Method for preparing high quality lead dioxide with plumbum mud in waste lead acid accumulator

A lead dioxide, high-quality technology, applied in the direction of lead dioxide, lead oxide, etc., can solve the problems of low purity of lead dioxide, complex equipment, lead slime utilization, etc., to save metal lead resources, less electricity consumption, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

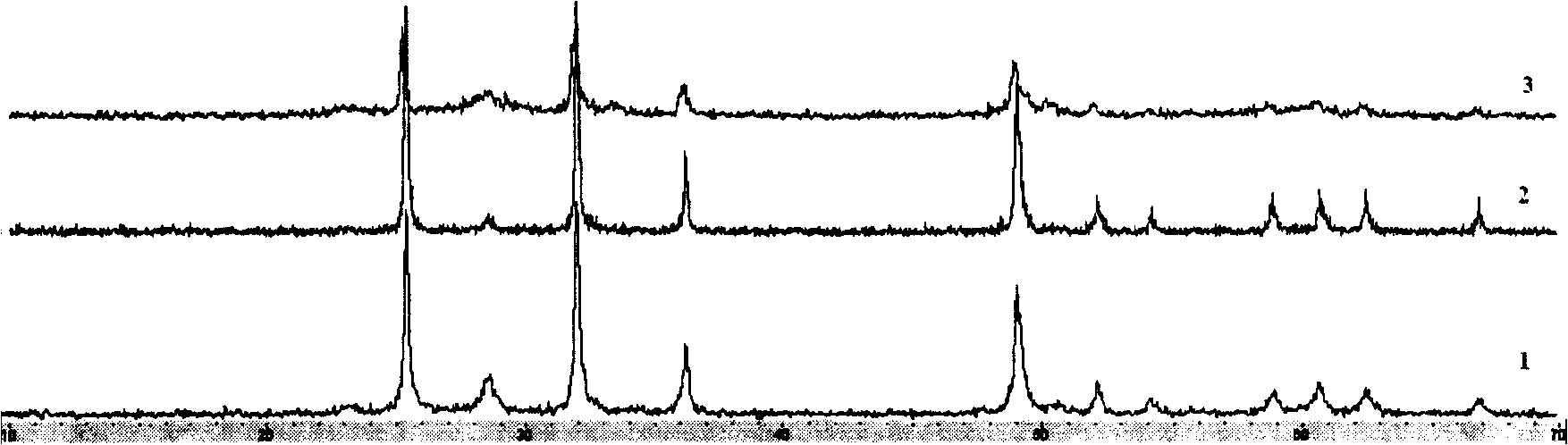

Image

Examples

Embodiment 1

[0031] The lead slime is taken out from the storage battery, washed repeatedly until neutral, then dried, ground to 200-300 mesh powder, and set aside. Dissolve 250 grams of sodium hydroxide and 20 grams of 12,000-15,000 polyvinyl alcohol dispersant in 2,600 grams of water, then add 1,000 grams of the above-mentioned lead mud powder, stir and react at 80°C for 2 hours, filter and separate, and filter the cake with water repeatedly. Wash until neutral. Dry the lead sludge obtained after desulfurization, add saturated sodium hypochlorite solution (available chlorine > 10%), the solid-to-liquid ratio (lead dioxide: sodium hypochlorite solution) is 1:4, stir and react at 80°C for 2 hours, take out, and filter and separate , then dry. The obtained solid powder sample is identified by XRD and confirmed to be lead dioxide; and identified by chemical analysis, the content of the obtained lead dioxide is 92.43%. The recovery rate of lead in the whole process is 94%. The particle siz...

Embodiment 2

[0033] The lead slime is washed repeatedly until neutral, then dried, and ground to 200-300 mesh powder. Dissolve 250 grams of sodium hydroxide and 20 grams of 12,000-15,000 polyvinyl alcohol dispersant in 2,600 grams of water, then add 1,000 grams of the above-mentioned lead mud powder, stir and react at 80°C for 2 hours, filter and separate, and wash the filter cake repeatedly with clean water until neutral. After the obtained desulfurized lead hydroxide is dried, add saturated sodium hypochlorite solution, the solid-to-liquid ratio (lead dioxide: sodium hypochlorite solution) is 1:4, stir and react at 25°C for 24 hours, take it out, separate by filtration, and then dry. The obtained solid powder sample was identified by XRD and confirmed to be lead dioxide. The sample is identified through chemical analysis, and the obtained lead dioxide content reaches 88.18%, the recovery rate of lead in the whole process reaches 93%, and the particle size is about 20 microns.

Embodiment 3

[0035] After repeatedly washing the lead mud to neutrality, dry it, grind it to 200-300 mesh powder, dissolve 331 grams of sodium carbonate and 20 grams of 12000-15000 polyvinyl alcohol dispersant in 2700 grams of water, and then add 1000 grams of the above-mentioned lead mud powder , stirred and reacted at 60° C. for 6 hours, separated by filtration, and the filter cake was repeatedly washed with water until neutral. After the obtained desulfurized lead slime is dried, add saturated sodium hypochlorite solution, the solid-to-liquid ratio (lead dioxide: sodium hypochlorite solution) is 1:4, stir and react at 60°C for 6 hours, filter and separate, and then dry. The obtained solid powder sample was identified by XRD and confirmed to be lead dioxide. The sample is identified through chemical analysis, and the obtained lead dioxide content reaches 91.17%, the recovery rate of lead in the whole process reaches 95%, and the particle size is about 20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com