Patents

Literature

456 results about "Lead dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead(IV) oxide, commonly called lead dioxide, plumbic oxide or anhydrous plumbic acid (sometimes wrongly called lead peroxide), is a chemical compound with the formula PbO₂. It is an oxide where lead is in an oxidation state of +4; bond type is predominantly covalent. It is an odorless dark-brown crystalline powder which is nearly insoluble in water. It exists in two crystalline forms. The alpha phase has orthorhombic symmetry; it was first synthesized in 1941 and was identified in nature as a rare mineral scrutinyite in 1988. The more common tetragonal beta phase was first identified as the mineral plattnerite around 1845 and later produced synthetically. Lead dioxide is a strong oxidizing agent which is used in the manufacture of matches, pyrotechnics, dyes and other chemicals. It also has several important applications in electrochemistry, in particular as the positive plate (anode) of lead acid batteries.

High performance energy storage devices

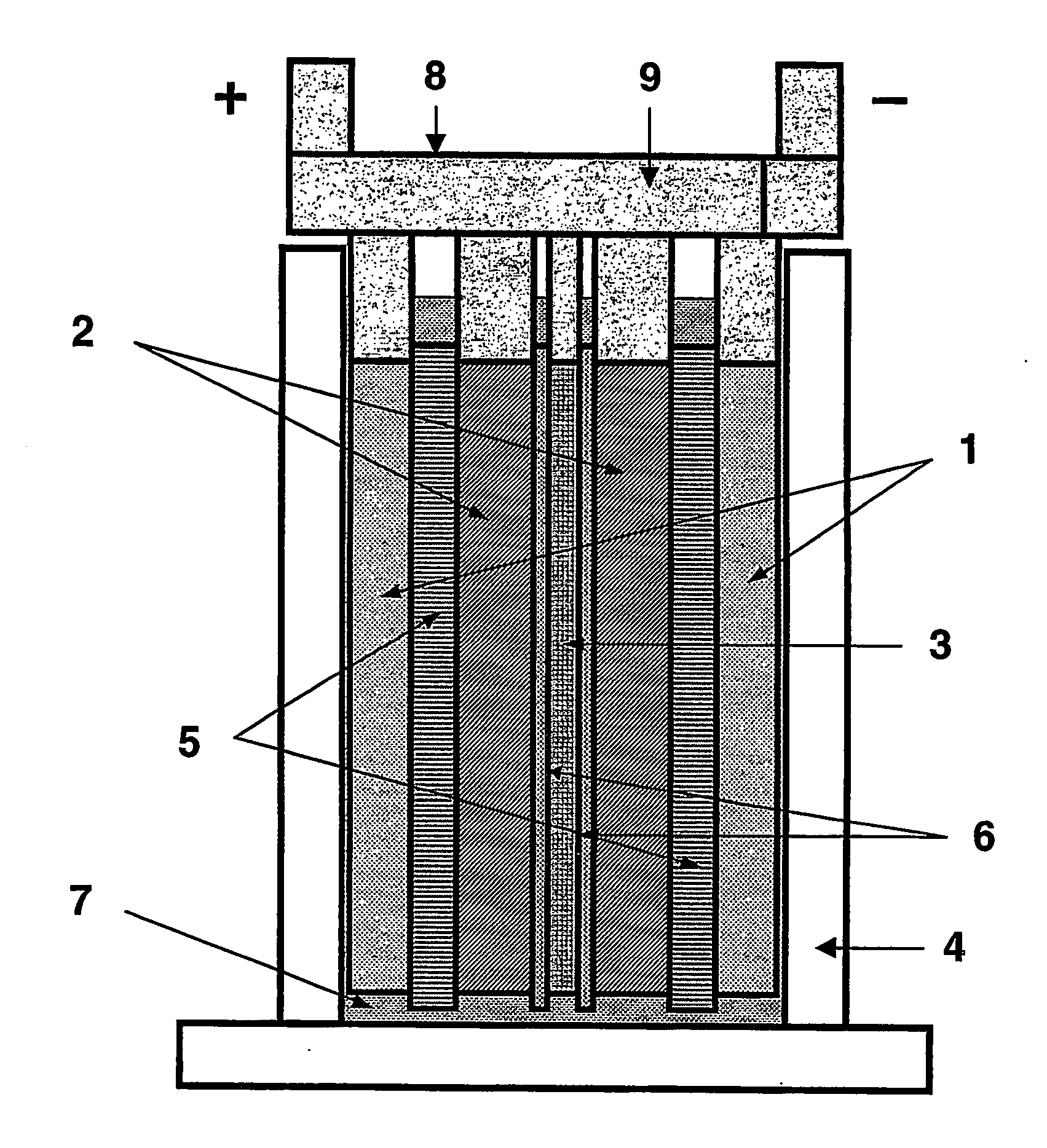

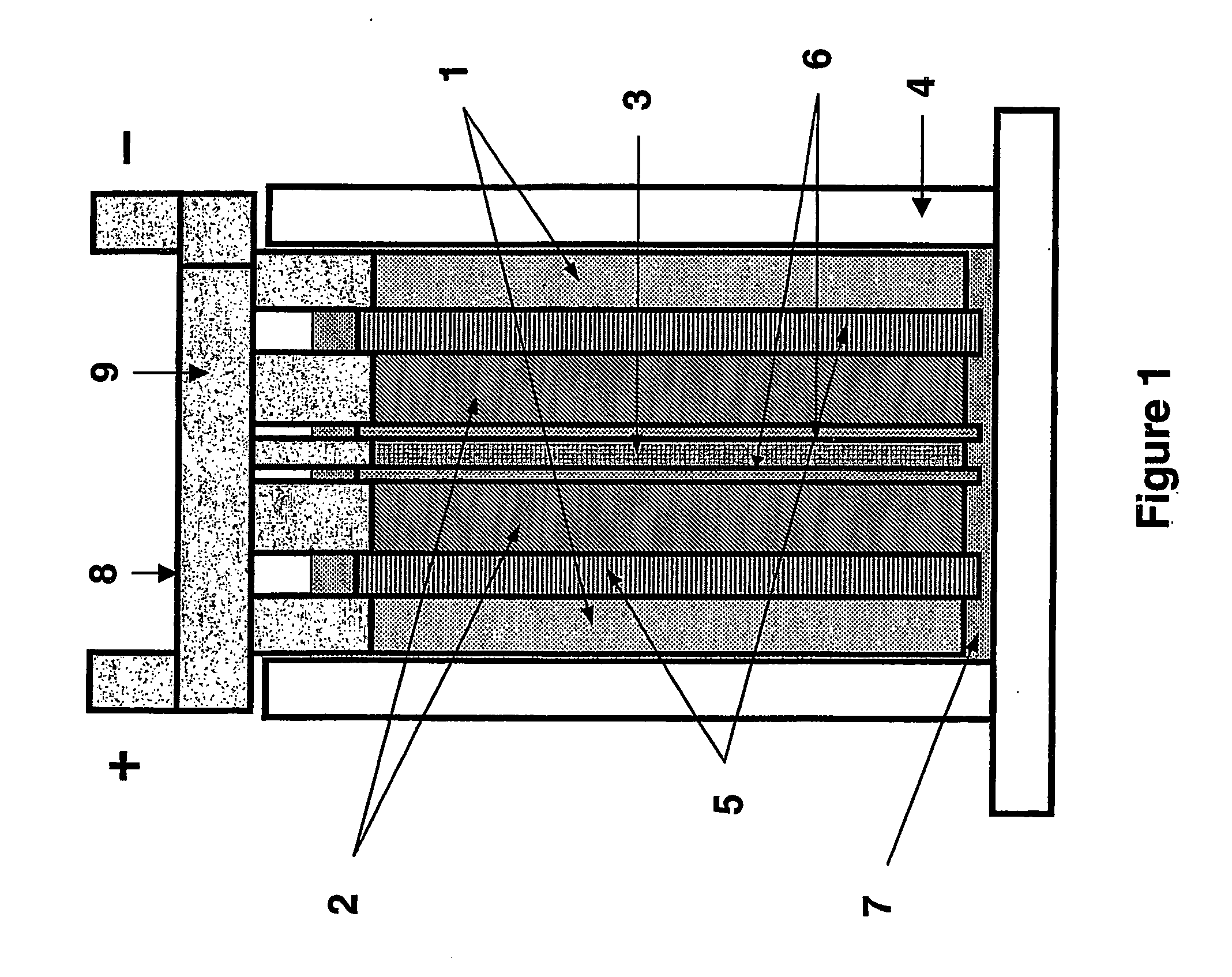

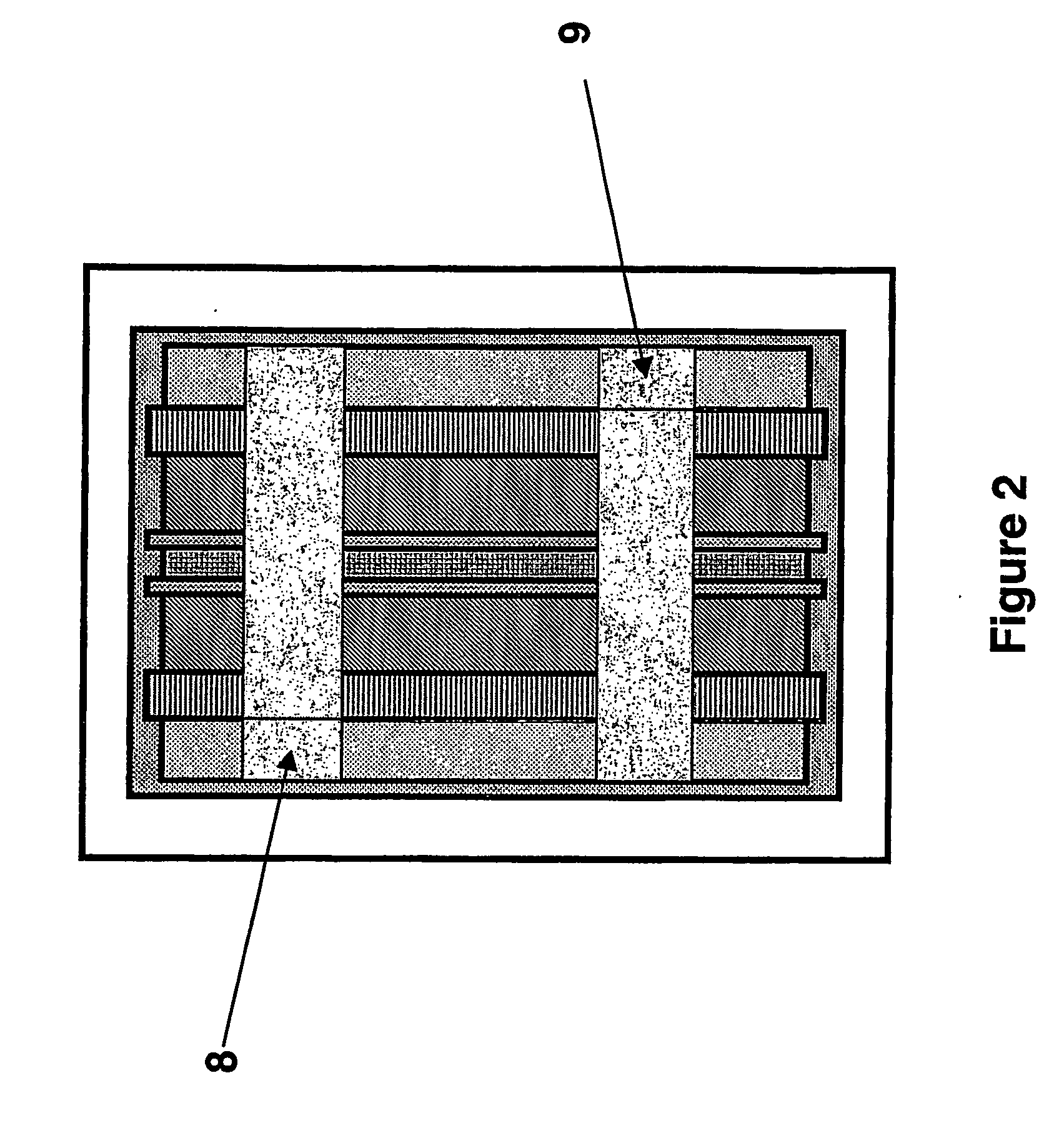

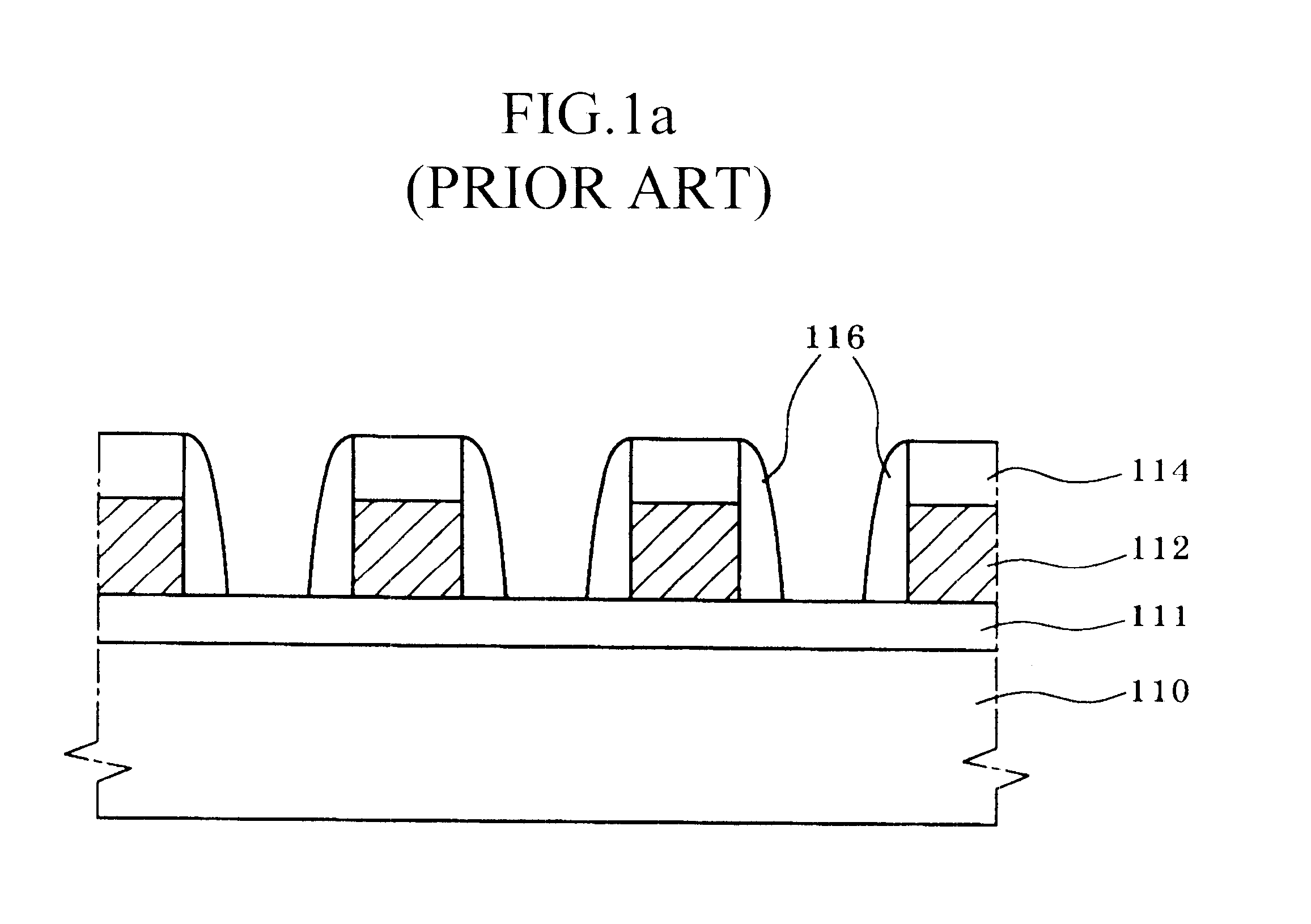

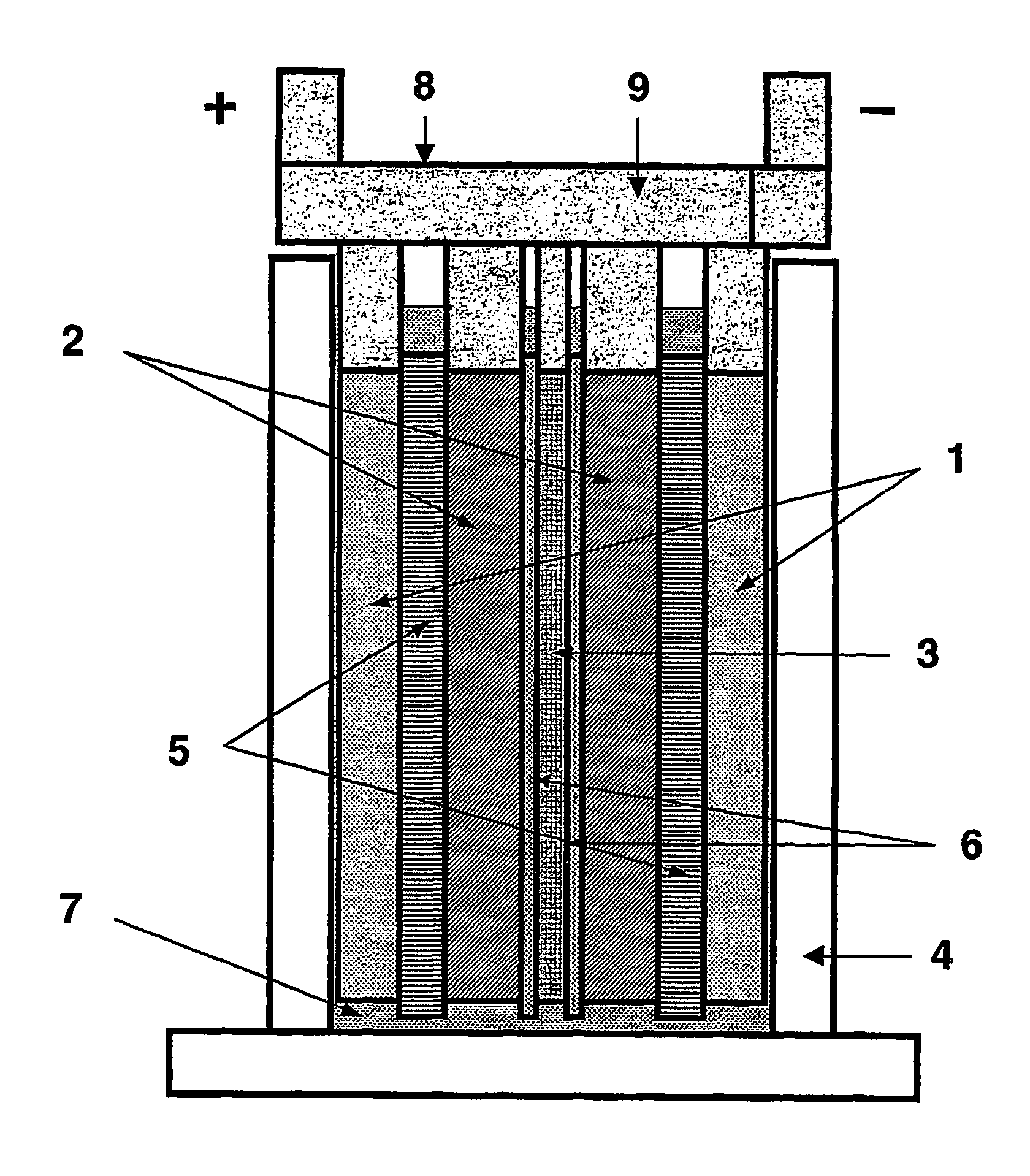

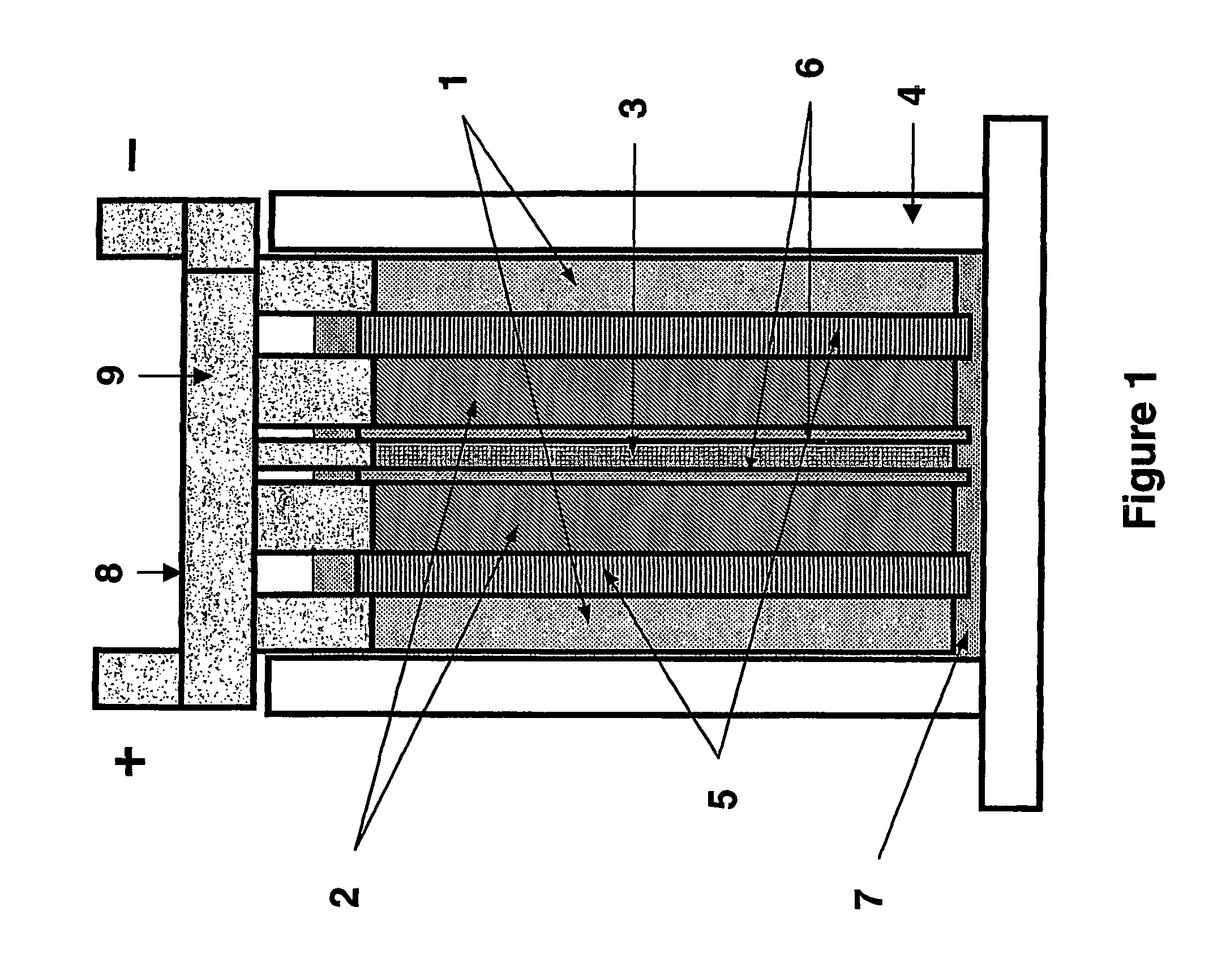

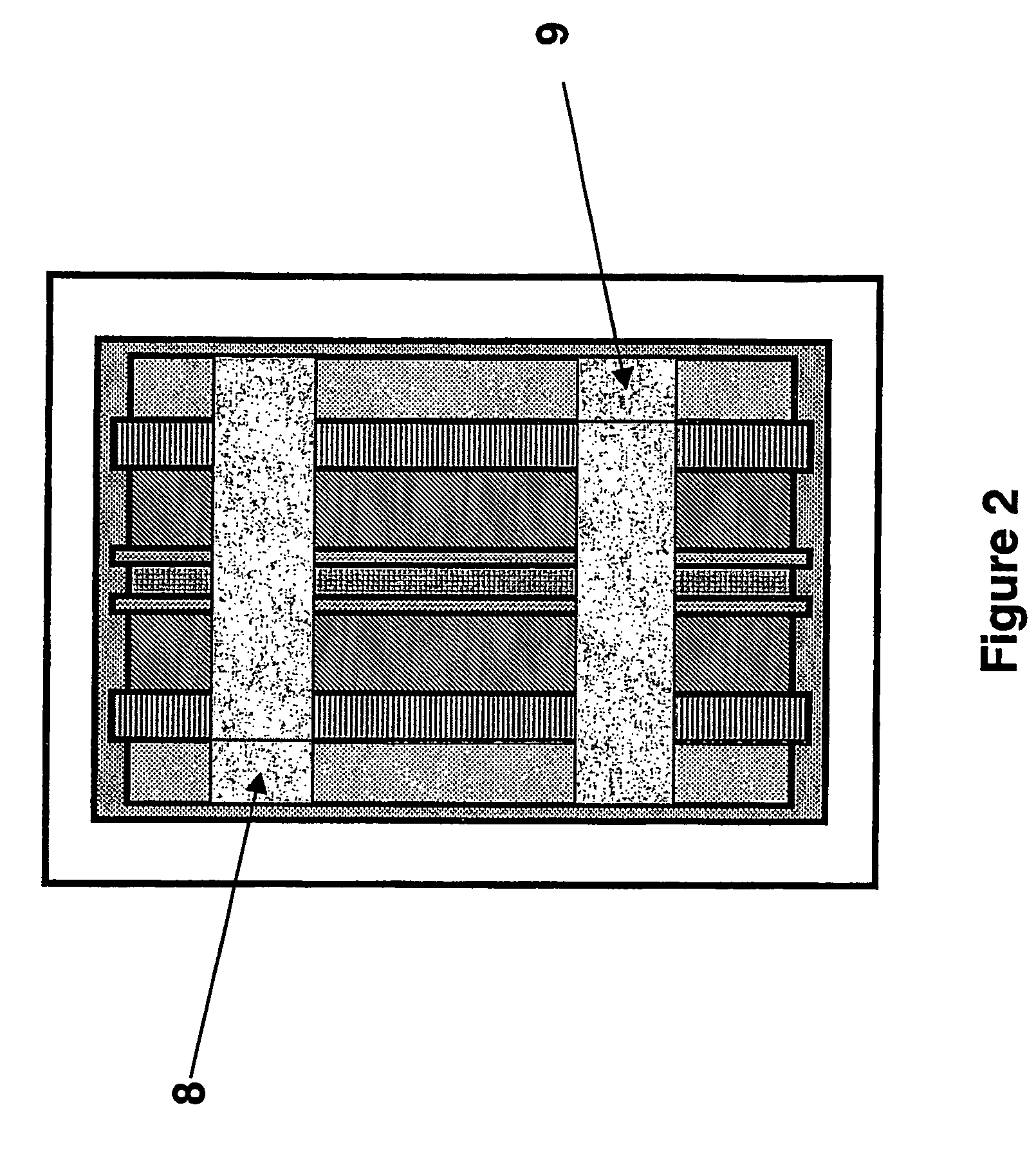

ActiveUS20070104981A1Avoid gasLower internal resistanceHybrid capacitor electrolytesCapacitor and primary/secondary cellsLead dioxideBusbar

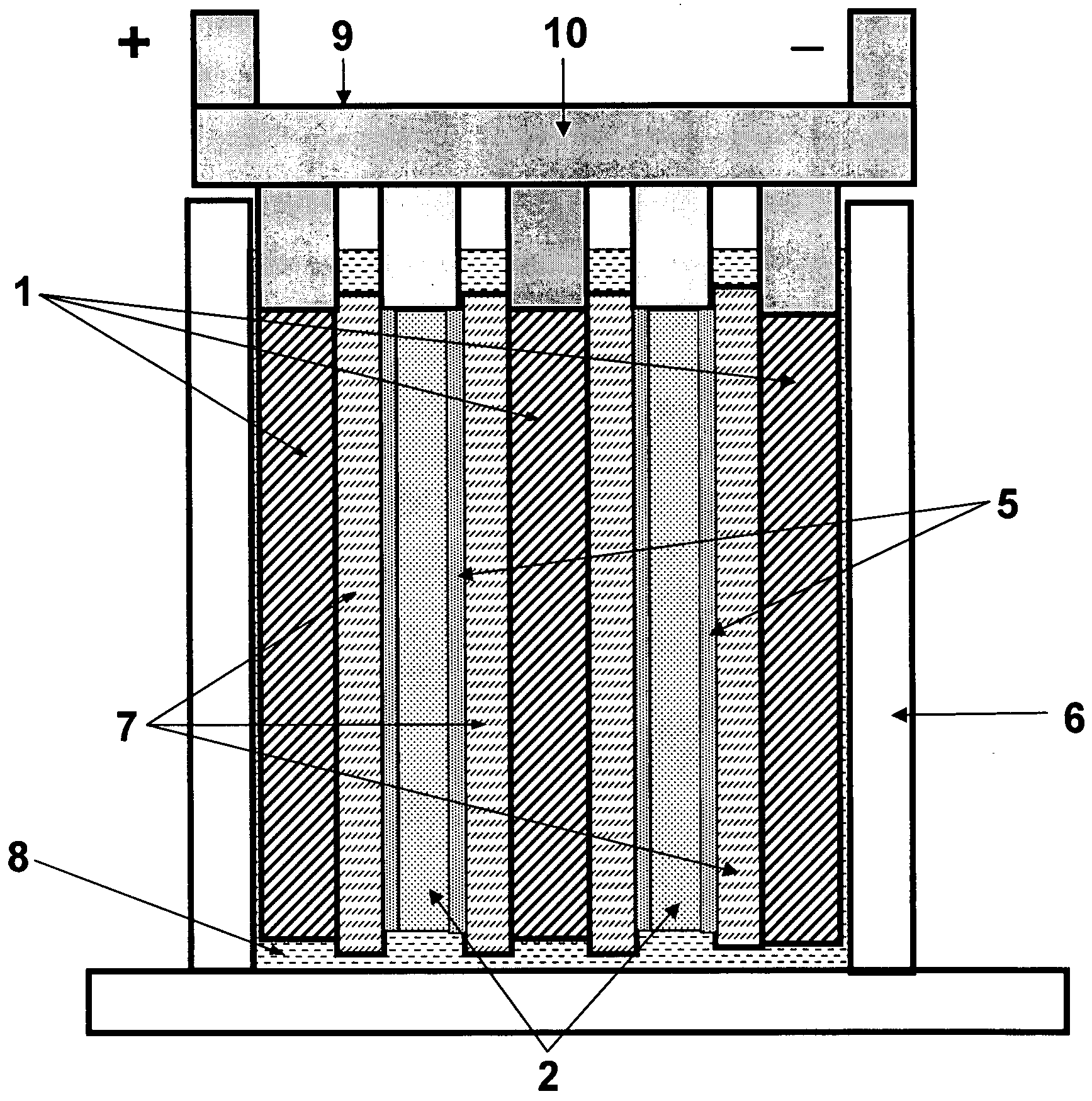

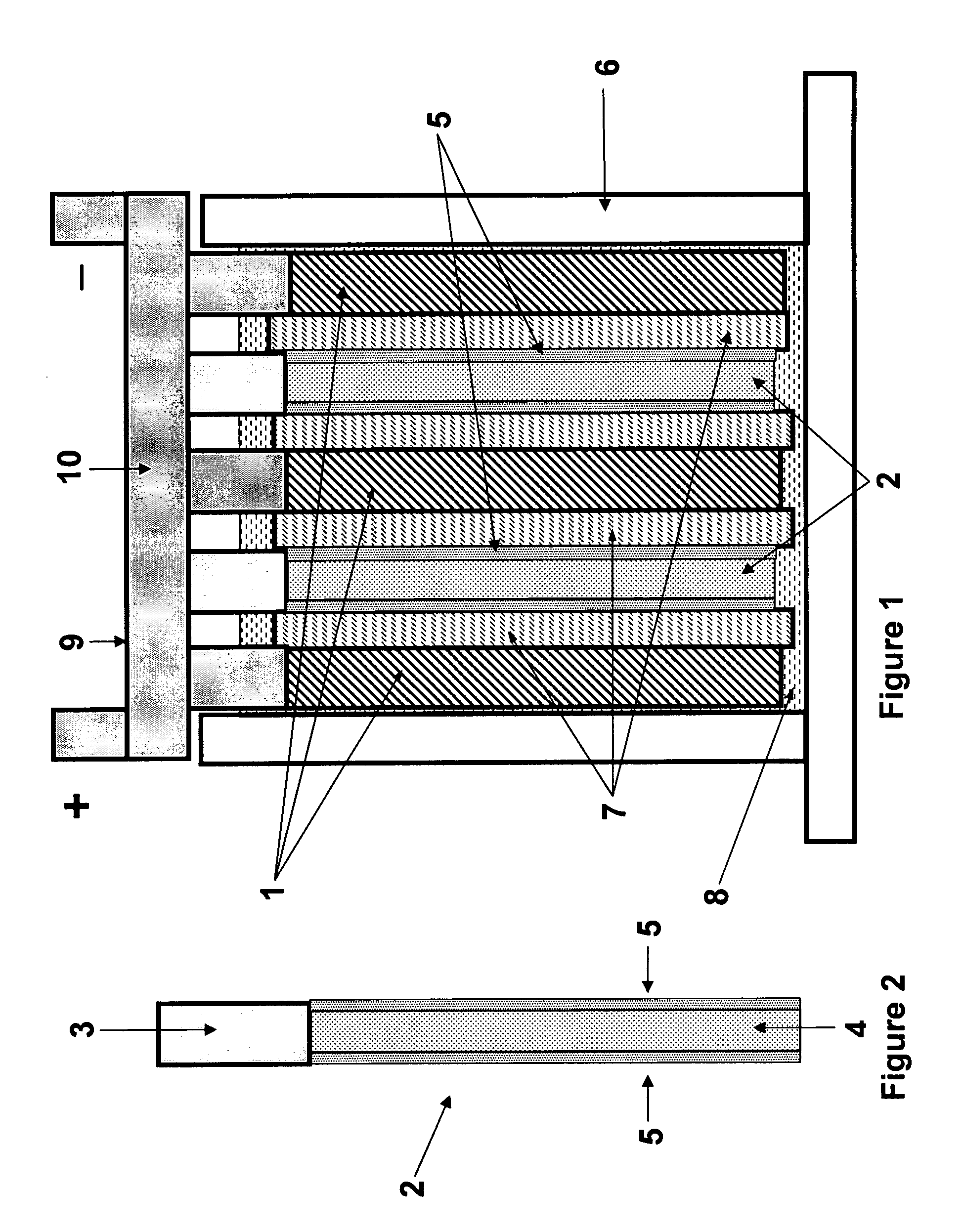

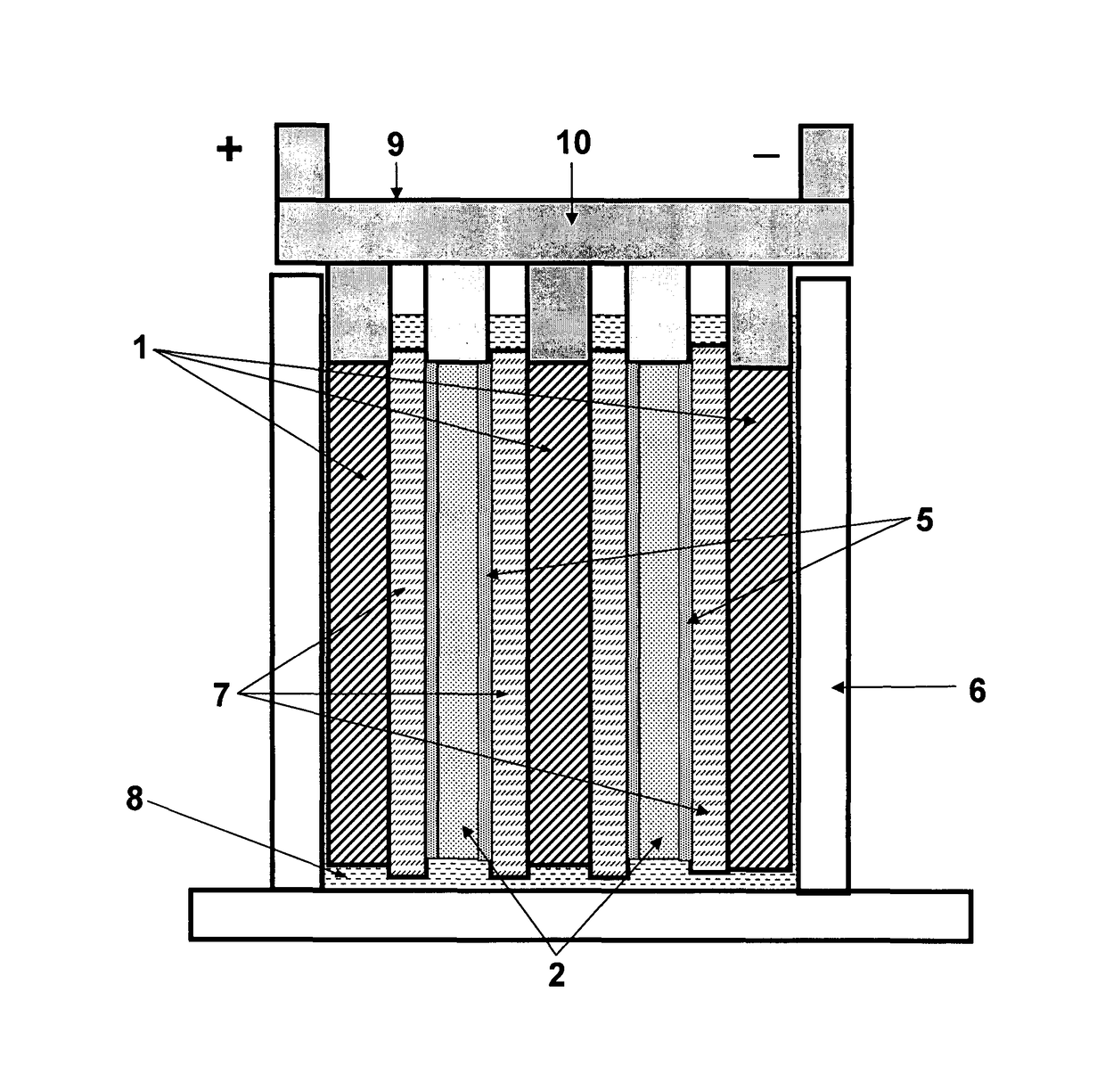

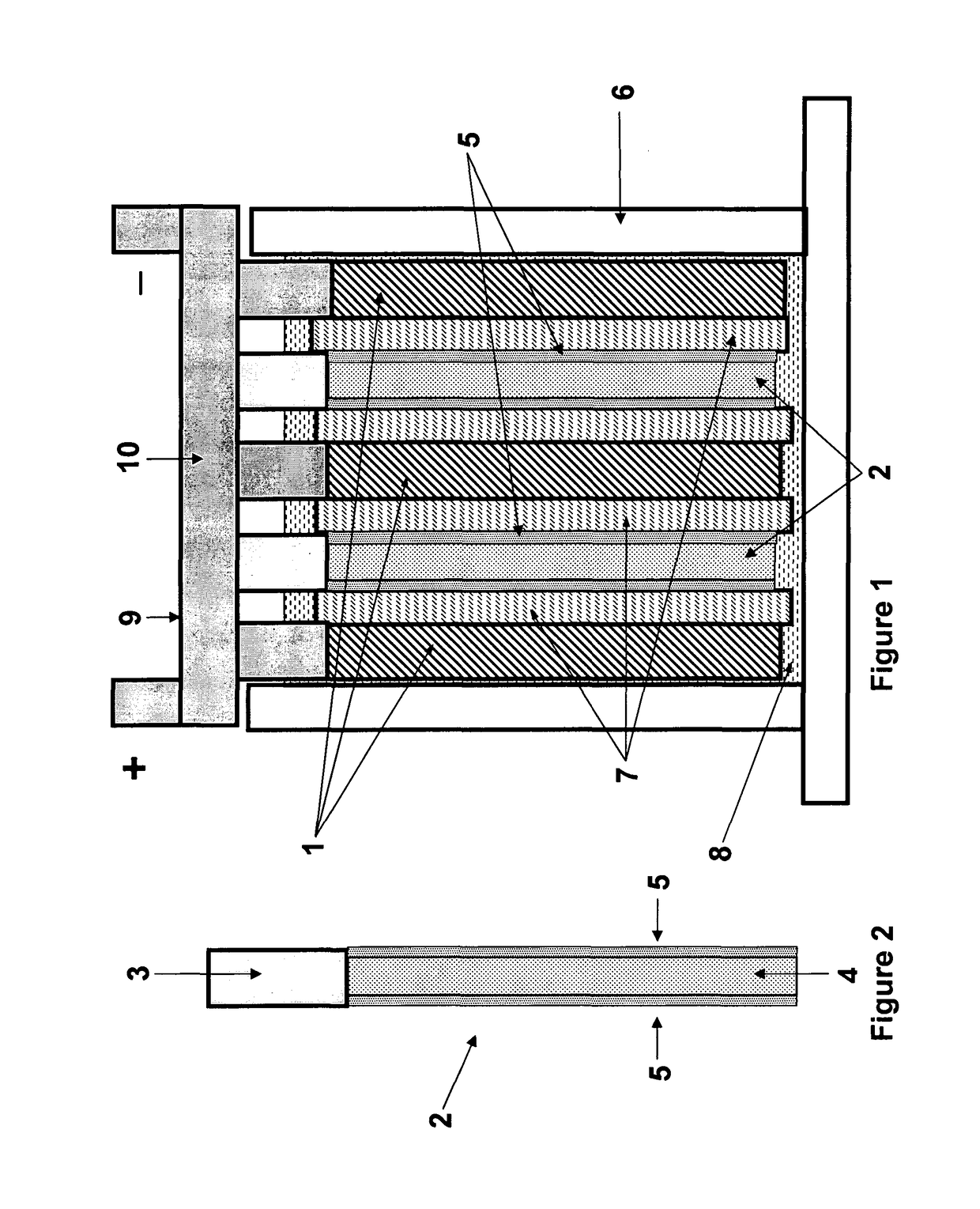

A lead-acid battery comprising: at least one lead-based negative electrode; at least one lead dioxide-based positive electrode; at least one capacitor electrode; and electrolyte in contact with the electrodes; wherein a battery part is formed by the lead based negative electrode and the lead dioxide-based positive electrode; and an asymmetric capacitor part is formed by the capacitor electrode and one electrode selected from the lead based negative electrode and the lead-dioxide based positive electrode; and wherein all negative electrodes are connected to a negative busbar, and all positive electrodes are connected to a positive busbar. The capacitor electrode may be a capacitor negative electrode comprising carbon and an additive mixture selected from oxides, hydroxides or sulfates of lead, zinc, cadmium, silver and bismuth, or a capacitor negative electrode comprising carbon, red lead, antimony in oxide, hydroxide or sulfate form, and optionally other additives. The capacitor electrode may be used in asymmetric capacitors and batteries of other types.

Owner:COMMONWEALTH SCI & IND RES ORG

Electric double layer capacitor

InactiveUS6466429B1Lower internal resistanceInhibit sheddingHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonLead dioxide

The present invention is directed to a novel capacitor. The capacitor may be used in electric double layer capacitors. The capacitors include a polarizable electrode including activated carbon and a non-polarizable electrode including lead dioxide and lead sulfate. The capacitors of the present invention provide considerably higher electric capacity, higher durability, and low resistance, while maintaining high conductivity. Additionally, the electrodes may be produced more quickly and inexpensively.

Owner:WAINWRIGHT D WALKER

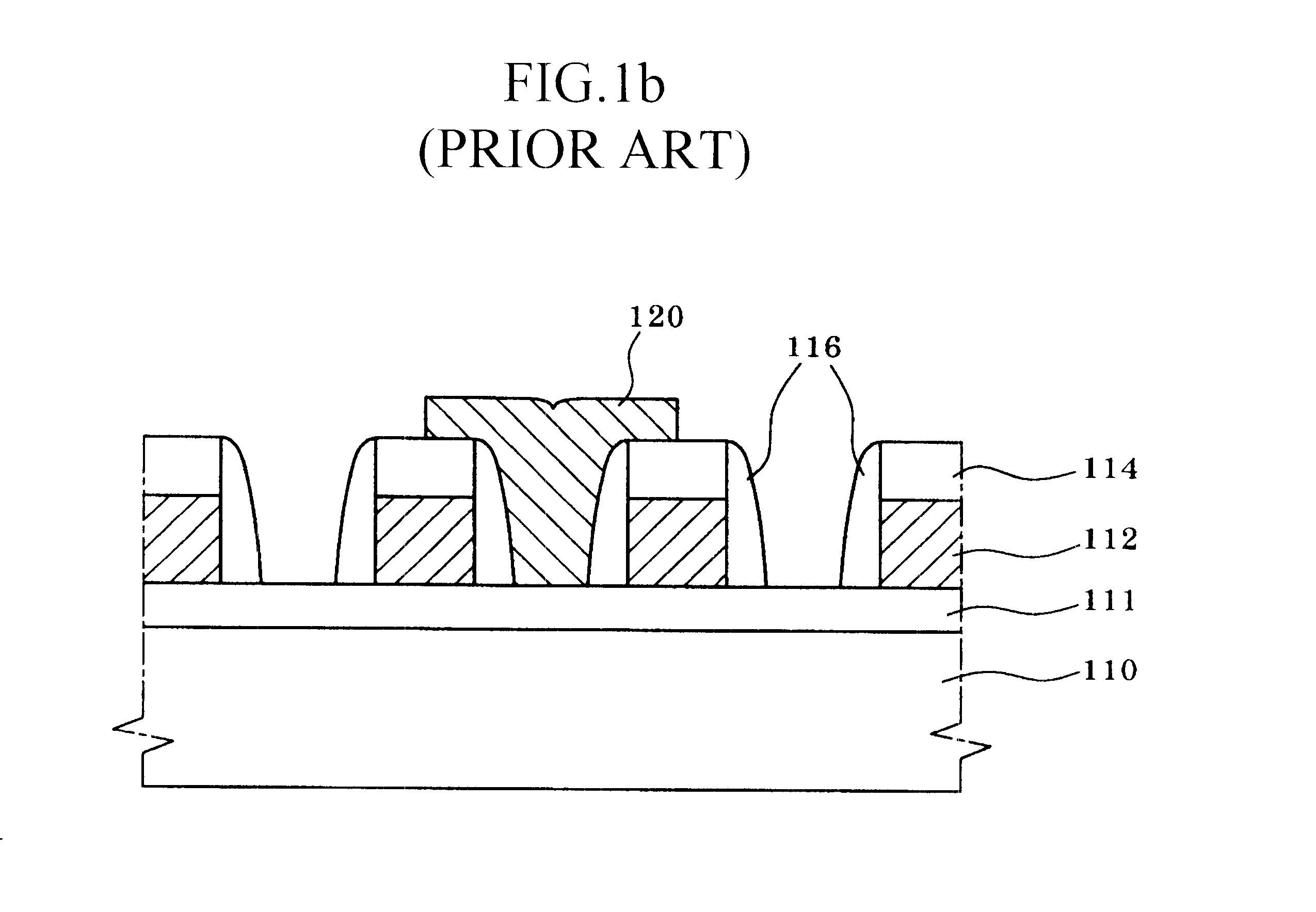

Waste lead recovering method for lead-acid storage batteries

InactiveCN101608264AAvoid harmLower decomposition temperaturePhotography auxillary processesProcess efficiency improvementLead dioxideEngineering

The invention discloses a waste lead recovering method for lead-acid storage batteries. The method comprises the following steps: fine stuff such as diachylon and the like are added in a reaction kettle with a stirring device; reducing agent (FeSO4) and dilute sulfuric acid are simultaneously added; stirring reaction is carried out at the temperature of 50-60 DEG C for 50-70 minutes so as to reduce lead dioxide into lead sulfate; the lead sulfate is added into the reaction kettle with the stirring device; water is simultaneously added into the reaction kettle for size mixing; then sodium carbonate is added; desulfuration is carried out at the temperature of 50-60 DEG C so as to obtain solid lead carbonate; the lead carbonate is put into a smelting furnace and then decomposed at the temperature of 320-350 DEG C so as to obtain lead oxide; and reducing agent (carbon) is added into the smelting furnace to reduce the lead oxide into metal lead at the temperature of 700-800 DEG C. The method recovers the lead by means of the combination of the wet and the dry processes, thereby avoiding the harm to the environment caused by lead dust, lead vapor, lead skim, sulfur dioxide gas, and the like by adopting fire smelting. The method has the advantages of high lead recovery rate, low energy consumption and no environment pollution.

Owner:张天任

Process for recovering lead oxides from exhausted batteries

ActiveUS7507496B1Speed up the processObtained inexpensivelySolvent extractionPrimary cell maintainance/servicingLead dioxideLead oxide

A process for recovering lead oxides from the spent paste of exhausted lead acid batteries. The process provides heating the spent paste with an alkali hydroxide solution at elevated temperatures prior to calcinations. Calcination is at various temperatures so that either lead mono-oxide, lead dioxide or red lead is obtained as the principal product. There is also provided the use of the lead oxide to prepare the paste for positive and negative electrodes or other lead compounds.

Owner:RETRIEV TECH +1

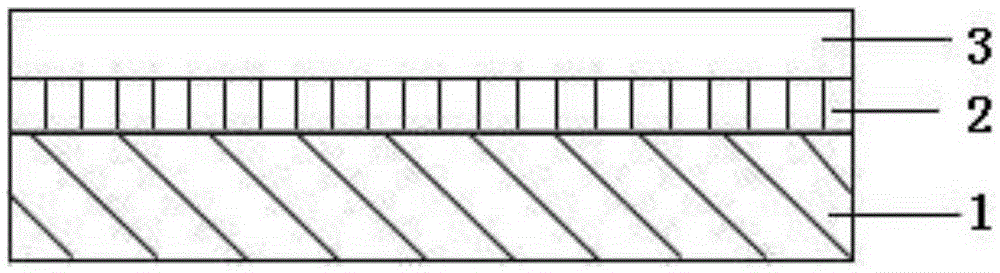

Novel ti-supported lead dioxide electric pole and preparation method thereof

InactiveCN101417831ALow costReduce internal stressWater/sewage treatment by sorptionAcid etchingLead dioxide

The invention relates to a novel titanium substrate lead dioxide electrode and a preparation method thereof, which belong to the field of water treatment technology application. The titanium substrate lead dioxide electrode adopts titanium material as a carrier; after the titanium substrate undergoes acid etching, pyrolytic process is adopted to plate a tin-stibium oxide bottom layer; alkaline solution is then used for electroplating an alpha-PbO2 intermediate layer; acidic composite electroplating solution is used for preparing a fluorine-containing beta-PbO2 surface layer doped with an active metal (such as bismuth, nickel, lanthanum, cerium and erbium) and a particle with high absorption performance (such as powdered activated carbon and chitosan), thus obtaining a novel titanium substrate lead dioxide electrode. The titanium substrate lead dioxide electrode prepared by the method has low cost and long service life. Using the electrode as an anode and applying certain applied voltage can realize efficient removal and mineralization to the organic contaminants in the water. With simple operation and convenient management, the method is applicable to small-scale and dispersible wastewater and feed water treatment.

Owner:BEIJING NORMAL UNIVERSITY

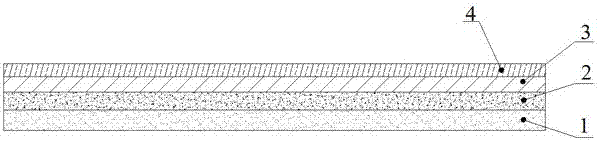

Method of preparing fluorine-containing lead dioxide electrode on titanium basal body

The present invention relates to a process for preparing fluorine containing lead dioxide electrode at titanium substrate. The plating structural of said fluorine containing lead dioxide electrode is as follows: from the titanium substrate surface and from inner to outer, in sequences, there are plated the tin-stibium oxidate bottom layer, alpha-PbO2 layer and fluorine contain containing beta- PbO2 layer. Said method comprises the steps of surface roughening treatment of titanium substrate, then plating the tin-stibium oxidate bottom layer through a thermal decomposition method, and then obtaining titanium substrate fluorine containing beta- PbO2 electrode through alkaline electric plating alpha-PbO2 and acidic composite electric plating beta- PbO2.The fluorine containing lead dioxide electrode prepared through the process and method in accordance with the present invention possesses strong bonding force between the plating layer and the substrate, small limiting surface electric resistance and inner stress, low price amd long service lifetime of electrode, can be applied widely in electrolytic industry fields of acidic system.

Owner:ZHEJIANG UNIV OF TECH

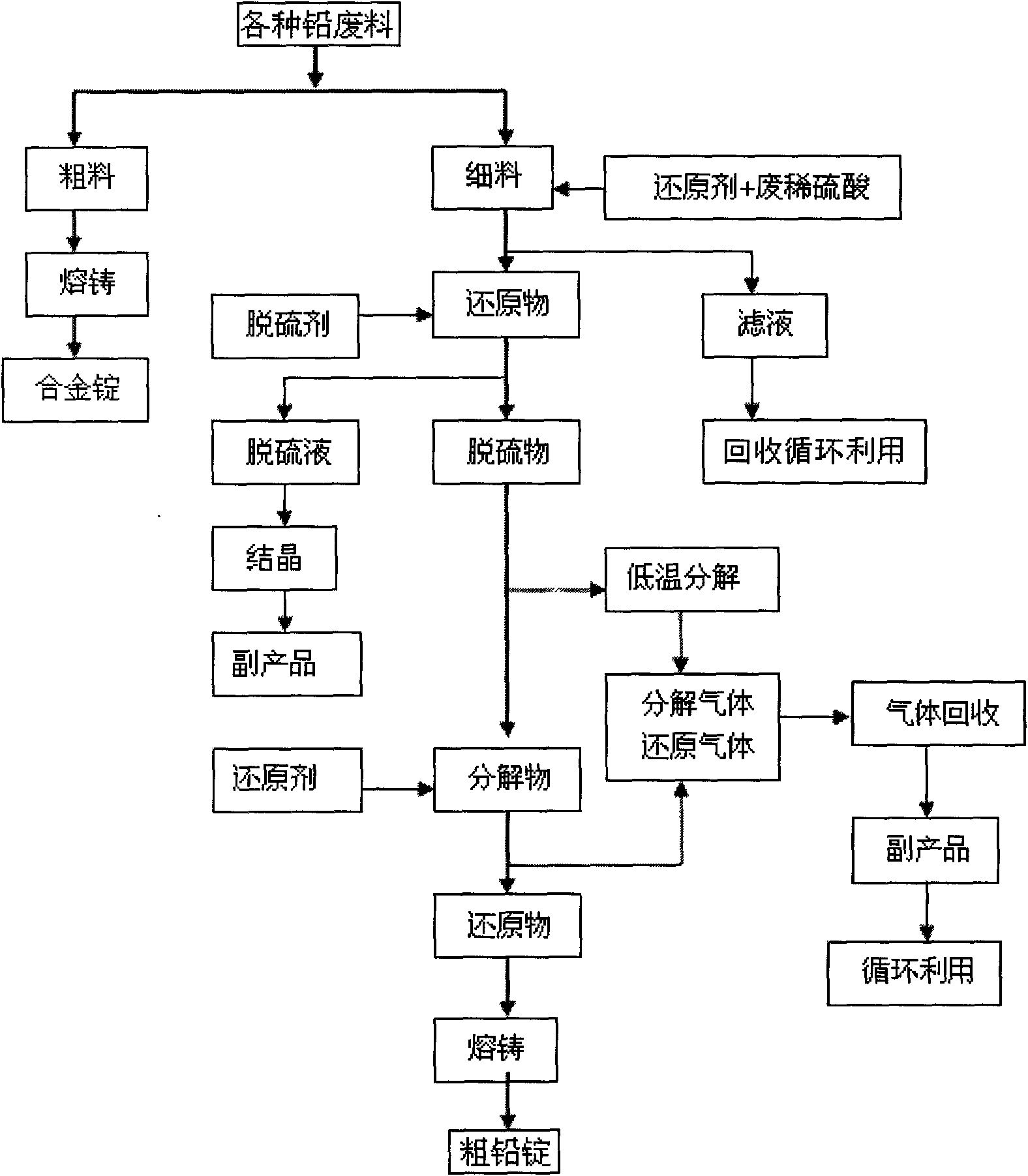

Lead regeneration method for recovering lead paste from waste lead acid storage battery by wet method

ActiveCN102618884AAvoid churnHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisLead dioxide

The invention discloses a lead regeneration method for recovering lead paste from a waste lead acid storage battery by a wet method, and belongs to the field of lead regeneration from the lead paste of the waste lead acid battery. The lead regeneration method comprises the following steps of: adding the lead paste into an acid liquor reaction kettle containing a catalyst to perform oxidation reduction reaction on lead and lead dioxide in the lead paste to obtain soluble lead salt solution; meanwhile, reacting lead oxide with acid to obtain lead salt; separating to obtain insoluble filter residue mainly containing soluble lead salt solution and lead sulfate; and electrolyzing the lead salt solution to obtain lead, oxygen and acidic electrolyte, wherein the electrolyte can be returned to a leaching process for recycling, and the filter residue A is treated by the conventional reselection process to obtain the lead sulfate and the filter residue D. According to the lead regeneration method, the production cost is reduced, and high comprehensive lead recovery rate is obtained.

Owner:北京绿色引领环保科技研究院有限公司

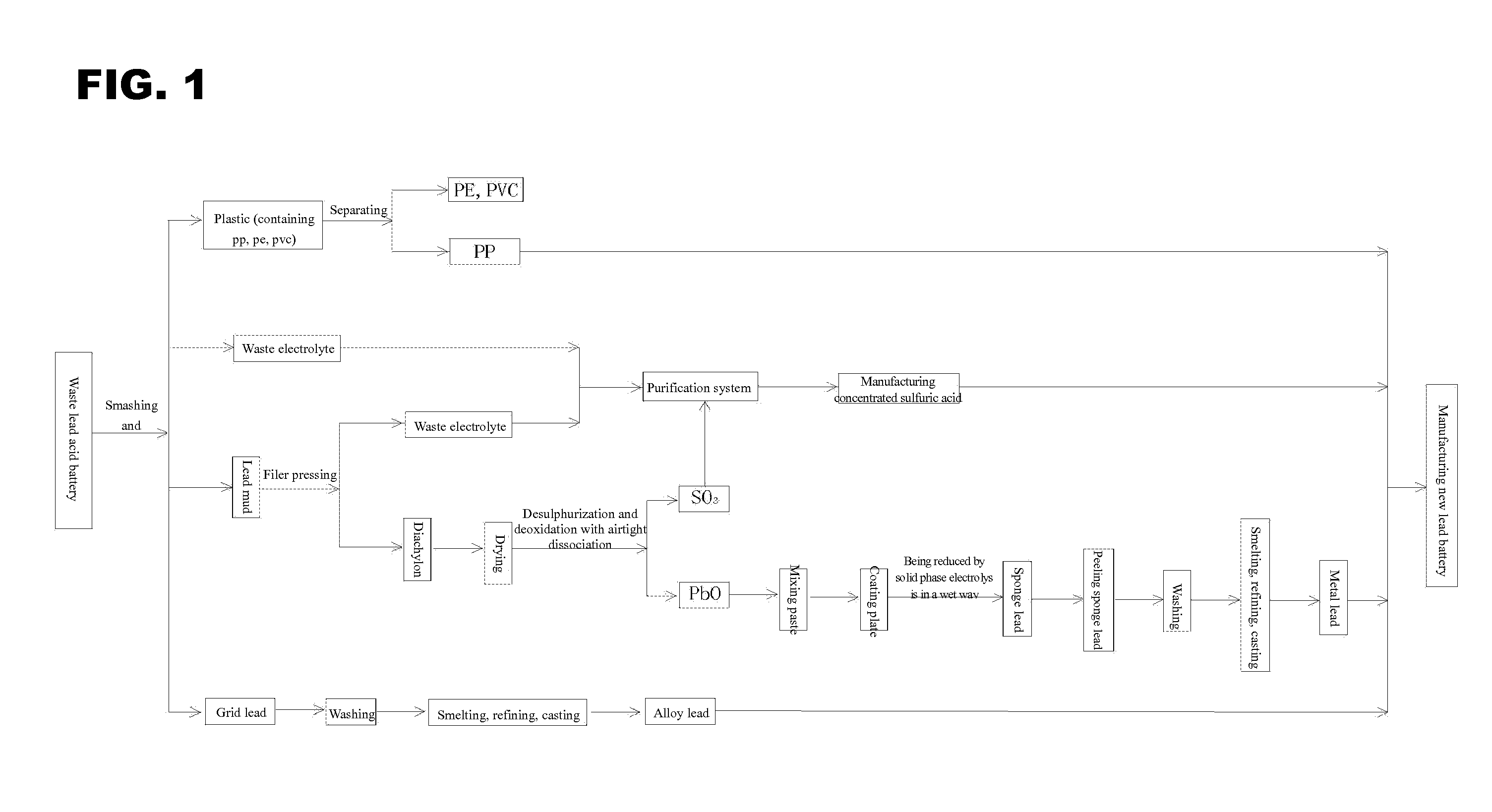

Method for waste lead-acid cell resourcization and lead-acid cell cyclic production

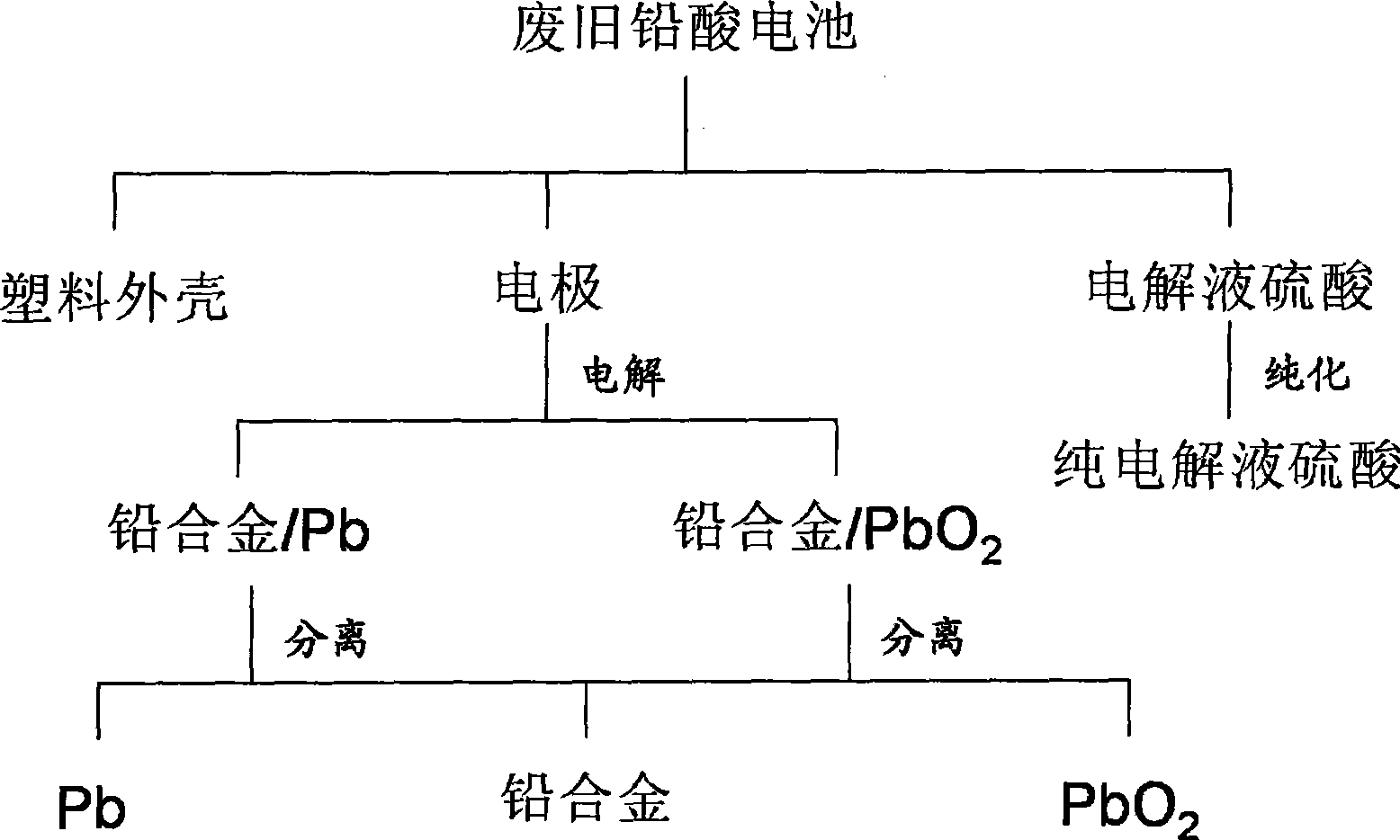

InactiveCN101488597AEliminate pollutionReserve availabilityWaste accumulators reclaimingBattery recyclingLead dioxideAlloy

The invention discloses a method for circularly producing lead acid batteries, aiming at thoroughly eliminating possible hazard of the lead acid battery on environment and leading the lead acid battery to be continuously useful in social life without causing negative effect. The method includes: the positive and negative plates of old and useless batteries are separated by a mechanical method, and then the positive and negative plates are subjected to electrochemical treatment, thus obtaining raw material for producing new lead acid battery and achieving the circular production of the lead acid battery including disassembly of the old and useless lead acid battery, purification of sulphuric acid electrolyte, the production of lead metal and lead dioxide by electrolyzing lead sulfate, the separation and regeneration of lead alloy as well as the production of new lead acid battery by the produced lead alloy, lead and lead dioxide. In theory, by the proposal, the raw material can be totally reused, thus achieving the aim of circularly producing the lead acid battery.

Owner:SOUTHEAST UNIV

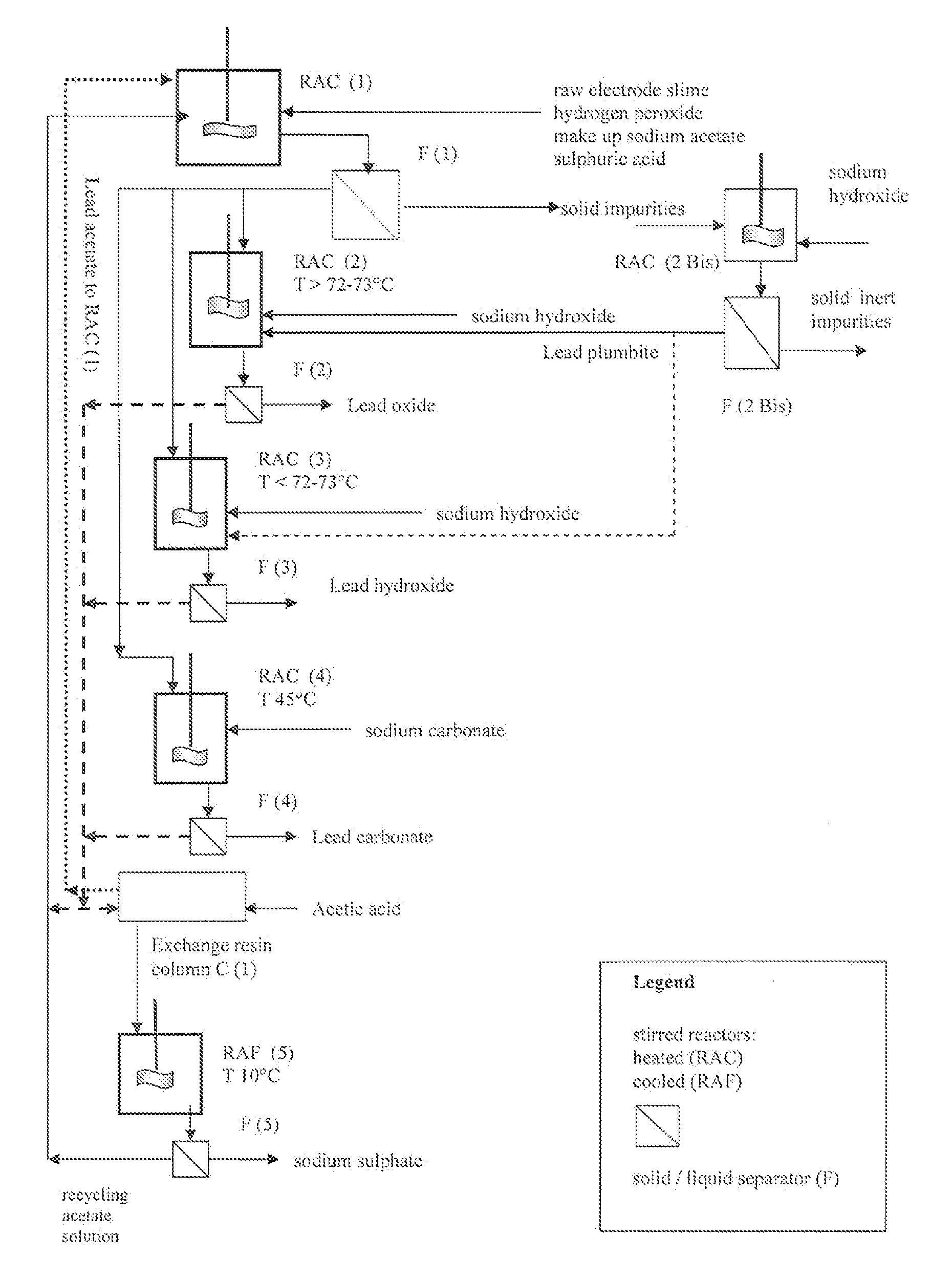

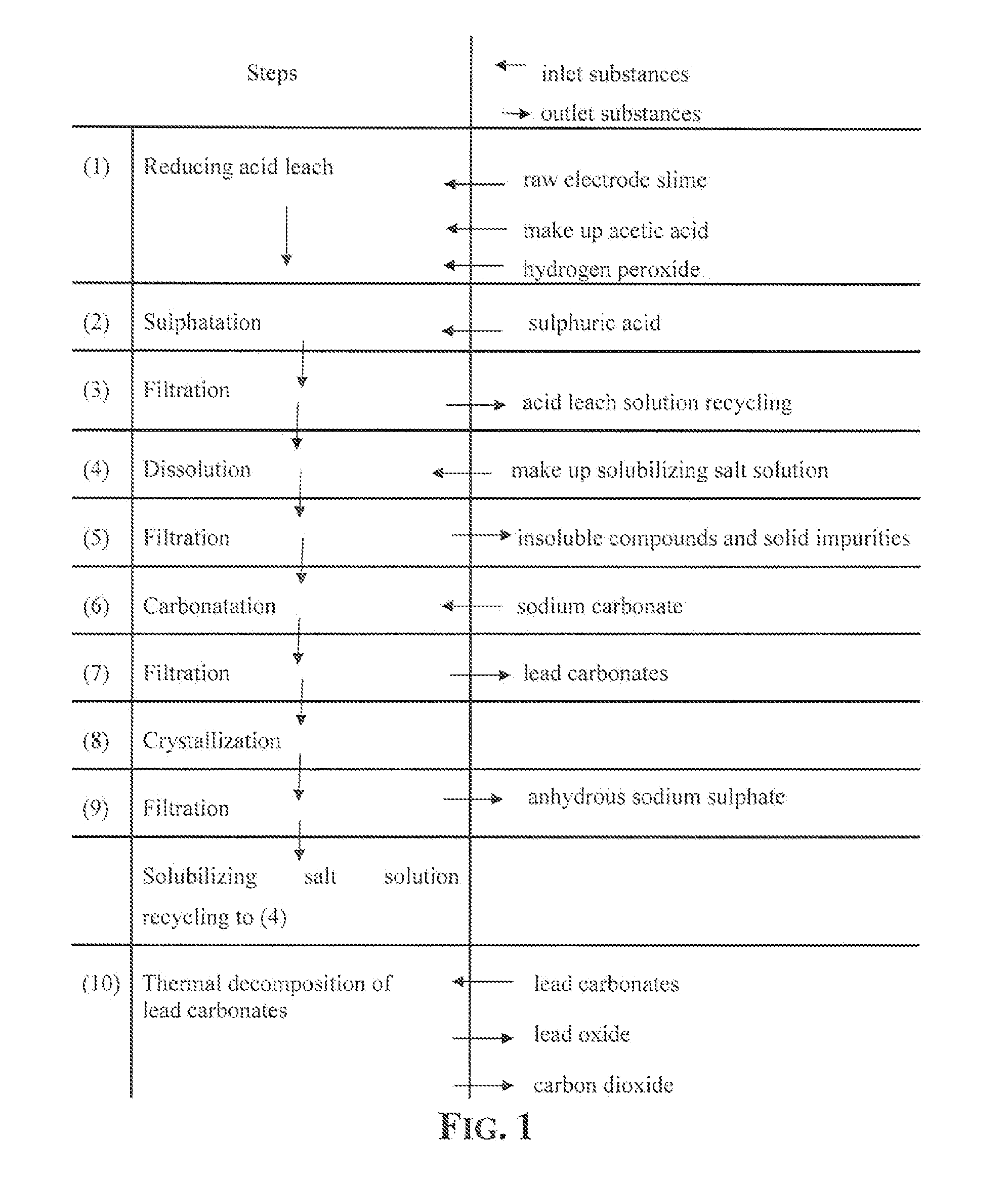

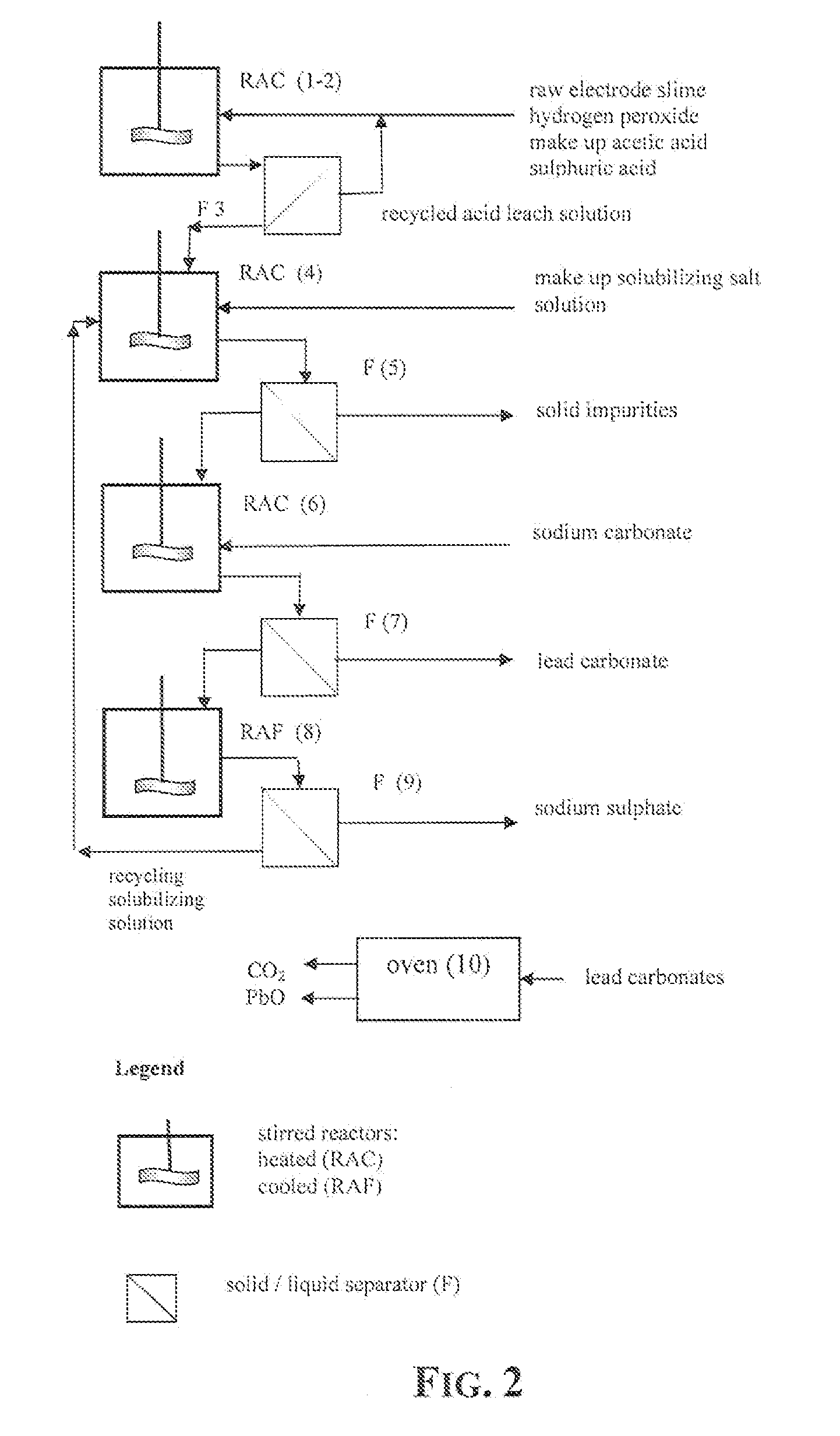

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

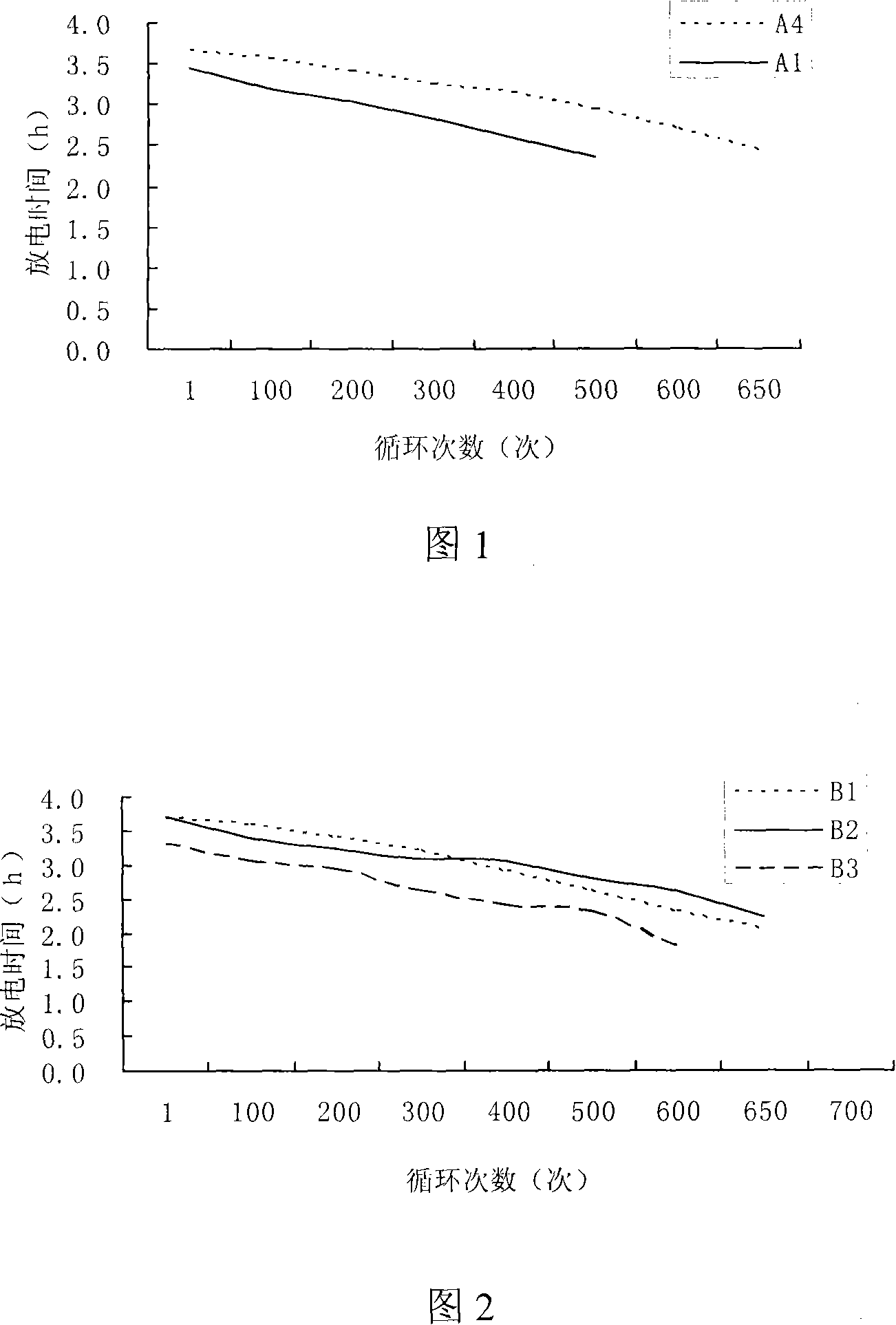

High performance energy storage devices

ActiveUS7923151B2Lower internal resistanceSolution to short lifeCapacitor and primary/secondary cellsElectrolytic capacitorsLead dioxideBusbar

A lead-acid battery comprising:at least one lead-based negative electrode;at least one lead dioxide-based positive electrode;at least one capacitor electrode; andelectrolyte in contact with the electrodes;wherein a battery part is formed by the lead based negative electrode and the lead dioxide-based positive electrode; and an asymmetric capacitor part is formed by the capacitor electrode and one electrode selected from the lead based negative electrode and the lead-dioxide based positive electrode; and wherein all negative electrodes are connected to a negative busbar, and all positive electrodes are connected to a positive busbar.The capacitor electrode may be a capacitor negative electrode comprising carbon and an additive mixture selected from oxides, hydroxides or sulfates of lead, zinc, cadmium, silver and bismuth, or a capacitor negative electrode comprising carbon, red lead, antimony in oxide, hydroxide or sulfate form, and optionally other additives. The capacitor electrode may be used in asymmetric capacitors and batteries of other types.

Owner:COMMONWEALTH SCI & IND RES ORG

Lead-acid accumulator anode lead plaster

InactiveCN101132065AIncrease profitImprove charge acceptanceLead-acid accumulator electrodesFiberCarbon fibers

This invention relates to the plus plate lead paste of lead-acid battery comprising (by weight percentages based on lead powder): lead powder 100%, 1.4g / cm3 sulfuric acid 8-12%, deionized water 9-11%, lead dioxide 3-4.2%, short fiber 0.05-0.06%, carbon fiber 0.10-0.15%, anisotropic graphite 0.2-0.4% and bismuth oxide 0.05-0.11%. In this invention, on the based on certain water and acid content in the active substance, additional positive pole active substances are added such as anisotropic graphite and bismuth oxide or the like. The changed components improve the primary battery volume and the ratio of weight / energy with prolonging battery service life.

Owner:SHENZHEN SUNNYWAY BATTERY TECH

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

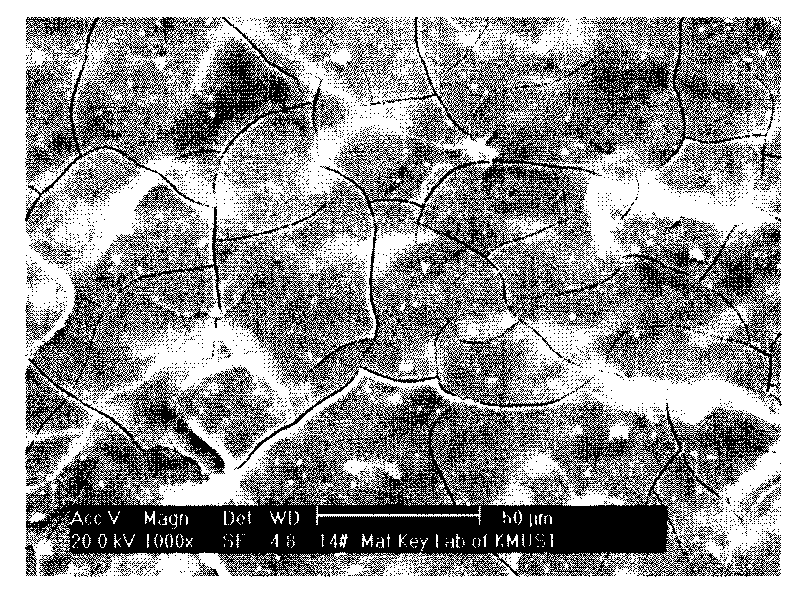

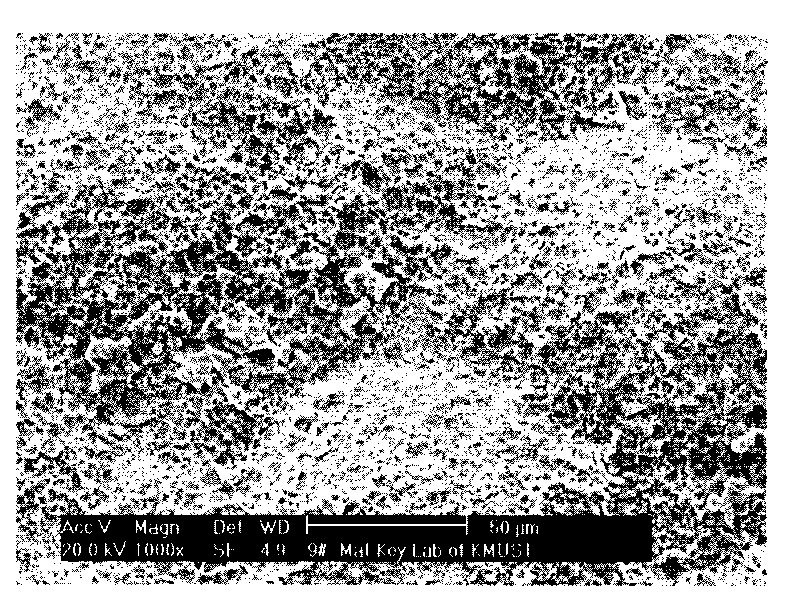

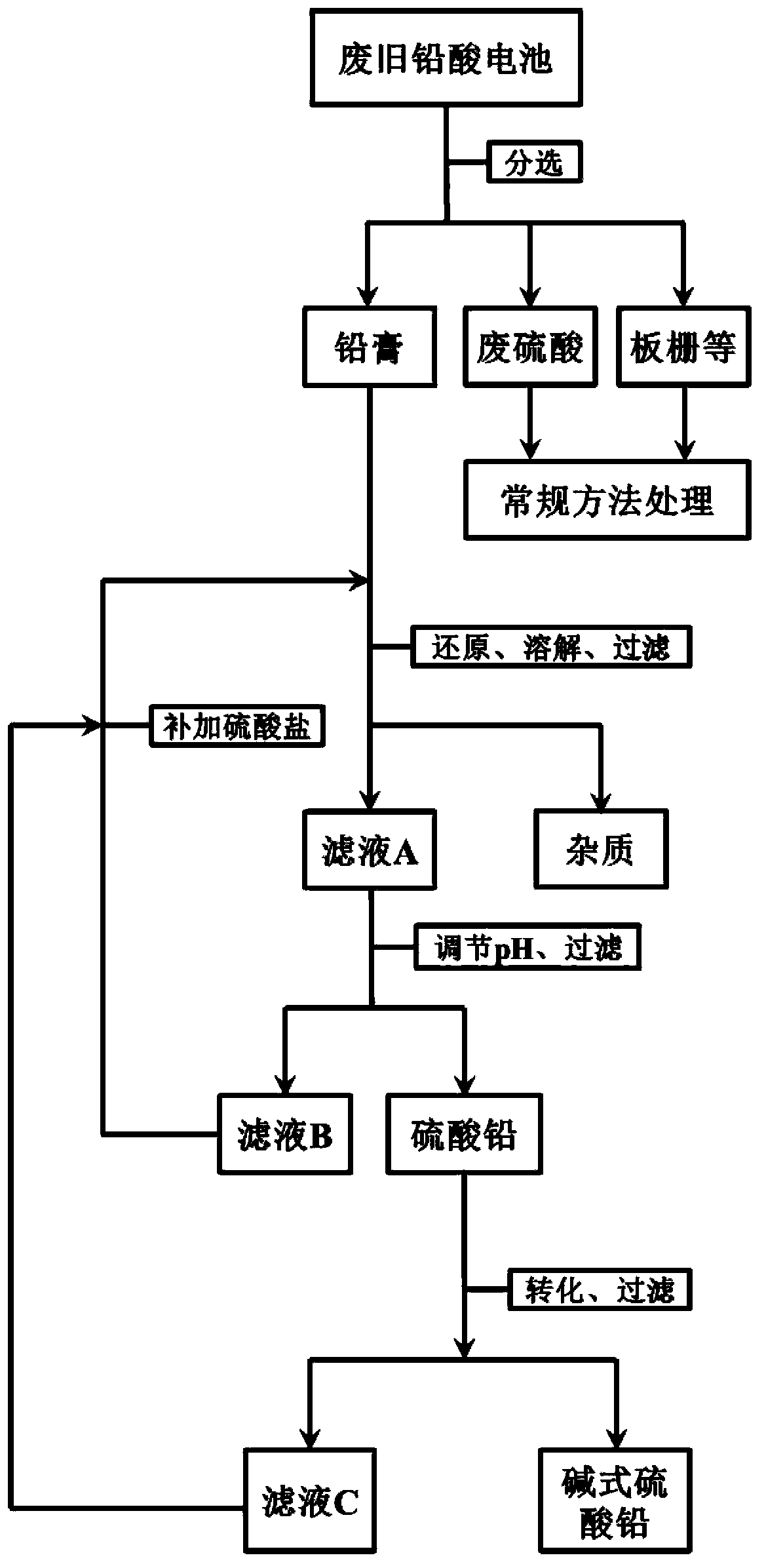

Method for recovering lead-containing raw material by using wet process

ActiveCN103526016AEnvironmentally Friendly Recycling MethodsEfficient recycling methodProcess efficiency improvementRecovery methodLead dioxide

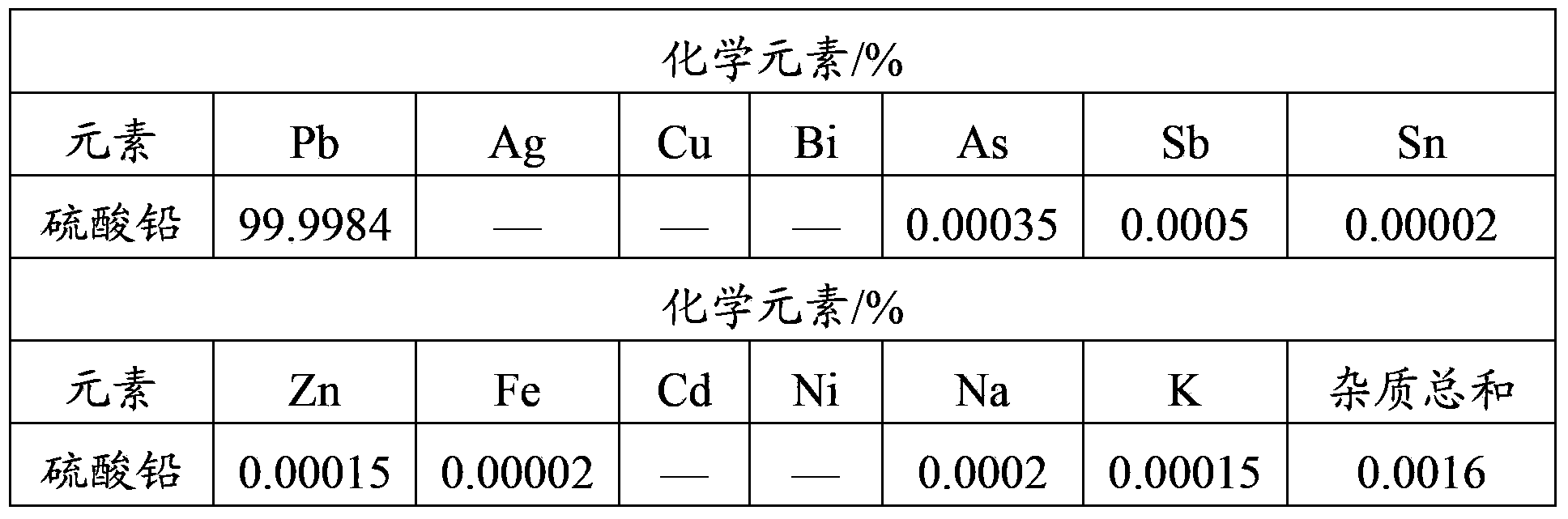

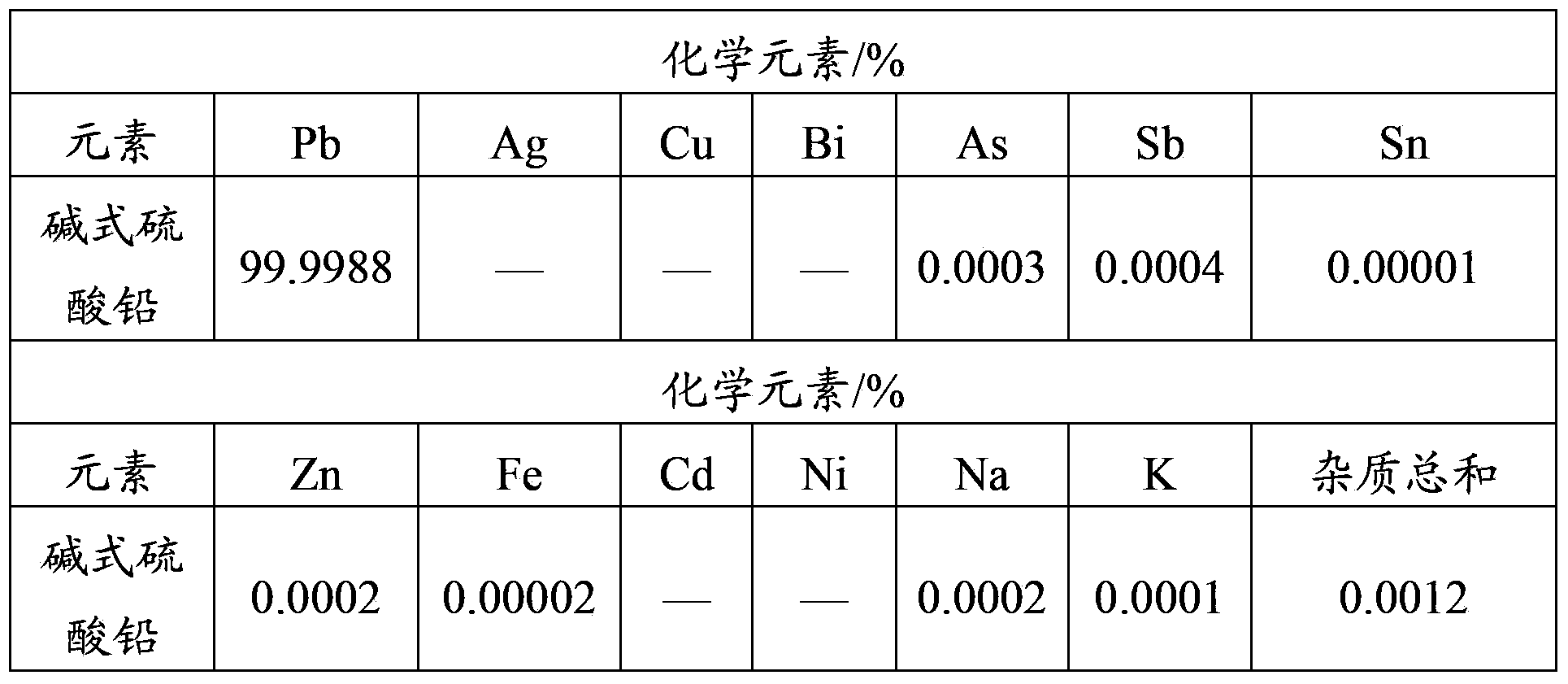

The invention discloses a method for recovering a lead-containing raw material by using a wet process. The method comprises the steps: (1) leaching the lead-containing raw material by using a solution, adding a reducing agent to reduce lead dioxide or lead orthoplumbate in the lead-containing raw material into a soluble lead salt, after a lead compound is completely dissolved, filtering the solution, and separating to obtain a filtrate A and an insoluble substance, wherein the solution contains sulfate, a complexing agent and a catalyst; (2) adjusting the pH value of the filtrate A, separating to obtain lead sulfate and a filtrate B, and returning the filtrate B to the step (1) after sulfate radicals are replenished and the pH value is adjusted; (3) directly using lead sulfate as battery materials or commodities, subjecting a sulfate-containing alkaline solution and lead sulfate to reaction, and separating to obtain basic lead sulfates and a filtrate C, wherein the basic lead sulfates include tribasic lead sulfate and tetrabasic lead sulfate. The method can be used for purifying the lead-containing raw material to form lead sulfate and basic lead sulfates directly used for producing lead-acid batteries, thereby being an environment-friendly wet-process recovery method.

Owner:北京中金瑞丰环保科技有限公司

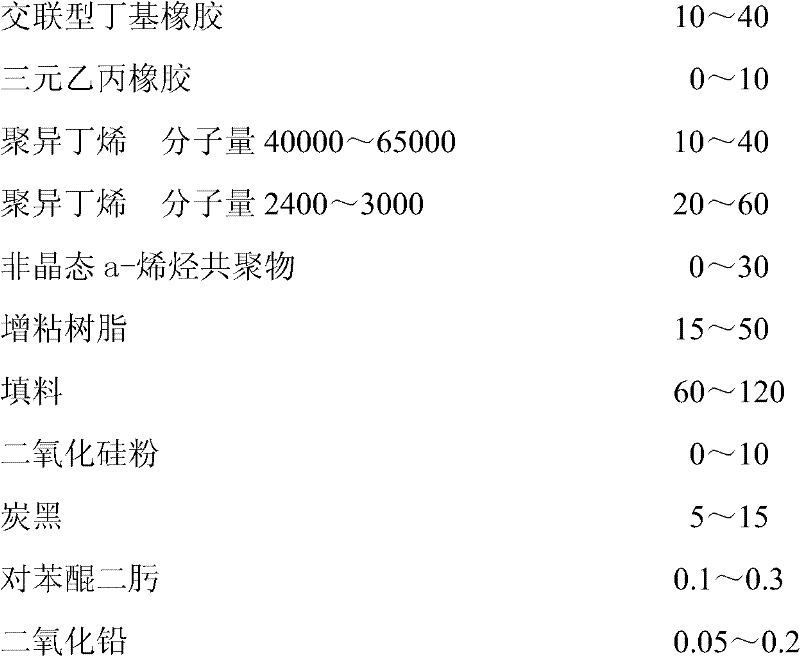

Sealing adhesive strip for ribbed self-adhesive glass and manufacturing method thereof

ActiveCN102504727AImprove sealingImprove aging resistanceNon-macromolecular adhesive additivesOther chemical processesCross-linkLead dioxide

The invention relates to a sealing adhesive strip for ribbed self-adhesive glass and a manufacturing method thereof. The sealing adhesive strip for the ribbed self-adhesive glass belongs to an elastic edge strip for sealing the edge of the glass of doors and windows, and comprises a built-in rubber strip rib and a butyl rubber sealant layer coated on the surface of the built-in rubber strip rib, wherein the butyl rubber sealant layer comprises the following raw material components in parts by weight: 30 parts of cross-linking butyl rubber, 5 parts of ethylene propylene diene rubber, 20 parts of polyisobutene of which the molecular weight is 40000, 40 parts of polyisobutene of which the molecular weight is 2400, 20 parts of amorphous state a-olefin copolymer, 30 parts of tackifying resin, 100 parts of filler, 5 parts of silicon dioxide, 10 parts of carbon black, 0.2 part of benzoquinone dioxime and 0.1 part of lead dioxide. The manufacturing method comprises the following steps: (1) banburying and kneading butyl rubber sealant; (2) coating and extruding. The invention provides the sealing adhesive strip for the ribbed self-adhesive glass, which has good low-temperature elasticity, simple construction process and low cost and is beneficial to environmental protection, a manufacturing method thereof. The sealing adhesive strip for the ribbed self-adhesive glass provided by the invention is suitable for sealing the glass of building doors and windows, curtain walls and automobile and ship doors and windows and the frame section bar of the glass.

Owner:SHANDONG SHUANGYUAN SEALING TECH CO LTD

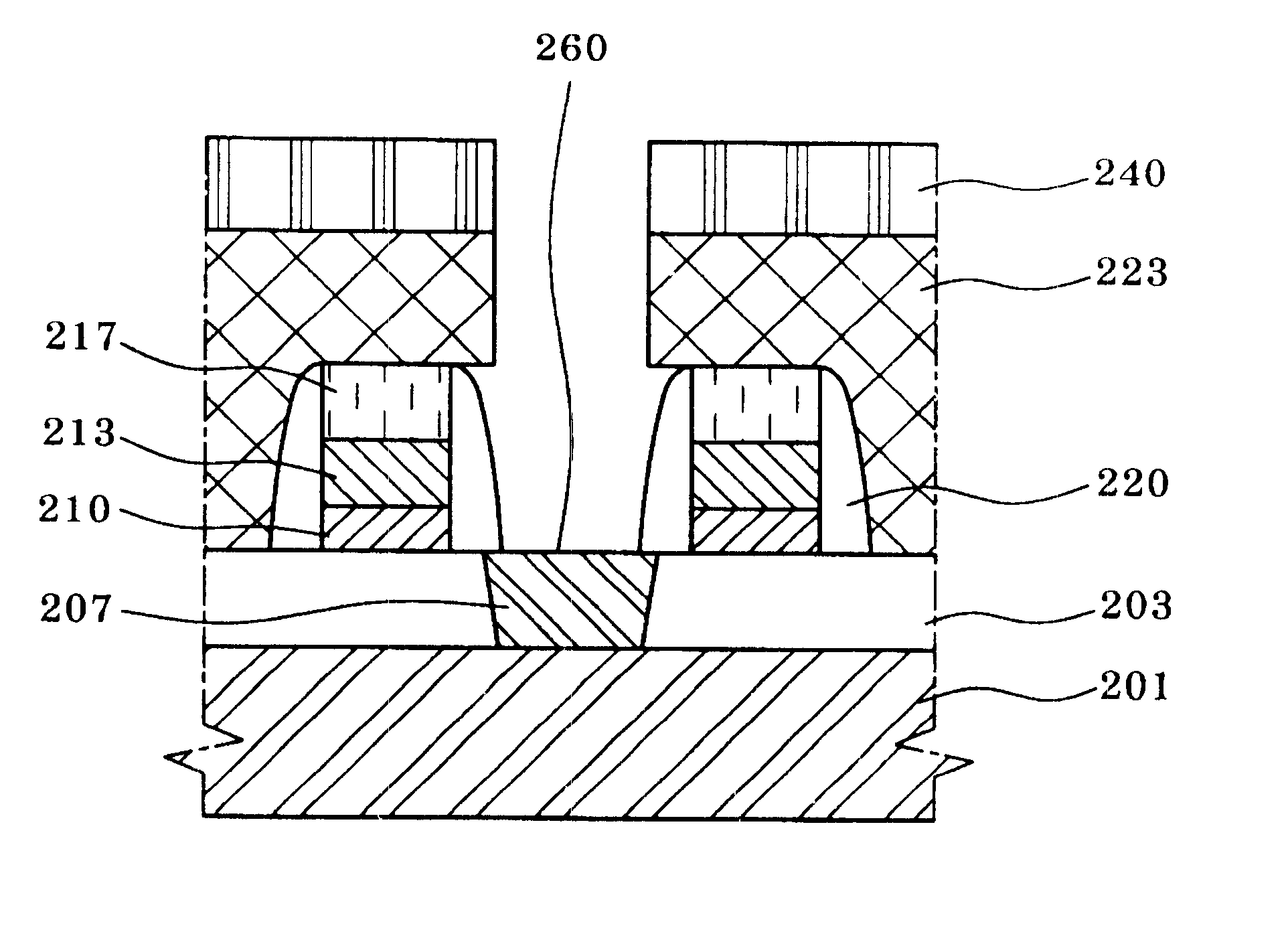

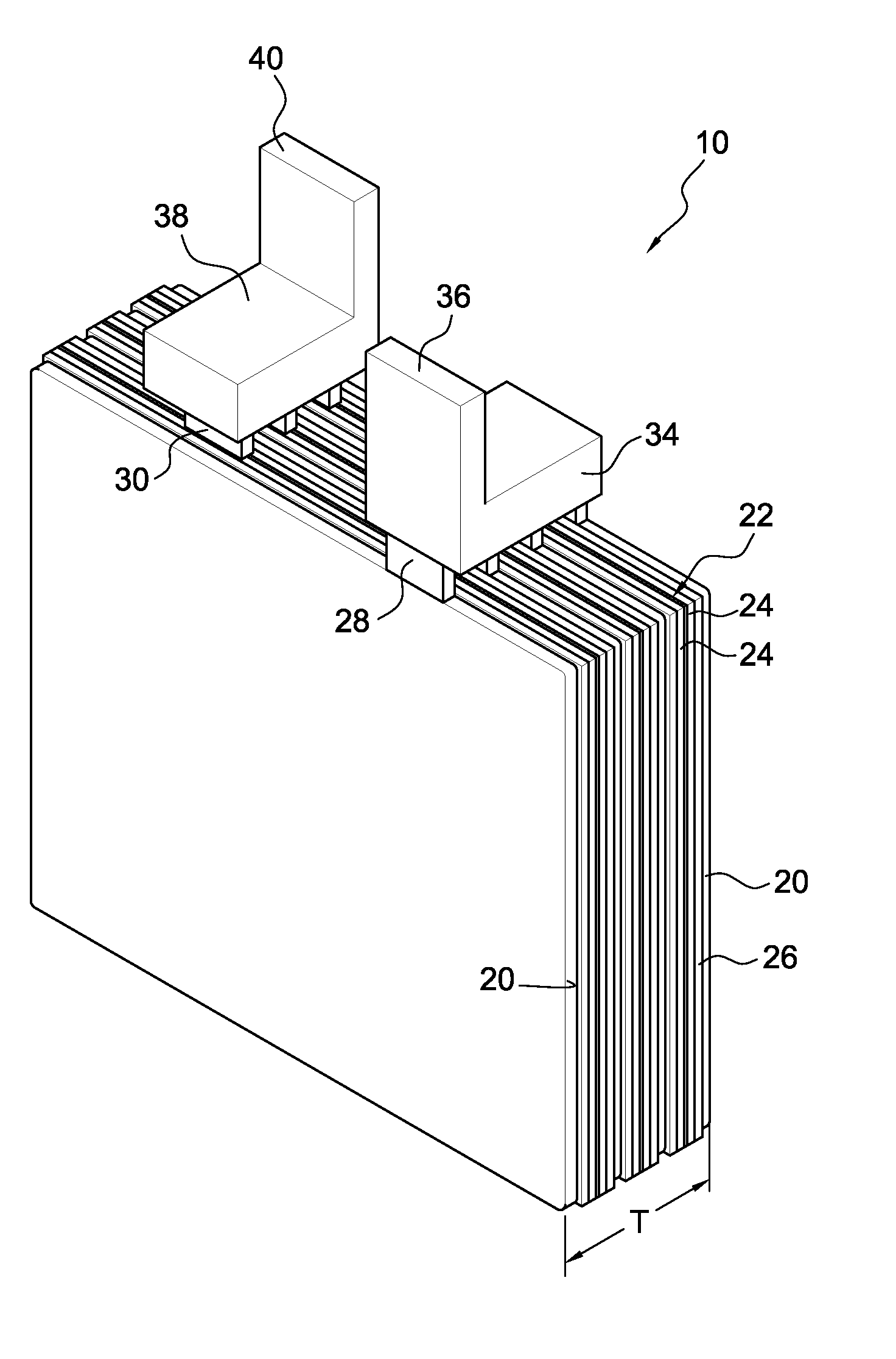

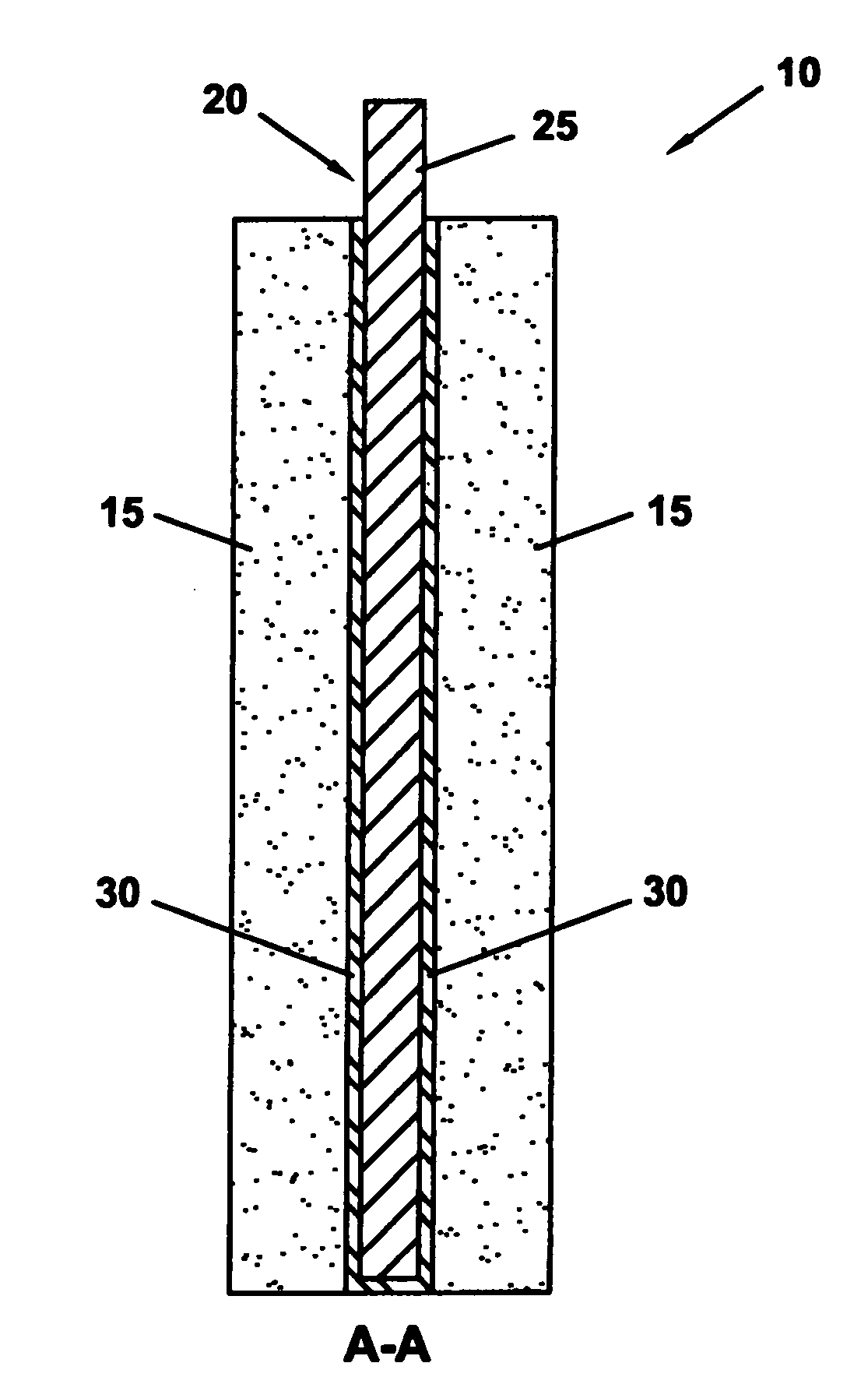

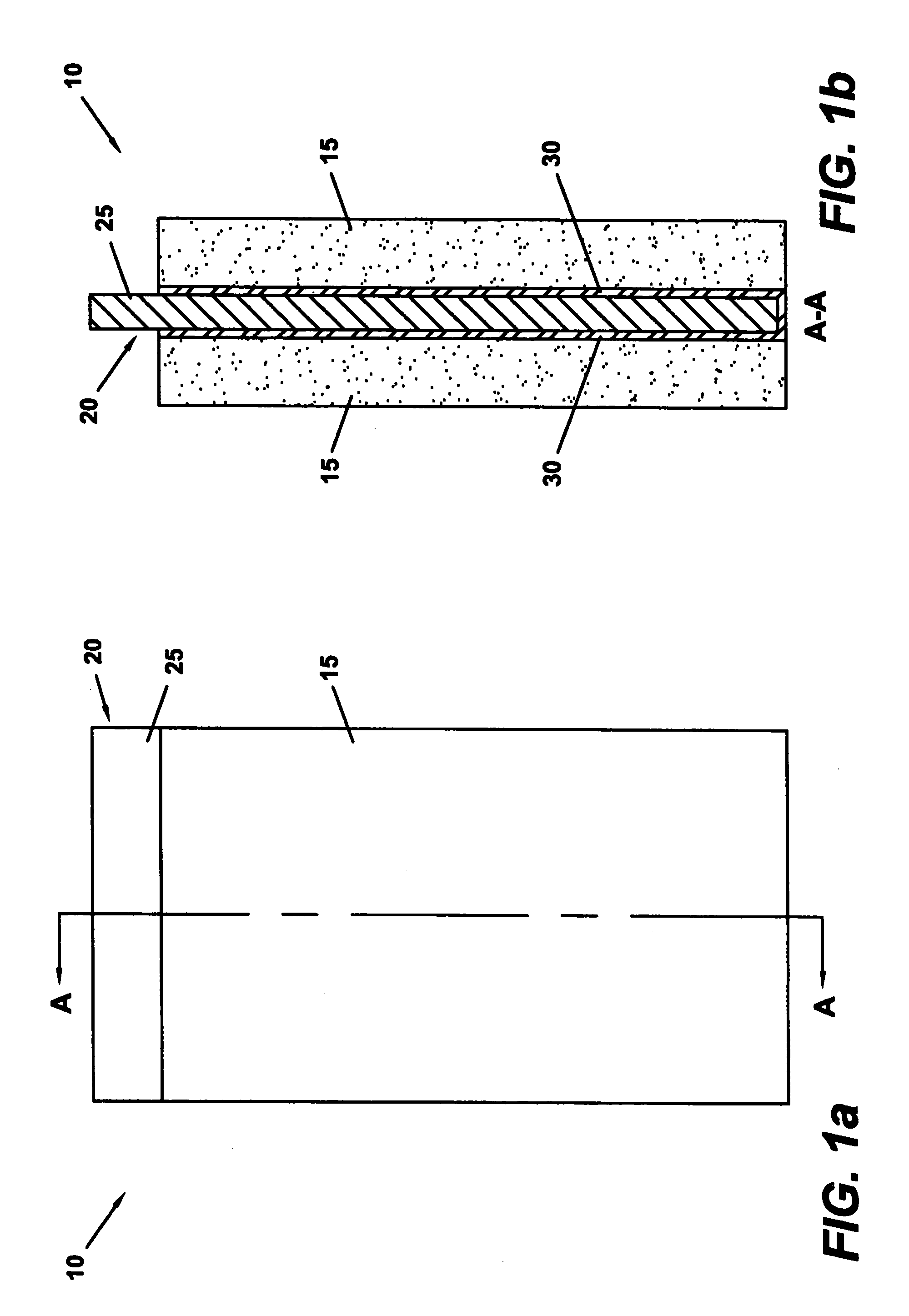

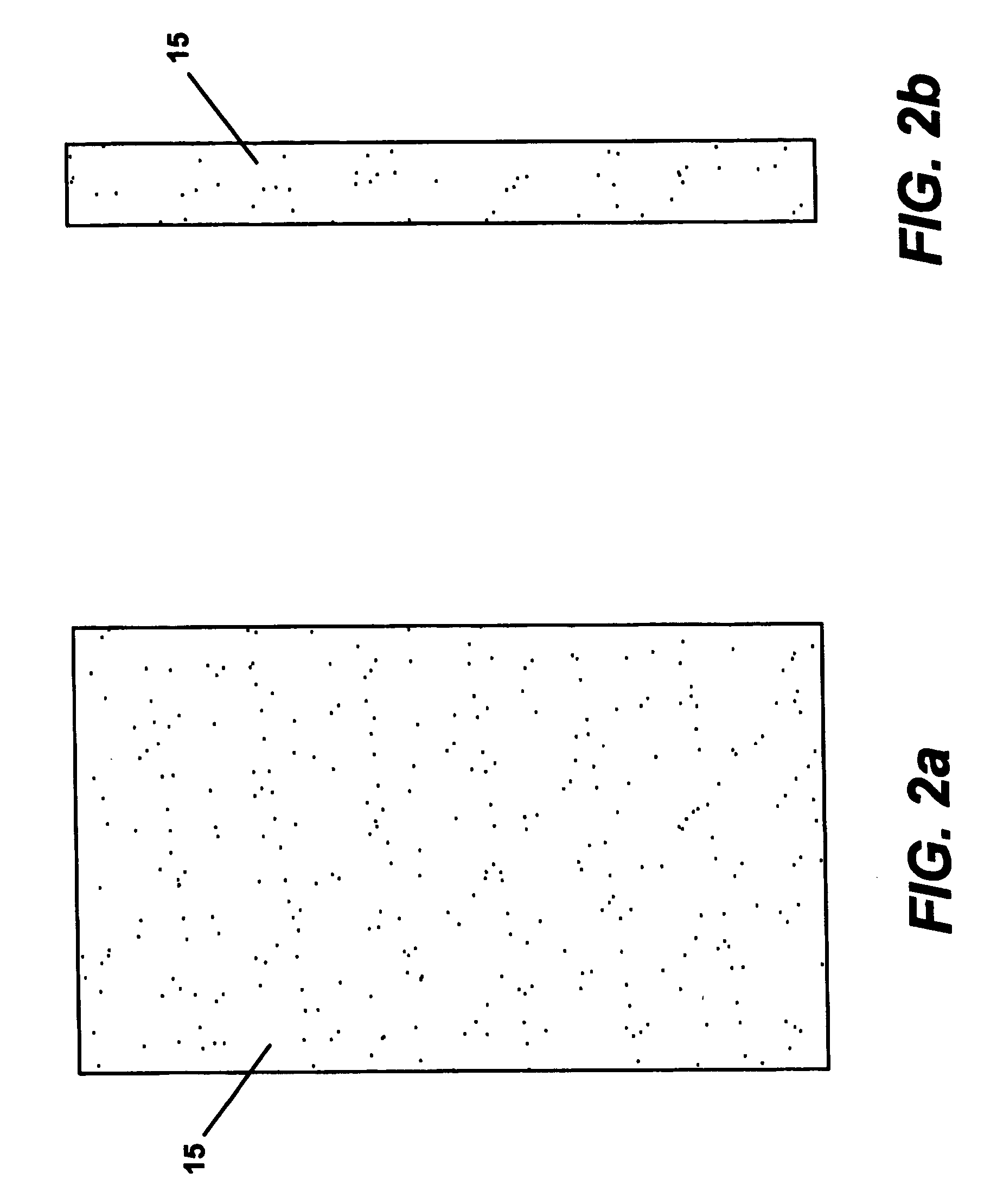

Electrode with Reduced Resistance Grid and Hybrid Energy Storage Device Having Same

InactiveUS20090103242A1Reduce the likelihood of failureCapacitor and primary/secondary cellsHybrid capacitor electrodesElectricityElectrical resistance and conductance

An energy storage device includes at least one positive electrode comprising a current collector comprising lead and having a plurality of raised and lowered portions with respect to a mean plane of the current collector and slots formed between the raised and lowered portions, wherein lead dioxide paste is adhered to and in electrical contact with the surfaces thereof; and a tab portion; and at least one negative electrode comprising a carbon material.

Owner:AXION POWER INT

Method for preparing high quality lead dioxide with plumbum mud in waste lead acid accumulator

The invention relates to a method for preparing high-quality lead dioxide through lead slime of waste lead acid storage batteries, comprising the following steps that: the lead slime in the waste lead acid storage batteries is taken out, washed repeatedly to neutrality, dried, and crushed into lead slime powder the granularity of which is over 200 meshes; the lead slime powder is mixed with a water solution which contains a dispersant and a desulfurizer according to a certain proportion, and then the mixture is fully stirred and desulfurized for 1 to 24 hours at a room temperature of 90 DEG C; separation is performed to remove a liquid part, and lead-bearing solid materials obtained are fully dried; the lead-bearing solid materials are mixed with a water solution which contains oxidant according to a certain proportion, and the mixture is fully stirred and oxidized for 1 to 2 hours at a room temperature of 90 DEG C; and separation is performed to remove a liquid part, and a solid part obtained is the lead dioxide after washing and drying. The method prepares the lead dioxide through the lead slime in the waste lead acid storage batteries, and has low cost and energy consumption, simple equipment, and high lead recovery rate and product quality of the lead dioxide.

Owner:HUNAN UNIV

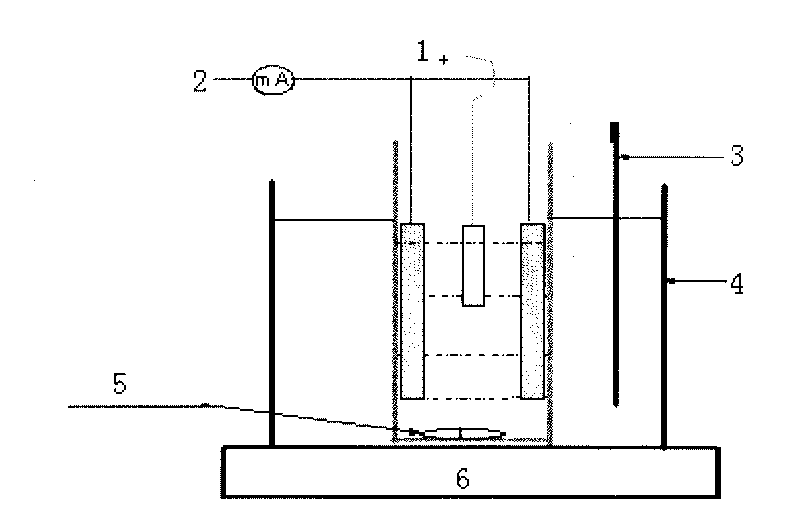

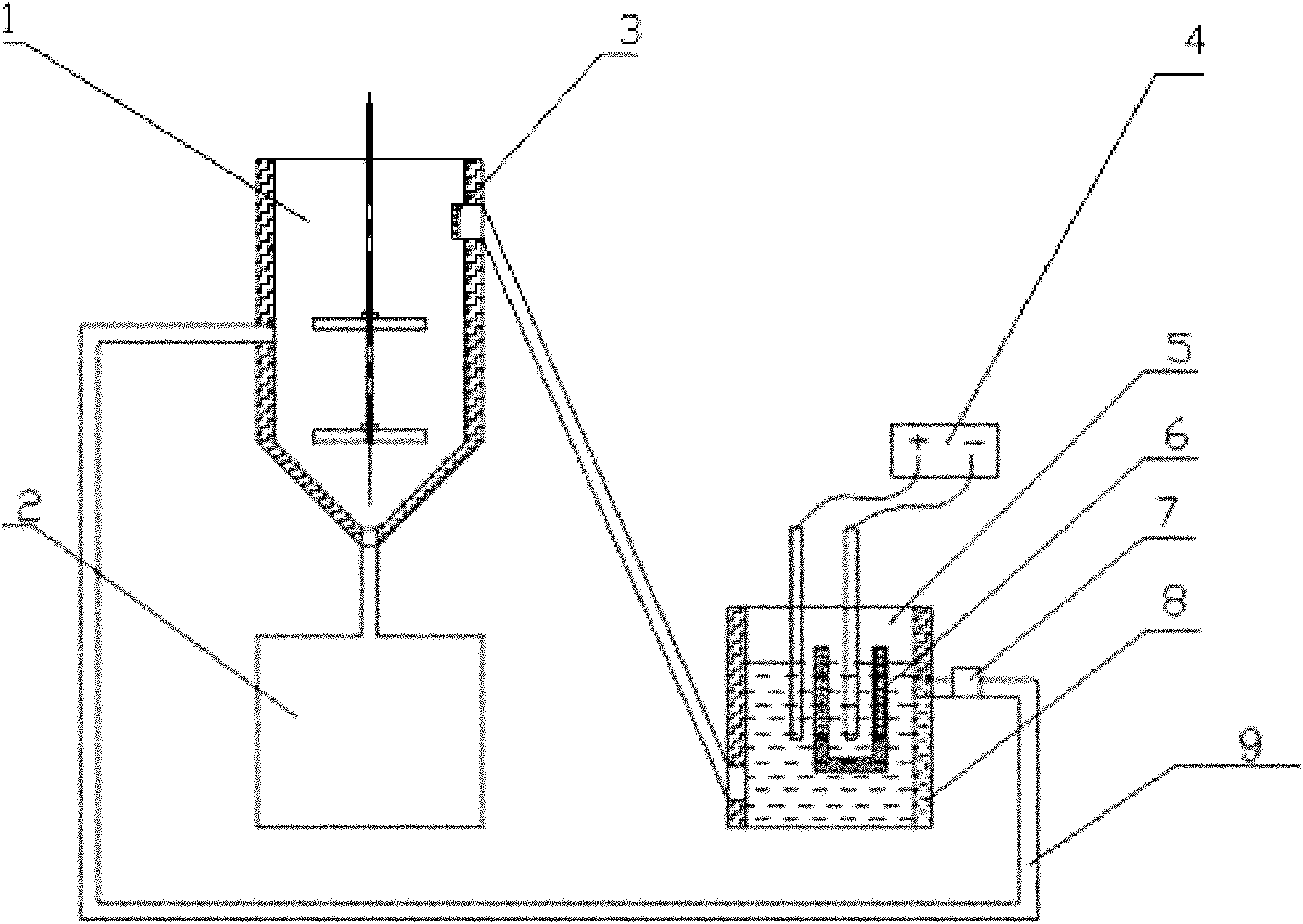

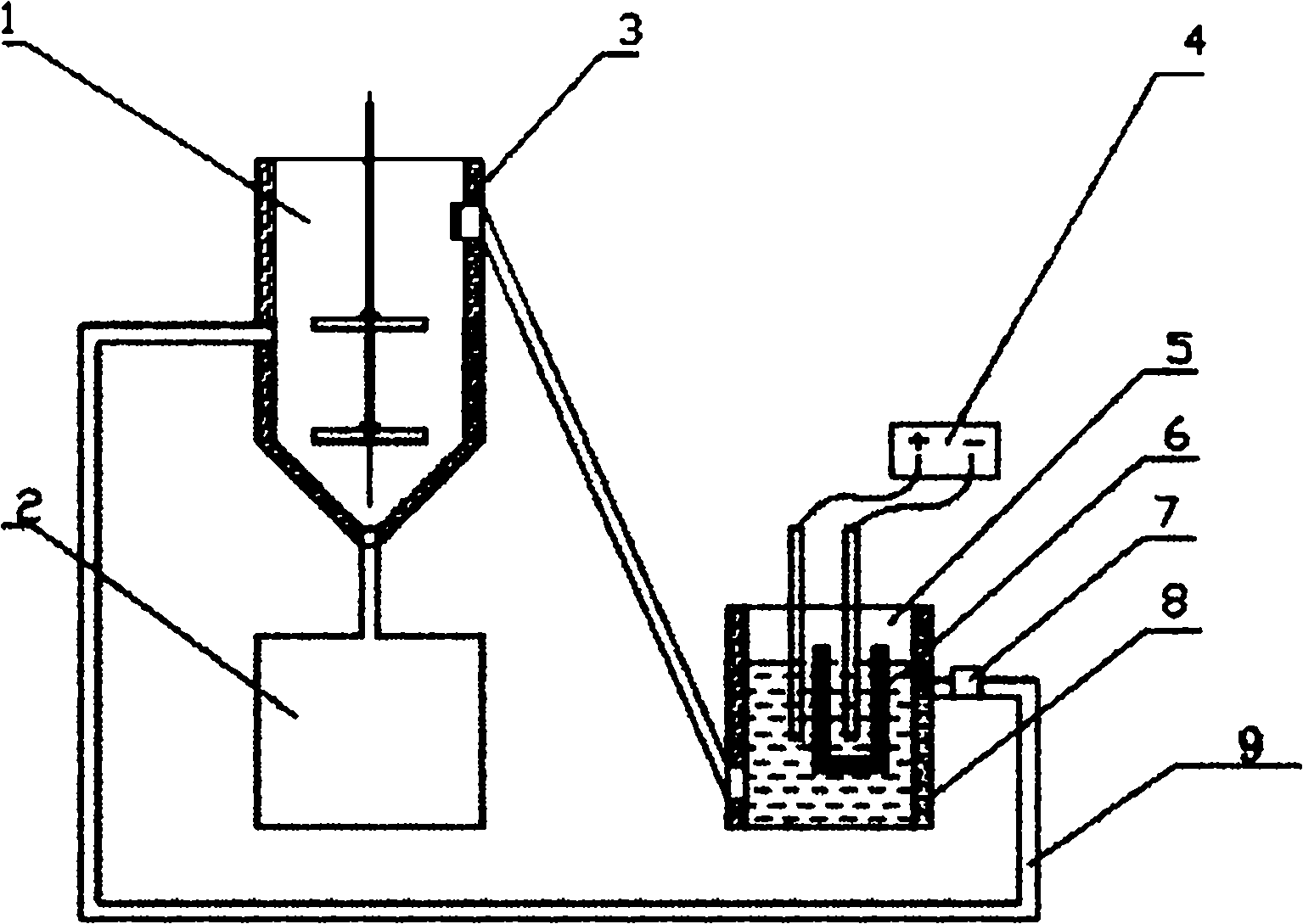

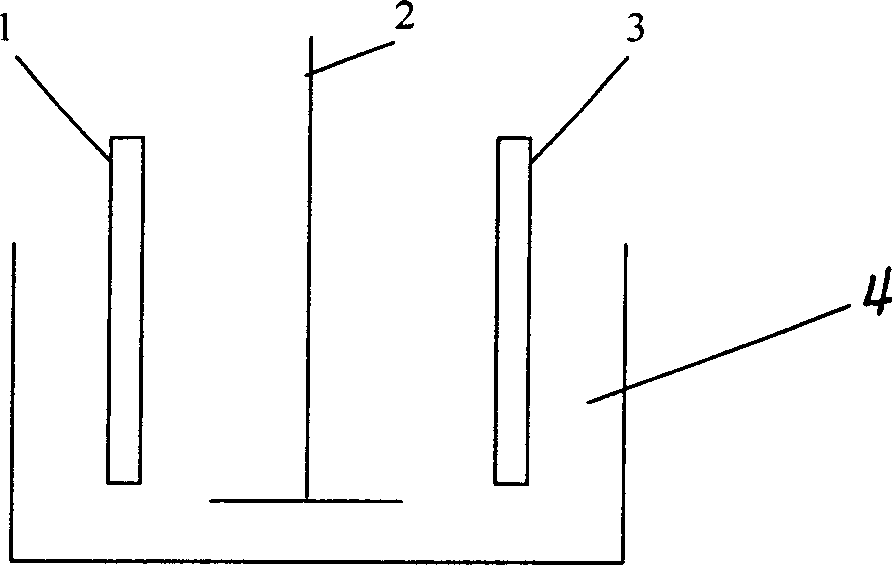

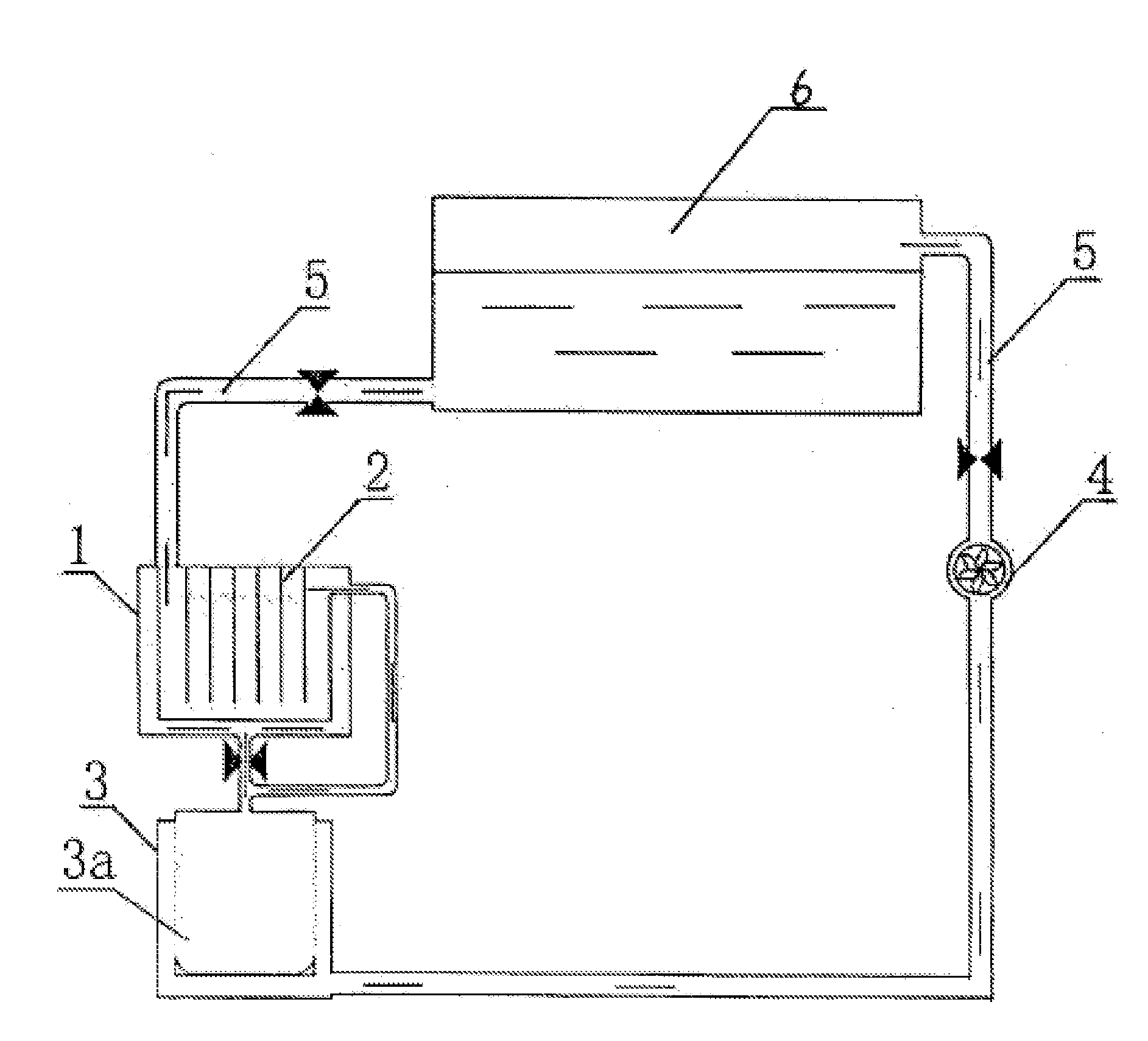

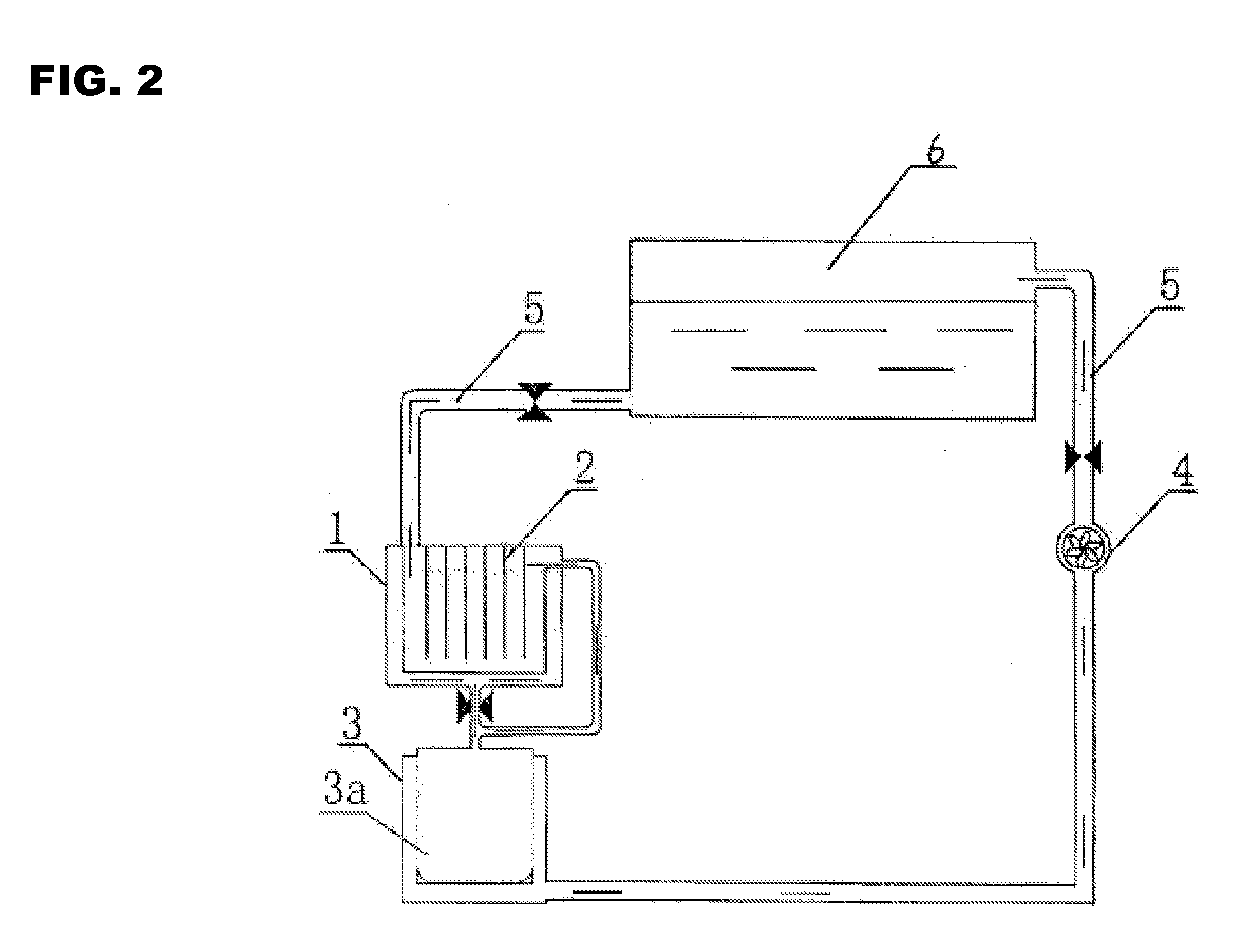

Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

ActiveCN102031380AHigh concentrationConcentration unchangedPhotography auxillary processesProcess efficiency improvementLead dioxideSlag

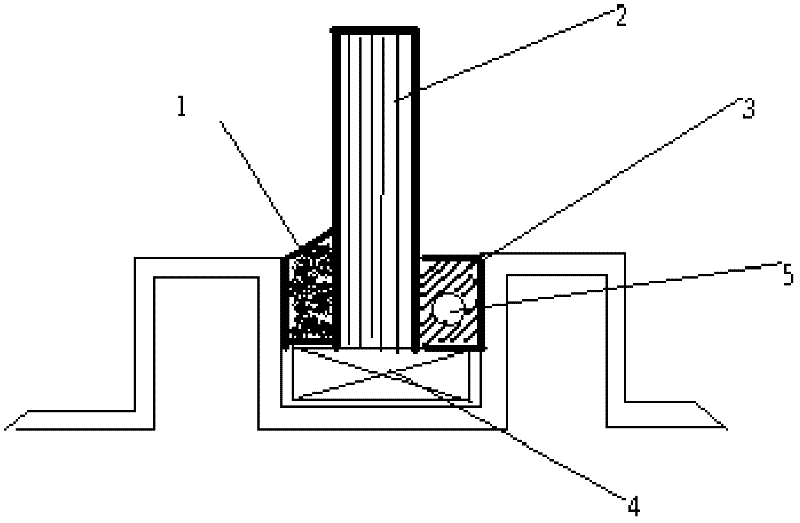

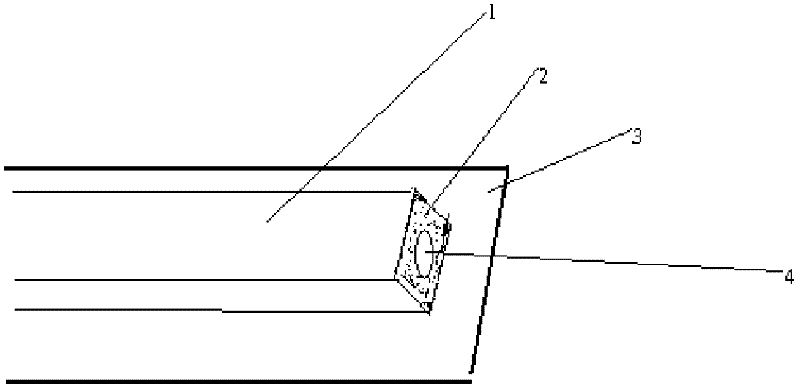

The invention belongs to recovery treatment on lead plaster of a waste lead-acid storage battery. The method comprises the following steps of: mixing the lead plaster of the waste lead-acid storage battery with waste sulfuric acid in the waste lead-acid storage battery according to the design requirement and roasting; adding roasting sand in a stirring kettle; adding tap water to a water level line of the device and stirring the roasting sand; adding a proper amount of calcium acetate, acetic acid and nitric acid; starting a solution circulating system pump, leaching out the roasting sand and maintaining the concentration of lead acetate to be saturated; adding a proper amount of bone glue and beta-naphthol, electrolyzing immersion liquid, recovering the metallic lead at the cathode and recovering lead dioxide at the anode; press filtering residues to obtain lead-off slag and filtrate; and adding calcium carbonate in the filtrate and recycling. The device mainly comprises a leaching part, a press filtration part, a circulating part and an electrolysis part, and concretely includes eight key components of the stirring kettle, a press filter, an overflow port, an electrolysis direct current power supply, an electrolytic cell, a cathode titanium basket, a corrosion resistant pump and a heating element.

Owner:北京绿色引领环保科技研究院有限公司

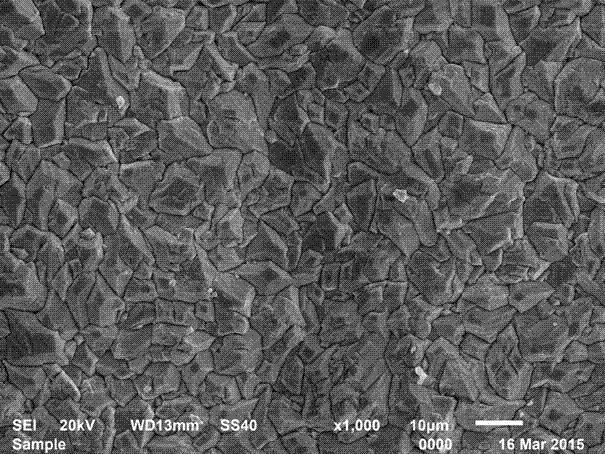

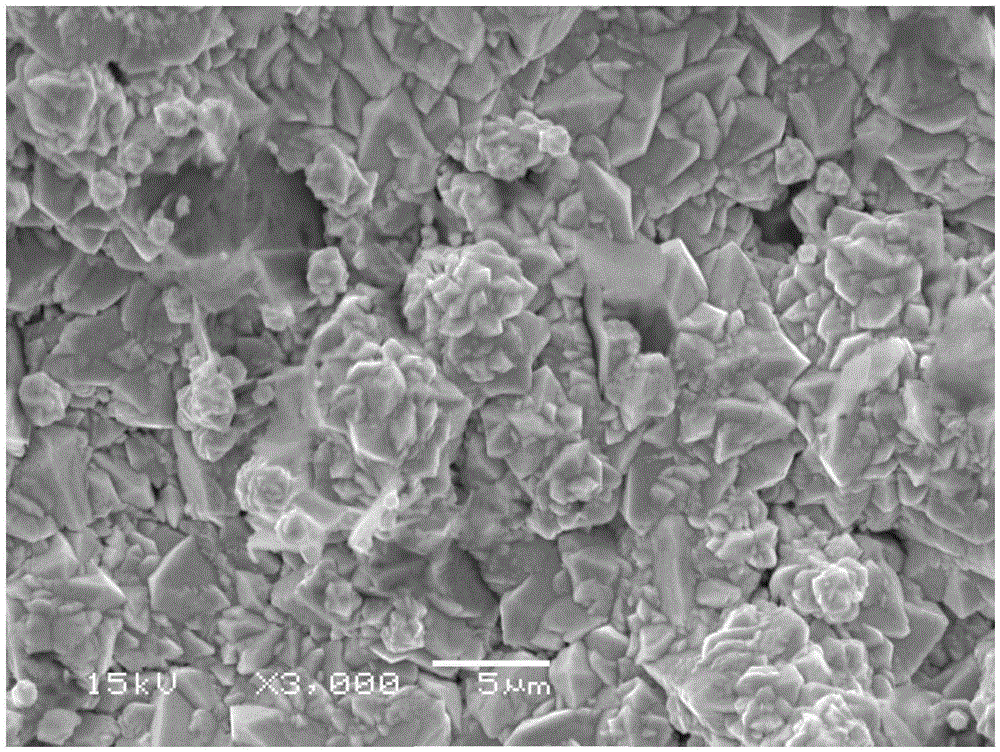

Graphene modified fluorine-contained lead dioxide electrode and preparation method thereof

ActiveCN106868509AImprove conductivityFast transferElectrolytic coatingsWater contaminantsLead dioxideMaterials science

The invention provides a graphene modified fluorine-contained lead dioxide electrode and a preparation method thereof. A tin antimony oxide bottom layer, an alpha-PbO2 middle layer and a beta-PbO2 active layer of the electrode all contain graphene. The preparation method comprises the steps of titanium plate pretreatment, thermal deposition of the tin antimony oxide bottom layer containing the graphene, acoustoelectric deposition of the alpha-PbO2 middle layer containing the graphene, and acoustoelectric deposition of the beta-PbO2 active layer containing the graphene. The graphene modified fluorine-contained lead dioxide electrode has the following advantages: the prepared graphene modified fluorine-contained lead dioxide electrode greatly is improved in electrocatalytic oxidation activity and largely prolonged in service life compared with a general fluorine-contained lead dioxide electrode, and is an anode material with development potential and suitable for electrocatalytic oxidation and degradation of organic pollutants in waste water.

Owner:JILIN NORMAL UNIV

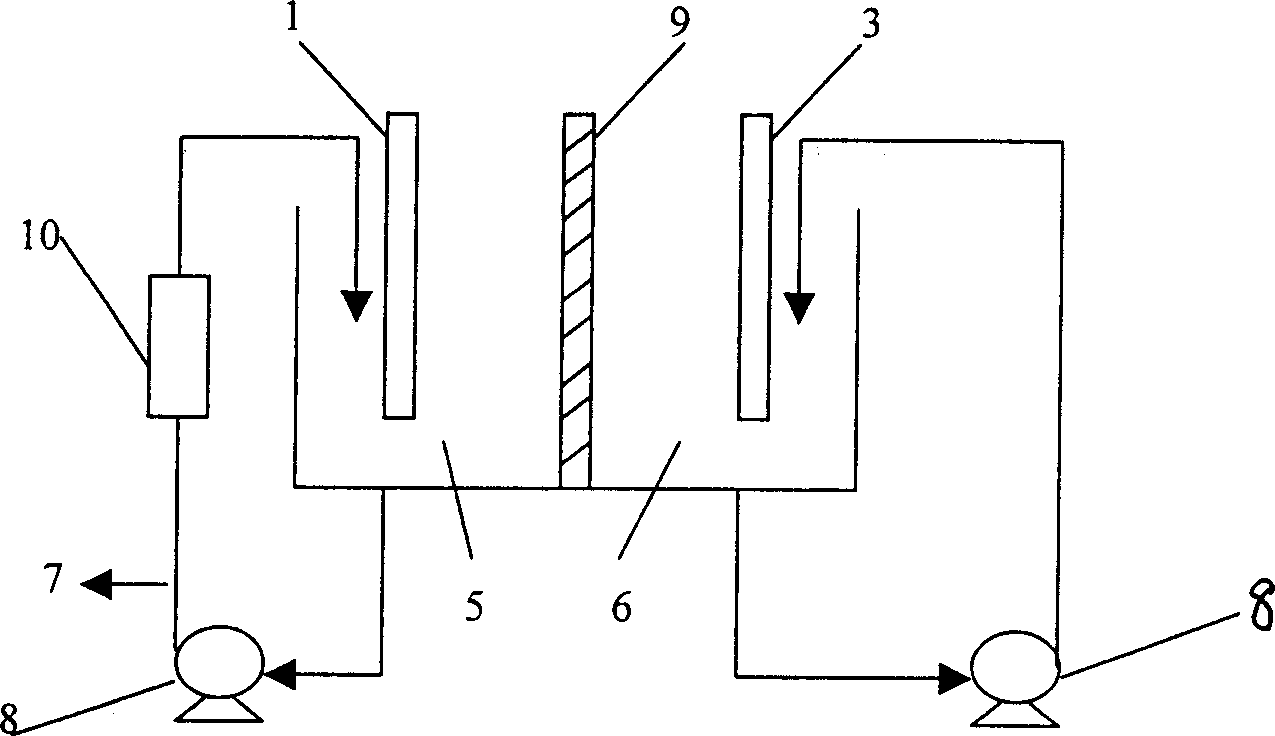

Method for degrading aminobenzene or/and nitrobenzene in waste water by electrolytic process

InactiveCN1850643AEffective oxidative degradationEasy to handleWater/sewage treatmentLead dioxideNitrobenzene

The invention is a method for degrading aniline or / and nitrobenzene in waste water by electrolysis process, adopting an electrobath with a dividing cation exchange membrane in the middle, adding the waste water containing aniline or / and nitrobenzene and salts into an anode chamber, adding thin NaOH solution into an cathode chamber, circulating by circulating pump, separately, where the anode material is Ti-base coated ruthenium or Ti-base coated lead dioxide, and the cathode material is stainless steel or graphite, electrolyzing by DC, and oxidizing and degrading and removing aniline or / and nitrobenzene, and besides, cations dissociated from the salts in the waste water pass through the cation exchange membrane into the cathode chamber under the action of the DC electric field and combine with OH groups to produce hydroxides, thus able to recover alkali solution and desalt the waste water so as to benefit follow-up biochemical processing units. And after the solutions in the anode and cathode chambers are circulated for a period of time, it samples them, and as the concentrations of the aniline or / and nitrobenzene in the solution in the anode chamber decrease to the required values, it stops operating and discharges the solutions.

Owner:NANJING UNIV

Optimised energy storage device

ActiveUS20100175934A1Weight increaseConvenience to workHybrid capacitor electrodesHybrid cell detailsElectricityLead dioxide

A lead-acid battery comprising:—at least one negative electrode comprising lead-based battery electrode material and at least one region of capacitor material overlying the lead-based battery electrode material, each electrode being in electrical connection to an outer terminal of the battery, and—at least one positive lead-dioxide based battery electrode, each positive electrode being in electrical connection to a second outer terminal of the battery,—separator interleaving the facing electrodes;—electrolyte filling at least the space of the electrodes and separators wherein the capacitor material overlying the lead-based battery electrode material comprises 20-65% by weight of a high electrical conductivity carbonaceous material, 30-70% of a high specific surface area carbonaceous material, at least 0.1% lead and binder.

Owner:COMMONWEALTH SCI & IND RES ORG +1

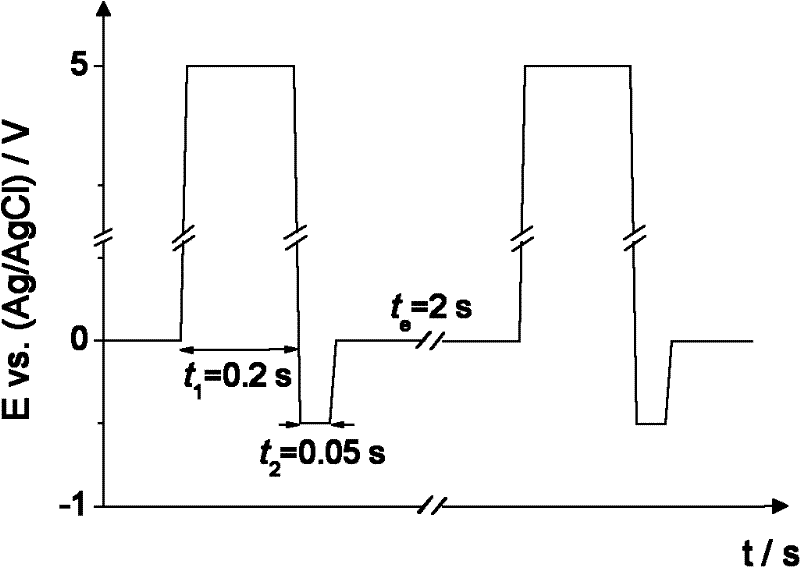

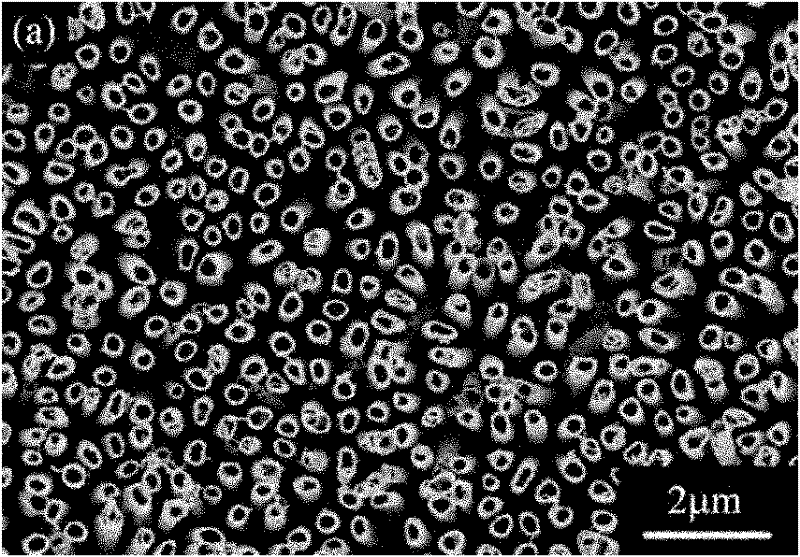

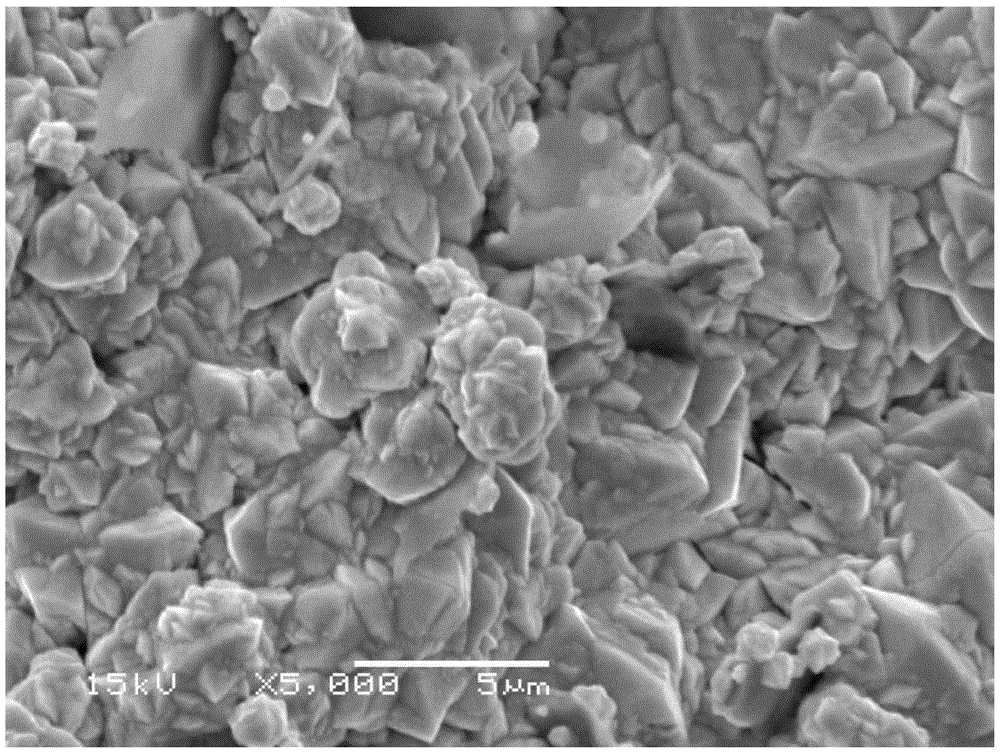

Method for preparing nanometer lead dioxide electrode

InactiveCN102173449AImprove electrocatalytic activityExtended service lifeLead dioxideNanotechnologyElectricitySocial benefits

The invention relates to a method for preparing a nanometer lead dioxide electrode, which comprises the following steps of: firstly, preparing a titanium dioxide nano tube array substrate; secondly, preparing lead dioxide electrodeposition solution; and finally, performing electrodeposition on the titanium dioxide nano tube array substrate to prepare the nanometer lead dioxide electrode. The method has the advantage that: compared with those of the ordinary titanium-base lead dioxide electrode obtained by direct-current deposition, the electro-catalytic activity of the nanometer lead dioxide electrode is improved greatly, and the service life of the nanometer lead dioxide electrode is prolonged greatly. By the method, a new concept is provided for the study of electrodes for water treatment, the study space is broadened, and the technology and the existing doping technology are combined to develop better electrodes; and by the method, the electro-catalytic activity of organic pollutants in oxidized waste water is high, a preparation process is simple, the cost is low, the cost for electrochemical water treatment can be reduced, and economic and social benefits are excellent.

Owner:TONGJI UNIV

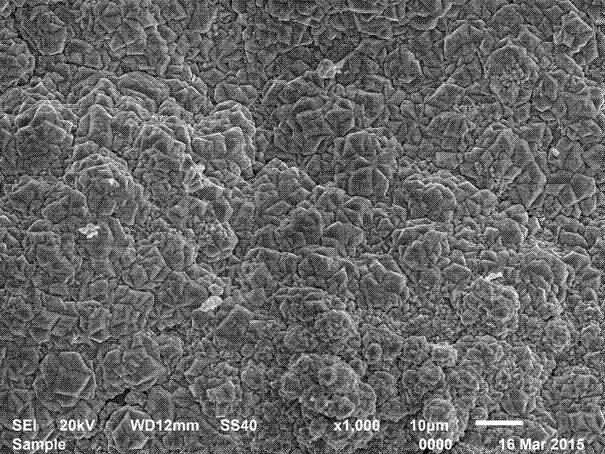

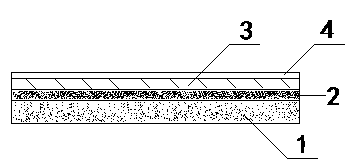

Transition-metal doped lead dioxide electrode for wastewater treatment as well as preparation method and application thereof

InactiveCN105621541AExtended service lifeDisperse tightly and evenlyElectrolytic inorganic material coatingWater/sewage treatmentLead dioxideAntimony

The invention discloses a transition-metal doped lead dioxide electrode for wastewater treatment and a preparation method thereof. The transition-metal doped lead dioxide electrode is prepared through the steps of performing thermal decomposition on a titanium material which serves as a substrate so as to prepare a tin-antimony oxide underlayer, then electroplating an alpha-PbO2 interlayer by use of an alkaline solution and finally preparing a transition-metal doped fluorine-containing beta-PbO2 surface active layer by use of acidic composite electroplating bath. The transition-metal doped lead dioxide electrode prepared by the method has the characteristics of low price, high oxygen evolution potential, high catalytic activity, long service life and the like; the electrode can be used for realizing effective removal of organic pollutants in wastewater through an electrochemical oxidation method, is simple to operate and convenient to manage and has wide social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

Graphene-doped and lanthanum-modified titanium-based lead dioxide electrode and preparation method thereof

ActiveCN105239094AImprove electrocatalytic activityImprove electrodegradabilityElectrolytic inorganic material coatingElectrodesLead dioxideMethyl orange

The invention discloses a graphene-doped and lanthanum-modified titanium-based lead dioxide electrode which comprises a titanium base body, a tin-antimony oxide bottom layer deposited on the titanium base body in a hydrothermal mode, graphene deposited on the tin-antimony oxide bottom layer in an electrolytic mode, and a lanthanum-modified beta-PbO2 active layer. Compared with the prior art, the titanium-based lead dioxide electrode at least can improve removal effect of methyl orange by 15.6% in case of keeping service life of the titanium-based lead dioxide electrode. The invention further discloses a preparation method for the titanium-based lead dioxide electrode. The preparation method comprises the following step: depositing the beta-PbO2 active layer in an acidic deposition liquid by taking the titanium base body which is deposited with the tin-antimony oxide bottom layer in the hydrothermal mode as an anode and taking equal-area graphite as a cathode, wherein the acidic deposition liquid comprises graphene, lanthanum nitrate, lead, nitrate, nitric acid and a surfactant. According to the preparation method, a preparation process for an alpha-PbO2 layer is cancelled, the preparation method for the titanium-based lead dioxide electrode is simplified, and foundation is laid for increasing a finished product qualified rate of an electrode product.

Owner:陕西恒悦材料科技有限公司

Carbon nanotube modified titanium based fluorine-containing lead dioxide electrode and preparation method thereof

InactiveCN103508517AImprove electrocatalytic activityImprove conductivityWater contaminantsWater/sewage treatmentLead dioxideActive agent

The invention relates to a carbon nanotube modified titanium based fluorine-containing lead dioxide electrode and a preparation method thereof. The carbon nanotube modified titanium based fluorine-containing lead dioxide electrode is prepared by: taking a titanium plate as a substrate, polishing and etching the titanium plate substrate, performing thermal deposition of a tin antimony oxide base layer, then conducting electrodeposition of an alpha-PbO2 intermediate layer in an alkaline plating solution, and finally performing electrodeposition of a beta-PbO2 active layer in an acidic plating solution containing fluoride ions, a surfactant and a carbon nanotube. Compared with ordinary titanium based fluorine-containing lead dioxide electrodes, the carbon nanotube modified titanium based fluorine-containing lead dioxide electrode has high catalytic activity and long service life. The electrode can be used as an anode to treat organic wastewater, can achieve a good degradation effect, and can realize mineralization on poisonous and harmful organic matters that are difficult to degrade. Being easy and convenient to operate, the electrode provided by the invention is a potential electrode suitable for water treatment.

Owner:JILIN NORMAL UNIV

Optimised energy storage device having capacitor material on lead based negative electrode

ActiveUS9666860B2Weight increaseConvenience to workHybrid cell detailsFinal product manufactureElectricityLead dioxide

A lead-acid battery comprising: —at least one negative electrode comprising lead-based battery electrode material and at least one region of capacitor material overlying the lead-based battery electrode material, each electrode being in electrical connection to an outer terminal of the battery, and —at least one positive lead-dioxide based battery electrode, each positive electrode being in electrical connection to a second outer terminal of the battery, —separator interleaving the facing electrodes; —electrolyte filling at least the space of the electrodes and separators wherein the capacitor material overlying the lead-based battery electrode material comprises 20-65% by weight of a high electrical conductivity carbonaceous material, 30-70% of a high specific surface area carbonaceous material, at least 0.1% lead and binder.

Owner:COMMONWEALTH SCI & IND RES ORG +1

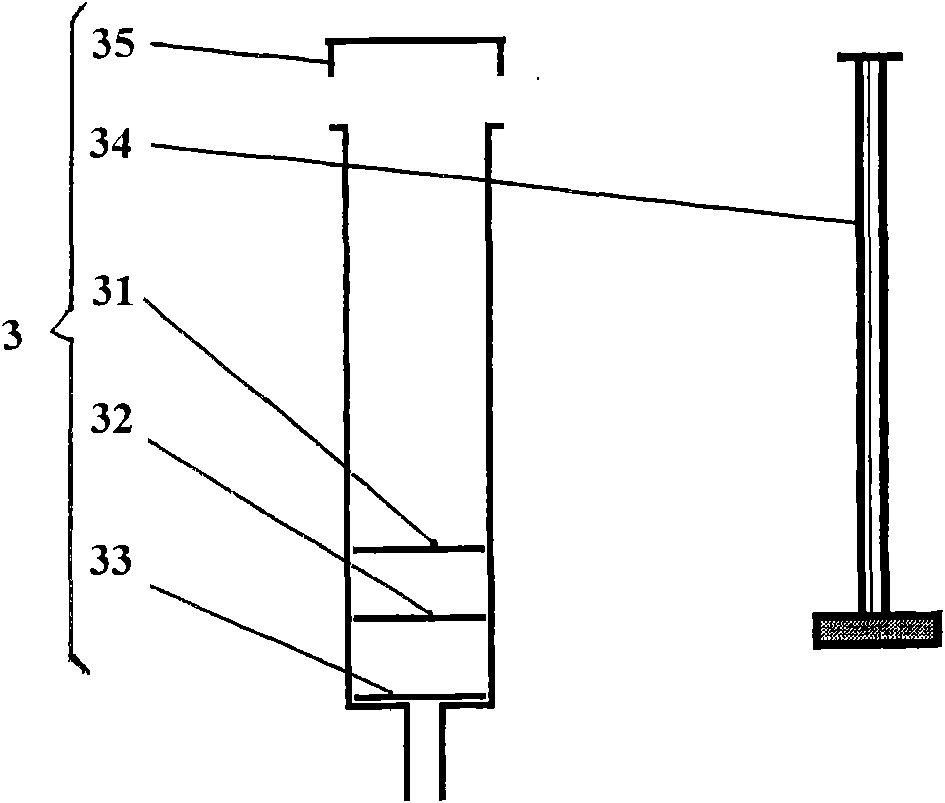

Electrode and current collector for electrochemical capacitor having double electric layer and double electric layer electrochemical capacitor formed therewith

An electrode and a DEL capacitor formed therewith. The electrode will typically be a polarizable electrode, and may be formed of an activated carbon material having a substantially zero ash percentage and a low percentage of transition metals. In constructing a DEL capacitor employing such an electrode, a non-polarizable electrode formed from a lead dioxide / lead sulfate compound is preferably also used. The DEL capacitor may utilize an acid-based electrolyte, such as an aqueous sulfuric acid electrolyte. Consequently, the present invention also includes a current collector that preferably comprises a base material formed from a lead or a lead compound and a protective coating material that is resistant to an acid-based electrolyte. Preferably, the protective coating material is formed from a polymer base and a conductive dope that may thereafter be applied to the current collector base material by a variety of methods.

Owner:UNIVERSAL SUPERCAPACITORS LLC

Water body, method for rapidly detecting residue of malachite green and colorless malachite green in aquatic product and detection box therewith

ActiveCN101566574AEasy to operateFew stepsComponent separationMaterial analysis by observing effect on chemical indicatorMalachite greenLead dioxide

The invention relates to a water body, a method for rapidly detecting the residue of malachite green and colorless malachite green in an aquatic product, belonging to the technical field of residue detection in a water body and an aquatic product. The method comprises the following steps: oscillating and mixing a sample to be detected and an extractant I uniformly; adding an extractant II, oscillating and mixing and then standing still; taking and adding an supernatant to an enrichment column; observing color change of a chromogenic reagent on the lowest layer; and determining that the sample contains the malachite green and colorless malachite green if a green circular strap is formed. The extractant I is a mixed solution of acetonitrile, dichloromethane, n-hexane and paratoluenesulfonic acid, the extractant II is a mixture of lead dioxide and acid alumina, and the sample to be detected is a water body sample to be detected or an aquatic product sample to be detected. The invention has the advantages of simple operation and fewer steps, does not need expensive instruments and equipment and can embody the convenience and the flexibility to on-site detection.

Owner:JIANGSU TRIGIANT TECH

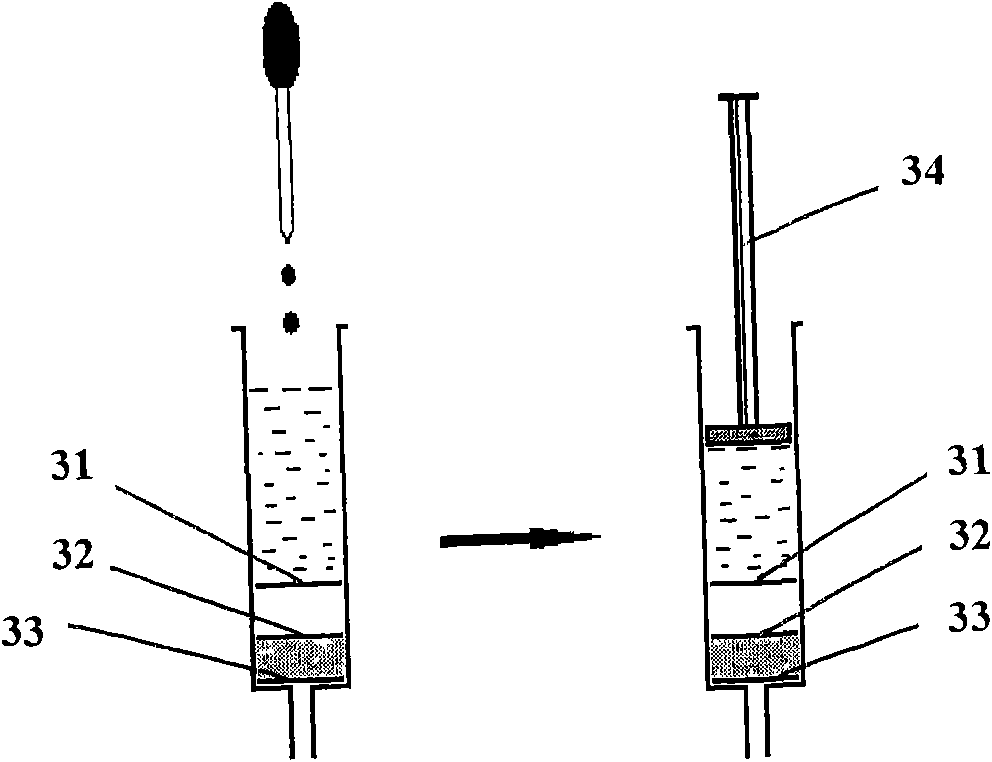

Method for implementing full cycle regeneration of waste lead acid batteries

InactiveUS20110265969A1Reduce power consumptionLow costPhotography auxillary processesLead-acid accumulatorsLead dioxideElectrolysis

A method for implementing full cycle regeneration of a waste lead acid battery is provided. The method includes the following steps. Step (1): the waste lead acid battery is smashed and separated so as to obtain grid lead, diachylon, plastic and waste electrolyte. Step (2): the obtained diachylon after being dried is positioned into an airtight reactor for desulphurization and deoxidation, wherein lead sulfate and the lead dioxide both in the diachylon react to obtain lead monoxide (PbO) and sulfur trioxide (SO3). Step (3): the obtained lead monoxide is reduced by solid phase electrolysis in a wet way so that the lead monoxide is reduced into sponge lead.

Owner:LIU ZHIQIANG +1

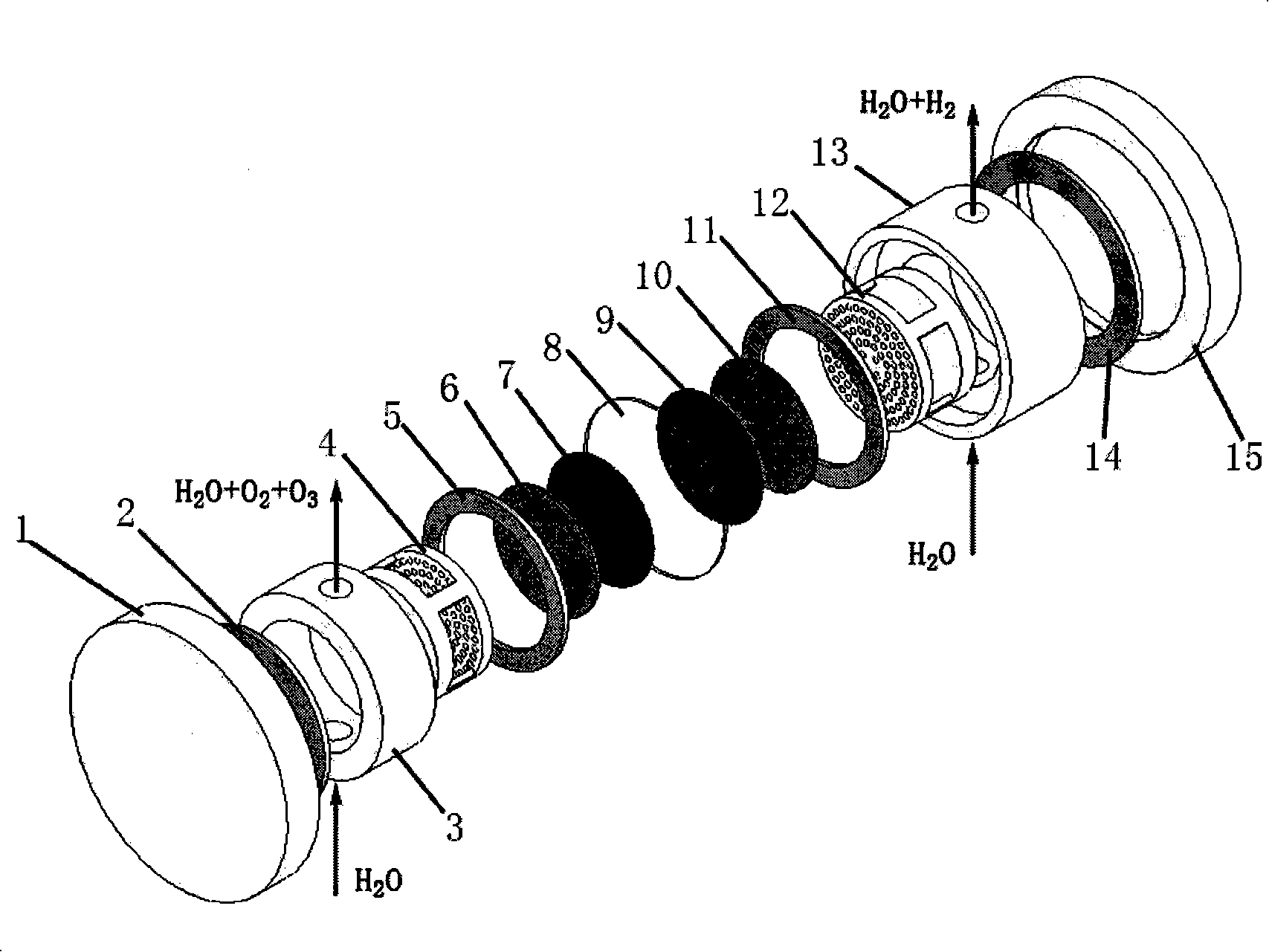

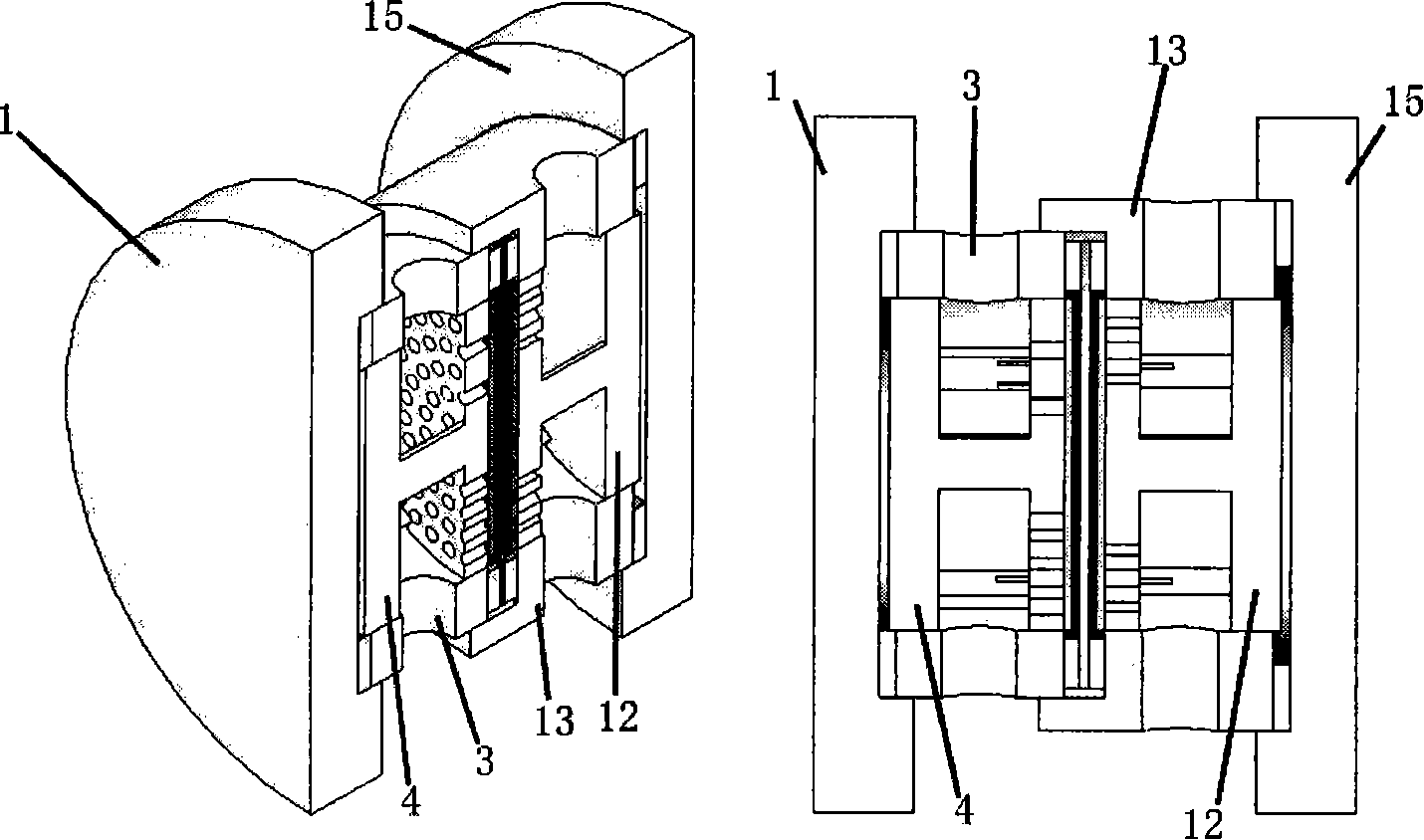

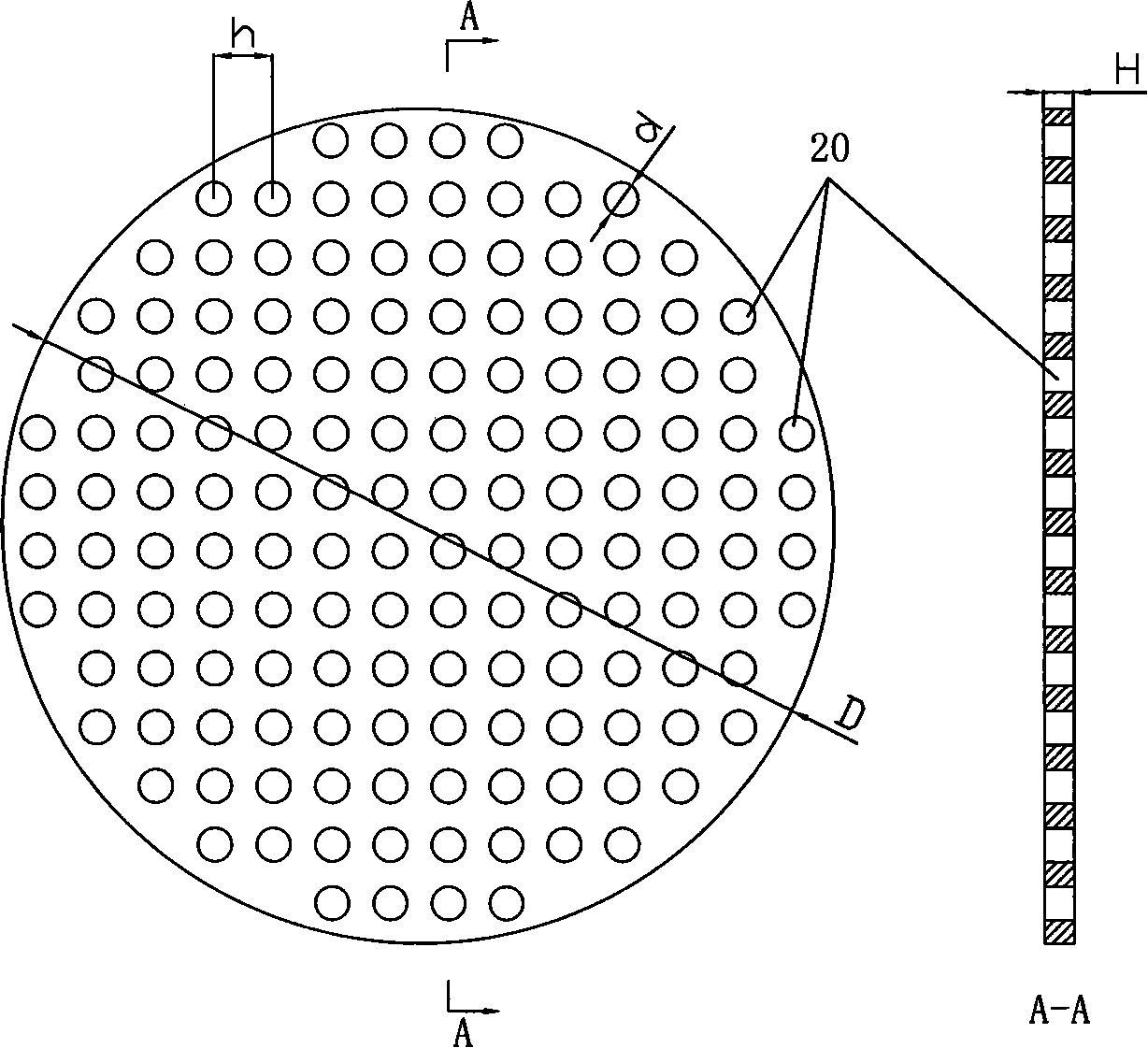

Electrolytic ozone generator and preparation technique for cathode catalysis layer thereof

InactiveCN101250710ALong continuous service lifeImprove current efficiencyElectrolysis componentsContinuous useDiamond electrodes

The invention relates to an electrolytic type ozone generator and a process for preparing a cathode catalyst layer of the electrolytic type ozone generator. The electrolytic type ozone generator comprises a round Nafion film, a round anode component and a round cathode component which are arranged on two axial sides of the Nafion film. The electrolytic type ozone generator adopts a diamond electrode which is doped with porous boron as an anode, the cathode catalyst layer adopts a process for preparing platinum-on-carbon and an electrolysis chamber for preparing ozone is optimally designed, not only the performance is greatly increased, but also the current efficiency of a borocarbon electrode to produce the ozone is greatly increased, the current efficiency can reach 30% under room temperature to the maximum, and the continuous service life of the electrodes can be greatly prolonged compared with lead dioxide electrodes which are used in a large number at present.

Owner:SHAANXI UNIV OF SCI & TECH

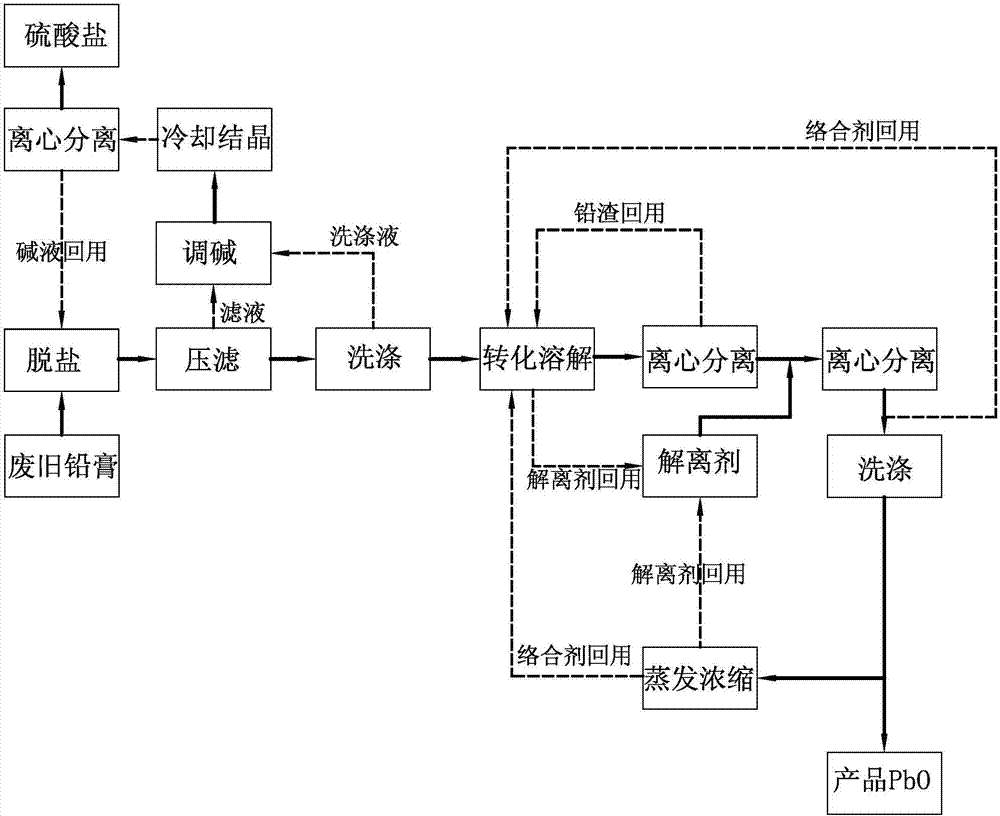

Method for recycling lead oxide from lead plaster of waste lead-acid storage battery

ActiveCN107460339AImprove economyAchieve a reversible cycleLead monoxideWaste accumulators reclaimingEnvironmental resistanceLead dioxide

The invention relates to the technical field of clean recycling of waste batteries and discloses a method for recycling lead oxide from lead plaster of a waste lead-acid storage battery. The method comprises the following steps that (1) pre-desalination is conducted, specifically, the lead plaster of the waste lead-acid storage battery is added with alkali liquor to be subjected to pre-desalination, so that lead acid, lead acetate, lead nitrate, lead perchlorate or lead carbonate in the lead plaster is removed; (2) dissolution is conducted, specifically, a complexing agent solution is added into the lead plaster subjected to pre-desalination, all PbO in the lead plaster reacts with a complexing agent to generate lead complex ions, and a lead-bearing solution and filter residues are obtained; (3) dissociation is conducted, specifically, the pH value of the lead-bearing solution is adjusted by adding a dissociation agent solution, so that the lead complex ions are dissociated, and the PbO and a mixed solution containing the complexing agent and a dissociation agent are obtained; and (4) separating is conducted, specifically, a lead oxide product is obtained after solid-liquid separation and washing. According to the method, the technological condition is mild, the technological process is environmentally friendly, the technological procedure is simple, energy consumption is small, the cost is low, the lead oxide recycling rate is high, the purity is high, and the method has very high industrial application value.

Owner:CHAOWEI POWER CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com