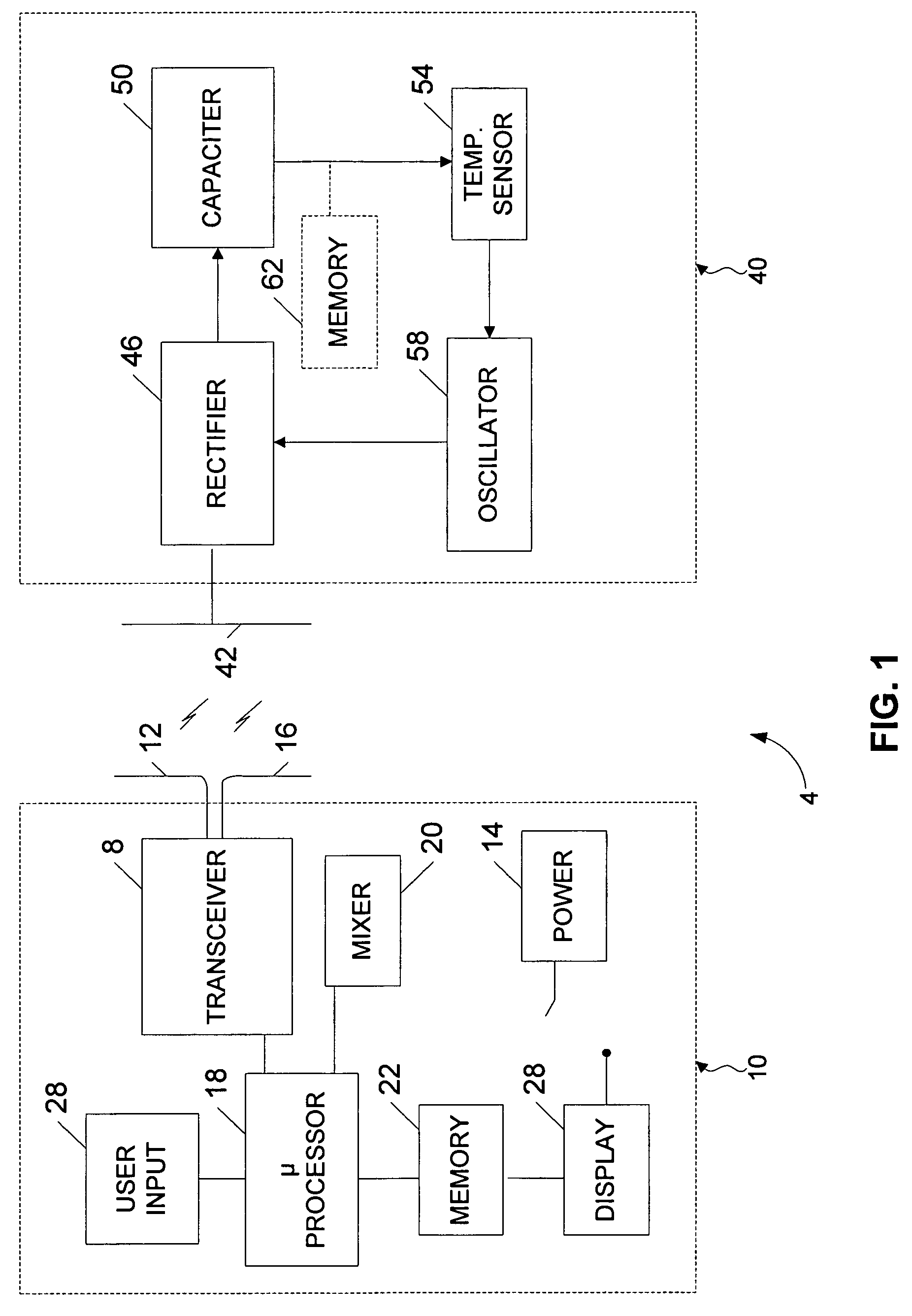

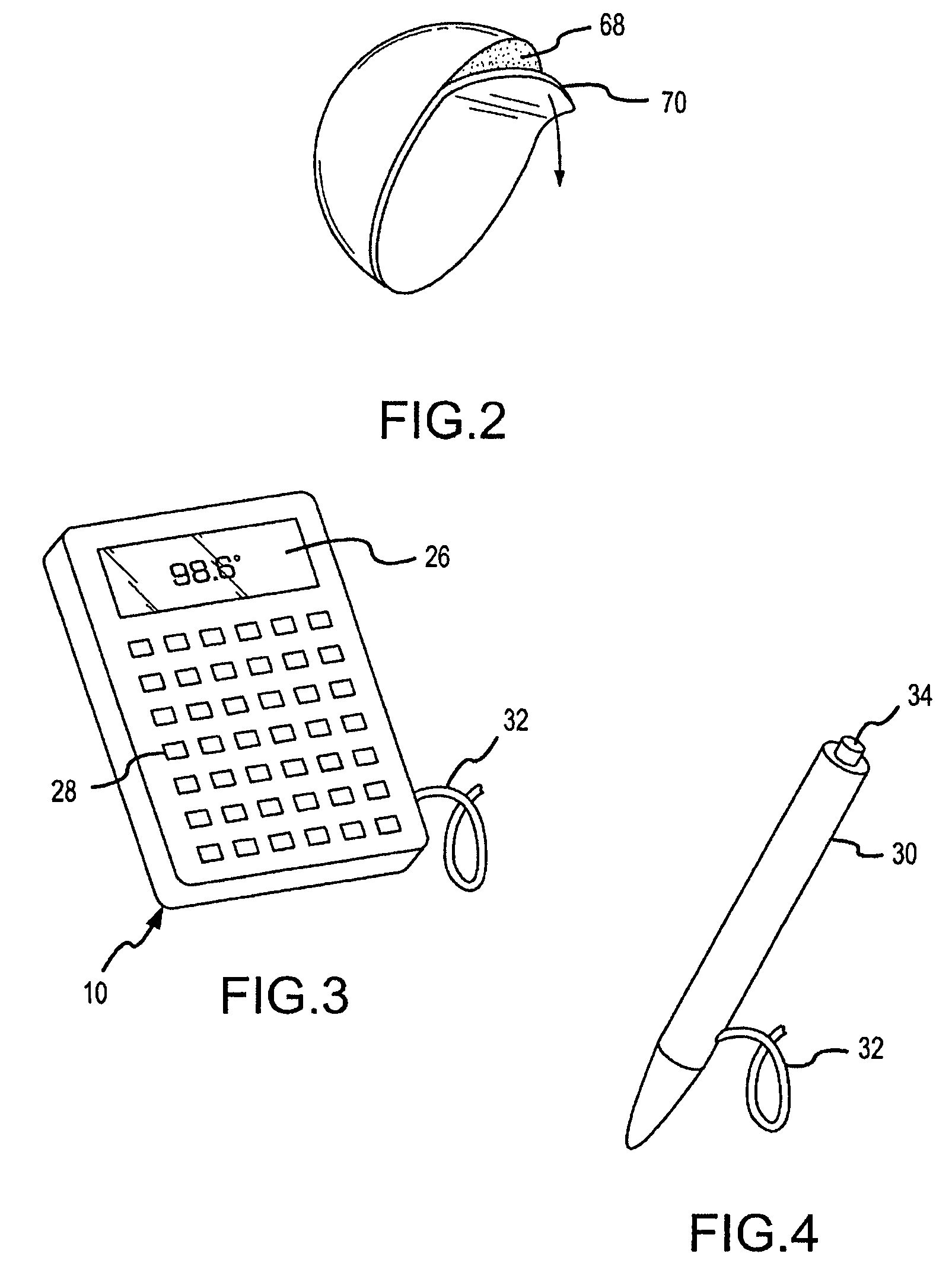

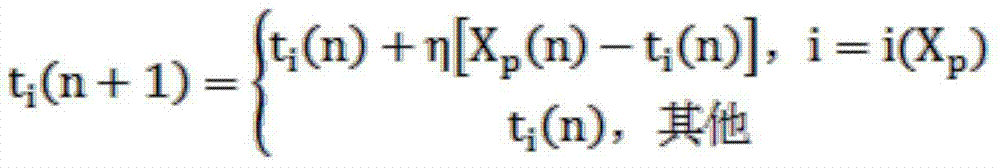

Non-contact patient temperature measurement

ActiveUS20050070811A1Increased complexityIncrease costThermometer detailsElectric signal transmission systemsBody temperature measurementAir interface

A method and system are provided for allowing non-contact temperature measurement of an animate body. More particularly, a transponder sensor device attached to an animate body is utilized to non-intrusively measure a temperature of the animate body in response to an interrogation signal transmitted over an air interface from a portable probe. In one embodiment, the sensor device is a passive device that is operative to collect energy from an interrogation signal emitted from the probe. In this regard, the sensor device does not require an internal power source. The collected energy is utilized to measure the temperature of the animate body and transmit a response signal containing temperature information back to the probe over the air interface.

Owner:DATEX OHMEDA

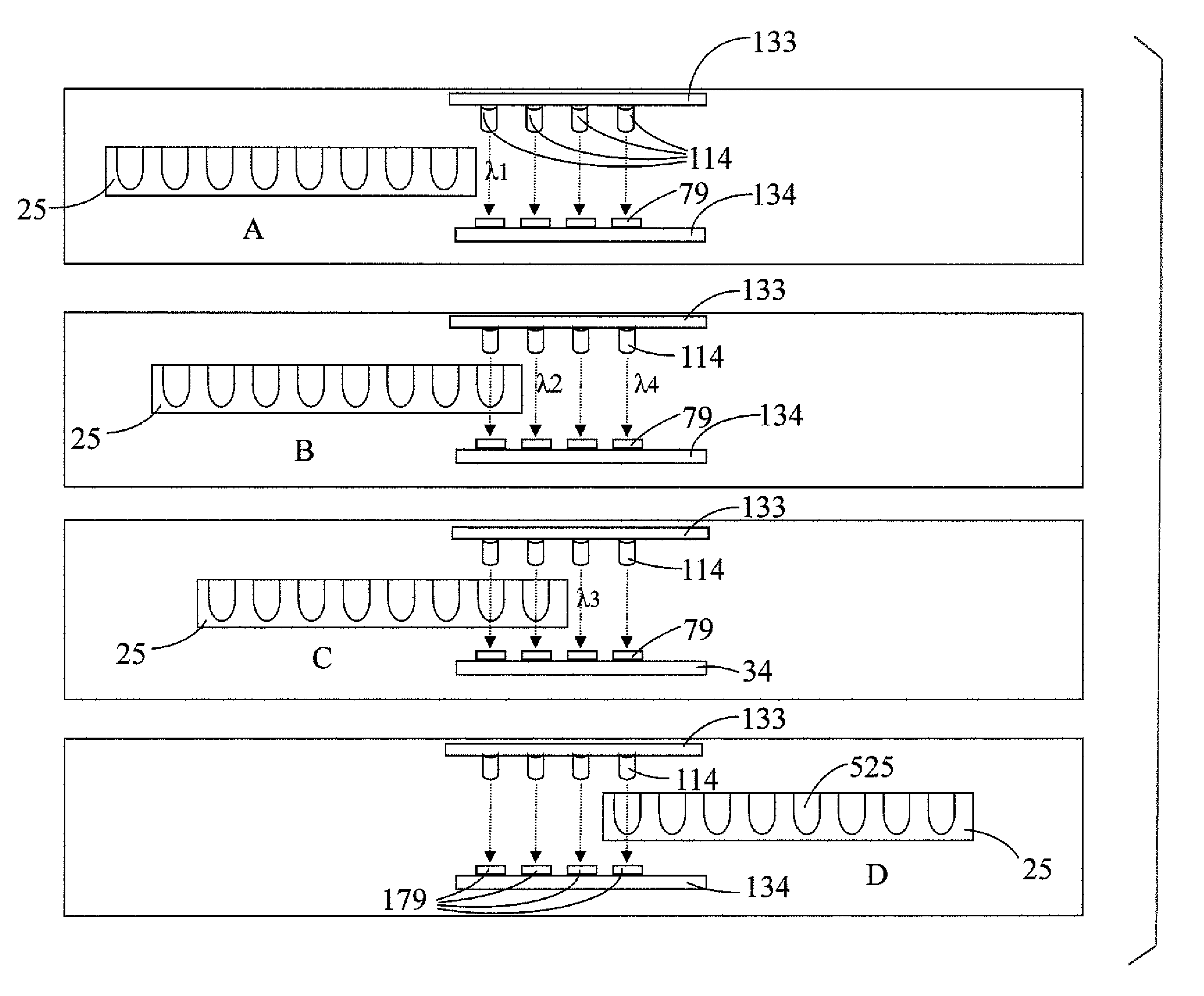

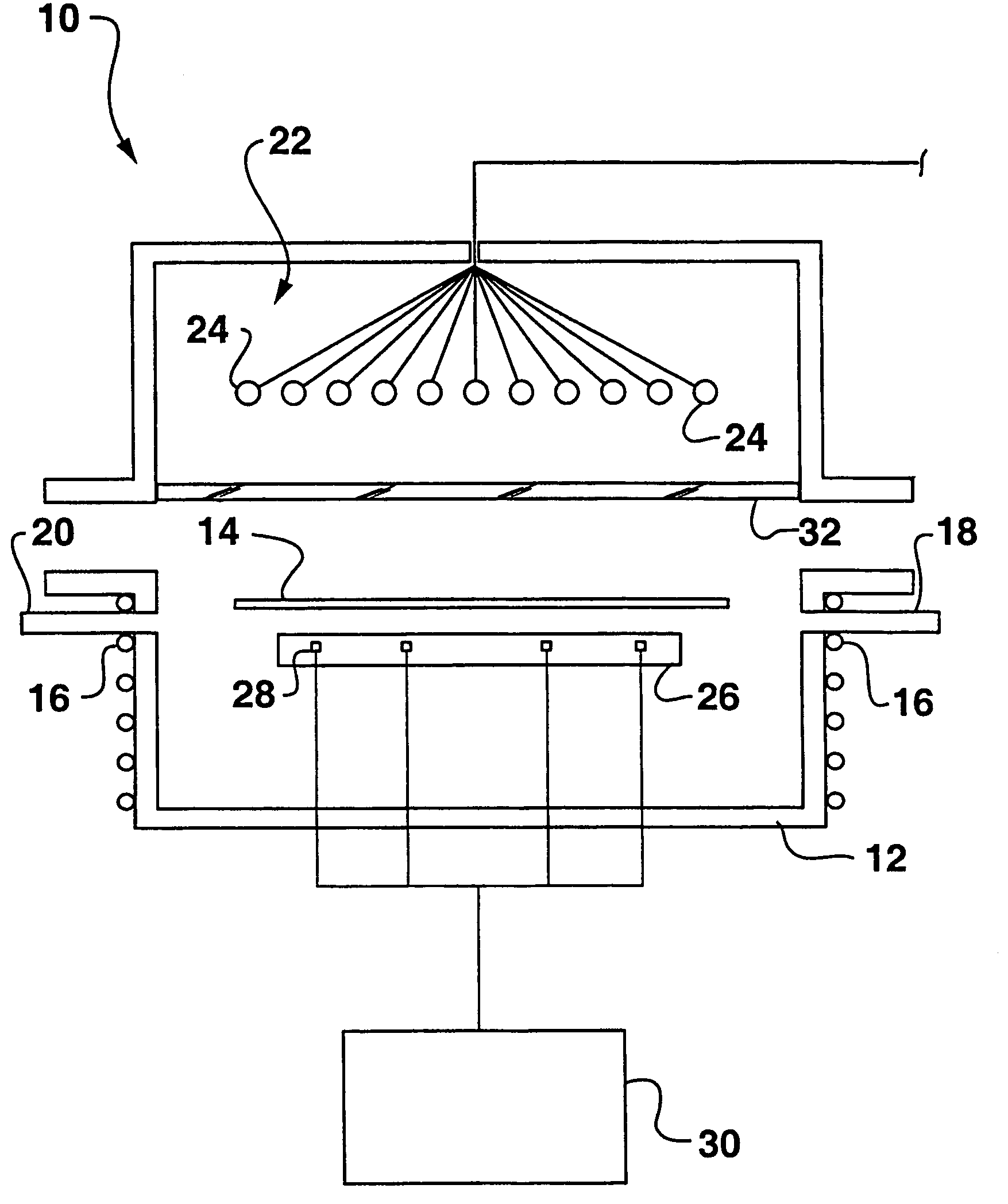

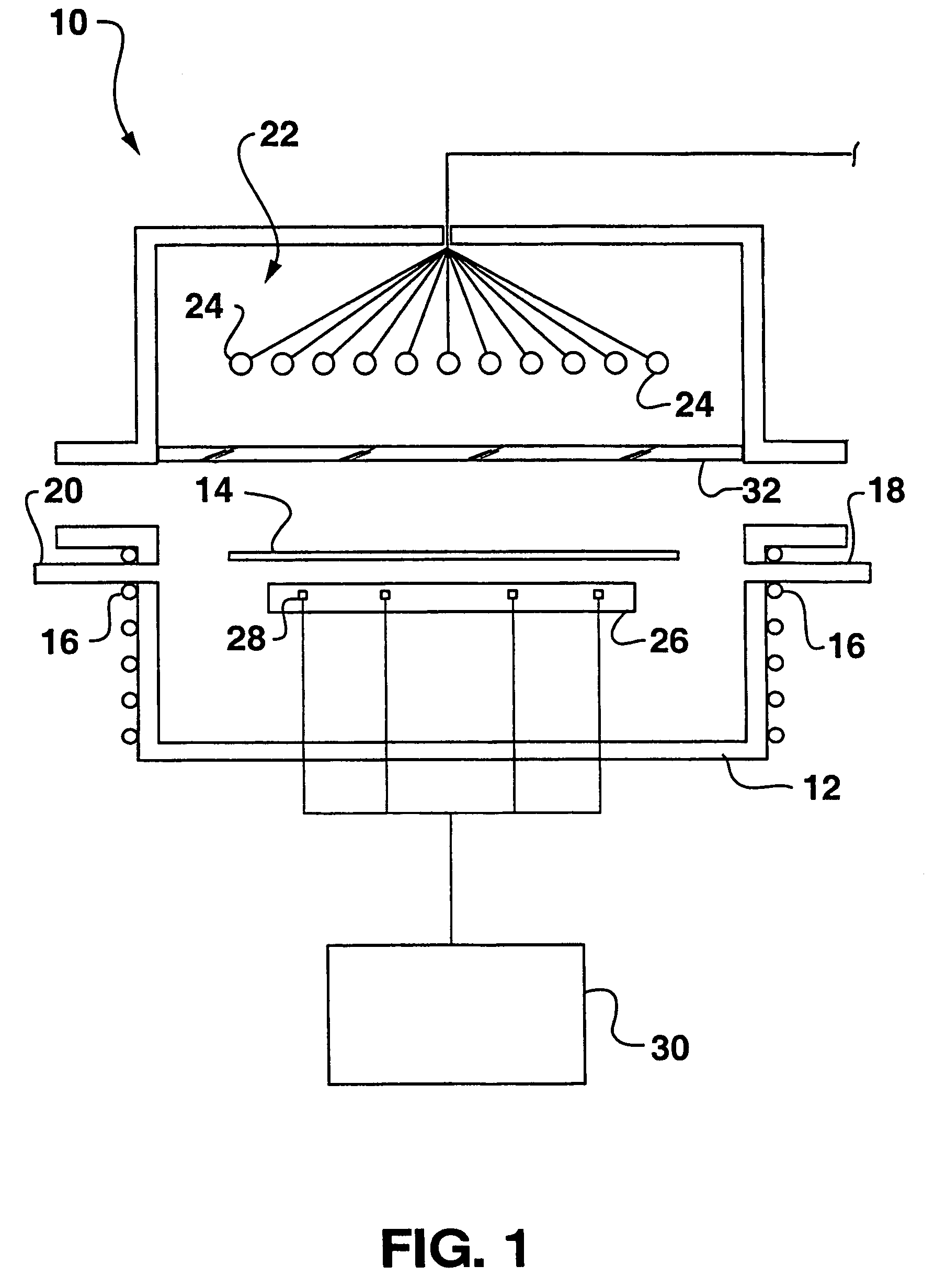

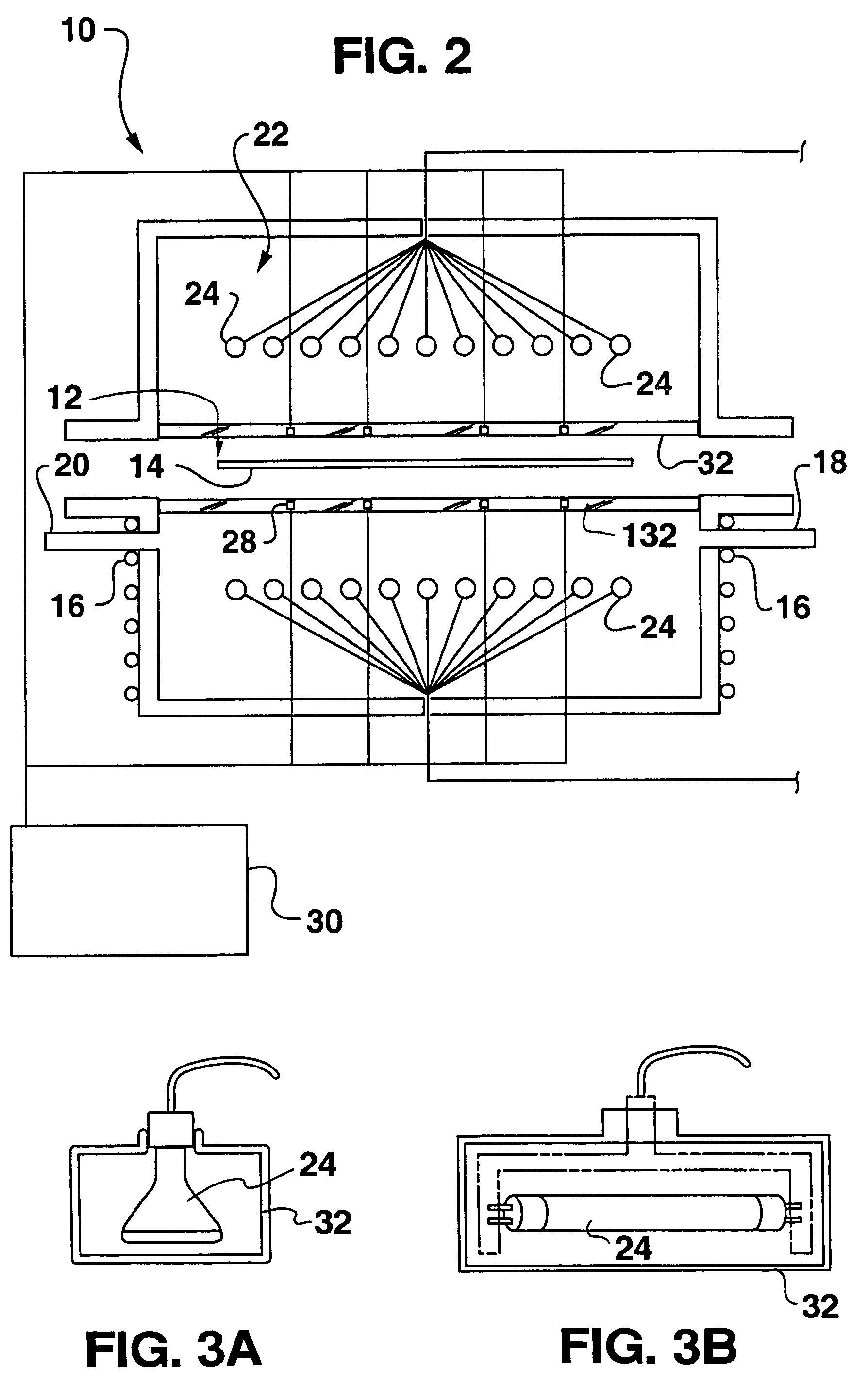

Compact multi-wavelength optical reader and method of acquiring optical data on clustered assay samples using differing-wavelength light sources

ActiveUS7733488B1Color/spectral properties measurementsColor measuring using electric radiation detectorsData acquisitionLength wave

An optical reader having an array of differing-color light sources and a controller for controlling the light sources and acquisition of optical data. The light sources are arranged, and the controller is configured, to allow rapid acquisition of optical data regarding individual sample wells of a cluster of such wells. In some embodiments, multiple ones of the differing-color light sources are illuminated simultaneously for acquiring optical data on a corresponding number of sample wells. Depending on the configuration of the array and number of differing-color light sources illuminated simultaneously, the optical reader can acquire optical data for several wavelengths in a fraction of the time of conventional optical readers. Other embodiments include one or more non-contact temperature sensors for acquiring temperature data substantially simultaneously with the optical data. The temperature data can be used, for example, to adjust the optical data or warn a user of out-of-specification temperature conditions.

Owner:REVOLUTION OPTICS

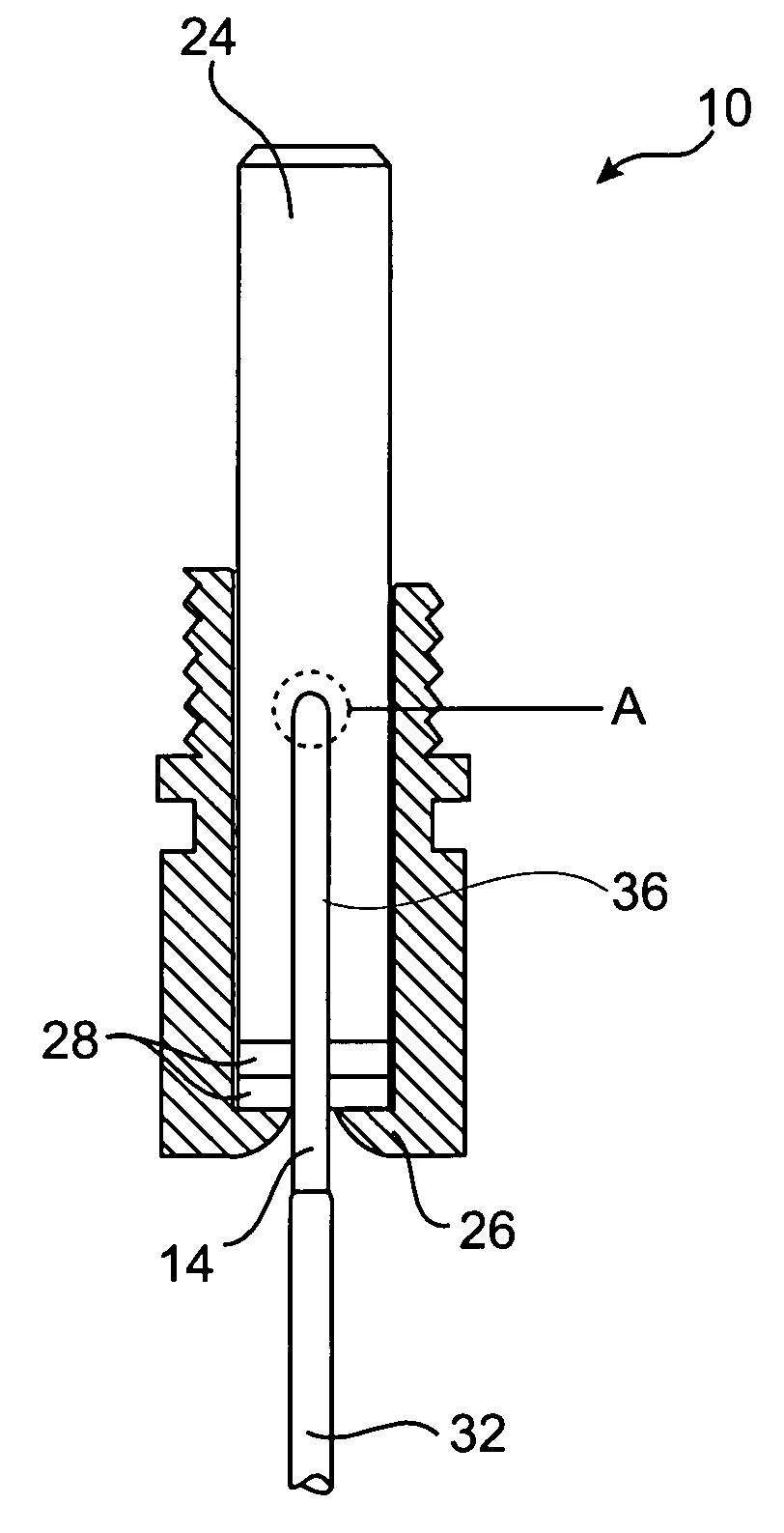

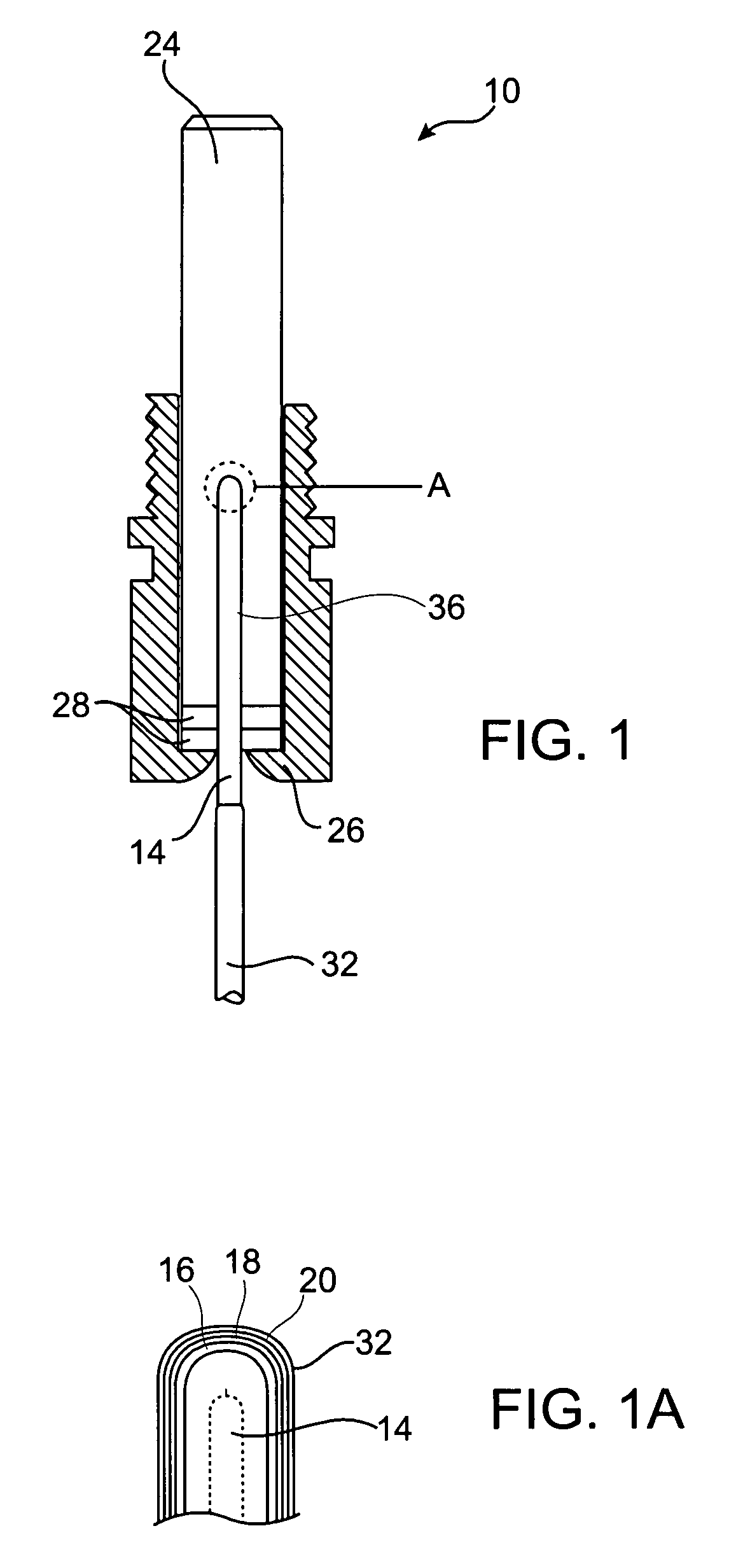

Temperature sensing system for temperature measurement in a high radio frequency environment

InactiveUS7080941B1Thermometer detailsThermometers using electric/magnetic elementsThermal insulationRadio frequency

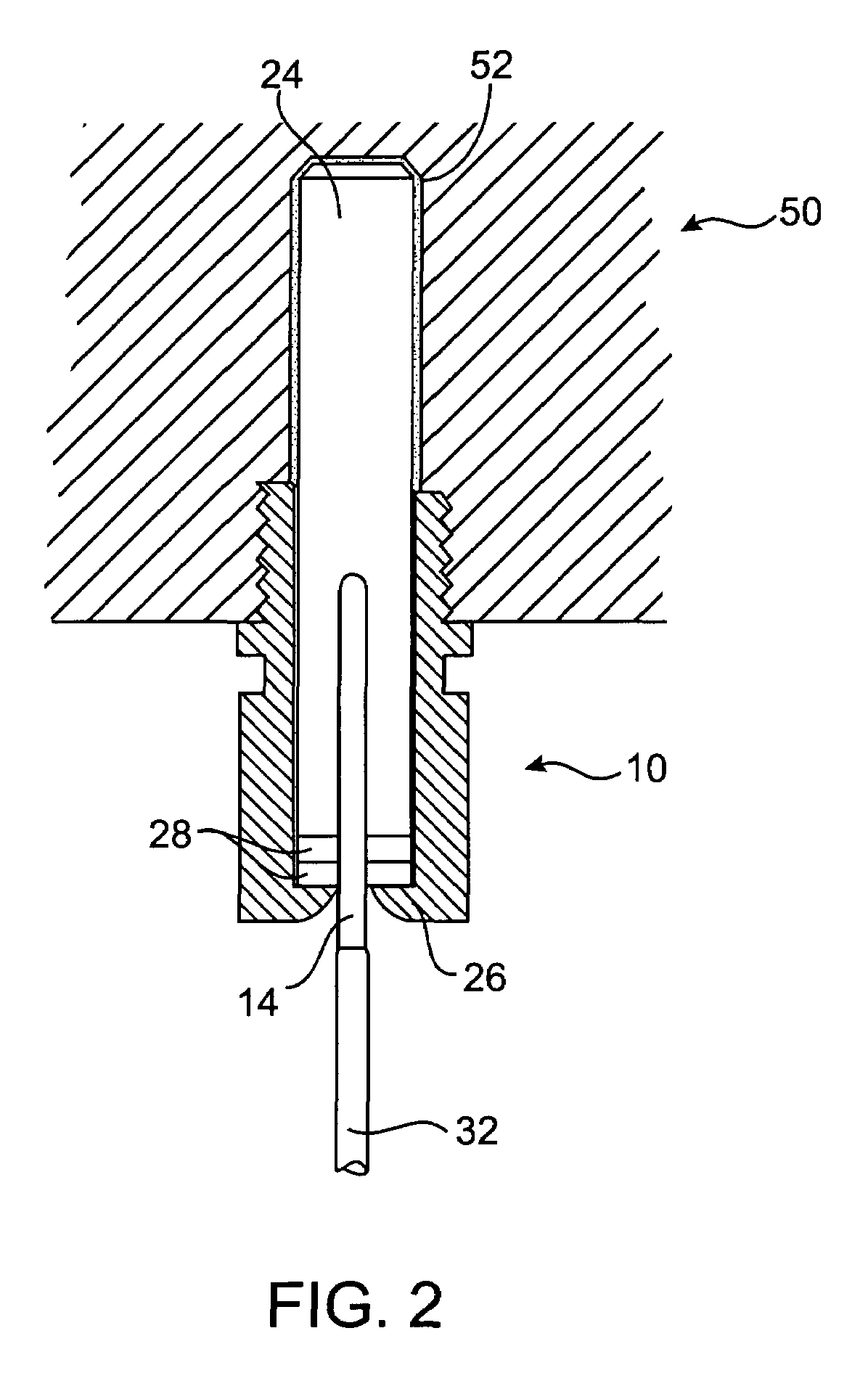

A temperature sensing system incorporates a contact temperature sensor probe for measuring the temperature of articles. The probe is able to operate effectively even in high radio frequency environments such as those present within radio frequency excited plasma processing chambers. The temperature sensing system includes a contact temperature sensor, such as a thermocouple, surrounded by a shielding sheath of a material such as aluminum which is clad with one or more layers of a cladding material. A tip insulator is provided surrounding the sheath for providing RF insulation and thermal coupling. An RF insulating and thermal insulating mounting member is connected to the tip insulator for mounting the probe on an article to be measured.

Owner:LAM RES CORP

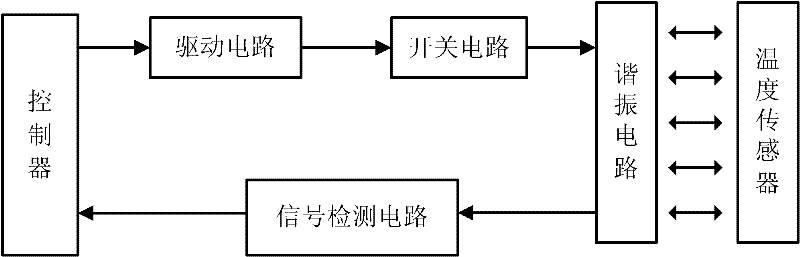

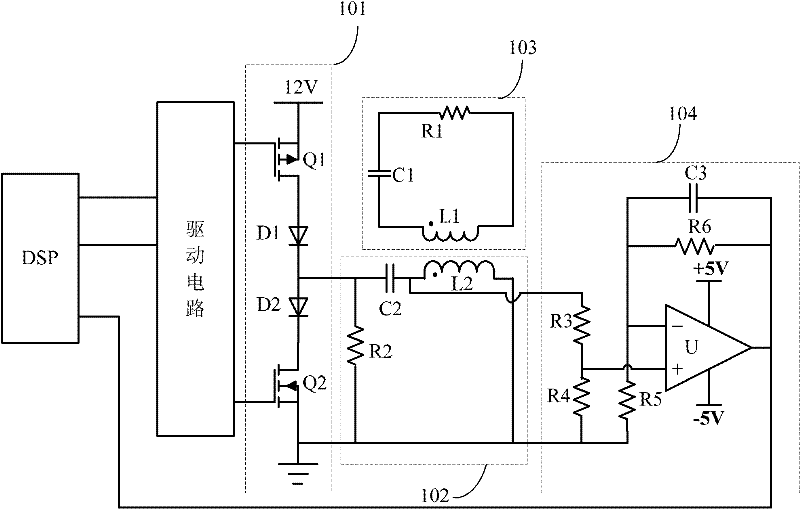

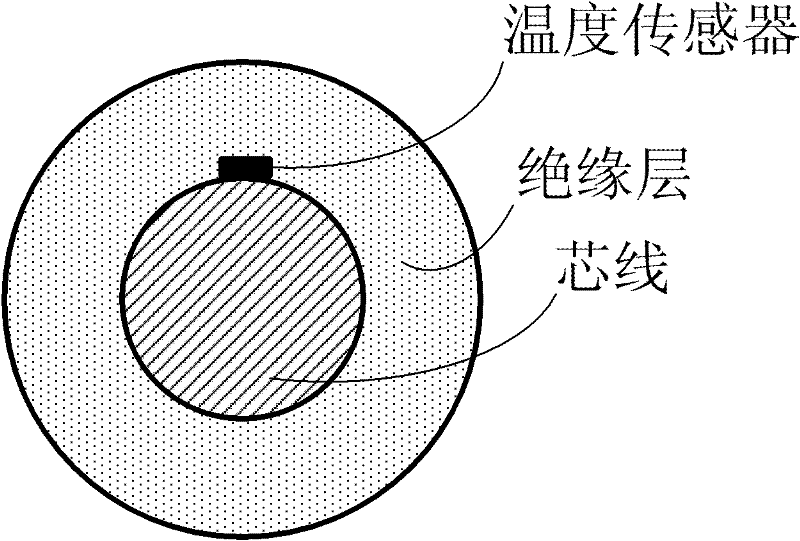

Coupling-based non-contact temperature measurement system and coupling-based non-contact temperature measurement method

ActiveCN102539005AEnables non-contact temperature measurementSuitable for miniaturization designThermometers using electric/magnetic elementsUsing electrical meansEngineeringHigh pressure

The invention discloses a coupling-based non-contact temperature measurement system, which comprises a controller, a drive circuit, a switch circuit, a resonant circuit, a temperature sensor and a signal detection circuit, wherein the drive circuit is connected with the controller, the switch circuit is connected with the drive circuit, the resonant circuit is connected with the switch circuit, the temperature sensor is coupled to the resonant circuit, and the signal detection circuit is connected with the resonant circuit and the controller. The temperature sensor is separated from other devices of the system, non-contact temperature measurement of an object is achieved by electromagnetic coupling, and the system with the simple circuits is low in cost, suitable for miniature design, andapplicable to a plurality of places. The invention further discloses a coupling-based non-contact temperature measurement method, which includes: transmitting temperature signals by electromagnetic coupling, calculating and analyzing according to the temperature signals, and accordingly achieving non-contact temperature measurement of the object. The method is applicable to reliable temperature measurement of inner core wires of a high-tension power cable.

Owner:ZHEJIANG UNIV +1

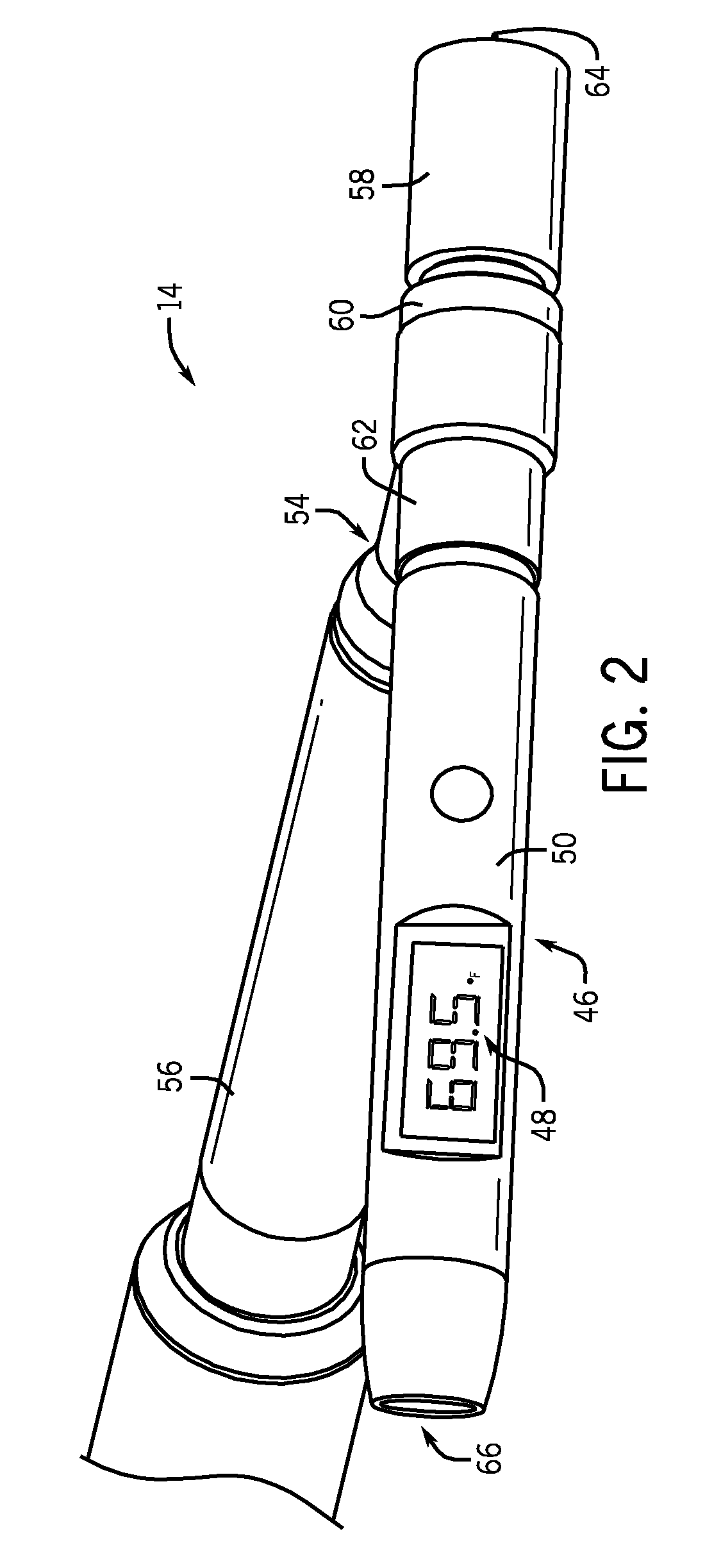

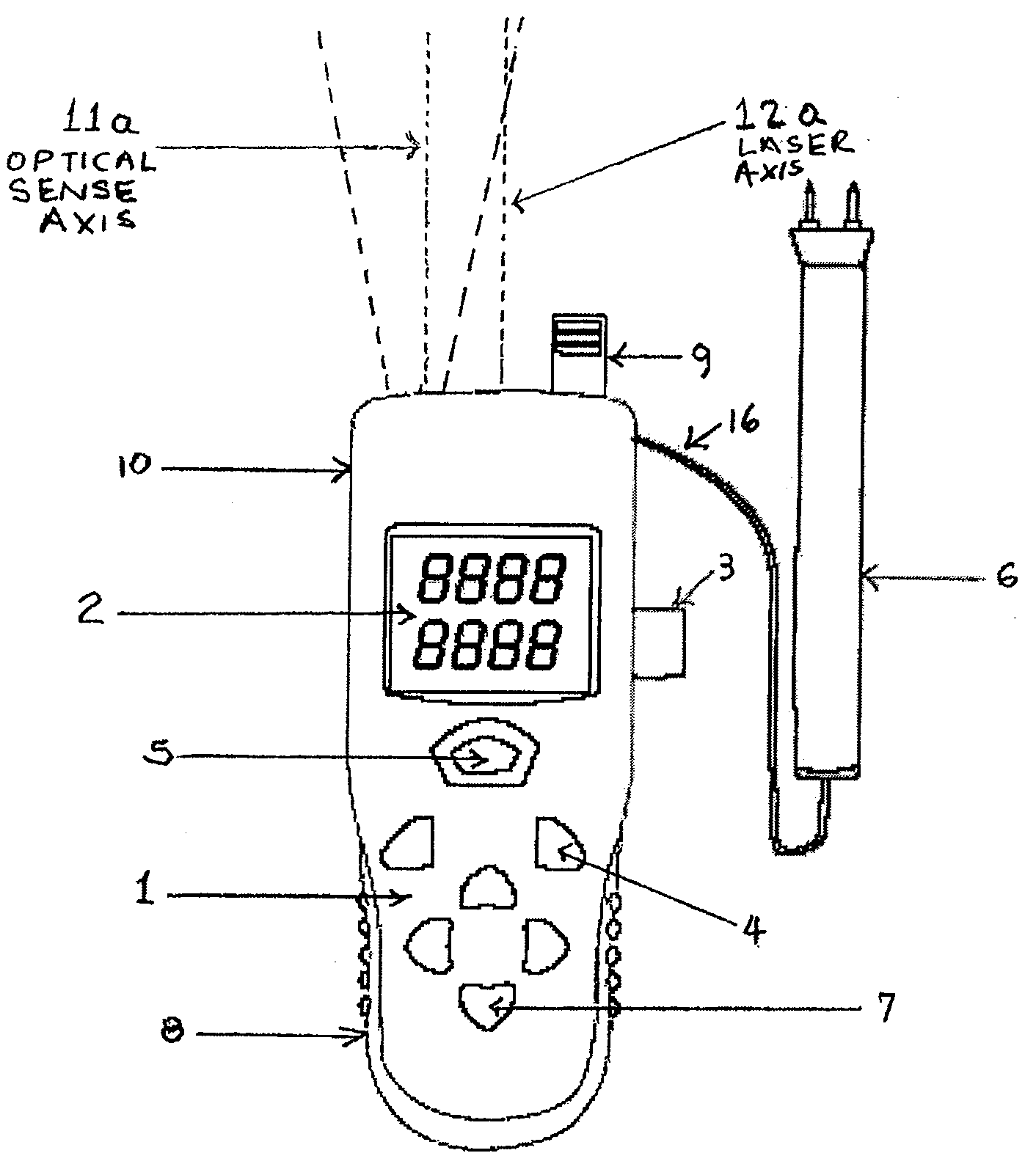

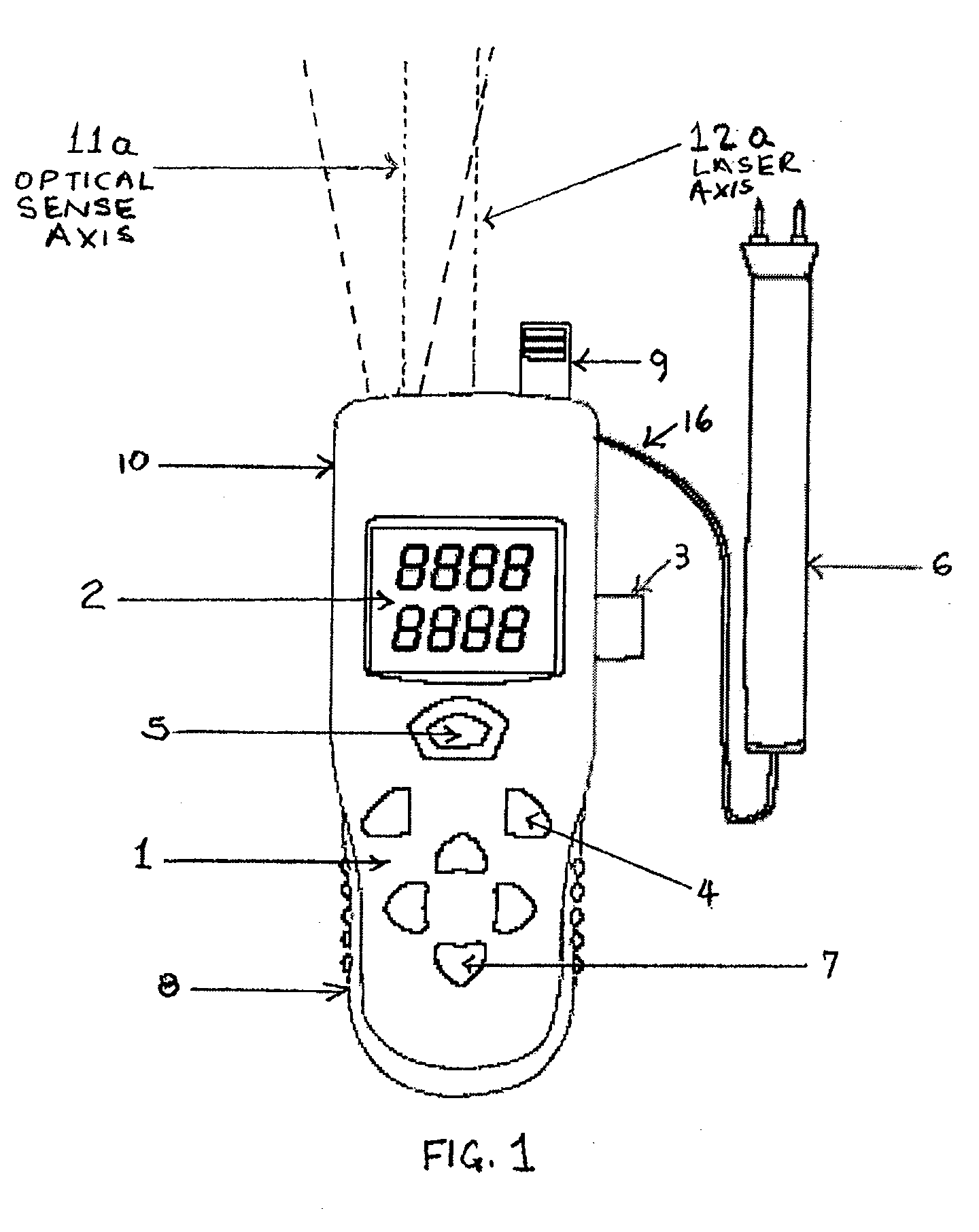

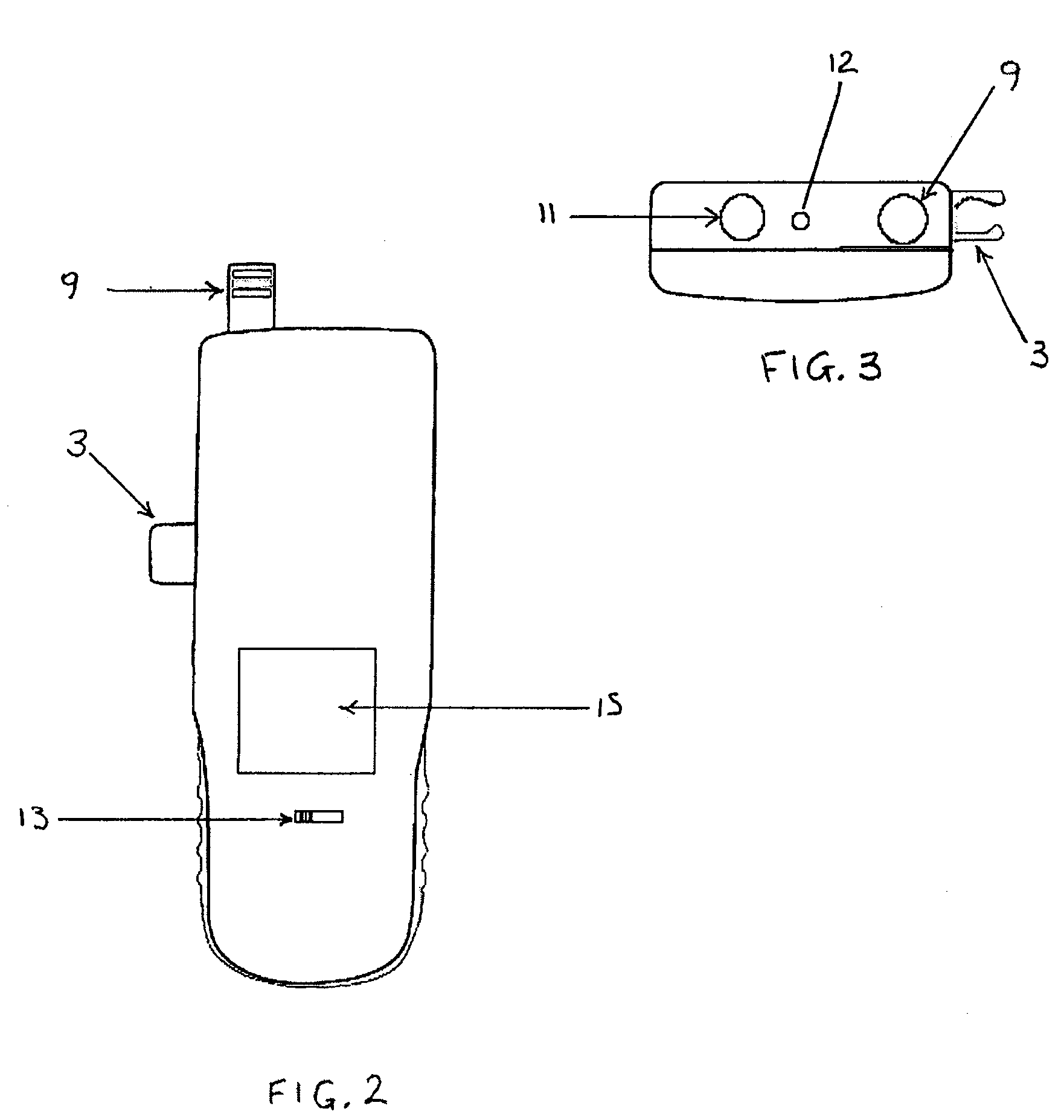

Moisture Meter with Non-Contact Infrared Thermometer

ActiveUS20080259993A1Easy to useImprove portabilityThermometer detailsRadiation pyrometryDisplay deviceHand held

A moisture meter with non-contact temperature measurement capability having a housing, a moisture-detecting device coupled to or contained at least partially in the housing, and having an output related to measured moisture parameters, a non-contact, optically-based temperature sensing device coupled to the housing, having an output related to sensed temperature, an output display contained in the housing, for displaying measurements to a user, and circuitry contained in the housing for processing both the moisture-detecting device output and the non-contact temperature sensing device output, and transmitting the processed outputs to the output display. The moisture-detecting device can be either one or both of a contact-type moisture-detecting device such as a pad on the rear side of the housing, and a pin-type moisture-detecting device in a hand-held probe, and electrically coupled to the circuitry in the housing through a cord.

Owner:TELEDYNE FLIR LLC

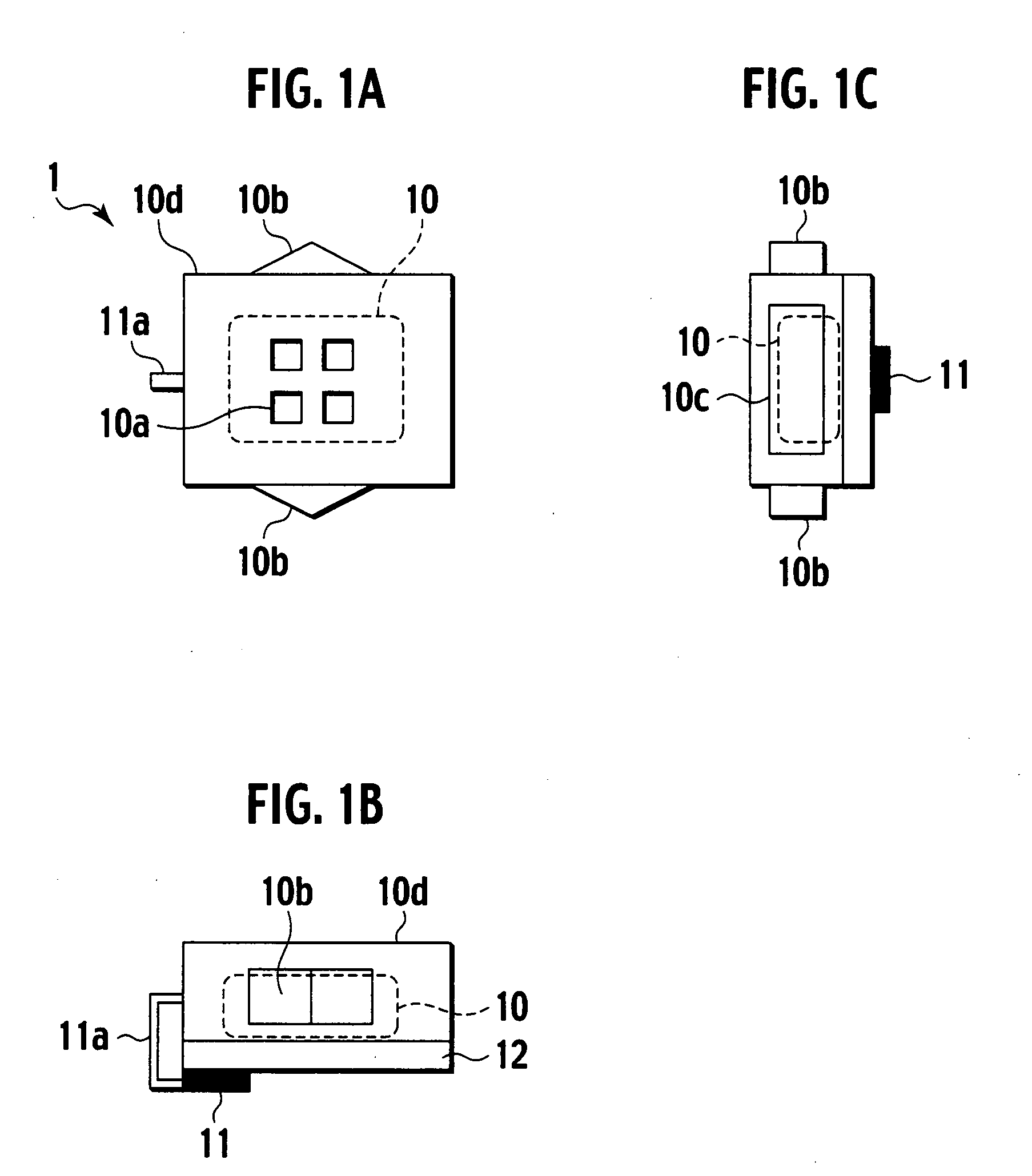

Glass temperature detecting system, window fog detecting system, air-conditioning system for vehicles, and window fog detecting method

InactiveUS20070235549A1Reduce manufacturing costWindowsAir-treating devicesEngineeringAir conditioning

A window fog detecting system for detecting fog on a windshield of a vehicle, including: a glass temperature detecting system including a contact temperature sensor attached to a portion of the windshield on the driver's seat side of the center in a width direction of the windshield, or to a portion where ceramic print is applied on the upper-side periphery of the windshield; a humidity detection device which detects the humidity of air in a vicinity of the inner surface of the windshield; and a judging device which judges the presence of fog on the windshield, on the basis of the detected values of the glass temperature detecting system and the detected values of the humidity detection device.

Owner:NISSAN MOTOR CO LTD

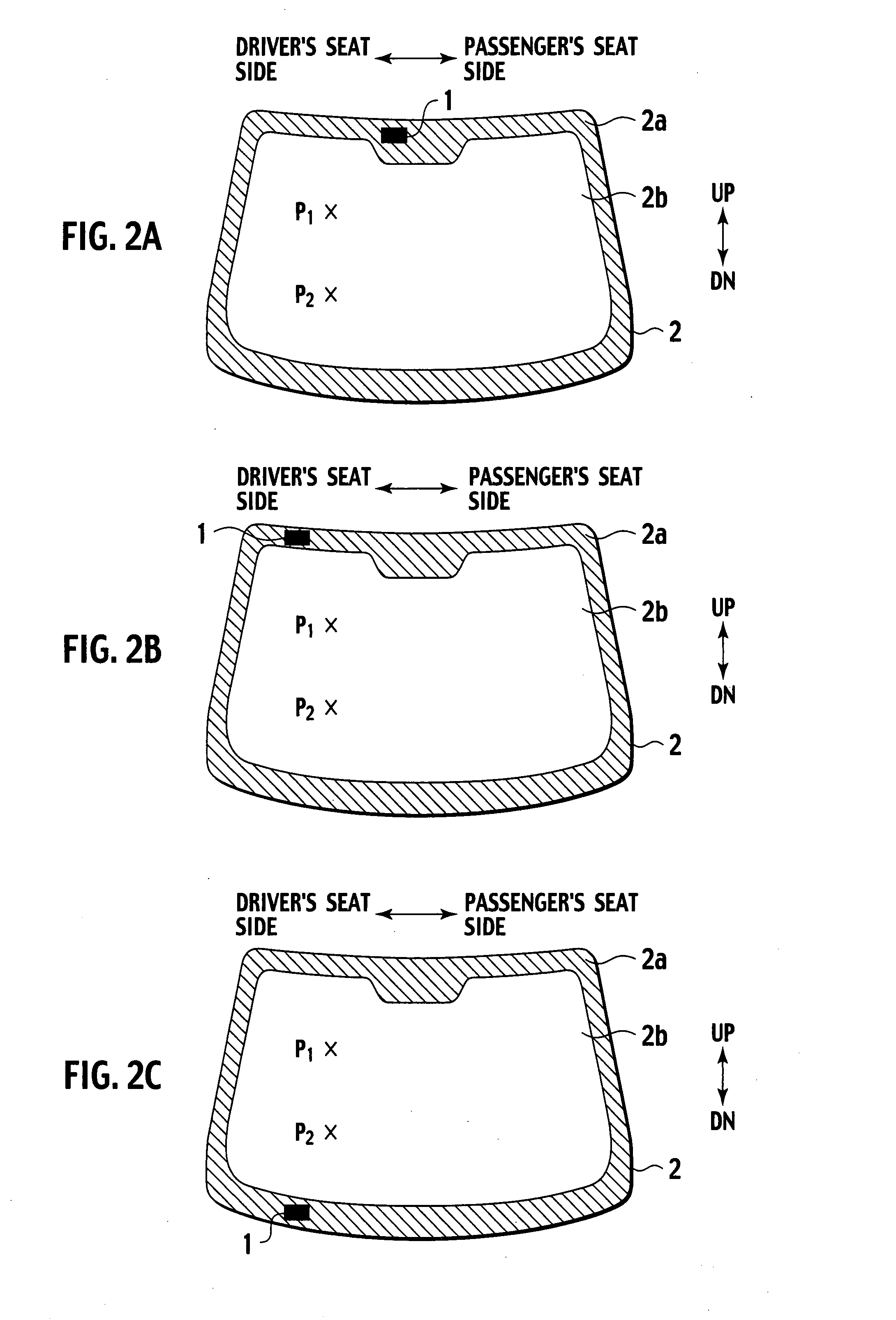

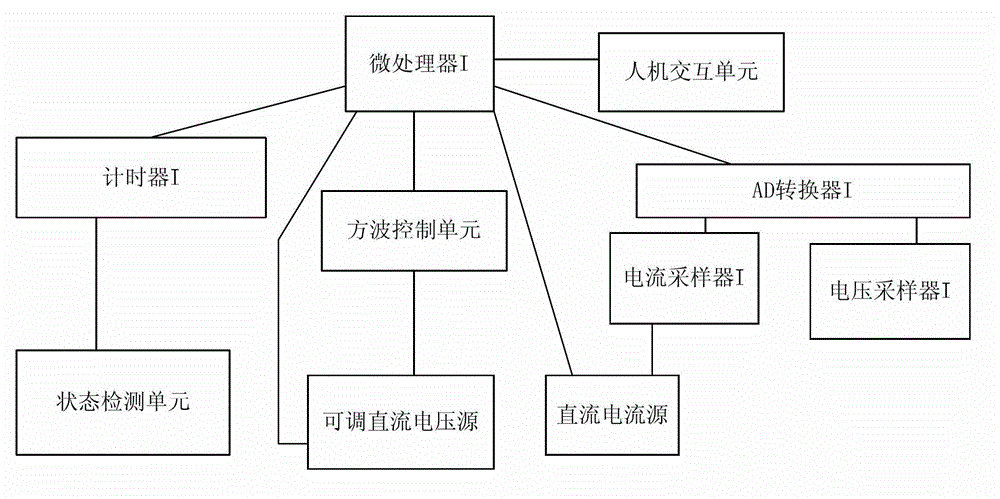

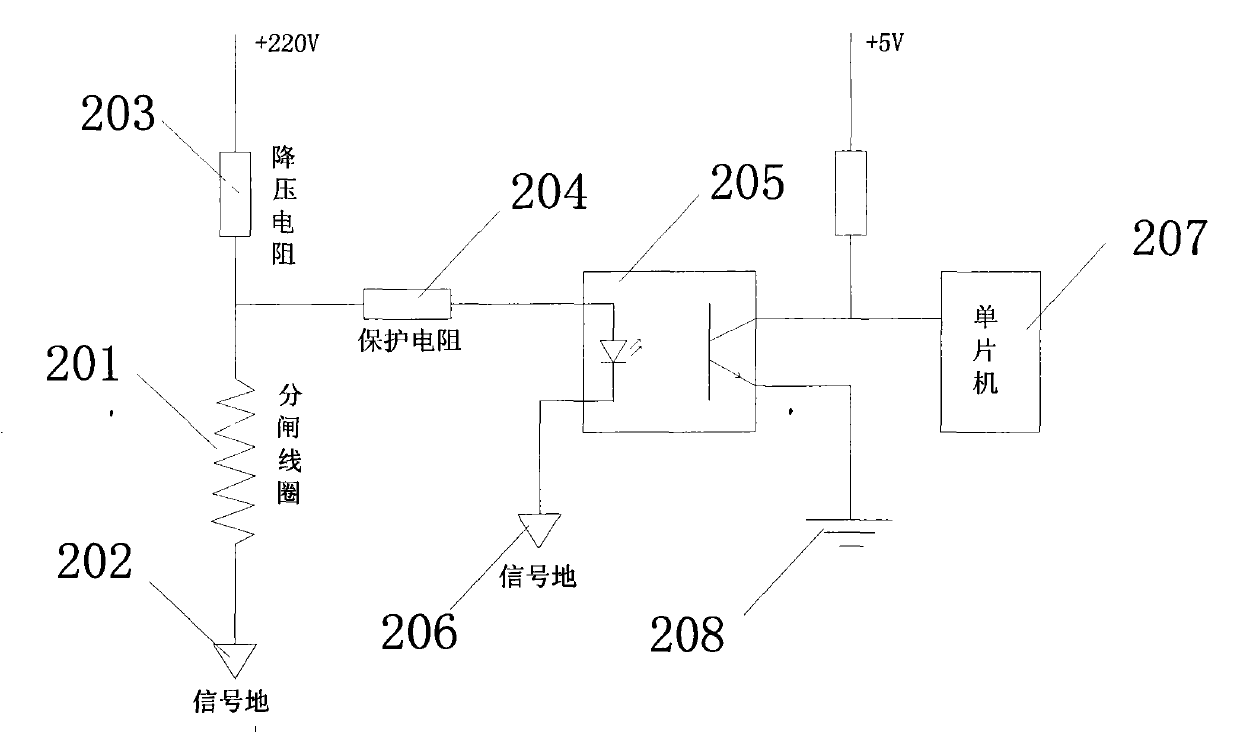

Full-performance detecting system of magnetic latching relay and detecting method thereof

ActiveCN102981120AWith alarm functionFunctionalMachine part testingCircuit interrupters testingResistive loadElectric power

The invention relates to the field of electrical equipment detection, in particular to a full-performance detecting system of a magnetic latching relay and a detecting method of the full-performance detecting system of the magnetic latching relay. The detecting system comprises a main control panel, an auxiliary control panel and a resistive load box, wherein the auxiliary control panel is communicated with the main control panel through a network port, the auxiliary control panel controls the resistive load box to work by controlling an air switch, and the main control panel is connected with the magnetic latching relay. An ongoing full-performance test of the magnetic latching relay comprises an initial operation voltage, a returned value voltage test, an operation time test, a four probe method and high current method coil resistance test, a contact temperature-rise test, a mechanical life test, an electrical endurance test and an overload test. The full-performance detecting system is simple in wiring, capable of automatically finishing an electrical performance test, a safety performance test and a service life test without manual intervention, comprehensive in test items, and simple in test process.

Owner:CHINA ELECTRIC POWER RES INST +1

Apparatus and method for reducing stray light in substrate processing chambers

InactiveUS7135656B2Accurately determinedEffective absorptionDrying solid materials with heatMuffle furnacesRare-earth elementSemiconductor materials

Owner:MATTSON TECHNOLOGY +1

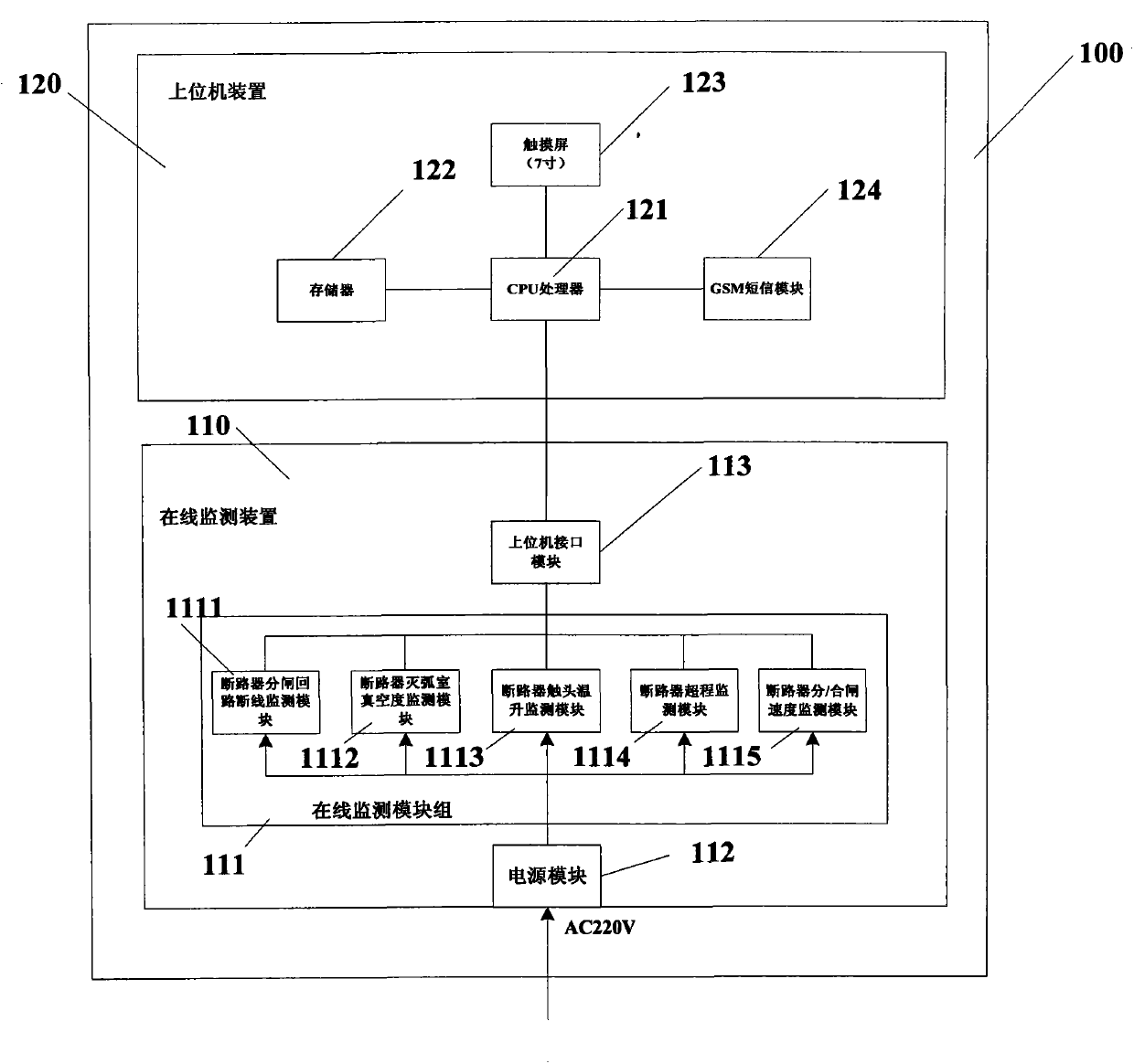

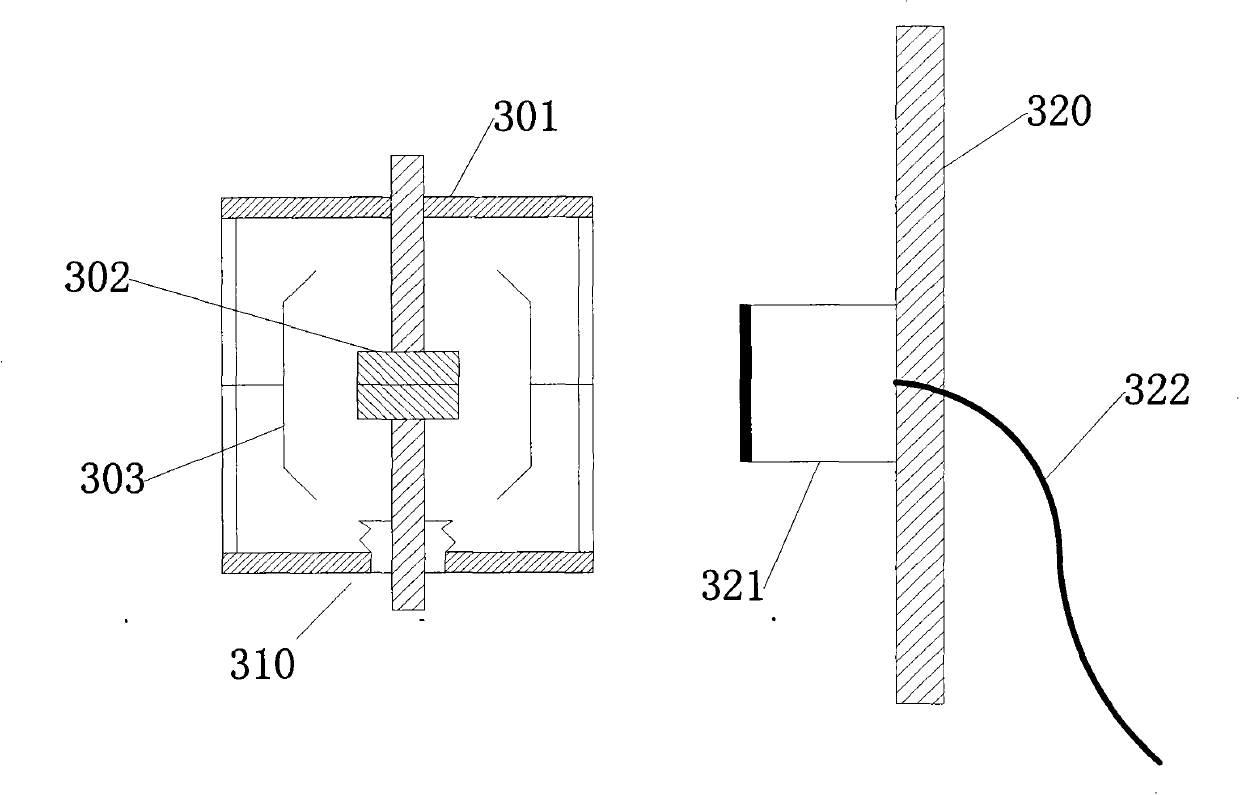

On-line monitoring system aiming at high-voltage circuit breaker

InactiveCN103744018AReal-time monitoring of mechanical propertiesEasy to identify automaticallyTransmission systemsCircuit interrupters testingState parameterMonitoring system

The invention discloses an intelligent on-line monitoring system aiming at a high-voltage circuit breaker. The intelligent on-line monitoring system comprises an on-line monitoring device consisting of an on-line monitoring module group, a power module and an upper computer interface module, and an upper computer device connected with the on-line monitoring device, wherein the on-line monitoring module group comprises a circuit breaker separating brake loop disconnection monitoring module, a circuit breaker arc extinguish chamber vacuum degree monitoring module, a circuit breaker contact temperature rise monitoring module, a circuit breaker over travel monitoring module and a circuit breaker separating / connecting brake speed monitoring module. The five sub monitoring modules are connected with the upper computer interface module to realize data interaction between the five sub monitoring modules and the upper computer device, and the upper computer device performs monitoring data search and parameter configuration on the five sub monitoring modules by the upper computer interface module. According to the system, the measurement of each piece of state information is mutually separated from a power source power supply module, the internal mechanism of the circuit breaker is analyzed again, and the current running state parameter and state of the high-voltage circuit breaker are obtained accurately and efficiently.

Owner:CHANGZHOU MECAN ELECTRIC TECH DEV

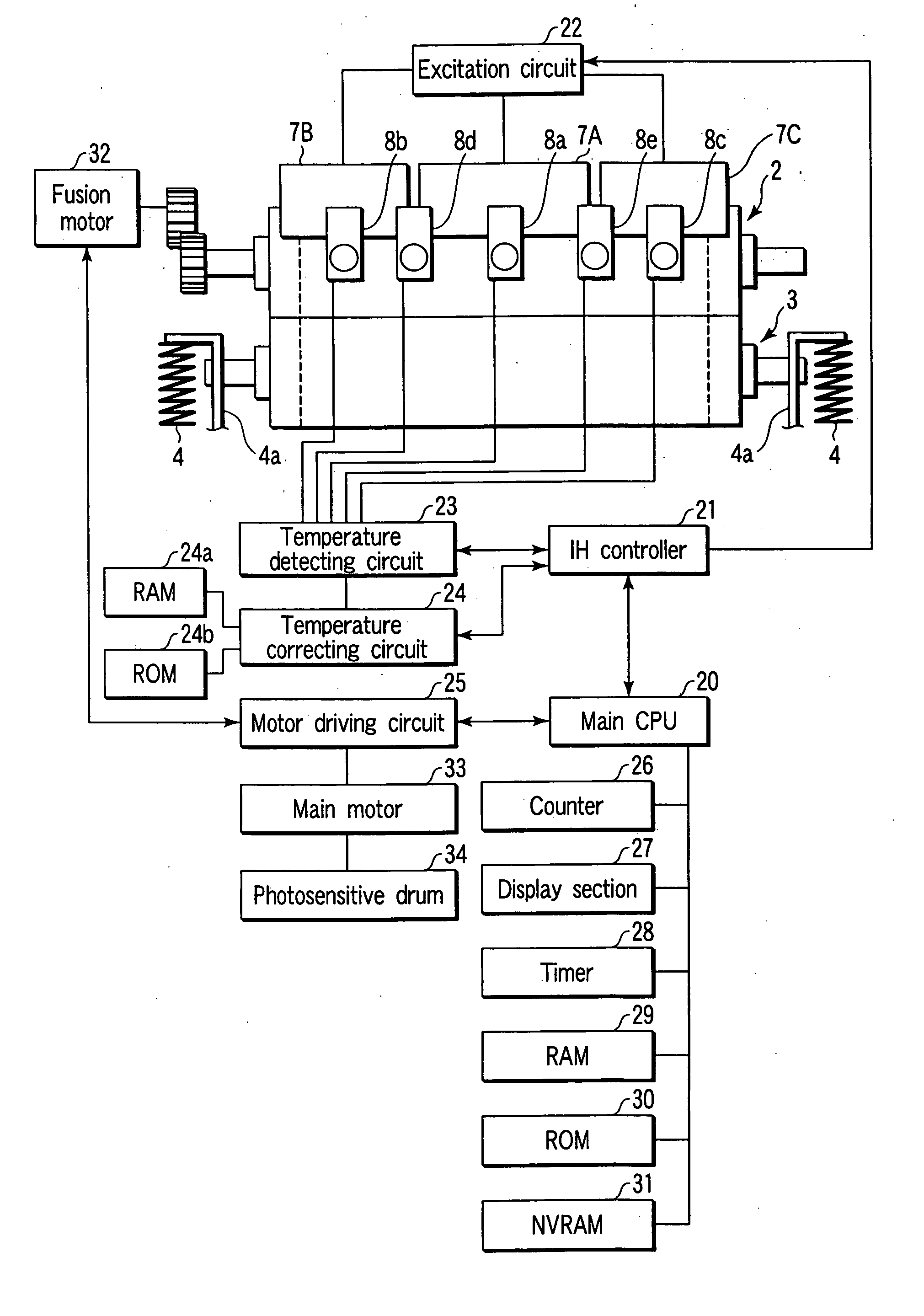

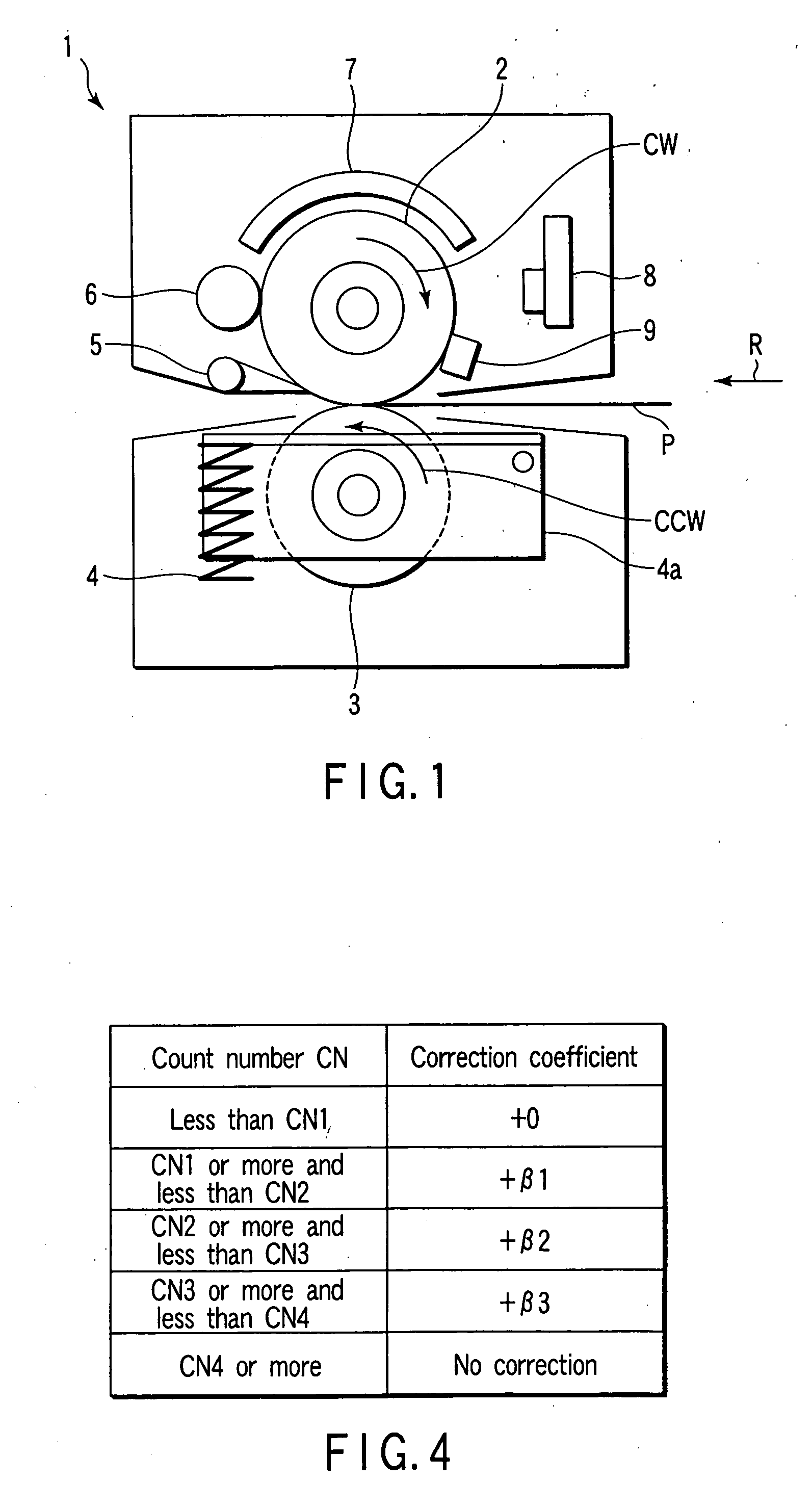

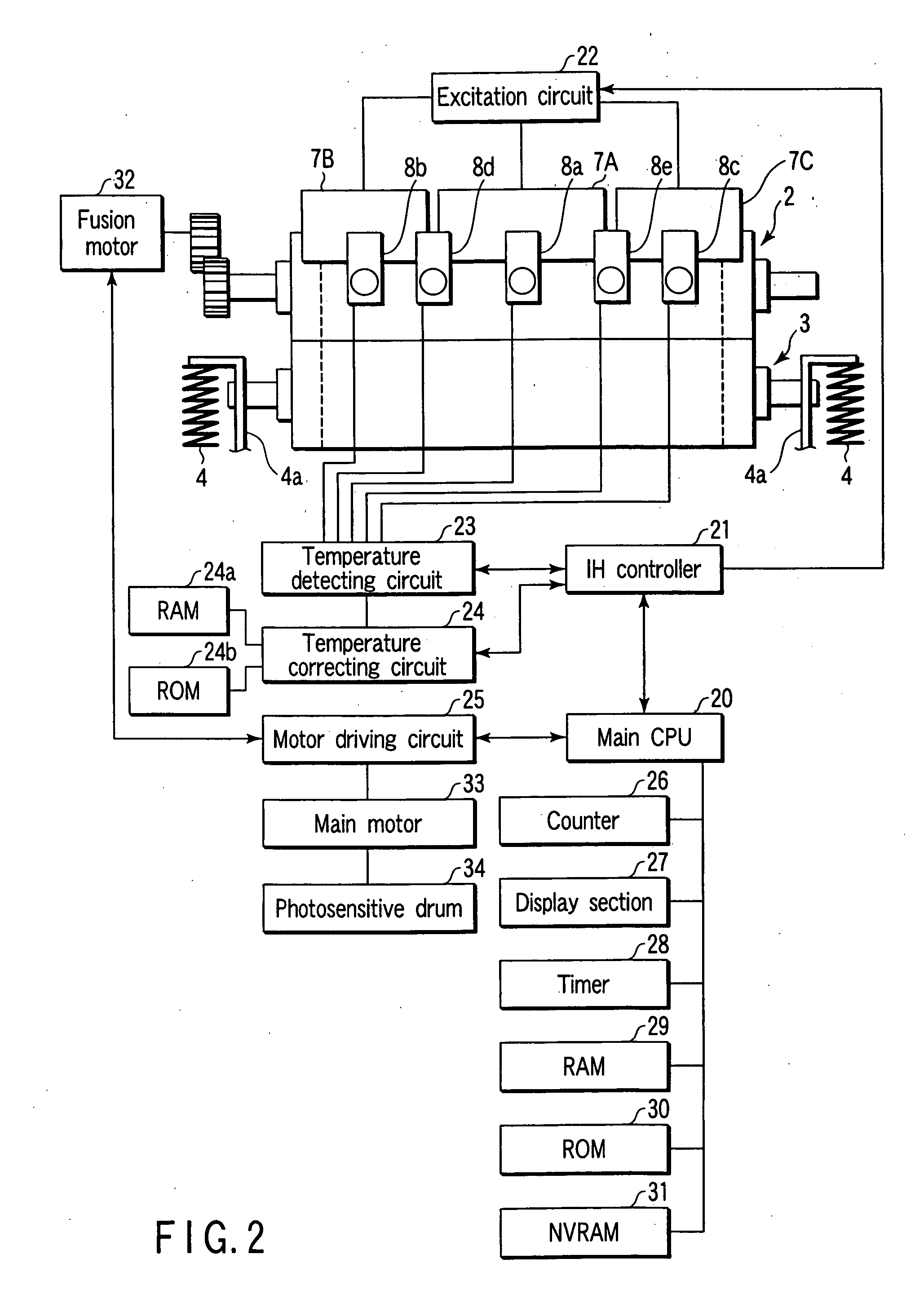

Fuser and temperature control method

ActiveUS20050207774A1Ohmic-resistance heatingElectrographic process apparatusInfraredTemperature control

According to one aspect of the present invention, there is provided a fixing apparatus having a non-contact temperature detecting unit which detects temperature by sensing infrared rays emitted from the a heating roller and a difference between real temperature and the temperature detected by the non-contact temperature detecting unit, produced by time-lag until reaching the infrared rays emitted from the heating roller is corrected.

Owner:KK TOSHIBA +1

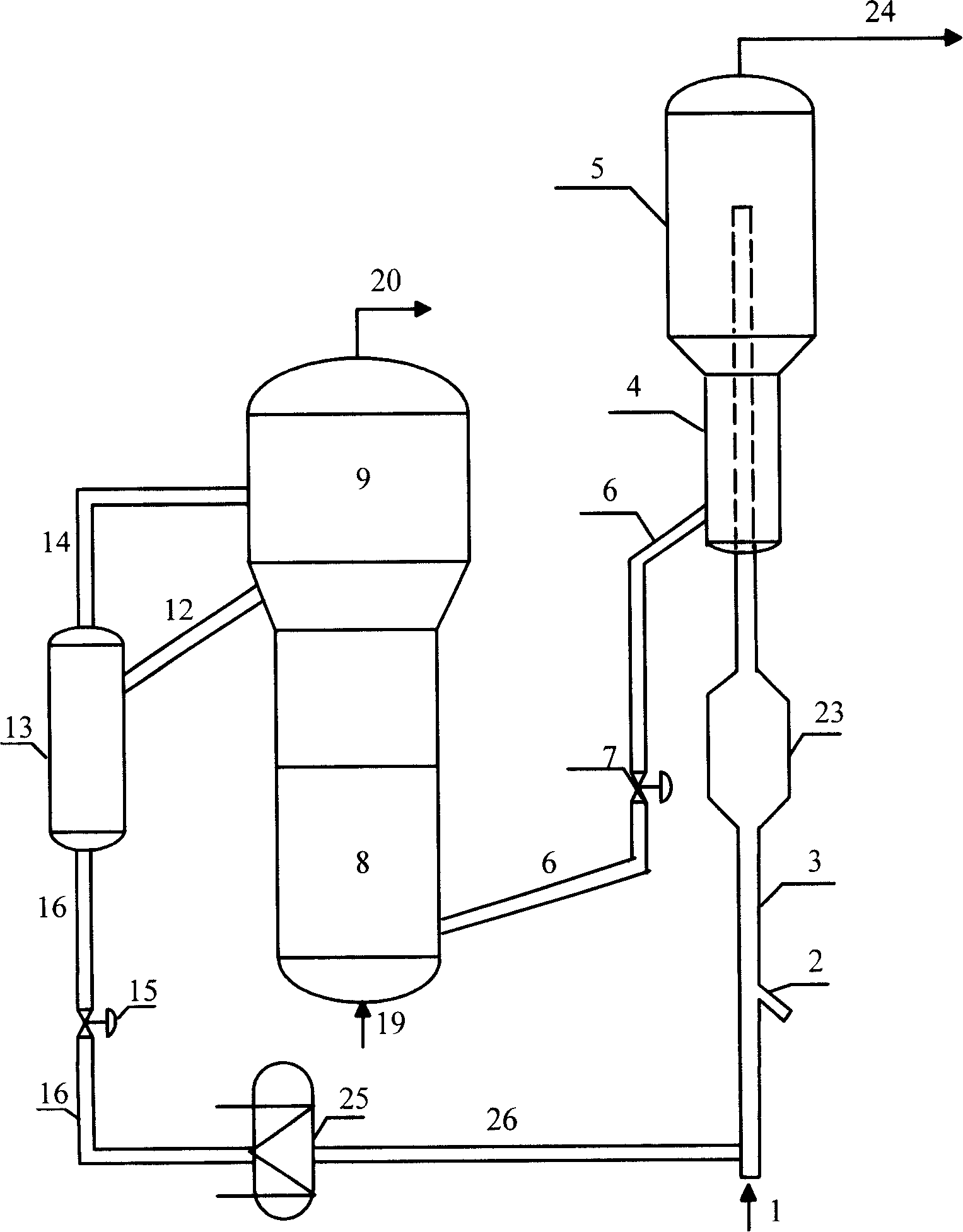

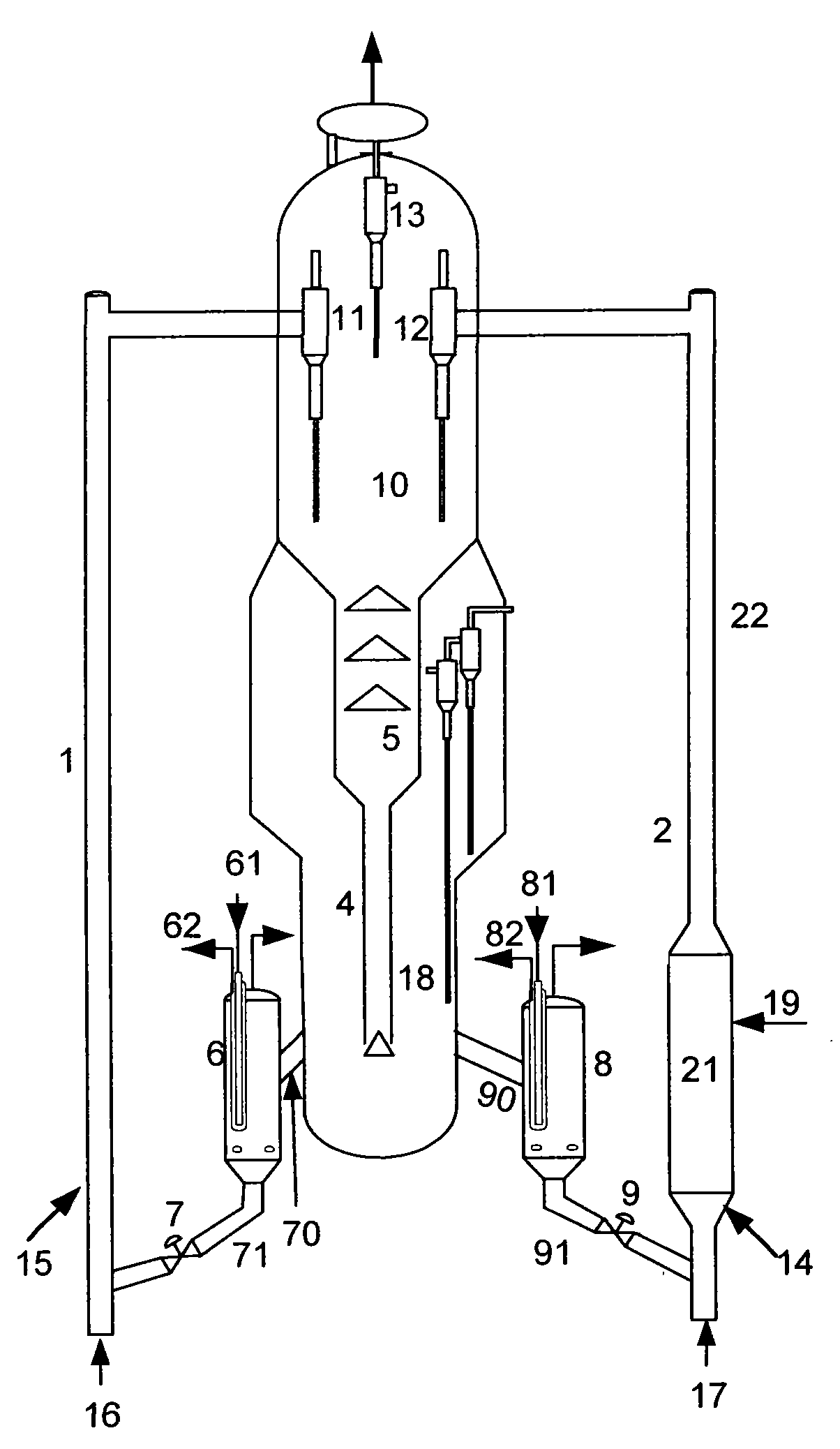

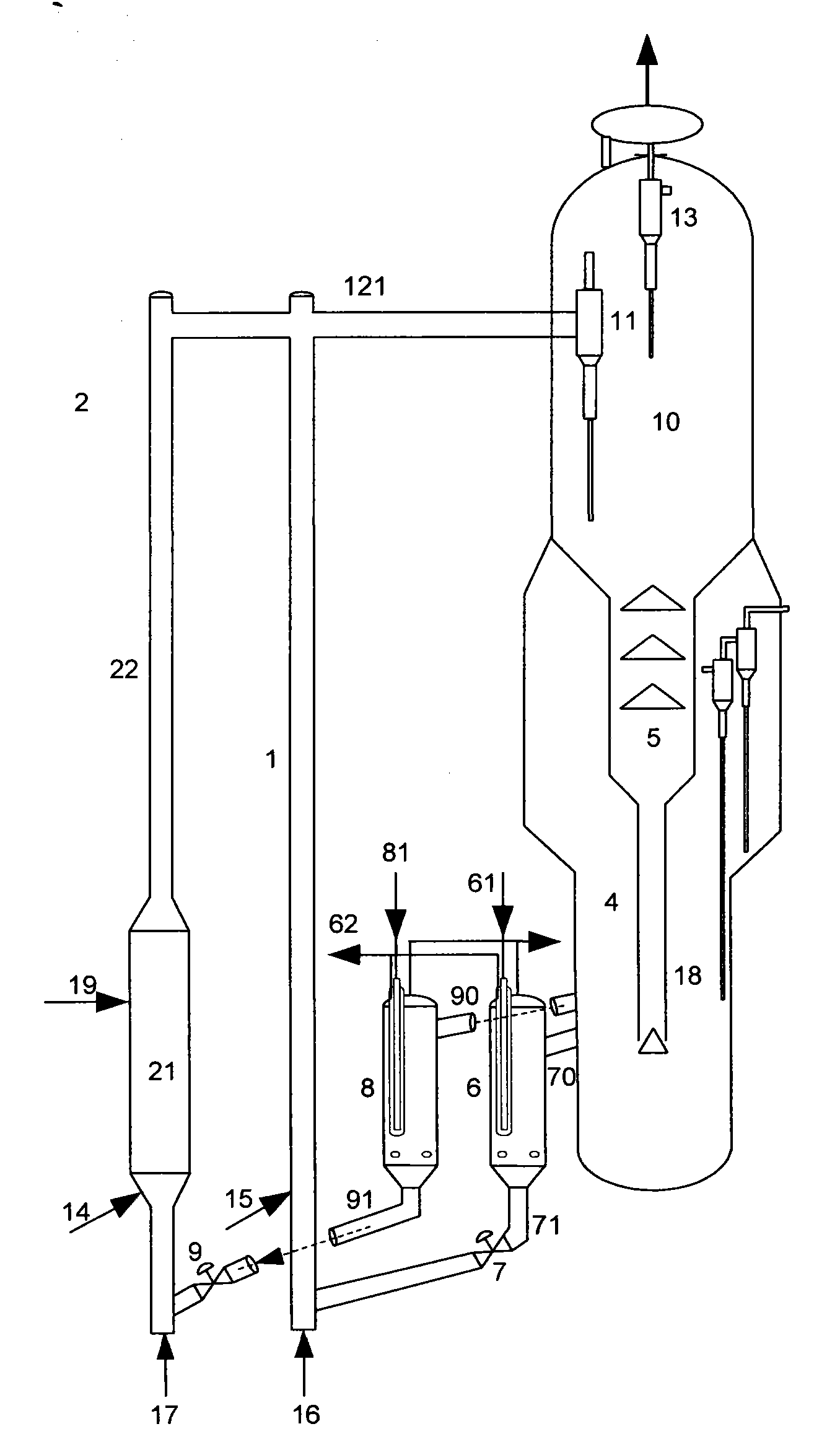

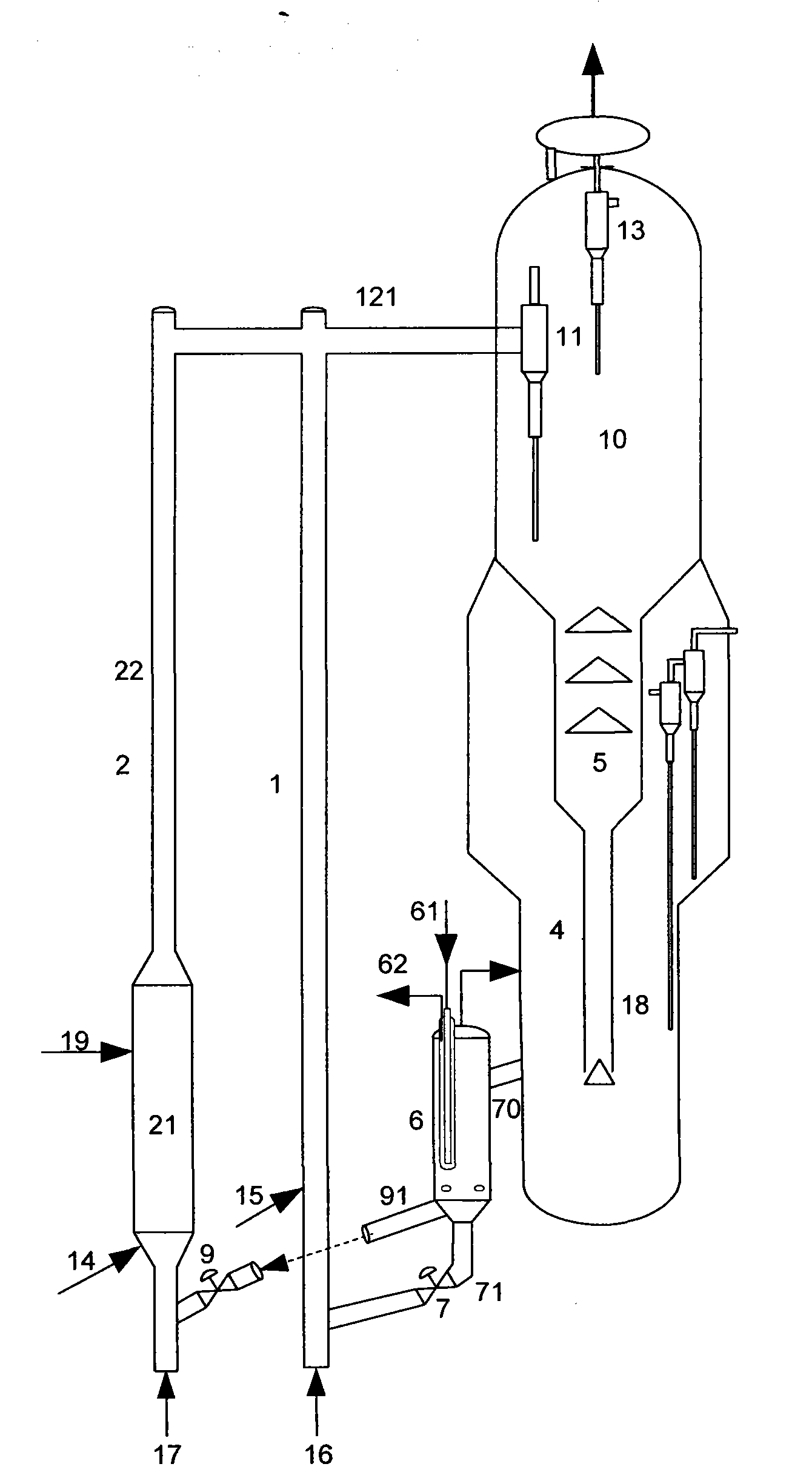

Catalytic cracking fractional and divisional transformation method and device for heavy oil

InactiveCN102102029AHigh activityHigh yieldTreatment with plural parallel cracking stages onlyCatalytic transformationHigh doses

The invention provides a catalytic cracking fractional and divisional transformation method and device for heavy oil. The method comprises the following steps of: classifying heavy oil raw materials into a high grade catalytic raw material and an ungraded catalytic raw material according to the difference between reaction properties, wherein a riser reactor is taken as the reaction area of the high grade catalytic raw material, and a combined reactor consisting of a turbulent bed or a fast bed and a conveying bed is taken as the reaction area of the ungraded catalytic raw material; undergoing a reaction under respectively optimized process conditions of low-dose oil contact temperature difference and high-dose oil ratio; separating reacted oil gas from a catalyst; leading the oil gas out of a reaction system; and introducing the catalyst into a catalyst regenerator for scorching and regenerating. The invention also provides a device for implementing the catalytic cracking fractional and divisional transformation method. In the method, malignant adsorption competition between the ungraded raw material and the high grade raw material in the conventional riser reactor and retardation on the reactions are effectively avoided, the problem of insufficient reaction deepness of the ungraded raw material is solved, and the yields of clean oil and liquid are remarkably increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

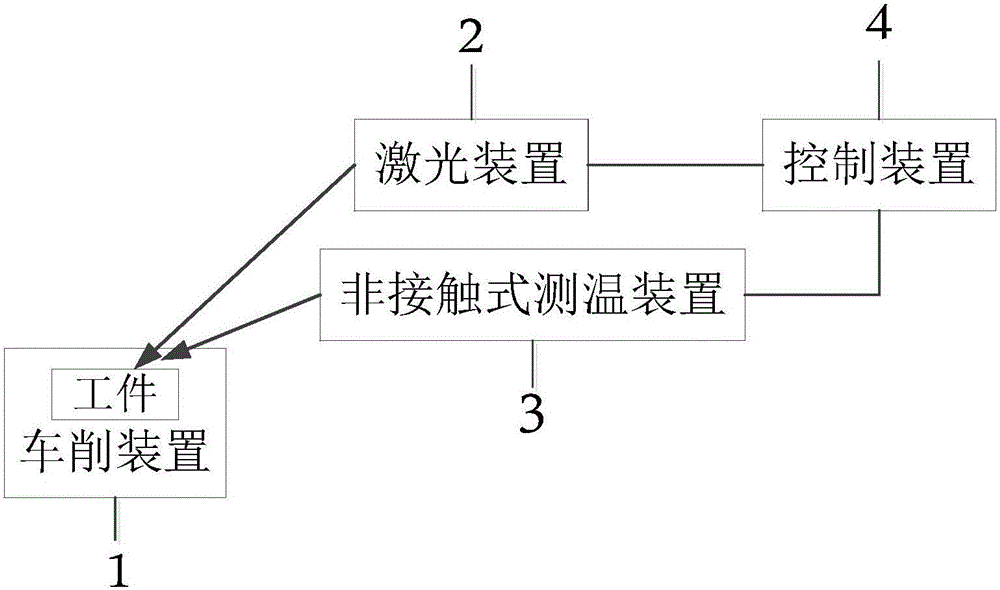

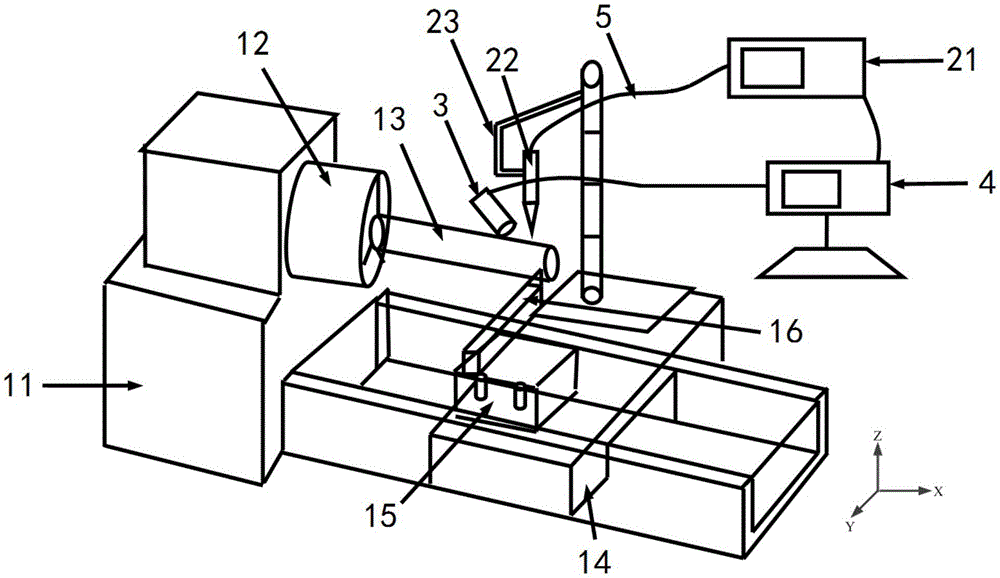

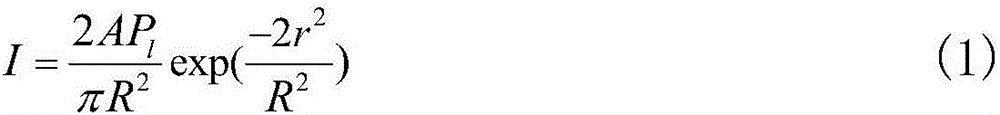

Laser heating assisted turning device and method

InactiveCN106001613ASolution to short lifeImprove surface qualityMeasurement/indication equipmentsMetal working apparatusData matchingMachined surface

The invention provides a laser heating assisted turning device and method. The laser heating assisted turning device comprises a turning device body, a laser device, a non-contact temperature measuring device and a control device, wherein a tool and a workpiece are fixed to the turning device body, the tool is detachably connected with the turning device body, the laser device is used for heating the workpiece through laser, the non-contact temperature measuring device is used for acquiring the temperature at the cutting position of the workpiece in real time, and the control device is used for comparing data of an optimum temperature field stored in the control device with temperature data acquired by the non-contact temperature measuring device in real time and controlling the laser device to adjust laser parameters so as to achieve the optimum temperature field if difference exists. The laser heating assisted turning device has the advantages that the laser parameters are adjusted in a data matching mode so that the temperature field at the cutting position of the workpiece can be always consistent to the optimum temperature field, the cutting performed in the temperature field makes the service life of the tool longest, the machined surface quality of the workpiece is the best, and the turning efficiency is the highest.

Owner:HARBIN INST OF TECH

Non-contact patient temperature measurement

InactiveUS7142114B2Easy to measureQuick and convenient mannerThermometer detailsElectric signal transmission systemsBody temperature measurementAir interface

A method and system are provided for allowing non-contact temperature measurement of an animate body. More particularly, a transponder sensor device attached to an animate body is utilized to non-intrusively measure a temperature of the animate body in response to an interrogation signal transmitted over an air interface from a portable probe. In one embodiment, the sensor device is a passive device that is operative to collect energy from an interrogation signal emitted from the probe. In this regard, the sensor device does not require an internal power source. The collected energy is utilized to measure the temperature of the animate body and transmit a response signal containing temperature information back to the probe over the air interface.

Owner:DATEX OHMEDA

Cable joint wire temperature prediction method based on RBF neural network

ActiveCN103886374AAvoid errorsImprove forecast accuracyNeural learning methodsFault analysisEngineering

The invention relates to a cable joint wire temperature prediction method based on an RBF neural network. The cable joint wire temperature prediction method based on the RBF neural network mainly includes the first step of collection of sample data, wherein factors such as environment humidity, environment temperature, sheath temperature, joint insulation temperature, contact temperature and various surface temperatures which are related with the cable joint wire temperature are measured in real time; the second step of network training, wherein the collected data in the step (1) are preprocessed, training data and prediction data are divided, various parameters are set, a network is built, and the data are predicted finally. As the neural network technology is applied to predication of the cable joint wire temperature, the cable joint wire temperature can be well monitored in a real-time and on-line mode, and faults can be well analyzed.

Owner:合肥珞珈创新研究院有限公司

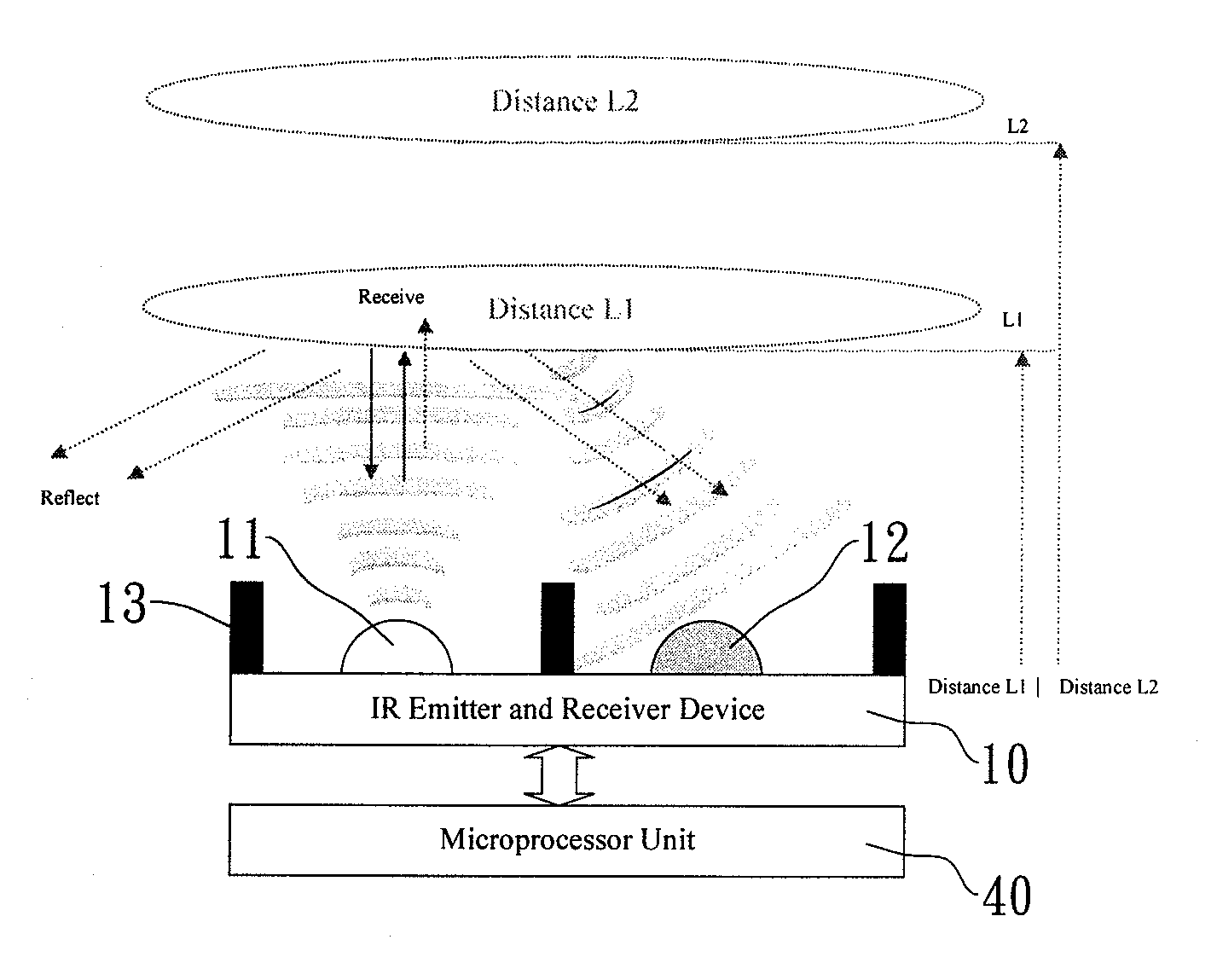

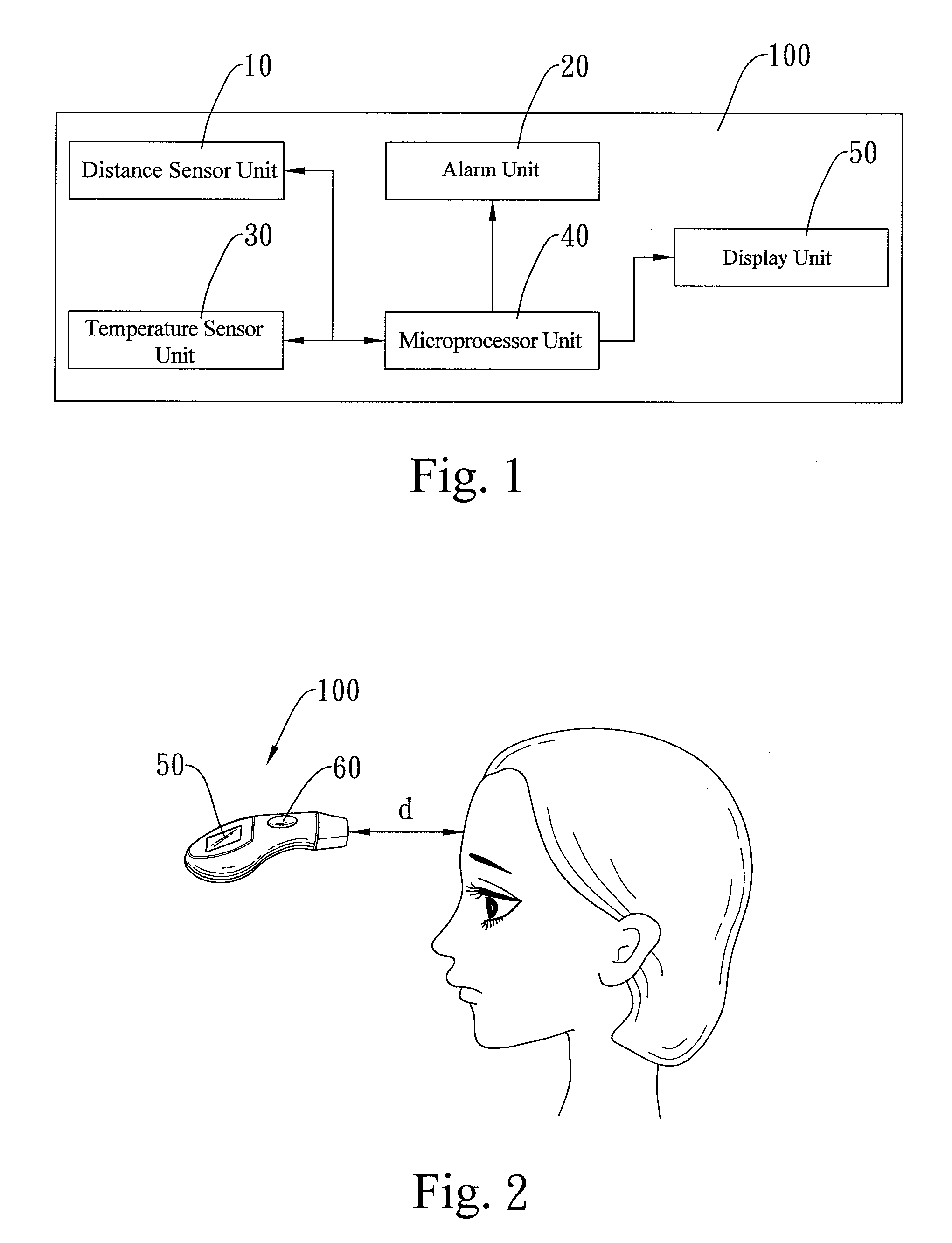

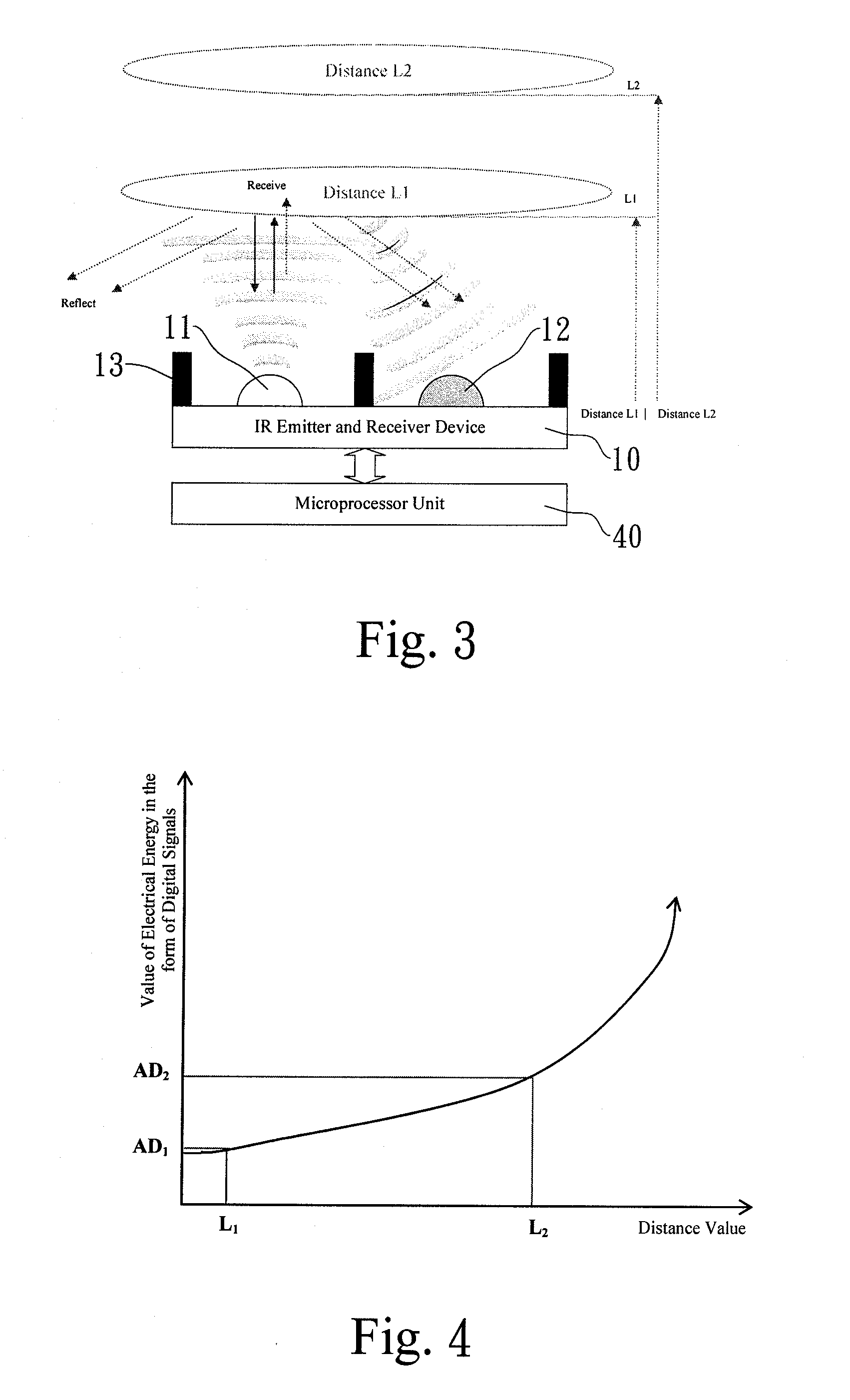

Non-contact temperature-measuring device and the method thereof

ActiveUS20080246625A1Reduce errorsAccurate measurementOptical rangefindersInvestigating moving sheetsDistance sensorsMeasuring equipment

This invention provides a non-contact temperature-measuring device including a distance sensor unit, an alarm unit, a temperature sensor unit, a microprocessor unit and a display unit. The distance sensor unit measures the distance between the device and a target. The alarm unit gives an alarm when the distance sensor unit measures a predetermined distance value. The temperature sensor unit measures a temperature of the target after the alarm unit gives the alarm. The microprocessor unit stores data of the predetermined distance value and the temperature value measured by the temperature sensor unit; the microprocessor unit also processes a distance signal emitted by the distance sensor unit and a temperature signal emitted by the temperature sensor unit. When the target's distance value equals the predetermined distance value, the microprocessor unit will further send a command for the alarm unit to give an alarm. The display unit of the device displays the temperature value that is measured by the temperature sensor unit and processed by the microprocessor unit subsequently.

Owner:AVITA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com