Patents

Literature

847results about "Nitrogen purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

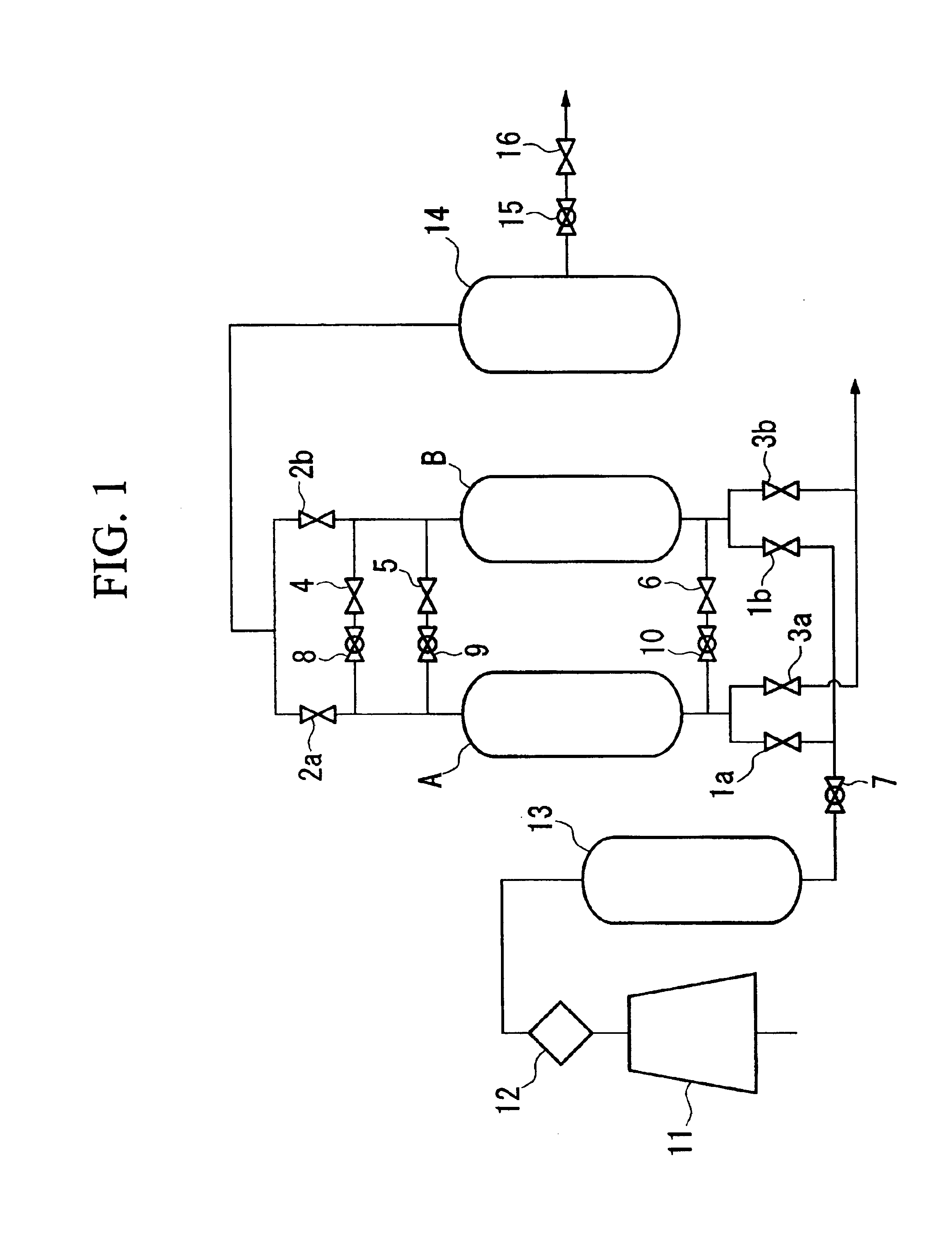

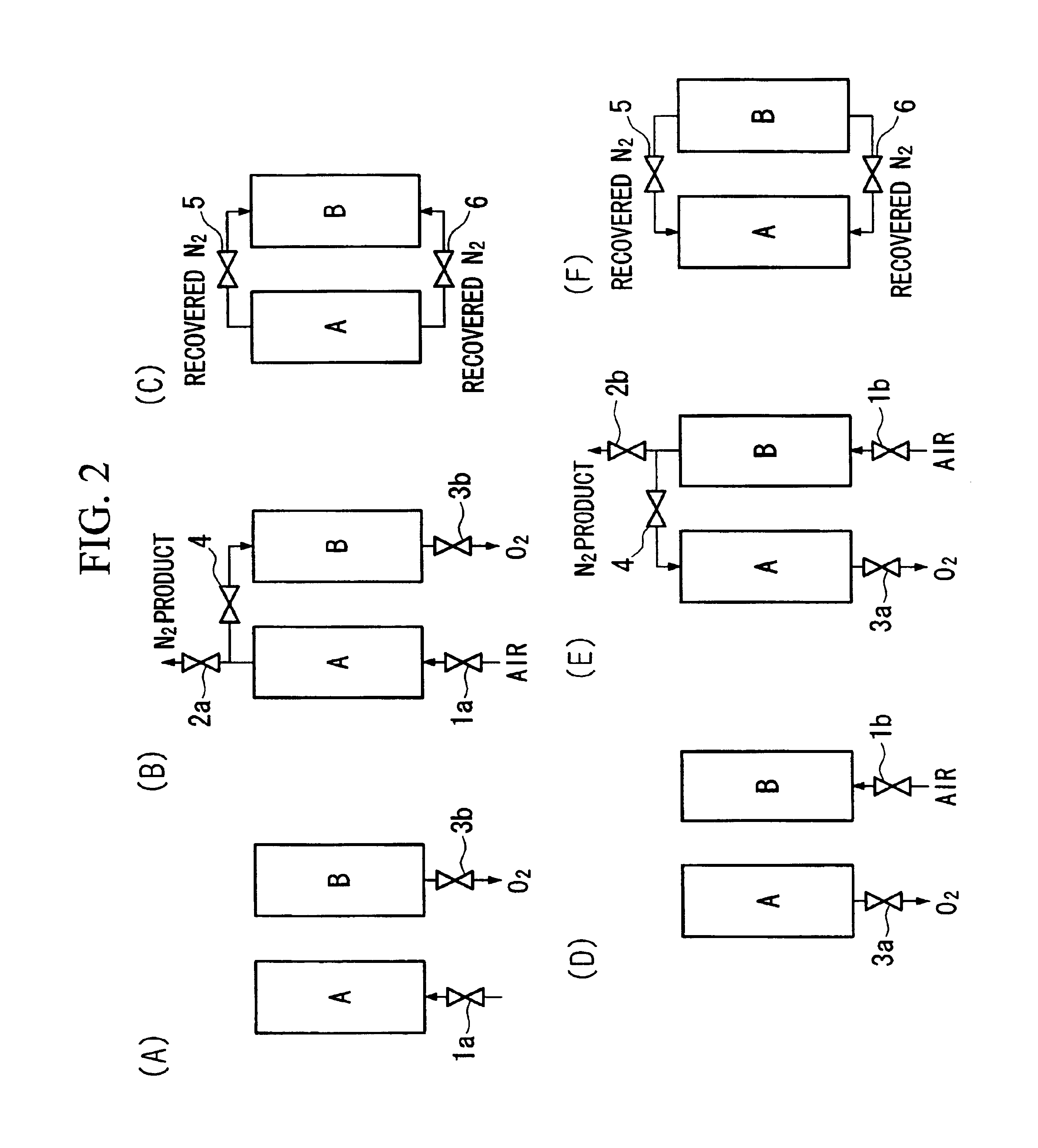

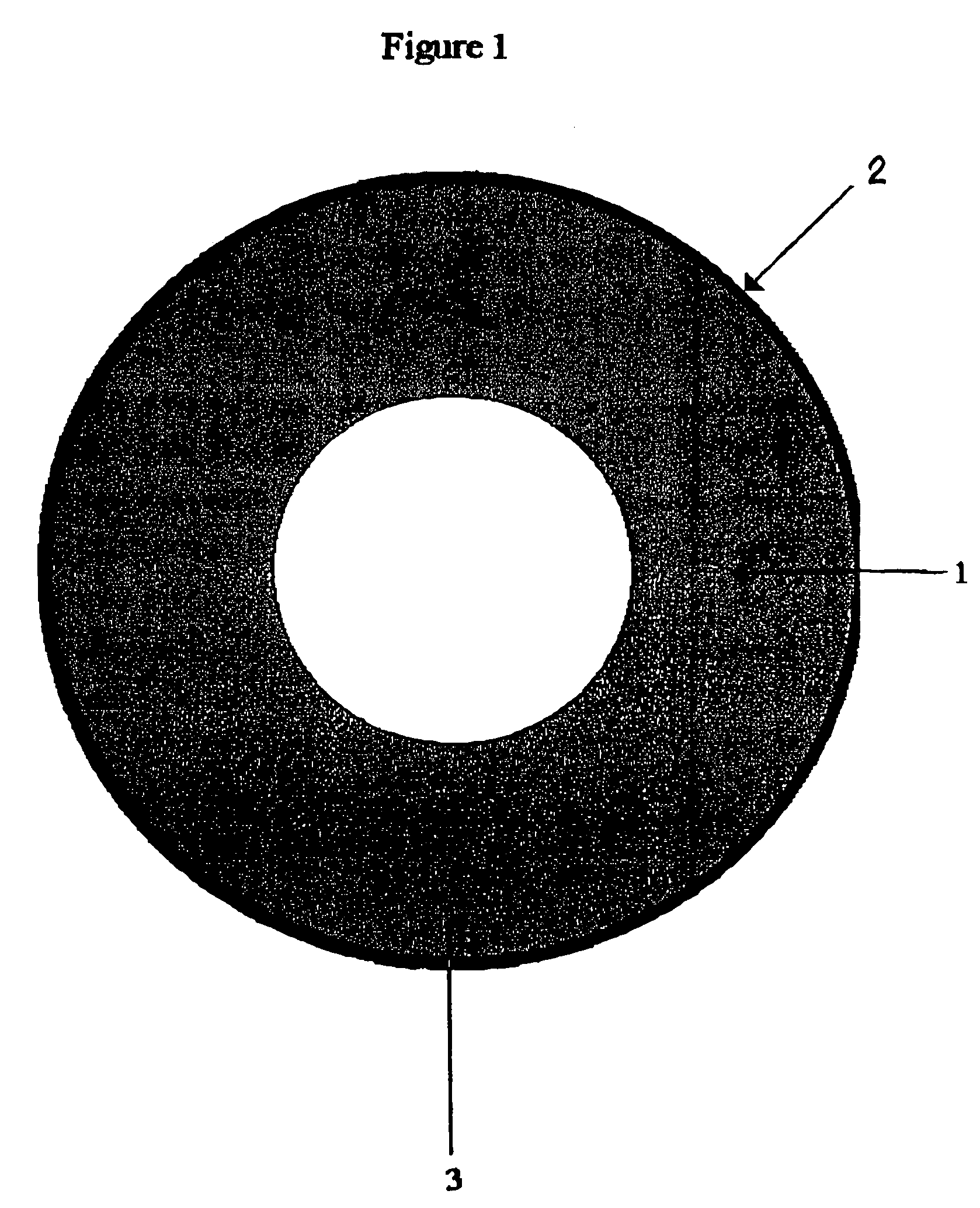

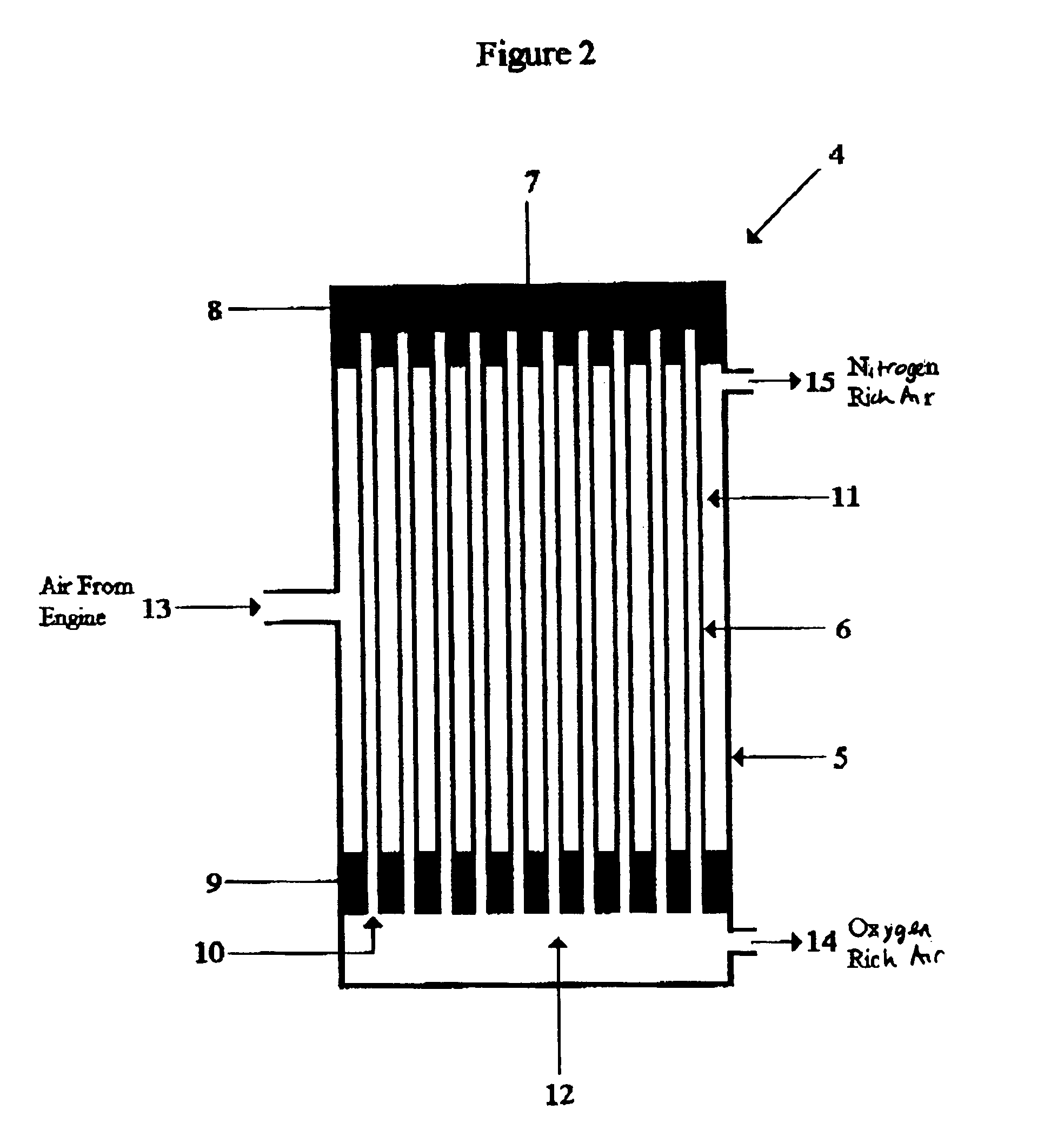

High frequency pressure swing adsorption

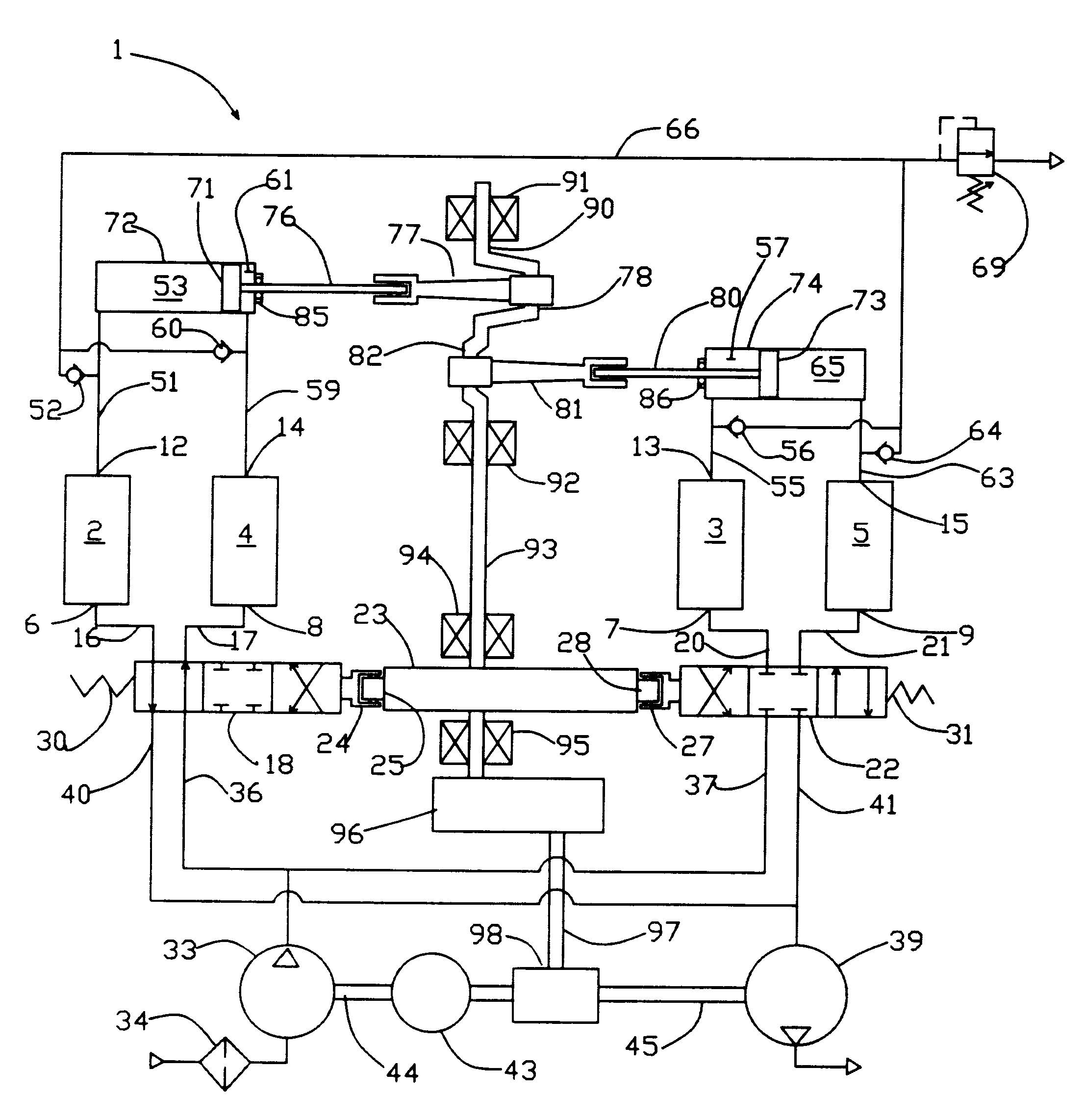

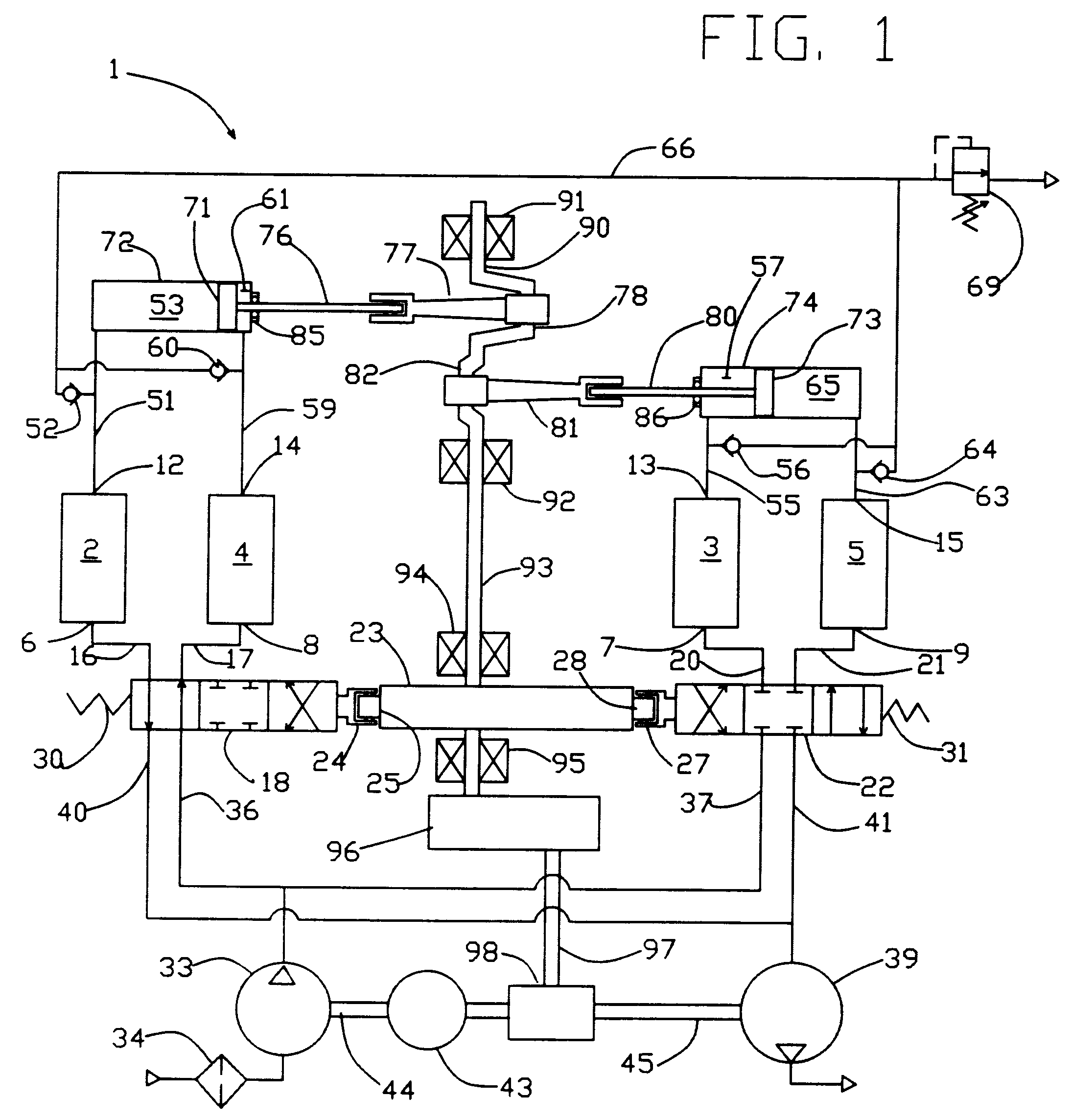

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

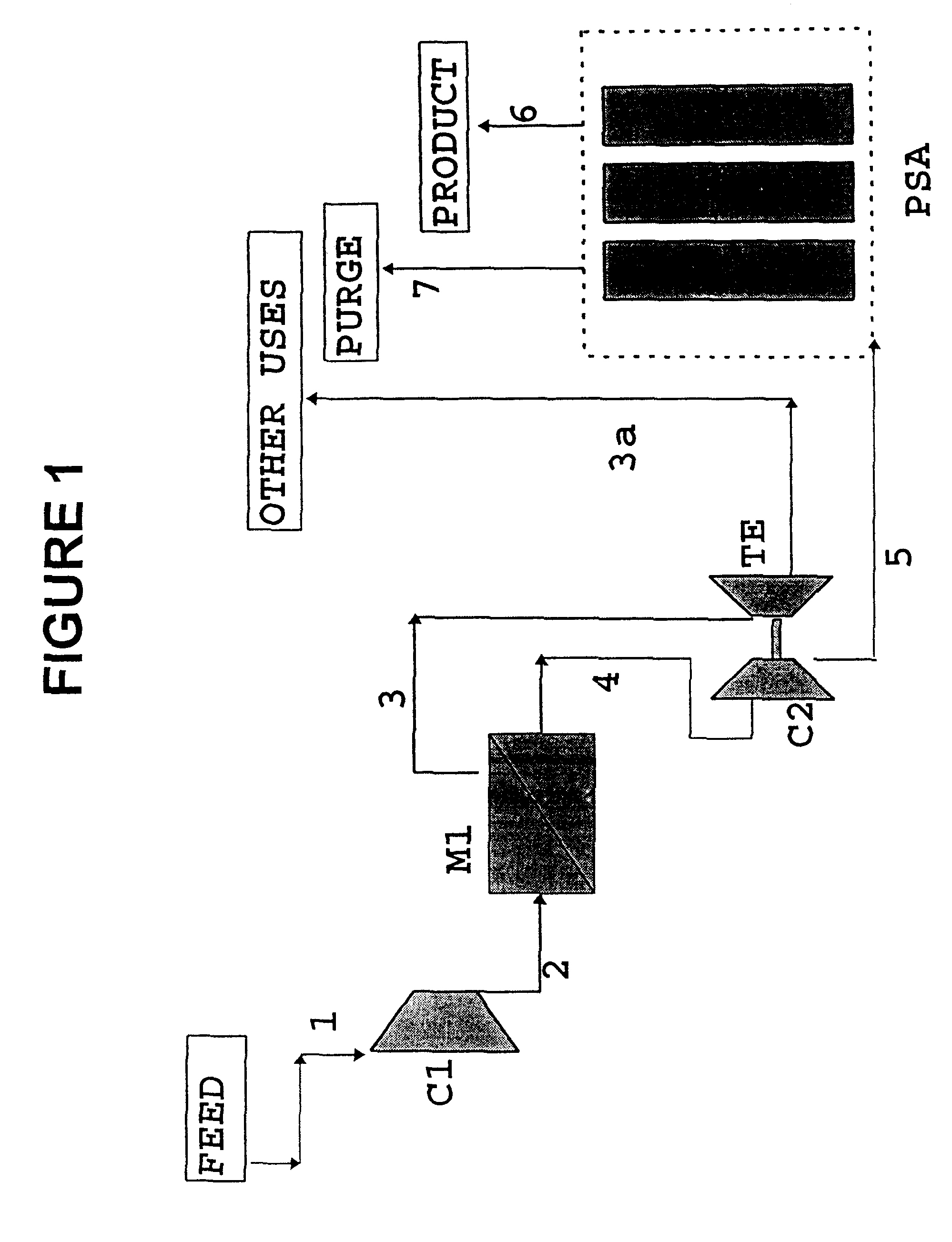

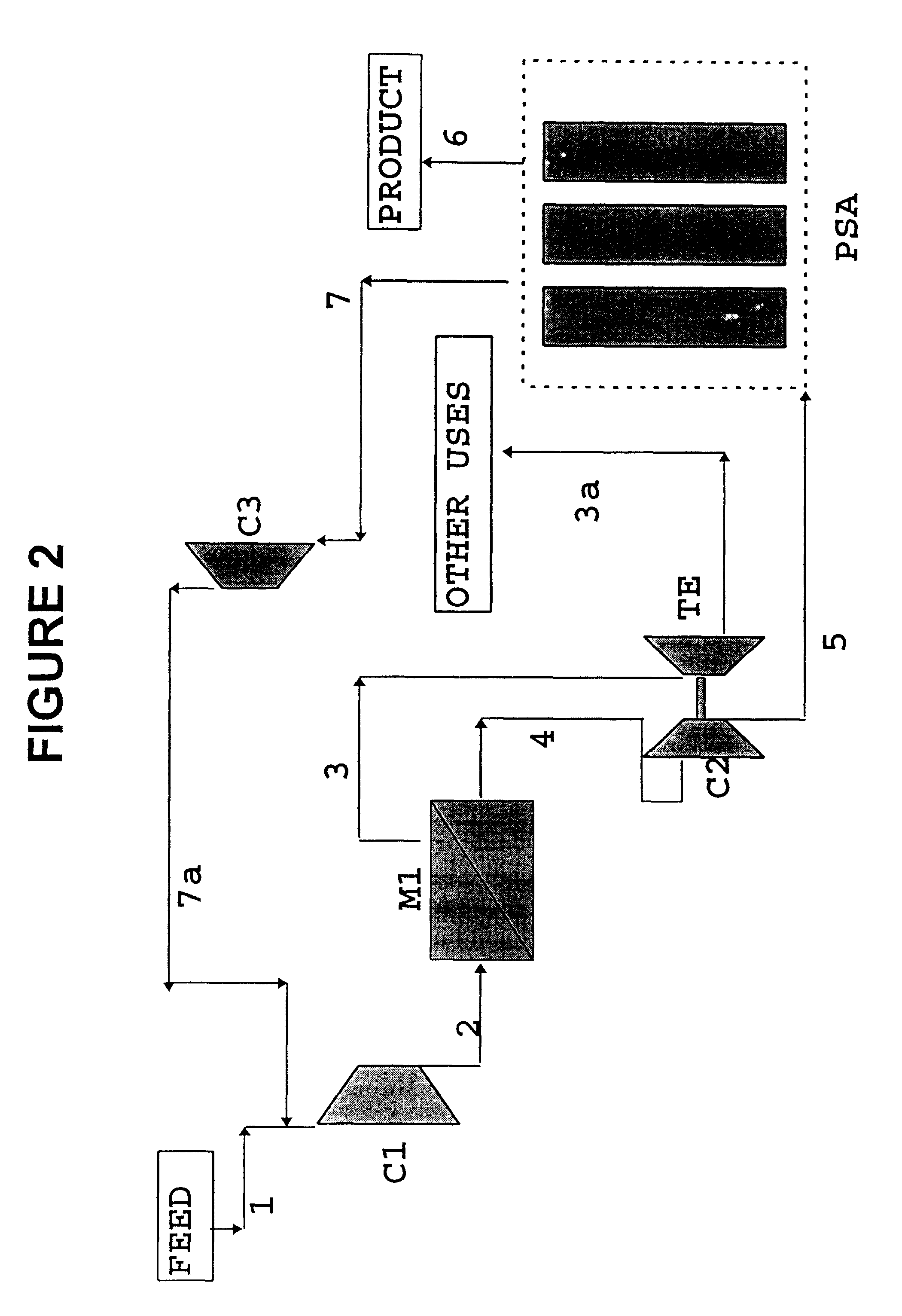

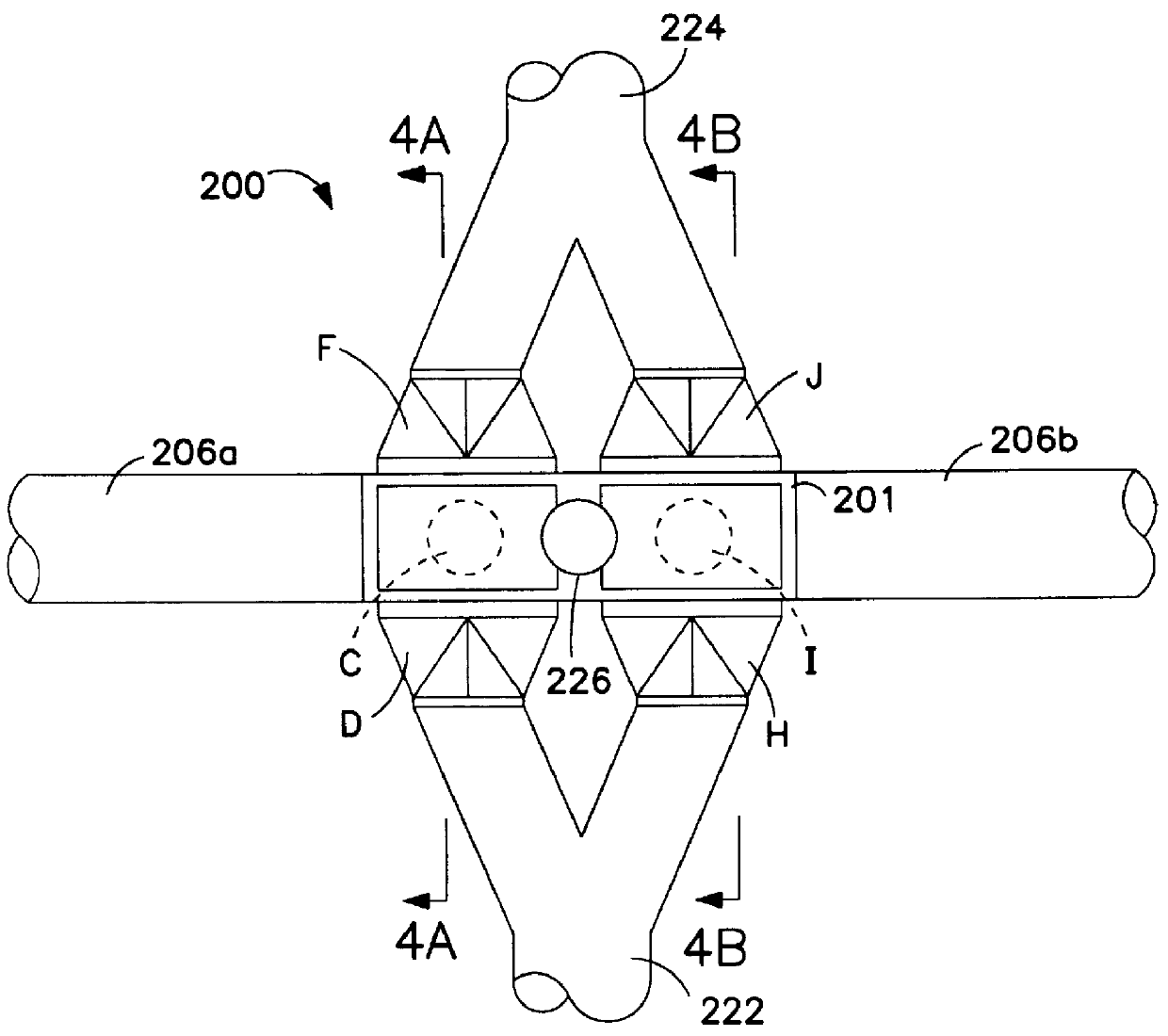

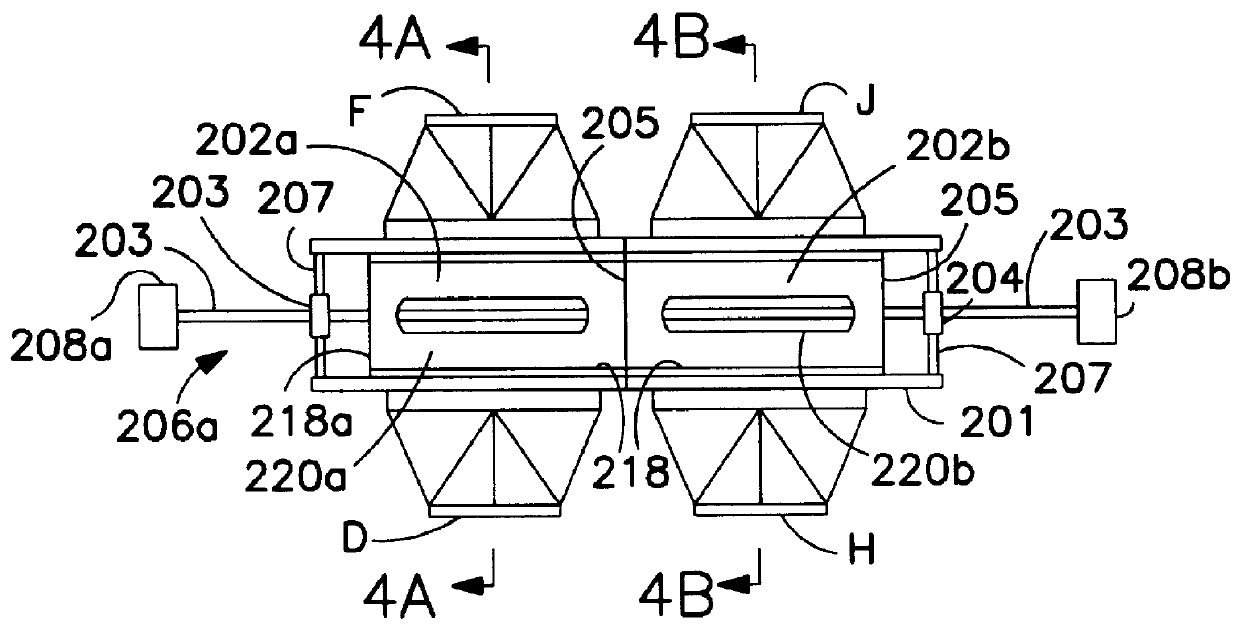

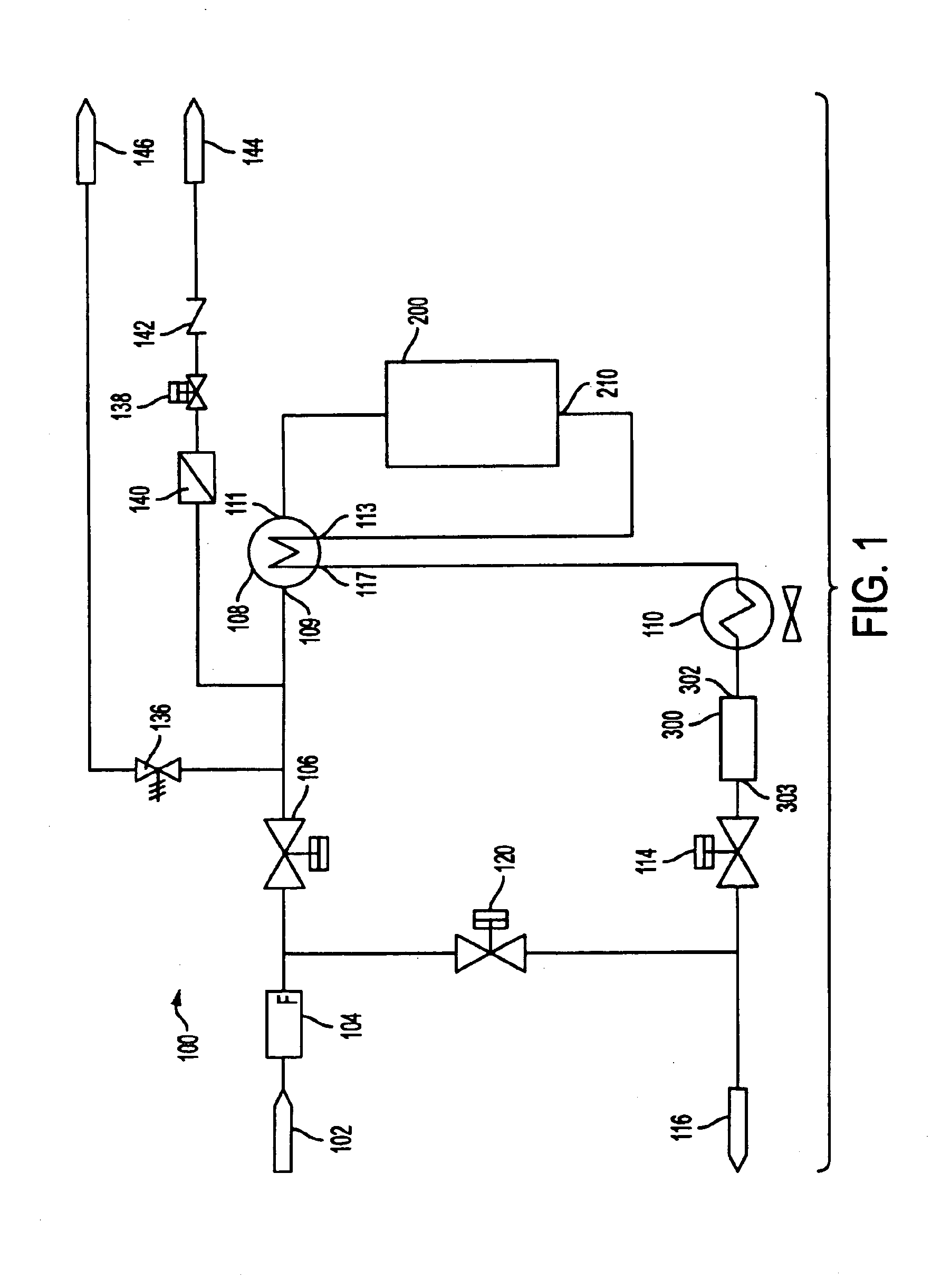

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

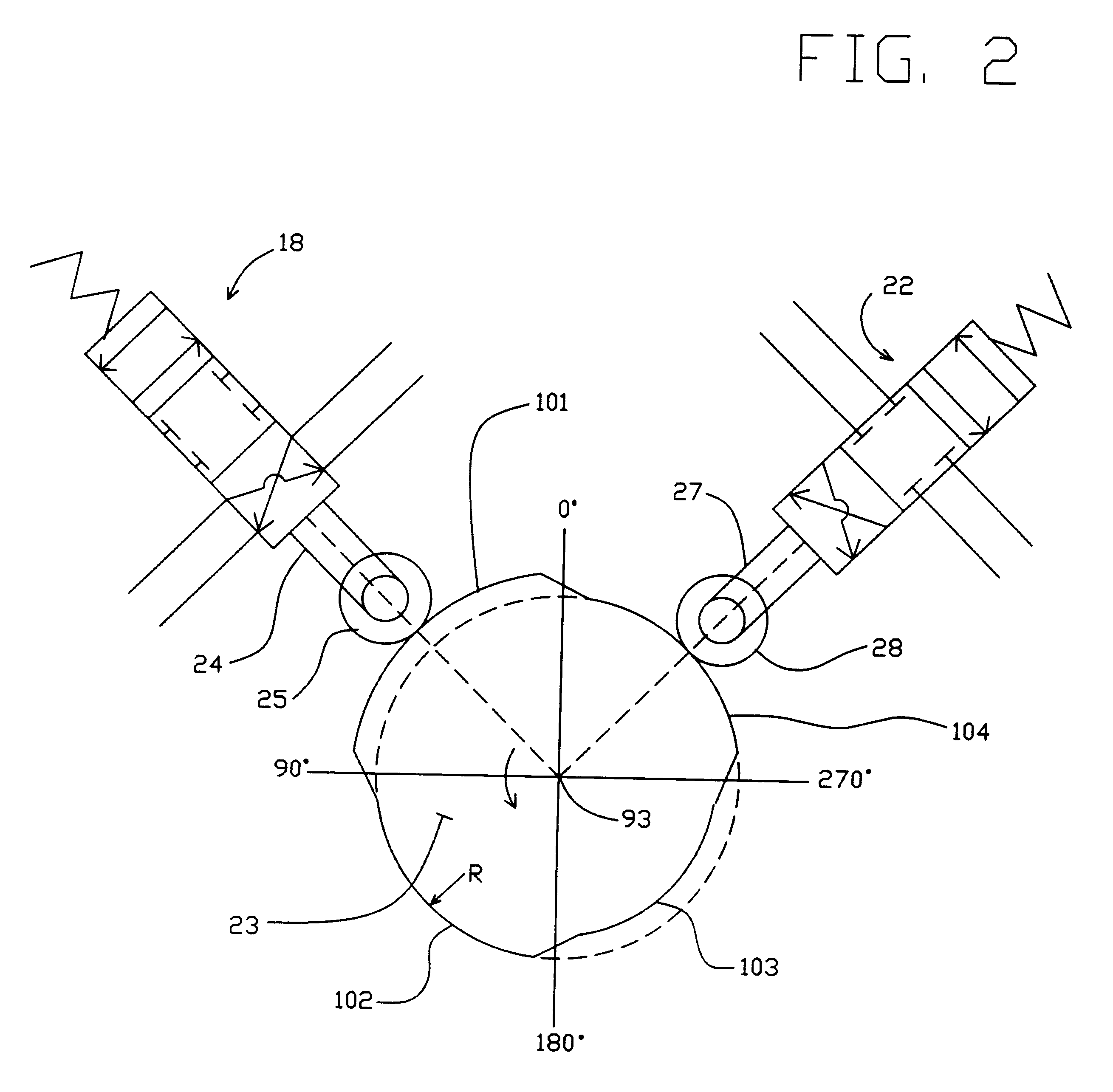

Process for the separation/recovery of gases

InactiveUS6179900B1Low costHigh purityNitrogen purification/separationGas treatmentHydrogenHigh pressure

A process for the separation / recovery of gases is described where the desired component to be separated from the gaseous mixture is present in low / very low molar amount and / or low / moderate pressure, the process comprising contacting the gaseous mixture with a separation membrane unit containing high permeability / medium selectivity membranes which separate the feed stream into a permeate stream, enriched in the desired component and at a lower pressure and a retentate stream lean in the desired component and at a higher pressure. The retentate stream is made to convey its pressure to the permeate stream which then is directed to an adsorption PSA unit for further purification of the permeate stream so that the effluent stream from the PSA unit which contains the purified component has a purity of up to 99.90%. The process is useful for separating hydrogen from refinery off gases such as FCC gases and can also be applied to other gases such as helium and any other valuable gases present in gaseous streams in low to very low molar contents and low to moderate pressures.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH +1

Process and catalyst for reducing nitrogen oxides

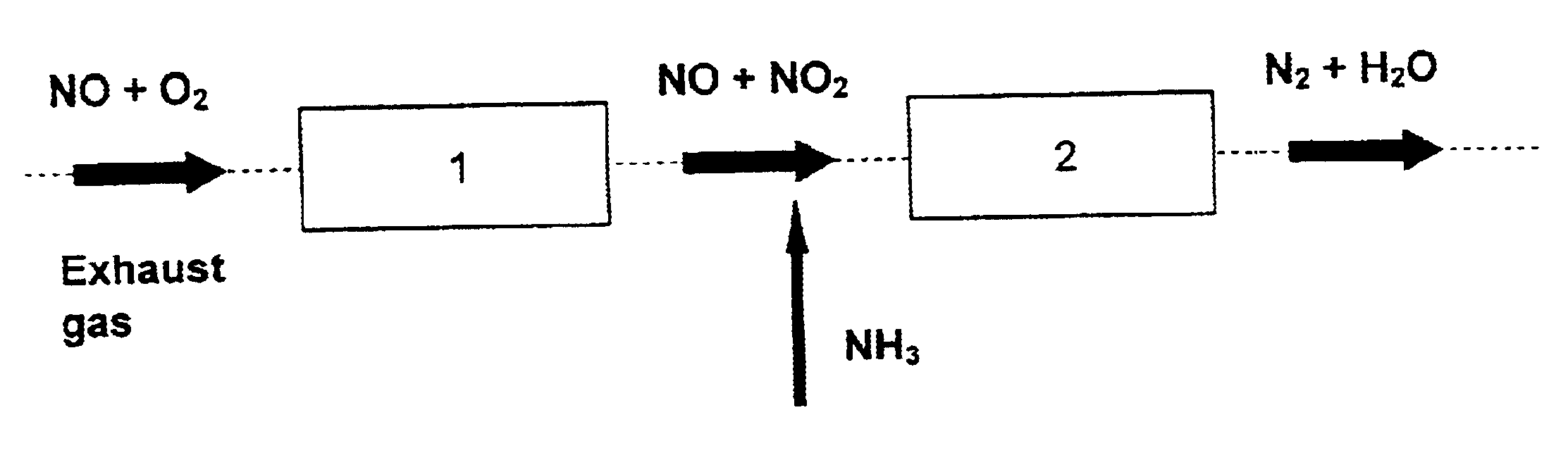

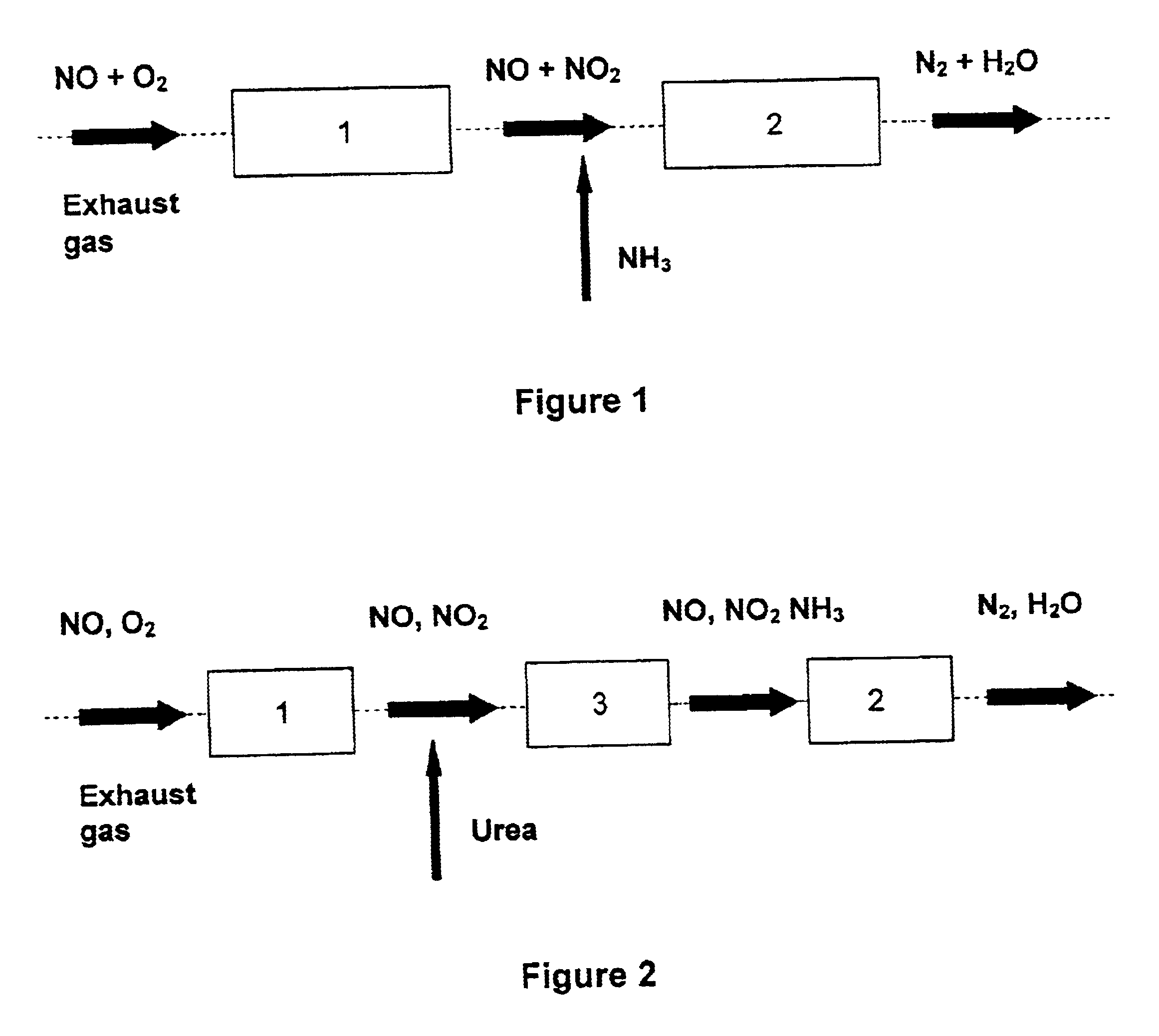

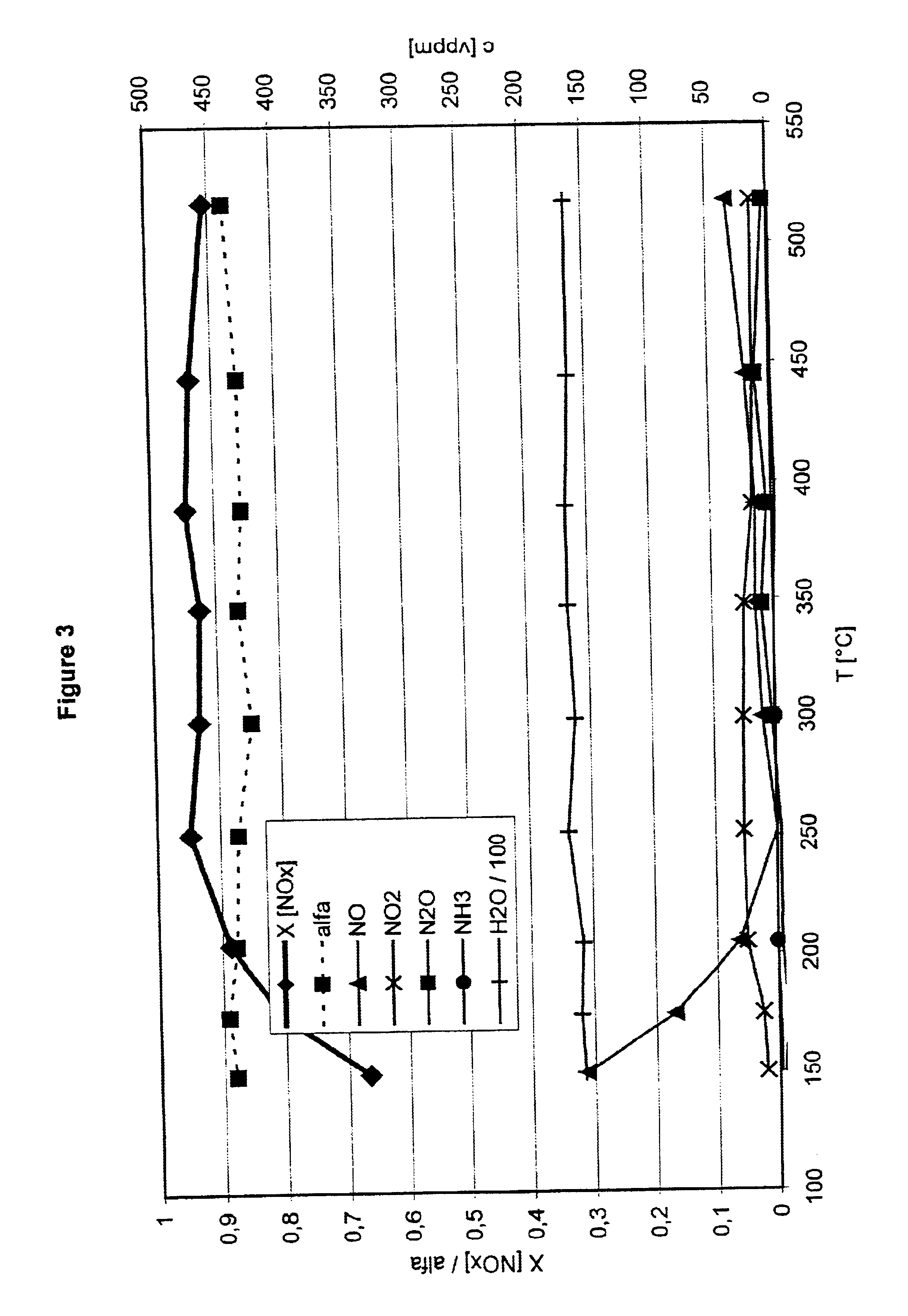

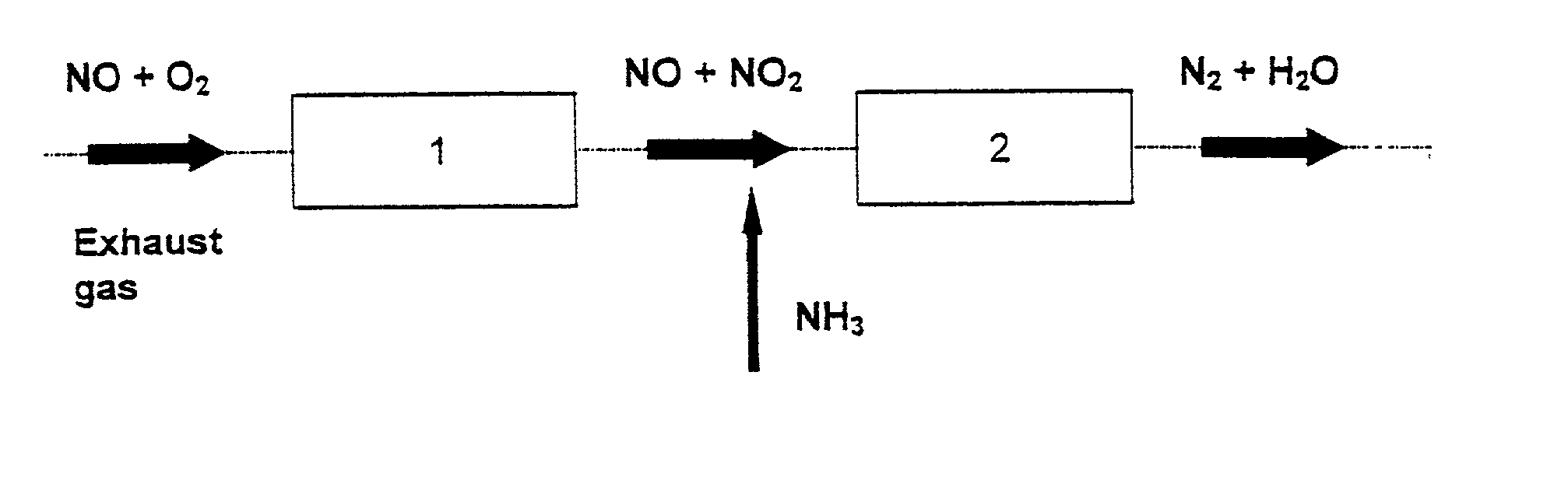

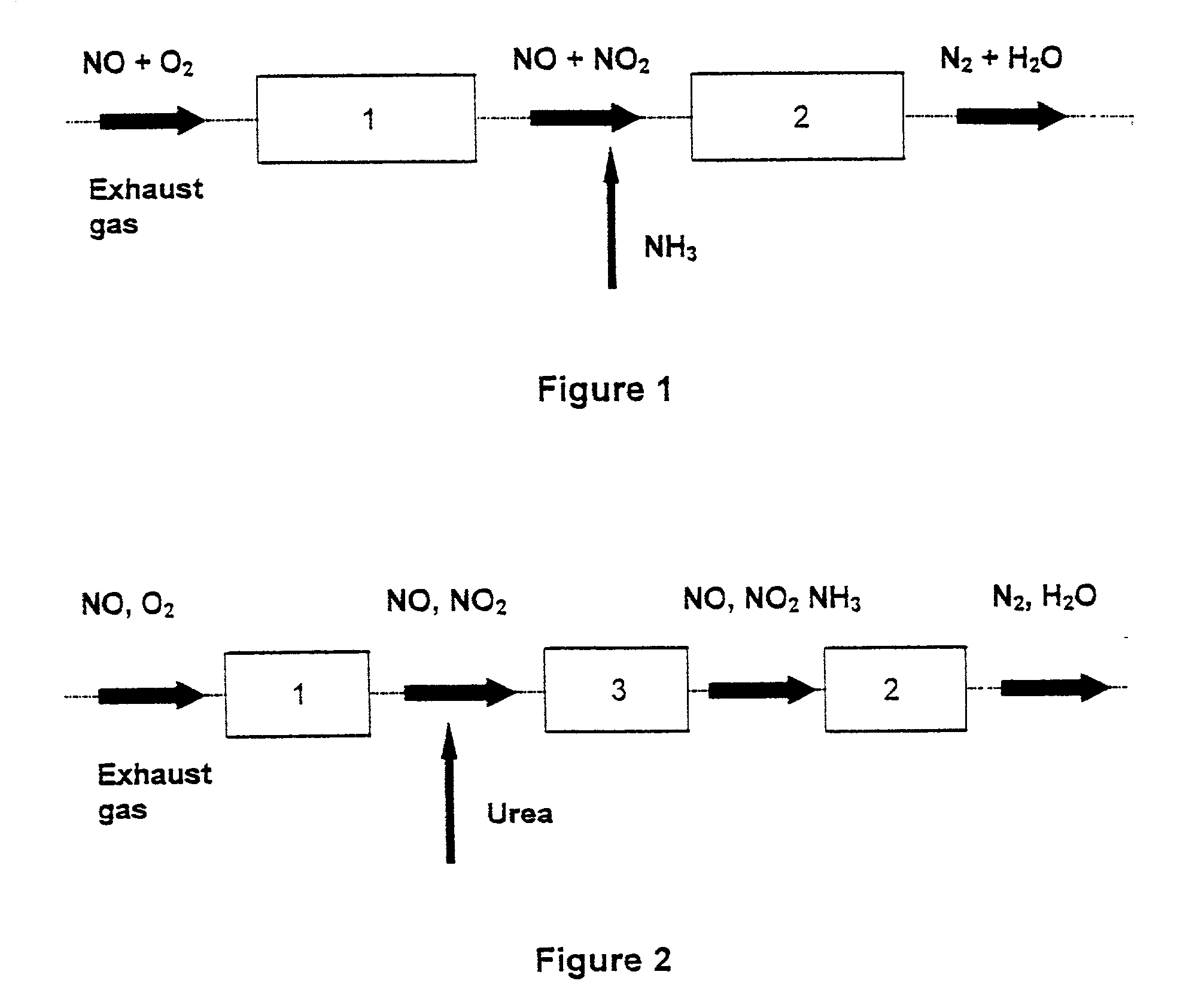

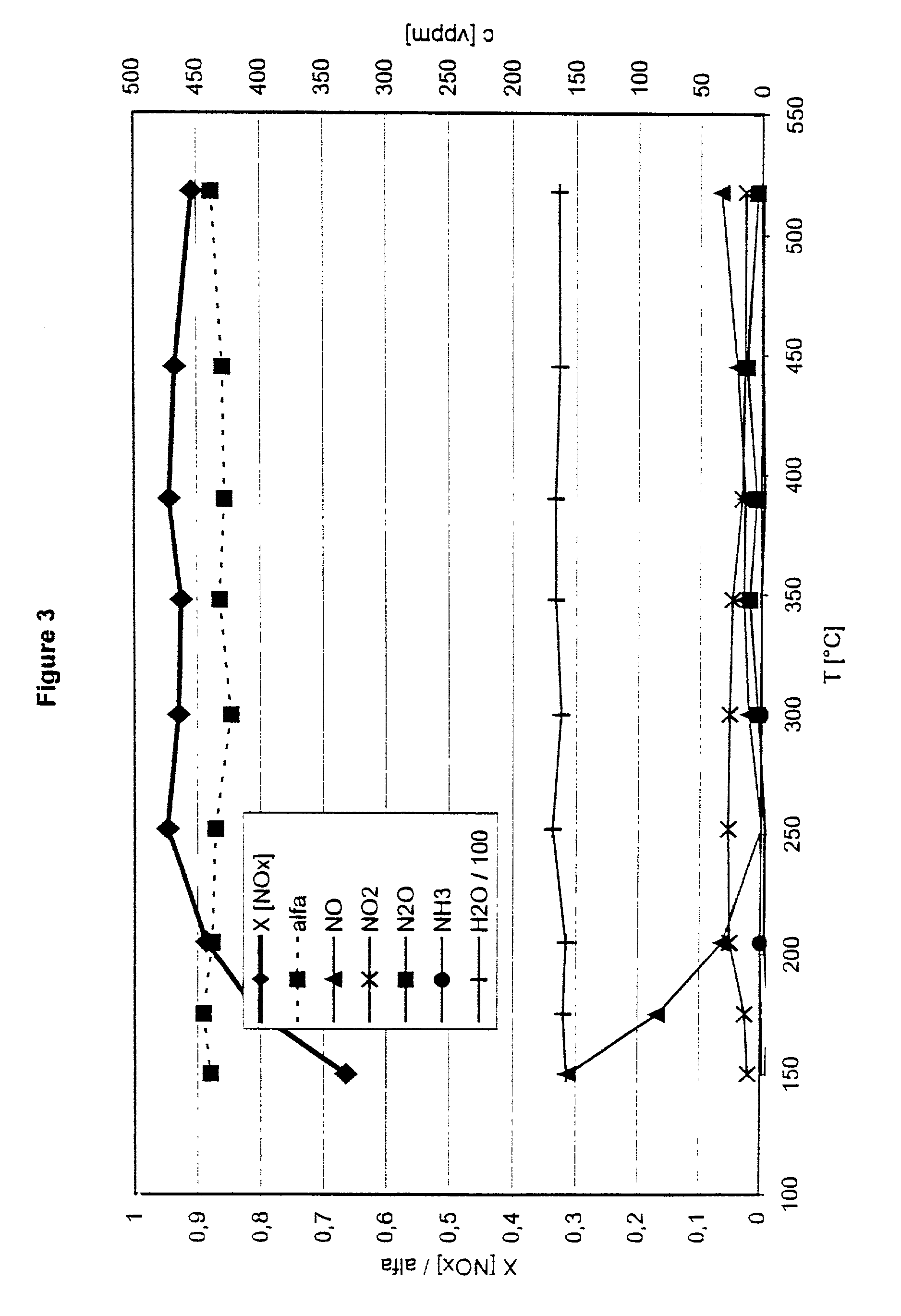

InactiveUS6843971B2High activityDelay agingCyanogen compoundsInternal combustion piston enginesInternal combustion engineChemistry

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

Process and catalyst for reducing nitrogen oxides

InactiveUS20020039550A1High activityDelay agingInternal combustion piston enginesExhaust apparatusNitric oxideInternal combustion engine

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

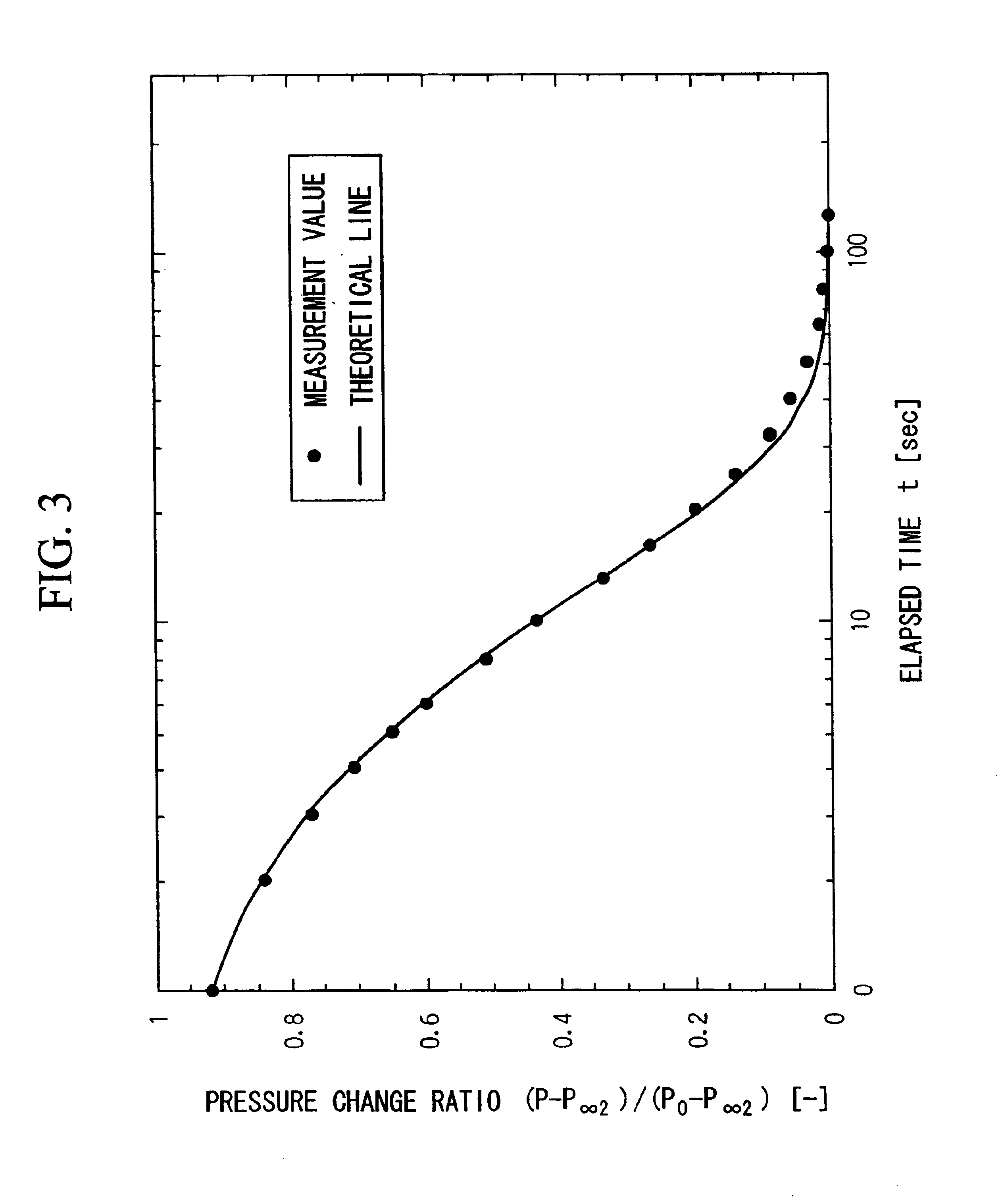

Adsorbent for separating nitrogen from mixed gas of oxygen and nitrogen

InactiveUS6916358B2Minimal operating costMore productiveNitrogen purification/separationGas treatmentSorbentNitrogen

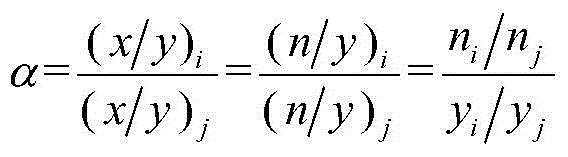

An adsorbent for separating nitrogen from a mixed gas of oxygen and nitrogen is MSC wherein an oxygen and nitrogen separation ratio α and a ratio (t95 / t50) of a time t50 required for adsorbing 50% of the oxygen equilibrium adsorption amount and a time t95 required for adsorbing 95% of the oxygen equilibrium adsorption amount satisfy the inequality(t95 / t50)<0.4×(α−24)α≧35.The amount of adsorbent used with respect to a predetermined amount of nitrogen generated can be reduced since a method is carried out which uses this adsorbent to produce nitrogen by separating nitrogen from the mixed gas of oxygen and nitrogen by means of a PSA method. By this method, it is possible to reduce the cost of the apparatus and reduce and miniaturize the scale of the apparatus, and the power consumption amount can be reduced.

Owner:NIPPON SANSO CORP

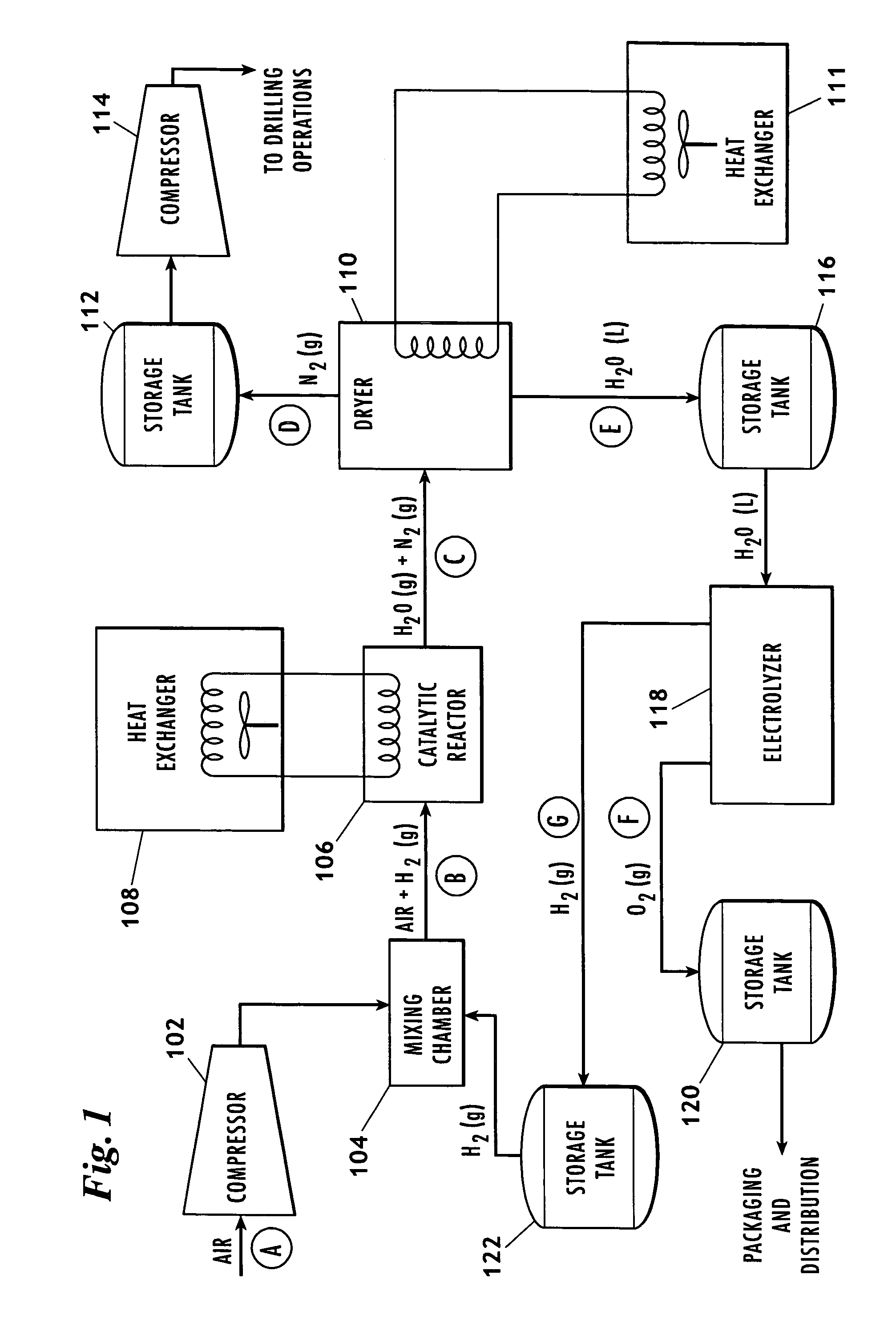

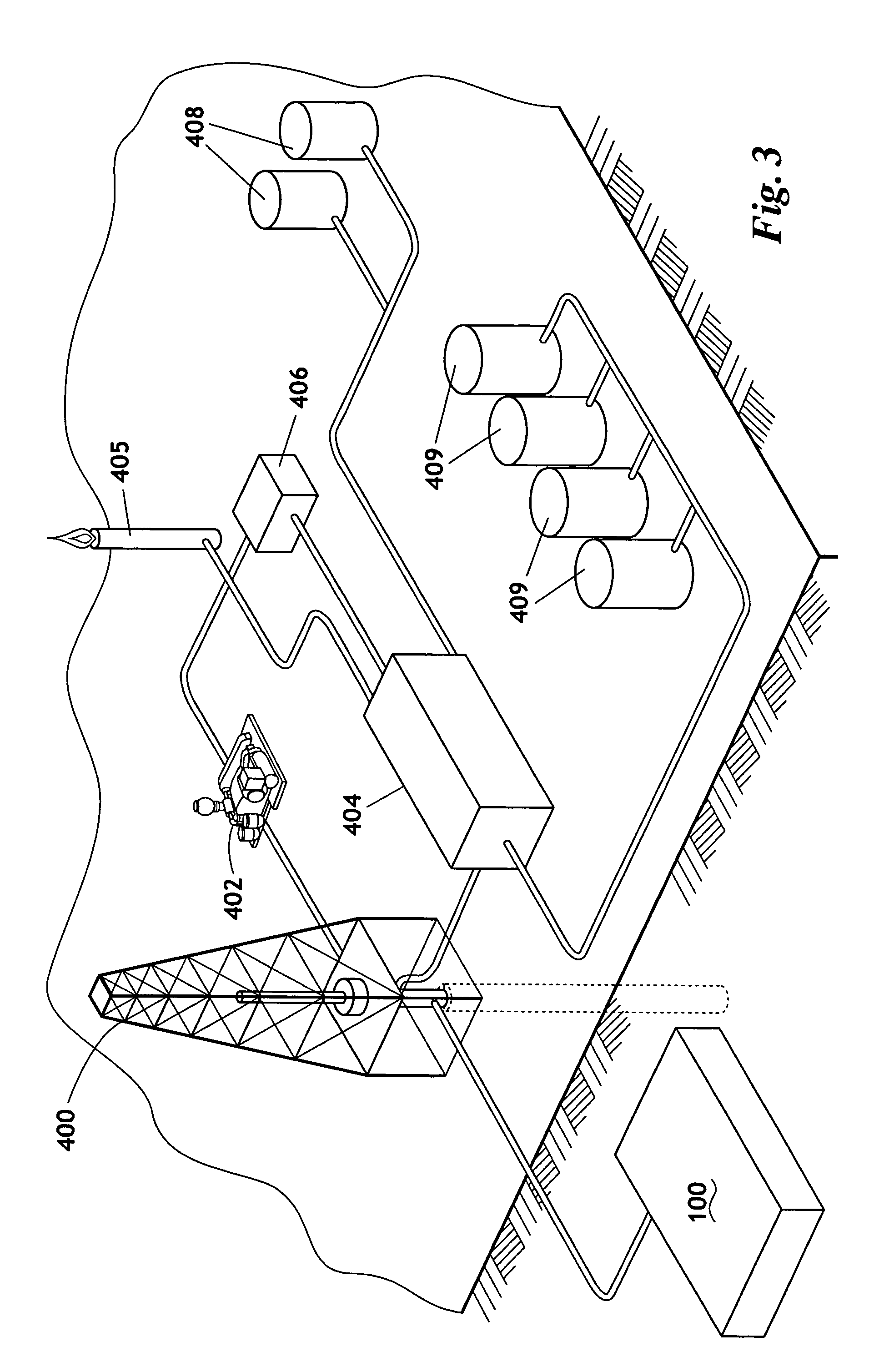

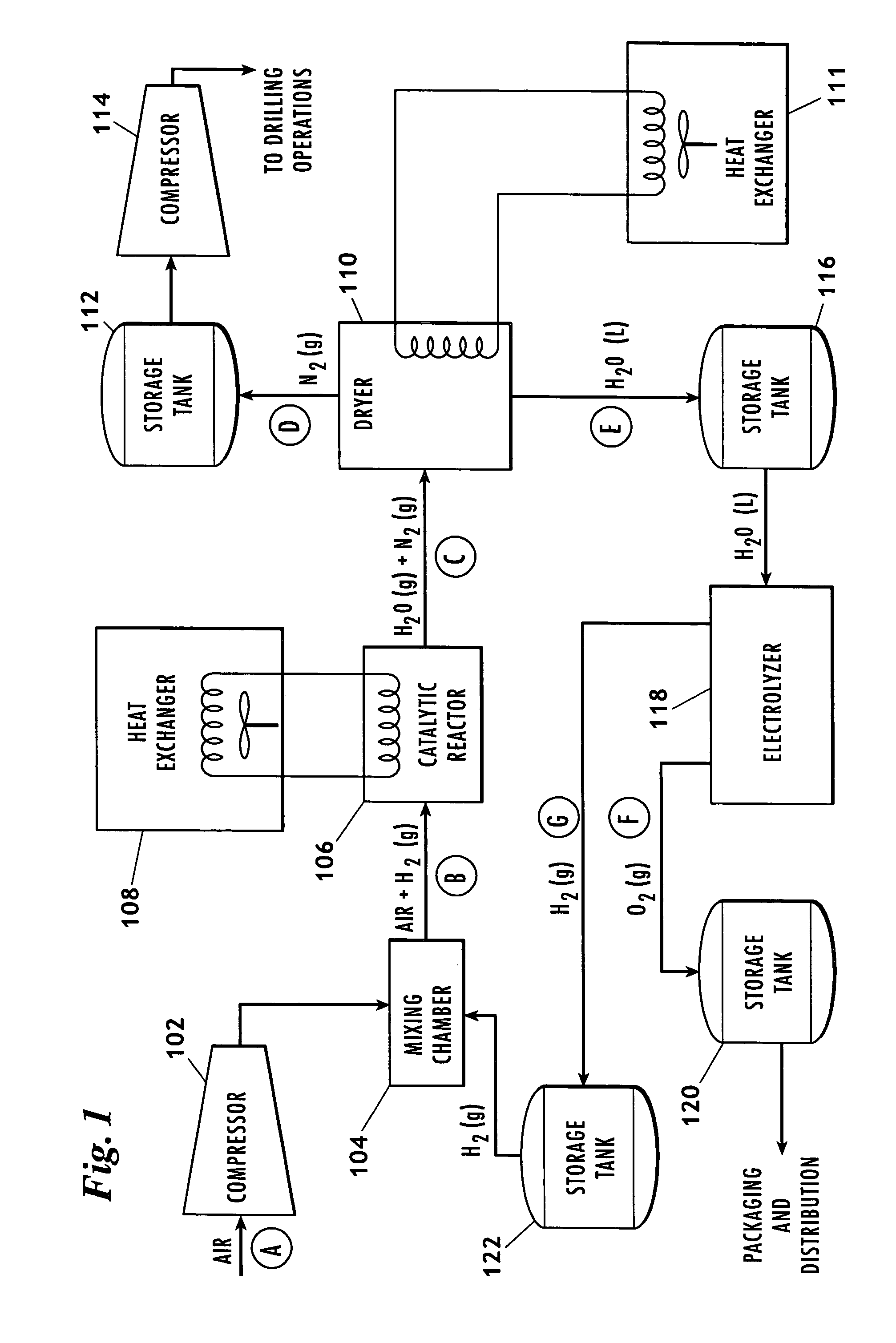

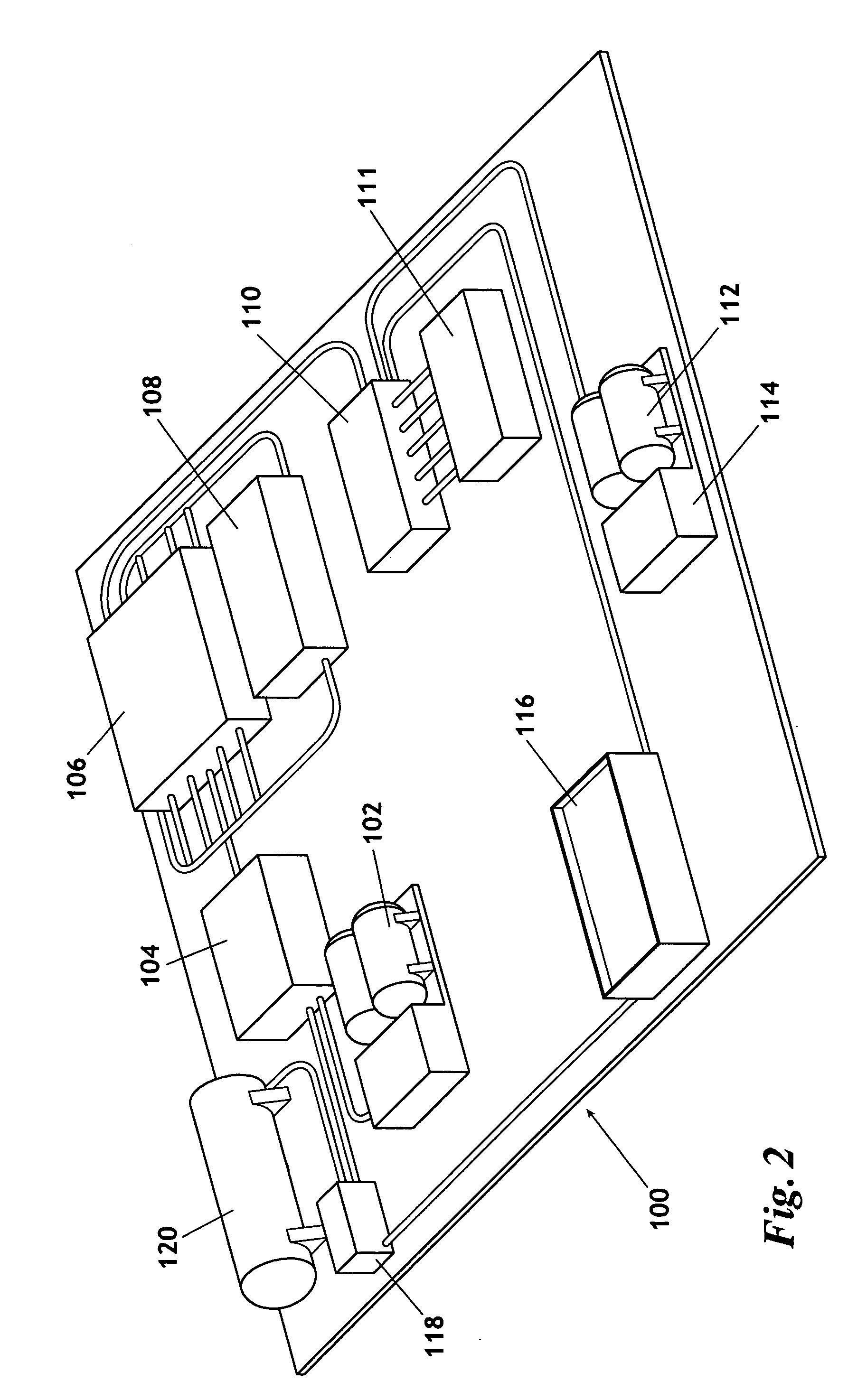

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS7468173B2Offsetting costsNitrogen purification/separationDispersed particle separationElectrolysisAtmospheric air

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

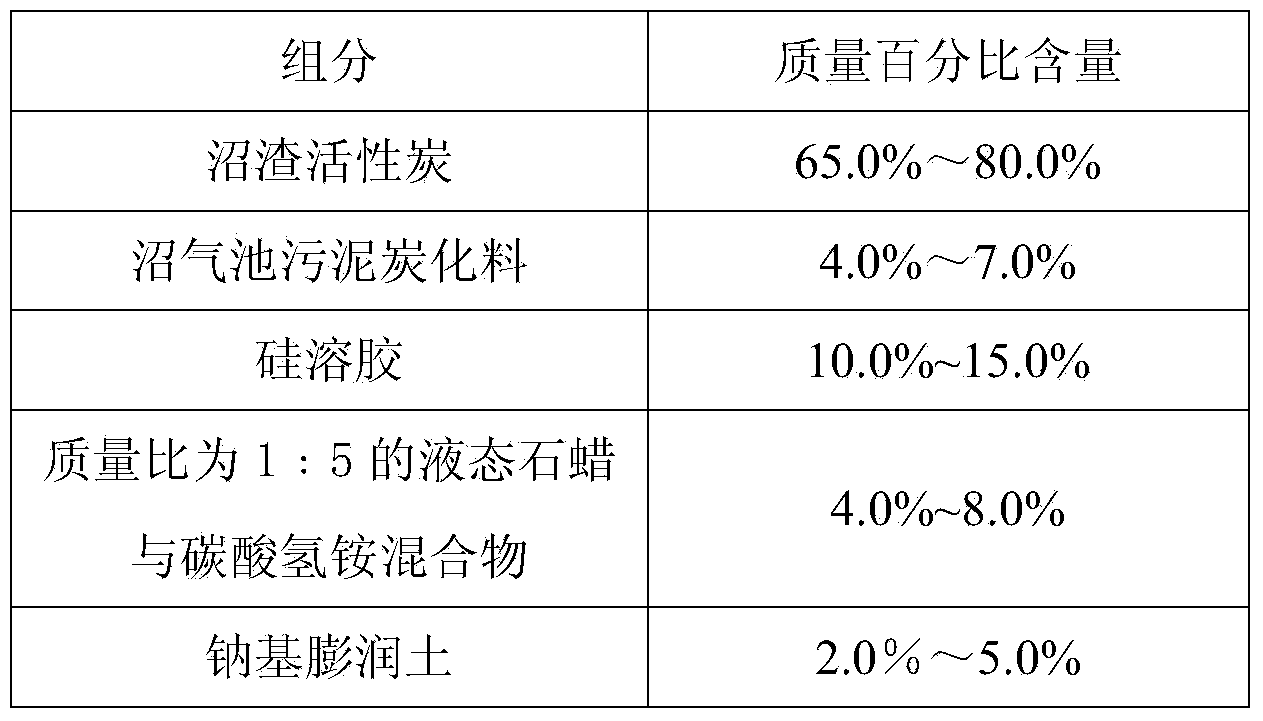

Agglomerated adsorbent, process for the production thereof and use thereof for the non-cryogenic separation of industrial gases

InactiveUS6652626B1Reduce the burden onReduce consumptionIsotope separationHydrogen/synthetic gas productionLithiumIndustrial gas

A description is given of agglomerates of faujasite X with an Si / Al ratio of 1, the inert binder of which, on the one hand, has been converted to active zeolite by conversion to zeolite in an alkaline liquor, and which have been subjected, on the other hand, to an exhaustive lithium exchange. These adsorbents develop a nitrogen adsorption capacity (1 bar / 25° C.) of at least 26 cm<3> / g, which makes them excellent adsorbents for the non-cryogenic separation of gases from air and for the purification of hydrogen.

Owner:ARKEMA FRANCE SA

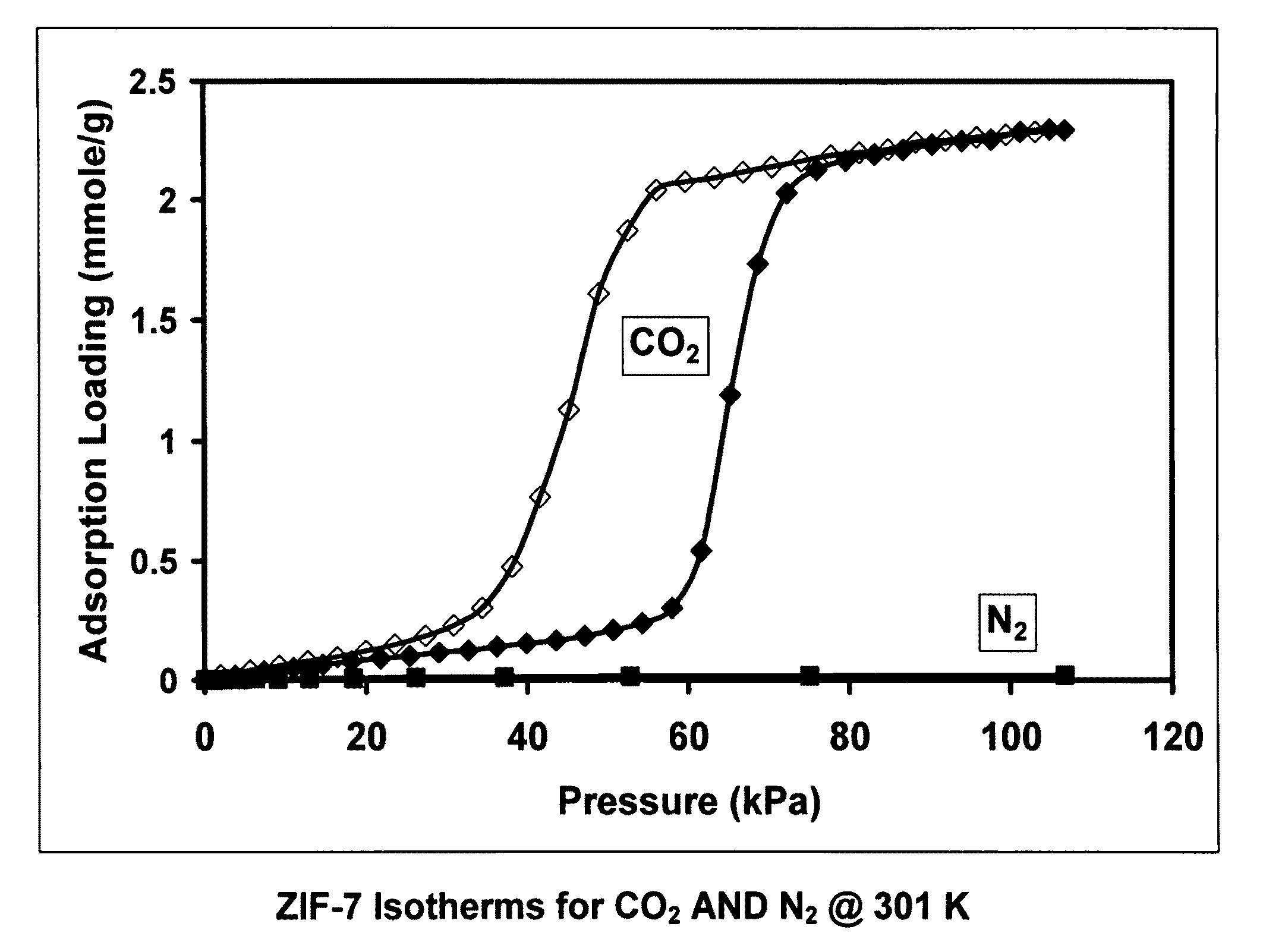

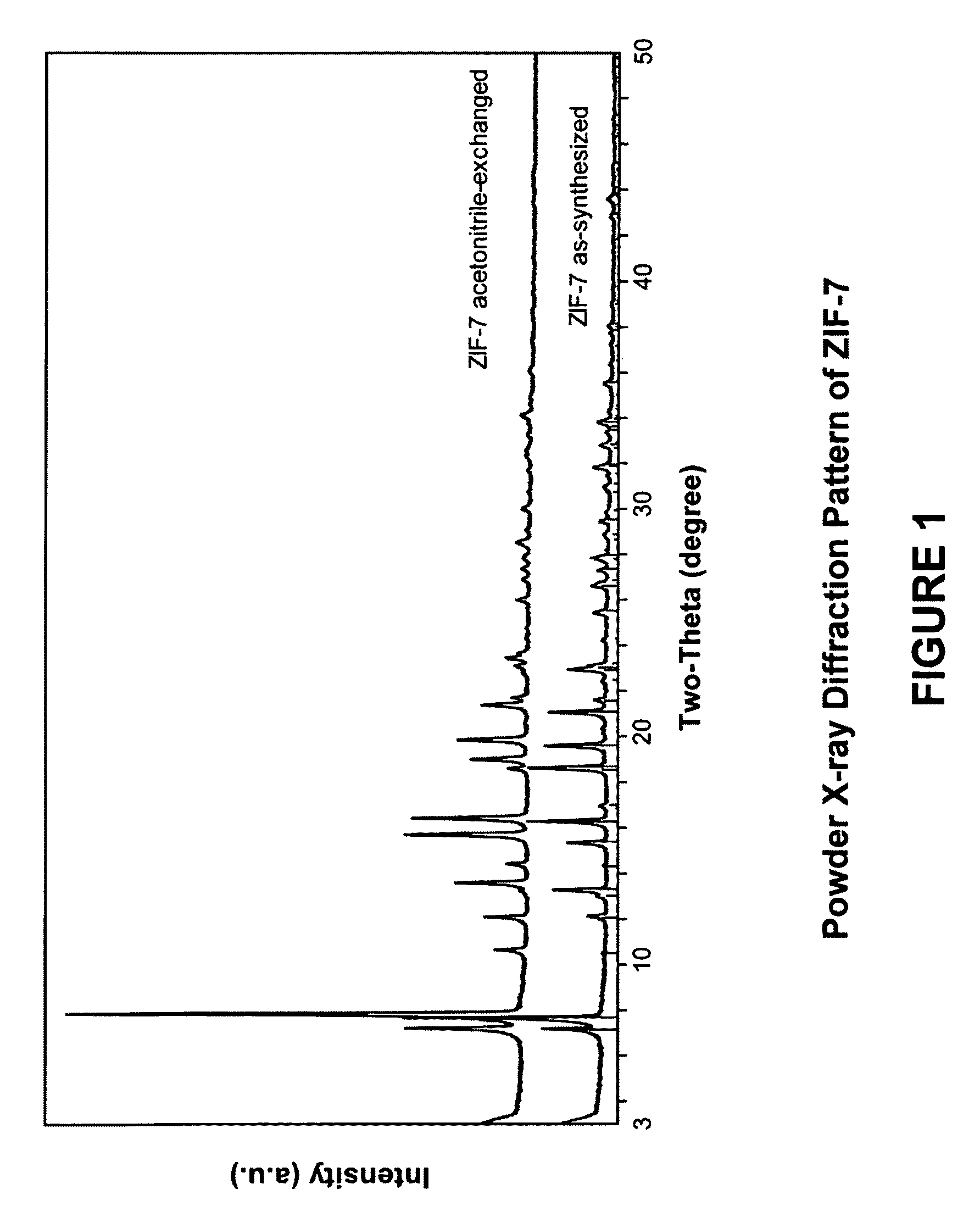

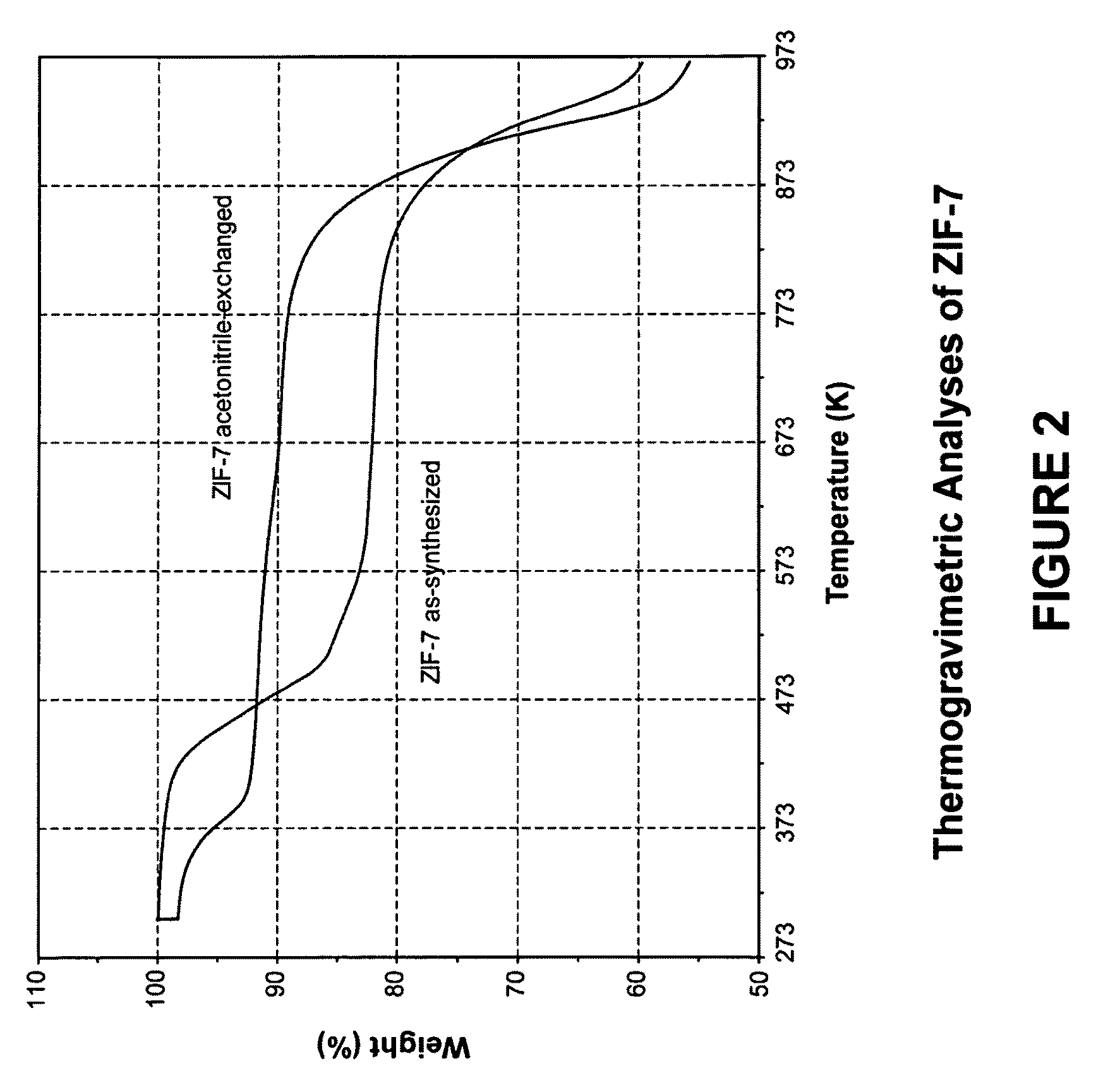

Separation of carbon dioxide from nitrogen utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from nitrogen (“N2”) in streams containing both carbon dioxide and nitrogen utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from combustion gas (e.g., flue gas) streams preferably for sequestration of at least a portion of the carbon dioxide produced in combustion processes.

Owner:EXXON RES & ENG CO

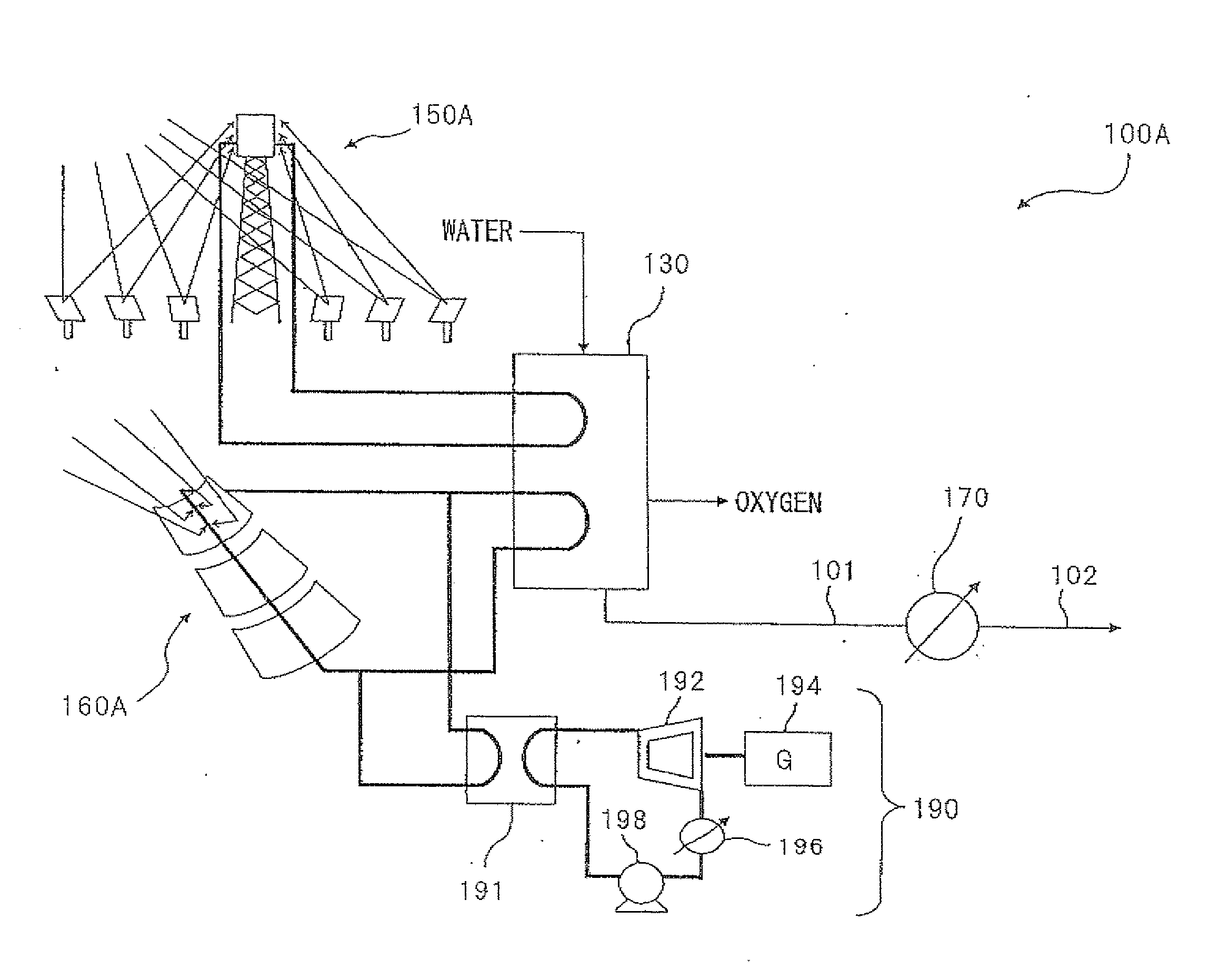

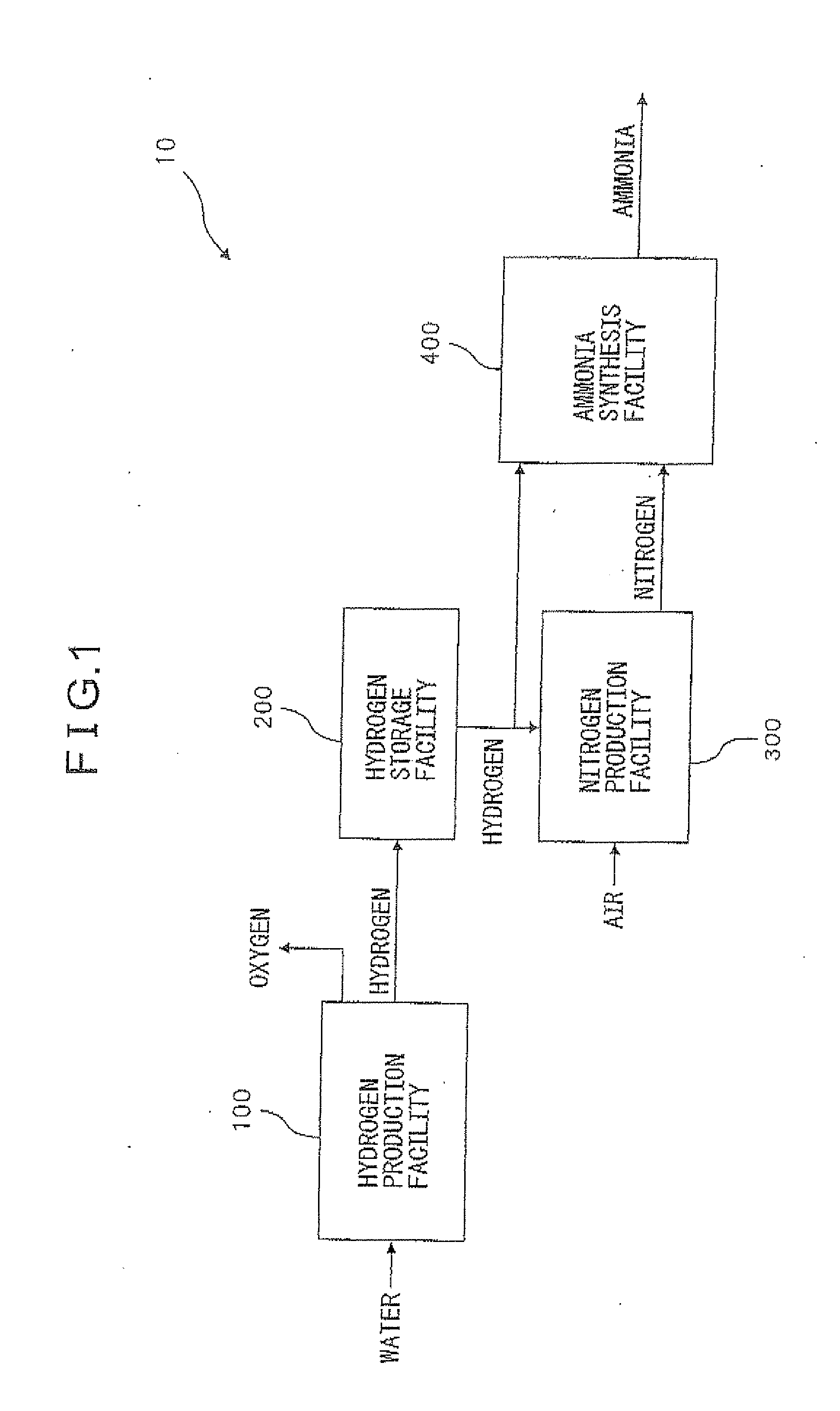

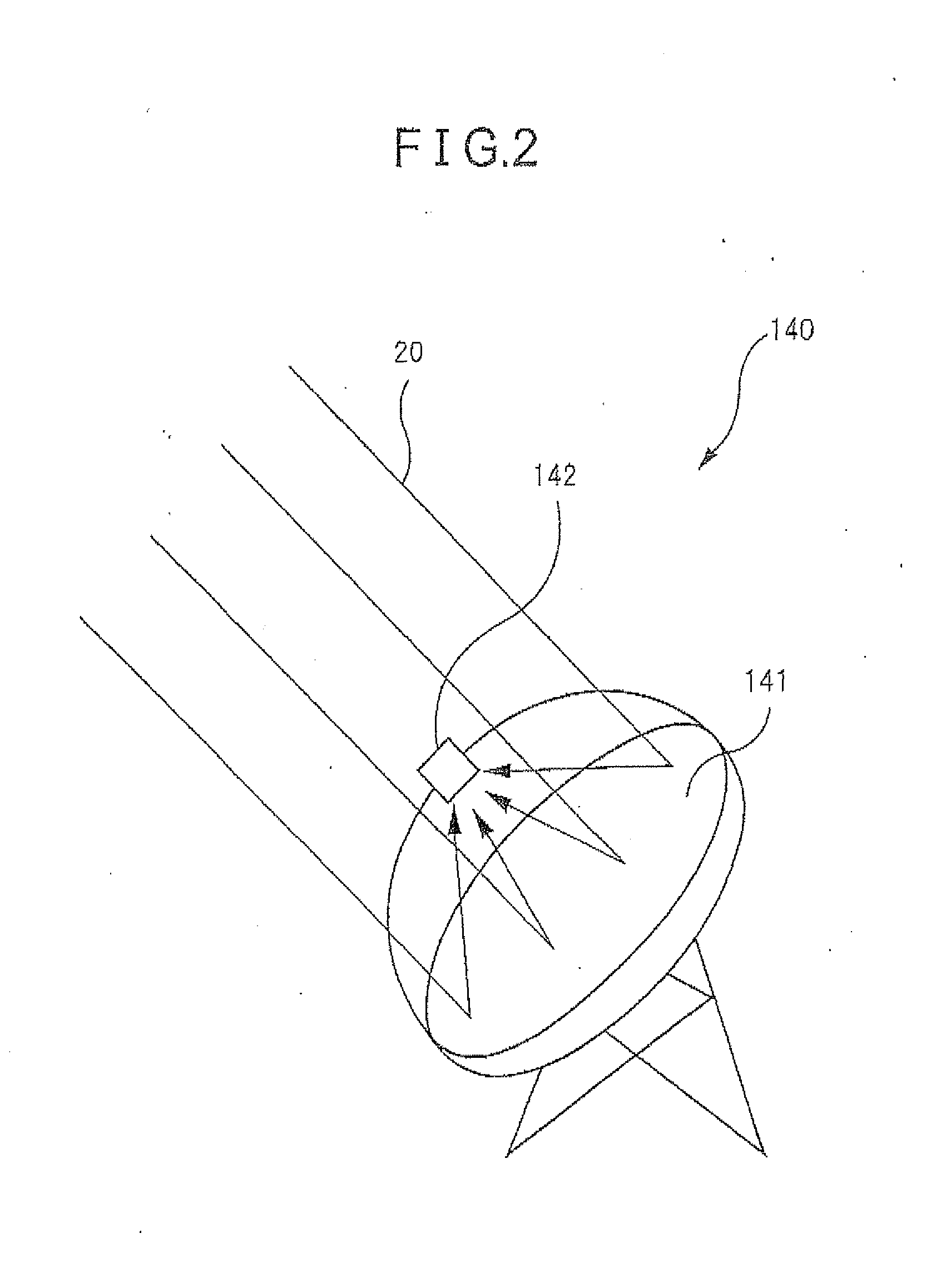

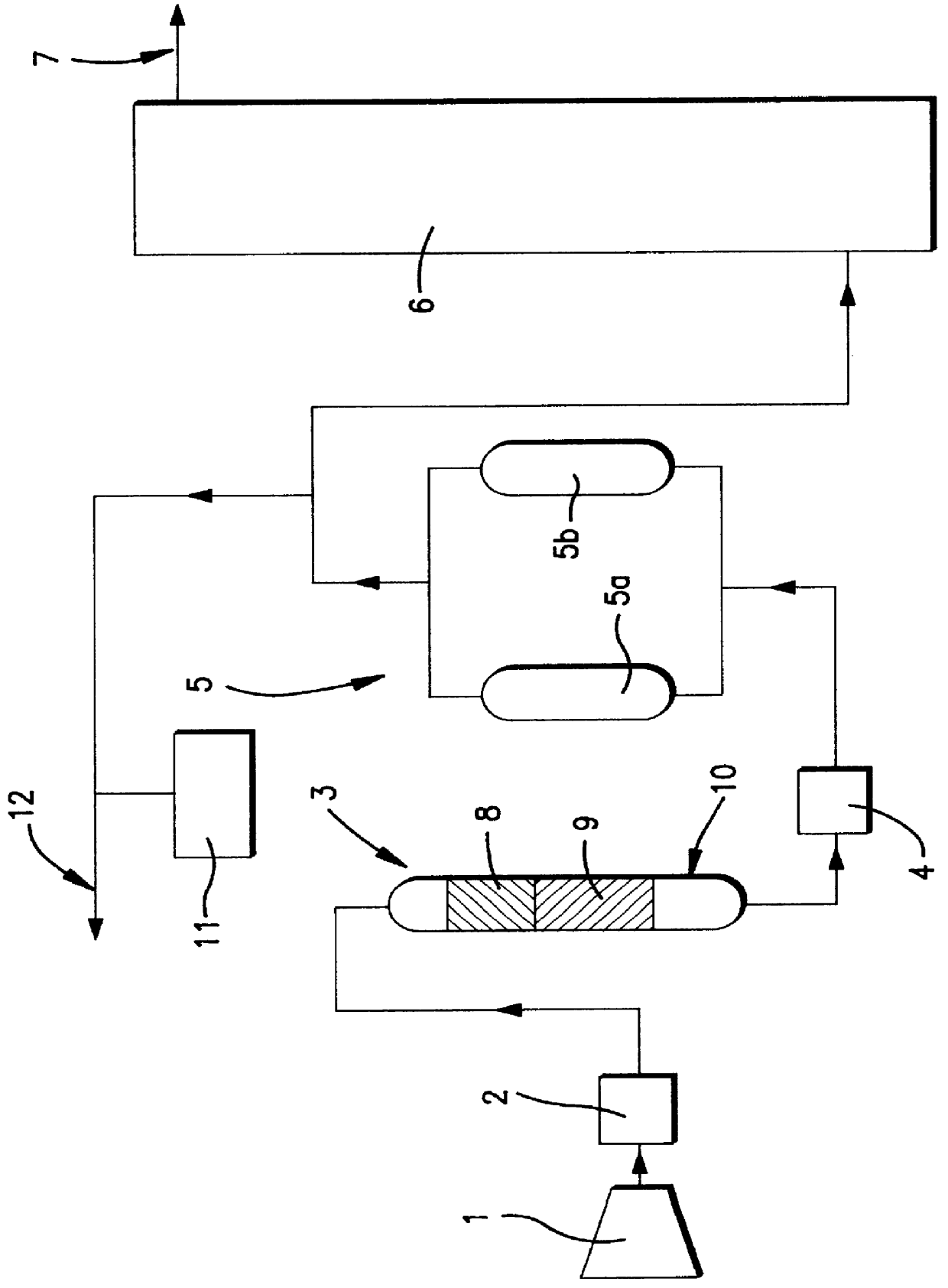

Combined plant

InactiveUS20120100062A1Obviates problemLower average energyNitrogen purification/separationHydrogen productionNitrogenNitrogen gas

A combined plant is provided. The combined plant of continuously supplying hydrogen and nitrogen to an ammonia synthesis facility that continuously synthesizes ammonia from hydrogen and nitrogen, the combined plant including: a hydrogen production facility for acquiring solar energy and producing hydrogen by utilizing a part of the acquired solar energy; a nitrogen production facility for producing nitrogen from air and supplying the nitrogen to the ammonia synthesis facility; and a hydrogen storage facility for storing the hydrogen produced by the hydrogen production facility and supplying the produced hydrogen to the ammonia synthesis facility.

Owner:NAKAMURA NORIHIKO +6

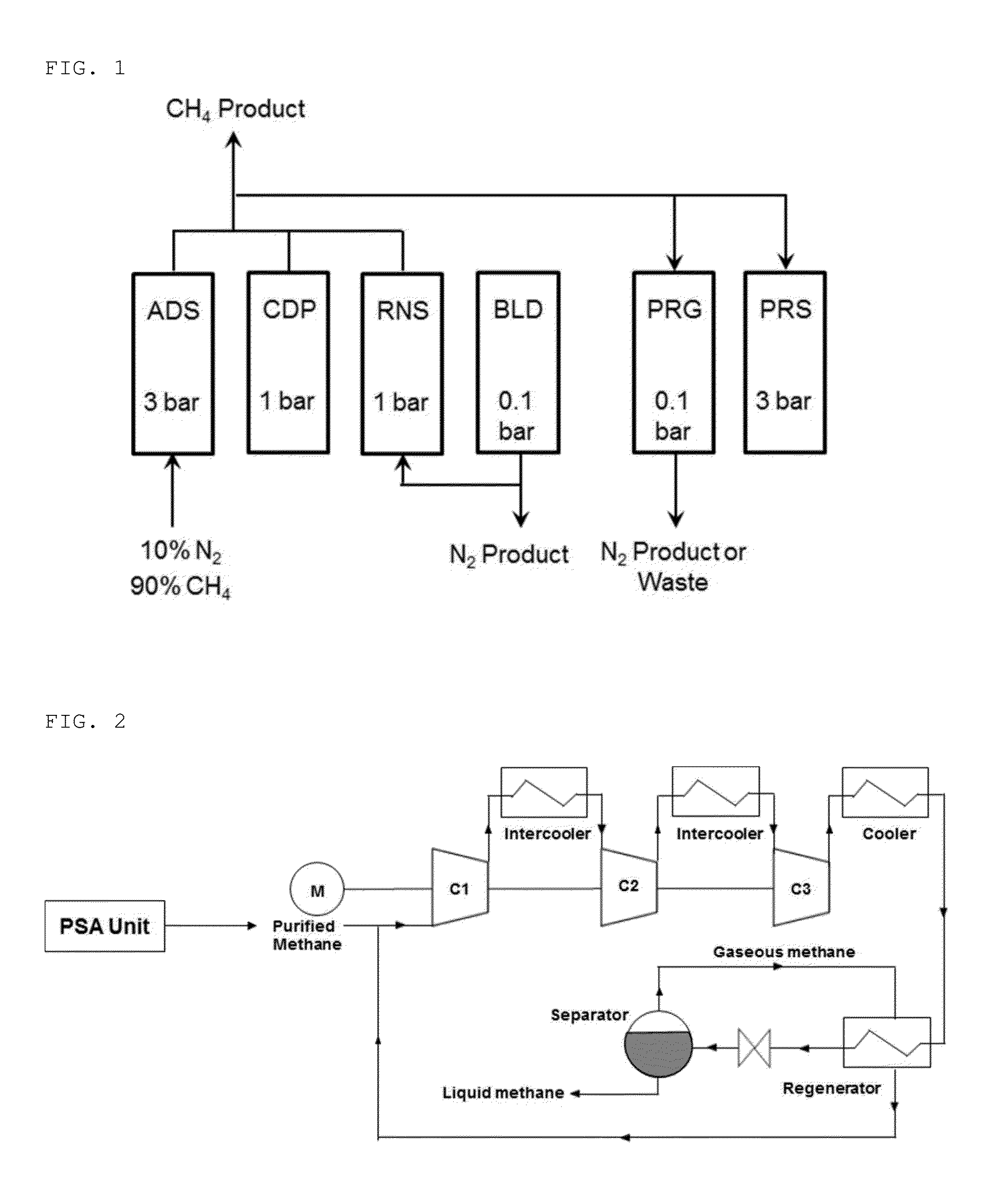

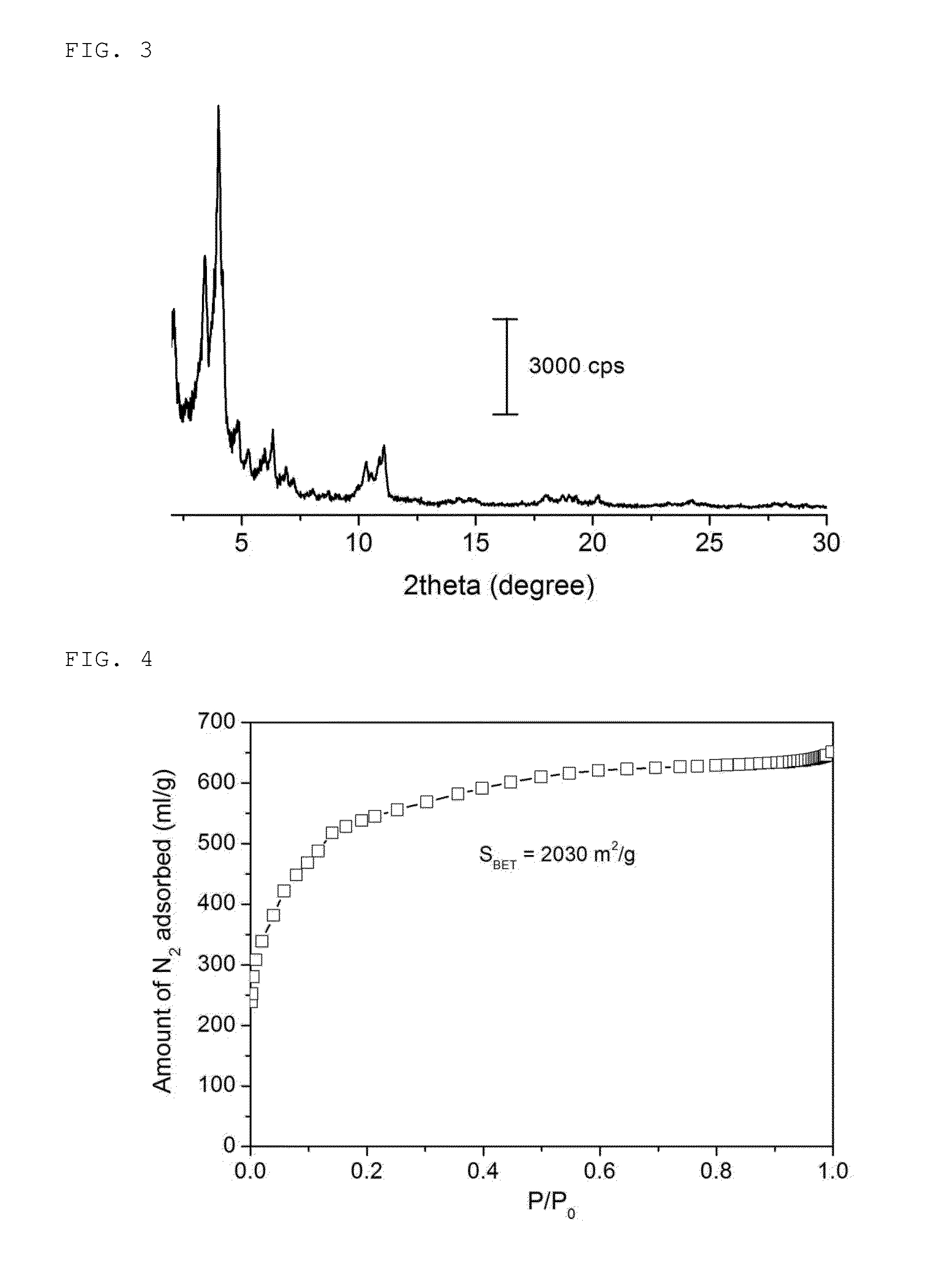

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

Process for production of molecular sieve adsorbent blends

InactiveUS6743745B2Improved performance characteristicsIncrease ratingsNitrogen purification/separationMolecular sieve catalystsMolecular sieveFiber

A process for the production of a molecular sieve adsorbent blend product with improved performance characteristics produced by preparing a zeolite powder, preparing a highly dispersed attapulgite fiber binder, mixing the zeolite powder with the highly dispersed attapulgite binder to form a mixture, forming molecular sieve adsorbent products into a shaped material and calcining the shaped material, wherein the tapped bulk density of the highly dispersed attapulgite fibers measured according to DIN / ISO 787 is more than about 550 g / ml.

Owner:ZEOCHEM LLC

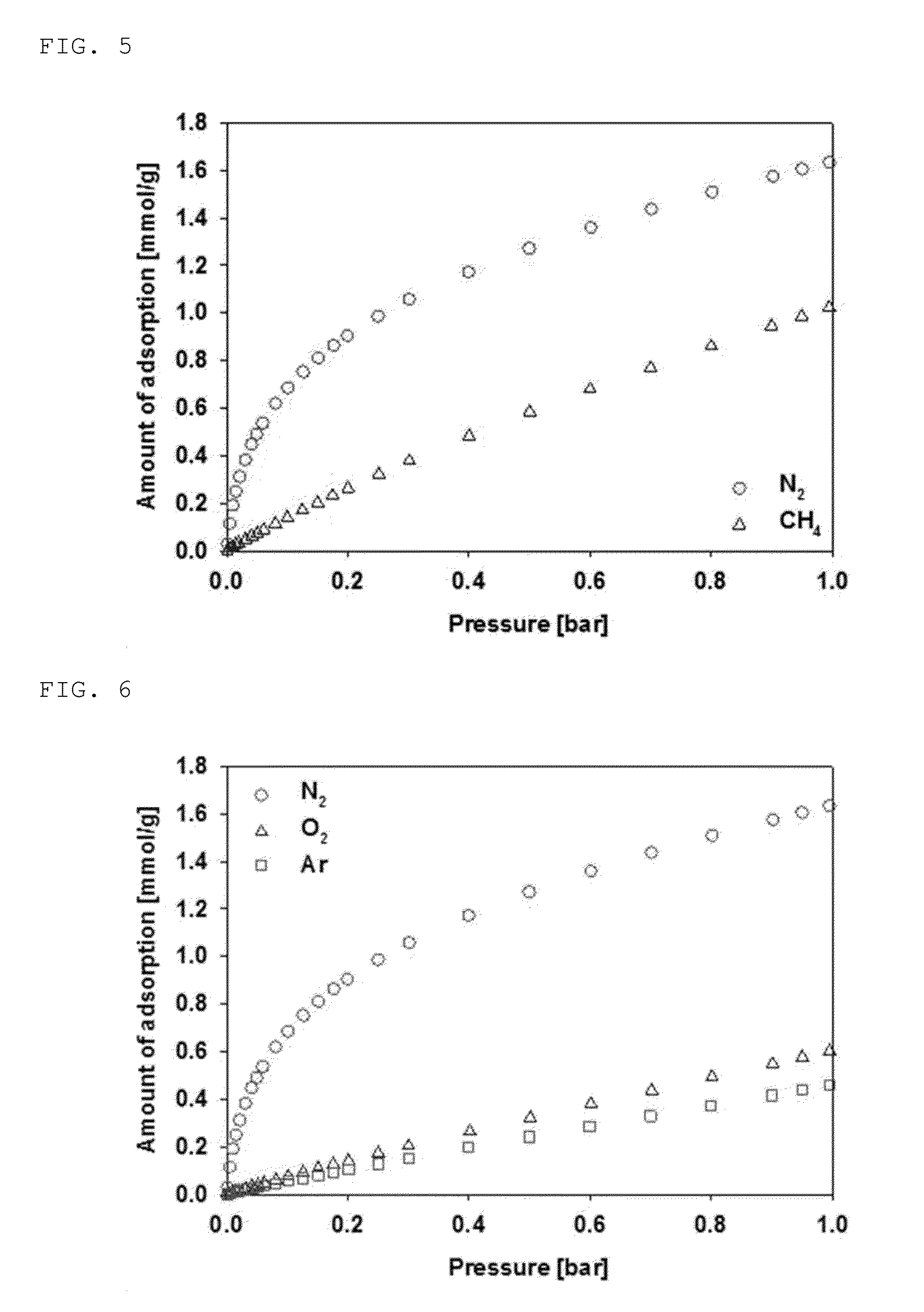

Inorganic-organic hybrid nanoporous material with nitrogen selective adsorptivity and method for separating nitrogen-contaning gas mixture using the same

ActiveUS20160089637A1Nitrogen purification/separationSemi-permeable membranesSorbentVolumetric Mass Density

The present invention relates to a nitrogen adsorbent having nitrogen selective adsorptivity by including an organic-inorganic hybrid nanoporous material having a coordinatively unsaturated metal site with density of 0.2 mmol / g to 10 mmol / g in a skeleton, surface or pore; and use thereof, such as a device separating nitrogen from a gas mixture containing nitrogen and methane, a pressure swing adsorption separation device and a temperature swing adsorption separation device for separating nitrogen provided, a method for separating nitrogen and methane from a gas mixture containing nitrogen and methane, a device for separating nitrogen, oxygen or argon, a method for separating nitrogen, oxygen or argon from a gas mixture containing nitrogen, oxygen or argon, and a method for preparing nitrogen or high purity inert gas all separated from a gas mixture containing nitrogen and inert gas.

Owner:KOREA RES INST OF CHEM TECH

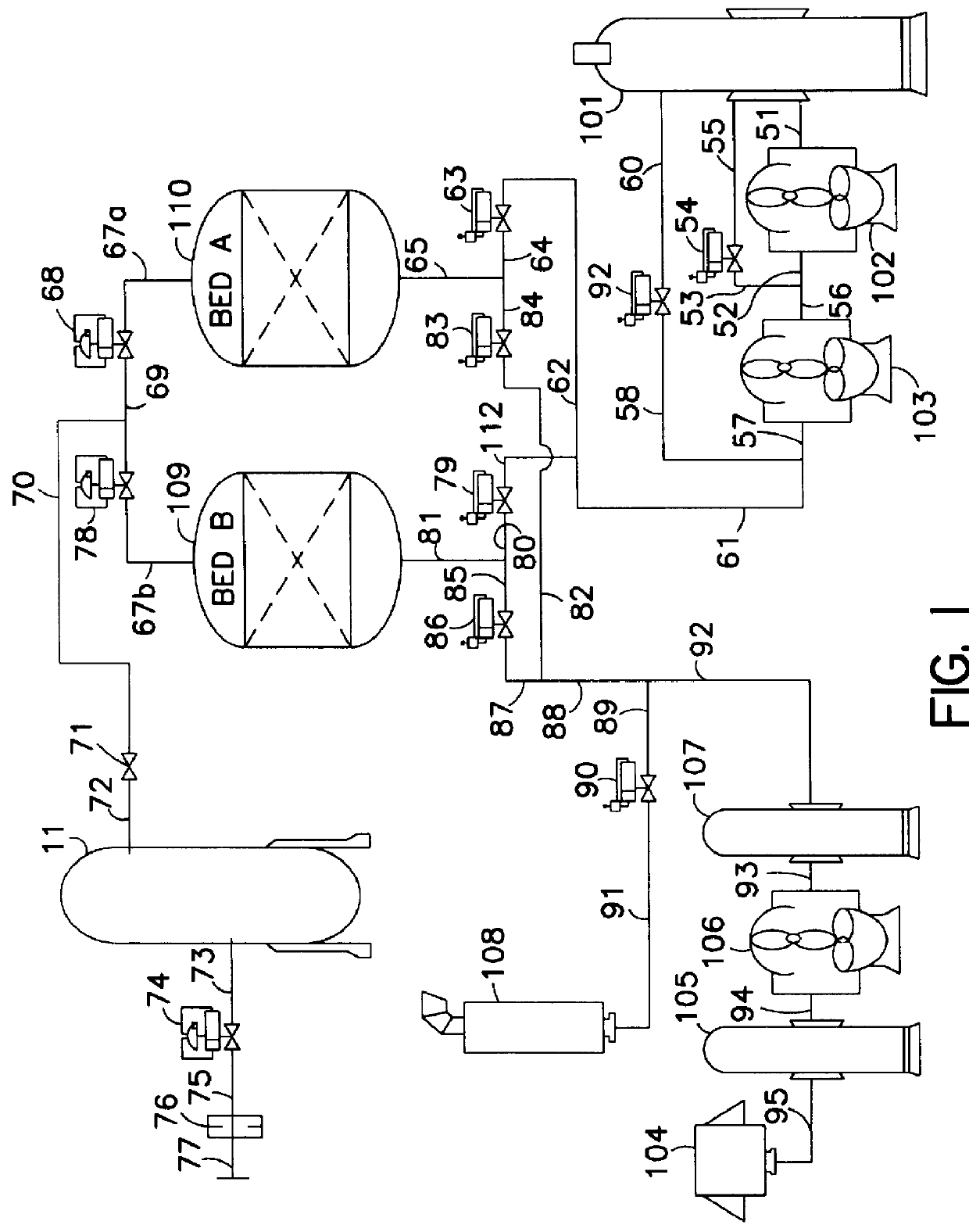

Rotary valve for two bed vacuum pressure swing absorption system

InactiveUS6143056AImprove cycle time and efficiencyLess powerNitrogen purification/separationGas treatmentVacuum pressureRotary valve

A dual-chambered, four-ported rotary valve with a rotatable drum having peripheral openings is used to selectively connect vacuum and / or air sources and a vent to absorption chambers in a two-bed VPSA (vacuum presssure swing absorption) system to replace separate valves and produce low cost enriched oxygen, via reduced power, increased reliability, and reduced complexity and cost.

Owner:PRAXAIR TECH INC

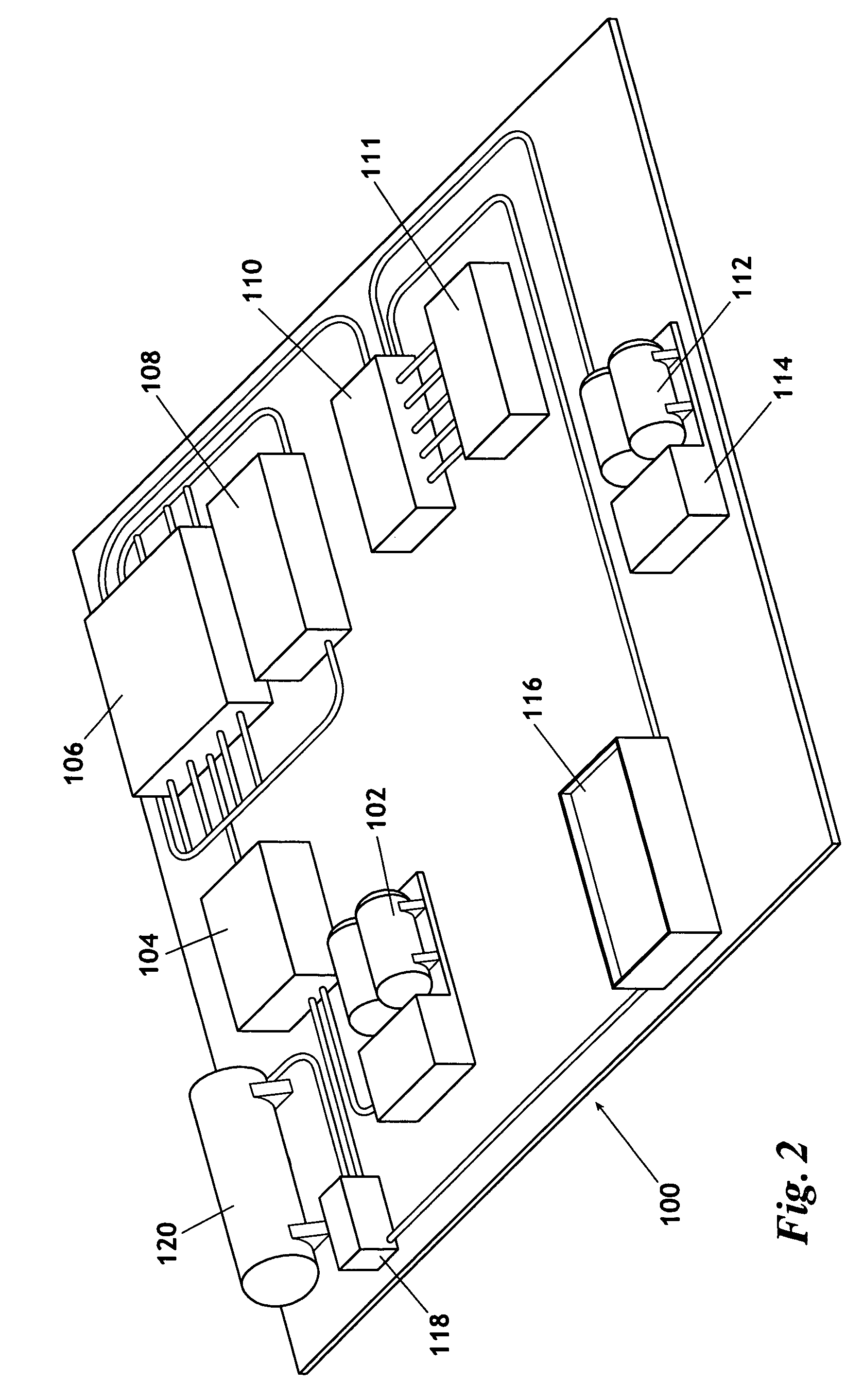

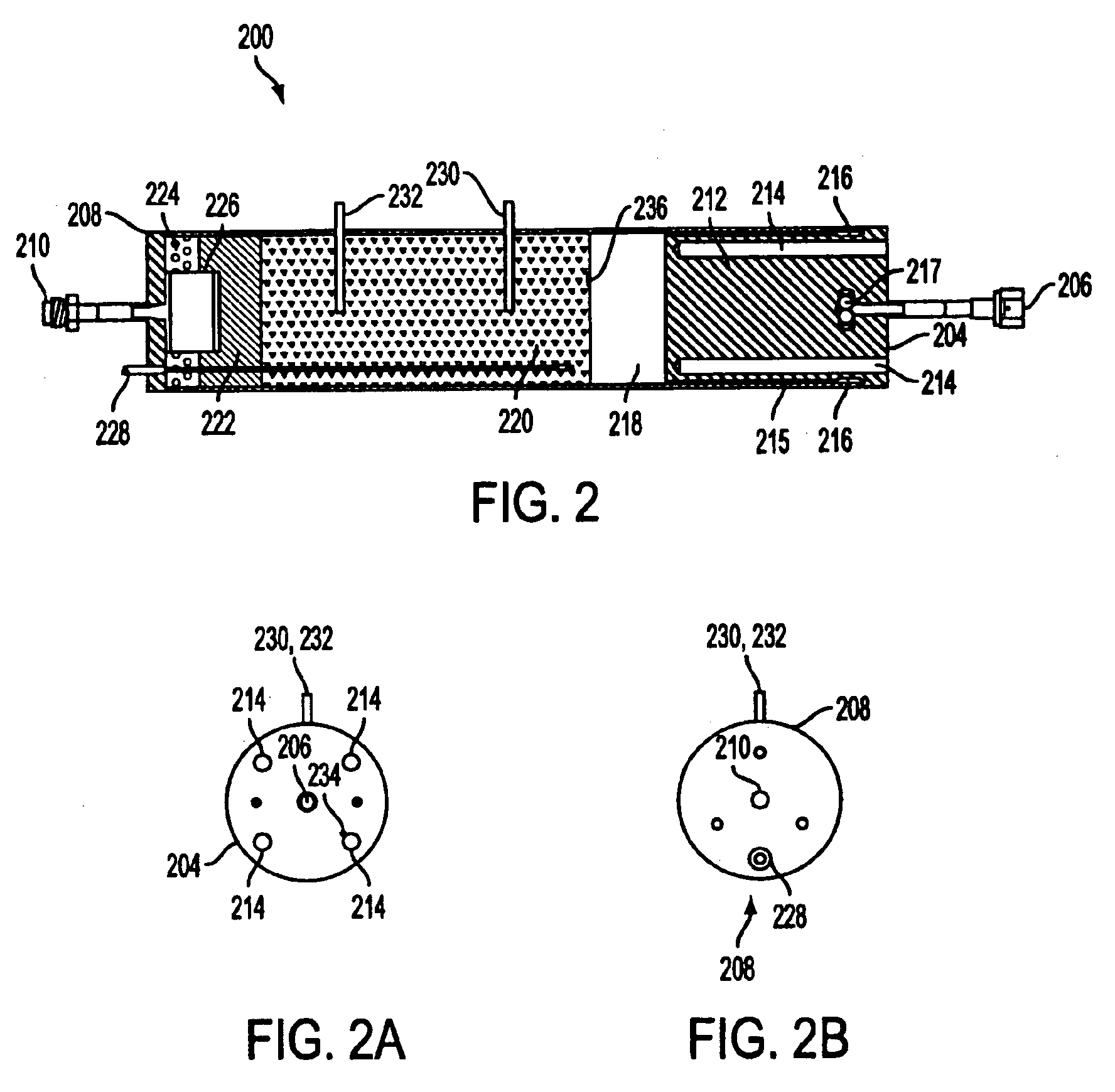

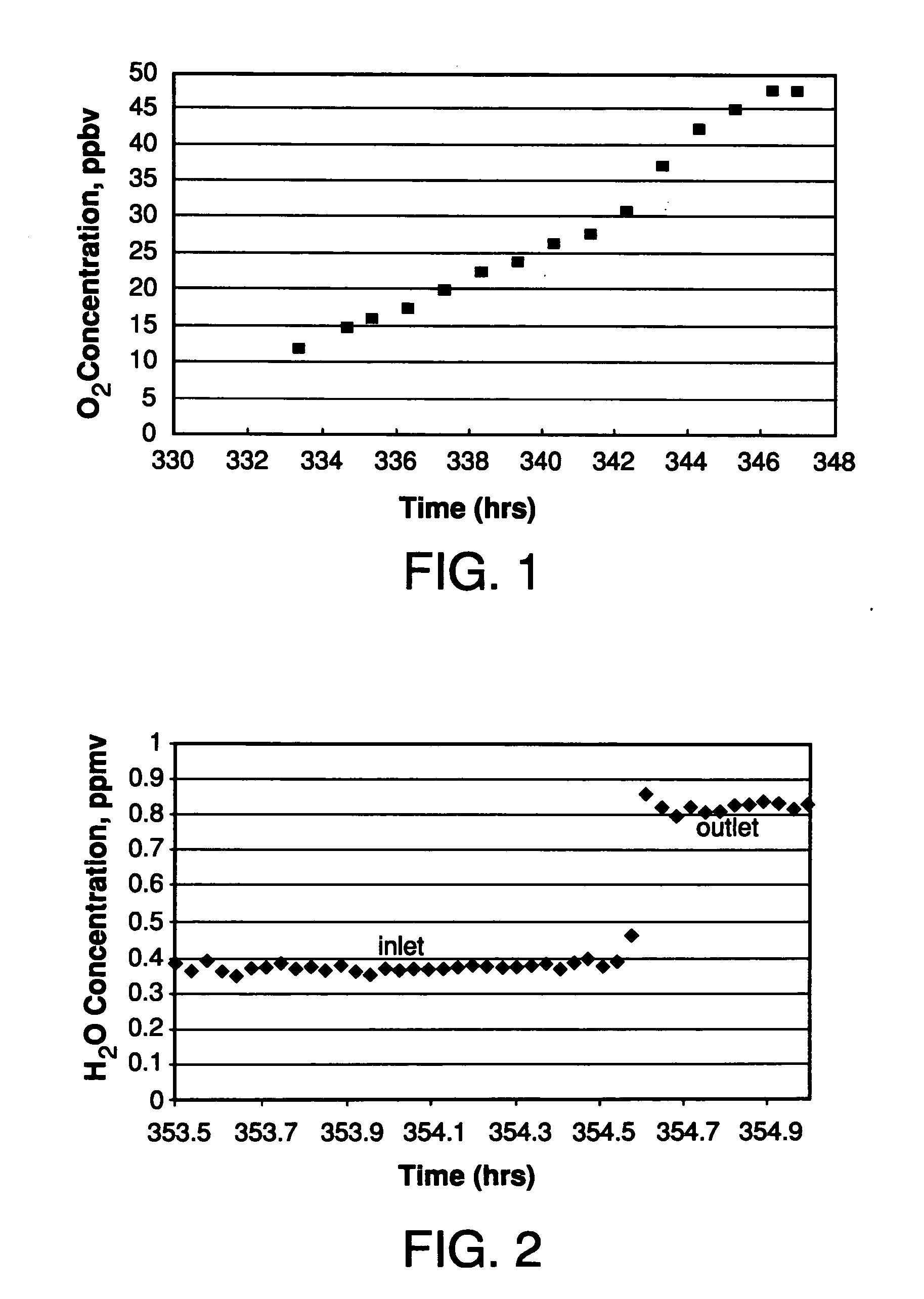

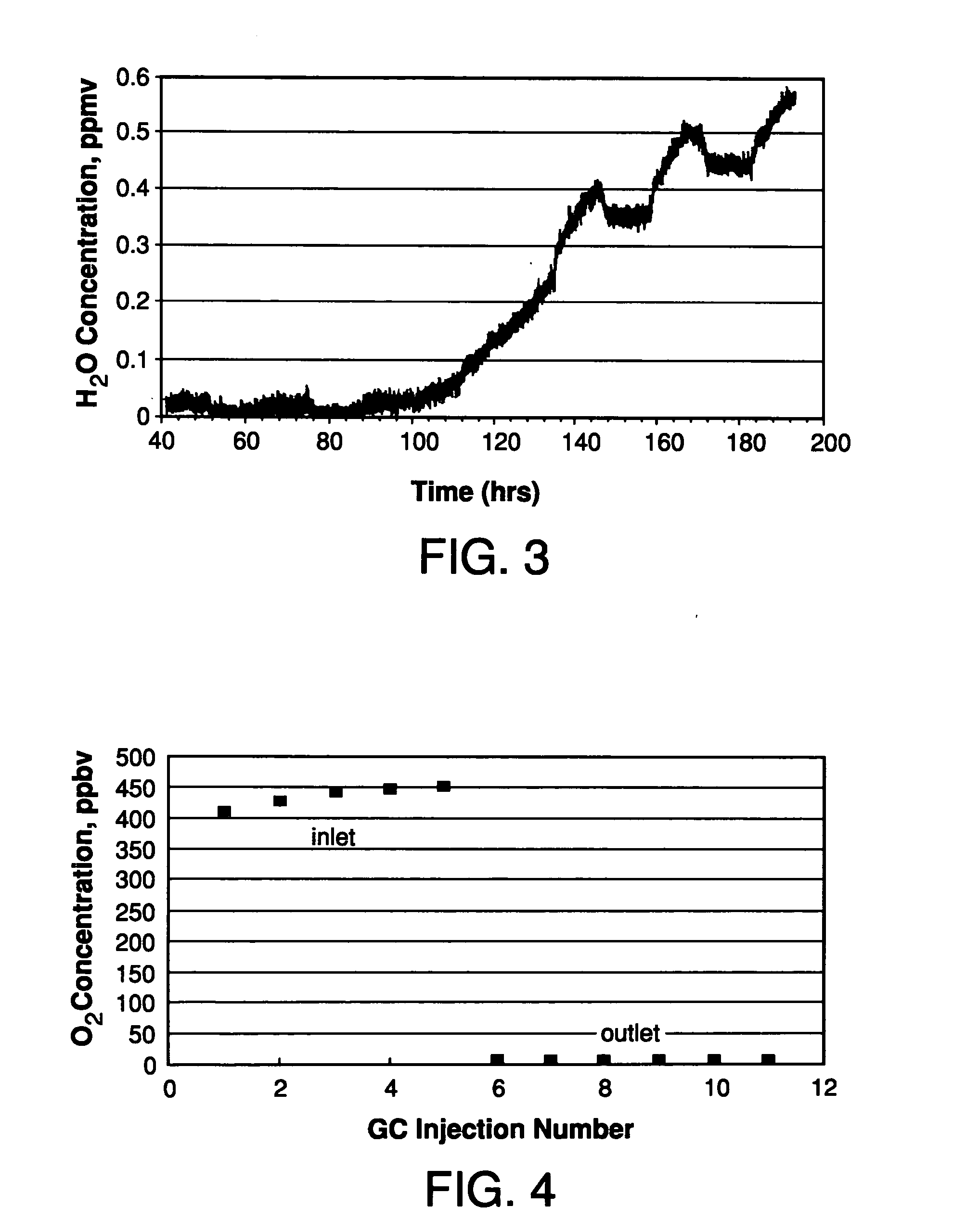

Gas purification system with an integrated hydrogen sorption and filter assembly

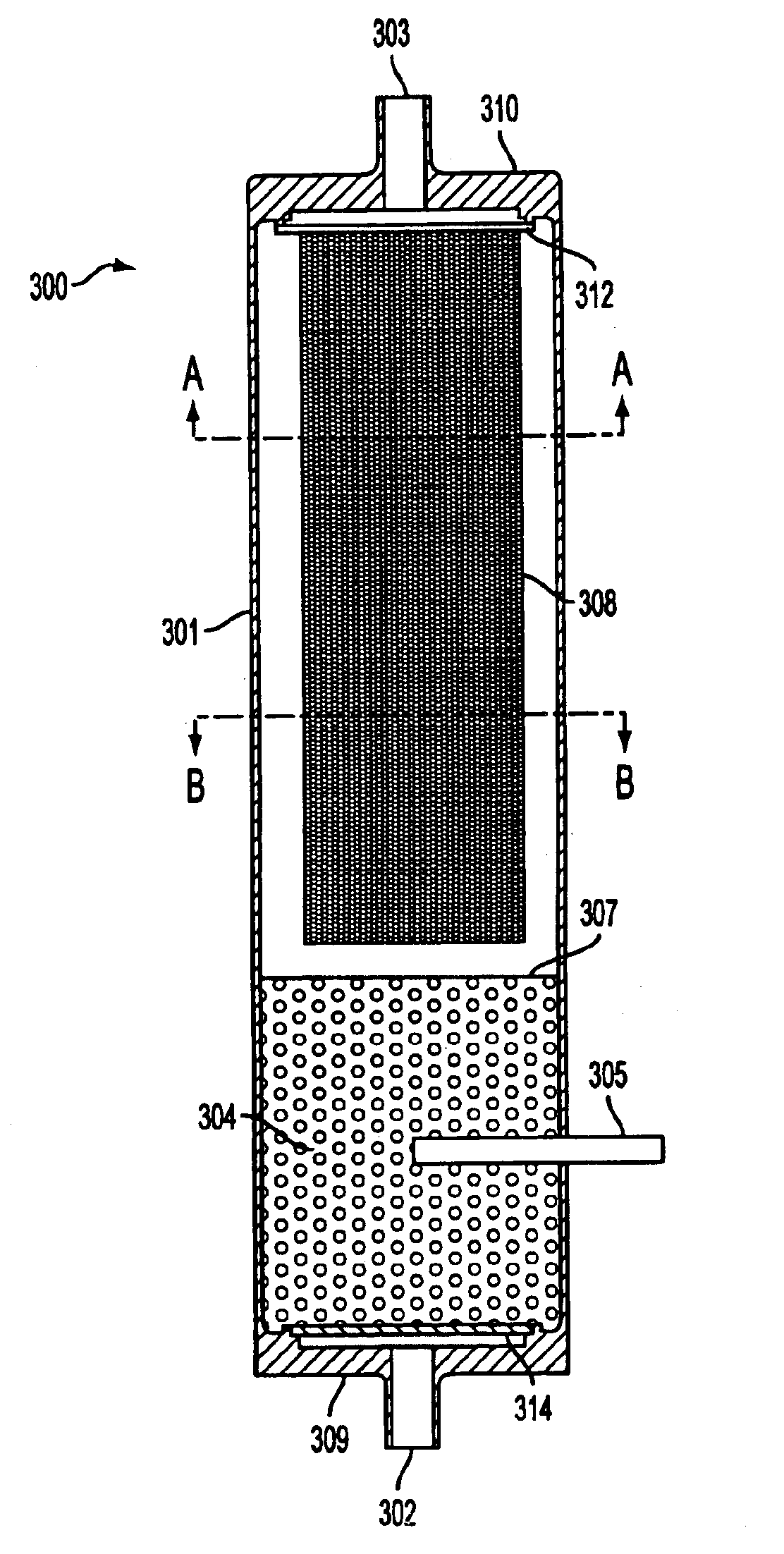

InactiveUS6890376B2Easy maintenanceManufacturing EaseCombination devicesNitrogen purification/separationThermal energyHydrogen

The present invention provides a gas purification system with improved efficiency, simpler construction, cost reductions, form factor improvements, and increased durability. The present invention provides cost and form factor improvements through fewer components overall and through utilizing multiple integrated components. Prior art gas purification systems are more bulky and complicated. The present invention achieves increased thermal efficiency through utilization of a regenerative heat exchanger to recapture a portion of the heat energy transferred to the gas during the purification process. Prior art purifiers lacked a regenerative heat exchanger. The present invention integrates the two components into one integrated heater and purification vessel assembly. The present invention integrates the two discrete components into one integrated hydrogen sorption and particle filter assembly. The integrated hydrogen sorption and particle filter assembly is also capable of operating at higher temperatures. This eases maintenance and manufacture. The resulting gas purification system is simpler through utilizing fewer components, smaller by utilizing fewer and integrated components, and reduced cost through fewer components, smaller components and through reduced manufacture labor requirements.

Owner:ENTEGRIS GP INC

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

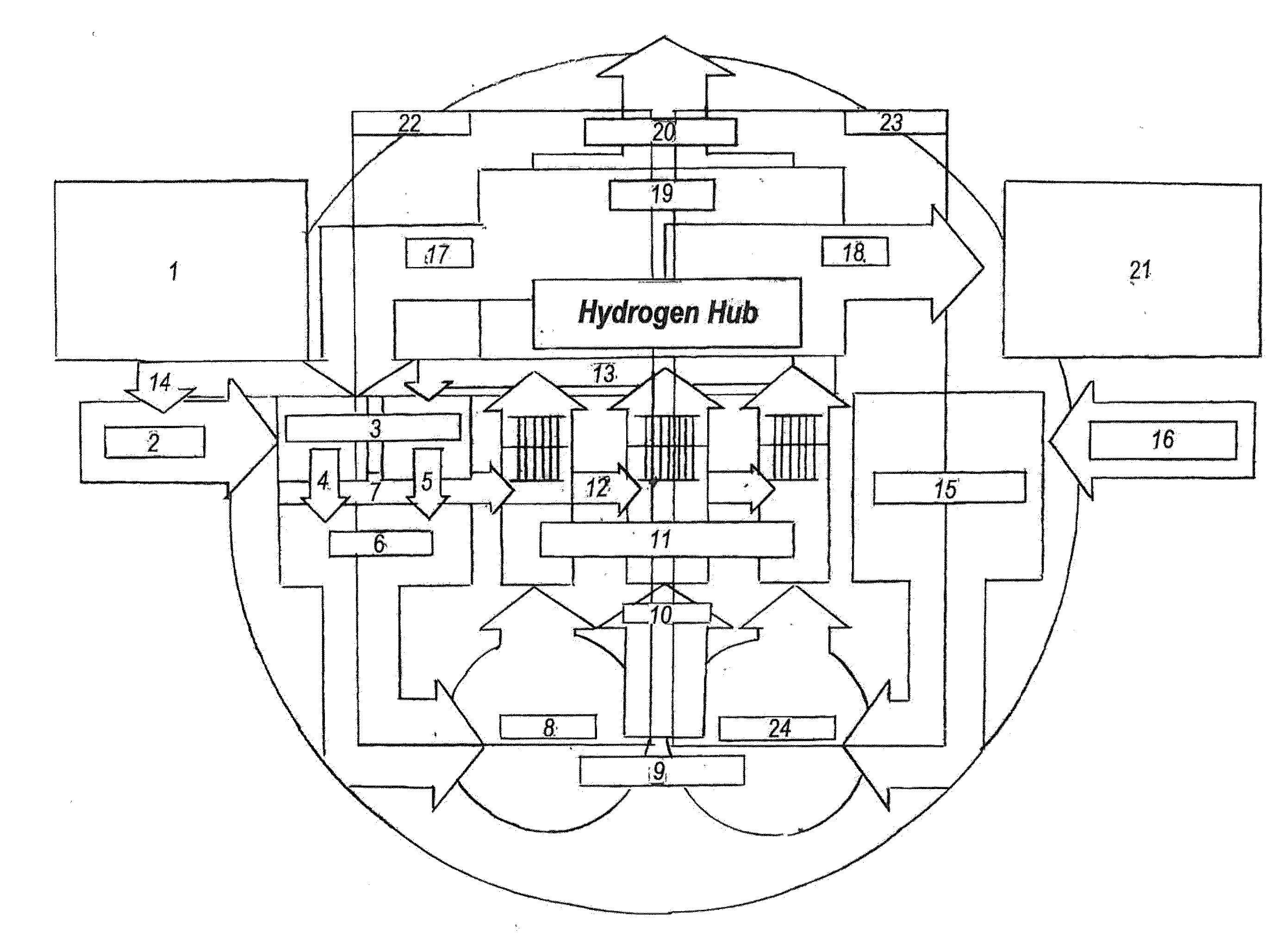

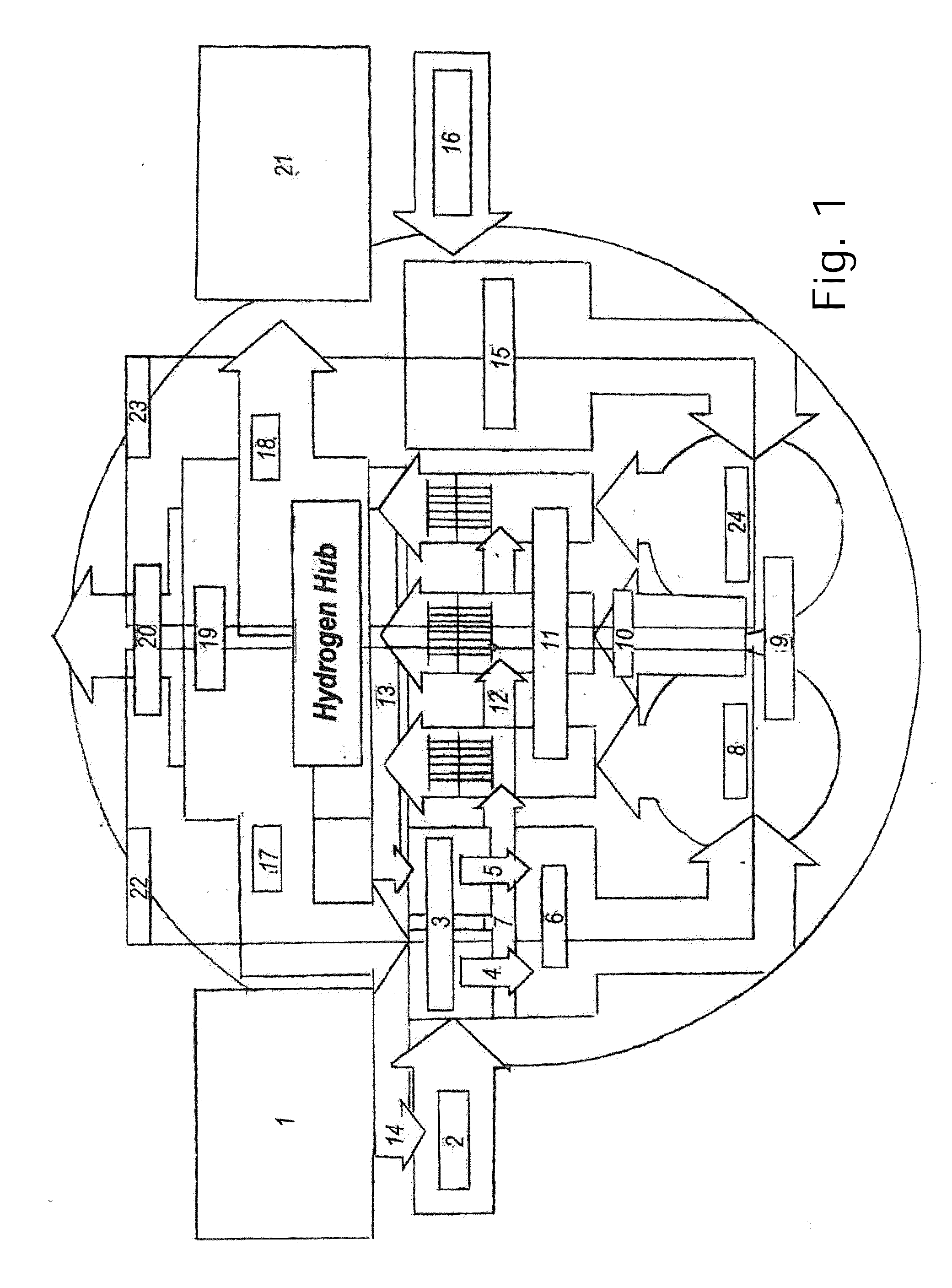

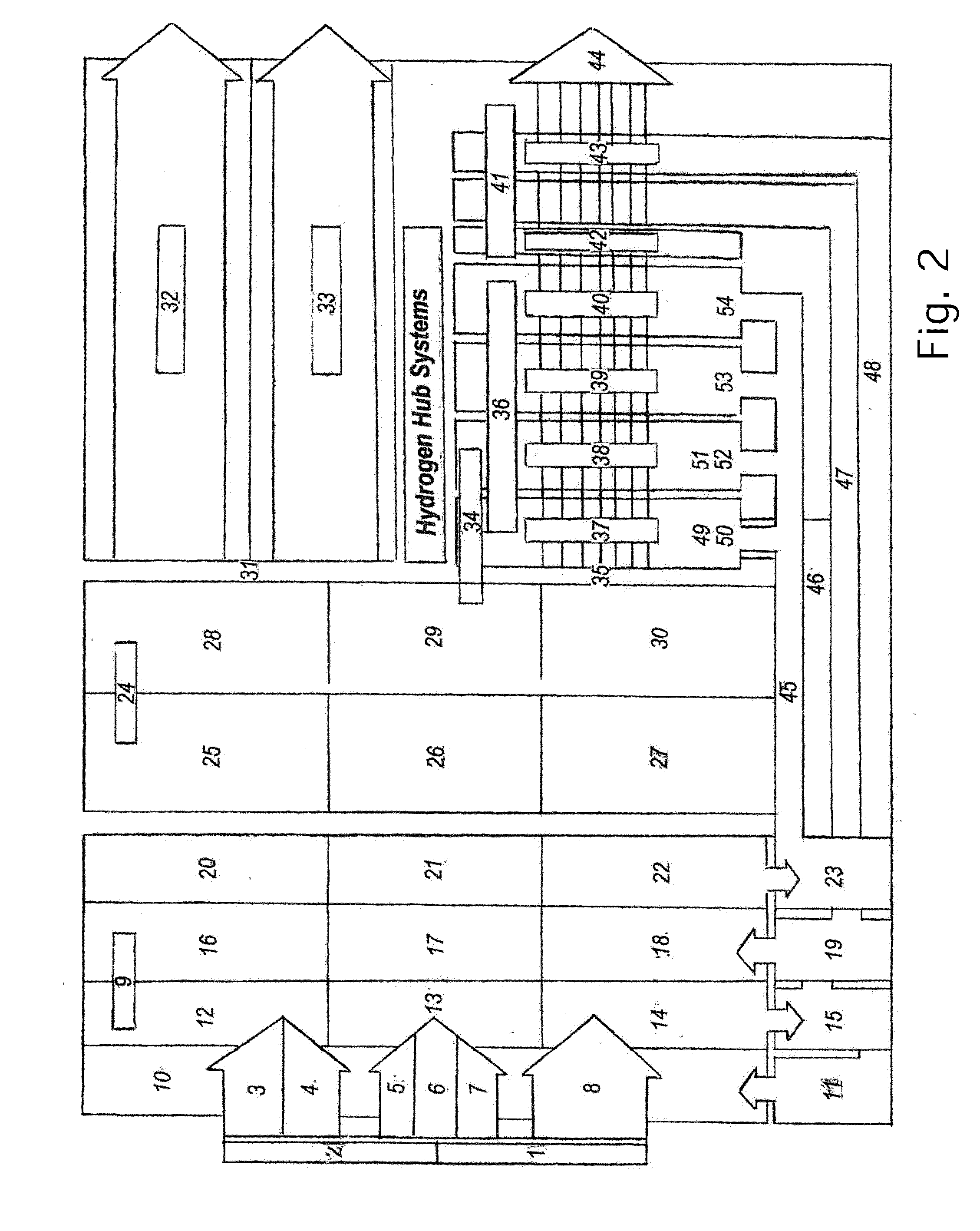

Energy conversion system

InactiveUS20160006066A1More energyEasy to operateElectrolysis componentsGeneral water supply conservationNuclear engineeringElectric power system

An improved system of hardware and controls, known as a Hyper Hub, that absorbs electric power from any source, including hydropower, wind, solar, and other renewable energy resources, chemically stores the power in hydrogen-dense anhydrous ammonia, then reshapes the stored energy to the power grid with zero emissions by using anhydrous ammonia to fuel diesel-type, spark-ignited internal combustion, combustion turbine, fuel cell or other electric power generators, and for other purposes.

Owner:ROBERTSON JOHN S

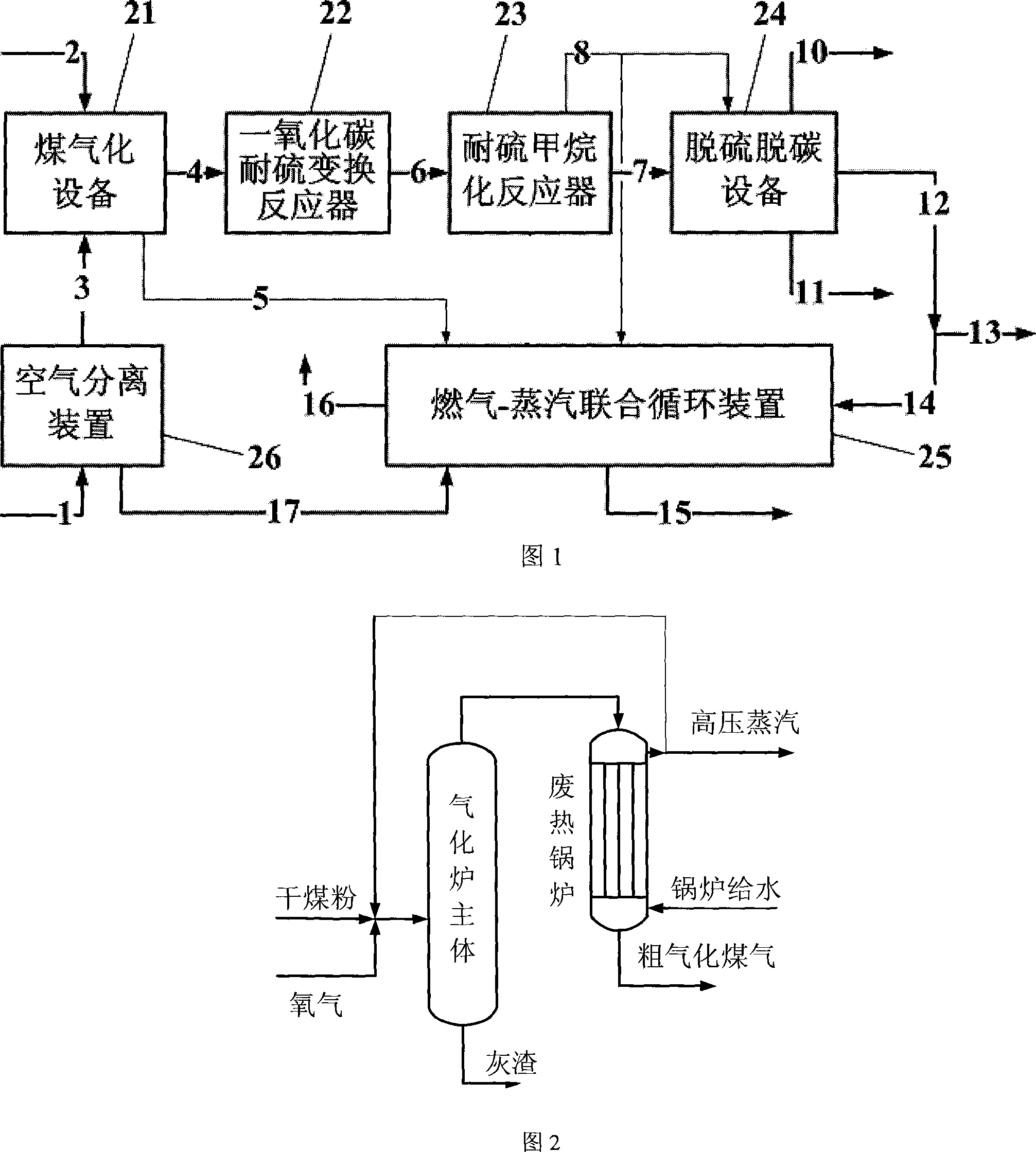

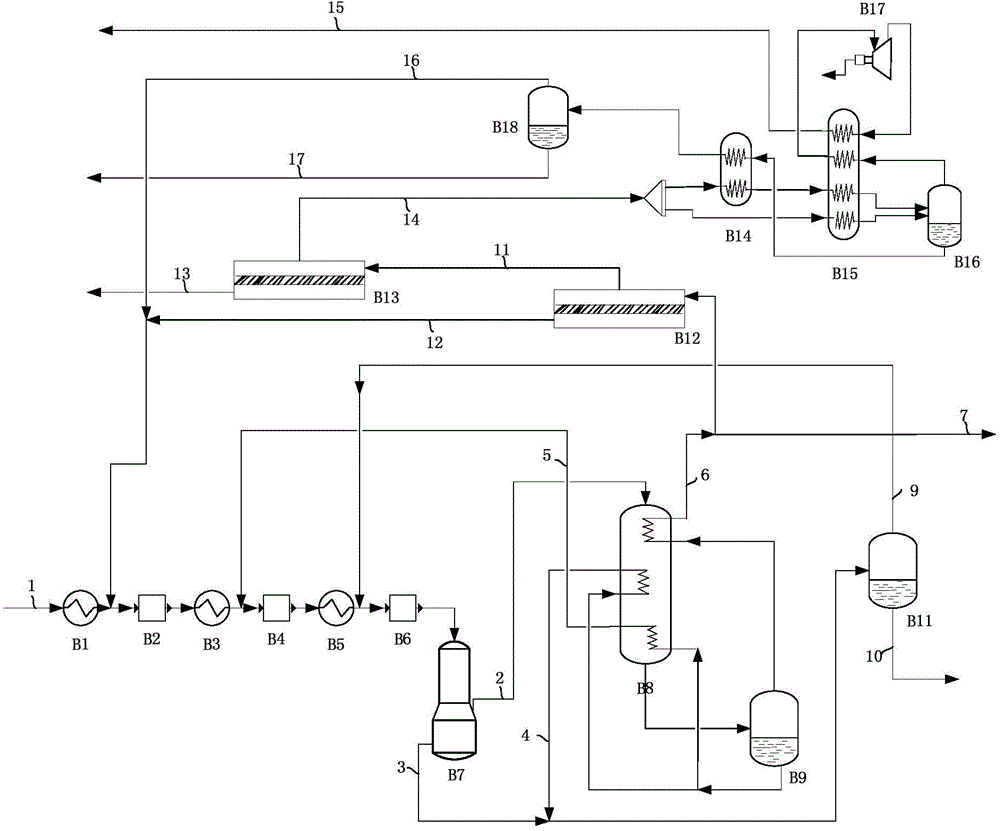

Gas-steam combined cycle system and technique based on coal gasification and methanation

ActiveCN101245262AReduce energy consumptionEasy to recycleNitrogen purification/separationCombustible gas chemical modificationMethanationSubstitute natural gas

A combined cycle system based on coal gasification and methanation gas-steam and a technique thereof, wherein, the method comprises the following steps: oxygen produced by an air separation unit and coal powder or water-coal-slurry are sent into coal gasification equipment, the produced crude gasification gas is sent to a carbon monoxide sulfur-tolerant shift reactor to adjust the ratio of hydrogen and carbon after the sensible heat recollecting, and is then sent into sulfur-tolerant methanation reactor to produce methane and carbon dioxide, then the reaction product is sent into desulfurization and decarbonization equipment so that element sulfur can be recovered and carbon dioxide can be separated so as to obtain substitute natural gas with high content of methane, part of which is sent to the gas-steam combined cycle equipment while the other part is sent to a urban gas system. The enriched CO2 density of the system can reach 50 to 60 percent, technical probability is provided for reasonably realizing low-energy-consumption reduced exhaust of CO2, no change needs to be done with gas turbines, each chemical unit operates according to established rated condition and needs not to change load owing to power conditioning so as to improve the economy of the operation of power plants; compared with the prior art, the energy utilization efficiency of the whole system is improved so as to realize the efficient clean utilization of coal.

Owner:TSINGHUA UNIV

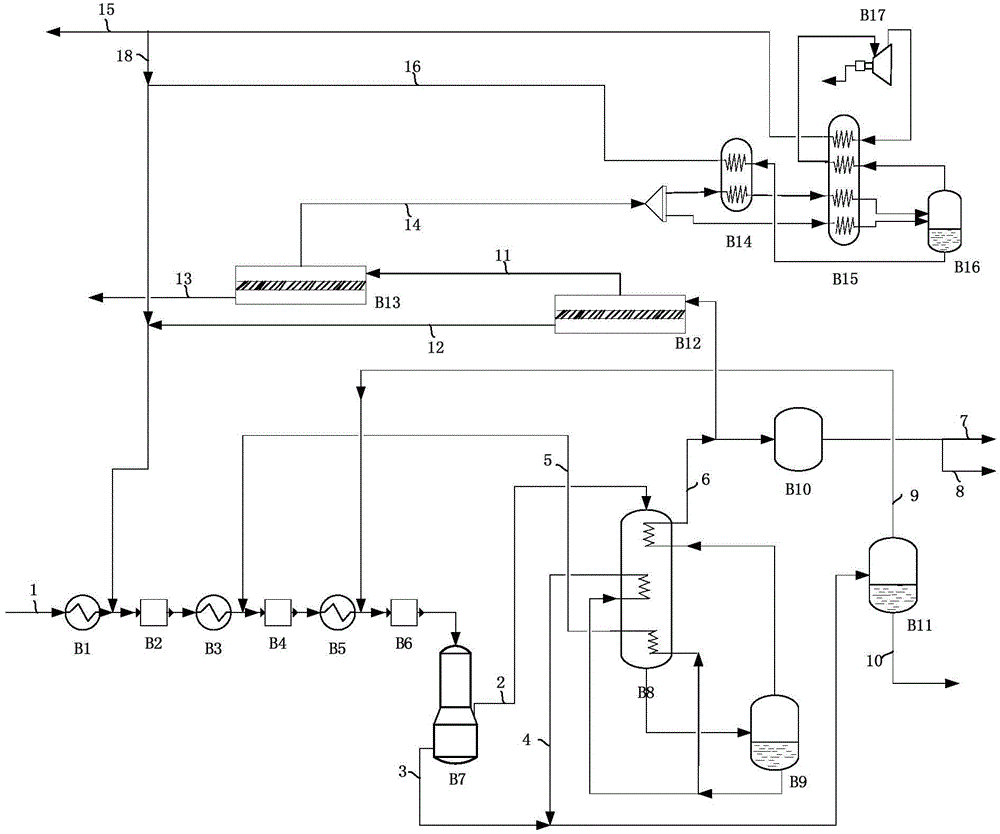

Method for recovering exhaust gas according to polyolefin gas phase method

ActiveCN104923029AHigh recovery rateHigh purityNitrogen purification/separationSolidificationRecovery methodPolyolefin

The invention relates to a method for recovering exhaust gas according to the polyolefin gas phase method. The method for recovering the exhaust gas comprises the following steps: 1) compression, condensation and separation steps are carried out; 2) after the compression, condensation and separation steps, gas enters a heat exchanger to be subjected to cryogenic separation; 3) compressed and condensed liquid and liquid subjected to cryogenic separation are subjected to gas-liquid separation through a separation tank, and after the flash evaporation, light component gas flows to a compressor to be recycled; 4) after cryogenic separation, part of uncondensed gas enters a membrane separation device to enable hydrocarbons to be further recovered; 5) after membrane separation, hydrocarbon-rich phase gas returns back to the compressor to be recycled, hydrogen-deficient phase gas flows to an unpowered expansion refrigeration device to enable hydrocarbons to be recovered, and obtained high-purity nitrogen is used as supplementation gas for sweeping gas of a product receiving bin or a degassing bin. According to the method for recovering the exhaust gas, unreacted monomers can be effectively recovered, the gas emission can be reduced, the total utilization of the monomers can be increased, the gas consumption amount of the sweeping gas can be reduced, the cost can be reduced, the power of the compressor can be reduced, and the energy consumption of the heat exchanger can be reduced.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Porous inorganic membrane containing carbon; a process for its preparation; and use thereof

InactiveUS20040251201A1Improve permeabilityHigh selectivityIsotope separationHydrogen/synthetic gas productionHydrogenPorous carbon

A porous inorganic membrane comprises at least one inorganic phase having separating properties. Said membrane has a carbon content representing 0.05% to 25% by weight with respect to the mass of said inorganic phase and is selective to non-condensable gases. It is obtained by means of a selectivation treatment of a porous carbon-free inorganic membrane using a hydrocarbon feed. It is used in processes for separating non-condensable molecules such as hydrogen, and in association with a catalyst in a catalytic membrane reactor.

Owner:INST FR DU PETROLE

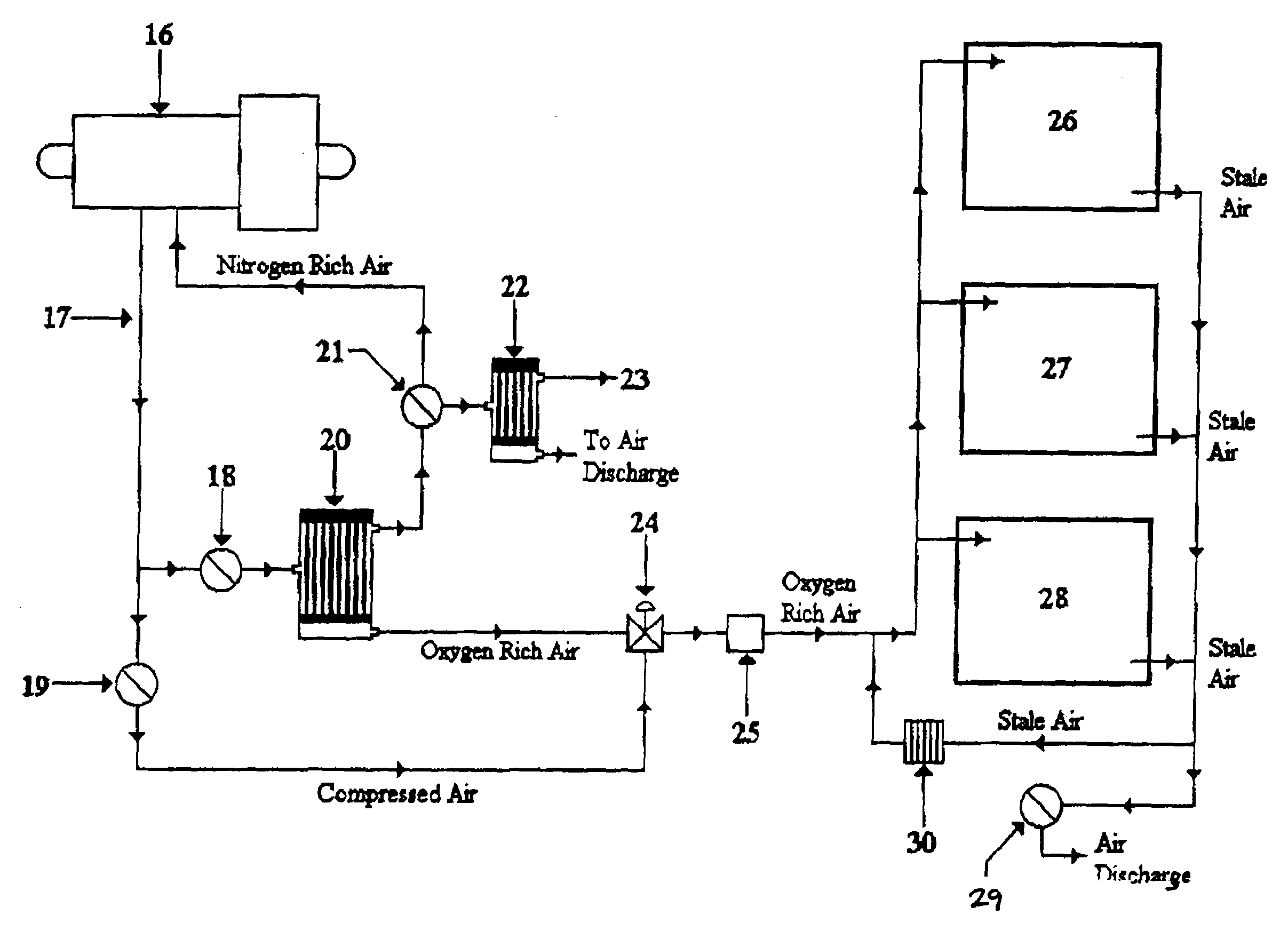

Oxygen and nitrogen enriched atmospheres in aircraft

InactiveUS7179322B2Mass productionReduce differential pressureNitrogen purification/separationMembranesOn boardNitrogen rich

A method of supplying oxygen rich air to the passengers and crew on board a passenger aircraft by use of a highly permeable oxygen enrichment unit, wherein the fiber tubes of the hollow fiber membranes used to separate normal air into oxygen rich and nitrogen rich fractions in the oxygen enrichment unit are subjected to a modification technique before the tubes are coated with a selective polymer.

Owner:SMARTMEMBRANE CORP

Magnesium-based metal organic framework material for methane-nitrogen adsorption separation and preparation

InactiveCN104415737ANitrogen purification/separationGas treatmentChemical compoundMetal-organic framework

The invention relates to a magnesium-based metal organic framework material for methane-nitrogen adsorption separation and a preparation method. The metal organic framework material is formed by coordination of at least one metal compound with at least one organic ligand to generate a framework material; the metal ions in the metal compound comprise one or more than one of Mg (II), Ni (II), Cu (II), Zn (II), Co (II), and Ca (II), and at least one metal ion is Mg (II); the organic ligand is a monodentate or polydentate organic compound of carboxylic acid or its derivatives. The invention also relates to an application of the porous magnesium-based organic framework material in methane-nitrogen adsorption separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process and device for treating gas flows

Process for purifying a gas flow with respect to at least one of the impurities capable of being oxidized and / or reduced which it contains, in which the gas flow is subjected to at least the following steps: (a) compressing the gas flow to a pressure in excess of atmospheric pressure, (b) bringing the compressed gas flow into contact with at least a first bed of particles of a material containing at least one metal peroxide, and (c) bringing the gas flow resulting from step (b) into contact with at least a second bed of at least one catalyst.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Carbon molecular sieve for concentrating and extracting CH4 from coal bed gas and preparation method thereof

InactiveCN103086354AObvious CH

<sub>4</sub>

/N

<sub>2</sub>

separation performanceEasy to separateNitrogen purification/separationMethane captureToxic industrial wasteCoal

The invention discloses a carbon molecular sieve for concentrating and extracting CH4 from coal bed gas and a preparation method thereof. The method comprises the following steps of: (1) mixing micro-powder phenolic resin waste, a bonder and water and performing extrusion forming to obtain a material strip; (2) carbonizing the material strip to obtain a carbonized material; and (3) adjusting the pores of the carbonized material by using a pore adjuster to obtain the carbon molecular sieve. The invention further provides a carbon molecular sieve prepared by the method. The carbon molecular sieve can be used for separating CH4 / N2 mixed gases. The preparation method which uses the phenolic resin industrial waste as a raw material has the advantages of environmental friendliness, wide source and low cost, and meanwhile is relatively simple in process and easier to industrialize and ensure the stable quality of products. The carbon molecular sieve product prepared by the invention has a remarkable CH4 / N2 separating performance, and absorbs N2 preferably. The product gas is directly enriched and recovered at the top of the tower, so that the operating cost of pressure swing adsorption can be lowered.

Owner:CCTEG CHINA COAL RES INST

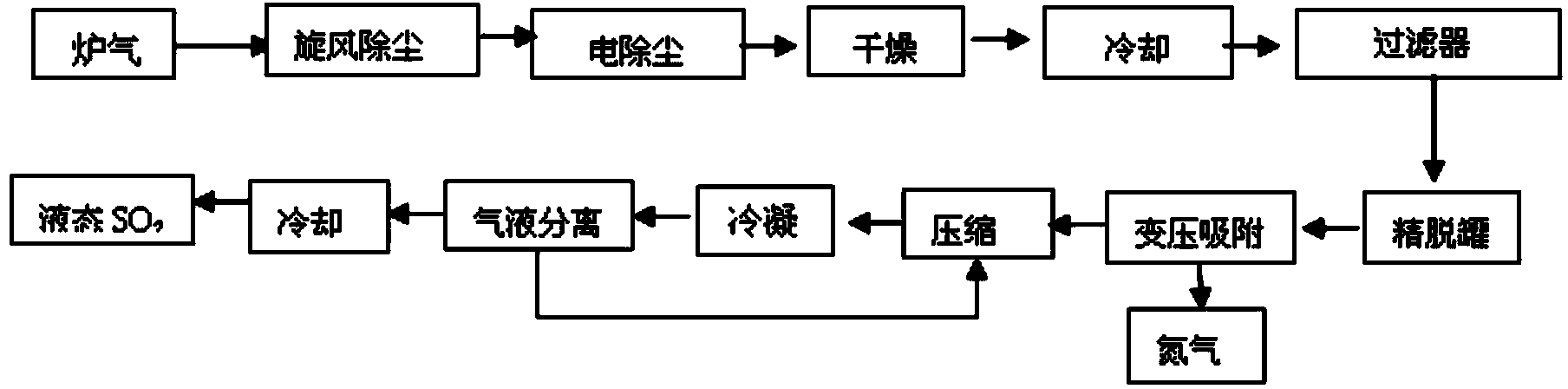

Method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption

ActiveCN103920365ARealize comprehensive utilizationLow costNitrogen purification/separationCombination devicesCyclic processNitrogen gas

The invention discloses a method for recycling nitrogen gas and sulfur dioxide from calcining iron pyrite burner gas through variable-voltage variable-frequency adsorption. The method comprises the following steps: dedusting, purifying, drying and cooling the calcining iron pyrite burner gas, and removing dust particles and rust by a refining sulfuric acid burner gas filter made of a 200-mesh polytetrafluoroethylene material; deeply dehydrating by a refining dehydrating tank in a refining manner, deoxidizing and removing carbon dioxide, separating N2 and SO2 through variable-voltage variable-frequency adsorption, compressing or cooling and performing gas-liquid separation to obtain liquid SO2, bottling the separated nitrogen gas and the liquid SO2 for industrial use, and enabling SO2 which is not liquefied and separated to enter a circulating process of compression or cooling and gas-liquid separation, so as to enable SO2 to be separated continuously. The method realizes comprehensive utilization and zero emission of mixed burner gas containing a great amount of nitrogen gas and sulfur dioxide caused by calcining of iron pyrite, the obtained liquid SO2 has high purity, the process is green, safe and energy-saving, and realizes zero emission and low cost.

Owner:GUANGXI UNIV

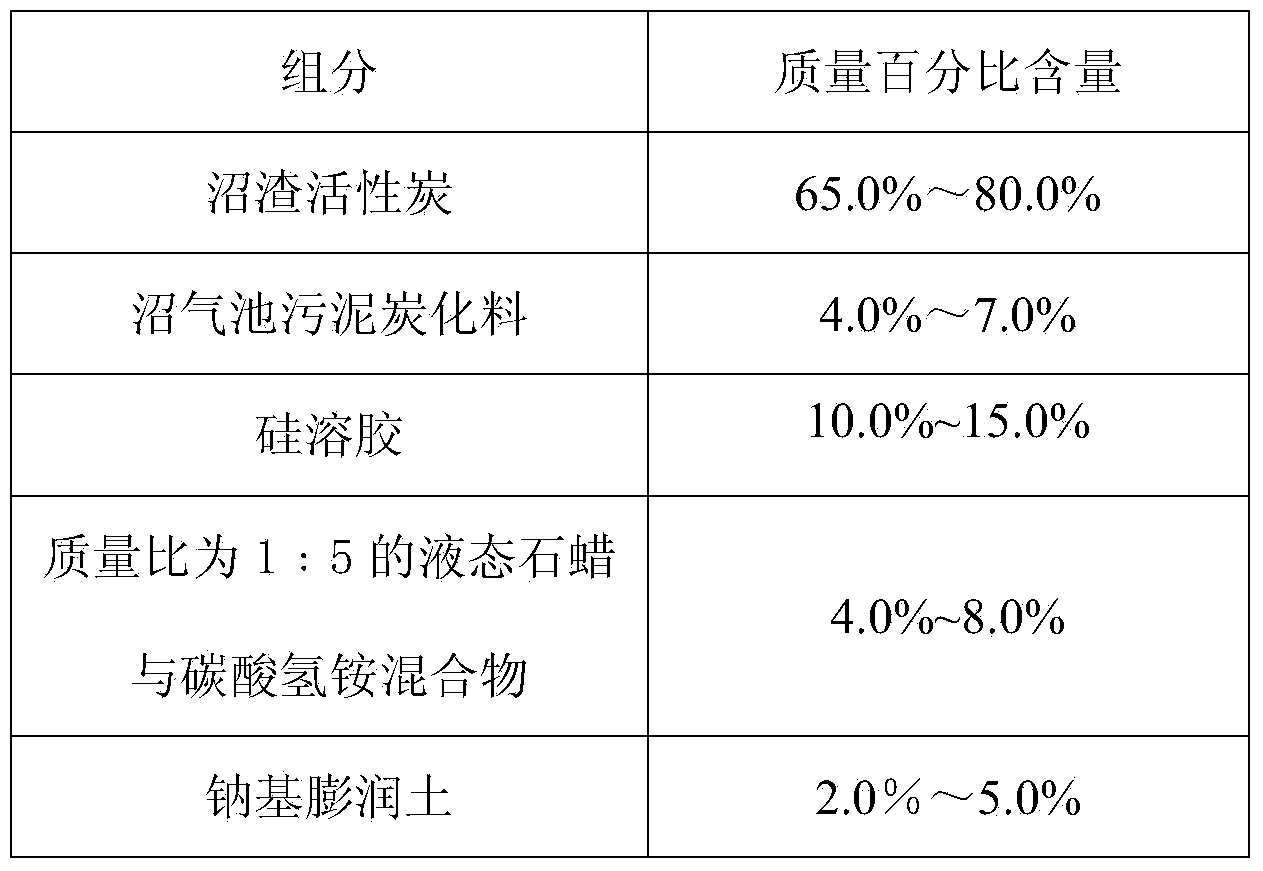

High-performance coconut shell activated carbon adsorbent for separating methane/nitrogen and preparation method of high-performance coconut shell activated carbon adsorbent

ActiveCN108057420ANarrow and uniform pore size distributionLarge specific surface areaNitrogen purification/separationMethane captureSoutheast asiaAdhesive

The invention discloses a high-performance coconut shell activated carbon adsorbent for separating methane / nitrogen and a preparation method of the high-performance coconut shell activated carbon adsorbent. The preparation method comprises the following steps: performing primary carbonization on coconut shells; grinding the coconut shells subjected to the primary carbonization to obtain carbon powder; mixing the carbon powder with an adhesive and water, and performing extrusion forming, thus obtaining a raw material rod; performing secondary carbonization on the raw material rod to obtain a carbonized material; performing immersion modification and activation treatment on the carbonized material in sequence, thus obtaining the high-performance coconut shell activated carbon adsorbent. Theinvention provides a preparation method of fruit shell-based columnar activated carbon. Compared with conventional coconut shell broken carbon, the high-performance coconut shell activated carbon adsorbent has the advantages of regular shape, small pressure drop, high intensity and the like. As the air flow speed is extremely high during adsorption and separation, certain pressure is generated; furthermore, cyclic and repeated use is required, so that the columnar coconut shell activated carbon is more suitable for being used in a pressure swing adsorption process. Compared with a carbon molecular sieve which adopts phenolic resin, the high-performance coconut shell activated carbon adsorbent adopts coconut shells, so that a large number of raw materials can be obtained in Hainan of Chinaand Southeast Asia regions; the raw materials are wide in source and reasonable in prices, so that stable quality and reasonable price can be guaranteed more easily.

Owner:CCTEG CHINA COAL RES INST

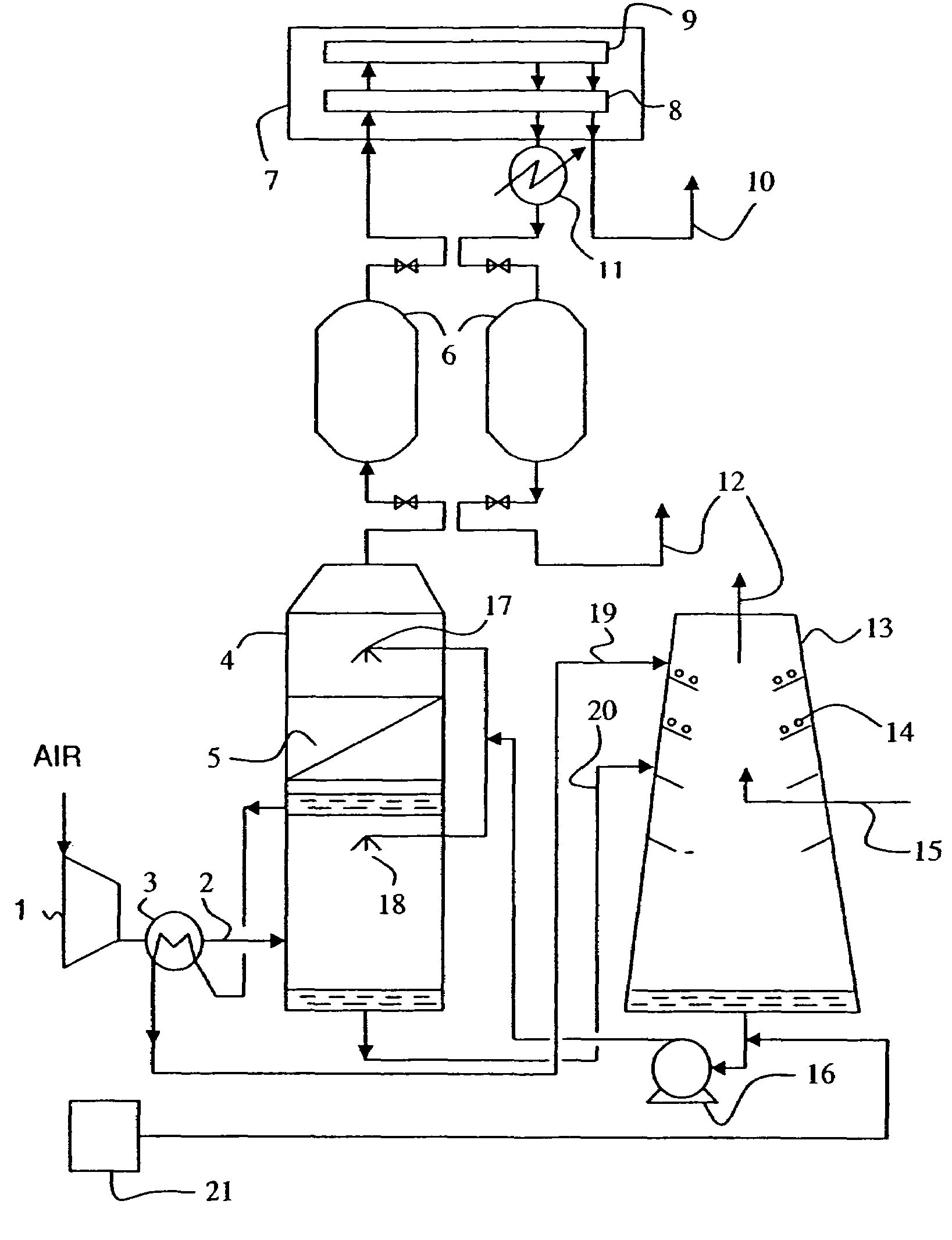

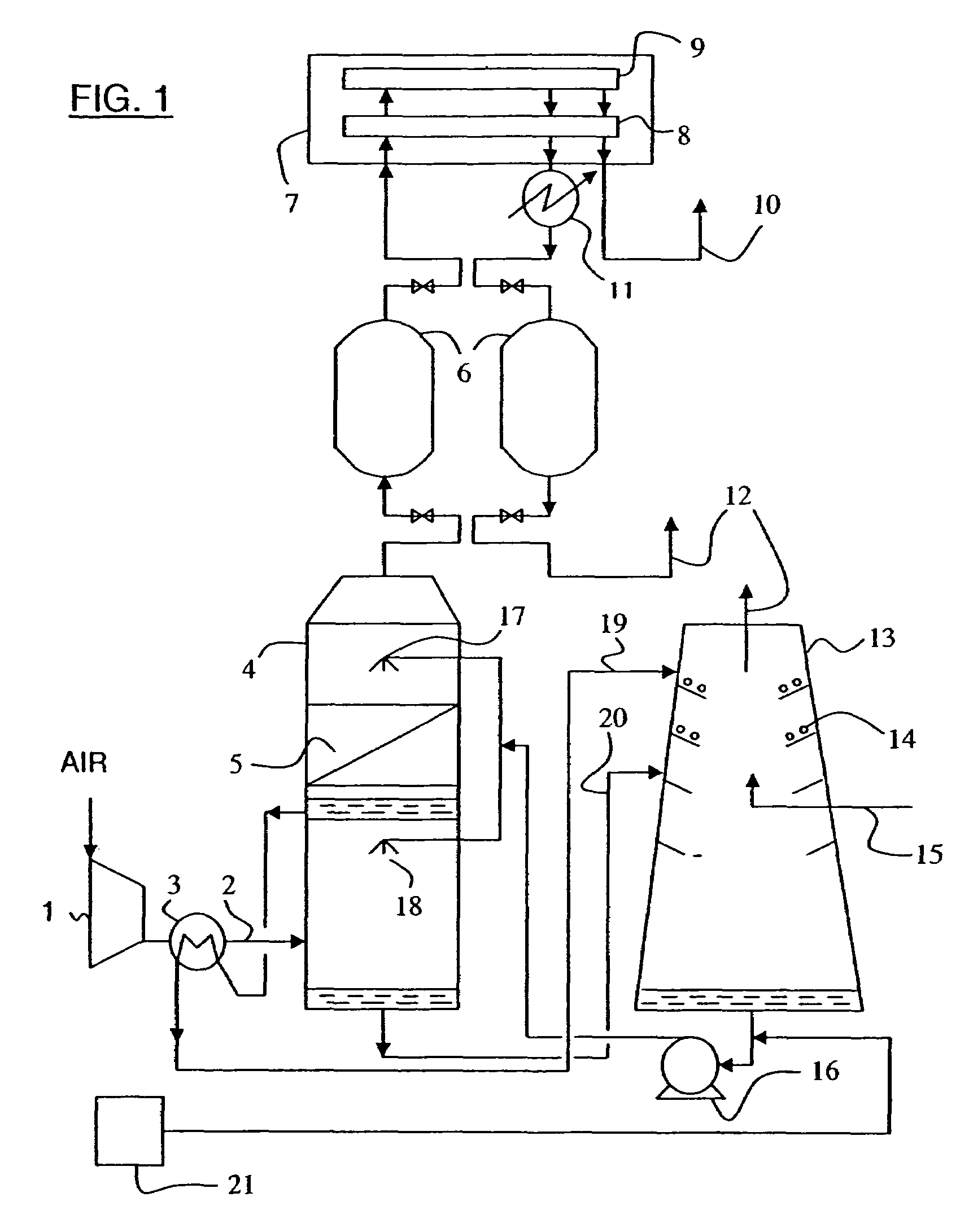

Process and installation for the fractionation of air into specific gases

InactiveUS7514056B2Improve conversion performanceBioreactor/fermenter combinationsSolidificationHydration reactionCooling tower

In order to reduce incoming atmospheric carbon dioxide levels in compressed air prior to cryogenic distillation, a water spray cooling tower equipped with biocatalytic packing, or fed with absorptive reagents, is used to convert gaseous carbon dioxide into bicarbonate ions which dissolve in the cooling water. The hydration reaction and refrigeration occur synergistically. The bicarbonate ions are subsequently removed from the solution using the heat from the compressed air in a regenerator re-boiler unit, and then fed to a percolation cooling tower for releasing CO2 and cooling.

Owner:CO2 SOLUTION

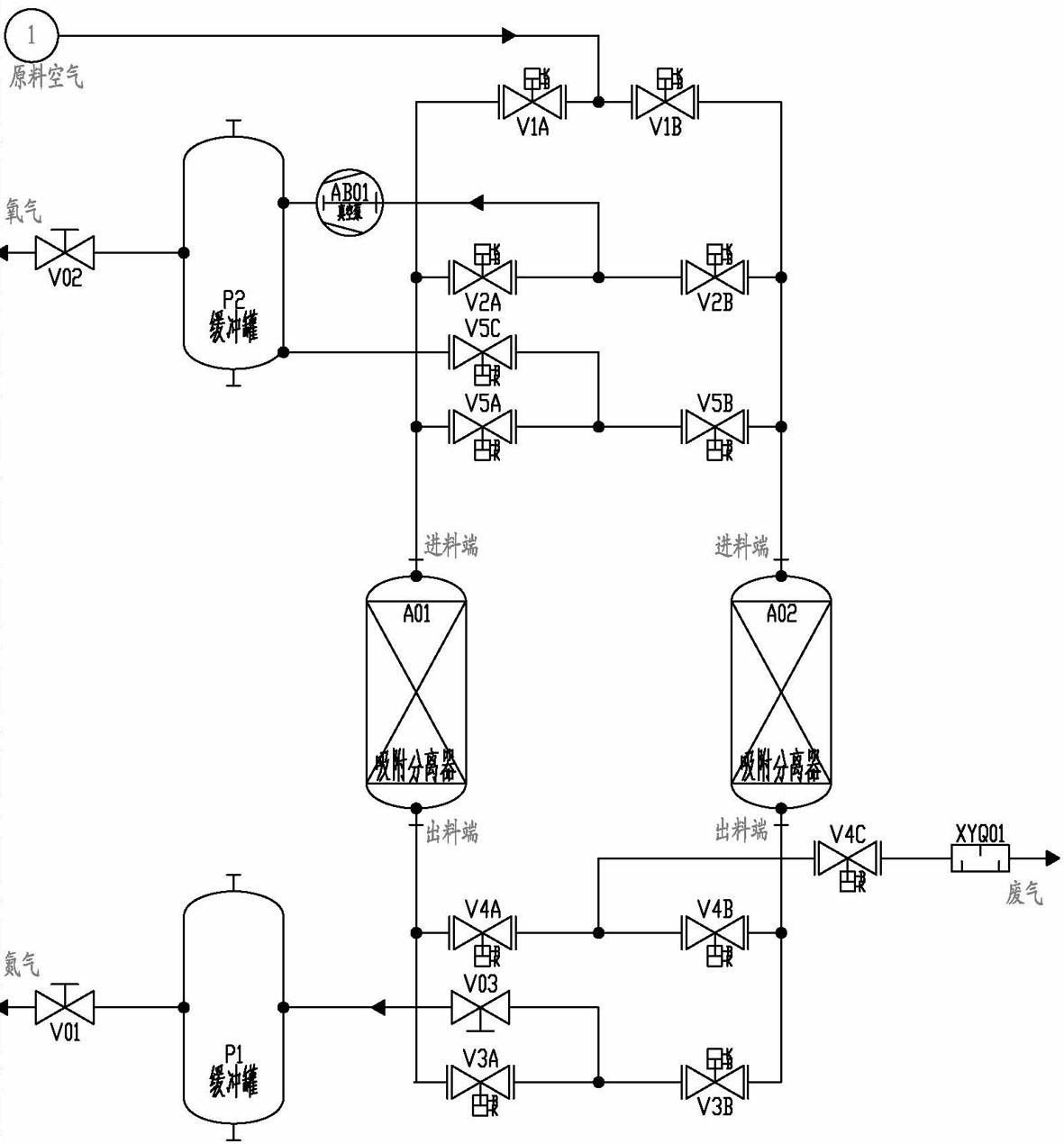

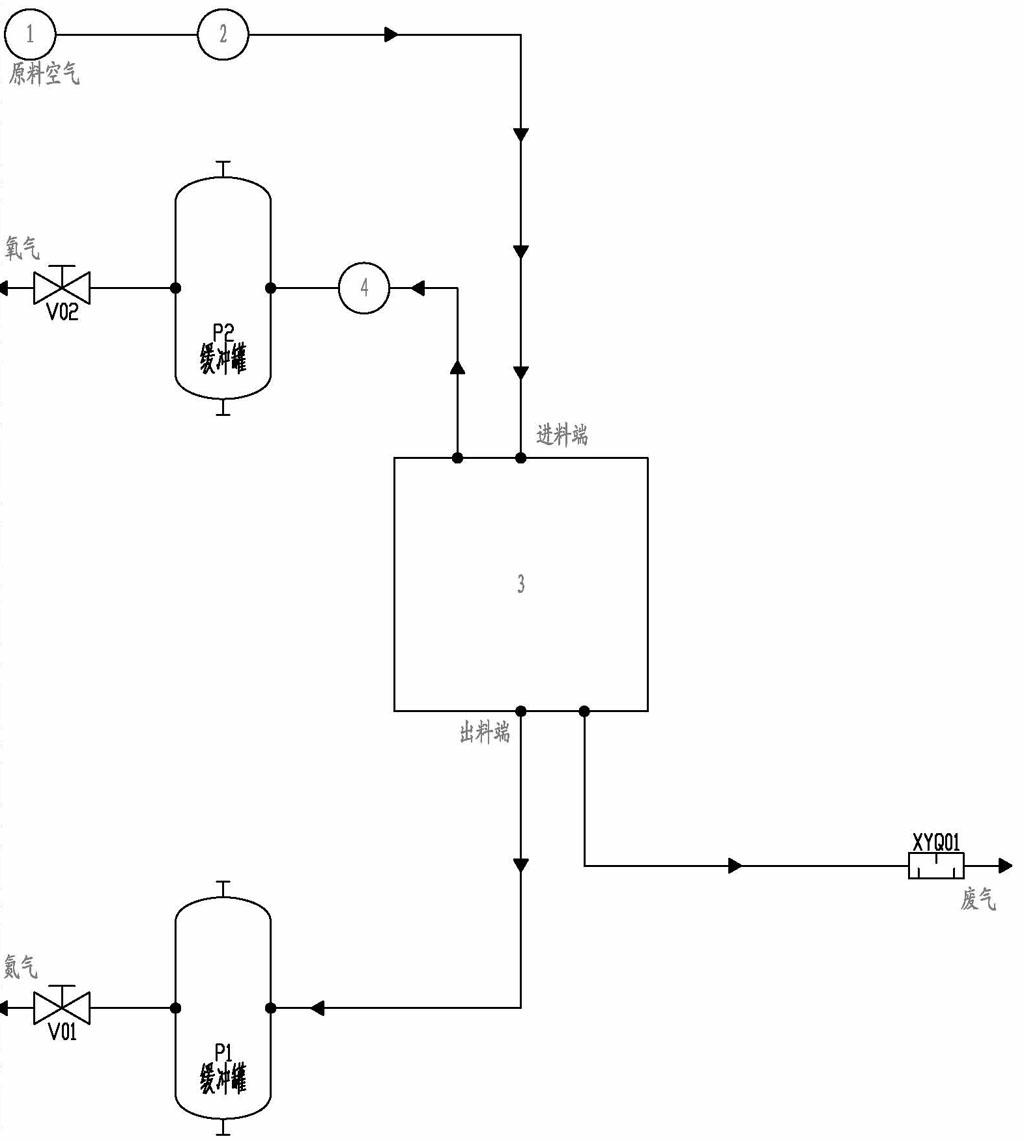

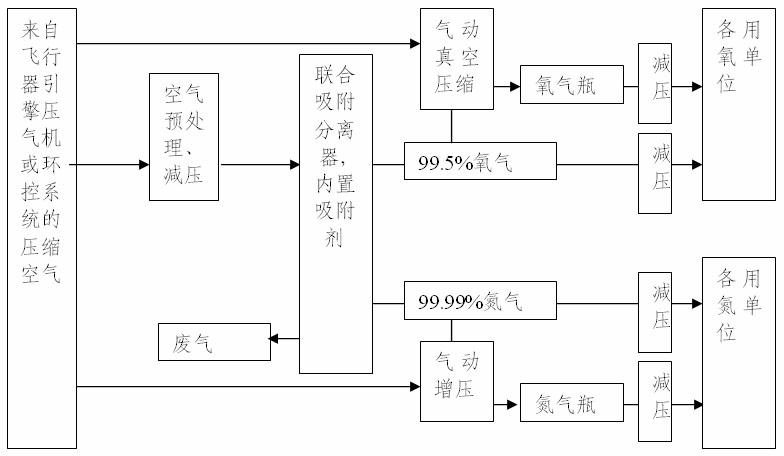

Variable pressure absorption oxygen and nitrogen combined separation method and device

ActiveCN102091500AIncrease consumptionRealize integration and separationNitrogen purification/separationOther chemical processesSorbentOn board

The invention belongs to the technical field of mixed gas separation, in particular to a variable pressure absorption oxygen and nitrogen combined separation method and a pressure absorption oxygen and nitrogen combined separation device. The device comprises at least two absorption towers filled with absorbent, pipelines for supplying raw material gas to the absorption towers, pipelines for taking product gas from the absorption towers respectively, pipelines for gas component and energy recovery and exchange between the absorption towers and gas kinetic energy transmission from an absorption tower reaching absorption saturation to another absorption tower, and an oxygen and nitrogen product gas buffering tank, wherein an oxygen product gas is connected to the cleaning pipeline and control valve of the feeding end of each absorption tower, and the nitrogen gas product is connected to the cleaning pipe line and the control valve of the discharge end of each absorption tower. In the separation method provided by the invention, two high-purity products, namely oxygen and nitrogen, can be obtained at the same time through a single absorption and separation process, and the oxygen meets the requirements of aerially breathable oxygen. The device can be highly integrated, and the volume and weight of the device are in accordance with the development direction of aerospace on-board oxygen and nitrogen extraction and the requirements of on-board equipment.

Owner:上海穗杉实业股份有限公司

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS20050186130A1Offsetting cost of projectEconomically feasibleNitrogen purification/separationDispersed particle separationElectrolysisPtru catalyst

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

Porous inorganic membrane containing carbon; a process for its preparation; and use thereof

A porous inorganic membrane comprises at least one inorganic phase having separating properties. Said membrane has a carbon content representing 0.05% to 25% by weight with respect to the mass of said inorganic phase and is selective to non-condensable gases. It is obtained by means of a selectivation treatment of a porous carbon-free inorganic membrane using a hydrocarbon feed. It is used in processes for separating non-condensable molecules such as hydrogen, and in association with a catalyst in a catalytic membrane reactor.

Owner:INST FR DU PETROLE

Treatment method of carbon black tail gas

InactiveCN102120120AHigh calorific valueHigh thermal efficiencyNitrogen purification/separationDispersed particle separationNitrogen gasMoisture

The invention discloses a treatment method of carbon black tail gas, and the method comprises the steps: (1) washing off the H2O and H2S in the tail gas, collecting a waste liquid and carrying out neutralization treatment; (2) introducing the washed tail gas in a pressure swing adsorption device, drying, and adsorbing the moisture which is not fully dried in the tail gas; (3) introducing the dried tail gas in a temperature swing adsorption device and removing the H2S and SO2 impurities in the tail gas; (4) storing the tail gas in a nitrogen storage tank for application; and (5) introducing the treated carbon black tail gas in a tail gas header pipe for combustion. The method has the following advantages: (1) the energy consumption is reduced, and the benefits of enterprises are improved; (2) the internal capacities of a tail gas combustion furnace and a tail gas boiler are reduced, related supporting facilities are reduced, and the one-time investment is lowered; (3) the pollution of the waste gas to the atmosphere is avoided after tail gas combustion; (4) the generated nitrogen can be used for multiple industries, and new benefit growth points of the carbon black enterprises are created; and (5) the method is applicable to treatment of tail gas generated by various carbon black production methods.

Owner:CHAOYANG BLACK CAT WUXINGQI CARBON BLACK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com