Laser heating assisted turning device and method

A laser heating and laser device technology, applied in turning equipment, turning equipment, metal processing, etc., can solve the problems of parts processing quality, low processing efficiency, tool wear, etc. The effect of excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

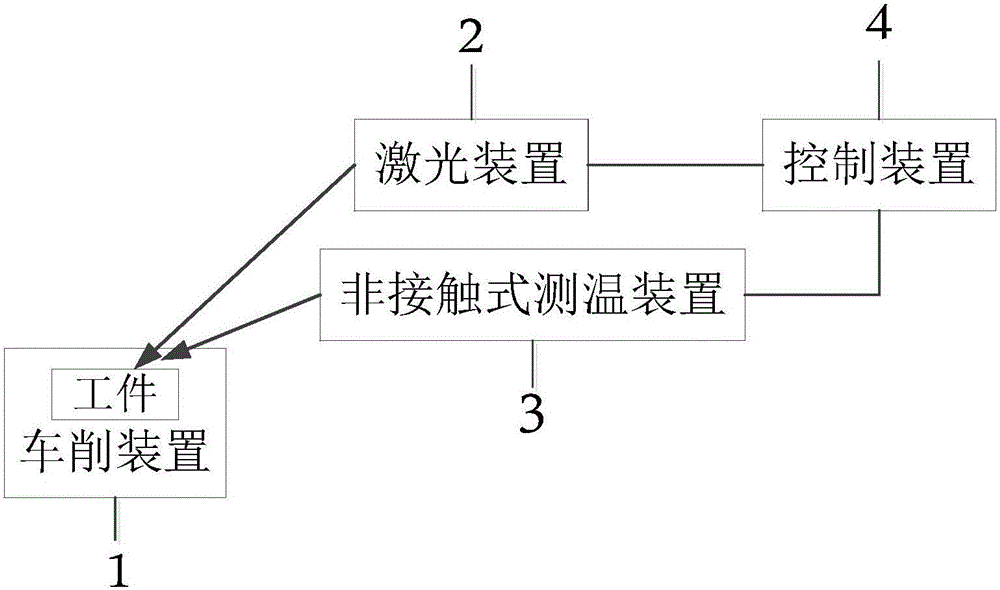

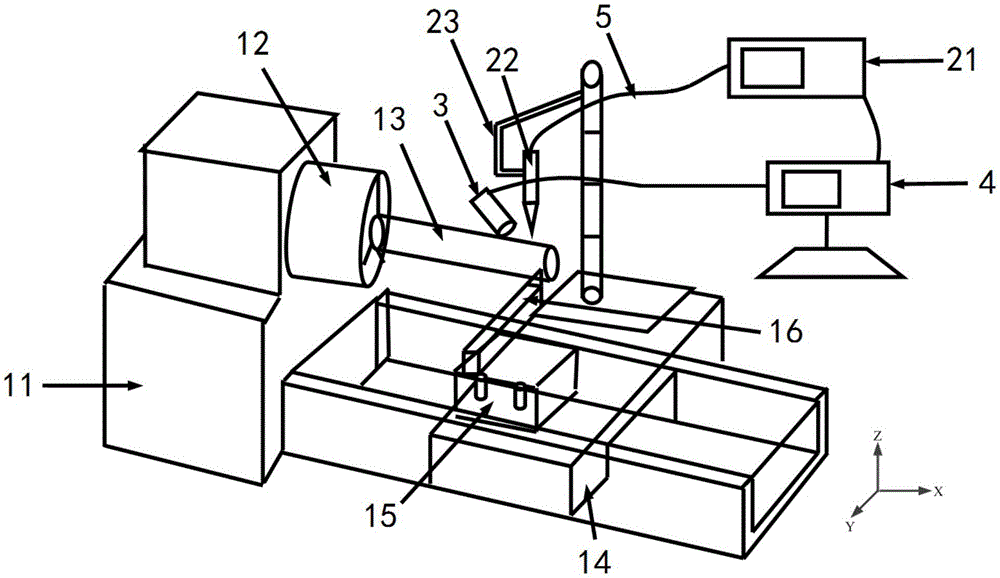

[0026] see figure 1 and figure 2 , which are respectively a functional structure block diagram and a structural schematic diagram of a laser heating assisted turning device of the present invention.

[0027] combine figure 1 and figure 2 As shown, a laser heating-assisted turning device includes a turning device 1, on which a workpiece 13 and a cutter 16 are fixed on the said turning device, and said cutter 16 is detachably connected with said turning device; a laser device 2 , for heating the workpiece 13 by laser; a non-contact temperature measuring device 3, for collecting the temperature at the cutting place of the workpiece 13 in real time; a control device 4, which is respectively connected with the laser device 2 and the The non-contact temperature measuring device 3 is connected, and the control device 4 is used to compare the data of the optimal temperature field stored in it with the temperature data collected in real time by the non-contact temperature measurin...

Embodiment 2

[0040] As mentioned above, the laser heating assisted turning device, the difference of this embodiment is that, as figure 2 As shown, the non-contact temperature measuring device 3 is one of an infrared thermal imager, an infrared thermometer and a non-contact temperature sensor.

[0041]In this embodiment, the non-contact temperature measuring device 3 is preferably the infrared thermal imager 3, the infrared thermal imager 3 is easy to realize online temperature monitoring of laser heating assisted turning, which not only has non-contact, high sensitivity , Large temperature measurement range, fast response, no need to stop during the monitoring process, etc., and can eliminate the influence of other environmental noises in the processing process, which improves the efficiency of laser heating assisted turning. In addition, the infrared thermal imager does not Limited by materials, almost all metal and non-metal materials have infrared radiation under certain conditions, a...

Embodiment 3

[0043] As mentioned above, the turning device assisted by laser heating, the difference of this embodiment is that, as figure 2 As shown, the laser device 2 includes a laser 21 and a laser focusing head 22. The laser focusing head 22 heats the workpiece 13 by emitting laser light. The control device 4, the laser 21 and the laser focusing head 22 are connected successively.

[0044] The laser device 2 also includes a focus head adjustment device 23, which is used to fix the laser focus head 22 and can adjust the laser incident direction of the laser focus head 22 and the incident laser beam on the surface of the workpiece 13. The diameter of the light spot, the thermal imaging camera 3 is installed on one side of the workpiece 13, and irradiates the area of the workpiece 13 to be cut at a certain angle.

[0045] Because the optical fiber has the advantages of large transmission capacity, strong anti-interference, stable signal, fast propagation speed, etc., the connection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com